Patents

Literature

238results about How to "Short oxidation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of high-concentration wastewater

InactiveCN103663860AReduce wasteReduce dosageMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a treatment method of high-concentration wastewater. The treatment method comprises the following steps: (1) pretreatment; (2) flocculent sedimentation treatment; (3) biochemical treatment; (4) membrane biological reaction treatment; (5) adsorption treatment; (6) oxidation treatment; (7) filtration treatment; (8) membrane treatment; (9) disinfection treatment; and (10) evaporative crystallization treatment. The method disclosed by the invention has the advantages that the wastewater with the COD (Chemical Oxygen Demand) concentration up to 96000mg / L can be treated and the COD removing rate is up to 99.98% to ensure that the treated wastewater meets the standards of drinking water and an unexpected technical effect is brought; compared with a dozen or dozens of hours in the prior art, the aerobic reaction time and the anaerobic reaction time are greatly shortened and the treatment efficiency is obviously increased; and the concentrated solution finally generated in the method only accounts for below 2% of water inflow, which is greatly reduced compared with the prior art, so that the waste of water is obviously reduced and the treatment cost is saved.

Owner:曹寅亮

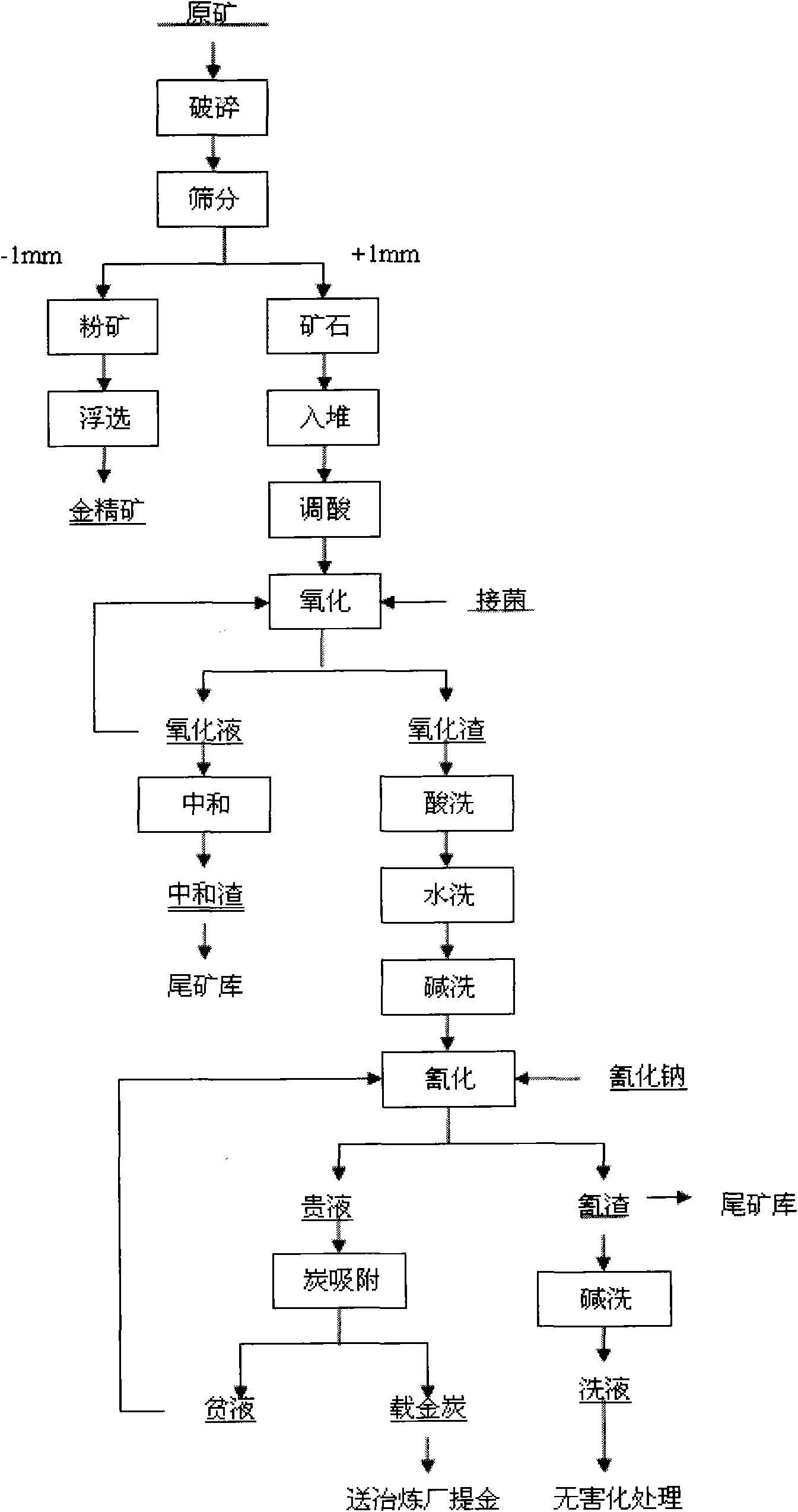

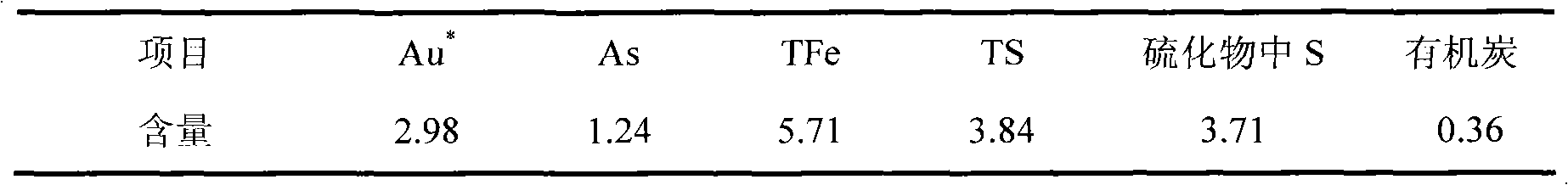

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

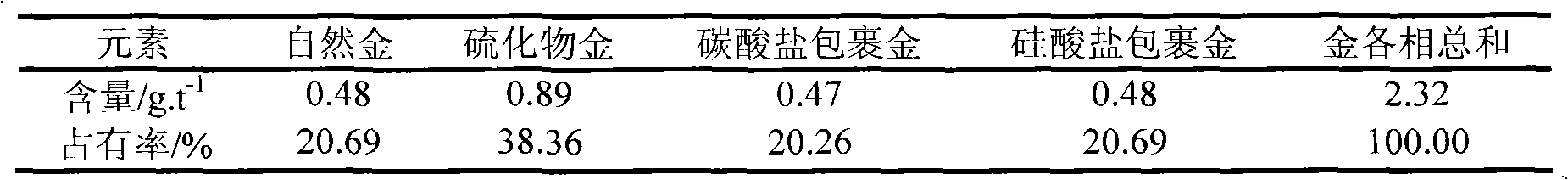

Method for treating coal gasification wastewater

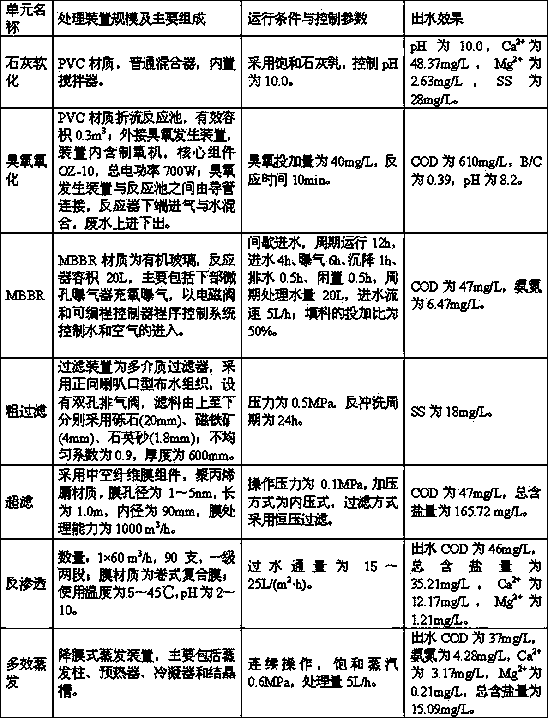

ActiveCN103771650AReduce hardnessHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentCoal gasification wastewaterFiltration

The invention discloses a method for treating coal gasification wastewater. The method comprises steps of: (1) lime softening by first adding lime milk to the coal gasification wastewater to conduct chemical precipitation on calcium salt and magnesium salt with the lime milk, standing the precipitation and filtering an supernatant; (2) ozone oxidation by sending the wastewater filtered in the step (1) into an ozone oxidation device for treatment; (3) MBBR treatment by sending the wastewater subjected to ozone oxidation into an MBBR for treatment; (4) coarse filtration; (5) continuous membrane filtration or ultrafiltration; (6) reverse osmosis; and (7) multi-effect evaporation by conducting multi-effect evaporation on the concentrate obtained by reverse osmosis treatment, and further crystallizing the concentrate obtained by multi-effect evaporation. The method of the invention can effectively remove the main pollutants such as COD, ammonia nitrogen and chroma in coal gasification wastewater, can also greatly reduce the salt content of the wastewater, ensure the efficient and long-term running of the double membranes, and achieve zero discharge of coal gasification wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

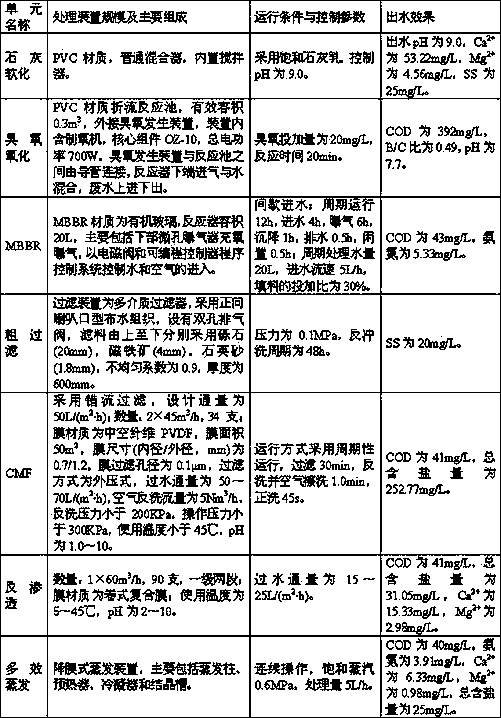

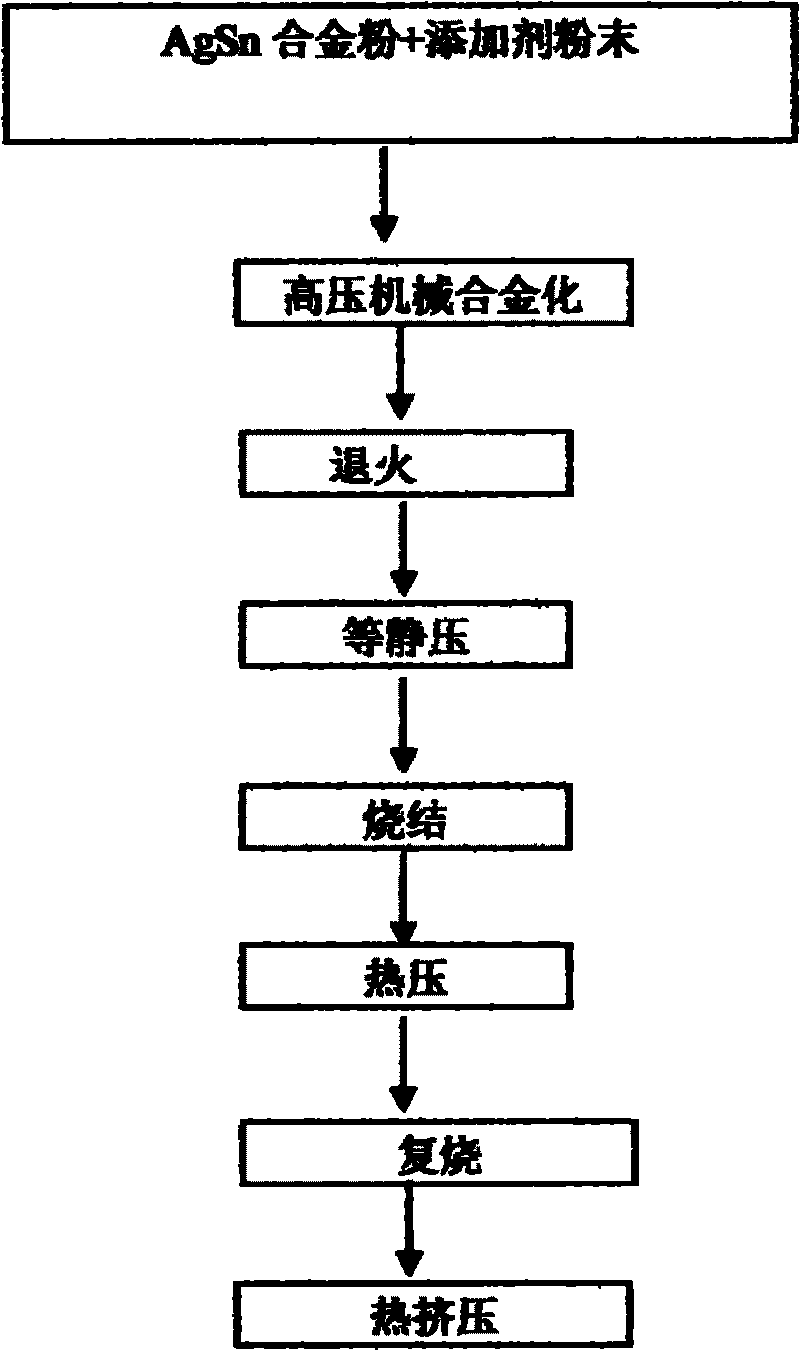

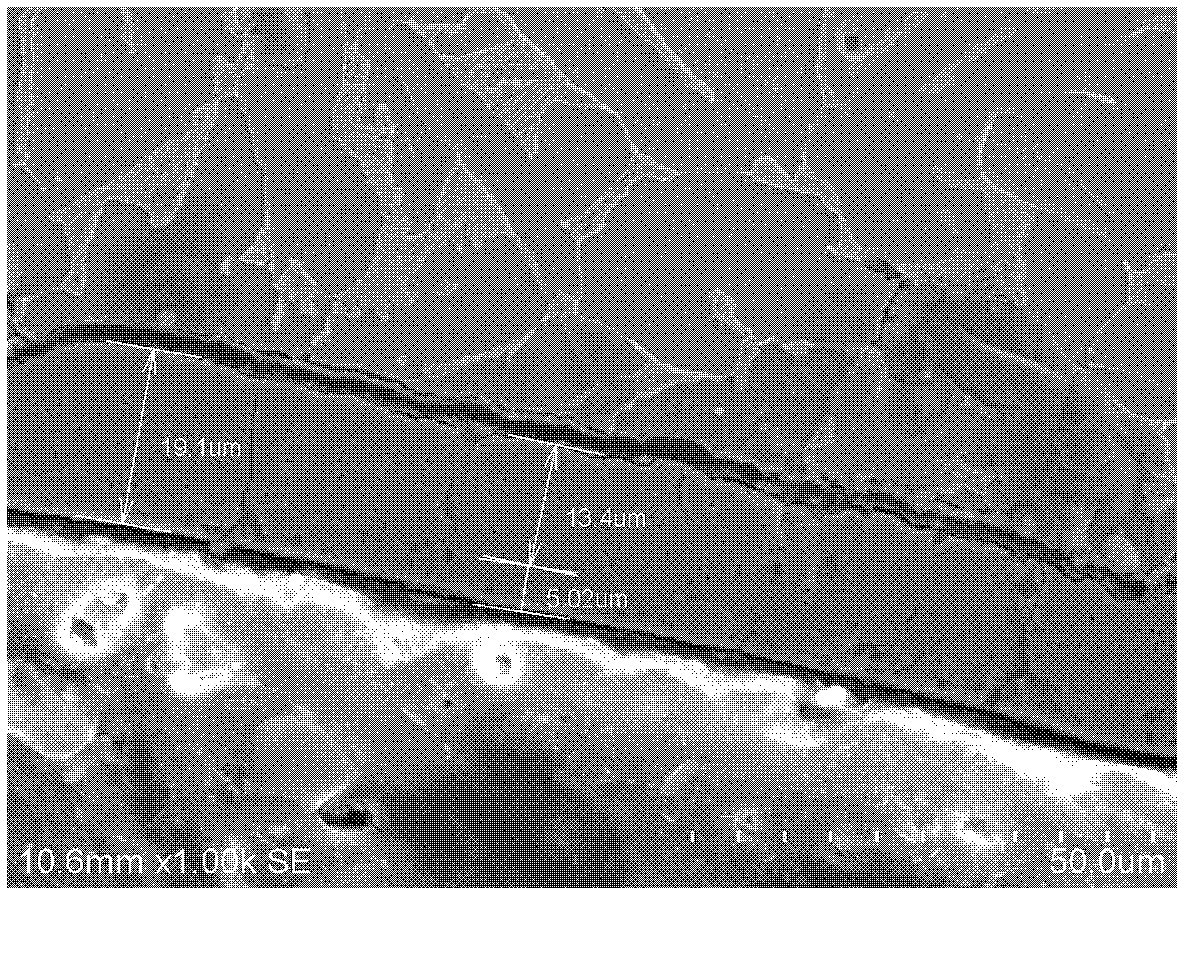

Preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material

The invention discloses a preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material, which adopts AgSn alloy powder to be mixed and collide mutually in the ball milling process, and keeps high-pressure oxidative atmosphere in the ball milling process simultaneously to lead the pre-oxidation of the AgSn alloy powder and the ball milling dispersing process to be conducted synchronously, thus greatly shortening the pre-oxidation time of the AgSn alloy, avoiding high-temperature oxidation and improving SnO2 distribution condition. The method has the characteristic of simple and flexible operation, and the silver tin oxide prepared by the method has the ideal structure of submicron or nanometer SnO2 particle reinforced phase dispersed distribution, thus leading the material to have high strength, high electrical conductivity and excellent electrical properties.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

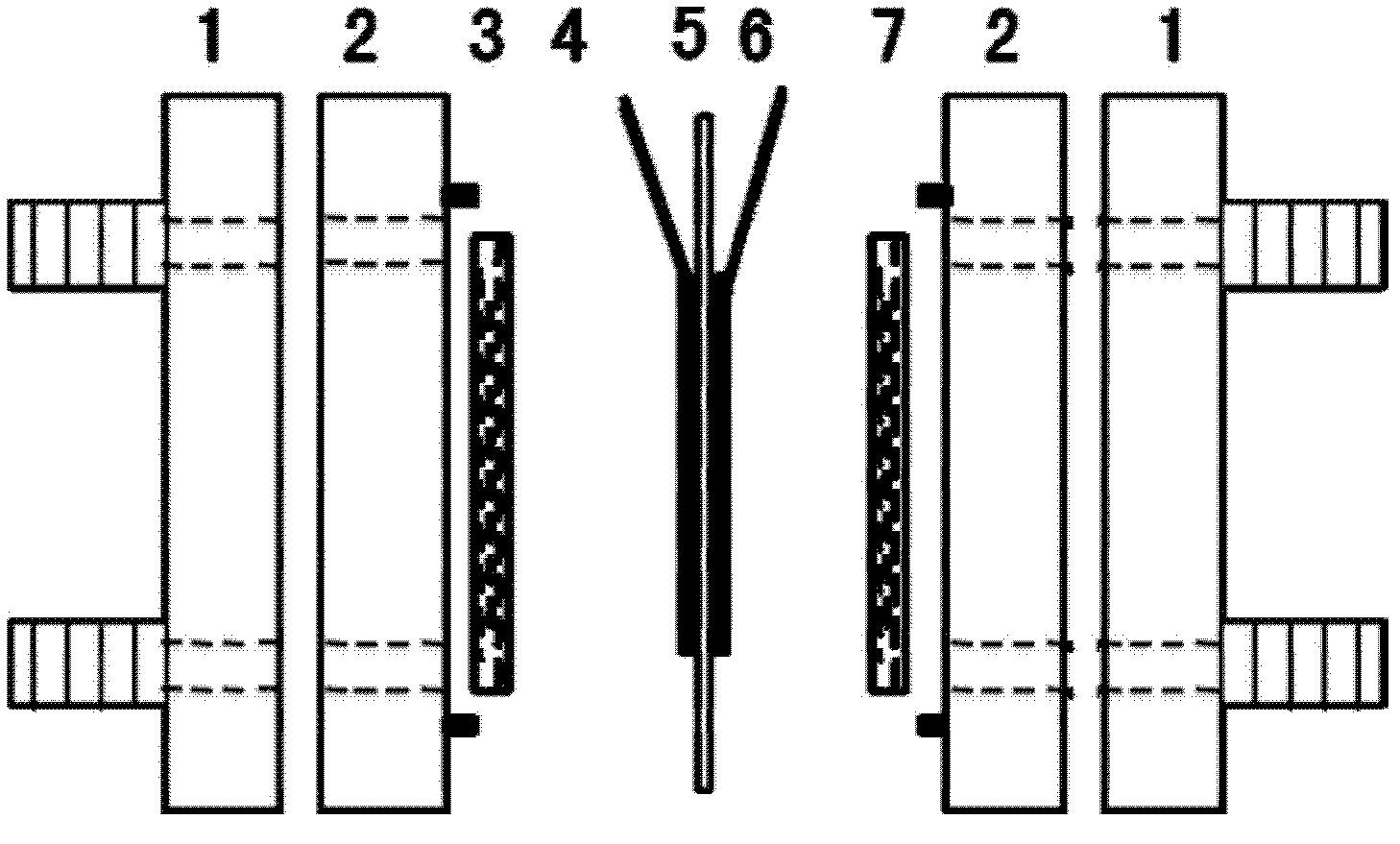

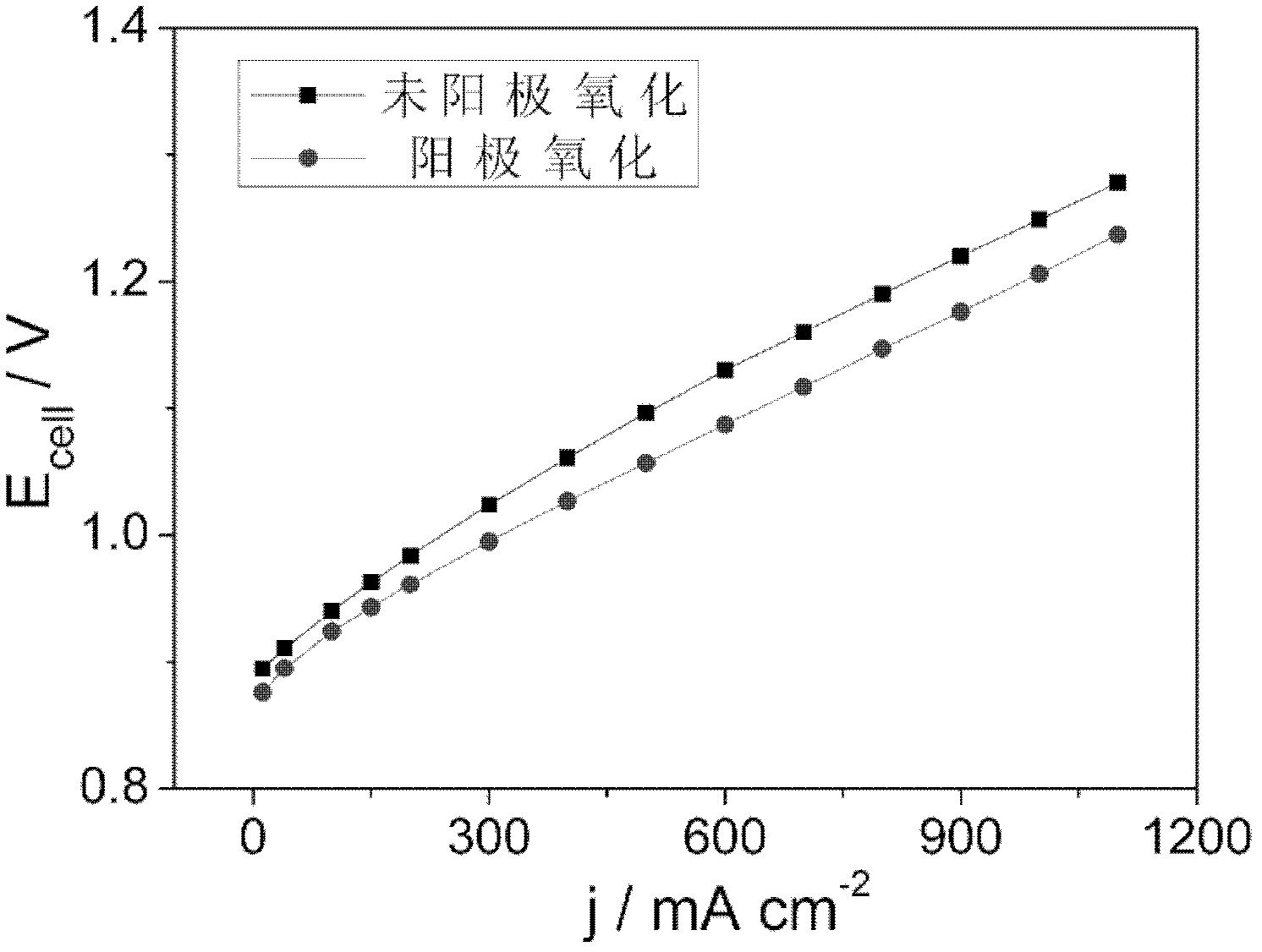

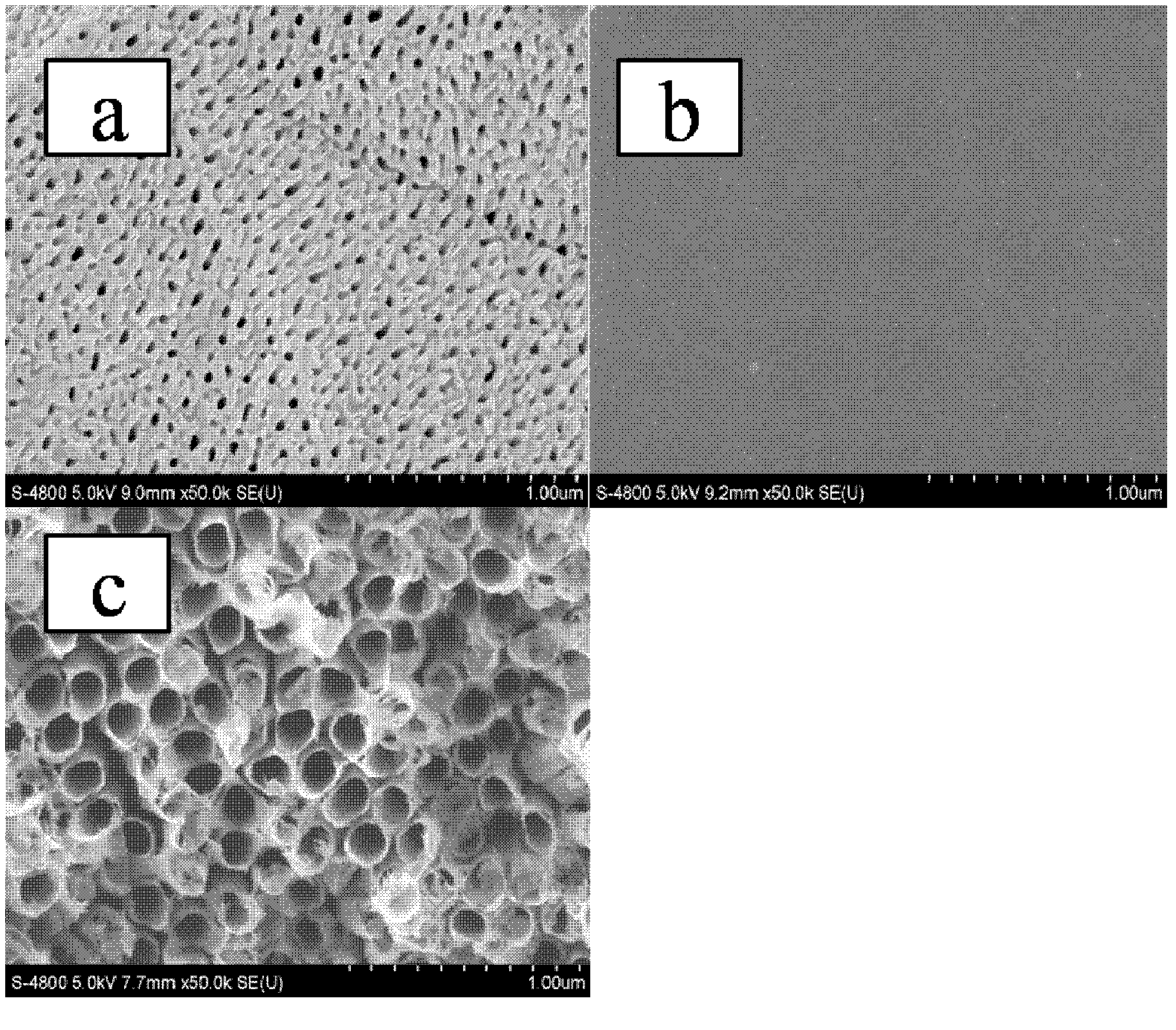

Treating method of metallic titanium material

ActiveCN103173835ASimple preparation processNo complex equipment requiredElectrolytic inorganic material coatingCell electrodesAnodizingFuel cells

The invention provides a treating method of a metallic titanium material. The metallic titanium material is sintered porous titanium, a titanium felt, a titanium mesh or foaming titanium. The treating method of the metallic titanium material comprises the following steps of: purifying the surface of the titanium material; taking the titanium material after purification as an anode to carry out anodizing; and electro-depositing a layer of catalyst or coating a catalyst precursor on the surface of the titanium material after oxidation, and carrying out high-temperature roasting to obtain the titanium material with high catalytic activity. The prepared titanium material with the catalytic activity can be used as a diffusion layer and also an electrode, has the advantages that the preparation method is simple, the catalytic activity is high, the decomposition voltage is greatly lowered, the energy utilization ratio is increased, and the like, is applied to a hydrobromic acid electrolytic cell and can also be used as the diffusion layer or the electrode in a hydrobromic fuel cell and a hydrobromic reproducible energy storage cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Wet flue gas desulphurization process for carbide slag slurry pretreatment

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

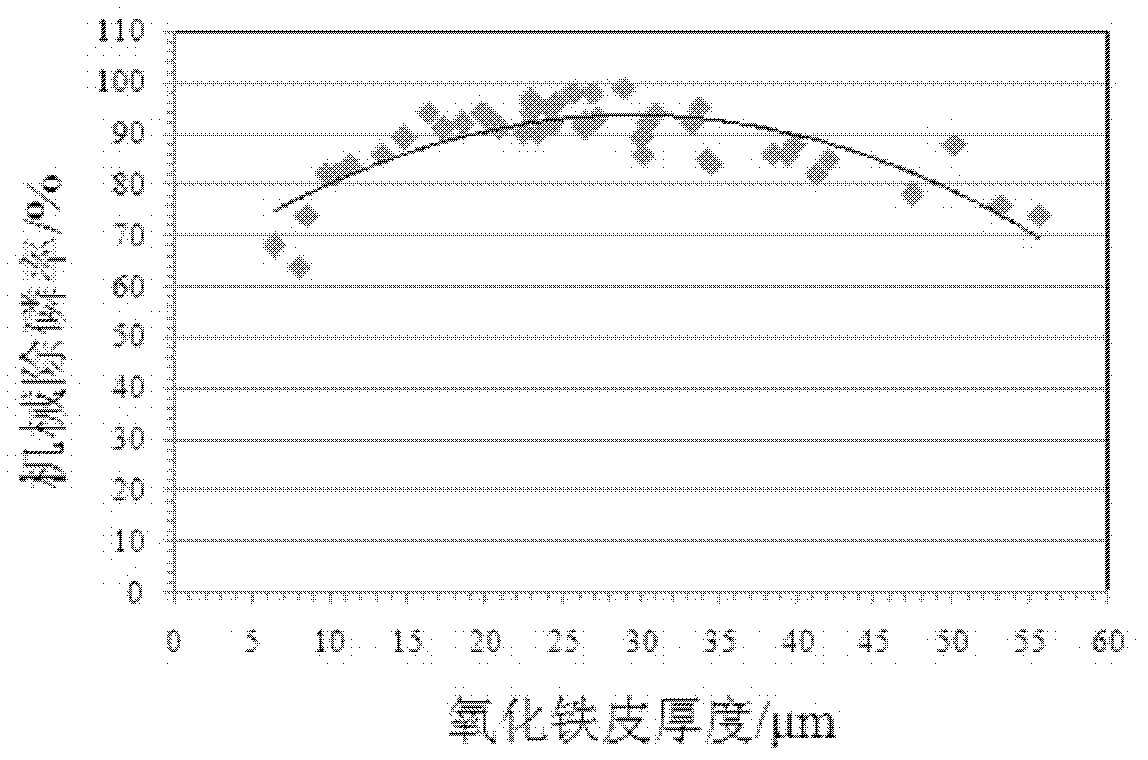

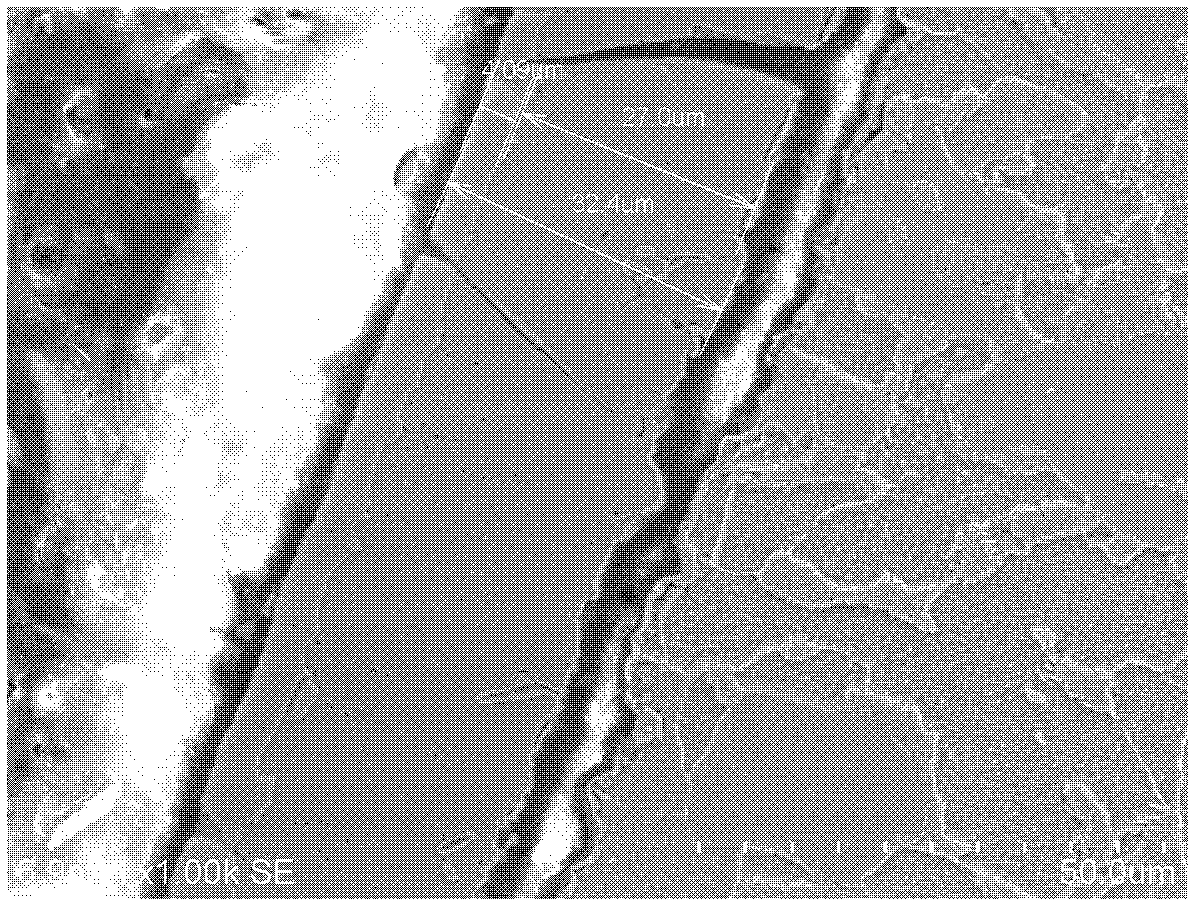

Controlling method for scales on surface of low-carbon cold heading steel hot-rolled wire rods

ActiveCN102601129AShort oxidation timeReduce lossTemperature control deviceTemperature controlWire rod

A controlling method for scales on surface of low-carbon cold heading steel hot-rolled wire rods belongs to the field of steel rolling. The method includes steps of precision rolling temperature control, spinning temperature control, and phase-change forepart cooling speed control for an air cooling line. The technical parameters of control includes: controlling the temperature of an entrance of a precision rolling mill in a range of from 900 DEG C to 950 DEG C; controlling the temperature rise in the precision rolling process in a range of from 80 DEG C to 100 DEG C; controlling the spinning temperature in a range of from 880 DEG C to 920 DEG C; adjusting a heat preservation hood of the air cooling line and blower level and controlling the cooling speed of the phase-change forepart of the spun rods in a range of from 2 DEG C per second to 5 DEG C per second; controlling the hood entry temperature in a range of from 760 DEG C to 700 DEG C; and advancing the phase-change area and controlling the time when the wire rods stay in a high-temperature oxidation section in a range of from 60 seconds to 100 seconds. By the method, the thickness of the scales on the surface of the hot-rolled wire rods is controlled evidently in the production of low-carbon cold heading steel SWRCH22A wire rods, mechanical dephosphorization capability is enhanced remarkably while falling during transportation is avoided, and broken rate in spinning and wastage of dies during drawing are reduced.

Owner:SHOUGANG CORPORATION

Sliver-oxide ternary alloy electrical contact material and production method thereof

InactiveCN102747248AImprove electrical contact performanceImprove wear resistanceSolid state diffusion coatingElectric switchesWire rodLow voltage

The invention discloses a sliver-oxide ternary alloy electrical contact material and a production method thereof. The sliver-oxide ternary alloy electrical contact material comprises, by weight percent, 6%-24% of total ternary alloy oxides, 0.72%-5% of total added element oxides, and the balance of silver. The production method includes smelting the raw materials to obtain ingots by stepwise smelting process or atomizing to produce alloy powder; performing rolling and temperature differential oxidation, or high energy ball milling and temperature differential oxidation; and performing isostatic pressing to obtain primary ingots, subjecting the primary ingots to sintering, hot re-pressing and hot extrusion to obtain wires or strips, and thereby obtaining highly dispersible organizational structure with even and small crystal grains. The obtained material is high in conductivity, low in temperature rise, high in welding resistance, high in arc suppressing and high in electric corrosion resistance, electrical life is prolonged greatly, advantages of comprehensive property are highlighted, and the demands of high-end low-voltage electric appliances are fully met.

Owner:浙江乐银合金有限公司 +1

Low-voltage rapid micro-arc oxidation technique

The invention relates to a low-voltage rapid micro-arc oxidation technique for micro-arc oxidation of valve metals such as aluminum, magnesium, titanium, zirconium and niobium by the aid of a constant-current pulse oxidation power supply and silicate system oxidation liquid. The peak current and the background current of the constant-current pulse oxidation power supply are continuously adjustable within the range of 10A-500A, the frequency of the constant-current pulse oxidation power supply is continuously adjustable within the range of 50Hz-100Hz, the duty ratio of the constant-current pulse oxidation power supply is continuously adjustable within the range of 10%-20%, and the voltage of the constant-current pulse oxidation power supply varies from 0V to 200V. The silicate system oxidation liquid comprises deionized water, sodium silicate, a regulator, a low-voltage arcing agent and a reinforcing agent. Compared with a common micro-arc oxidation technique, the low-voltage rapid micro-arc oxidation technique has the advantages that oxidation voltage is reduced to be below 200V, time for preparing ceramic films with the same thickness is shortened to be one third to one eighth of the original, micro-arc oxidation energy consumption is basically unchanged, the thickness of a loose layer of each ceramic film is obviously reduced, and the hardness is averagely improved by about HV300 and reaches more than HV1000.

Owner:SOUTHWEST PETROLEUM UNIV

Method for synthesizing polymeric ferric sulphate

InactiveCN101249987AEfficient use ofAvoid pollutionIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateSlag

The invention discloses a method for synthesizing polymeric ferric sulfate, which employs air, oxygen or oxygen-enriched air as an oxidizing agent, uses ferric persulfate, sulfuric acid or waste acid of titanium white by sulfuric acid process raw materials, using acid nitric ferric sulfate as an accelerating agent and synthesizing the polymeric ferric sulfate in an enamel autoclave which is provided with a packed tower, finally, using ferric persulfate to process the oxidation off-gas. The invention has the advantages of low energy consumption, low cost and convenient operation, not only effectively utilizing the industrial waste acid and the industrial waste slag, but also avoiding polluting to the environment.

Owner:李绍通

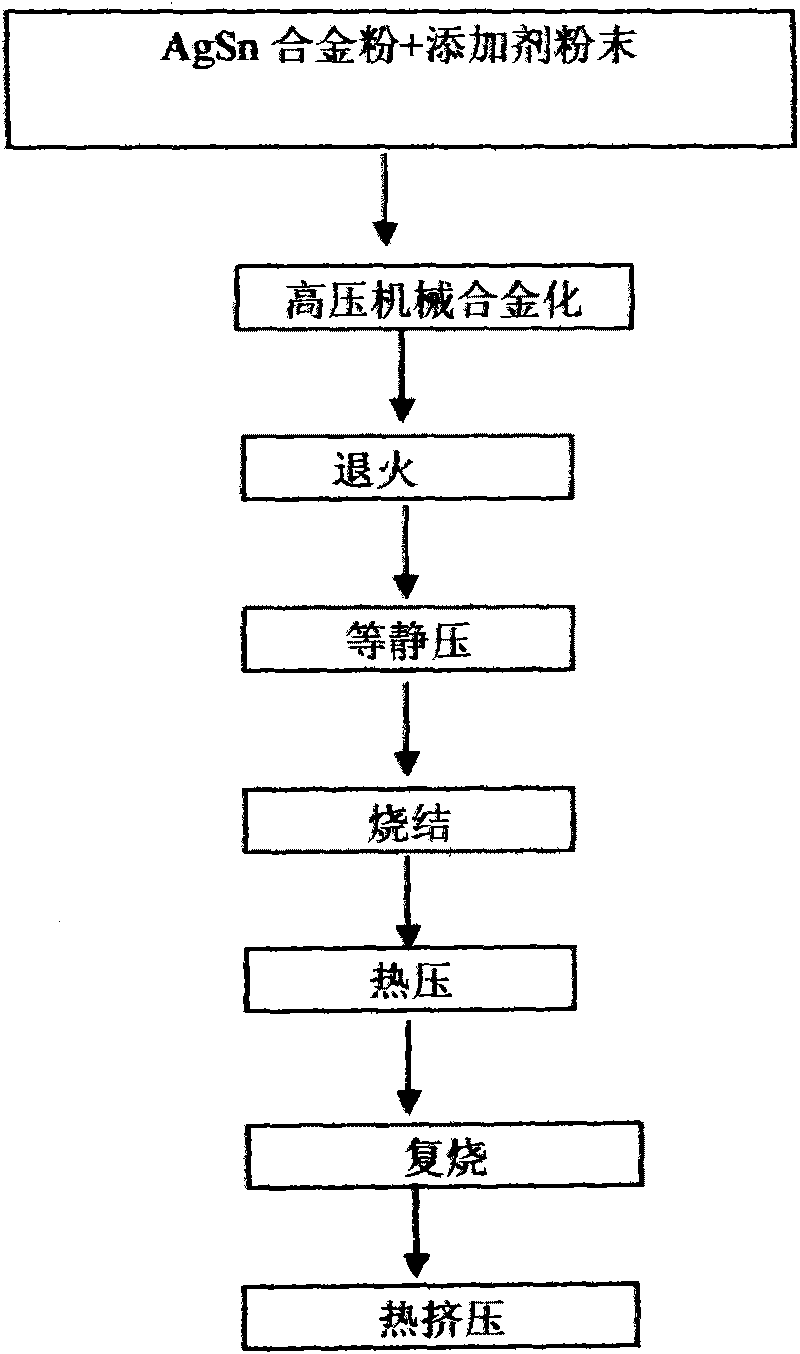

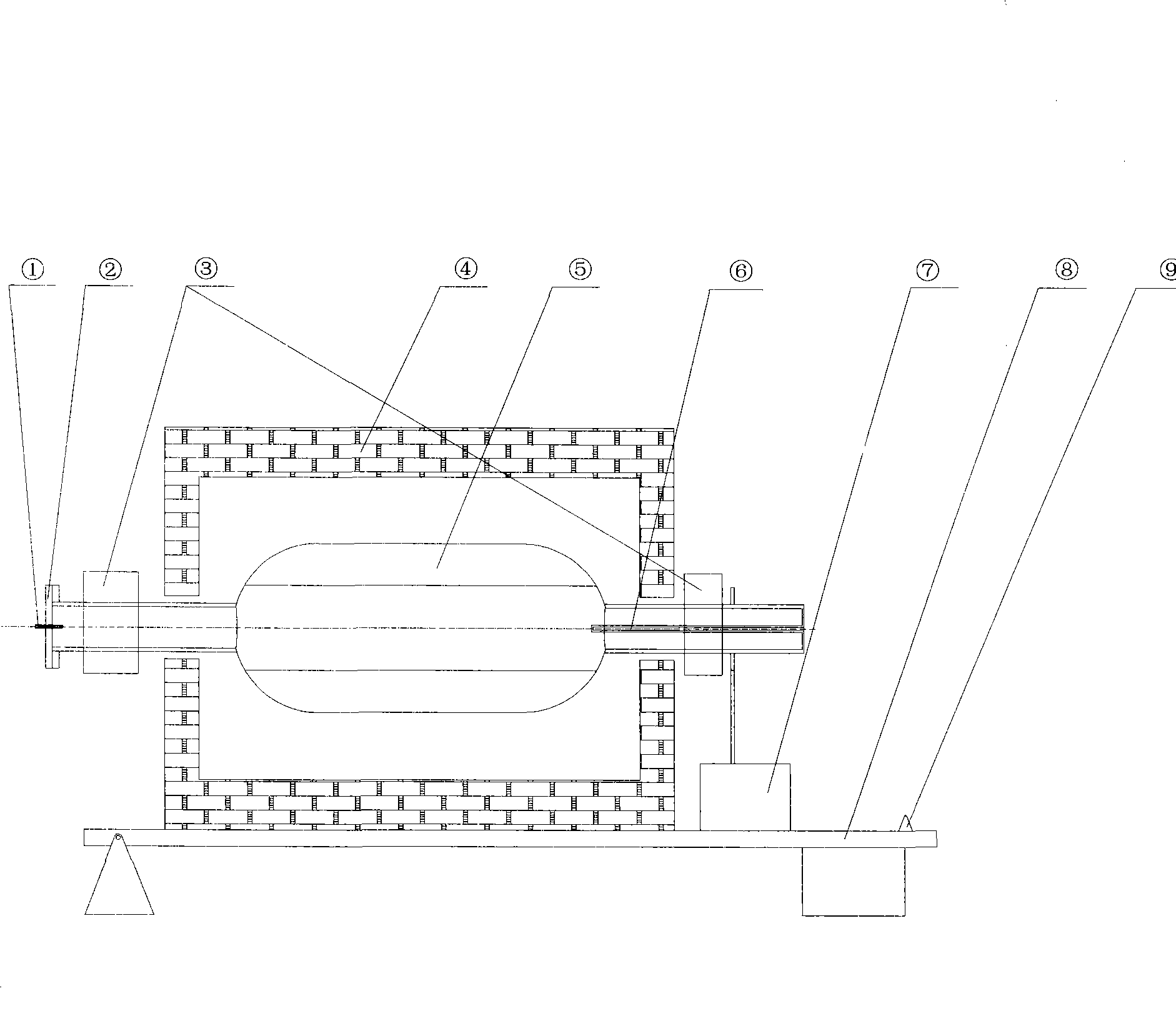

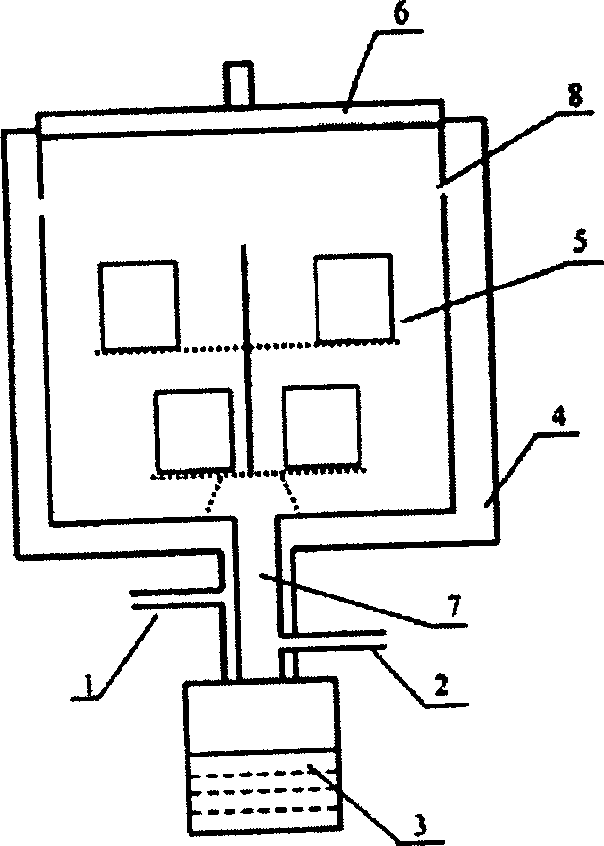

Design and structure for controllable atmosphere rotating furnace for oxidizing albronze alloy powder

ActiveCN101392987AFully contactedIncrease productivityRotary drum furnacesElectrical resistance and conductanceDifferential pressure

The invention provides a gas atmosphere controllable revolving furnace structure for the oxygen distribution in the oxidation of copper-aluminum alloy powder, which mainly consists of an air inlet(pumping) pipe, a roller cover, water cooling sleeves, a resistance furnace, rollers, an electrothermal couple pipe, a transmission mechanism, a furnace body bracket and a lifting hook, wherein the resistance furnace is fixed on the furnace body bracket, one end of the furnace body bracket is provided with the lifting hook and is supported by a lower end platform, the other end of the furnace body bracket is provided with a lower end triangular support which can rotate around the triangular support; the inside of the resistance furnace is provided with the roller rotating around the resistance furnace, two ends of the roller(5) arranged outside the resistance furnace are additionally provided with the water cooling sleeves, and the extension end of the roller, which is close to the triangular support end, is provided with the electrothermal couple pipe and is also provided with the transmission mechanism making the rollers rotate. The revolving furnace structure has the advantages that the production efficiency is high; and during the rotation of the rollers, power is fully contacted with the gas atmosphere, and the oxidation time is reduced by increasing the oxygen differential pressure in the rollers. The oxidation time is one-tenth of the oven baking time, so that the oxidation time is shortened.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

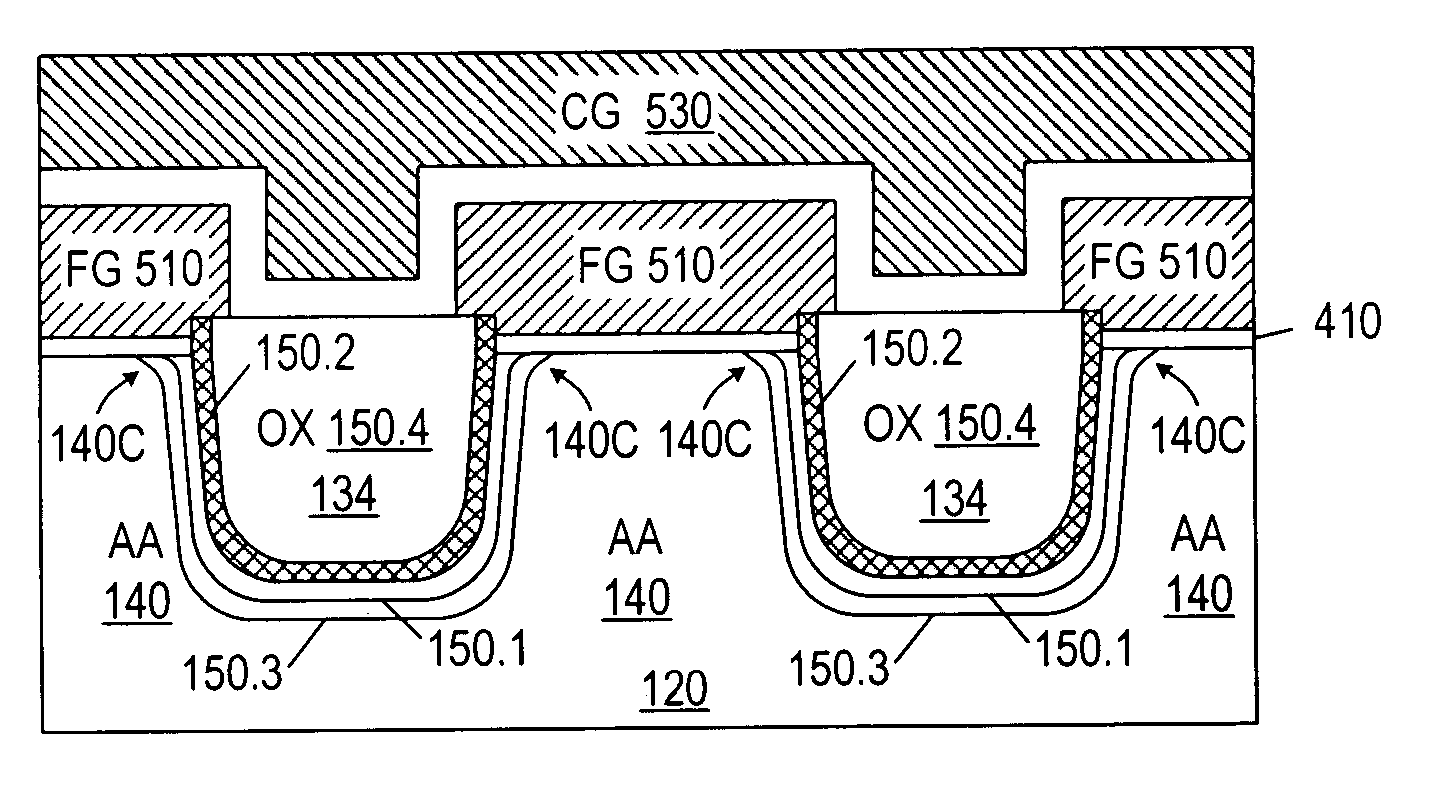

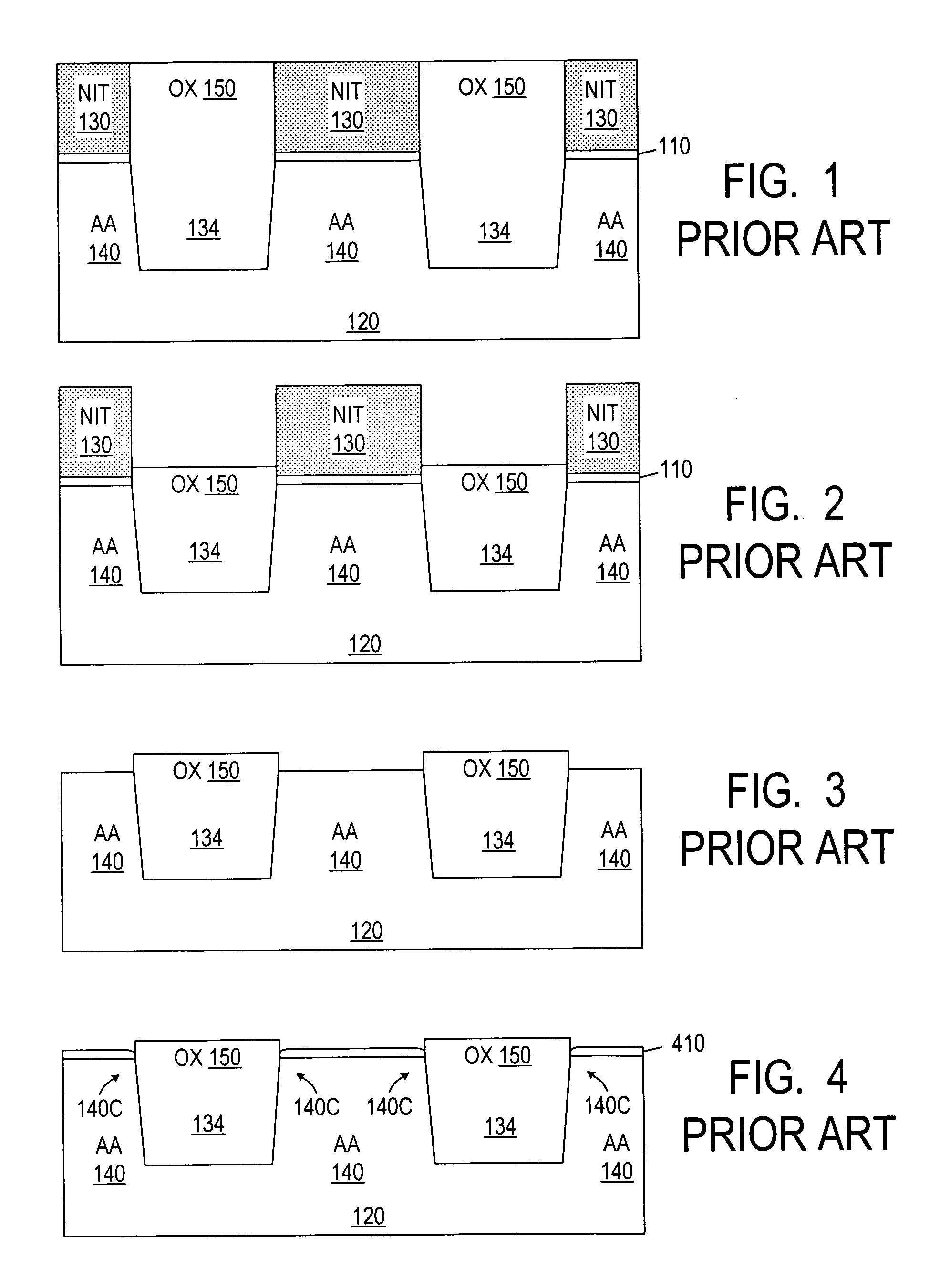

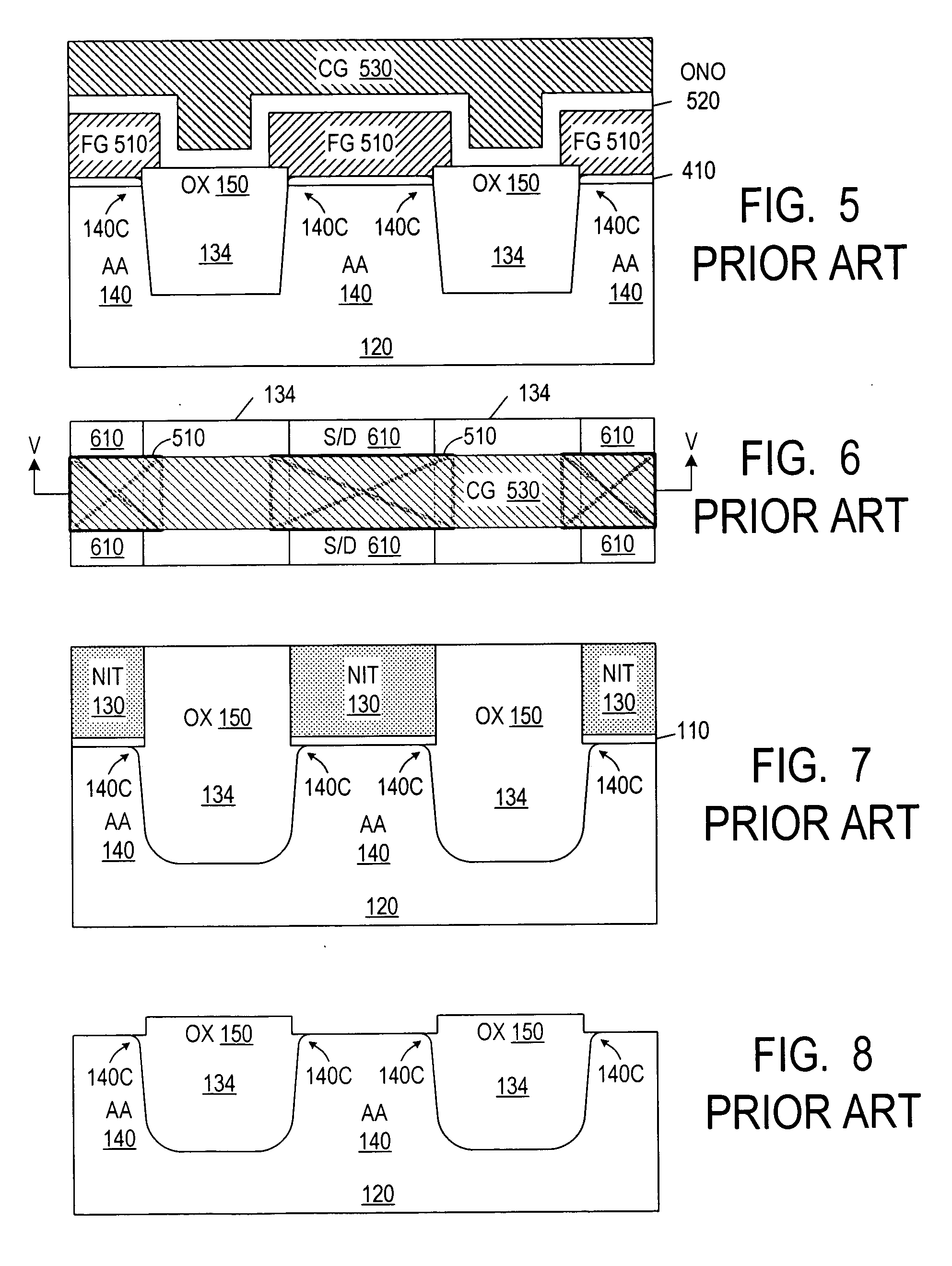

Use of chlorine to fabricate trench dielectric in integrated circuits

ActiveUS20070004136A1Facilitated DiffusionIncrease oxidation rateSolid-state devicesSemiconductor/solid-state device manufacturingDielectricRounding

Chlorine is incorporated into pad oxide (110) formed on a silicon substrate (120) before the etch of substrate isolation trenches (134). The chlorine enhances the rounding of the top corners (140C) of the trenches when a silicon oxide liner (150.1) is thermally grown on the trench surfaces. A second silicon oxide liner (150.2) incorporating chlorine is deposited by CVD over the first liner (150.1), and then a third liner (150.3) is thermally grown. The chlorine concentration in the second liner (150.2) and the thickness of the three liners (150.1, 150.2, 150.3) are controlled to improve the corner rounding without consuming too much of the active areas (140).

Owner:PROMOS TECH INC

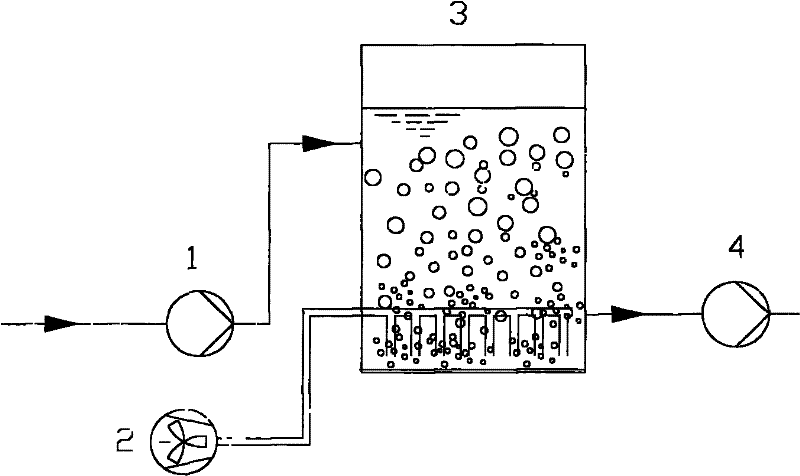

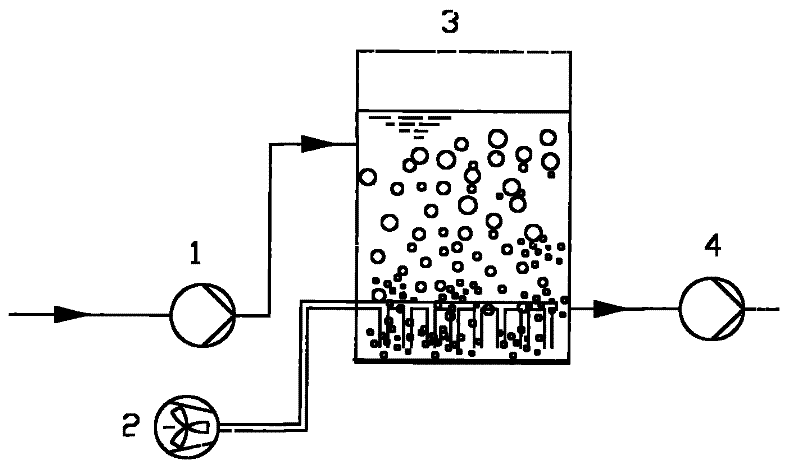

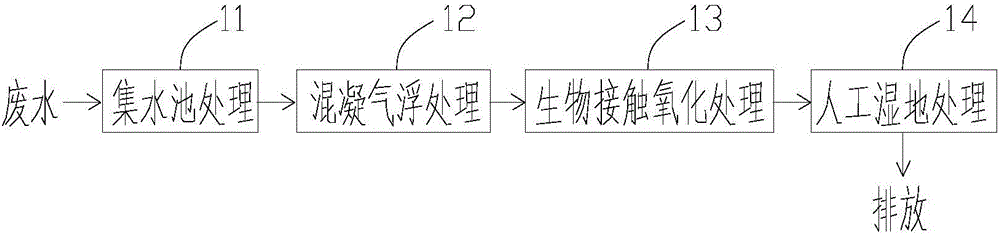

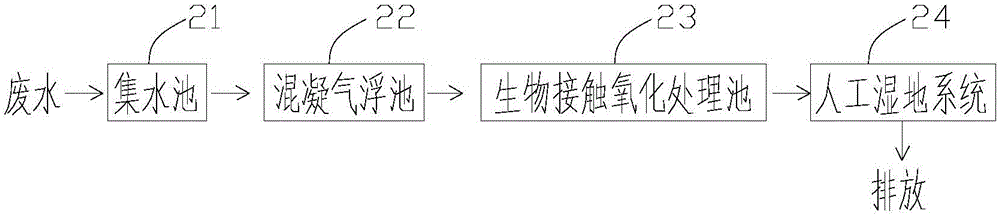

Wastewater treatment technology and device beneficial to removing black and odorous water

InactiveCN105819620AWon't happenTo avoidTreatment using aerobic processesMultistage water/sewage treatmentConstructed wetlandTherapeutic effect

The invention provides a wastewater treatment technology beneficial to removing black and odorous water.The technology sequentially comprises the following steps of collecting basin treatment, coagulation and air floatation treatment, bio-contact oxidation treatment and constructed wetland treatment.The technology is easy to operate and good in water drainage effect, and produces no odor in the treatment process.The invention further provides a wastewater treatment device beneficial to removing black and odorous water.The device sequentially comprises a collecting basin, a coagulation and air floatation basin, a bio-contact oxidation treatment basin and a constructed wetland treatment system.The device is simple in structure, convenient to maintain and good in wastewater treatment effect.

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD +1

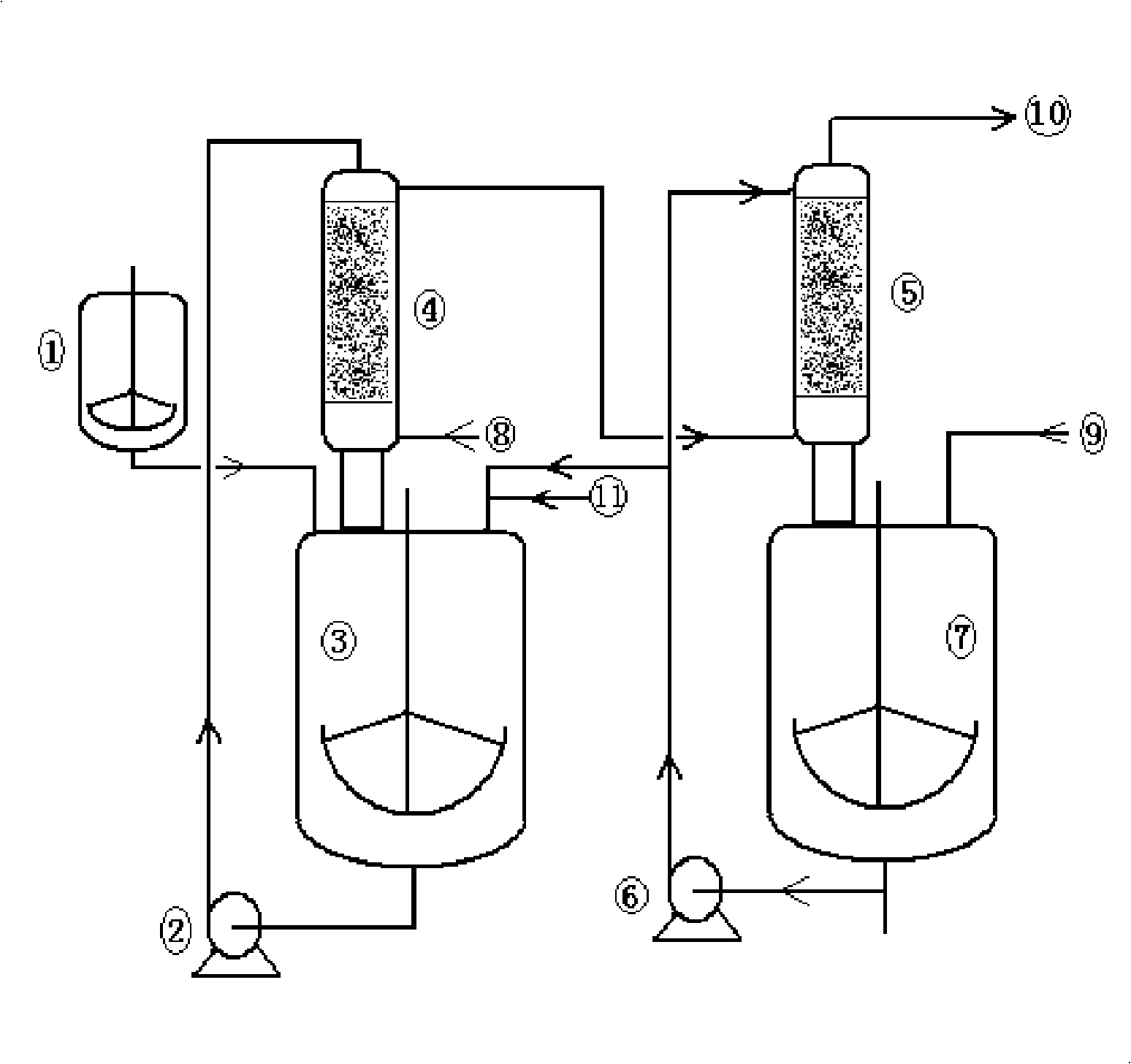

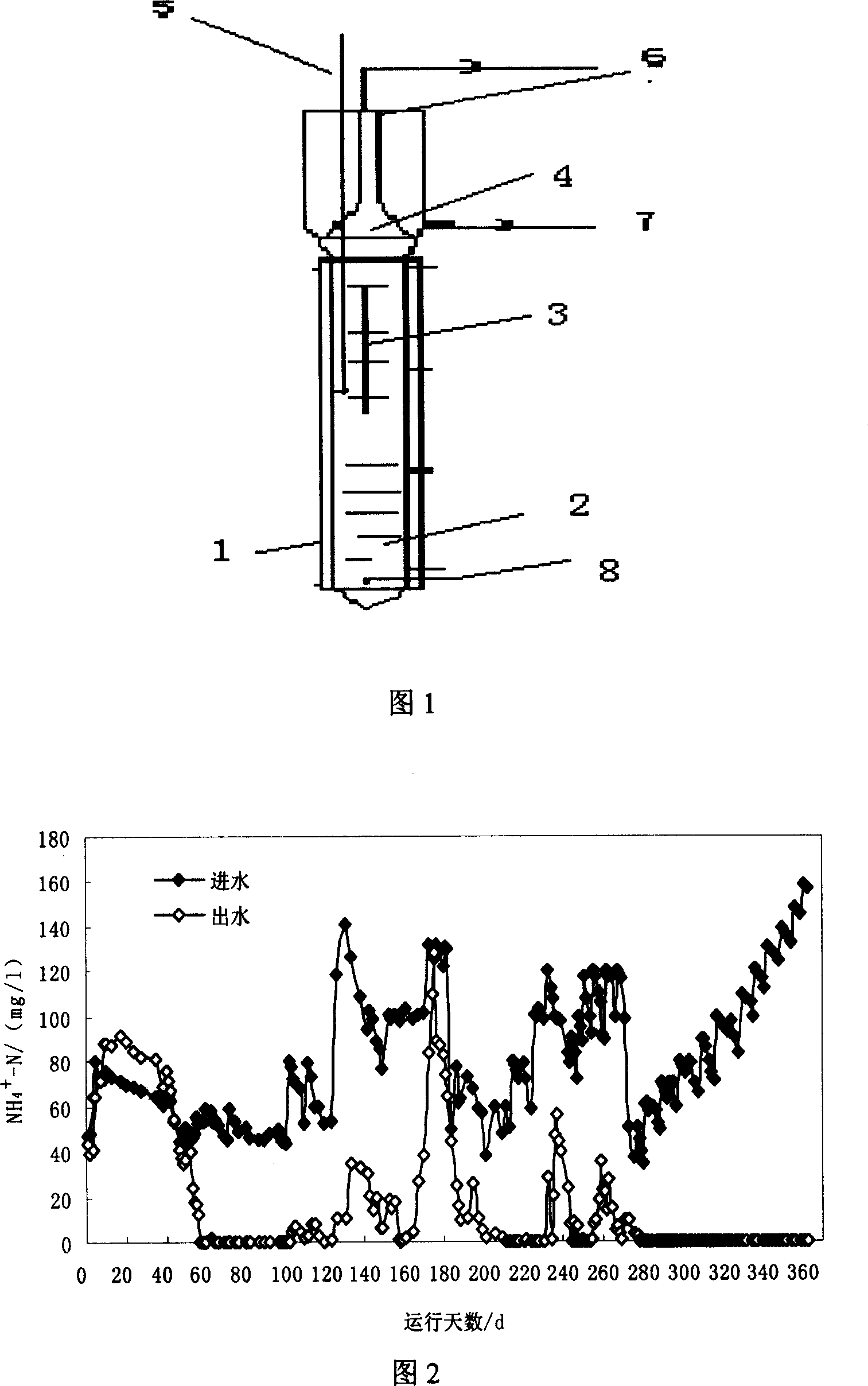

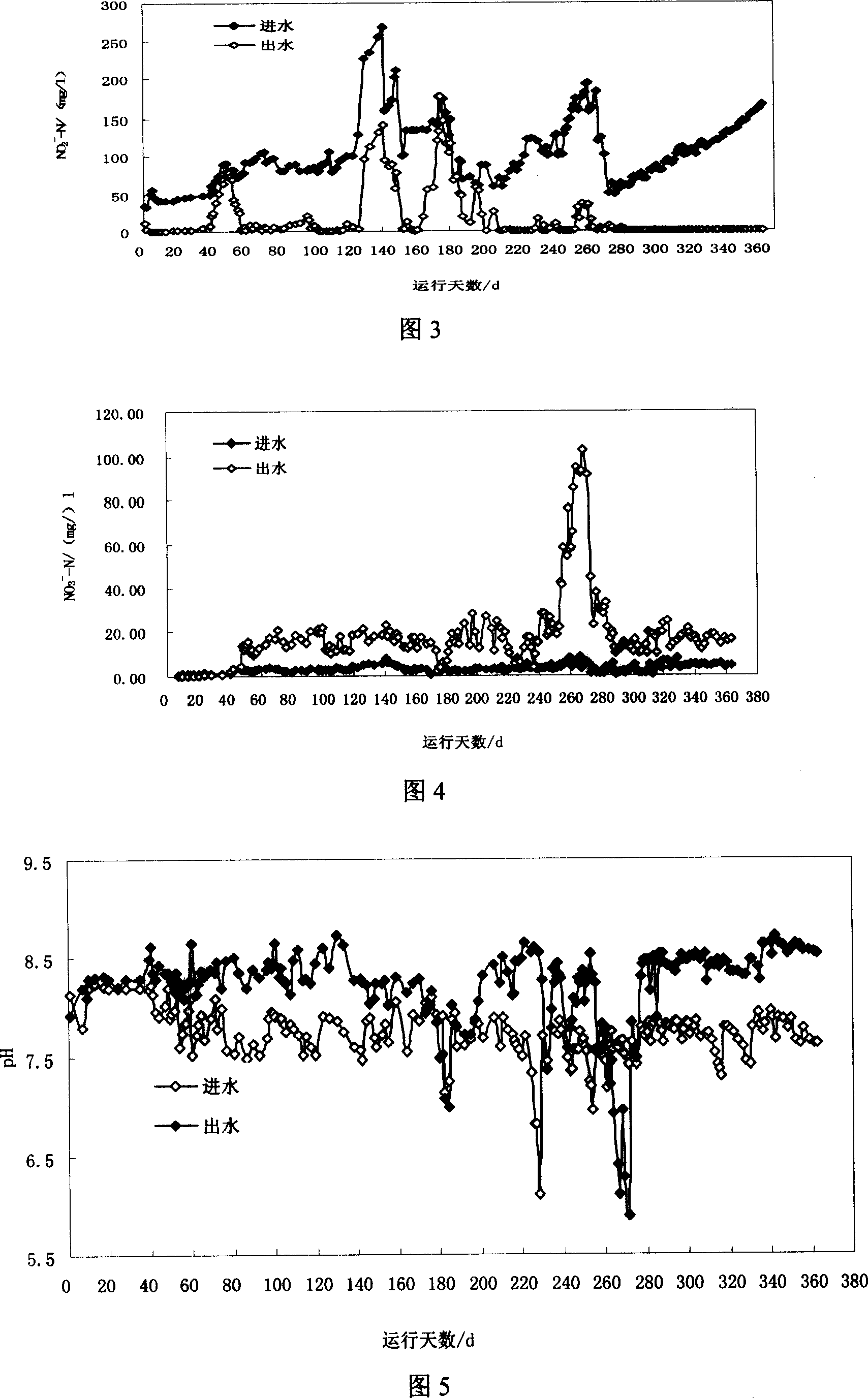

USAB -biological membrane anaerobic ammoxidation strain denitrogenation method and its apparatus

InactiveCN101007679AShort oxidation timeGood removal effectTreatment with anaerobic digestion processesTemperature controlEngineering

The invention discloses a temperature-control UASB anaerobic ammoxygen denitrifying method and equipment, which comprises the following parts: cylinder (1) of UASB biological reactor, sludge bed (2) on the lower part of cylinder (1), three-phased separator (4) on the top, biomembrane of flexible fill between sludge bed (2) and three-phased separator (4), wherein multiple microbe is set on the bottom of sludge bed (2), which contains anaerobic ammoxygen bacteria on the microbe layer to denitrify partial wastewater.

Owner:SOUTH CHINA UNIV OF TECH

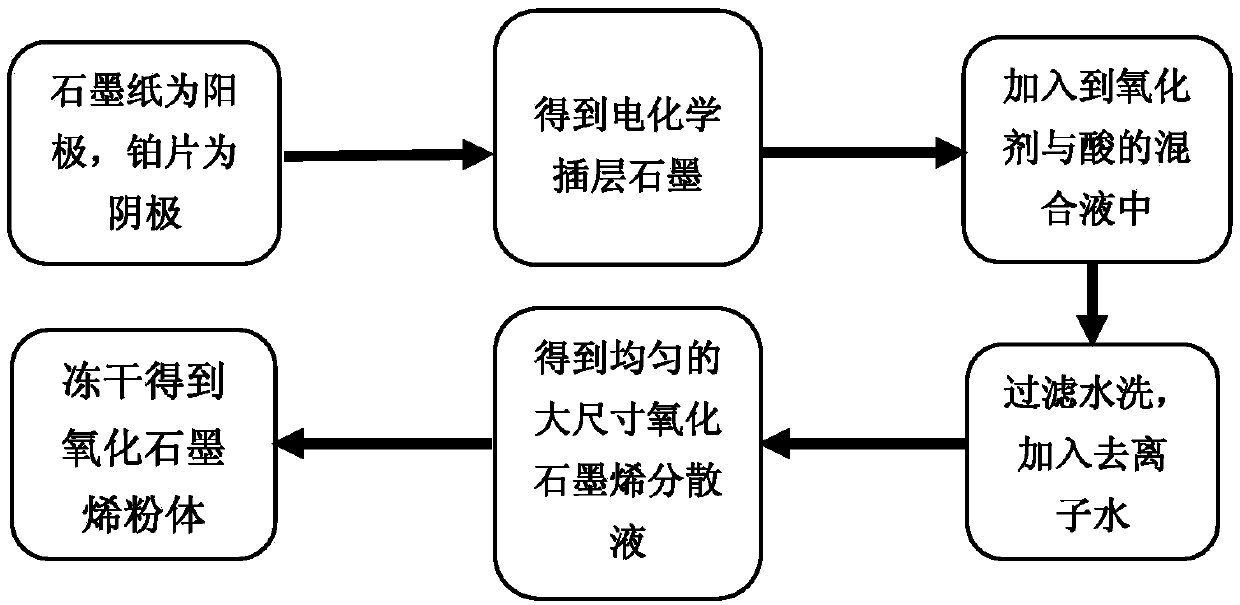

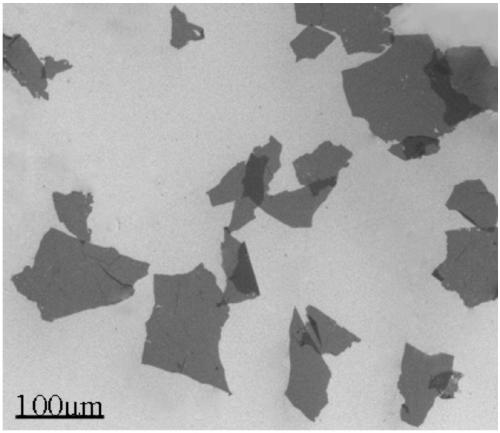

Preparation method of large-dimension graphene oxide and large-dimension graphene oxide obtained by method

The invention relates to a preparation method of large-dimension graphene oxide. The method comprises the following steps of using graphite paper as an anode; using a platinum sheet as a cathode; performing electrochemical pretreatment in electrolyte; performing intercalation on an anode material; peeling graphite; adding the materials into a mixed solution of an oxidizing agent and acid for oxidization reaction; peeling the graphene oxide under the oscillator oscillation or magnetic power stirring conditions, so that the multilayer graphene oxides are peeled into single-layer and few-layer graphene oxides and are dispersed into deionized water to form large-dimension graphene oxide dispersion liquid; performing centrifugal separation to obtain graphene oxide slurry; performing freeze drying treatment to obtain large-dimension graphene oxide powder. The invention also provides the large-dimension graphene oxide obtained by the preparation method. The electrochemical intercalation graphene is used as raw materials to perform oxidization reaction to realize the fast oxidization on the graphene; through natural settling cleaning and mild mechanical peeling, the fast peeling on the large-dimension graphene oxide is realized; the characteristics of high efficiency, high yield and low cost are achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

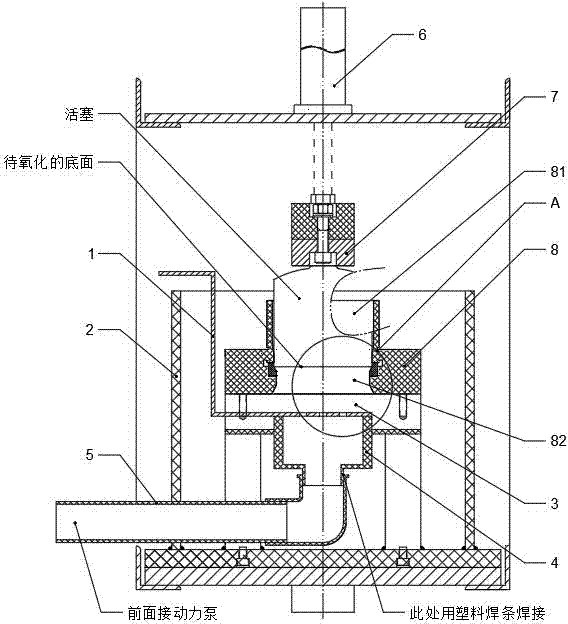

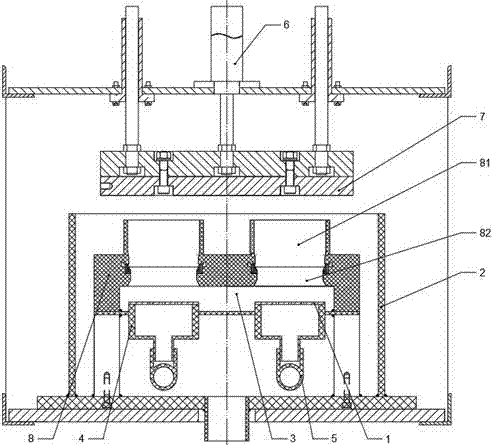

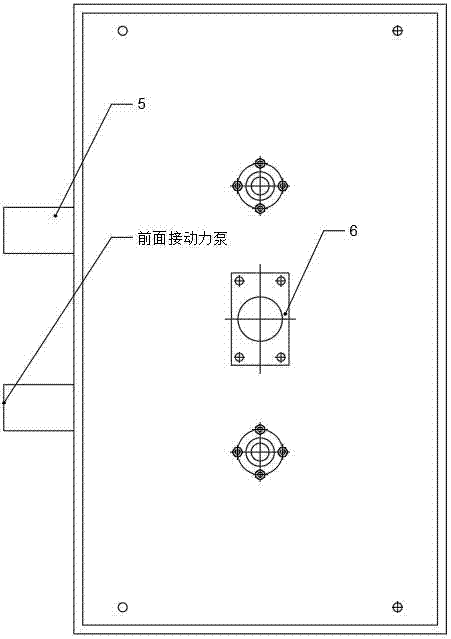

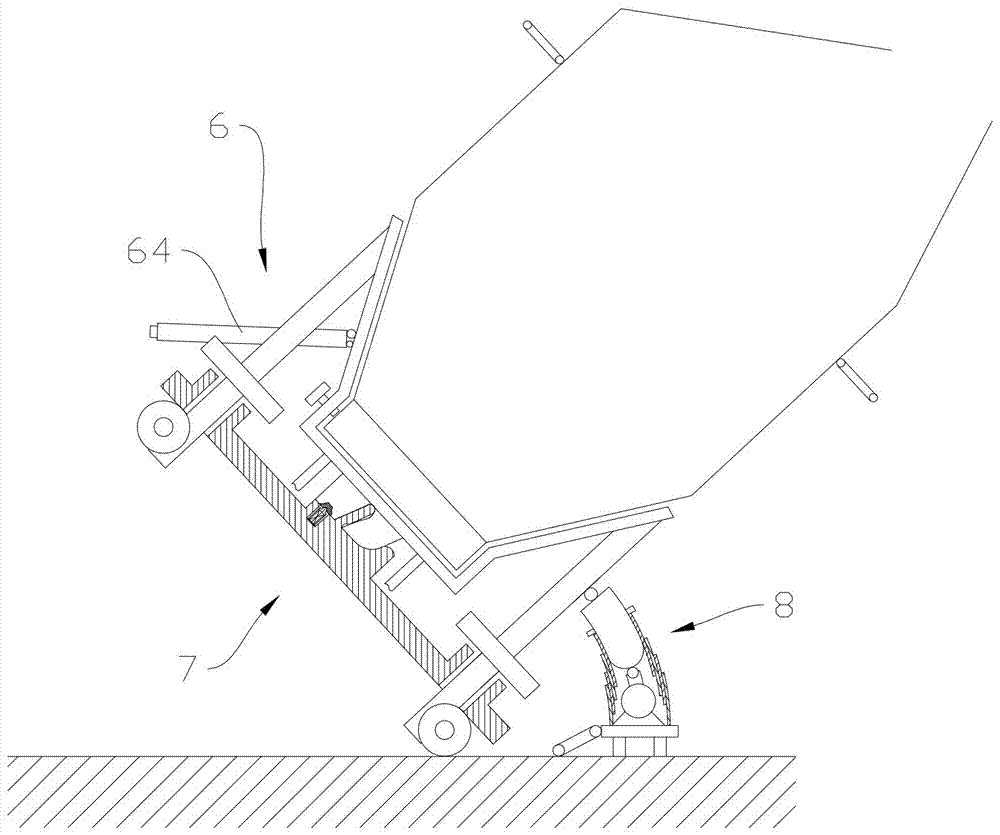

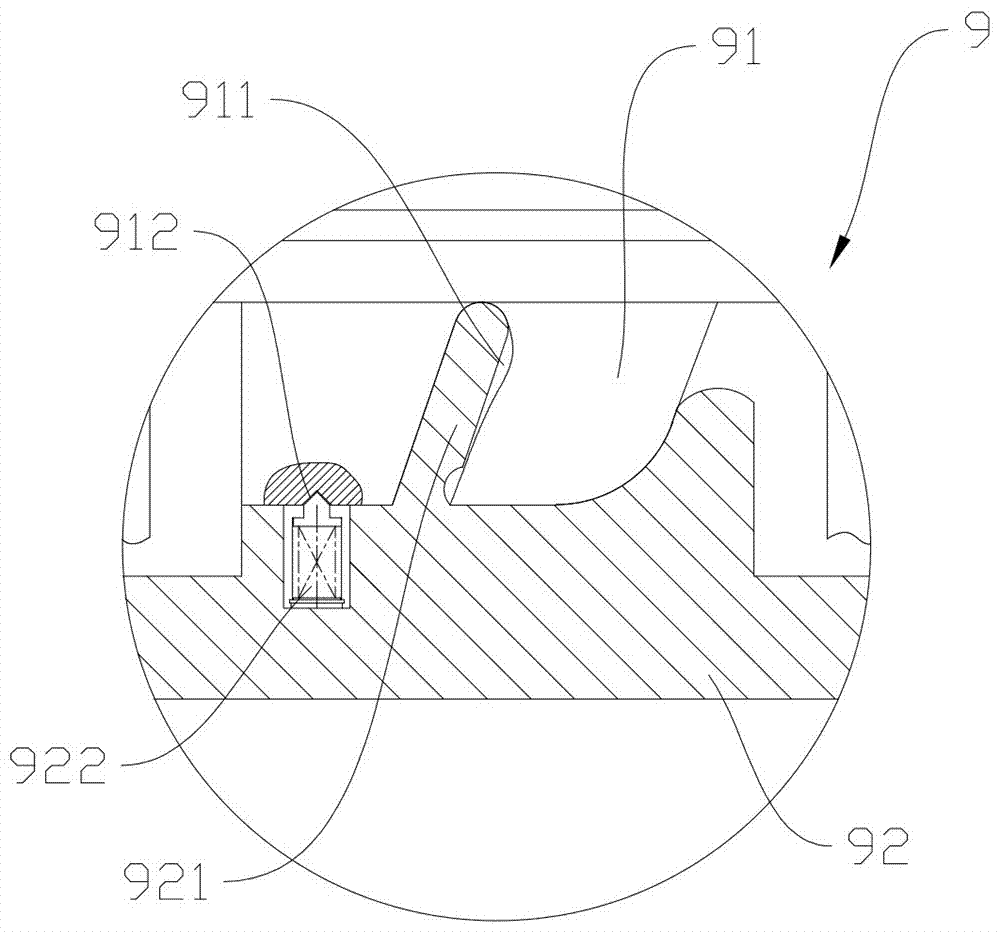

Anodic oxidation device and piston anodic oxidation processing process

The invention belongs to the technical field of alloy surface anodic oxidation hard treatment and provides an anodic oxidation device and a piston anodic oxidation processing process. The anodic oxidation device comprises a power source, an electrolyte storage cavity, an anode component, an anode plate, an oxidation tank, a power pump and a current controller. The piston anodic oxidation processing process which adopts the anodic oxidation device includes steps: A, mounting a piston into a workpiece clamping hole to make a to-be-oxidized bottom surface downward; B, starting an air cylinder to make a conducting plate abutted against the piston; C, starting the power source and the power pump, enabling electrolyte to be sprayed out vertically through a water storage sprayer nozzle to contact with the to-be-oxidized bottom surface of the piston to form a current circuit, and adjusting current density through the current controller to finish anodic oxidation processing. The anodic oxidation device has advantages that quick heat radiation is realized to prevent overburning, and accordingly product quality can be improved.

Owner:CHONGQING XIECHENG AUTO PARTS

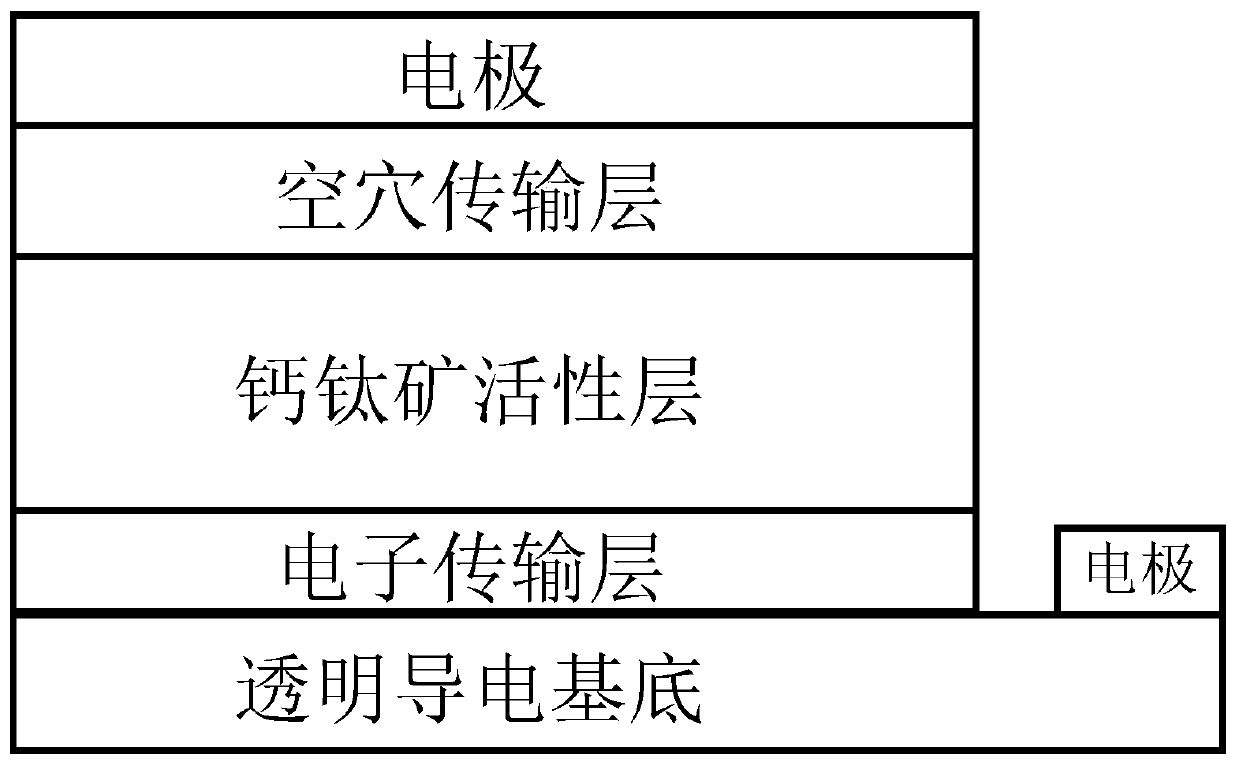

Post-processing method for obtaining large-grain high-quality perovskite thin film and application thereof

ActiveCN109860403ALarge grainQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingBatch processingSolvent

The present invention belongs to the technical field of photoelectric devices, and discloses a post-processing method for obtaining a large-grain high-quality perovskite thin film and an application thereof. A post-processing technology of a perovskite thin film adopts a gradient annealing technology assisted by mixed solvent steam, and comprises a specific process of: first, conducting thermal annealing at a slightly low temperature; then conducting thermal annealing assisted by mixed solvent steam; and finally conducting thermal annealing at a slightly high temperature to prepare a large-grain high-quality perovskite thin film. The perovskite thin film of the present invention has simple preparation technology, low cost, good repeatability and strong practicability, and is suitable for large-area thin films and large-scale batch processing.

Owner:湖州市鹑火光电有限公司

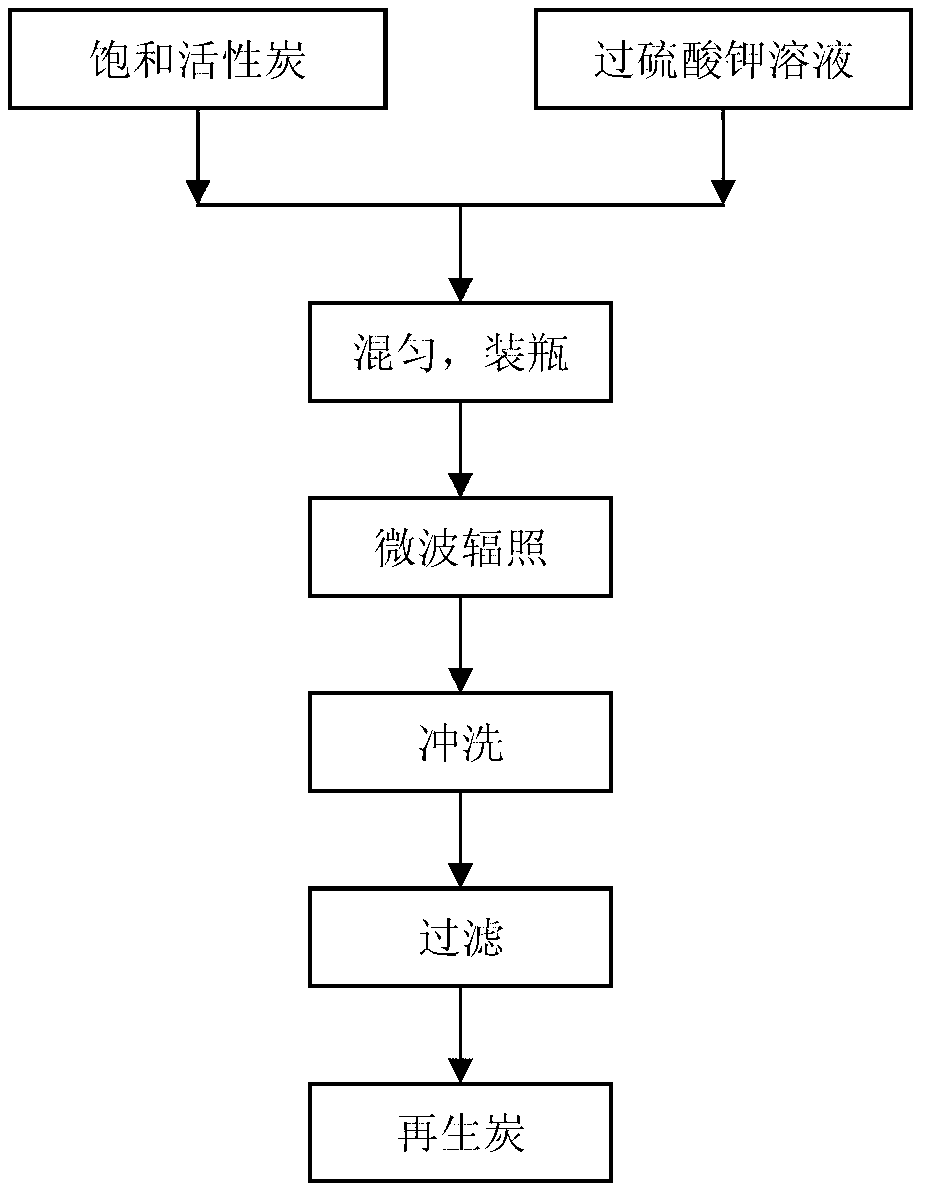

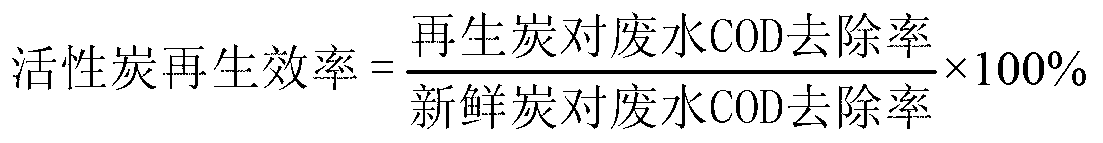

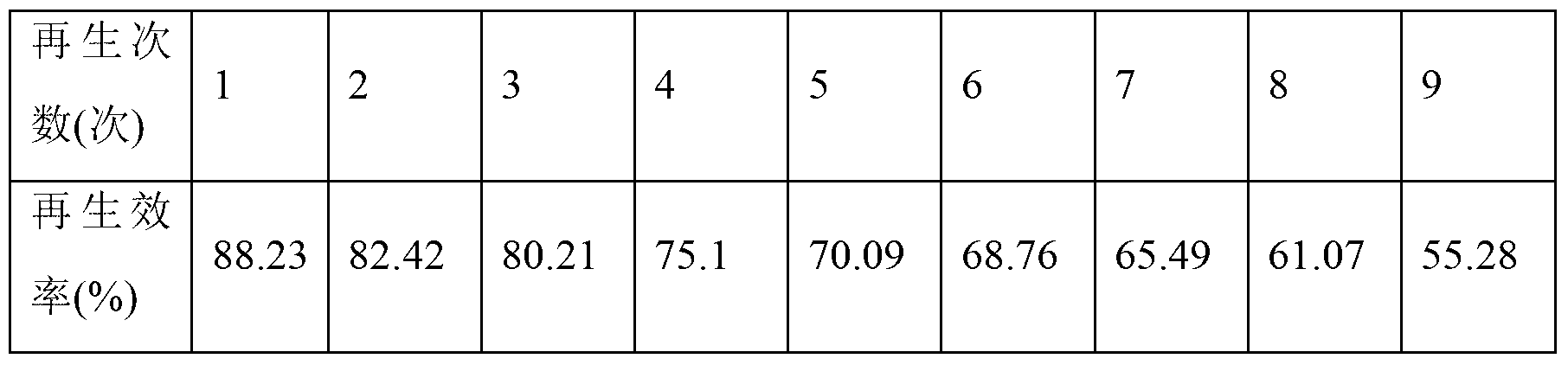

Method for regenerating saturated active carbon adsorbing organic matters through microwave activation of potassium persulfate

InactiveCN103252223AIncrease profitRestore adsorption capacityOther chemical processesCombustible gas purificationPotassium persulfatePersulfate

The invention relates to a method for regenerating saturated active carbon adsorbing organic matters through microwave activation of potassium persulfate. The method comprises the following steps of: adding a potassium persulfate solution into saturated active carbon; performing microwave irradiation for 5 to 30 minutes; cooling to room temperature; and filtering and cleaning to obtain regenerated carbon, wherein the mass ratio of the saturated active carbon to the potassium persulfate is (1-5):1. Compared with the traditional active carbon regeneration method, the method has the advantages that the regeneration cost is reduced and the regeneration efficiency is improved. Advanced oxidation and microwave irradiation of persulfate are organically combined, so the regeneration efficiency of the active carbon is improved. A chemical catalyst is not used, so new pollutants are not introduced. Due to the action of microwave, the oxidation time is short, the regeneration time is shortened, and the regeneration efficiency is improved and can reach about 80 percent. According to the method, regeneration can be performed for times, namely more than eight times, and the mass loss and the strength loss of the active carbon after regeneration are small.

Owner:DONGHUA UNIV

Sample pretreating method for metal content analysis

InactiveCN1743831AOperational securityReduce environmental pollutionPreparing sample for investigationPre treatmentOxide

A sample pretreatment method for metal content analyzing, which contains heating the oil sample in inert gas to 450-700 degree centigrade to evaporate the volatile matter and remain metal element in residue, oxidizing the residue to convert metal element into metal oxide, added with inorganic acid to dissolve oxide and prepare into aqueous solution of sample. Said invention can be used in oil sample pretreatment of emission spectrum, atom absorption spectrum and color matching etc test.

Owner:CHINA PETROLEUM & CHEM CORP +1

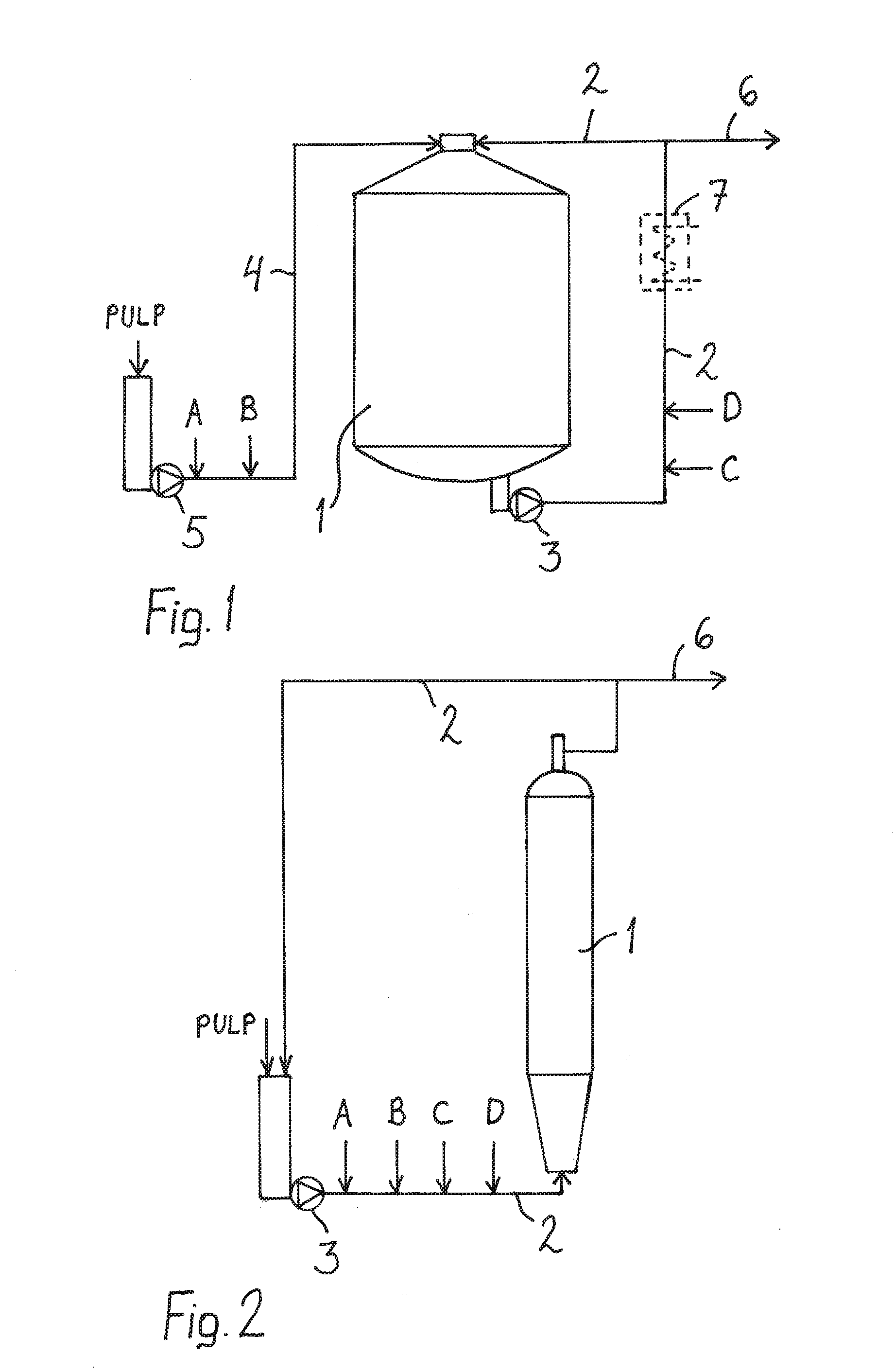

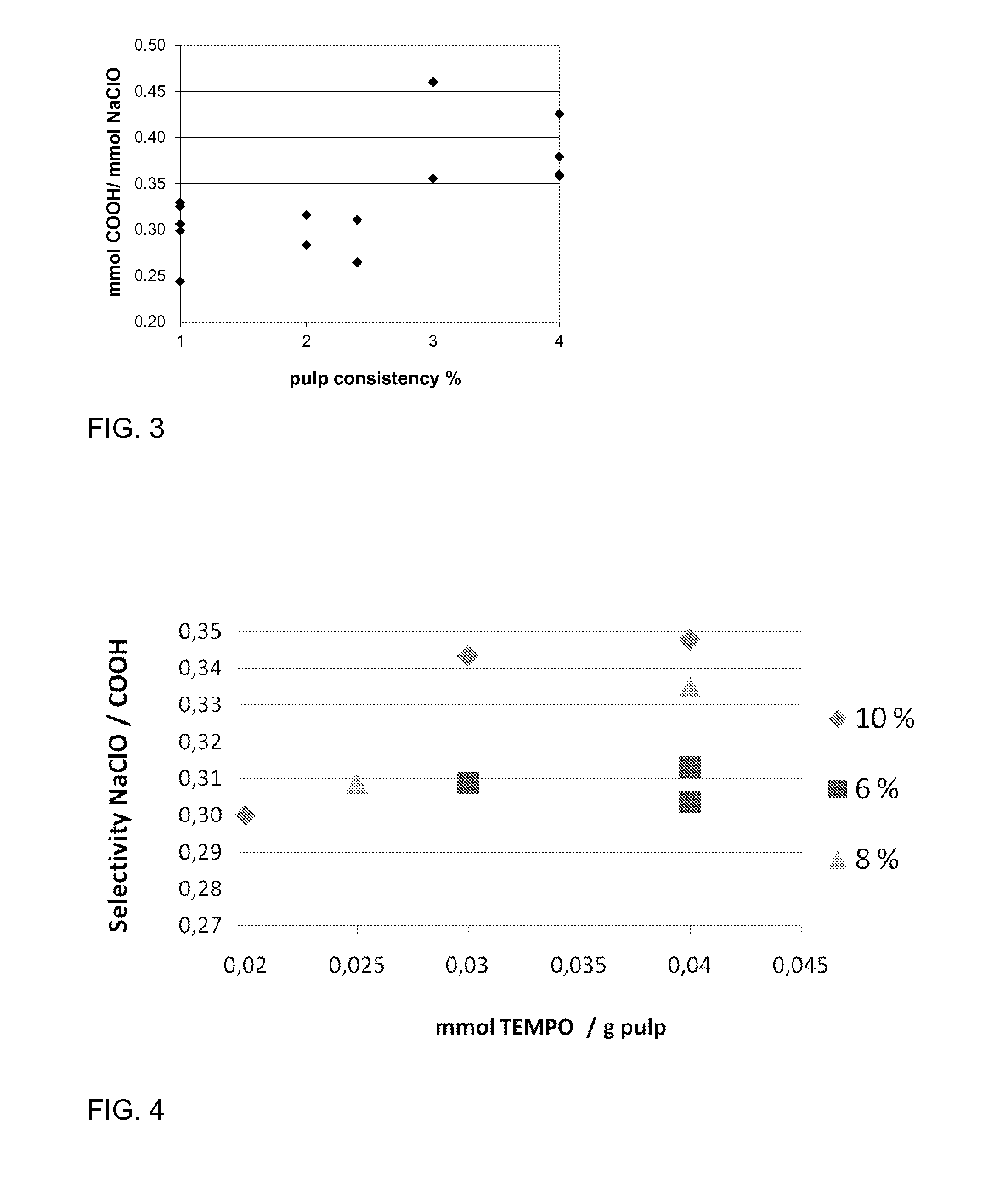

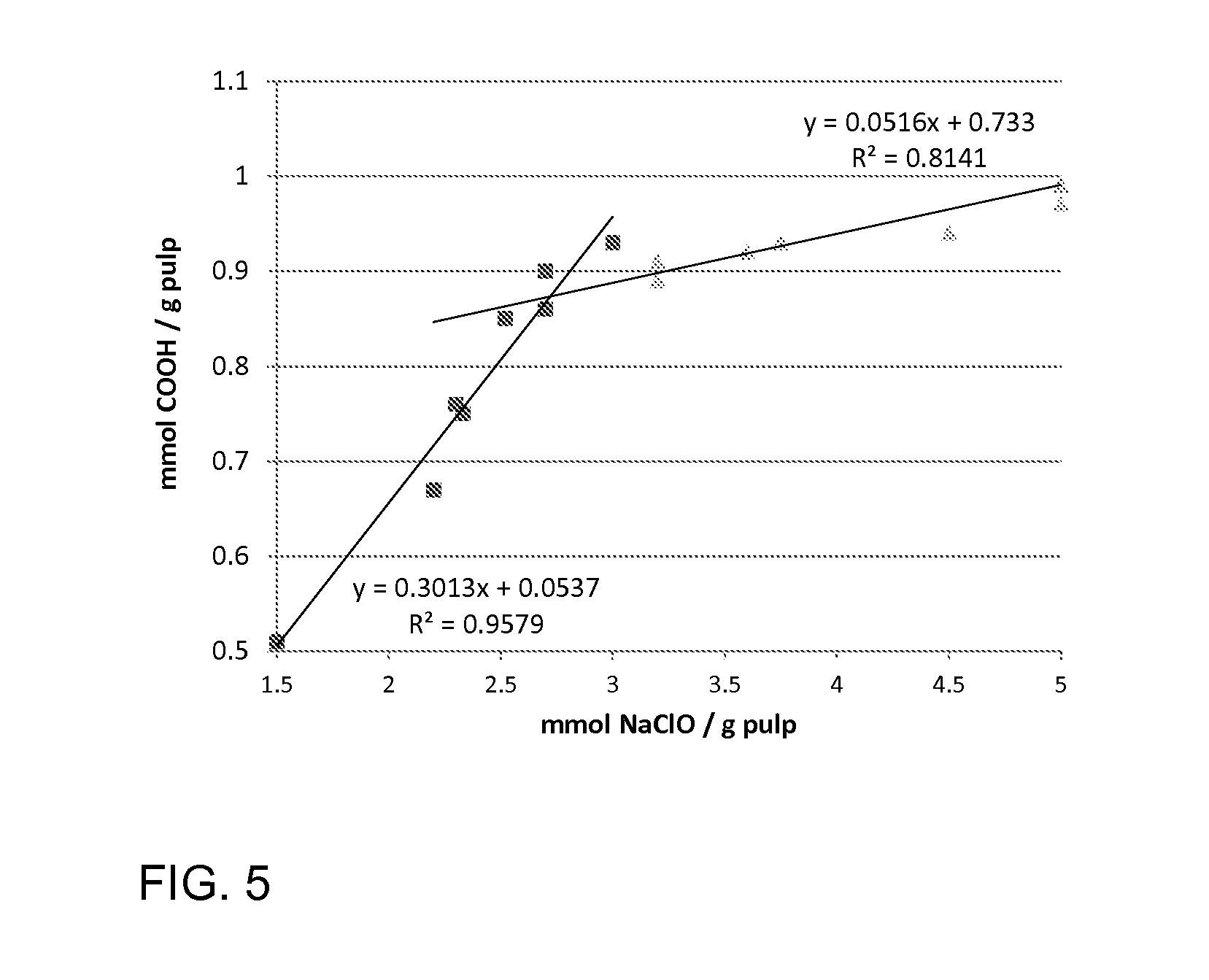

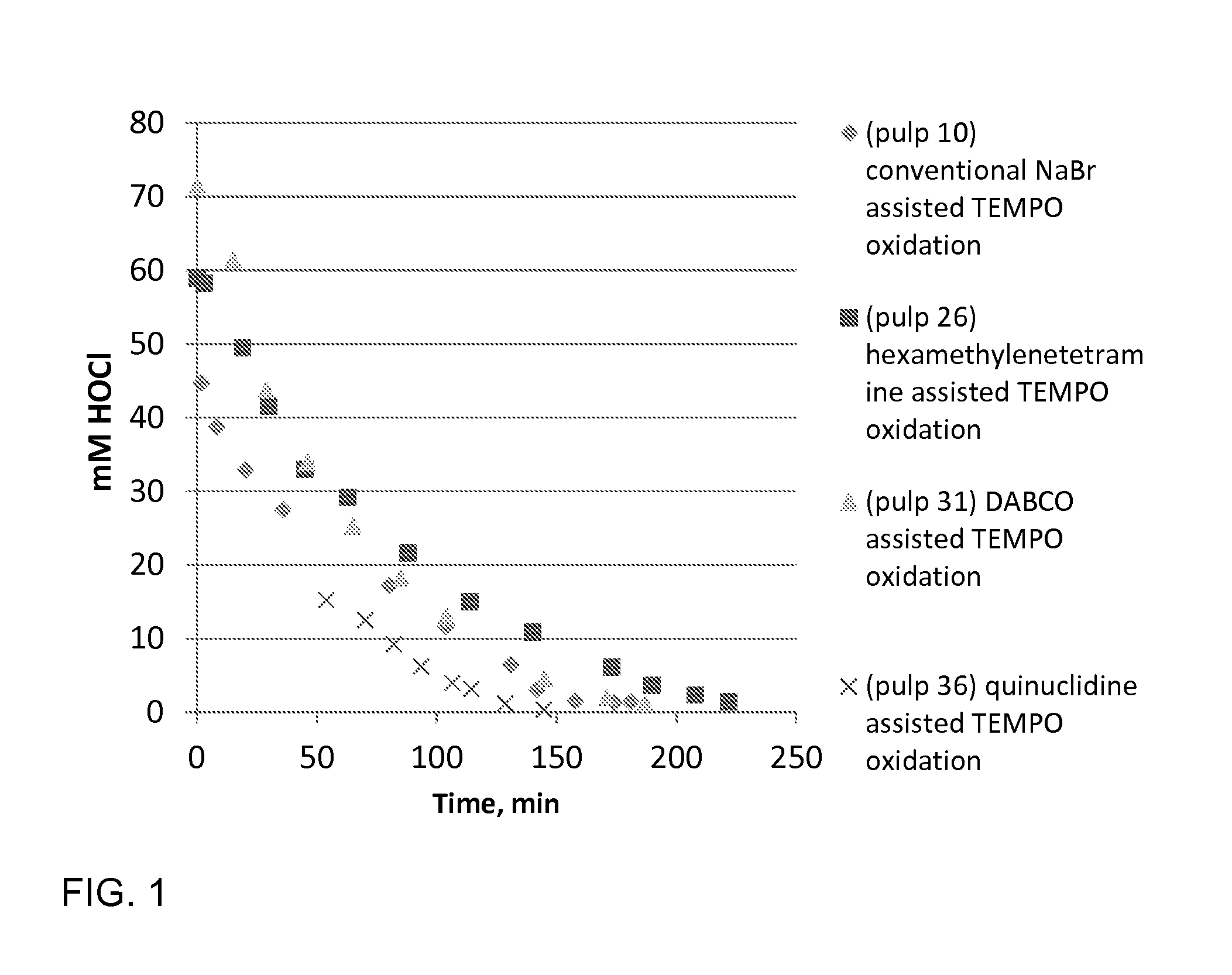

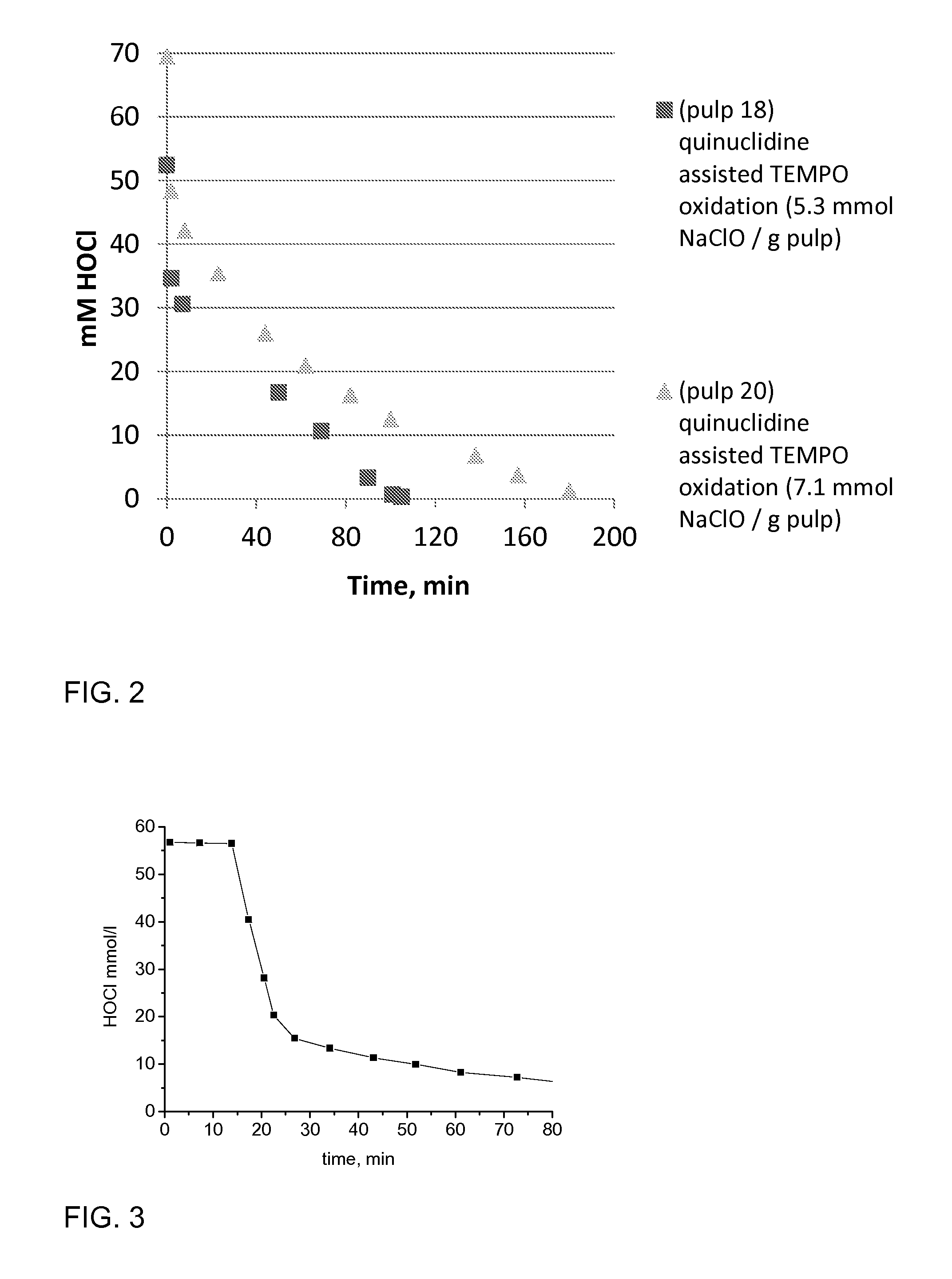

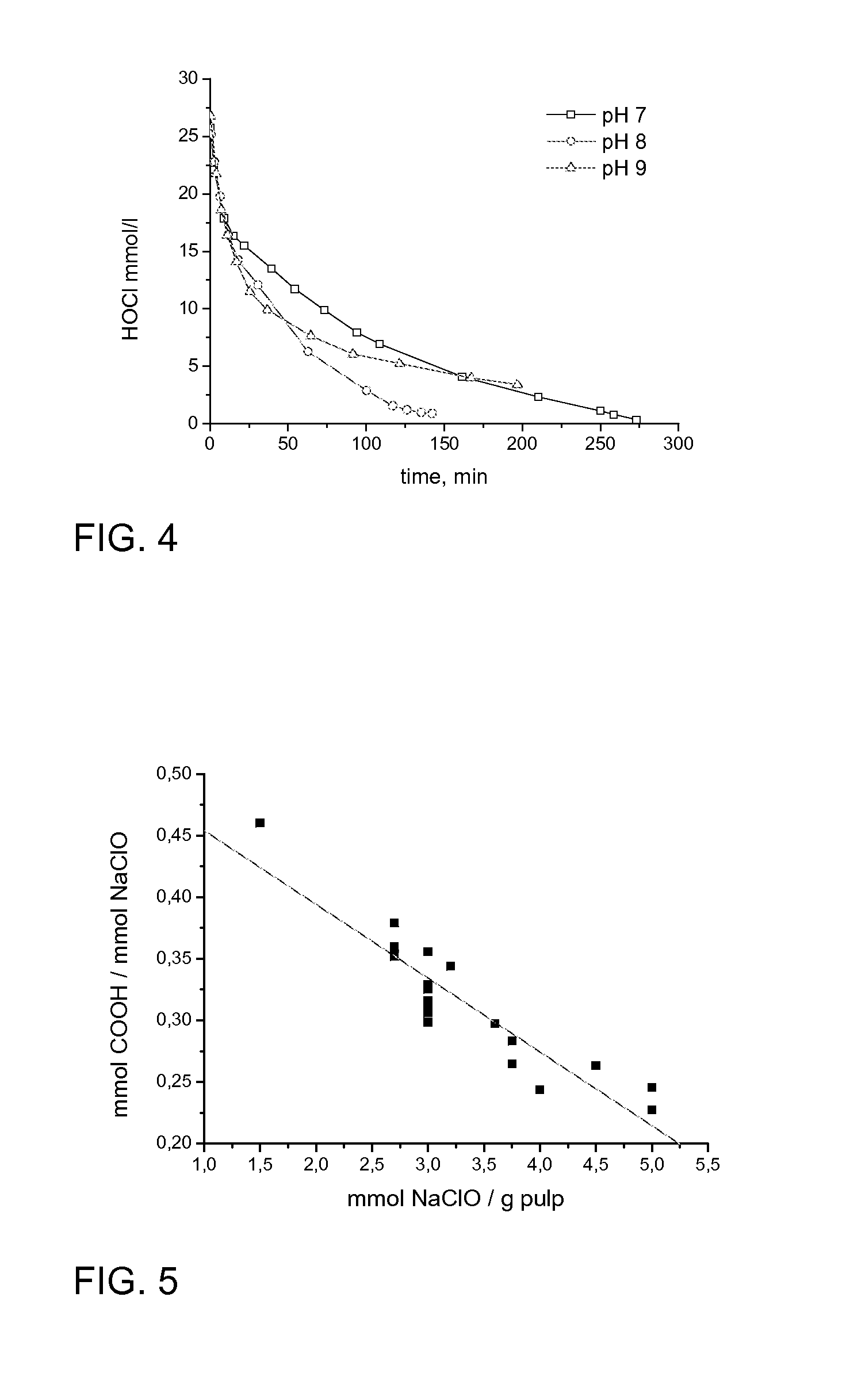

Method for catalytic oxidation of cellulose and method for making a cellulose product

ActiveUS20150322171A1Effectively and selectively oxidizing C-Without compromising efficiency of reactionPulp properties modificationYarnNitroxyl radicalsCatalytic oxidation

Cellulose is oxidized catalytically using a heterocyclic nitroxyl radical as catalyst, main oxidant acting as oxygen source, and an activator of the heterocyclic nitroxyl radical. The oxidation is performed in a reaction medium which is at medium consistency of cellulosic pulp, which is above 6%, more preferably equal to or higher than 8%, and most preferably in the range of 8-12%. The reaction medium is mixed in a reactor through circulation of the reaction medium back to the reactor.

Owner:UPM-KYMMENE OYJ

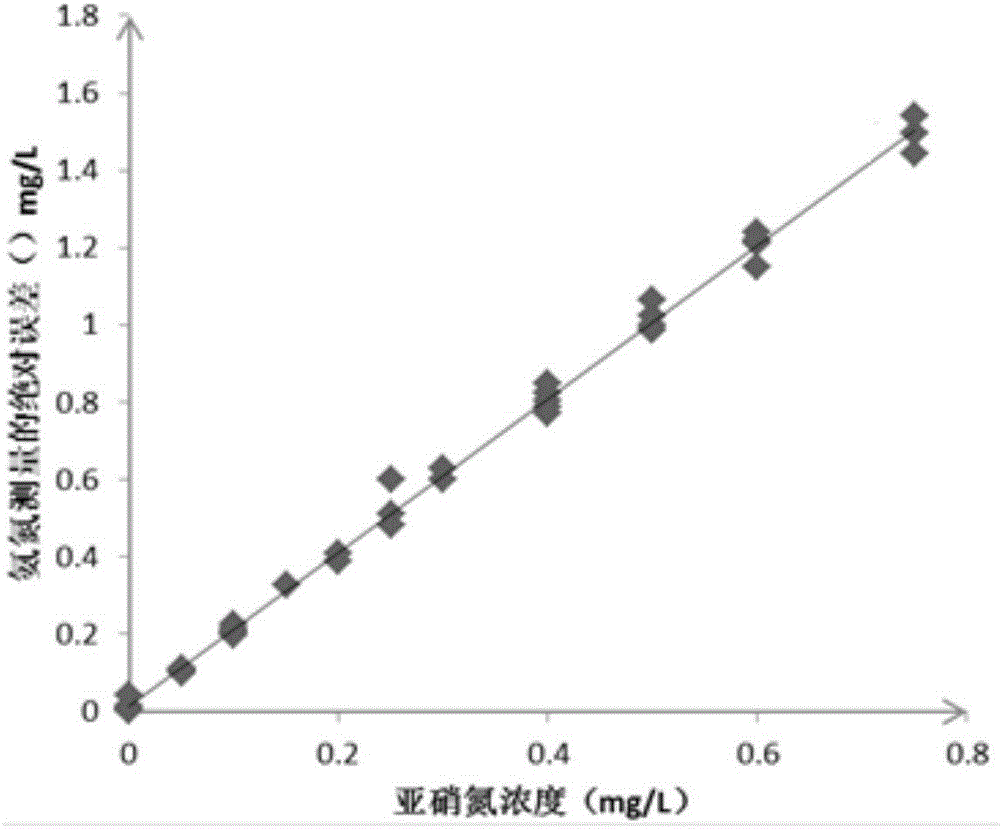

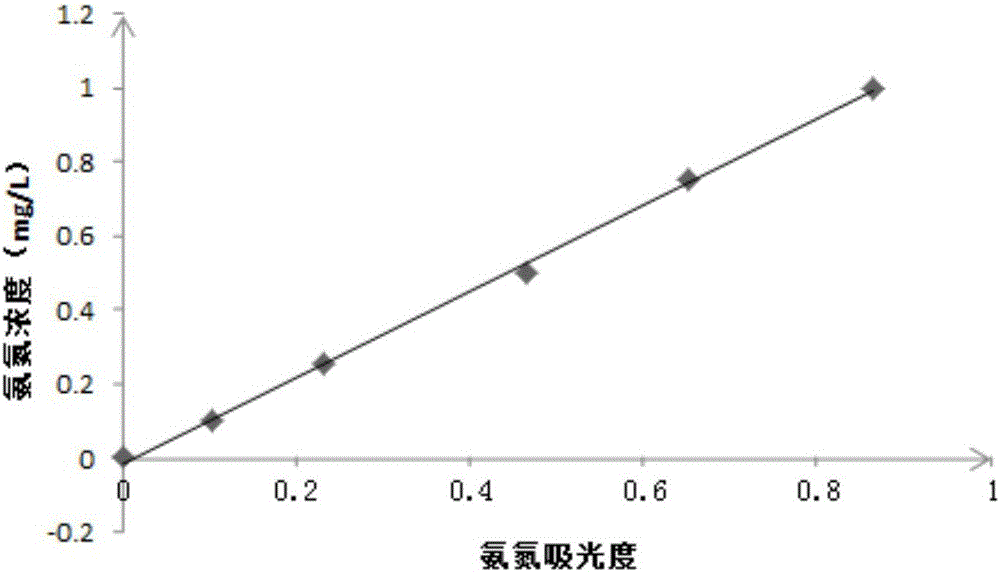

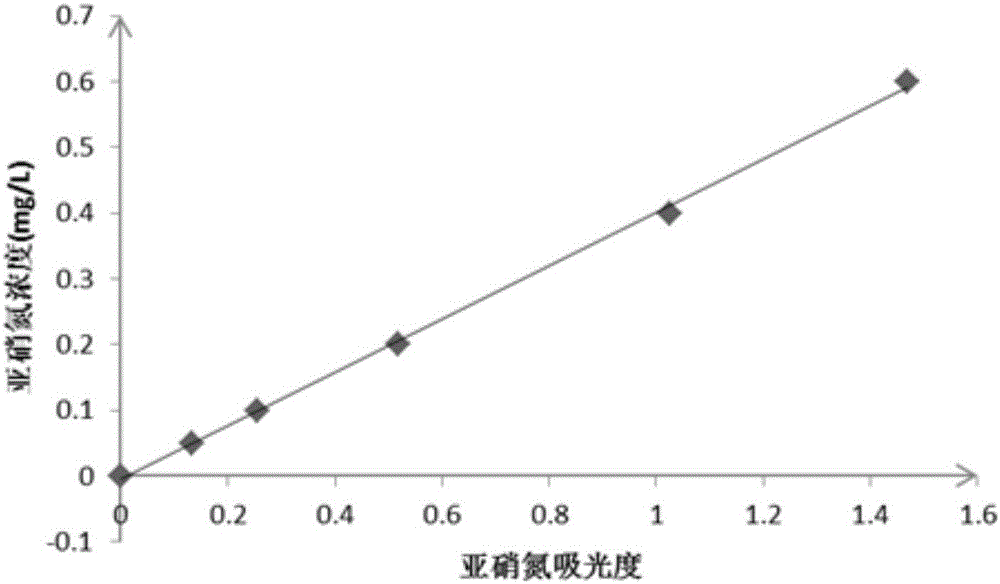

A method of measuring the ammonia nitrogen concentration of a water body

ActiveCN106525739AImprove accuracyWide range of concentration measurementPreparing sample for investigationColor/spectral properties measurementsETHYLENEDIAMINE DIHYDROCHLORIDEWater quality

The invention belongs to the technical field of water quality monitoring, and relates to a method of measuring the ammonia nitrogen concentration of a water body. The method includes a step of preparatory work, a step of mapping an ammonia nitrogen standard curve, a step of mapping nitrite nitrogen standard curve, a step of mapping a curve of influences of nitrite nitrogen concentrations on ammonia nitrogen measurement absolute errors and a step of measuring the ammonia nitrogen concentration, which are five steps. Wider-range ammonia nitrogen and nitrite nitrogen concentrations in a high-salinity water body can be measured. Hypobromite oxidation time is shortened from 30 min to 10 min. Hydrochloric acid is adopted in place of phosphoric acid for a nitrite nitrogen color developing agent, thus reducing pollution. A hydrochloric acid solution of sulfanilamide and an aqueous solution of N-(1-naphthyl)ethylenediamine dihydrochloride are mixed, and therefore nitrite nitrogen concentration measuring steps are simplified. The upper limit of nitrite nitrogen concentration measurement is increased to a value that is three or more times of the upper limit in the national standard method in China. In a nitrite nitrogen concentration range of 0-0.75 mg / L, accuracy of measurement of ammonia nitrogen concentrations in a range of 0-1.25 mg / L is good. The method has characteristics of a simple process, reliable principles, short operation time, environment protection, energy conservation, a low economic cost, high operationality and high measurement result accuracy.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for catalytic oxidation of cellulose and method for making a cellulose product

ActiveUS20140110070A1Effectively and selectively oxidizing C-Reduce usageNon-fibrous pulp additionSpecial paperCelluloseHypochlorite

In a method for catalytic oxidation of cellulose a heterocyclic nitroxyl radical is used as catalyst, hypochlorite is used as main oxidant acting as oxygen source, and a tertiary amine or chlorine dioxide as an activator of the heterocyclic nitroxyl radical.

Owner:UPM-KYMMENE OYJ

Method for smelting high-manganese stainless steel through AOD and AOD furnace

ActiveCN107245637APreferential oxidationReduce oxidationProcess efficiency improvementFurnace temperatureSlag

The invention discloses a method for smelting high-manganese stainless steel through AOD. The method comprises a preparatory process, a decarburization process, a prereduction process and a reduction process, wherein in the prereduction process, a ferrosilicon alloy serves as a deoxidizing agent and an alloying agent for deoxidization, manganese is added in a concentrated manner for manganese alloying, manganese is added in a batched manner in the manganese alloying process, heating is conducted while manganese is added, and meanwhile various technological parameters are reasonably controlled. According to the method for smelting the high-manganese stainless steel through AOD, for AOD smelting on the high-manganese stainless steel with the manganese content larger than 15%, the manganese alloying technology is improved, furnace temperature, an oxygen blowing parameter and the using dosage and time of the deoxidizing agent and the alloying agent are reasonably controlled, oxidization or burning loss of manganese are greatly reduced, and not only is the recycling rate of manganese increased, but also the loss, caused by high temperature, of an AOD furnace lining is reduced. The invention further discloses an AOD furnace. Installing of a bottom air blowing tube can be convenient to achieve, pouring of the AOD furnace is uniform and adjustable, slag flowing is uniform and capable of saving labor, the workload is reduced, the slag flowing speed is increased, the slag flowing quality is improved, and the manganese alloying process is accelerated.

Owner:YONGXING SPECIAL STAINLESS STEEL

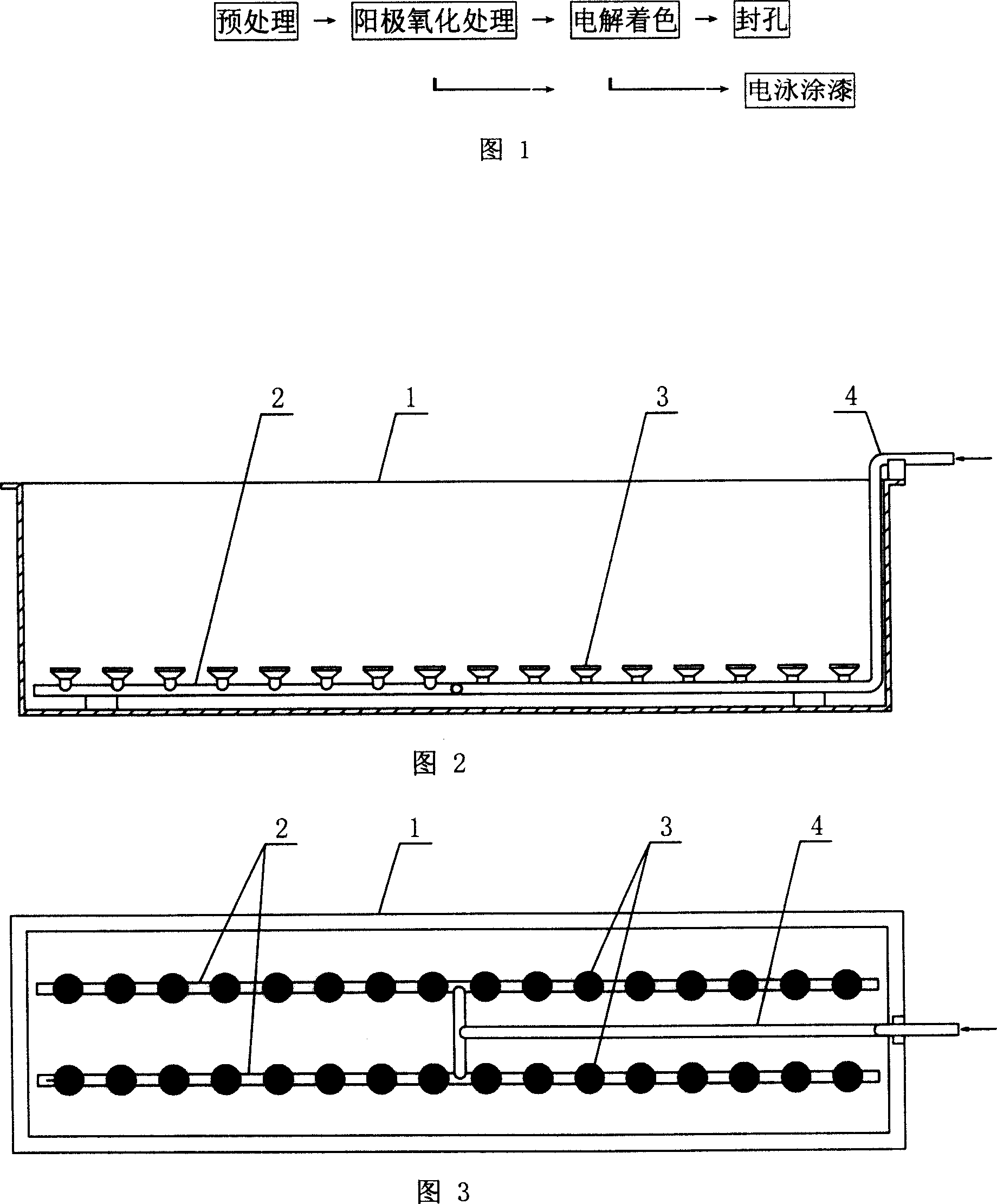

Aluminum alloy section bar anode oxidation surface processing process and processing tank device

InactiveCN1995478AReduce energy consumptionImprove the speed of oxidation film formationAnodisationSprayerOxidative treatment

The invention discloses an aluminum alloy typed anode oxidization surface disposing technique and disposing groove device, which is characterized by the following: (1) allocating groove liquid with 150-180g / L sulfuric acid, 5g / L-20g / L Al3+, 1-4% polyol and 1-4% organic carboxyl acid with hydroxy; (2) setting the oxidizing disposing time of each 10um oxide film for 16-18 min under 15-35 deg. c with current density at 0.5-3A / dm2 and pressure at 13-18V; (3) aerating air to do micropore stirring; (4) adding ammonia sulfate or ammonium persulphate when Al3+ is not less than 20g / L; cooling to below 15 deg. c; removing partial Al3+ sediment; setting multiple PE micropore sprayers in the groove; utilizing air bubble to microstir the groove liquid.

Owner:周国斌 +1

Preparation method for silver zinc oxide electrical contact

The invention discloses a preparation method for a silver zinc oxide electrical contact. The method comprises the following steps of: forming a pressed blank in a die pressing mode by adopting silver zinc alloy powder, wherein the relative density of the pressed blank is 65 to 80 percent; treating the formed pressed blank for 1 to 3 hours at the temperature of between 350 and 600 DEG C in hydrogen atmosphere, putting the treated pressed blank into an oxidation furnace with oxygen pressure of 0.02 to 1.5MPa and temperature of 500 to 750 DEG C, and performing oxidation; and for obtaining the high-compactness silver zinc oxide electrical contact, sintering the internal oxidized blank in the air at the temperature of between 700 and 900 DEG C, performing hot repressing on the blank at the temperature of between 500 and 900 DEG C, and thus obtaining an electrical contact product with relative density of over 99 percent. The silver zinc oxide granules prepared by the method are fine and uniform in metallographic structure; and the method has the advantages of an internal oxidation process and does not produce 'poor oxide bright bands'.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

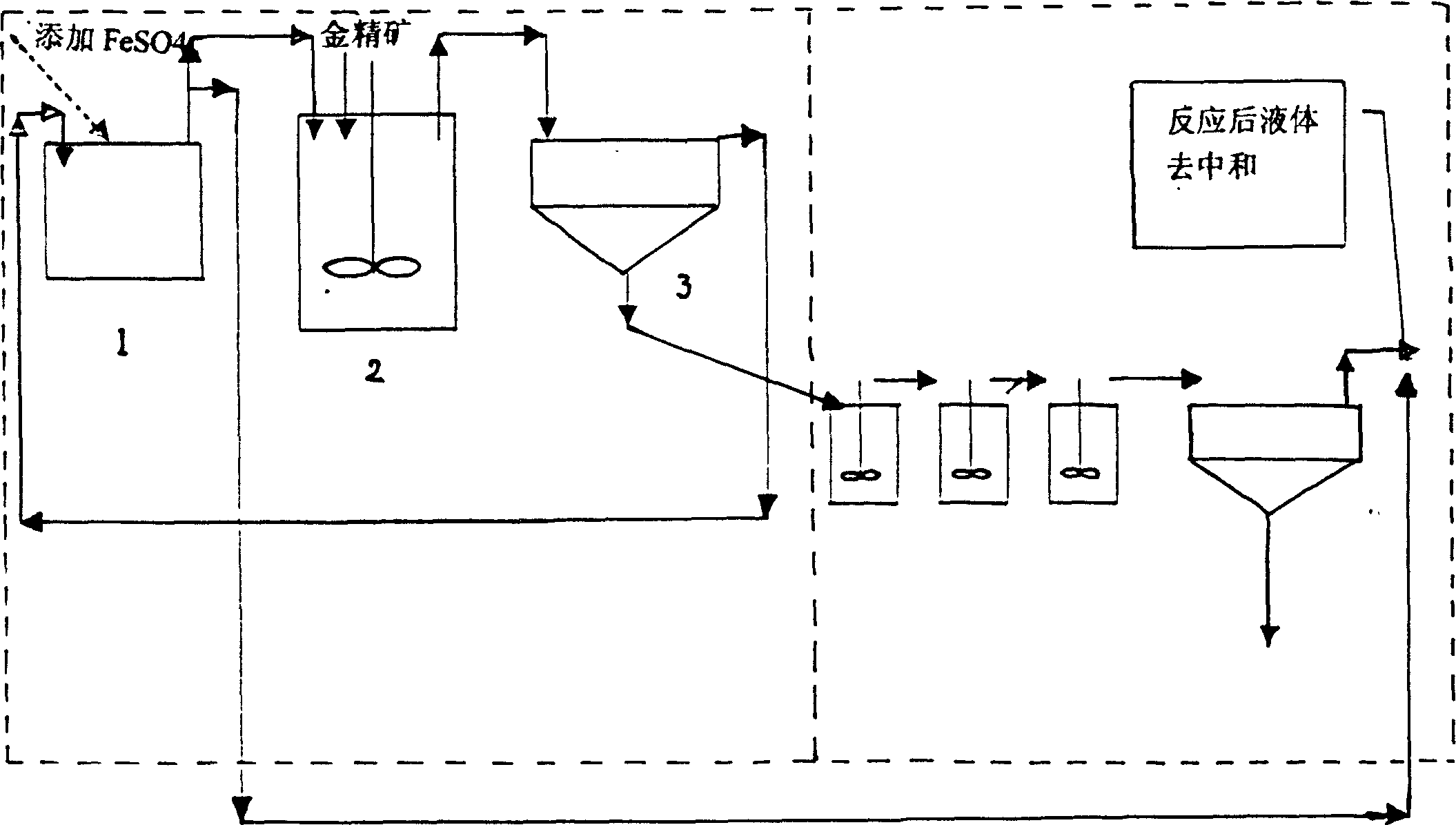

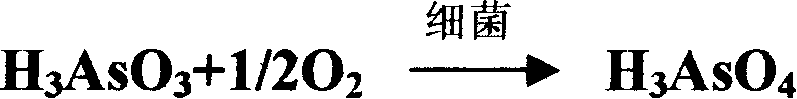

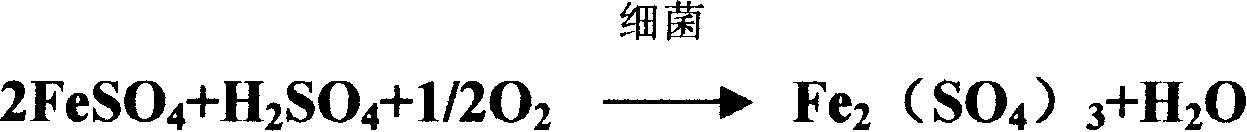

Gold extracting process for high arsenic gold mine

InactiveCN1683571AReduce contentBio-withdrawal went smoothlyProcess efficiency improvementOxidative treatmentMaceral

The present invention discloses a kind gold extracting process from high arsenic gold ore. High arsenic gold ore is first high iron pre-treated to make As content lowered to below 8 %, reaching the requirement of bacteria oxidation to extracting gold, and then gold is extracted biologically. The present invention has simple and effective technological process, can oxidize toxic sand in raw ore in short time and has low apparatus investment.

Owner:莱州泰源冶金技术有限公司

Synthetic method of oxidized cellulose

The invention discloses a synthetic method of oxidized cellulose. According to the method, firstly, cellulose materials are pretreated through an NaOH or LiOH solution by combining an ultrasonic technology; then, an NaClO4 and K2FeO4 oxidation system is used for further oxidizing the materials through regulating the pH values in the mixed material via NaAc; the oxidation temperature is 30 to 42 DEG C; the oxidization time is 1 to 3h; finally, an oxidized product is cleaned and dried. The method has the advantages that the cellulose oxidization time can be greatly shortened; in addition, the obtained oxidized cellulose has high-content carboxyl; the content of the carboxyl can reach 21.6 percent to 35.8 percent; the oxidized cellulose belongs to a medical material with better application prospects.

Owner:JIANGSU LANWAN BIOTECH

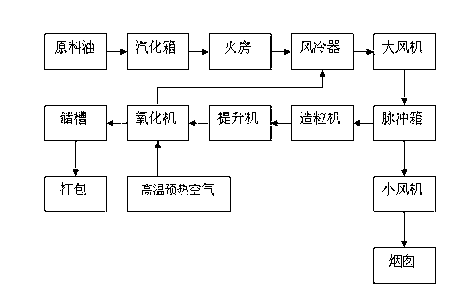

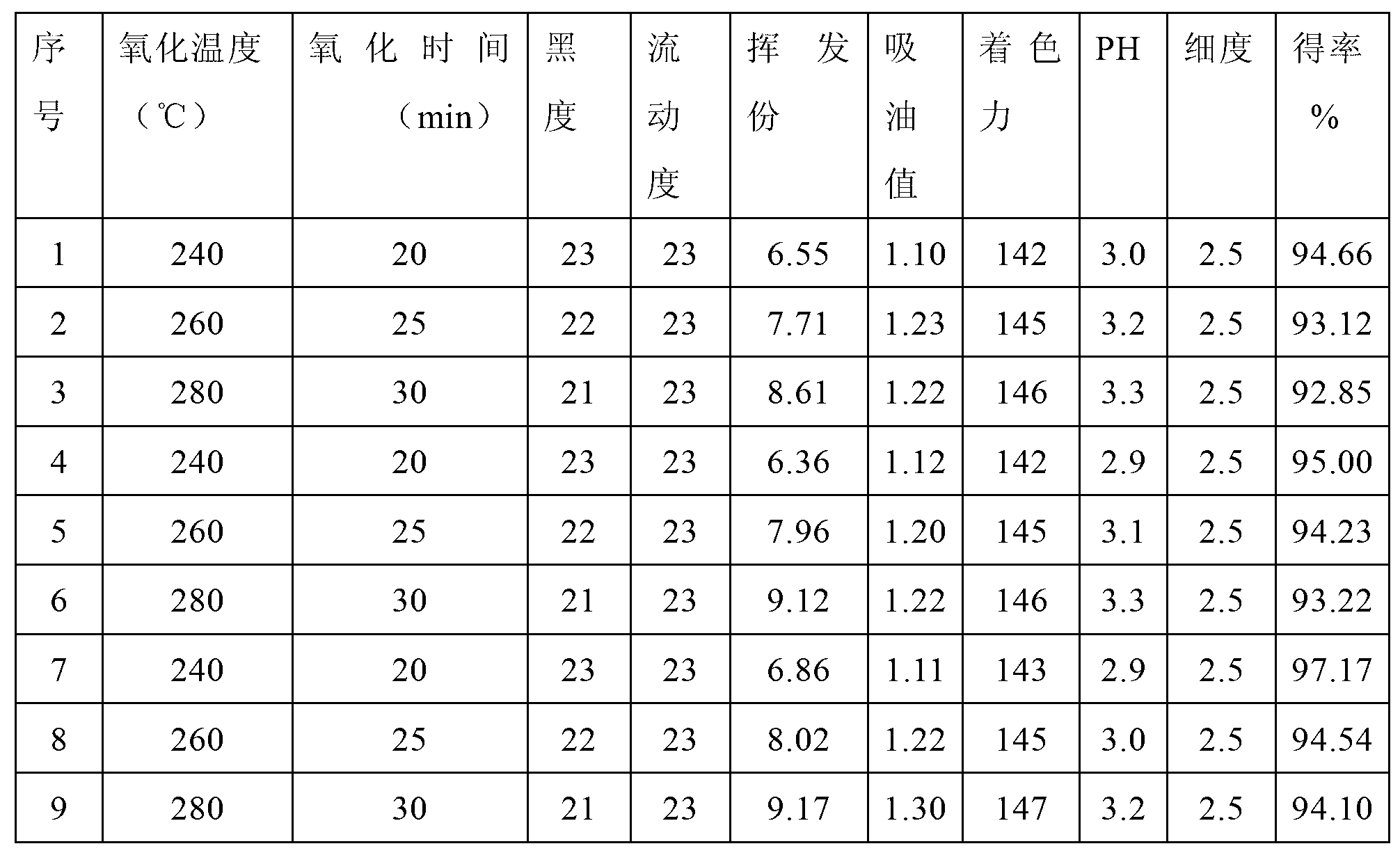

Improved method for producing pigment carbon black

The invention relates to an improved method for producing pigment carbon black. The method comprises the following steps: heating and dehydrating raw oil, conveying the heated raw oil to a vaporizing tank through a pipeline, heating the vaporizing tank so as to vaporize the raw oil, enabling preheated combustible gas to pass through a liquid level of the raw oil in the vaporizing tank so as to mix the oil vapor with the combustible gas, conveying the mixed gas to a carbon black reactor for incomplete combustion and cracking through an oil gas header pipe to produce carbon black, cooling the carbon black and then conveying the cooled carbon black into a pelletizer for pelletizing, performing magnetic separation on the pelletized carbon black, then conveying into an oxidizing machine for performing thermal oxidation treatment, conveying the thermal oxidation-treated carbon black into a cooling tank for cooling to normal temperature, and then conveying to a carbon black storage tank for packaging and storing. The water-soluble pigment carbon black produced by adopting the method is high in volatile matters and dispersity as well as color intensity and low in pH value. The application performances of the pigment carbon black on oil ink, leather, coating, paint and the like can be greatly improved.

Owner:上海焦化化工发展商社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com