Patents

Literature

40results about How to "Low ignition energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

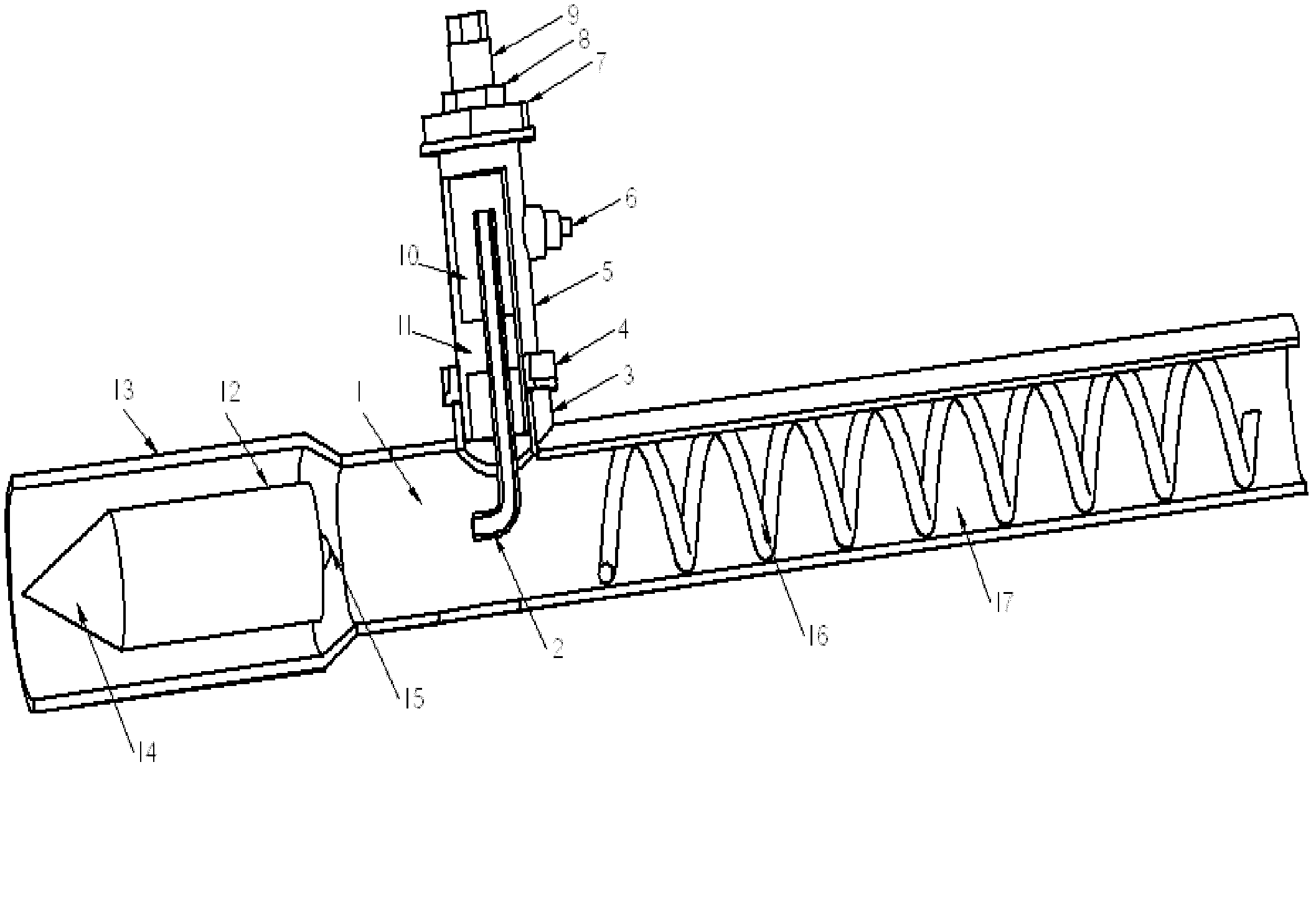

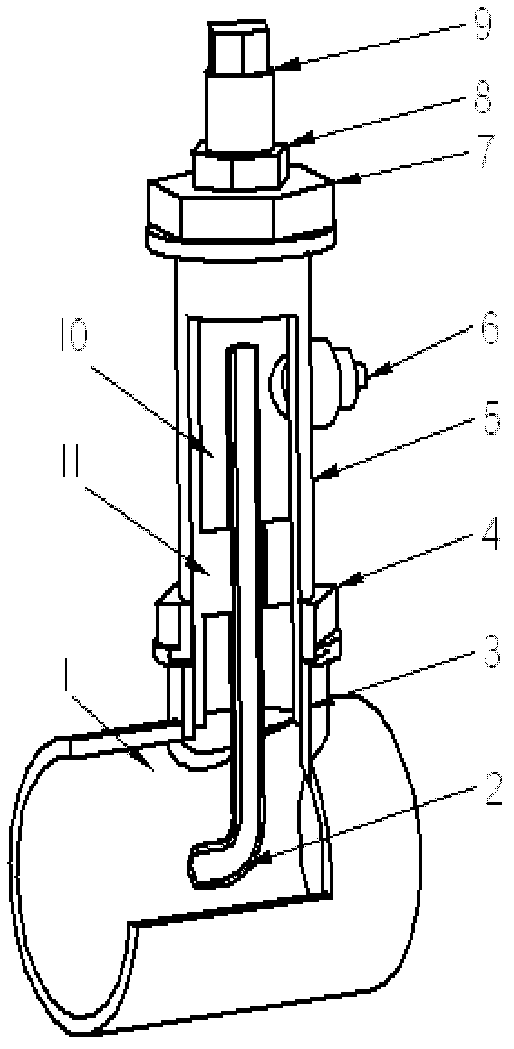

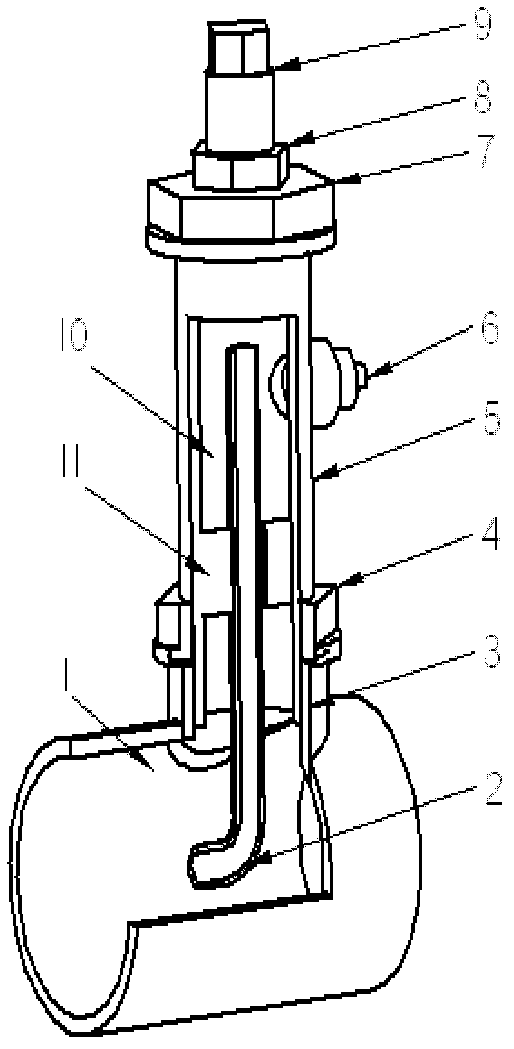

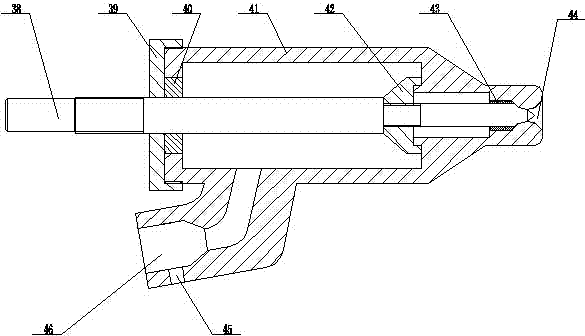

Jet ignition device of pulse detonation engine

InactiveCN102619643AIncrease working frequencyImprove convenienceIntermittent jet plantsRocket engine plantsDraining tubeDeflagration to detonation transition

The invention relates to a jet ignition device of a pulse detonation engine, which is characterized in that a jet tube is fixedly connected with a mixing chamber through a sealing clamp nut, an adjusting plug is mounted at the top end of the jet tube through a sealing nut and a clamping nut; a drain tube is arranged in a jet chamber inside the jet tube and is connected with the jet tube through a fixing rib, and the lower end of the drain tube extends into the mixing chamber; and an ignition seat is arranged on one side of the jet tube and is located at one end of an outlet of the drain tube. Compared with the time and the distance for generating detonation waves by normal ignition devices, the time and the distance for generating the detonation waves by the jet ignition device are shorter, accordingly the DDT (deflagration to detonation transition) time and distance is shortened. In this case, length of a detonation chamber can be further shortened so as to improve working frequency of the pulse detonation engine. After the detonation chamber is shortened, exhausting burden in the pulse detonation engine is reduced, so that expansion wave-beams generated from the outlet of the pulse detonation engine can catch up with pressure waves transmitted before, pressure disturbance in an air-inlet passage is reduced, and working stability of the pulse detonation engine is enhanced while better propulsive performance is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

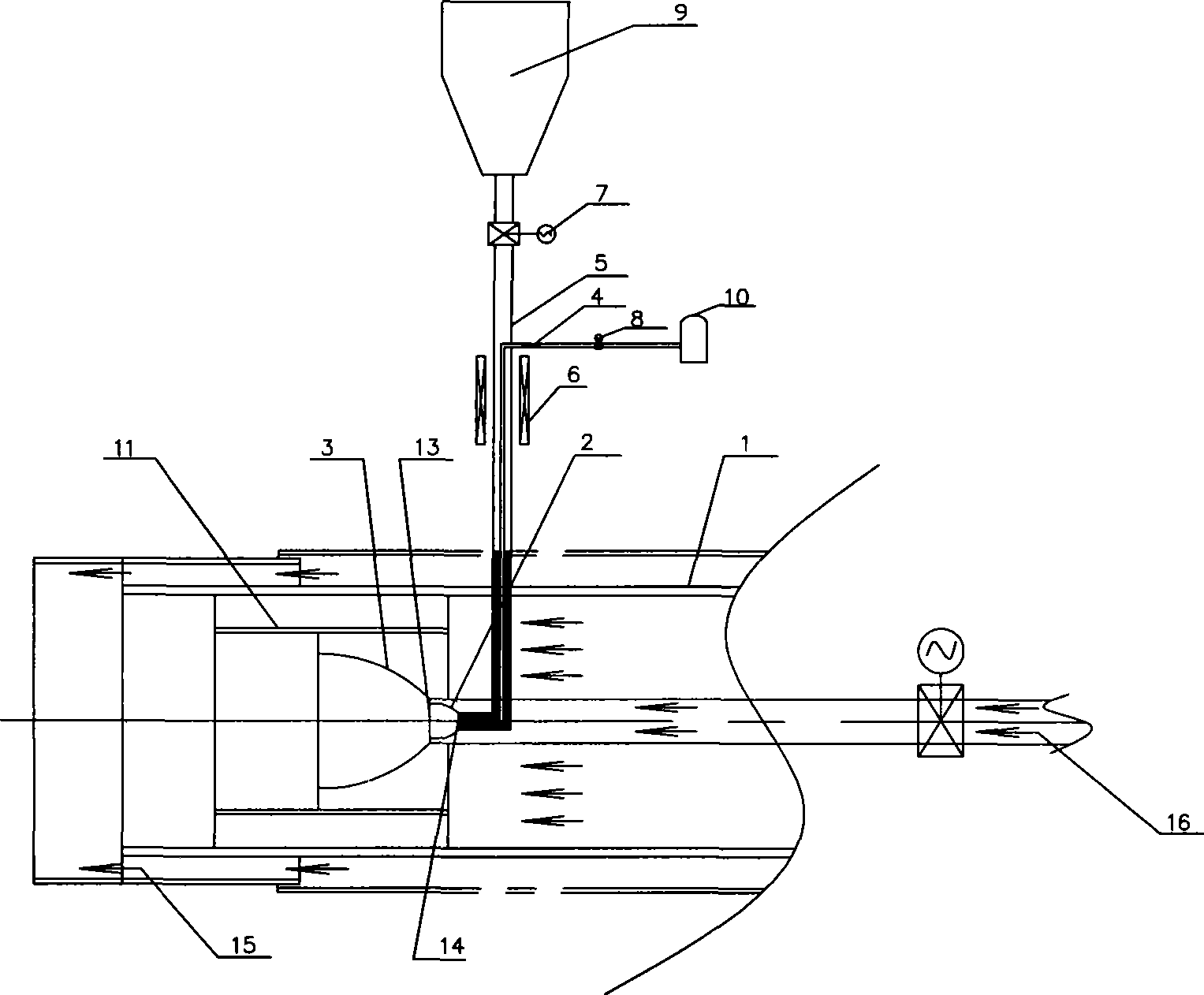

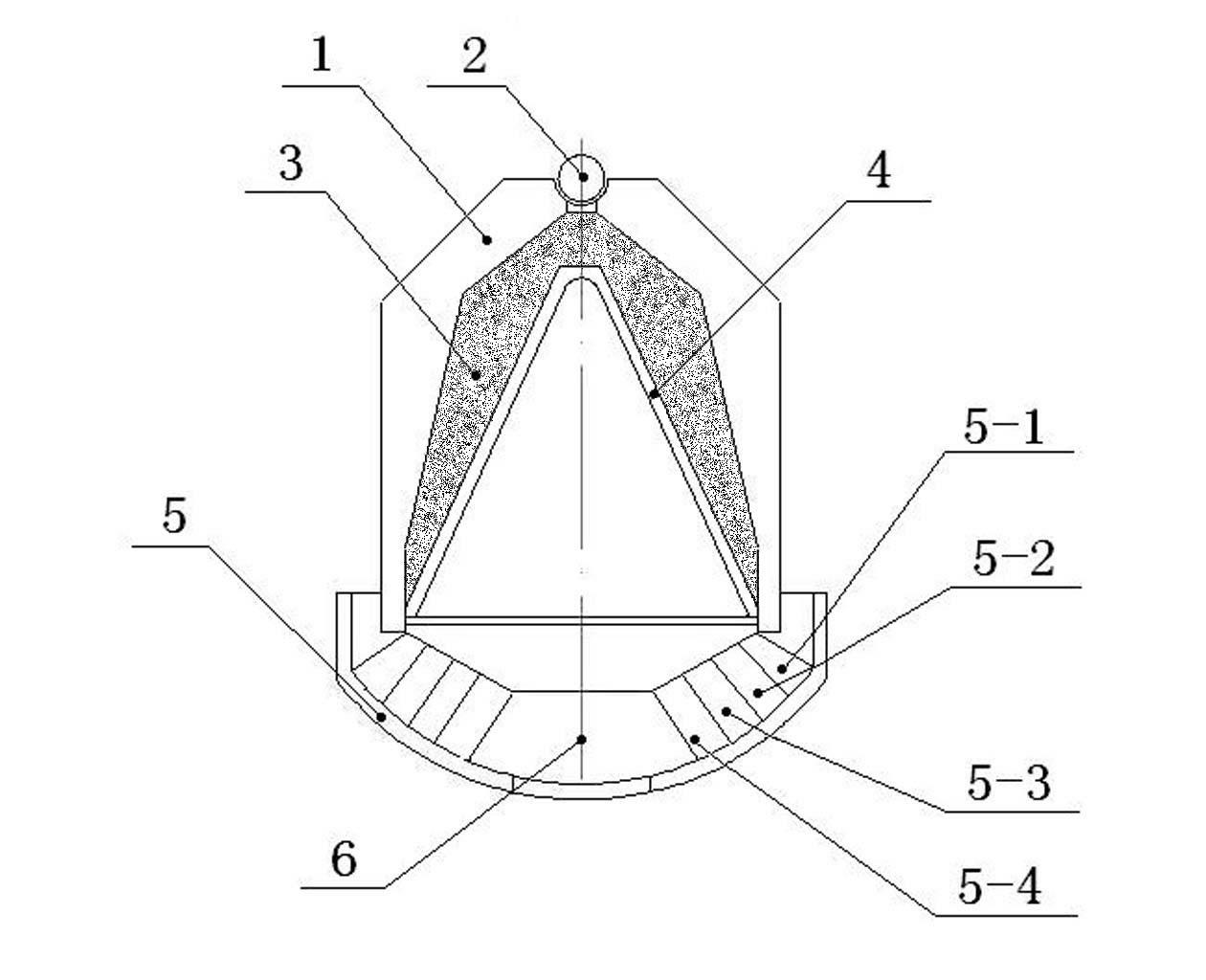

Concentrated phase high-temperature oxygen-enriched oilless ignition combustion apparatus

ActiveCN101424398ALow ignition energyLow ignition temperaturePilot flame ignitersPulverulent fuel combustion burnersOil freeOxygen delivery

The invention relates to a dense-phase high-temperature oxygen-enriched oil-free ignition combustion device, which solves the defects that the prior art is high in energy consumption, unstable in fire, low in combustion intensity, easily worn in equipment and narrow in the adaptation range to coal types. The device comprises an ignition pulverized-coal nozzle which is arranged in the center of a shell. An outer port of the ignition pulverized-coal nozzle and an ignition chamber are connected with a central shaft, and an inner port of the ignition pulverized-coal nozzle is communicated with an ejection opening of an ignition device, wherein the ignition device comprises a pulverized-coal conveying pipe the inside of which is provided with an oxygen conveying pipe; an outlet of the pulverized-coal conveying pipe and a gas outlet of the oxygen conveying pipe are communicated with the inner port of the ignition pulverized-coal nozzle respectively so as to form the ejection opening; and a heating system is arranged outside the pulverized-coal conveying pipe the inside of which is provided with the oxygen conveying pipe. The device has the advantages of low energy consumption, stable reliable fire, high combustion intensity, equipment not easy to wear and wide adaptation range to coal types.

Owner:郑平安

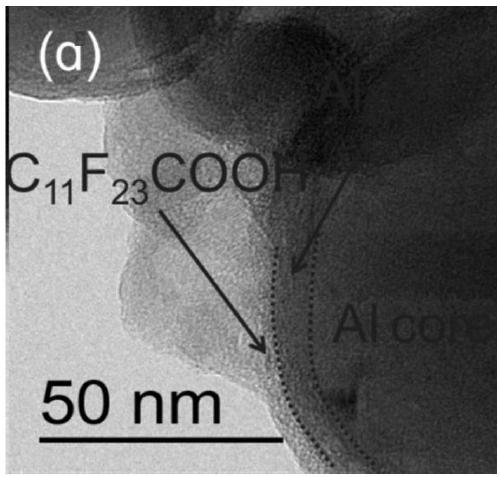

Aluminum powder surface self-activation method

InactiveCN109293463APrevent reoxidationRapid responseExplosive ingredient compoundingIgnition delayAluminium powder

The invention discloses an aluminum powder surface self-activation method. The method includes steps: adding aluminum powder into an anhydrous solvent, mixing, and stirring to disperse uniformly to form aluminum powder dispersion liquid; dissolving organic fluoride into a solvent to form organic fluorine solution, adding the organic fluorine solution into the aluminum powder dispersion liquid by acertain rate, and stirring to volatilize the solvent in which the organic fluoride is dissolved at a certain temperature, so that organic fluoride is slowly separated out by crystallization on the aluminum powder surface to form a compact surface activation layer; centrifugally separating to remove the solvent, washing, and performing vacuum drying at 60 DEG C to obtain organic fluorine surface self-activated aluminum powder. By forming of the organic fluorine self-activation layer on the aluminum powder surface, the aluminum powder ignition temperature can be effectively lowered while ignition delay time is shortened, combustion efficiency of aluminum powder in oxidants is improved while the energy releasing rate is increased, and the organic fluorine surface activation layer is effective in aluminum powder oxidation, so that stability is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

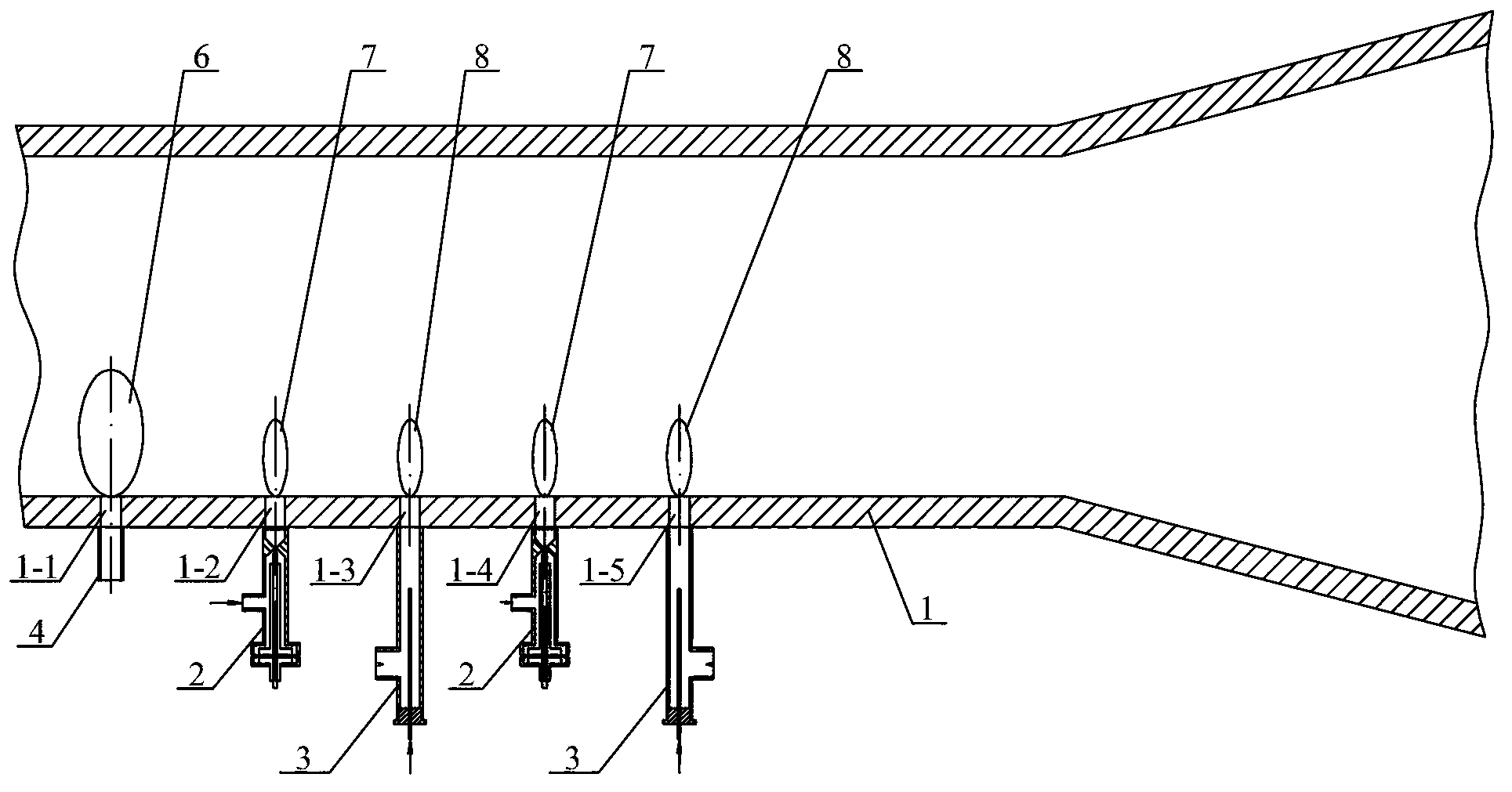

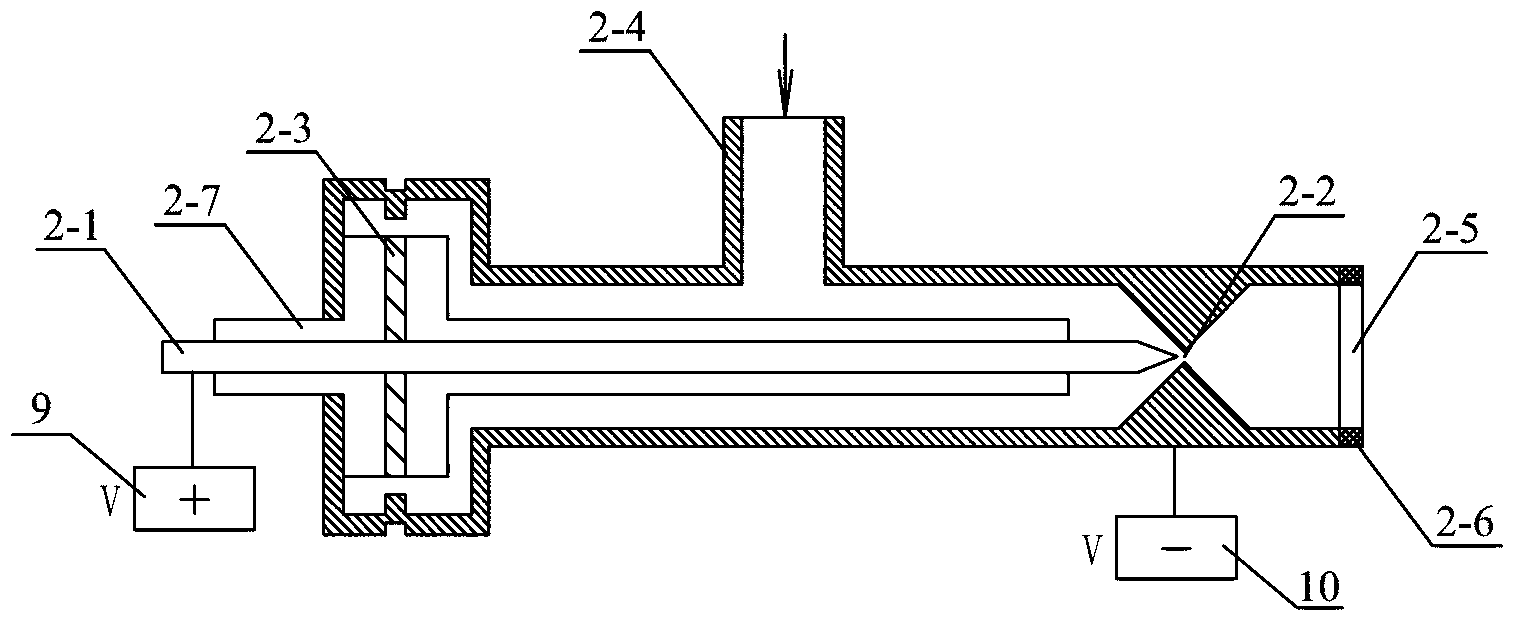

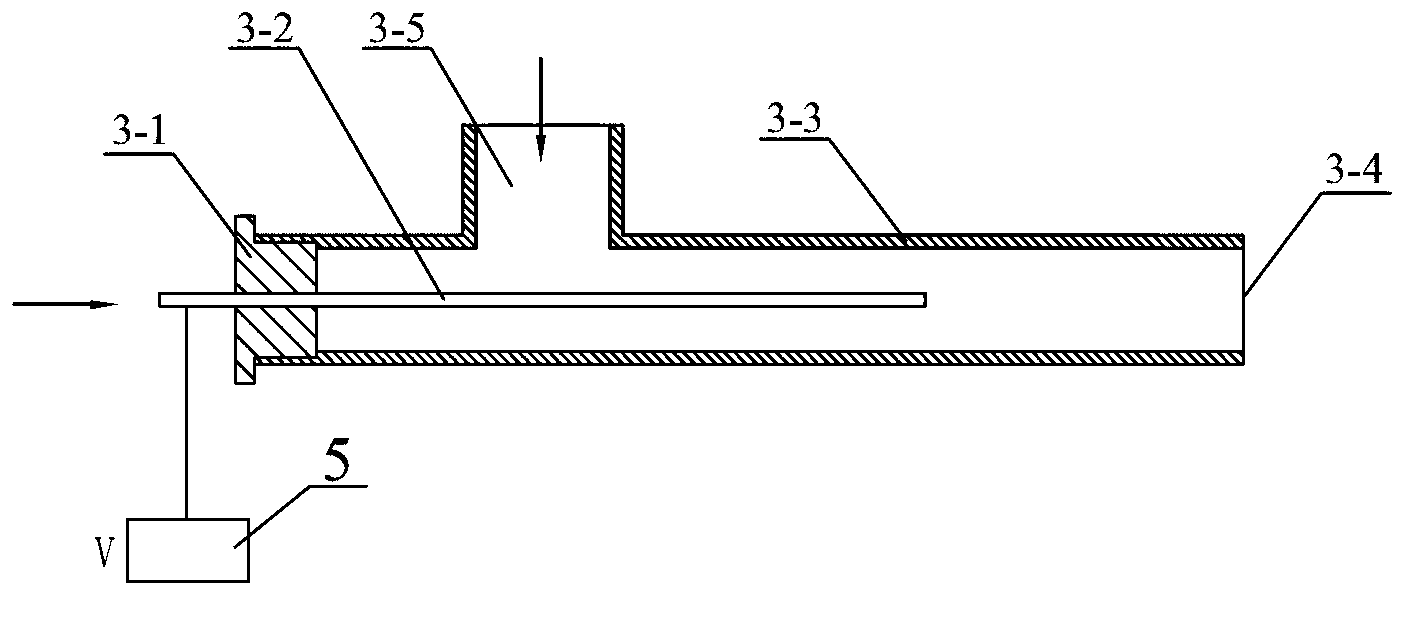

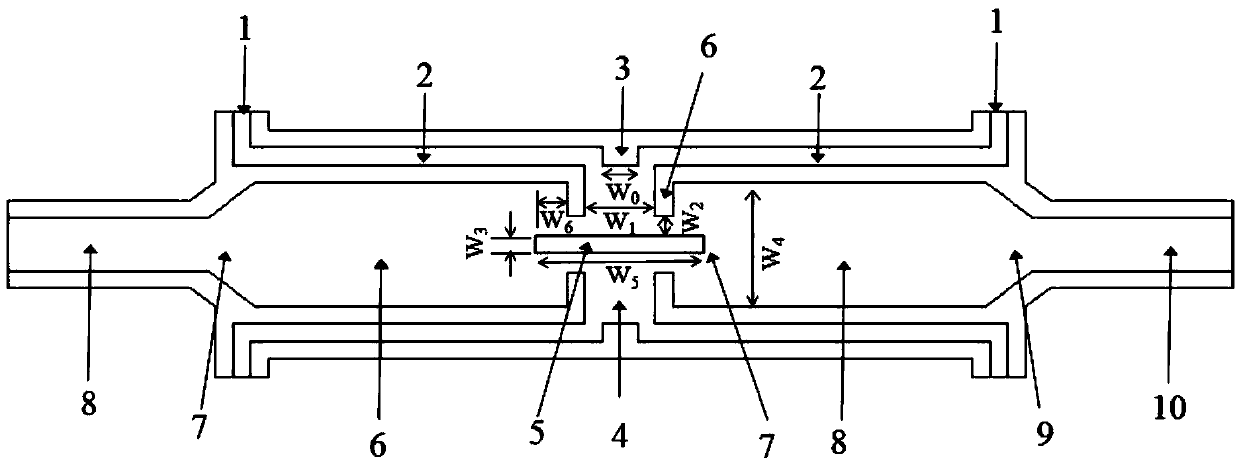

Supersonic combustion method actuated by combination plasma

InactiveCN103216317AAvoid layoutAvoid technical requirements for placing ionization electrodesInternal combustion piston enginesCombustion-air/fuel-air treatmentDiffusion flameCombustion chamber

The invention discloses a supersonic combustion method actuated by combination plasma, relates to the supersonic combustion method for an engine combustion chamber, and solves the problems that by using an existing concave chamber type combustion method, the concave chamber dimensions are large, the flow loss is large, and the supersonic combustion performance is poor. The method comprises the steps that 1) a ceramic membrane is plated on the inner surface of each through hole; 2) the first through hole is connected with a fuel oil outlet pipe, the second through hole and the fourth through hole are connected with a thermal equilibrium plasma generator respectively, and the third through hole and the fifth through hole are connected with a non-thermal equilibrium plasma generator respectively; 3) fuel oil is injected into the combustion chamber through the first through hole; 4) a working medium is ejected from the thermal equilibrium plasma generator, is injected into a combustion area of the engine combustion chamber and ignites the fuel oil at the combustion area to form diffusion flame and realize ignition; and 5) jet cooling plasma is ejected from the non-thermal equilibrium plasma generator, and is injected into different positions of the combustion chamber through the third through hole and the fifth through hole for forming reliable combustion. The method provided by the invention is used for organizing supersonic combustion.

Owner:HARBIN INST OF TECH

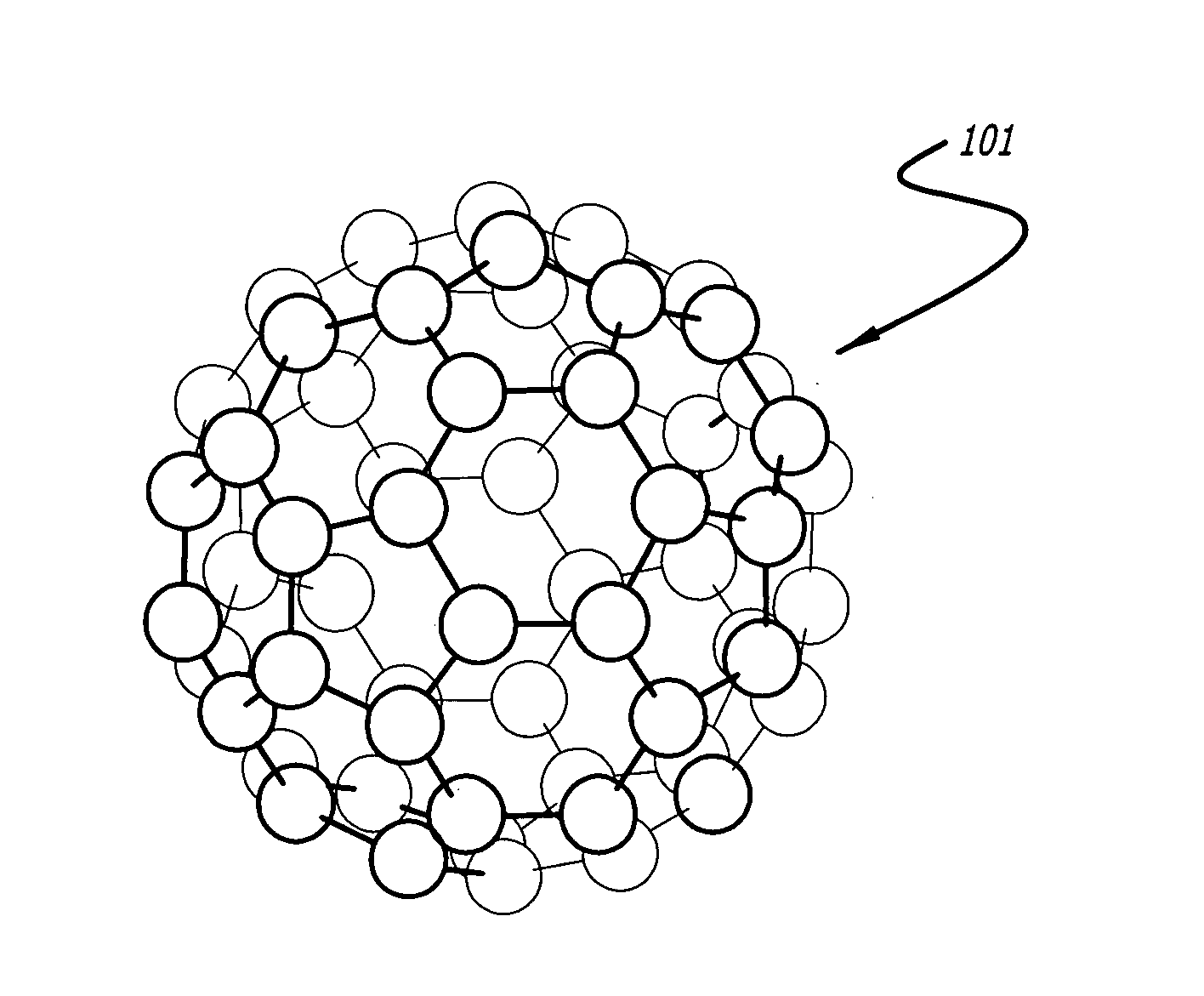

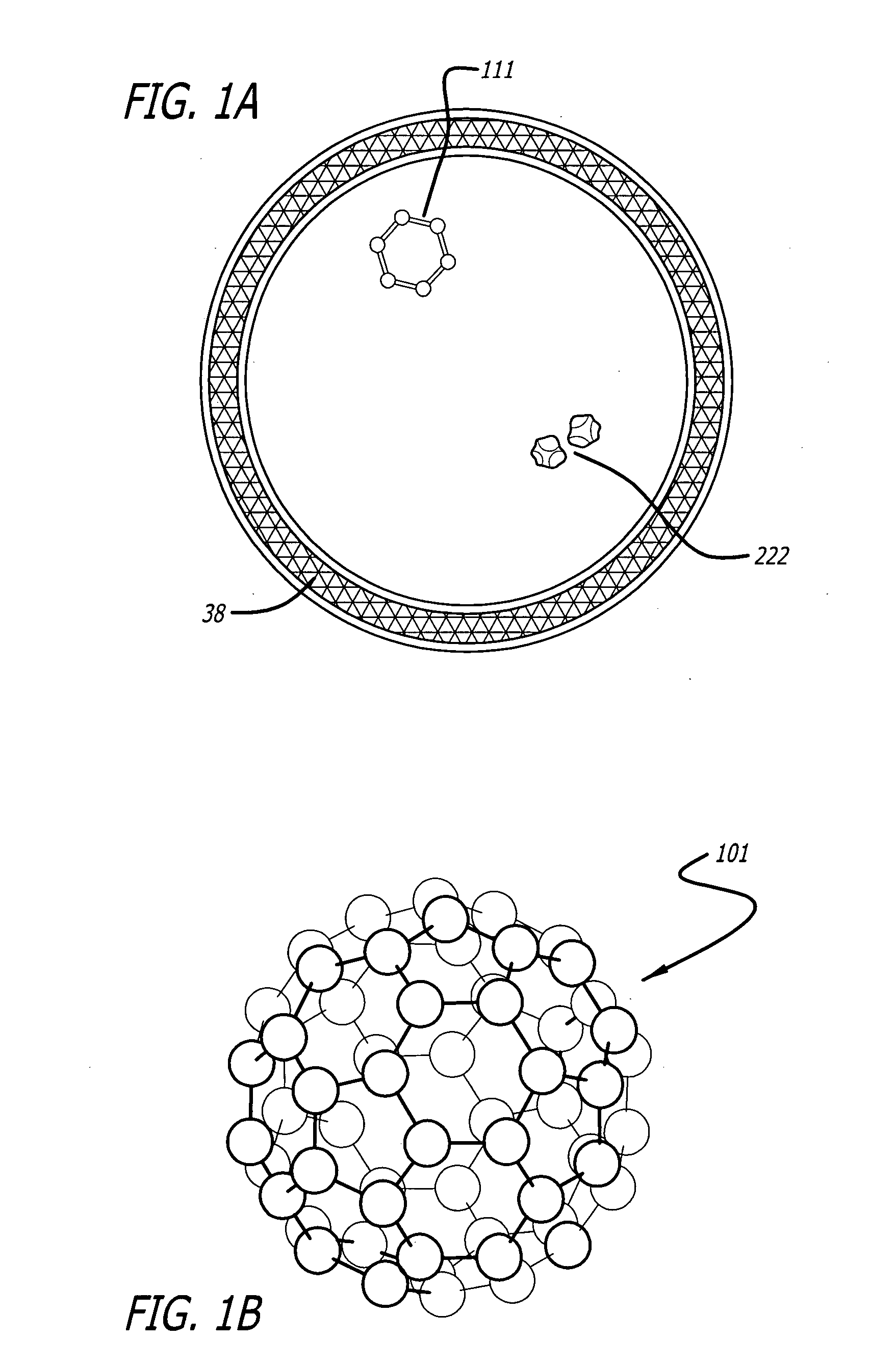

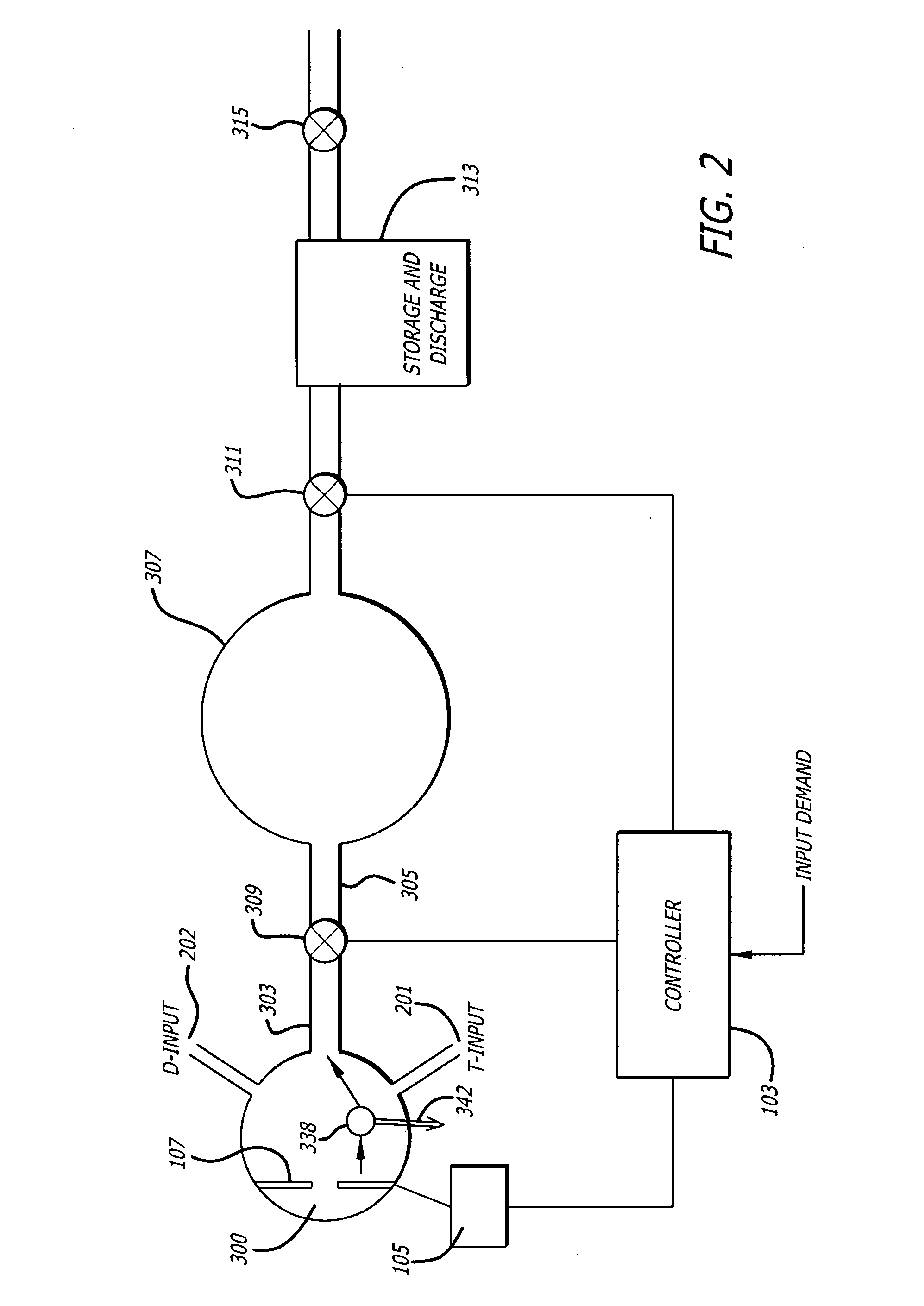

Nano-fusion reaction

InactiveUS20080247930A1Low ignition energyEasy to useMaterial nanotechnologyFullerenesChemistryShock wave

A nano-fusion reactor comprised of nano-particles such as carbon based nanotubes, endohedral fullerenes and other nano materials encapsulating fusible fuels such as the hydrogen isotopes, deuterium, and tritium. The nano-devices encapsulate the fusible materials and ignite fusion reactions which in some of the embodiments consume the nano-fusion reactor device requiring the replenishment of these devices so to continue the fusible reactions. The reactions can be controlled and scaled through modulated presentation of fusion targets to the ignition chamber. The fusion reactions are ignited in the embodiments through one or more of the applied forces in the fusion reactor: electromagnetic compressive, electrostatic, and thermo. These applied forces in conjunction with the extreme structural strength, the ablation forces and purity of the nano-fusion device produces maximum forces necessary for the production of a shock wave on the nano-encapsulated device to ignite one or a plurality of fusion reactions. The lower ignition energy is due to a smaller device with less fuel, more efficient coupling of applied energy by the nano-device, along with purer encapsulated fuels, and improved geometries has provided improvements over conventional ICF reactions.

Owner:HOTTO ROBERT

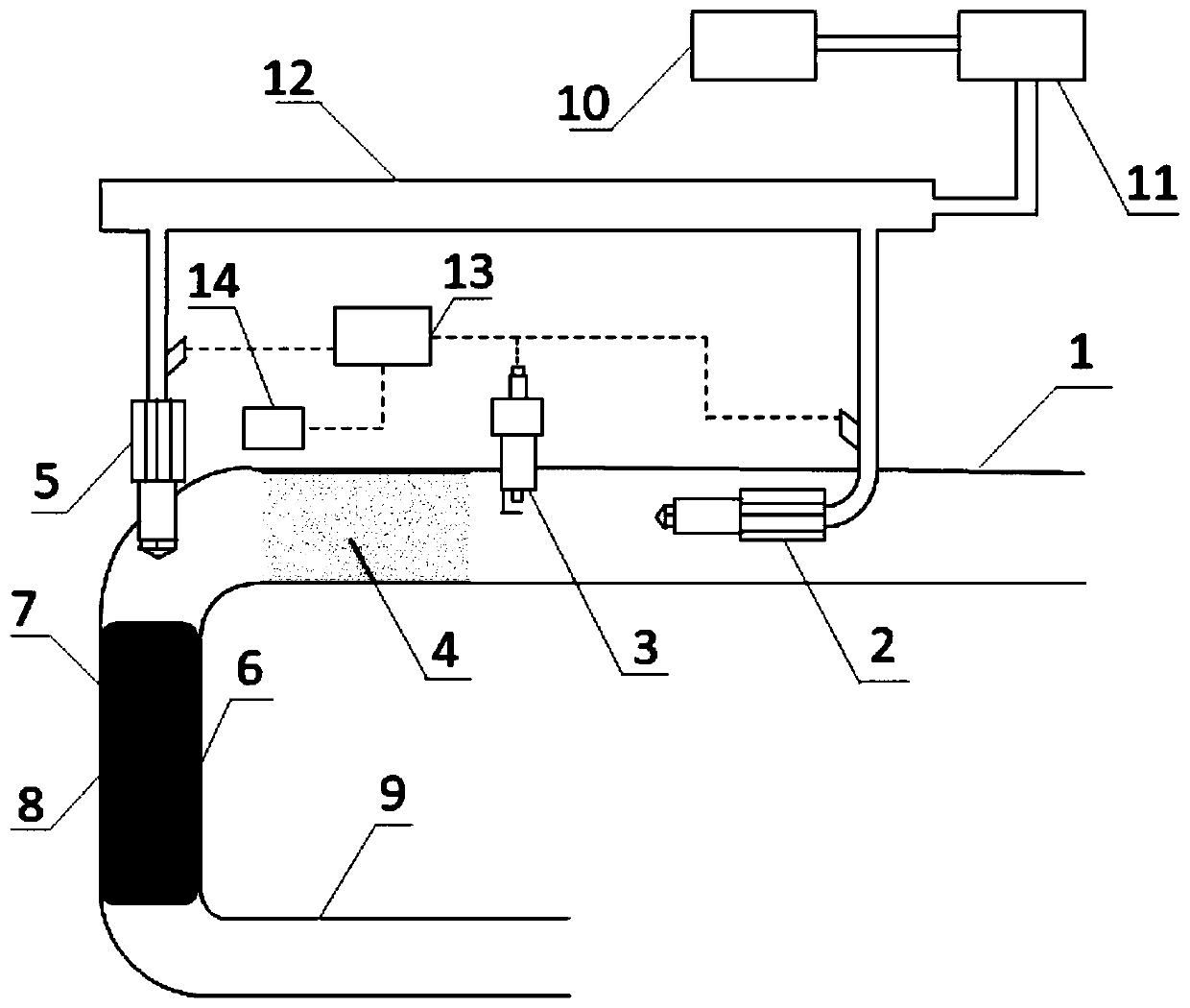

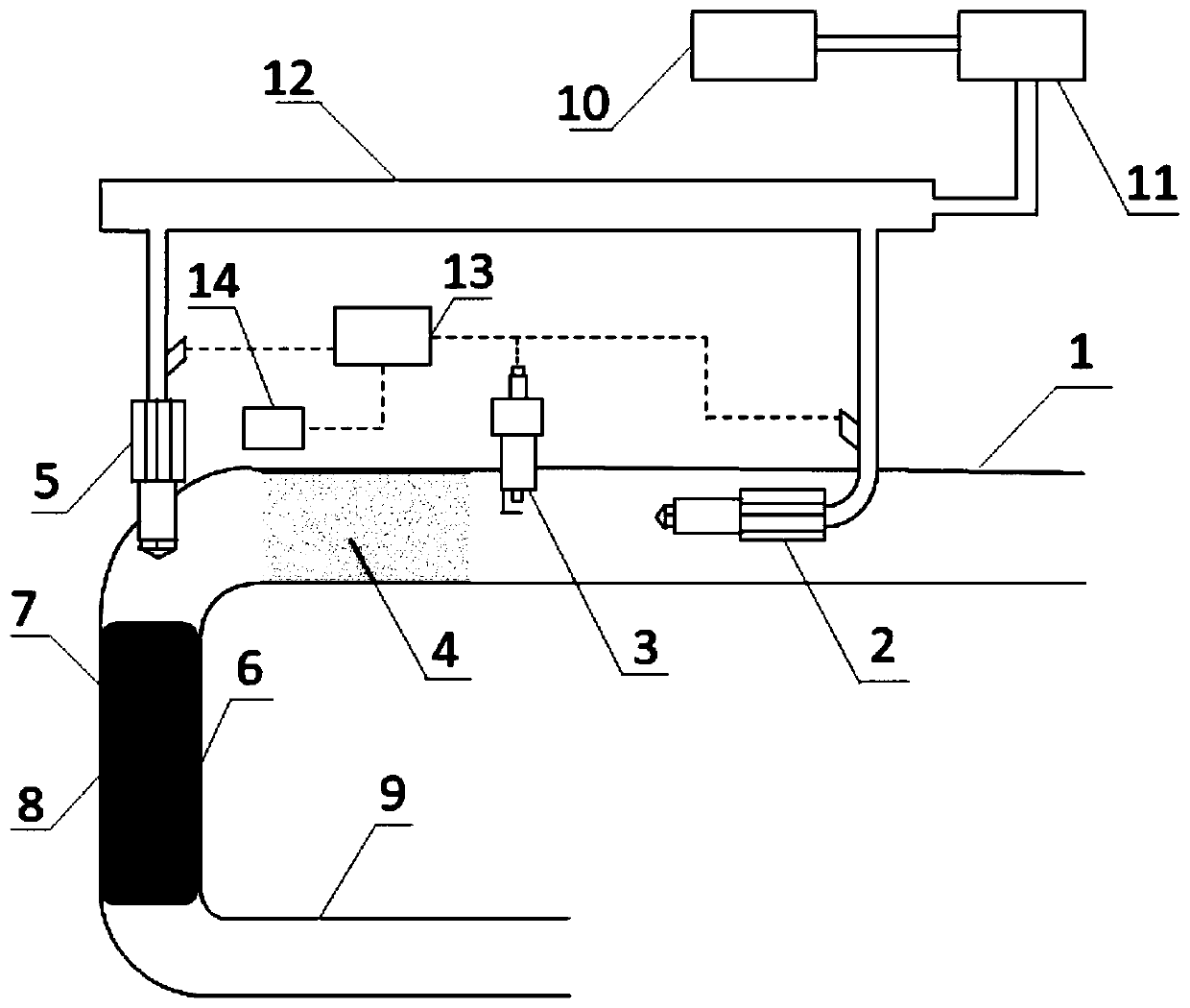

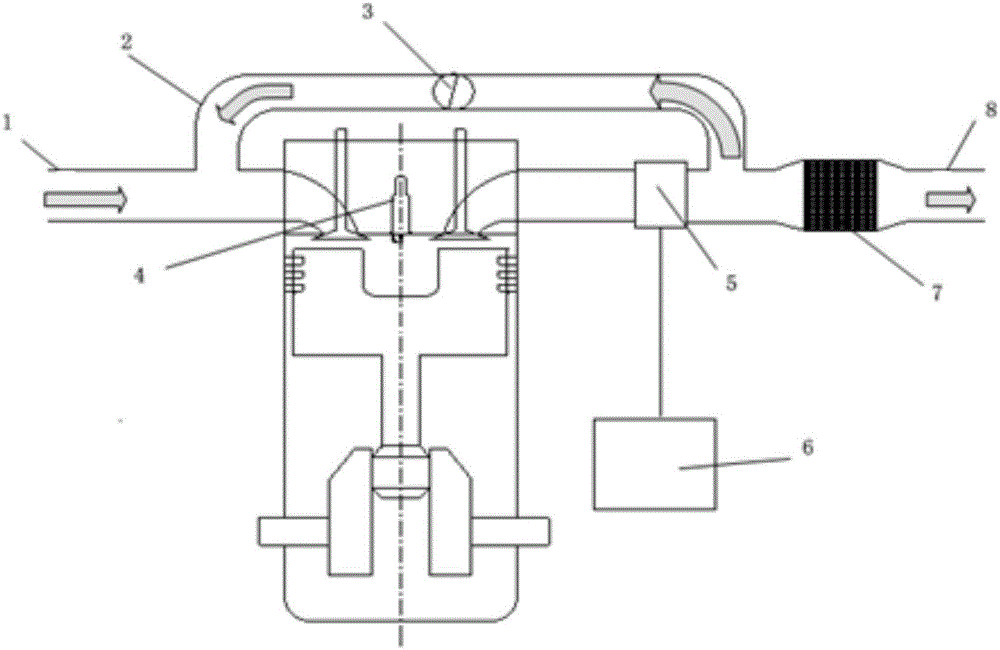

Multi-stage injection methanol engine cold start device and method

ActiveCN109973266AFast cold startLow ignition energyInternal combustion piston enginesThermal treatment of fuelElectricityCombustion chamber

The invention belongs to the field of methanol engine cold start, and discloses a multi-stage injection methanol engine cold start device and method. The device comprises a methanol evaporation and cracking module and a methanol multi-stage injection and ignition module, the methanol evaporation and cracking module comprises a first air inlet passage, a combustion chamber, an evaporation and cracking chamber and an exhaust pipe which are sequentially connected, and the methanol multi-stage injection and ignition module comprises a methanol box, a methanol high-pressure oil rail, a methanol pump, a first-stage methanol injector, a second-stage methanol injector, a sparking plug and a controller. The invention further discloses a multi-stage injection methanol engine cold start method. Methanol cracking gas can be prepared under the condition of low ambient temperature by multi-stage methanol injection and single ignition under the condition of cold start, and the methanol cracking gas and the uncracked methanol gas are introduced into an engine together to realize rapid cold start of the pure methanol engine. The device has the advantages of being high in stability, low in electricity consumption and easy to produce in an industrialized mode.

Owner:HUAZHONG UNIV OF SCI & TECH

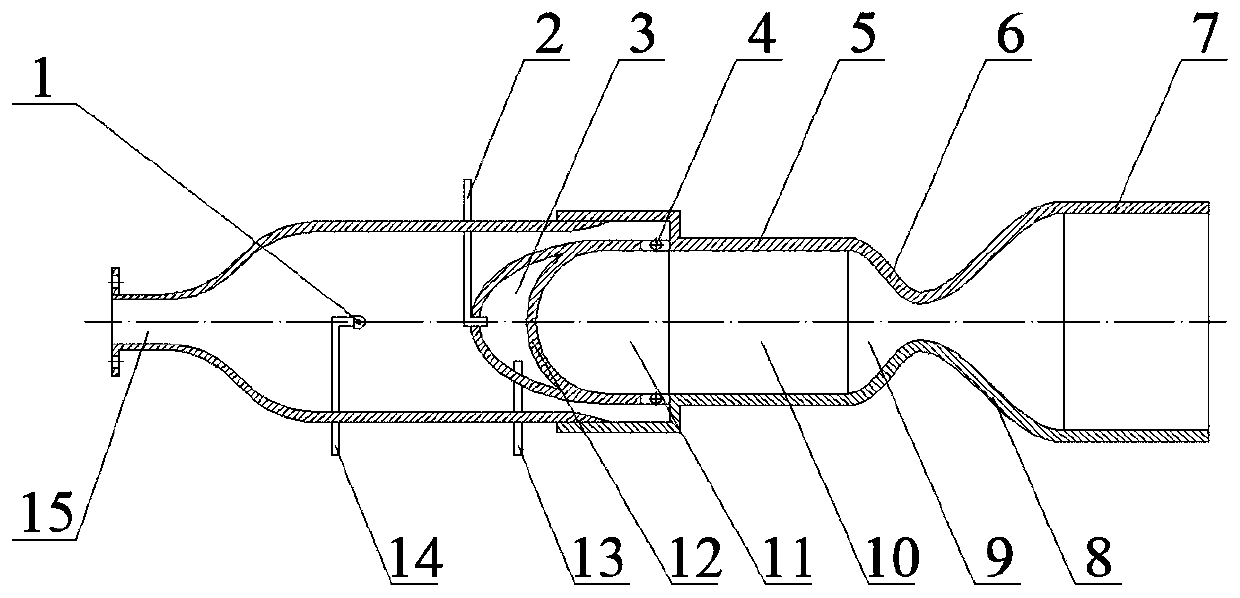

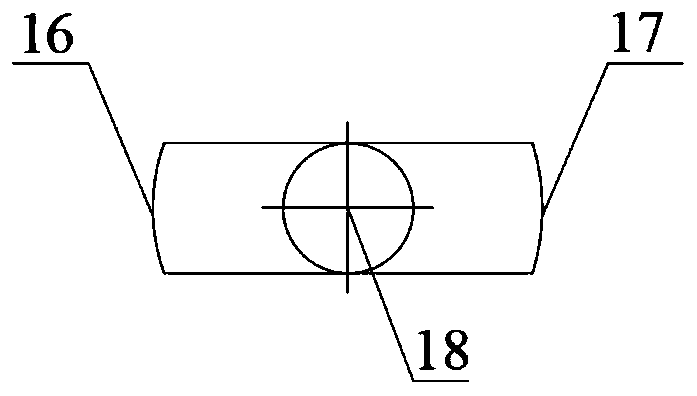

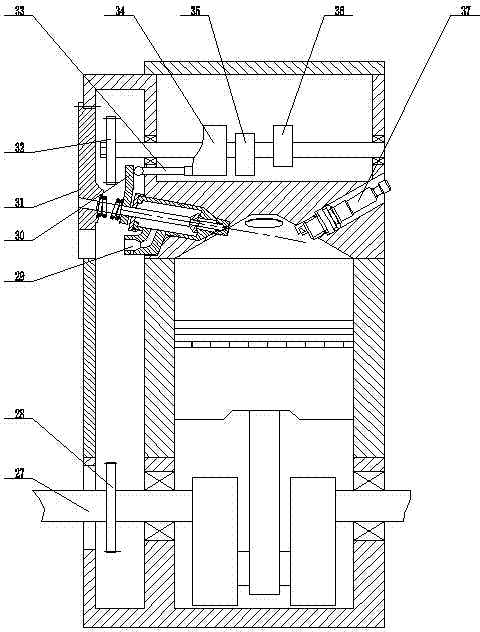

Suction type two-stage shock wave focusing ignition engine combustion chamber and working method thereof

ActiveCN110410231AImprove reliabilityImprove combustion chamber qualityGas turbine plantsIntermittent jet plantsShock waveCombustion chamber

The invention discloses a suction type two-stage shock wave focusing ignition engine combustion chamber and a working method thereof, and belongs to the technical field of detonation engines. The combustion chamber comprises a first cavity body, a first combustion chamber shell, a first shock wave focusing concave surface, two rotating valve flaps, a pre-cooling chamber concave surface, a second shock wave focusing concave surface, a divergent section, a second combustion chamber cavity body, a cold oil pipe, a first heat oil pipe, a second heat pipe and a rotary fuel atomization nozzle. By rotating the rotating valve flaps, intermittent jet flow of air is controlled, so that intermittent shock wave focusing ignition detonating mixed combustible gas in a shock wave focusing chamber is realized, and the reliability of detonation of the engine combustion chamber is further improved through the forward and reverse arranged two-stage shock wave focusing concave cavities. According to the combustion chamber and the working method, the combustion chamber can stably realize high-frequency shock-wave-focused ignition while axially air sucking like a traditional engine, the engine combustion chamber quality is effectively improved, the thrust performance of the engine is improved, and a new technical way is provided for developing a practical high-power detonation engine.

Owner:HUAZHONG UNIV OF SCI & TECH

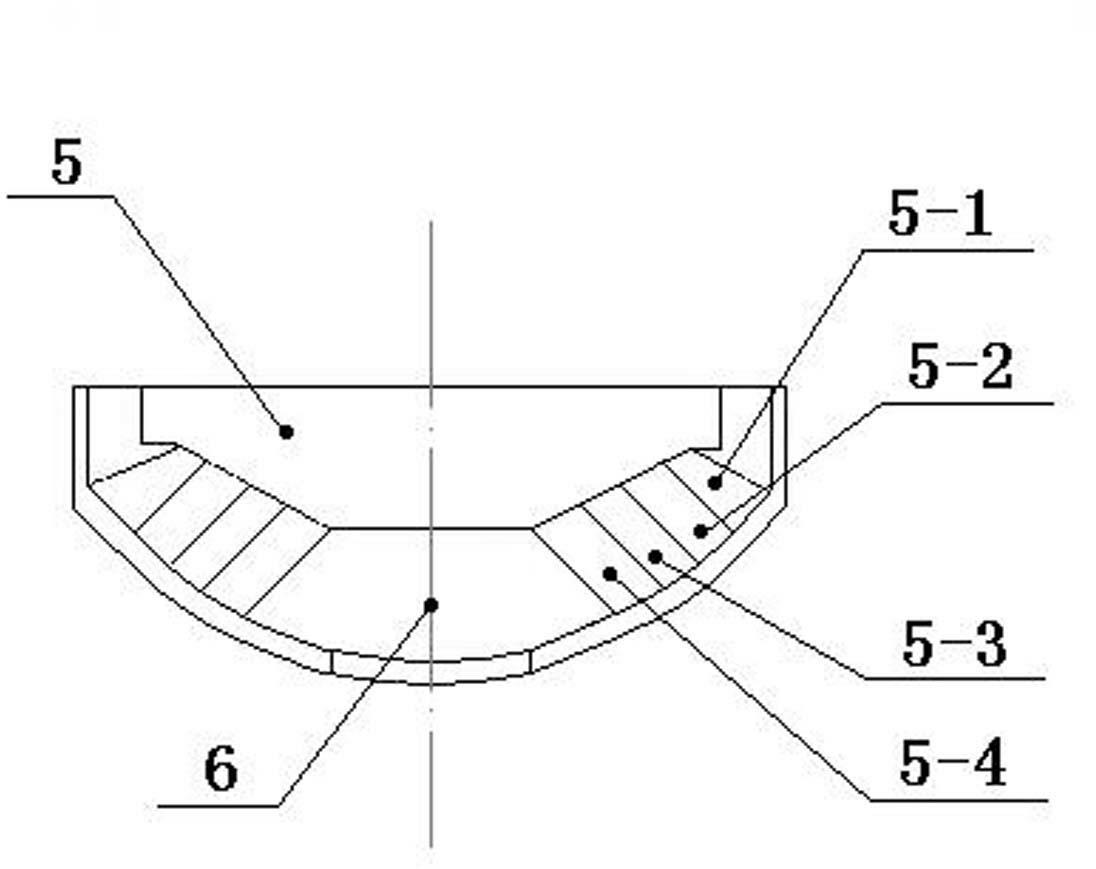

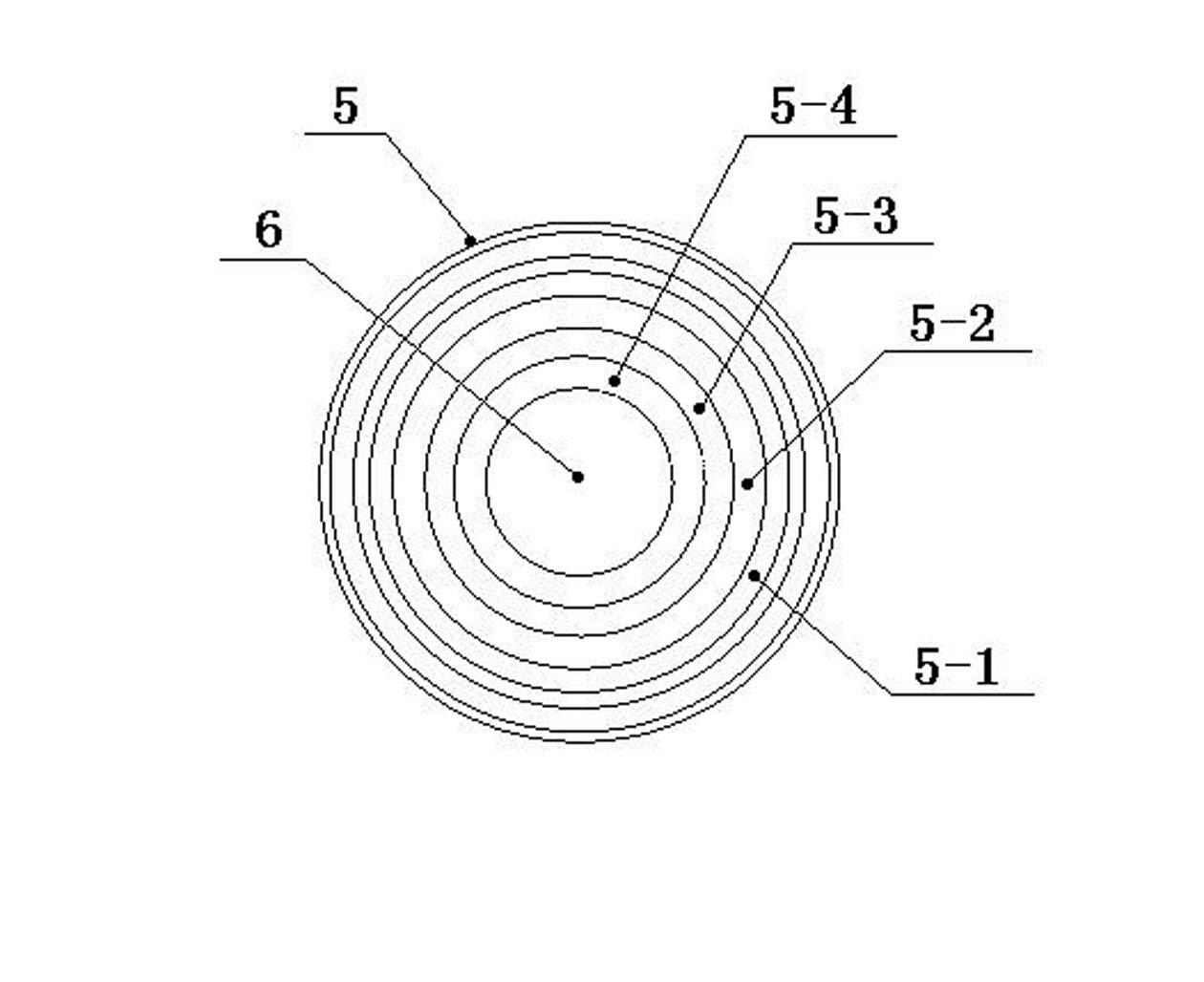

Variable burning rate synergistic perforating charge

The invention discloses a variable-burning rate synergistic perforating propellant which can be used for solving the problems of insufficient ignition, incomplete burning, short acting time and small amount of gas production resulting from the single propellant and unreasonable propellant structure of the conventional composite perforation technology. The variable-burning rate synergistic perforating propellant disclosed by the invention comprises a perforating bullet and a propellant front bin which is mounted at the port of the inner cavity of the perforating bullet, wherein a jet flow channel is arranged in the center of the bottom plate of the propellant front bin; an ignition powder coil, a delay powder coil, a speed-up powder coil and a deflagration powder coil are sequentially arranged from high to low between the circumference and the jet flow channel in the propellant front bin; the four powder coils have the same height at a width ratio of (1-2):(2-4):(2-4):(10-15); and the four powder coils consist of powder of four different formulas and can realize gradual variable-burning rate synergy from the ignition powder coil to the deflagration powder coil. The variable-burning rate synergistic perforating propellant disclosed by the invention has the advantages of simple structure, low ignition power, strong burning resistance and long blast acting time, is convenient to operate, has the reaming pressure increased by 60%, can at least double the synergistic time, and be used for remarkably improving the producing efficiency of an oil gas well.

Owner:ZHONGBEI UNIV

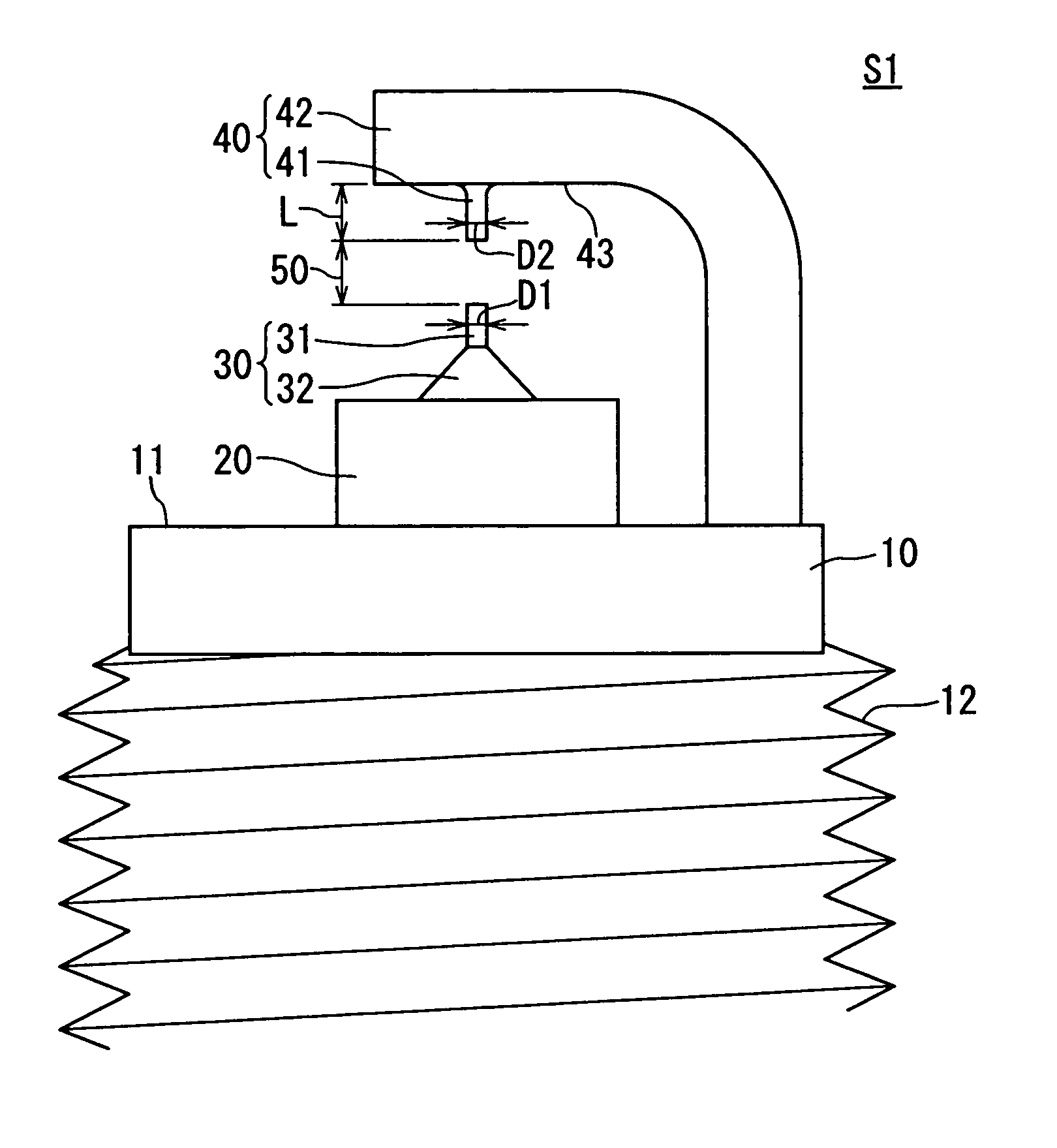

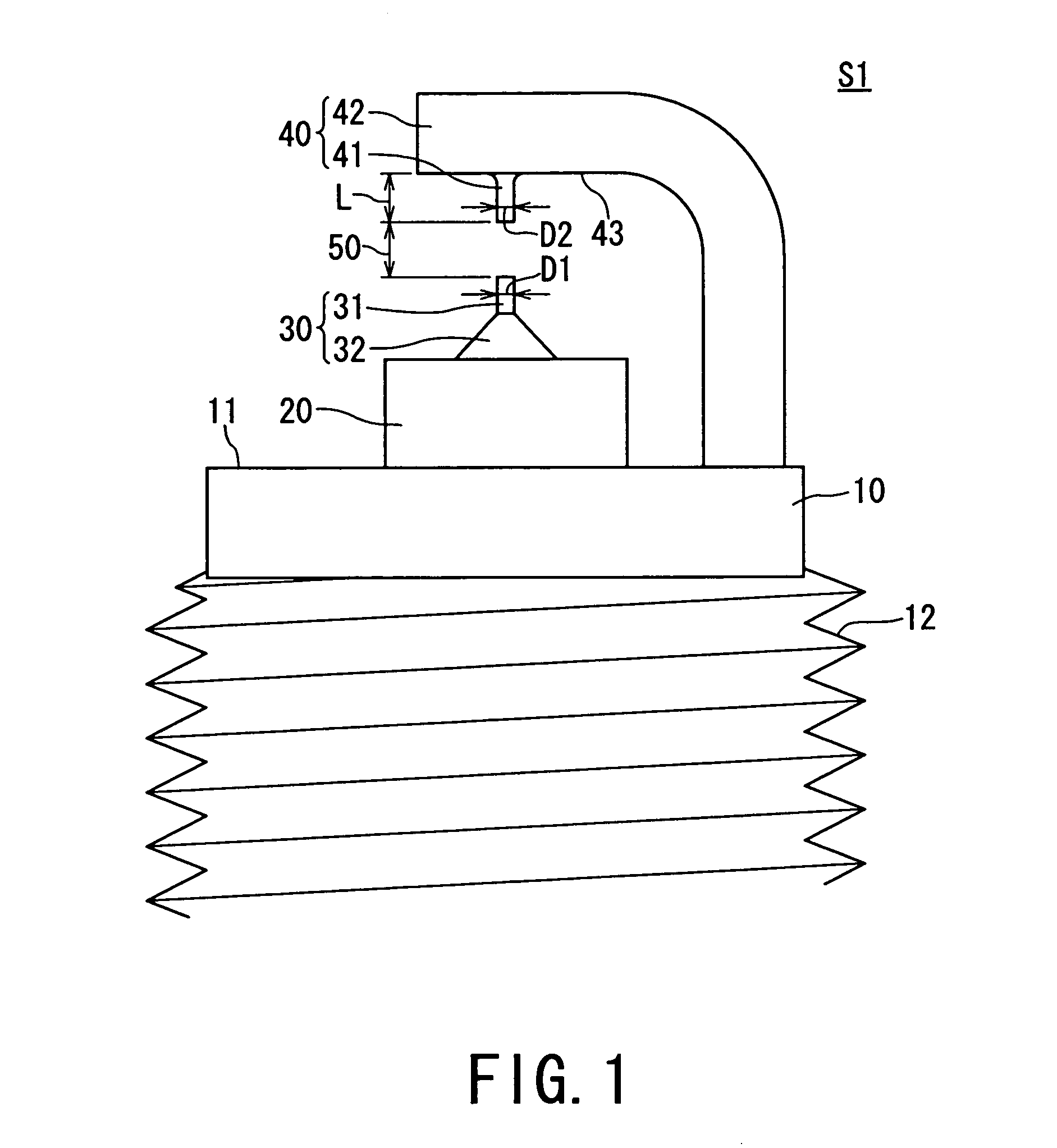

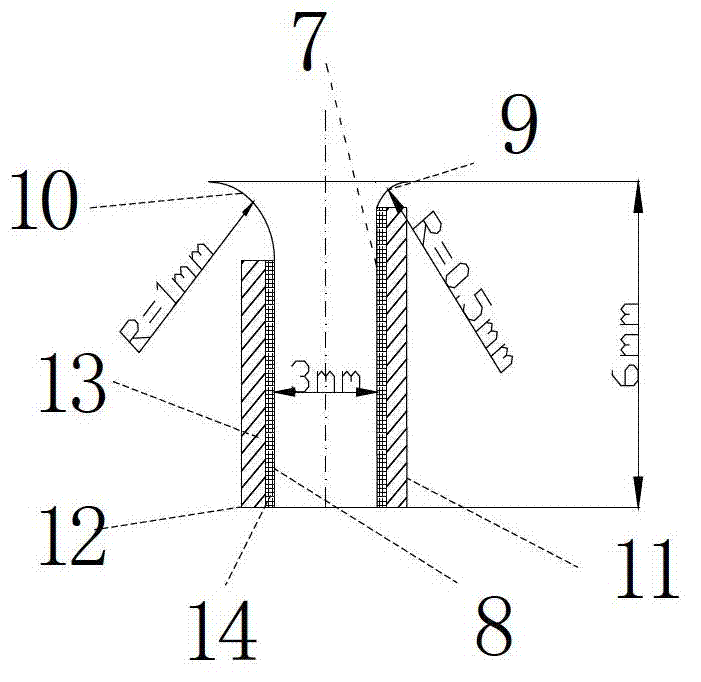

Spark plug and ignition apparatus using same

InactiveUS7086363B2Low ignition energySave energy consumptionSparking plugsGenerator generated ignition energyEngineeringSpark plug

A power-saving type of ignition apparatus is provided with a spark plug of which electrodes (30, 40) are regulated in their shapes to lower an amount of energy required for its ignition. To face to a tip (31) of a center electrode (30) extending from a mounting bracket (10), a cylindrical protrusion (41) is built on one surface (43) of an earth electrode (40). The protrusion extends toward the center electrode to form a discharge gap (50) between the protrusion and the tip of the center electrode. Both of the tip of the center electrode and the protrusion of the earth electrode are 2.3 [mm] or less in each diameter (D1, D2), thus an amount of energy required for ignition being limited to 17 [mJ] or less.

Owner:DENSO CORP +1

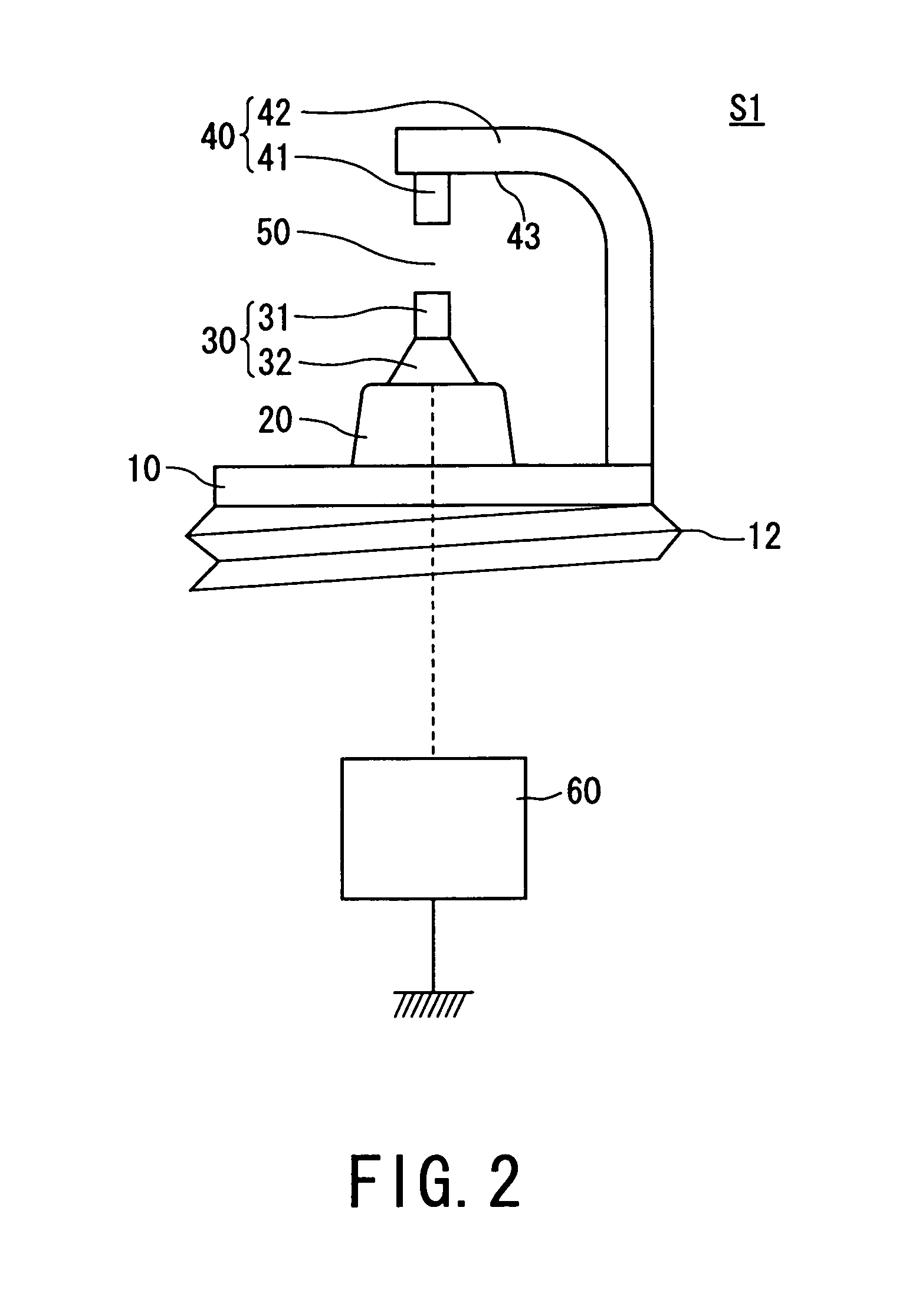

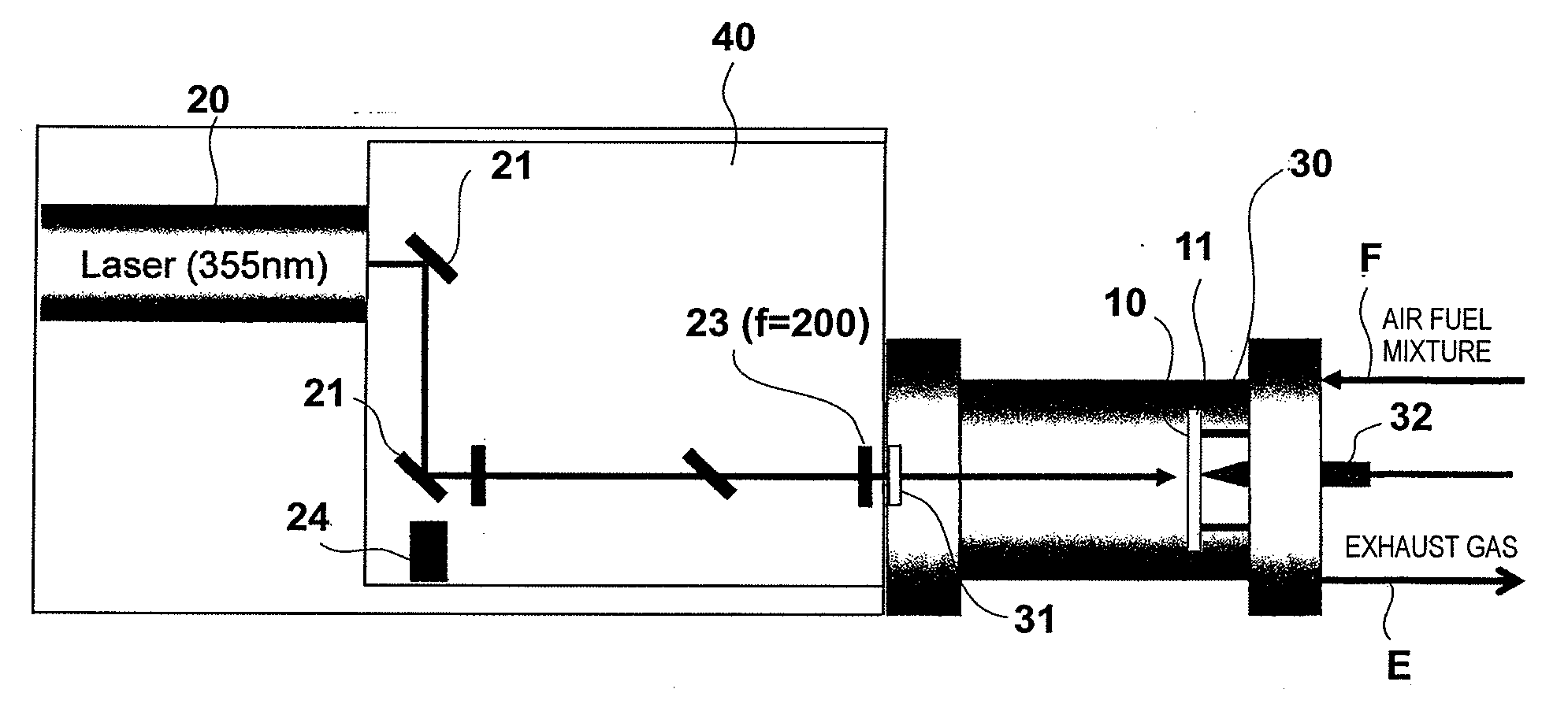

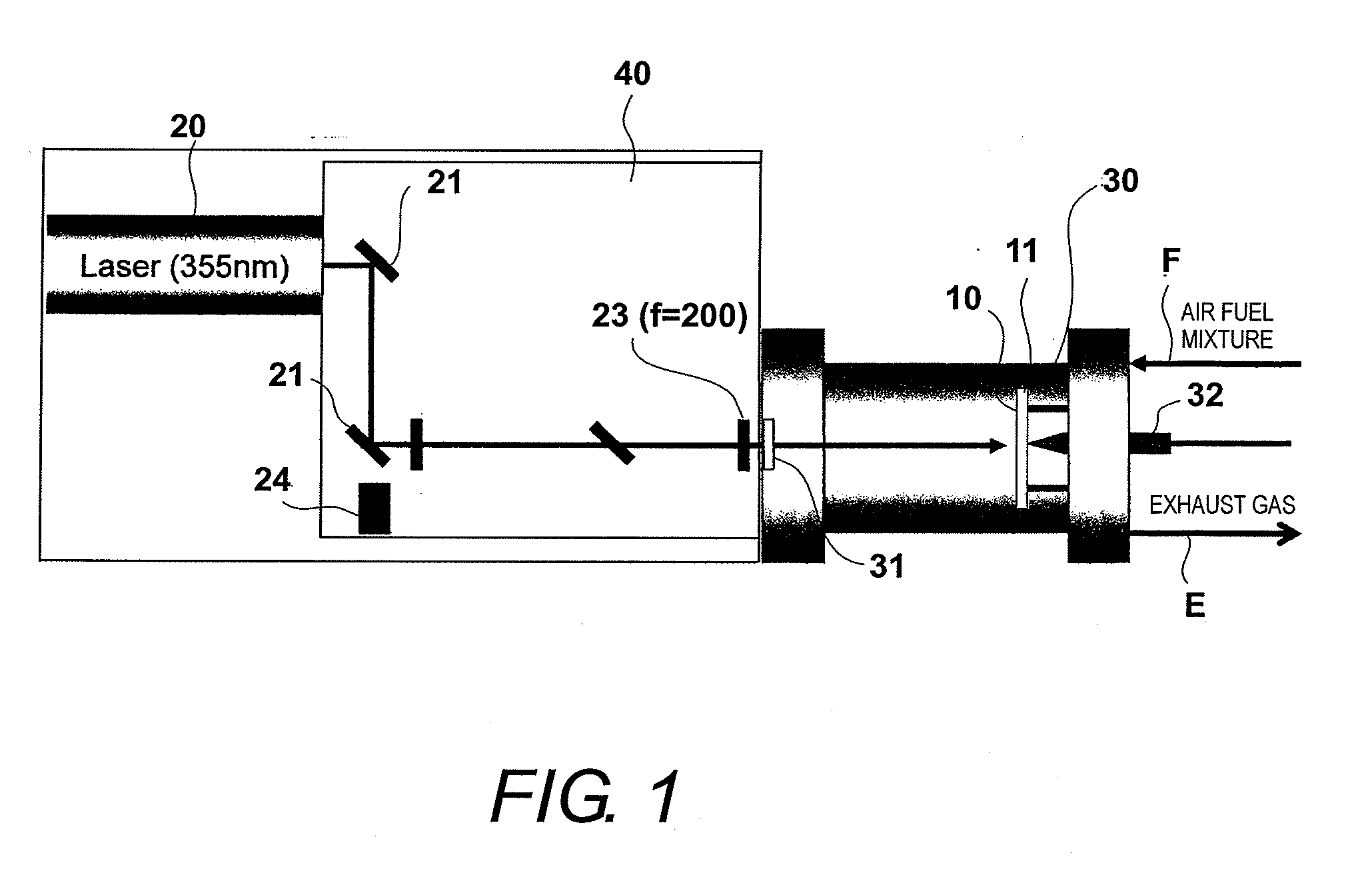

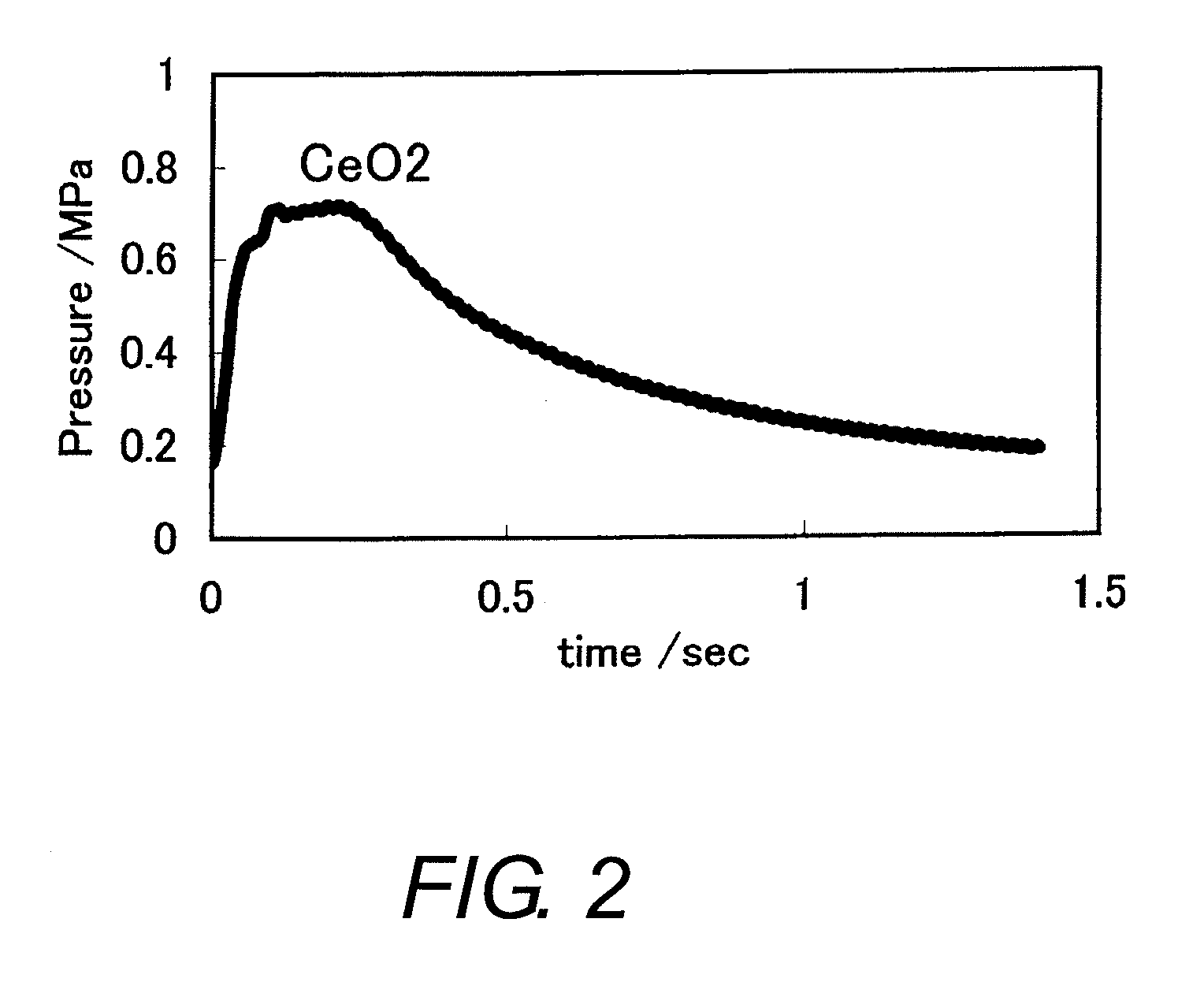

Photocatalytic ignition system

InactiveUS20090035711A1Minimum ignition energyLow ignition energyCatalytic ignitersMachines/enginesLight energyEngineering

A photocatalytic ignition system is provided that basically comprises an ignition chamber, a photocatalyst and a light source. The ignition chamber is configured to receive an air fuel mixture. The photocatalyst is arranged in the ignition chamber to contact an air fuel mixture. The light source is arranged to shine light on the photocatalyst. The photocatalyst includes a photocatalytic material having an oxygen absorbing and a desorbing function. The photocatalytic ignition system is capable of igniting a lean air fuel mixture with a greatly reduced amount of light energy.

Owner:NISSAN MOTOR CO LTD

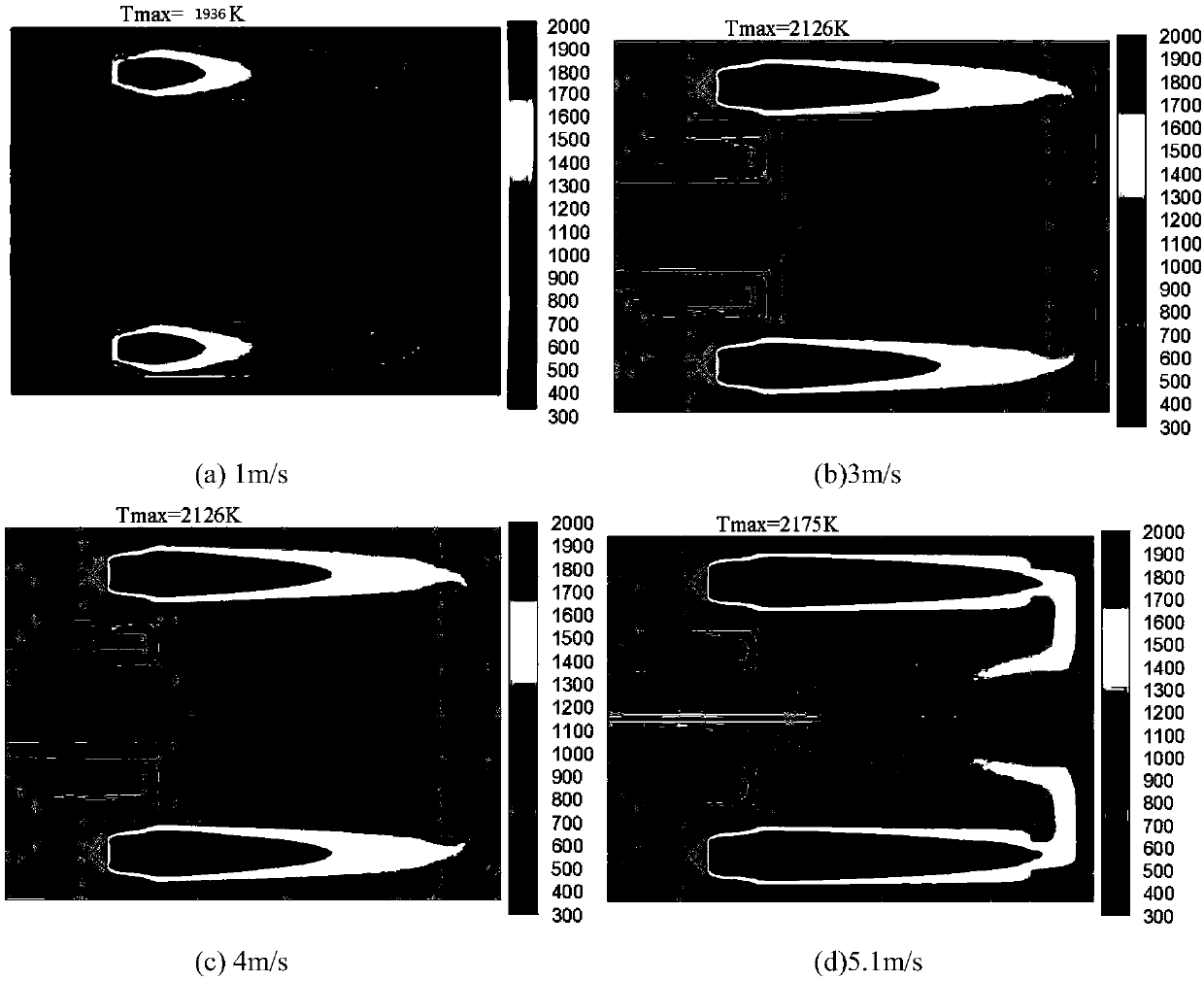

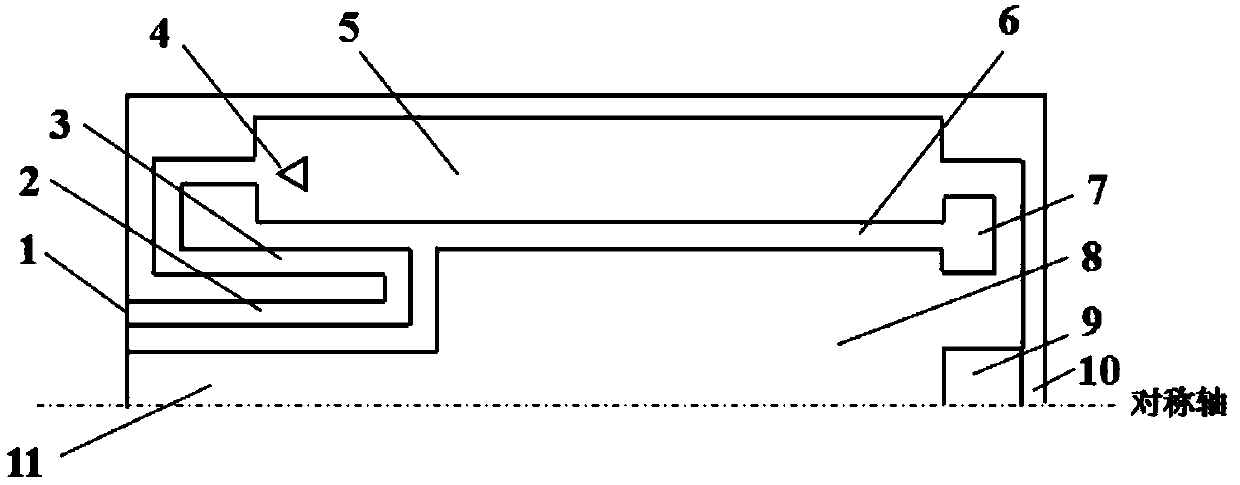

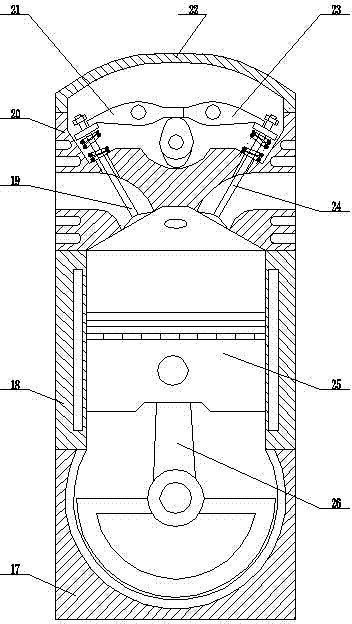

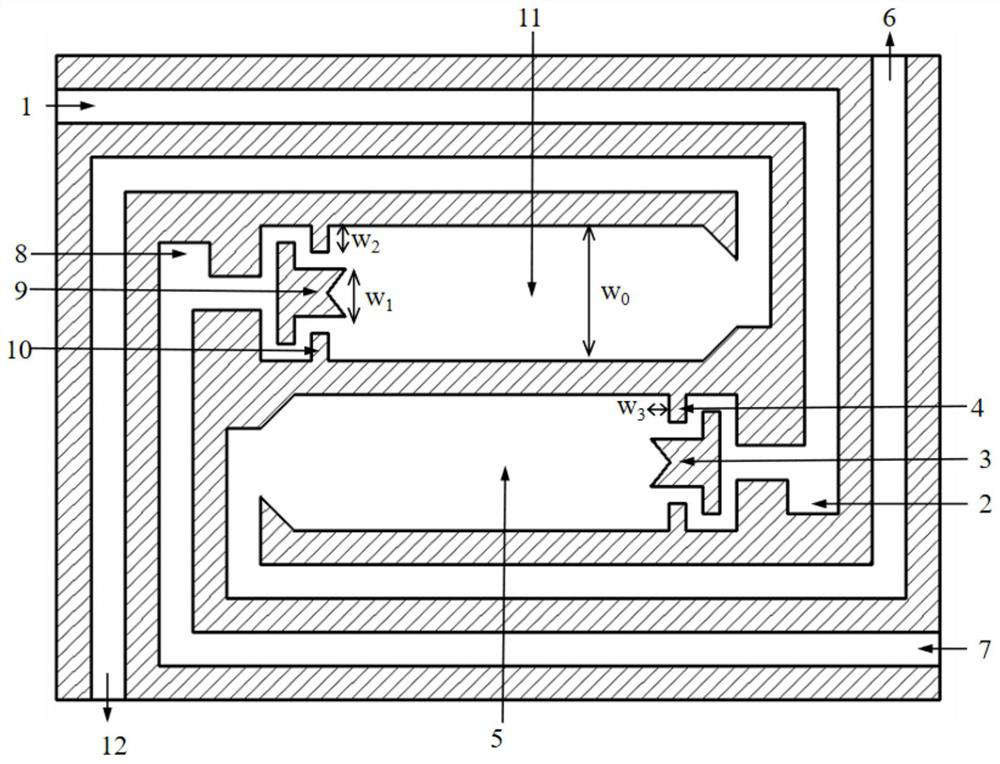

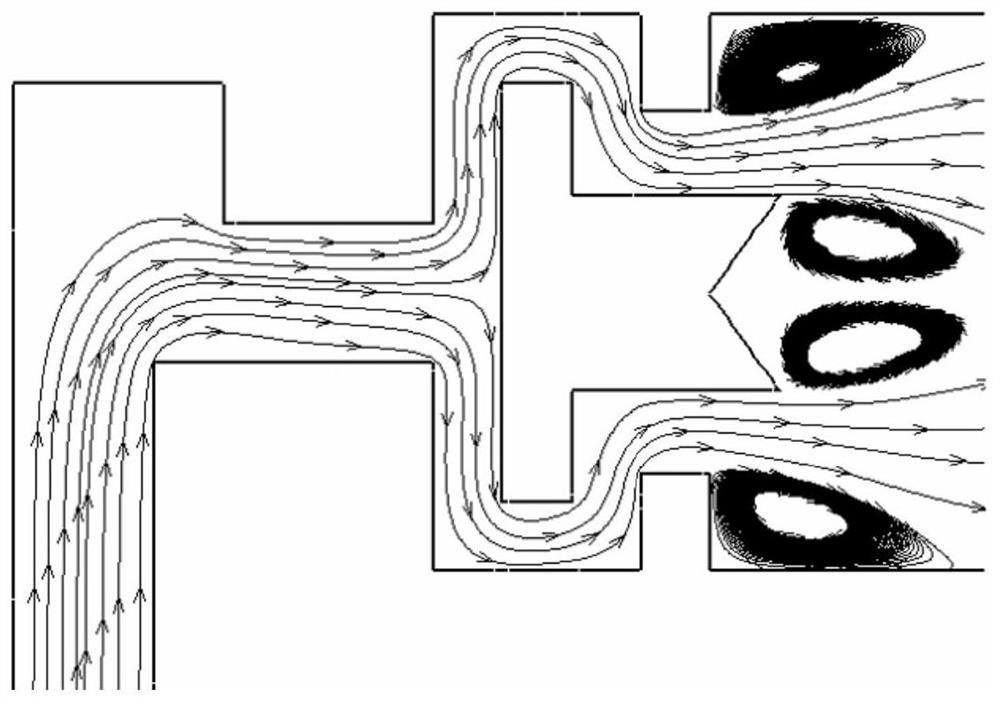

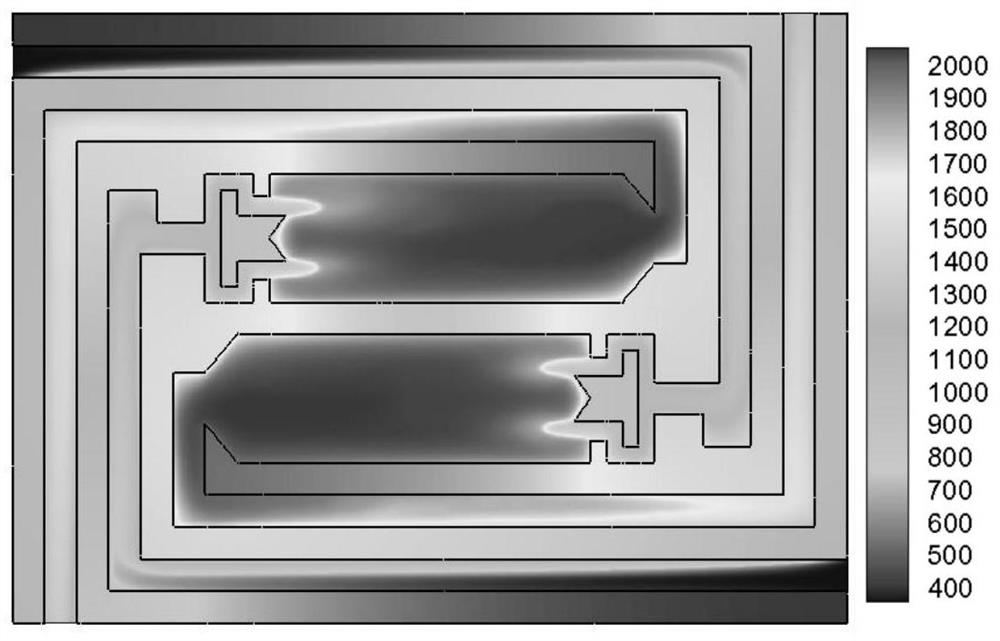

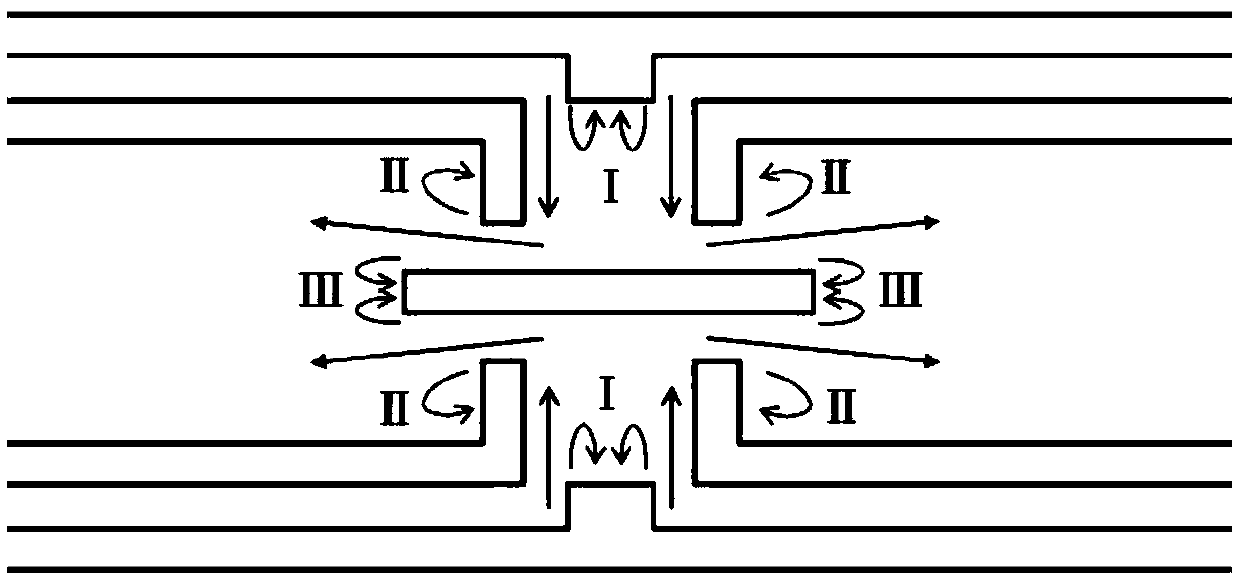

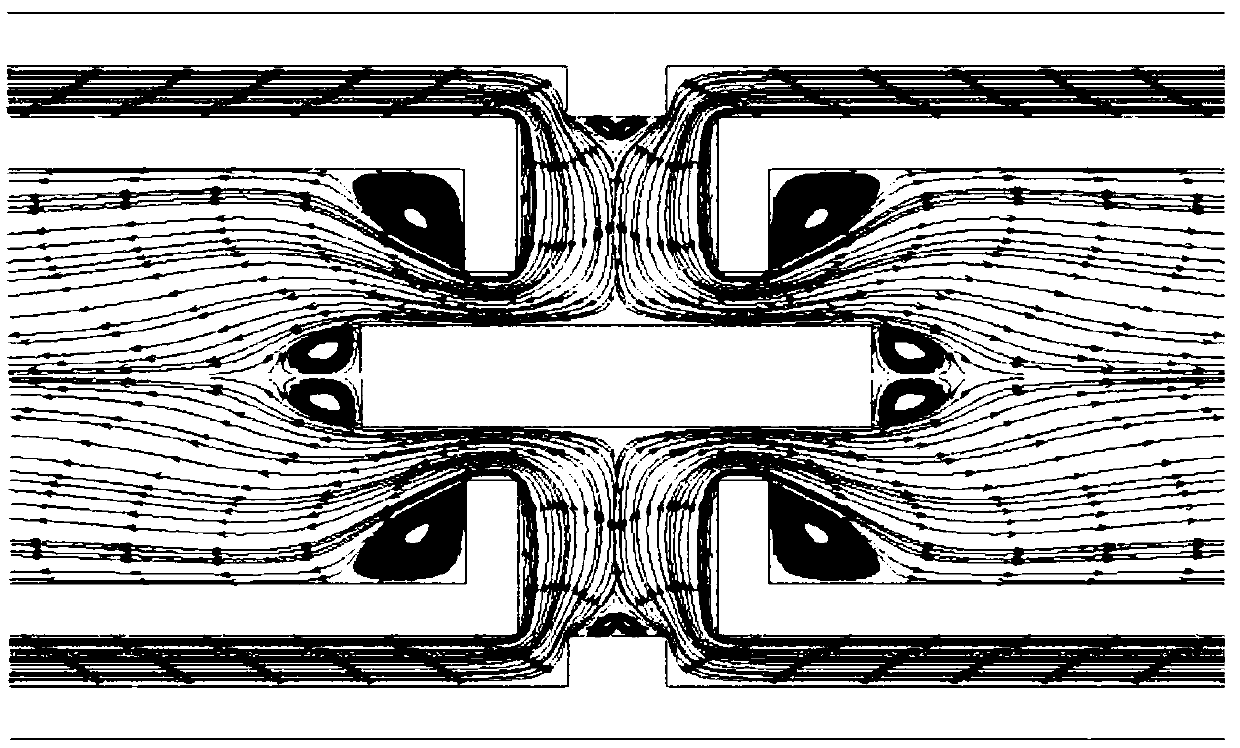

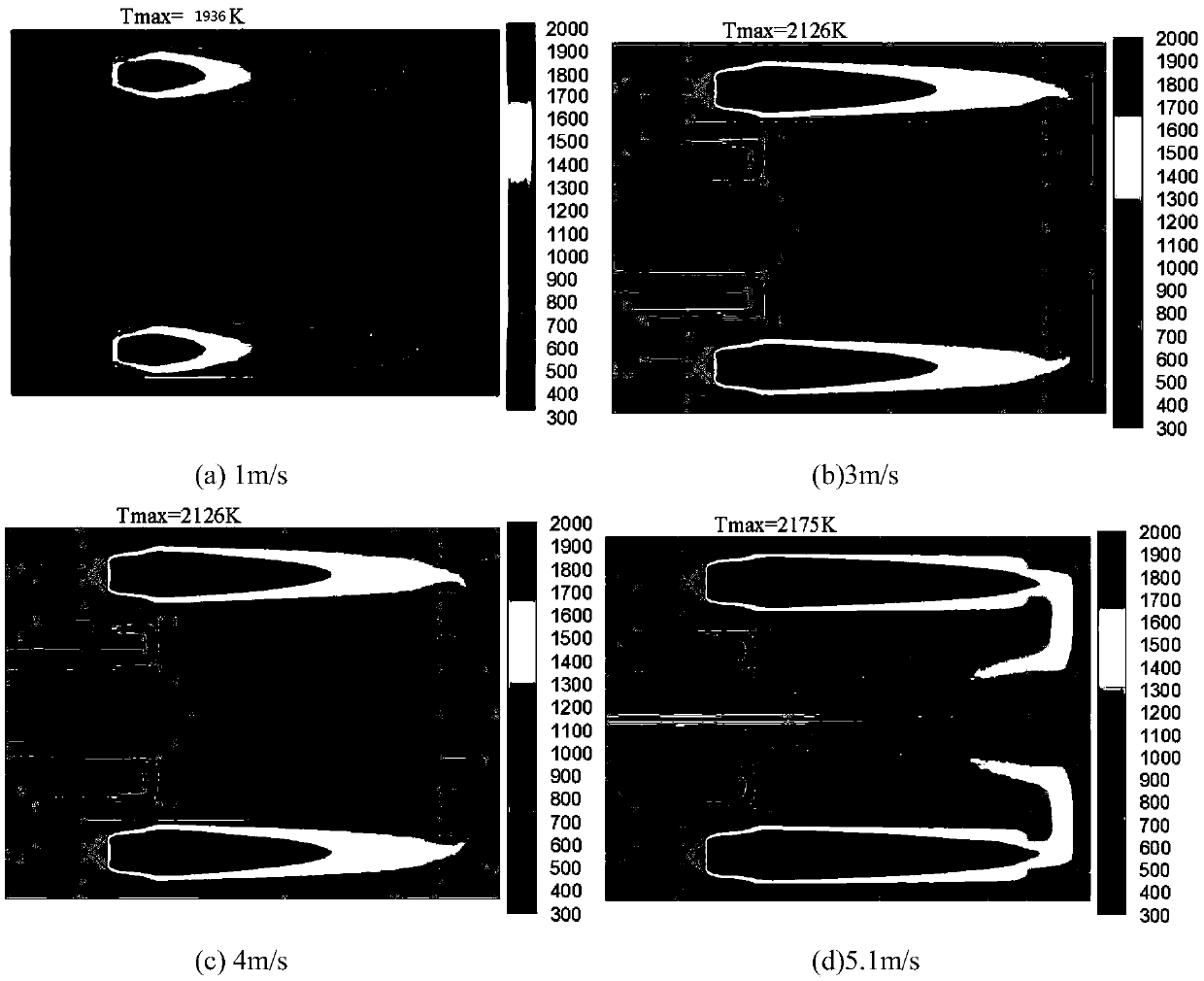

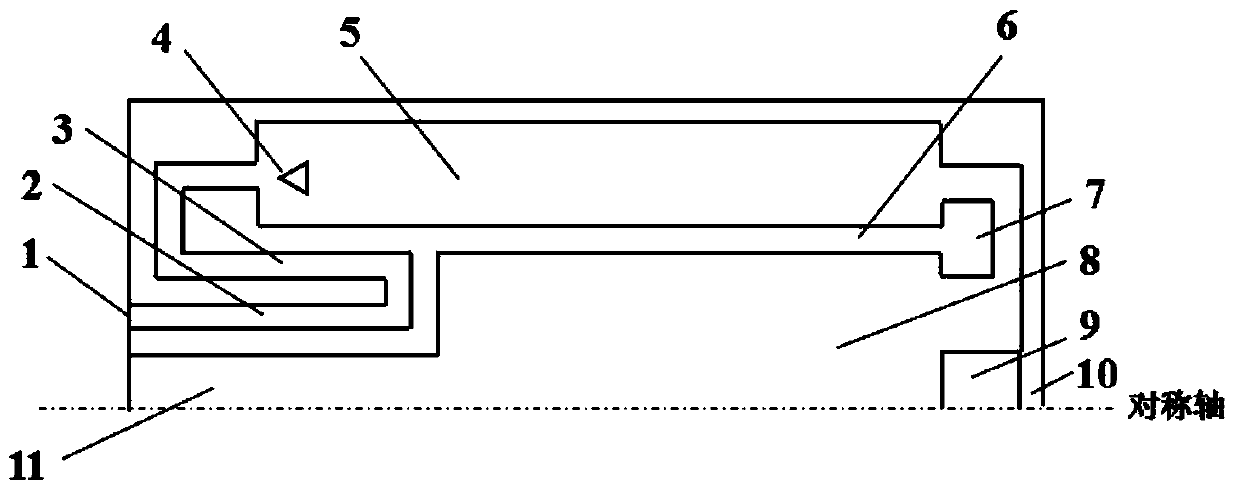

Micro-combustor for enhancing flame stability through gas preheating

The invention discloses a micro-combustor for enhancing flame stability through gas preheating. The micro-combustor comprises two primary combustion chambers and a secondary combustion chamber arranged between the two primary combustion chambers, and a gas inlet channel is further arranged between each of the two primary combustion chambers and the secondary combustion chamber; gas enters the gasinlet channels, and then enters the primary combustion chambers after being preheated sequentially by tail gas and main combustion gas; primary flame stabilizing blunt bodies are arranged at the parts, communicating with the gas inlet channels, of the primary combustion chambers; and high-temperature tail gas generated by combustion in the primary combustion chambers enters the secondary combustion chamber, a secondary flame stabilizing blunt body is arranged at the part, communicating with the two primary combustion chambers, of the secondary combustion chamber, and the high-temperature tailgas generated by continuous combustion in the secondary combustion chamber is discharged as a heat source. According to the micro-combustor, combusting preheating is carried out so that the energy needed by ignition can be reduced, the ignition delay time can be shortened and the exhaust heat loss can be reduced; and meanwhile, the two stages of combustion chambers are arranged so that the ignition quenching limit can be improved, and the inlet speed can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

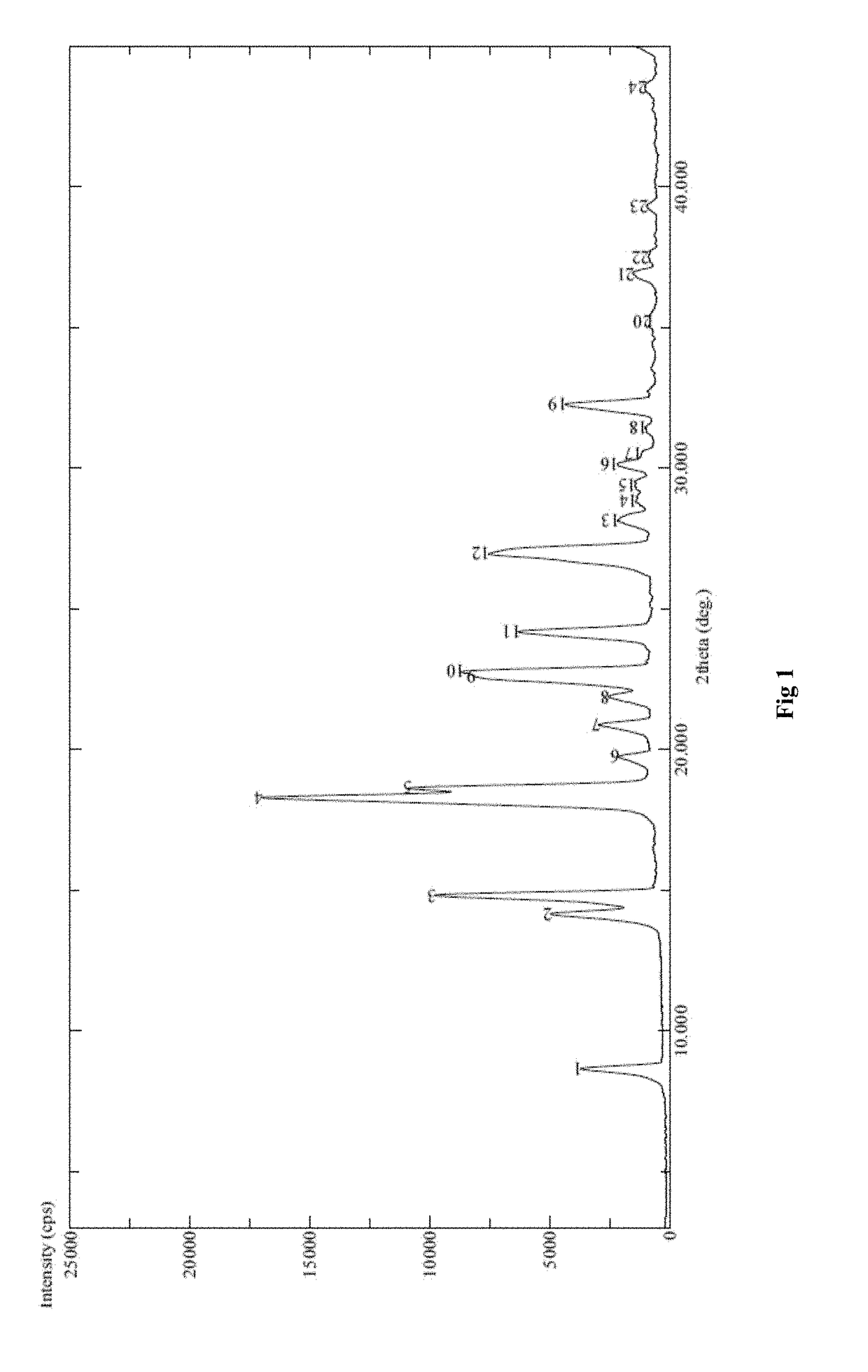

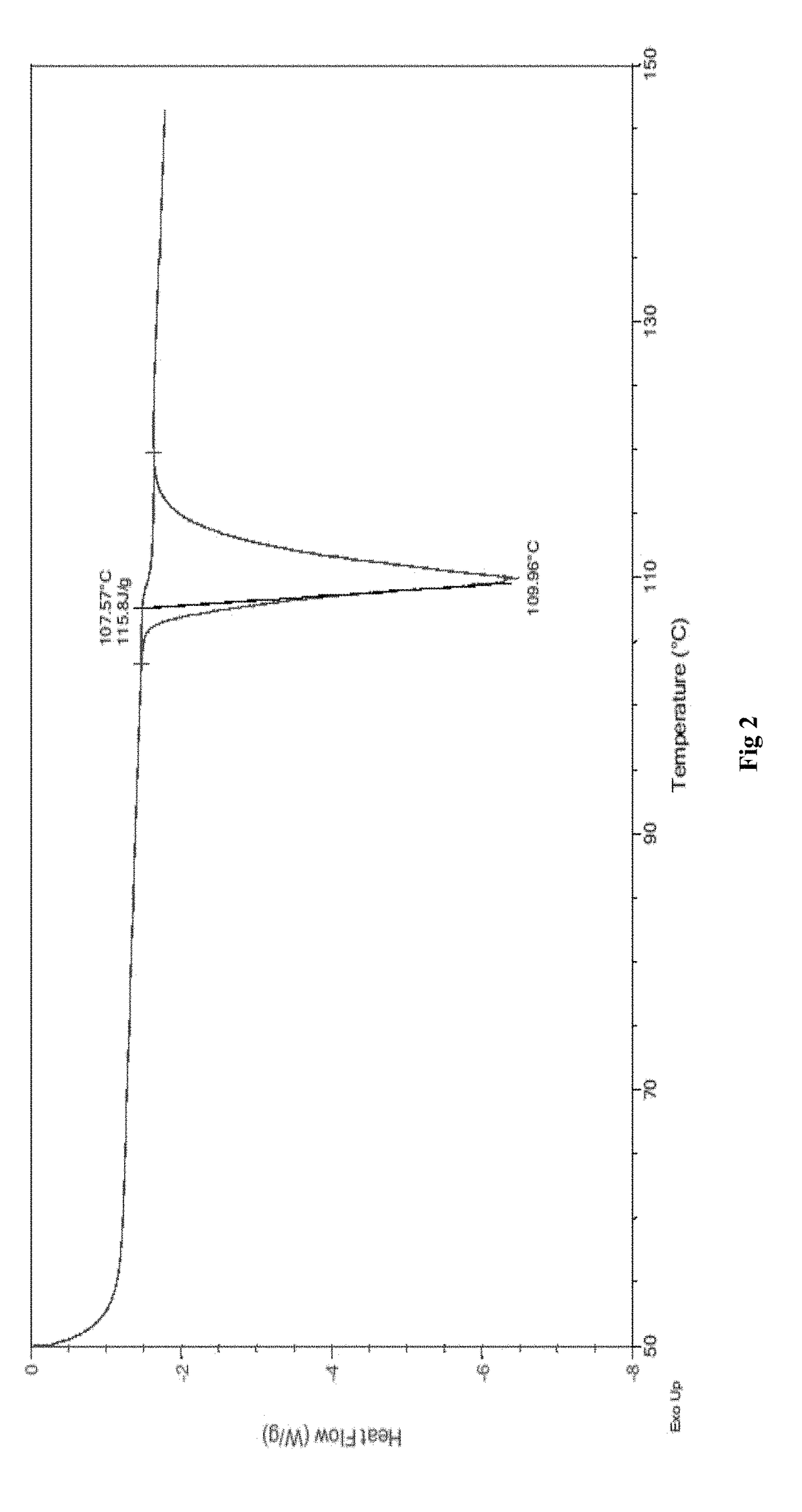

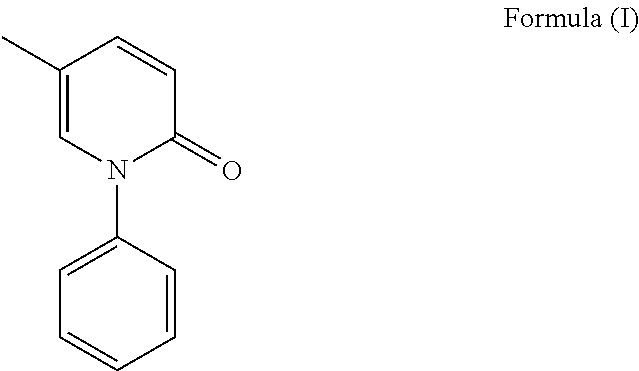

Process for the preparation and particle size reduction of pirfenidone

The present invention relates to an improved process for the preparation of pure pirfenidone having a particular particle size distribution, a crystalline form of pirfenidone, and pharmaceutical compositions thereof, as well as methods for particle size reduction of pirfenidone, and methods for particle size reduction of pirfenidone by wet milling techniques using colloid mill, ultrasonicator, or high speed homogenizer devices.

Owner:LAURUS LABS

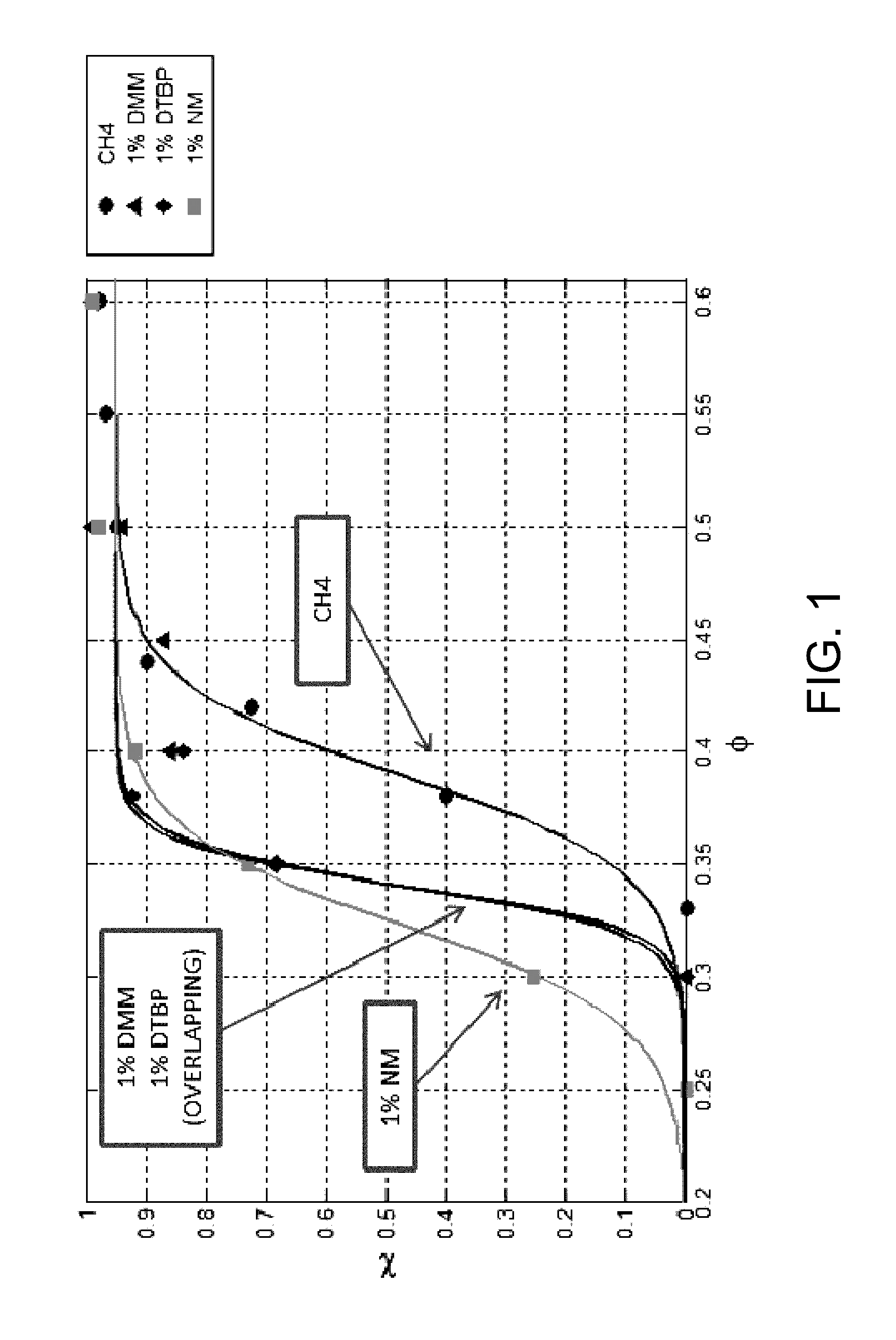

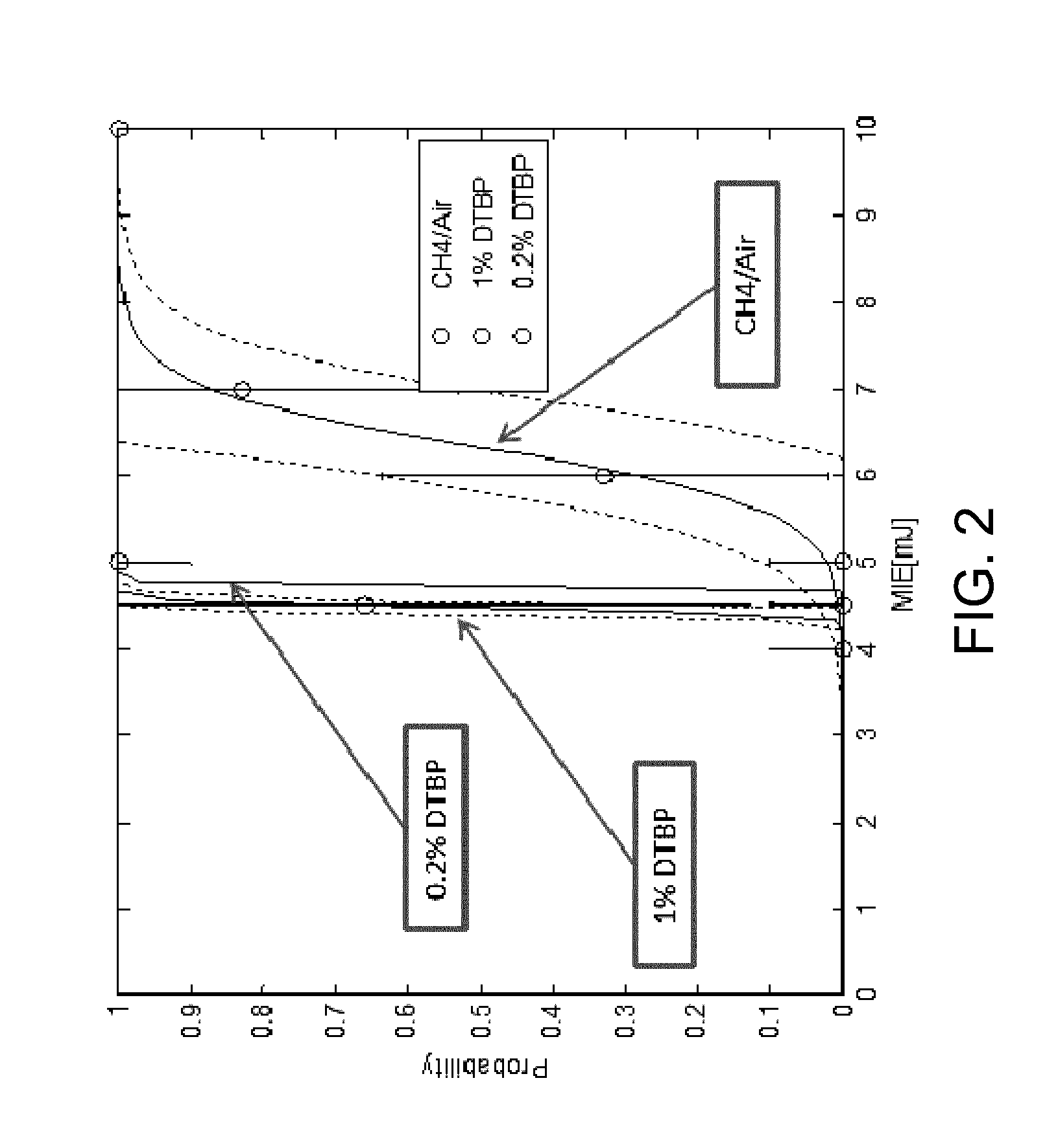

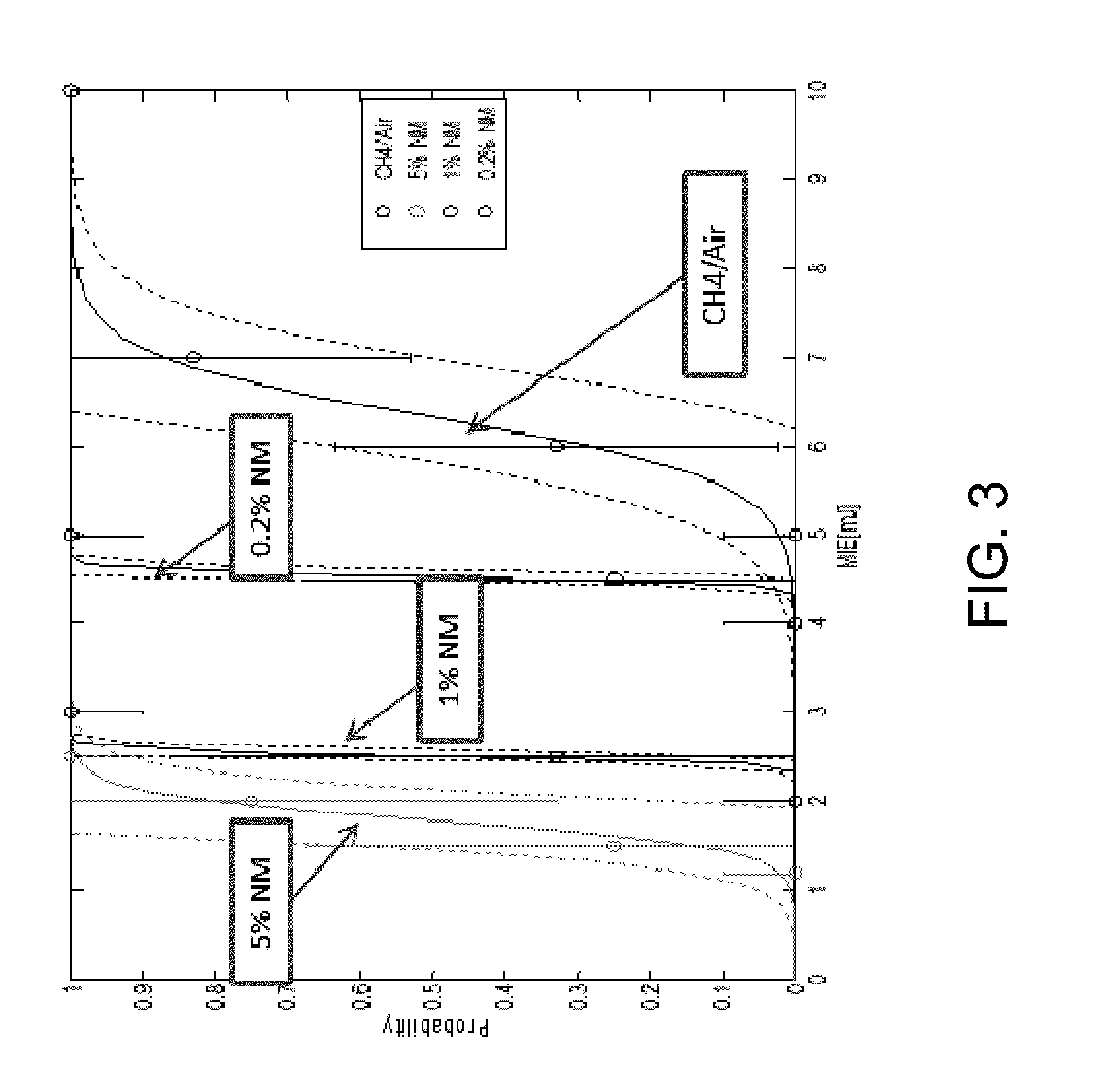

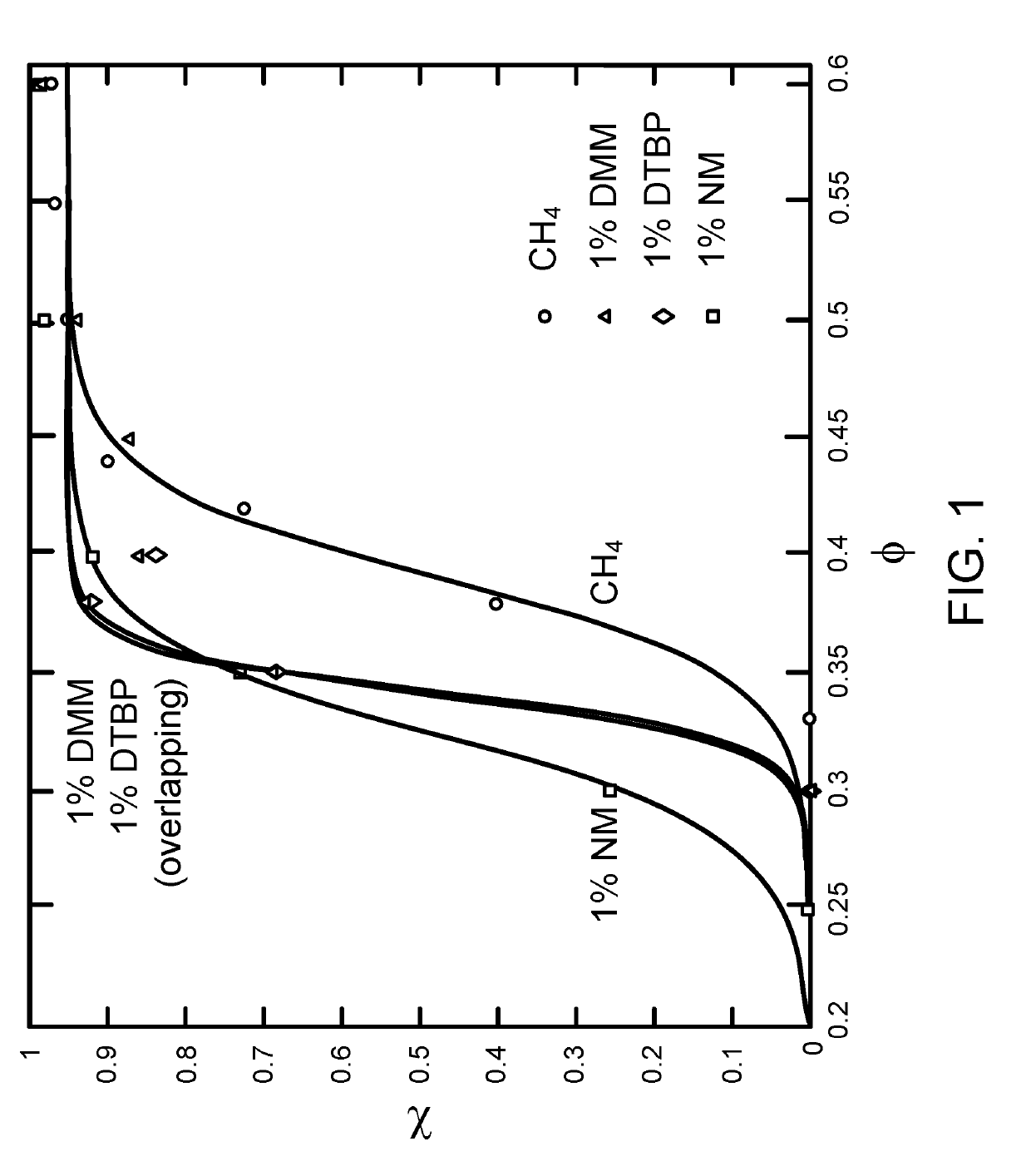

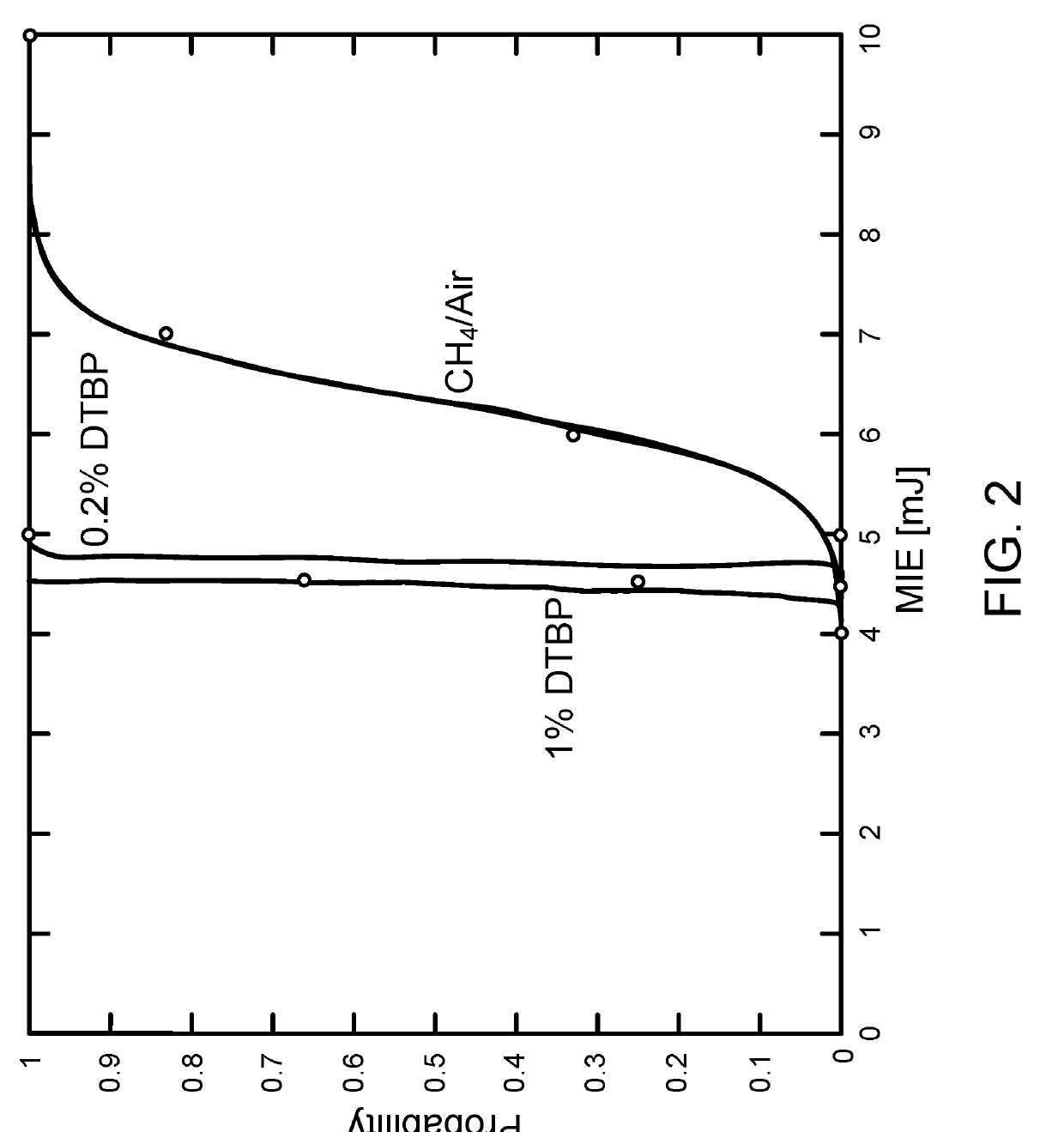

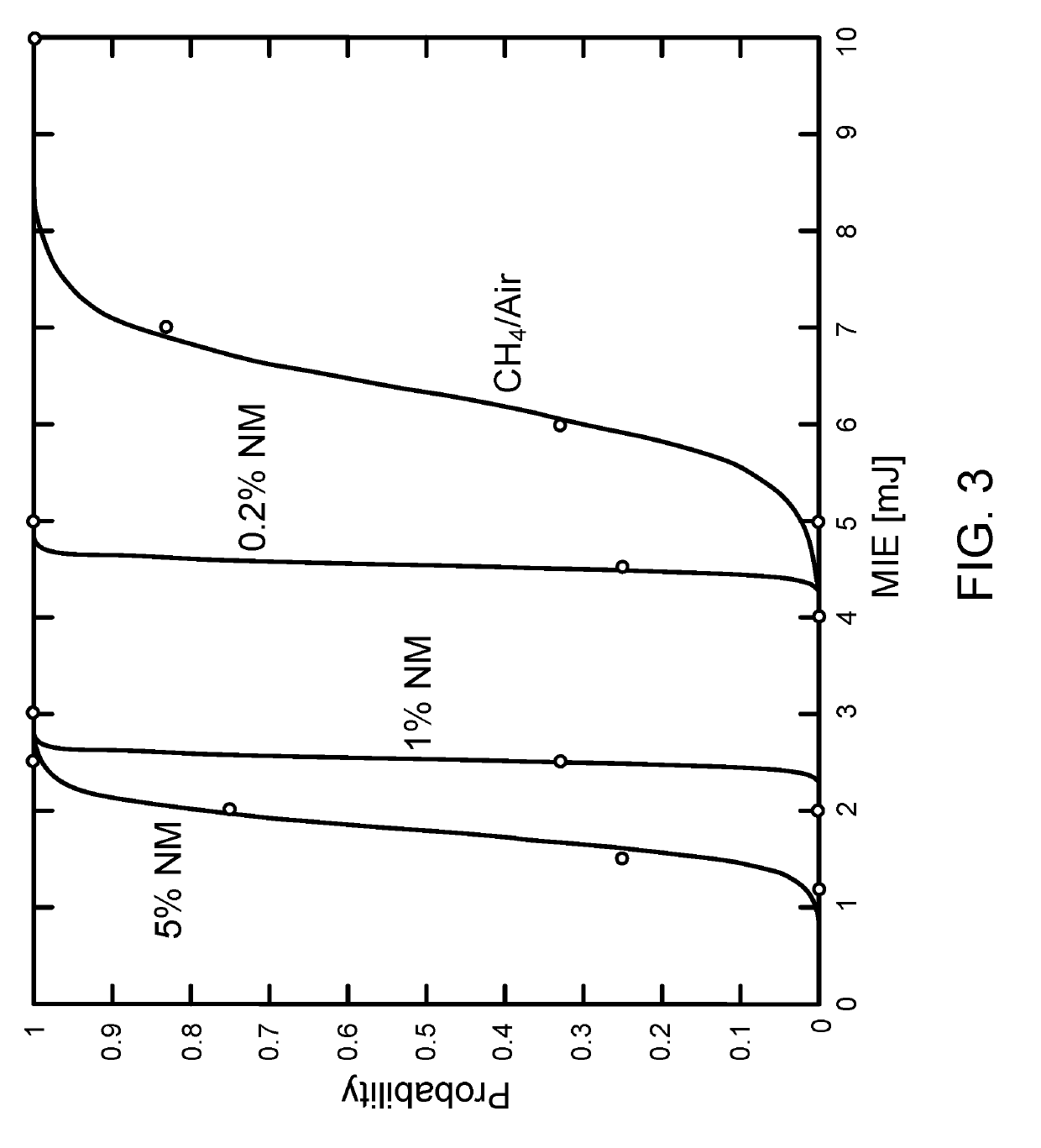

Fuel modifiers for natural gas reciprocating engines

InactiveUS20170009166A1Low ignition energyReduction tendencyGaseous fuelsFuel additivesEngineeringRadical initiator

Described herein are fuel modifiers for natural gas reciprocating engines, while recognizing the application of the inventions herein may be applied more broadly, to other natural gas-based engine systems. The fuel modifiers are primarily free-radical initiators, and the presence of this fuel modifier allows the engine operator to operate the engine under leaner conditions because, while employing the same ignition energy, more free-radicals are formed, thus overcoming the problems associated with dilution of the pool of free-radicals in the flame.

Owner:CHEVROU USA INC

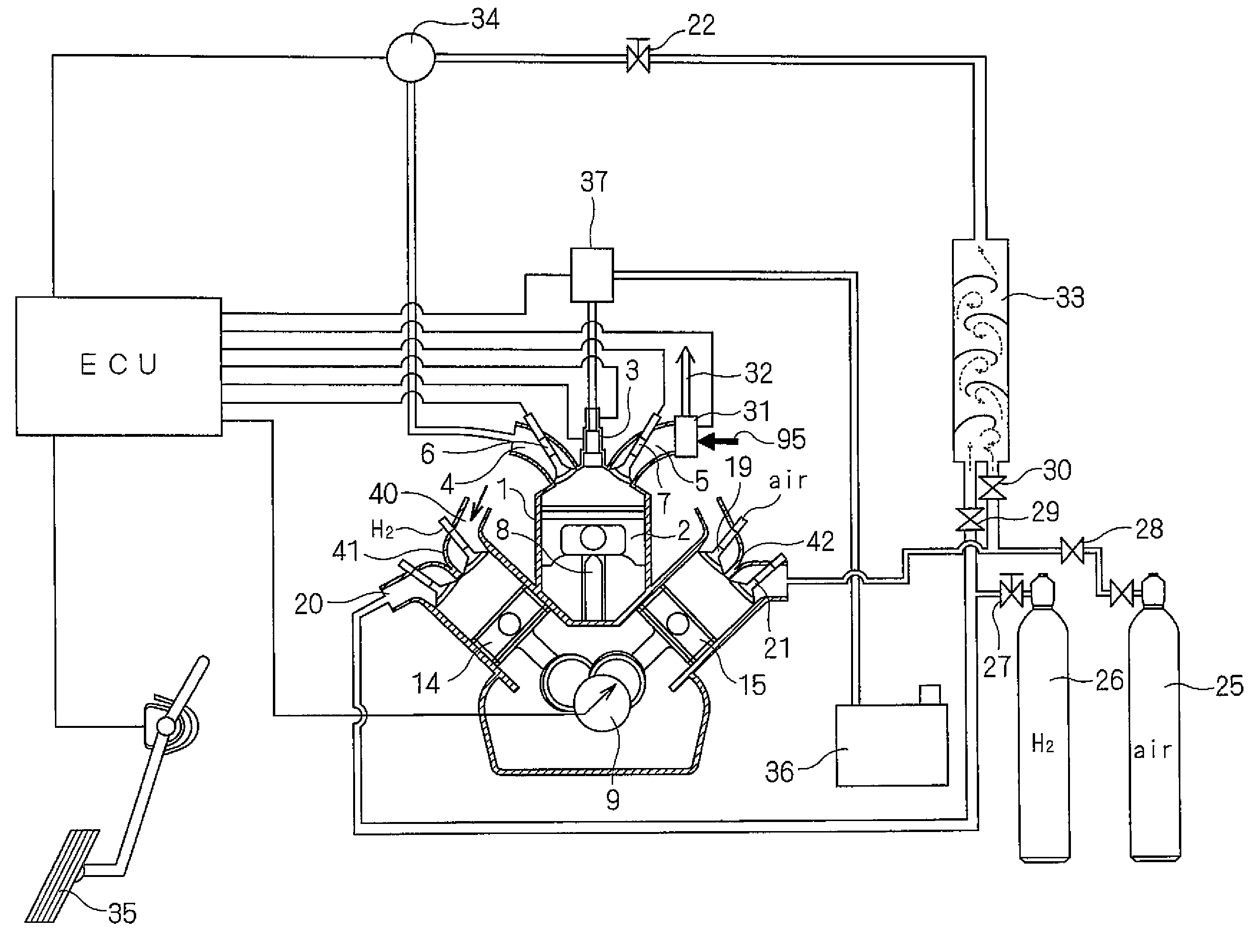

Plasma system of natural gas engine

InactiveCN106050485AShorten ignition delayImprove the problem of decreased combustion stabilityExhaust apparatusExhaust gas recirculationFlame propagationControl manner

The invention discloses a plasma system of a natural gas engine. The plasma system of the natural gas engine comprises a gas inlet pipe, an exhaust pipe, an EGR pipe, a plasma generator and a catalyst. One end of the EGR pipe communicates with the exhaust pipe, and the other end of the EGR pipe communicates with the gas inlet pipe. The EGR pipe is provided with an EGR adjusting valve connected with an ECU in a controlled manner. The plasma generator is arranged on the exhaust pipe and located on the upstream side of the communication position between the EGR pipe and the exhaust pipe. The catalyst is arranged on the exhaust pipe and located on the downstream side of the communication position between the EGR pipe and the exhaust pipe. The plasma system of the natural gas engine can shorten the ignition delay time of the engine, increase the flame propagation velocity in a cylinder and widen the knock border, so that the combustion efficiency is improved, and HC discharge is lowered. Meanwhile, the ignition energy of an ignition system can also be lowered, and the reliability of the ignition system is improved. Besides, the plasma system of the natural gas engine can improve the conversion efficiency of the three pollutants of CH4, NOx and CO.

Owner:GUANGXI YUCHAI MASCH CO LTD

Oxygen-enriched combustion engine system

InactiveCN104847541AIncrease contentIncrease concentrationInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberEngineering

The invention discloses an oxygen-enriched combustion engine system and belongs to the field of energy conservation and emission reduction of engines. The system comprises an oxygen supply device, an oxygen nozzle, a cylinder head, a distribution machine and a chain wheel cover, wherein high-concentration oxygen is directly jetted into an engine combustor through the oxygen nozzle, the cylinder head contains the oxygen nozzle, and the distribution machine controls timing work of the oxygen nozzle; the oxygen supply device is driven by an engine crankshaft through a belt wheel mechanism and controlled by an electromagnetic valve to be reversed, a first adsorption tower and a second adsorption tower work alternately, and therefore low-pressure oxygen is generated continuously; the oxygen is cached in an air storage tank, pressurized through a booster pump to reach the pressure higher than the maximum pressure in an engine cylinder, and finally jetted into the combustor through the oxygen nozzle; the distribution machine controls intake and exhaust distribution of the engine and also controls timing opening and closing of the oxygen nozzle through a cylindrical cam mechanism. The oxygen-enriched combustion engine system is low in cost, and can greatly improve engine power, reduce fuel consumption, reduce emission of a part of harmful gas of the engine, improve coldstart performance of the engine and increase the response speed of the engine.

Owner:TAIYUAN UNIV OF TECH

Fuel modifiers for natural gas reciprocating engines

InactiveUS20190100708A1Low ignition energyReduction tendencyGaseous fuelsFuel additivesEngineeringReciprocating engine

Owner:CHEVROU USA INC

A dimethyl ether compression ignition rotary engine and its control method

ActiveCN110486151BOvercome the disadvantage that the flame is difficult to reach the rear of the combustion chamberImprove combustion efficiencyElectrical controlInternal combustion piston enginesPressure riseCombustion chamber

Owner:BEIJING UNIV OF TECH

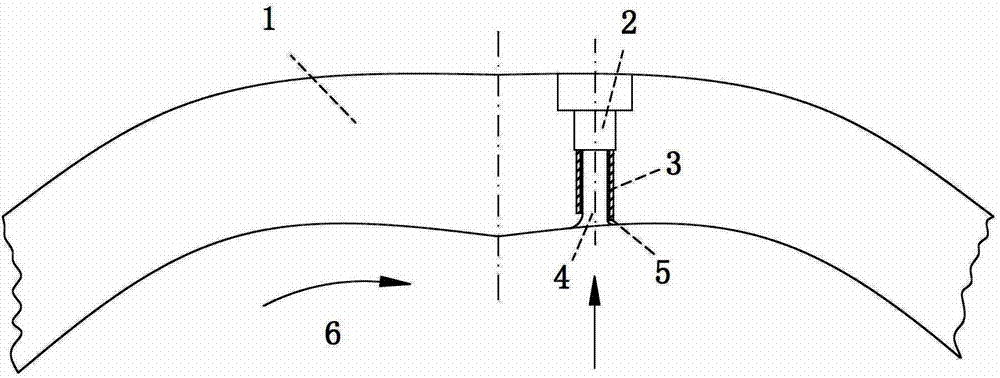

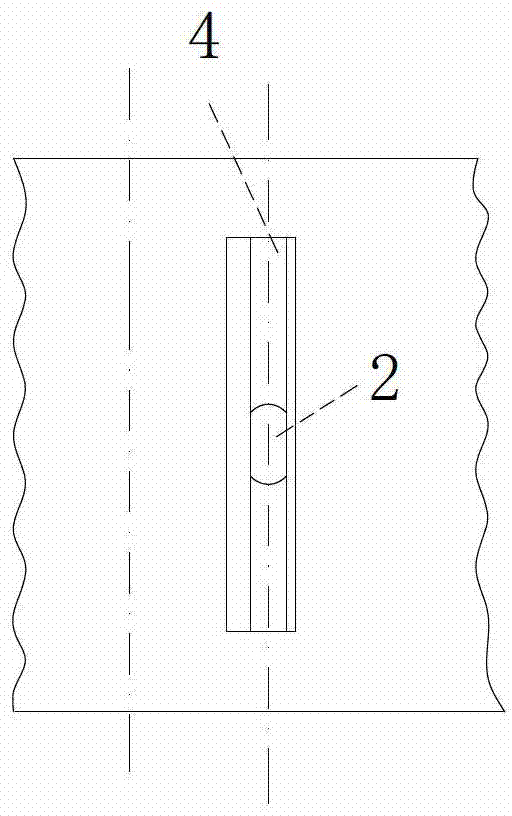

Ignition groove of natural gas rotary engine

InactiveCN103089416AImprove stabilityIncrease success rateInternal combustion piston enginesCombustionCylinder mold

An ignition groove of a natural gas rotary engine comprises a front wall face, a back wall face and a groove channel which is arranged between the front wall face and the back wall face. The front wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet, and the back wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet. The front wall face and the back wall face extend parallelly from the bottom to an air cylinder molded surface, and respectively extend from the position close to the air cylinder molded surface to form arc-shaped wall faces. The radius of an arc on one side of the front wall face is smaller than that of one side of the back wall face. A rectangular concave pit is formed in a non-arc wall face of the groove channel, and is embedded with a carborundum sheet which is coated with a platinum catalyst coating. The depth of the concave pit is equal to the thickness of the carborundum sheet, and therefore the arc sections of the front wall face and the back wall face and the non-arc sections which are embedded with the carborundum sheets of the front wall face and the back wall face are enabled to be respectively connected smoothly. According to the ignition groove of the natural gas rotary engine, the engine ignition is enabled to be convenient, combustion is promoted and accelerated by utilizing of a stable flame back frontal surface after ignition, combustion efficiency is improved, and whole performance of the engine is improved.

Owner:JIANGSU UNIV

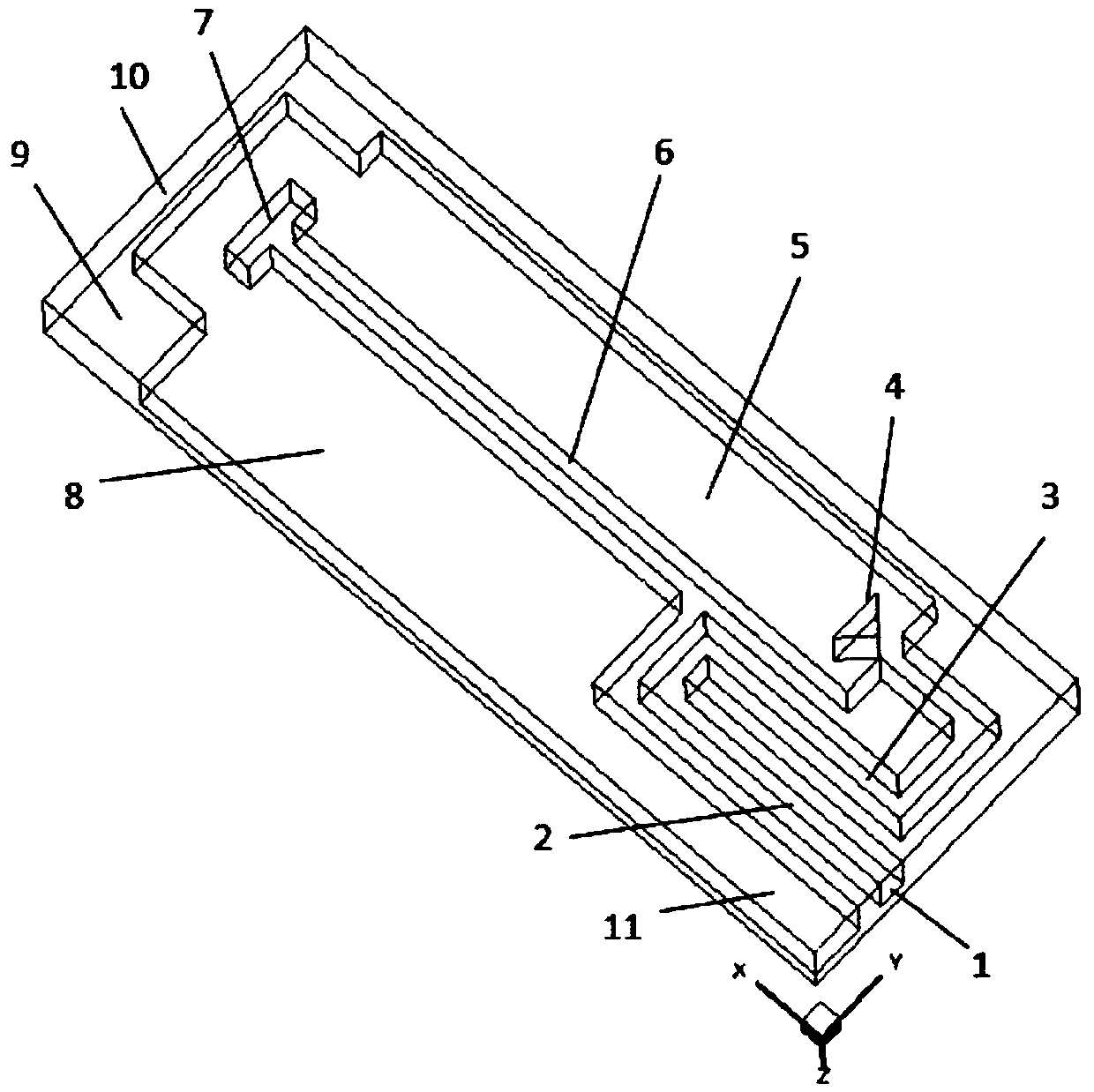

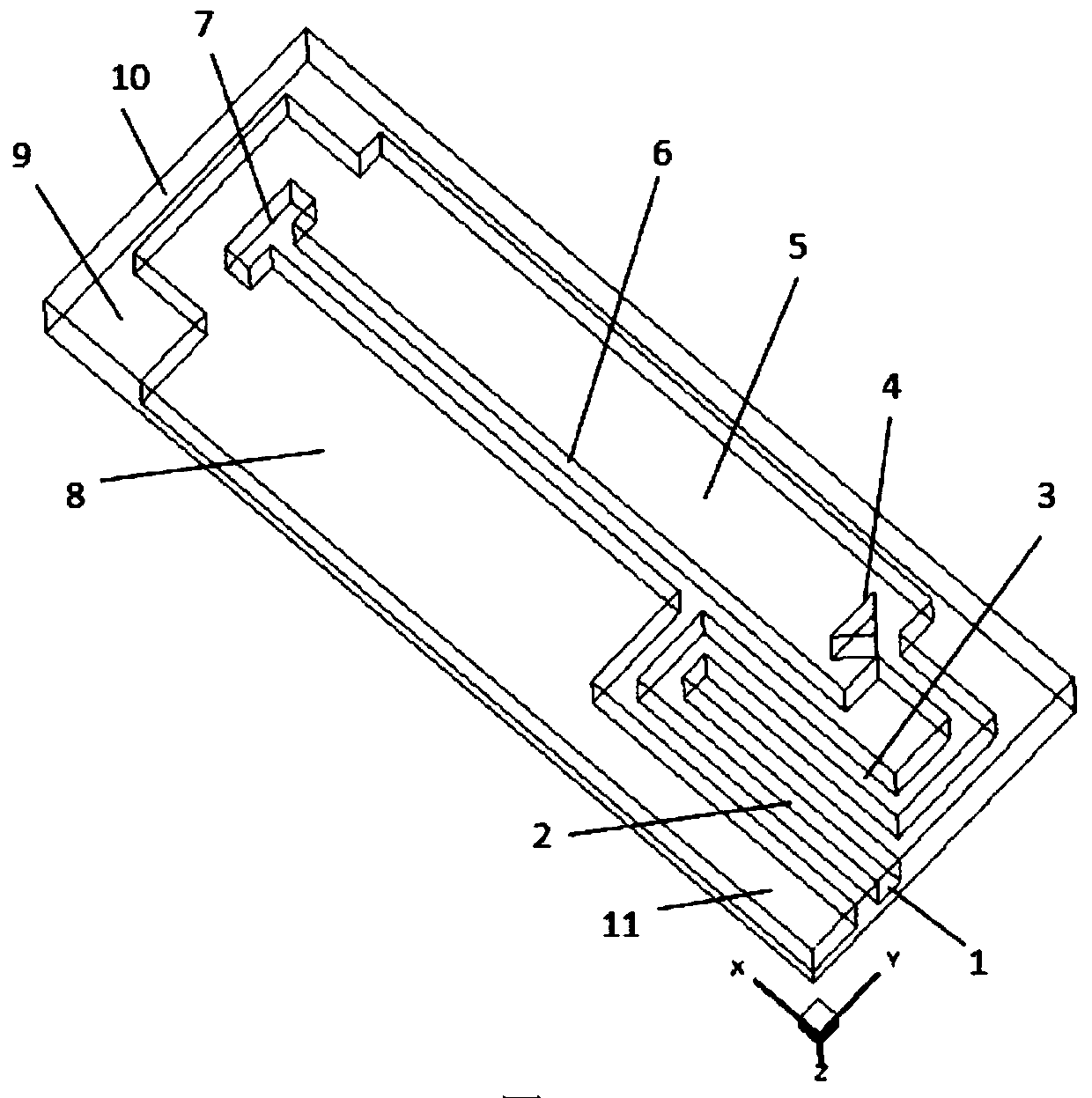

Dual-cavity annular micro burner based on Swiss roll structure

ActiveCN111623349AExtended flame stability limitImprove combustion efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberMicro-combustion

The invention belongs to the technical field of micro scale power generation, and particularly discloses a dual-cavity annular micro burner based on a Swiss roll structure. The micro burner comprisesa first burning structure and a second burning structure; the first burning structure comprises a first air inlet passage, a first rectification cavity, a first burning chamber and a first air outletpassage which communicate with each other in sequence; the second burning structure comprises a second air inlet passage, a second rectification cavity, a second burning chamber and a second air outlet passage which communicate with each other in sequence; the first burning chamber and the second burning chamber are inversely and symmetrically arranged on the upper side and the lower side of the center of the micro burner, so an inlet end of the first burning chamber is adjacent to an outlet end of the second burning chamber and an outlet end of the first burning chamber is adjacent to an inlet end of the second burning chamber; and the first air inlet passage is adjacent to the second air outlet passage and the first air outlet passage is adjacent to the second air inlet passage. Throughthe arrangement of dual burning cavities which are inversely and symmetrically arranged and an annular pre-heating passage, energy required for ignition can be lowered, ignition delay duration is shortened, and the inlet speed is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

A micro-combustor based on gas preheating and enhanced reflux to improve flame stability

ActiveCN107726321BLow ignition energySave energyIndirect carbon-dioxide mitigationGaseous fuel burnerRefluxCombustion chamber

Owner:HUAZHONG UNIV OF SCI & TECH

A micro burner with gas preheating and enhanced flame stability

The invention discloses a micro-combustor for enhancing flame stability through gas preheating. The micro-combustor comprises two primary combustion chambers and a secondary combustion chamber arranged between the two primary combustion chambers, and a gas inlet channel is further arranged between each of the two primary combustion chambers and the secondary combustion chamber; gas enters the gasinlet channels, and then enters the primary combustion chambers after being preheated sequentially by tail gas and main combustion gas; primary flame stabilizing blunt bodies are arranged at the parts, communicating with the gas inlet channels, of the primary combustion chambers; and high-temperature tail gas generated by combustion in the primary combustion chambers enters the secondary combustion chamber, a secondary flame stabilizing blunt body is arranged at the part, communicating with the two primary combustion chambers, of the secondary combustion chamber, and the high-temperature tailgas generated by continuous combustion in the secondary combustion chamber is discharged as a heat source. According to the micro-combustor, combusting preheating is carried out so that the energy needed by ignition can be reduced, the ignition delay time can be shortened and the exhaust heat loss can be reduced; and meanwhile, the two stages of combustion chambers are arranged so that the ignition quenching limit can be improved, and the inlet speed can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

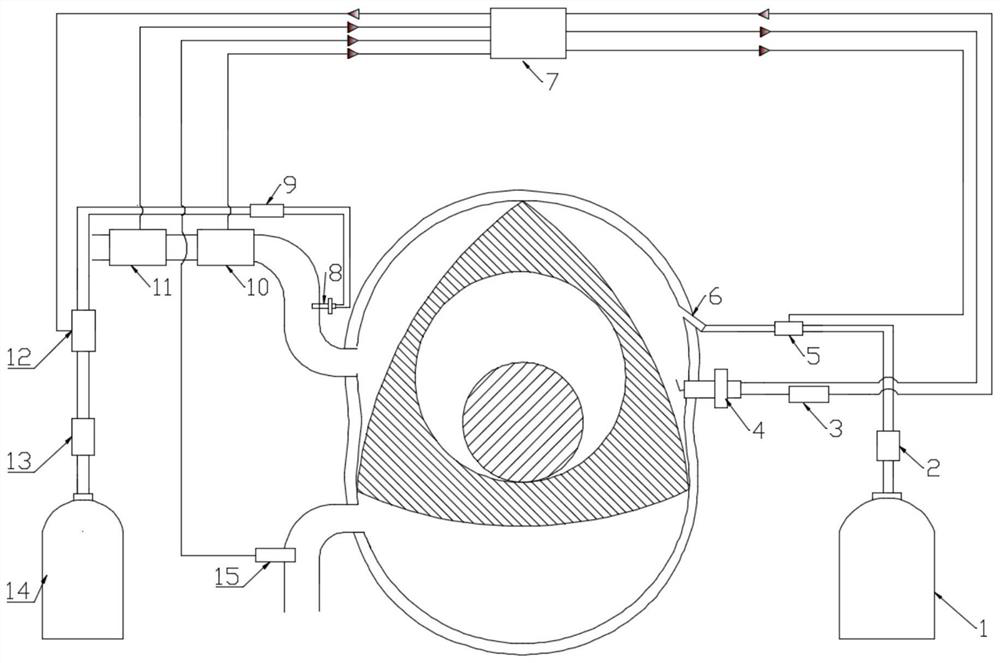

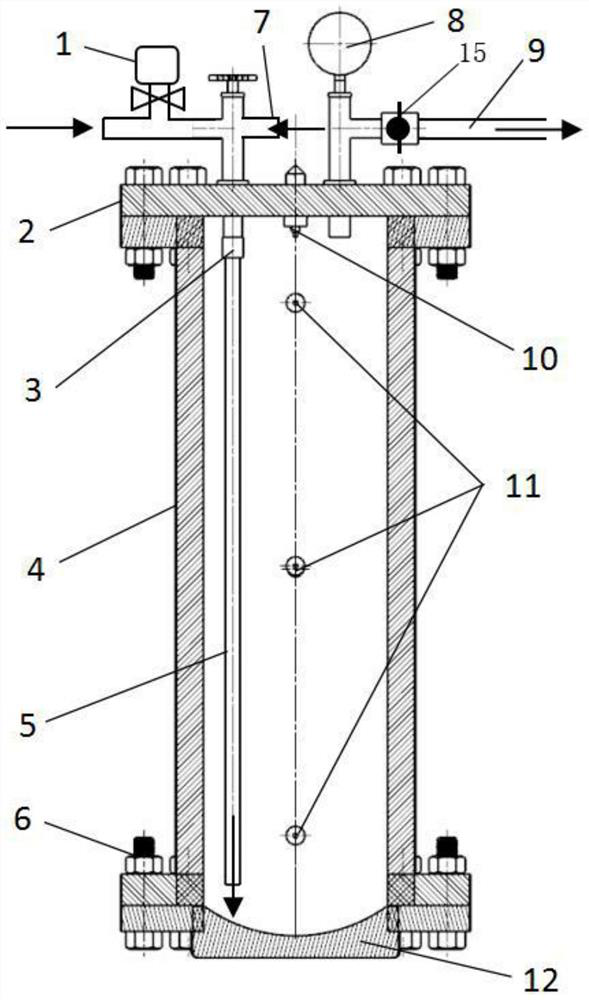

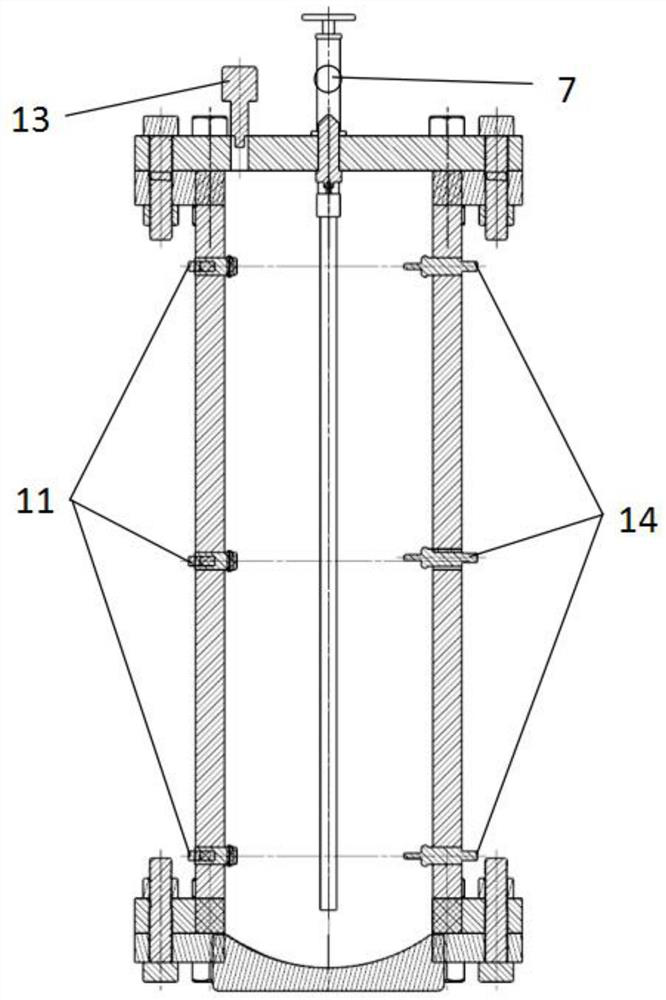

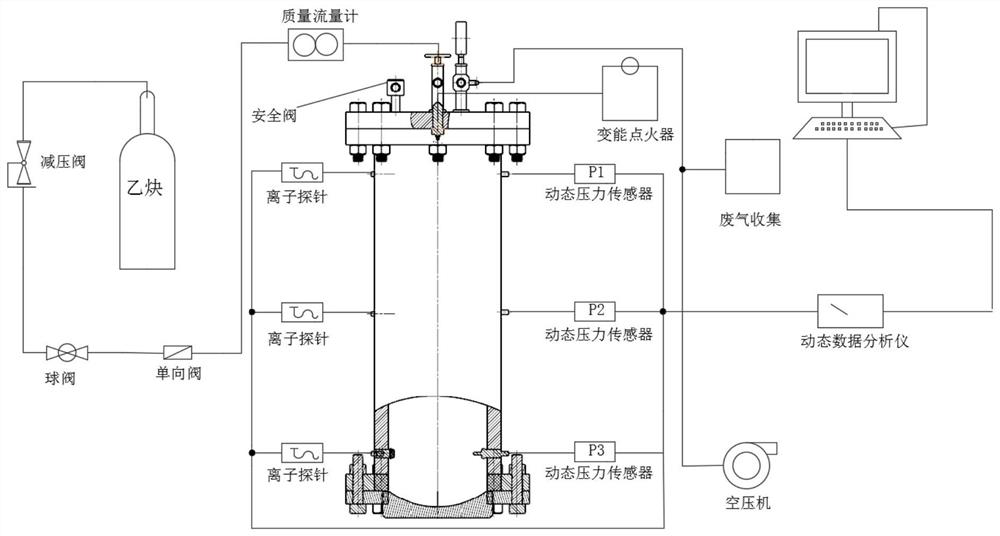

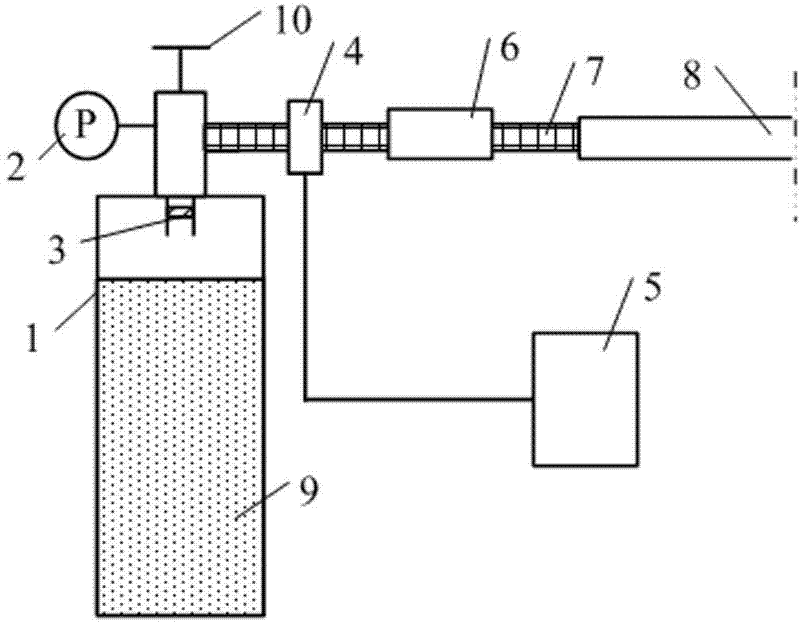

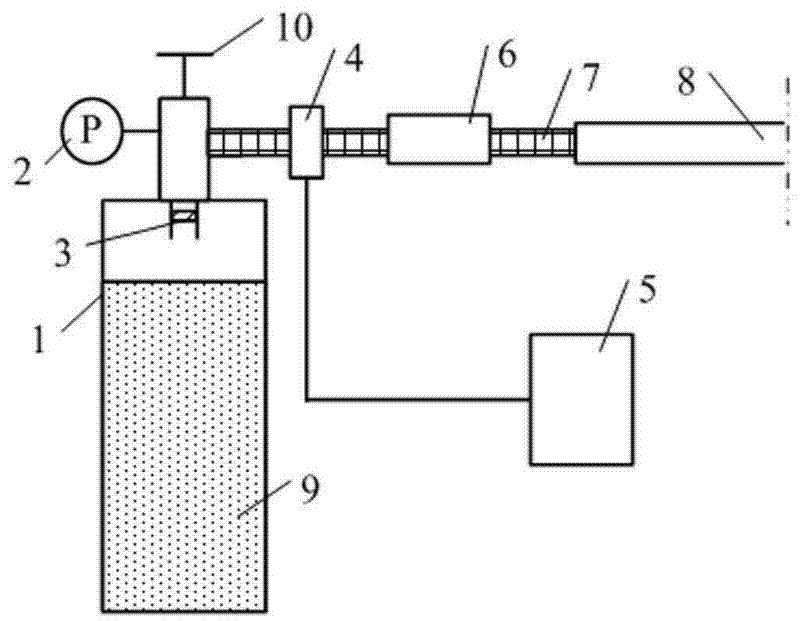

Direct initiation device under two different ventilation modes and test method

PendingCN112630264AIncrease pressureHigh speedElectric spark ignitersMaterial exposibilityDetonationCombustible gas

The invention discloses a direct initiation device under two different ventilation modes, which comprises a top cover, a tank body and a bottom cover, and is characterized in that the top cover and the bottom cover are respectively fixed at the top and the bottom of the tank body to form an integrally sealed cavity; an air inlet system, an exhaust system, a safety valve and an igniter are arranged on the top cover, the air inlet system and the exhaust system are both communicated with the interior of the tank body, and the air inlet system is connected with a powder spraying system; and a plurality of pressure sensors and ion probes are arranged on the side wall of the tank body. The device and the method are applied to a detonation experiment, the combustible gas explosion pressure and speed under the same condition can be increased, the detonation ignition energy is reduced, the detonation forming distance is reduced, the purpose of direct detonation is achieved, and the device and the method have positive significance in detonation engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Oil-saving emission reduction device of gasoline-powered automobile and application method thereof

InactiveCN102330623AImprove distributionReduce use costInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberFuel oil

The invention discloses an oil-saving emission reduction device of a gasoline-powered automobile and an application method thereof. The device is composed of a hydrogen store tank, a valve and a hydrogen pipeline, wherein a hydrogen storage alloy is arranged in the hydrogen store tank, and the lower end of the valve is provided with a cellular material filter; an electromagnetic valve and a flow controller are serially connected in the hydrogen pipeline, and the electromagnetic valve is connected with an oil pump relay of an engine; one end of the hydrogen pipeline is connected with the hydrogen store tank through the valve, and the other end of the hydrogen pipeline is connected with an inlet manifold of the engine; the application method comprises the following steps: when the engine is opened, the electromagnetic valve of the hydrogen pipeline is opened along with the oil pump of the engine, and the hydrogen released by the hydrogen storage alloy in the hydrogen store tank is mixed with the gas of an air inlet pipe through the inlet manifold of the engine so as to enter a combustor of the engine to support combustion of a fuel oil. The emission reduction device provided by the invention has the advantages of being capable of saving the fuel oil by 5-22%, obviously reducing discharging smoke, and increasing the power output of the automobile, reducing the use cost of the gasoline-powered automobile; and the hydrogen stored by the hydrogen storage alloy can be reused by filling hydrogen again after being completely used.

Owner:NORTHEASTERN UNIV

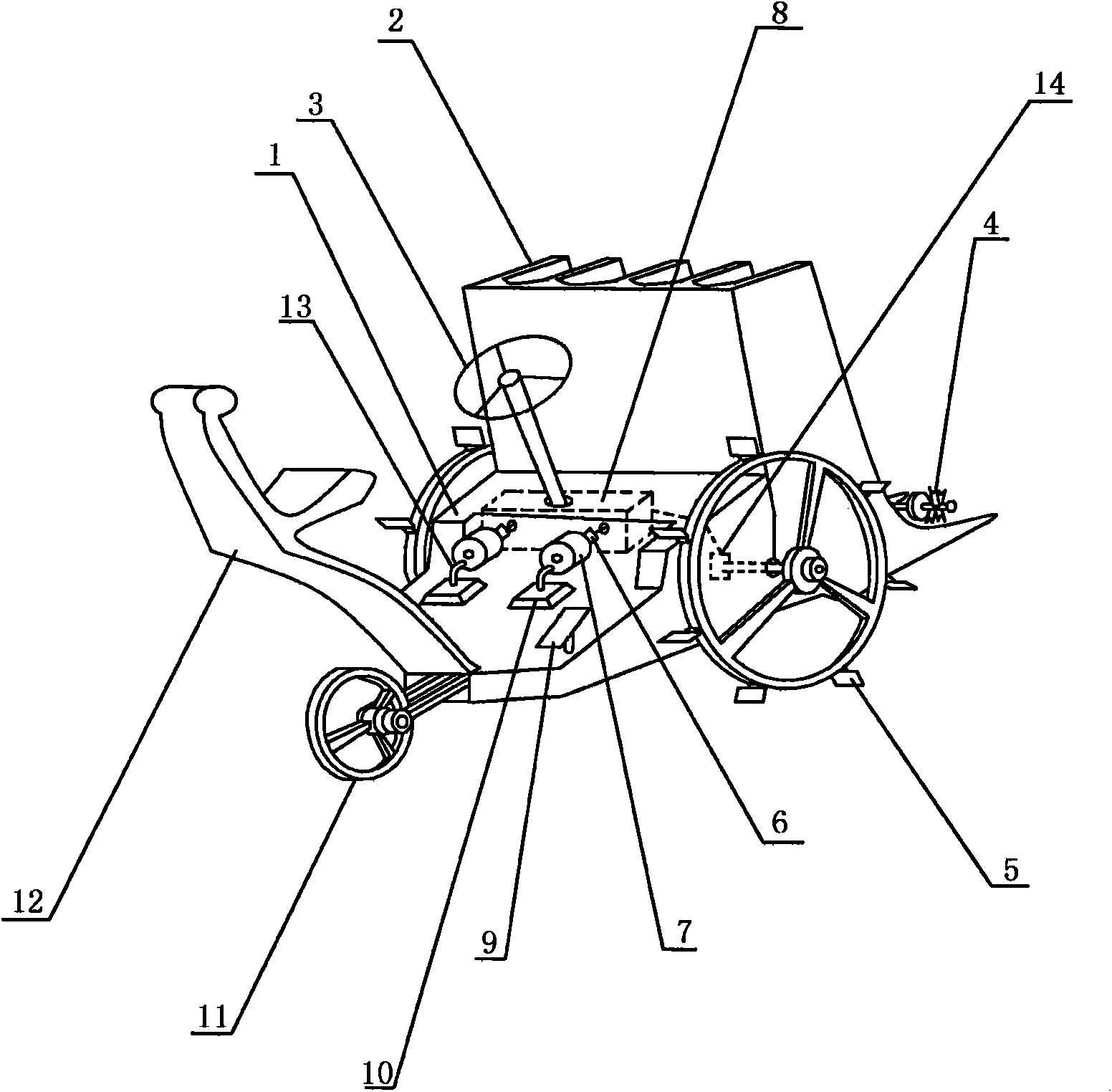

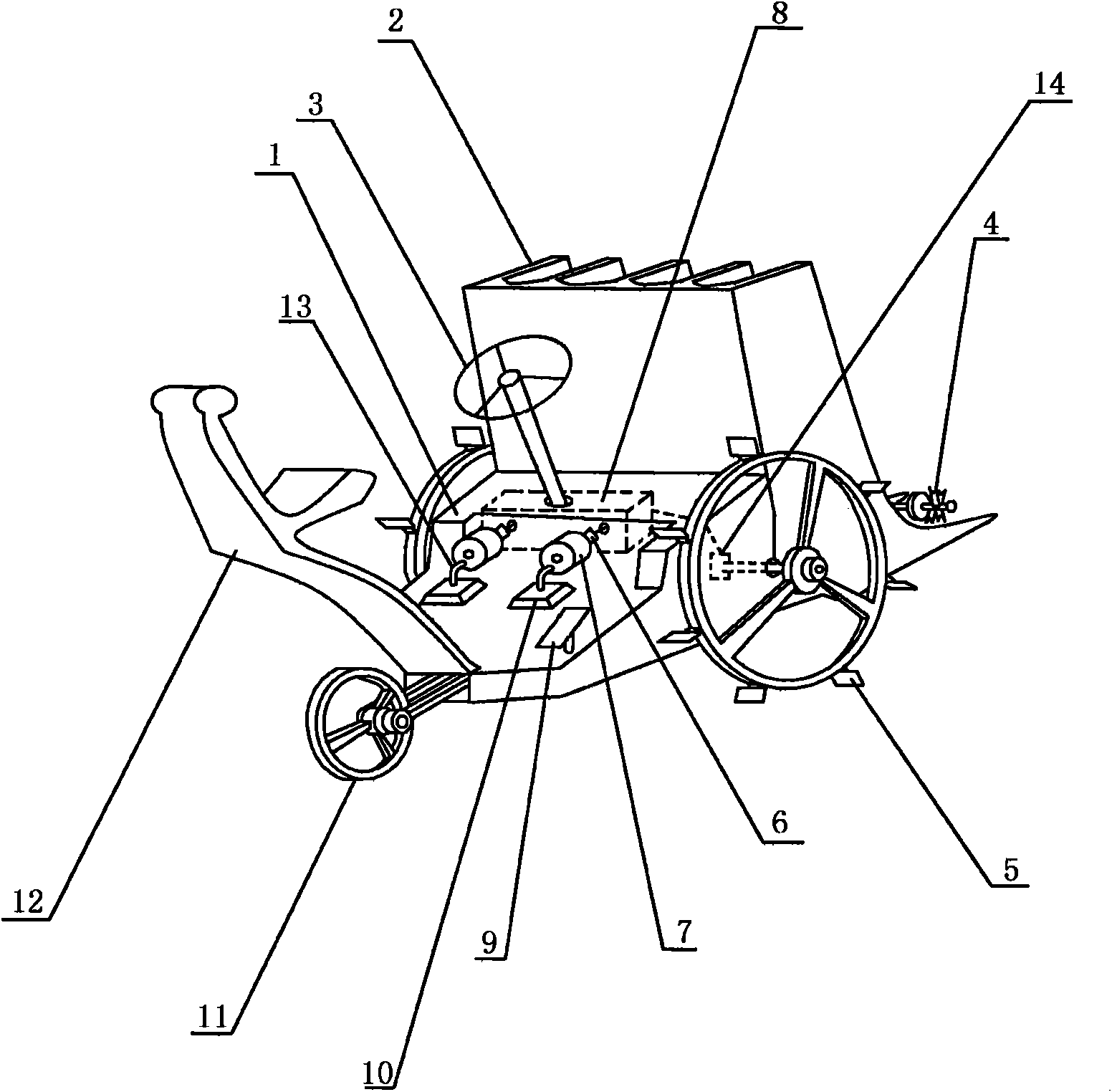

Rice transplanter taking new-energy hydrogen fuel cell as power device

InactiveCN101933423AHigh calorific valueLow ignition energyTransplantingElectrochemical responseDriver/operator

The invention relates to a rice transplanter taking a new-energy hydrogen fuel cell as a power device and belongs to the technical field of the application of new energy. On a bottom plate of a hydrogen fuel cell-based rice transplanter, hydrogen fuel output from a hydrogen fuel container is fed into the hydrogen fuel cell by a hydrogen fuel conveying pipe, generates water through an electrochemical reaction in the hydrogen fuel cell and releases electrical energy; a current is transmitted into a motor by electric leads to convert the electrical energy into mechanical energy; and a computer control device controls a mechanical driving device to drive paddy wheels and rice transplanting pawls to rotate according to a control program and transplant rice seedlings in paddy fields by using the mechanical energy. A rice transplanter driver performs auxiliary regulation and control on the operation of the rice transplanter through a manual control device and a foot control device so as to fulfill the aim of high-quality low-cost and zero-discharge operation of the rice transplanter.

Owner:WUXI TONGCHUN NEW ENERGY TECH

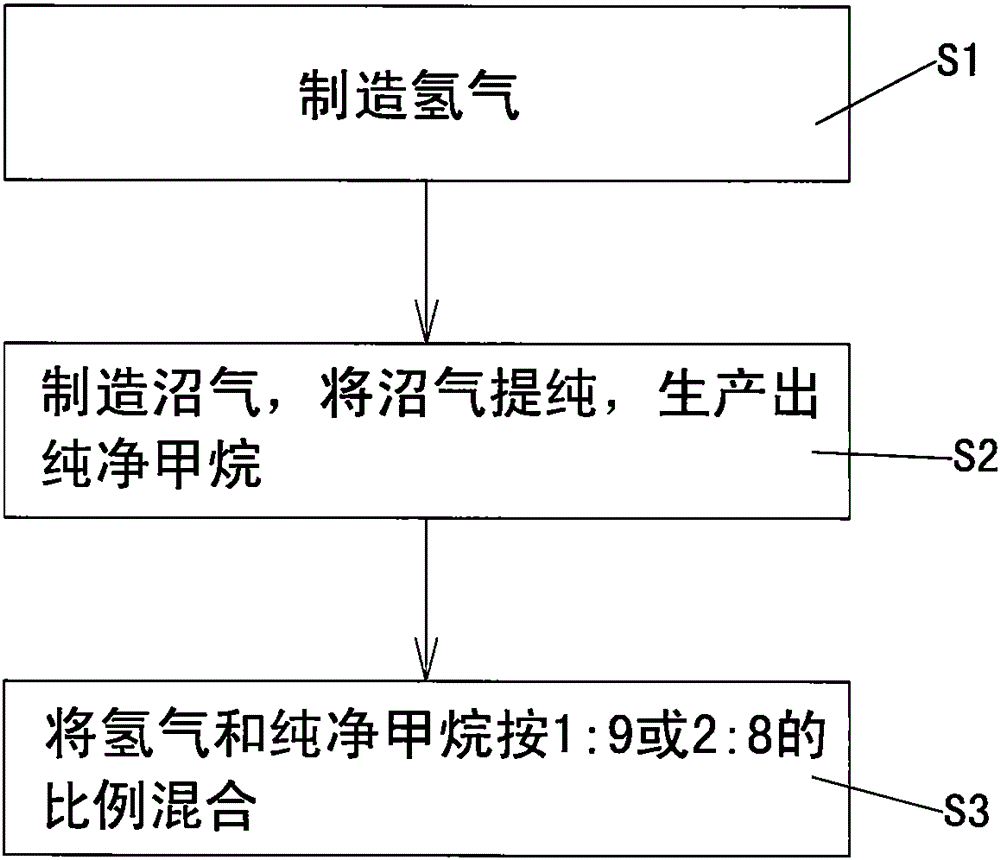

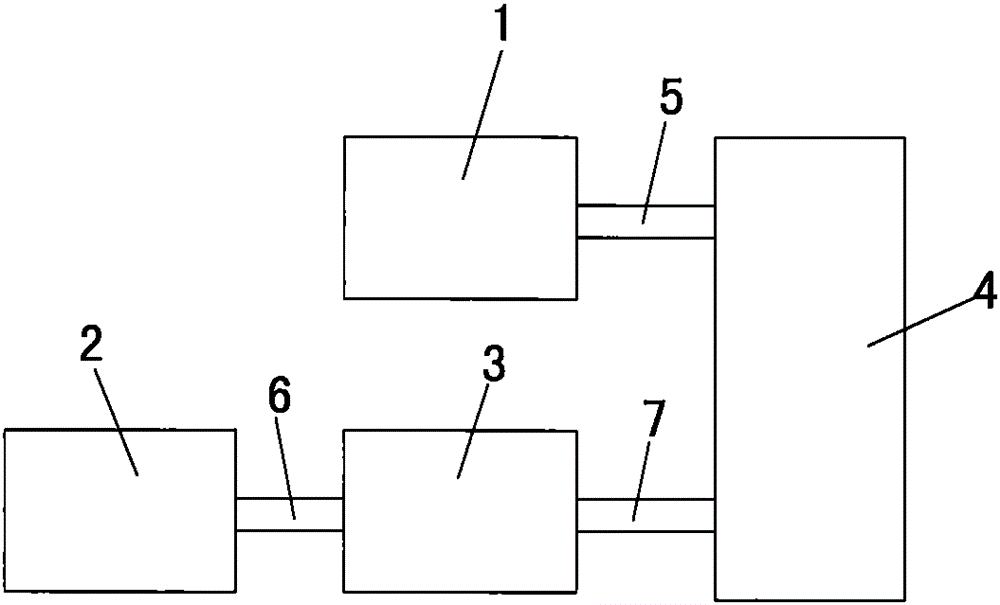

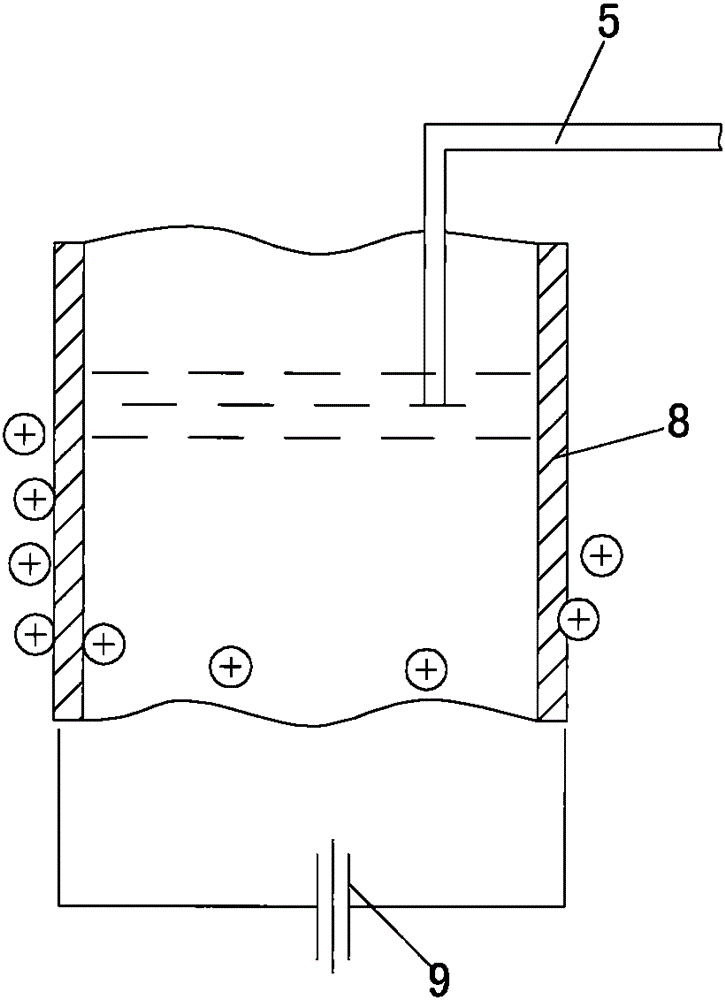

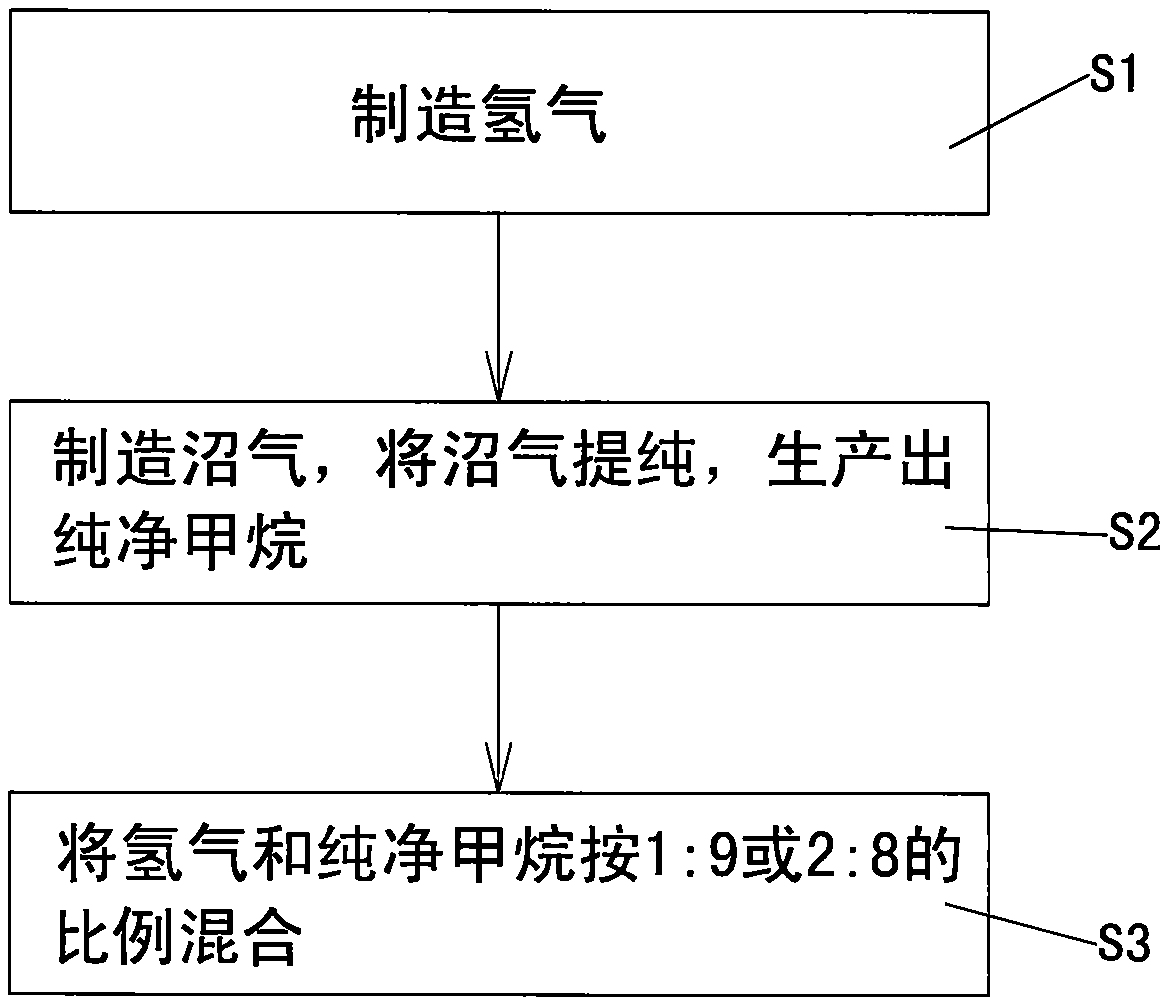

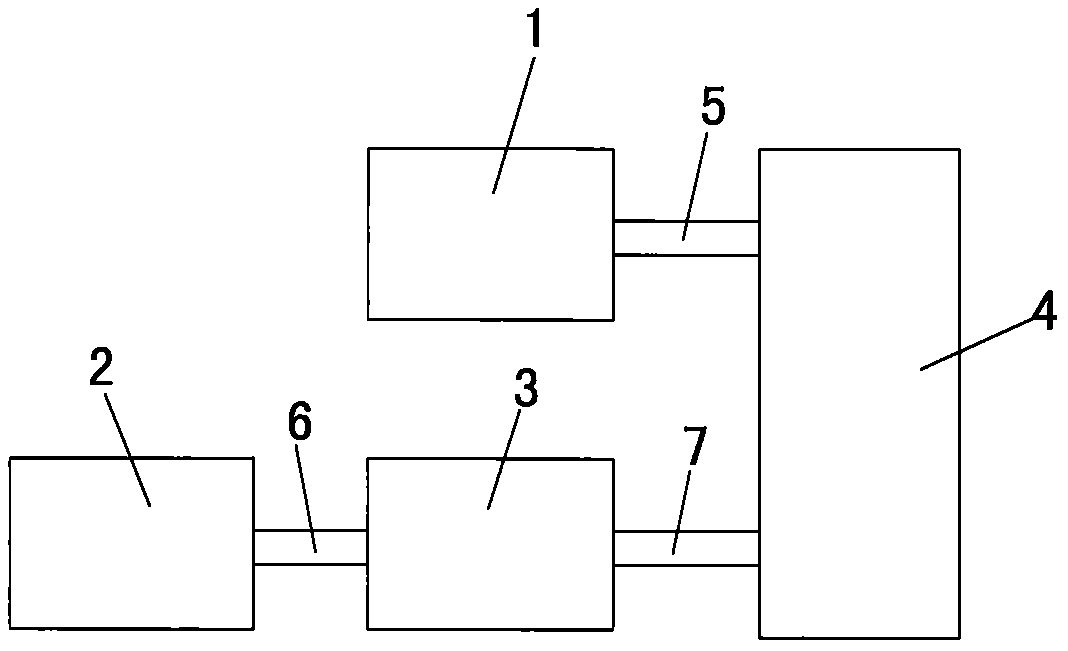

Preparation method and preparation system of modified HCNG fuel

The invention discloses a preparation method and a preparation system of modified HCNG fuel. The preparation system comprises the following steps: producing hydrogen; producing biogas; purifying the biogas; producing clean methane; and mixing the produced hydrogen with the extracted clean methane in proportion; the preparation system comprises a hydrogen production device, a biogas production device, a biogas purification device and a fuel production device; the biogas production device is used for preparing the biogas from crop straws; the biogas purification device is used for extracting methane from the biogas; the fuel production device is used for preparing the modified HCNG fuel from produced hydrogen and the extracted methane; the hydrogen production device is communicated with the fuel production device through a hydrogen exhaust pipe; the biogas production device is communicated with the biogas extraction device through a biogas exhaust pipe; the biogas purification device is communicated with the fuel production device with a methane exhaust pipe. The fuel mixed gas prepared by the preparation method of the modified HCNG fuel is high in combustion rate; the combustion performance and emission performance of an engine can be improved; exhausting of greenhouse gases is effectively lowered; the preparation system is simple in structure and low in cost.

Owner:蓝鹏 +2

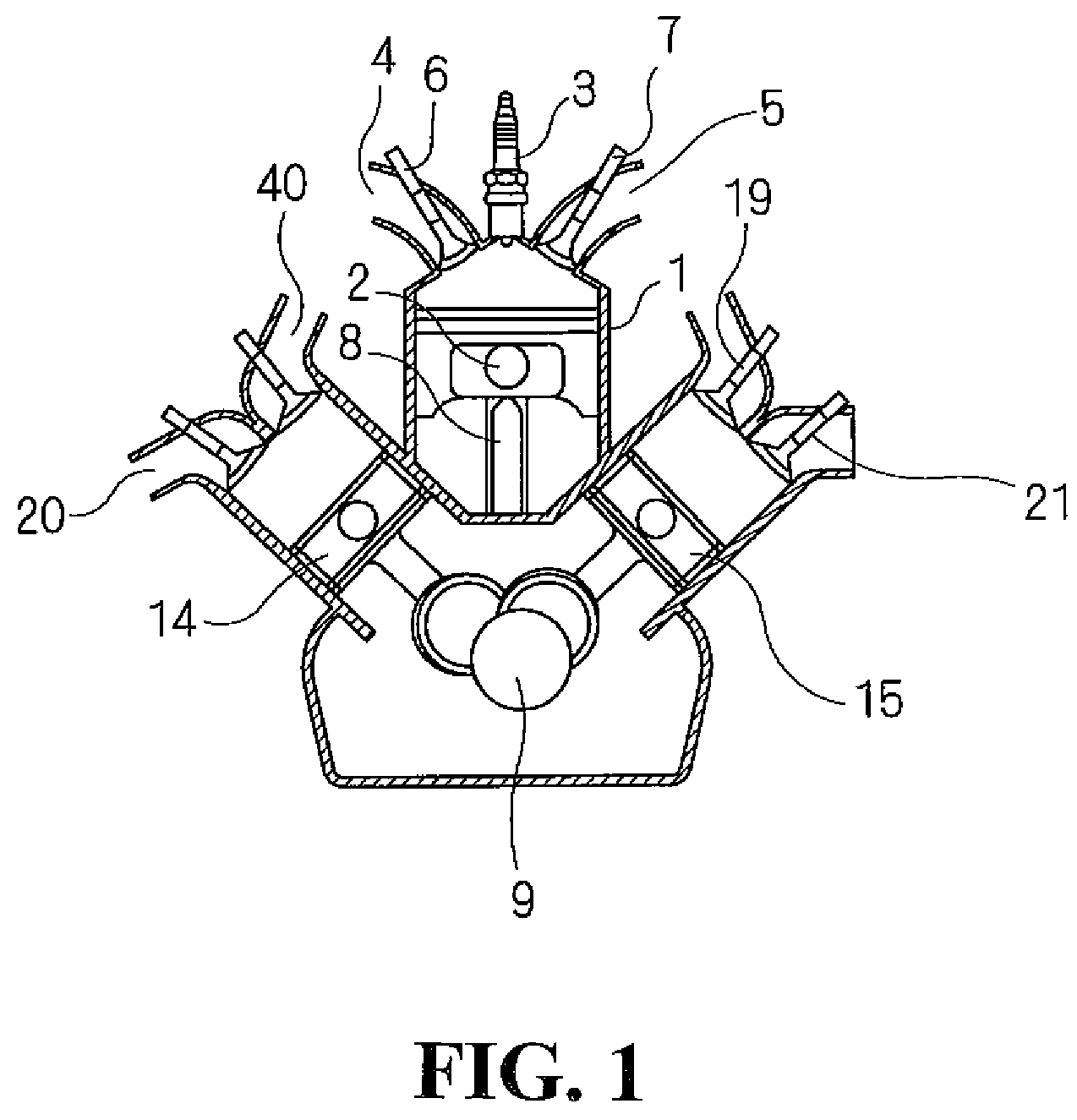

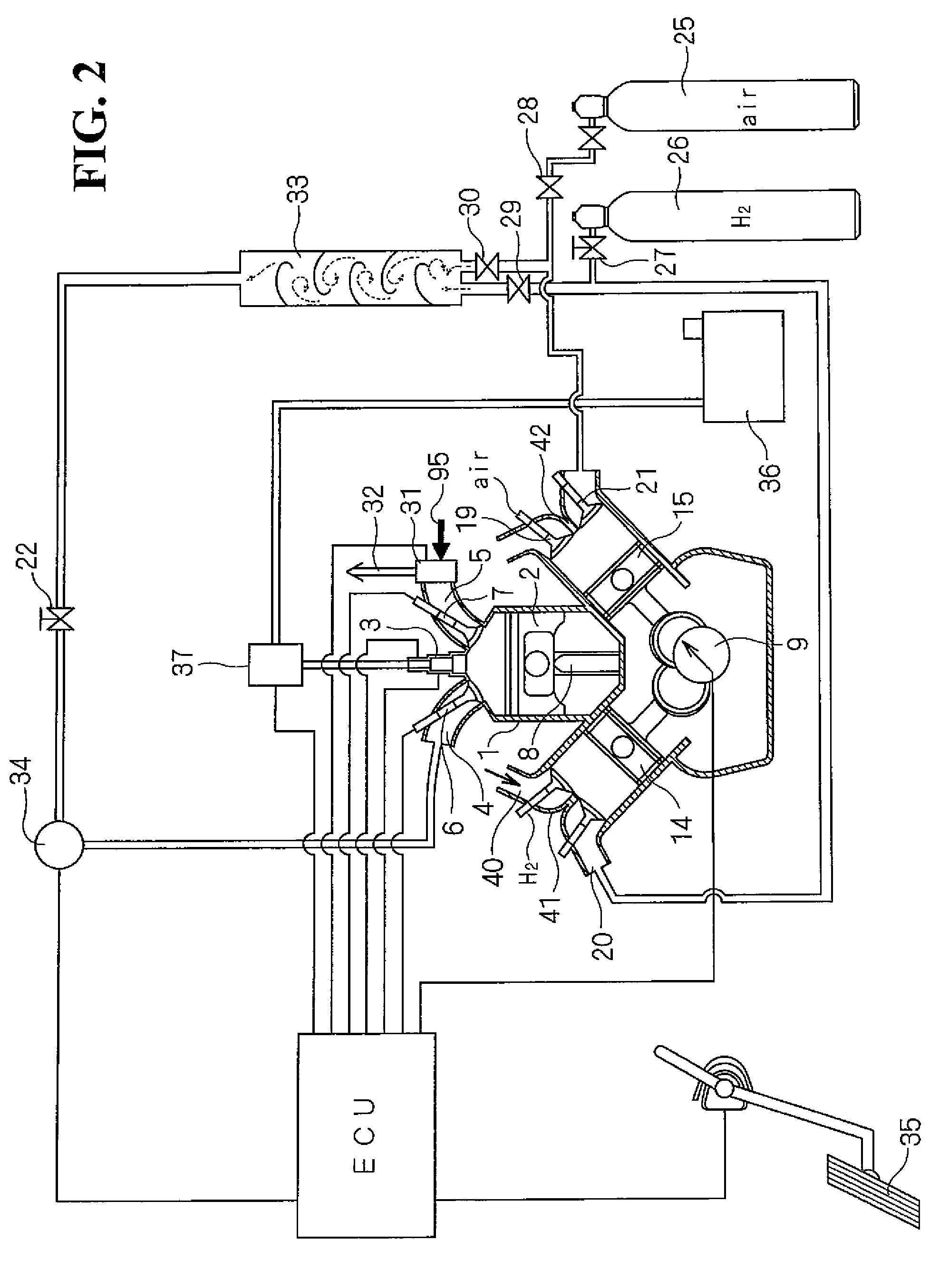

Hydrogen-only 6-stroke engine

InactiveUS20100077988A1Low ignition energyReduce the temperatureAnalogue computers for vehiclesInternal combustion piston enginesCold airHigh pressure hydrogen

There are no prospects for engines using hydrogen as fuel to be put to practical use due to significant small output, knocking, and backfire. An object of the present invention is to obtain a stable automobile engine at high drive that can be commercially put to practical use. A hydrogen-only 6-stroke engine realizing high output by 6-strokes for premixing two to seven atmospheric pressure or high pressure hydrogen and air at equivalent weight, spraying the pre-mixture into a cylinder cooled by filling the cylinder with cold air in advance, spraying, compressing, and exploding the mixture, discharging the mixture from a lower exhaust hole, and discharging remaining waste gas from an upper exhaust hole is proposed.

Owner:JAPAN HYDROGEN

Modified HCNG fuel preparation method and preparation system

InactiveCN105219462BIncrease burn rateSimple processGaseous fuelsBiogas productionProcess engineering

The invention discloses a preparation method and a preparation system of modified HCNG fuel. The preparation system comprises the following steps: producing hydrogen; producing biogas; purifying the biogas; producing clean methane; and mixing the produced hydrogen with the extracted clean methane in proportion; the preparation system comprises a hydrogen production device, a biogas production device, a biogas purification device and a fuel production device; the biogas production device is used for preparing the biogas from crop straws; the biogas purification device is used for extracting methane from the biogas; the fuel production device is used for preparing the modified HCNG fuel from produced hydrogen and the extracted methane; the hydrogen production device is communicated with the fuel production device through a hydrogen exhaust pipe; the biogas production device is communicated with the biogas extraction device through a biogas exhaust pipe; the biogas purification device is communicated with the fuel production device with a methane exhaust pipe. The fuel mixed gas prepared by the preparation method of the modified HCNG fuel is high in combustion rate; the combustion performance and emission performance of an engine can be improved; exhausting of greenhouse gases is effectively lowered; the preparation system is simple in structure and low in cost.

Owner:蓝鹏 +2

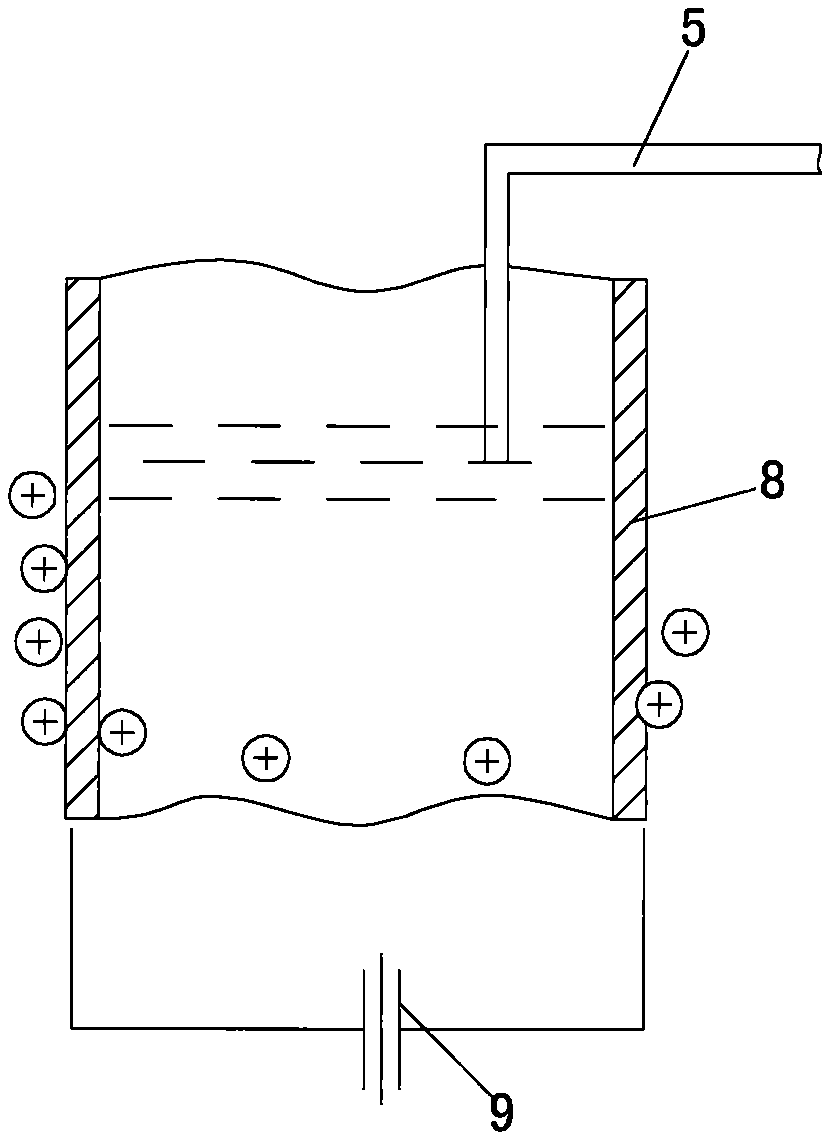

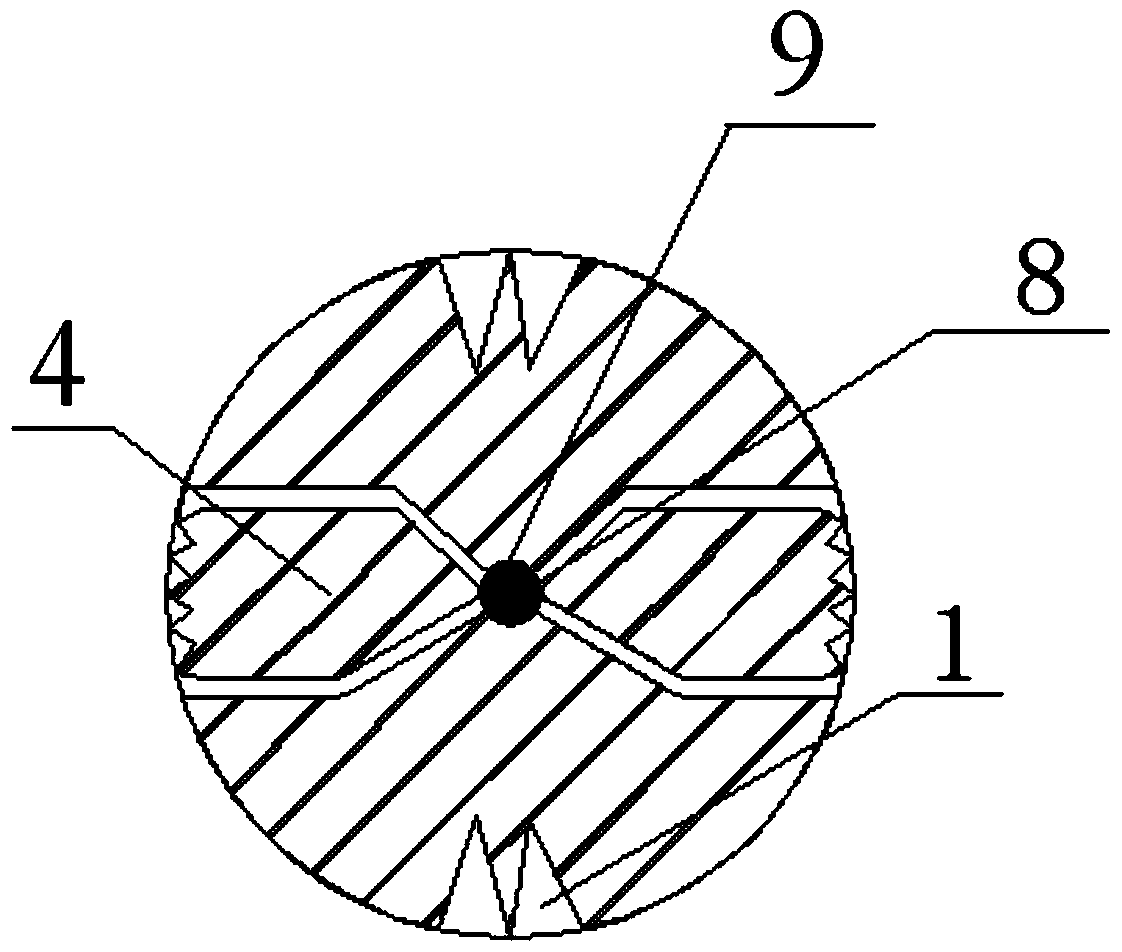

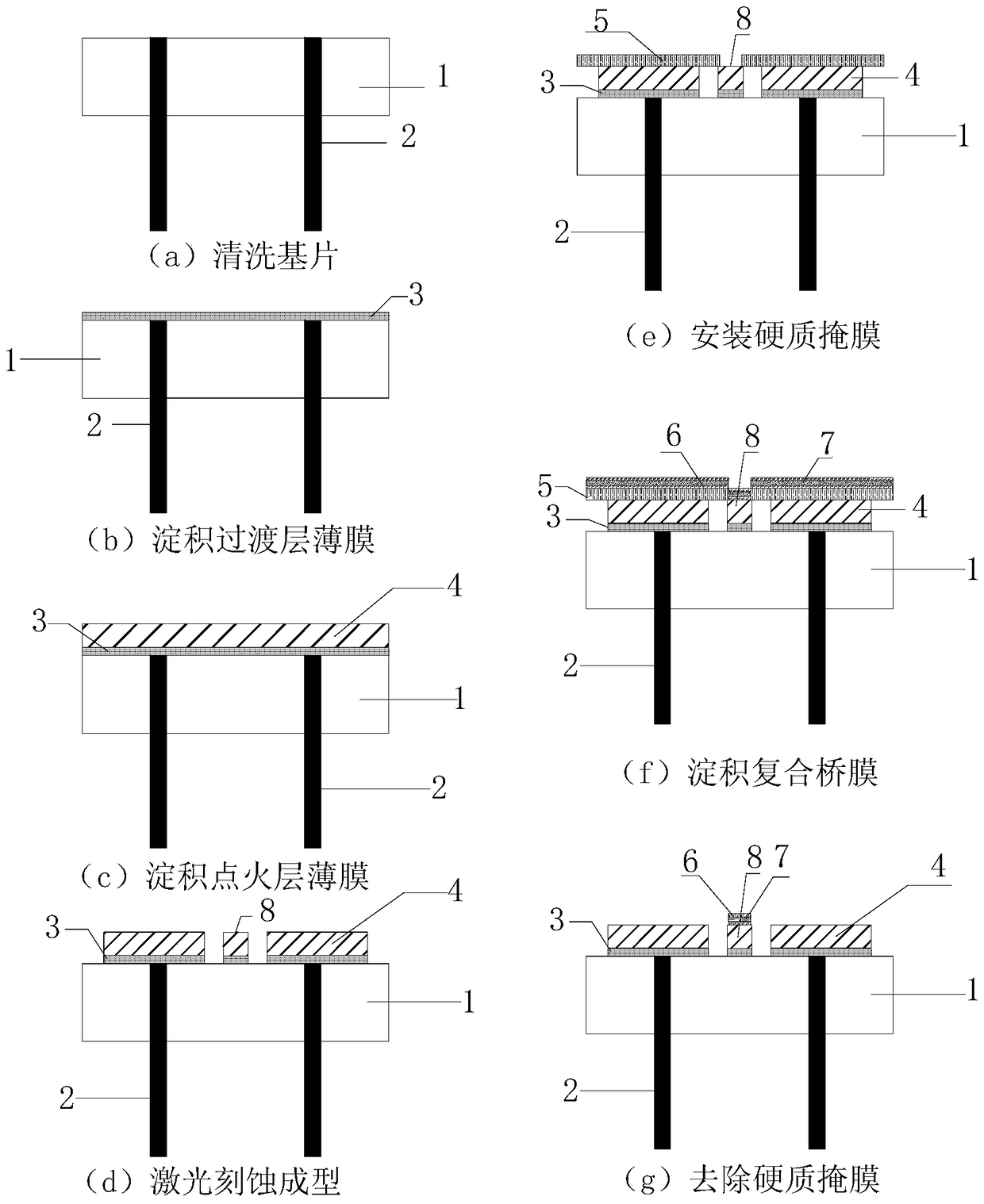

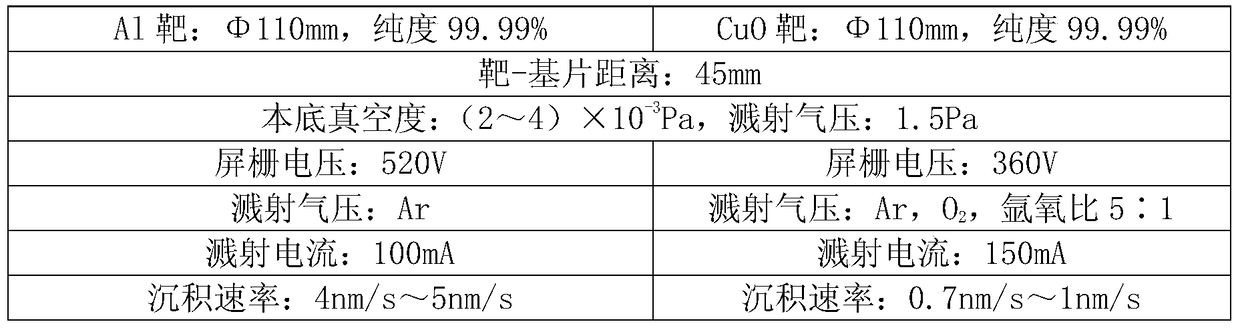

Integrated membrane bridge igniter and preparation method thereof

ActiveCN105423340BReduce wire bonding processNo encapsulation requiredCombustion ignitionLaser etchingPeriodic alternating

The invention discloses an integrated thin film bridge igniter and a preparation method thereof. The integrated thin film bridge igniter sequentially comprises a base body overall element, a transition layer thin film, an ignition layer thin film and a composite bridge film layer from bottom to top. The preparation method comprises the steps that (1), the transition layer thin film and the ignition layer thin film are sequentially deposited on the surface of the base body overall element; (2), a zigzag thin film bridge area is etched on the ignition layer thin film through a laser etching process; and (3), a CuO thin film layer and an Al thin film layer are periodically and alternately deposited on the zigzag thin film bridge area to obtain the integrated thin film bridge igniter. The integrated thin film bridge igniter is free of packaging and capable of achieving low-energy reliable ignition, ignition energy can be effectively reduced, and ignition time can be effectively shortened; and the preparation method is low in cost, and batch production can be achieved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

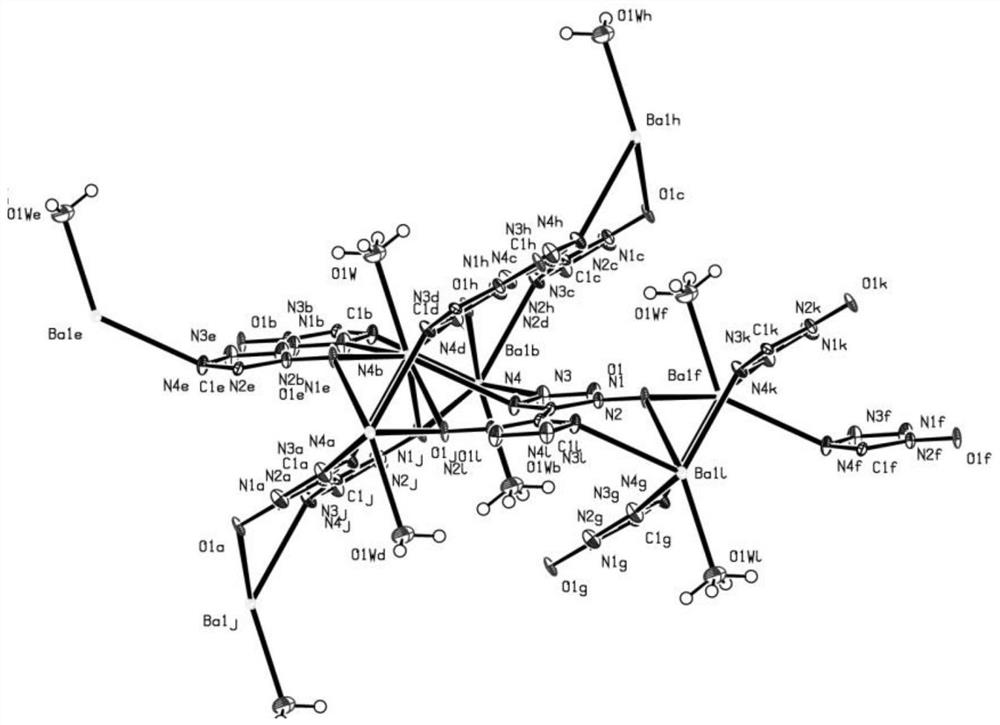

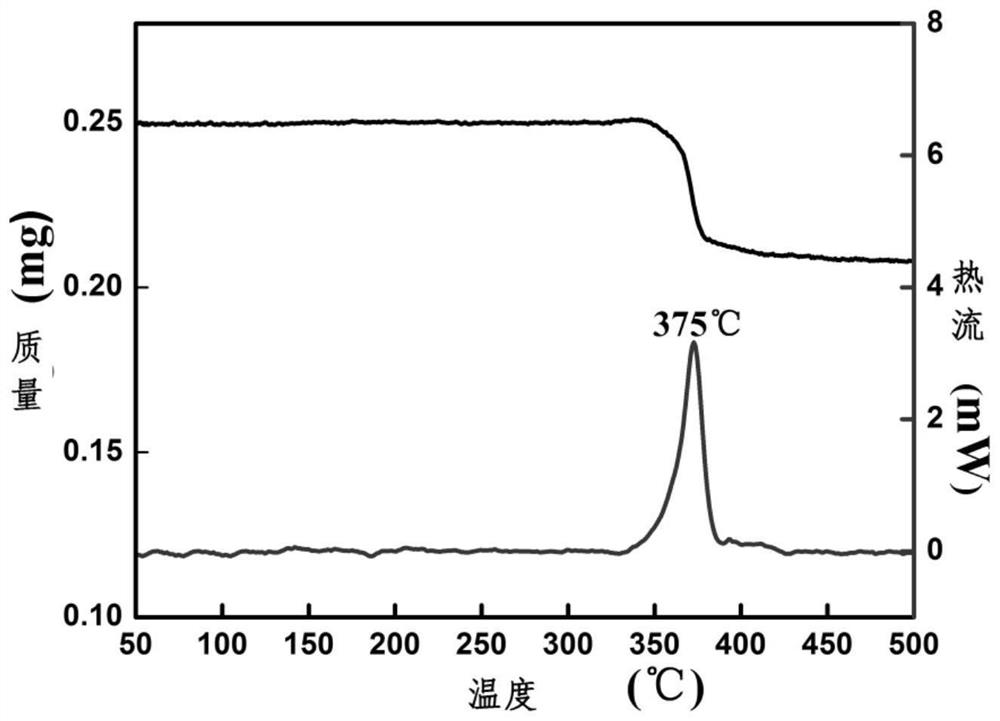

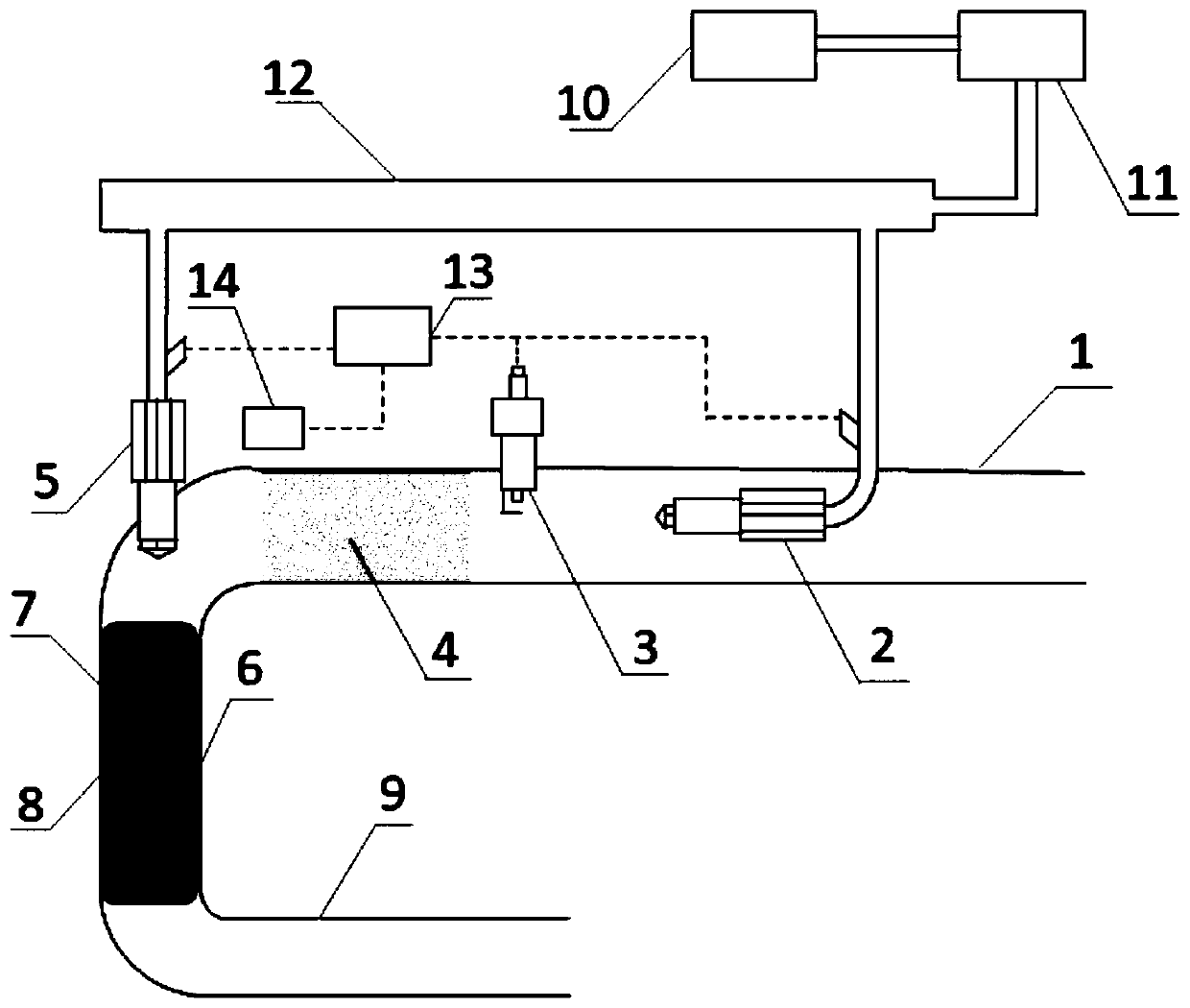

A barium-based energetic metal-organic framework directly detonated by 800nm laser, preparation method and application

ActiveCN112300403BHigh ignition responseSpeed up the processDetonatorsPyrophoric compositionsNanosecond laserChemical physics

The invention discloses a barium-based energetic metal-organic framework directly detonated by an 800nm laser, a preparation method and an application thereof, and its chemical formula is [Ba(BTO)(H 2 O)] n , where BTO is a 5,5'-tetrazole-1,1'-dioxanion ligand. Including the following steps: Step 1: Energy-containing metal-organic framework material [Ba(BTO)(H 2 O)] n Preparation; Step 2: Based on the energetic metal-organic framework material [Ba(BTO)(H 2 O)] n Production of laser detonators; step 3: use 800nm nanosecond laser to conduct laser direct detonation performance experiments, and obtain detonation characteristic parameters.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

A kind of multi-stage injection methanol engine cold start device and method

ActiveCN109973266BFast cold startLow ignition energyInternal combustion piston enginesThermal treatment of fuelCombustion chamberExhaust pipe

The invention belongs to the field of methanol engine cold start, and discloses a multi-stage injection methanol engine cold start device and method. The device comprises a methanol evaporation and cracking module and a methanol multi-stage injection and ignition module, the methanol evaporation and cracking module comprises a first air inlet passage, a combustion chamber, an evaporation and cracking chamber and an exhaust pipe which are sequentially connected, and the methanol multi-stage injection and ignition module comprises a methanol box, a methanol high-pressure oil rail, a methanol pump, a first-stage methanol injector, a second-stage methanol injector, a sparking plug and a controller. The invention further discloses a multi-stage injection methanol engine cold start method. Methanol cracking gas can be prepared under the condition of low ambient temperature by multi-stage methanol injection and single ignition under the condition of cold start, and the methanol cracking gas and the uncracked methanol gas are introduced into an engine together to realize rapid cold start of the pure methanol engine. The device has the advantages of being high in stability, low in electricity consumption and easy to produce in an industrialized mode.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com