Lipid type antirust oil with gaseous phase antirust function

A technology of gas-phase antirust agent and antirust oil, which is applied in the petroleum industry, additives, lubricating compositions, etc. It can solve the problems of difficult removal, dry shrinkage of oil film, pollution of the environment, etc., and achieve easy removal, transparent oil film, and coating property Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

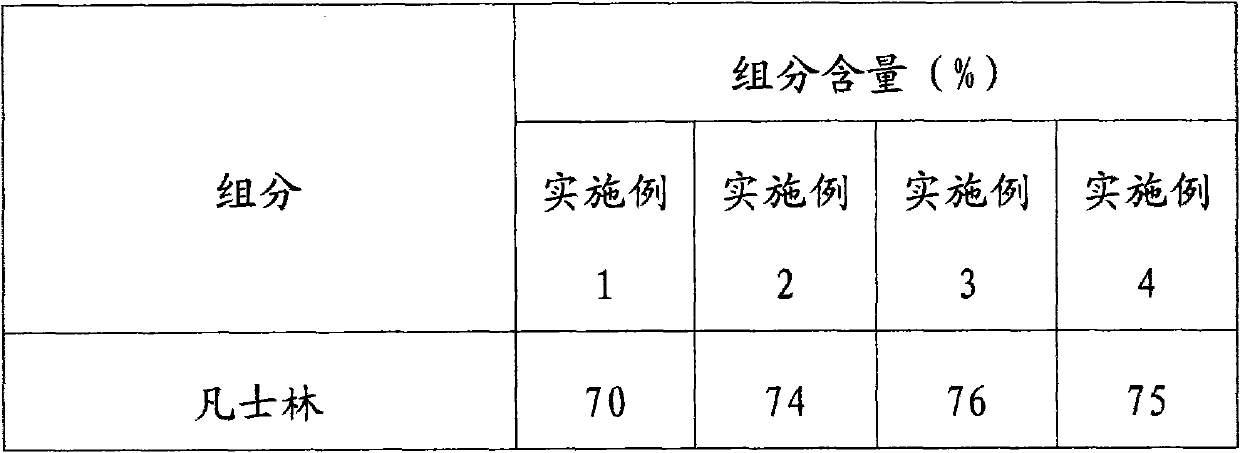

Examples

Embodiment 5

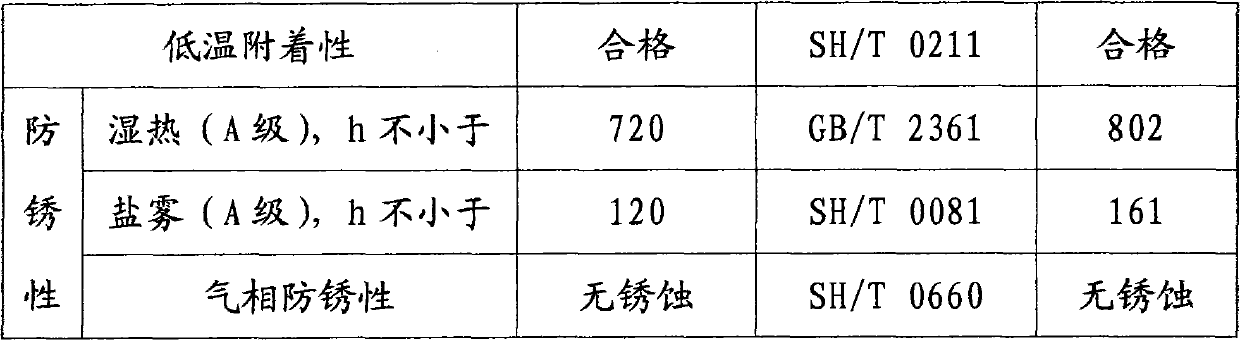

[0028] Example 5 Detection of performance indicators of fat-type anti-rust oil of the present invention

[0029] According to the test method shown in table 2, the grease type antirust oil prepared by embodiment 3 is detected, and the detection results are shown in table 2

[0030] Table 2 The performance testing result table of fat type antirust oil of the present invention

[0031] project

Quality Index

experiment method

test results

Dropping melting point, ℃ not lower than

55

GB / T 8026

57

Flash point, ℃ not lower than

175

GB / T 3536

181

Precipitation value, ml is not greater than

0.05

SH / T 0215

0.04

no scars

SH / T 0215

no scars

Flow down point, ℃ not lower than

40

SH / T 0082

43

[0032]

[0033] As can be seen from the data in Table 2, the fat-type antirust oil of the present invention not only meets the technical indicators of the L-RK...

Embodiment 6

[0034] Example 6 Comparison test of antirust performance of grease type antirust oil of the present invention

[0035] In order to verify that the fat-type anti-rust oil of the present invention has excellent gas-phase anti-rust function, according to the SH / T 0660 test method, the commercially available Lanxing brand LX-85 anti-rust grease, Kebanglite brand 903 anti-rust grease, , Shell state special brand 663 anti-rust grease for gas-phase anti-rust performance comparison test. The comparison experiment results are shown in Table 3

[0036] Table 3 Comparison test results of vapor phase antirust performance

[0037]

[0038] From the data in Table 2 and Table 3, it can be seen that the fat-type antirust oil of the present invention has a transparent fat film, is soft, has good construction performance, is resistant to sunlight and rain, and has excellent gas phase antirust properties, making it impossible to apply antirust oils. Oiled metals are also protected ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com