Patents

Literature

77results about "Catalytic igniters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

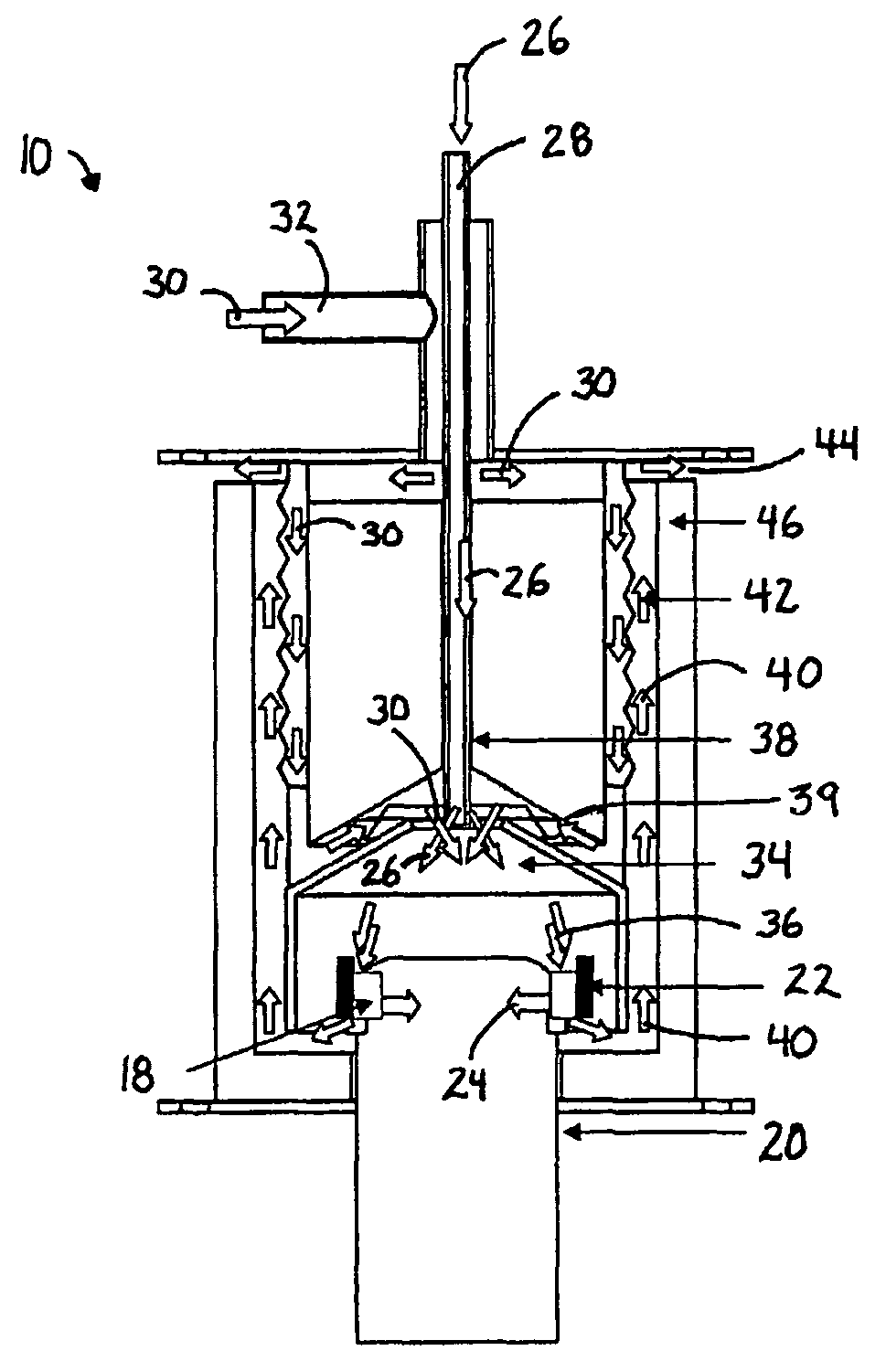

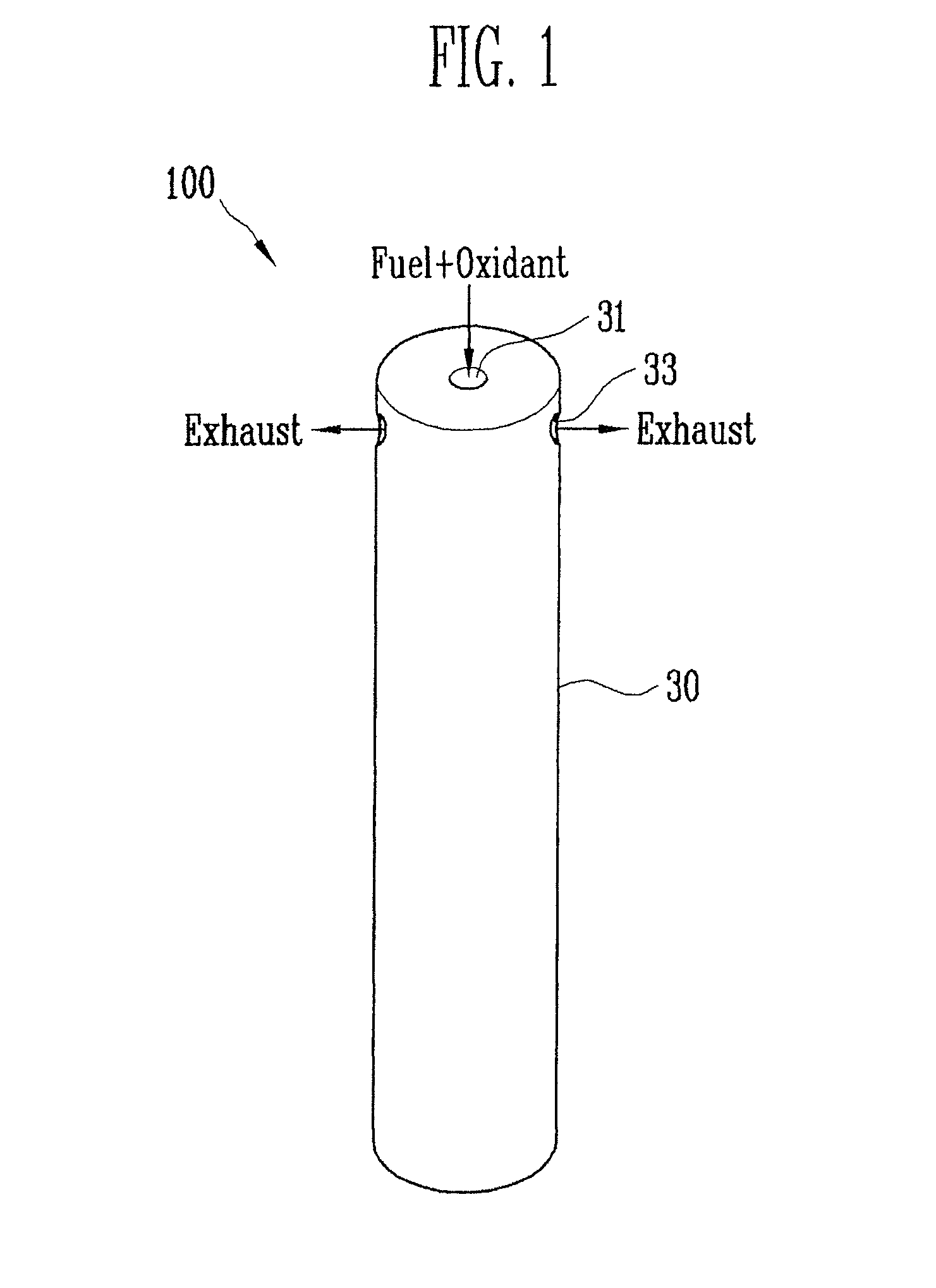

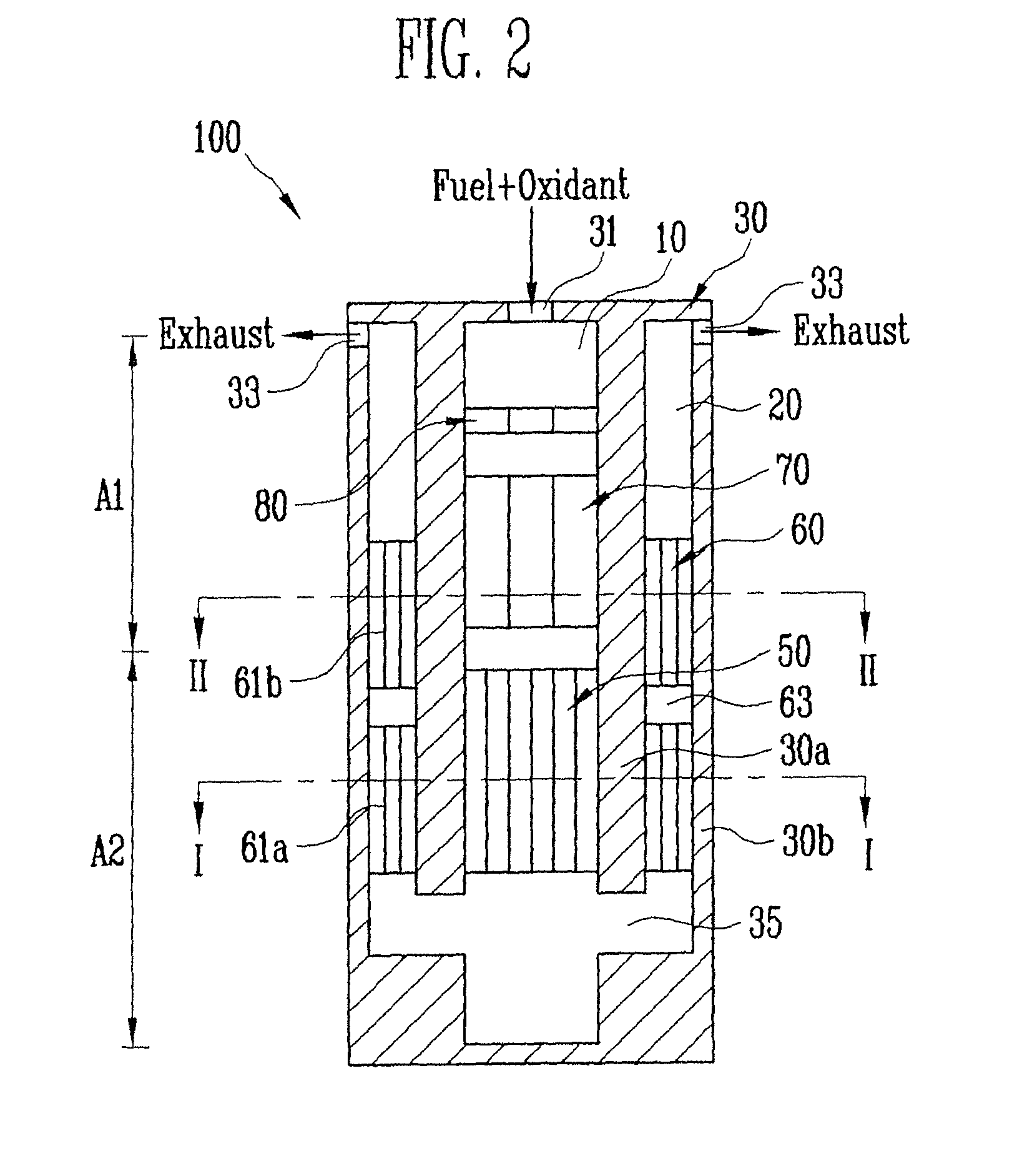

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

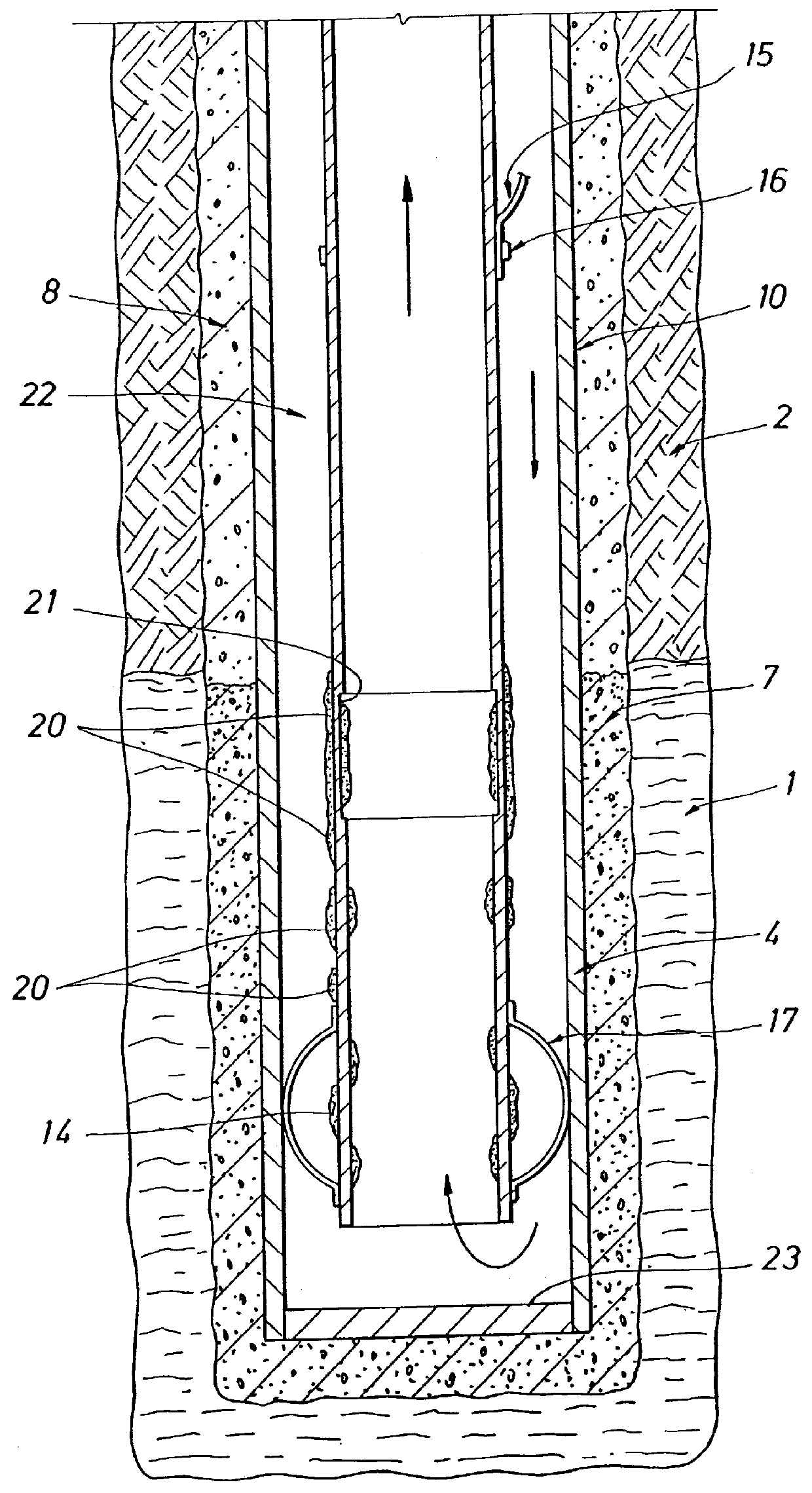

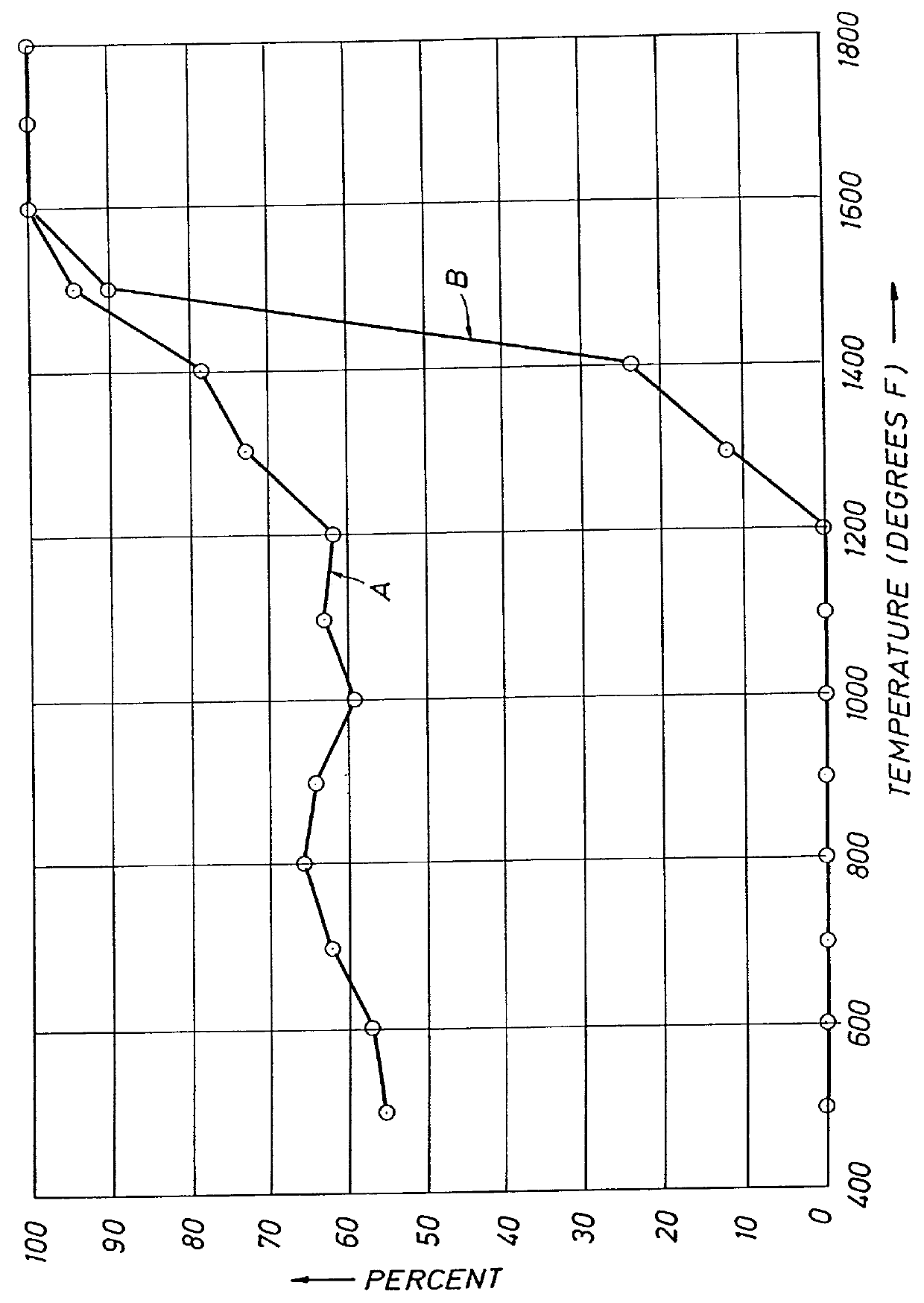

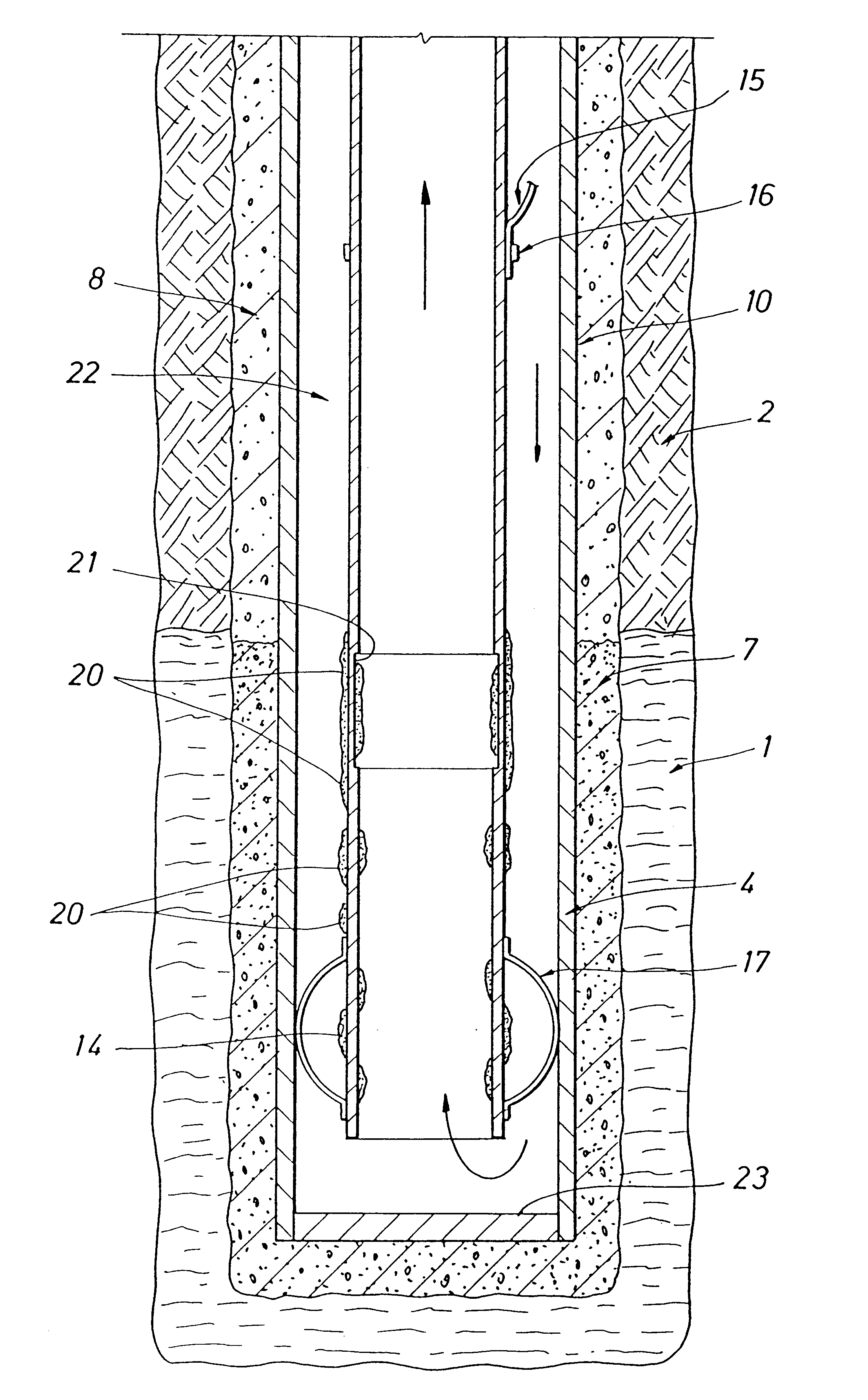

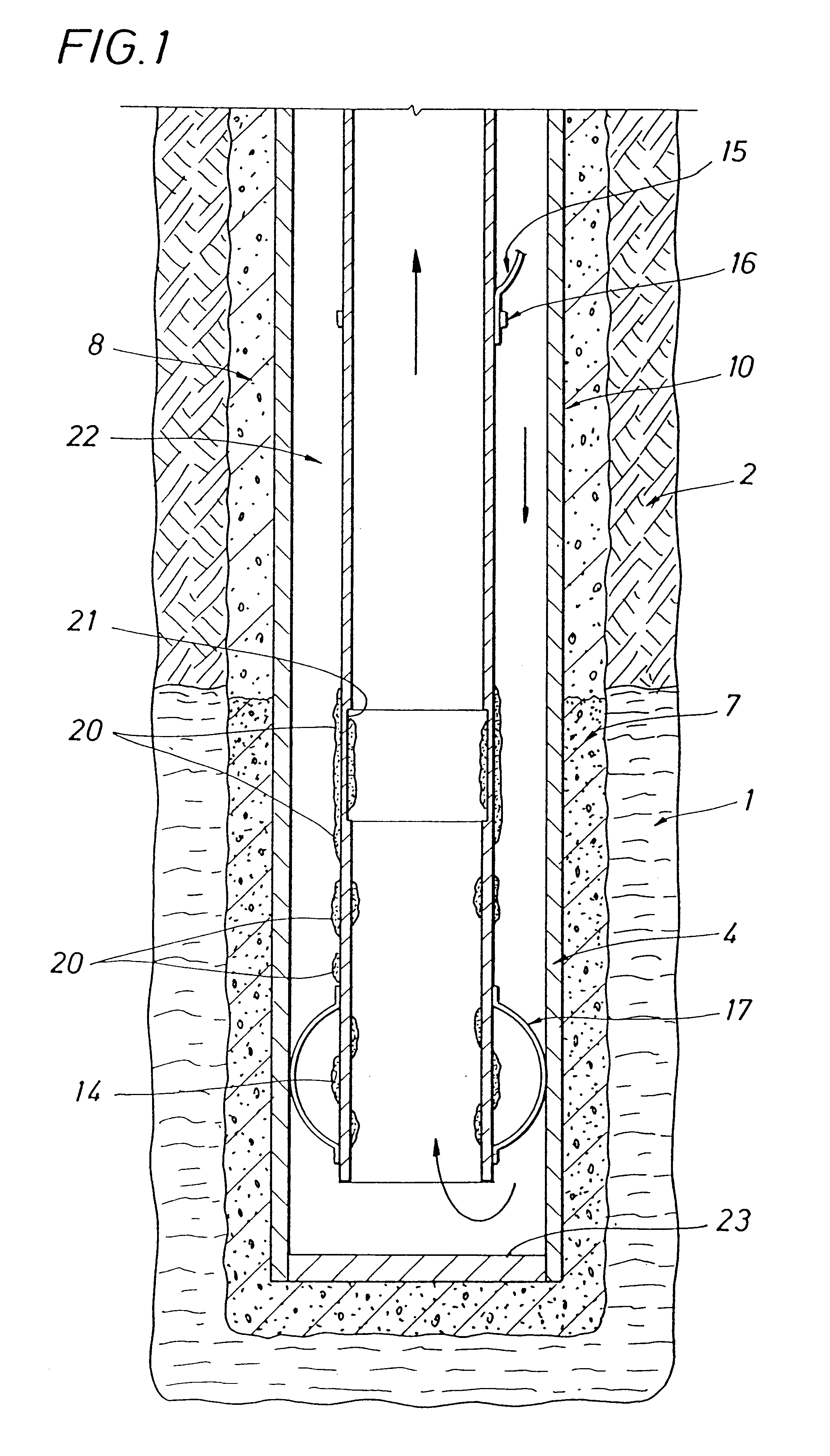

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

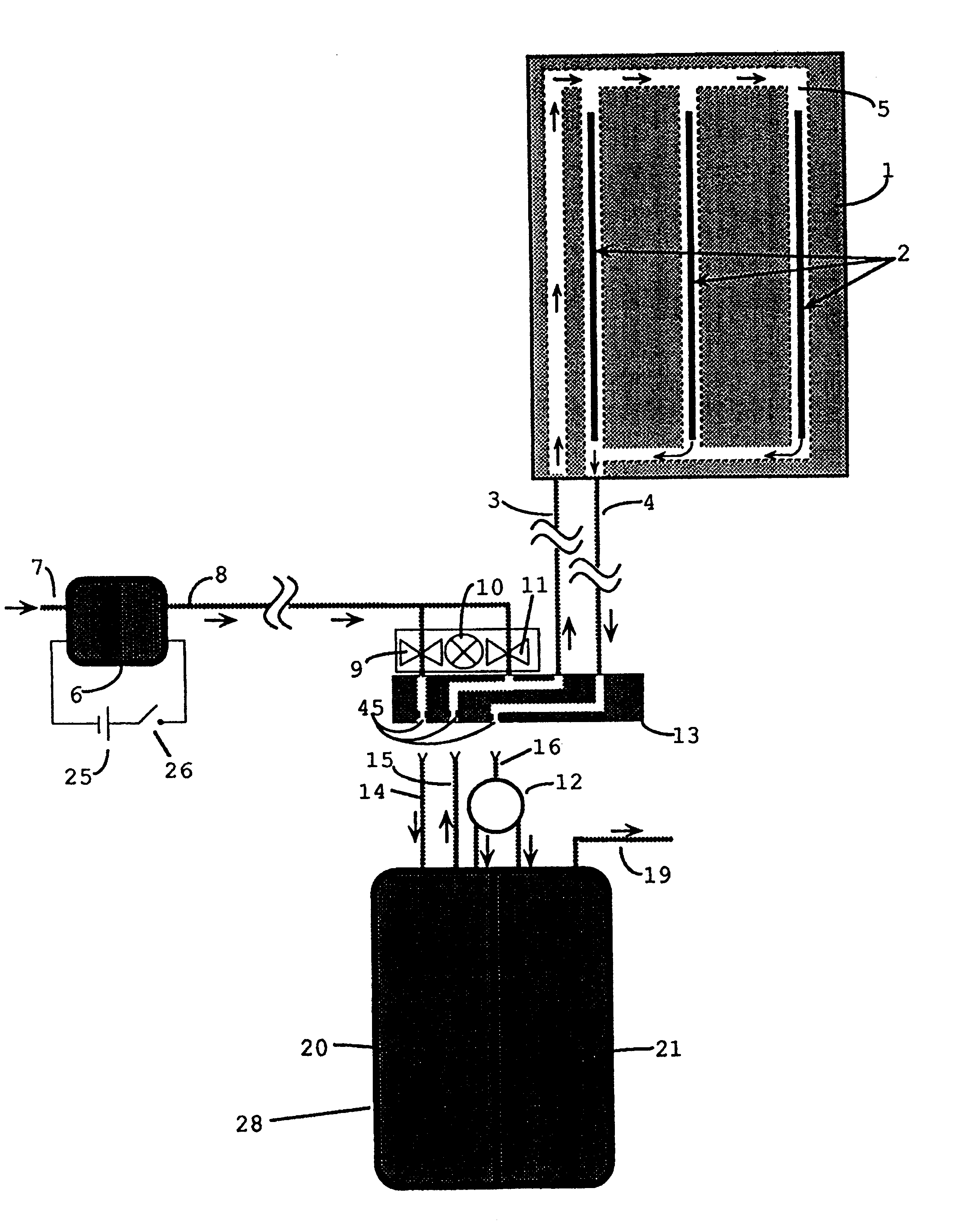

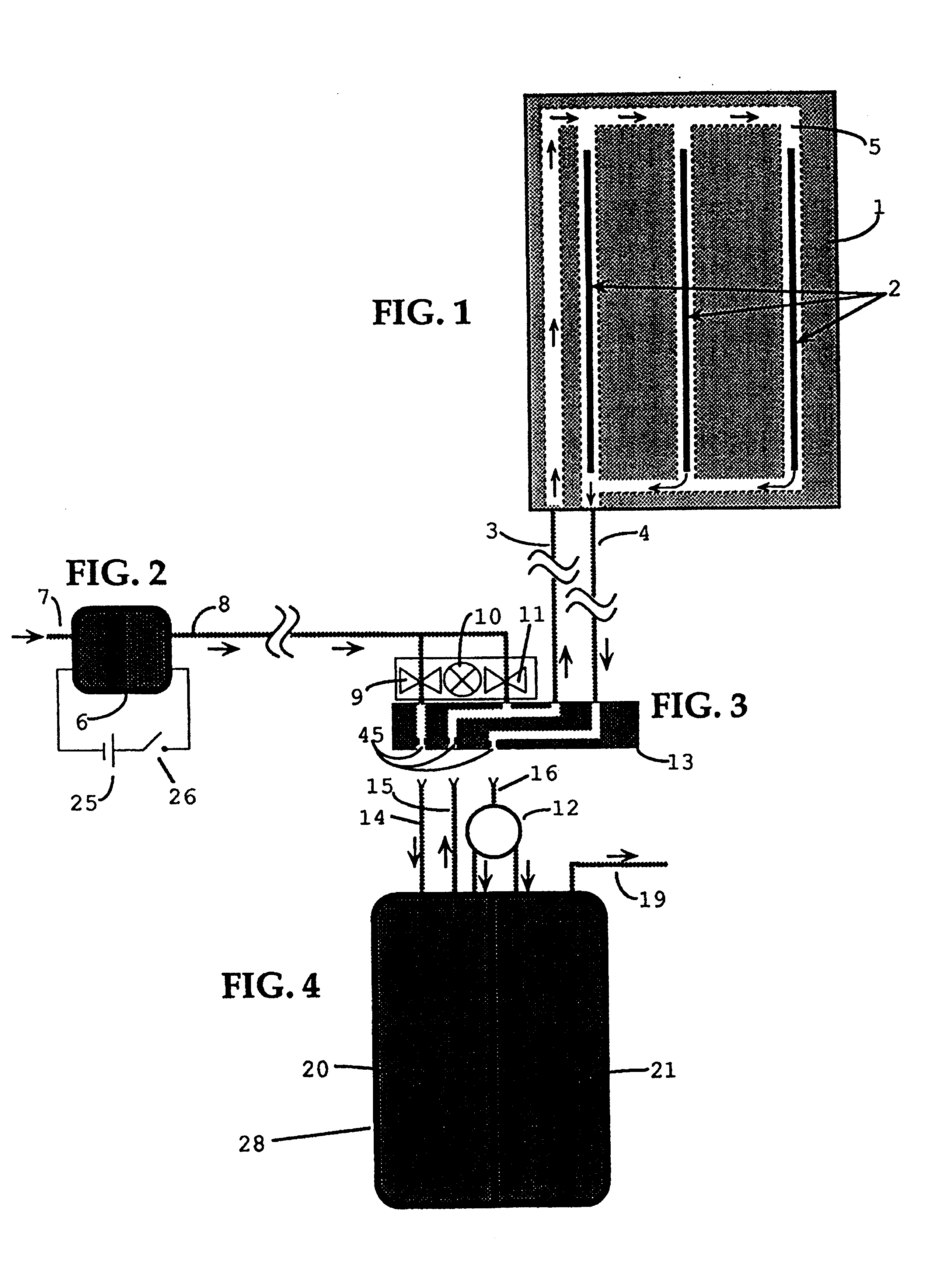

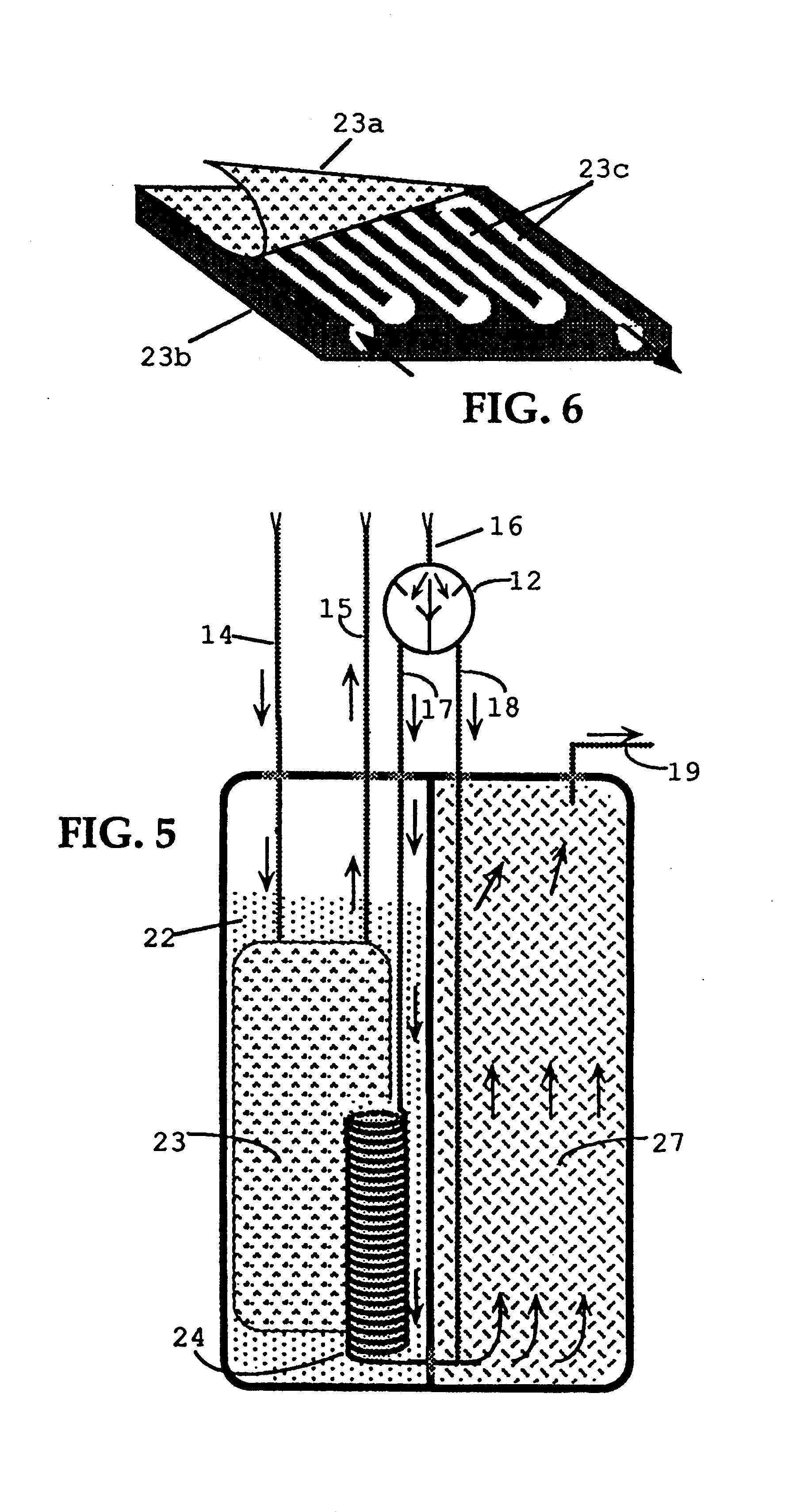

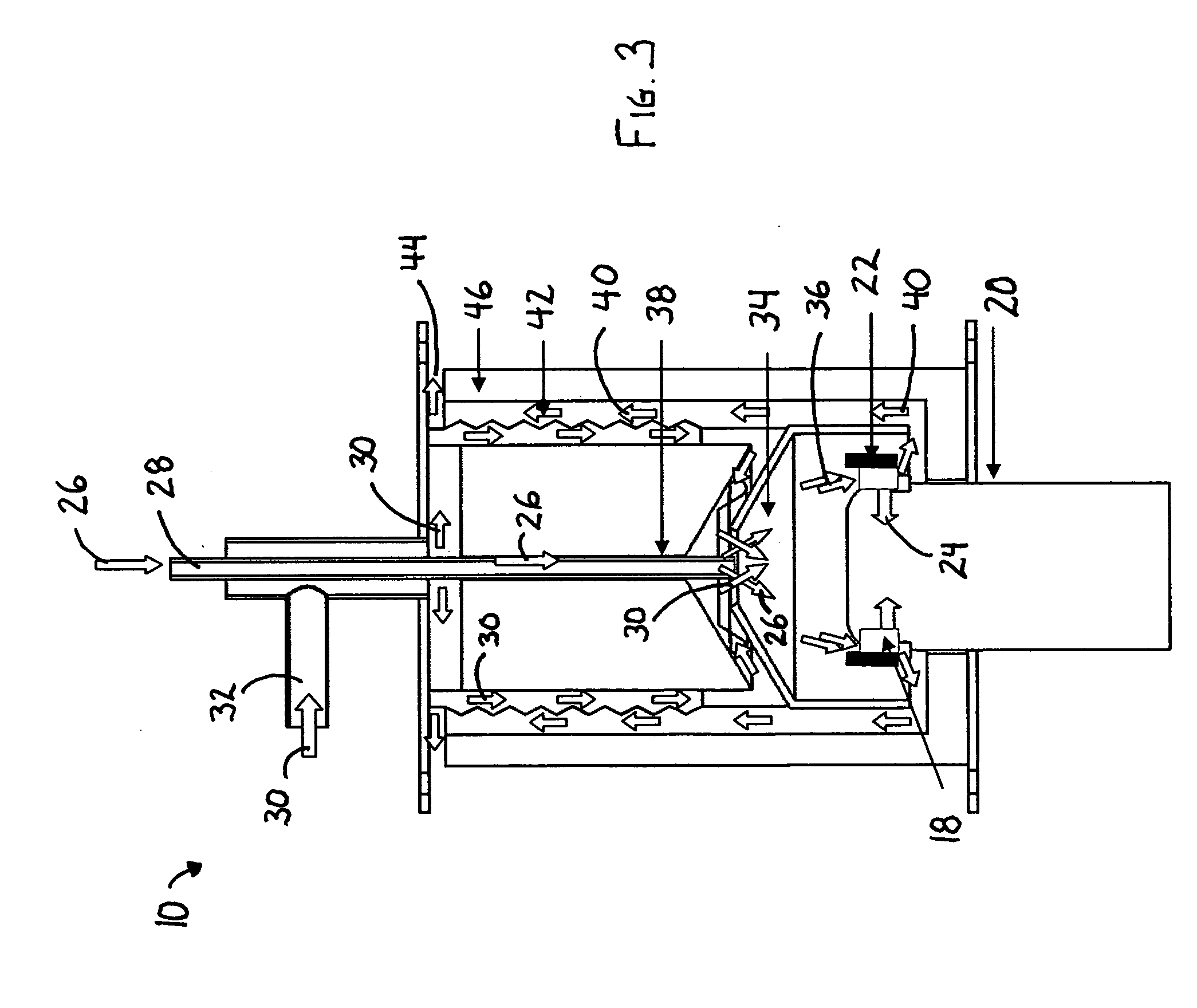

Portable heat generating device

InactiveUS6062210APromotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesElastomerThermal energy

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during start-up or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

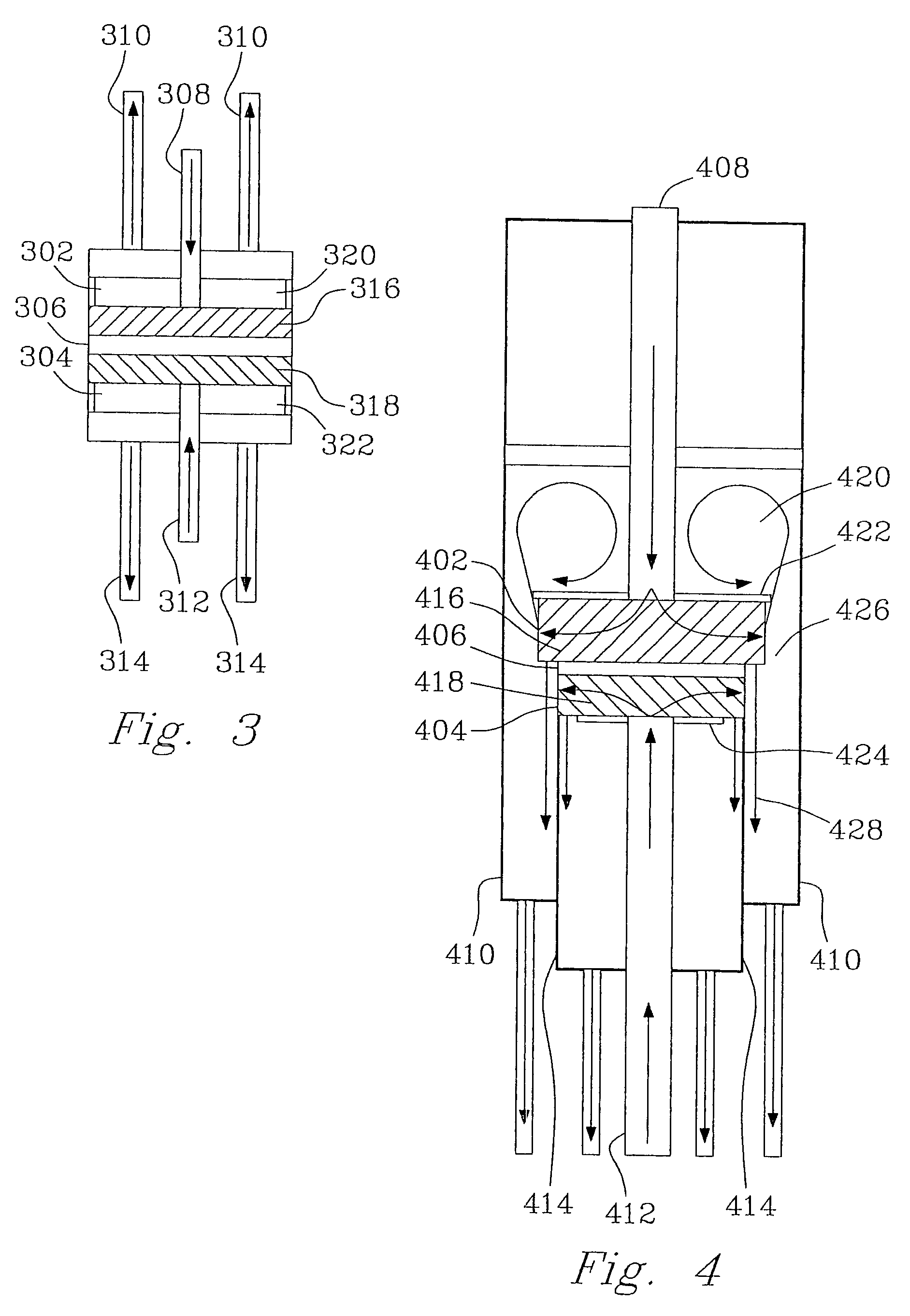

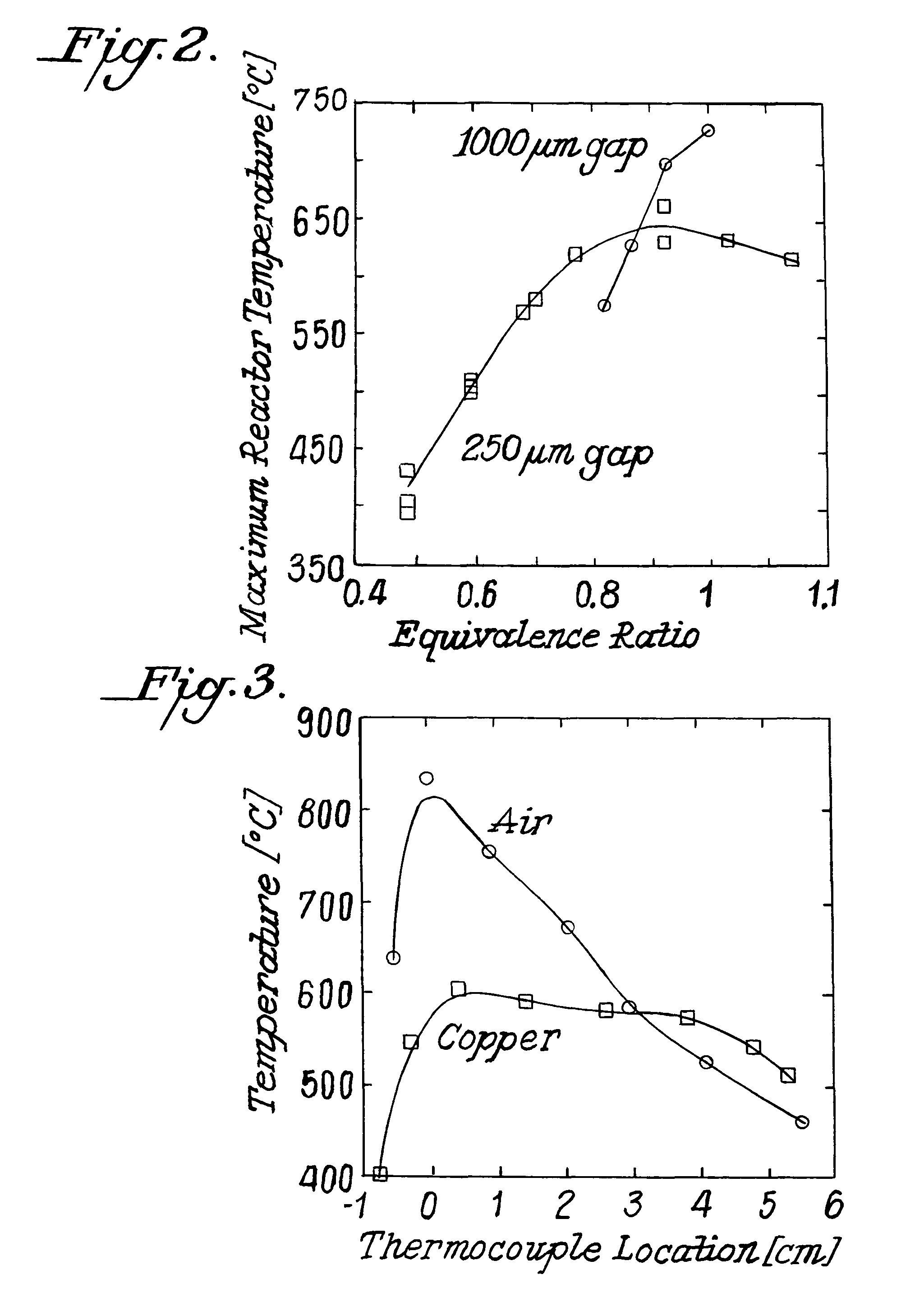

Microcombustors, microreformers, and methods for combusting and for reforming fluids

InactiveUS7077643B2Desirable performance capabilitySmall sizeHydrogenFurnace componentsSteam reformingCombustor

The present invention provides microcombustors, microreformers, and methods of steam reforming alcohols over a catalyst. The microcombustors can be manufactured with a very small size and can operate at very low temperature. Surprisingly superior results and properties obtained in methods of the present invention are also described.

Owner:BATTELLE MEMORIAL INST

Portable heat generating device

InactiveUS6289888B1Promotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesThermal energyElastomer

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a. thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during startup or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

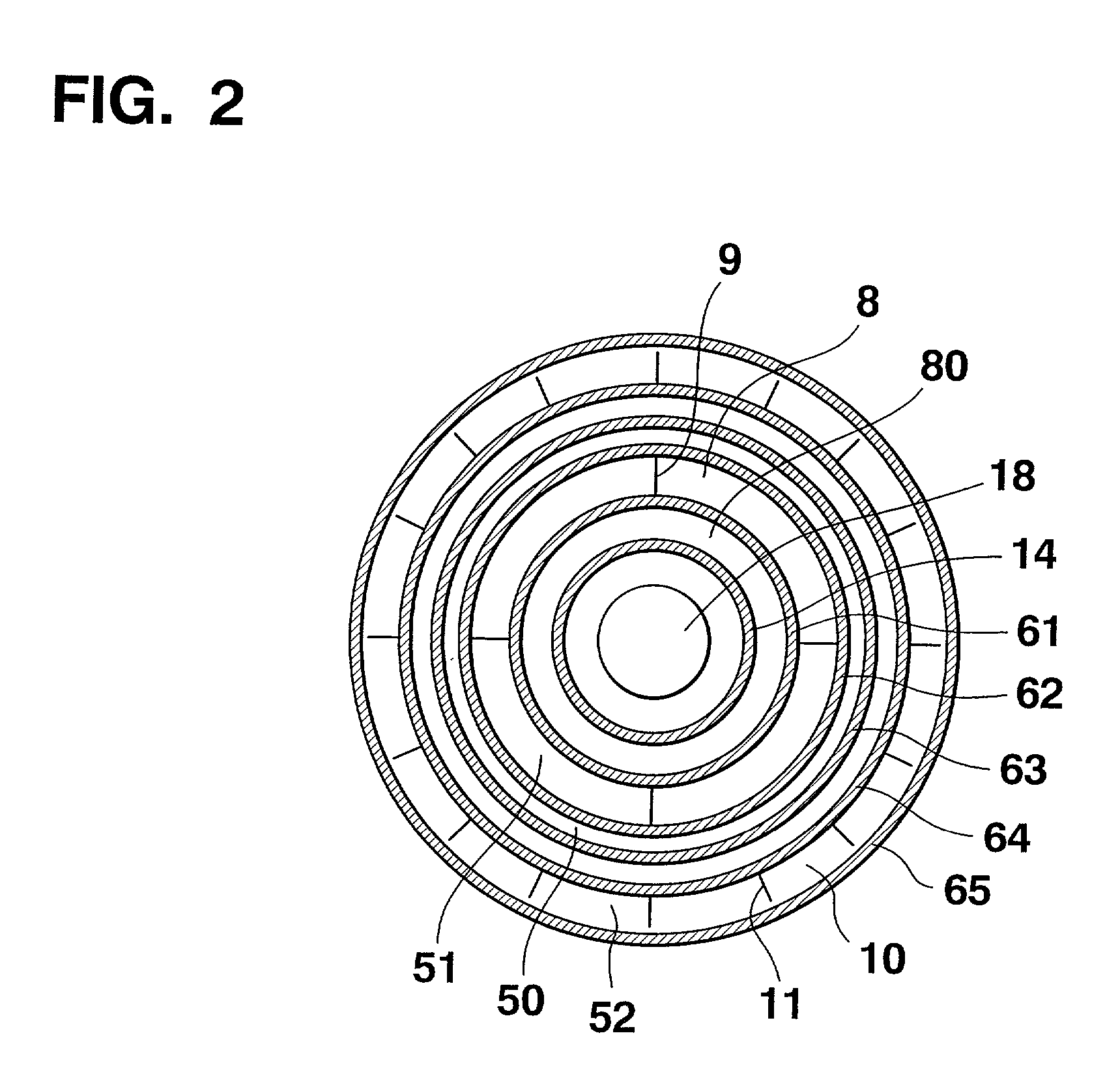

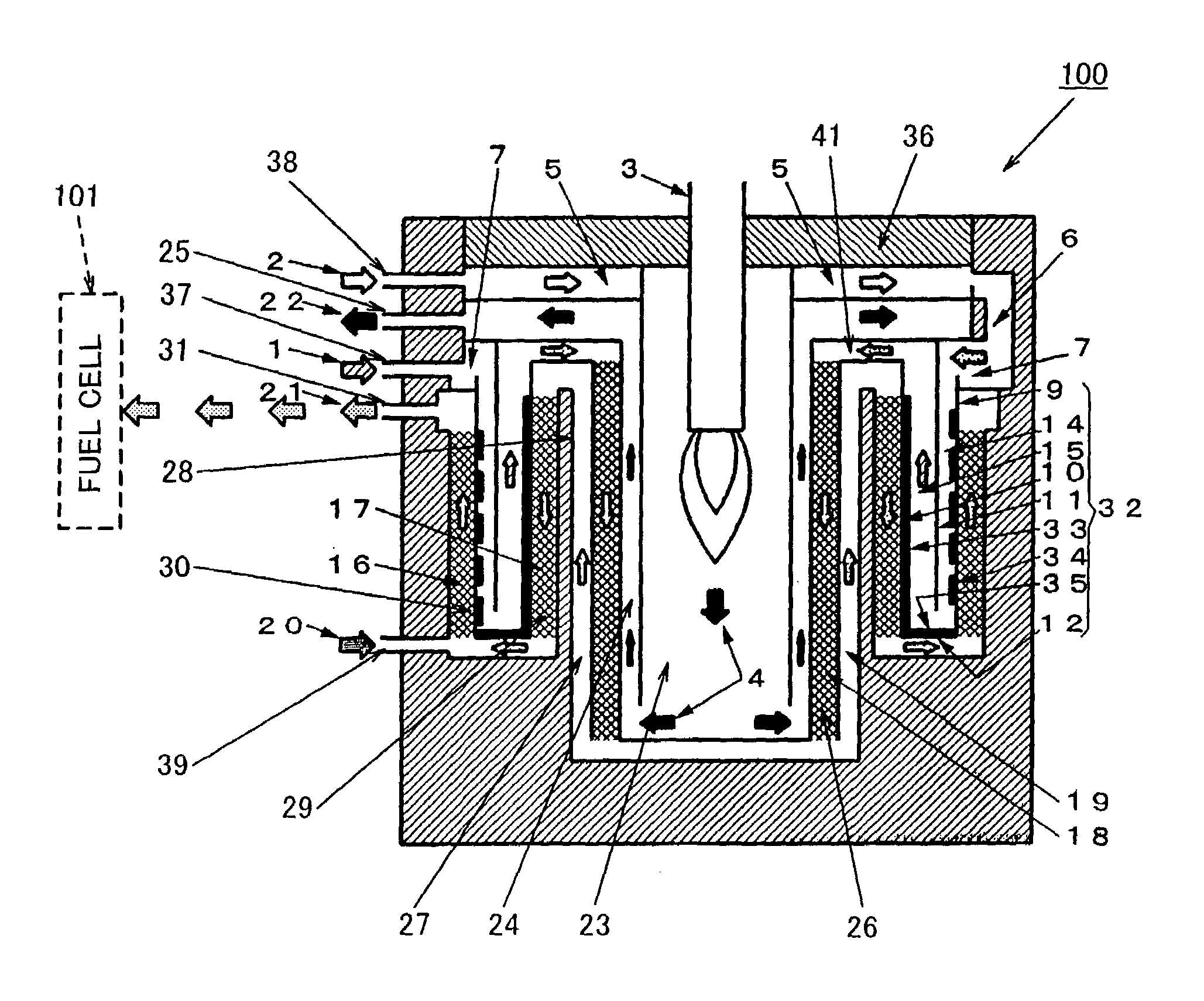

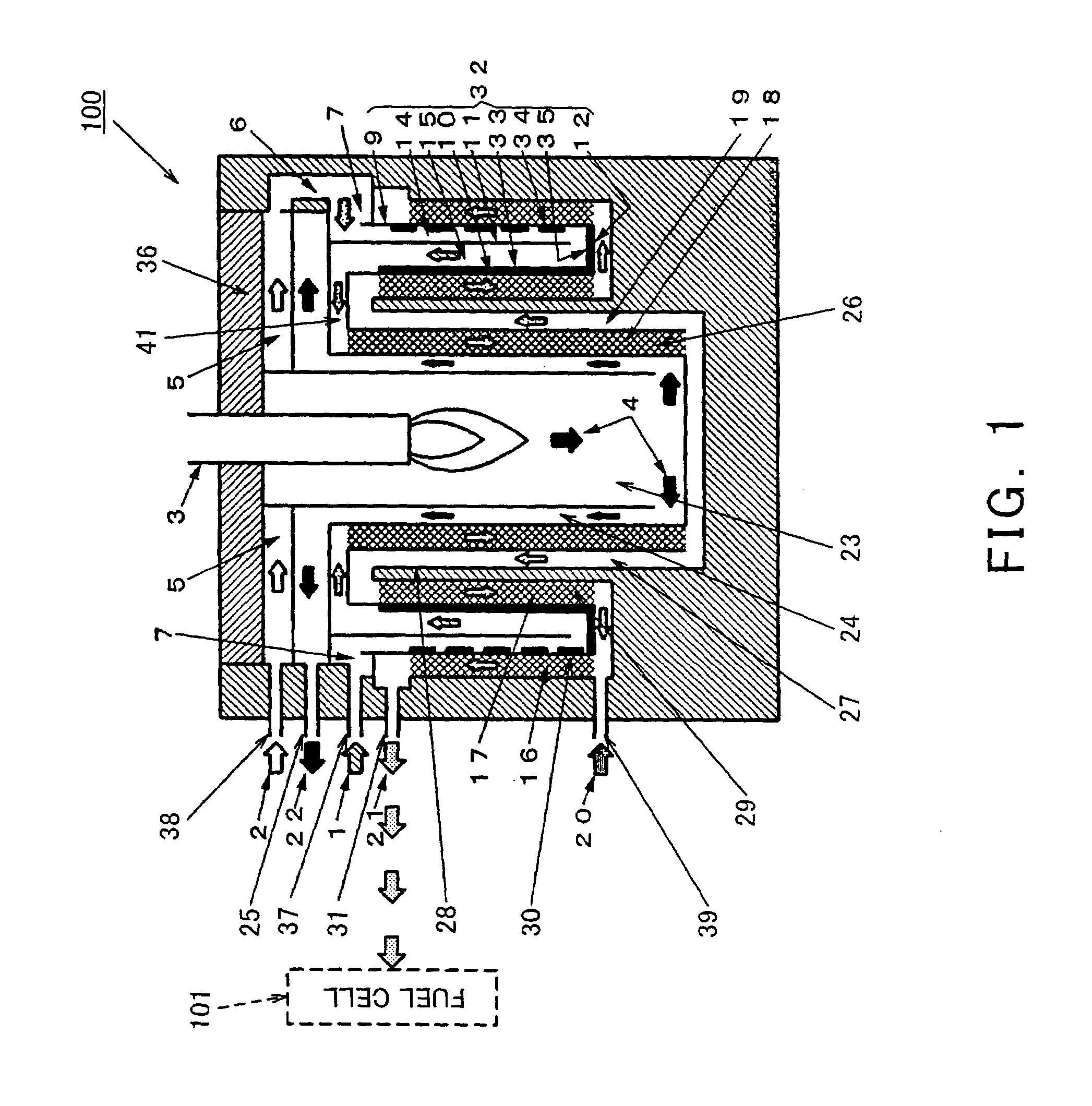

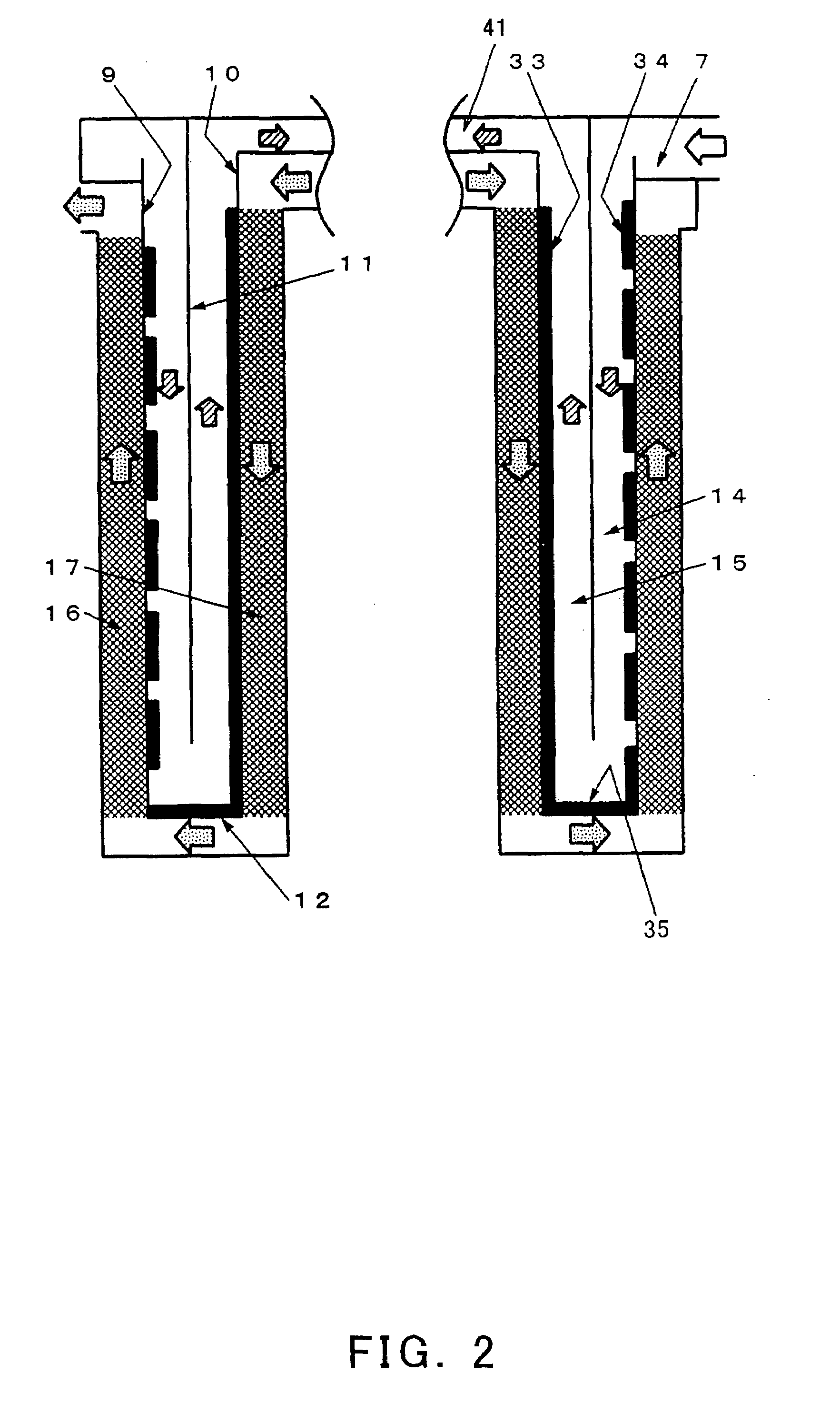

Single-pipe cylinder type reformer

InactiveUS20020042035A1Efficient executionReduce heatPhysical/chemical process catalystsHydrogen separation using solid contactCombustorEngineering

A single-pipe cylinder type reformer of the invention includes a plurality of circular cylinders standing upright coaxially, a radiation cylinder coaxially arranged inside the plurality of circular cylinders, and a burner arranged at one end of the center of the radiation cylinder, and has a reforming catalyst layer obtained by packing with a reforming catalyst at least a first gas flow path closest to the burner among a plurality of gas flow paths divided by the plurality of circular cylinders and having annular cross-sections. A pre-heat layer formed on one end side (upstream) of the reforming catalyst layer packed with the reforming catalyst is packed with a metal packing. Helical dividing means are provided in the respective gas flow paths to extend in the axial direction of the circular cylinders. The helical dividing means helically divide a gas and makes it flow through the first gas flow path.

Owner:TOKYO GAS CO LTD

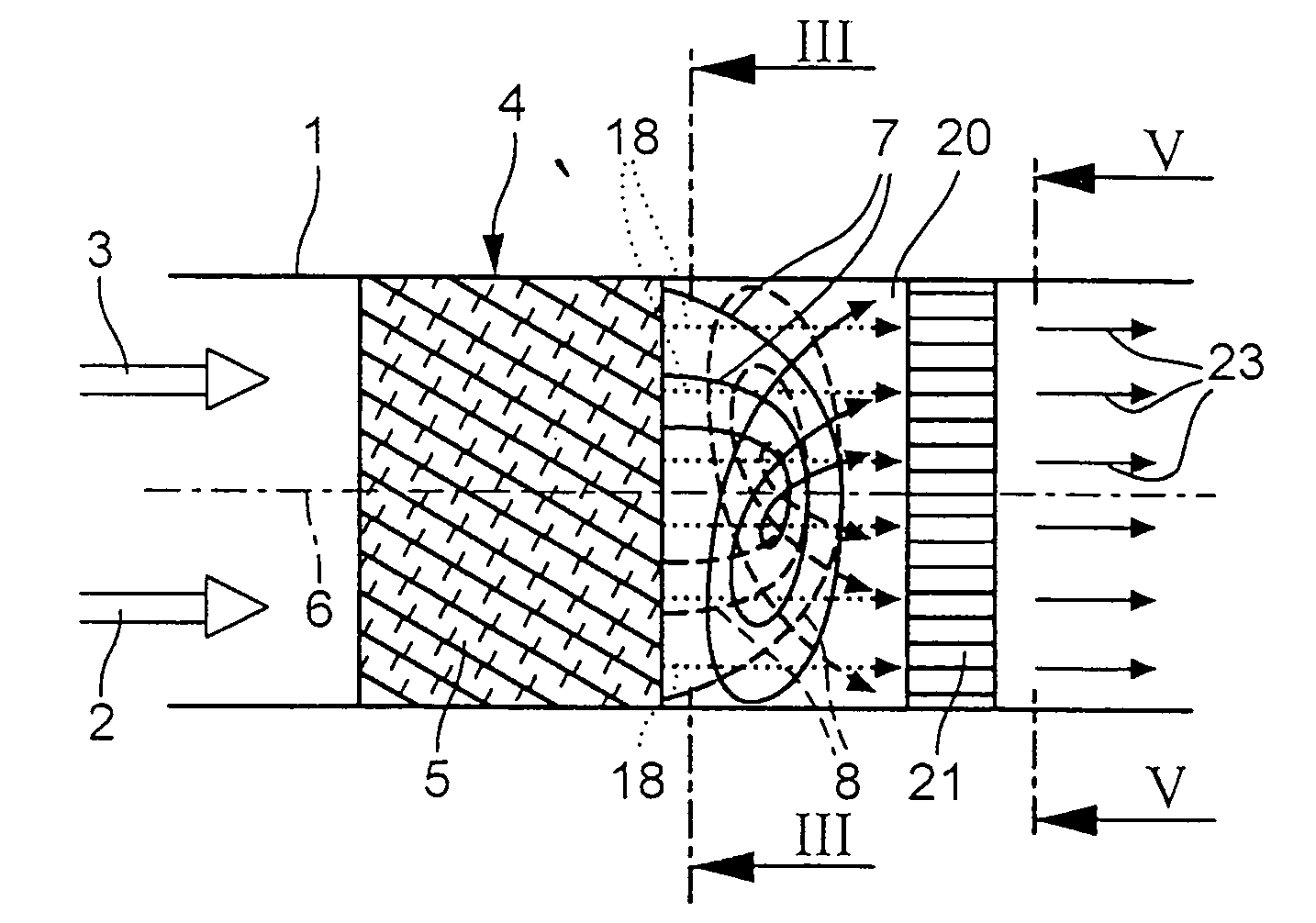

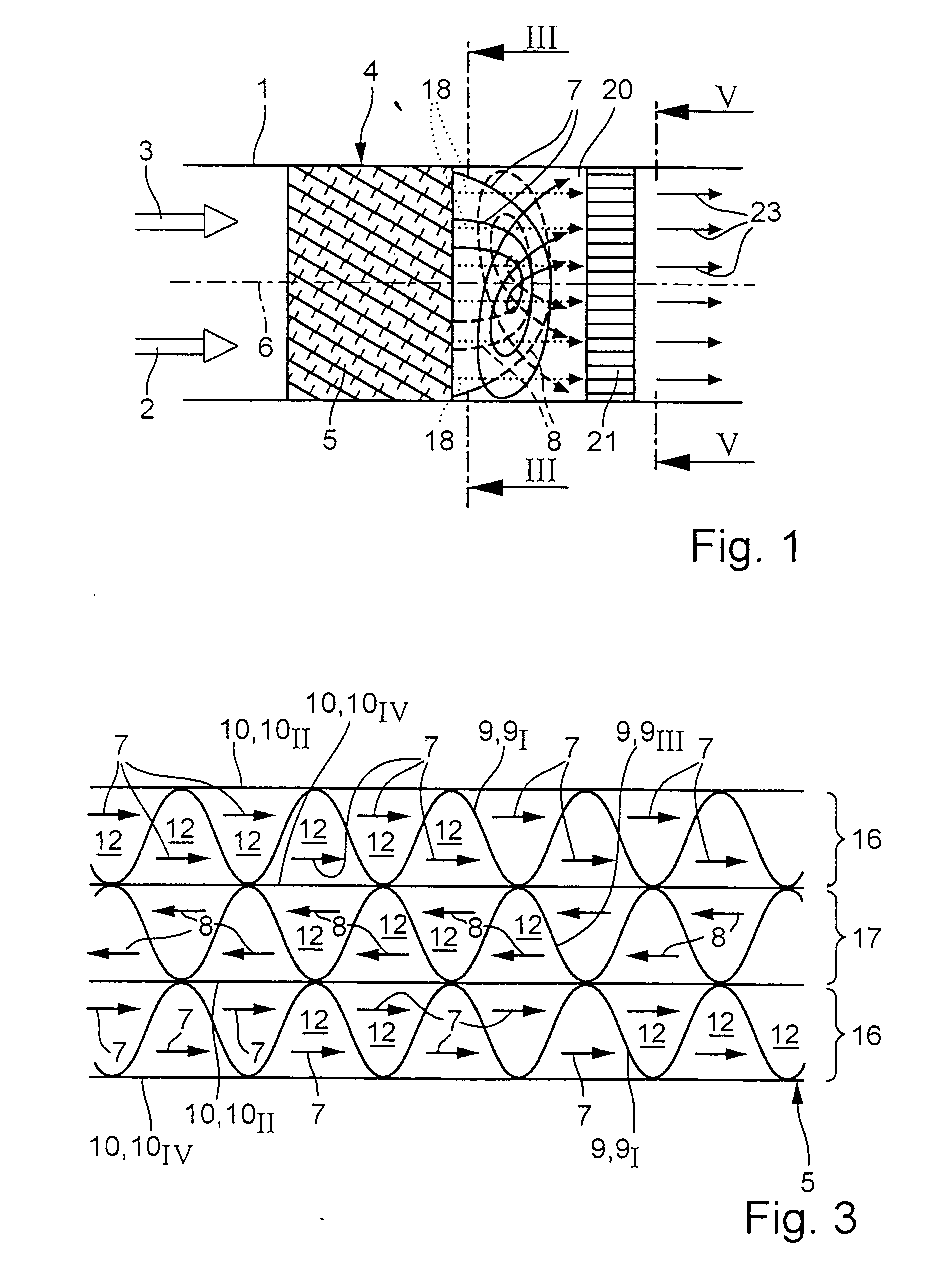

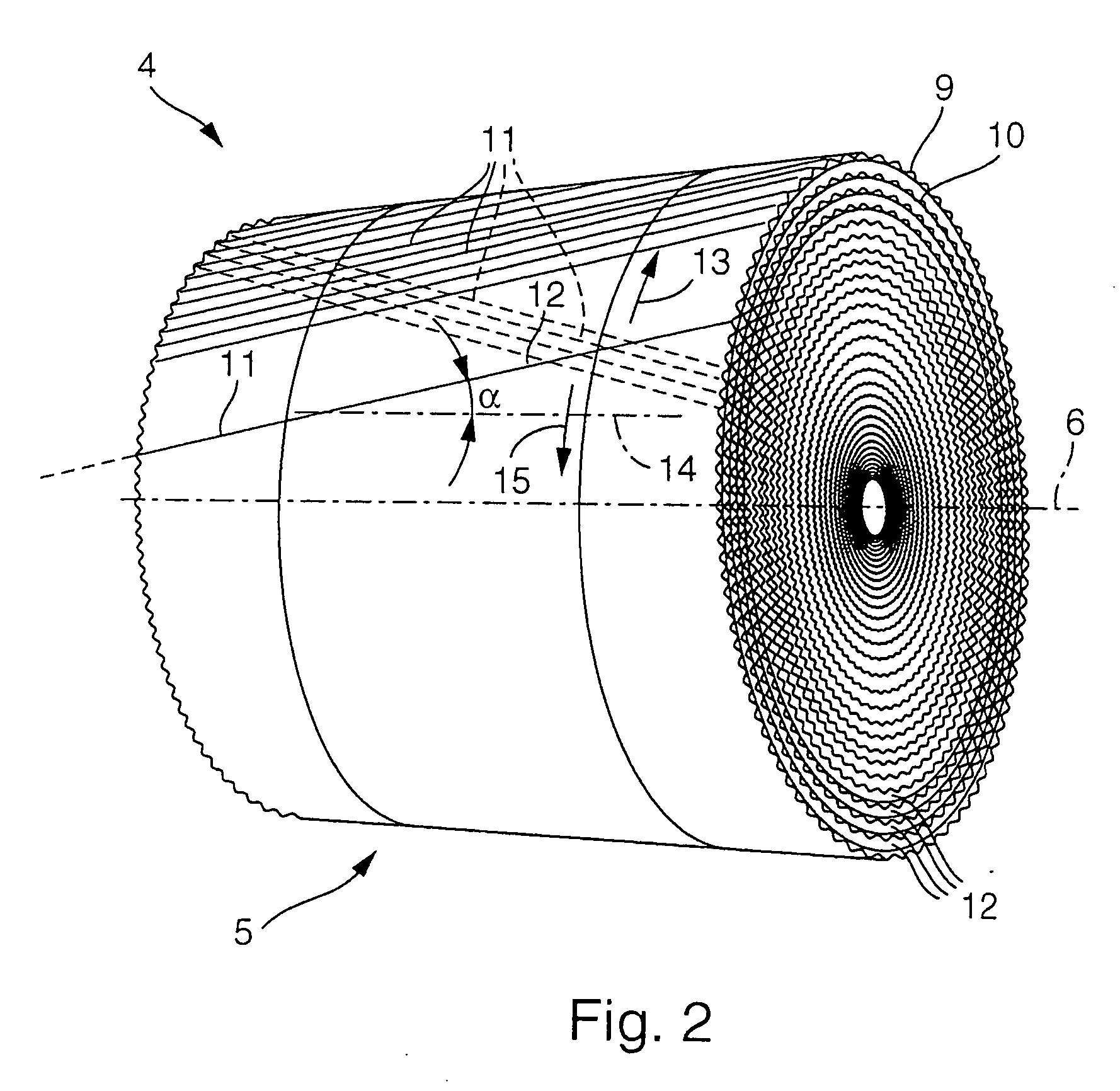

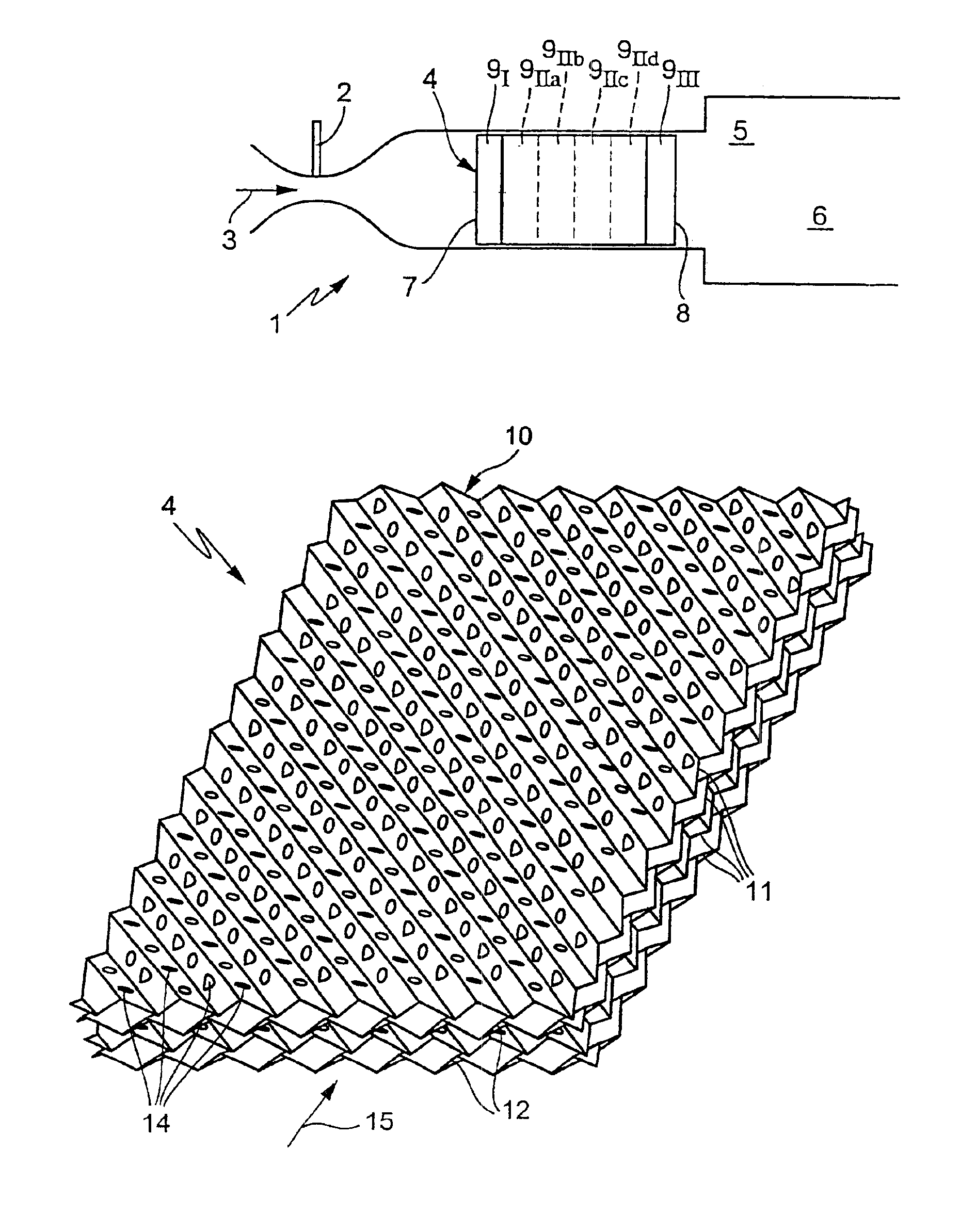

Method and device for mixing fluid flows

The present invention relates to a method for mixing at least two separate fluid flows (2, 3), in particular for a burner of a power plant. To improve the mixing, a plurality of swirl flows (7, 8), which are annular and concentric with respect to a longitudinal center line (6), are generated from the fluid flows (2, 3), in such a manner that radially adjacent swirl flows (7, 8) have opposite directions of rotation.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Low vapor pressure fuels for use in catalytic burners

Low vapor pressure compound-based fuels are provided. These fuels are useful in catalytic burner systems that can be used to disperse fragrances, insecticides, insect repellants (e.g., citronella), aromatherapy compounds, medicinal compounds, deodorizing compounds, disinfectant compositions, fungicides and herbicides.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

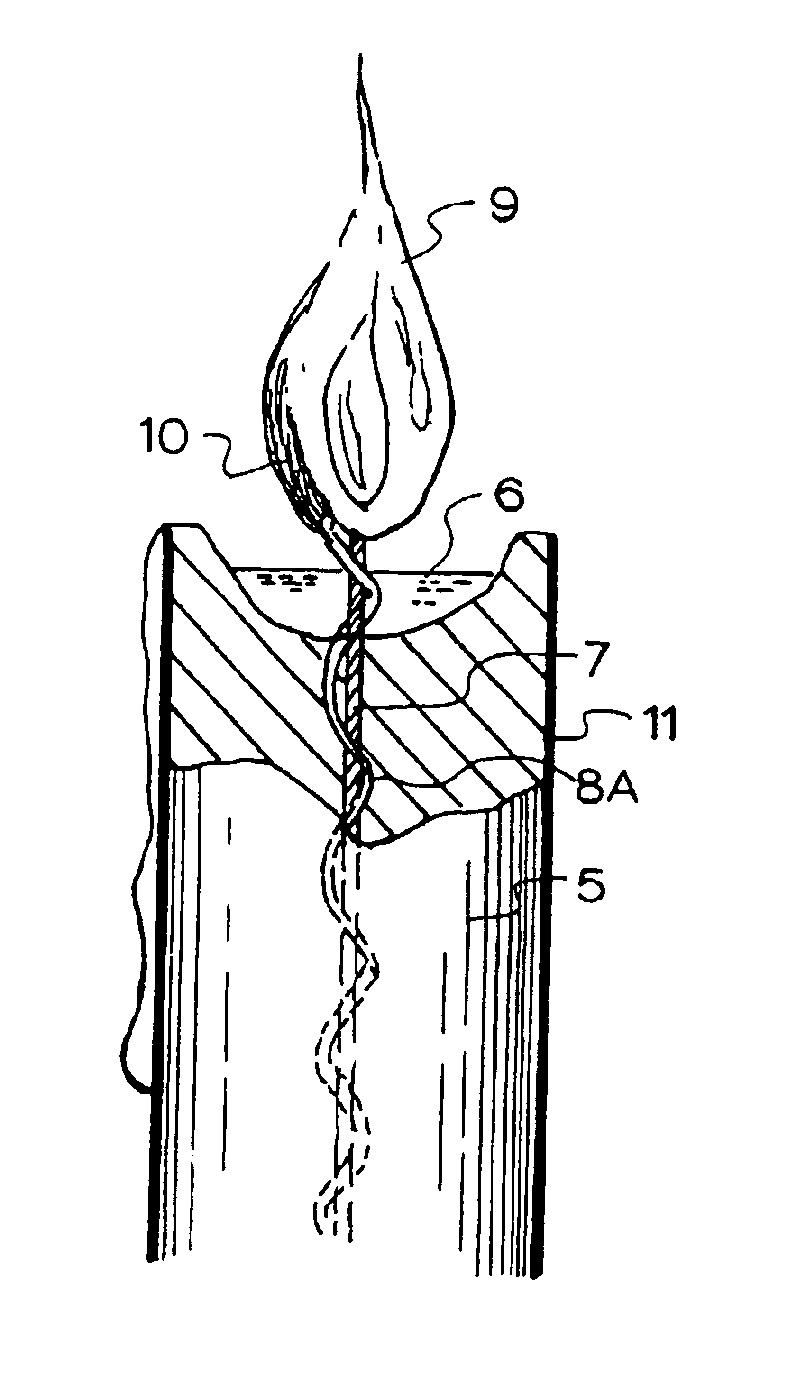

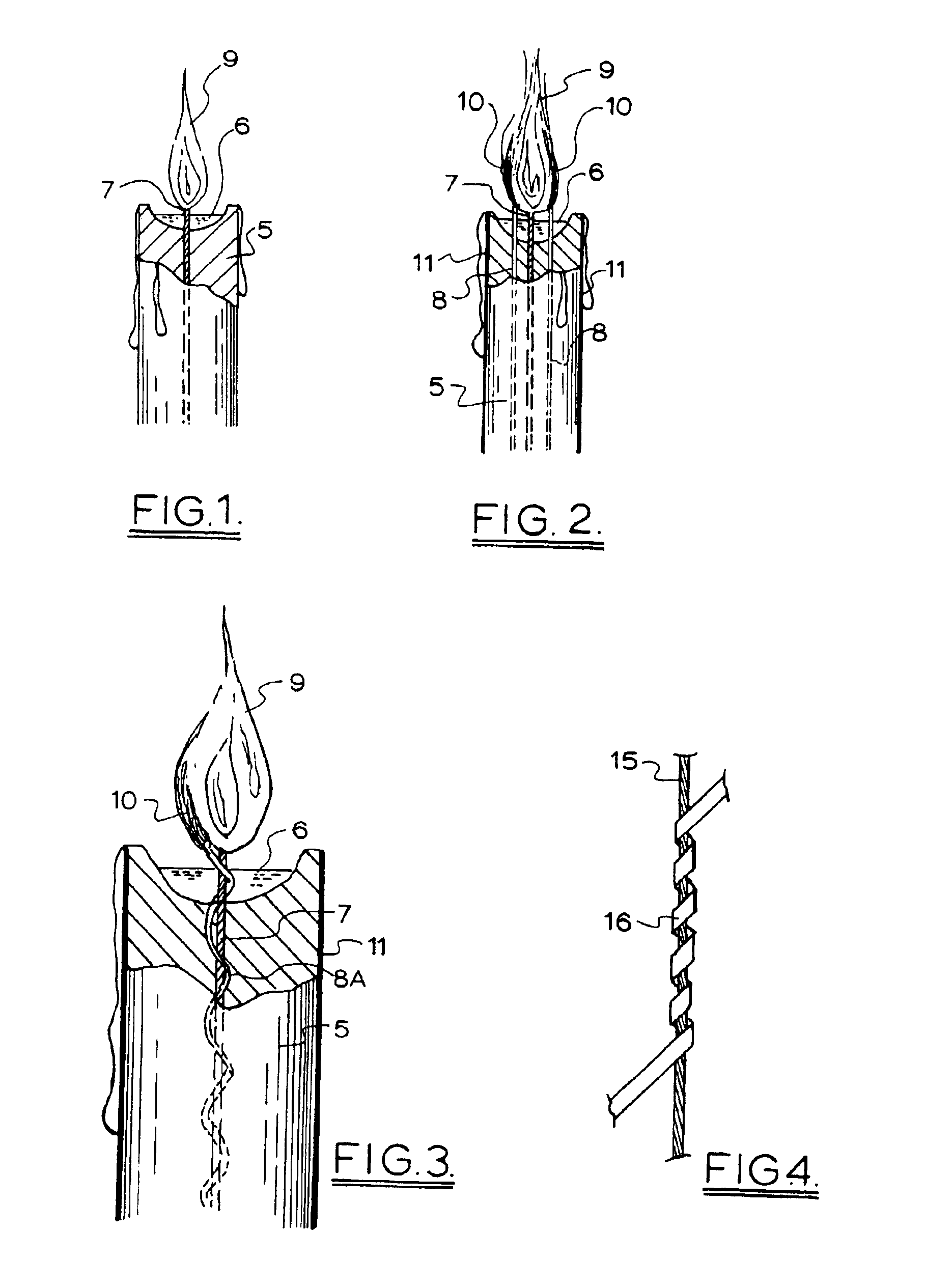

Candles with colored flames

A candle with transparent flame and flame temperature higher than paraffin candles consists of a fuel mix consisting of sorbitol, ethane diol and glycerol with a polyaramid wick. The candle can be used in catering and for the production of colored flames. For colored flames a colorant wick delivers the colorant to the portion of the flame that maximises the temperature and the residence time of the colorant in the flame. The colorant wick may be spirally wound around a former, heat set and then threaded with the combustion wick so that when alight the free end of the colorant wick relaxes to lie in the hottest portion of the flame.

Owner:NOVAFLAME

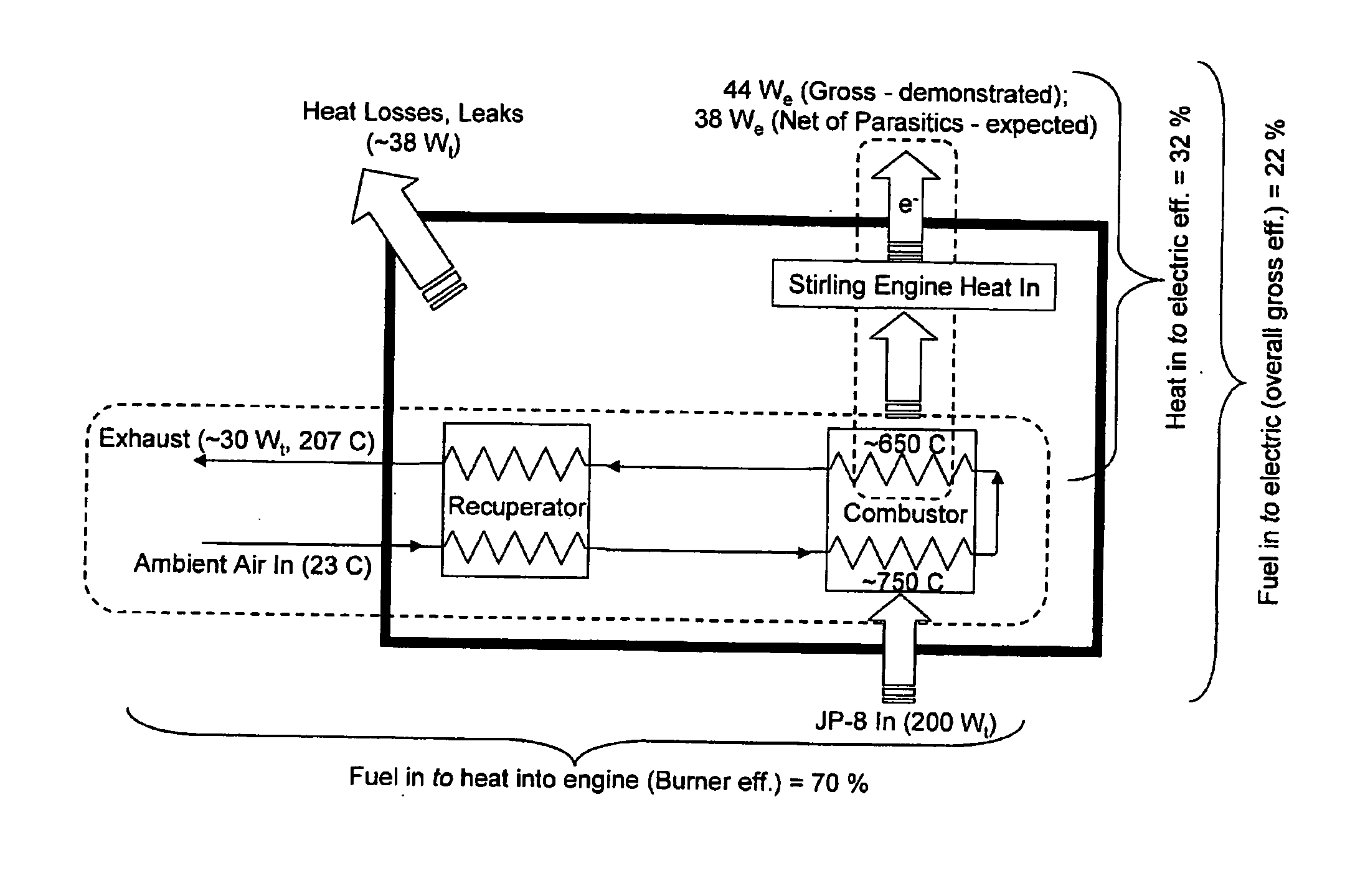

Catalytic burner for stirling engine

InactiveUS20090113889A1Simple and efficient and effectiveEffective at generating heatBurnersCatalytic ignitersExternal combustion engineEngineering

The invention provides a method for transferring heat by conduction to the internal heat acceptor of an external combustion engine. Fuel and air are introduced and mixed to form an air / fuel mixture. The air / fuel mixture is directed into a catalytic reactor that is positioned substantially adjacent to the heater head. Heat is transferred via conduction from the catalytic reactor to the heater head and the catalytic reaction products are exhausted.

Owner:PRECISION COMBUSTION

Jet Cavity Catalytic Heater

ActiveUS20100192937A1Heat generationReduced advantageCombination devicesExothermal chemical reaction heat productionAlcohol fuelThermopile

The present invention is a method of delivering vaporized alcohol fuel through a thermally conductive porous nozzle to a catalytic burner with a plasma cavity and a surrounding porous catalytic cavity with fuel vapor and air supplied separately and inter diffusing into each other from different routes to the catalyst to achieve an efficient, steady, and complete combustion of the hydrogen bearing fuels. This heating system with passive auto thermostatic behavior, coupled to thermopiles, heat pipes and fluid heating systems may provide useful heat and electricity to applications of floors, roadways, runways, electronics, refrigerators, machinery, automobiles, structures, and fuel cells.

Owner:GHT GLOBAL HEATING TECH

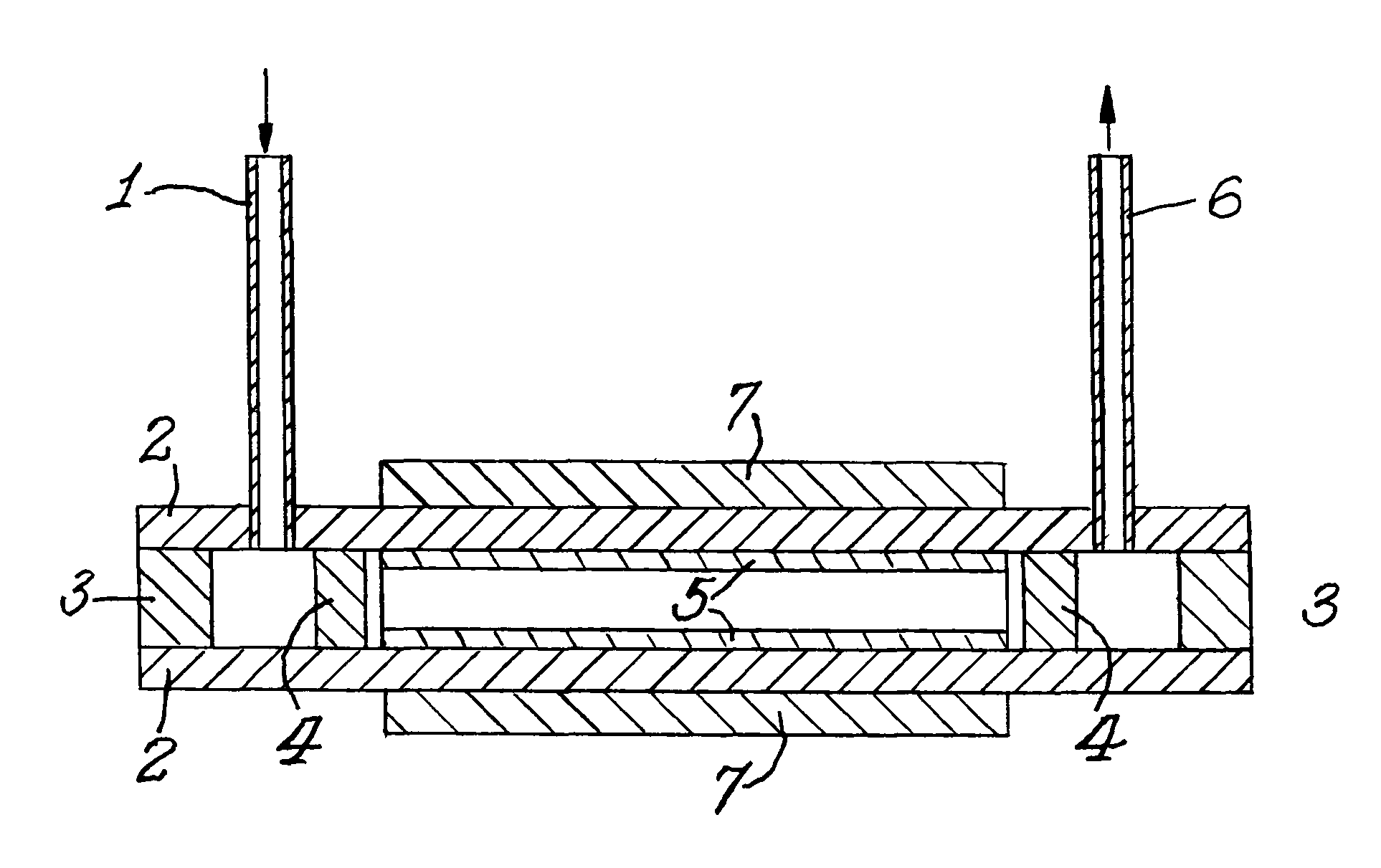

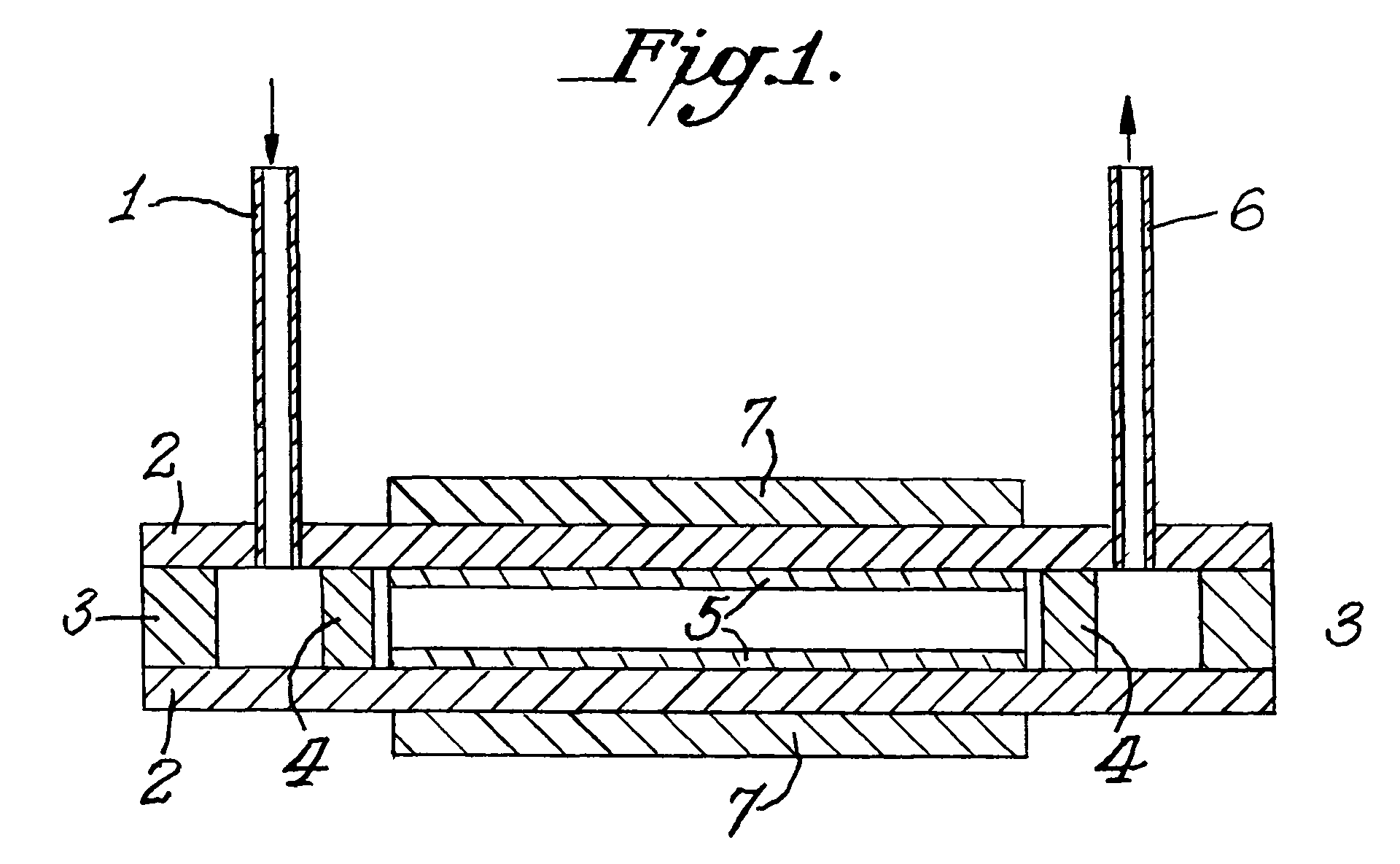

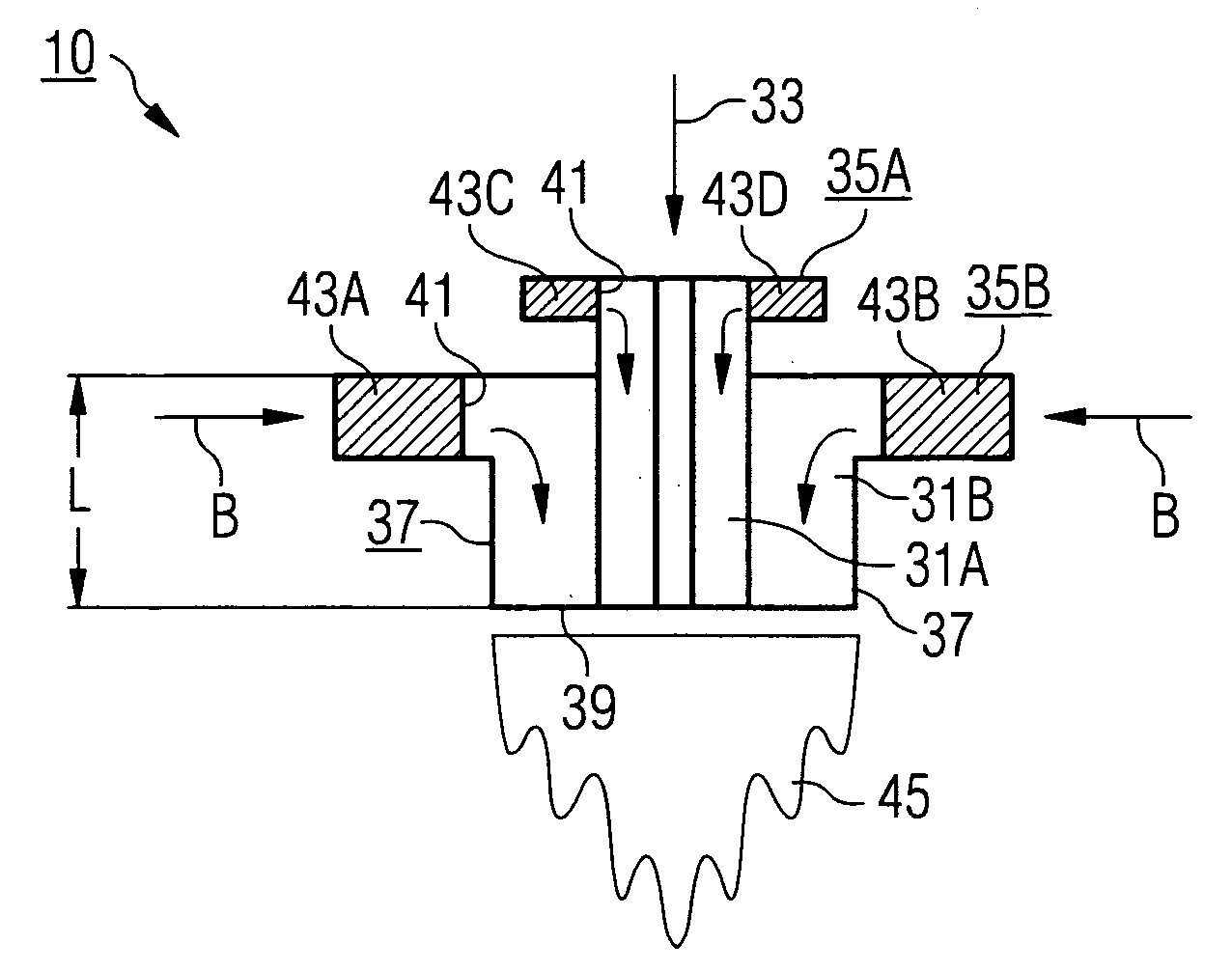

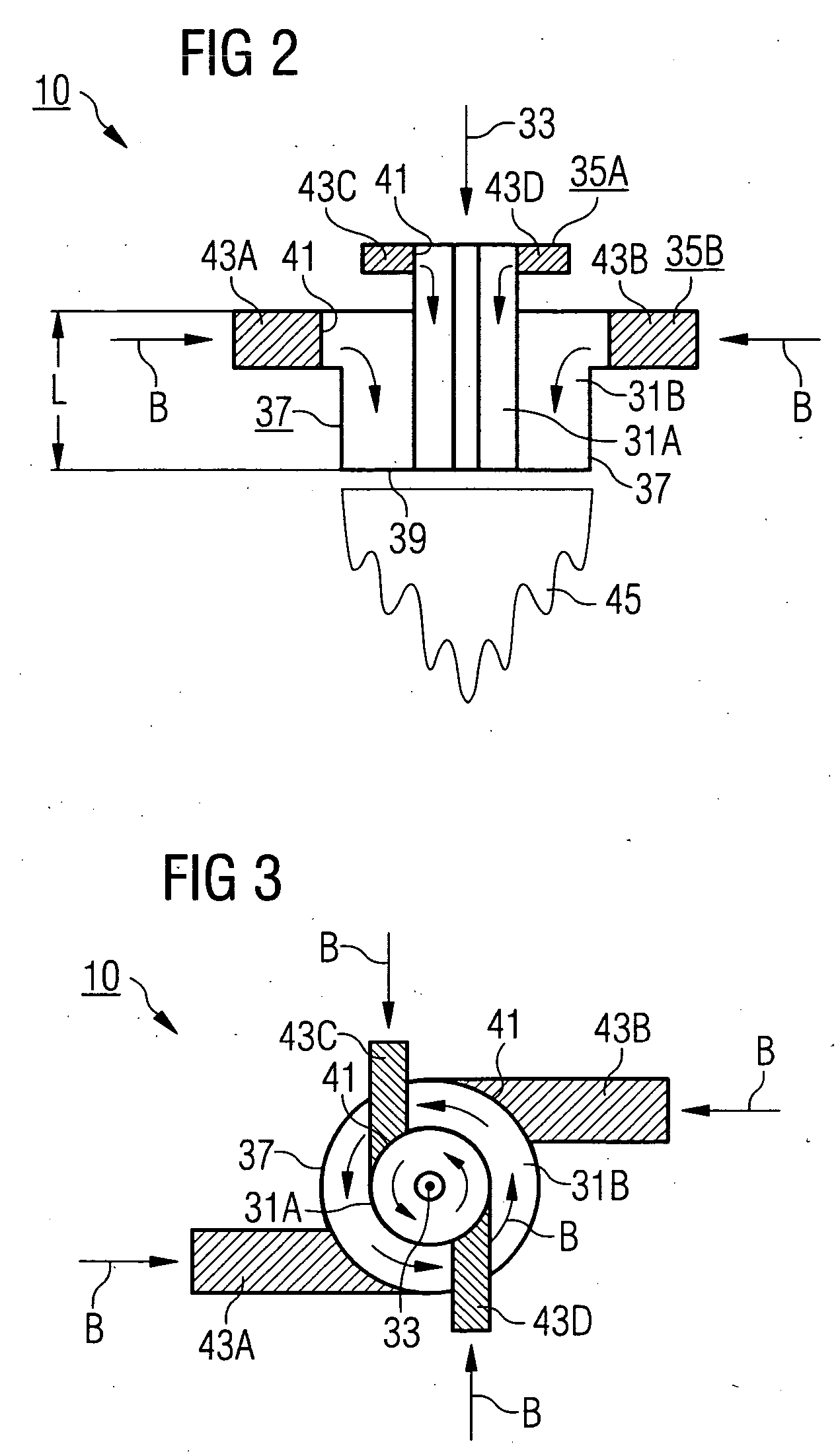

Catalytic microcombustors for compact power or heat generation

InactiveUS7862331B2Increase energy densityHigh yieldInternal combustion piston enginesThermoelectric device with peltier/seeback effectCombustion chamberEngineering

The present invention comprises a device which utilizes catalytic microcombustion for the production of heat or power and which exhibits a low pressure drop and has a high catalytic surface area. The catalytic microcombustor includes catalyst inserts in the reaction chamber separated by a sub millimeter distance. Thermal spreaders ensure temperature uniformity and maximum thermal efficiency. A mixing zone is prior to the combustion zone. Thermally conductive and / or insulating inserts are in the vicinity of the reaction zone.

Owner:DELAWARE UNIV OF A DE

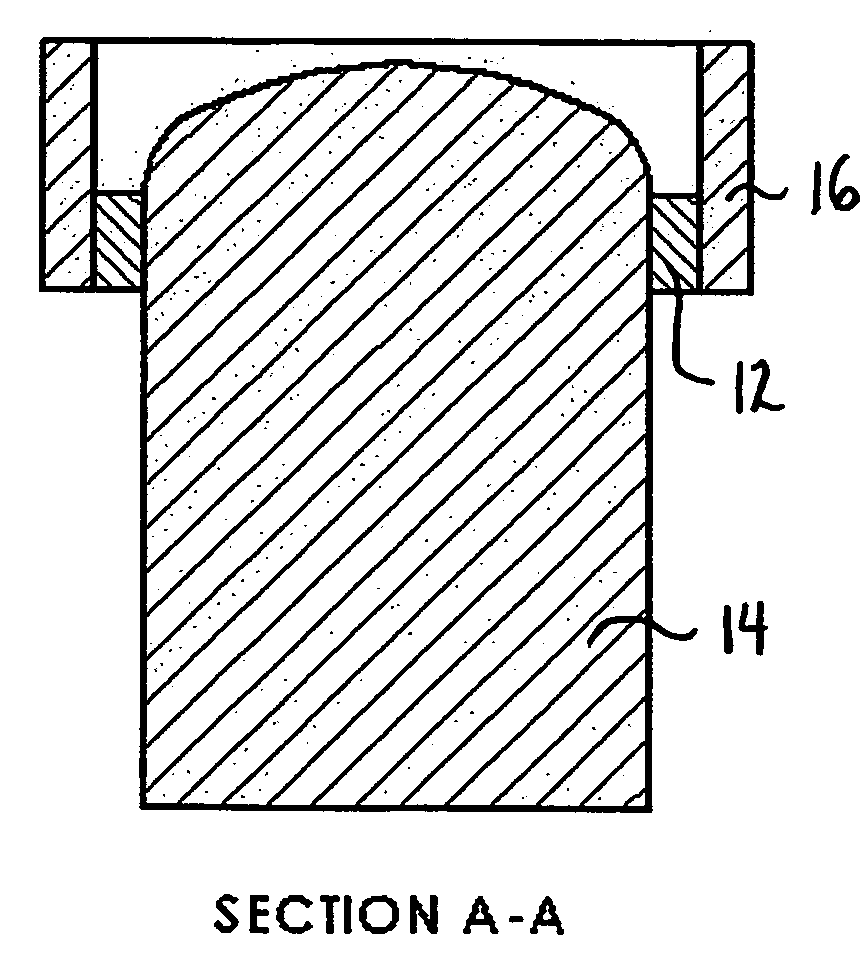

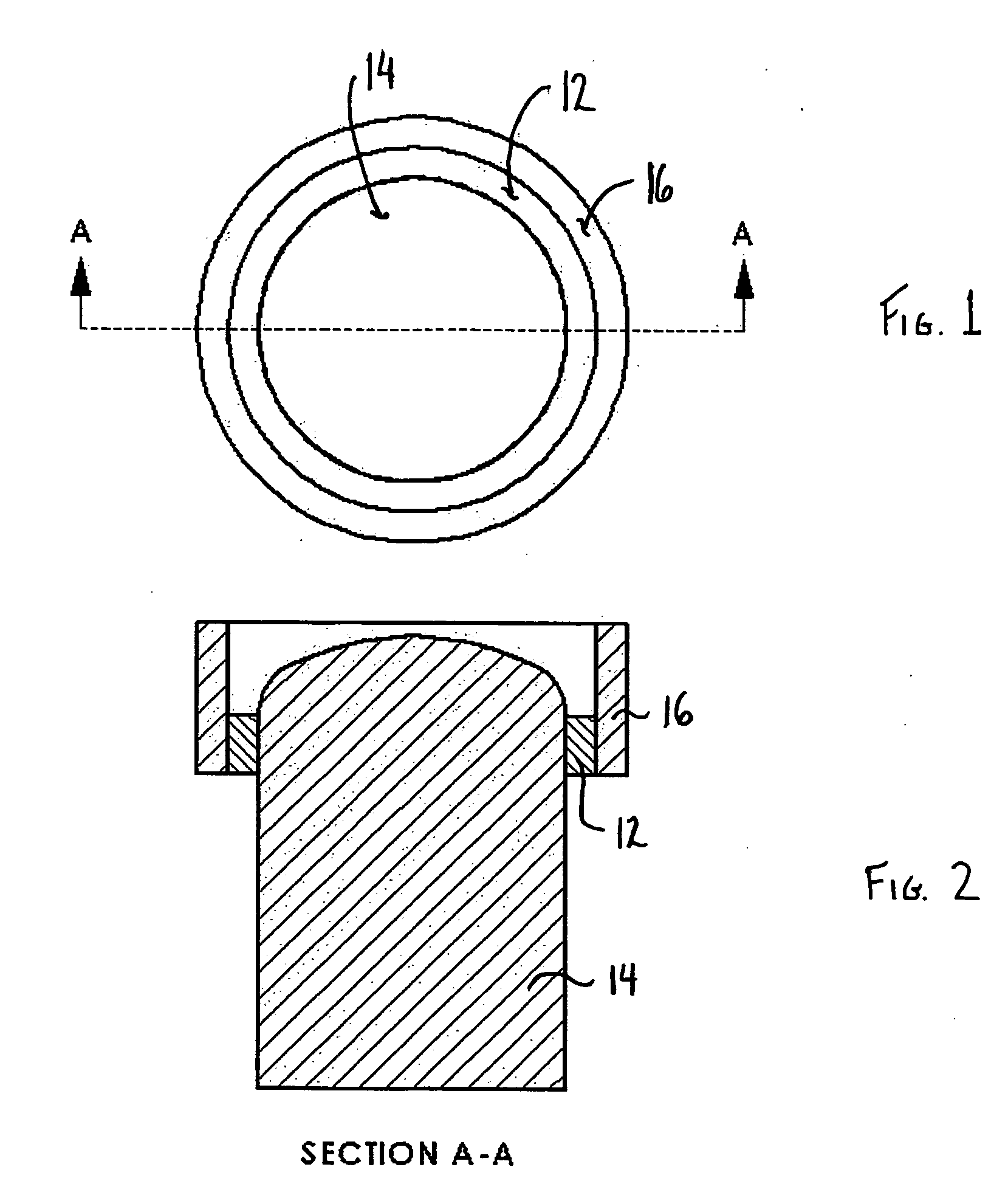

Flow conditioner for fuel injector for combustor and method for low-NOx combustor

InactiveUS8528334B2Continuous combustion chamberTurbine/propulsion engine ignitionCoated surfaceCombustor

An injector for a gas turbine combustor including a catalyst coated surface forming a passage for feed gas flow and a channel for oxidant gas flow establishing an axial gas flow through a flow conditioner disposed at least partially within an inner wall of the injector. The flow conditioner includes a length with an interior passage opening into upstream and downstream ends for passage of the axial gas flow. An interior diameter of the interior passage smoothly reduces and then increases from upstream to downstream ends.

Owner:SOLAR TURBINES

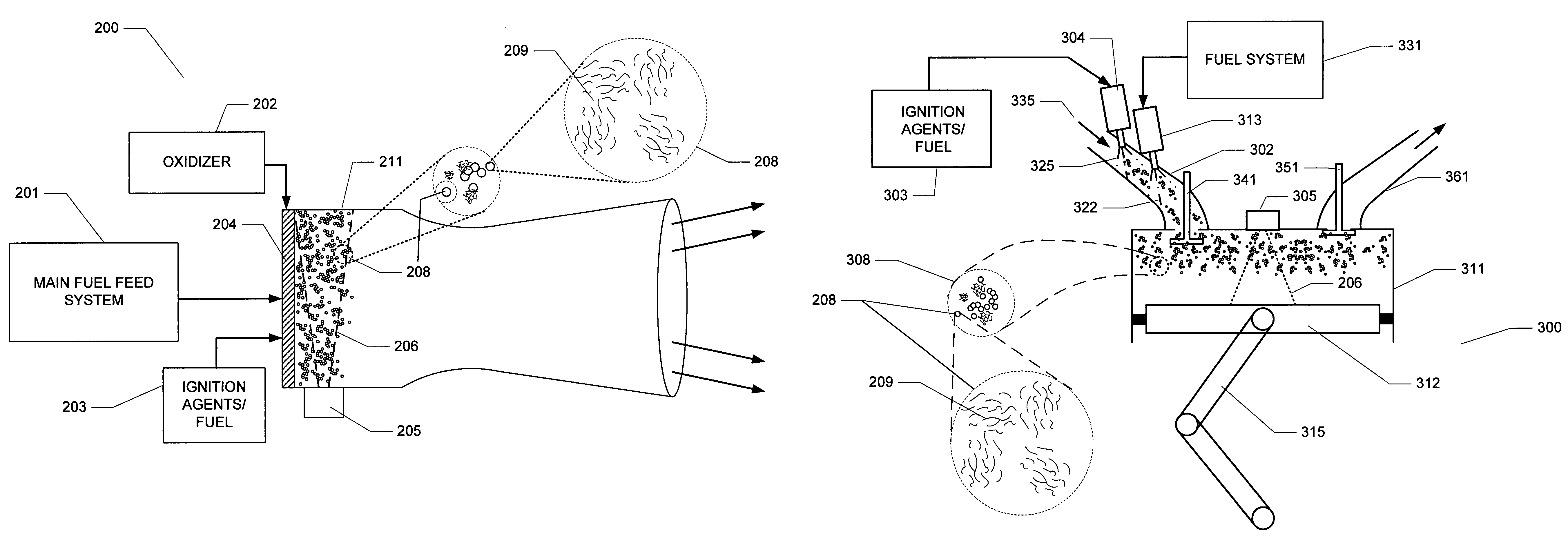

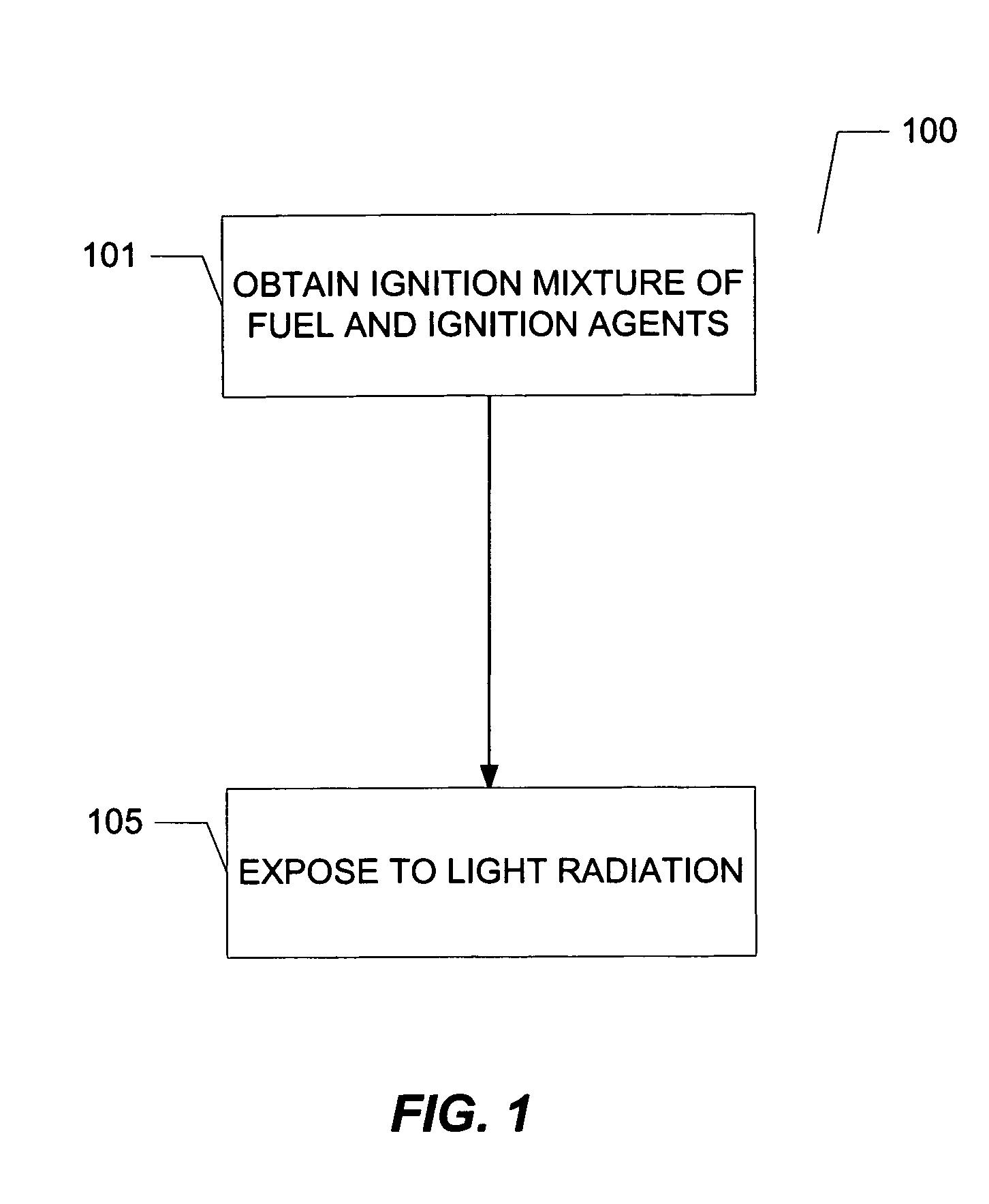

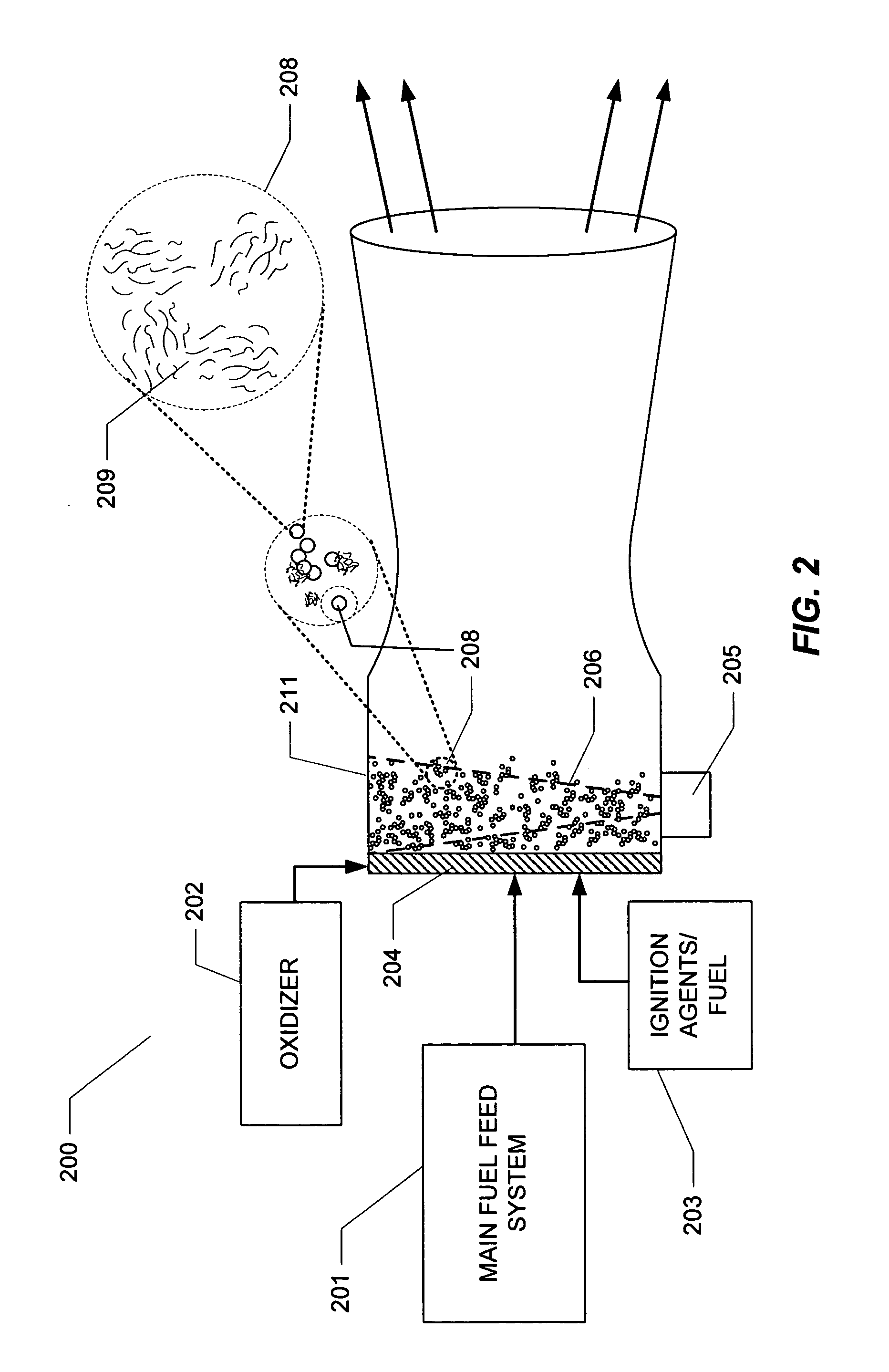

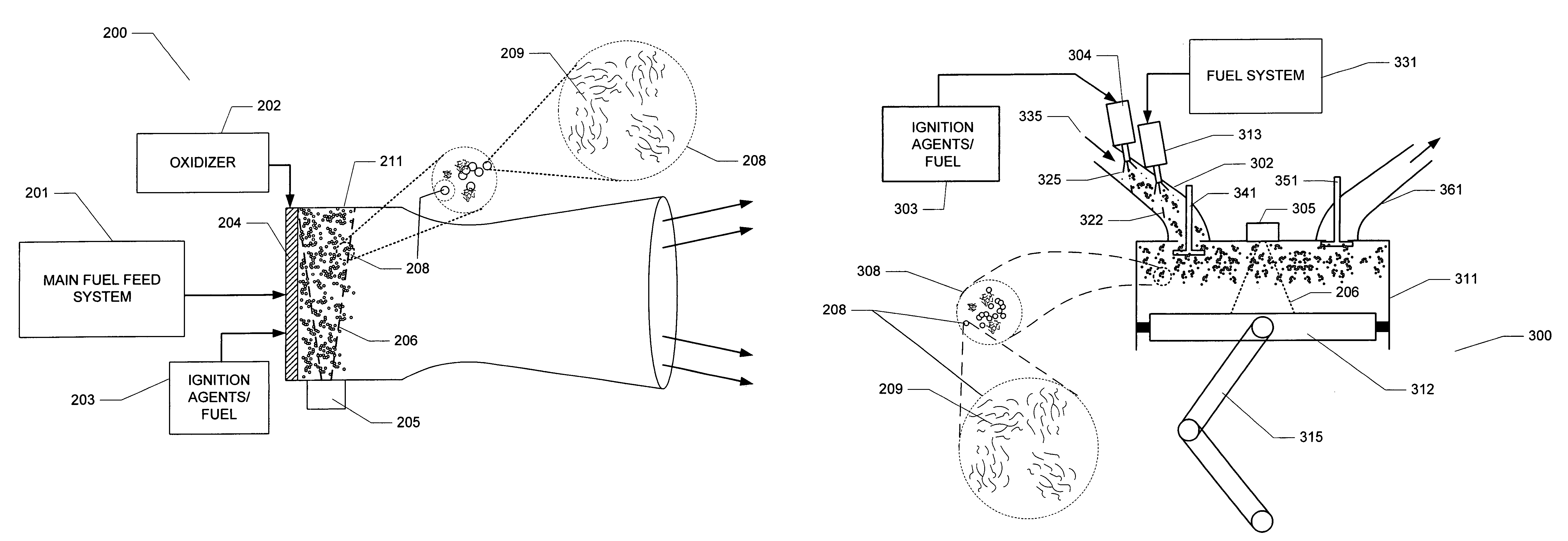

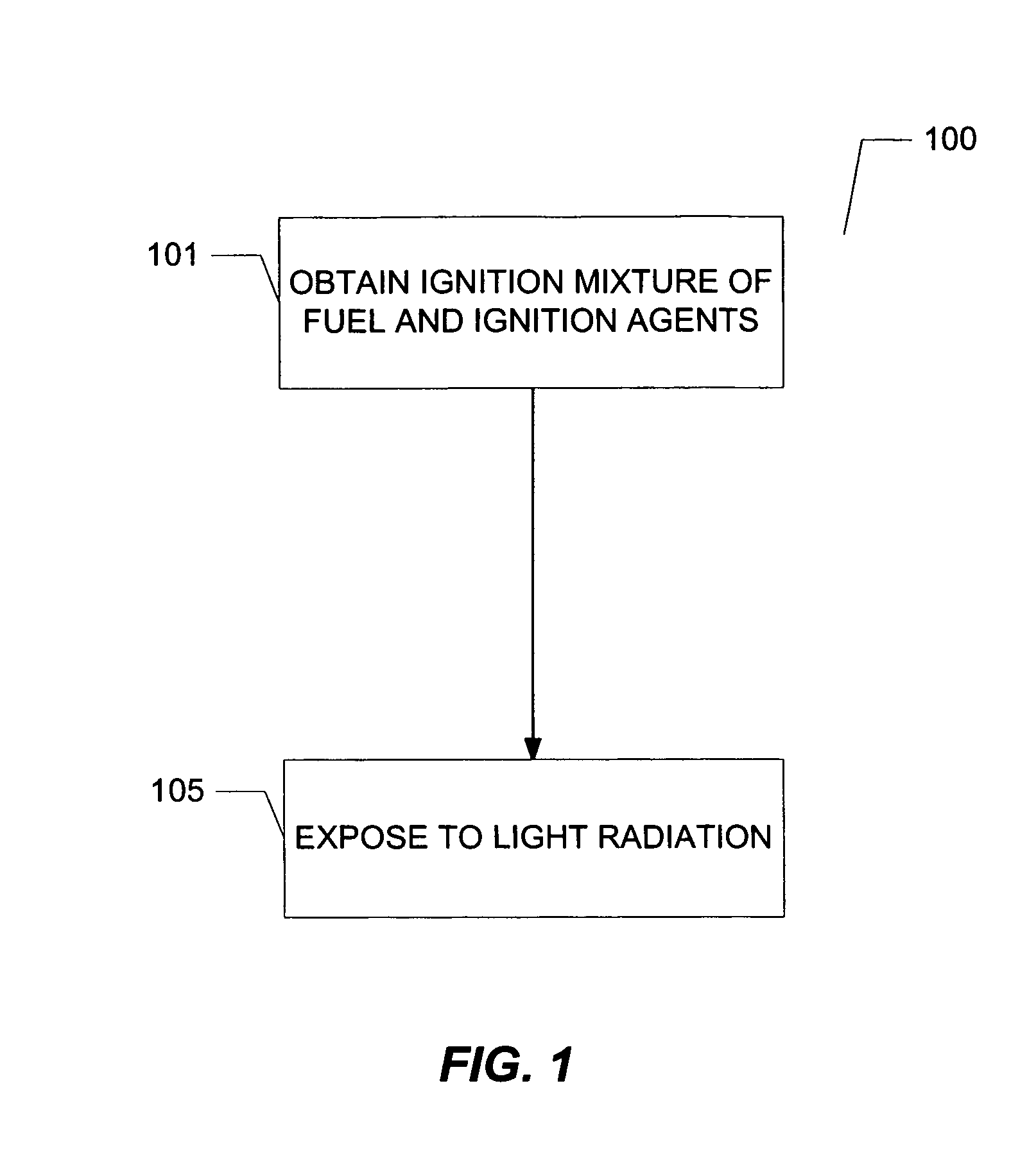

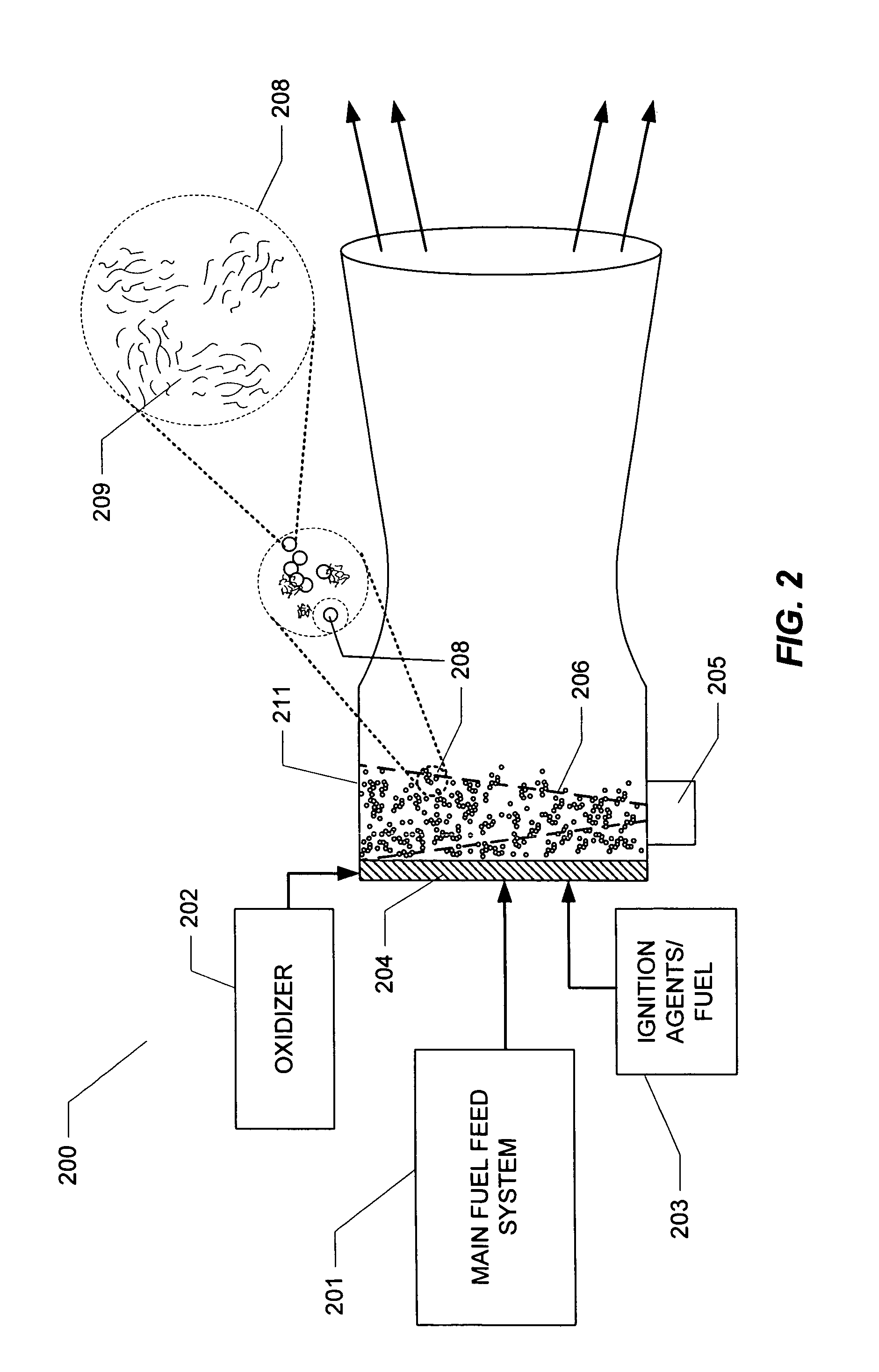

Method for distributed ignition of fuels by light sources

A method for distributed ignition is disclosed wherein a combustion fuel and an ignition mixture are combined where the ignition mixture comprises ignition agents and fuel and where ignition agents can be nano-metallic particles in combination with single-walled carbon nano-tubes (SWCNTs). The combination of ignition mixture and combustion fuel in the presence of oxygen are exposed to light causing heating of the ignition agents and combustion of the fuel within which the ignition agents are interspersed. A system for igniting fuels using the method is also disclosed.

Owner:ERC

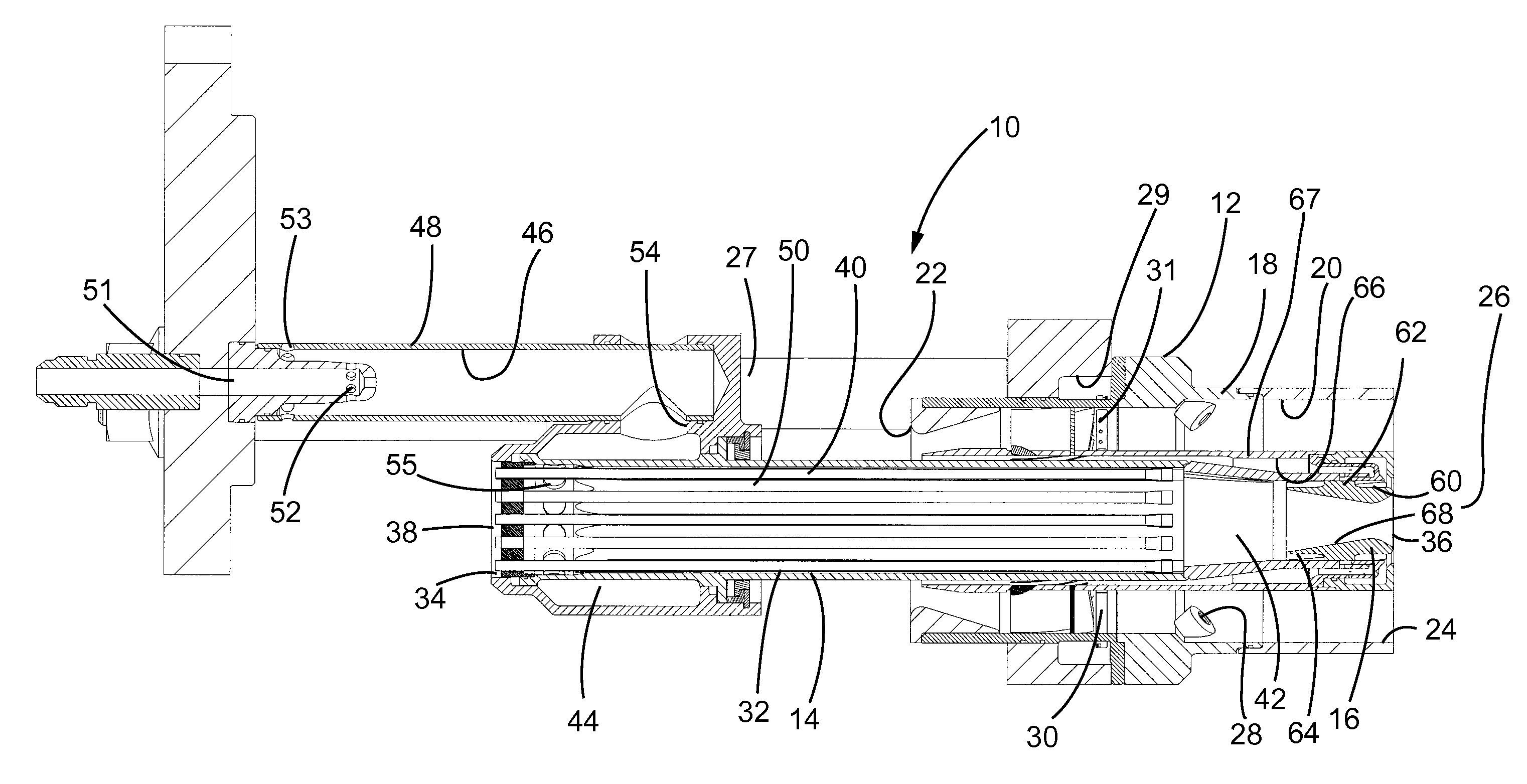

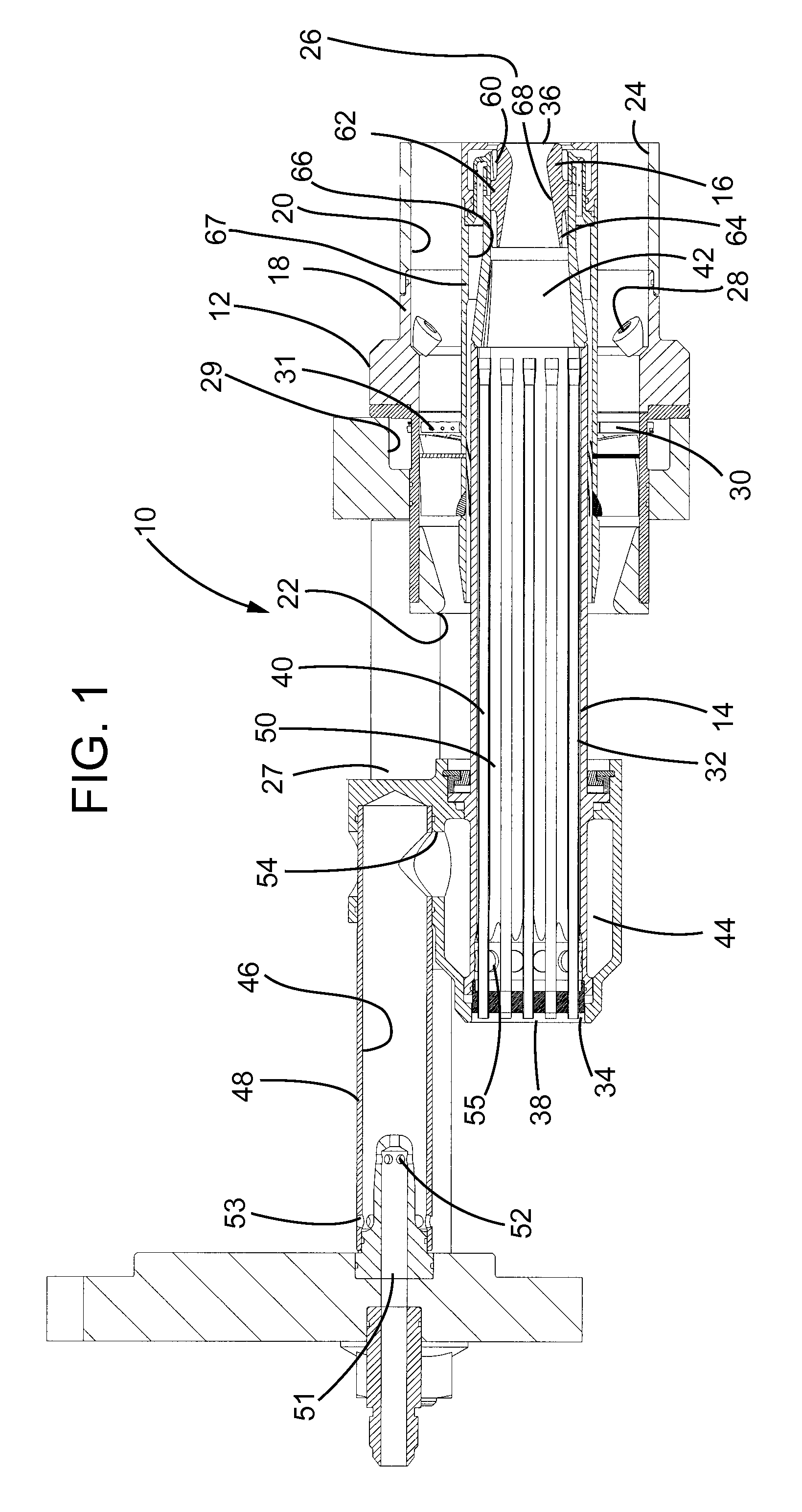

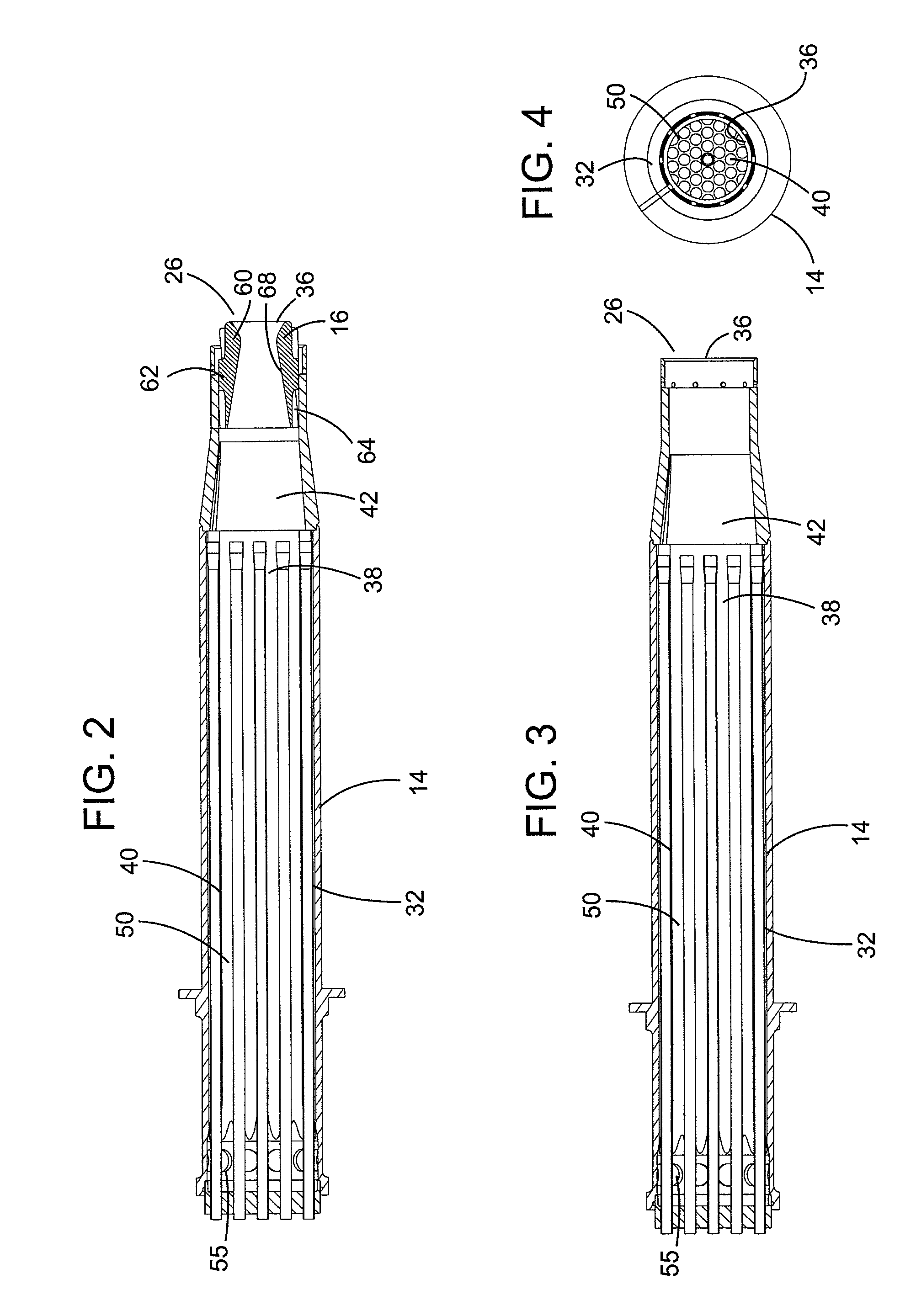

Catalytic burner apparatus for stirling engine

ActiveUS20100126165A1Increase the reaction areaPrevent buildupCatalytic ignitersRegenerative heat exchangersExternal combustion engineEngineering

The invention provides an apparatus and a method for transferring heat by conduction to the internal heat acceptor of an external combustion engine. Fuel and air are introduced into a combustion chamber and mixed to form an air / fuel mixture. The air / fuel mixture is directed into a catalytic reactor that is positioned in direct contact (non-spaced-apart relation) with the heater head. Heat is transferred via conduction from the catalytic reactor to the heater head; and the catalytic reaction products are exhausted with heat recuperation.

Owner:PRECISION COMBUSTION

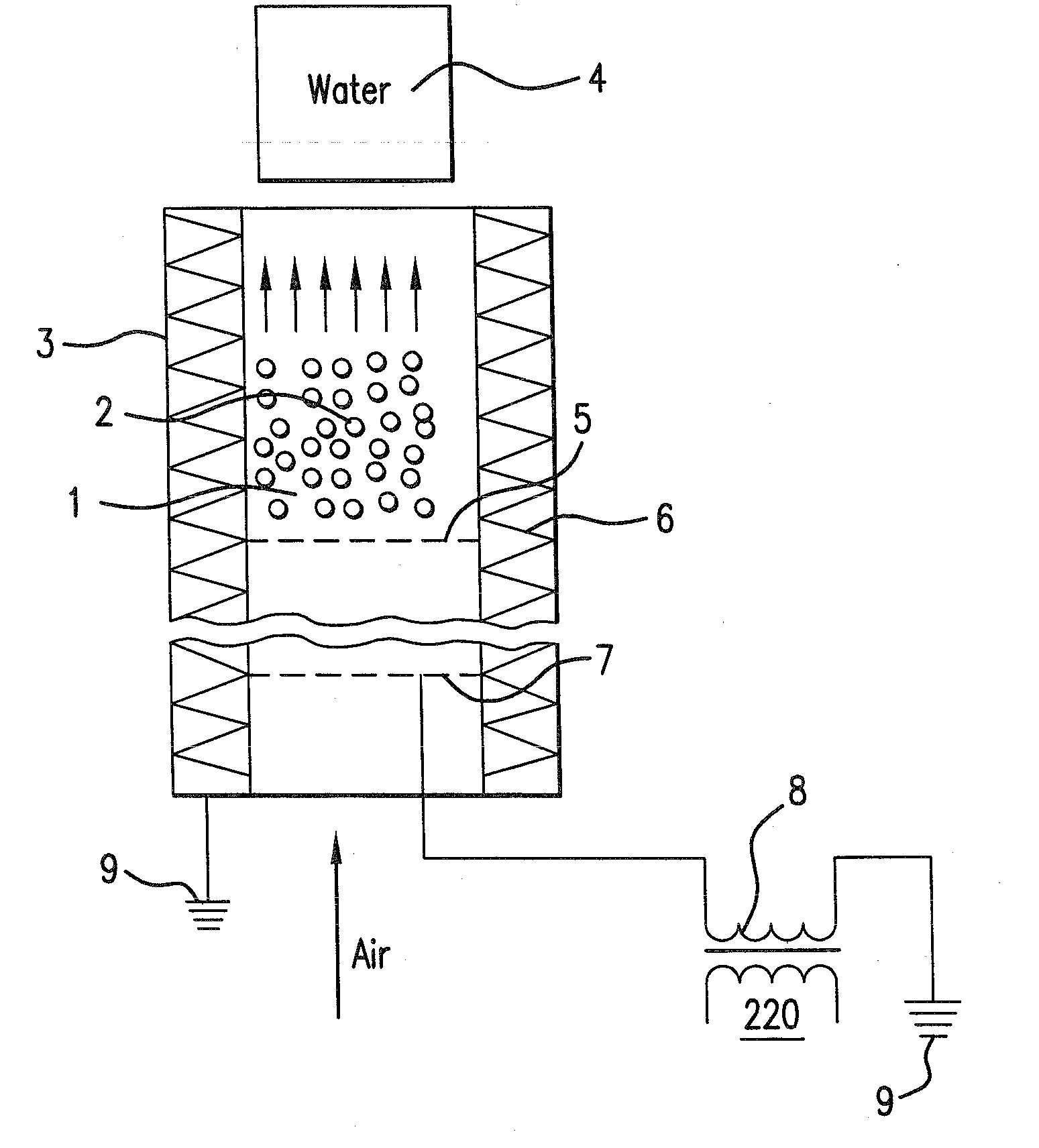

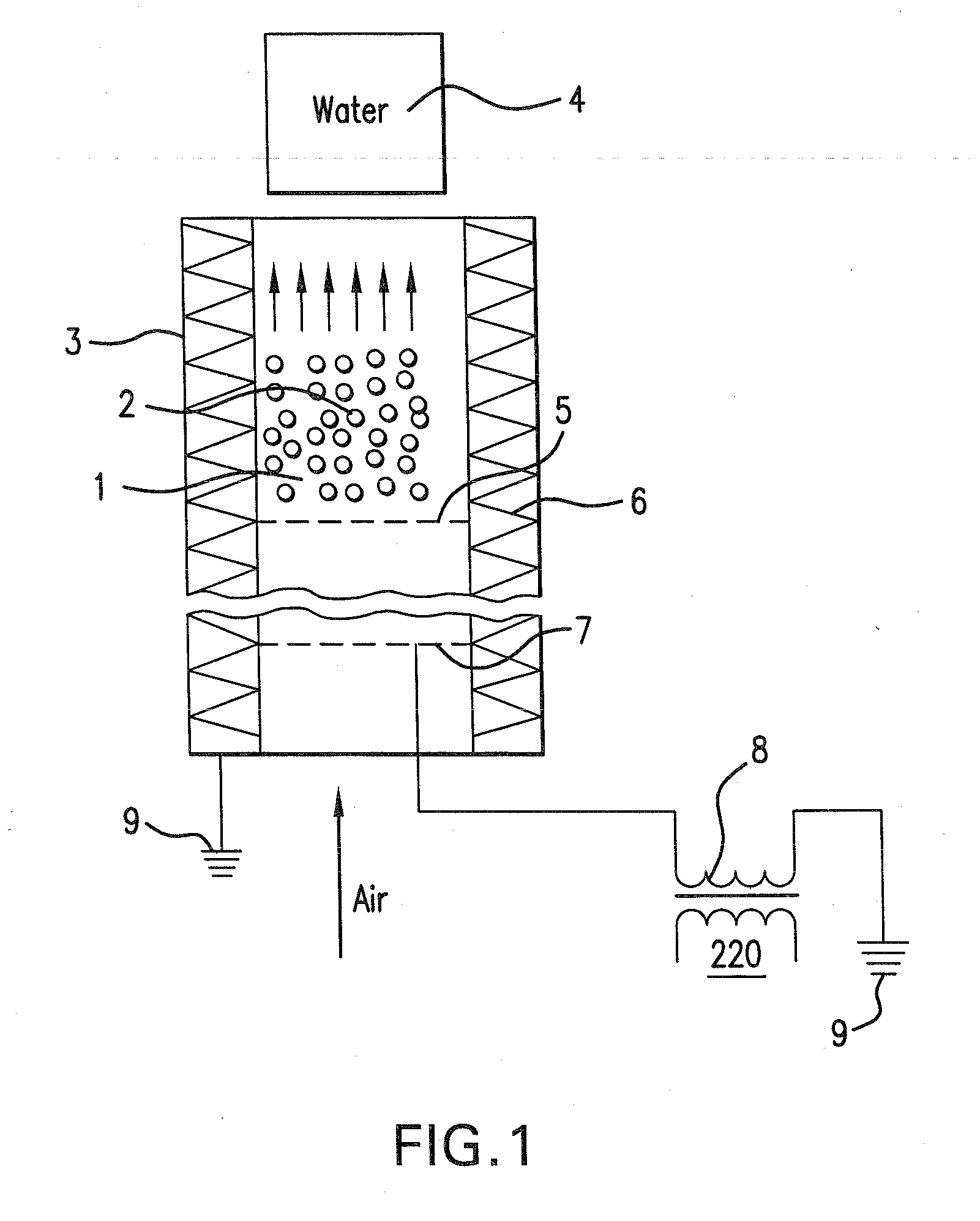

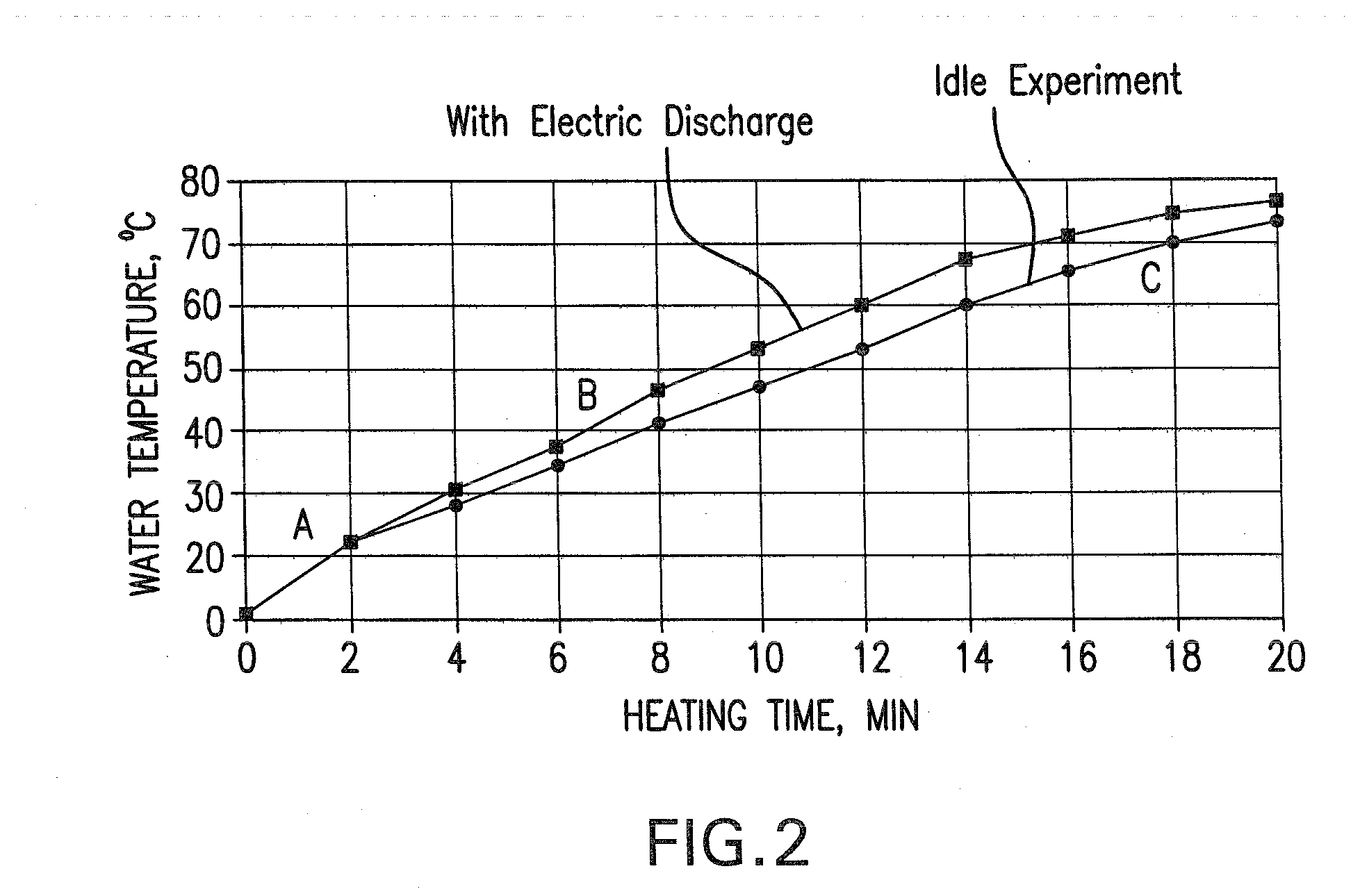

Method of solid fuel combustion intensification

InactiveUS20080044781A1Increase oxidation rateDegree of improvementIncandescent ignitionCatalytic ignitersOxygenEnergy expenditure

The substance of the invention consists in the combustion of the fuel-air mixture in the electric field by means of the catalyst located in the combustion zone and to which high voltage is applied, which results in reduction of activation energies of all endothermic combustion phases due to the formation of oxygen atoms, carbon radicals and oxygen-containing radicals.Technical result: introduction of the catalyst in the combustion zone minimizes energy expenditure for creation of the low-temperature plasma, allows to increase the temperature in the combustion zone, to reduce activation energy of all endothermic processes taking place at the initial phase of combustion and to reduce carbon content in the ash and to achieve considerable fuel economy.

Owner:LIMITED LIABILITY RES AND PRODION COMPANY UKRTRANSKOM +1

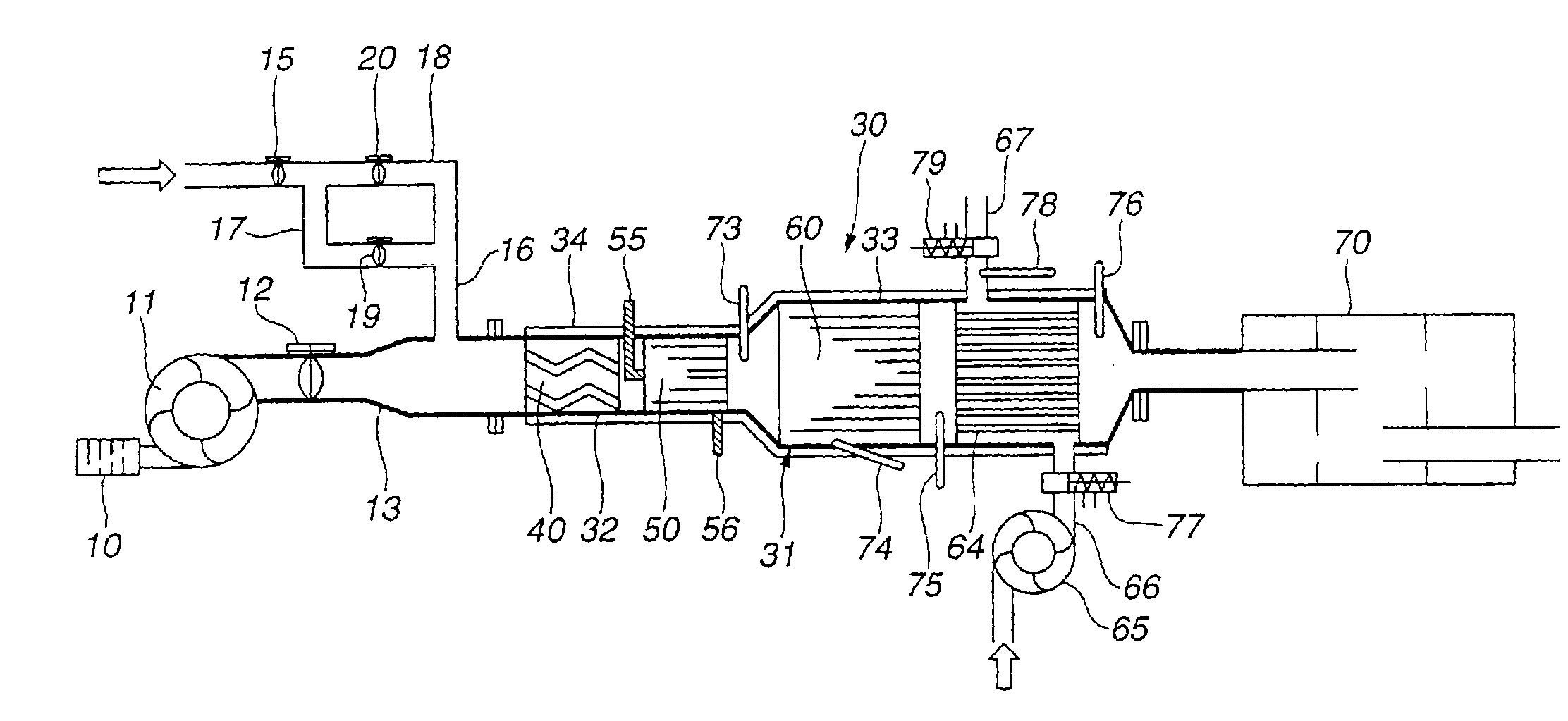

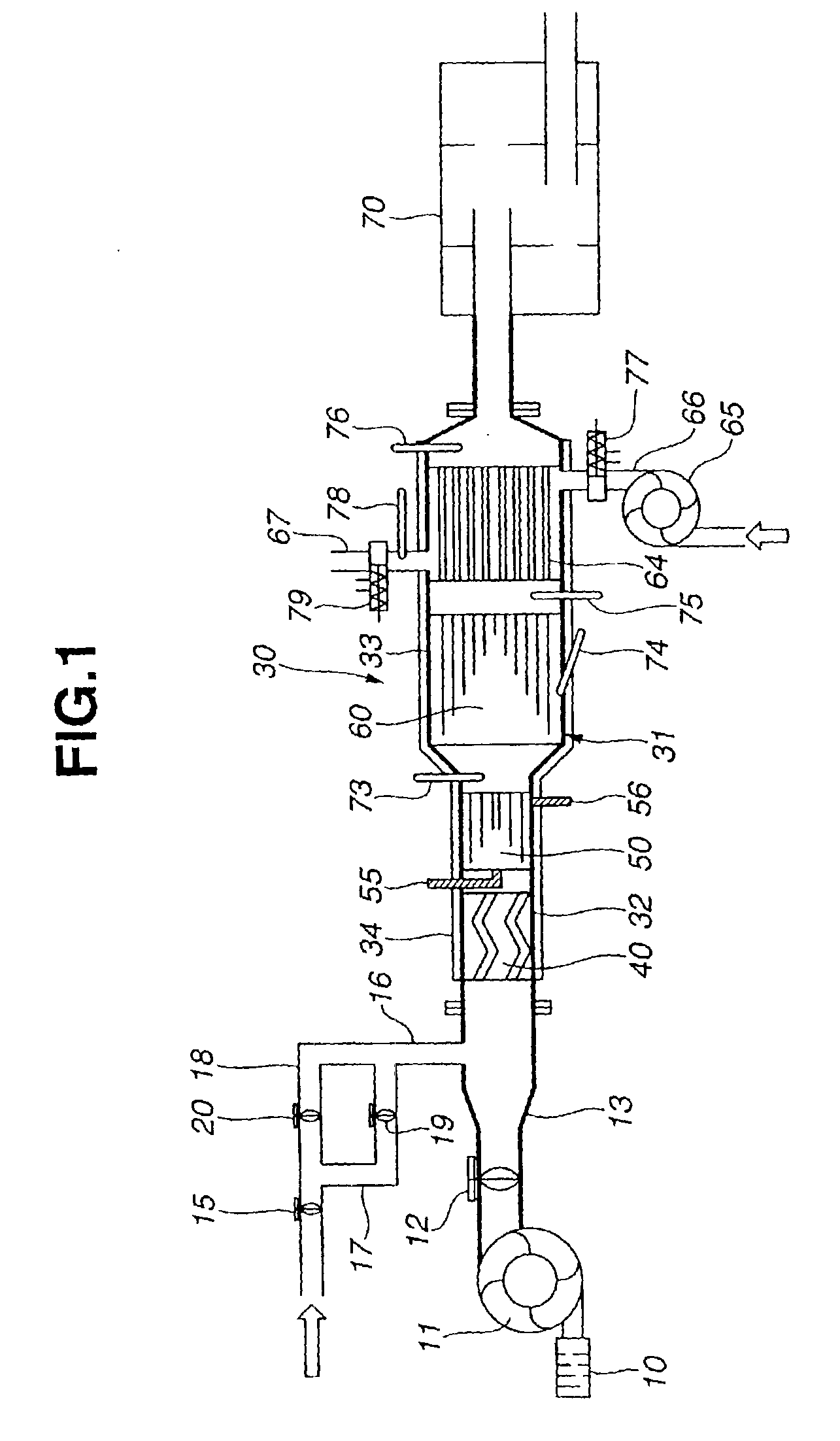

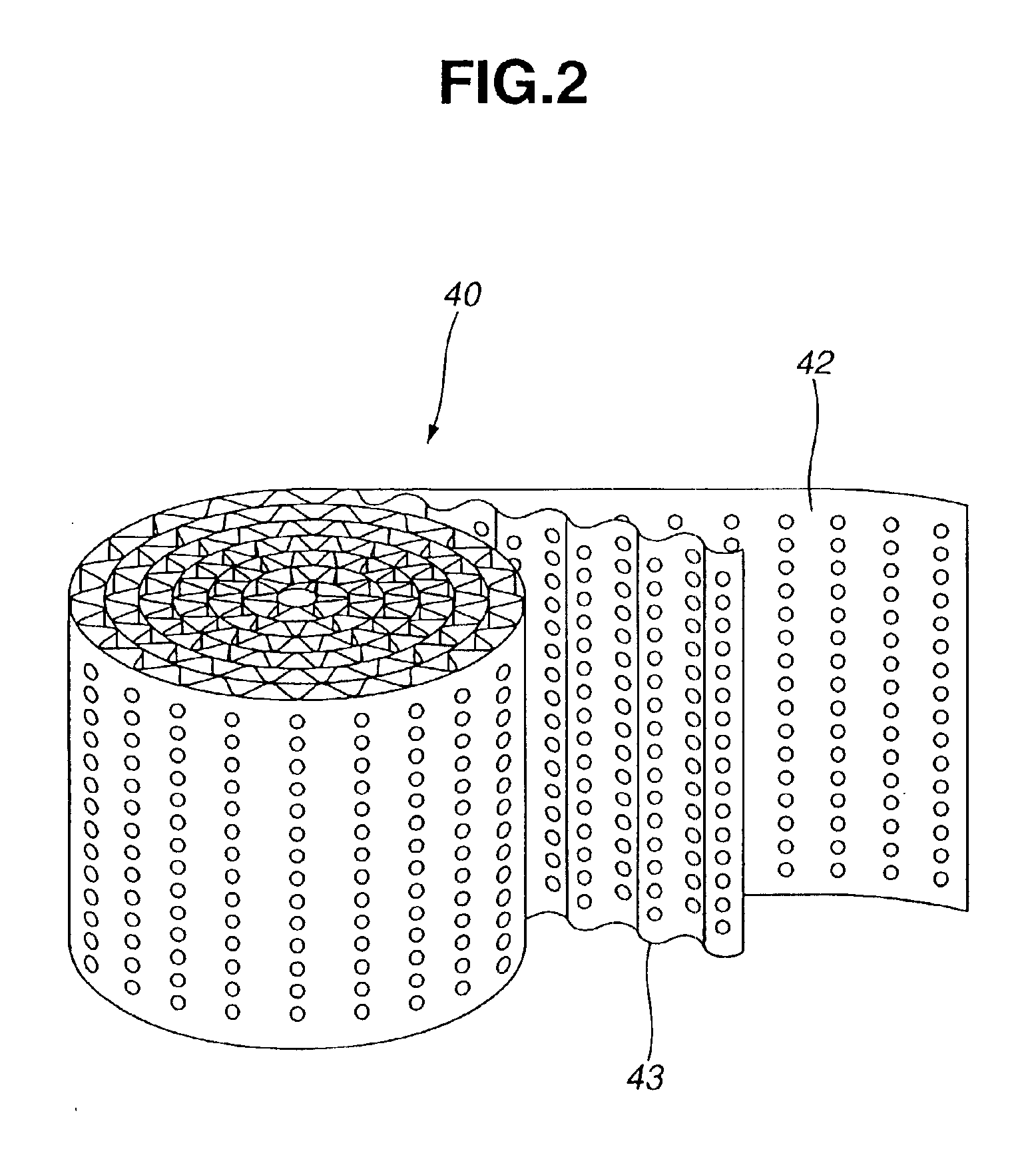

Hydrogen combustion heater

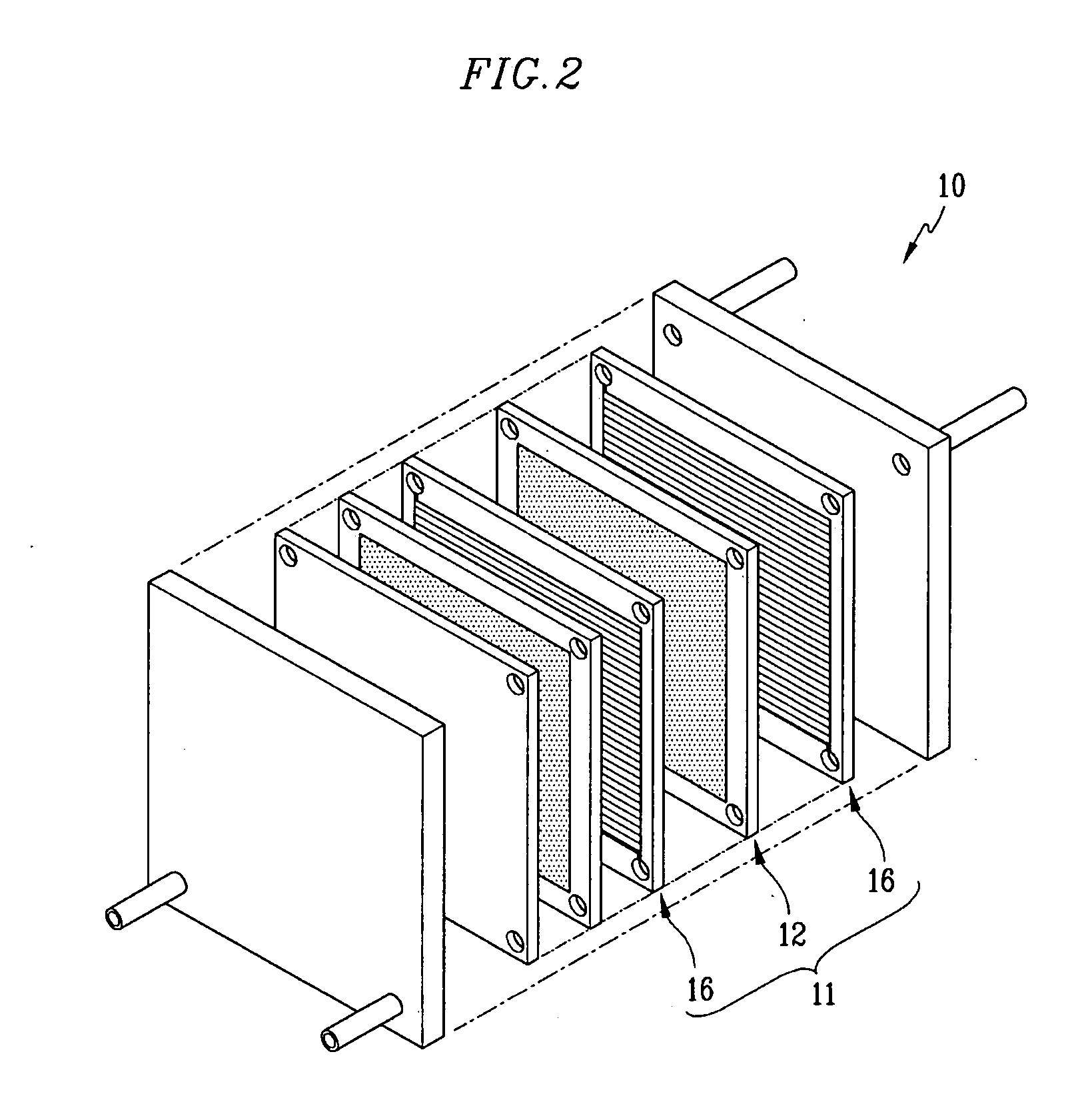

InactiveUS6851947B2Easy constructionStable in heating capabilityCapillary burnersCatalytic ignitersElectricityPlate heat exchanger

The invention relates to a hydrogen combustion heater. This heater includes (a) a passage for allowing hydrogen gas and air to flow therethrough; (b) a first catalyst provided in the passage, the first catalyst being heated, when electricity is applied thereto, thereby starting a first combustion of a first mixture of the hydrogen gas and the air in the first catalyst; and (c) a heat exchanger provided downstream of the first catalyst in the passage, the heat exchanger being adapted to transfer heat generated by the first combustion to a heating medium of the heat exchanger.

Owner:CALSONIC KANSEI CORP

FLOW CONDITIONER FOR FUEL INJECTOR FOR COMBUSTOR AND METHOD FOR LOW-NOx COMBUSTOR

InactiveUS20130125548A1Continuous combustion chamberTurbine/propulsion fuel supply systemsCoated surfaceCombustor

An injector for a gas turbine combustor including a catalyst coated surface forming a passage for feed gas flow and a channel for oxidant gas flow establishing an axial gas flow through a flow conditioner disposed at least partially within an inner wall of the injector. The flow conditioner includes a length with an interior passage opening into upstream and downstream ends for passage of the axial gas flow. An interior diameter of the interior passage smoothly reduces and then increases from upstream to downstream ends.

Owner:SOLAR TURBINES

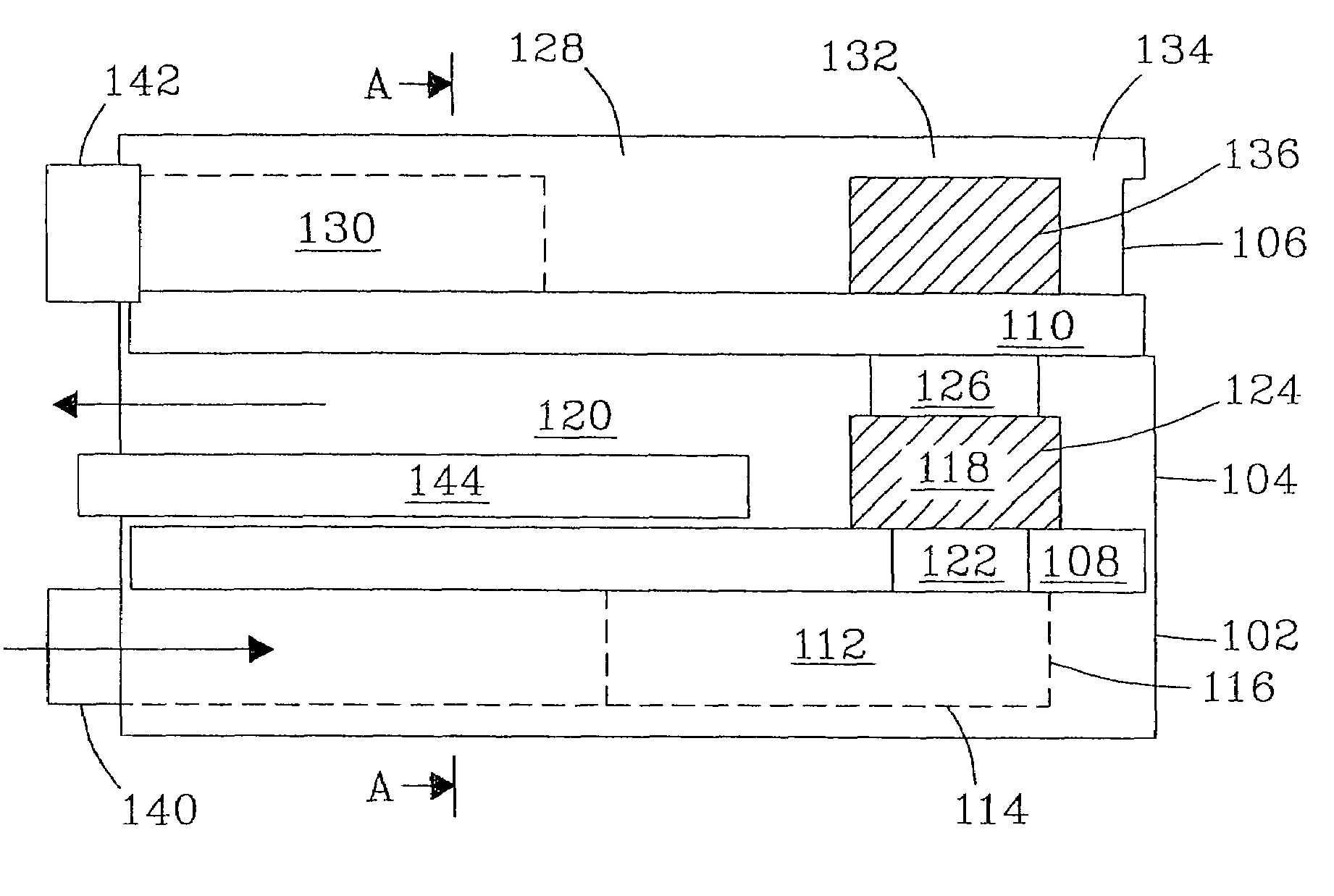

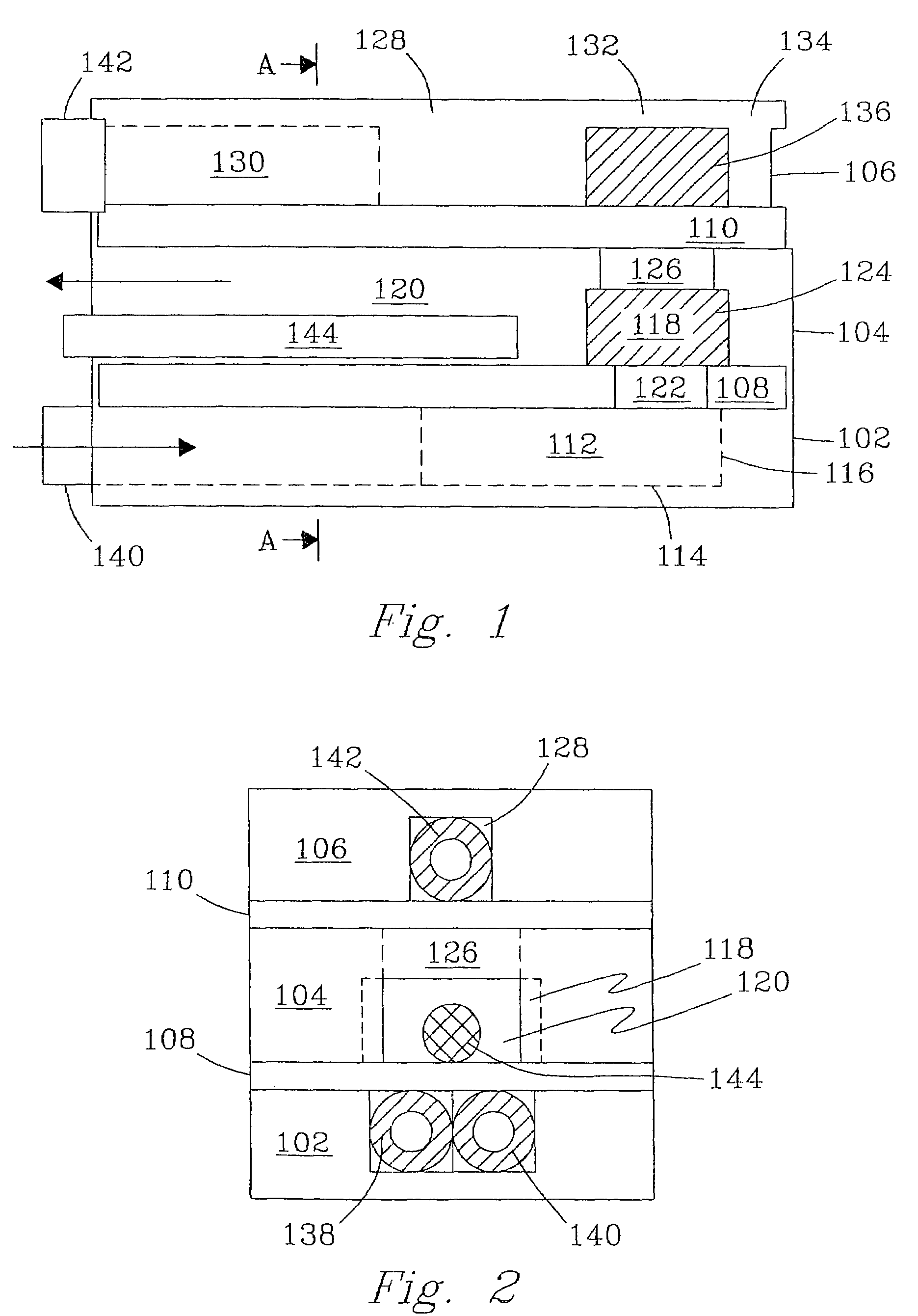

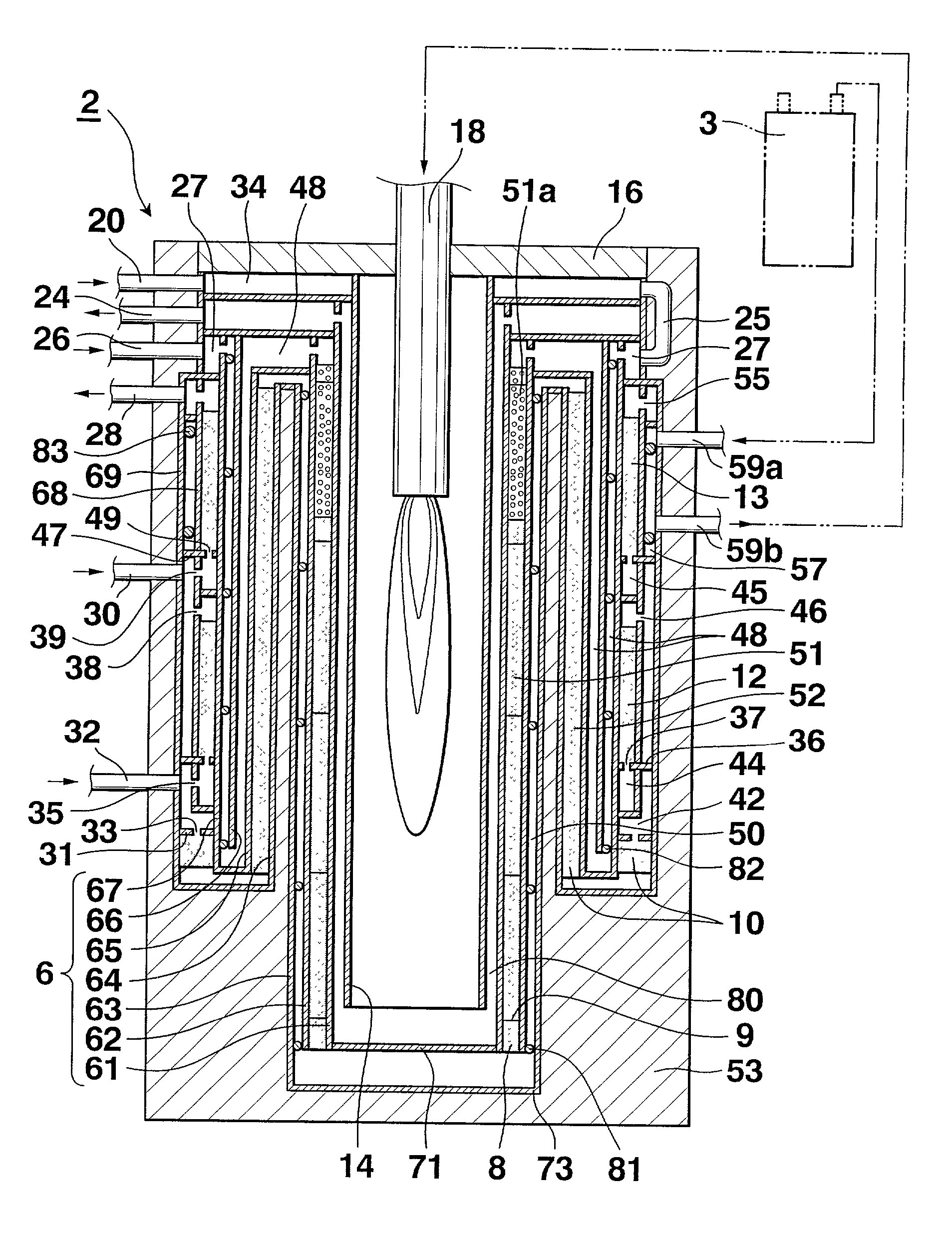

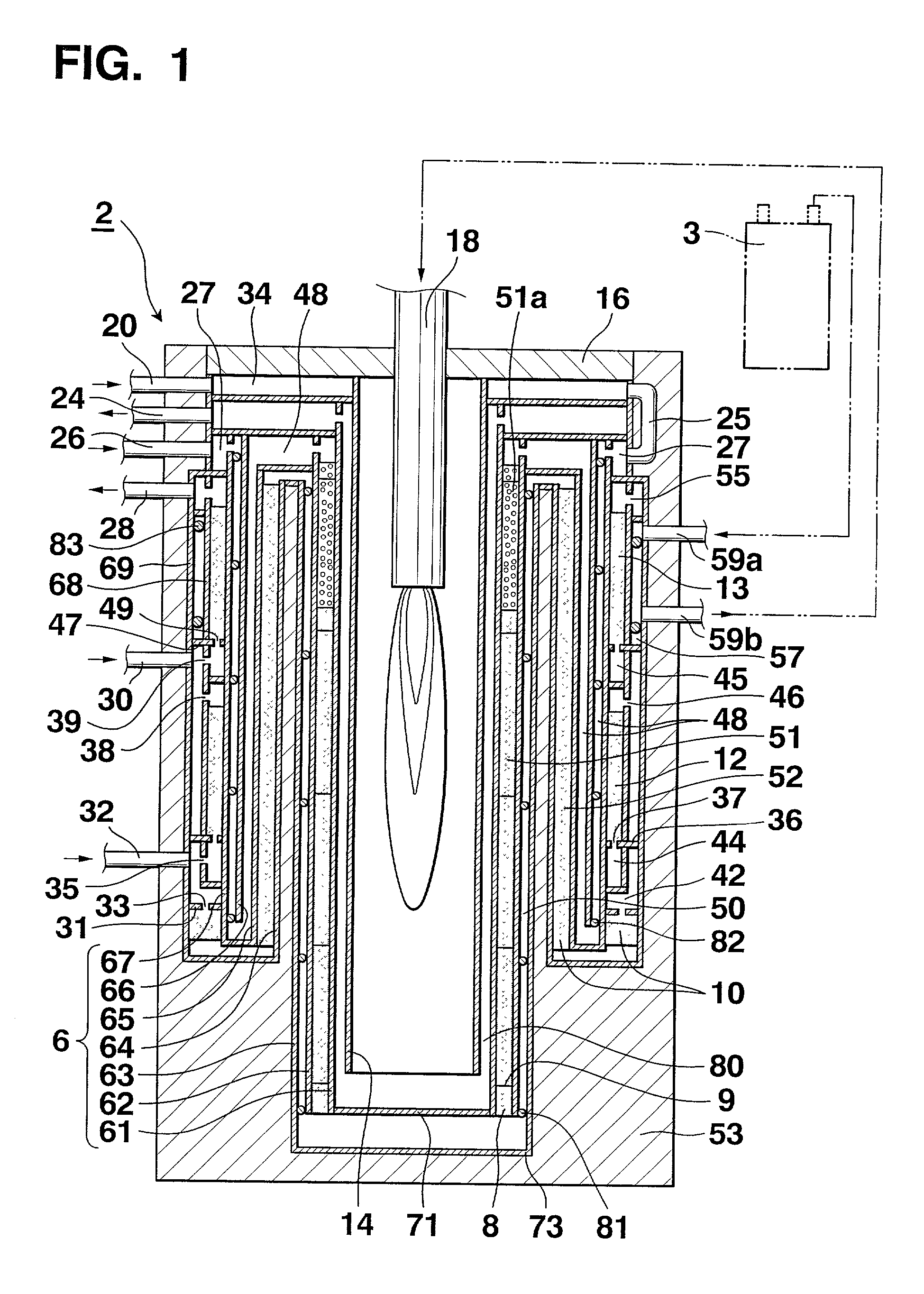

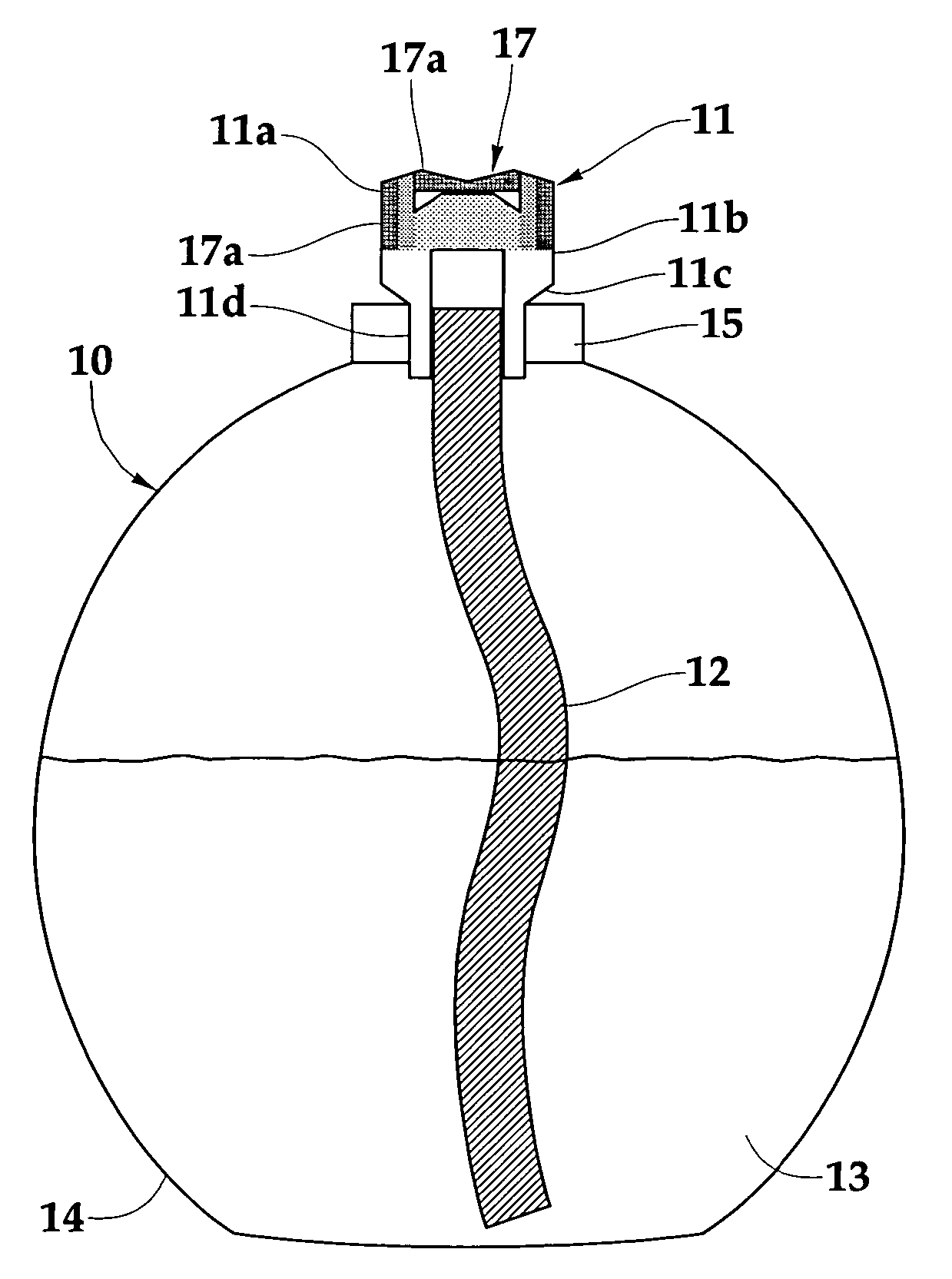

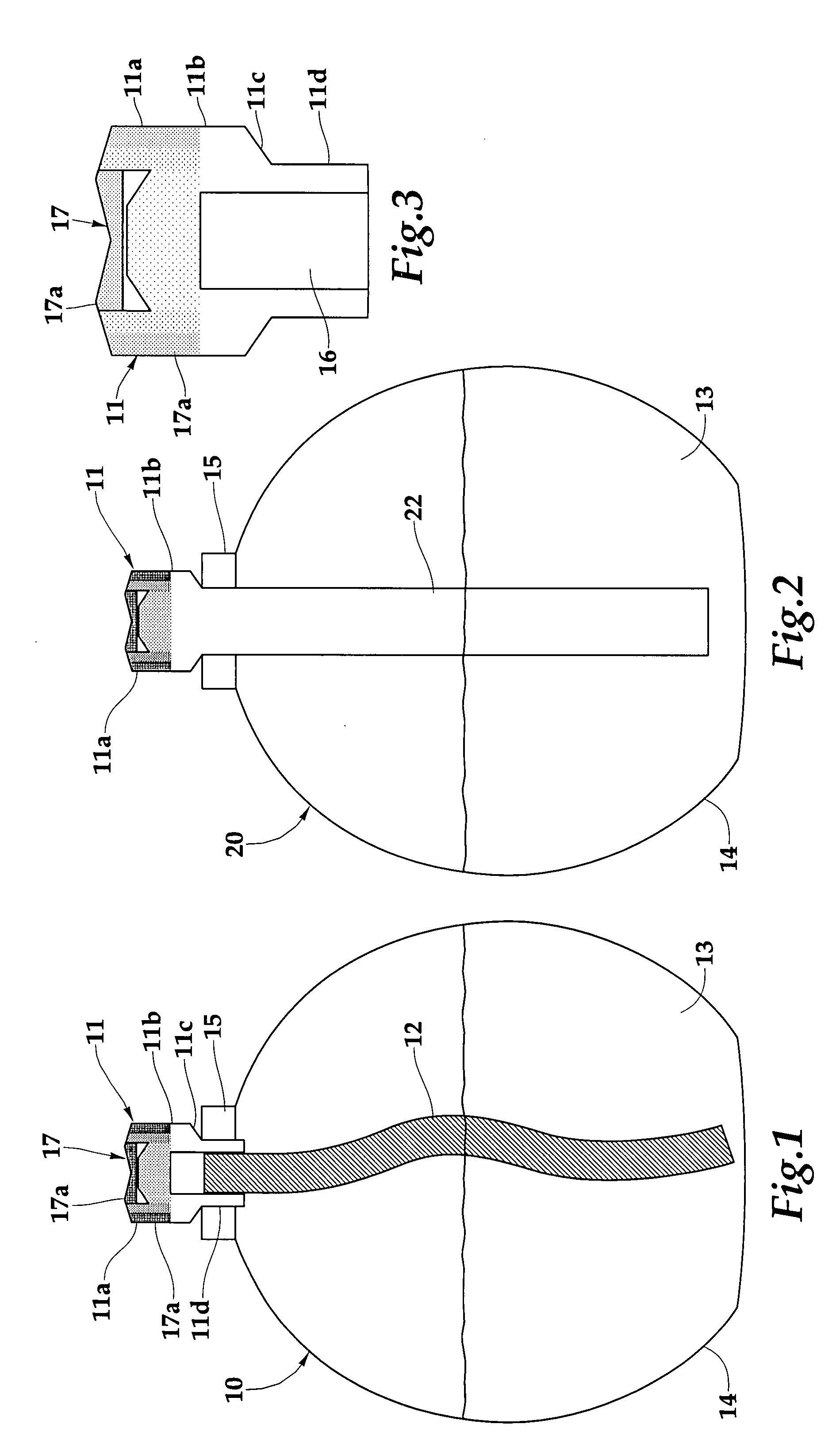

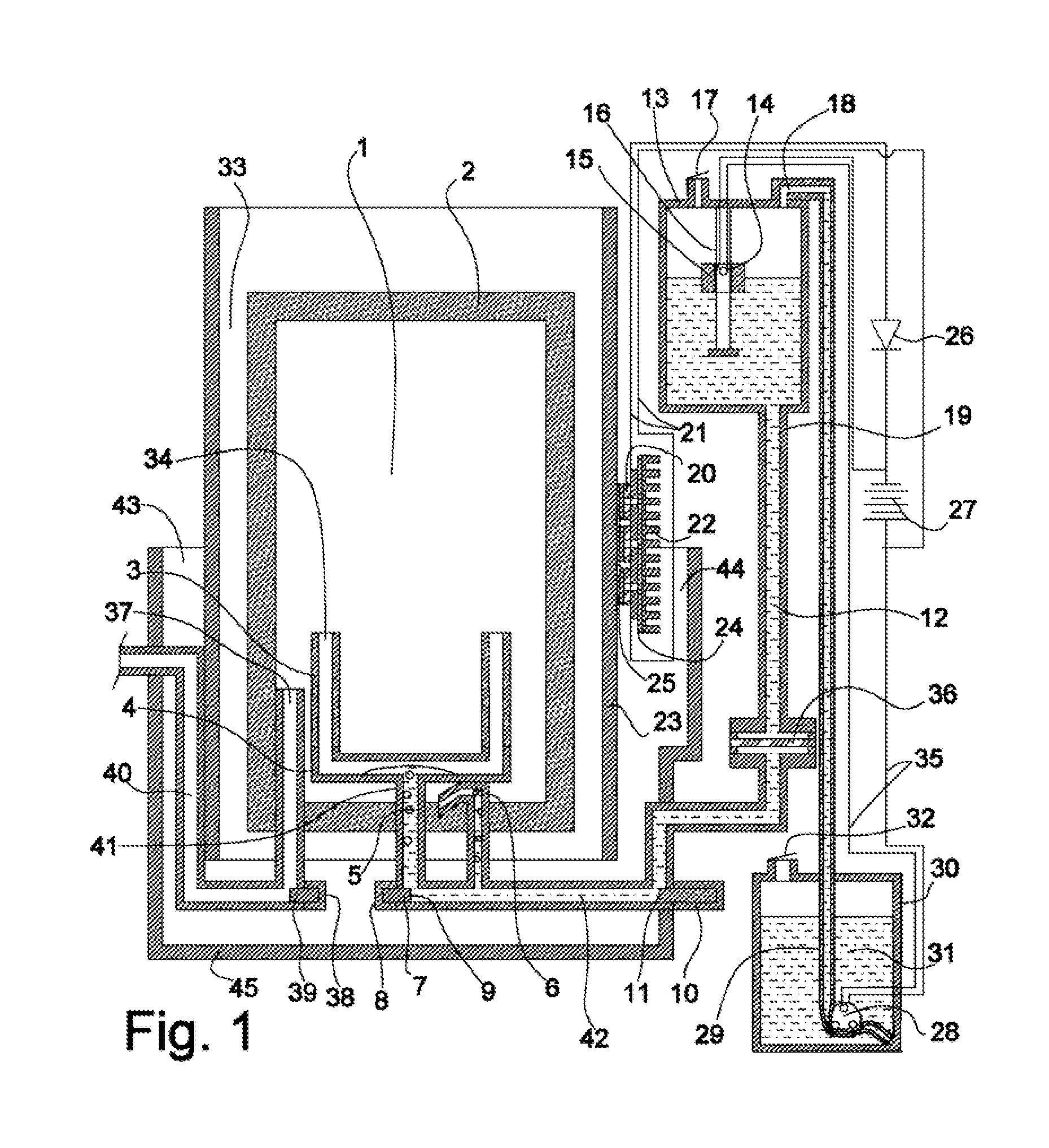

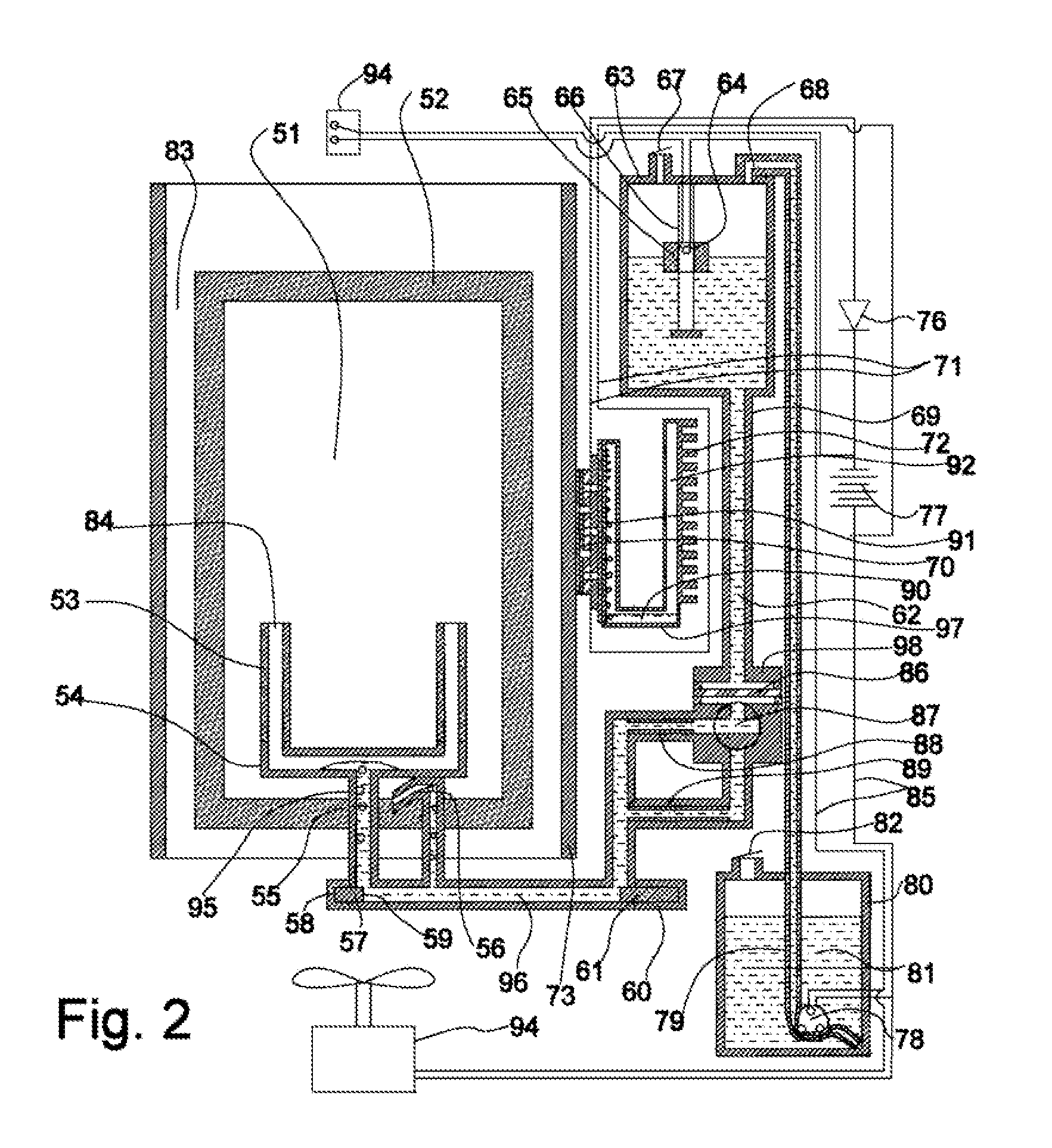

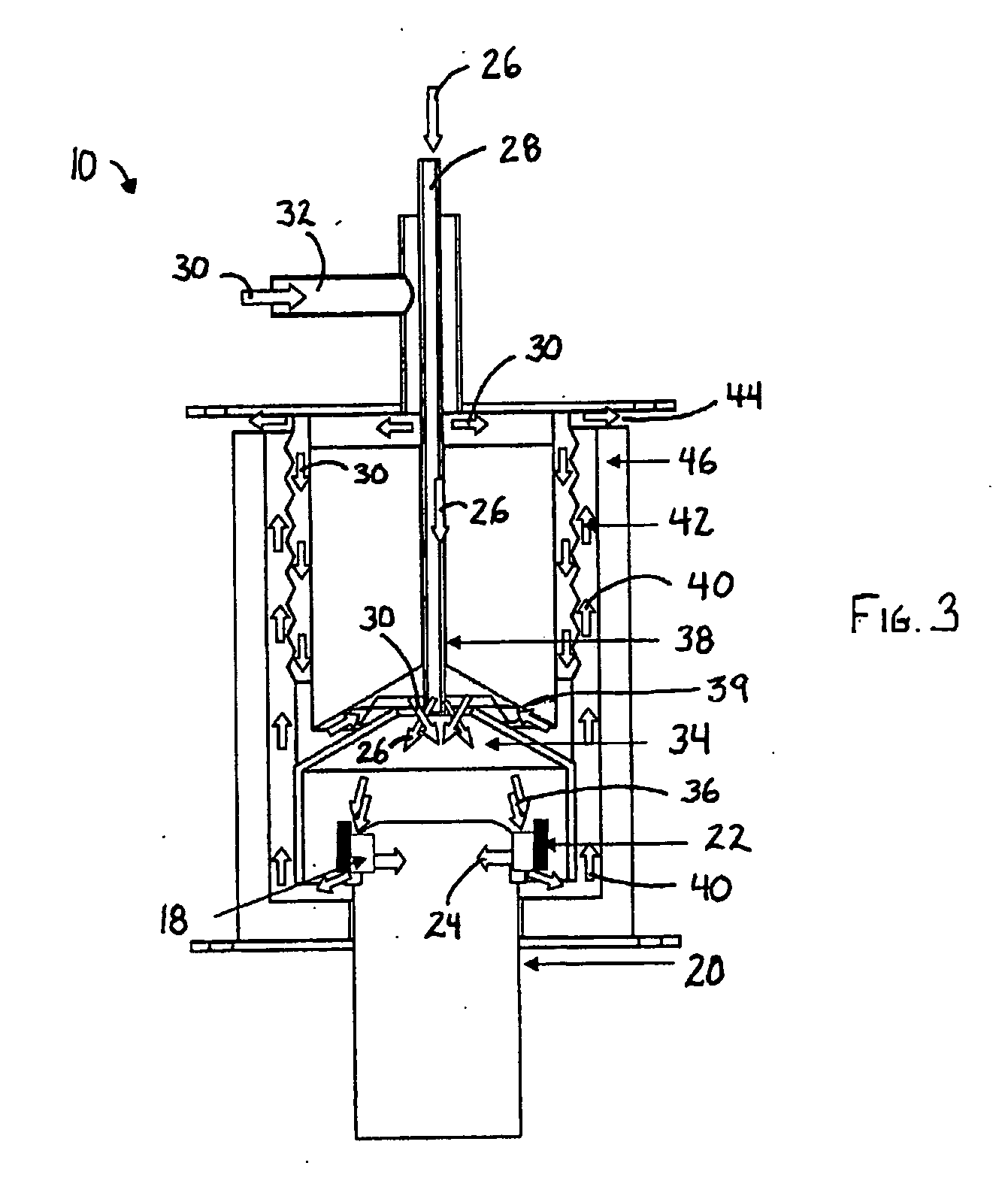

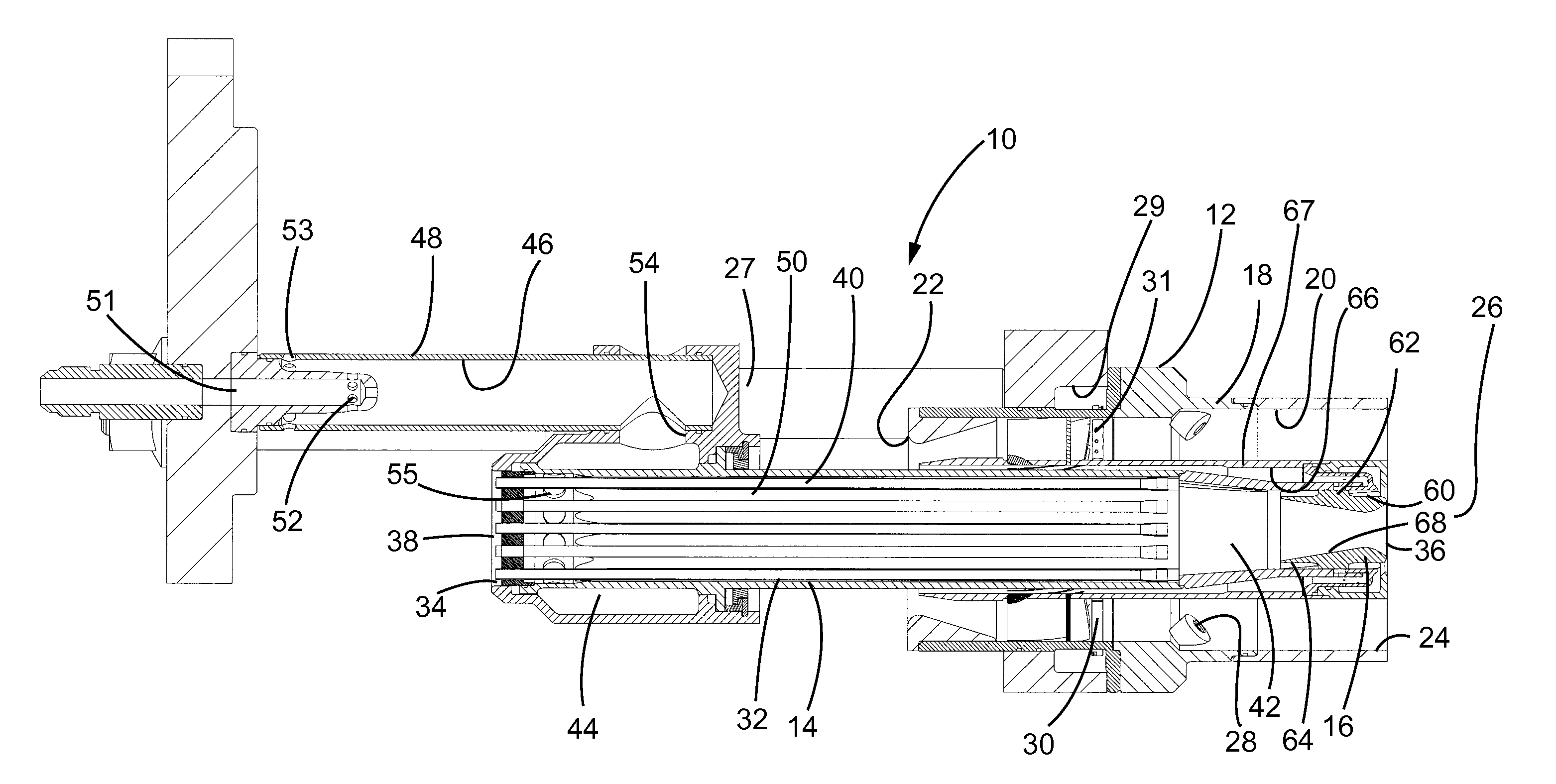

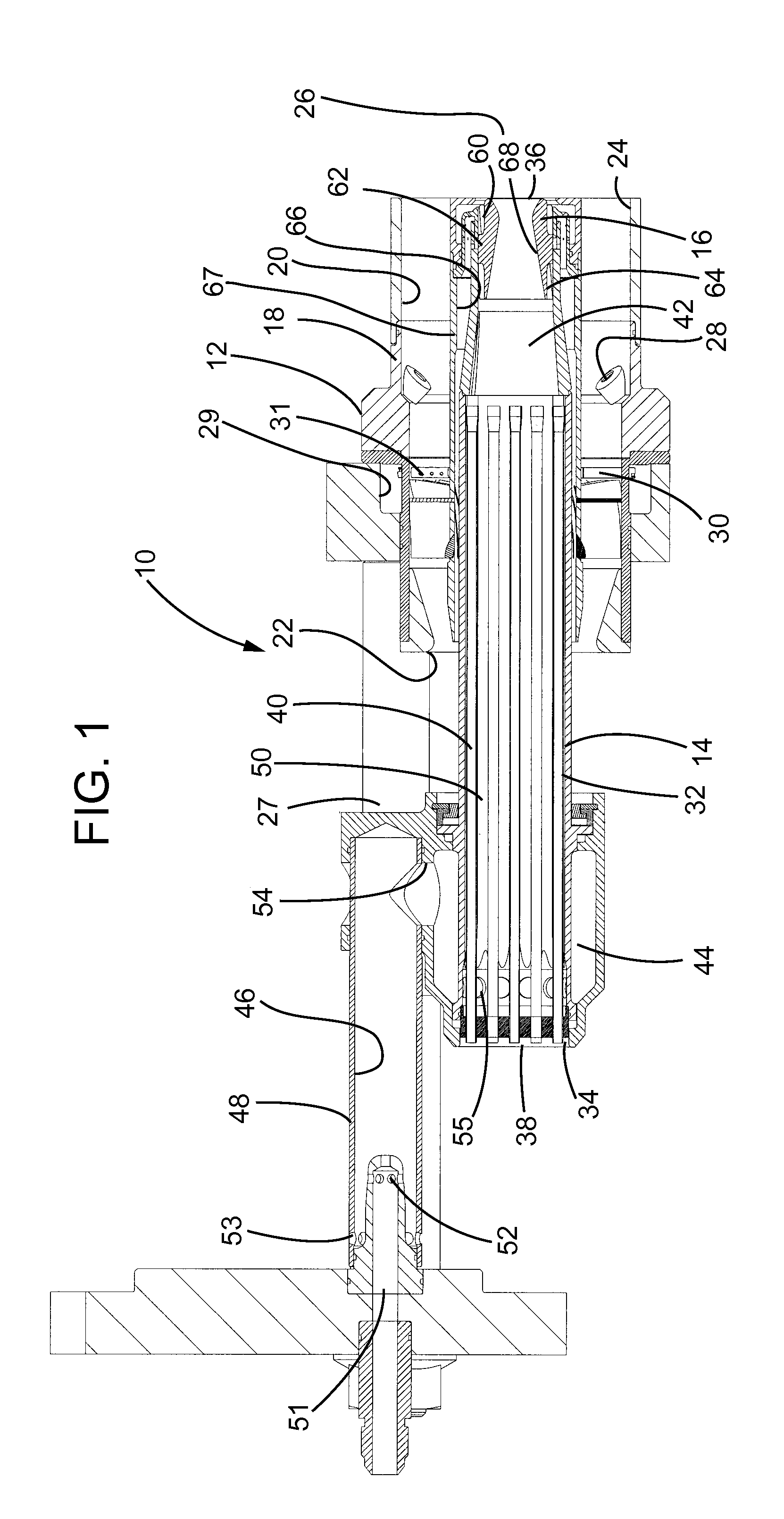

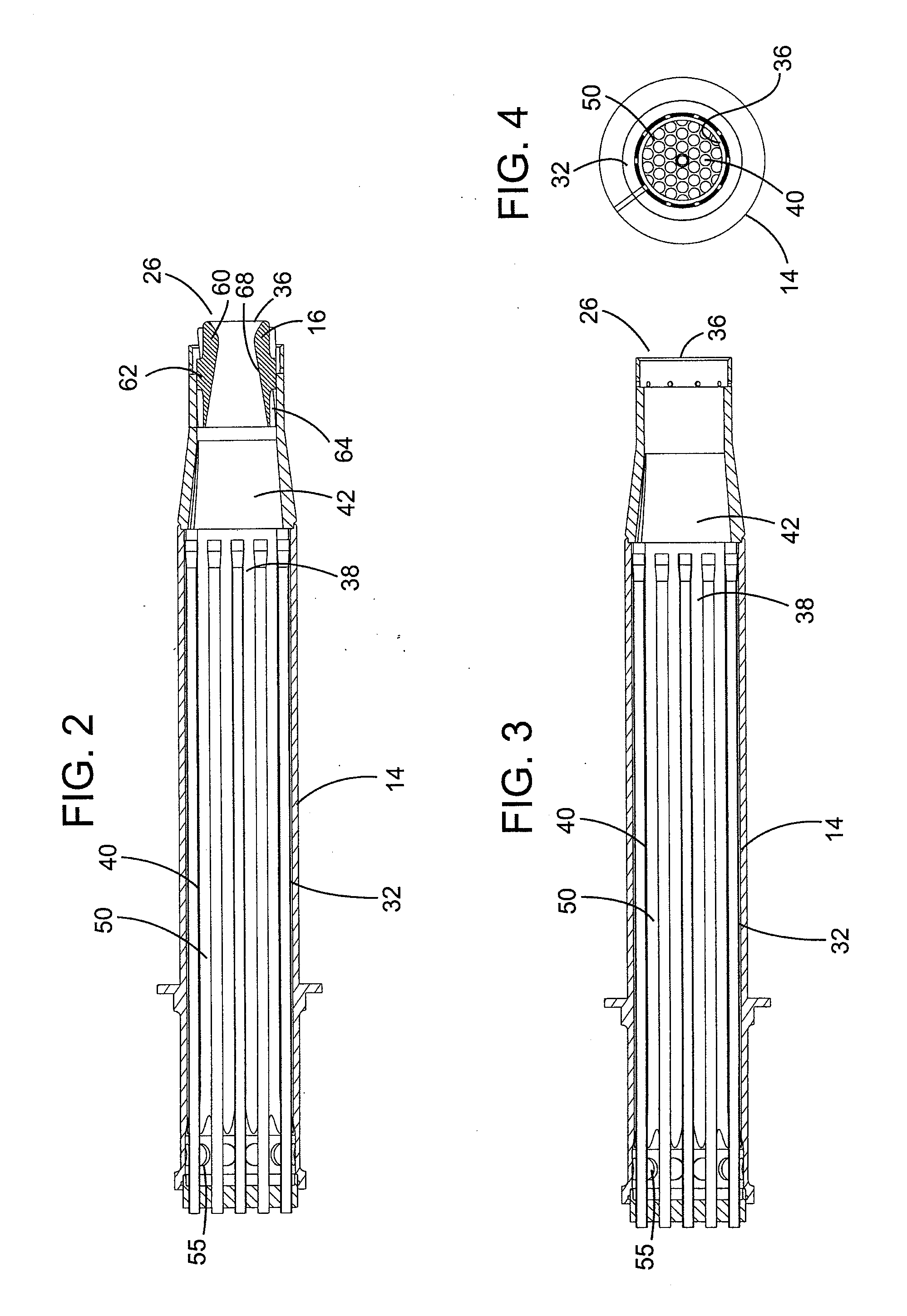

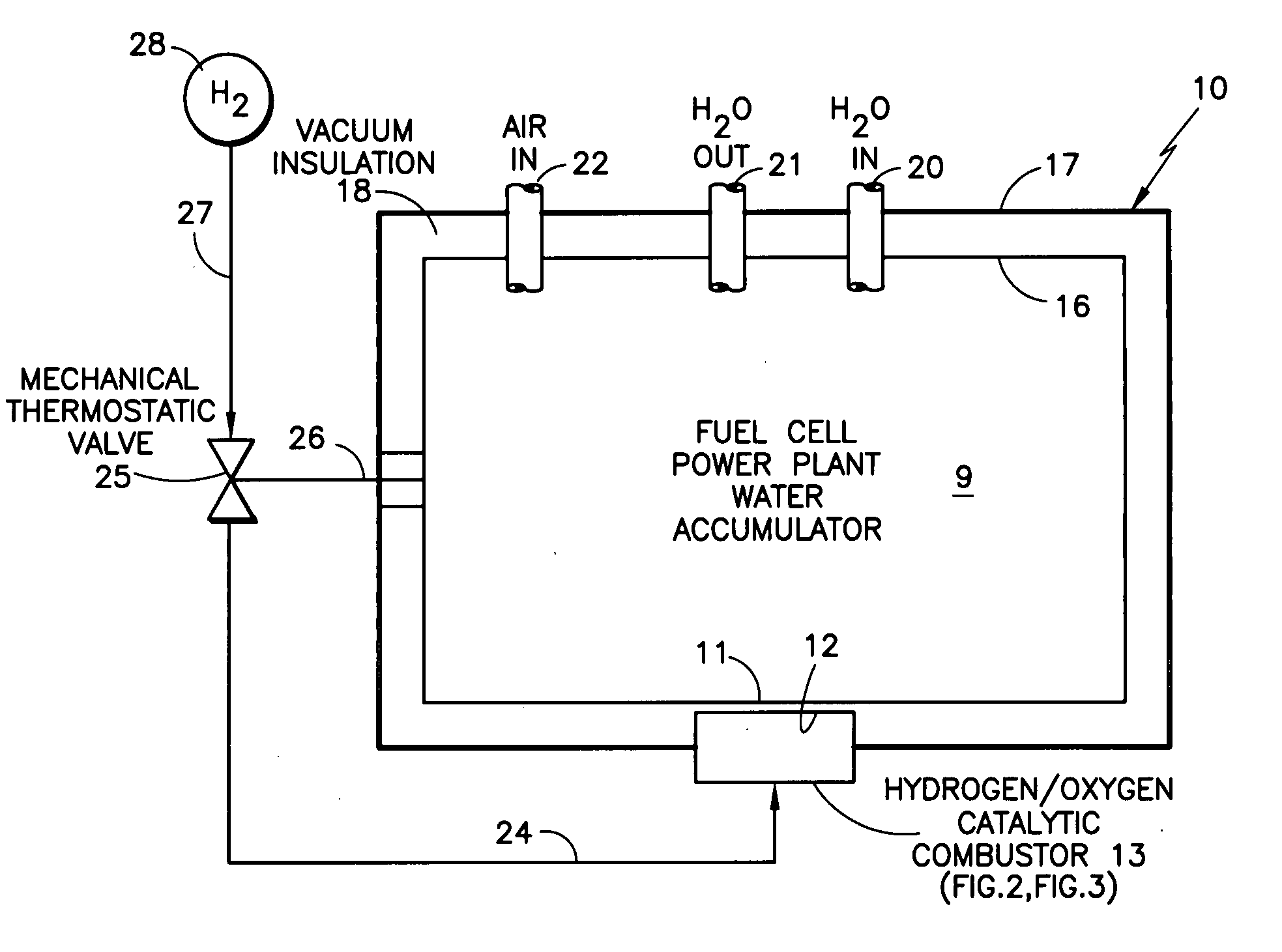

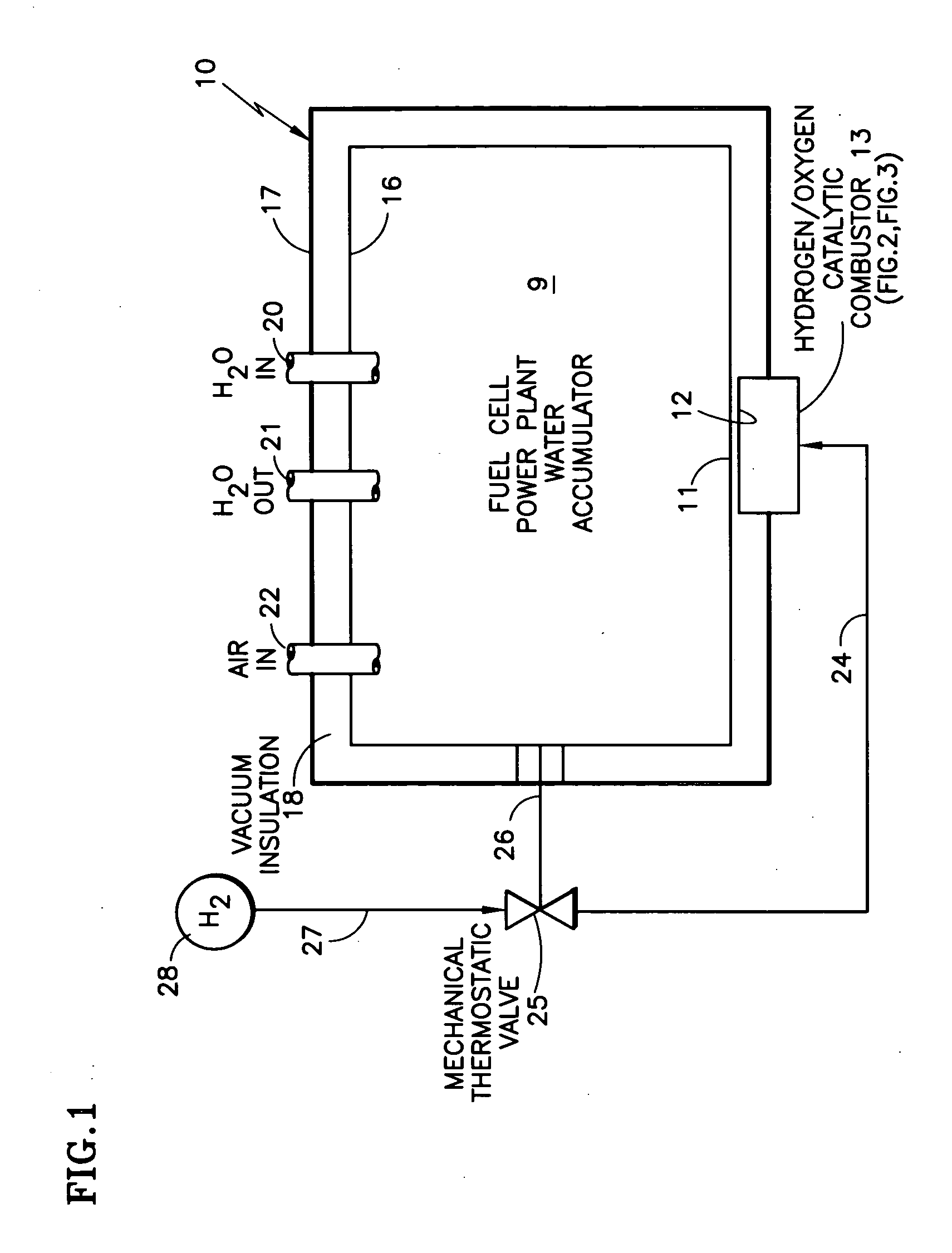

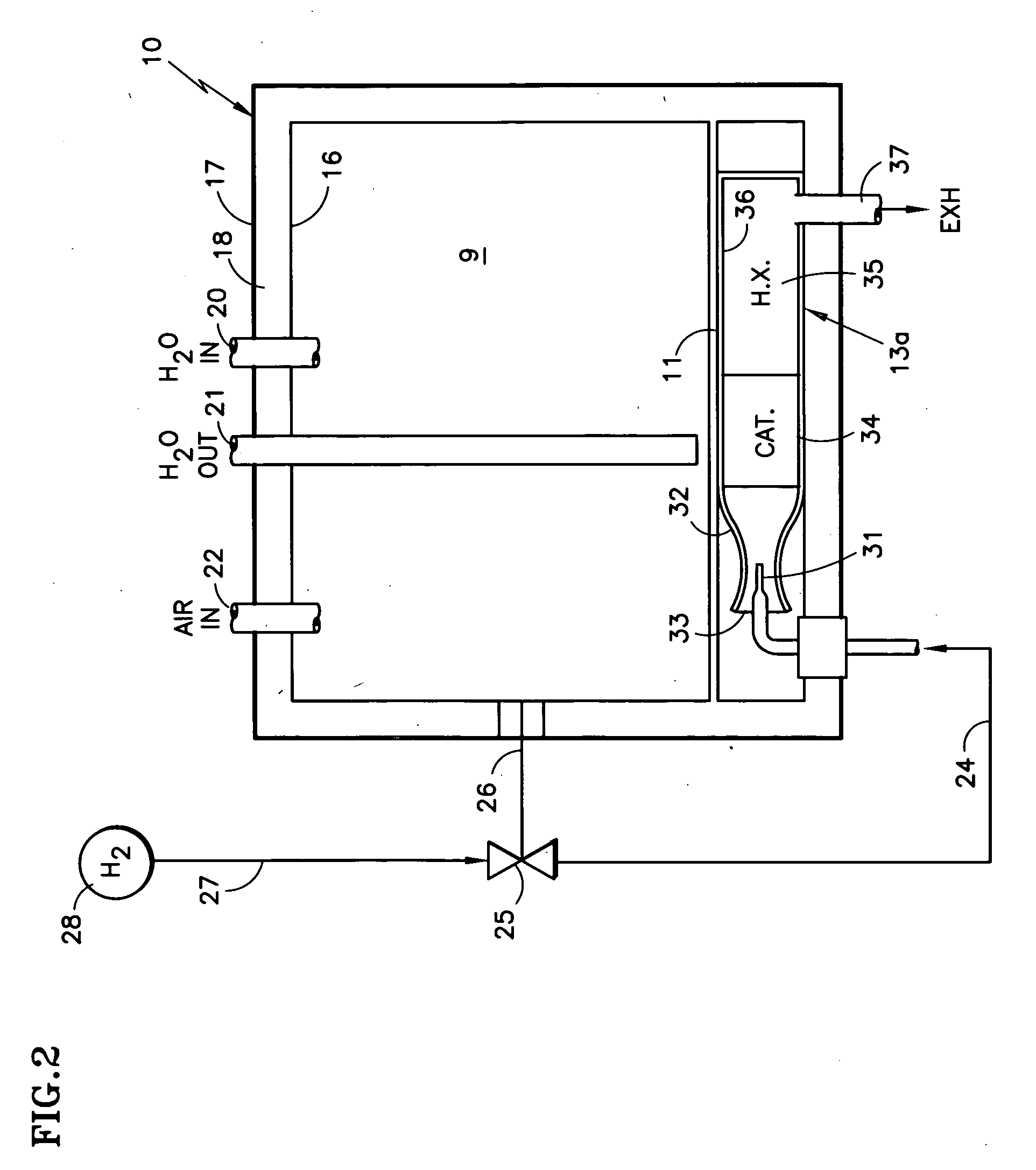

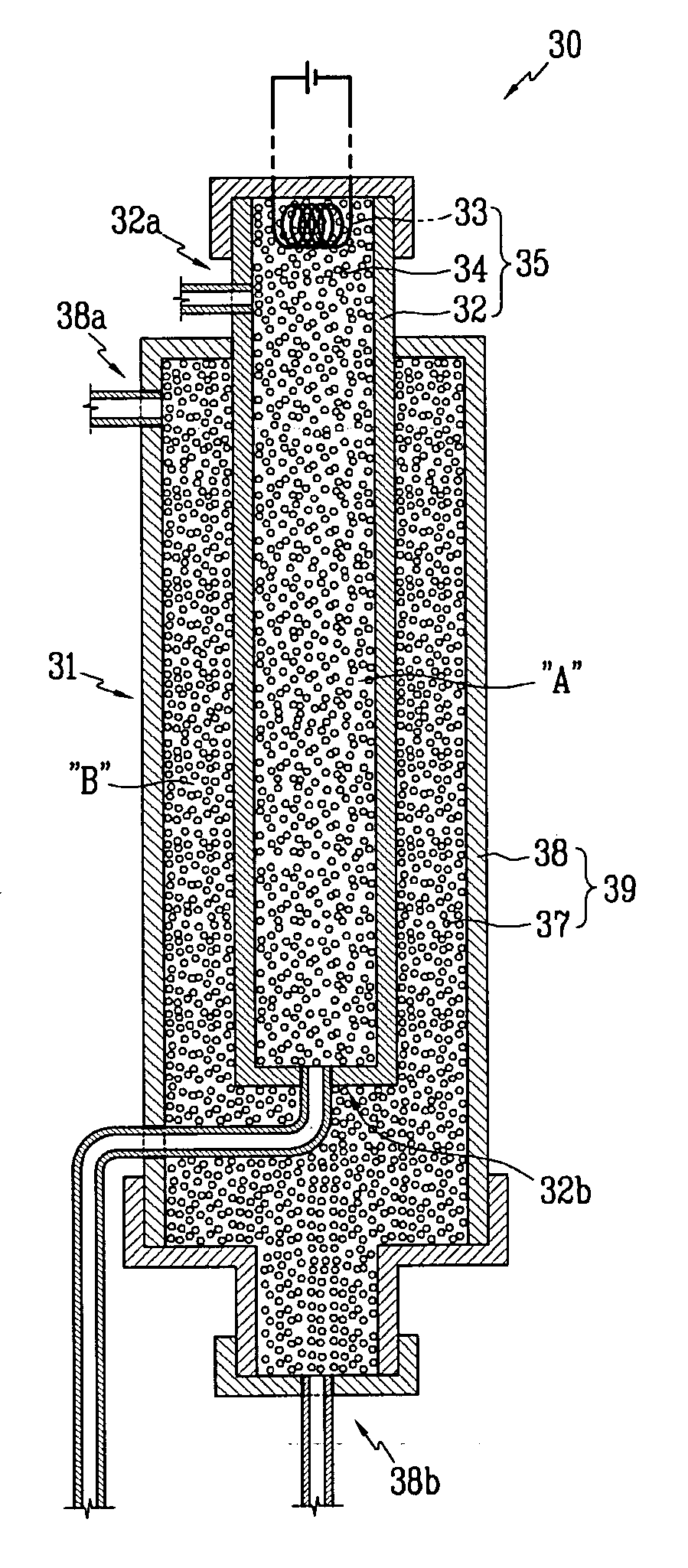

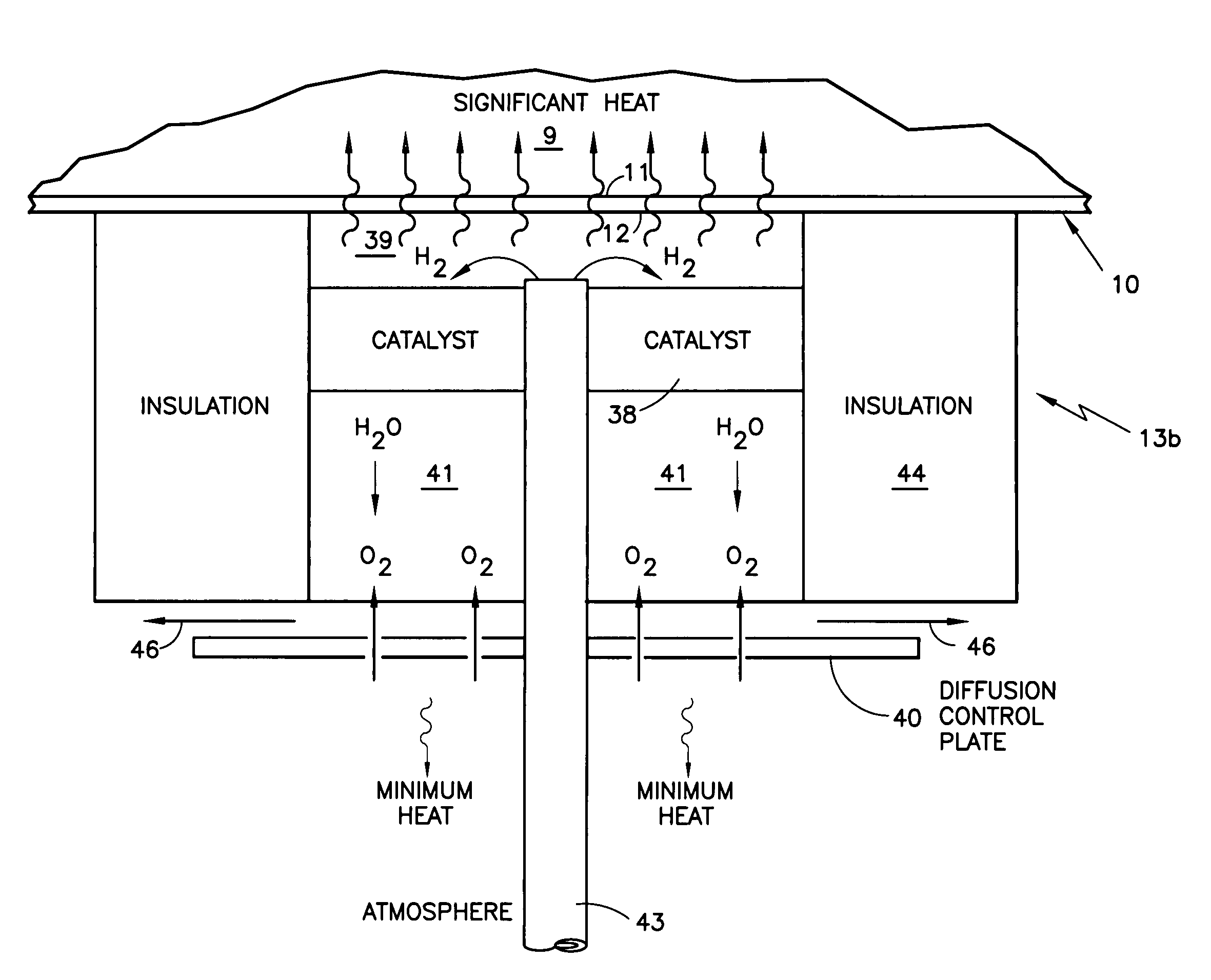

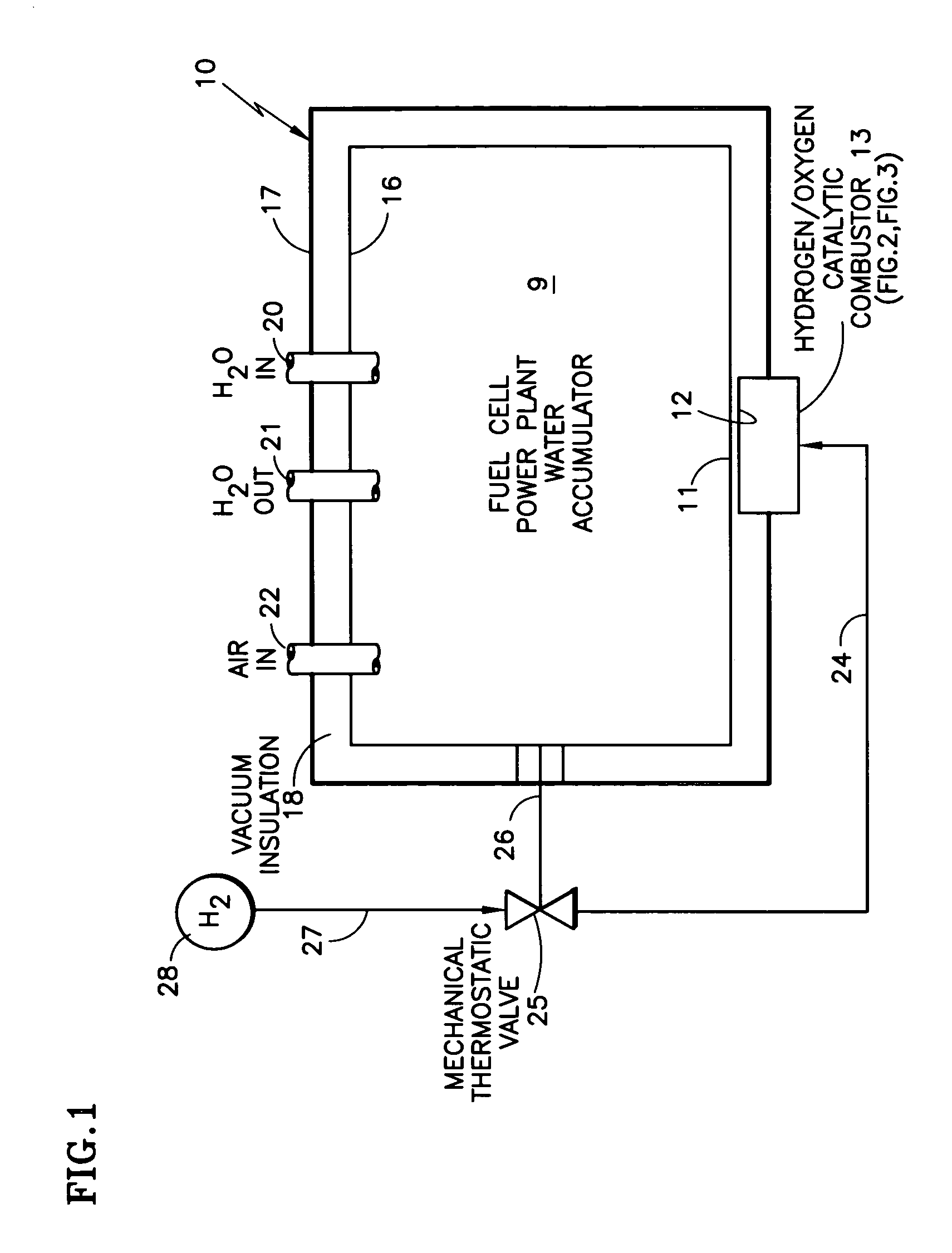

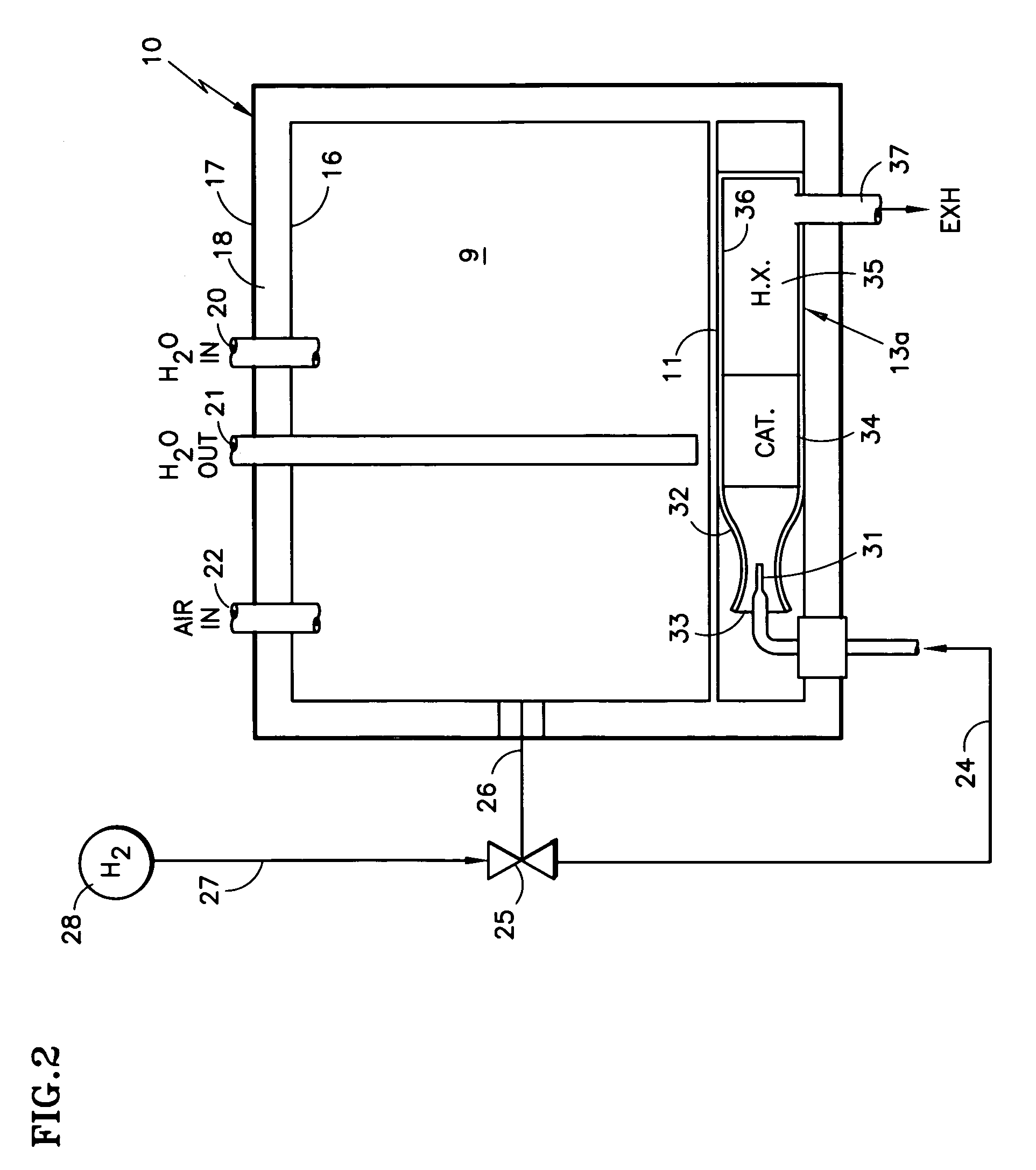

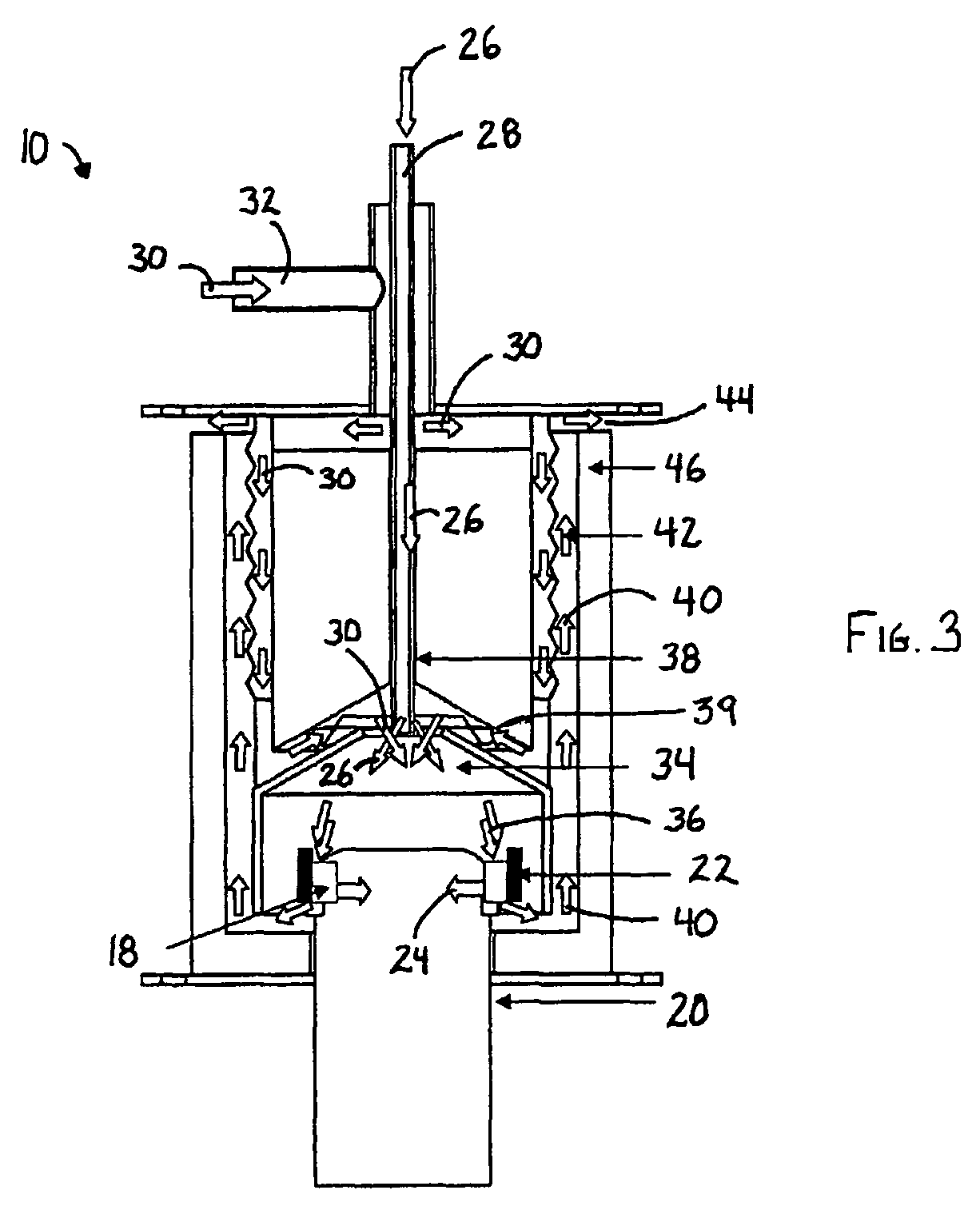

Catalytic combustors keeping contained medium warm in response to hydrostatic valve

ActiveUS20060154190A1Improve efficiencyEfficient combustionExhaust apparatusFuel cell auxillariesPtru catalystAtmospheric air

The medium (9), such as water, of a container (10), such as a fuel cell accumulator, is kept above freezing by a hydrogen / oxygen catalytic combustor (13) fed hydrogen from a source comprising a mechanical thermostatic valve (25) in thermal communication (26) with the container (10) and connected to a hydrogen supply (28). The combustor may comprise an ejector (32) having hydrogen through its primary inlet (31) drawing air through a secondary inlet (33). The combustor may comprise a diffusion combustor having a catalyst (38) spaced from a heating surface (30) and a diffusion control plate (40) low partial pressure of oxygen at the catalyst causing diffusion through the barrier. Water vapor from combustion condenses on a surface (146) and is led by hydrophilic woven carbon paper (126) to wicking material (133), which has smaller pores than the carbon paper, which leads the water downwardly, through a disk (140) and plugs (147) to atmospheric air. The noble metal catalyst mixture includes TEFLON® to permit water generated by combustion to flow by gravity out of the catalyst.

Owner:AUDI AG

Burner for a reformer of a fuel cell system, and reformer and fuel cell system with the same

InactiveUS20060154123A1Short oxidation timeReduce power consumptionProductsHydrogenFuel cellsCombustor

A burner for a reformer of a fuel cell system includes a body having a catalyst inside thereof; and a heating member partially embedded within the catalyst to provide an auxiliary thermal source to the catalyst.

Owner:SAMSUNG SDI CO LTD

Catalytic combustors keeping contained medium warm in response to hydrostatic valve

ActiveUS7410619B2Improve efficiencyEfficient combustionExhaust apparatusFuel cell auxillariesAtmospheric airWater vapor

The medium (9), such as water, of a container (10), such as a fuel cell accumulator, is kept above freezing by a hydrogen / oxygen catalytic combustor (13) fed hydrogen from a source comprising a mechanical thermostatic valve (25) in thermal communication (26) with the container (10) and connected to a hydrogen supply (28). The combustor may comprise an ejector (32) having hydrogen through its primary inlet (31) drawing air through a secondary inlet (33). The combustor may comprise a diffusion combustor having a catalyst (38) spaced from a heating surface (30) and a diffusion control plate (40) low partial pressure of oxygen at the catalyst causing diffusion through the barrier. Water vapor from combustion condenses on a surface (146) and is led by hydrophilic woven carbon paper (126) to wicking material (133), which has smaller pores than the carbon paper, which leads the water downwardly, through a disk (140) and plugs (147) to atmospheric air. The noble metal catalyst mixture includes TEFLON® to permit water generated by combustion to flow by gravity out of the catalyst.

Owner:AUDI AG

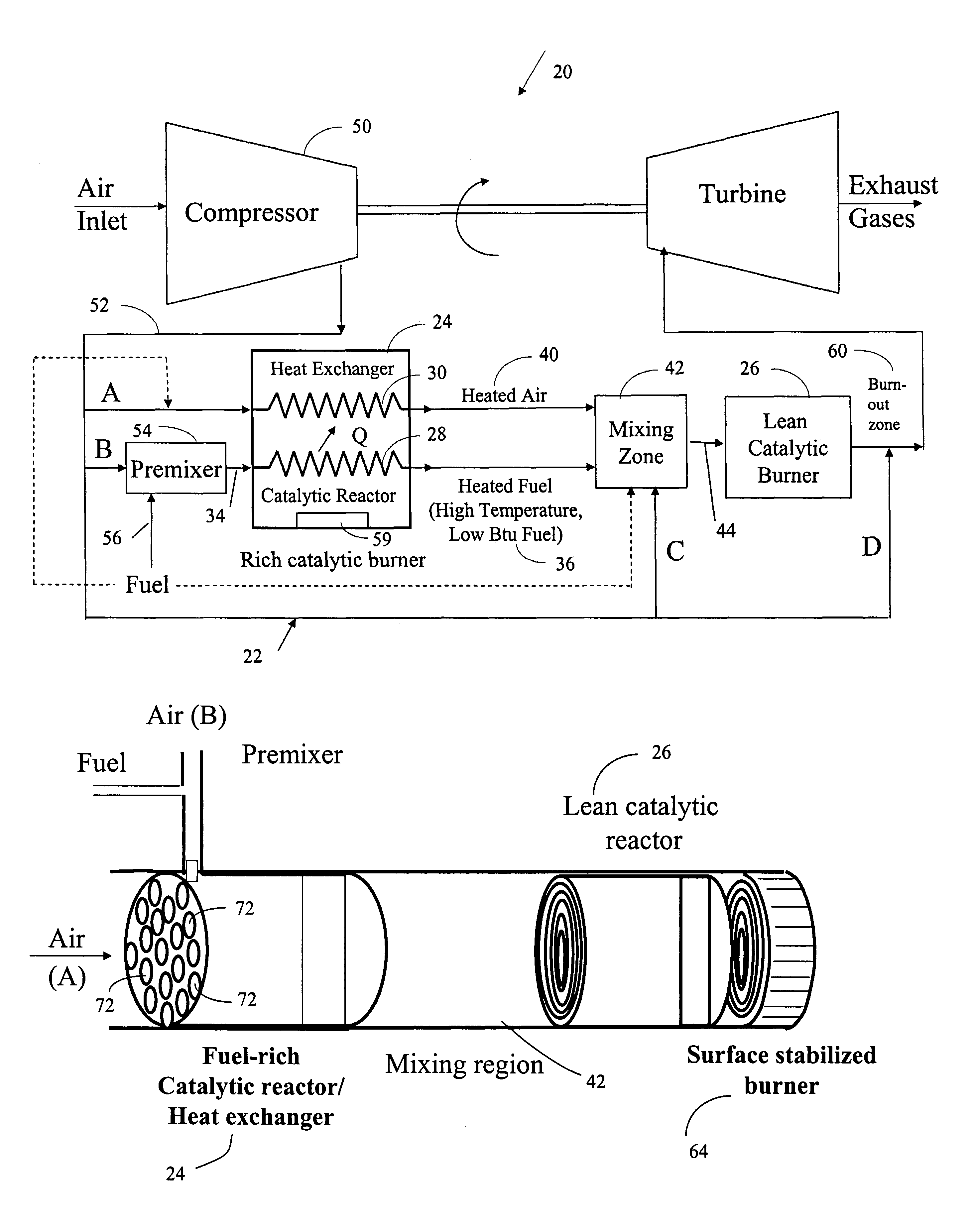

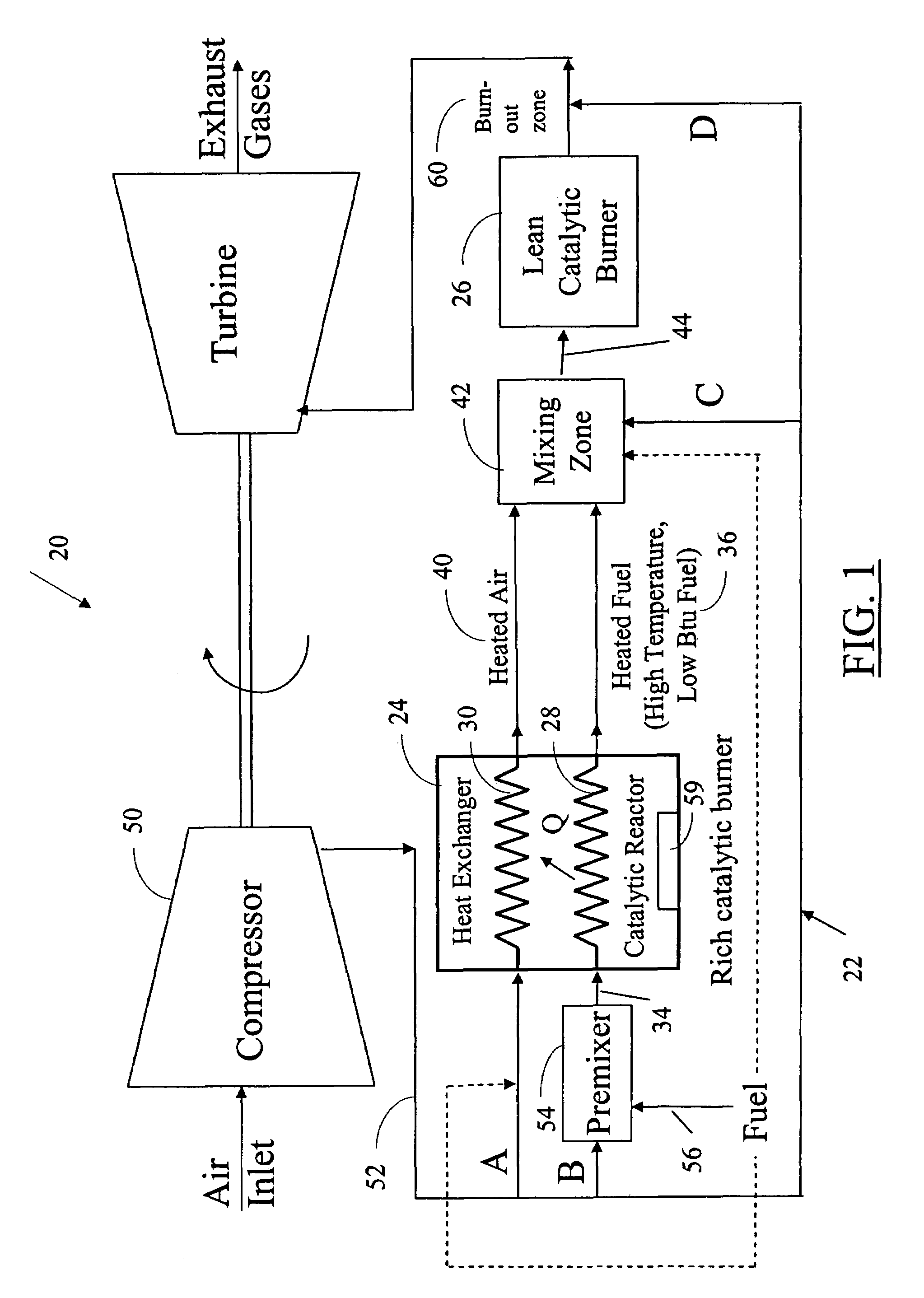

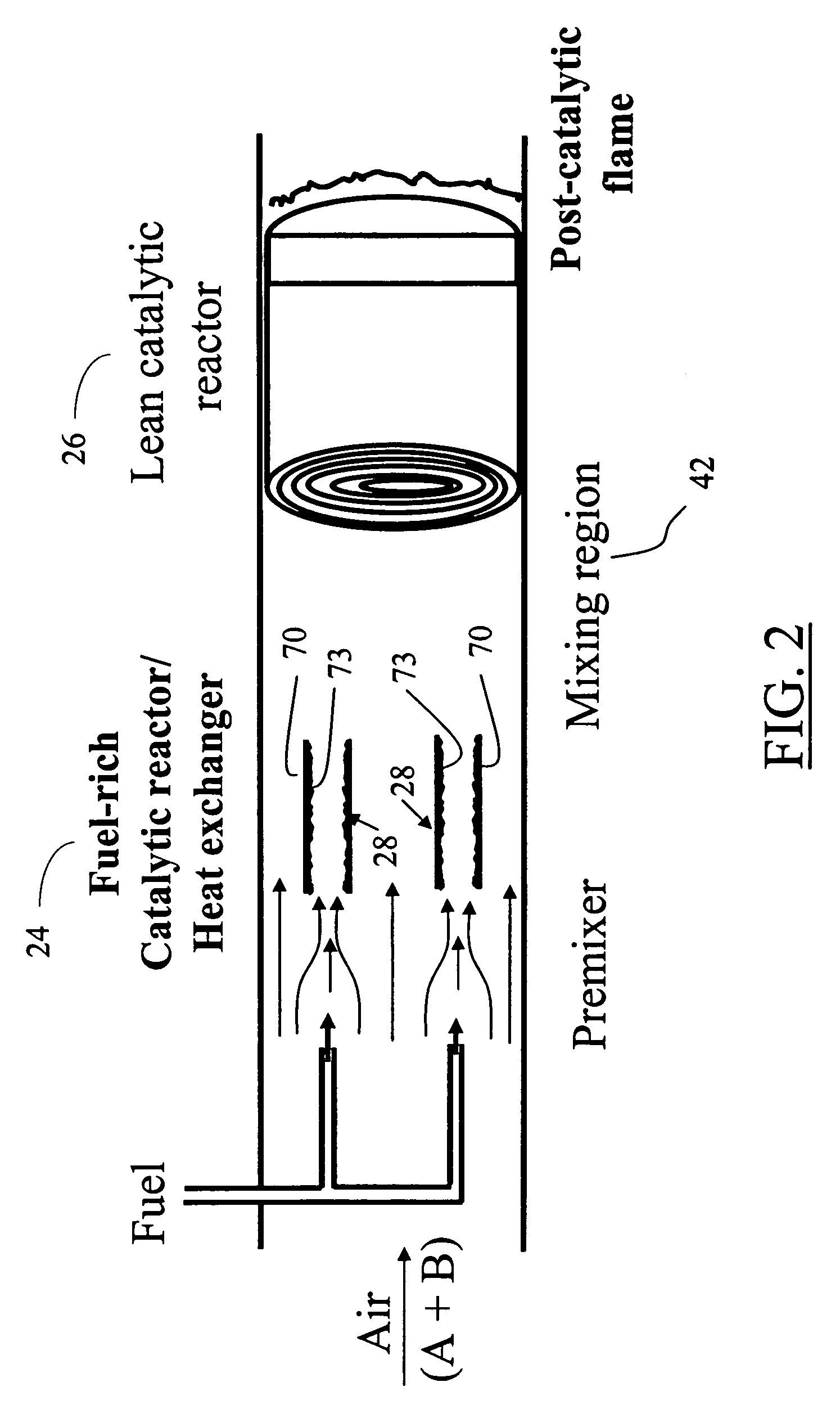

Method and system for rich-lean catalytic combustion

InactiveUS7444820B2Continuous combustion chamberTurbine/propulsion fuel supply systemsProcess engineeringThreshold temperature

A gas turbine engine using a rich-lean catalytic combustion system includes a rich catalytic burner and a lean catalytic burner. The rich catalytic burner includes a rich catalytic reactor and a heat exchanger. The rich catalytic reactor catalytically burns a fuel rich mixture to provide a heated fuel. The heat exchanger receives a stream of air that absorbs a portion of the heat from the catalytic burning of the fuel rich mixture to keep the reaction in the rich catalytic reactor at or below a threshold temperature. A resulting heated air from the heat exchanger and the heated fuel are mixed in a mixing zone to provide a heated fuel-air mixture. The lean catalytic burner receives and burns the heated fuel-air mixture.

Owner:UNITED TECH CORP

Catalytic burner apparatus for Stirling Engine

ActiveUS8387380B2Efficient mannerPrevent buildupCatalytic ignitersRegenerative heat exchangersExternal combustion engineProcess engineering

Owner:PRECISION COMBUSTION

Apparatus for distributed ignition of fuels by light sources

An apparatus for distributed ignition is disclosed wherein a combustion fuel and an ignition mixture are combined where the ignition mixture comprises ignition agents and fuel and where ignition agents can be nano-metallic particles in combination with single-walled carbon nano-tubes (SWCNTs). The combination of ignition mixture and combustion fuel in the presence of oxygen are exposed to light causing heating of the ignition agents and combustion of the fuel within which the ignition agents are interspersed. A system for igniting fuels using the method is also disclosed.

Owner:ERC

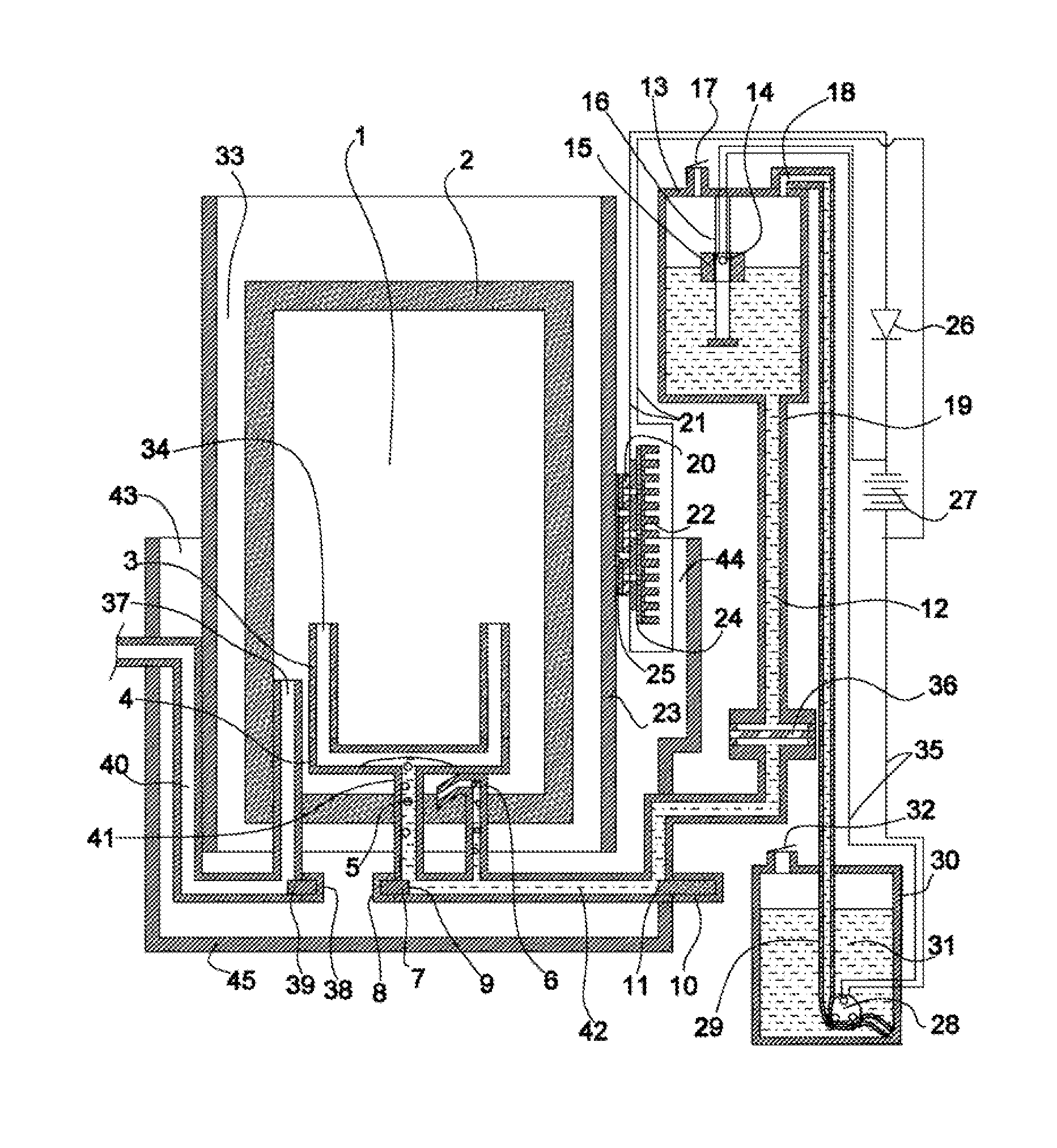

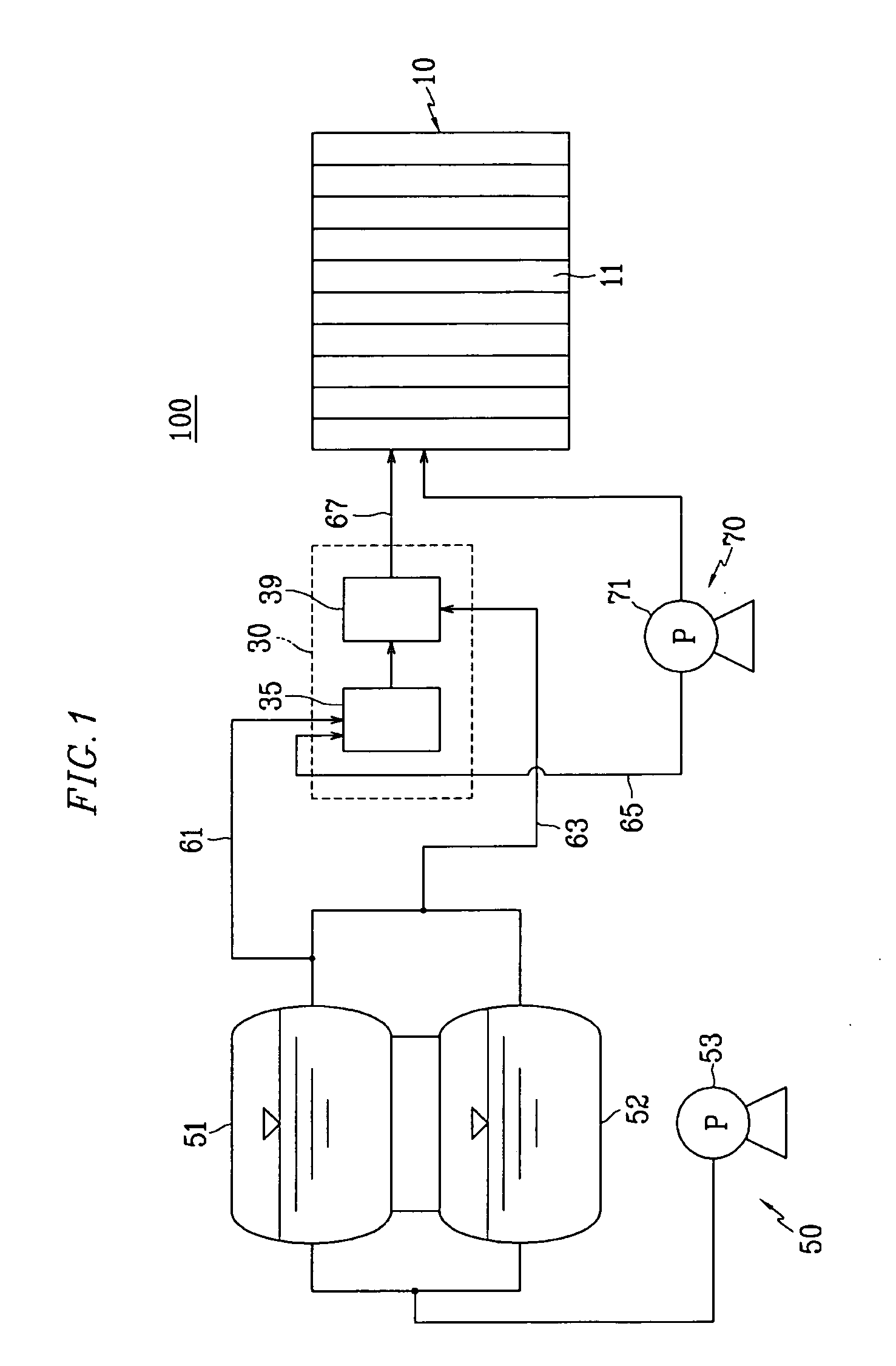

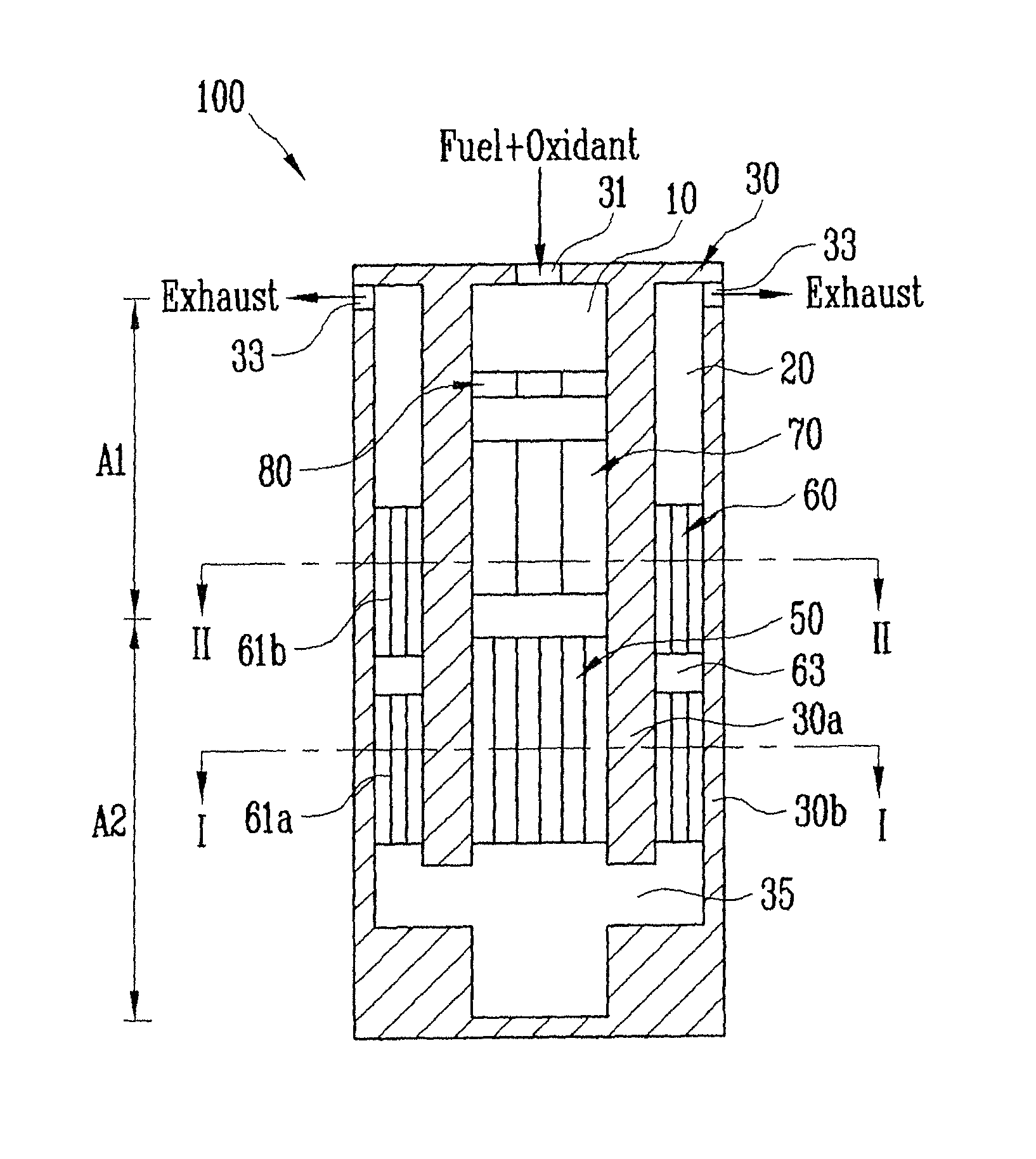

Hydrogen generator and fuel cell system comprising the same

InactiveUS7232471B2Simple configurationImprove abilitiesHydrogenExhaust apparatusSteam reformingFuel cells

A hydrogen generator comprises a burner for generating a combustion gas, a reformer provided around the burner to generate a reformed gas containing hydrogen by a steam reforming reaction based on a feed material comprising a compound containing at least carbon and hydrogen and a steam, using heat transmission from a combustion gas generated by the burner, and an evaporator having an inner tube provided around the burner, an outer tube provided around the inner tube, and a bottom plate that closes a lower portion of a tubular space formed between the inner tube and the outer tube, the evaporator being configured to evaporate water supplied to the tubular space to generate a steam to be supplied to the reformer, wherein a water absorbing member having a water absorbing capability is provided in the tubular space.

Owner:PANASONIC CORP

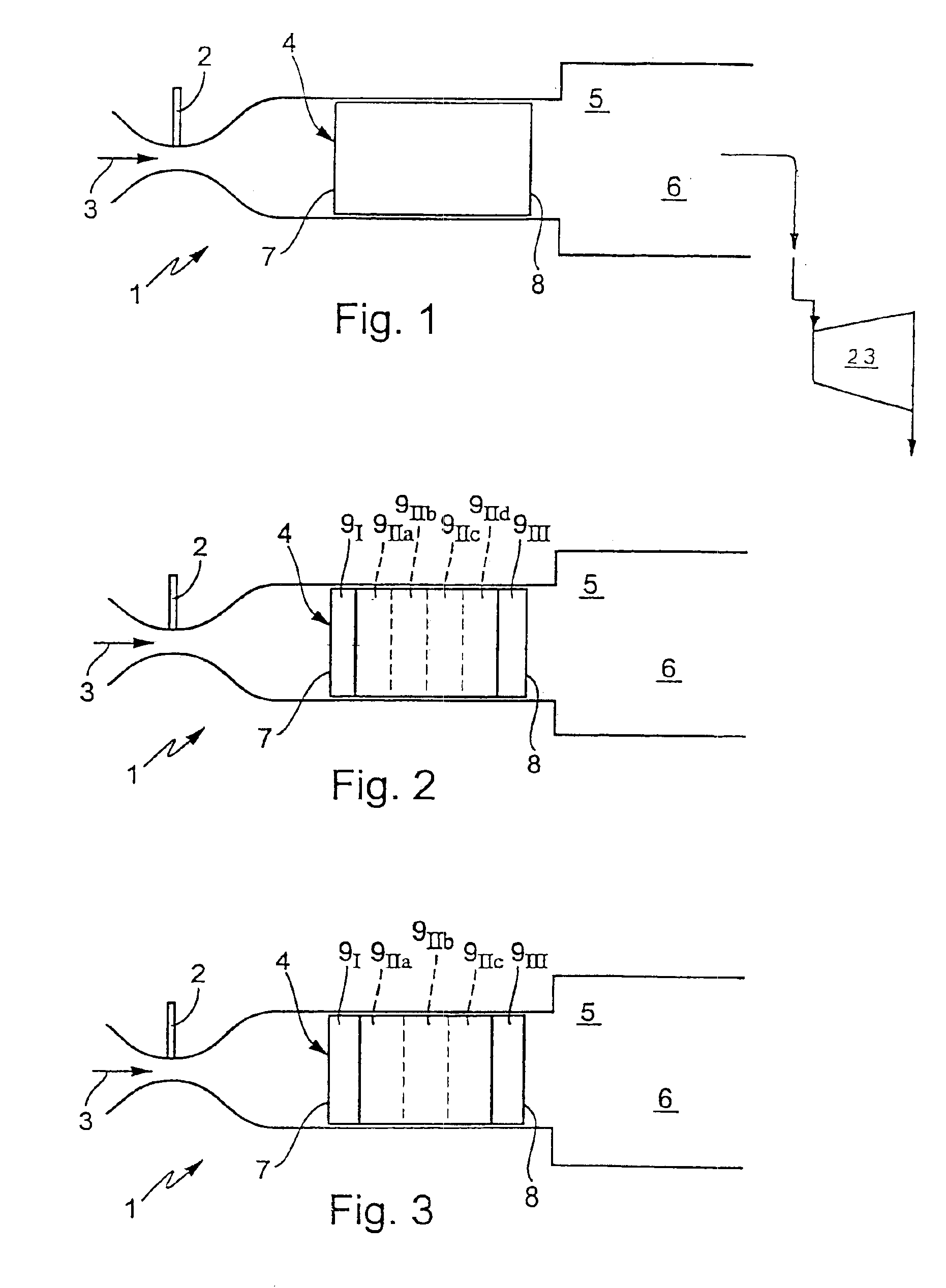

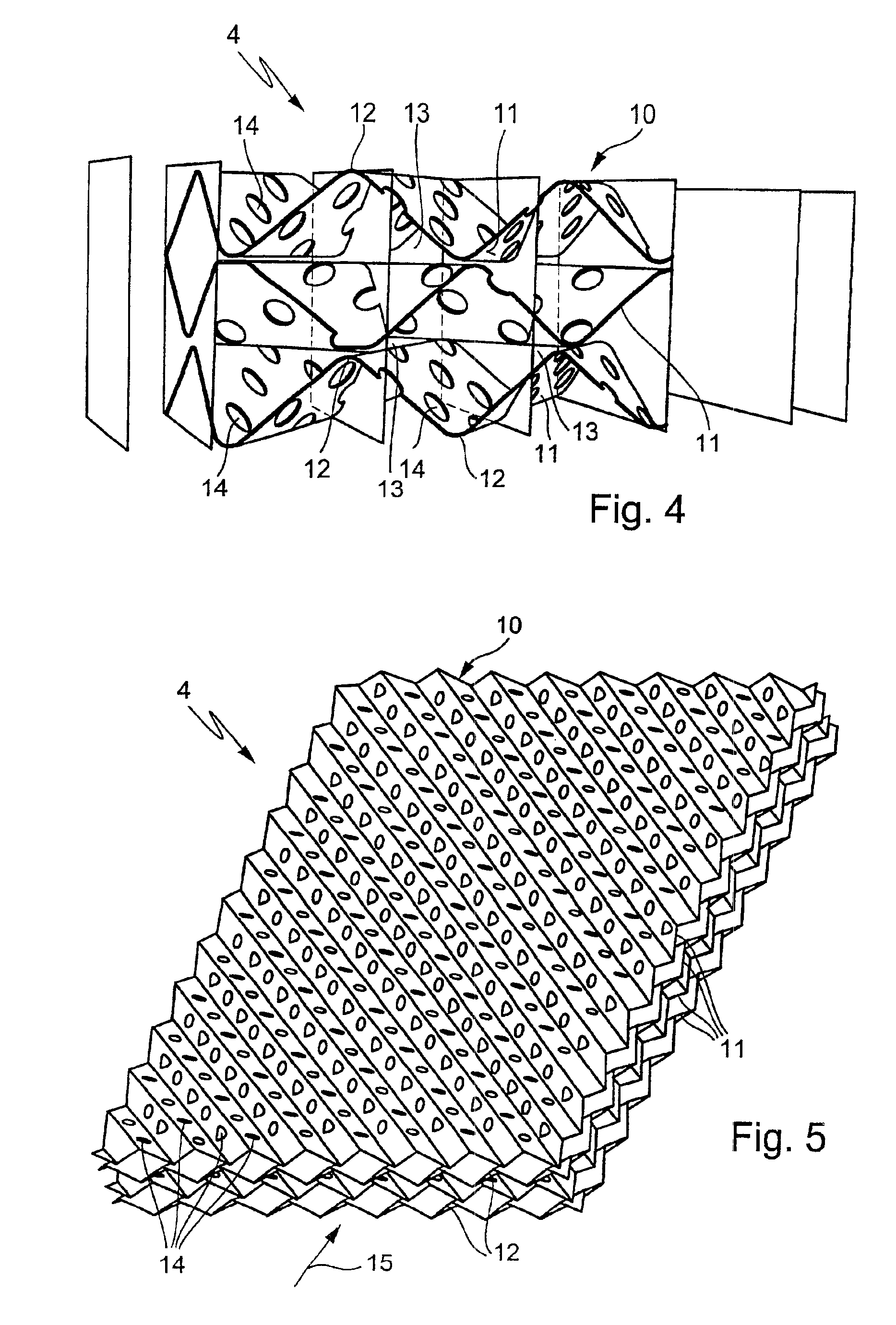

Catalytically operating burner

InactiveUS6887067B2Improve homogeneous gas phase reactionShorten design lengthContinuous combustion chamberPhysical/chemical process catalystsEngineeringCatalytic burner

A catalytically operating burner with a catalyzer structure (4), useful in particular for a gas turbine system, has a heat-resistant carrier material (10) that forms the walls of several adjoining channels (13). The channels (13) pervade the catalyzer structure (4) in longitudinal direction and permit that a gaseous reaction mixture flows through the catalyzer structure (4). The walls are coated at least in part with a catalyst. In order to improve the catalytic conversion within the catalyzer structure (4), communicating openings (14) are constructed in the walls between an inlet end and an outlet end of the catalyzer structure (4). Adjoining channels (13) are able to communicate with each other through the communicating openings (14).

Owner:ALSTOM TECH LTD

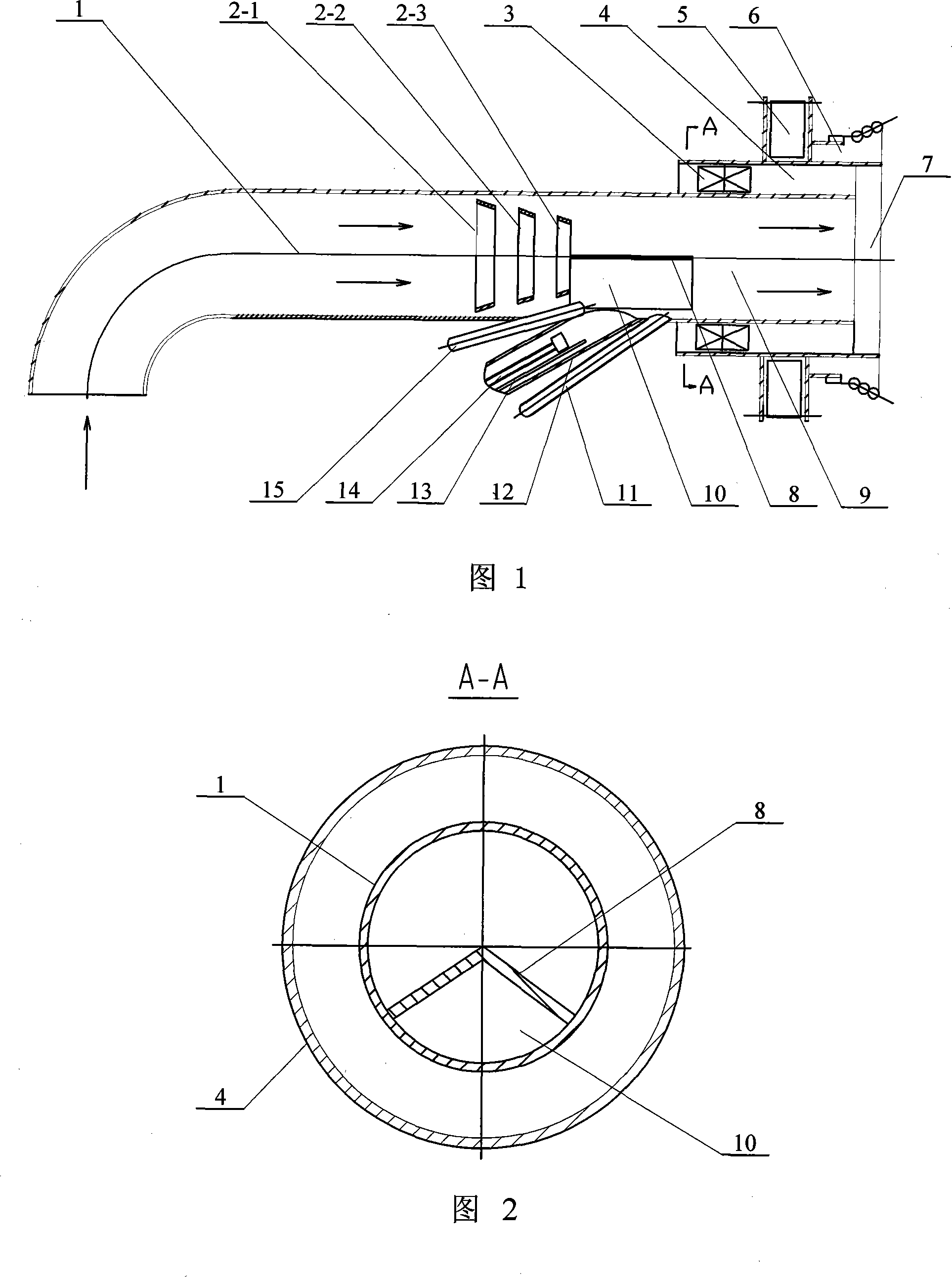

Little oil gasification and burning lateral-igniting center coal powder-feeding swirling burner

InactiveCN101101115ASolve the fuel saving problemSolve wear and tearCatalytic ignitersPulverulent fuel combustion burnersStart stopCombustor

The invention relates to swirl-flow burner. The first, second, and third truncated cone shape separating rings are orderly set at the middle of the burner primary flue in which the backward V shape separator is fixed at the right of the third truncated cone shape separating ring. The invention can greatly reduce initiation energy, satisfy the demands of start stop, and under load stable combustion for boiler, prolong coal dust residence time, control NOx production, form fractional combustion to combine with center feeding, realize NOx low discharge owing to secondary draft is divided into inner and outer two parts.

Owner:HARBIN INST OF TECH

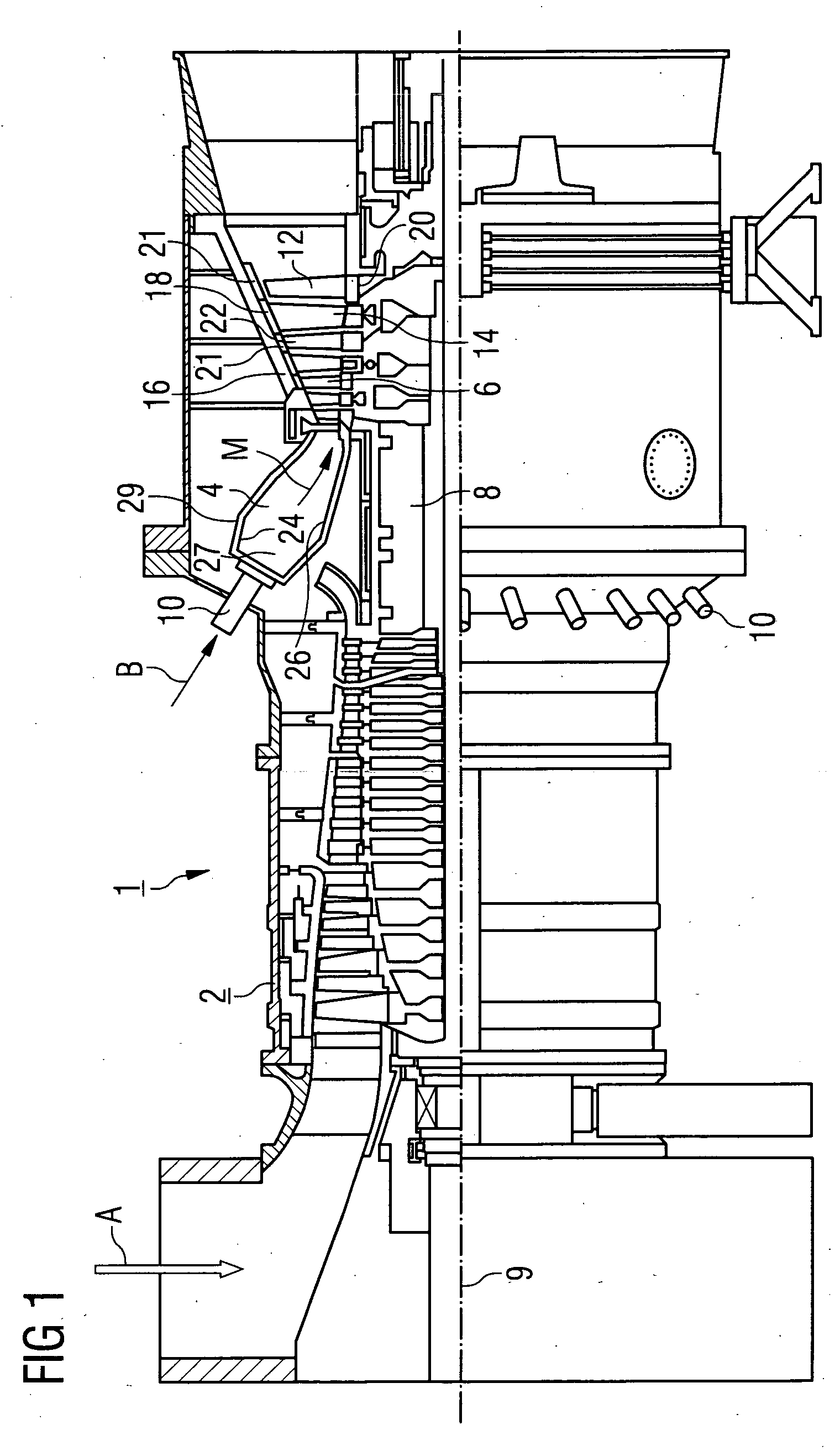

Method for the combustion of a fluid fuel, and burner, especially of a gas turbine, for carrying out said method

InactiveUS20060260322A1Low level of pollutant emissionLower levelTurbine/propulsion fuel supply systemsFurnace componentsCombustion chamberControl manner

The invention relates to a method for burning a fluid fuel, in which fuel is reacted in a catalytic reactions whereupon catalytically pre-reacted fuel continues to be burned in a secondary reaction. A swirling component is impressed onto the pre-reacted fuel, allowing the secondary reaction to be ignited in a spatially controlled manner, resulting in complete burnout. The invention further relates to a burner for burning a fluid fuel, in which the fuel outlet of a catalytic burner is disposed upstream of the fuel outlet of a primary burner in the direction of flow of the fuel within a flow channel such that the fuel is catalytically reacted. The catalytic burner is provided with a number of catalytically effective elements which are arranged such that a vortex is created in the flow channel. The invention can be applied particularly to combustion chambers of gas turbines.

Owner:SIEMENS AG

Catalytic combustor and fuel reformer having the same

InactiveUS8617269B2Improve thermal efficiencyHigh catalytic efficiencyHydrogenChemical industryDouble tubeEngineering

Owner:SAMSUNG SDI CO LTD

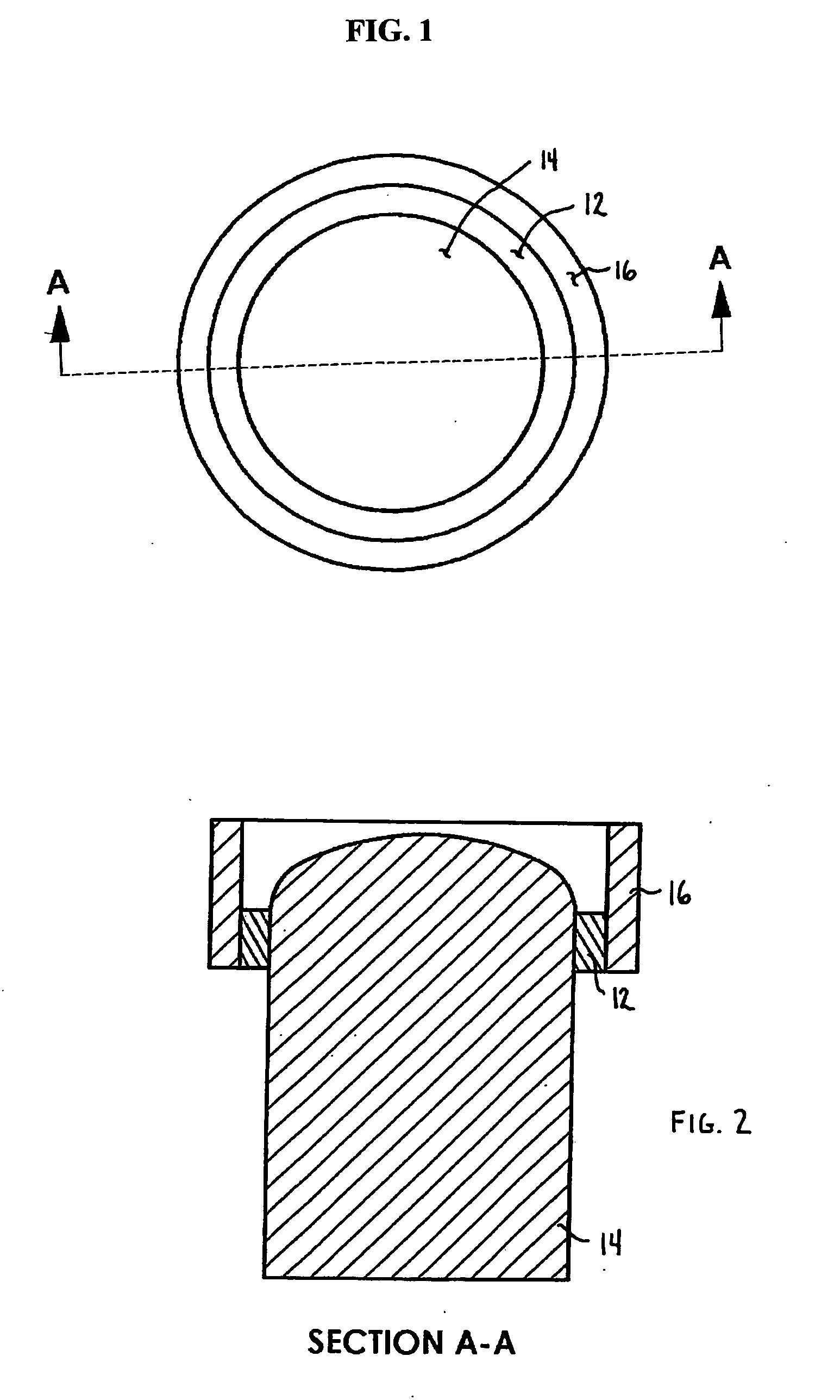

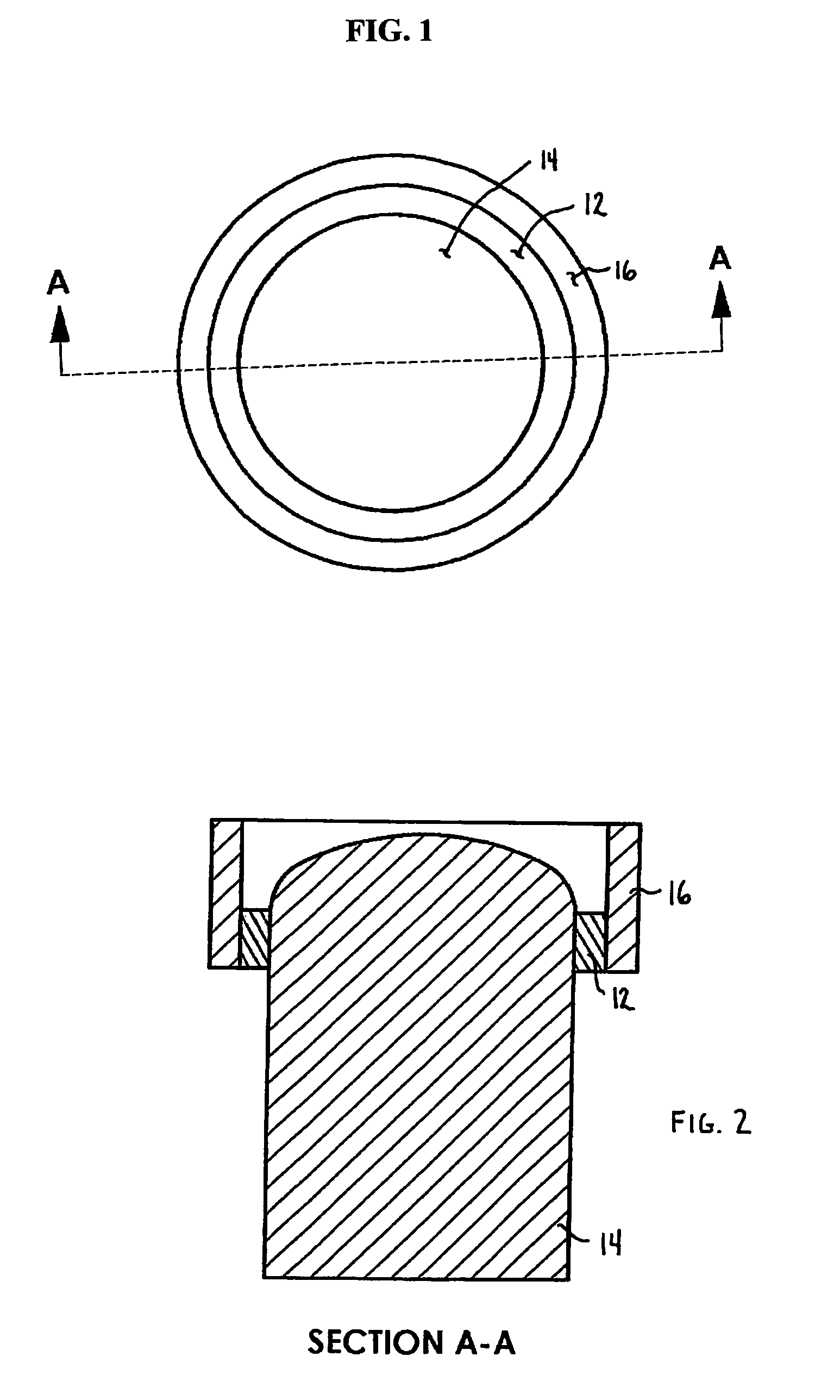

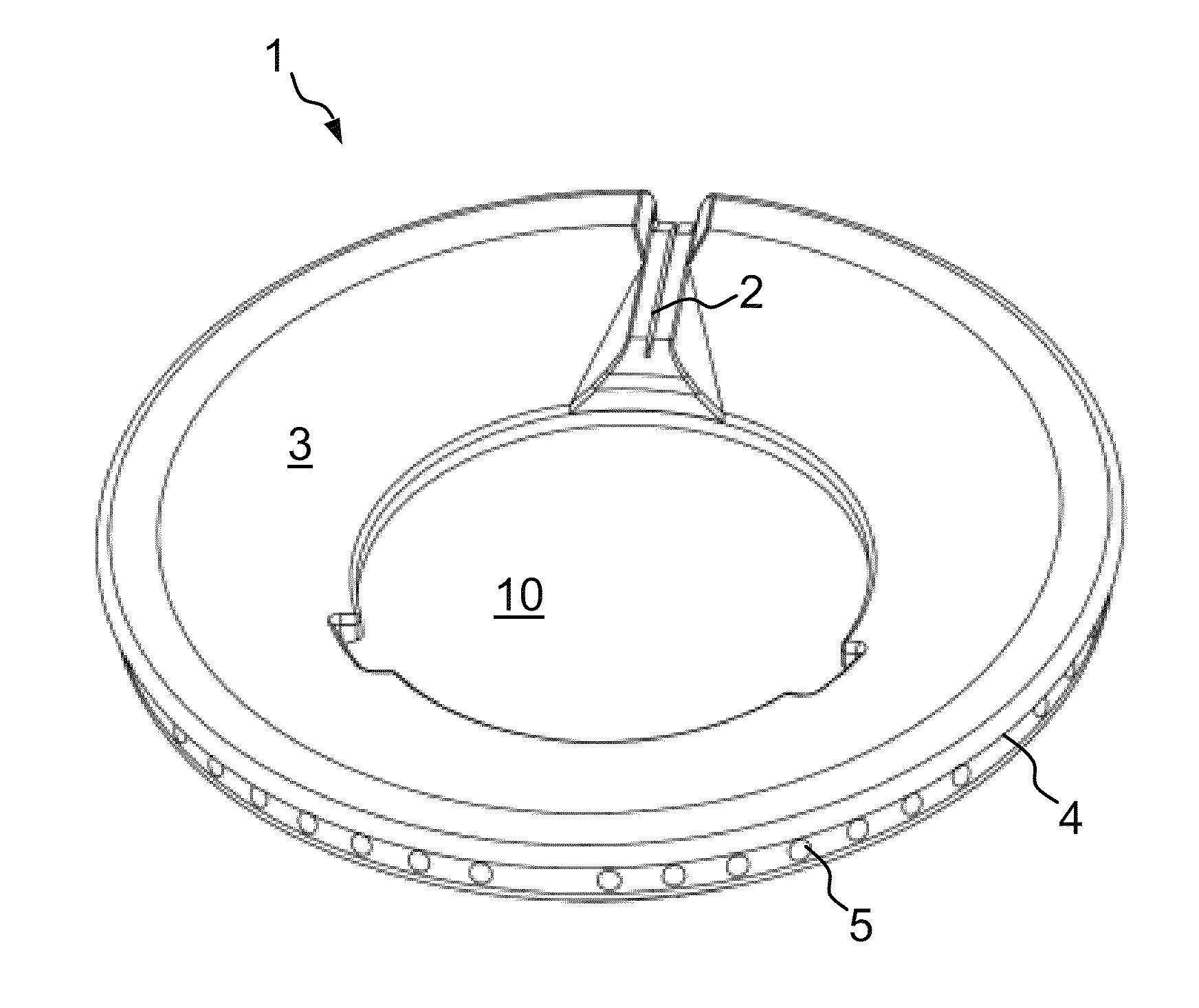

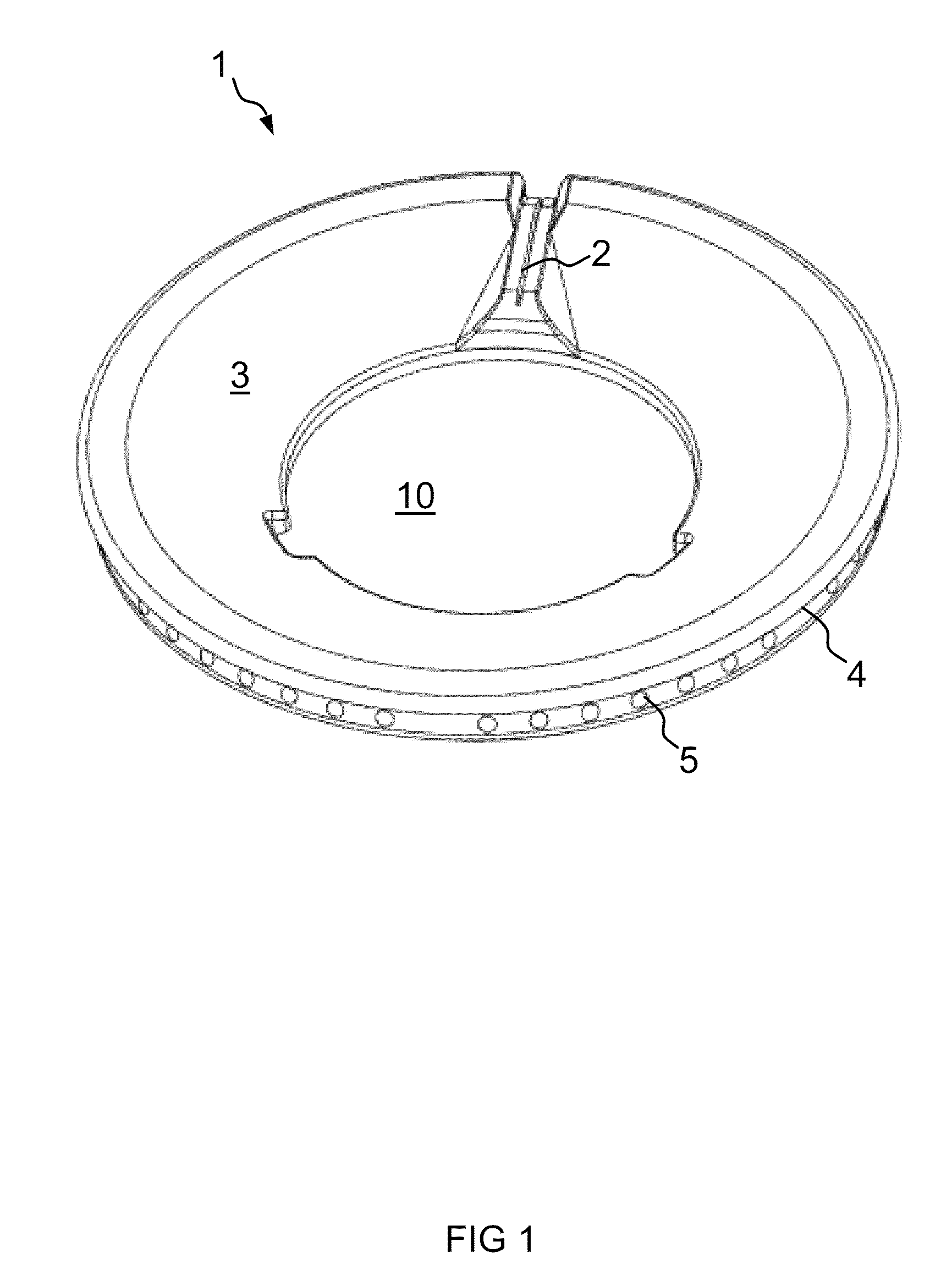

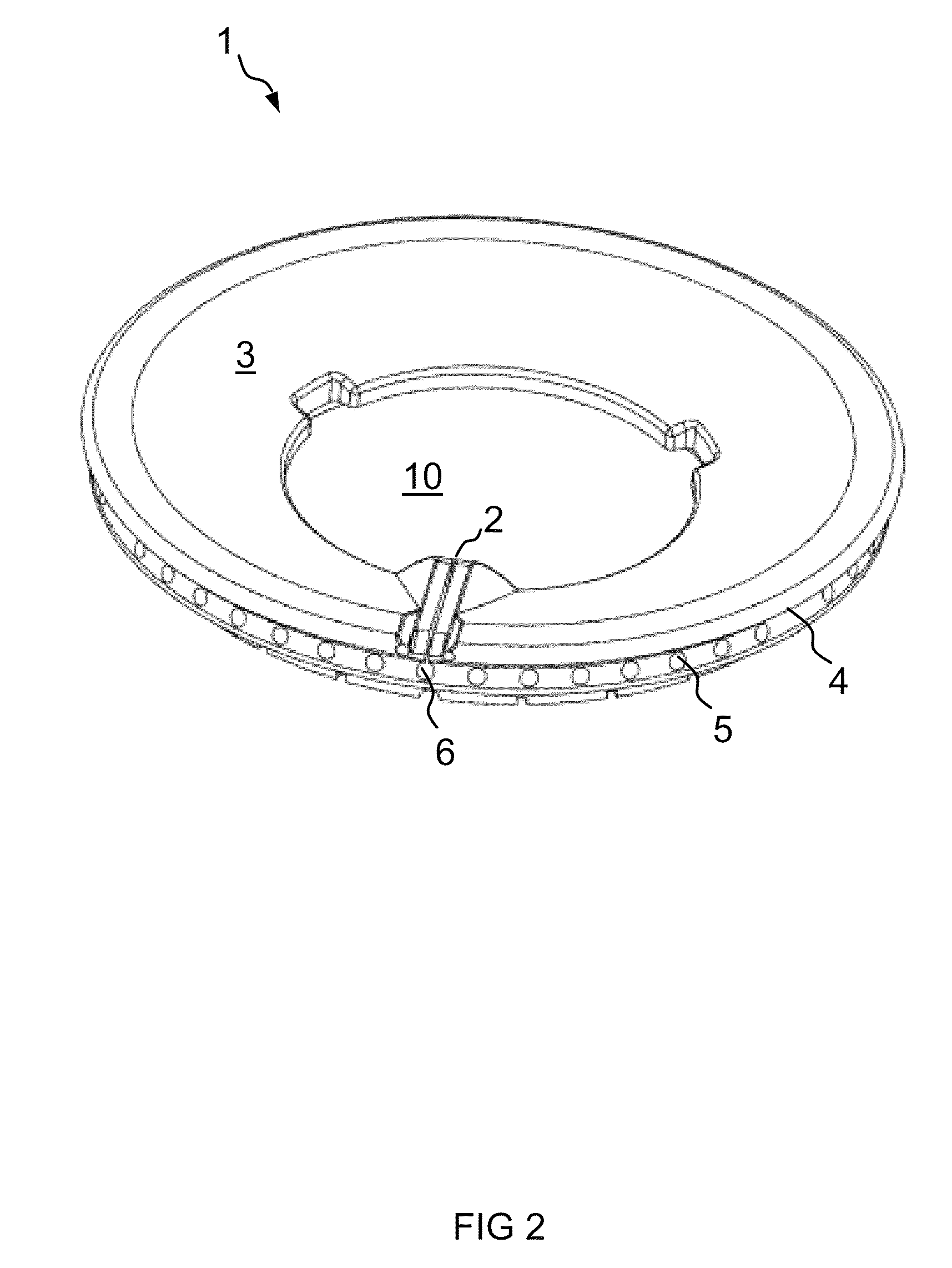

Burner ring

ActiveUS8245703B2Reduce concentrationIncreased soot formationDomestic stoves or rangesElectric spark ignitersEngineeringGas supply

A burner ring for a gas burner, the burner ring including an outer circumference and an inner circumference, a distribution chamber having gas outlets to the outer circumference of the burner ring, a transfer ignition groove that is outwardly open on one side and extends between the inner circumference of the burner ring and the outer circumference of the burner ring, a gas conducting channel into which the transfer ignition groove opens at least partially, and at least one gas supply opening between the distribution chamber and the gas conducting channel, wherein the gas conducting channel and the transfer ignition groove are arranged mutually symmetrically, and wherein the at least one gas supply opening is offset in a region of the gas conducting channel at an angle relative to the transfer ignition groove.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com