Preparation method of large-dimension graphene oxide and large-dimension graphene oxide obtained by method

A large-size graphene technology, which is applied in the preparation of large-size graphene oxide and the field of large-size graphene oxide, can solve the problems of small size, low yield, and long time consumption, and achieve large size, uniform structure, and rapid peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

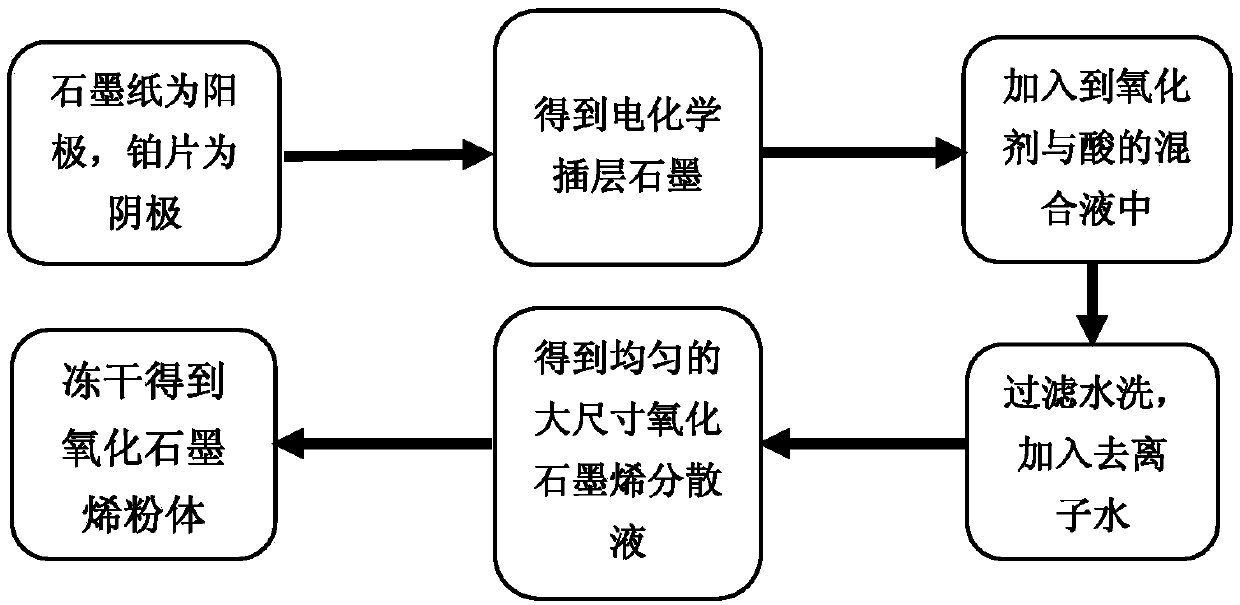

Method used

Image

Examples

Embodiment 1

[0023] Graphite paper with a length of 9cm, a weight of 0.5g, and a thickness of 1mm (prepared from expanded graphite with a radial dimension of 500 μm) was used as the anode, a platinum sheet of 4cm*2cm*0.15mm was used as the cathode, and concentrated sulfuric acid was used as the electrolyte. The voltage was constant at 5V, and the reaction was carried out at room temperature. The graphite was electrochemically intercalated and exfoliated for 40 minutes, and separated with a 150-mesh nylon sieve to obtain electrochemically intercalated graphite.

[0024] Put the intercalation graphite into the mixture of 23ml concentrated sulfuric acid and 1g potassium permanganate, 35°C, 150rpm magnetic stirring for 1h, filter and wash with deionized water, add 500ml deionized water, stir for 30min under 150rpm magnetic stirring , to obtain a uniform graphene oxide dispersion.

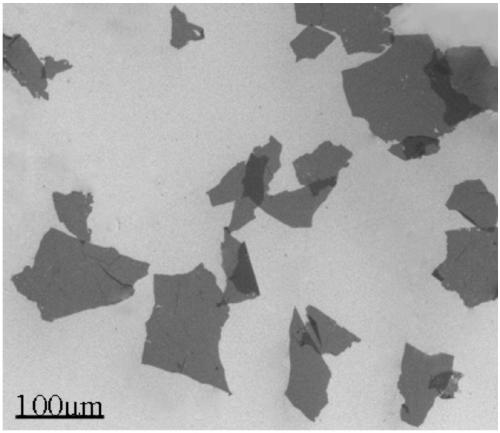

[0025] Such as figure 2 The scanning electron microscope image (SEM) results shown show that the obtained graph...

Embodiment 2

[0027] Graphite paper with a length of 9cm, a weight of 0.5g, and a thickness of 1mm (prepared from expanded graphite with a radial dimension of 1500 μm) was used as the anode, a platinum sheet of 4cm*2cm*0.15mm was used as the cathode, and concentrated sulfuric acid was used as the electrolyte. The voltage was constant at 5V, and the reaction was carried out at room temperature. The graphite was electrochemically intercalated and exfoliated for 40 minutes, and separated with a 150-mesh nylon sieve to obtain electrochemically intercalated graphite.

[0028] Put the intercalation graphite into the mixture of 23ml concentrated sulfuric acid and 1g potassium permanganate, 35°C, 150rpm magnetic stirring for 1h, filter and wash with deionized water, add 500ml deionized water, stir for 30min under 150rpm magnetic stirring , to obtain a uniform graphene oxide dispersion, with an average radial size of more than 80 microns, and a single-layer and double-layer ratio of more than 80%.

Embodiment 3

[0030]Graphite paper with a length of 9cm, a weight of 0.5g, and a thickness of 1mm (prepared from expanded graphite with a radial dimension of 5000 μm) was used as the anode, a platinum sheet of 4cm*2cm*0.15mm was used as the cathode, and concentrated sulfuric acid was used as the electrolyte. The voltage was constant at 5V, and the reaction was carried out at room temperature. The graphite was electrochemically intercalated and exfoliated for 40 minutes, and separated with a 150-mesh nylon sieve to obtain electrochemically intercalated graphite.

[0031] Put the intercalation graphite into the mixture of 23ml concentrated sulfuric acid and 1g potassium permanganate, 35°C, 150rpm magnetic stirring for 1h, filter and wash with deionized water, add 500ml deionized water, stir for 30min under 150rpm magnetic stirring , to obtain a uniform graphene oxide dispersion, with an average radial size of more than 80 microns, and a single-layer and double-layer ratio of more than 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com