Preparation method of alkoxy magnesium carrier for olefin polymerization catalyst

A technology for alkoxymagnesium carrier and olefin polymerization, which is applied in the preparation of metal alcohols, organic chemistry, and magnesium organic compounds. The effect of tight structure and easy control of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

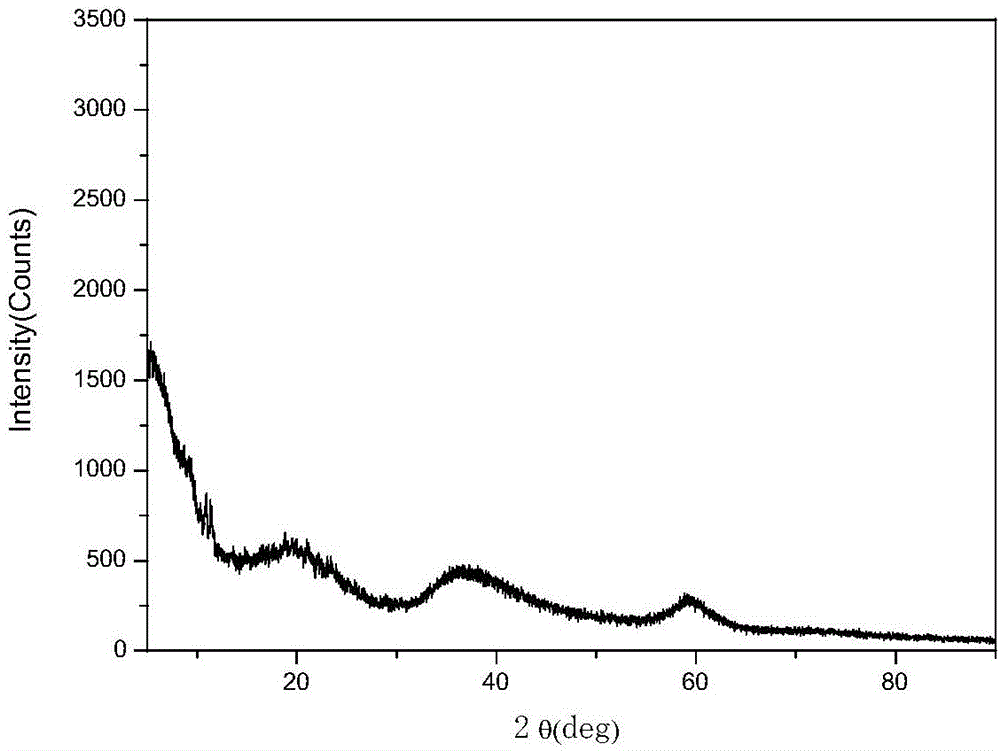

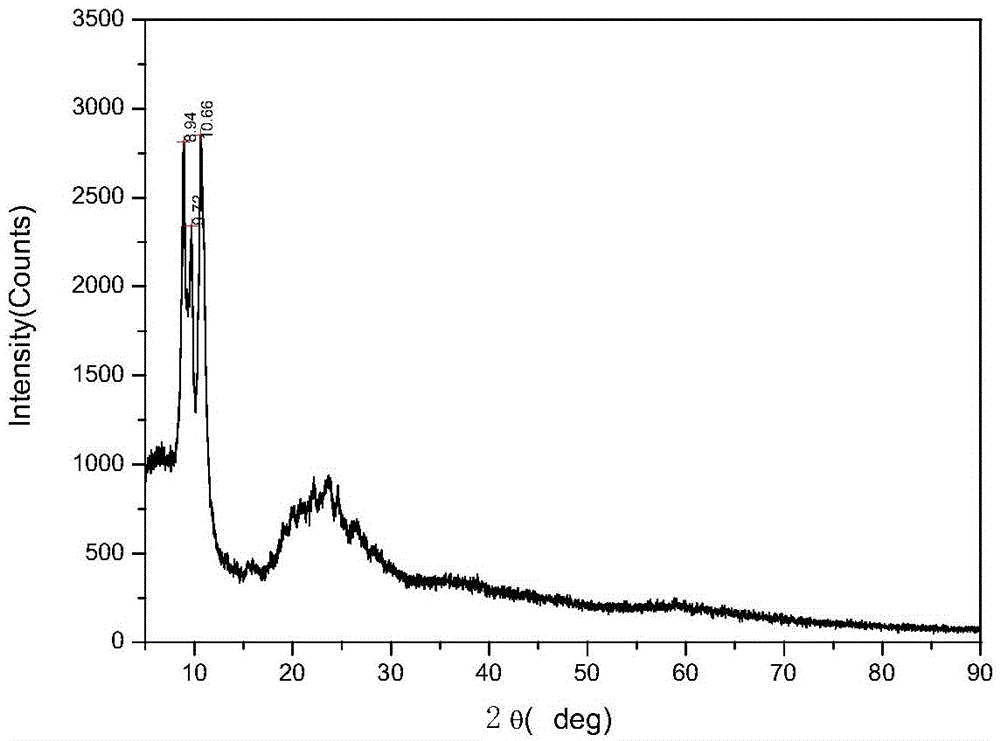

Image

Examples

Embodiment 1

[0059] 1) In a reactor with a stirrer, a reflux condenser, a thermometer and a burette are installed. The top of the reflux condensing pipe is connected to the conduit, and the other end of the conduit is connected to the oil seal device, which is convenient for observing the H 2 generation. After fully replaced with nitrogen, add 0.2g of magnesium powder, 10ml of decane and 0.2ml of iodine in absolute ethanol (0.0266g / ml) to the reactor, activate the reaction for 15min, and then add 10ml of absolute ethanol. Start to heat up until reaching the reaction temperature of the reaction system, each time the reaction system no longer discharges H 2 Add the dehydrated ethanol solution (0.0266g / ml) and decane of the same magnesium powder, alcohol, iodine as the previous charging amount, add altogether 5 times, add the last raw material and the reaction does not produce H 2 After that, the aging reaction was continued for 2h.

[0060] 2) After the aging reaction, 1.418g of pentaeryt...

Embodiment 2

[0063] Carry out the same method as Example 1, the difference is to add 1.418g pentaerythritol (n pentaerythritol: n metal magnesium=0.25) in the reaction system, react at 80 ℃ for 5 hours, after the end of the final reaction, the product is washed and separated and drying to obtain a white solid powder with good fluidity.

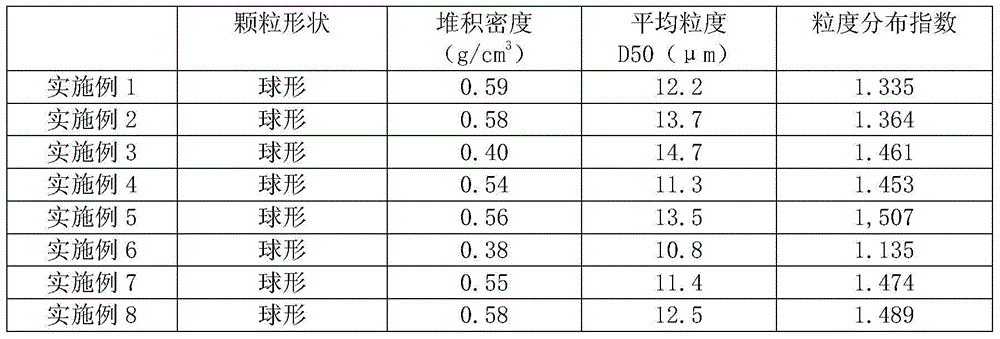

[0064] The obtained product was characterized using the same method as in Example 1. The results are shown in Table 1.

Embodiment 3

[0066] Carry out the same method as Example 1, the difference is to add 1.418g pentaerythritol (n pentaerythritol: n metal magnesium=0.25) in the reaction system, react at 80 ℃ for 3 hours, after the end of the final reaction, the product is washed and separated and drying to obtain a white solid powder with good fluidity.

[0067] The obtained product was characterized using the same method as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com