Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1048 results about "Glass film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

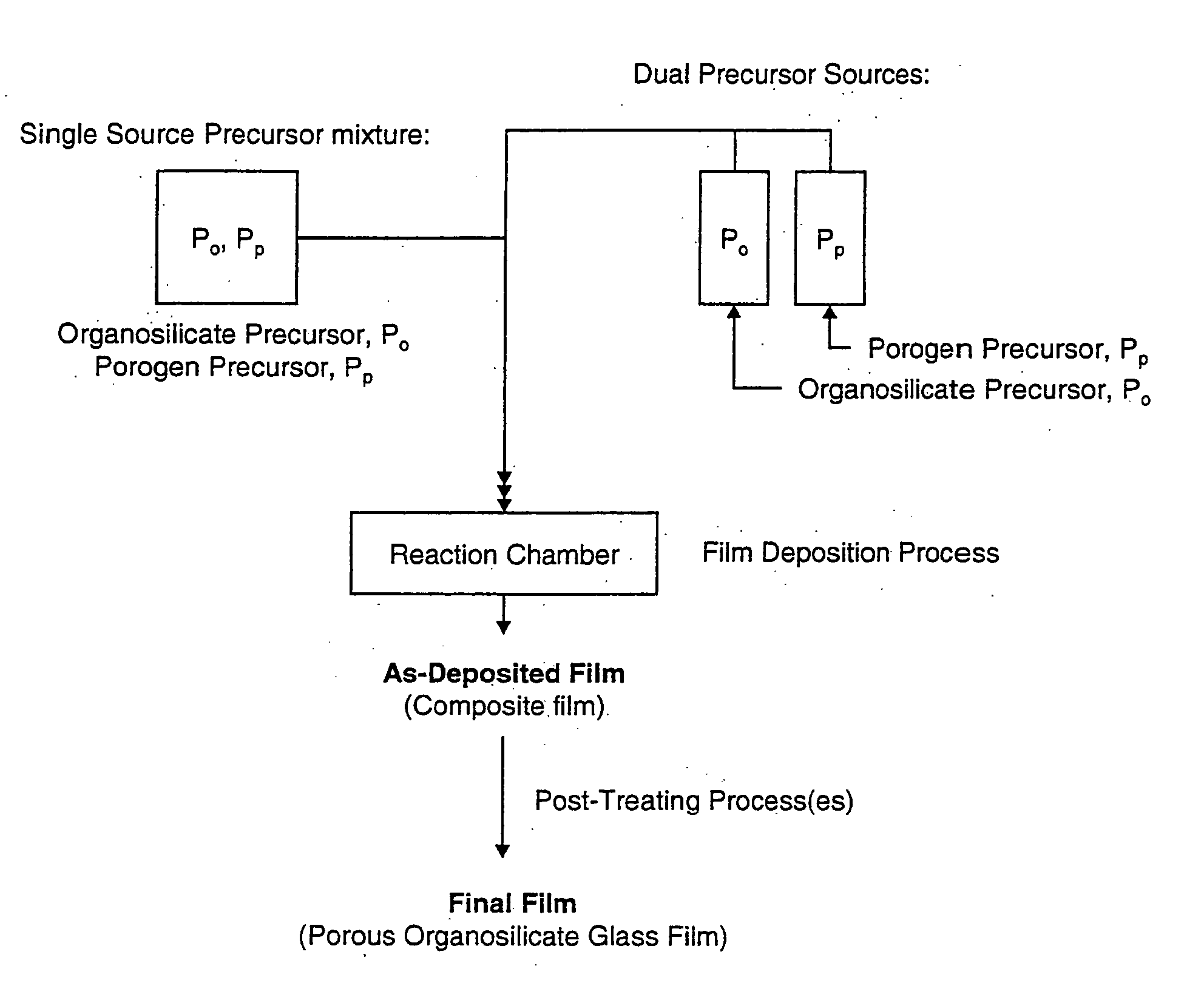

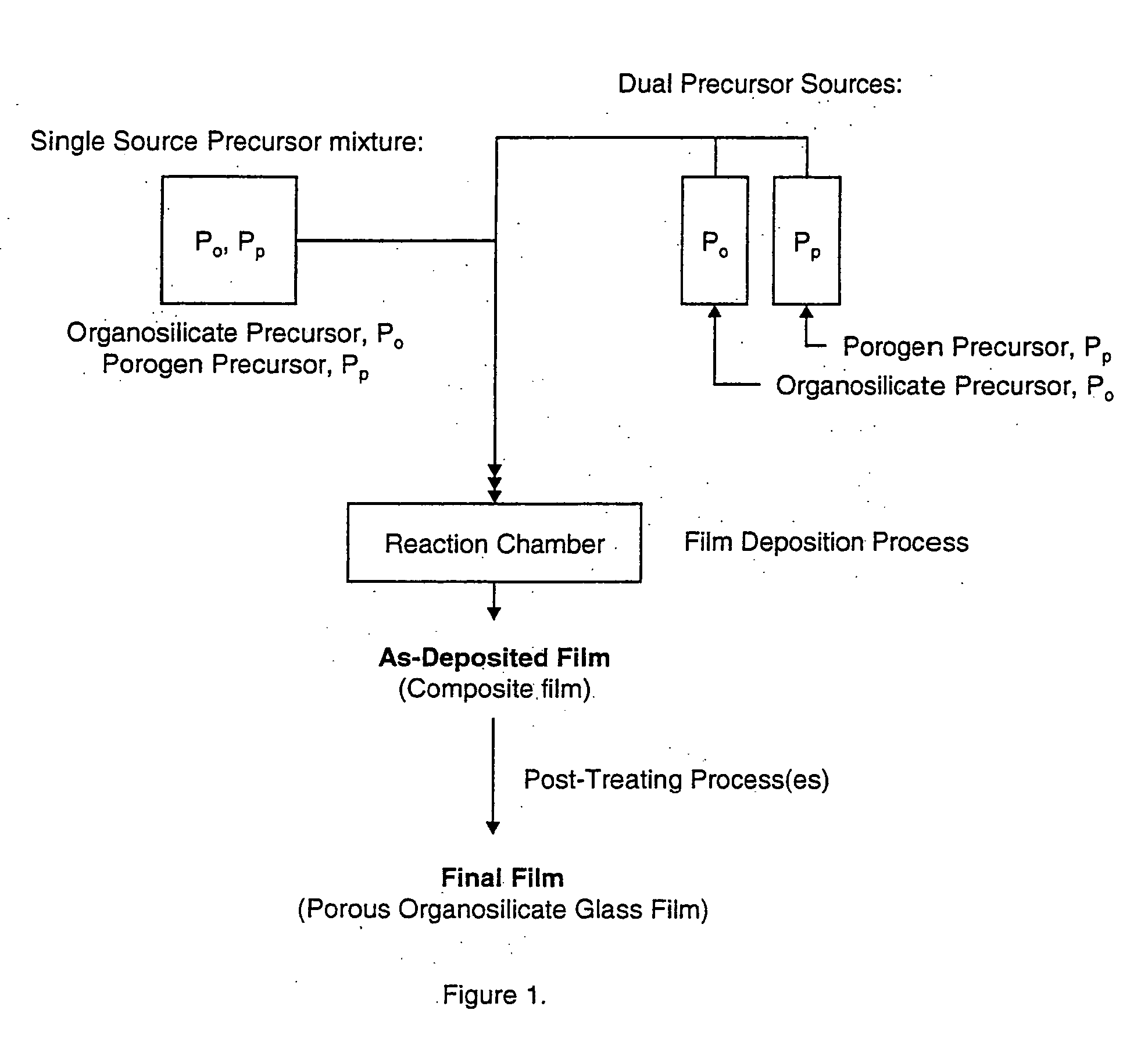

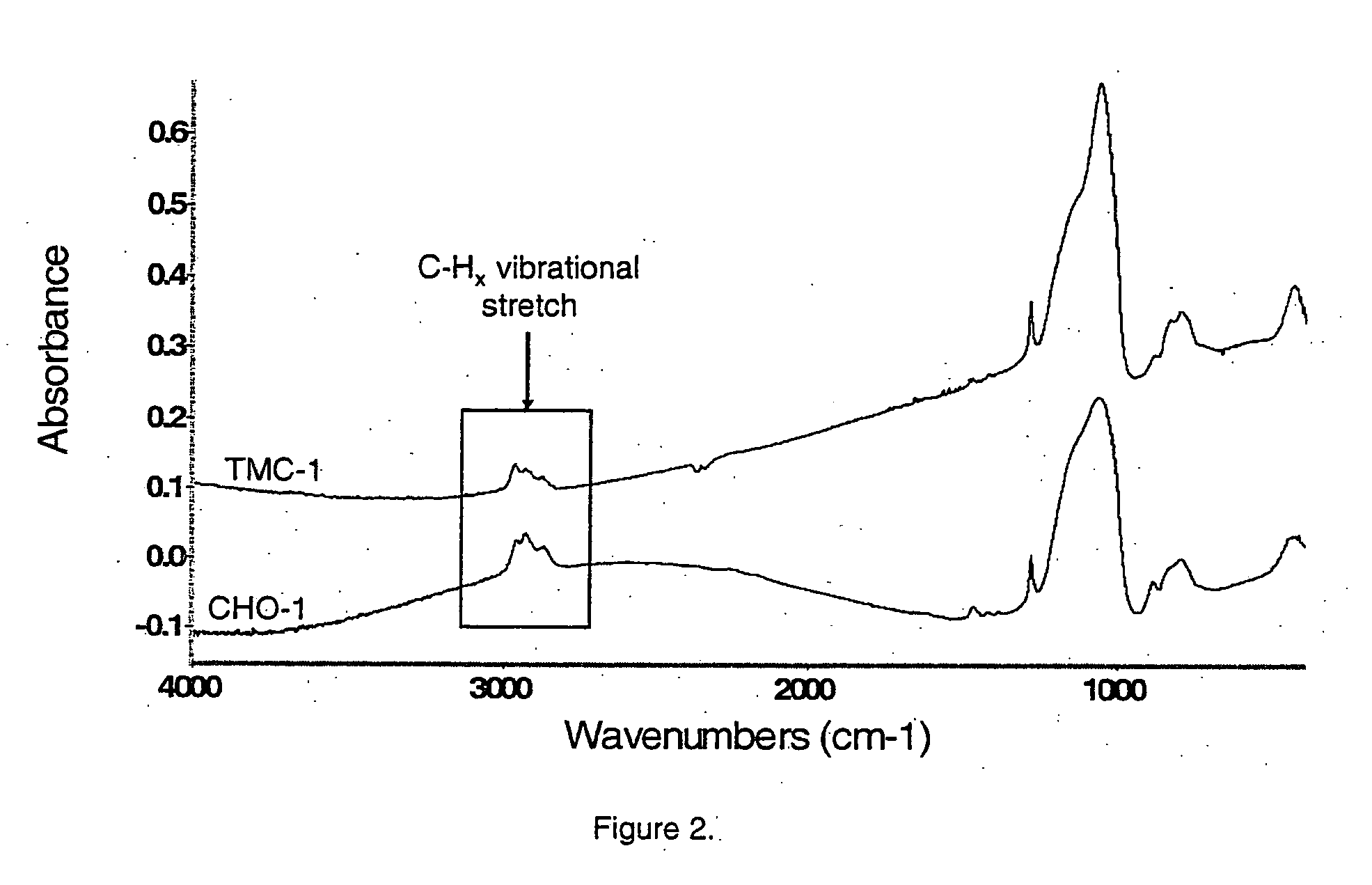

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7098149B2Low dielectric constantIncrease modulusSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricUltraviolet lights

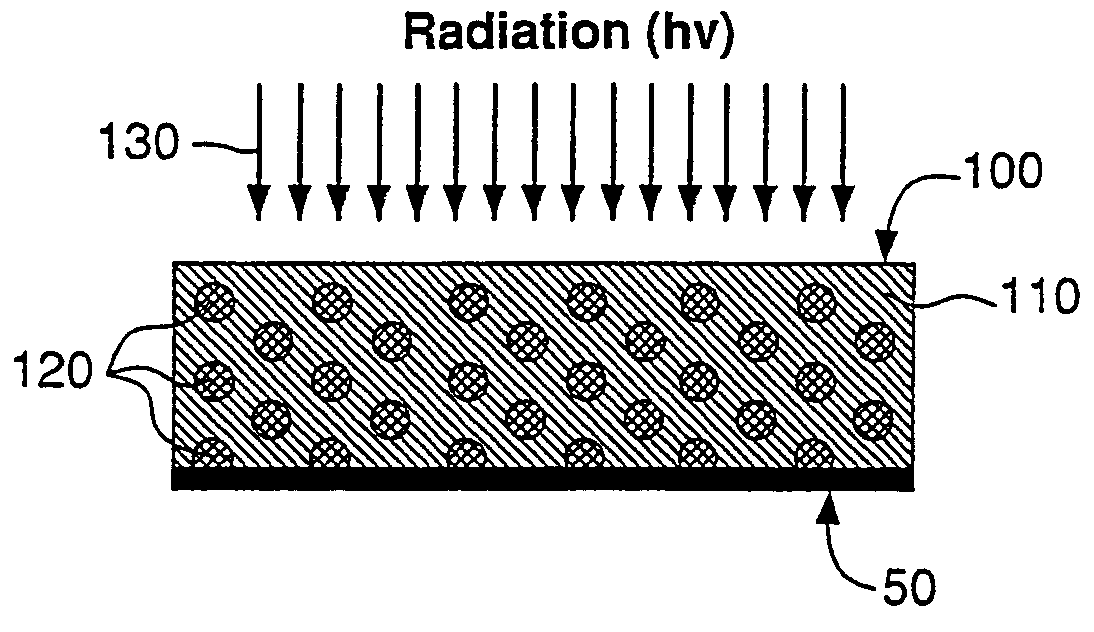

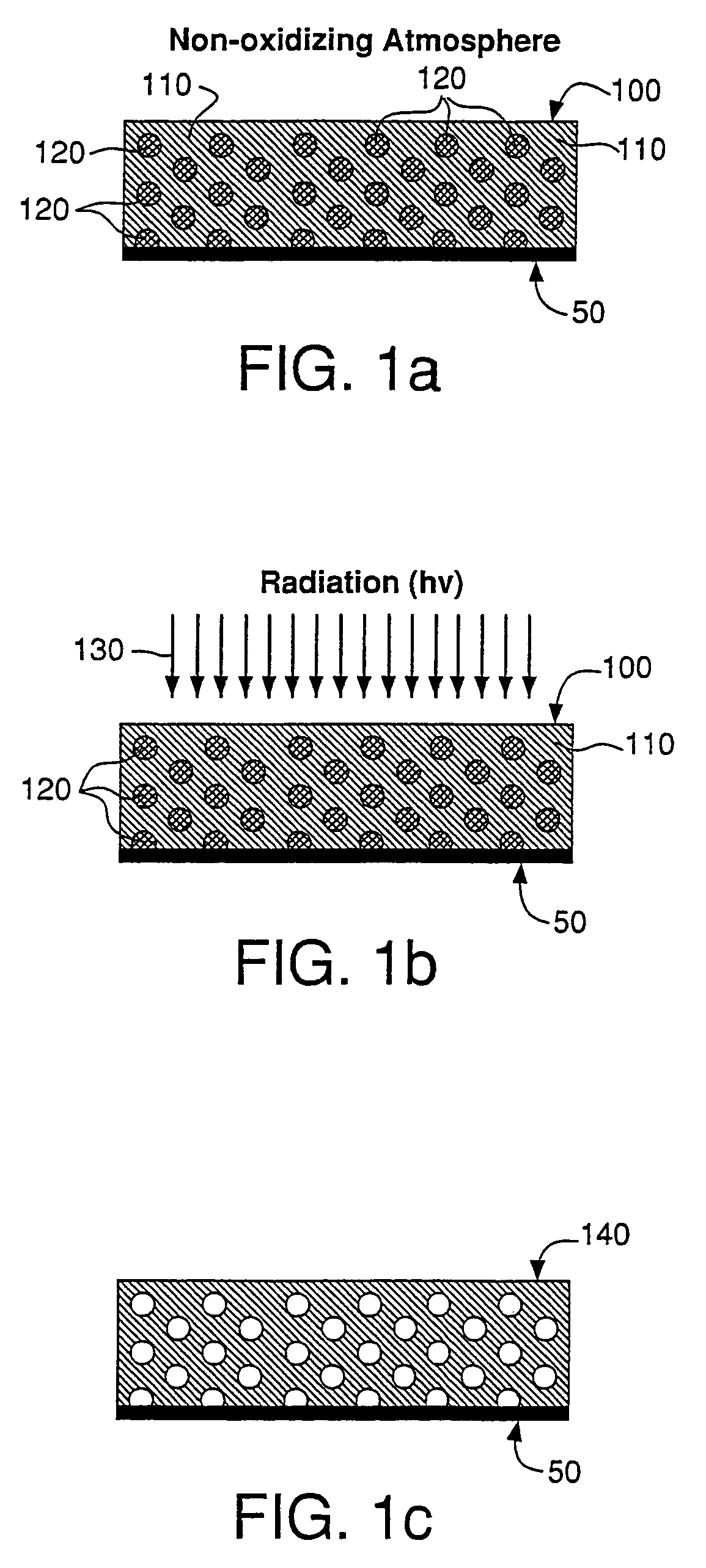

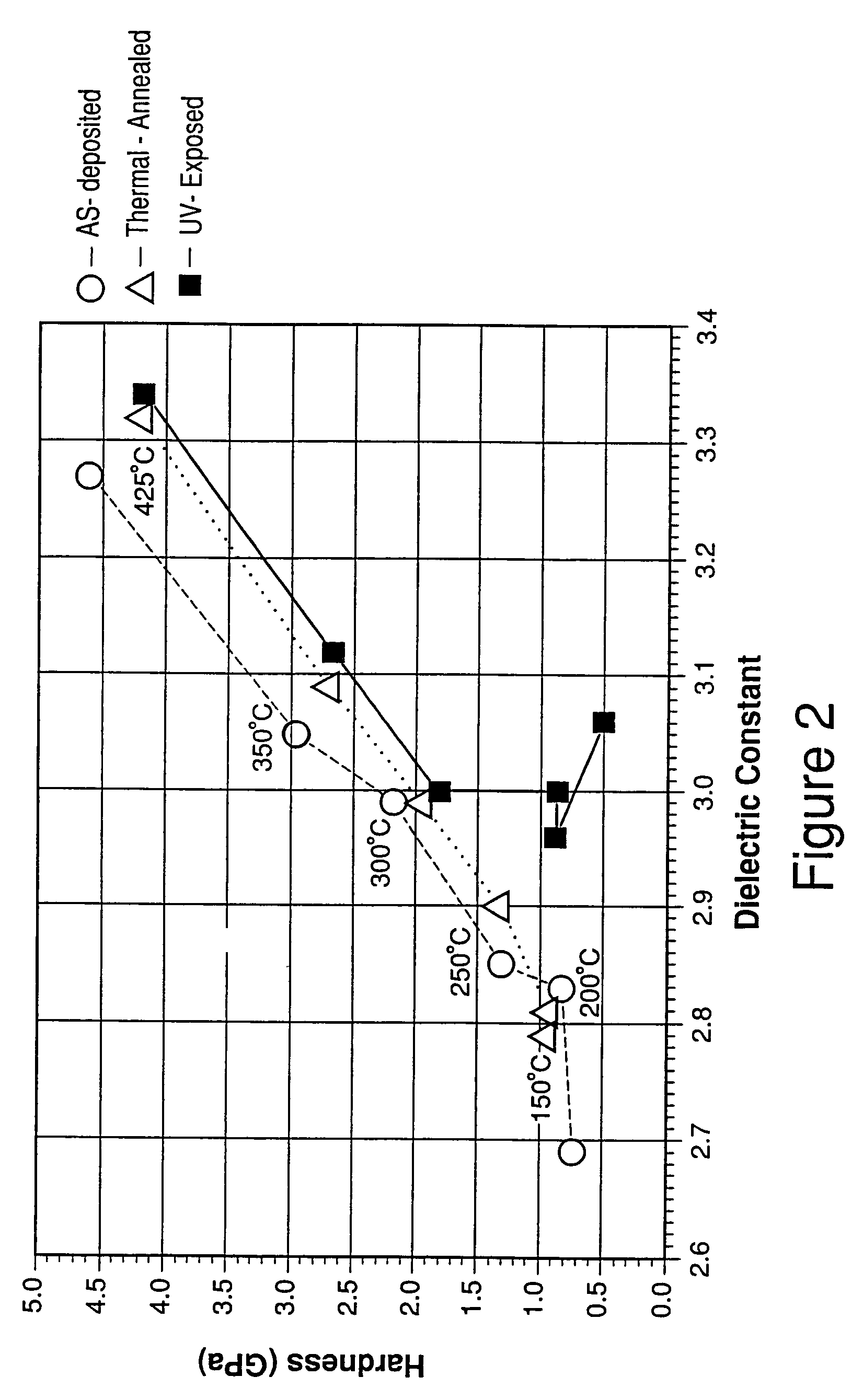

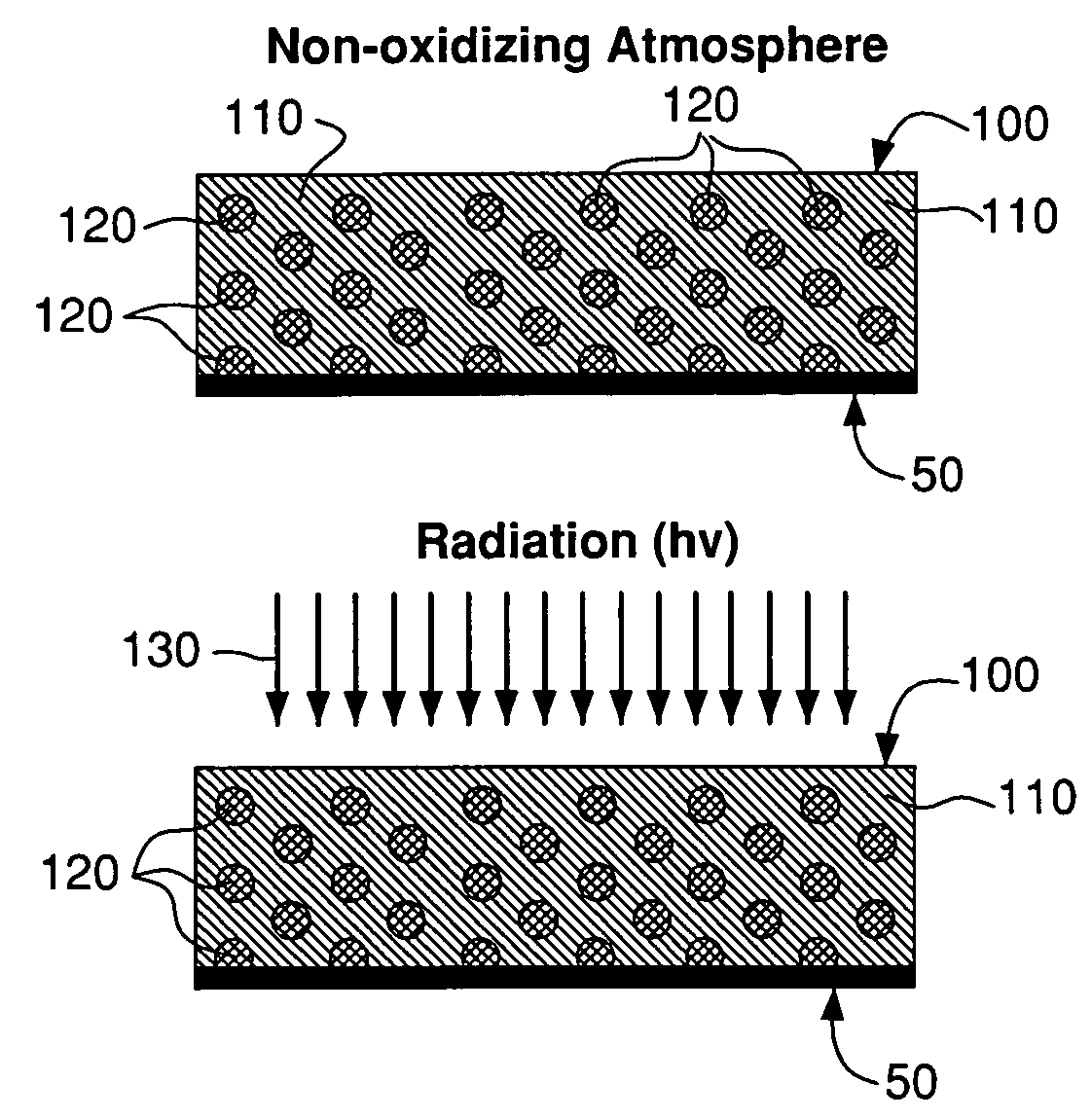

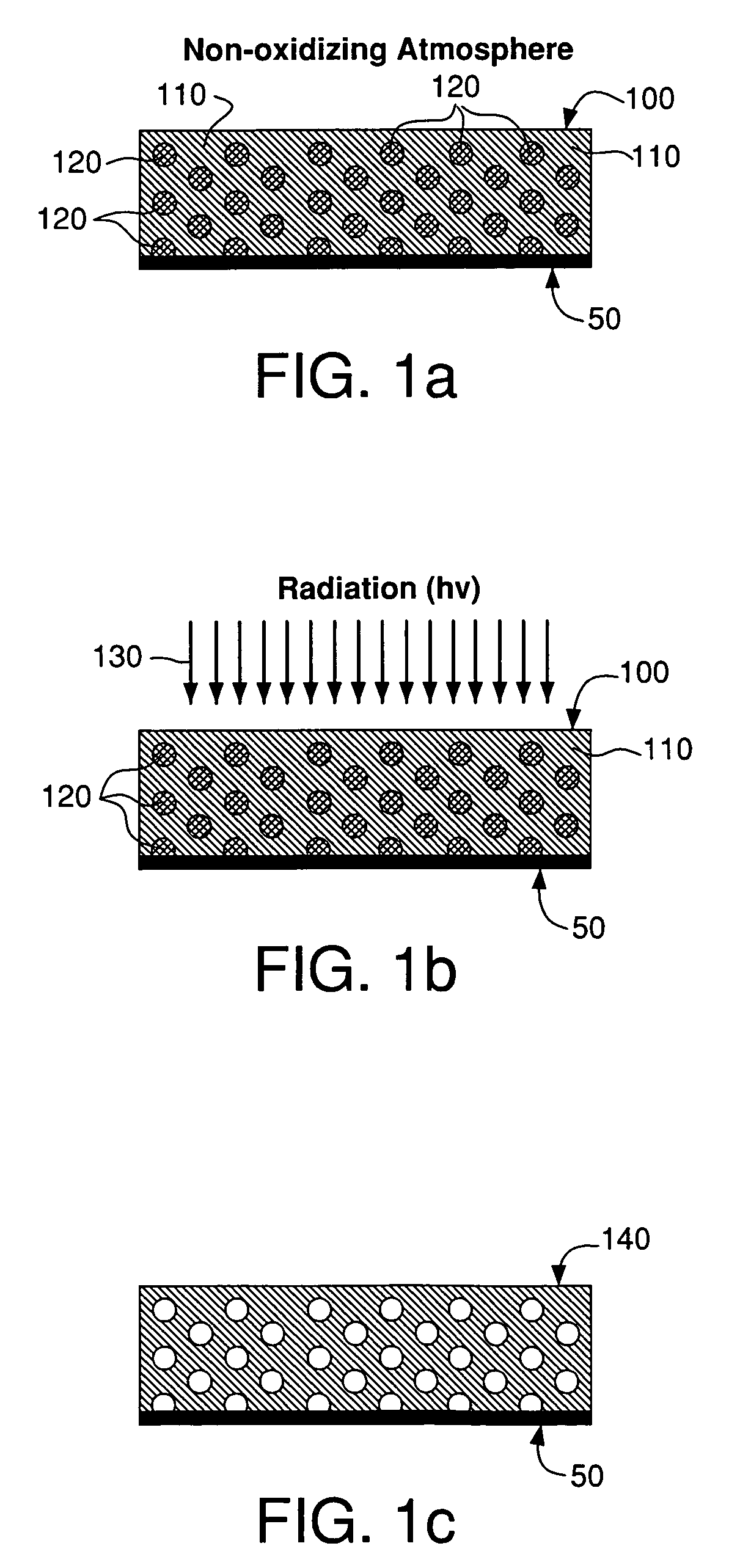

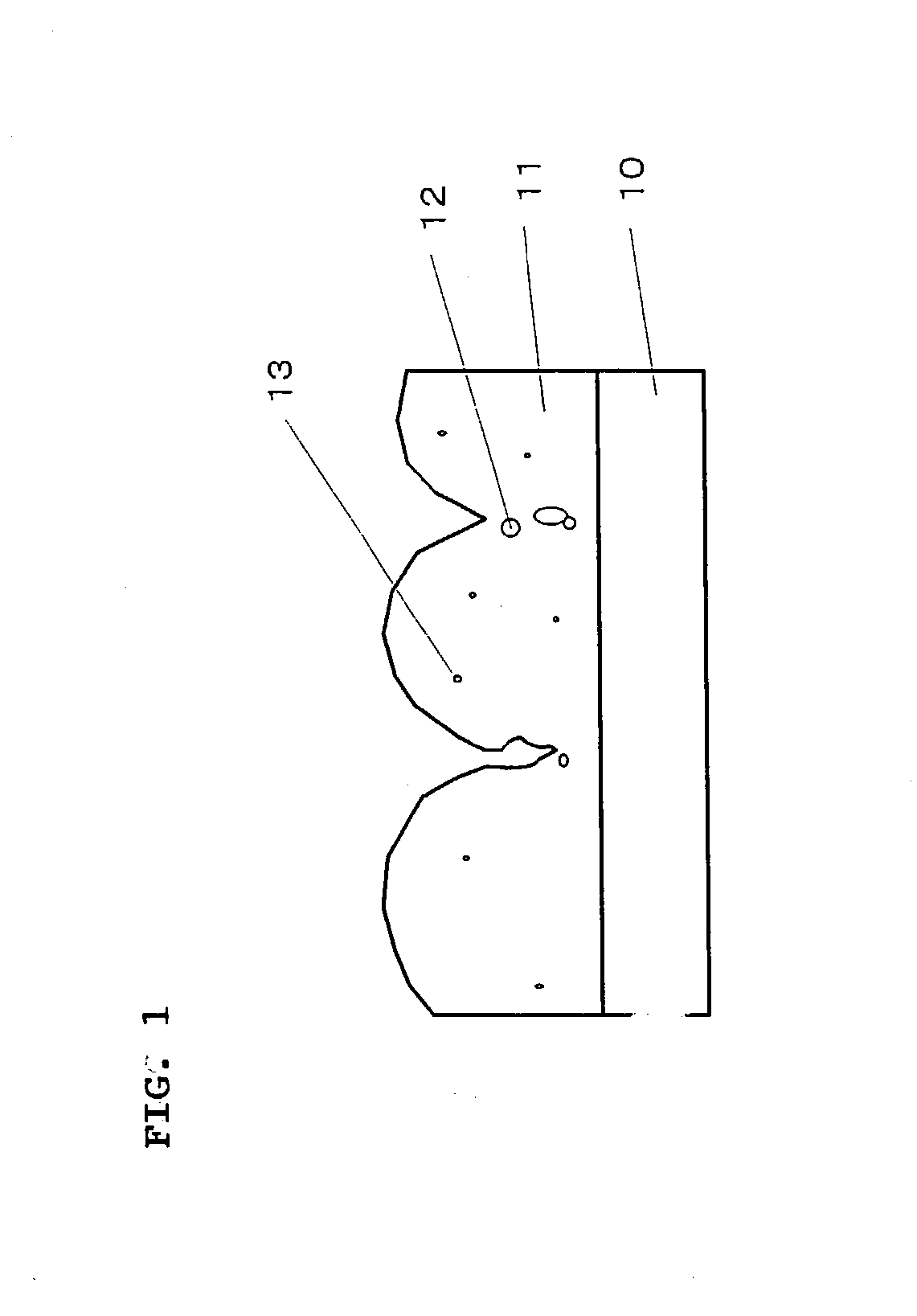

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

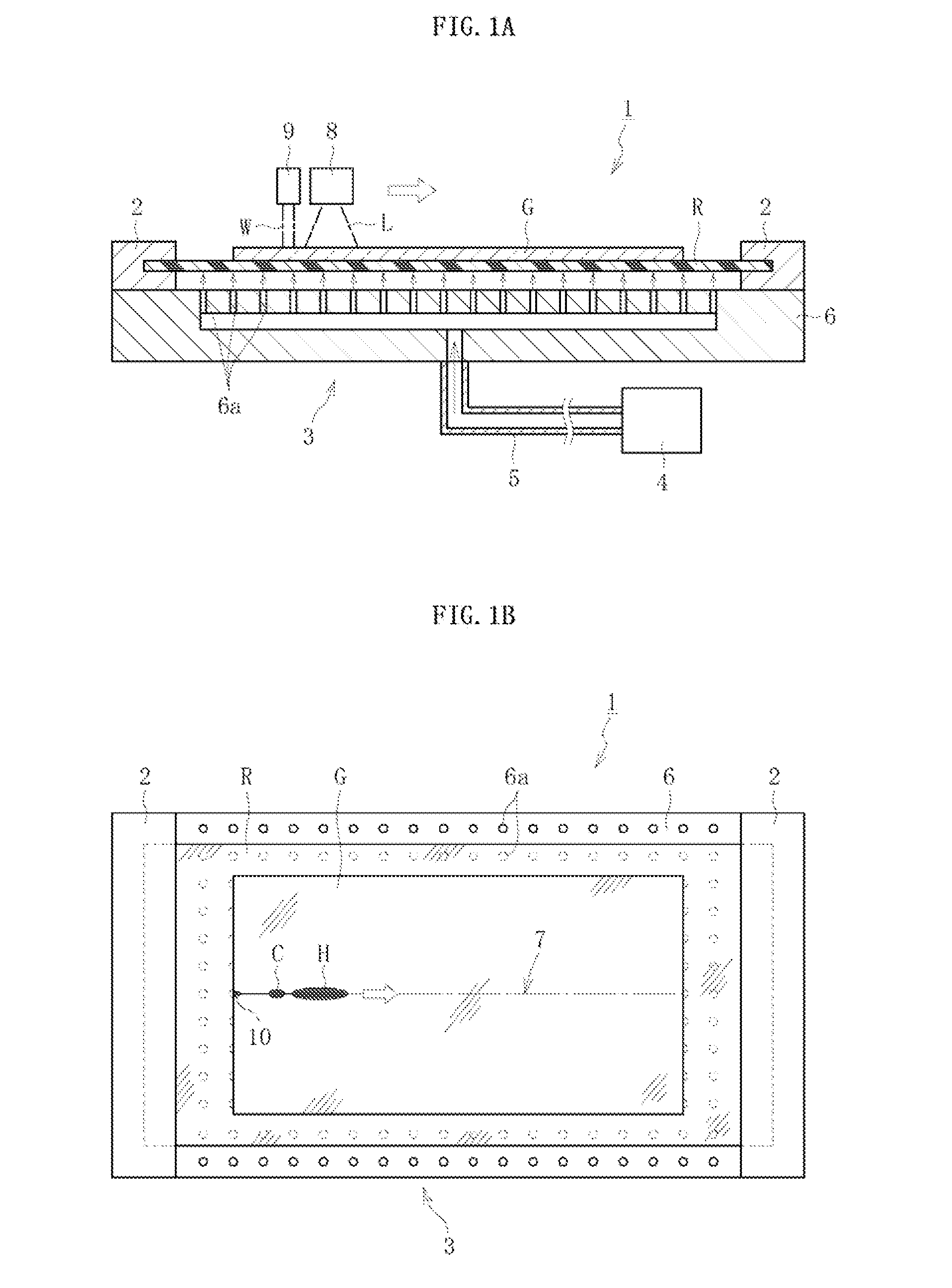

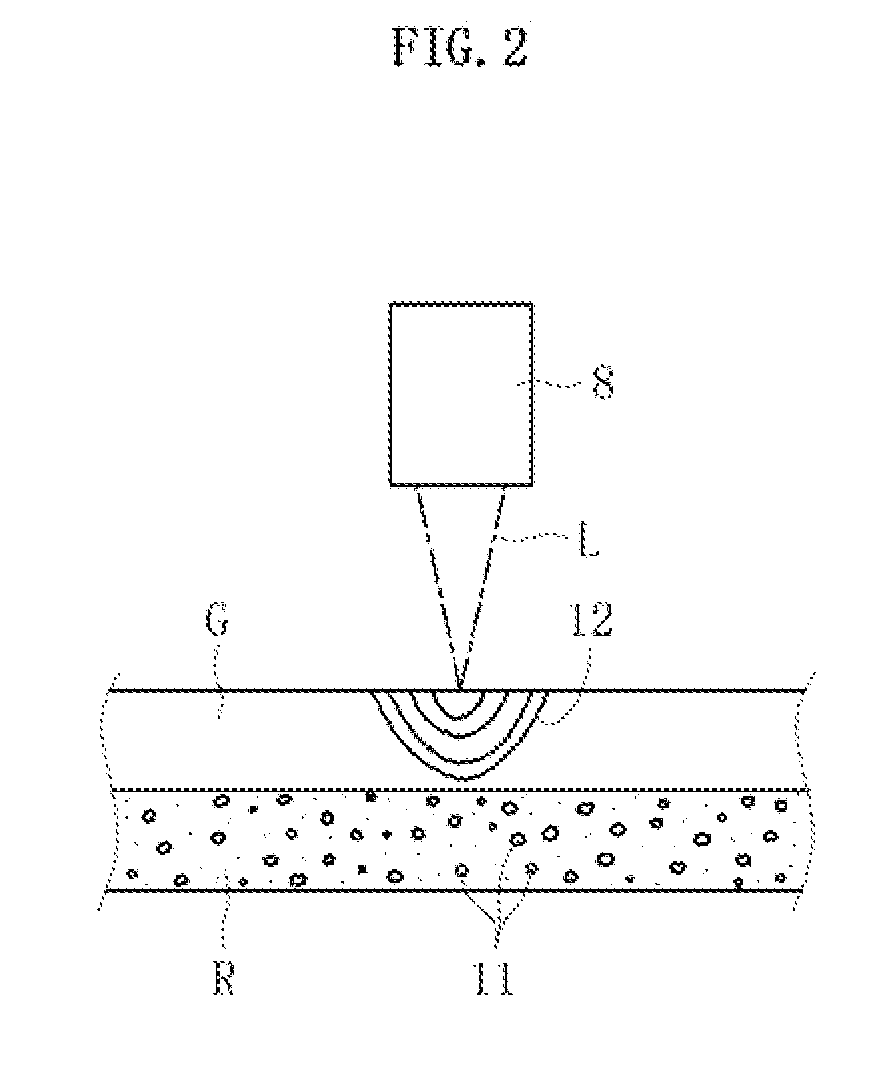

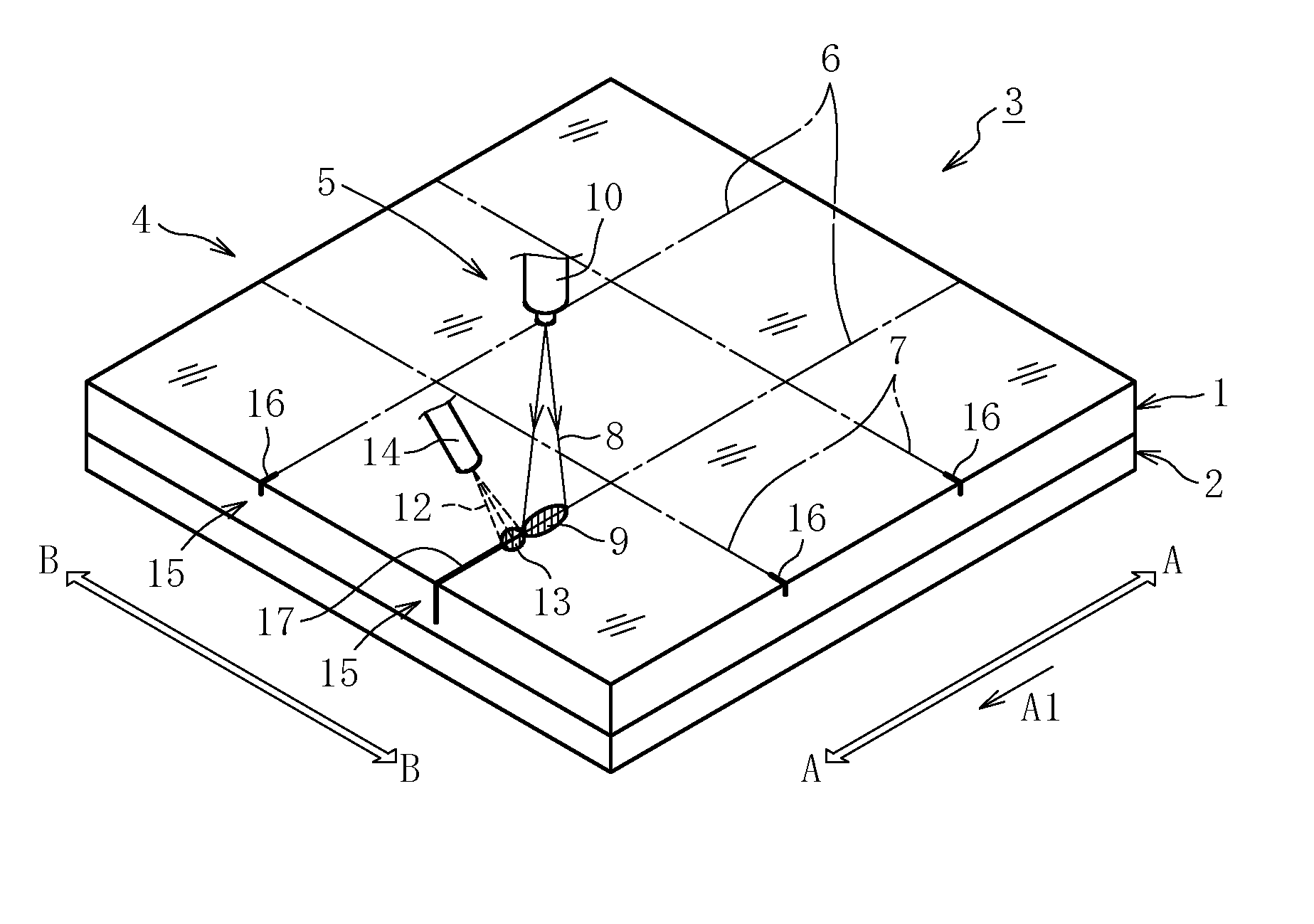

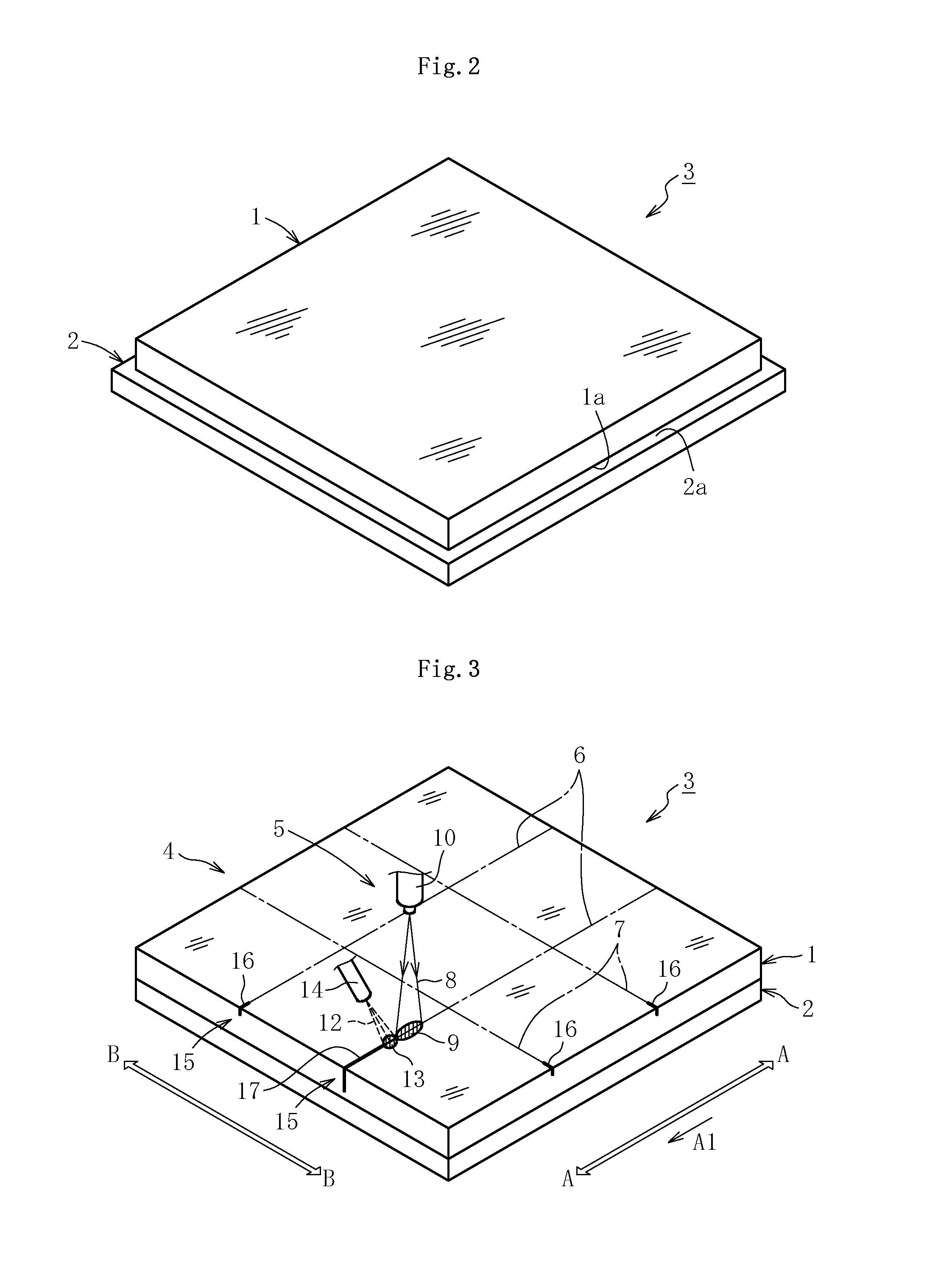

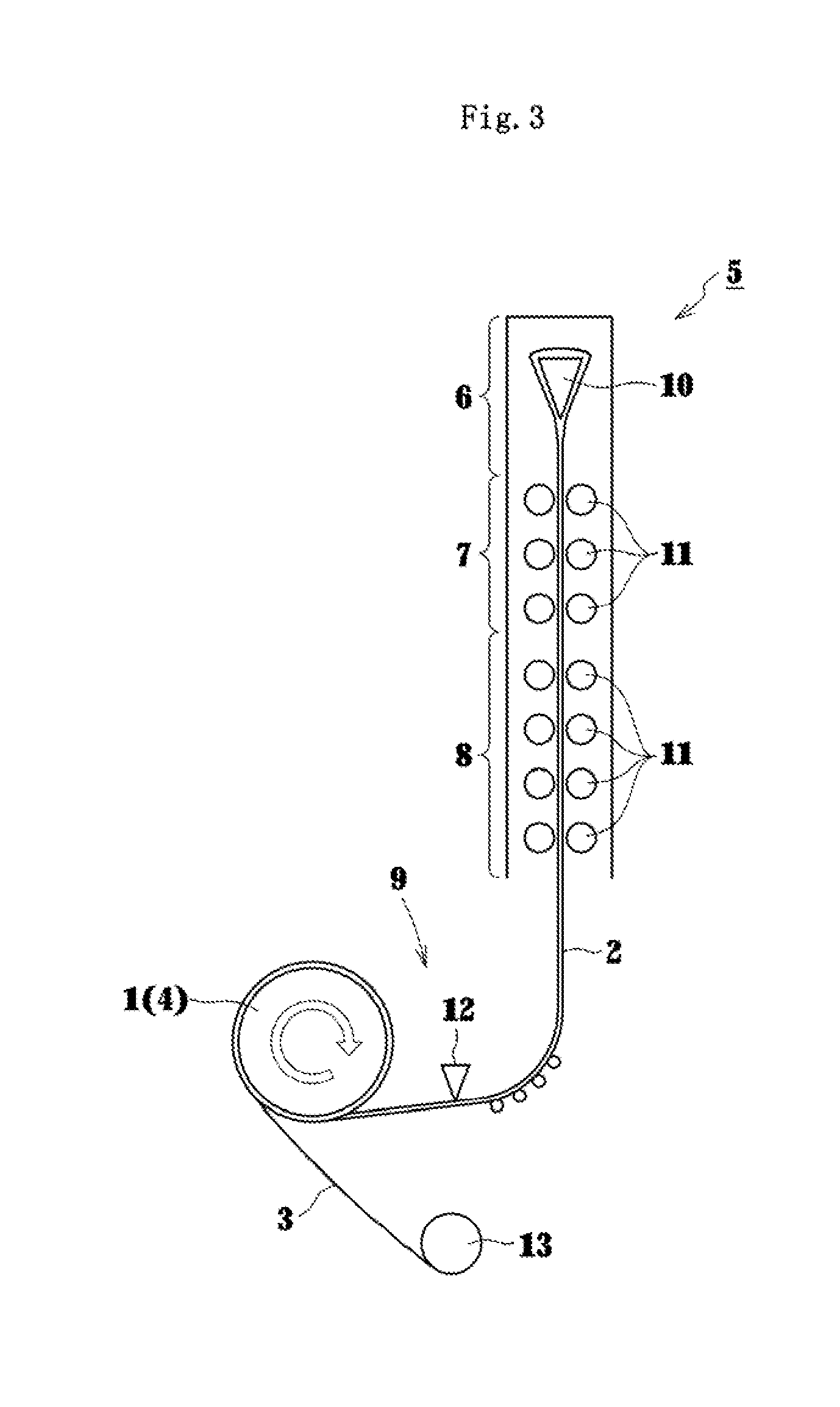

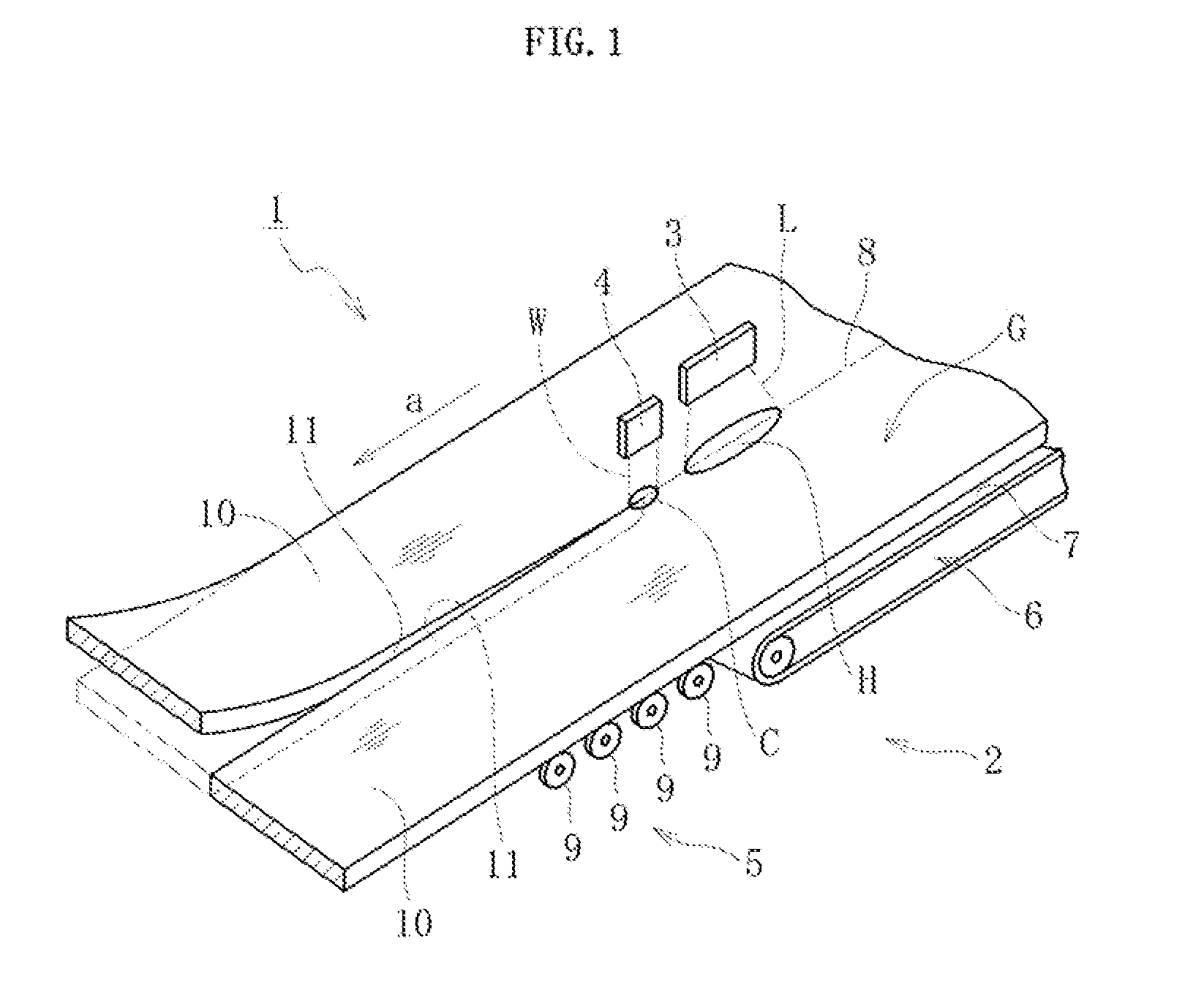

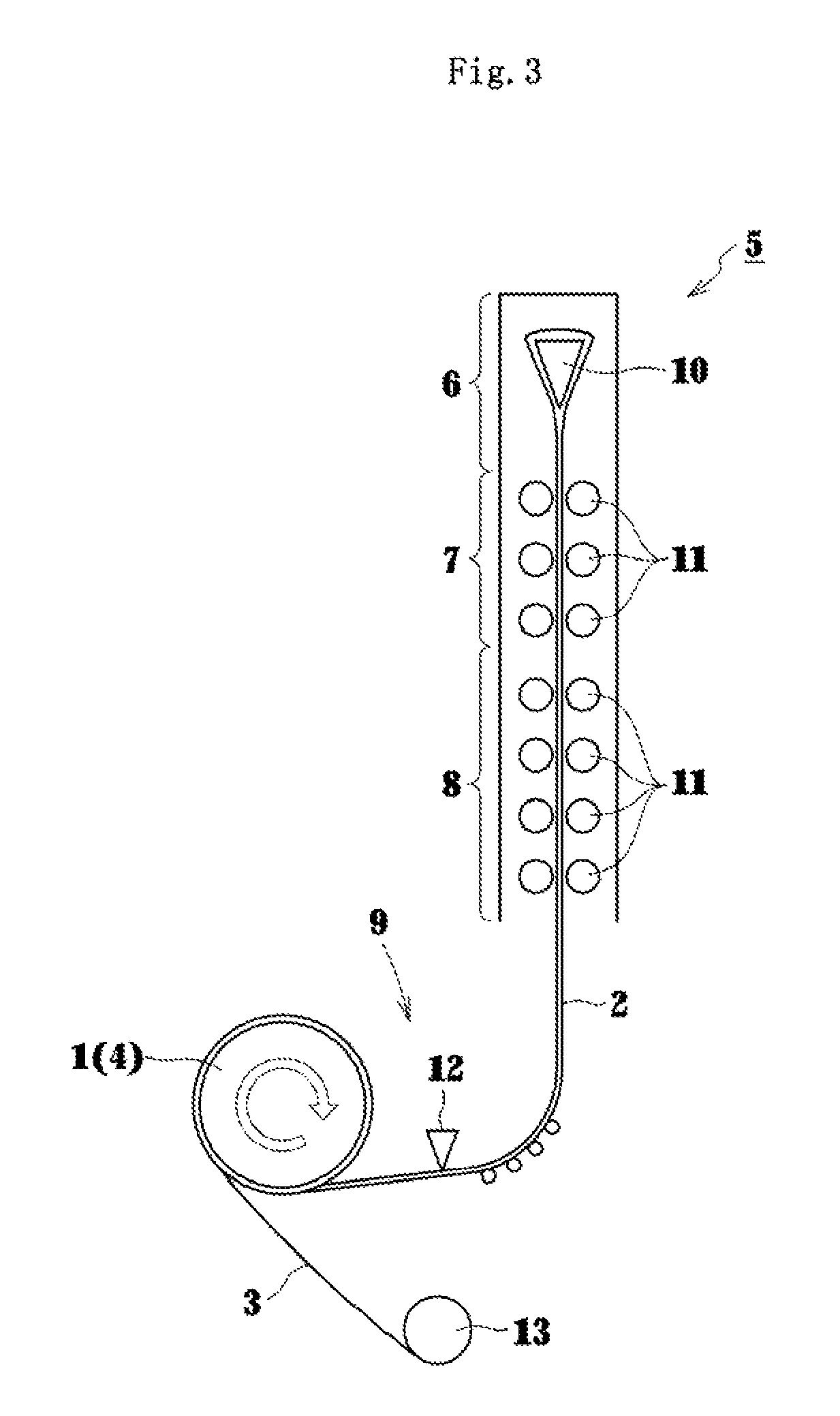

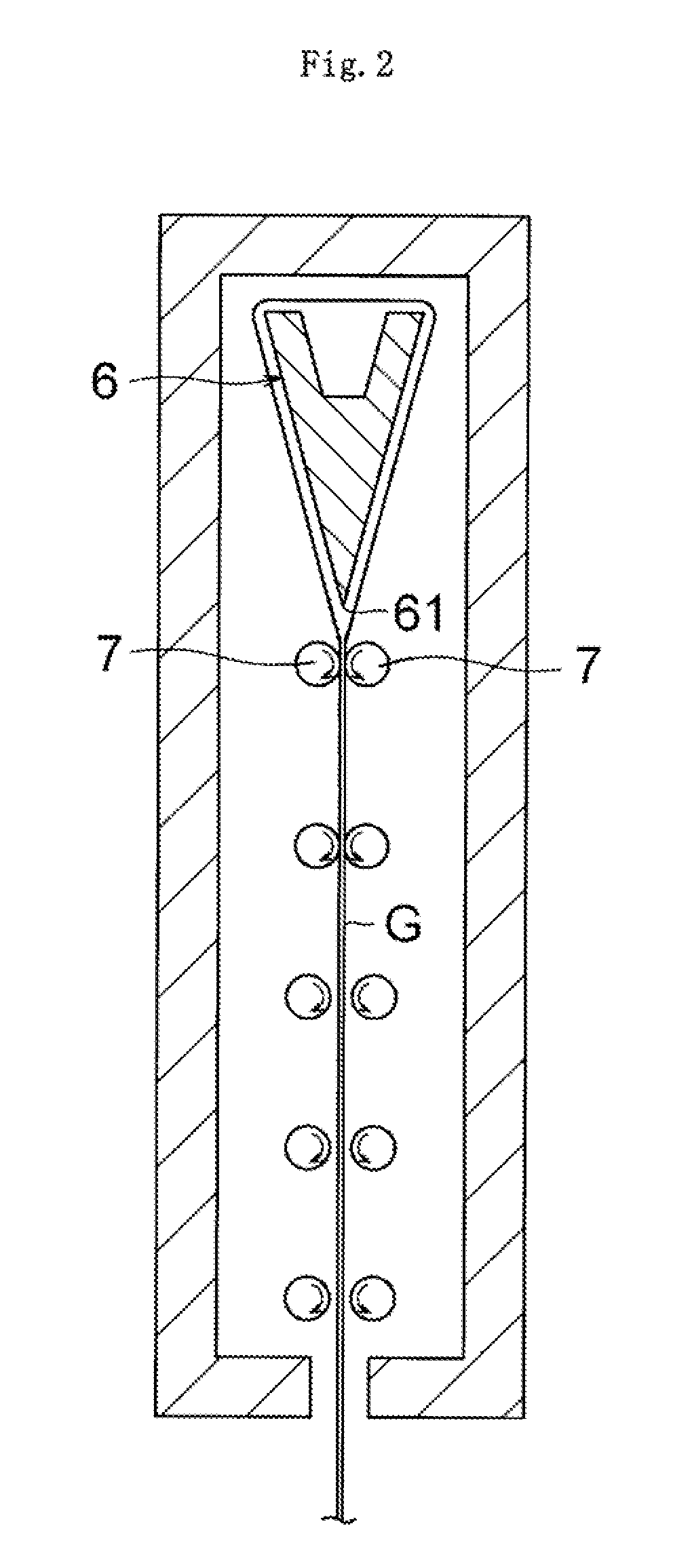

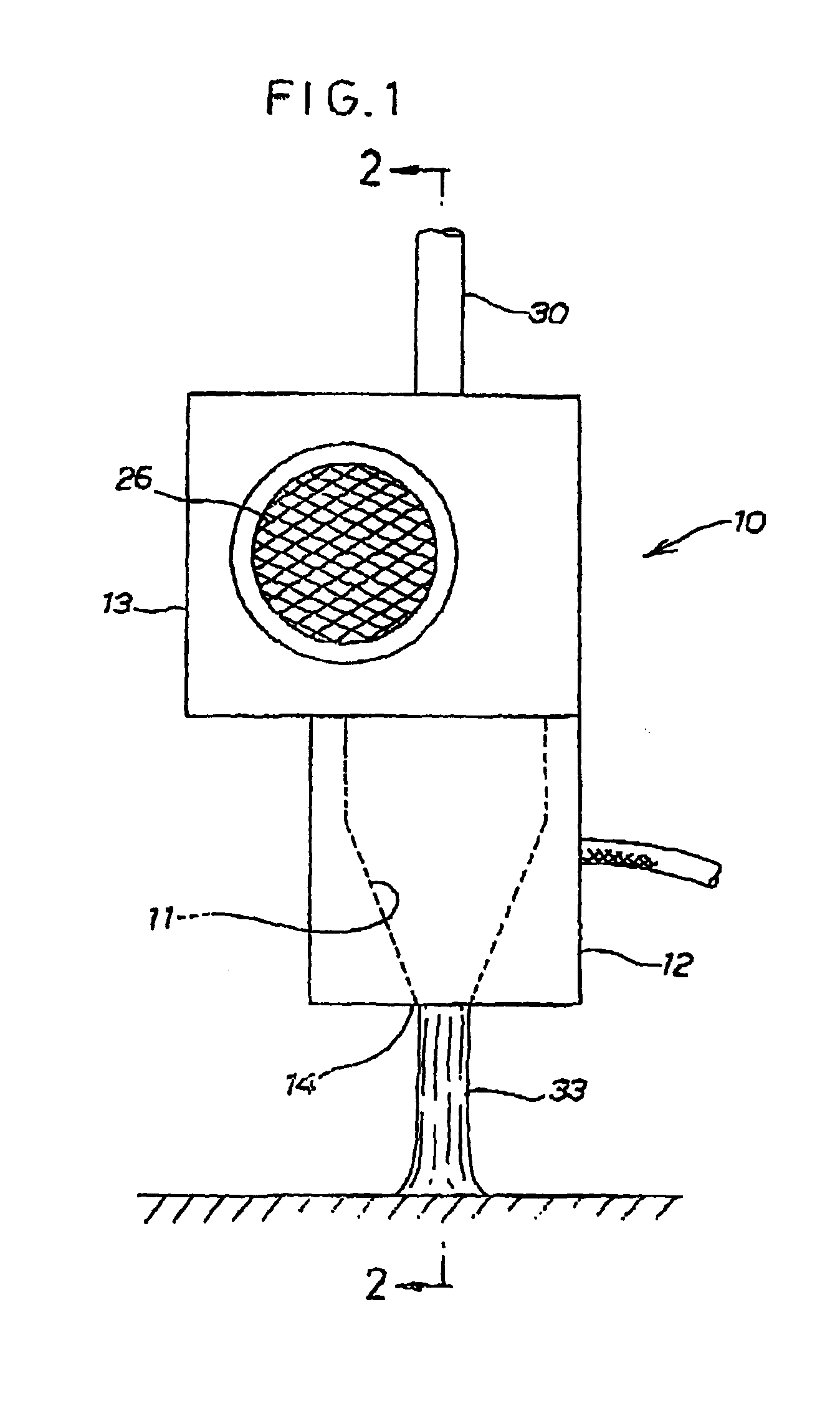

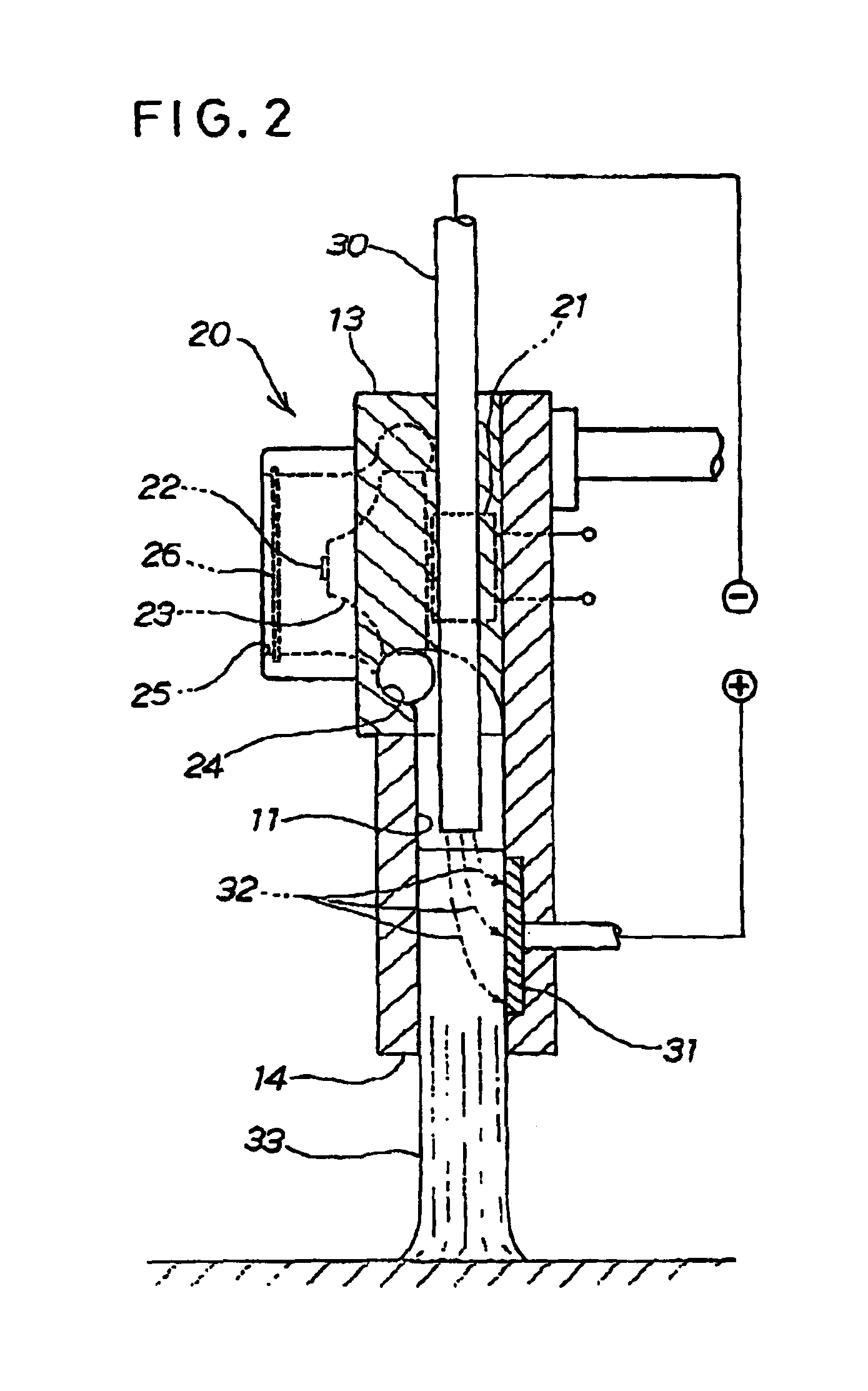

Cleaving method for a glass film, manufacturing method for a glass roll, and cleaving apparatus for a glass film

ActiveUS20120017642A1Efficient cuttingGlass drawing apparatusGlass transportation apparatusMaterials scienceGlass film

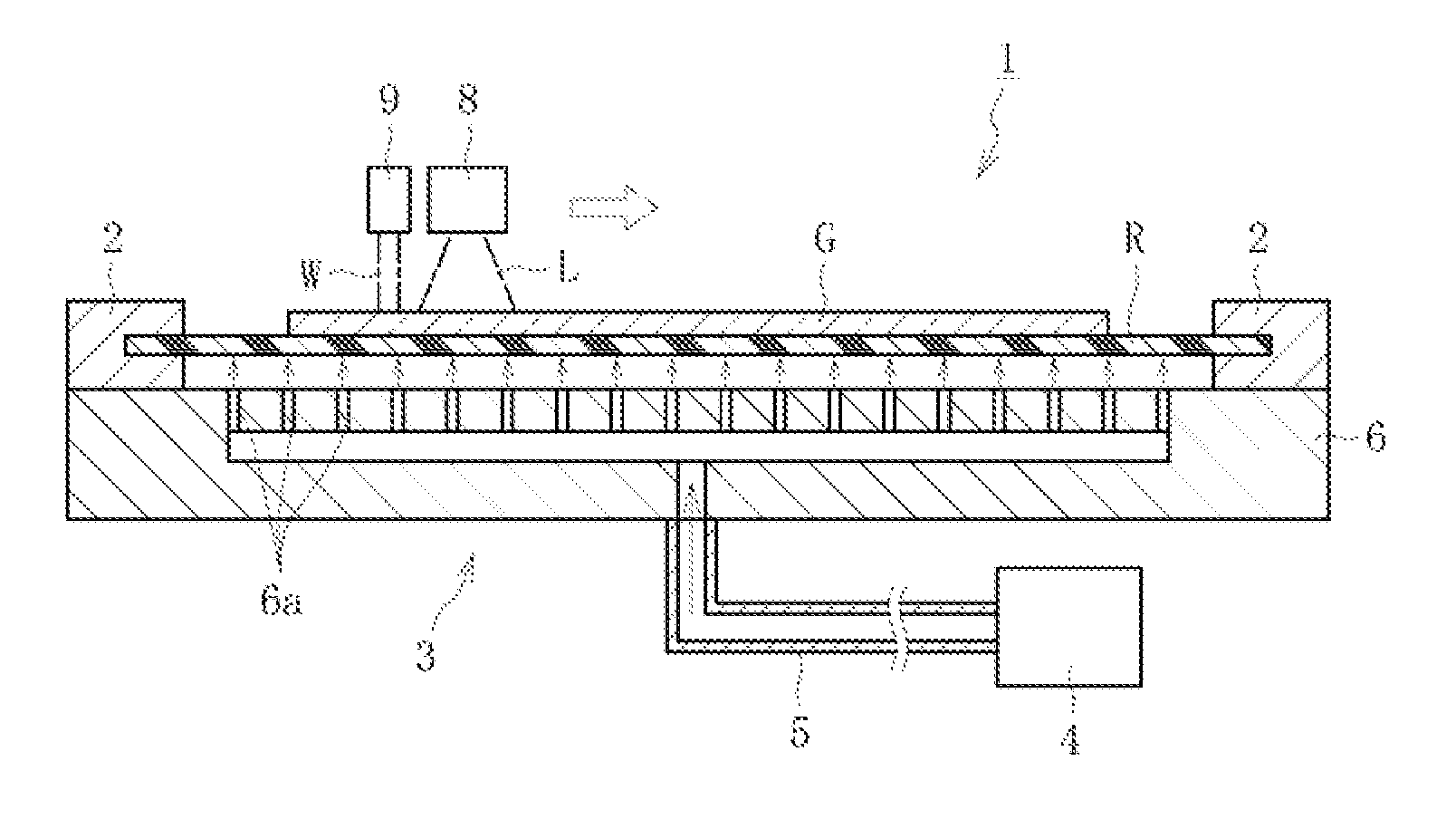

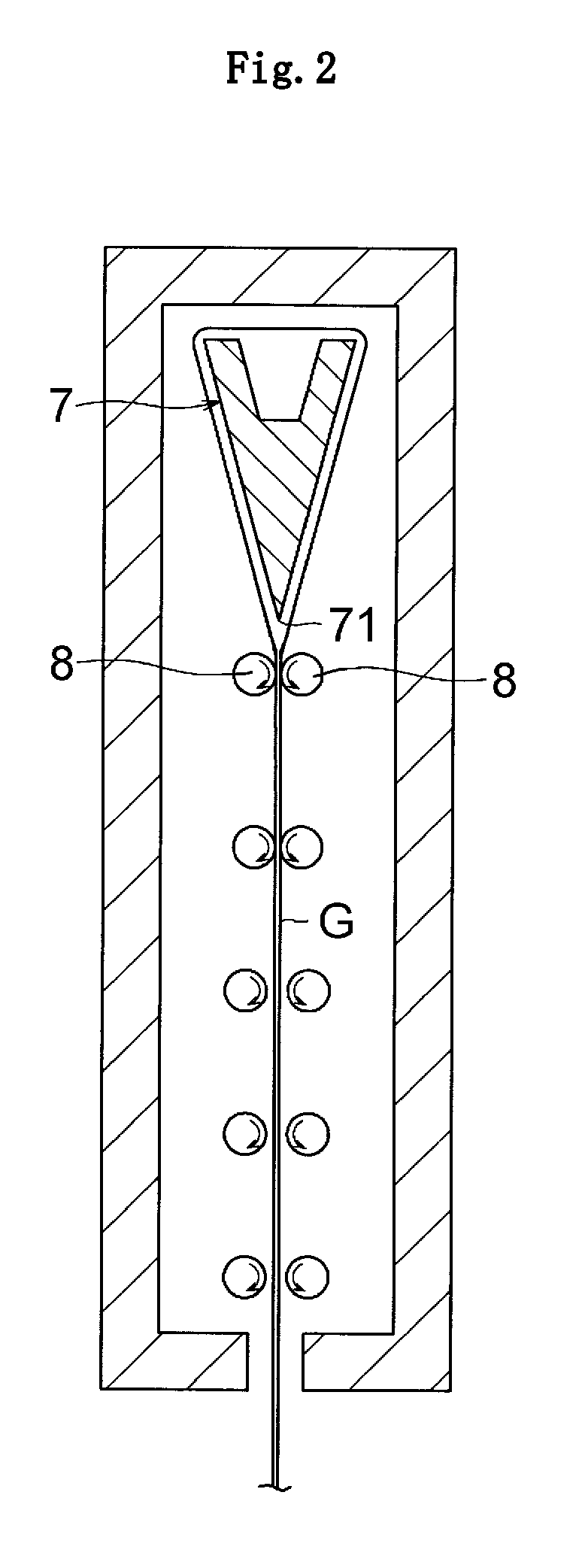

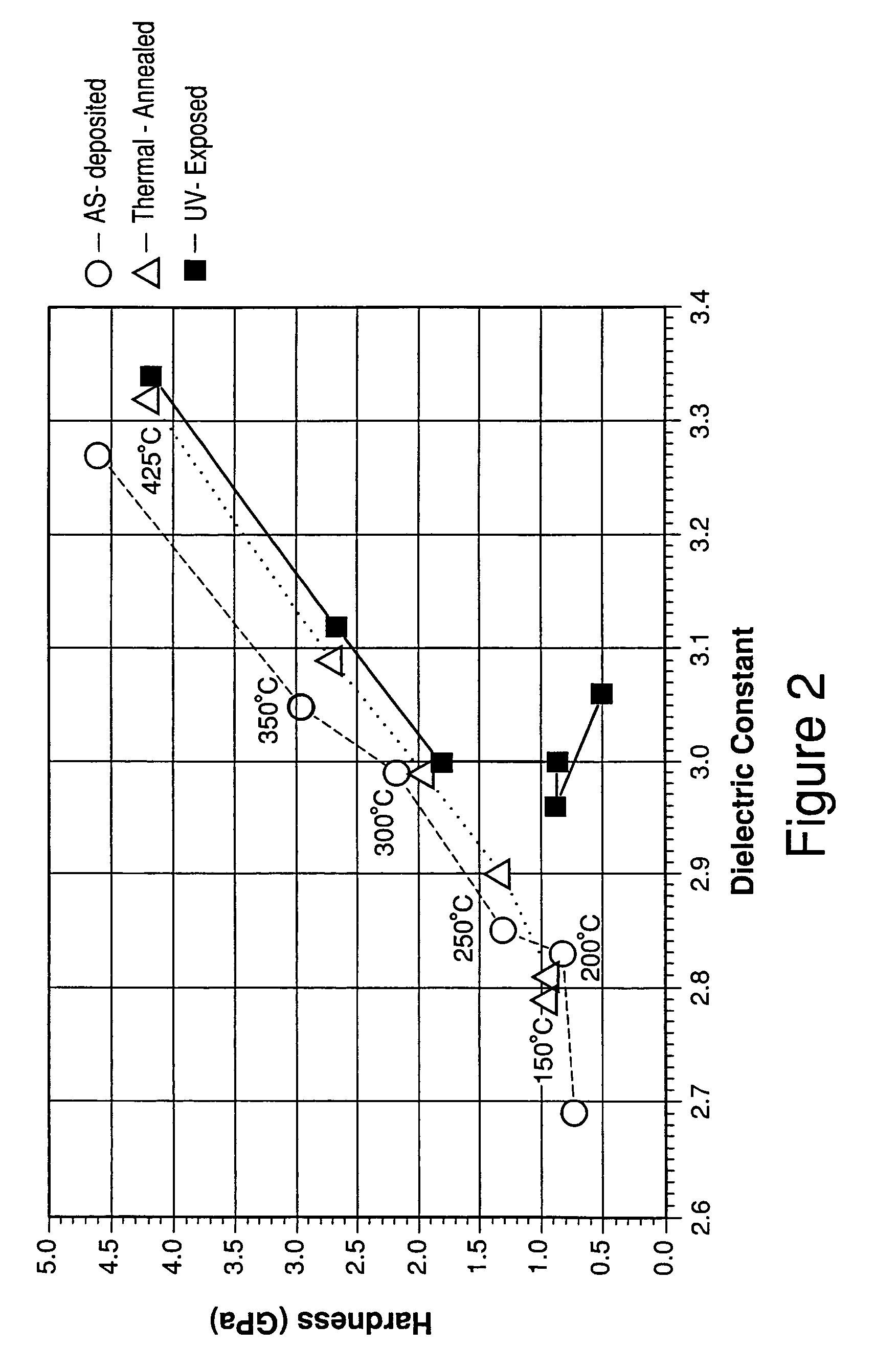

In a cleaving apparatus (1) for a glass film, an initial crack (10), which is formed at a leading end portion of a preset cleaving line (7) of a glass film (G), is propagated along the preset cleaving line (7) by a thermal stress generated in the glass film (G) through localized heating performed along the preset cleaving line (7) and cooling of a heated region resulting from the localized heating. At this time, a resin sheet (R) having higher flexibility than the glass film (G) is arranged in a cleaving region, and the resin sheet (R) is floated by blowing a gas on a lower surface of the resin sheet (R) by a floating unit (3). Then, a preset cleaving portion of the glass film (G) including the preset cleaving line (7) is lifted and supported while being covered with the floated resin sheet (R) from below, and in this state, the glass film (G) is cleaved.

Owner:NIPPON ELECTRIC GLASS CO LTD

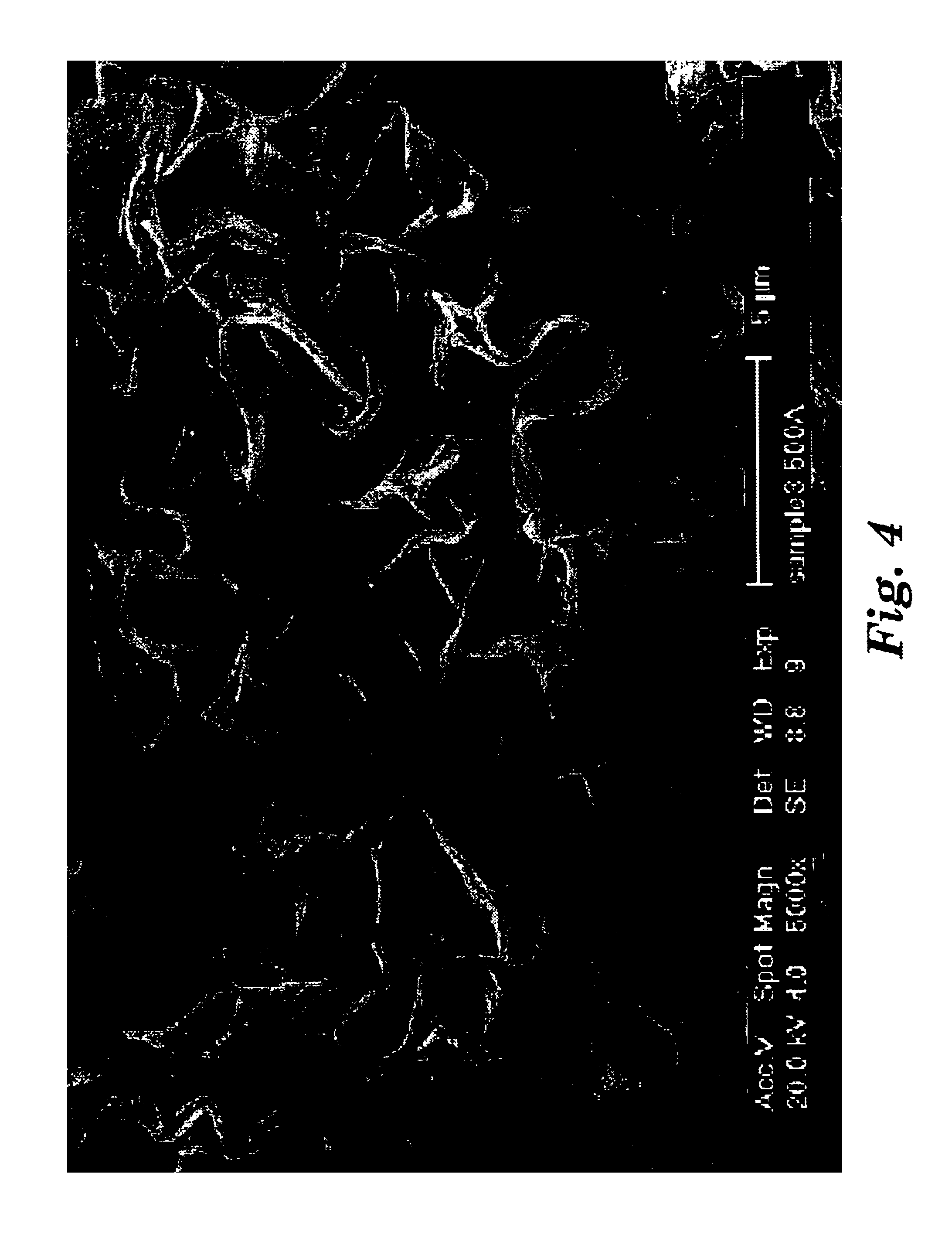

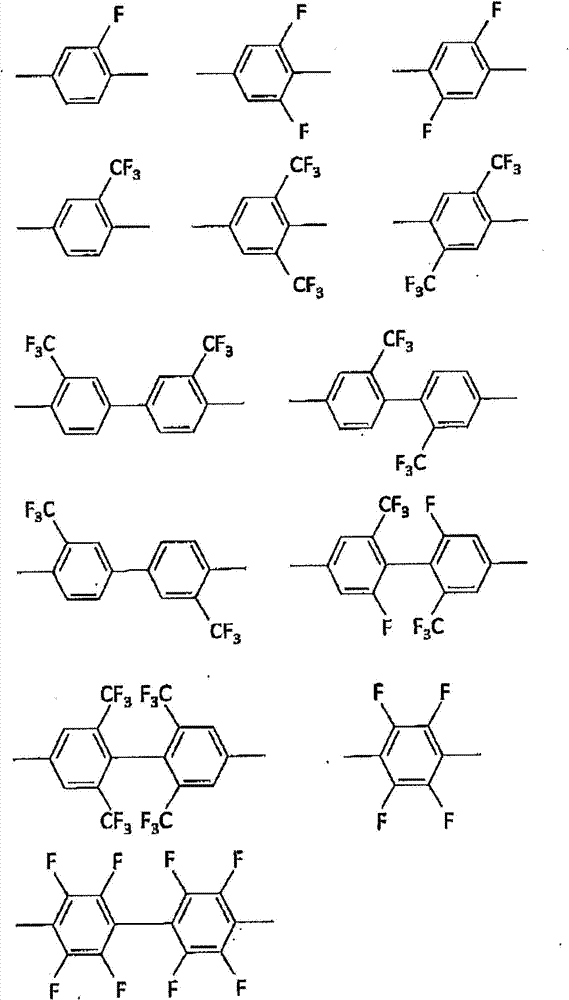

Porous low dielectric constant compositions and methods for making and using same

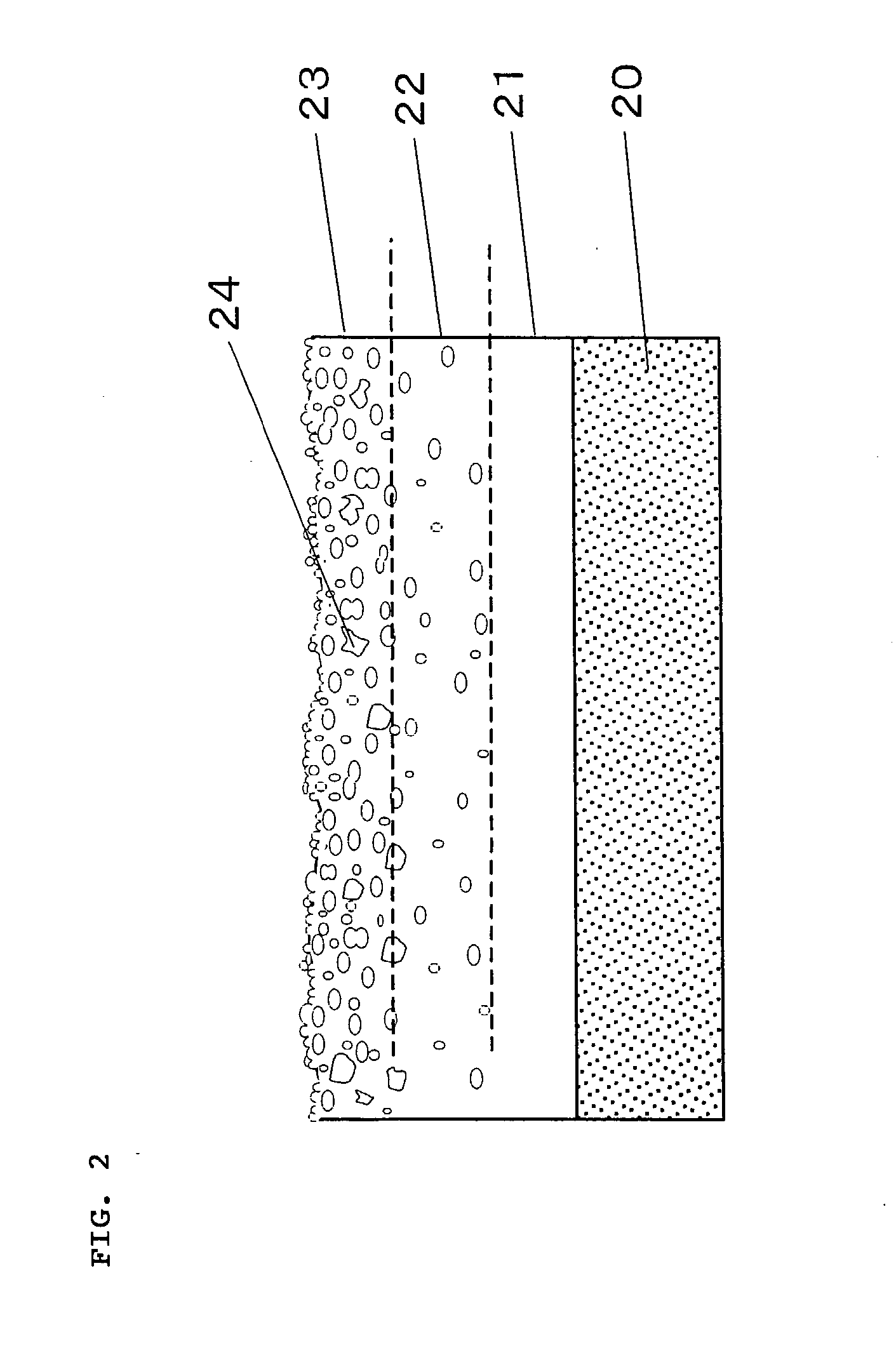

ActiveUS20060078676A1Semiconductor/solid-state device manufacturingPretreated surfacesConstant compositionCarboxylic acid

A porous organosilicate glass (OSG) film: SivOwCxHyFz, where v+w+x+y+z=100%, v is 10 to 35 atomic %, w is 10 to 65 atomic %, x is 5 to 30 atomic %, y is 10 to 50 atomic % and z is 0 to 15 atomic %, has a silicate network with carbon bonds as methyl groups (Si—CH3) and contains pores with diameter less than 3 nm equivalent spherical diameter and dielectric constant less than 2.7. A preliminary film is deposited by a chemical vapor deposition method from organosilane and / or organosiloxane precursors, and independent pore-forming precursors. Porogen precursors form pores within the preliminary film and are subsequently removed to provide the porous film. Compositions, film forming kits, include organosilane and / or organosiloxane compounds containing at least one Si—H bond and porogen precursors of hydrocarbons containing alcohol, ether, carbonyl, carboxylic acid, ester, nitro, primary amine, secondary amine, and / or tertiary amine functionality or combinations.

Owner:VERSUM MATERIALS US LLC

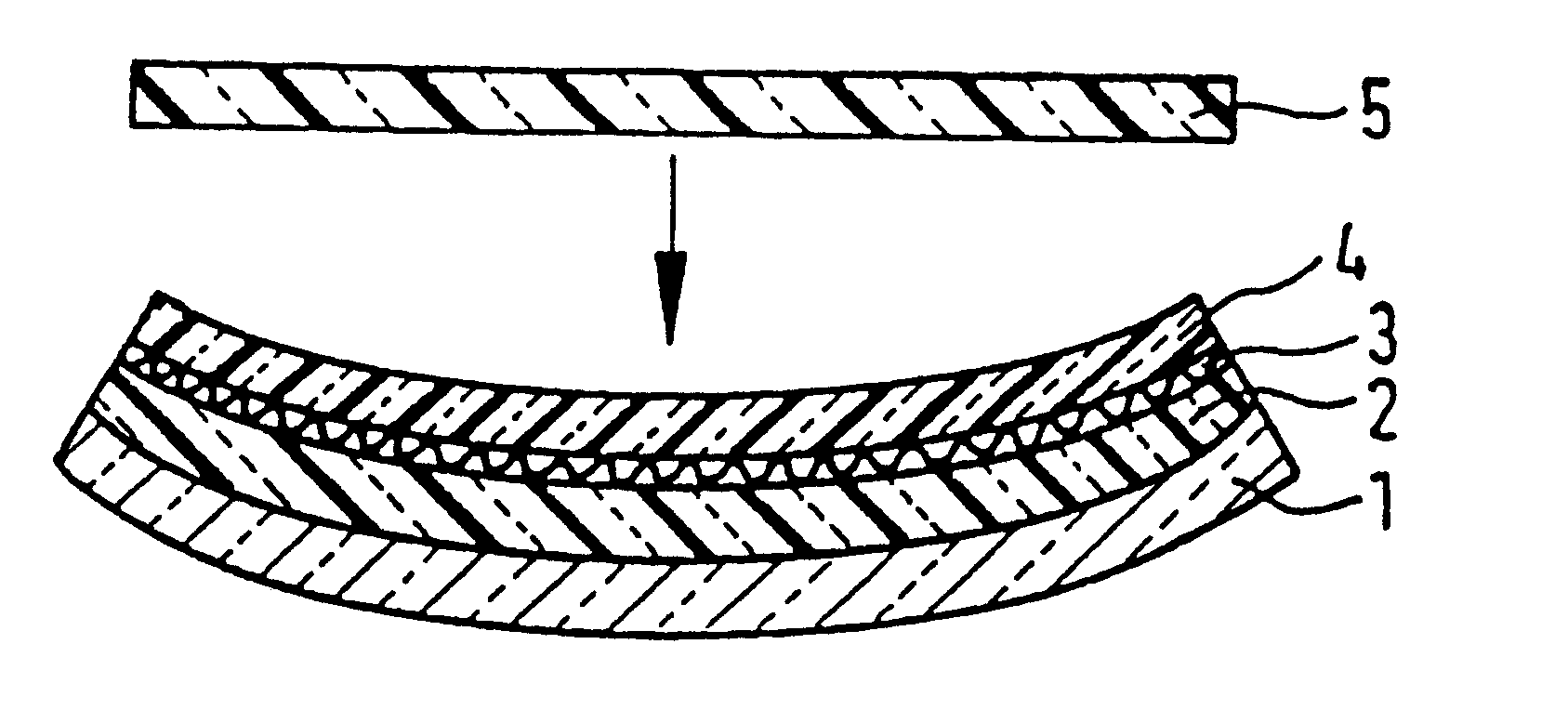

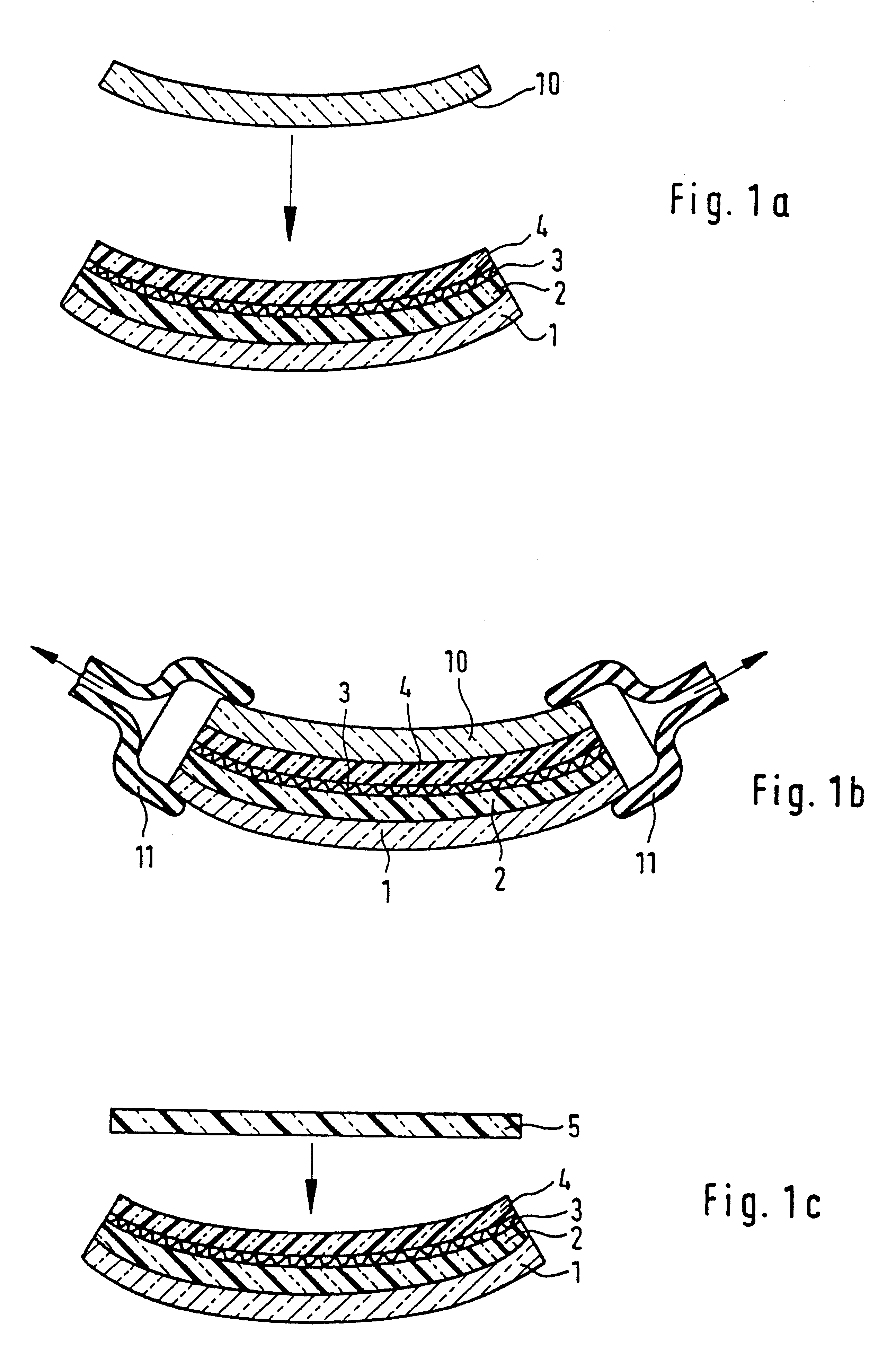

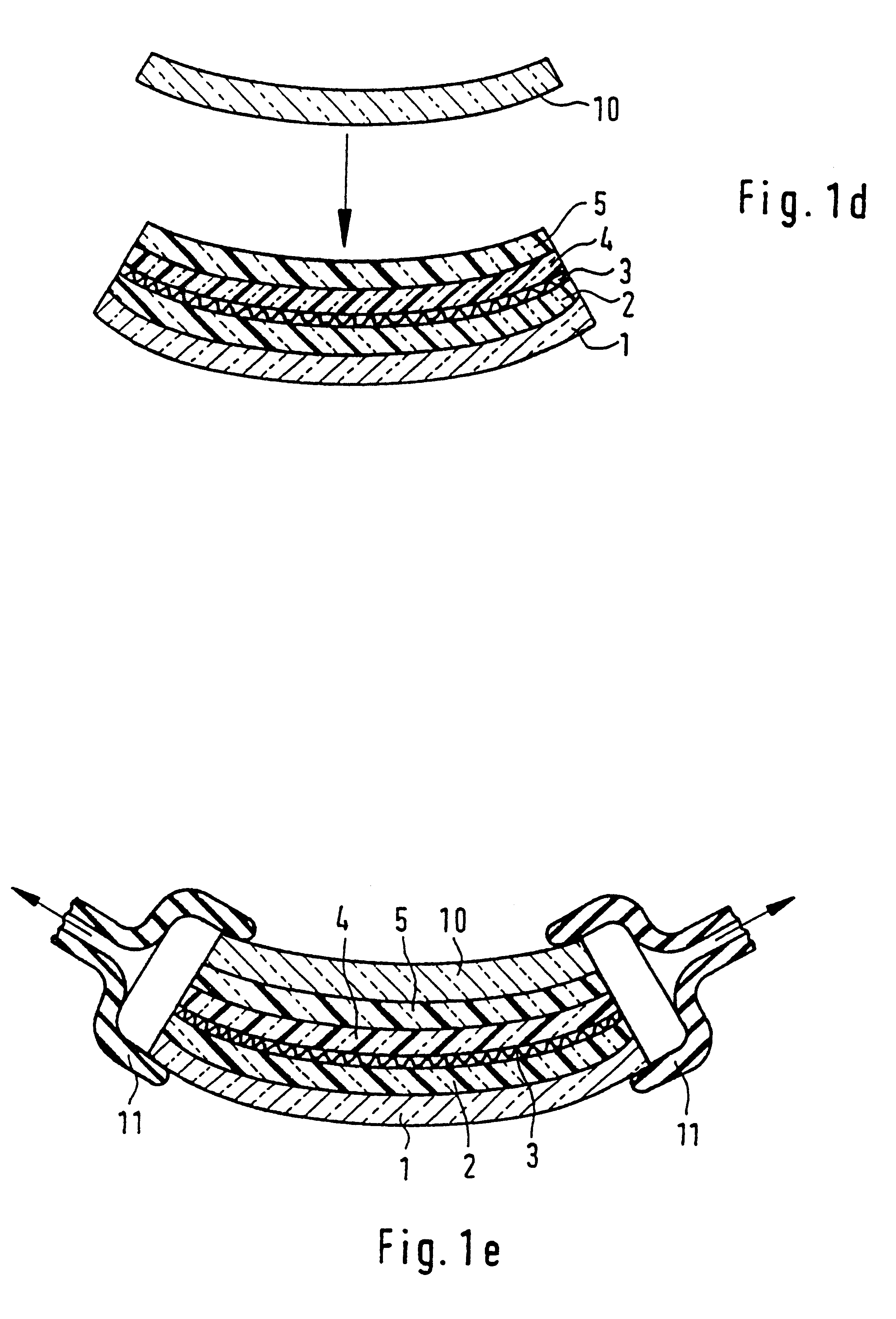

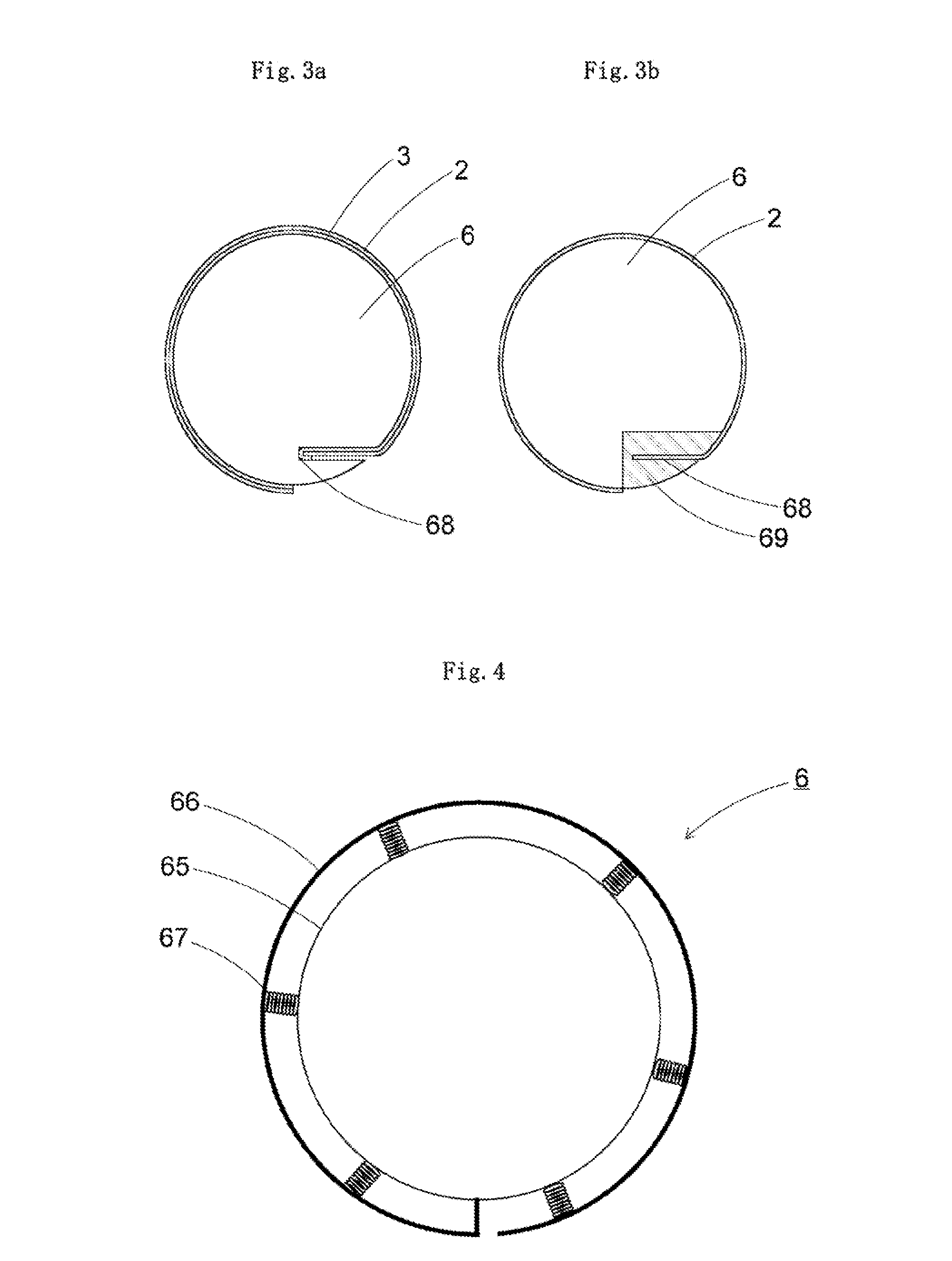

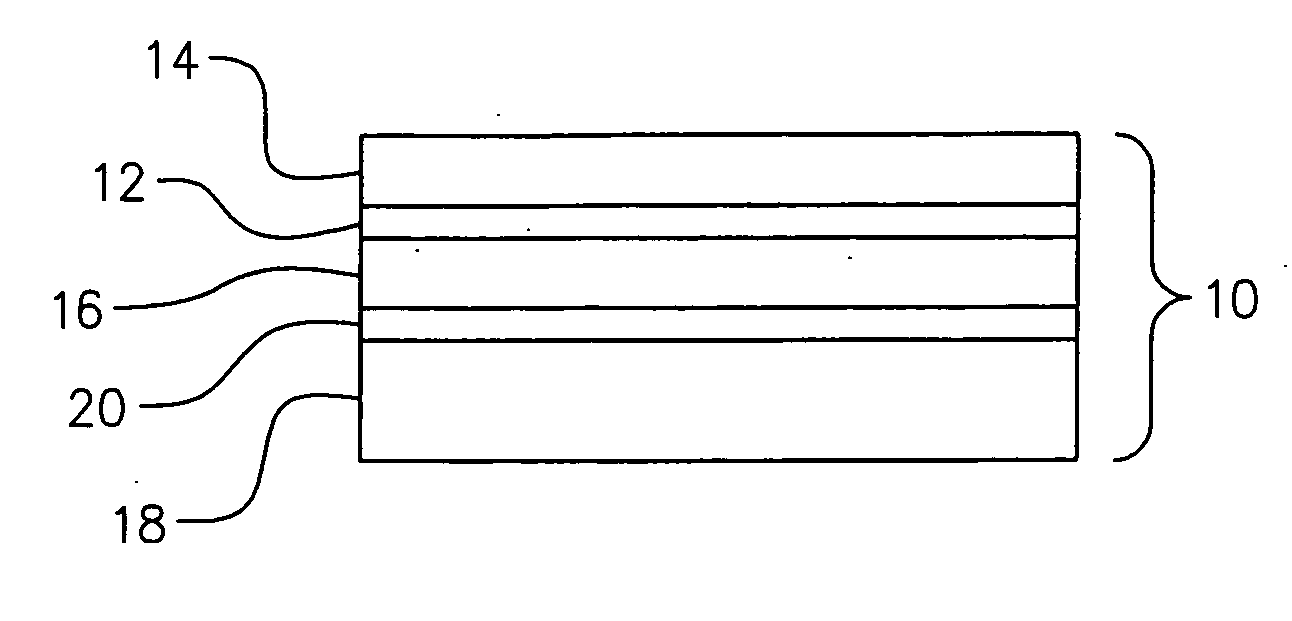

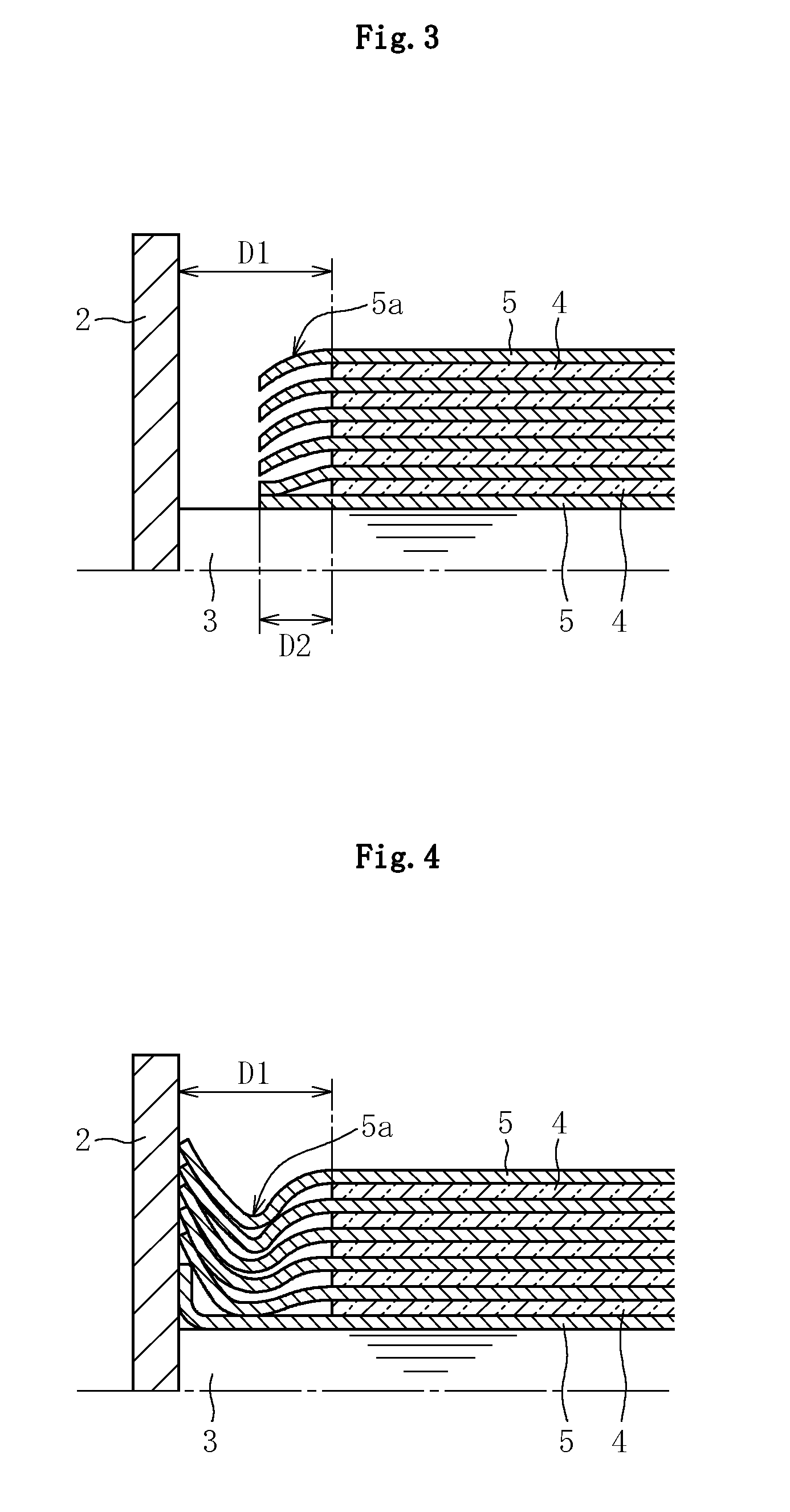

Process for producing a curved laminated safety glass sheet

InactiveUS6261398B1Avoid wrinklesSimple preparation processLaminationLamination apparatusThin layerEngineering

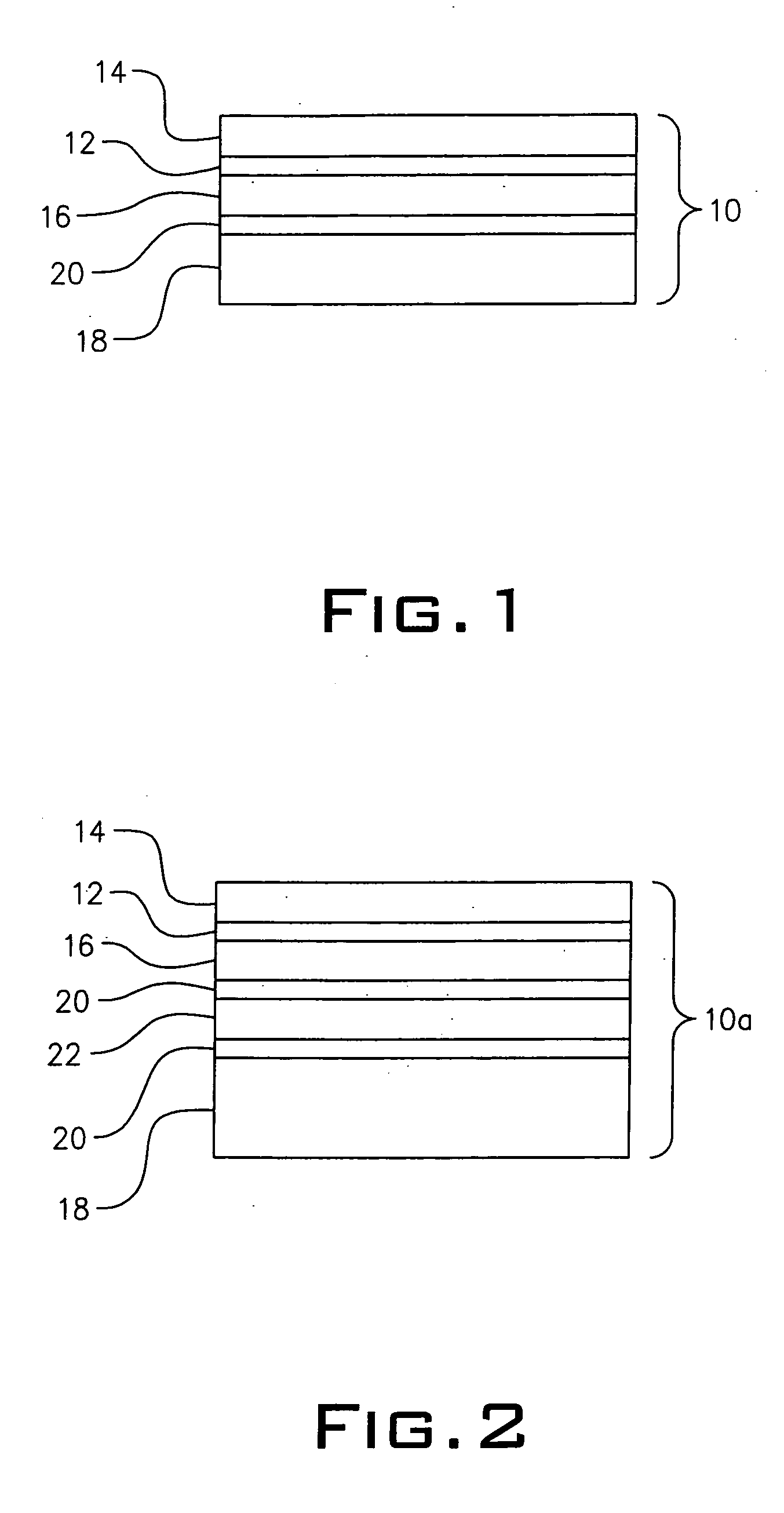

This invention concerns a process for producing a curved, laminated safety glass sheet from a first curved glass sheet (1), a first laminated layer (2), a thermoplastic substrate sheet (4) with a biaxially drawn thin-layer system (3), a second laminated layer (5), and a second curved glass sheet (10) conforming to the first one. To avoid formation of folds in the substrate layer, the process has the following steps: (a) a prelaminated sheet consisting of the first laminated layer (2) and the substrate sheet (4) is superimposed with its laminated layer facing the first glass sheet, (b) a bend-resistant cover sheet (10) conforming to the first glass sheet (1) is superimposed on the prelaminated sheet, (c) the glass layer packet formed out of the first glass sheet (1) and the prelaminated sheet with the cover sheet (10) superimposed upon it is preliminarily bonded by removing the air and subjecting it to pressure and heat, (d) the cover sheet (10) is removed, (e) the second laminated layer (5) and the second glass sheet (10) are superimposed on the preliminarily bonded glass-film pocket, (f) the laminate so formed is preliminarily bonded by removing the air and subjecting it to pressure and heat, (g) the preliminarily bonded laminate is finally bonded into a laminated safety glass sheet by subjecting it to pressure and heat.

Owner:PILKINGTON AUTOMOTIVE DEUT GMBH

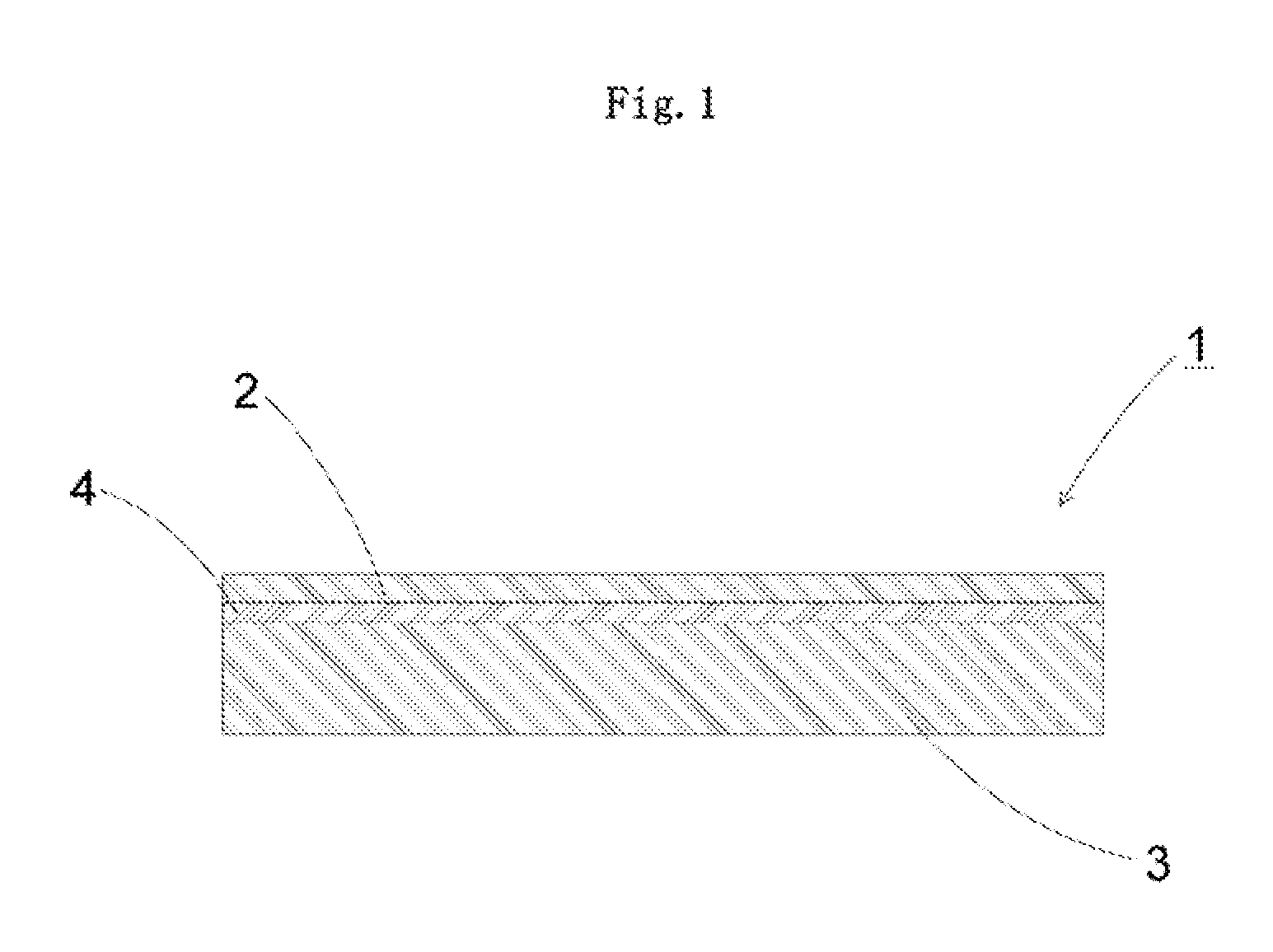

Glass film cutting method and glass film laminate

InactiveUS20130280495A1Appropriate adhesionGlass/slag layered productsGlass reforming apparatusSurface roughnessLaser scribing

Owner:NIPPON ELECTRIC GLASS CO LTD

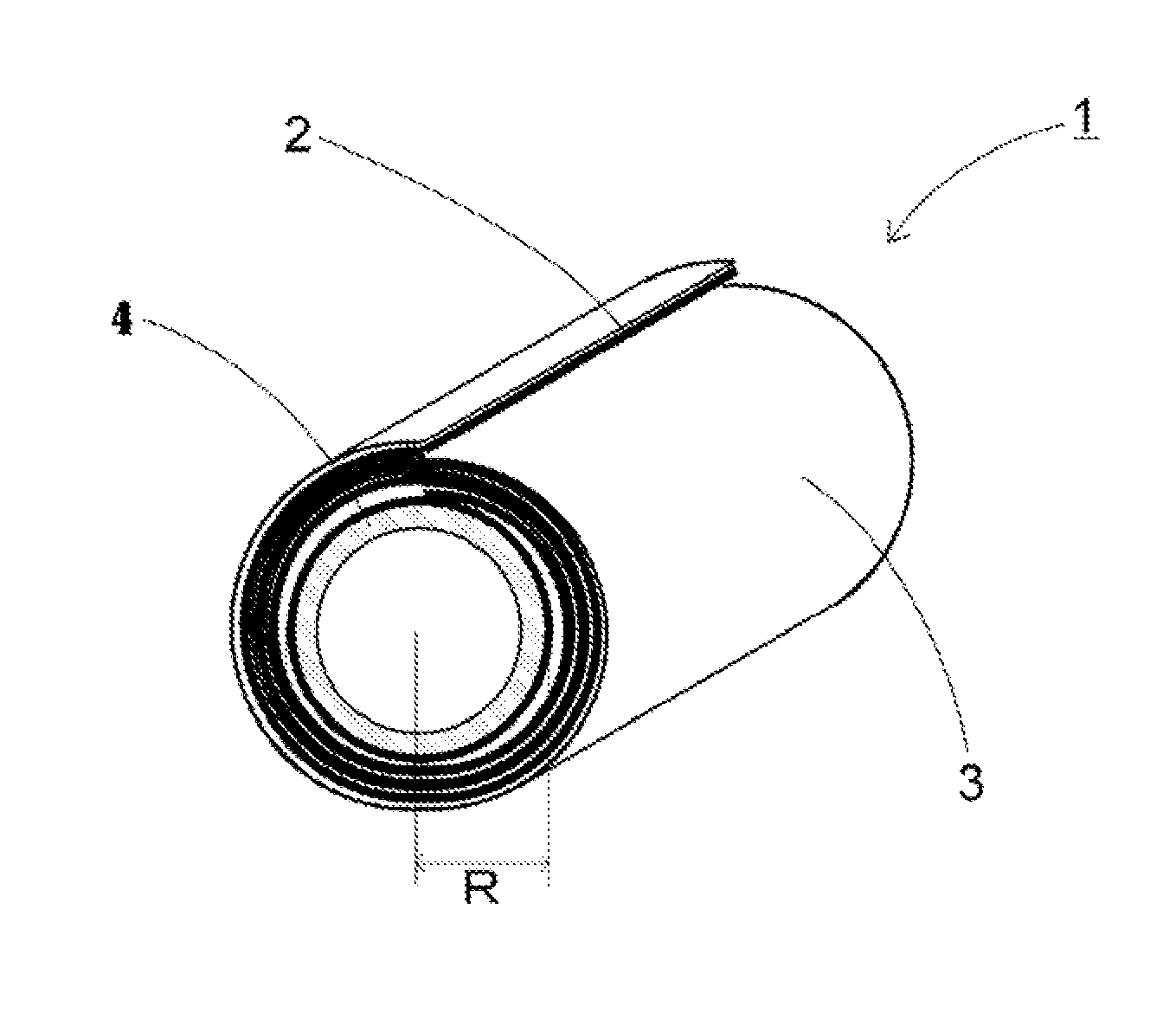

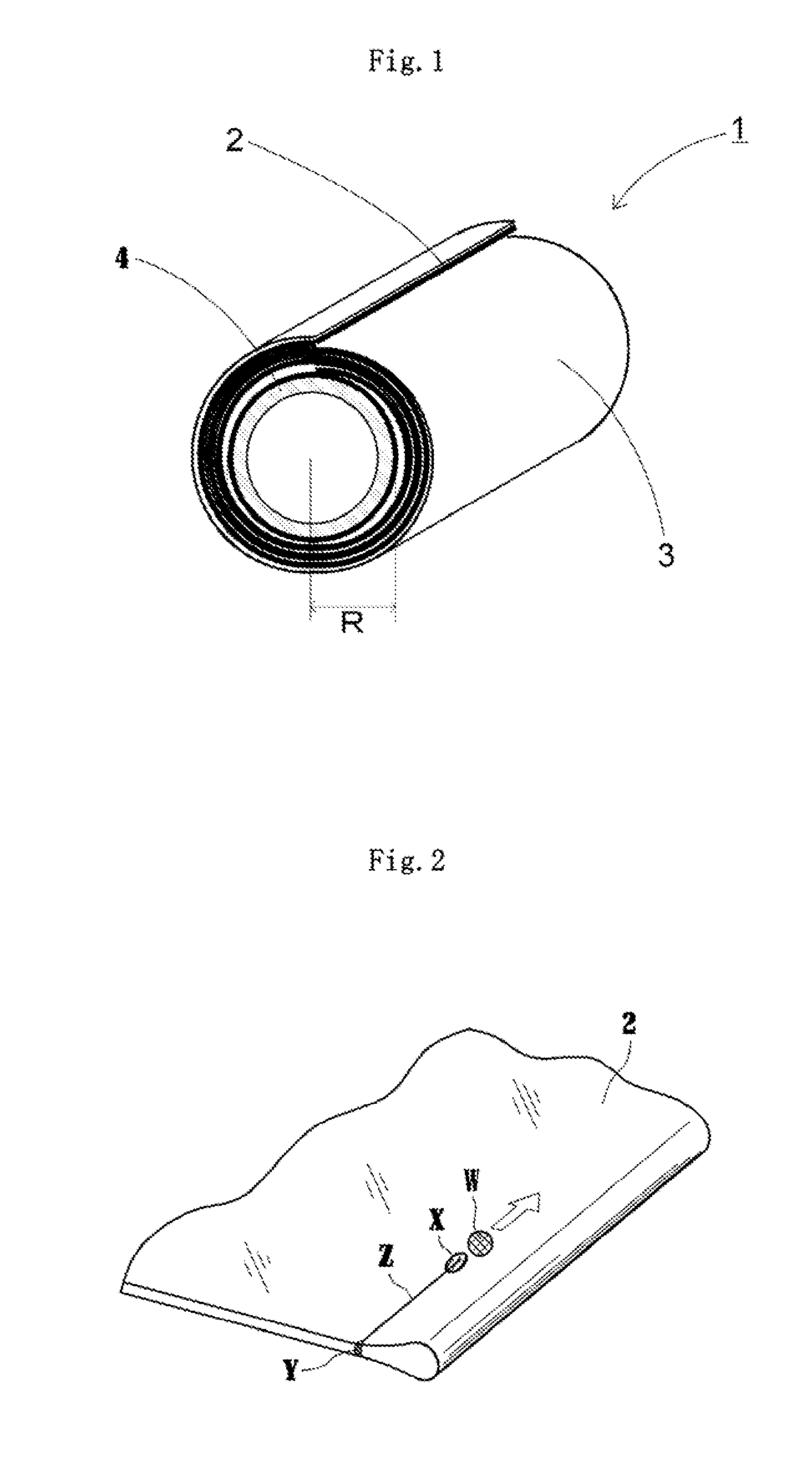

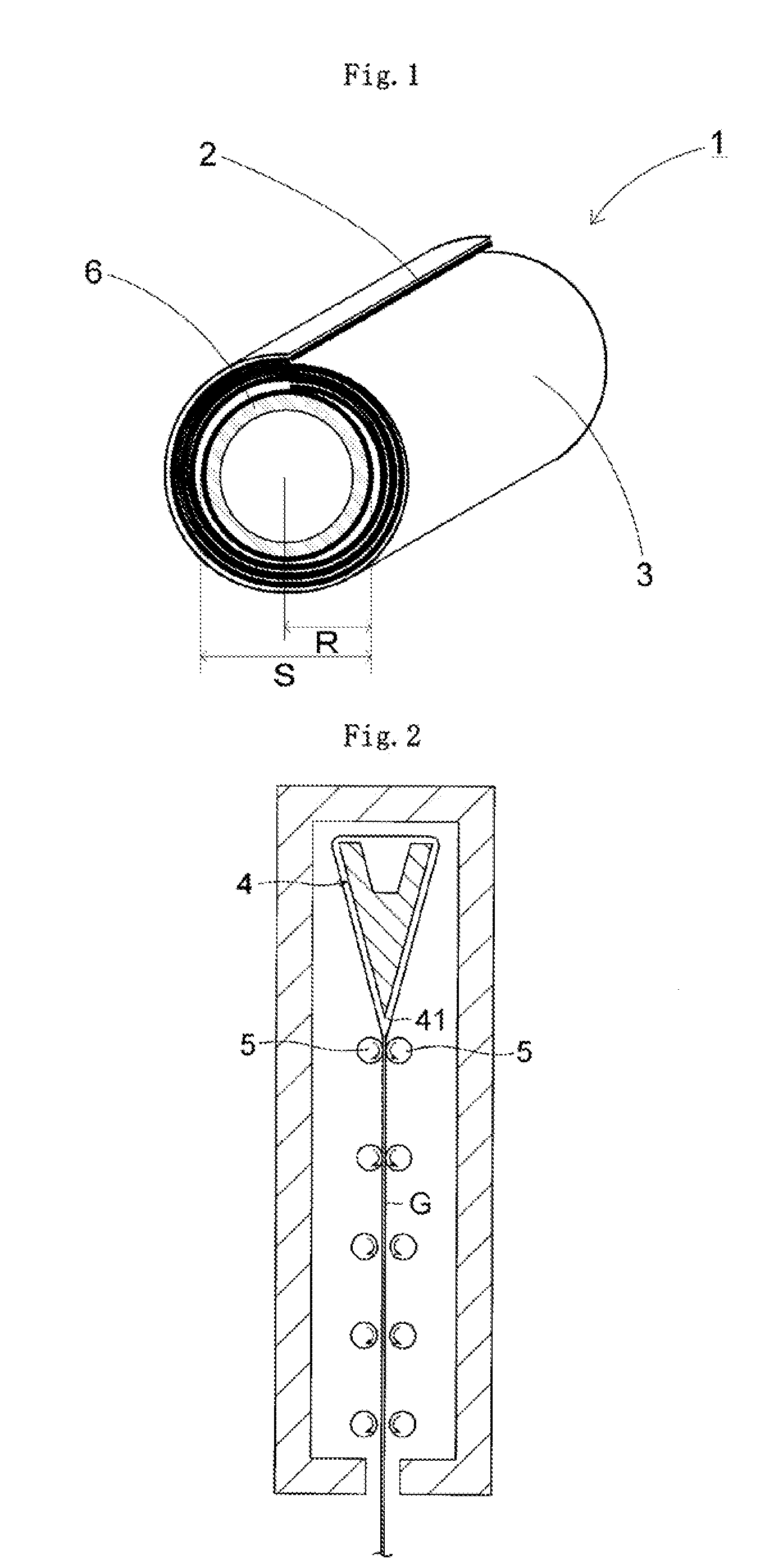

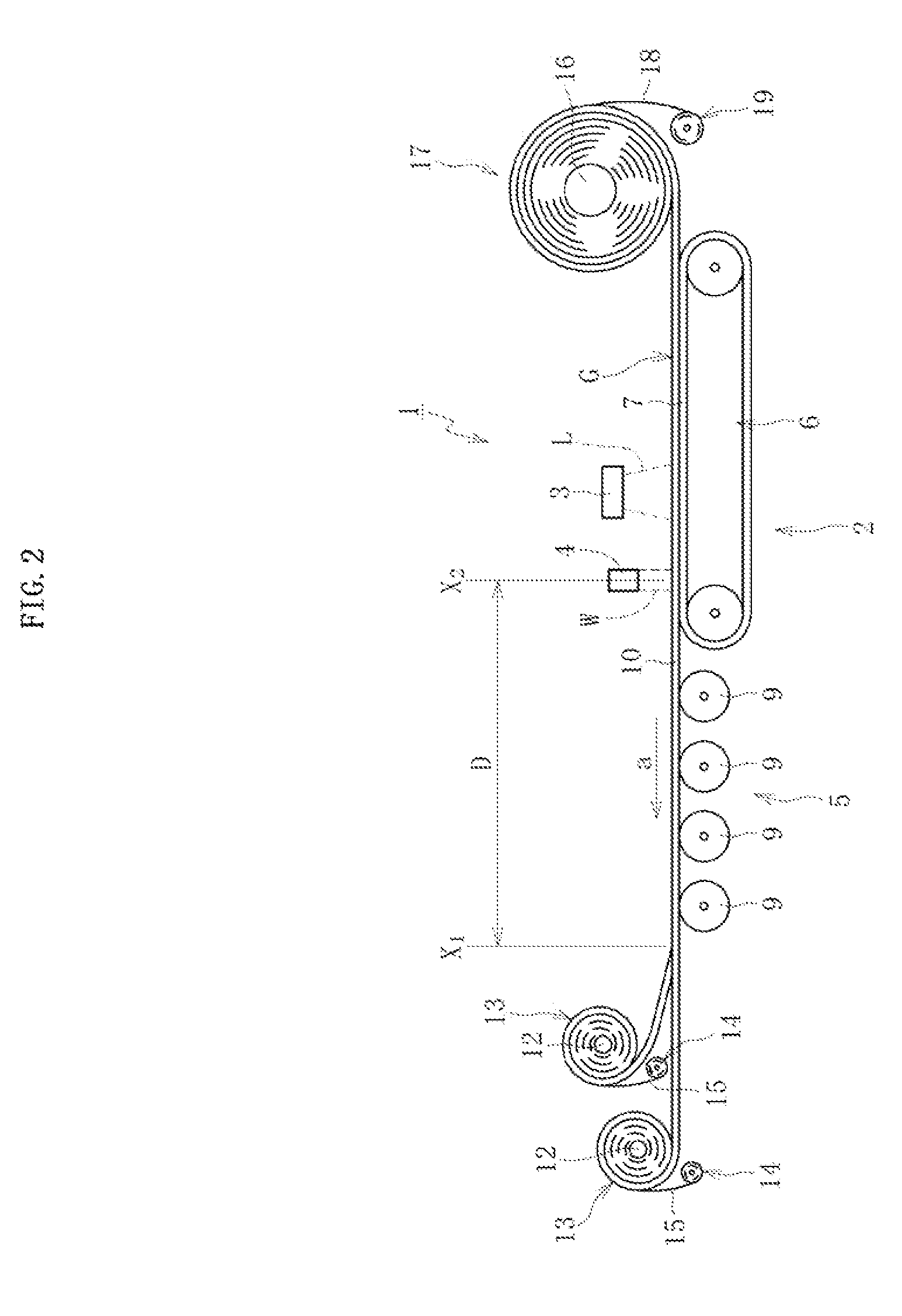

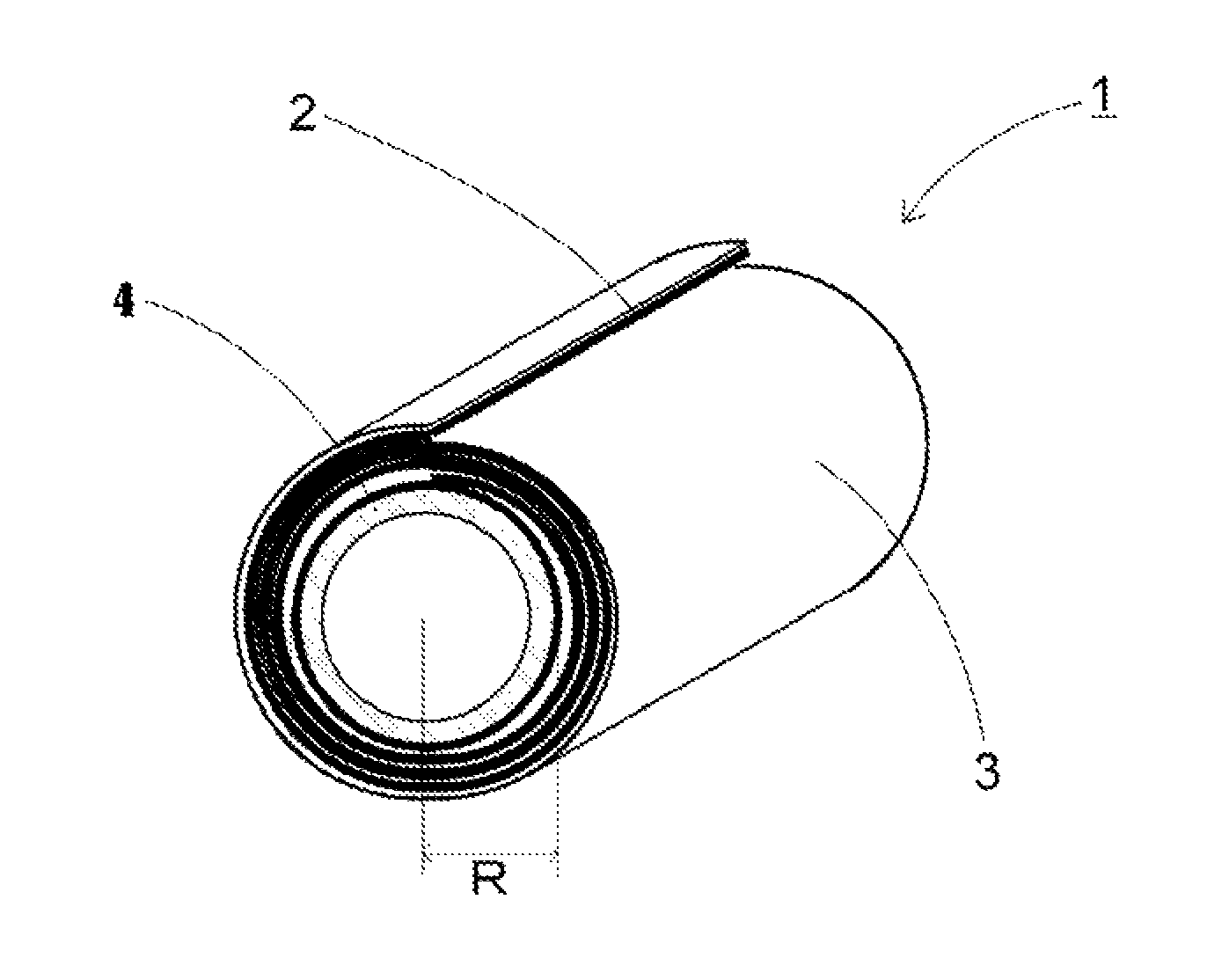

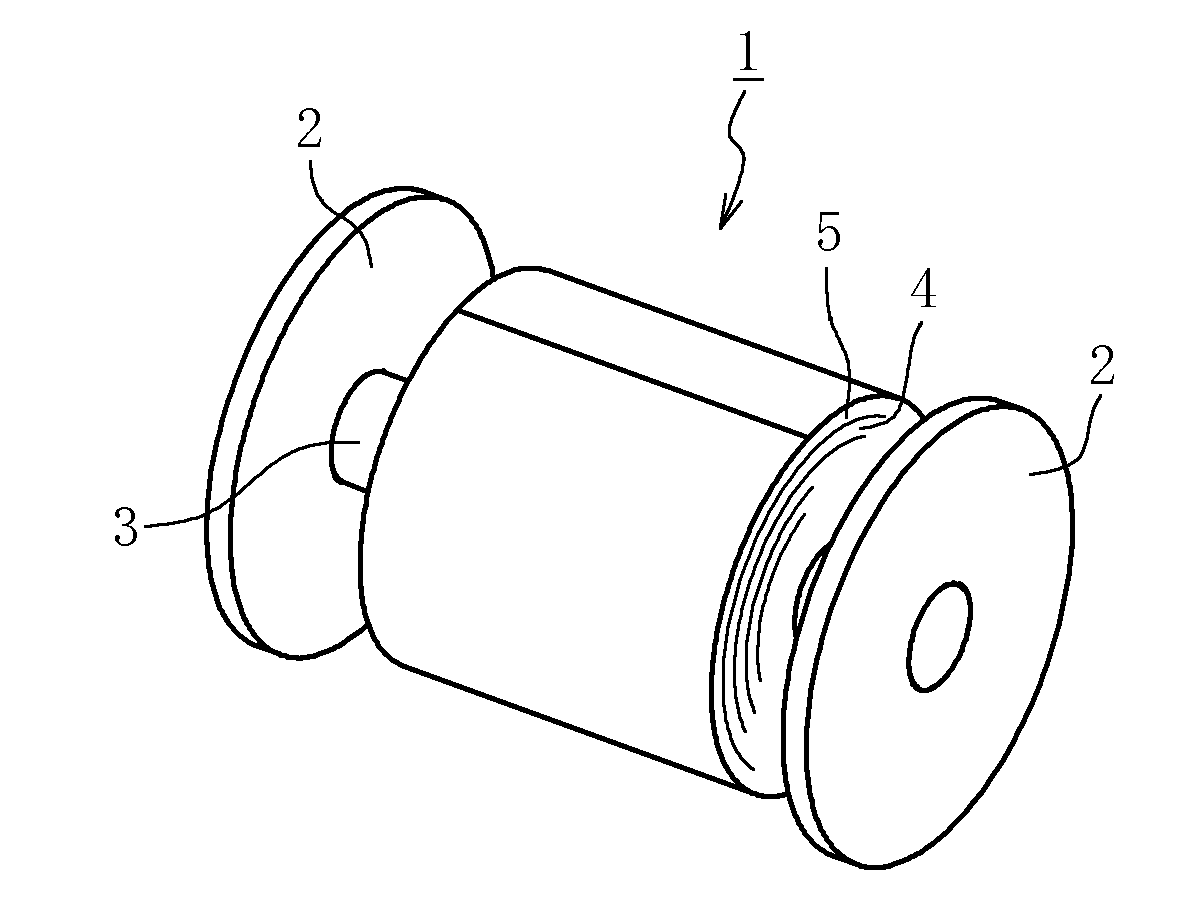

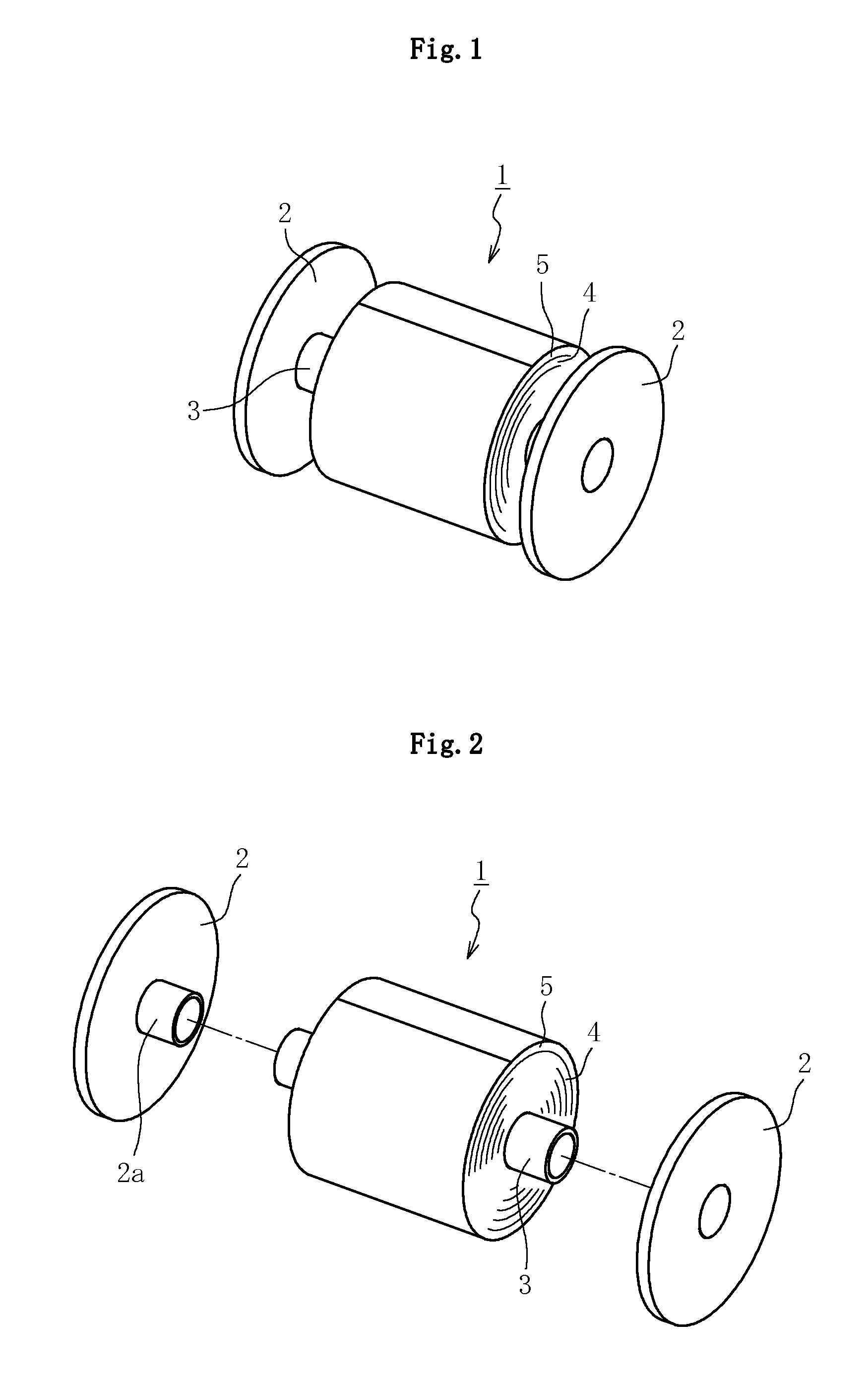

Glass roll and process for producing glass roll

ActiveUS20110200812A1Suppress situationReliable manufacturingShaft and bearingsGlass drawing apparatus3 point bendingFlexural strength

Provided is a glass roll formed by winding a glass film into a roll, in which a minimum winding radius of the glass film is optimized. Thus, the glass film is reliably prevented from breaking due to static fatigue, and is able to be stored for long periods. A glass roll (1), which is formed by winding a glass film (2) into a roll, has a configuration in which the glass film has a minimum winding radius (R) satisfying the following relation: R≧(T / 2)[(2.3 / σ)×E−1], where σ represents flexural strength of the glass film (2) obtained by a 3-point bending test, T represents a thickness of the glass film, and E represents a Young's modulus of the glass film.

Owner:NIPPON ELECTRIC GLASS CO LTD

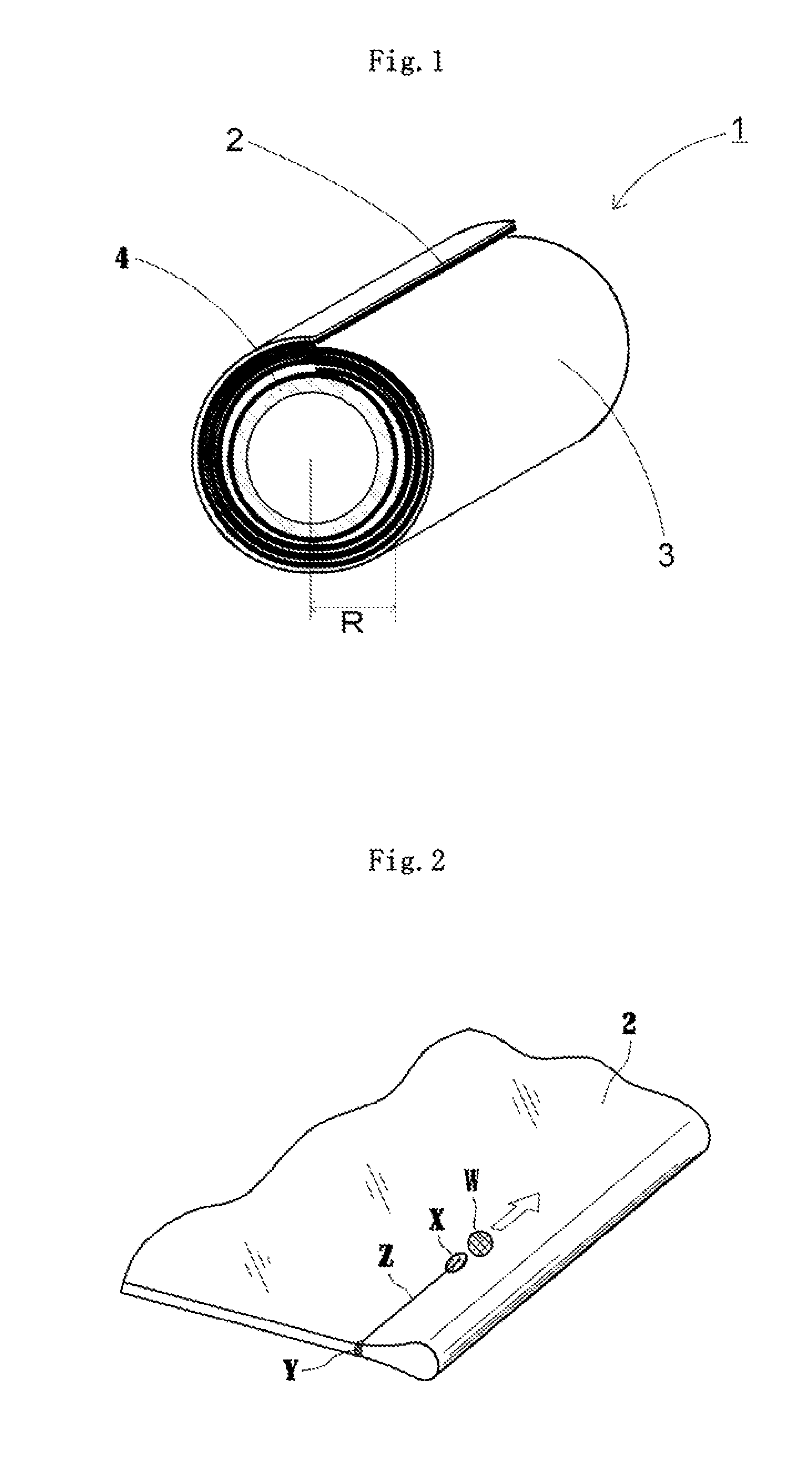

Glass roll, device for producing glass roll, and process for producing glass roll

ActiveUS20110177325A1High strengthReliable preventionInternal framesGlass drawing apparatusOverflow downdraw methodOptoelectronics

To provide a glass roll capable of reliably preventing a glass film from breaking from an end surface of the glass film as an origin of breakage, a glass roll (1) is formed by winding a glass film (2) into a roll while superposing the glass film (2) on a protective sheet (3), the glass film (2) being formed by an overflow downdraw method to have a thickness of 1 μm or more and 200 μm or less, and to have each end surface in a width direction to form a cut surface cut by laser splitting.

Owner:NIPPON ELECTRIC GLASS CO LTD

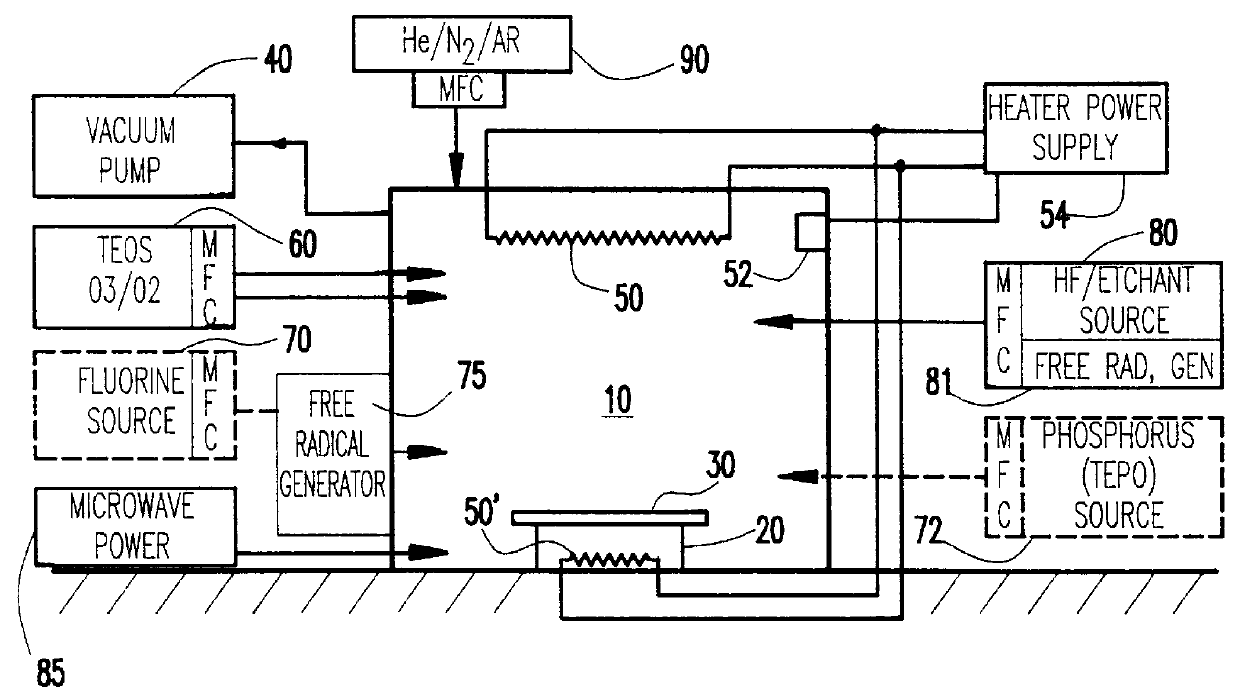

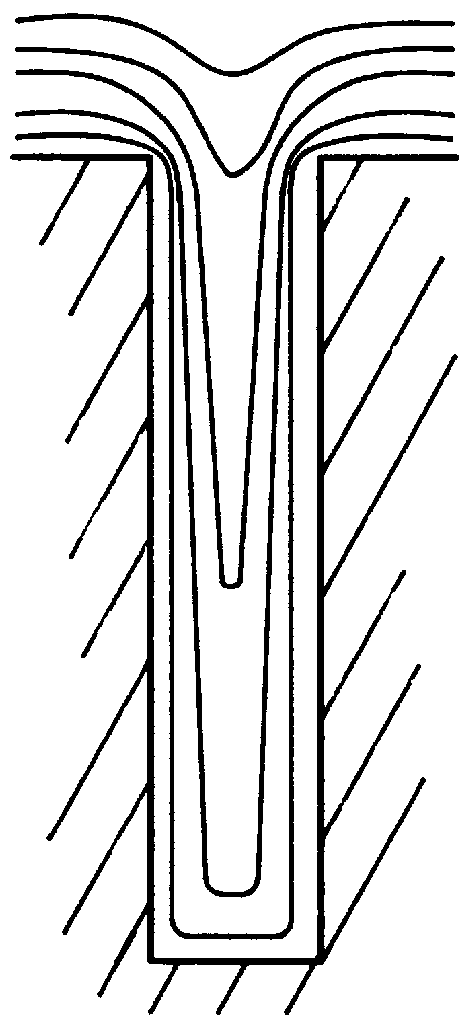

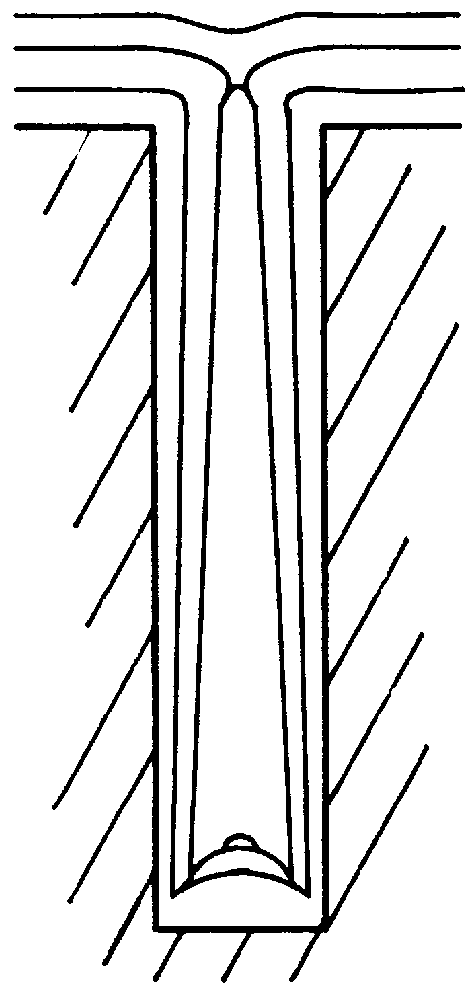

Methods and apparatus for filling high aspect ratio structures with silicate glass

InactiveUS6077786ADecorative surface effectsSemiconductor/solid-state device manufacturingGas phaseDeposition rate

Filling of narrow and / or high aspect ratio gaps and trenches with silicate glass is accomplished at reduced temperatures and without reflow by etching the glass concurrently with thermal chemical vapor deposition of the glass such that the deposition rate will exceed the etching rate by a relatively small net deposition rate near the surface with the excess deposition rate increasing over the depth of the trench or gap. The as-deposited glass film is made dense and stable by carrying out the concurrent etch and deposition process at an elevated temperature but which is within the maximum temperature and heat budget which can be tolerated by structures formed by previously performed processes. Fluorine can be incorporated in the silicate glass film as a dopant in sufficient concentration to reduce dielectric constant of the film. Phosphorus and / or boron can be incorporated into the film, as well, and may enhance void-free filling of trenches and gaps.

Owner:IBM CORP

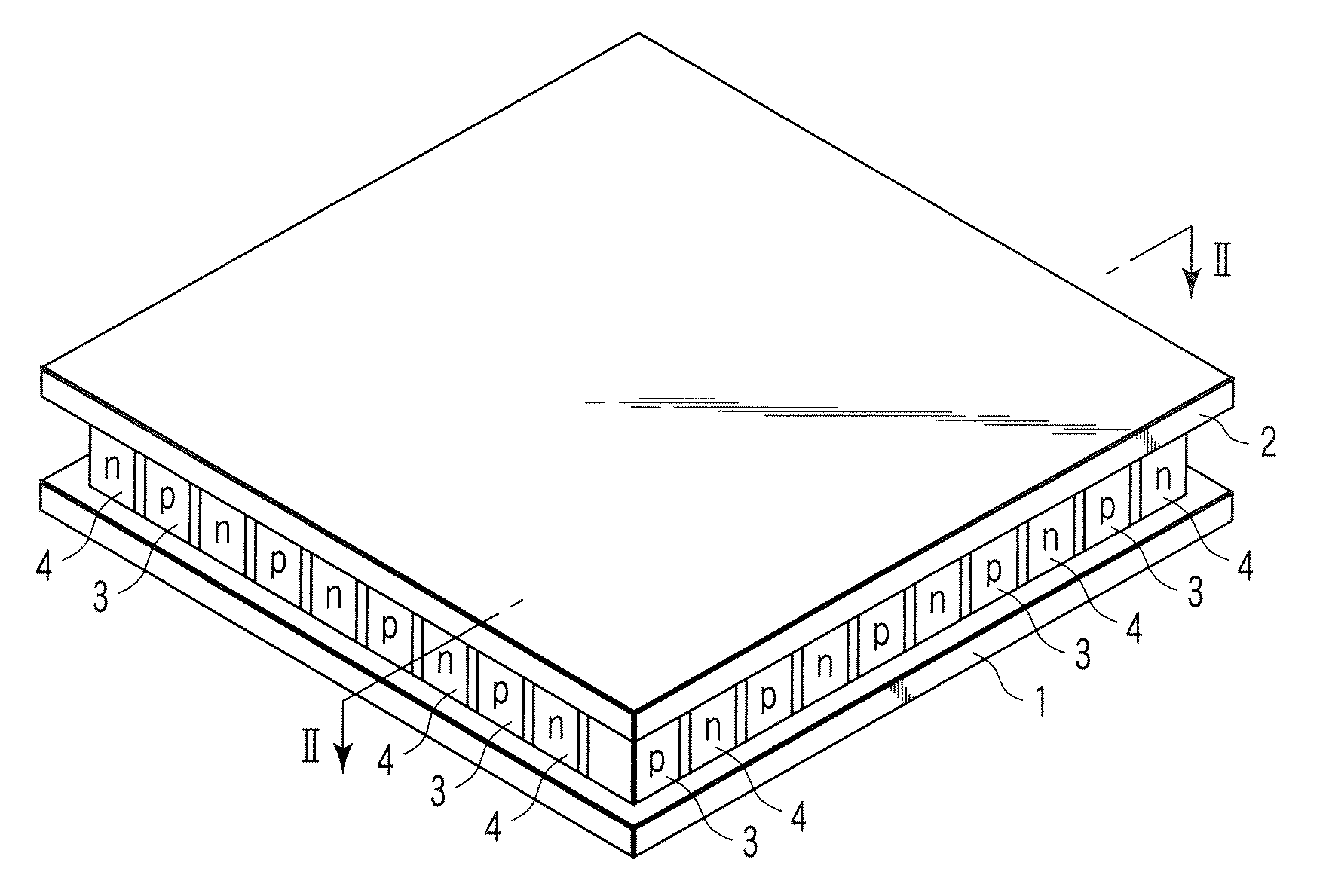

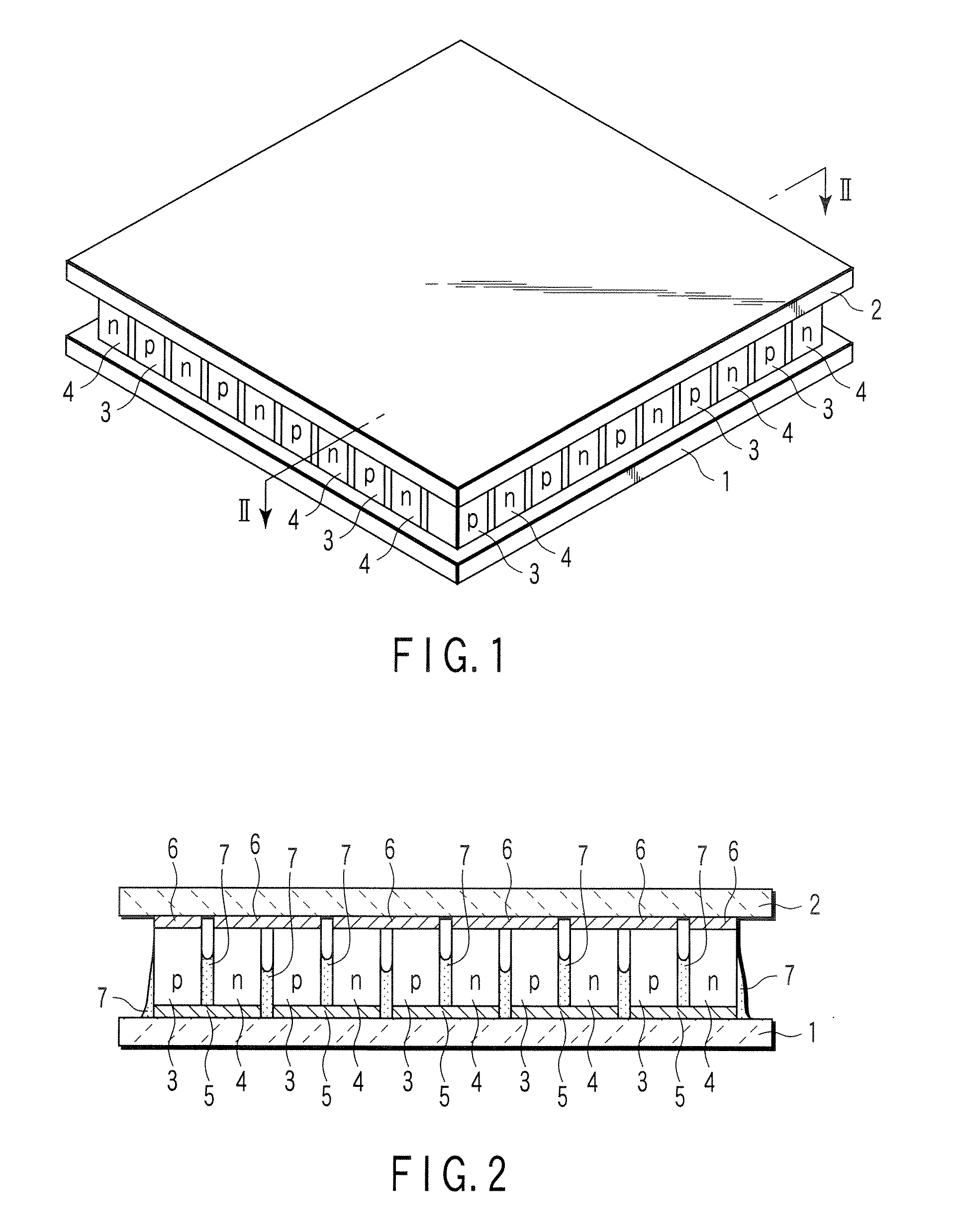

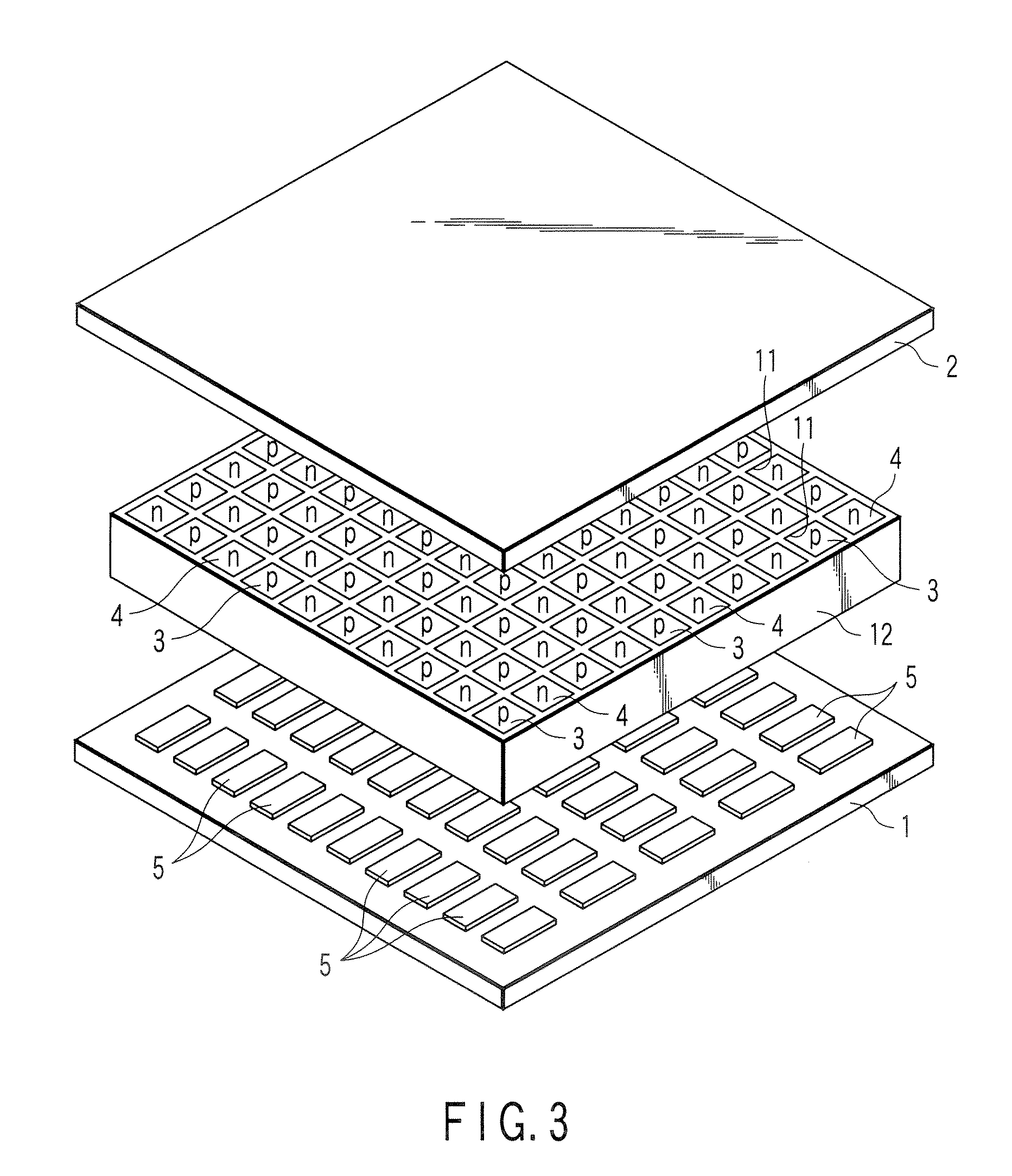

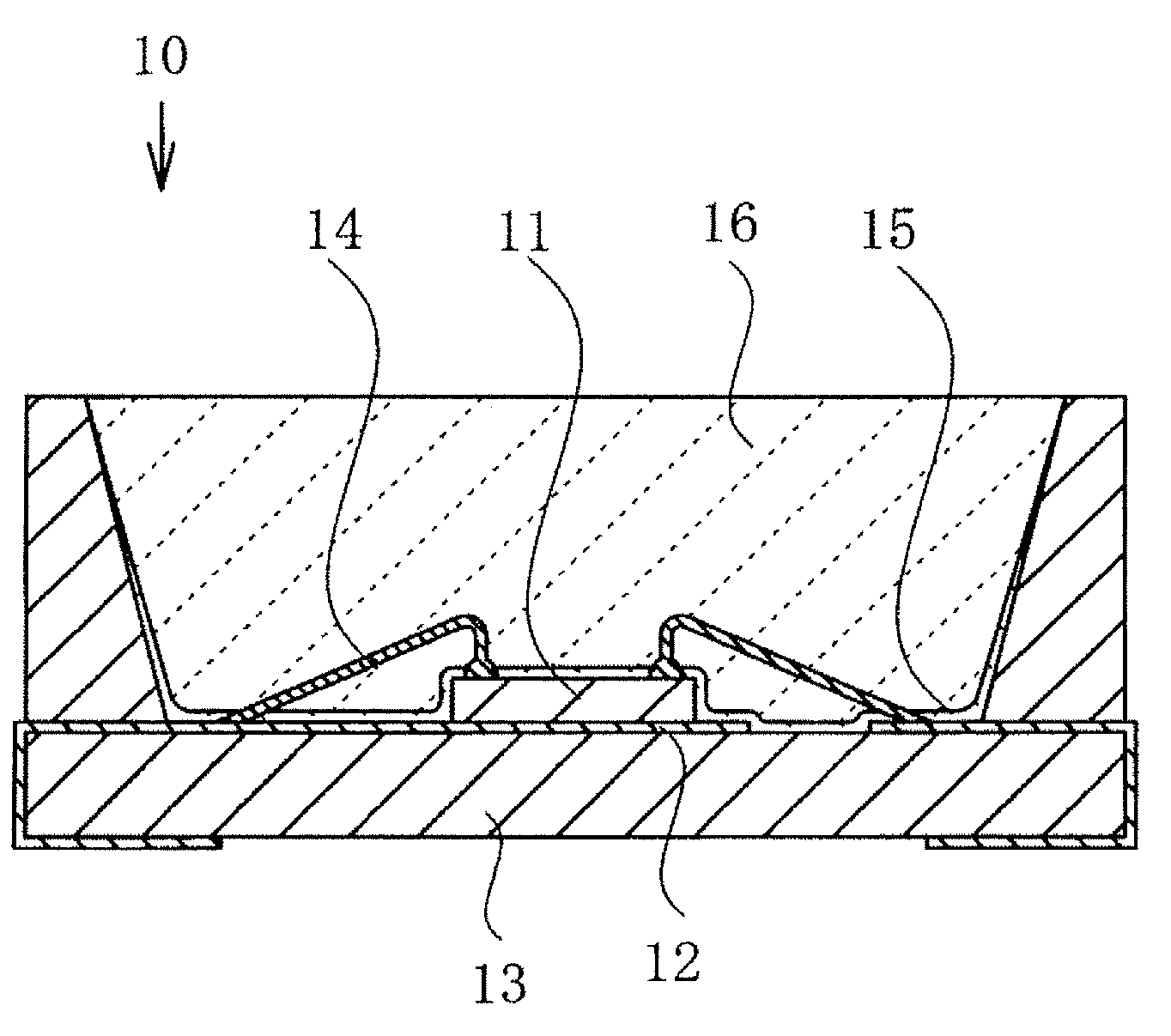

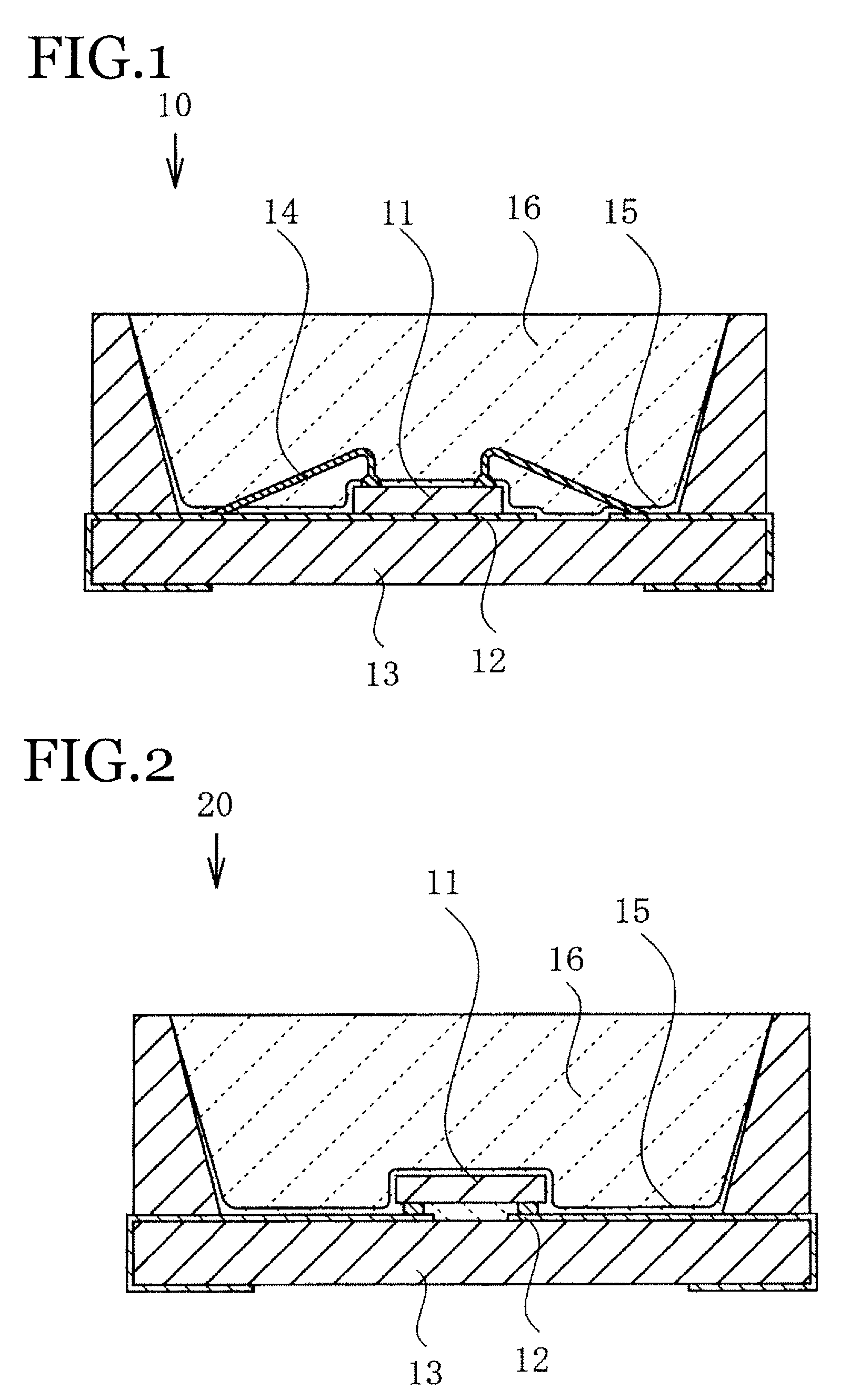

Thermoelectric conversion module and method of manufacturing the same

InactiveUS20070221264A1Thermoelectric device with peltier/seeback effectTransducerThermoelectric conversion

There is provided a thermoelectric conversion module comprising a first insulated substrate, a plurality of columnar p-type and n-type semiconductor thermoelectric transducers alternately arranged on the first insulated substrate, a second insulated substrate arranged so as to face the first insulation with interposition of the semiconductor thermoelectric transducers, first electrodes arranged between the first insulated substrate and the respective semiconductor thermoelectric transducers, and second electrodes arranged between the second insulated substrate and the respective semiconductor thermoelectric transducers, the first and second electrodes electrically connecting the p-type and n-type semiconductor thermoelectric transducers in series, and a glass film coated on the exposed surface of each first electrode at the first insulated substrate side and on a part of the exposed surfaces of the p-type and n-type semiconductor thermoelectric transducers directed from the first electrode to the second electrode.

Owner:KK TOSHIBA

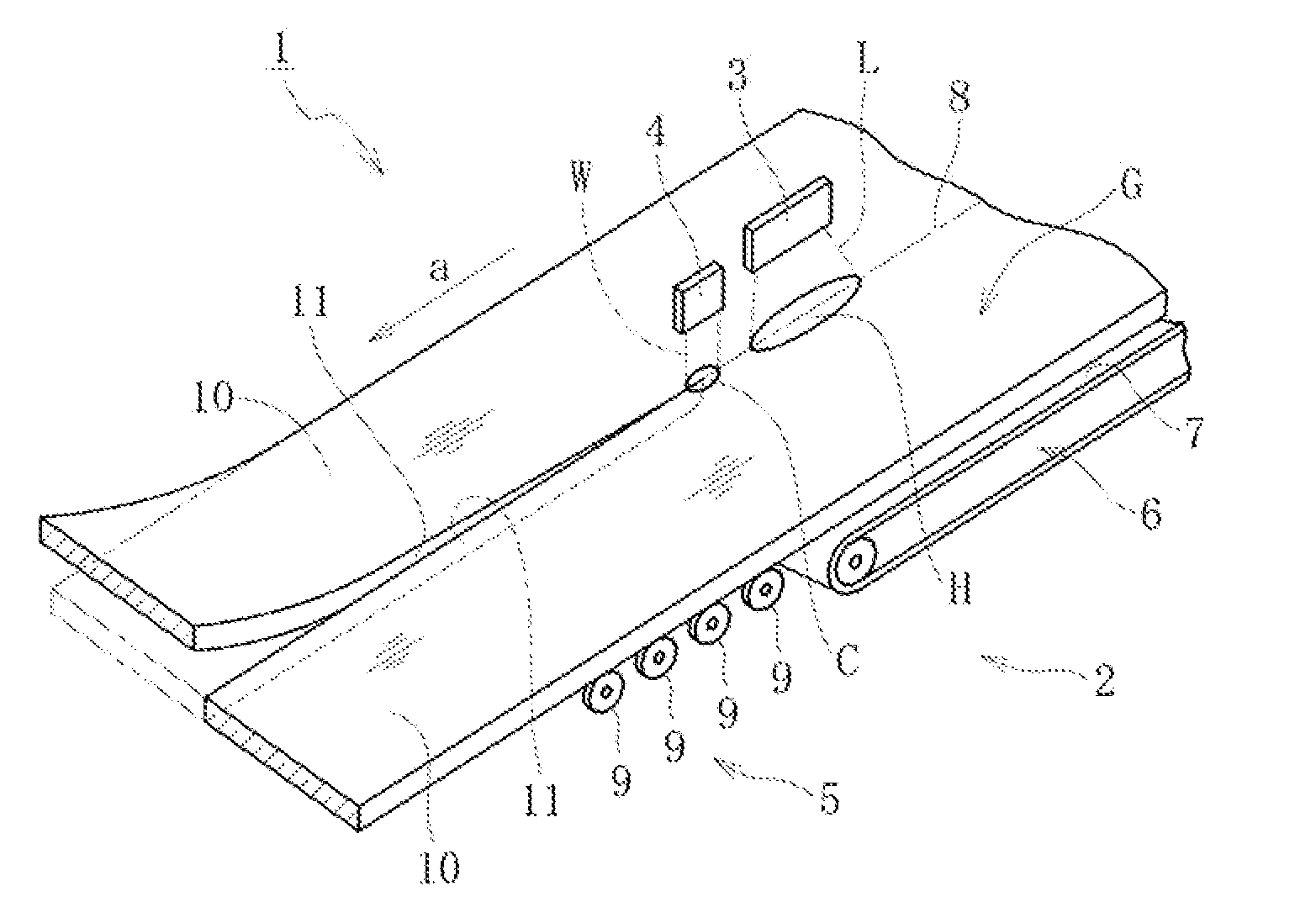

Cleaving method for a glass film

ActiveUS20120024928A1Stable jobInterferenceGlass transportation apparatusGlass severing apparatusGlass filmElectrical and Electronics engineering

Provided is a cleaving method for a glass film (G) including: cleaving, during conveyance of the glass film (G) in a predetermined direction, the glass film (G) continuously along a preset cleaving line (8) extending in a predetermined conveying direction (a) by a thermal stress generated through localized heating performed along the preset cleaving line (8) and through cooling of a locally heated region (H); dividing the glass film (G) in a width direction of the glass film (G) ; diverting, after the dividing, adjacent divided glass films (10) , which are obtained by the dividing, so that the adjacent divided glass films (10) are separated in a front and rear direction of the adjacent divided glass films; and forming a predetermined widthwise clearance between the adj acent divided glass films after the dividing of the glass film (G) and before the diverting of the adjacent divided glass films (10).

Owner:NIPPON ELECTRIC GLASS CO LTD

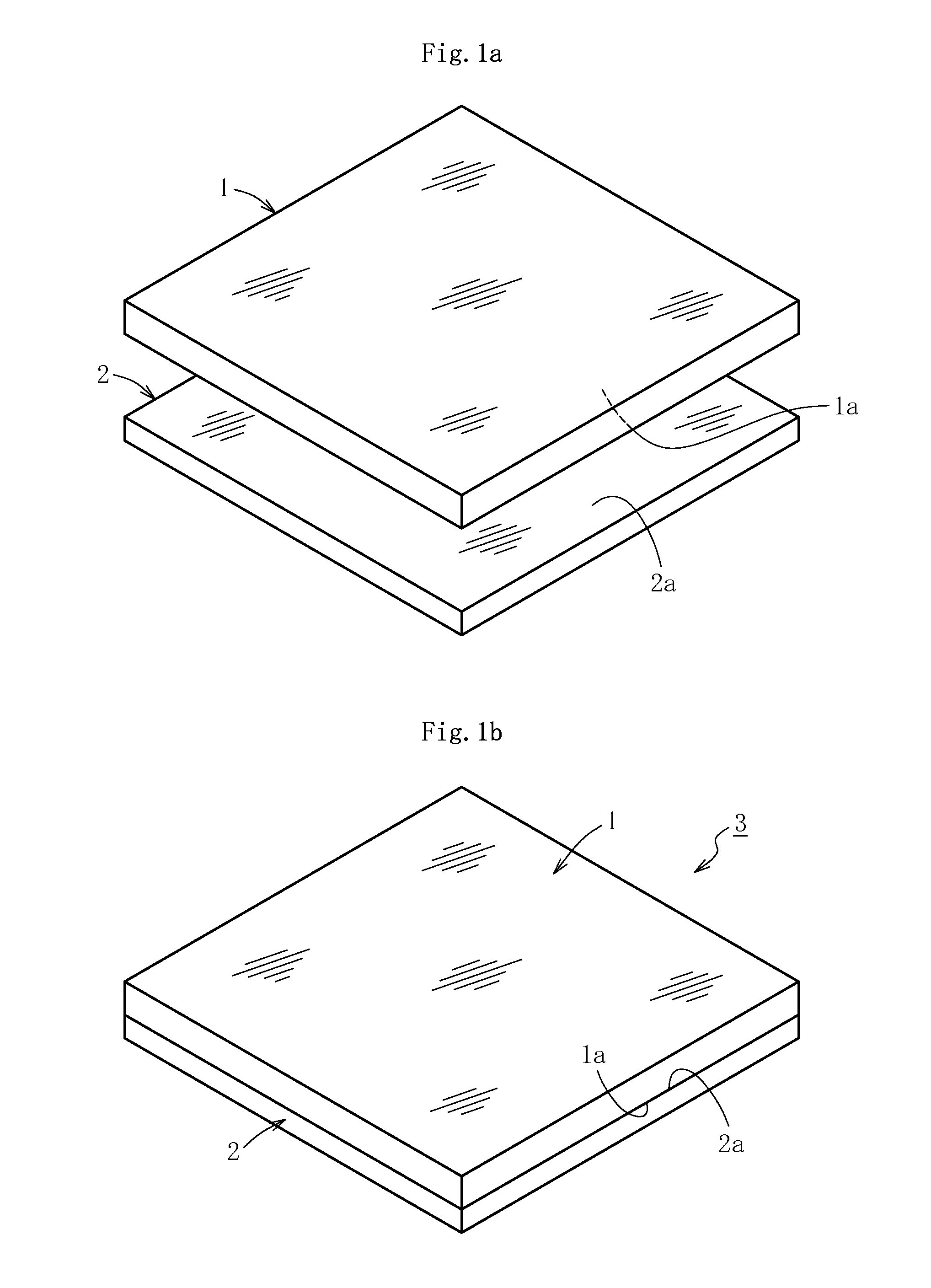

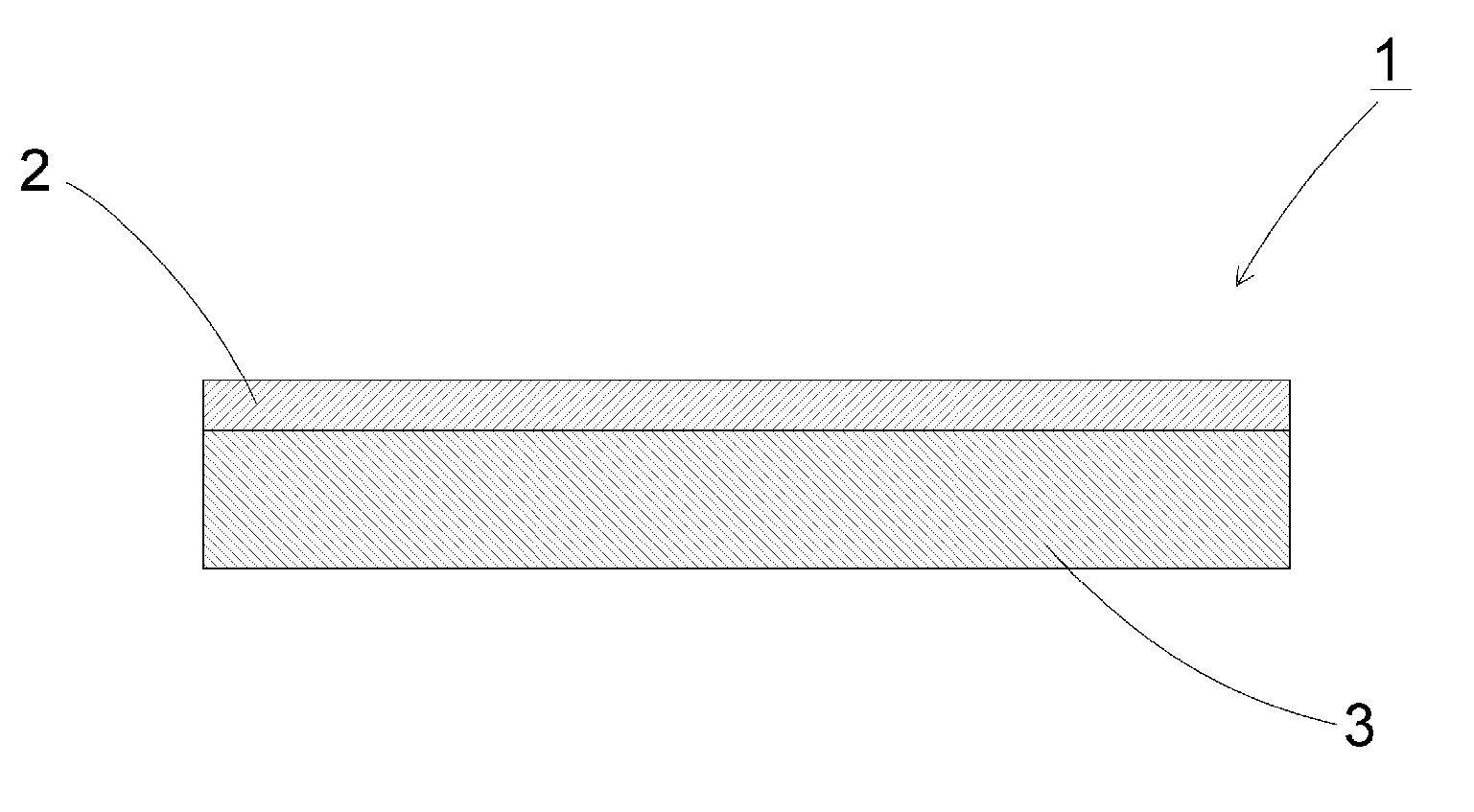

Glass film laminate

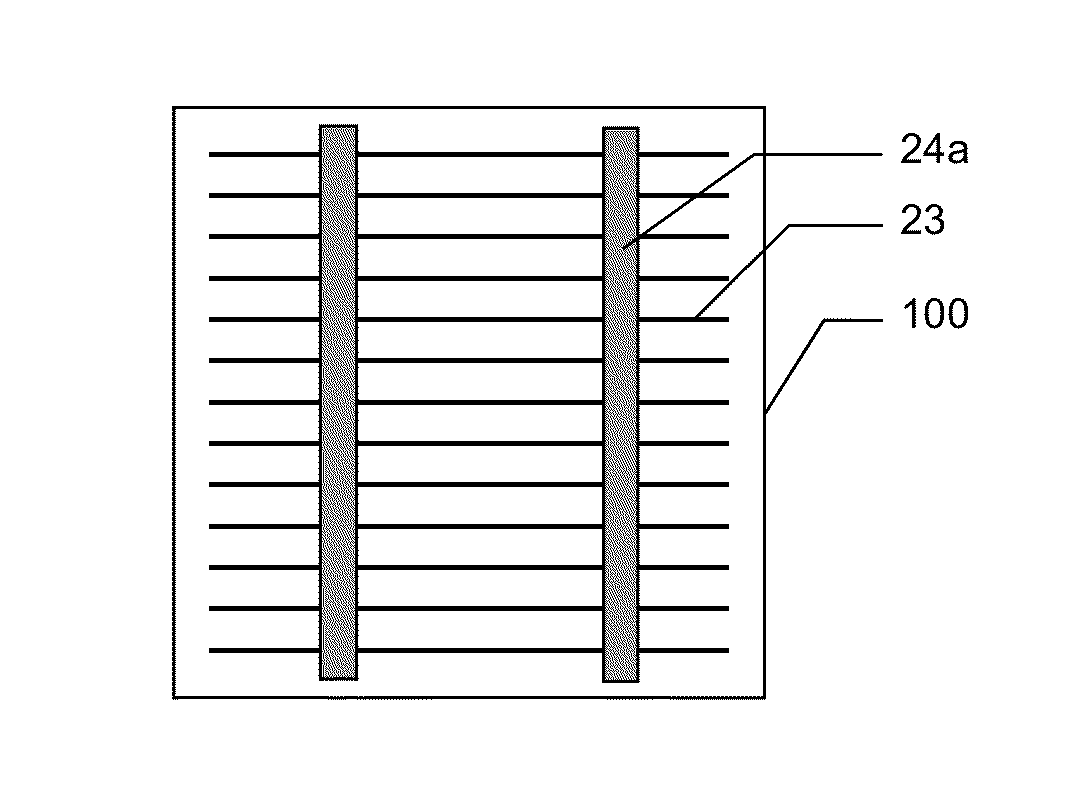

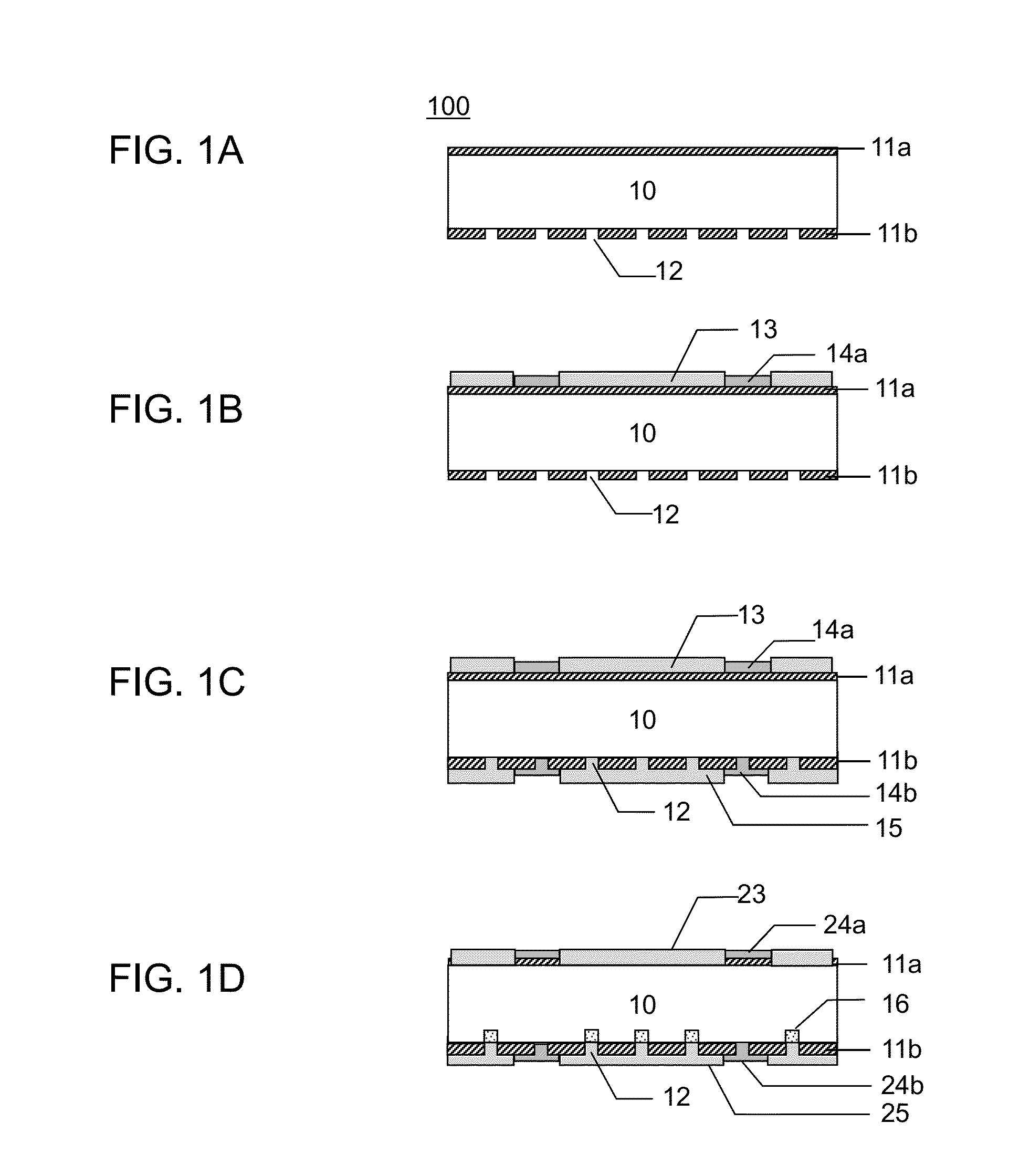

ActiveUS20110045239A1Enhances handling easinessWithout usingFinal product manufactureSolid-state devicesSurface roughnessGlass film

The glass film laminate comprises a glass film and a supporting glass. The glass film and the supporting glass have surfaces being brought into contact with each other, and each of the surfaces has a surface roughness Ra of 2.0 nm or less.

Owner:NIPPON ELECTRIC GLASS CO LTD

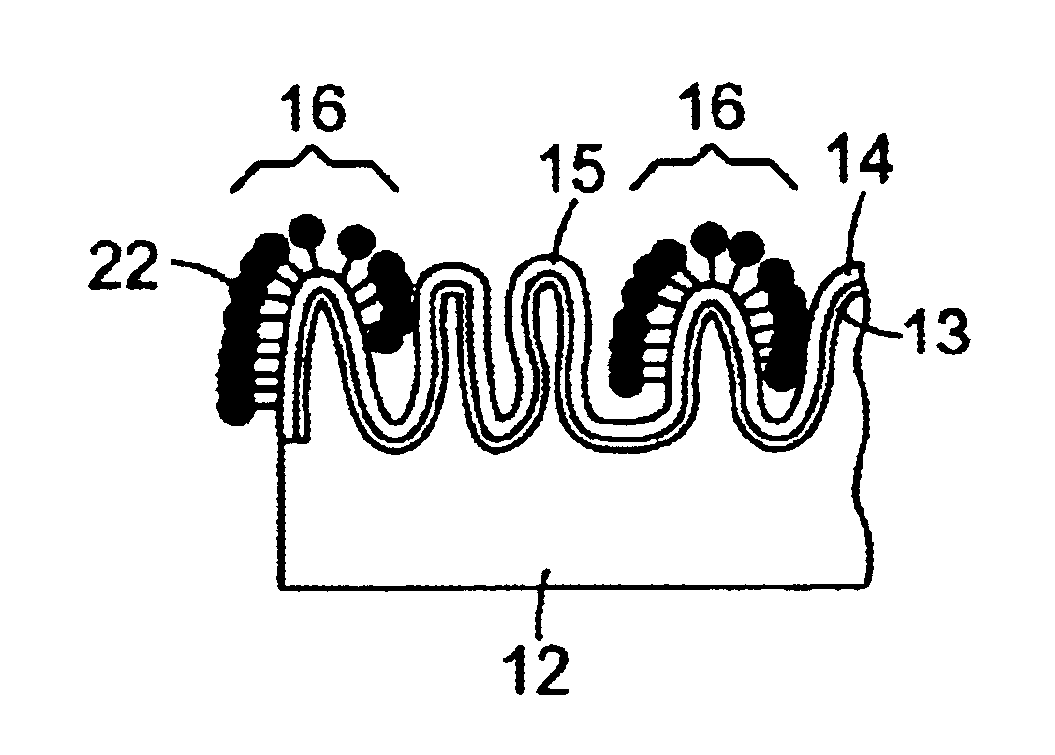

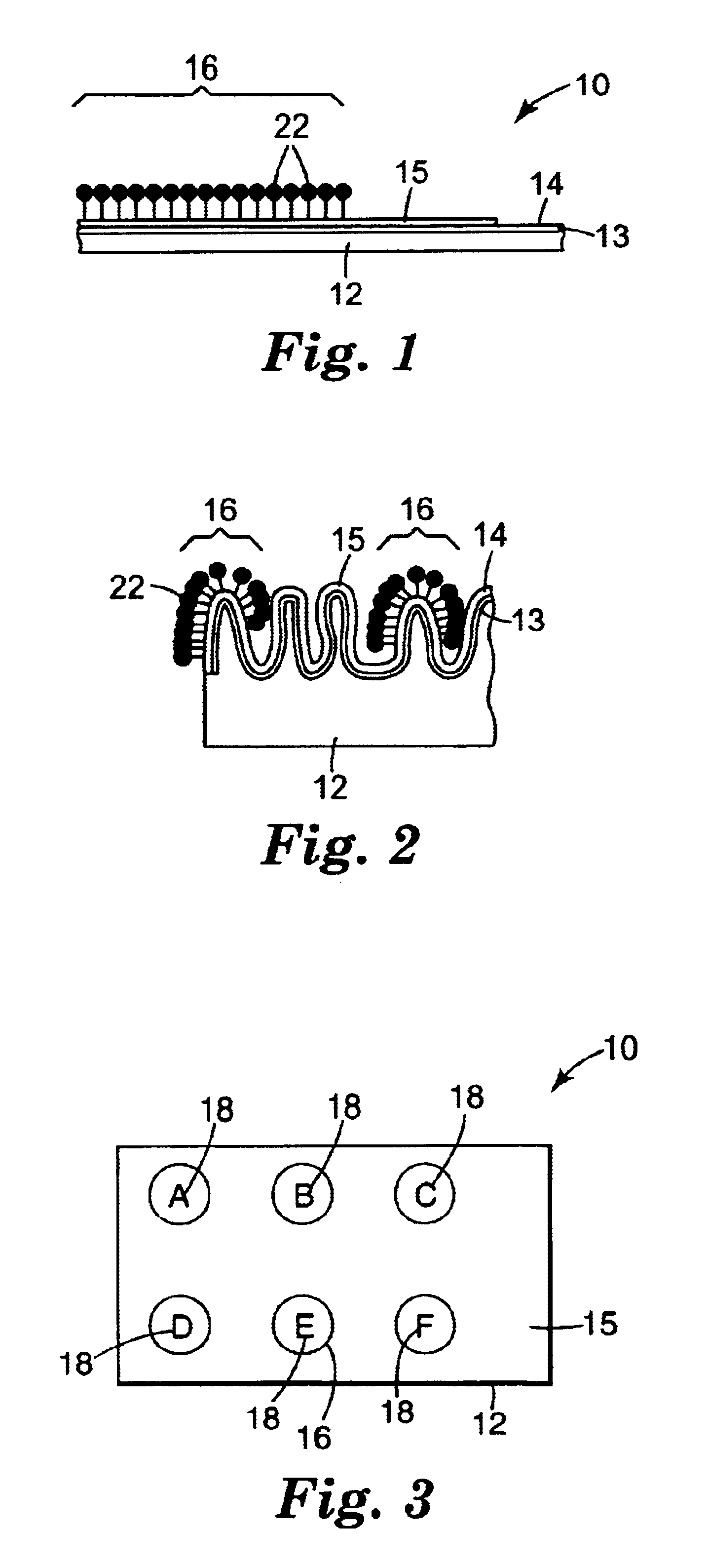

Array comprising diamond-like glass film

InactiveUS6881538B1Increase signal strengthWide rangeBioreactor/fermenter combinationsSequential/parallel process reactionsSiliconMaterials science

Materials for use in miniaturized arrays, the arrays, and methods of manufacturing. Materials for making arrays described include a substrate with a silicon-containing layer, optionally with linking agents and reactants.

Owner:3M INNOVATIVE PROPERTIES CO

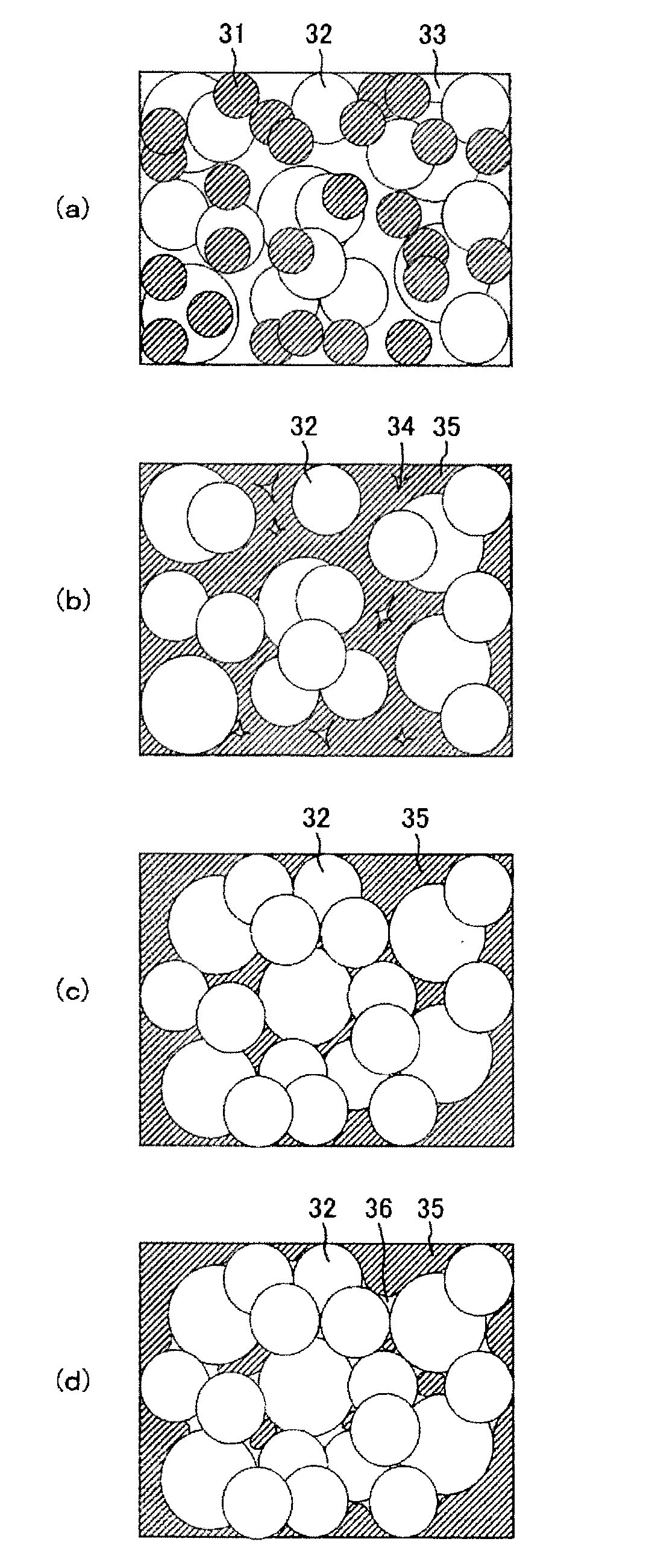

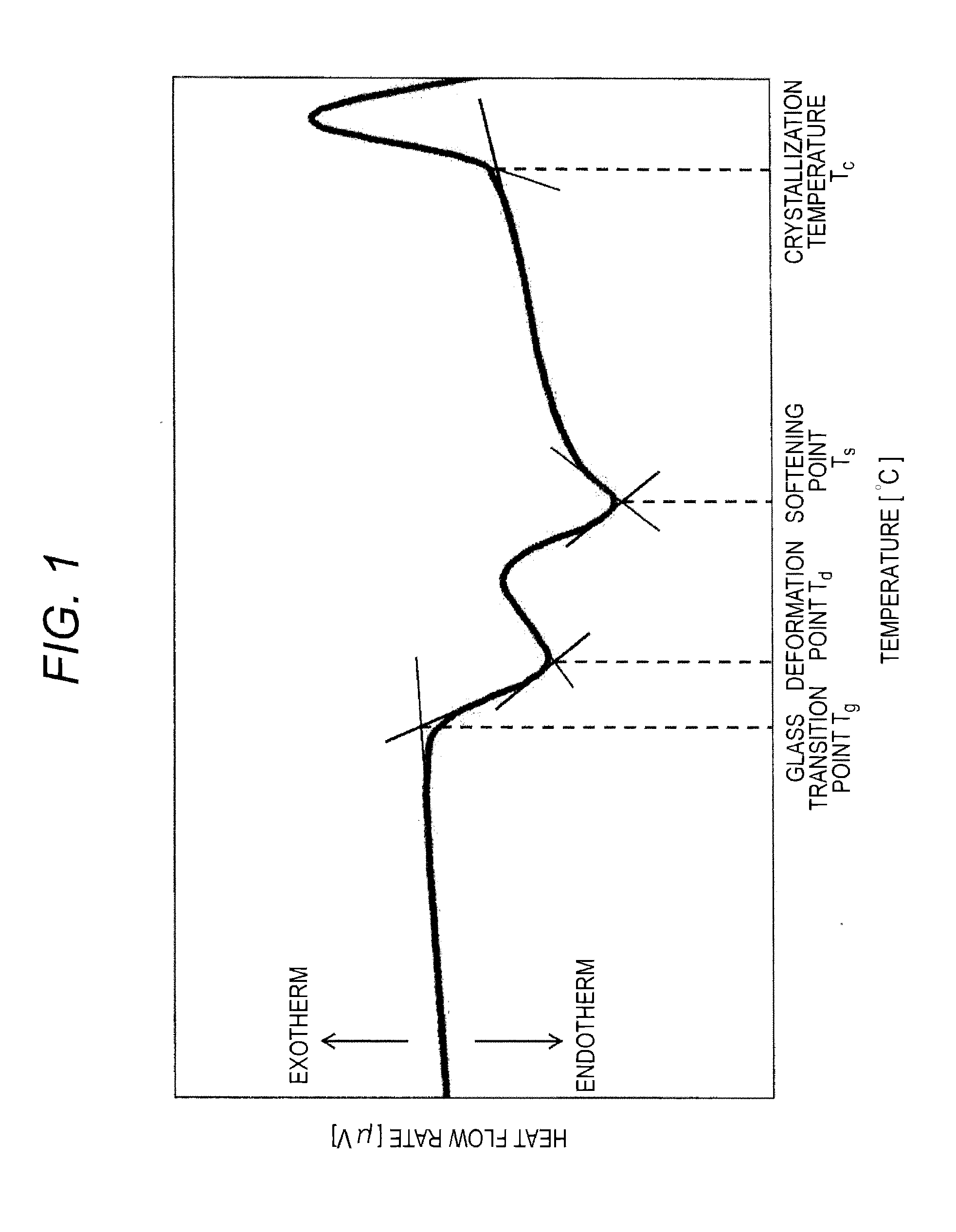

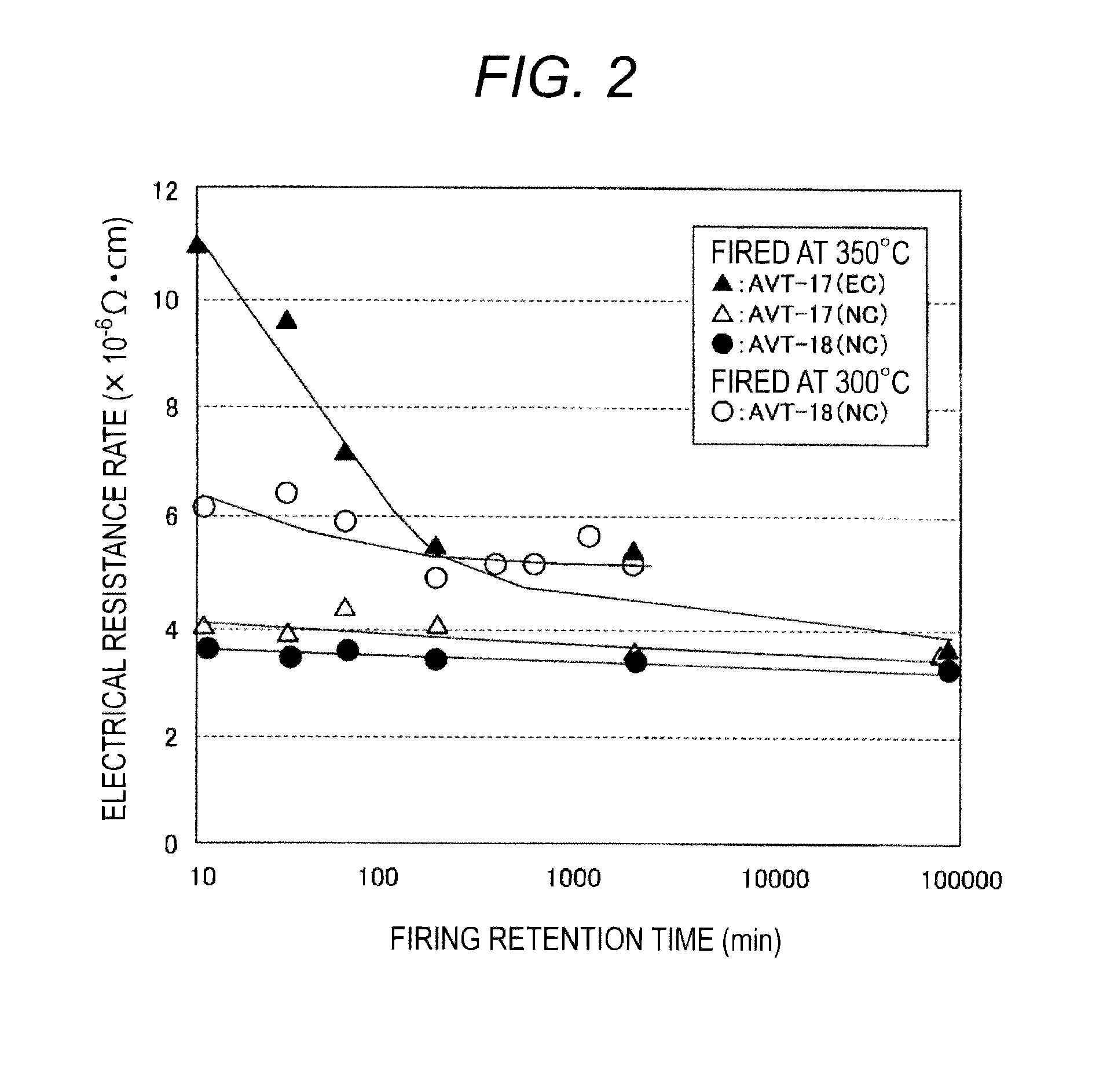

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS20140145122A1Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritThermal stability

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

Light emitting device

ActiveUS20090010017A1Excellent gas barrier propertiesNo deterioration in light reflecting performanceSolid-state devicesSemiconductor devicesLight emitting deviceGlass film

A light emitting device comprises; a metal reflecting member, a light emitting element fixed to the metal reflecting member, a glass film that covers the metal reflecting member and has Si—N bonds, and a translucent resin that covers the glass film. The present invention provides a light emitting device with which, even when this device is used in a harsh environment, there will be no deterioration in the light reflecting performance of the metal reflecting member, and light can be emitted at high output over an extended period.

Owner:NICHIA CORP

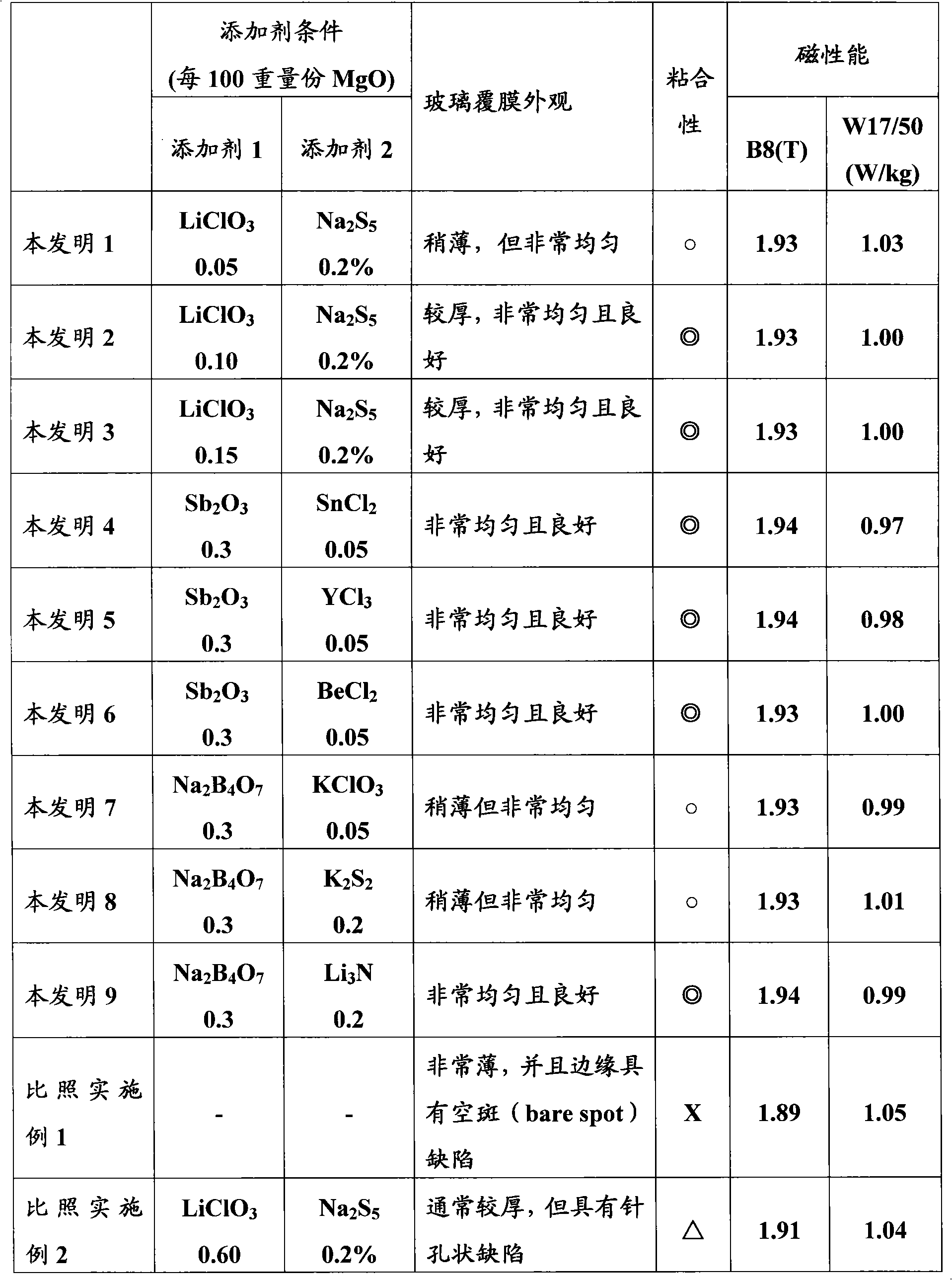

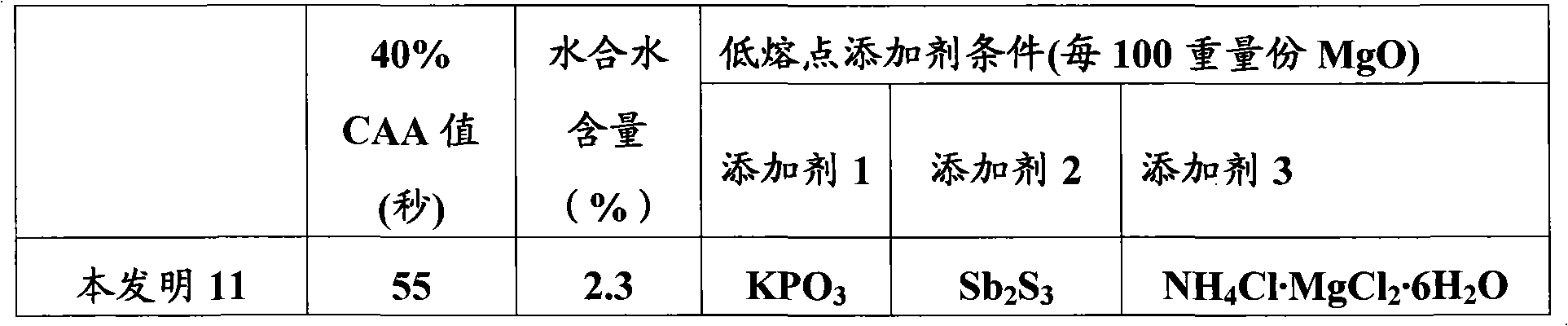

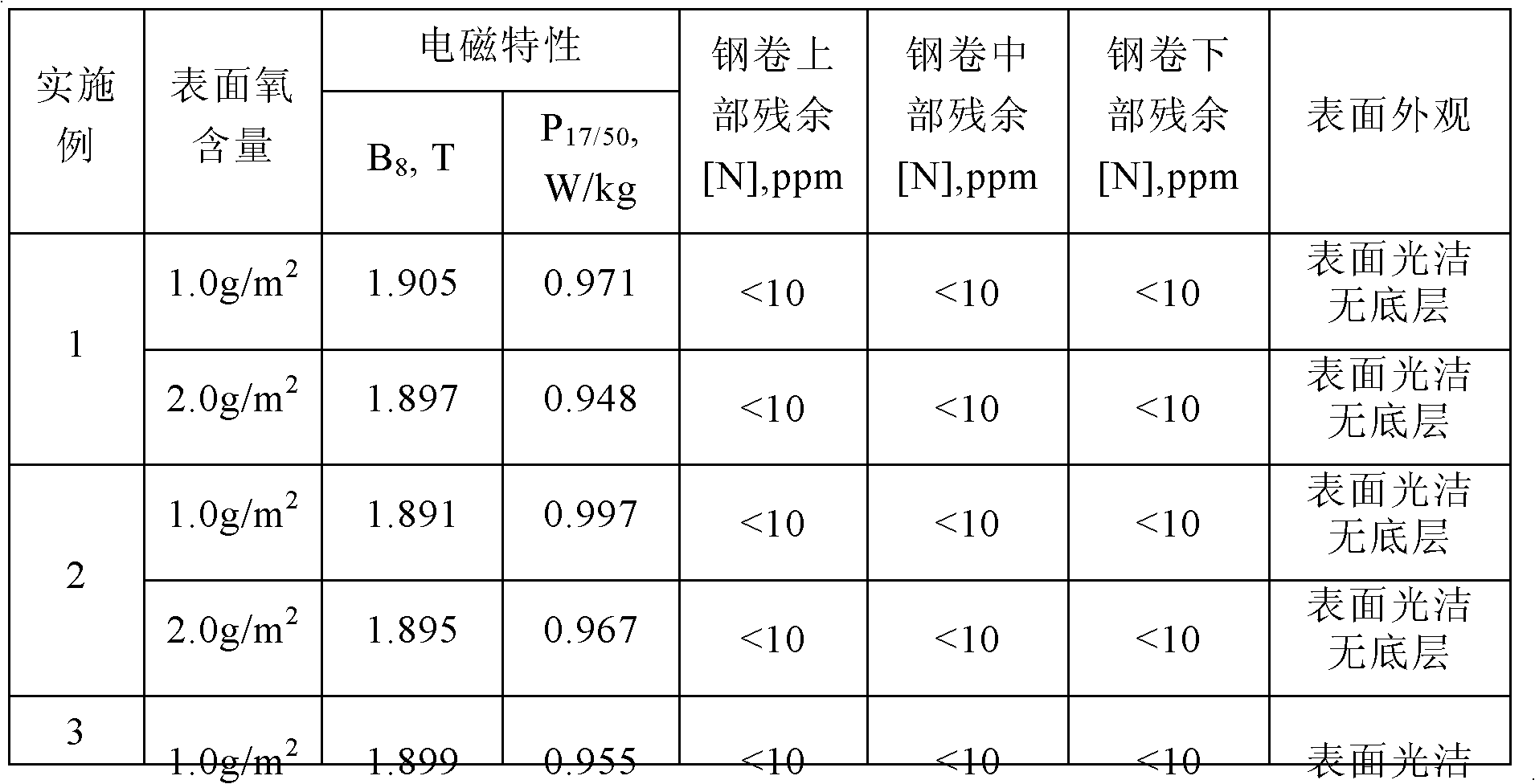

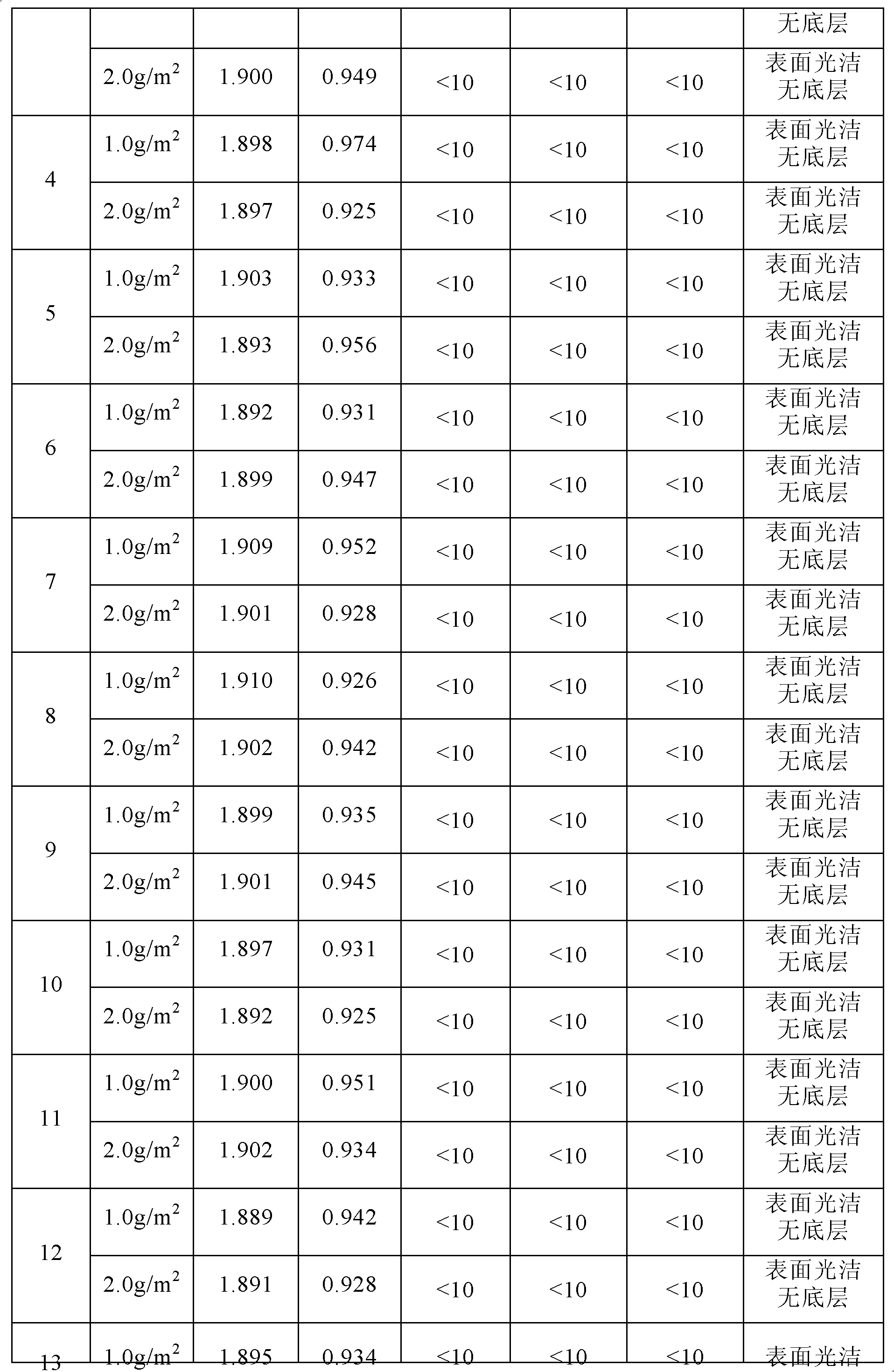

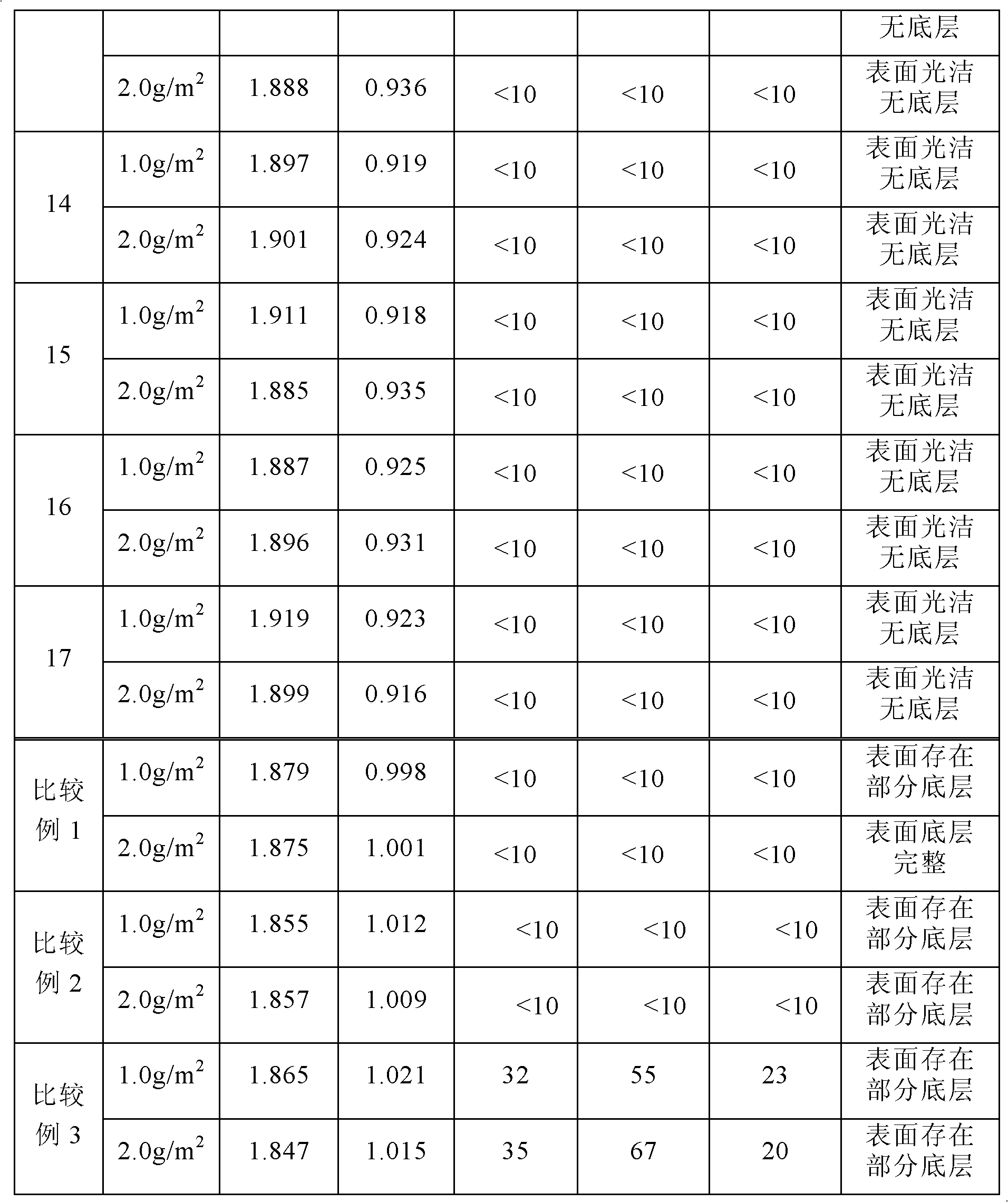

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

Glass roll and process for producing glass roll

ActiveUS8241751B2Suppress situationReliable manufacturingShaft and bearingsGlass drawing apparatus3 point bendingFlexural strength

Provided is a glass roll formed by winding a glass film into a roll, in which a minimum winding radius of the glass film is optimized. Thus, the glass film is reliably prevented from breaking due to static fatigue, and is able to be stored for long periods. A glass roll (1), which is formed by winding a glass film (2) into a roll, has a configuration in which the glass film has a minimum winding radius (R) satisfying the following relation: R≧(T / 2)[(2.3 / σ)×E−1], where σ represents flexural strength of the glass film (2) obtained by a 3-point bending test, T represents a thickness of the glass film, and E represents a Young's modulus of the glass film.

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for manufacturing spandrel glass film with metal flakes

A film laminating adhesive is formed by admixing a polyester resin and encapsulated metallic flakes. The metallic flakes are encapsulated with a silane in a hydrolyzed condition modified with a surfactant or dispersion agent. A mounting adhesive is applied to an outside surface of a first clear PET film. A silicone liner is adhered to the outside surface. A second PET film is bonded to another side of the first clear film with the film laminating adhesive containing encapsulated metallic flakes to form the spandrel glass film composite adapted for bonding to a glass surface after removal of the silicone liner.

Owner:MADICO INC

Encapsulated nanoparticles for the absorption of electromagnetic energy

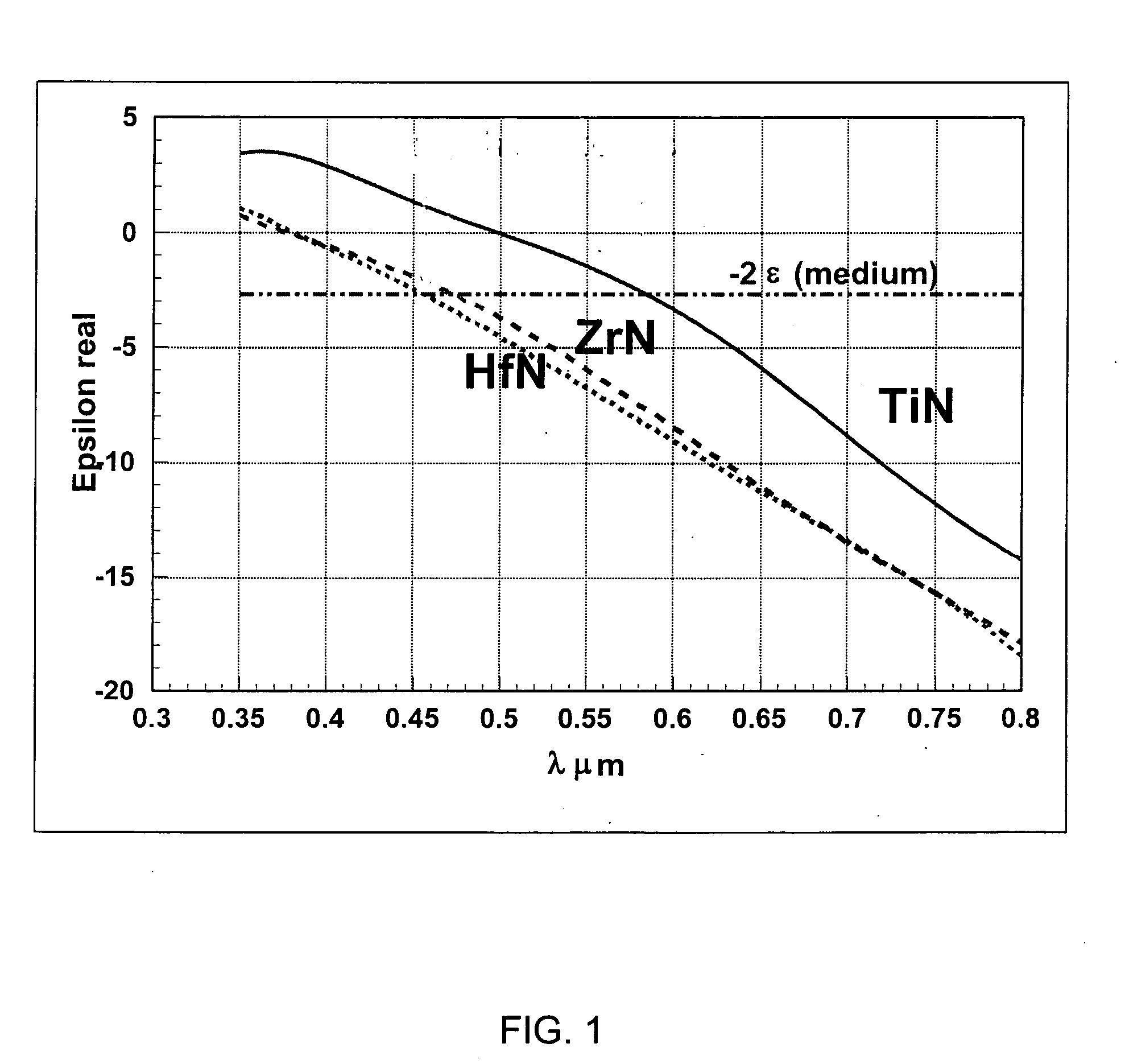

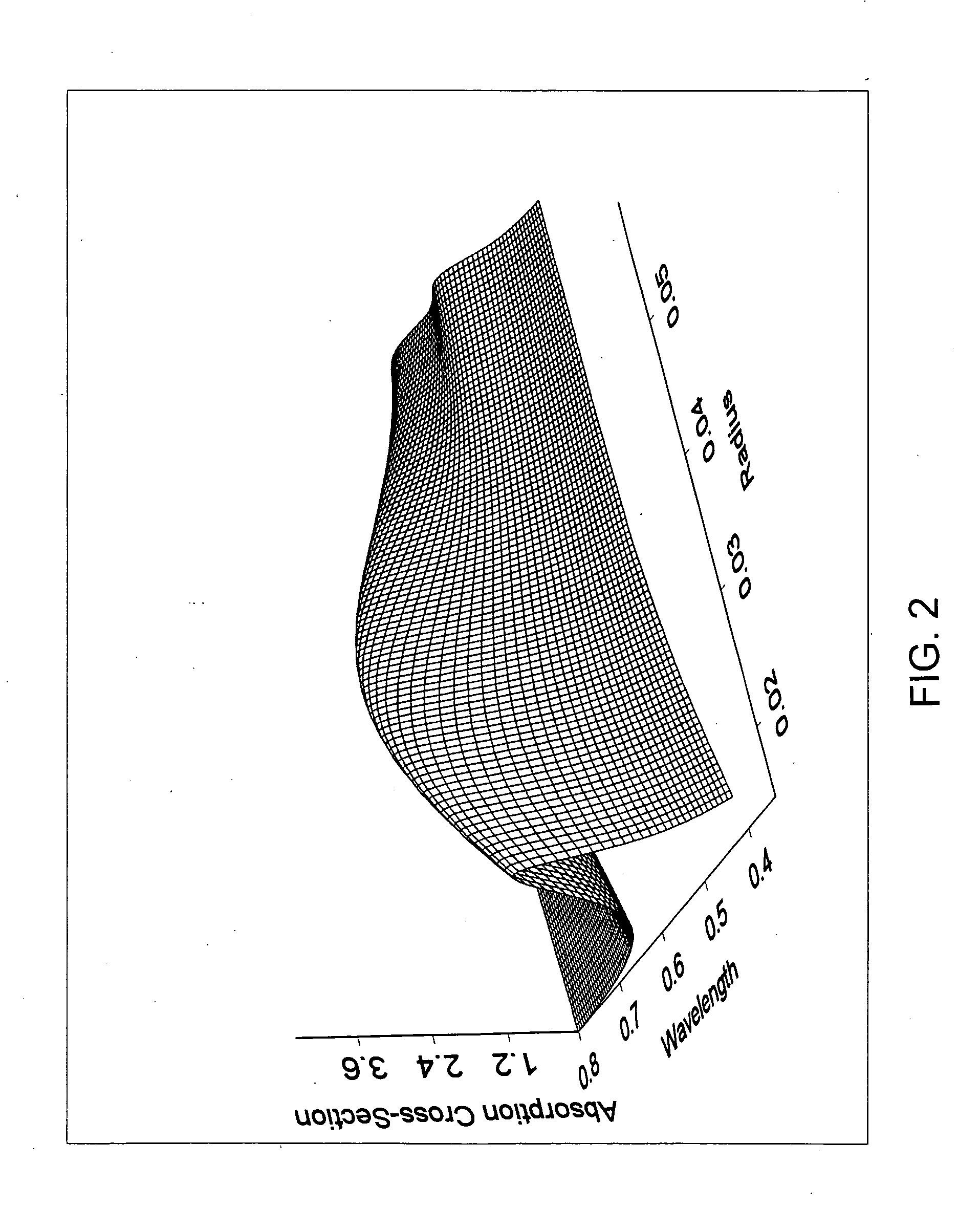

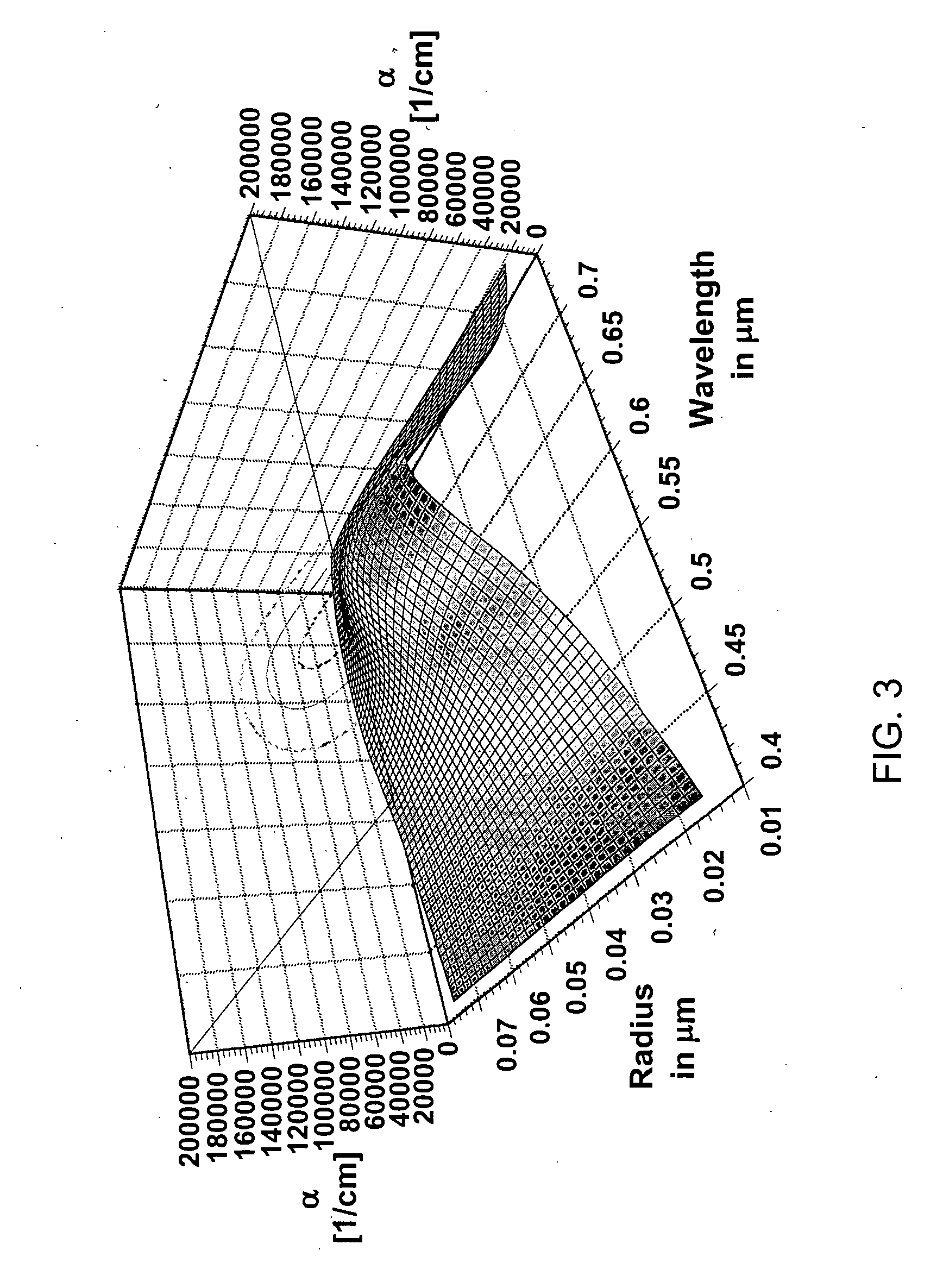

InactiveUS20050074611A1Material nanotechnologyLiquid surface applicatorsSpectral bandsResonance wavelength

Composite materials that can be used to block radiation of a selected wavelength range or provide highly pure colors are disclosed. The materials include dispersions of particles that exhibit optical resonance behavior, resulting in the radiation absorption cross-sections that substantially exceed the particles' geometric cross-sections. The particles are preferably manufactured as uniform nanosize encapsulated spheres, and dispersed evenly within a carrier material. Either the inner core or the outer shell of the particles comprises a conducting material exhibiting plasmon (Froehlich) resonance in a desired spectral band. The large absorption cross-sections ensure that a relatively small volume of particles will render the composite material fully opaque (or nearly so) to incident radiation of the resonance wavelength, blocking harmful radiation or producing highly pure colors. The materials of the present invention can be used in manufacturing ink, paints, lotions, gels, films, textiles and other solids having desired color properties. The materials of the present invention can be used in systems consisting of reflecting substances such as paper or transparent support such as plastic or glass films. The particles can be further embedded in transparent plastic or glass beads to ensure a minimal distance between the particles.

Owner:KUEHNLE MANFRED R

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7468290B2Solid-state devicesSemiconductor/solid-state device manufacturingDielectricUltraviolet lights

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

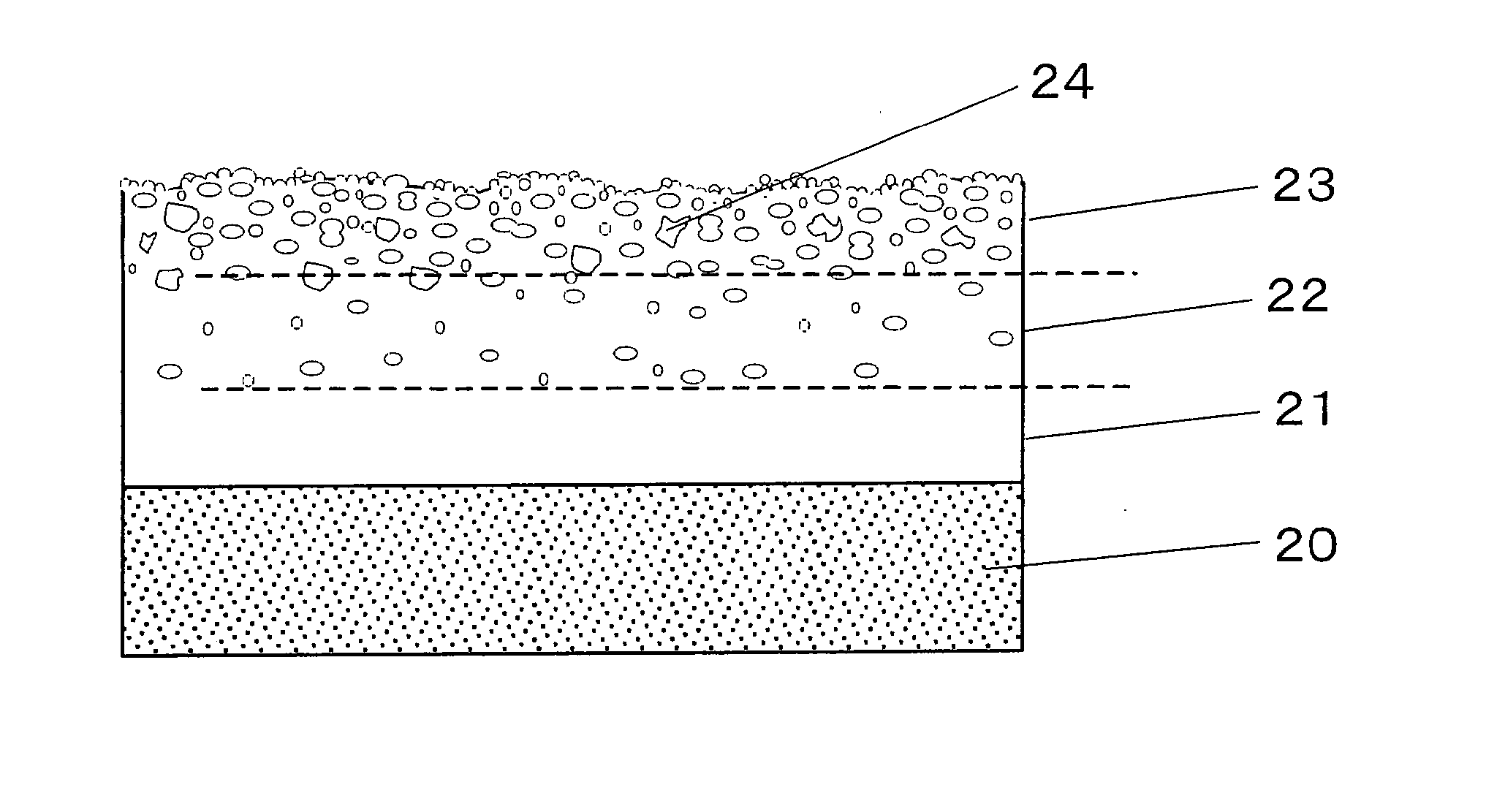

Method for producing glass film, method for treating glass film and glass film laminate

InactiveUS20110123787A1Increase contactEasy to peelLamination ancillary operationsFilm/foil adhesivesSurface roughnessOptoelectronics

A method of producing a glass film comprises a first step of forming an inorganic thin film on a surface of a supporting glass so that a surface of the inorganic thin film after being formed has a surface roughness Ra of 2.0 nm or less after film formation, a second step of forming a glass film laminate by laminating a glass film having a surface roughness Ra of 2.0 nm or less on the surface of the inorganic thin film in a state of being in contact with each other, a third step of carrying out treatment involving heating with respect to the glass film laminate, and a fourth step of peeling off the glass film from the supporting glass after the treatment involving heating.

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for preparing high- stable neutral mixed crystal nanometer TiO2 hydrosol

ActiveCN101306838AHigh transparencyImprove stabilityPhysical/chemical process catalystsTitanium dioxideSpectral responseHYDROSOL

The invention relates to a method for preparing a neutral mixed crystal nano TiO2 hydrosol with high stability, belonging to the photocatalytic active nano titanium dioxide material preparation process technical field. The method comprises the main steps that: 1. a titanium compound is hydrolyzed by aqueous slkali and deposited, filtered and washed; 2. products obtained are added in an acid solution and peptized at the temperature of between 60 and 100 DEG C, and added with a certain amount of SiO2 sols used as a stabilizer and metal salt used as a doping agent to be continuously reacted for a period of time; 3. the mixture is added with alkaline liquor for adjusting the pH value to between 7 and 8; 4. the mixture is filtered and washed, and filter cakes are dissolved in a certain amount of water and redispersed, and finally the neutral mixed crystal nano TiO2 sol with high stability is obtained. The TiO2 compound hydrosol prepared by the invention is neutral and has good transparency and stability, and the crystal form ratio of anatase and rutile is controllable, and the spectral response range is wide; the TiO2 hydrosol prepared by the invention is convenient in coating operation; moreover, the hydrosol can utilize the solar energy to complete sewage disposal, air purification, antibiotic treatment and glass film coating treatment, etc.

Owner:SHANGHAI UNIV

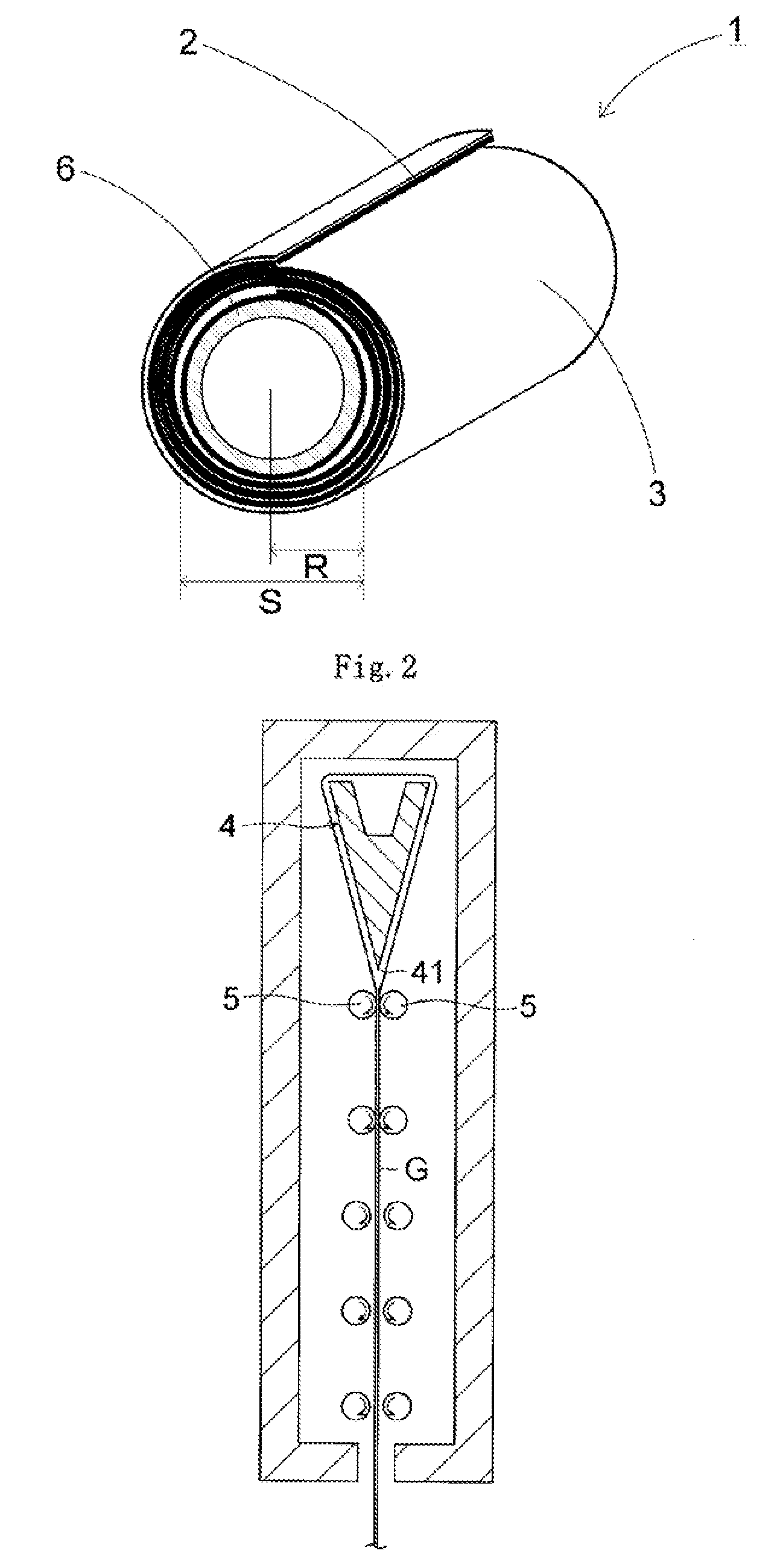

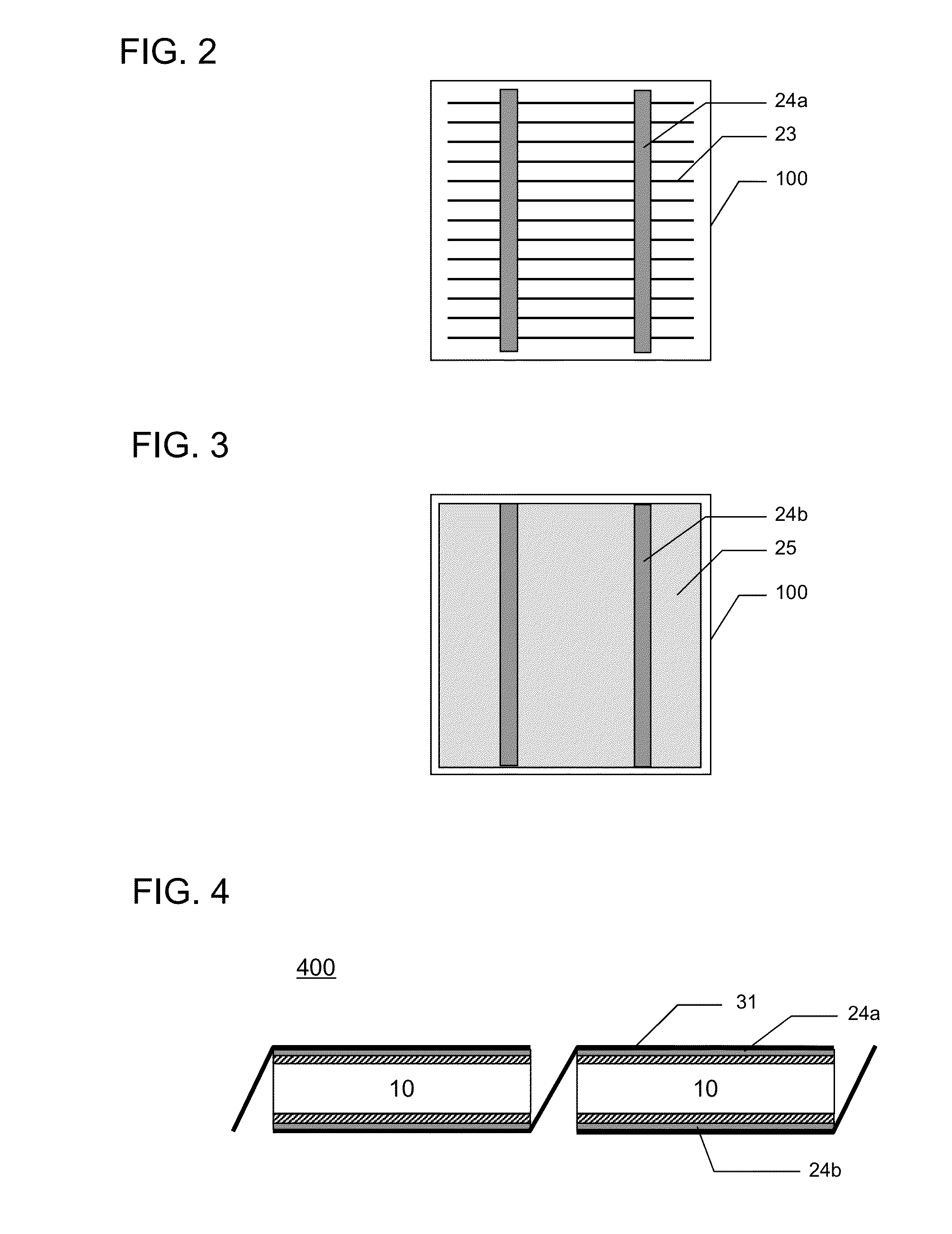

Glass roll

ActiveUS20110177347A1Inhibit the glass film from breakingSatisfy the protective effectInternal framesGlass/slag layered productsFlangeCushion

Provided is a glass roll utilizing a flanged roll core, and reliably inhibiting a glass film from breaking from an end portion in a width direction thereof as an origin of breakage. A glass roll (1) is formed by winding a glass film (4) and a cushion sheet (5), under a state of being superposed, around a roll core (3) including a flange (2) at each end portion thereof, in which an end portion in a width direction of the glass film (4) is separated from the flange (2) on each side in the width direction of the glass film (4), and the cushion sheet (5) is extended beyond the end portion in the width direction of the glass film (4) to the flange (2) side, to thereby form an extension portion (5a).

Owner:NIPPON ELECTRIC GLASS CO LTD

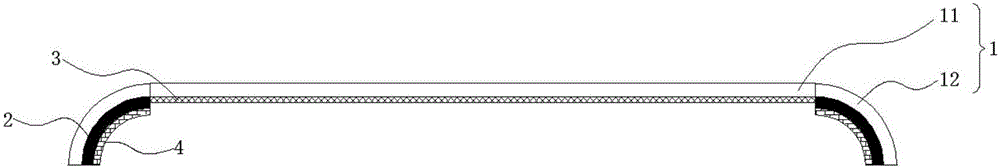

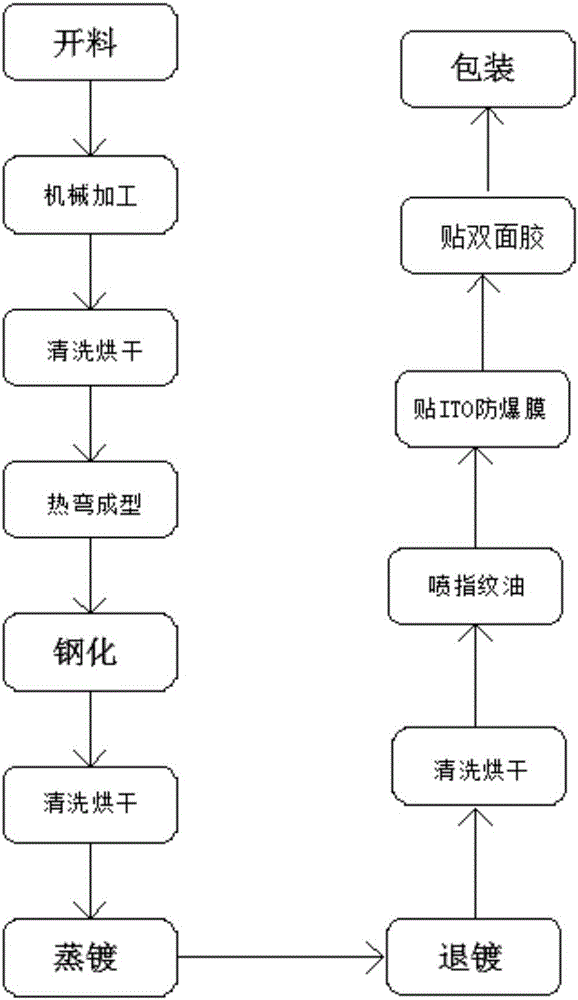

Full-screen curved-plane evaporation mobile phone glass film and production process thereof

ActiveCN106045328ANo sense of obtrusivenessImprove visual effectsGlass reforming apparatusEvaporationAlloy

The invention relates to a full-screen curved-plane evaporation mobile phone glass film and a production process thereof. The glass film is applied to a full-screen frameless curved-plane mobile phone and comprises a tempered glass layer and an alloy layer, the tempered glass layer comprises a center transparent portion and four side bent portions, the bent portions fit the frame curved plane of the full-screen mobile phone, the alloy layer is formed under the bent portions by evaporation, the color of the alloy layer is similar to that of a mobile phone shell, and the alloy layer shields black edges of the frame curved plane of a mobile phone screen. By the alloy layer formed under the bent portions through evaporation, the black edges of the frame curved plane of the mobile phone screen can be effectively shielded. In use of the mobile phone, a user can see images on the screen clearly through the transparent portion of the tempered glass layer without being distracted by the black edges, so that better visual effects are obtained. Since the color of the alloy layer is similar to that of the mobile phone shell, attractiveness and elegance in appearance and freeness of incongruity are realized.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

Method of manufacturing thick-film electrode

ActiveUS20130337604A1Improve solder adhesionConductive materialSemiconductor/solid-state device manufacturingConductive pasteFrit

A method of manufacturing a thick-film electrode comprising the steps of: applying onto a substrate a conductive paste comprising a conductive powder, a glass frit, 3.5 to 12.5 weight percent of an organic polymer, and a solvent, wherein the weight percent is based on the total weight of the conductive powder, the glass frit, and the organic polymer; firing the applied conductive paste to form the thick-film electrode, wherein thickness of the thick-film electrode is 1 to 10 μm; and soldering a wire to the thick-film electrode.

Owner:SOLAR PASTE LLC

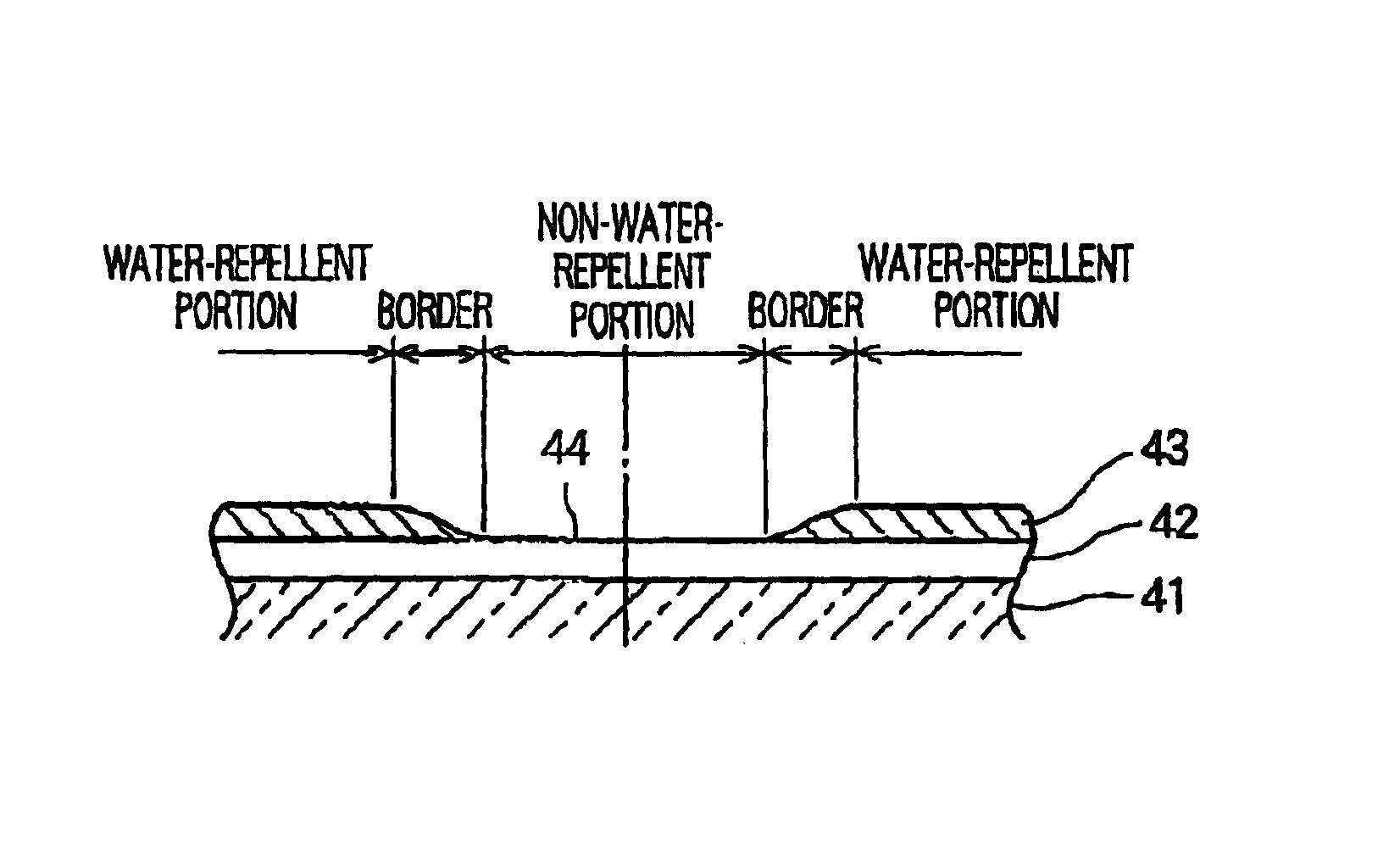

Partially treated water-repellent glass sheet

A method for partially treating a water-repellent glass sheet is disclosed which comprises irradiating part of a water-repellent glass film, formed on the water-repellent glass sheet, with a stream of plasma jets generated by a plasma jet irradiating gun. By such plasma jet irradiation, the film part can be removed easily even when the glass sheet has a curved surface. A water-repellent glass sheet with the film part removed is also disclosed.

Owner:NIPPON SHEET GLASS CO LTD

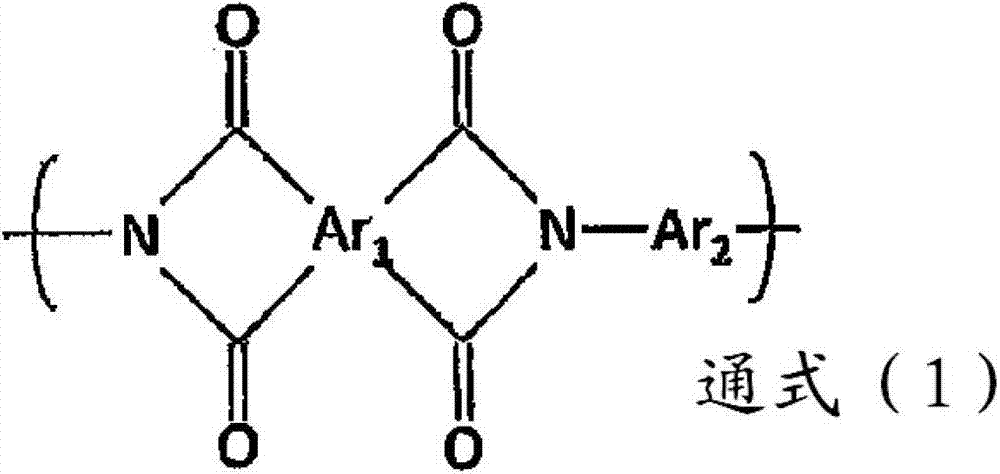

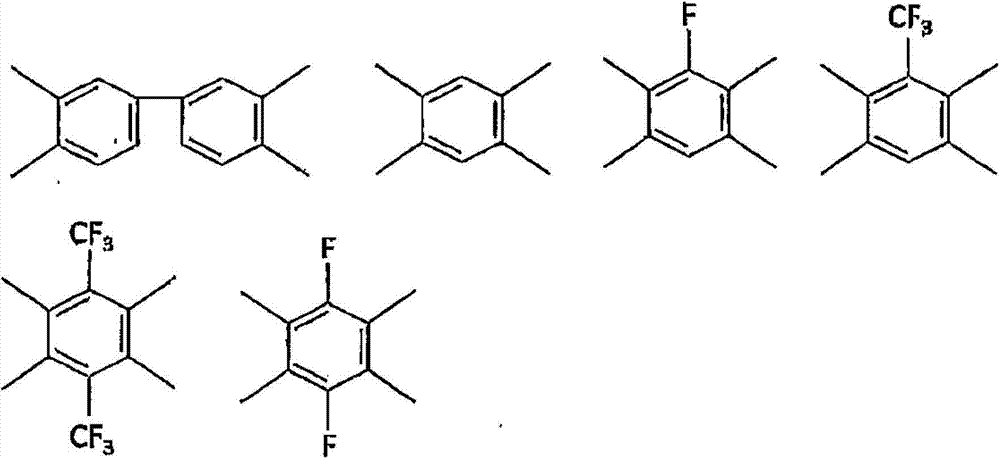

Transparent flexible laminate and laminate roll

InactiveCN103240936ASynthetic resin layered productsElectrical equipmentHeat resistanceDisplay device

The invention provides a laminate and a laminate roll. The laminate has excellent flexibility and transparency, is applicable to displays, solar cells, and the like; warping of the laminate itself is inhibited; and the laminate has excellent heat resistance and gas barrier properties. The transparent flexible laminate is characterized in that the laminate comprises a glass film with a thick ness of 20-200 microns, and a polyimide resin layer; the polyimide resin layer has a coefficient of thermal expansion of below 10 ppm / K, and has a light transmittance of more than 80% at a wavelength of 500 nm. In addition, a laminate roll formed by rolling the transparent flexible laminate is provided.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

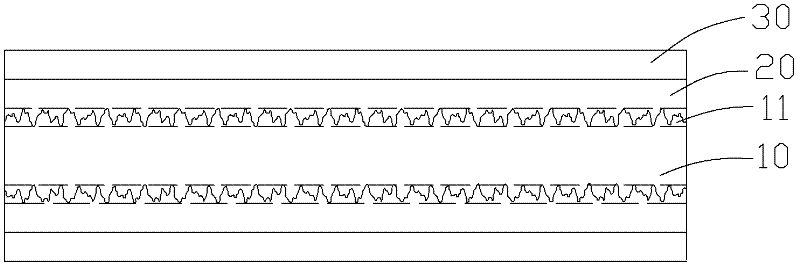

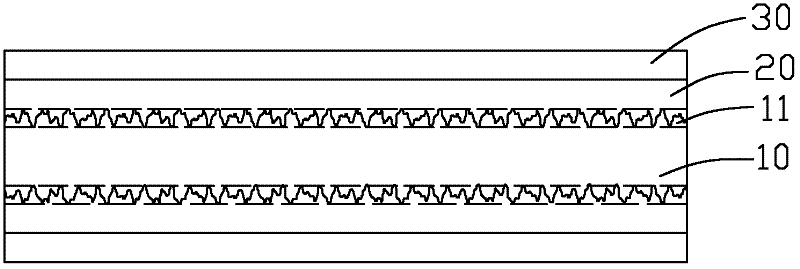

Circuit board and manufacturing method thereof

InactiveCN102548200AImprove bindingSimple preparation processPrinted circuit manufactureGlass/slag layered productsMetal foilEngineering

The invention relates to a circuit board which comprises a glass film with rough layers formed through surface roughening treatment, resin adhesive layers respectively positioned on the rough layers at two sides of the glass film and metal foils positioned at the outer sides of the resin adhesive layers, wherein the glass film, the resin adhesive layers and the metal foils are integrated through pressing. The circuit board provided by the invention adopts the glass film with the rough layers formed through surface roughening treatment as a carrier material, so that the resin adhesive layers and the surface of the glass film have good adhesion; the circuit board also has the characteristic that the difference of dielectric constants at directions X, Y, Z is small. The invention also relates to a manufacturing method of the circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

Quartz glass thermal sprayed parts and method for producing the same

InactiveUS20040018361A1Good heat insulationGood adhesivenessLiquid surface applicatorsMolten spray coatingQuartzMaterials science

Parts, especially those formed of quartz glass, for film-forming devices, plasma-treating devices and the like have a problem of inner pollution of the devices with particles given by dropping of deposit films from the parts, a problem of hermetical sealing reduction due to bonding failure of the parts to other parts, and a problem of energy efficiency reduction due to the heat insulation failure in the parts. Parts having a thermal sprayed quartz glass film formed on a substrate have an increased ability to hold a deposit thereon, and have an increased ability to hermetically bond to other parts. The parts having a thermal sprayed black quartz glass film have an increased ability of heat insulation property. Even when washed with acid, the abilities of the parts do not lower. The parts can be used for a long period of time and their life is long.

Owner:TOSOH CORP

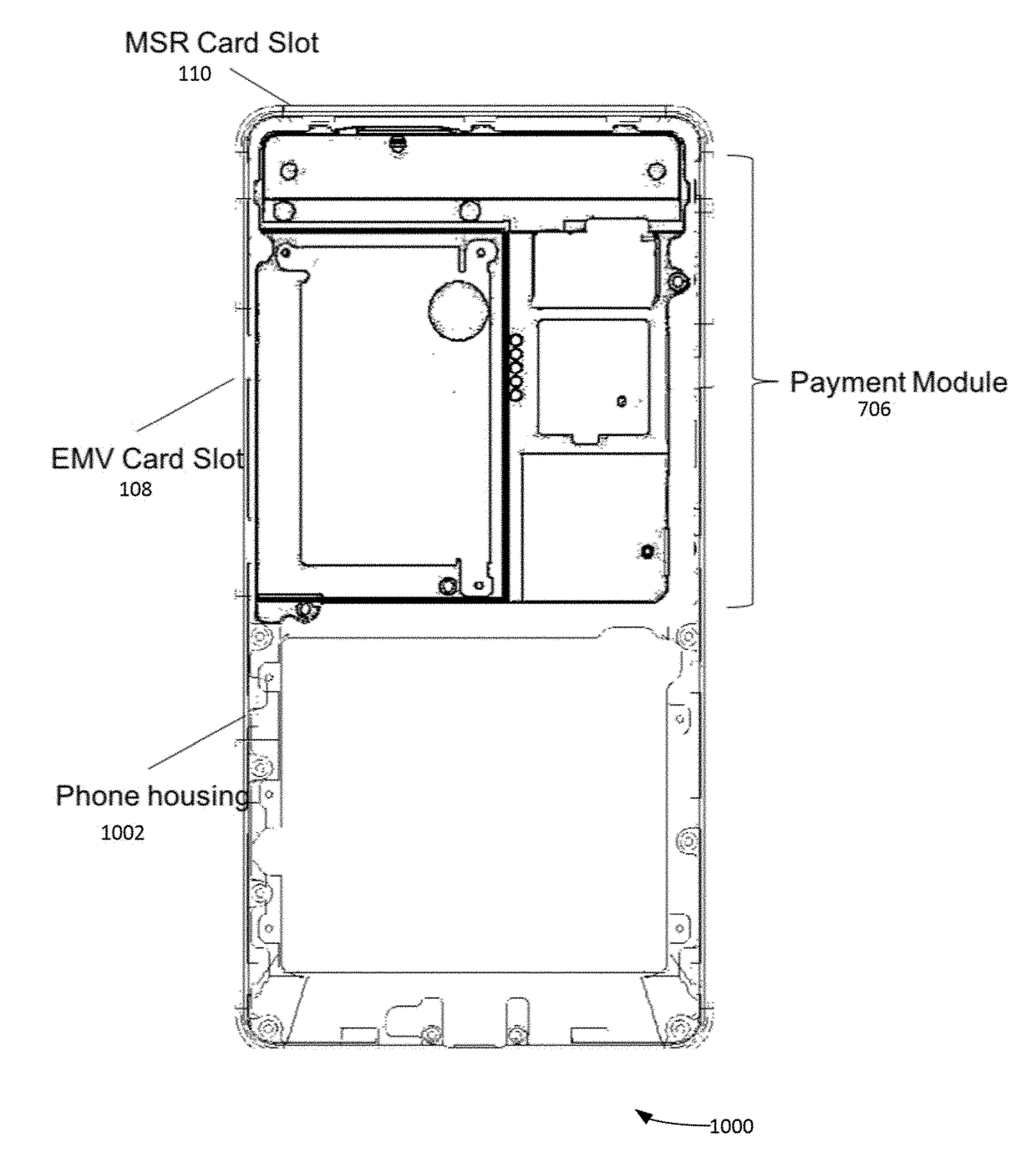

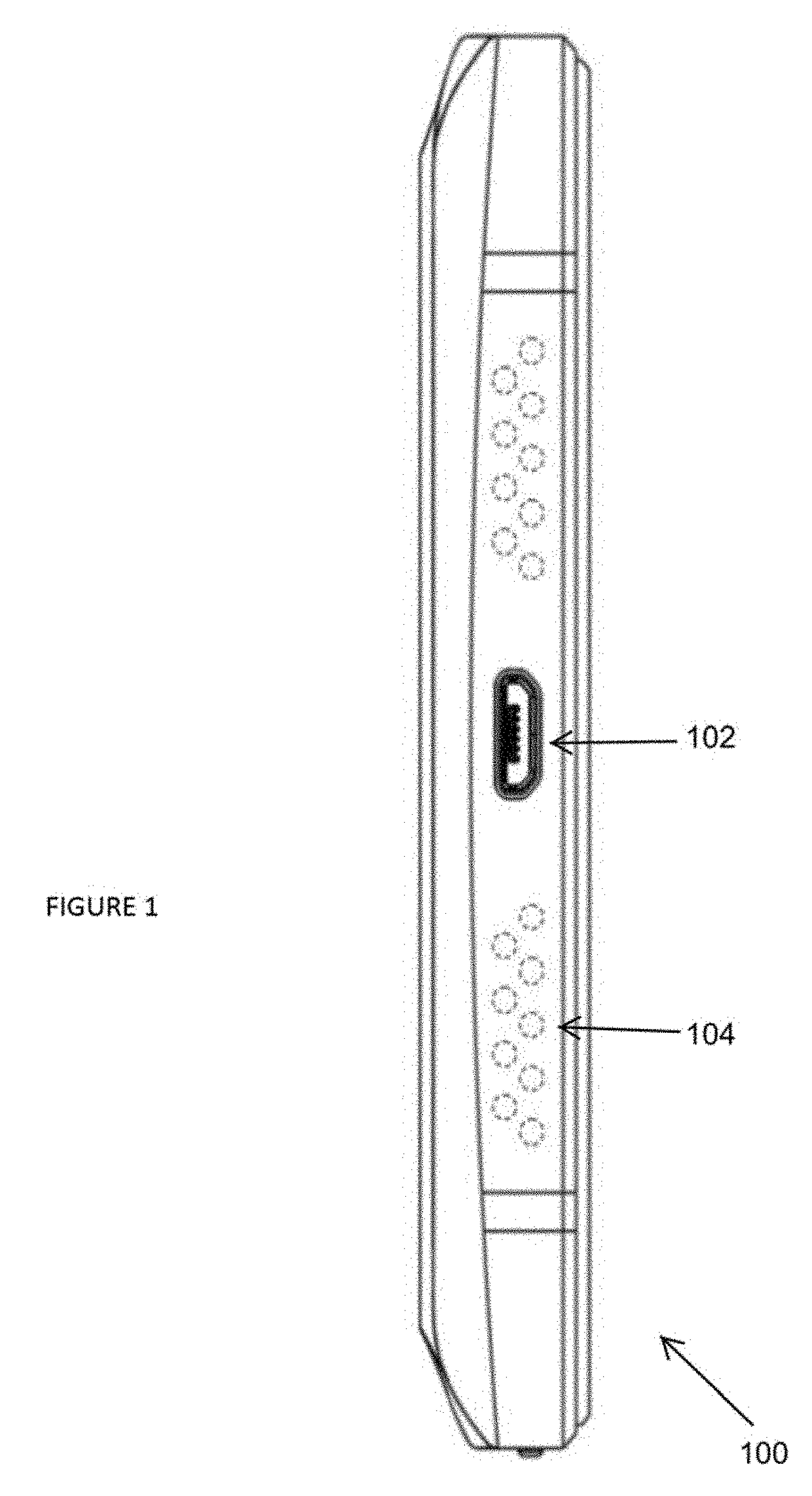

Integrated point of sale (POS) mobile device and methods of manufacture

In one example aspect, an integrated point of sale (POS) mobile device includes a mobile-device processor; a secure payment processor; a memory, coupled to the mobile device-processor and the secure payment processor, for storing executable instructions that comprise a mobile-device payment system and a set of payment data; a glass film film (GFF) touch sensor, wherein the GFF touch sensor can be drivers by a secure-touch integrated circuit (IC) that encrypts any touch data going to the secure payment processor; an EMV (Europay, MasterCard, and Visa) card reader system; an NFC (Near field communication) reader system; a Magnetic stripe reader (MSR); a housing comprising the mobile-device processor, the secure payment processor; the memory, the EMV (Europay, MasterCard, and Visa) card reader system, the NFC (Near field communication) reader system, the Magnetic stripe reader (MSR); a mobile-device payment system receiving input from the EMV card reader system, the MSR system, and the NFC reader system; and a security mesh comprising the secure payment processor.

Owner:SAEED FAISAL +2

Manufacturing method of mirror surface oriented silicon steel with good magnetic performance and annealing parting agent

ActiveCN103014285AStrong magnetismFlat surfaceFurnace typesHeat treatment furnacesCorrosion reactionMetal chloride

The invention discloses a manufacturing method of mirror surface oriented silicon steel with good magnetic performance and an annealing parting agent. The manufacturing method comprises the following steps of: 1) smelting; 2) hot rolling and normalizing; 3) cold rolling; 4) decarbonization and nitriding; and 5) parting agent coating and high-temperature annealing. The annealing parting agent comprises the following components in parts by mass: 65-96 parts of Al2O3 powder, 2-15 parts of silicate powder with a particle size of 0.1-100 microns, 1-10 parts of alkaline earth metal oxide and 1-10 parts of metal chloride. According to the invention, through the annealing parting agent consisting of Al2O3 powder, silicate powder, alkaline earth metal oxide and metal chloride, a glass film bottom layer is not formed on the surface of a steel plate in a high-temperature annealing process, and the steel can be effectively purified; and meanwhile, the embedded oxide on the near surface of a substrate is removed through the corrosion reaction of chloride so as to obtain a product with a smooth and clean surface and stable magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com