Patents

Literature

49 results about "Carbide-derived carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

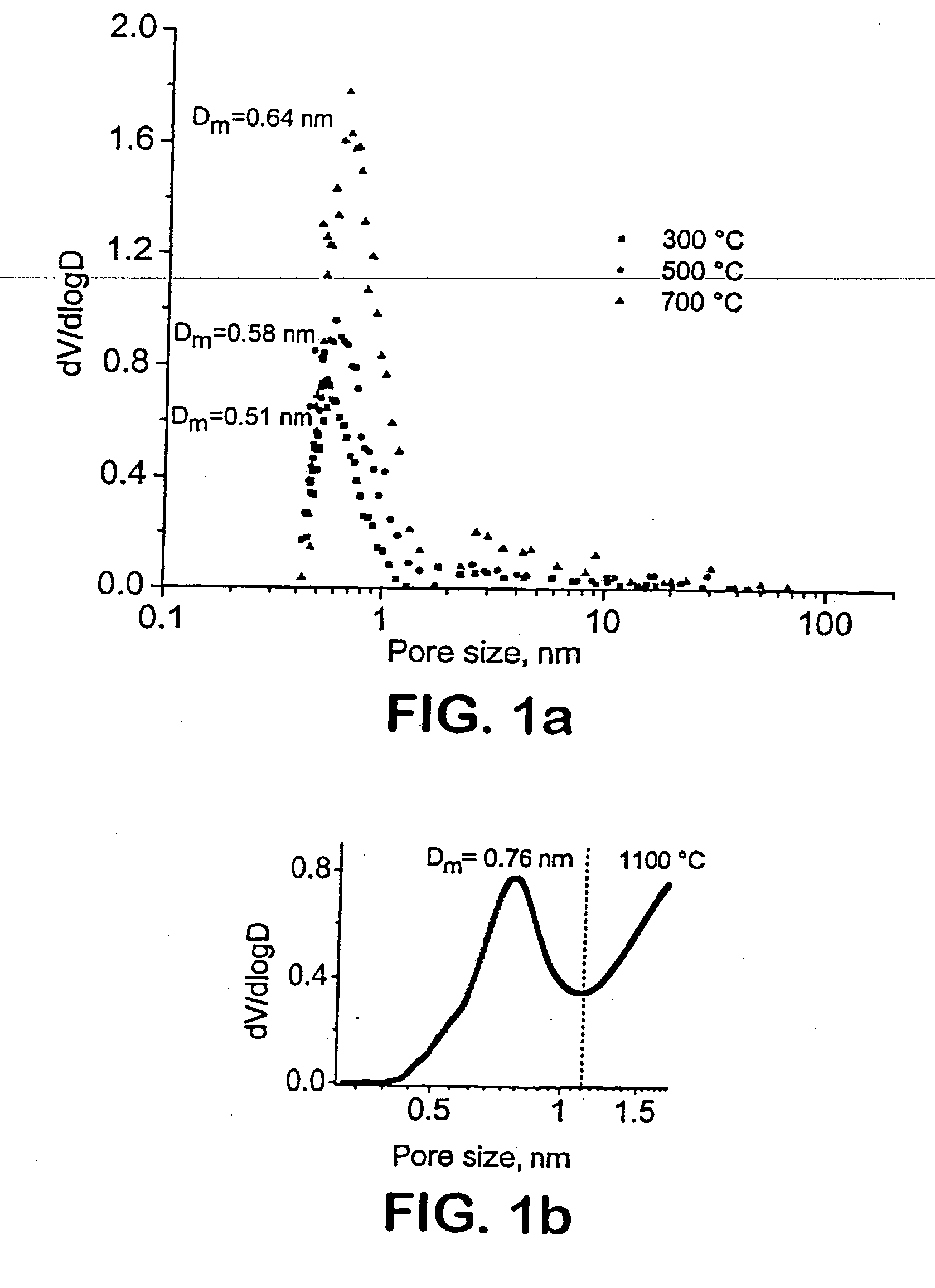

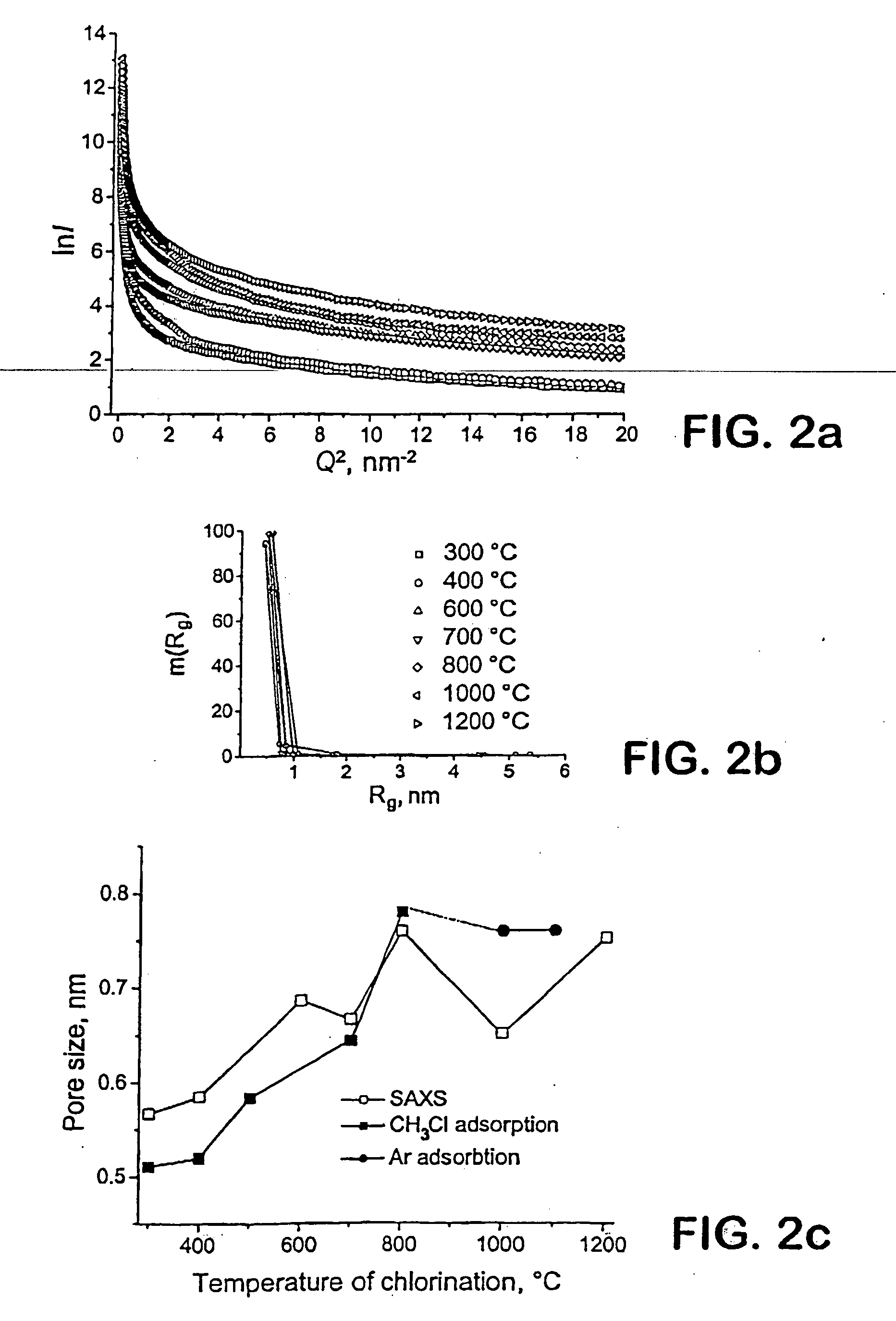

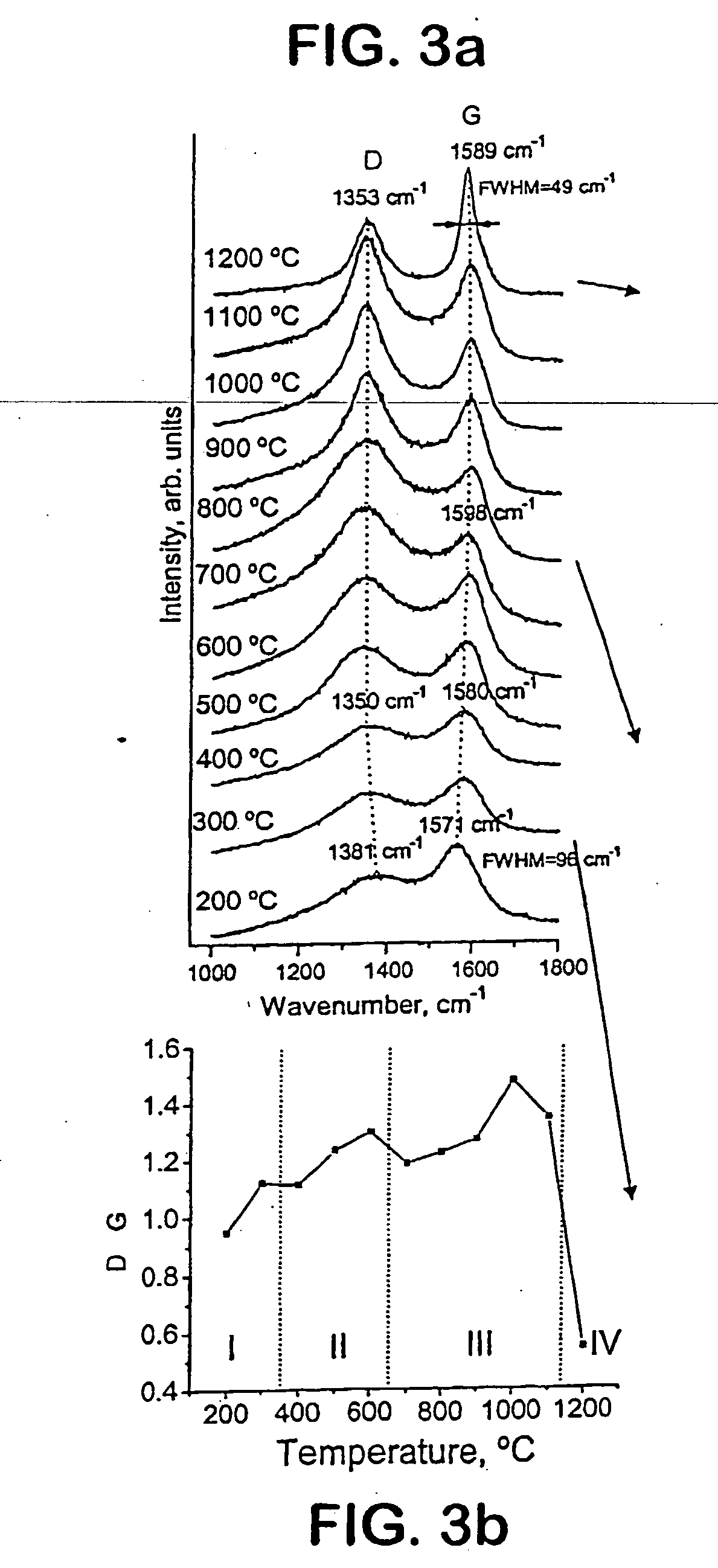

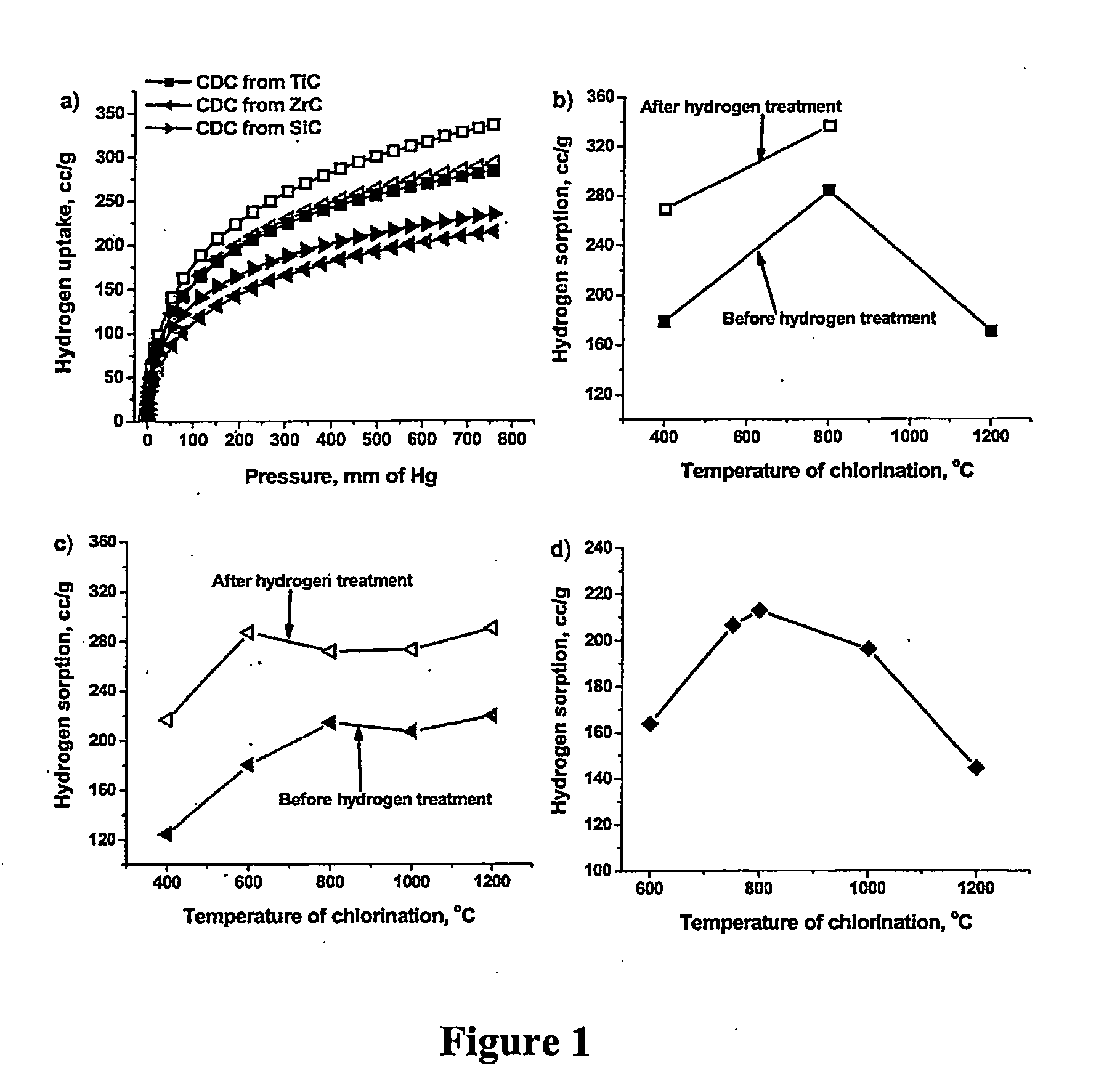

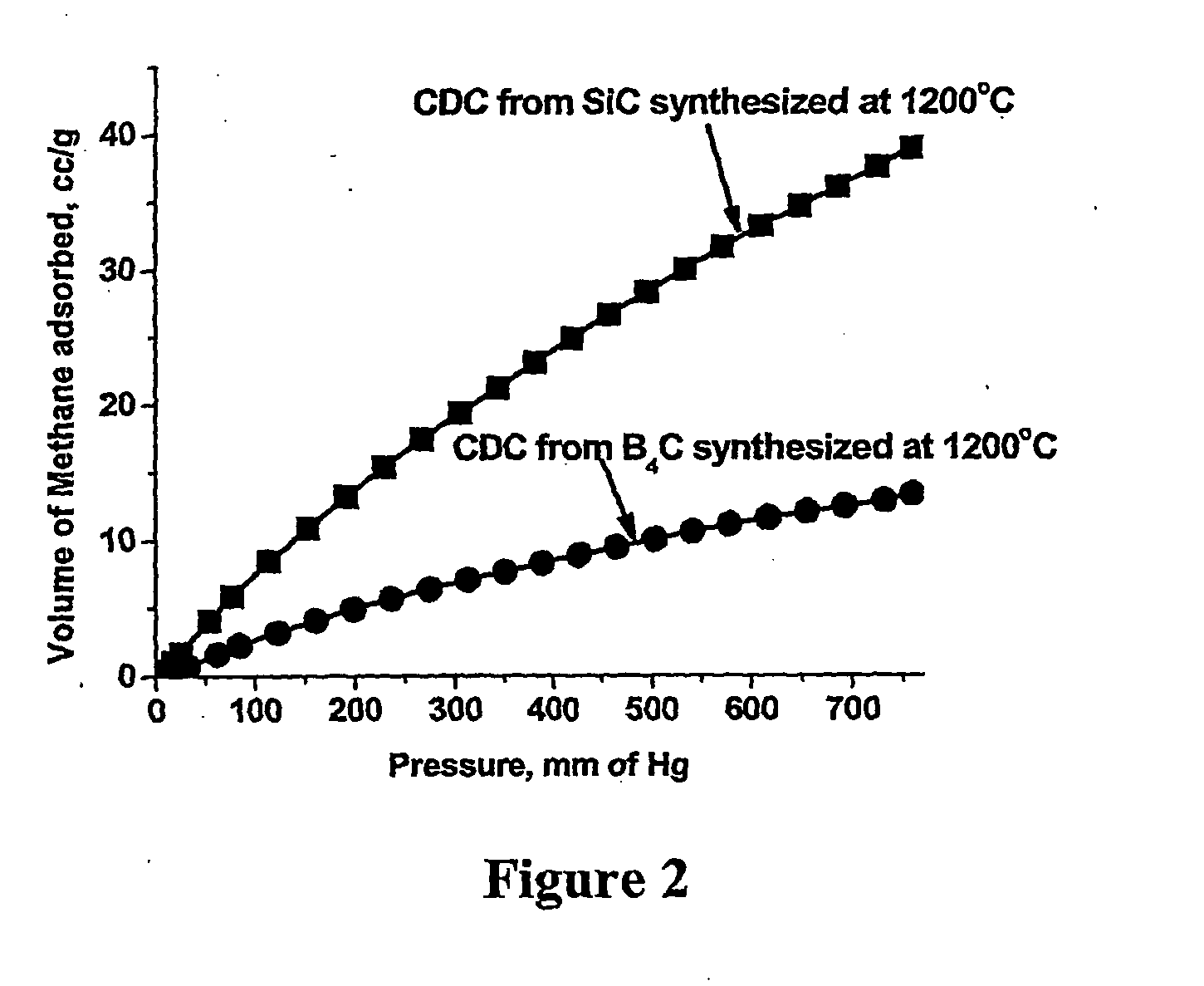

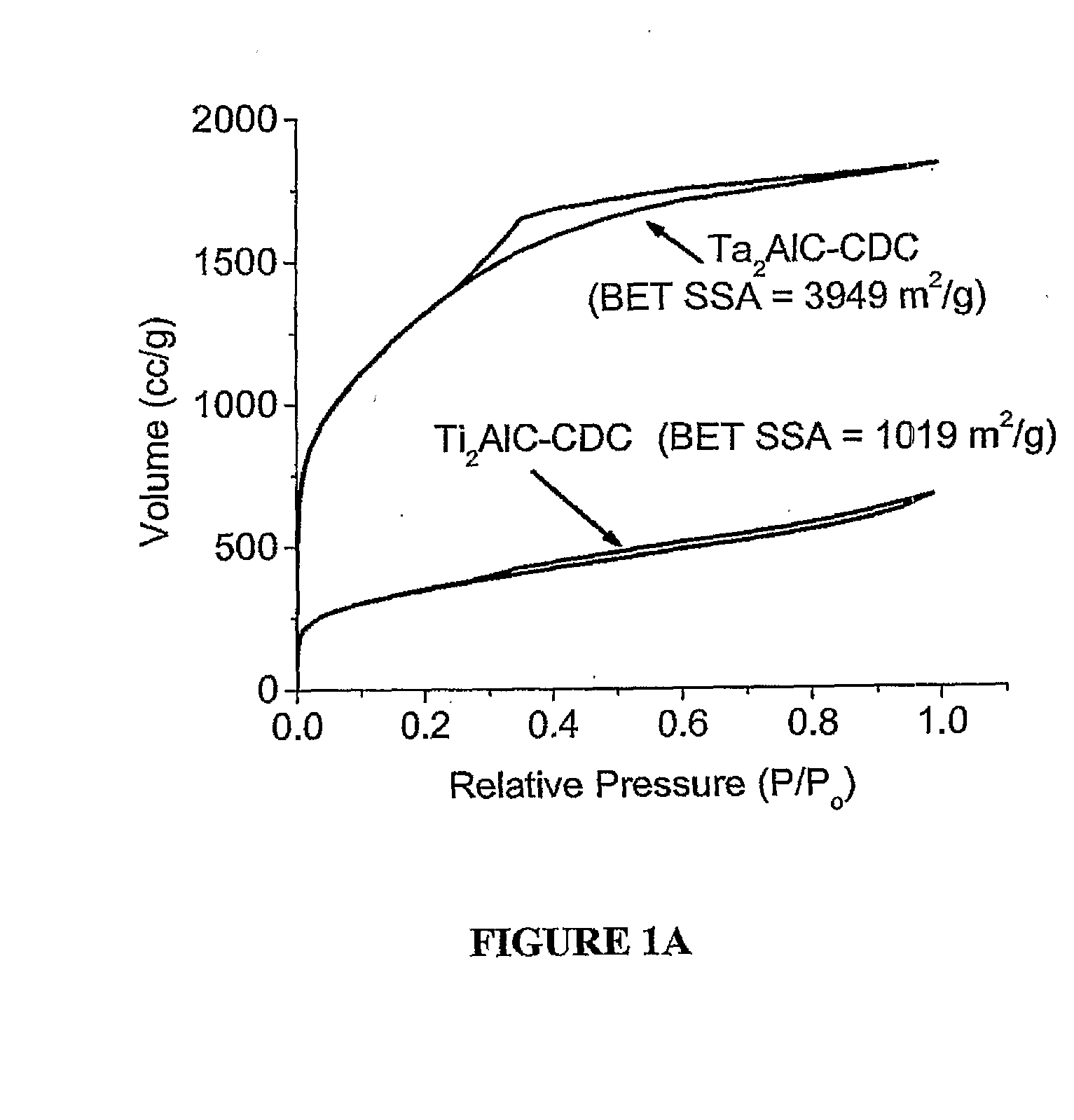

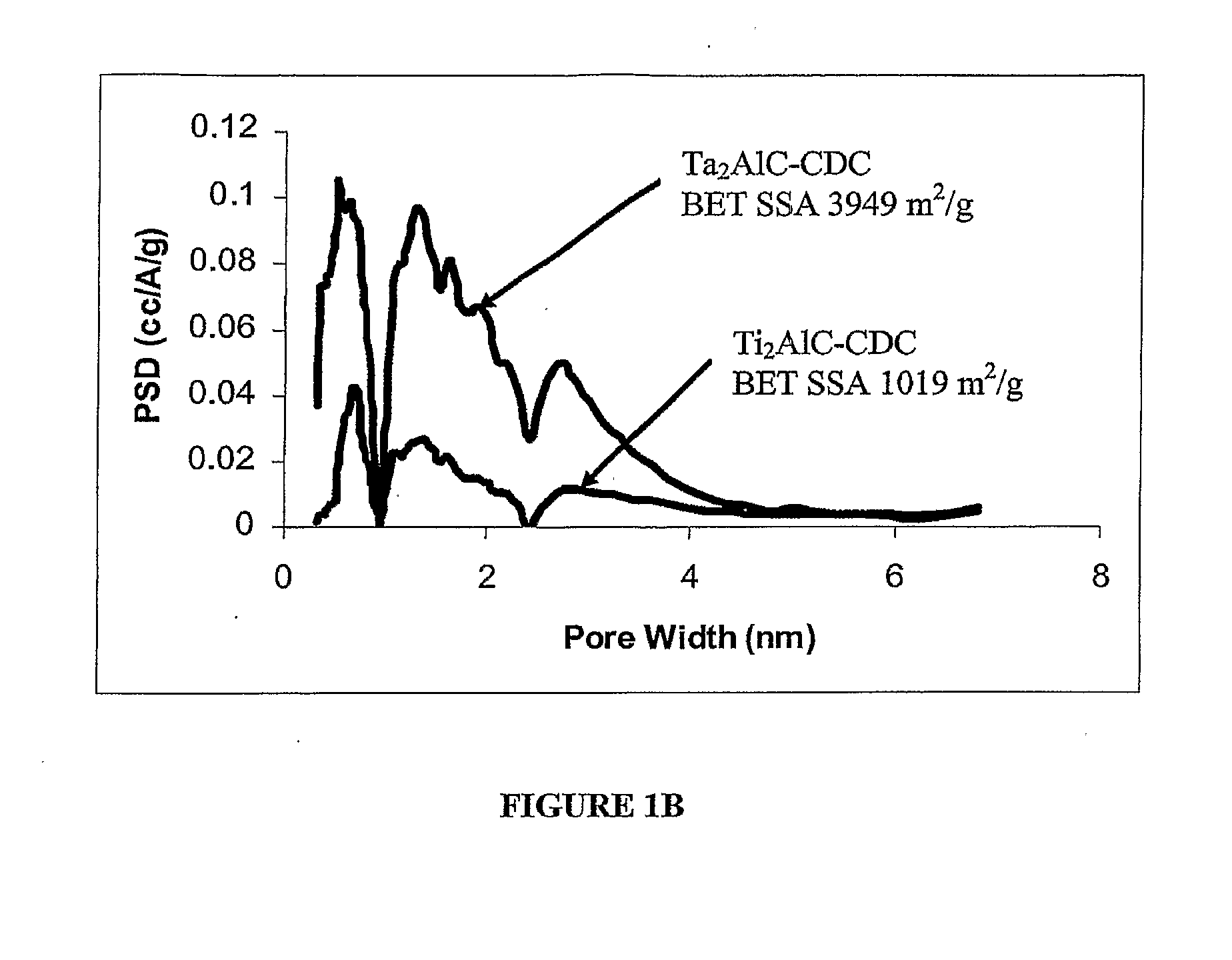

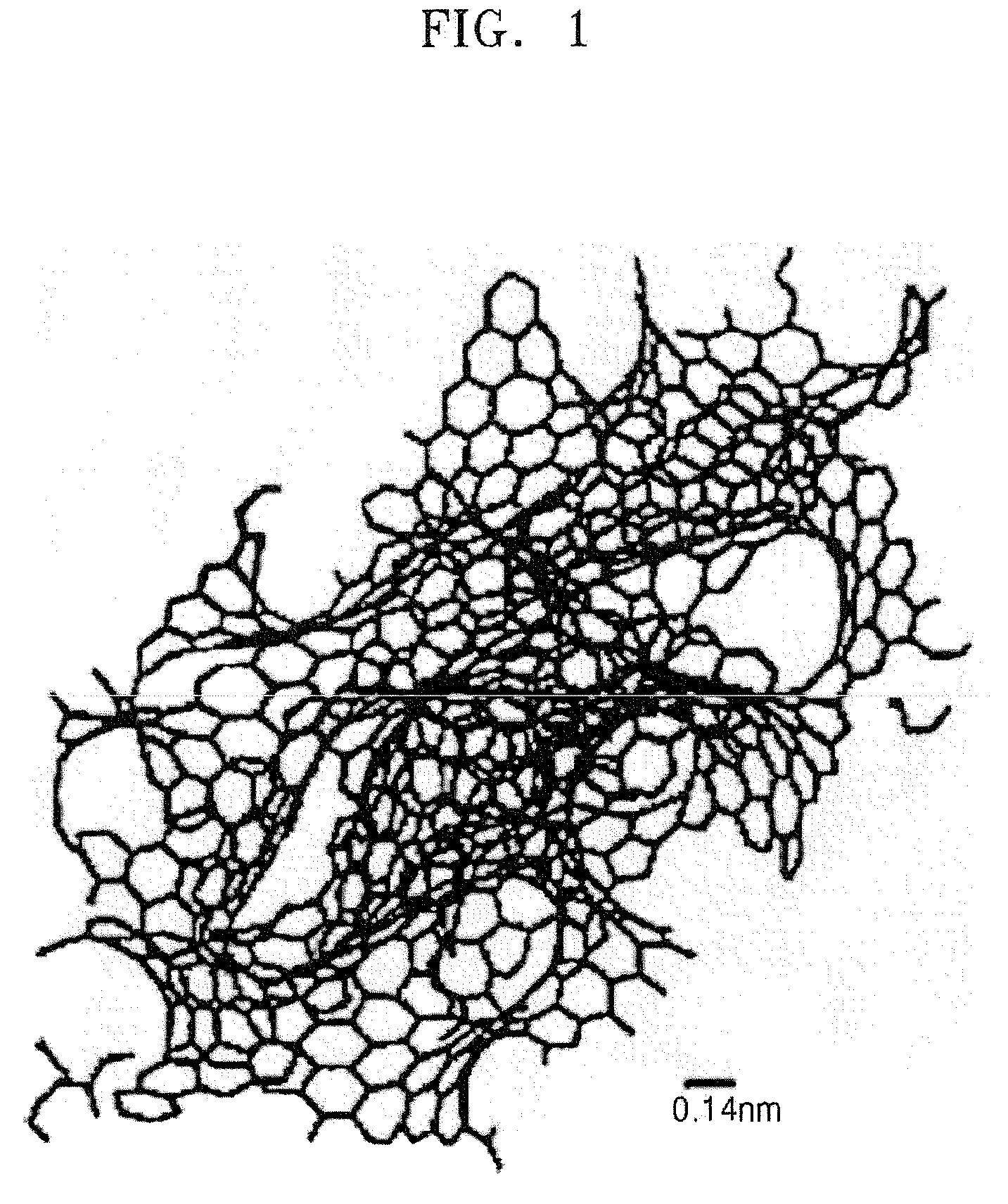

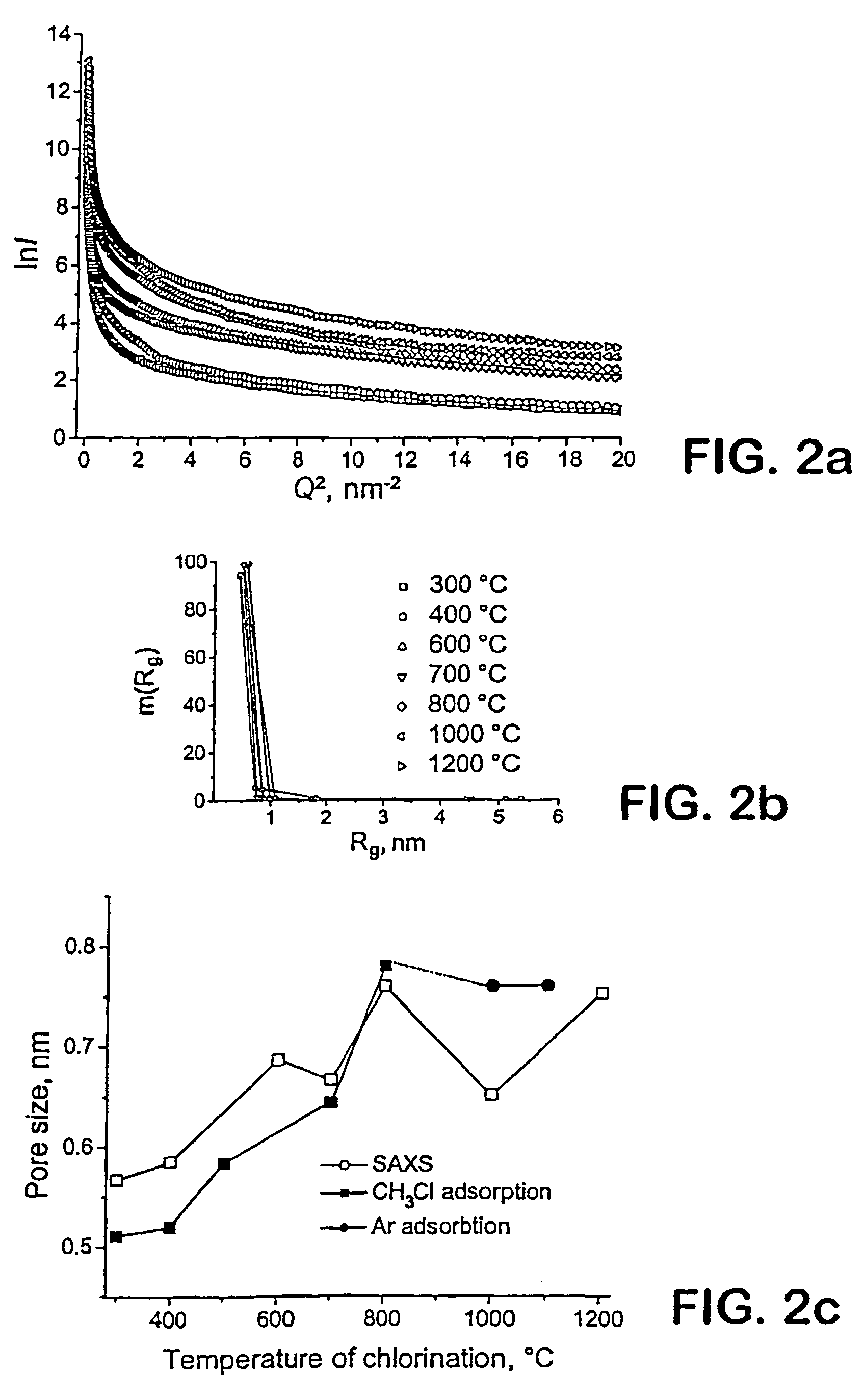

Carbide-derived carbon (CDC), also known as tunable nanoporous carbon, is the common term for carbon materials derived from carbide precursors, such as binary (e.g. SiC, TiC), or ternary carbides, also known as MAX phases (e.g., Ti₂AlC, Ti₃SiC₂). CDCs have also been derived from polymer-derived ceramics such as Si-O-C or Ti-C, and carbonitrides, such as Si-N-C. CDCs can occur in various structures, ranging from amorphous to crystalline carbon, from sp²- to sp³-bonded, and from highly porous to fully dense. Among others, the following carbon structures have been derived from carbide precursors: micro- and mesoporous carbon, amorphous carbon, carbon nanotubes, onion-like carbon, nanocrystalline diamond, graphene, and graphite. Among carbon materials, microporous CDCs exhibit some of the highest reported specific surface areas (up to more than 3000 m²/g). By varying the type of the precursor and the CDC synthesis conditions, microporous and mesoporous structures with controllable average pore size and pore size distributions can be produced. Depending on the precursor and the synthesis conditions, the average pore size control can be applied at sub-Angstrom accuracy. This ability to precisely tune the size and shapes of pores makes CDCs attractive for selective sorption and storage of liquids and gases (e.g., hydrogen, methane, CO₂) and the high electric conductivity and electrochemical stability allows these structures to be effectively implemented in electrical energy storage and capacitive water desalinization.

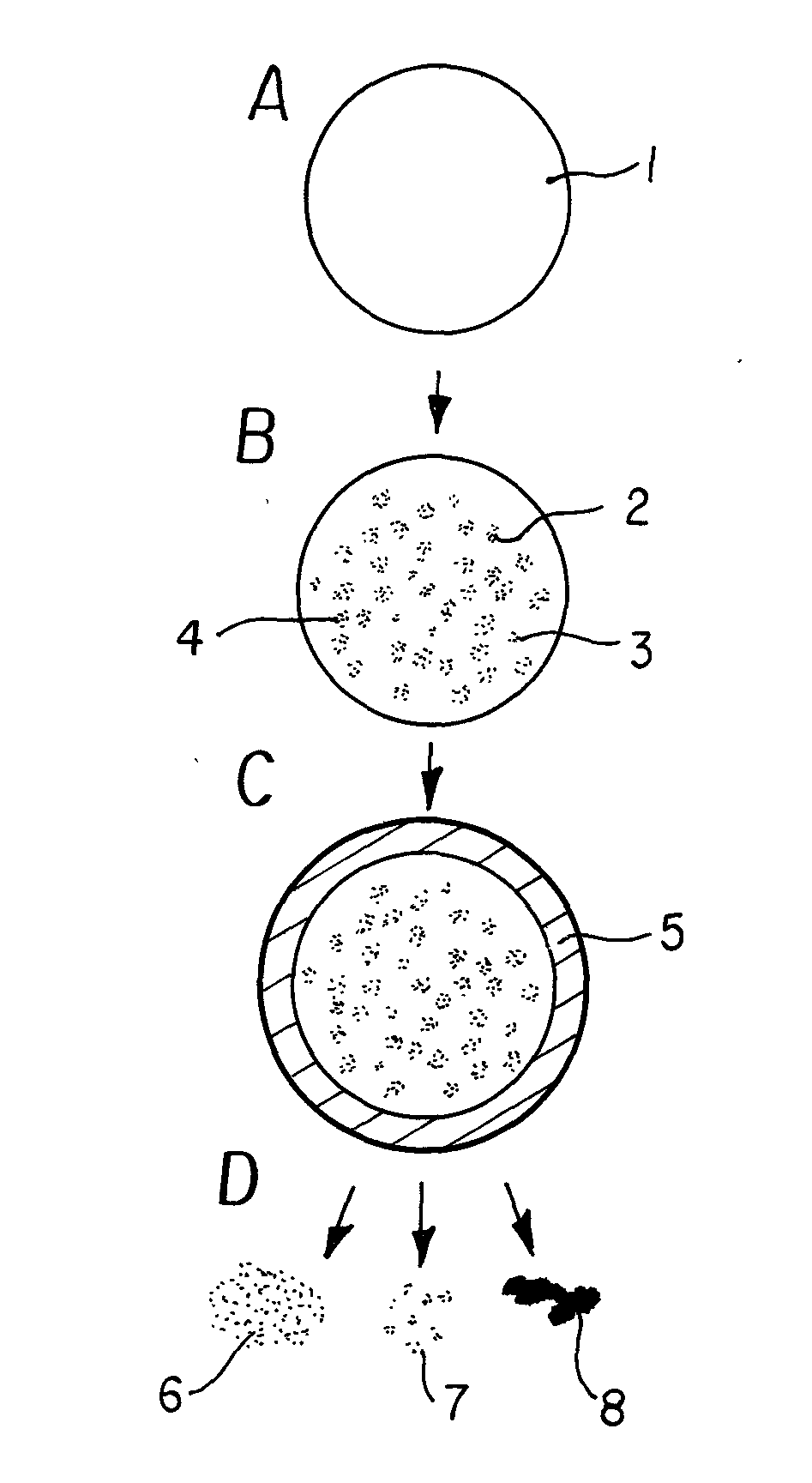

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

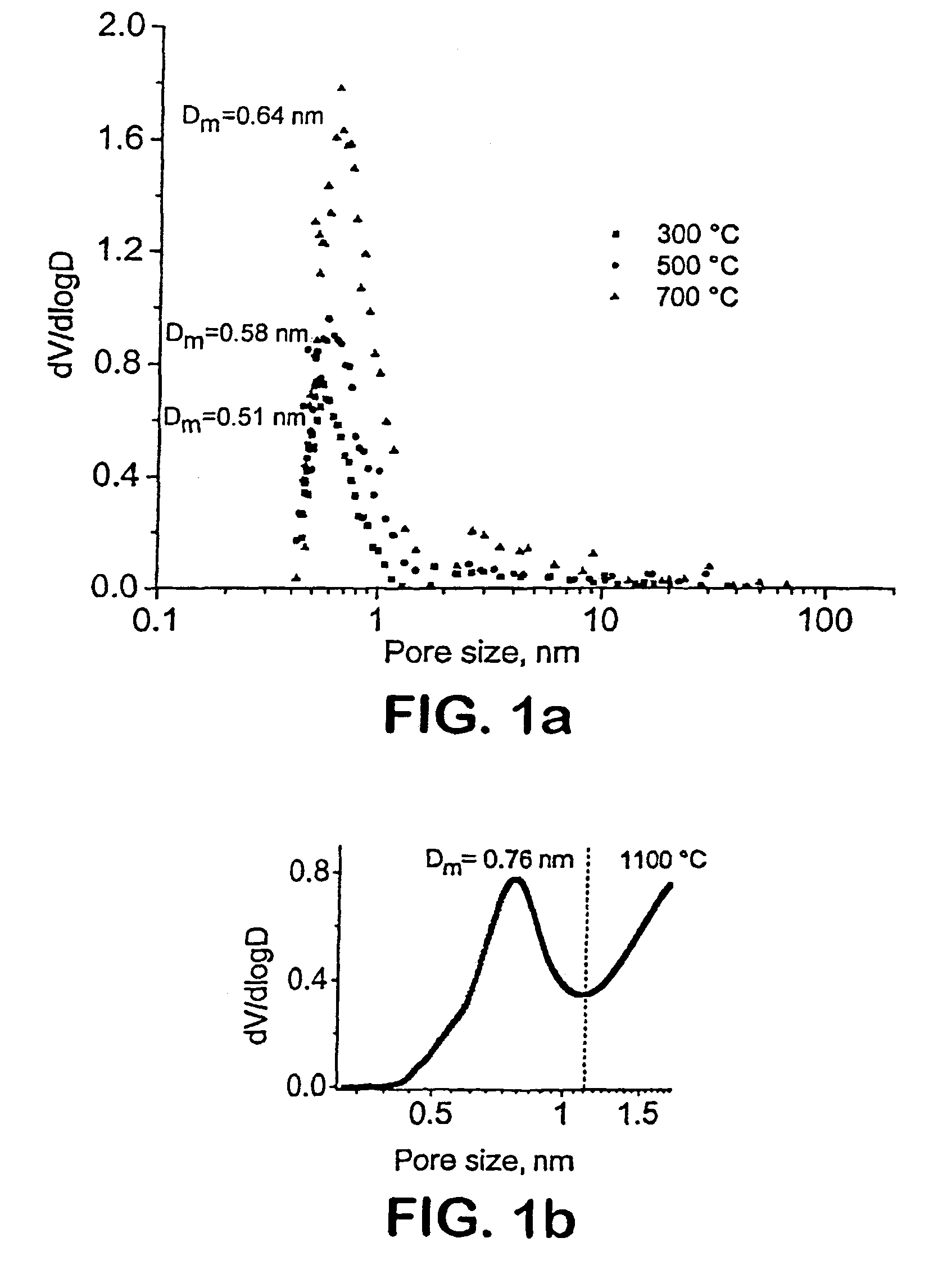

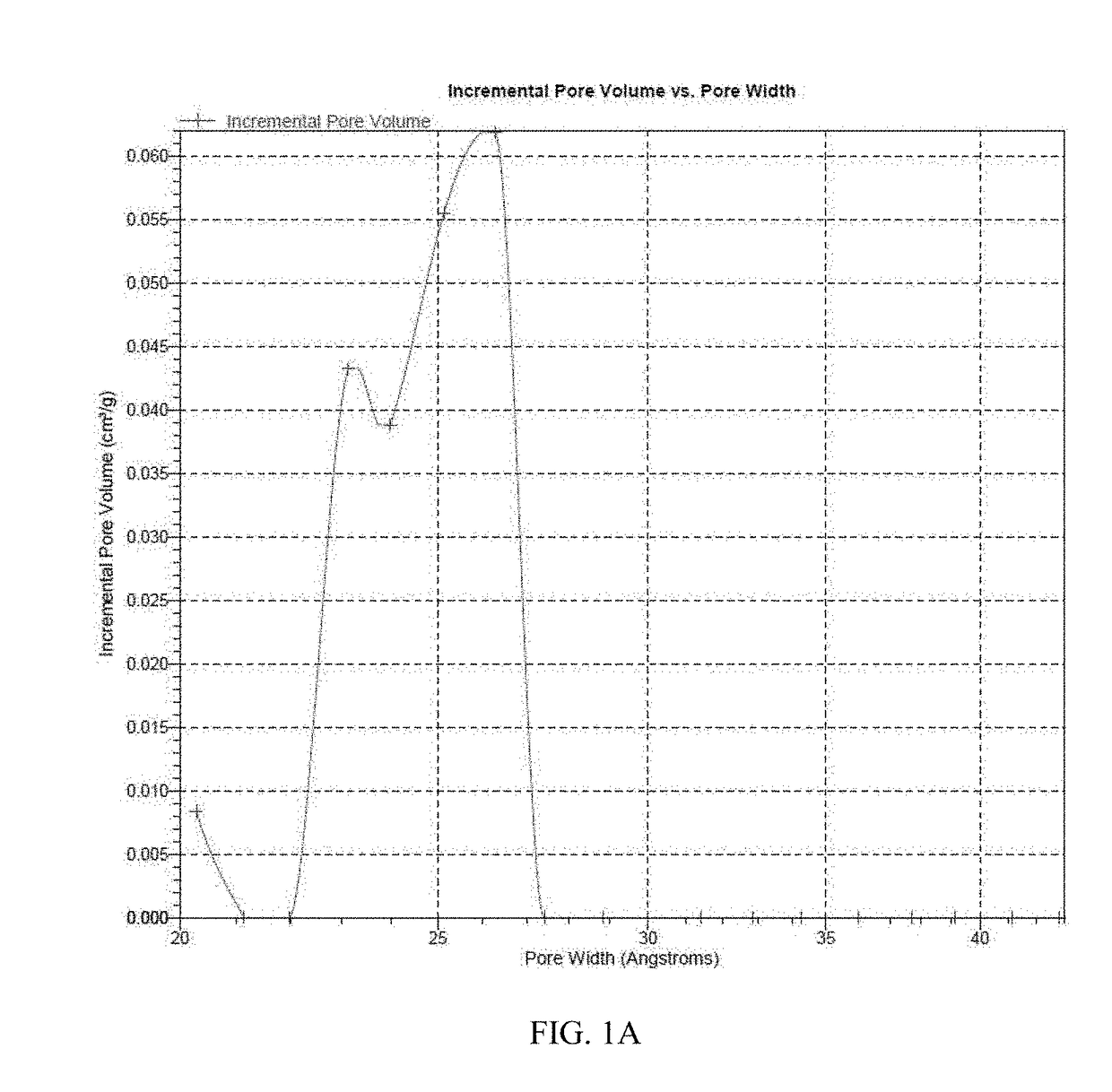

Nanoporous carbide derived carbon with tunable pore size

The present invention provides a method for producing a nanoporous carbide-derived carbon composition with a tunable pore structure and a narrow pore size. Also provided are compositions prepared by the method.

Owner:DREXEL UNIV

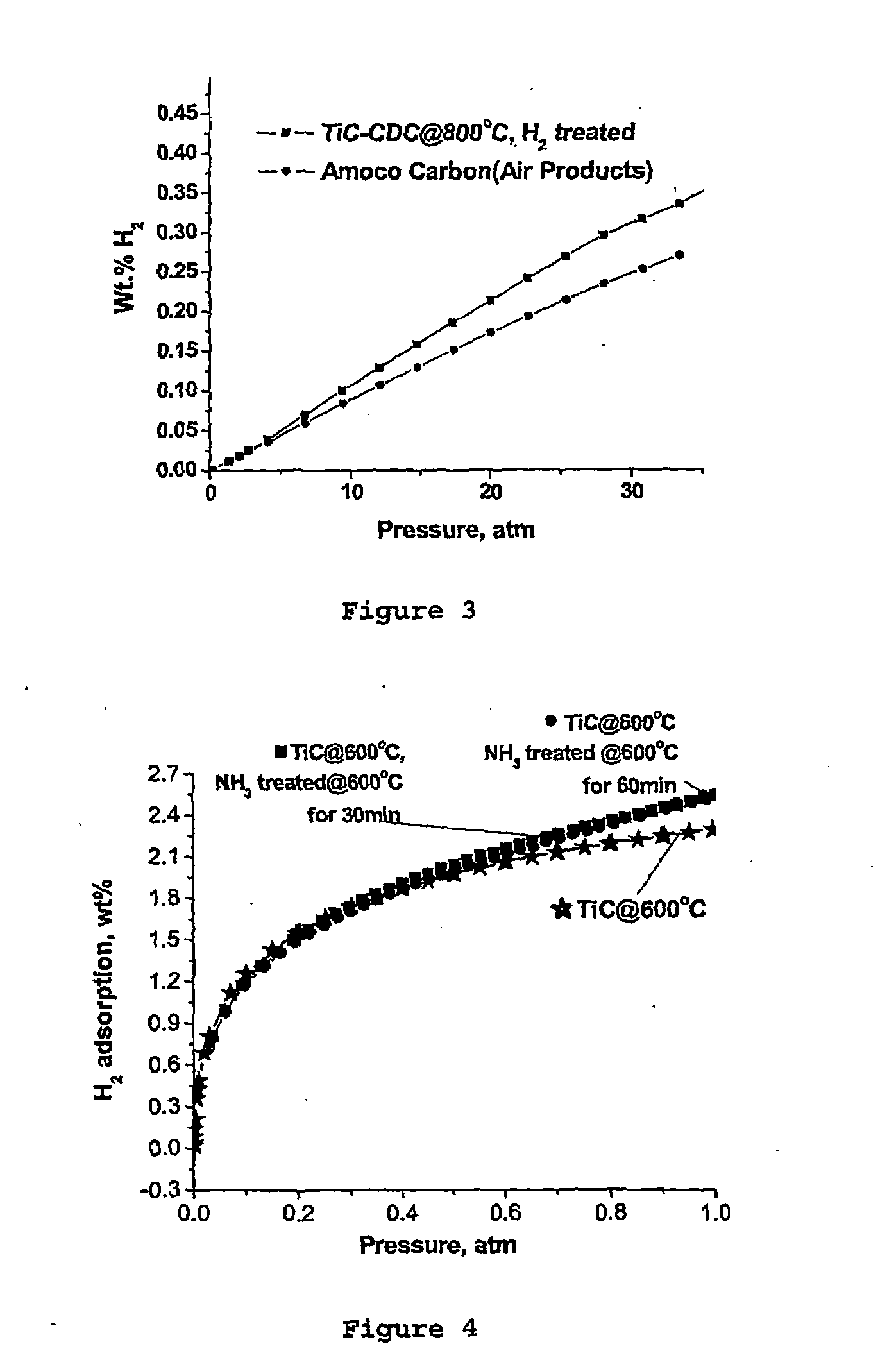

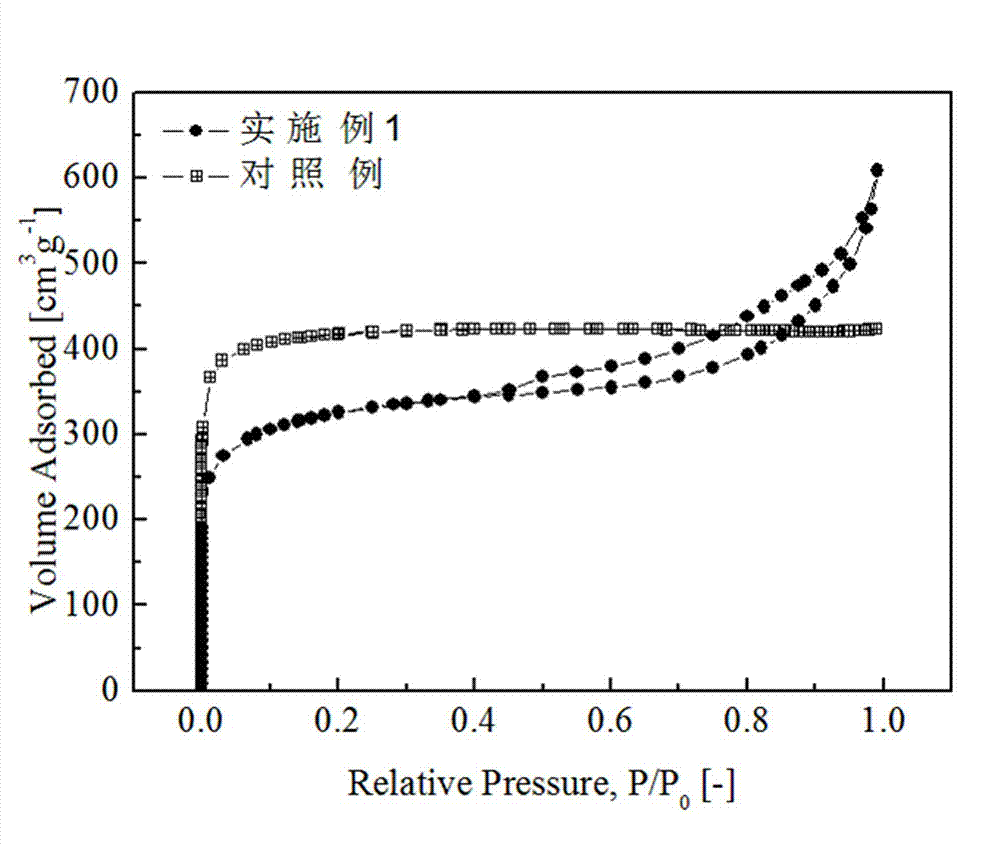

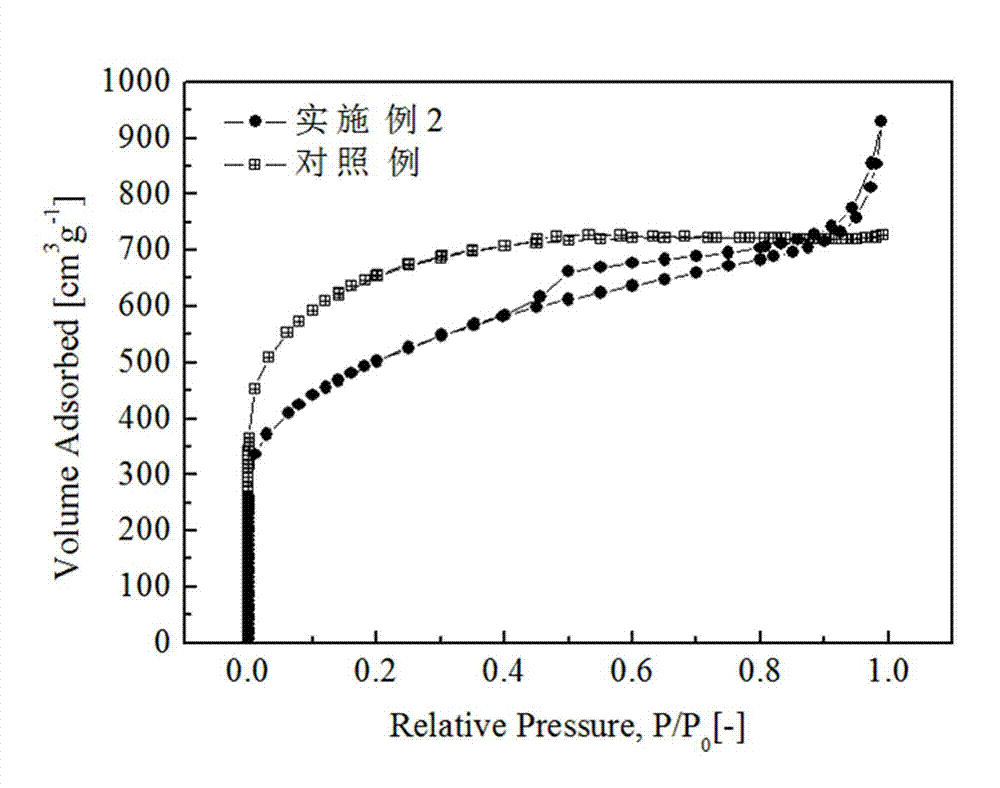

Process for producing nanoporous carbide-derived carbon with increased gas storage capability

InactiveUS20090301902A1Improve gas storage capacityCarbon preparation/purificationFixed capacity gas holdersProduct gasNanoporous carbon

Methods for producing and using nanoporous carbide-derived carbon in applications involving gas storage are provided.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

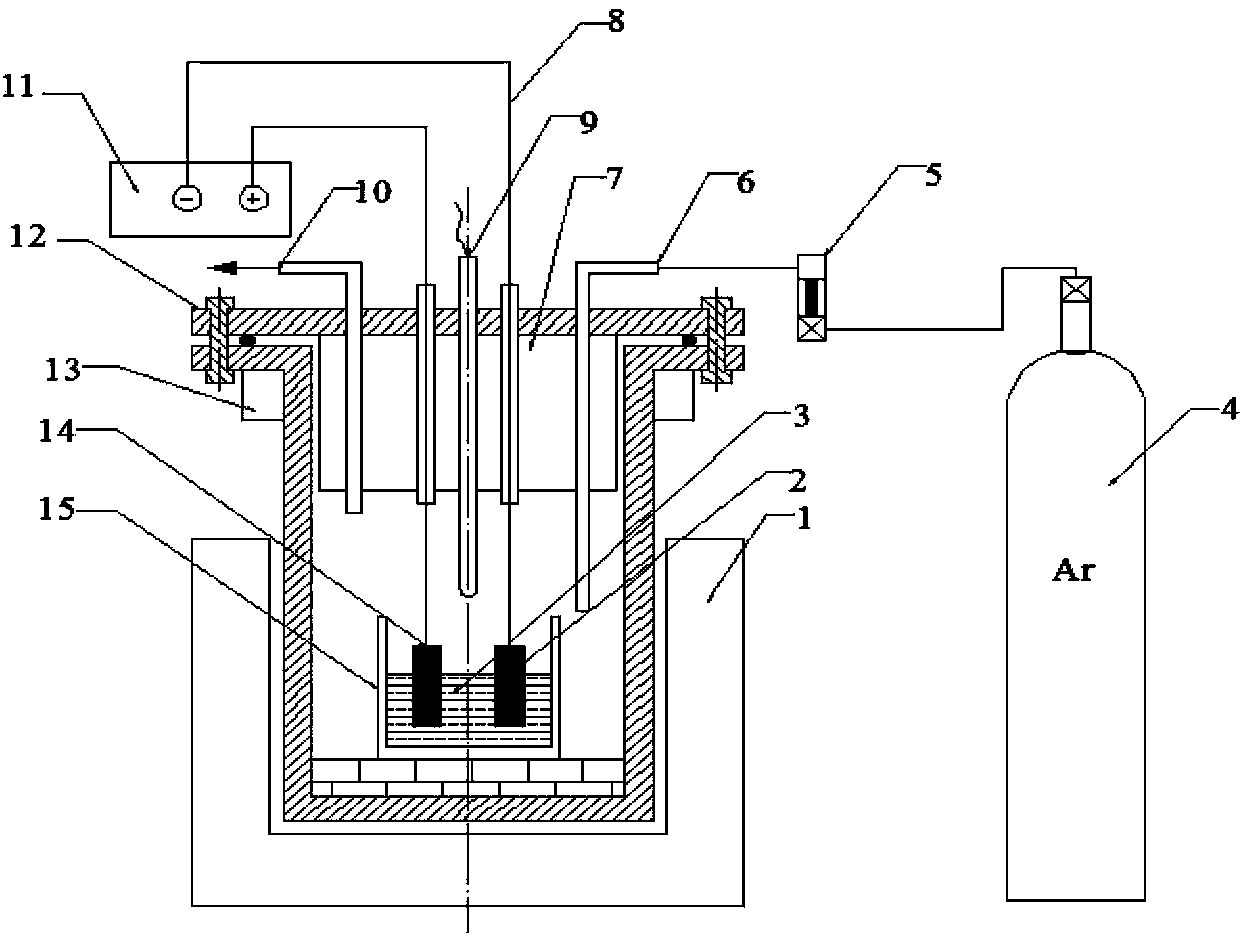

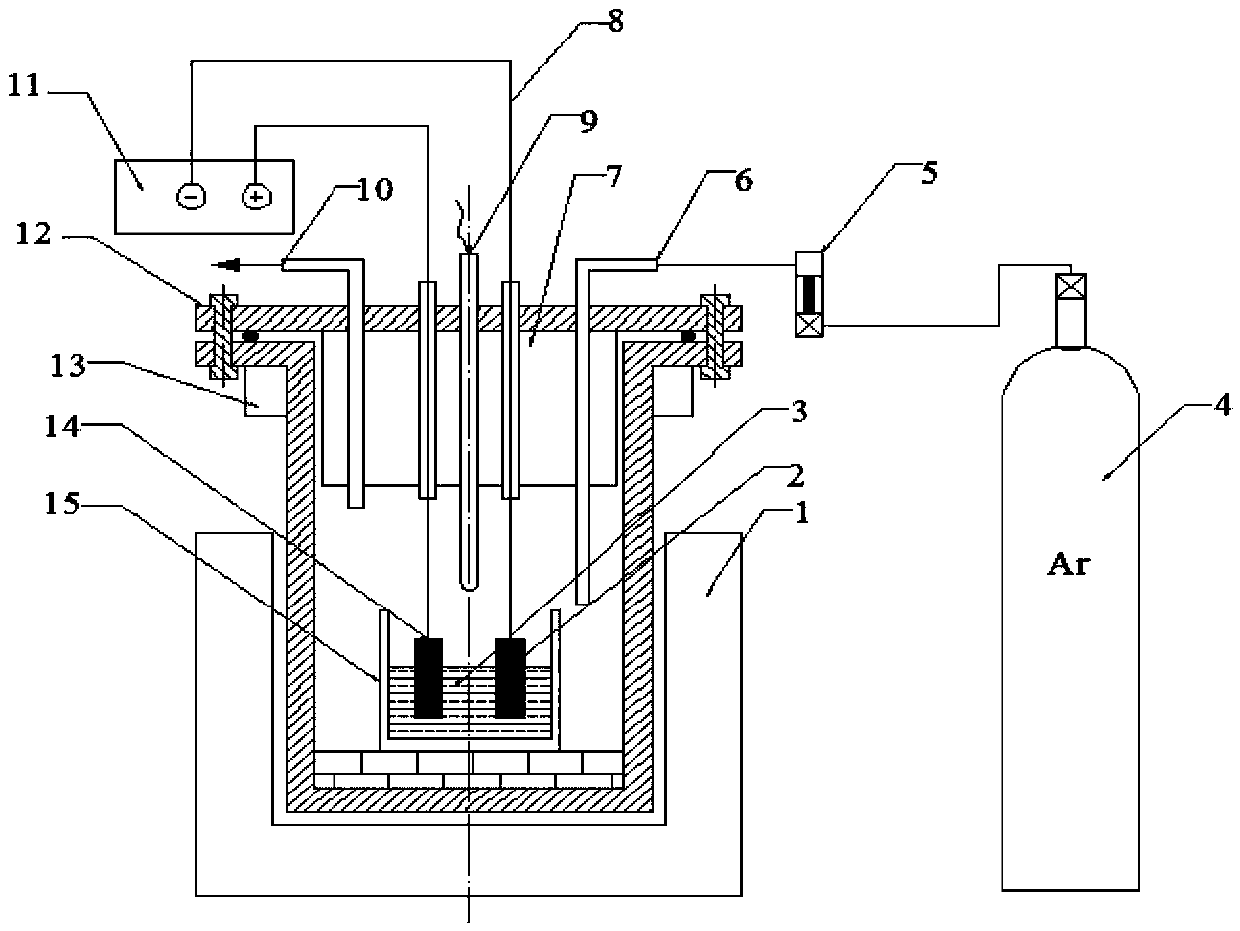

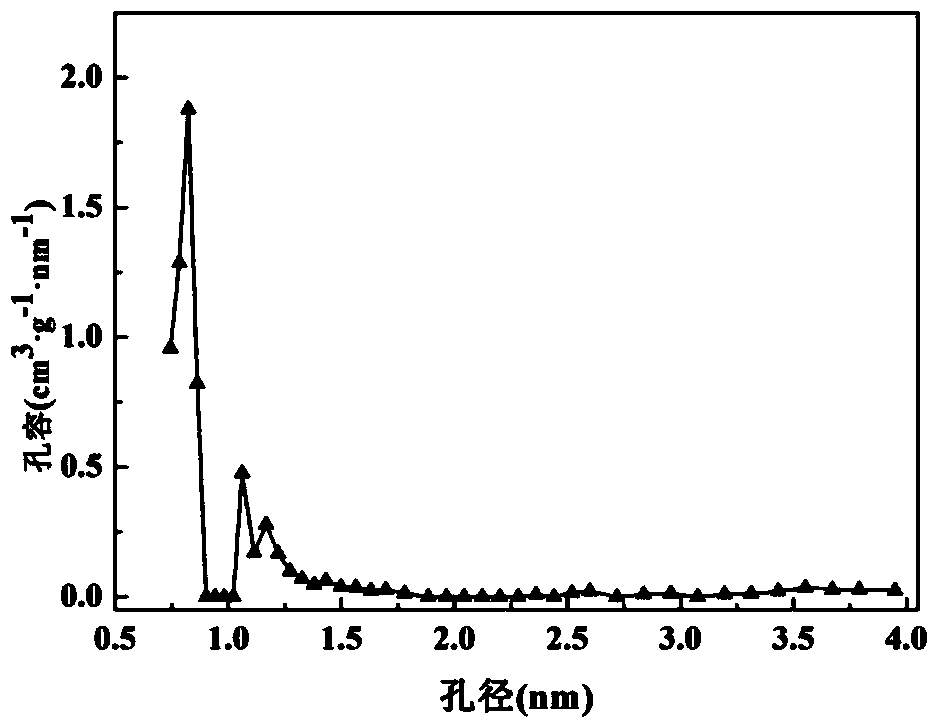

Method for preparing carbide derived carbon by fused salt electrolysis method

InactiveCN103436904AHigh purityUniform pore size distributionElectrolysis componentsCarbon preparation/purificationElectrolysisArgon atmosphere

The invention discloses a method for preparing carbide derived carbon by a fused salt electrolysis method. The method mainly comprises the steps that metal carbide serves as a raw material, and is subjected to die pressing sintering to form a metal carbide sheet to serve as an anode; by taking fused salt as an electrolyte, and a high-purity and high-density graphite rod as a cathode, fused salt electrolysis is performed in an electrolysis furnace in an argon atmosphere with the electrolysis temperature of 400-1300 DEG C, the electrolysis voltage of 1.8-3.2V, and the electrolysis time of 2-60h; after the electrolysis, an anode product is taken out, and subjected to water washing, ultrasonic-assisted pickling, water washing and drying treatment; and the carbide derived carbon is prepared. According to the method, the low-cost metal carbide can serve as the raw material for preparing the carbide derived carbon by the fused salt electrolysis method, so that a preparation technology is simplified; the cost is lowered; and the prepared carbide derived carbon serves as an electrode material of a supercapacitor, and has high specific capacity and good cycling stability.

Owner:YANSHAN UNIV

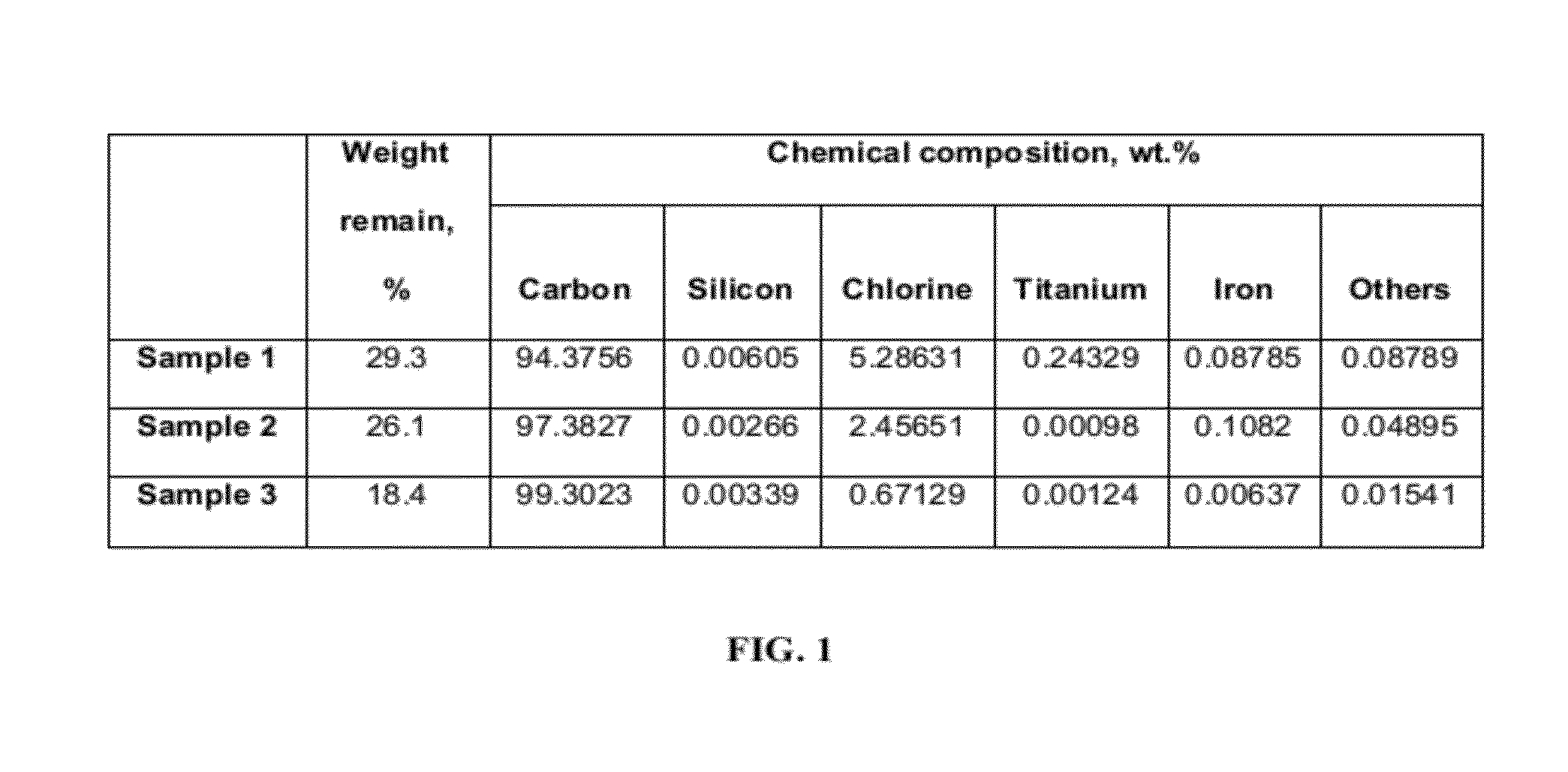

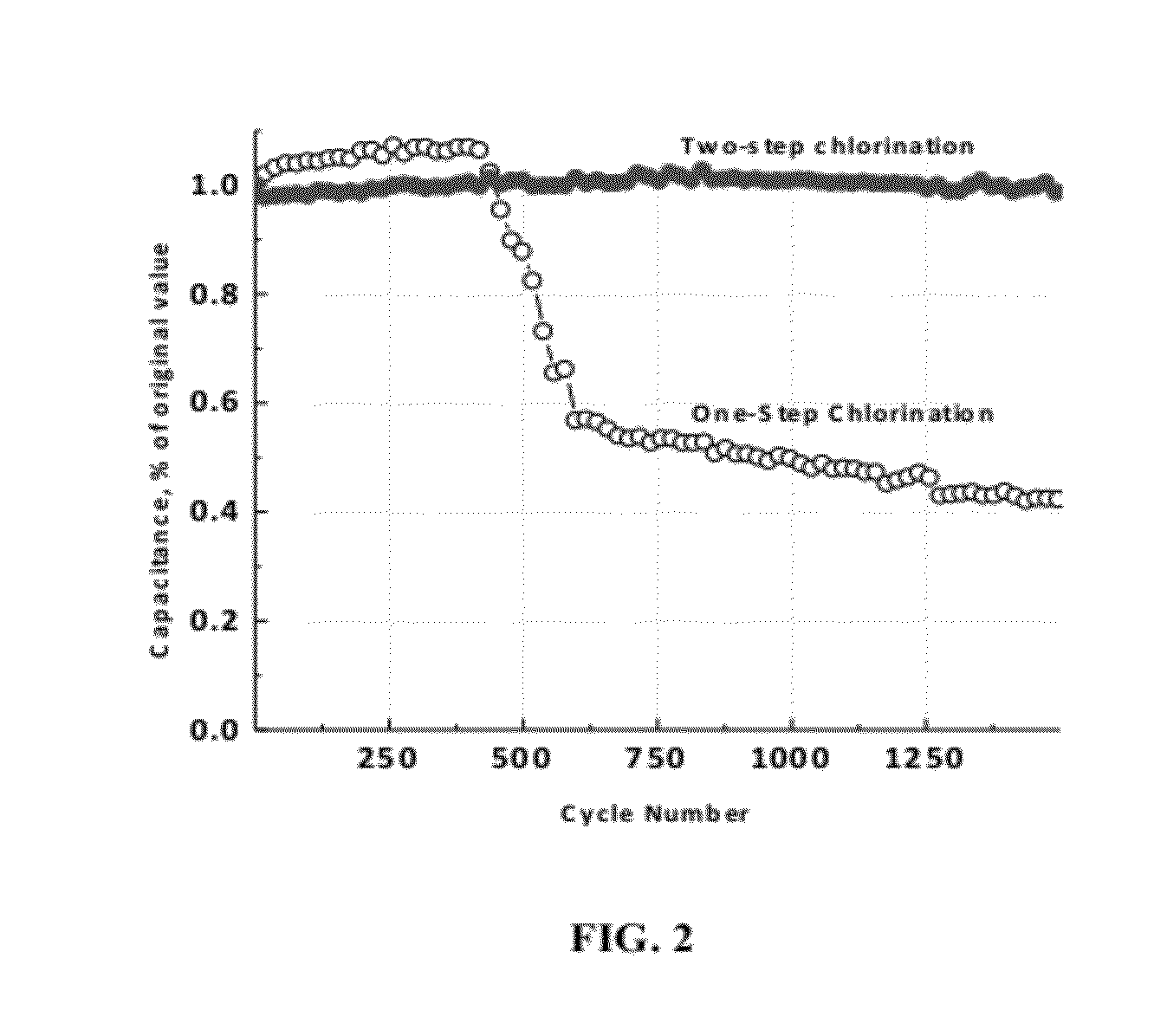

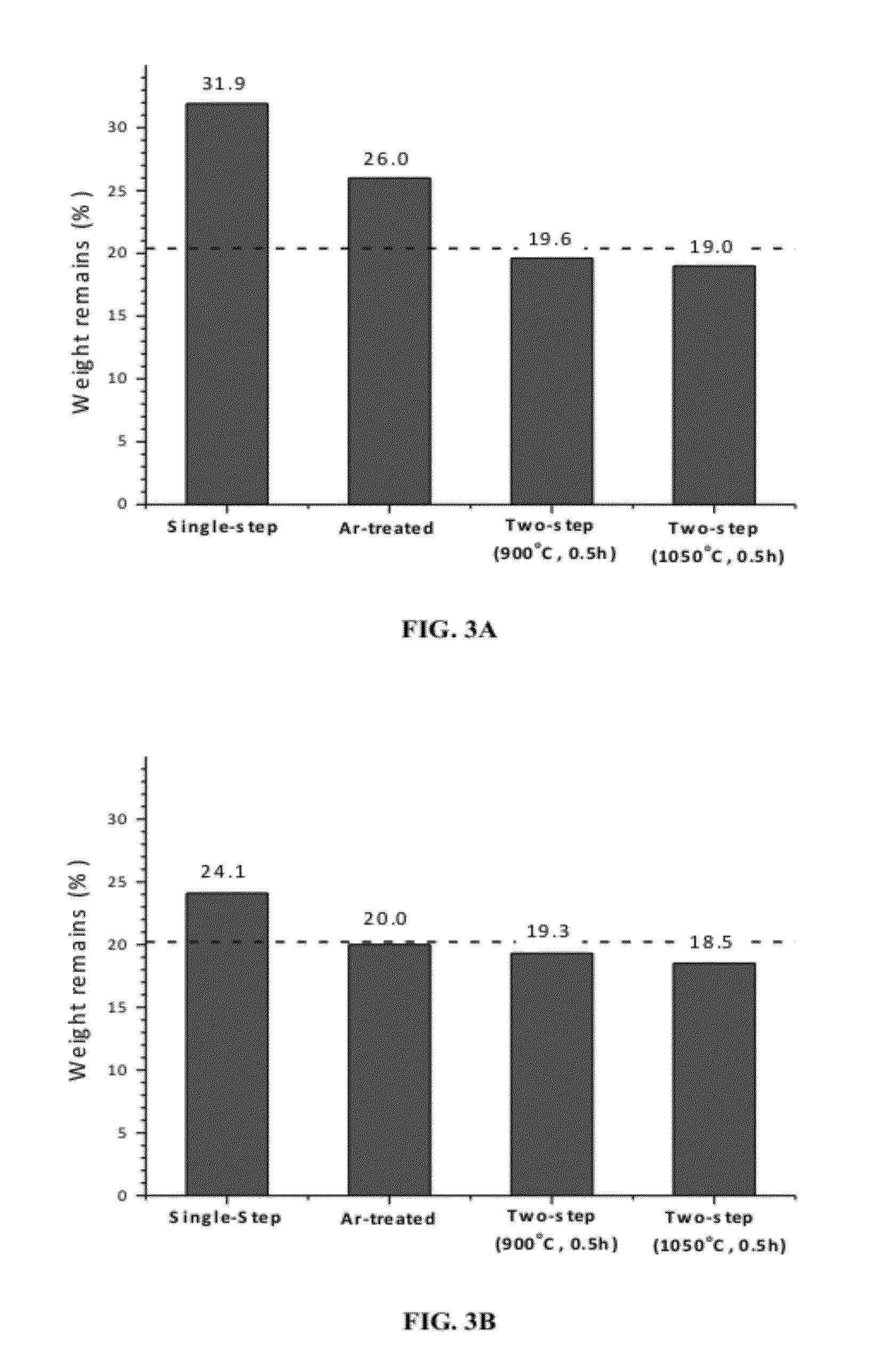

Method of making carbide derived carbon with enhanced porosity and higher purity

Purity (chemical composition) and porosity of carbons are important for most of their applications. There are several methods of making porous carbons. Carbide derived carbon represents a method of manufacturing carbon from metal carbides by thermochemical etching of metals and / or metalloids at elevated temperatures. This invention provides a method of manufacturing carbide derived carbon with higher purity. The produced carbons can be used in several applications where higher purity carbons are desired including but not limited to gas chromatography, liquid chromatography, supercapacitors, batteries, fuel cells, hemodiafiltration, enterosorbent, and toxin removal from biological fluids.

Owner:Y CARBON

Process for producing nanoporous carbide derived carbon with large specific surface area

InactiveUS20090036302A1Large specific surface areaOther chemical processesLayered productsHalogenCarbide

Processes for the synthesis of high specific surface area nanoporous carbons by reacting select carbides with one or more halogens to produce compositions comprising carbon and halogens and contacting the reacted carbides with a species capable of removing the halogen are provided. Methods for removing halogen impurities from carbon compositions having pores and for modifying the surface terminations of carbon compositions having pores are also provided.

Owner:DREXEL UNIV

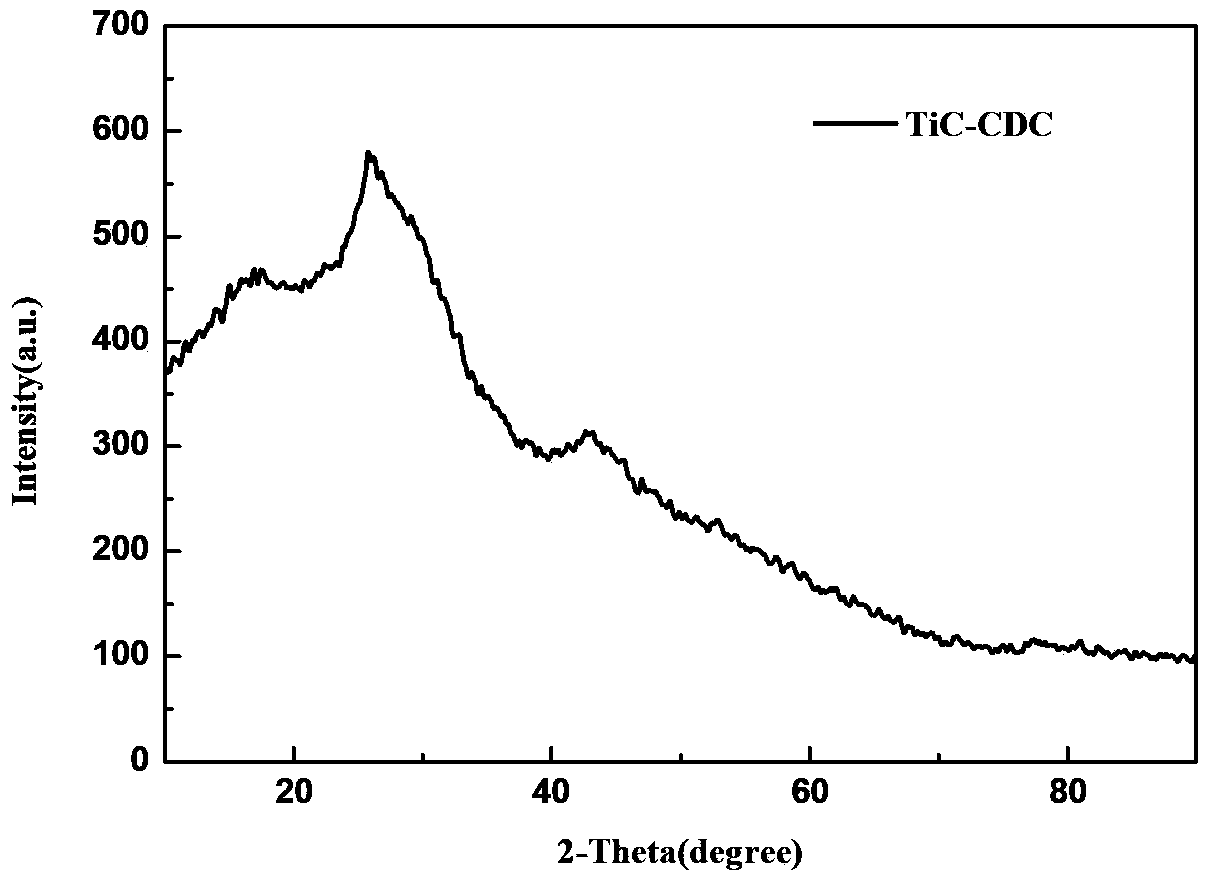

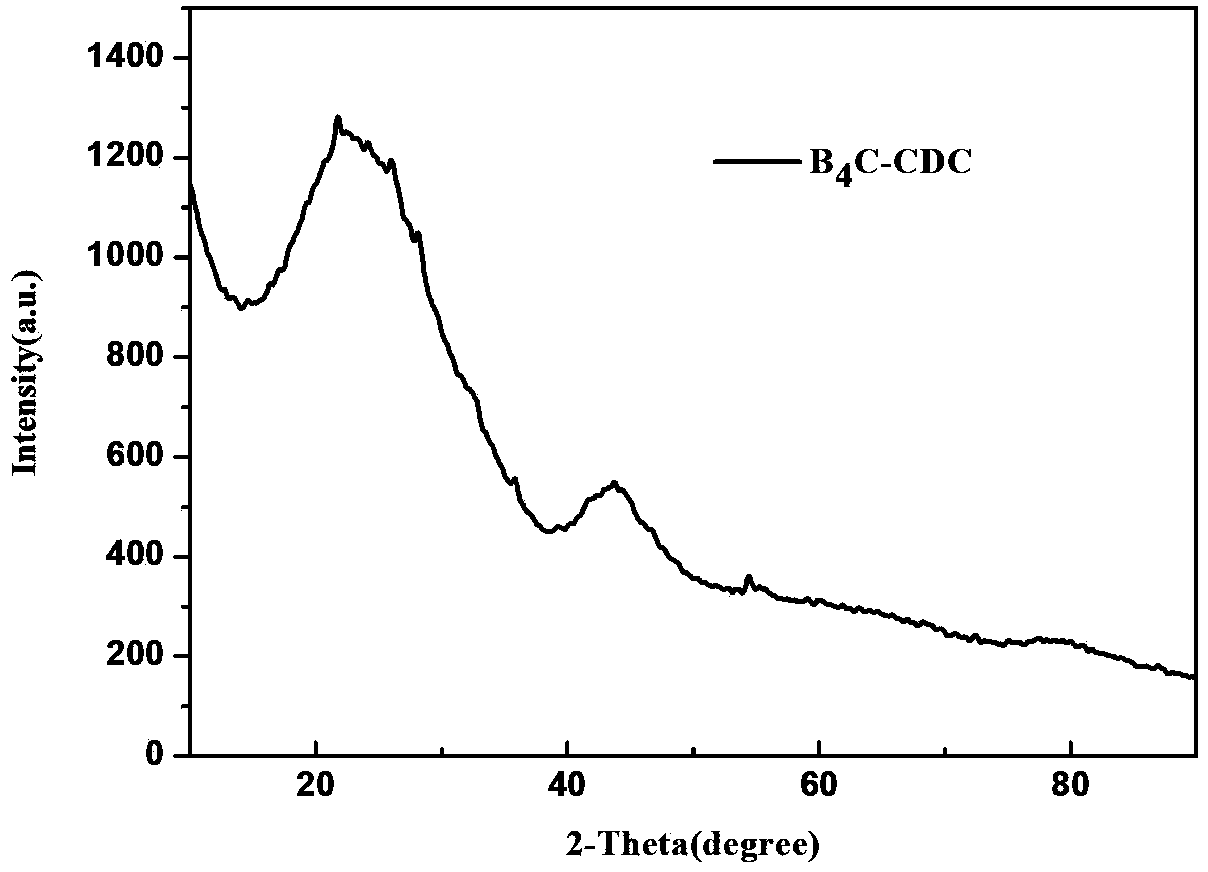

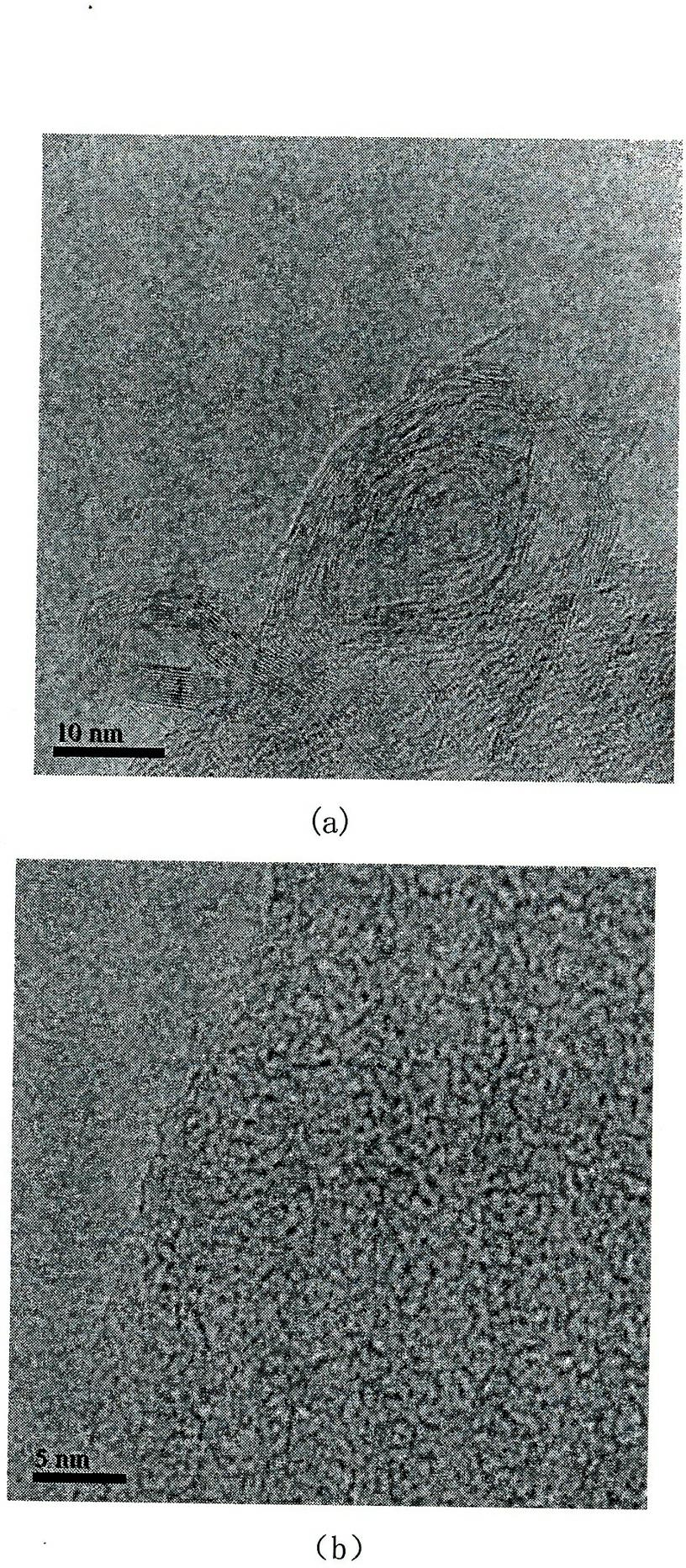

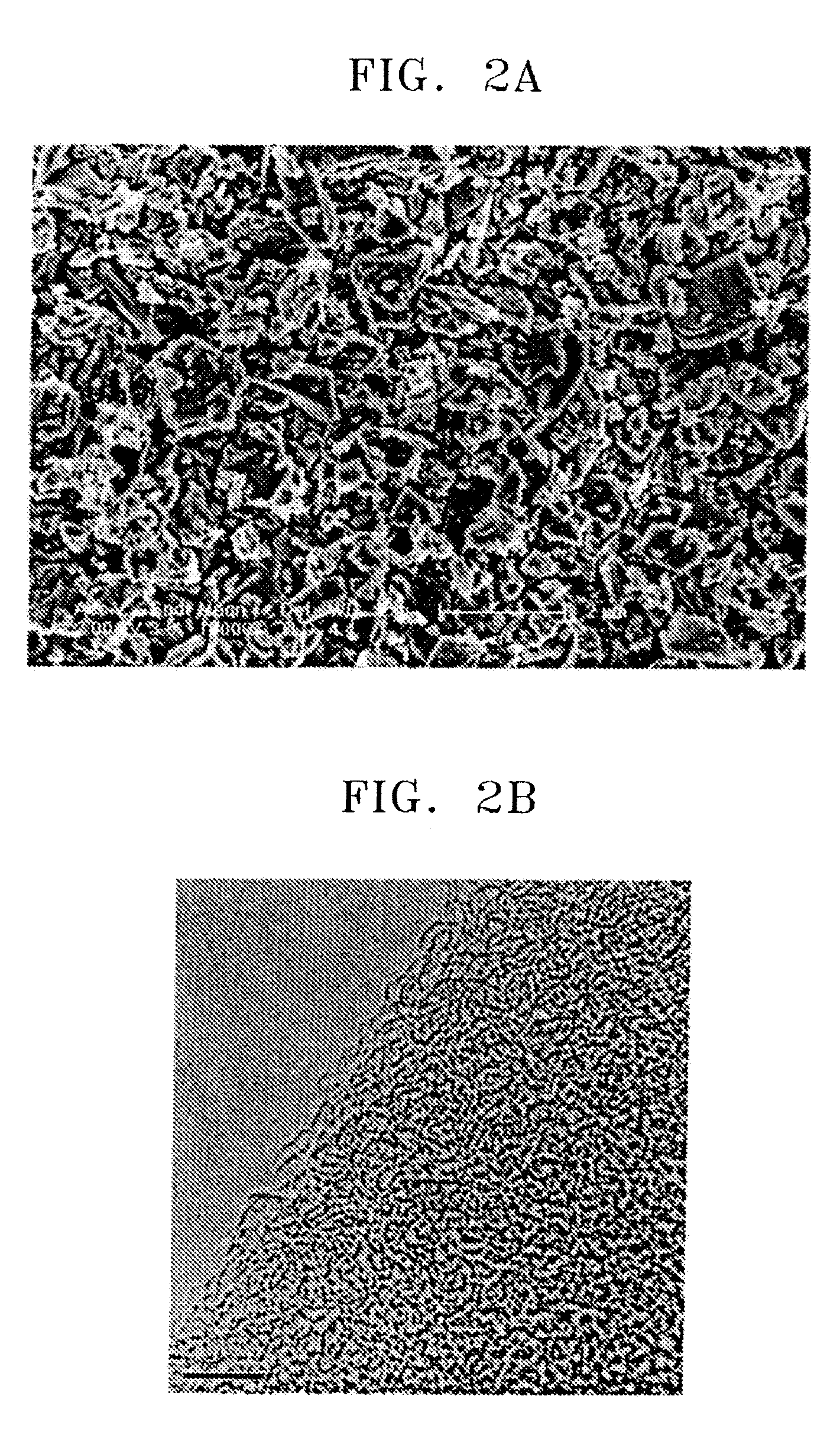

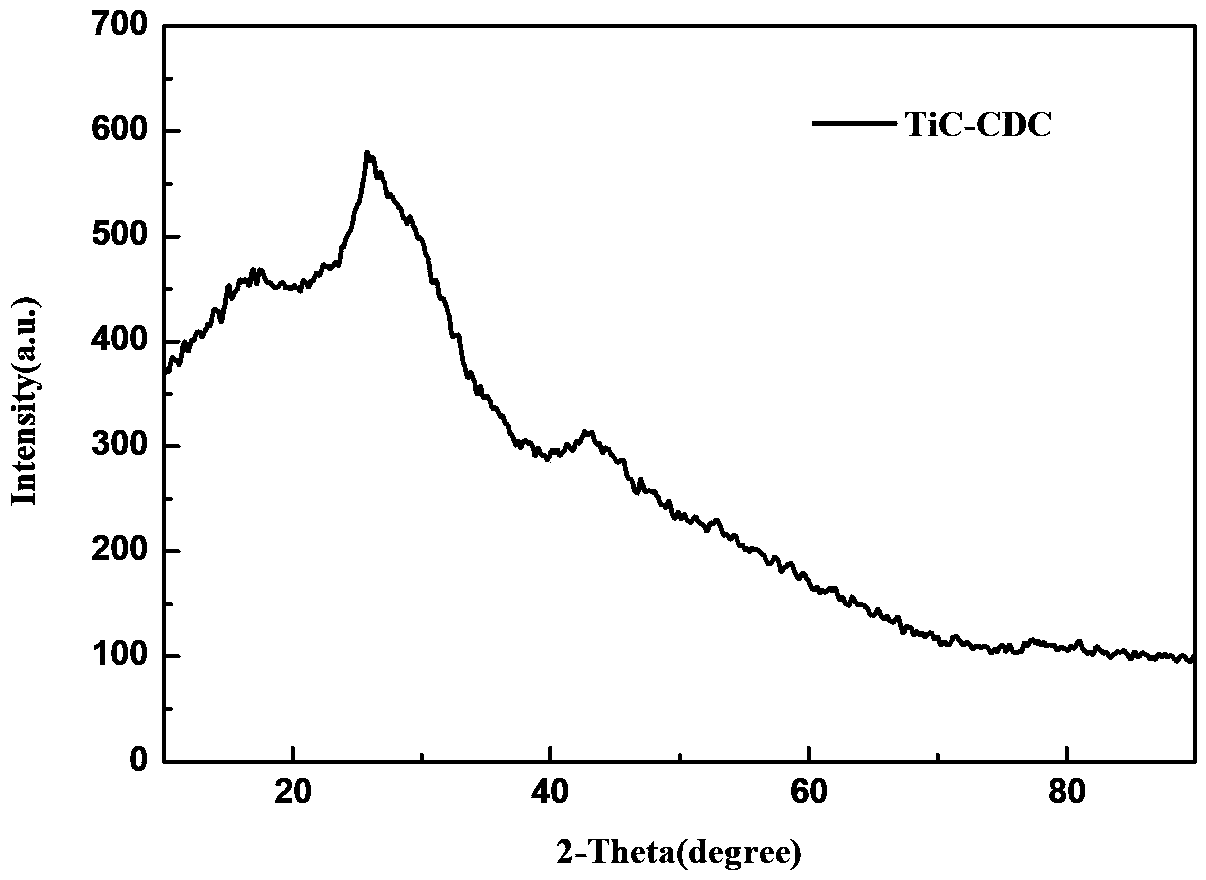

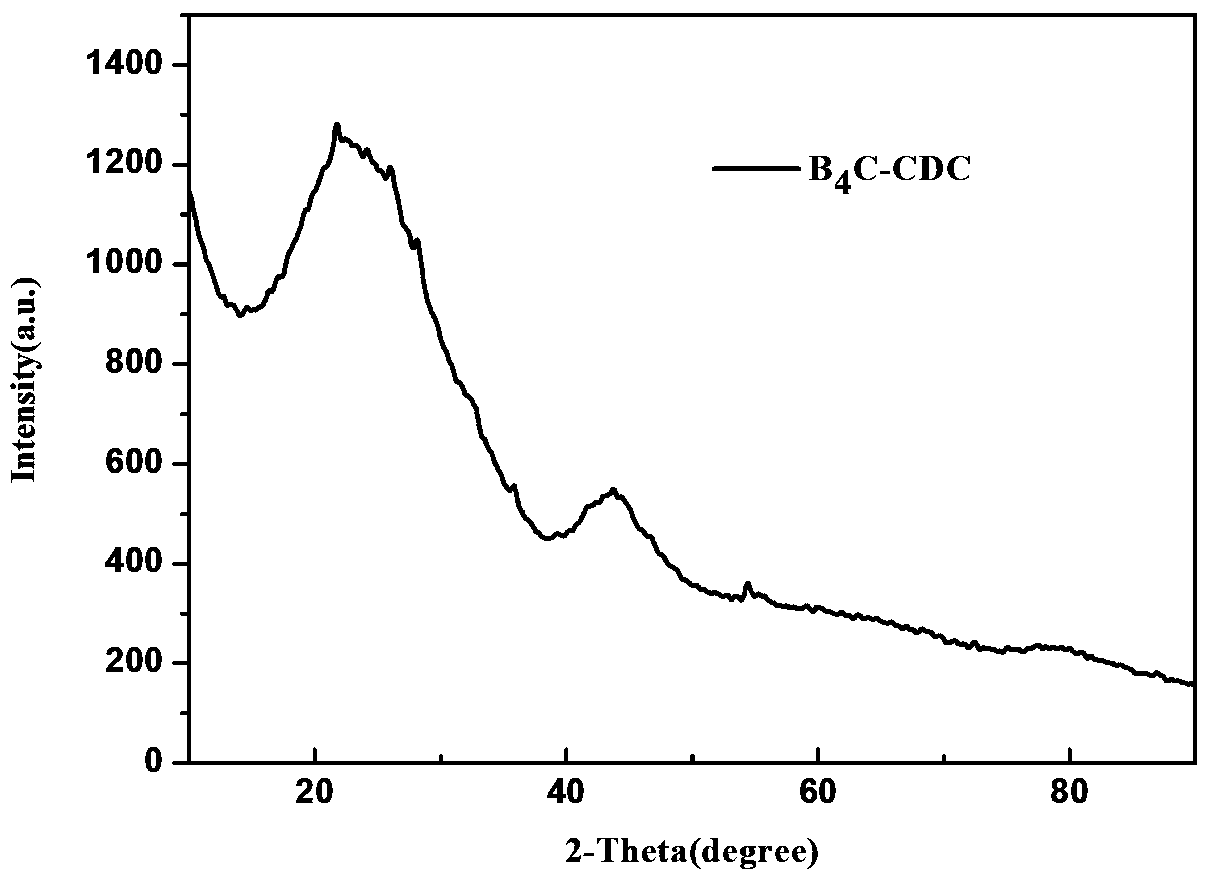

Carbide derived carbon, emitter for cold cathode including the same and electron emission device including the emitter

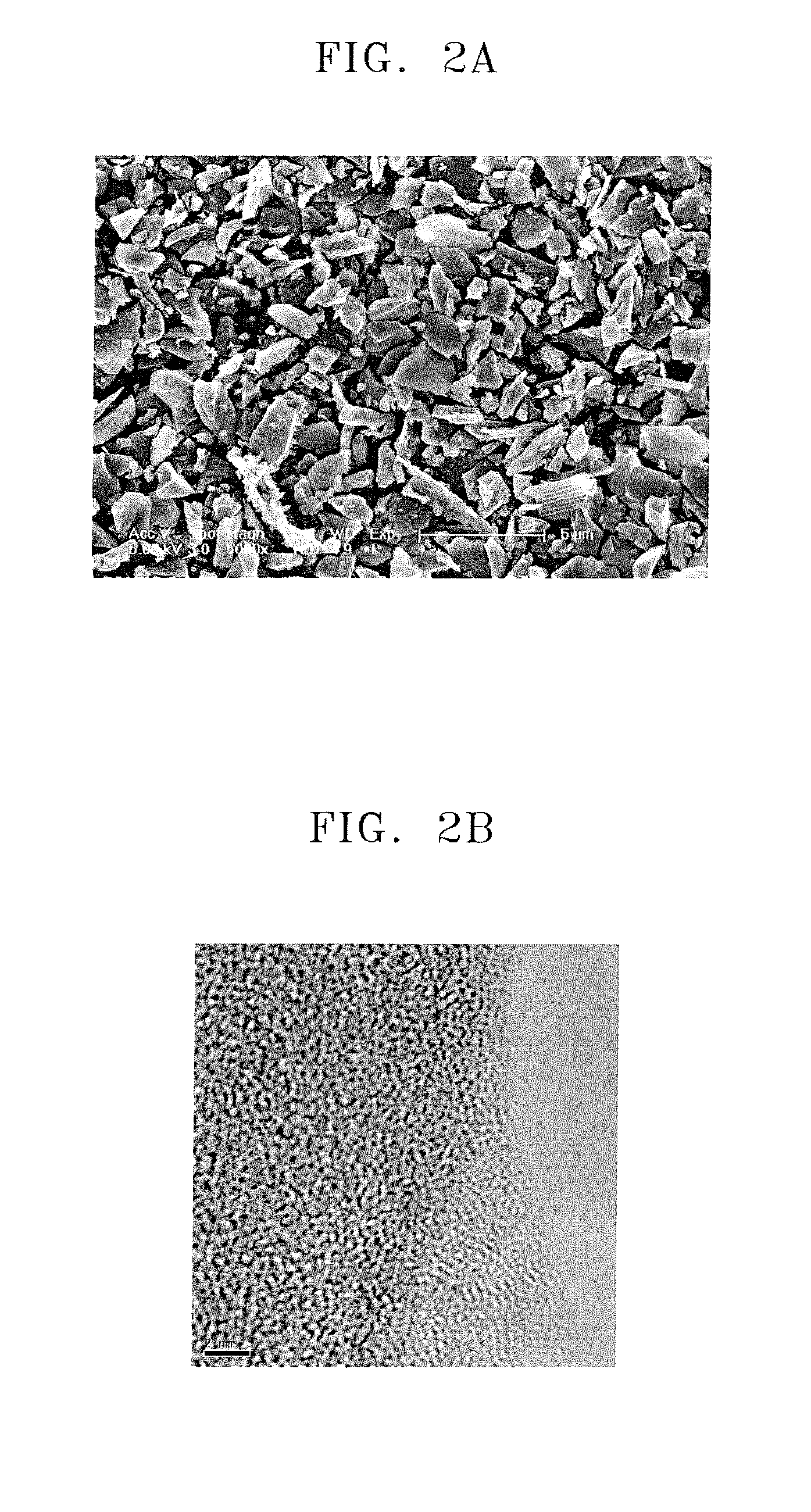

InactiveUS20080169749A1Improve uniformityLong life-timeDischarge tube luminescnet screensElectric discharge tubesChemical reactionX-ray

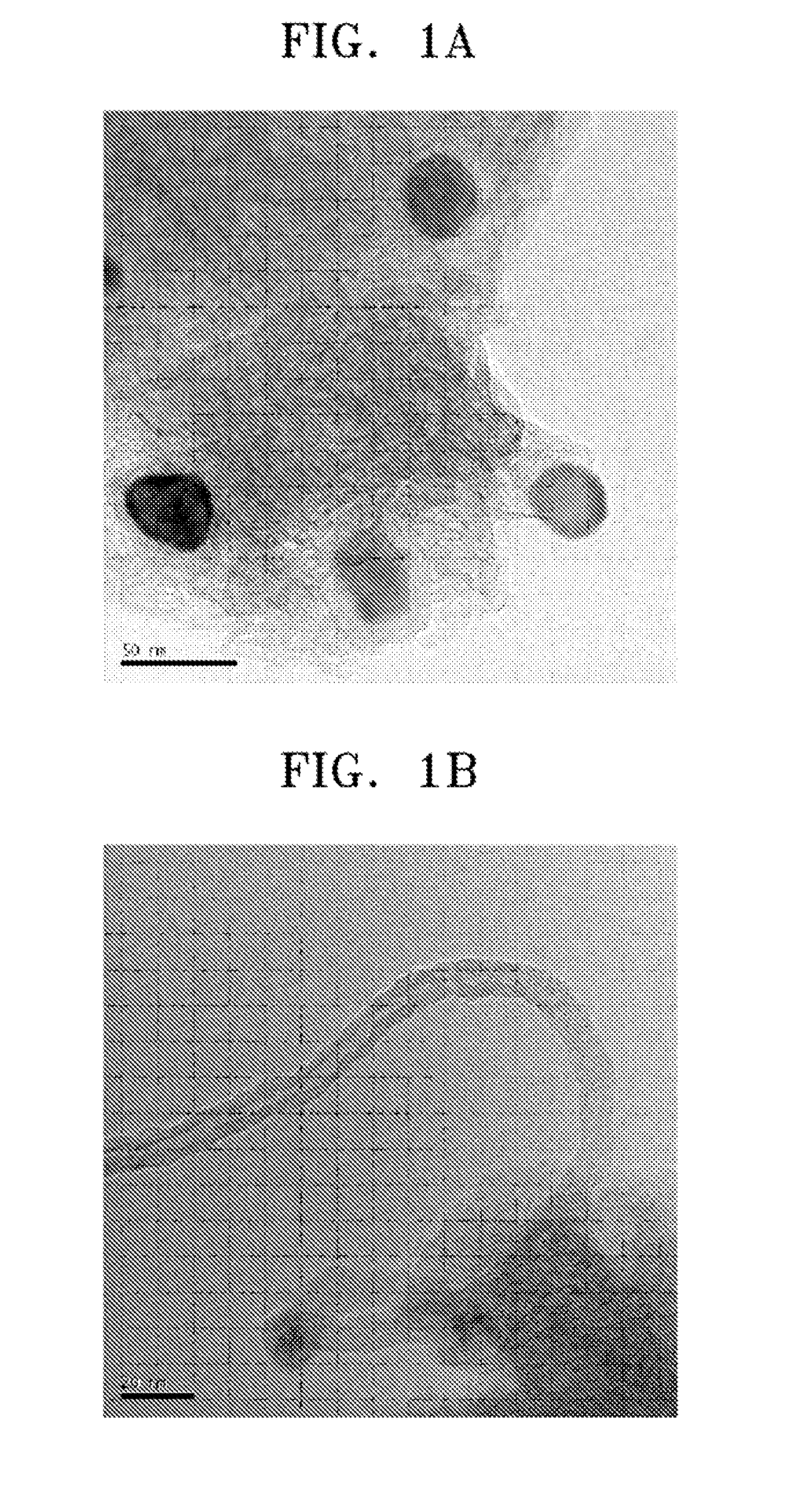

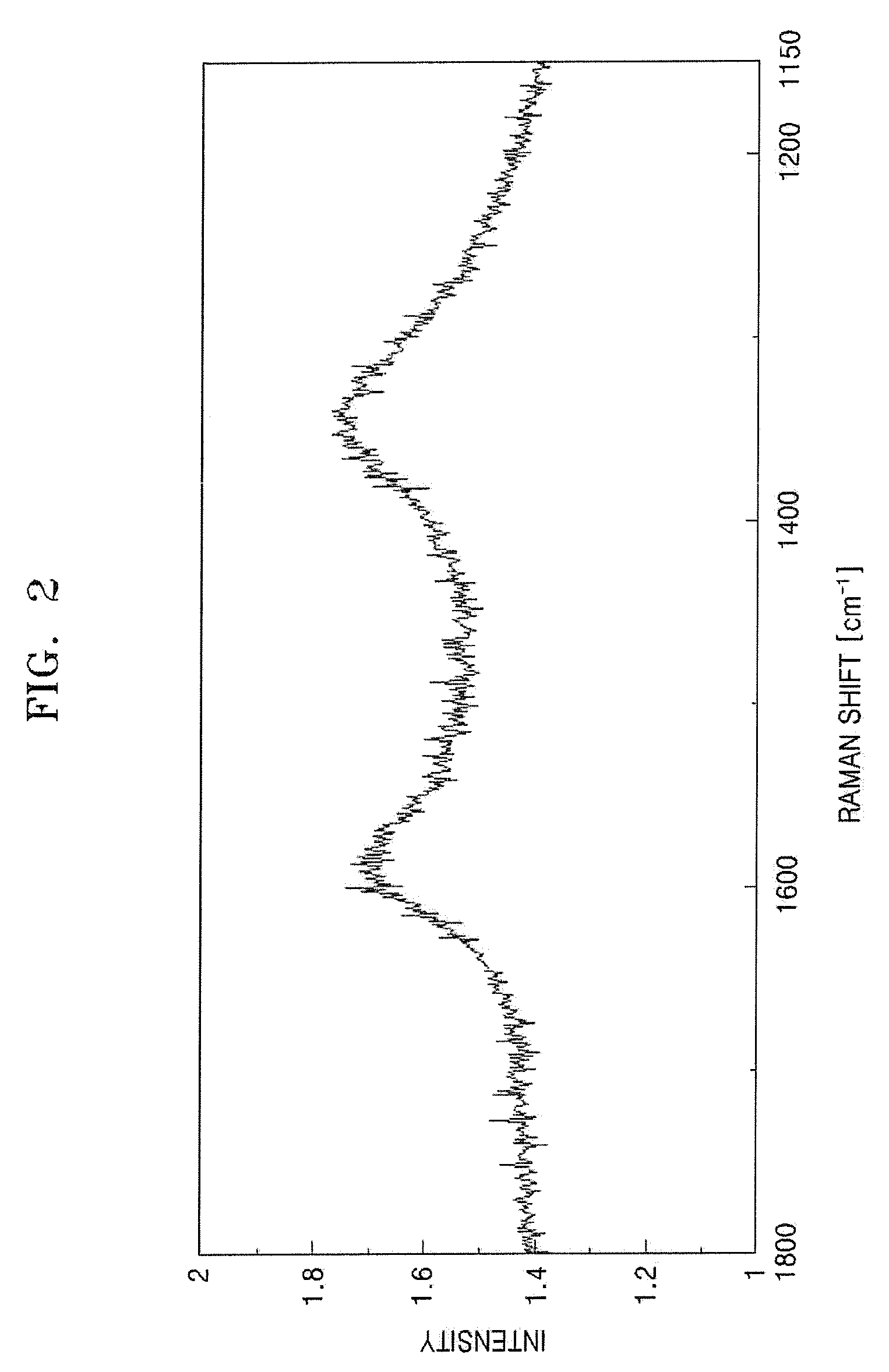

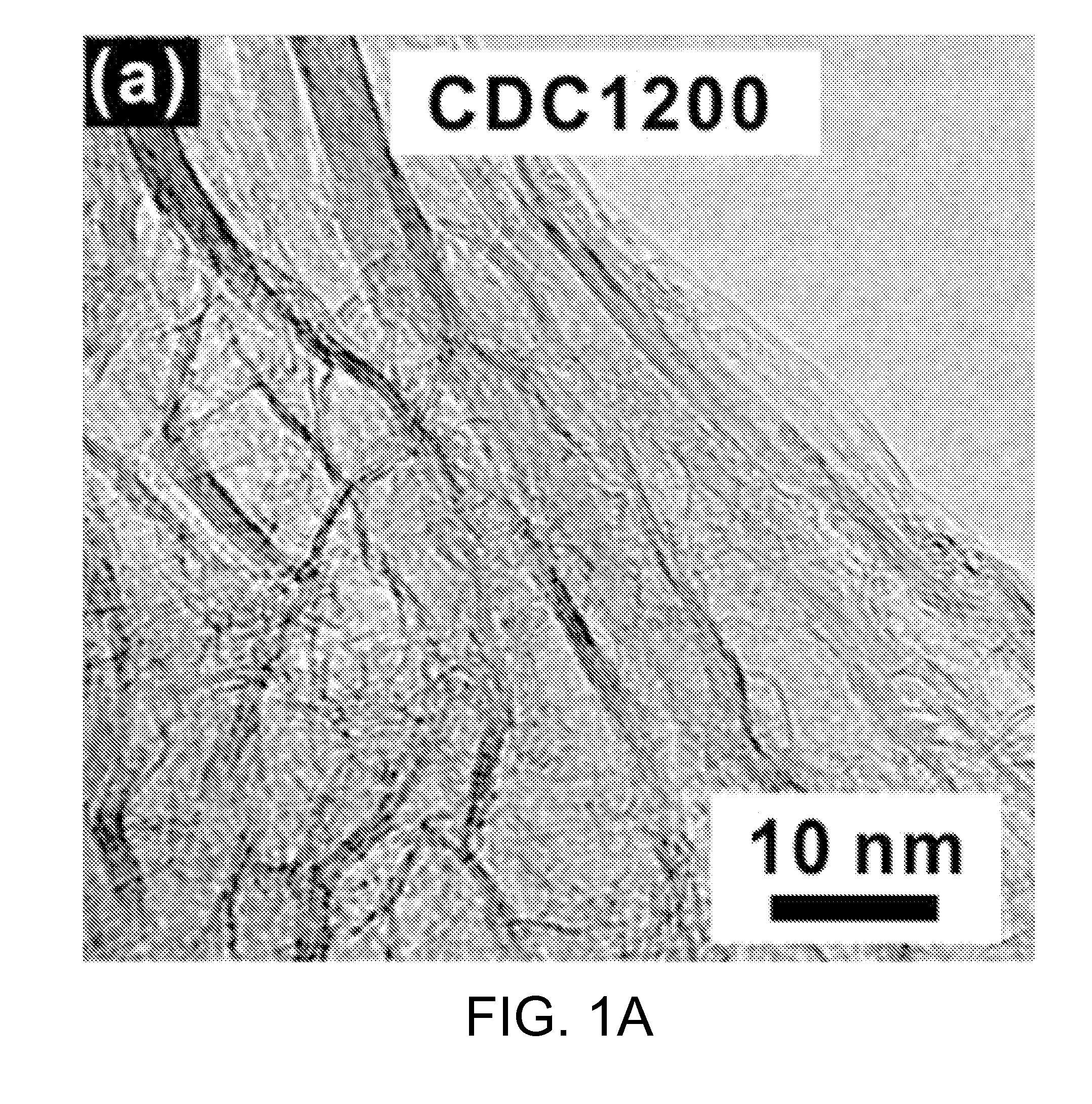

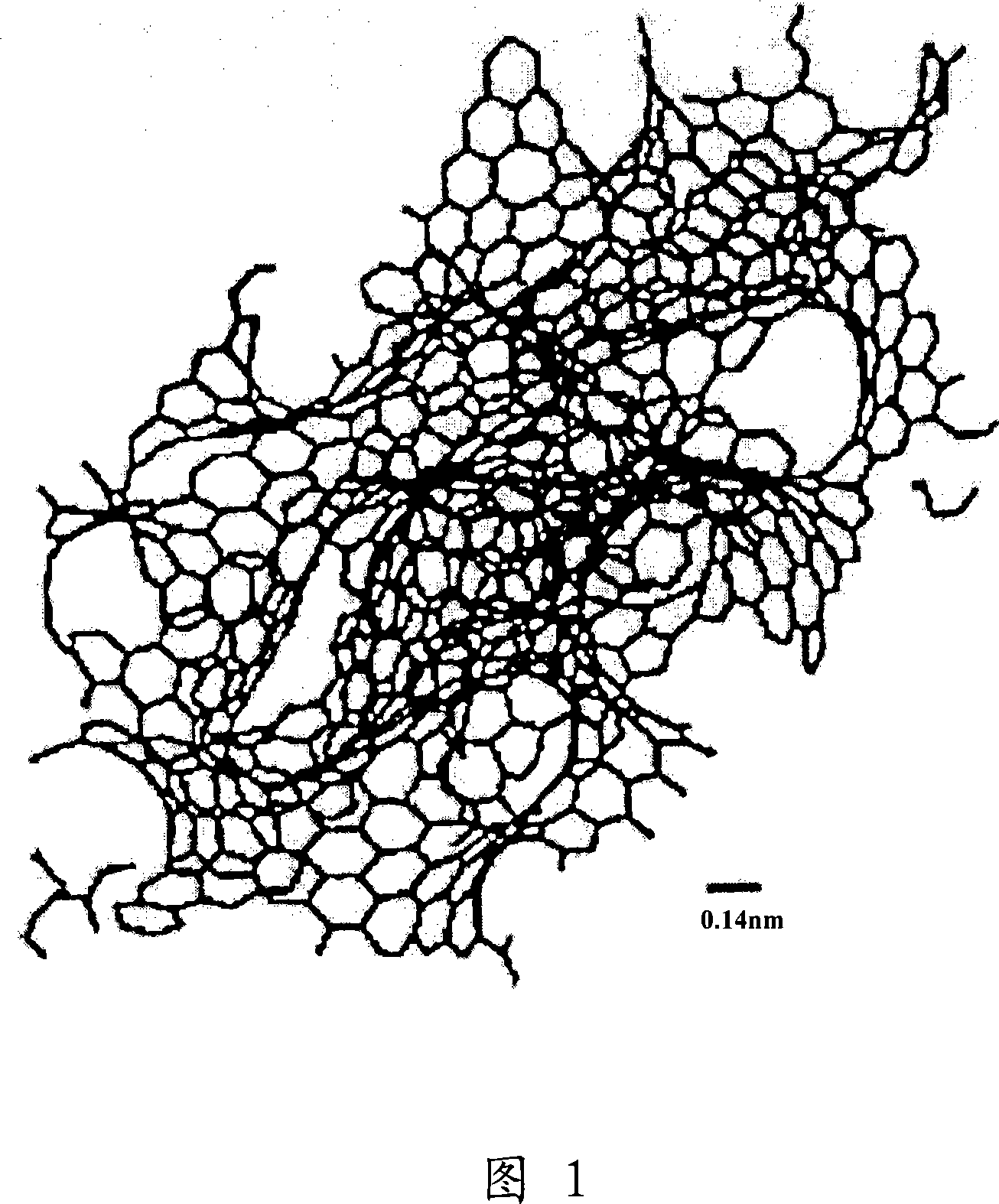

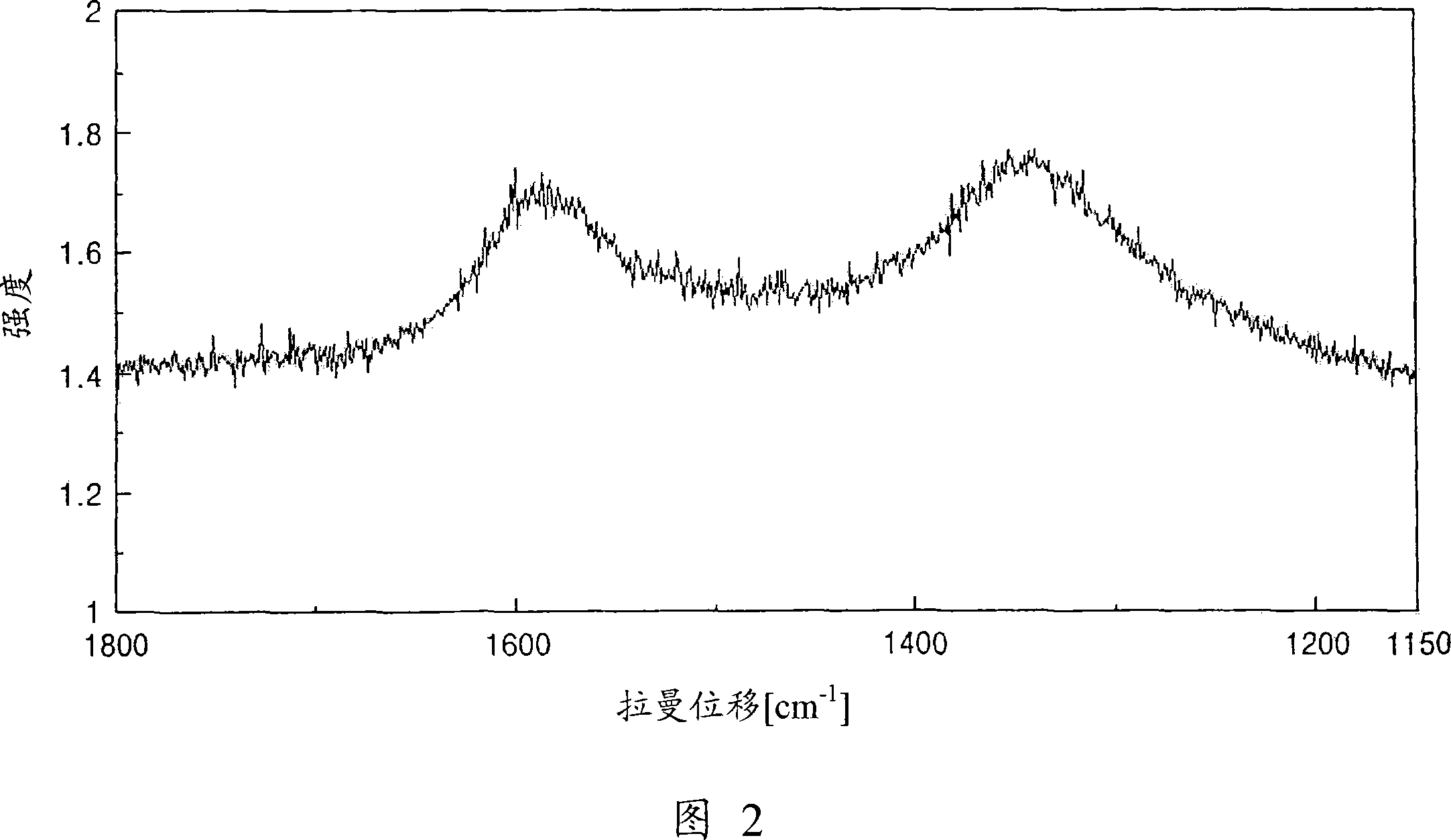

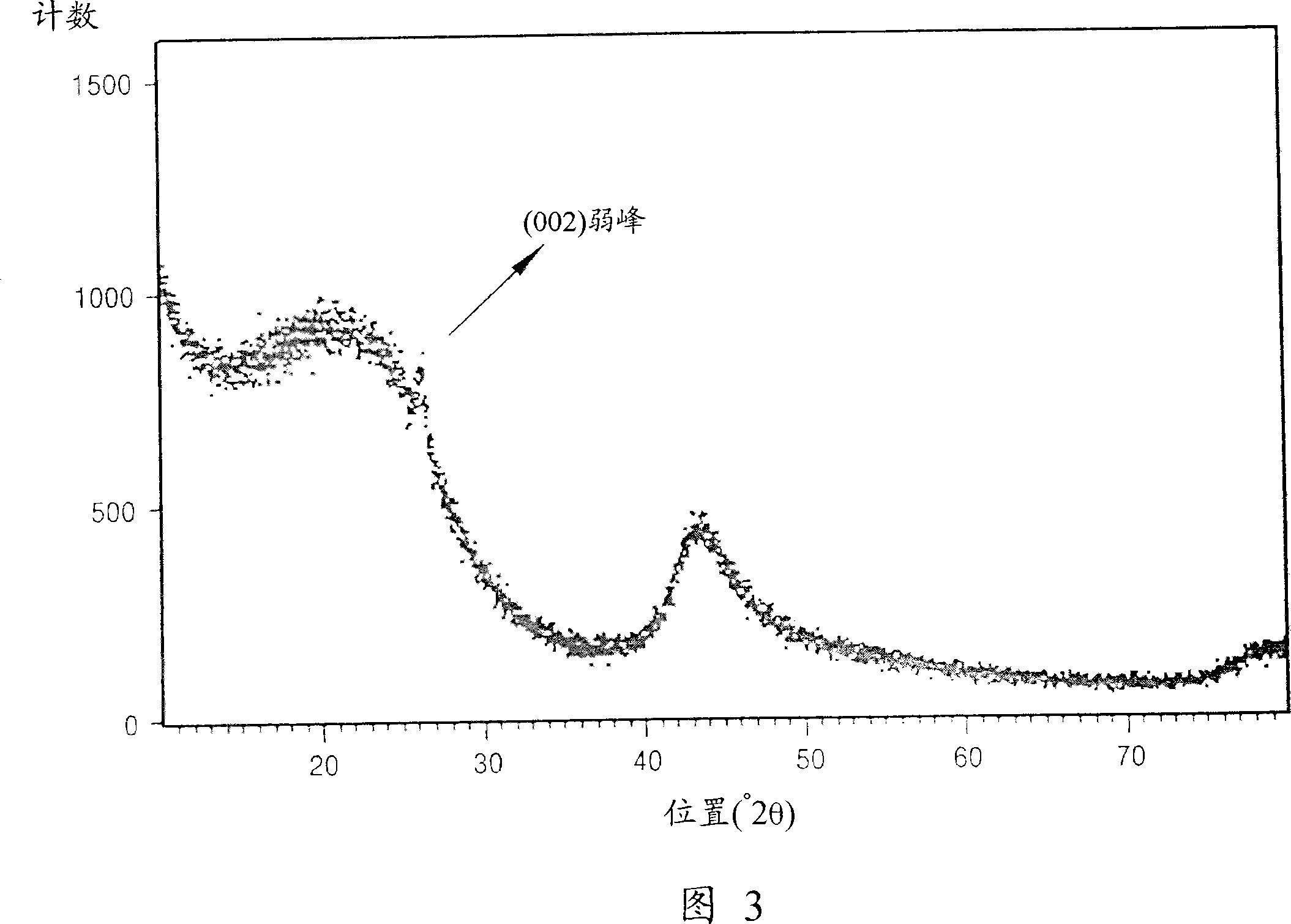

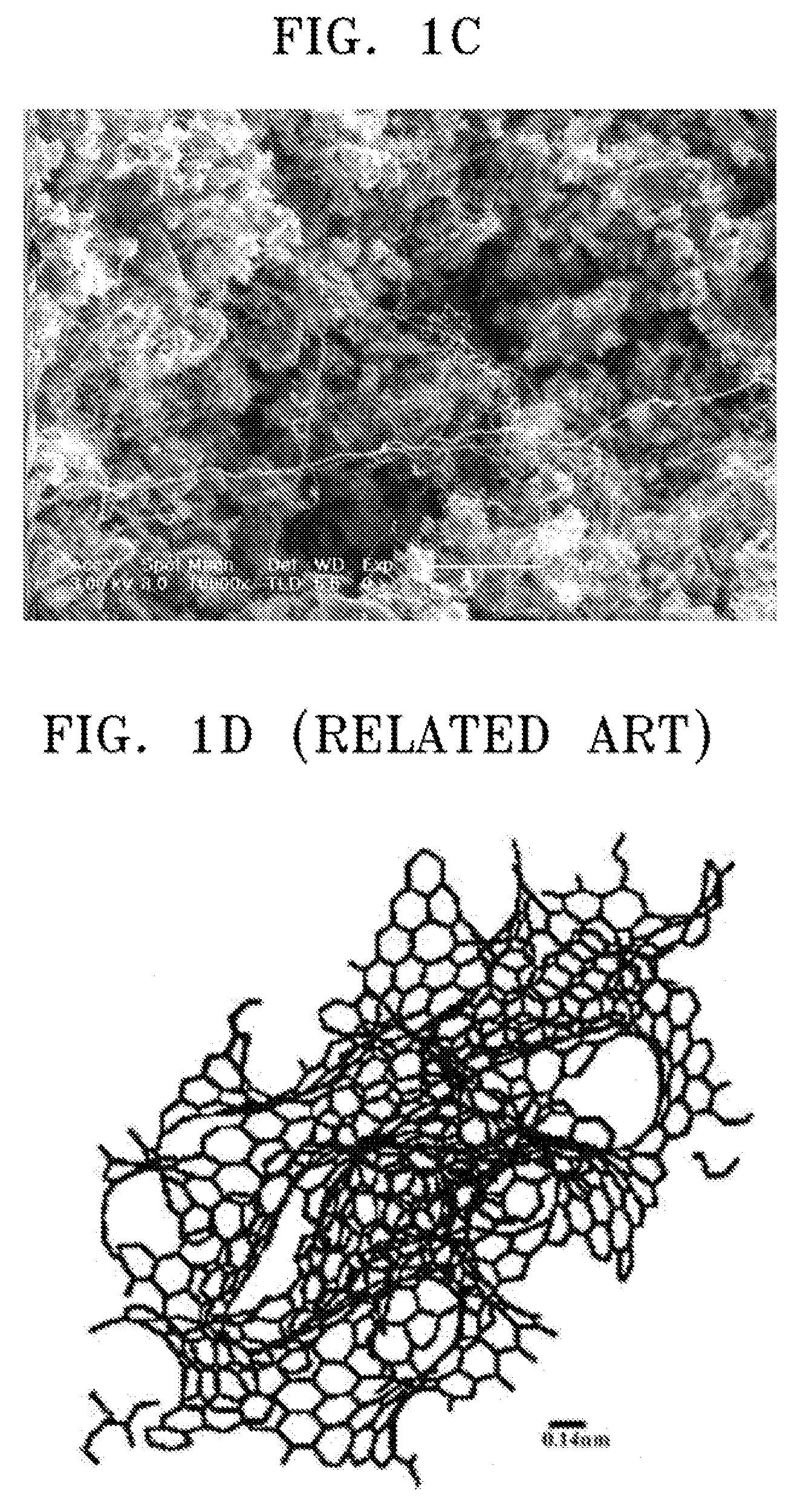

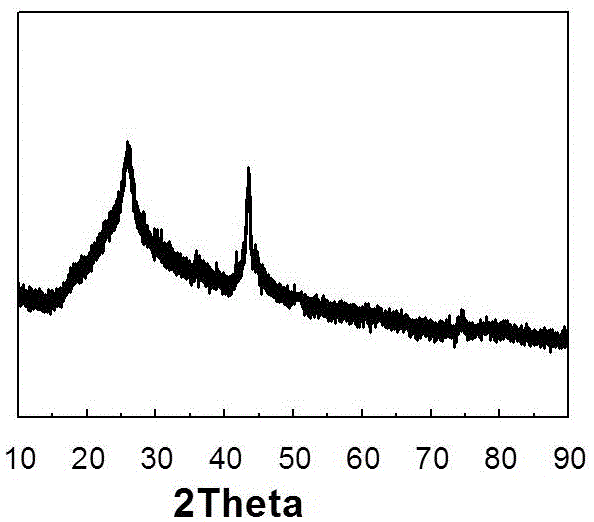

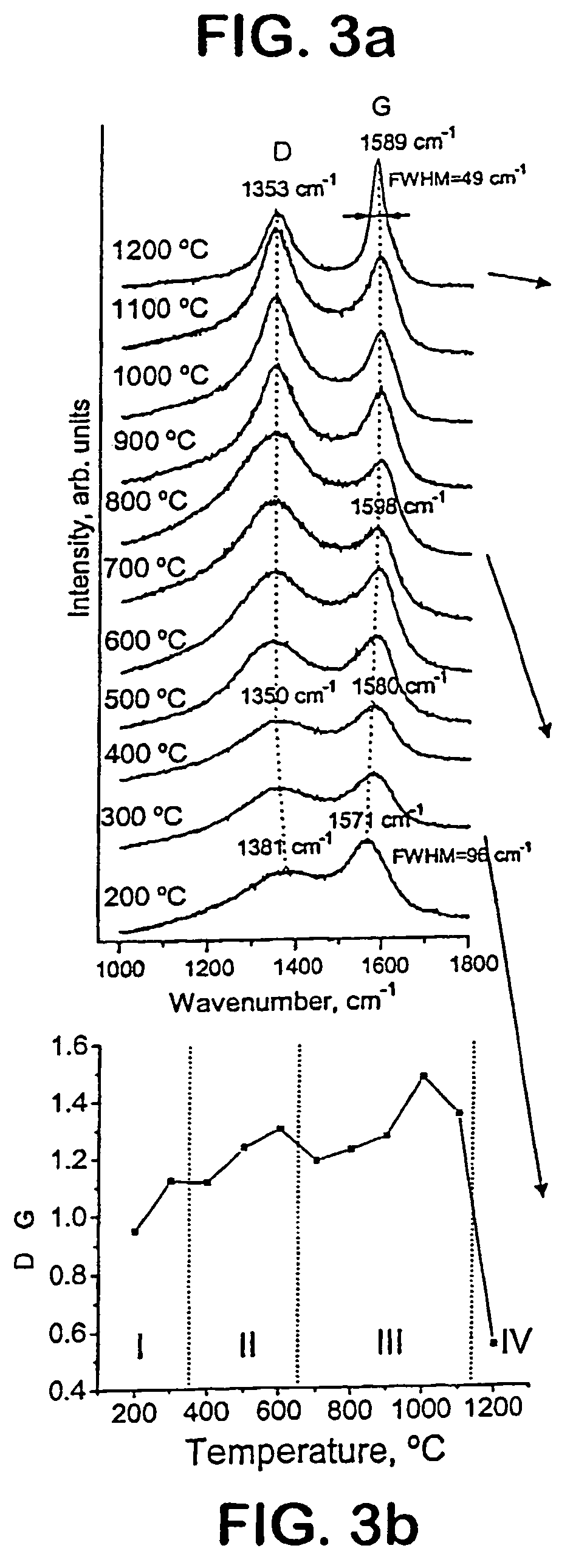

Provided are carbide derived carbon prepared by thermochemically reacting carbide compounds and a halogen element containing gas and extracting all atoms of the carbide compounds except carbon atoms, wherein the intensity ratios of the graphite G band at 1590 cm−1 to the disordered-induced D band at 1350 cm−1 are in the range of 0.3 through 5 when the carbide derived carbon is analyzed using Raman peak analysis, wherein the BET surface area of the carbide derived carbon is 1000 m2 / g or more, wherein a weak peak or wide single peak of the graphite (002) surface is seen at 2θ=25° when the carbide derived carbon is analyzed using X-ray diffractometry, and wherein the electron diffraction pattern of the carbide derived carbon is the halo pattern typical of amorphous carbon when the carbide derived carbon is analyzed using electron microscopy. The emitter has good uniformity and a long lifetime. An emitter can be prepared using a more inexpensive method than that used to manufacture conventional carbon nanotubes.

Owner:LOFFE PHYSICO TECHN INST OF RUSSIAN ACADEMY OF SCI +1

Method of preparing graphene and anode mixture for lithium secondary battery including graphene prepared thereby

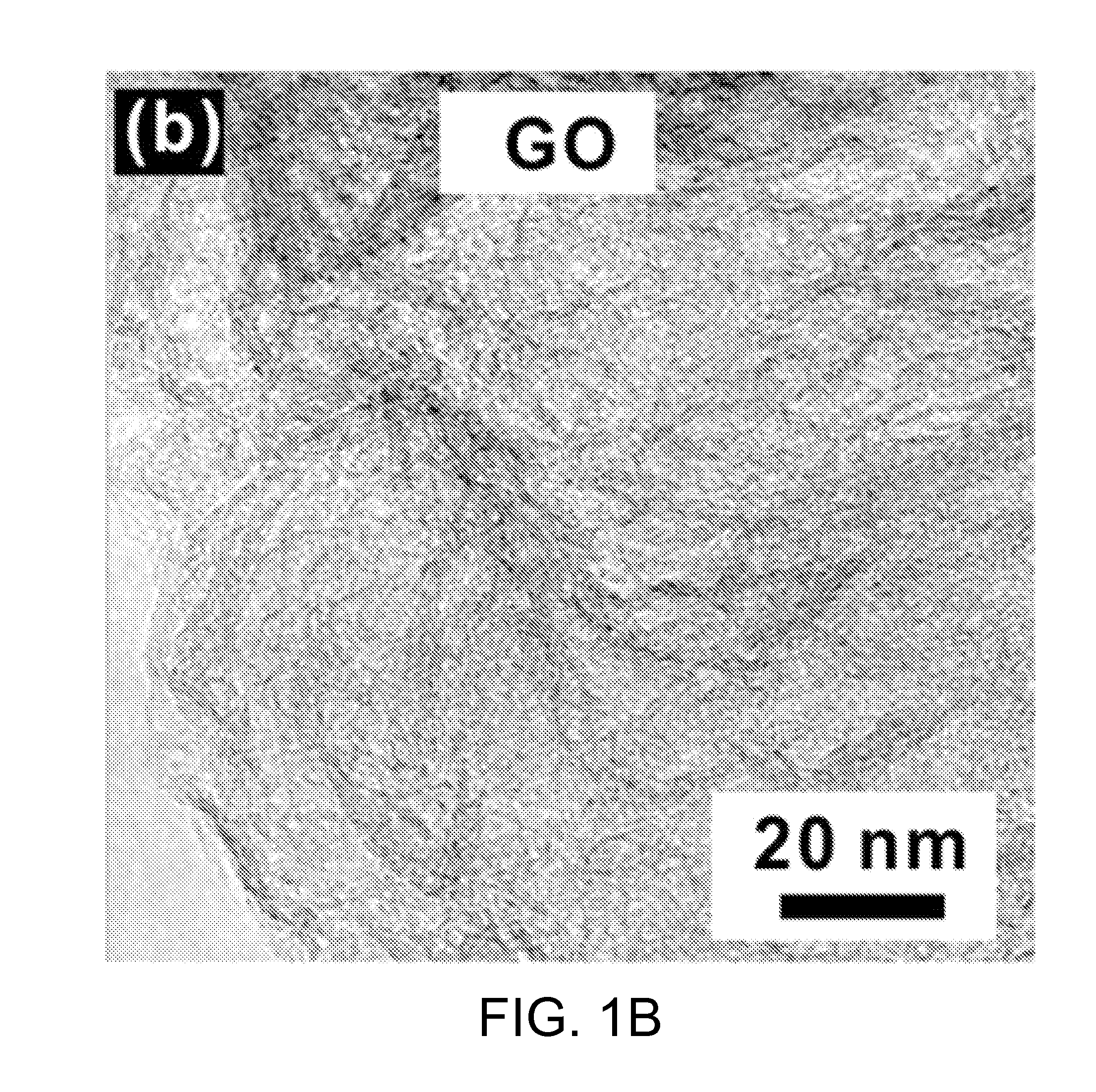

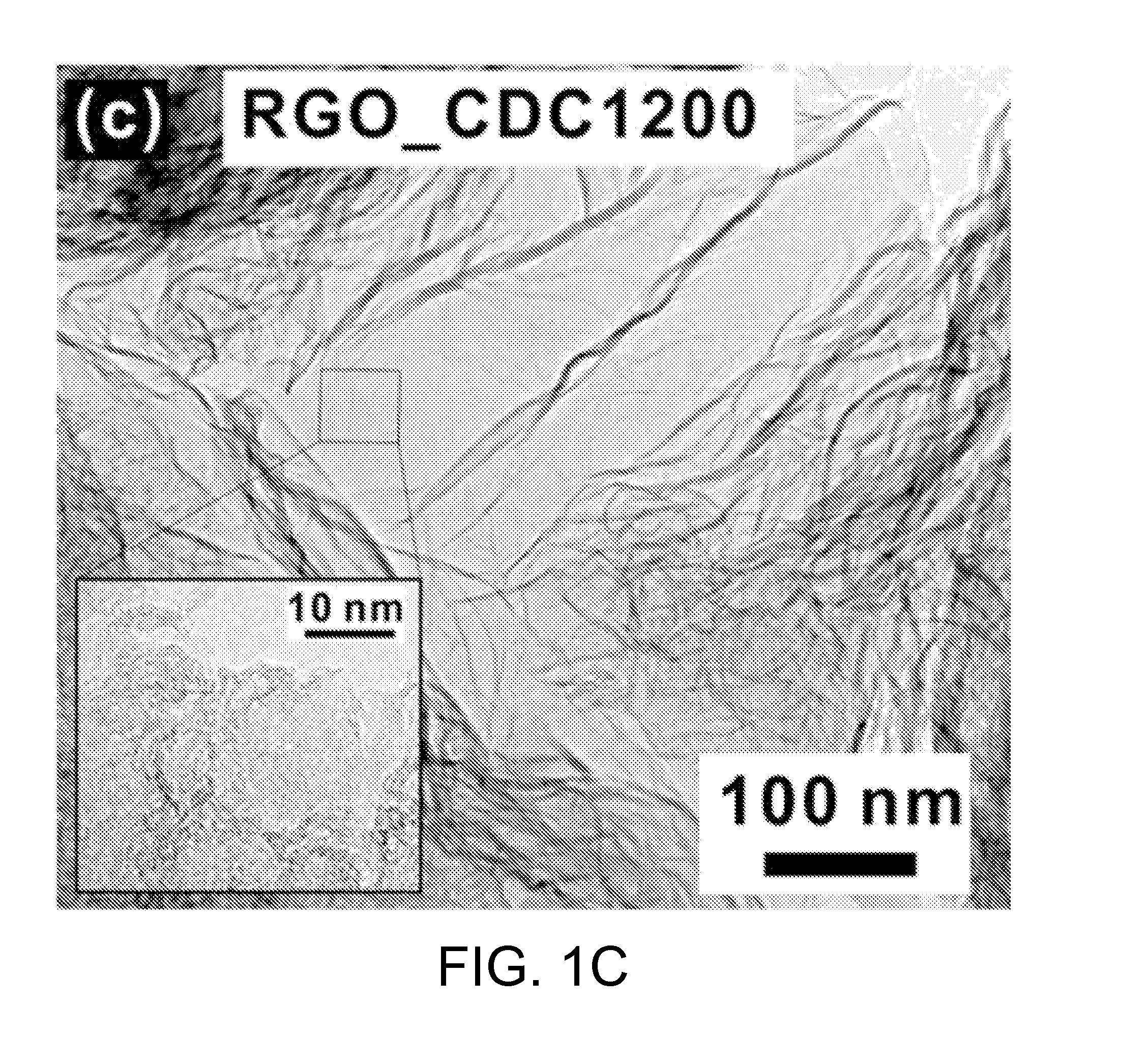

ActiveUS20150132654A1Increased ion mobilityNon-metal conductorsConductive materialPorous grapheneOxocarbon

Disclosed herein is a method of preparing porous graphene from porous graphite, including 1) thermochemically reacting a highly crystalline carbide compound with a halogen element-containing gas to give a porous carbide-derived carbon; 2) treating the carbide-derived carbon with an acid, thus preparing a carbide-derived carbon oxide; and 3) reducing the carbide-derived carbon oxide. An anode mixture for a secondary battery including the graphene and an anode for a secondary battery including the anode mixture are also provided.

Owner:KOREA INST OF ENERGY RES

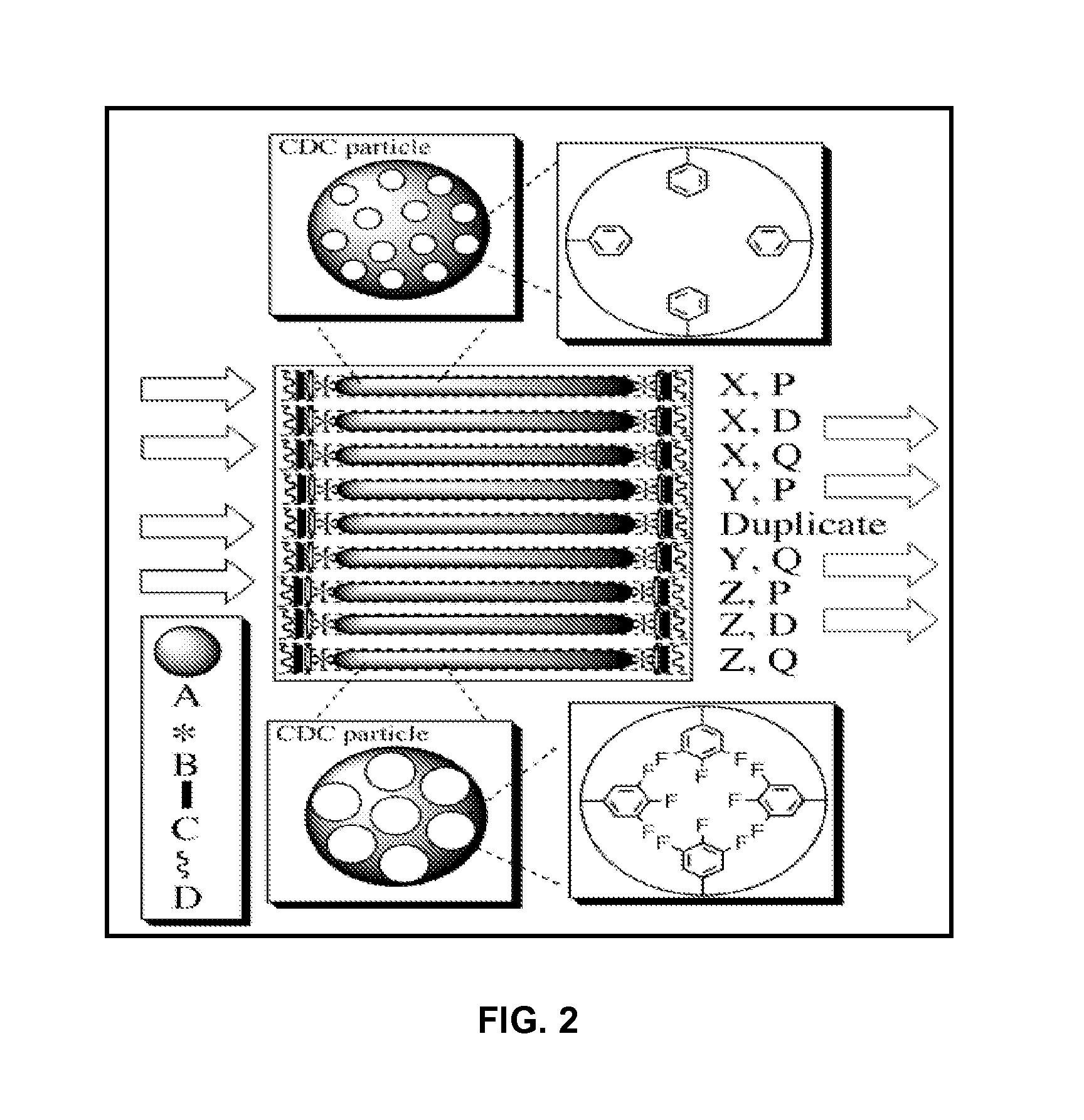

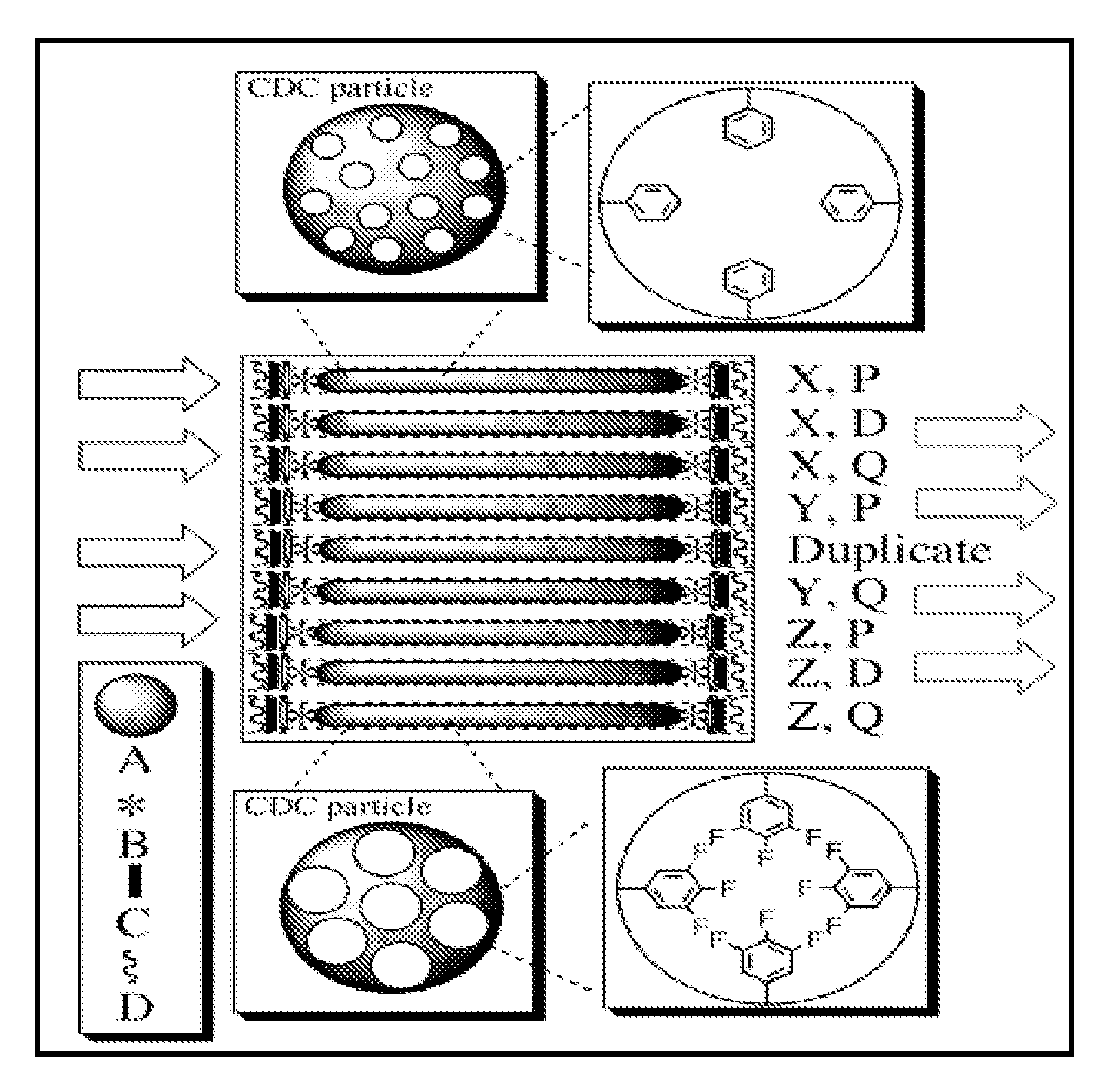

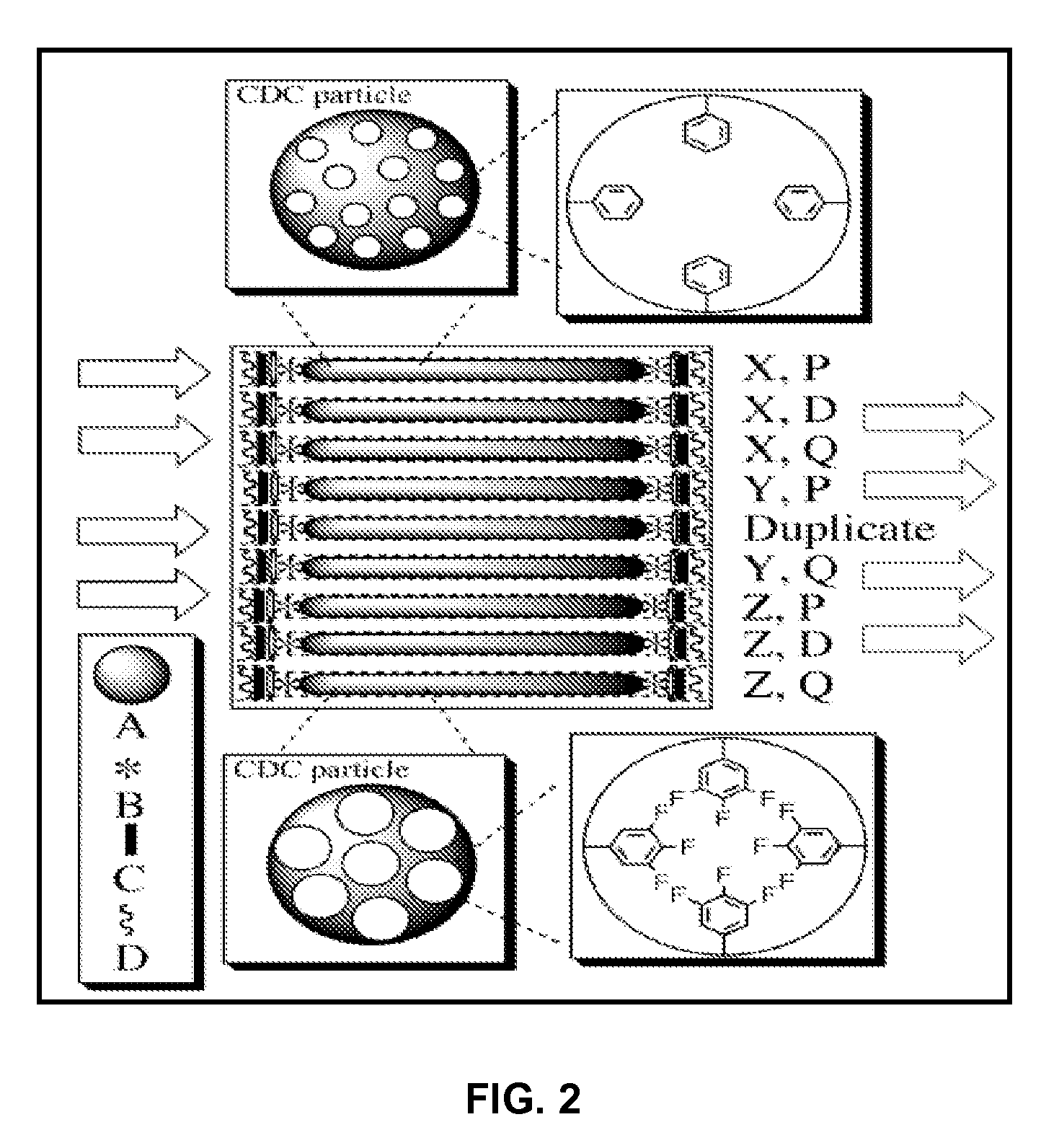

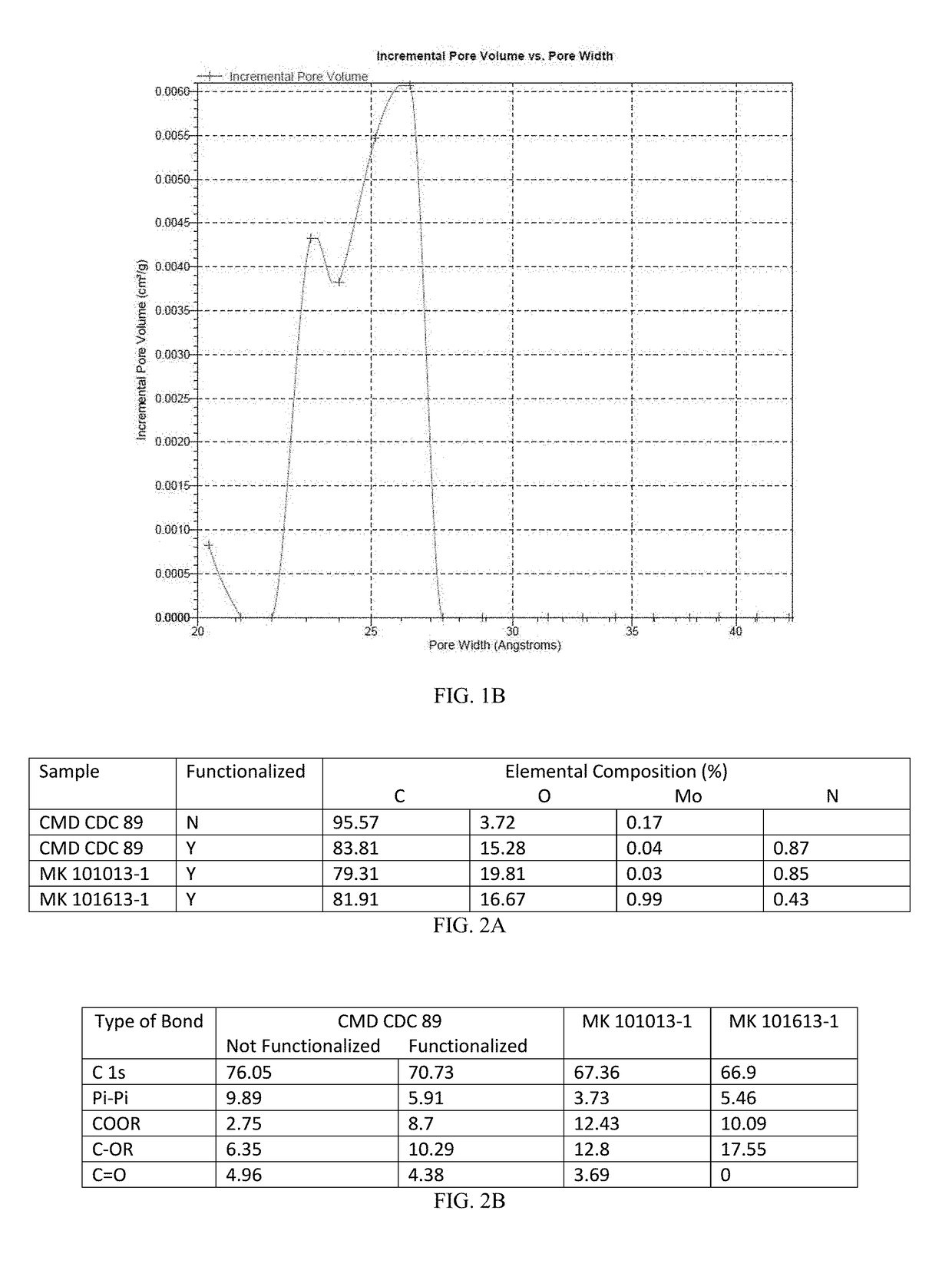

Chemically modified organic cdc based rapid analysis system

ActiveUS20100107731A1Large specific surface areaImprove accuracyComponent separationWithdrawing sample devicesCarbideChemical basis

A method of performing chemical analysis is disclosed. The method includes the steps of forming carbide-derived carbon (CDC) material having a plurality of pore size, surface chemistry, and surface electrical properties. An array of the surface functionalized CDCs are used for atmospheric sampling, in which chemicals in the atmosphere are adsorbed on the CDCs. The adsorbed samples are desorbed later for analysis by a plurality of individual mass spectrometers.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

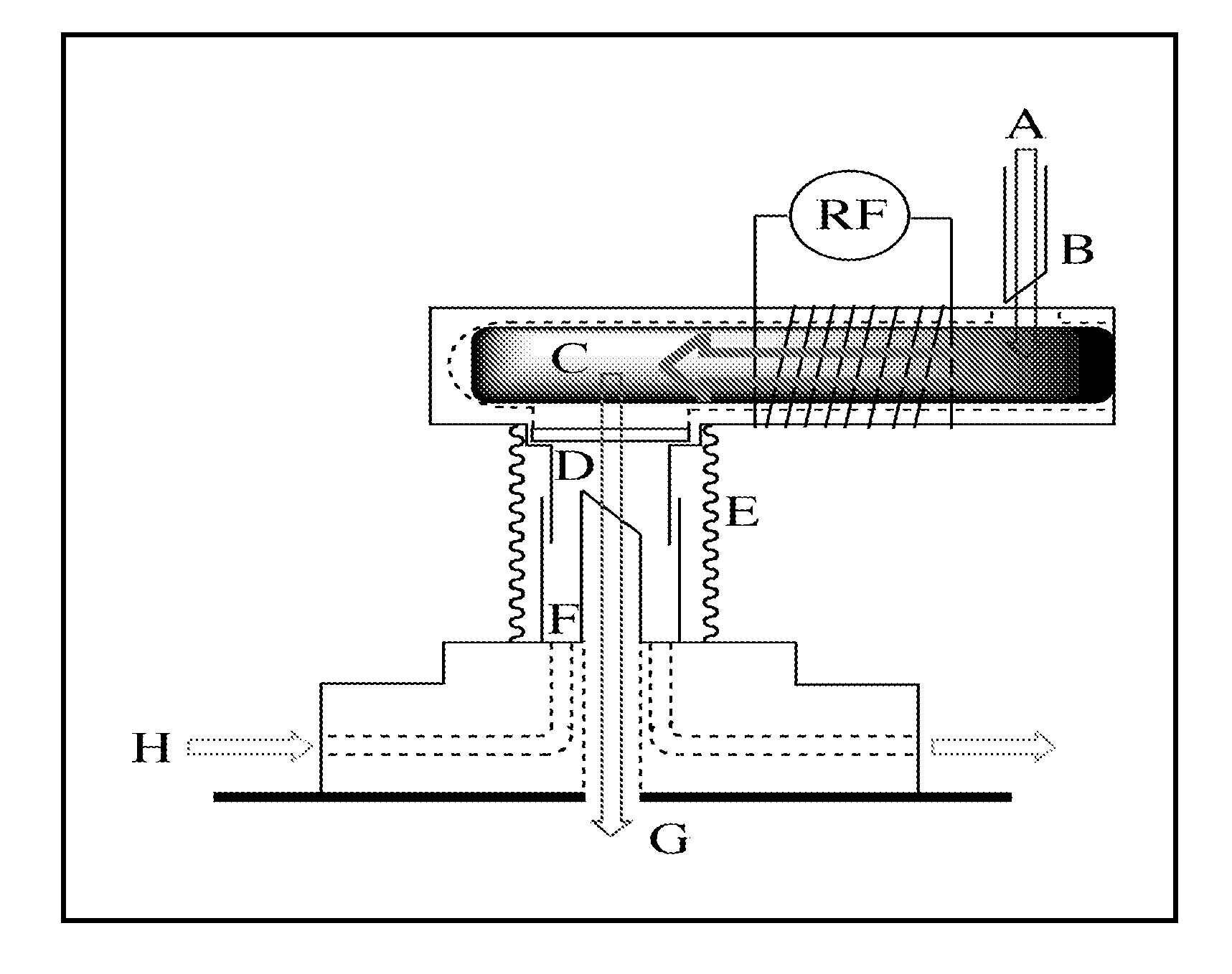

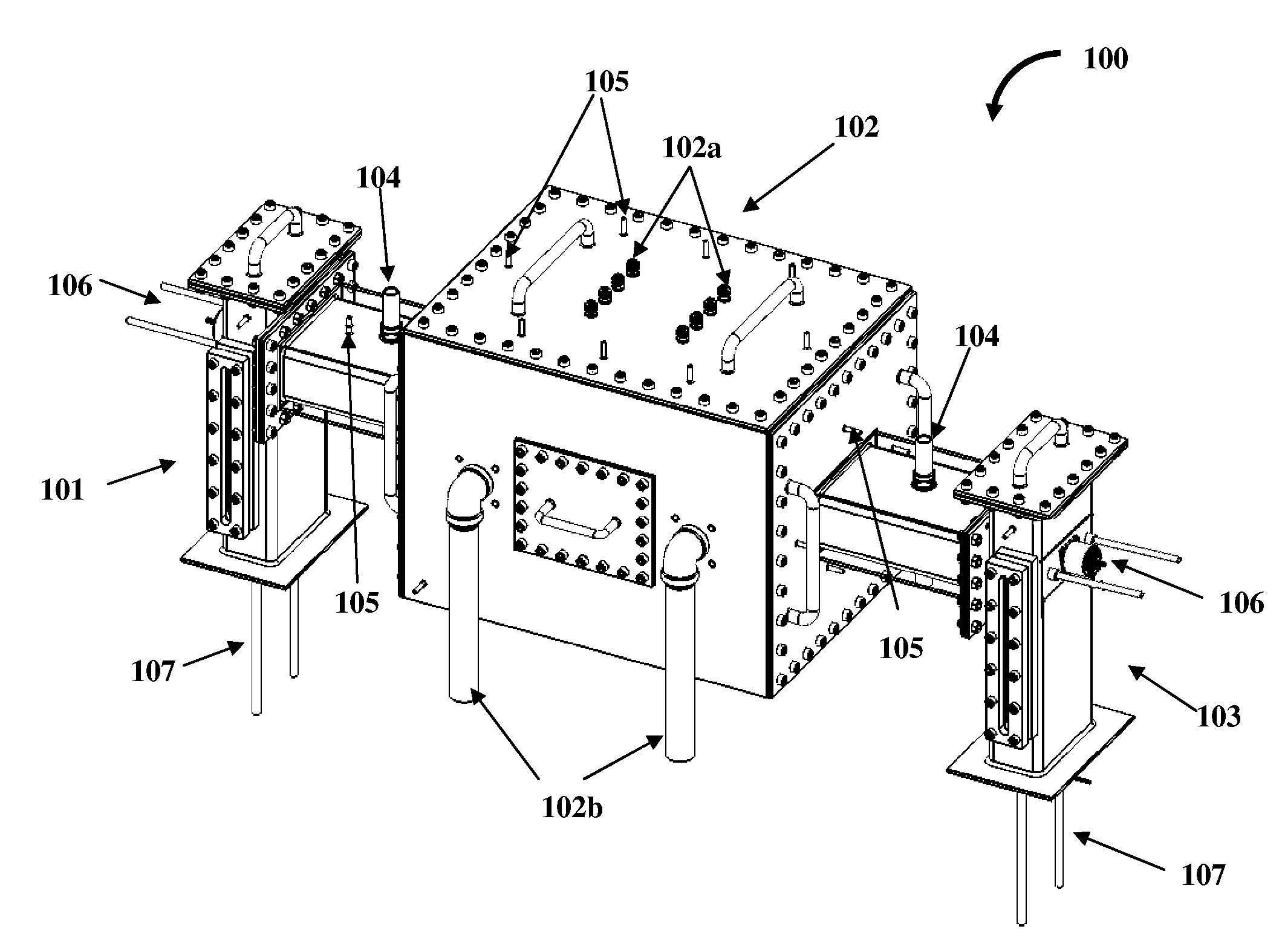

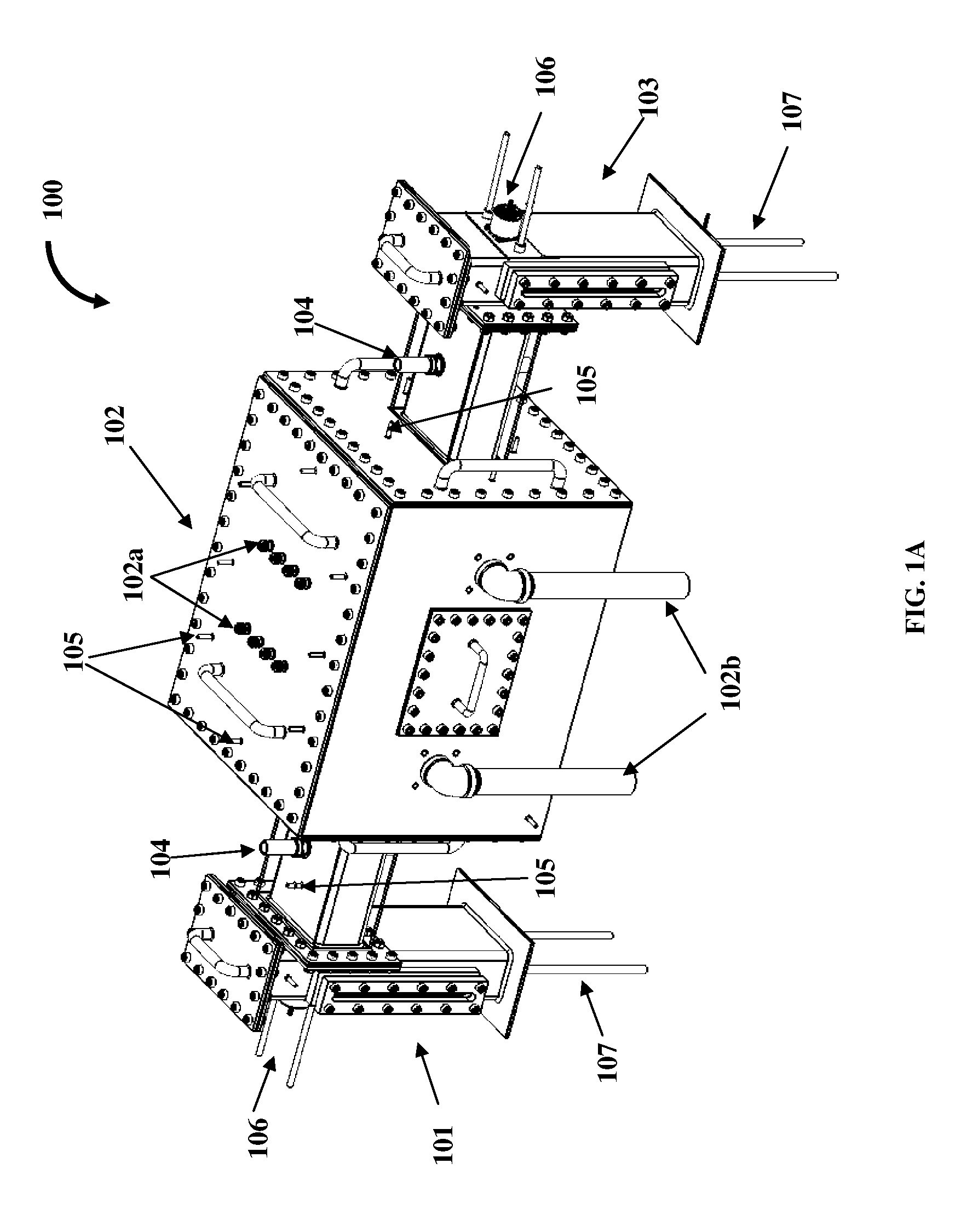

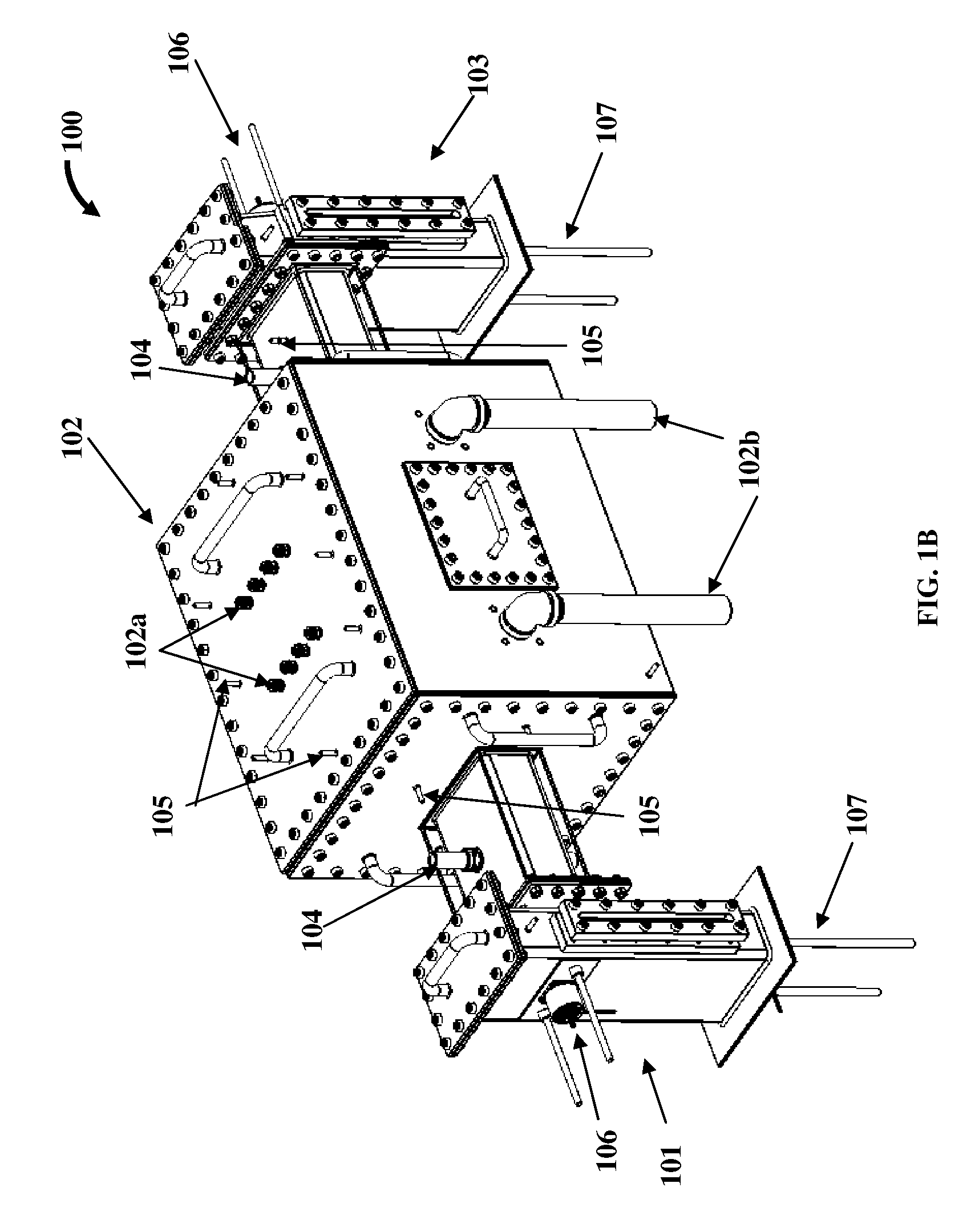

Continuous manufacture of carbide derived carbons

InactiveUS20120219488A1Reduce manufacturing costCarbon compoundsChemical/physical/physico-chemical stationary reactorsHalogenPorous carbon

A reactor apparatus for continuous manufacturing of porous carbon material by halogenation of carbides is provided. The reactor apparatus comprises a sample loading assembly, a reactor positioned within a metal housing and in closed circuit communication with the sample loading assembly, and a material receiving assembly. The sample loading assembly loads samples of carbides into the reactor. The metal housing maintains an inert atmosphere around the reactor. The reactor defines one or more process paths for transporting samples of carbides through a halogen atmosphere and / or a post-treatment atmosphere for yielding porous carbon material. Process vents, positioned on the reactor and the metal housing, pass inert gases and reactant gases past the samples of carbides at predetermined temperatures and exit process gases through a condenser unit. The condenser unit traps metal halide by-products. The material receiving assembly, in closed circuit communication with the reactor, removes and stores the porous carbon material.

Owner:Y CARBON

Composition for preparing emitter, method of preparing the emitter using the composition, emitter prepared using the method and electron emission device including the emitter

InactiveUS20080100195A1Easy to superviseLess expensiveDischarge tube luminescnet screensElectric discharge tubesChemical reactionCarbon nanotube

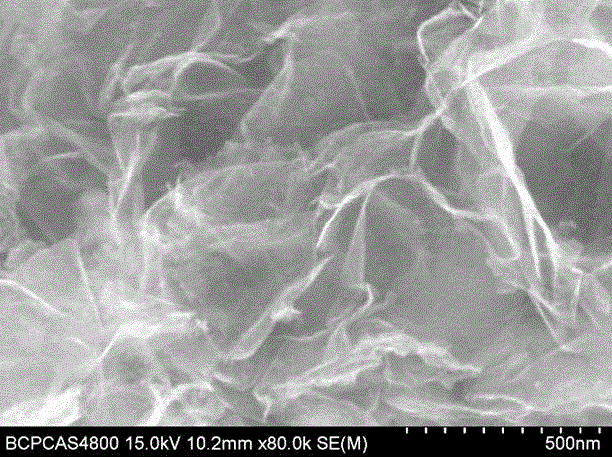

A composition for preparing an emitter including: flake type carbide-derived carbon which is prepared by thermochemically reacting carbide compounds with halogen-containing gases to extract all elements of the carbide compounds except carbon, an organic solvent and a dispersant. A method of preparing the emitter using the composition for forming the emitter, an emitter prepared using the method and an electron emission device. The emitter has good uniformity and a long lifetime. It can be prepared using a more inexpensive method than using conventional carbon nanotubes. A pattern can be formed by easily regulating the size of the manufactured emitter using an ink jet printer. Non-uniform emission generated by residue when using a conventional printing method can be avoided. Thus, a micro electrode, in which an arc discharge does not occur even in the presence of a strong electric field, can be conveniently manufactured.

Owner:SAMSUNG SDI CO LTD

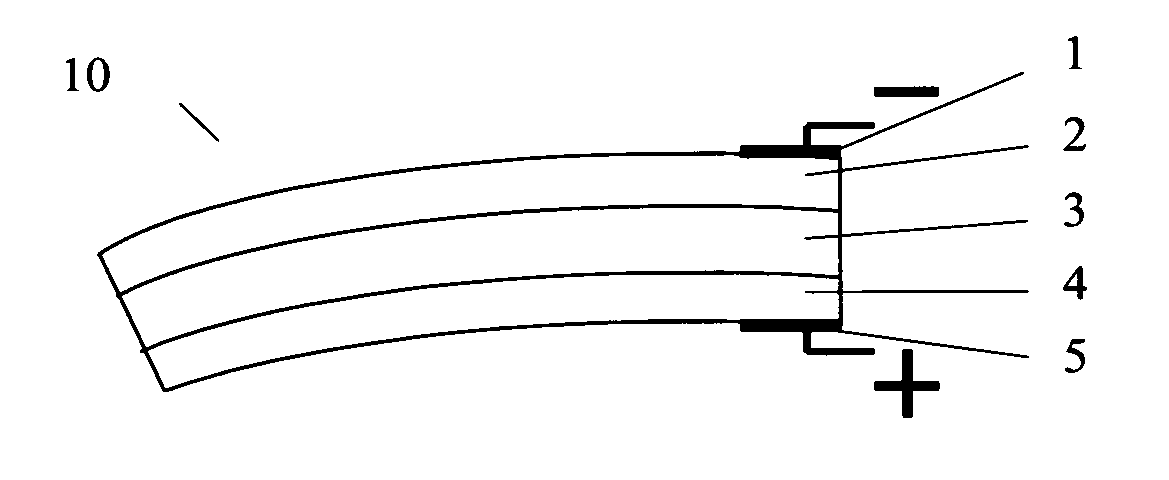

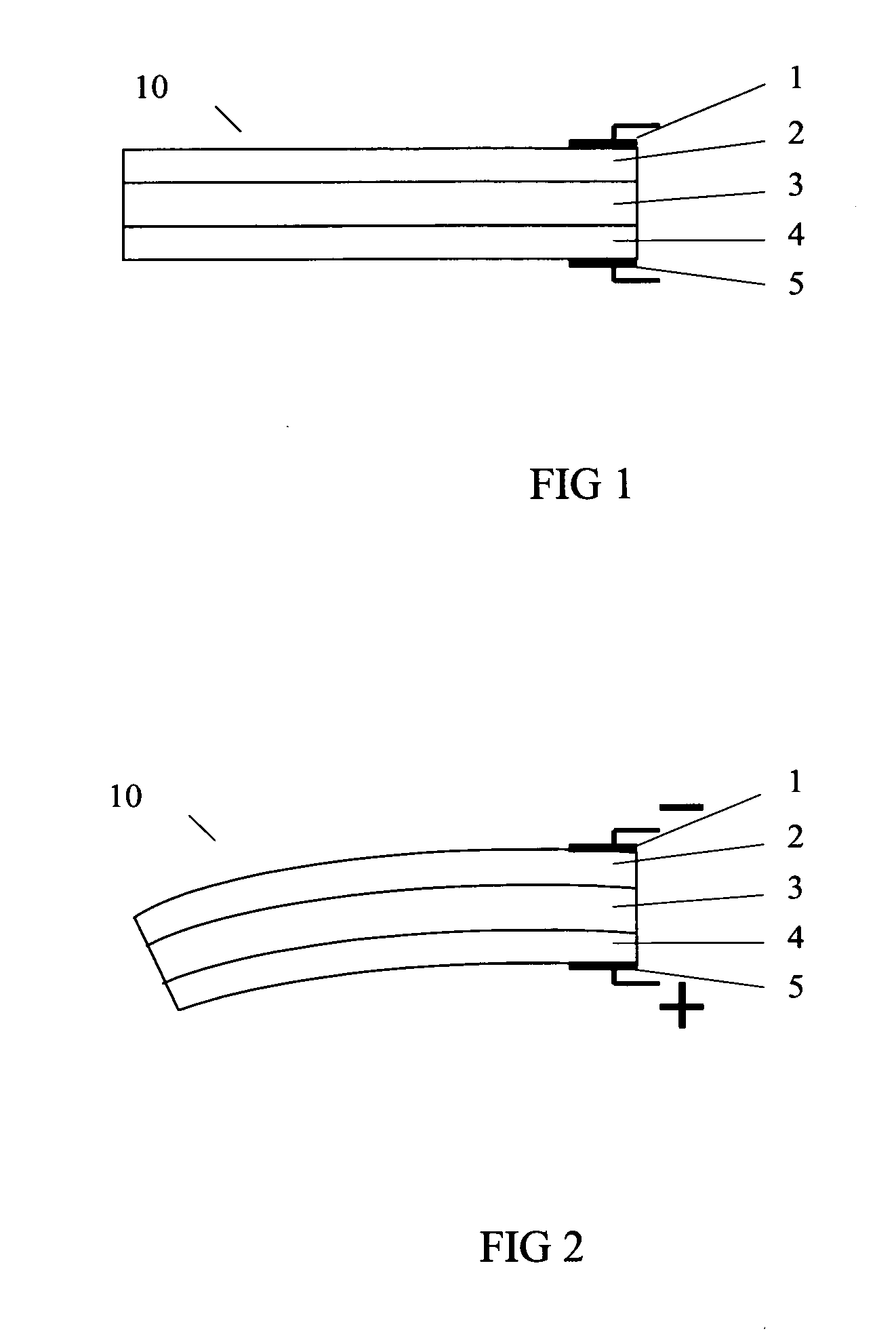

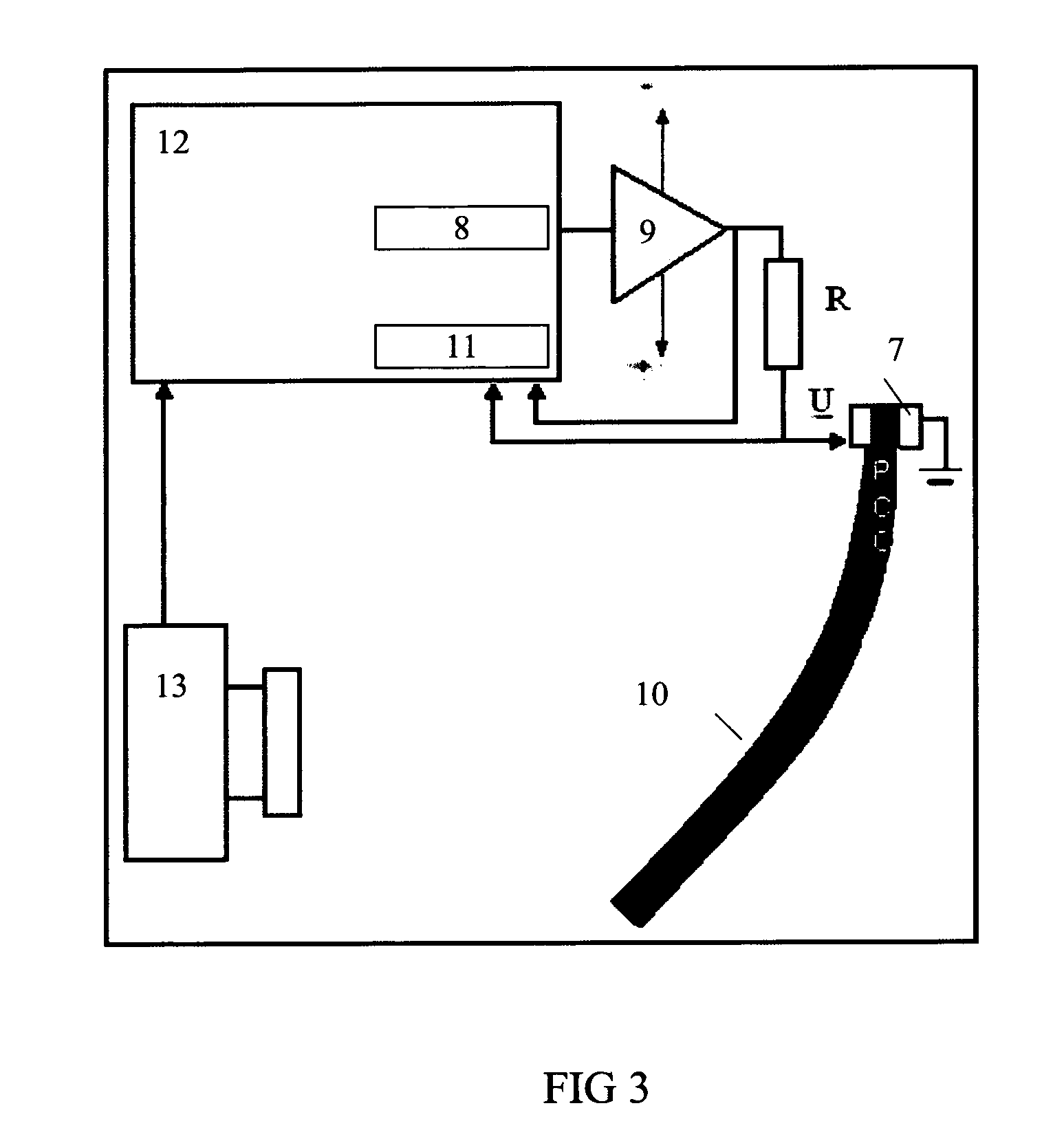

Layered actuator

InactiveUS20120211261A1Improve conductivityQuick bendingNon-insulated conductorsMachines/enginesCarbideEngineering

The layered actuator comprises at least two electrode layers and an electronically nonconductive membrane in between, where the electrode layer contains carbide-derived carbon, a polymer material and an ionic liquid. The layered actuator bends due to relocation of the membrane ions when direct current is applied to the electrodes.

Owner:UNIV OF TARTU

Method of preparing a carbonaceous material for an emitter of an electron emission device

Provided are carbide derived carbon materials prepared by thermochemically reacting carbide compounds and a halogen containing gas and extracting all atoms of the carbide compounds except carbon atoms, wherein the intensity ratios of the graphite G band at 1590 cm -1 to the disordered-induced D band at 1350 cm-1 are in the range of 0.3 through 5 when the carbide derived carbon is analyzed using Raman peak analysis, wherein the BET surface area of the carbide derived carbon is 1000 m 2 / g or more, wherein a weak peak or wide single peak of the graphite (002) surface is seen at 2 = 25 DEG when the carbide derived carbon is analyzed using X-ray diffractometry, and wherein the electron diffraction pattern of the carbide derived carbon is the halo pattern typical of amorphous carbon when the carbide derived carbon is analyzed using electron microscopy.

Owner:SAMSUNG SDI CO LTD +1

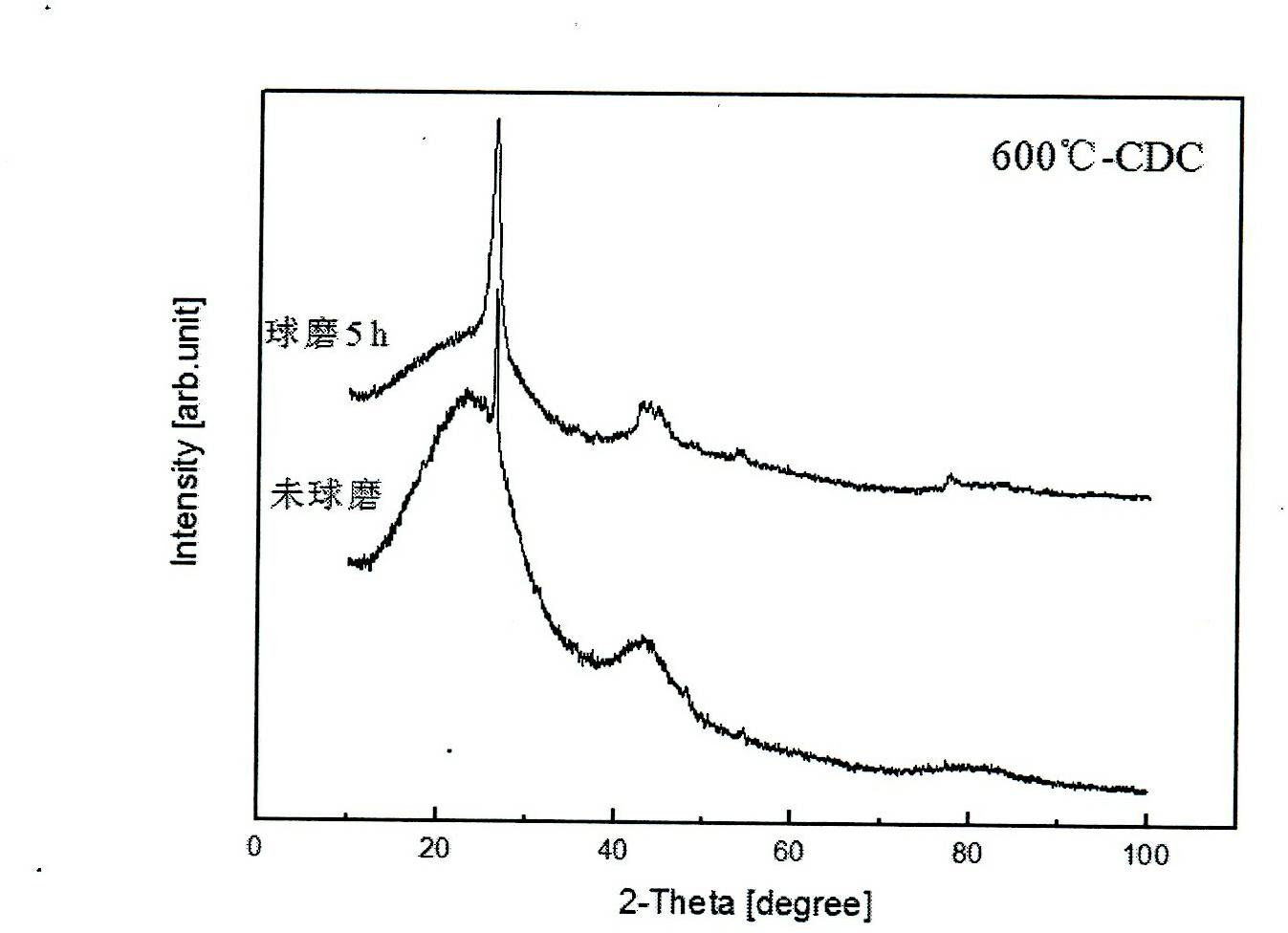

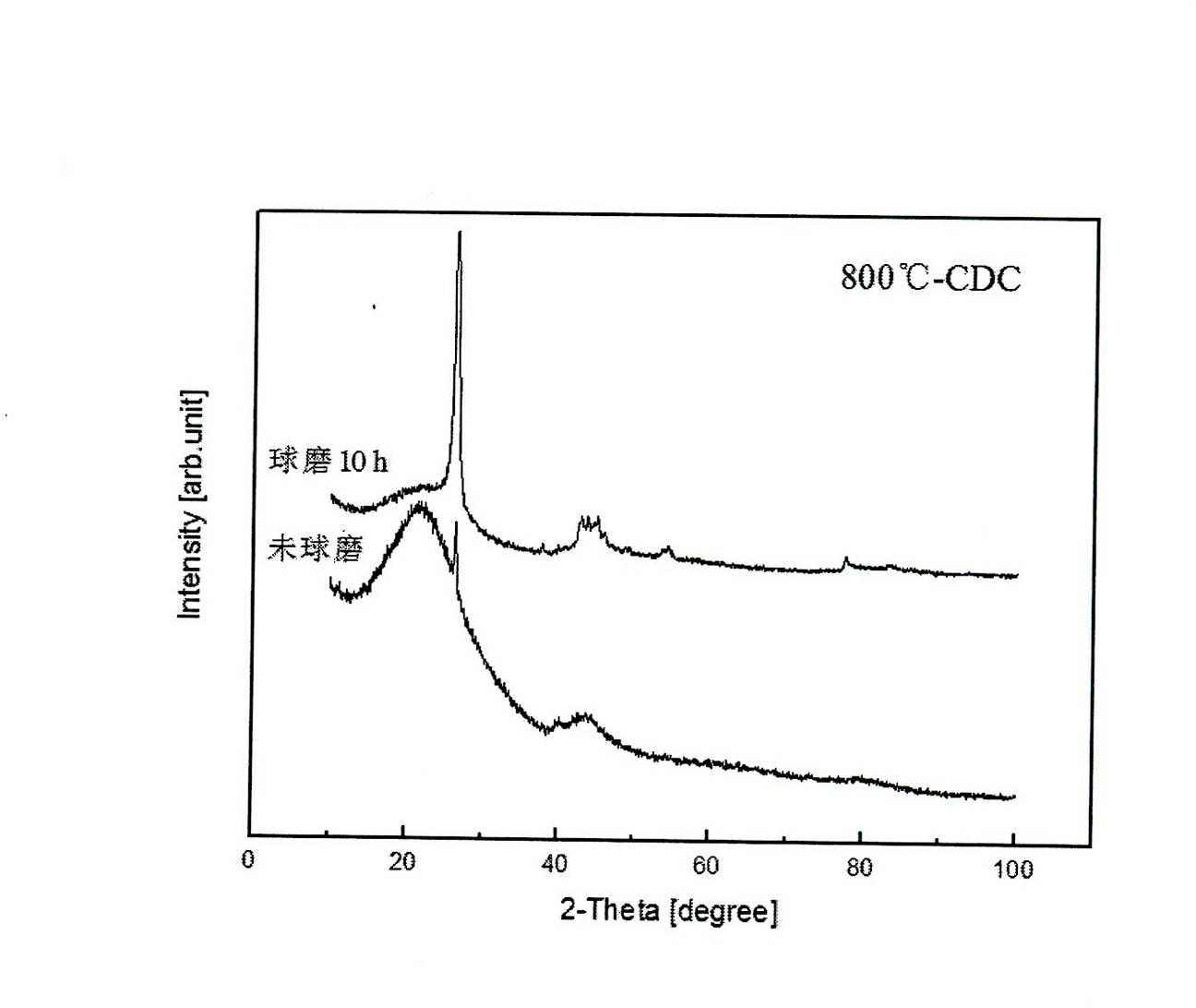

Method for regulating pore structure of carbide derived carbon

InactiveCN102786043ASimple processSolve the problem of sharp decrease in specific surfaceCarbon preparation/purificationTube furnaceChloride

A method for regulating a pore structure of carbide derived carbon (CDC). The method comprises the following steps of: putting titanium carbide powder into a high-energy ball mill in the ball-material ratio of 6-8 : 1 at a rotating speed of 240-280 revolutions per minute for 8-12 hours, and smashing and refining the particle size of the titanium carbide powder to 0.6-1.2 [mu]m; and putting the ball-milled titanium carbide powder into a melting quartz tubular furnace, vacuumizing to 0.05-1Pa, introducing argon gas, heating the tubular furnace to 600-1000 DEG C, introducing chlorine gas at a flow speed of 20-30 ml / min for 1-3 hours, introducing argon gas once again after a reaction, removing chlorides such as titanium tetrachloride and the like left on the surface of the titanium carbide powder under the scouring effect of the argon gas flow, and cooling to the room temperature. The method has the advantages of simple and convenient process, simple reaction equipment and capability of effectively controlling the pore structure of CDC and resolving the problems of sharply reduced specific surface when mesoporous appearances.

Owner:YANSHAN UNIV

Carbide-derived-carbon-based oxygen carriers

InactiveUS20110151007A1Low cost mass productionIncrease productionPowder deliveryPeptide/protein ingredientsCombat casualtyCarbide

An oxygen delivery system is disclosed. The basis of the oxygen deliver system is a carbide-derived carbon (CDC). The CDC can be tuned to carry O2 directly (CDC OC), or hemoglobin can be adsorbed to provide a hemoglobin-based oxygen carrier (CDC HBOC). The delivery system allows the use of a variety of hemoglobins which differ in their oxygen dissociation profiles, including variant and mutant hemoglobins from other species. The delivery system is biocompatible and stable, and is able to irreversibly bind and hold large amounts of functional hemoglobin variants. The CDC HBOC and CDC OC provide a safe and effective blood substitute for combat casualty care, as well as being useful for oxygen delivery in other contexts.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Method for enhancing structural order of carbide derived carbon

InactiveCN102583317AImprove orderSimple processCarbon preparation/purificationHigh energyTitanium carbide

The invention discloses a method for enhancing the structural order of carbide derived carbon. The method comprises the following steps of: putting titanium carbide powder into a high-energy ball mill in the ball-material ratio of 4:1-6:1 at the rotating speed of 180-220 revolutions per minute for 5-10 hours, and smashing and refining the particle size of the titanium carbide powder to 0.8-2.0 mum; and putting the ball-milled titanium carbide powder into a melting quartz tubular furnace, vacuumizing to 0.05-1Pa, introducing argon gas, heating the tubular furnace to 600-800 DEG C, introducing chlorine gas at the low speed of 20-30 ml / min for 1-2 hours, introducing argon gas once again after a reaction, removing chlorides such as titanium tetrachloride and the like left on the surface of the titanium carbide powder under the erosion action of argon gas flow, and cooling to the room temperature to obtain the carbide derived carbon with high structural order. The method has the advantages of simple and convenient process, simple reaction equipment and capability of remarkably enhancing the order of a carbide derived carbon structure.

Owner:YANSHAN UNIV

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS7678452B2Improve uniformityLong lastingMaterial nanotechnologyNanostructure manufactureHalogenHybrid system

Owner:SAMSUNG SDI CO LTD

Method for preparing carbide-derived carbon from molten sodium carbonate at high temperature

ActiveCN106082175AHigh puritySimple preparation processHybrid capacitor electrodesCell electrodesFiltrationMetal impurities

The invention discloses a method for preparing carbide-derived carbon from molten sodium carbonate at a high temperature and belongs to the technical field of carbon materials. Transition metal carbides and solid-phase sodium carbonate are mixed, high-temperature calcination is conducted at 500-1000 DEG C under the protection of inert gases, metal impurities are washed off with hydrochloric acid, and suction filtration and washing are conducted to obtain the carbide-derived carbon. The preparing process is simple, operation is convenient, pollution to the environment is small, control is easy, and the prepared carbon material has a two-dimensional layered structure like graphene.

Owner:BEIJING UNIV OF CHEM TECH

Chemically modified organic CDC based rapid analysis system

ActiveUS8365575B2Increase heatImprove accuracyParticle separator tubesComponent separationElectricityCarbide

A method of performing chemical analysis is disclosed. The method includes the steps of forming carbide-derived carbon (CDC) material having a plurality of pore size, surface chemistry, and surface electrical properties. An array of the surface functionalized CDCs are used for atmospheric sampling, in which chemicals in the atmosphere are adsorbed on the CDCs. The adsorbed samples are desorbed later for analysis by a plurality of individual mass spectrometers.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTEGRATION INC

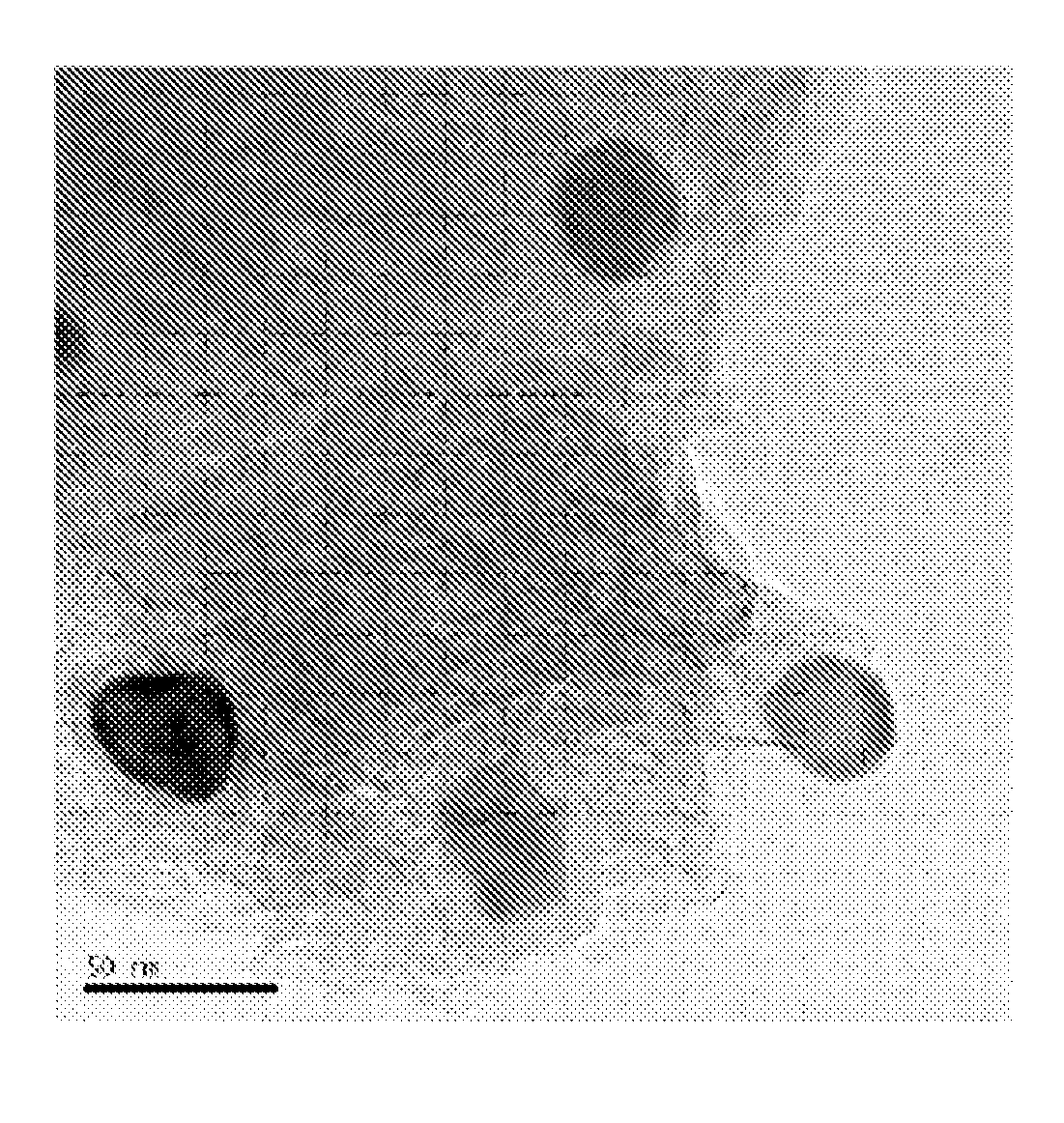

Hybrid composite including carbon nanotube and carbide-derived carbon, electron emitter including the hybrid composite, method of preparing the electron emitter, and electron emission device including the electron emitter

InactiveUS20090026424A1Prevents screen effectImprove brightness uniformityNanoinformaticsConductive materialChemical reactionHalogen

Hybrid composites including carbon nanotubes and a carbide-derived carbon material, electron emitters including the hybrid composites, methods of preparing the electron emitters, and electron emission devices including the electron emitters are provided. Specifically, a hybrid composite includes at least one carbon nanotube and a carbide-derived carbon material. The carbide-derived carbon material is prepared by thermochemically reacting a carbide compound with a halogen-containing gas to extract substantially all of the elements except for the carbon in the carbide compound. Since the carbon nanotubes and the carbide-derived carbon material are hybridized and composited, a screen effect that may occur when large amounts of carbon nanotubes are used can be prevented, and an electron emitter including the hybrid composite has excellent electron emission capabilities, excellent uniformity, and a long lifetime.

Owner:SAMSUNG SDI CO LTD

Nanoporous carbide derived carbon with tunable pore size

The present invention provides a method for producing a nanoporous carbide-derived carbon composition with a tunable pore structure and a narrow pore size. Also provided are compositions prepared by the method.

Owner:DREXEL UNIV

Negative plate additive for lead storage battery

InactiveCN104681792ALong pulse cycle lifeStrong charge acceptanceLead-acid accumulator electrodesFiberPolypyrrole

The invention relates to a negative plate additive for a lead storage battery. The additive is activated carbon, carbon black, graphene, carbon nano tube, carbon fiber, carbon aerogel, template carbon, mesoporous carbon, carbide derived carbon, polyaniline, polypyrrole, polythiophene, poly-alkylthiophene, poly-p-fluorophenyl thiophene or hydrogen evolution inhibition additive; after the negative plate additive is used, the lead storage battery has excellent pulse cycle life, and the charge acceptance of the lead storage battery is improved; the negative plate additive is used for lead storage batteries in the fields of electric vehicles, energy storage, electric tools, pulse emission, etc.

Owner:NO 63971 TROOPS PLA

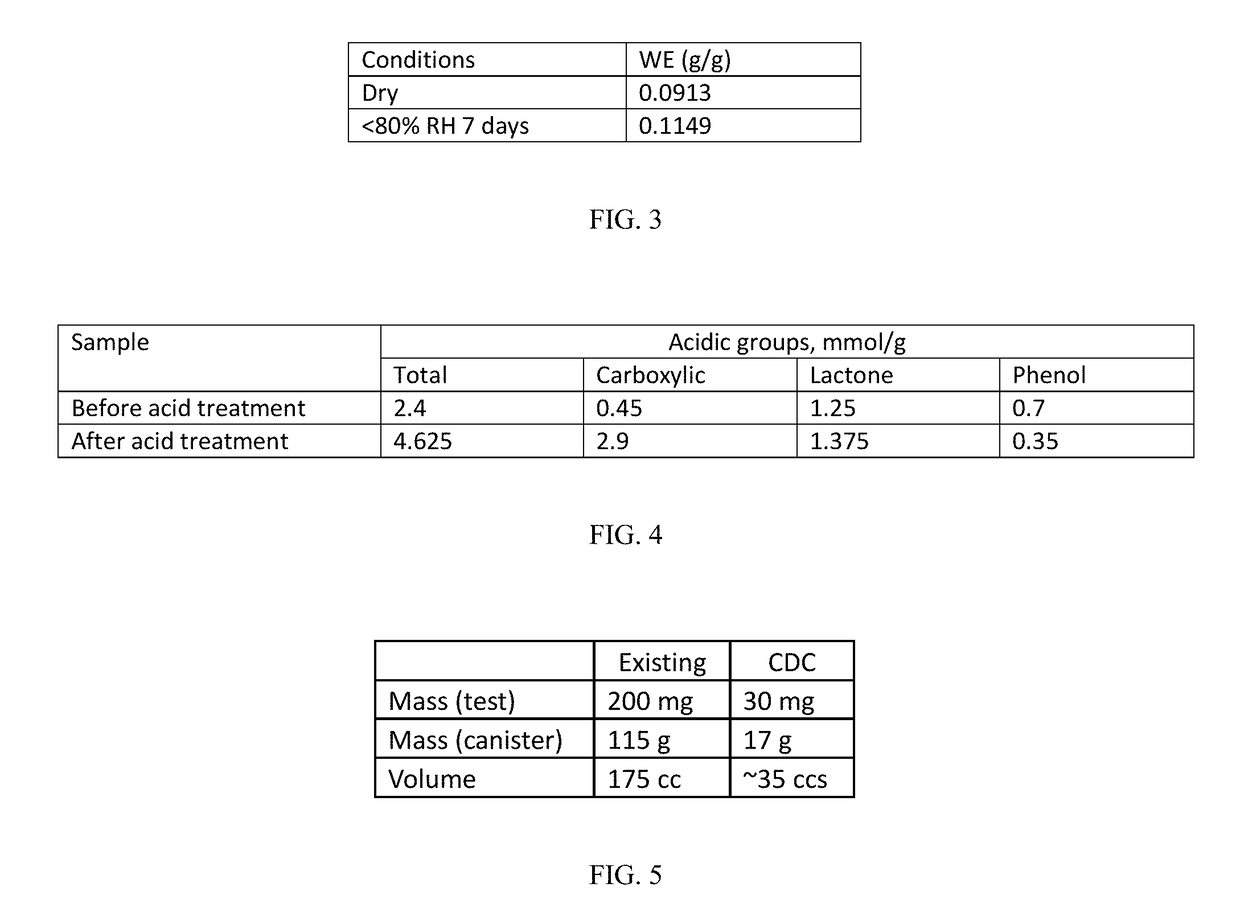

Chemical sampling in high water environments

The system and method of using carbide derived carbon as a sorbent material in high humidity environments. In some cases, the sorbent material is used for breath analysis. In some cases, the sorbent material is used in a gas mask. In certain cases, the sorbent material is functionalized for detection or capture of particular chemicals.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

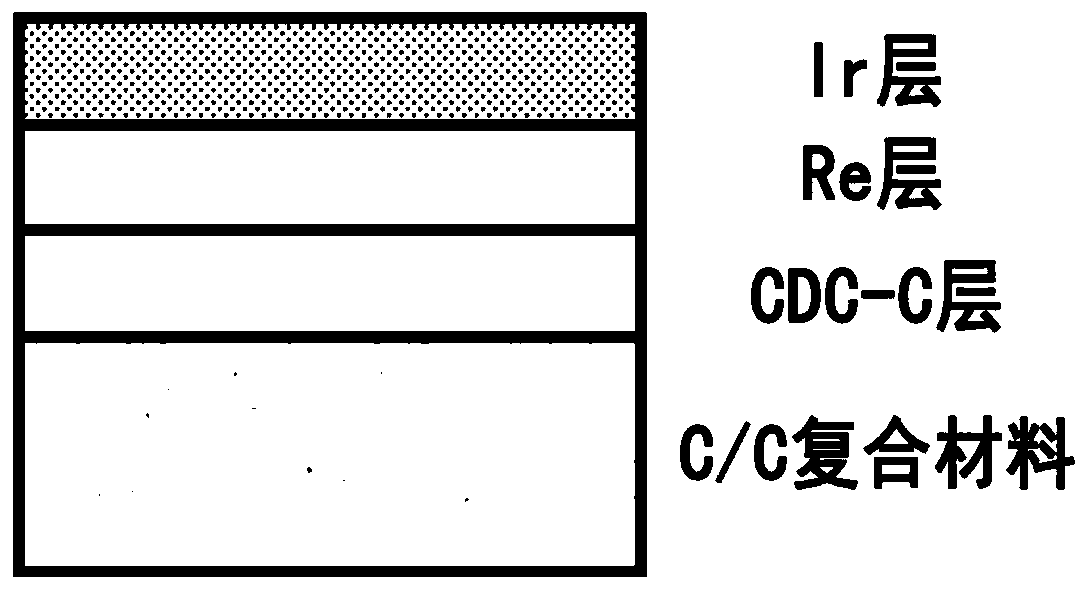

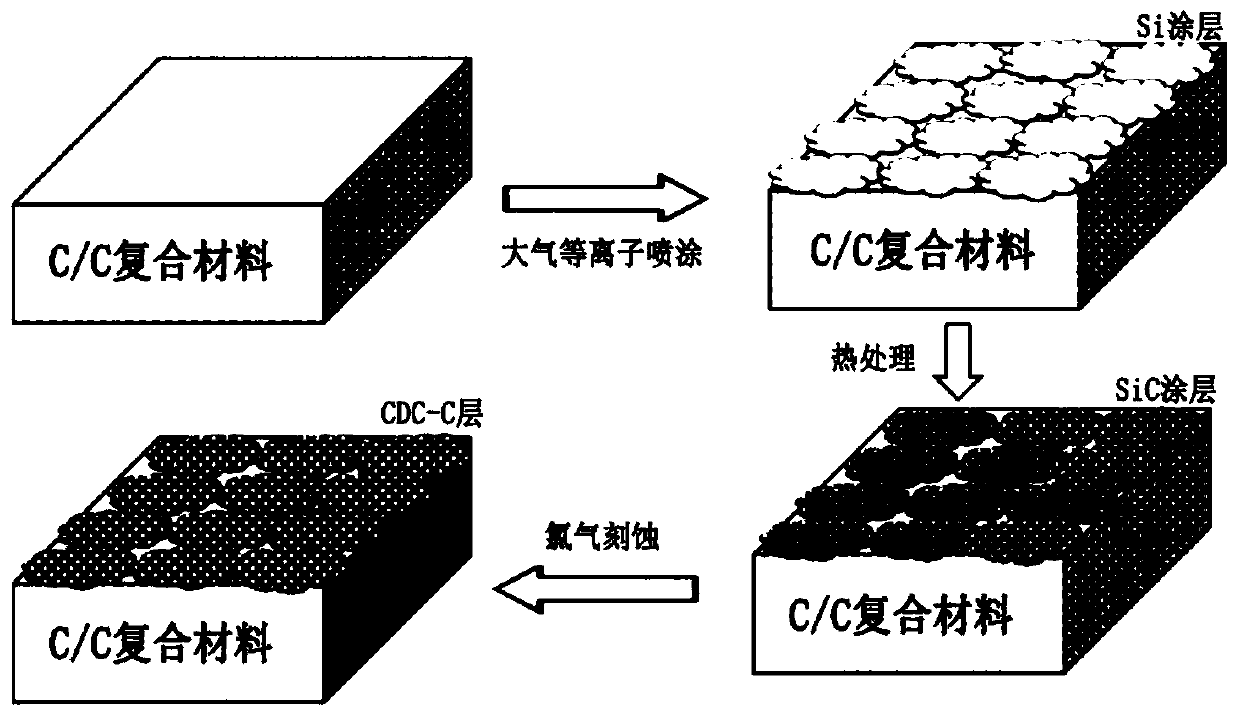

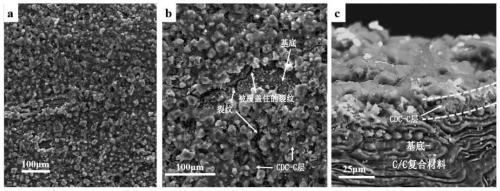

C/C composite material surface carbide derived carbon/rhenium/iridium coating layer and preparation method thereof

The invention discloses a C / C composite material surface carbide derived carbon / rhenium / iridium coating layer and a preparation method thereof. The coating layer takes a C / C composite material as a matrix; a carbide-derived carbon layer, a rhenium coating layer and an iridium coating layer are sequentially arranged on the surface of the C / C composite material from bottom to top. The preparation method comprises the steps: preparing a pure Si layer on the C / C composite material matrix, carrying out heat treatment to obtain an SiC layer, carrying out chlorine etching to form the carbide-derivedcarbon layer, and sequentially depositing the rhenium coating layer and the iridium coating layer on the carbide-derived carbon layer. The carbide-derived carbon / rhenium / iridium coating layer can perfectly consider coating layer combination, coating layer matrix thermal mismatch alleviation and coating layer system high-temperature thermochemical compatibility, and has a wide application prospect.

Owner:NAT UNIV OF DEFENSE TECH

A method for preparing carbide-derived carbon by molten salt electrolysis

InactiveCN103436904BHigh purityUniform pore size distributionElectrolysis componentsCarbon preparation/purificationElectrolysisRaw material

The invention discloses a method for preparing carbide derived carbon by a fused salt electrolysis method. The method mainly comprises the steps that metal carbide serves as a raw material, and is subjected to die pressing sintering to form a metal carbide sheet to serve as an anode; by taking fused salt as an electrolyte, and a high-purity and high-density graphite rod as a cathode, fused salt electrolysis is performed in an electrolysis furnace in an argon atmosphere with the electrolysis temperature of 400-1300 DEG C, the electrolysis voltage of 1.8-3.2V, and the electrolysis time of 2-60h; after the electrolysis, an anode product is taken out, and subjected to water washing, ultrasonic-assisted pickling, water washing and drying treatment; and the carbide derived carbon is prepared. According to the method, the low-cost metal carbide can serve as the raw material for preparing the carbide derived carbon by the fused salt electrolysis method, so that a preparation technology is simplified; the cost is lowered; and the prepared carbide derived carbon serves as an electrode material of a supercapacitor, and has high specific capacity and good cycling stability.

Owner:YANSHAN UNIV

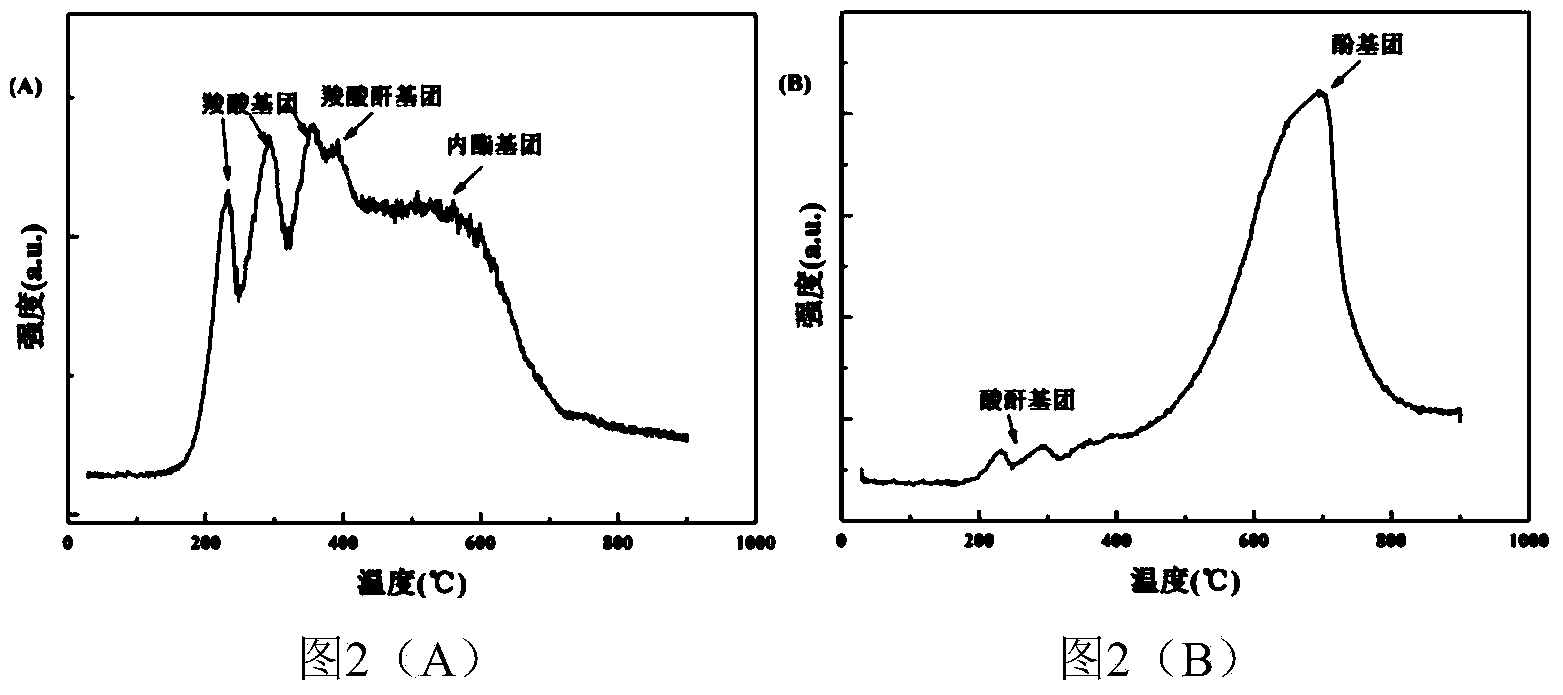

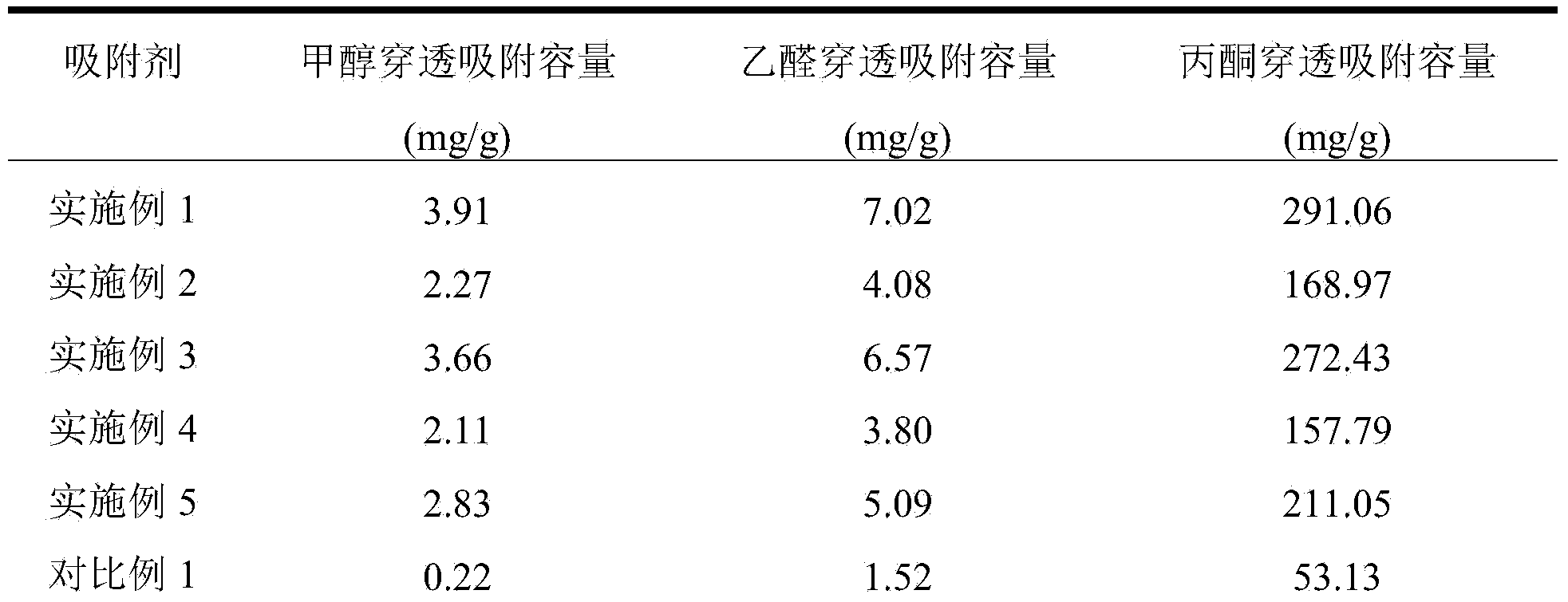

Carbide derived carbon adsorbent for removing low-concentration low-molecular-weight VOCs (volatile organic compounds) as well as preparation method of adsorbent

InactiveCN103861561AImprove adsorption capacityLarge adsorption capacityOther chemical processesDispersed particle separationSorbentDisposal Technique

The invention discloses a carbide derived carbon adsorbent for removing low-concentration low-molecular-weight VOCs (volatile organic compounds) as well as a preparation method of the adsorbent, and belongs to the technical field of gas purification treatment technique. The preparation method comprises the following steps: firstly, heating commercial carbide in an inert atmosphere to 600-900 DEG C, and then introducing chlorine for 2-4 hours and etching at high temperature at the flow rate of 30-50ml / min; then introducing inert atmosphere again and cooling down to room temperature so as to obtain the primary carbide derived carbon product; then adding the carbide derived carbon primary product to an oxidizing solution and performing immersion treatment for 6-12 hours; and then washing by deionized water to be neutral, and drying at 105 DEG C for 3-8 hours, thereby obtaining the finished carbide derived carbon adsorbent product. Compared with existing commercial activated carbon, the adsorbent designed by the invention can efficiently adsorb low-concentration low-molecular-weight VOCs at high air speed, is high in adsorption capacity, has long service life, and is suitable for air purification treatment in rooms of buildings, airtight cabins and other limited spaces.

Owner:山东航源环境科技有限公司

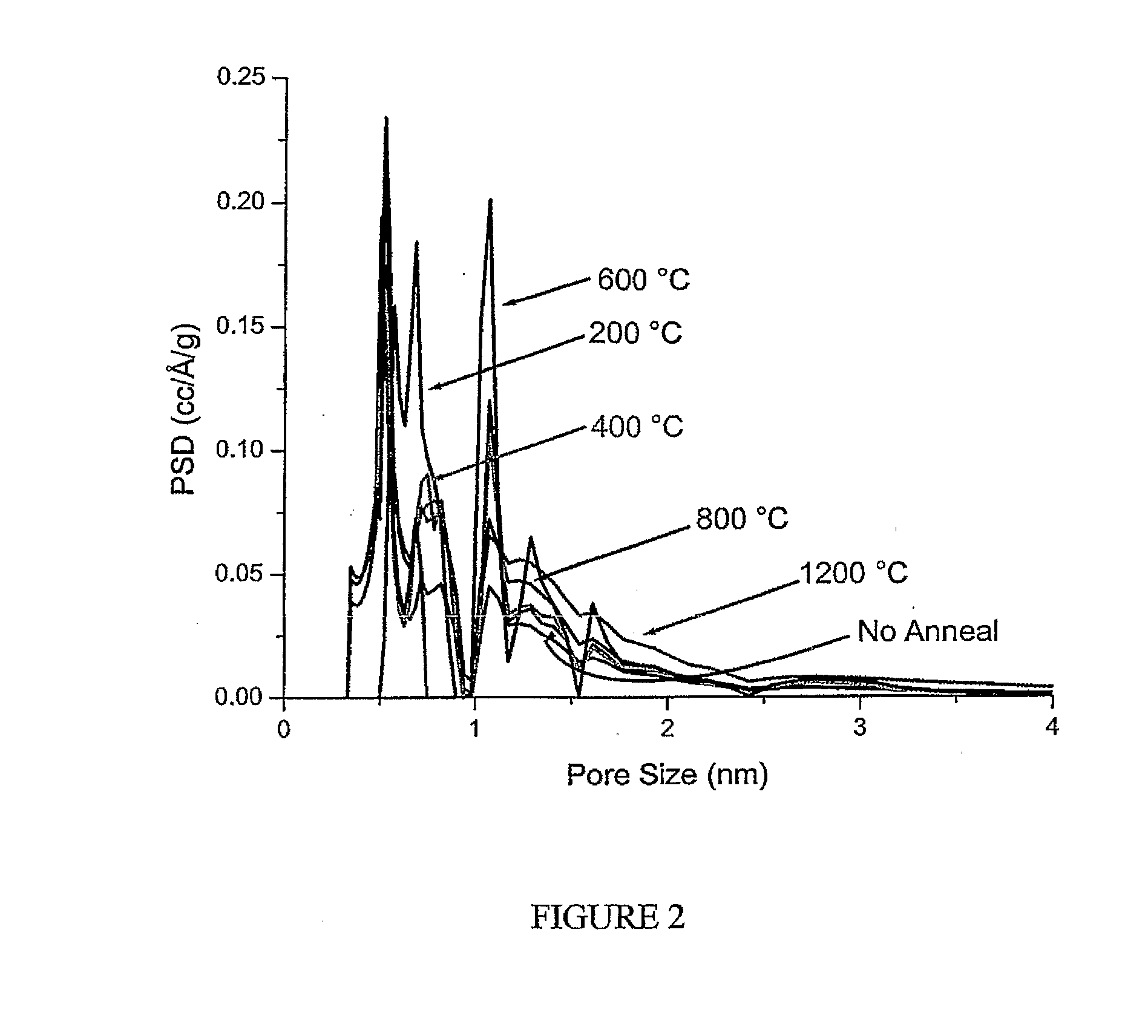

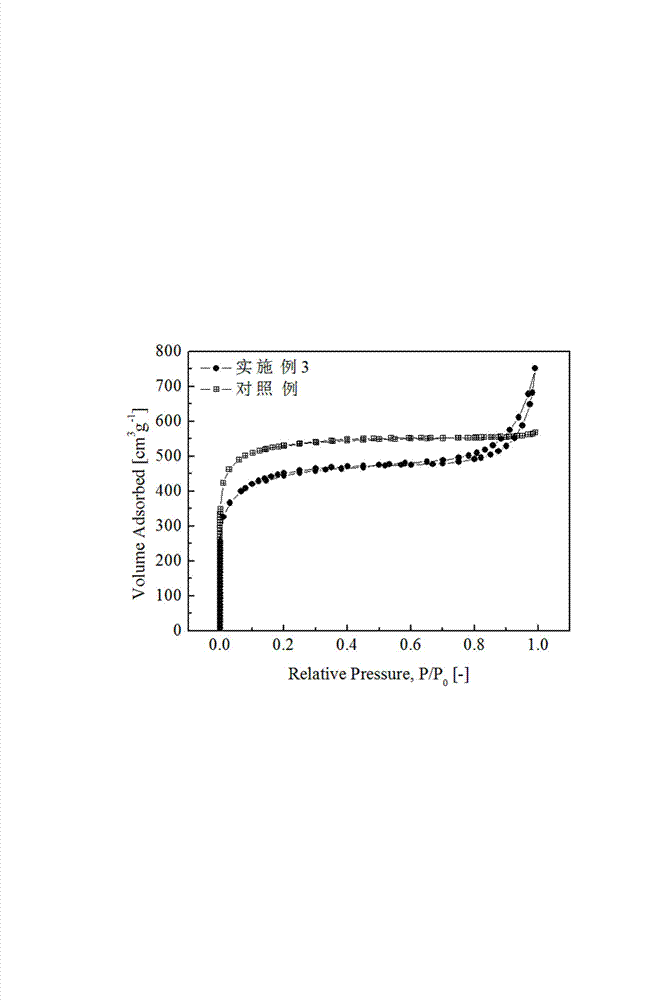

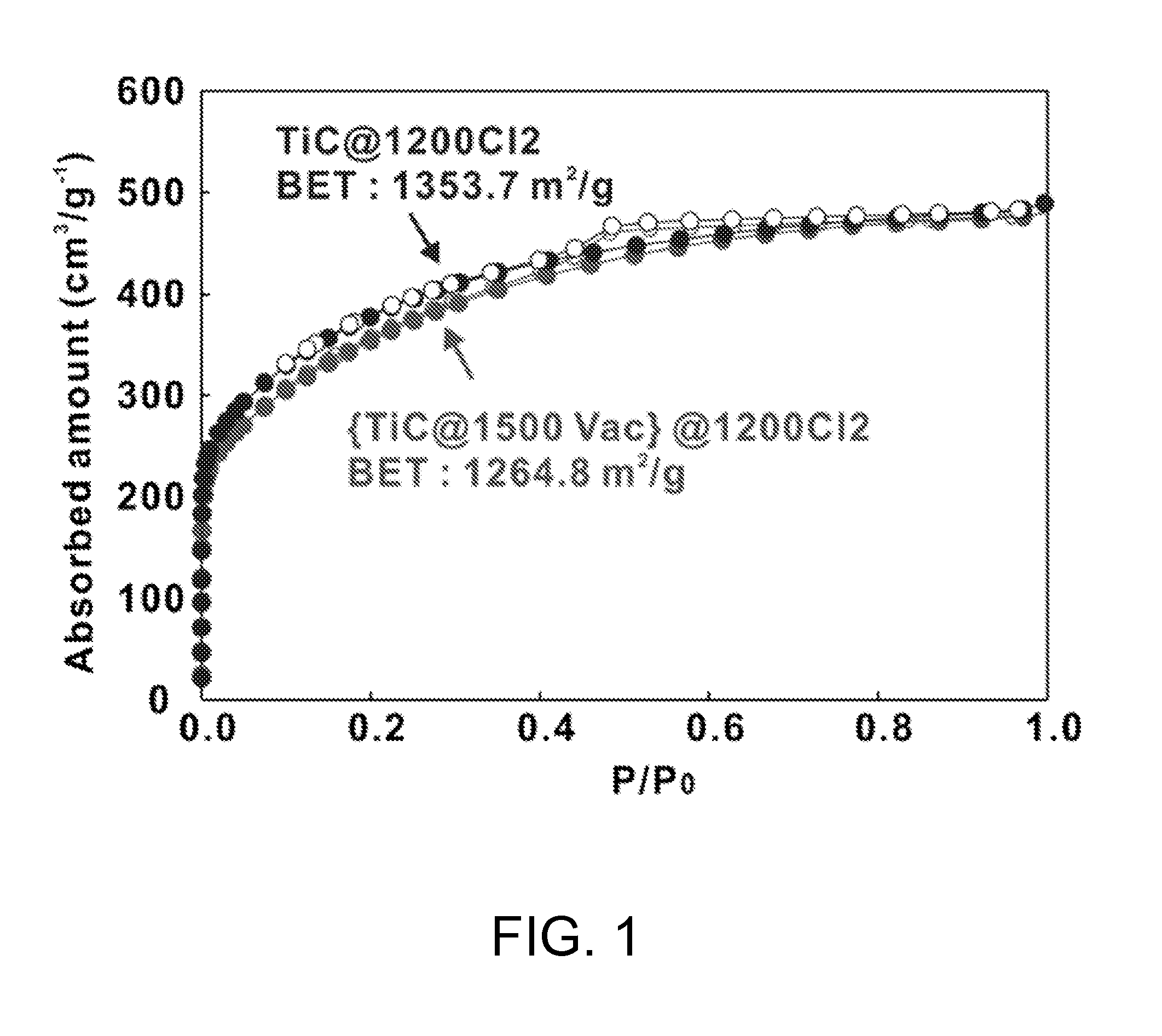

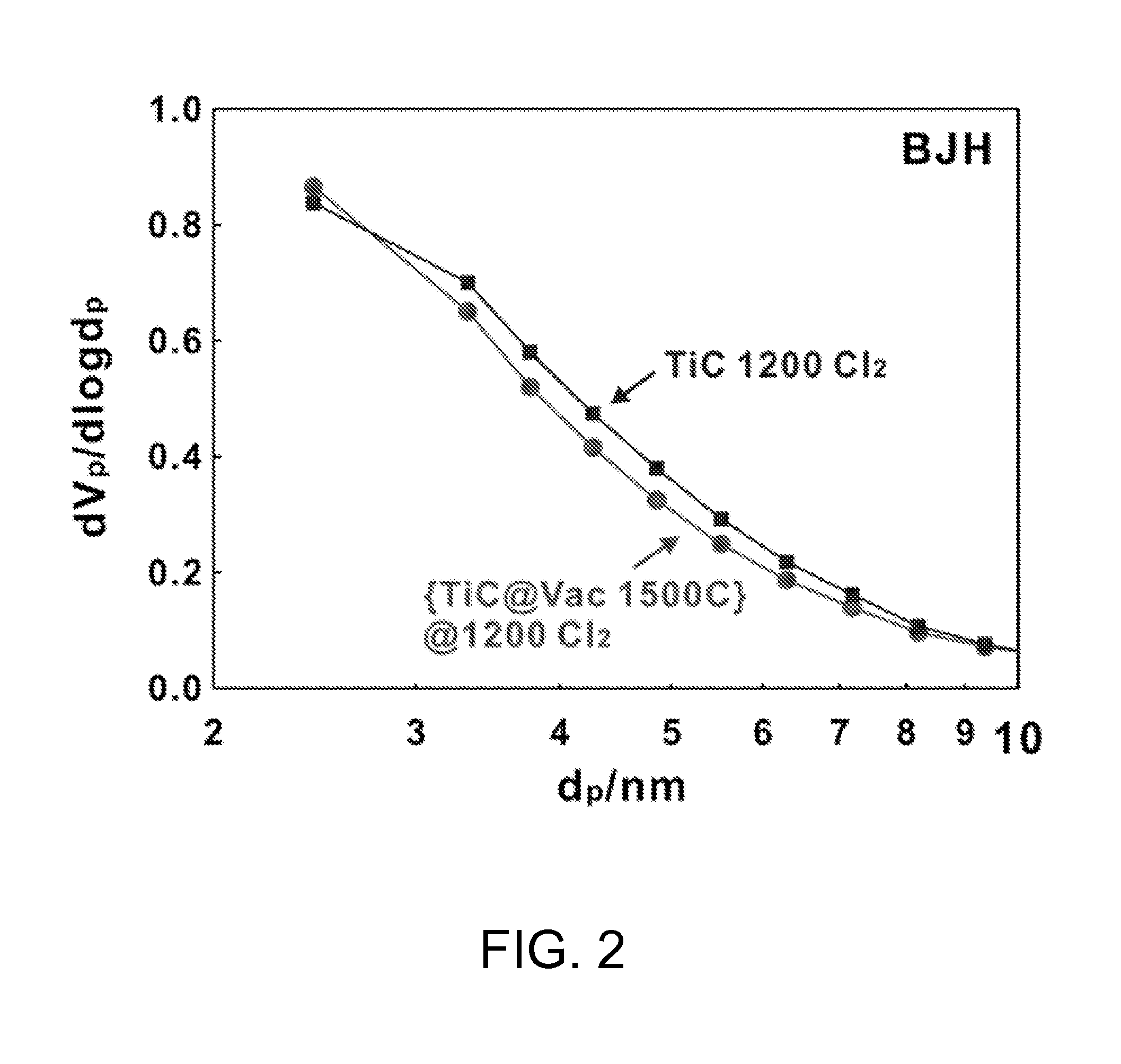

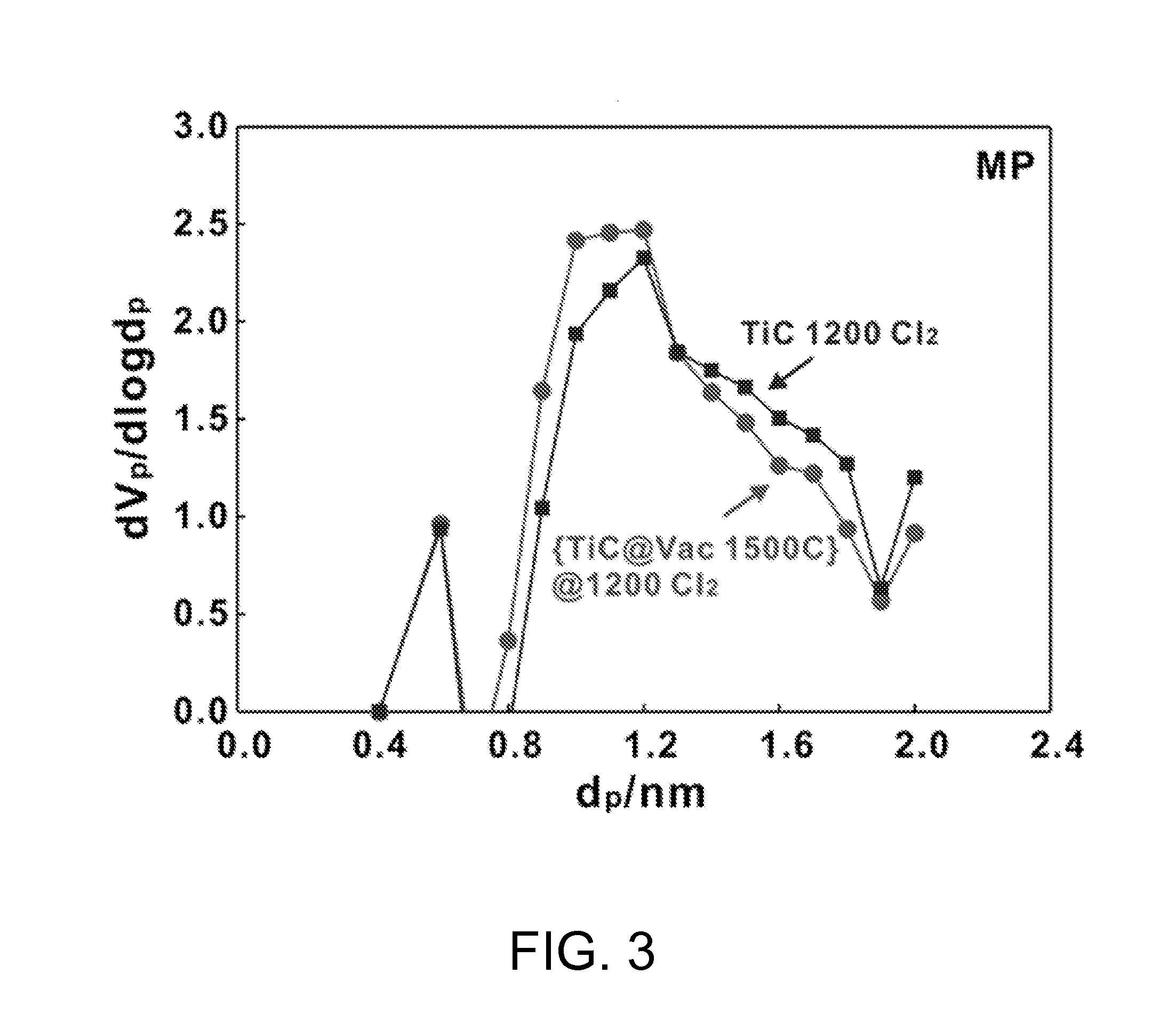

Carbide-Derived Carbon Manufactured by Using Heat Treatment at Vacuum and Method Thereof

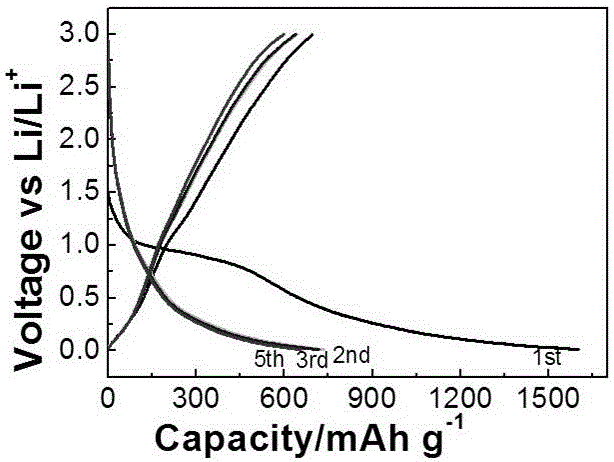

ActiveUS20160130146A1Stable charge/discharge efficiencyIncreased ion mobilityNitrogen compoundsElectrode thermal treatmentPore distributionChemical reaction

Disclosed is a method of preparing a carbide-derived carbon having high ion mobility for use in a lithium battery anode material, a lithium air battery electrode, a supercapacitor electrode, and a flow capacitor electrode, including thermally treating a carbide compound in a vacuum, thus obtaining a vacuum-treated carbide compound; and thermochemically reacting the vacuum-treated carbide compound with a halogen element-containing gas, thus extracting the element other than carbon from the vacuum-treated carbide compound, wherein annealing can be further performed after thermochemical reaction. This carbide-derived carbon has a small pore distribution, dense graphite fringe, and a large lattice spacing and thus high ion mobility, compared to conventional carbide-derived carbon obtained only by thermochemical reaction with a halogen element-containing gas.

Owner:KOREA INST OF ENERGY RES

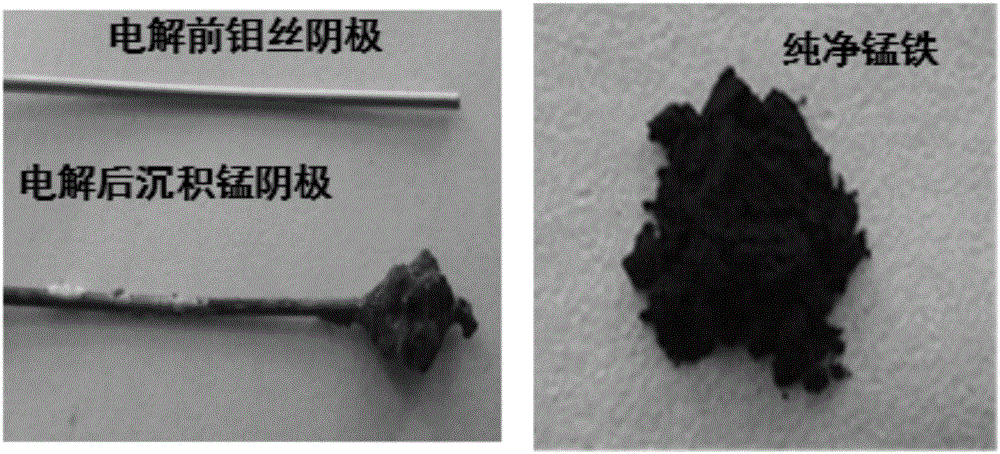

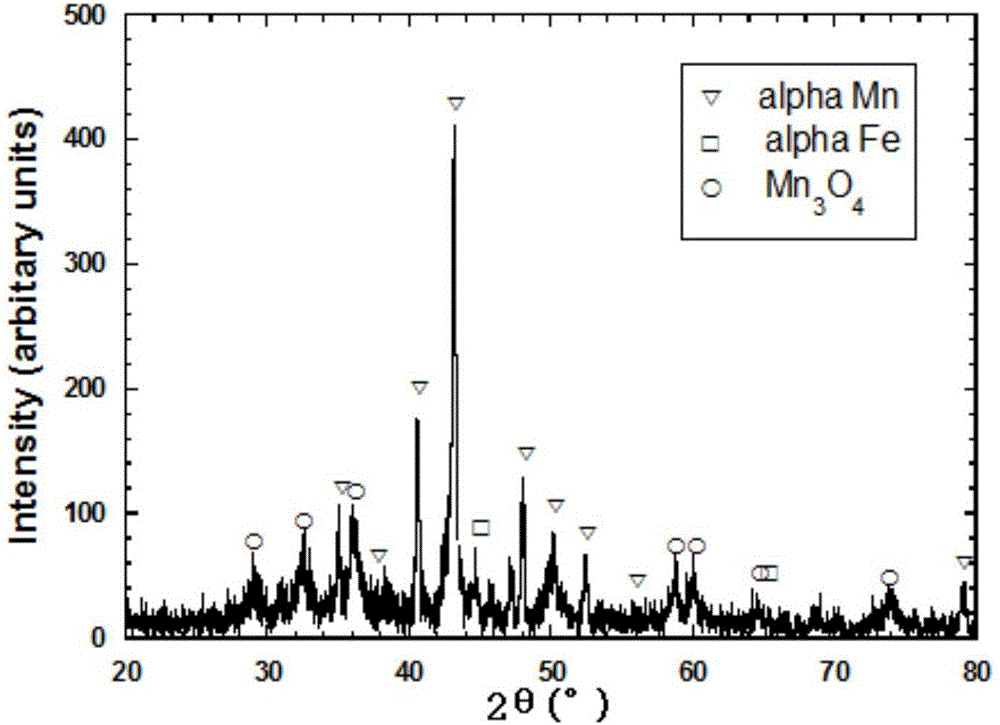

Method for simultaneously preparing pure iron alloy and carbide derived carbon by using carbon iron alloy as raw material

ActiveCN106011943AReduce manufacturing costReduce in quantityElectrolysis componentsElectrolysisAcid washing

The invention discloses a method for simultaneously preparing a pure iron alloy and carbide derived carbon by using a carbon iron alloy as a raw material and belongs to the technical field of iron alloy refining and preparation of novel carbon materials. According to the method, the carbon-iron alloy is used as the raw material to manufacture a platy or rod-like molten salt electro-refining anode; a chloride molten salt is used as an electrolyte, high-melting-point metal materials such as tungsten and molybdenum are used as a cathode to perform molten salt electrolysis in an inert atmosphere such as argon; after electrolysis finishes, the anode material is taken out and is subjected to water-washing, acid-washing, water-washing and drying treatment to obtain the carbide derived carbon; a pure iron alloy deposited on the cathode is taken out, is remelted in a resistance furnace and is cast to form a pure iron alloy product. By adopting a molten salt electro-refining method, the method disclosed by the invention is capable of simultaneously preparing high-additional-value pure iron alloy and carbide derived carbon by using a cheap carbon iron alloy raw material, and is short in technological process, simple in equipment and low in environmental pollution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

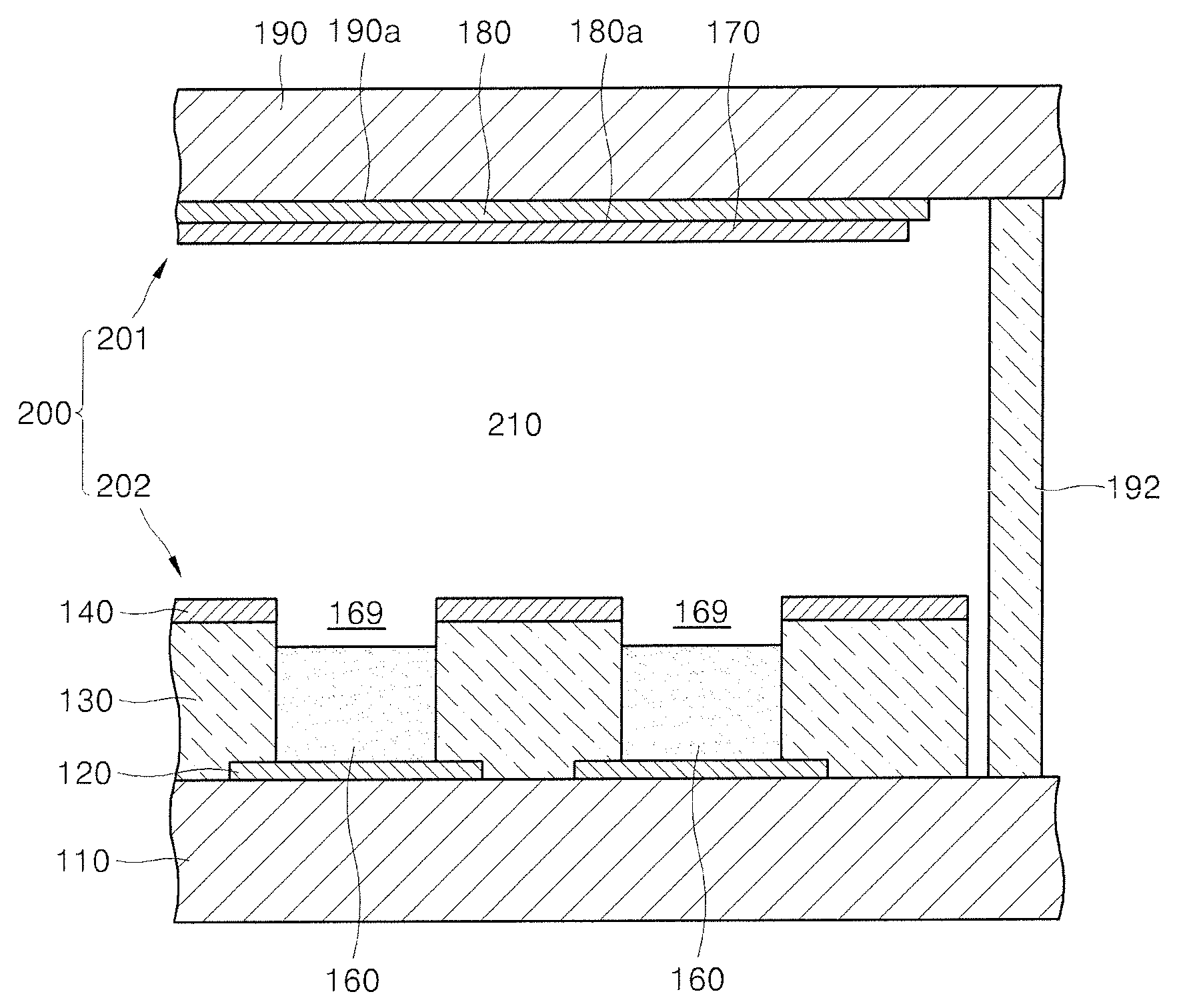

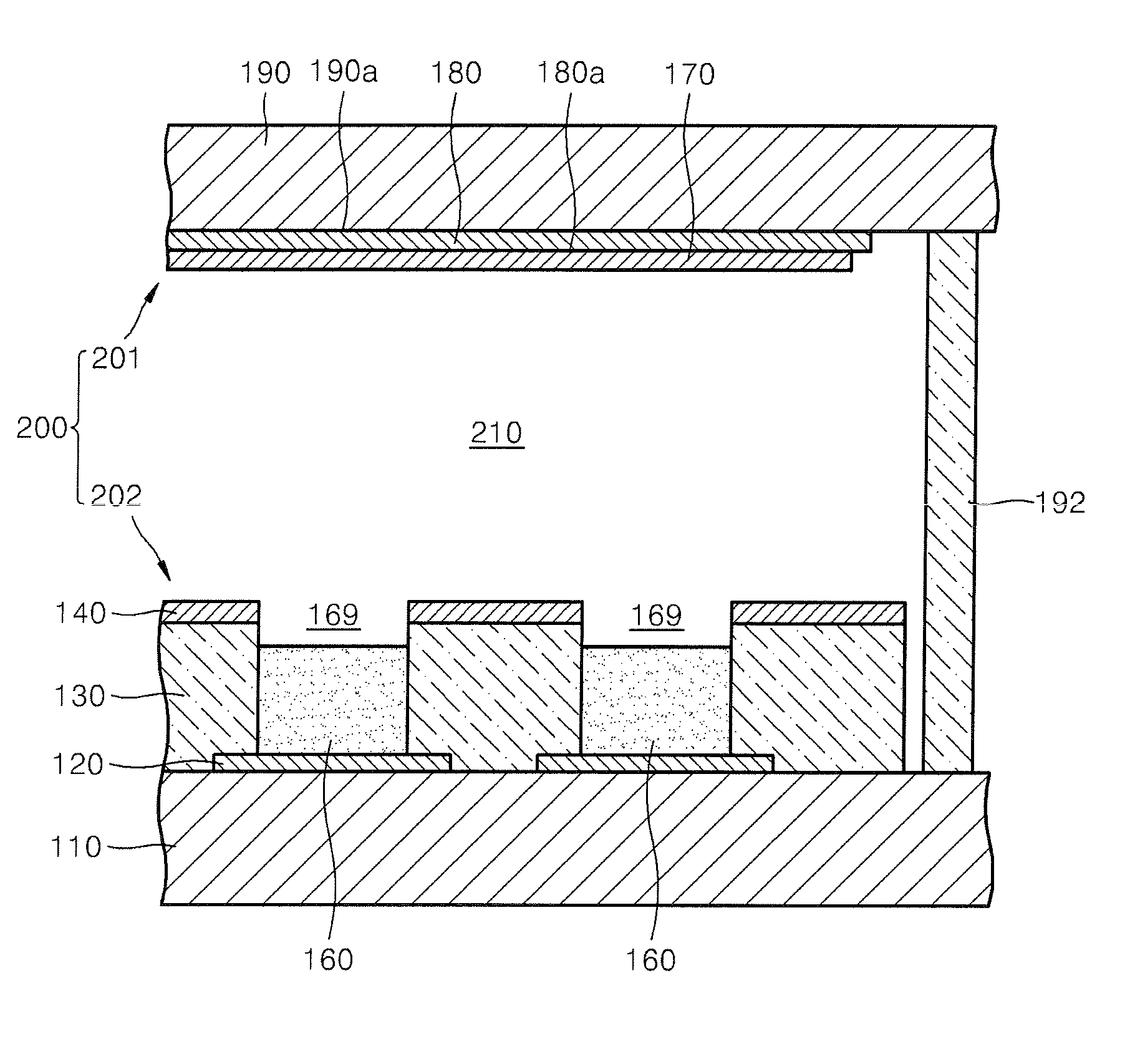

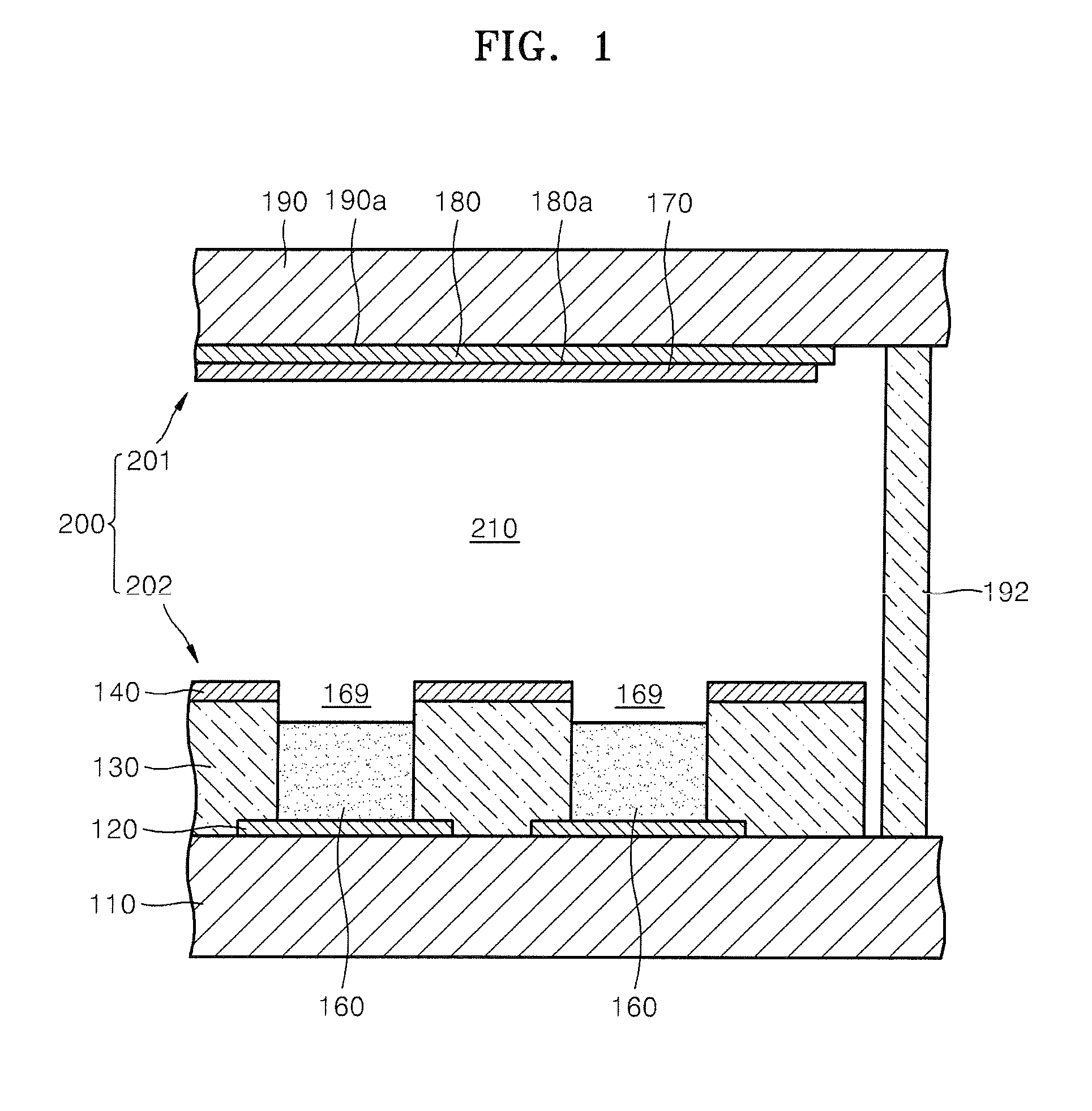

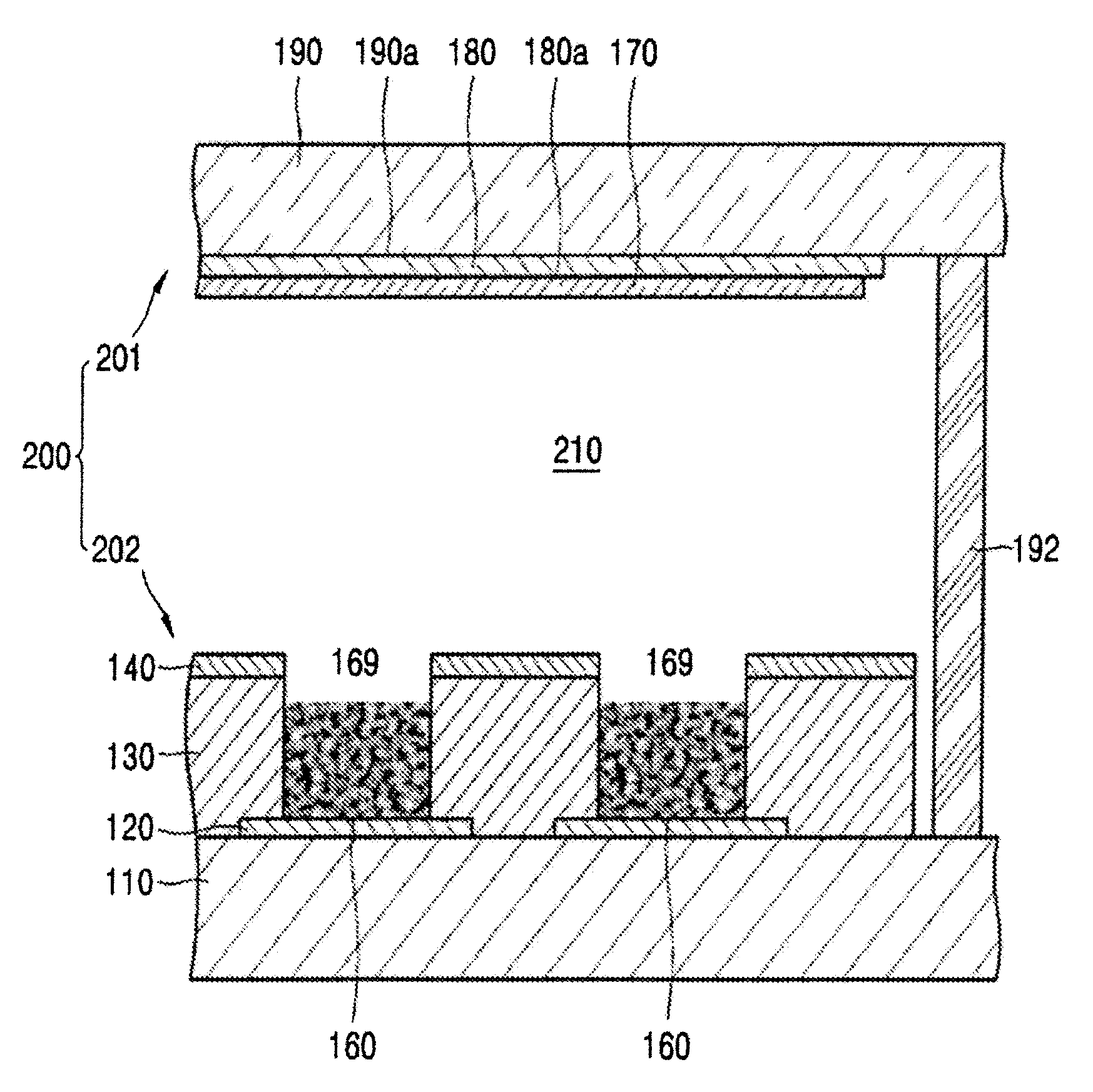

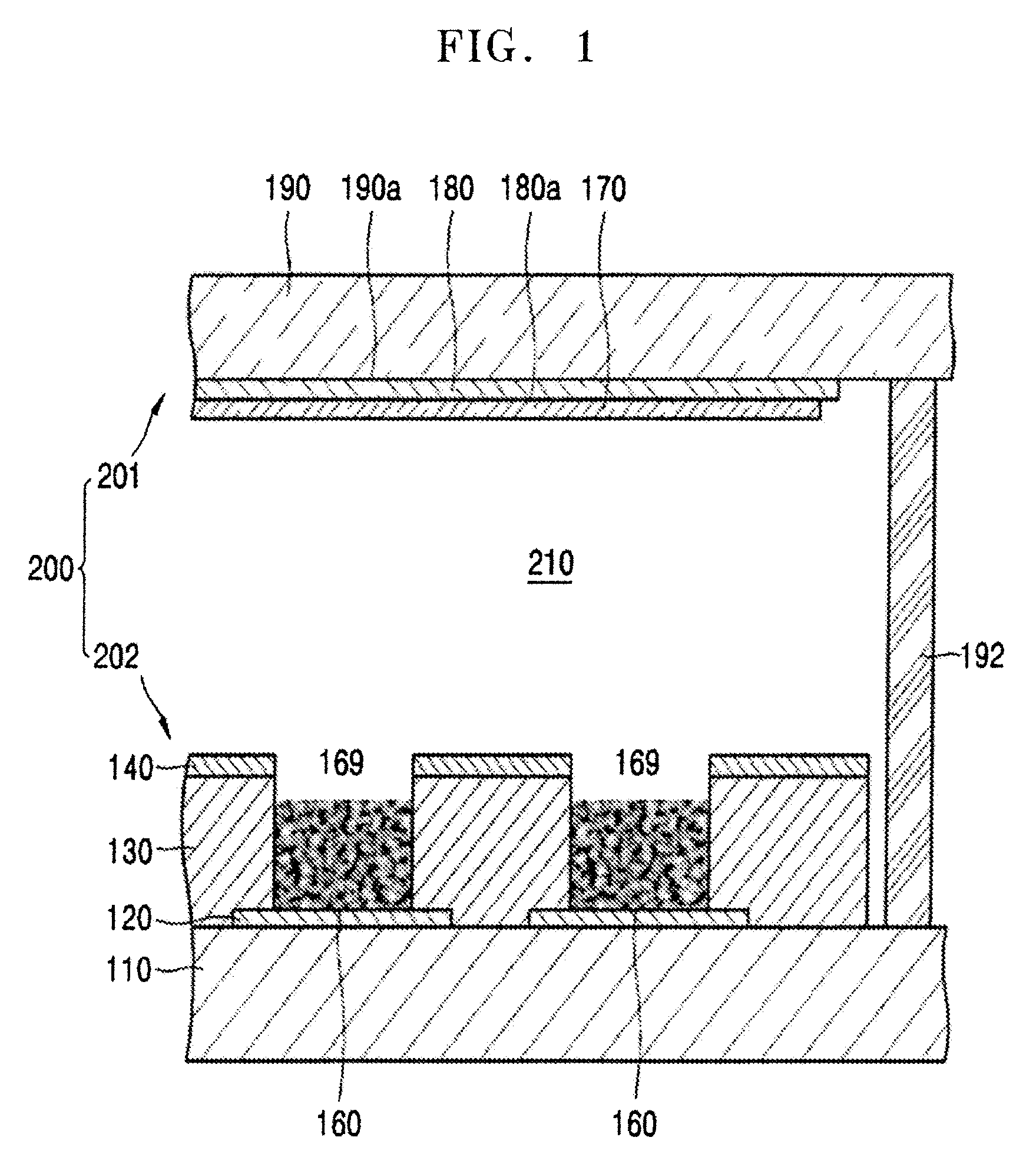

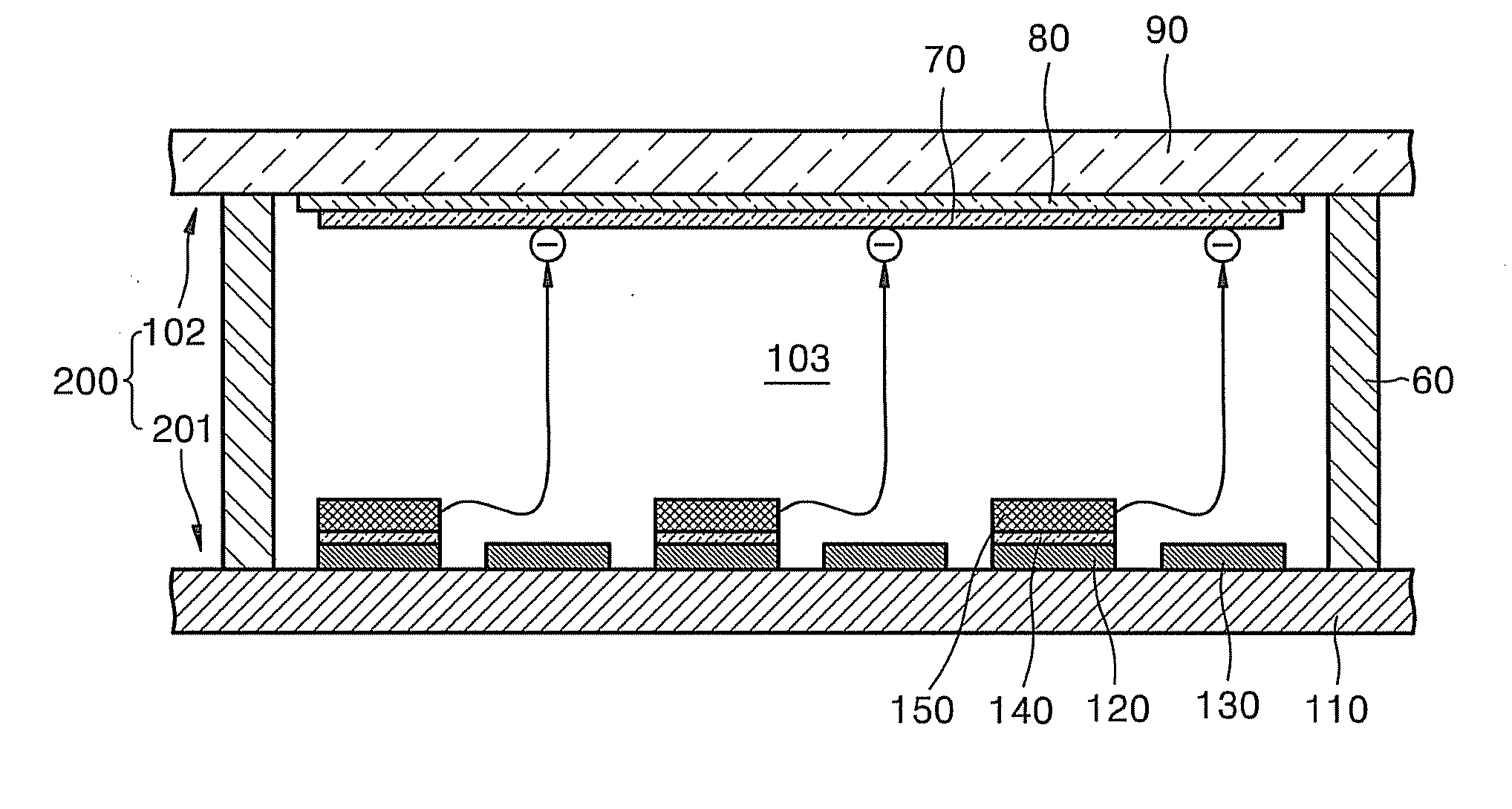

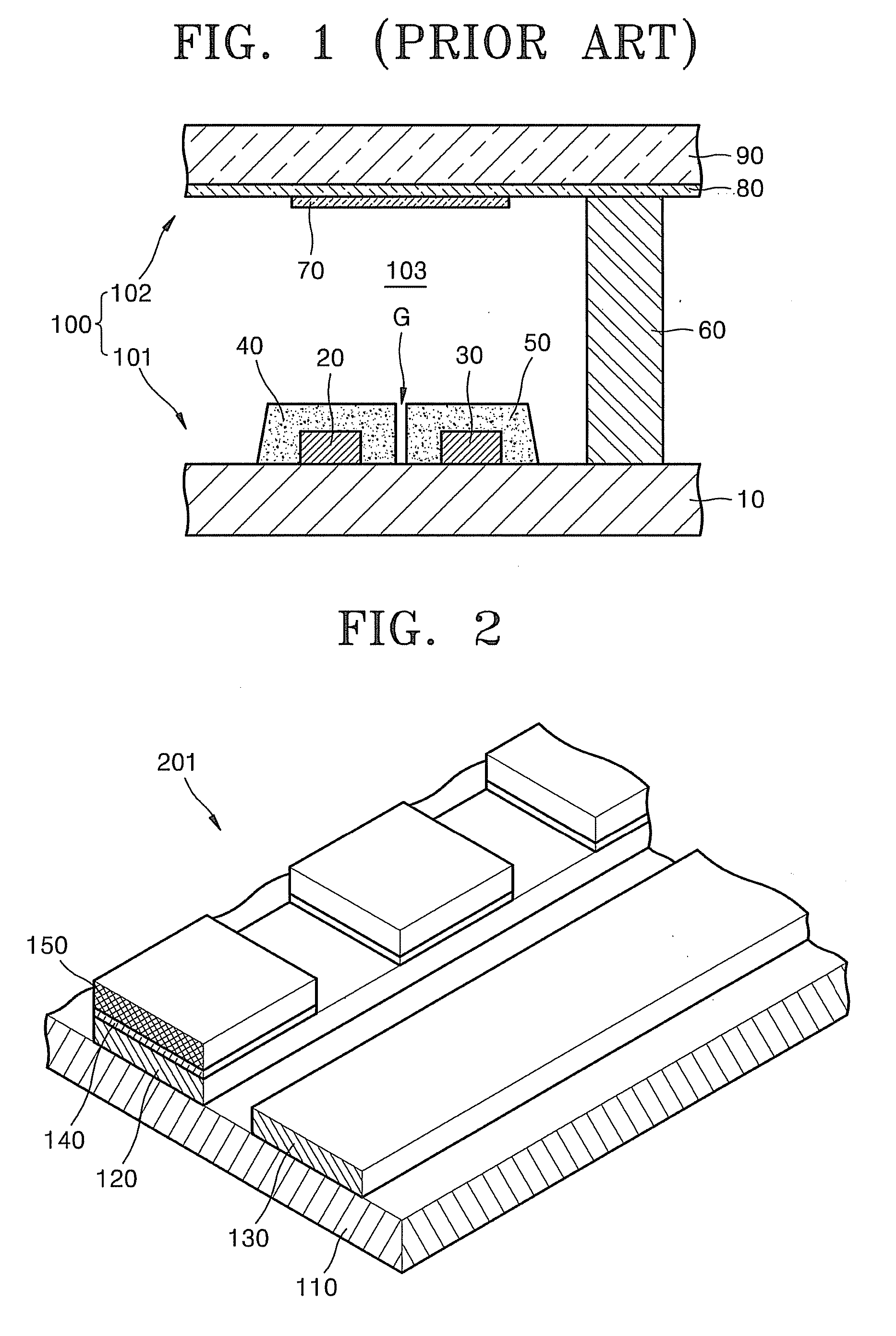

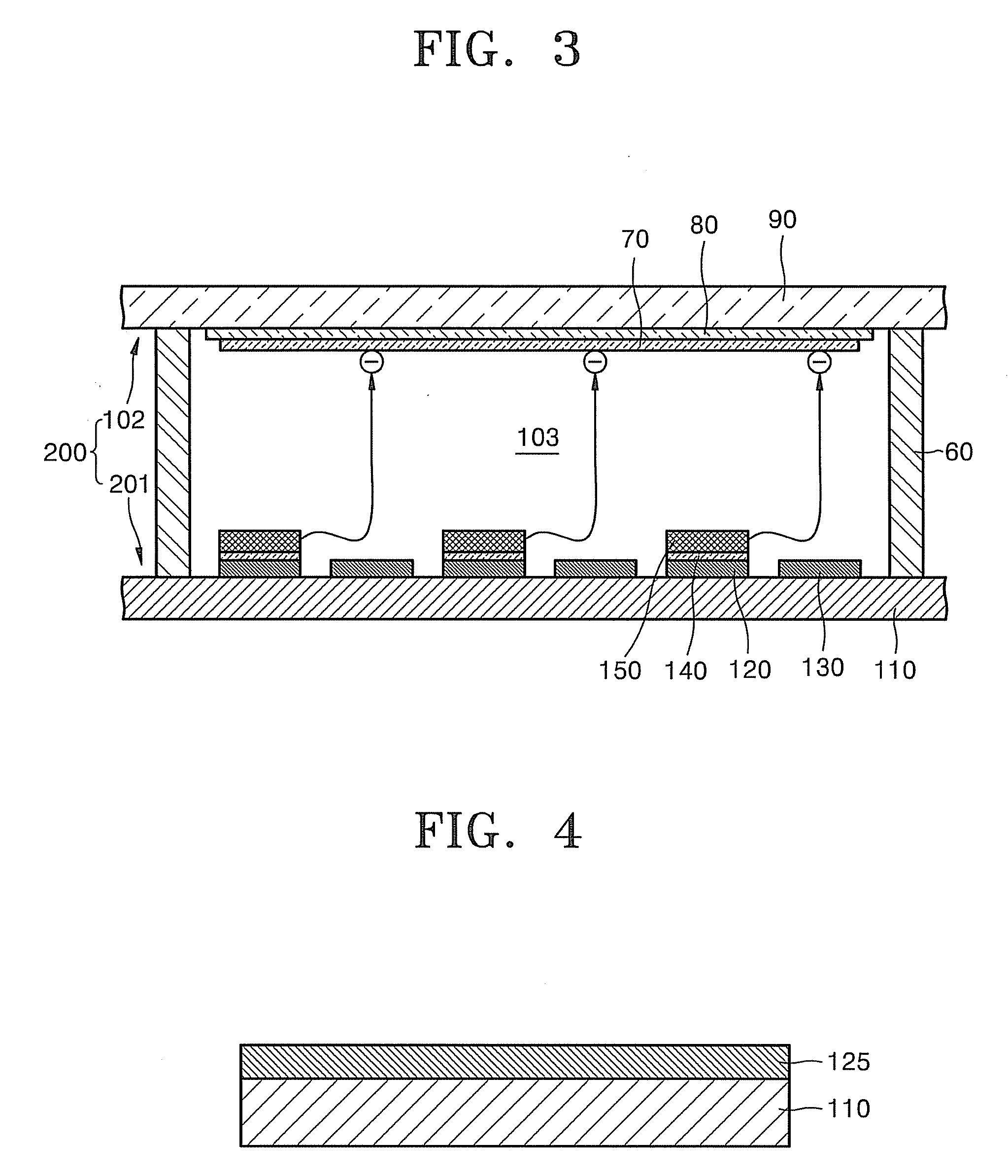

Electron emission device, electron emission type backlight unit including electron emission device, and method of fabricating electron emission device

InactiveUS20080061677A1Meet brightness requirementsDischarge tube luminescnet screensLamp incadescent bodiesManufacturing technologyDisplay device

An electron emission device to regularly emit electrons and a method of manufacturing the same. Also, an electron emission type backlight unit including the electron emission device in which a high voltage can be applied to an anode and required brightness can be obtained. In addition, the electron emission device can be manufactured using a simplified manufacturing process. The electron emission device includes a first electrode, a second electrode formed opposite the first electrode, and an electron emission layer which is electrically connected to one or each of the first and second electrodes and comprising carbide-derived carbon. The electron emission device may be a display device to form static or dynamic images.

Owner:SAMSUNG SDI CO LTD

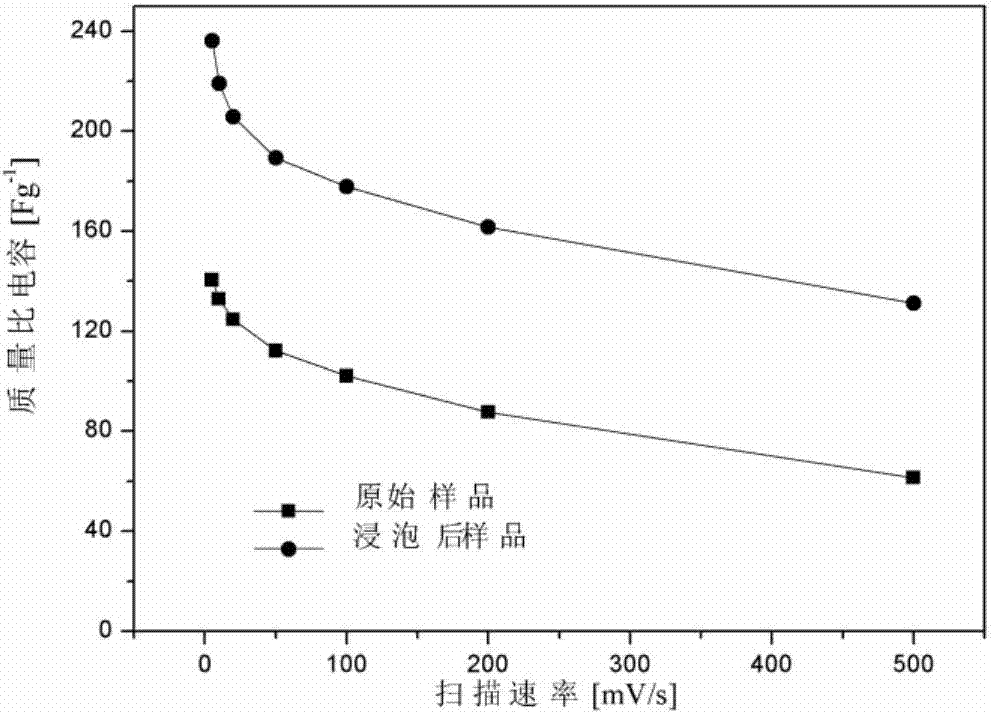

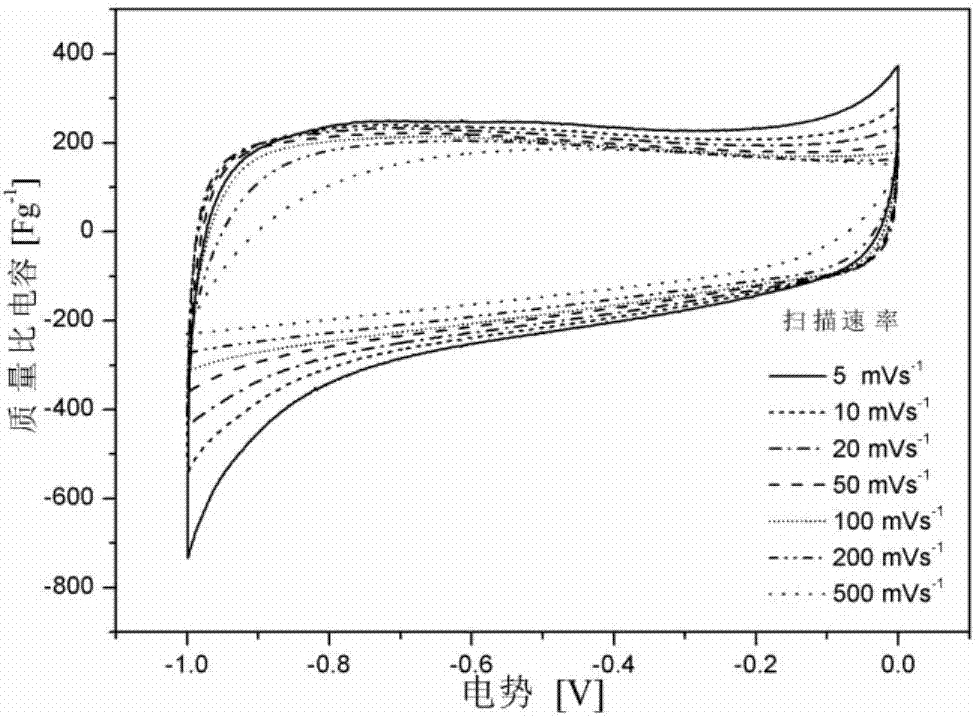

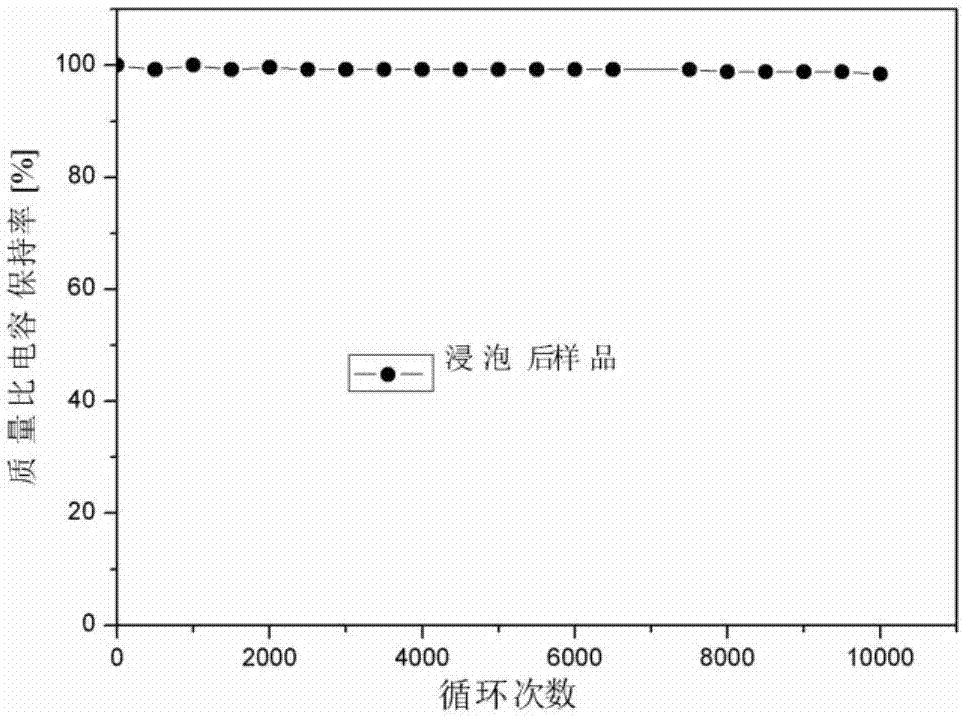

Method for improving carbide derived carbon super capacitor performance

The invention relates to a method for improving carbide derived carbon super capacitor performance. The method mainly comprises steps that firstly, acid solution of nitric acid and hydrofluoric acid is prepared according to a mole proportion of MHNO3:MHF of 1:2-2:1, secondly, to-be-treated carbide derived carbon is completely dipped into the acid solution, through ultrasonic concussion, air left on the carbide derived carbon is removed, under the 25-40 DEG C environment temperature, standing dipping for 48-264 hours is carried out, and lastly, washing is carried out till neutral property is realized, drying is then carried out, treatment on the carbide derived carbon is accomplished. The method is advantaged in that the method is simple and easy, cycle utilization of the acid solution can be realized, a raw material utilization rate is high, on the condition that excellent power characteristics of the carbide derived carbon and double electric layer characteristics are kept, a specific capacitance value is substantially improved, and excellent super capacitor performance is presented.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com