Method for preparing carbide-derived carbon from molten sodium carbonate at high temperature

A carbide-derived carbon and sodium carbonate technology, which is applied in the manufacture of hybrid/electric double layer capacitors, structural parts, electrical components, etc., can solve the problems of complex devices and high energy consumption, and achieve high safety, low preparation costs, and environmental protection. The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

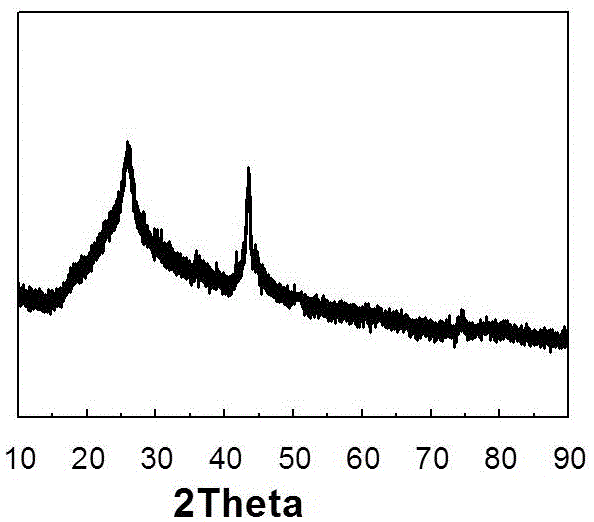

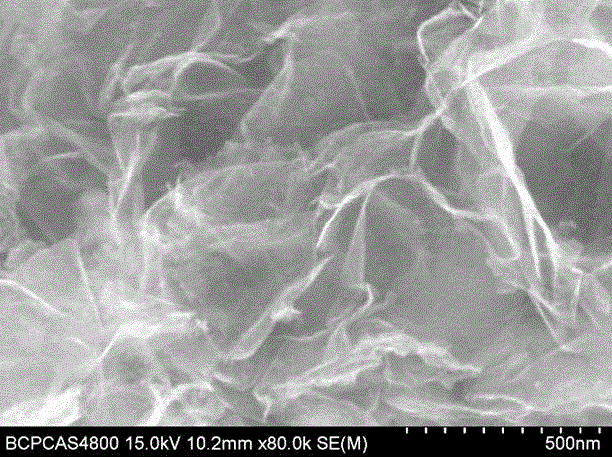

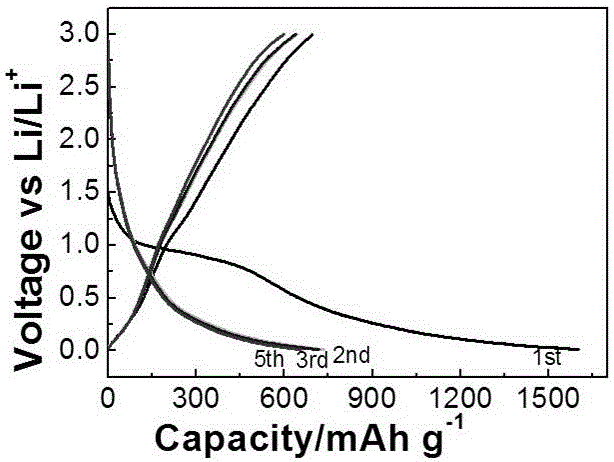

[0035] 2g Ti 3 AlC 2 Mix homogeneously with 6g of anhydrous sodium carbonate, fill in a nickel boat and place it in the center of a tube furnace, heat up to 500°C under nitrogen protection, and keep 500°C for 10h. After the material was naturally cooled to room temperature, the calcined product was dissolved in 3M HCl and reacted at room temperature (20±5°C) for 2 h. The reaction product was suction-filtered, washed with water until neutral, and dried at 120°C to obtain a carbide-derived carbon material. The XRD curve of the obtained carbide-derived carbon is as follows figure 1 It can be seen from the test that a carbide-derived carbon material is prepared by the above method. The scanning electron microscope of the obtained carbon material is as follows figure 2 As shown, the carbon material has a graphene-like two-dimensional layered structure. The Raman spectrum of the resulting carbide-derived carbon is shown in image 3 As shown, the obvious 2D peak indicates that...

Embodiment 2

[0037] 2g Ti 3 SiC 2 Mix evenly with 20g of anhydrous sodium carbonate, put it in a nickel boat and place it in the center of the tube furnace, heat up to 880°C under the protection of argon, and keep it warm for 5h. The calcined product was dissolved in 5M HCl and reacted at room temperature for 2 h. The reaction product was suction-filtered, washed with water until neutral, and dried at 120°C to obtain a carbide-derived carbon material. The scanning electron microscope picture of the obtained carbide-derived carbon material is as follows Figure 6 As shown, it indicates that a two-dimensional layered material was prepared. The carbide-derived carbon is used as an electrode material for supercapacitors. The mass specific capacitance is 220 F / g in 6mol / L KOH electrolyte, and the capacity remains 91% after 10,000 cycles.

Embodiment 3

[0039] 1g Ti 2 AlC and 20g of anhydrous sodium carbonate were mixed evenly and placed in a nickel boat. The nickel boat was placed in a tube furnace, and the temperature was raised to 1000°C under the protection of nitrogen and argon mixed gas (volume ratio 1:1), and kept for 1h. The calcined product was dissolved in 3M HCl and reacted at room temperature for 2 h. The reaction product was suction-filtered, washed with water until neutral, and dried at 120°C to obtain a carbide-derived carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com