Patents

Literature

4272 results about "Flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most frequently employed, in which a specimen having either a circular or rectangular cross-section is bent until fracture or yielding using a three point flexural test technique.

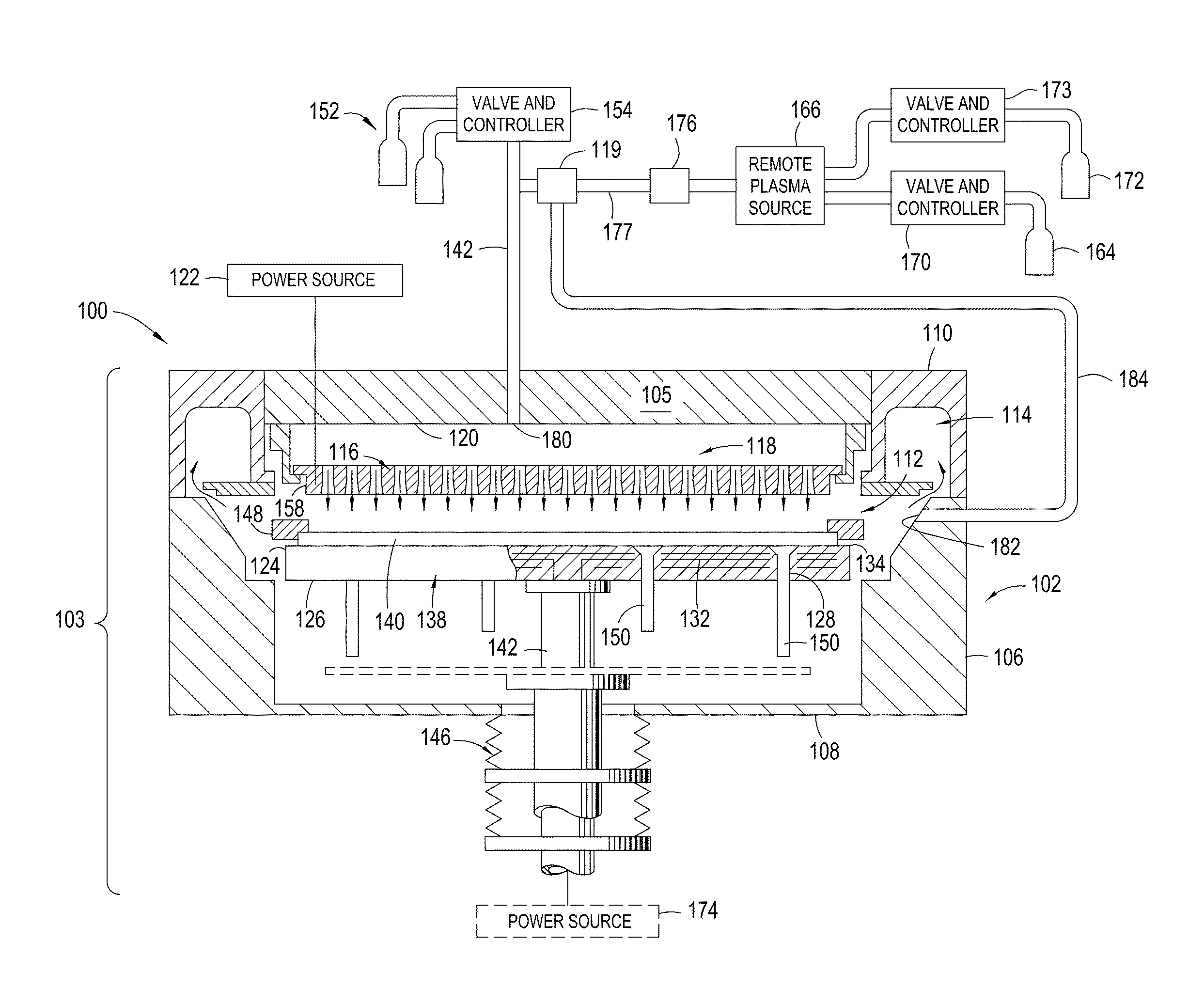

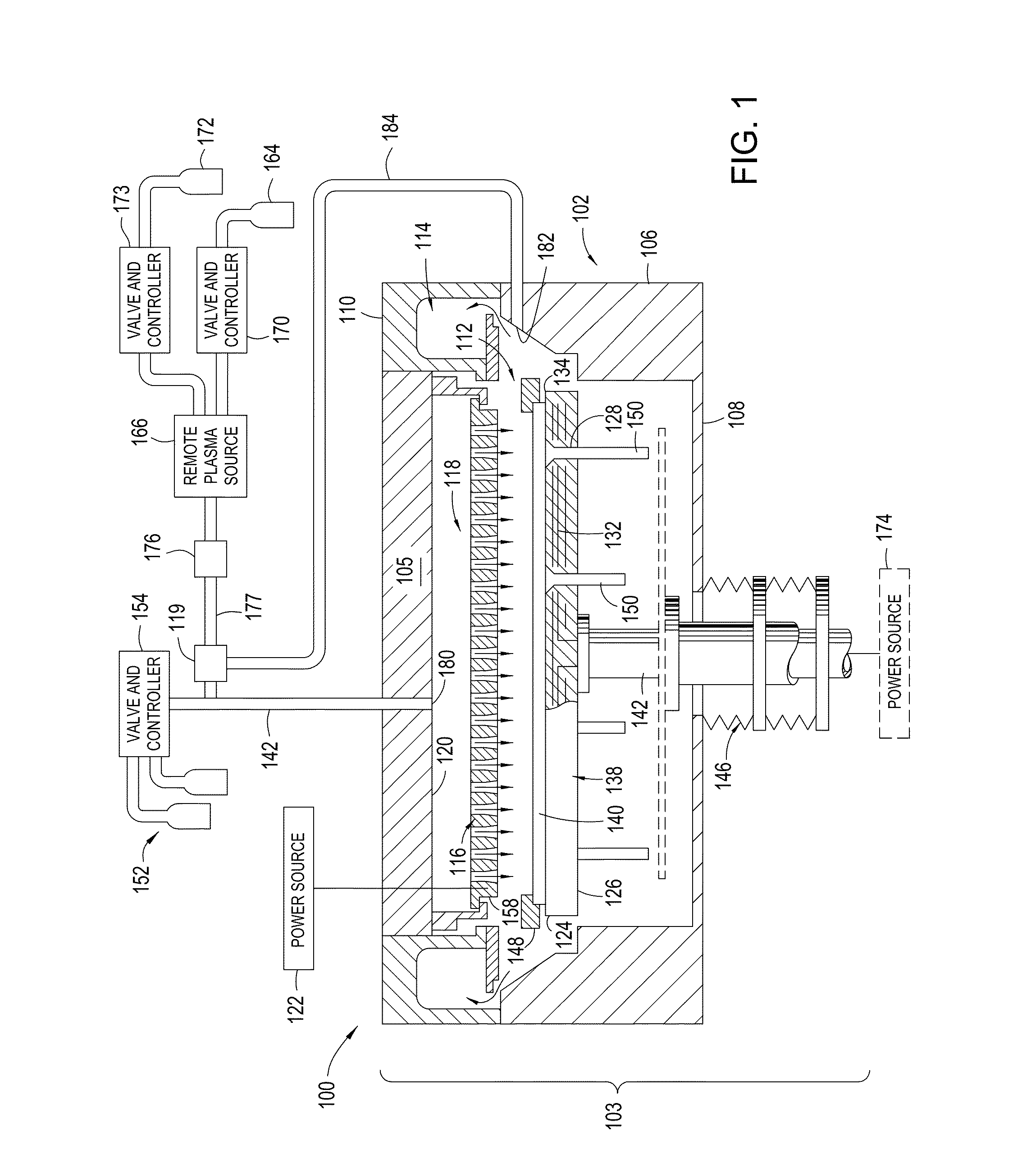

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

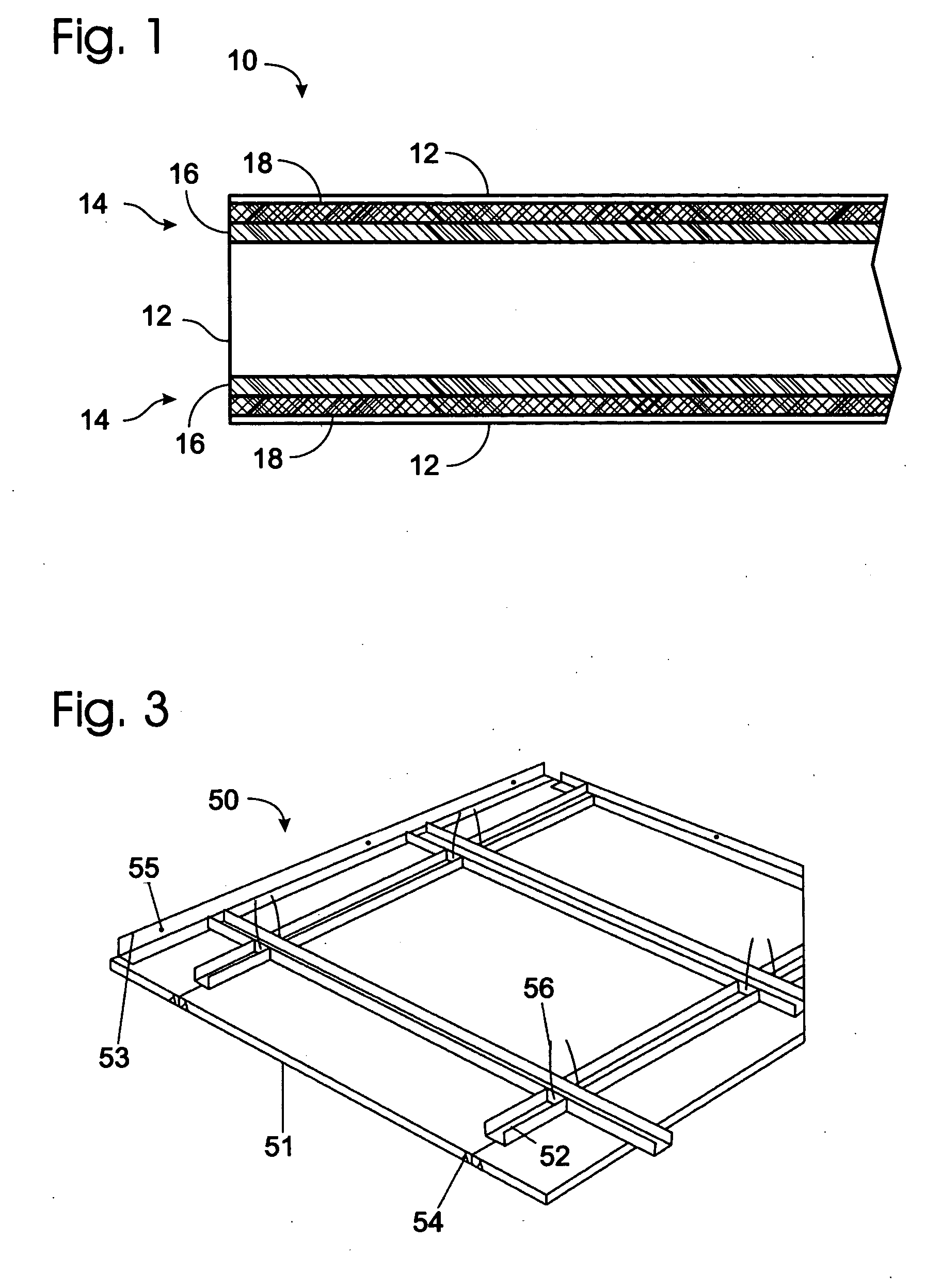

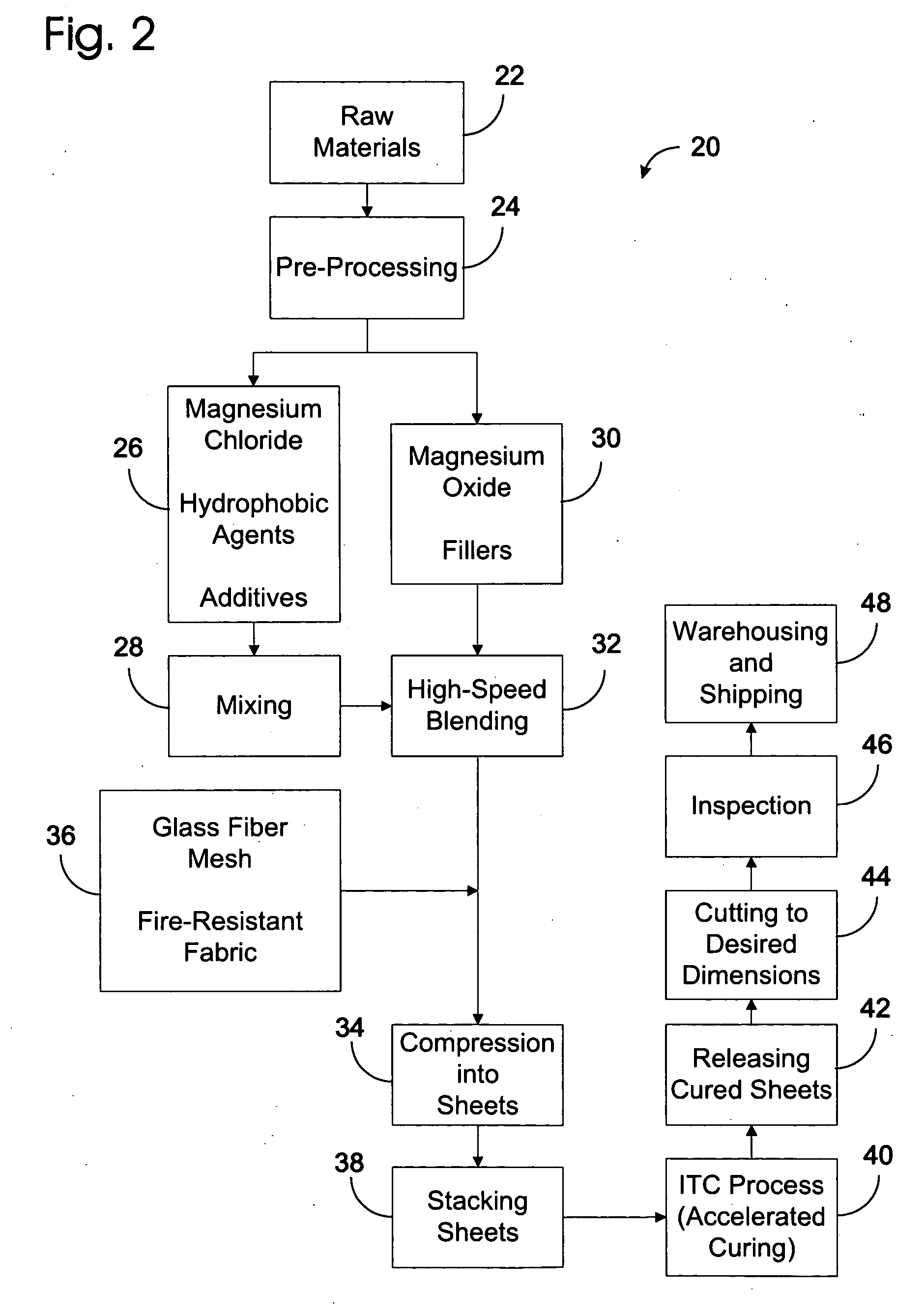

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

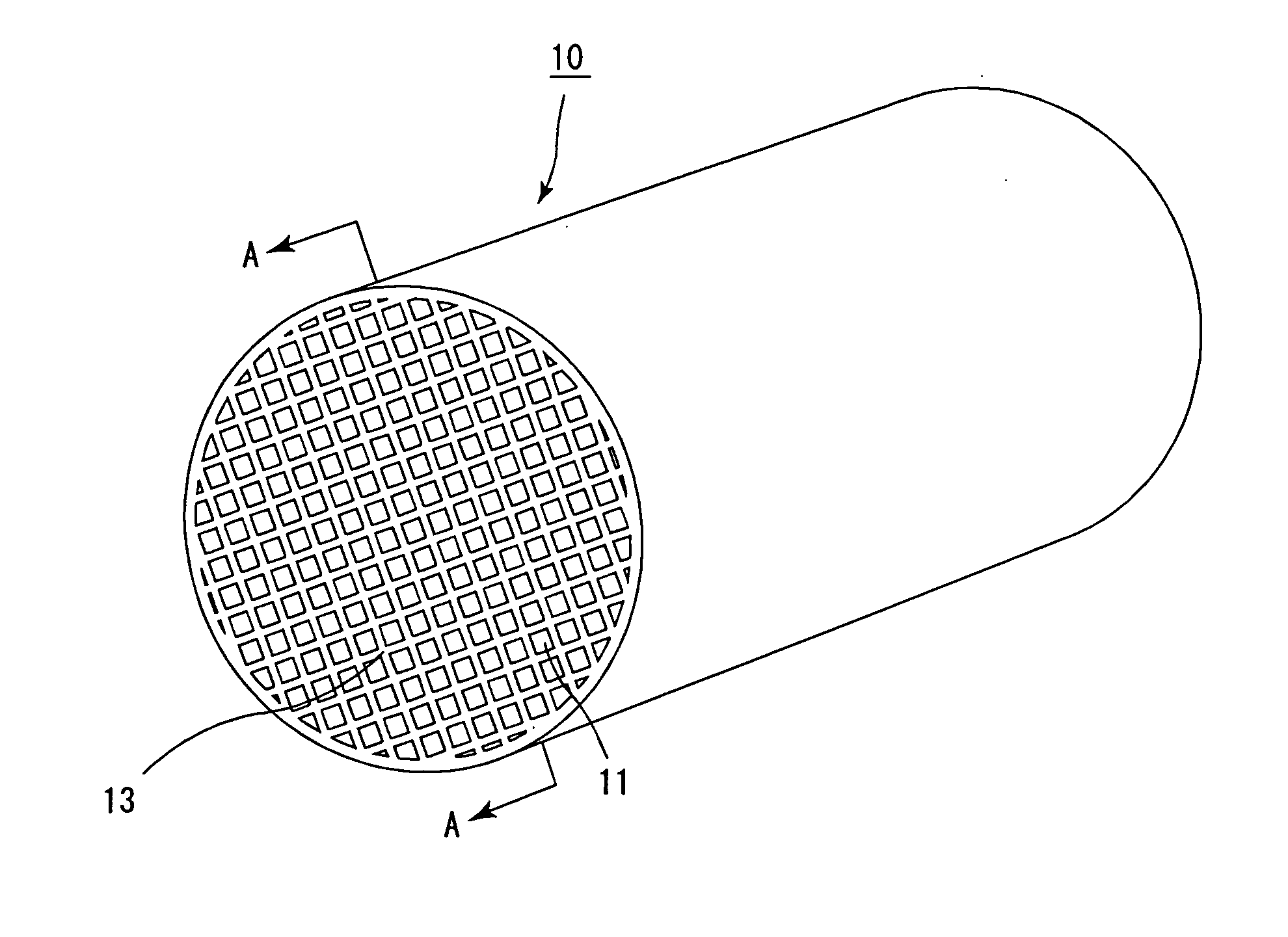

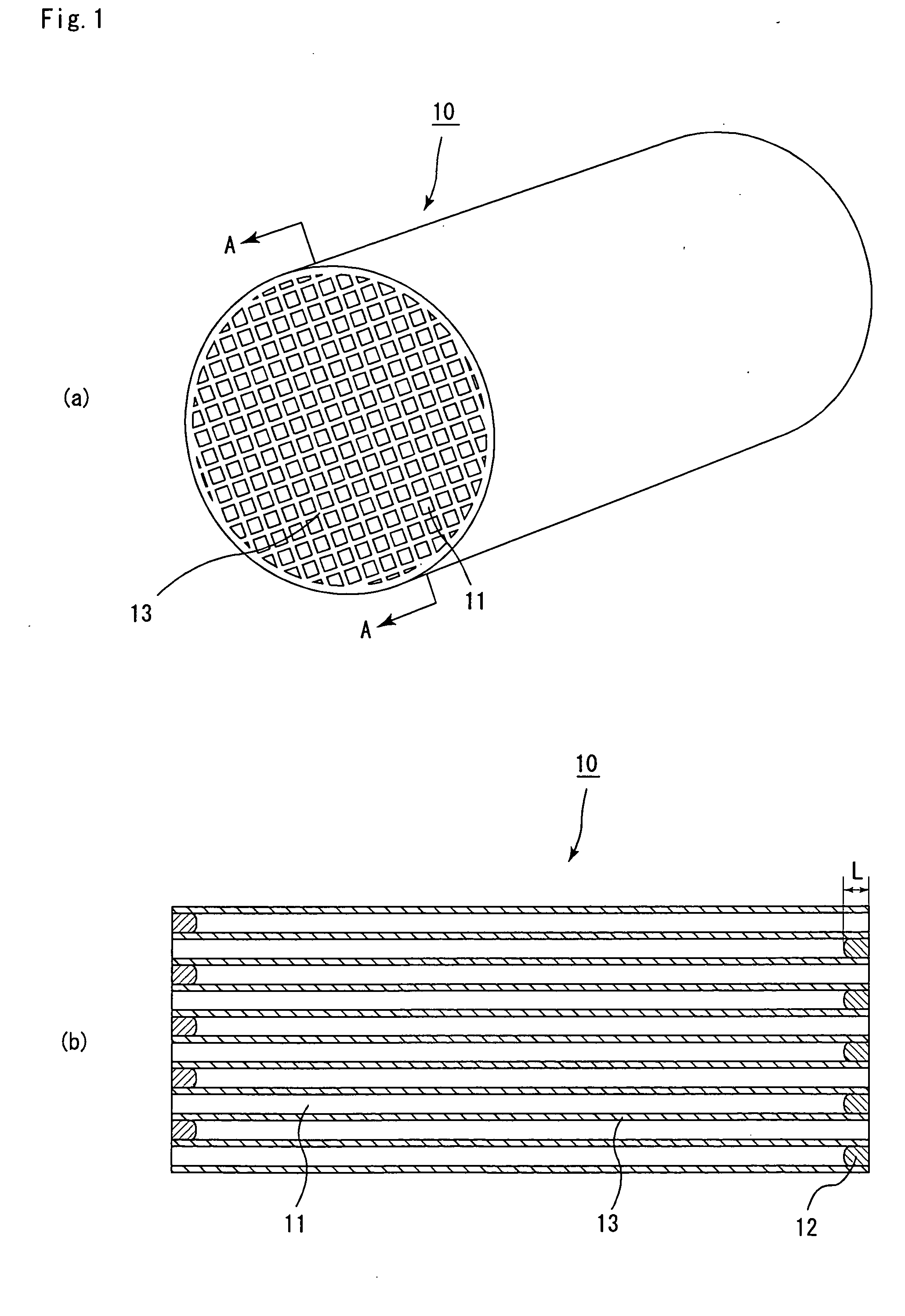

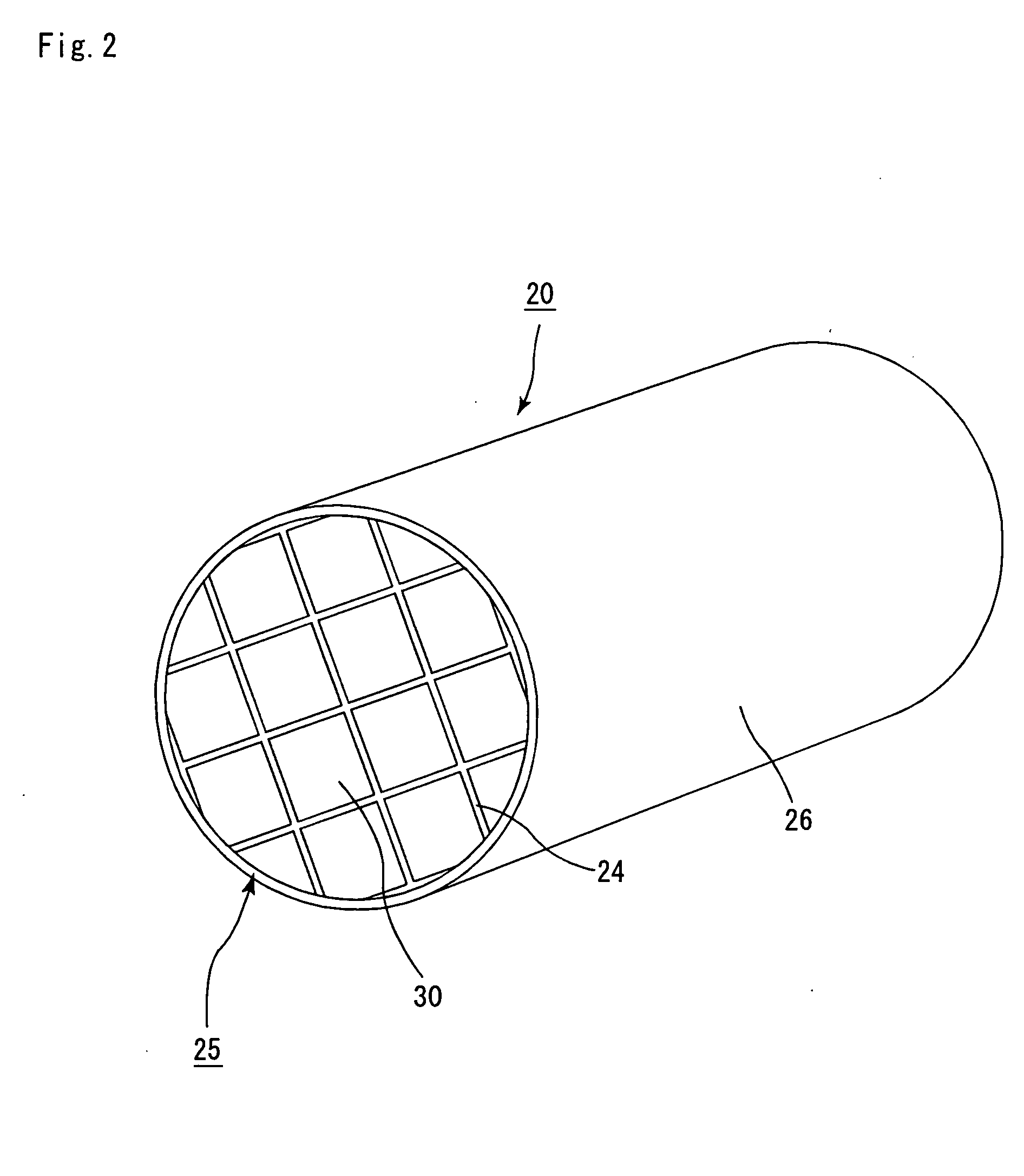

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

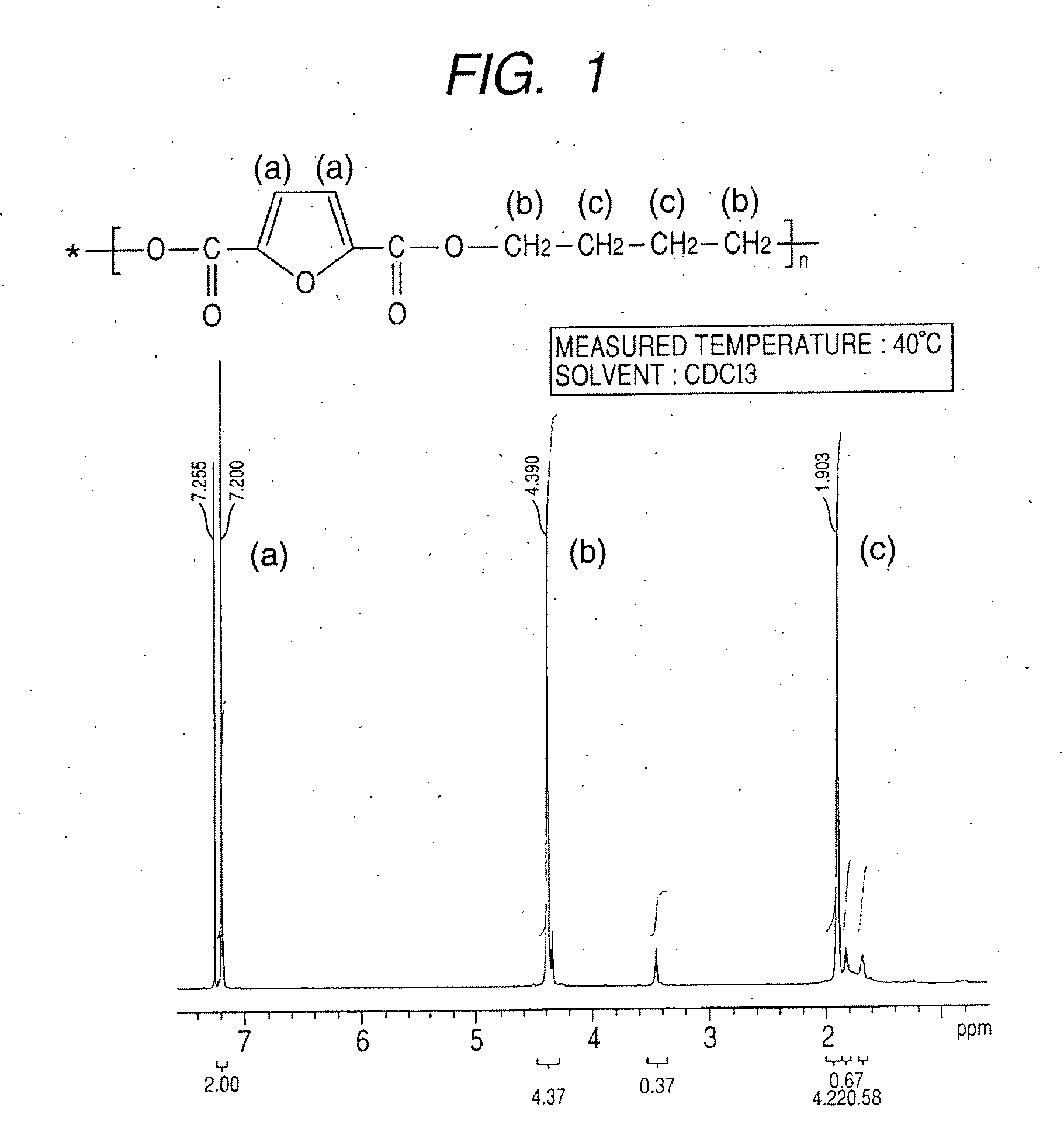

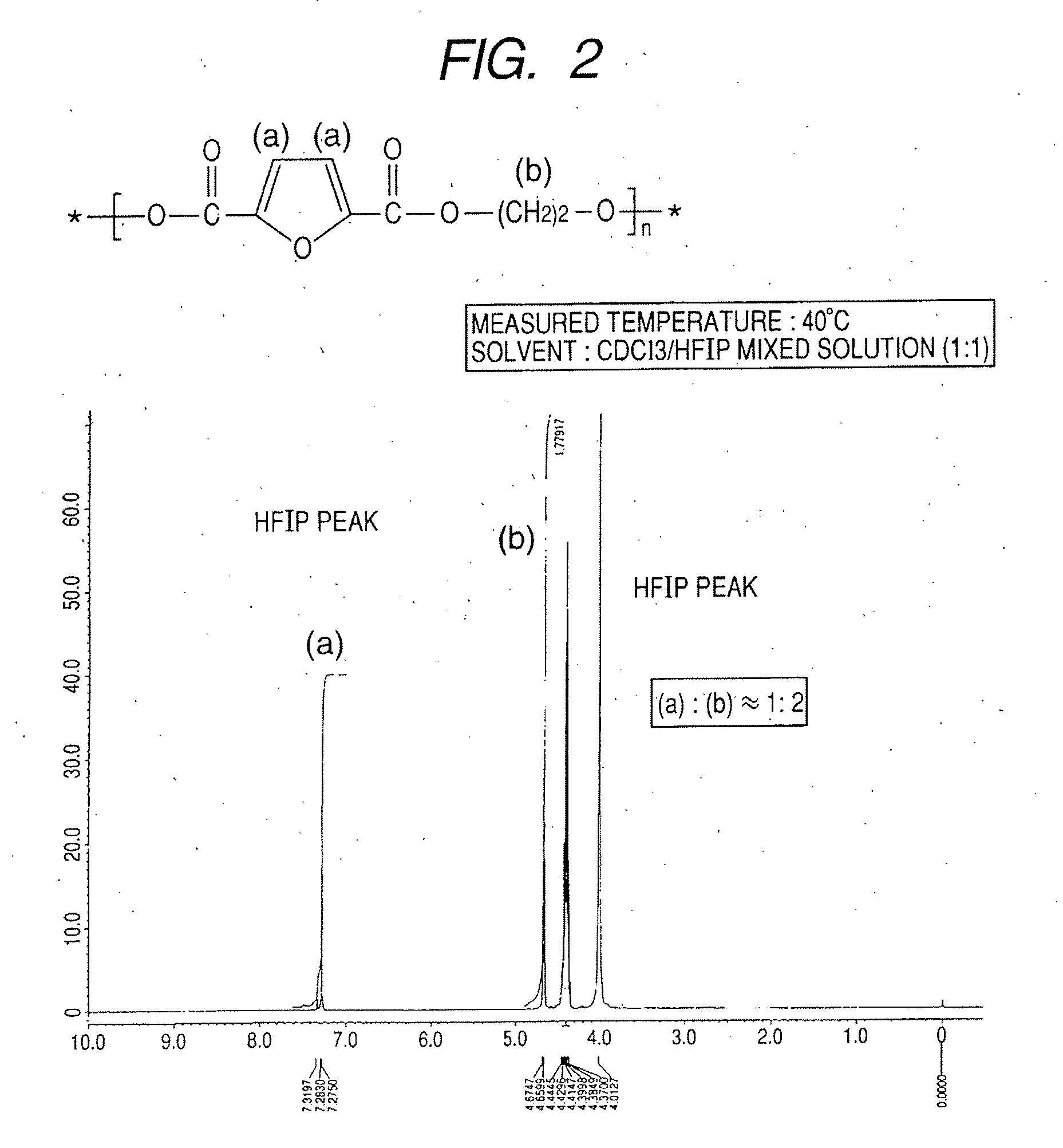

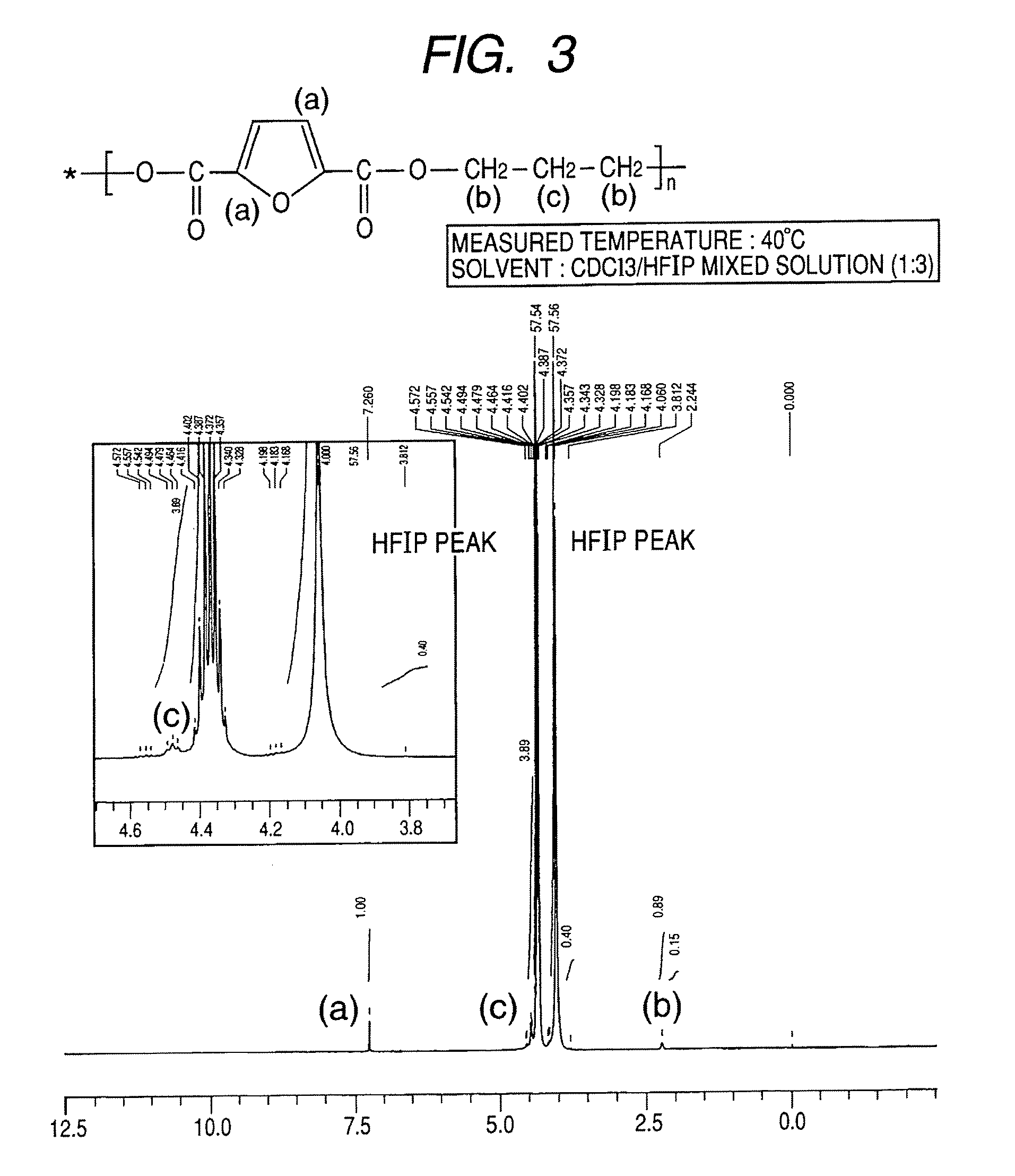

Polymer compound and method of synthesizing the same

ActiveUS20090124763A1High mechanical strengthGood moldabilityThin material handlingPolymer chemistryFlexural strength

Provided is a polymer compound having a furan ring having a degree of polymerization of 185 or more and 600 or less. This polymer compound has excellent mechanical strength (flexural strength).

Owner:CANON KK

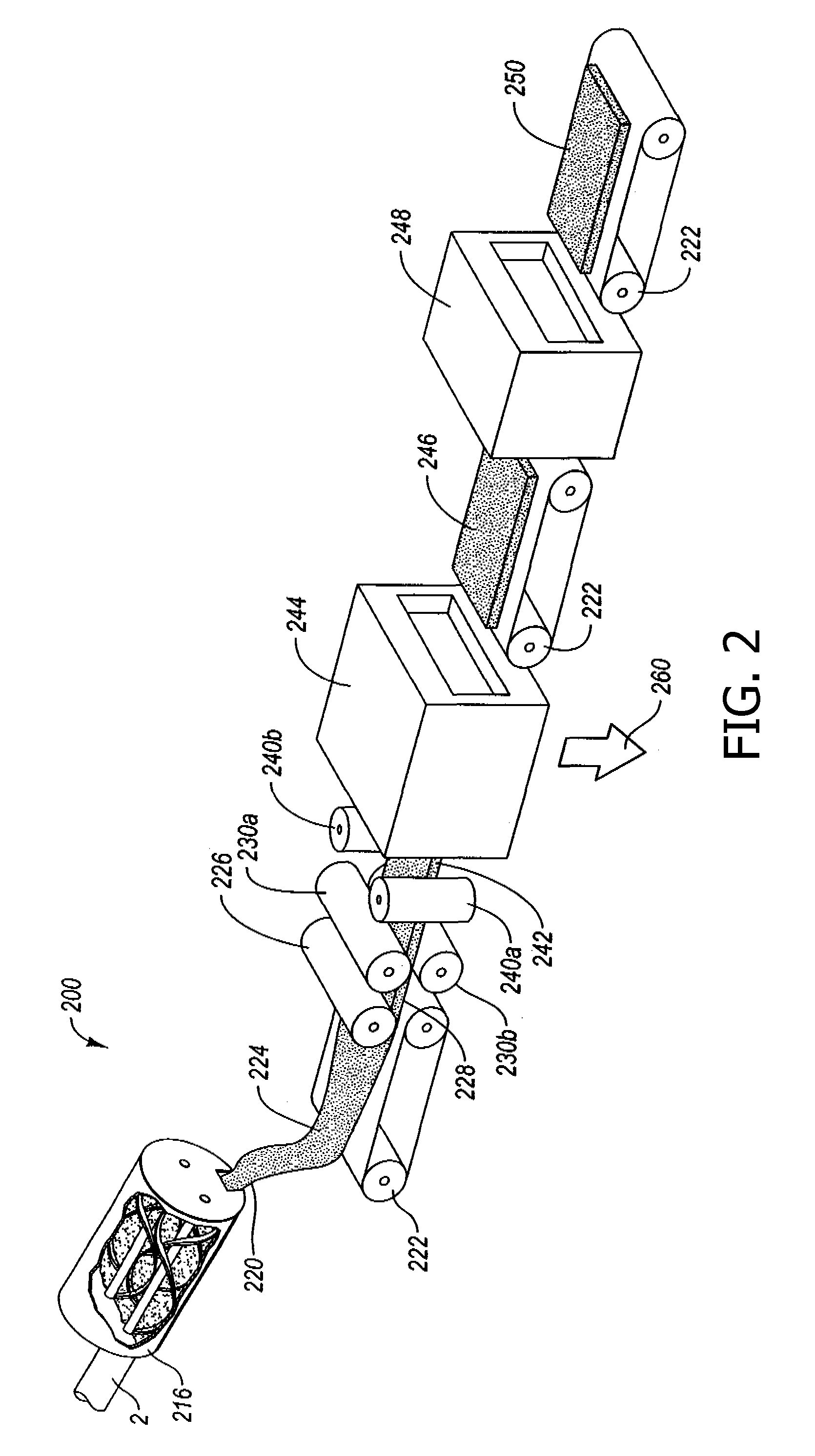

Strengthened, light weight wallboard and method and apparatus for making the same

InactiveUS6319312B1Easy to optimizeReduce amountConstruction materialCeramic shaping plantsSingle plateFlexural strength

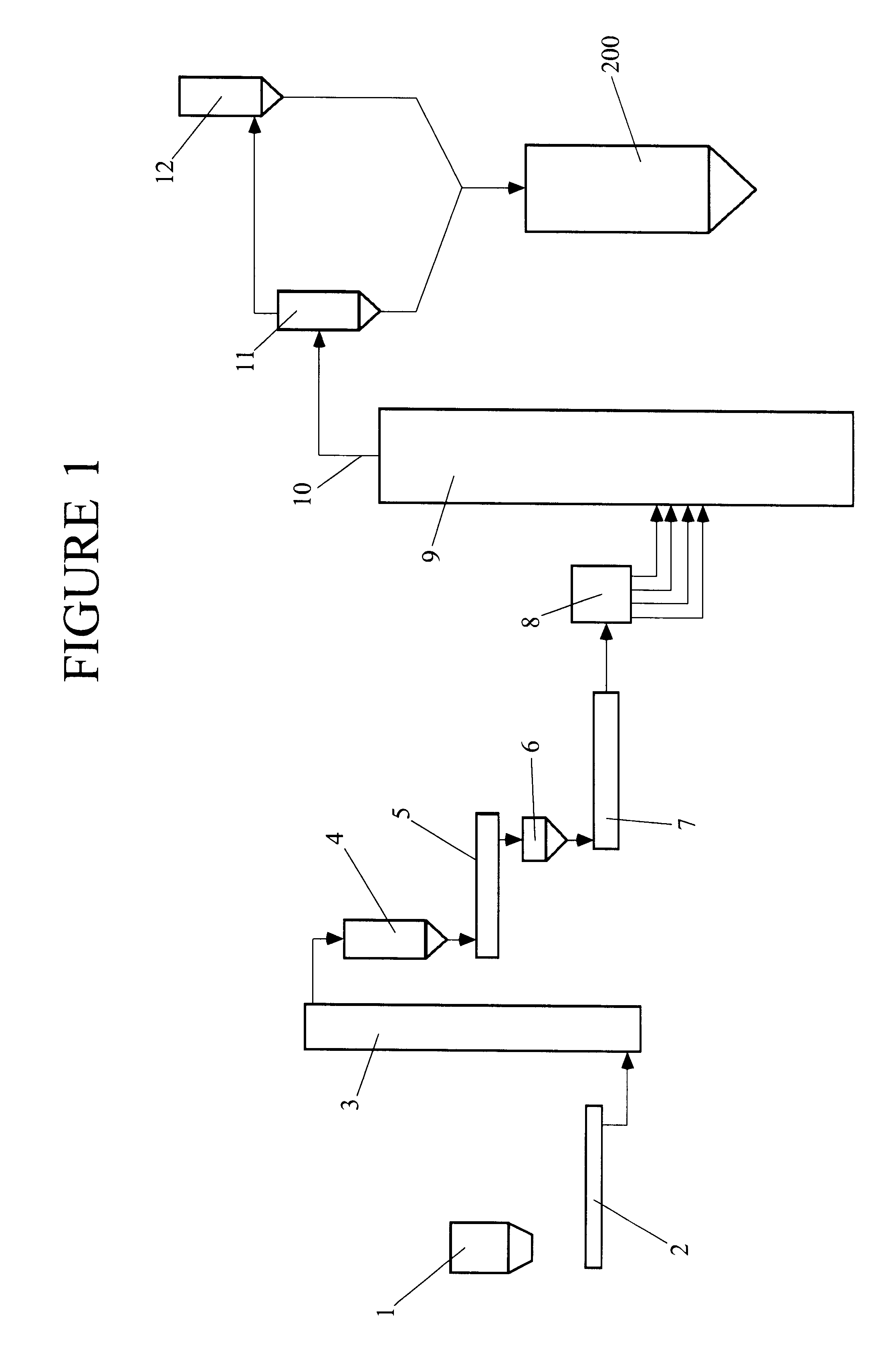

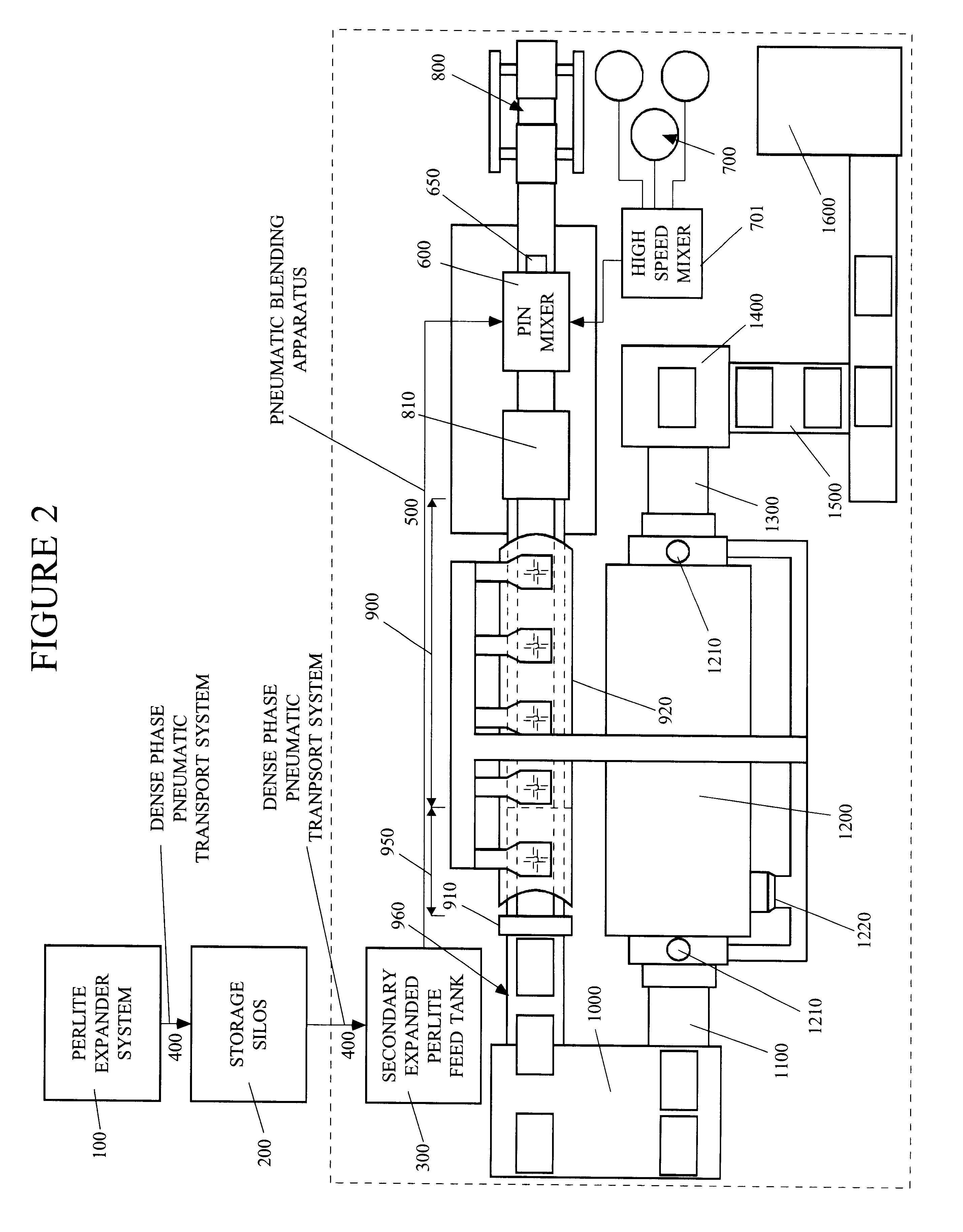

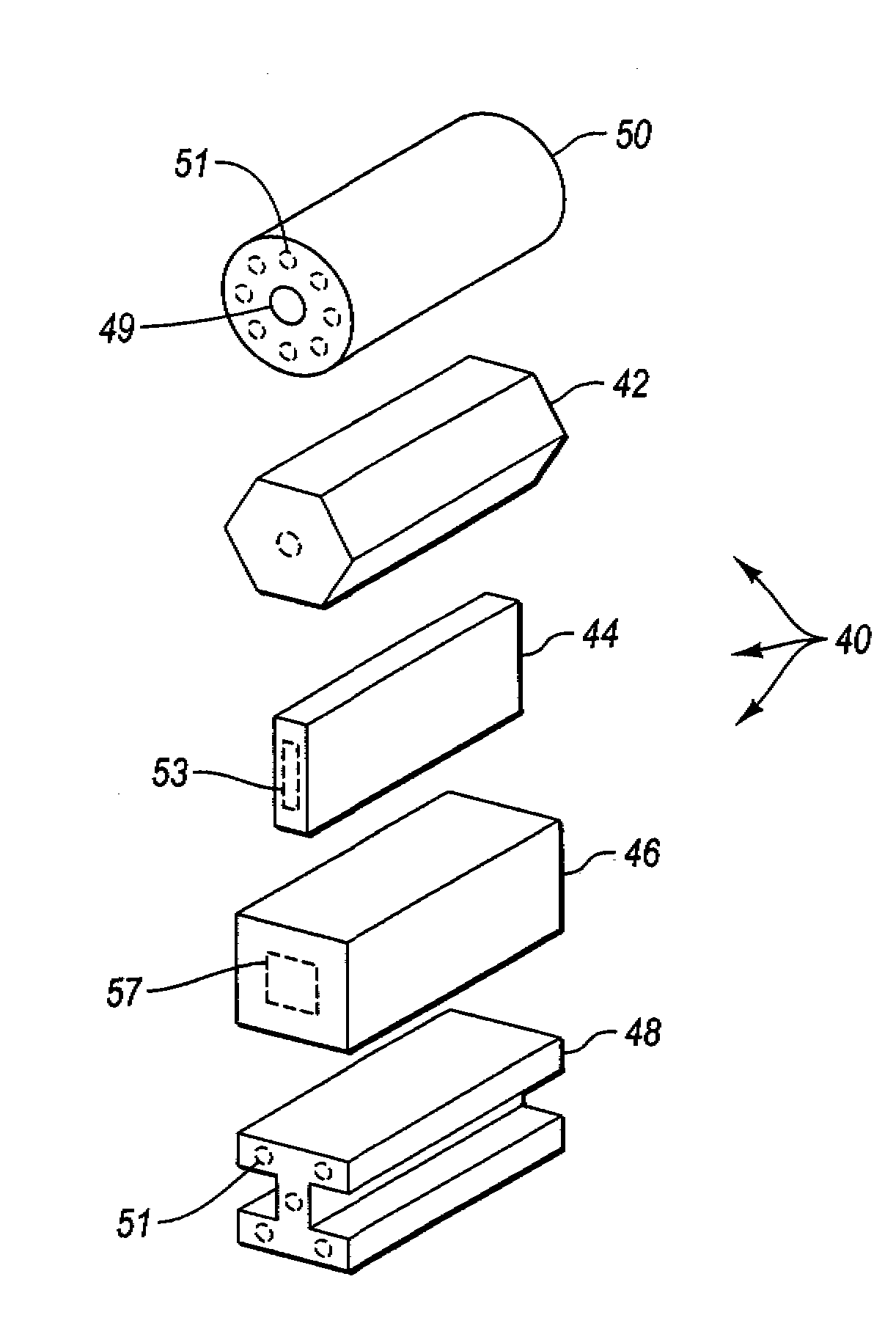

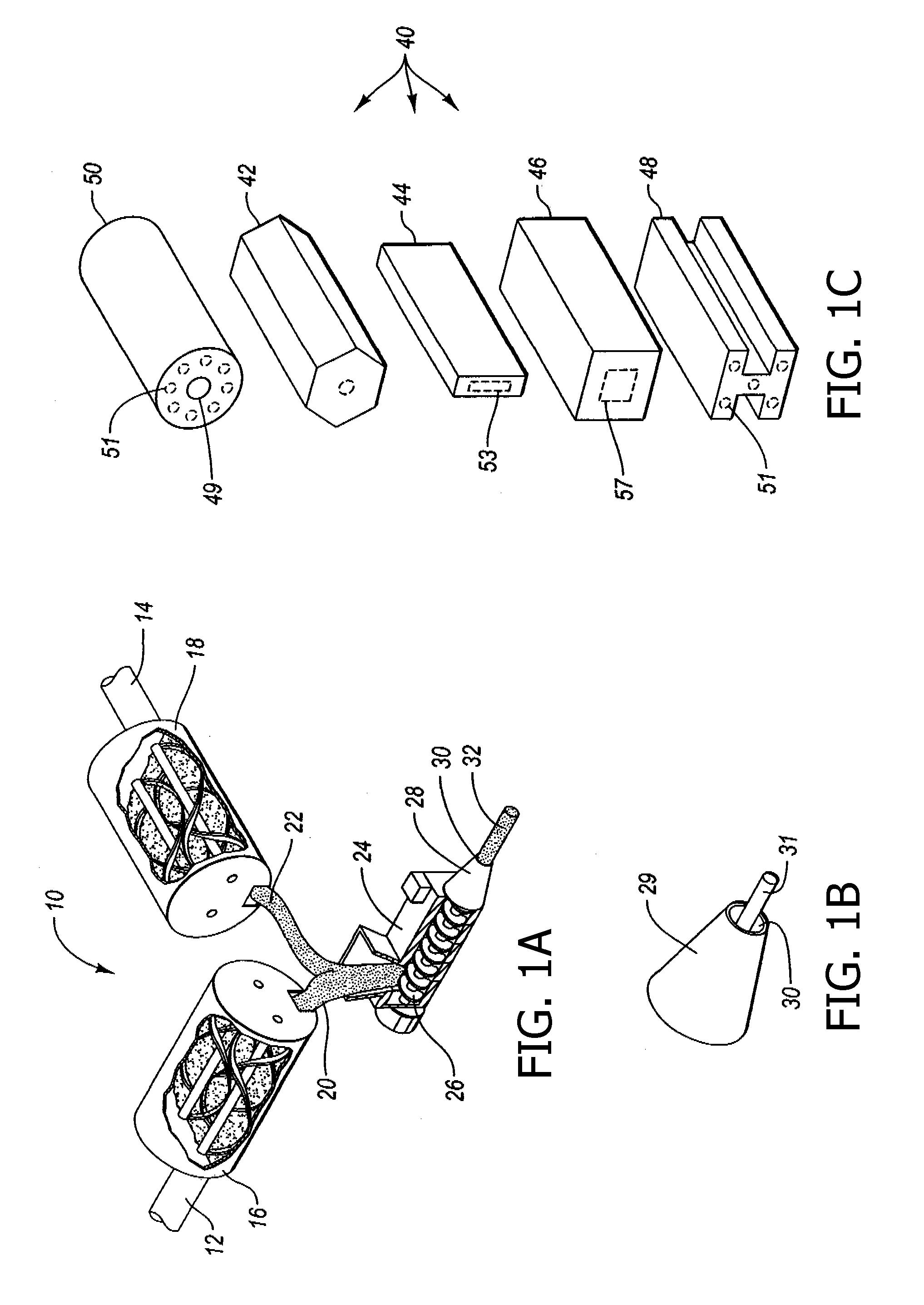

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

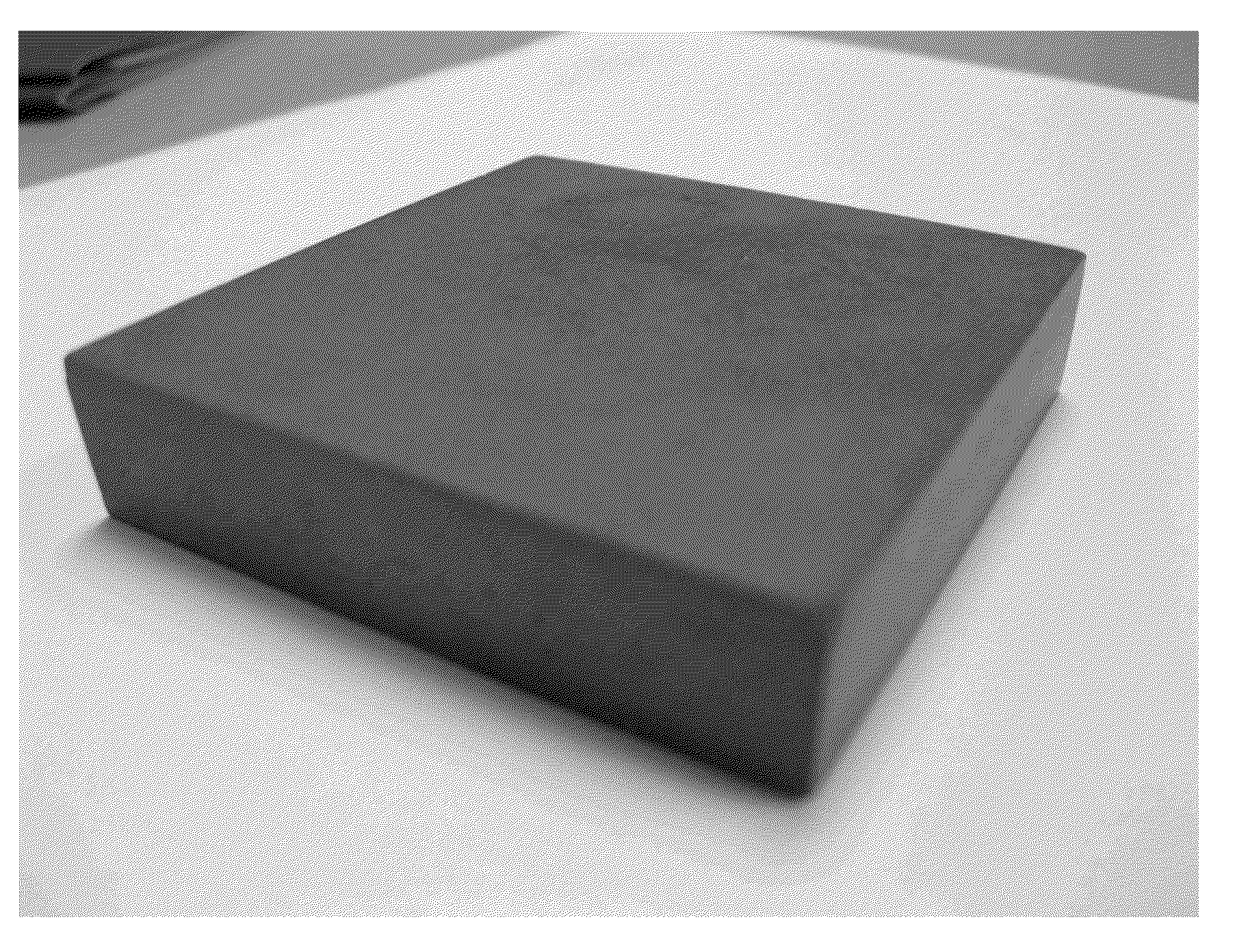

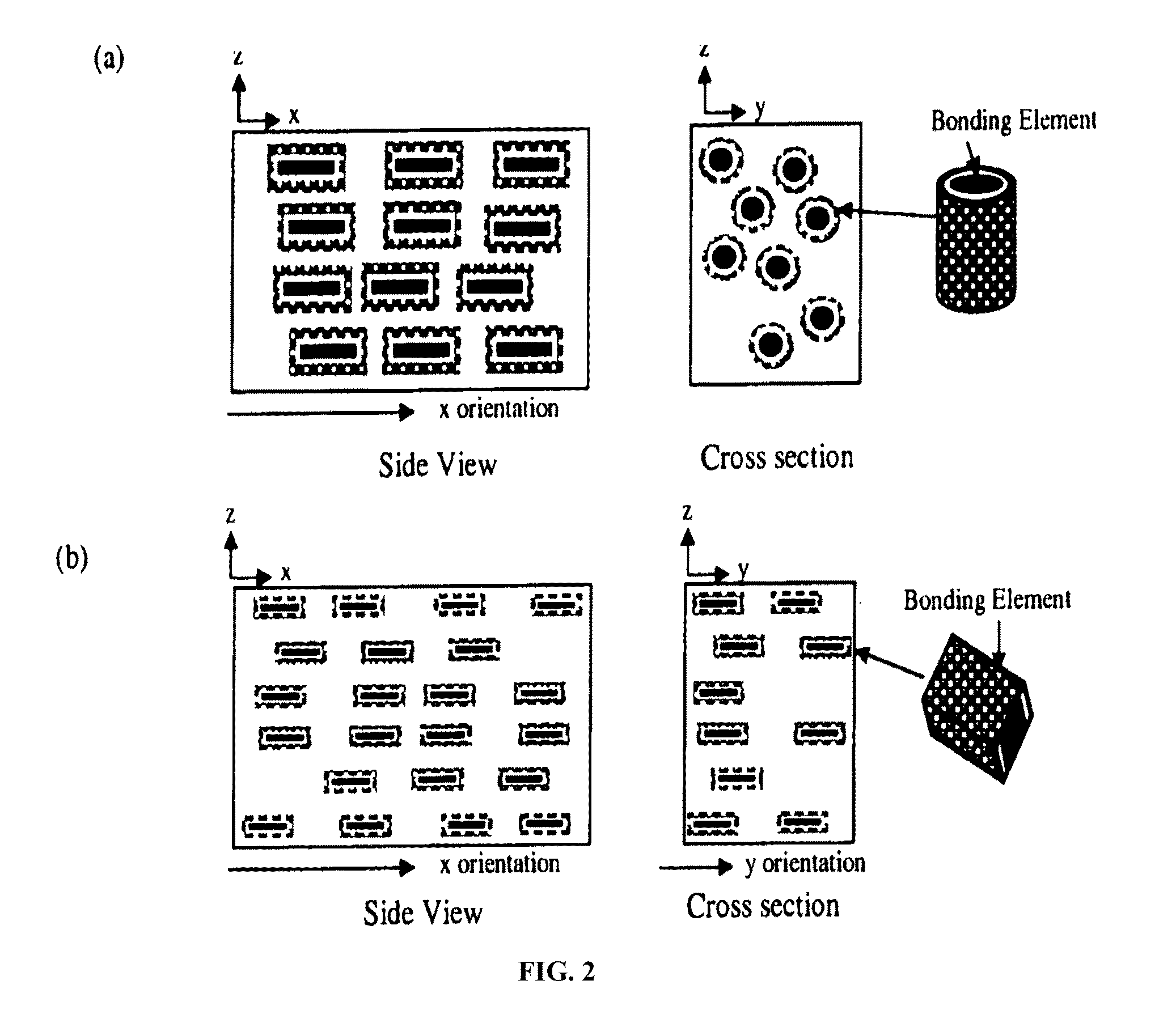

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

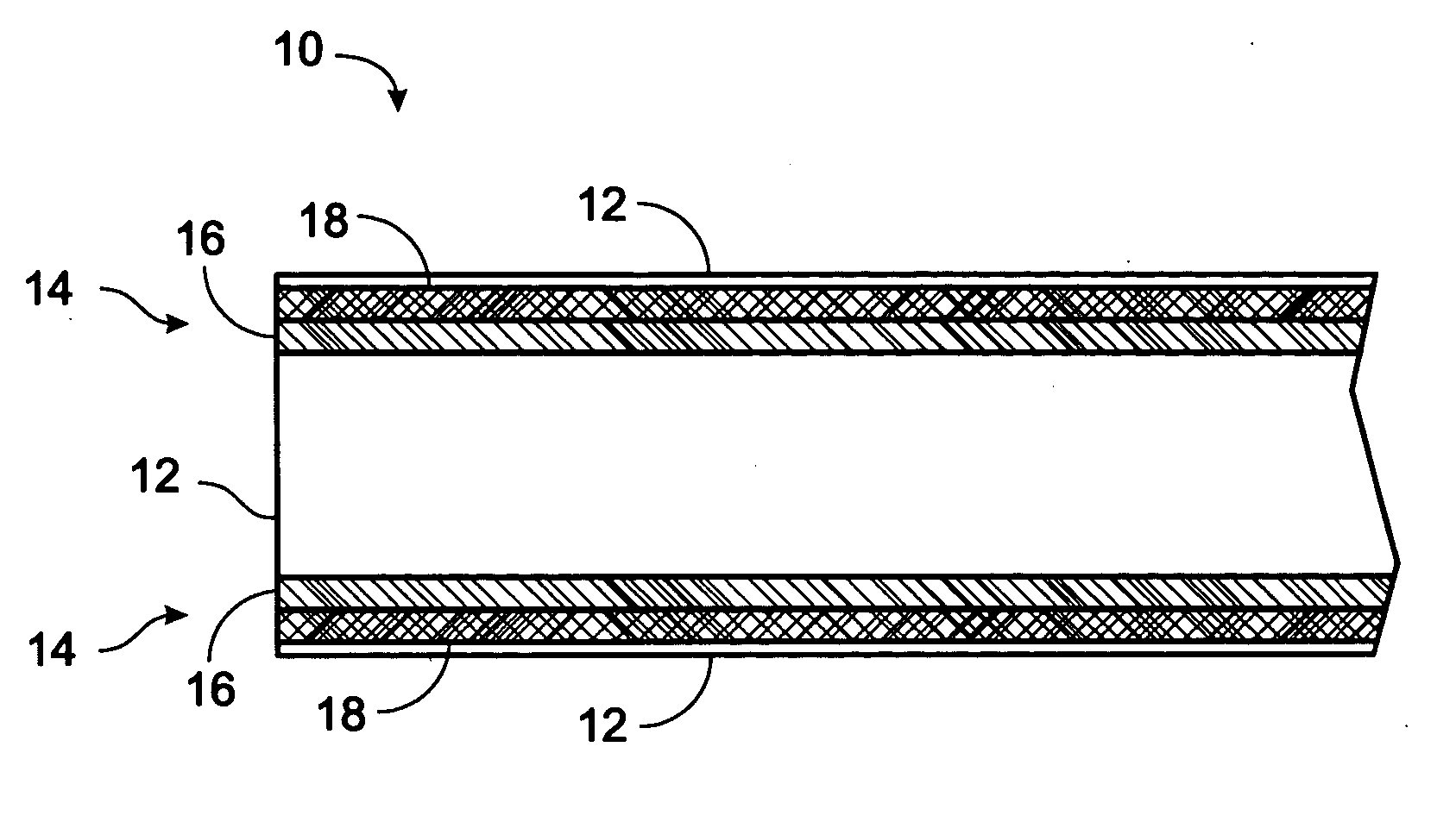

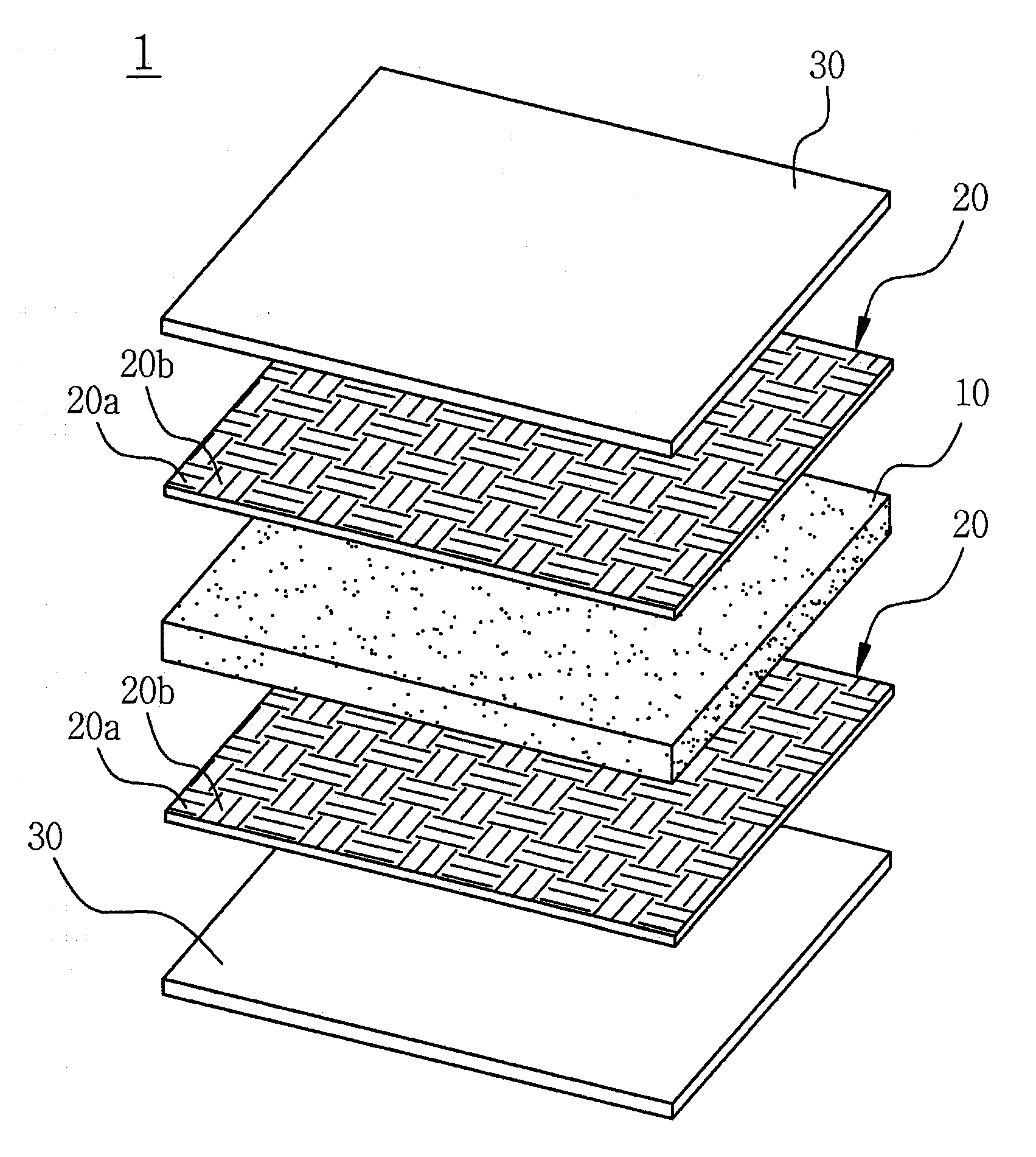

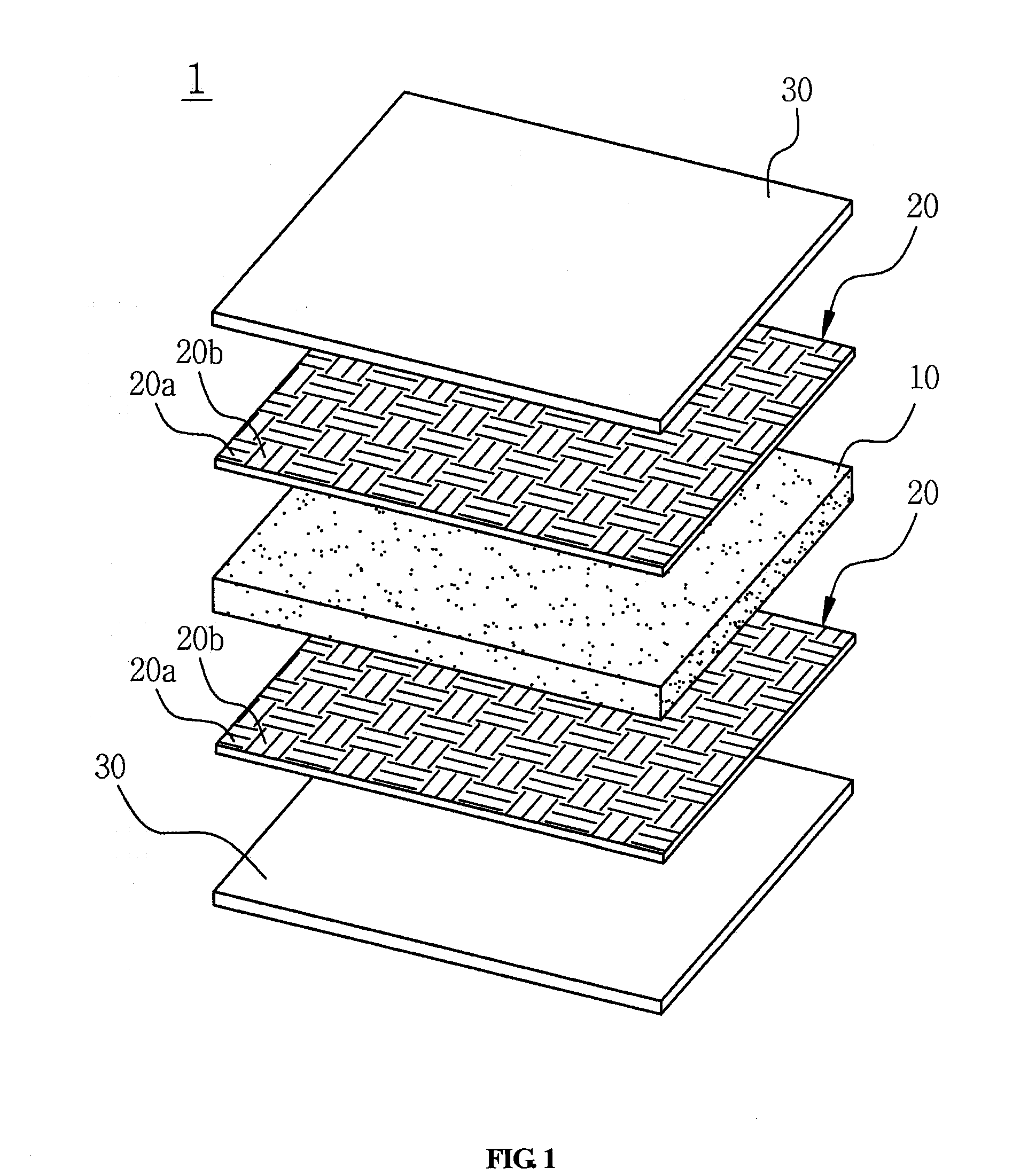

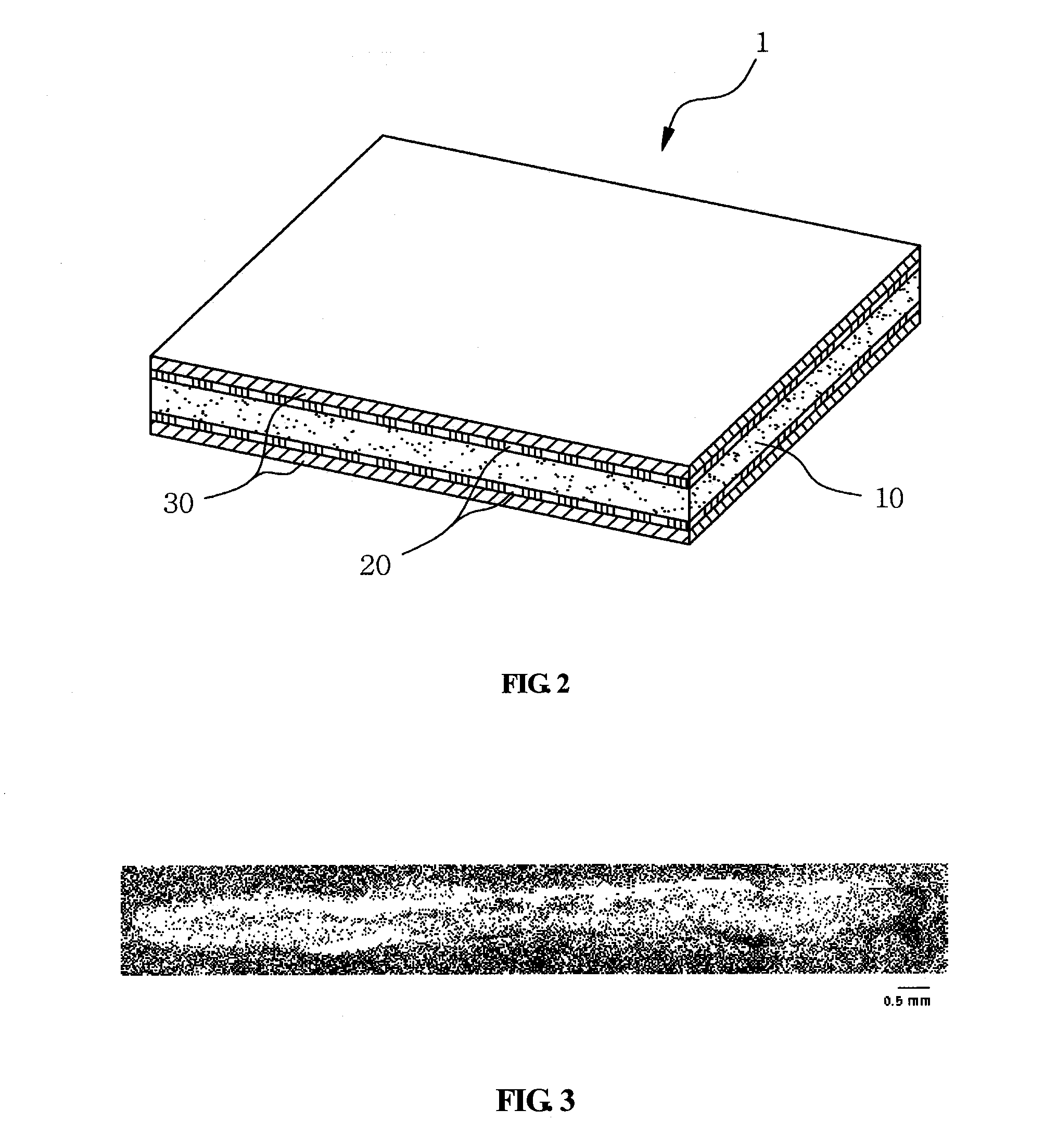

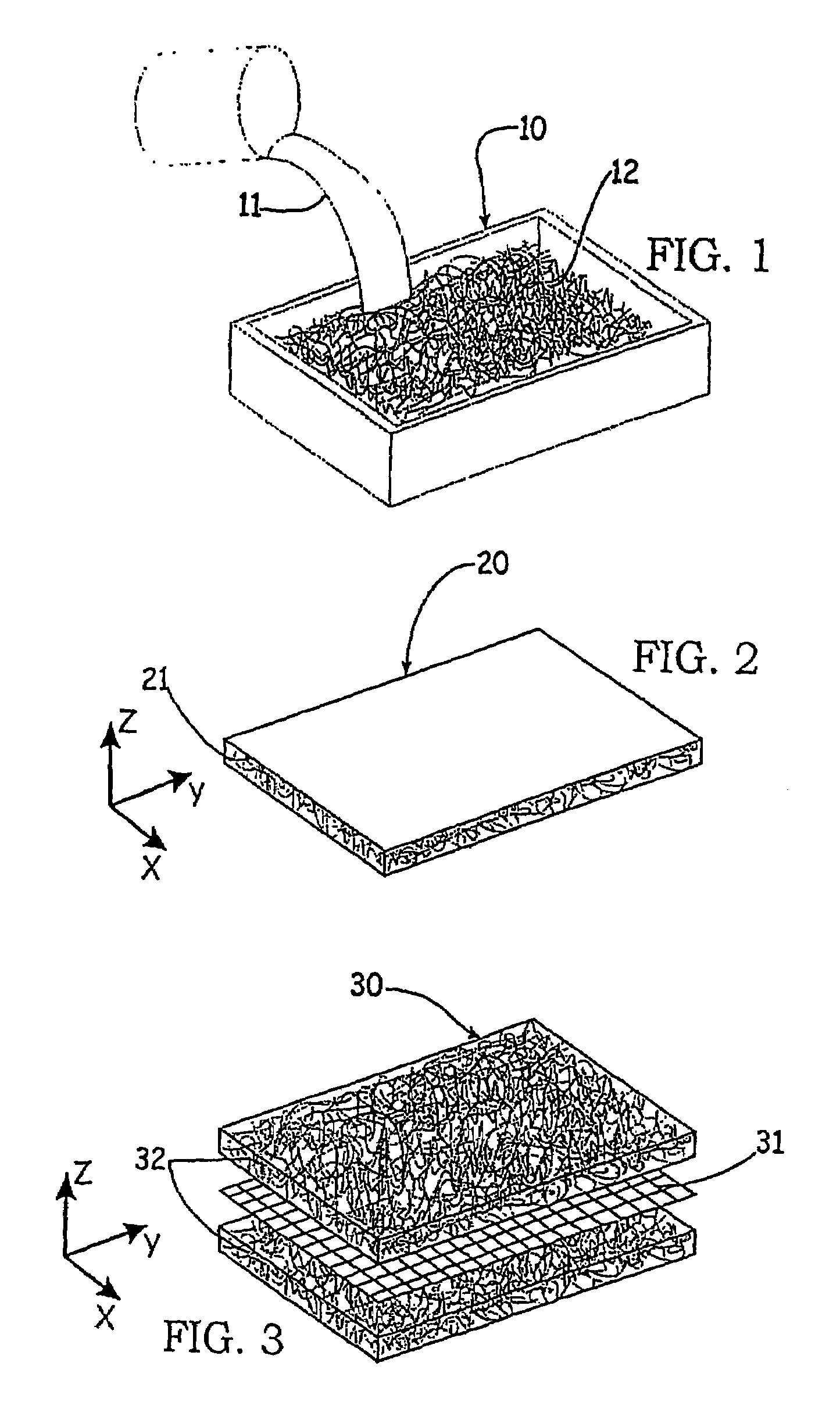

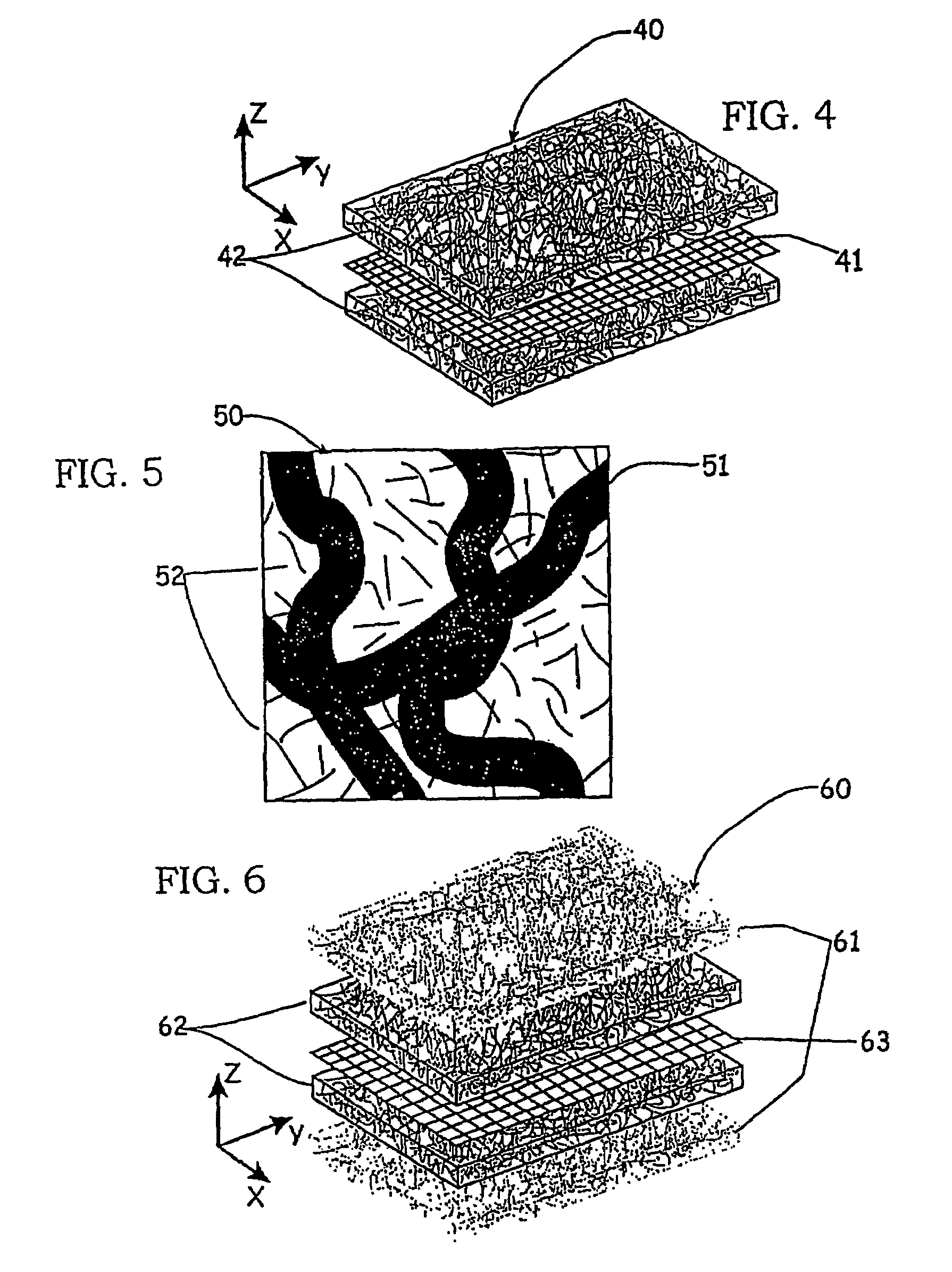

Thermoplastic Compound Plate-Shaped Material, Method For Manufacturing And Articles Manufactured Using The Same

InactiveUS20070202314A1Excellent in not mechanical propertySynthetic resin layered productsBuilding componentsFlexural strengthThermal expansion

The present invention relates to a recyclable thermoplastic composite sheet which is excellent in mechanical properties, such as bending strength, bending elastic modulus, impact strength and linear thermal expansion coefficient, and also in secondary processability, and suitable for molding into various structures, such as panels for use as building materials, and automobile parts, as well as a manufacturing method thereof and an article manufactured therefrom. The sheet comprises: a center layer of a thermoplastic composite material comprising 40% by weight of reinforcing fibers with an average length of 1-30 mm and 60% by weight of a thermoplastic resin containing an organic filler; and a continuous reinforcing fiber-impregnated prepreg layer laminated on at least one surface of the upper surface and lower surface of the center layer, the prepreg layer comprising 5-65% by weight of reinforcing fibers and 35-95% by weight of a thermoplastic resin containing a small amount of inorganic filler.

Owner:SAMBARK

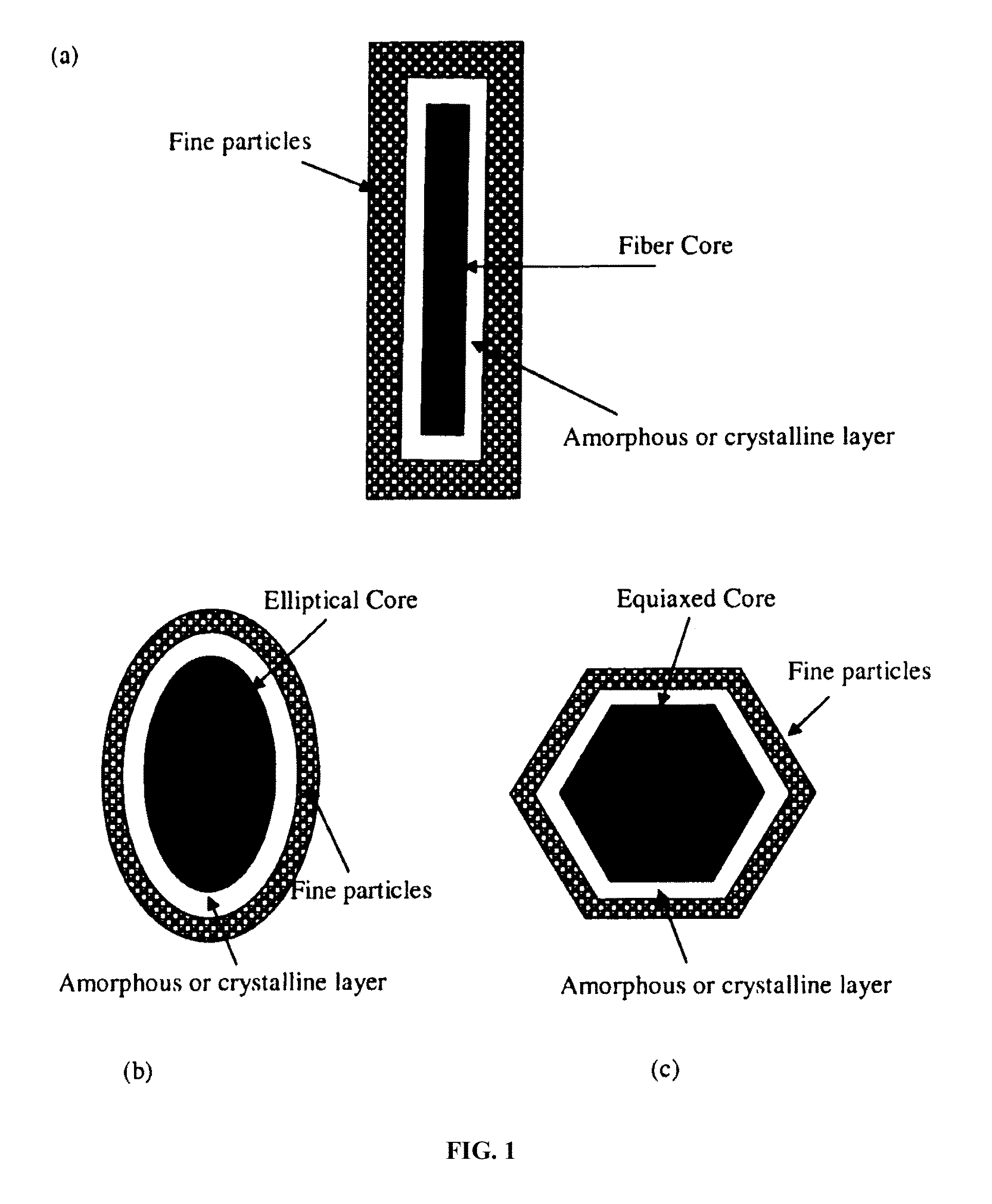

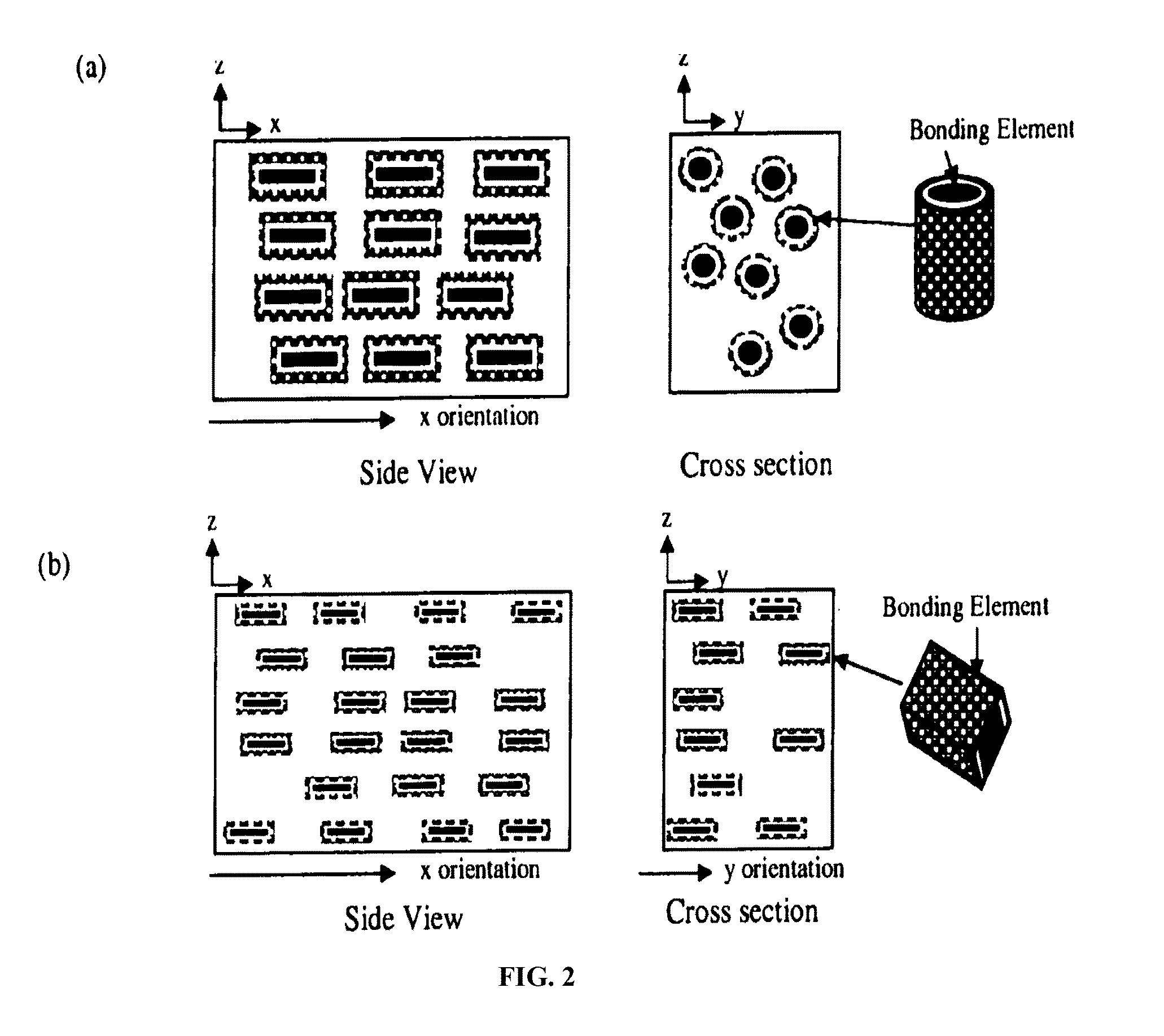

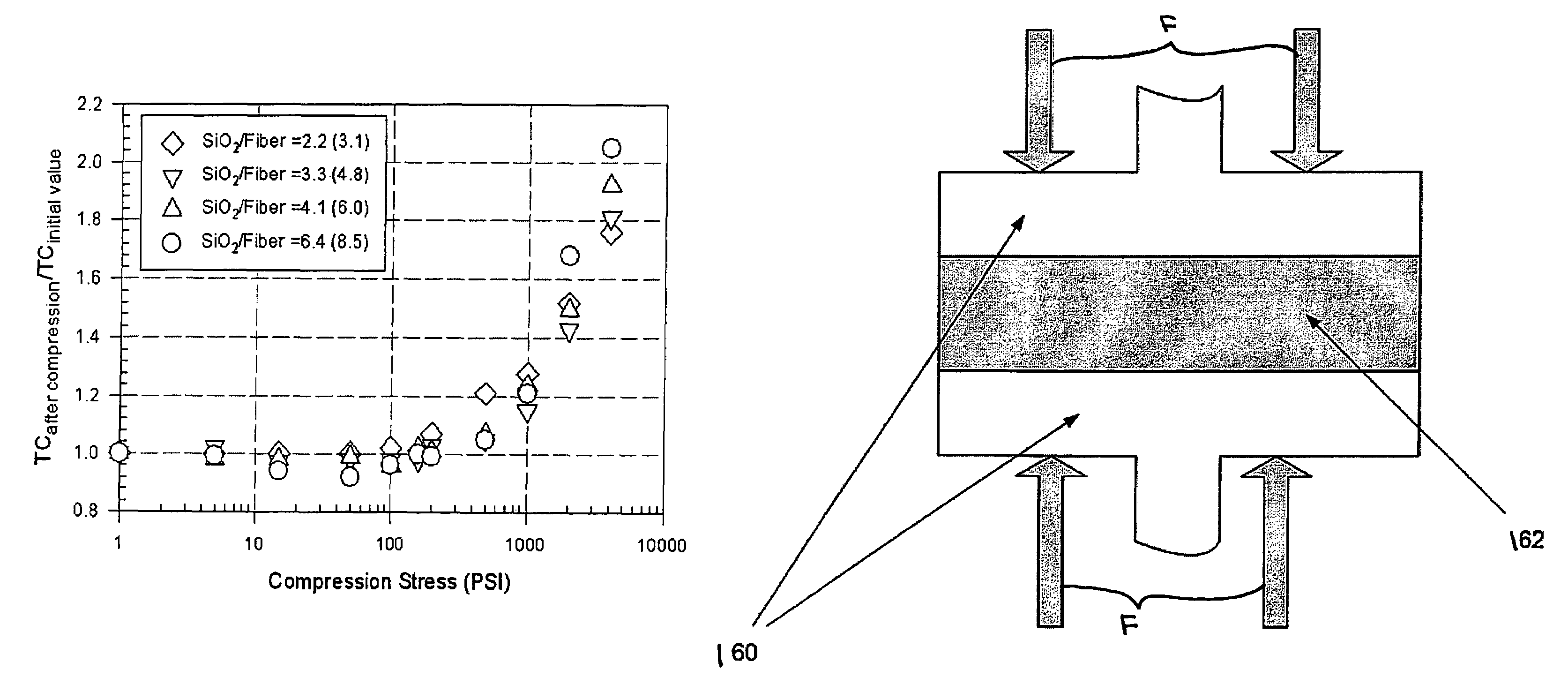

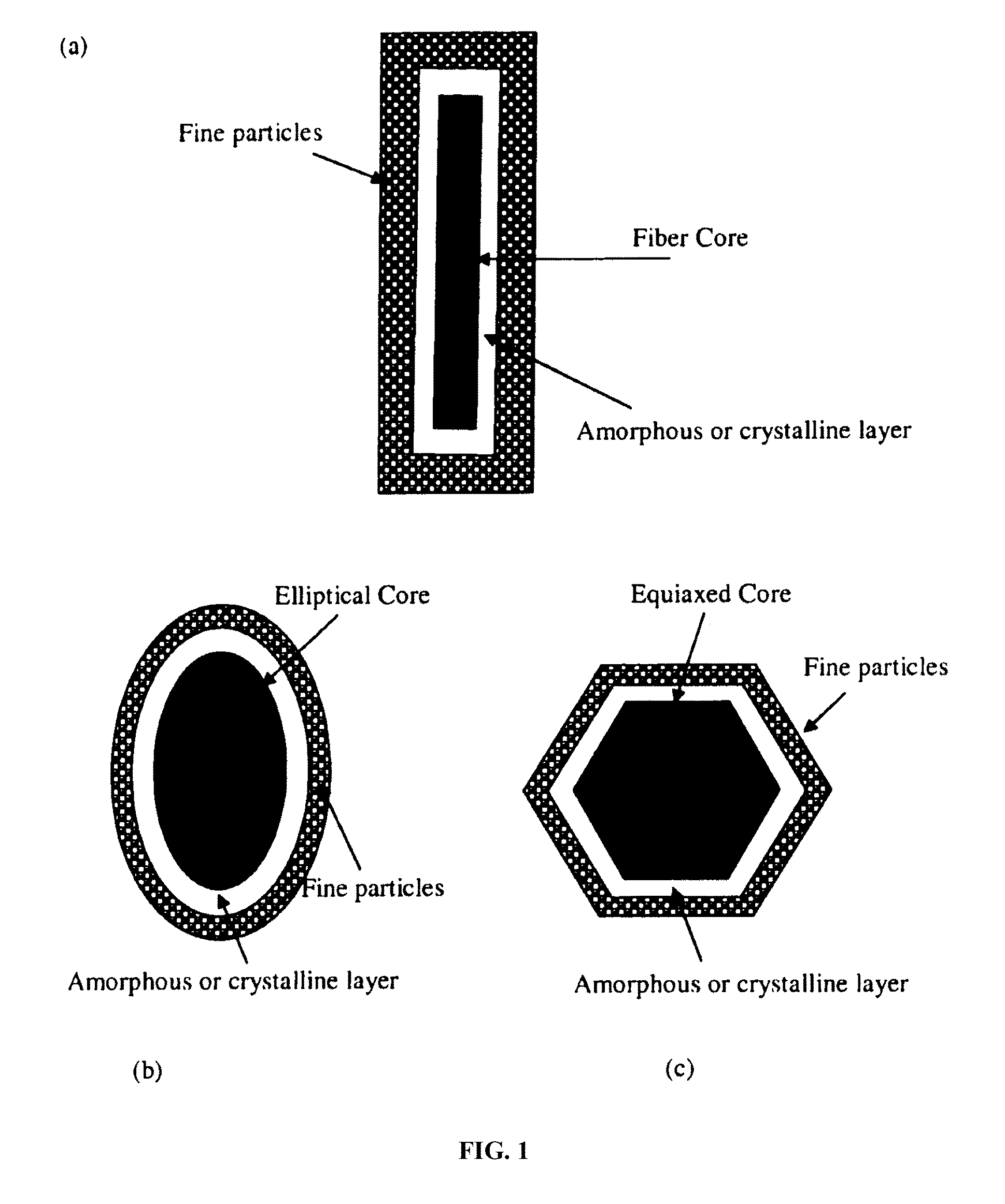

High strength, nanoporous bodies reinforced with fibrous materials

ActiveUS7560062B2High modulusHigh strengthLayered productsOrnamental structuresFlexural strengthHigh intensity

This invention discloses improvements that can be achieved in thermal or mechanical performance of aerogel composites via densification. Densified aerogels and aerogel composites can display higher compressive strength, modulus, flexural strength, and maintains or insubstantially increases the thermal conductivity relative to the pre-densified form. In the special case of fiber reinforced aerogel composites densification via mechanical compression can prove highly beneficial.

Owner:ASPEN AEROGELS INC

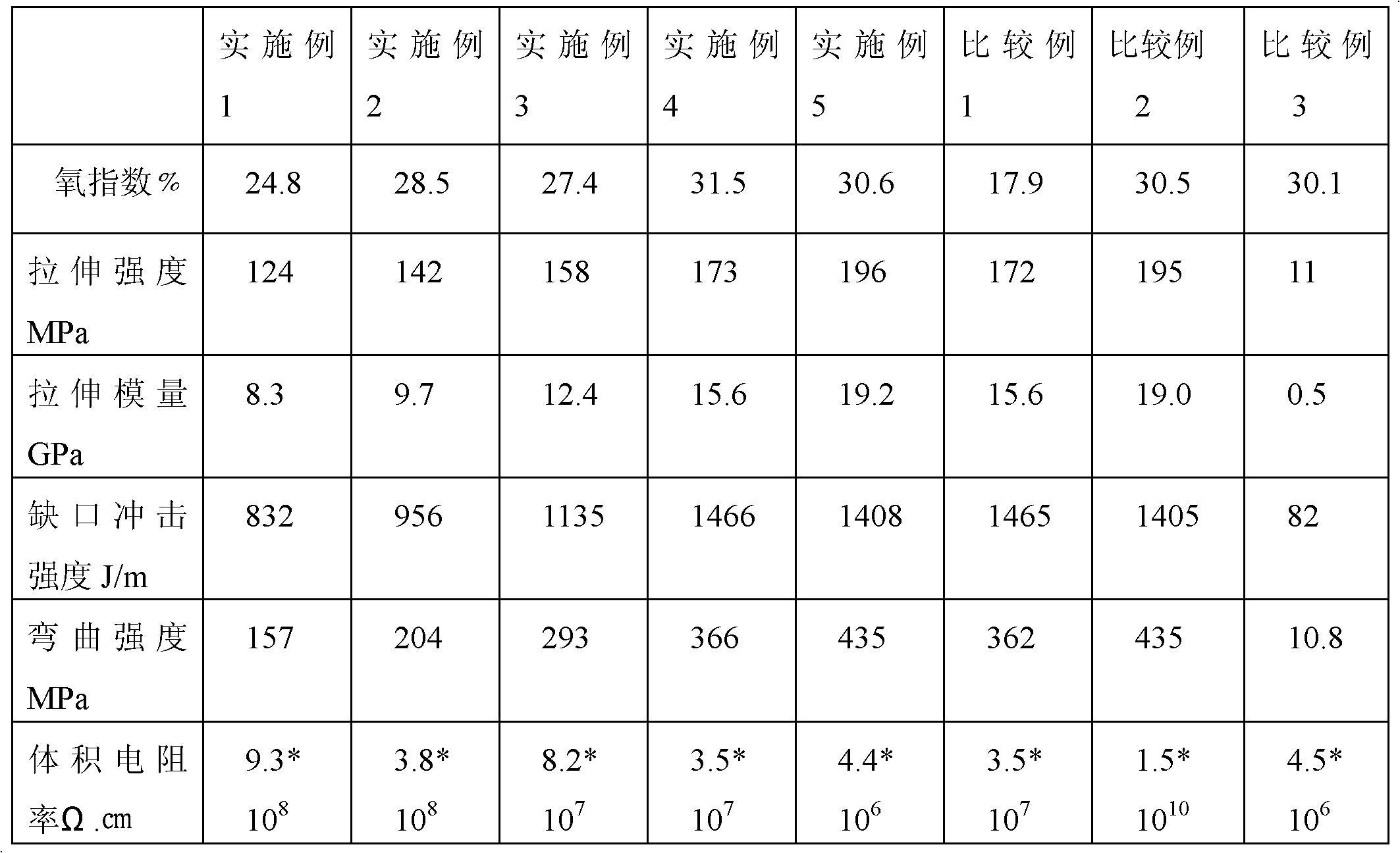

Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

The invention belongs to polymer modification technical field and processing technology field, and discloses a flame-retardant antistatic high-strength thermoplastic composite material and its preparation method. The material comprises (by weight share) 80-100 thermoplastic resin, 50-120 reinforcing fiber, 8-18 flame retardant, 0-5 flame retardant synergistic agent, 0.5-1.8 antistatic agent, 15-30 compatibilizer, 4-10 composite antioxidants, and 0-80 other additives. The invention also discloses the thermoplastic composite material preparation method. The inventive lame-retardant antistatic high-strength thermoplastic composite material has high tension and bending strength, high impact resistance property at low and high temperature, obvious antistatic property, high flame-retardant and fire proof performance. It can reach UL-94 V-O level standard.

Owner:杭州电力设备制造有限公司建德冠源成套电气制造分公司

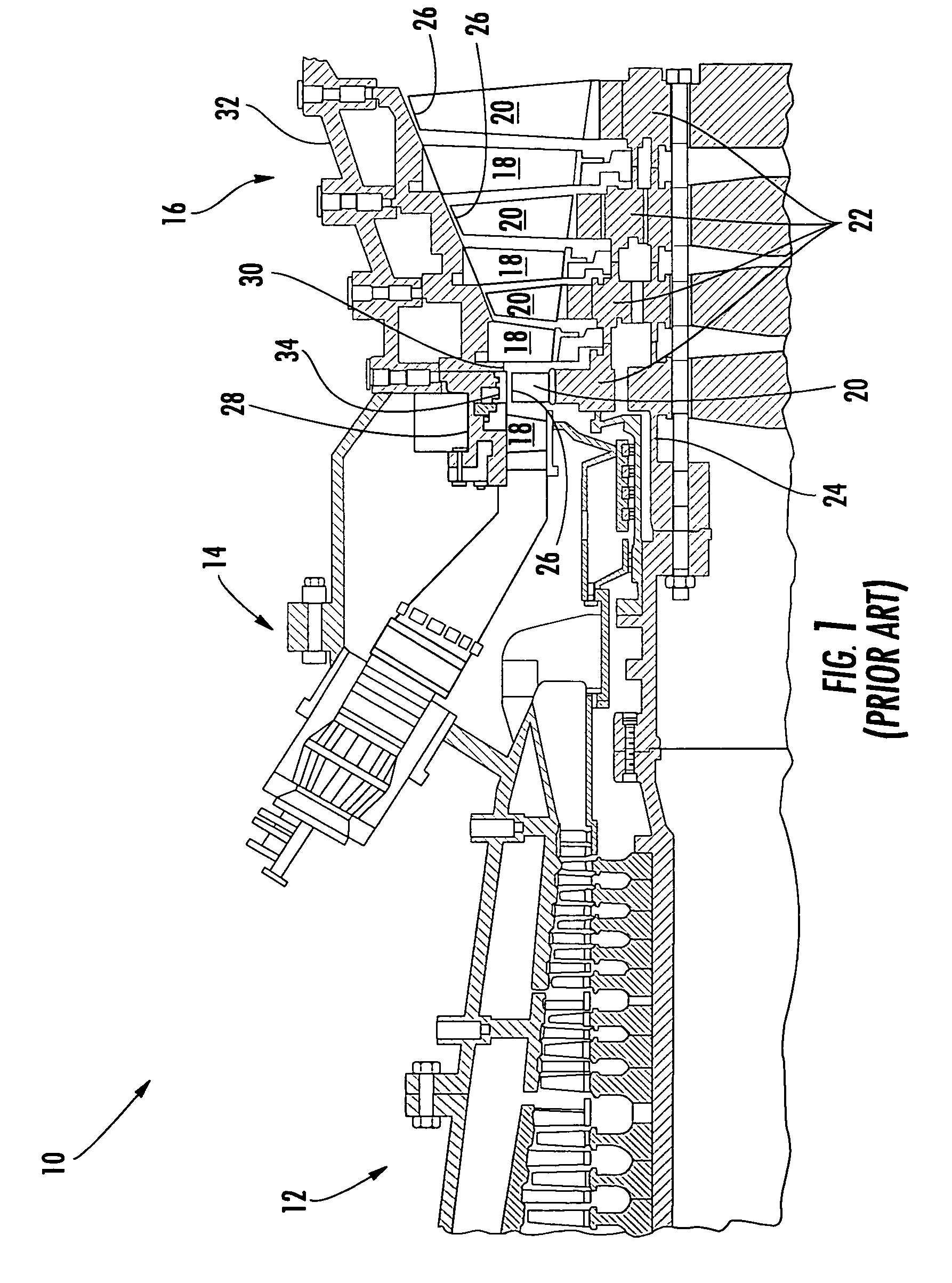

Ceramic matrix composite turbine engine components with unitary stiffening frame

Owner:SIEMENS ENERGY INC

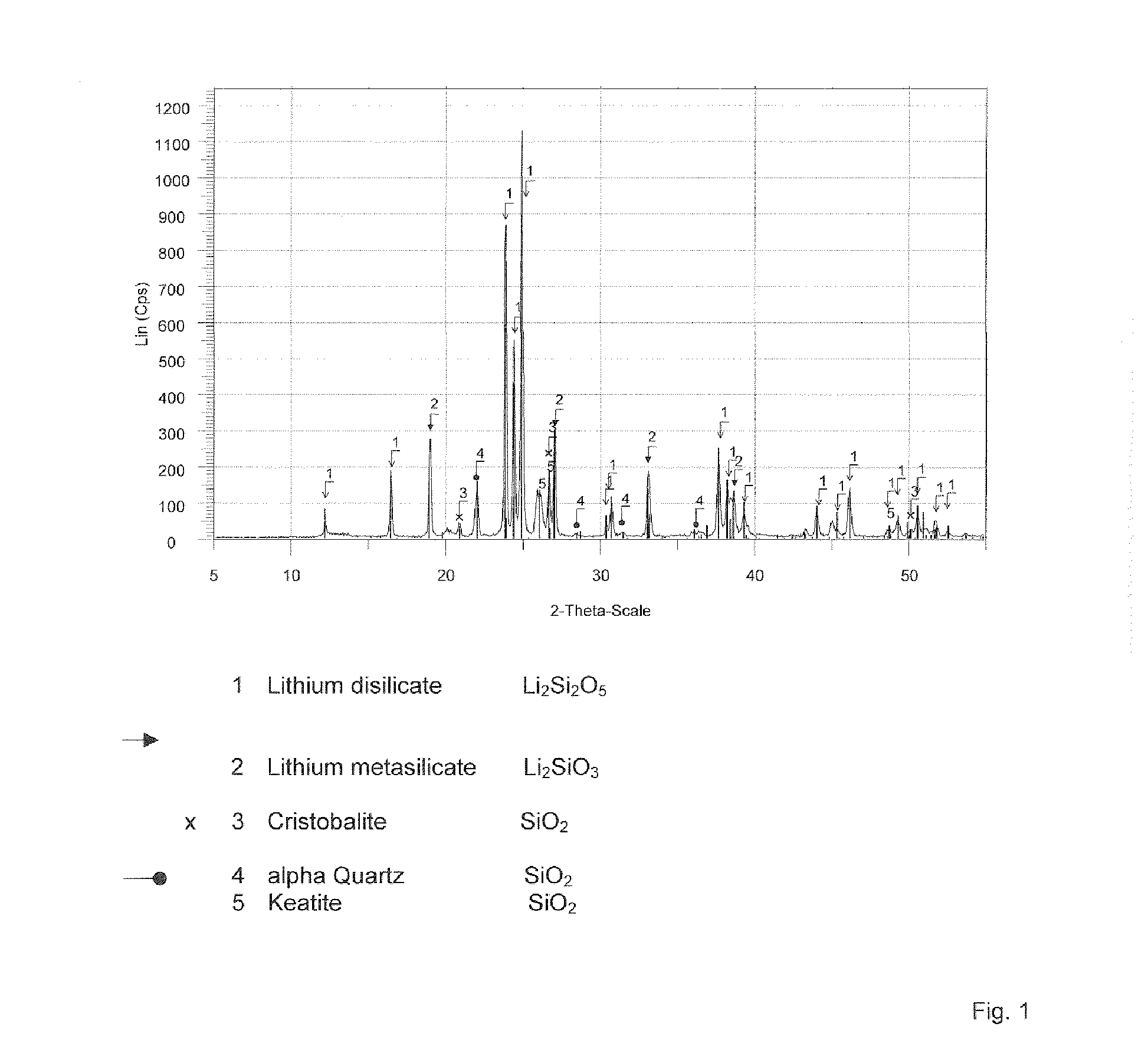

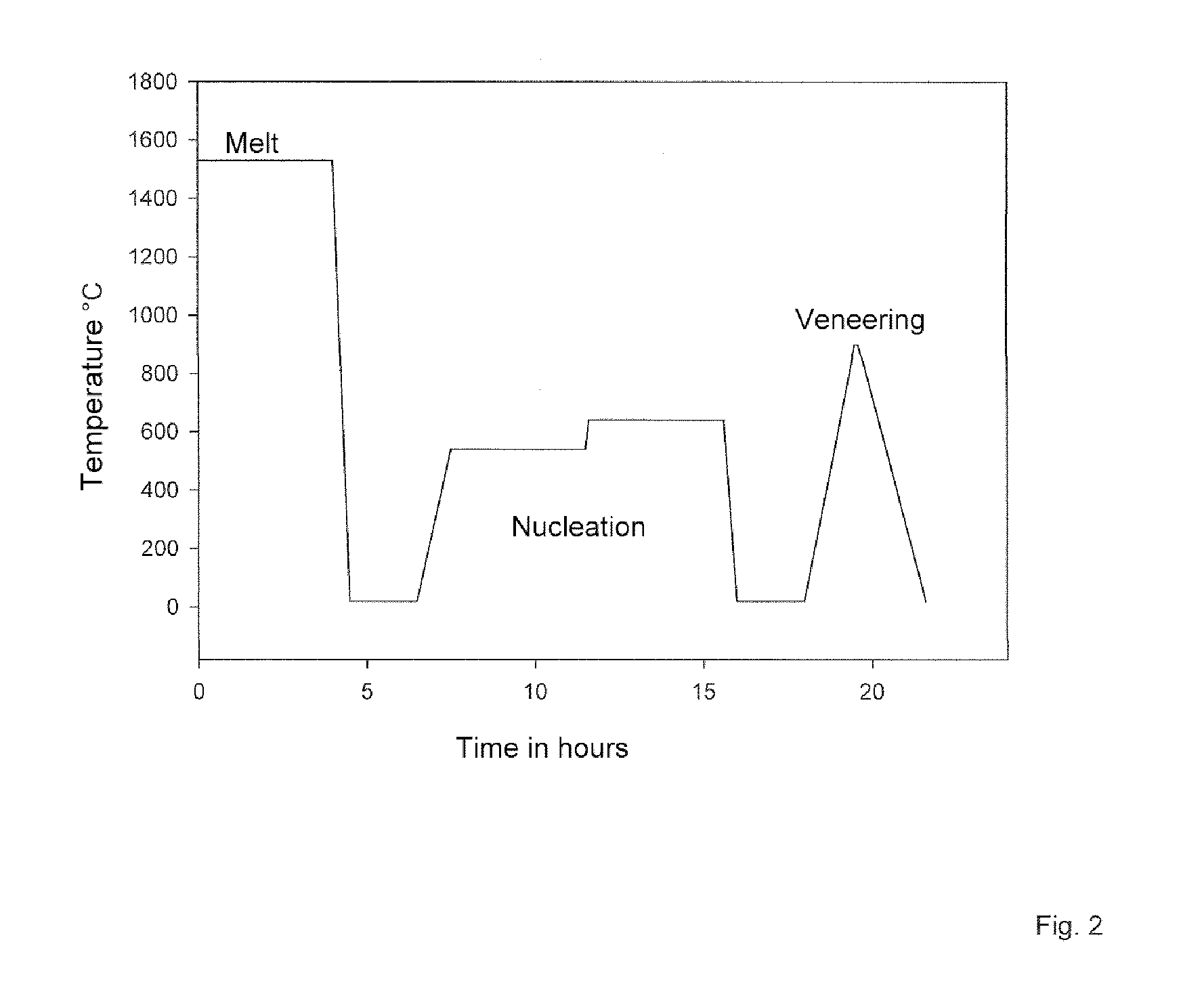

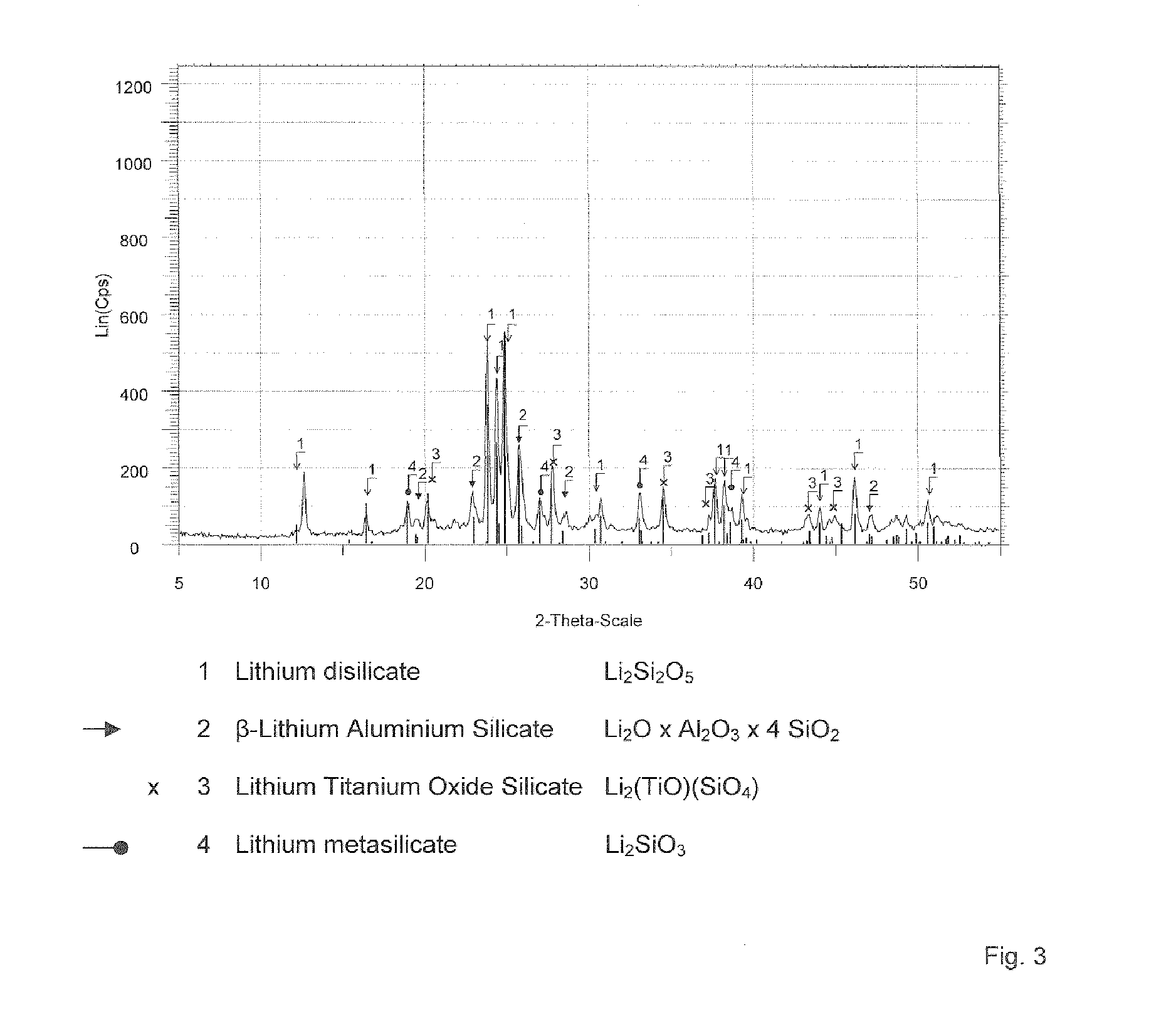

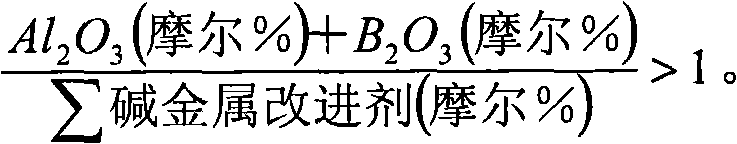

Veneer Ceramic for Dental Restorations and Method for Veneering Dental Restorations

ActiveUS20110030423A1Improve flexural strengthImprove adhesionDental implantsImpression capsFlexural strengthYttrium

The invention is directed to veneer ceramics for dental restorations of framework ceramics comprising yttrium-stabilized zirconium dioxide. It is the object of the invention to make possible a translucent veneer ceramic which has high flexural strength as well as excellent adhesion to the framework ceramic of yttrium-stabilized zirconium dioxide. According to the invention, this object is met in a veneer ceramic for dental restorations made of yttrium-stabilized zirconium dioxide which is produced from the following components:a)SiO258.0-74.0 percent by weightb) Al2O3 4.0-19.0 percent by weightc)Li2O 5.0-17.0 percent by weightd)Na2O 4.0-12.0 percent by weighte) ZrO2 0.5-6.0 percent by weight.

Owner:IVOCLAR VIVADENT AG

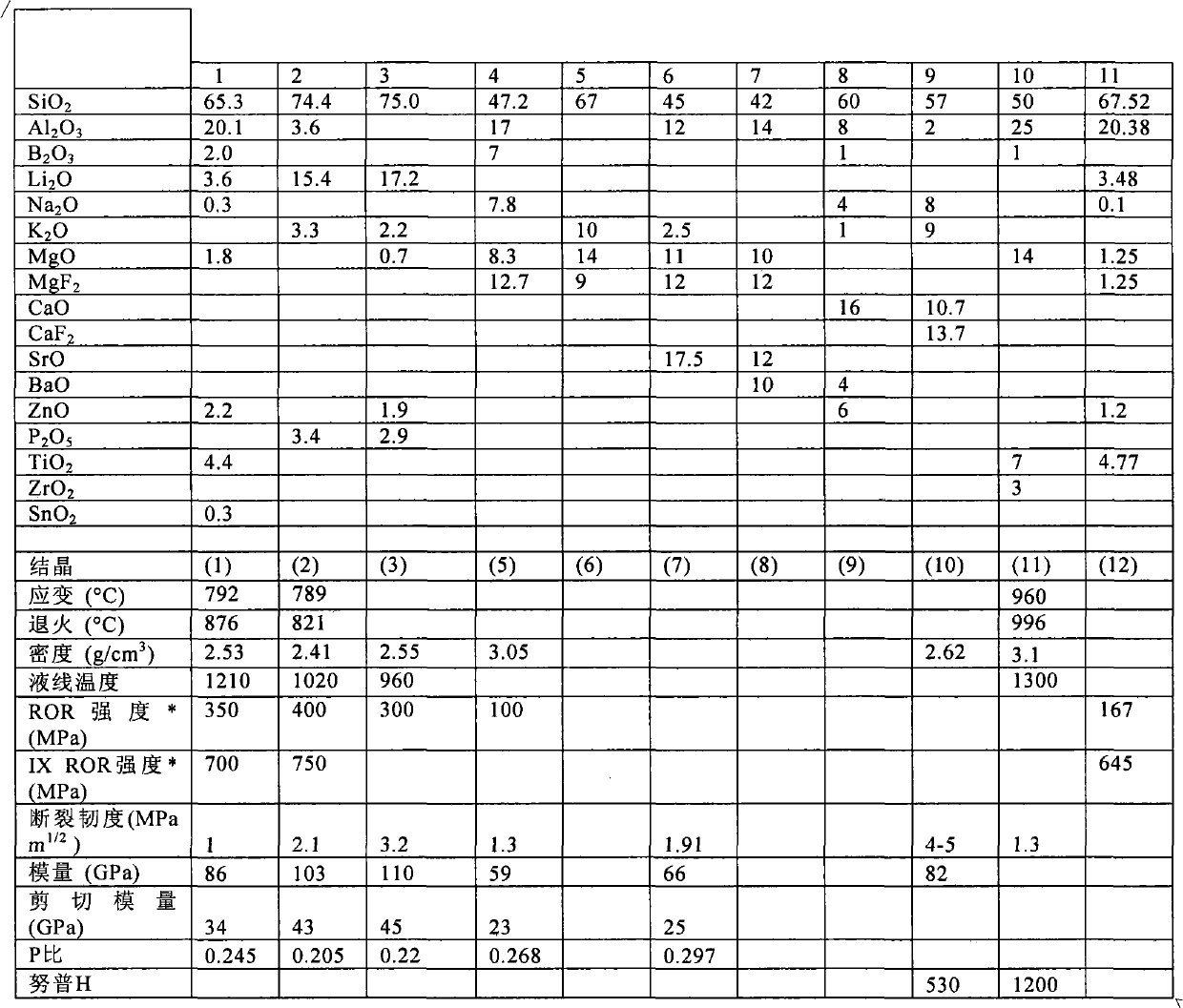

Durable glass-ceramic housings/enclosures for electronic devices

The invention relates glass ceramic articles suitable for use as electronic device housing or enclosures which comprise a glass-ceramic material. Particularly, a glass-ceramic article housing / enclosure comprising a glass-ceramic material exhibiting both radio and microwave frequency transparency, as defined by a loss tangent of less than 0.5 and at a frequency range of between 15 MHz to 3.0 GHz, a fracture toughness of greater than 1.5 MPam 1 / 2 , an equibiaxial flexural strength (ROR strength) of greater than 100 MPa, a Knoop hardness of at least 400 kg / mm2, a thermal conductivity of less than 4 W / m DEG C and a porosity of less than 0.1 %.

Owner:CORNING INC

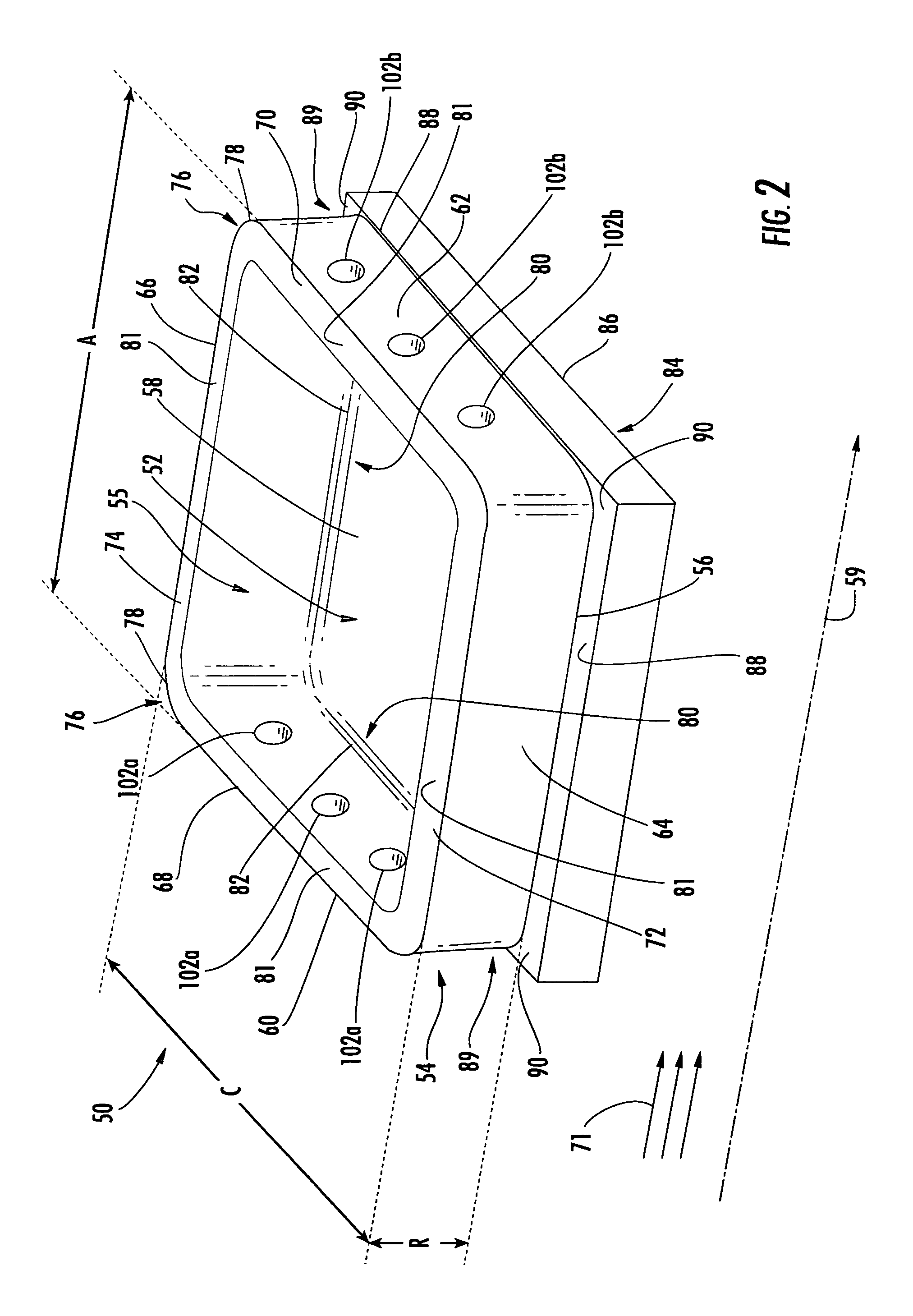

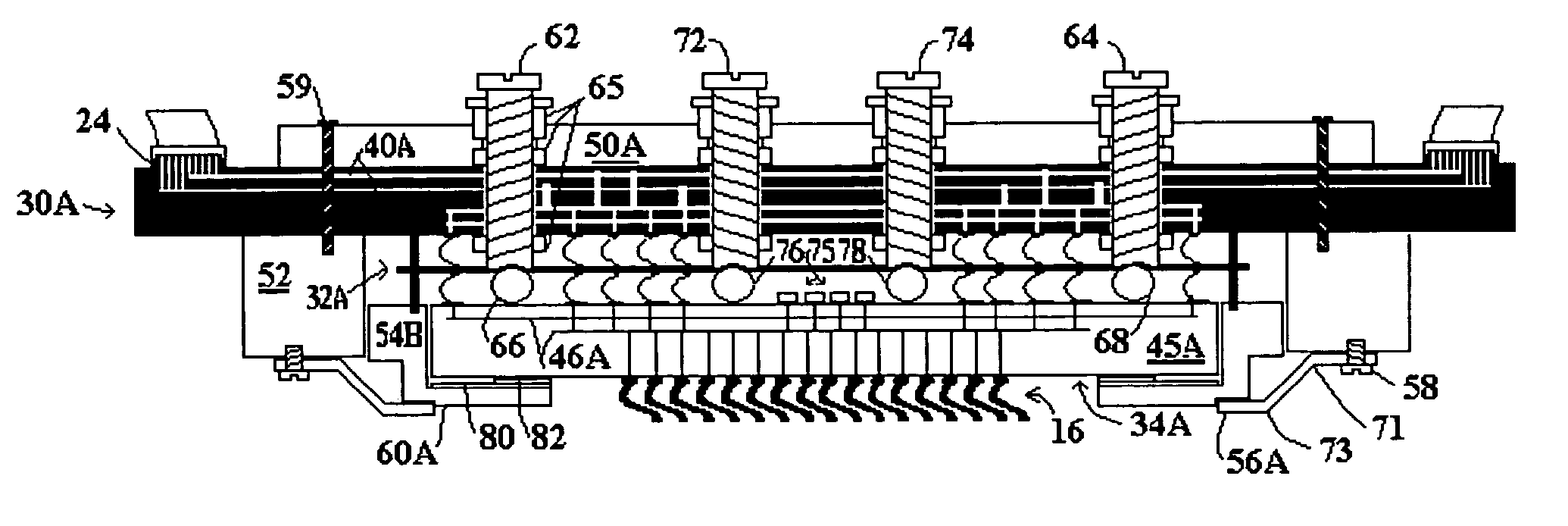

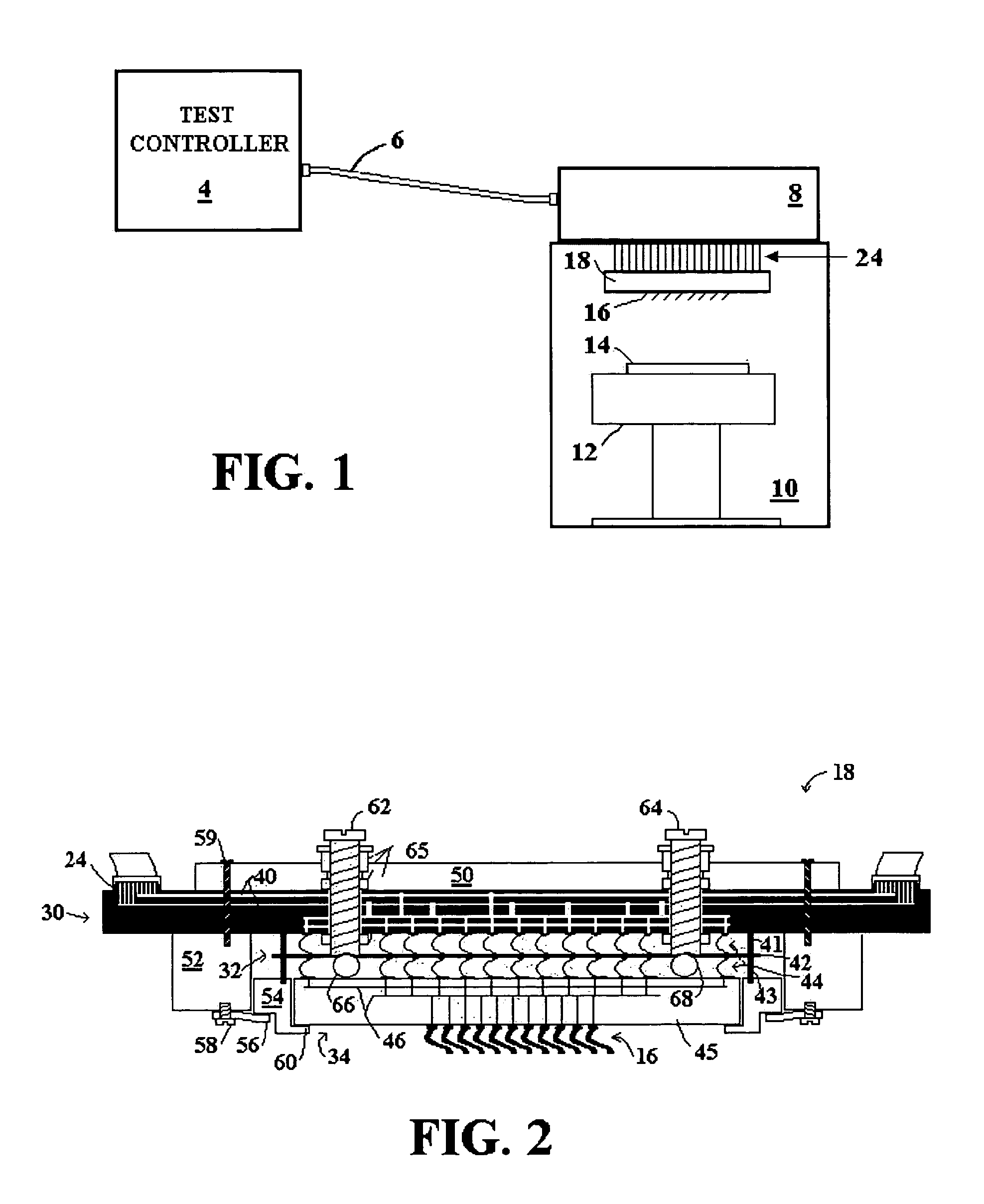

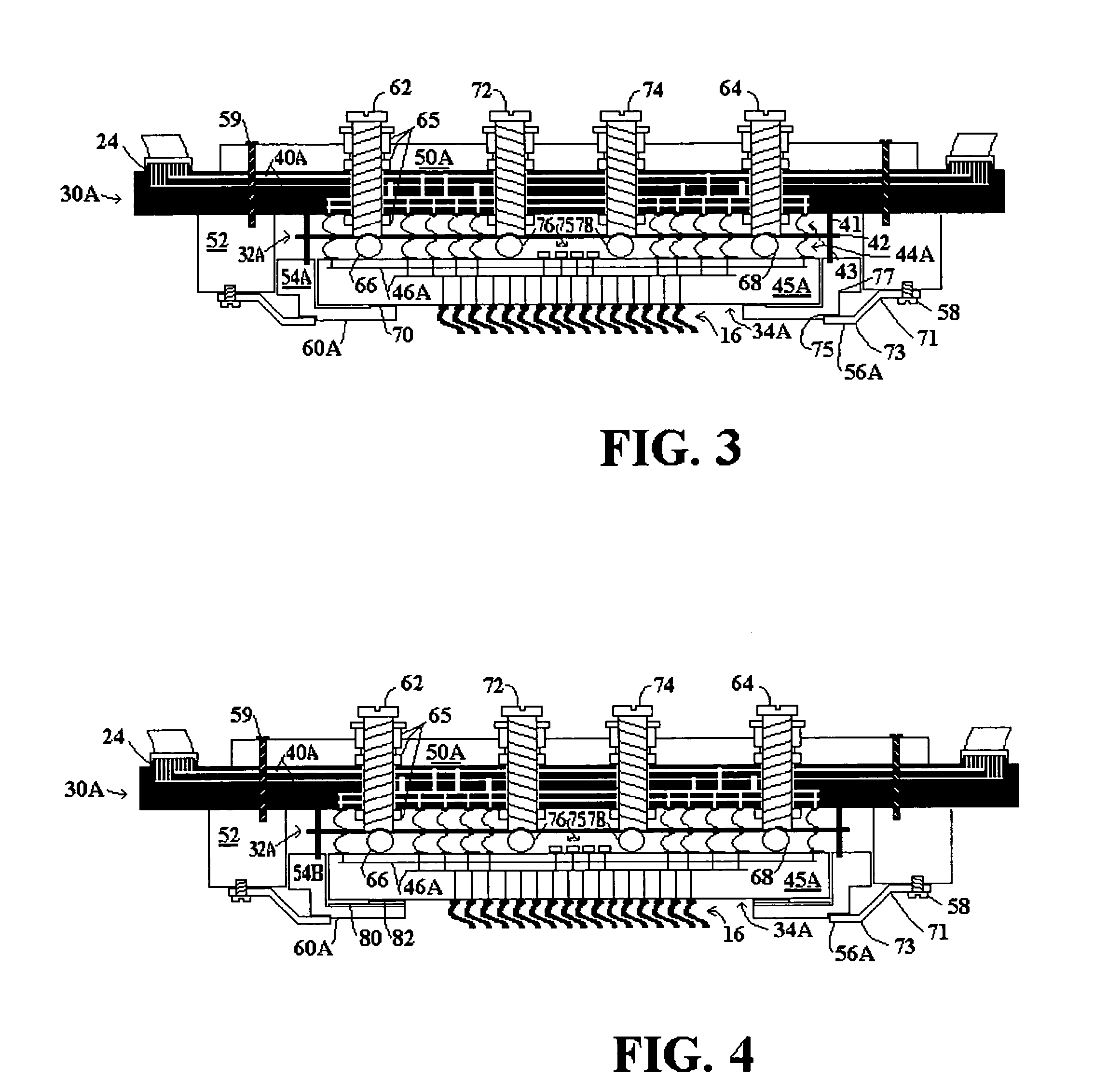

Probe card configuration for low mechanical flexural strength electrical routing substrates

InactiveUS7071715B2Add supportLow flexural stiffness/strength substrateSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardTransformer

A mechanical support configuration for a probe card of a wafer test system is provided to increase support for a very low flexural strength substrate that supports spring probes. Increased mechanical support is provided by: (1) a frame around the periphery of the substrate having an increased sized horizontal extension over the surface of the substrate; (2) leaf springs with a bend enabling the leaf springs to extend vertically and engage the inner frame closer to the spring probes; (3) an insulating flexible membrane, or load support member machined into the inner frame, to engage the low flexural strength substrate farther away from its edge; (4) a support structure, such as support pins, added to provide support to counteract probe loading near the center of the space transformer substrate; and / or (5) a highly rigid interface tile provided between the probes and a lower flexural strength space transformer substrate.

Owner:FORMFACTOR INC

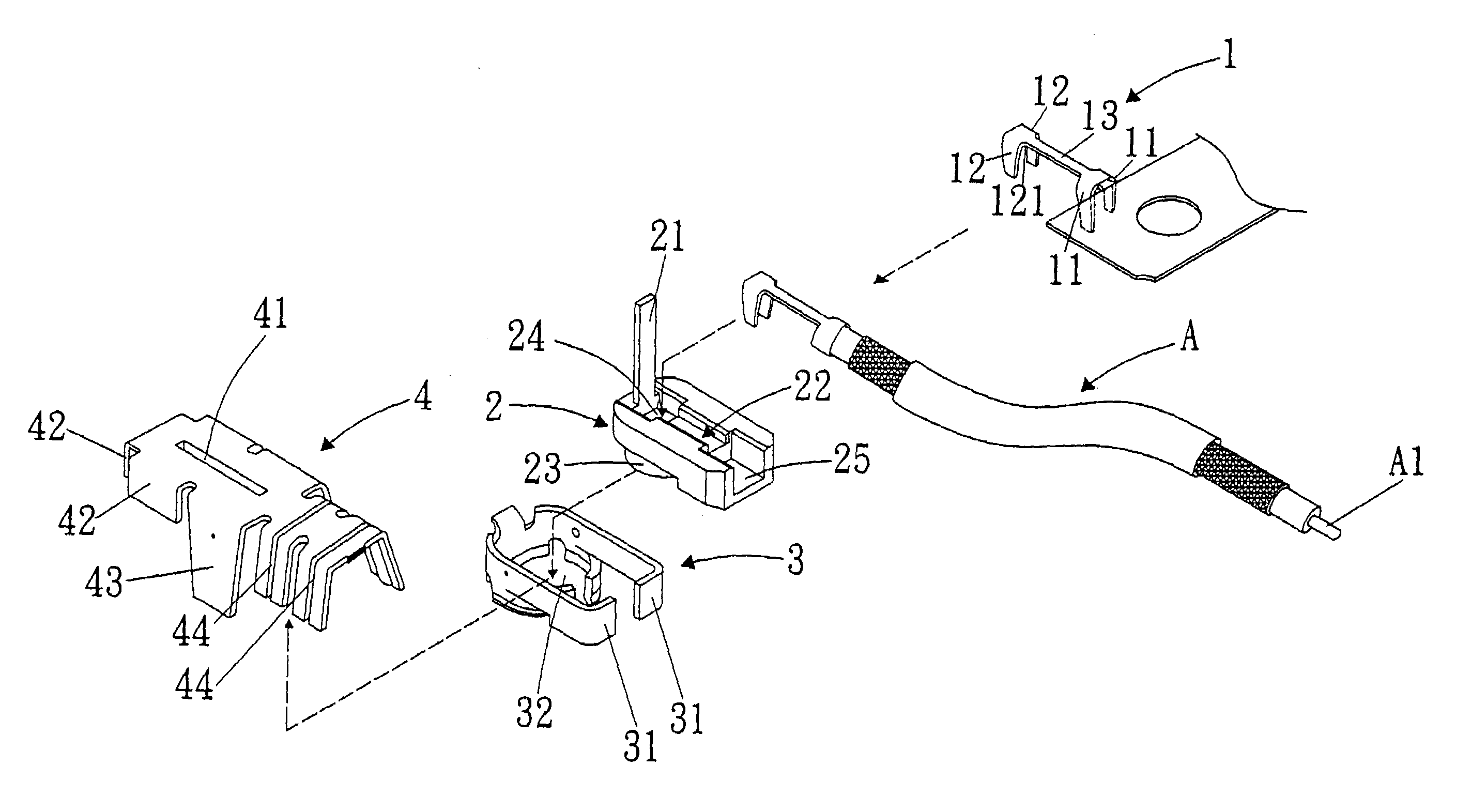

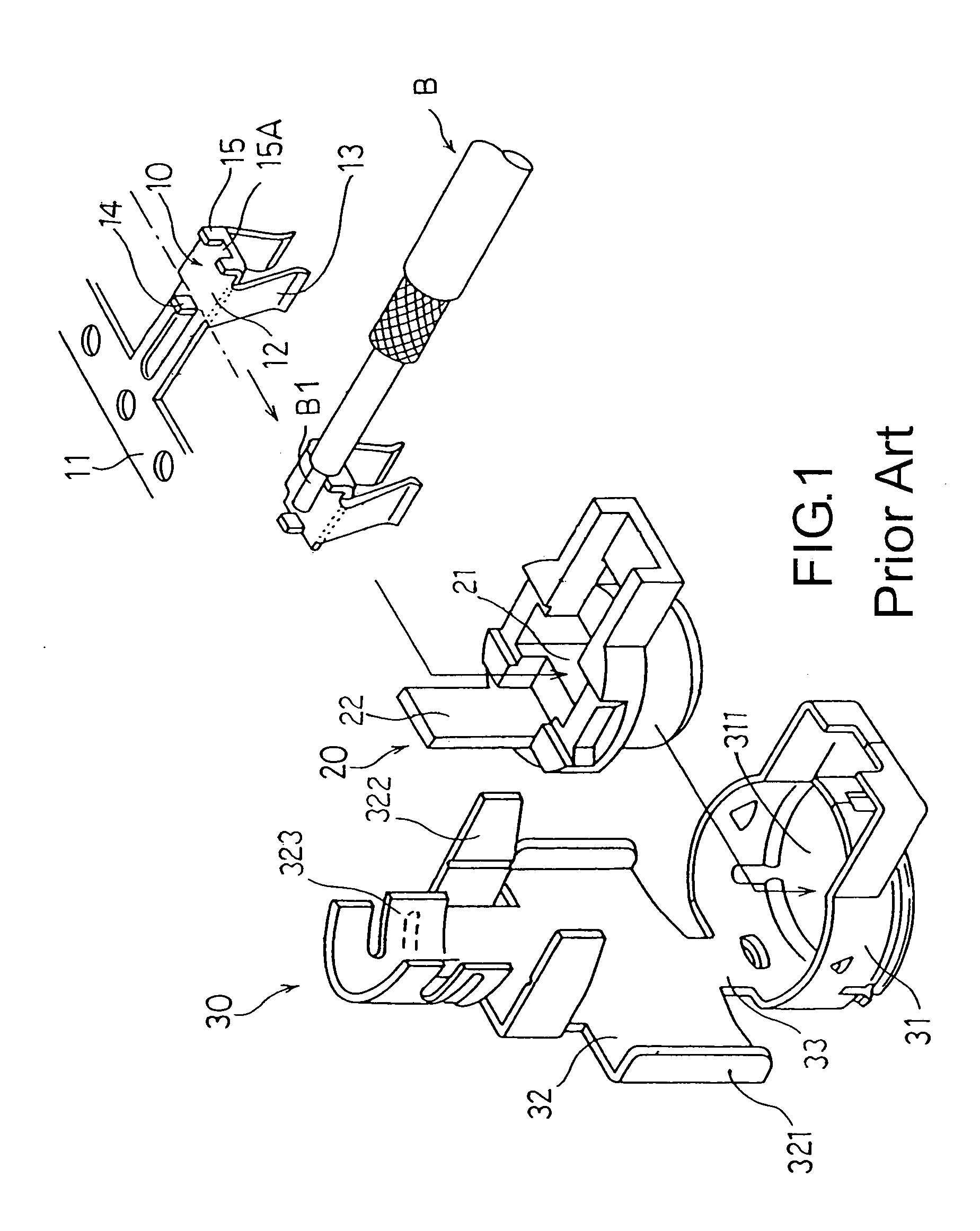

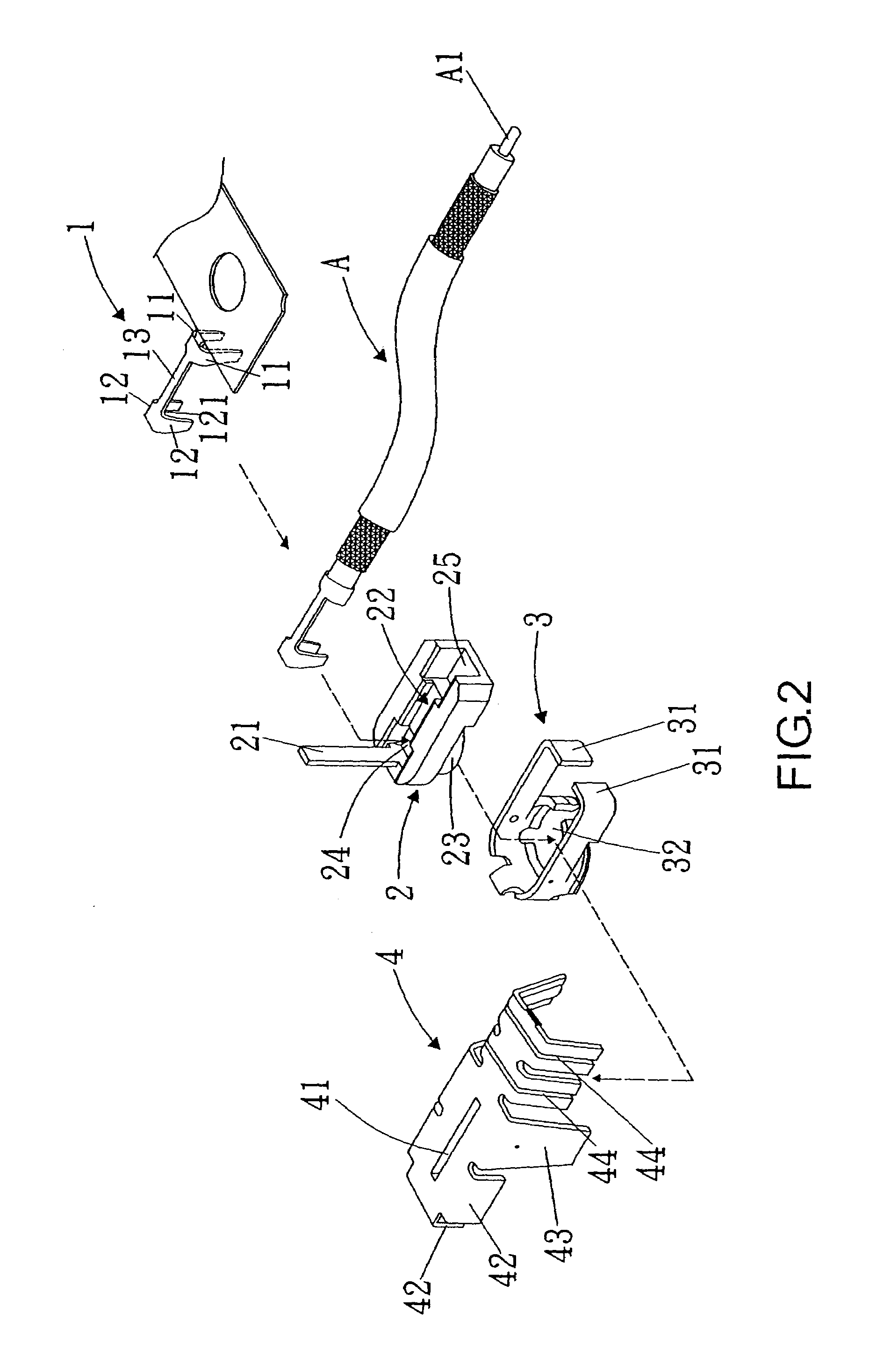

Micro coaxial connector

InactiveUS6971913B1Lower manufacturing requirementsIncrease productionElectrically conductive connectionsTwo pole connectionsCoaxial cableFlexural strength

The micro coaxial connector includes a signal terminal, a main body, and two grounding elements. The signal terminal has a pair of tag-like contact arms and bending arms at a front and rear end thereof, and a strip plane at a middle section thereof. The contact arms are for contacting with a base of a printed circuit board (PCB). The main body is for receiving the signal terminal and serving as an insulation. The two grounding elements are separated designs. The cylindrical-shaped first grounding element is for receiving and fastening the main body, and has a pair of extension arms for providing the coaxial cable with suitable clamping forces. The second grounding element is a cover-like body, and has a strip-like projection for increasing strength against bending of the second grounding element and preventing loosening of components.

Owner:SPEED TECH

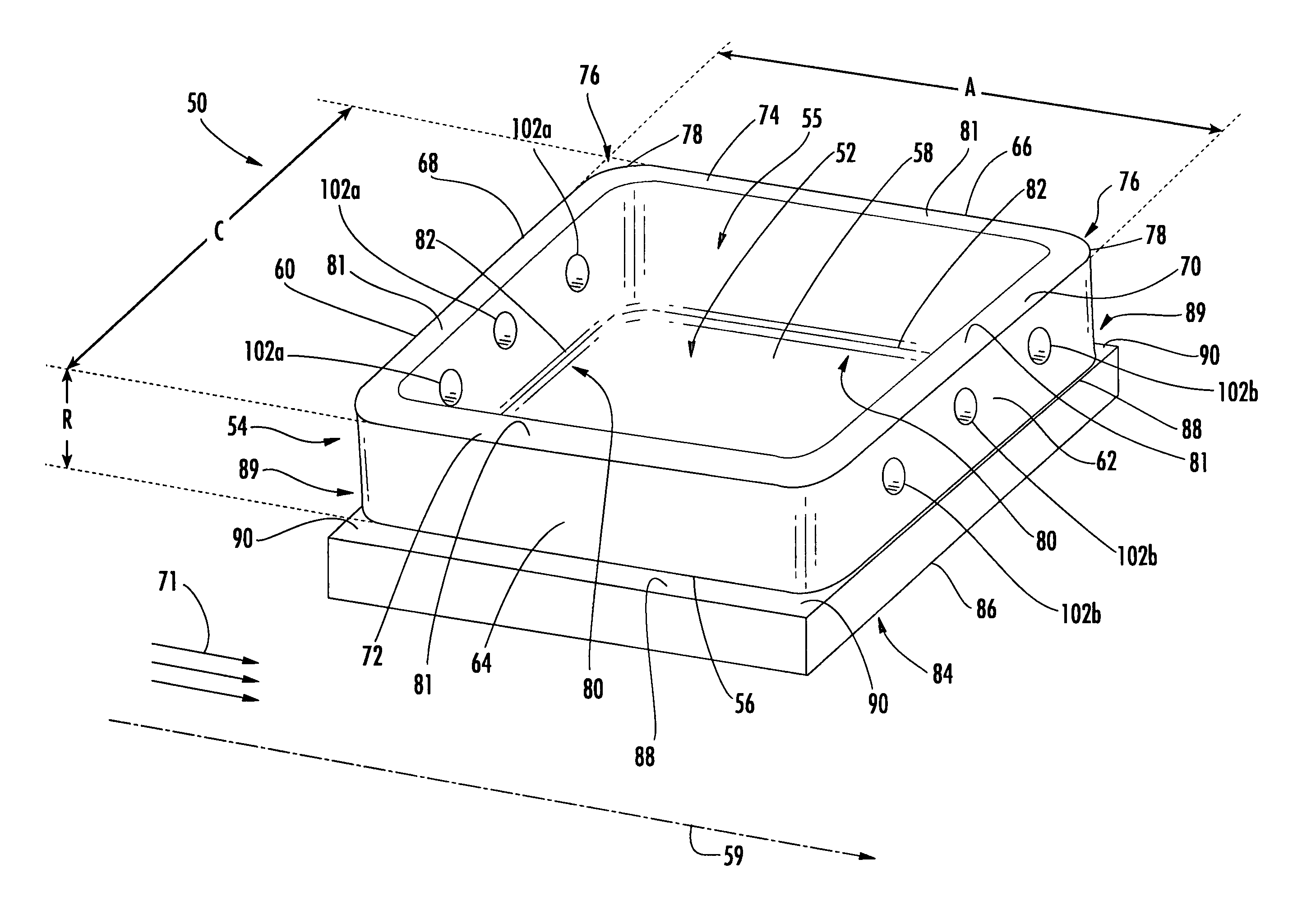

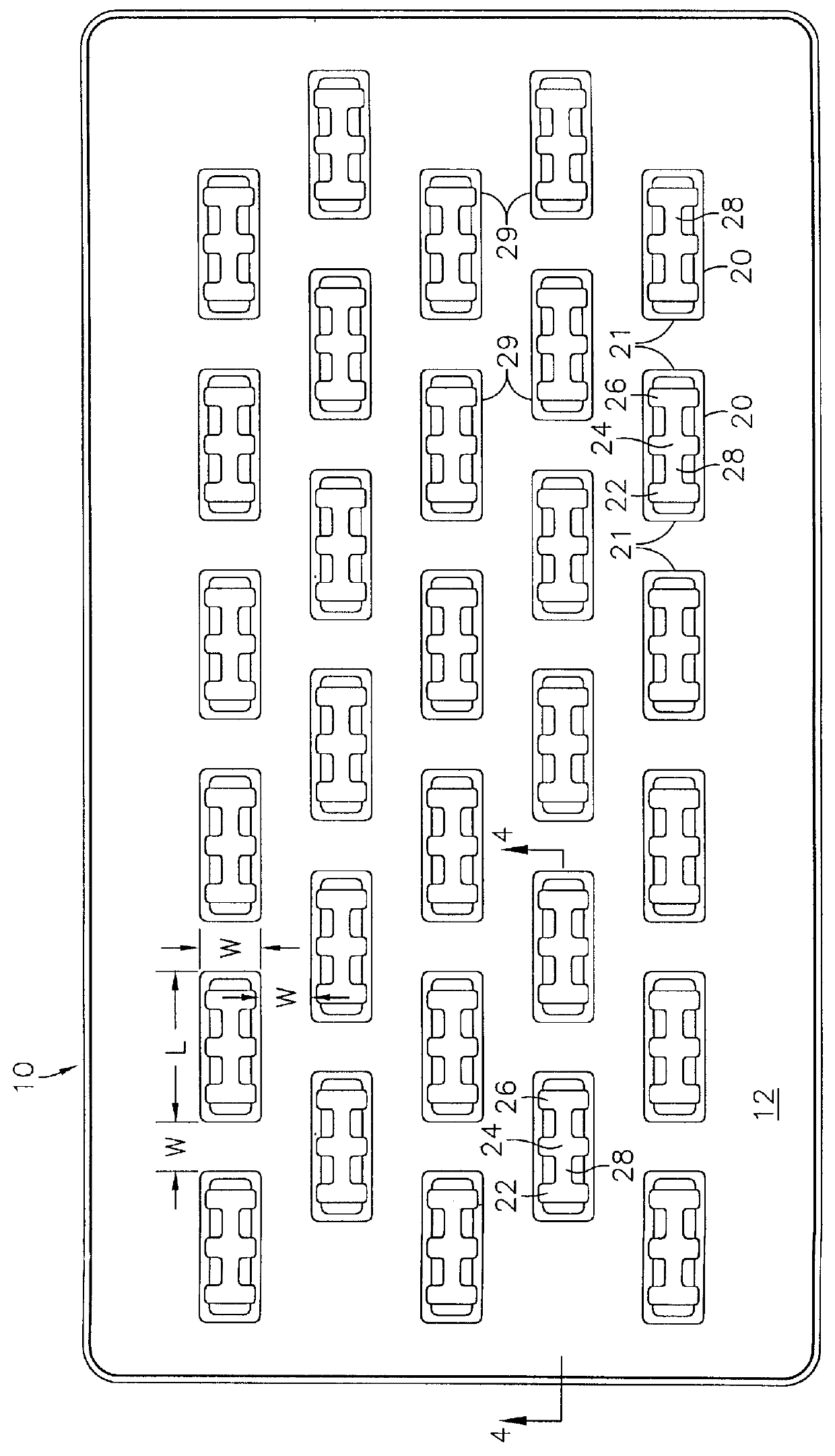

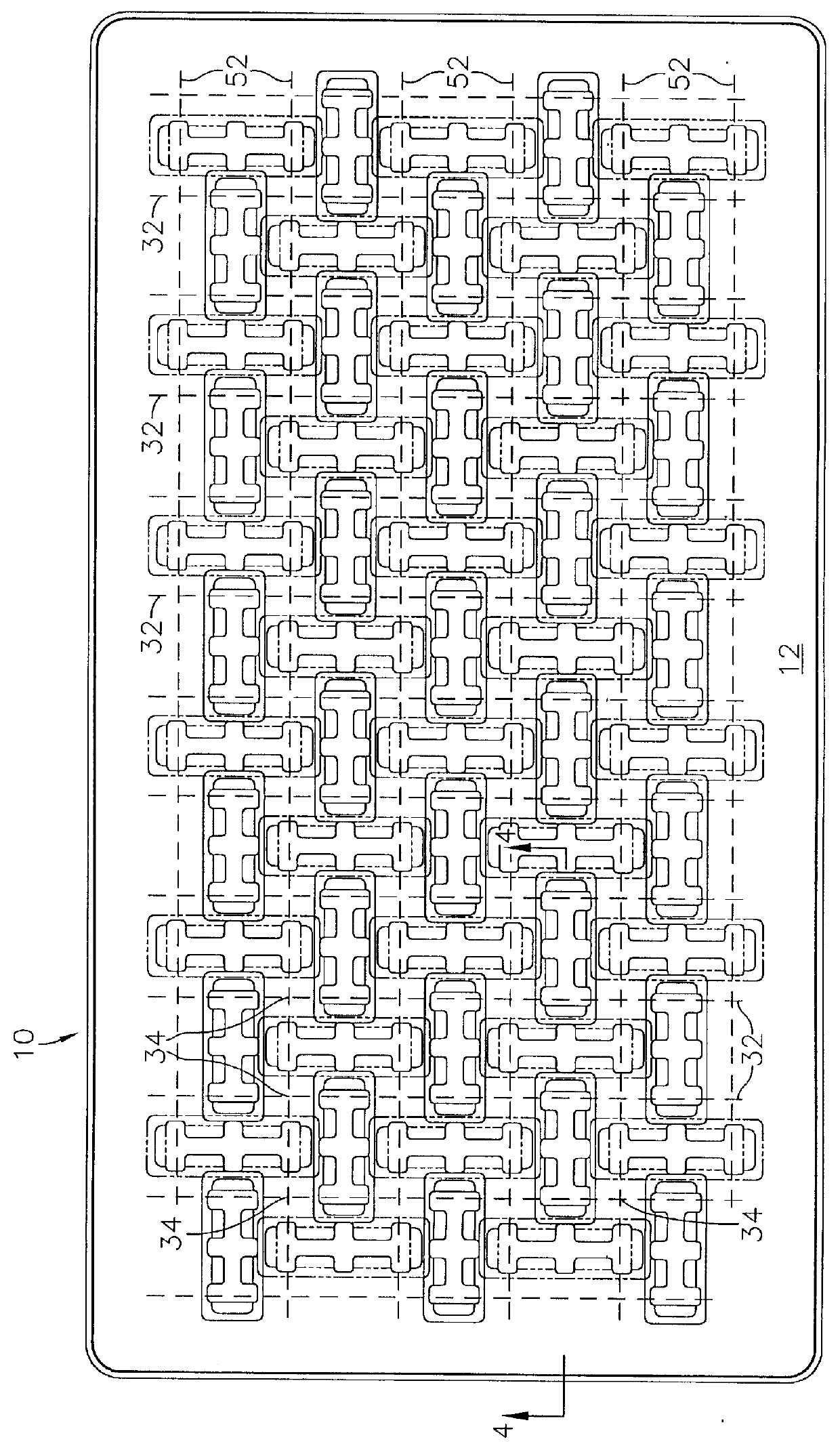

Thermoformed twin-sheet panel

InactiveUS6018927AImprove cooling effectConstruction materialLayered productsFlexural strengthEngineering

A structural, load bearing panel is fabricated with twin-sheets of thermoformed polymer material to provide-substantially equal bending strength about each of substantially normal polar moment axes. Parallel rows of generally rectangular depressions in the top sheet surface are fused with a corresponding row pattern of depressions in the bottom sheet surface oriented substantially 90.degree. to the top sheet rows. End walls of top sheet depressions are fused with side walls of bottom sheet depressions. Conversely, end walls of bottom sheet depressions are fused with side walls of top sheet depressions. An orthogonal matrix of interconnected gas flow channels vent substantially all void spaces between the top and bottom sheets.

Owner:FORMALL

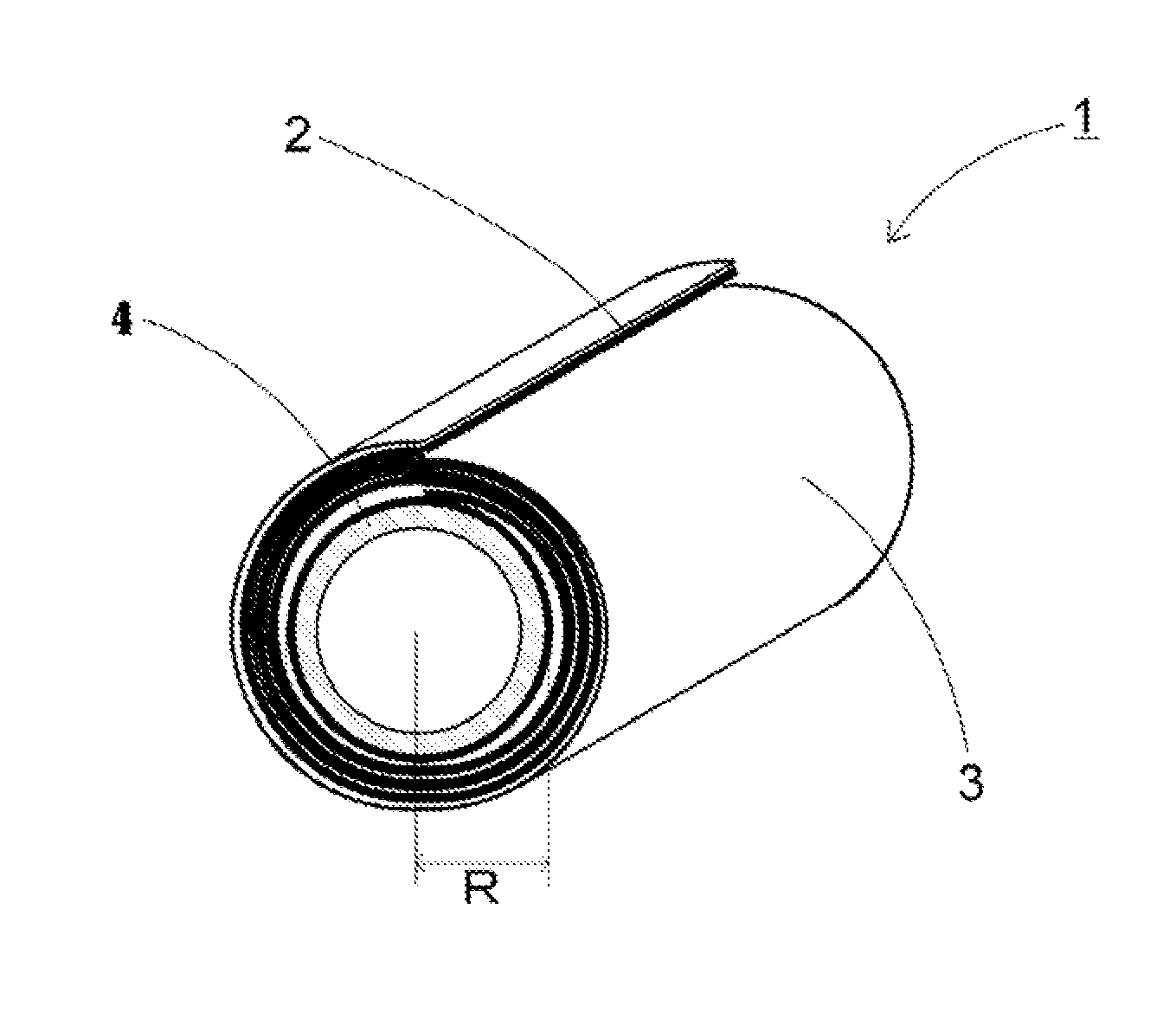

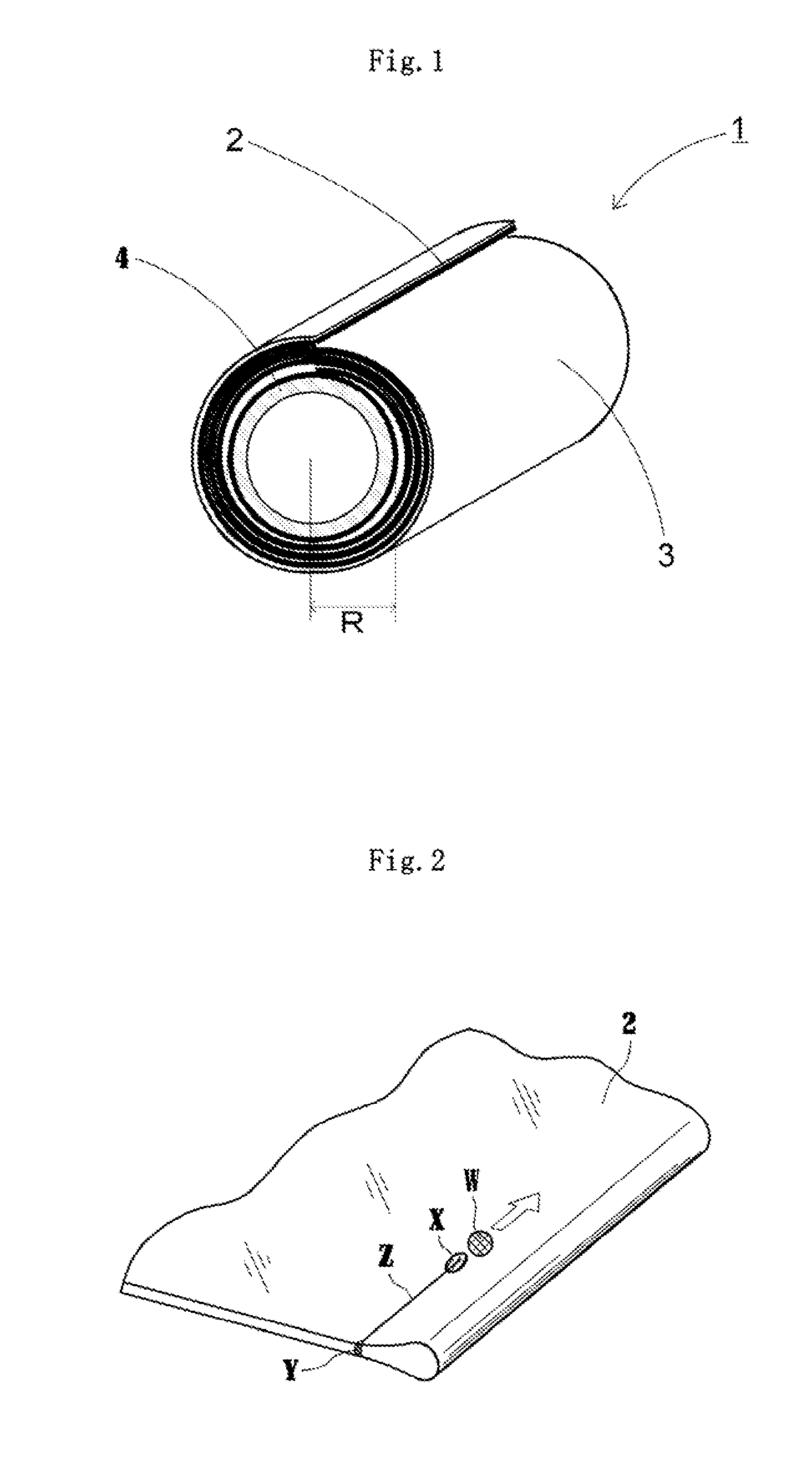

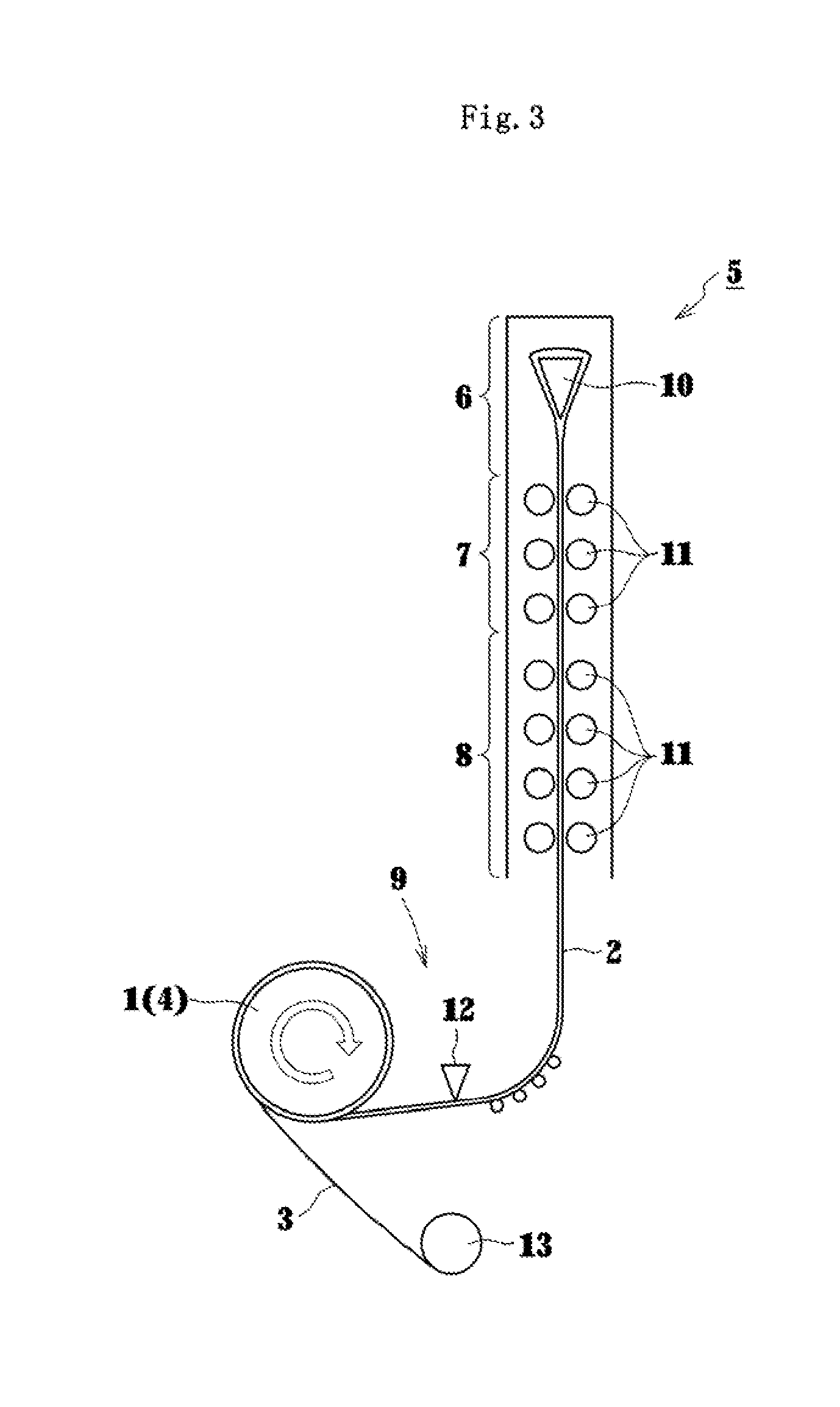

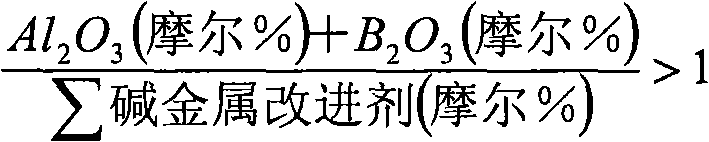

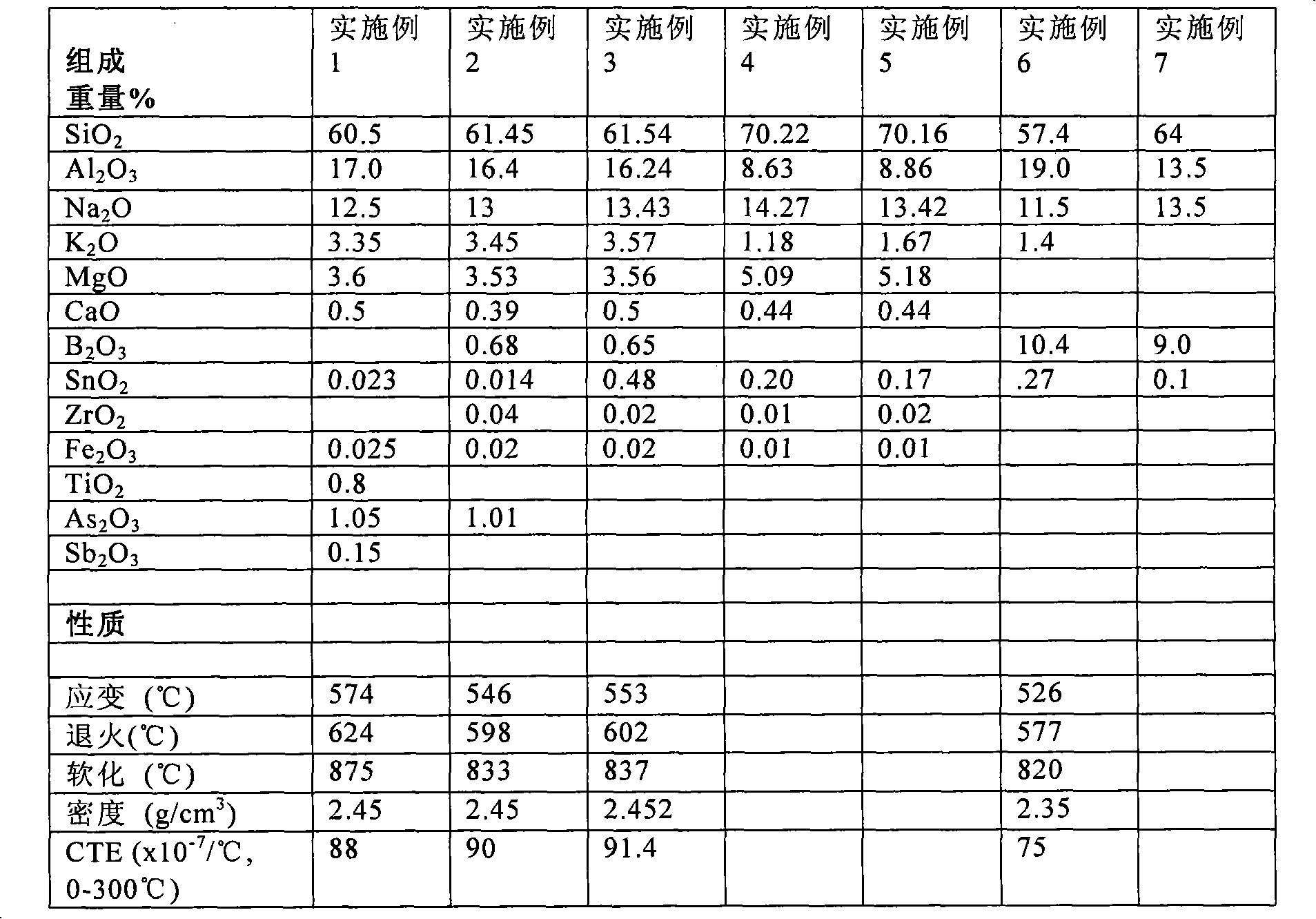

Glass roll and process for producing glass roll

ActiveUS20110200812A1Suppress situationReliable manufacturingShaft and bearingsGlass drawing apparatus3 point bendingFlexural strength

Provided is a glass roll formed by winding a glass film into a roll, in which a minimum winding radius of the glass film is optimized. Thus, the glass film is reliably prevented from breaking due to static fatigue, and is able to be stored for long periods. A glass roll (1), which is formed by winding a glass film (2) into a roll, has a configuration in which the glass film has a minimum winding radius (R) satisfying the following relation: R≧(T / 2)[(2.3 / σ)×E−1], where σ represents flexural strength of the glass film (2) obtained by a 3-point bending test, T represents a thickness of the glass film, and E represents a Young's modulus of the glass film.

Owner:NIPPON ELECTRIC GLASS CO LTD

Durable glass housings/enclosures for electronic devices

The invention relates to glass articles suitable for use as electronic device housing / enclosure or protective cover which comprise a glass material. Particularly, a housing / enclosure / cover comprising an ion-exchanged glass exhibits the following attributes: (1) radio, and microwave frequency transparency, as defined by a loss tangent of less than 0.03 and at a frequency range of between 15 MHz to 3.0 GHz; (2) infrared transparency; (3) a fracture toughness of greater than 0.6 MPa*m<1 / 2>; (4) a 4-point bend strength of greater than 350 MPa; (5) a Vickers hardness of at least 450 kgf / mm<2> and a Vickers median / radial crack initiation threshold of at least 5 kgf; (6) a Young's Modulus ranging between about 50 to 100 GPa; (7) a thermal conductivity of less than 2.0 W / m DEG C; and (9) at least one of the following attributes: (i) a compressive surface layer having a depth of layer (DOL) greater and a compressive stress greater than 400 MPa, or, (ii) a central tension of more than 20 MPa.

Owner:CORNING INC

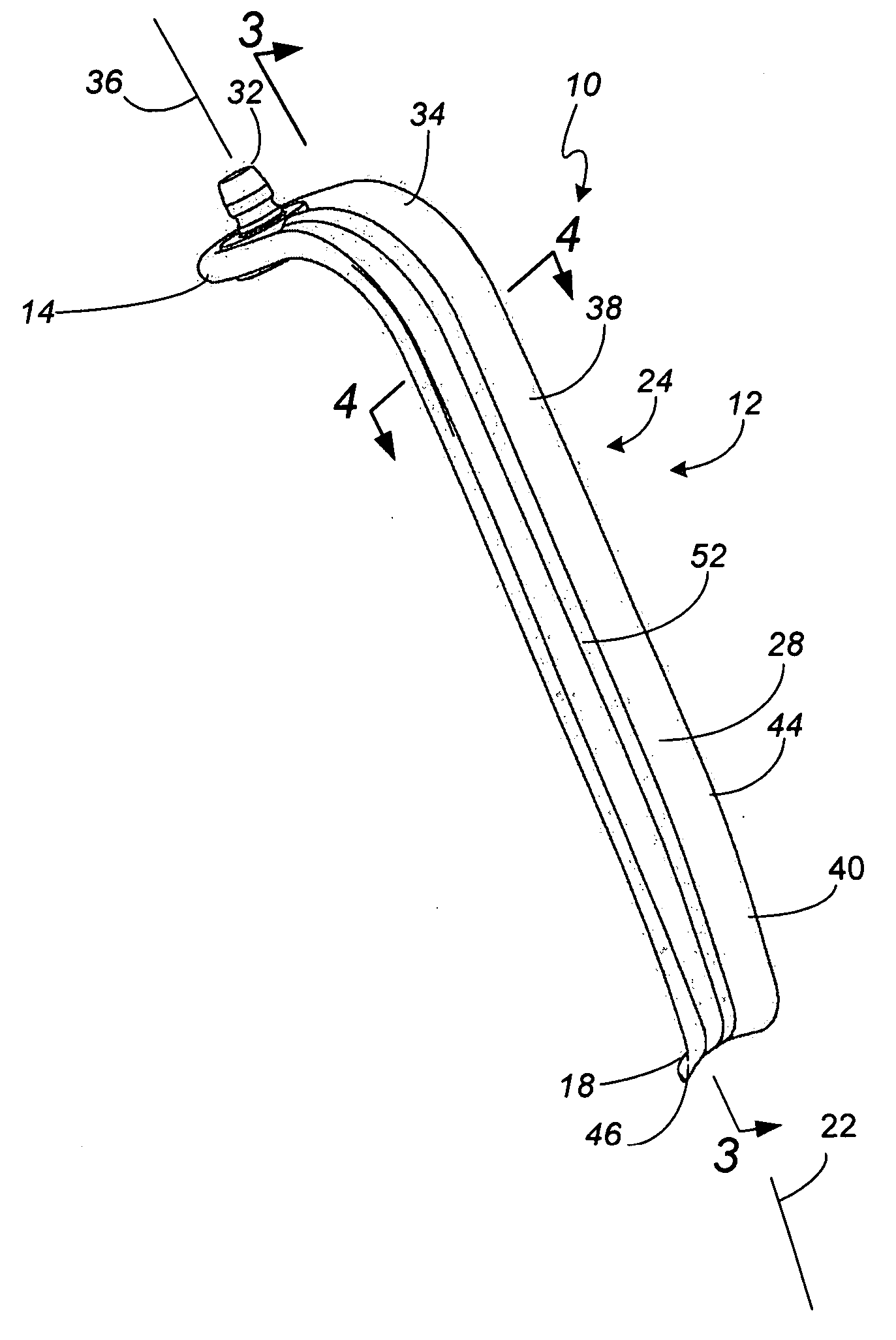

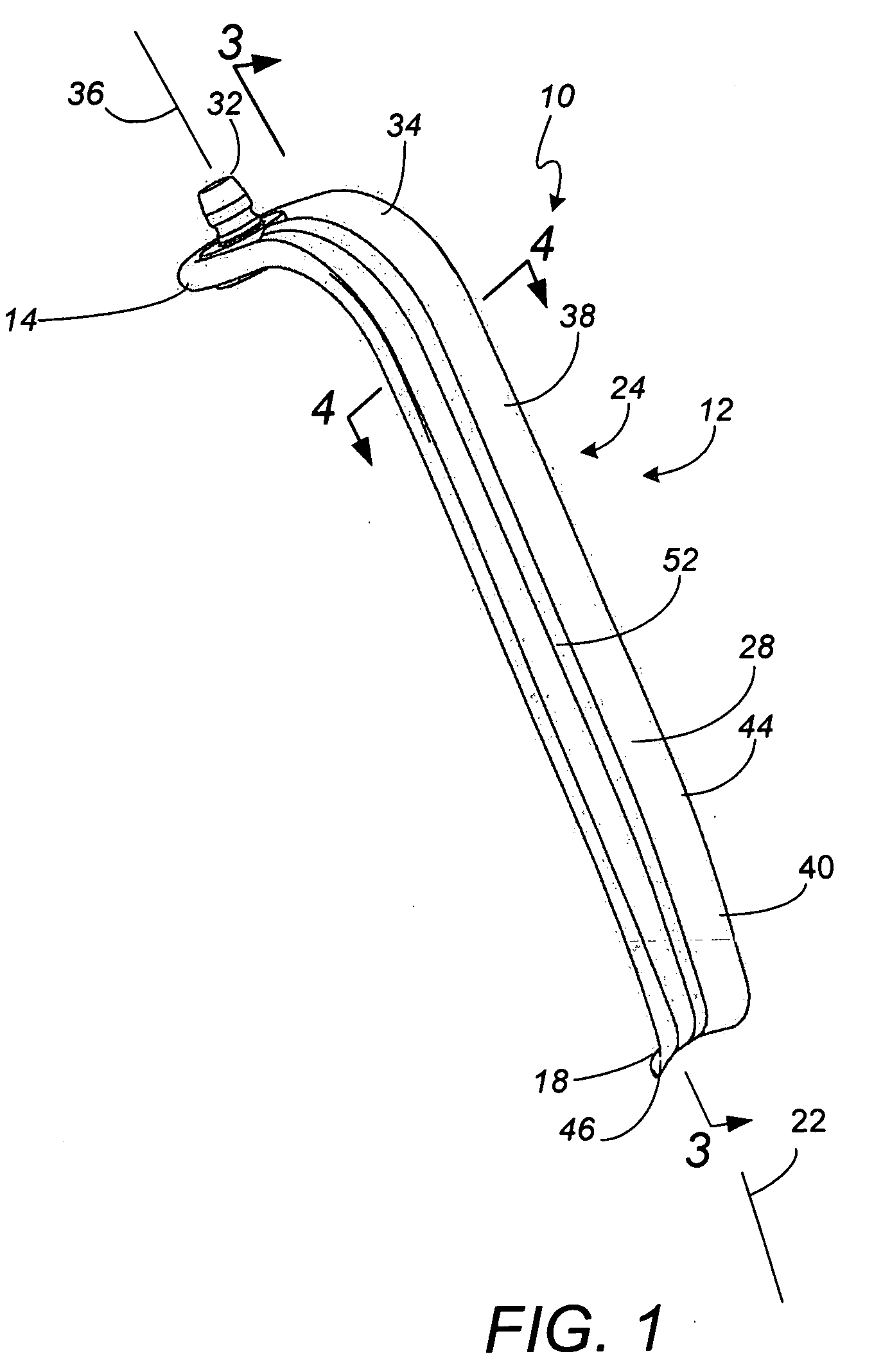

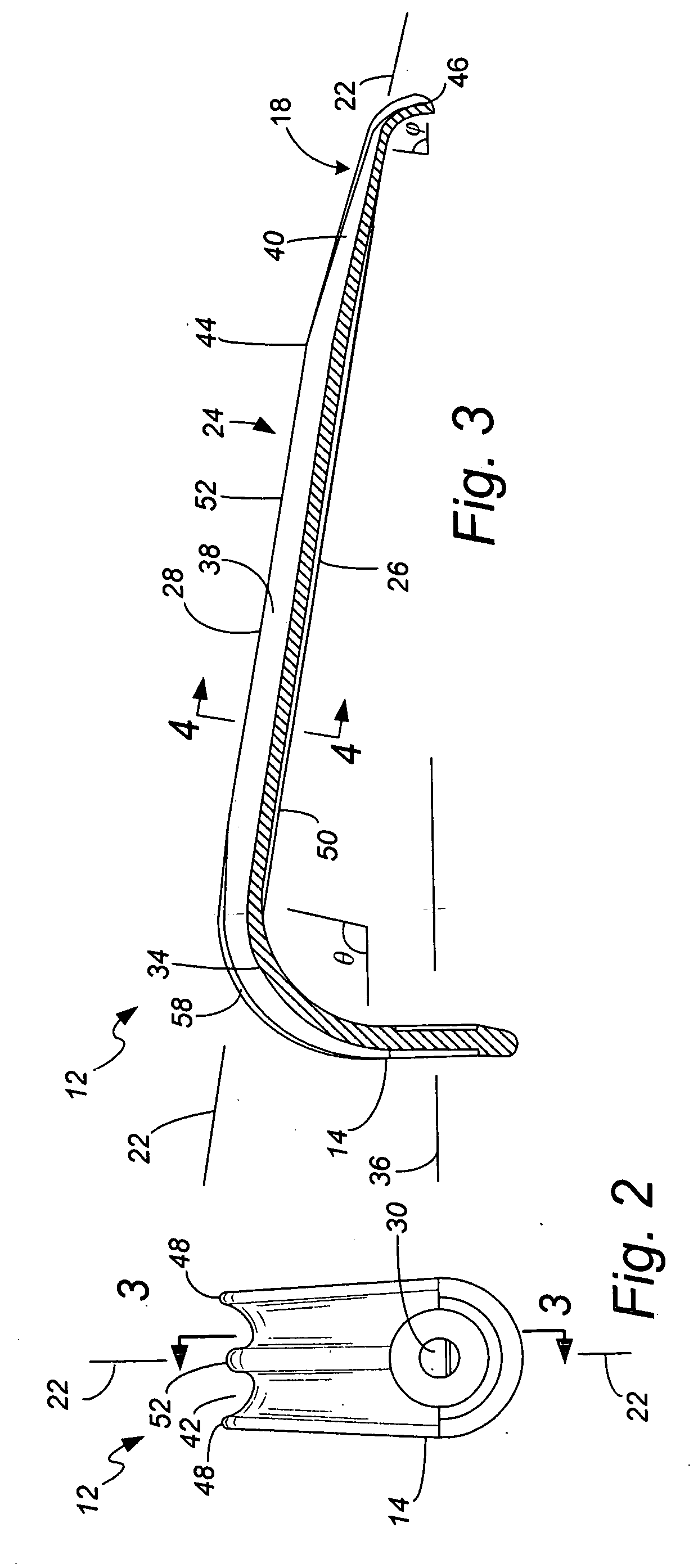

Shaped retractor blade

A shaped surgical retractor blade is used in a surgical retractor assembly. The shaped retractor blade is not formed of sheet material but rather is formed to have a non-uniform thickness between the tissue contacting side and the surgical arena side. The non-uniform thickness can be provided by a longitudinally running rib running between two recesses on surgical arena side of the retractor blade. The recesses provide openings through which the surgeon can better view the surgical arena. The rib provides additional bending strength to the retractor blade. The tissue contacting side of the blade can have a convex curvature, minimizing the possibility of tissue damage at the location that the blade contacts the tissue. The retractor blade can have a constant longitudinally extending section and a distal, tapering section. The uniquely shaped retractor blade can be formed, for instance, such as by injection molding a high tensile strength polymer material which provides desired optical / fluoroscopic / magnetic resonance imaging properties.

Owner:MINNESOTA SCI

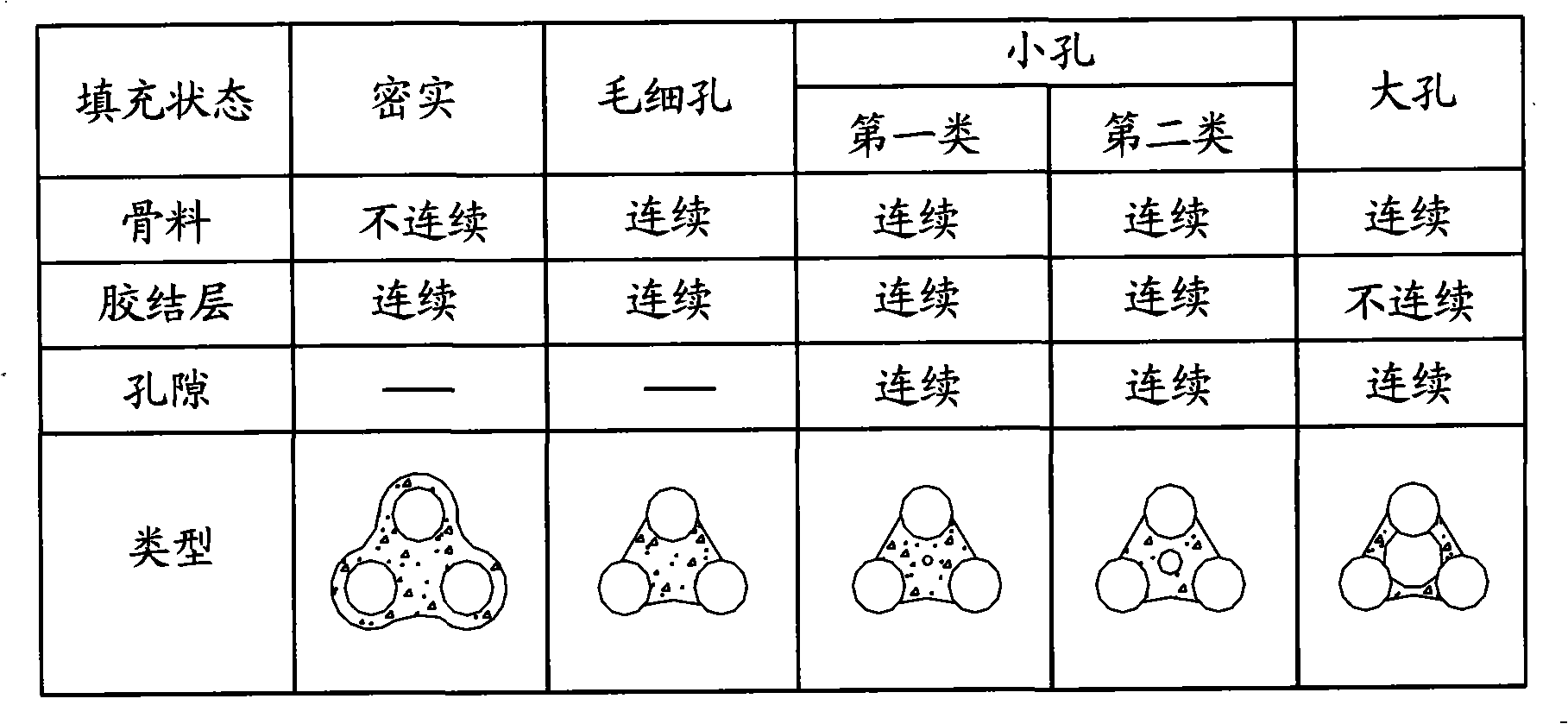

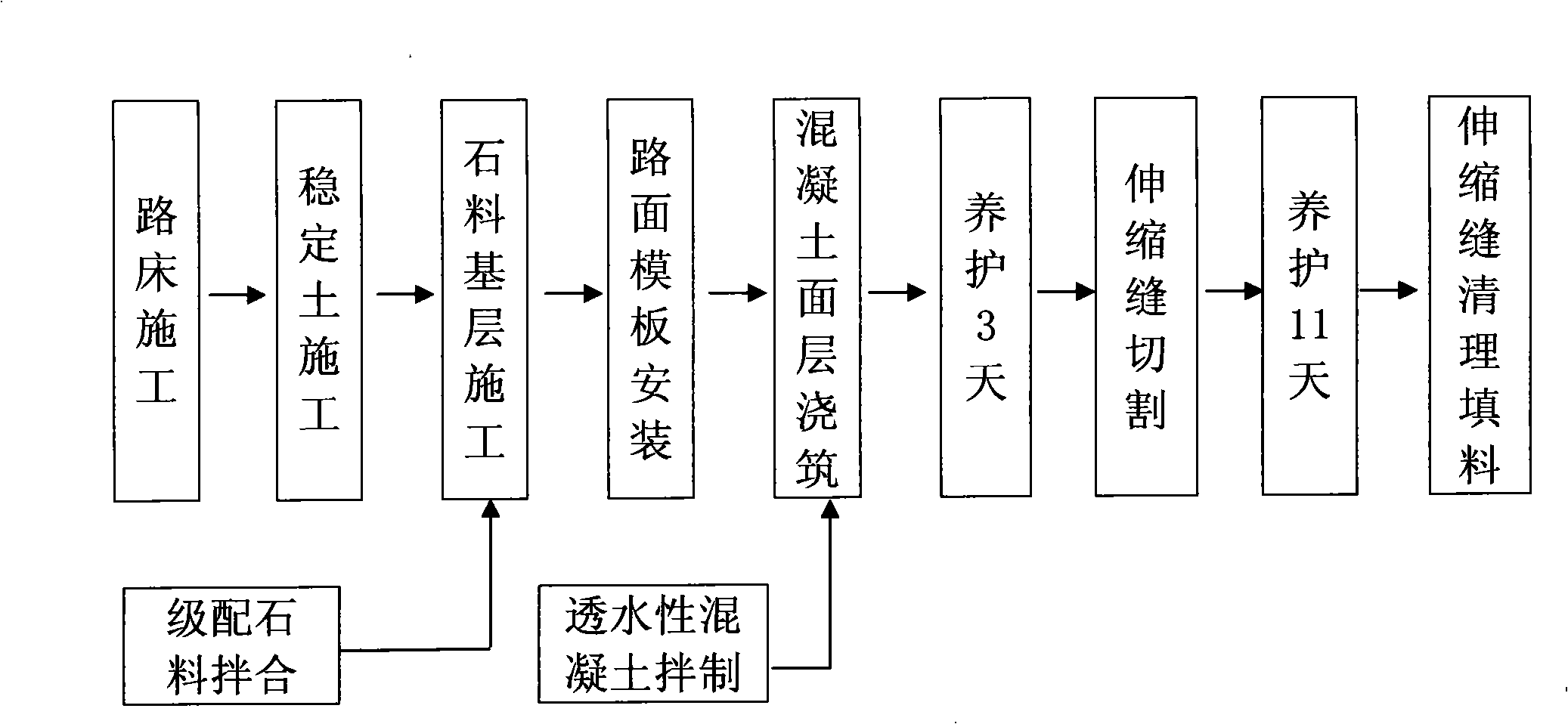

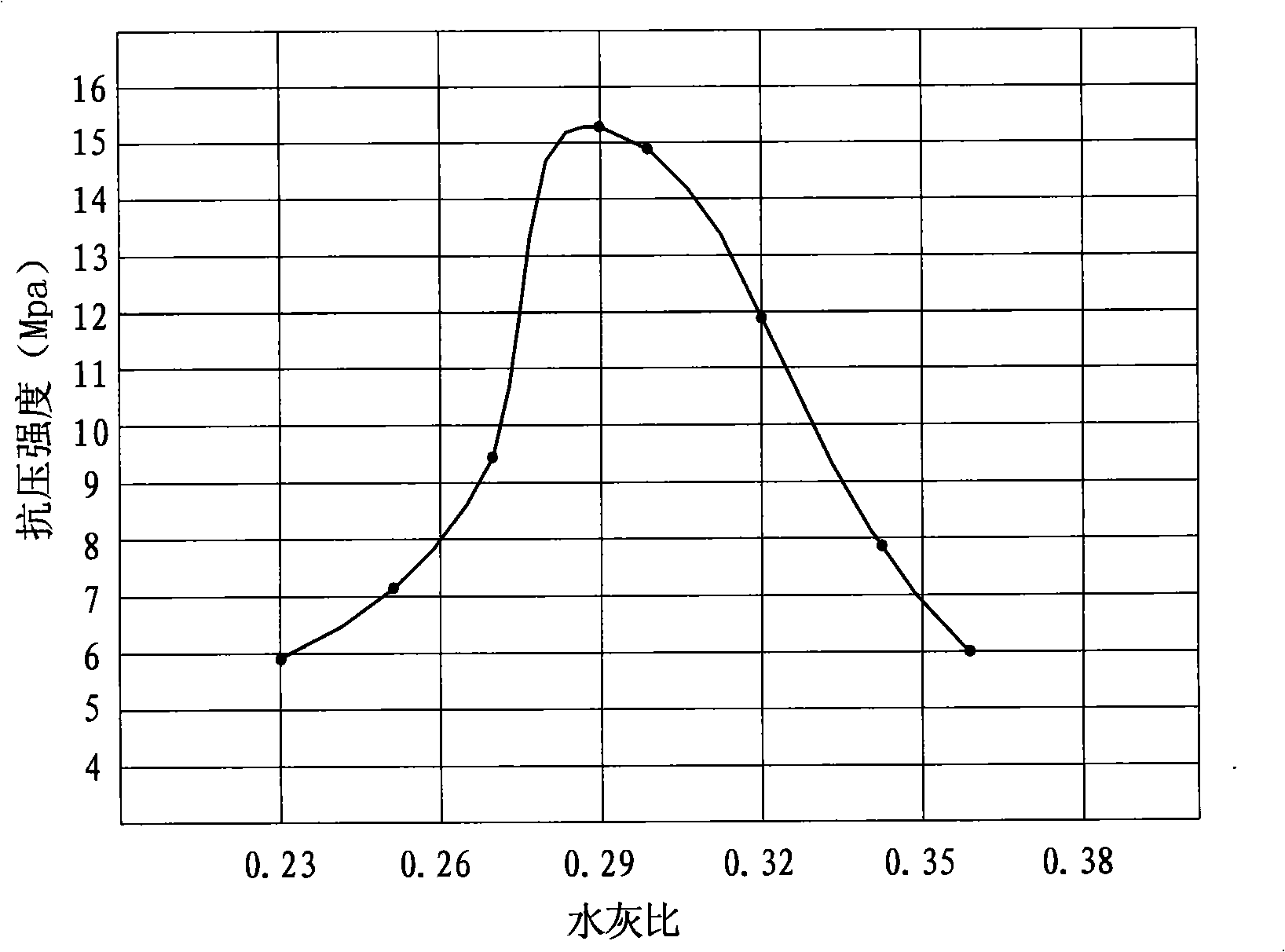

Water permeable concrete and pavement construction method

InactiveCN101293763AHigh strengthGood water permeabilityIn situ pavingsSolid waste managementFlexural strengthRoad surface

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Owner:HENAN GUOJI CONSTR GRP +1

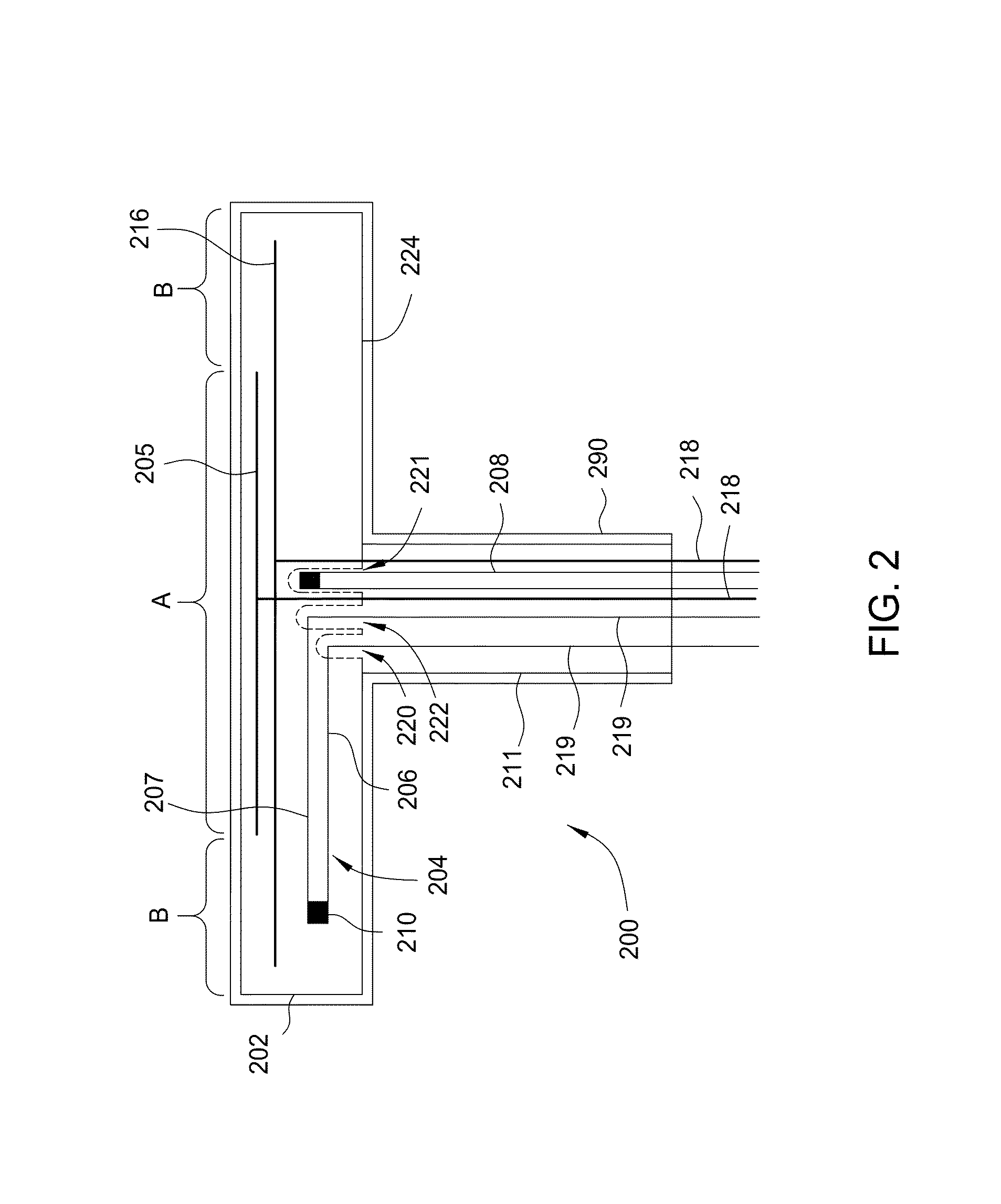

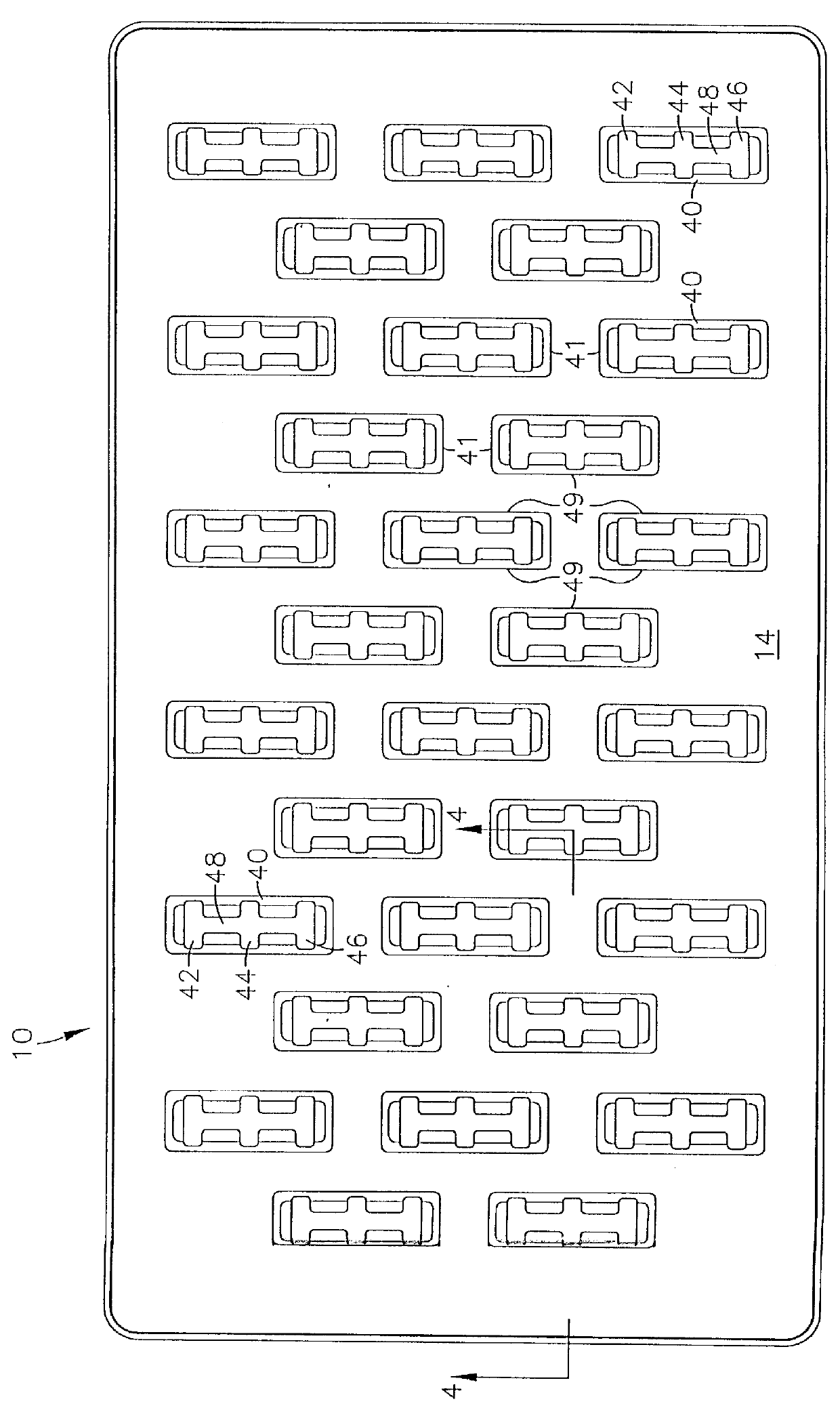

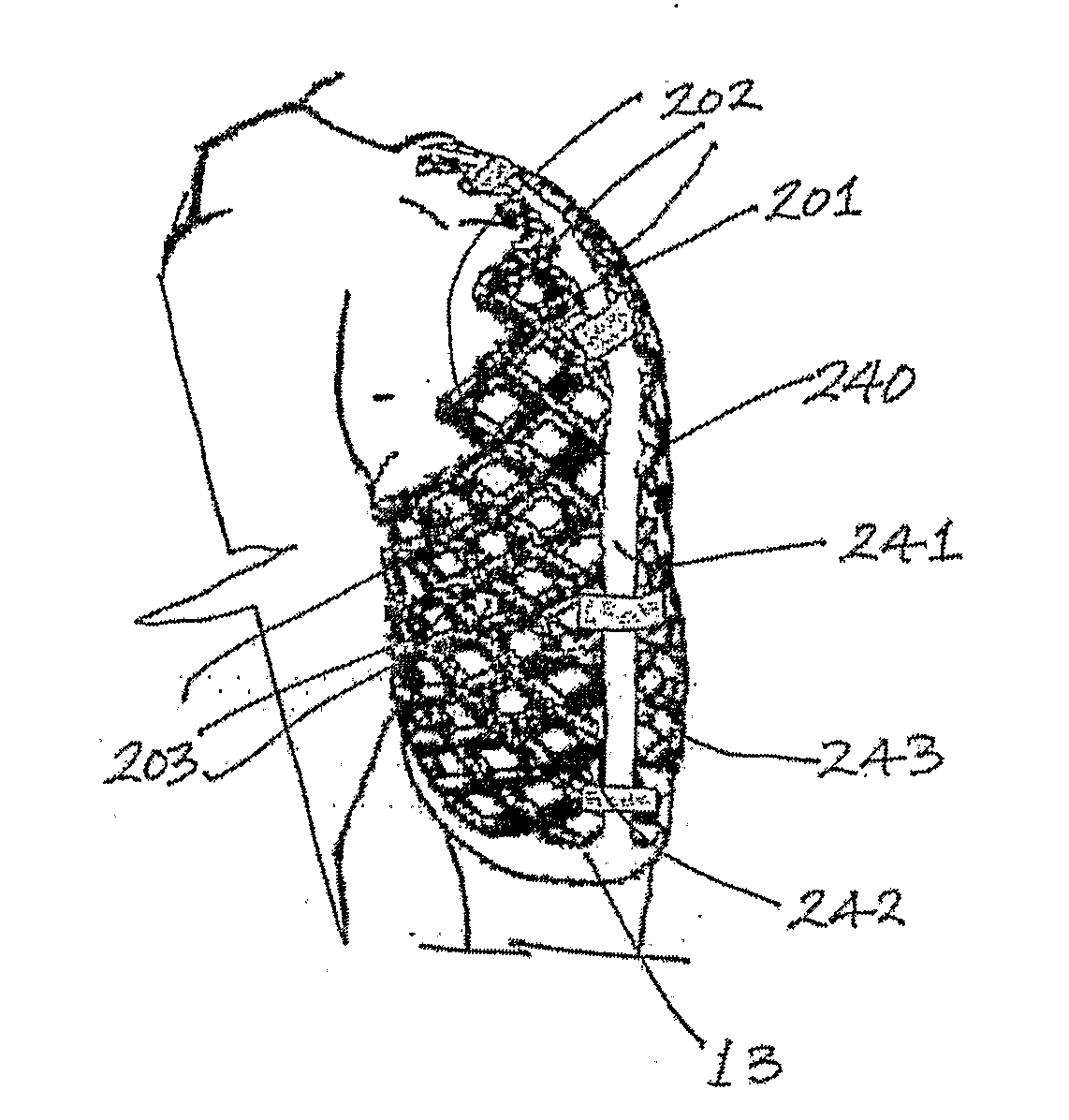

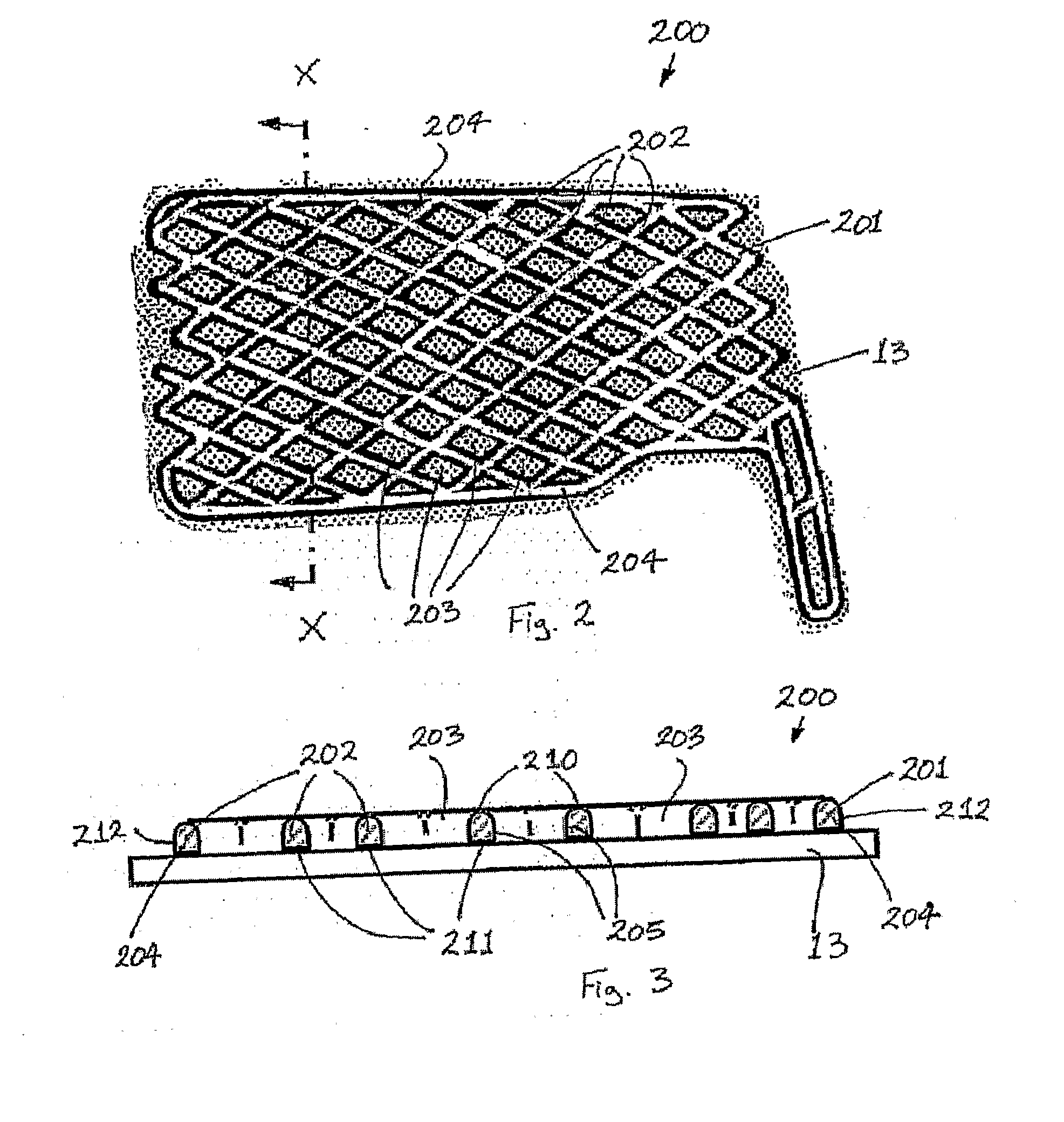

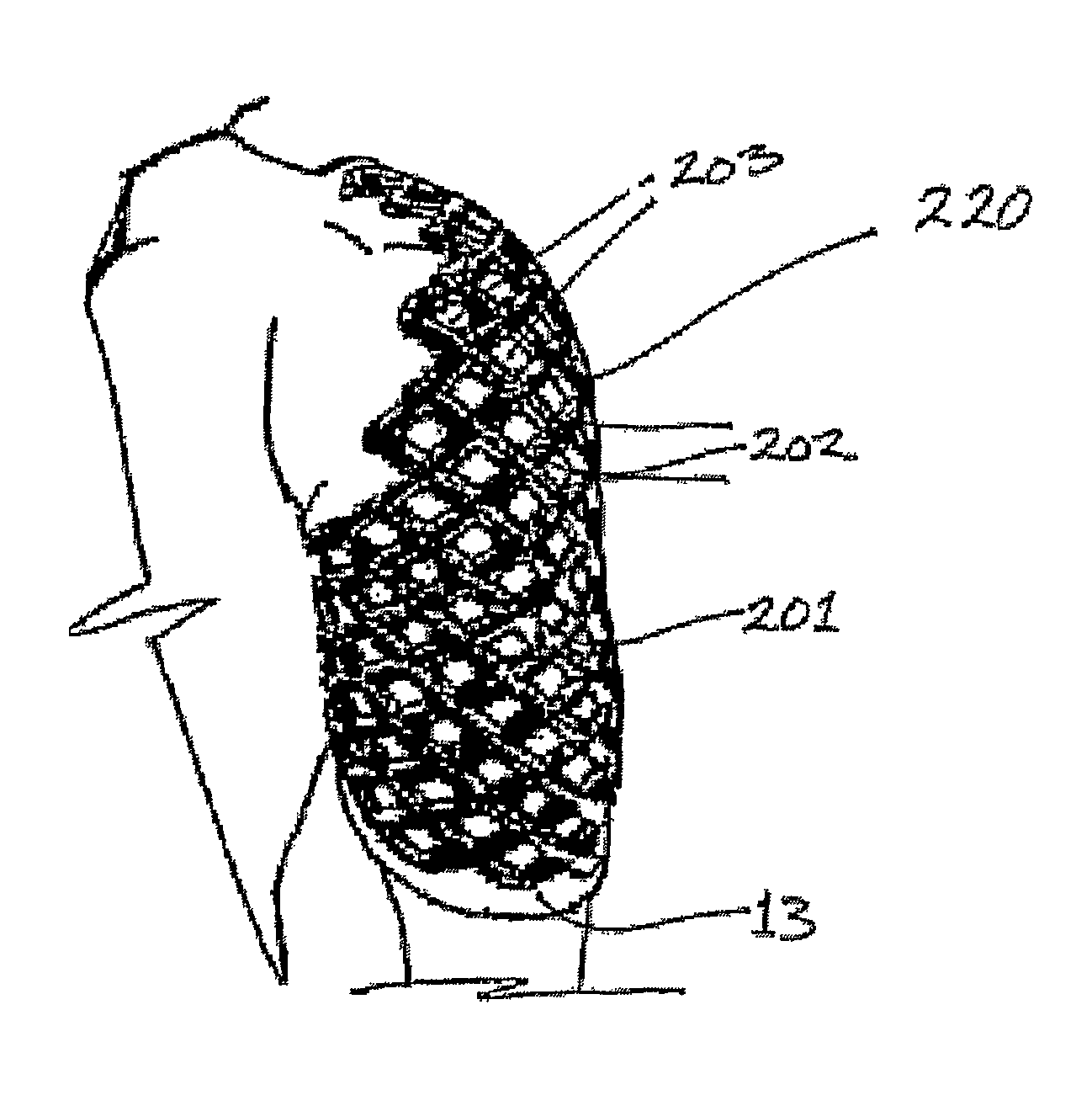

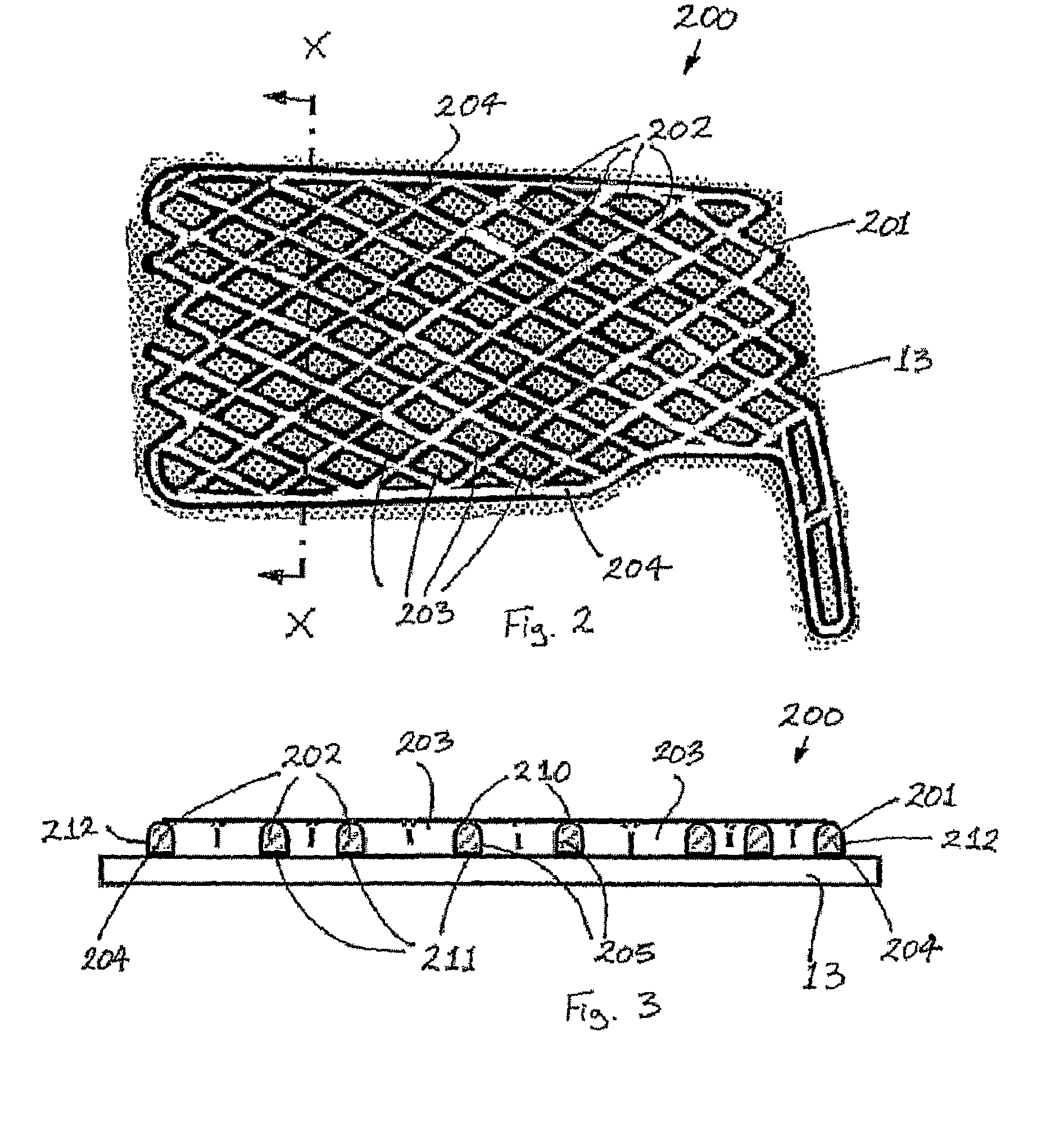

Geometrically Apertured Protective and/or Splint Device Comprising a Re-Mouldable Thermoplastic Material

ActiveUS20080154164A1Convenient ArrangementReduction in tackCosmetic preparationsImpression capsCelluloseMedicine

A protective and / or splint device, for example a distal radial splint device (200), comprises a protective and / or splint member (201) and a spacer member (13). The protective and / or splint member (201) comprises a composite protective and / or splint material and is formable at a forming temperature and is substantially rigid at ambient temperature. The material comprises a polycaprolactone and a ligno-cellulose additive material. The protective and / or splint member (201) comprises a mesh of elements (202), with a plurality of openings (203) through the protective and / or splint member (201). Away from the periphery of the splint member (201), the openings (203) are diamond-shaped. Two border elements (204) extend along the two sides of the periphery of the splint member (201). The three point bending strength to openness ratio of the member is greater than 0.1 and the unidirectional bending strength to openness ratio of the member is greater than 4. This results in a device (200) with sufficient strength, which is breathable with open surfaces, and the volume of material used is optimized. The strength of the member (201) parallel to the longitudinal direction of the arm is greater than the strength parallel too the circumferential direction. At the forming temperature the member (201) is stretchable. The member (201) is rounded between the outer surface of the member (201) and the edges around the openings (203).

Owner:FASTFORM RES

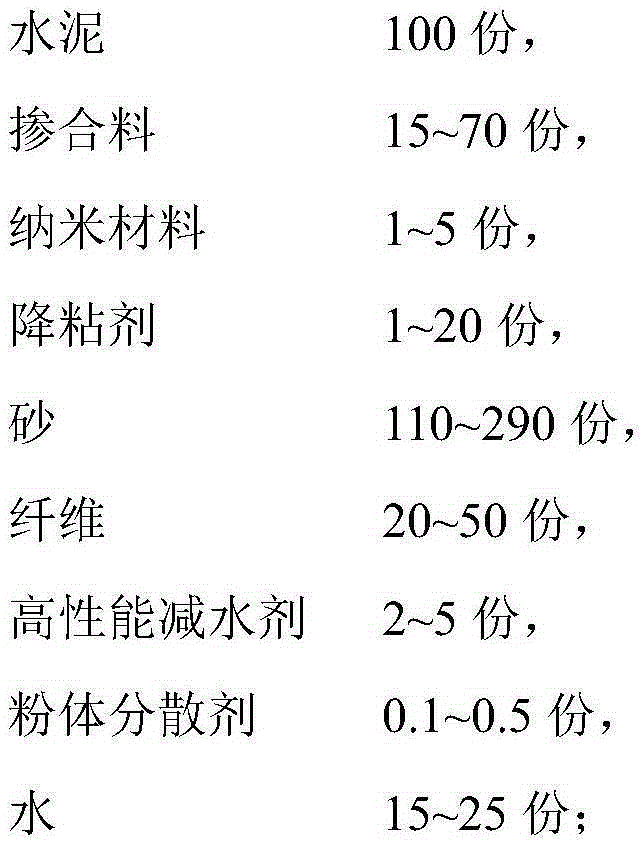

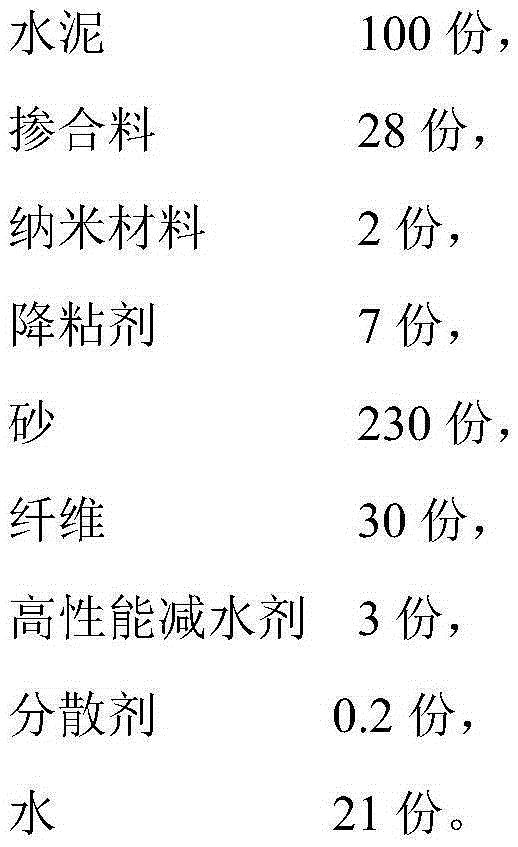

Ultra-high performance concrete with compressive strength of 300MPa or more and preparation method

The present invention discloses an ultra-high performance concrete with compressive strength of 300MPa or more and a preparation method, and the ultra-high performance concrete comprises the following components in parts by mass: 100 parts of cement, 15 to 70 parts of an admixture, 1 to 5 parts of a nanomaterial, 1 to 20 parts of a viscosity reducer, 110 to 290 parts of sand, 20-50 parts of fibers, 2 to 5 parts of a superplasticizer, 0.1 to 0.5 part of a powder dispersing agent and 15 to 25 parts of water. The ultra-high performance concrete has ultrahigh mechanical properties, the compressive strength after heat curing at 85 DEG C-90 DEG C in standard atmospheric pressure environment can be 300MPa or more, the flexural strength is greater than 55MPa, and the ultra-high performance concrete has excellent working performance and ultrahigh durability.

Owner:JIANGSU SOBUTE NEW MATERIALS

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Geometrically apertured protective and/or splint device comprising a re-mouldable thermoplastic material

ActiveUS7985192B2Improve insulation performanceReduction in tackCosmetic preparationsImpression capsCelluloseMedicine

A protective and / or splint device, for example a distal radial splint device (200), comprises a protective and / or splint member (201) and a spacer member (13). The protective and / or splint member (201) comprises a composite protective and / or splint material and is formable at a forming temperature and is substantially rigid at ambient temperature. The material comprises a polycaprolactone and a ligno-cellulose additive material. The protective and / or splint member (201) comprises a mesh of elements (202), with a plurality of openings (203) through the protective and / or splint member (201). Away from the periphery of the splint member (201), the openings (203) are diamond-shaped. Two border elements (204) extend along the two sides of the periphery of the splint member (201). The three point bending strength to openness ratio of the member is greater than 0.1 and the unidirectional bending strength to openness ratio of the member is greater than 4. This results in a device (200) with sufficient strength, which is breathable with open surfaces, and the volume of material used is optimized. The strength of the member (201) parallel to the longitudinal direction of the arm is greater than the strength parallel too the circumferential direction. At the forming temperature the member (201) is stretchable. The member (201) is rounded between the outer surface of the member (201) and the edges around the openings (203).

Owner:FASTFORM RES

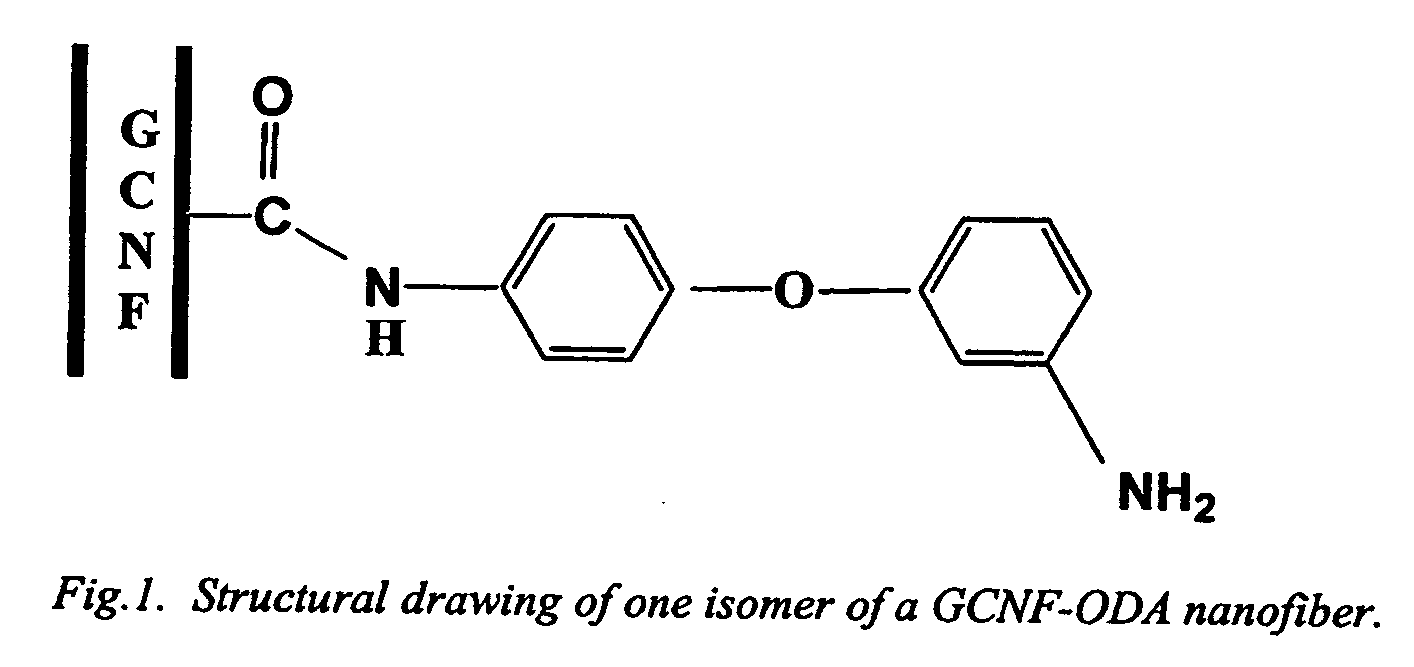

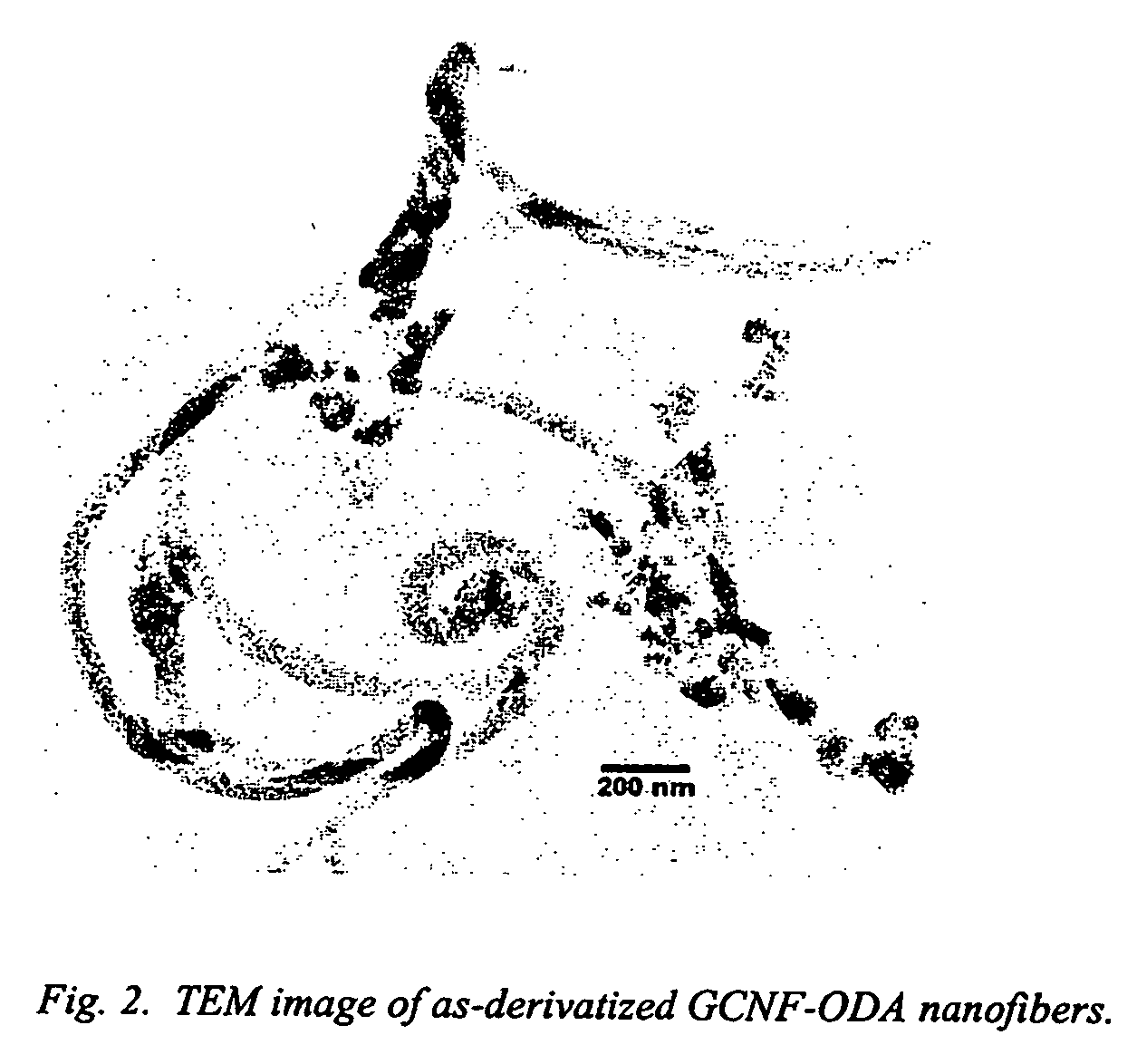

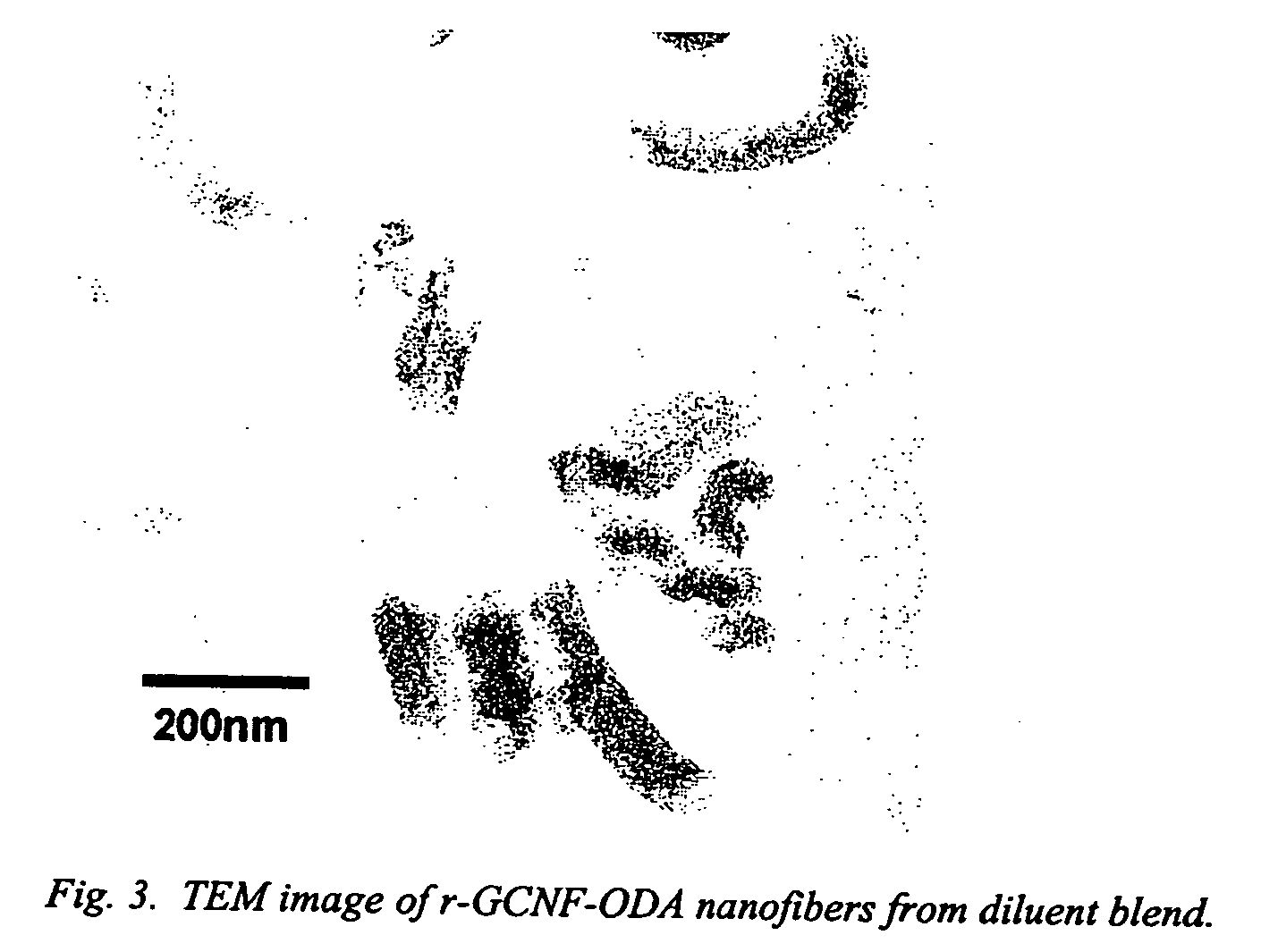

Reactive graphitic carbon nanofiber reinforced polymeric composites showing enhanced flexural strength

Composites comprising at least one graphite-carbon nanofiber (GCNF) and a polymer phase covalently linked to a surface thereof.

Owner:VANDERBILT UNIV

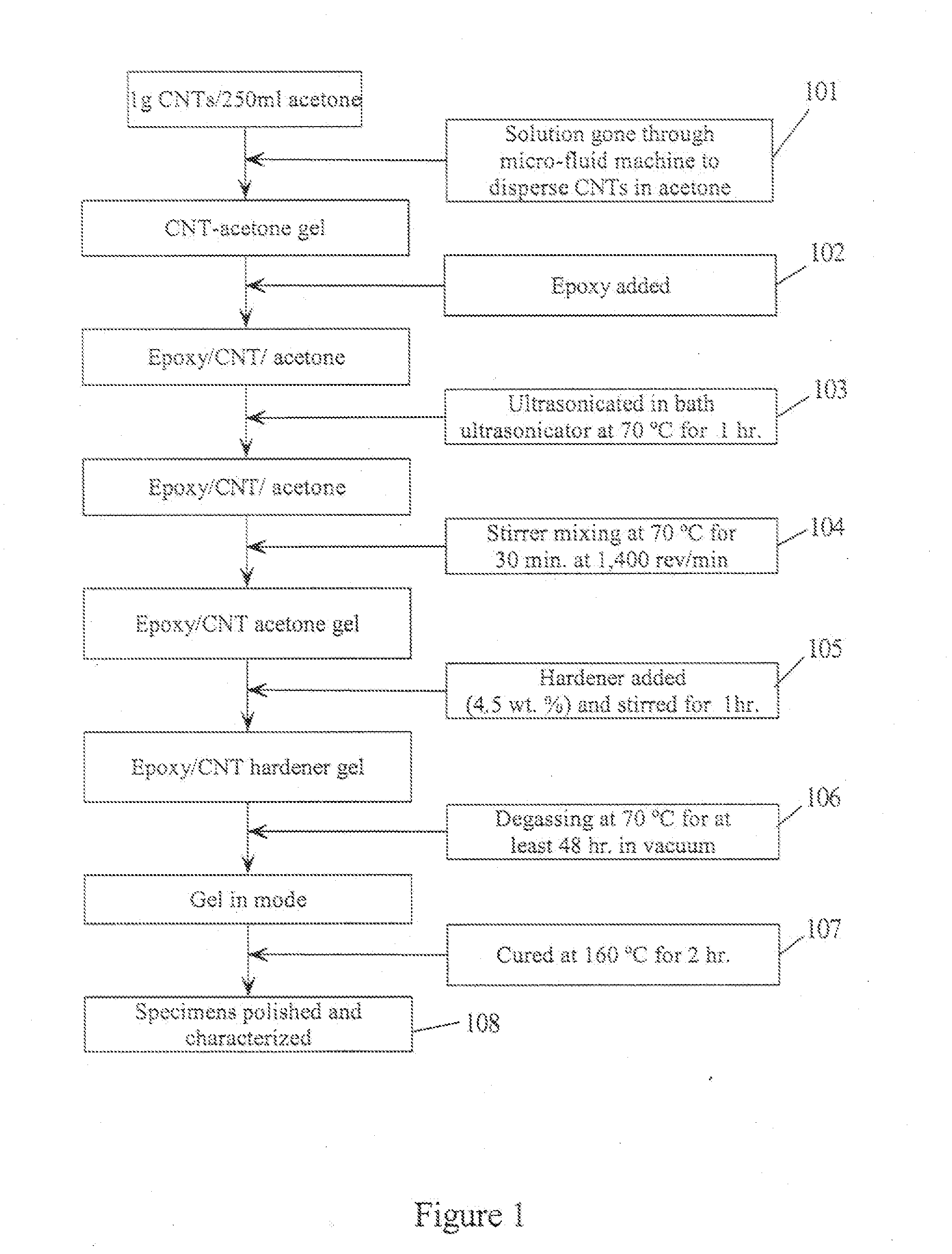

Dispersion by Microfluidic Process

Improved mechanical properties of both clay and carbon nanotube (CNT)-reinforced polymer matrix nanocomposites are obtained by dispersing those nanoparticles using a microfluidic process. Well-dispersed particles are obtained that sufficiently improve mechanical properties of the nanocomposites, such as flexural strength and modulus.

Owner:NANO

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

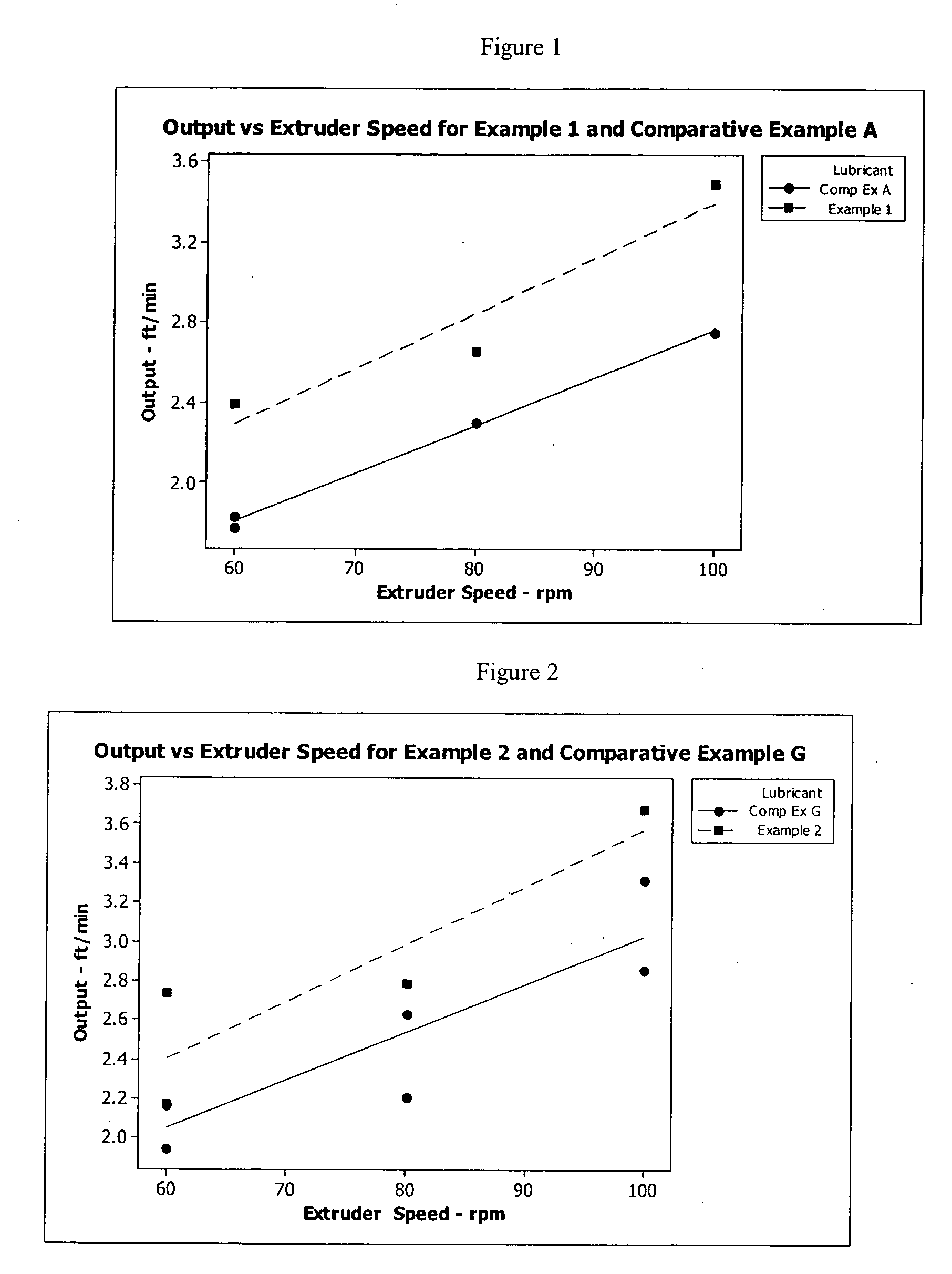

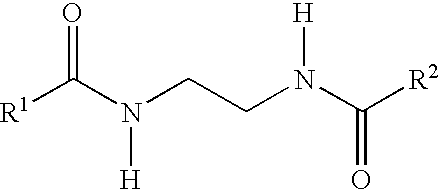

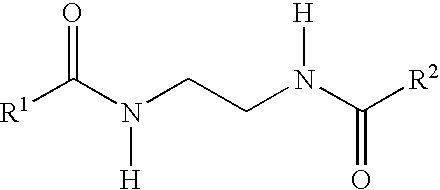

Cellulosic-thermoplastic composite and method of making the same

Provided is a composition comprising fatty acid bis-amide, inorganic particulate such as pumice, cellulosic particulate, thermoplastic and maleic anhydride grafted polyolefin. The combination of an ethylene bis-amide and a minor amount of pumice produces cellulosic-thermoplastic composite that has superior extrusion properties over conventional metal stearate / ethylene bis-stearamide (EBS) compositions such as improved flex strength and resistance to water absorption.

Owner:ADDIVANT USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com