Patents

Literature

2561 results about "Halogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogenation is a chemical reaction that involves the addition of one or more halogens to a compound or material. The pathway and stoichiometry of halogenation depends on the structural features and functional groups of the organic substrate, as well as on the specific halogen. Inorganic compounds such as metals also undergo halogenation.

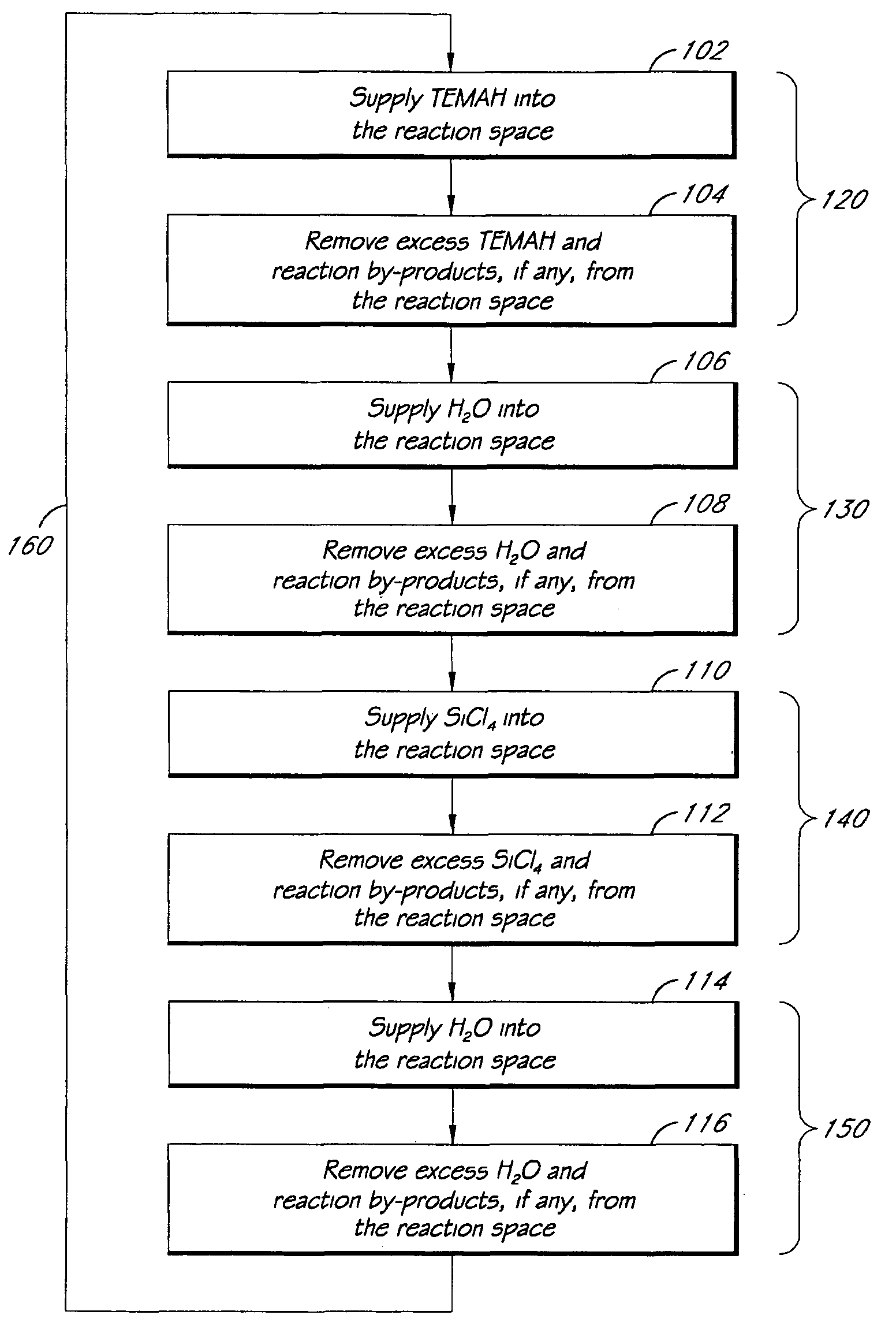

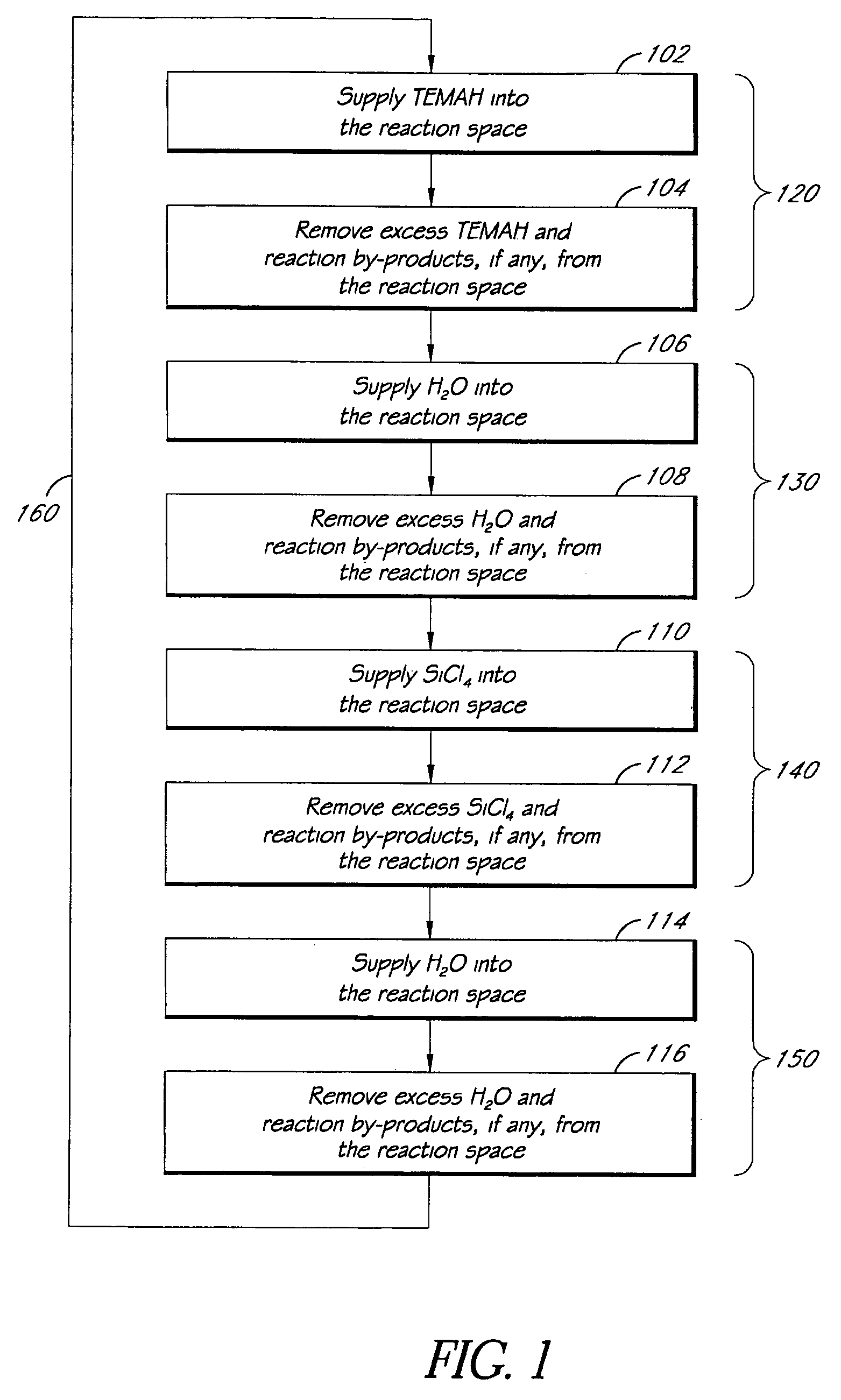

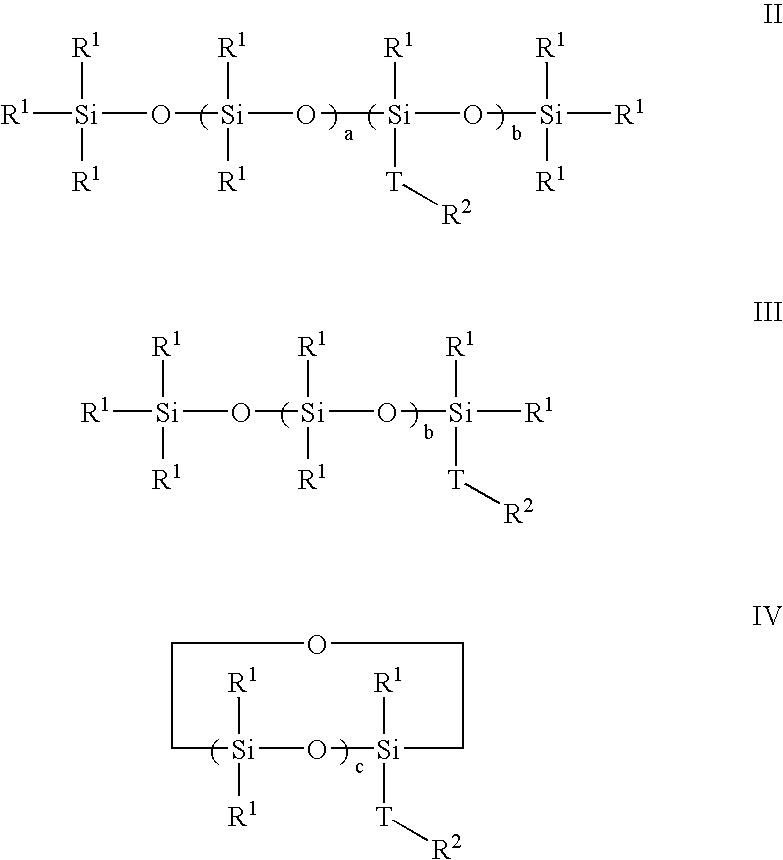

ALD of metal silicate films

ActiveUS7795160B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Owner:ASM IP HLDG BV

Polymerization of halogen-containing monomers using siloxane surfactant

Halogenated polymers are prepared by a process comprising polymerizing at least one halogen-containing monomer in an aqueous medium containing monomer, radical initiator, and siloxane surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

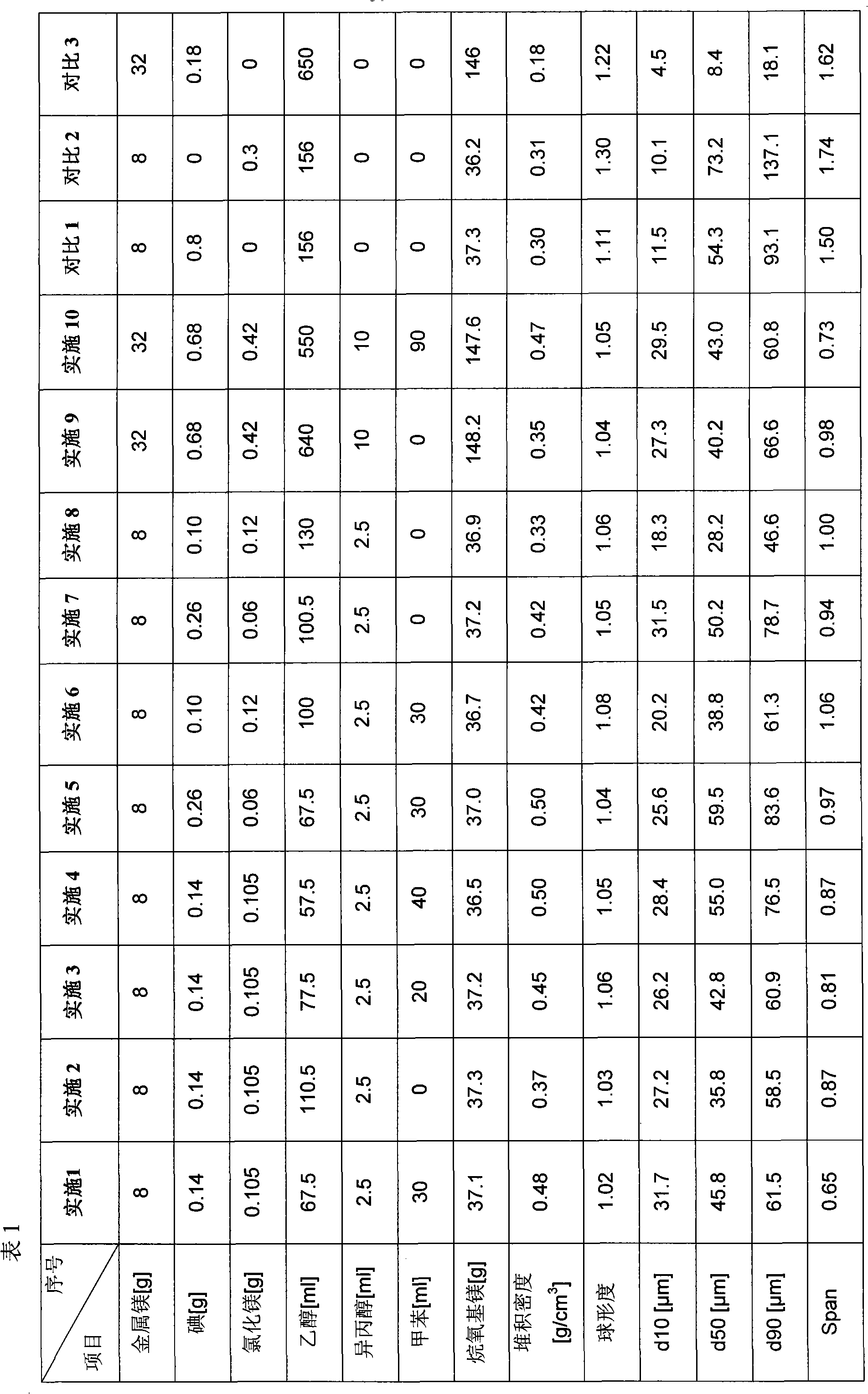

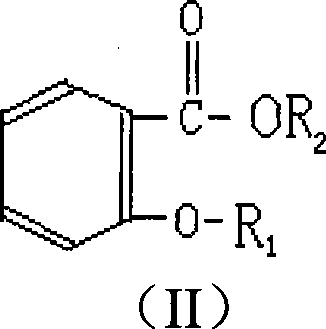

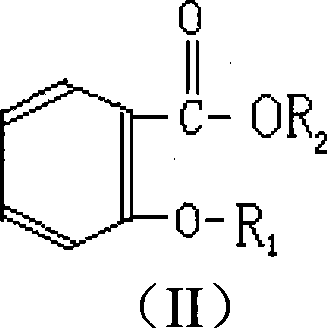

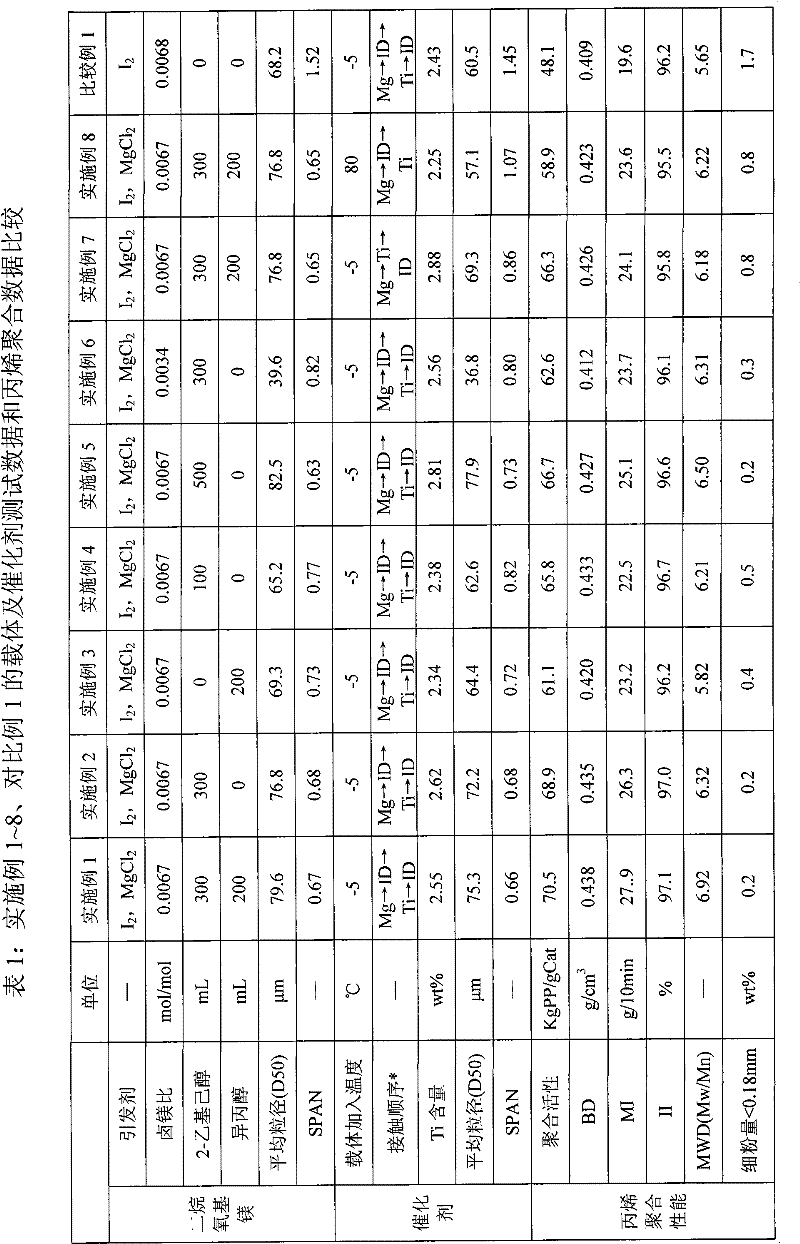

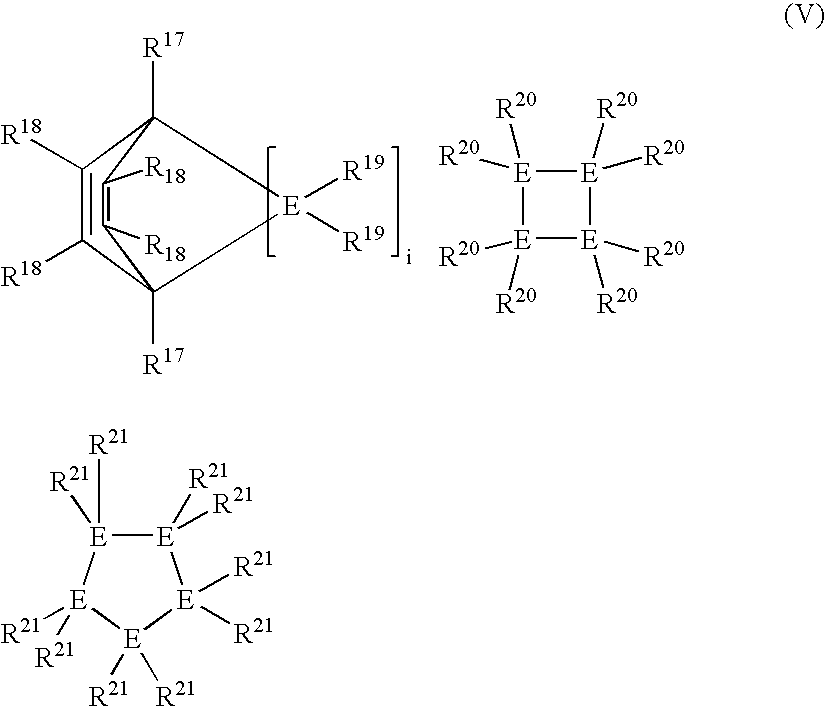

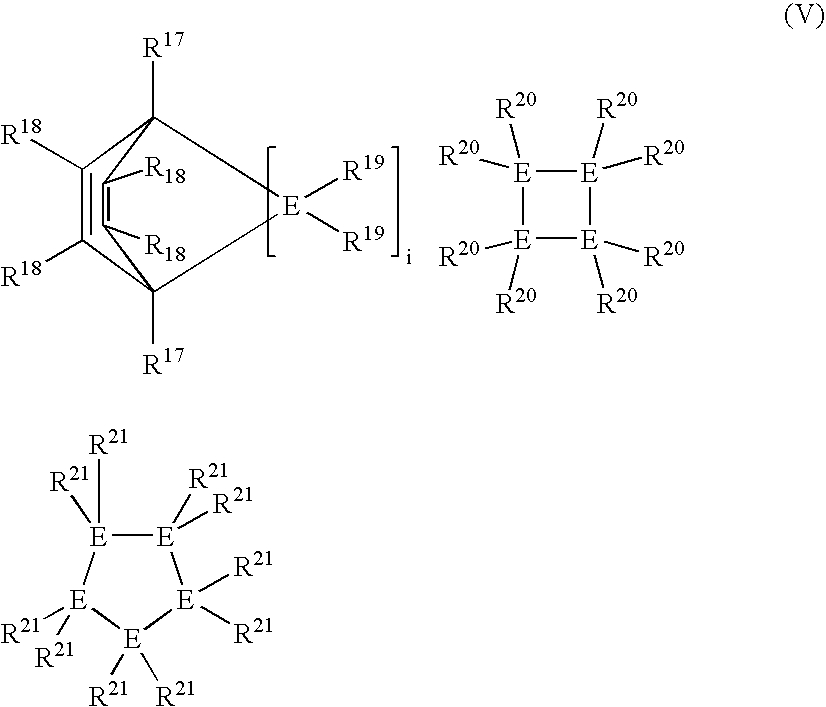

Adduct of magnesium halides, preparation method, and application

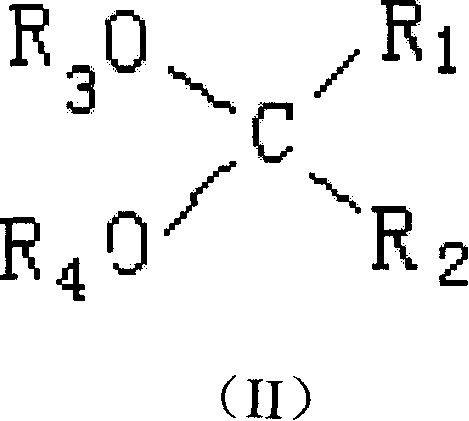

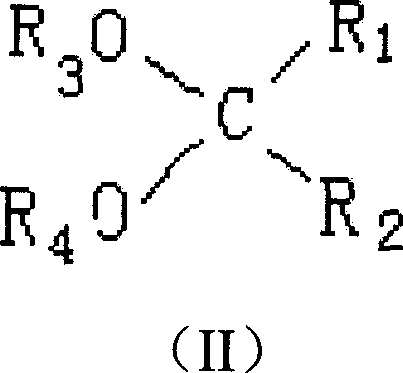

This invention provides a kind of magnesium halide adducts, whose general chemical formula is MgX2-mROH-nE-pH2O (I), wherein, X is Cl or Br; R is C1-C12 alkyl, C3-C10 cycloalkyl or C6-C10 aryl; E is dialkoxy hydrocarbon compound as shown in formula (II); m is 1-5; n is 0.005-1.0; p is 0-0.8. In formula (II), R1, R2, R3 and R4 are the same or different, and are H or C1-C10 linear or branched alkyl, C3-C10 cycloalkyl, C6-C10 aryl, C7-C10 alkylaryl or arylalkyl; two or more groups of R1 and R2 can bond into one or several fused rings; H is aryl or alkylaryl or H in benzene ring of arylalkyl can be substituted by halogen.

Owner:CHINA PETROLEUM & CHEM CORP +1

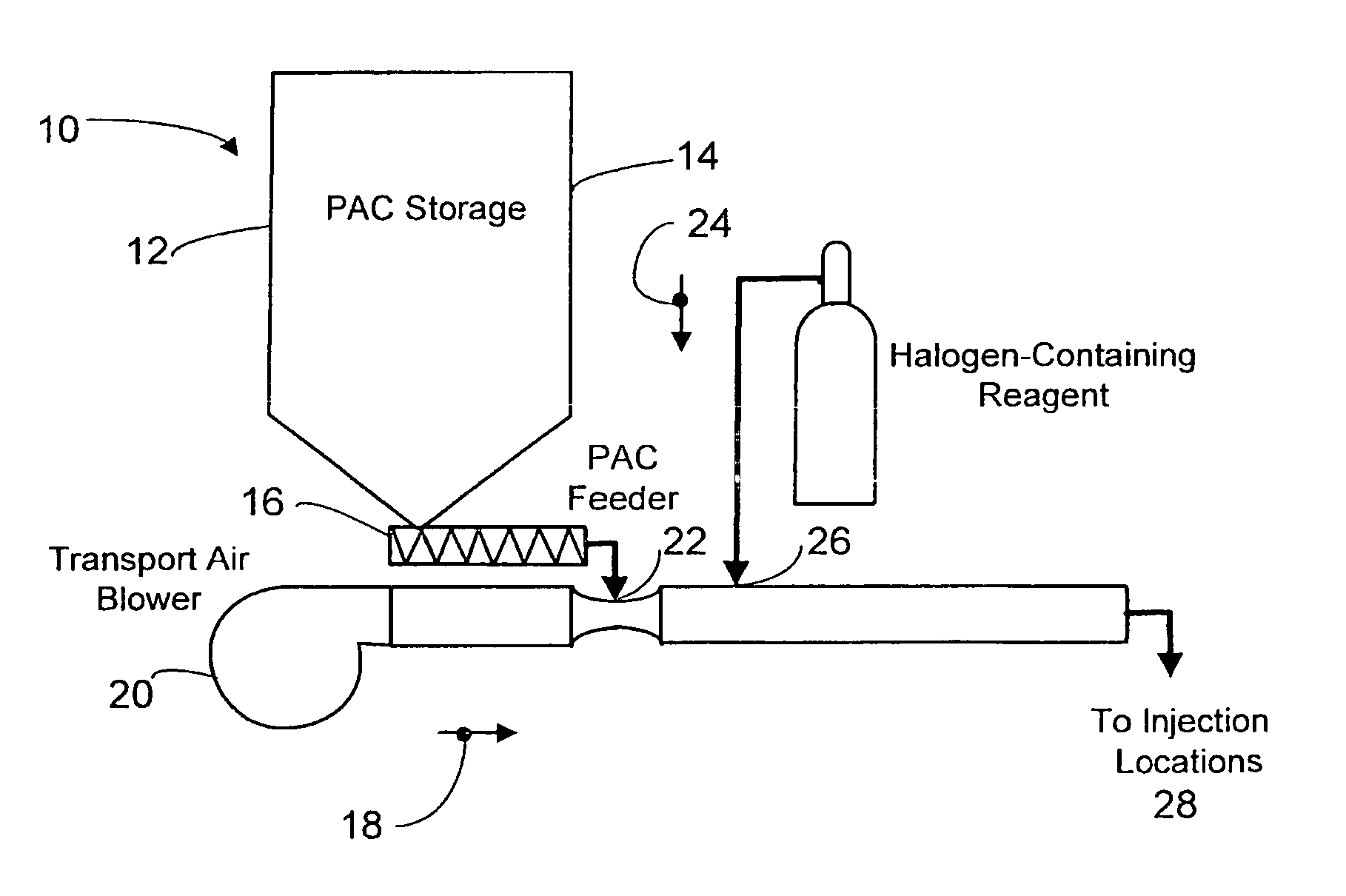

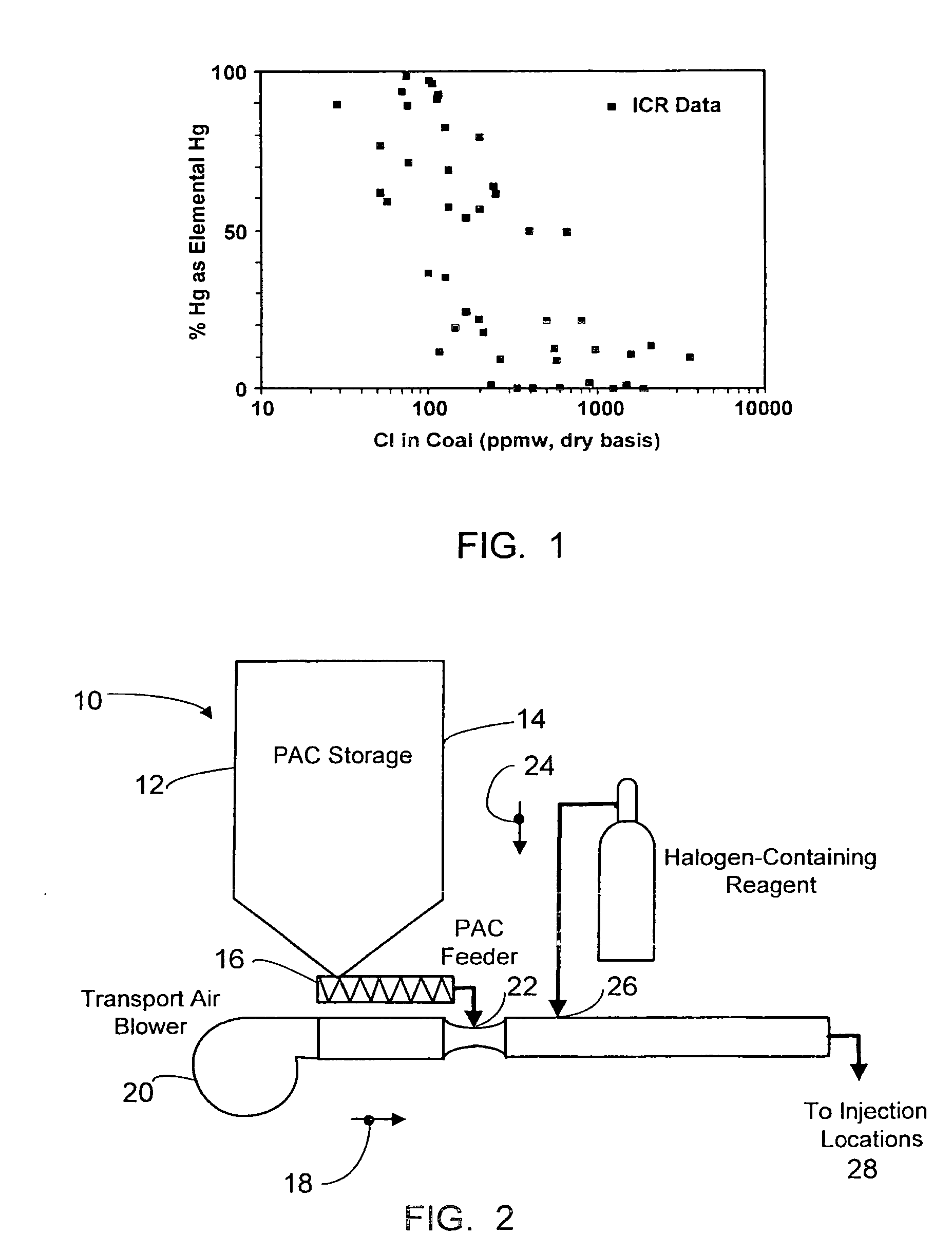

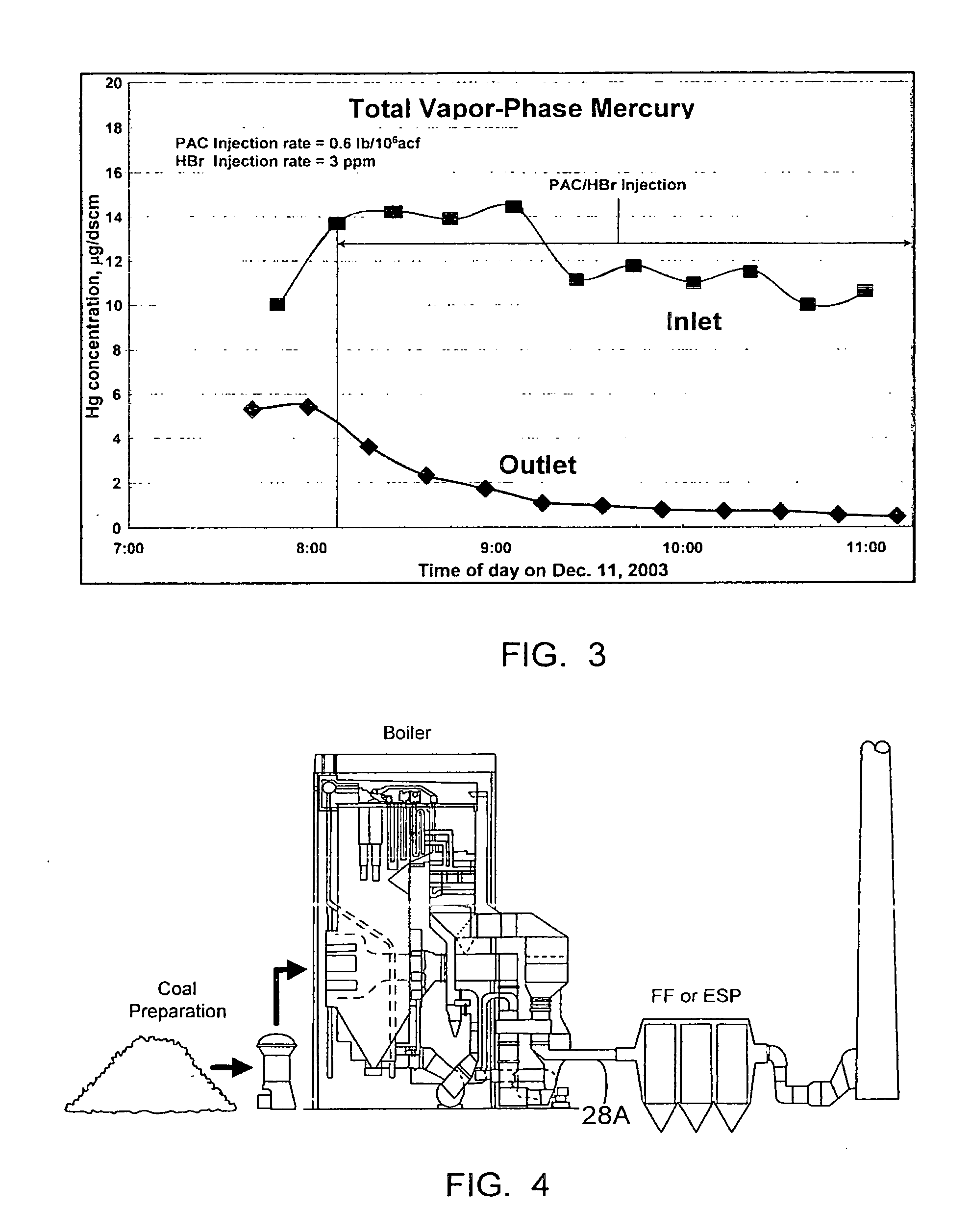

Dynamic halogenation of sorbents for the removal of mercury from flue gases

InactiveUS20070180990A1Efficient ConcentrationEasy to captureGas treatmentUsing liquid separation agentHalogenSorbent

A halogen-containing gas is injected into a flowing transport air / sorbent stream at a point close to the point where the sorbent and transport air first mix to maximize the residence time available for the halogen-containing compound to be adsorbed onto the sorbent surface prior to the sorbent being injected into a flue gas containing mercury. This process maximizes the benefit and utilization of the halogen-containing reagent by placing it exactly where it is needed to facilitate elemental mercury removal—on the surface of the sorbent. The sorbent particles with their loading of adsorbed halogen-containing reagent enter the flue gas with a high reactivity for the removal of elemental mercury.

Owner:THE BABCOCK & WILCOX CO

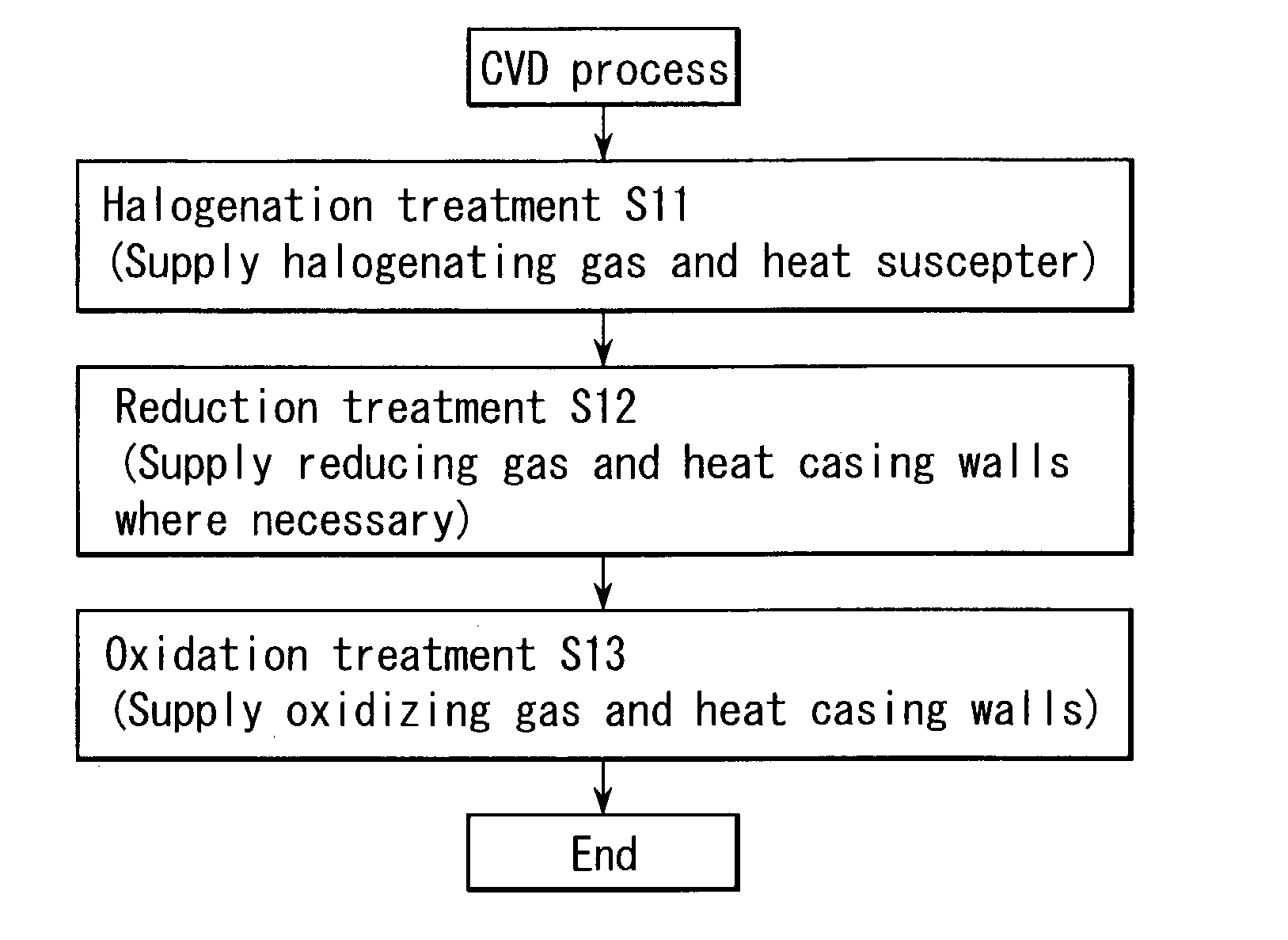

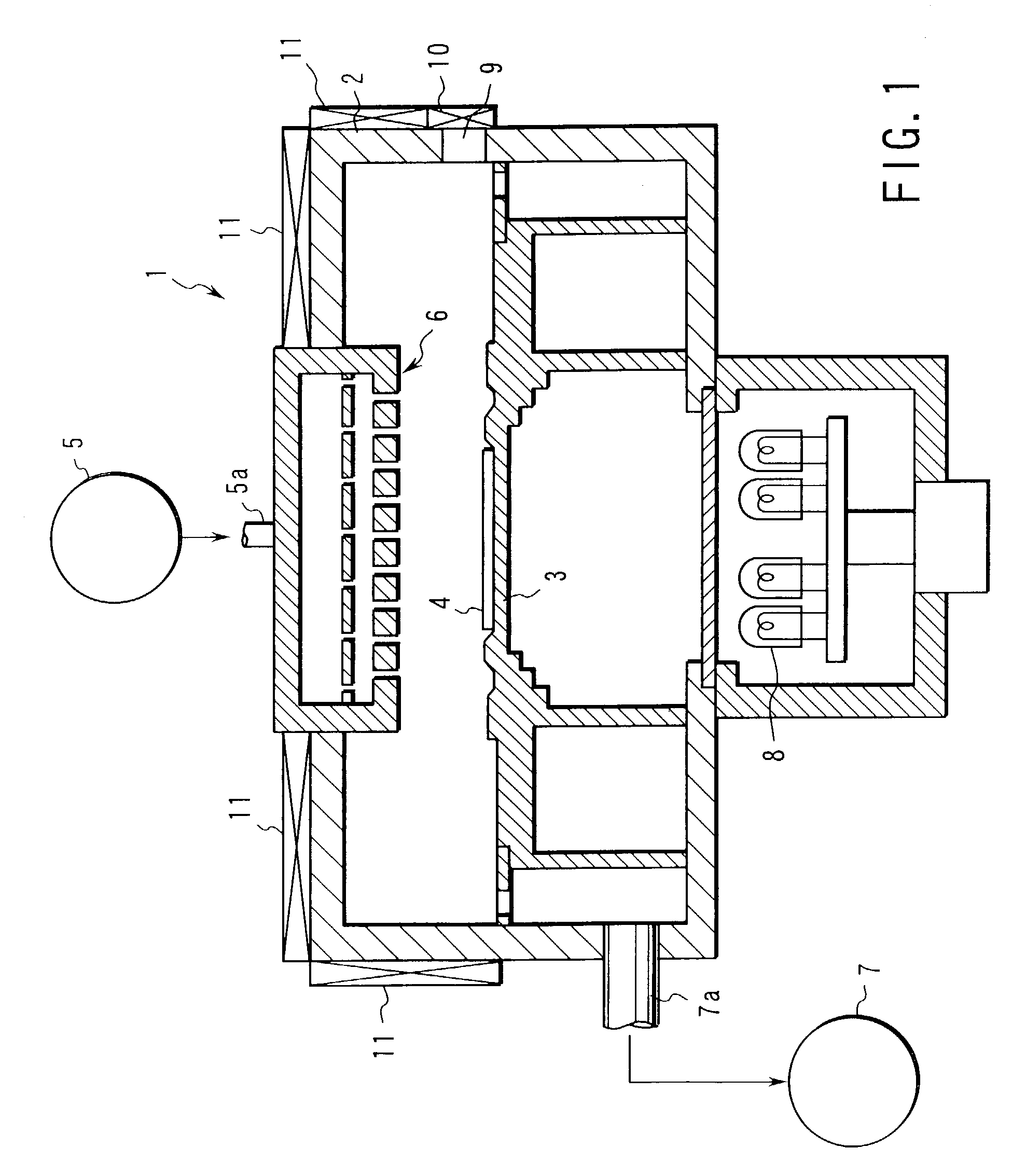

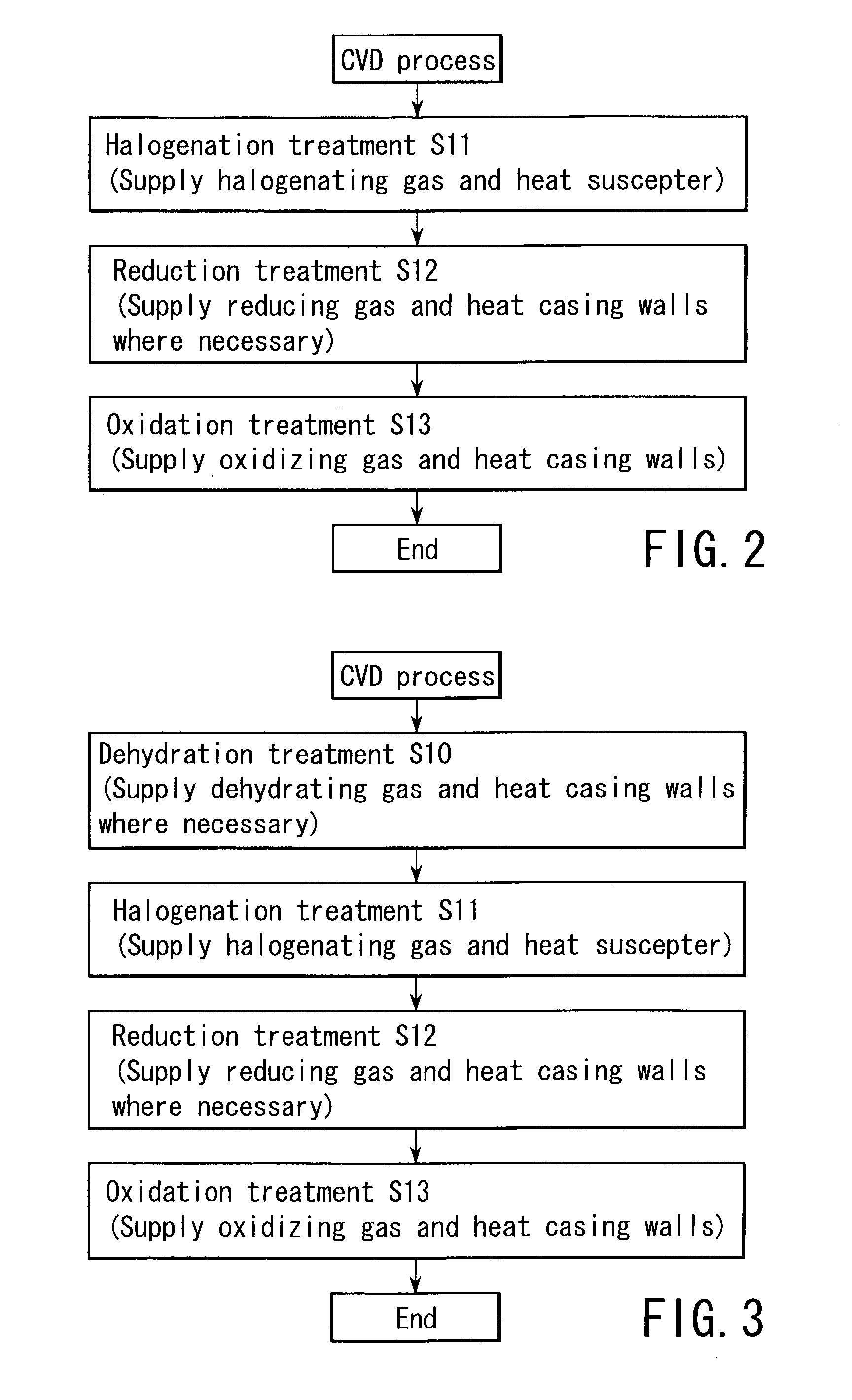

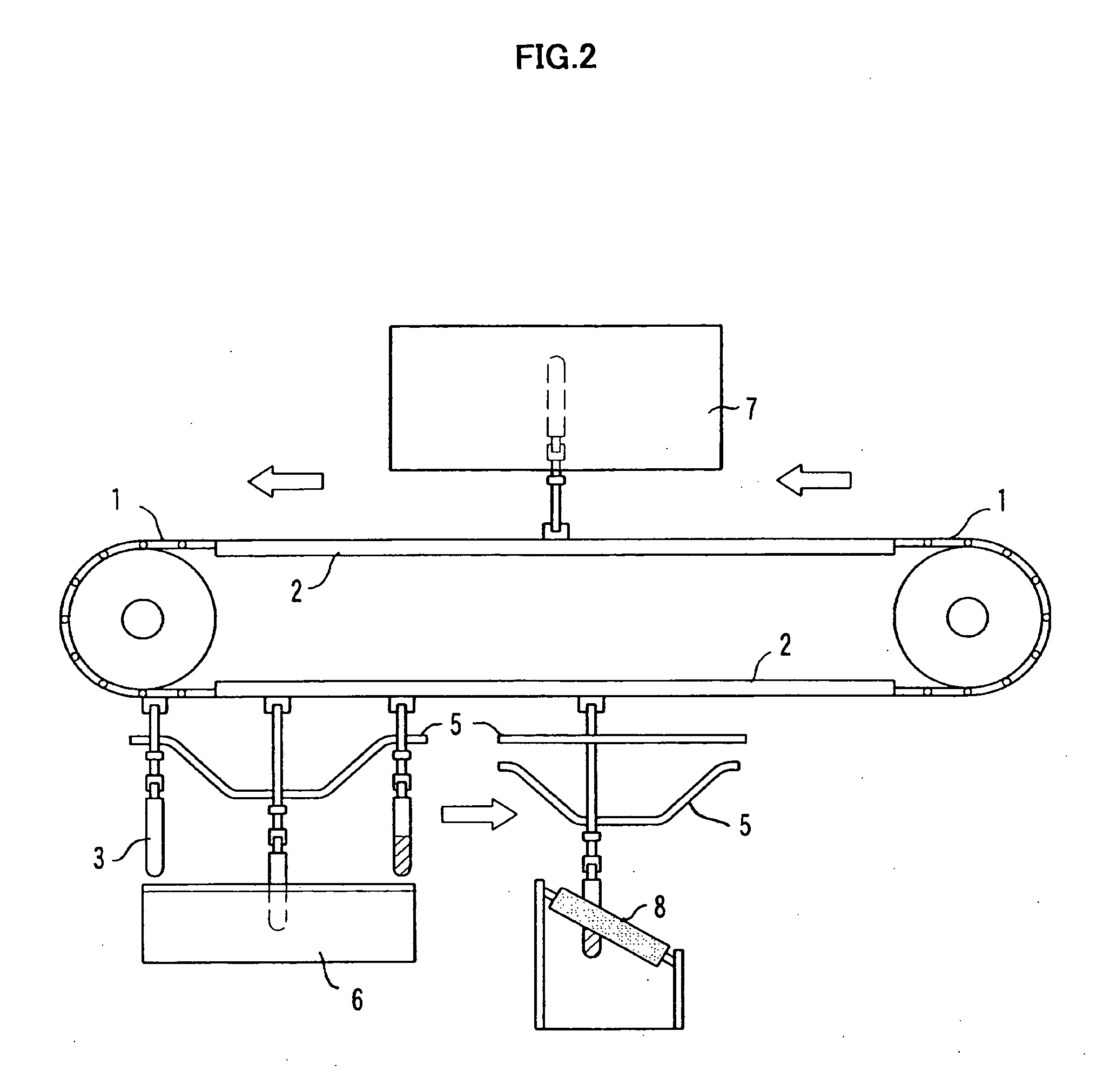

Method of cleaning processing chamber of semiconductor processing apparatus

InactiveUS20030205237A1Hollow article cleaningElectrostatic cleaningReduction treatmentSemiconductor

A method of cleaning the interior of a processing chamber first performs a halogenation treatment by supplying a treatment gas containing a halogenating gas into the processing chamber and heating a support member for a target substrate, thereby halogenating a metal element in a by-product film. A reduction treatment is then performed by supplying a treatment gas containing a reducing gas into the processing chamber, thereby reducing a halide of the metal element and liberating the metal element. An oxidation treatment is then performed by supplying a treatment gas containing an oxidizing gas into the processing chamber and heating the casing walls of the processing chamber, thereby passivating the liberated metal element by oxidation.

Owner:TOKYO ELECTRON LTD

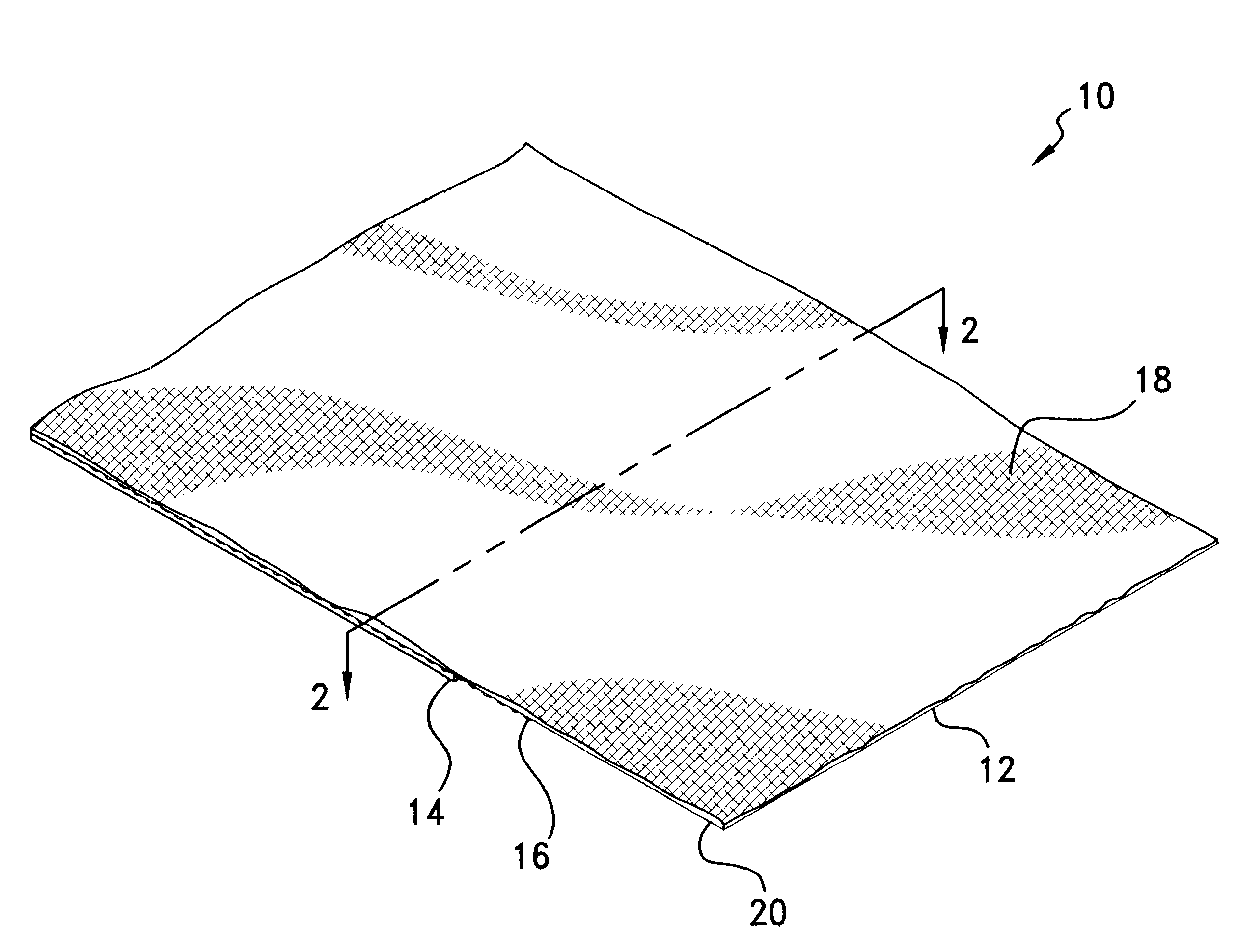

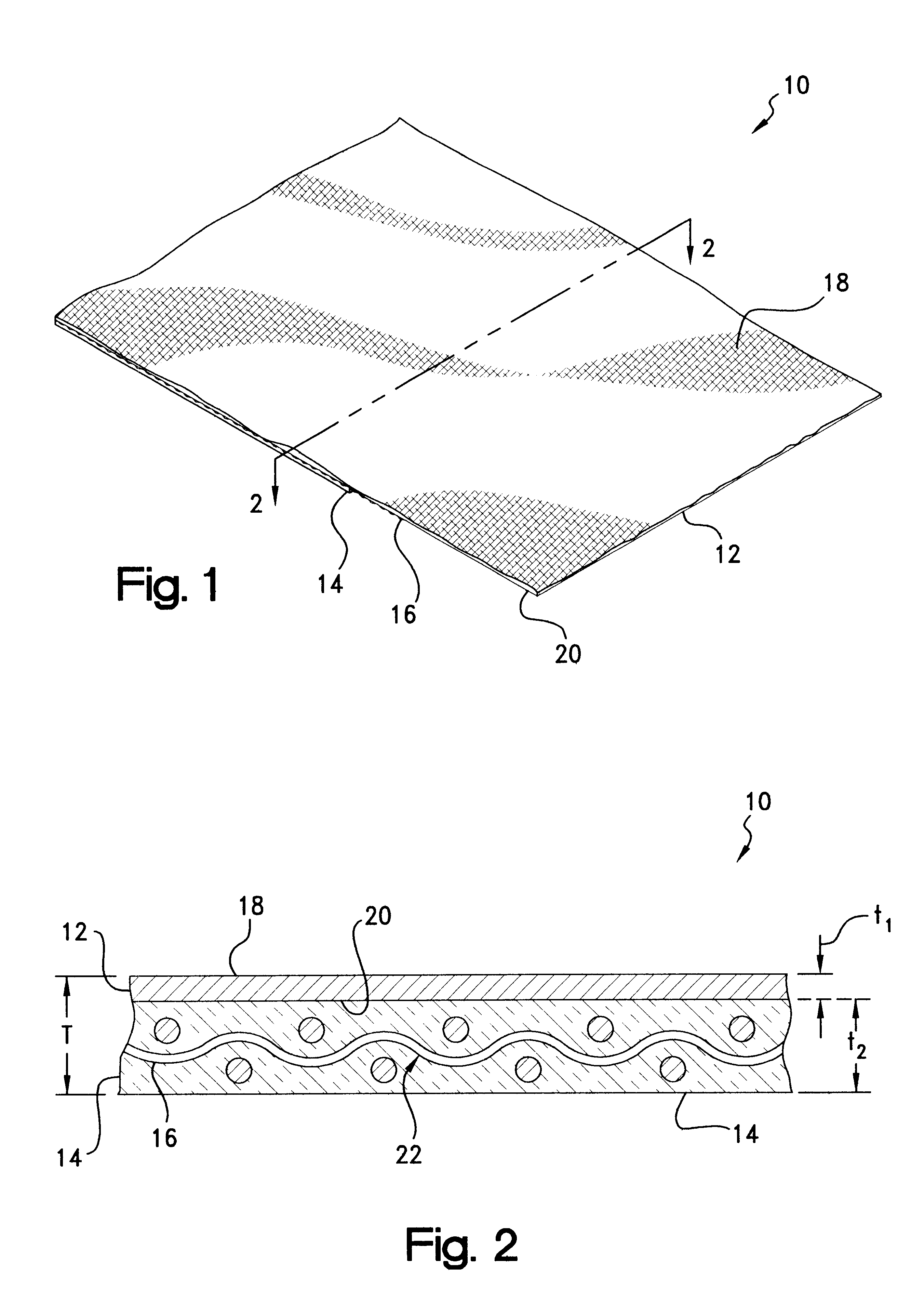

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

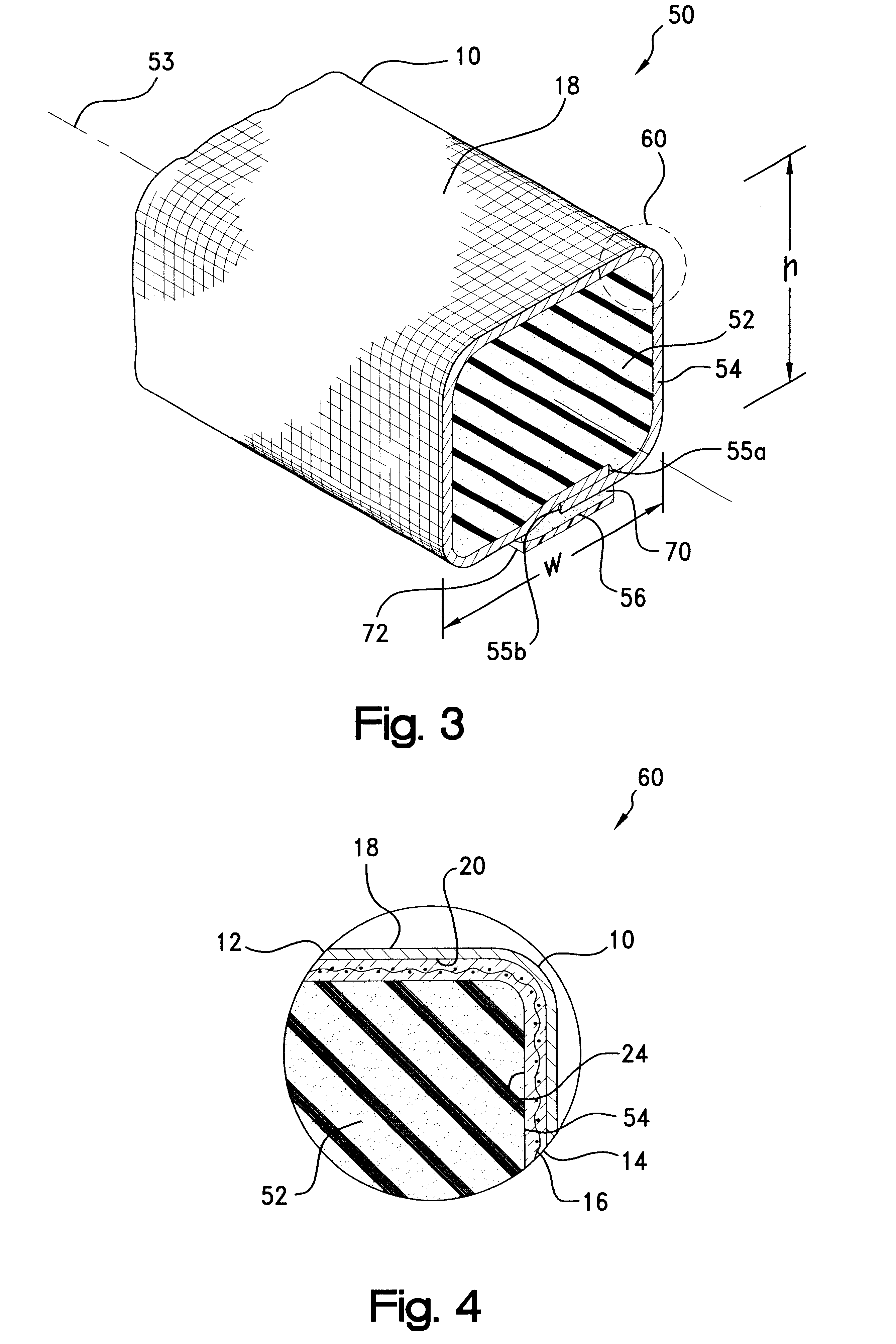

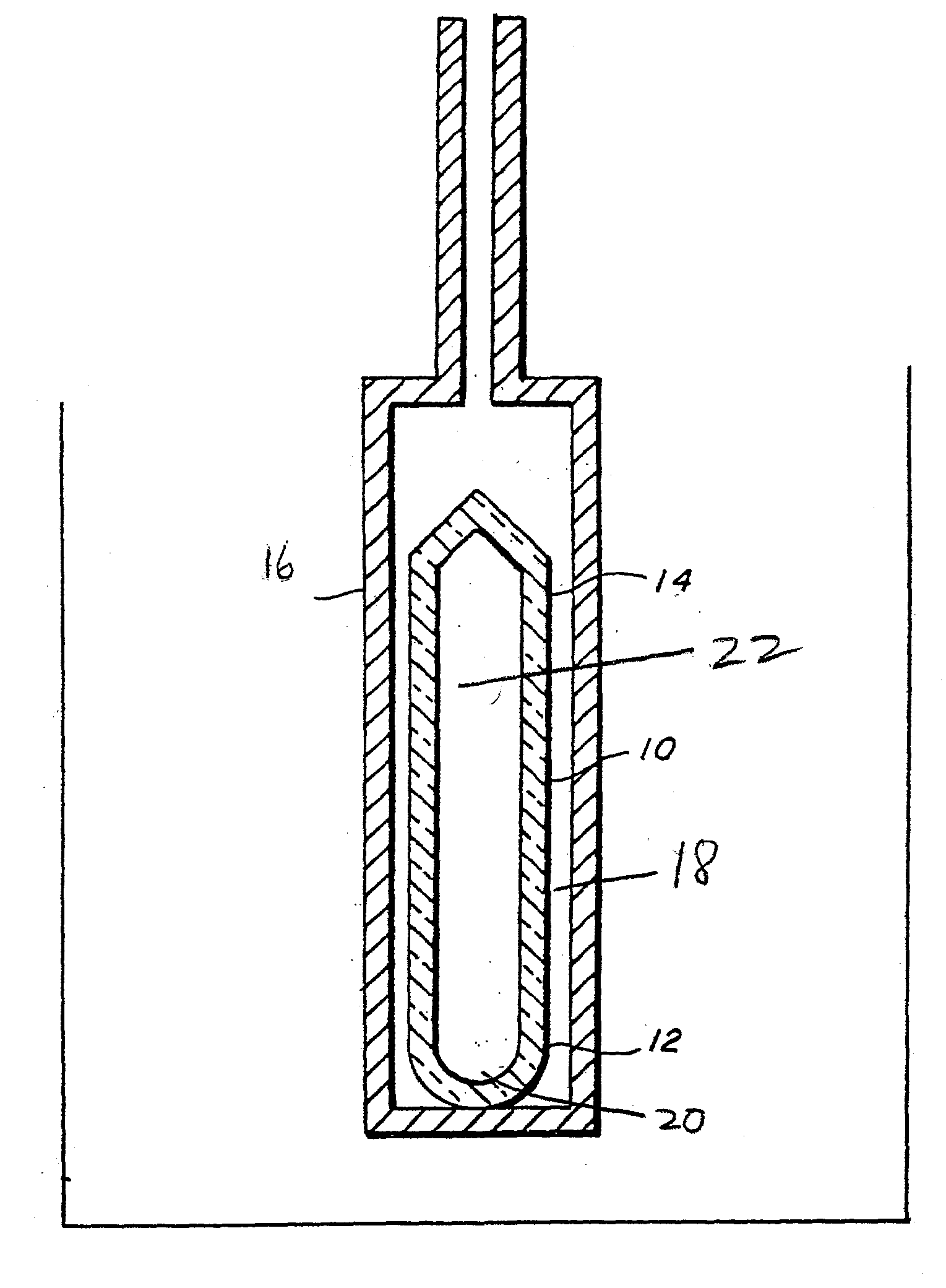

Ammonothermal process for bulk synthesis and growth of cubic GaN

InactiveUS20030209191A1Easy to transportQuality improvementPolycrystalline material growthFrom chemically reactive gasesLanthanideSingle crystal

A method of growing single-crystals of a cubic (zinc blende) form of gallium nitride, the method comprising the steps of: placing into a reaction tube or acid resistant vessel a gallium source, anhydrous ammonia, an acid mineralizer and a metal halide salt selected from the group consisting of alkali metal halides, copper halides, tin halides, lanthanide halides and combinations thereof; closing said reaction tube or vessel; heating said reaction tube; cooling said reaction tube or vessel; and collecting single-crystals of cubic (zinc blende) form of GaN; wherein said reaction tube or vessel has a temperature gradient with a hot zone of at least 250° C., wherein said reaction tube or vessel has a temperature gradient with a cool zone of at least 150° C., and wherein said acid mineralizer has a sufficient concentration to permit chemical transport of GaN in said reaction tube or vessel from said hot zone to said cool zone due to said temperature gradient within said reaction tube or vessel.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

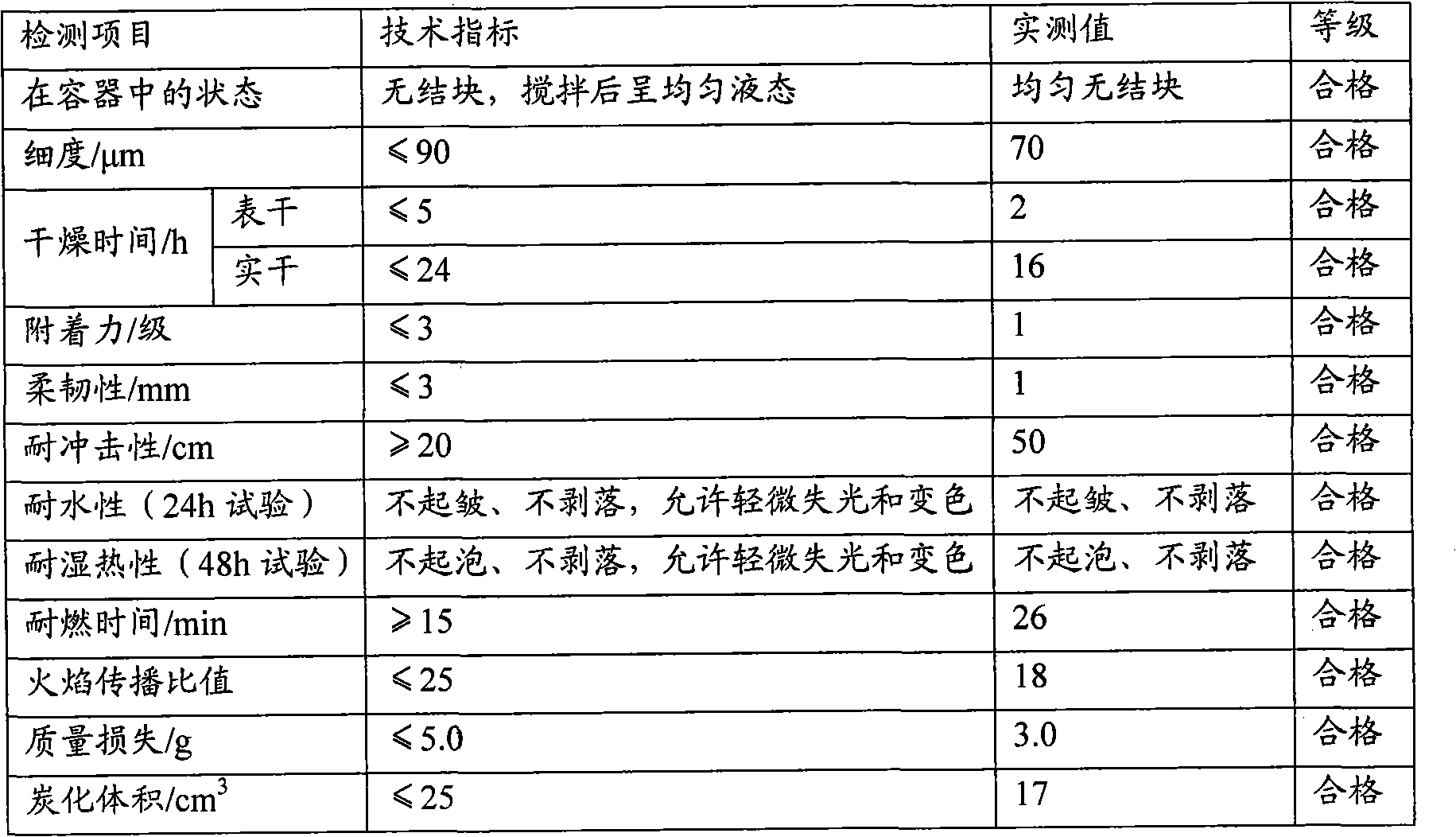

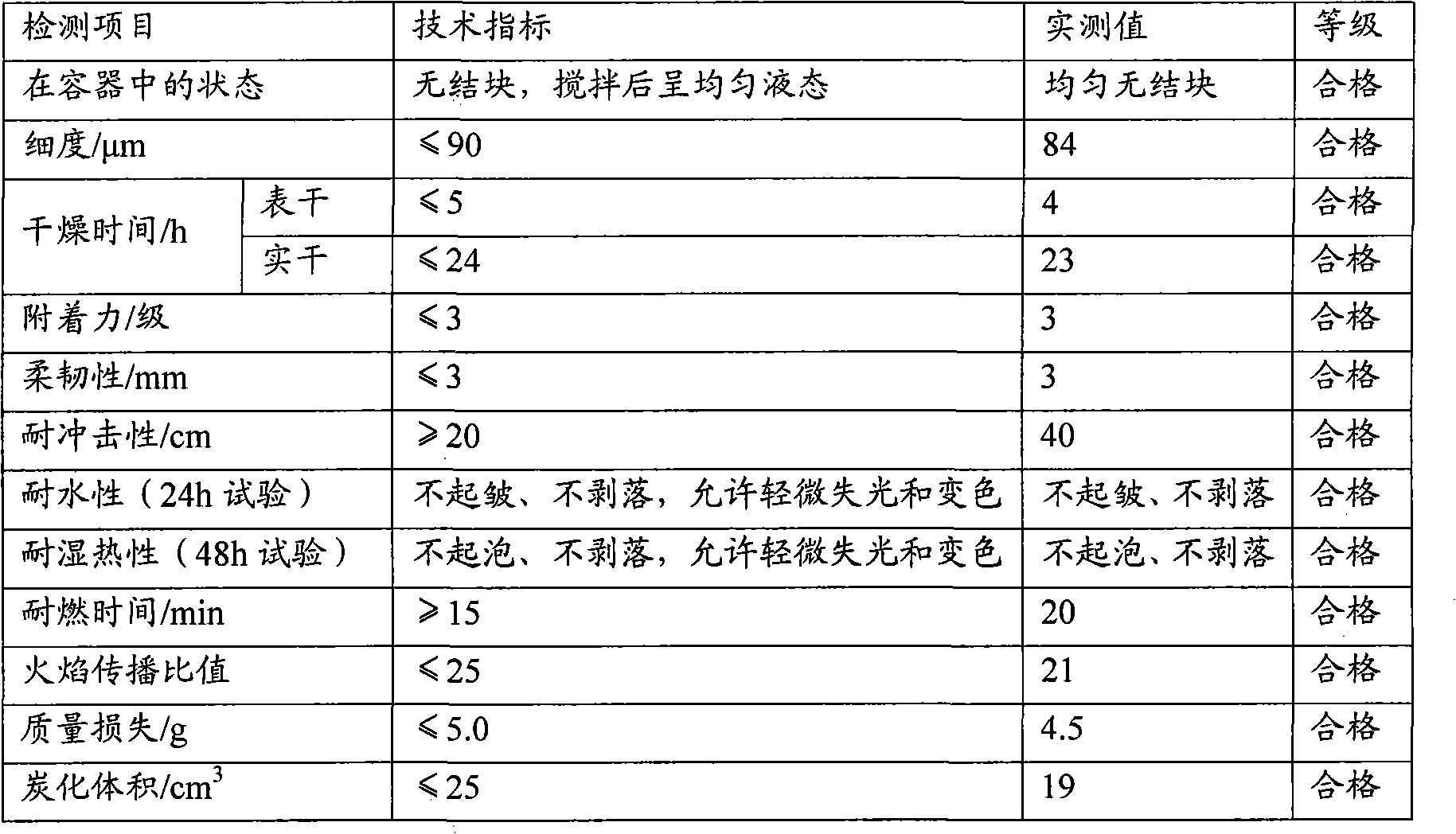

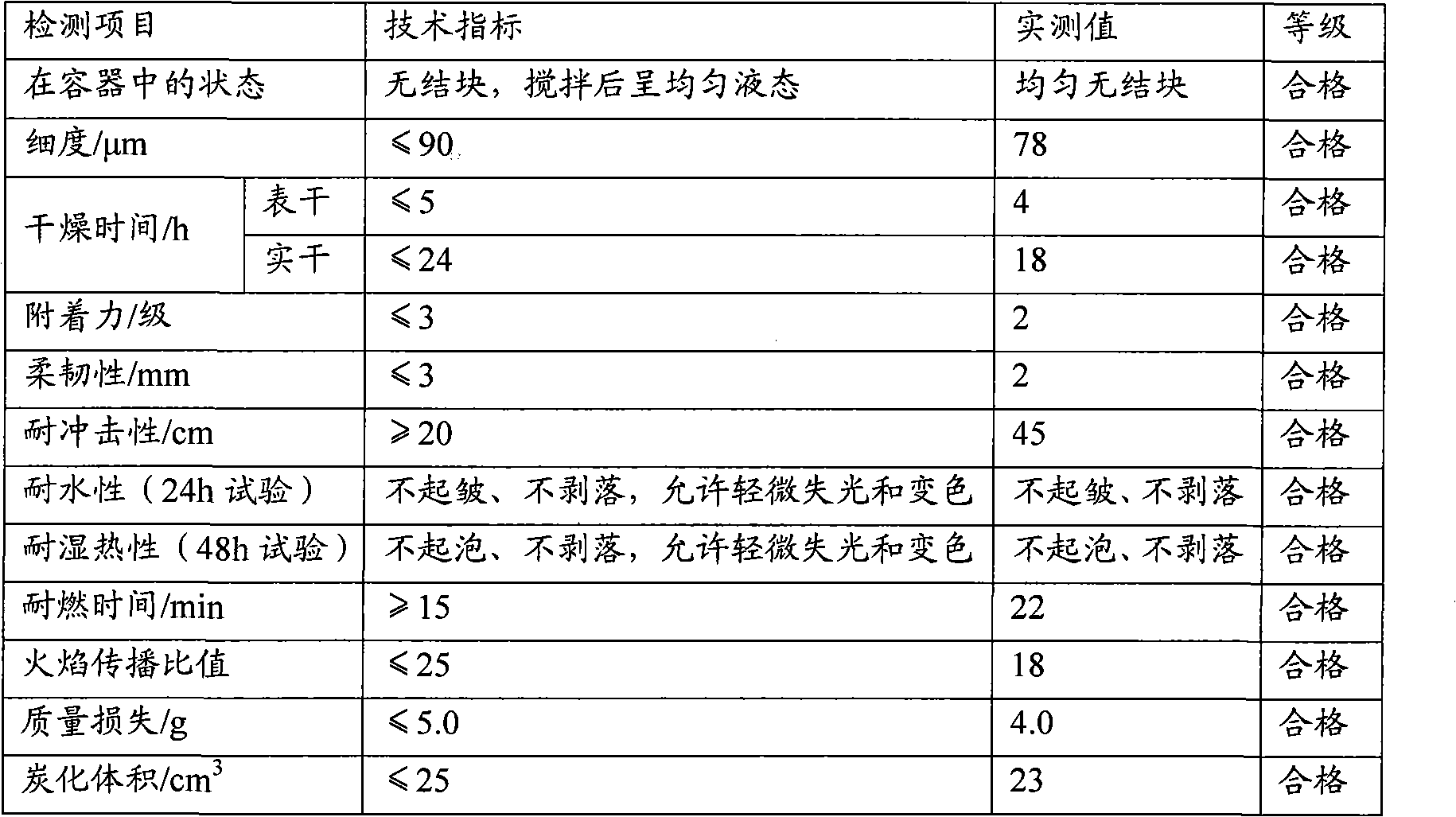

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

Automatic dishwashing compositions containing a halogen dioxide salt and methods for use with electrochemical cells and/or electrolytic devices

InactiveUS6921743B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsElectrolysed waterPhosphate

The present invention relates to automatic dishwashing detergent compositions and methods of using compositions comprising halogenated salts, phosphate and / or silicate in conjunction with electrolyzed water in automatic dishwashing appliances comprising an electrochemical cell and / or electrolytic device for treating tableware to improve cleaning, sanitizing and stain removal by controlling hardness, corrosion and dispersancy.

Owner:PROCTER & GAMBLE CO

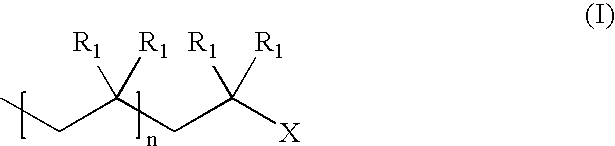

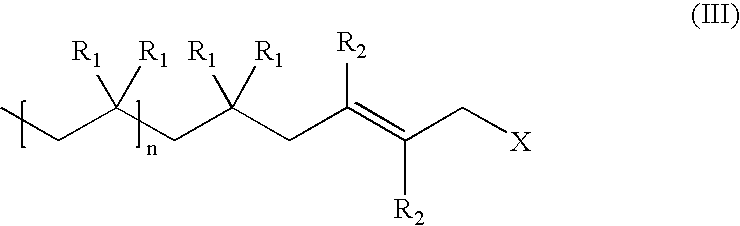

Method for preparing alkoxyl magnesium solid particles

InactiveCN101906017AReduce dosageReduce manufacturing costPreparation of metal alcoholatesAlcoholPhysical chemistry

The invention provides a method for preparing spherical alkoxyl magnesium particles with excellent properties. In the method, magnesium, alcohol and a halogenating agent are reacted at a reflux temperature, so that the alkoxyl magnesium particles are obtained. The alkoxyl magnesium particles have the advantages of higher bulk density, good particle shape and particular suitability for serving as a catalyst carrier of an olefin polymerization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

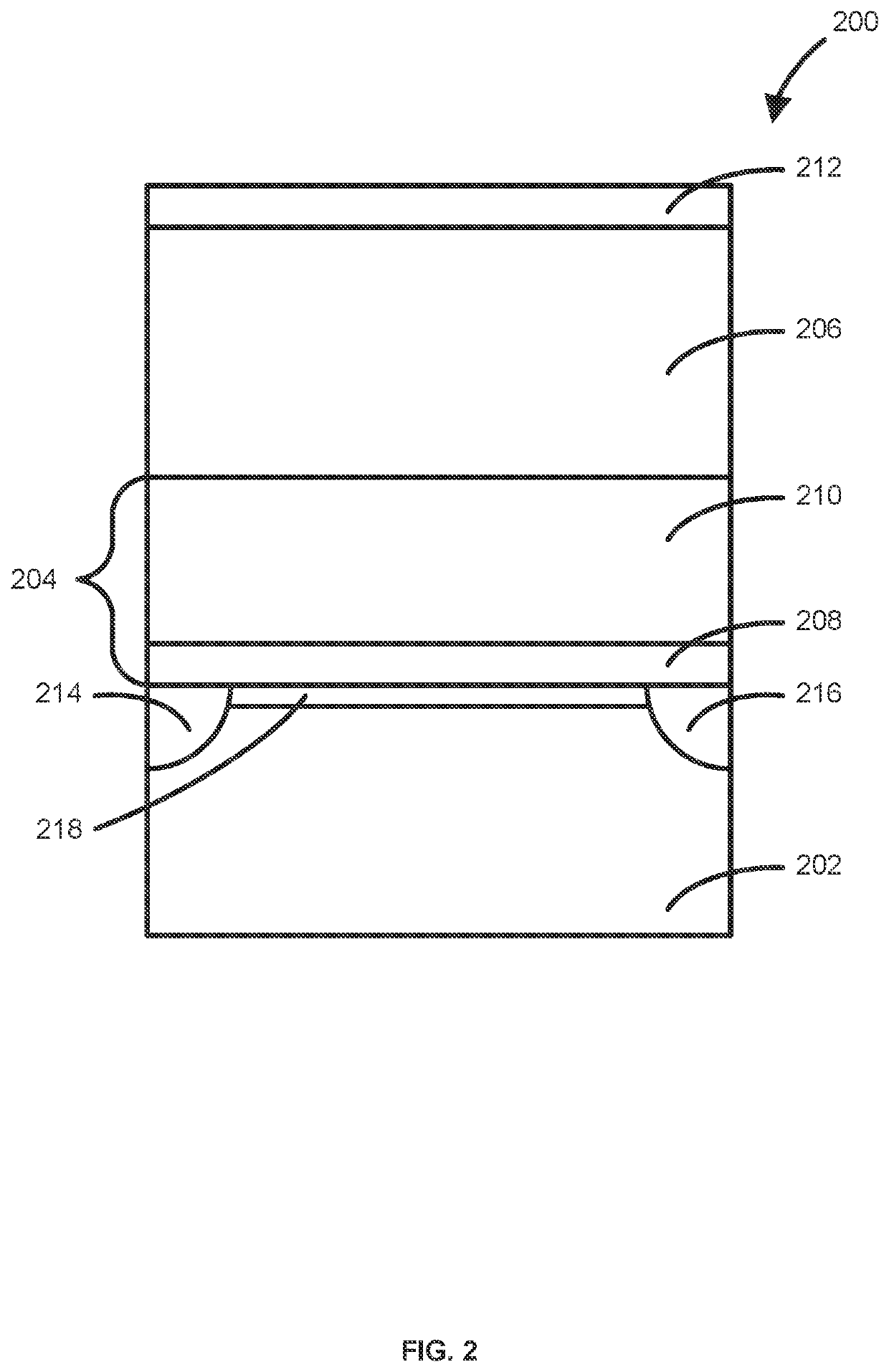

Method of forming vanadium nitride layer and structure including the vanadium nitride layer

PendingUS20210180184A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVanadium nitrideVanadium atom

Methods and systems for depositing vanadium nitride layers onto a surface of the substrate and structures and devices formed using the methods are disclosed. An exemplary method includes using a cyclical deposition process, depositing a vanadium nitride layer onto a surface of the substrate. The cyclical deposition process can include providing a vanadium halide precursor to the reaction chamber and separately providing a nitrogen reactant to the reaction chamber. The cyclical deposition process may desirably be a thermal cyclical deposition process.

Owner:ASM IP HLDG BV

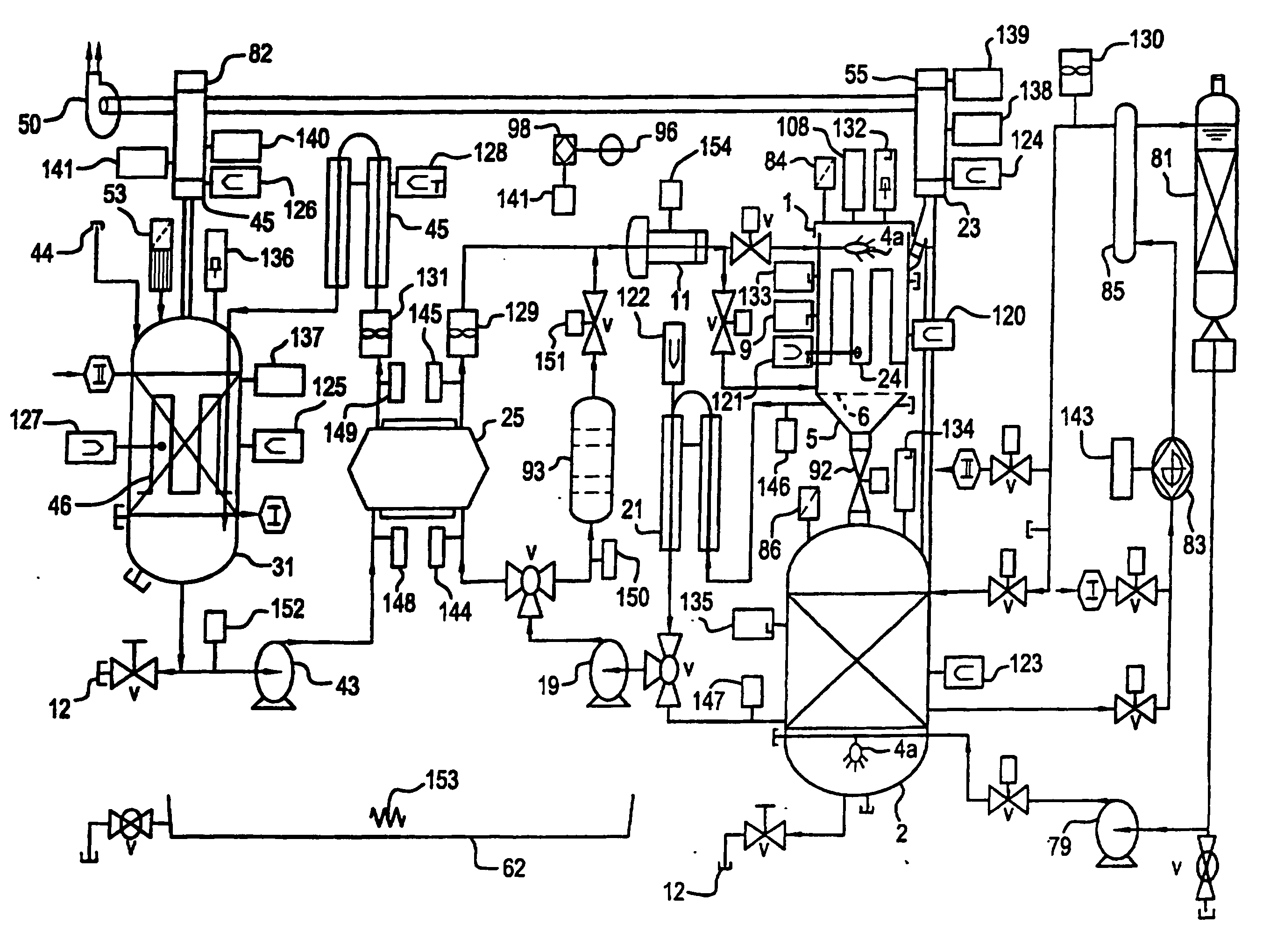

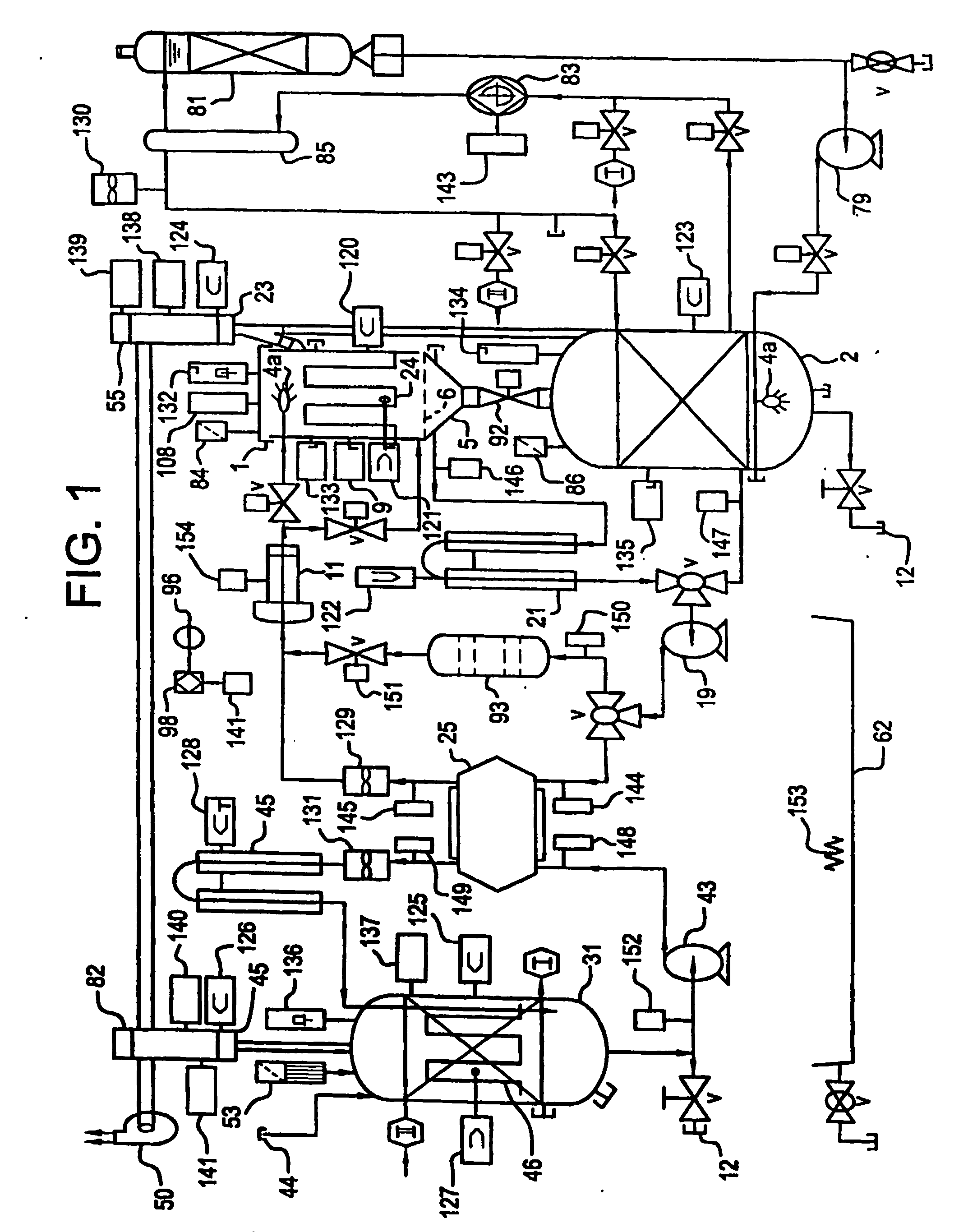

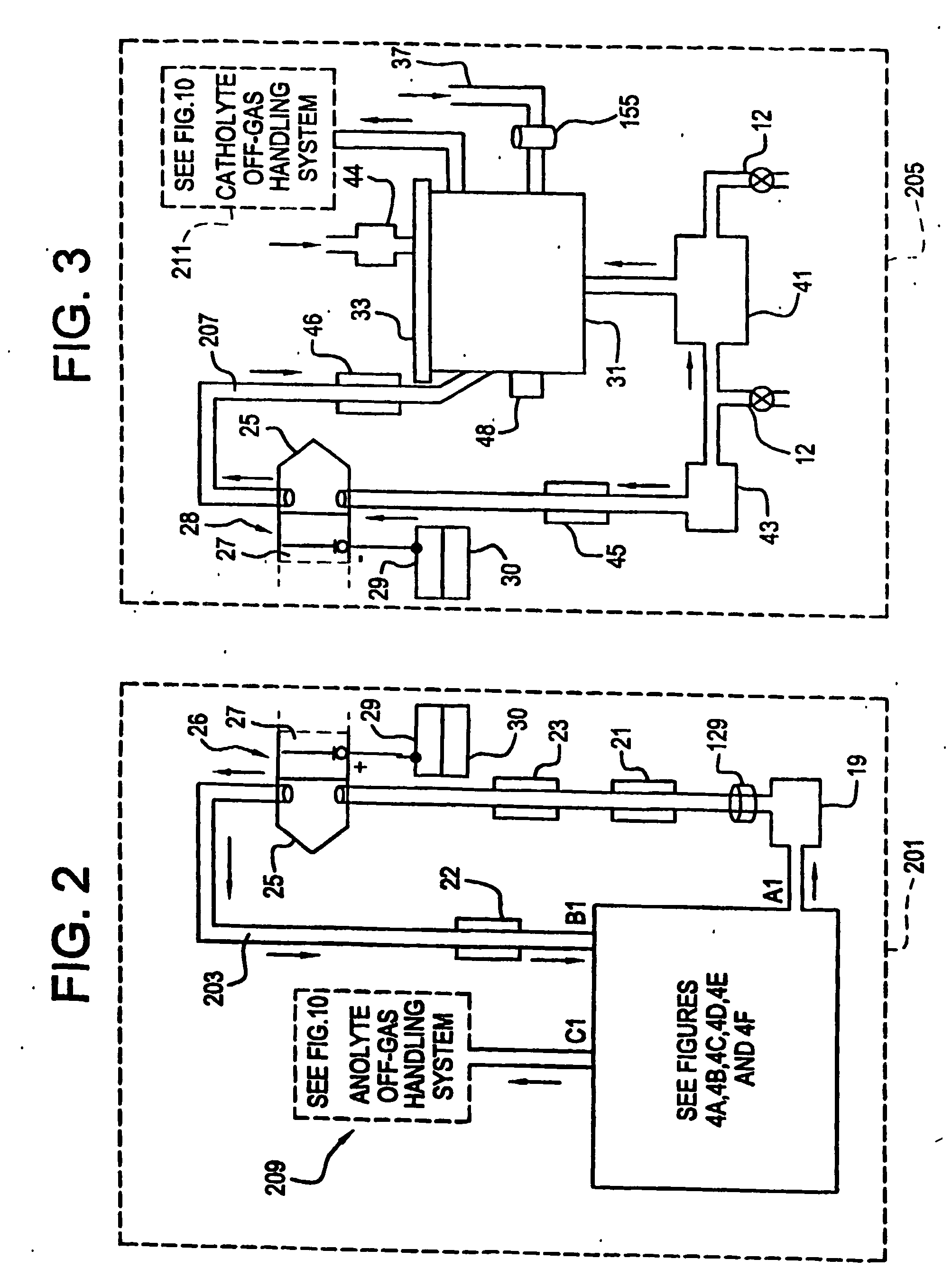

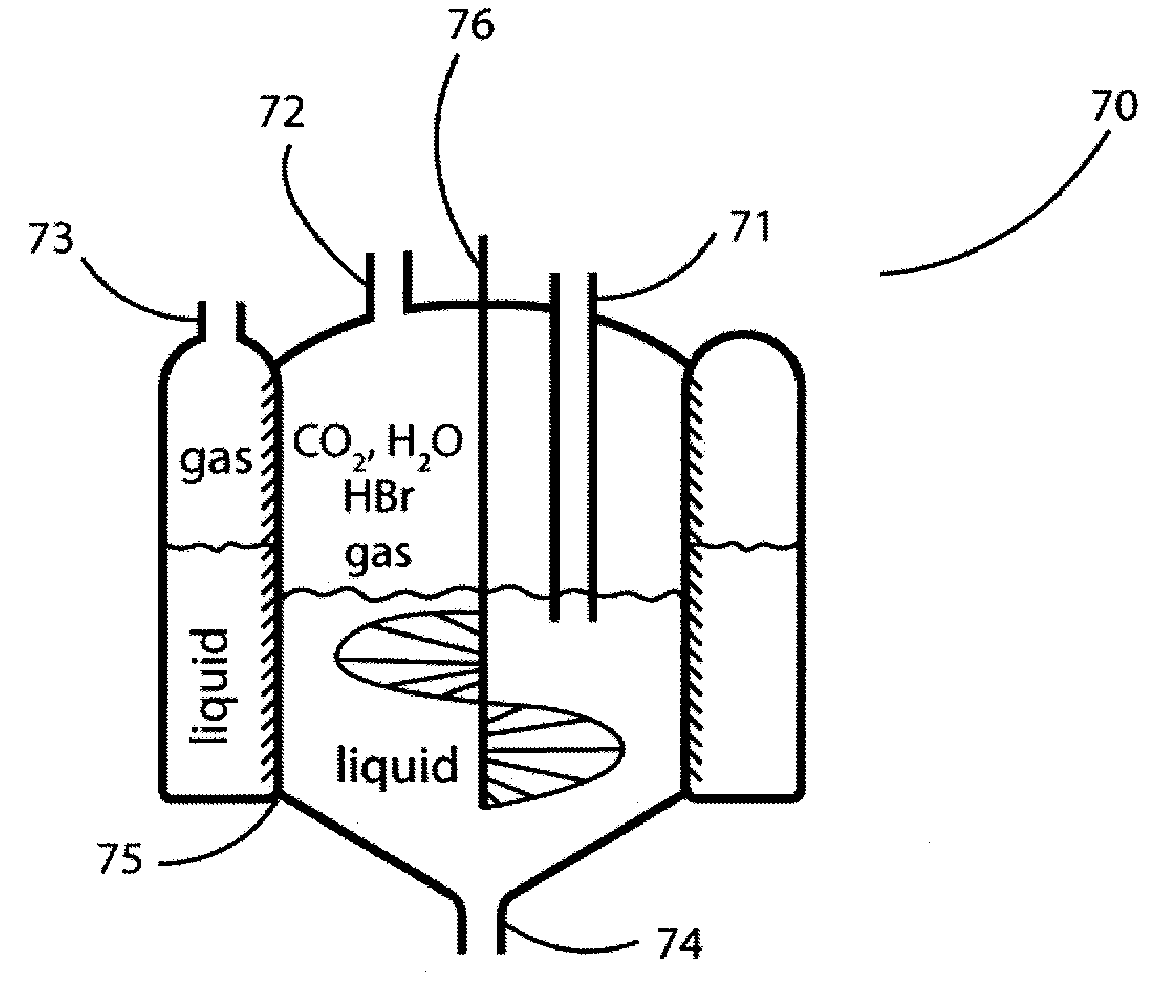

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

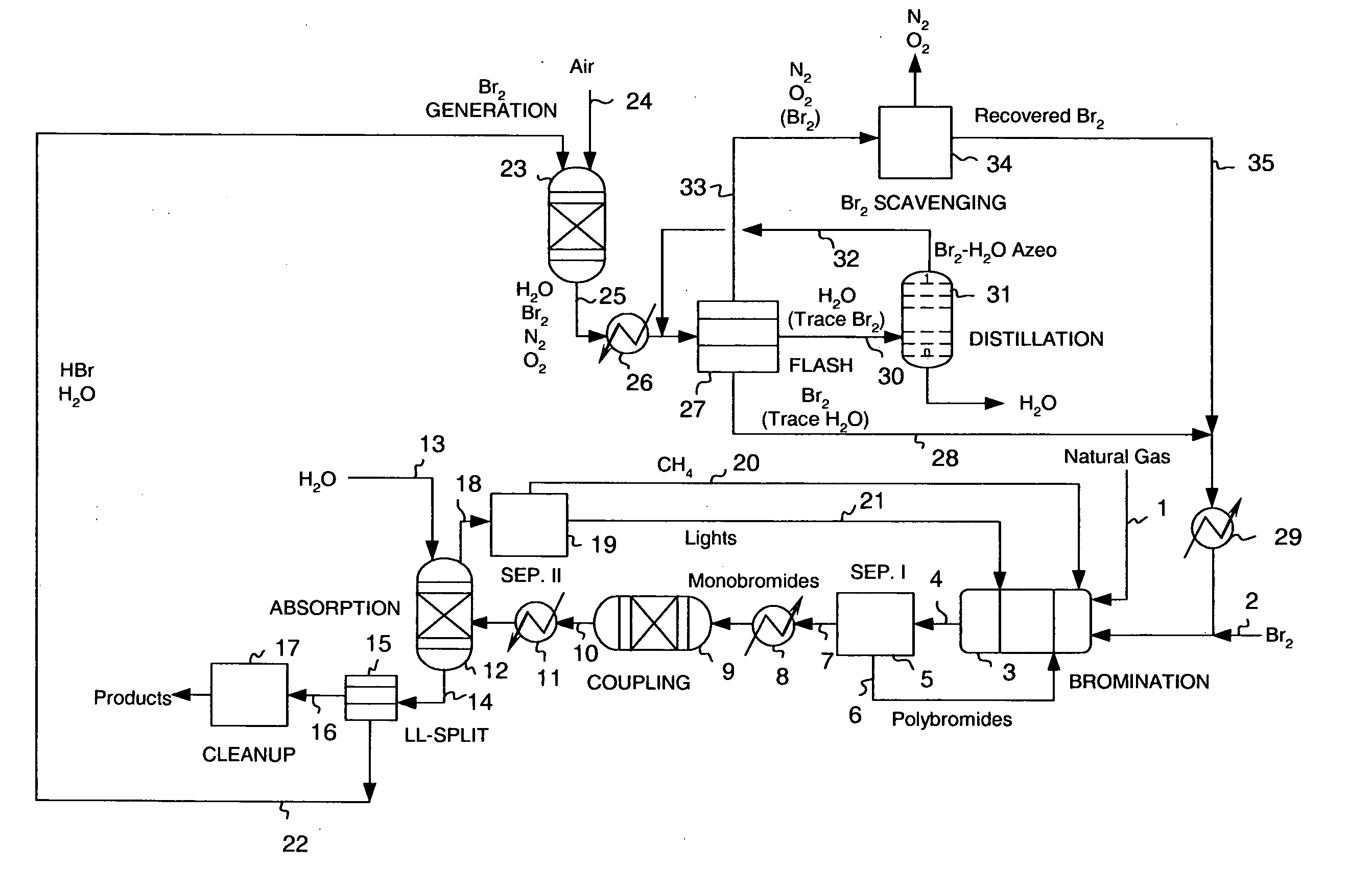

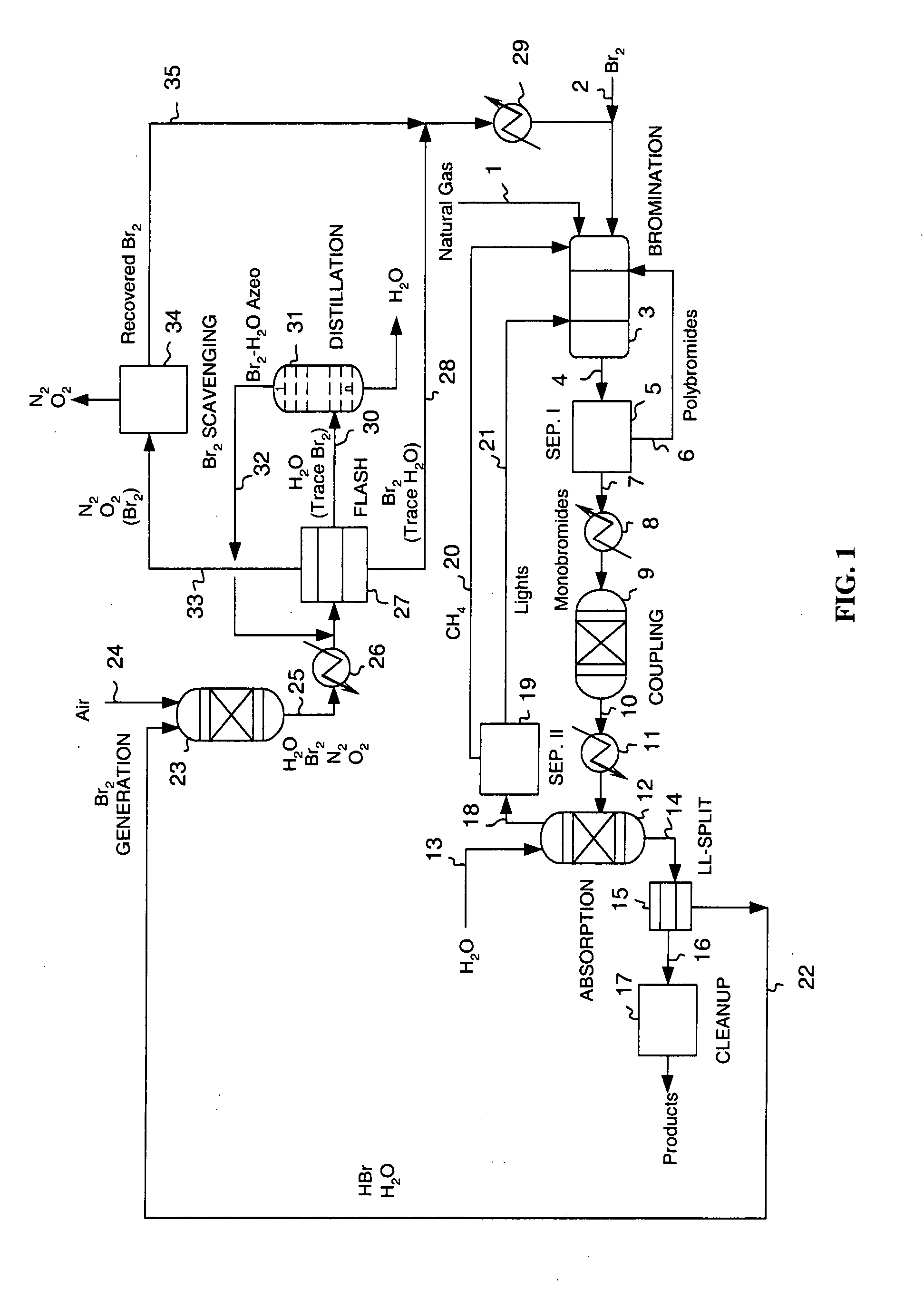

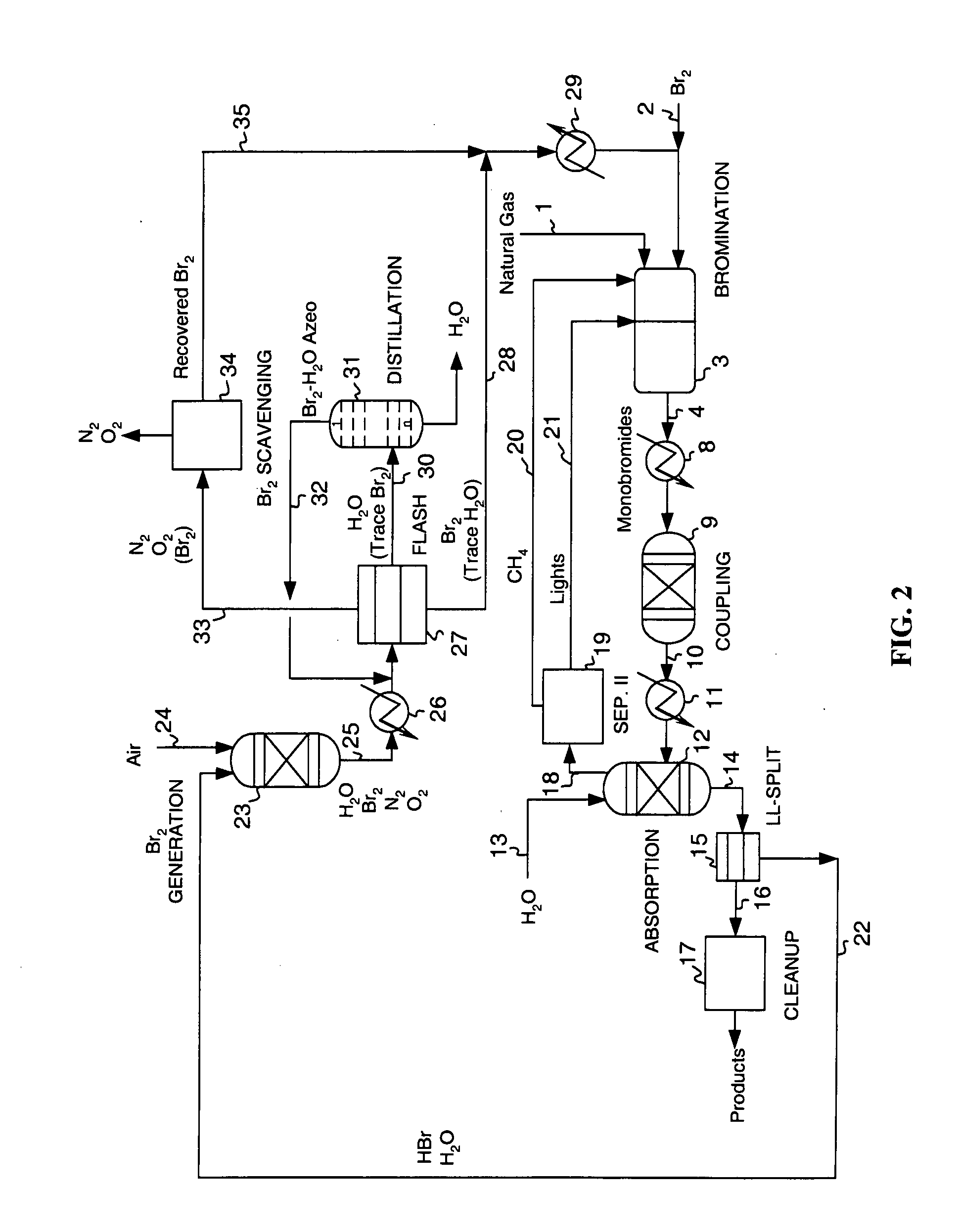

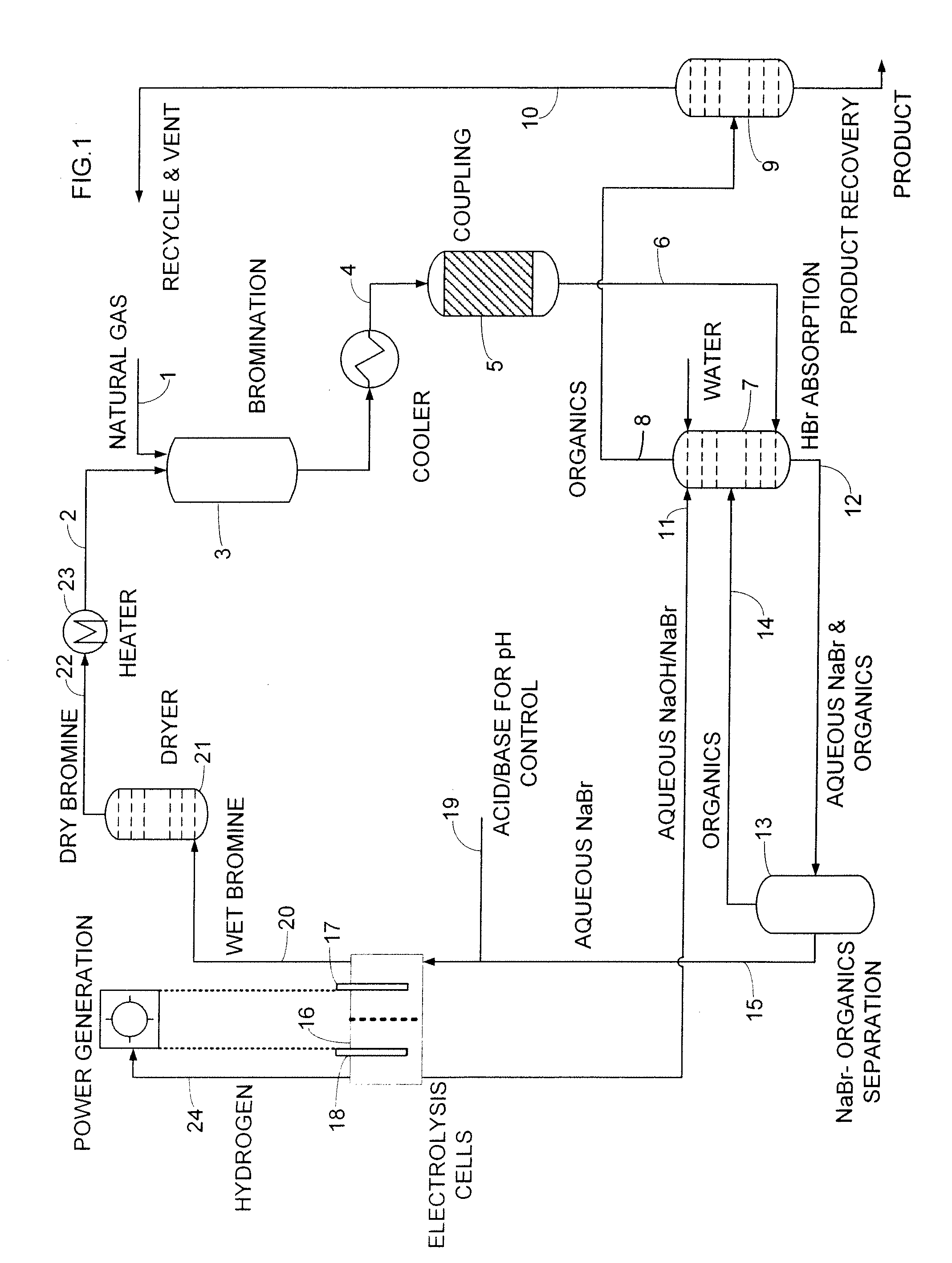

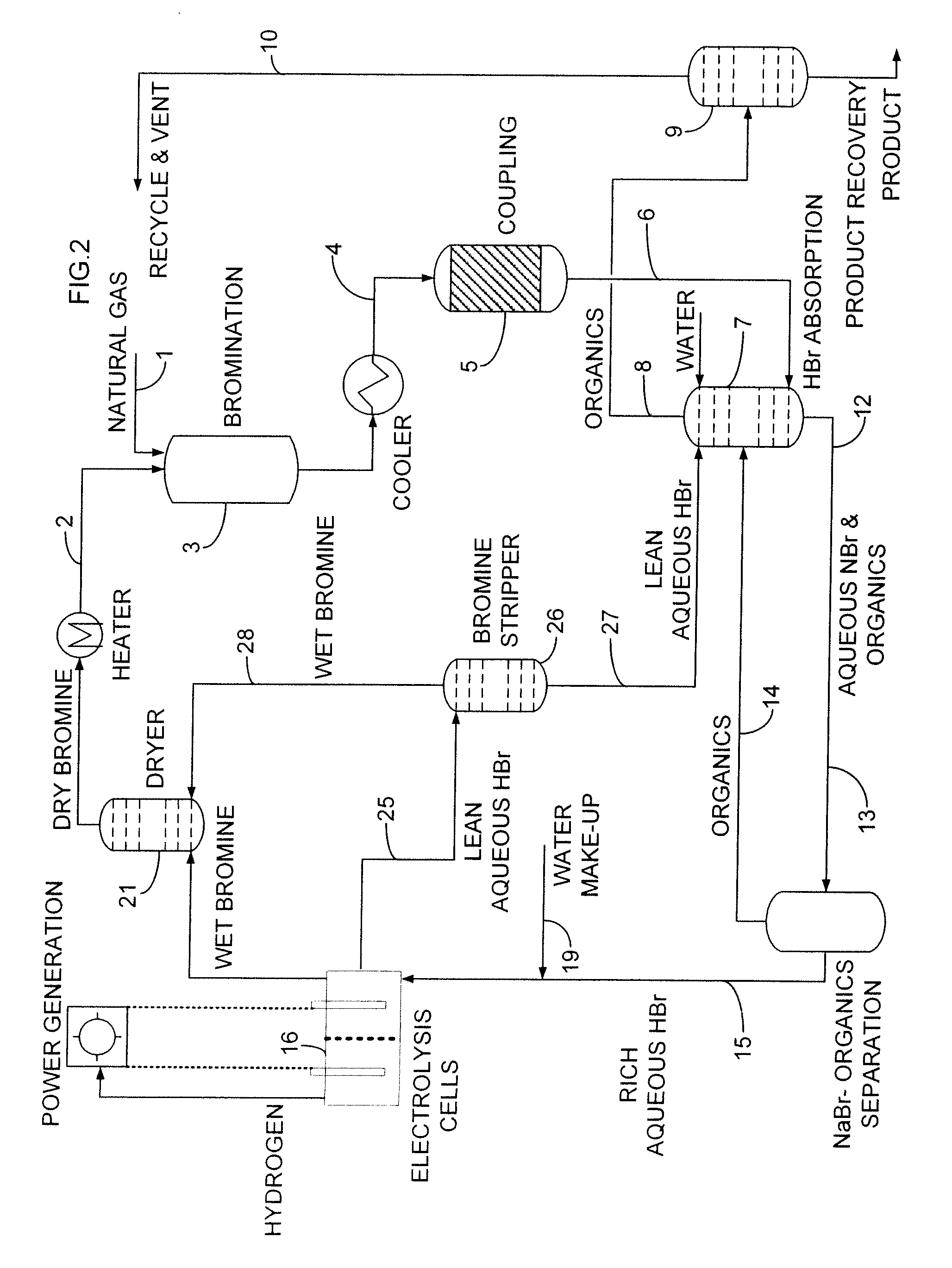

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS20070238909A1Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

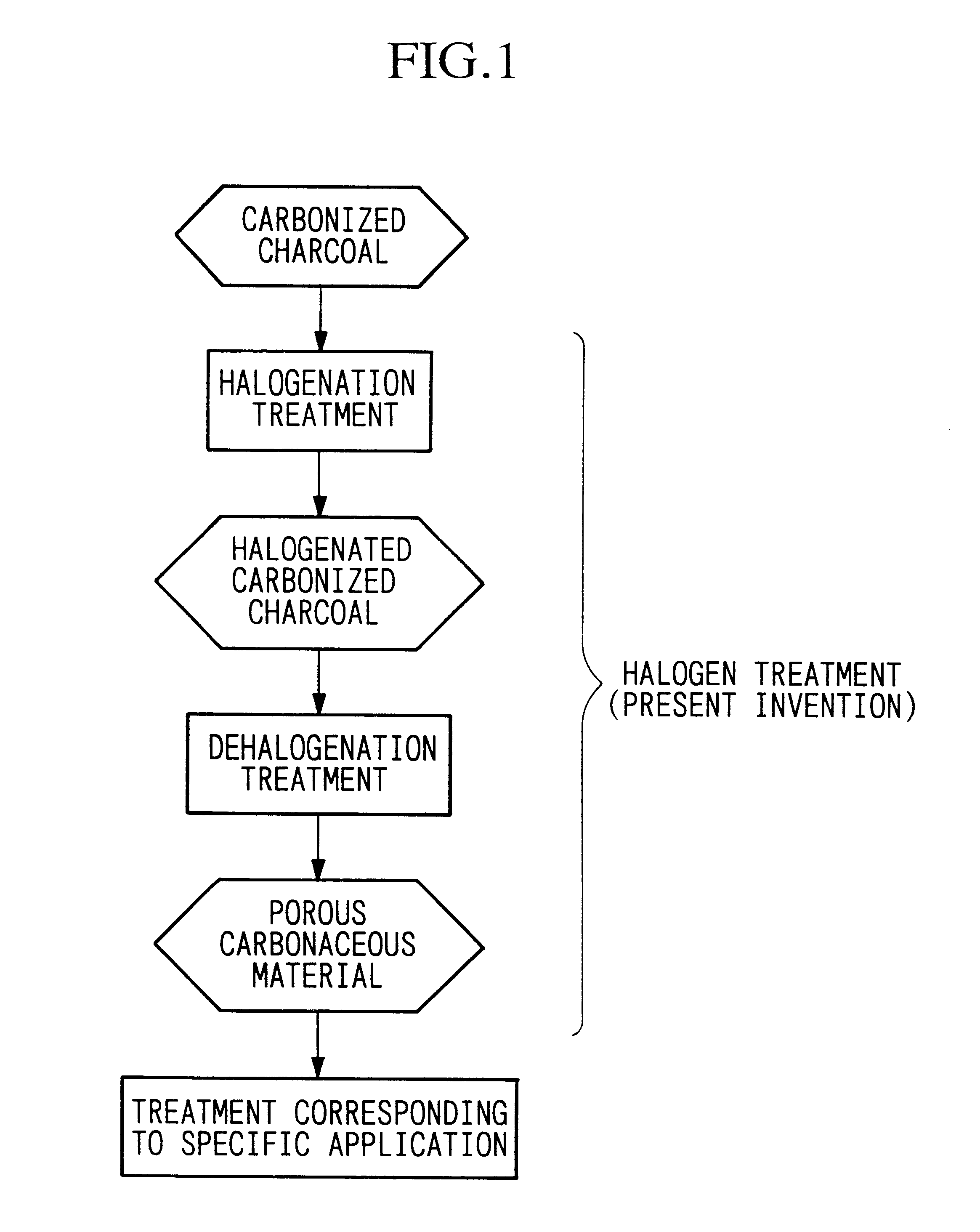

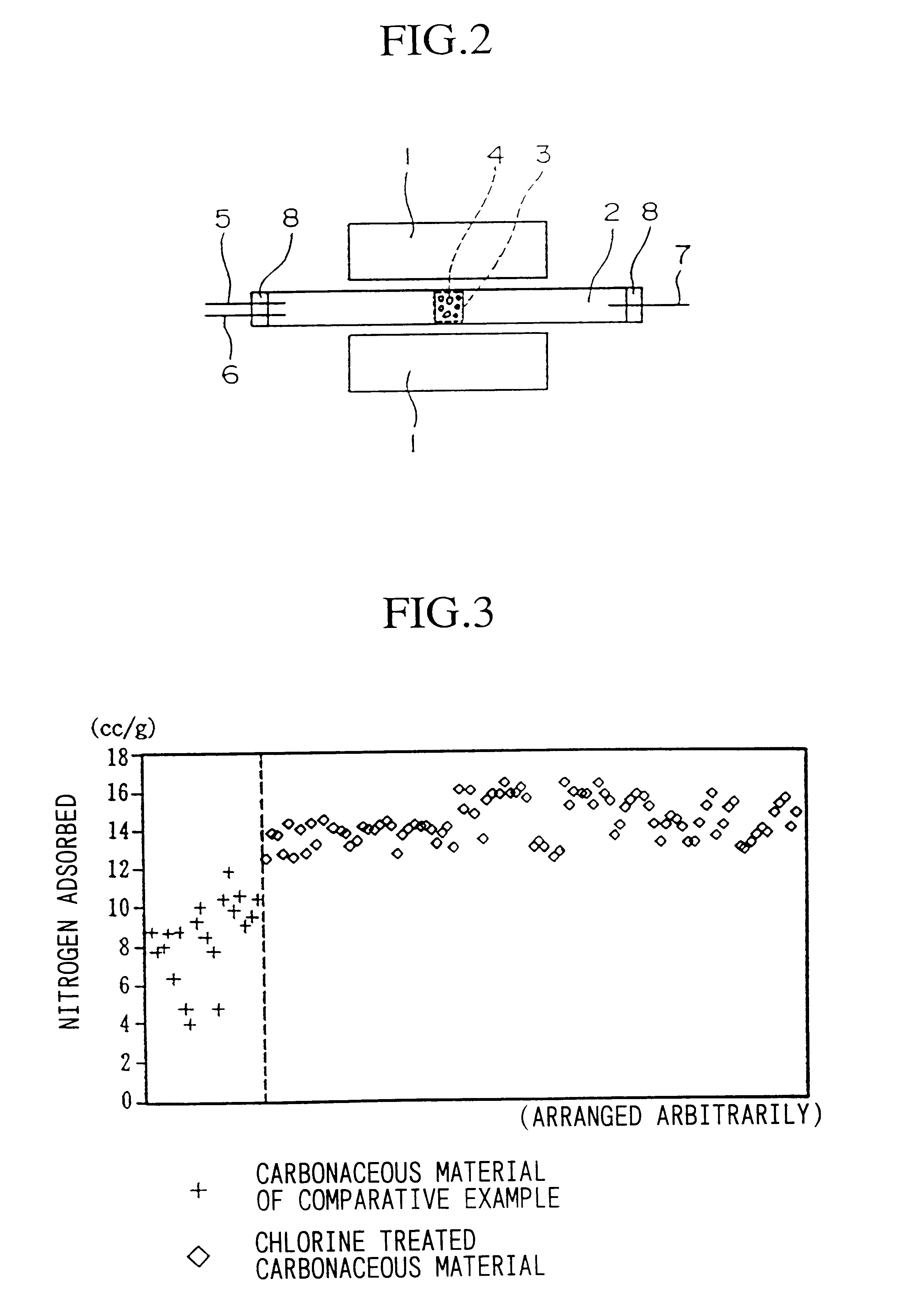

Porous carbonaceous material, manufacturing method therefor and use thereof

InactiveUS6475461B1Facilitate dissociationImprove adsorption strengthPigmenting treatmentPhysical/chemical process catalystsElectrochemistryOxygen

A halogen treatment is conducted comprising: a halogenation step wherein a halogenation heat treatment for preparing a halogenated carbonized charcoal is conducted in which the carbonized charcoal is brought into contact with halogen; and a dehalogenation step wherein a dehalogenation treatment is conducted in which a part of or all halogen atoms in the halogenated carbonized charcoal are eliminated. A porous carbonaceous material is obtained at a high yield, and the amounts of nitrogen, oxygen, carbon dioxide, and methane adsorbed by this porous carbonaceous material are large. When this porous carbonaceous material is used as an electrical double layer capacitor carbon, the electrostatic capacity is increased compared to conventional carbonaceous materials. Consequently, a carbonaceous material is obtained which has micopores and / or sub-micropores which are suitable for the adsorption of small molecules such as nitrogen, and for storage of electrochemical energy.

Owner:NIPPON SANSO CORP

Magnesium halide adduct, preparation and use thereof

ActiveCN101486722AImprove melt indexFine powder (broken) reductionMagnesium organic compoundsArylBromine

The invention provides a magnesium halide addition compound shown as general formula MgX2-mROH-nE-pH2O, wherein, X refers to chlorine or bromine, R refers to the alkyl of C1-C12; naphthene base of C3-C10 or the aryl of the C6-C10; E refers to o-alkoxybenzoic ether compound shown in the general formula (II); m ranges from 1 to 5; n ranges from 0.005 to 1.0; and P ranges from 0 to 0.8.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS20090043136A1Physical/chemical process catalystsPreparation by hydrogen halide split-offHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

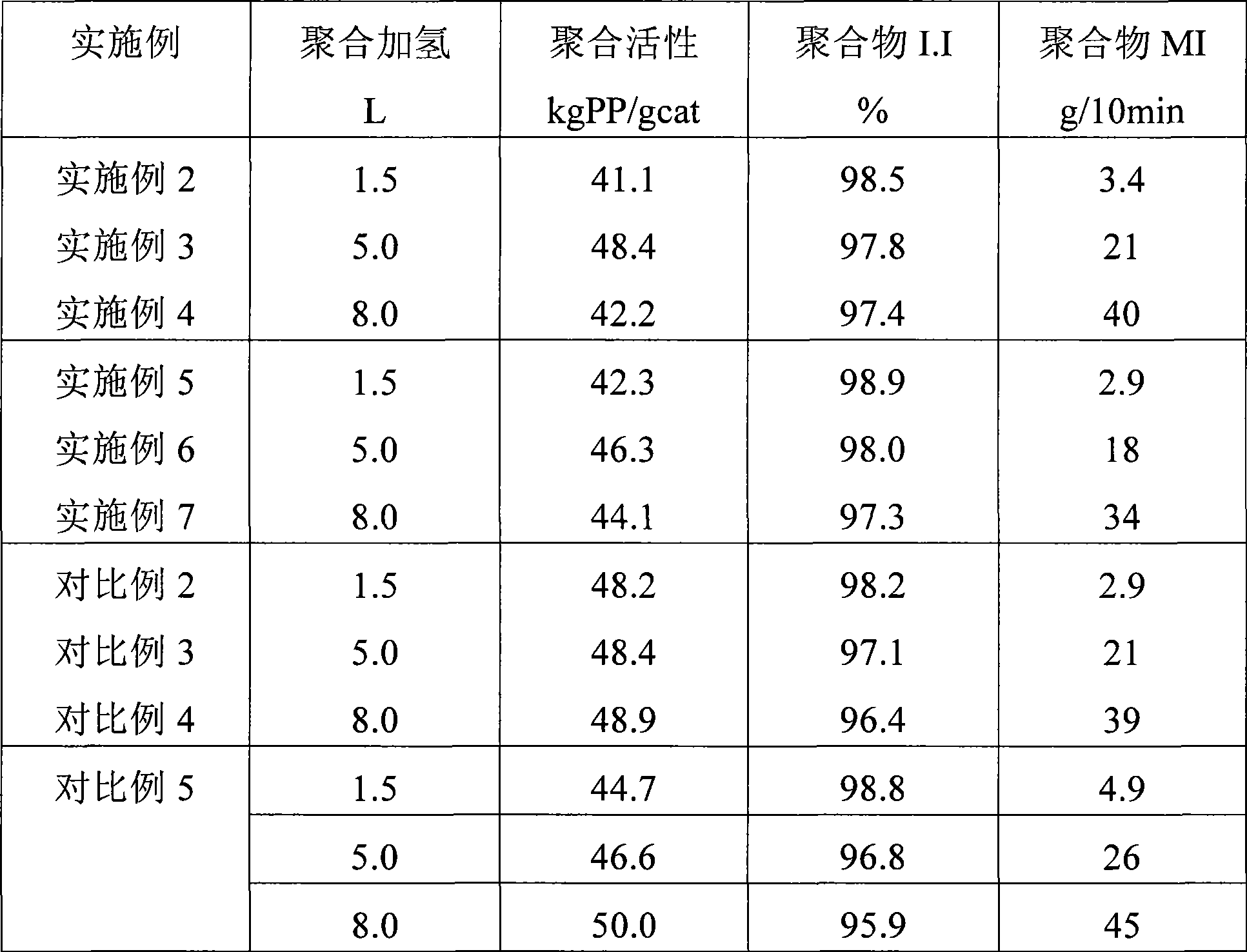

Support of olefinic polymerization catalyst and preparation method thereof, solid catalyst components for olefinic polymerization and olefinic polymerization catalyst

The invention relates to a support of an olefinic polymerization catalyst and a preparation method thereof, solid catalyst components for olefinic polymerization and an olefinic polymerization catalyst. The support of the olefinic polymerization catalyst is dialkoxy magnesium. The preparation method of the support of the olefinic polymerization catalyst comprises the following steps: in an inert gas protective atmosphere, reacting magnesium and alcohol, which serve as raw materials, in the presence of a halogenating agent under reflux to prepare the dialkoxy magnesium, wherein the weight ratio of alcohol to magnesium is (4-50):1; the halogenating agent is at least one of halogen simple substances and halides, and the mol ratio of halogen atom to magnesium is (0.0002-0.2):1; and the dialkoxy magnesium is spherical particles of which the average particle size is 10-150 um and the particle size distribution index SPAN is smaller than 1.1. The olefinic polymerization catalyst prepared by the support has high activity, and the polymer has the advantages of high bulk density, good particle shape and uniform distribution; and thus, the olefinic polymerization catalyst is suitable for producing propylene homopolymer and copolymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

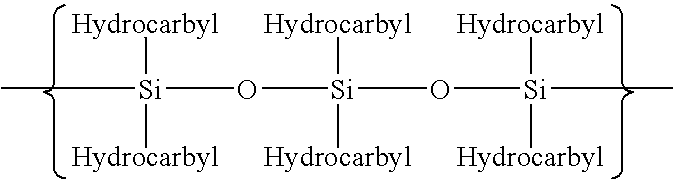

Linear and cross-linked high molecular weight polysilanes, polygermanes, and copolymers thereof, compositions containing the same, and methods of making and using such compounds and compositions

Methods are disclosed of making linear and cross-linked, HMW (high molecular weight) polysilanes and polygermanes, polyperhydrosilanes and polyperhydrogermanes, functional liquids containing the same, and methods of using the liquids in a range of desirable applications. The silane and germane polymers are generally composed of chains of Si and / or Ge substituted with R′ substituents, where each instance of R′ is, for example, independently hydrogen, halogen, alkenyl, alkynyl, hydrocarbyl, aromatic hydrocarbyl, heterocyclic aromatic hydrocarbyl, SiR″3, GeR″3, PR″2, OR″, NR″2, or SR″; where each instance of R″ is independently hydrogen or hydrocarbyl. The cross-linked polymers can be synthesized by dehalogenative coupling or dehydrocoupling. The linear polymers can be synthesized by ring-opening polymerization. The polymers can be further modified by halogenation and / or reaction with the source of hydride to furnish perhydrosilane and perhydrogermane polymers, which are used in liquid ink formulations. The synthesis allows for tuning of the liquid properties (e.g., viscosity, volatility, and surface tension). The liquids can be used for deposition of films and bodies by spincoating, inkjetting, dropcasting, etc., with or without the use of UV irradiation. The deposited films can be converted into amorphous and polycrystalline silicon or germanium, and silicon or germanium oxide or nitride by curing at 400-600 DEG C. and (optionally) laser- or heat-induced crystallization (and / or dopant activation, when dopant is present).

Owner:ENSURGE MICROPOWER ASA

Capping reactions in cationic polymerization; kinetic and synthetic utility

A method of synthesizing an endcapped polymer, comprising reacting in a solvent a cationic living polymer with an optionally substituted conjugated diene as an endcapping reagent, whereby the solvent causes termination by halogenation to be faster than the addition of additional molecules of the conjugated diene, thereby producing an endcapped polymer having a halogenated endcap group.

Owner:MASSACHUSETTS LOWELL UNIV OF

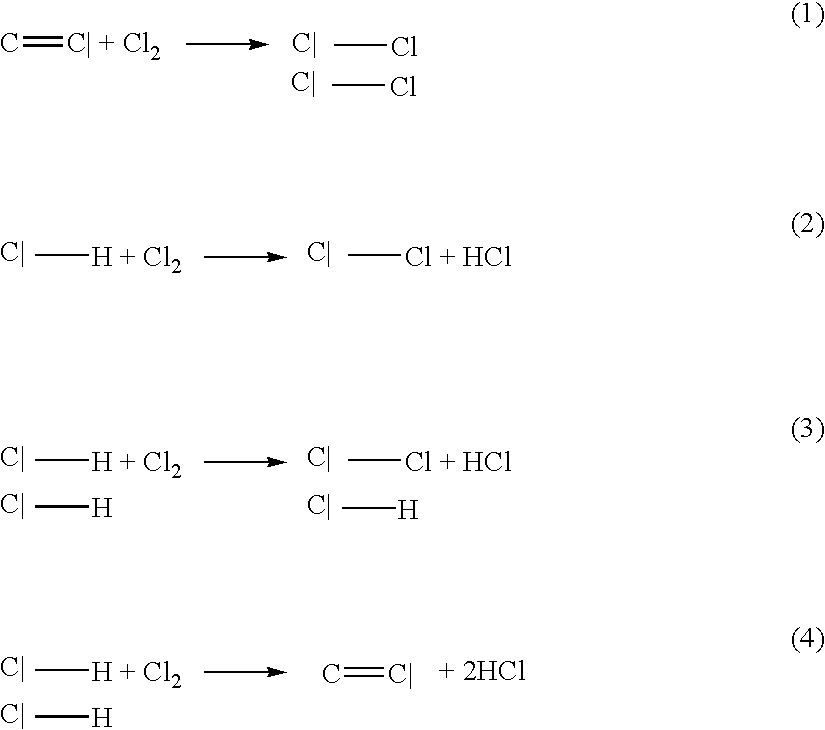

Hydrocarbon synthesis

InactiveUS20050171393A1Valid conversionMolecular sieve catalystLiquid hydrocarbon mixtures productionHydrogen halideOxygen

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC

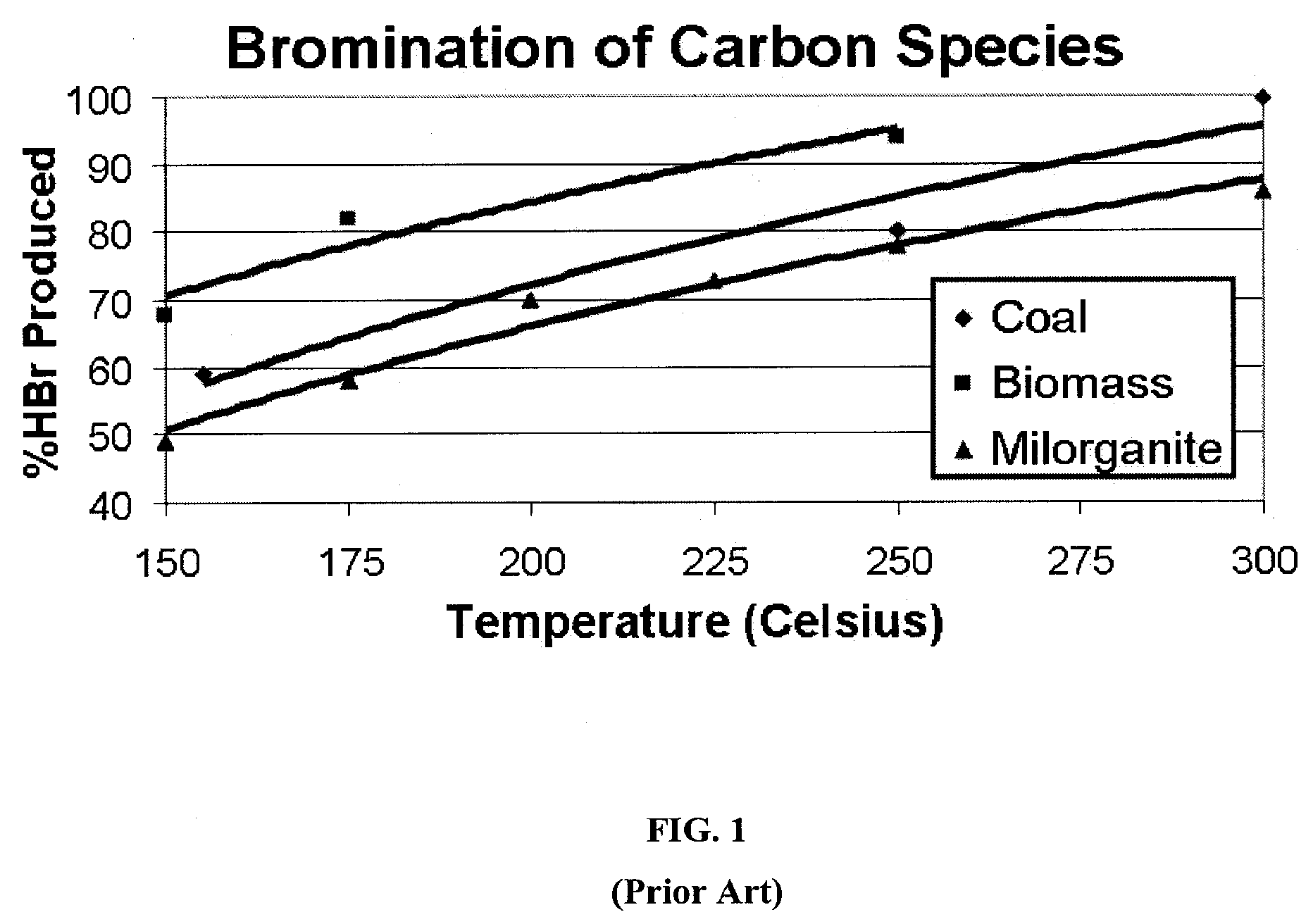

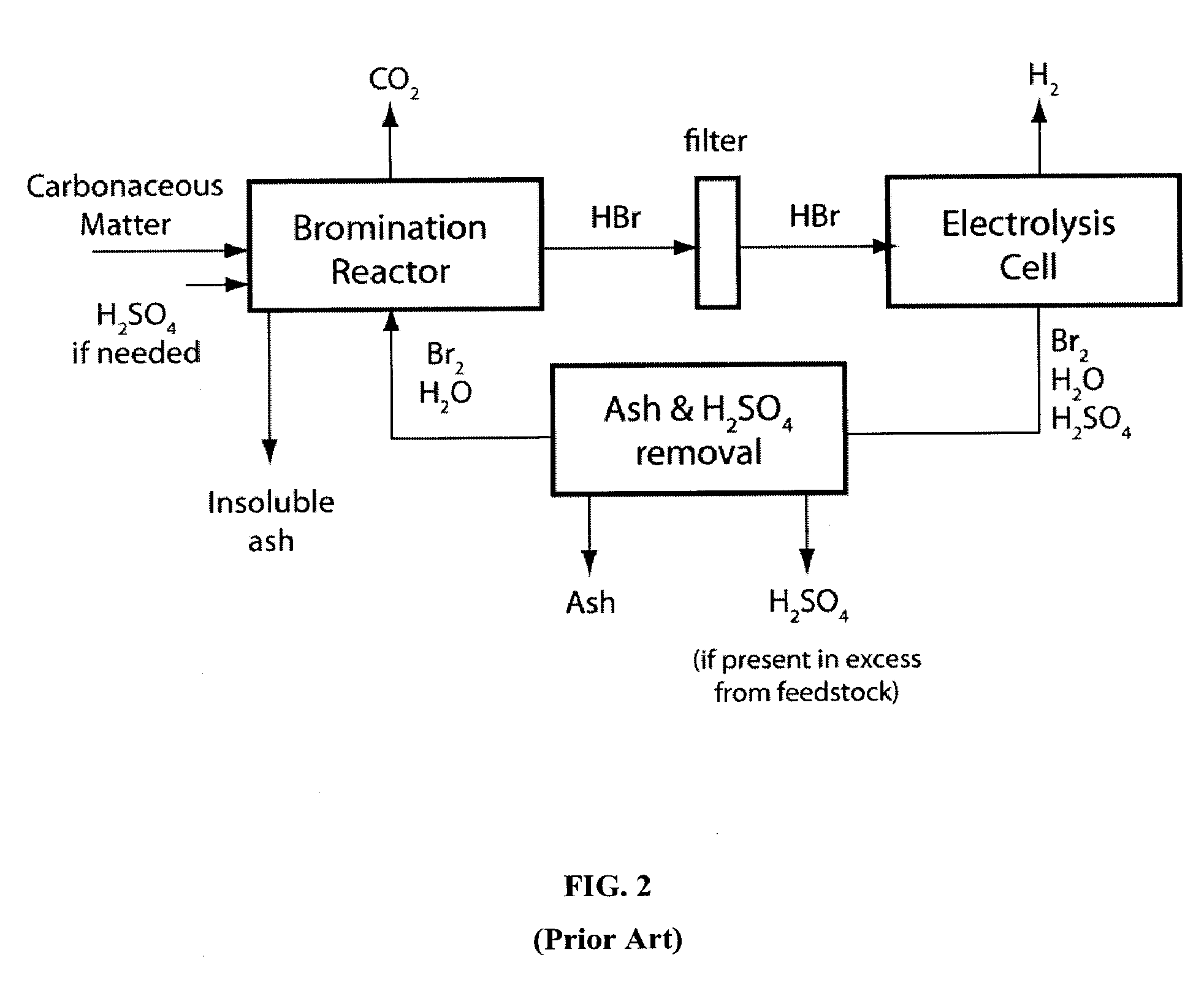

Waste Treatment and Energy Production Utilizing Halogenation Processes

InactiveUS20090028767A1Reduce needEfficient processingPhotography auxillary processesElectrolysis componentsCelluloseEngineering

A method for generating energy and / or fuel from the halogenation of a carbon-containing material and / or a sulfur-containing chemical comprises supplying the carbon-containing material (e.g., coal, lignite, biomass, cellulose, milorganite, methane, sewage, animal manure, municipal solid waste, pulp, paper products, food waste) and / or the sulfur-containing chemical (e.g., H2S, SO2, SO3, elemental sulfur) and a first halogen-containing chemical to a reactor. The carbon-containing material and / or the sulfur-containing chemical and the halogen-containing chemical are reacted in the reactor to form a second halogen-containing chemical and carbon dioxide, sulfur and / or sulfuric acid. The second halogen-containing chemical is dissociated (e.g., electrolyzed) to form the first halogen-containing chemical and hydrogen gas (H2). The first halogen-containing chemical can be Br2 and the second halogen-containing chemical can be HBr. Any carbon dioxide formed during reaction can be directed to a prime mover (e.g., turbine) to generate electricity. Any ash and / or sulfur formed can be removed. In some cases a sulfur-containing chemical can be supplied to the reactor with the carbon-containing material.

Owner:SRT GROUP

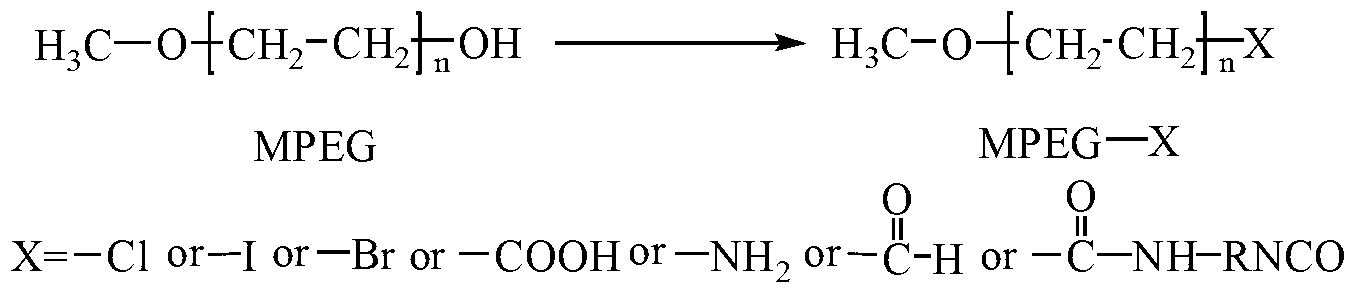

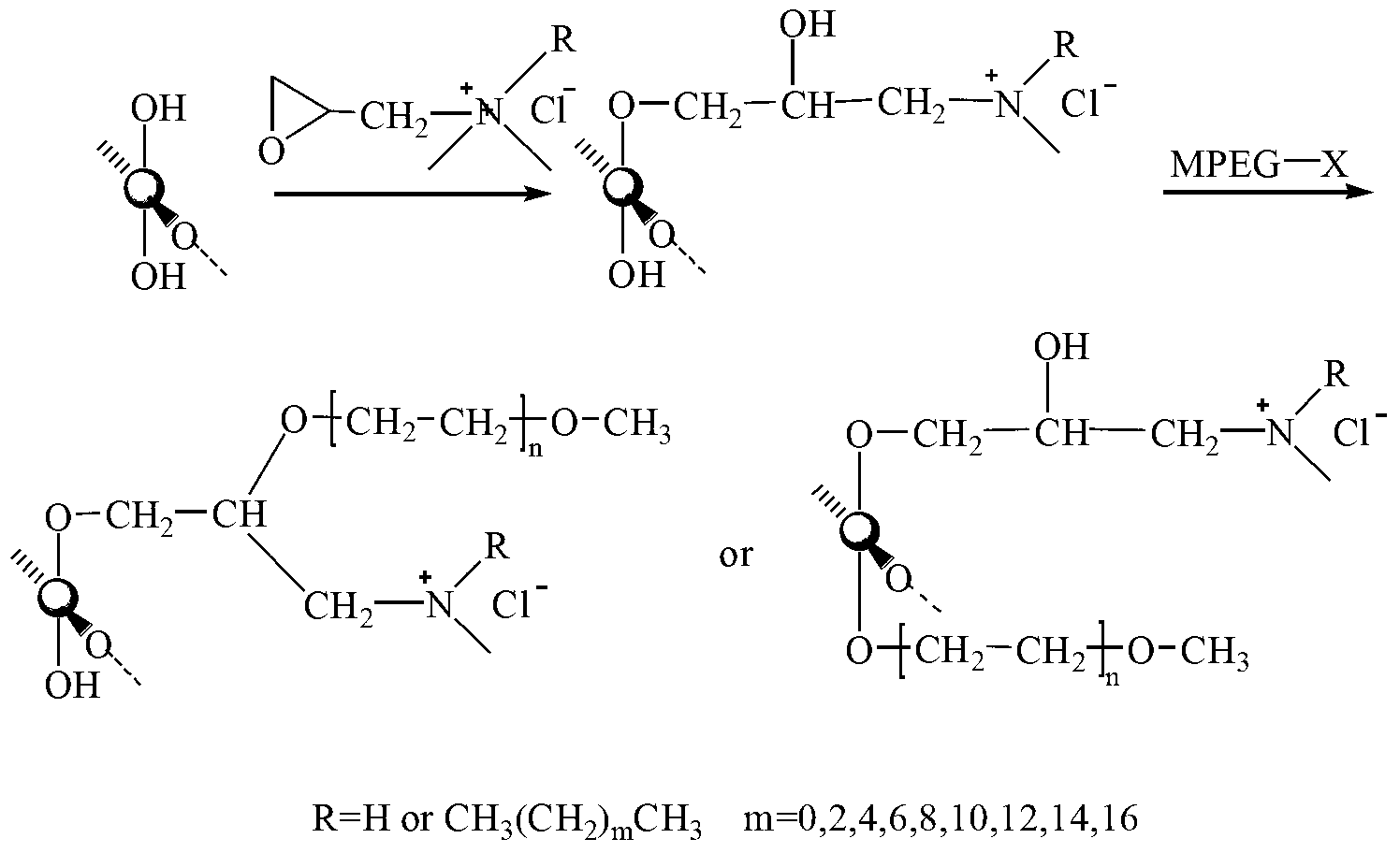

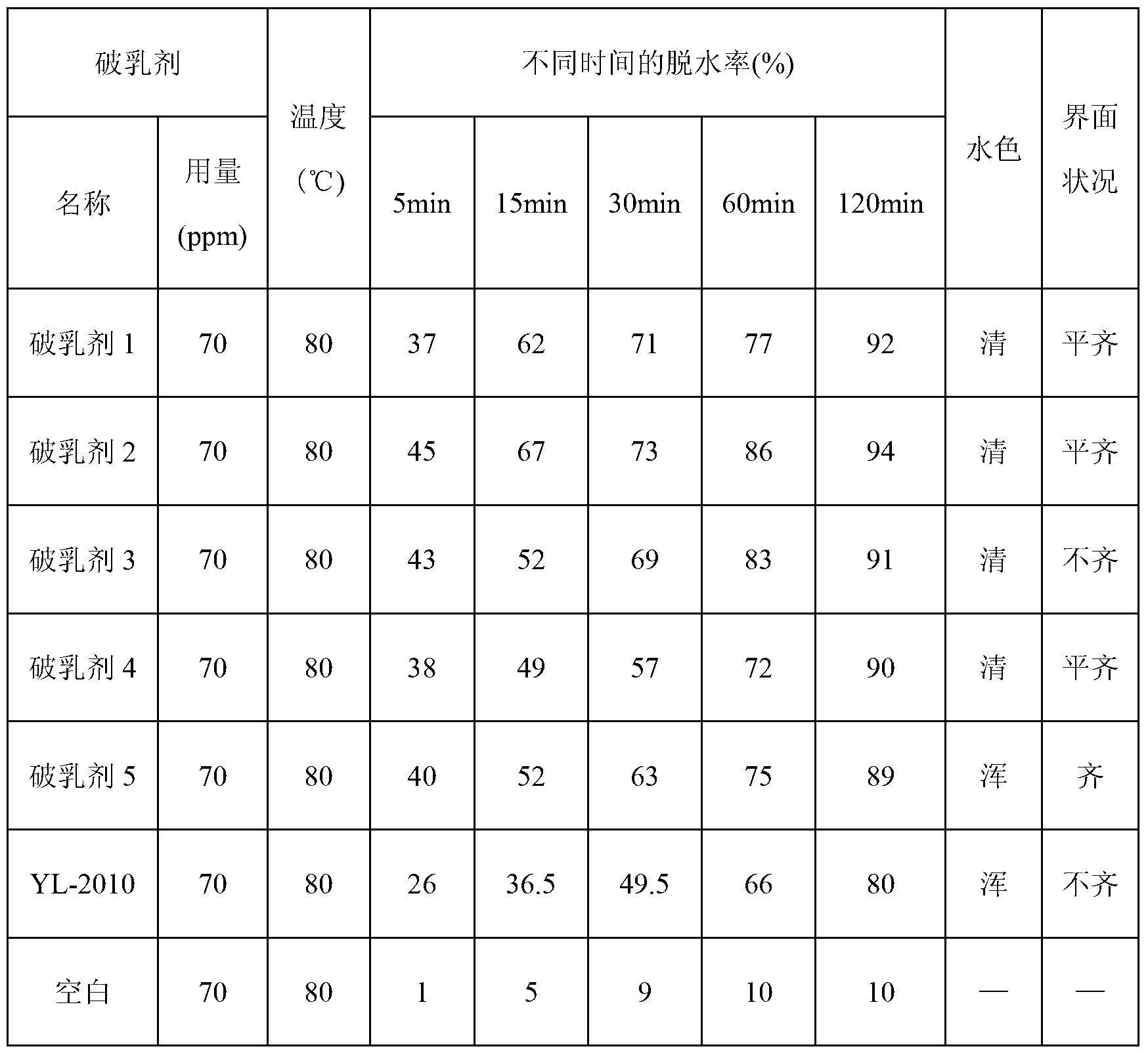

Natural polysaccharide macromolecule-modified crude oil demulsifier

InactiveCN103320158ASustainableWide variety of sourcesDewatering/demulsification with chemical meansAminationIsocyanic acid

The invention relates to a crude oil demulsifier, and discloses a natural polysaccharide macromolecule-modified crude oil demulsifier. The demulsifier is prepared by adopting the following operation steps: (1) conducting halogenation modification, carboxylation modification, amination modification, formylation modification, or isocyanic acid esterification modification on polyethylene glycol monomethyl ether; (2) preparing glycidyl dimethyl alkyl ammonium chloride; (3) preparing quaternized polysaccharide; and (4) reacting the modified polyethylene glycol monomethyl ether with quaternized polysaccharide to obtain a product, namely the natural polysaccharide macromolecule-modified crude oil demulsifier. According to the crude oil demulsifier, as the raw material, the natural polysaccharide macromolecule compound has multiple advantages of being wide in source, natural, non-toxic, sustainable, good in usage safety and the like; and the prepared demulsifier has good demulsifying and dewatering effects; in addition, the molecules of the demulsifier contain a great deal of groups of hydroxyl and the like, which have certain chelating capability to metal ions, thus being capable of removing a certain amount of metal ions while demulsifying.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

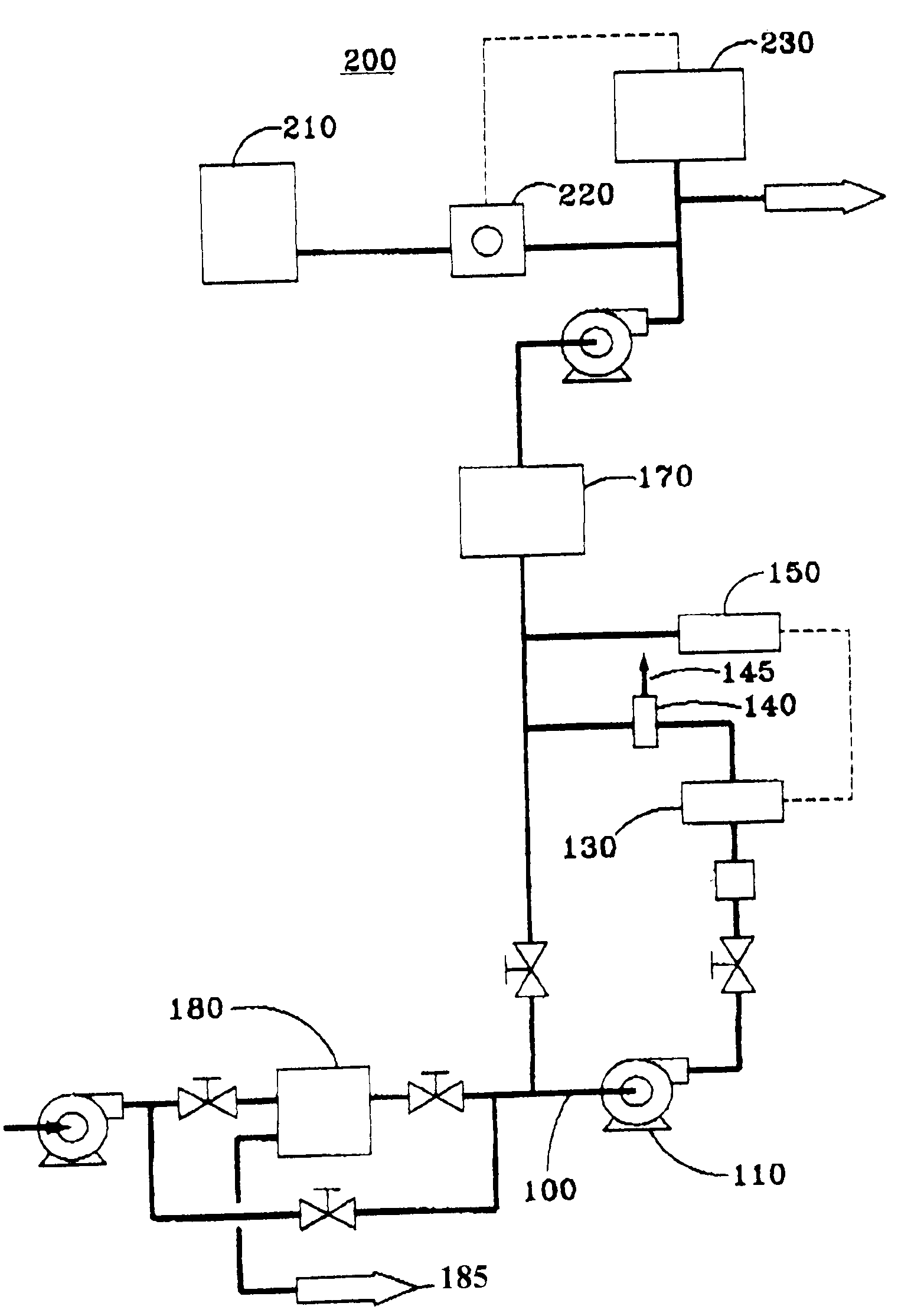

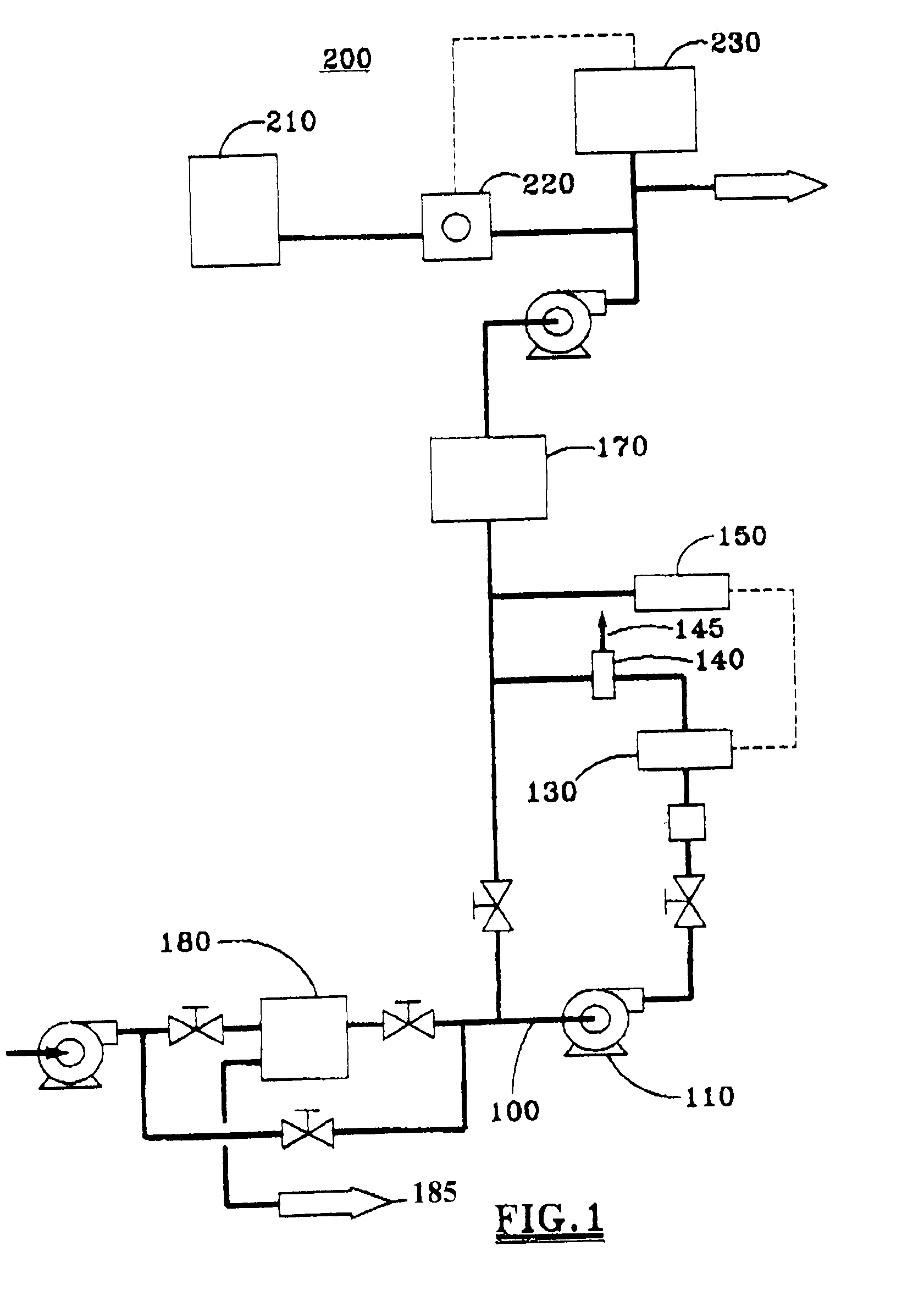

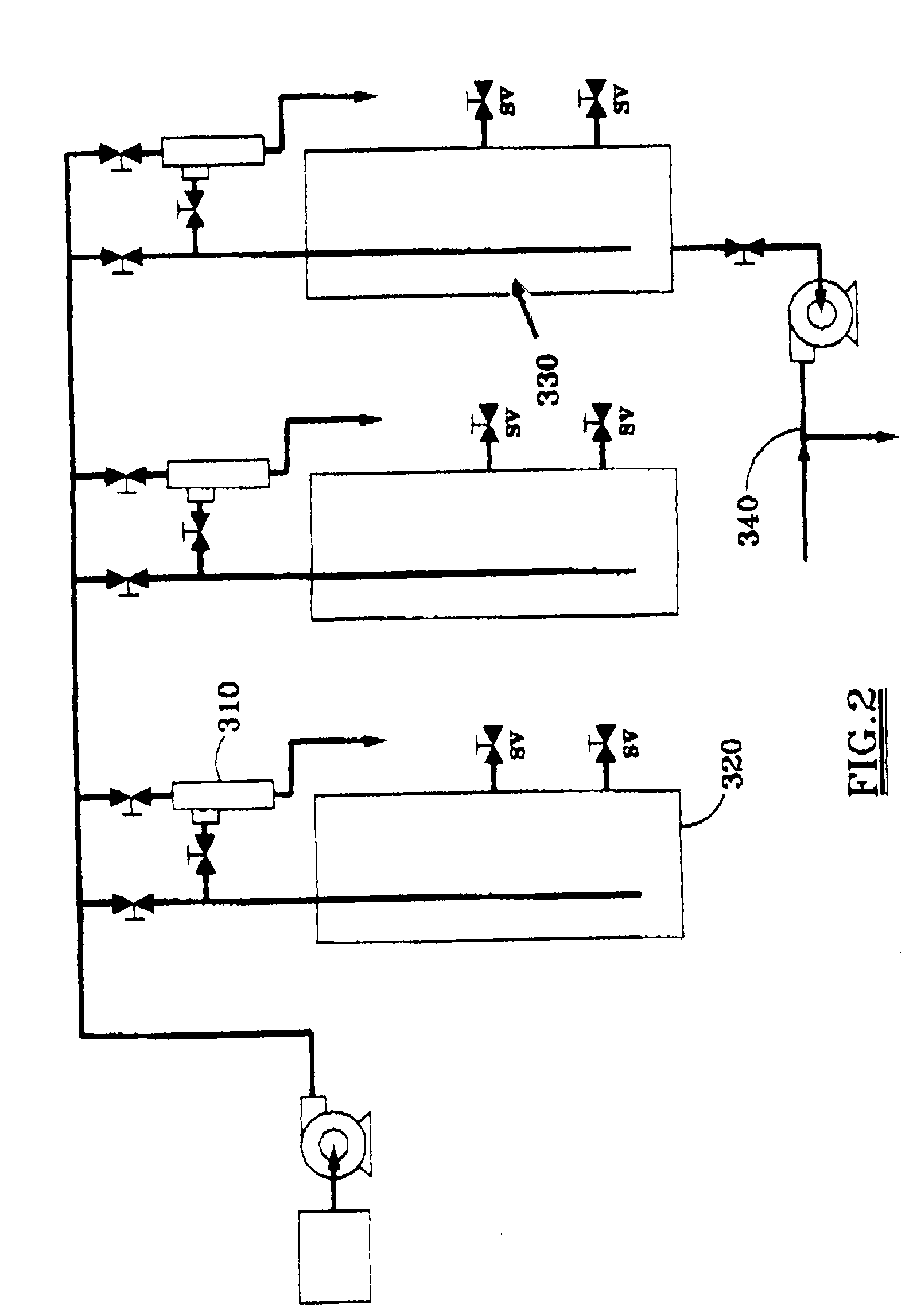

System and Process for Treatment and De-halogenation of Ballast Water

A system and process for de-halogenating ballast water before releasing the ballast water from the vessel. In one embodiment, the system comprises a means for measuring the halogen content of the ballast water, a reducing agent source in fluid communication with the ballast water, and a means for controlling the amount of reducing agent supplied to the ballast water. In one aspect, the means for measuring the halogen content comprises one or more oxidation / reduction potential analyzers. In another embodiment, the system comprises one or more hypochlorite electrolytic cells for generating hypochlorite to treat the ballast water.One embodiment of the process for de-halogenating ballast water comprises measuring the oxidation / reduction potential of the ballast water and adding one or more reducing agents to the ballast water to de-halogenate the ballast water in response to the measured oxidation / reduction potential. In one aspect, the oxidation / reduction potential is modulated so that excess reducing agent is present in the ballast water.

Owner:DE NORA WATER TECH

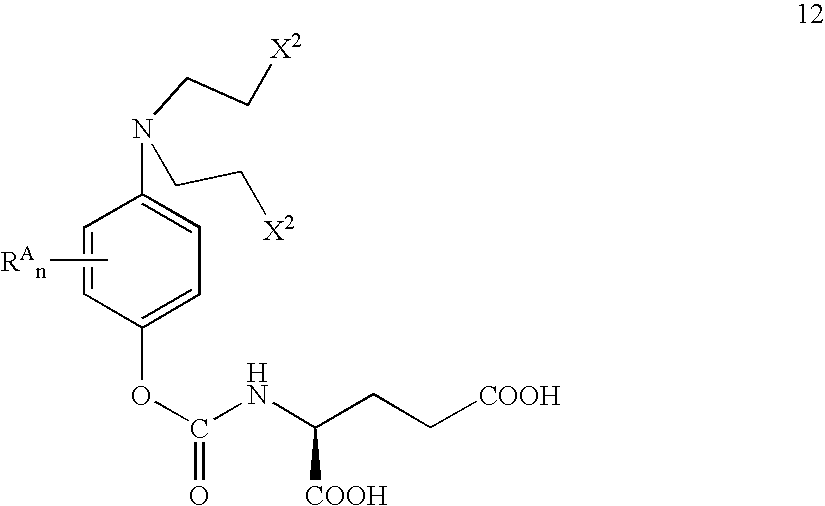

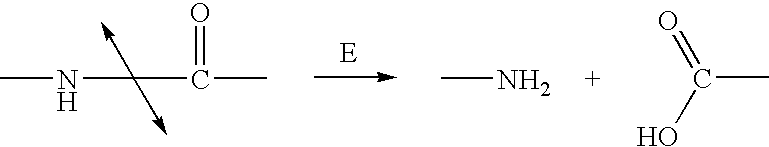

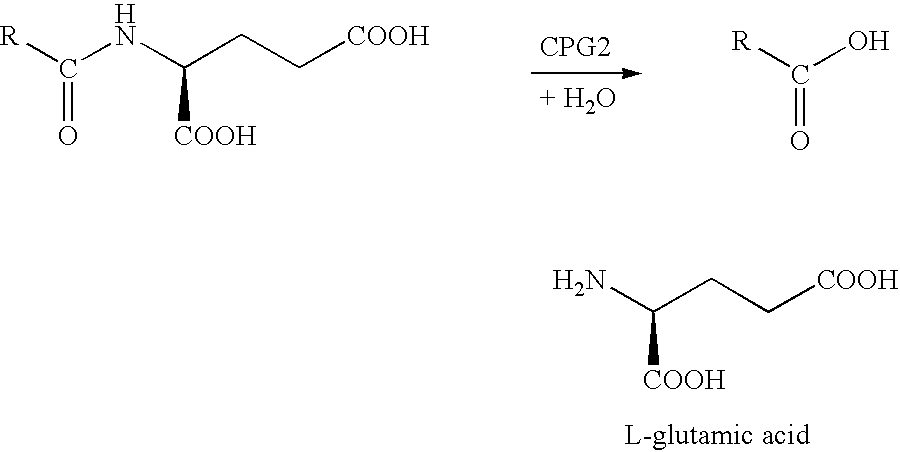

Methods of chemical systhesis of phenolic nitrogen mustard prodrugs

InactiveUS6916949B2Group 4/14 element organic compoundsCarbamic acid derivatives preparationNitrogen mustardChemical synthesis

This invention pertains to novel methods for the synthesis of certain nitrogen mustard prodrugs, such as N-{4-[N,N-bis(2-haloethylamino)-phenoxycarbonyl}-L-glutamic acid: wherein: X2 is a halo group, and is —F, —Cl, —Br, or —I; n is an integer from 0 to 4; and, each RA is an aryl substituent. The methods comprise, at least, the steps of: glutamate conjugation (GC); silyloxy deprotection (SD); and, sulfonic esterification (SU). Certain preferred methods comprise the steps of: amine substitution (AS); silyloxy protection (SP); phenolic deprotection (PD); activation (AC); glutamate conjugation (GC); silyloxy deprotection (SD); sulfonic estenfication (SU); halogenation (HL); glutamate deprotection (GD); and glutamic acid protection (GP).

Owner:THE INST OF CANCER RES ROYAL CANCER HOSPITAL

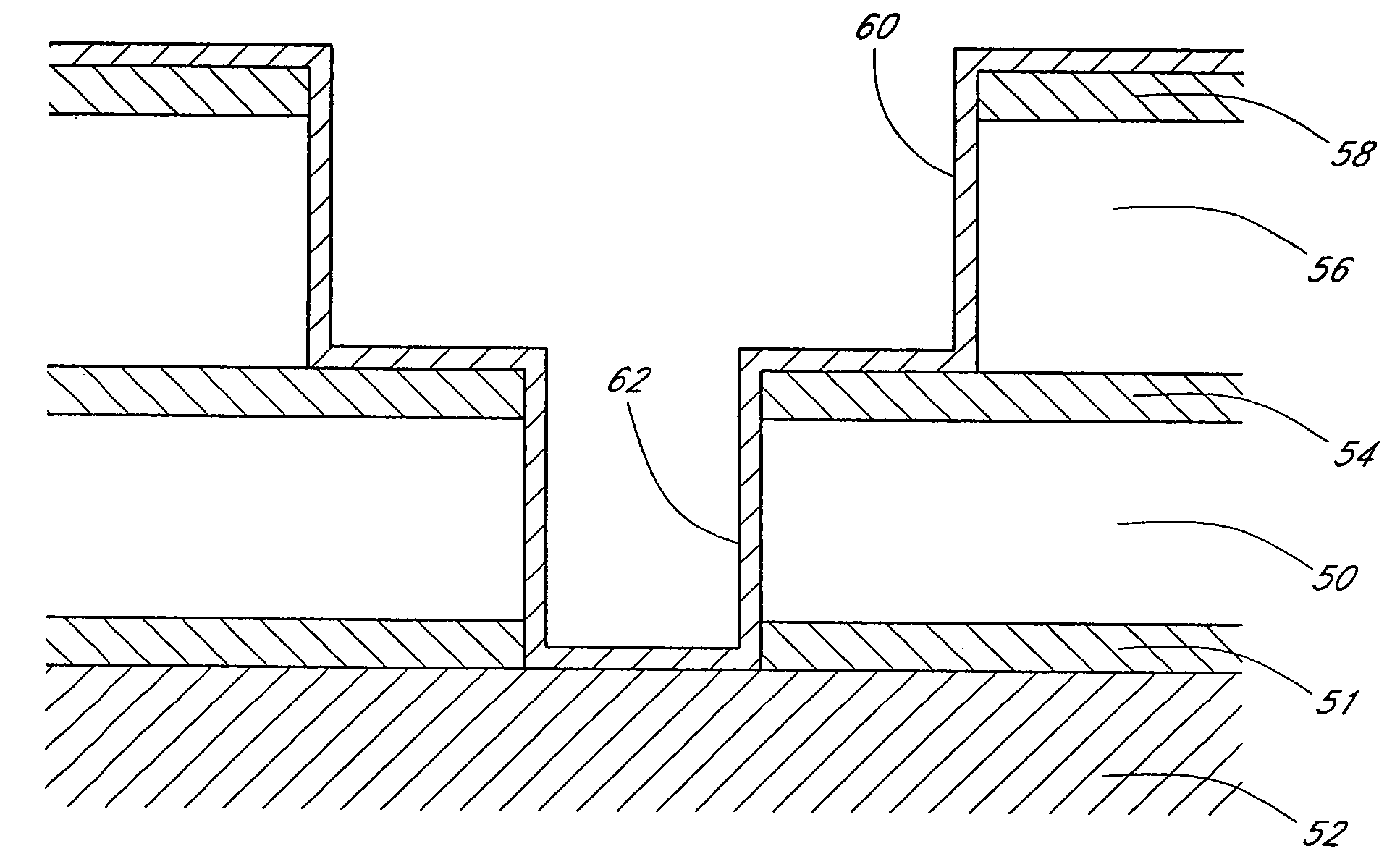

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20060079090A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

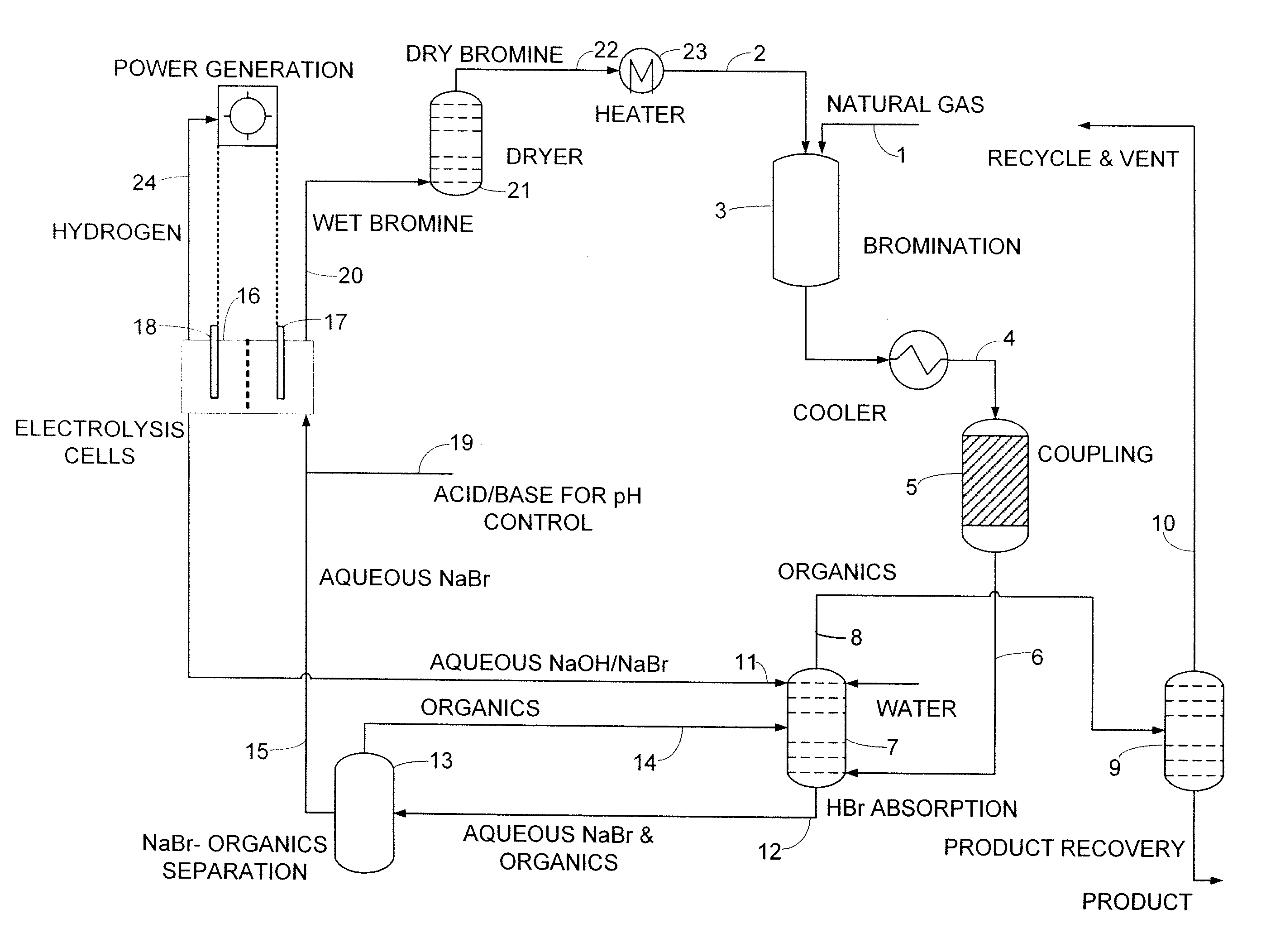

Process for converting hydrocarbon feedstocks with electrolytic recovery of halogen

InactiveUS20080314758A1Improve efficiencyReduced Power RequirementsSolid-state devicesHydroxy compound preparationHalogenHydrocotyle bowlesioides

An improved continuous process for converting methane, natural gas, and other hydrocarbon feedstocks into one or more higher hydrocarbons, methanol, amines, or other products comprises continuously cycling through hydrocarbon halogenation, product formation, product separation, and electrolytic regeneration of halogen, optionally using an improved electrolytic cell equipped with an oxygen depolarized cathode.

Owner:REACTION 35 LLC

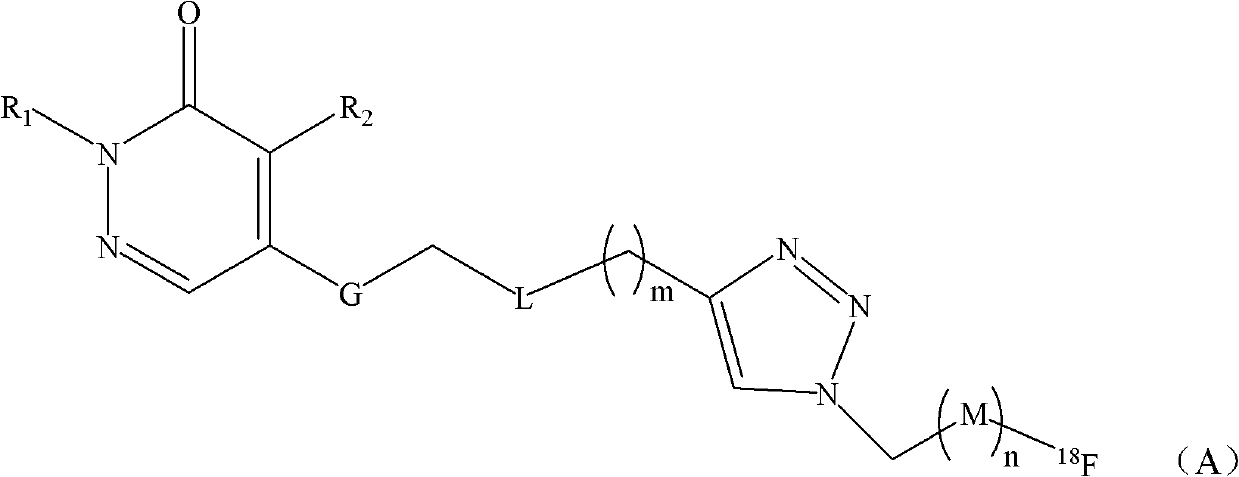

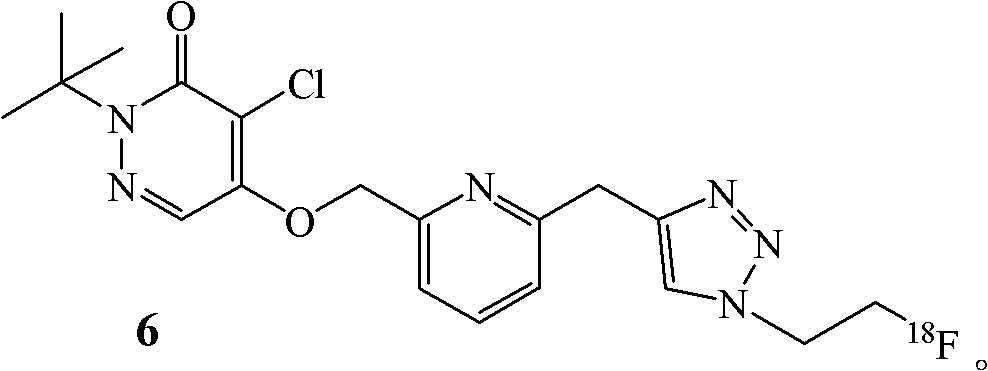

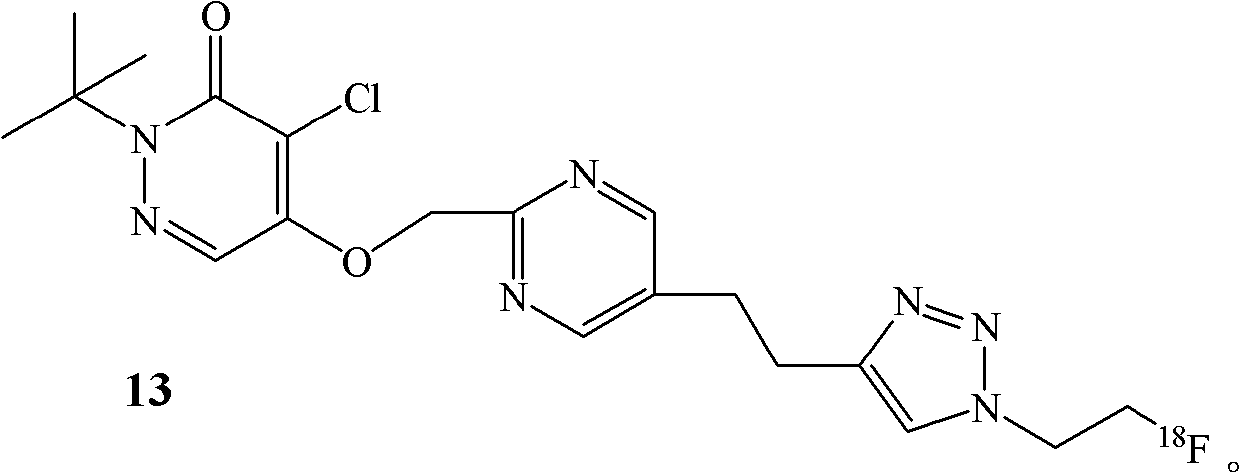

Fluorine-18-marked myocardial perfusion developing agent and preparation method and application thereof

ActiveCN102336741AHigh radiochemical yieldStability advantageOrganic chemistryRadioactive preparation carriersStructural formulaPerfusion

The invention provides a fluorine-18-marked pyridazinone analogue. The general structural formula of the analogue is shown as a formula (A), wherein G is selected from S, O or NH; R1 is alkyl with 1-6 carbon atoms; R2 is halogen or halogenation alkyl; L is phenyl, cyclohexyl or a hexa-heterocycle radical containing heteroatoms; m is 1, 2, 3, 4, 5 or 6; n is an integer of 1-15; and M is methylene or ethoxy. A compound marking method is simple, and has high radiation chemistry yield, high stability, a high myocardium initial uptake value, high target to non-target ratio and low using cost. The pyridazinone analogue is applied to the technical fields of radiopharmaceutical chemistry and clinical nuclear medicine as a novel fluorine-18-marked myocardial perfusion developing agent.

Owner:BEIJING NORMAL UNIVERSITY +1

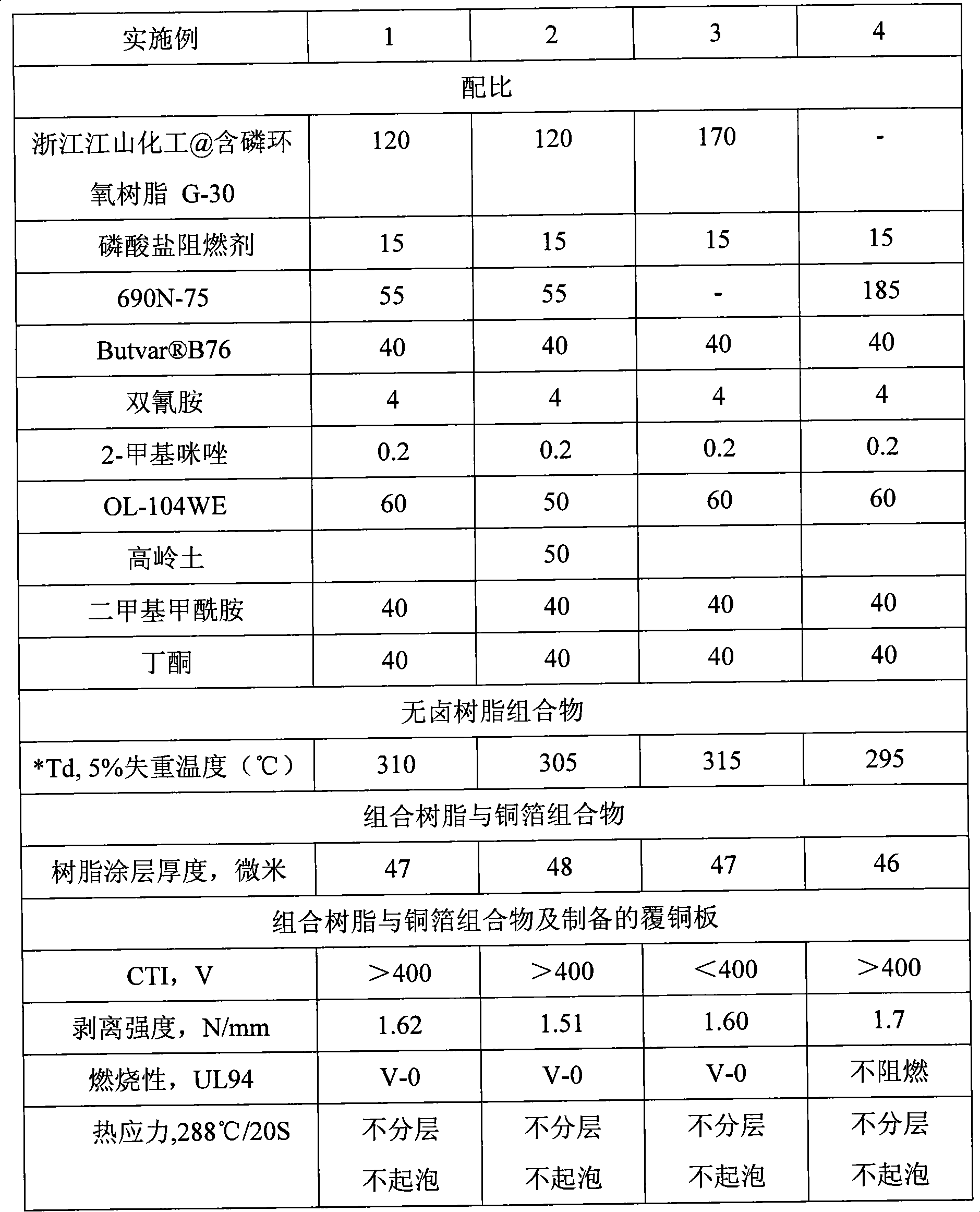

Resin composition and copper clad laminate prepared by metal foil coated with resin composition

ActiveCN101457012AExtended shelf lifeEasy to manageInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentChemical compoundMetal foil

The invention belongs to a chemical compound field, particularly referring to a resin compound and using the resin compound to coat a metal foil and applying a copper clad laminate made from the resin compound. The invention provides a halogen-free functional resin compound that has an excellent comparison tracking index or leakage resistance tracking characteristic, and a resin coated copper foil that is prepared by using the resin compound to coat a copper foil, namely a complex of the resin compound and the copper foil. The coated clad laminate prepared by the resin copper foil is used and has excellent comprehensive property, with the CTI of which being equal to and more than 400V. The resin compound of the invention overcomes the problems that in the prior art, the coated clad laminate with the CTI being equal to and more than 400V has dry flowers, exposed cloth marks and thickness and precision control, which is caused by the pre-leaching materials or bonding sheets when using reinforcing materials, meanwhile, product halogen free is realized, and the complex material of the resin compound and the copper foil has thinness, long storage period, flexible use and convenient management.

Owner:GUANGDONG SHENGYI SCI TECH

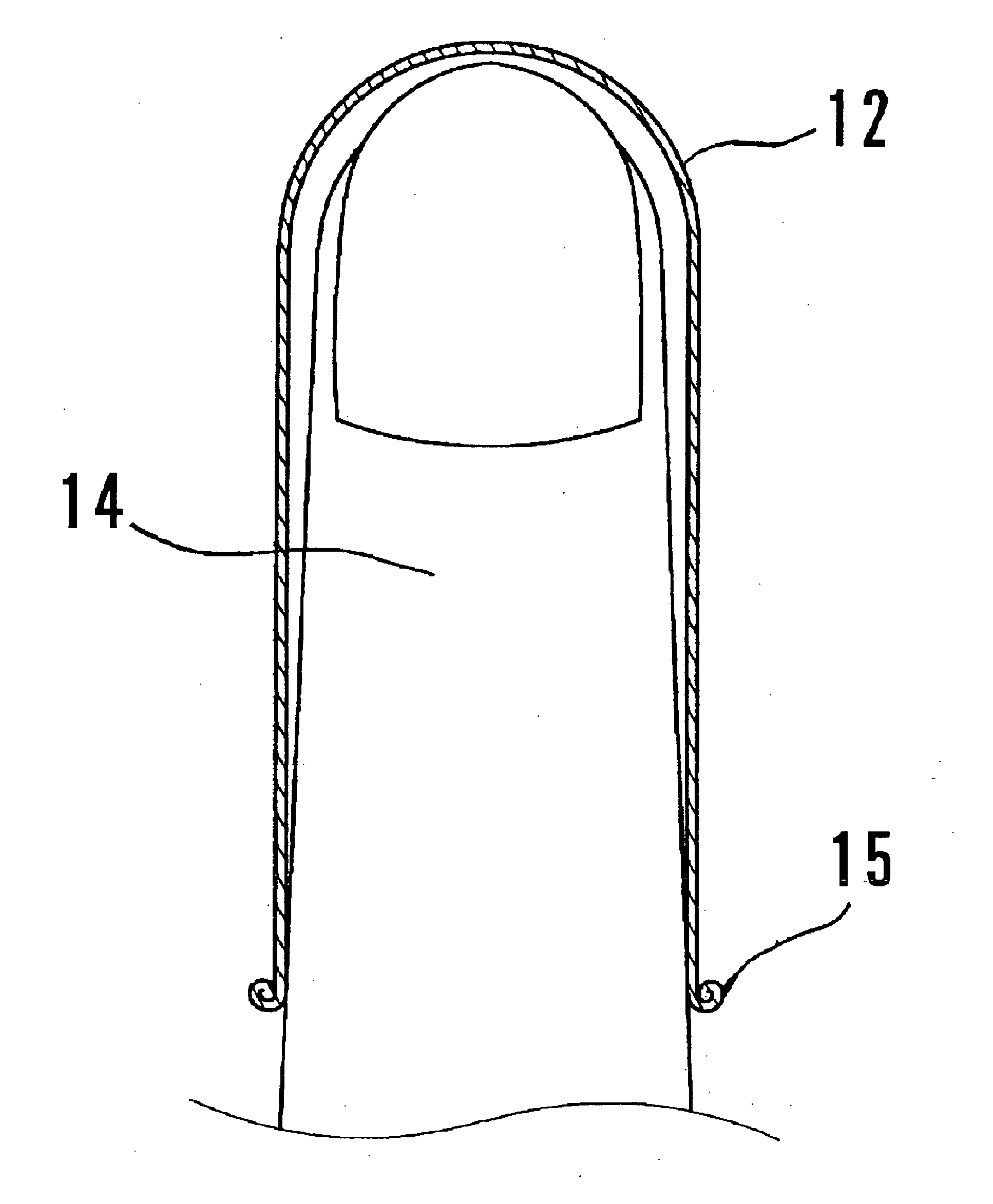

Latex products

InactiveUS20050031884A1Reduce in quantitySynthetic resin layered productsCarboxyl rubber coatingsPolymer scienceLatex rubber

The present invention finds that a detackified natural rubber latex product can be provided by a combination of treatment with a hydrophilic group sealant, coating with a detackifying polymer, halogenation and the like. The present invention also finds that a detackified natural rubber latex product which causes no discoloration of a metallic product surface can be provided by coating it with a detackifying, carboxylated latex vulcanized without using sulfur. The present invention also finds that a detackified natural rubber latex product of controlled protein elution can be provided by chemically modifying protein present in the natural rubber latex with an anionic group, cationic group or the like.

Owner:SUZUKI LATEX IND

Halogenated alkene heat transfer composition with improved oil return

The invention relates to heat transfer agents and heat transfer compositions containing hydrocarbon lubricating oils and halogentaed alkene heat transfer fluid that promote oil flow and provide for improved oil return. The heat transfer compositions are useful in various heat transfer systems such as refrigeration, cooling, air conditioning, chiller operations.

Owner:ARKEMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com