Patents

Literature

2193results about How to "Good coating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

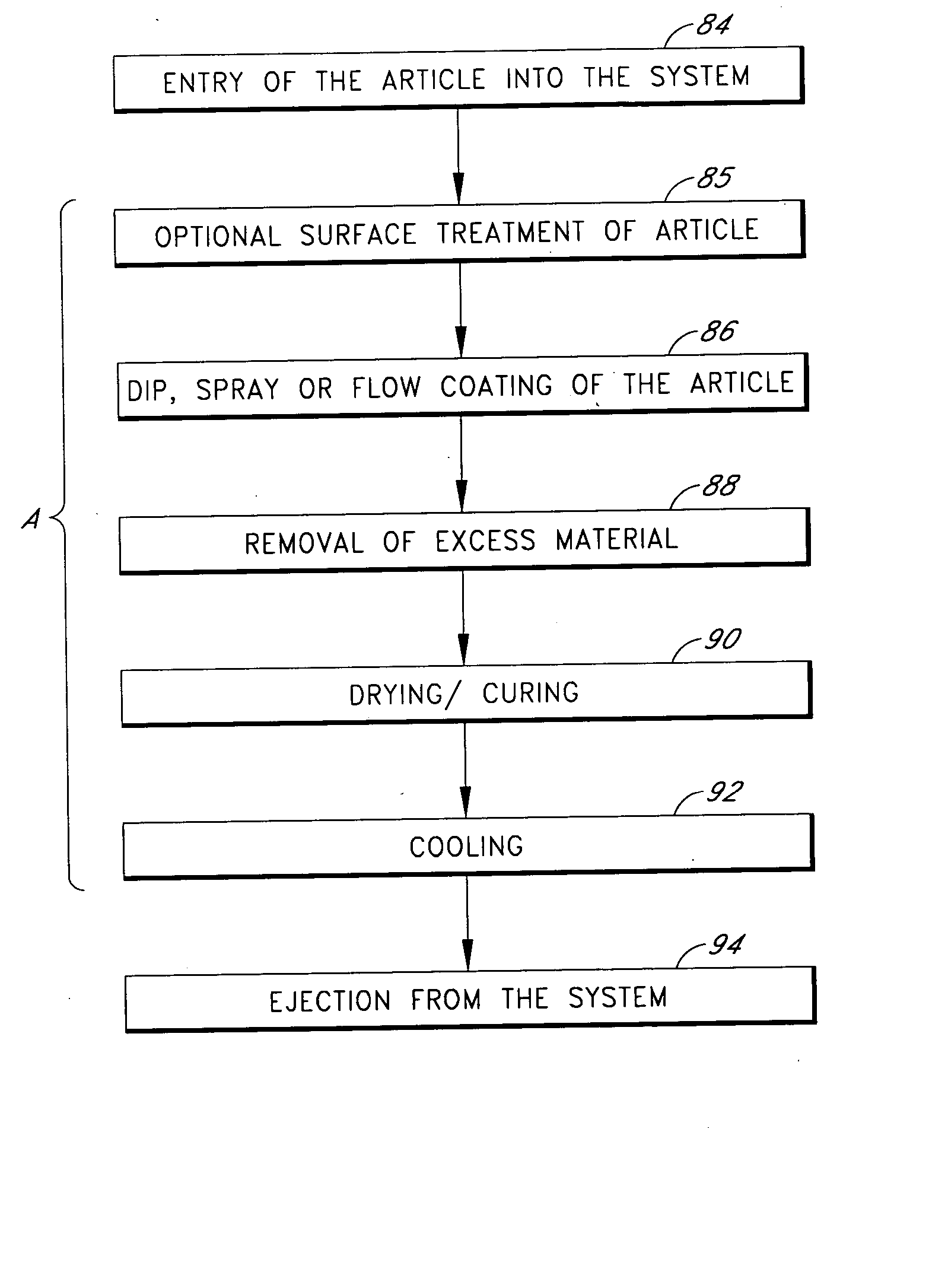

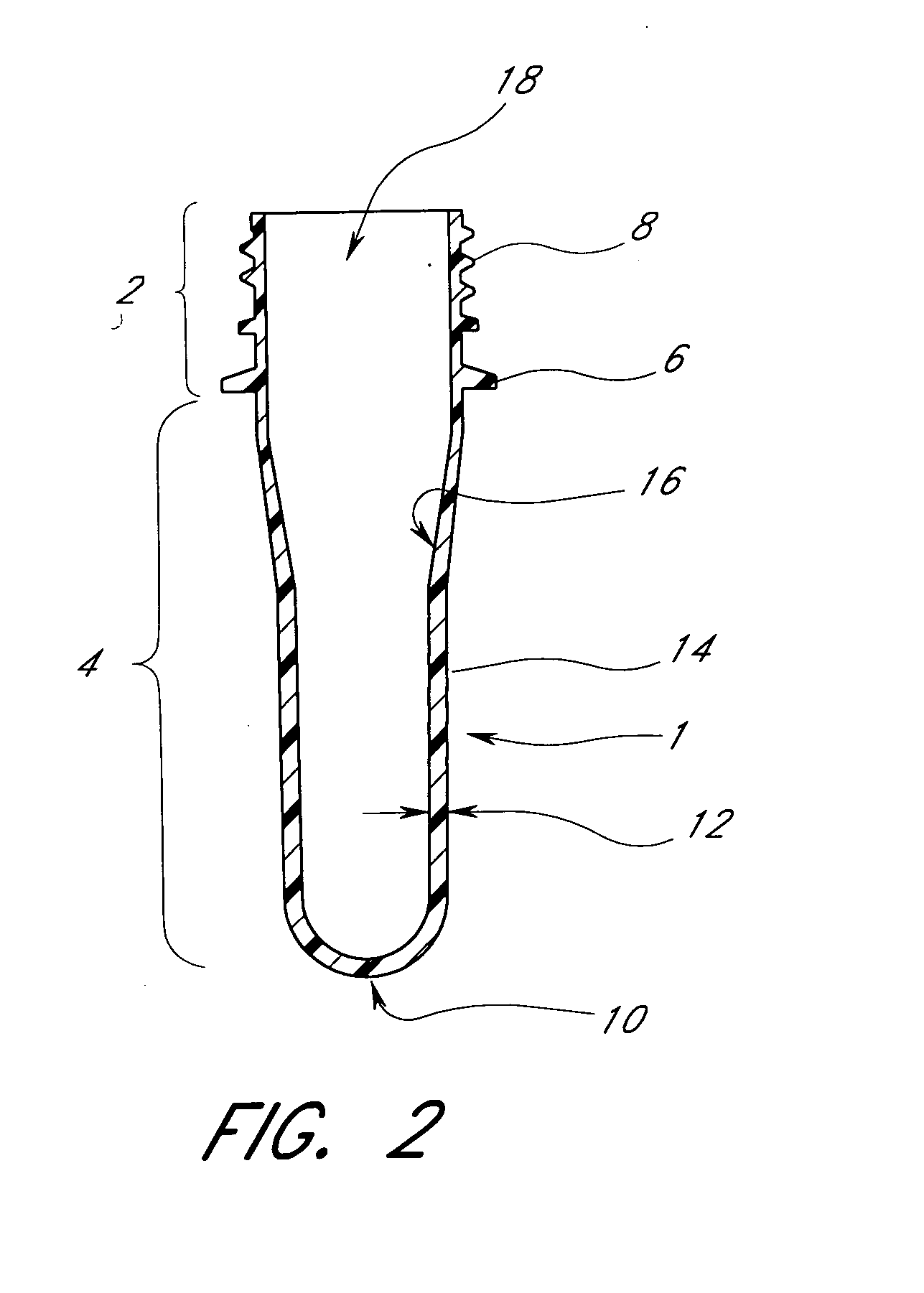

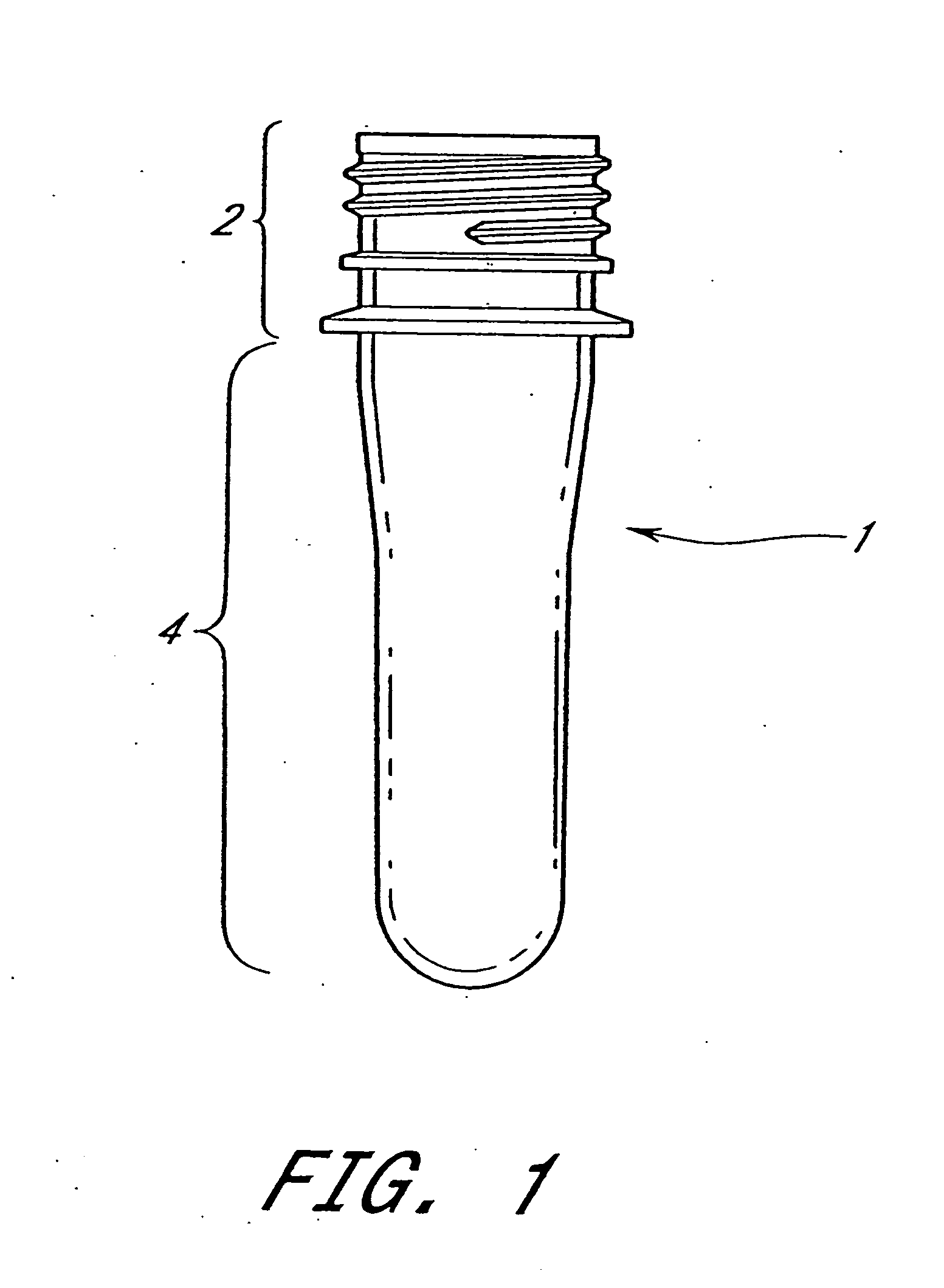

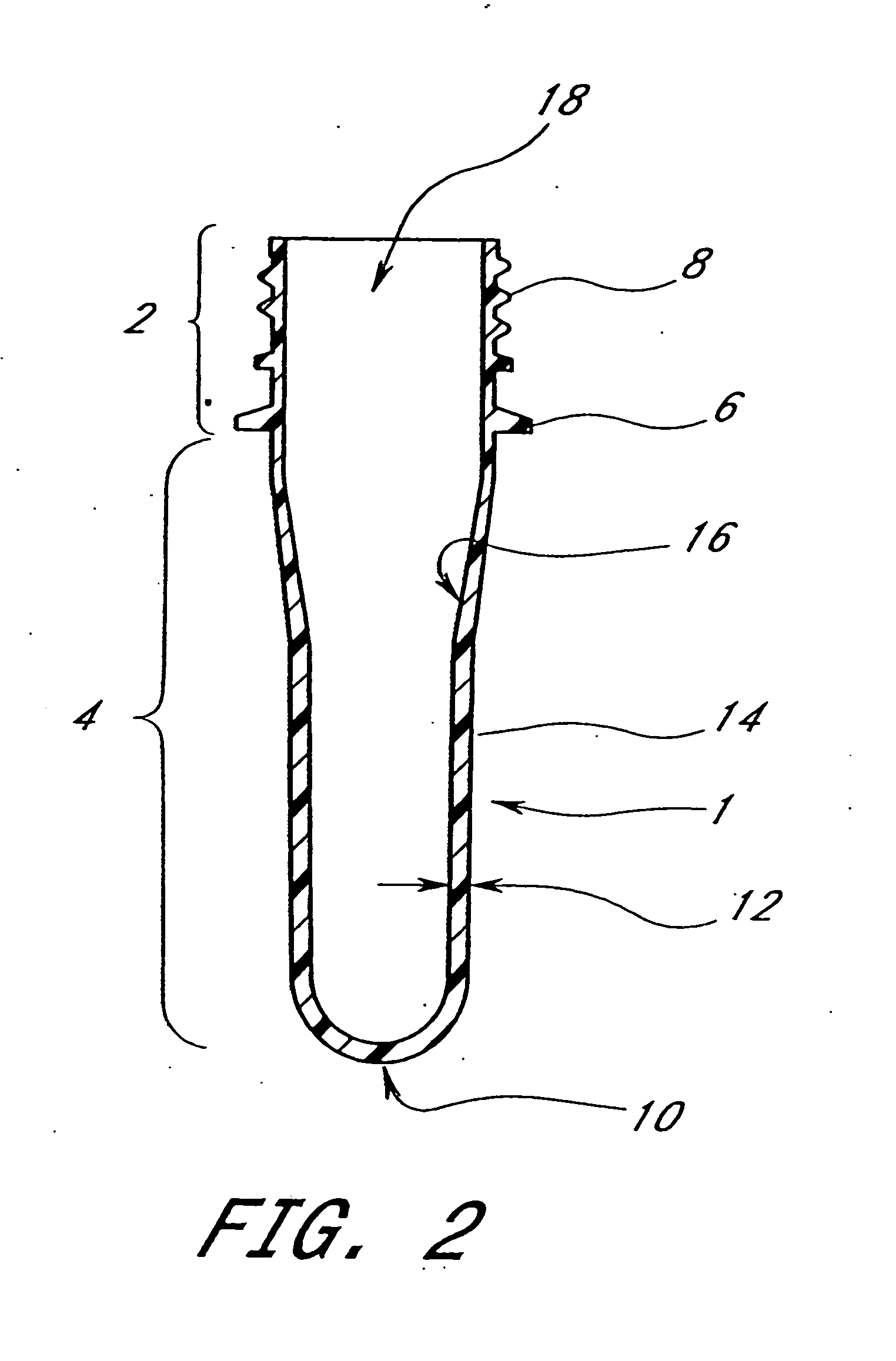

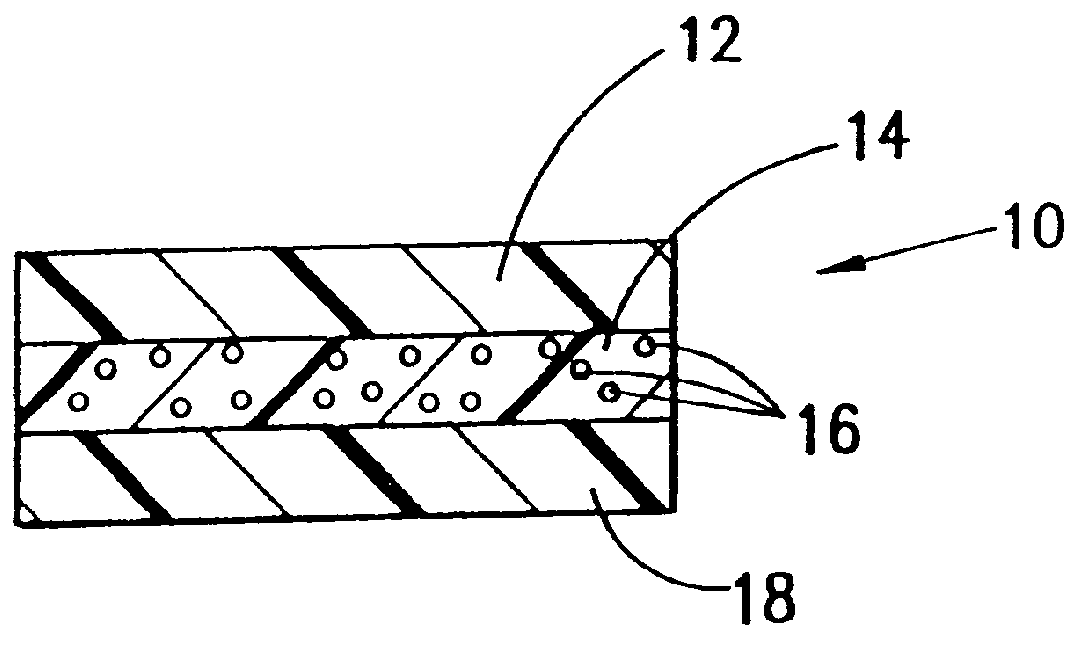

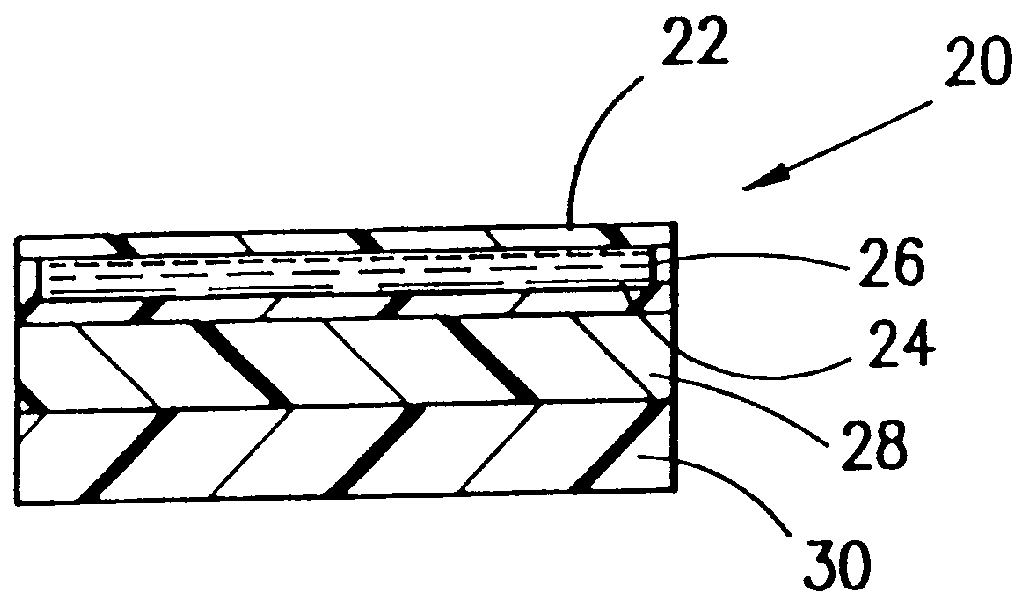

Methods of forming multilayer articles by surface treatment applications

InactiveUS20070087131A1Low water vapor transmission rateImprove adhesionPretreated surfacesCoatingsAir treatmentFlame treatment

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

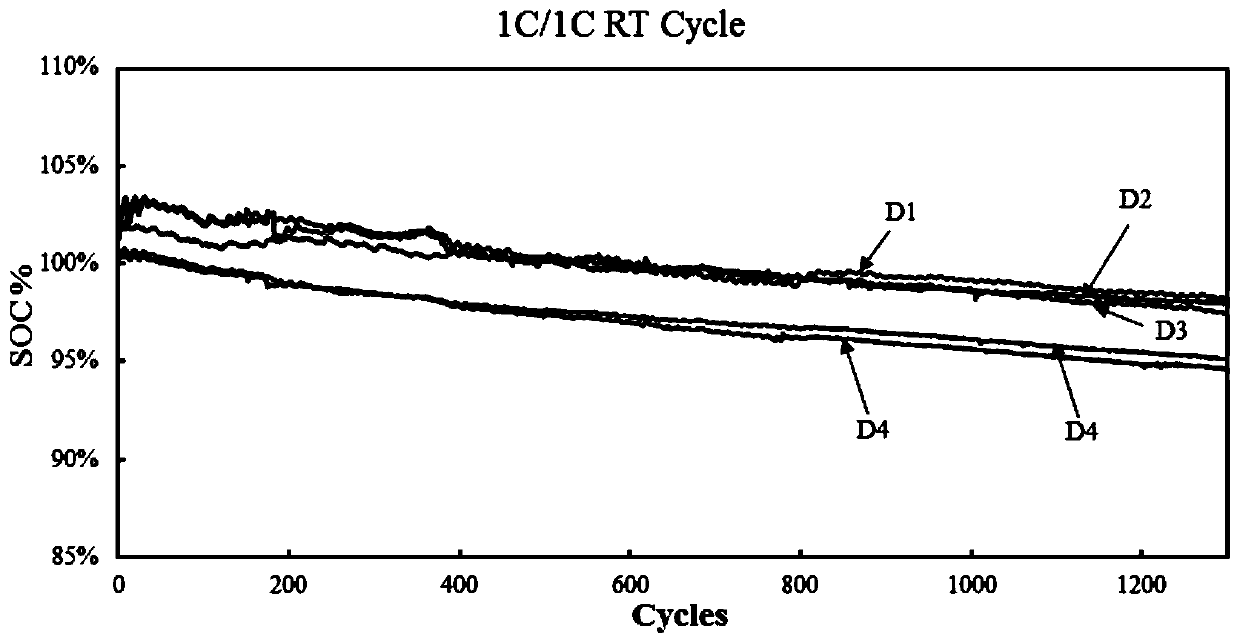

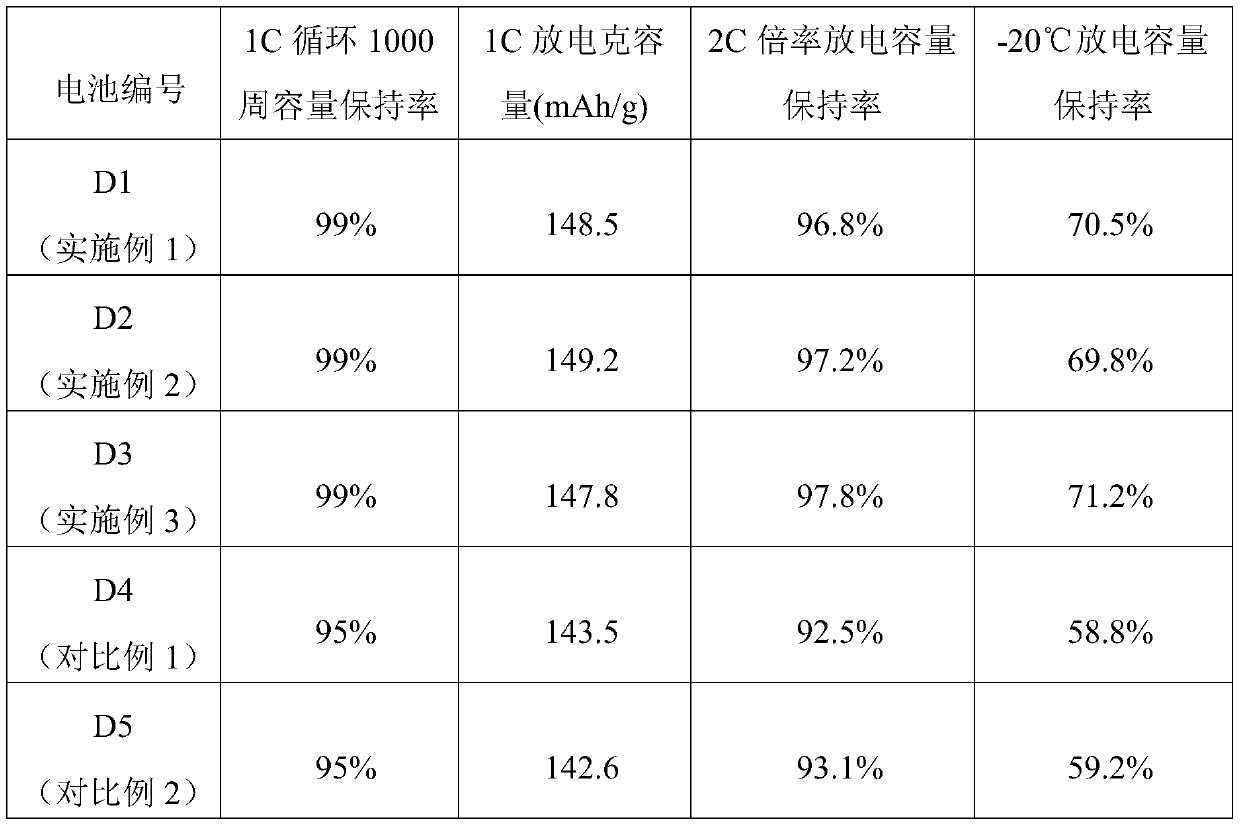

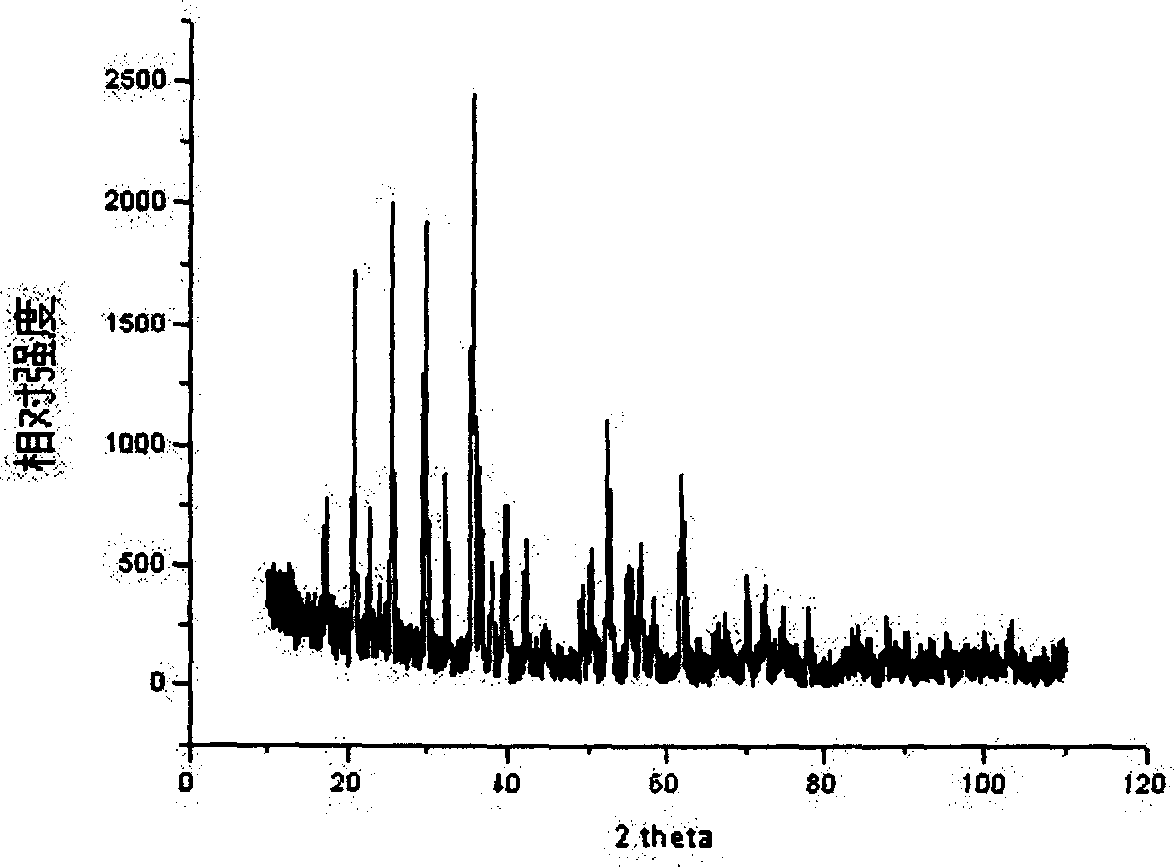

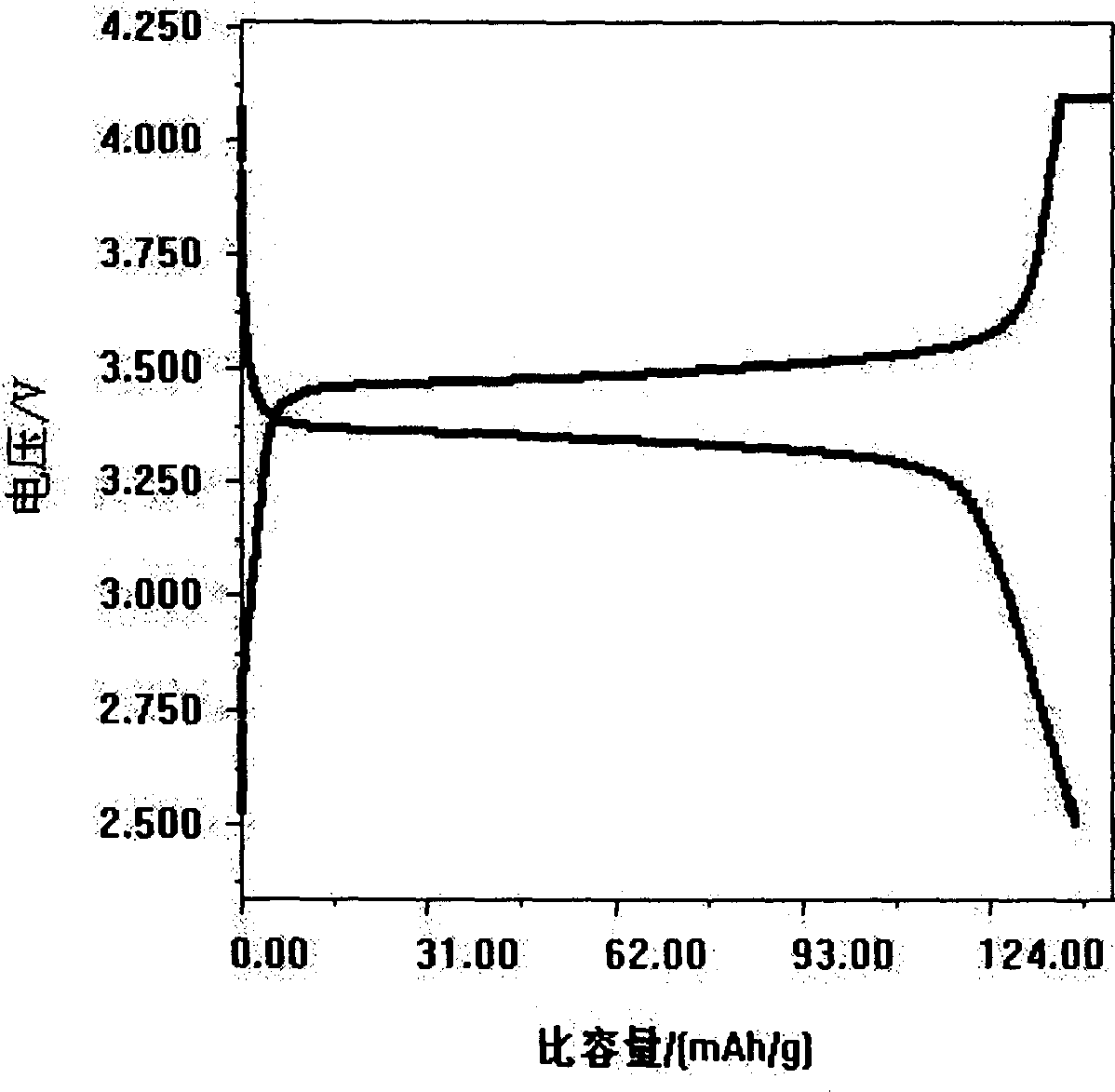

Lithium manganese oxide material and preparation method thereof

InactiveCN102054985AEasy to prepareNormal temperature is goodCell electrodesHigh temperature storagePhysical chemistry

The invention discloses a lithium manganese oxide material and a preparation method thereof, in particular to a high-crystallinity lithium manganese oxide material and a preparation method thereof, wherein the high-crystallinity lithium manganese oxide material is used for coating a lithium ion battery. The lithium manganese oxide material is obtained by being coated on a lithium manganese oxide precursor with the one-time crystal particle of 0.01-20mum and has the general formula of LiaMn2-b-cMbGcO4-d-eXdZe, wherein M and X are doped elements, G and Z are coating elements of which the concentration is distributed in a decreasing gradient from outside to inside, a is not less than 0.9 and is not more than 1.2, b is not less than 0 and is not more than 0.2, c is more than 0 and is not more than 0.2, d is not less than 0 and is not more than 0.2, and e is not less than 0 and is not more than 0.2. The material serves as the positive pole material of the lithium ion battery, has better normal-temperature and high-temperature cycle performance and excellent high-temperature storage performance, is simple in preparation and easy to operate, control and carry out industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

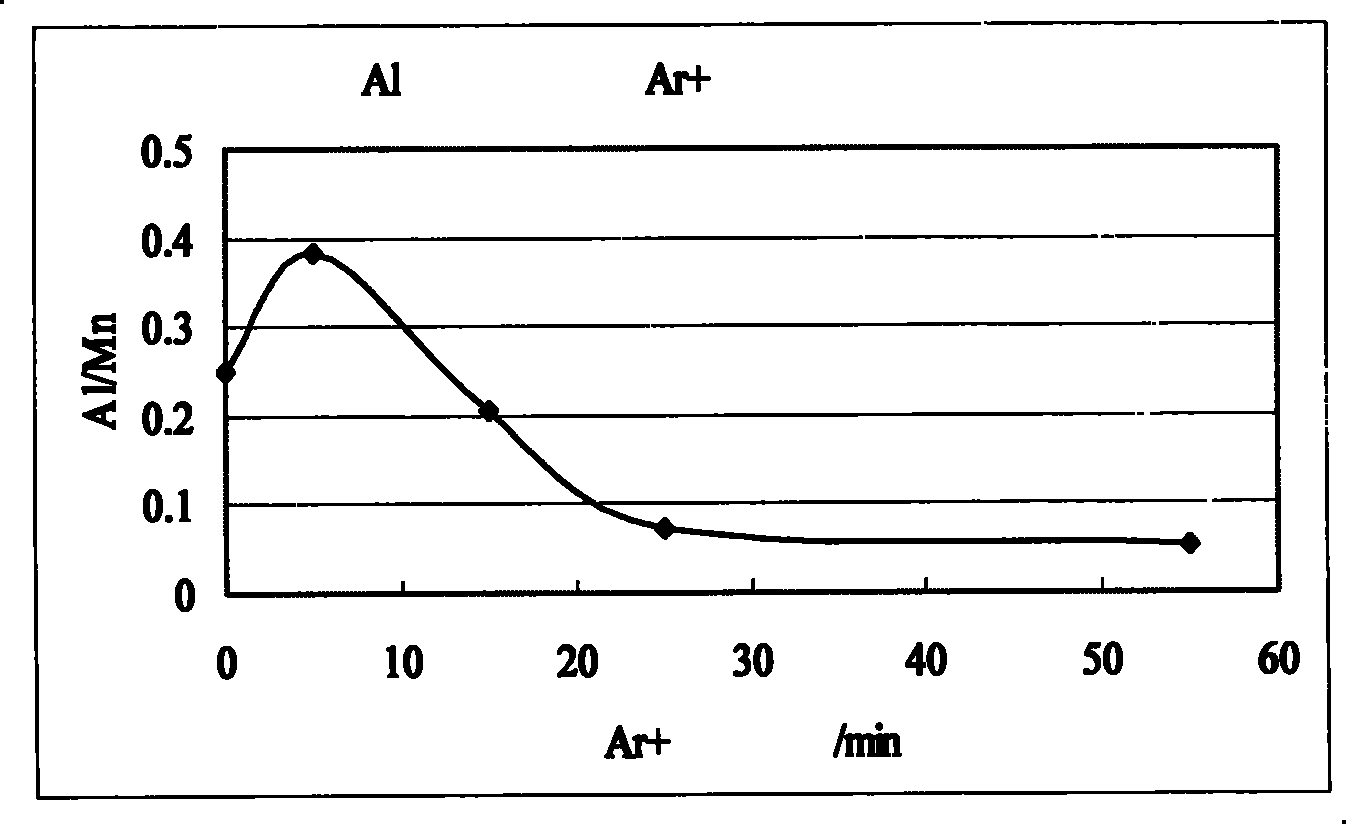

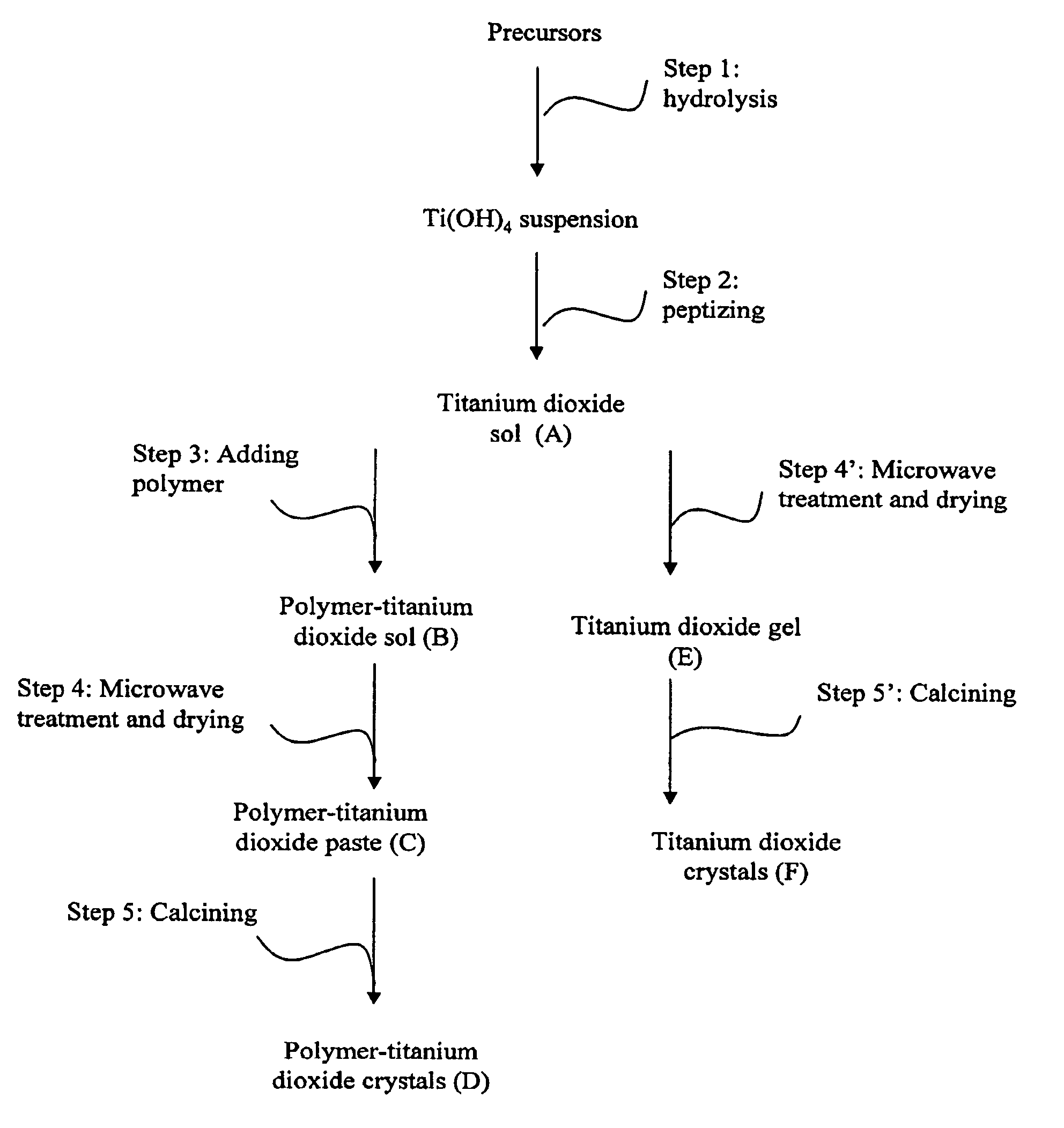

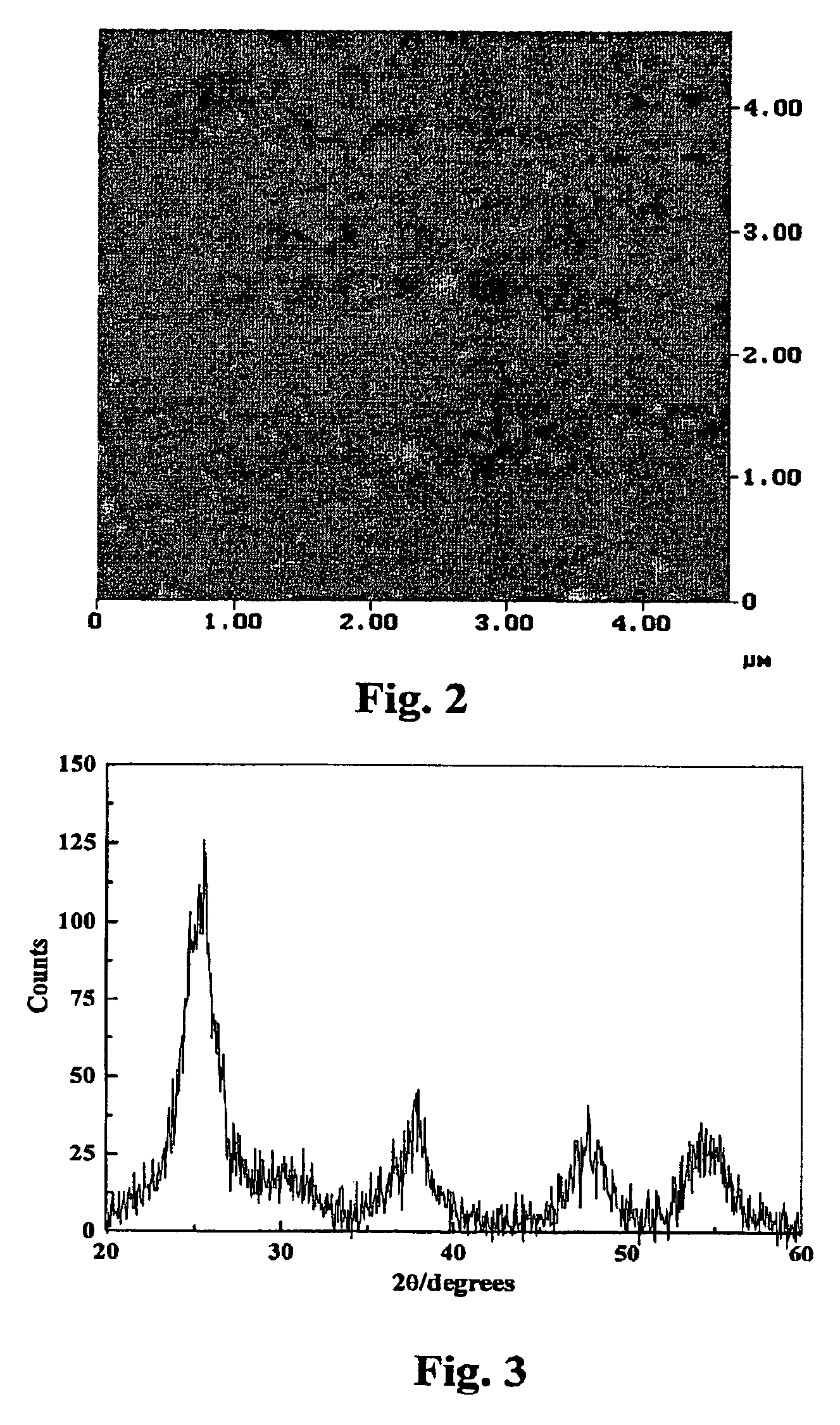

TiO2 material and the coating methods thereof

ActiveUS7144840B2Reduce moistureInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAir purificationTitanium dioxide

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

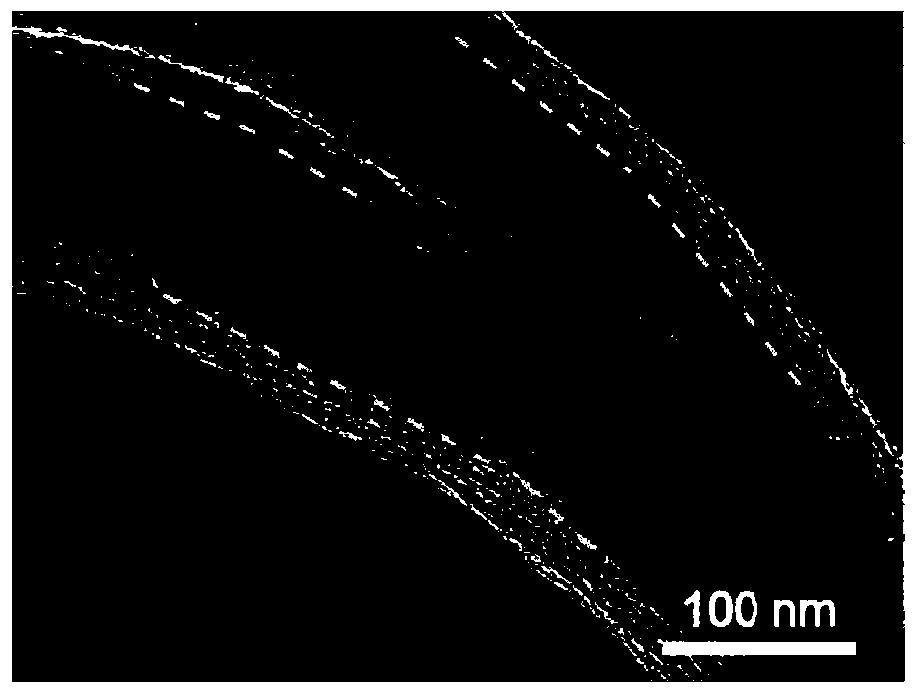

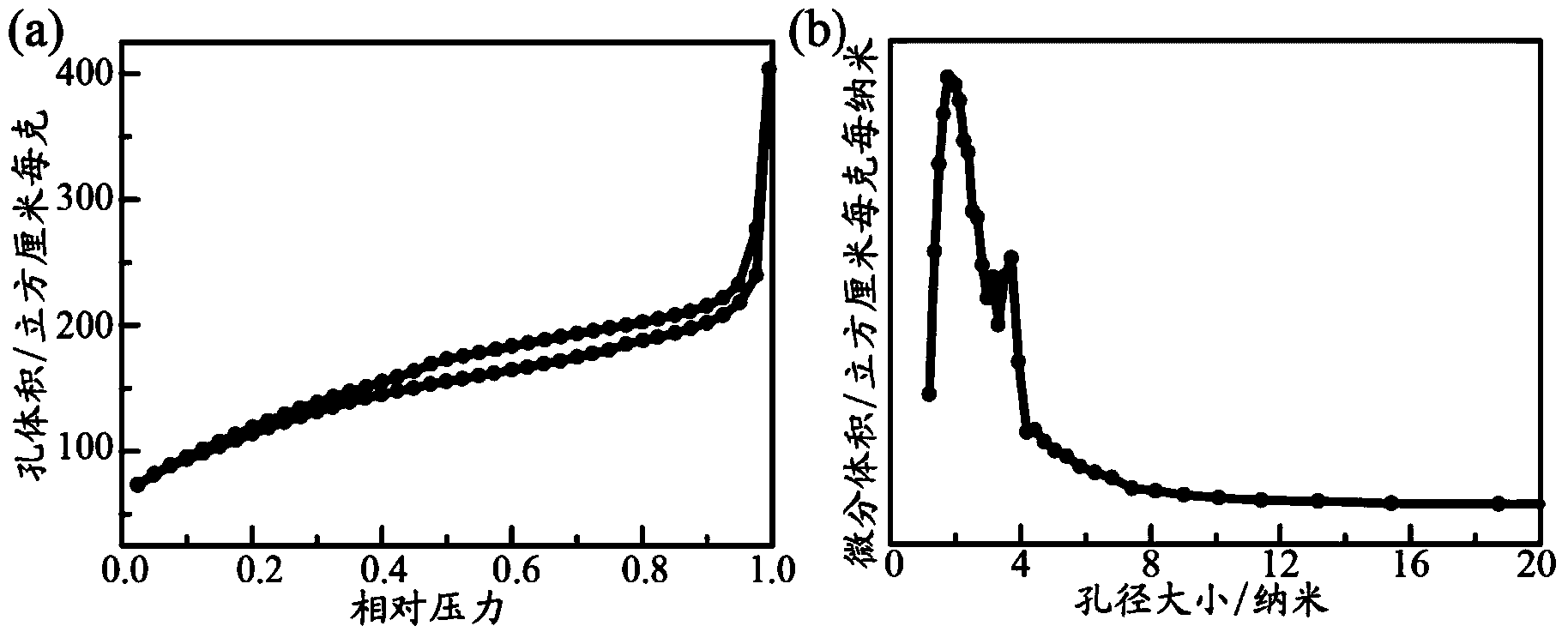

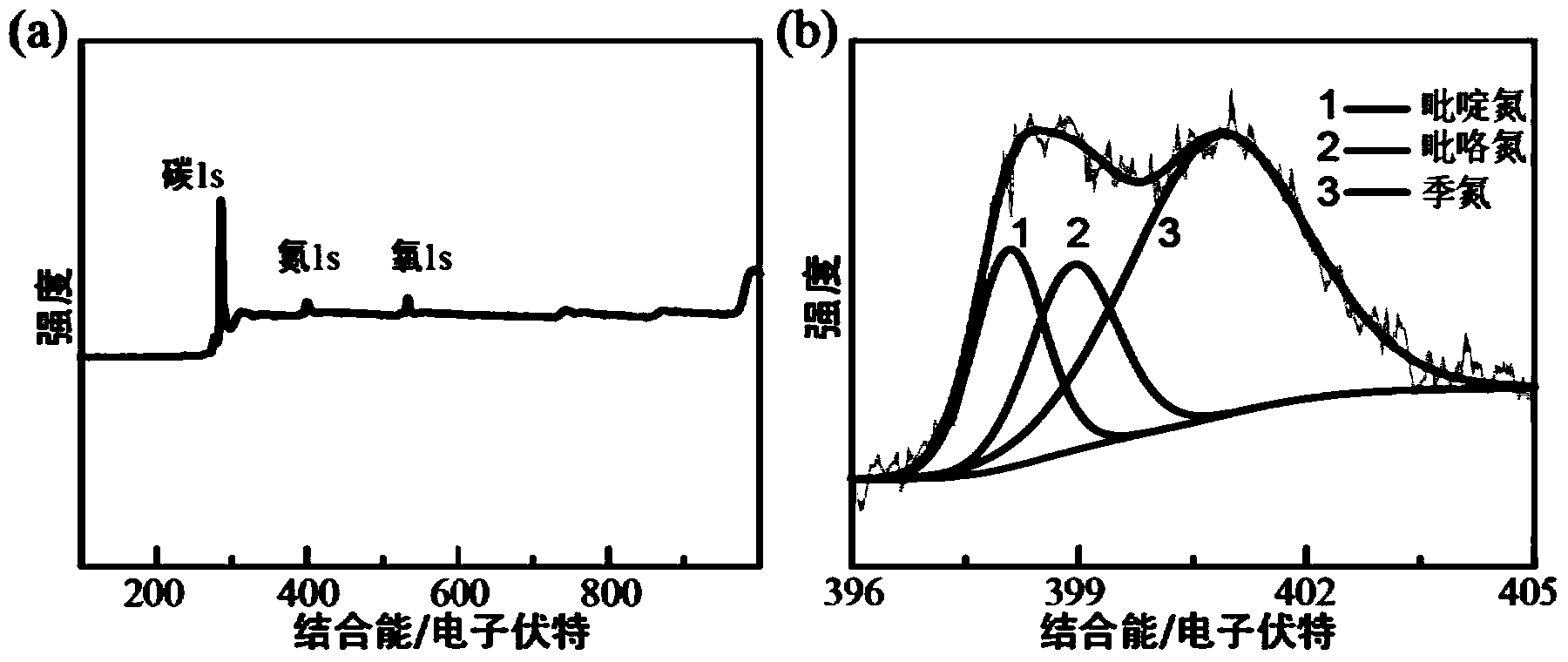

Composite material of nitrogen-doped porous carbon-wrapped carbon nano tube as well as preparation method and application of material

ActiveCN103706388AEasy to prepareEconomical method of preparationMaterial nanotechnologyPhysical/chemical process catalystsCarbon layerPorous carbon

The invention relates to a composite material of a nitrogen-doped porous carbon-wrapped carbon nano tube as well as a preparation method and an application of the composite material. The preparation method comprises the following steps: dispersing the carbon nano tube in water, adding a carbon source to obtain a reaction system, subsequently performing hydrothermal reaction, performing thermal treatment on the carbon nano tube wrapped with a carbon layer on the surface, and a nitrogen source at the high temperature so as to obtain the composite material of the nitrogen-doped porous carbon-wrapped carbon nano tube. According to the preparation method, the carbon source is polymerized under a hydrothermal reaction condition so as to obtain the carbon layer, the outer surface of the carbon nano tube is wrapped with the carbon layer, subsequently the carbon layer is carbonized and decomposed to generate a porous structure under high temperature treatment, and at the same time, the gasified nitrogen source is diffused to the carbon layer through ducts to be subjected to in-situ doping. The composite material provided by the invention can be used as a cathode oxidation reduction catalyst of a fuel battery, is excellent in catalysis, and is high in oxidation activity when being compared with other nitrogen-doped materials reported in documents. The preparation method provided by the invention is simple and economic in process, convenient to operate and easy to achieve the large-scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

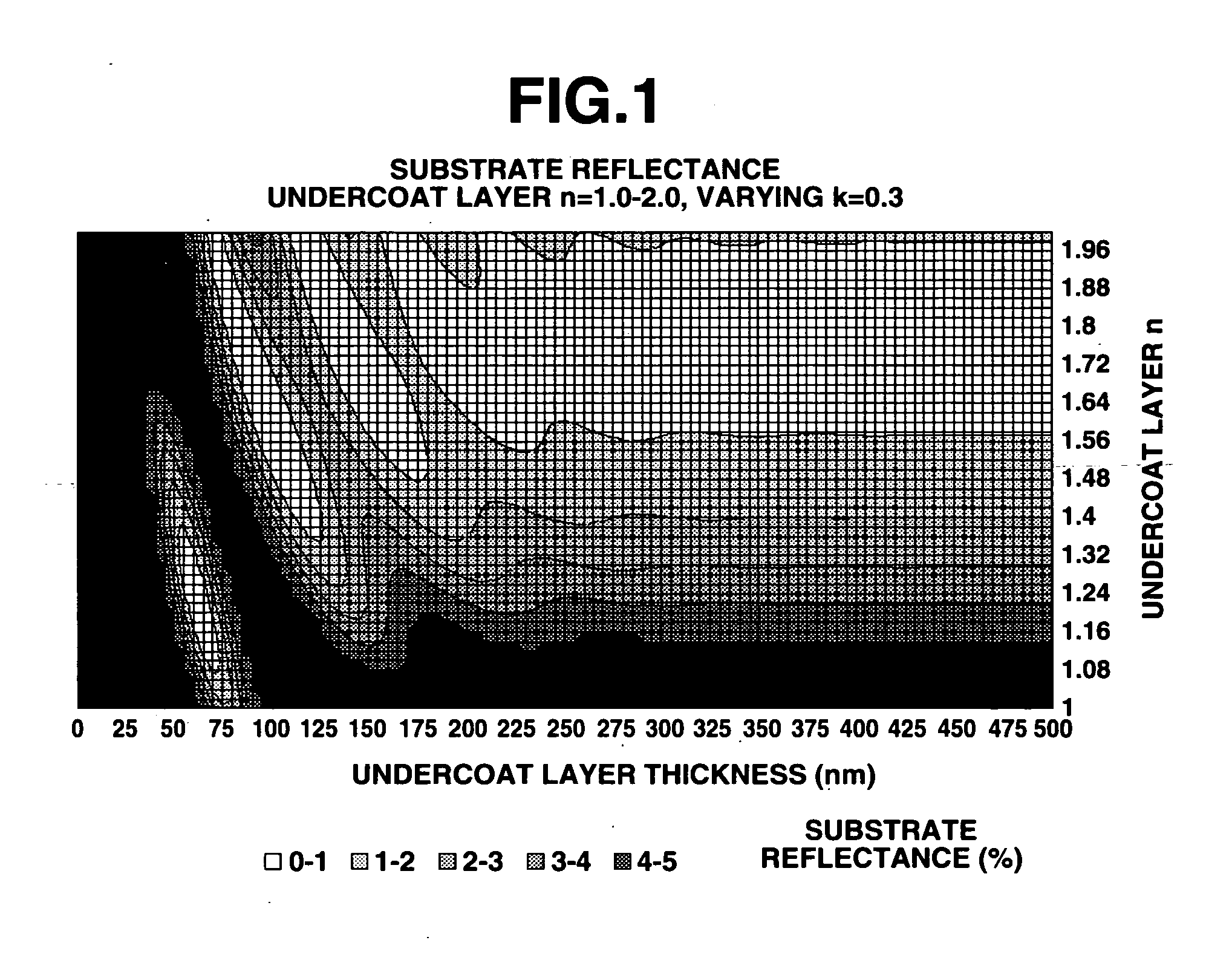

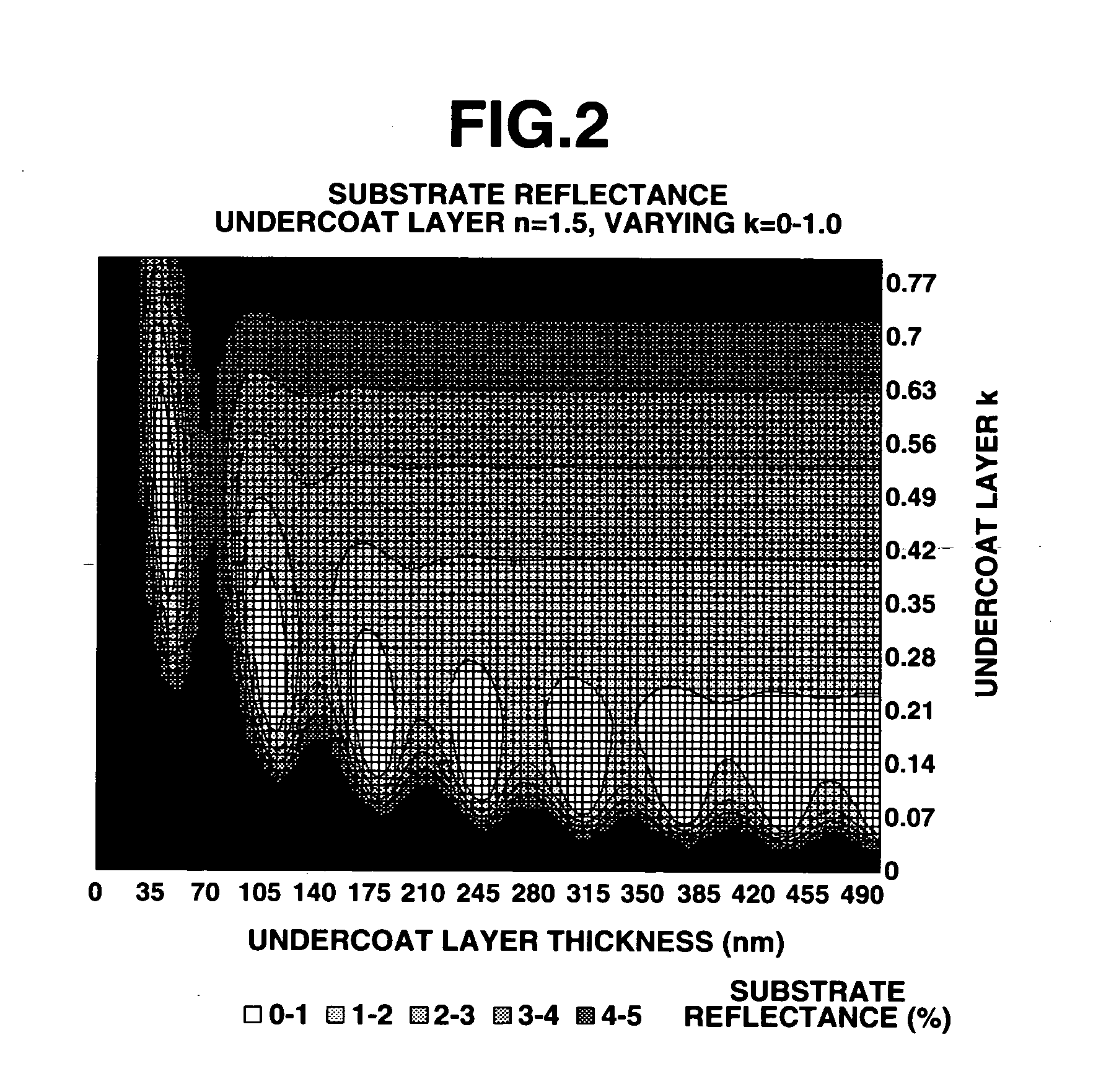

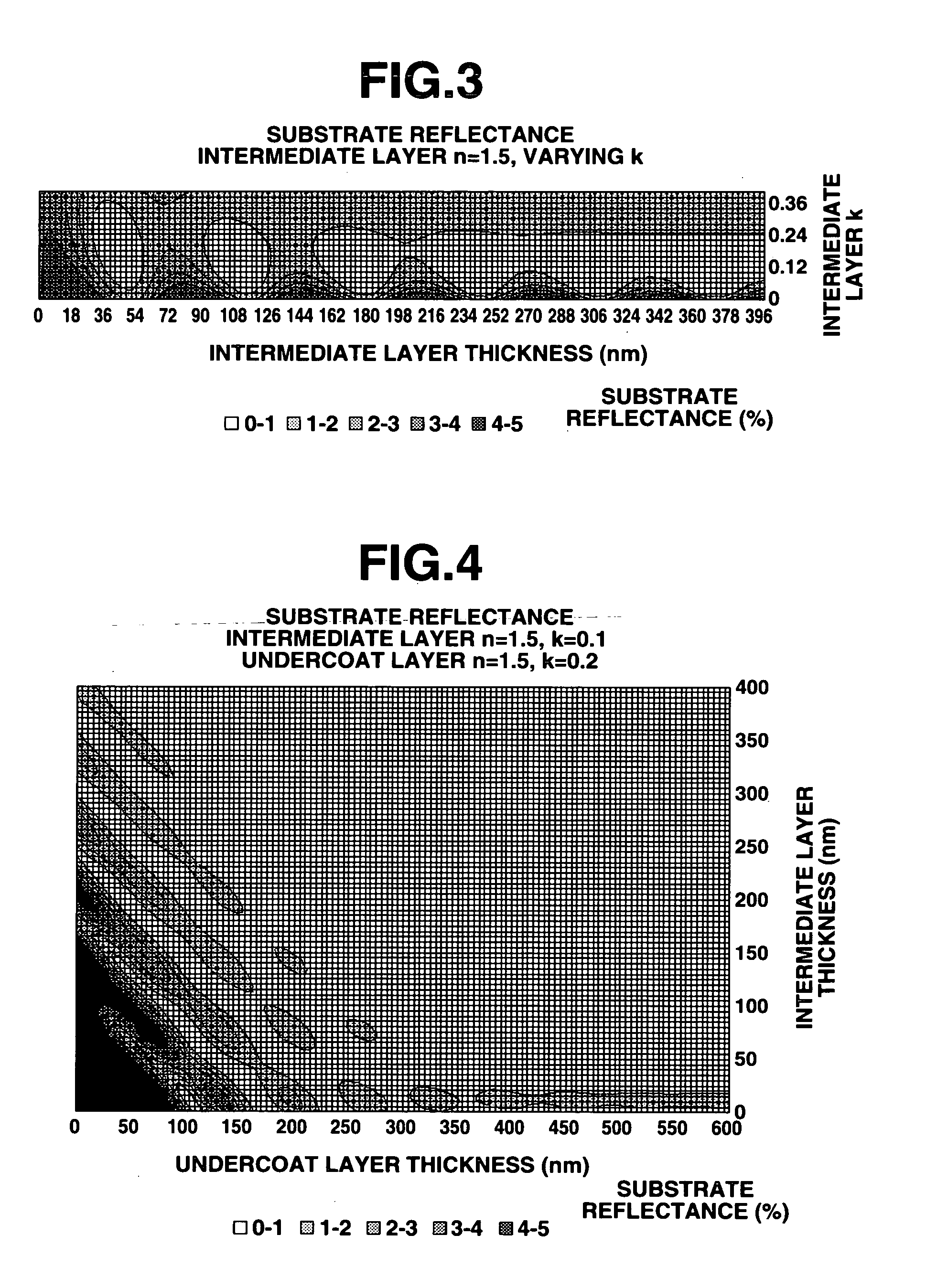

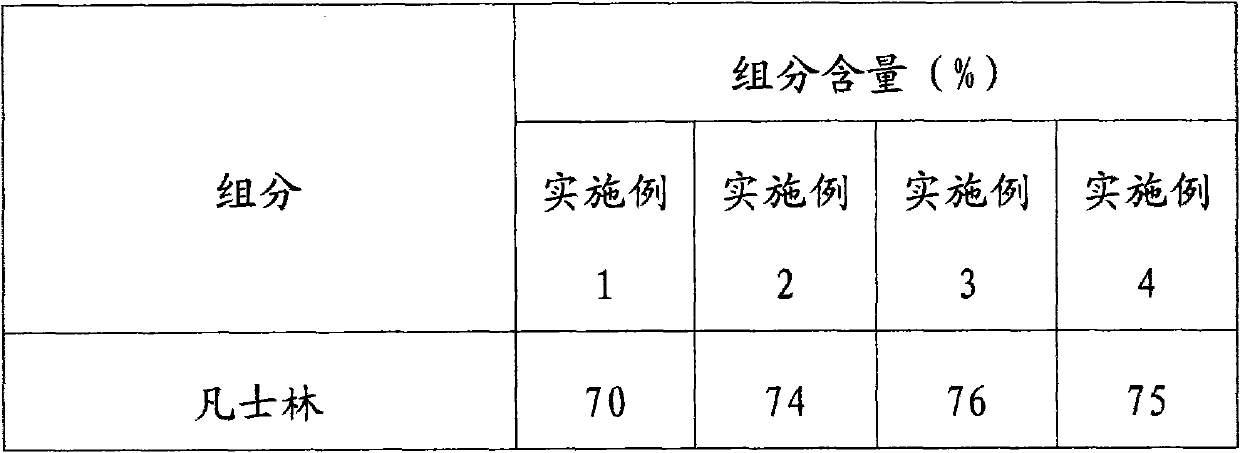

Resist undercoat-forming material and patterning process

ActiveUS20070122740A1High transparencyExcellent etch resistancePhotosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

In the lithographic multilayer resist process, a material comprising a copolymer of a hydroxy-containing vinylnaphthalene with hydroxy-free olefins is useful in forming a resist undercoat. The undercoat-forming material has a high transparency and optimum values of n and k so that it functions as an antireflective coating during short-wavelength exposure, and has etching resistance during substrate processing by etching.

Owner:SHIN ETSU CHEM IND CO LTD

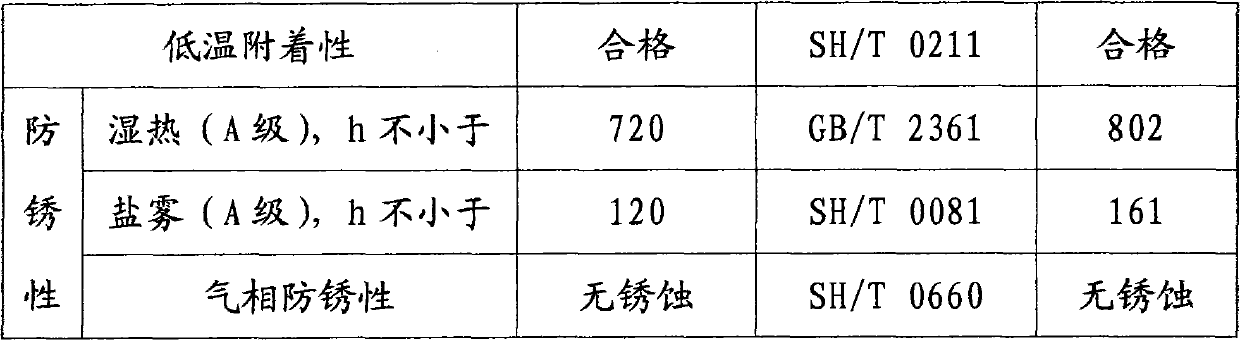

Lipid type antirust oil with gaseous phase antirust function

The invention discloses a lipid type antirust oil with gaseous phase antirust function; the composition of the lipid type antirust oil in weight percent is as follows: 70-90% of base lipid, 4-15% of antirust agent, 1-5% of gaseous phase antirust agent and 5-10% of oil film modifying agent; the inventive antirust oil has long protection period, sun and rain exposure resistance, non-leakage at hightemperature, non-cracking at low temperature, transparent and soft oil film, good paintability, and easy removal, and is mainly applied for antirusting for various metalwares, precise instruments, mechanical equipments, metal rotation sequence of workshops in machining industry, etc.

Owner:天津蓝星清洗有限公司

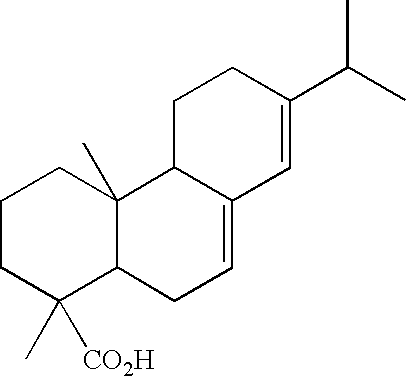

Low-VOC additives for extending wet edge and open times of coatings

A low VOC coating additive employing a water-dispersible rosin, a high glass transition temperature water-dispersible polymer, and optionally an amphiphilic component. The additive can be added to a coating to improve the performance characteristics of the coating, such as wiped wet edge time, open time, block resistance, gloss, scrub resistance, tack-free time, dry-to-touch time, and yellowing.

Owner:EASTMAN CHEM CO

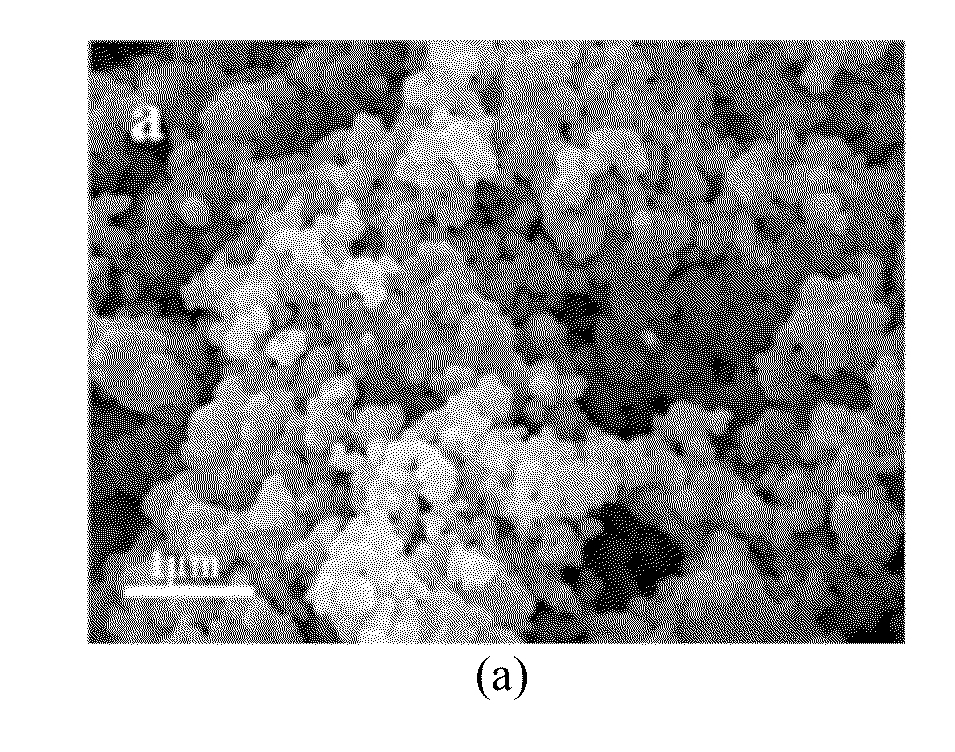

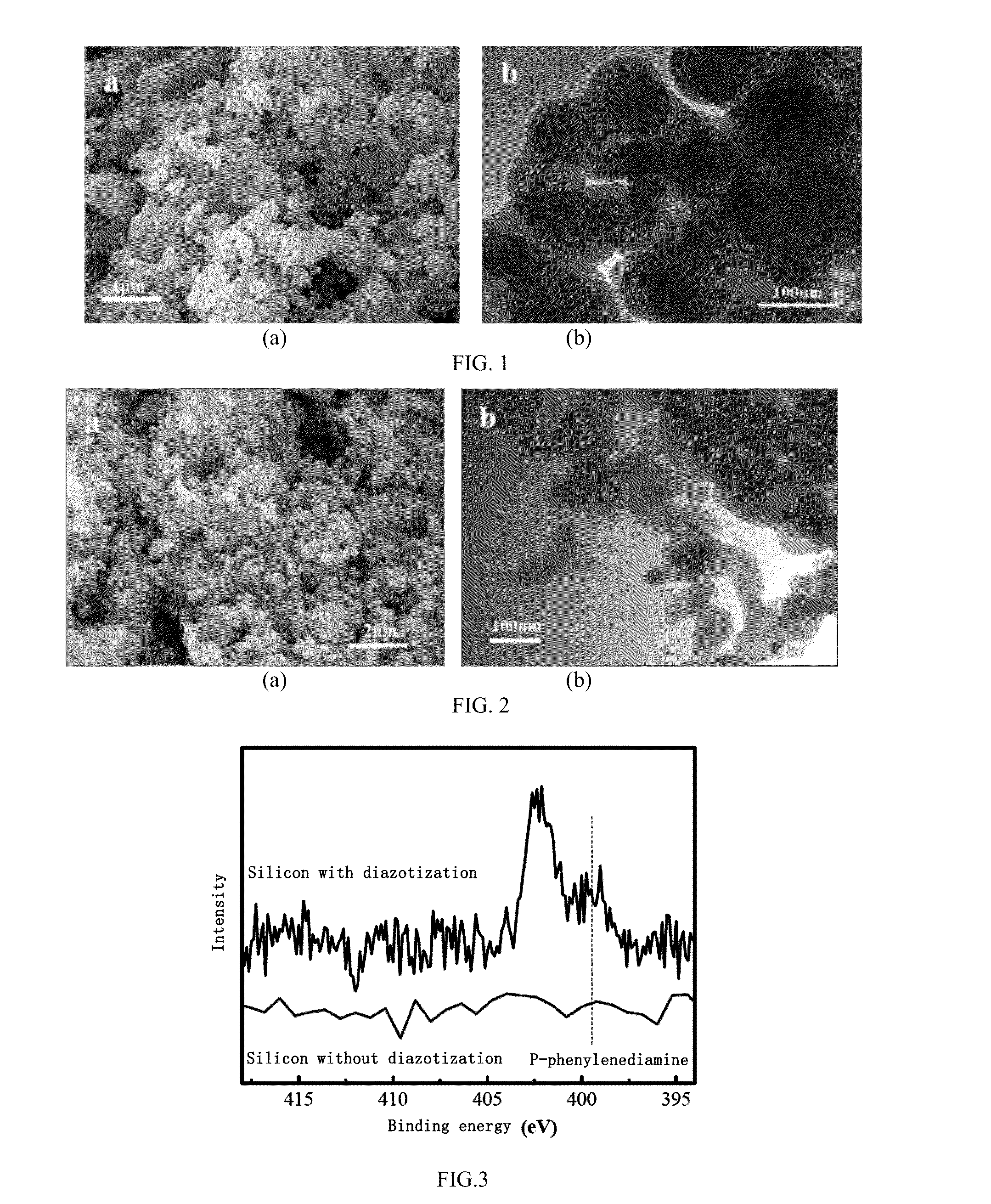

Silicon based composite material, and preparation method and use thereof

InactiveUS20140295267A1Good coating effectSlow down aggregationNon-aqueous electrolyte accumulator electrodesSpecial surfacesSilicon particlePolyaniline

The present disclosure provides a silicon based composite material, and a preparation method and a use thereof. The silicon based composite material comprises silicon nano-particles and polyaniline coating layers on surfaces of the silicon nano-particles, and Si—C covalent bonds are formed between the silicon nano-particles and the polyaniline coating layers. The silicon based composite material provided by the present disclosure is advantageous in improving the coating effect of polyaniline on silicon particles.

Owner:DONGGUAN AMPEREX TECH +1

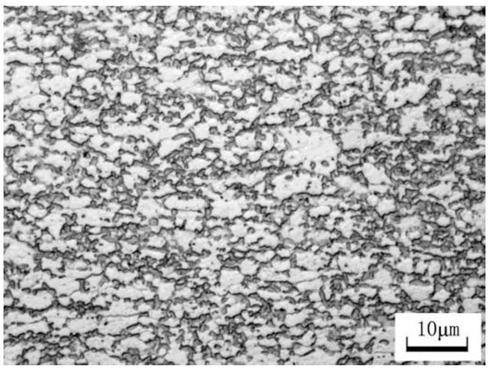

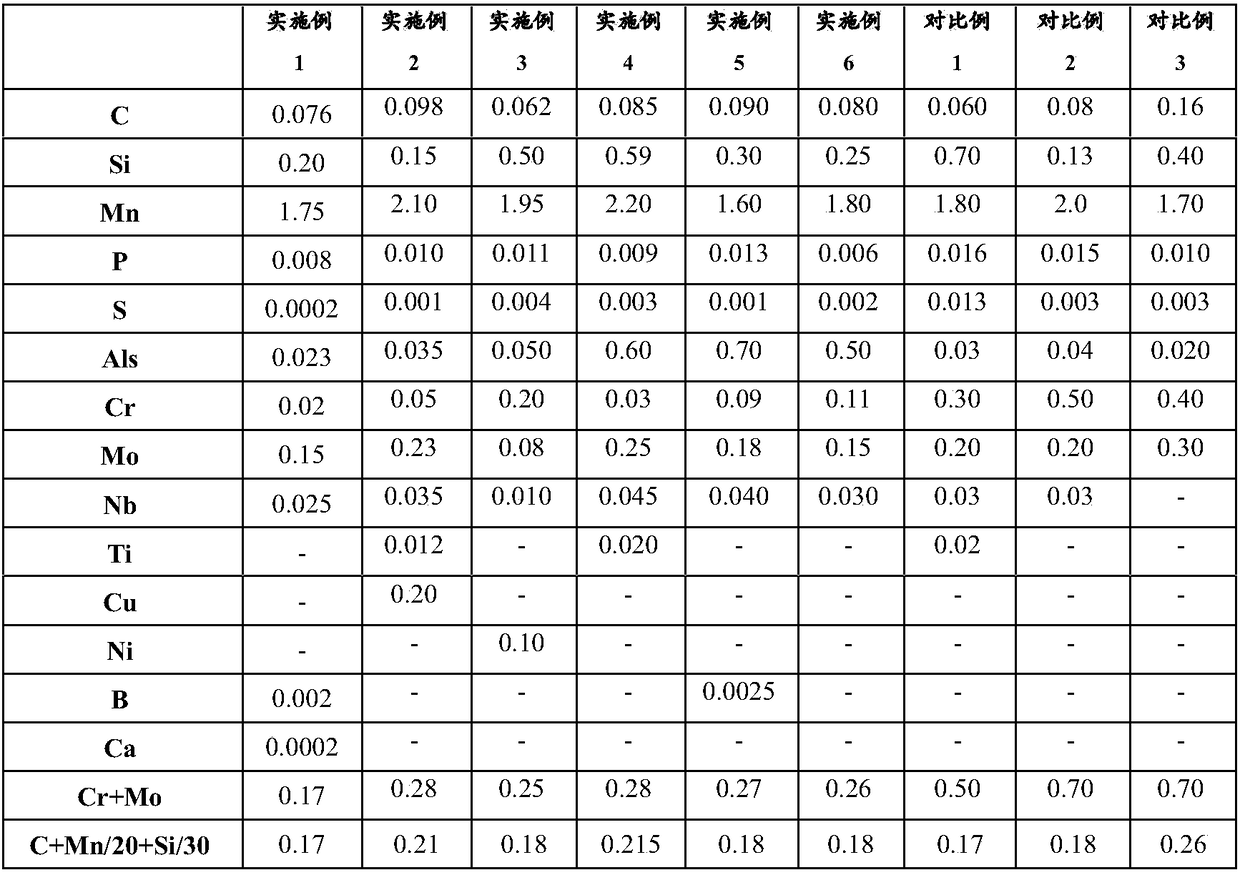

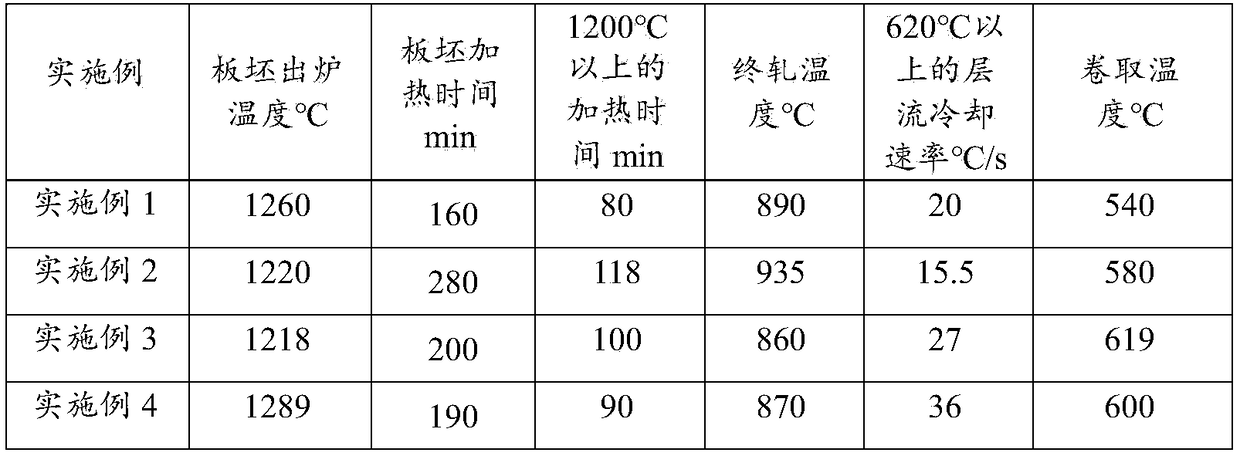

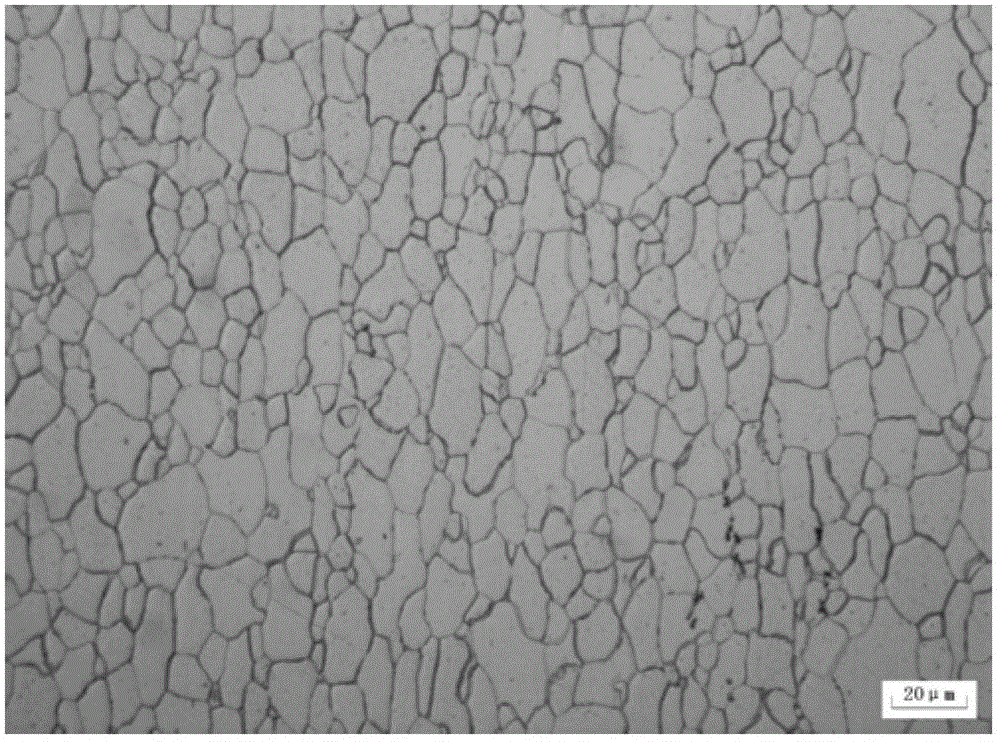

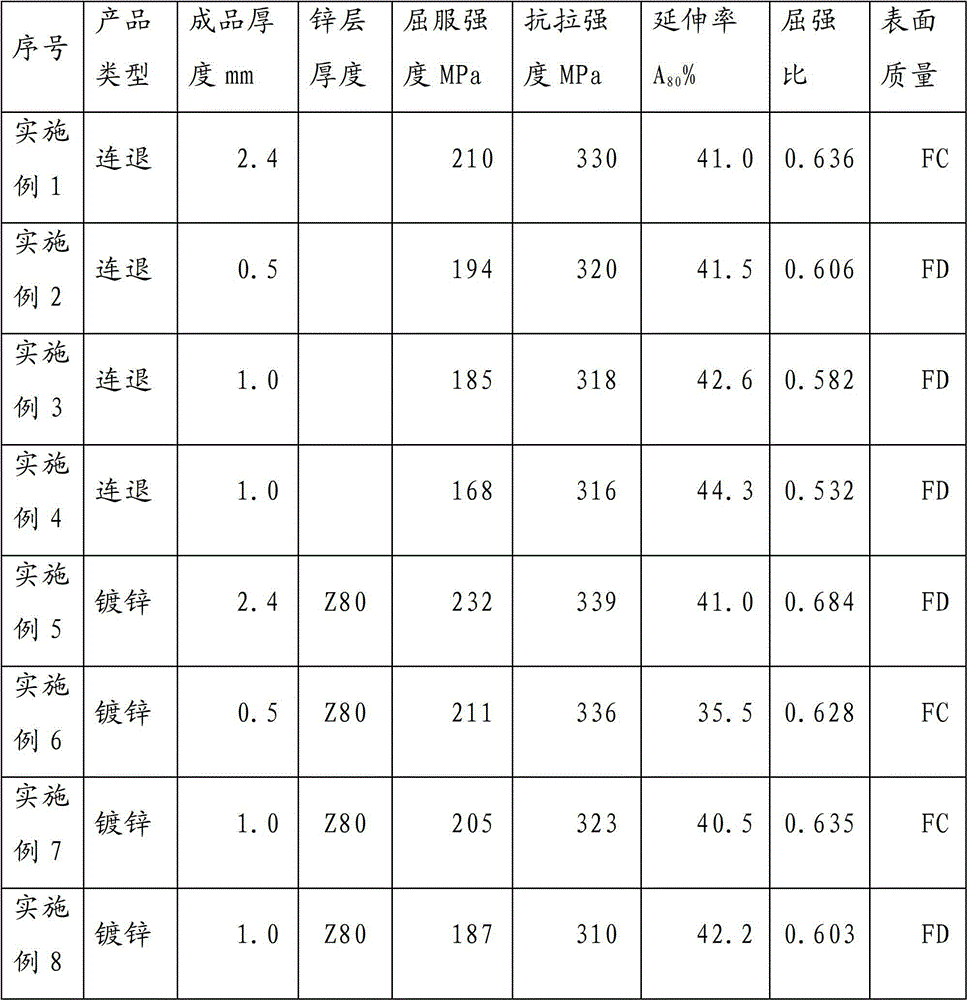

800MPa-grade cold-rolled hot-galvanizing dual-phase steel and production method thereof

The invention discloses 800MPa-grade cold-rolled hot-galvanizing dual-phase steel. The 800MPa-grade cold-rolled hot-galvanizing dual-phase steel comprises the following raw materials taken as chemicalcomponents in percentage by mass (%): 0.05% to 0.10% of C, 1.60% to 2.30% of Mn, 0.010 to 1.0% of Als, 0.10% to 0.60% of Si, 0.010 to 0.050% of Nb, 0.05 to 0.30% of Cr, 0.05 to 0.30% of Mo, P not smaller than 0.015%, S not greater than 0.010%, N not greater than 0.008%, and the balance of Fe and inevitable impurities, and noble metal elements Cr and Mo satisfy the relation that Cr+Mo is not smaller than 0.05 and not greater than 0.30, and C+Si / 30+Mn / 20 is not greater than 0.22. The production method for the hot-galvanizing steel for an automobile wheel cover comprises the steps of smelting, continuous casting, heating, hot rolling, cooling, coiling, pickling, cold rolling, annealing and coat-plating. According to the invention, the obtained cold-rolled hot-galvanizing dual-phase steel hasless precious alloying elements, so that the product has good mechanical properties, surface quality, formability and welding performances. Furthermore, the 800MPa-grade cold-rolled hot-galvanizing dual-phase steel disclosed by the invention can be produced on the existing conventional production line without additional equipments.

Owner:武汉钢铁有限公司

Method for preparing artificial graphite cathode material of lithium ion battery

ActiveCN1691374AEasy to implementGood coating effectElectrode manufacturing processesNon-aqueous electrolyte accumulatorsGraphiteSodium-ion battery

The invention discloses a making method for lithium ion battery negative materials, comprising the steps of: (1) mixing the black lead, clad material and solvent, evacuating, stripping solvent and cladding the natural black lead in the clad materials; (2) polymerizing the materials and the surface of the natural black lead will get the microencapsulation cladding layer; (3) charring or charring the products of step (2) to get the carbon negative materials with the artificial black lead layer coated on the surface, this is the lithium ion battery negative materials. The detecting results of the battery negative materials are: tap density is more than 1.02, specific surface area is lese than 2.0, the first discharging capacity is more than 350mAh / g (non-reversible capacity is less than 25mAh / g), the first charging efficiency is more than 93%, after circulating 460 times, the rest first capacity is more than 90%.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

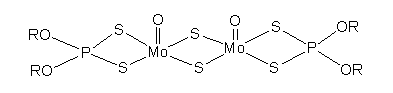

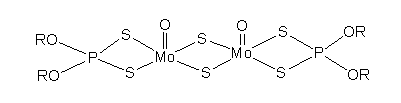

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Modified epoxy mortar abrasion-resistant patching material

The invention relates to a modified epoxy mortar abrasion-resistant patching material which comprises a component A and a component B. The mass ratio of the A component and the B component is 4:1. The A component comprises, by weight, 15-20 parts of epoxy resin, 1.5-2 parts of flexibilizer, 1.5-3 parts of reactive diluent and 75-82 parts of abrasive aggregates. The B component comprises, by weight, 18-24 parts of hardening agent, 1-1.5 parts of coupling agent and 75-80 parts of abrasive aggregates. The abrasive aggregates are quartz-sand-class aggregates or diamond-sand-class aggregates. The mass ratio of aggregates with the particle diameter of 10-20 meshes to aggregates with the particle diameter of 20-40 meshes to aggreates with the particel diameter of 40-70 to aggreates with the particel diameter of 100-200 meshes is 0-1 to 1-2 to 0-2 to 0-1. The hardening agent is a polyether amine hardening agent. According to the modified epoxy mortar abrasion-resistant patching material, the abrasion-resistant strength and the anti-impact strength are improved, the hardening reaction speed is lowered and micro cracks in the early stage of epoxy mortar are avoided.

Owner:WUDA JUCHENG STRUCTURE CO LTD

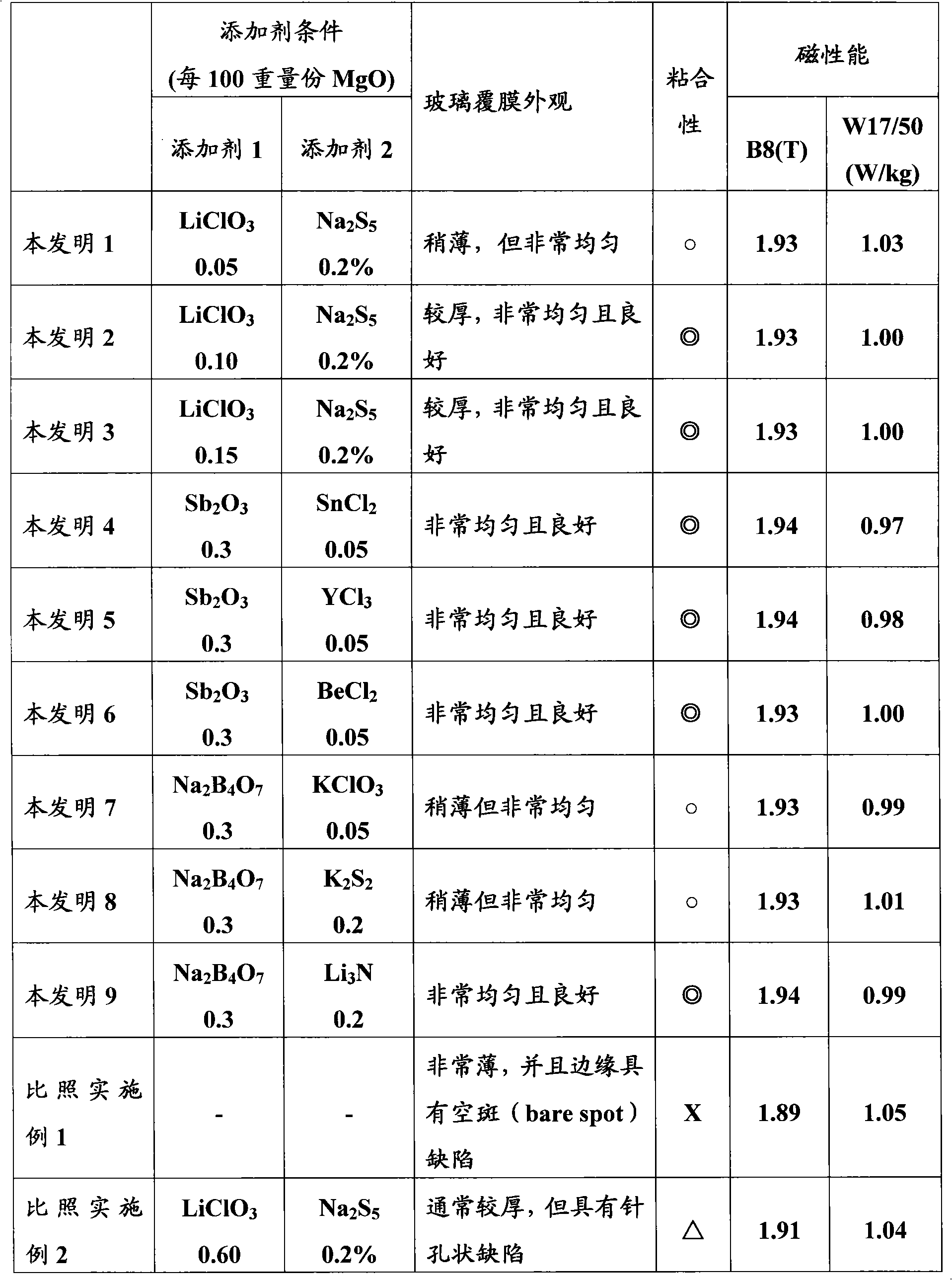

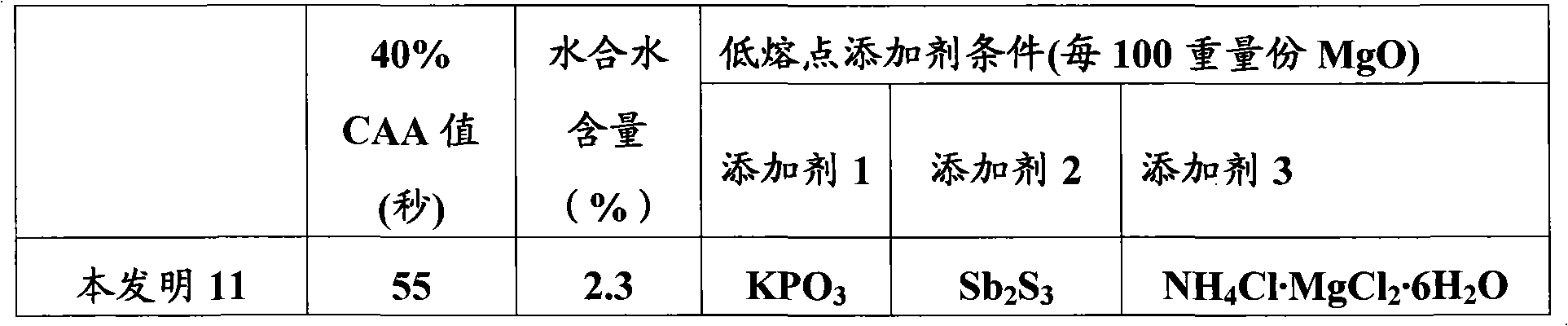

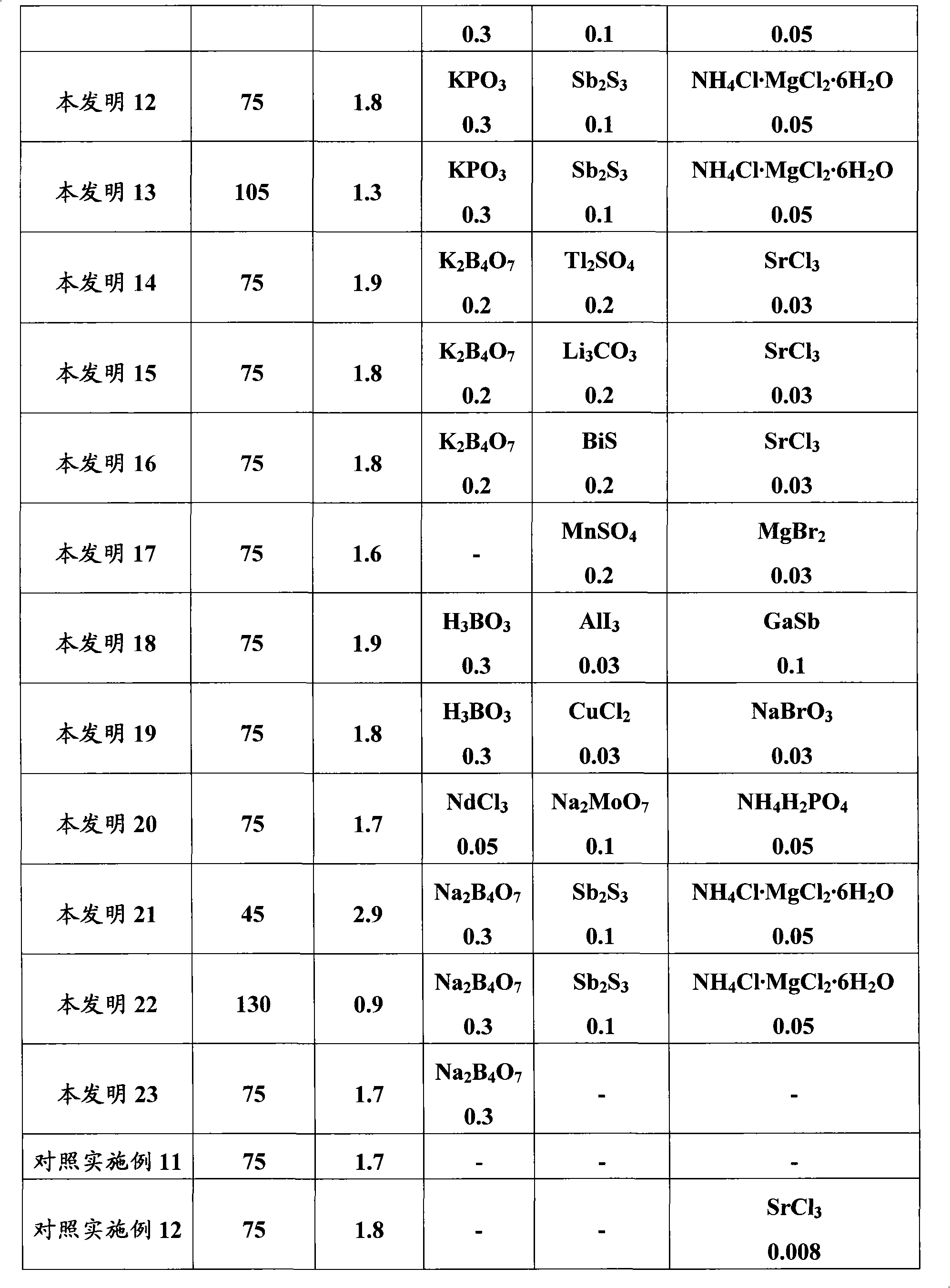

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

Lithium ion battery positive electrode slurry, preparation method thereof and lithium ion battery

PendingCN110797536AGood dispersionLarge specific surface areaCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention relates to lithium ion battery positive electrode slurry, a preparation method thereof and a lithium ion battery. The positive electrode slurry comprises a positive electrode active substance, a solvent, a composite binder, a composite conductive agent and a dispersing agent, wherein the composite conductive agent is a mixture composed of a conductive agent A and a conductive agent B; the conductive agent A is a conductive agent capable of forming a point-to-point conductive network; the conductive agent B is a conductive agent capable of forming a point-to-line or surface-contact conductive network; and the conductive agent A and the conductive agent B respectively account for 80-90% and 10-20% of the total weight of the conductive agent. According to the method disclosed bythe invention, the positive electrode slurry is processed and modified by changing the adding sequence of different substances in the positive electrode slurry, adjusting the stirring time, the stirring speed and the proportioning ratio and using the dispersing agent, the positive electrode slurry which enables all the components to be uniformly mixed and is relatively good in dispersion, moderate in viscosity and relatively small in fineness can be prepared, and the positive electrode slurry can improve the processing performance of the lithium battery and also can keep the battery to have excellent electrochemical performance.

Owner:桑顿新能源科技(长沙)有限公司

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

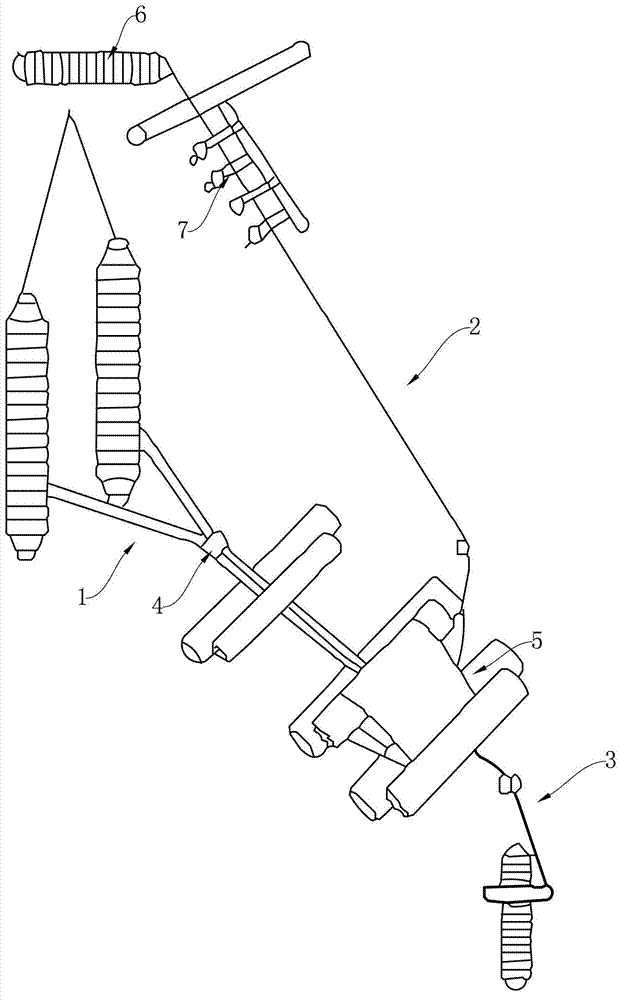

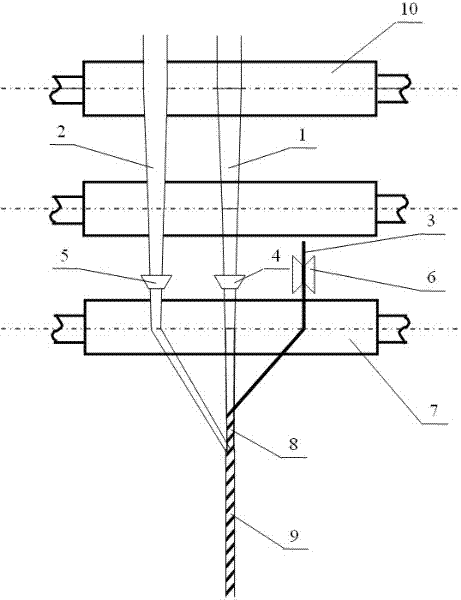

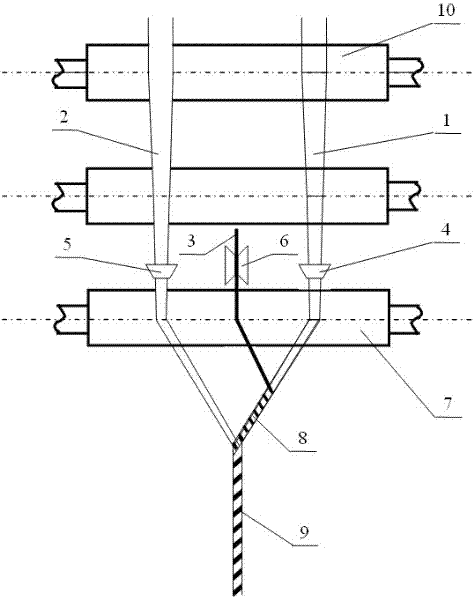

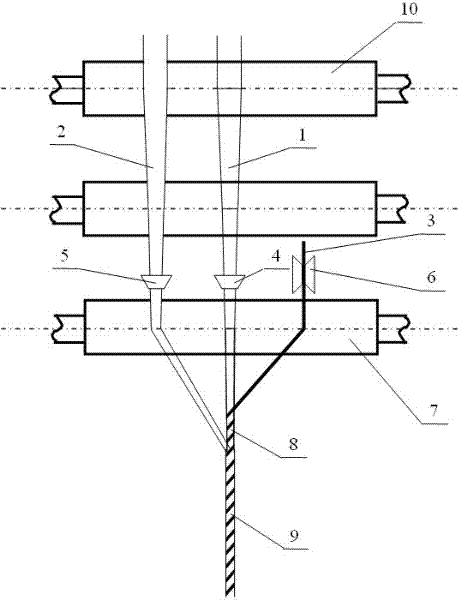

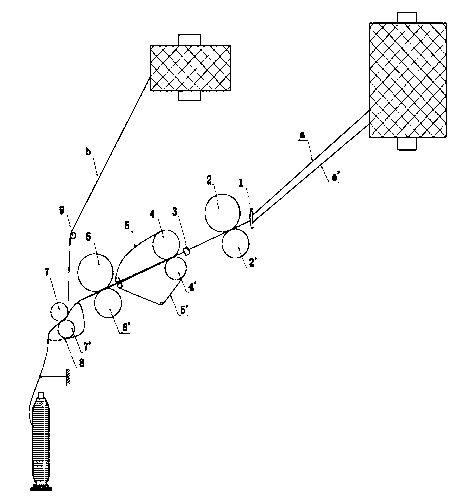

Three-axis-system composite spinning device and spinning method for tow-apt-to-fall staple

The invention provides a three-axis-system composite spinning device and a spinning method for tow-apt-to-fall staple. The three-axis-system composite spinning method is characterized in that the method comprises the steps of: feeding roving silvers containing the tow-apt-to-fall staple and cotton roving silvers into the back roller of a ring spinning machine, and conducting drafting to form a tow-apt-to-fall staple strand and a cotton strand which stretch straight in parallel; after the tow-apt-to-fall staple strand and the cotton strand are respectively positioned by using a tow-apt-to-fall staple strand positioner and a cotton strand positioner, feeding the tow-apt-to-fall staple strand and the cotton strand into the jaw of a front roller and directly feeding filament adjustable tension pulley into the jaw of the front roller; and after the tow-apt-to-fall staple strand, the cotton strand and the filament are output from the jaw of the front roller, twisting the tow-apt-to-fall staple strand and the filament at a first converging point outside the jaw of the front roller to form a structural section, and twisting the structural section and the cotton strand at a second converging point to form a three-axis-system composite yarn. The device and the method provided by the invention has the advantages that not only can the content of the tow-apt-to-fall staples in the spun composite yarn be improved, but also the situations of fiber damage and tow falling can be effectively avoided.

Owner:DONGHUA UNIV

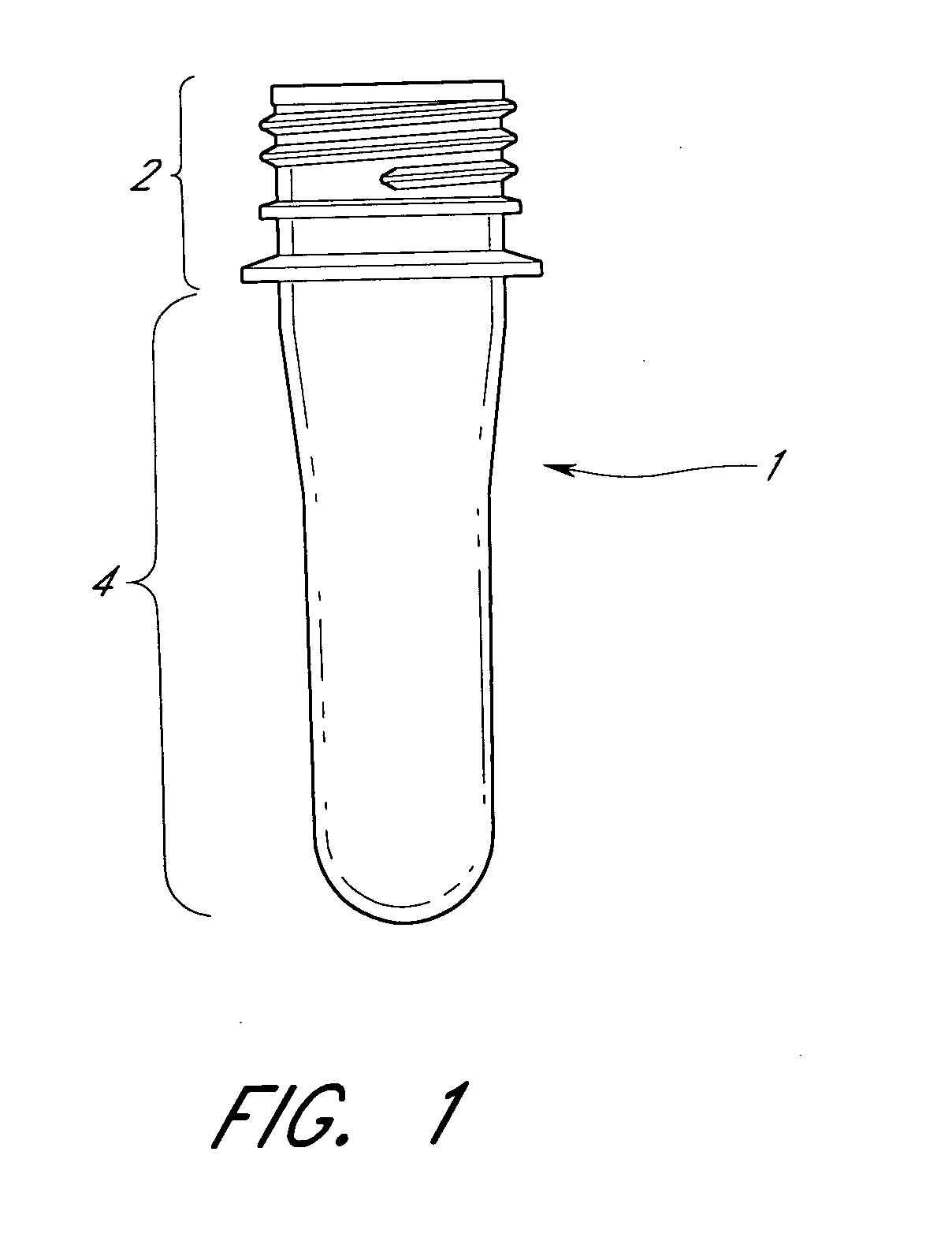

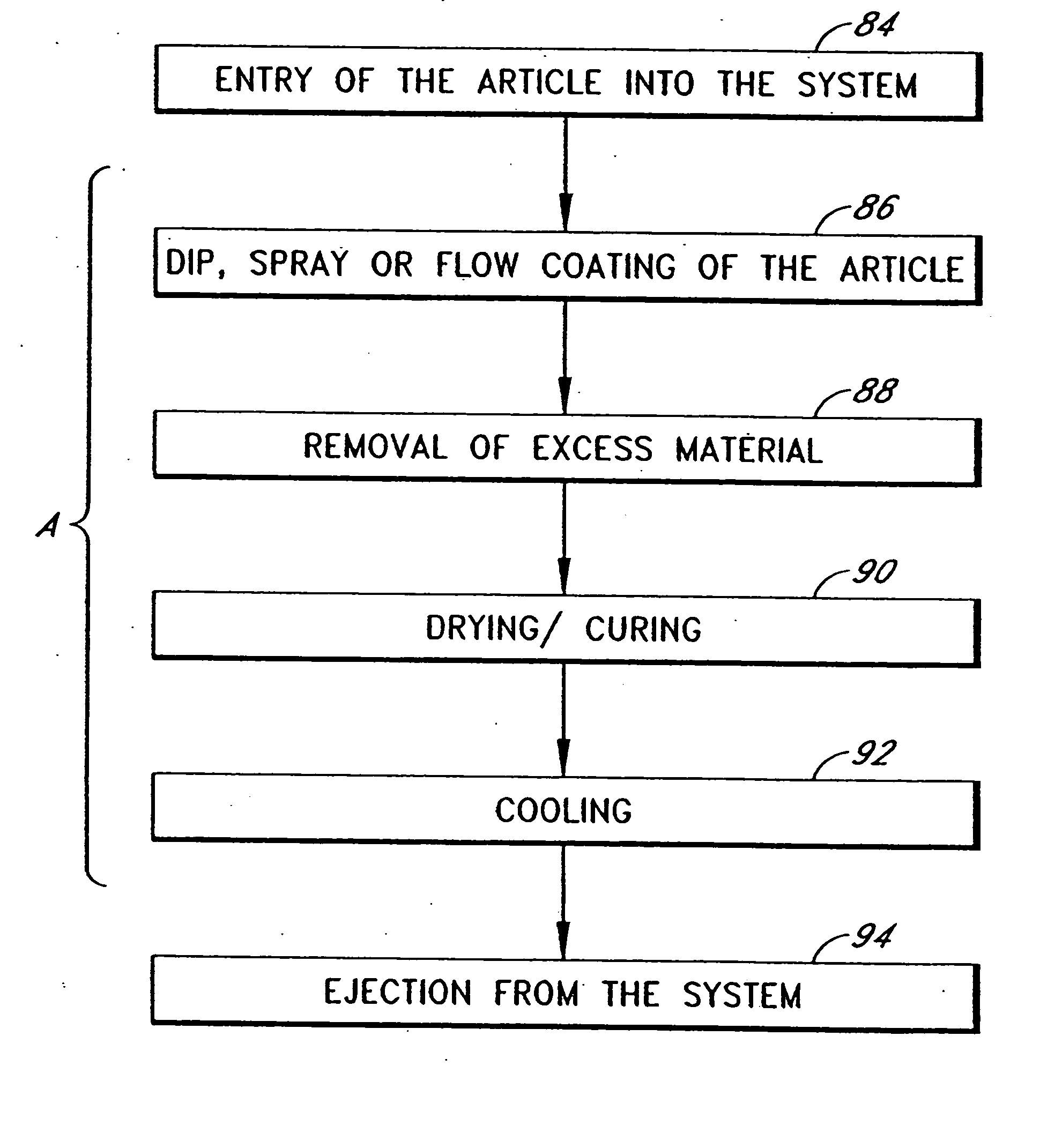

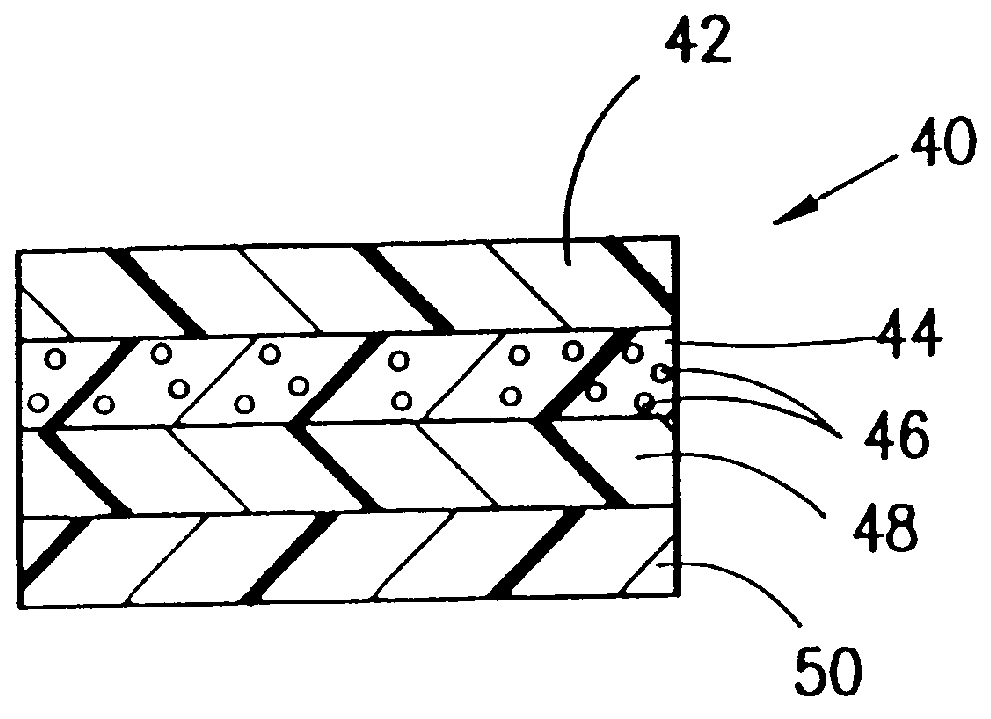

Water-resistant coated articles and methods of making same

InactiveUS20060292323A1Good coating effectReduction of surface voidLiquid surface applicatorsLayered productsEmulsionPolyethylene terephthalate

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by dip, spray or flow coating. The methods can make coated containers, preferably comprising polyethylene terephthalate, from coated preforms. In some methods, the aqueous solutions, dispersions, or emulsions are substantially or completely free of VOCs.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Method for synthesizing carbon-cladded ironic lithium phosphate

InactiveCN1775666AEasy to wrapHeating evenly inside and outsideCell electrodesPhosphorus compoundsPhosphateChemical measurement

The invention relates to a carbon coated lithium iron phosphate microwave-synthesizing method, relating to the preparation of anode material of a Li-ion battery. The invention weighs lithium carbonate, iron oxalate and ammonium diacid phosphate, proper amount of heat conduction agent and organic matter in chemical gauging ratio, using anhydrous alcohol as dispersant to fully grind and mix them, drying and pressing the mixture into blocks, placing the blocks in a pot holding activated carbon, and placing the pot in microwave field for irradiative heating so as to be able to make uniform- phase carbon coated lithium iron phosphate. The invention can realize carbon coating of lithium iron phosphate and more rapidly and uniformly heat the raw materials, beneficial to uniform and rapid reaction of massive raw materials. The method can shorten production cycle and reduce energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

Insulative adhesive for preparing metallic and soft magnetic composite material and using method thereof

ActiveCN104031601AImprove thermal stabilityImprove insulation performanceNon-macromolecular adhesive additivesInorganic material magnetismAdhesiveOrganosilicon

The invention discloses an insulative adhesive for preparing a metallic and soft magnetic composite material and a using method thereof. The insulative adhesive disclosed by the invention is a nano-modified organic silicon resin insulative adhesive which comprises organic silicon resin and an inorganic nano dispersion liquid. The insulative adhesive greatly improve the heat-resisting temperature of the organic silicon resin and improve the mechanical strength of a magnetic powder core, is reasonable in component selection and good in using effect and has a good insulative adhering effect to Fe-based, nickel-based and metallic soft magnetic powder of other metals. The magnetic powder core prepared by the insulative adhesive prepared by the invention has excellent magnetic performance and mechanical performance.

Owner:ZHEJIANG UNIV

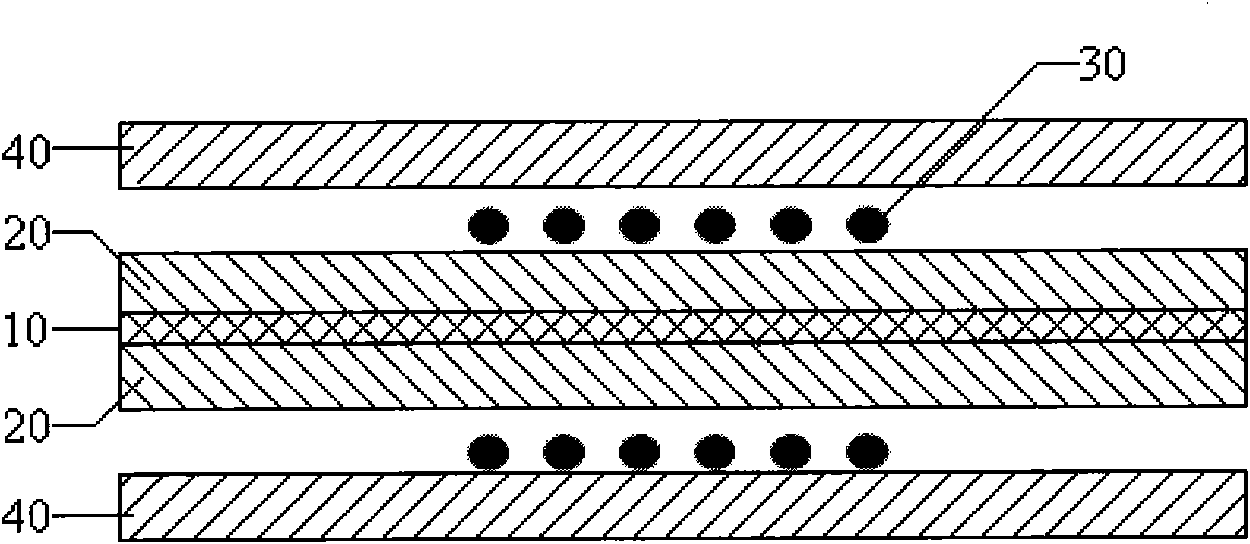

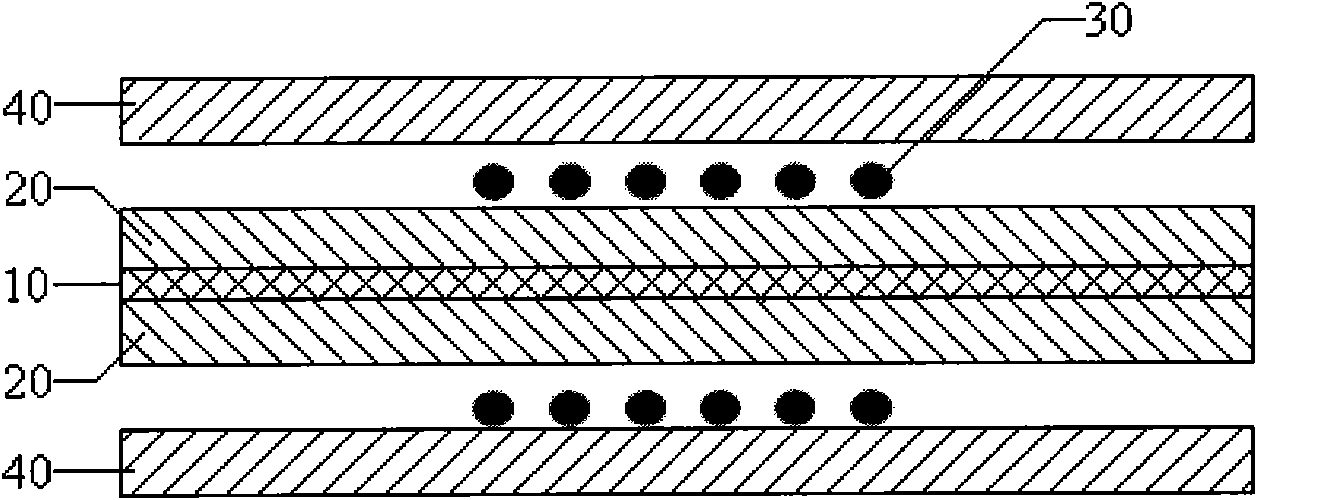

Lithium-ion secondary battery and preparation method for pole piece thereof

InactiveCN101969114AGood lookingImprove electrochemical performanceCell electrodesSecondary cellsLithiumSlurry

The invention discloses a method for preparing a lithium-ion secondary battery pole piece. The method comprises the following steps of: providing a collector; coating first slurry on the collector and drying the slurry to form a first membrane layer; wetting the first membrane layer by using a solvent; and coating second slurry on the first membrane layer and drying the slurry to form a second membrane layer. In the method for preparing the lithium-ion secondary battery pole piece, the dried first membrane layer is wetted by adopting the solvent, and the wetted first membrane layer does not absorb or absorbs little solvent in the second slurry, so the second membrane layer can be uniformly spread, and the appearance of the lithium-ion secondary battery pole piece is improved. Moreover, the invention also discloses a lithium-ion secondary battery with good safety performance.

Owner:DONGGUAN AMPEREX TECH

Cleaning composition

InactiveCN102965214AGood coating effectAvoid corrosionOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsPolyethylene glycolSolvent

The invention discloses a cleaning composition which can endow the surface of a substrate with hydrophilicity. The composition includes: 0.0001-5wt% of at least one water-soluble high molecular compound selected from the group composed of polyvinyl alcohol, polyethylene glycol (PEG), cellulose, polyacrylic acid (PAA), polyethyloxazoline and polyvinylpyrrolidone; 0.01-5wt% of a polyol compound; 0.05-10wt% of quaternary ammonium hydroxide; 0.05-40wt% of a glycol ether-based solvent expressed by the following molecular formula; and the balance water.

Owner:DONGWOO FINE CHEM CO LTD

Method for producing cold-rolled sheet for surface coating and plating base plate

ActiveCN102716905ABright and clean surfaceGood formabilityHot-dipping/immersion processesMetal rolling arrangementsAcid washingContinuous annealing

The invention discloses a method for producing a cold-rolled sheet for a surface coating and plating base plate. A steel billet comprises the following compositions by weight percentage: at most 0.12 percent of C, at most 0.05 percent of Si, at most 0.60 percent of Mn, at most 0.04 percent of P, at most 0.04 percent of S, and the balance of Fe. The steel billet comprising the compositions is sequentially subjected to hot rolling, acid washing and cold rolling to obtain a cold-rolled steel coil, and then the cold-rolled steel coil is made into the cold-rolled sheet for the surface coating and plating base plate through a continuous annealing or galvanizing method. Continuous annealing coating and plating bases plate and galvanizing coating and plating base plates produced through the method for producing the cold-rolled sheet for the surface coating and plating base plate have a good formability, meanwhile also have a good surface quality and paintability, and can be used as base plates of high-grade electric galvanized sheets, prepainted steel sheets, tinning sheets and aluminized steel sheets.

Owner:SHOUGANG CORPORATION

Devices using silicone pressure sensitive adhesives containing organic wax

InactiveUSRE36754E1Less viscousImproves adhesive coatabilityAdhesive dressingsAbsorbent padsWaxHot melt

Hot-melt silicone pressure sensitive adhesive compositions containing organic waxes, methods of using the compositions and devices made using the compositions are disclosed. The hot-melt silicone pressure sensitive adhesive compositions include a mixture of (i) a silicate resin, (ii) a silicone fluid, and (iii) an organic wax having a melting point of between 30 DEG C. and 150 DEG C. The organic wax decreases dynamic viscosity of the adhesive at temperatures equal to or below about 200 DEG C.

Owner:DOW CORNING CORP

Hole sealing moisture-proof anticorrosive composite coating material and its prepn process

The pore sealing moisture-proof anticorrosive composite coating material includes pore sealing material and moisture-proof anticorrosive material. The pore sealing material includes gel with high solid phase content as the basic phase and filler(s) in the amount of 10-100 % of the solid phase component. The moisture-proof anticorrosive material is sol, hydrophobic organic matter or their mixture. The pore sealing moisture-proof anticorrosive composite coating material is prepared through the four steps of preparing pore sealing material, preparing moisture-proof anticorrosive material, preparing pore sealing coating and preparing moisture-proof anticorrosive coating. The pore sealing moisture-proof anticorrosive composite coating material has excellent water permeation arresting performance, high hydrophobicity and high corrosion resistance.

Owner:WUHAN UNIV OF TECH

Integrated spinning method combined with compact spinning, siro spinning and sirofil spinning

The invention relates to an integrated spinning method combined with compact spinning, siro spinning and sirofil spinning. The method comprises the steps that two pieces of rough yarn are unwound from a rough yarn roll on a compact spinning ring spinning frame, and then enter a drafting area in parallel after passing through a three-way yarn-dividing device respectively, the drafting area is composed of a rear leather roller, a rear roller, a three-way horn mouth, a middle leather roller, a leather ring, a middle roller, a lower leather ting, a front leather roller and a front roller, two root hairs formed after drafting enter a negative pressure gathering area of a two-row-hole leather ring or a double-groove-hole special pipe in parallel, the two root hairs after being gathered enter a holding roller in a way of being parallel with a filament, the filament is located between the two root hairs, and after being held, the two root hairs and the filament are gathered, twisted and wound into yarn. According to the integrated spinning method, the yarn with the special core-spun structure is spun, the coating effect of the yarn is good, the spun yarn with high polyester content has the advantages of being less and short in hairiness, high in strength, uniform in evenness and the like, the use range of the filament is widened, and spinning efficiency is improved.

Owner:SHANDONG NANSHAN TEXTILE GARMENT

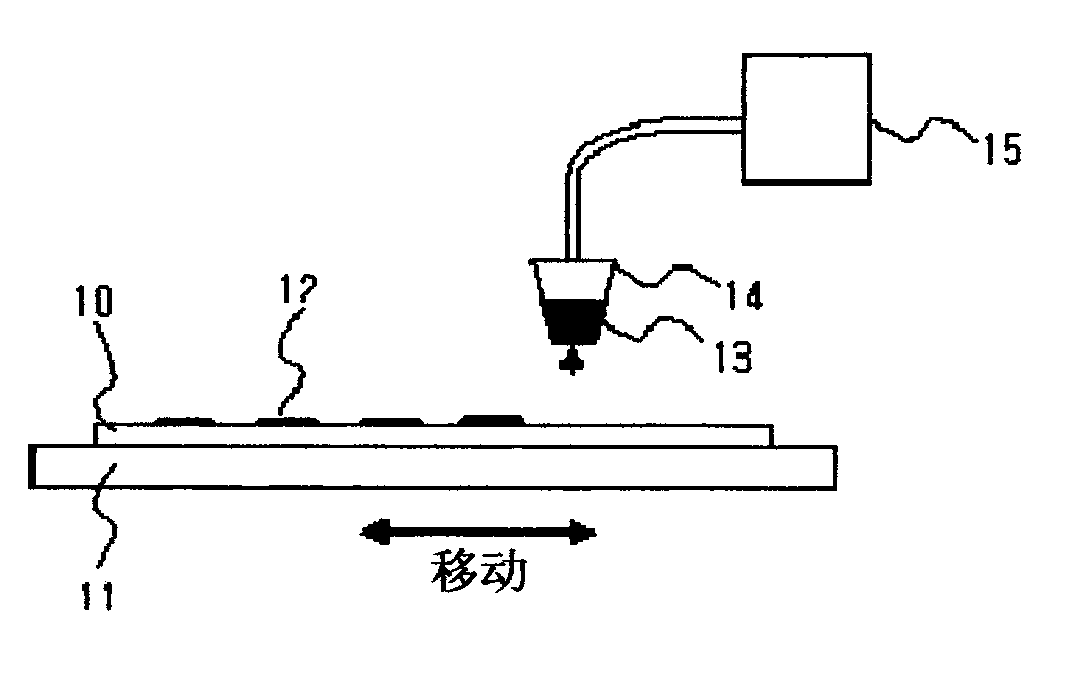

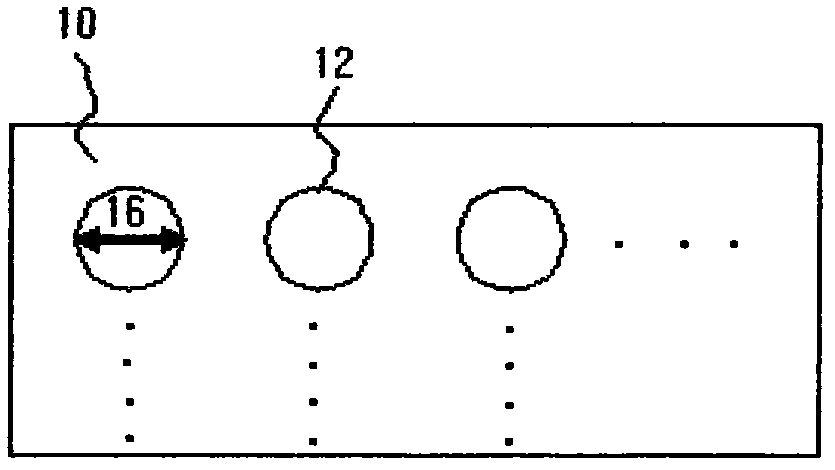

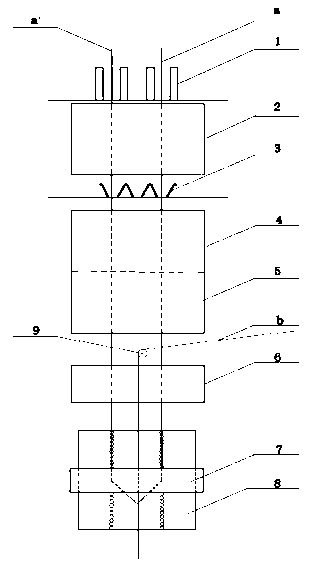

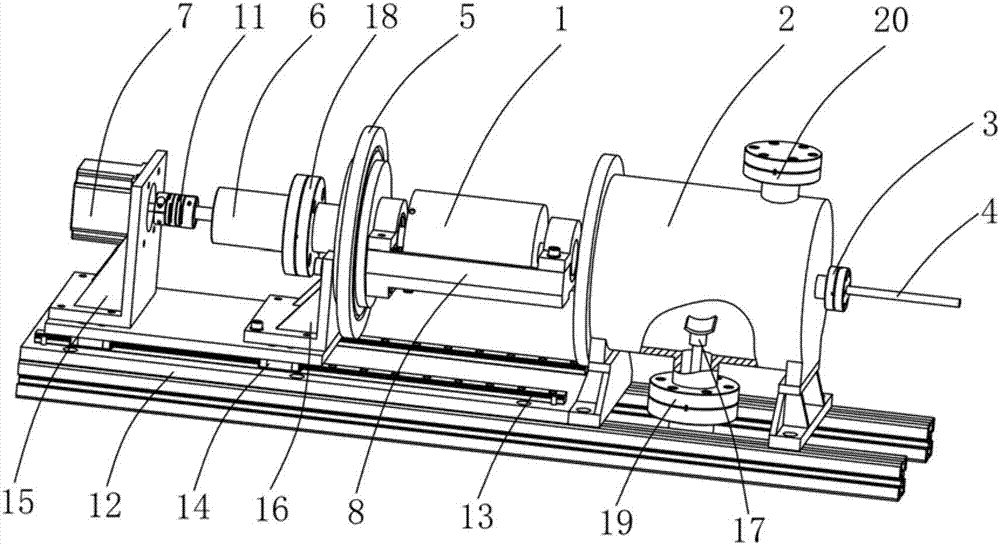

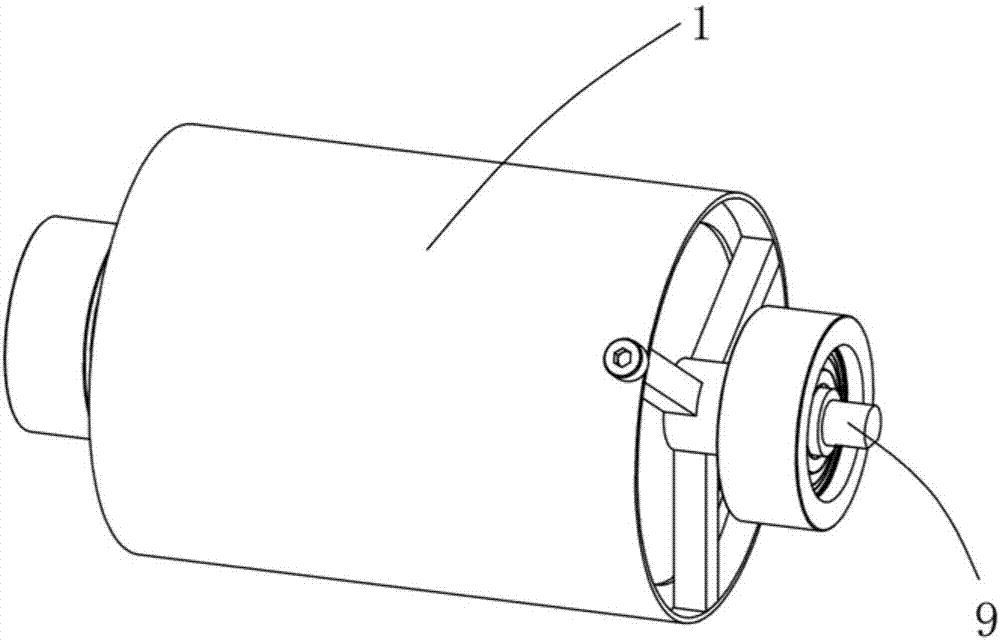

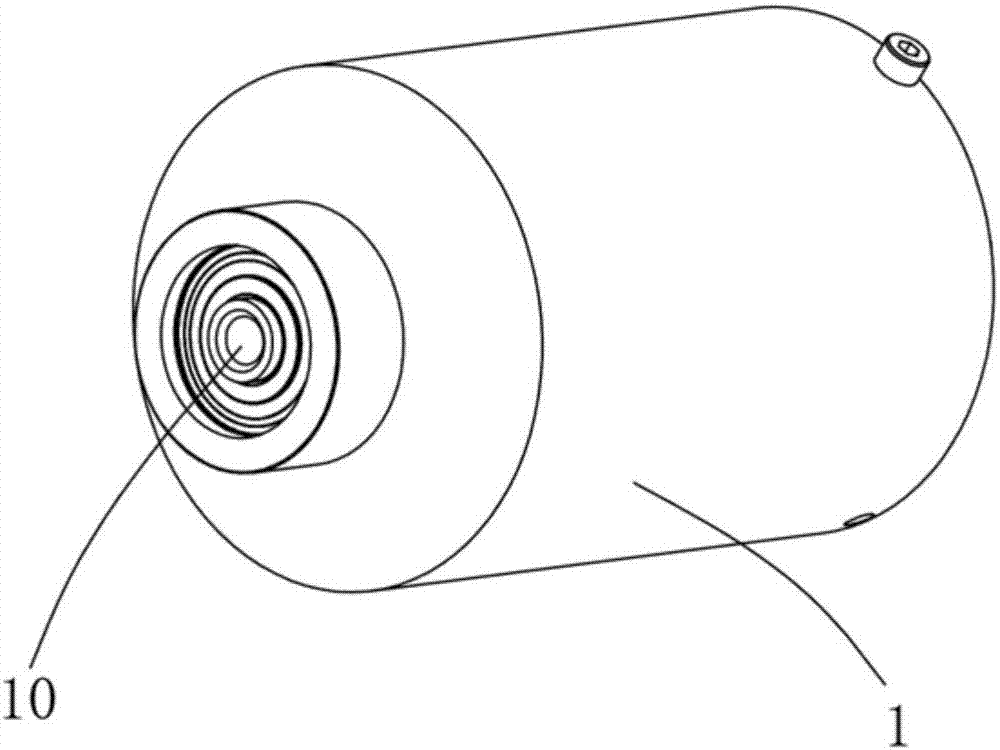

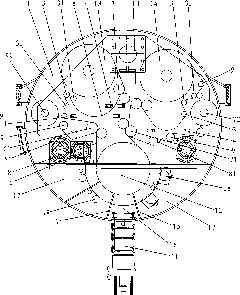

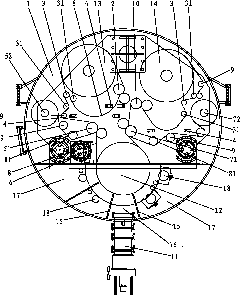

Powder-coated atomic layer deposition device

ActiveCN107502873AFully coveredCoated evenlyChemical vapor deposition coatingRotation methodEngineering

The invention discloses a powder-coated atomic layer deposition device. The powder-coated atomic layer deposition device comprises a powder container and a reaction cavity, wherein an inlet source hole is formed in one end of the reaction cavity; a gas inlet tube used for inputting reaction gas or carrier gas is arranged in the inlet source hole in a sealing mode; a cavity door is arranged at the other end of the reaction cavity; the powder container is arranged inside the cavity door; under driving of a power device, rotation can be realized; a gas inlet is formed in the powder container; the gas inlet tube enters an inner cavity of the powder container through the gas inlet; an ultrasonic vibrating rod is arranged inside the reaction cavity; and after the powder container enters the reaction cavity through a guide device, the outer side wall of the powder container is in contact with the ultrasonic vibrating rod. According to the powder-coated atomic layer deposition device disclosed by the invention, a rotary method is combined with an ultrasonic vibrating method, contact possibility of powder and reaction gas can be increased by rotation, and powder agglomeration can be relieved by energy generated by vibrations, so that powder is dispersed, and a uniform and compact film is finally coated on the surface of the powder.

Owner:HUST WUXI RES INST

Winding-type vacuum coater

InactiveCN101798681AUniform platingConstant surface tensionVacuum evaporation coatingSputtering coatingEngineeringDrive motor

The invention relates to a winding-type vacuum coater which comprises a vacuum cavity, wherein the vacuum cavity is provided with an unwinding device, a coating chamber and a winding device; the coating chamber is provided with a coating roller connected with the output shaft of a drive motor; the unwinding device comprises an unwinding roller and an active feed rolling wheel pair; a tension release roller is arranged between the active feed rolling wheel pair and the coating roller and used for keeping the loose state of the material roll between the feed rolling wheel pair and the tension release roller; the winding device comprises an active winding roller; a feed rolling wheel pair is arranged between the coating roller and the winding roller; and a tension release roller is arranged between the feed rolling wheel pair and the winding roller. Since the material is kept loose between the feed rolling wheel pair and the tension release roller, the tension change of the unwinding roller and the winding roller due to the gradual change of the material roll diameter can not be transferred to the coating roller, thus, the surface tension of the coated material winding the coating roller is constant, so that the film is uniformly coated with favorable effect.

Owner:袁惠芬

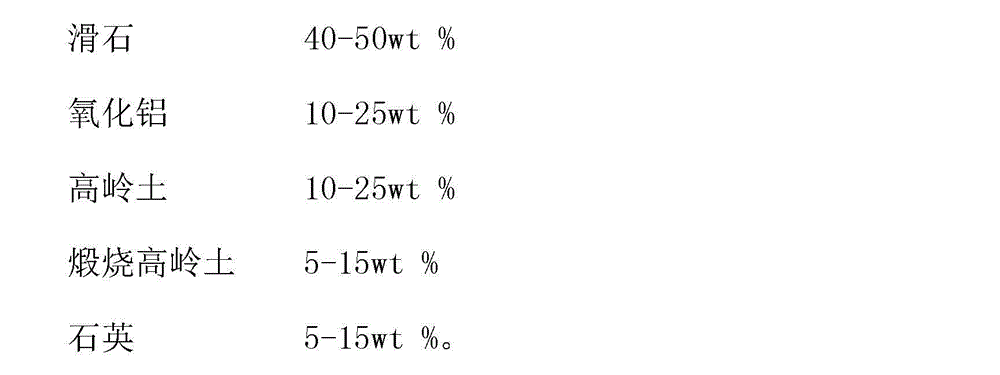

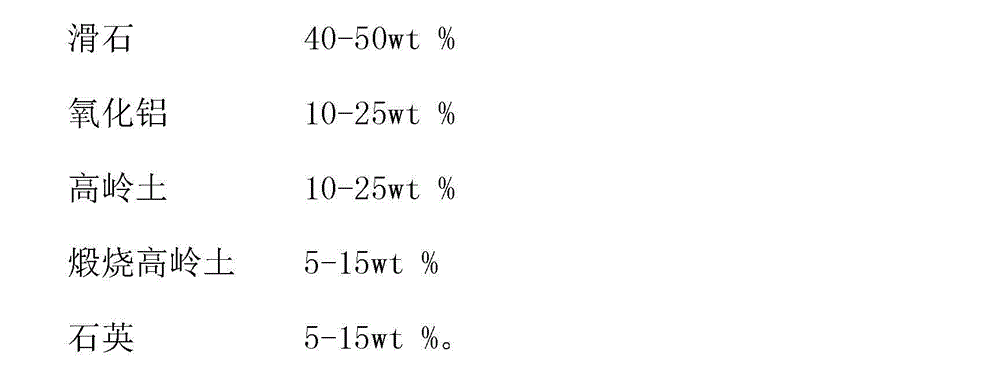

Honeycombed porous ceramic having high thermal conductivity and ultralow expansion coefficient

ActiveCN103145439AGood coating effectImprove mechanical propertiesCeramicwareCeramic moldingCrystal orientation

A honeycombed porous ceramic having a high thermal conductivity and an ultralow expansion coefficient relates to the technical field of the silicate industry. The ceramic having a low even negative thermal expansion coefficient and a high thermal conductivity is obtained through treating a rare earth mixture, potassium phosphotungstate, zirconium oxide and amorphous quartz particles as a sintering aid, and expansion coefficient and thermal conductivity adjustment agents, and the ceramic has a high-orientation sheet iolite structure and has a good catalyst coating performance and good mechanical strengths; and ethylene oxide having different molecular weights are adopted as a ceramic molding binder, rapeseed oil or peanut oil is treated as a primary molding lubrication agent, a paste goes through a high-pressure extruder orientation extruding channel, a crystal orientation carding die and a honeycombed porous die to obtain a green body having high-orientation arranged crystals, and a special sintering curve is adopted to obtain the ceramic. The above whole ceramic preparation process flow and the above formula are economic, stable and environmentally-friendly.

Owner:安徽中鼎美达环保科技有限公司

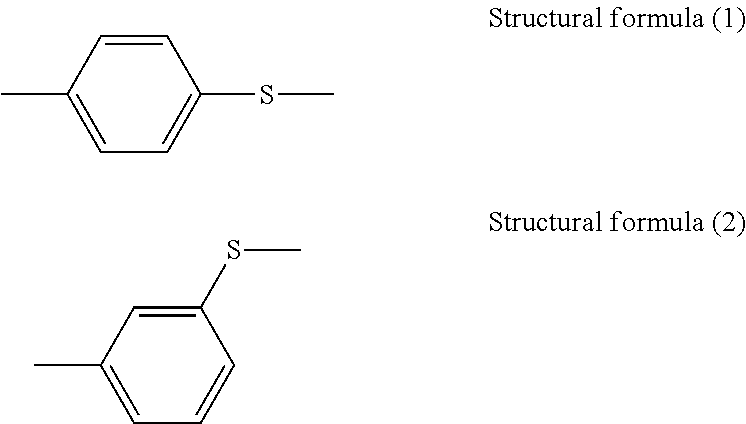

Insulated wire

ActiveUS20110226508A1Excellent solvent resistance and abrasion resistanceHigh voltagePlastic/resin/waxes insulatorsInsulated cablesResilient modulusMelt viscosity

An inverter surge-resistant insulated wire, having an enamel baked layer, an adhesive layer, and an extrusion-coated resin layer, around the outer periphery of a conductor, wherein the sum of the thickness of the enamel baked layer, the extrusion-coated resin layer, and the adhesive layer is 60 μm or more, wherein the thickness of the enamel baked layer is 50μm or less, and wherein the extrusion-coated resin layer is formed from a polyphenylene sulfide resin composition, which contains a polyphenylene sulfide polymer having a melt viscosity at 300° C. of 100 Pa·s or more, 2 to 8 mass % of a thermoplastic elastomer, and an antioxidant, and which has a tensile modulus of elasticity at 25° C. of 2,500 MPa or more, and a tensile modulus of elasticity at 250° C. of 10 MPa or more.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD +2

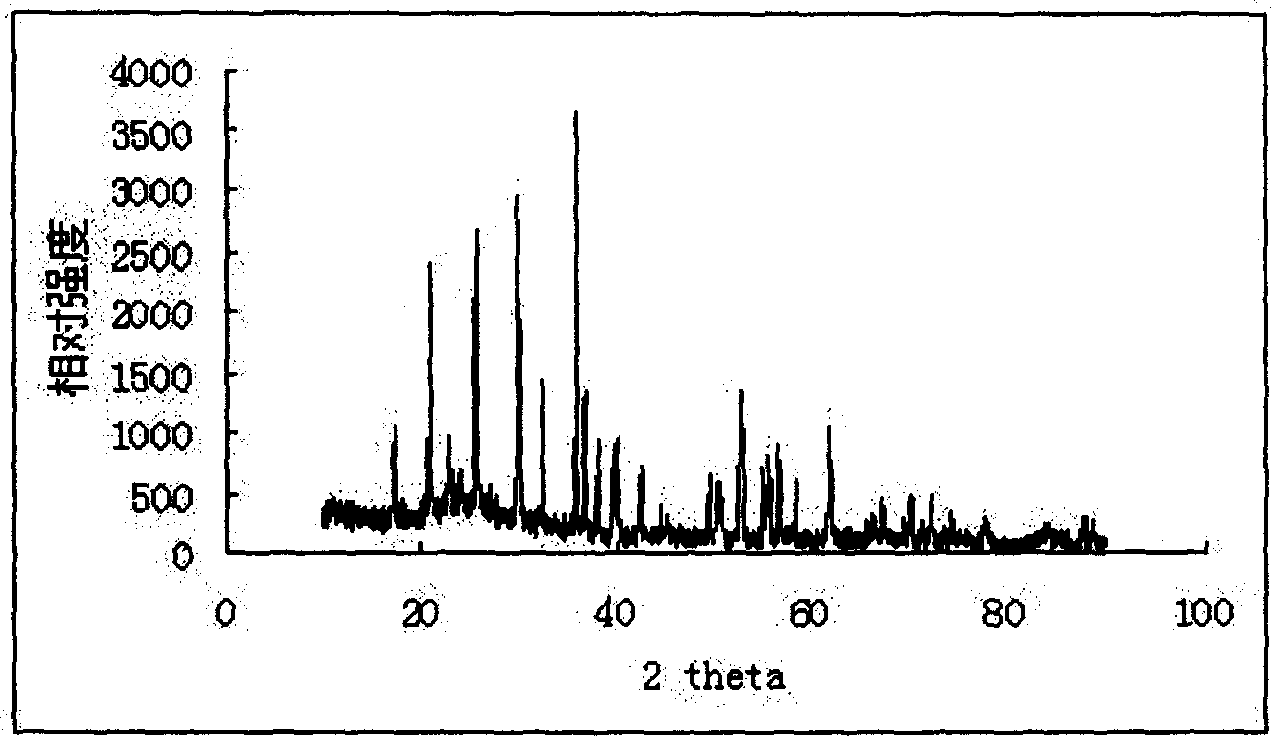

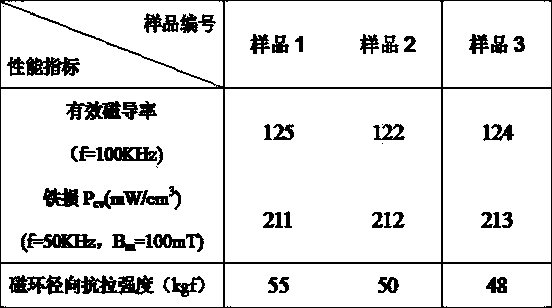

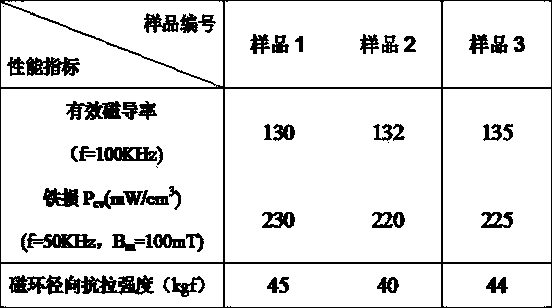

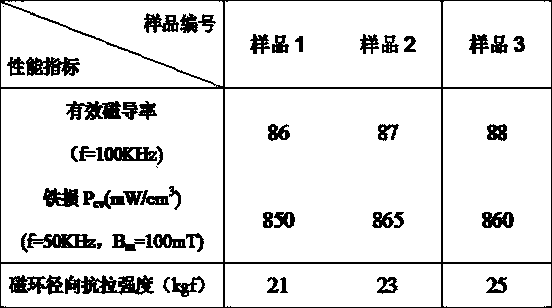

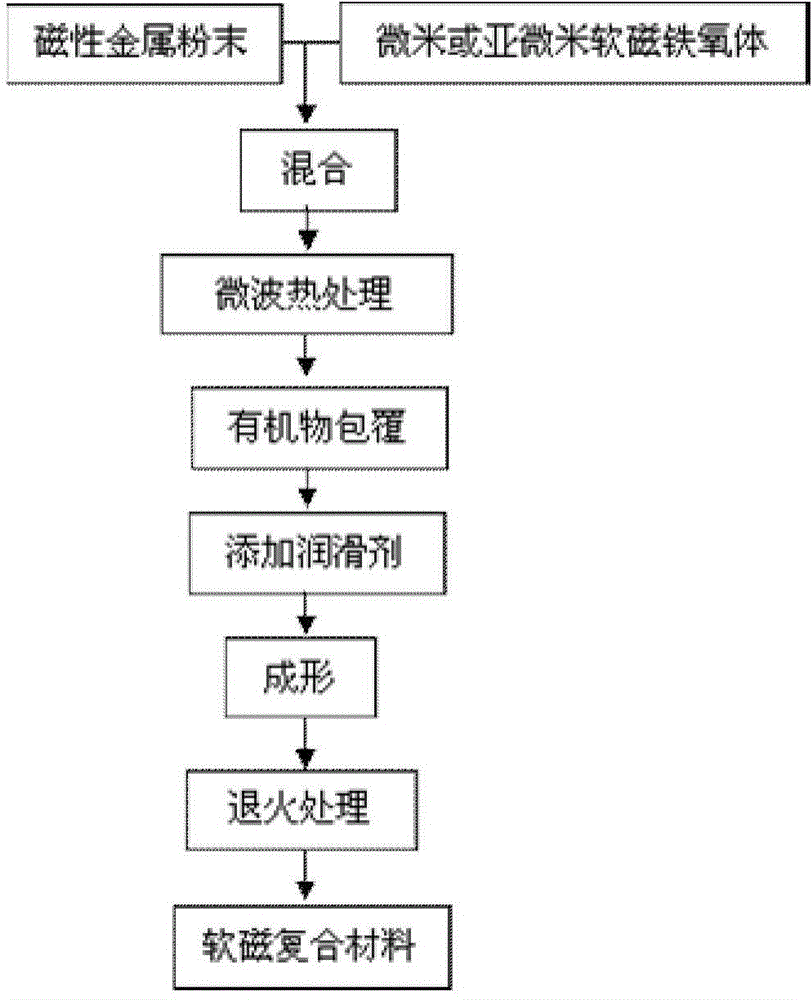

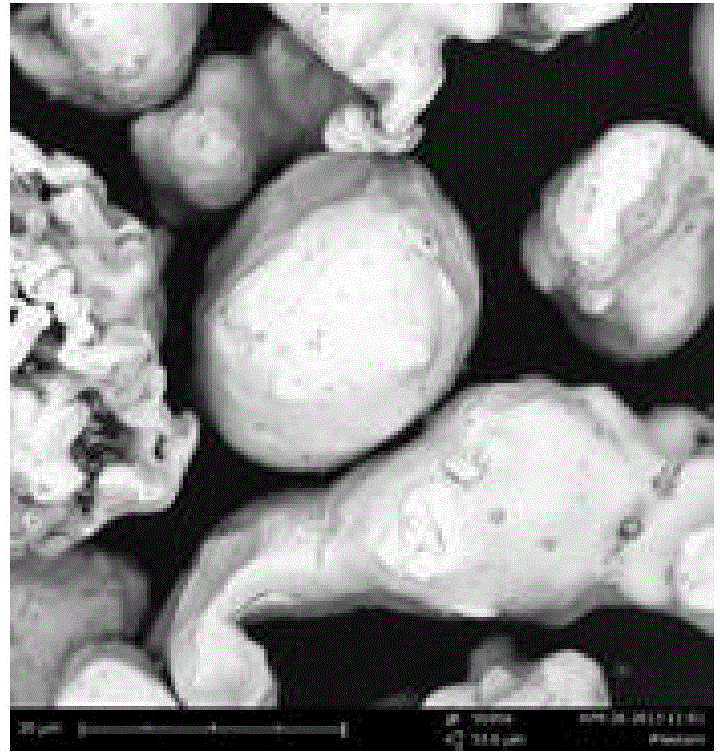

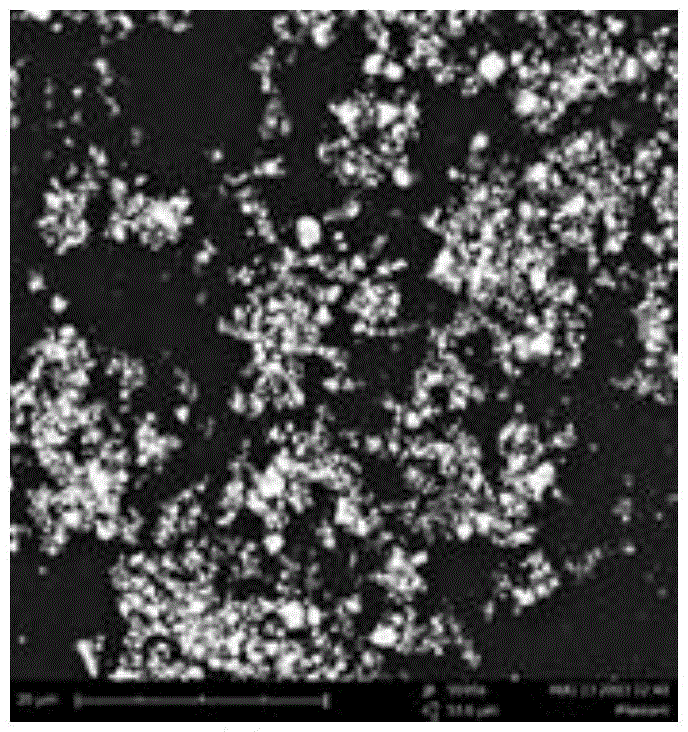

Method for coating metal magnetic powder on soft magnetic ferrites and method for preparing soft magnetic composite materials

ActiveCN104550940AConvenient sourceGood coating effectInorganic material magnetismTemperature resistanceNon magnetic

The invention provides a method for coating metal magnetic powder on soft magnetic ferrites. According to the method, the metal magnetic powder is mixed with trace micron or submicron soft magnetic ferrites, and then, a coating layer is formed through microwave high-temperature heat treatment. The invention also discloses a method for preparing the metal soft magnetic composite materials by adopting the coating powder. According to the method, the coating powder is subjected to organic matter coating, lubricating agents are added, pressing and forming are carried out, finally, annealing treatment is carried out, and the soft magnetic composite materials are obtained. The method has the advantages that the characteristics of magnetism, high electrical resistivity and high-temperature resistance of ferrite soft magnetic materials are sufficiently used, the two kinds of soft magnetic materials are compounded, non-magnetic substances are less than other kinds of soft magnetic composite materials, and in addition, a higher heat treatment temperature is realized, so that better magnetic performance is realized. The soft magnetic composite materials prepared by adopting the method provided by the invention have higher magnetic conductivity and low loss, the frequency stability is good, the magnetic loss at high frequency is low, in addition, the preparing process is simple, the environment is protected, the operation is easy, the cost is low, and the method is suitable for industrial mass and large-scale production.

Owner:NBTM NEW MATERIALS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com