Patents

Literature

1846 results about "Argon atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description Argon (Ar) is an inert gas that comprises 0.93 percent of the earth’s atmosphere. Argon is Colorless, odorless, tasteless and nontoxic, argon forms no known chemical compounds. A specific gravity of 1.38 makes argon 25 percent heavier than air.

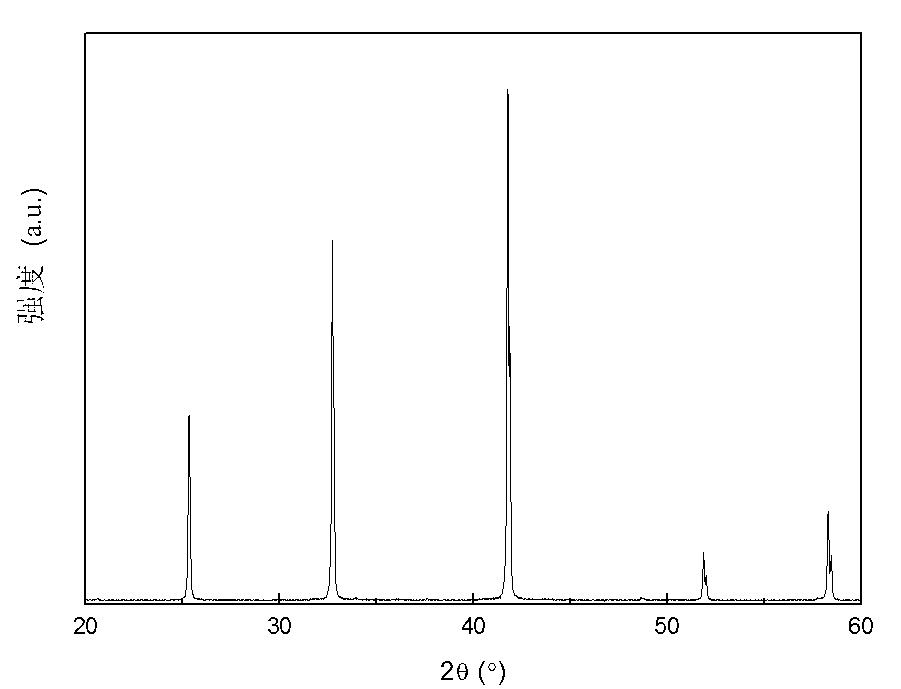

Infrared shielding material microparticle dispersion infrared shield, process for producing infrared shield material microparticle and infrared shielding material microparticle

ActiveUS20060178254A1Improve featuresEffective shieldingPigmenting treatmentTungsten oxides/hydroxidesArgon atmosphereRoom temperature

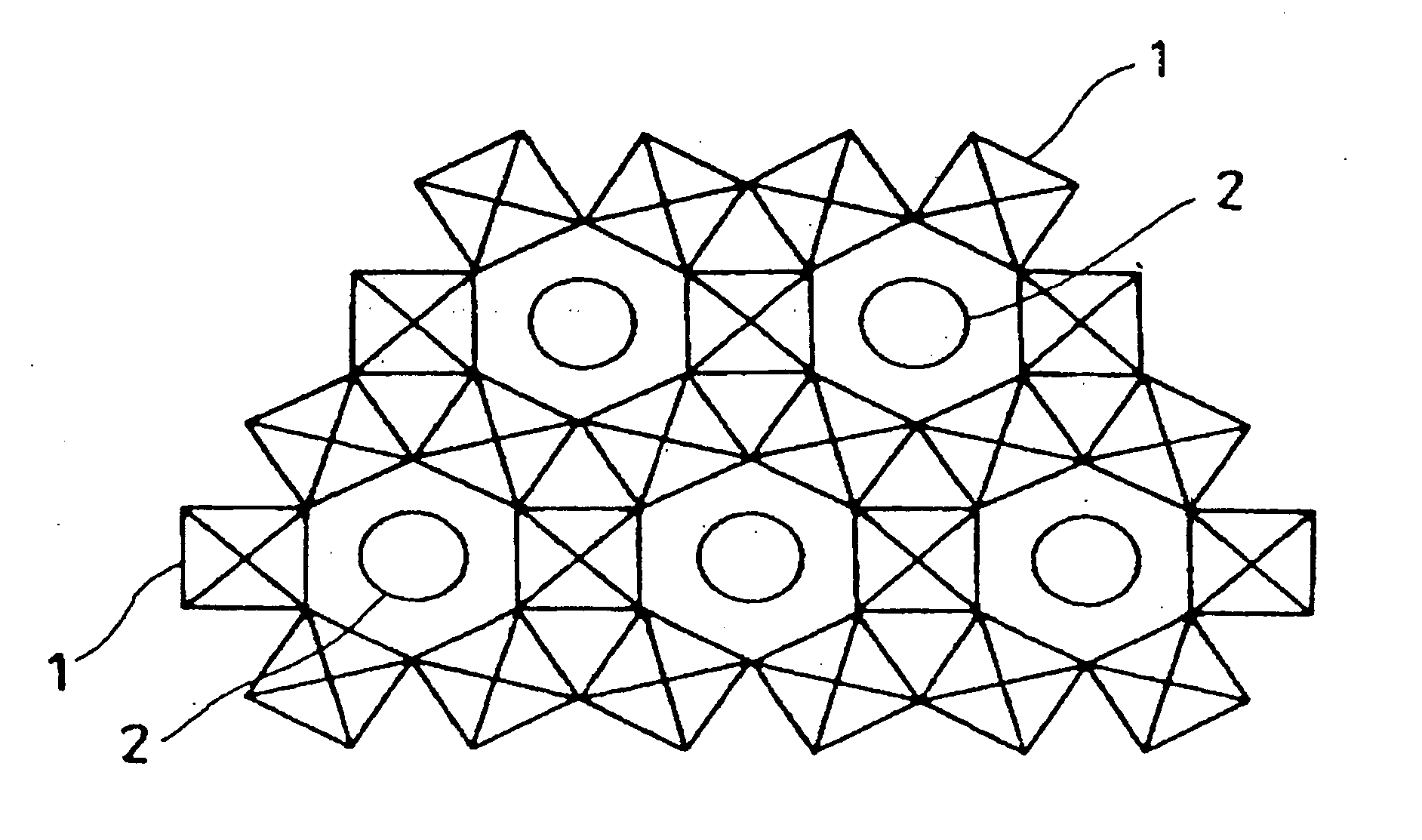

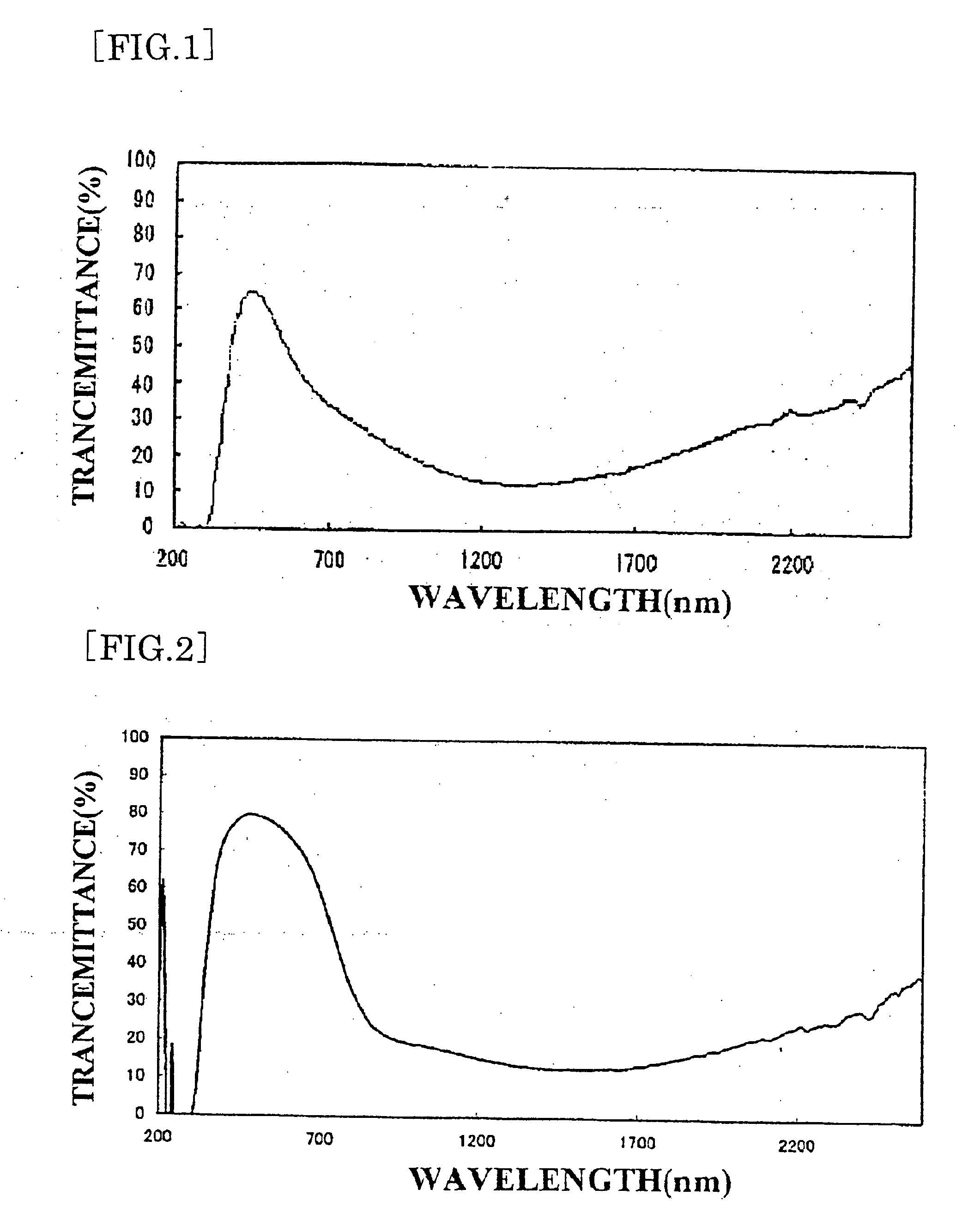

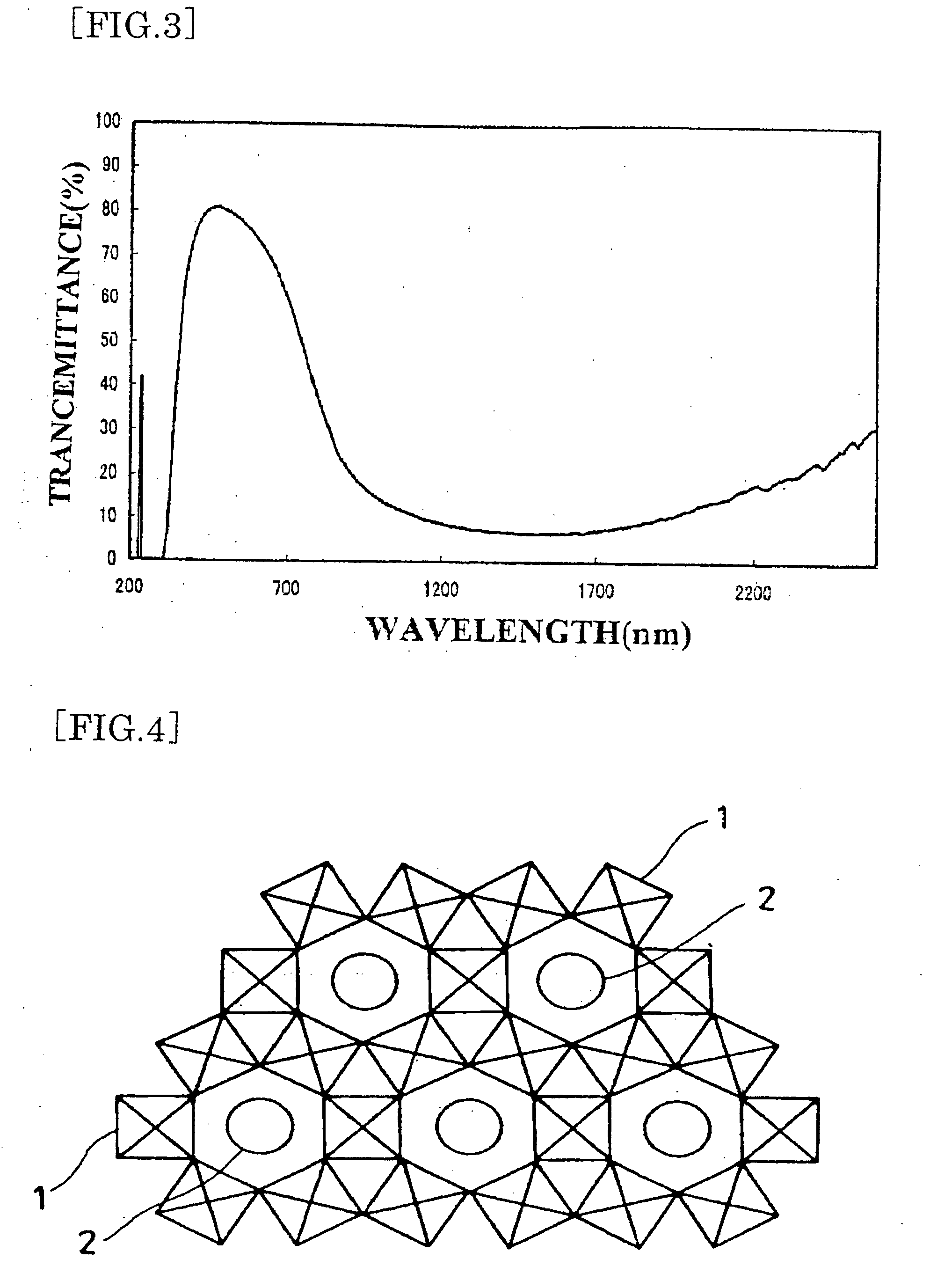

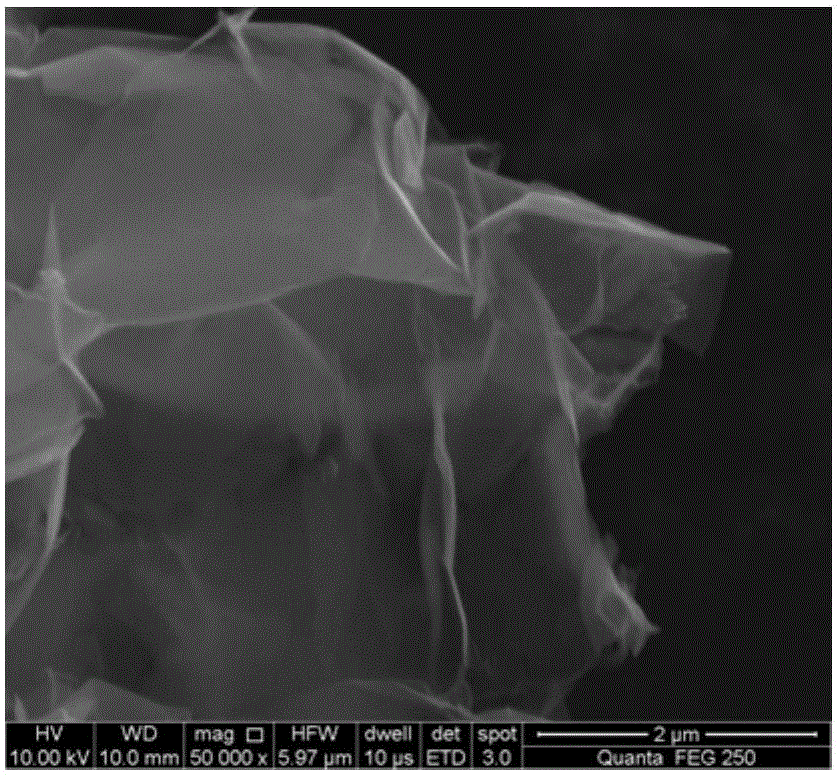

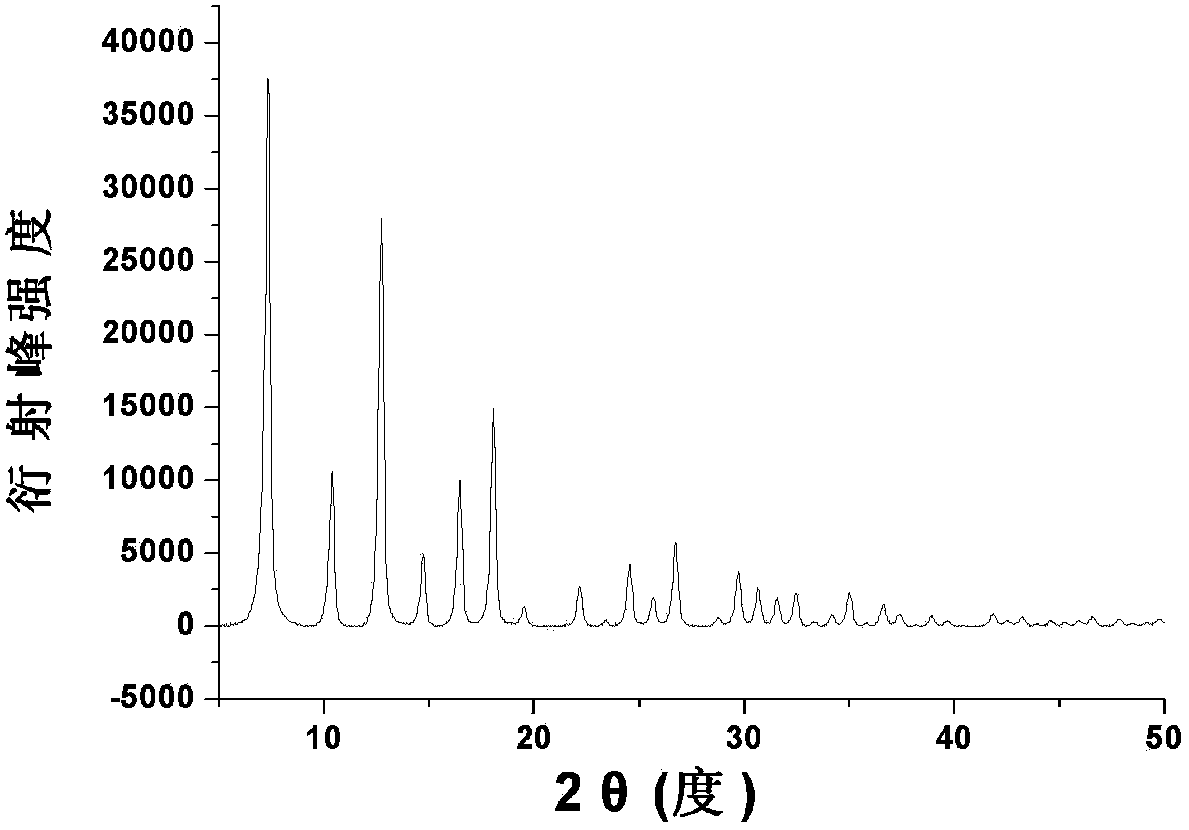

To provide an infrared-shielding body sufficiently transmitting visible rays, having no half-mirror shaped appearance, requiring no large-scale apparatus when forming a film on a substrate, efficiently shutting invisible near-infrared rays with wavelength range of 780 nm or more, while eliminating a heat treatment at high temperature after film formation, and having a spectral characteristic such as transparency with no change of color tone. The starting material, which is a mixture containing a predetermined amount of a tungsten compound, is heated at 550° C. in a reductive atmosphere for 1 hour, then cooled to room temperature once in an argon atmosphere, thus producing powder of W18O49. Then, the powder, the solvent, and the dispersant are mixed, then subjected to dispersion treatment to obtain a dispersion solution. The dispersion solution and a UV-curable hardcoat resin are mixed to obtain a solution of fine particle dispersion of infrared-shielding material. The solution of the fine particle dispersion of infrared-shielding material is applied on a PET resin film to form a film, which is then cured, and an infrared-shielding film having a transmission profile shown in the figure is thereby obtained.

Owner:SUMITOMO METAL MINING CO LTD

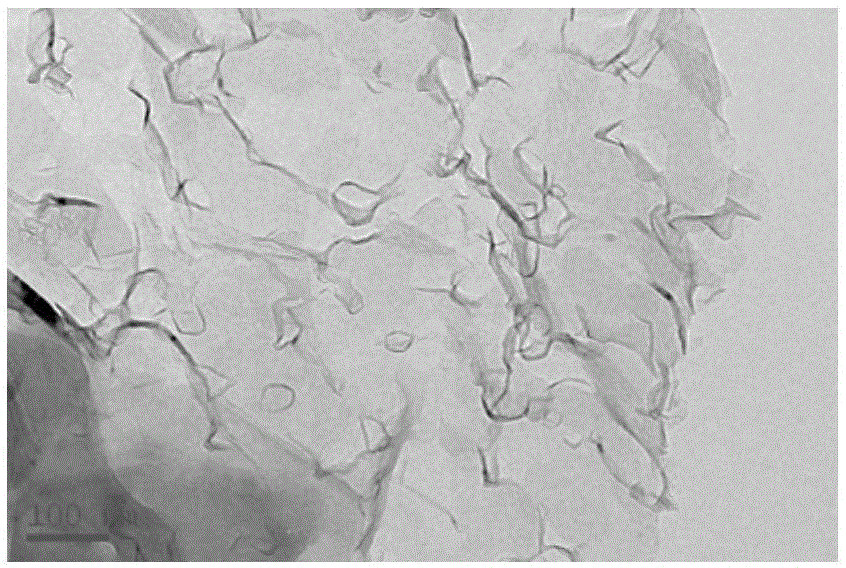

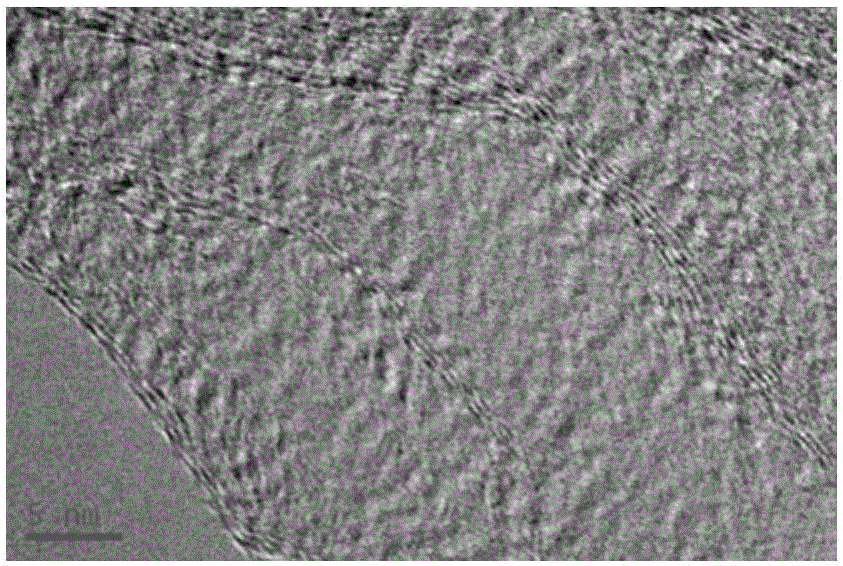

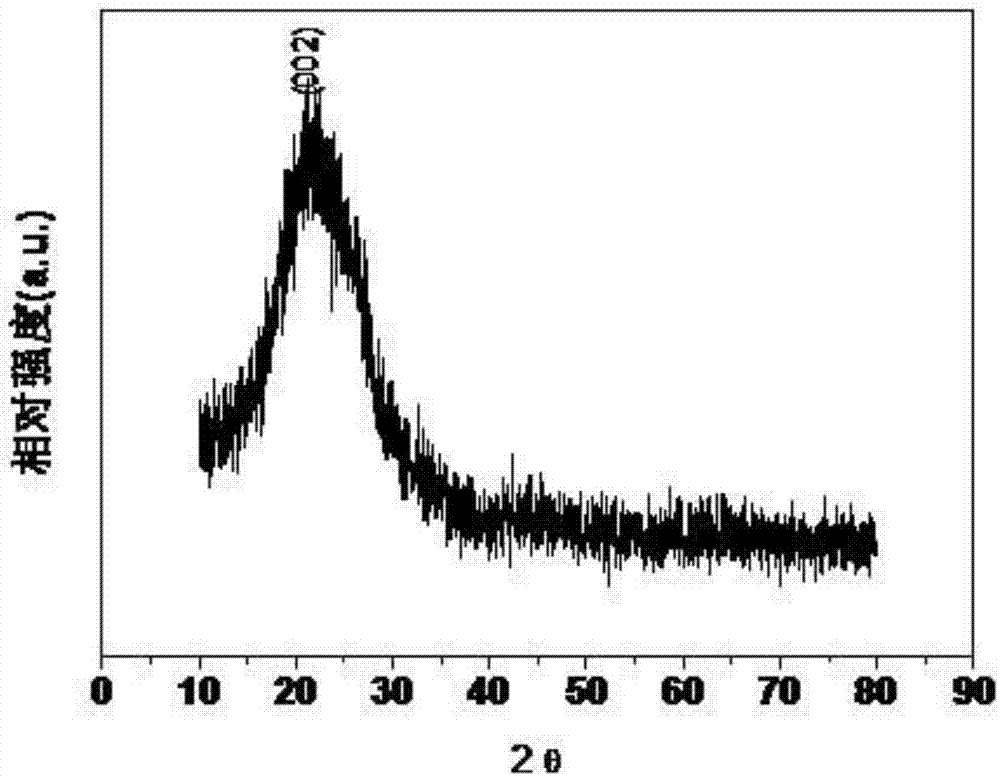

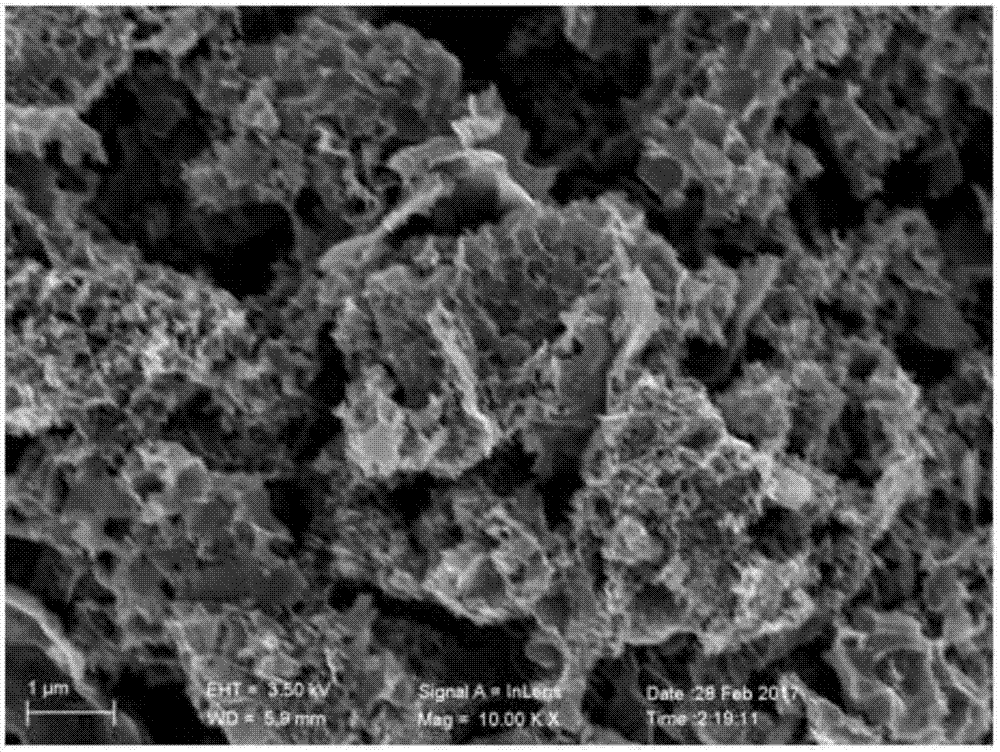

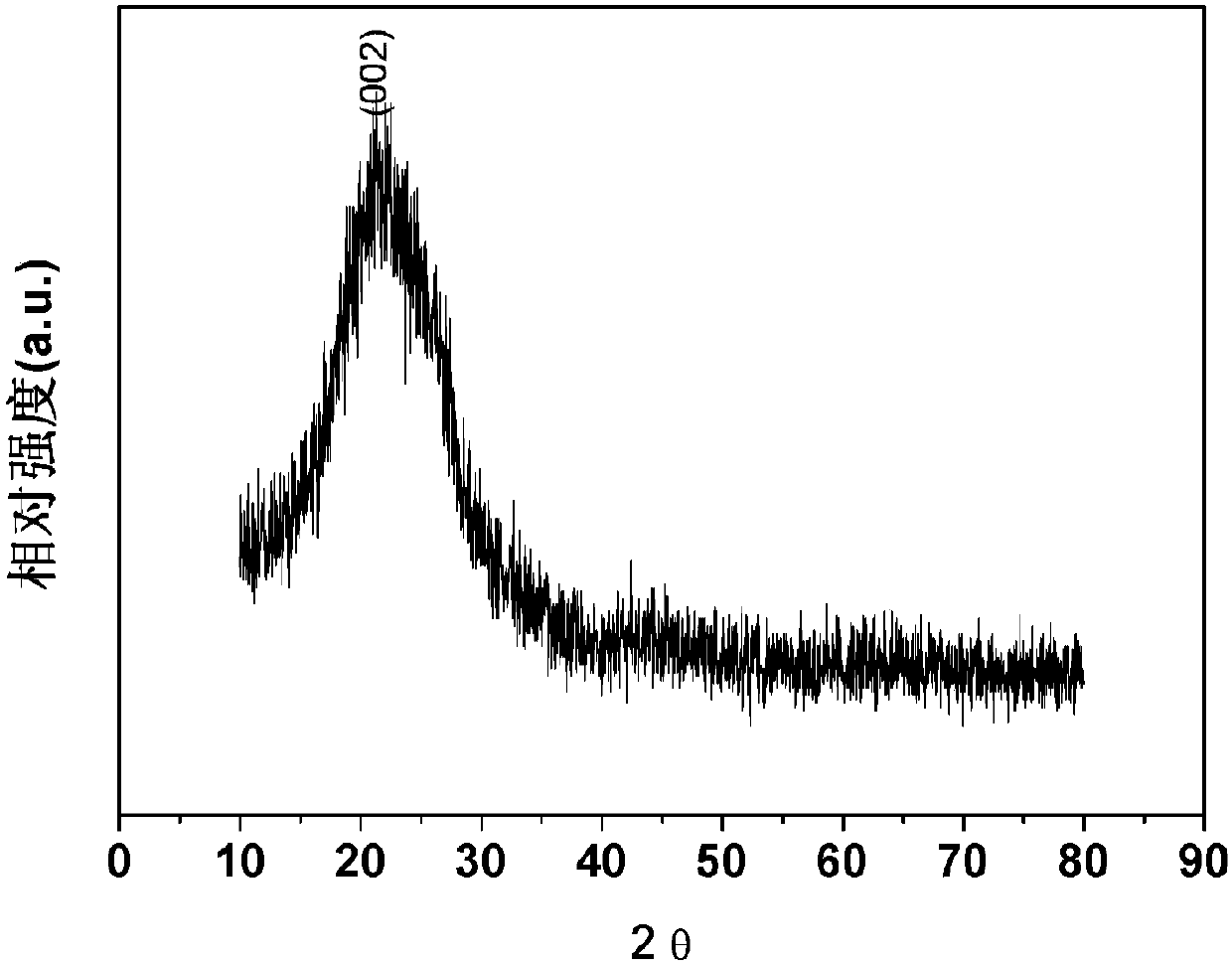

Method for preparing fewer-layer graphene on basis of biomass waste

ActiveCN105060289AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerArgon atmosphere

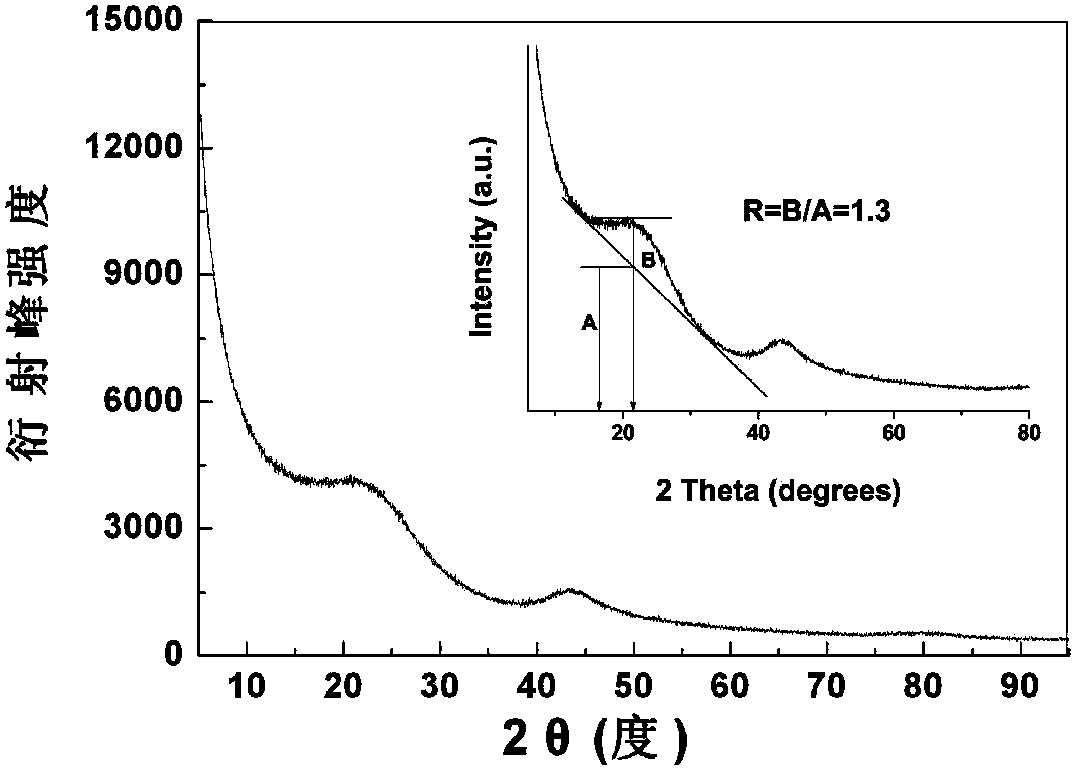

The invention discloses a method for preparing fewer-layer graphene on the basis of biomass waste, which comprises the following steps: carrying out hydrothermal treatment on the biomass waste, and carrying out carbonization by heating and calcination, thereby obtaining a carbonization material; immersing the carbonization material in an acid solution to remove impurities, thereby obtaining biomass carbon; and quickly heating the biomass carbon in an argon atmosphere, and carrying out high-temperature graphitization to obtain the biomass fewer-layer graphene. The hydrothermal process is combined with the high-temperature graphitization to directly strip the biomass waste, and the carbonization and high-temperature graphitization are carried out. Thus, the prepared biomass fewer-layer graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The method is simple to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production. The prepared biomass fewer-layer graphene can be used in the fields of lithium ion batteries, supercapacitors and the like, is beneficial to green production of battery industry, and has important practical value and favorable application prospects.

Owner:湖南宸宇富基新能源科技有限公司

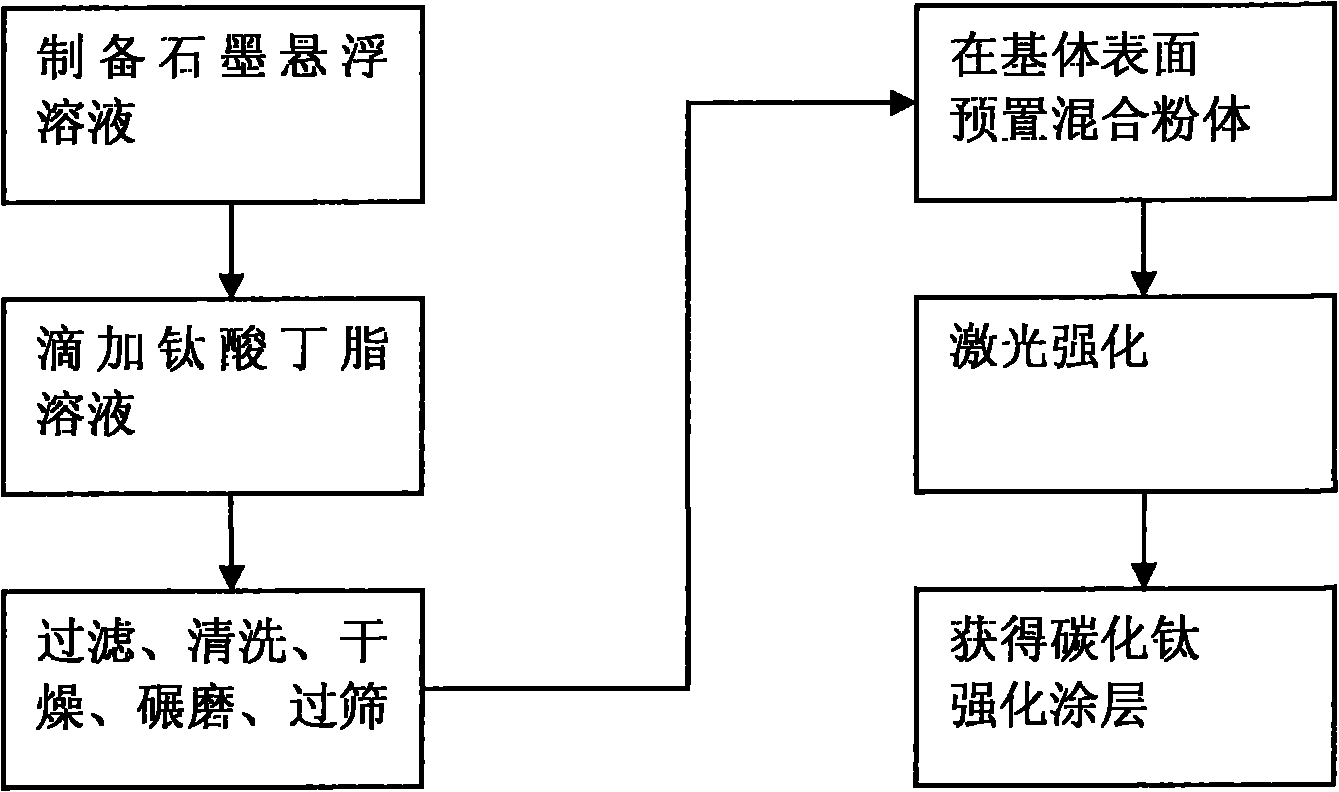

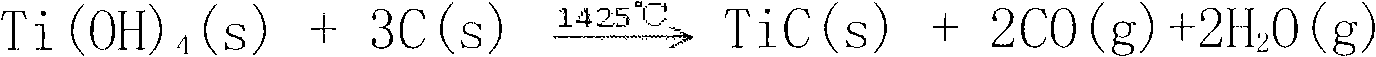

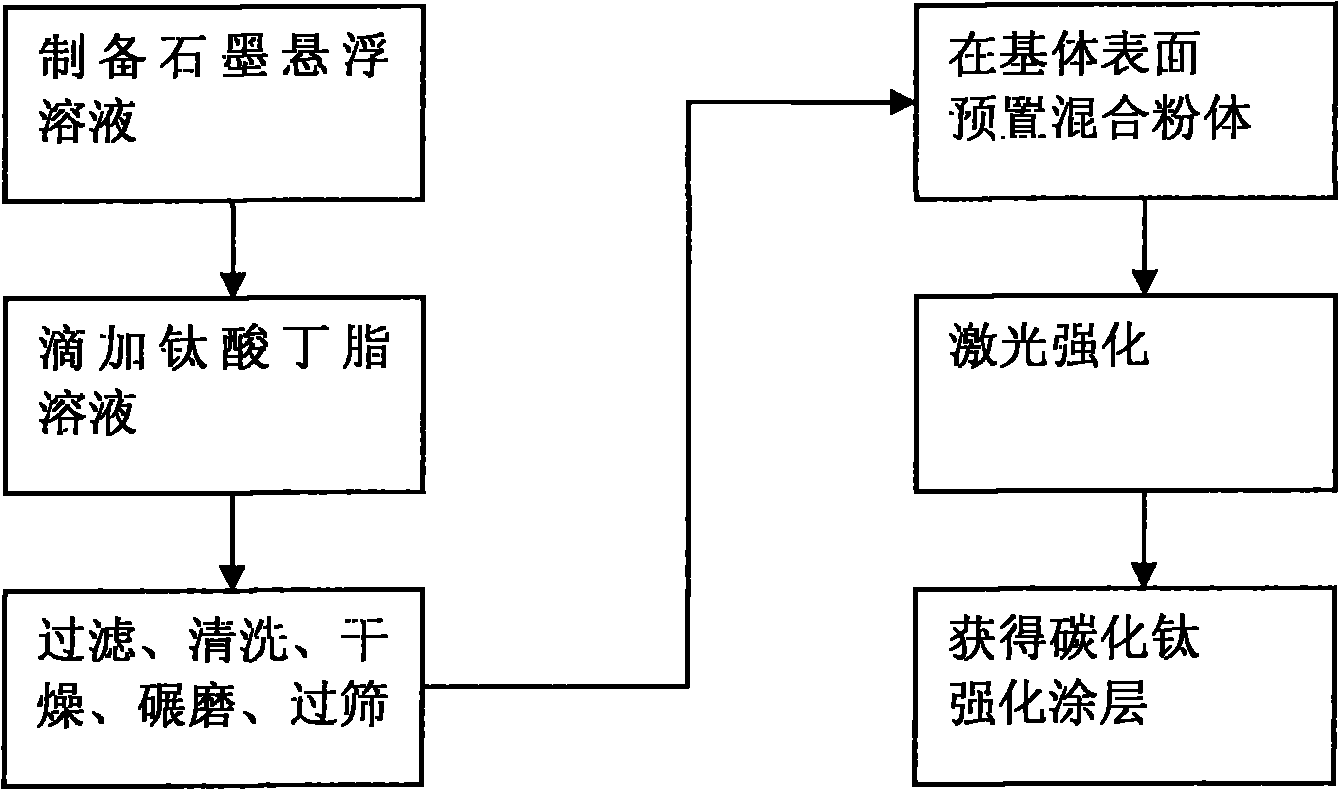

Method for preparing metal surface laser strengthened coat

InactiveCN101812684AIncrease profitImprove the strengthening effectMetallic material coating processesChemical reactionArgon atmosphere

The invention discloses a method for preparing a metal surface laser strengthened coat, which comprises the following steps: preparing uniformly mixed powder of titanium dioxide hydrate and graphite powder by using a wet chemistry method; pre-placing the mixed powder on the surface of a basal body; and irradiating the surface of the basal body by using laser as a heat source under an argon atmosphere to form a molten pool, performing a carbon-thermal chemical reaction on the pre-placed mixed powder under a high-temperature environment to generate titanium carbide, and finally forming a titanium carbide composite coat on the surface of the basal body. In the same way, the method is also suitable for preparing a TiN enhanced composite coat by mixing hydrated oxide thereof and graphite by the wet chemistry method, then mixing the mixture and urea to form pre-placed powder and cladding the pre-placed powder on the basal body by laser. The surface of the enhanced coat prepared by the technical scheme is smooth, and has no cracks or pores; enhancing particles are uniformly distributed in the coat; the enhanced coat and the basal body are metallurgically combined; and the mixed powder prepared by adopting the wet chemistry method is uniformly mixed, ensures complete reaction, and is suitable for industrial popularization and application.

Owner:姚建华

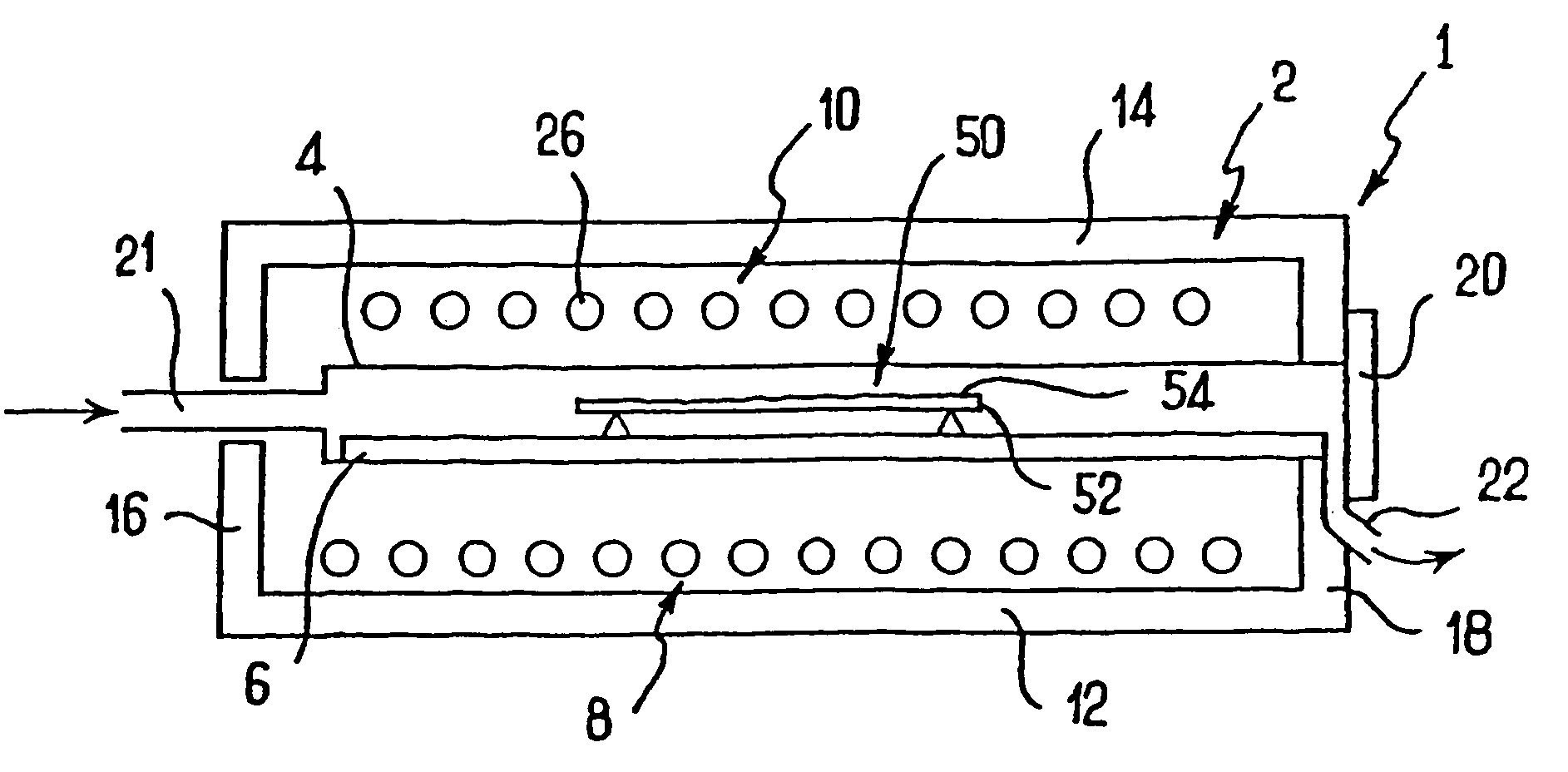

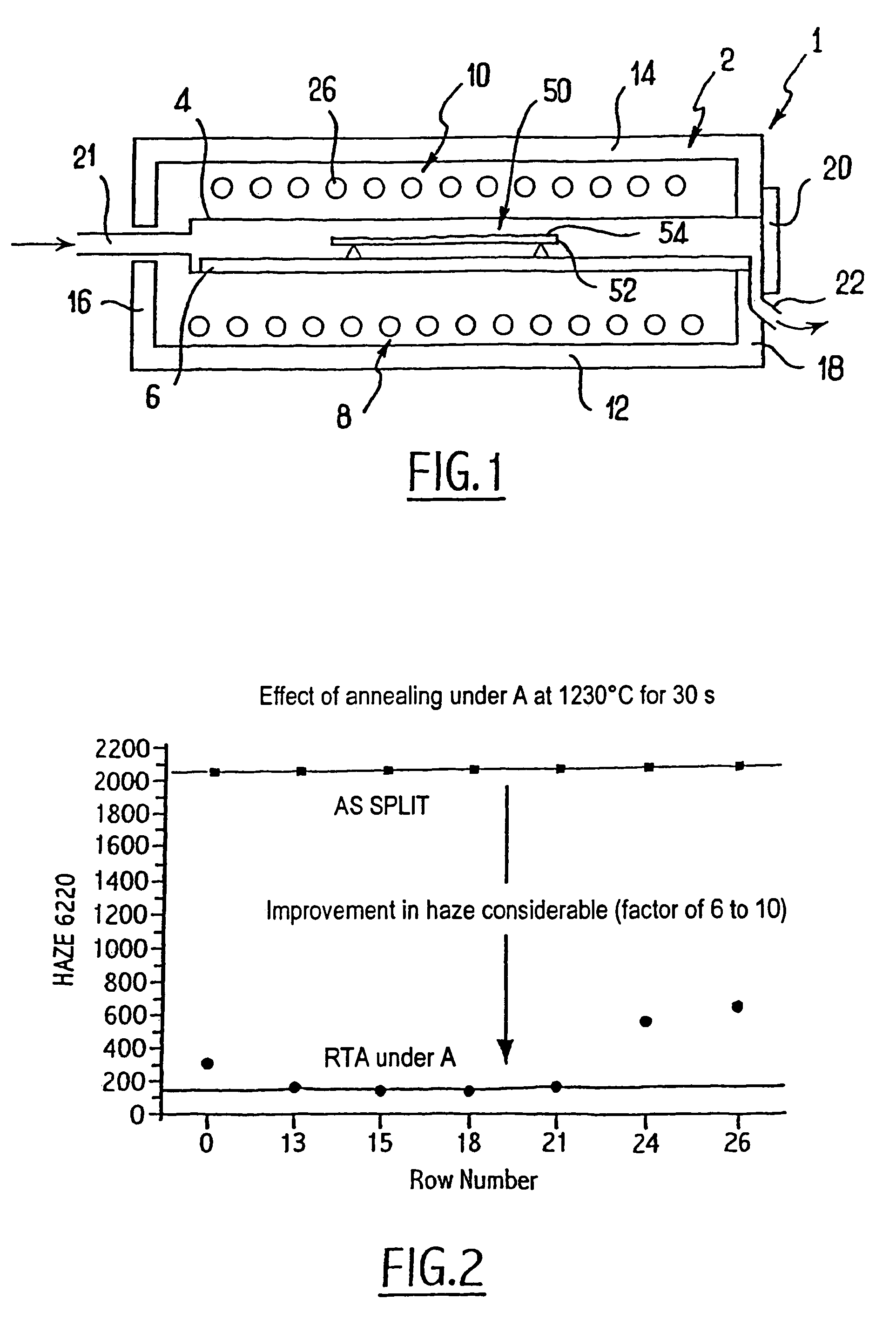

Method for reducing free surface roughness of a semiconductor wafer

InactiveUS6962858B2Reduce roughnessSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSemiconductor materials

The invention provides a method of reducing the roughness of the free surface of a wafer of semiconductor material by applying a rapid thermal annealing process under a pure argon atmosphere for a time sufficient to uniformly heat and smooth the free surface of the wafer.

Owner:SOITEC SA

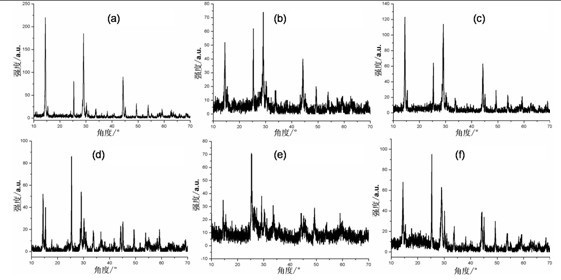

Preparation method for vanadium dioxide and doped powder thereof

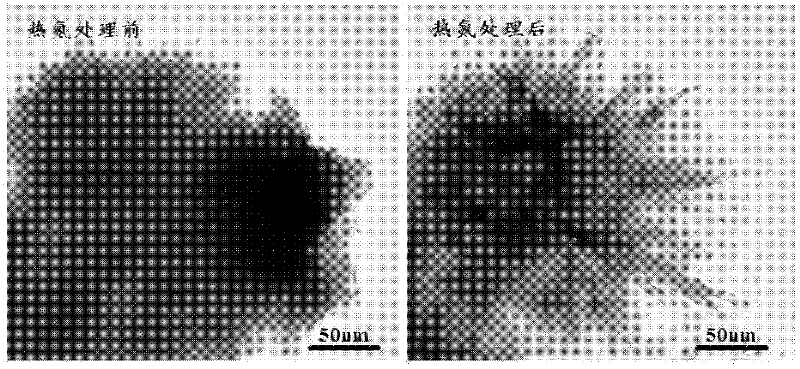

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

Preparation method of spinel-type magnetic MFe2O4/graphene composite material

InactiveCN102745675AHigh purityImprove bindingIron oxides/hydroxidesZinc oxides/hydroxidesNitrogen gasSolvent

The invention discloses a preparation method of a spinel-type magnetic MFe2O4 / graphene composite material. The preparation method utilizes a water-soluble metal M<2+> salt and a Fe<3+> salt as precursors and graphite oxide as a matrix and comprises the following steps of carrying out ultrasonic dispersion of graphite oxide in ethanol or water as a solvent to obtain a graphene oxide dispersion, adding a M<2+> salt and Fe<3+> salt-containing aqueous solution having a M<2+> / Fe<3+> mole ratio of 1: 2 into the graphene oxide dispersion, fully stirring to obtain a mixed solution, adjusting a pH value of the mixed solution to a value more than 10 by an alkali liquor, adding a reducing agent into the mixed solution, stirring at a temperature of 80 to 150 DEG C for a reaction lasting for 4 to 10 hours, after the reaction is finished, carrying out separation, washing, drying and grinding, and carrying out calcination of the grinded powder at a temperature of 300 DEG C in a nitrogen or argon atmosphere for 2 to 10 hours. Magnetic MFe2O4 nano particles of the spinel-type magnetic MFe2O4 / graphene composite material have high loading capacity, stable structures, good uniformity, good dispersibility and strong adhesion with graphene. The spinel-type magnetic MFe2O4 / graphene composite material can be widely used in the fields of magnetic targeting materials and other related function materials.

Owner:HEFEI UNIV OF TECH

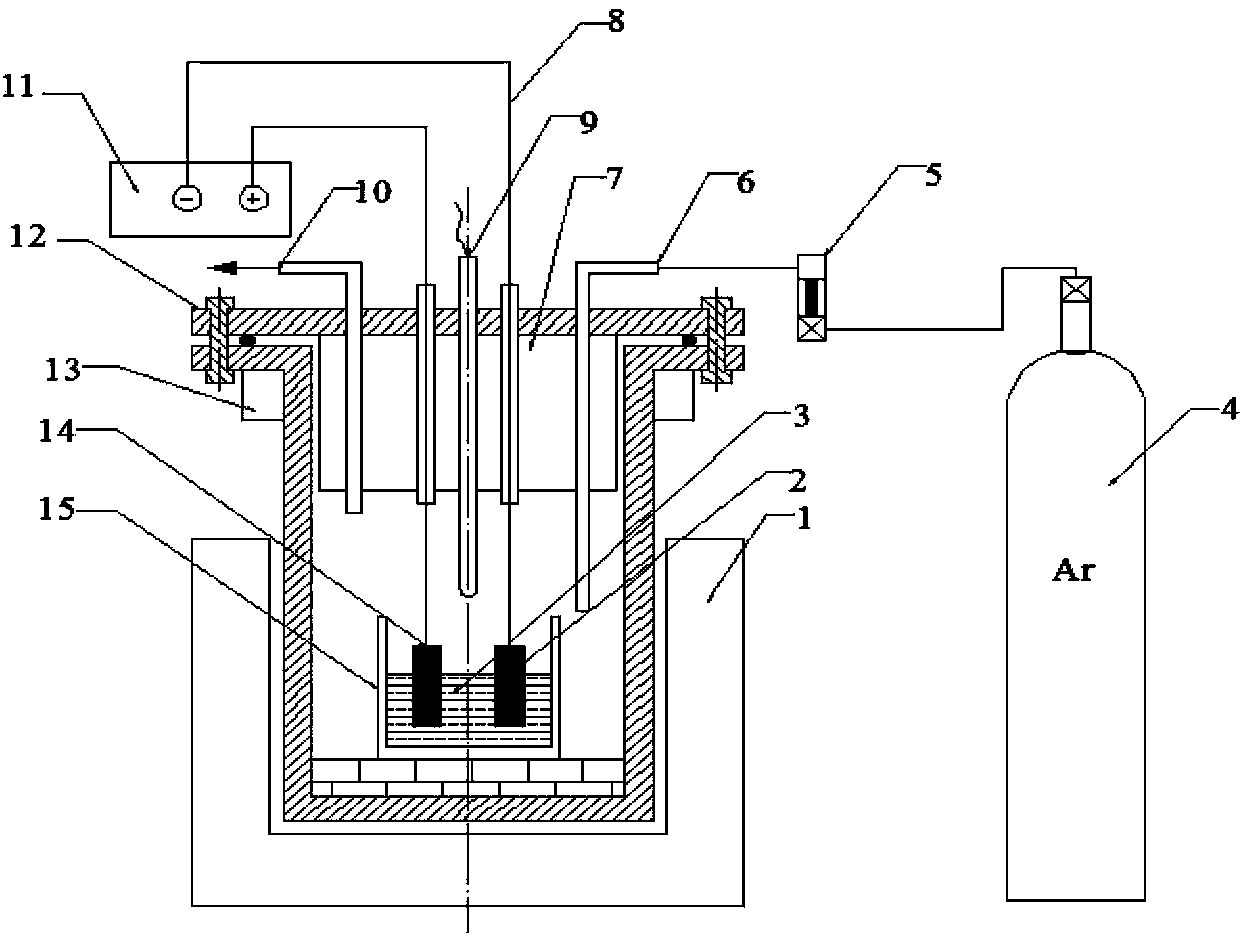

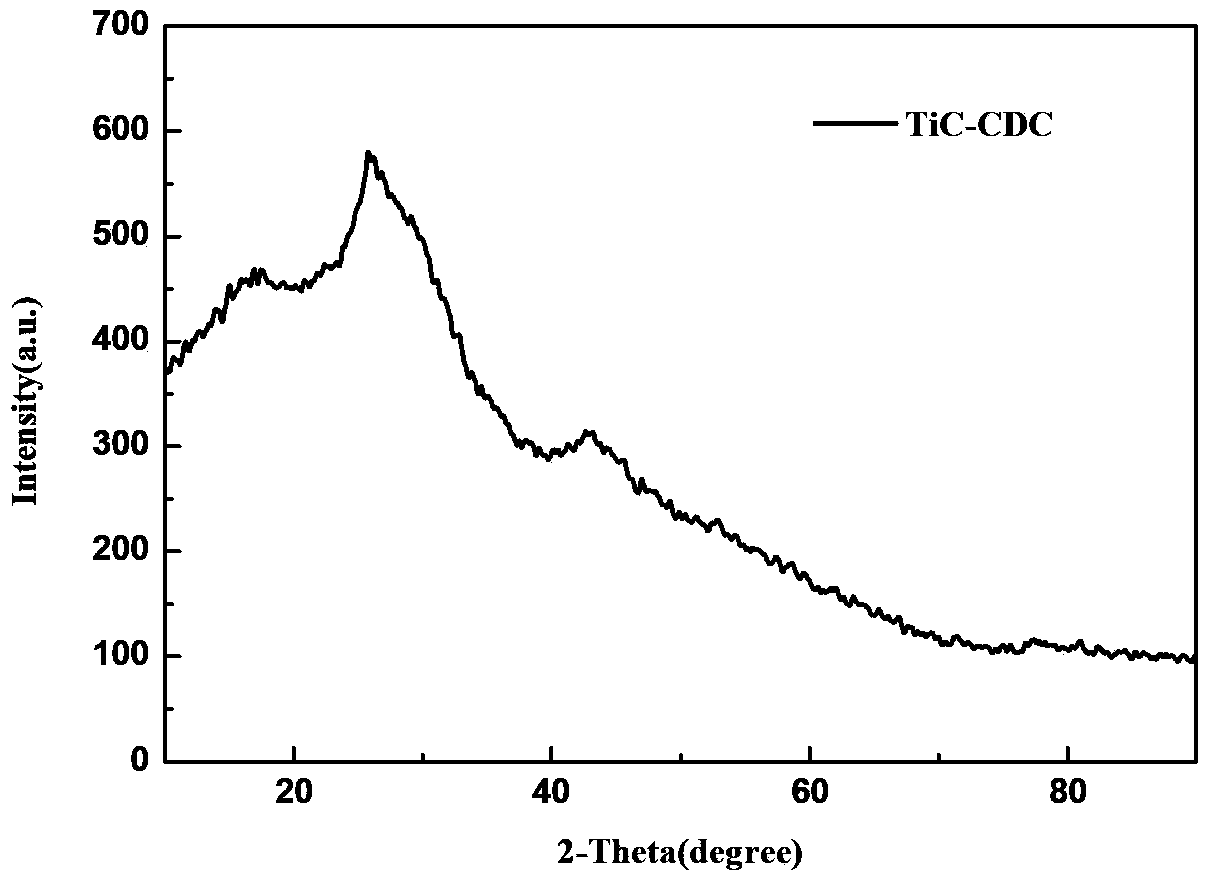

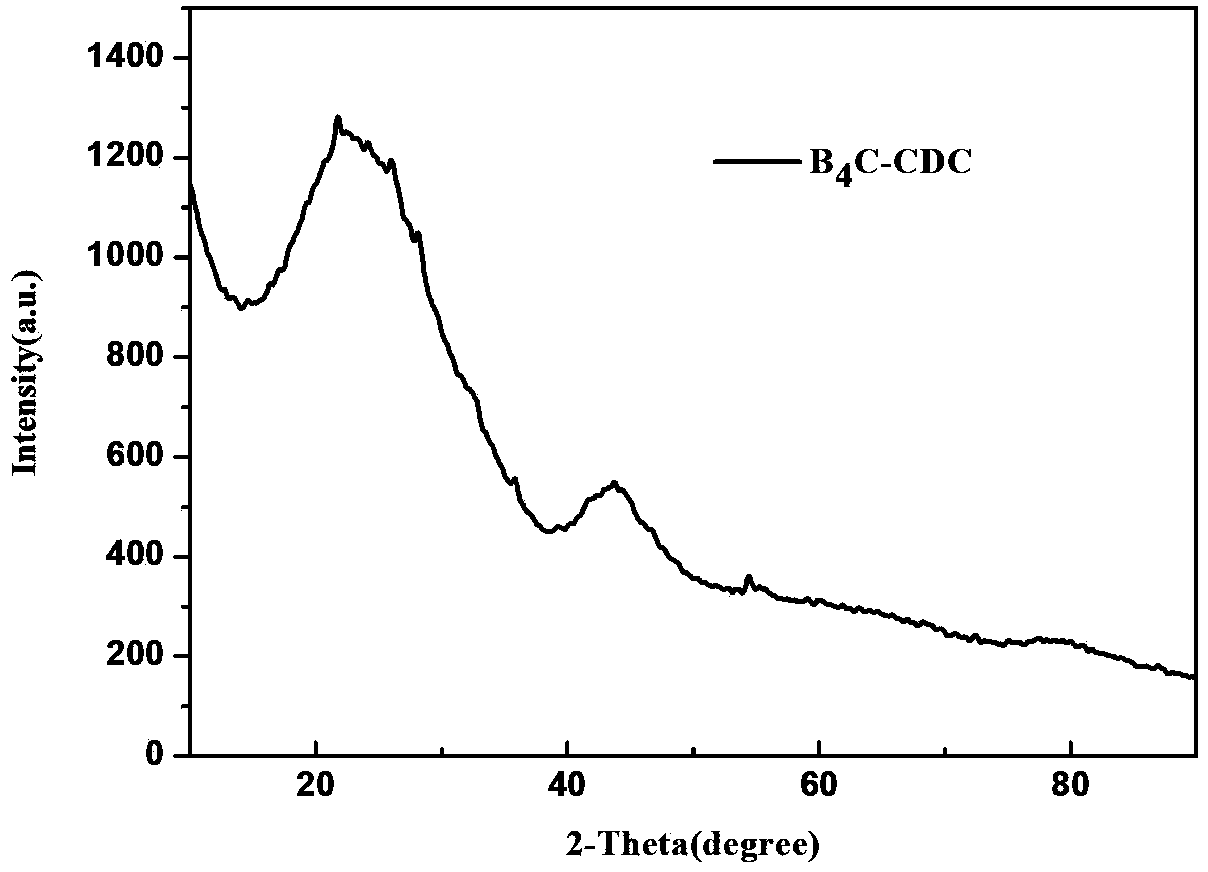

Method for preparing carbide derived carbon by fused salt electrolysis method

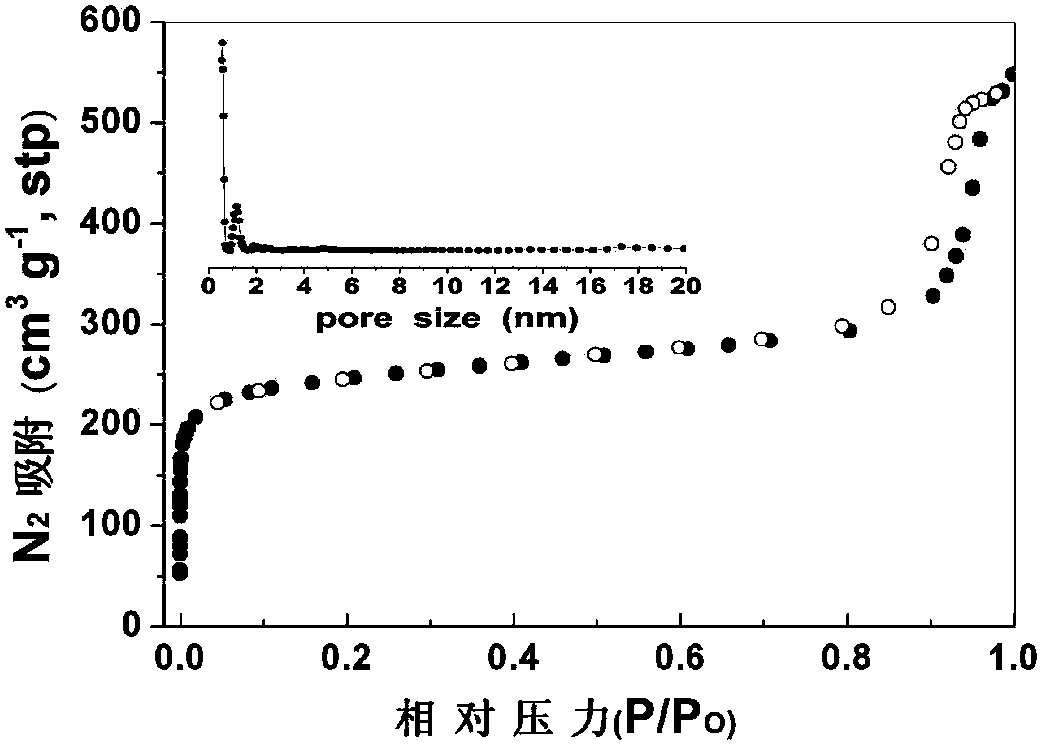

InactiveCN103436904AHigh purityUniform pore size distributionElectrolysis componentsCarbon preparation/purificationElectrolysisArgon atmosphere

The invention discloses a method for preparing carbide derived carbon by a fused salt electrolysis method. The method mainly comprises the steps that metal carbide serves as a raw material, and is subjected to die pressing sintering to form a metal carbide sheet to serve as an anode; by taking fused salt as an electrolyte, and a high-purity and high-density graphite rod as a cathode, fused salt electrolysis is performed in an electrolysis furnace in an argon atmosphere with the electrolysis temperature of 400-1300 DEG C, the electrolysis voltage of 1.8-3.2V, and the electrolysis time of 2-60h; after the electrolysis, an anode product is taken out, and subjected to water washing, ultrasonic-assisted pickling, water washing and drying treatment; and the carbide derived carbon is prepared. According to the method, the low-cost metal carbide can serve as the raw material for preparing the carbide derived carbon by the fused salt electrolysis method, so that a preparation technology is simplified; the cost is lowered; and the prepared carbide derived carbon serves as an electrode material of a supercapacitor, and has high specific capacity and good cycling stability.

Owner:YANSHAN UNIV

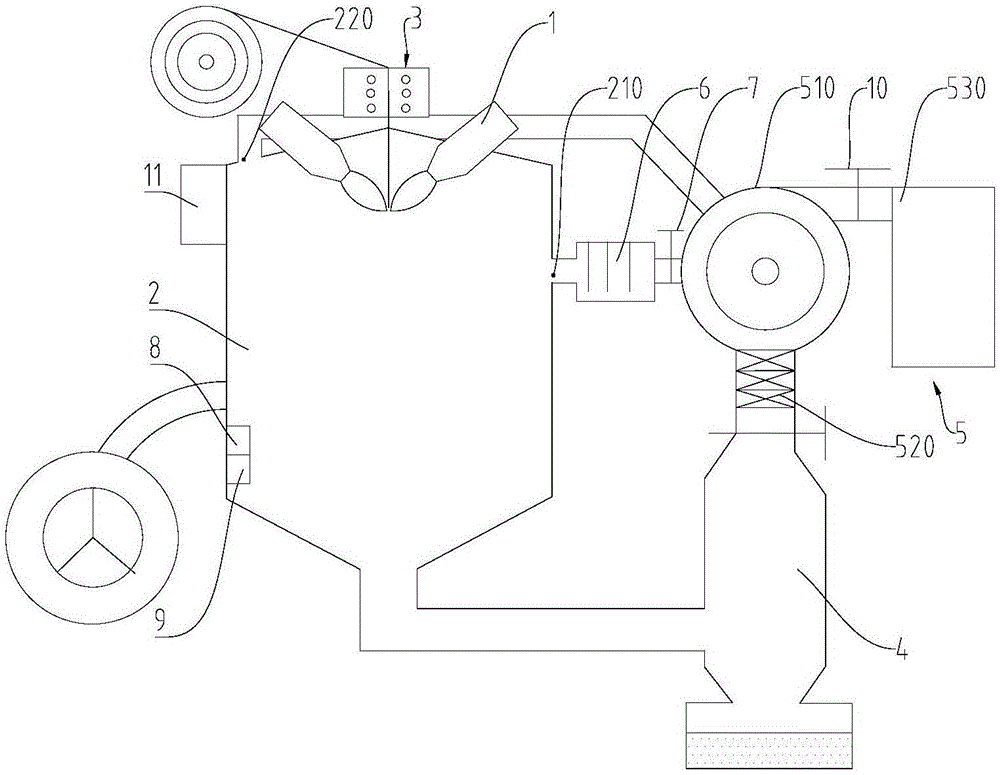

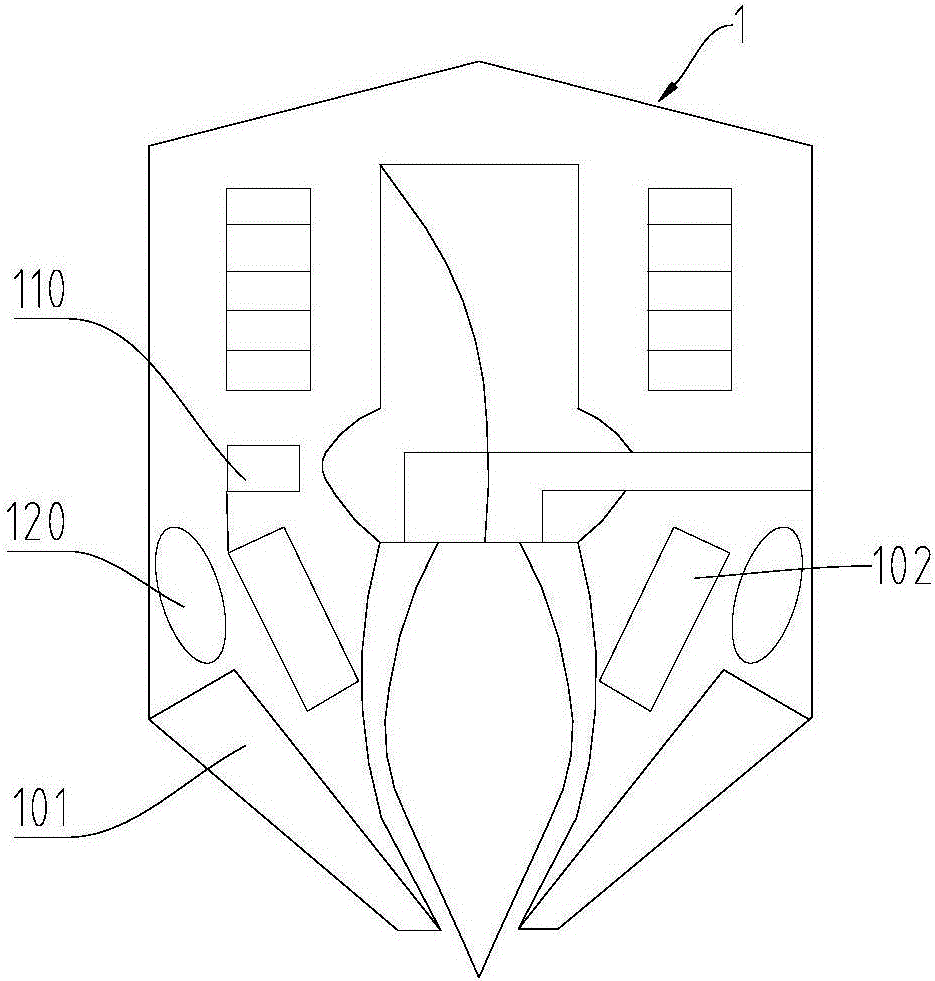

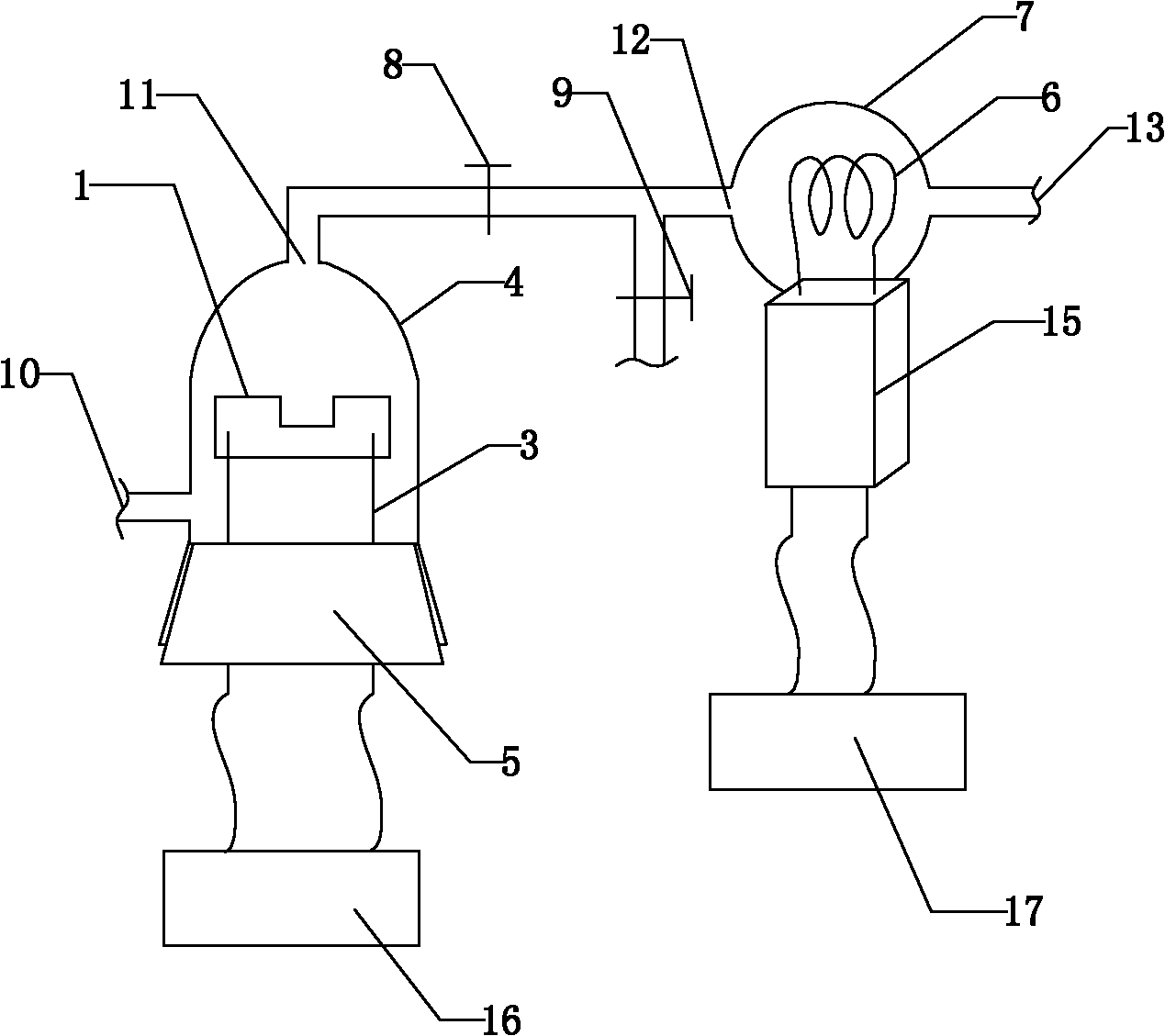

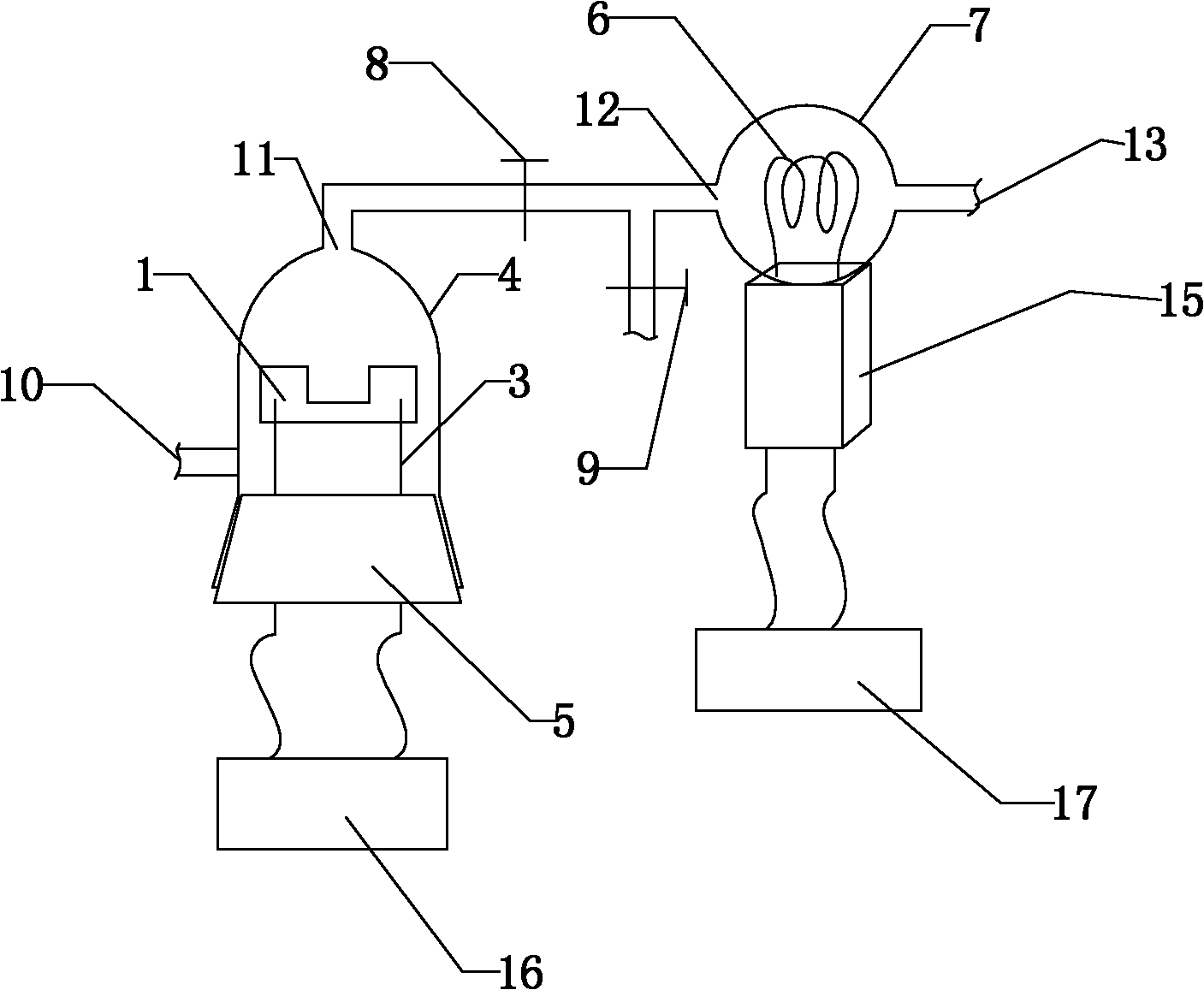

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

Method for preparing G/Sn/PAN-base carbon nanometer fiber membrane

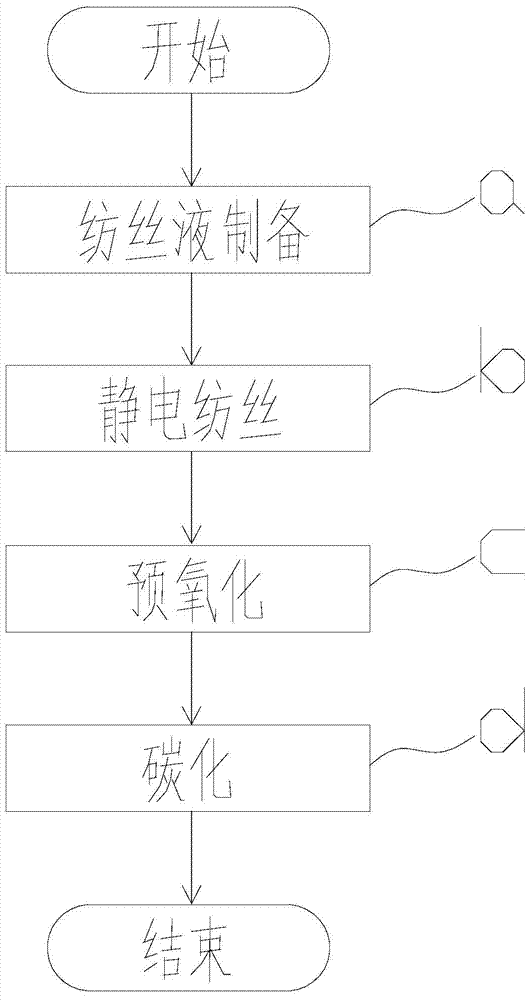

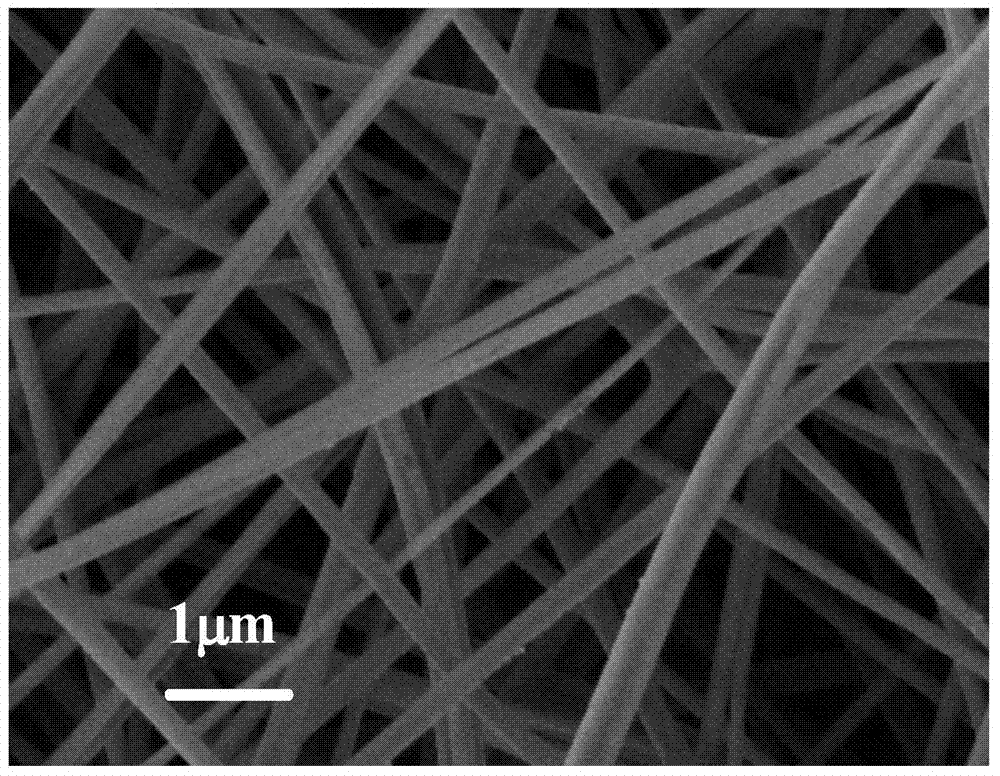

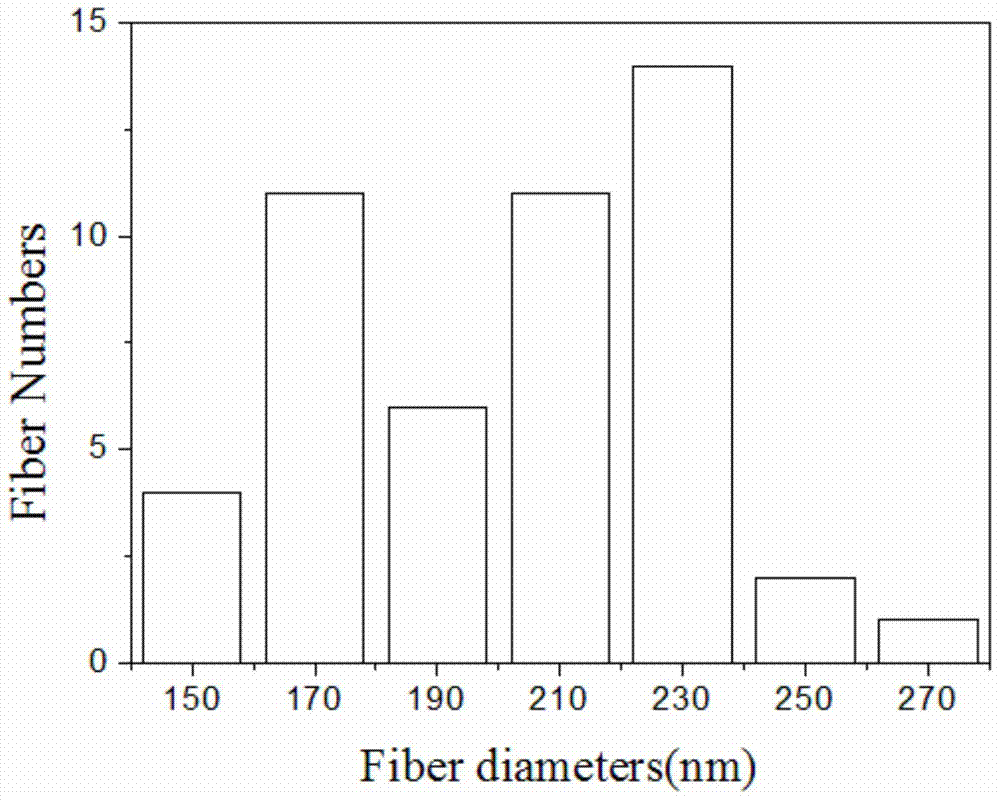

InactiveCN103757823AEvenly distributedWrappedFilament/thread formingHeating/cooling textile fabricsPorosityAir atmosphere

The invention discloses a method for preparing a G / Sn / PAN-base carbon nanometer fiber membrane. The method for preparing the G / Sn / PAN-base carbon nanometer fiber membrane includes: 1) preparing spinning solution, to be more specific, weighing polyacrylonitrile, nanometer tin powder and graphene nanometer film according to certain mass ratio, blending and dissolving in N-N dimethyl formamide, and stirring to obtain the uniformly dispersed electrostatic spinning solution; b) electrostatic spinning, to be more specific, carrying out electrostatic spinning on the electrostatic spinning solution of the step a) to obtain a graphene / tin / polyacrylonitrile nanometer fiber membrane; c) pre-oxidizing, to be more specific, pre-oxidizing the graphene / tin / polyacrylonitrile nanometer fiber membrane of the step b) in air atmosphere to obtain the pre-oxidized nanometer fiber membrane; d) carbonizing, to be more specific, carbonizing the pre-oxidized nanometer fiber membrane in argon atmosphere to obtain the G / Sn / PAN-base carbon nanometer fiber membrane. The method for preparing the G / Sn / PAN-base carbon nanometer fiber membrane is easy to operate, the graphene coats the nanometer fiber well; the G / Sn / PAN-base carbon nanometer fiber membrane has advantages of large specific surface area, high porosity, and high electrical conductivity and so on, and has broad expanding space.

Owner:ZHEJIANG SANZHI TEXTILES

Preparation method of boron/nitrogen-doped microporous carbon material

InactiveCN103508434AGood hydrogen storage performanceStrong selective adsorption performanceOther chemical processesCarbon preparation/purificationArgon atmosphereNitrogen gas

The invention relates to a preparation method and gas adsorption properties of a boron / nitrogen-doped microporous carbon material, particularly a boron / nitrogen-doped microporous carbon material prepared by using metal organic framework ZIF-8 (zeolitic imidazolate framework-8) and boron nitrogen compounds as precursors by a high-temperature sintering method and gas adsorption properties of the boron / nitrogen-doped microporous carbon material for hydrogen, carbon dioxide, nitrogen and the like. The preparation method comprises the following steps: 1) preparing the porous metal organic framework ZIF-8; 2) limiting the boron nitrogen compounds (such as ammonia borane) to the inside of the pores of the metal organic framework ZIF-8 by a solution impregnating method; and 3) carrying out high-temperature sintering on the composite material in an argon atmosphere to obtain the boron / nitrogen-doped microporous carbon material. The preparation technique is simple; and the prepared carbon material implements simultaneous doping of boron and nitrogen and centralized distribution of micropore sizes, and has favorable adsorption property for hydrogen and selective adsorption property for carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

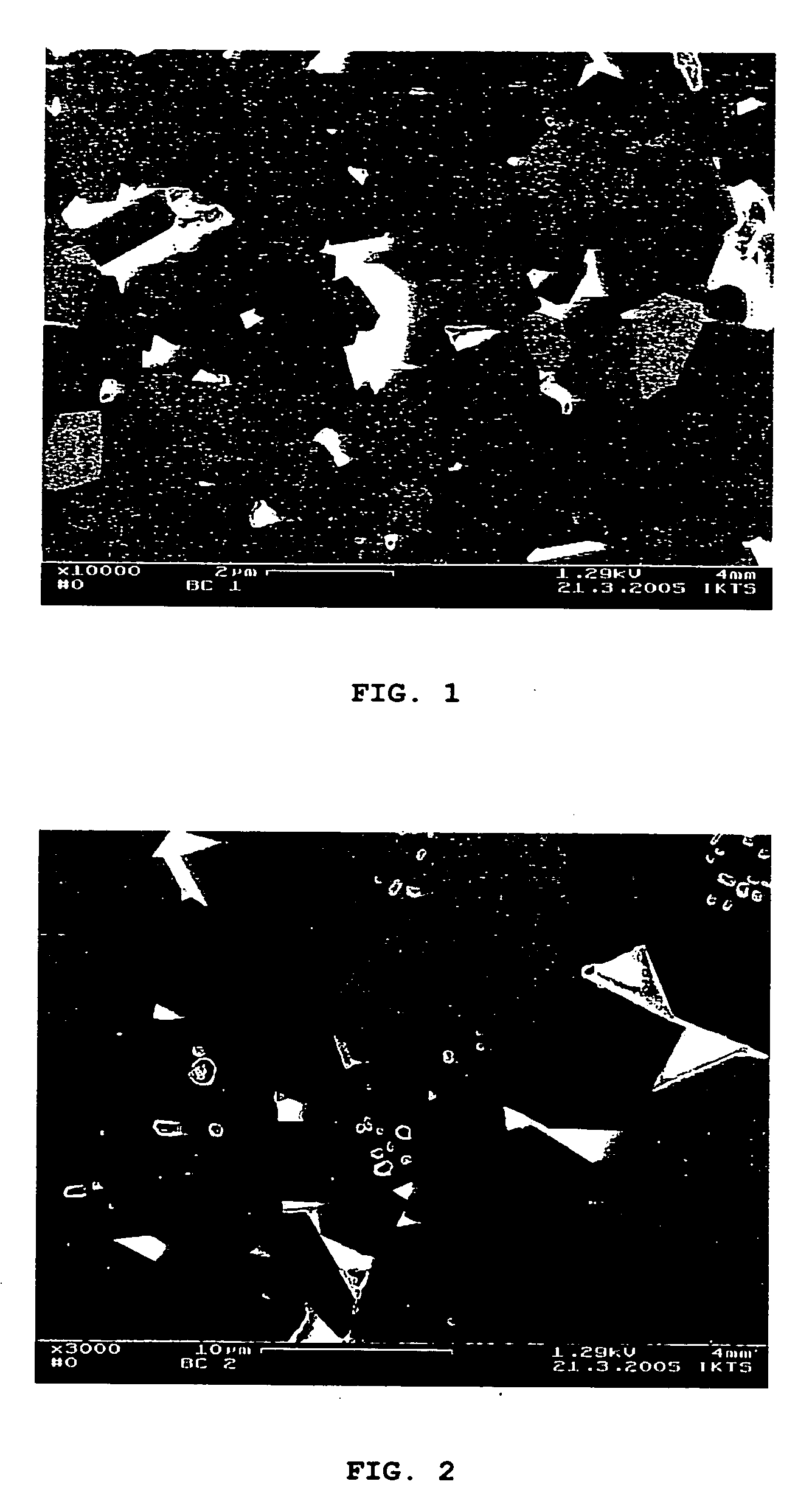

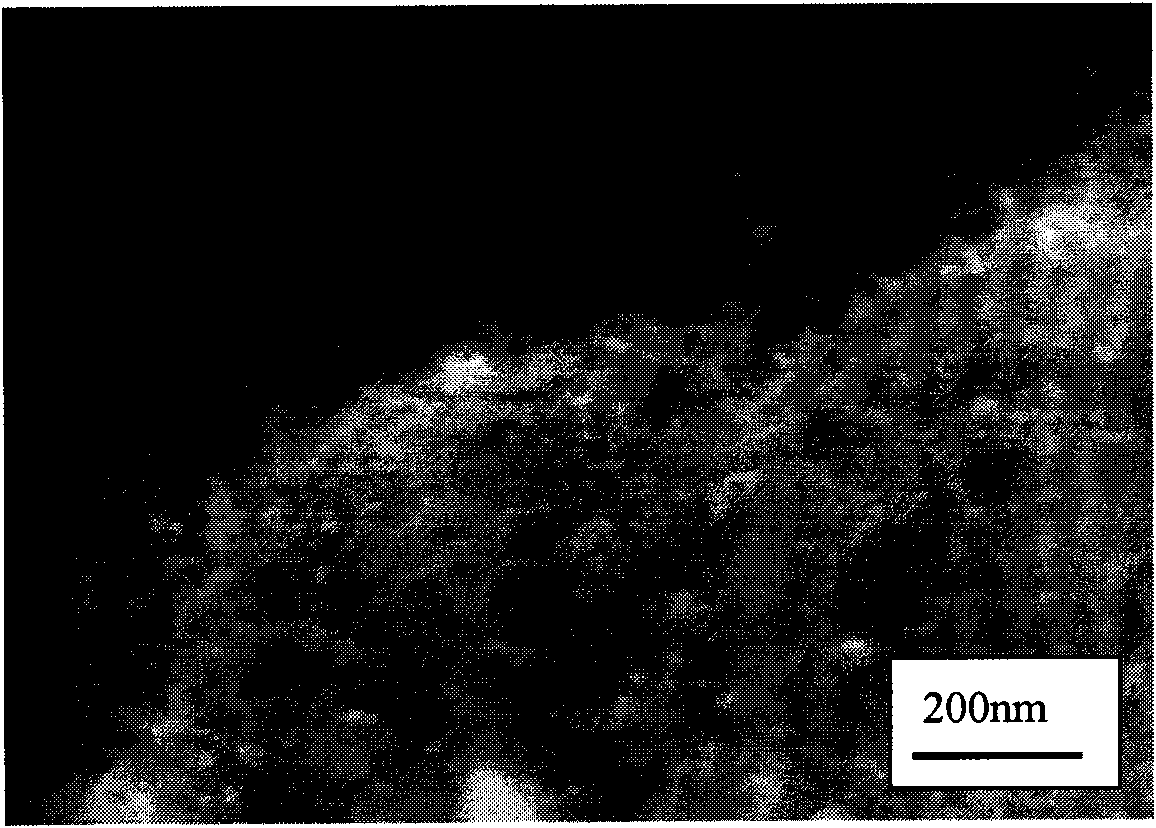

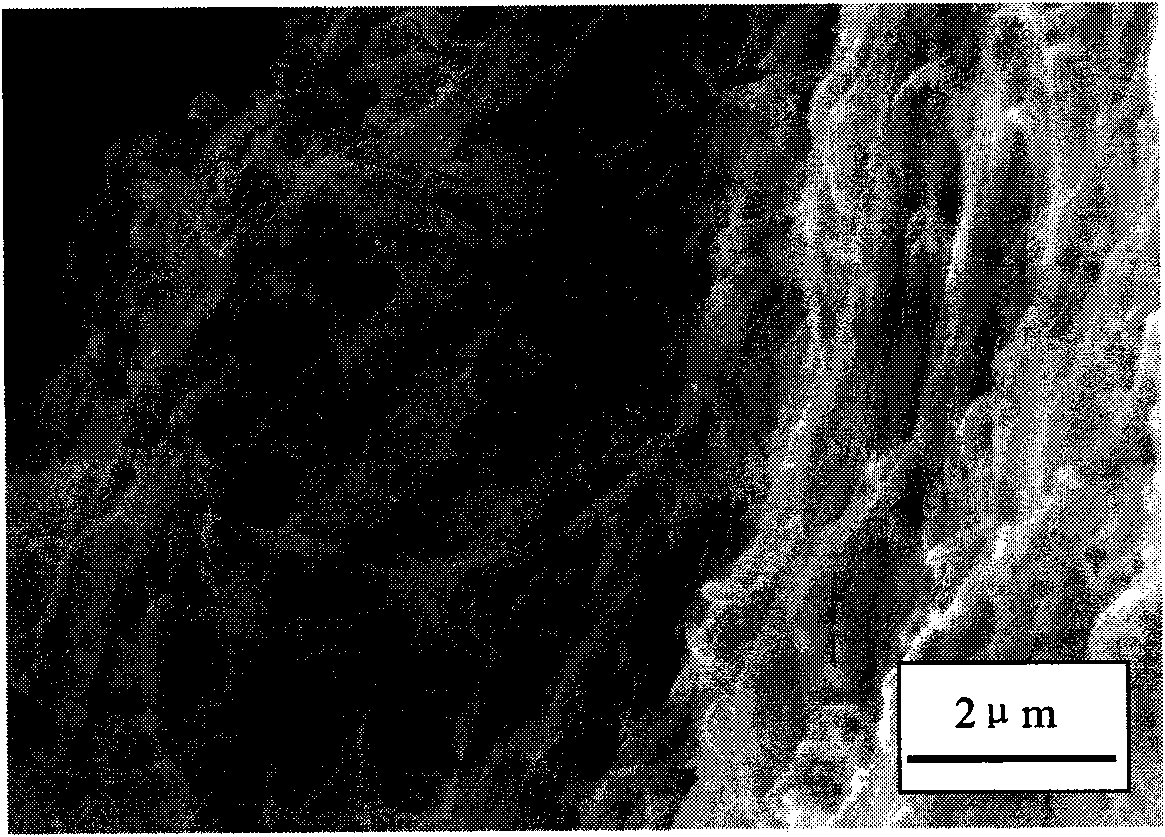

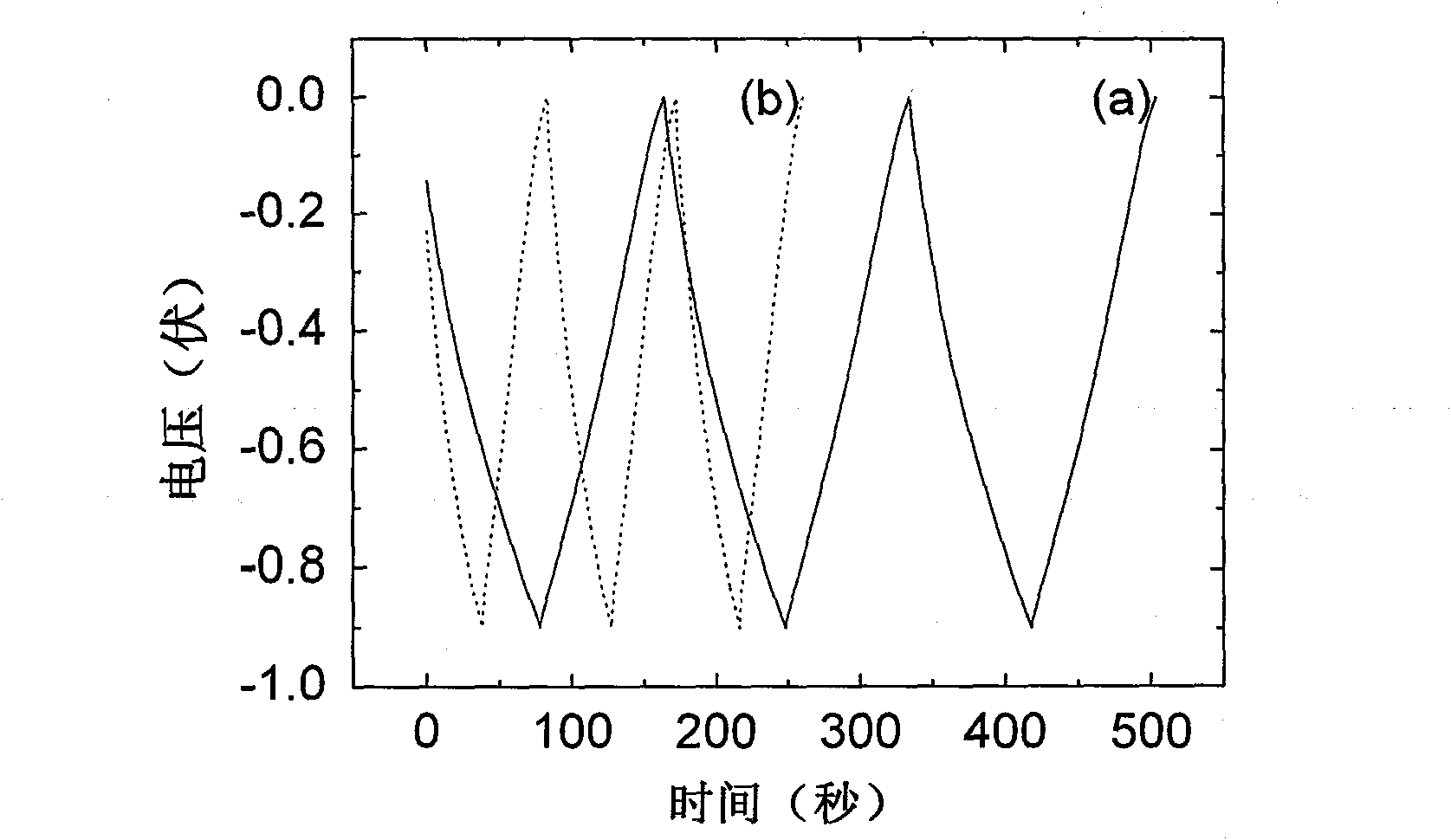

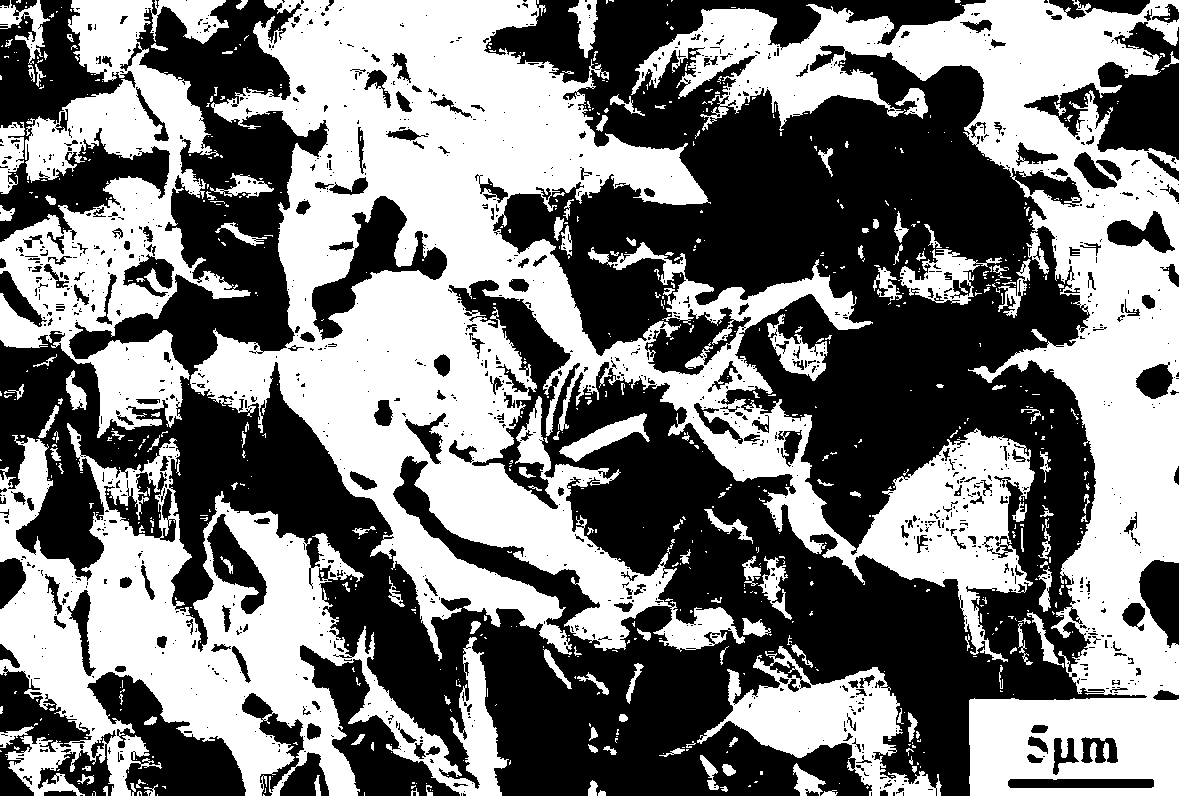

Lightweight boron carbide materials with improved mechanical properties and process for their manufacture

This disclosure describes sintered bodies comprising about 90 wt % to about 99 wt % of boron carbide, wherein the B:C atomic ratio ranges from 3.8 to 4.5:1; 0 to 1 wt % free carbon; 0 to 1 wt % BN or AlN, remainder an oxide binder phase; said sintered body having a uniform microstructure composed of substantially equiaxed grains of said boron carbide; the oxide binder phase comprising a least a rare earth aluminate and optionally other ternary or binary phases of rare earth oxide—alumina systems; the binder phase being present in form of pockets at the multiple grain junctions and the density of no more than 2.6 g / cm3. Also described is a manufacturing process for the above described substantially pore-free, sintered boron carbide materials with high strength and fracture toughness, which can be used for production of large-area parts. It is achieved by liquid phase low temperature—low pressure hot pressing of boron carbide in an argon atmosphere.

Owner:CERADYNE

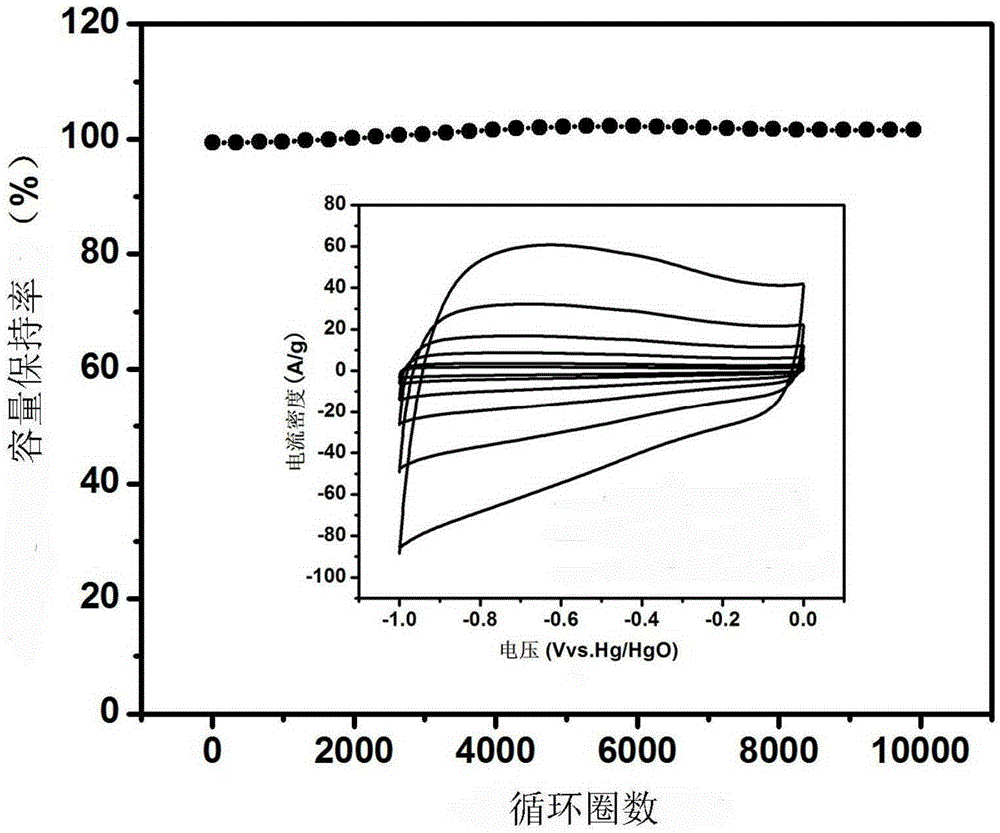

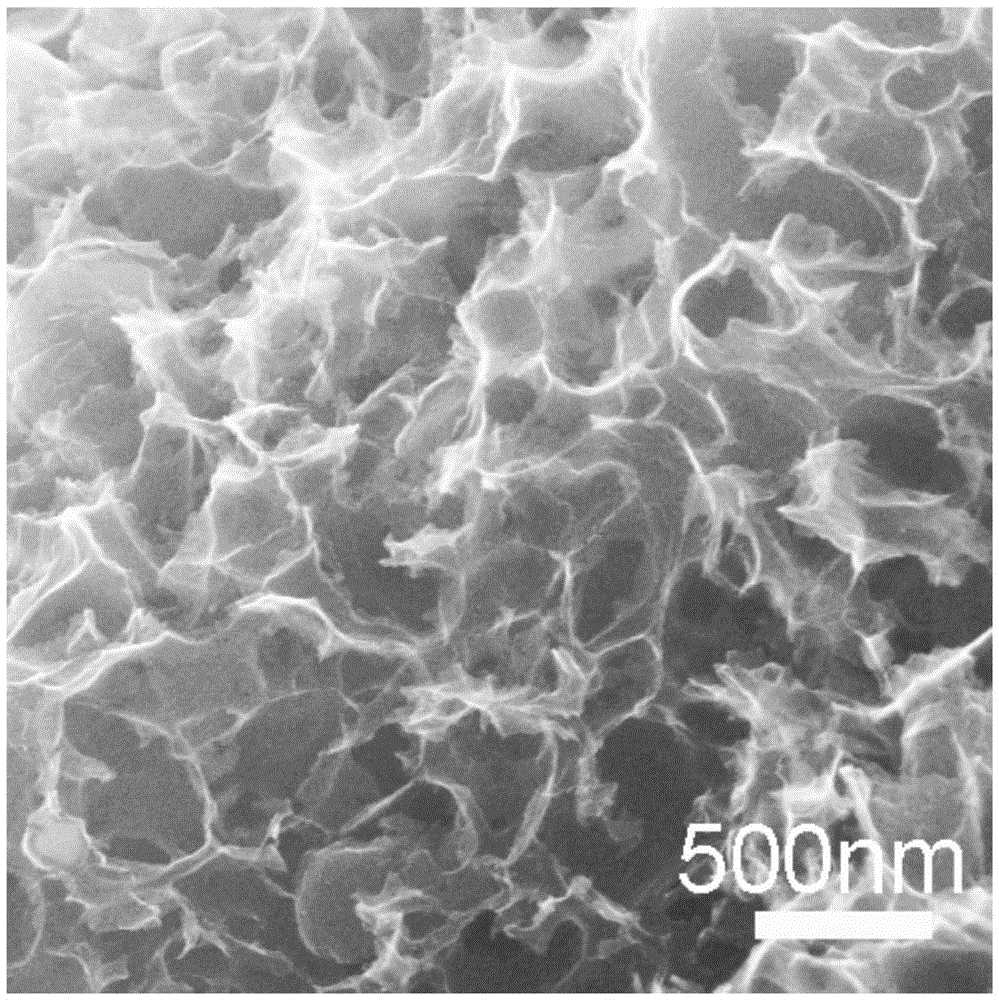

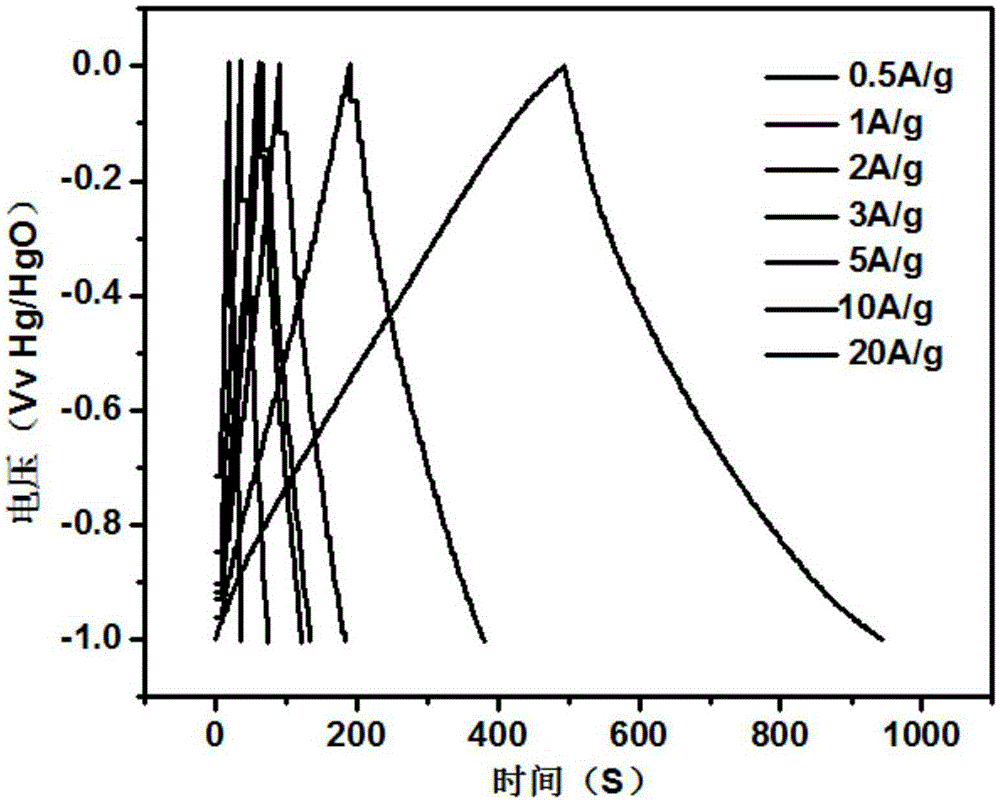

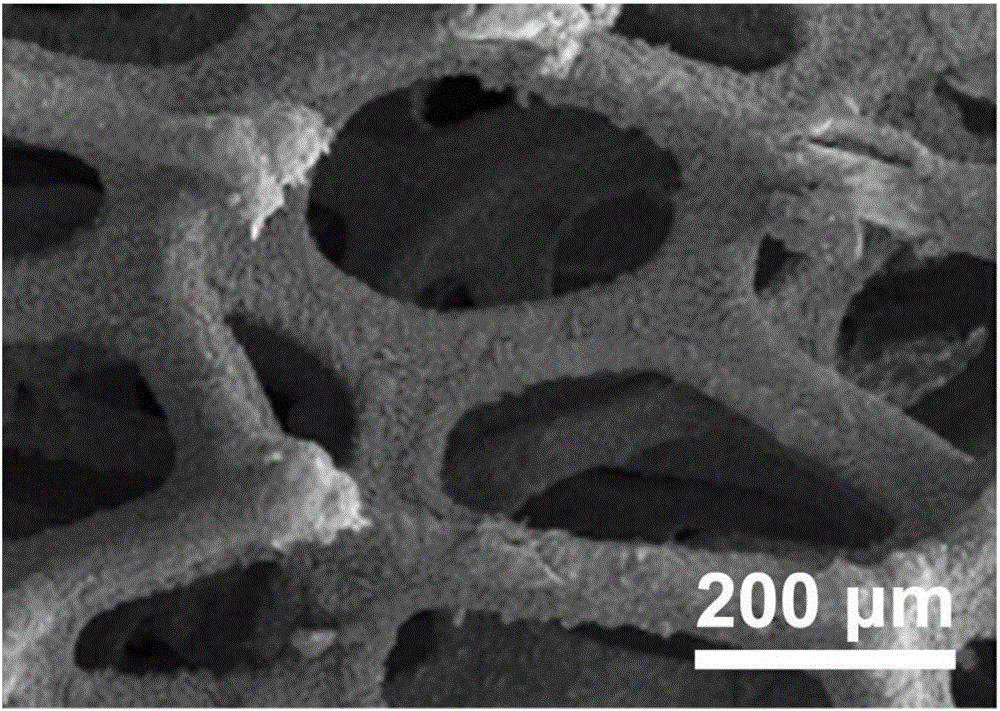

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

Metal sulfide single crystal material and preparation method

ActiveCN101792931ASmall granularityGranularity can be controlledPolycrystalline material growthFrom solid stateSemiconductor materialsHigh energy

A metal sulfide single crystal material comprises metal element M and sulfur element S; the chemical formula thereof is MSx, wherein x is not more than 3 and not less than 1, the metal elements are In, Sn, Sb, Ti, V, Mo, Mn, Co, Cu or Zn; the material is prepared with a method in combination with high energy ball milling method and high temperature solid phase method, comprising the following steps: mixing the sulfur powder with metal powder, and placing in a ball mill tank to carry out ball milling in argon atmosphere; thermostatically baking at low temperature and high temperature for a long time in the argon atmosphere and mixed atmosphere of argon atmosphere and air; cooling, and repeating the steps of 2-6. The preparation method uses simple device, the process conditions are simple and easy, the production cost is low, and the process is environment-friendly and is suitable for production in a large scale. The material can be widely applied to the fields such as high temperature lubricant, hydrogenation catalyst, high energy power supply, hydrogen storage material, semiconductor material, or even super conductive material.

Owner:NANKAI UNIV

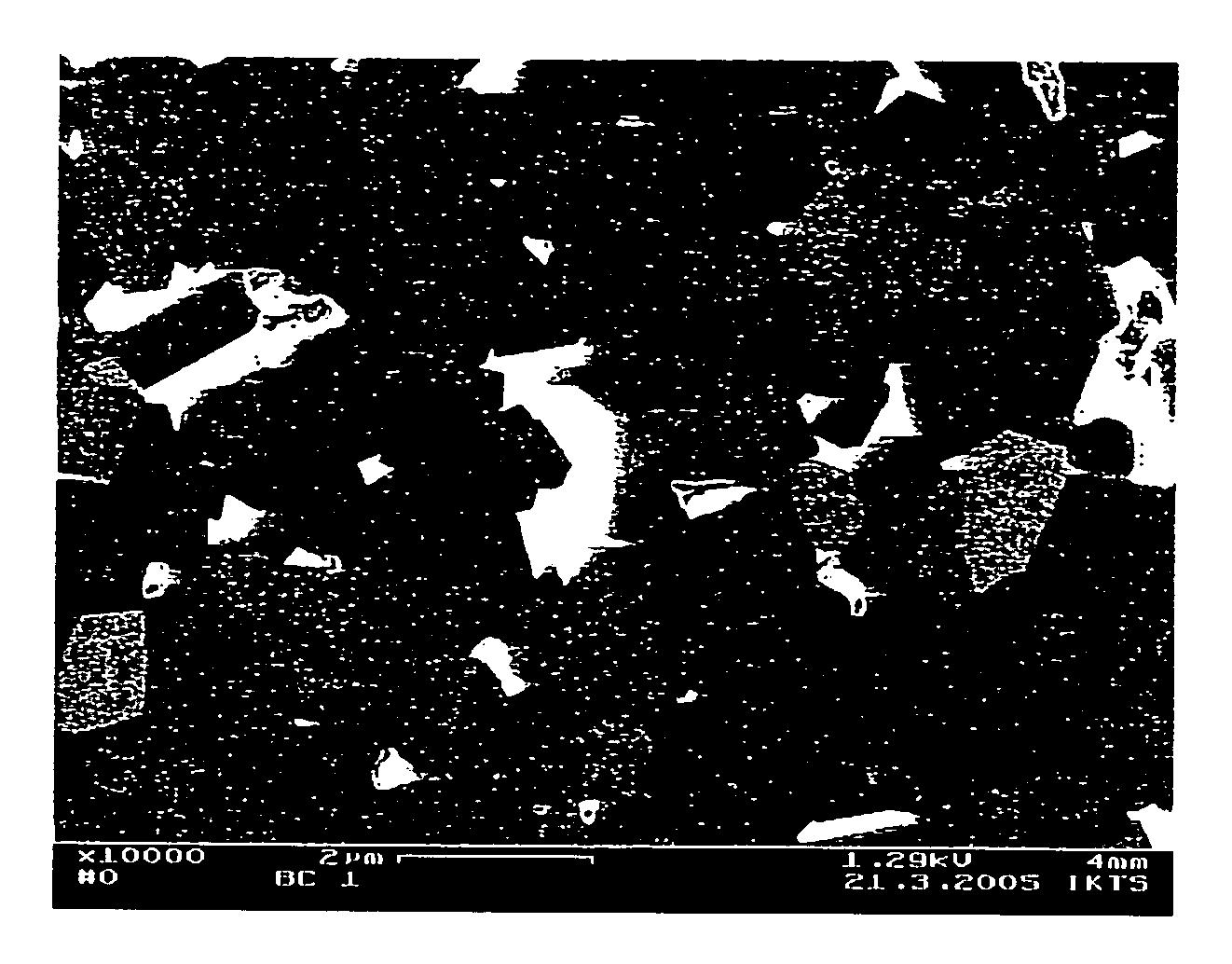

Mesoporous silicon carbide material and mfg. method thereof

A powdered mesoporous silicon carbide material with beta crystal form, 3-50 nm of pore size distribution and 60-120 sq.m / g of specific surface area is prepared through dissolving phenolic resin in absolute alcohol or acetone, adding transition metal salt, stirring while adding ethyl (methyl or propyl) silicate and inorganic acid, hydrolysis, adding cross-linking agent, gelatinizing, thermal reactino in argon atmosphere, cooling, high-temp treating, acid washing, water washing, filtering and drying. It has low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for directly preparing co-doping three-dimensional graphene electrode material through biomass carbon sources

The invention discloses a method for directly preparing a co-doping three-dimensional graphene electrode material through biomass carbon sources. The method mainly includes the steps that biomass such as eggshells of artemia cysts, bean pulp and shrimp shells are used as the carbon sources, red phosphorus or boric acid is added to serve as a stripping agent, metal nickel salt is added to serve as a catalyst, and oxygen-nitrogen-phosphor multi-atom co-doping three-dimensional porous graphene is synthesized in a roasted mode at the temperature of 700 DEG C to 900 DEG C under argon atmosphere; the obtained graphene is ground into powder, the graphene, acetylene black and PTFE are ultrasonically dispersed into absolute ethyl alcohol in the mass ratio of 85:10:5, the mixture is dried at the temperature of 80 DEG C to be pasty, 0.5 mg to 5 mg of the mixture is taken and evenly smeared on 1*1-cm foam nickel, vacuum drying is carried out at the temperature of 120 DEG C for 12 h, plate pressing is carried out at the pressure of 12 MPa, and an electrode plate is obtained. According to the method, the source of the required raw materials is wide, the price is low, devices are simple, repeatability is good, and low-cost large-scale industrial production can be achieved easily; the prepared graphene electrode material has the advantages of being good in electrochemical activity, large in specific area, not prone to repeated accumulation and the like; the broad application prospects are achieved in the aspects such as electrode materials and catalyst carriers of supercapacitors and lithium ion batteries.

Owner:YANSHAN UNIV

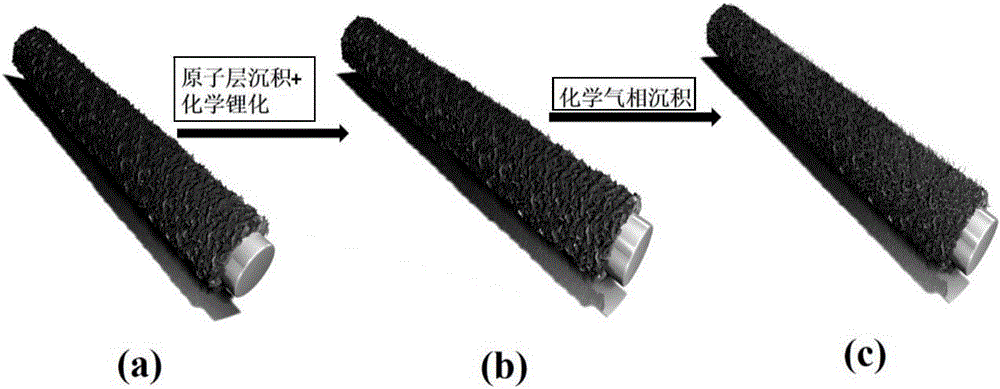

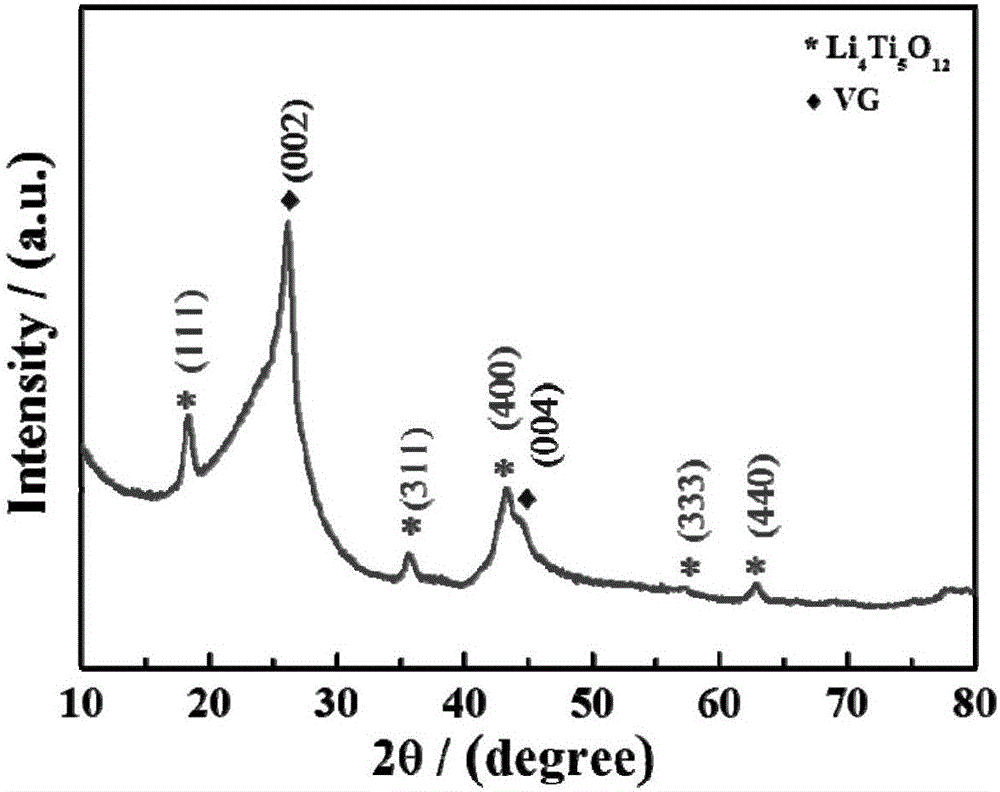

Graphene array-loaded lithium titanate/carbon nanotube composite array electrode and preparation method and application thereof

ActiveCN106784692AUniform coverageImprove performanceSecondary cellsVapour deposition manufacturingHigh rateGas phase

The invention discloses a graphene array-loaded lithium titanate / carbon nanotube composite array electrode and a preparation method and application thereof. The preparation method comprises the following steps of utilizing a microwave plasma enhanced chemical vapor phase deposition technique to vertically grow a graphene array on a carbon cloth; utilizing an atom layer deposition technique to grow TiO2 (titanium dioxide) on the obtained graphene array; dissolving lithium hydroxide into water to form a solution A; putting the vertical graphene-loaded TiO2 composite electrode material into the solution A, performing hydrothermal reaction, washing, drying and calcining; utilizing a chemical vapor phase deposition technique, using acetylene as a carbon source, and growing a carbon nanotube on the graphene array-loaded lithium titanate composite array electrode under the hydrogen and argon atmospheres, so as to obtain the graphene array-loaded lithium titanate / carbon nanotube composite array electrode. When the graphene array-loaded lithium titanate / carbon nanotube composite array electrode is used as the negative electrode material of lithium ion batteries, the high-rate property and circulating stability are excellent.

Owner:ZHEJIANG UNIV

Nanometer Al contained Ni and the preparing method

The invention discloses a nanometer nickel-coated aluminum powder and the preparing method. On the surface of ball aluminum powder a layer of nanometer nickel is coated. The preparing method is that nickel salt and aluminum powder are stock; borohydride and hydrazine hydrate are used as reducing agent; the water solution of nickel salt is poured into the container of ball aluminum powder with water solution of reducing agent; it is not mixed rapidly until when the water solution of nickel salt becomes colorless the nanometer nickel-coated aluminum powder is generated. When the mixing is stopped, after the nanometer nickel-coated aluminum powder is sunk to the bottom rapidly, residual nanometer nickel powder on the upper of water solution is abandoned. After it is washed by water in many times and it is set statically, upper clearing solution is abandoned. Finally as it is filtered and it is dried in flow argon atmosphere, the nanometer nickel-coated aluminum powder with good dispersion is prepared. The invention is provided with high burning efficiency and large releasing energy. The preparing method is provided with simple producing process and easy operation. It can be produced in a large scale and the thickness of nanometer nickel layer can be controlled.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

Method for high-efficiency hydrogen reduction preparation of transition metal oxide defects

ActiveCN106861681AEfficient preparationGreen and convenient preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenOxygen vacancy

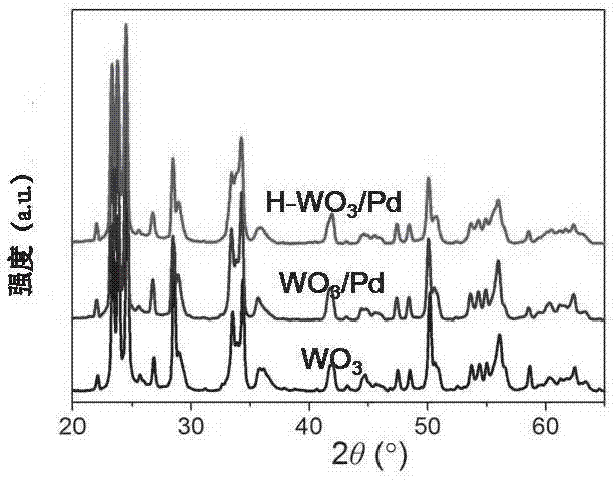

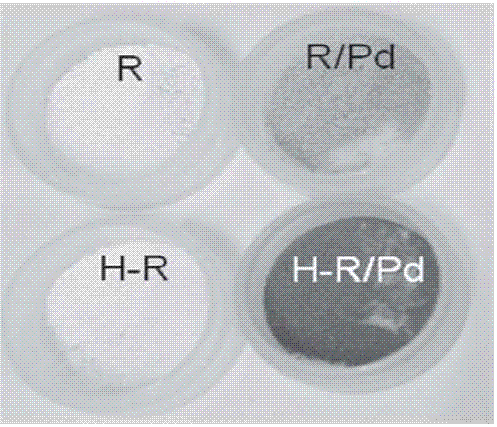

The invention relates to a method for high-efficiency hydrogen reduction preparation of transition metal oxide defects, wherein the method includes the steps: loading with a noble metal to obtain a noble metal-loaded transition metal oxide, and carrying out a reduction reaction of the obtained noble metal-loaded transition metal oxide in a reductive atmosphere, to obtain a transition metal oxide containing defects. The noble metal is loaded to the transition metal oxide, so a reaction potential barrier of turning molecular hydrogen into atomic hydrogen can be reduced to a great extent, then the transition metal oxide material having a large number of defects (including the transition metal low valence reduction state and oxygen vacancies) can be prepared by hydrogen reduction with an ordinary hydrogen argon atmosphere under conditions of room temperature and ordinary pressure, and the defects can stably exist for a long term. The method is simple and feasible to implement, ingenious and novel, low in cost and high in efficiency, and the prepared the defect transition metal oxide has a strong catalytic stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

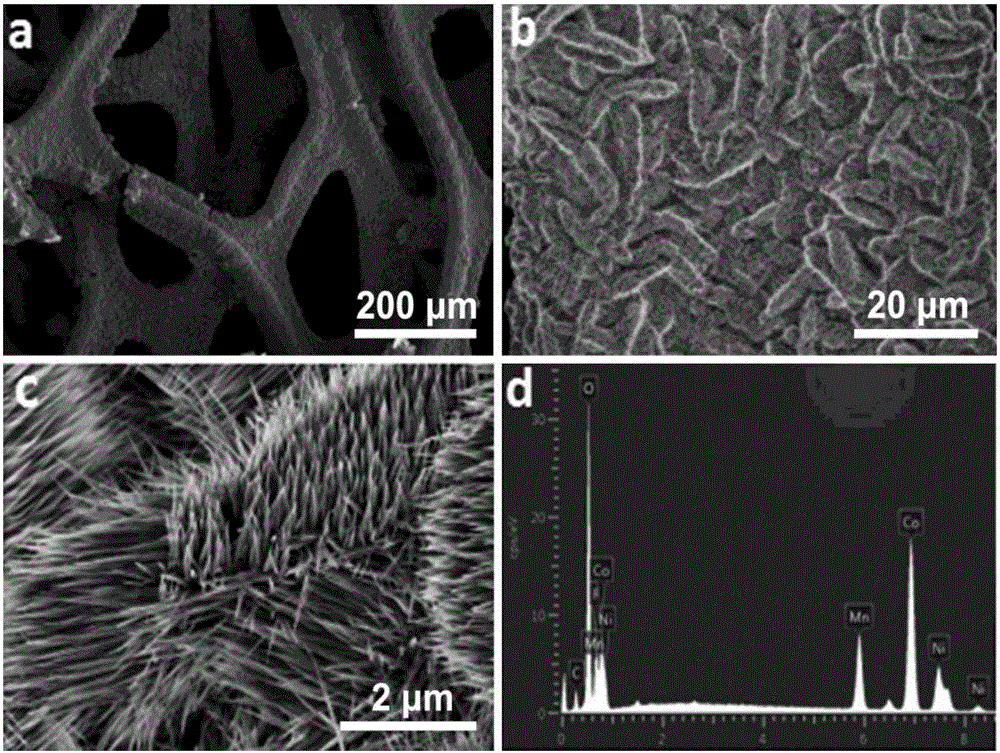

Preparation method of alkali oxygen evolution reaction electrocatalyst

InactiveCN106732649AImprove electrocatalytic performanceImprove adsorption capacityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsArgon atmosphereDecomposition

The invention discloses a preparation method of an alkali oxygen evolution reaction electrocatalyst. The preparation method comprises the following steps: firstly, carrying out ultrasonic cleaning on a conductive substrate, then preparing aqueous solution with soluble cobalt salt, soluble manganese salt, ammonium fluoride and urea, and in a reaction kettle, vertically growing a manganese cobalt subcarbonate nano array multilevel structure on the surface of the substrate; then preparing aqueous solution with soluble alkali and a reducing agent, carrying out secondary treatment, and carrying out structure and performance optimization on the manganese cobalt subcarbonate nano array multilevel structure; finally, in a tube furnace, in nitrogen or argon atmosphere, carrying out calcination at a temperature of 200 to 1,000 DEG C to prepare the alkali oxygen evolution reaction electrocatalyst with a manganese-doped cobalt oxide nano array multilevel structure. The preparation method disclosed by the invention adopts a simple hydro-thermal synthesis / calcination treatment method, is simple in process and is easy to regulate and control; the prepared product is excellent in performance and is an electrocatalyst with wide prospect in the application process of alkali water decomposition.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

MgB2 superconducting material and its preparation method

InactiveCN1329370AEnhanced pinningGrain refinementSuperconductors/hyperconductorsSuperconductor detailsArgon atmosphereMetal

The present invention relates to a novel MgB2 superconductivity material with high critical current density and its preparation method. It is characterized by that in the MgB2 superconductivity material, one method element Me selected from Ti, Zr, Mo, Nb, W or Hf is doped, and the mole ratio of its composition is Mg:Me:B=(0.8-0.9):(0.1-0.2):2. Its preparation method includes the steps of proportioning Mg powder, Me powder and B material component, mixing them uniformly and sintering at normal pressure in argon atmosphere. This invented MgB2 superconductivity material possesses high critical curcent density at above 10K temp., and its performance also is excellent under the magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

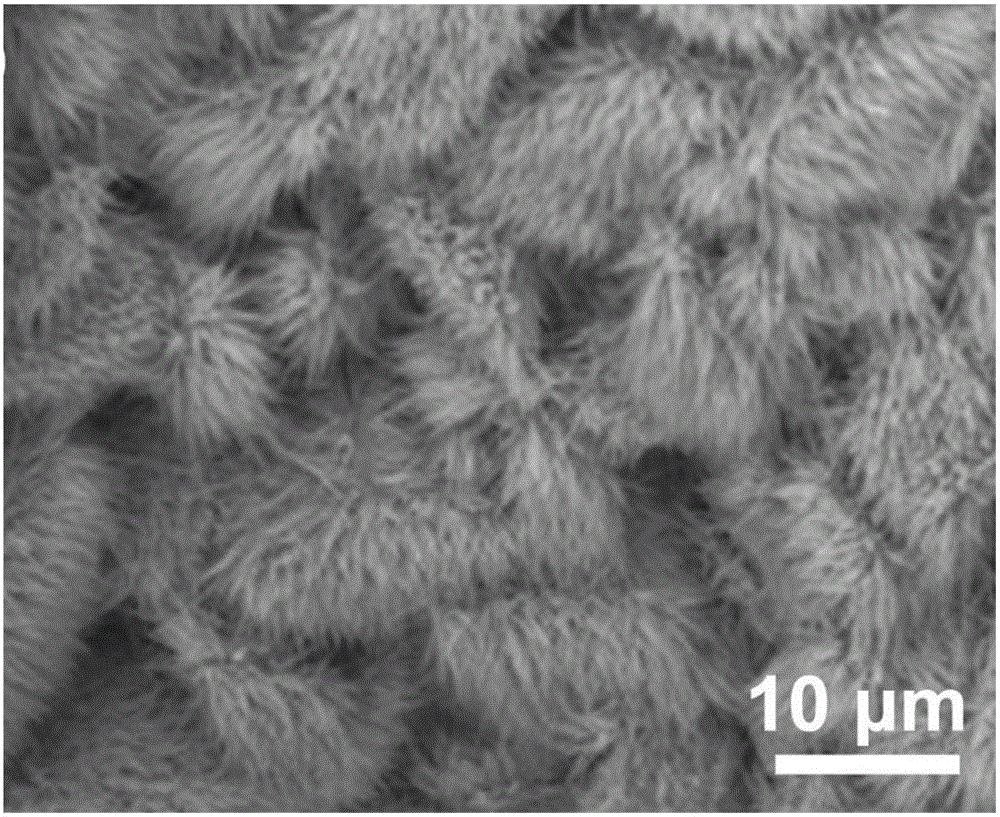

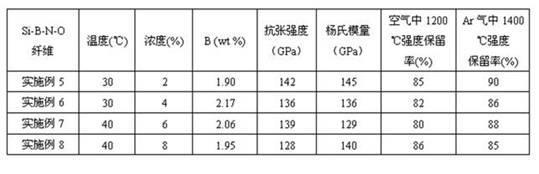

Method for continuously preparing Si-B-N-O fiber by using PCS (Polycarbosilane) fiber

The invention discloses a method for continuously preparing an Si-B-N-O fiber by using a PCS fiber, which comprises the following steps of: after air curing treatment is carried out on the PCS fiber, firstly carrying out nitrogen treatment on a PCS curing fiber and then carrying out boronization treatment or firstly carrying out the boronization treatment and then carrying out the nitrogen treatment; then sintering the PCS curing fiber after the nitrogen treatment and the boronization treatment under the high temperature condition of 1200-1400 DEG C under the protection of high-purity N2 gas or argon atmosphere to prepare the Si-B-N-O fiber. Compared with an Si-N-O fiber, the prepared Si-B-N-O fiber has better temperature resistance, lower dielectric performance and simpler preparation process and is easy to realize industrialized batch preparation.

Owner:NAT UNIV OF DEFENSE TECH

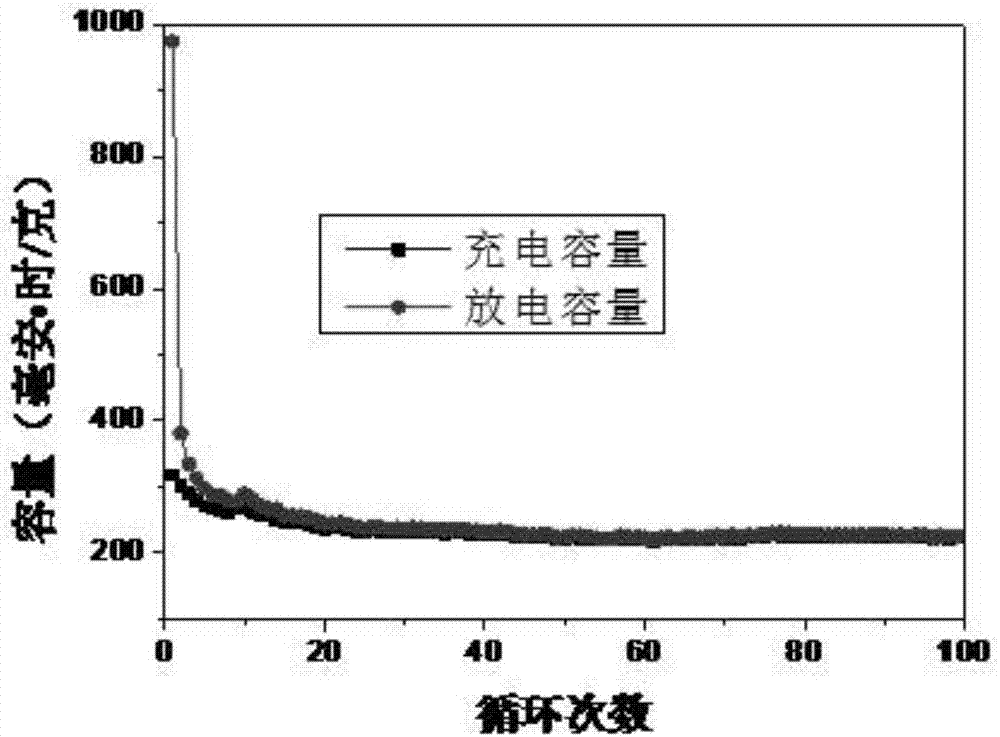

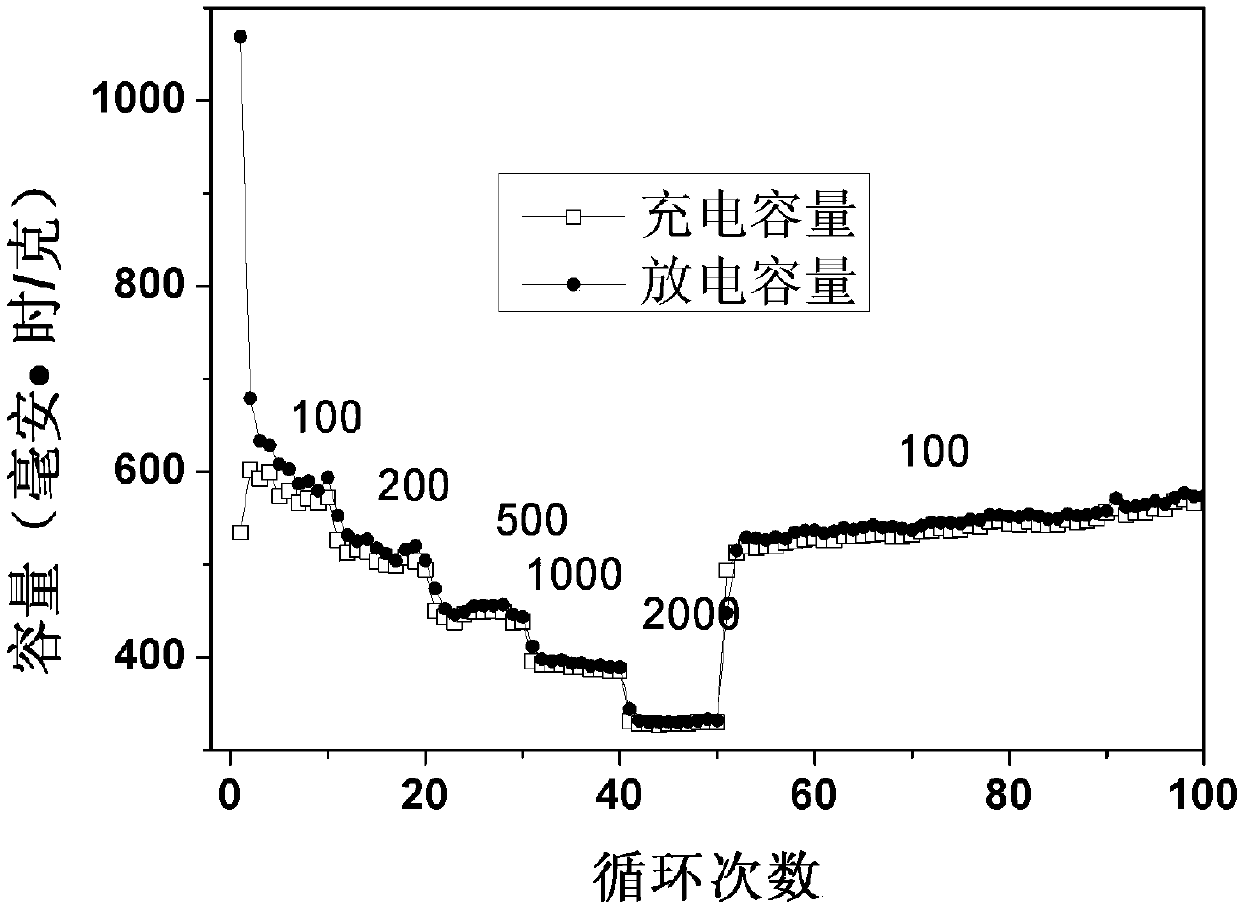

Method for preparing nitrogen-doped porous carbon material used as sodium ion battery cathode

ActiveCN107331867AImprove cycle stabilityOvercome the disadvantage of low specific capacityCell electrodesSecondary cellsPorous carbonSynthesis methods

The invention provides a method for preparing a nitrogen-doped porous carbon material used as a sodium ion battery cathode, and belongs to a method for preparing nitrogen-doped porous carbon. The nitrogen-doped carbon material is controlled and synthesized by regulating and controlling each parameter in the reacting process by means of a simple and feasible high-temperature solid phase reaction method, and is applied to a sodium ion battery cathode material. The method comprises the following steps: dissolving a selected nitrogen source in a solvent to form a transparent solution A; adding a proper amount of carbon source into the solution A, and constantly adding into solvent to sufficiently disperse the nitrogen source under a stirring state; drying the materials in a lyophilizer for 2-12 hours; putting a proper amount of the materials into a crucible, heating to 300-1100 DEG C and insulating for 1-6 hours in a vacuum tube furnace under an argon atmosphere at a speed of 2-8 DEG C / minute; and separating and purifying the generated product to obtain a product. The preparation method has the advantages of low-price and easily available raw materials, simple synthesis method and high controllability of operation steps, and is easy for expanded production. The nitrogen-doped porous carbon material can be used as a sodium ion battery cathode material, and shows excellent electrochemical performance.

Owner:CHINA UNIV OF MINING & TECH

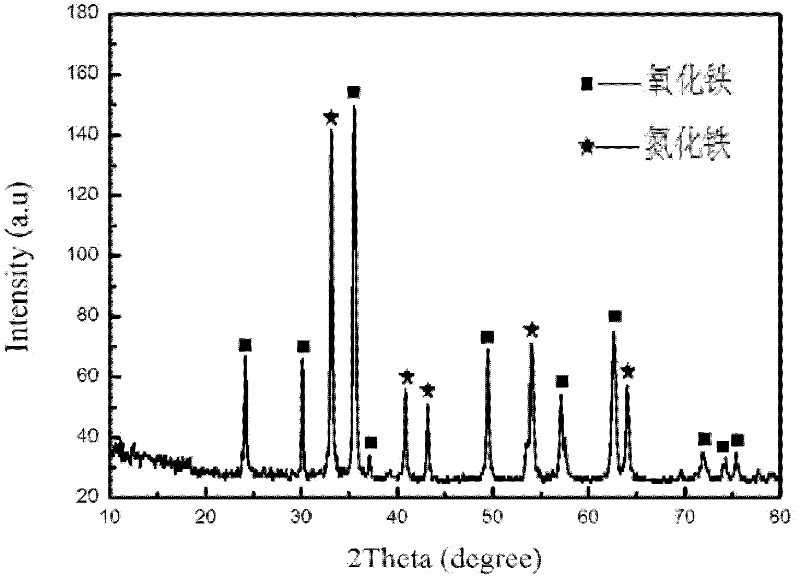

Composite electrocatalyst material used for Li-air batteries and preparation method thereof

InactiveCN102694185AImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesArgon atmosphereLithium–air battery

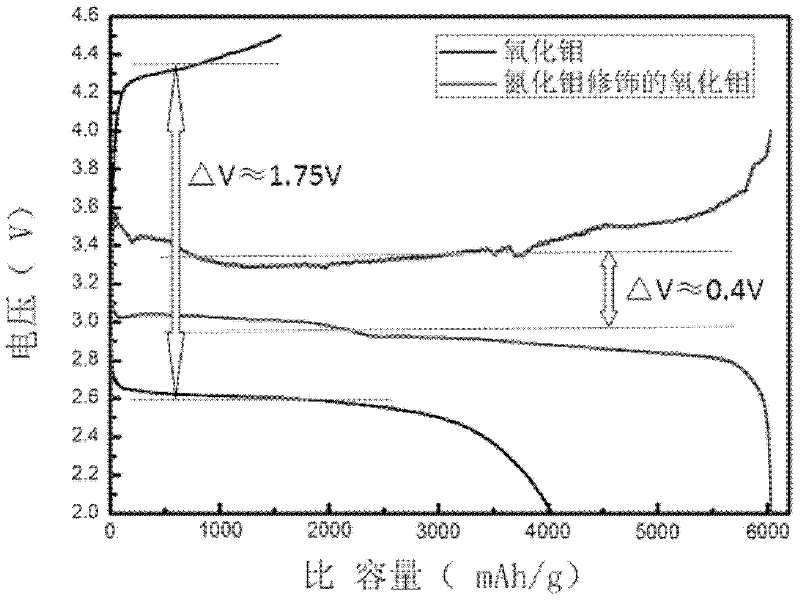

A composite electrocatalyst material used for Li-air batteries and a preparation method thereof. The transition metal oxide composite electrocatalyst modified by surface conductive transition metal nitride is obtained by conducting thermal nitrogen treatment, in an ammonia atmosphere or an ammonia and argon atmosphere, for transition metal oxide powder or transition metal oxide powder pretreated by nitrogen overlying, wherein the technology of the thermal nitrogen treatment is heating up the powder at a rate of 2-10 DEG C / min to reach the thermal nitrogen treatment temperature of 300-800 DEG C, preserving heat for 10min to 2h and then cooling in furnace. By controlling the content and flow rate of ammonia and the temperature and time of sintering, the thickness of the surface transition metal nitride can be controlled selectively. The method of the invention is simple in technology, convenient for operation, low in cost and strong in controllability. In addition, the obtained composite electrical catalyst has good conductivity and stability and can reduce the charging and discharging polarization of Li-air batteries effectively. The catalyst decreases the inner resistance of batteries and has good discharge capacity. The industrialization prospect of the catalyst is good.

Owner:CENT SOUTH UNIV

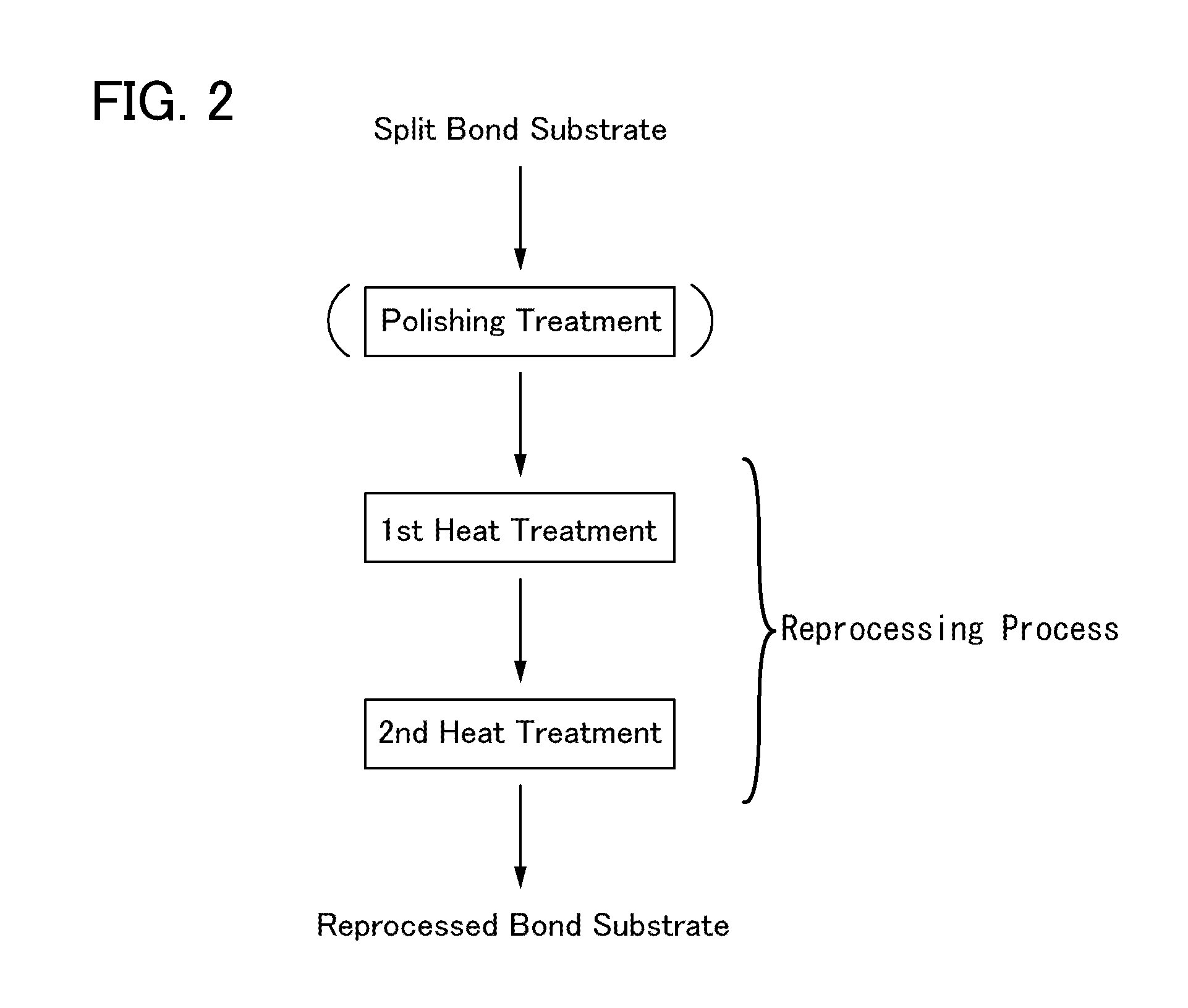

Method of manufacturing soi substrate

InactiveUS20100273310A1Improve propertiesDeterioration of property of bond can be suppressedSemiconductor/solid-state device manufacturingSolid-state devicesArgon atmosphereNitrogen

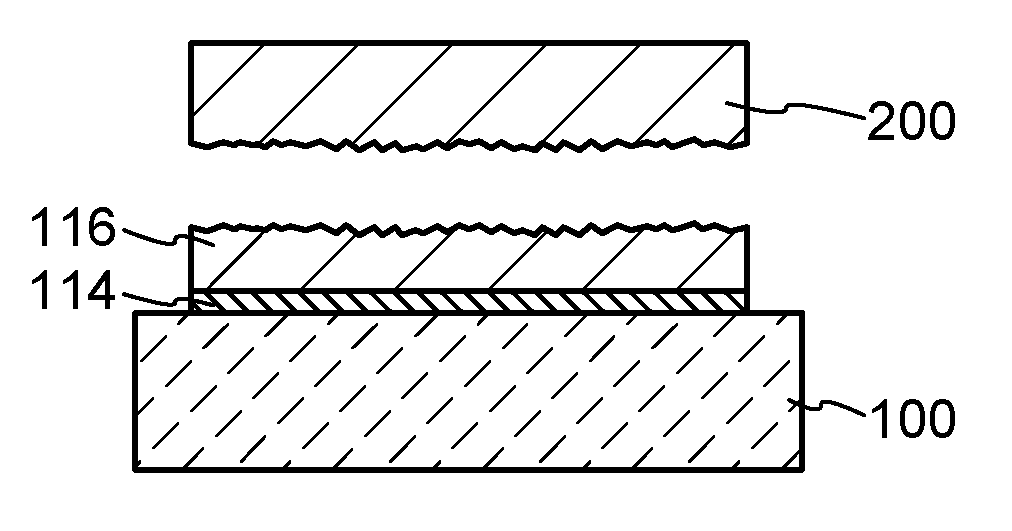

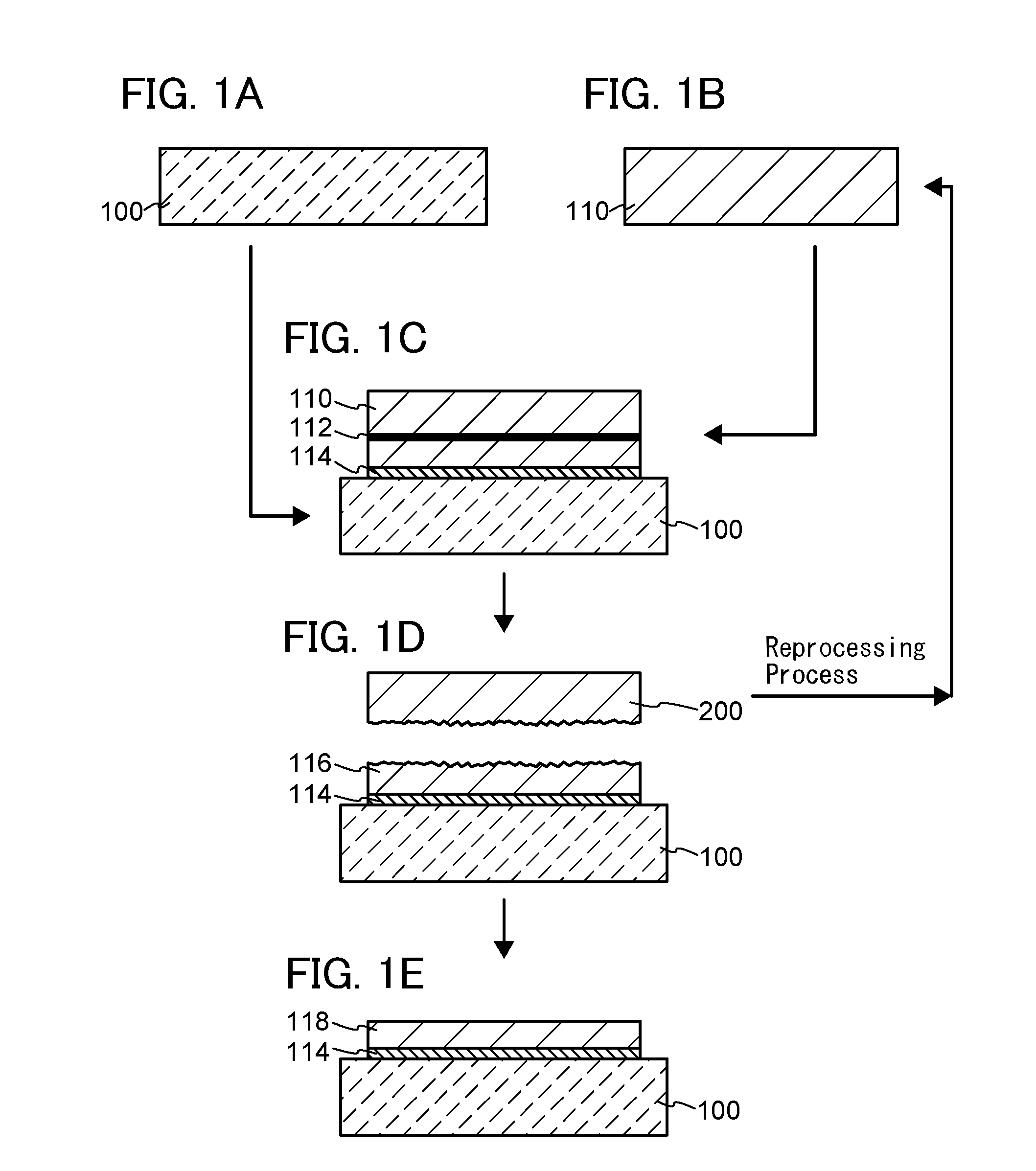

The method of one embodiment of the present invention includes: a first step of irradiating a bond substrate with ions to form an embrittlement region in the bond substrate; a second step of bonding the bond substrate to a base substrate with an insulating layer therebetween; a third step of splitting the bond substrate at the embrittlement region to form a semiconductor layer over the base substrate with the insulating layer therebetween; and a fourth step of subjecting the bond substrate split at the embrittlement region to a first heat treatment in an argon atmosphere and then a second heat treatment in an atmosphere of a mixture of oxygen and nitrogen to form a reprocessed bond substrate. The reprocessed bond substrate is used again as a bond substrate in the first step.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of zirconium diboride ceramic with in-situ-introduced boron as additive

InactiveCN103011827AAvoid introducingGood for maintaining excellent performanceArgon atmosphereZirconium dioxide

The invention relates to the field of structural ceramic manufacturing, in particular to a preparation method of zirconium diboride ceramic with in-situ-introduced boron as an additive. The preparation method comprises the following steps: firstly, performing ball milling and mixing zirconium dioxide and elemental boron in a mol ratio of (1: 3.5)-(1: 4.5), and drying to obtain ZrO2 / B mixed powder; secondly, putting the ZrO2 / B mixed powder into a graphite crucible, and performing high-heat treatment at the air pressure of below 200Pa to obtain ZrB2 / B powder; and finally, sieving the obtained ZrB2 / B powder, performing isostatic pressing, putting the ZrB2 / B powder into the graphite crucible, performing pressureless sintering in an argon atmosphere, controlling the sintering temperature at 1800 -2100 DEG C, the heat-preserving time at 1-3 hours and the heating rate at 10-50 DEG C / min, and preserving heat for 0.5 hours at 1500-1700 DEG C to obtain the compact zirconium diboride ceramic. By the preparation method, a ball milling medium is not introduced, the impurity content is reduced, excellent performance of the zirconium diboride ceramic can be maintained easily, and the sintering compactness of the zirconium diboride ceramic is realized at a relatively low temperature (2000 DEG C).

Owner:FUDAN UNIV

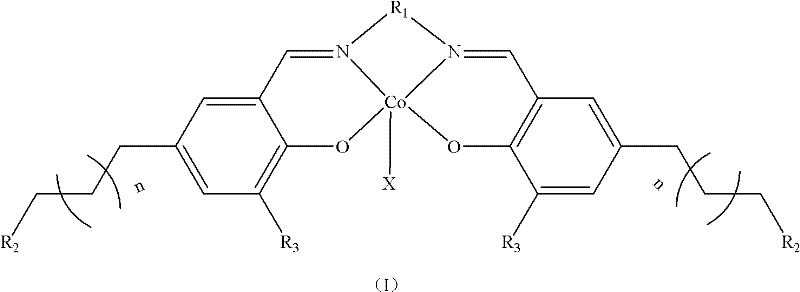

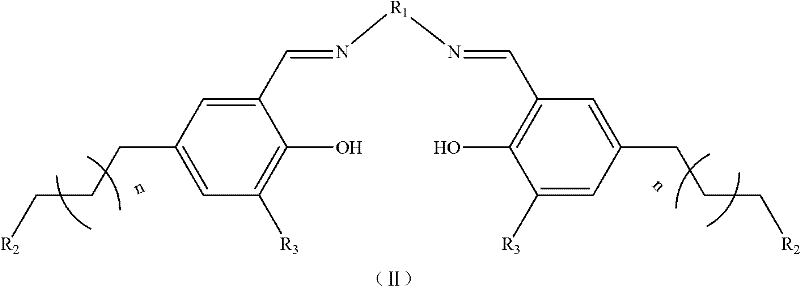

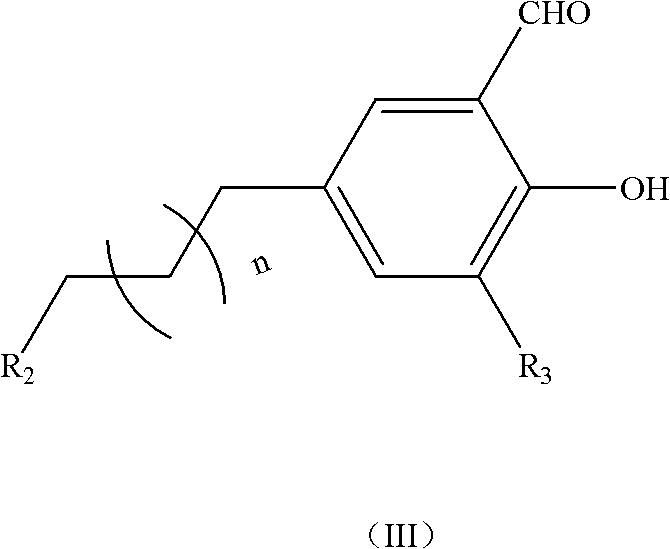

Method for preparing Salen-metal complex

InactiveCN102212085ALow costHigh catalytic efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsSodium methoxideFiltration

The invention provides a method for preparing a Salen-metal complex. The method comprises the following steps of: under the argon atmosphere, adding ligands(II), sodium methoxide, absolute methanol soluble ligands(II) and sodium methoxide into a reactor in sequence; stirring the mixture for 2 minutes, and adding 1mol / L cobalt acetate anhydrous / methanol solution dropwise, wherein the molar ratio of the ligands(II) to sodium methoxide to cobalt acetate is 1:1:1; and making the mixture reacted at the room temperature for 24 hours, adding anionic salt which has the same molar weight as the cobalt acetate, stirring the mixture for three days in the air, stopping the reaction, concentrating the mixture, performing dissolution and filtration by adding methylene chloride, drying the filtrate by anhydrous sodium sulfate overnight, filtering the mixture, concentrating under reduced pressure, and drying the mixture under the vacuum condition to obtain the Salen-metal complex. The Salen-metal complex prepared by the method has the advantages of simple method, low cost and high catalytic efficiency.

Owner:HEBEI UNIV OF TECH

Electro-thermal vaporization atomic fluorescence spectrometry method and spectrometer used for determining cadmium

ActiveCN102338745AAccurate measurementEliminate distractionsAnalysis by thermal excitationHydrogenArgon atmosphere

The invention discloses an electro-thermal vaporization atomic fluorescence spectrometry method and a spectrometer used for determining cadmium. An atomizer of the electro-thermal vaporization atomic fluorescence spectrometer comprises an atomizing apparatus and a collecting trap. The collecting trap is composed of a tungsten filament or a molybdenum filament, a support, a housing and a power source. A sealed space is formed by the housing and the support. The tungsten filament or the molybdenum filament is arranged on the support. The tungsten filament or the molybdenum filament is positioned in the sealed space formed by the housing and the support. An inlet and an outlet are arranged on the housing. The electro-thermal vaporization atomic fluorescence spectrometry method used for determining cadmium comprises steps that: a sample requiring testing is dried in air, and is cinerated, such that ash is obtained; under an argon atmosphere, the ash is heated to 1600 to 2000 DEG C, and the obtained vapor contacts the tungsten filament or the molybdenum filament; under an atmosphere of hydrogen and argon, the temperature of the tungsten filament or the molybdenum filament is increased to 1600 to 2000 DEG C, cadmium atoms are released, and the content of the cadmium atoms are analyzed by using a fluorescence spectrometry method. With the electro-thermal vaporization atomic fluorescence spectrometry method and the spectrometer used for determining cadmium provided by the invention, matrix interference can be effectively eliminated, and accurate measuring of cadmium can be realized.

Owner:BEIJING JITIAN INSTR CO LTD

Preparation method of nitrogen-doped porous carbon and application of nitrogen-doped porous carbon in lithium-ion batteries

InactiveCN107555412ARaw materials are easy to getEasy to prepareCell electrodesSecondary cellsSynthesis methodsArgon atmosphere

The invention discloses a preparation method of nitrogen-doped porous carbon and application of the nitrogen-doped porous carbon in lithium-ion batteries. The method comprises the following steps: (1)dissolving a nitrogen source into a solvent to prepare a transparent solution, adding right amount of a carbon source into the transparent solution to form a fluffy snow-shaped material, putting thesnow-shaped material into a freeze dryer, and drying for 1-10h; (2) heating the mixture, obtained after drying in the step (1), up to 300-1200 DEG C at the speed of 1-8DEG C / min under the argon atmosphere in a vacuum tubular furnace, carrying out heat preservation for 1-8h, separating and purifying to obtain the target product. The preparation method is easy in obtaining of the used raw materials,simple in synthesis method and high in controllability of operation steps; furthermore, the obtained product is high in purity, uniform in particle size and easier for production expansion. The prepared nitrogen-doped porous carbon material shows excellent electrochemical performance when being used as an anode material for the lithium-ion batteries.

Owner:江苏福瑞士电池科技有限公司

Hard nanometer layered ZrO2/TiN coating

InactiveCN1888124AHigh hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingCeramic coatingArgon atmosphere

The present invention is one kind of multilayer hard nanometer ZrO2 / TiN coating and belongs to the field of ceramic coating technology. The multilayer hard nanometer ZrO2 / TiN coating includes alternately deposited ZrO2 layers of 2-8 nm thickness and TiN layers of 0.4-1.2 nm thickness on the substrate of hard alloy, ceramic or metal, and has total thickness of 2-5 microns. It is prepared through a double-target sputtering process in argon atmosphere. It has not only excellent high temperature oxidation resistance, but also hardness as high as 19.1-23 GPa. The multilayer hard nanometer ZrO2 / TiN coating of the present invention may be formed on high speed cutting tool and other high temperature wear and corrosion resistant workpieces.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com