Patents

Literature

186 results about "Few layer graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

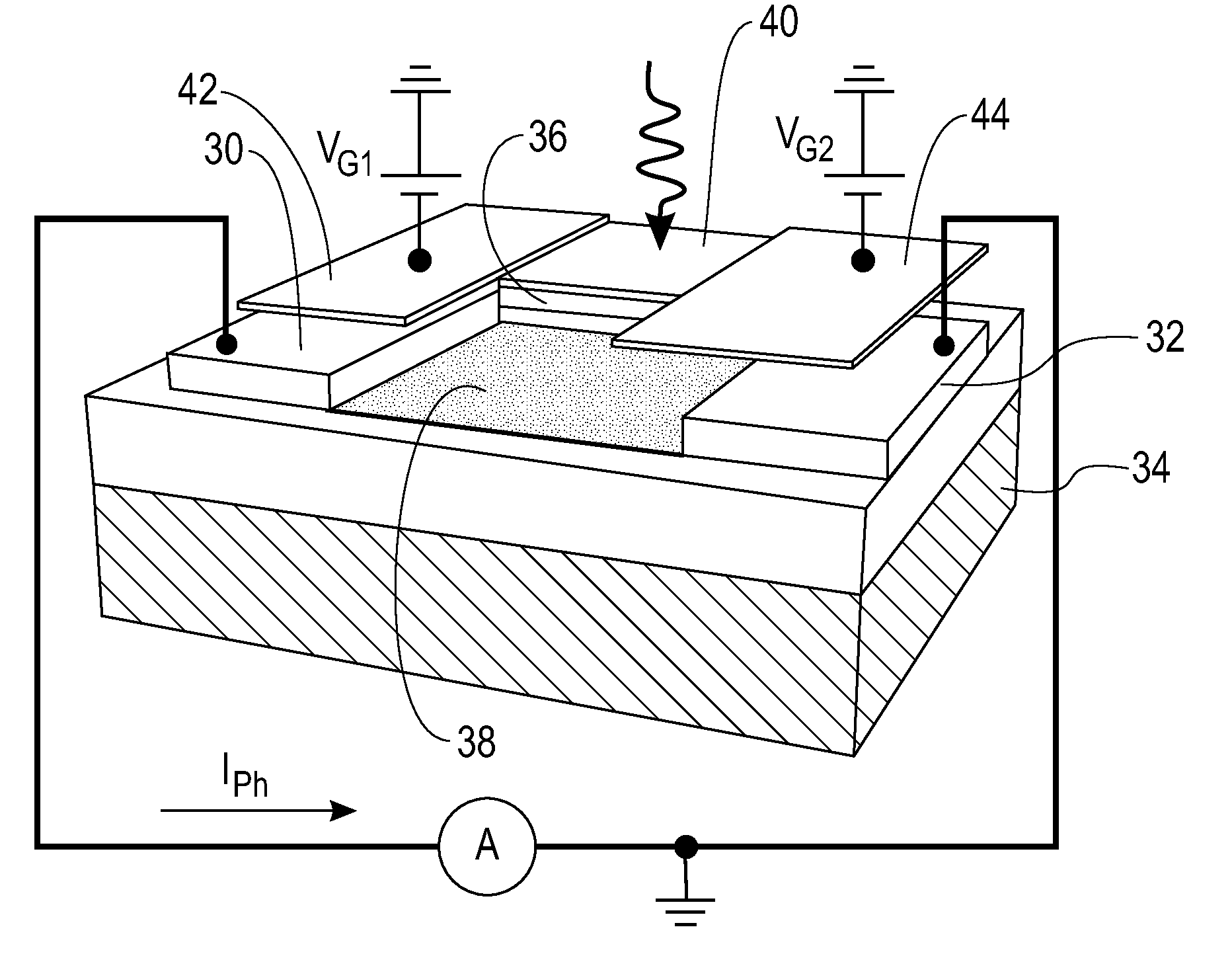

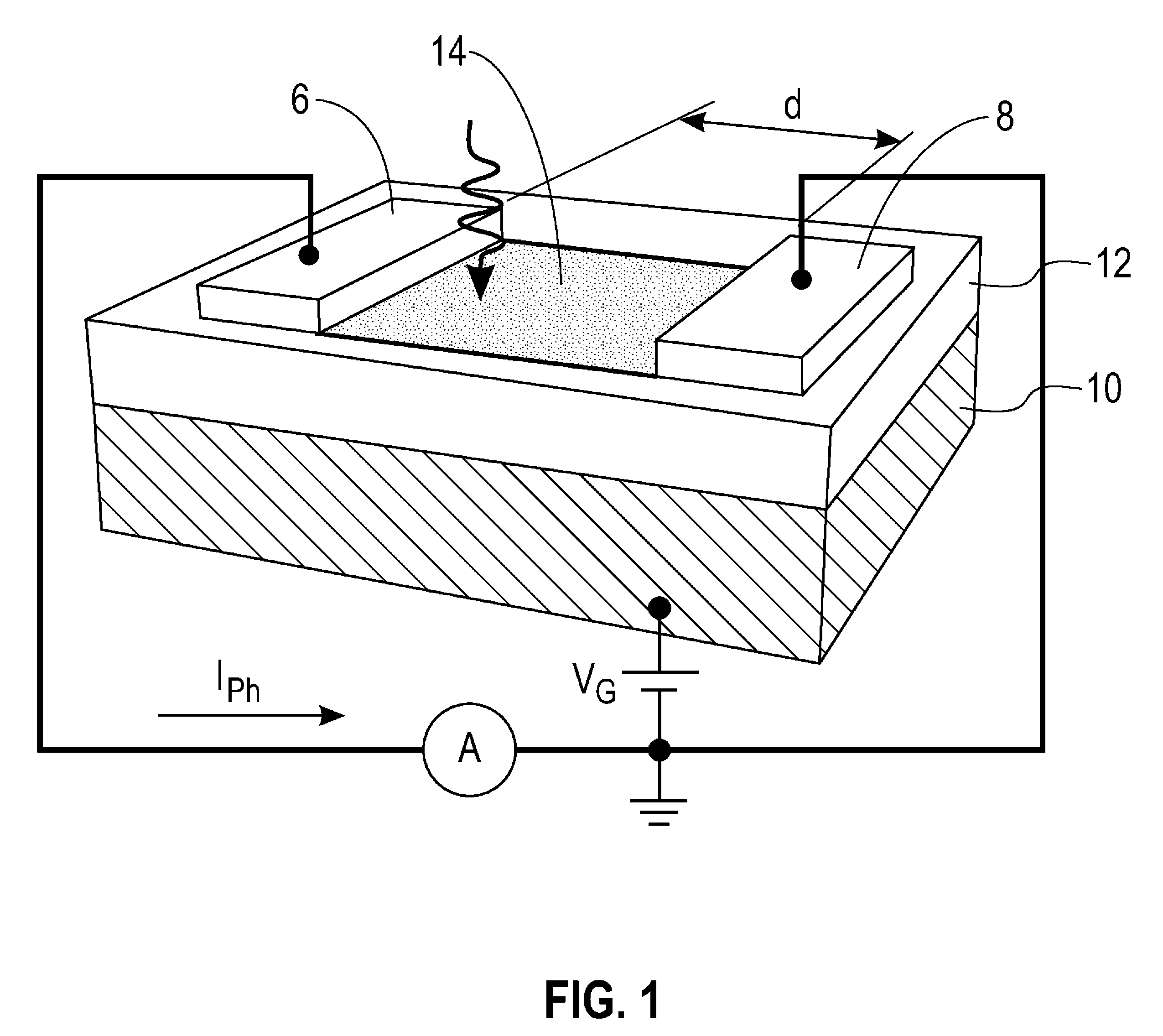

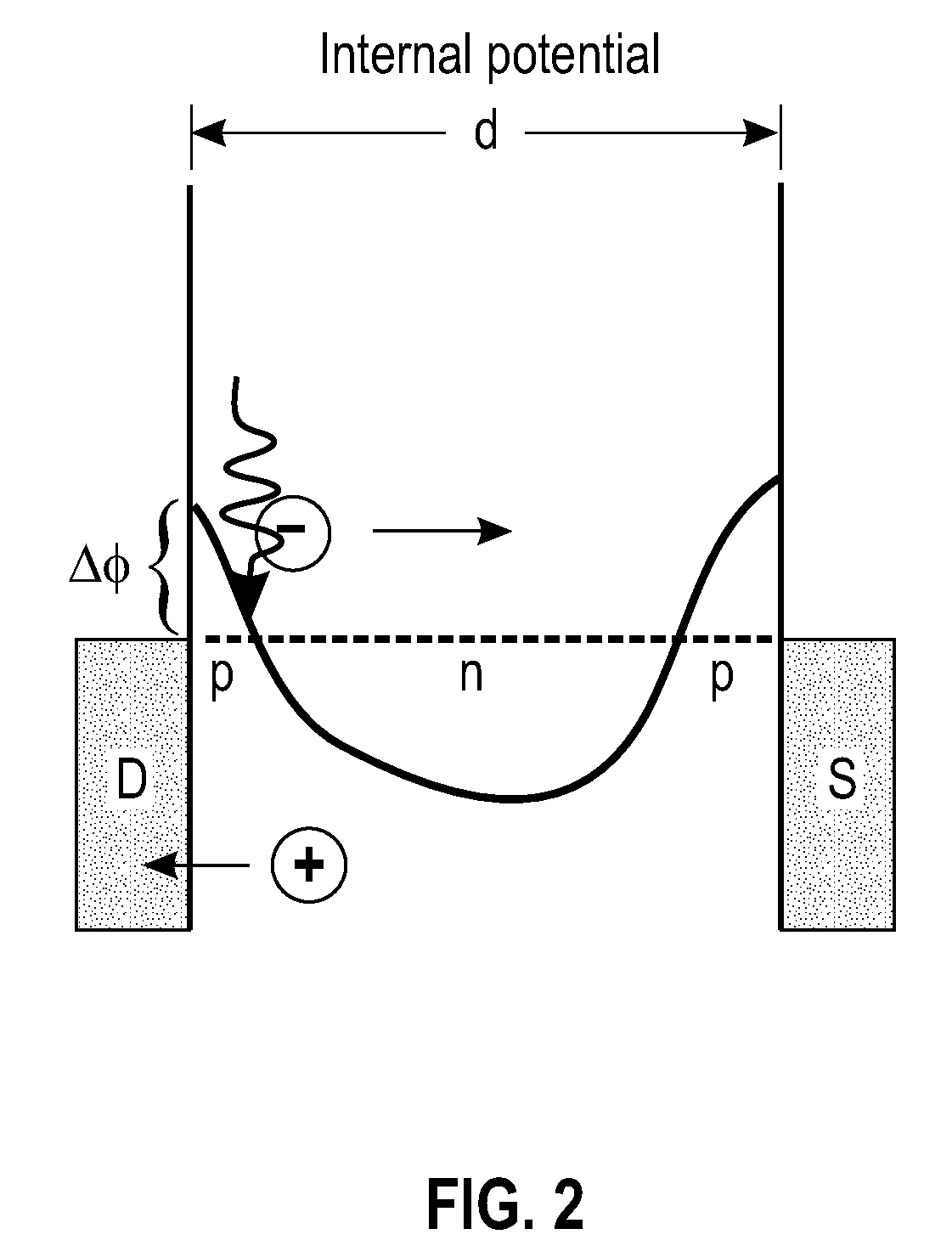

Single and few-layer graphene based photodetecting devices

ActiveUS20110042650A1Final product manufactureSolid-state devicesPhotovoltaic detectorsPhotodetector

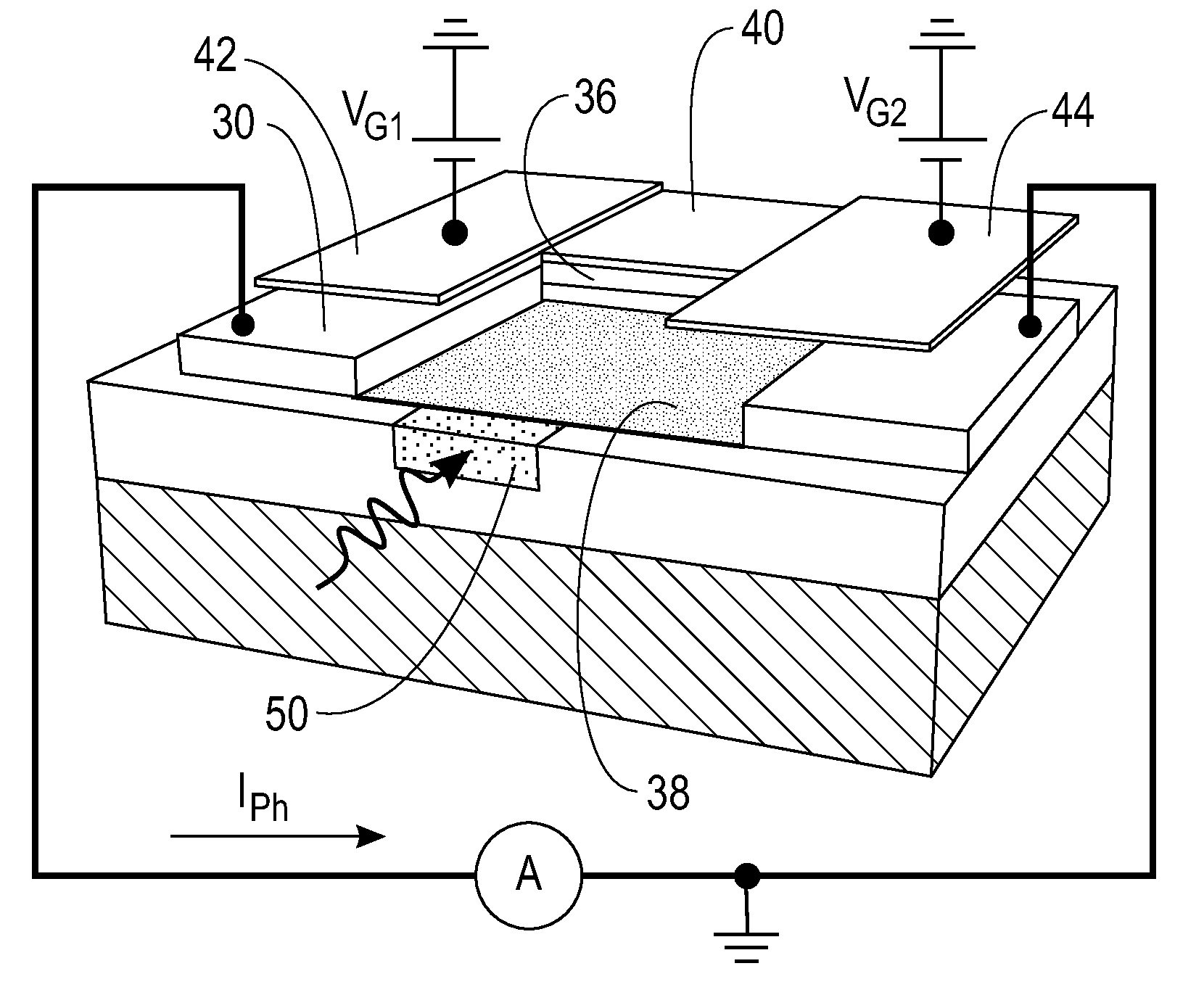

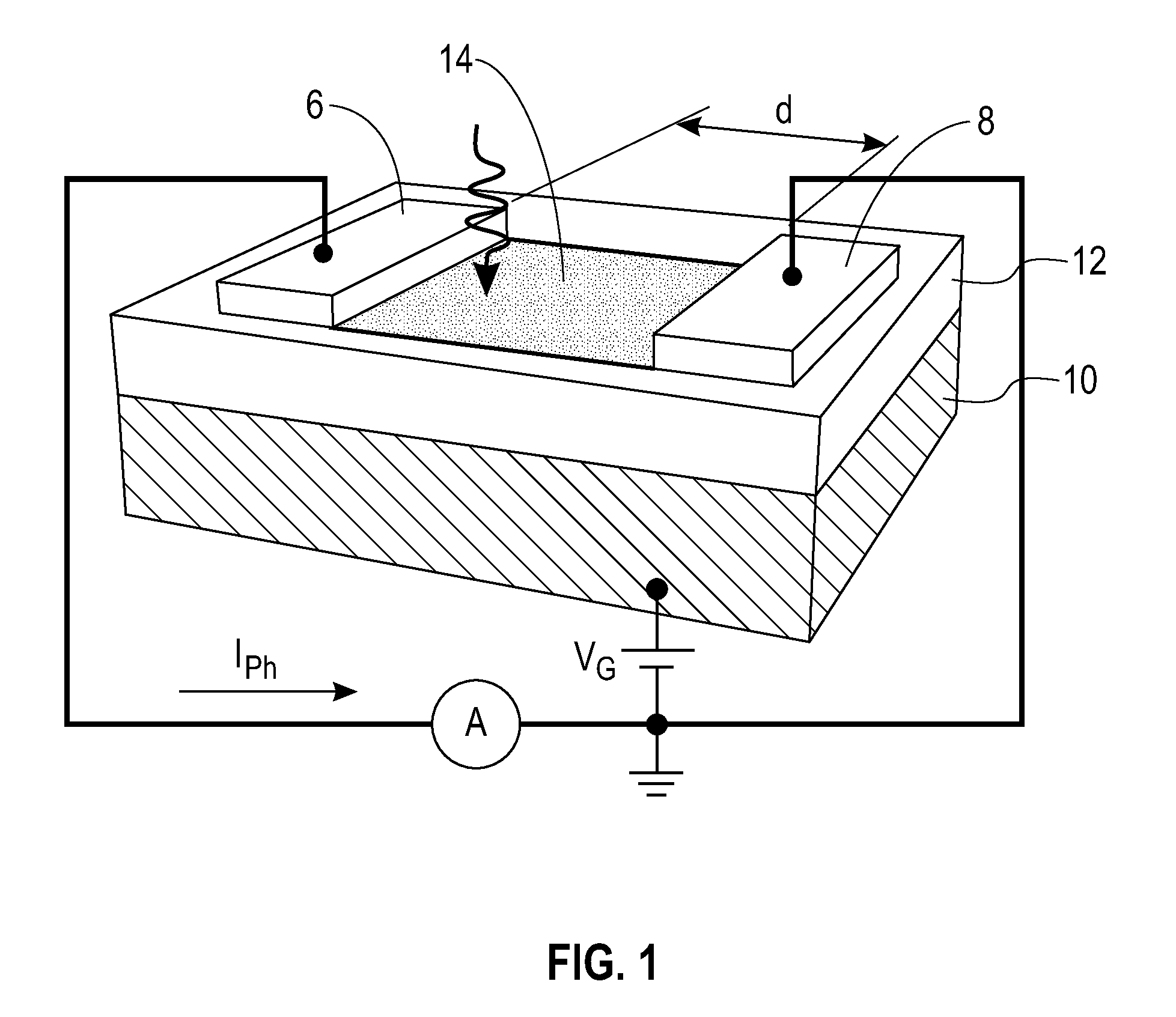

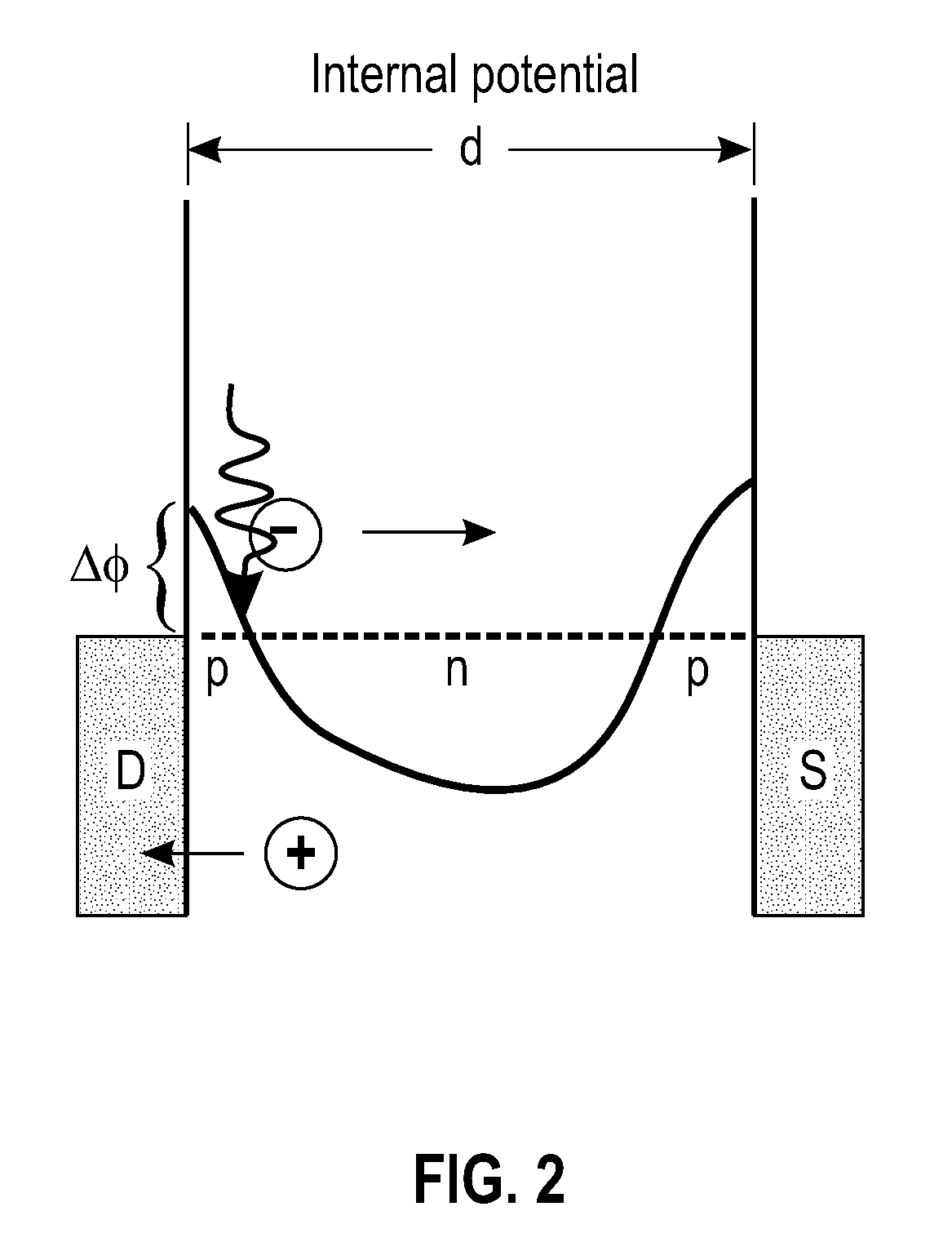

A photodetector which uses single or multi-layer graphene as the photon detecting layer is disclosed. Multiple embodiments are disclosed with different configurations of electrodes. In addition, a photodetector array comprising multiple photodetecting elements is disclosed for applications such as imaging and monitoring.

Owner:GLOBALFOUNDRIES US INC

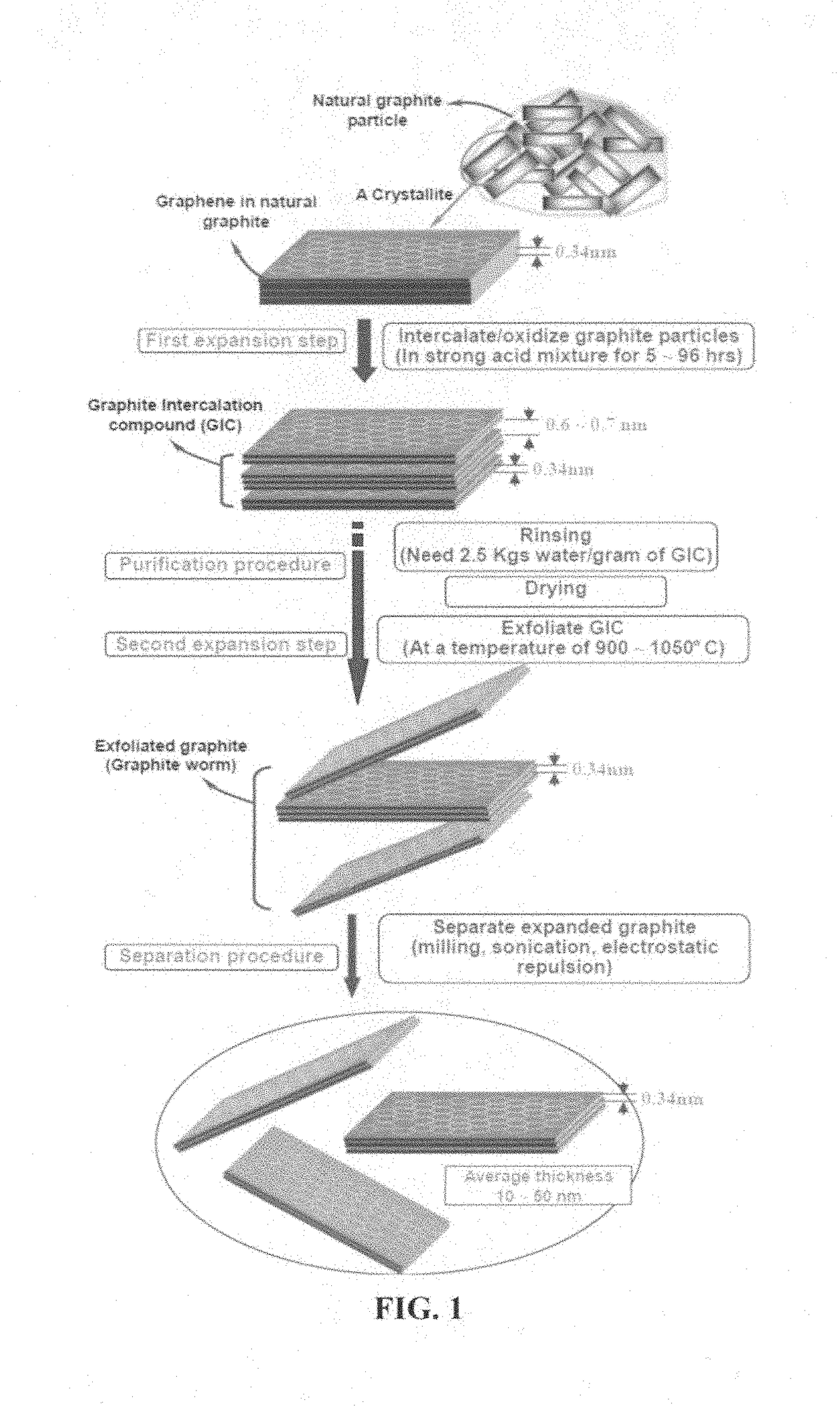

Monolayer and/or Few-Layer Graphene On Metal or Metal-Coated Substrates

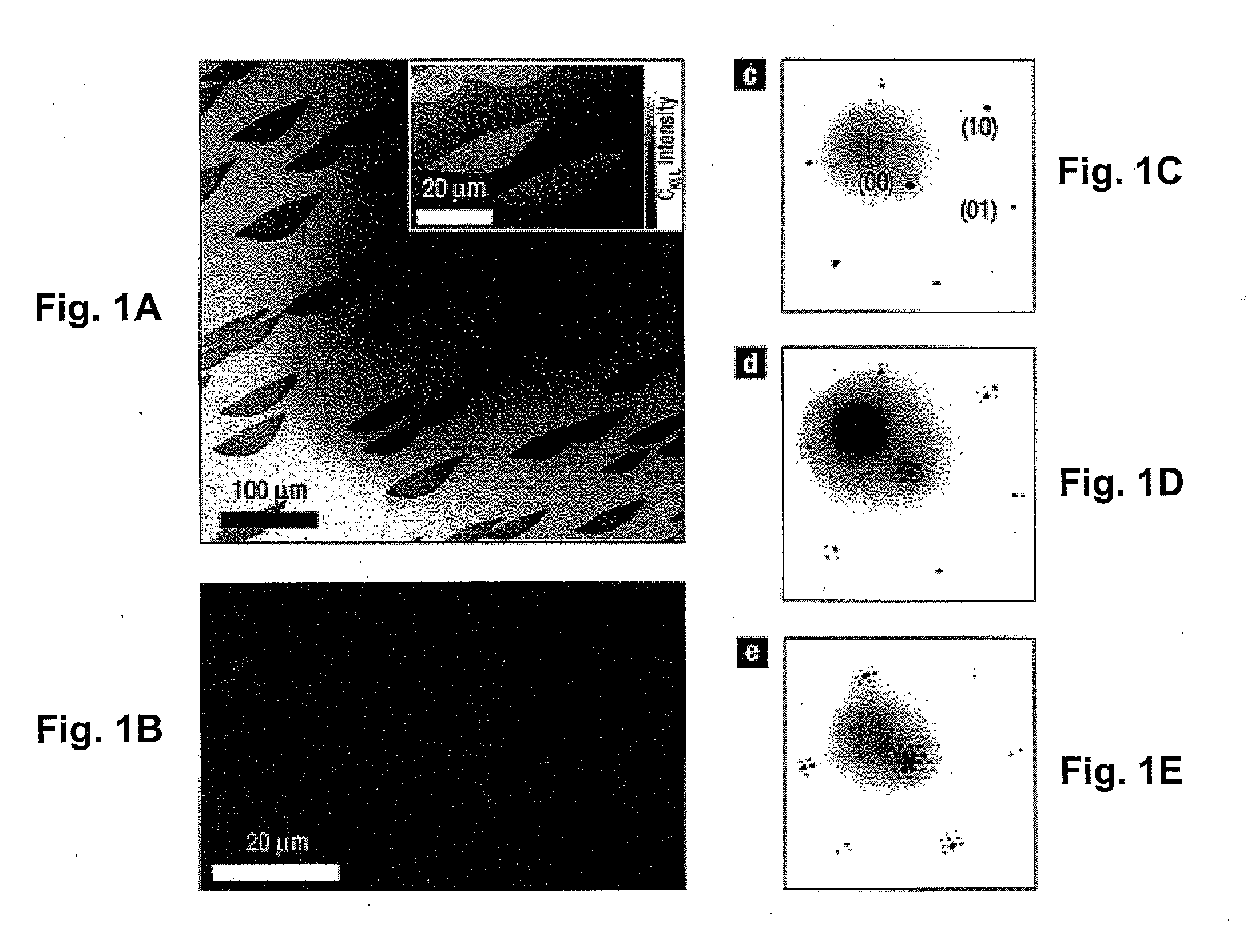

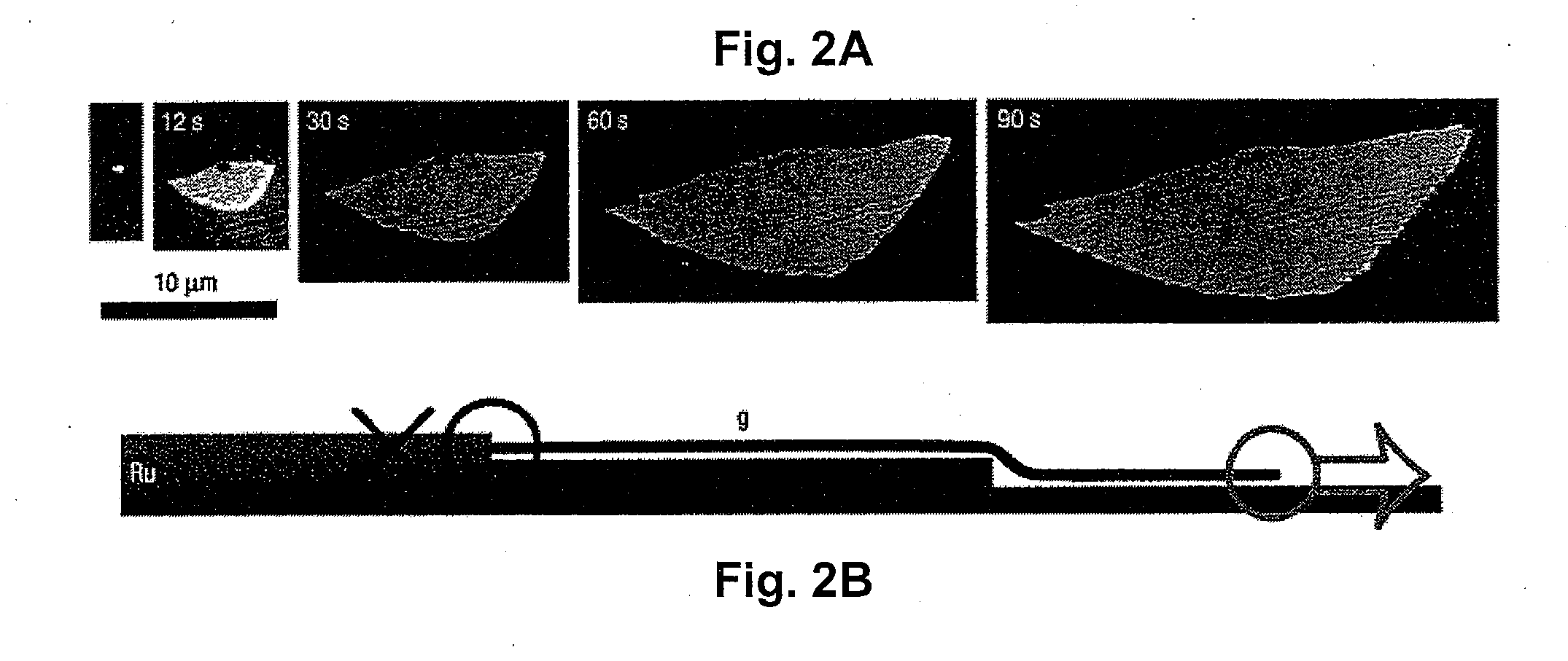

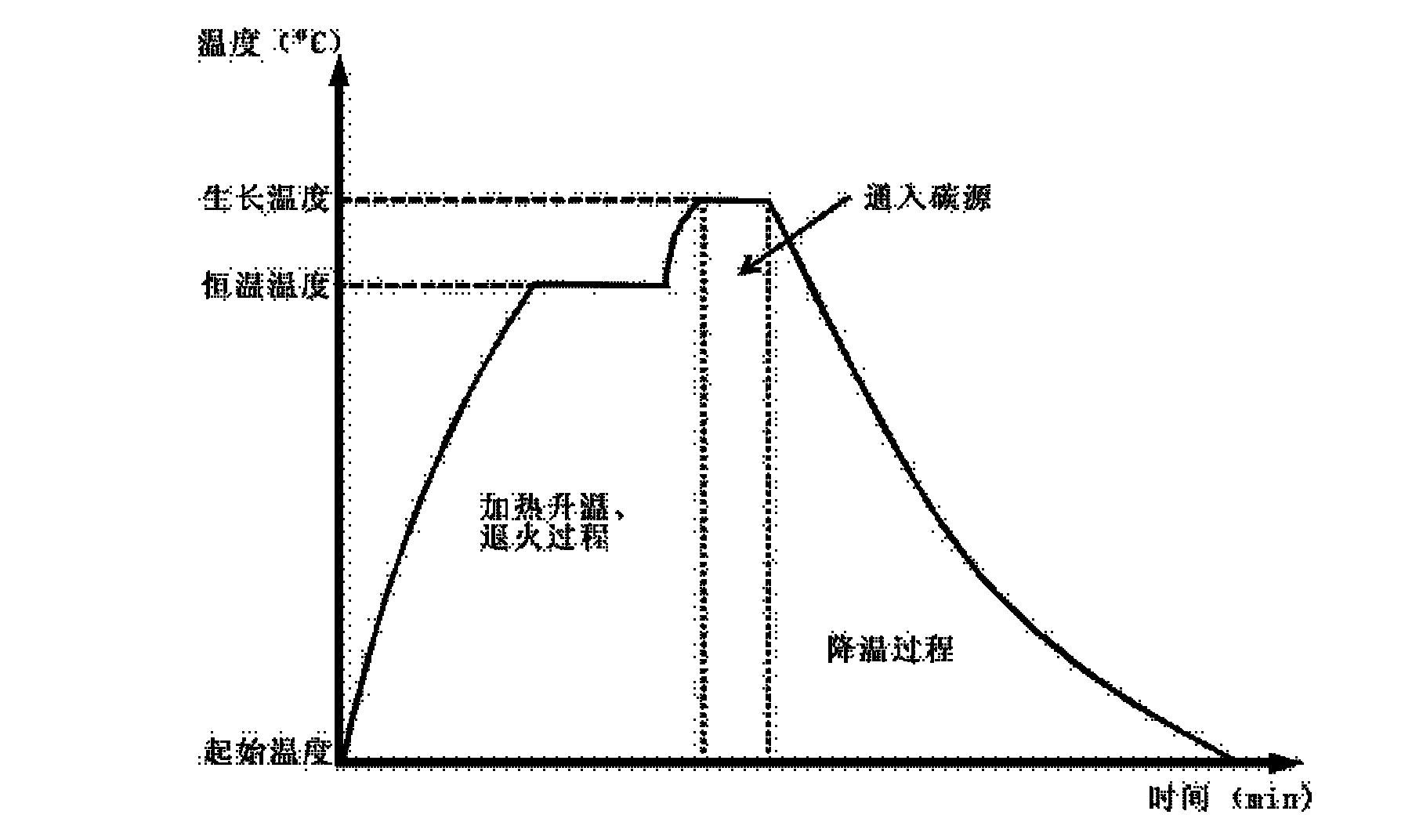

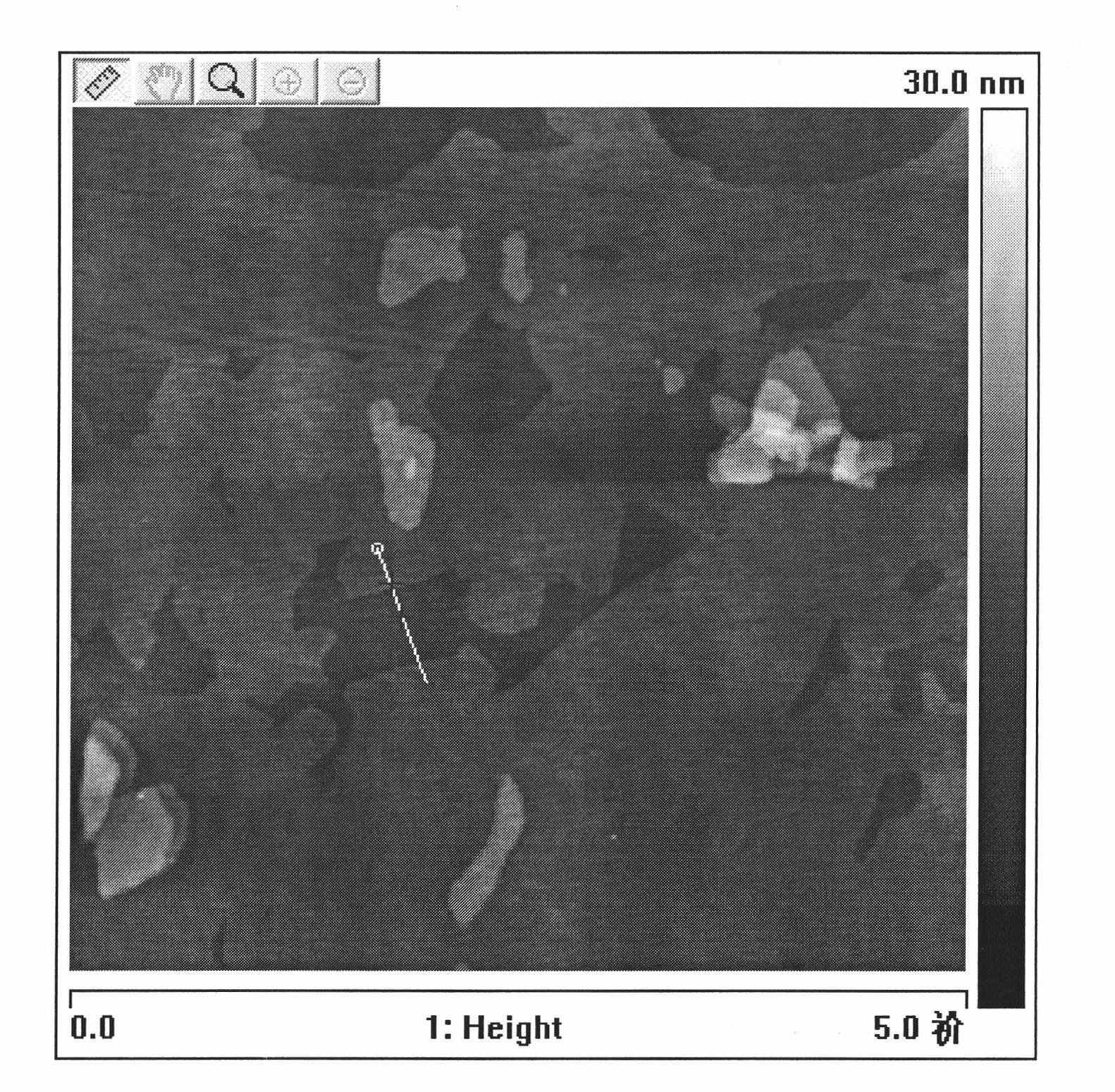

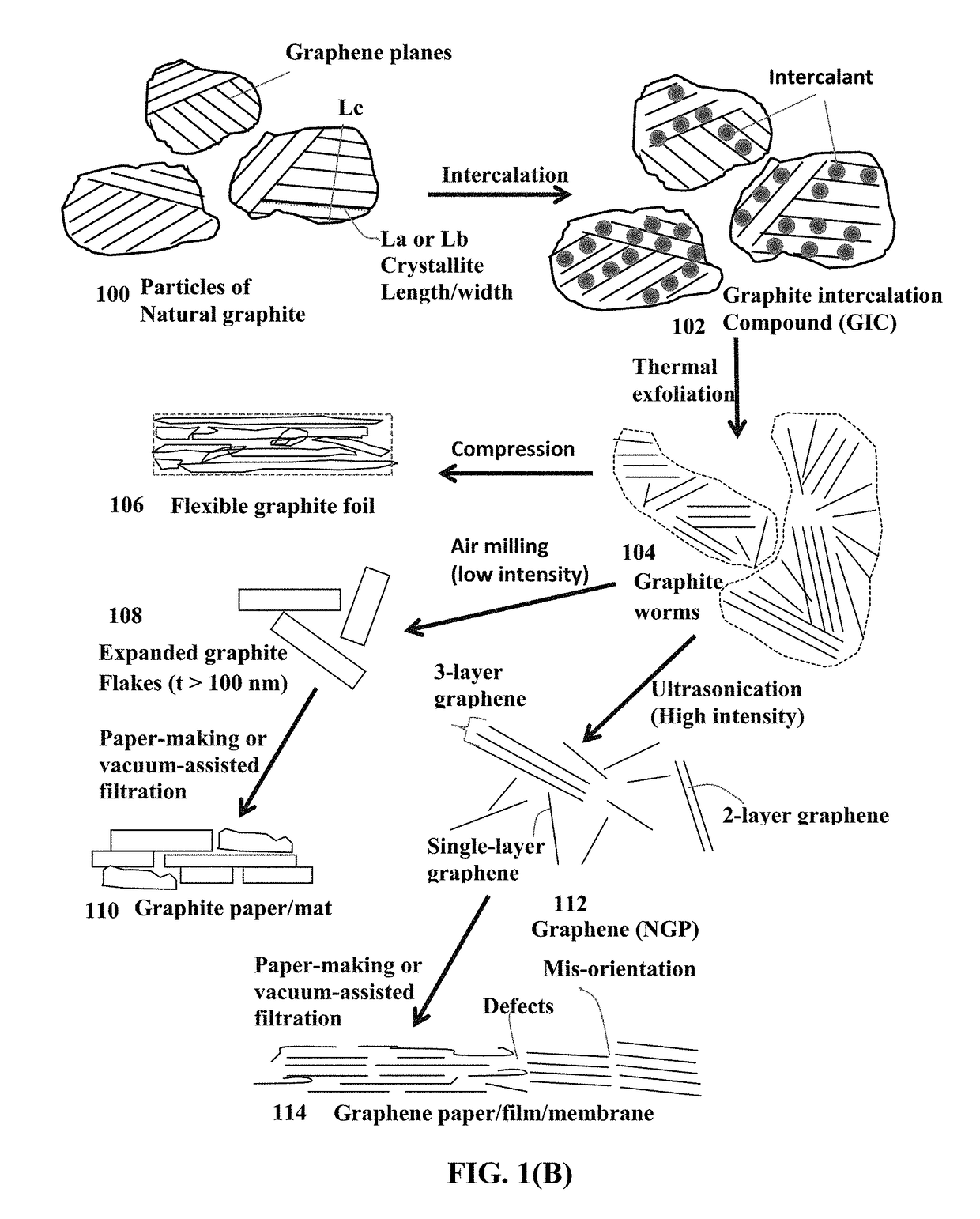

InactiveUS20100255984A1Easy to disassembleMaterial nanotechnologyParticle separator tubesHigh concentrationIn plane

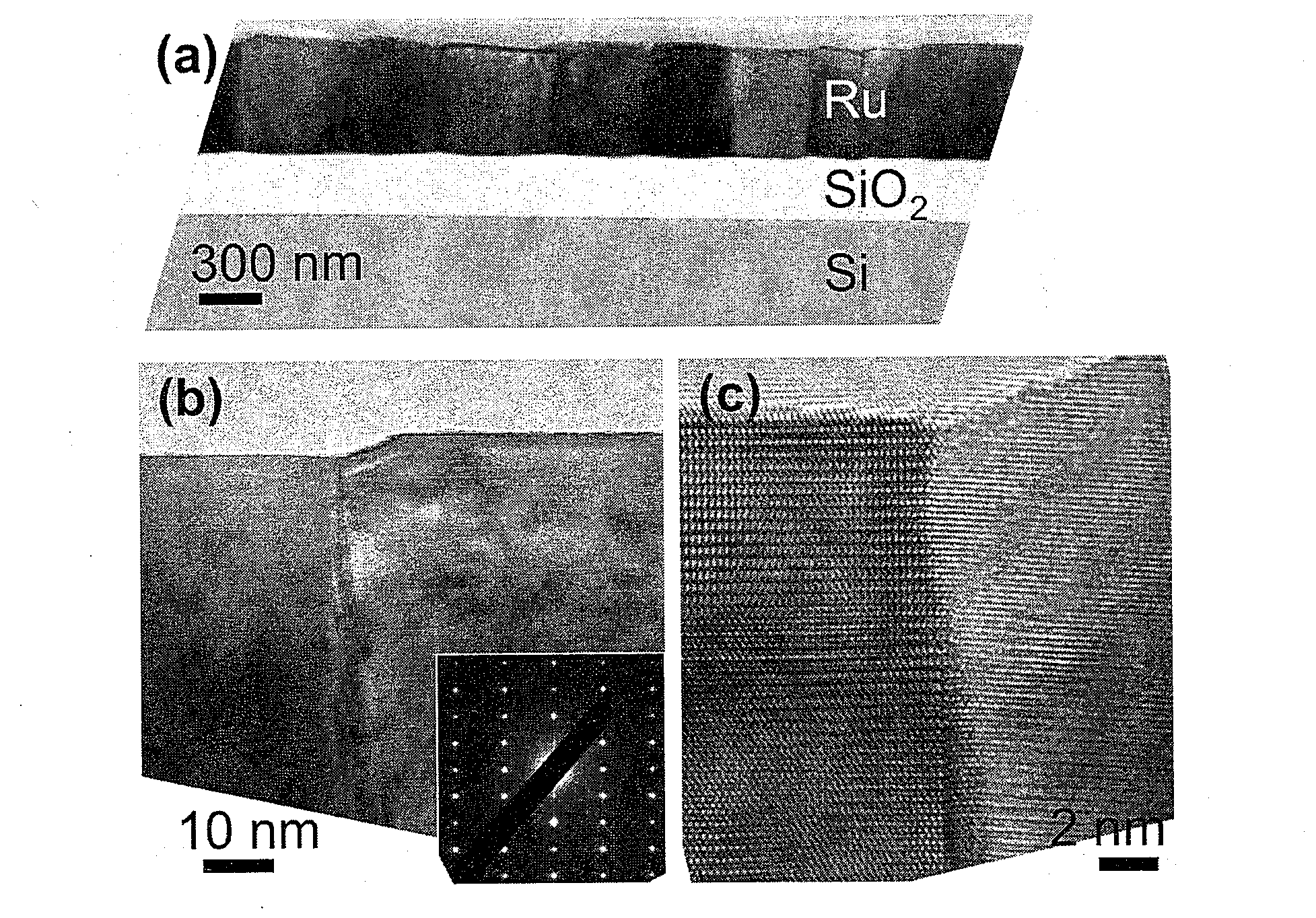

Graphene is a single atomic layer of sp2-bonded C atoms densely packed into a two-dimensional honeycomb crystal lattice. A method of forming structurally perfect and defect-free graphene films comprising individual mono crystalline domains with in-plane lateral dimensions of up to 200 μm or more is presented. This is accomplished by controlling the temperature-dependent solubility of interstitial C of a transition metal substrate having a suitable surface structure. At elevated temperatures, C is incorporated into the bulk at higher concentrations. As the substrate is cooled, a lowering of the interstitial C solubility drives a significant amount of C atoms to the surface where graphene islands nucleate and gradually increase in size with continued cooling. Ru(0001) is selected as a model system and electron microscopy is used to observe graphene growth during cooling from elevated temperatures. With controlled cooling, large arrays of macroscopic single-crystalline graphene domains covering the entire transition metal surface are produced. As the graphene domains coalesce to a complete layer, a second graphene layer is formed, etc. By controlling the interstitial C concentration and the cooling rate, graphene layers with thickness up to 10 atomic layers or more are formed in a controlled, layer-by-layer fashion.

Owner:BROOKHAVEN SCI ASSOCS

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

Method for preparing fewer-layer graphene on basis of biomass waste

ActiveCN105060289AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerArgon atmosphere

The invention discloses a method for preparing fewer-layer graphene on the basis of biomass waste, which comprises the following steps: carrying out hydrothermal treatment on the biomass waste, and carrying out carbonization by heating and calcination, thereby obtaining a carbonization material; immersing the carbonization material in an acid solution to remove impurities, thereby obtaining biomass carbon; and quickly heating the biomass carbon in an argon atmosphere, and carrying out high-temperature graphitization to obtain the biomass fewer-layer graphene. The hydrothermal process is combined with the high-temperature graphitization to directly strip the biomass waste, and the carbonization and high-temperature graphitization are carried out. Thus, the prepared biomass fewer-layer graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The method is simple to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production. The prepared biomass fewer-layer graphene can be used in the fields of lithium ion batteries, supercapacitors and the like, is beneficial to green production of battery industry, and has important practical value and favorable application prospects.

Owner:湖南宸宇富基新能源科技有限公司

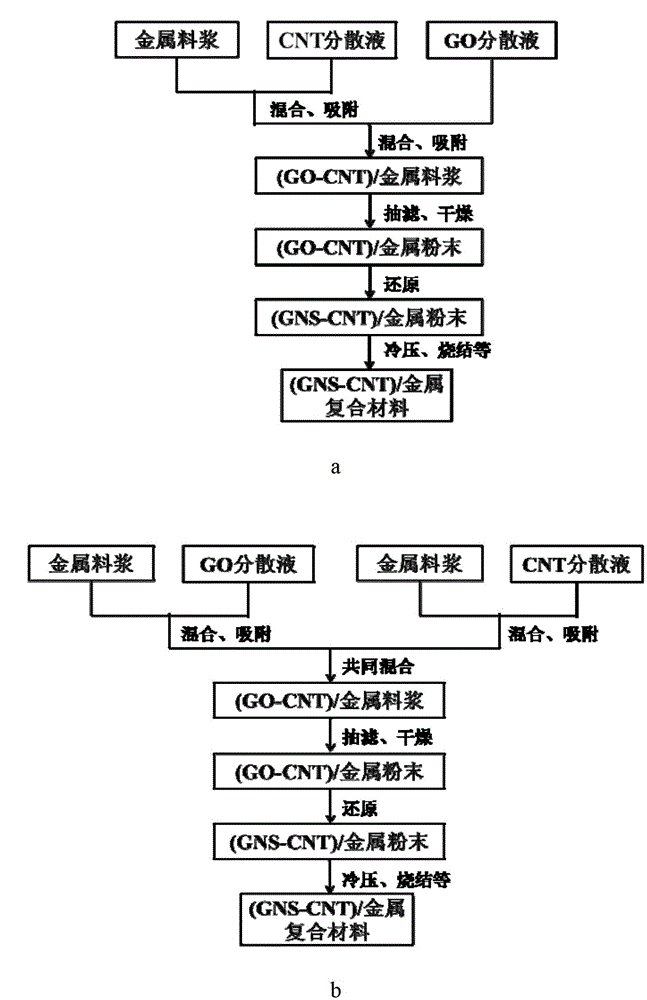

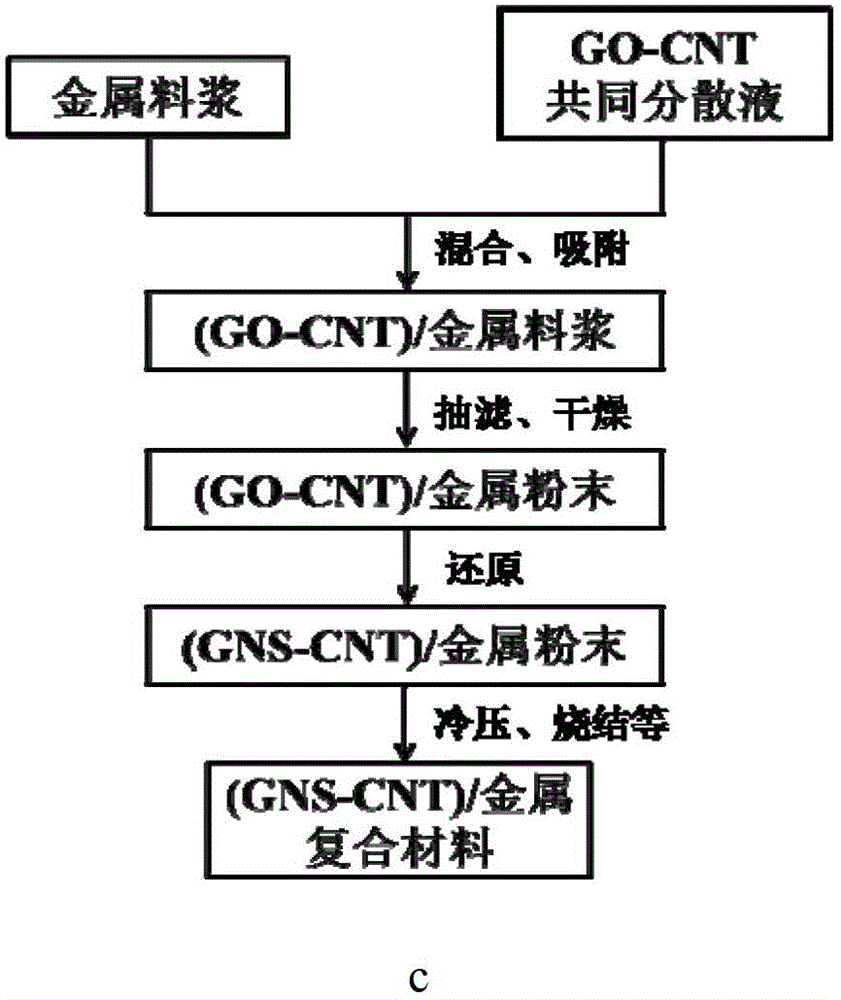

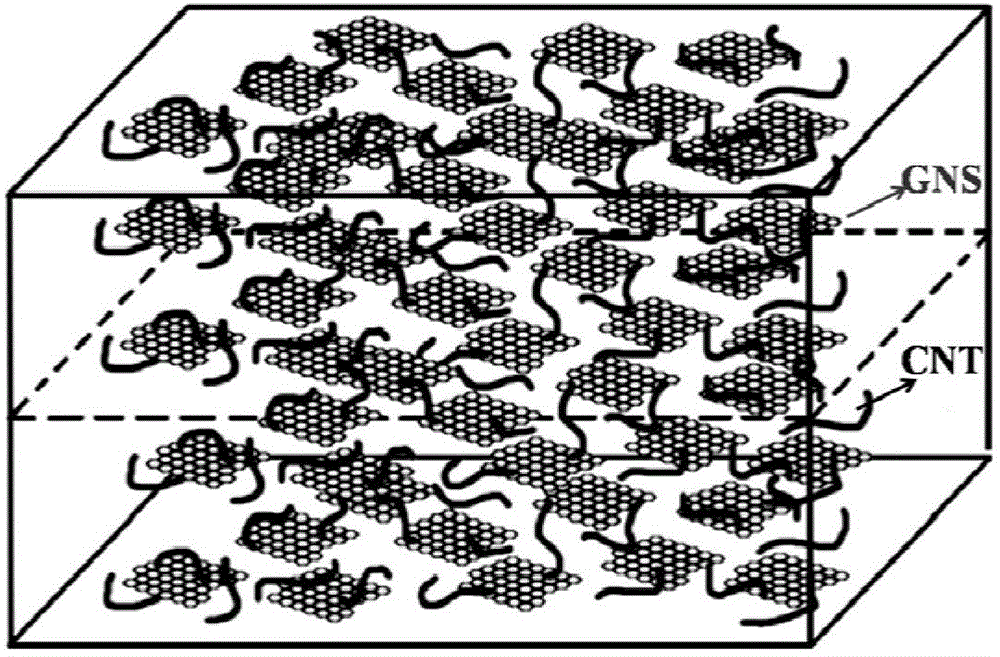

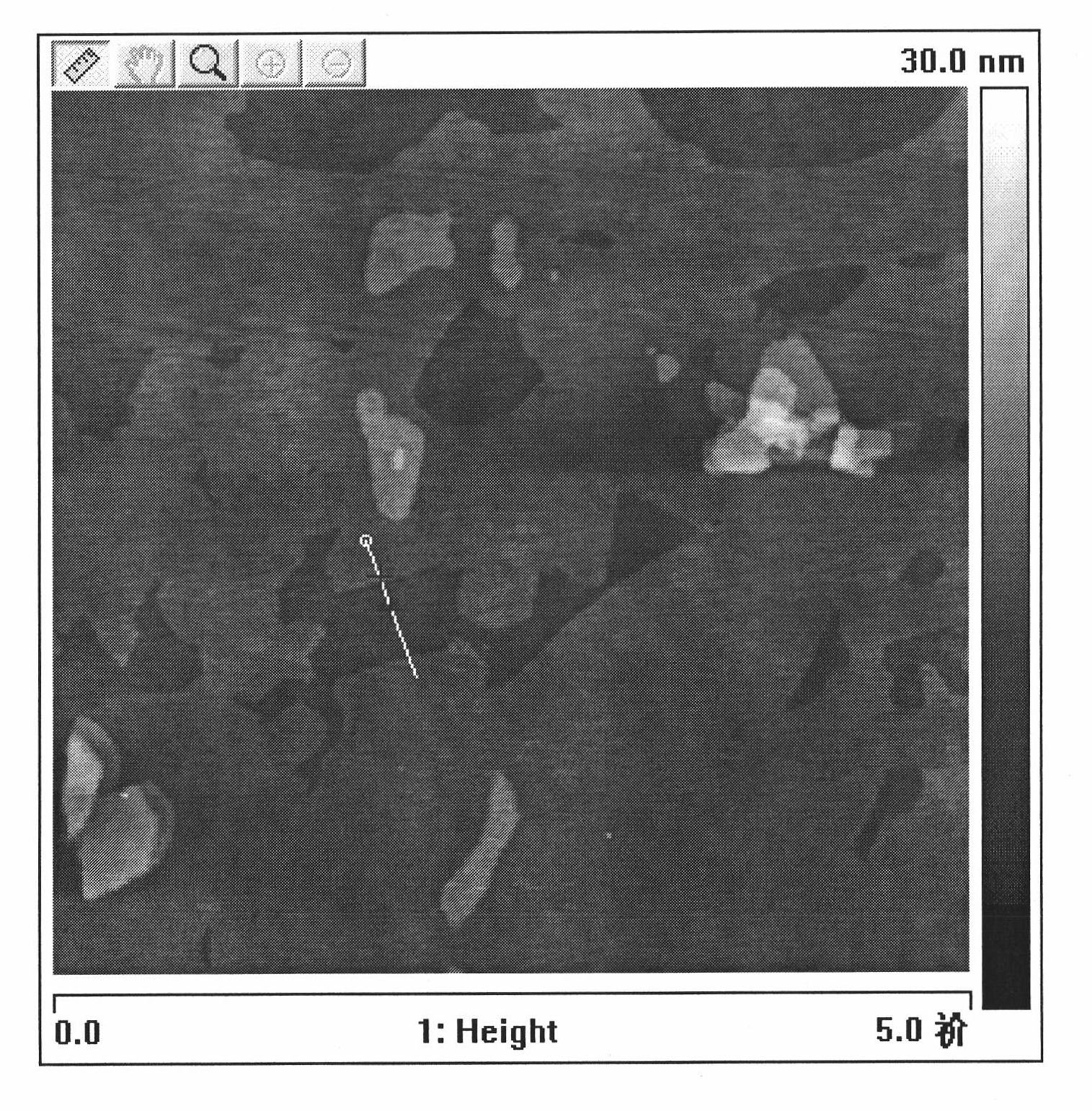

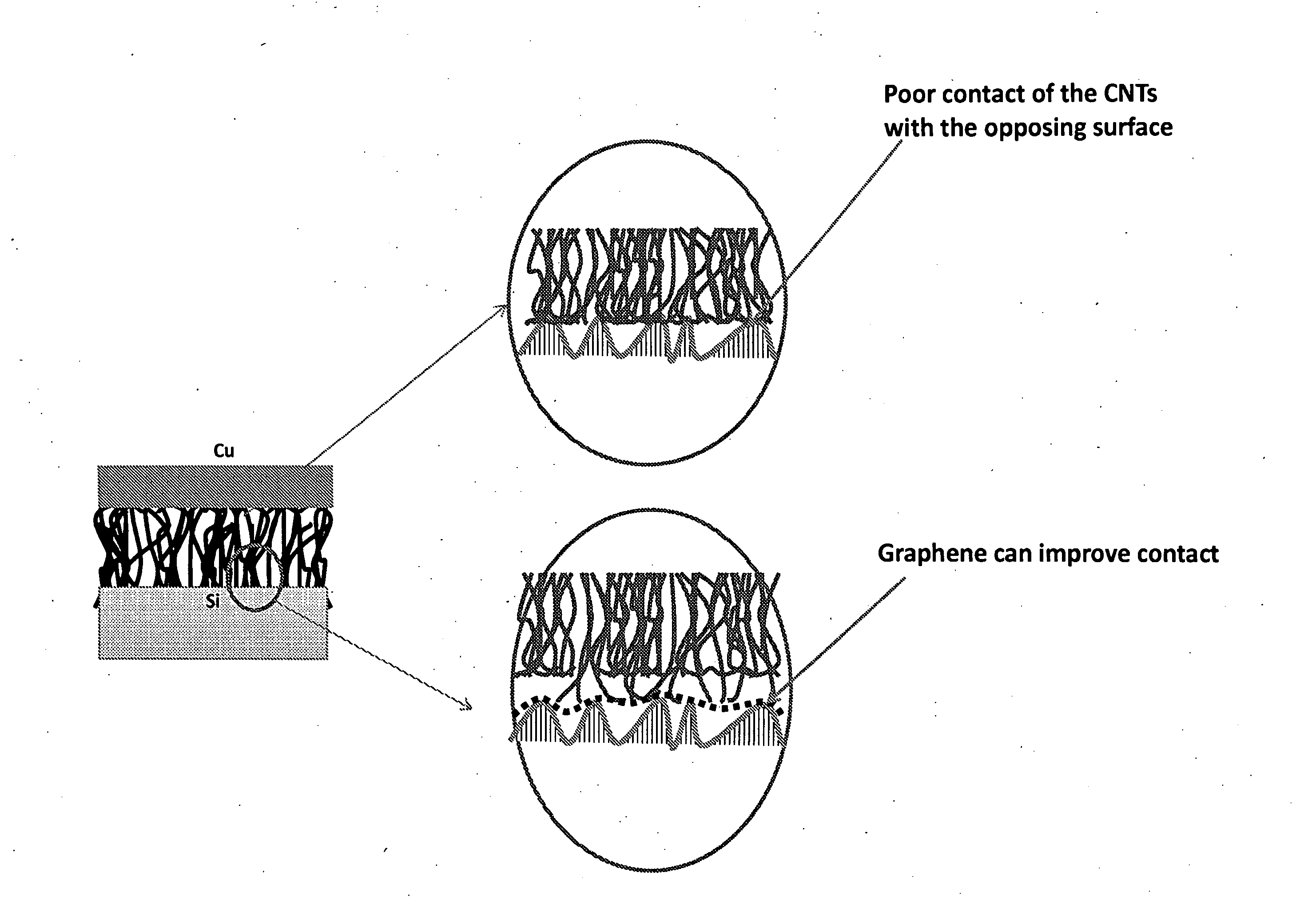

Graphene and carbon nanotube mixed enhanced metal-matrix composite material and preparation method thereof

The invention discloses a graphene and carbon nanotube mixed enhanced metal-matrix composite material and a preparation method thereof. The graphene and carbon nanotube mixed enhanced metal-matrix composite material is characterized in that graphene and a carbon nanotube are mutually connected to constitute an enhanced network in a metal matrix, wherein the graphene is few-layer graphene with 10 layers or less, the radius-thickness ratio of the graphene is larger than 200, and the volume fraction of the graphene is 0.1-1%; and the carbon nanotube is a single-wall, double-wall or multi-wall carbon nanotube, the length-diameter ratio of the carbon nanotube is larger than 20, and the volume fraction of the carbon nanotube is 0.5-5%. Compared with the composite material enhanced only by the carbon nanotube, the graphene and carbon nanotube mixed enhanced metal-matrix composite material disclosed by the invention not only has greatly improved mechanical properties, but also has more excellent electric conduction and heat conduction properties, and is a multi-purpose structure and function integrated material. In addition, the preparation method provided by the invention based on slurry blending and graphene oxide reduction is simple and efficient and is easy for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

Lubricating oil additive based on single-layer or more-layer graphene

The invention relates to a lubricating oil additive based on single-layer or more-layer graphene, belonging to new high-tech materials and application field thereof and being mainly used for improving the property of lubricating oil. The lubricating oil additive is characterized in that single-layer or more-layer graphene and a dispersing agent are added into base oil, the content of the single-layer or more-layer graphene in the base oil is 0.0001-10 percent by mass, and the content of the dispersing agent in the lubricating oil is 0.001-2 percent by mass. The graphene has high specific surface area and thickness of 0.34-10 nanometers, is shaped as a sheet, is combined with the dispersing agent after being subjected to surface modification, and has excellent stability and dispersity in the base oil without easily precipitating like other additives. Under same filling amount, compared with the sheet graphite and the traditional graphite, more graphene can be absorbed on the secondary surface of the friction, the lubricating and anti-wear property of the base oil is improved, and the bearing capacity is enhanced.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

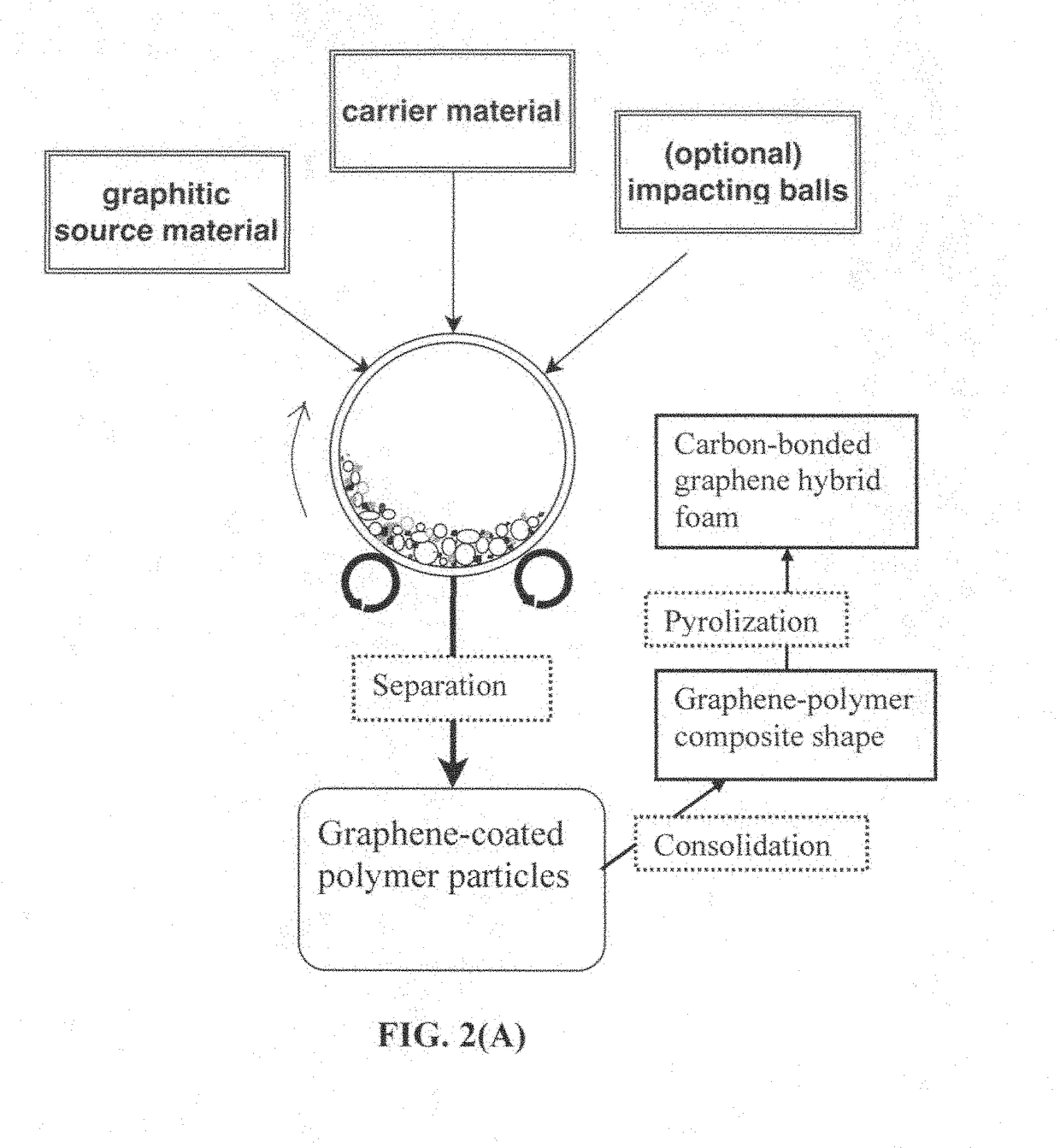

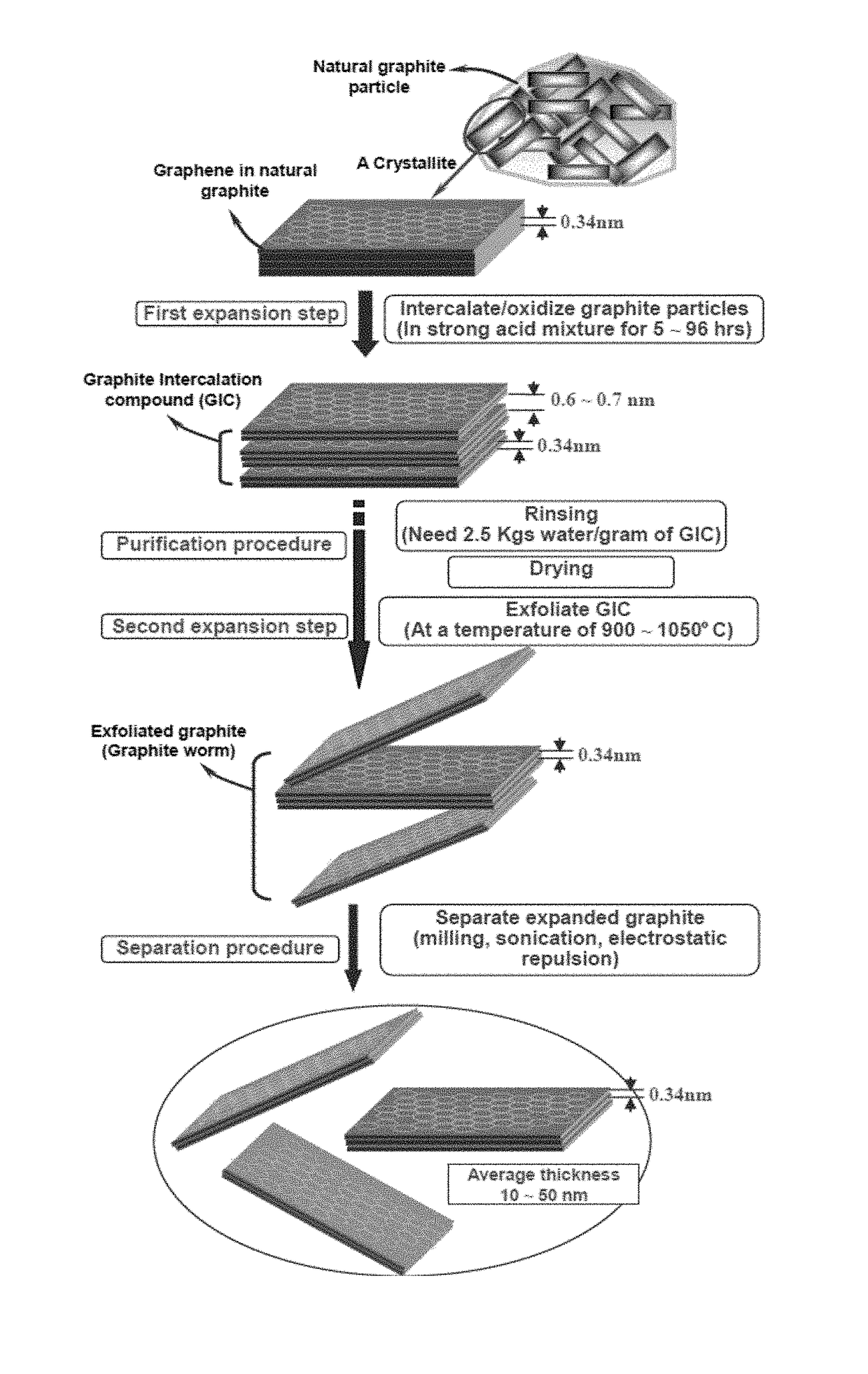

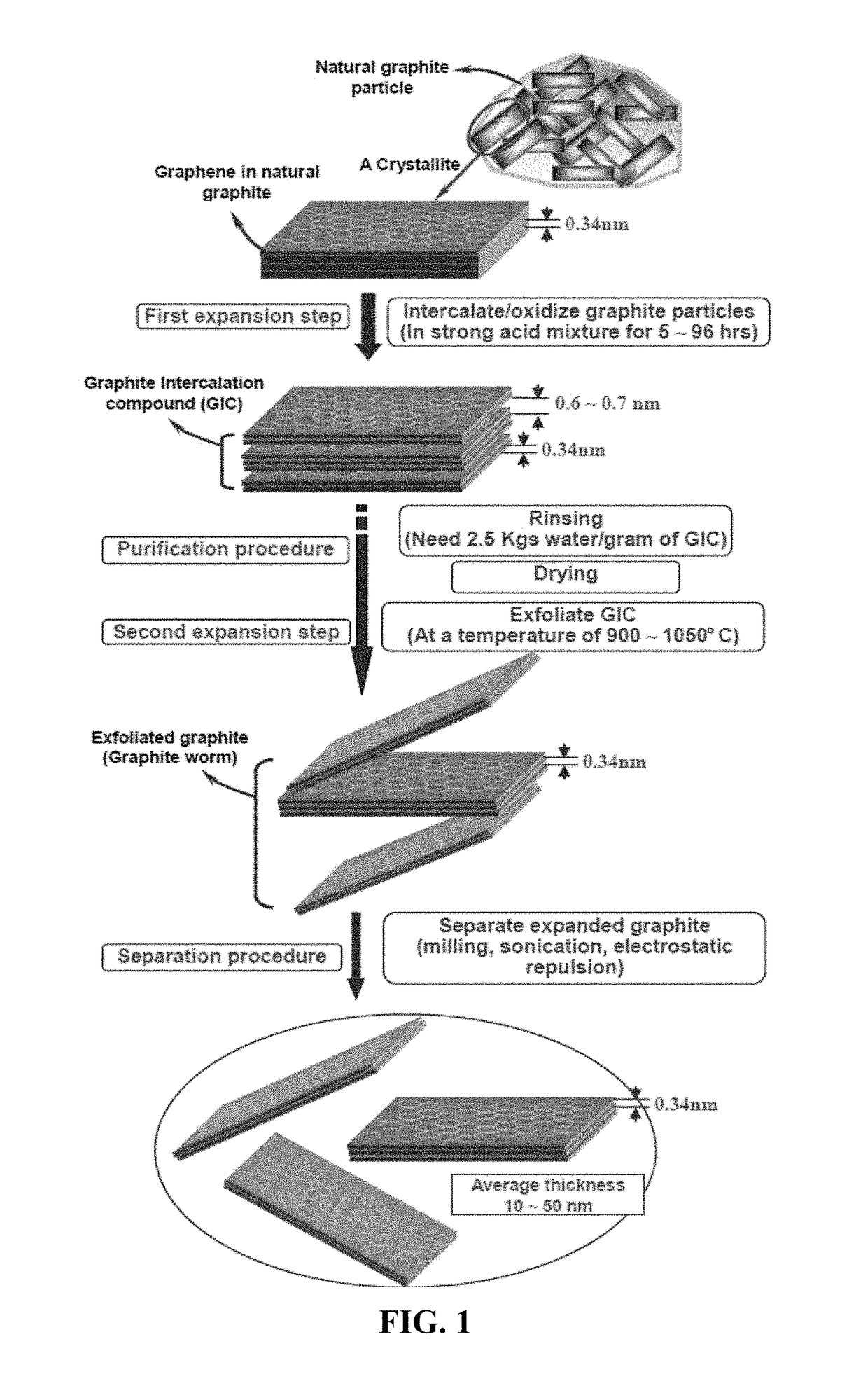

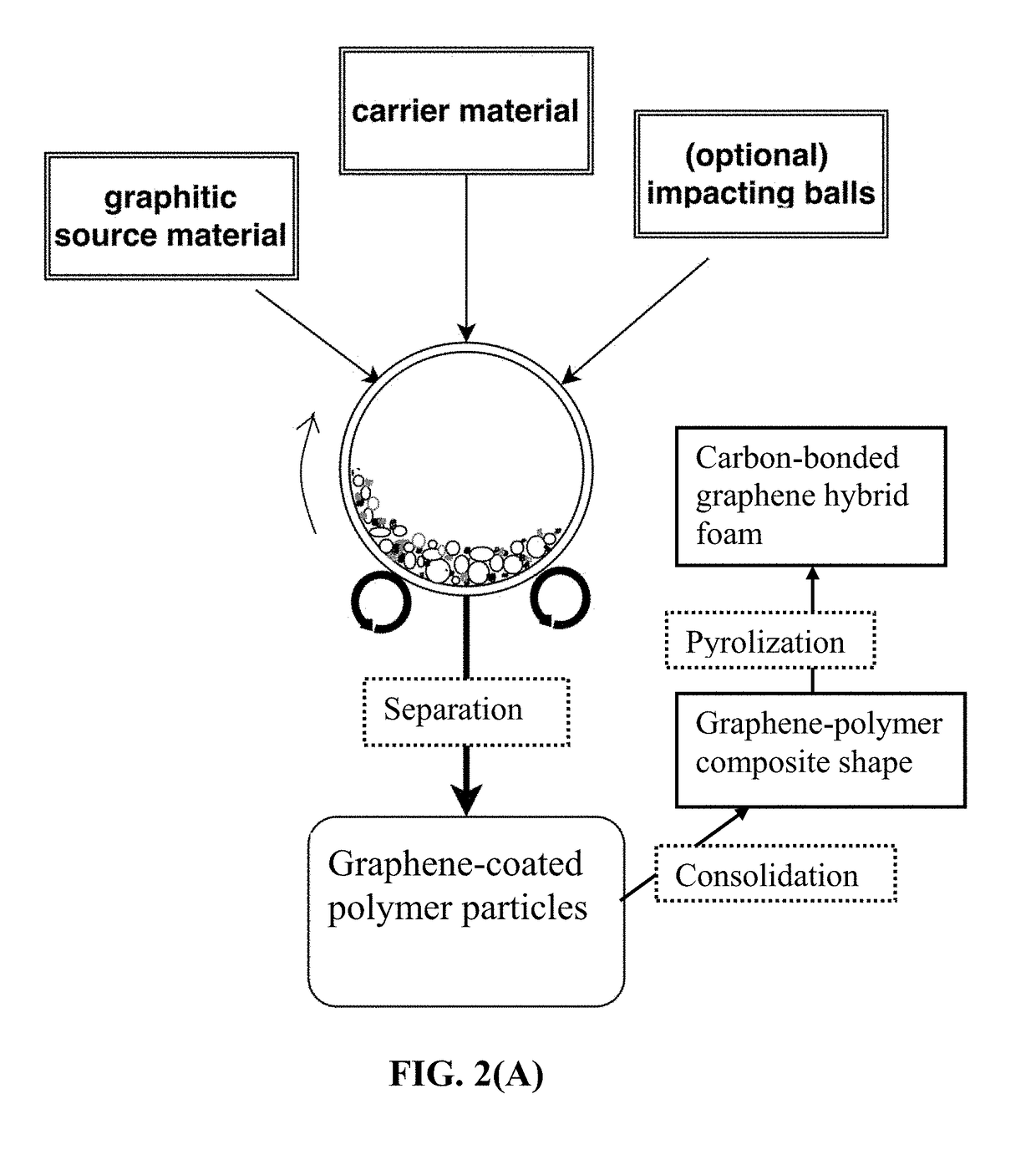

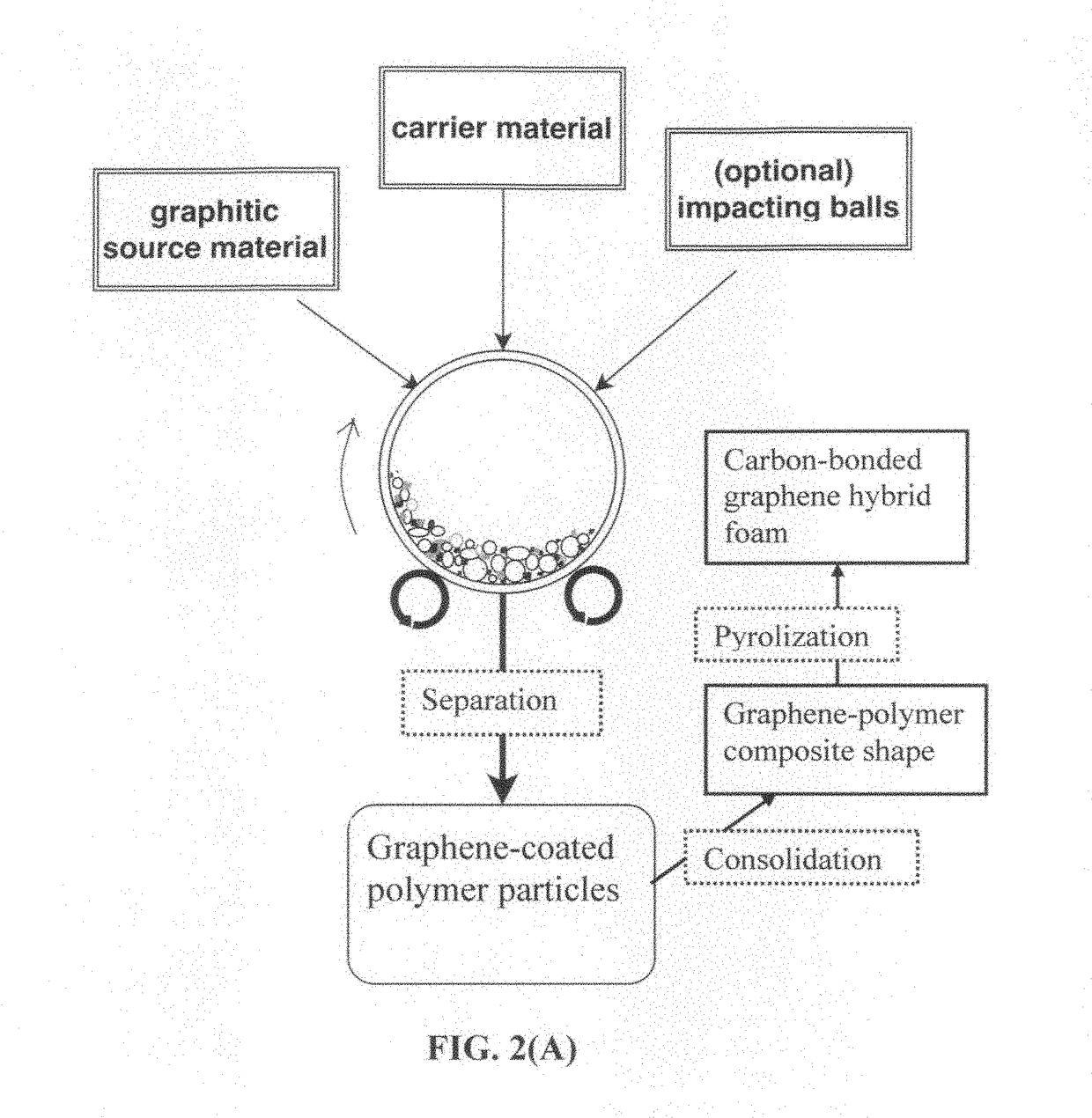

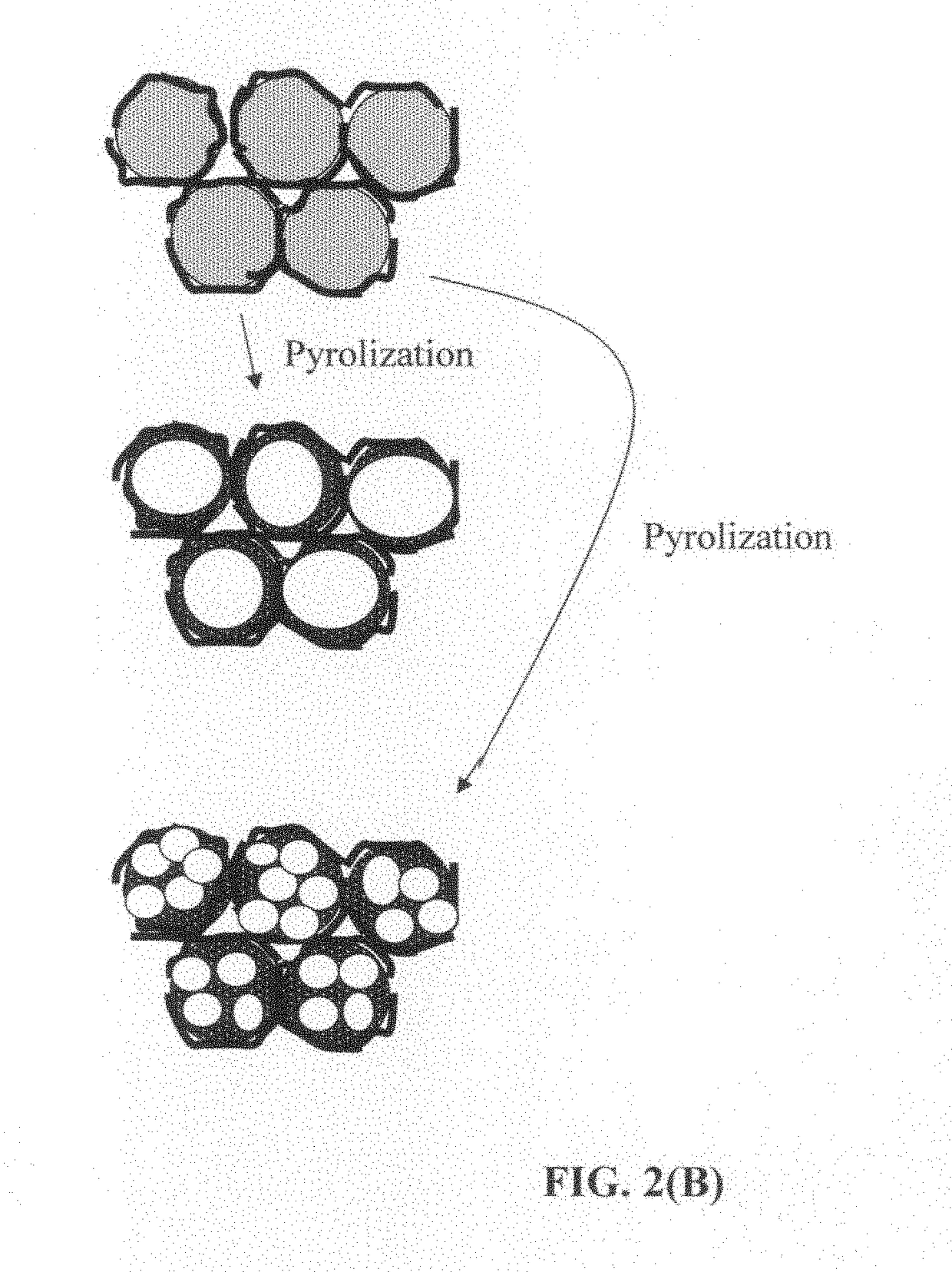

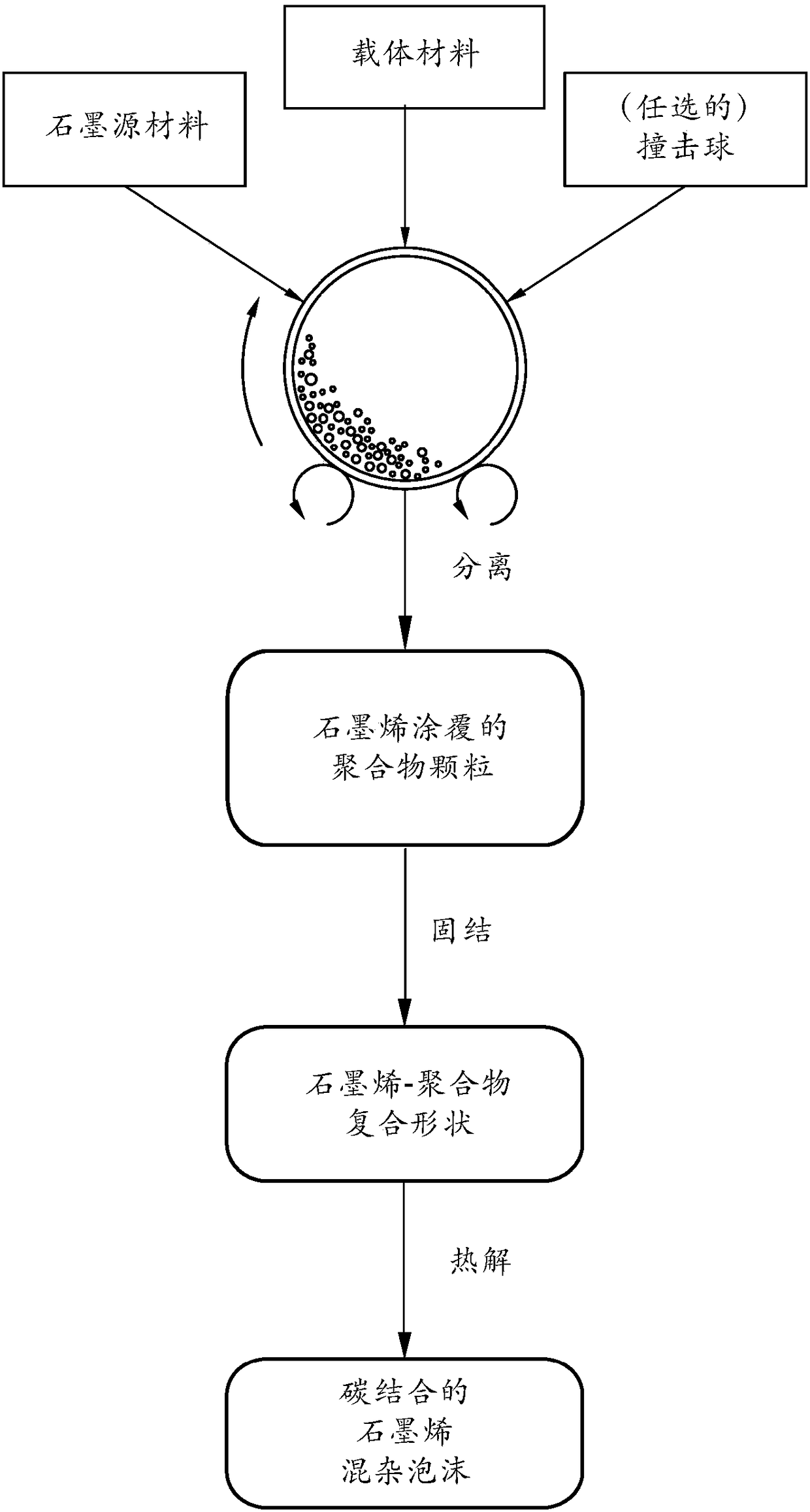

Integral 3D graphene-carbon hybrid foam and devices containing same

ActiveUS20170182474A1Increase heightReduce yieldIon-exchange process apparatusOther chemical processesDoped grapheneIodide

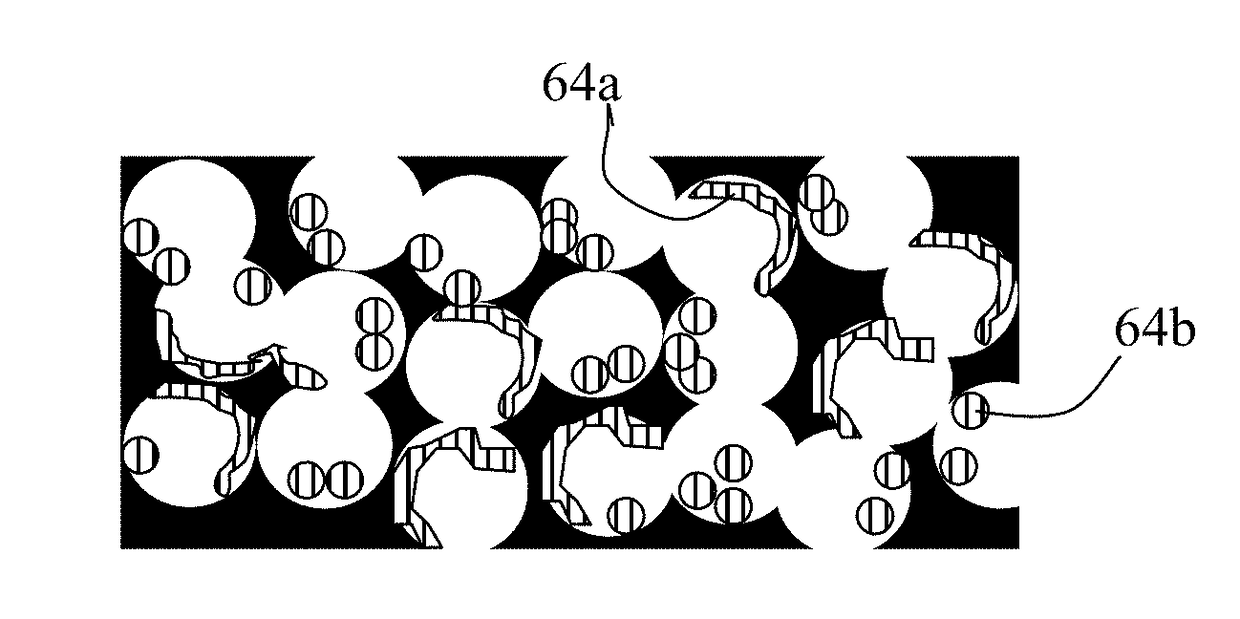

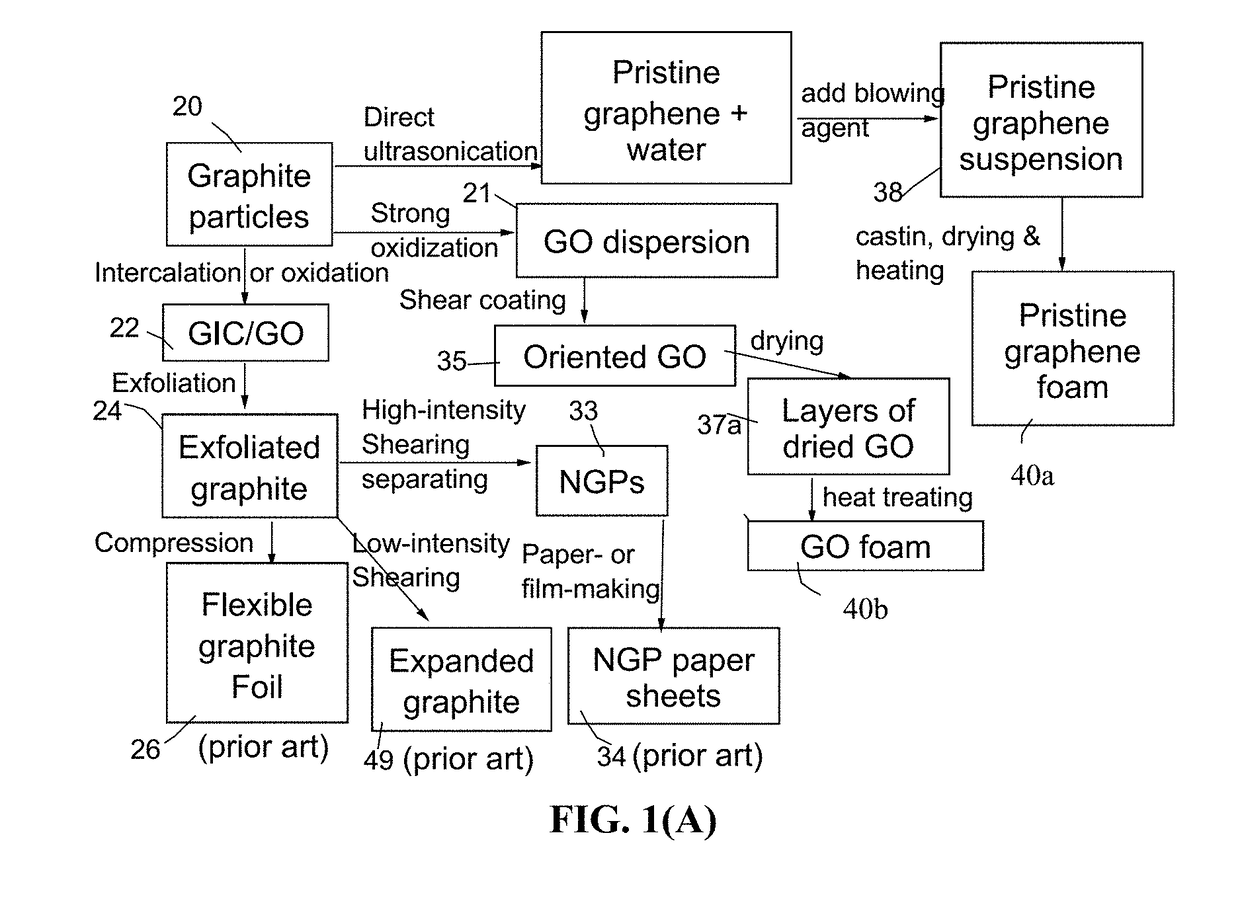

Provided is an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing d002 from 0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. Also provided are a process for producing the hybrid form, products containing the hybrid foam, and its applications.

Owner:GLOBAL GRAPHENE GRP INC

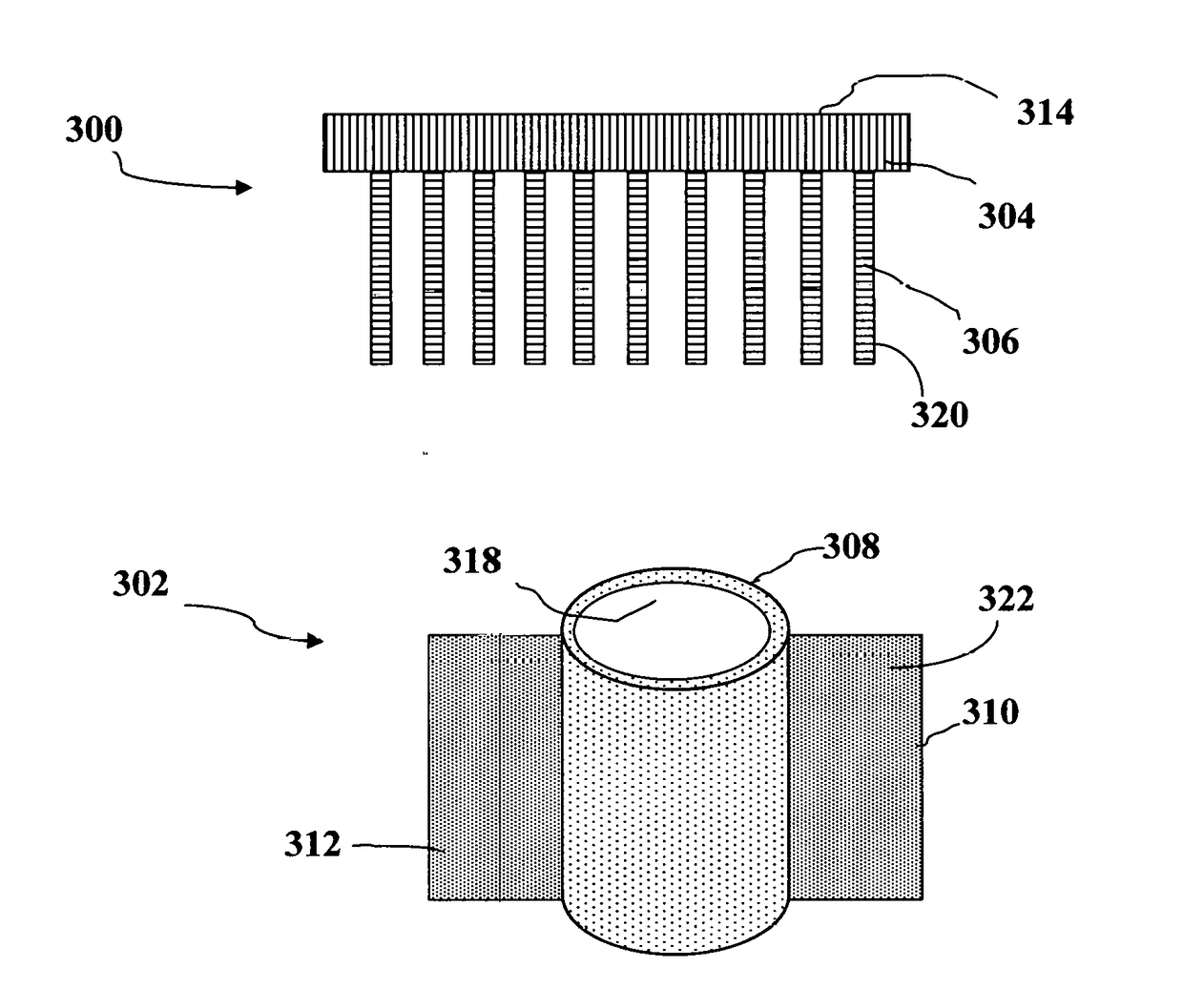

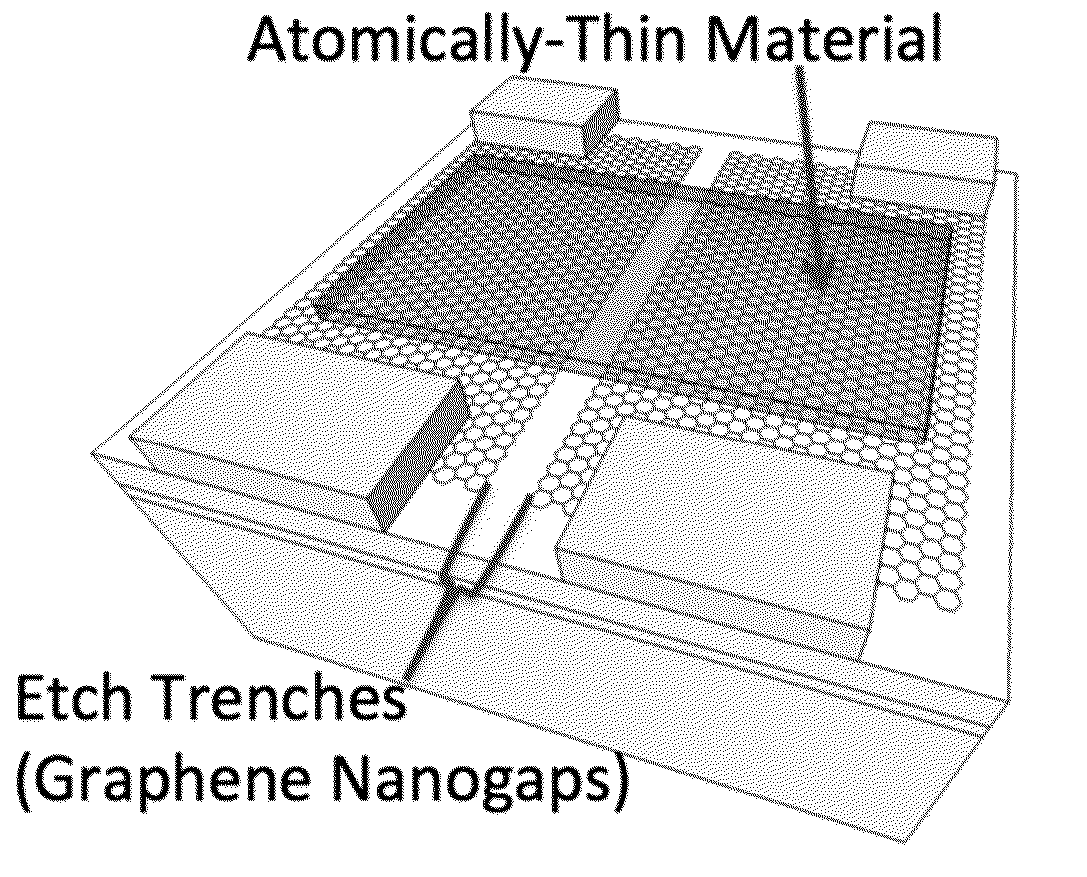

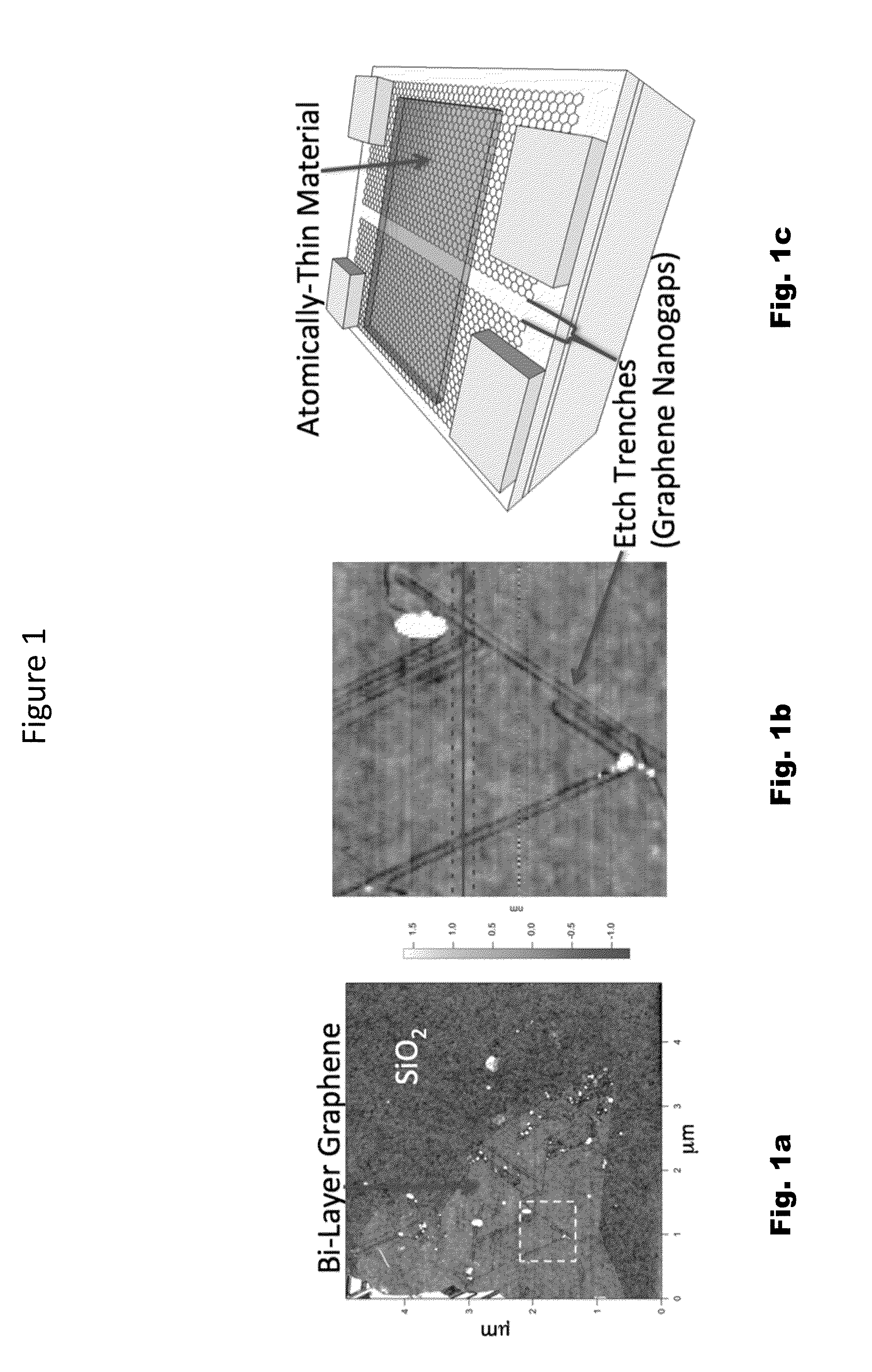

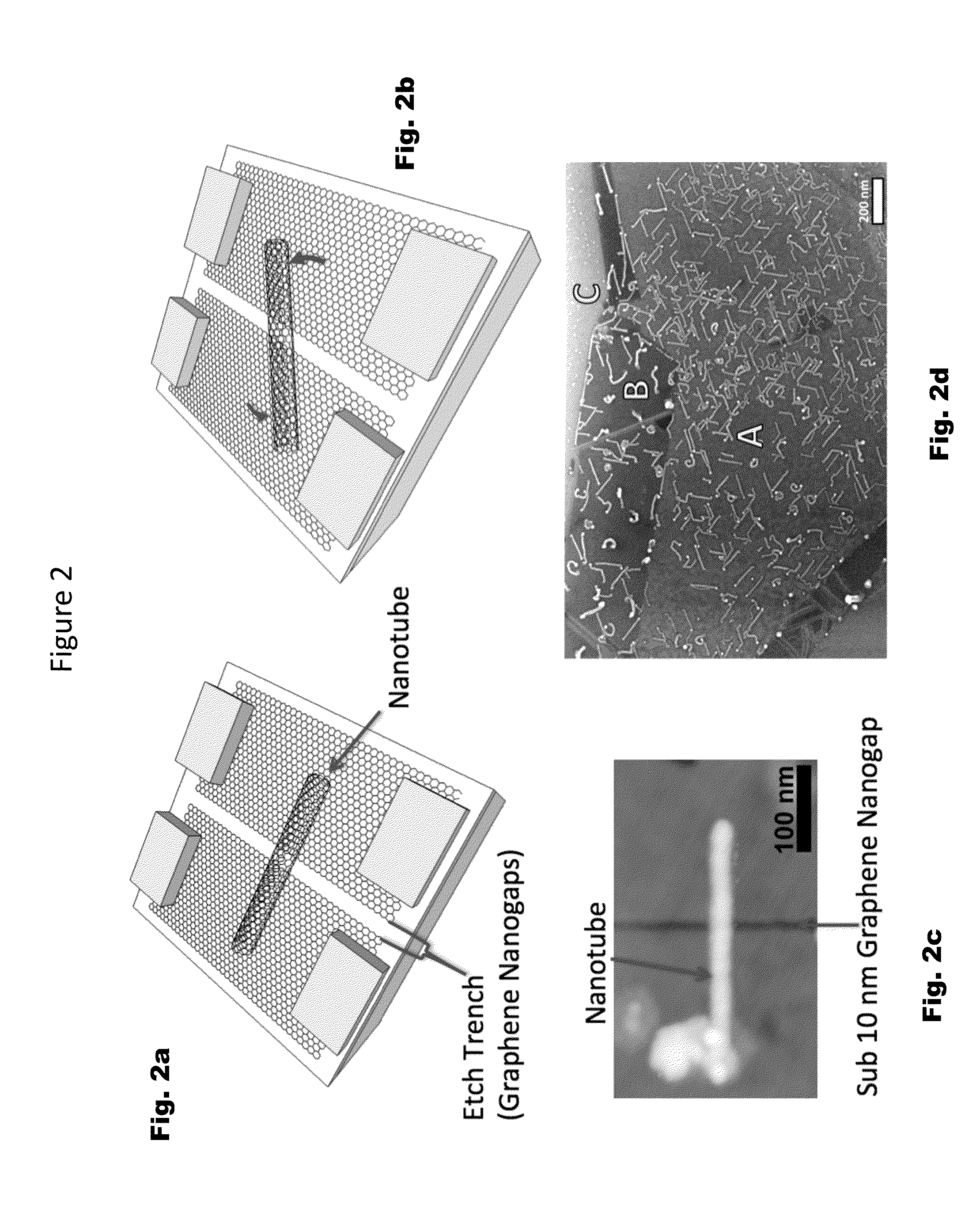

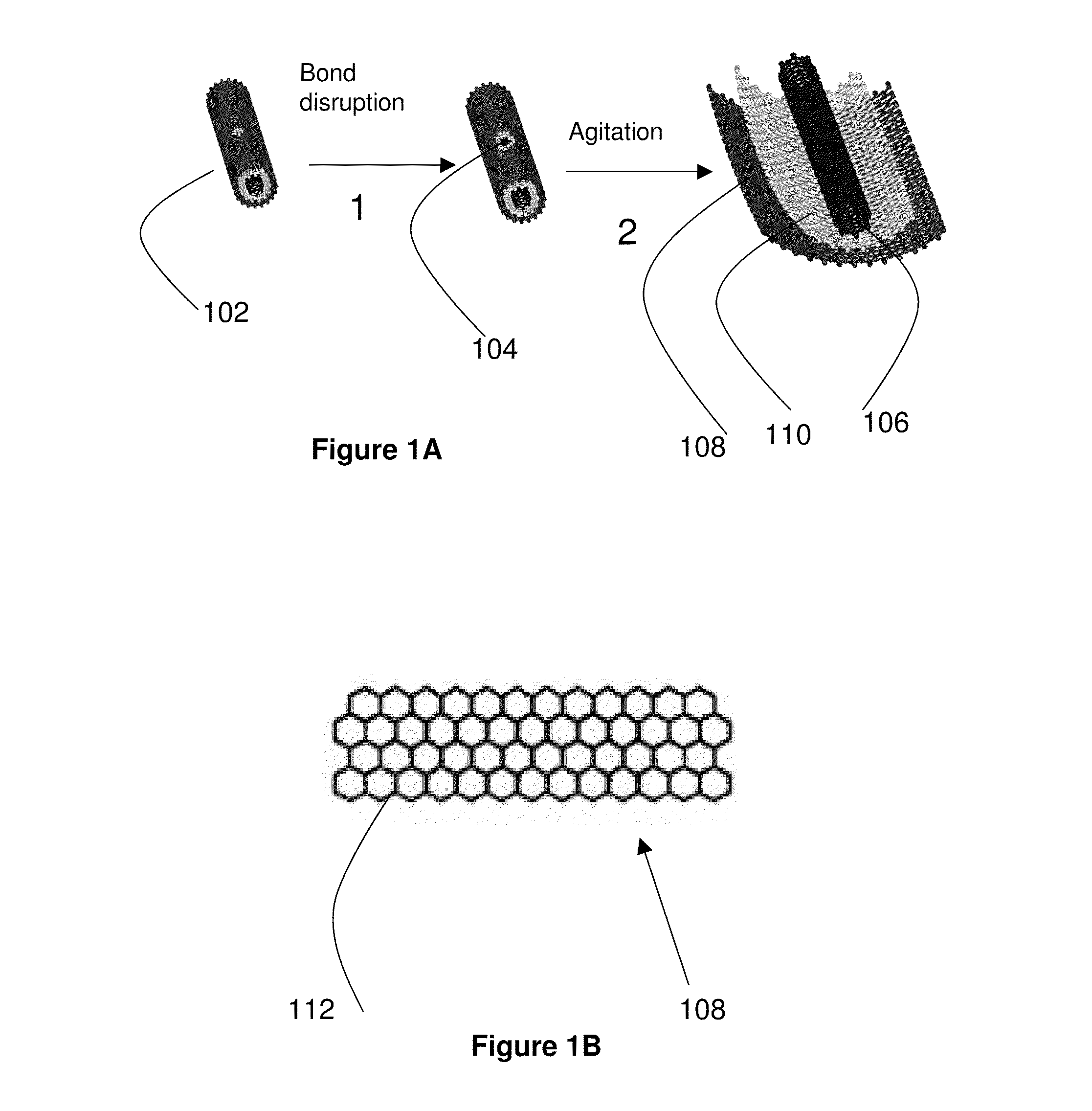

Integrated multi-terminal devices consisting of carbon nanotube, few-layer graphene nanogaps and few-layer graphene nanoribbons having crystallographically controlled interfaces

ActiveUS20160155971A1Solid-state devicesSemiconductor/solid-state device manufacturingQuantum transportGraphene nanoribbons

The present invention relates to atomically-thin channel materials with crystallographically uniform interfaces to atomically-thin commensurate graphene electrodes and / or nanoribbons separated by nanogaps that allow for nanoelectronics based on quantum transport effects and having significantly improved contact resistances.

Owner:UNIV OF KENTUCKY RES FOUND

Single and few-layer graphene based photodetecting devices

A photodetector which uses single or multi-layer graphene as the photon detecting layer is disclosed. Multiple embodiments are disclosed with different configurations of electrodes. In addition, a photodetector array comprising multiple photodetecting elements is disclosed for applications such as imaging and monitoring.

Owner:GLOBALFOUNDRIES U S INC

Preparation method of fewer-layer graphene

The invention discloses a preparation method of fewer-layer graphene, which comprises the following steps of: putting graphite into solution containing a tetraalkyl-substituted quaternary ammonium cation and OH- for ultrasonic treatment in combination with a liquid phase intercalation technology and a microwave irradiation technology, so that the tetraalkyl-substituted quaternary ammonium cation is inserted into the middle of a graphite layer to form an intercalation layer, and the spacing of the graphite layer is increased; then carrying out microwave irradiation on the treated graphite, so that the graphite intercalation layer is decomposed to generate a large quantity of gas and further increase the spacing of the graphite layer; successively dispersing the treated graphite in a low-polarity organic solvent for ultrasonic treatment, so that the graphite is stripped to generate the grapheme; and finally carrying out centrifugal treatment to obtain upper-layer liquid after treatment, i.e. fewer-layer graphene dispersion liquid. The preparation method has the advantages of simplicity in operation, short time consumption, low cost, high grapheme yield, good repeatability and easy realization of industrialized mass production; and the fewer-layer graphene prepared by the preparation method is below 10 in quantity of layers and has the advantages of fewer defects, fewer oxygen-contained groups and high conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method for lubricating oil of graphene loaded nanometer oxides

ActiveCN105176628AImprove the lubrication effectImprove carrying capacityAdditivesCarrying capacityFreeze-drying

The invention relates to a preparation method for lubricating oil of graphene loaded nanometer oxides, and belongs to the technical field of lubricating oil. The preparation method adopts the technical scheme that a graphene oxide solution is subjected to low-speed separation, and supernatant liquid is taken for use; the supernatant liquid and nanometer oxides are mixed and are subjected to freeze drying to obtain fluffy few-layer graphene oxide and nanometer oxide composite powder; the composite powder is heated in a vacuum state until the constant drying condition is reached, the composite powder in the constant drying condition and base oil are blended to be put in a sealed reaction kettle for heating treatment, and after the filtering or centrifugal separation, the repeated washing is carried out for 3 to 5 times to obtain an oleophylic graphene nanometer oxide compound; the oleophylic graphene nanometer oxide compound is uniformly mixed with composite additives and the base oil to obtain the lubricating oil of the graphene loaded nanometer oxides. The preparation method has the advantages that the process is simple; the performance price ratio is high; all ingredients have excellent dispersibility and stability. The prepared lubricating oil has good lubricating performance and high carrying capacity, and the beneficial influence can be generated on the lubricating oil in the aspects of viscosity-temperature characteristics, heat conduction effect and the like.

Owner:TANGSHAN XIRUN SCI TECH DEV CO LTD

Preparation method of graphene dispersion liquid

ActiveCN103253656APhysicochemical properties influenceAdvanced technologyMaterial nanotechnologyCarbon compoundsOrganic solventRoom temperature

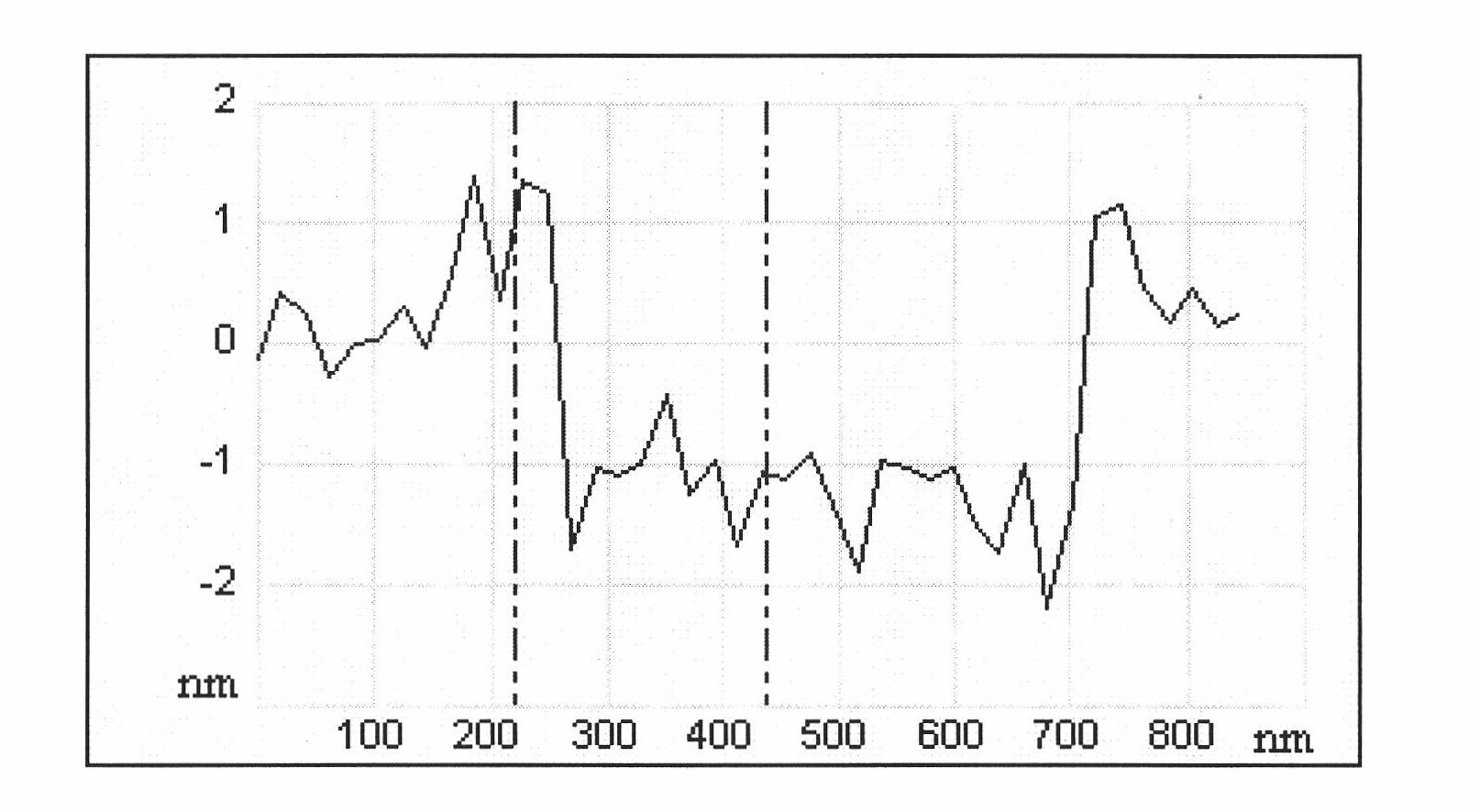

The invention provides a preparation method of graphene dispersion liquid. The preparation method of graphene dispersion liquid comprises the following steps of: preparing dispersion liquid by using a dispersing agent; then adding the graphene into the dispersion liquid to obtain graphene liquid; and carrying out ultrasonic, refining and dispersing treatment on the graphene liquid to obtain the graphene dispersion liquid. The graphene suspension liquid prepared by the method is good in dispersion fissility and even in grain size and can exist stably; the performance of the graphene is not affected; the size distribution of the few-layer graphene ranges from 300 nanometers to 1 micro; the thickness is 2-10 layers; and the stable storage period is more than three months under the room-temperature condition. By adopting the preparation method, the technical problems that the dispersibility of graphene nanometer materials is poor in water and normal-temperature organic solvent, and the like are solved, the compatibility and the dispersibility of graphene in various composite materials are improved, the application fields of graphene are greatly improved, and the unitization, the standardization and the micromation of the graphene application can be realized well.

Owner:青岛科孚纳米技术有限公司

Alkali Metal Battery Having an Integral 3D Graphene-Carbon-Metal Hybrid Foam-Based Electrode

ActiveUS20170352868A1Long and stable charge-discharge cycle lifeIncrease surface areaFuel and secondary cellsElectrochemical processing of electrodesDoped grapheneIodide

Provided is a lithium or sodium metal battery having an anode, a cathode, and a porous separator and / or an electrolyte, wherein the anode contains an integral 3D graphene-carbon hybrid foam composed of multiple pores, pore walls, and a lithium-attracting metal residing in the pores; wherein the metal is selected from Au, Ag, Mg, Zn, Ti, Na, K, Al, Fe, Mn, Co, Ni, Sn, V, Cr, or an alloy thereof and is in an amount of 0.1% to 50% of the total hybrid foam weight or volume, and the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 200 to 1 / 2, wherein graphene sheets contain a pristine graphene or non-pristine graphene selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Graphene-Metal Hybrid Foam-Based Electrode for an Alkali Metal Battery

ActiveUS20170352869A1Increase surface areaHigh densityGrapheneNegative electrodesDoped grapheneIodide

Provided is a lithium or sodium metal battery having an anode, a cathode, and a porous separator and / or an electrolyte, wherein the anode contains a graphene-metal hybrid foam composed of multiple pores, pore walls, and a lithium- or sodium-attracting metal residing in the pores; wherein the metal is selected from Au, Ag, Mg, Zn, Ti, Na (or Li), K, Al, Fe, Mn, Co, Ni, Sn, V, Cr, or an alloy thereof and is in an amount of 0.1% to 90% of the total hybrid foam weight or volume, and the pore walls contain single-layer or few-layer graphene sheets, wherein graphene sheets contain a pristine graphene or non-pristine graphene selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

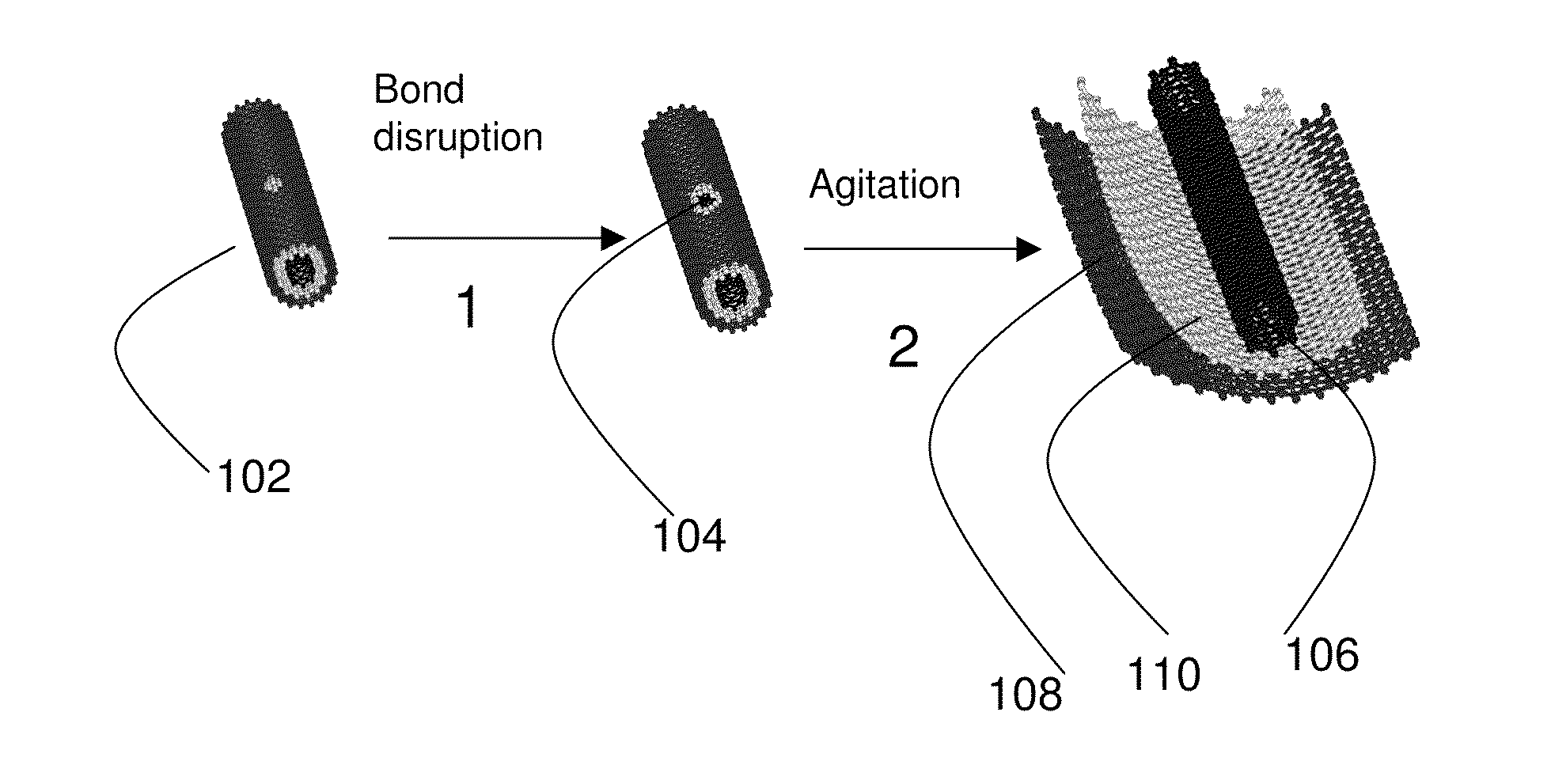

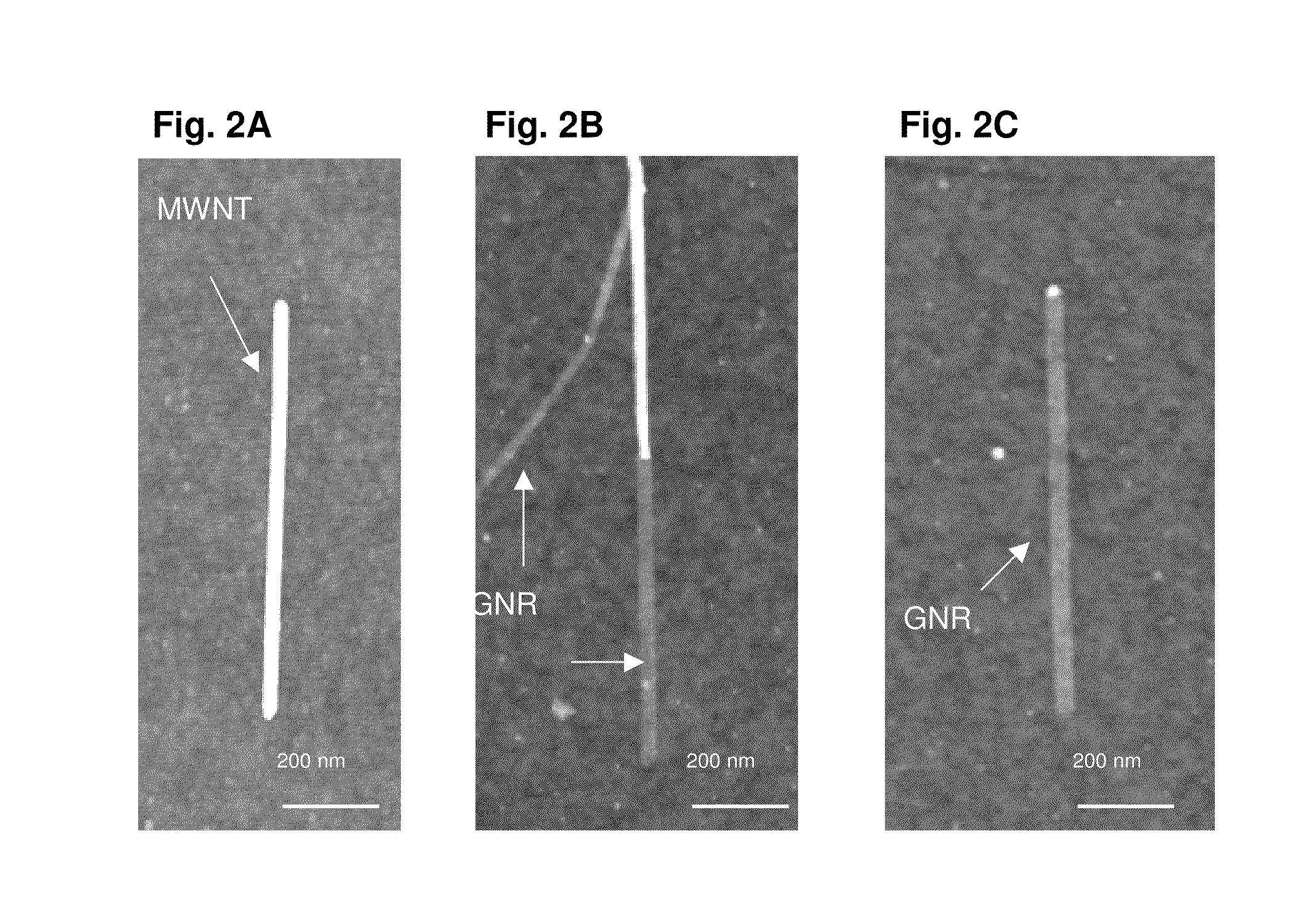

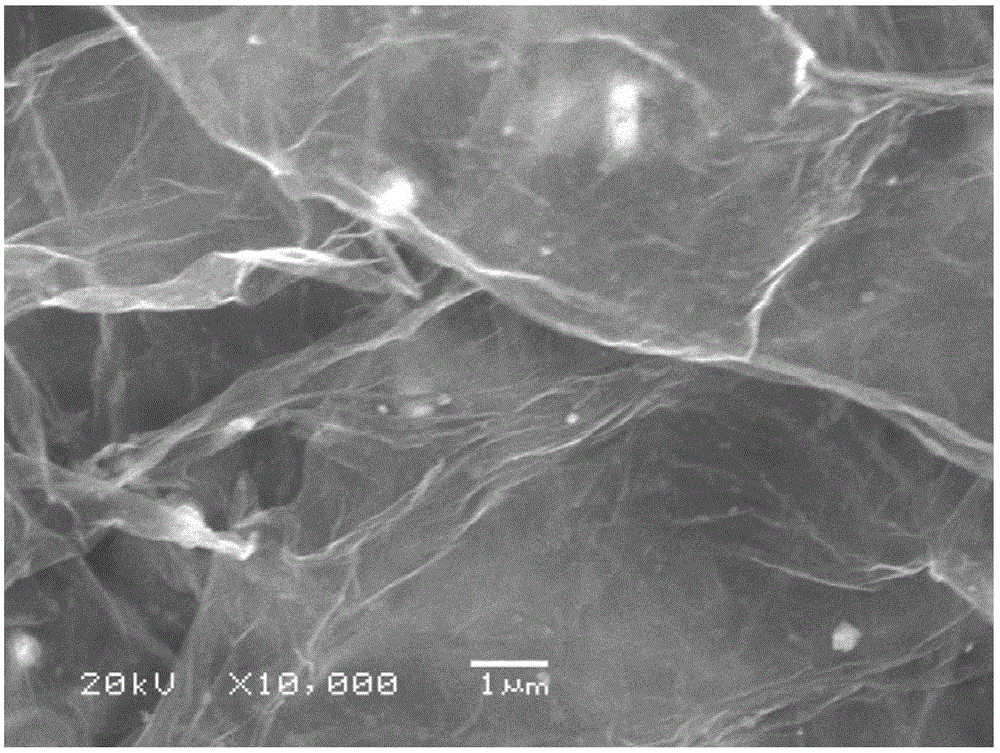

Large Scale High Quality Graphene Nanoribbons From Unzipped Carbon Nanotubes

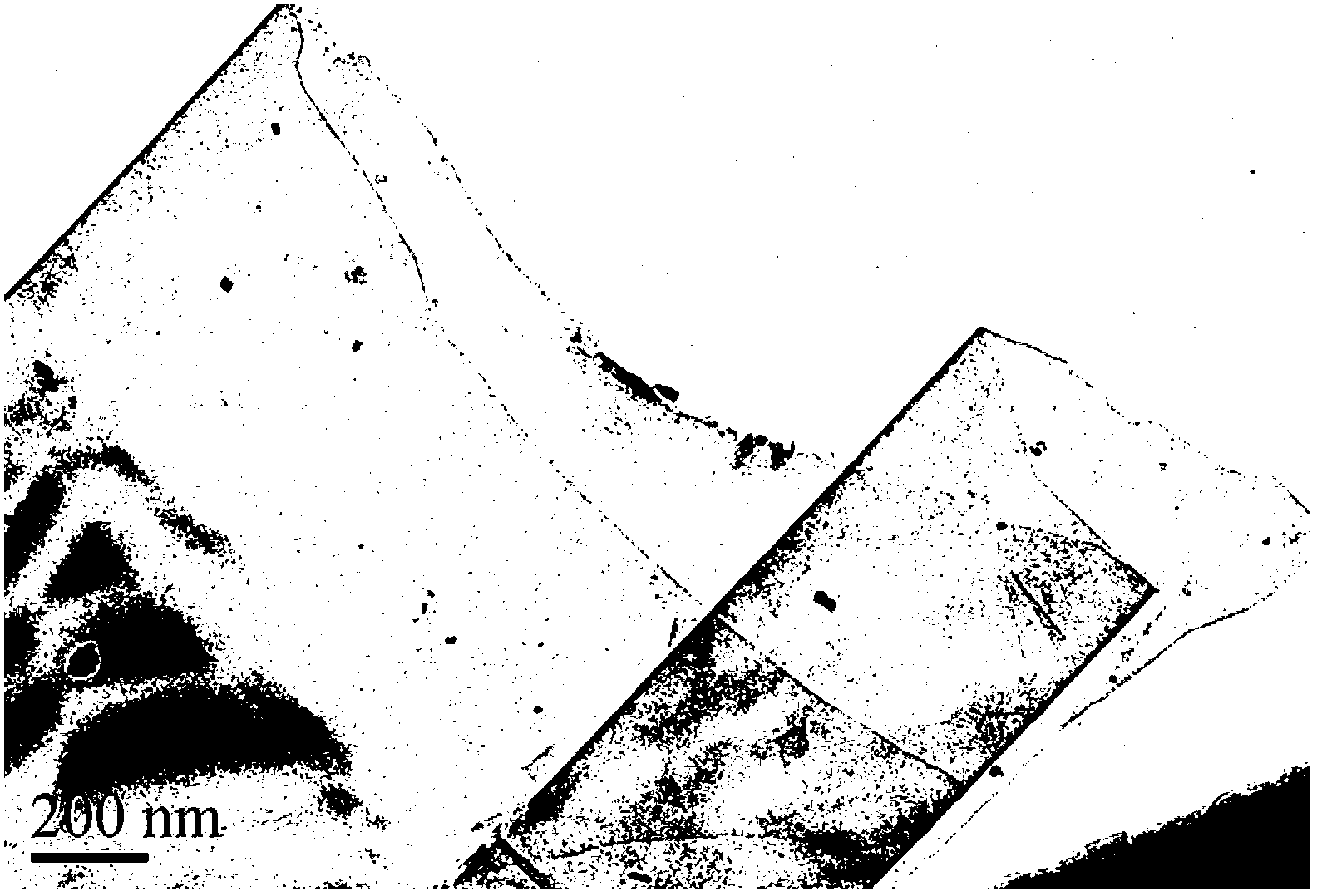

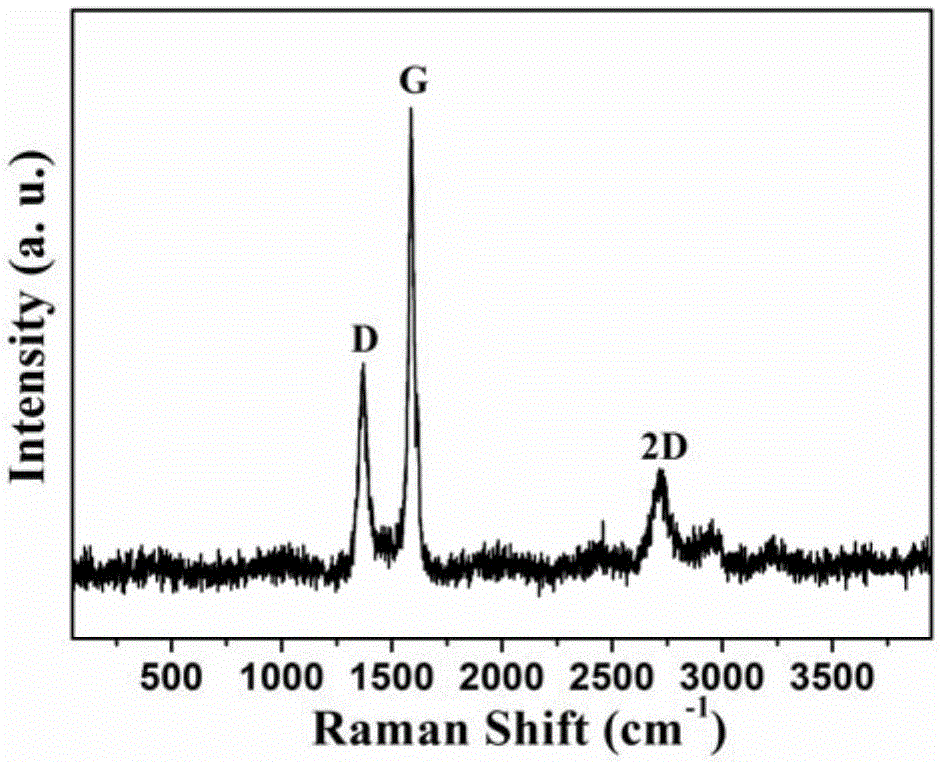

A new method is disclosed for large-scale production of pristine few-layer graphene nanoribbons (GNRs) through unzipping of mildly gas-phase oxidized, and, optionally, metal-assisted oxidized, multiwalled and few-walled carbon nanotubes. The method further comprises sonication in an organic solvent. High-resolution transmission electron microscopy revealed nearly atomically smooth edges for narrow GNRs (2-30 nm). The GNRs exhibit ultra-high quality with low ratios of disorder (D) to graphitic (G) Raman bands (ID / IG). Further electrical transport through the valence-band of the GNRs exhibits metallic behavior with little disorder effect. At low temperatures, the GNRs exhibit high conductance and phase coherent electron transport through entire lengths. Sub 10 nm GNRs exhibit high on / off electrical switching useful for field effect transistors may also be prepared according to the present methods. The high yield synthesis of pristine GNRs enables facile fabrication of GNR devices, making these materials easily accessible for a wide range of fundamental and practical applications.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method for preparing graphene from biomass waste

ActiveCN105060288AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerCarbonization

The invention discloses a method for preparing graphene from biomass waste, which comprises the following steps: pretreating biomass waste with white lime to obtain a biomass residue; and carrying out desilication hydrolysis, carbonization and carbonization material decalcification impurity removal on the biomass residue, and quickly heating to perform high-temperature graphitization. The prepared graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The prepared biomass fewer-layer graphene has a certain mesoporous structure, and is especially suitable to be used in the fields of lithium ion batteries, supercapacitors and the like. The method is simple in technique and convenient to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production.

Owner:CENT SOUTH UNIV

Supercapacitor having an integral 3D graphene-carbon hybrid foam-based electrode

ActiveUS20170194105A1High specific capacitanceHybrid capacitor separatorsHybrid capacitor electrodesDoped grapheneIodide

Provided is a supercapacitor having an anode, a cathode, a porous separator / electrolyte, wherein at least one of electrodes contains an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing d002 from 0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:NANOTEK INSTR GRP LLC

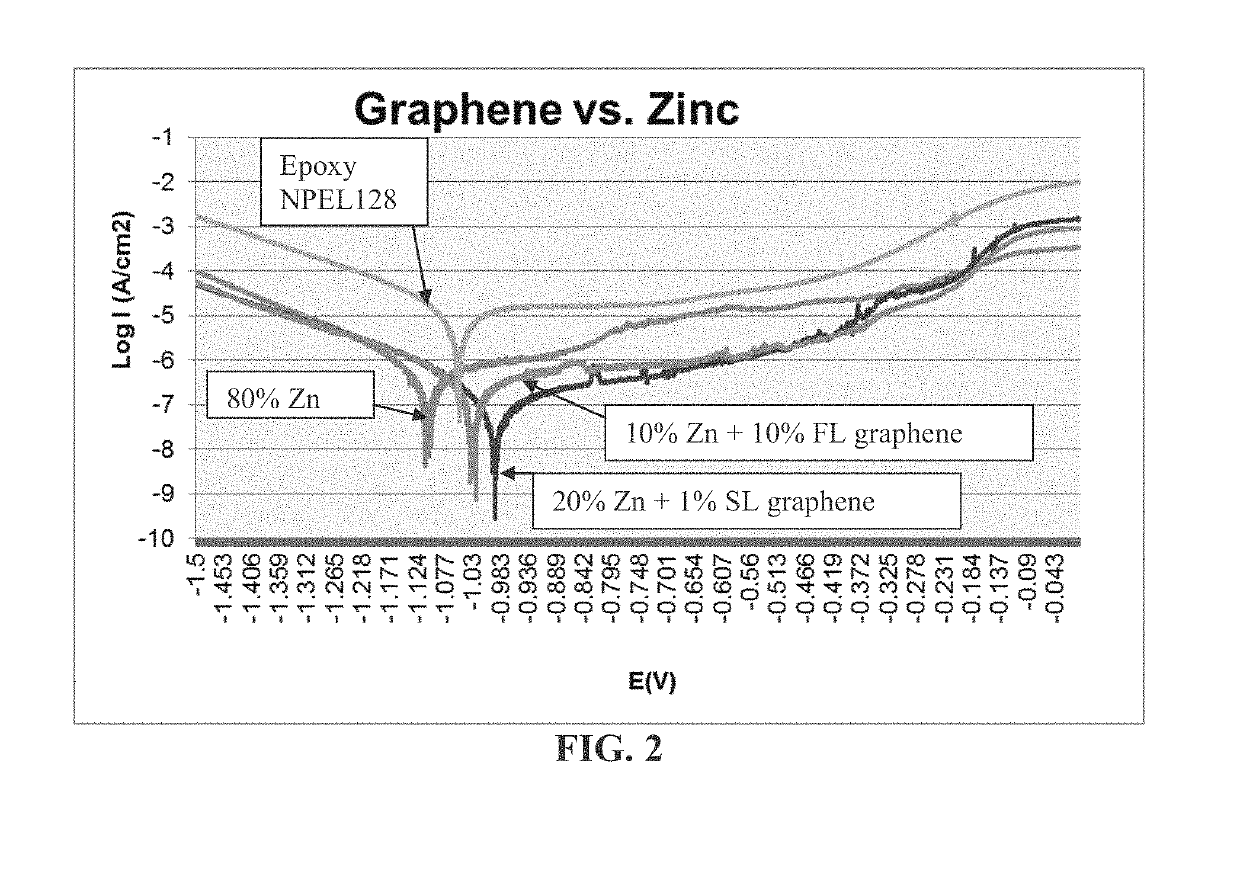

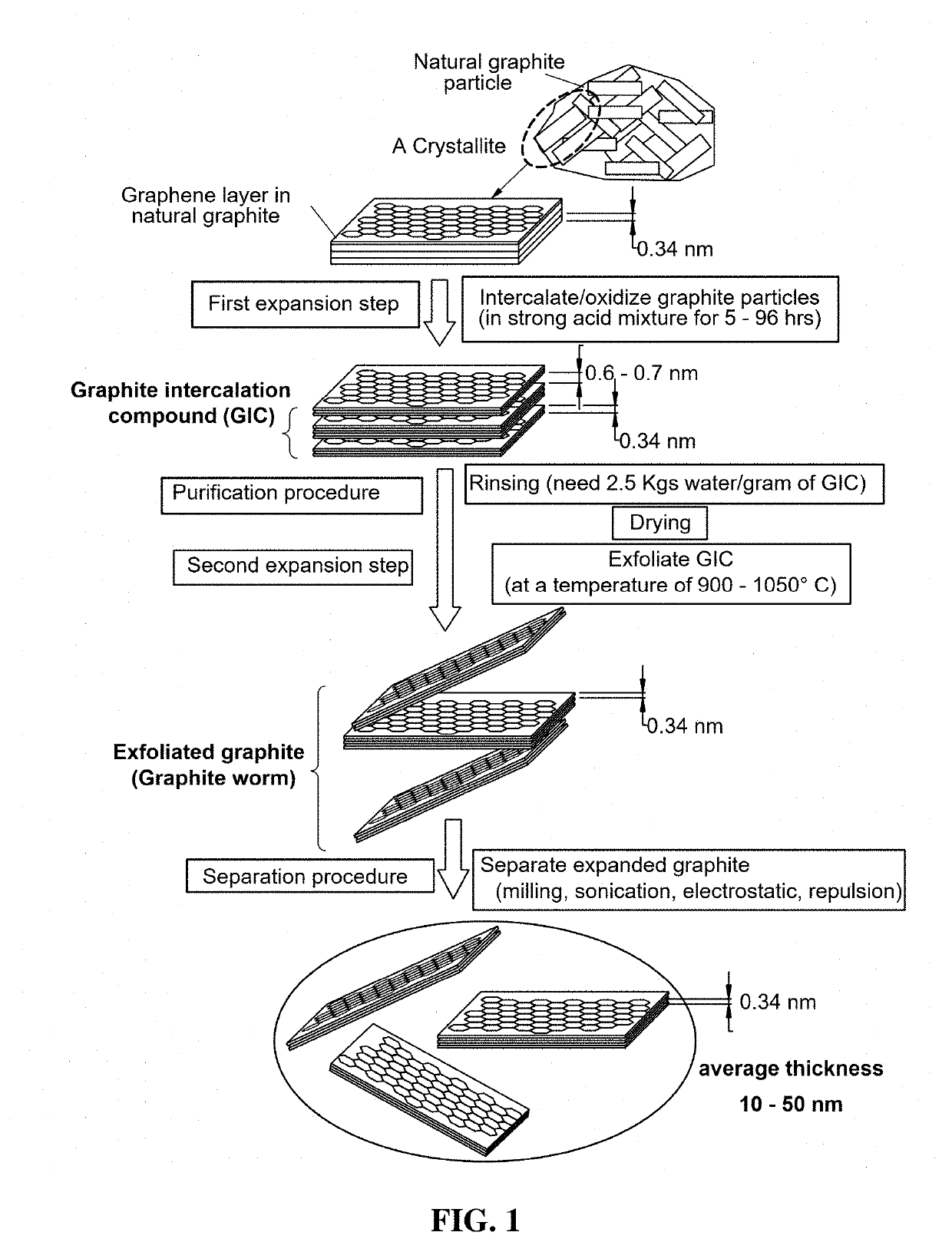

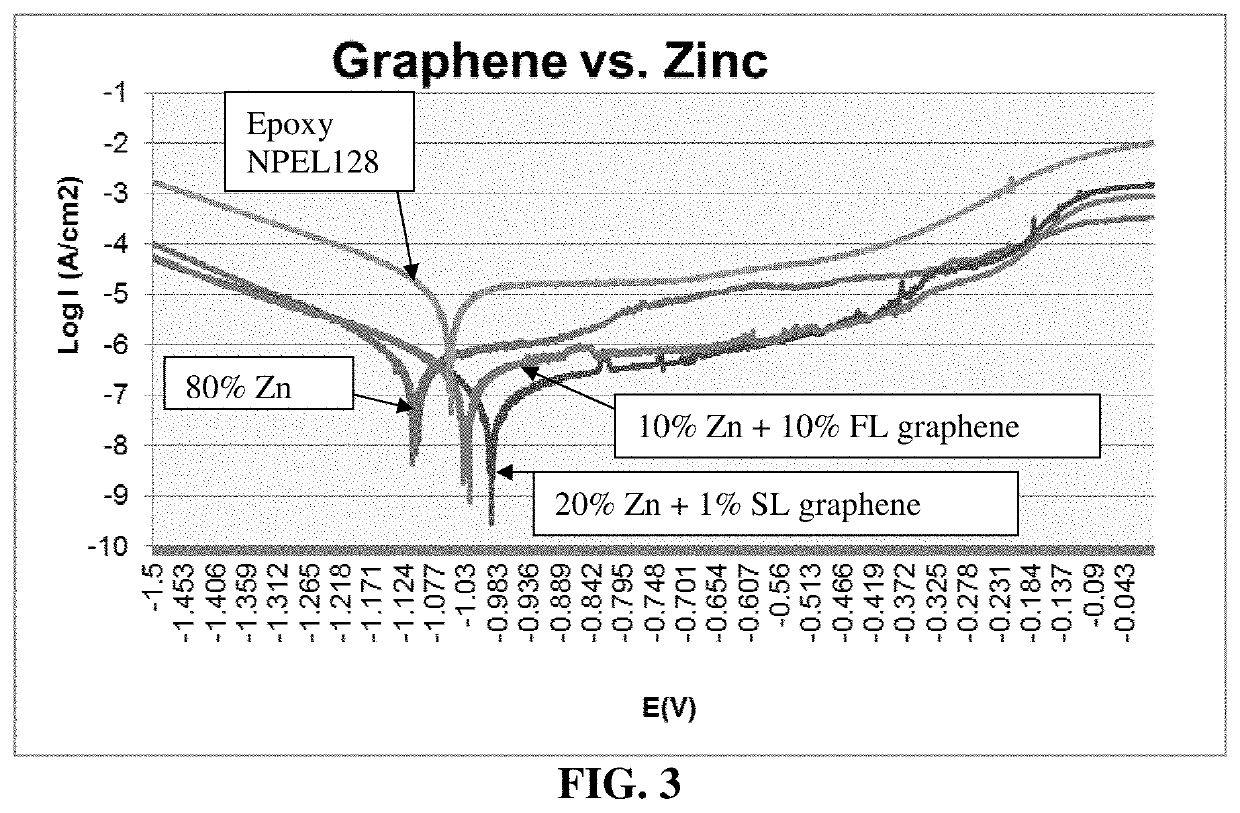

Graphene-Enabled Anti-Corrosion Coating

Provided is a graphene-based aqueous coating suspension comprising multiple graphene sheets, particles of an anti-corrosive pigment or sacrificial metal, and a waterborne binder resin dissolved or dispersed in water, wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 47% by weight of non-carbon elements wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the coating suspension does not contain a silicate binder or microspheres dispersed therein. Also provided is an object or structure coated at least in part with such a coating.

Owner:GLOBAL GRAPHENE GRP INC

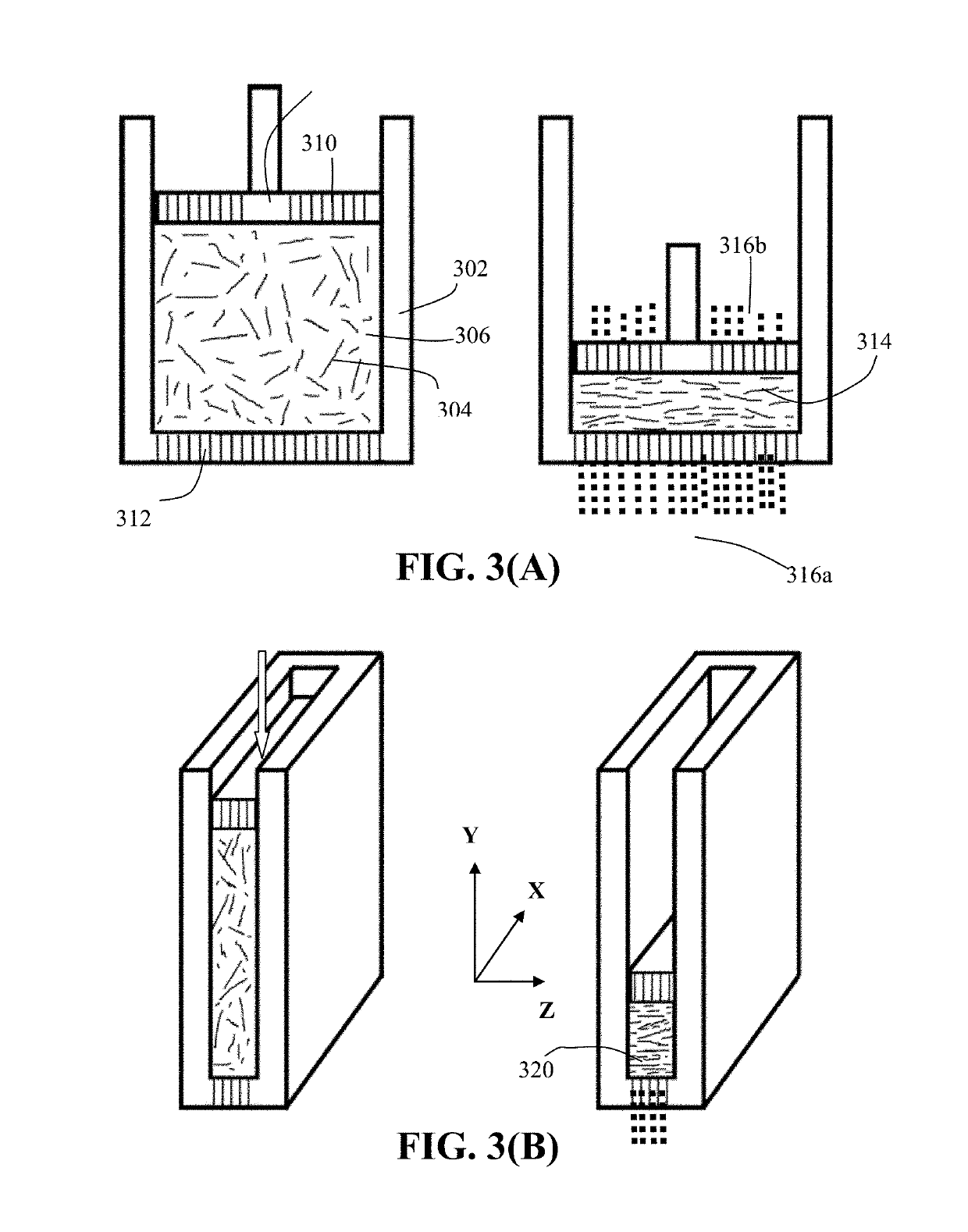

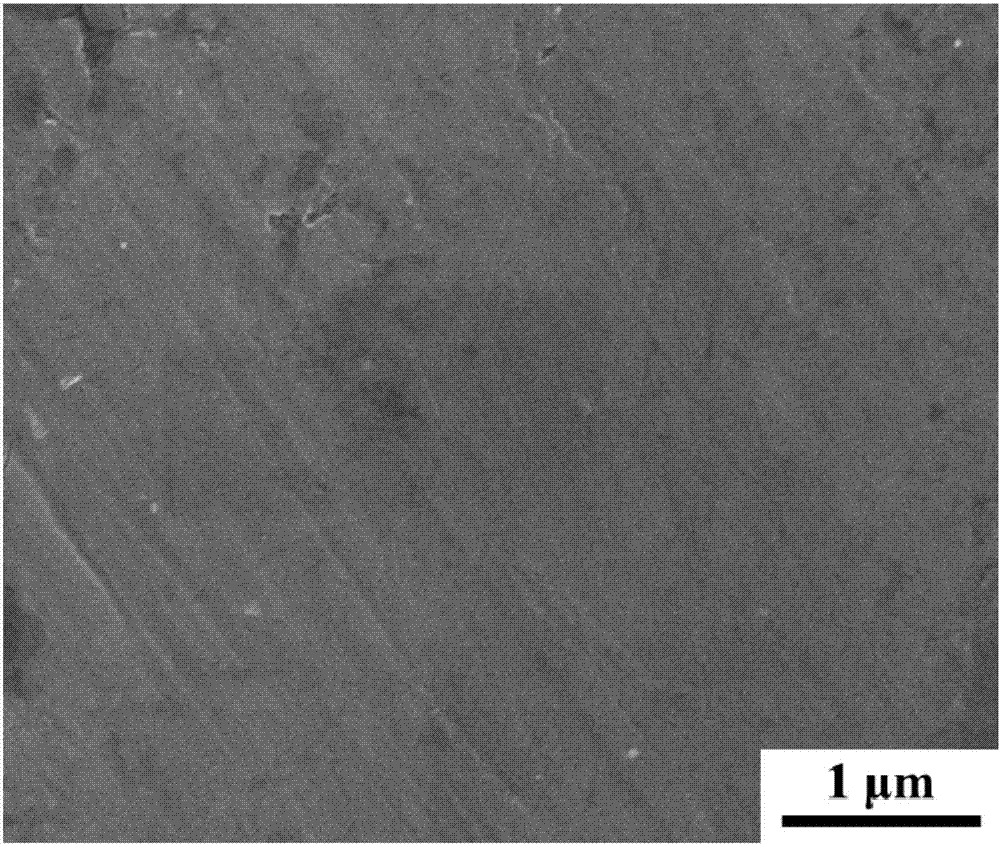

Metal matrix nanocomposite containing oriented graphene sheets and production process

PendingUS20190292671A1Reduce thicknessImprove directionMagnetic/electric field screeningTransportation and packagingDoped grapheneMetal alloy

Provided is a metal matrix nanocomposite comprising: (a) a metal or metal alloy as a matrix material; and (b) multiple graphene sheets that are dispersed in said matrix material, wherein said multiple graphene sheets are substantially aligned to be parallel to one another and are in an amount from 0.1% to 95% by volume based on the total nanocomposite volume; wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from pristine graphene, graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the chemically functionalized graphene is not graphene oxide. The metal matrix exhibits a combination of exceptional tensile strength, modulus, thermal conductivity, and / or electrical conductivity.

Owner:GLOBAL GRAPHENE GRP INC

Method for preparing graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials

The invention discloses a method for preparing a graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials, and relates to a method for the graphene reinforced aluminum-based composite. The method aims to solve the problems that the dispersion difficulty of single-layer or few-layer graphene is high in the preparation method of a graphene reinforced aluminum-based composite at present and the cost of the graphene reinforced aluminum-based composite is high. The preparation method comprises the steps that the multi-layer graphene nanoplatelets, aluminum metal and commercial pure aluminum blocks are weighed; secondly, the multi-layer graphene nanoplatelets are dispersed, and precast blocks are molded; thirdly, the aluminum metal is infiltrated; fourthly, severe plastic deformation treatment is conducted; and fifthly, composition homogenization treatment is conducted. The low-cost multi-layer graphene nanoplatelets are used as reinforcement raw materials, so that the cost is obviously lowered compared with composites with few-layer graphene as reinforcements directly; and the prepared graphene reinforced aluminum-based composite is excellent in comprehensive performance, and industrialization production and application can be achieved easily. The method is suitable for preparation of the graphene reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

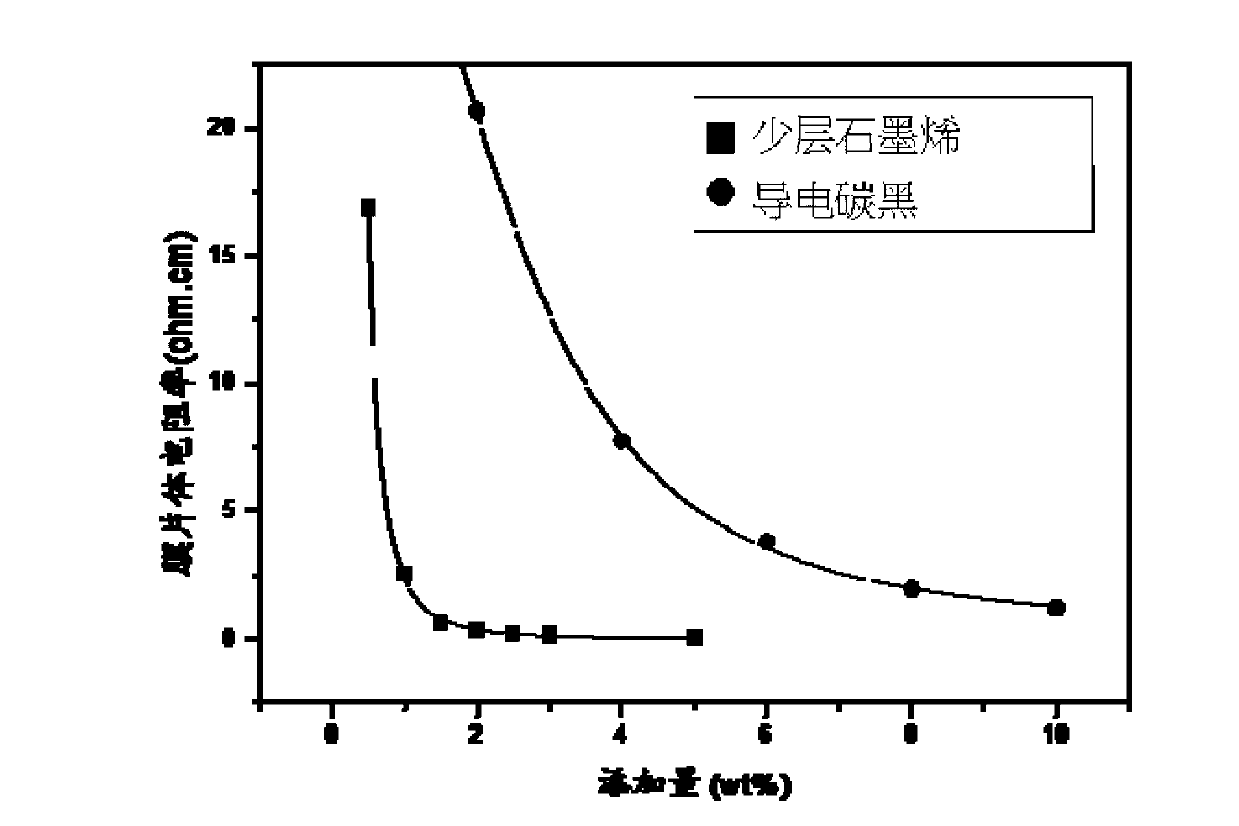

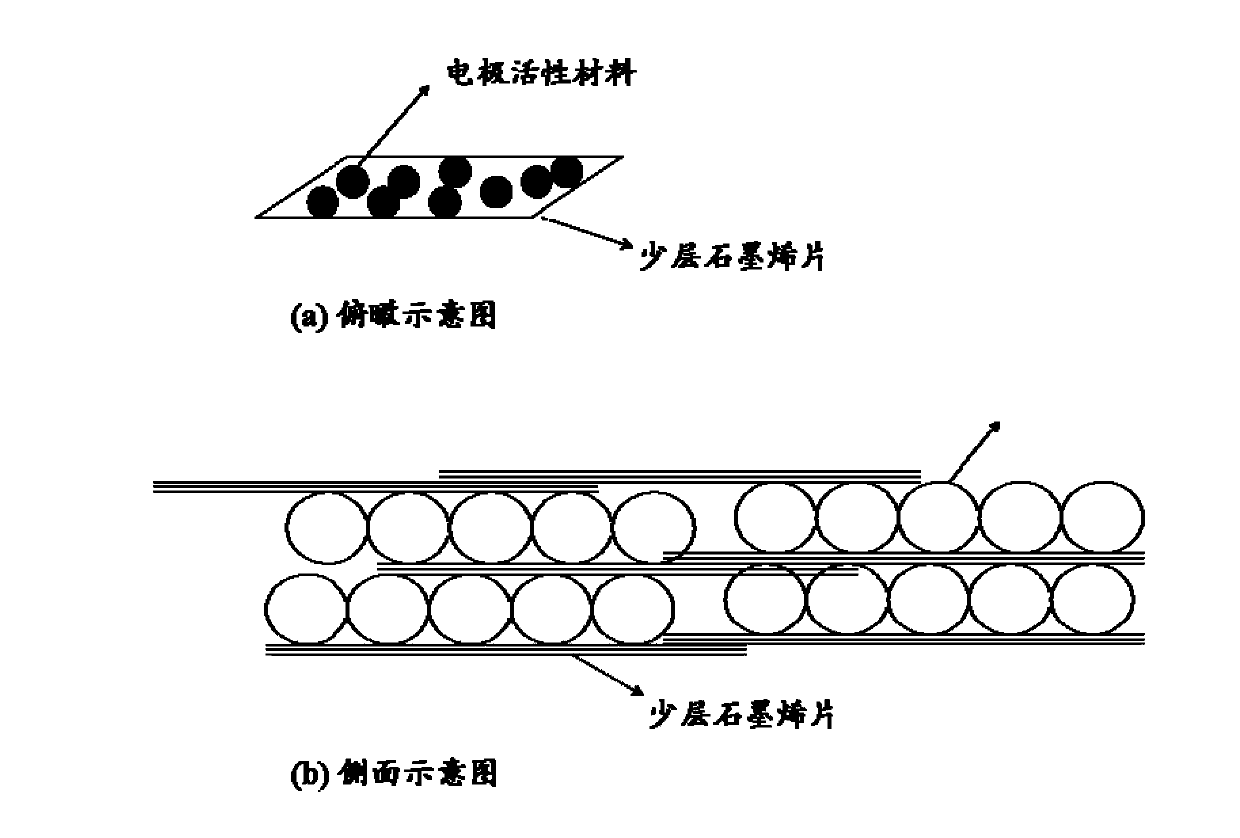

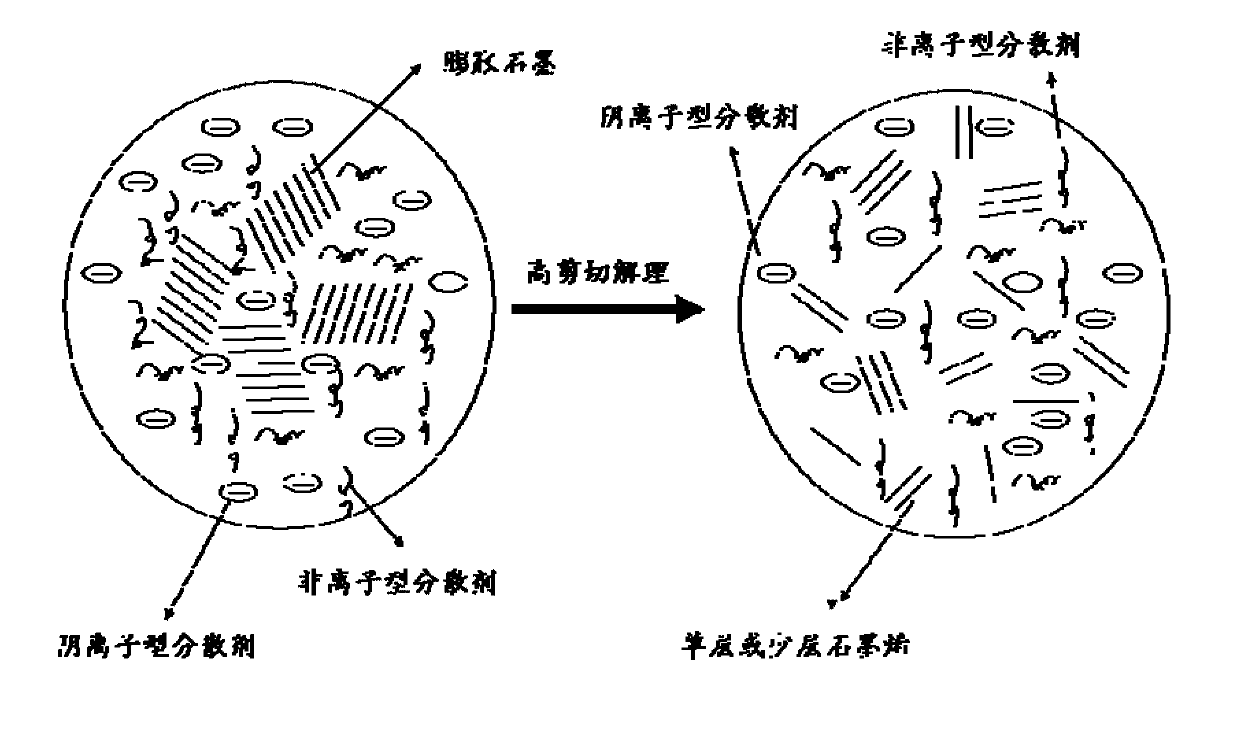

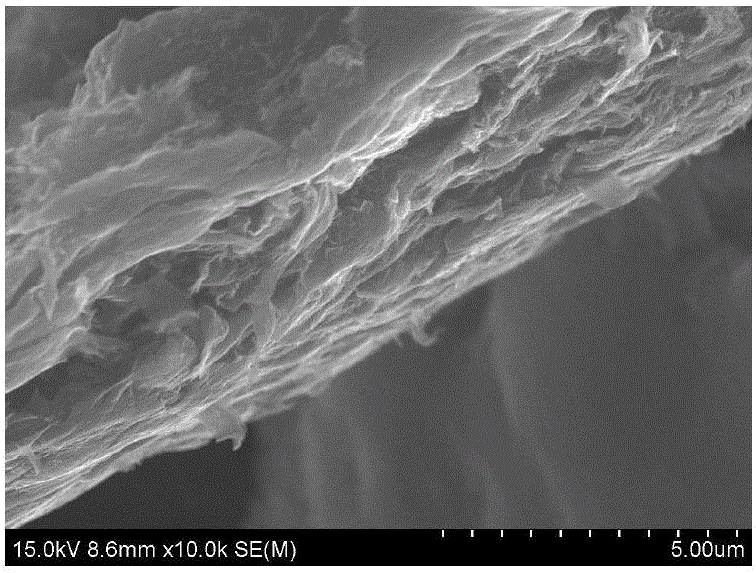

High-concentration few-layer graphene composite material, component of lithium battery electrode and preparation

ActiveCN103035887AImprove processing efficiencyHigh yieldCell electrodesHigh concentrationInternal resistance

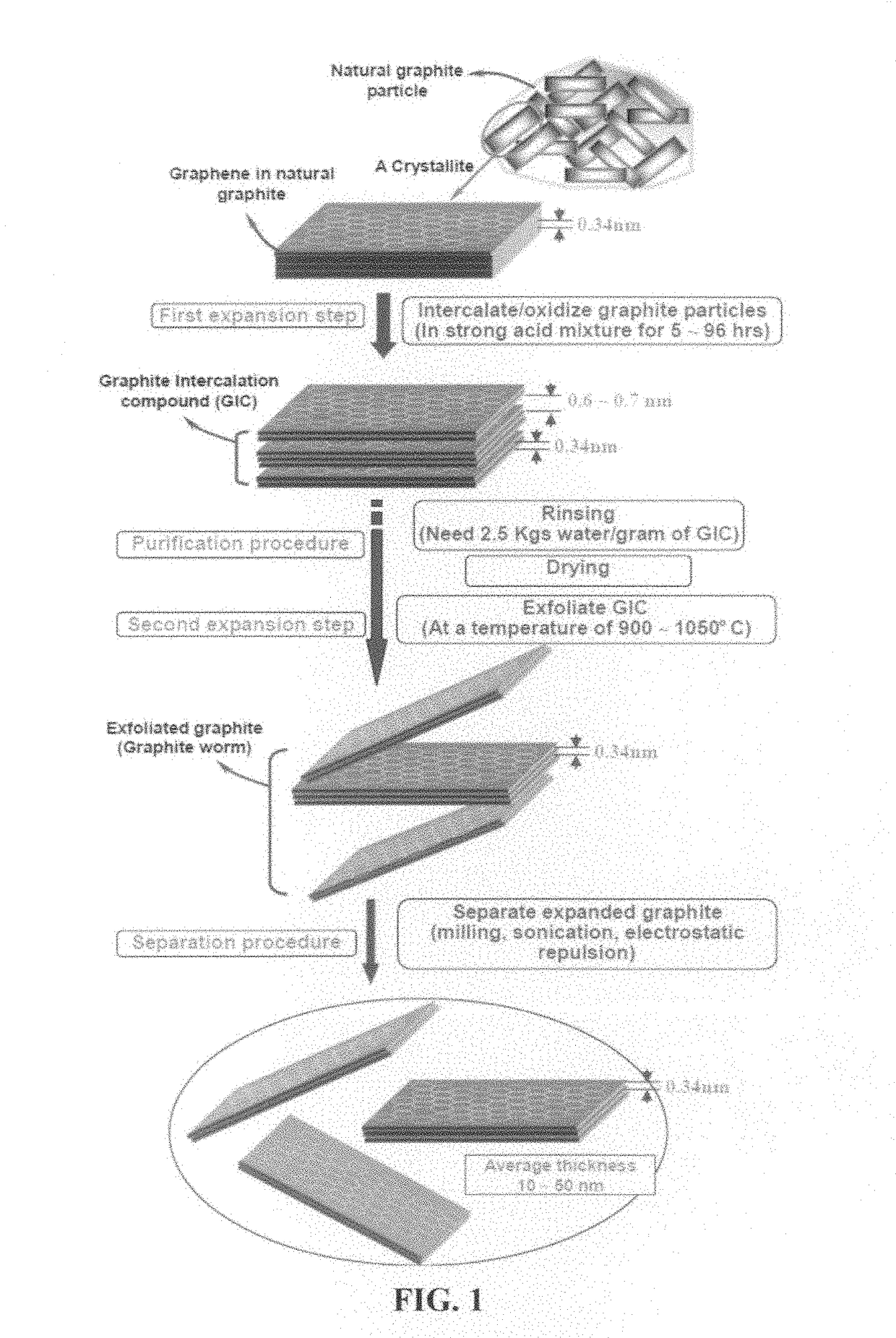

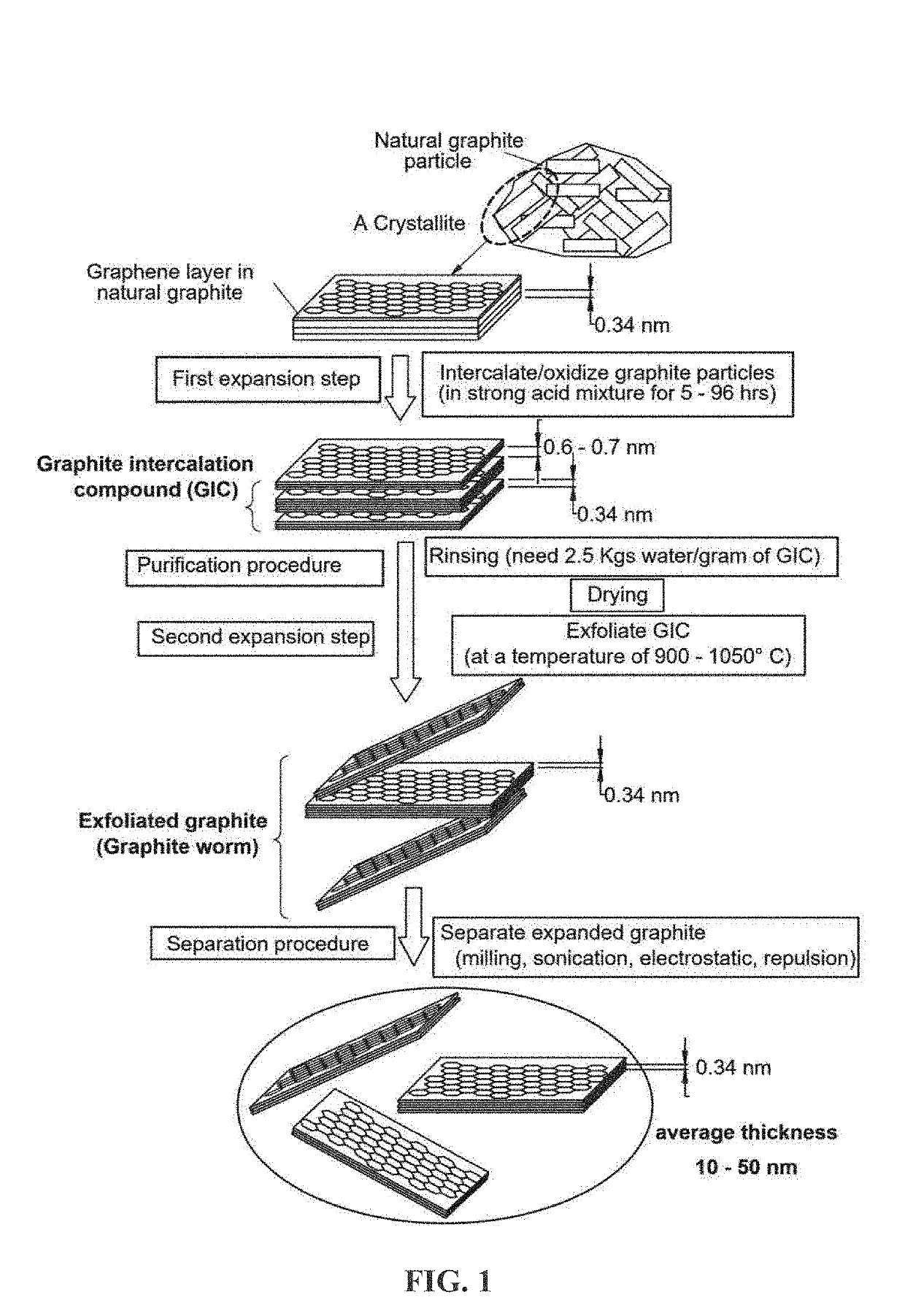

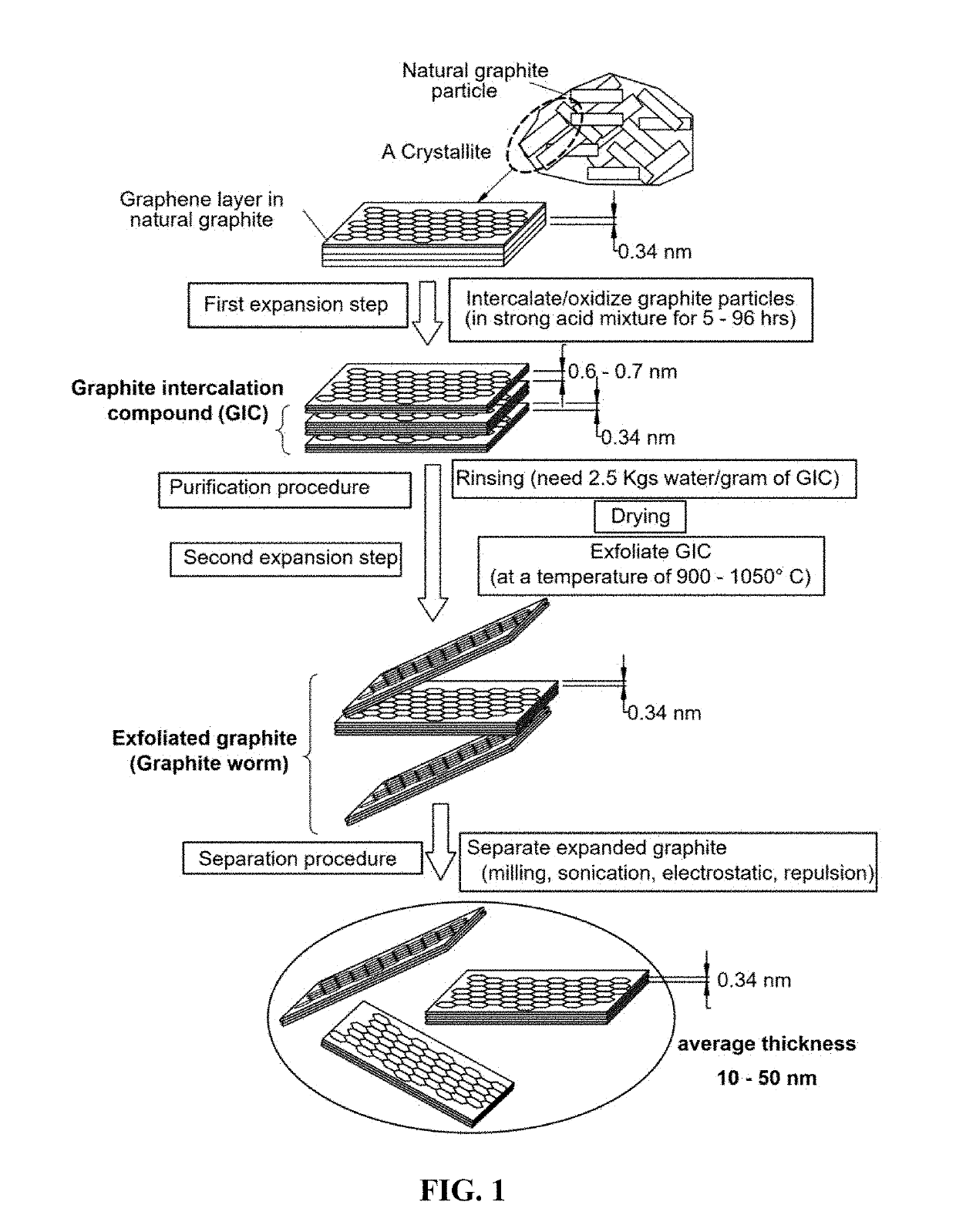

The invention discloses a high-concentration few-layer graphene composite material, a component of a lithium battery electrode and preparation, belonging to the technical field of preparation of electrode materials. The preparation method disclosed by the invention comprises the following steps: firstly preparing expansion graphite, then mixing and stirring a dispersing agent, a liquid carrier, an anion type surface active agent and a defoaming agent to prepare mixed liquor, then adding the expansion graphite into the mixed liquor, performing cleavage through a high-shearing cleavage device to get high-concentration few-layer graphene, finally mixing with a binding agent and a lithium battery active material to form electrode slurry, and coating to prepare an electrode. The prepared graphene in the invention has the properties of high electric conduction, high thermal conductivity, high concentration and easiness in dispersion, the material is doped into positive and negative pole materials of a lithium battery for preparing pole pieces, the electron conductivity can be effectively increased, the internal resistance of the battery can be greatly reduced, the heat produced by the battery during charge and discharge can be reduced, and the power density, the energy density, the safety and the cycle life of the battery can be further upgraded.

Owner:SUPERCDONGGUAN TECH

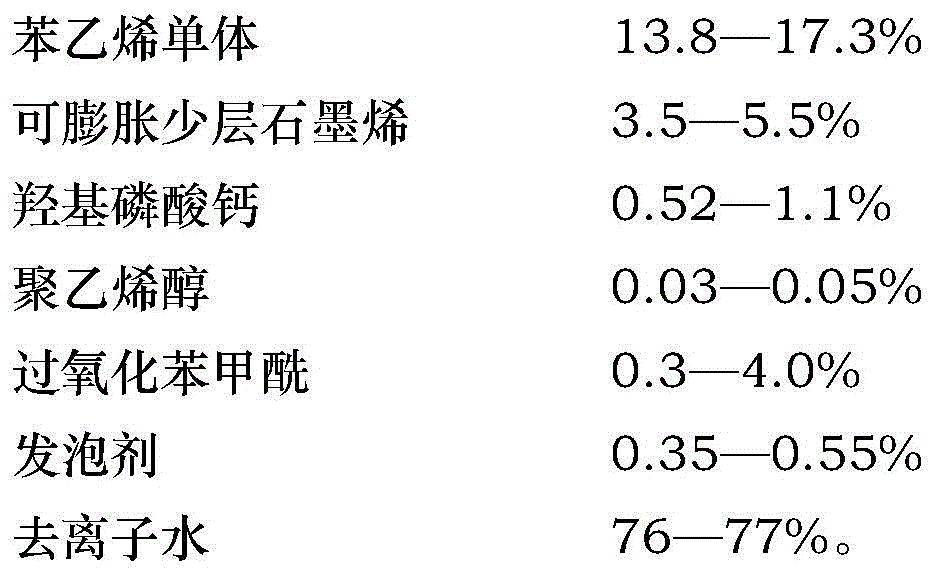

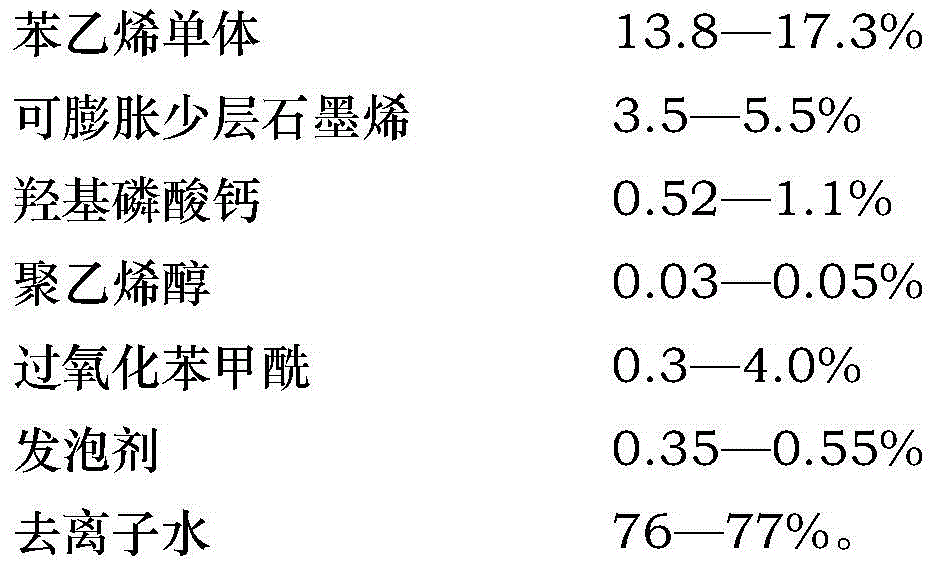

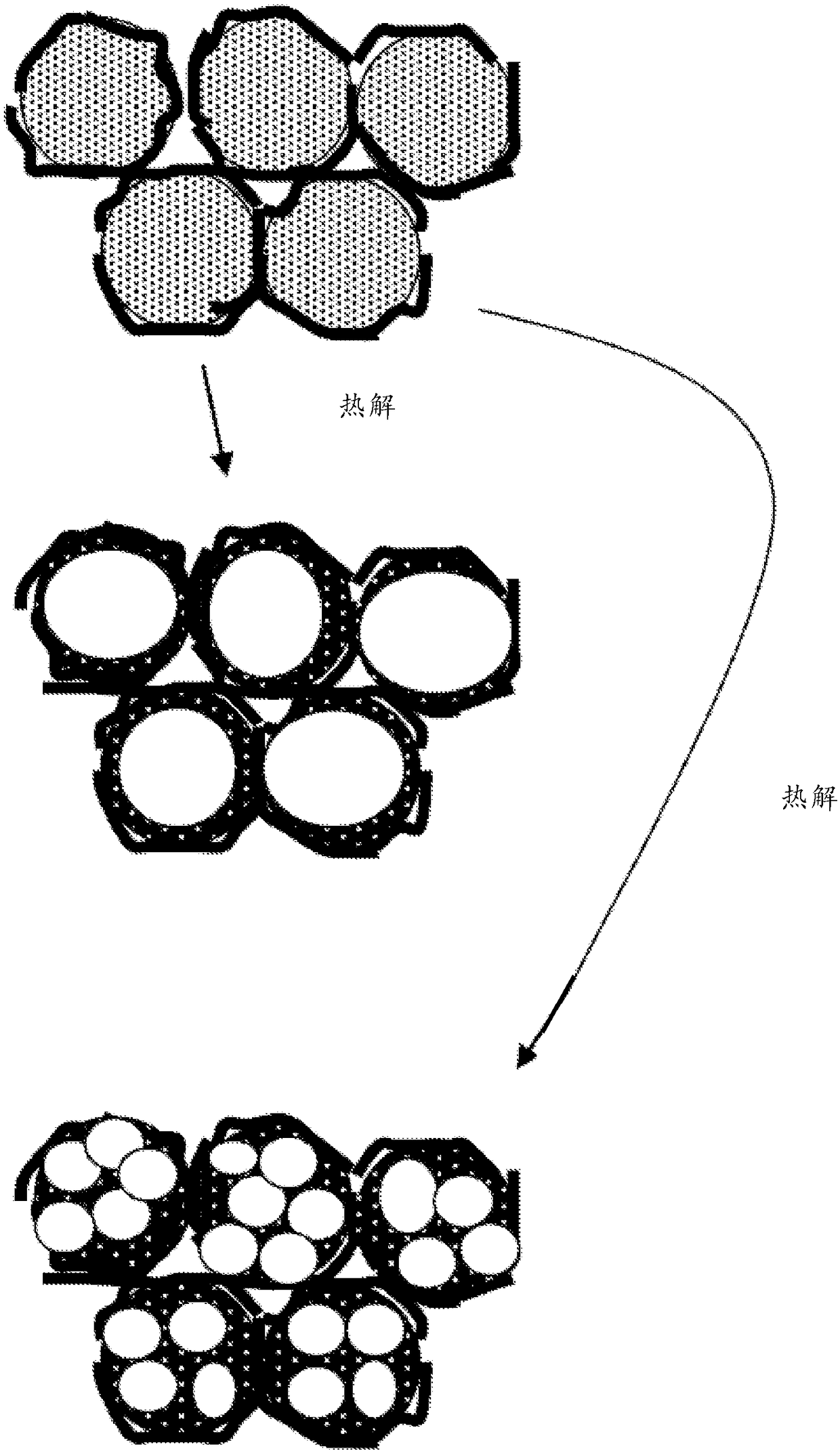

Expandable polystyrene beads prepared from expandable few-layer graphene and preparing method of expandable polystyrene beads

The invention relates to expandable polystyrene beads prepared from expandable few-layer graphene and a preparing method of the expandable polystyrene beads.Electrochemical intercalation is carried out on natural flake graphite with concentrated sulfuric acid, and a graphite interlayer compound with the interlayer space enlarged is obtained; few-layer graphene is obtained through ultrasonic concussion layer removing, the few-layer graphene is subjected to secondary intercalation with a chemical method, water washing and drying, and the expandable few-layer graphene is obtained; then, the expandable few-layer graphene and polystyrene monomers are subjected to suspension polymerization, and the expandable polystyrene beads prepared from the expandable few-layer graphene is obtained.According to the expandable polystyrene beads prepared from the expandable few-layer graphene and the preparing method of the expandable polystyrene beads, the expandable few-layer graphene is introduced into expandable polystyrene, and expandable graphene can be highly and uniformly dispersed in the expandable polystyrene beads, so that high infrared reflectivity in a cavity of expandable polystyrene is ensured, the heat insulation performance is good, and the expandable few-layer graphene can show the flame-retardant effects of smothering flames and insulating heat radiation.The flame retardant grade of a foam plate prepared from the expandable polystyrene beads reaches the B1 grade, and the heat conductivity value ranges from 0.028 W / (m.K) to 0.032 W / (m.K).

Owner:JILIN YUNTING ENERGY SAVING TECH CO LTD

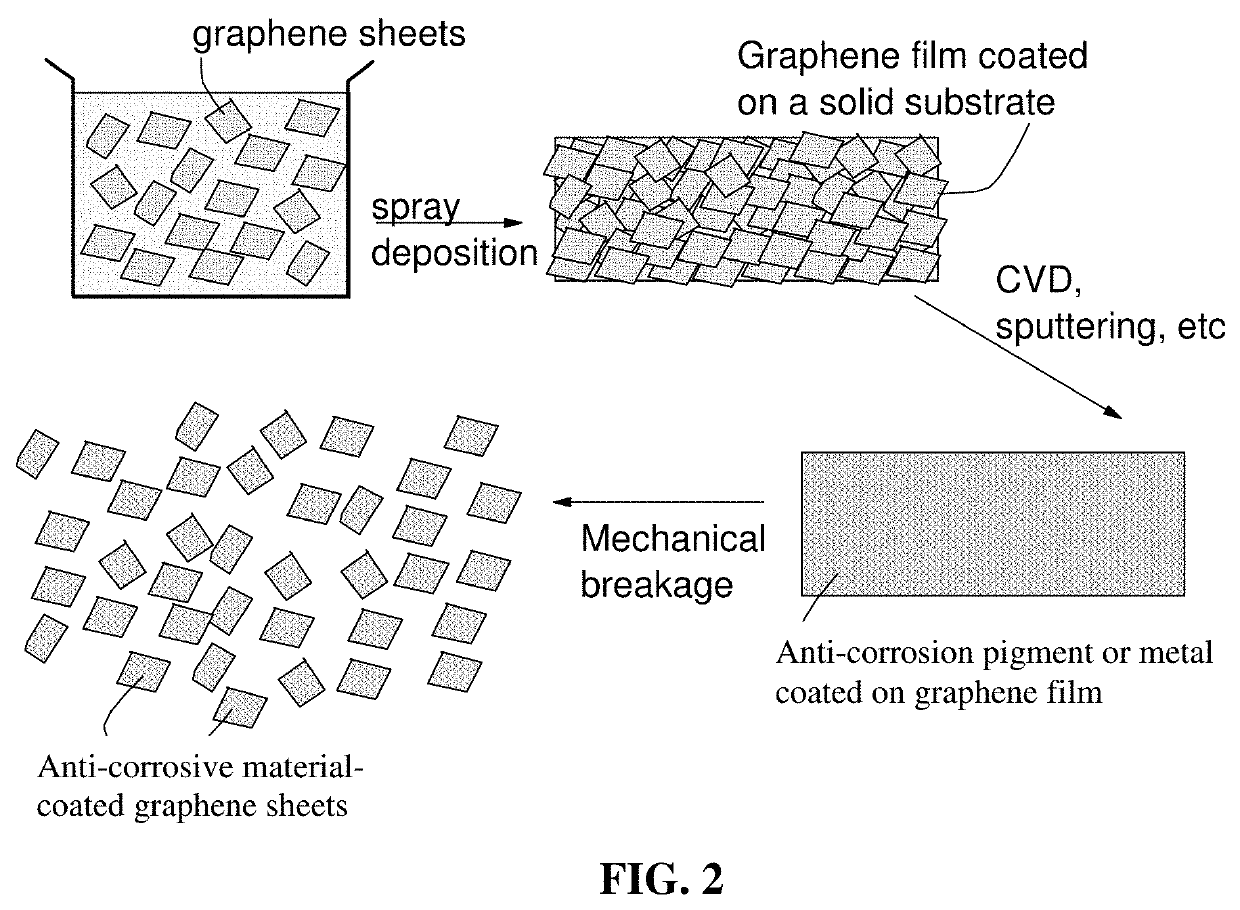

Anti-corrosion material-coated discrete graphene sheets and Anti-corrosion coating composition containing same

PendingUS20190345344A1Avoid corrosionEffective protectionAnti-corrosive paintsPolyurea/polyurethane coatingsLiquid mediumDoped graphene

Provided is a graphene-based coating suspension comprising multiple graphene sheets, thin film coating of an anti-corrosive pigment or sacrificial metal deposited on graphene sheets, and a binder resin dissolved or dispersed in a liquid medium, wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 47% by weight of non-carbon elements wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. The invention also provides a process for producing this coating suspension. Also provided is an object or structure coated at least in part with such a coating.

Owner:GLOBAL GRAPHENE GRP INC

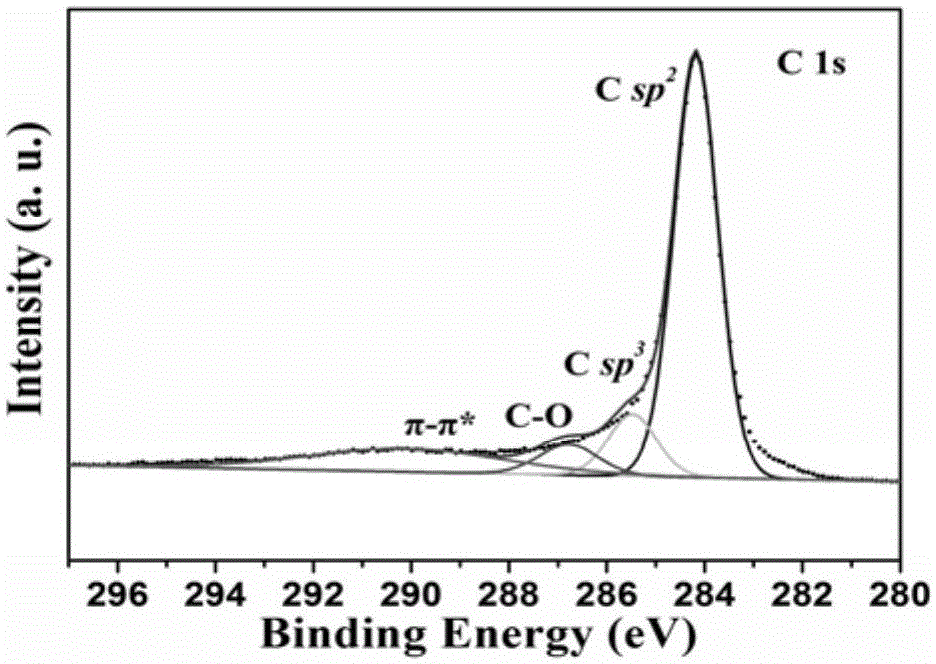

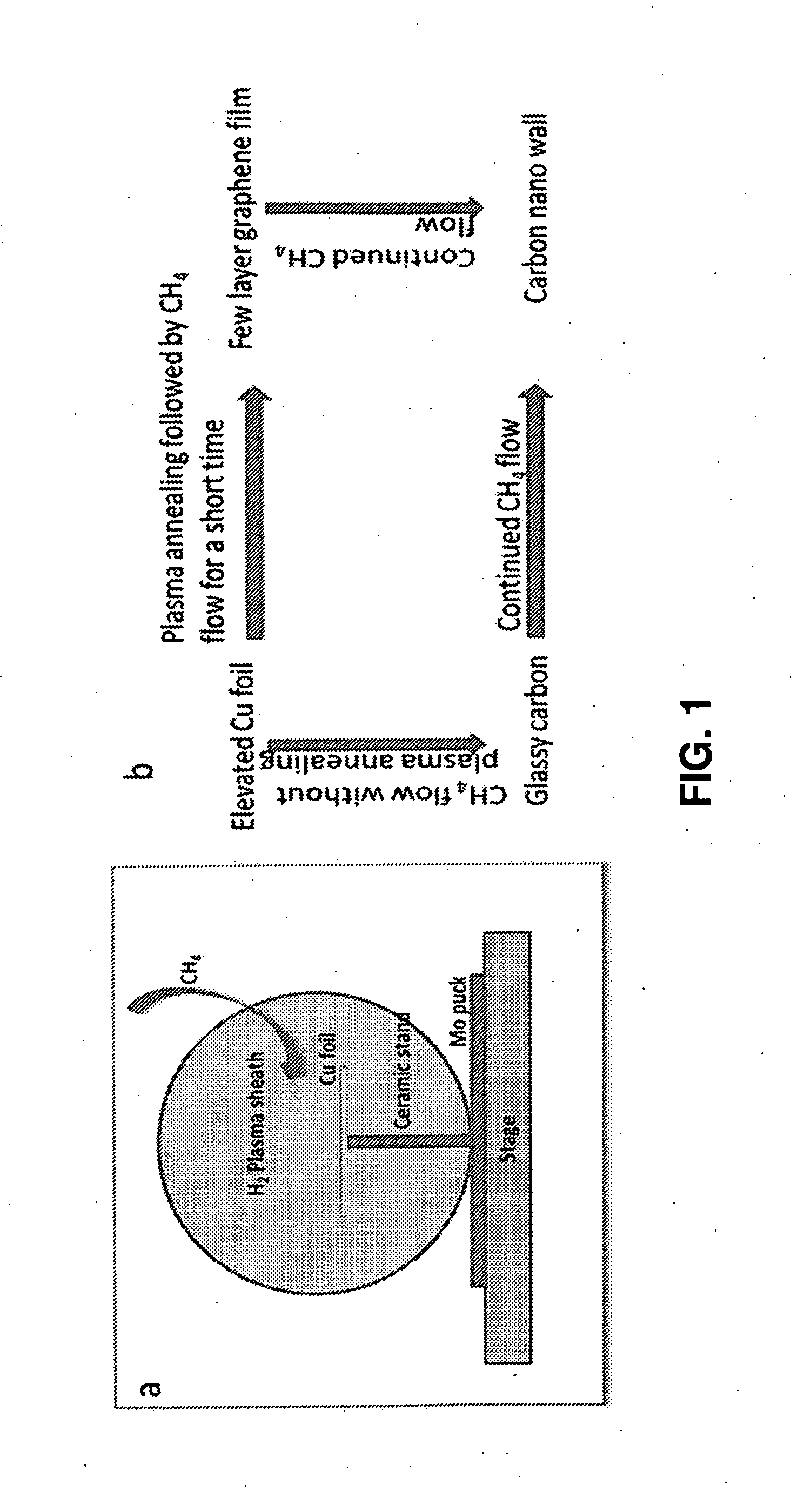

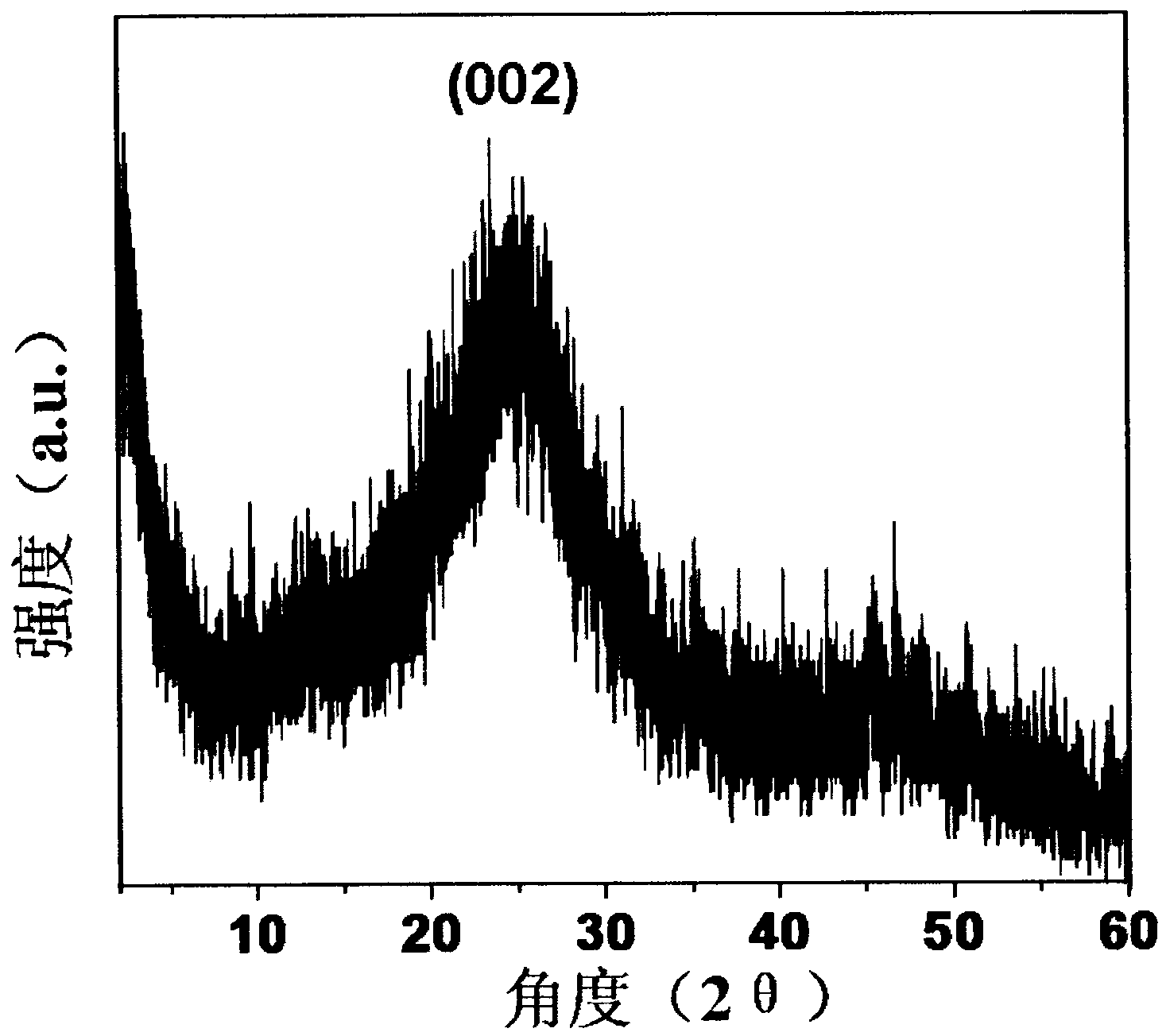

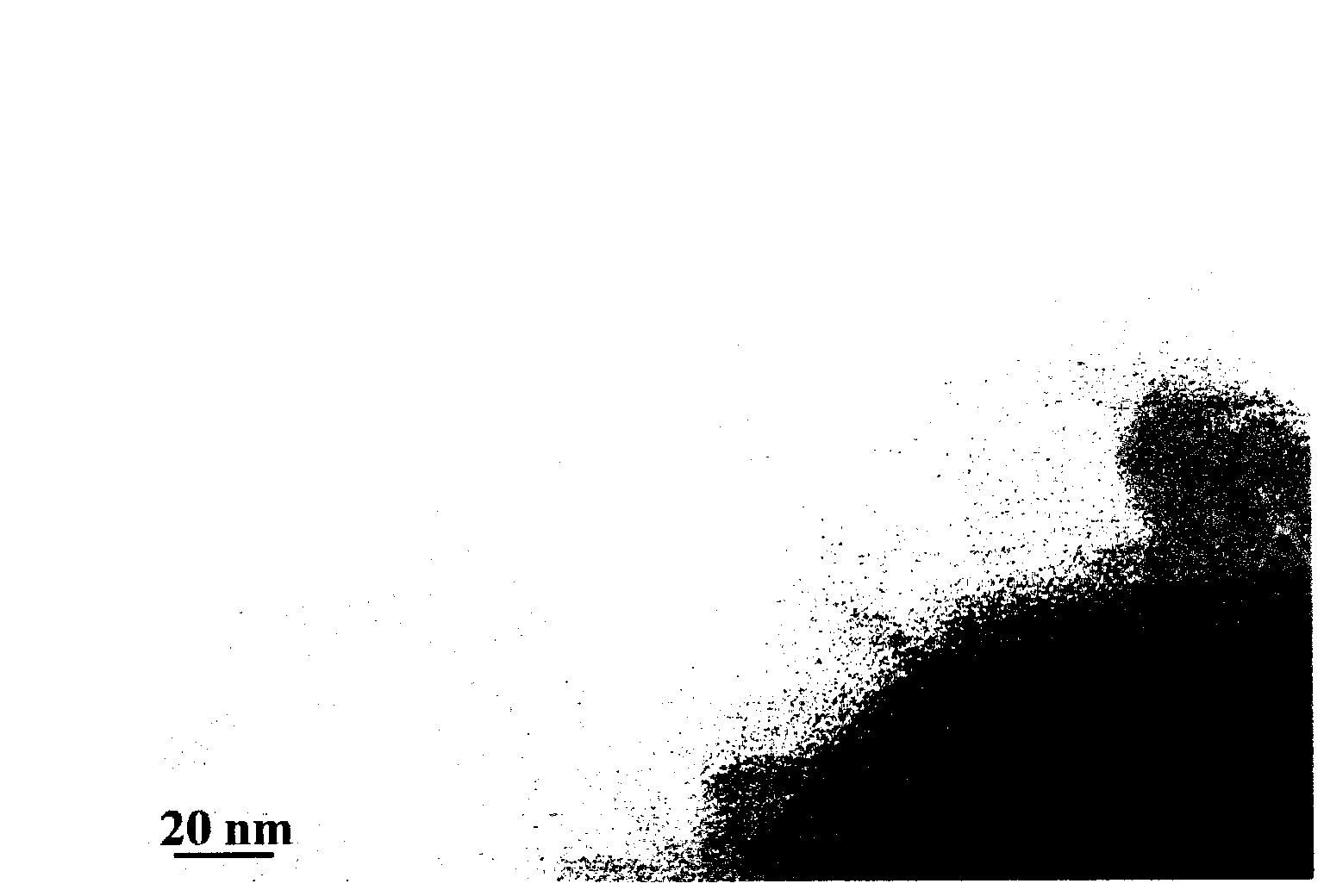

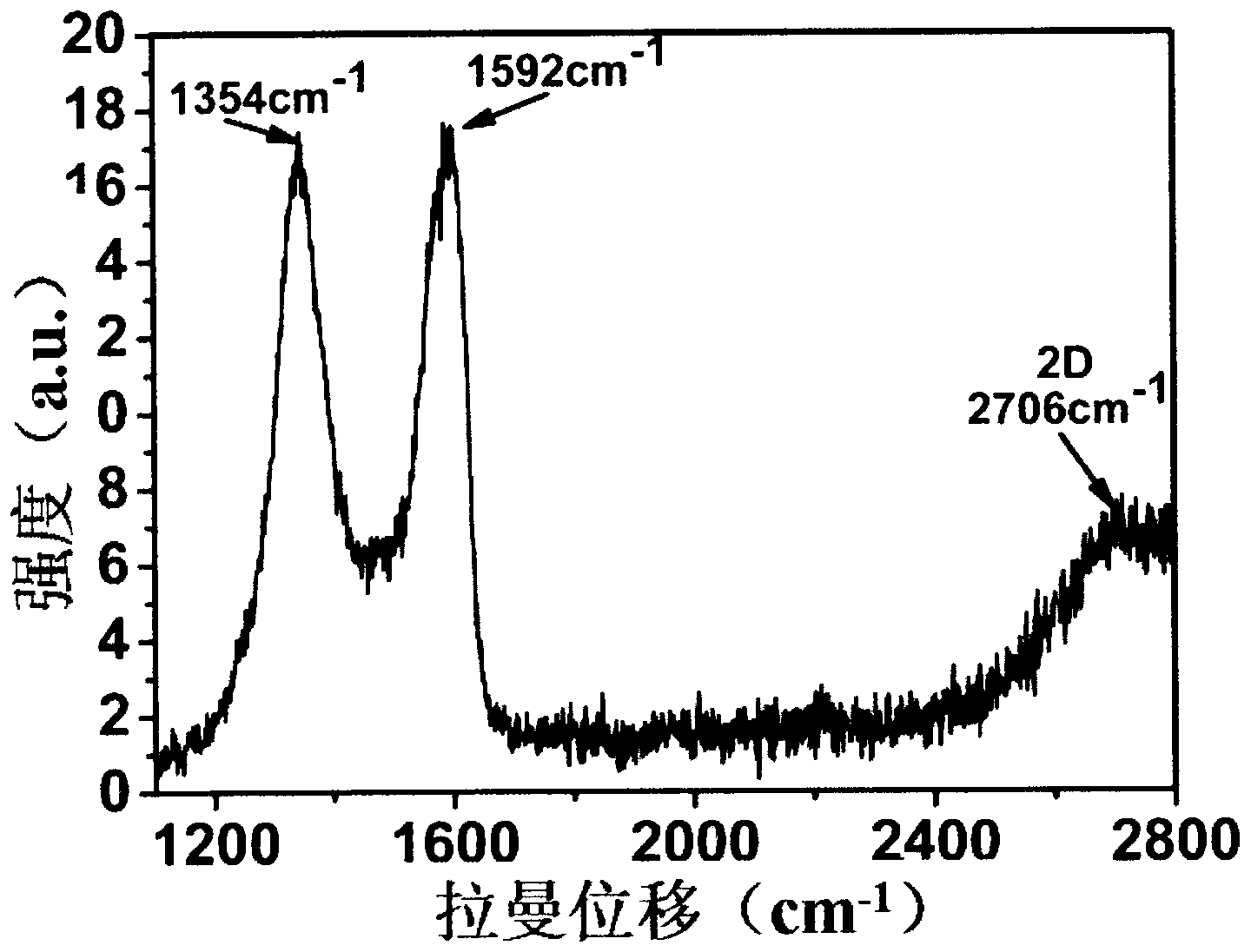

Rapid synthesis of graphene and formation of graphene structures

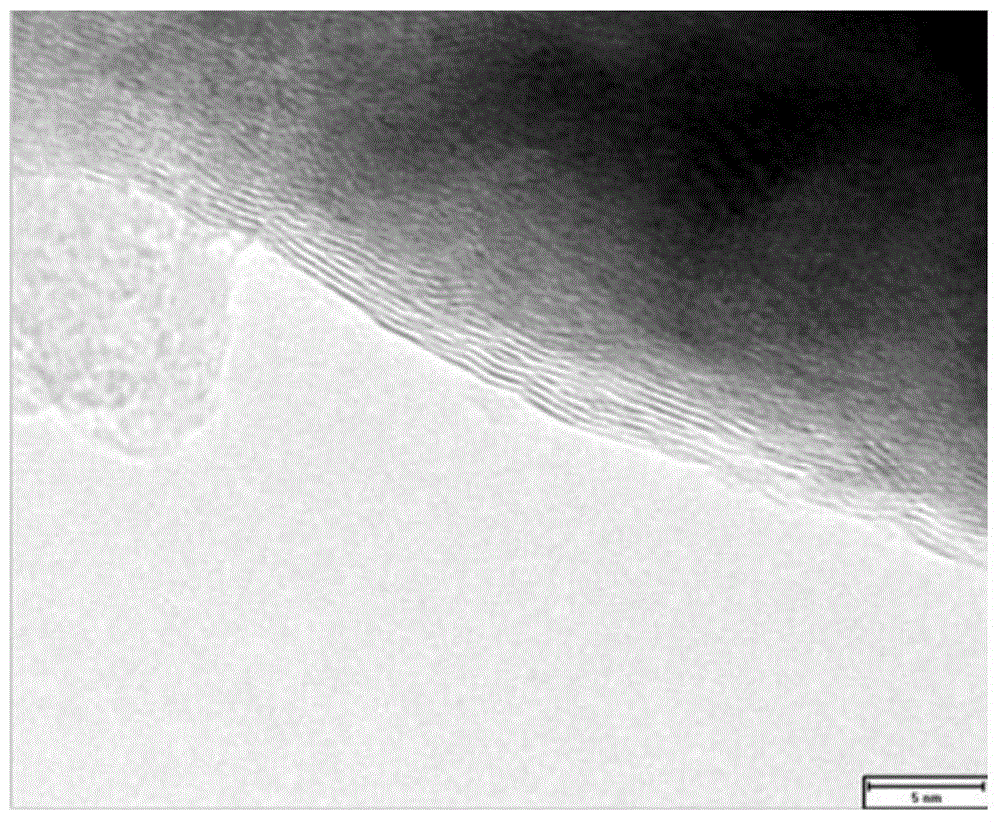

ActiveUS20150037515A1Shorten the timeReduce the temperatureMaterial nanotechnologyGrapheneDoped grapheneX-ray

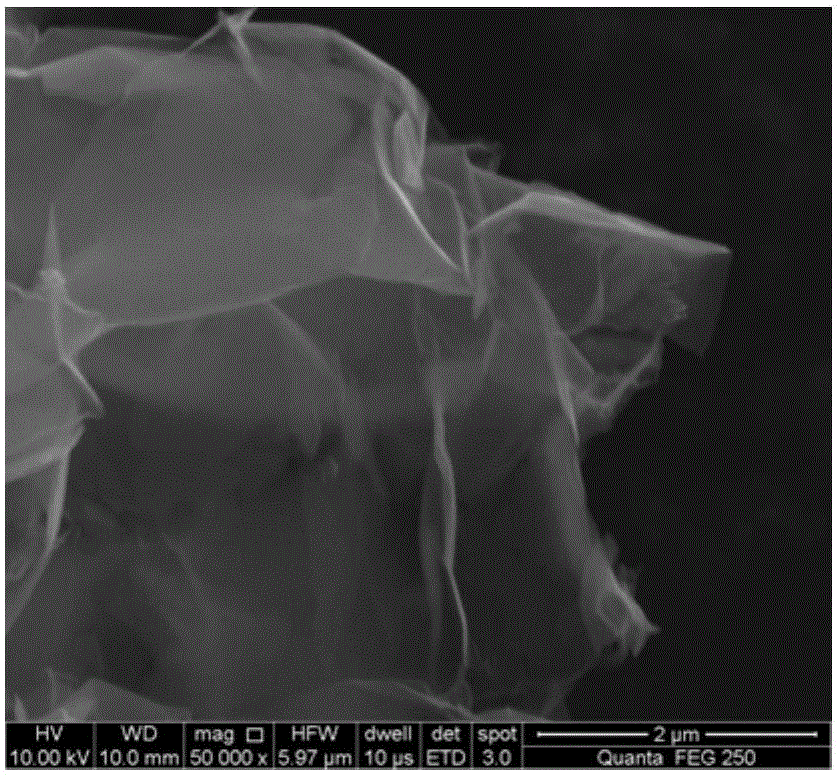

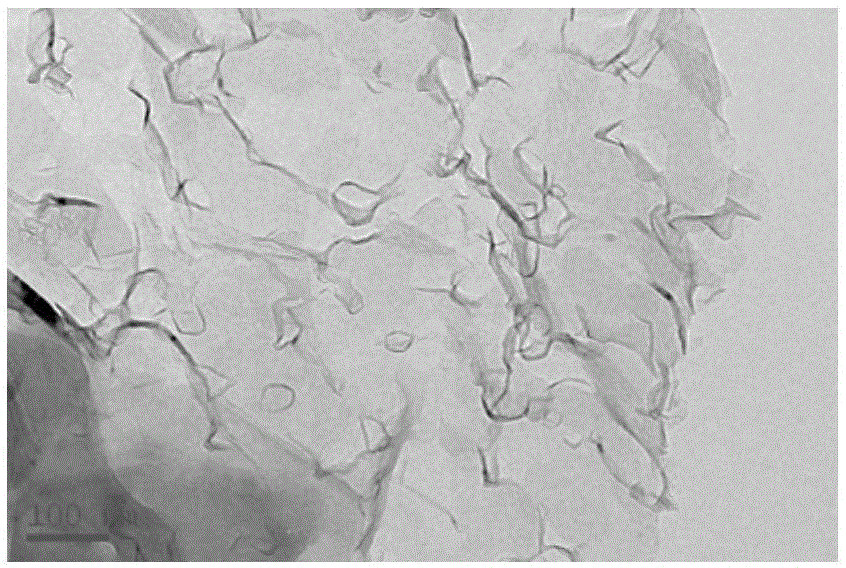

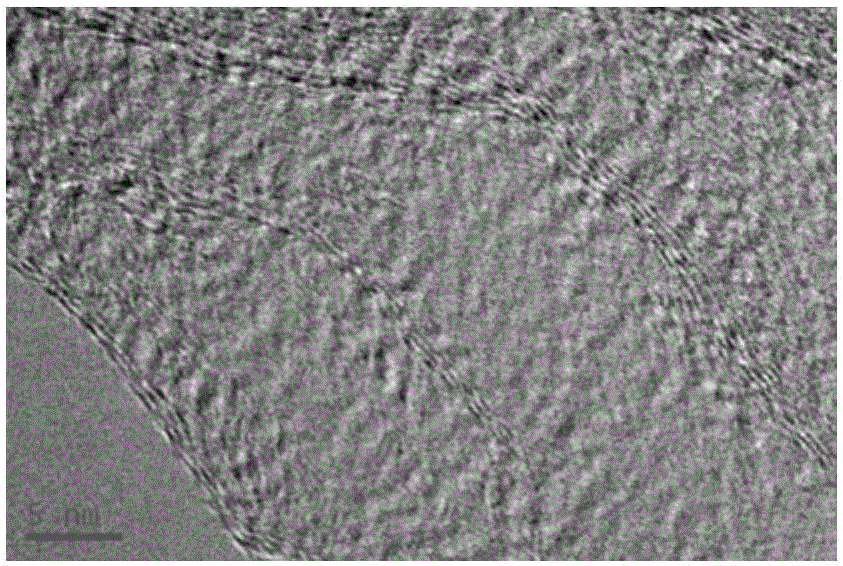

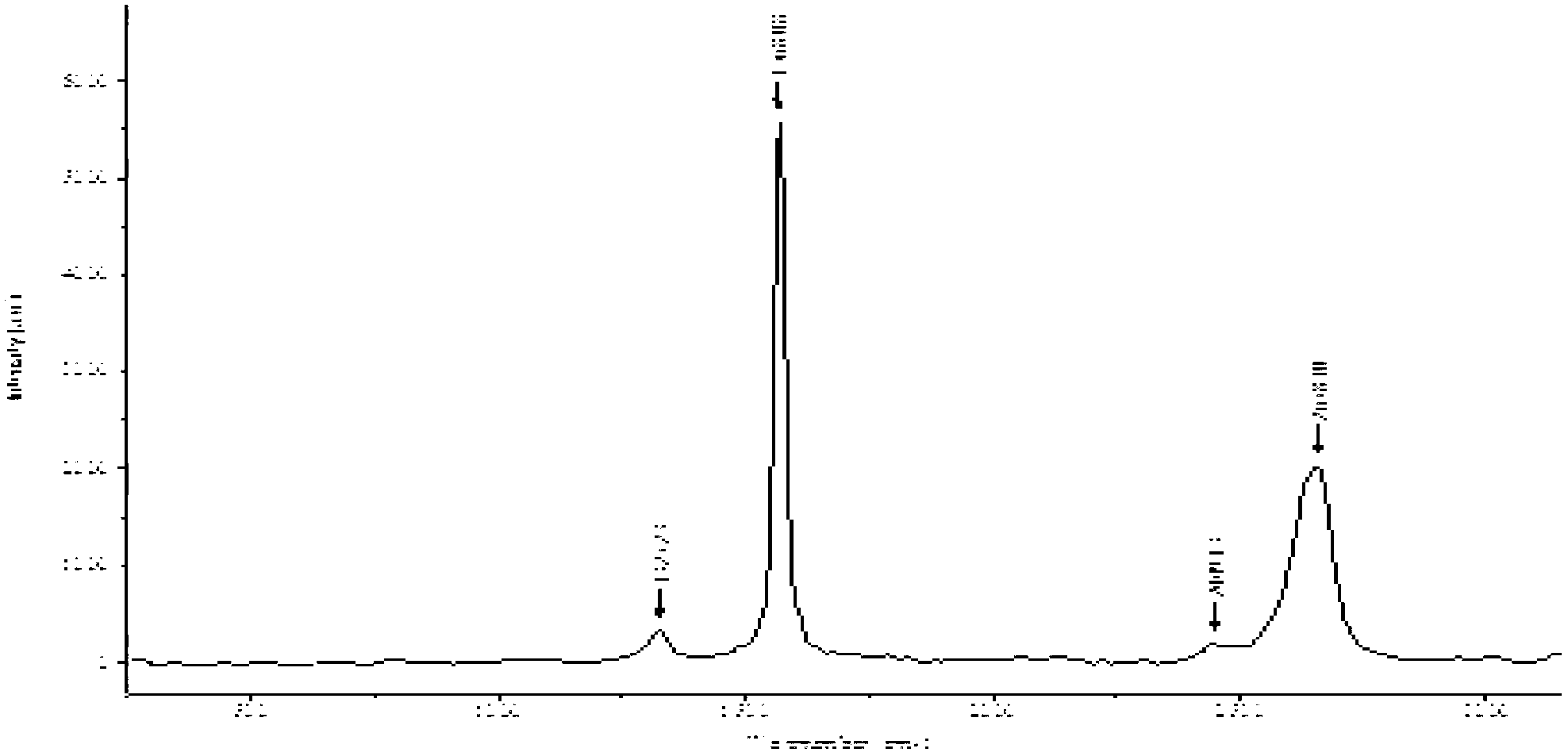

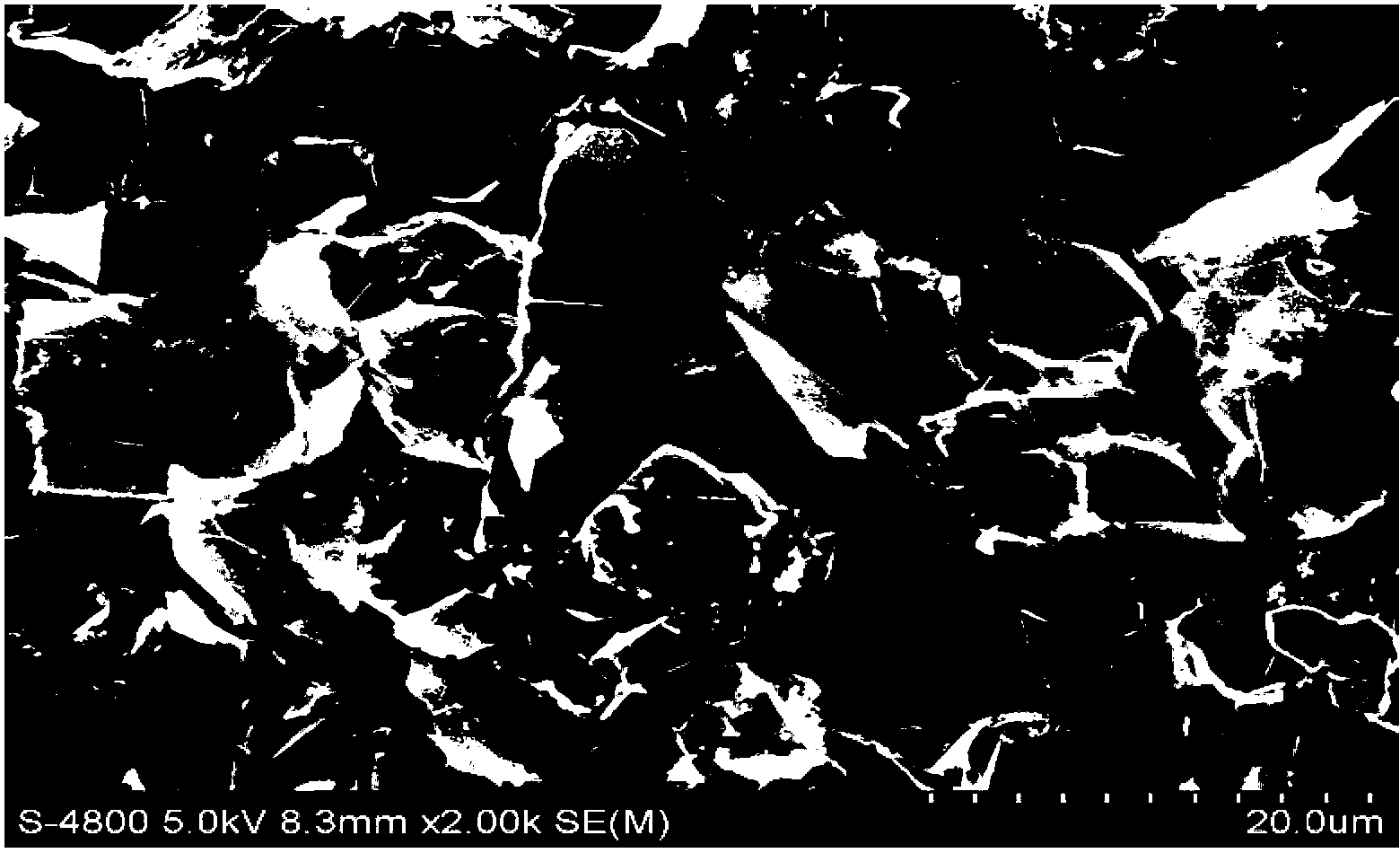

A process for rapid synthesis of few-layer graphene films on Cu foil by microwave plasma chemical vapor deposition (MPCVD). The plasma / metal interaction can be useful for a rapid synthesis of such thin films. The process can produce films of controllable quality from amorphous to highly crystalline by adjusting plasma conditions during growth processes of ˜100 sec duration and with little or no supplemental substrate heating. Films have been characterized using Raman spectroscopy, scanning electron microscopy, transmission electron microscopy and X-ray photoelectron spectroscopy. The results help to identify the stages involved in the MPCVD deposition of thin carbon films on Cu foil. In yet other embodiments, the films are doped during synthesis by introduction of nitrogen gas in the reactor. Raman spectroscopy, X-ray photoelectron spectroscopy, transmission electron microscopy and scanning tunneling microscopy reveal crystal structure and chemical characteristics. Nitrogen concentrations up to approximately 2 atomic % are observed. The growth process requires only a few minutes without supplemental substrate heating and offers a promising path toward large-scale synthesis of nitrogen-doped graphene films.

Owner:PURDUE RES FOUND INC

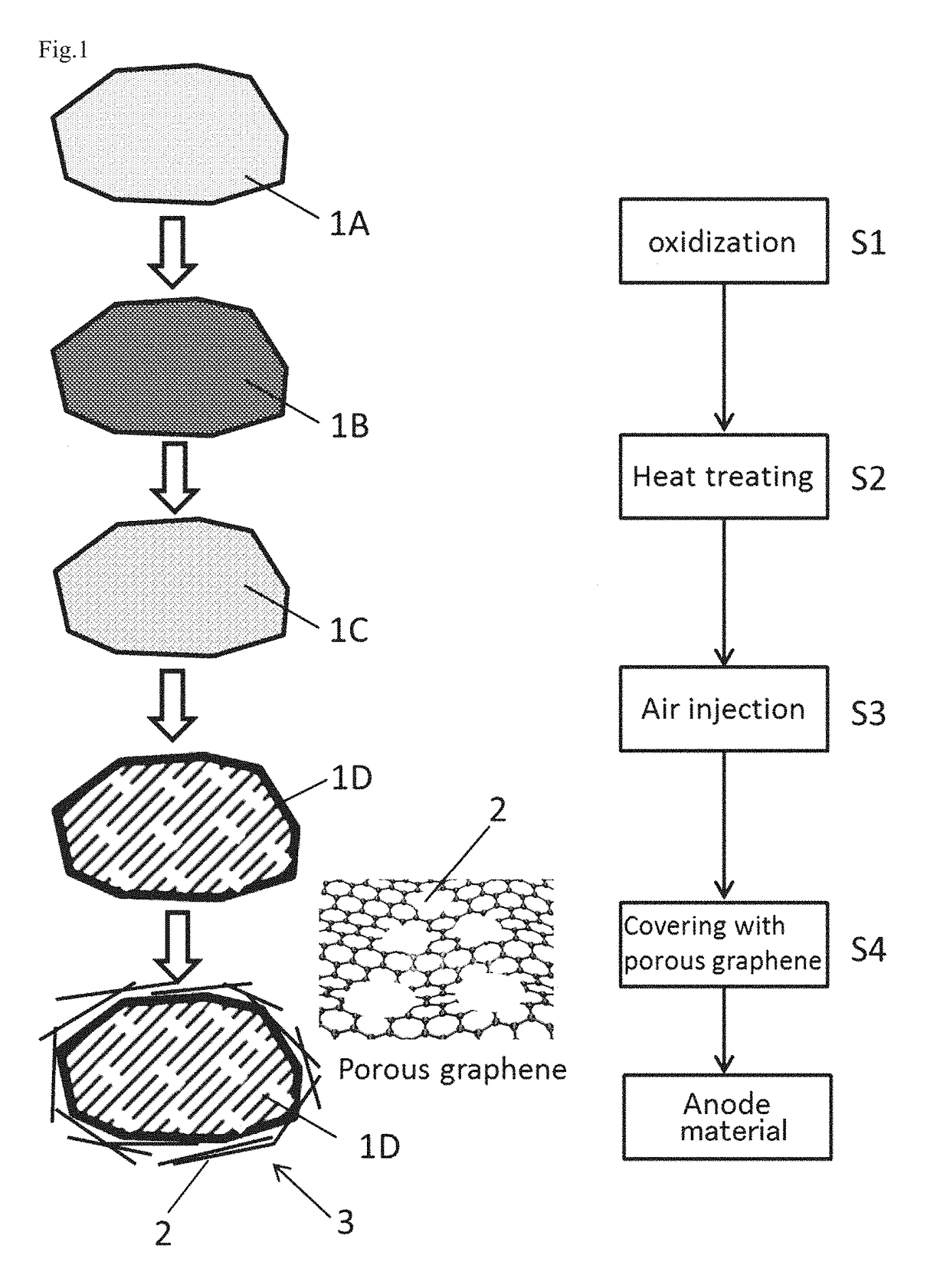

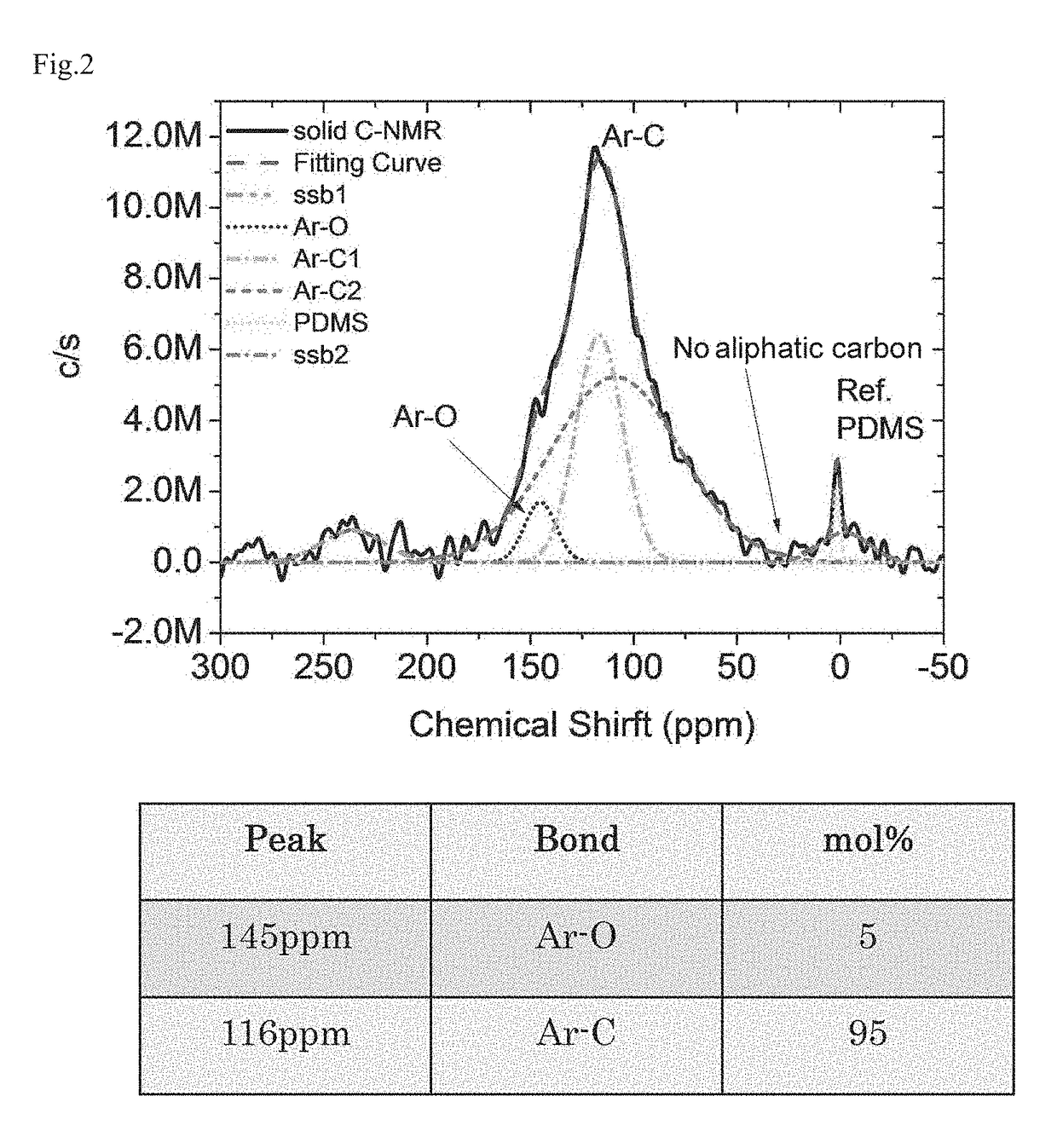

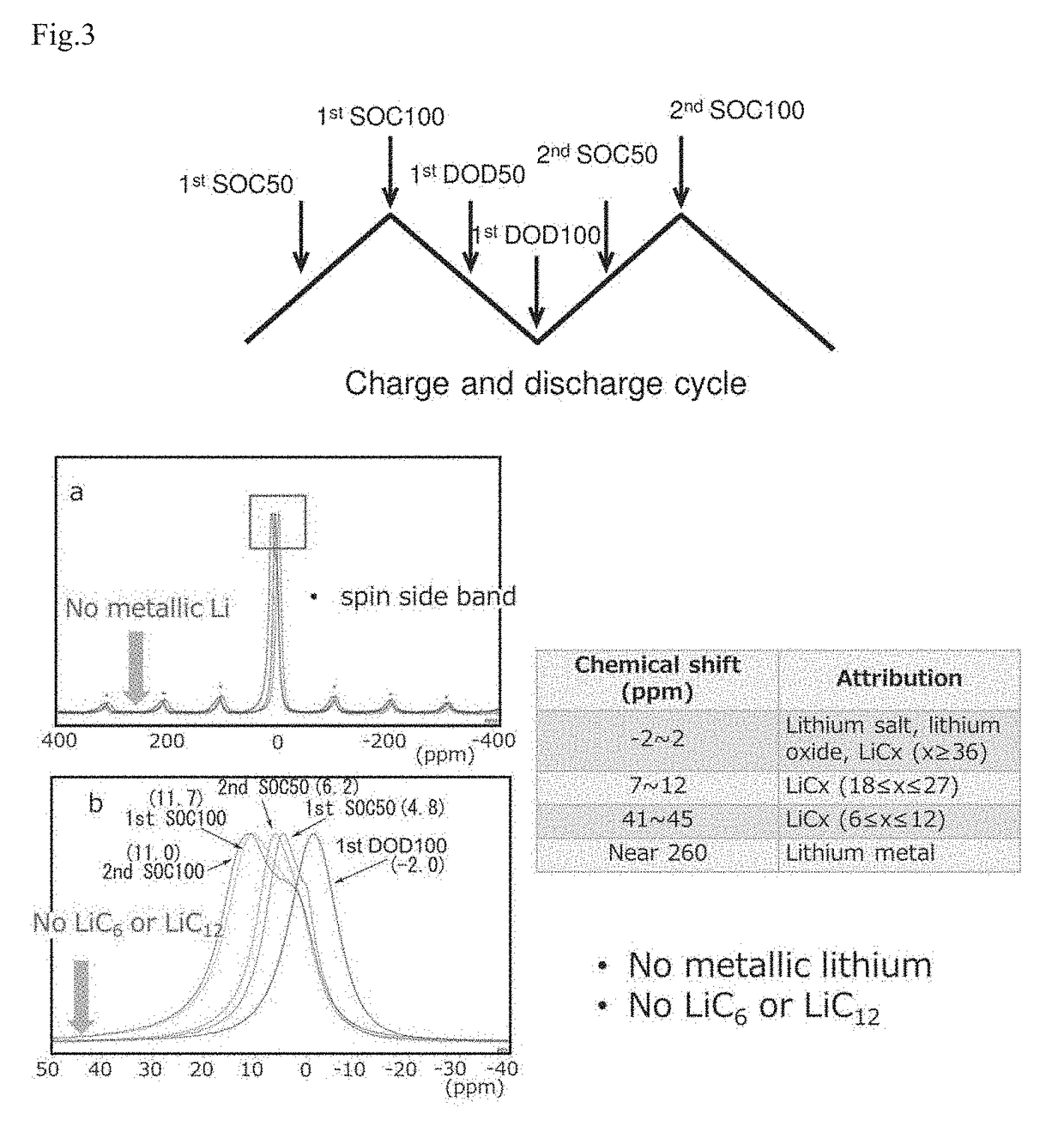

Hierarchical oxygen containing carbon anode for lithium ion batteries with high capacity and fast charging capability

ActiveUS20190006675A1Large capacityFast chargingElectrode thermal treatmentGraphitePorous grapheneFast charging

An anode material for a lithium ion battery, comprising an oxygen-containing carbon where oxygen is in the form of functional groups, the oxygen being distributed gradient from the surface to the inside of the carbon, and the carbon having an interlayer space d002 larger than 0.3357 nm; and a porous graphene layer covering the oxygen-containing carbon, the graphene being in the form of monolayer or few-layer graphene.

Owner:NEC CORP +1

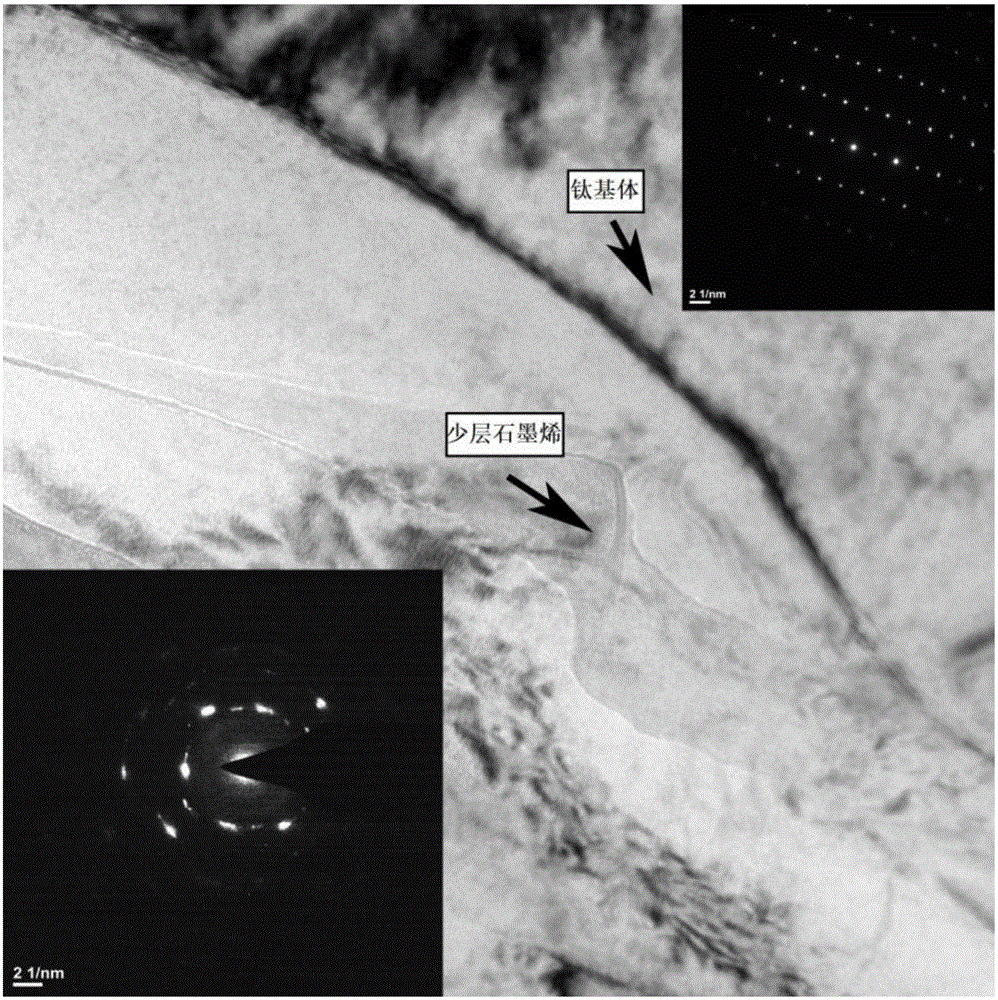

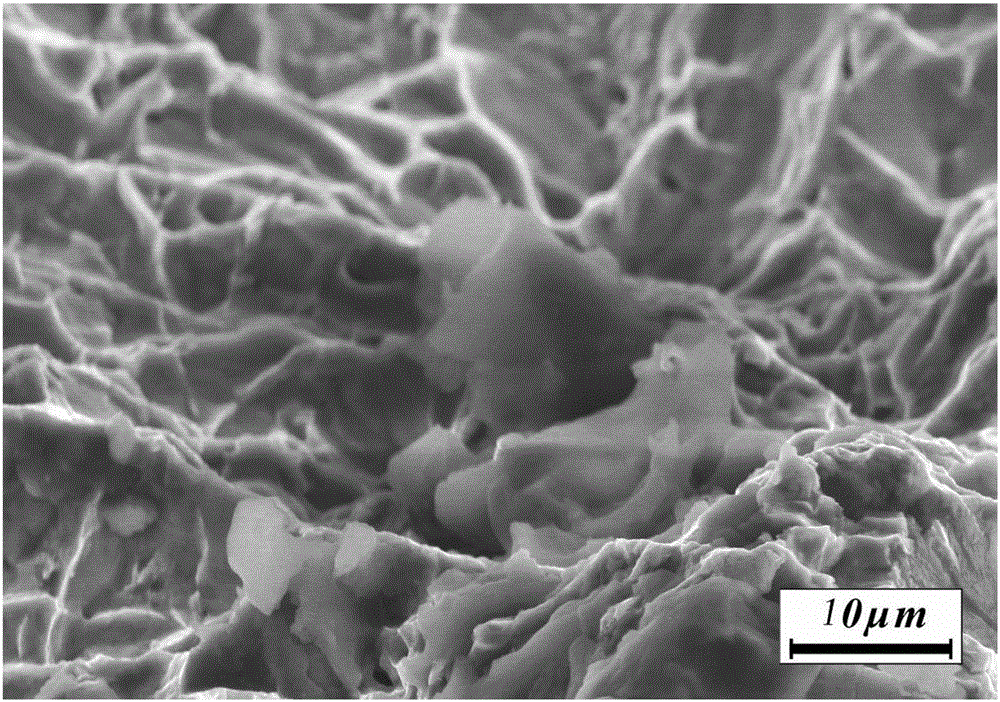

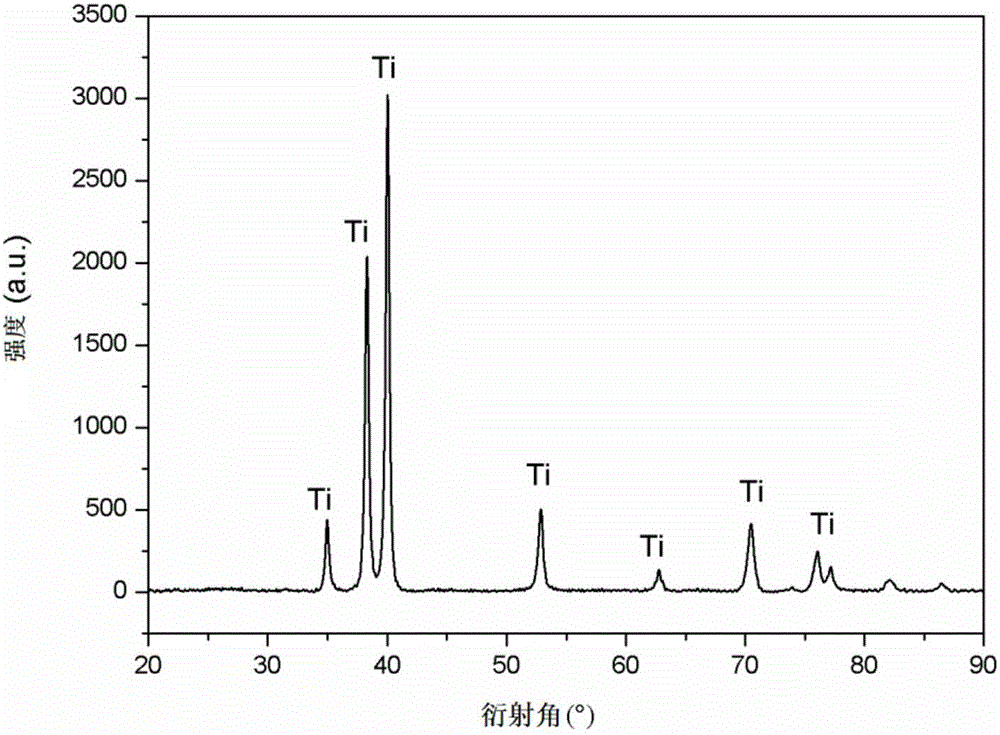

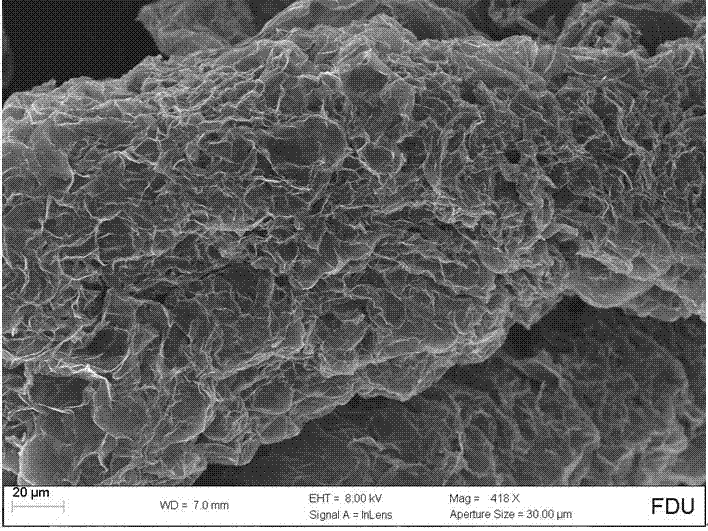

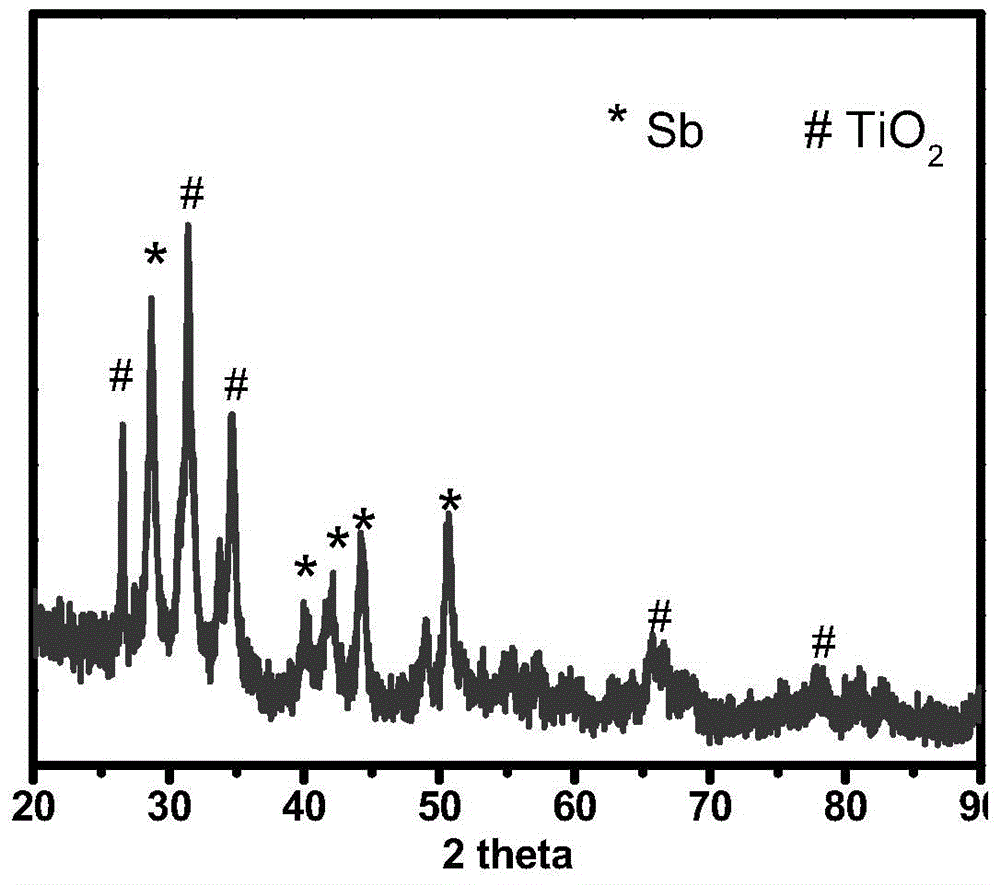

Low-content few-layer graphene intensified titanium-based composite material and preparation method

The invention relates to a low-content few-layer graphene intensified titanium-based composite material and a preparation method, and belongs to the technical field of metal-based composite materials. The composite material has excellent tensile mechanical performance and is intensified through the characteristics of few-layer graphene, and the few-layer graphene is distributed in the composite material uniformly in the fixed direction. The preparation method includes the steps that few-layer graphene powder is mixed with absolute ethyl alcohol at first, and titanium powder is added to the mixture while the mixture is stirred, so that mixed slurry is obtained; the mixed slurry is subjected to ball grinding, the absolute ethyl alcohol in the ball-grinded slurry is removed, and drying is conducted on the vacuum condition; the dried power is injected into a steel mold, then the steel mold is pressed and heated, and a rough blank is obtained after natural cooling; and the rough blank is heated and then hot-rolled, the blank is cooled in air after being rolled, and then the low-content few-layer graphene intensified titanium-based composite material is obtained. The method is simple in process and high in repeatability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

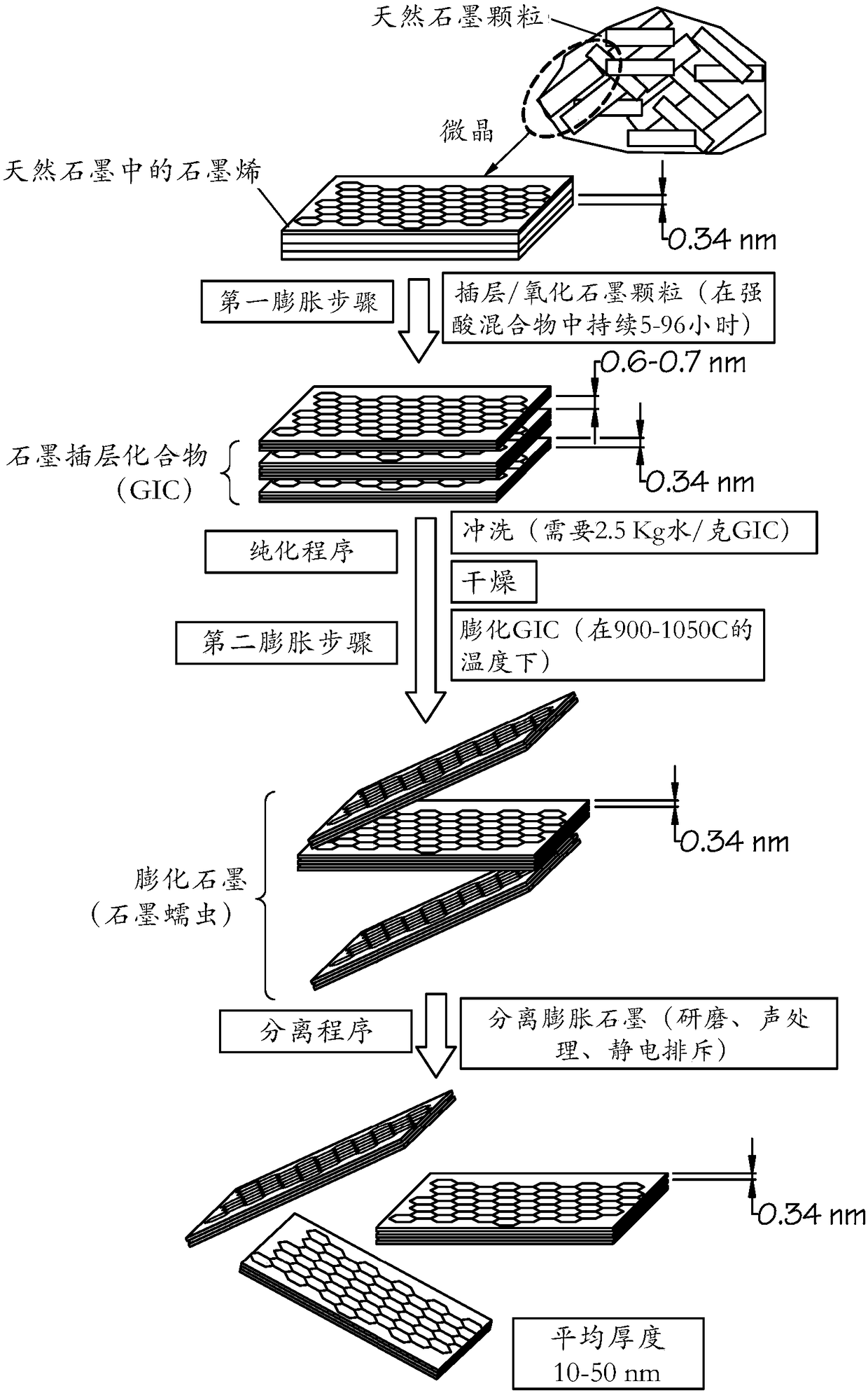

Preparation method of three-dimensional graphene structure/high-quality graphene

ActiveCN106882796AEfficient large-scale preparationSolve the key problems of large-scale preparationSingle layer grapheneCarbon nitrideMetallic sulfide

The invention provides a preparation method of three-dimensional graphene structure / high-quality graphene. The method comprises the steps of carrying out intercalation treatment on natural flake graphite or synthetic graphite to prepare a graphite intercalation compound; and carrying out expansion treatment on the obtained graphite intercalation compound in an expanding agent to obtain a three-dimensional graphene structure with high specific surface area. A high-quality single-layer or few-layer graphene dispersion liquid is obtained through ball-milling, shearing, high-speed fluid grinding or ultrasonic treatment. The obtained three-dimensional structure has the specific surface area of over 1,000m<2> / g; and the lamellar lattice structure is kept intact. The graphene lattice structure obtained through mechanical exfoliation is kept intact, and has excellent electrical properties; the volume conductivity of a thin film can reach over 1,000S / cm. The prepared graphene material can be widely applied to the fields of energy storage, a composite material, conductive ink, a conductive film and the like. The three-dimensional graphene structure can be directly used as a carbon skeleton with high specific surface area, and can be compounded with various materials such as a polymer, a metal oxide, a metal sulfide and carbon nitride to prepare a composite material with special functionality.

Owner:FUDAN UNIV

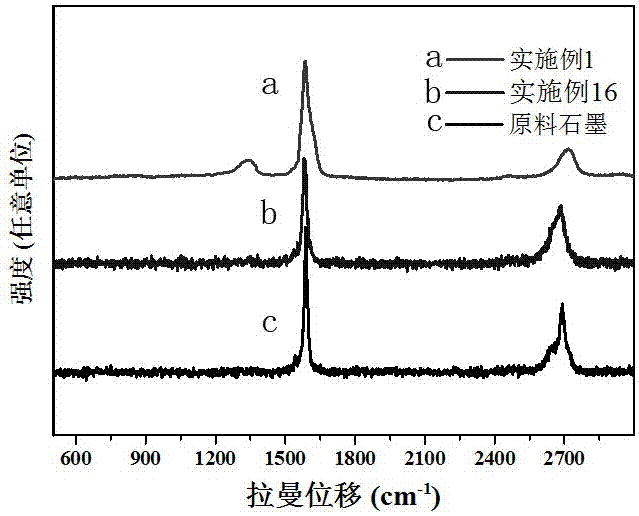

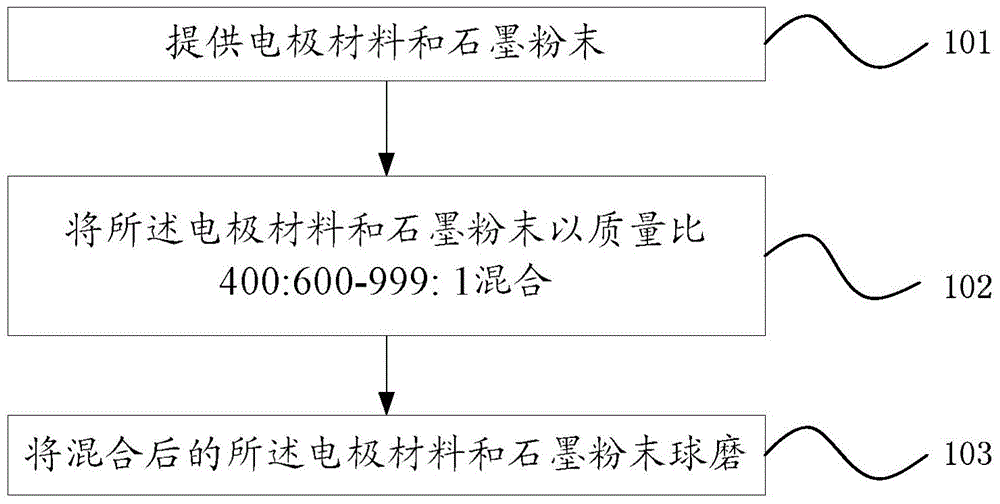

Graphene composite material and preparation method thereof

The present invention relates to a preparation method of a graphene composite material, and the method comprises the following stesp: providing an electrode material and graphite powder; mixing the electrode material and the graphite powder in a mass ratio of 400: 600-999: 1; and ball-milling the mixture of the electrode material and the graphite powder. In the preparation process, a few-layer-graphene-coated electrode material is formed to facilitate embedding and removal of lithium ions, conductive performance and cycle performance of lithium ion battery electrode materials can be improved, and the overall electrochemical properties of lithium-ion batteries can be greatly improved. At the same time, the graphene composite material is low in cost and is suitable for mass production and application.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Graphene-Carbon Hybrid Foam

ActiveCN108602046AWon't disintegrateMaterial nanotechnologyOther chemical processesDoped grapheneIodide

Provided is an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbonmaterial having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing doo2 from0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenatedgraphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. Also provided are a process for producing the hybrid form, products containing the hybridfoam, and its applications.

Owner:NANOTEK INSTR

Preparation method of graphene

The invention provides a preparation method of graphene. A few-layer graphene is prepared by the steps of mixed solvent preparation, crude product preparation, product primary treatment, product fine treatment and product acquiring. The few-layer graphene has 1-8 layers, a specific surface area of 450-800m<2> / g, a conductivity of 20-60S.m<-1>, and a weight loss of 1-2wt%within 900DEG C. Compared with the prior art, the preparation method disclosed in the invention has the advantages of simplicity, high yield, low production cost, low equipment requirement, and green and environment-friendly preparation process, thus being worthy of promotion.

Owner:湖南元素密码石墨烯高科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com