Patents

Literature

391results about "Preparation of metal alcoholates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

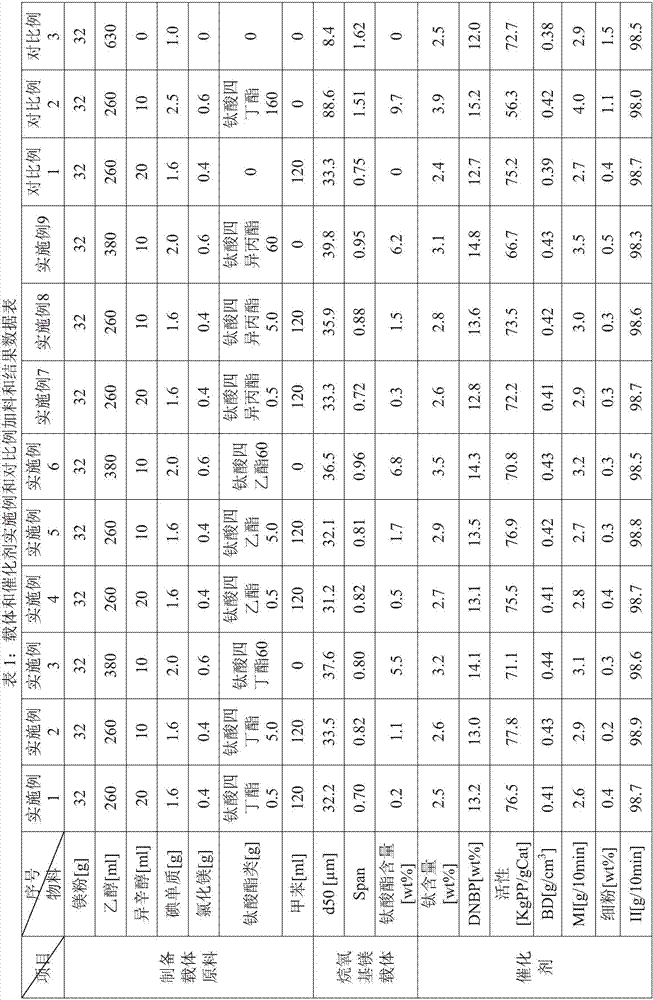

Method for preparing alkoxyl magnesium solid particles

InactiveCN101906017AReduce dosageReduce manufacturing costPreparation of metal alcoholatesAlcoholPhysical chemistry

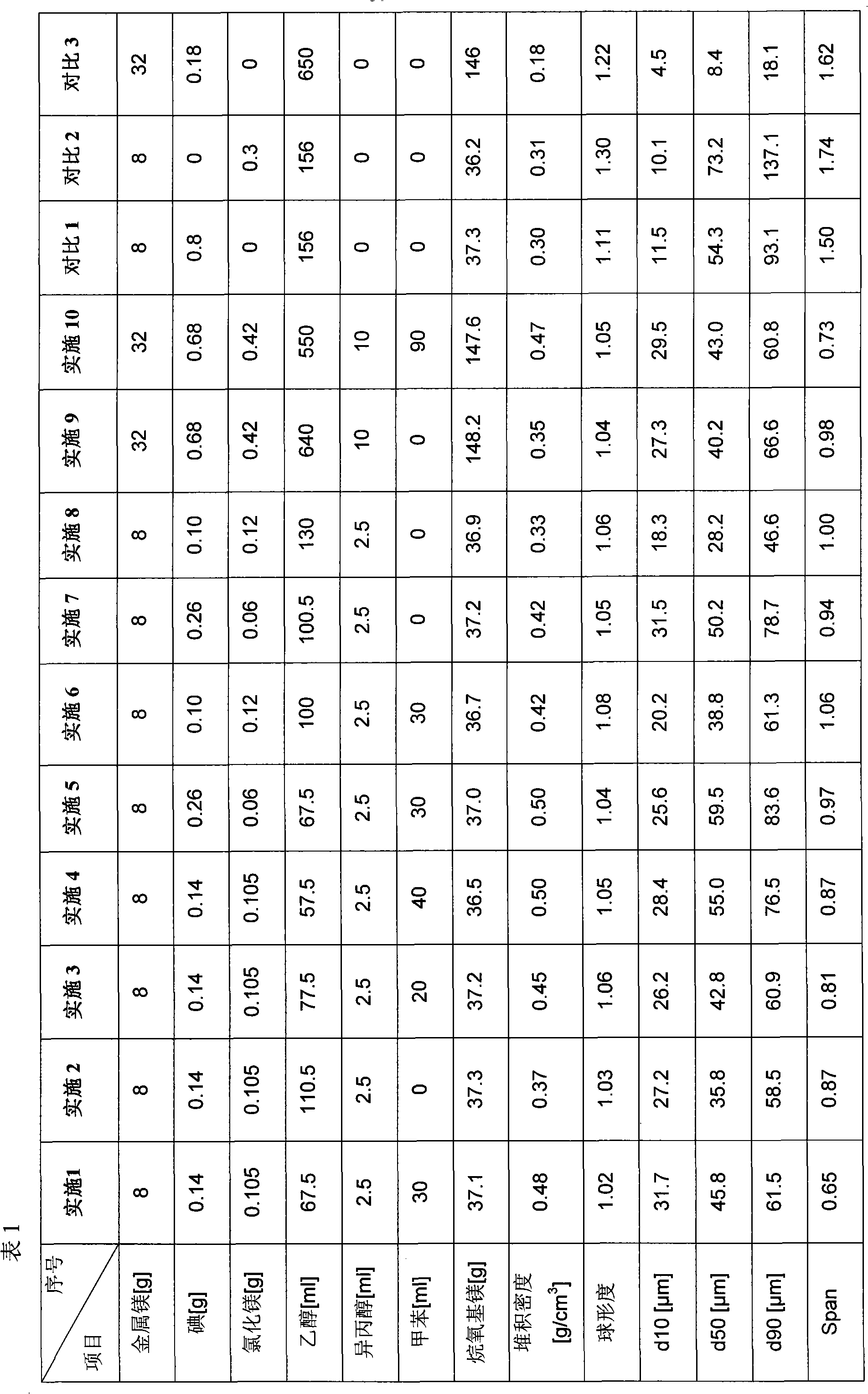

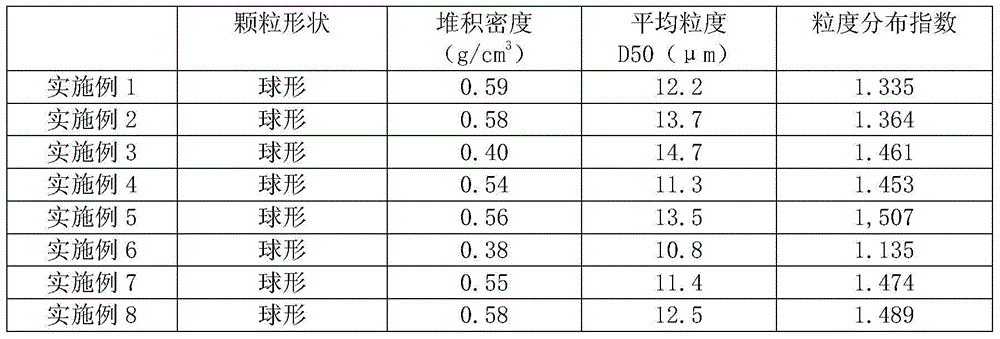

The invention provides a method for preparing spherical alkoxyl magnesium particles with excellent properties. In the method, magnesium, alcohol and a halogenating agent are reacted at a reflux temperature, so that the alkoxyl magnesium particles are obtained. The alkoxyl magnesium particles have the advantages of higher bulk density, good particle shape and particular suitability for serving as a catalyst carrier of an olefin polymerization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis of gallium and indium alkoxides

InactiveUS20090112012A1Eliminate chlorine contaminationGroup 4/14 element organic compoundsOrganic compound preparationAlkaline earth metalPotassium

A method of synthesising gallium or indium alkoxide from the corresponding gallium or indium halide, the method comprising the step of reacting the gallium or indium metal halide with the alkoxide of an alkali earth metal, to produce the desired metal alkoxide essentially free of chlorine contamination. The method provides a composition comprising a solution of gallium or indium alkoxide of high purity, the composition having a chloride content of less than 30 ppm, a barium or strontium content of less than 30 ppm, and a sodium or potassium content of less than 30 ppm, without requiring any additional steps.

Owner:MULTIVALENT

Method for preparing amorphous alkoxy magnesium

ActiveCN102020534AReduce dosageReduce manufacturing costPreparation of metal alcoholatesBulk chemical productionGas phasePolypropylene

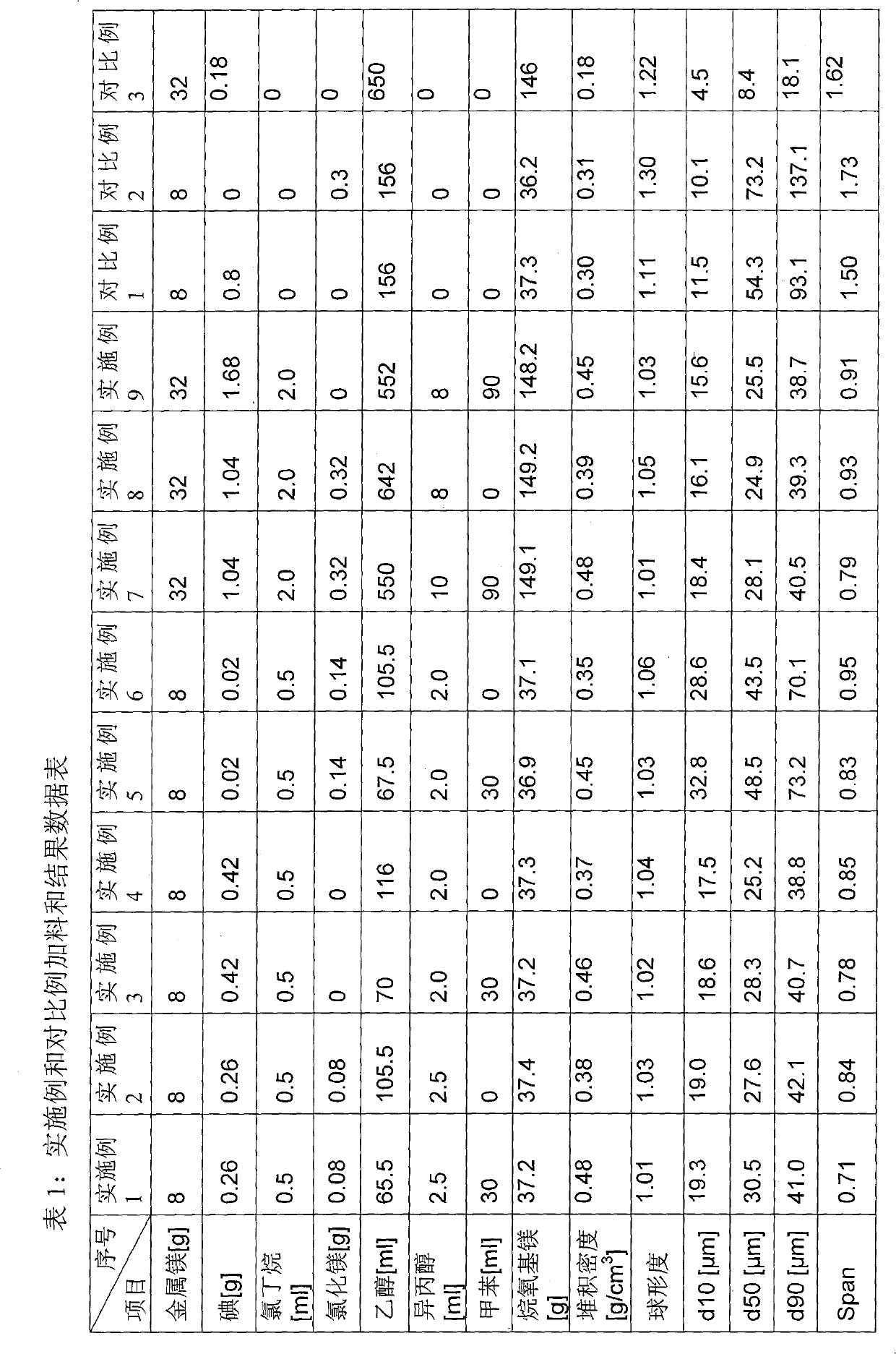

The invention provides a method for preparing amorphous spherical particle alkoxy magnesium. In the method for preparing the amorphous spherical particle alkoxy magnesium, magnesium powder and mixed alcohol are used as raw materials, halogen monomer and / or inorganic halide are / is used as a halogenating agent, an organic halogen-containing compound is used as a modifier, and one or more inertial organic solvents are used as a dispersing agent; and the obtained spherical particle alkoxy magnesium has higher stacking density, more perfect particle shape and higher particle size distribution uniformity. The alkoxy magnesium is particularly suitable to be used as an olefin polymerization catalyst carrier. The obtained catalyst has high activity, higher stacking density, good particle shape and uniform distribution and is suitable for devices for producing polypropylene by gas-phase processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

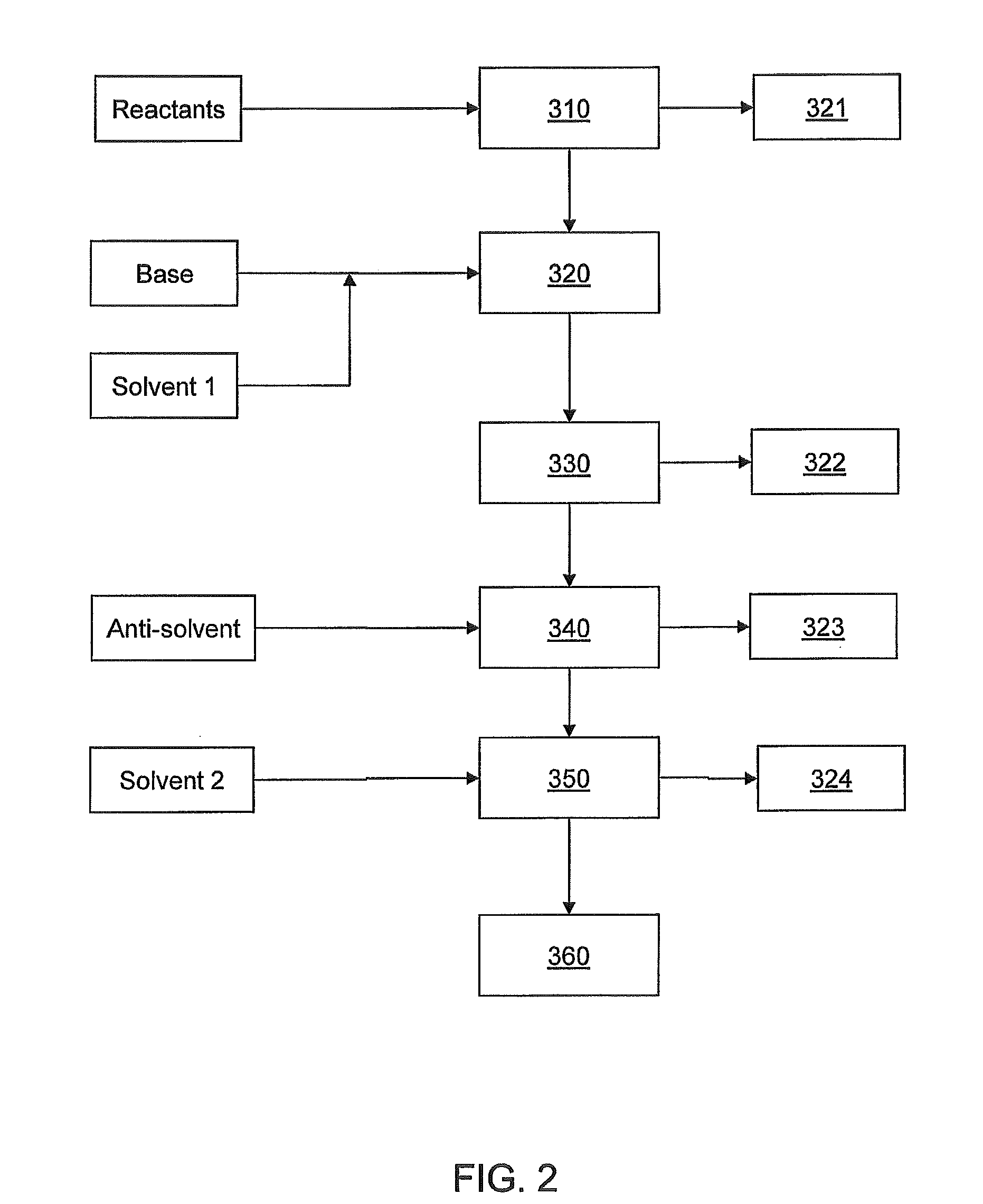

Method for making salts hydroxy-substituted hydrocarbons

ActiveUS7115785B2Oxygen-containing compound preparationOrganic compound preparationOrganic solventBoiling point

Disclosed is a method for preparing an alkali metal salt of a hydroxy-substituted hydrocarbon which comprises the steps of (i) contacting in solvent media at least one hydroxy-substituted hydrocarbon with a base comprising an alkali metal cation; and (ii) devolatilizing the solvent media comprising alkali metal salt by adding or spraying the solvent media into a substantially water-immiscible organic solvent, said solvent being at a temperature greater than the boiling point of solvent media at the prevailing pressure. In one embodiment the solvent media comprises water, and optionally at least one water-soluble protic organic solvent.

Owner:SHPP GLOBAL TECH BV

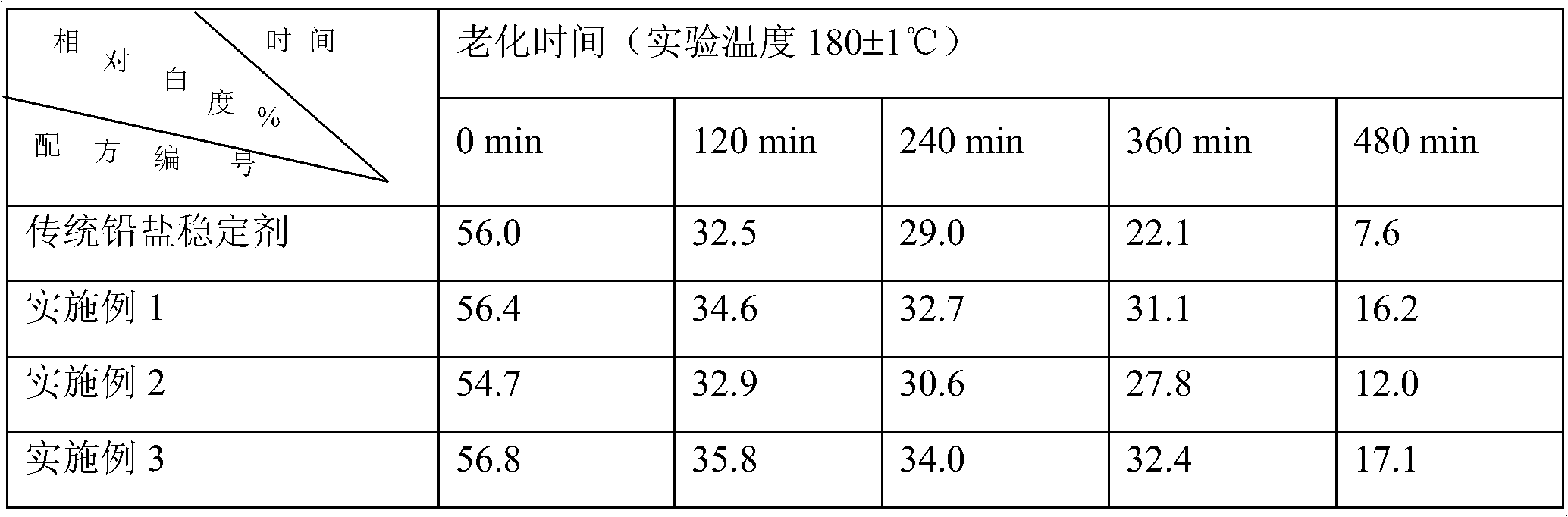

Process for synthesizing zinc pentaerythritol in heat stabilizer

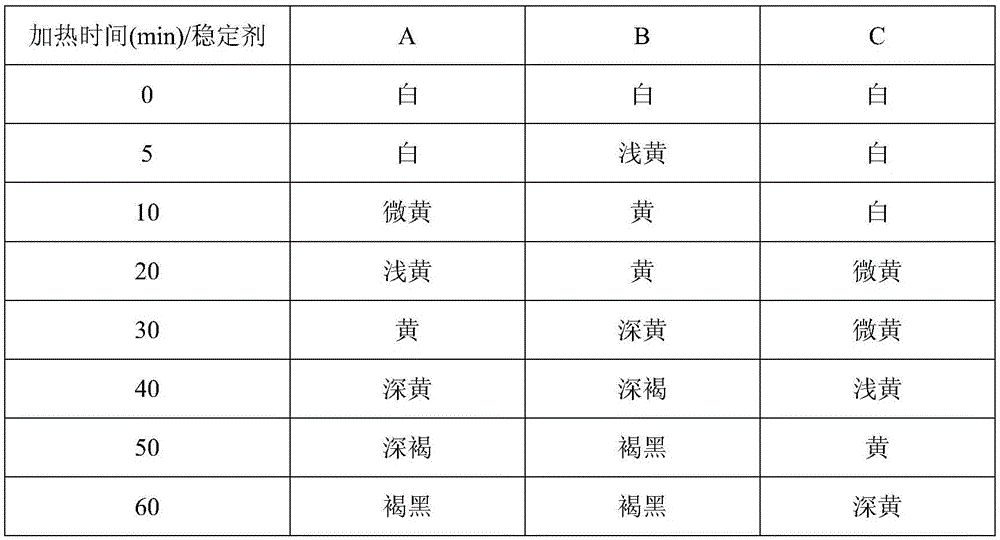

InactiveCN106316790AResistant to initial colorationStrong long-term thermal stabilityPreparation of metal alcoholatesPentaerythritolRoom temperature

The invention discloses a process for synthesizing zinc pentaerythritol in a heat stabilizer, and relates to the technical field of chemical preparation. The particular process includes respectively weighing activated zinc oxide and pentaerythritol powder according to a molar mass ratio of 3:2; placing the activated zinc oxide and the pentaerythritol powder in a high-speed mixer, mixing the activated zinc oxide and the pentaerythritol powder in the high-speed mixer at the rotational speed of 1300-1500 r / min, mixing and stirring the activated zinc oxide and the pentaerythritol powder for 20 minutes to obtain mixtures and carrying out reaction on the mixtures in a reactor for the reaction time of 45-90 min; cooling products until the temperatures of the products reach the room temperature; grinding the products by the aid of an ultrafine grinder to obtain the zinc pentaerythritol. The process has the advantages that the process for preparing the zinc pentaerythritol is simple, and the zinc pentaerythritol prepared by the aid of the process has initial-stage coloring resistance just like zinc stearate and is high in zinc burning inhibiting capacity and long-term heat stability.

Owner:广东鑫达新材料科技有限公司

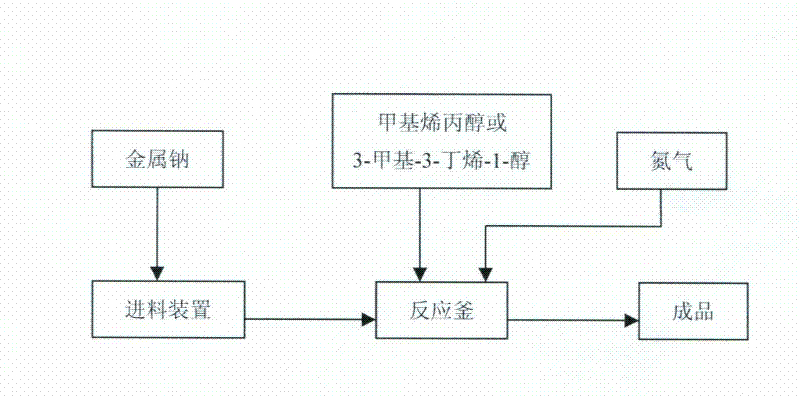

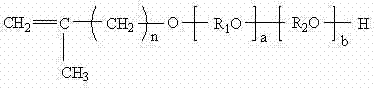

Catalyst for preparing polycarboxylate water reducing agent macromonomer and preparation method thereof

The invention discloses a catalyst for preparing a polycarboxylate water reducing agent macromonomer, which is a methallyl alcohol solution of sodium methallyl alcohol or a 3-methyl-3-butene-1-alcoholic solution of 3-methyl-3-butene-1-sodium alcoholate; and the solution contains 5-20 percent by mass of sodium methallyl alcohol or 3-methyl-3-butene-1-sodium alcoholate. The preparation method comprises the following steps of: putting methallyl alcohol or 3- methyl-3-butene-1-sodium alcoholate into a reaction kettle, cutting sodium metal into small blocks, and adding into a feeding device; keeping an emptying valve in an open state and introducing nitrogen; and adding metal sodium in batch, controlling the temperature of a reaction system not to surpass 120 DEG C, closing a feed valve after the metal sodium is added, continually reacting till a reaction liquid does not produce air bubbles, closing the emptying valve, stopping introducing nitrogen, and discharging. Due to the adoption of the catalyst, byproducts are not generated in the preparation process of macromonomer methylallyl polyoxyethylene ether and prenyl polyoxyethylene ether, and the purity of the macromonomer can be effectively increased.

Owner:山西山大合盛新材料股份有限公司

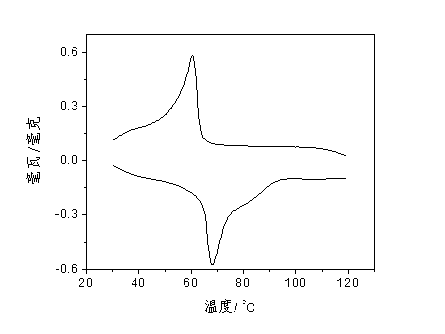

Preparation method of vanadyl ethylene glycol and method for preparing M-phase vanadium dioxide powder from vanadyl ethylene glycol

InactiveCN102795968ASimple processProcess safetyVanadium oxidesPreparation of metal alcoholatesVanadium dioxideLow emissivity

The invention relates to a preparation method of vanadyl ethylene glycol and a method for preparing M-phase vanadium dioxide powder from vanadyl ethylene glycol. The method comprises the following steps: adding a vanadium source into an ethylene glycol organic alcohol solvent, carrying out ultrasonic dispersion for 2-5 minutes, stirring in a 100-200 DEG C heating bath for 5-600 minutes, cooling to room temperature, and carrying out vacuum filtration to obtain the vanadyl ethylene glycol; and in a non-closed environment, carrying out heat treatment at 160-400 DEG C for 5-300 minutes to obtain the M-phase vanadium dioxide powder. The invention does not need special large-scale equipment or harsh medium atmosphere, and can obtain the M-phase vanadium dioxide powder by directly carrying out low-temperature heat treatment on the vanadyl ethylene glycol in a non-closed environment; the dopant is introduced to implement adjustable vanadium dioxide phase transition temperature within the range of 20-70 DEG C; and the compound filler is introduced to obtain the M-phase vanadium dioxide product which has different color tones and low emissivity. The M-phase vanadium dioxide prepared by the method provided by the invention has the advantages of high purity, simple preparation technique, low cost, safe and reliable production process and no pollutant emission, and can easily implement large-scale industrial production.

Owner:SOUTHWEST UNIVERSITY

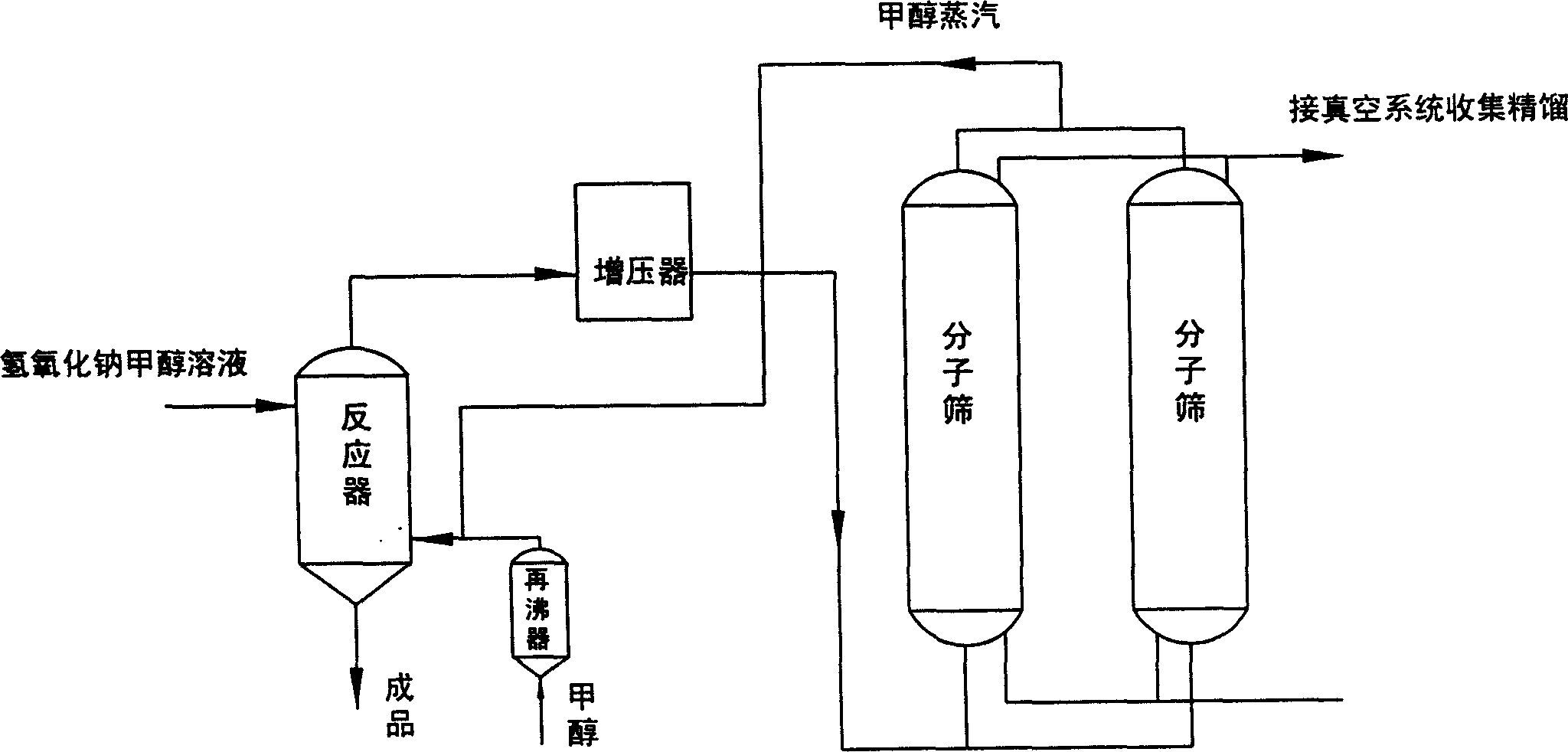

Technique of alkaline process for producing sodium methoxide/sodium ethylate

InactiveCN1626488AQuick responseContinuous responsePreparation of metal alcoholatesSodium methoxideMolecular sieve

A process for preparing sodium methoxde (or ethoxide) by alkali method includes reaction between excess methanol (or ethanol) and sodium hydroxide to obtain product, dewatering the vapour of methanol (or ethanol) by parallel two molecular sieves for alternative adsorption and desorption, and rectifying the solution of methanol (or ethanol) for reuse. Its advantage is no pollution.

Owner:于志波

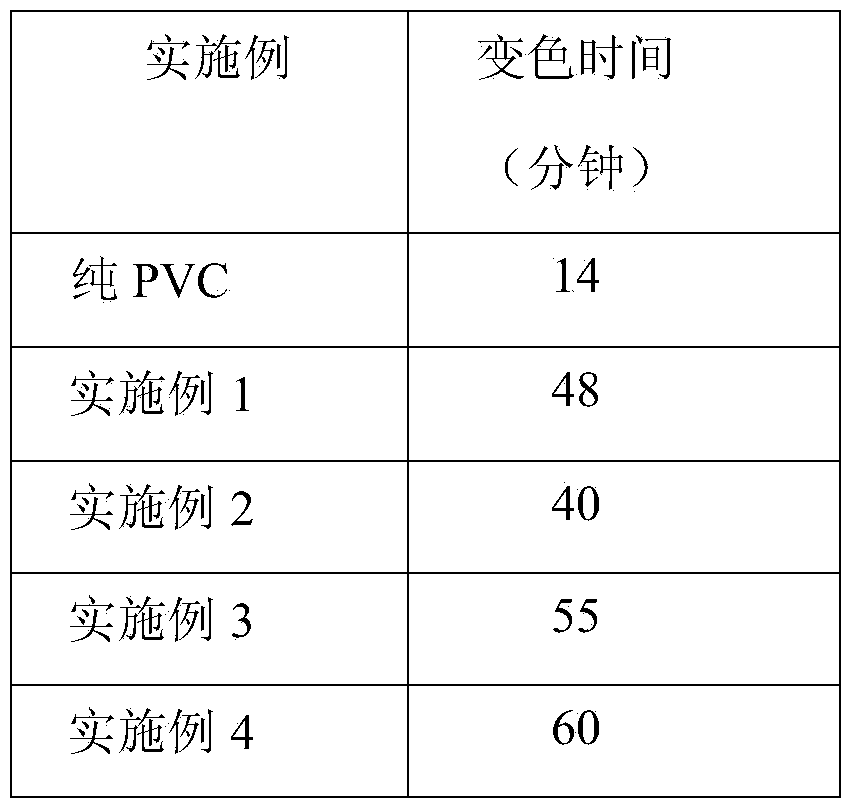

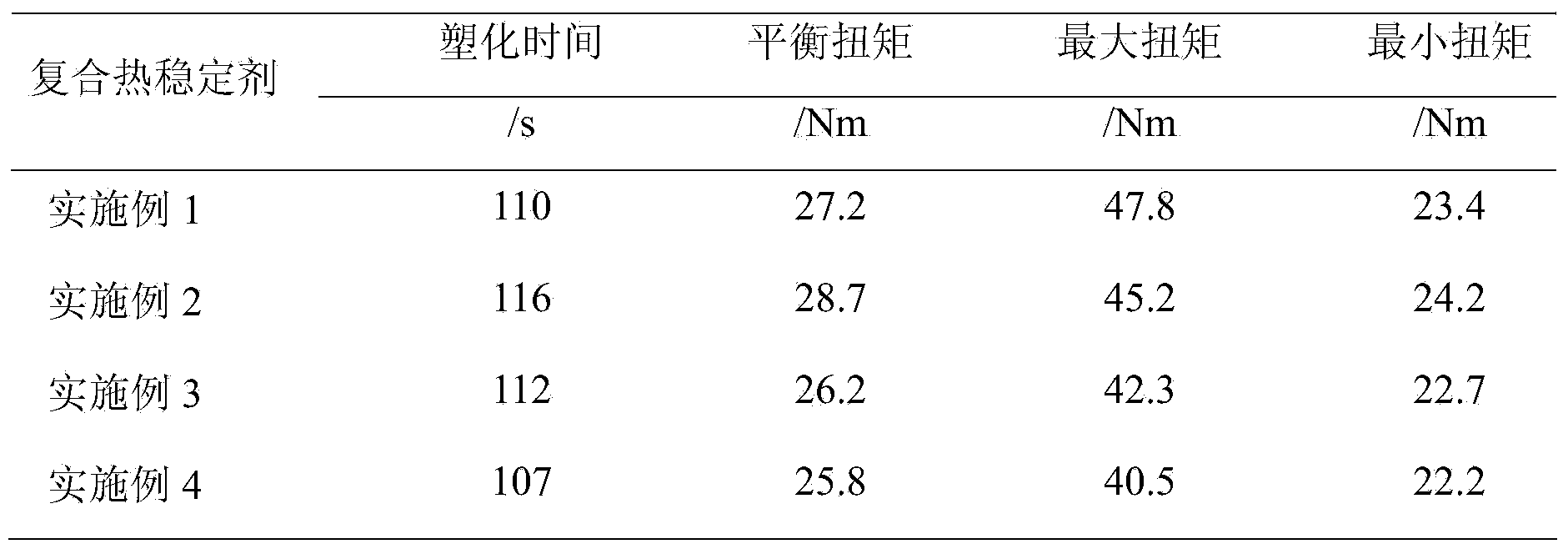

Environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and preparation method of environmental-friendly high-efficiency composite heat stabilizer

InactiveCN102153824AImprove thermal stabilityGood initial colorabilityPreparation of metal alcoholatesEnvironmental resistancePentaerythritol

The invention belongs to the field of a heat stabilizer for PVC (polyvinyl chloride) and relates to an environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and a preparation method of the environmental-friendly high-efficiency composite heat stabilizer. The environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) is prepared by performing a reaction of tribasic zinc, calcium stearate, a lubricant and an auxiliary heat stabilizer, wherein the tribasic zinc is prepared by mixing pentaerythritol and zinc oxide according to a weight ratio of 6-8:3 and performing a reaction for 4 to 6 hours at a temperature of 140 to 180 DEG C. The preparation method comprises the following steps of: adding the tribasic zinc and the calcium stearate into a reaction kettle for sufficiently mixing; adding the mixed materials into a kneading machine to knead for 15 to 25 minutes at a temperature of 100 to 120 DEG C; adding a lubricating agent and the auxiliary heat stabilizer in the kneading machine to knead and stir for 25-35min; and carrying out discharging, tabletting, sieving and packaging to obtain the finished product. The prepared environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the characteristics that the environmental-friendly high-efficiency composite heat stabilizer is difficult to separate out and has good stabilizing effect; the balancing torque can be reduced; and the processing property is improved. Moreover, the environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the advantages of high efficiency and environment protection.

Owner:慧科高新科技股份有限公司

Spheroidal particles for olefin polymerization catalyst

ActiveUS20110054129A1High mechanical strengthOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsAlcoholPolymer resin

The invention relates to a process for the synthesis of spheroidal magnesium alkoxide having improved mechanical strength and narrow particle size distribution, the process comprising reacting magnesium metal, in the presence of iodine, with a mixture of alcohols by step-wise heating first in the range of 40° C. to 65° C. for a period of 2 hours and then in the range of 65° C. to 80° C. for a period of 1 hour, further by maintaining reaction temperature at 80° C. for a period of 6-10 hours, the vapours of the mixture produced during the reaction being condensed in an overhead condenser, hydrogen gas produced during the reaction being vented off and the mixture of alcohols left after the reaction being filtered and reused. The invention also relates to spheroidal magnesium alkoxide particles synthesized by the method, to the Ziegler natta procatalyst synthesized by using the alkoxide and to the polymer resin synthesised using the procatalyst.

Owner:RELIANCE INDUSTRIES LIMITED

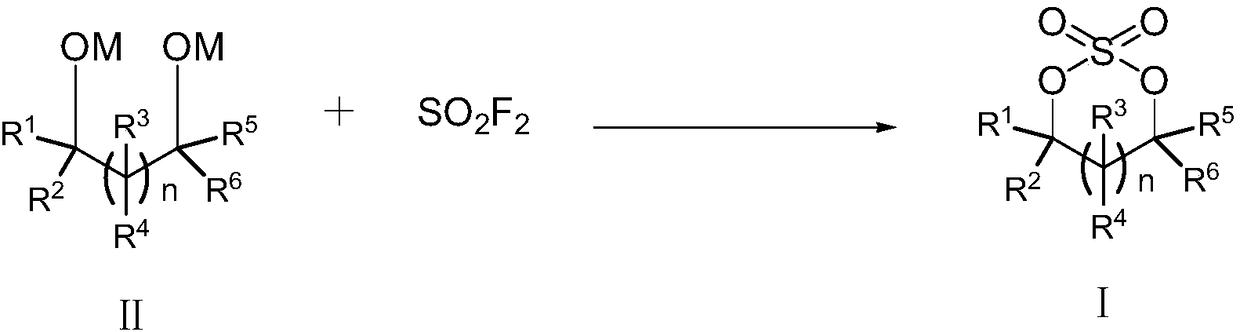

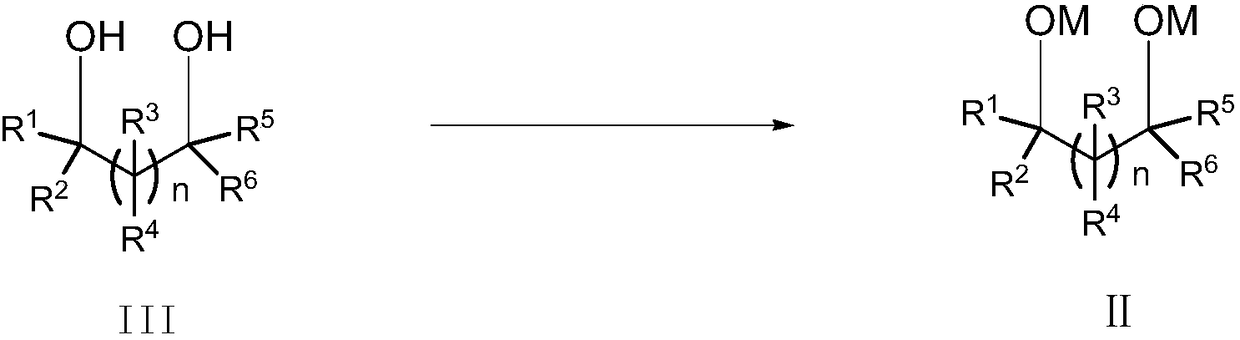

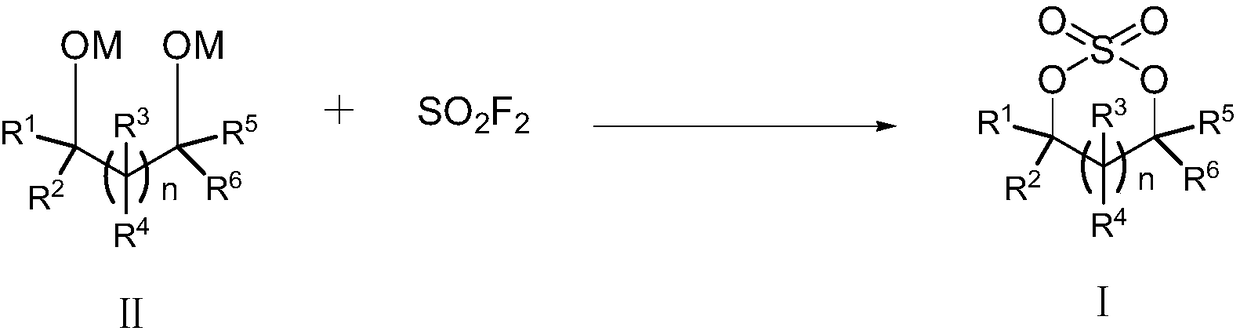

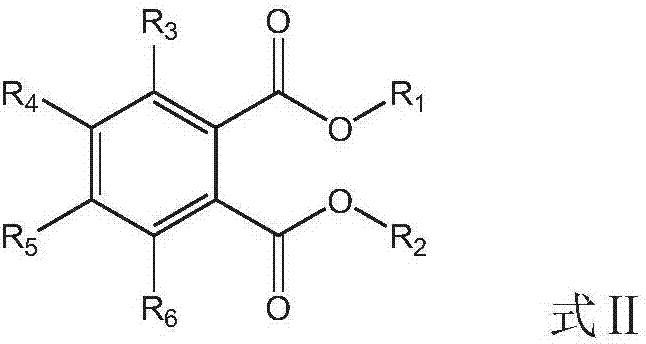

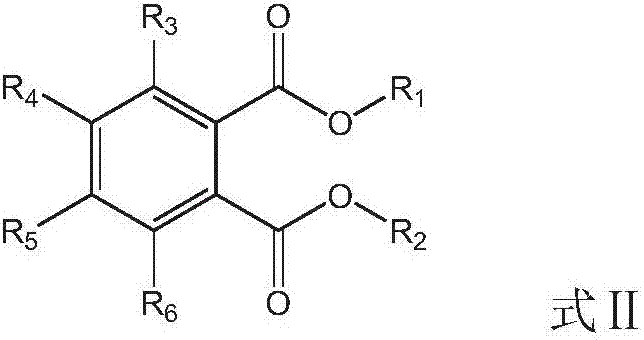

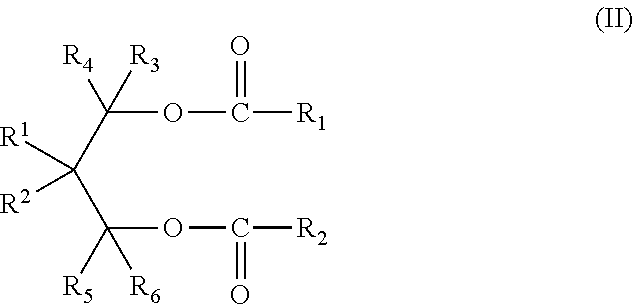

Sulfate preparation method

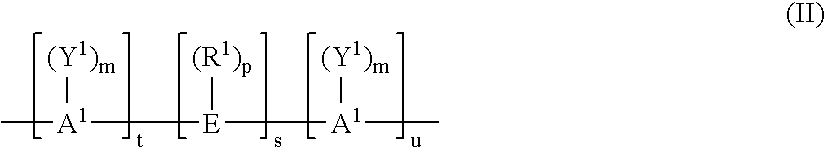

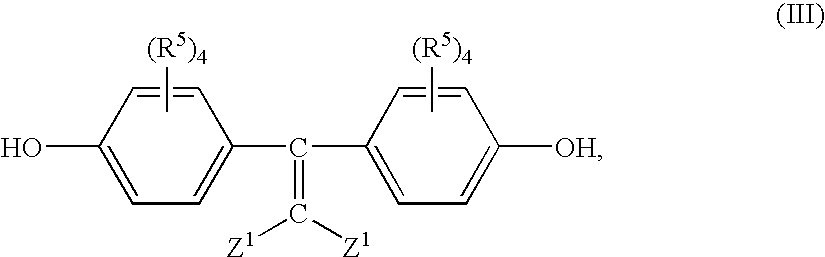

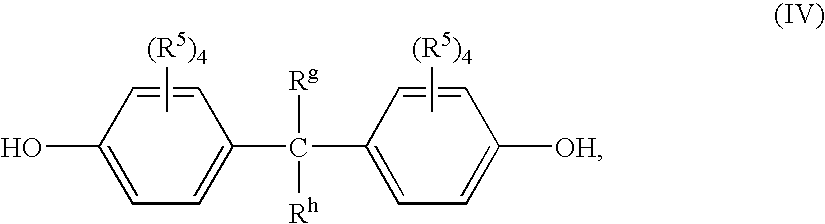

The invention relates to the field of organic synthesis, and especially relates to a sulfate preparation method. The invention provides a sulfate preparation method. According to the preparation method, a compound represented by a formula (II) reacts with sulfuryl fluoride in the presence of a reaction solvent to prepare a compound represented by a formula (I). During the sulfate preparation process, the introduction of water and chlorine ions is avoided effectively, the situation that the product is degraded and the chlorine ion content is high is avoided therefore; moreover, the steps of thepreparation method are simple and short, the raw material are common chemical products on the market, the kinds of raw materials and the side reactions are few, and the yield is high. The manufacturing cost is low, only recyclable organic solvents are used, the reaction byproduct is a single inorganic salt solid and can be easily recovered, no wastewater is generated, the environment is better protected, and the sulfate preparation method is green and environmentally friendly and is suitable for industrial large scale production.

Owner:SHANGHAI CHEMSPEC CORP +1

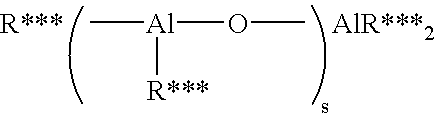

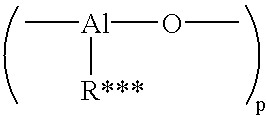

Mixed metal alkoxide complexes and polymerization catalysts made therefrom

InactiveUS20030050184A1High yieldLow fineGroup 4/14 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsOxidation statePolymerization catalysts

A mixed metal-containing precursor is disclosed whereby the precursor includes: a) a mixed metal component represented by the following formula: (M1M2)x(T1T2)y where M1 and M2 may be the same or different and are selected from one or more metals having a +2 oxidation state, T1 and T2 may be the same or different and are selected from one or more metals having oxidation states selected from the groups consisting of +3, +4, and +5, the molar ratio of x / y is from about 2.5 to about 3.75, with the proviso that if M1 and M2 are both Mg then T1 and T2 cannot both be chosen from Zr and Ti+4; and b) at least one moiety complexed with component a) selected from alkoxide groups, phenoxide groups, halides, hydroxy groups, carboxyl groups, amide groups, and mixtures thereof. A polymerization procatalyst prepared from the mixed metal containing precursor, methods of making the precursor and procatalyst, as well as polymerization methods using the procatalyst also are disclosed.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

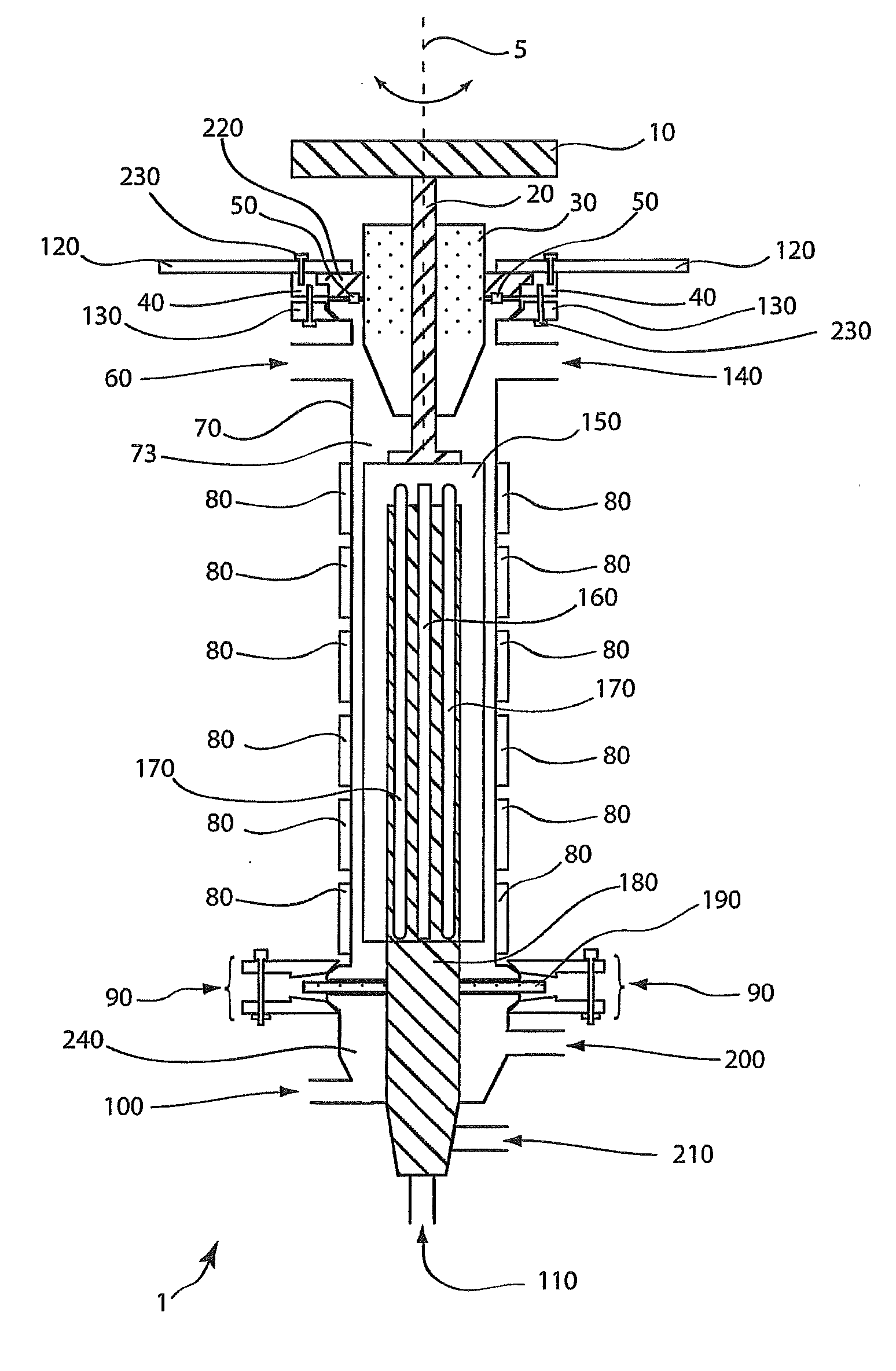

Metal alkoxides, apparatus for manufacturing metal alkoxides, related methods and uses thereof

InactiveUS20090134369A1Organic compound preparationGroup 4/14 organic compounds without C-metal linkagesAlcoholFire retardant

Owner:AUTERRA INC

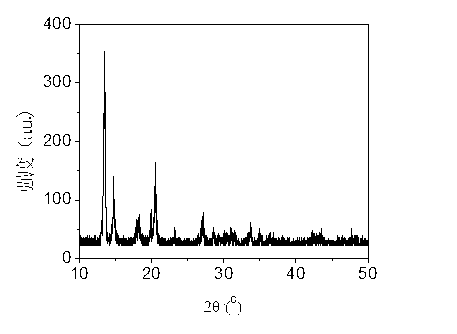

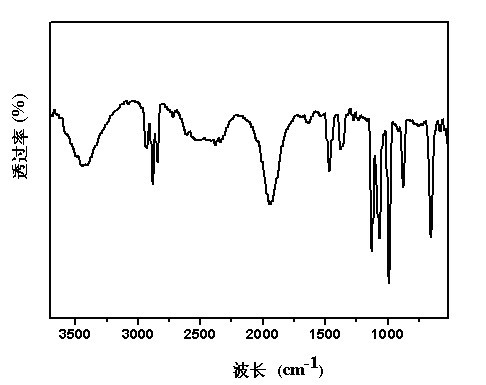

Method for preparing glyzinc under high pressure

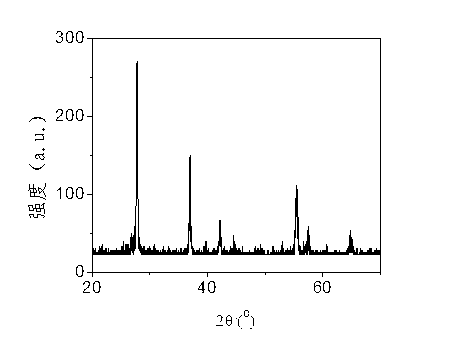

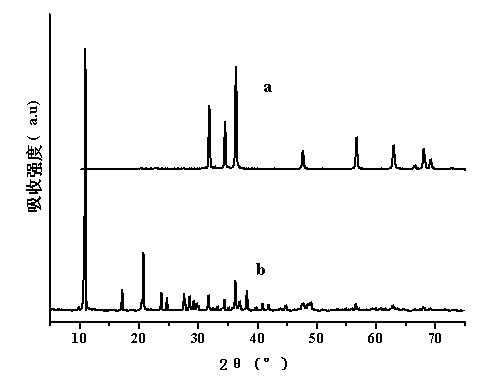

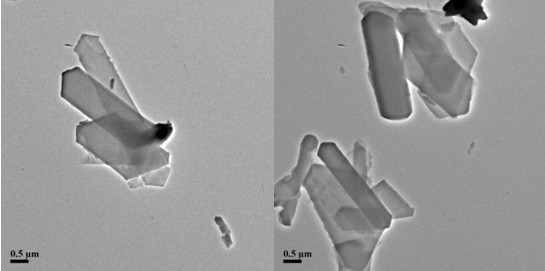

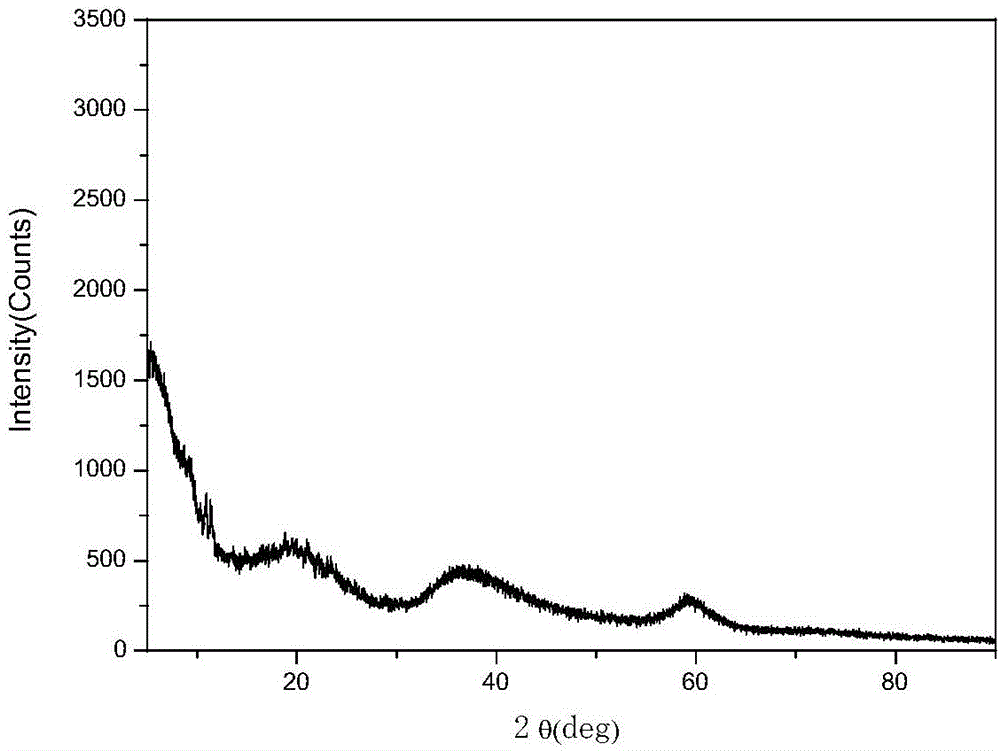

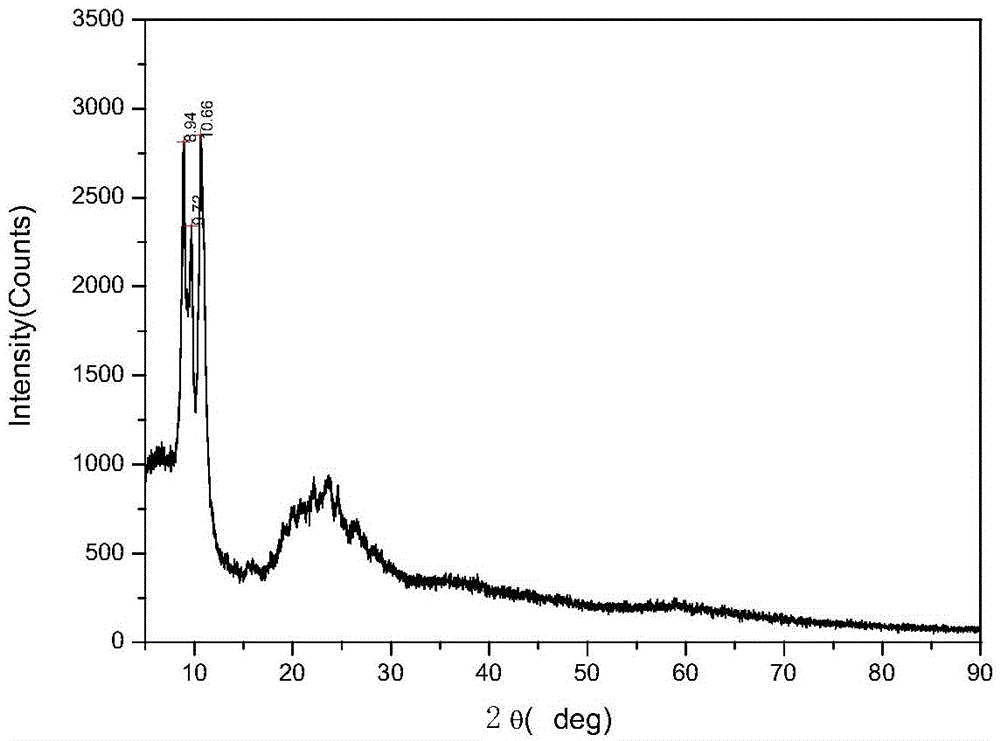

InactiveCN102093165AWill not generateConditions to avoid excessively high temperature reactionsPreparation of metal alcoholatesChemical synthesisX-ray

The invention discloses a method for preparing glyzinc under the high pressure, which belongs to the technical field of chemosynthesis. In the method, the glyzinc is prepared from living being or animal and plant oil base hydrolysis byproduct glycerin serving as a raw material. The method comprises the following steps of: stirring and heating zinc oxide and glycerin for a reflux reaction, wherein the mass ratio of the zinc oxide to the glycerin is 1:10-30; and transferring a reaction mixture into a high-pressure reaction kettle for continued reacting, washing, separating and drying to obtain white product of glyzinc. The structure of the glyzinc is represented and proved by infrared spectrum and X-ray diffraction. By TEM (Transmission Electron Microscope) observation, obtained glyzinc particles have tablet irregular polygonal structures with the side lengths of between 0.5 mu m and 3.5 mu m. The obtained glyzinc can be taken as a novel main component of a non-toxic heat stabilizer. The invention has the advantages of readily available raw materials, low cost, easy synthesis, easiness and convenience in operating and easy biodegradation of a product.

Owner:JIANGNAN UNIV

Preparation method of alkoxy magnesium carrier for olefin polymerization catalyst

ActiveCN105713116AEasy to controlCrystal phase changeMagnesium organic compoundsPreparation of metal alcoholatesReaction temperatureDolichol

The invention relates to a preparation method of an alkoxy magnesium carrier for an olefin polymerization catalyst. The preparation method comprises that magnesium, monohydric alcohol, a halogenation agent and an inert organic solvent are added into a reactor in an inert gas atmosphere and undergo a reaction in the inert gas atmosphere at a temperature of 0-90 DEG C for 1-30h to produce an alkoxy magnesium carrier, polyol is added into the alkoxy magnesium carrier, the mixture undergoes a reaction at a reaction temperature of 30-100 DEG C for 1-30h, the reaction product is stood and filtered and the filter residues are washed so that the alkoxy magnesium carrier for an olefin polymerization catalyst is obtained. The amorphous alkoxy magnesium carrier has a good particle form and high bulk density.

Owner:PETROCHINA CO LTD

Self-catalyzed one-step synthesis method of high-purity aluminum isopropoxide

ActiveCN104355967ALow purityHigh purityPreparation of metal alcoholatesAutocatalysisSynthesis methods

The invention discloses a self-catalyzed one-step synthesis method of high-purity aluminum isopropoxide. The high-purity aluminum isopropoxide is synthesized in an autocatalysis manner by use of the high-purity aluminum isopropoxide as the catalyst. The high-purity aluminum isopropoxide is taken as the catalyst instead of HgCl2, AlCl3, I2, CuCl2 and the like to realize the autocatalysis of the aluminum isopropoxide synthesis process, and no impurity element is introduced so that the purity of the aluminum isopropoxide can be improved; and as a result, reliable raw material guarantee is provided for subsequent production of related high-purity materials by use of the aluminum isopropoxide.

Owner:SHANDONG HENGJING NEW MATERIAL CO LTD

Method for preparing alkoxy aluminum

ActiveCN102050700ASimplify purification operationsThorough responsePreparation of metal alcoholatesAlcoholBoiling point

The invention discloses a method for preparing alkoxy aluminum. The method comprises the following steps: aluminium powder and / or aluminium yarns and aluminium ingots are put in a reaction vessel; fatty alcohol between C3-C10 is used for reacting in an inert environment, and is divided into two parts; the weight of one part is 10-35 percent of the total weight of the fatty alcohol; the first partof the fatty alcohol is added into the reaction vessel, and is contacted with the aluminium powder or aluminium yarns at the temperature which is 5-25 DEG C lower than the boiling point of the fatty alcohol for initiating the reaction; the second part of the fatty alcohol which is left is continuously added into the reaction vessel after the reaction is initiated, and is continuously reacted withthe aluminium powder or aluminium yarns until the reaction is fully carried out at the temperature which is lower than the boiling point of the fatty alcohol; and the weight of the aluminium powder or aluminium yarns is 0.5-5.0 percent of the total weight of the aluminium powder and / or aluminium yarns and the aluminium ingots. The method has the advantages that a catalyst is not used, the preparation is simple, and the reaction can be carried out fully, stably and fast.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of glyzinc

ActiveCN105906473ASimple processEasy to operatePreparation of metal alcoholatesChemical synthesisAlcohol

The invention relates to a preparation method of glyzinc, and belongs to the field of chemical synthesis. The preparation method comprises the following steps of adding a zinc source, a catalyst and an aprotic solvent into a reactor according to a mass ratio being 1:(0.05 to 0.15): (2 to 10); performing stirring for 5 to 30min; then, adding dispersing agents accounting for 0.3 to 3 percent of the mass of the zinc source; performing stirring for 5 to 10 min so that the zinc source and the catalyst are uniformly dispersed in a solvent; then, adding glycerol (the mol ratio of the glycerol to the zinc source is (1 to 1.2):1); raising the temperature to 100 to 150 DEG C under the stirring condition; taking a reaction for 2 to 4 hours; performing cooling and suction filtration; performing washing by C<1 to 3> monohydric alcohol, and then performing suction filtration and drying to obtain the glyzinc. The invention provides the preparation method with the advantages that the process is simple; the operation is convenient; the reaction conditions are mild; the temperature can be easily controlled. The glyzinc synthesis is performed in the aprotic solvents; through the addition of dispersing agents, reaction substances cannot agglomerate or deposit on the device wall; after the reaction, the filtering and the separation can be directly performed; the washing is easy.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

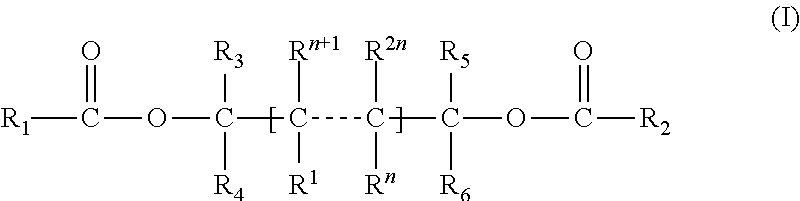

Metallic alkoxy complex, catalyst composition and preparation method of poly-caprolactone or poly-lactide

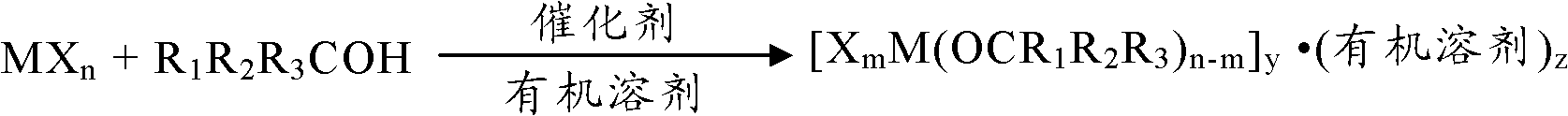

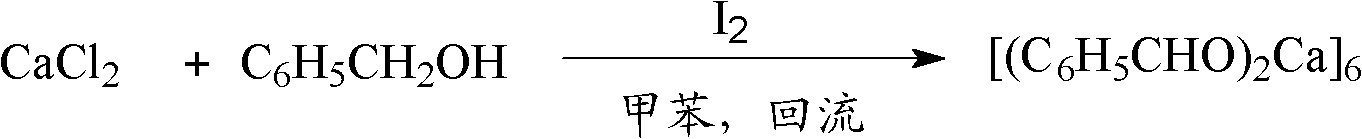

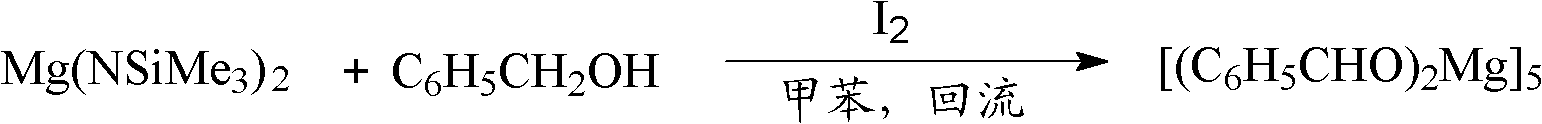

ActiveCN102491874AReduce dosageHigh molecular weightOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPoly(lactide)Hydroxy group

The invention provides a metallic alkoxy complex of which the molecular formula is disclosed as Formula (I). The invention also provides a catalyst composition which comprises the metallic alkoxy complex and a hydroxy compound, wherein the mol ratio of the metallic alkoxy complex to the hydroxy compound is 1:(0.1-1000). The preparation method of the poly-epsilon-caprolactone or poly-actide comprises the following steps: reacting an epsilon-caprolactone monomer or lactide monomer under the action of the metallic alkoxy complex or the catalyst composition to obtain poly-epsilon-caprolactone or poly-actide. The metallic alkoxy complex and the catalyst composition thereof can efficiently catalyze the synthesis of the poly-epsilon-caprolactone or poly-actide. The molecular weight of the poly-caprolactone or poly-actide can be controlled by the mol ratio of the metallic alkoxy complex to the hydroxy compound, and can be adjusted within the range of 1-600 thousand, and the molecular weight distribution ranges from 1.03 to 1.50.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Process for producing 2-alkyl-2-adamantyl ester

InactiveCN1429195AExcellent yieldHigh yieldPreparation from carboxylic acid halidesOrganic compound preparationLithium metalMetal

A process for producing a 2-alkyl-2-adamantyl ester, characterized by mixing and reacting a solution or suspension containing 2-adamantanone and a halogenoalkyl compound with lithium metal to obtain a lithium 2-alkyl-2-adamantyl alcoholate and subsequently reacting the lithium 2-alkyl-2-adamantyl alcoholate with an acid halide.

Owner:TOKUYAMA CORP

Alkoxy magnesium particles and application thereof

ActiveCN107987197AReaction is easy to controlParticles in good shapeTitanium organic compoundsPreparation of metal alcoholatesCross-linkAlcohol

The invention provides alkoxy magnesium particles and an application thereof. The alkoxy magnesium particles comprise reaction products of following components: 1) magnesium powder, 2) mixed alcohol,3) a halogenating agent and 4) a cross-linking agent, wherein the cross-linking agent is titanate compounds. When the alkoxy magnesium particles are applied to preparation of a catalyst for olefin polymerization, the obtained catalyst is high in activity, good in particle morphology and distributed uniformly, and stacking density of polymers is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

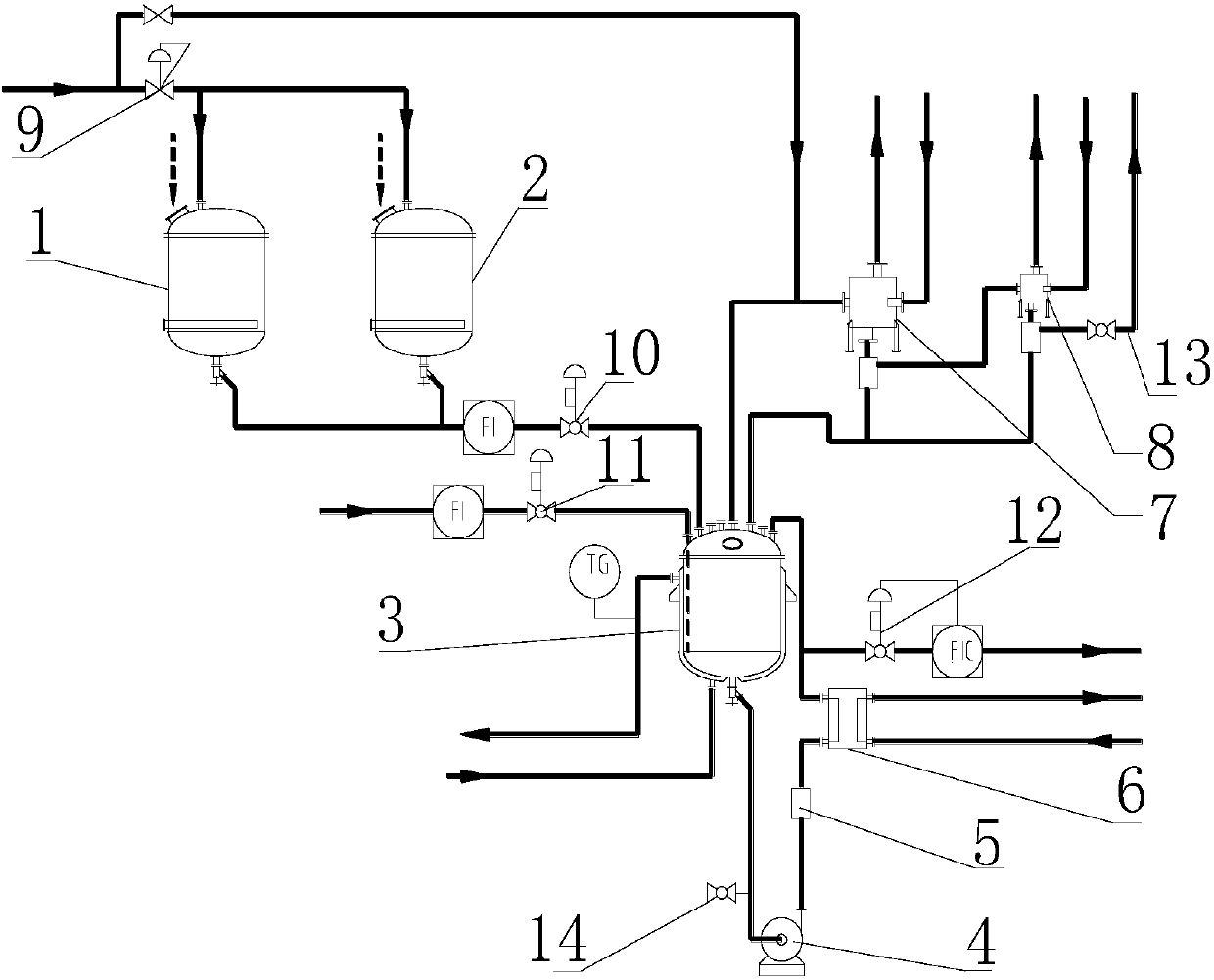

Continuous production process for sodium methoxide by using metal sodium method

InactiveCN107602346APossibility of avoiding contact with waterEnsure safetyPreparation of metal alcoholatesSodium methoxideShielding gas

The invention discloses a continuous production process for sodium methoxide by using a metal sodium method. The process is innovated in that an intermittent production process for sodium methoxide byusing the metal sodium method is changed into a continuous production process. The process has the characteristics that the continuous production process for sodium methoxide by using a solid metal sodium method is realized; solid metal sodium is heated to be fused into liquid metal sodium by using an electric heating method in the process, so that the possibility that metal sodium is in contactwith water is avoided, and nitrogen gas is used as a shielding gas in the process, so that the possibility that metal sodium is in contact with air is avoided, and the safety is greatly guaranteed; solid metal sodium is fused into liquid metal sodium to realize liquid flow for automatic and continuous feeding; the process is simple, convenient to operate and capable of realizing mass production, and the product is stable; and the continuous production process is low in investment and small in floor area.

Owner:ANHUI PROVINCE CHEM IND DESIGN INST

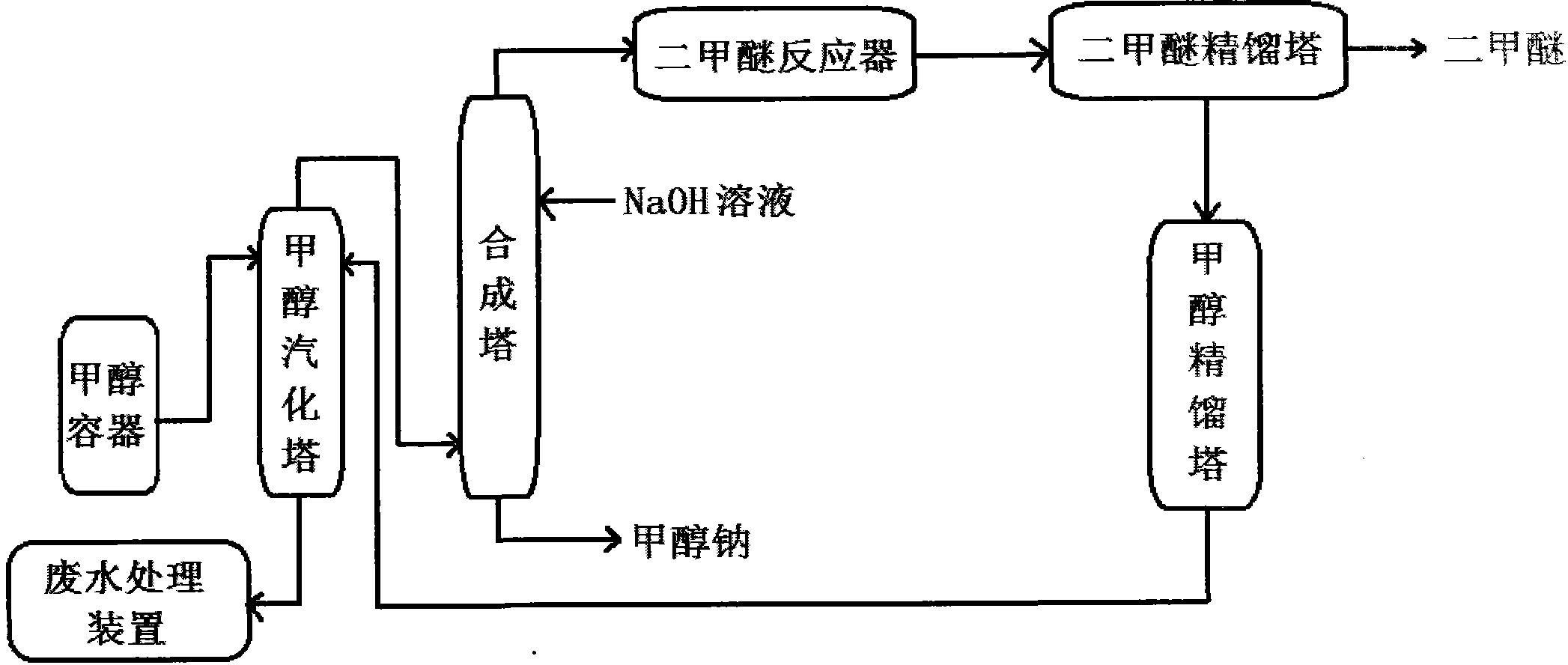

Sodium methoxide and dimethyl ether combined production technology

InactiveCN104341270AReduce manufacturing costReduce energy consumptionPreparation of metal alcoholatesEther preparation by compound dehydrationSodium methoxideVaporization

The invention relates to a sodium methoxide and dimethyl ether combined production technology, which comprises the following steps: a raw material methanol is introduced in a methanol vaporization tower for vaporization, the vaporized methanol in introduced in a synthetic tower, sodium hydroxide and methanol in the synthetic tower are reacted to obtain reaction products containing sodium methoxide, methanol steam and water, sodium methoxide is discharged from the bottom of the synthetic tower and then collected, the aqueous methanol steam is introduce4d in a dimethyl ether reactor, after dehydration reaction, dimethyl ether is extracted from upper side line of a dimethyl ether rectifying tower, methanol and water are introduced in a methanol rectifying tower, and the rectified methanol is recovered and utilized in the methanol vaporization tower. According to the invention, a dimethyl ether production apparatus is used for producing a lot of absolute methanol steam, the absolute methanol steam is introduced in a sodium methoxide synthesis reaction tower, sodium methoxide is generated at bottom of the tower, and the aqueous methanol steam from the tower top is send to the dimethyl ether reactor for producing dimethyl ether. The technology effectively use the heat released through sodium methoxide generation reaction by methanol, energy consumption and equipment investment are reduced, and the dimethyl ether and sodium methoxide production cost can be reduced.

Owner:黄志忠

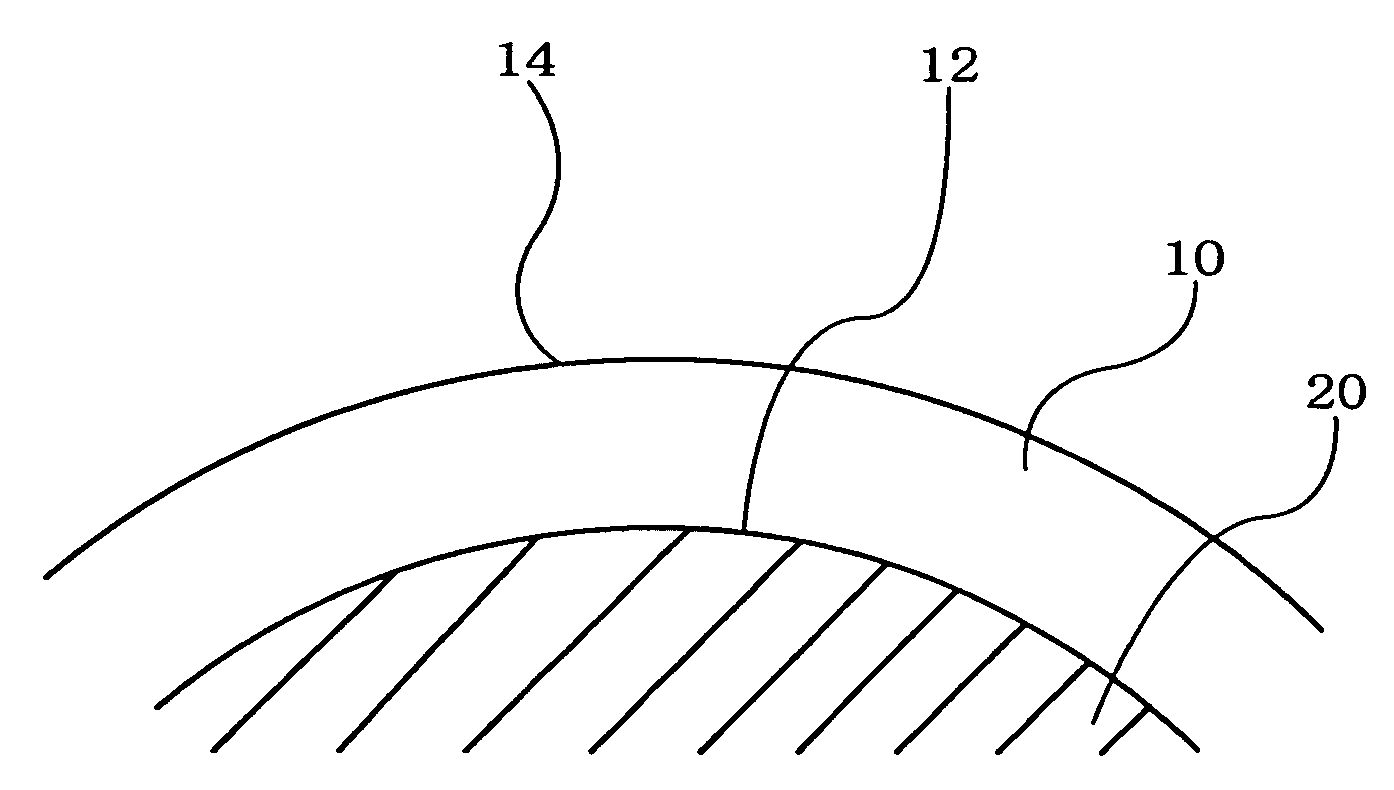

Catalyst carrier for olefin polymerization, solid catalyst component and catalyst

InactiveUS20130196847A1Particles in good shapeHigh polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholIodine

The invention relates to a dialkoxyl magnesium carrier, which is a product produced by a reflux reaction of magnesium, an alcohol and mixed halogenated agents under an inert atmosphere. The mixed halogenated agents are iodine and magnesium chloride, and the weight ratio between iodine and magnesium chloride is 0.05:1-1:0.01. The dialkoxyl magnesium carrier is spheroid with uniform particle size distribution, excellent particle morphology and high bulk density. A solid catalyst component and a catalyst based on this carrier for olefin polymerization are also provided, and olefin polymers having a wide molecular weight distribution, good stereoregularity, excellent particle morphology and a low content of fine powders can be obtained.

Owner:CHINA PETROCHEMICAL CORP +1

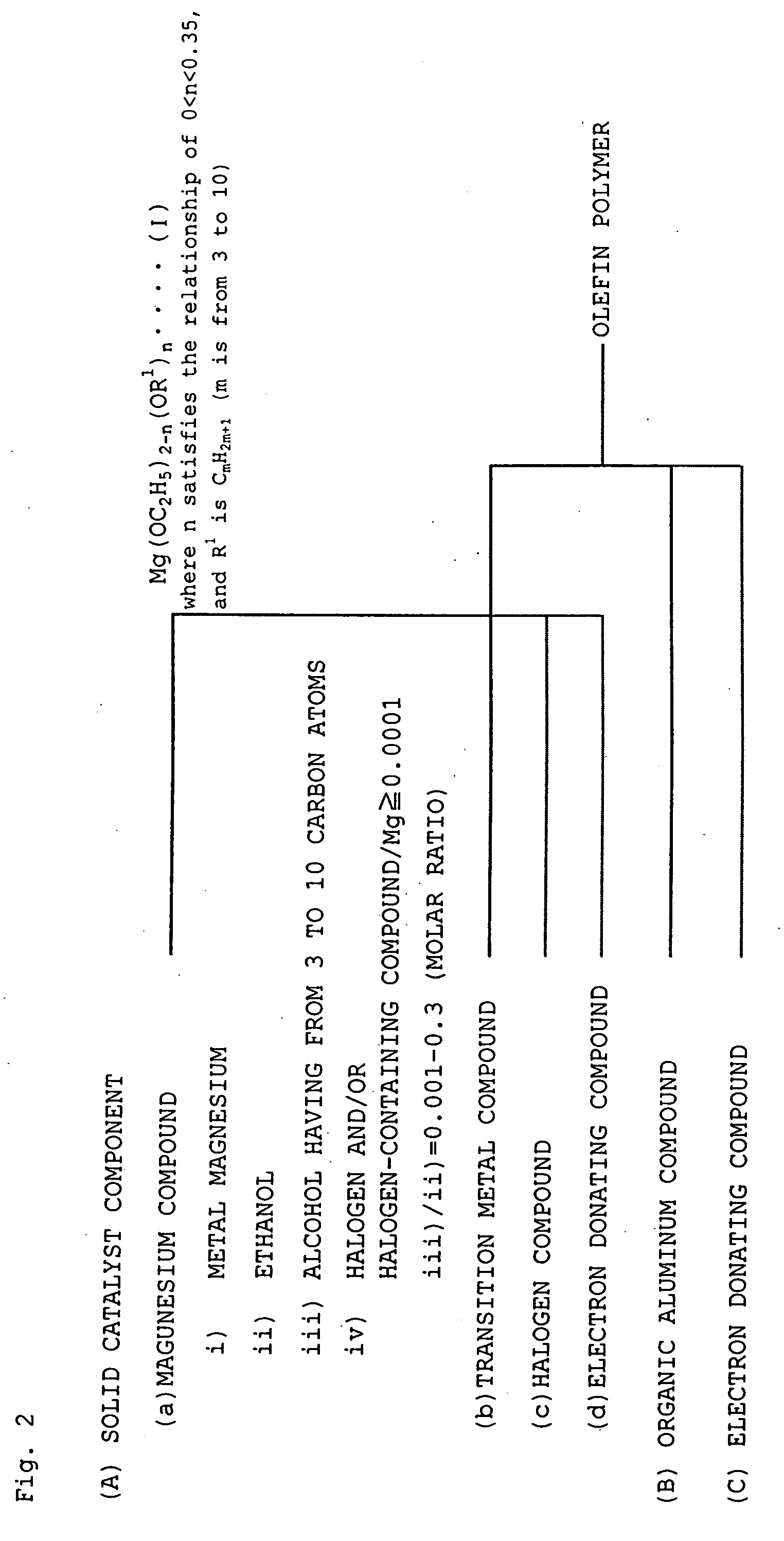

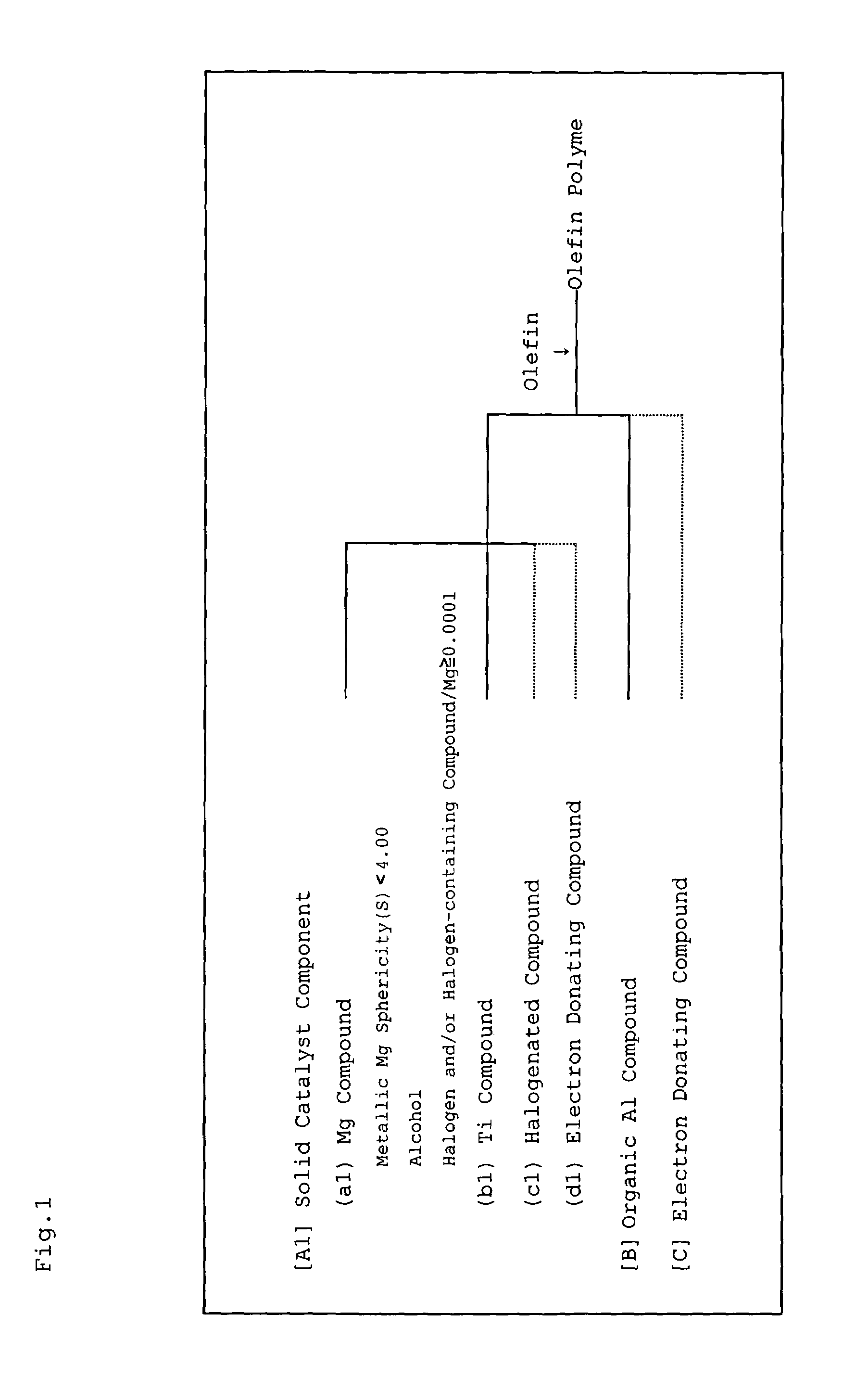

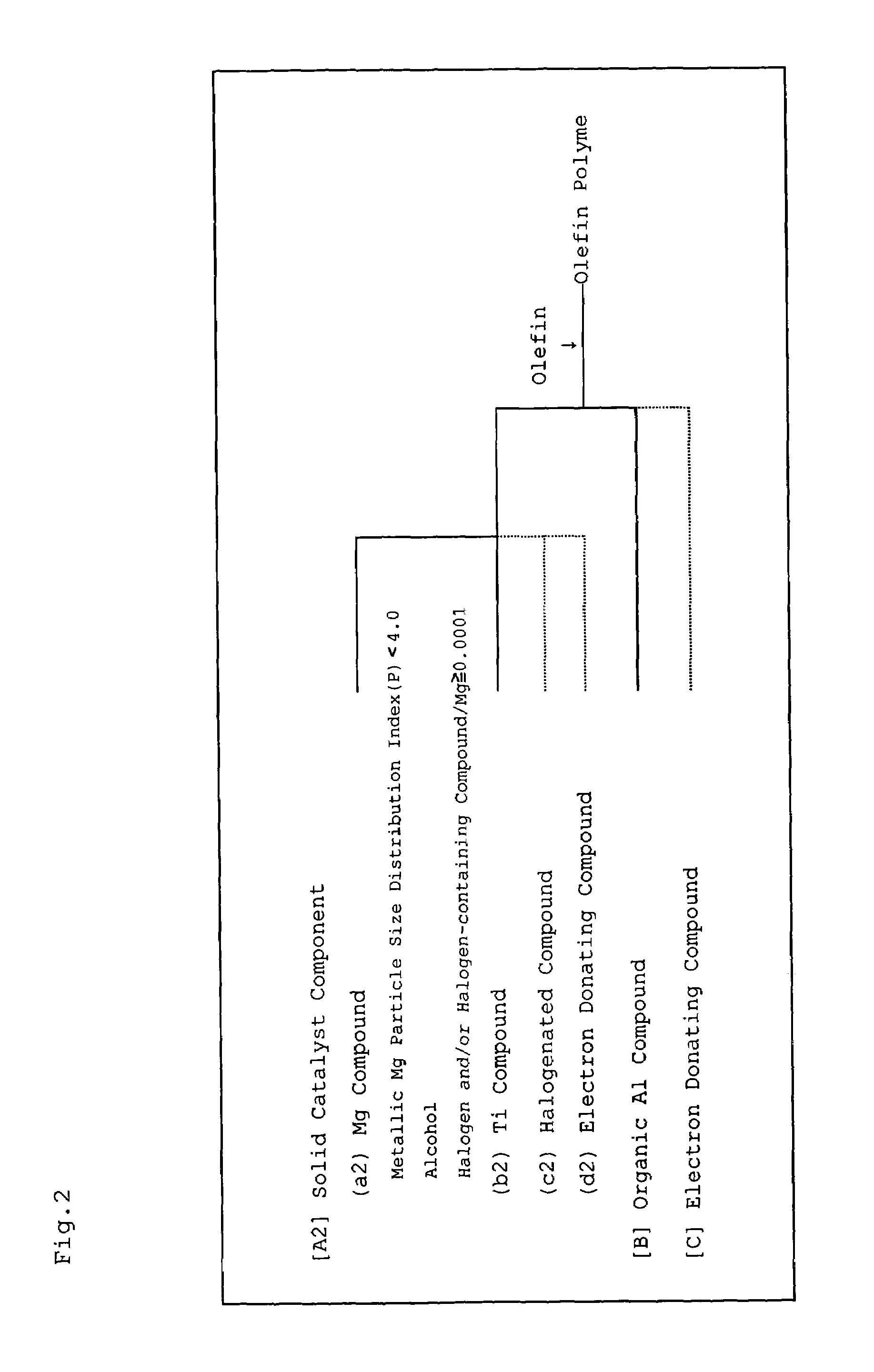

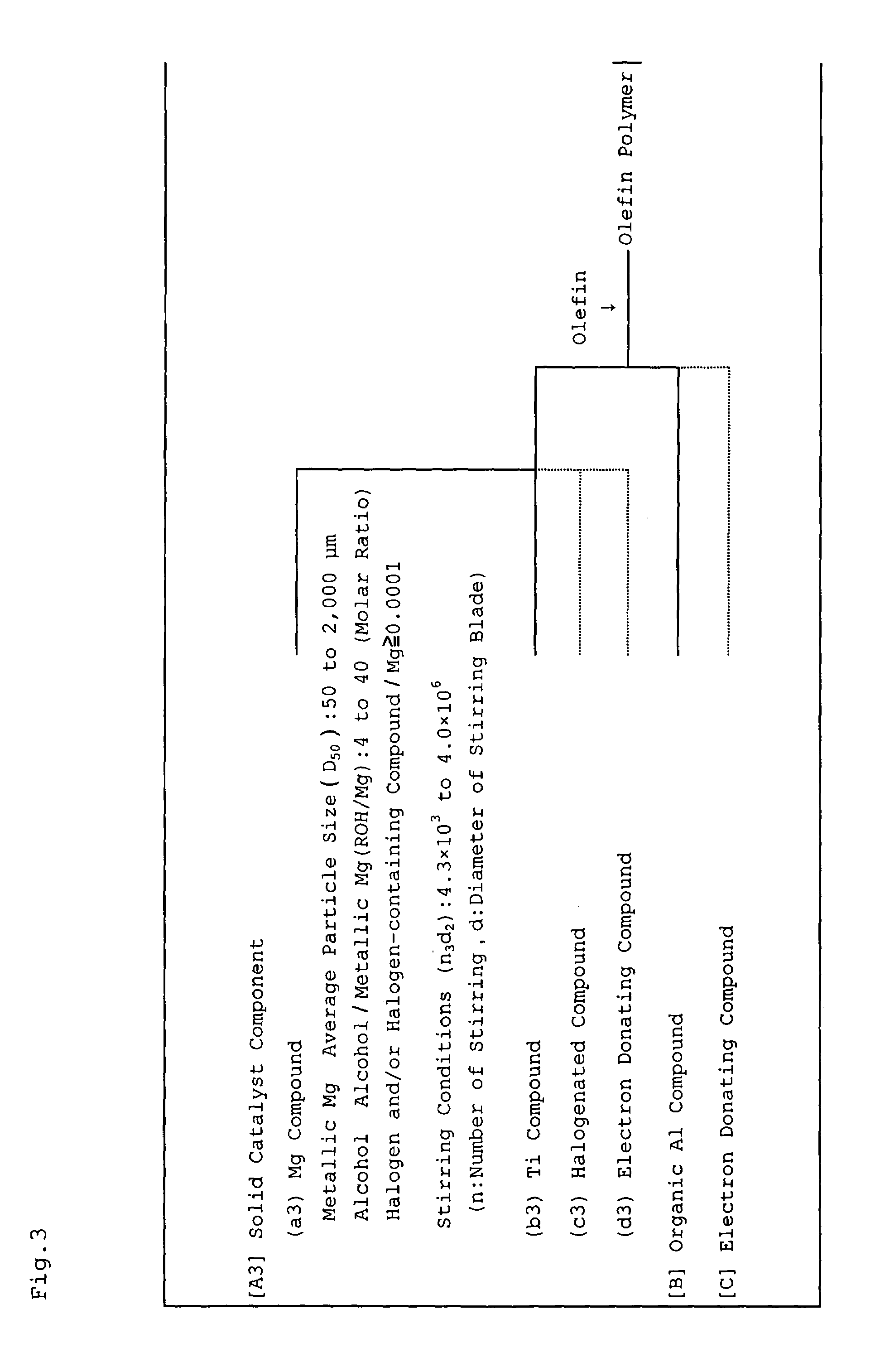

Magnesium Compound, Catalyst for Olefin Polymerization and Method for Producing Olefin Polymer

ActiveUS20080281059A1High activityGood fluidity of powderOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsPolymer scienceOlefin polymerization

A magnesium compound represented by the formula (I):Mg(OC2H5)2−n(OR1)n (I)where R1 is CmH2m+1 (where m is an integer of from 3 to 10), and n is a numerical value satisfying 0<n<0.35; a solid catalyst component for olefin polymer using the magnesium compound; a catalyst for olefin polymer; and methods of producing olefin copolymers such as a propylene-based random copolymer and propylene-based block copolymer by using the catalyst for olefin polymer.

Owner:IDEMITSU KOSAN CO LTD

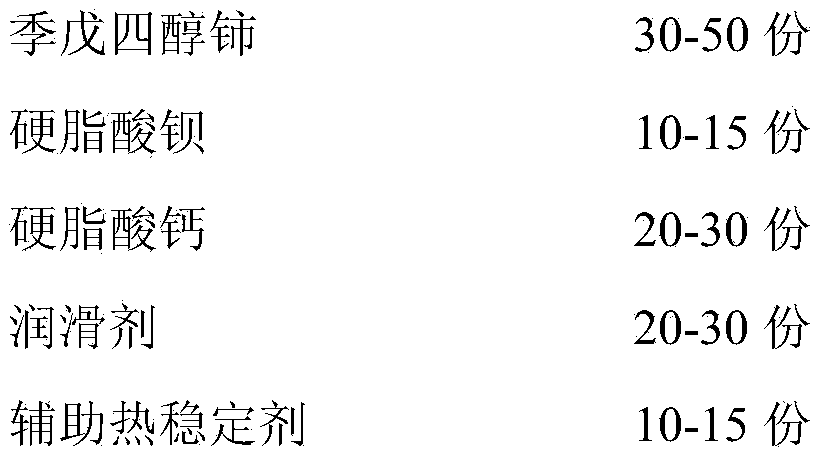

Efficient composite heat stabilizer for pentaerythritol cerium-based PVC and preparation method of heat stabilizer

ActiveCN103627117AIdeal initial hueImprove long-term thermal stabilityPreparation of metal alcoholatesPolymer sciencePentaerythritol

The invention belongs to the technical field of chemical engineering, and particularly relates to an efficient composite heat stabilizer for pentaerythritol cerium-based PVC and a preparation method of the heat stabilizer. The efficient composite heat stabilizer is prepared from the following raw materials in weight part: 30-50 parts of pentaerythritol cerium, 10-15 parts of barium stearate, 20-30 parts of calcium stearate, 20-30 parts of a lubricant and 10-15 parts of an auxiliary heat stabilizer. The preparation method comprises the following steps: firstly the pentaerythritol cerium, barium stearate and calcium stearate are added into a reaction kettle for fully mixing, the well mixed material is added into a kneading machine and kneaded for 20-30 minutes at the temperature of 100-120 DEG C, then the lubricant and the auxiliary heat stabilizer are added into the kneading machine, and kneaded and mixed for 30-40 minutes, the material is discharged, and the tabletting, sieving and packing are performed, so that the efficient composite heat stabilizer is obtained. The efficient composite heat stabilizer prepared through the preparation method has the characteristics that the heat stabilizer is difficult to separate out, excellent in stability, low in cost, non-toxic and environmentally friendly, and the raw material is easy to obtain. The preparation method provided by the invention causes no pollution, is low in energy consumption, is scientific, reasonable and simple, and is easy to realize.

Owner:慧科高新科技股份有限公司

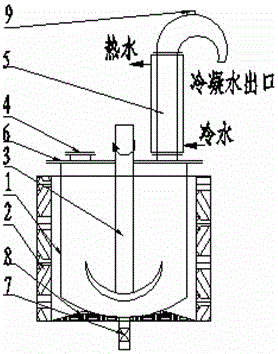

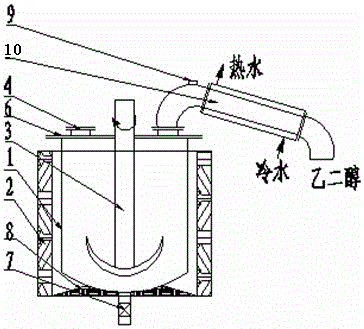

Method and device for preparing ethylene glycol antimony through microwave reaction

ActiveCN105732327AHigh speedFully contactedPreparation of metal alcoholatesEnergy based chemical/physical/physico-chemical processesPolymer scienceLiquid ratio

Provided are a method and device for preparing ethylene glycol antimony through a microwave reaction. The method comprises the following steps of 1, reaction synthesis, wherein the raw materials of antimonous oxide and ethylene glycol are put into a microwave reaction kettle provided with a microwave heating device, a reflux condensation device and a stirrer according to the solid-to-liquid ratio of 1:(2-10), the microwave heating device is started, the reaction temperature and reaction time are controlled, and the temperature of gas at the outlet of the reflux condensation device is controlled; 2, purification and decoloration; 3, cooling crystallization, 4 drying, wherein an ethylene glycol antimony product is obtained; 5, mother liquid distillation, wherein obtained ethylene glycol mother liquid is added into a microwave distillation kettle provided with a microwave heating device, the temperature of a distillation outlet is controlled, ethylene glycol is distilled out and returns back for use, and distillation residues are recycled. The invention further discloses the device for preparing ethylene glycol antimony through the microwave reaction. The method for preparing ethylene glycol antimony through the microwave reaction has the advantages that the heating speed is high, the reaction time is short, the conversion ratio is high, the direct yield of final products is high, the productivity is high, the cost is low and the like.

Owner:锡矿山闪星锑业有限责任公司

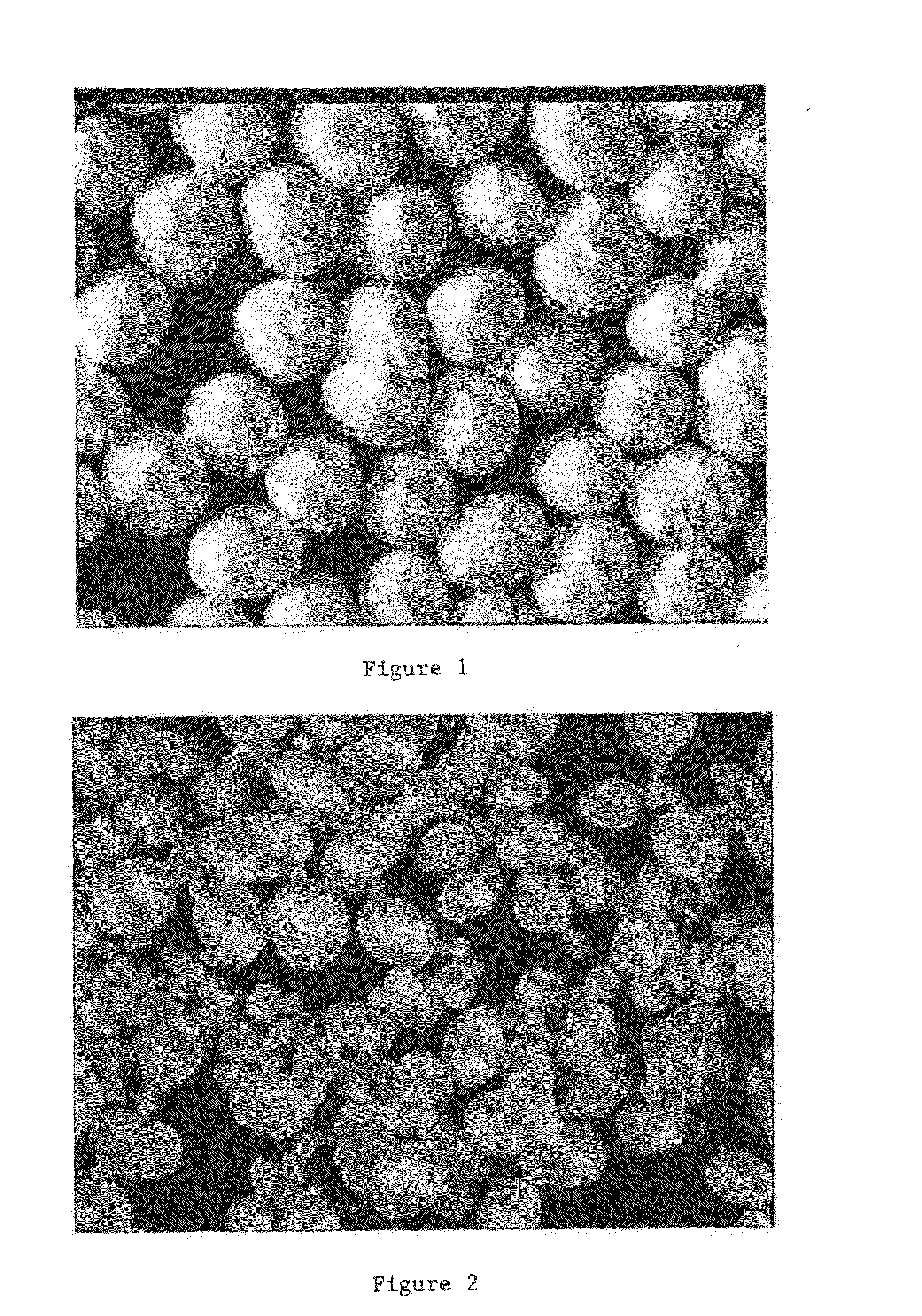

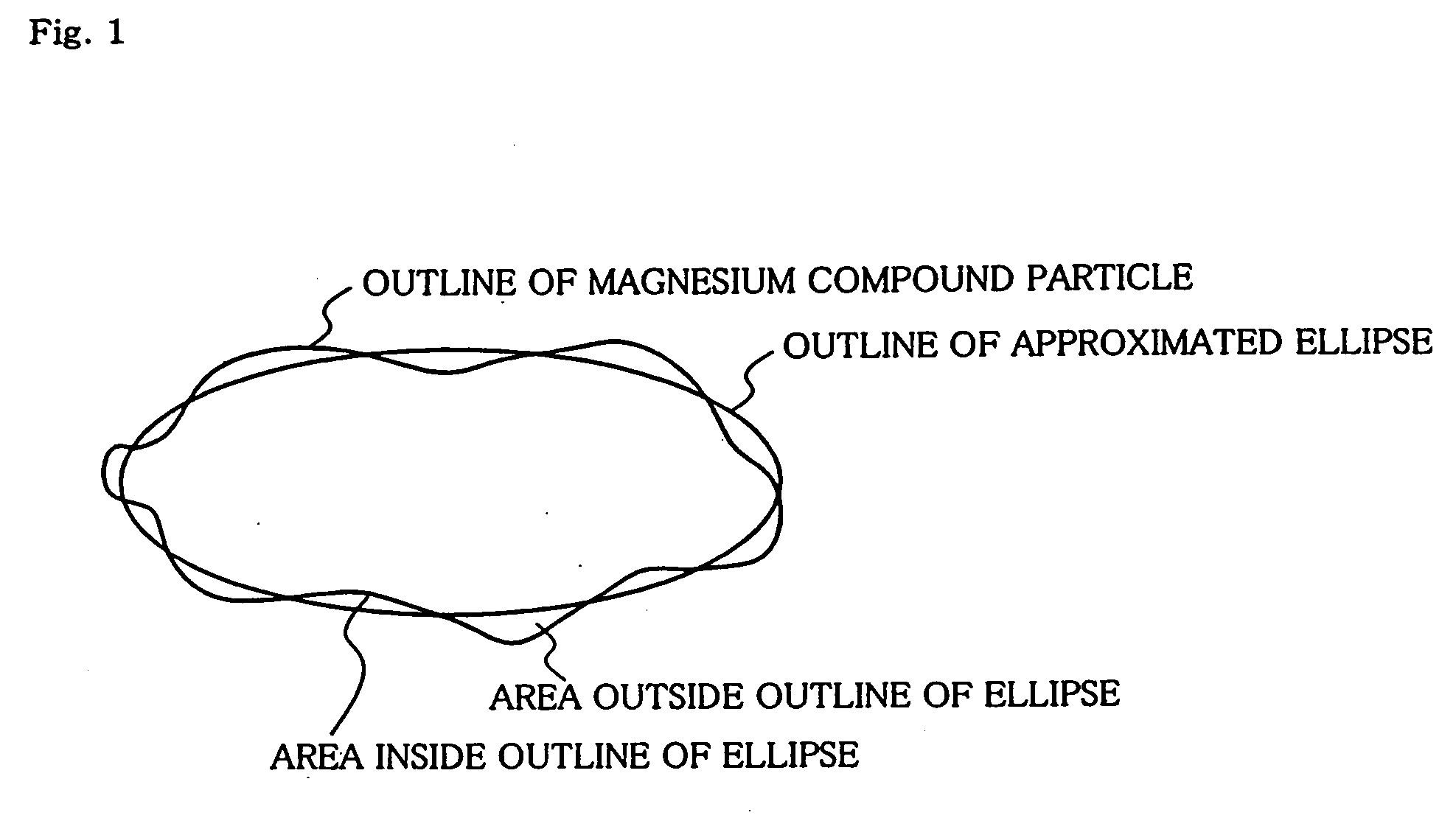

Magnesium compound, solid catalyst component for olefin polymerization, catalyst for olefin polymerization and method for producing polyolefin

InactiveUS7387979B2Magnesium halidesOrganic-compounds/hydrides/coordination-complexes catalystsPolyolefinMaximum diameter

A magnesium compound obtained by reacting metallic magnesium having a sphericity (S) of less than 4.00, the sphericity (S) being represented by the following formula (I), an alcohol, and a halogen and / or a halogen-containing compound containing halogen atoms in an amount of 0.0001 gram atom or more relative to one gram atom of the metallic magnesium,S=(L1 / L2)3 (I)wherein L1 represents the maximum diameter of projection views of metallic magnesium determined by photographing with a scanning electron microscope and thereafter an image processing, and L2 represents a diameter of a circle having an area equal to the area of the projection view of metallic magnesium. A solid catalyst component is obtained from the magnesium compound and a titanium compound, and a catalyst for olefin polymerization is obtained using the solid catalyst component.

Owner:IDEMITSU KOSAN CO LTD

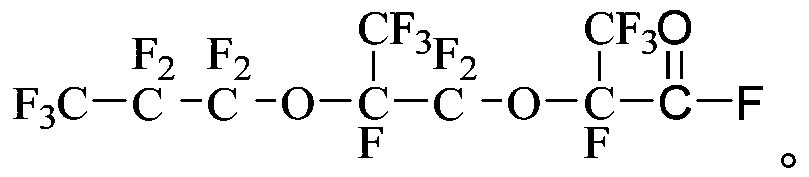

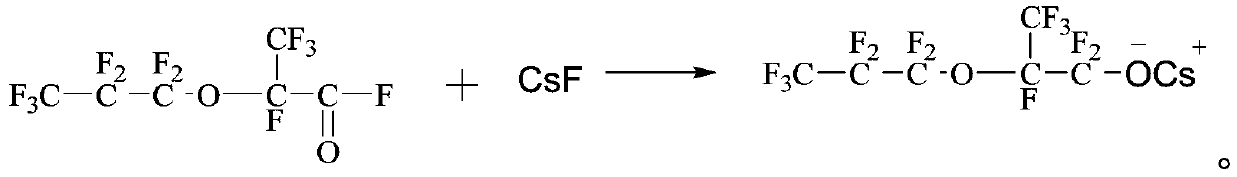

Method for preparing hexafluoropropylene oxide trimer

ActiveCN110041192AImprove conversion rateHigh selectivityPreparation of metal alcoholatesCarboxylic acid halides preparationHexafluoropropylene oxideFluorine containing

The invention relates to the field of fluorine-containing fine chemistry, in particular to a method for preparing a hexafluoropropylene oxide trimer. Hexafluoropropylene oxide is used as a raw material, hexafluoropropylene oxide dimer alkoxide and fluorinated alkali metal salt are used as composite catalytic initiators, a chain transfer polymerization inhibitor is added, and the hexafluoropropylene oxide trimer is prepared after a reaction. The conversion rate of hexafluoropropylene oxide and the selectivity of the hexafluoropropylene oxide trimer are high in the method, and the operation method is simple, feasible, easy to control industrially and suitable for mass industrial production.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

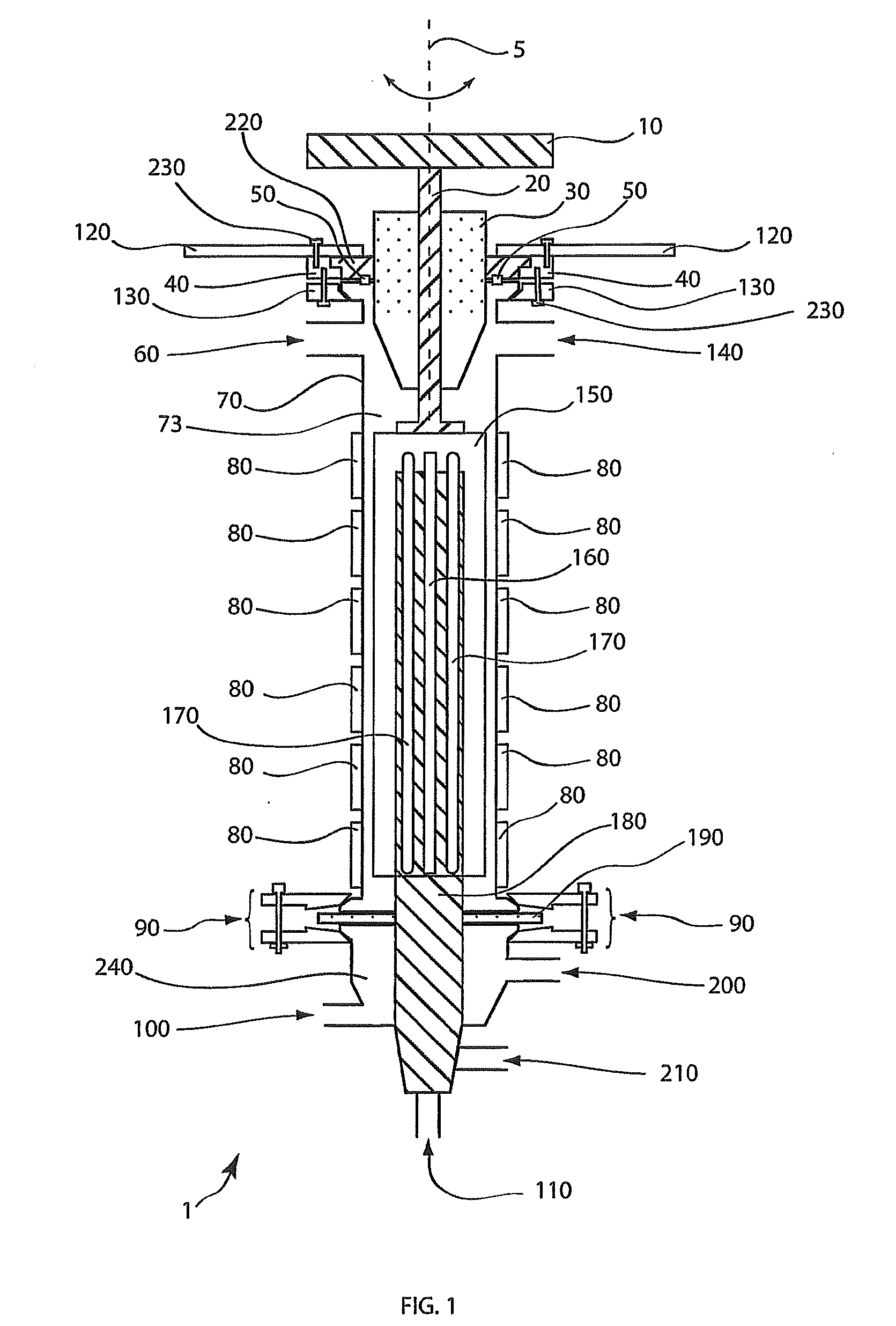

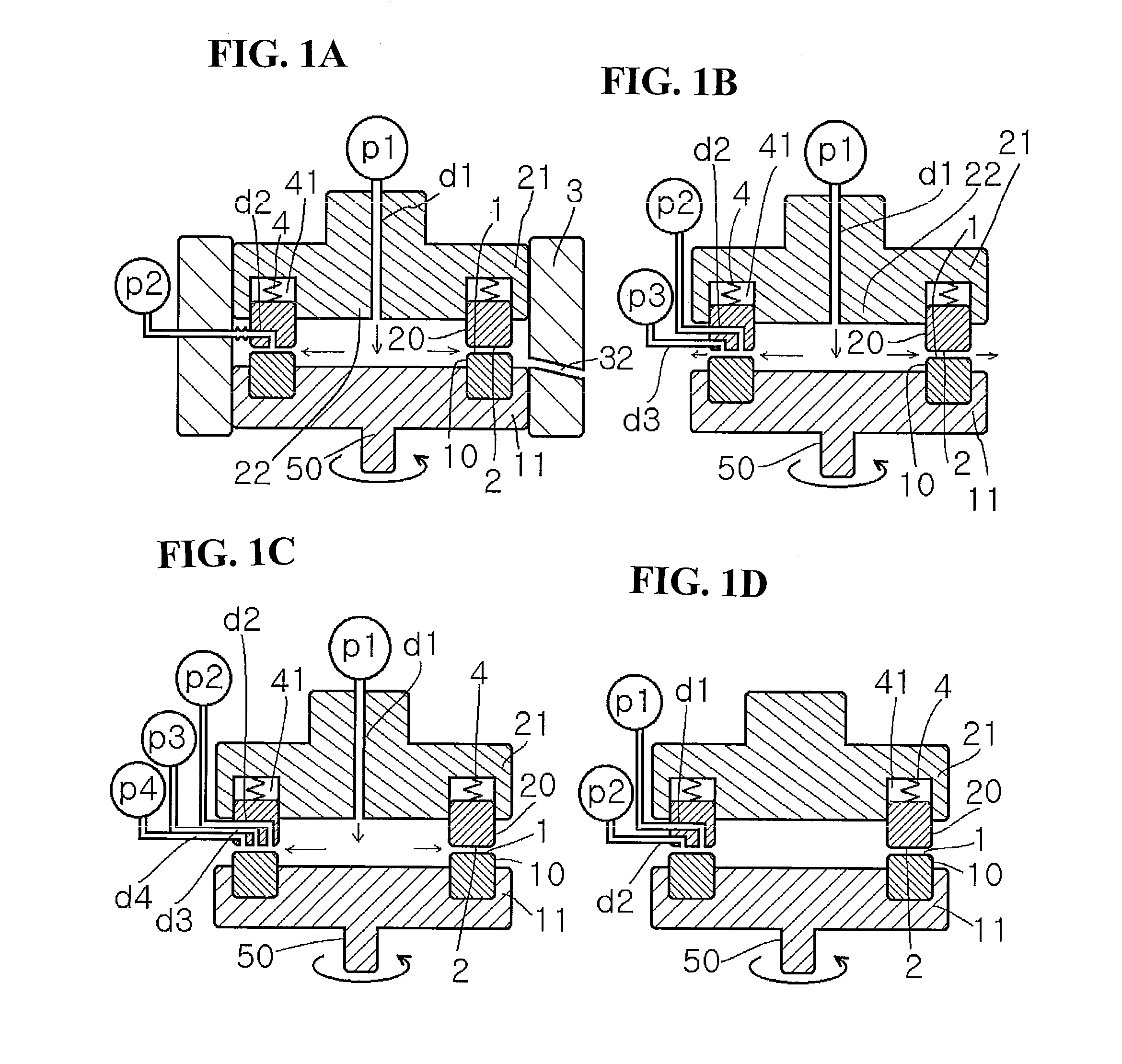

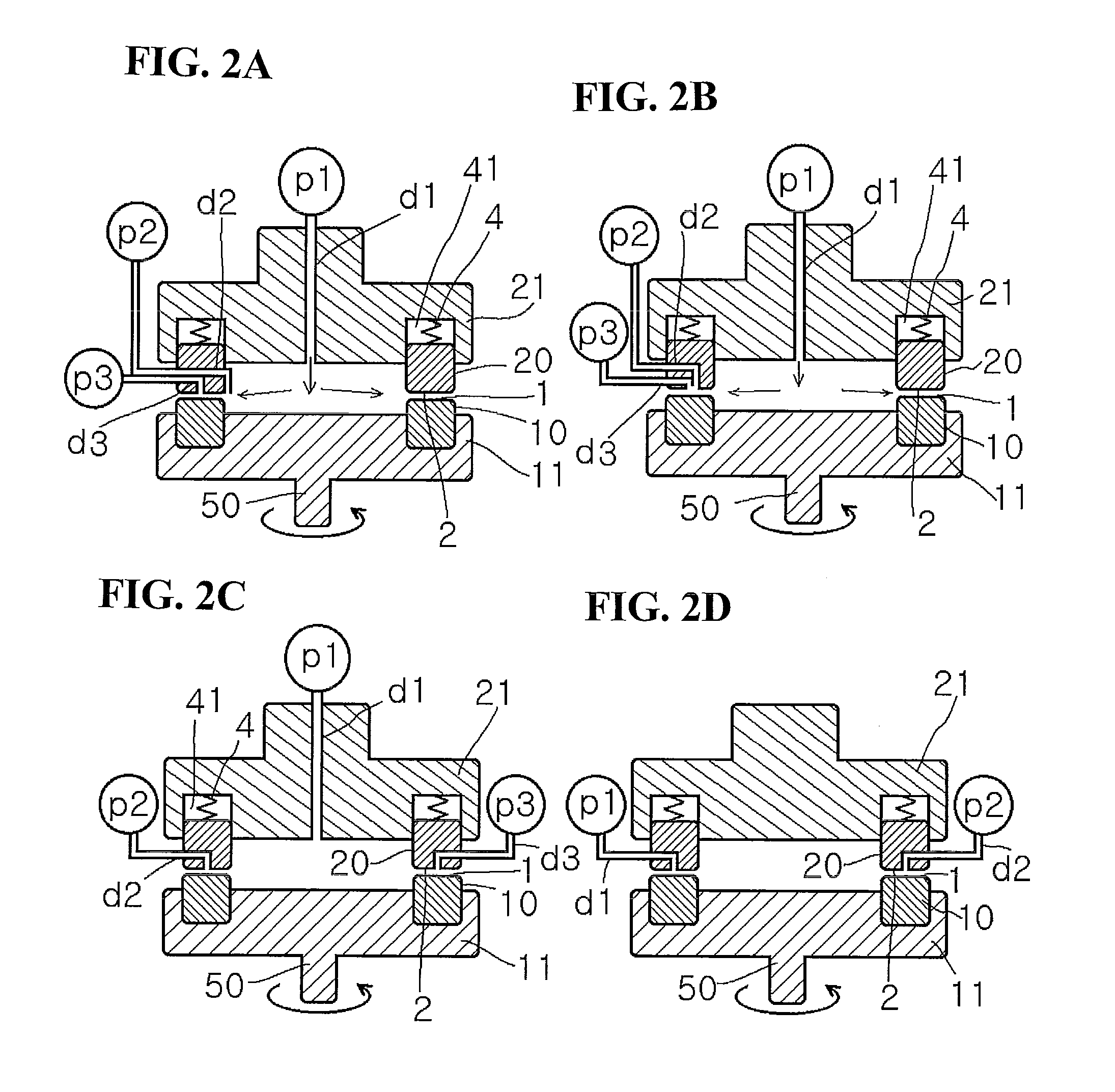

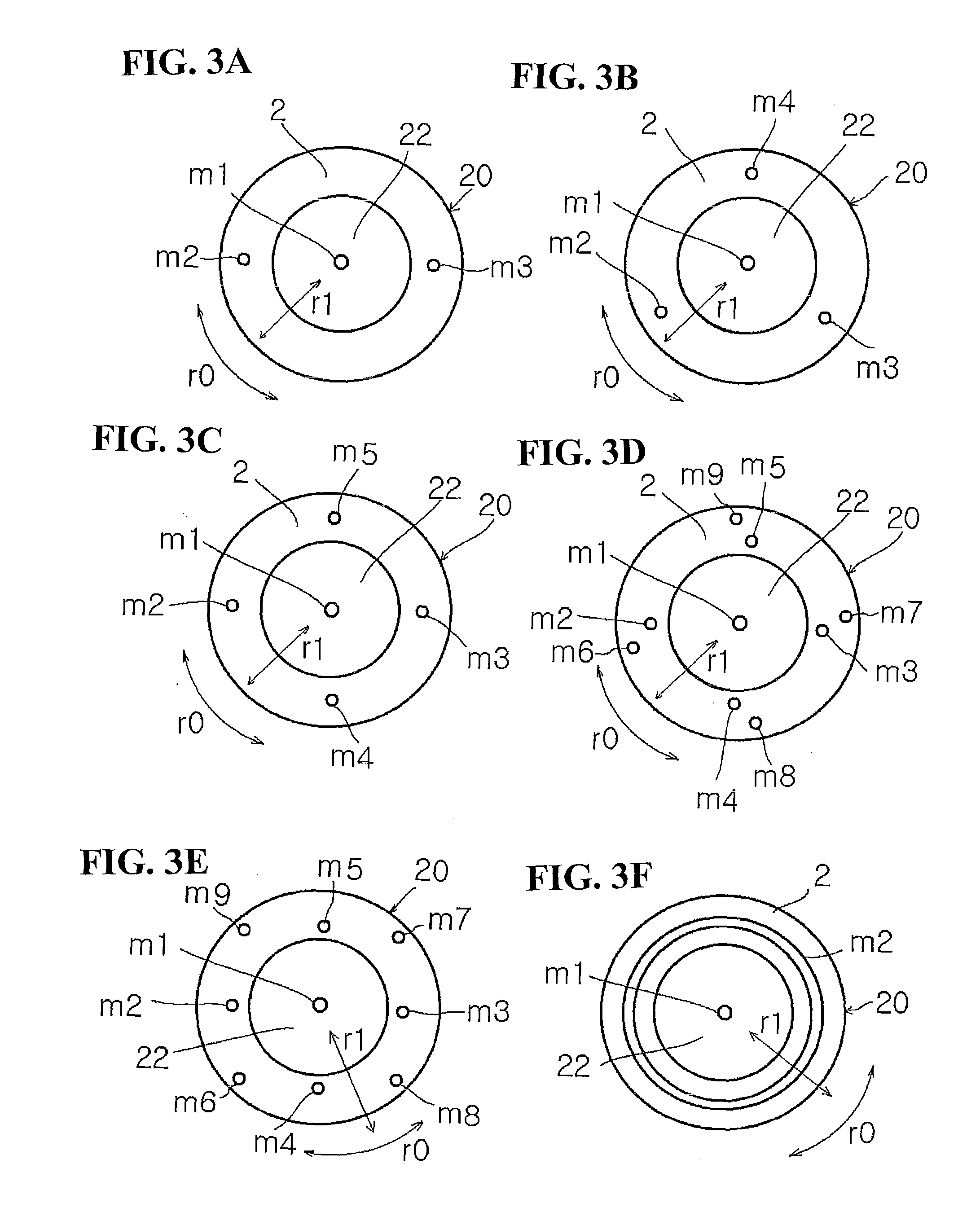

Method for producing organic compound and organic compound obtained by the method

ActiveUS8592498B2Improve the level ofHigh reaction yieldCarboxylic acid nitrile preparationRotary stirring mixersProduction rateOrganic reaction

Disclosed herein are a reaction method and a production method of an organic compound which are capable of achieving high reaction selectivity according to the purpose and a high production rate of a target substance. The methods include at least two fluids, wherein at least one kind of the fluids is a fluid containing at least one organic compound and at least one kind of the fluids other than the above fluid is a fluid containing at least one reactant in the form of a liquid or solution, and the respective fluids join together in a thin film fluid foamed between processing surfaces arranged to be opposite to each other so as to be able to approach to and separate from each other, at least one of which rotates relative to the other, whereby an organic reaction is performed in the thin film fluid.

Owner:M TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com