Photocatalytic ignition system

a photocatalytic ignition and photocatalytic technology, applied in the field of photocatalytic ignition systems, can solve the problems of insufficient ability of existing photocatalytic materials to reduce the low efficiency of high-efficiency photocatalytic materials, and the inability to propose a practical photocatalytic ignition system, etc., to achieve the effect of high efficiency and reducing the minimum ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example 1

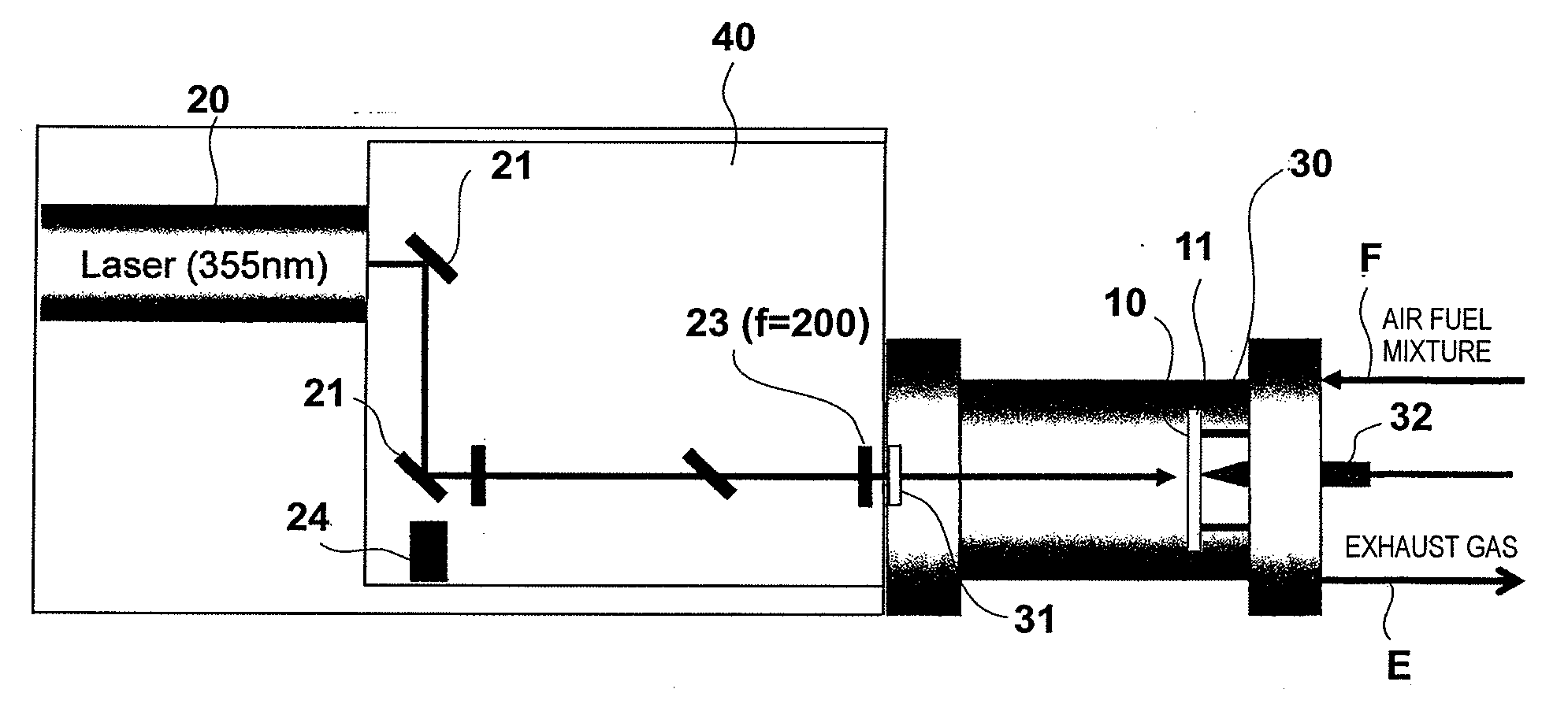

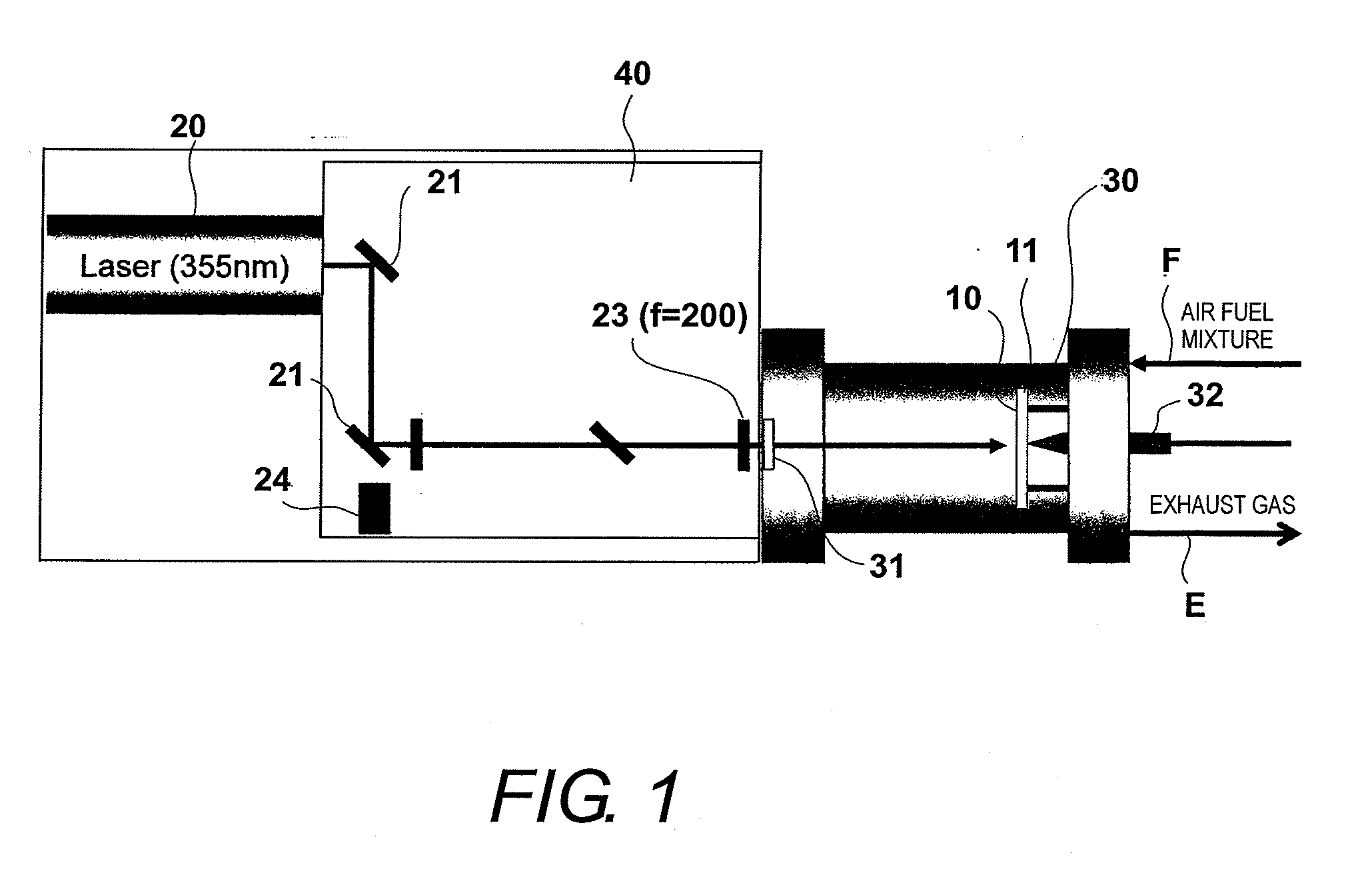

[0040]The photocatalytic ignition system shown in FIG. 1 was fabricated and the performance thereof was evaluated. The procedures of the fabrication and performance evaluation of the system will now be explained.

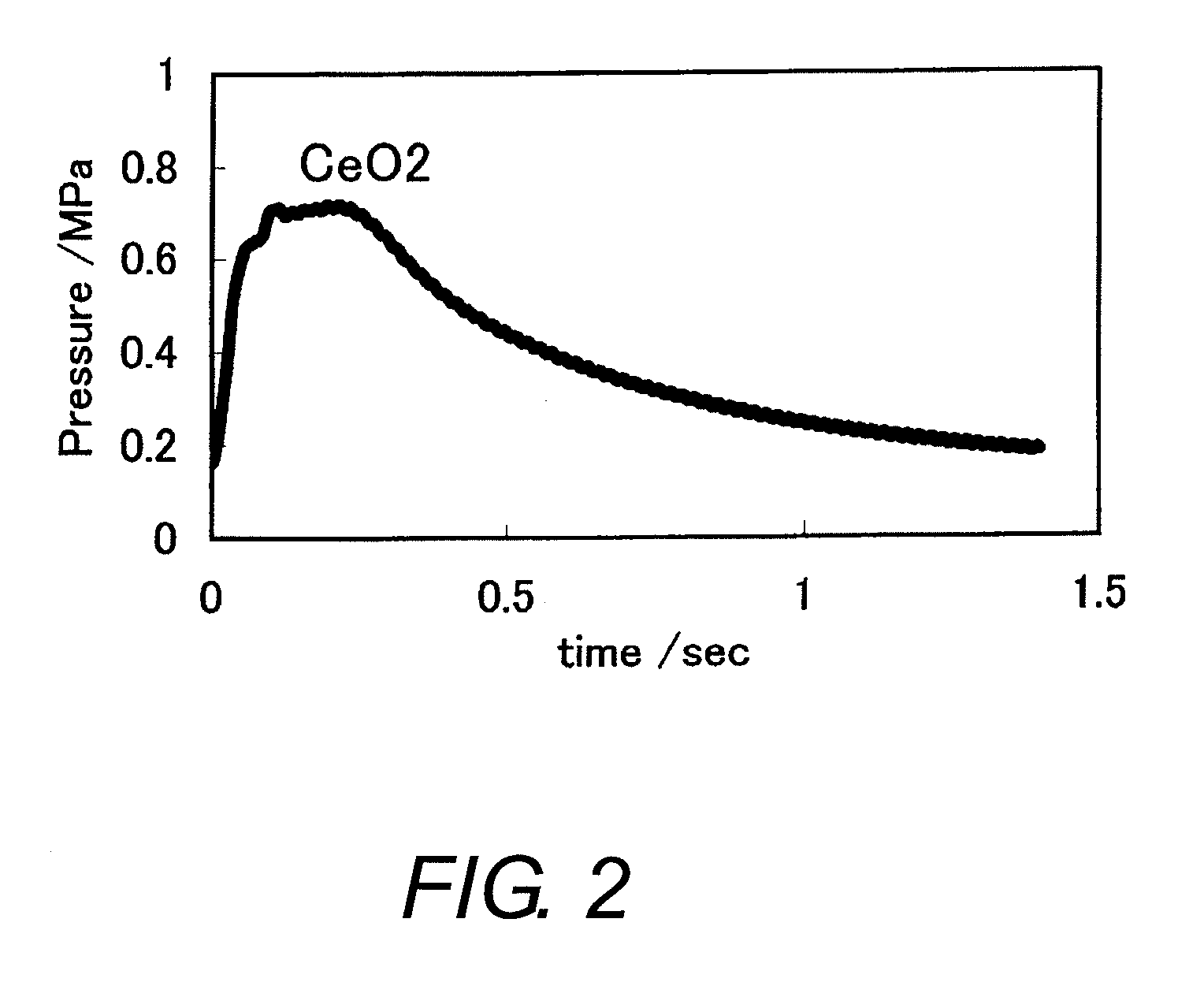

[0041]An aluminum plate having a diameter of 60 mm was used as the substrate plate 11. Oil was removed from the aluminum plate by treating it with alcohol and, afterwards, an inorganic adhesive (main ingredient: a alumina) was coated onto the aluminum plate. Next, the photocatalyst 10 was made by spraying cerium oxide sol having a particle size of 20 nm to a thickness of several micrometers and firing to remove moisture.

[0042]The laser light was provided by a Nd-YAG laser (355 nm) and pulsed at a pulse width of 5 to 7 nsec. The laser light was passed through a 355 nm wavelength separator mirror, an attenuator (½ wavelength plate and polarizer plate), a light collecting lens (f=200), and a quartz glass window and shone onto the photocatalyst inside the ignition chamber. A mix...

working example 2

[0044]An aqueous solution was prepared with ferric nitrate and cerium nitrate at a mole ratio of Fe to Ce (Fe / Ce) equal to 0.8 / 0.2. The solution was agitated one day and one night while gradually dripping in an aqueous solution containing 28% ammonia such that a pH of 8 was achieved. The resulting solid material was then filtered out, rinsed with deionized water, and heated to 600° C. for five hours to obtain Fe0.8Ce0.2. The Fe—Ce material was used as the photocatalyst. Otherwise, the same operations as were performed in Working Example 1 were repeated. Table 1 shows the minimum ignition energy (mJ) for the photocatalyst used in this working example.

working example 3

[0045]An aqueous solution was prepared with ferric nitrate and cerium nitrate at a mole ratio of Fe to Ce (Fe / Ce) equal to 0.2 / 0.8. Otherwise the same operations as were performed in Working Example 2 were repeated. The minimum ignition energy (mJ) is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com