Patents

Literature

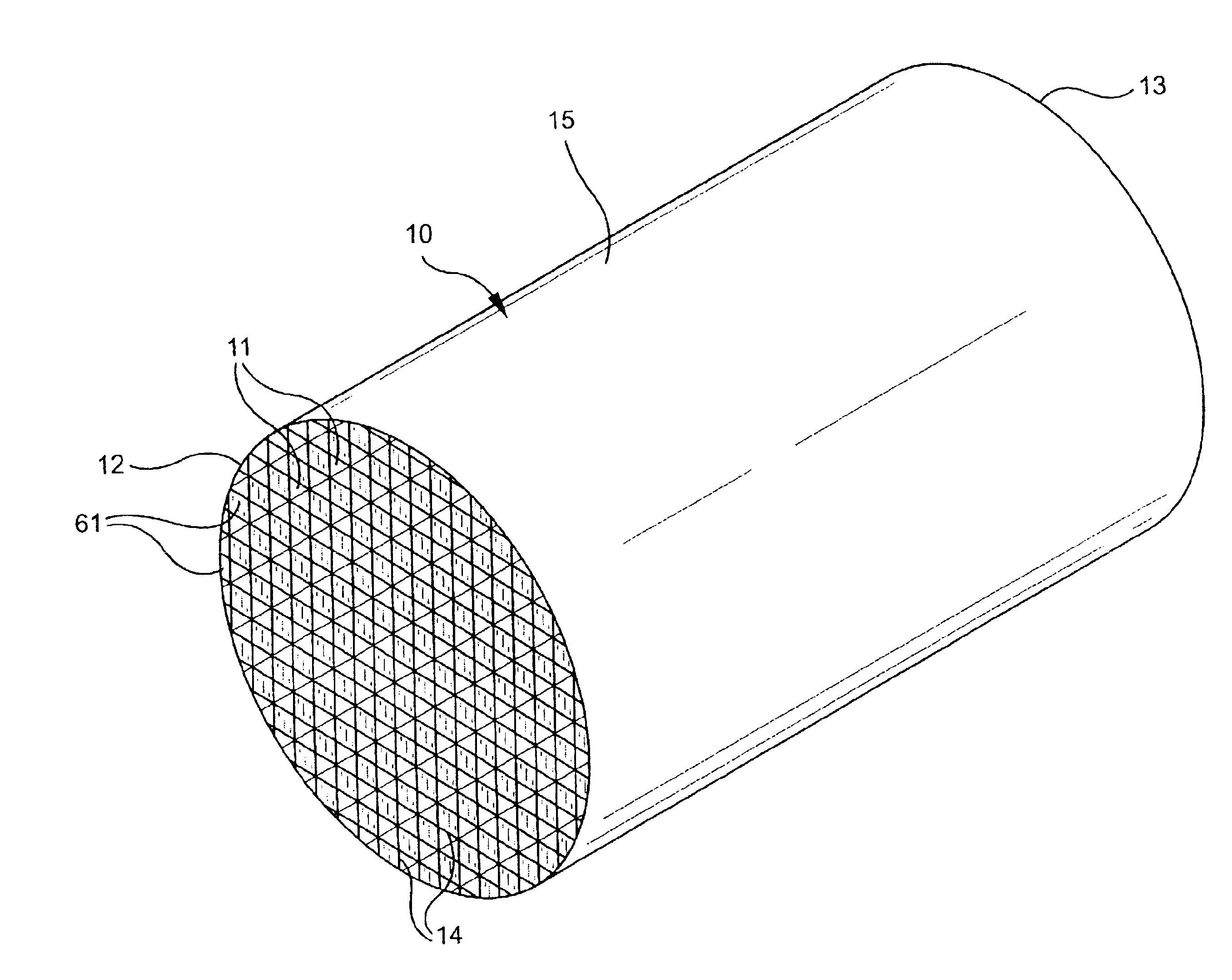

4324 results about "Porous ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous Ceramics. Porous ceramics are a class of highly reticulated ceramic material that covers a wide range of structures, such as foams, honeycombs, interconnected rods, fibers, or hollow spheres. Porous ceramics are featured in their unique combination of valuable properties, which makes them useful in a variety of special...

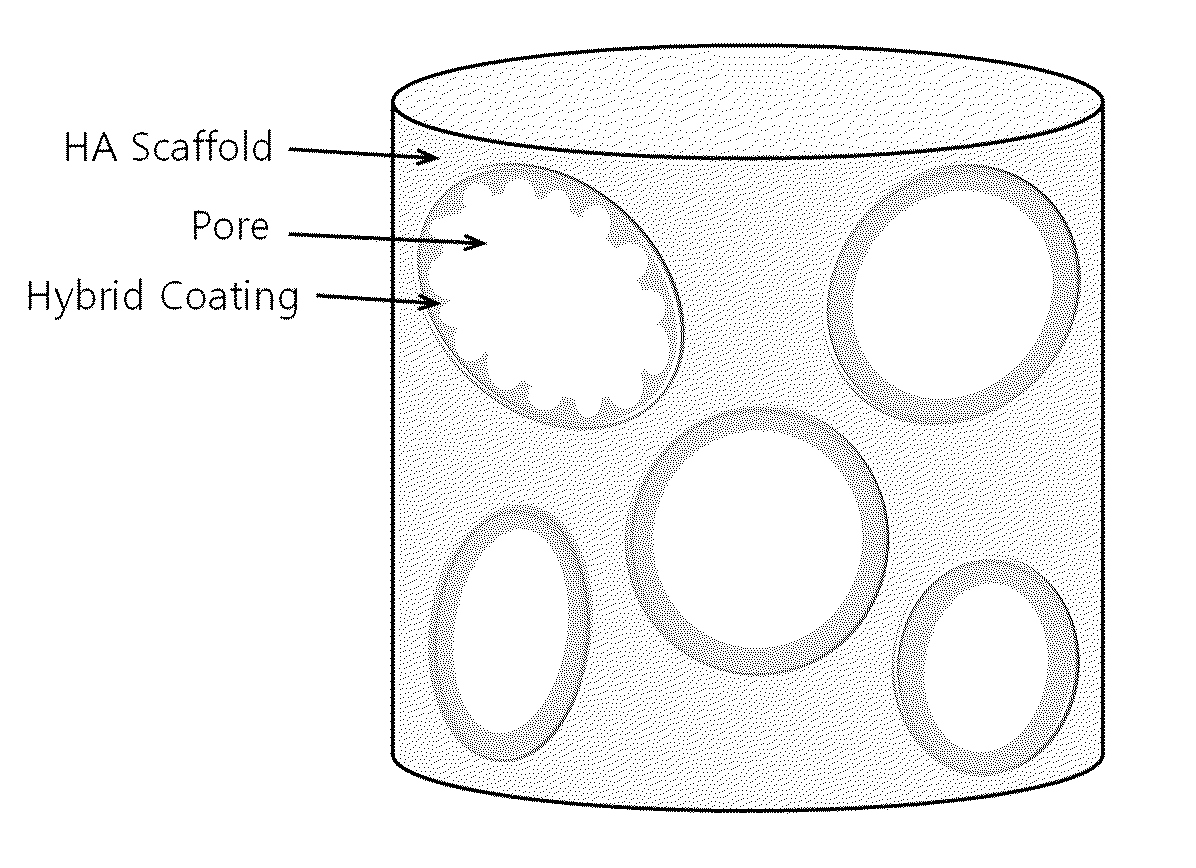

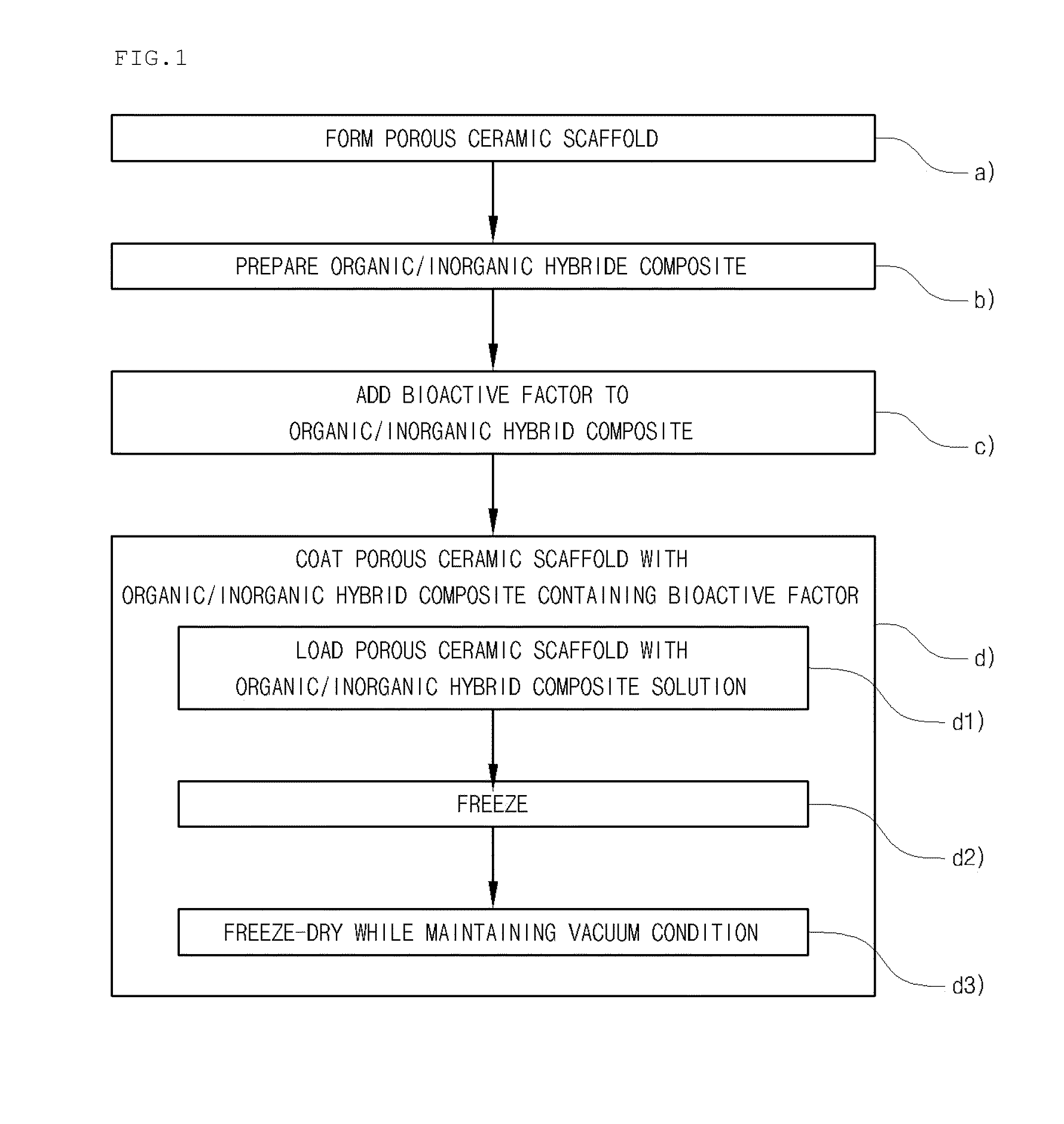

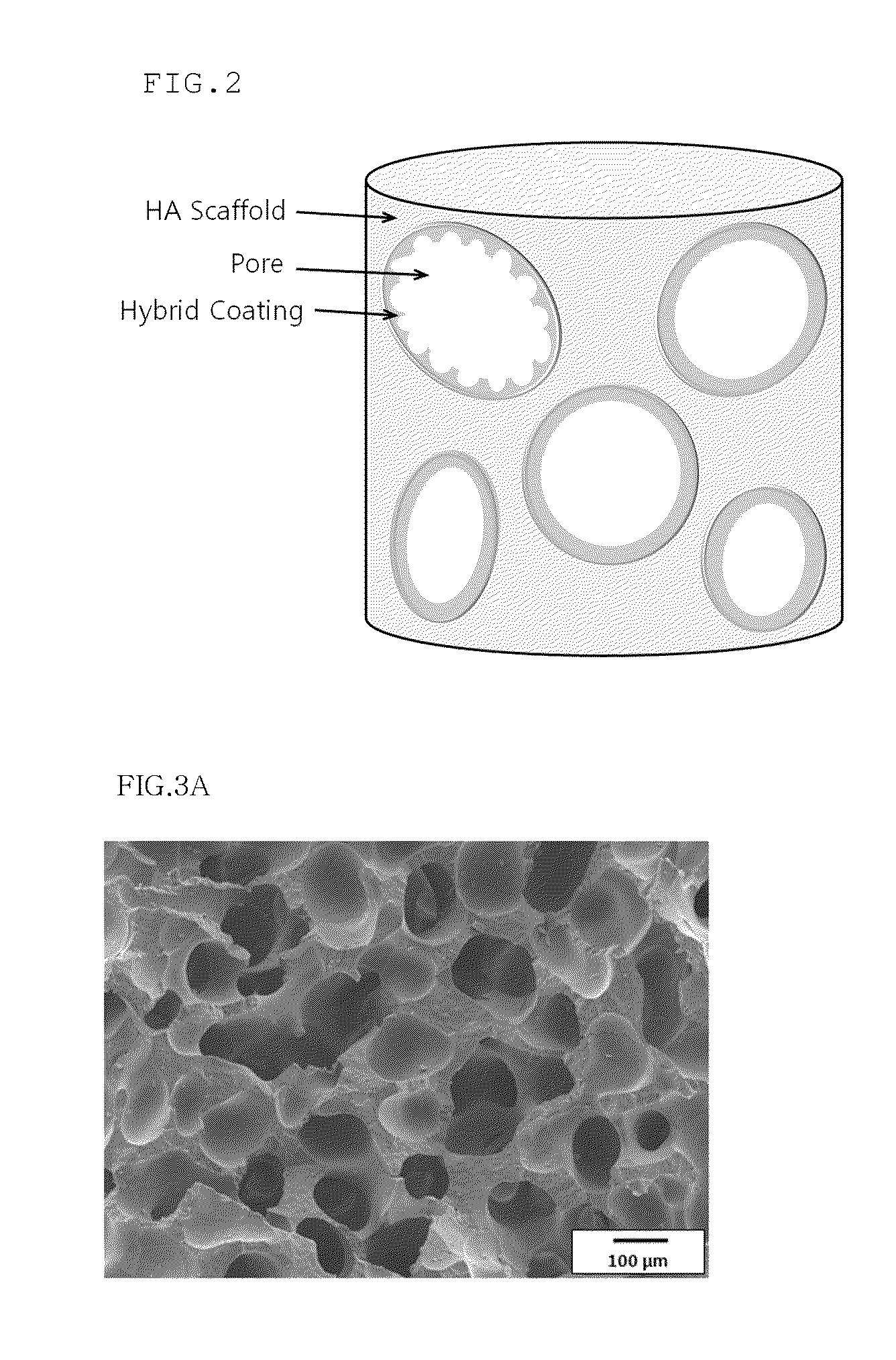

Method for manufacturing a porous ceramic scaffold having an organic/inorganic hybrid coating layer containing a bioactive factor

ActiveUS8734831B2Good biocompatibilityEasy to controlBiocideSurgical adhesivesOrganic matterPorous ceramics

A method for manufacturing a porous ceramic scaffold having an organic / inorganic hybrid coating layer containing a bioactive factor includes (a) forming a porous ceramic scaffold; (b) mixing a silica xerogel and a physiologically active organic substance in a volumetric ratio ranging from 30:70 to 90:10 and treating by a sol gel method to prepare an organic / inorganic hybrid composite solution; (c) adding a bioactive factor to the organic / inorganic hybrid composite solution and agitating until gelation occurs; and (d) coating the porous ceramic scaffold with the organic / inorganic composite containing the bioactive factor added thereto. In accordance with the method, the porous ceramic scaffold may be uniformly coated with the organic / inorganic hybrid composite while maintaining an open pore structure, and stably discharge the bioactive factor over a long period of time.

Owner:SEOUL NAT UNIV R&DB FOUND

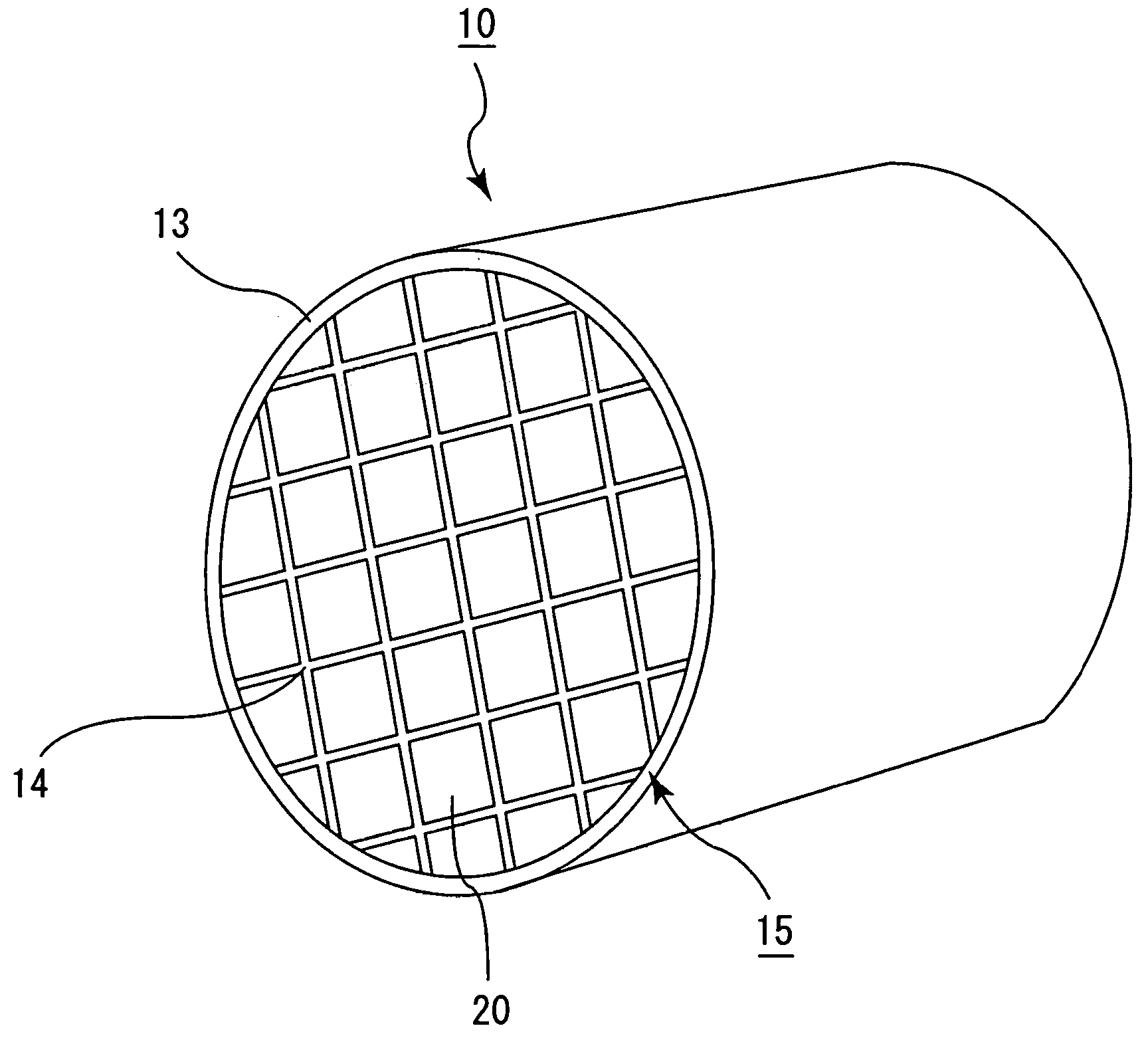

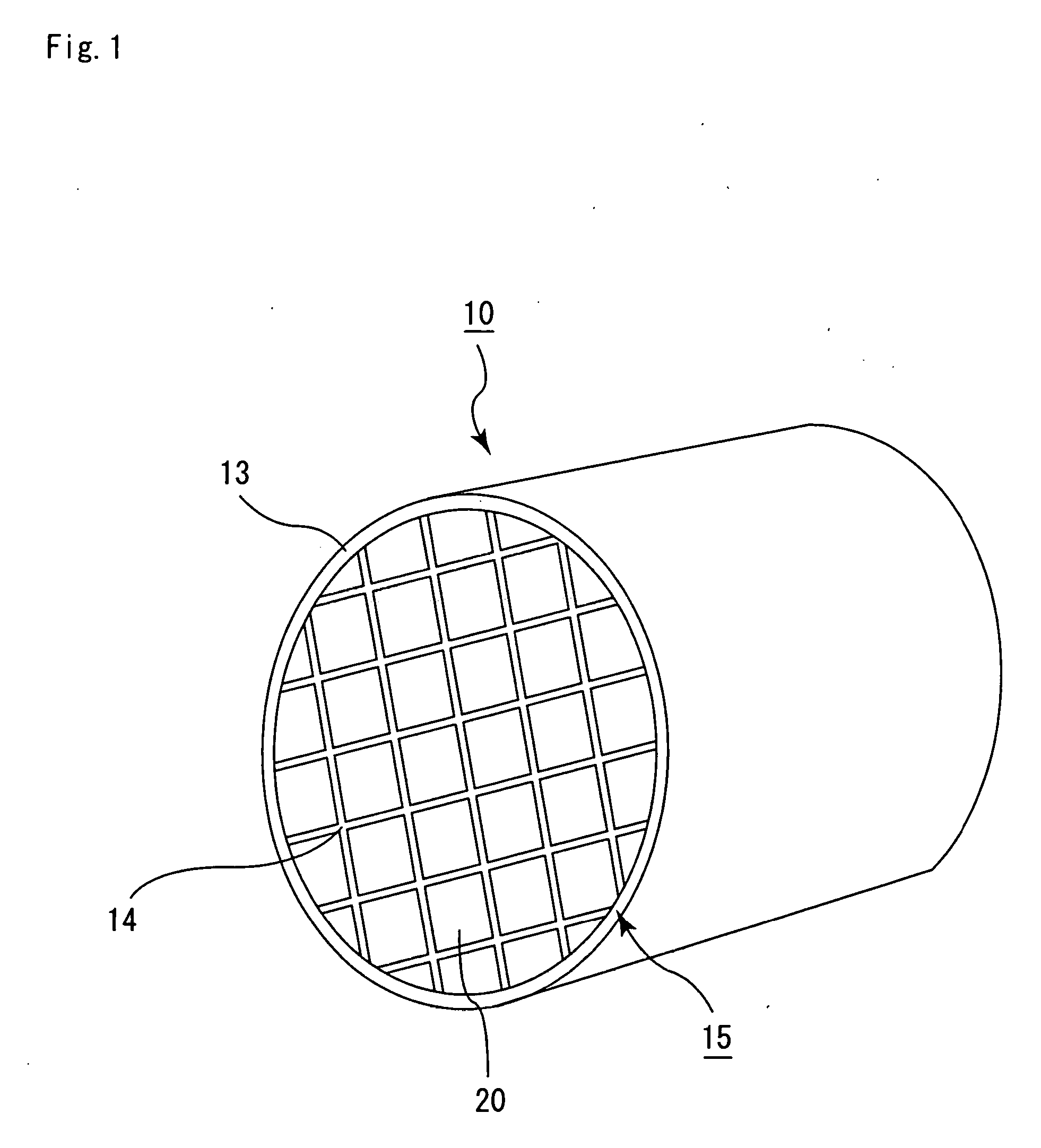

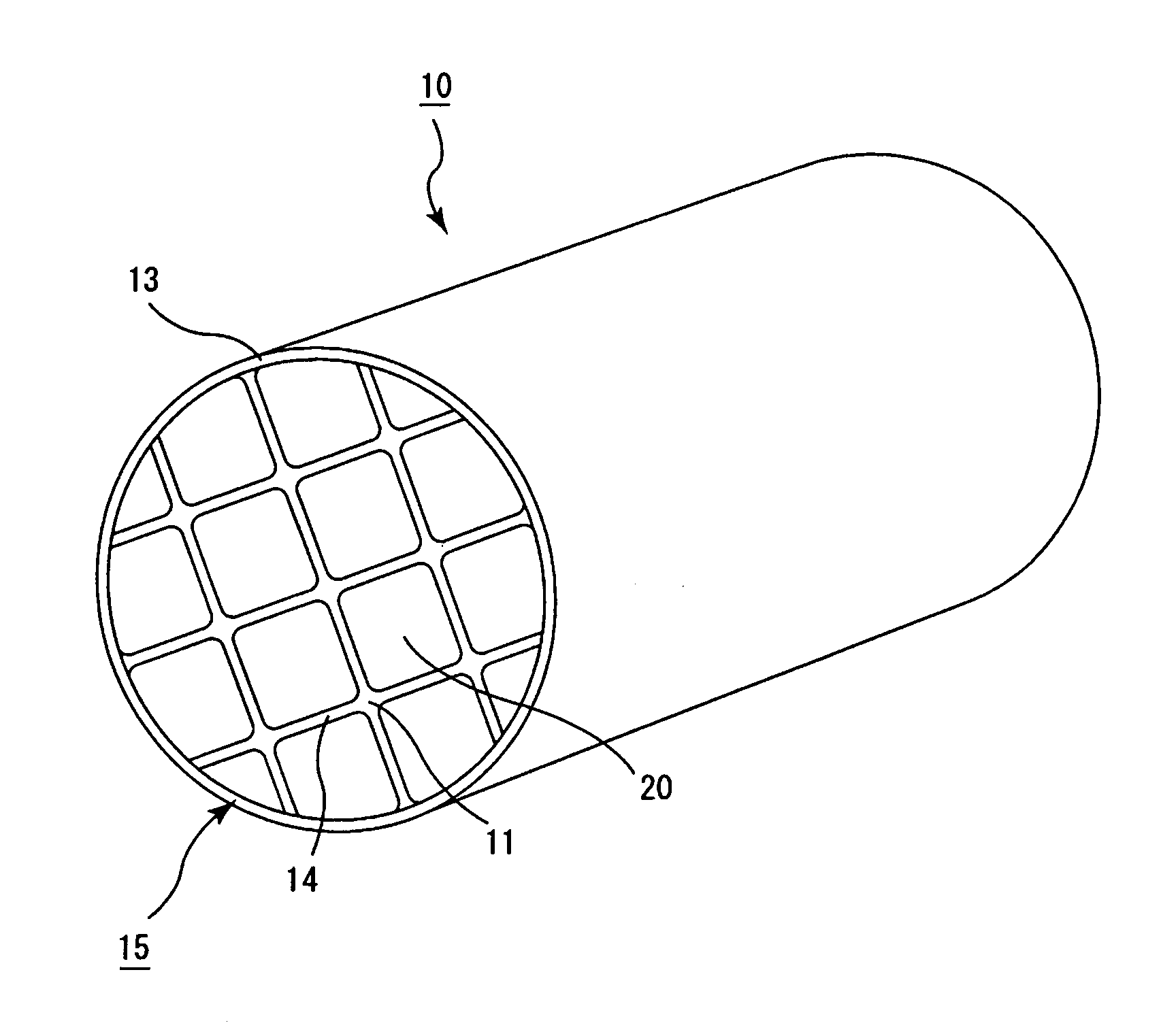

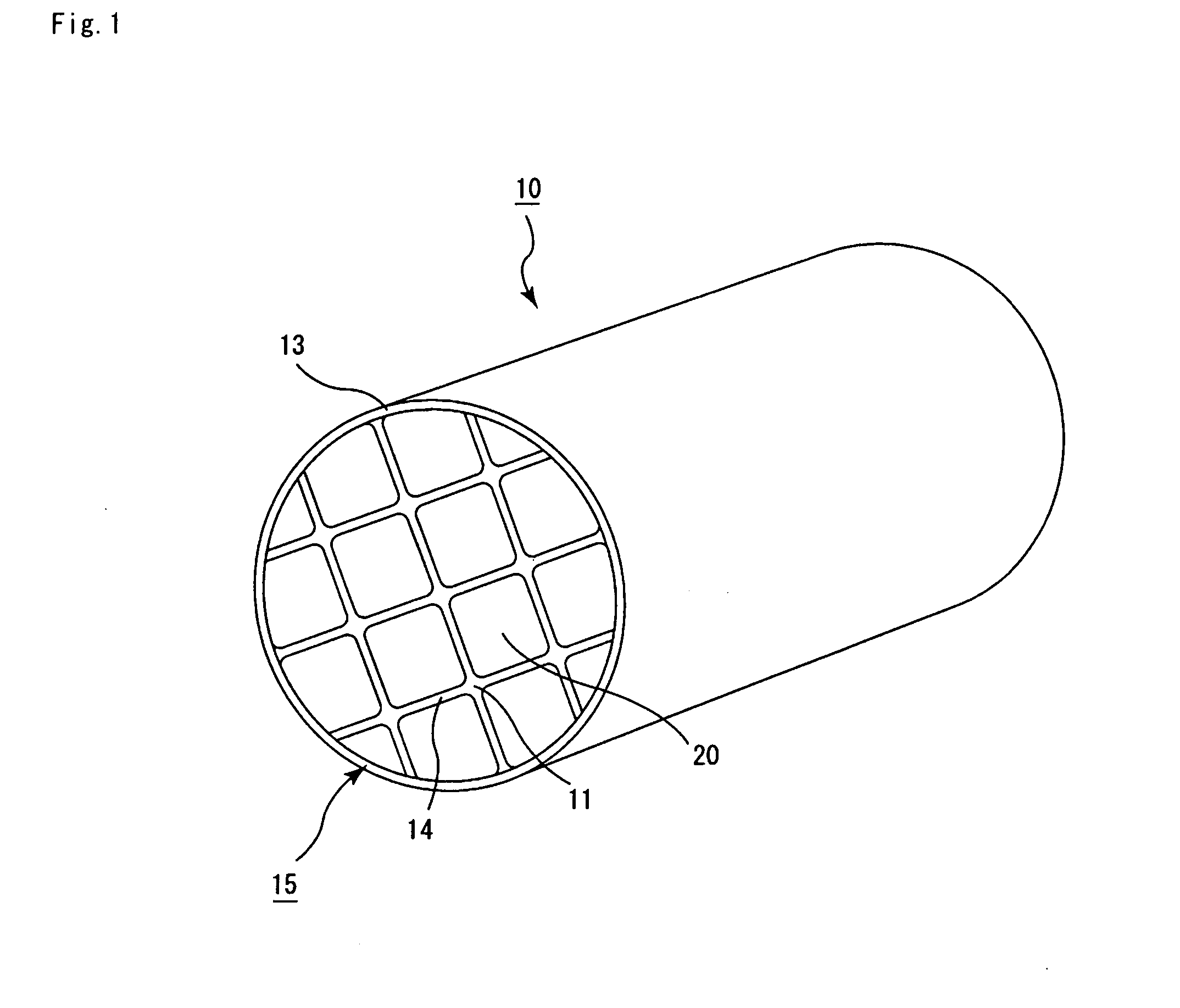

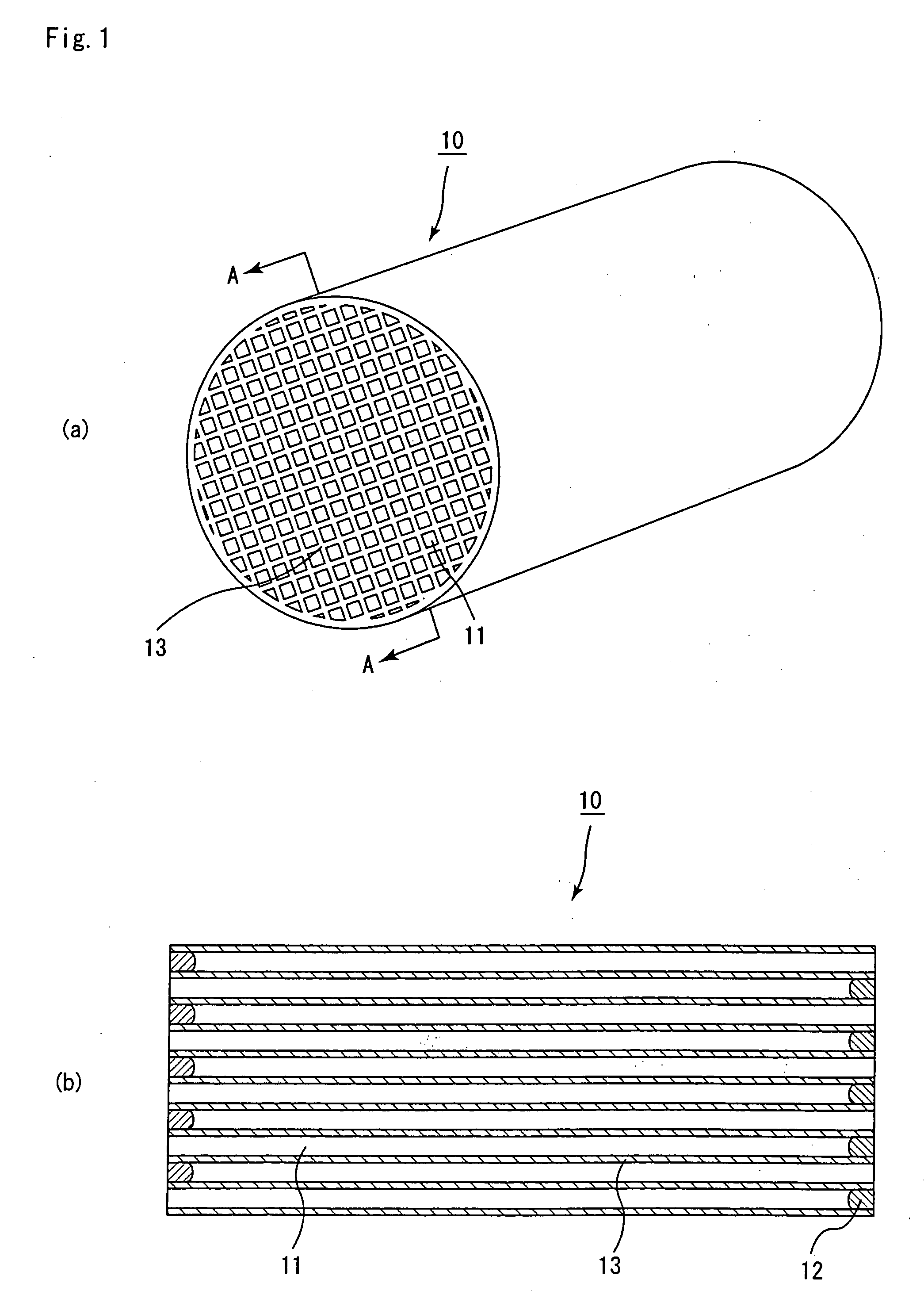

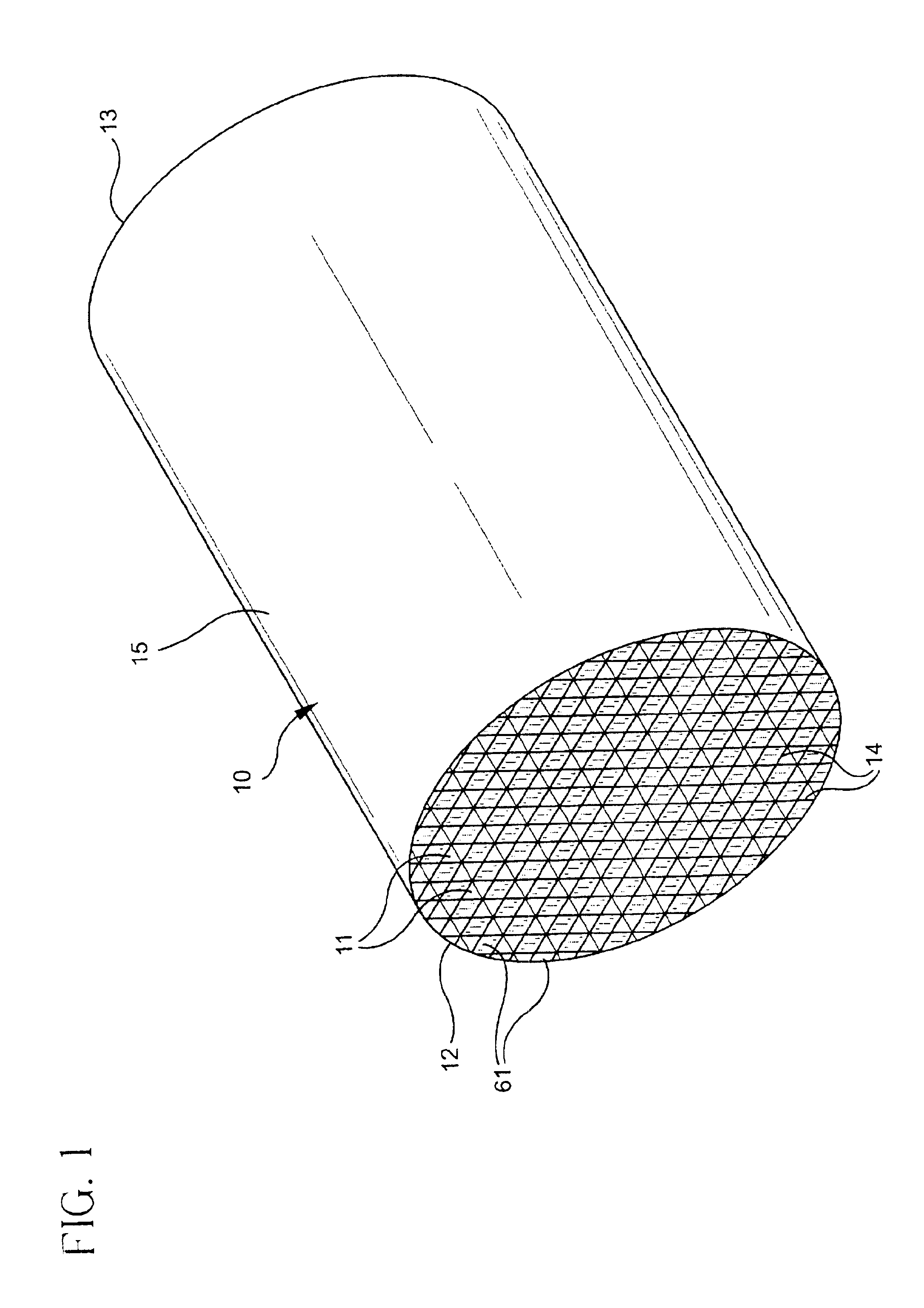

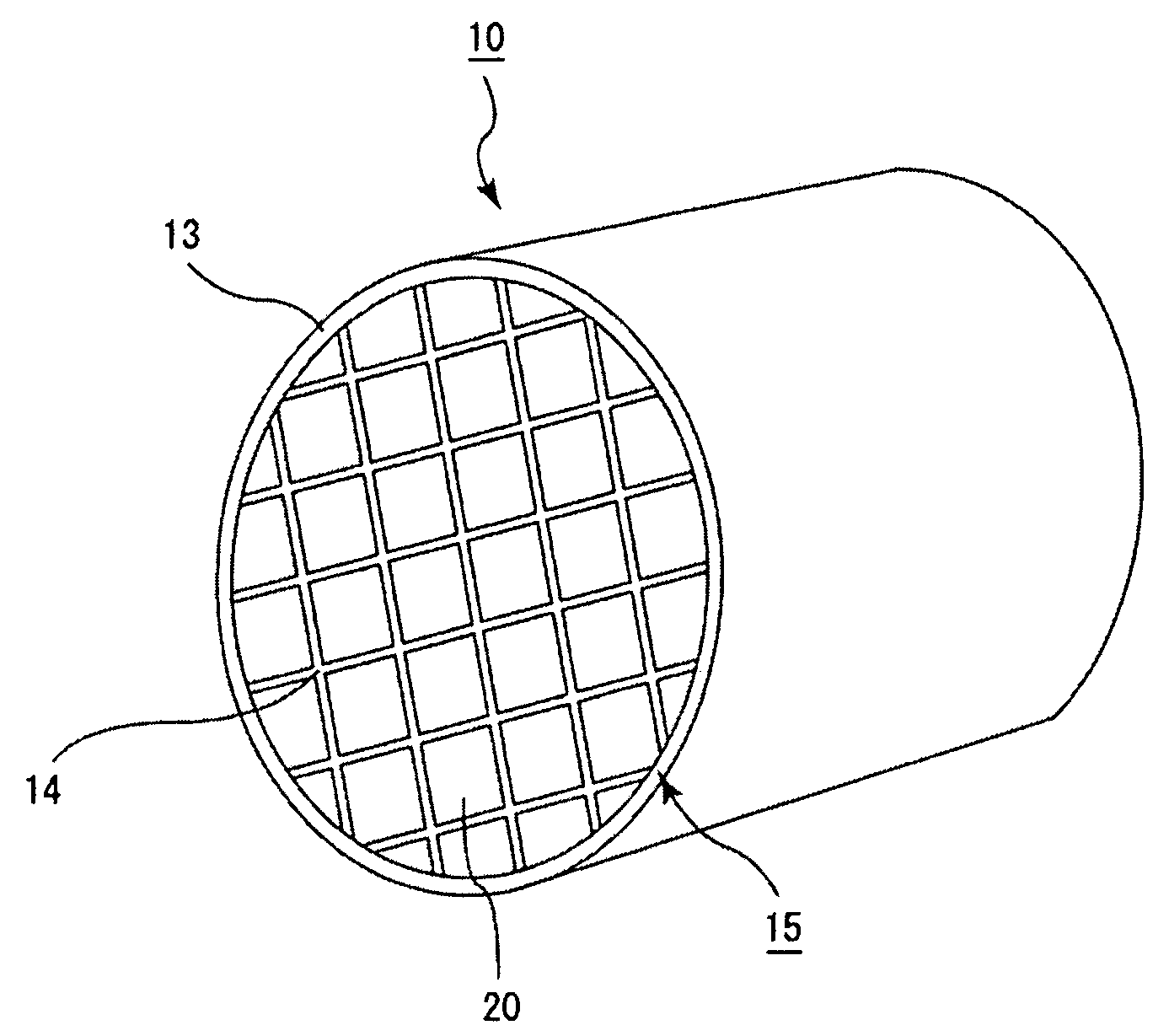

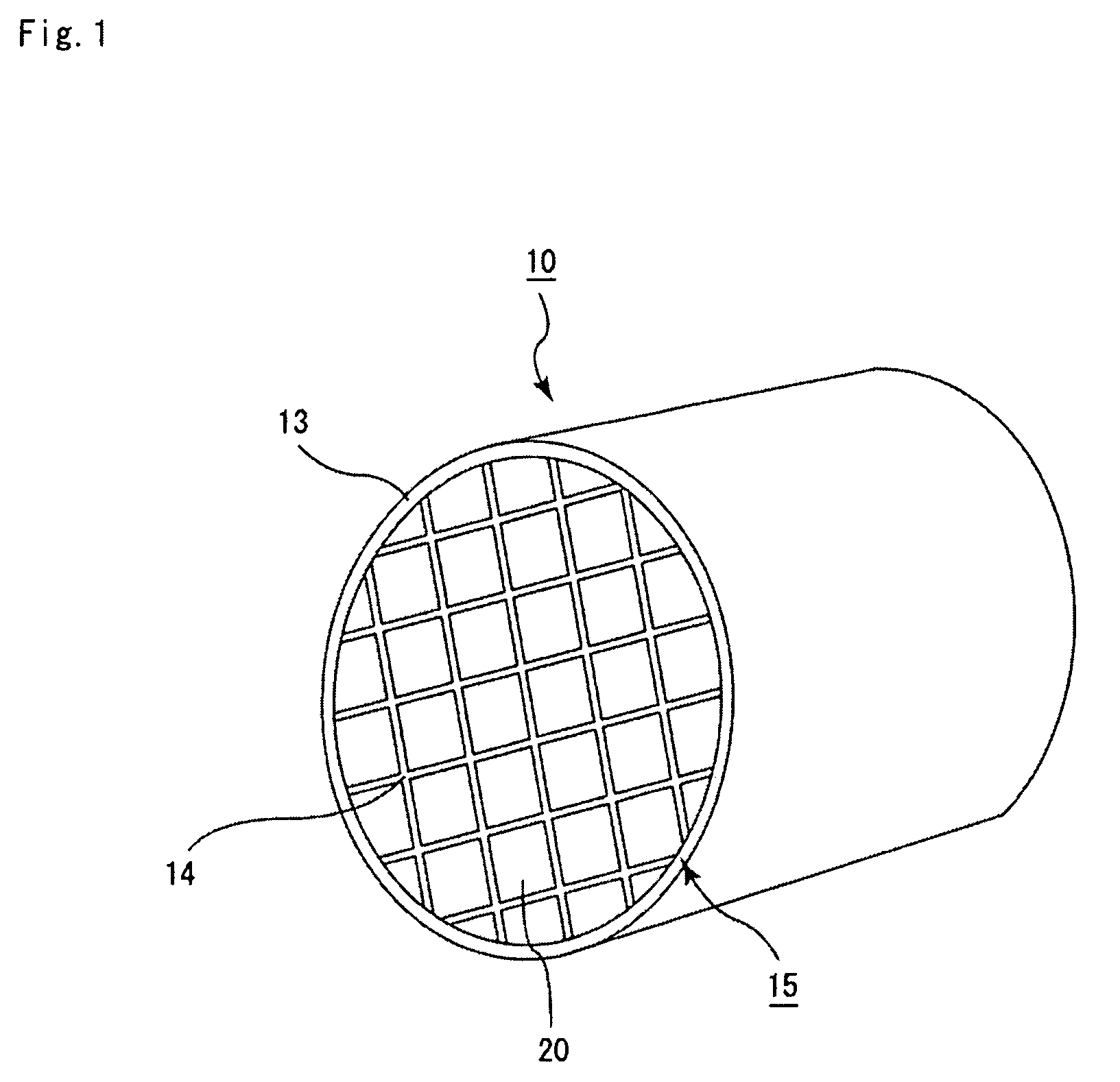

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

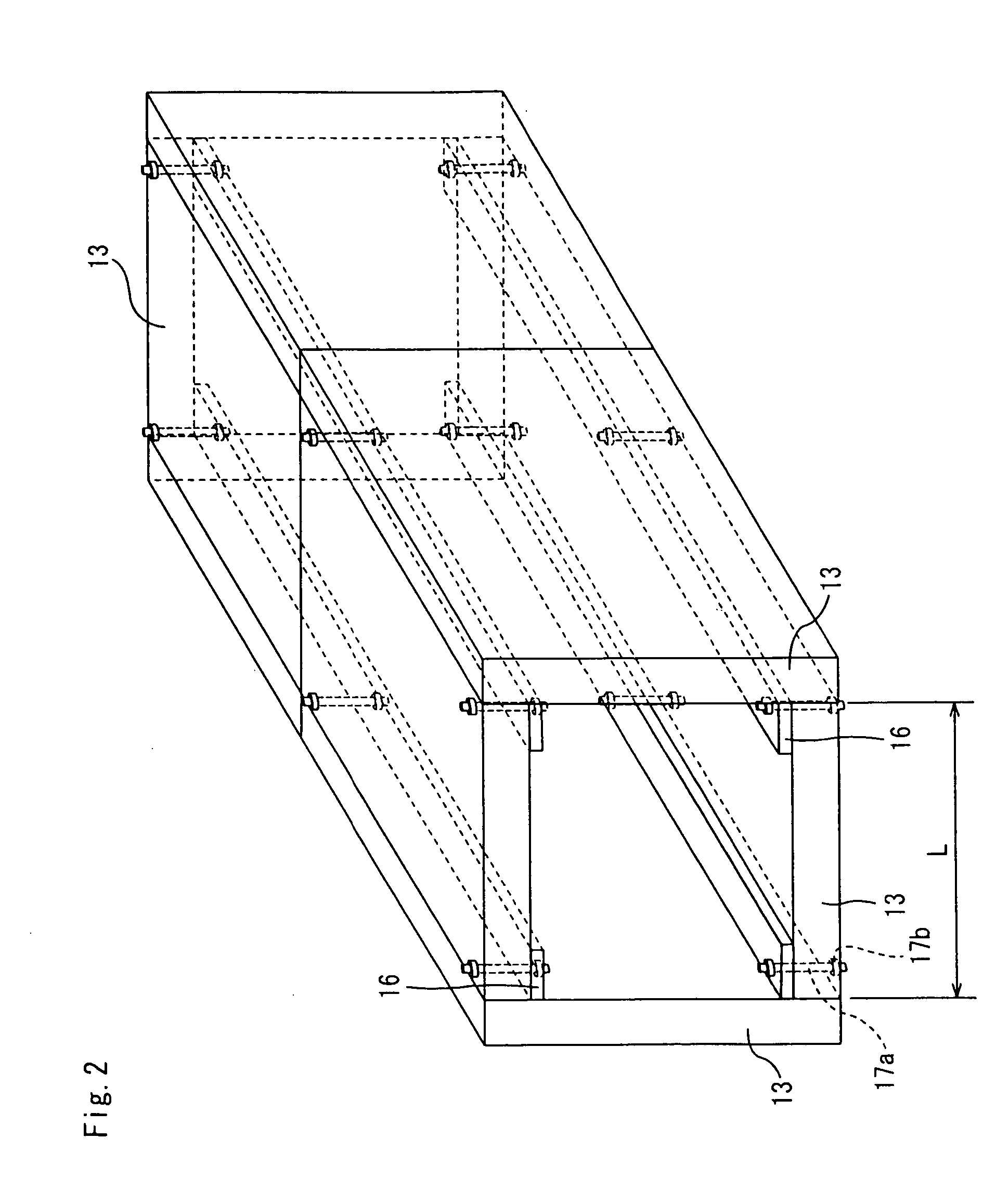

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

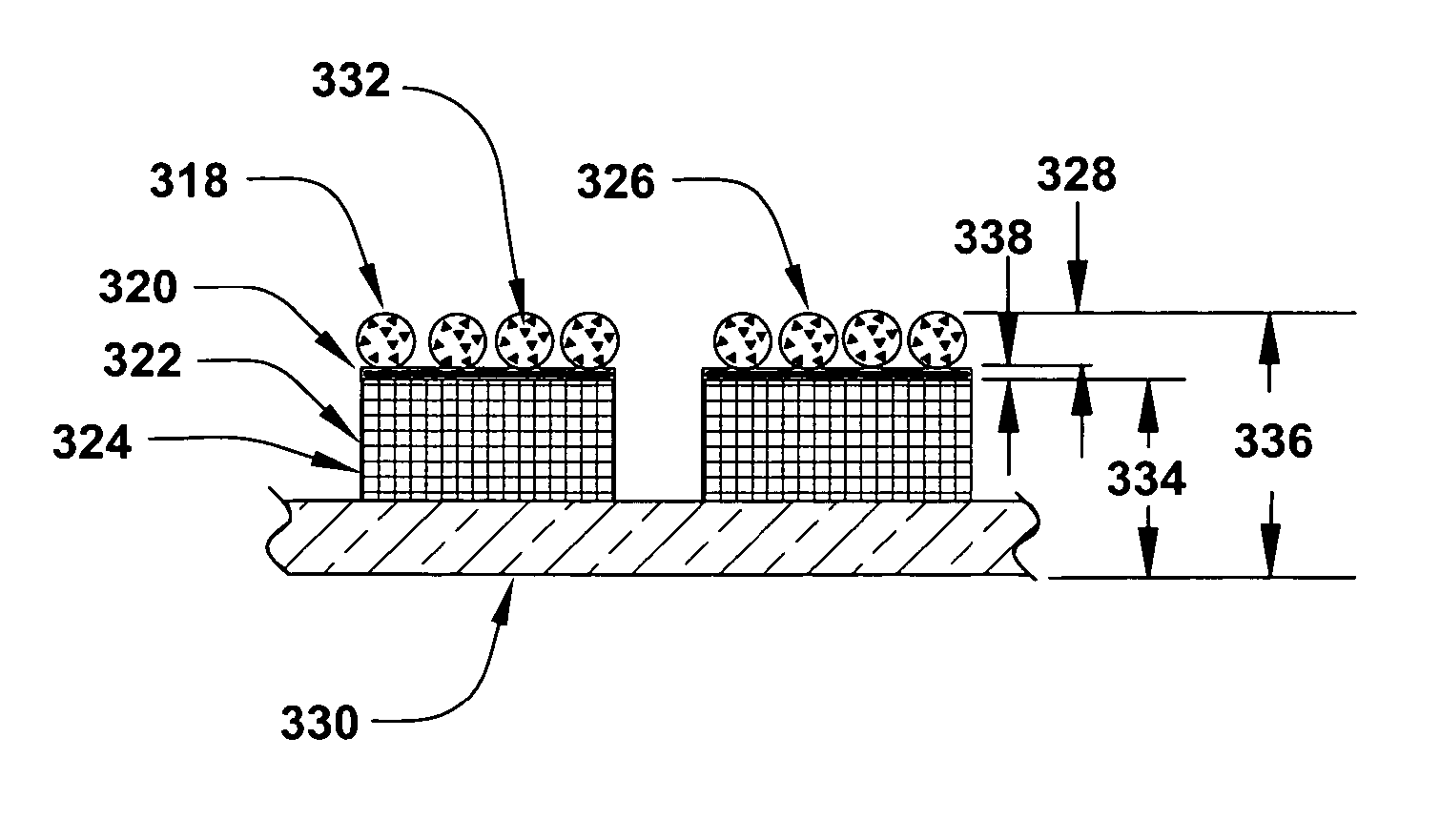

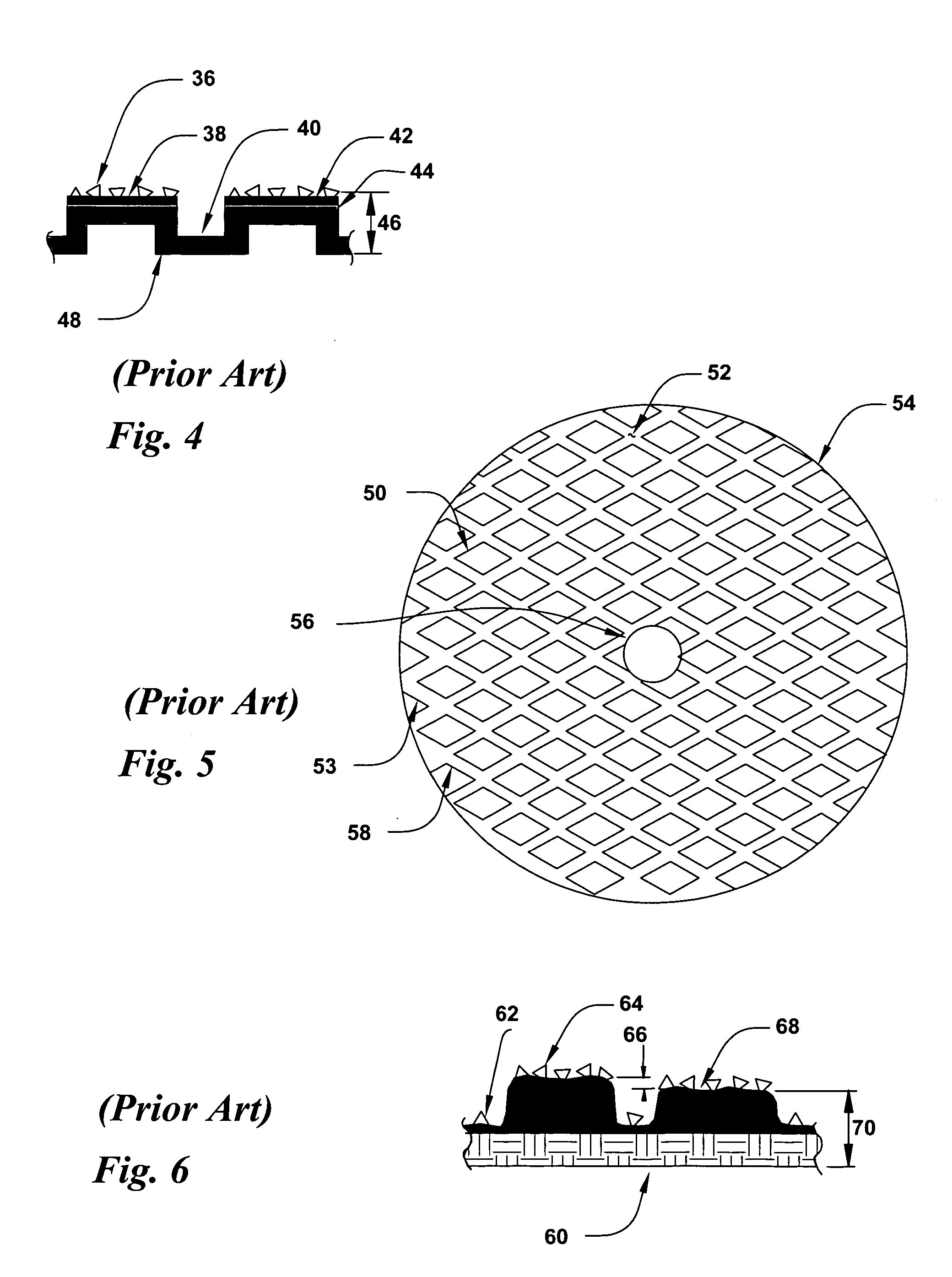

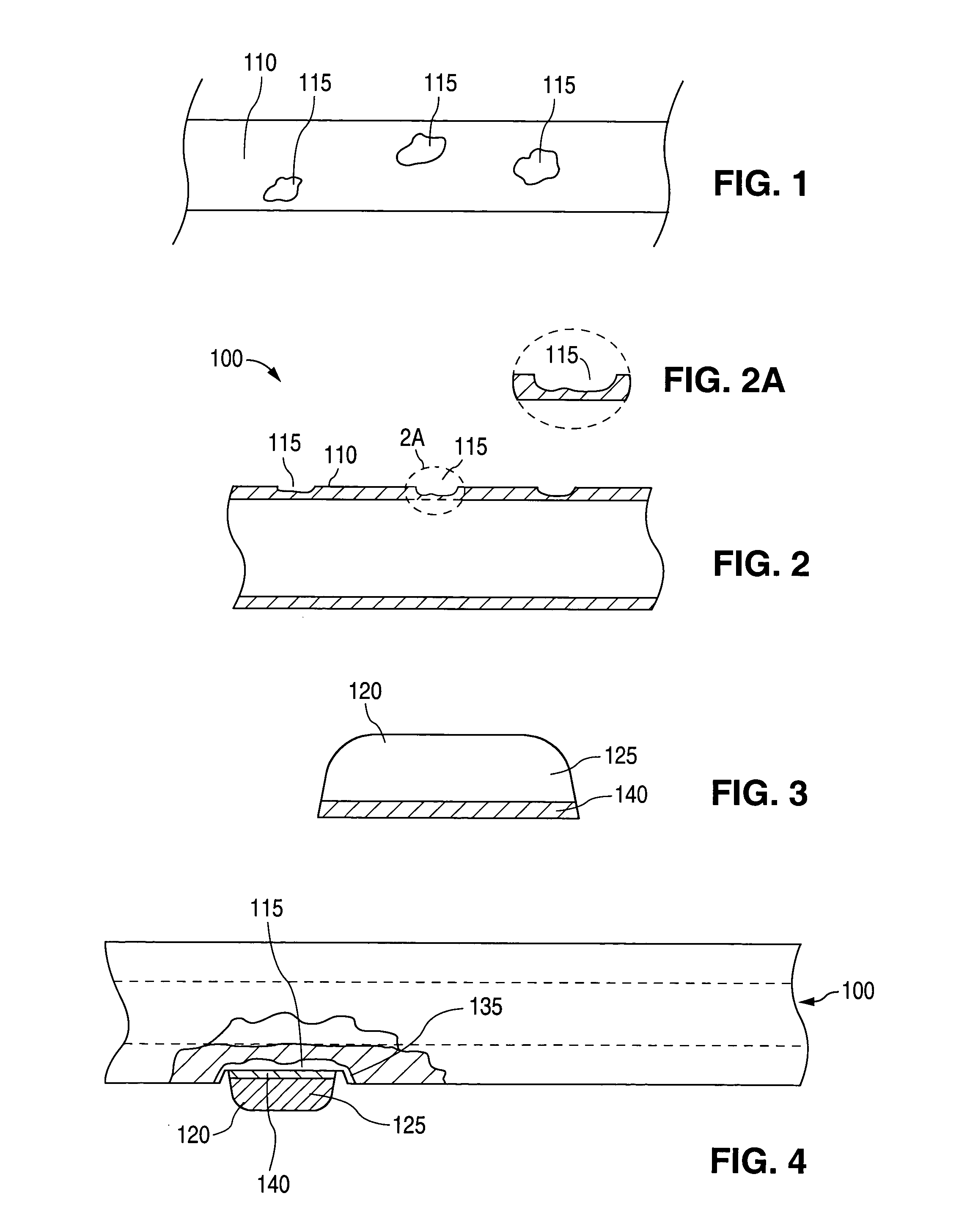

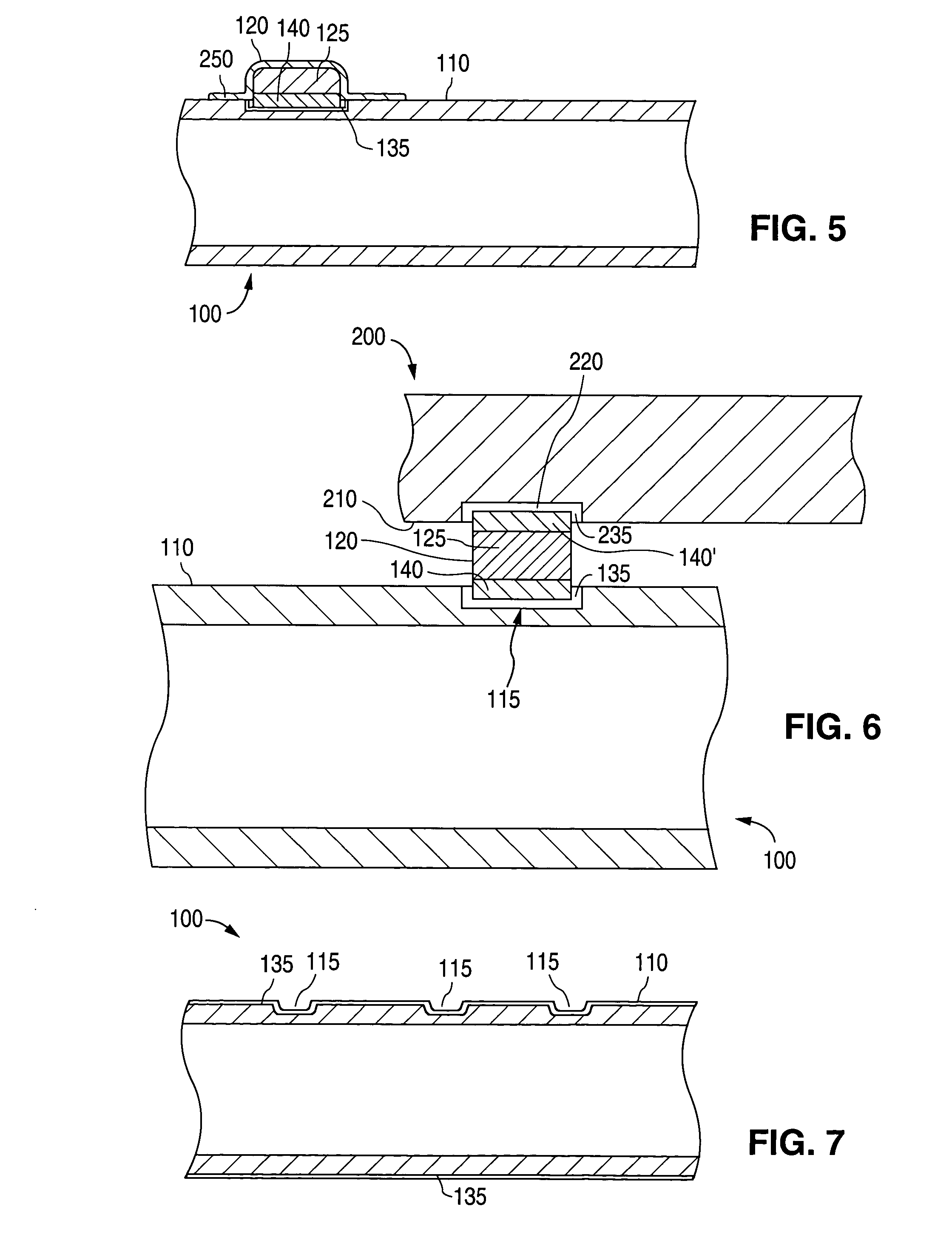

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

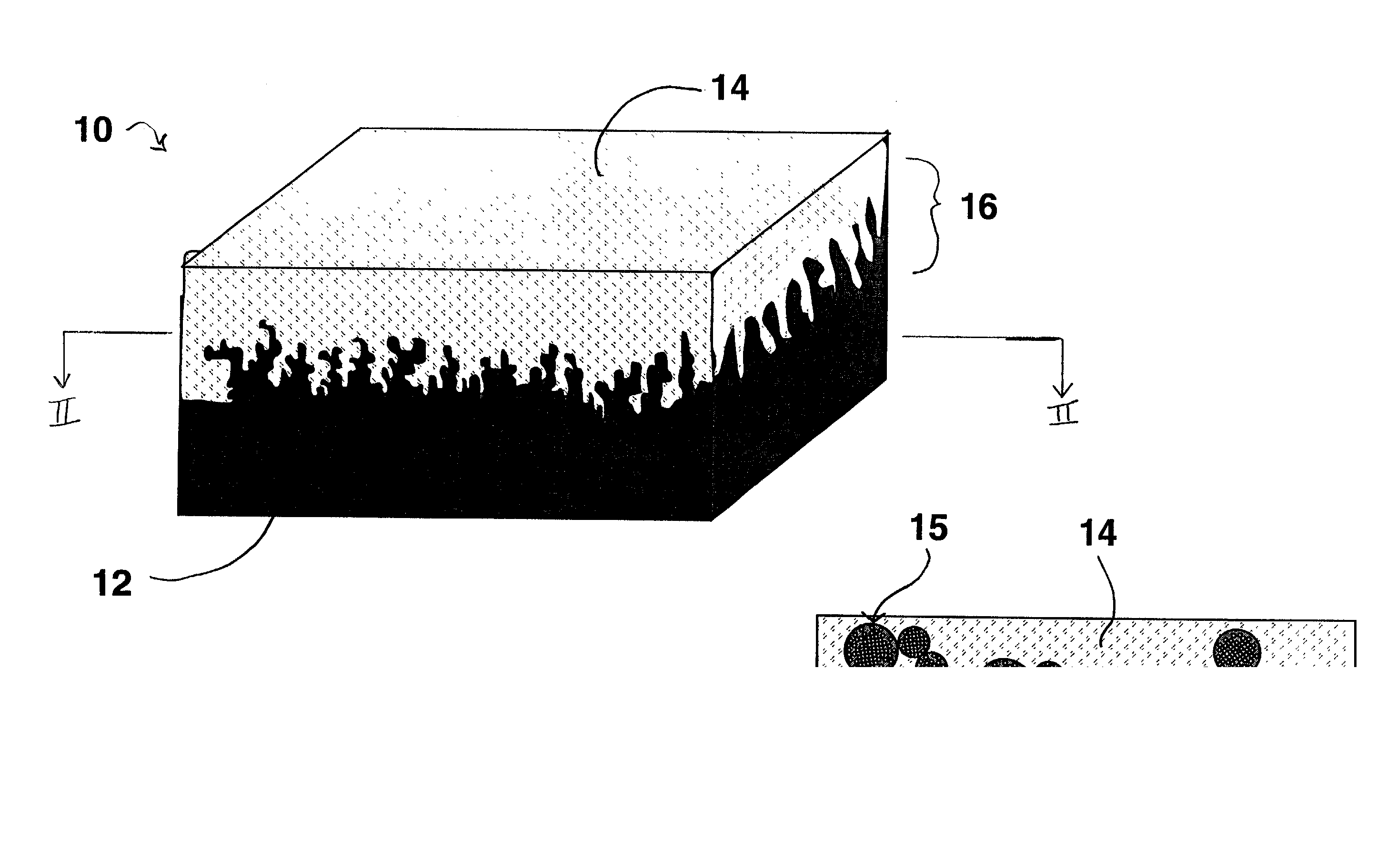

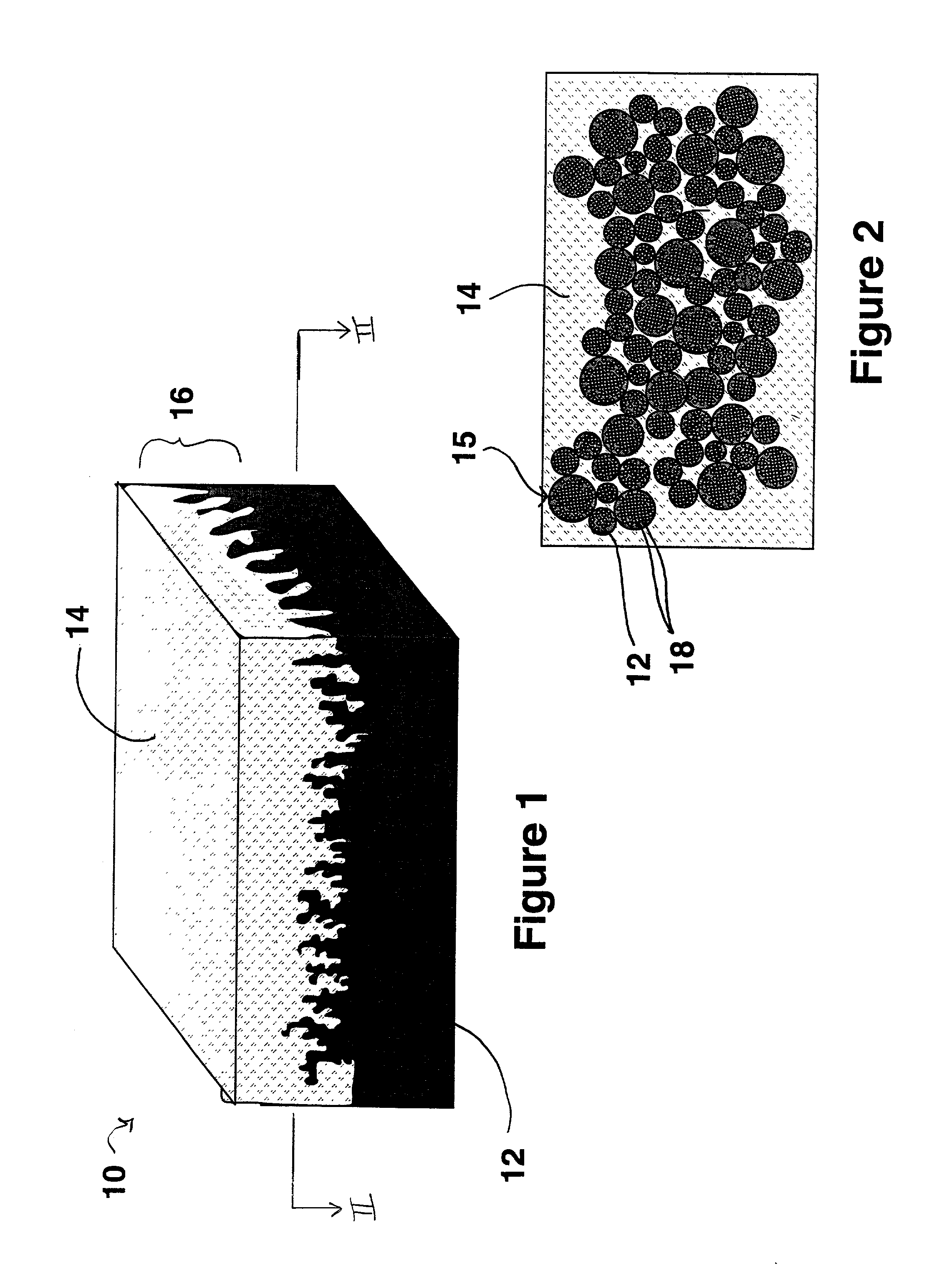

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

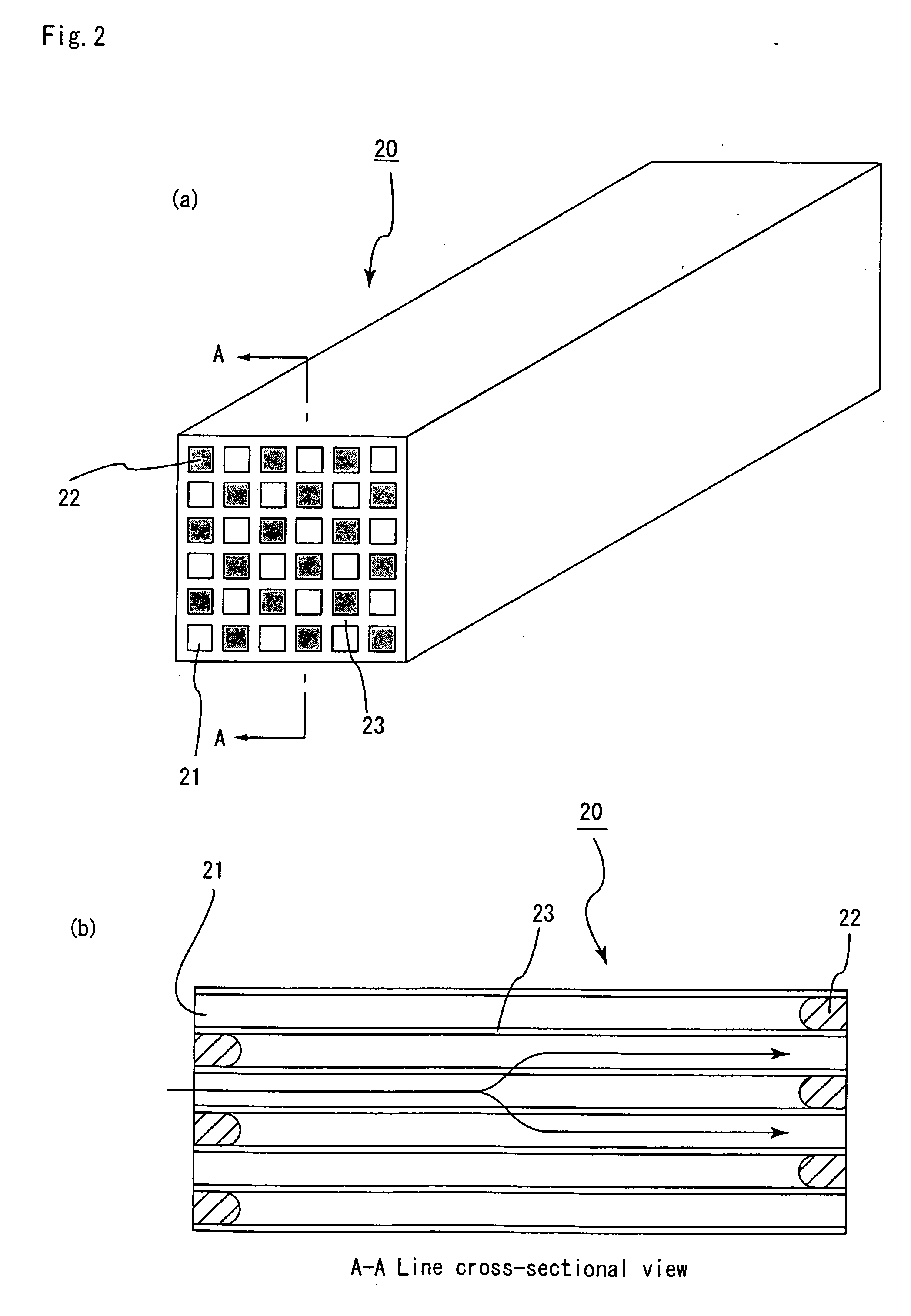

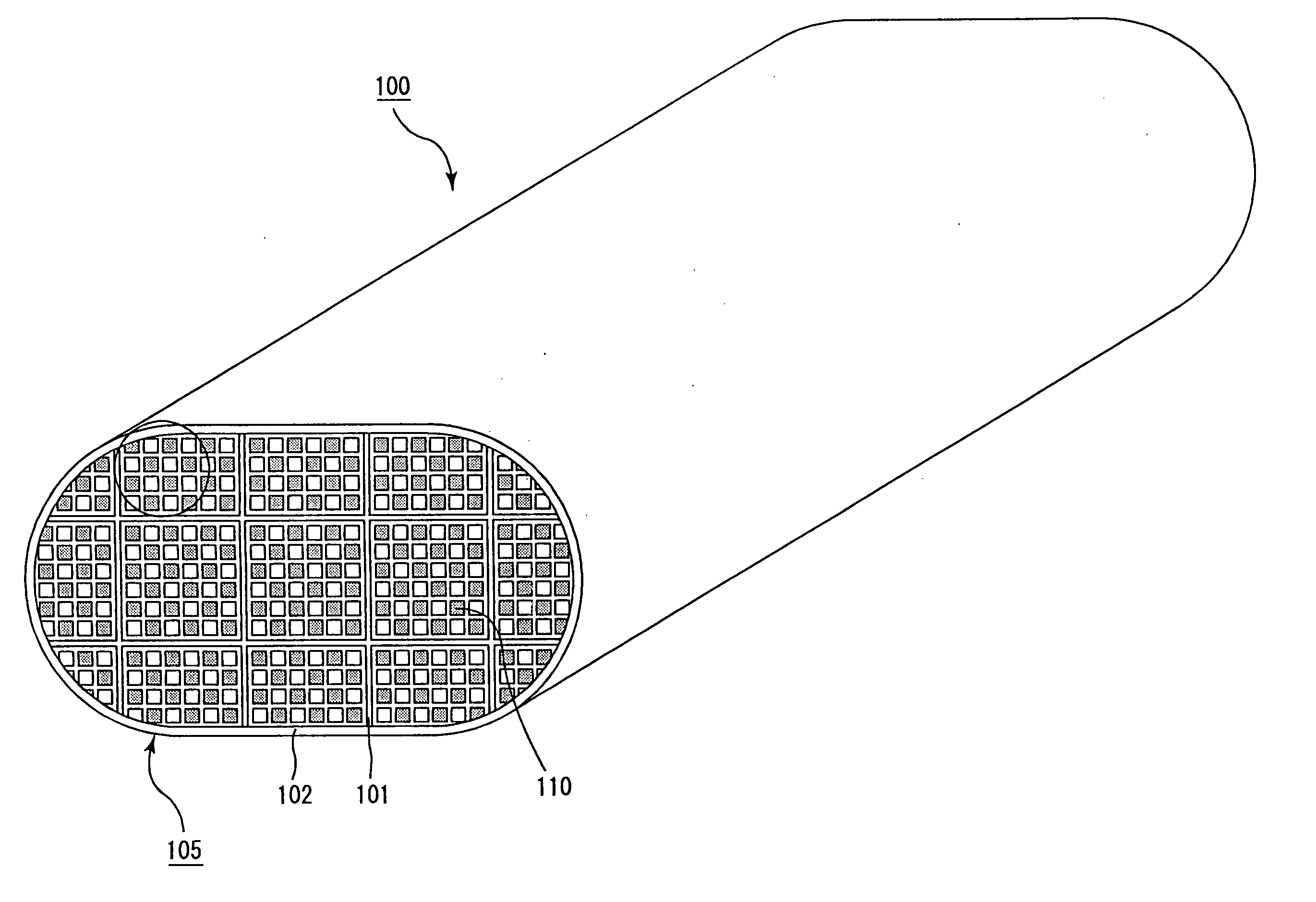

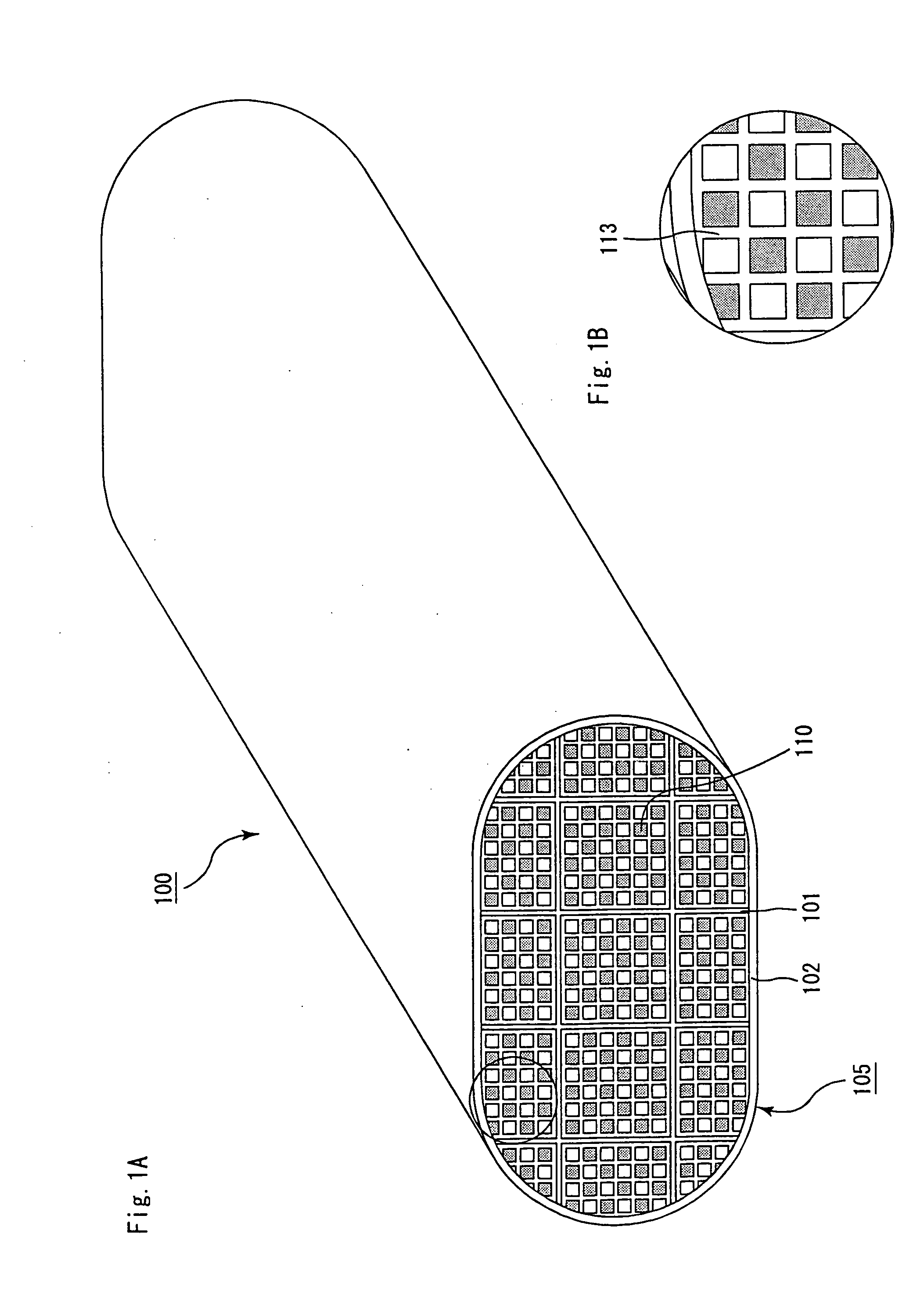

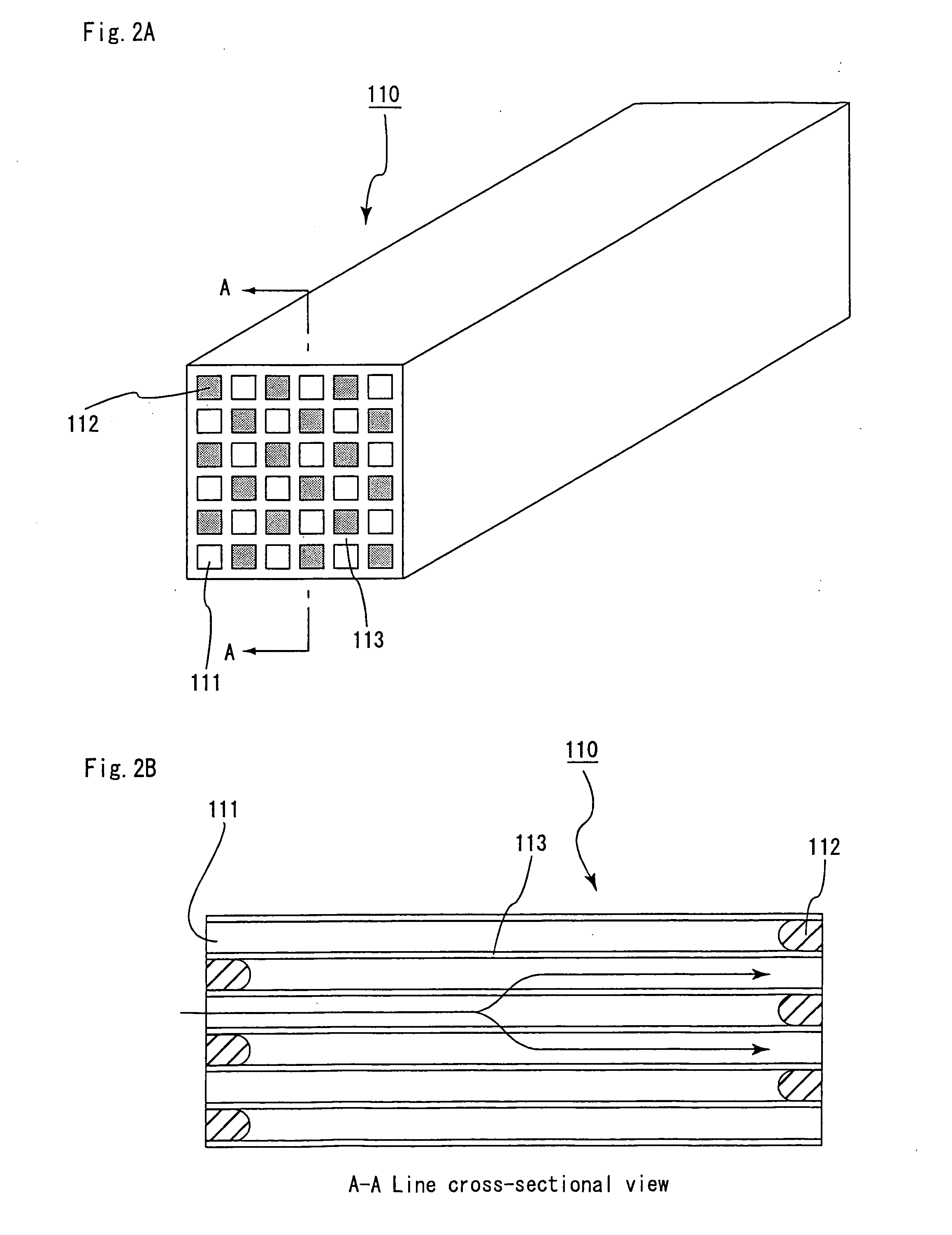

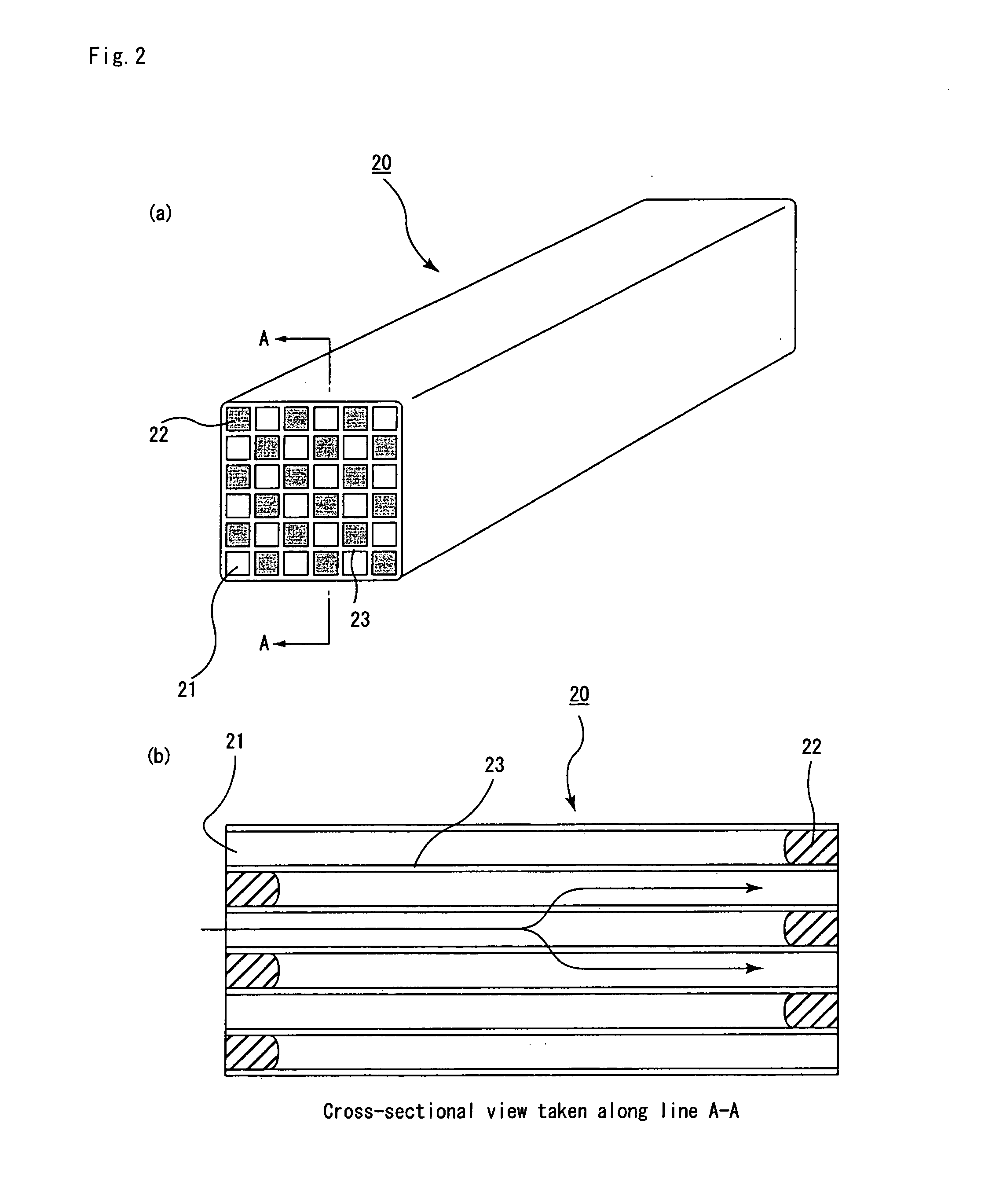

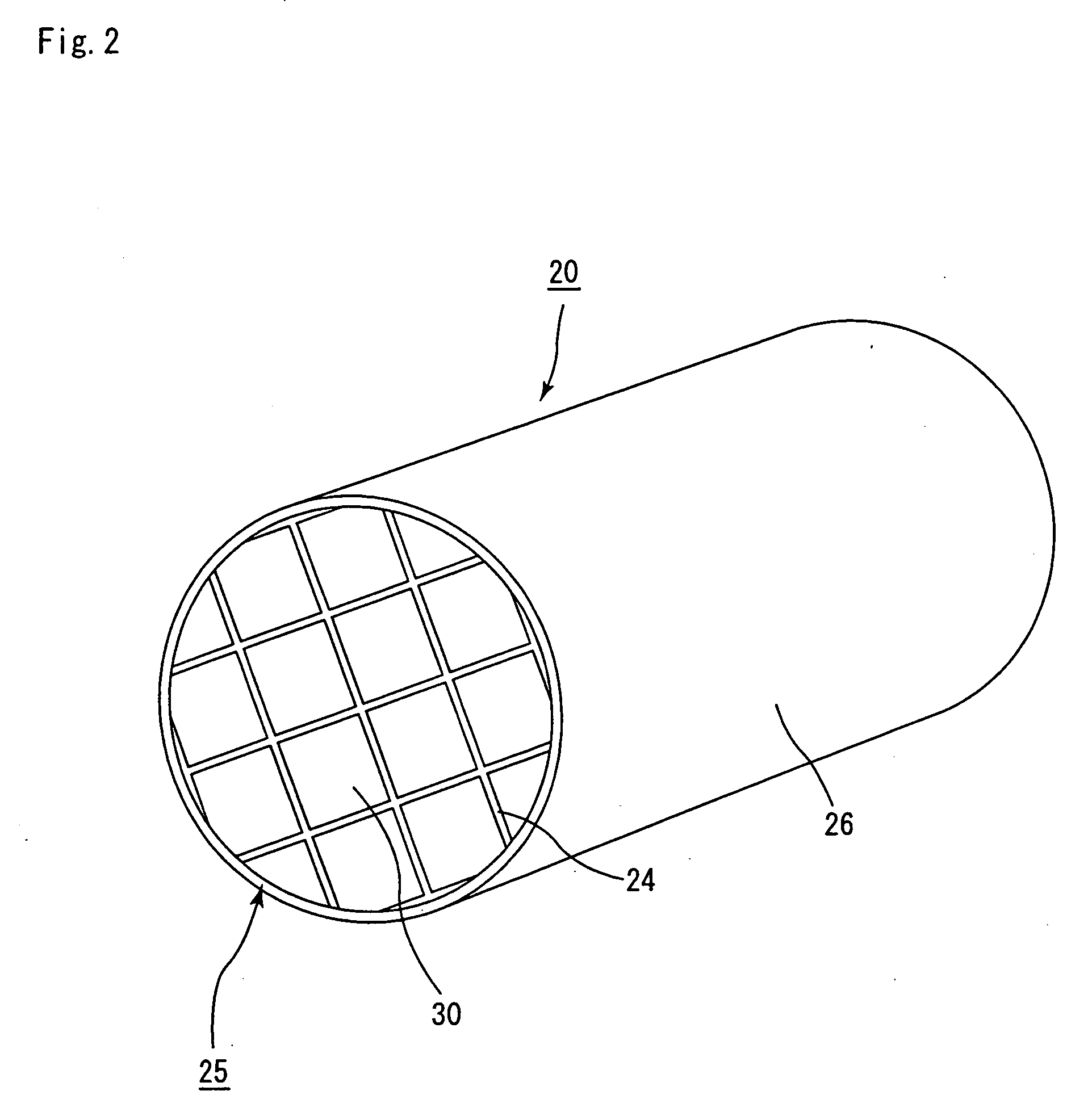

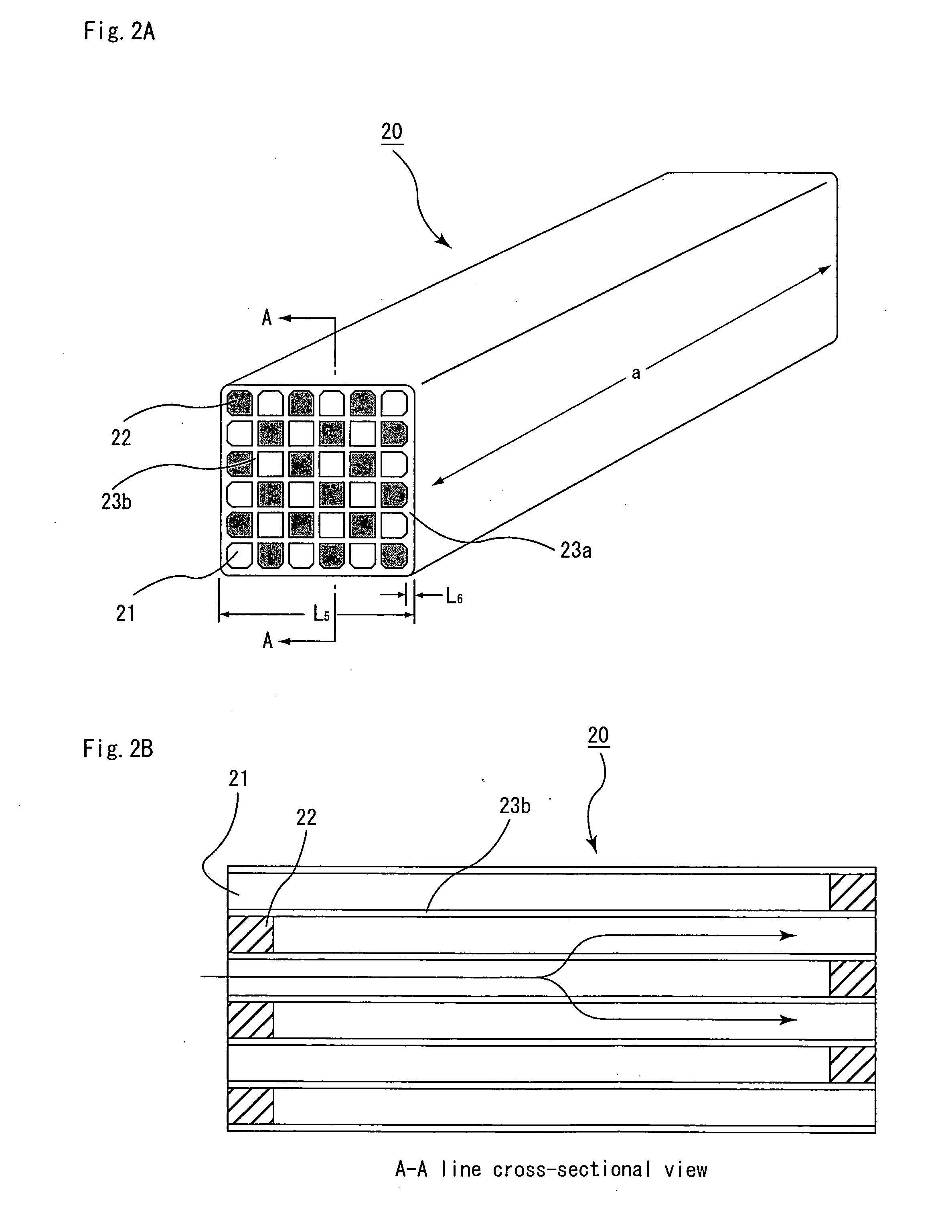

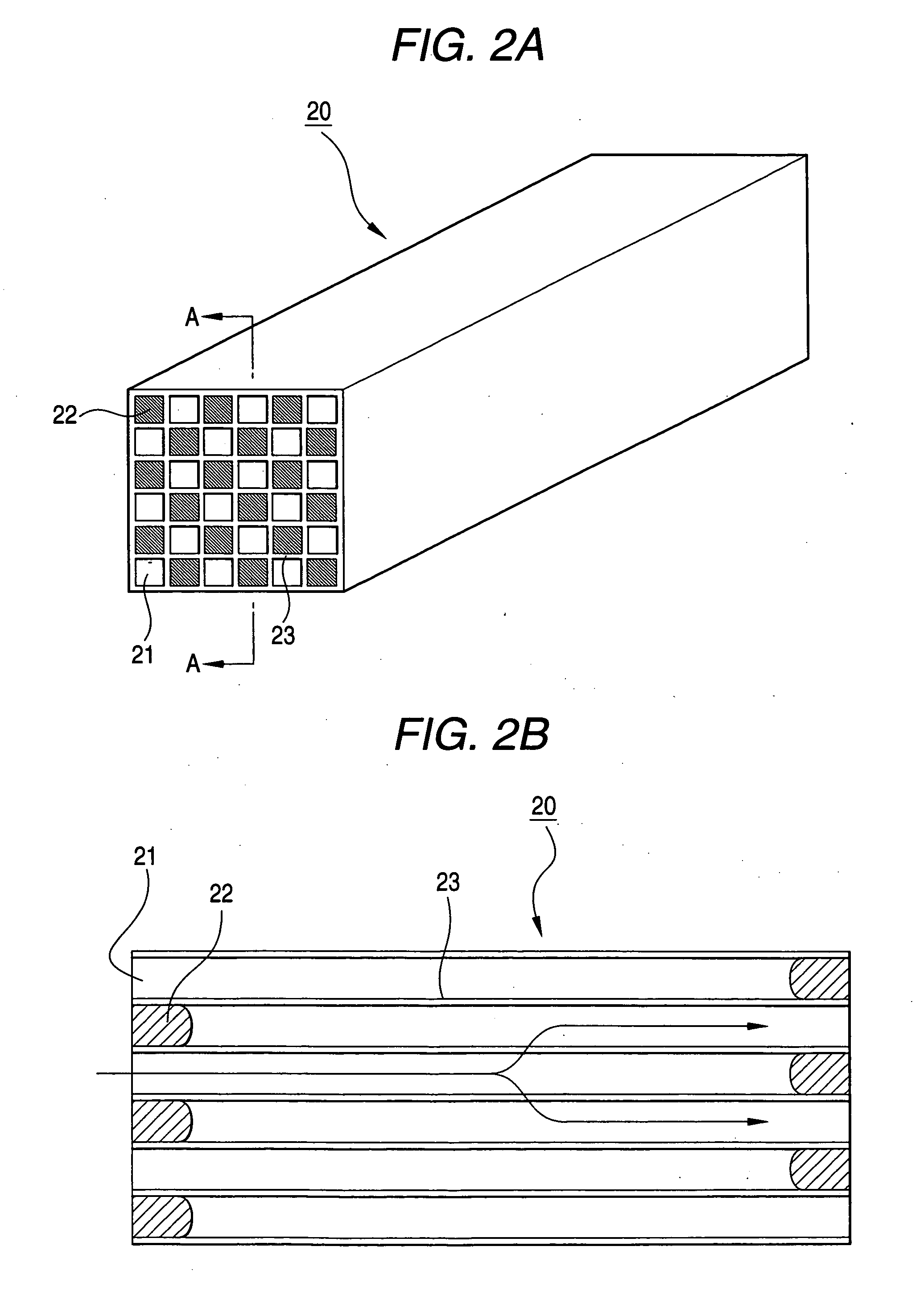

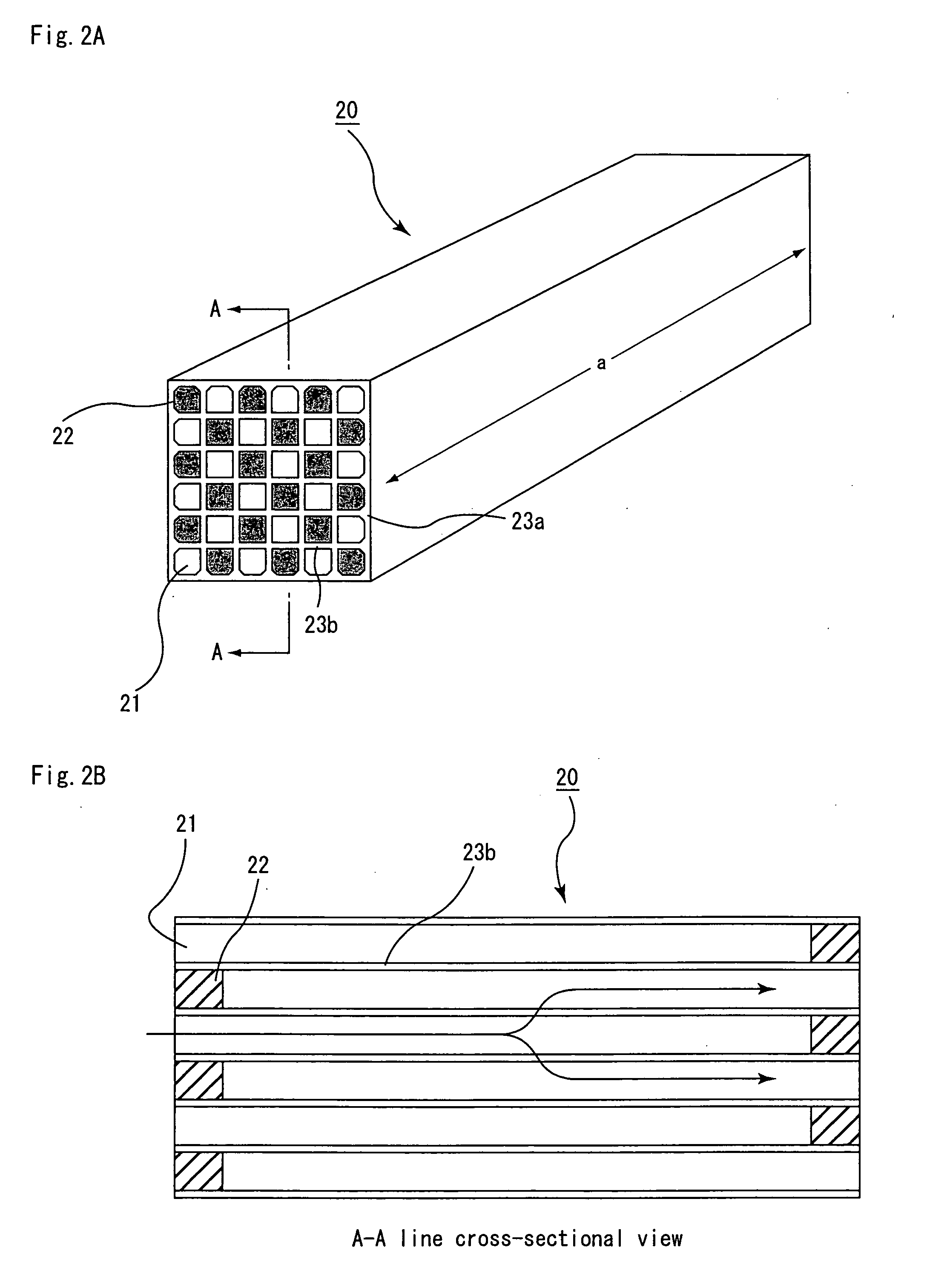

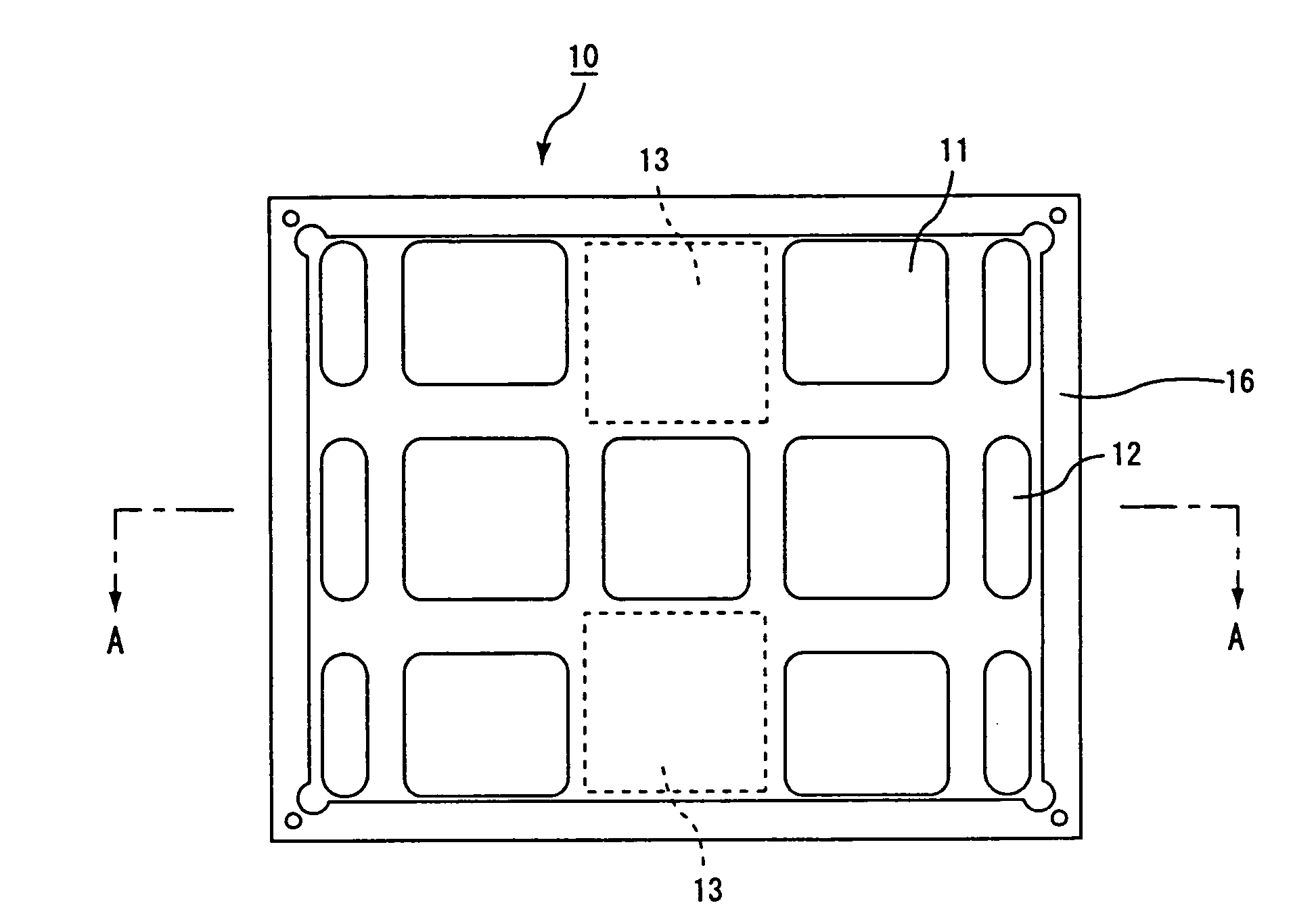

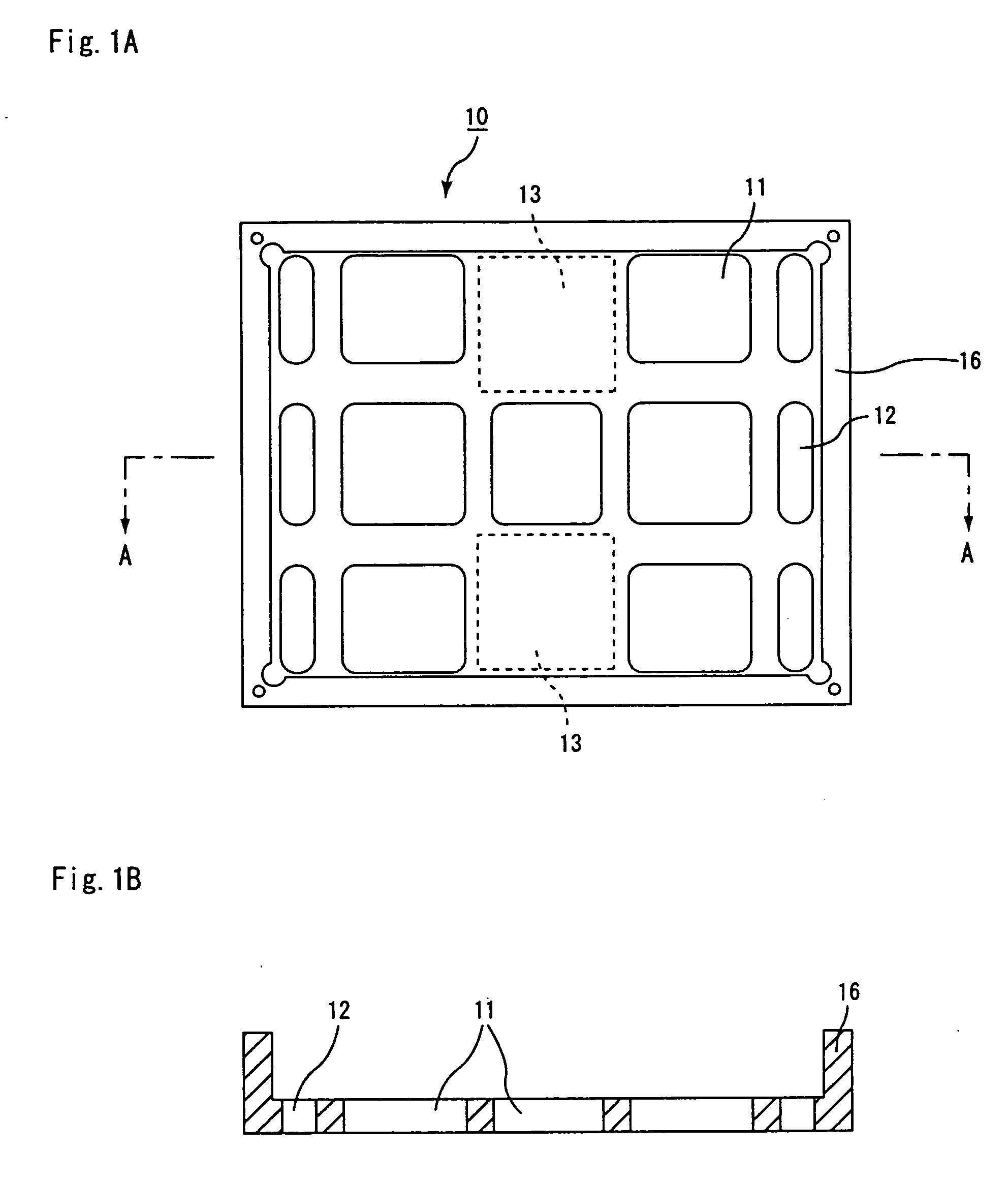

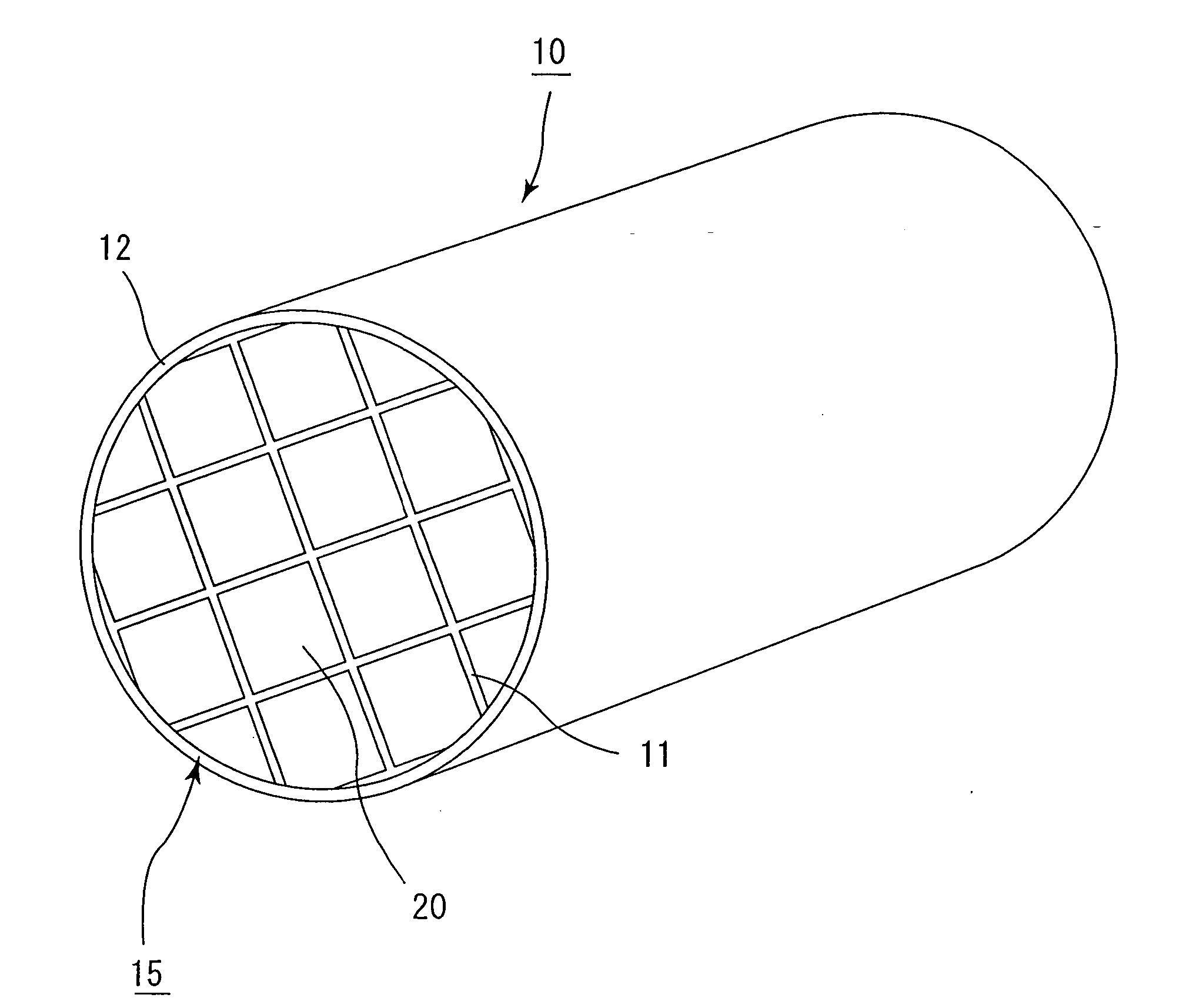

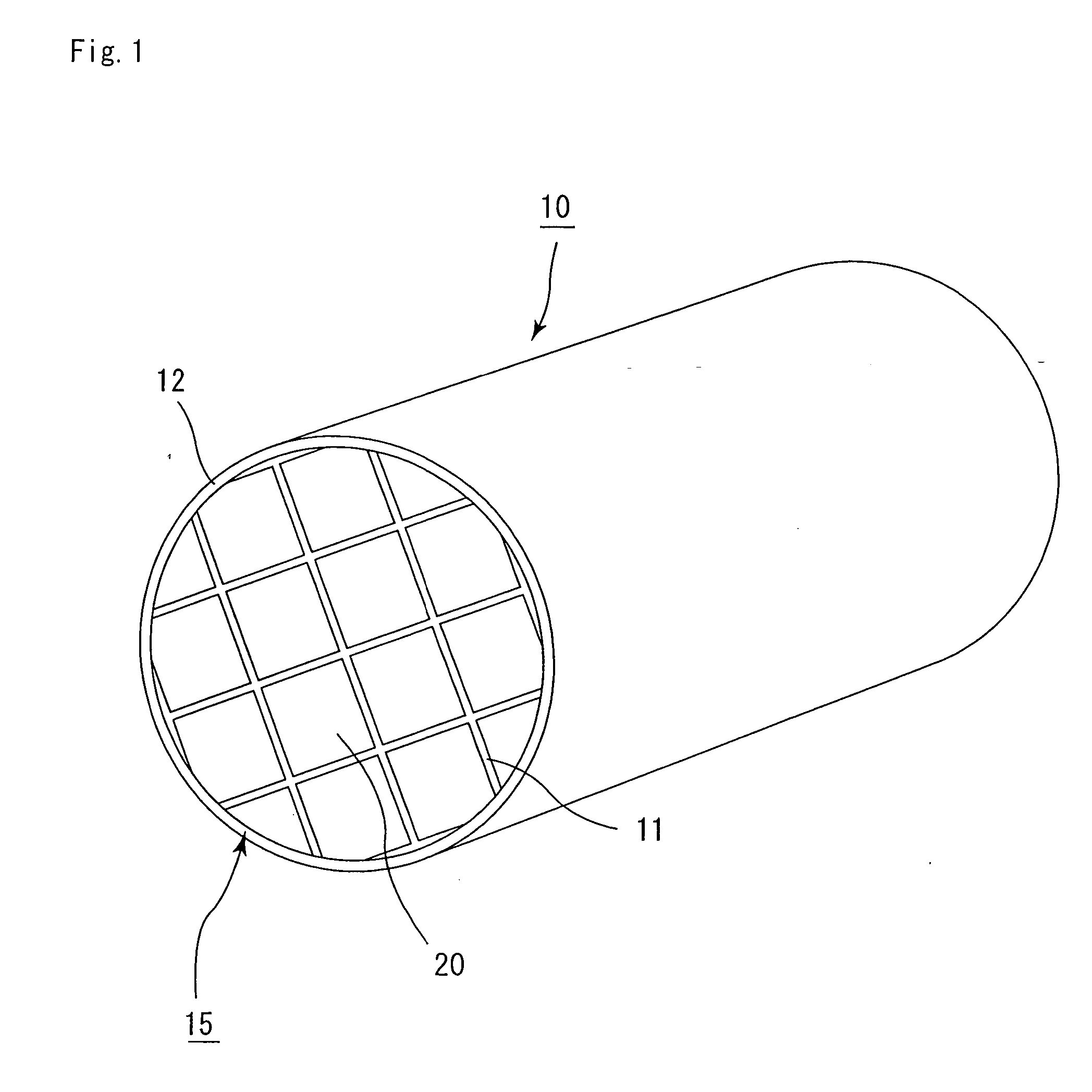

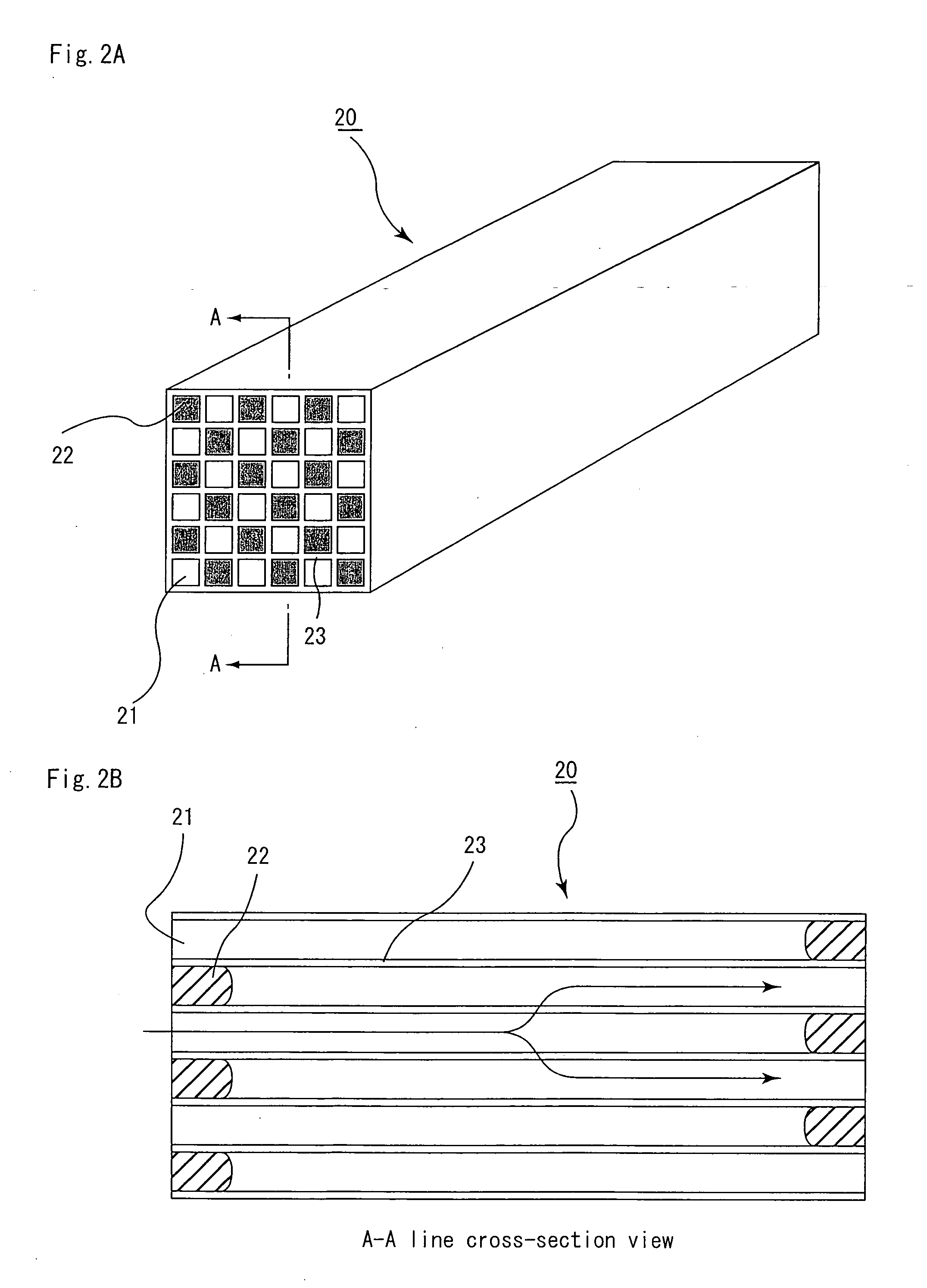

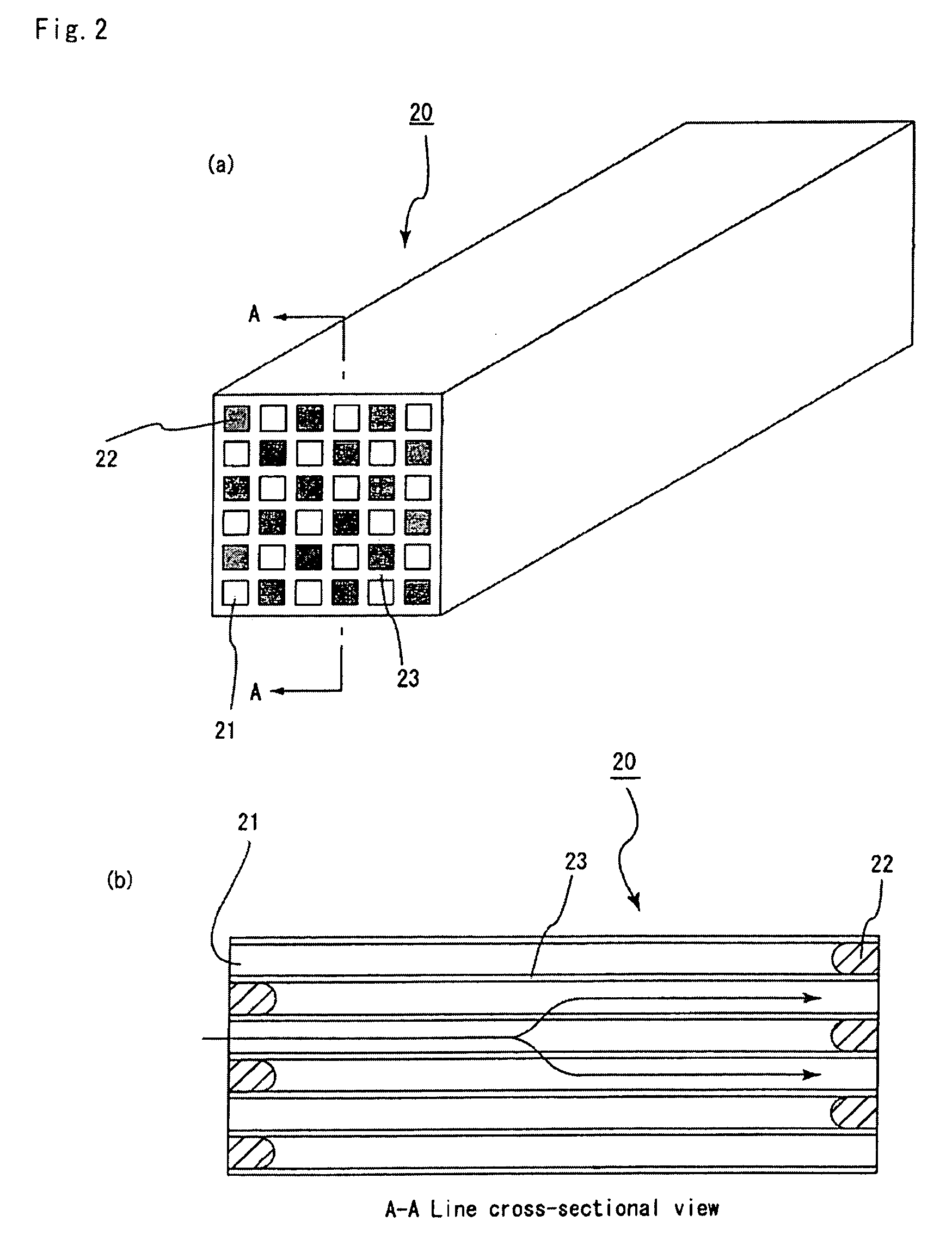

Honeycomb structural body and manufacturing method thereof

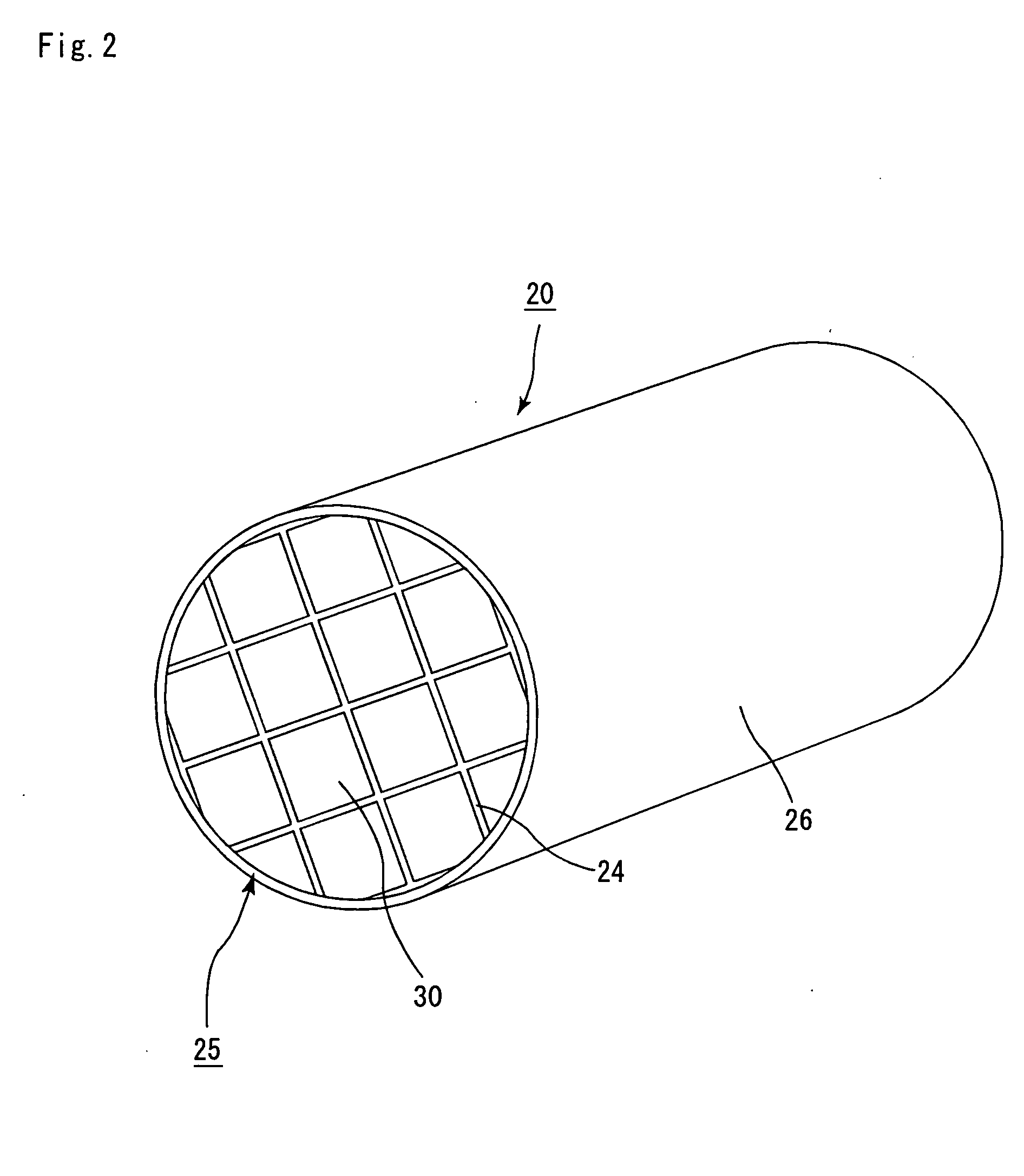

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

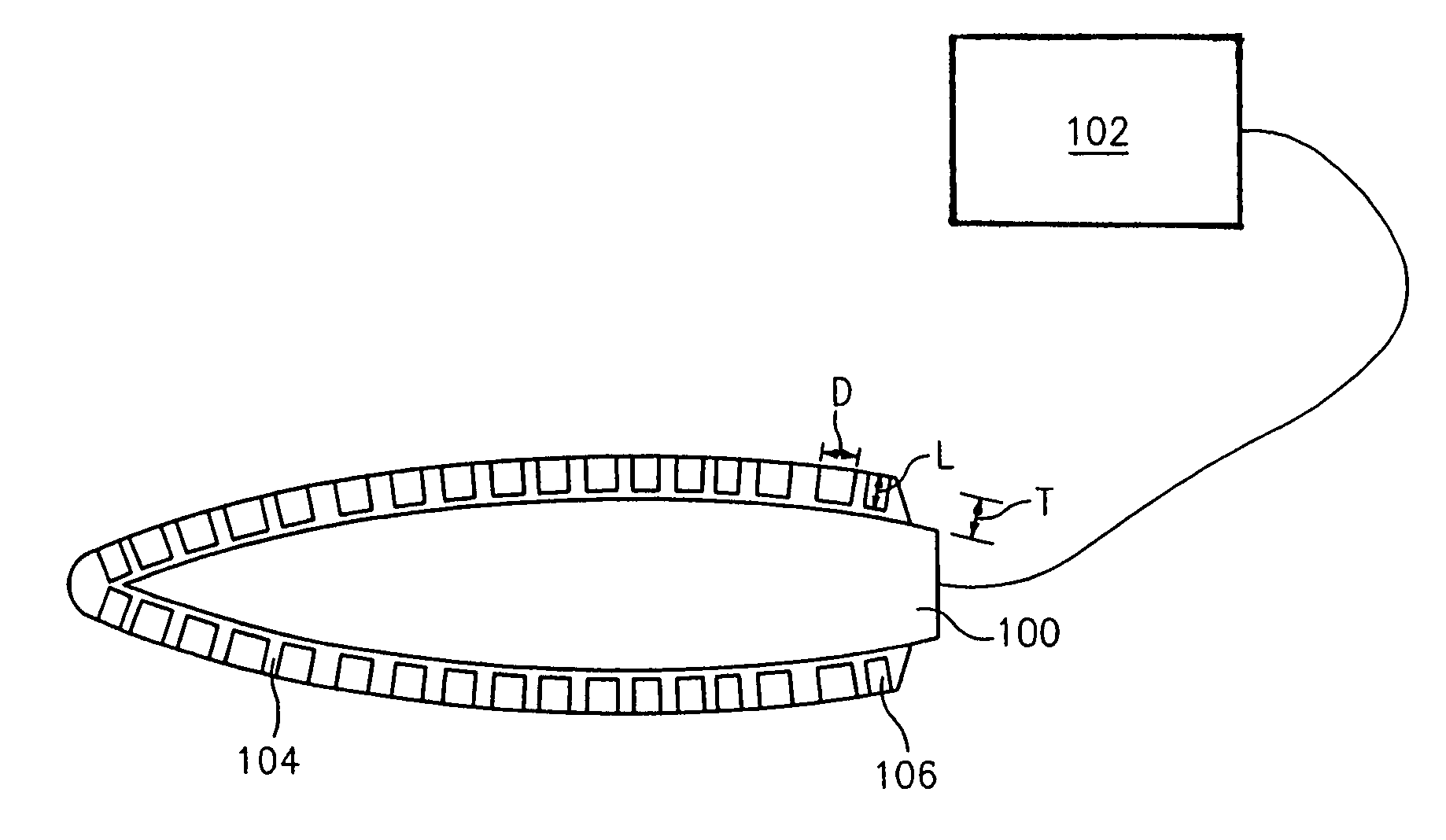

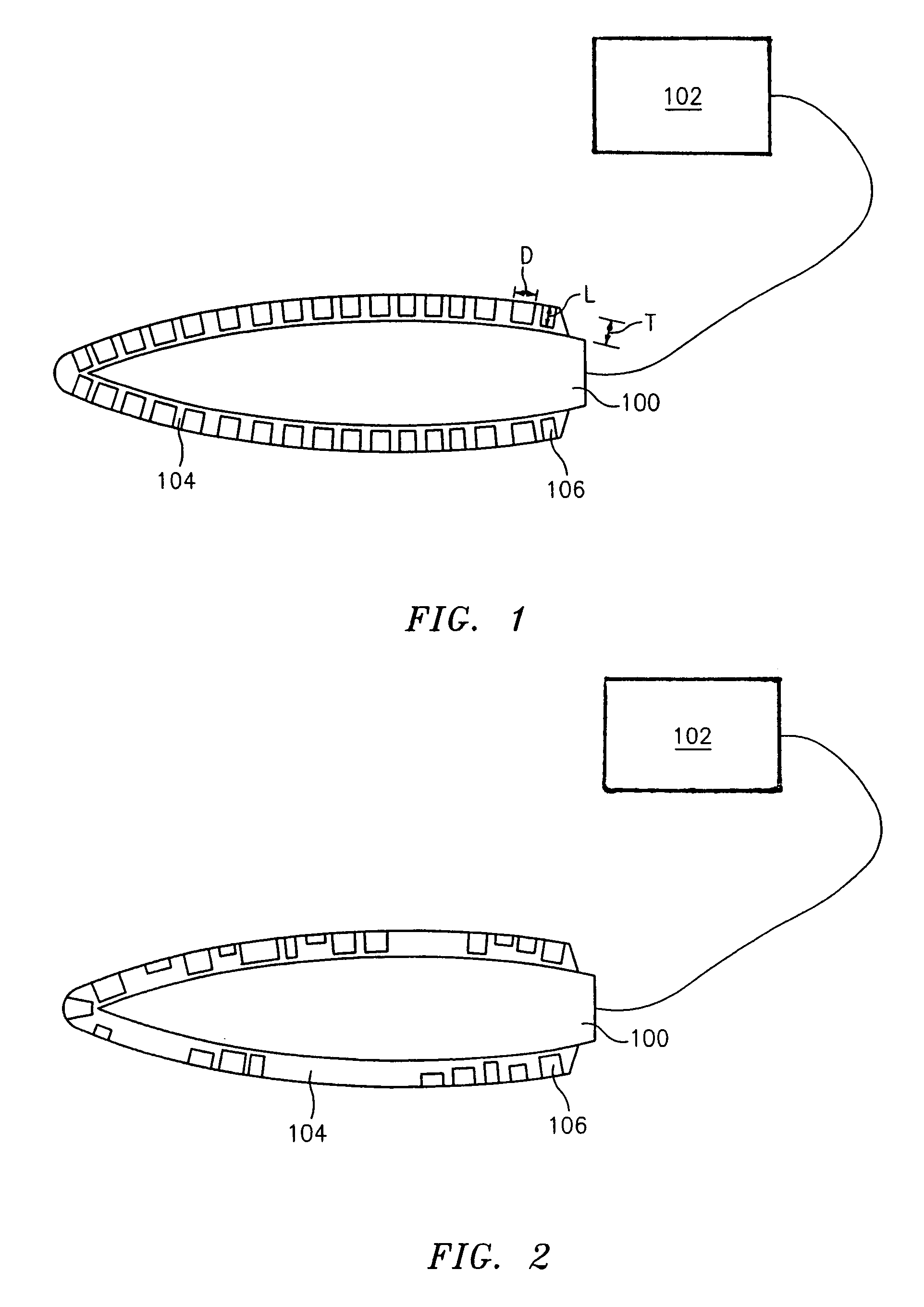

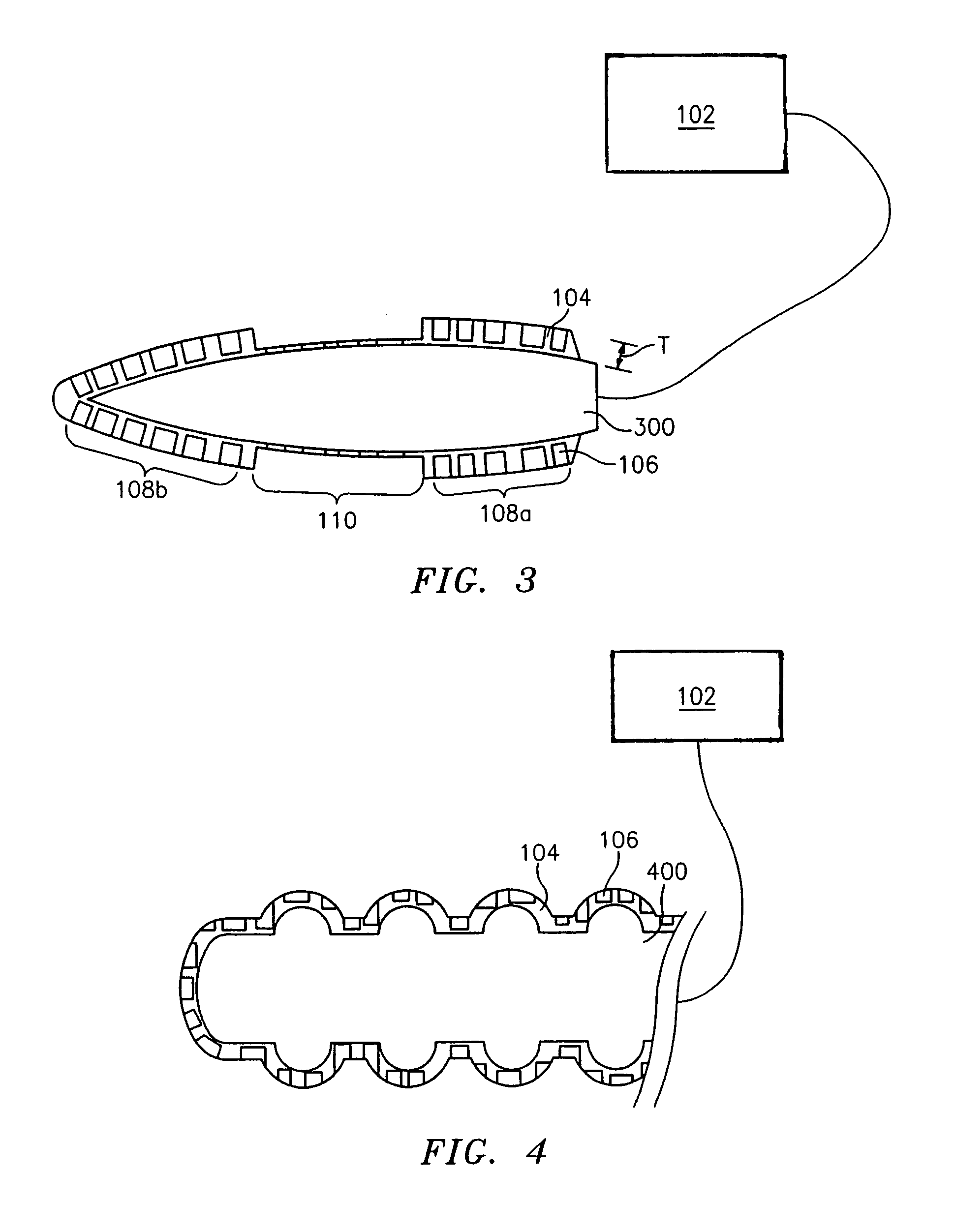

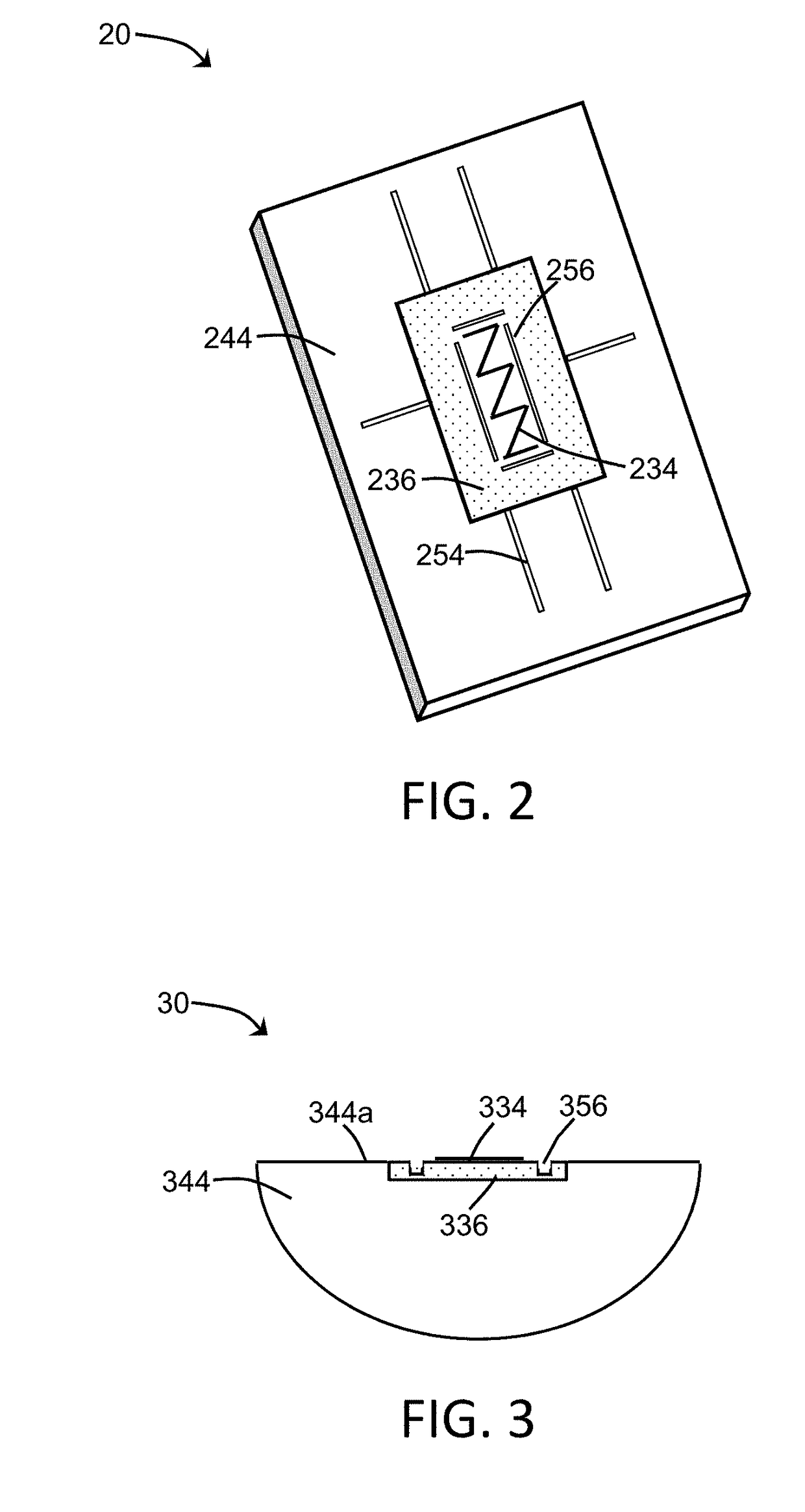

Electrosurgical electrode having a non-conductive porous ceramic coating

ActiveUS7033354B2Minimizing and preventing thermal damageHigh frequencySurgical instruments for heatingCoatingsElectrosurgeryPorous ceramics

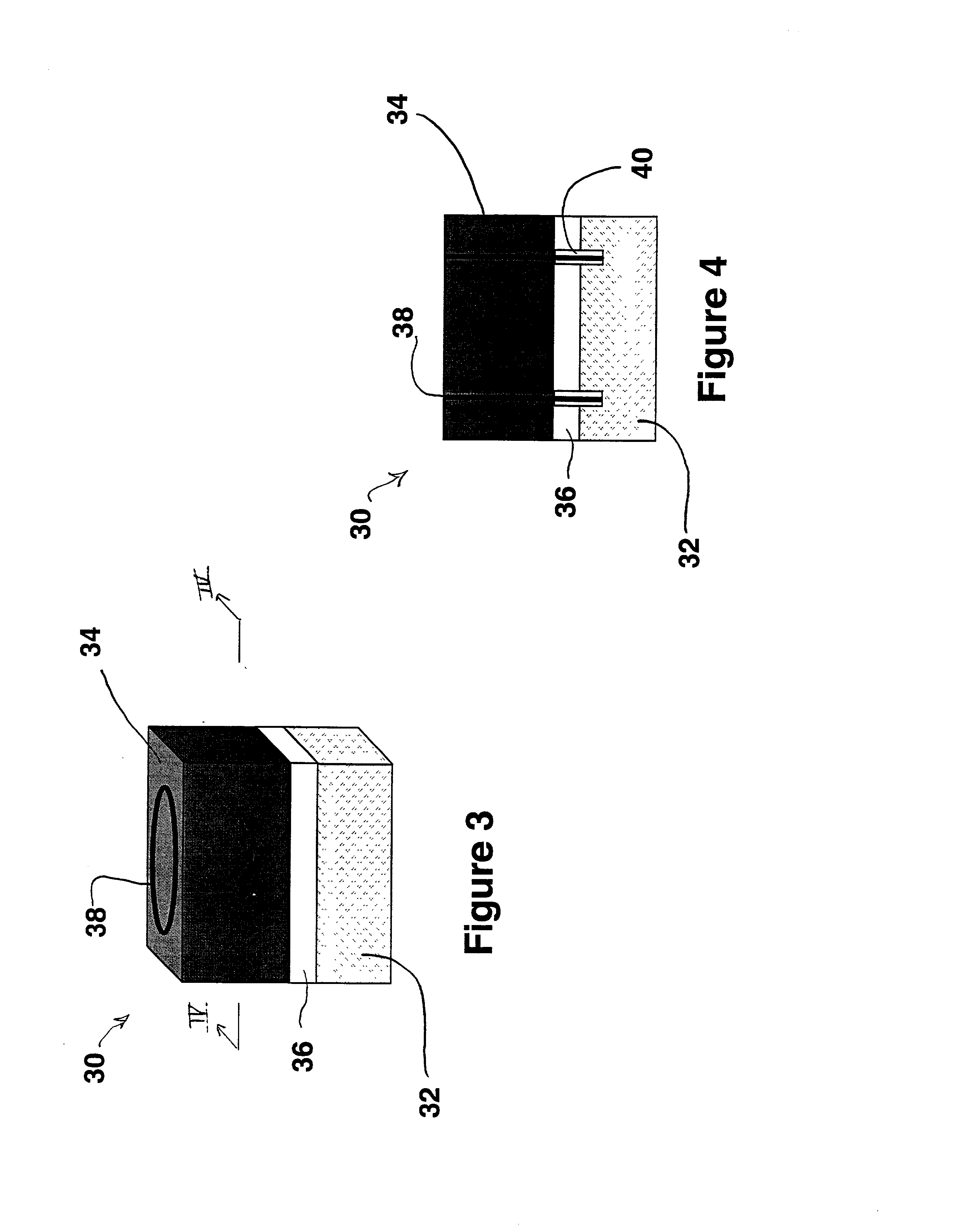

An electrosurgical electrode and electrosurgical generator system utilizing the same are disclosed capable of controlling or limiting the current per arc in real-time during an electrosurgical procedure. The conductive electrosurgical electrode is configured for being connected to an electrosurgical generator system and has a non-conductive, porous ceramic coating that “pinches” or splits the arc current generated by the electrosurgical generator system into the smaller diameter pores of the coating, effectively keeping the same current and voltage, but creating several smaller diameter arcs from one larger diameter arc. This has the effect of separating the arc current, effectively increasing the current frequency, resulting in a finer cut or other surgical effect. That is, the non-conductive, porous ceramic coating enables a low frequency current to achieve surgical results indicative of a high frequency current, while minimizing or preventing thermal damage to adjacent tissue.

Owner:COVIDIEN AG

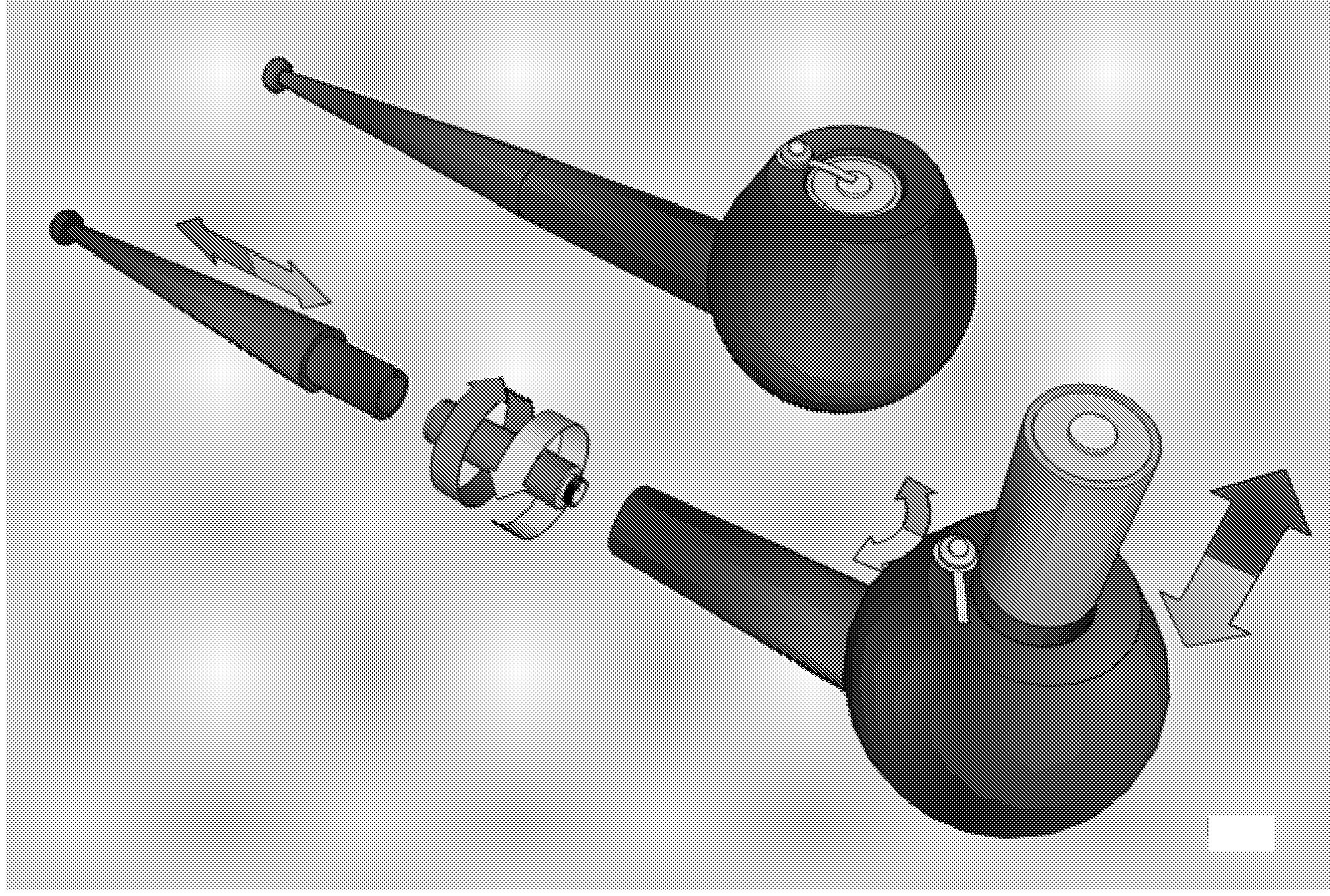

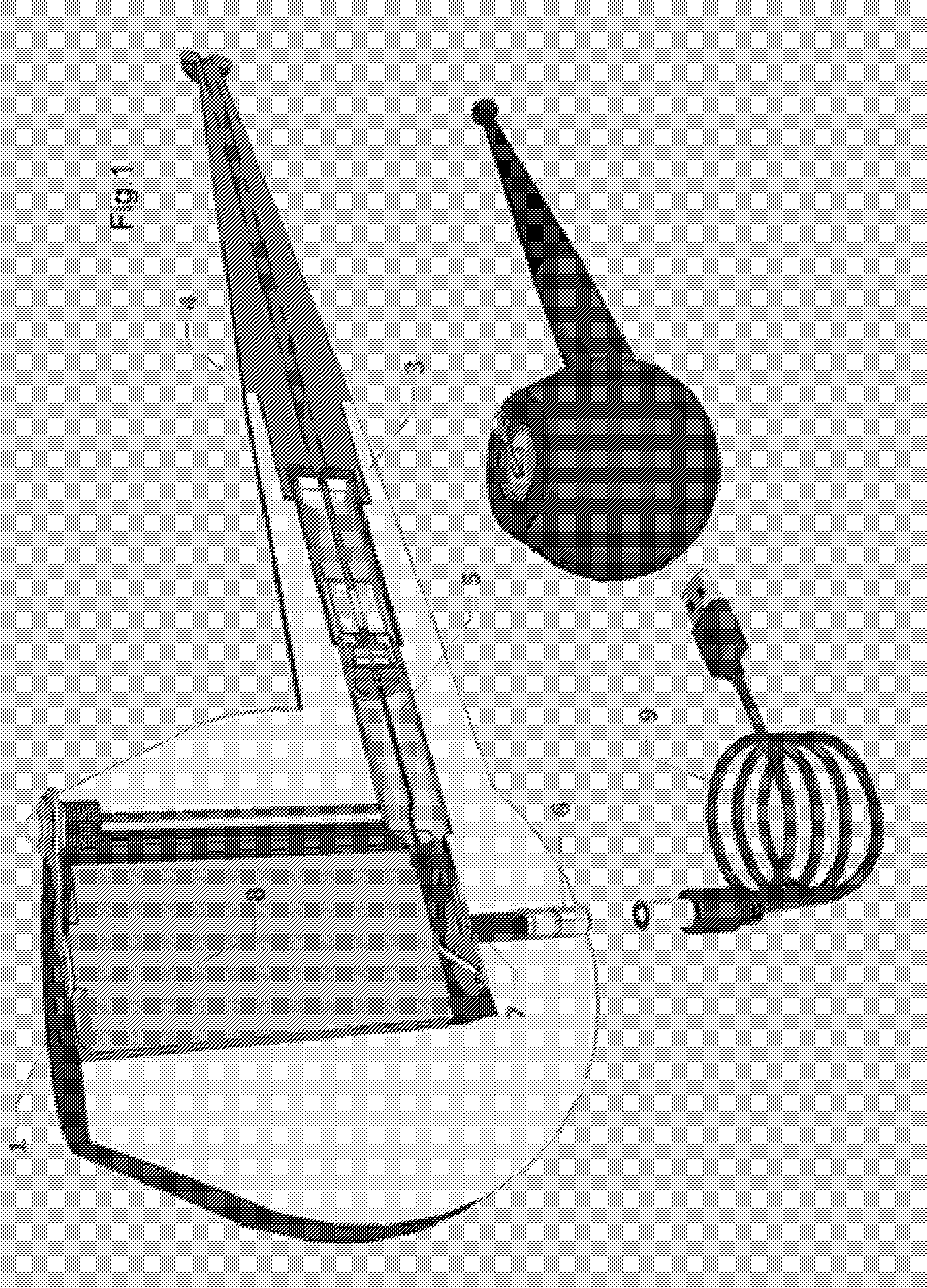

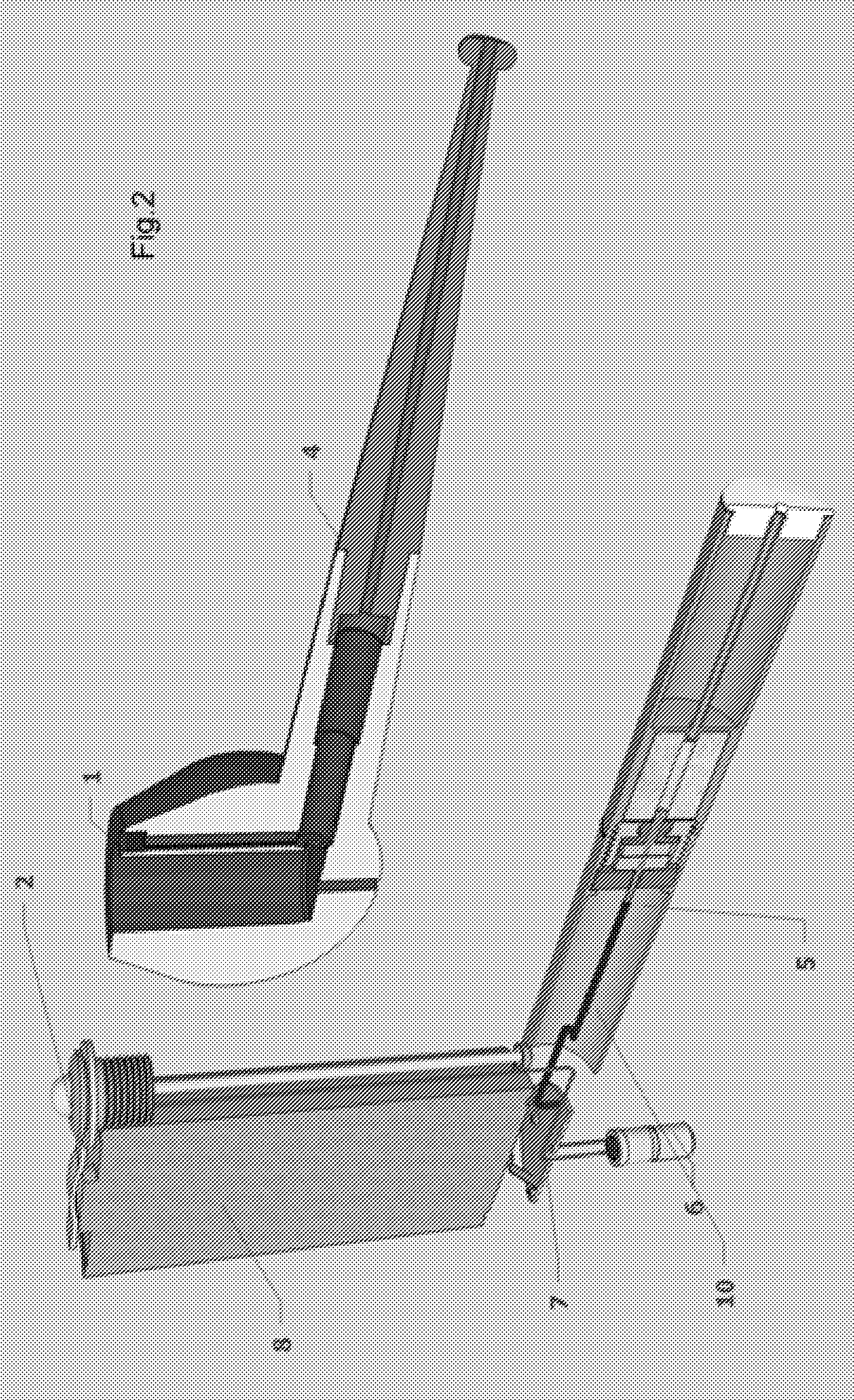

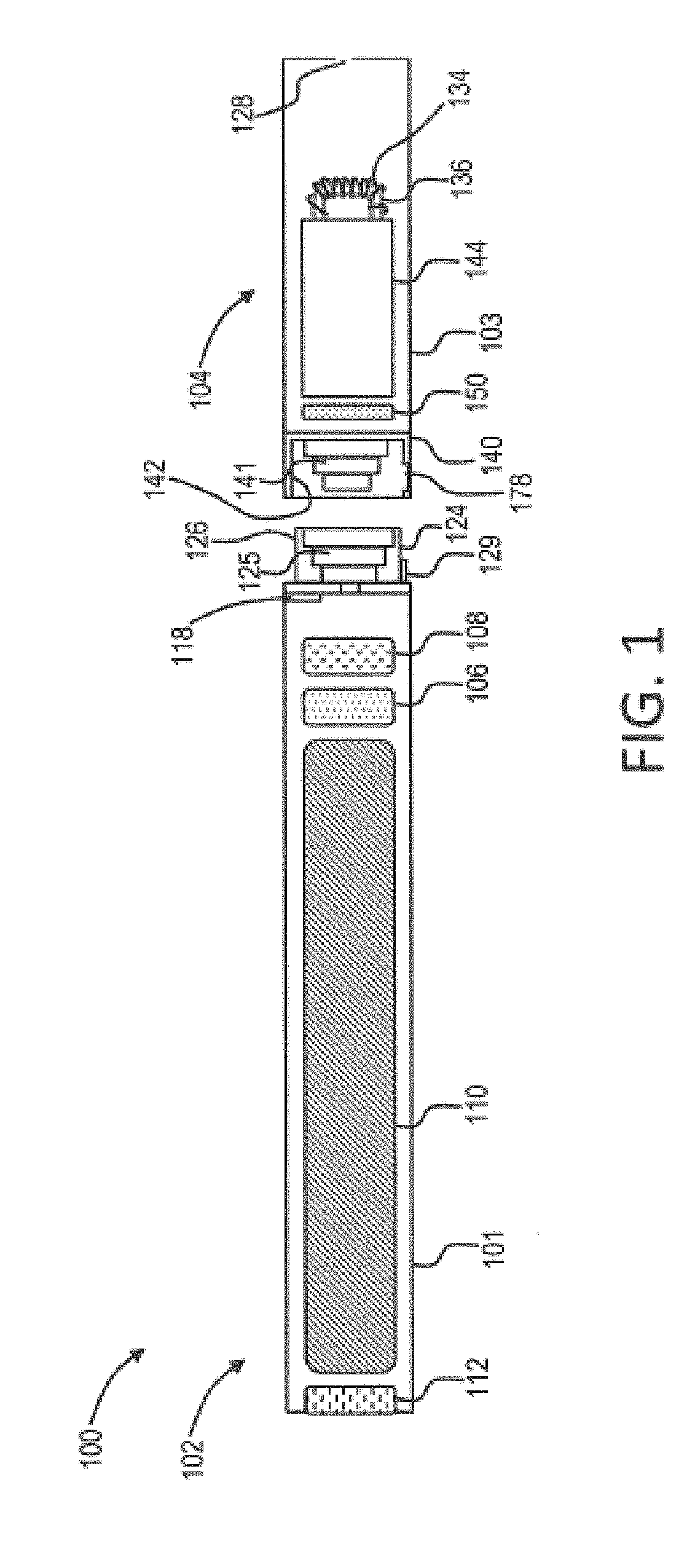

Electronic pipe personal vaporizer with concealed removable atomizer/ cartomizer

InactiveUS20130087160A1Avoid accidental activationAvoid problemsTobacco pipesTobacco devicesCircular discControl power

A porous ceramic atomized cartridge contains a heating element, a porous ceramic wick, and the liquid to be vaporized removably concealed within the body of an electronic simulated smoking pipe. Adjustment of the spacing of a circular disc heating element relative to the porous ceramic wick adjusts the level of atomization. All components are easily removable and replaceable and cleaned. A bowl of the pipe is used as an open battery chamber to allow any battery fumes to escape and allow easy removal and replacement of the battery. A conductive contact arm pivots between contact with the battery and the pipe body to control power. Vapor is activated by a manual push button switch or an automatic sound activated switch responsive to the puffing sound of a user.

Owner:GHERGHE ALEXANDRU

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

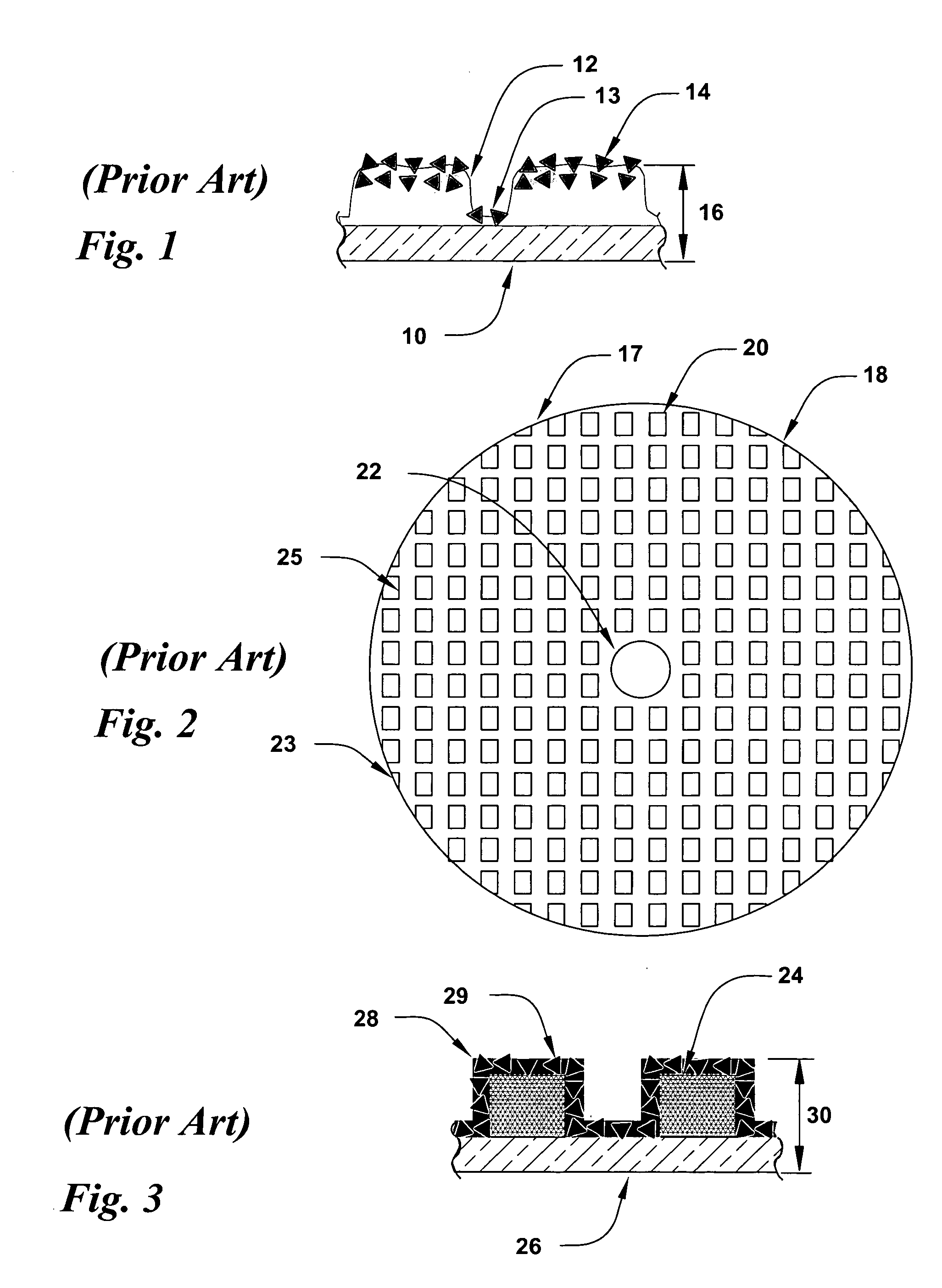

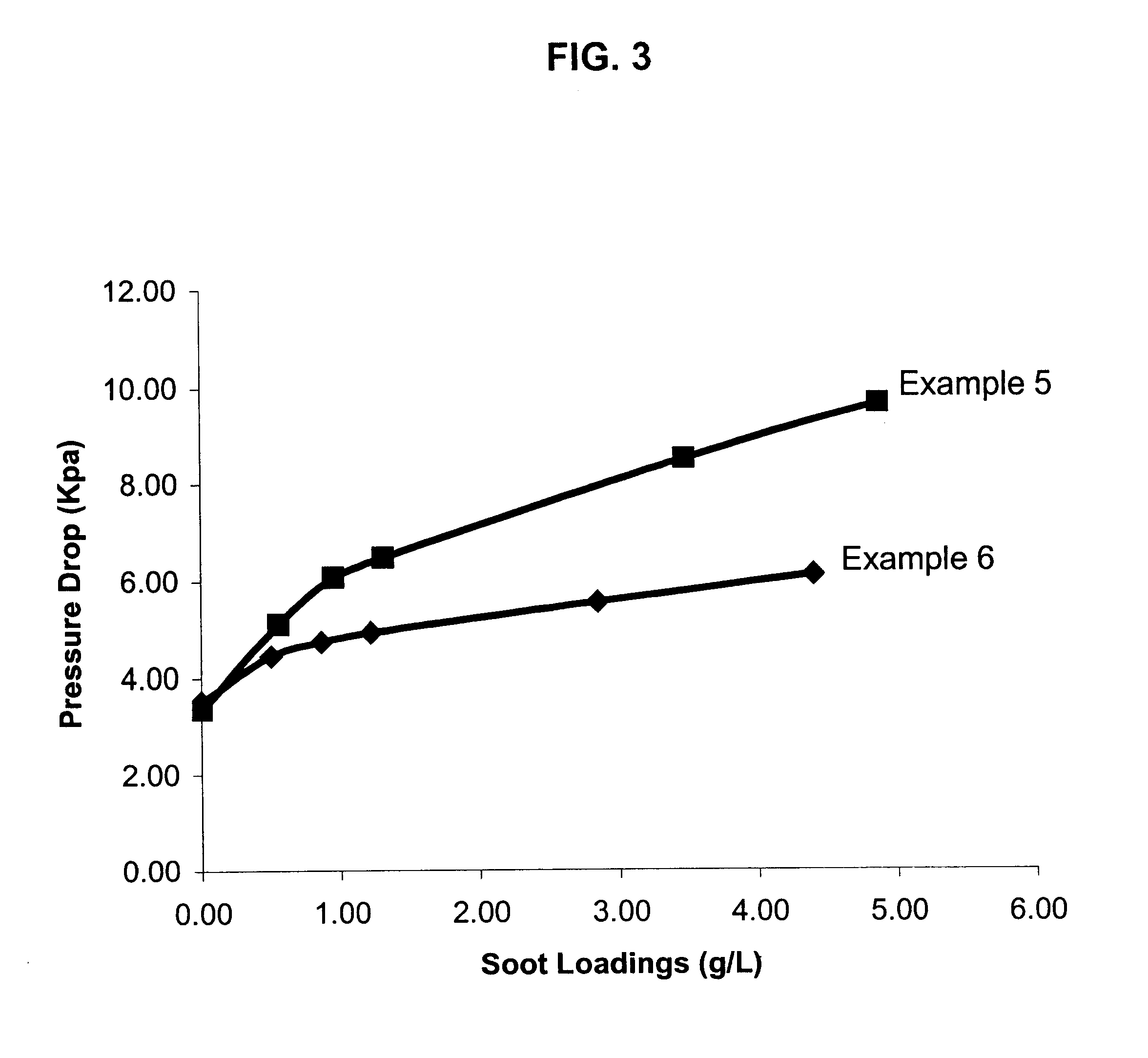

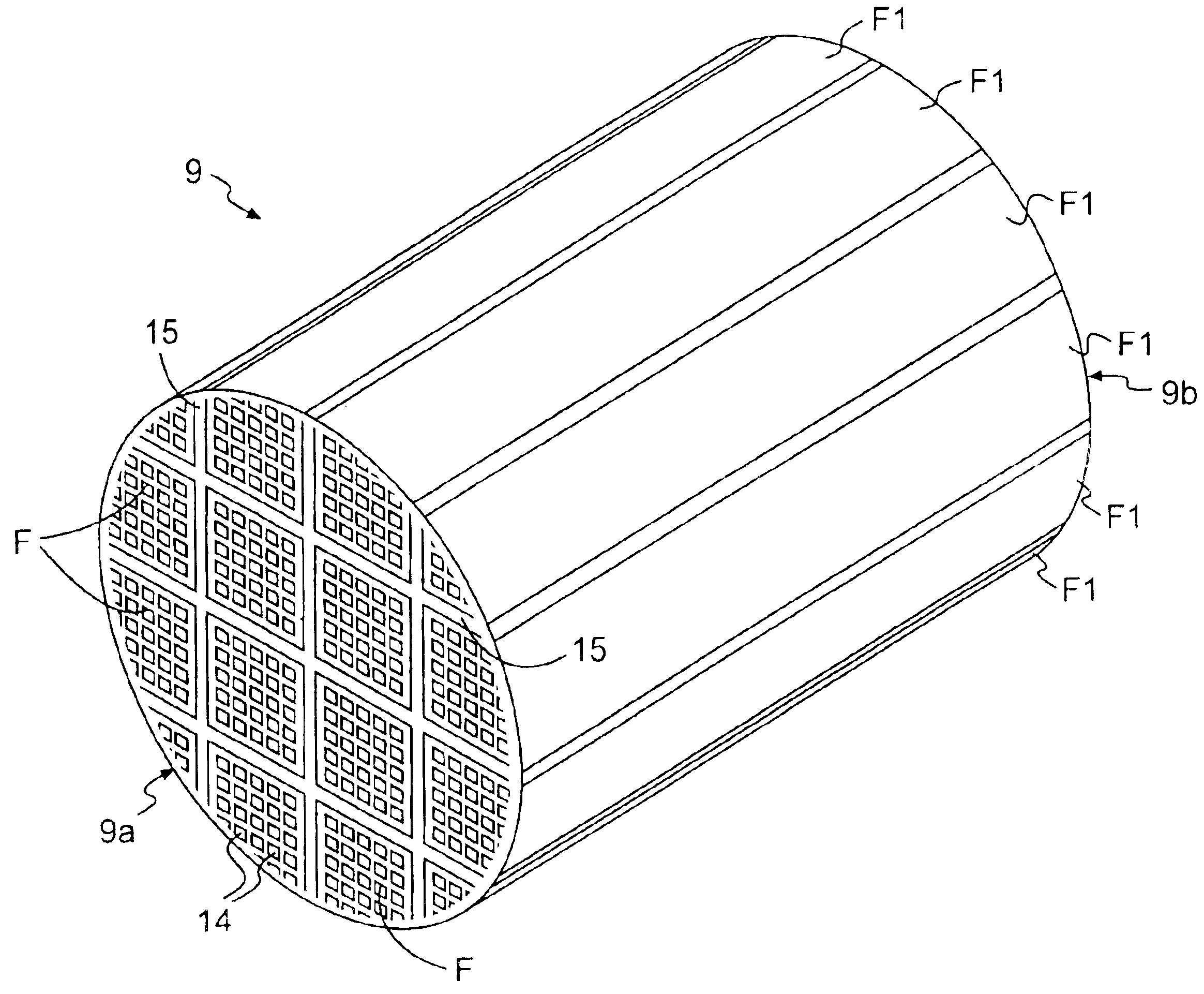

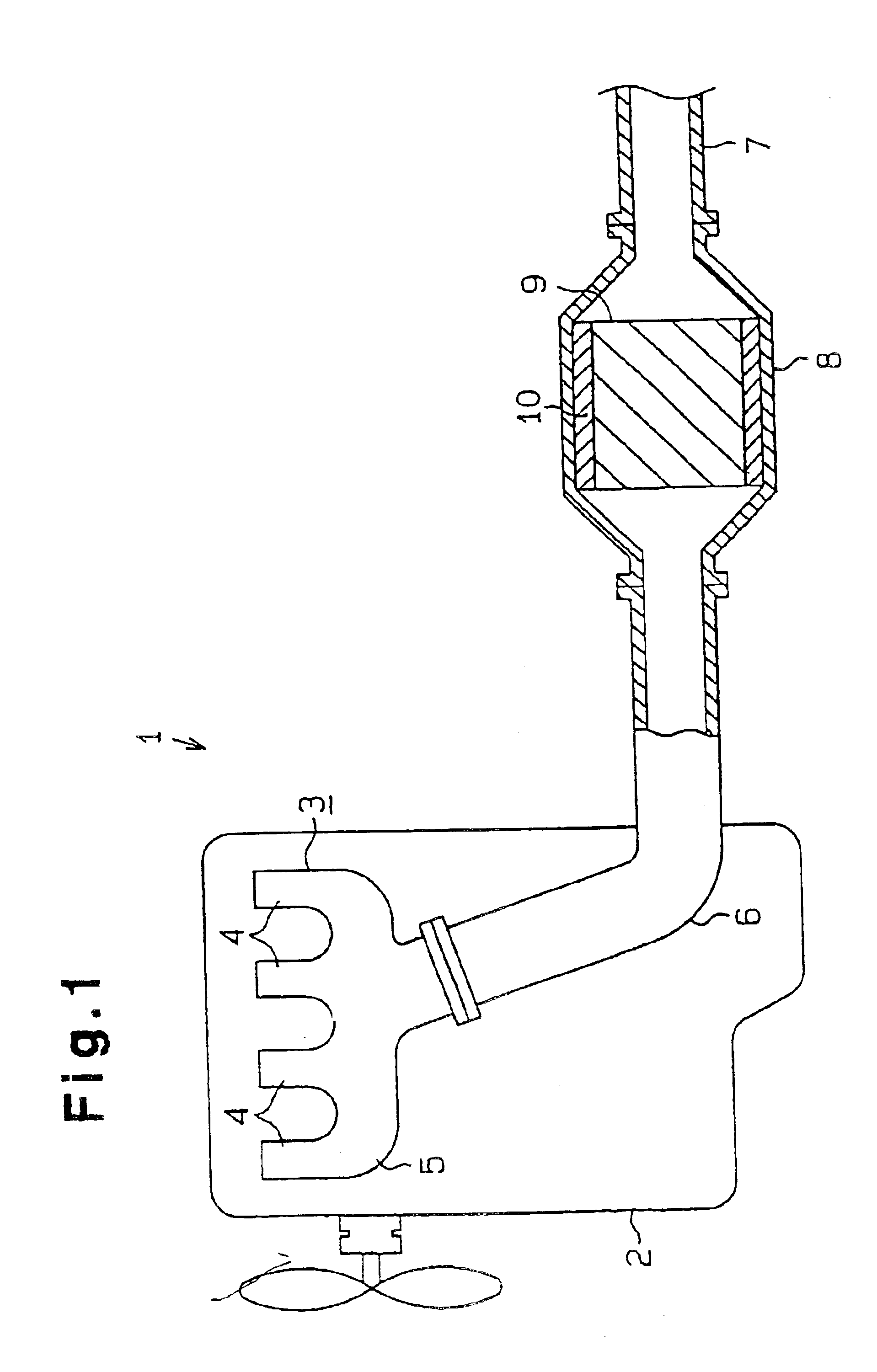

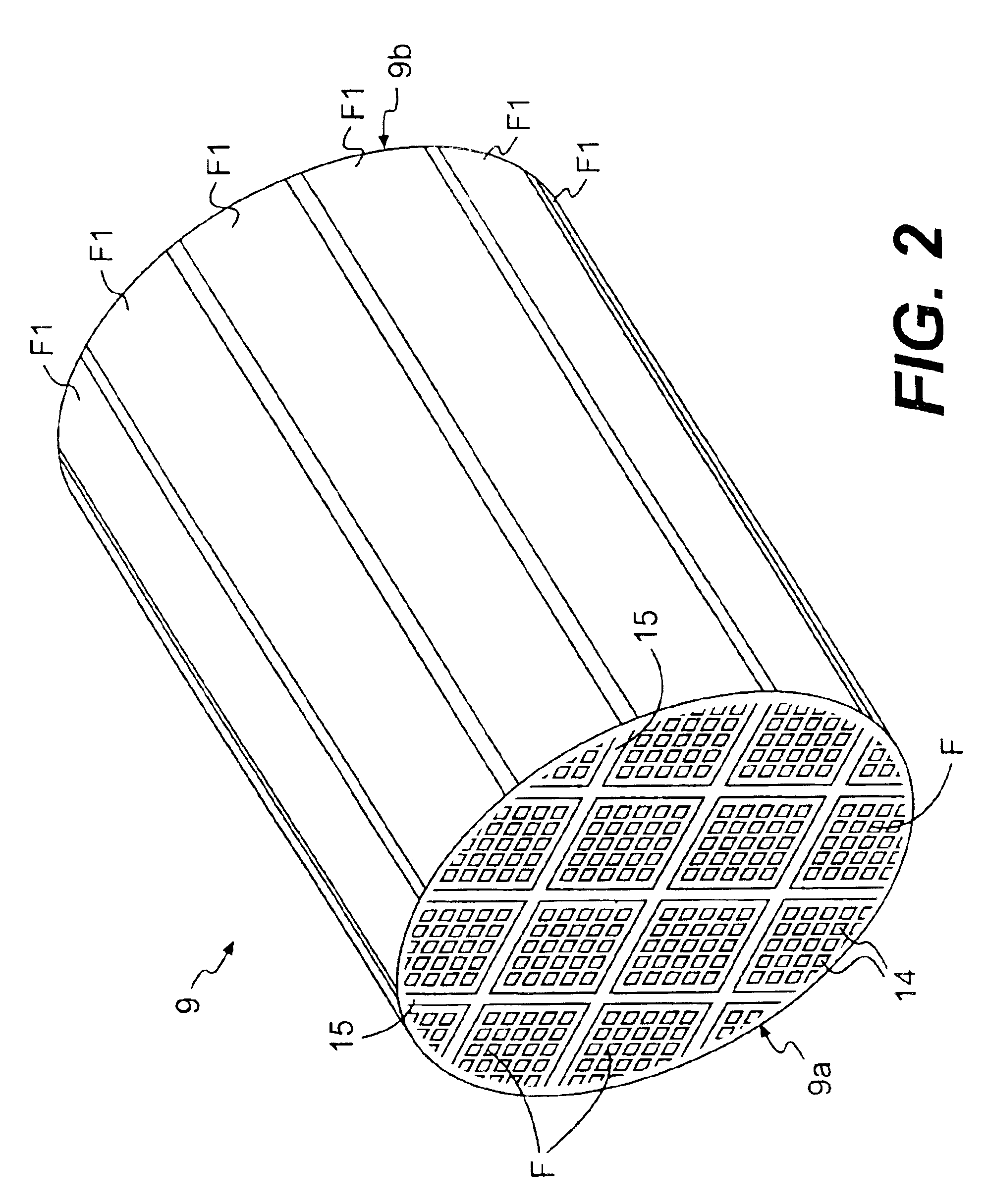

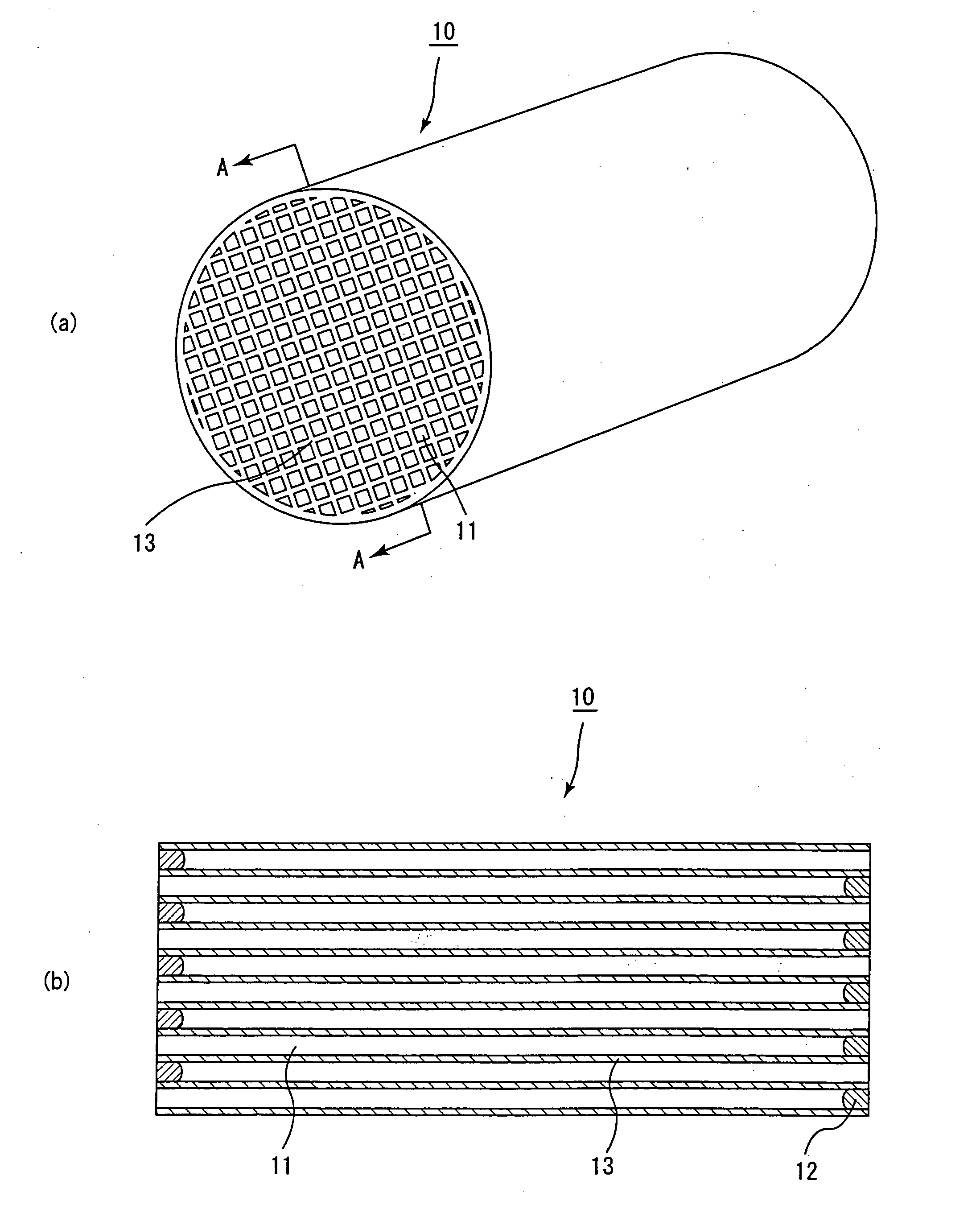

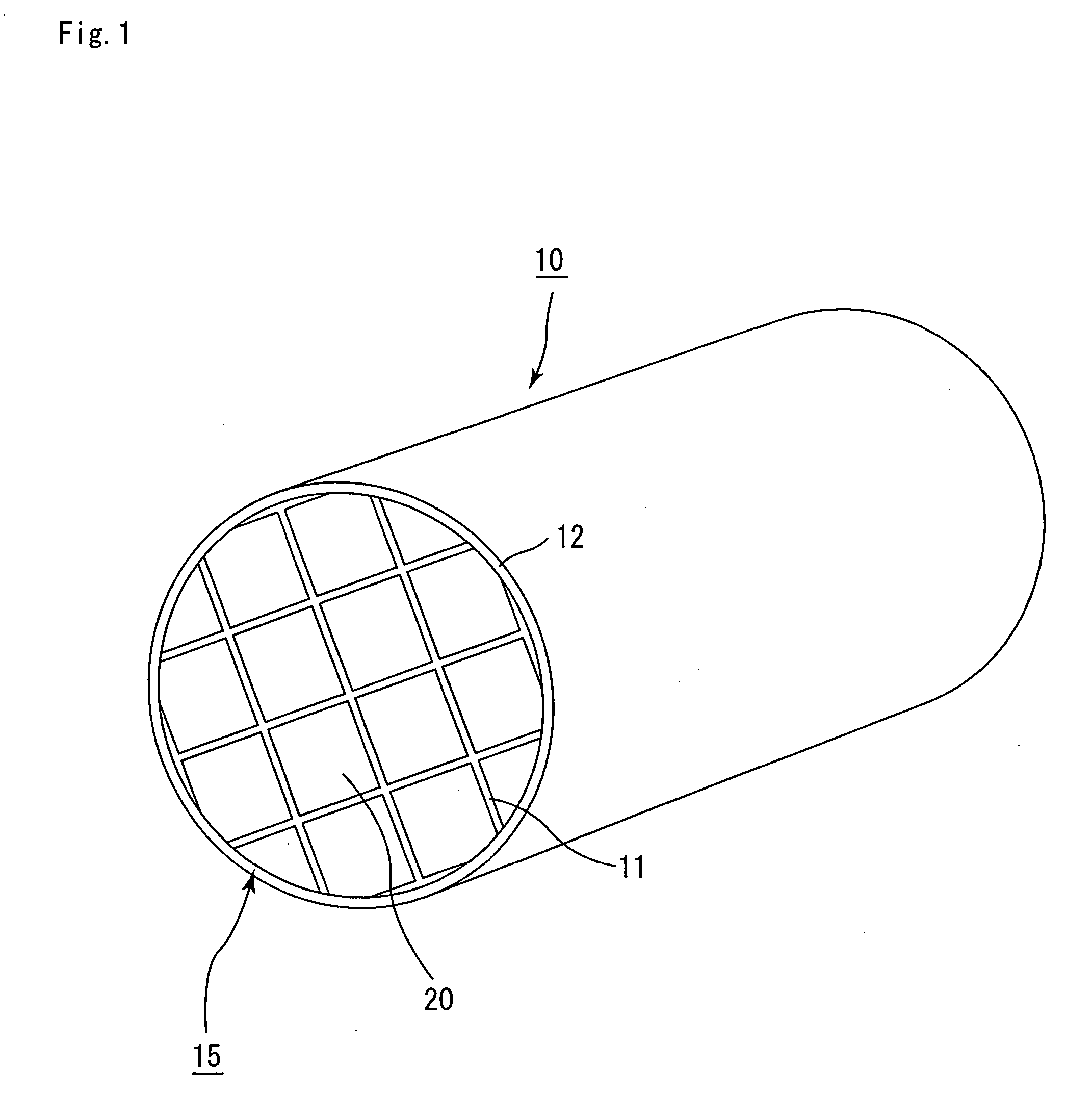

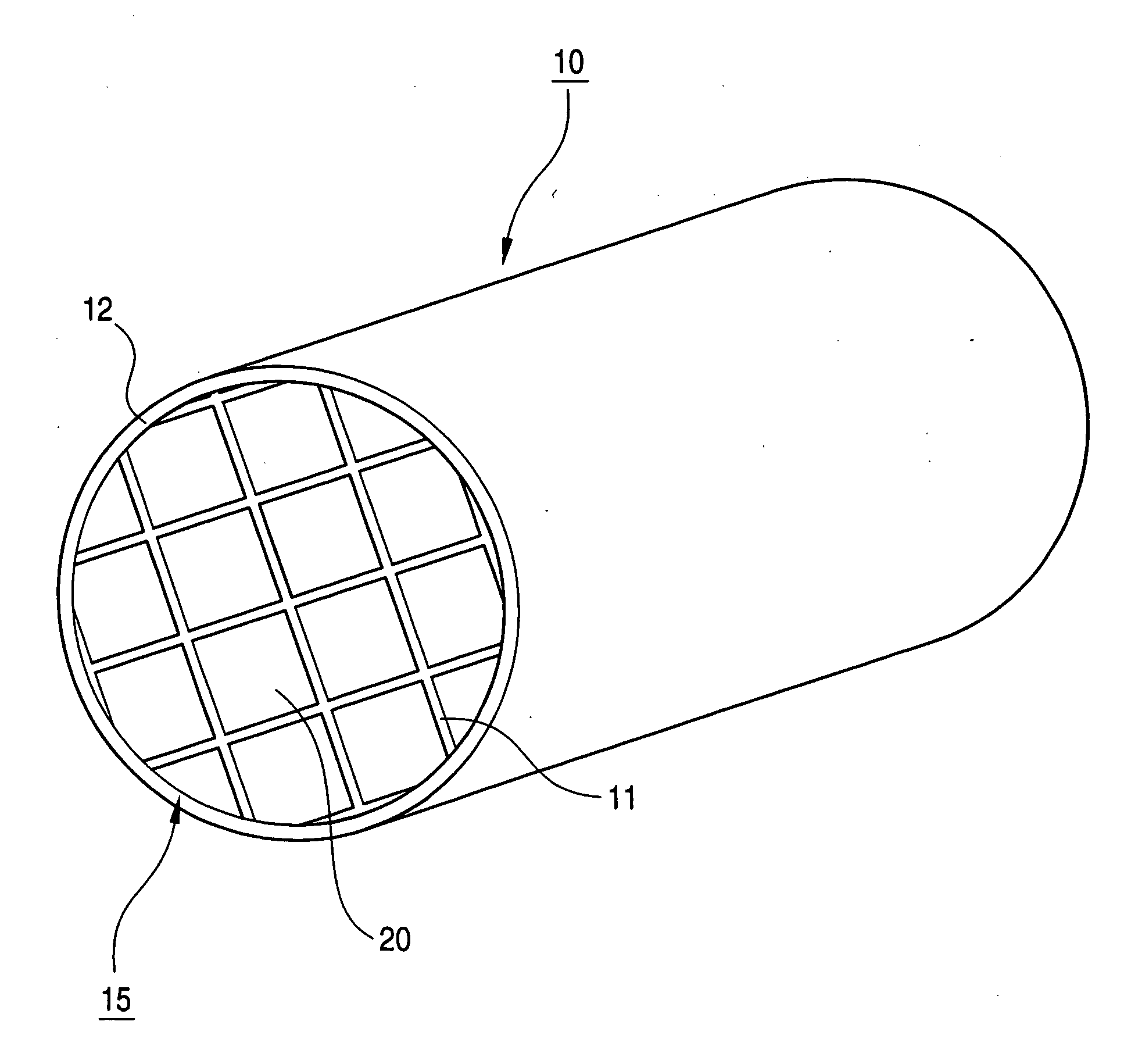

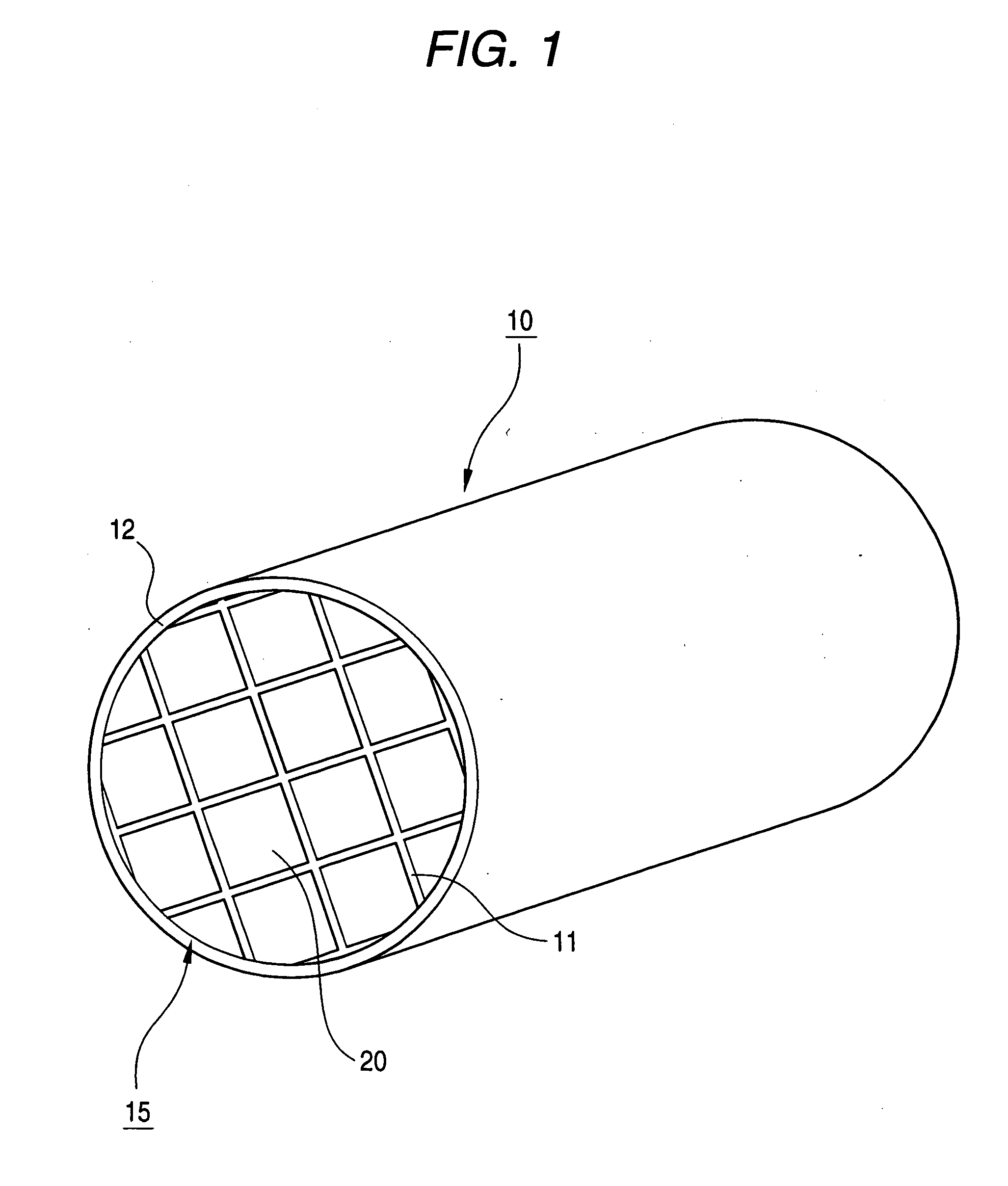

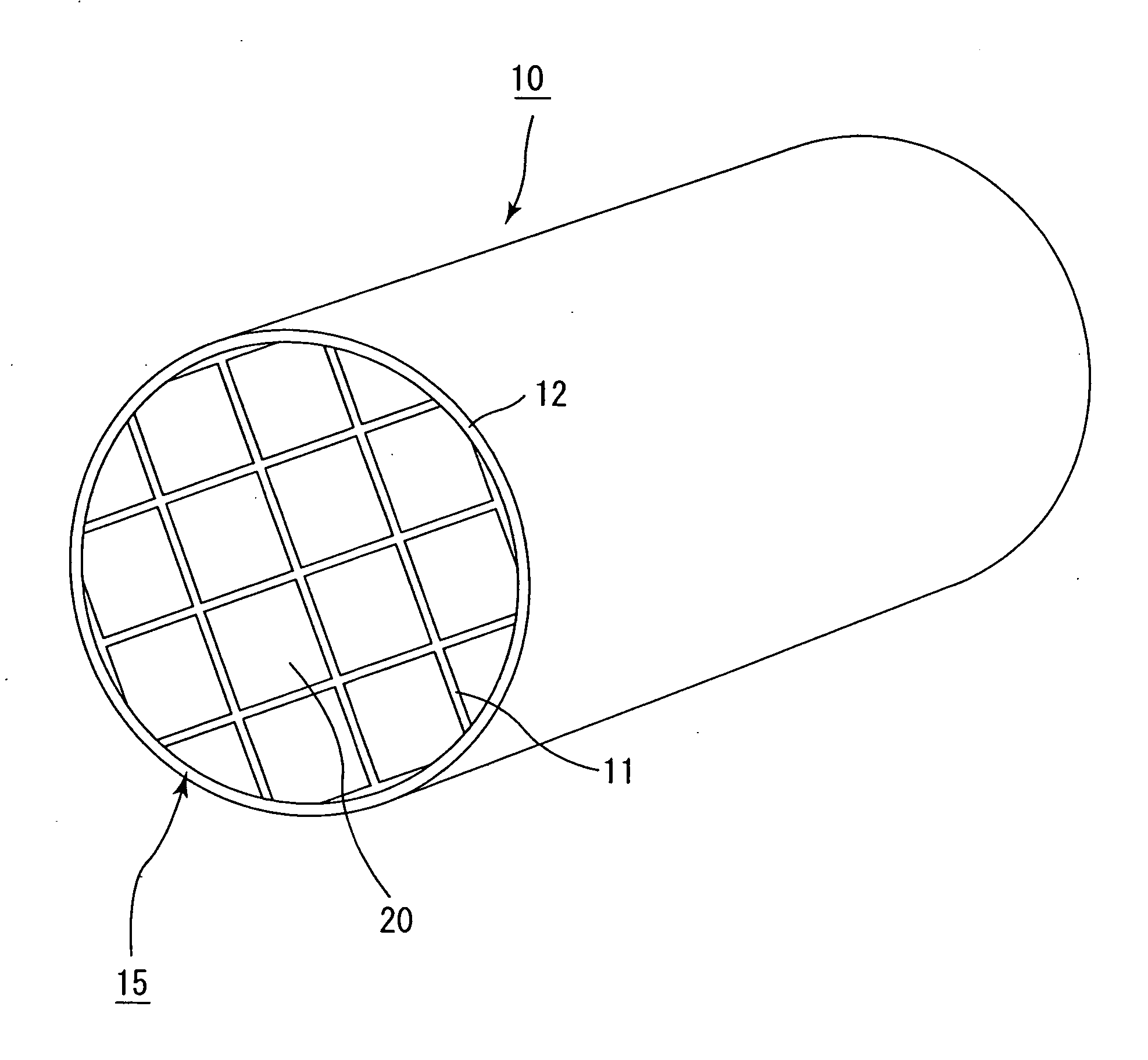

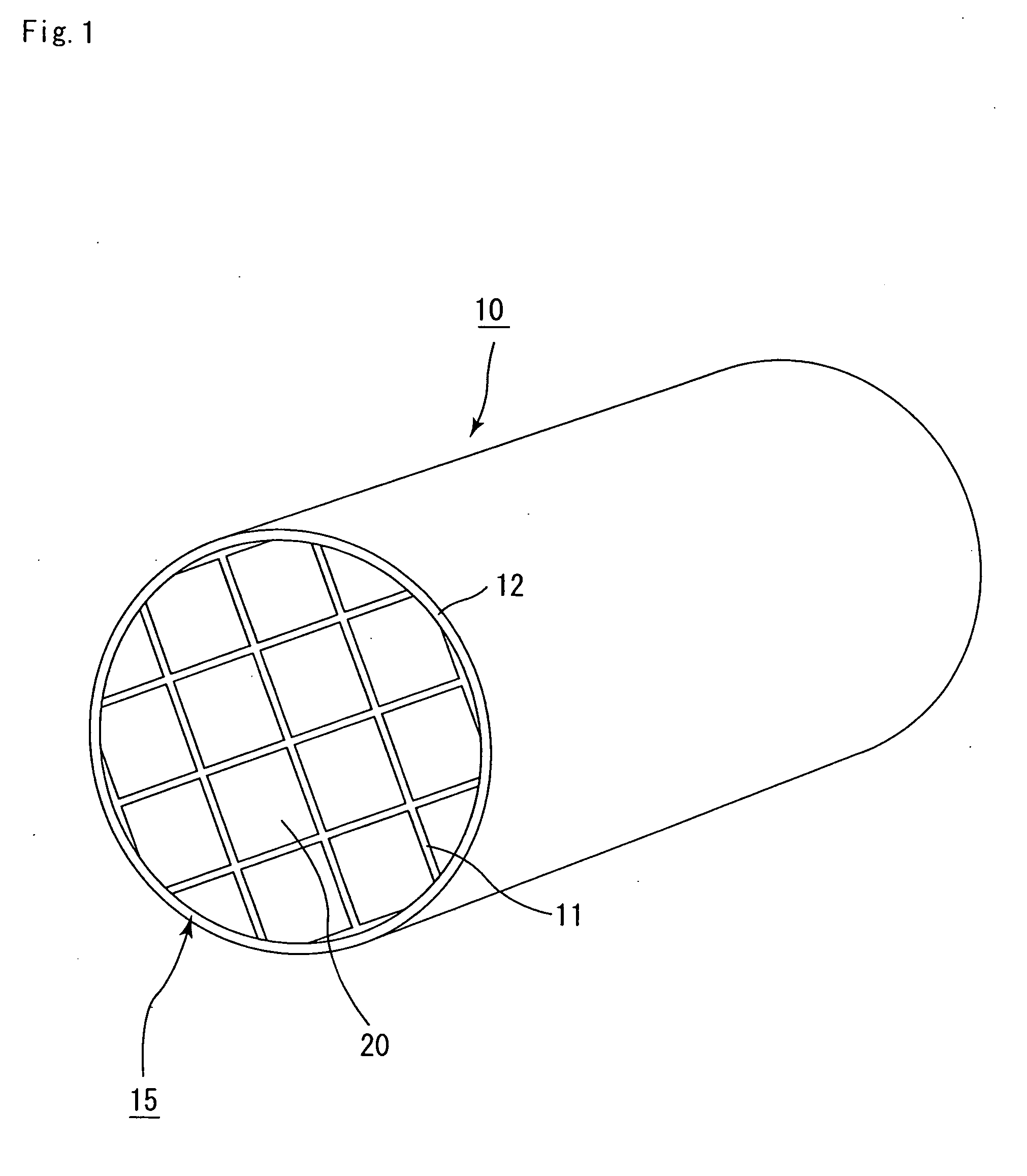

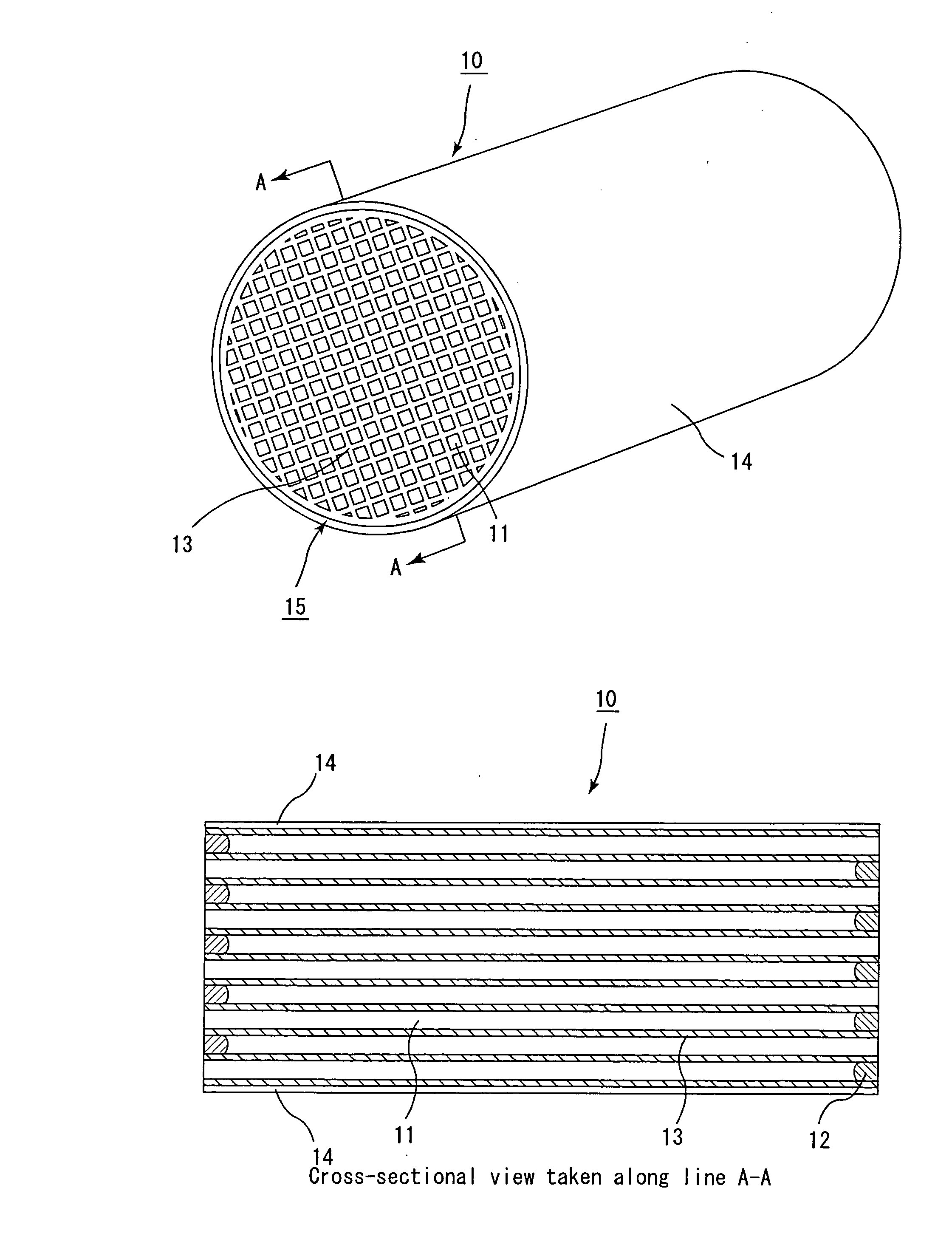

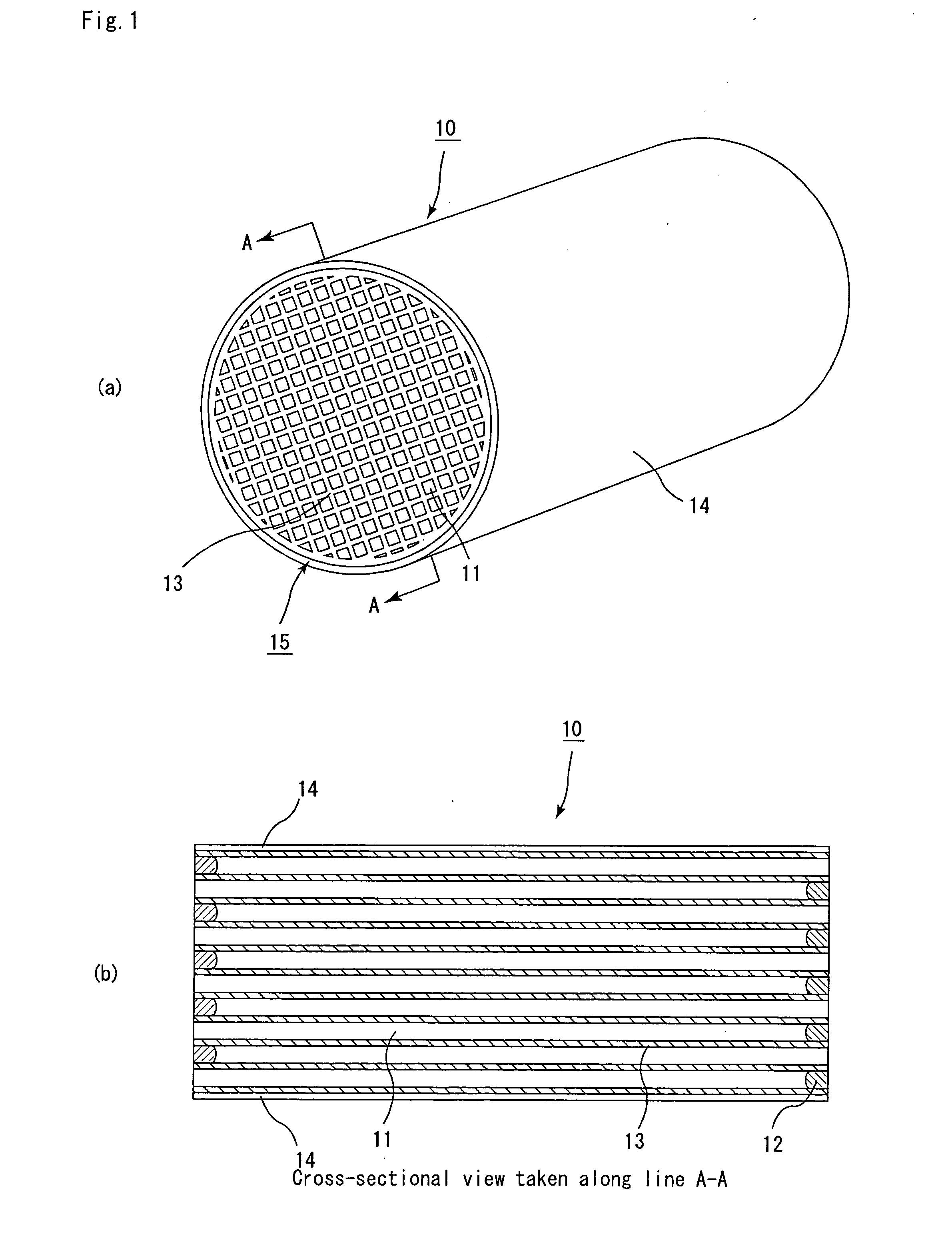

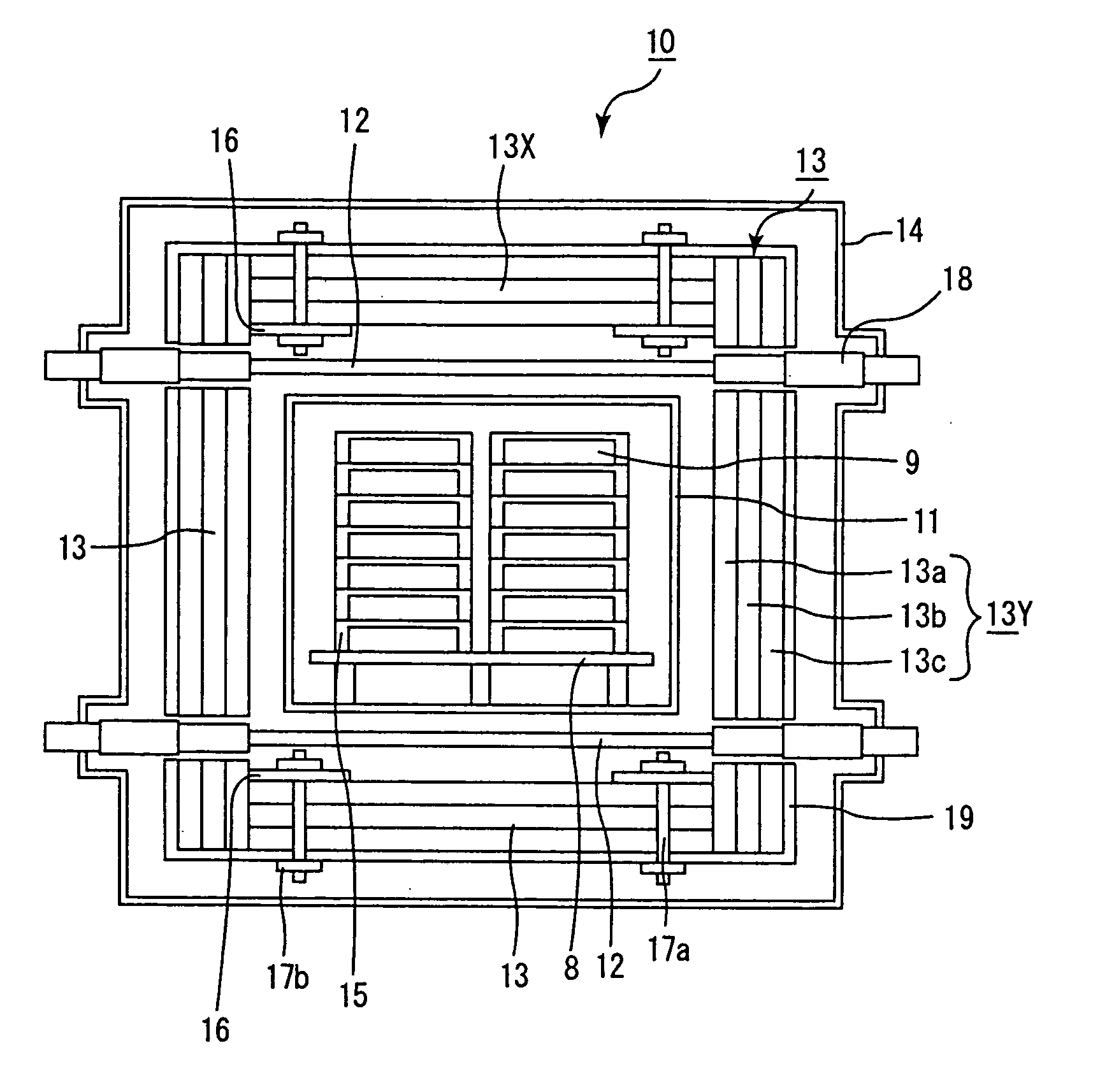

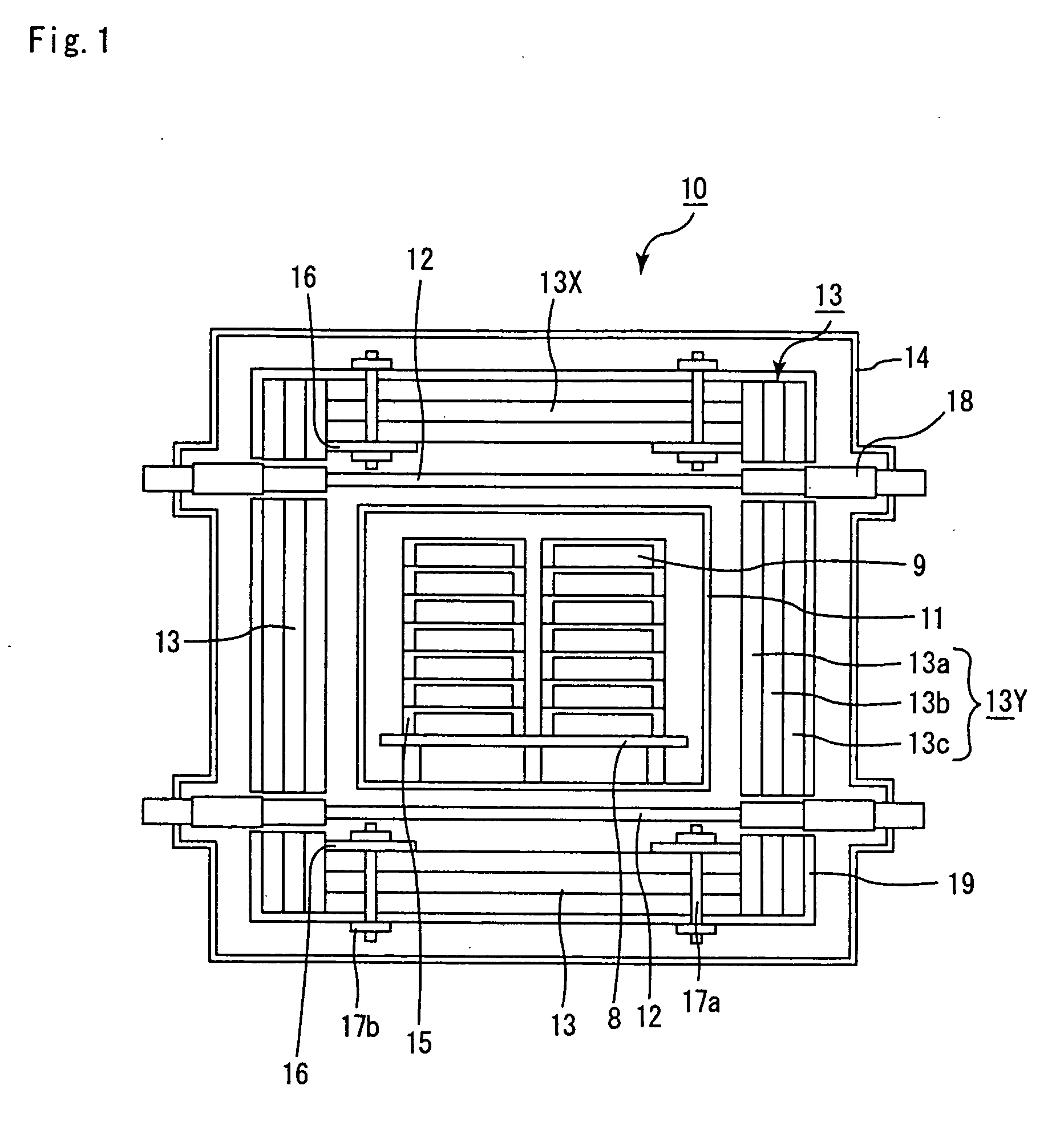

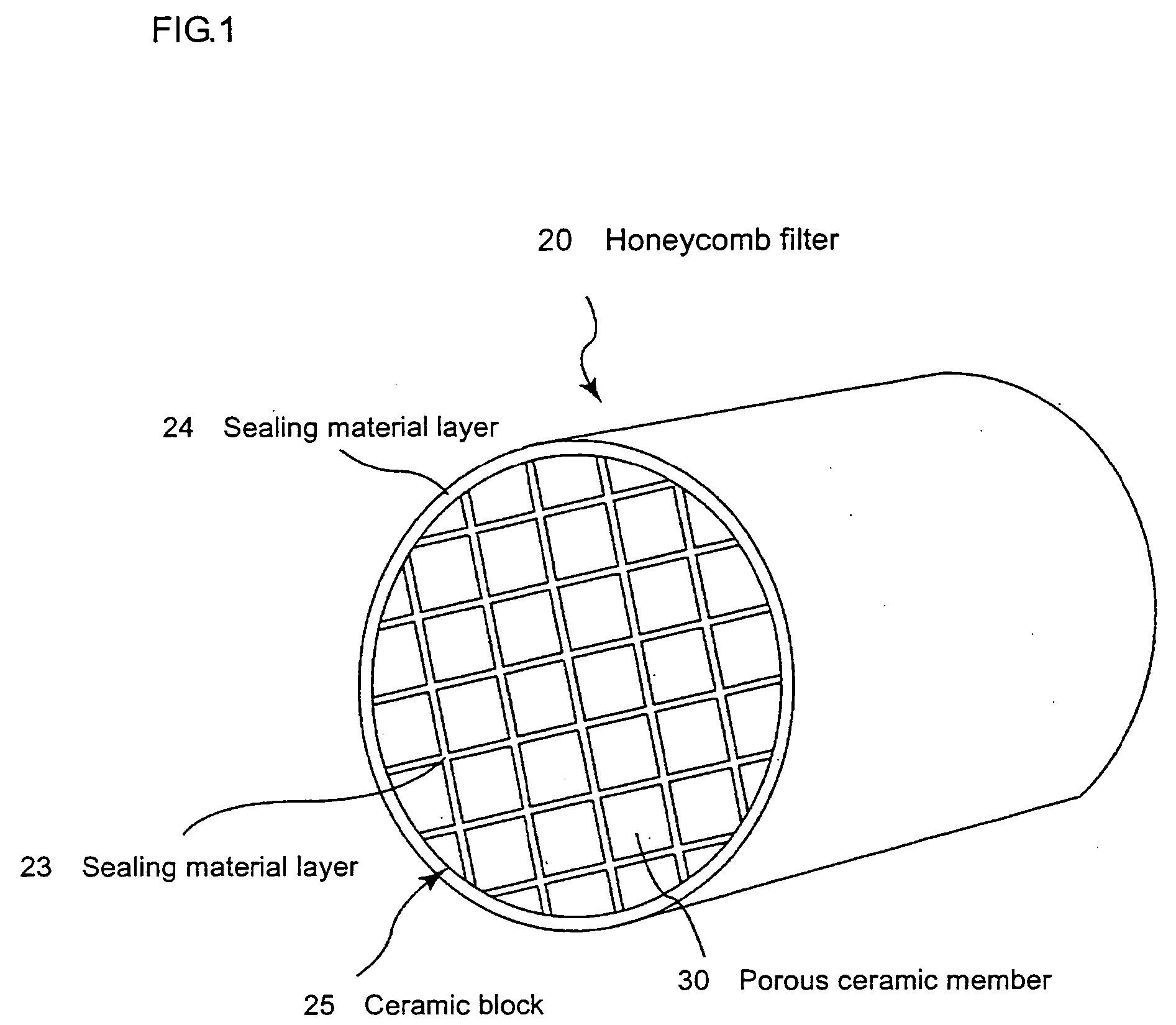

Honeycomb filter and ceramic filter assembly

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

Honeycomb filter for clarification of exhaust gas

InactiveUS20050180898A1Increased durabilityReduce crackingCombination devicesInternal combustion piston enginesParticulatesHoneycomb

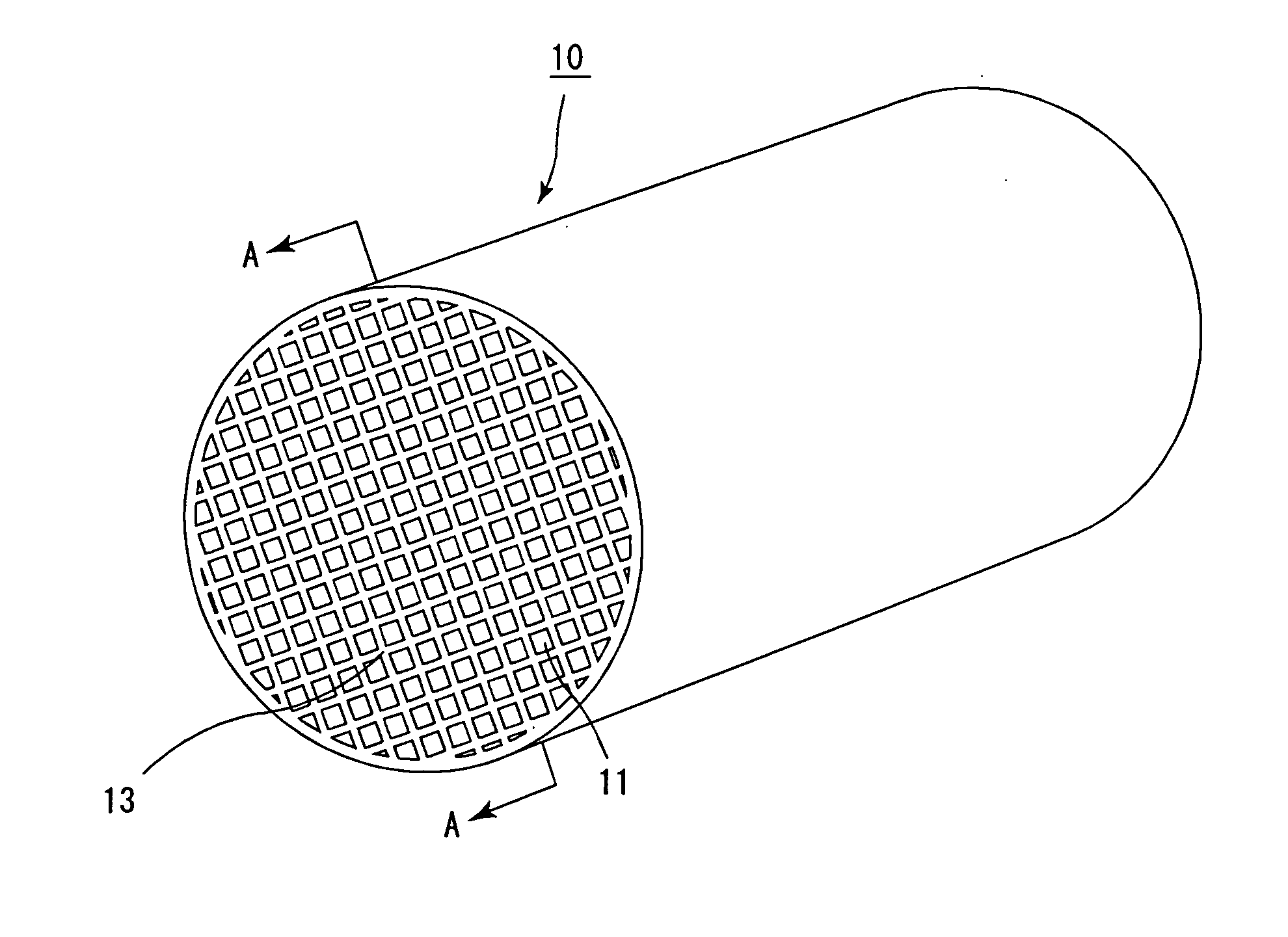

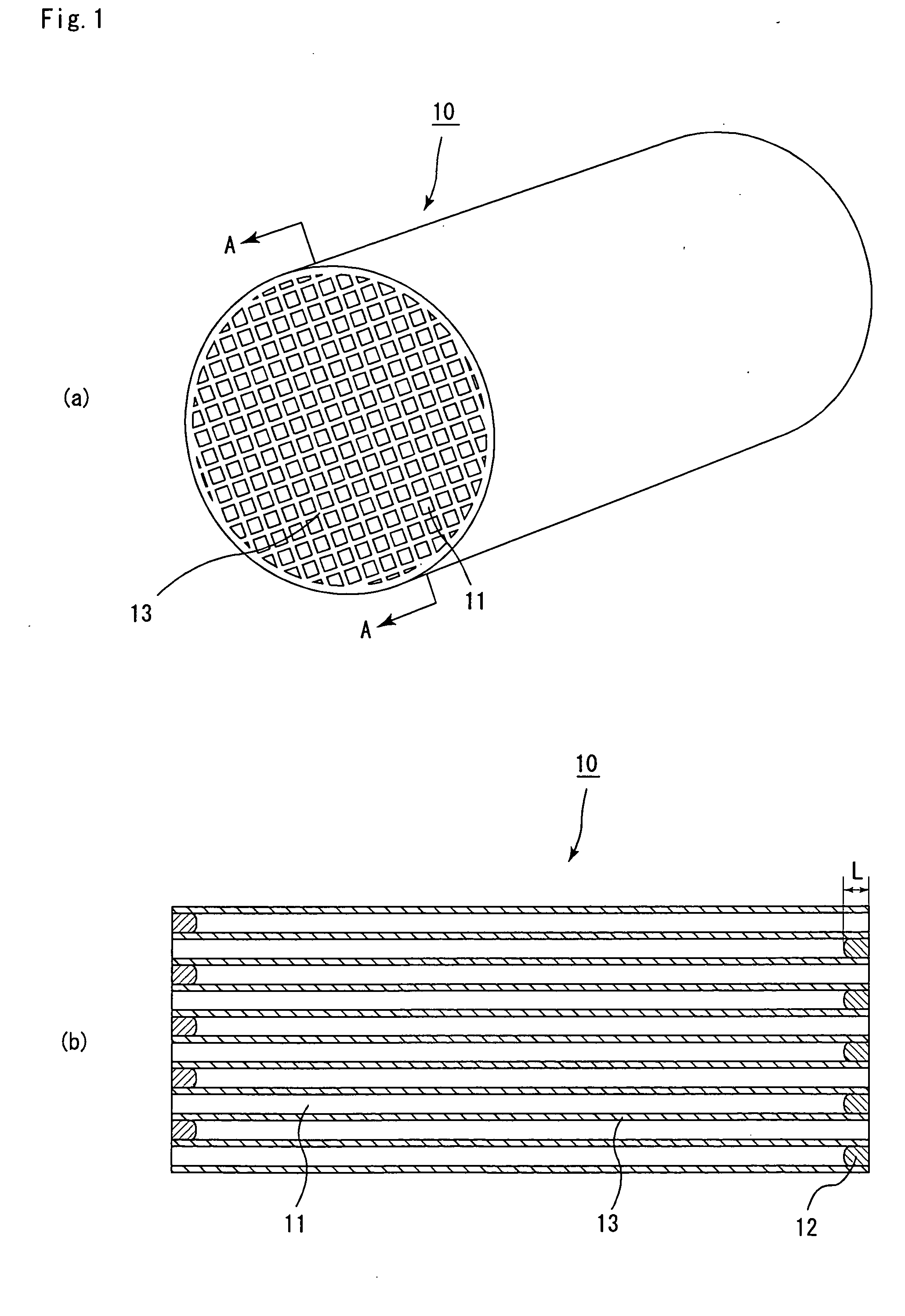

A honeycomb filter for purifying exhaust gases. A plurality of rectangular columnar porous ceramic members are combined with one another through a sealing material layer to constitute a ceramic block, each of the rectangular columnar porous ceramic member including a number of through holes that are placed in parallel with one another in the length direction with a partition wall interposed therebetween. A sealing material layer is also formed on a circumference portion of the ceramic block, and the partition wall that separates the through holes functions as a filter for collecting particulates. On a cross section perpendicular to the length direction of the porous ceramic member of the ceramic block, the maximum width L (mm) of the crisscross portion of the sealing material layer is 1.5 to 3 times greater than the minimum width I (mm) of the sealing material layer.

Owner:IBIDEN CO LTD

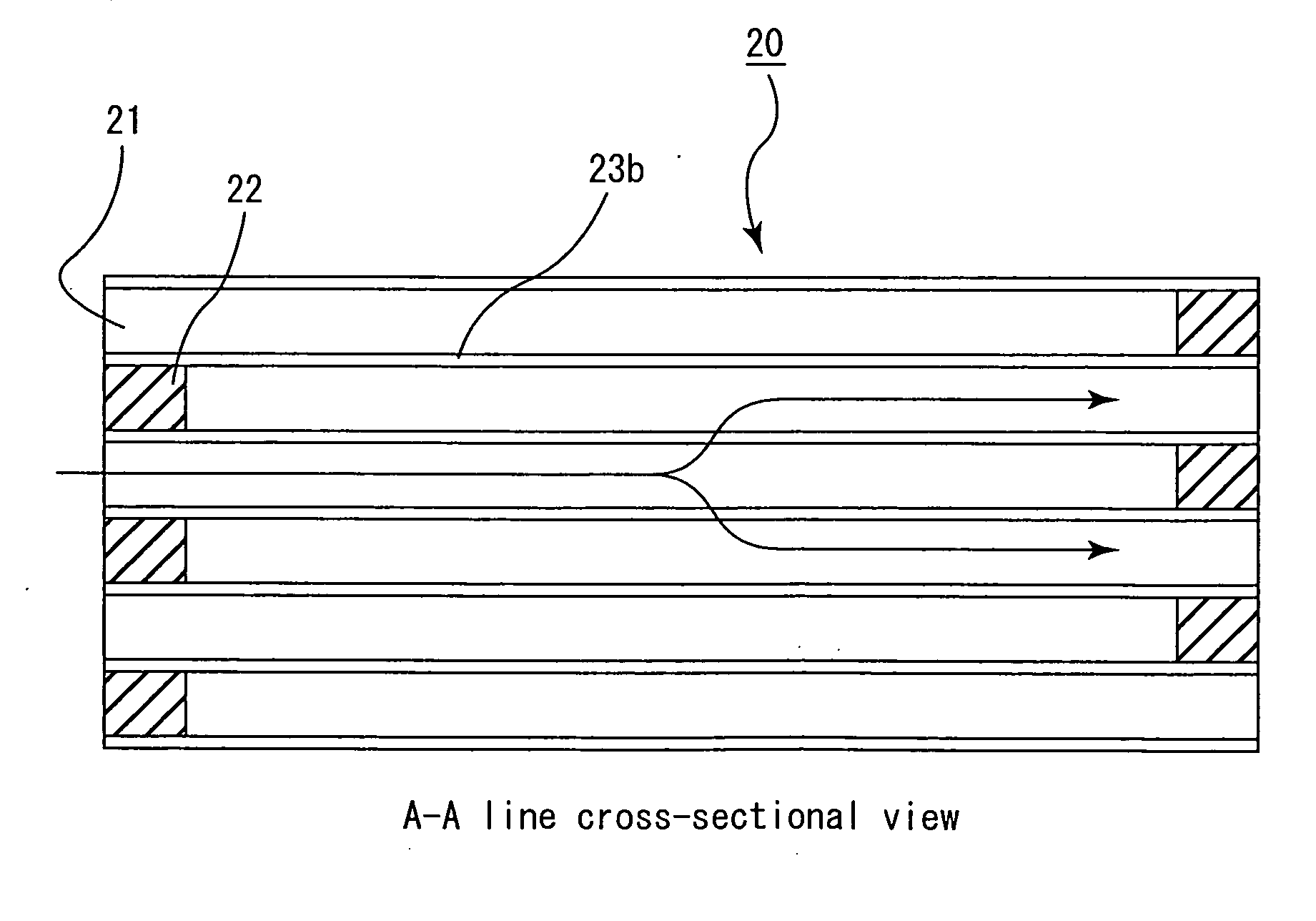

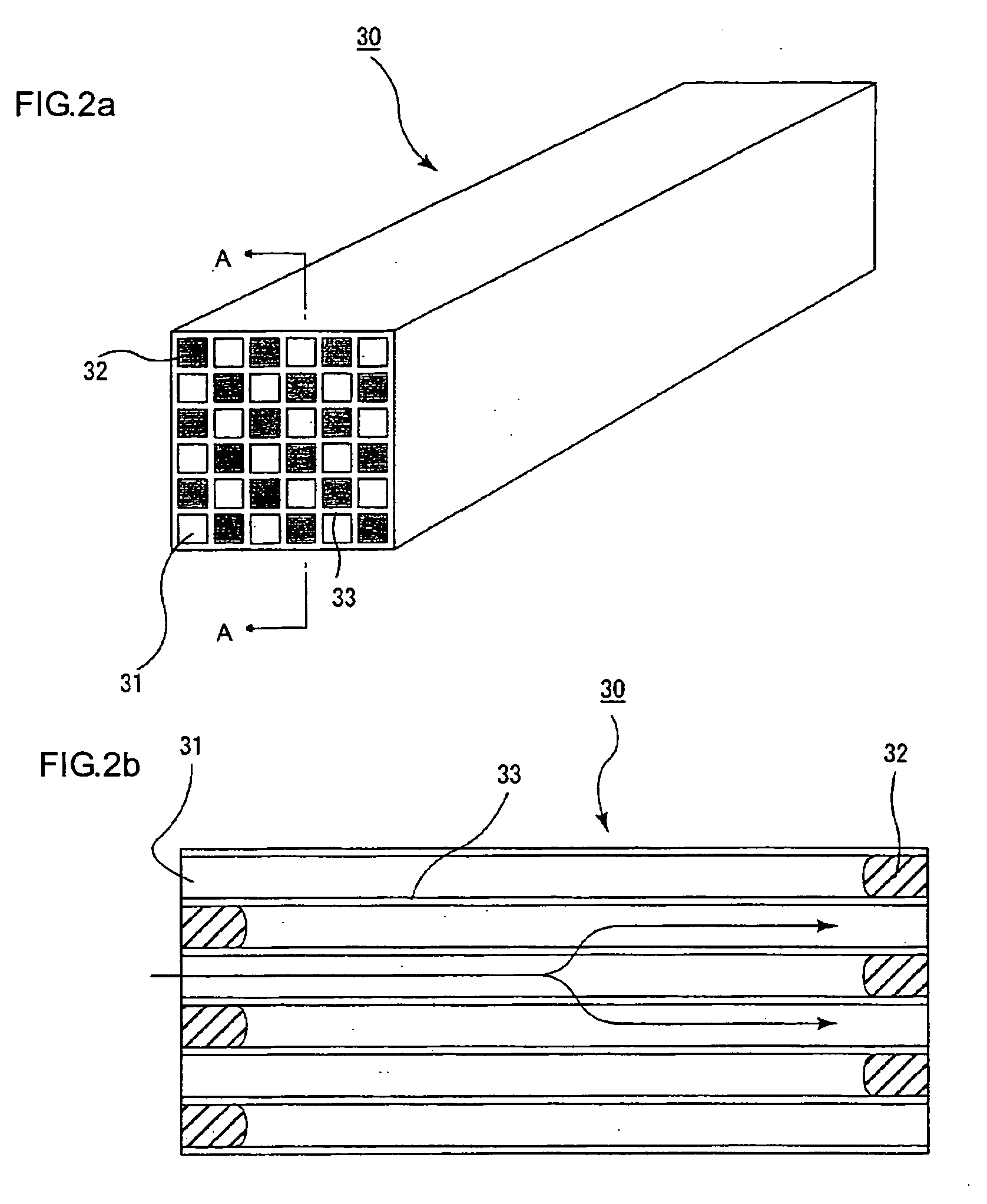

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

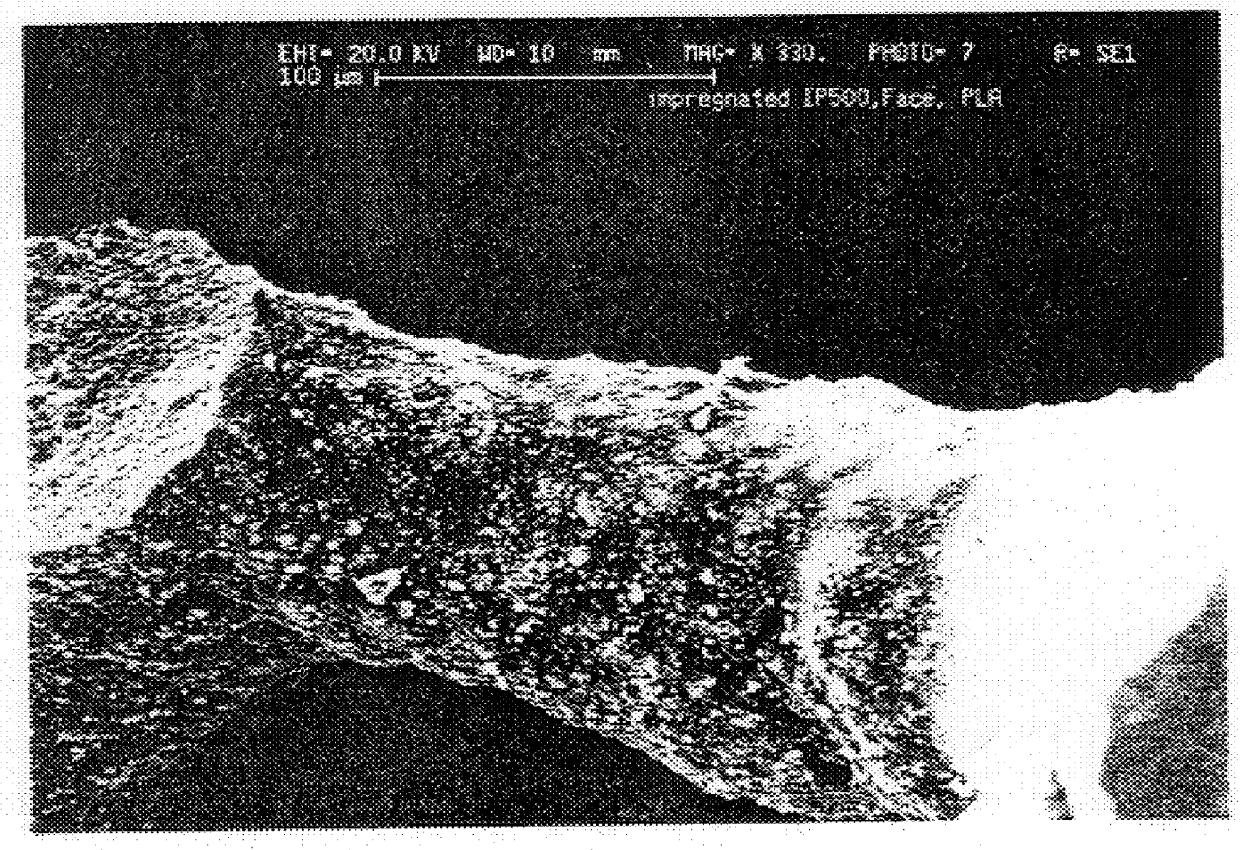

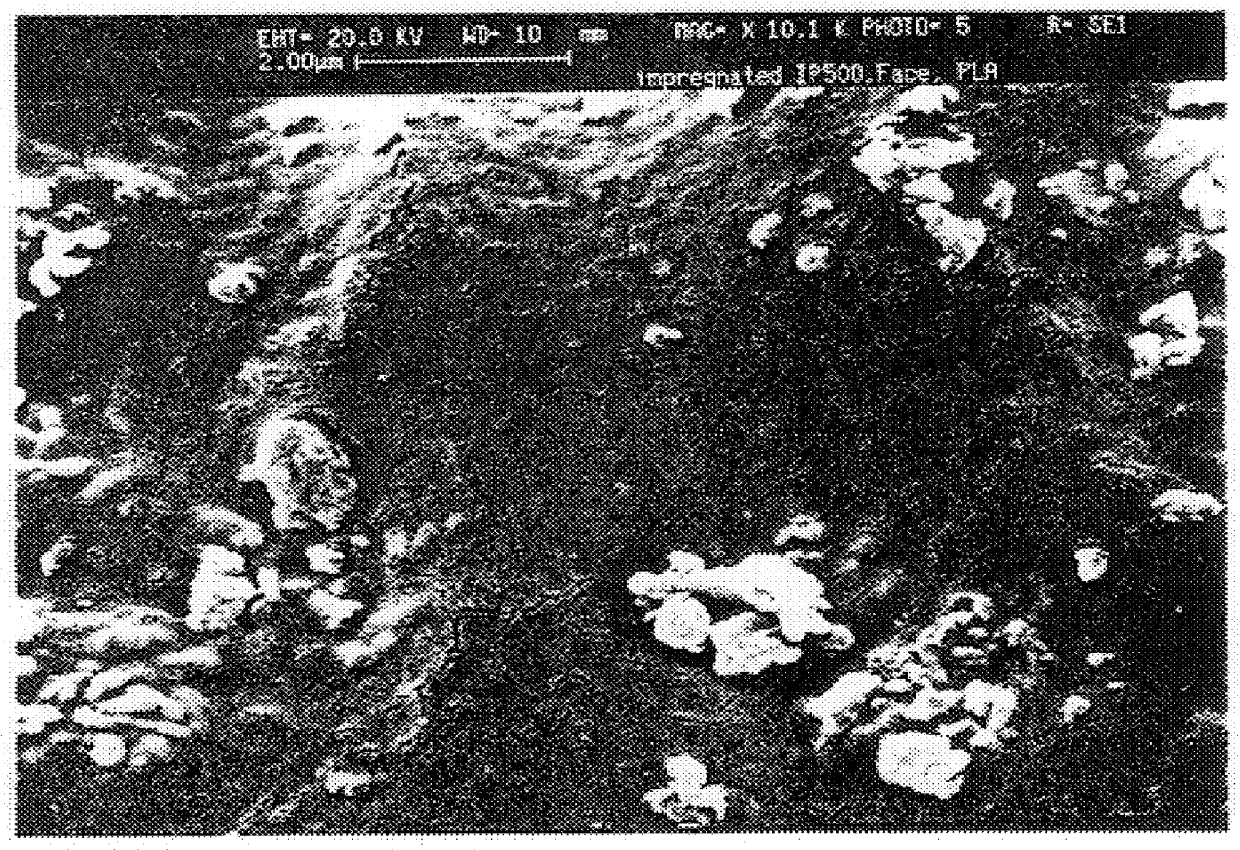

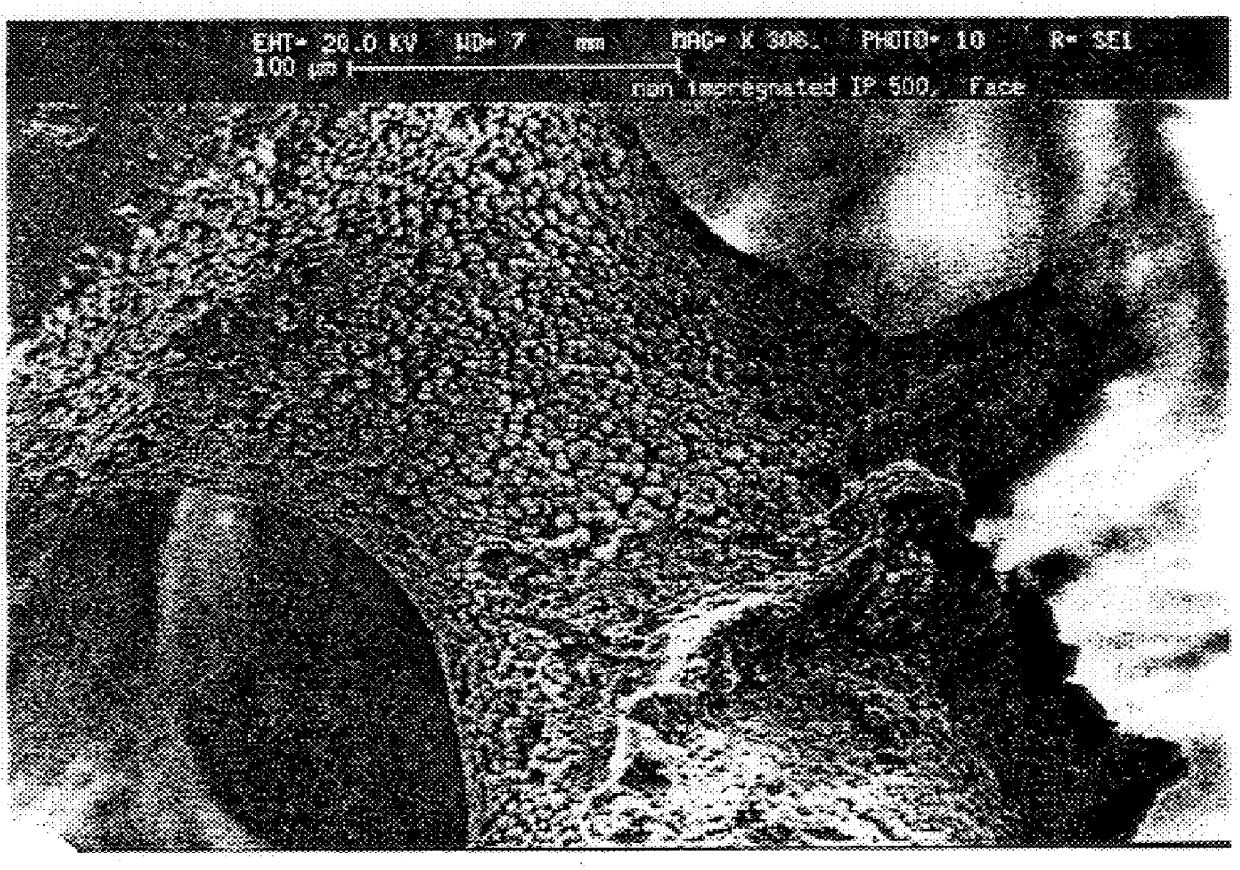

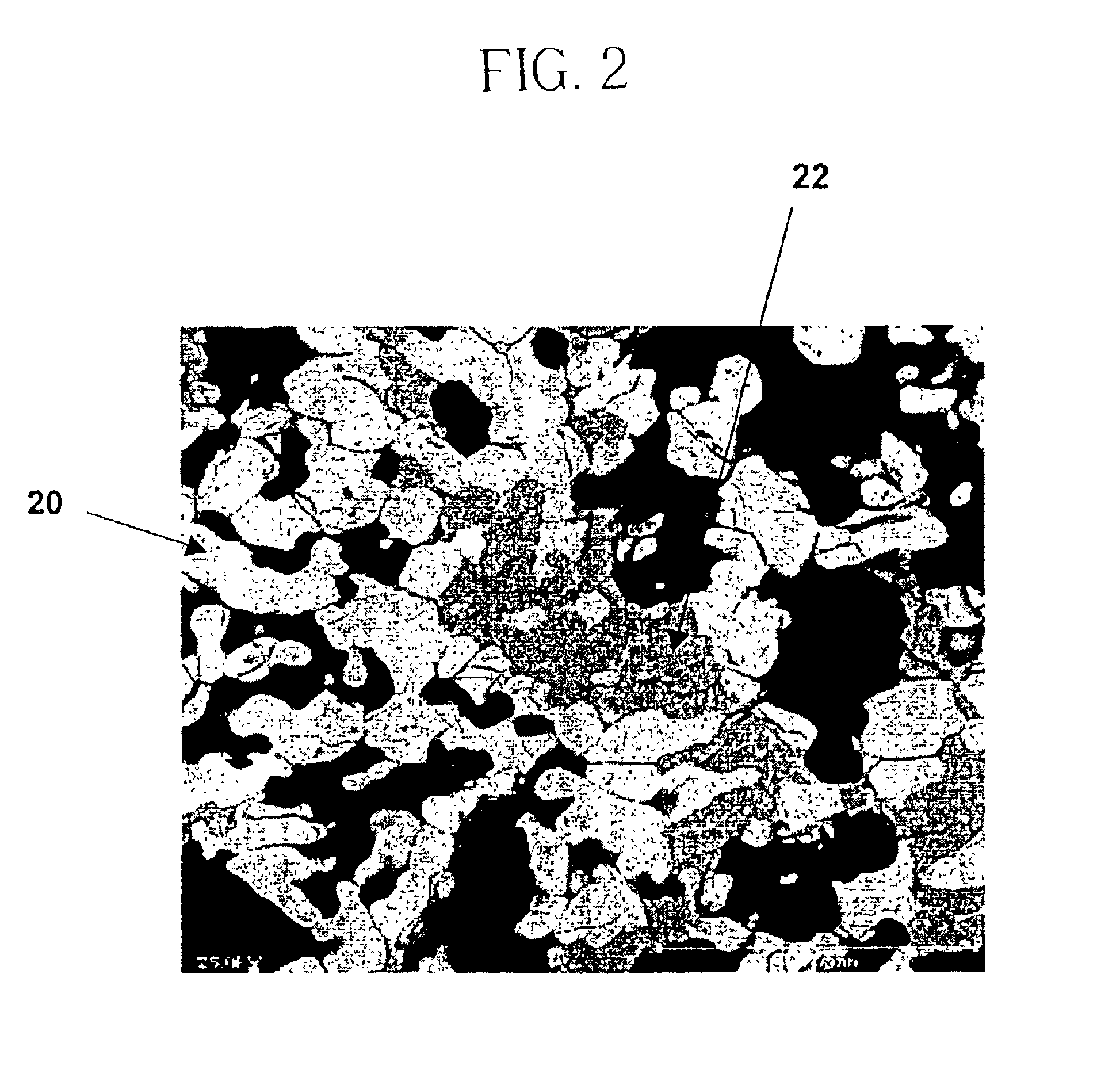

Porous biomaterials and methods for their manufacture

InactiveUS6376573B1High strengthOvercome disadvantagesImpression capsBone implantUltimate tensile strengthPorous ceramics

An improved porous ceramic biomaterial is disclosed in which a polymer such as polylactic acid is polymerized in situ to fill the micropores substantially without filling the macropores. The polymer reinforcement helps improve the strength of the implant while preserving its ability to support ingrowth of bone to help integrate the implant into its surgical environment.

Owner:BIOMET MFG CORP

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

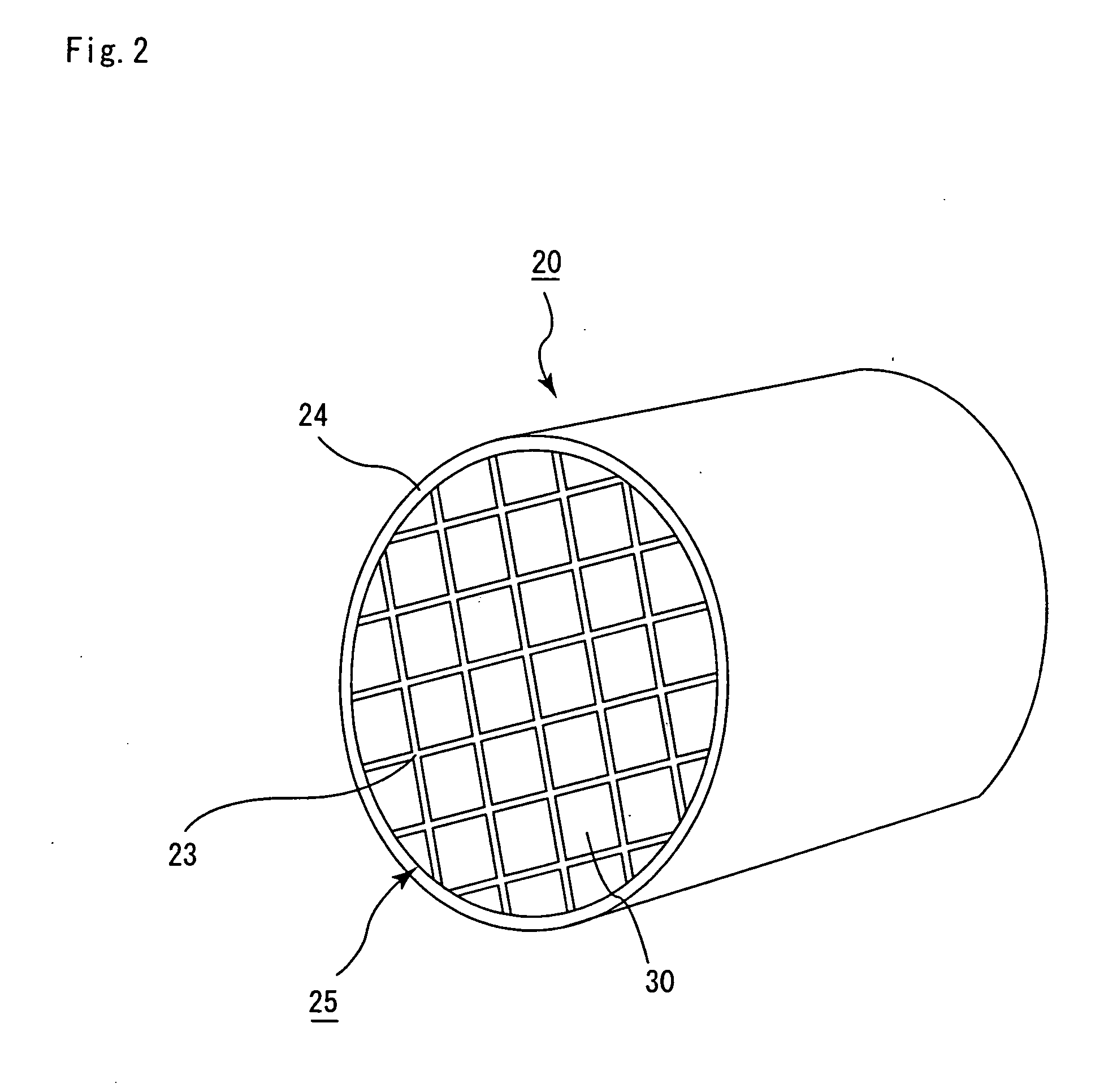

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

Honeycomb filter for purifying exhaust gas

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases having a structure in that, even when comparatively large sealing material layer is included therein, there is hardly any increase in the amount of organic components contained in exhaust gases to be discharged. The present invention provides a honeycomb filter for purifying exhaust gases, having a structure in that a sealing material layer is formed on a circumference of a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, and the wall portion which separate the through holes from each other functions as a filter for collecting particulates, wherein the rate Sα of an area occupied by the sealing material layers to the total area of a cross-section including the through holes in the direction perpendicular to the through holes is set to 0.5% or more, and the rate Vα of organic components to the honeycomb filter for purifying exhaust gases is set to 0.5% by weight or less.

Owner:IBIDEN CO LTD

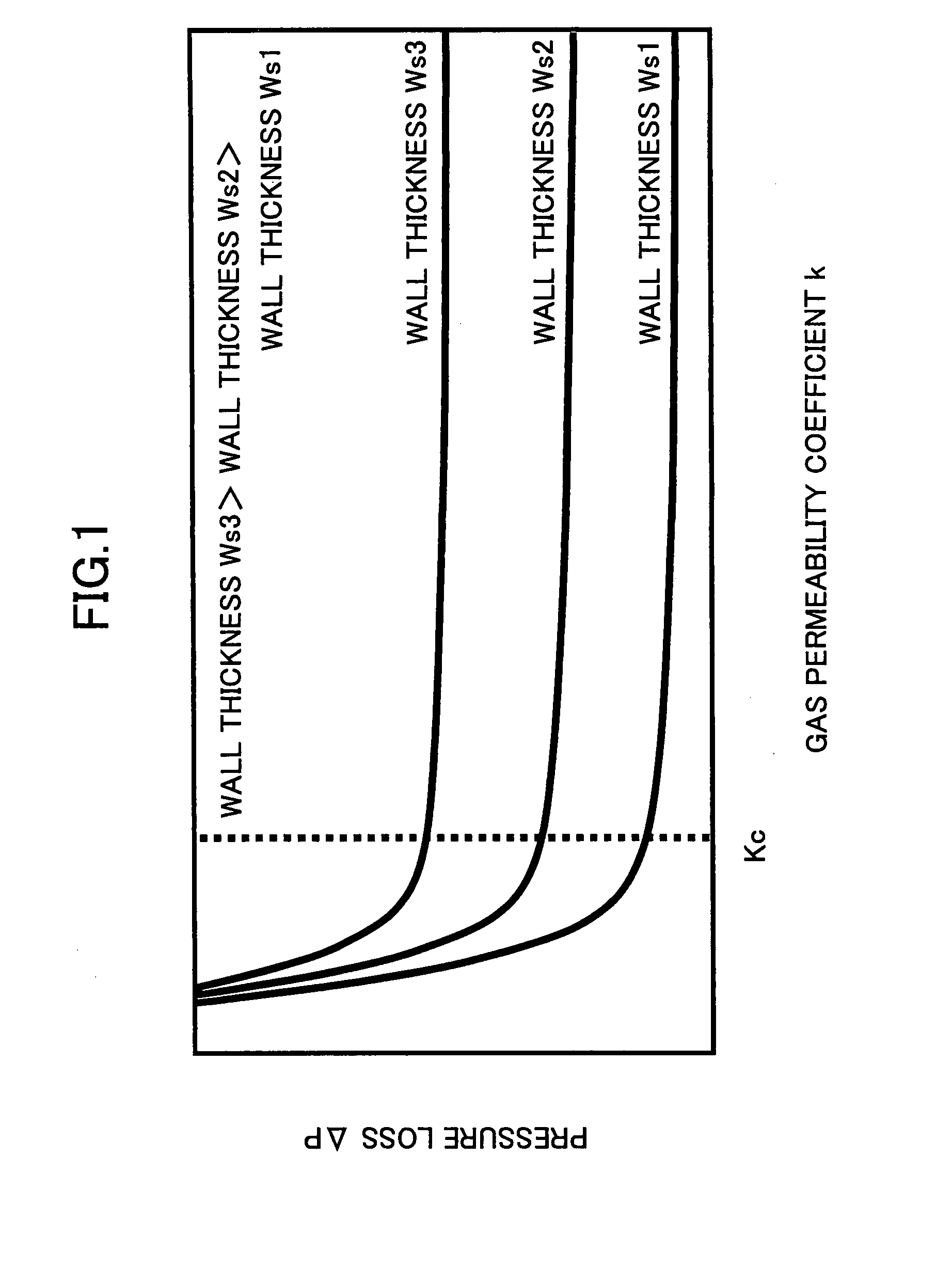

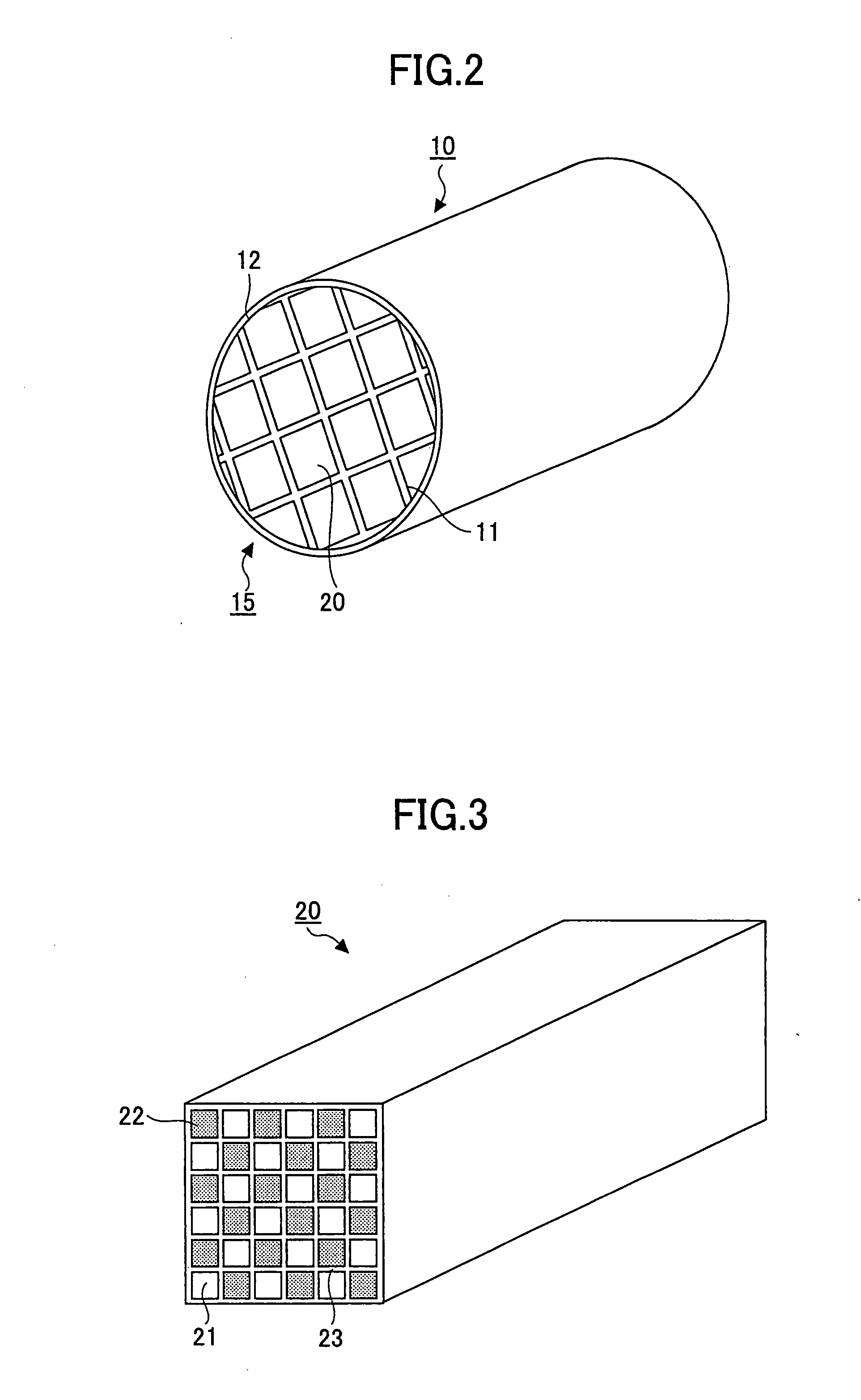

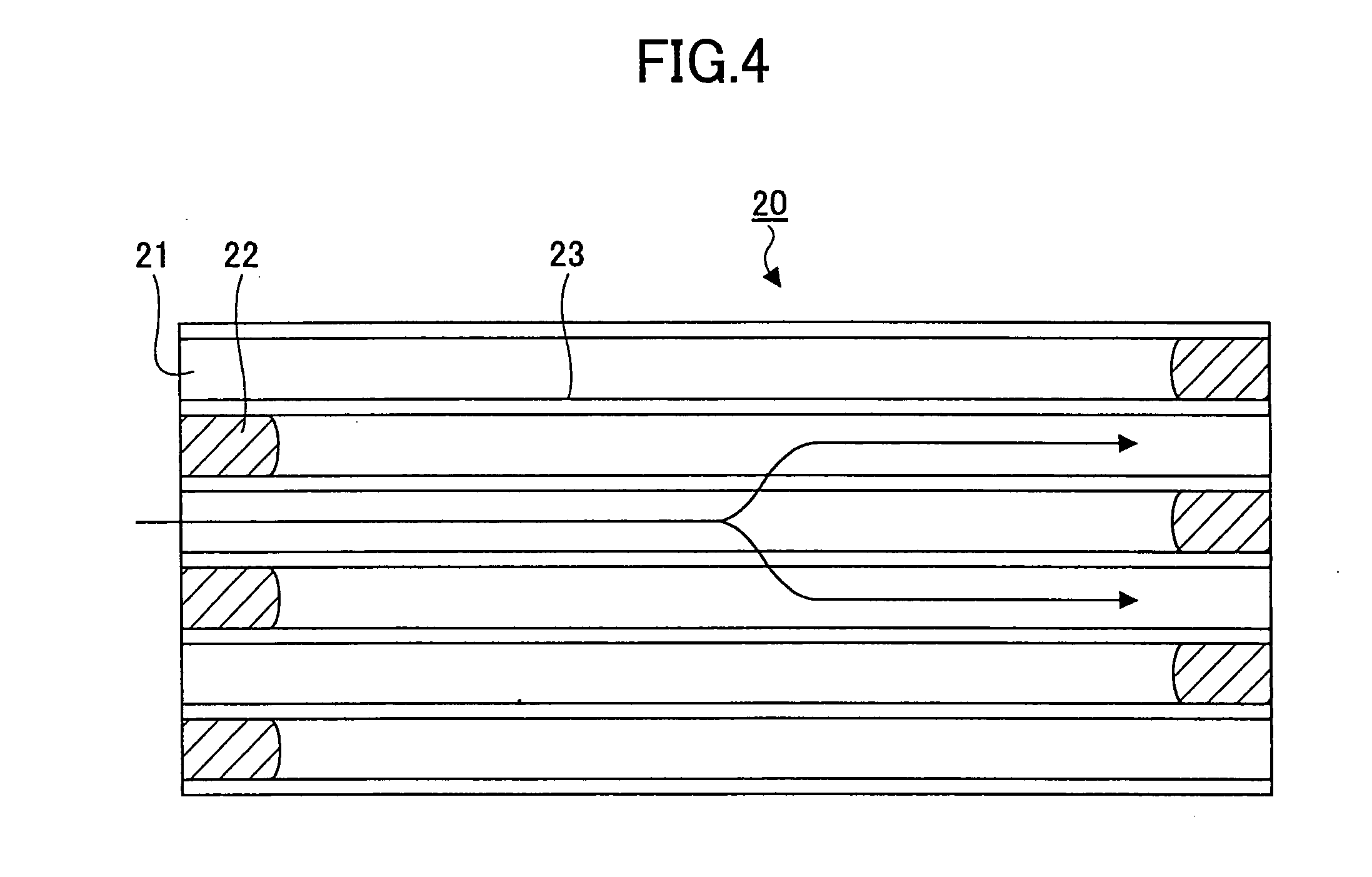

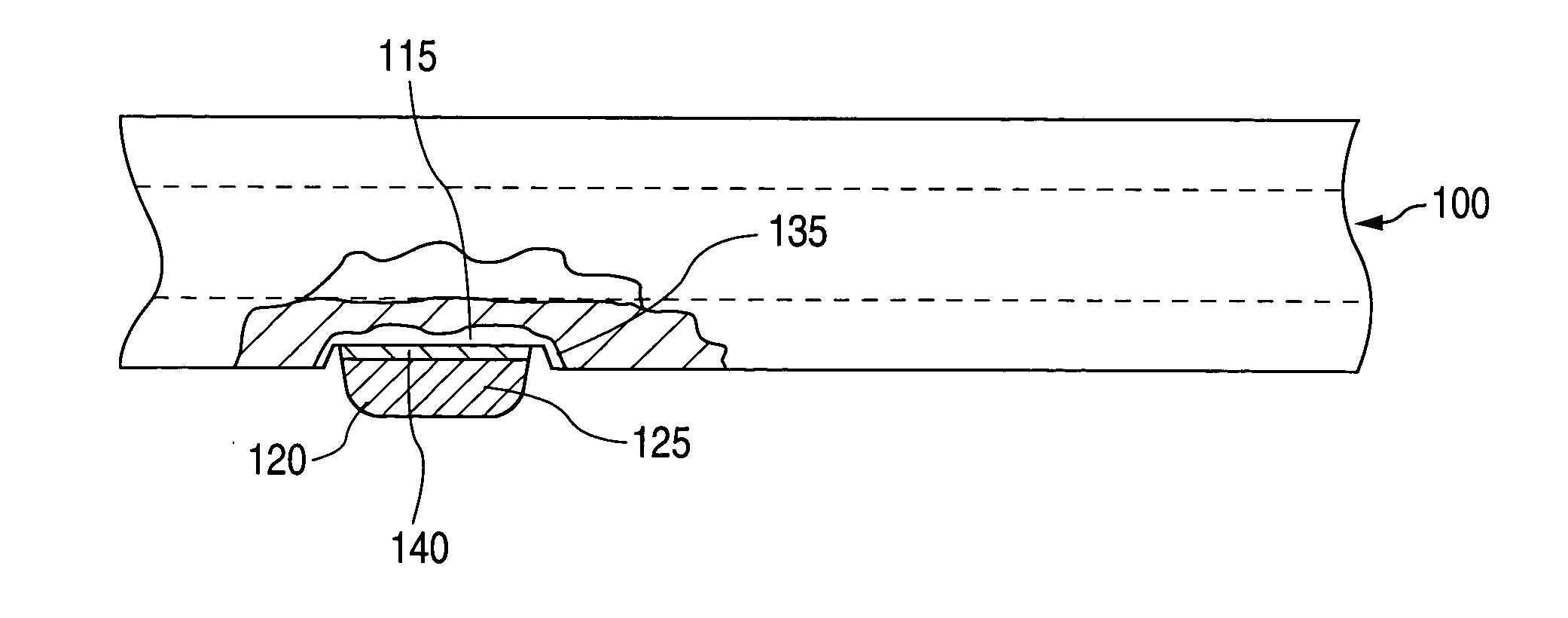

Honeycomb structure and exhaust gas purifying device

ActiveUS20070196620A1Combination devicesInternal combustion piston enginesCell wallPermeability coefficient

Owner:IBIDEN CO LTD

Porous glass fused onto stent for drug retention

Owner:ABBOTT CARDIOVASCULAR

Firing furnace, porous ceramic member manufacturing method using the same, and porous ceramic member manufactured by the manufacturing method

ActiveUS20060029898A1Avoid warpingEnsuring spaceMuffle furnacesIncreasing energy efficiencyPorous ceramicsMaterials science

Owner:IBIDEN CO LTD

Porous ceramic/porous polymer layered scaffolds for the repair and regeneration of tissue

InactiveUS20030003127A1Synthetic polymeric active ingredientsProsthesisComposite scaffoldArticular cartilage

A composite scaffold with a porous ceramic phase and a porous polymer phase. The polymer is foamed while in solution that is infused in the pores of the ceramic to create a interphase junction of interlocked porous materials. The preferred method for foaming is by lyophilization. The scaffold may be infused or coated with a variety of bioactive materials to induce ingrowth or to release a medicament. The multi-layered porous scaffold can mimic the morphology of an injured tissue junction with a gradient morphology and cell composition, such as articular cartilage.

Owner:ETHICON INC

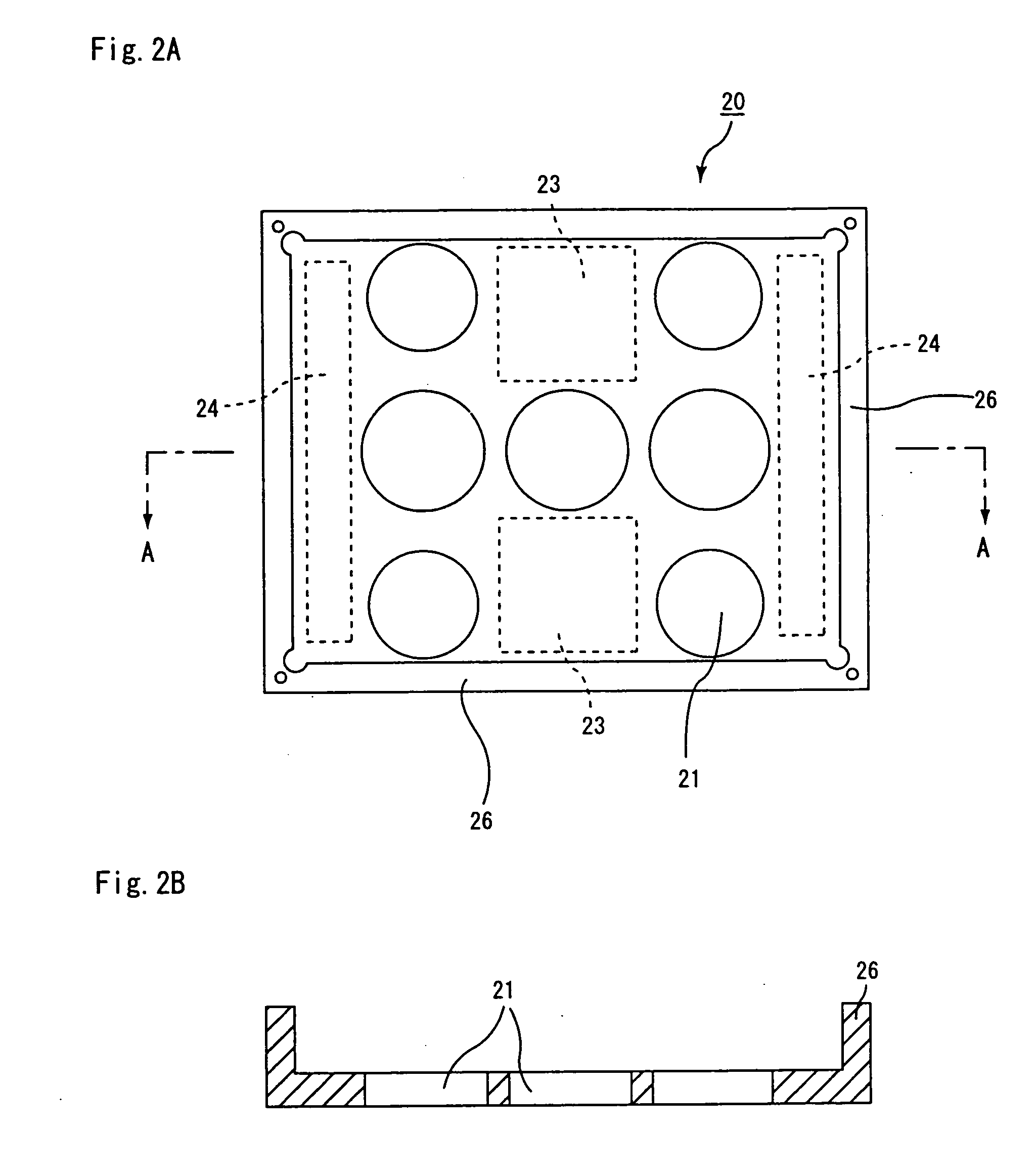

Jig for firing ceramics, manufacturing method for a porous ceramic body, and porous ceramic body

A jig for firing ceramics, which is used by being piled up in multiple stages upon firing a ceramic formed body, of the present invention has a through hole and / or a cut-out portion formed in a portion thereof.

Owner:IBIDEN CO LTD

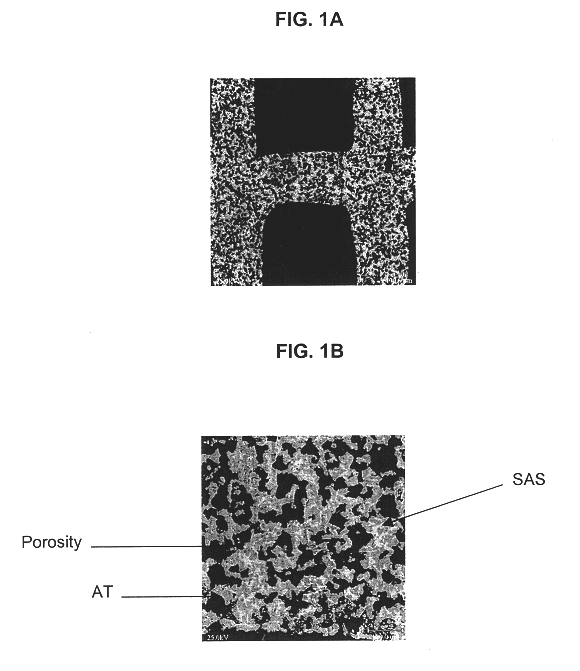

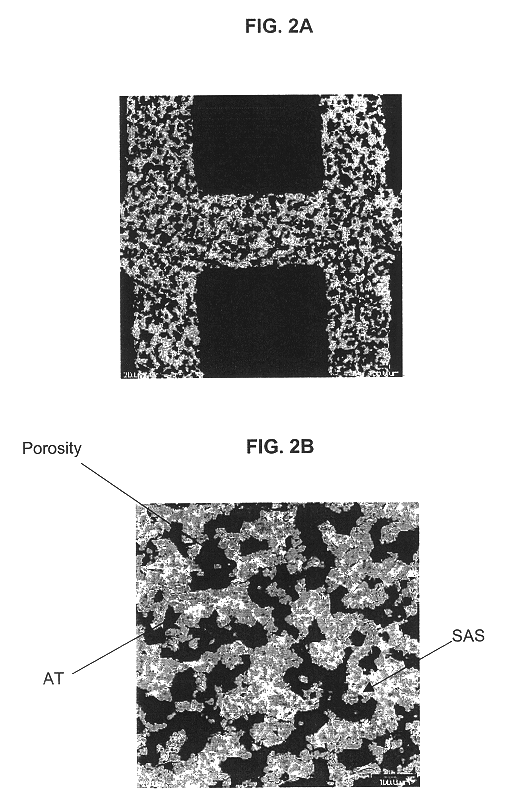

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

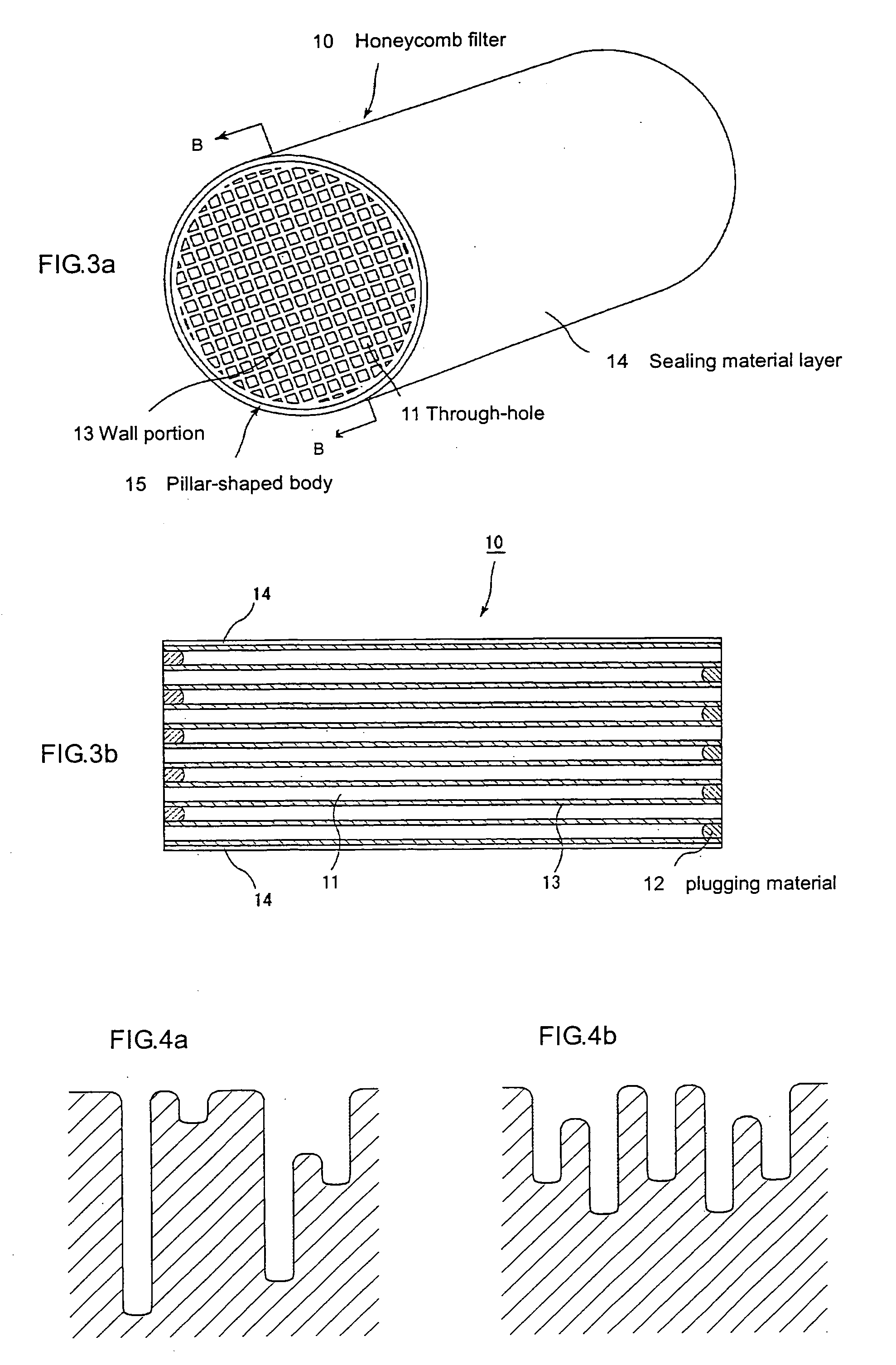

Ceramic honeycomb structure

ActiveUS20060166820A1Excellent in pressure loss and catching efficiencyHigh catalytic activityDispersed particle filtrationExhaust apparatusPore distributionSurface roughness

A honeycomb structural body comprises one or plural pillar-shaped porous ceramic members in which many through-holes are arranged side by side in a longitudinal direction through partition walls and either one end portions of these through-holes are sealed. The partition wall forming the structural body has a surface roughness of not less than 10 μm as a maximum roughness Rz defined in JIS B0601-2001 and an average pore size of 5-100 μm in a pore distribution measured by a mercury pressure method, and satisfies the following relationship: A≧90−B / 20 or A≦100−B / 20 when a ratio pores having a pore size of 0.9-1.1 times the average pore size to total pore volume is A (%) and a thickness of the partition wall is B (μm), and there is proposed an effective honeycomb structural body having excellent pressure loss and catching efficiency and a high catalyst reactivity.

Owner:IBIDEN CO LTD

High-efficiency multifunctional modular interior air purification device

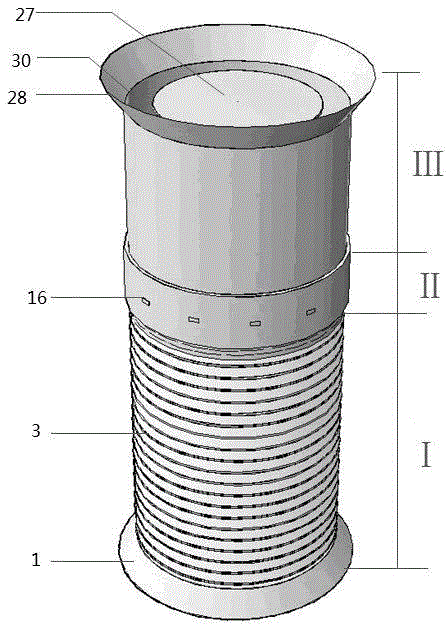

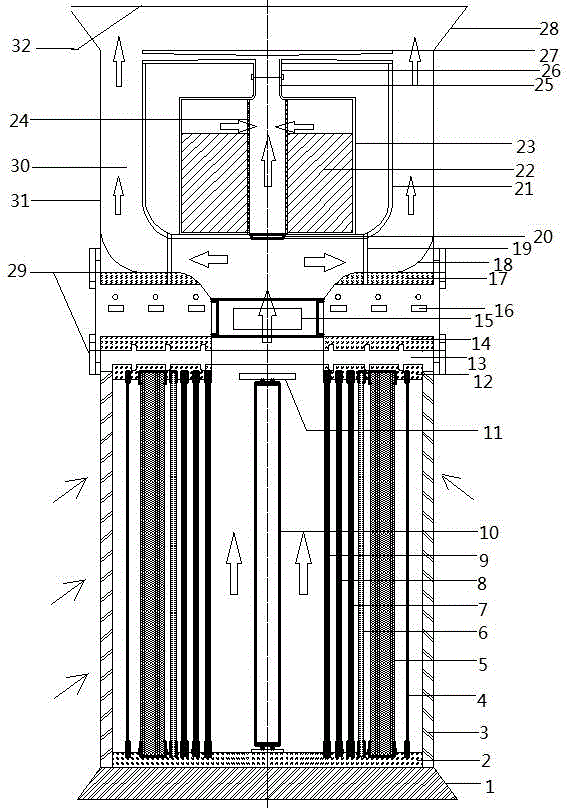

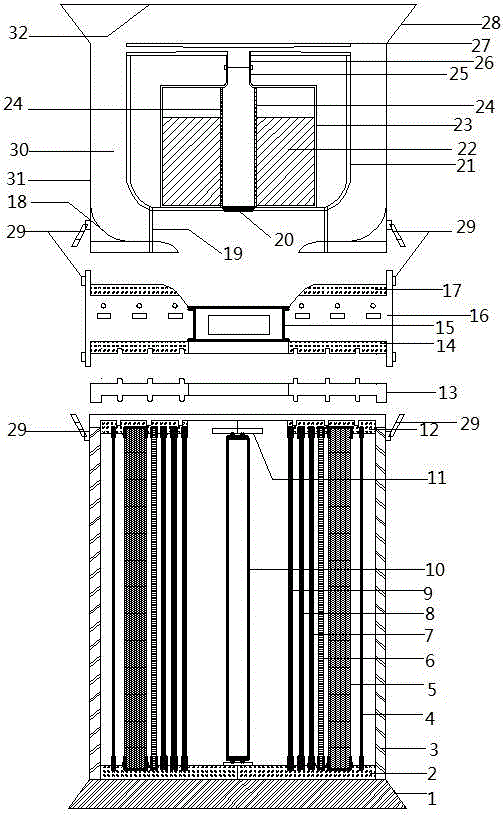

InactiveCN102748817AEasy to disassemble and maintainMeet general functional requirementsSpace heating and ventilation safety systemsLighting and heating apparatusFree rotationPorous ceramics

The invention relates to a high-efficiency multifunctional modular interior air purification device. A device main body is cylindrical and consists of three cylindrical function modules which are combined and include a main l function module, a power control module and an additional function module from bottom top. The main function module with 360-degree omnibearing intake air design consists of a protective hood, a free rotating guide plate, a washable prefiltering glass fiber layer, an attached active carbon adsorption layer, an attached nano active carbon adsorption layer, a high-efficient PTFE filter layer, a load nano TiO2 porous ceramic sequentially from bottom top, as well as a UV lamp in the middle from the outside to the inside; the power control module consists of a power cord, a multifunctional power jack, a fan and a control panel; and the additional function module consists of a cylindrical guide plate, a guide protective hood and a solid essential oil dispersion box / negative ion generator / humidifier and the like. The high-efficiency multifunctional modular interior air purification device is compact in design structure, has no noise pollution, low energy consumption and an obvious purification effect, and is suitable for use in various interior places.

Owner:TONGJI UNIV

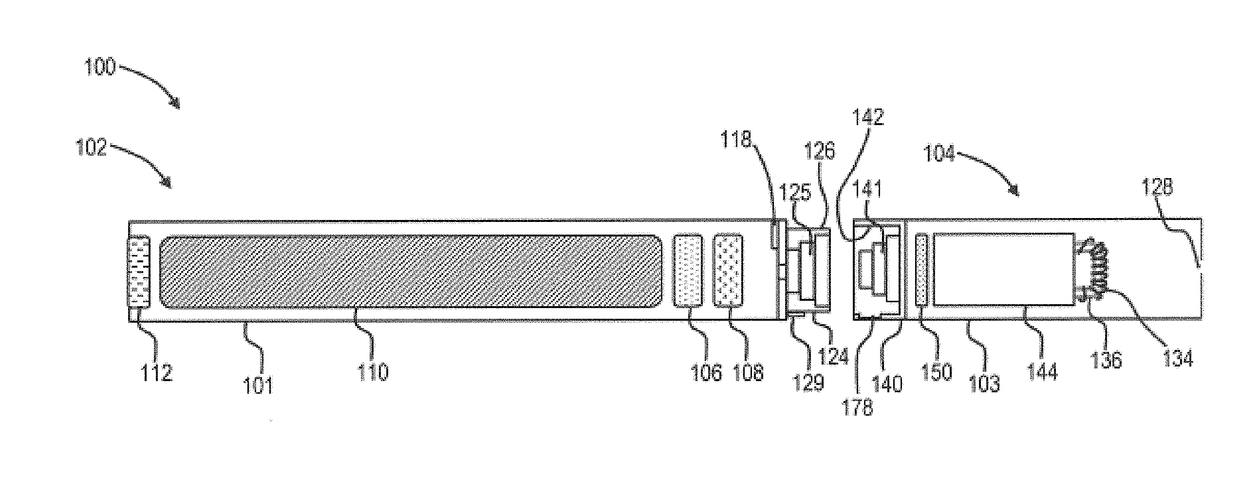

Aerosol delivery device with improved fluid transport

ActiveUS20170188626A1Suitable for useTobacco treatmentTobacco devicesFluid transportAerosol delivery

The present disclosure relates to aerosol delivery devices, methods of forming such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition that is stored in and / or transported to a heater by a porous monolith, which can be, for example, a porous glass or a porous ceramic. A heater can be in a heating arrangement with an external portion of the porous monolith or can be substantially internal to the porous monolith.

Owner:RAI STRATEGIC HLDG INC

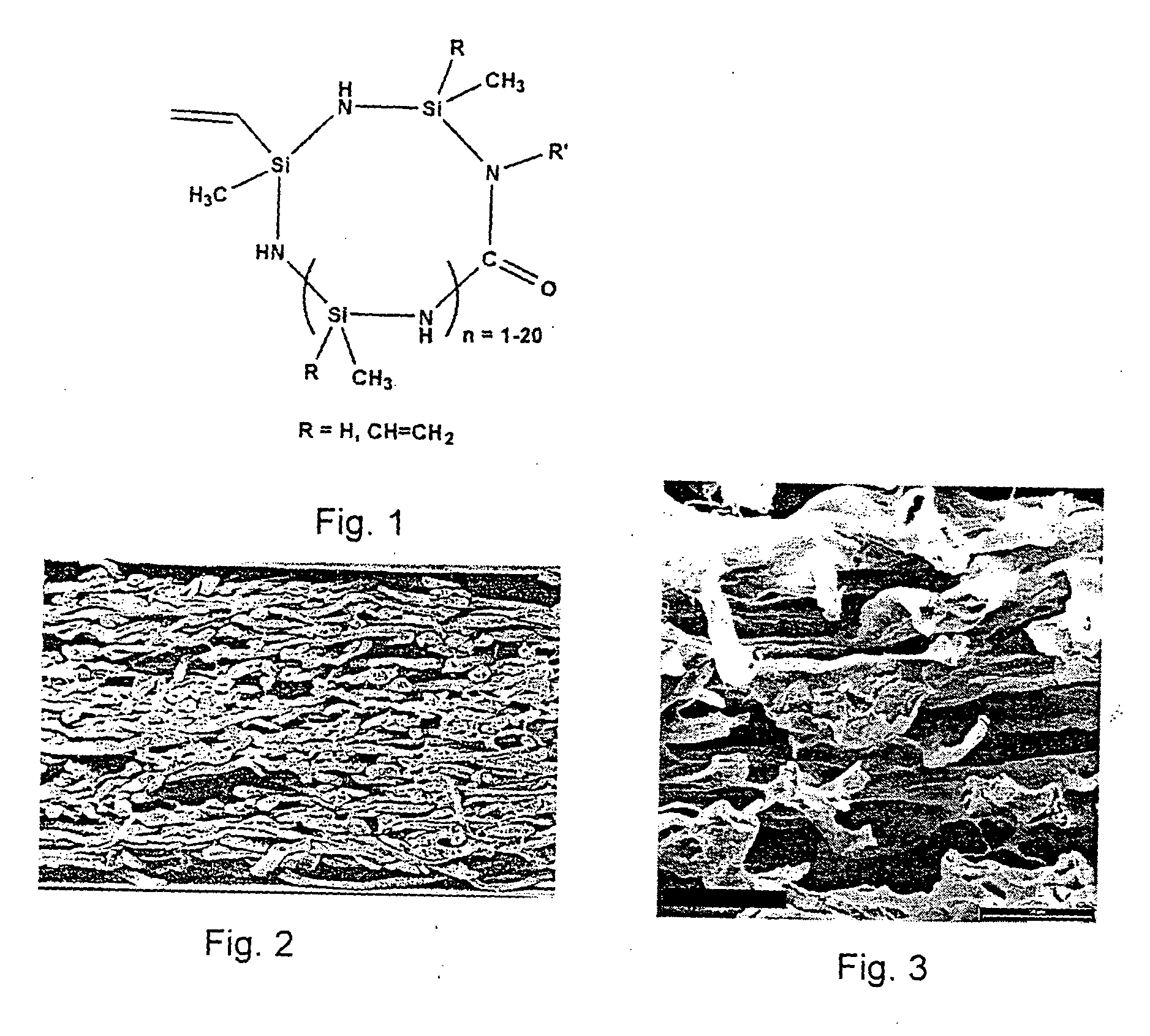

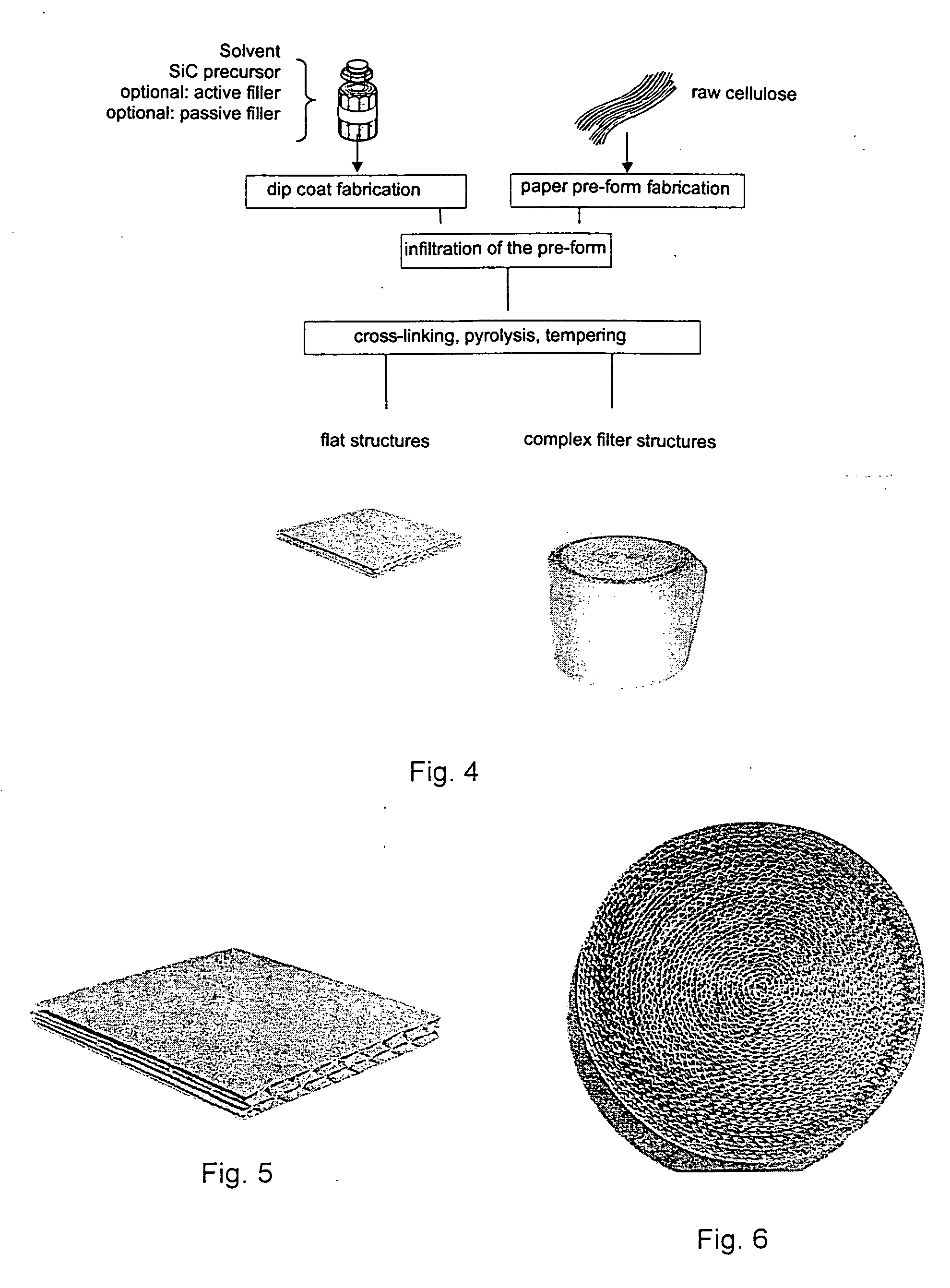

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

Honeycomb filter for purifying exhaust gases, adhesive, coating material, and manufacturing method of honeycomb filter for purifying exhaust gases

InactiveUS20080241015A1Increased durabilityHigh strengthCombination devicesPhysical/chemical process catalystsParticulatesAdhesive

Owner:IBIDEN CO LTD

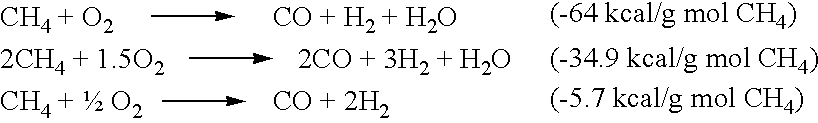

Catalytic oxidation process

InactiveUS6447745B1Hydrocarbon from carbon oxidesCatalyst activation/preparationElemental compositionPartial oxidation

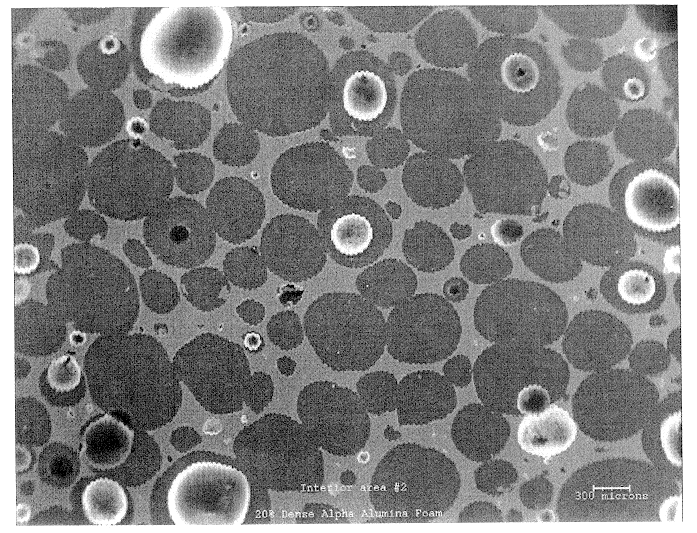

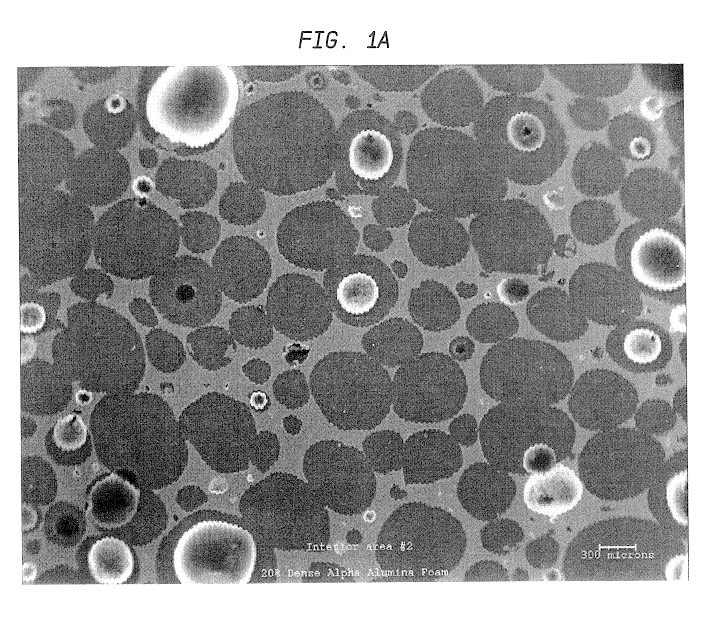

A process for the partial catalytic oxidation of a hydrocarbon containing feed comprising contacting the feed with an oxygen-containing gas in the presence of a catalyst retained within a reaction zone in a fixed arrangement, wherein the catalyst comprises at least one catalytically active metal selected from the group consisting of silver and Group VIII elements supported on a porous ceramic carrier. The porous ceramic carrier has a distribution of total pores wherein about 70% of the total pores (1) have a volume-to-surface area (V / S) ration that is within about 20% of the mean V / S value for the total pores and no pores have a V / S ration that is greater than twice the mean V / S value for the total pores; (2) have a pore-to-pore distance between neighboring pores that is within about 25% of the mean pore-to-pore distance between neighboring pores; and (3) have a pore throat area that is within about 50% of the mean pore throat are for the pores. Additionally, about 50% of the total pores have a coordination number between neighboring pores that is within about 25% of the mean coordination number between neighboring pores. Preferably, the oxidation process comprises a multistage, staged oxygen, catalytic partial oxidation process having fewer than or equal to about five stages and including a first stage preheat temperature of greater than about 550° C., and wherein the temperature of the product mixture in each stage following the first stage is at least about 700° C.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com