Patents

Literature

577 results about "Iron metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron is another transition metal with chemical symbol Fe and atomic number 26. Iron is a silvery metal, which is very abundant and is used for multiple purposes. Commonly it is alloyed together with carbon and other elements, to become steel.

Surface oxidised nickel-iron metal anodes for aluminium production

InactiveUS20050205431A1Reduce solubilityPremature depletionIsotope separationElectrodesElectrolysisSurface oxidation

An anode for the electrowinning of aluminium by the electrolysis of alumina in a molten fluoride electrolyte has an electrochemically active integral outside oxide layer obtainable by surface oxidation of a metal alloy which consists of 20 to 60 weight % nickel; 5 to 15 weight % copper; 1.5 to 5 weight % aluminium; 0 to 2 weight % in total of one or more rare earth metals, in particular yttrium; 0 to 2 weight % of further elements, in particular manganese, silicon and carbon; and the balance being iron. The metal alloy of the anode has a copper / nickel weight ratio in the range of 0.1 to 0.5, preferably 0.2 to 0.3.

Owner:MOLTECH INVENT

High Corrosion Resistance Hot dip Galvanized Steel Material

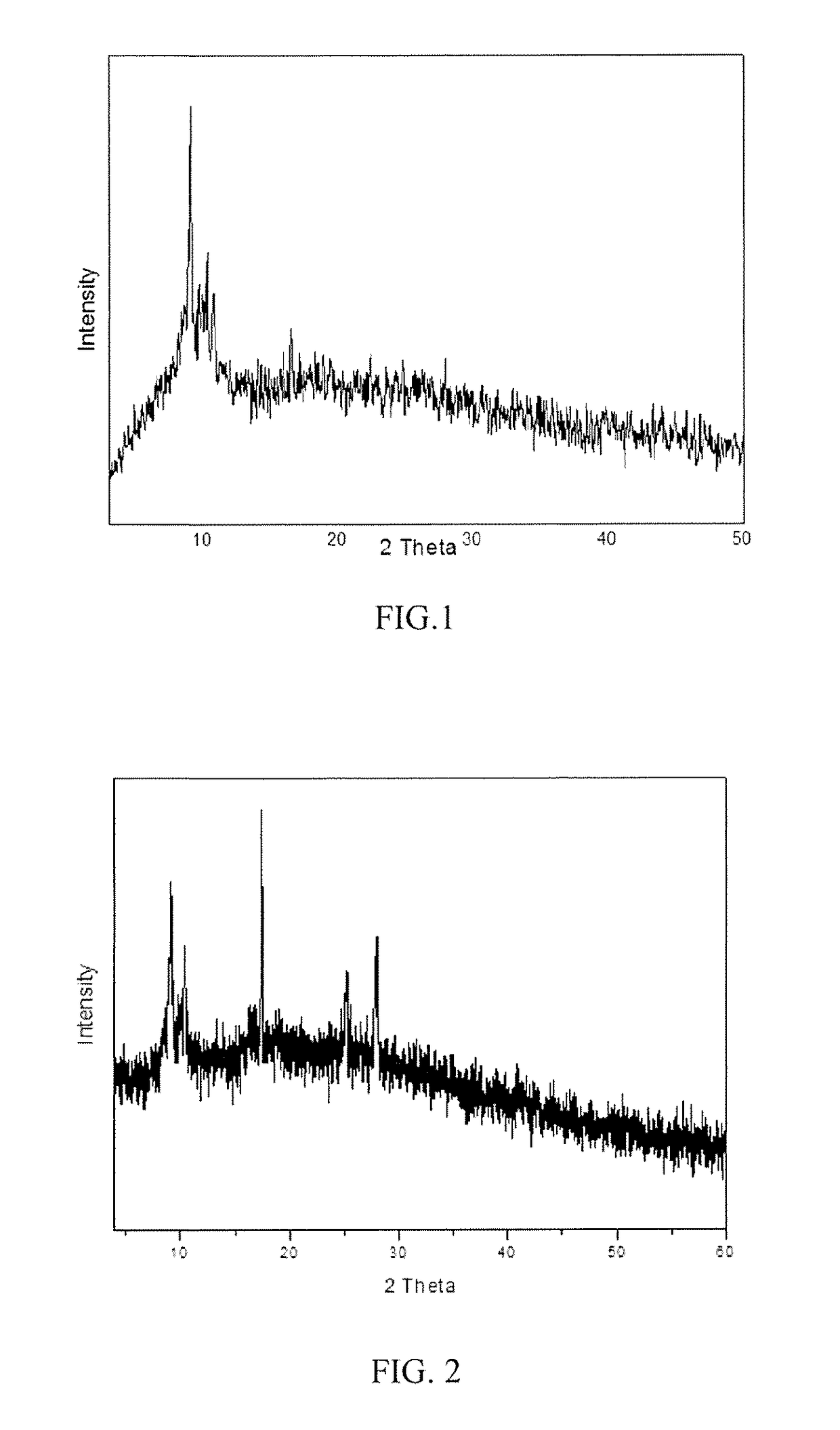

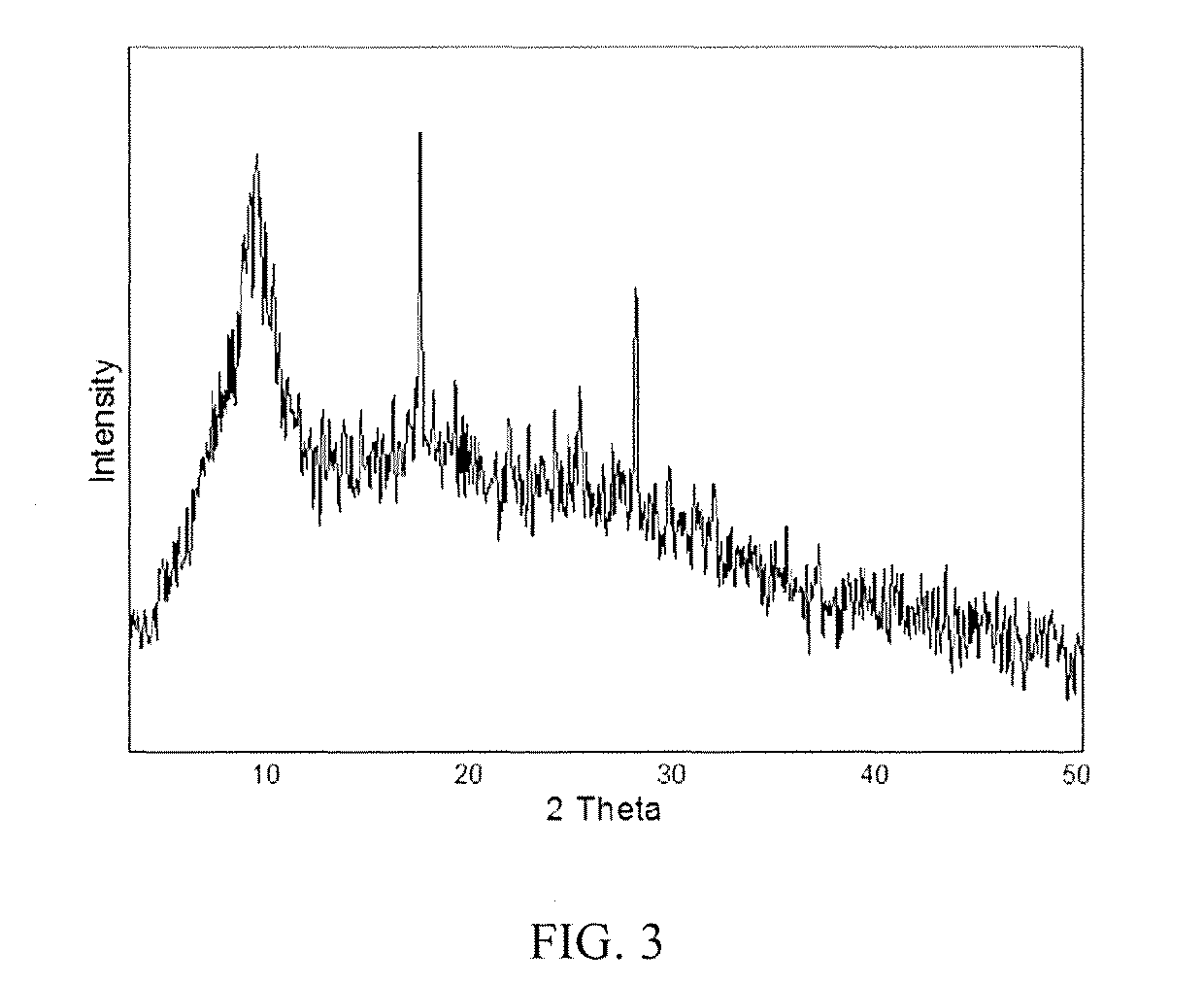

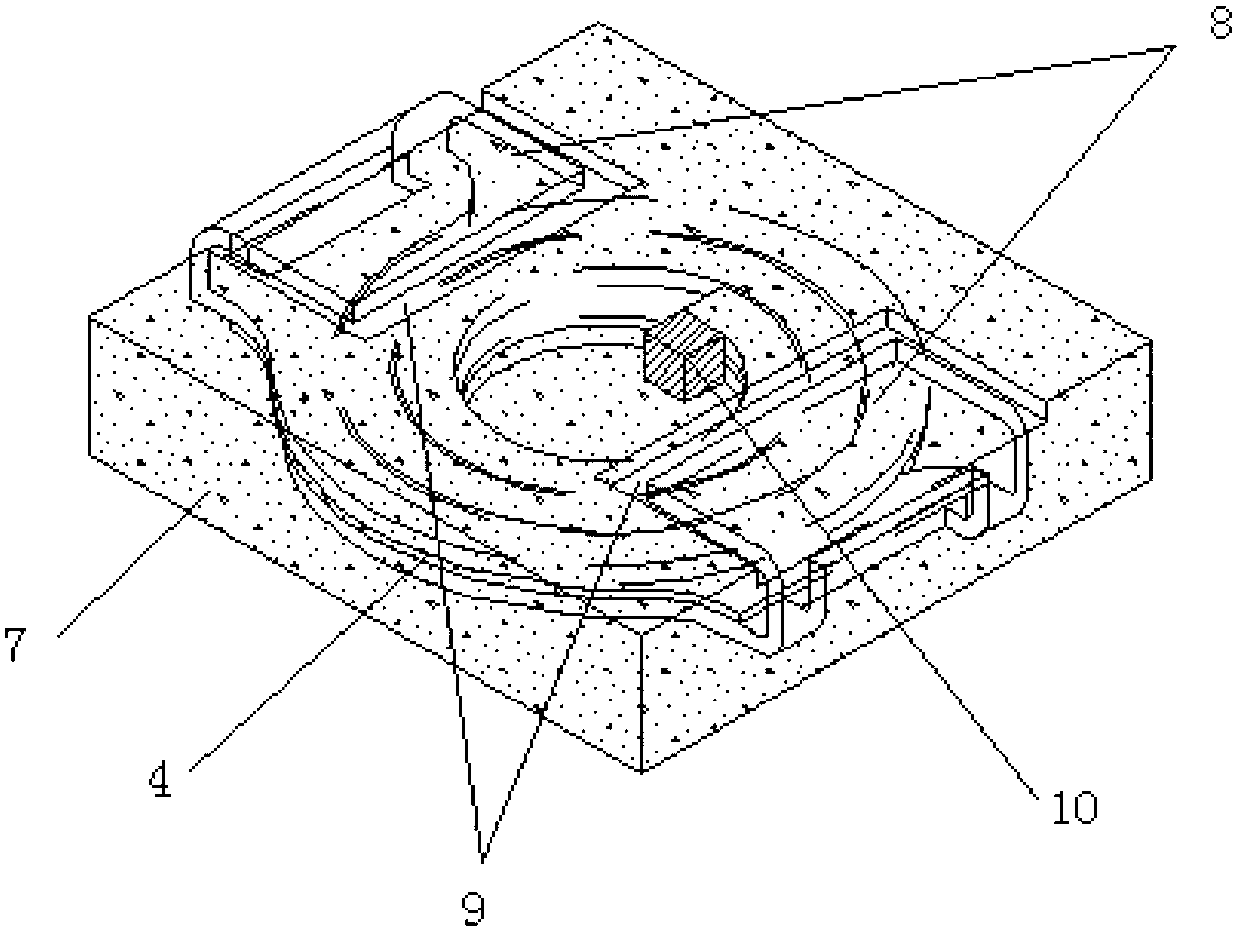

InactiveUS20090053555A1Improve corrosion resistanceSuppressing degradationHot-dipping/immersion processesThin material handlingAmorphous phaseAlloy

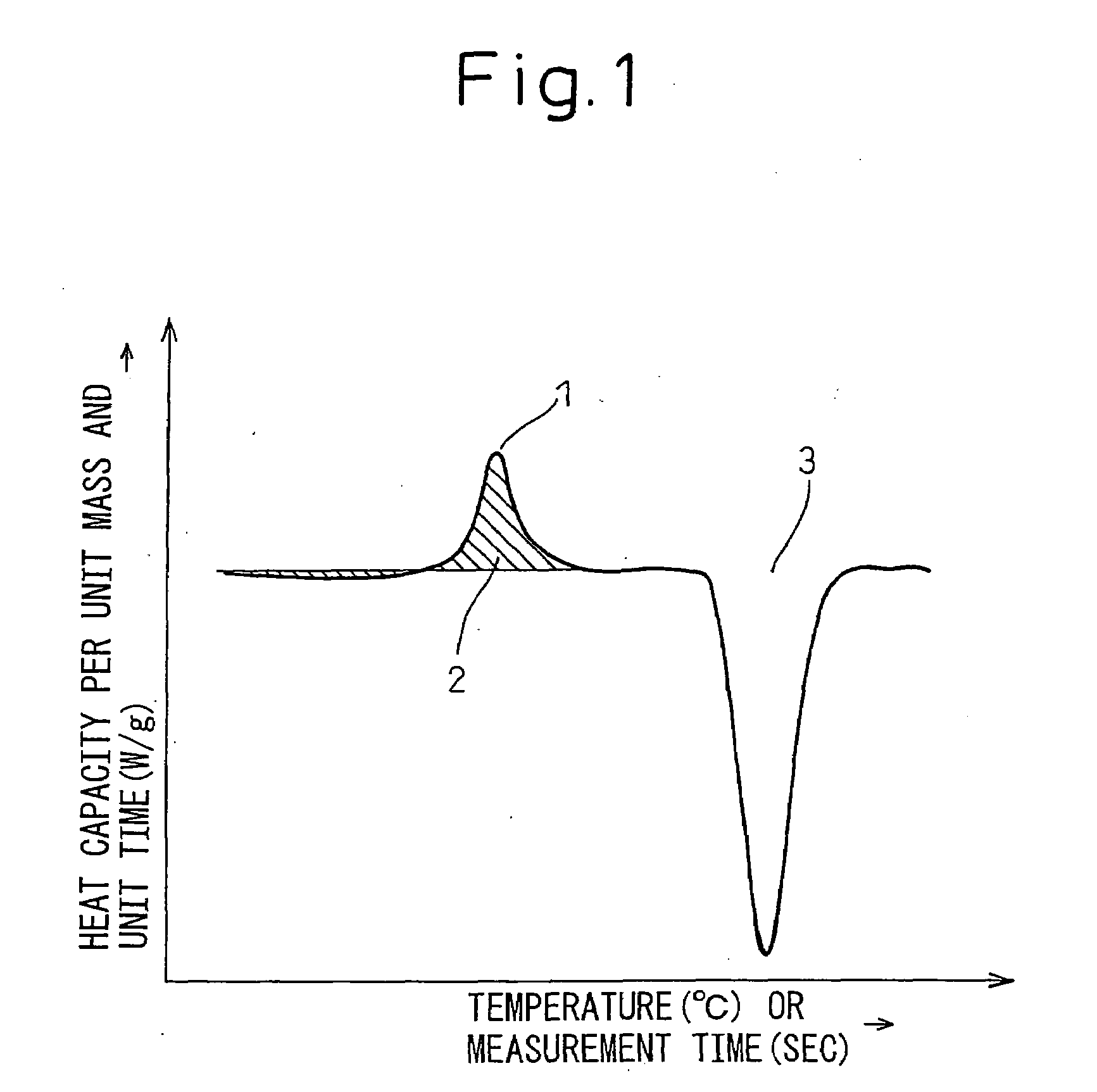

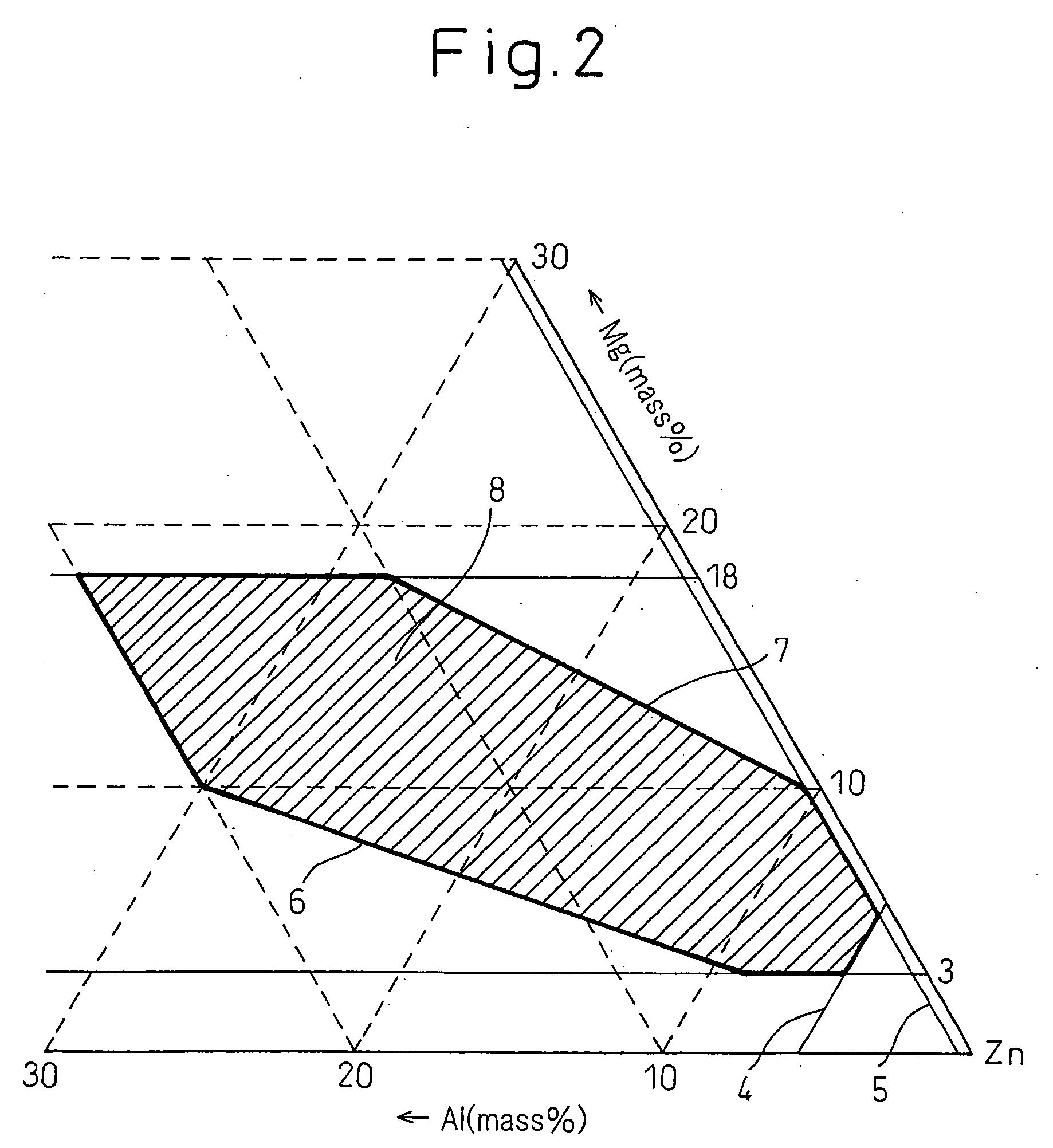

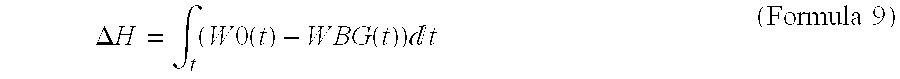

The present invention provides a high corrosion resistance hot dip galvannealed steel material comprised of a Zn-based hot dip plated steel material achieving both a higher corrosion resistance of the plated layer itself by the added elements and sacrificial protection of iron metal by the plated layer or workability free of degradation caused of formation of intermetallic compounds by added elements, that is, a high corrosion resistance hot dip Zn plated steel material characterized in that an alloy plated layer containing Zn: 35 mass % or more, preferably 40 mass % or more, contains a non-equilibrium phase having a heat capacity by differential scanning calorimetry of 1 J / g or more. Furthermore, 5% or more, preferably 50% or more in terms of vol % is an amorphous phase. The alloy layer may contain, by mass %, Mg: 1 to 60% and Al: 0.07 to 59%, may further contain one or more elements selected from Cr, Mn, Fe, Co, Ni, and Cu in a total of 0.1 to 10%, and may in addition contain one or more elements of 0.1 to 10% of La, 0.1 to 10% of Ce, 0.1 to 10% of Ca, 0.1 to 10% of Sn, 0.005 to 2% of P, and 0.02 to 7% of Si.

Owner:NIPPON STEEL CORP

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

CoFe2O4/N/C hollow nanosphere and preparation and application thereof

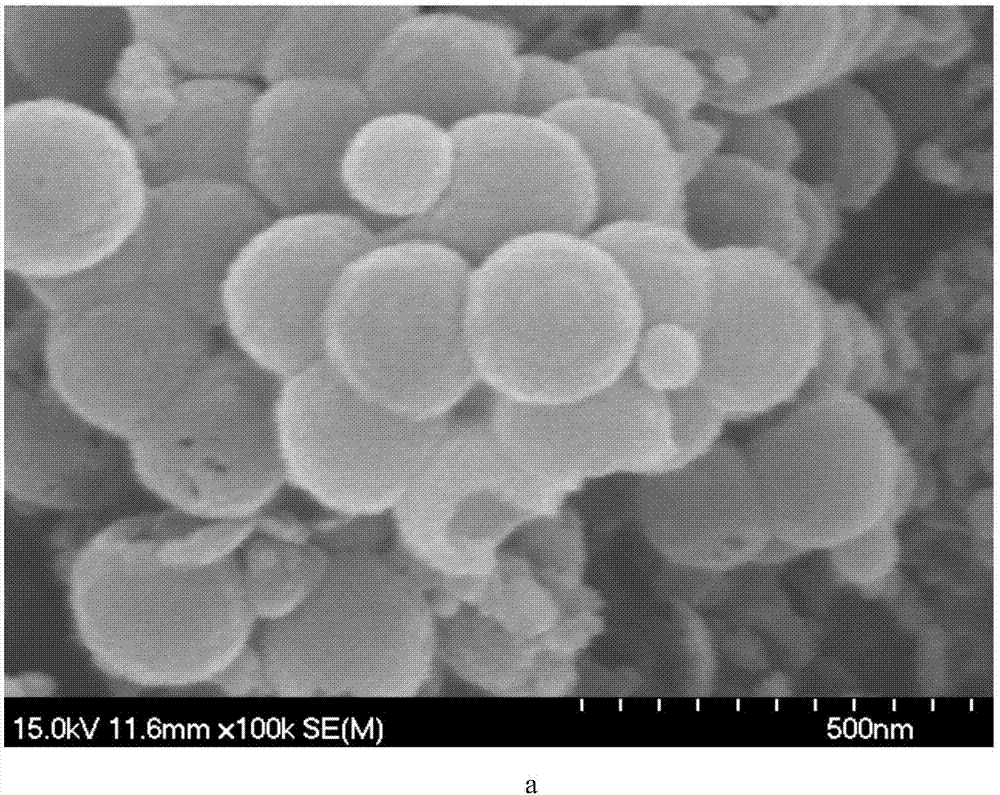

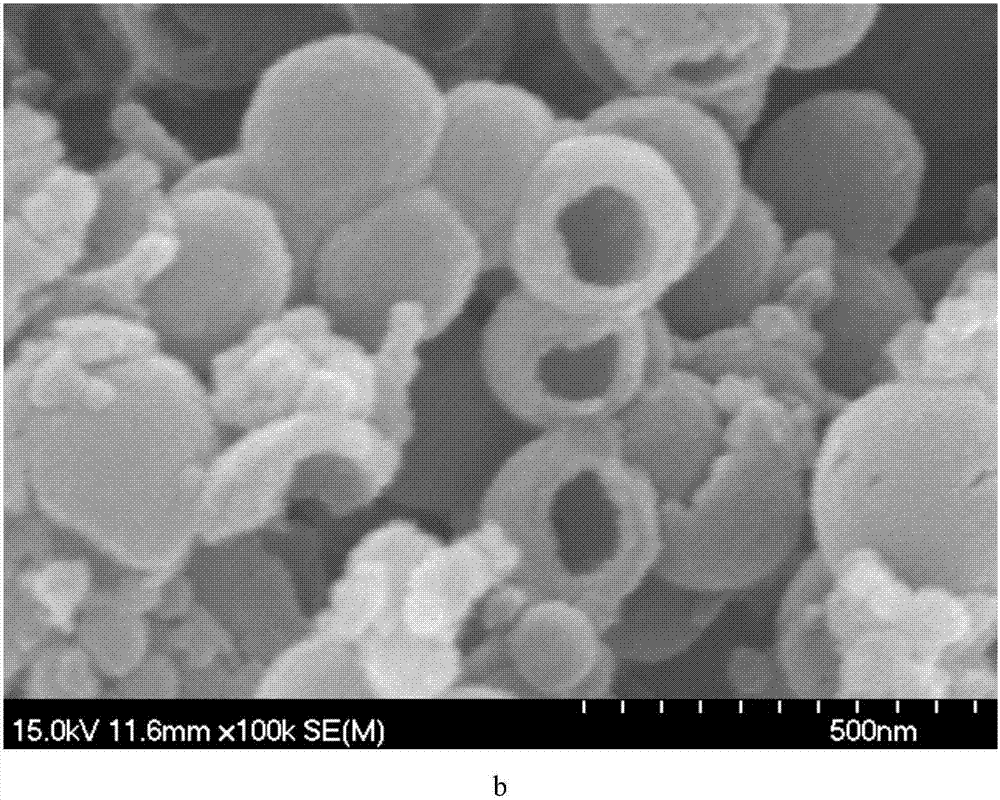

InactiveCN106984261AImprove distributionImprove adsorption capacityPhysical/chemical process catalystsOther chemical processesMicrosphereCarbonization

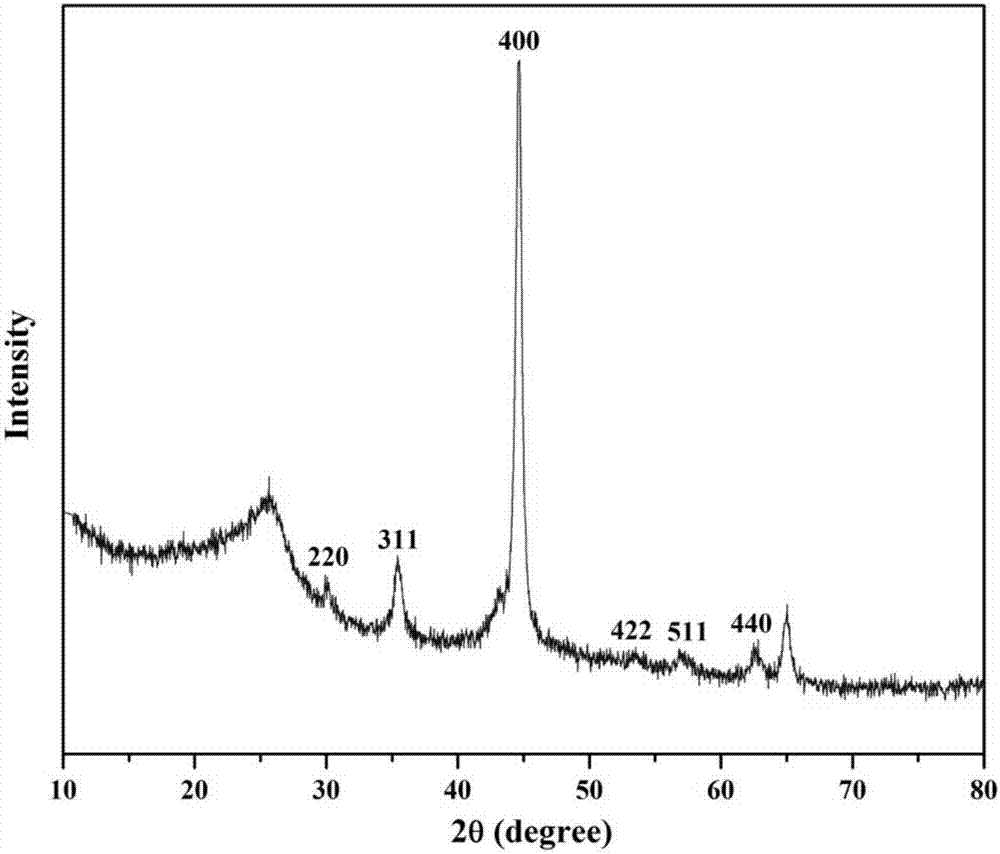

The invention discloses a CoFe2O4 / N / C hollow nanosphere and preparation and application thereof. The preparation comprises: complexing dopamine with cobalt and iron metal ions under the condition of pH8-9 on a template as a SiO2 nanometer sphere to form a polymer shell layer, carbonization annealing to form N-doped carbon material loaded with CoFe2O4 metal nanoparticles, and finally, removing the SiO2 template with strong alkali to obtain CoFe2O4 / N / C hollow nanosphere. In the invention, the N / C matrix hollow structure is prepared by using the SiO2 nanosphere as the sacrificial template, theCoFe2O4 / N / C hollow nanosphere has a relatively large specific surface area and porosity, and can improve the distribution of CoFe2O4 nano metal particles loaded on the shell layer, enhance adsorption and catalytic activity on organic pollutants in waste water, and broaden the pH application range; the CoFe2O4 / N / C hollow nanosphere can be recycled due to magnetic performance, thus saving resources.

Owner:ZHEJIANG UNIV OF TECH

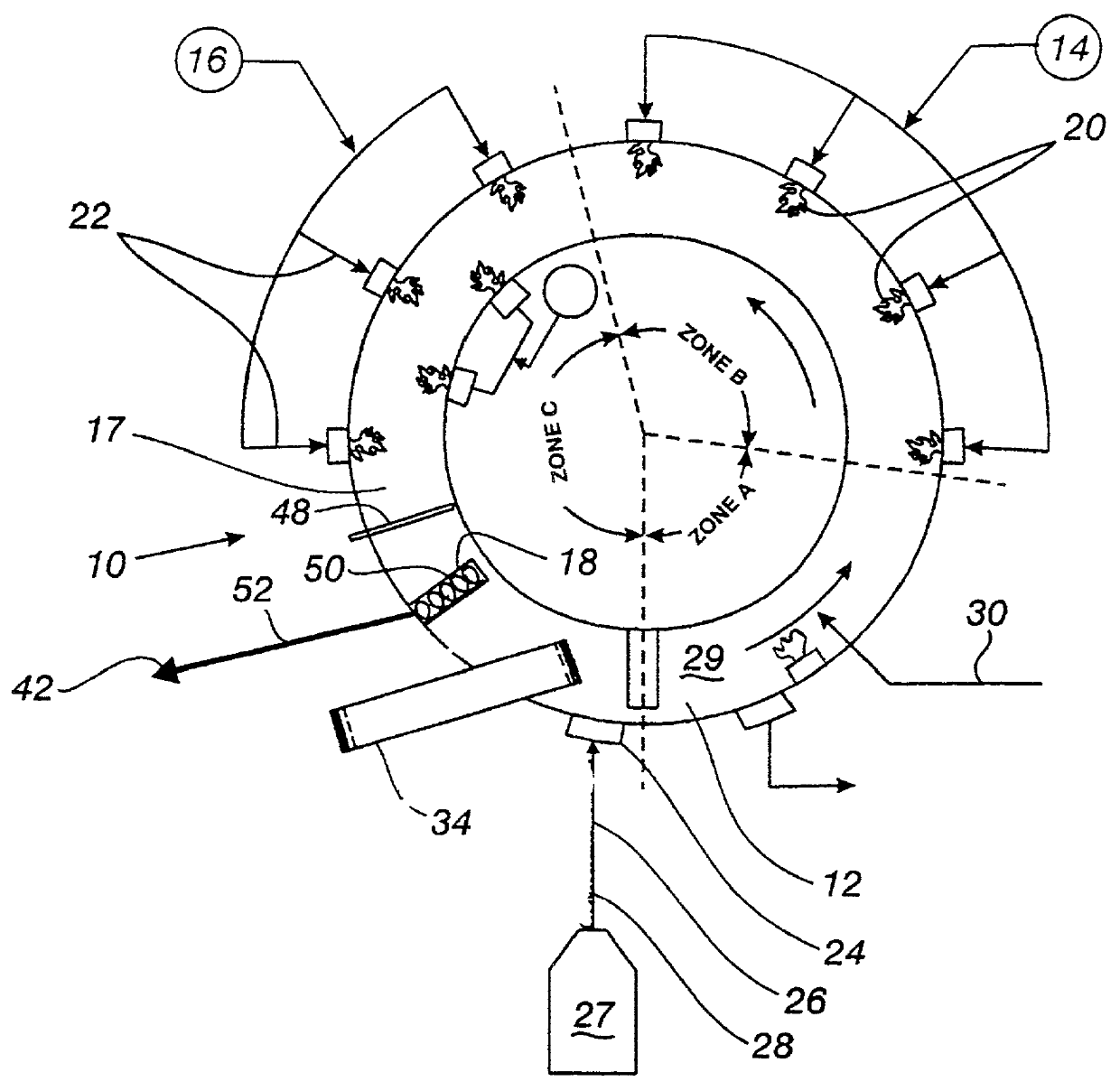

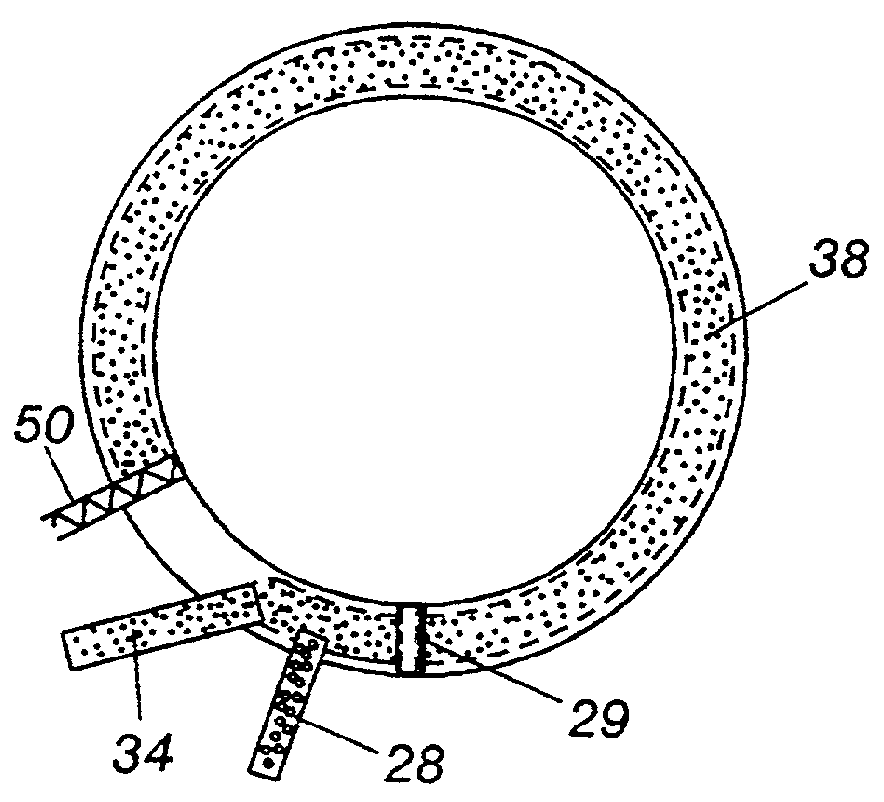

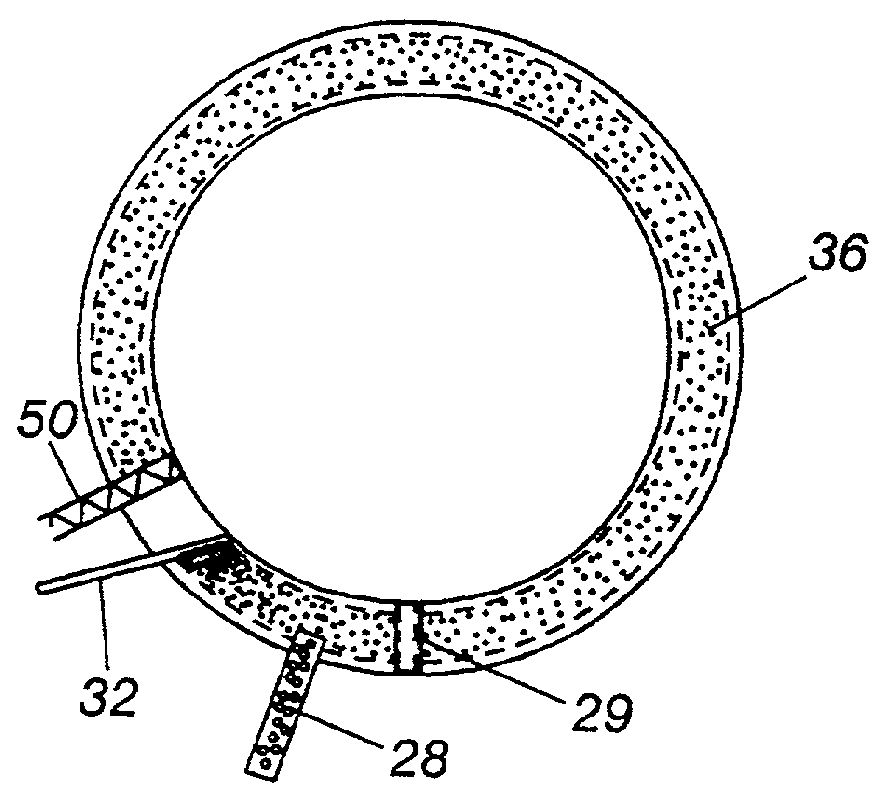

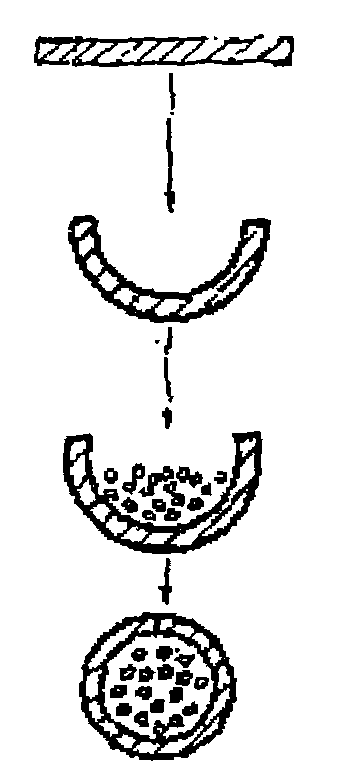

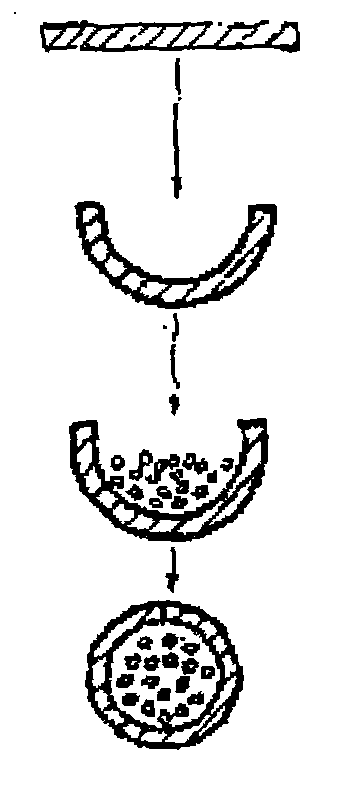

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

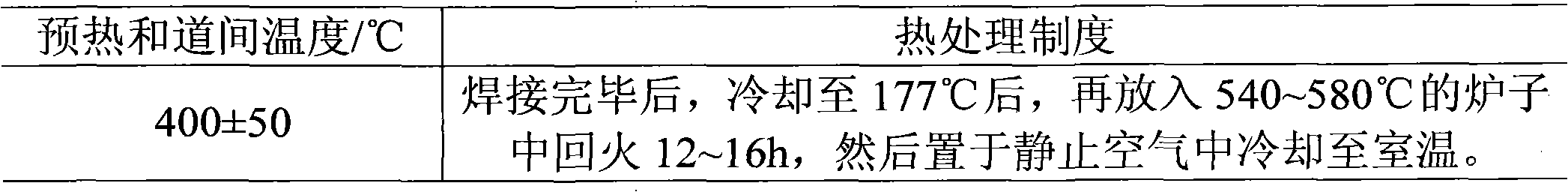

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

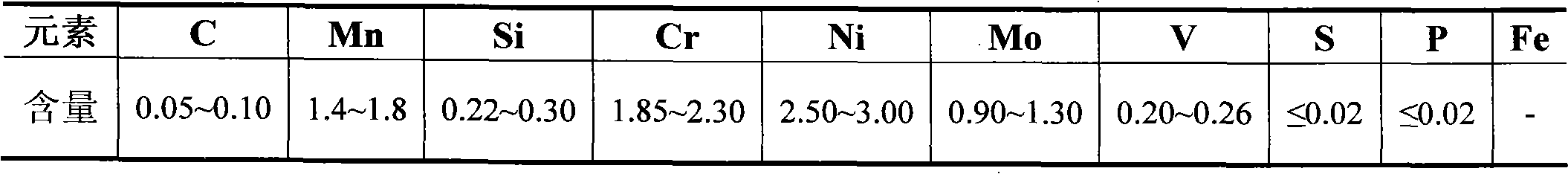

Ultra supercritical heat-resistant steel welding rod and production method thereof

InactiveCN103737199AGood workmanshipGood mechanicalWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ultra supercritical heat-resistant steel welding rod which is composed of an H08A core wire and coating wrapping the surface of the core wire, wherein contents of sulfur, phosphorus, arsenic, aluminum and the like in the H08A core wire are low, and the coating comprises components of 30%-39% of marbles, 22%-30% of fluorites, 6%-9% of rutiles, 7.5%-8.6% of ferromolybdenum, 29%-31% of chromium metal, 5%-9% of silica powder, 2%-5% of ferrosilicon, 1%-1.8% of ferrovanadium, 0.4%-0.8% of ferroniobium, 1.8%-2.8% of nickel powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxyl methyl cellulose (CMC), 0.2%-0.6% of amorphous graphite, 0.6%-1.5% of nitrogen-bearing ferrochromium, 1.6%-3% of electrolytic manganese, 3%-3.8% of cobalt powder and 4%-5% of ferroboron.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

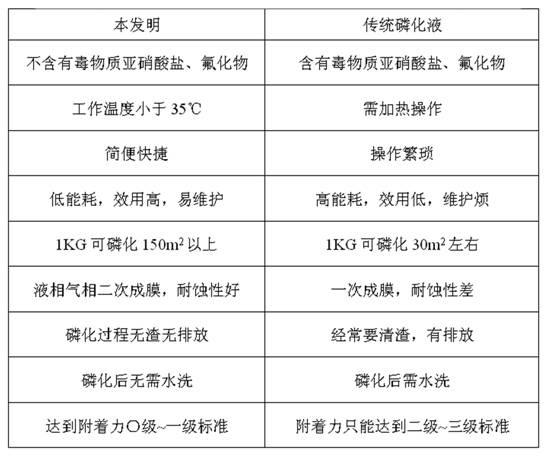

Zinc-iron metal alramenting liquid capable of being recycled at normal temperature

InactiveCN101935832ALow investment costReduce energy consumptionMetallic material coating processesSlagPhosphoric acid

The invention relates to a zinc-iron metal alramenting liquid capable of being recycled at normal temperature. The invention is characterized in that the alramenting liquid is prepared by the following raw materials by weight percent: 14-28% of phosphoric acid, 3.5-7% of zinc oxide, 12.6-17.5% of zinc nitrate, 0.14-0.56% of citric acid, 0.14-0.7% of tartaric acid and 0.14-0.84% of molybdate, and balance of water.In the invention, phosphorization is carried out in one process after oil removing and rust removing are carried out, the processes of neutralizing, surface conditioning, passivating and washing are eliminated, and a compact and uniform phosphorization membrane with strong adhesive force is rapidly formed on the surface of ferrous metal. The process greatly reduces operation procedure, the phosphorization process produces no slag, thus reducing pollution to the environment and greatly improving utilization factor of material; and energy consumption at normal temperature is reduced and water is saved. The invention has the advantages of wide application range, less investment, high efficiency and high safety, and bath solution has good stability, no deterioration or volatilization is caused, and maintenance is easy, thus being beneficial to follow-up spraying processes.

Owner:NANJING YOUWEI CHEM

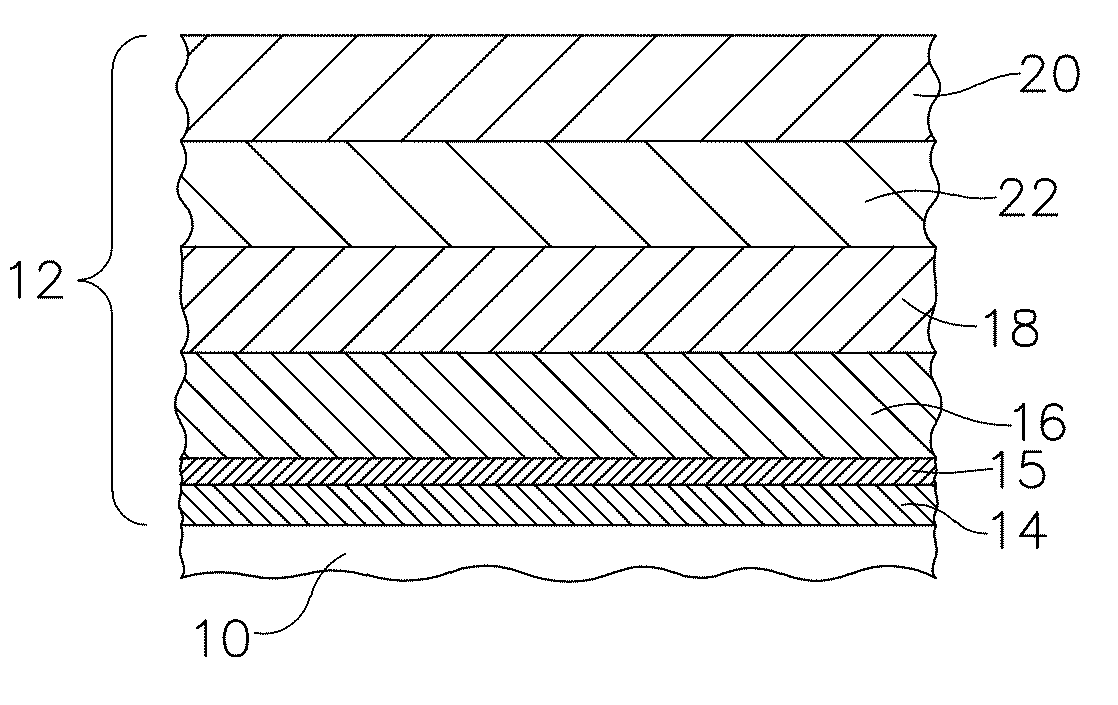

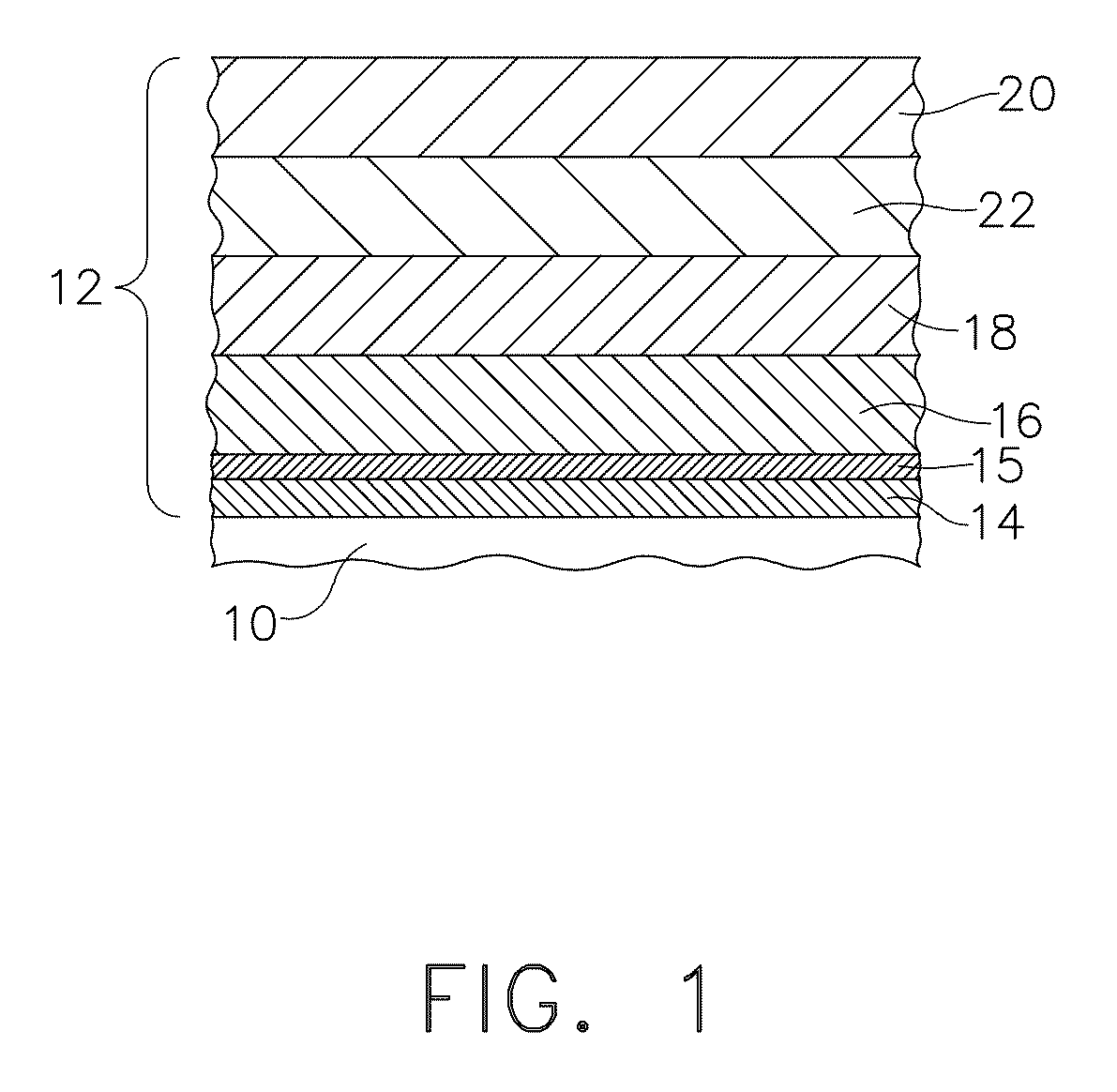

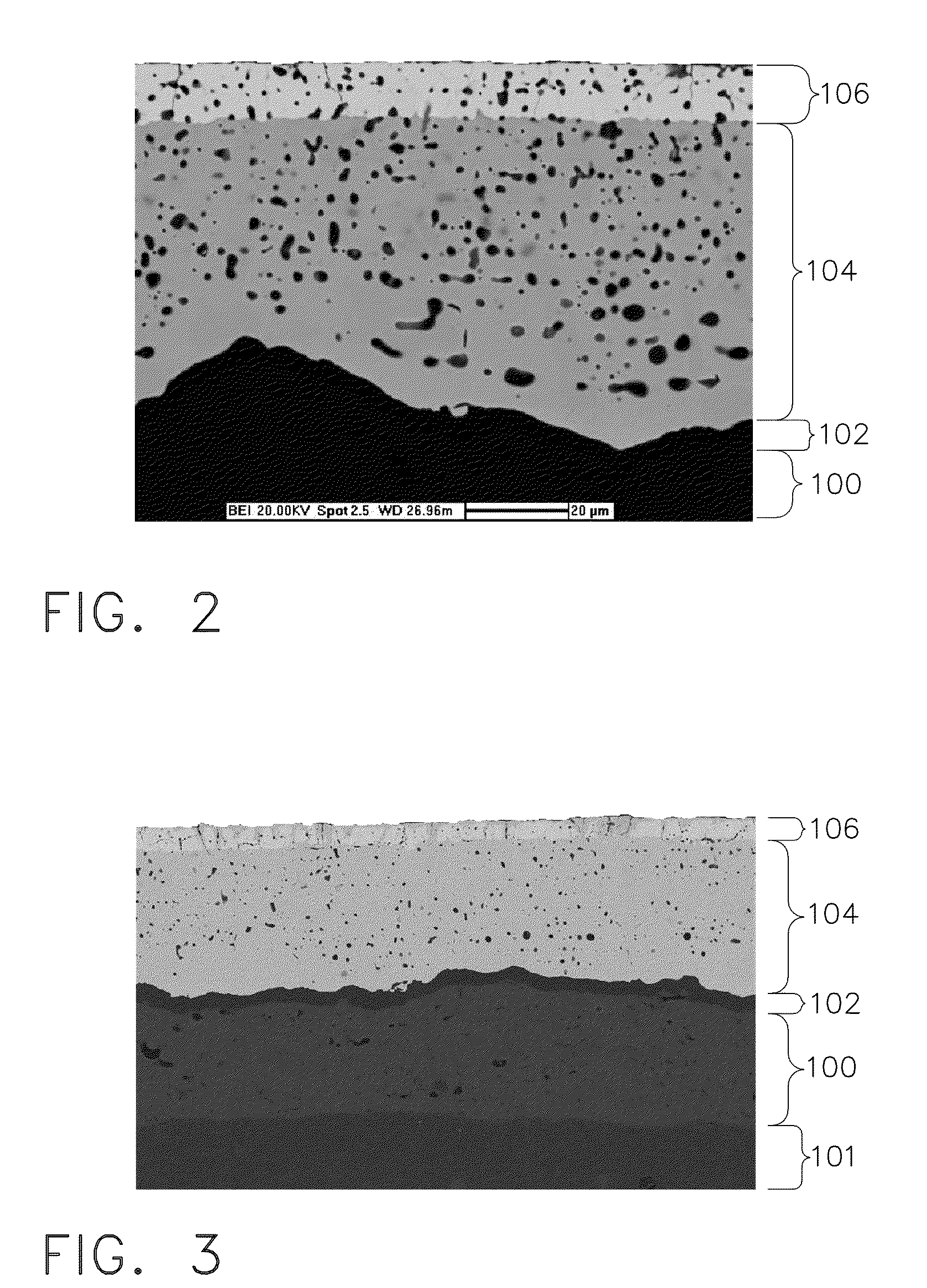

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

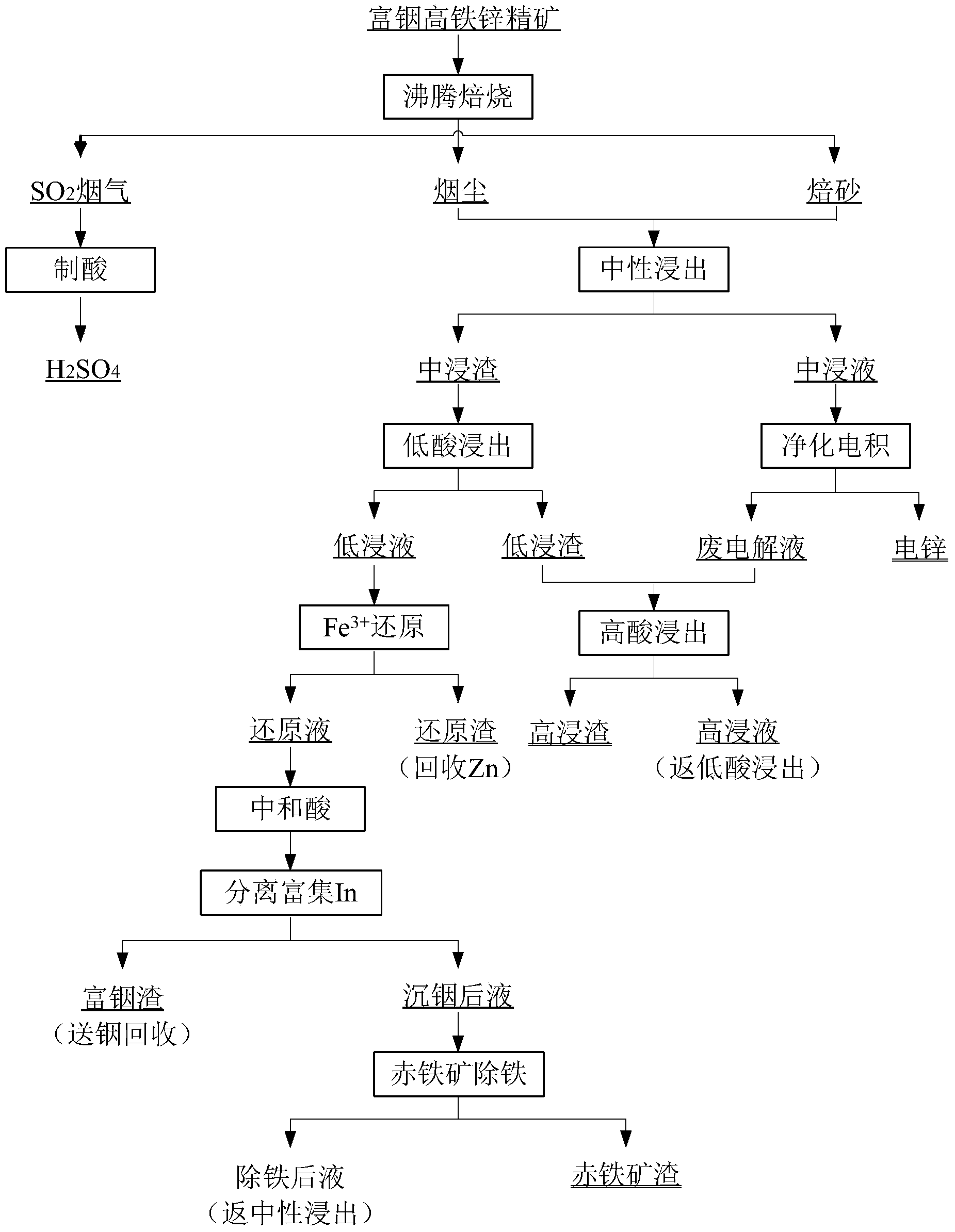

Clean and environment-friendly comprehensive novel recycling process by virtue of high-indium high-iron zinc concentrate

ActiveCN103526024AHigh recovery rateEasy to separateFerric oxidesProcess efficiency improvementIndiumResource utilization

The invention discloses a clean and environment-friendly comprehensive recycling method by virtue of high-indium high-iron zinc concentrate, and relates to a method for comprehensively recycling zinc, indium and iron by taking the high-indium high-iron zinc concentrate as a raw material by using a hydrometallurgy method. The method is characterized in that in a comprehensive recycling process, Fe3+ in a zinc calcine thermal acid leaching liquid is reduced into Fe2+ by using a reducing agent, In / Fe is separated in two-stage process, indium is further recycled from high-indium slag, iron is removed from liquid by a hematite process after In / Fe is separated, iron slag which can be utilized as iron concentrate can be obtained, and the liquid after iron is removed is fed back to subject to neutral leaching. The method disclosed by the invention is simple and short in procedure, thorough in separation of zinc, indium and iron metals, high in metal recycling rate and environment-friendly, and resource utilization of iron slag is achieved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for extracting metal from laterite mine

InactiveCN101245414AReduce energy consumptionImprove solubilityRotary drum furnacesCrucible furnacesPregnant leach solutionSlag

The invention relates to a method for selectively extracting metal from lateritic ore containing nickel and cobalt in an economic, effective and energy-saving way. The method comprises the steps that (1) the grinded lateritic ore is blended with substance containing sulfur and added with sulfuric acid or not; the obtained mixture is then roasted to cause non-ferrous metals in the mixture to selectively convert into respective sulphate and iron converts into oxide; (2) water is used for leaching the roasted mixture and the nickel, the cobalt and the copper are extracted out of the mixture into leachate; and (3) the leachate and leached slag are separated and the nickel, the cobalt and the copper are extracted out of the leachate with methods of precipitation, solvent extraction or ion exchange.

Owner:邓彤

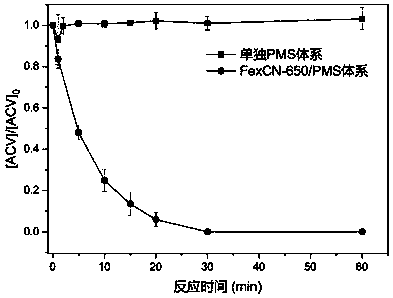

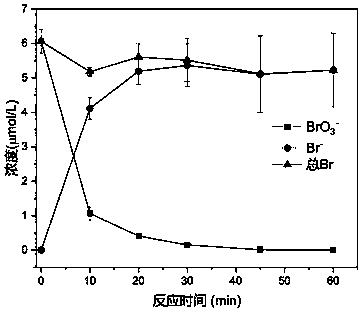

Copper-doped iron metal-organic framework, preparation method thereof, and application method for activation of persulfate to treat organic wastewater

InactiveUS20180185828A1Easy to operateGood repeatabilityWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSulfate radicalsMetal-organic framework

The present invention discloses a copper-doped iron metal-organic framework, a preparation method thereof, and an application method for activation of persulfate to treat organic wastewater. The copper-doped iron metal-organic framework is prepared by solution impregnation method, using relatively large specific surface area and more hollow structures of the iron metal-organic framework to effectively load copper ion. This method uses the unsaturated-coordinate iron active center on the iron metal-organic framework and copper ions on the load as a catalyst body, utilizing catalytic synergies of both to efficiently and continuously activate persulfate to produce sulfate radical anion for degradation of organic pollutants. This method is suitable for various organic wastewater, with high catalytic activity, good durability, easy operation and easy recovery, and activation effect of this heterogeneous catalyst is still high even after being used repeatedly, having a great application prospect in degradation of organic pollutants in water.

Owner:SOUTH CHINA UNIV OF TECH

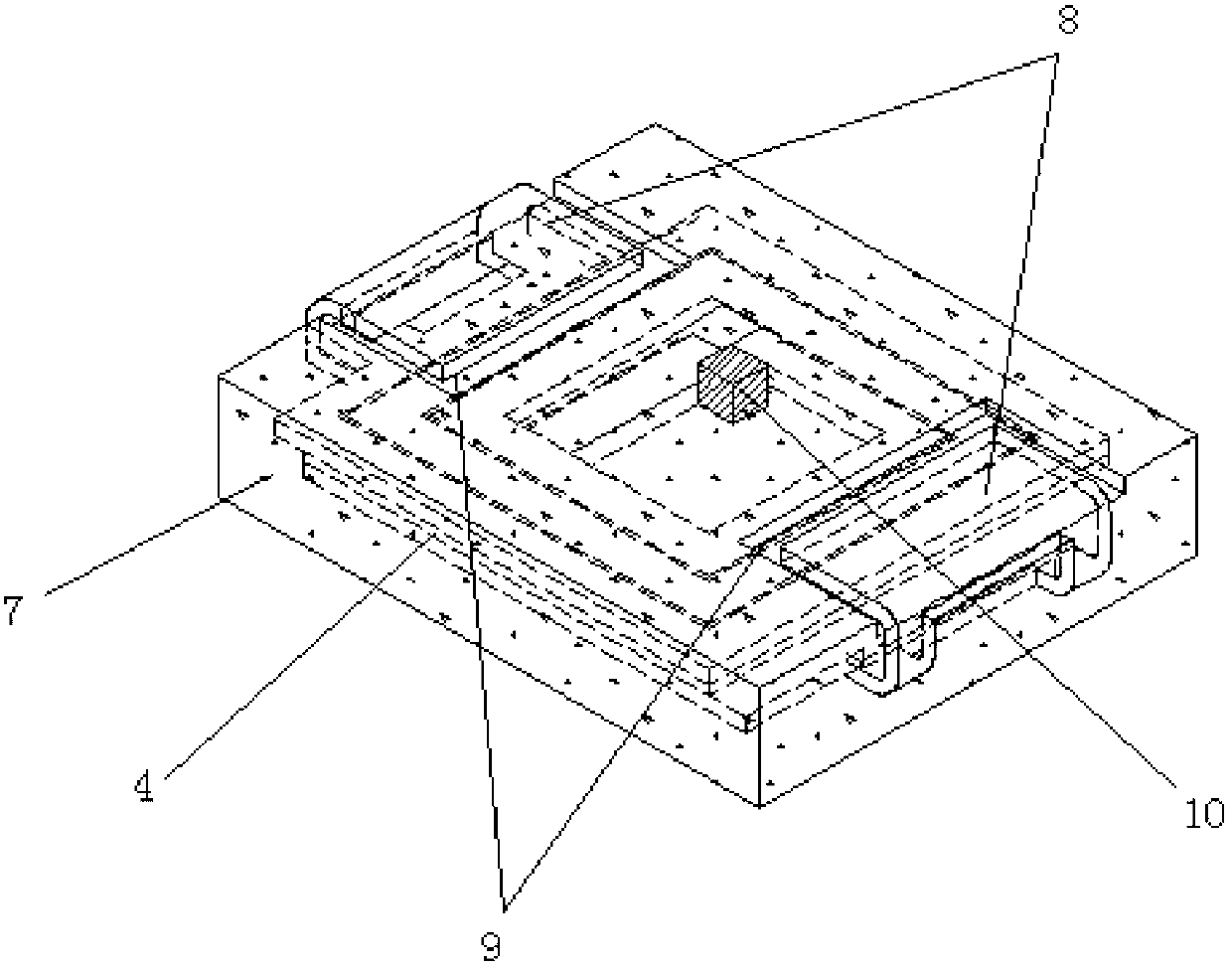

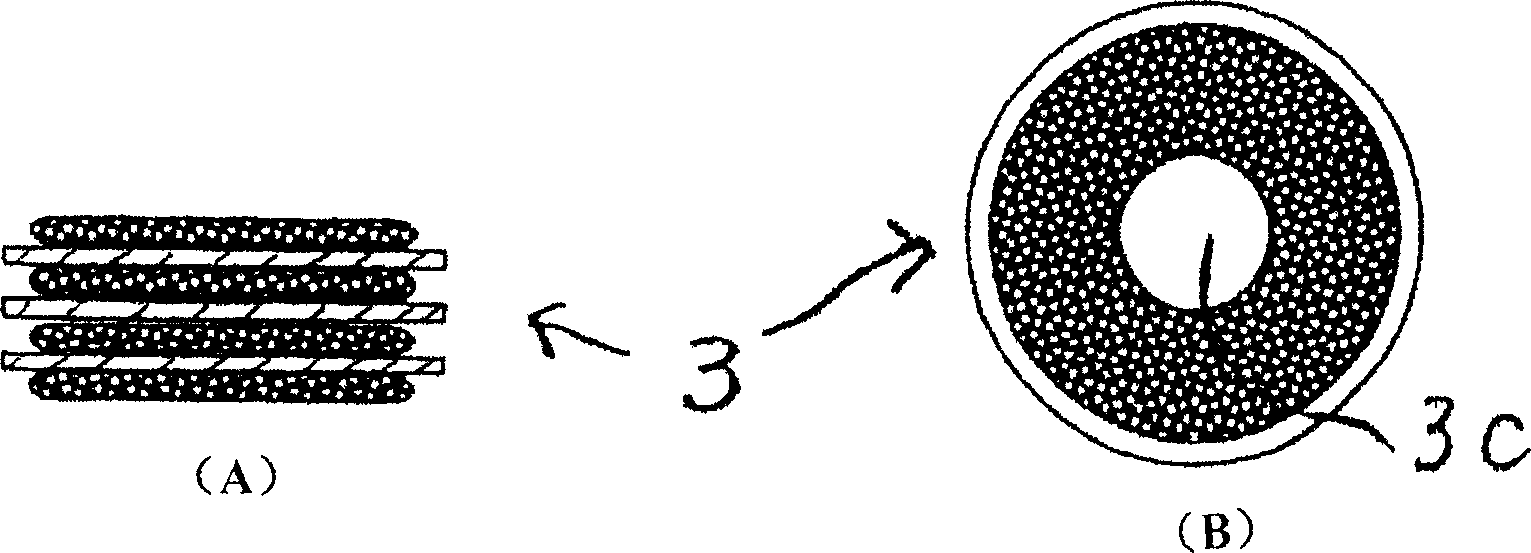

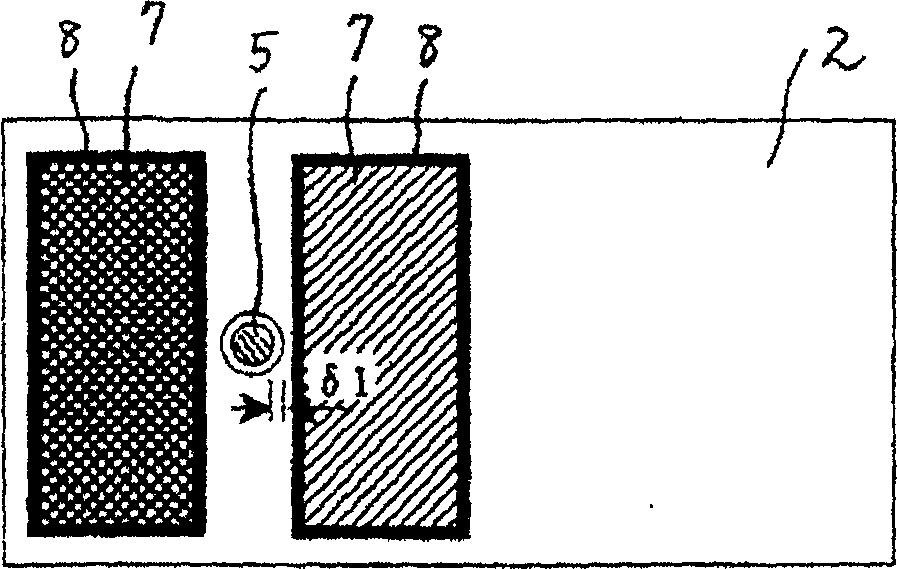

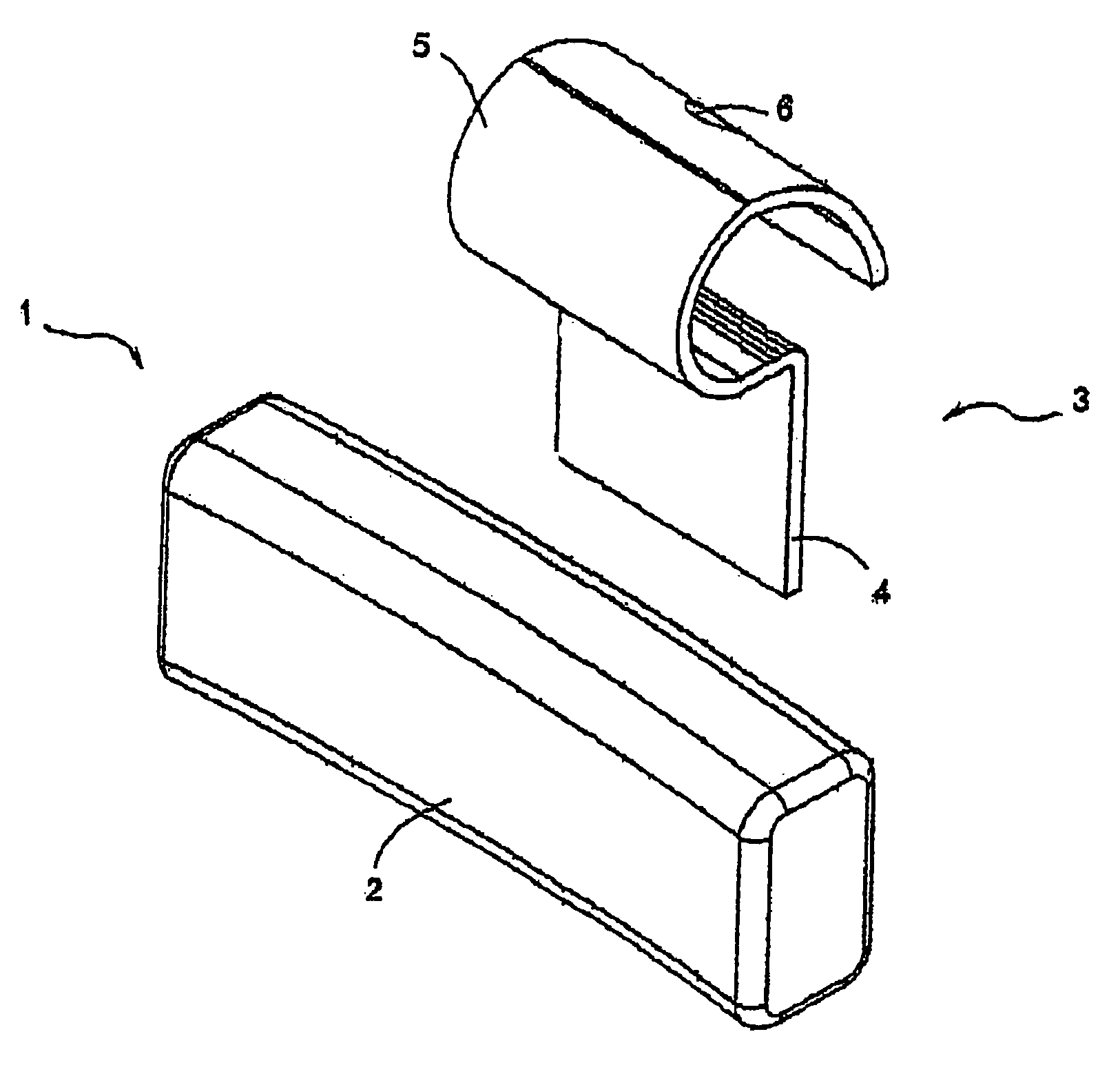

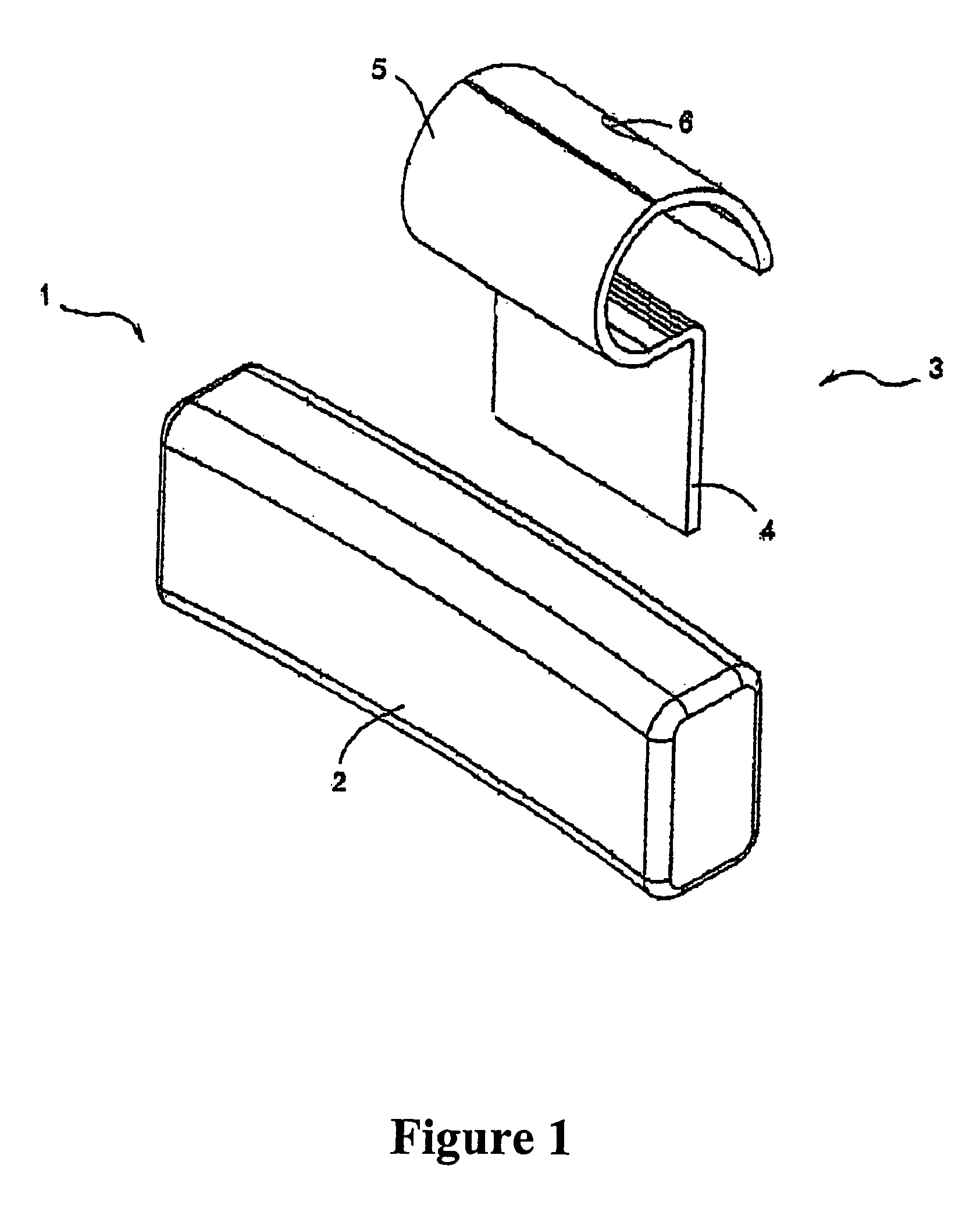

Inductance coil and laser-cutting manufacturing method of inductance coil

InactiveCN103280298AReduce negative impactOvercome immobilityTransformers/inductances coils/windings/connectionsWelding apparatusLaser cuttingLaser light

The invention provides an inductance coil and a laser-cutting manufacturing method of the inductance coil. The inductance coil comprises an upper copper foil coil, a lower copper foil coil, a heat-resistant organic thin film and magnetic material layers, wherein the outer surface of the upper copper foil coil and the outer surface of the lower copper foil coil are provided with insulating coatings for insulating treatment, the heat-resistant organic thin film is arranged between the upper copper foil coil and the lower copper foil coil, and the magnetic material layers wrap the periphery of the upper copper foil coil and the periphery of the lower copper foil coil. Coil patterns of the upper copper foil coil and the lower copper foil coil are formed through cutting by a laser light source. The insulating coatings are heat-resistant coatings. The magnetic material layers are formed through compression molding, and a magnetic material is iron metal alloy soft magnetic powder. The laser-cutting manufacturing method comprises laser cutting on the upper copper foil coil, the lower copper foil coil and the heat-resistant organic thin film. The inductance coil is formed by copper foil in a laser-cutting mode, parameters including line width, thickness, distance between lines, coil center pillars and the like can be adjusted to form the coil patterns on normal positions, and target characteristic specifications can be designed quite easily. The inductance coil and the laser-cutting manufacturing method of the inductance coil overcome the shortcomings that an existing inductance coil is difficult to fix and loses efficacy in an open circuit and a short circuit, and end electrodes are difficult to design, and better accord with the development tendency that a power inductor is small, thin and low in cost.

Owner:SHENZHEN SUNLORD ELECTRONICS

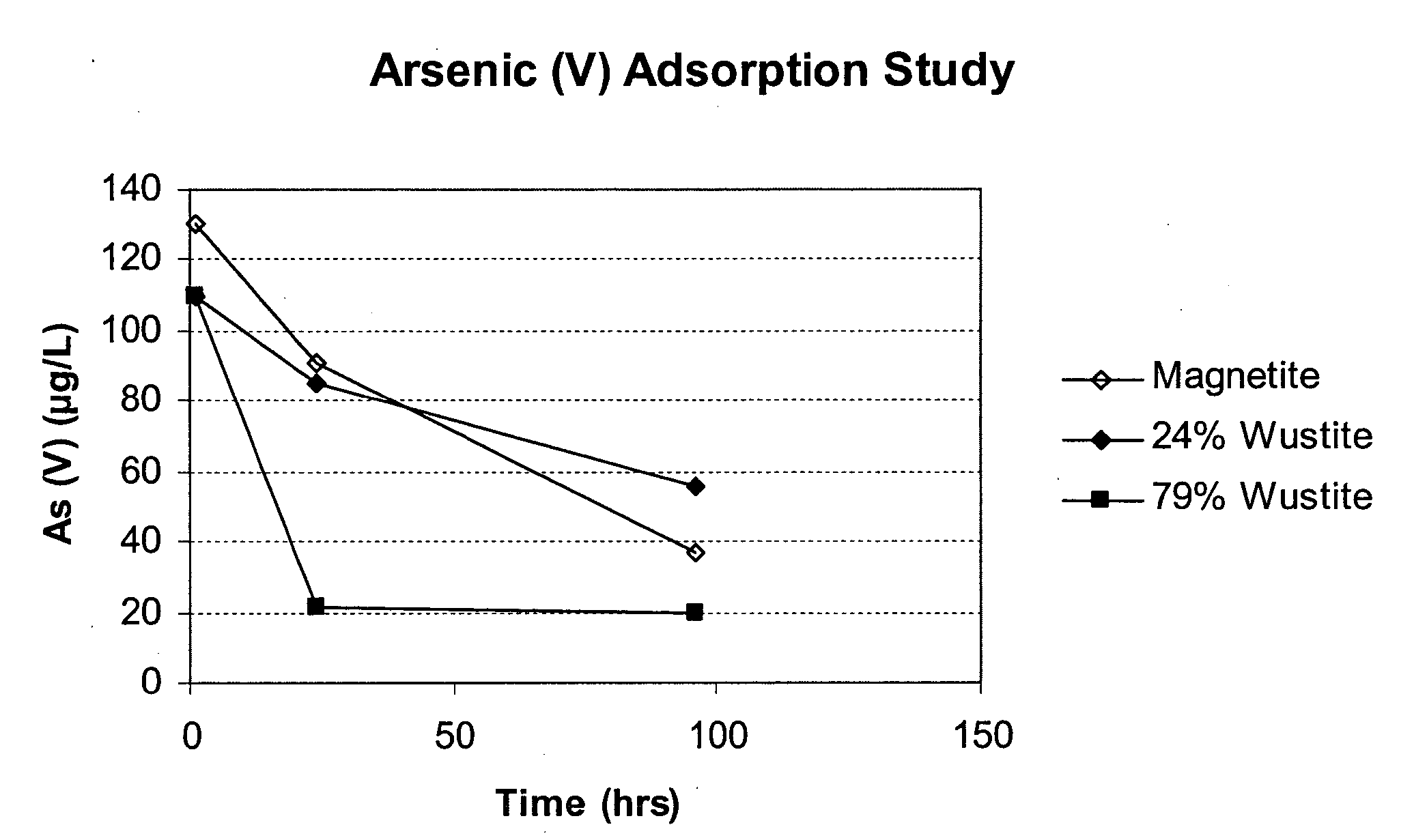

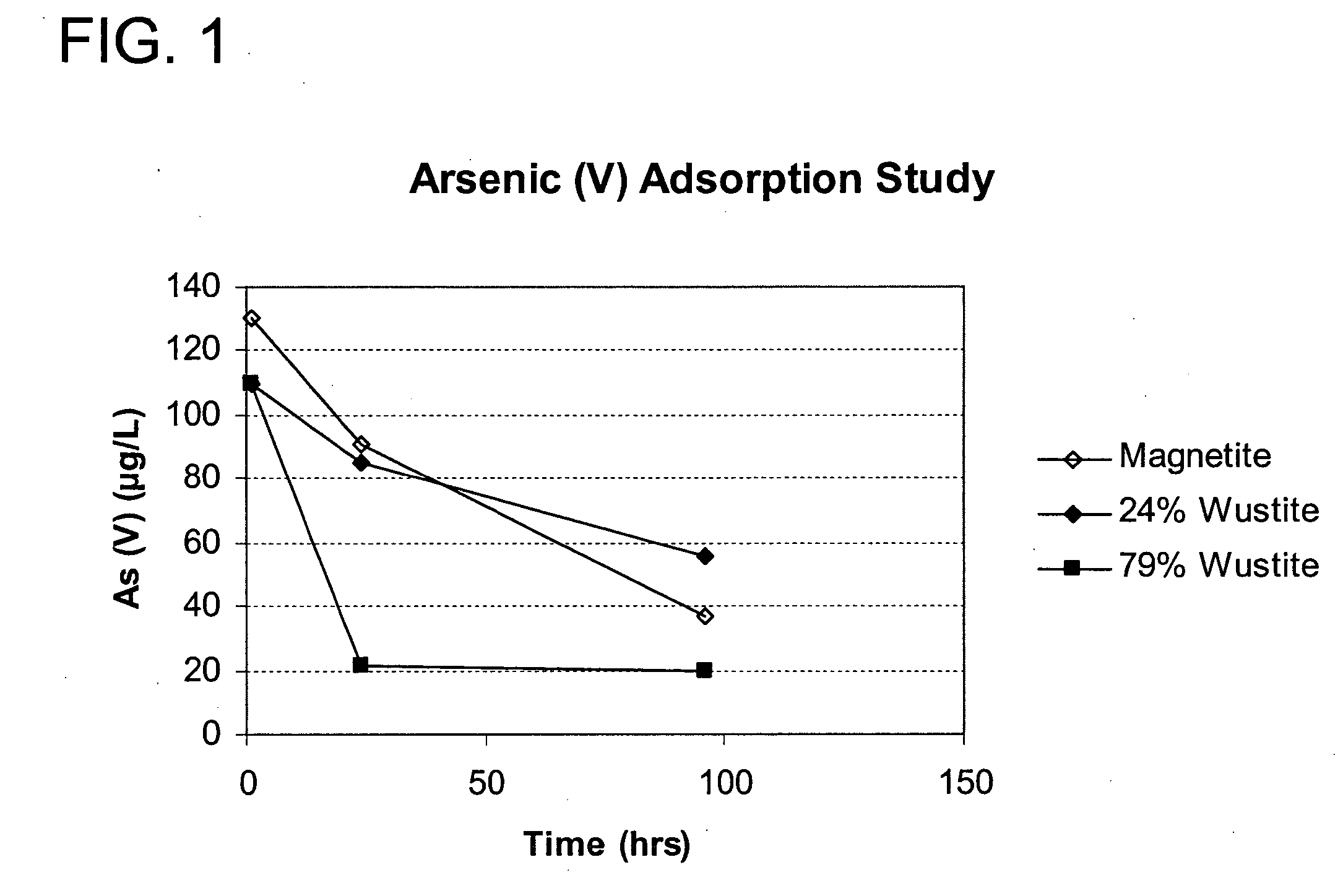

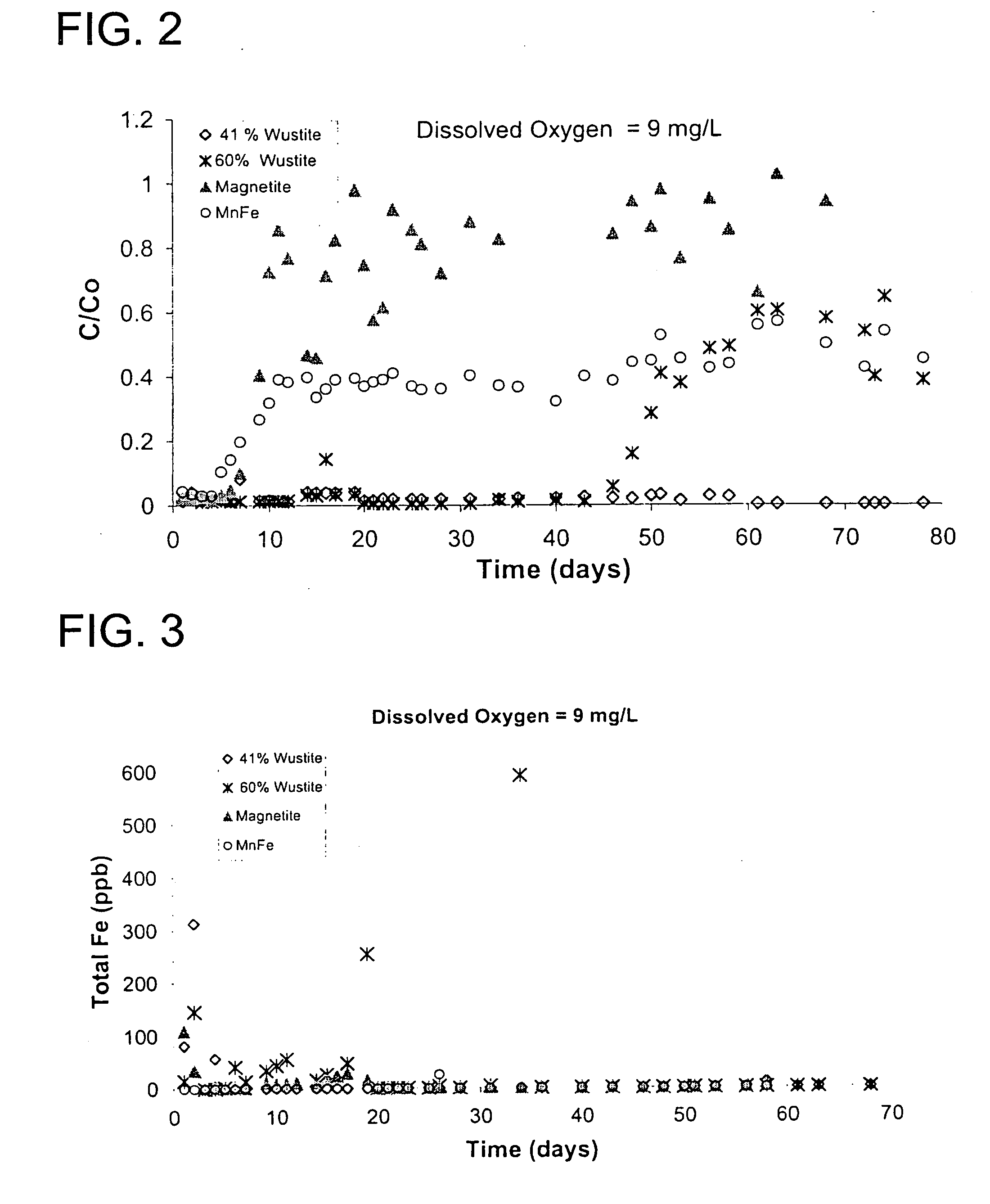

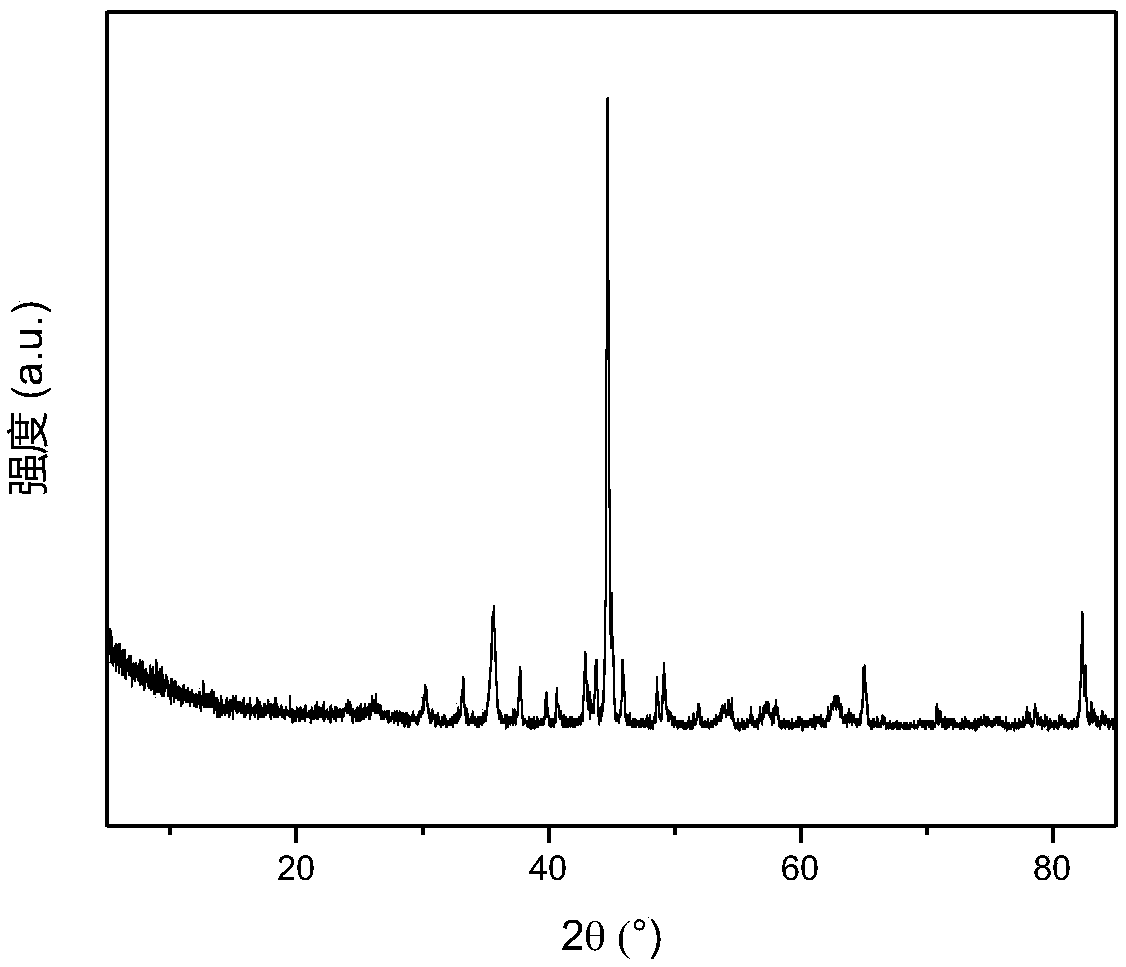

Reactive adsorbent for heavy elements

InactiveUS20060049091A1Improve the level ofReduce manufacturing costWater treatment parameter controlWater/sewage treatment by irradiationSorbentFerrous

An adsorbent is disclosed which uses an iron-containing metal oxide as an adsorbent for removing heavy elements from contaminated waters and method for the use of the same. The bed includes a non-stoichiometric ferrous oxide Fe1-xO, which is structurally in a Wustite crystal phase form having the rock salt, face-centered cubic lattice.

Owner:PELTECH +1

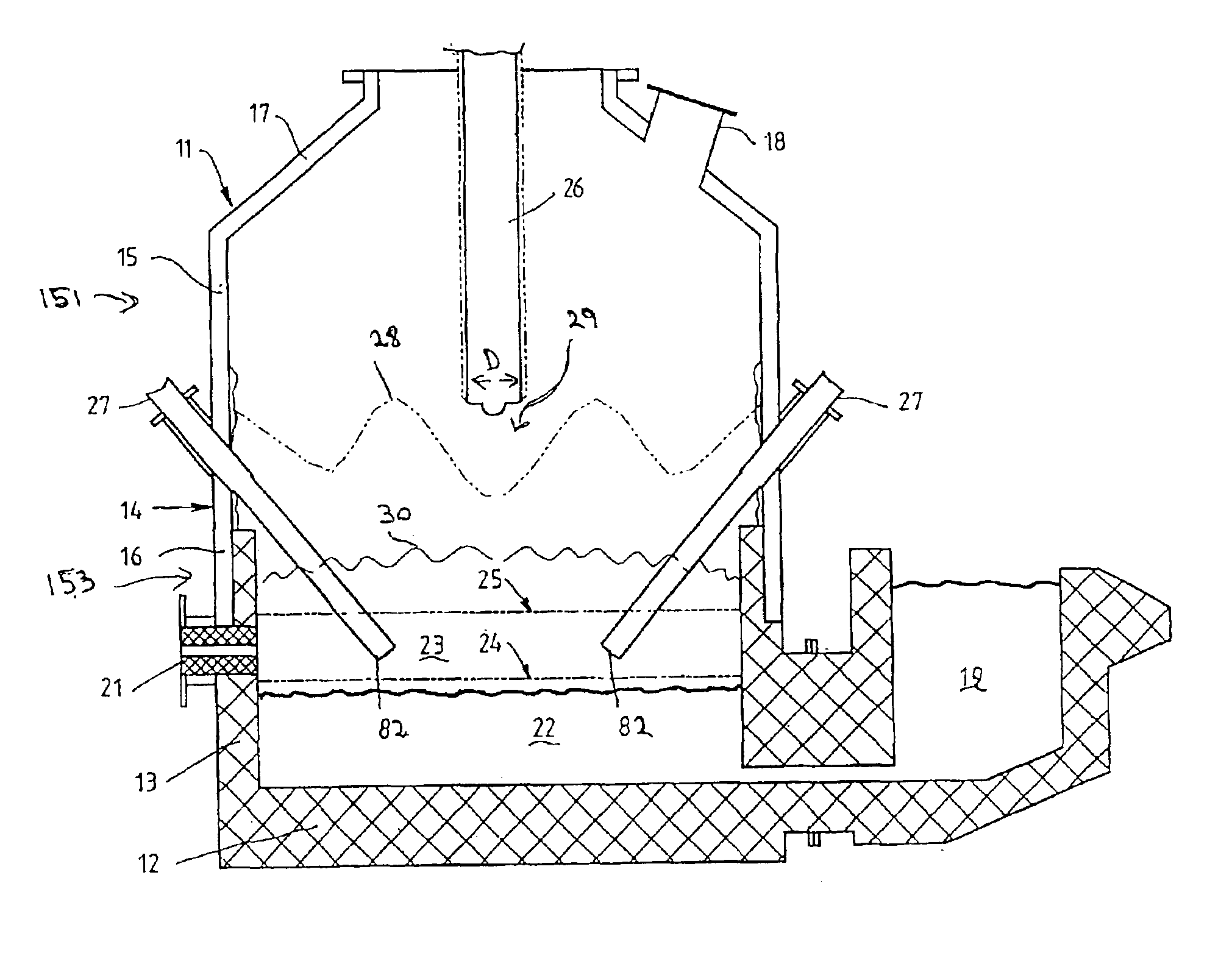

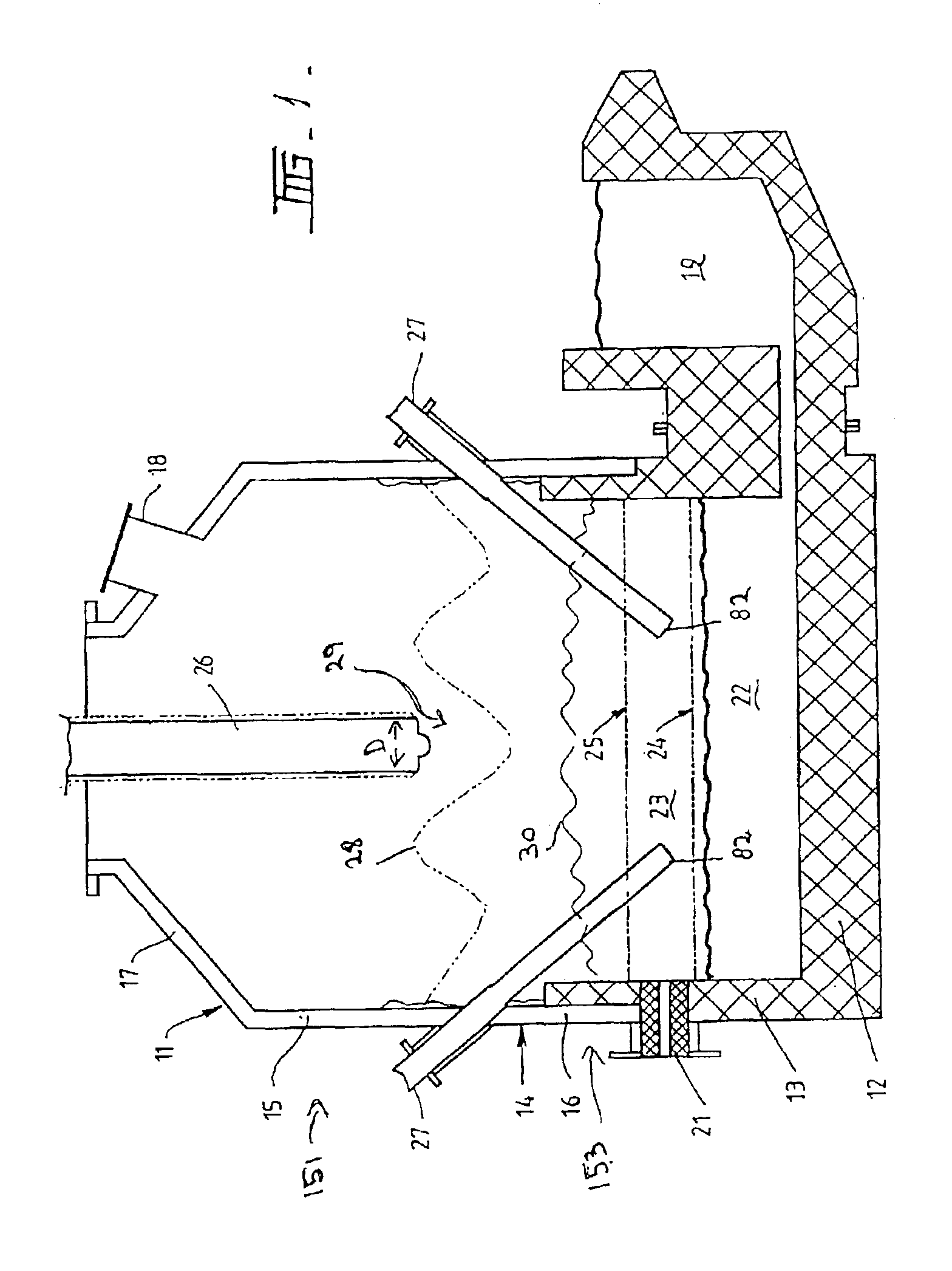

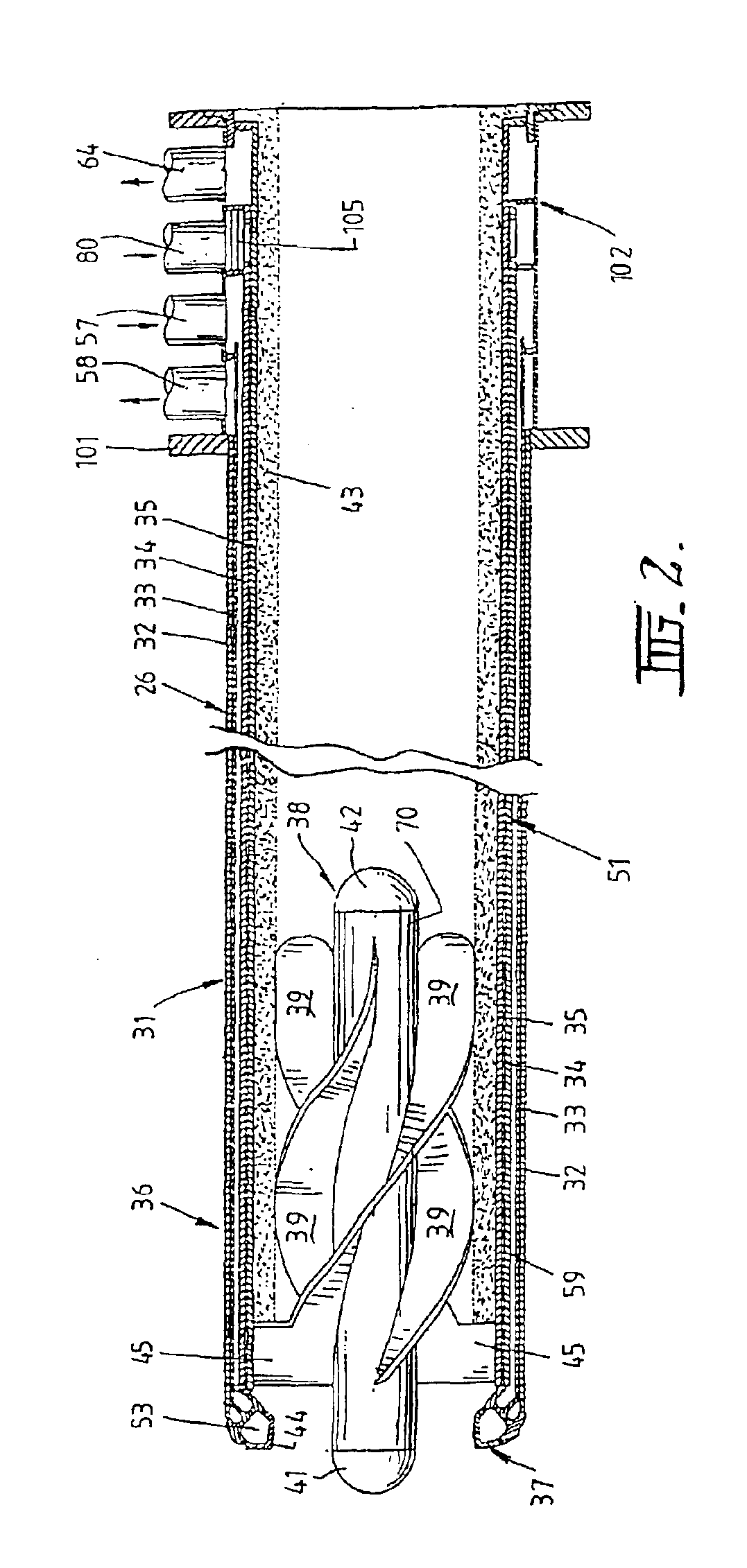

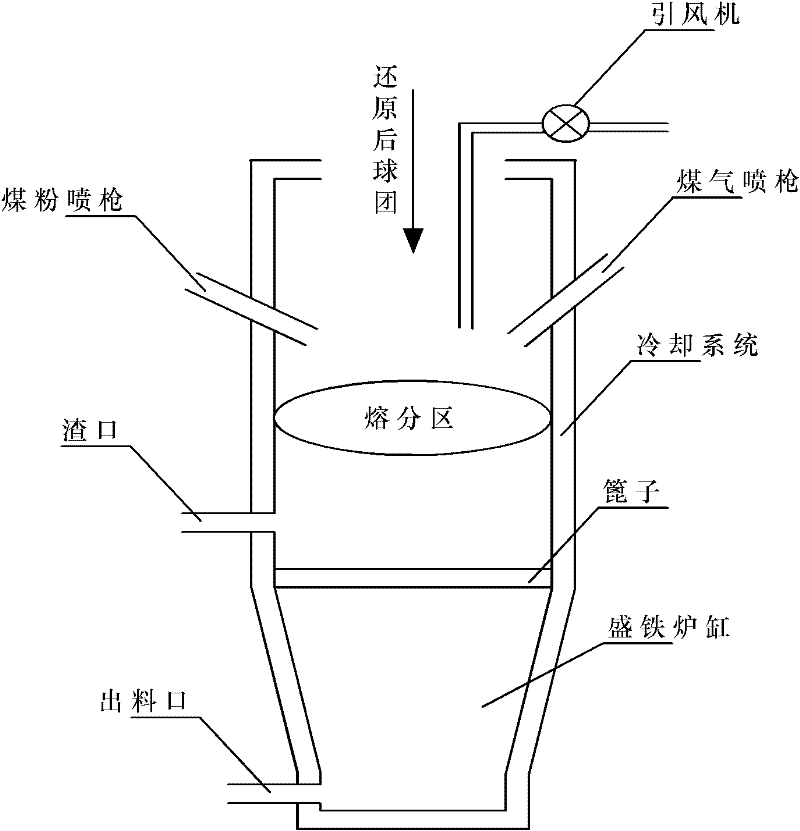

Direct smelting process and apparatus

InactiveUS6939391B2Increase exposurePromote oxidationManufacturing convertersGas emission reductionSmelting processMolten bath

A molten bath-based direct smelting process for producing ferrous metal from a ferrous feed material is disclosed. The process is characterised by injecting pro-heated air downwardly into metallurgical vessel at an angle of 20 to 90° C. relative to a horizontal axis and at a temperature of 800-1400 ° C. and at a velocity of 200-600 m / s via at least one lance (27) . This step forces molten material in the region of a lower end of the lance away from the lance and forming a “free”space around the lower end of the lance that has a concentration of molten material that is lower than the molten material concentration in the raised bath. The process is further characterised in that the lance is located so that: (i) the lance extends into the vessel a distance that is at least the outer diameter of he lover end of the lance; and (ii) the lower end of the lance is at least 3 times the outer diameter of the lower end of the lance above a quiescent surface of the molt bath.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

High-hardness self-protecting cold roll build-up welding flux-cored wire

The invention discloses a high-hardness self-protecting cold roll build-up welding flux-cored wire, and belongs to the field of welding in material processing. The flux-cored wire is mainly applied to build-up welding repair of cold rolls of steel mills. The flux-cored wire is characterized in that: the outer surface of the powder cored wire is an H08A cold rolling steel strip; and the powder of the powder cored wire comprises the following components in percentage by mass: 25 to 45 percent of high carbon ferrochrome, 5 to 15 percent of chromium metal, 4 to 8 percent of ferromolybdenum, 5 to 10 percent of manganese metal, 4 to 8 percent of No.75 silicon iron, 4 to 10 percent of aluminum magnesium alloy, 6 to 12 percent of ferrocolumbium, 4 to 10 percent of ferrotungsten, 4 to 12 percent of nickel powder and 4 to 18 percent of iron powder. A coating prepared by build-up welding has high hardness (Rockwell hardness (HRC): 55 to 60) and excellent abrasion resistance; and a self-protecting build-up welding mode is adopted, namely a protective gas source and a flux are not needed in the build-up welding process, and slag knocking is not needed in the build-up welding process, so automatic production is easy to realize.

Owner:BEIJING SURYEE SCI & TECH

Molten steel deoxygenating agent and its prepn

The molten steel deoxygenating agent is Fe-base alloy containing Al, Mg and RE, and comprises Mg 8-12 wt%, RE alloy 0.03-1 wt%, Al 48-58 wt% and Fe for the rest, with metal Mg being added while the Al-containing molten steel at the temperature of 900-1100 deg.c. The molten steel deoxygenating agent has great density, Al and Mg yield, high S and O eliminating capacity, and other advantages.

Owner:邹杰

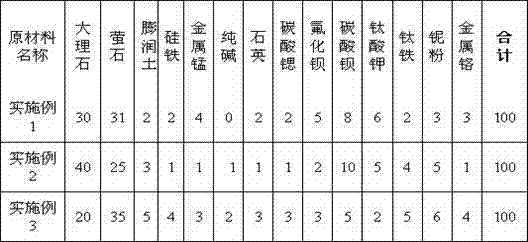

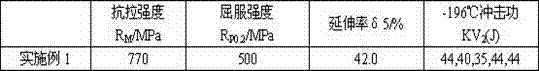

Nickel base welding rod of Ni-Cr-Mo alloy system

InactiveCN102962603AHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention introduces a nickel base welding rod of a Ni-Cr-Mo alloy system. The nickel base welding rod comprises a core wire and a coating and is characterized in that the core wire is an ERNiCrMo-3 core wire; and the coating comprises 20-40% of marble, 25-35% of fluorite, 2-5% of bentonite, 1-4% of ferrosilicon, 1-4% of manganese metal, 0-2% of sodium carbonate, 1-3% of quartz, 1-3% of strontium carbonate, 2-5% of barium fluoride, 5-10% of barium carbonate, 2-6% of potassium titanate, 2-5% of ferrotitanium, 3-6% of niobium powder and 1-4% of chromium metal. The nickel base welding rod produced by the invention is relatively high in strength, has deposited metal tensile strength which is up to more than 760MPa, is better in low-temperature impact toughness, has an impact powder average value of more than 40J at minus 196 DEG C, and is favorable in welding technological efficiency, stable in arcing during welding, easy in operation, good in formation of welding seams, convenient in deslagging, simple in production process and lower in cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

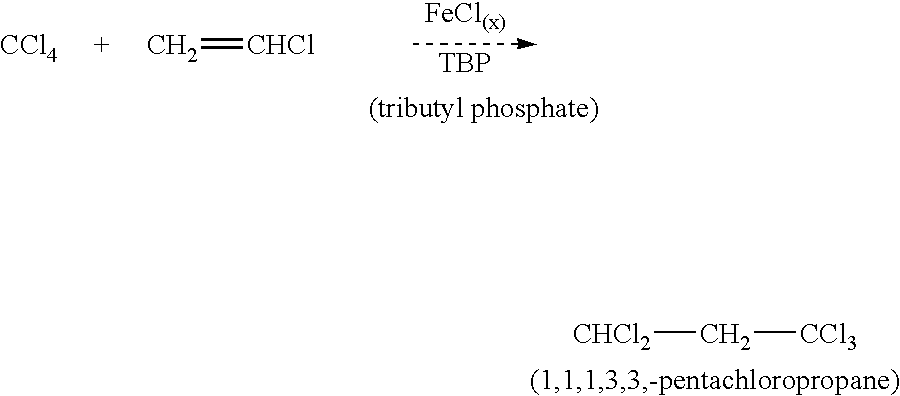

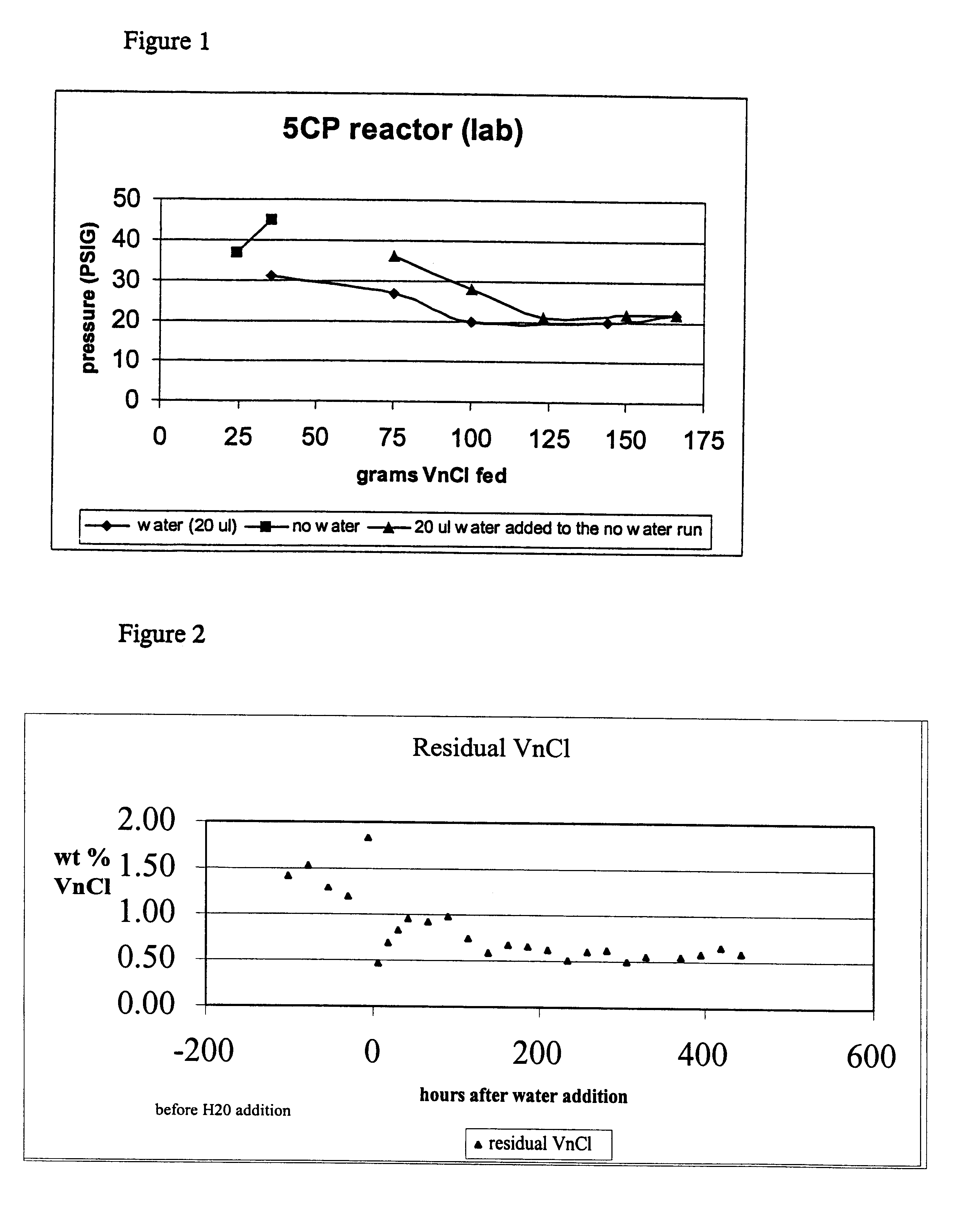

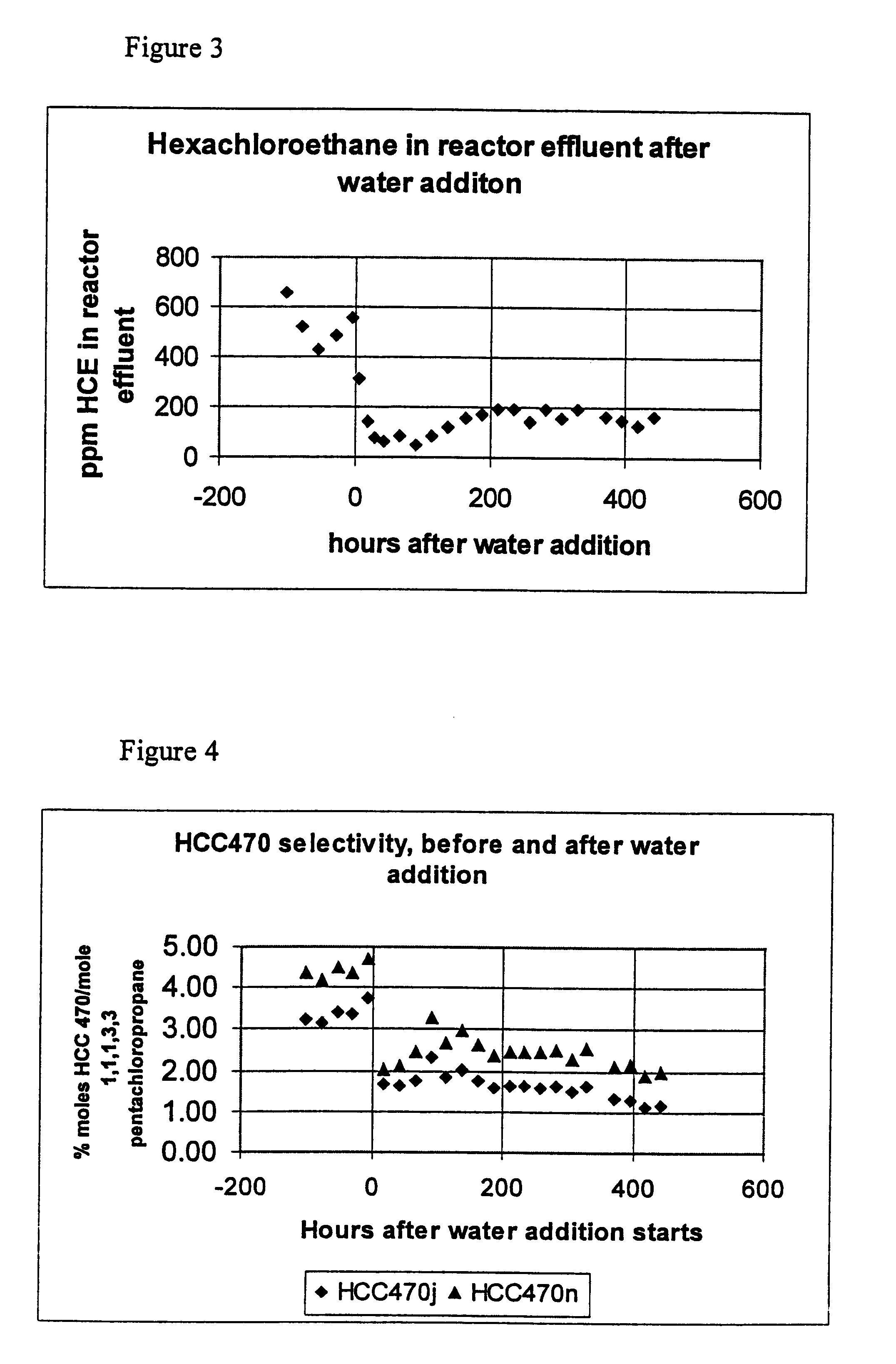

Water-enhanced production of 1,1,1,3,3,-pentachloropropane

InactiveUS6500995B1Increase productionOrganic chemistry methodsHalogenated hydrocarbon preparationAlkanePhosphate

A process is provided by which addition of water is used to enhance the production of any hydrochlorocarbon feedstock through the use of Kharasch chemistry, i.e. the combination of a polychlorinated alkane with an olefin to produce a chlorinated or hydrochlorinated alkane with the use of a transition metal compound in homogeneous solution as catalyst. Preferably, water is added to increase the production of 1,1,1,3,3-pentachloropropane by the reaction of carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture of organo phosphate solvent, iron metal and ferric chloride.

Owner:OCCIDENTAL CHEM CORP

Gas-phase antirust master batches for multiple metals and preparation method and application thereof

The invention provides gas-phase antirust master batches for multiple metals. The gas-phase antirust master batches comprise the following components in percentage by mass: 45-55 percent of thermoplastic resin, 35-45 percent of compound gas-phase inhibitor and 15-25 percent of processing aid. By adding an appropriate quantity of materials into the thermoplastic resin, and performing methods such as blow molding, curtain coating, foaming, extruding, jetting and the like, various high-efficiency gas-phase antirust products such as films, buffering materials, pipe pieces, sections, containers and the like which are protected by the multiple metals can be produced and manufactured. The gas-phase antirust master batches do not contain harmful components such as nitrite, are environmentally-friendly and safe for using, have wide application range, and can meet the anti-rust requirements of iron and nonferrous metals such as iron, chrome, cadmium, tin, nickel, zinc, copper, aluminum and the like or alloys thereof in various links such as production, storage, transportation and the like.

Owner:SUZHOU RUSTOP PROTECTIVE PACKAGING

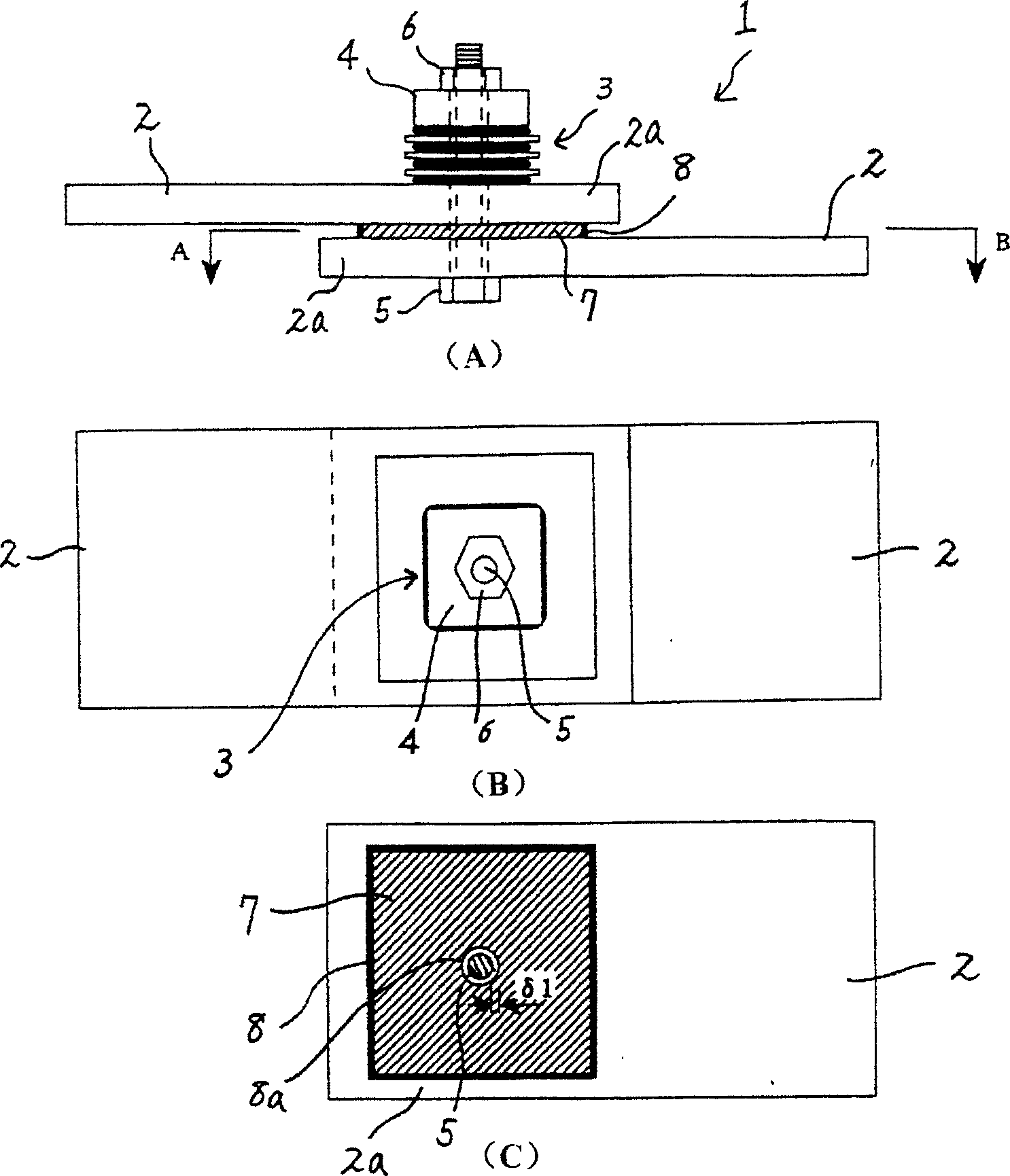

Bolt connection structure and damper structure

InactiveCN1641243AIncrease coefficient of frictionAvoid corrosionWallsProtective buildings/sheltersPull forceEngineering

The invention relates to a screw connection structure and a damper structure. In the invention, elastic materials and pressure plates are arranged on the outside of the overlap section of plates for building structure, a pulling force is inducted into screws which run through the elastic materials, at least one nonferrous metal plate or composite ceramic plate is inserted into the plates for building structure, and at least the peripheral surface of the surface of the nonferrous metal plate or the composite ceramic plate caught between the steels is carried on waterproof processing. The invention also applies the screw connection structure in the damper structure. The invention can keep a friction coefficient stable by increasing the friction coefficient to save screws, and lower cost and simple structure are realized.

Owner:佐藤 孝典

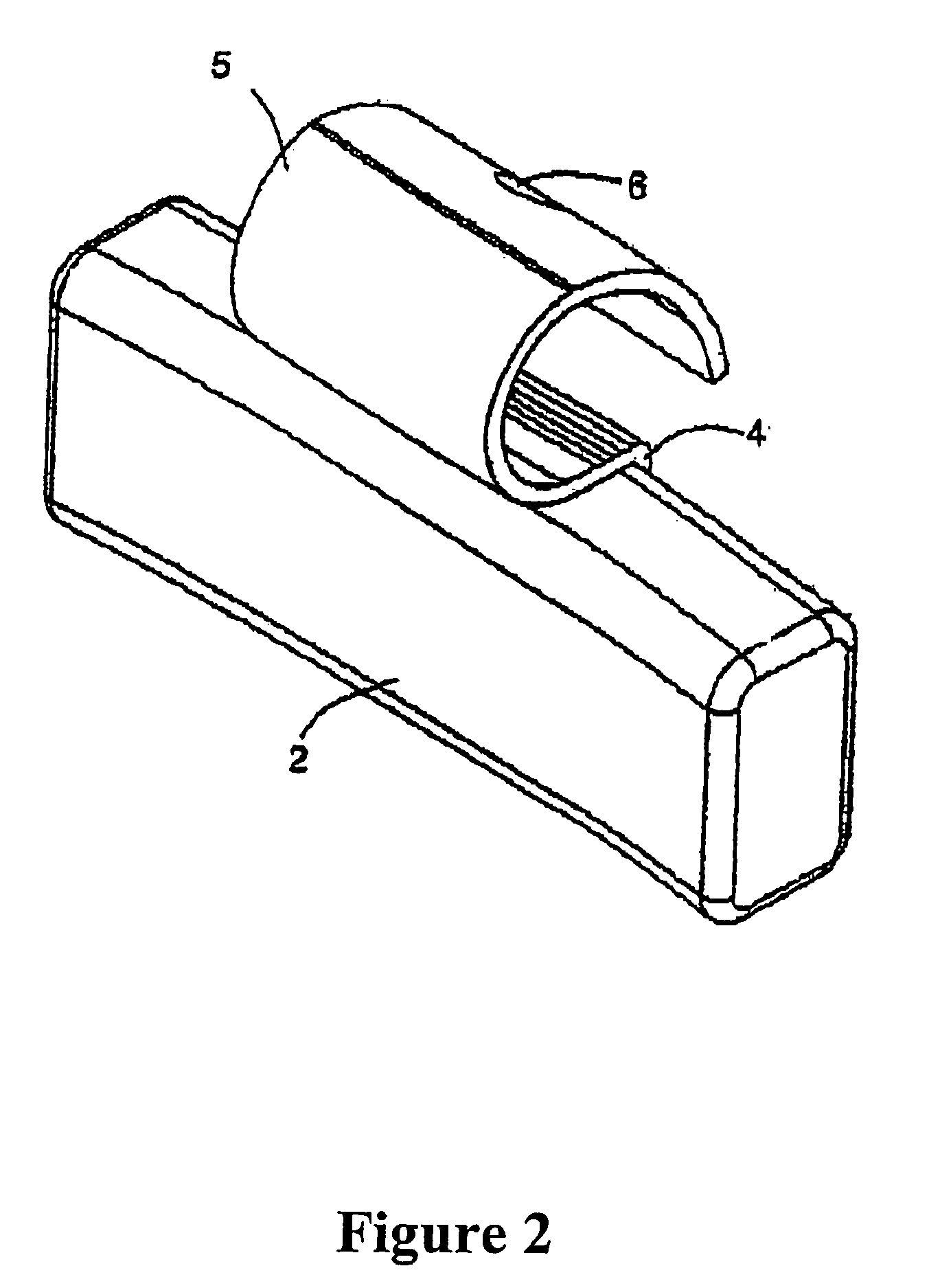

Wheel balancing device

A wheel balancing device of this invention comprising a wheel balancing body having a wheel rim engaging bar made of iron metal or iron-based metal component to be formed in any shape as required. Being provided on one side of the wheel balancing body is an engaging part fixed thereto. The engaging part is composed of an engaging plate having one end engaged and fixed to one end of the wheel rim engaging bar by a locking means and the other end is bent as an upper curve to be locked and fixed to a wheel rim of an automobile. The wheel rim engaging bar and a part of engaging plate are enwrapped by the outer cover plate made of plastic or plastic-contained composition.

Owner:P C PRODS INT

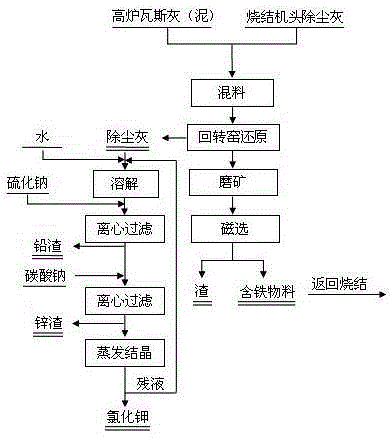

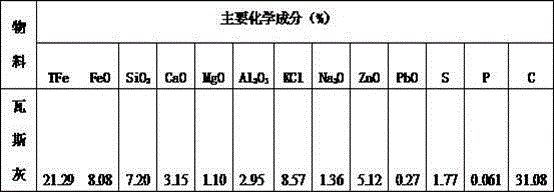

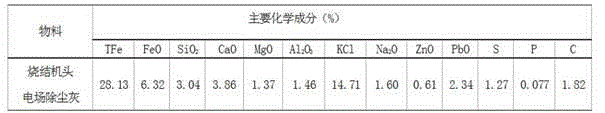

Method for comprehensively utilizing electric field dust-removal ash at head end of sintering machine and blast furnace gas ash

InactiveCN104532007AEfficient recyclingEfficient use ofProcess efficiency improvementAlkali metal chloridesRecovery methodEnvironmental resistance

The invention belongs to the field of ferrous metallurgy and environmental protection and particularly relates to a method for comprehensively utilizing electric field dust-removal ash at a head end of a sintering machine and blast furnace gas ash. By-products generated in two metallurgical production processes, namely, electric field dust-removal ash at an electrical dust remover located at the head end of the sintering machine and blast furnace gas ash have different contents of potassium salt, iron metal compounds, carbon nonmetal elementary substance, heavy metal compounds of lead and zinc, however, the chemical compositions of the by-products are complementary, by virtue of scientific and reasonable combination and matching of two materials, certain process conditions and recovery methods, iron-containing compounds and potassium salt in the two iron and steel smelting by-products are recovered, heavy metal compounds of lead and zinc are separated so as to achieve the efficient recycling and comprehensive utilization of multiple elements in two solid wastes and meet the requirements of resourceful treatment of the solid wastes, energy conservation and emission reduction.

Owner:ANYANG IRON & STEEL

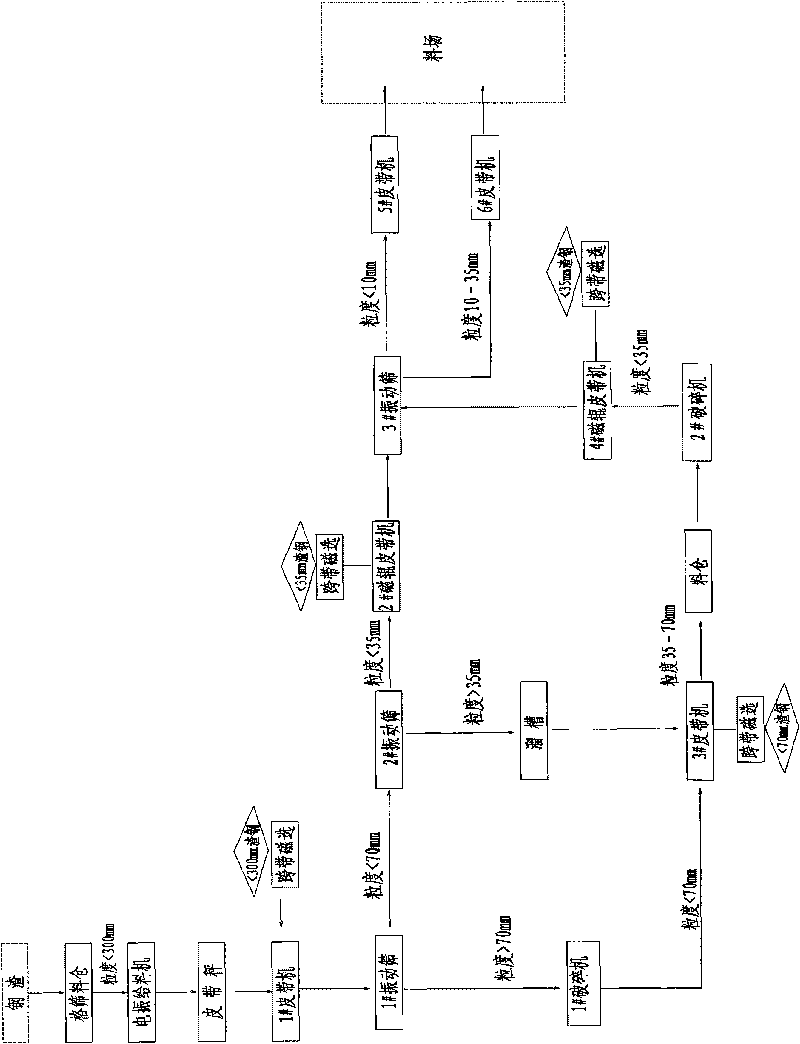

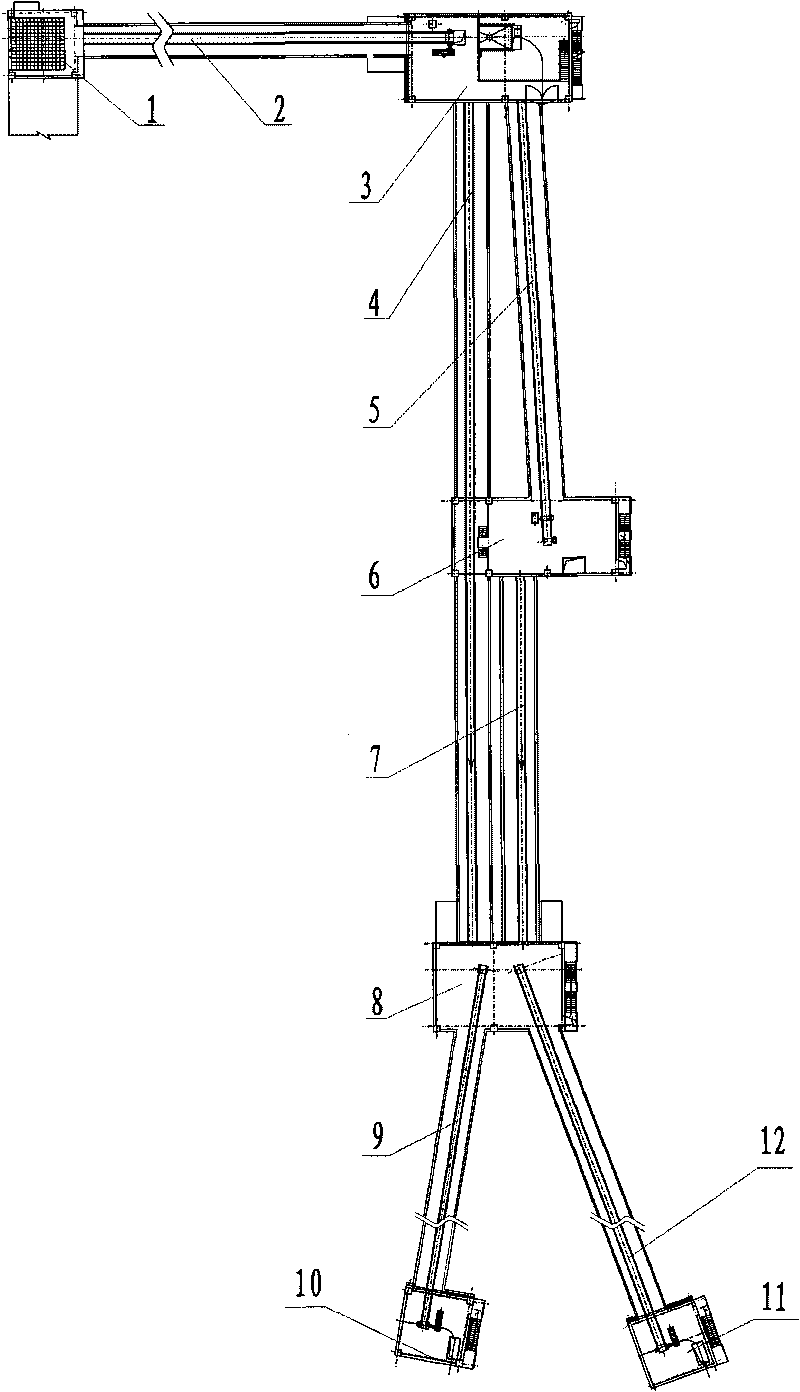

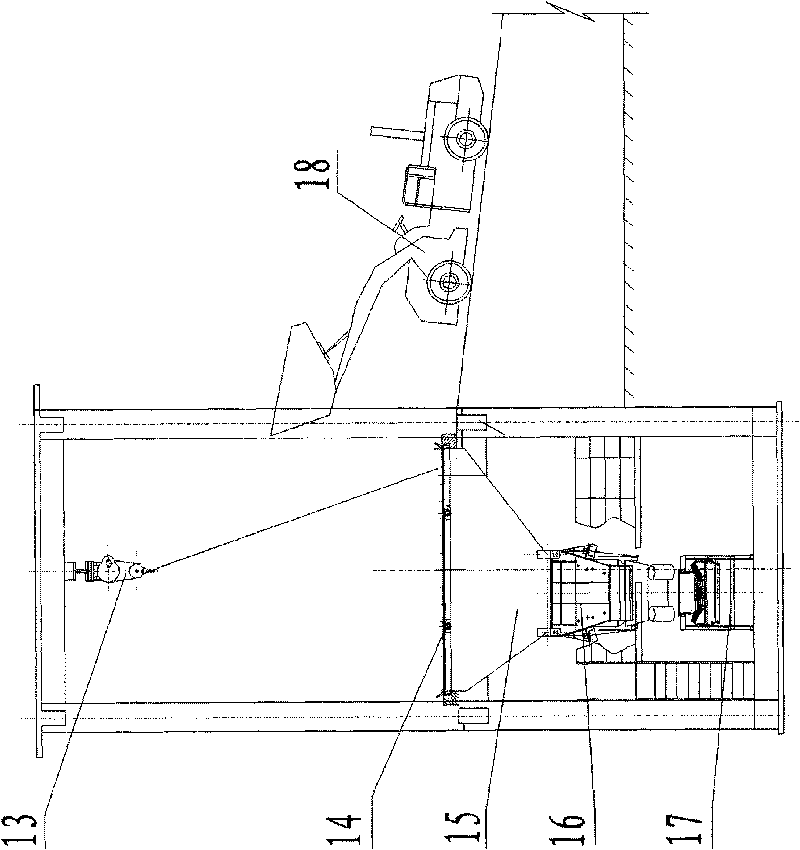

Secondary treatment system for steel slag and method thereof

ActiveCN101736099ASmall footprintShort processSolid separationRecycling and recovery technologiesSlagThree stage

The invention discloses a secondary treatment system for steel slag and a method thereof, and belongs to the technical field of comprehensive utilization of resources and environmental protection. The system comprises a transfer station, a primary crushing and screening compartment, a secondary screening compartment, a third screening compartment, a secondary crushing compartment and a belt conveying system, and is mainly used for reclaiming iron metal in the steel slag of a converter. In the system, the steel slag is subjected to two-stage crushing, three-stage screening and seven-stage magnetic separation, and the iron metal content in the tailings of the final steel slag is less than 1 percent. The system ensures that the secondary treatment process for the steel slag has the advantages of compactness, energy conservation and environmental protection. The secondary treatment system for the steel slag has the advantages of small floor area, simple process and low investment, and can furthest reclaim the iron metal in the steel slag and realize efficient reclamation and utilization of the resources. The system can prompt the rapid development of recycling economy of steel enterprises, propels the comprehensive utilization of solid wastes, and fully achieves the targets of energy saving and emission reduction.

Owner:BEIJING SHOUGANG INT ENG TECH

Advanced redox water treatment technology based on nitrogen-doped iron-carbon material with core-shell structure and for magnetic field recovery

ActiveCN108940335ASimple methodReduce heat consumptionPhysical/chemical process catalystsWater contaminantsMaterials science and technologyCarbon composites

The invention relates to the fields of new material science and technology and environmental protection technology and particularly discloses a preparation method of a nitrogen-doped iron-carbon material with a core-shell structure and suitable for magnetic field recovery and an application method thereof in an advanced redox water treatment technology. The nitrogen-doped iron-containing metal organic framework is a high-performance iron-carbon composite material obtained through precursor one-step carbonization. The iron element in the material is mainly fixed in the form of zero-valent ironin the porous carbon material so that a core-shell structure is formed. The nitrogen-doped carbon material shell can protect the zero-valent iron and prolong the service life of the iron-carbon composite material. The iron-carbon composite material has the catalytic oxidation ability of an activated peroxide oxidant, can be applied to the advanced oxidation system, has good interface reducing ability of zero-valent iron and realizes efficient removal of multiple pollutants in the water.

Owner:BEIJING FORESTRY UNIVERSITY

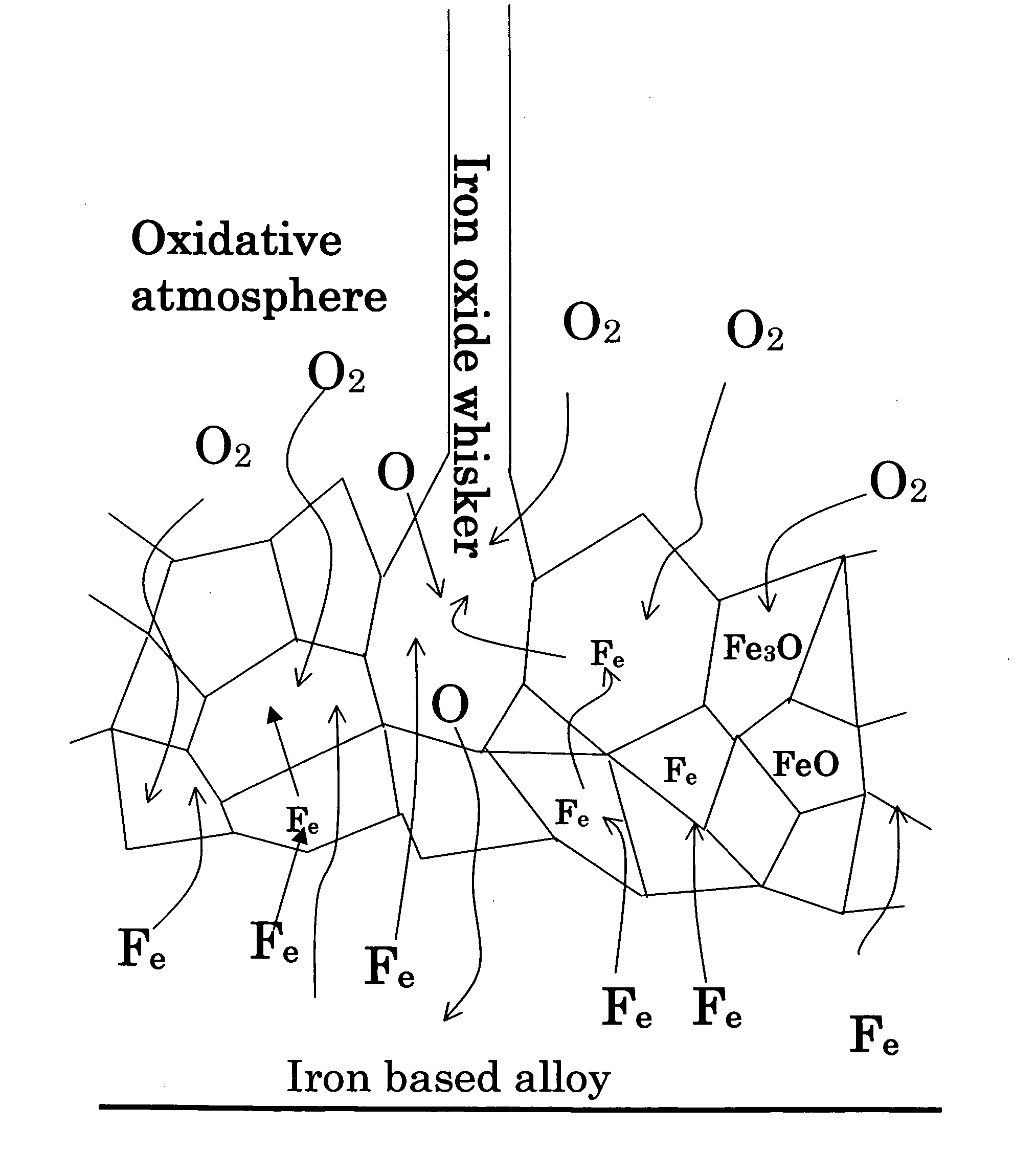

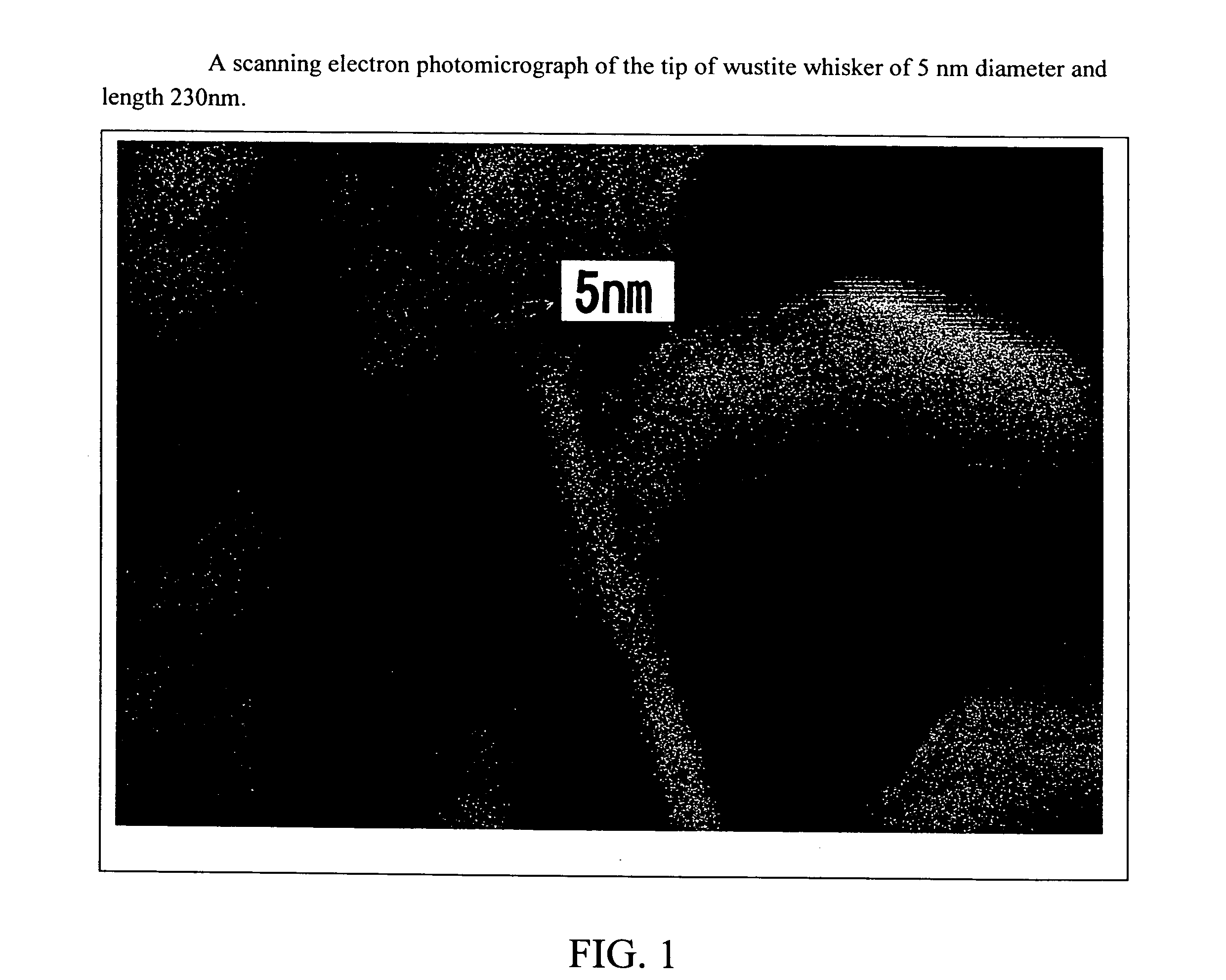

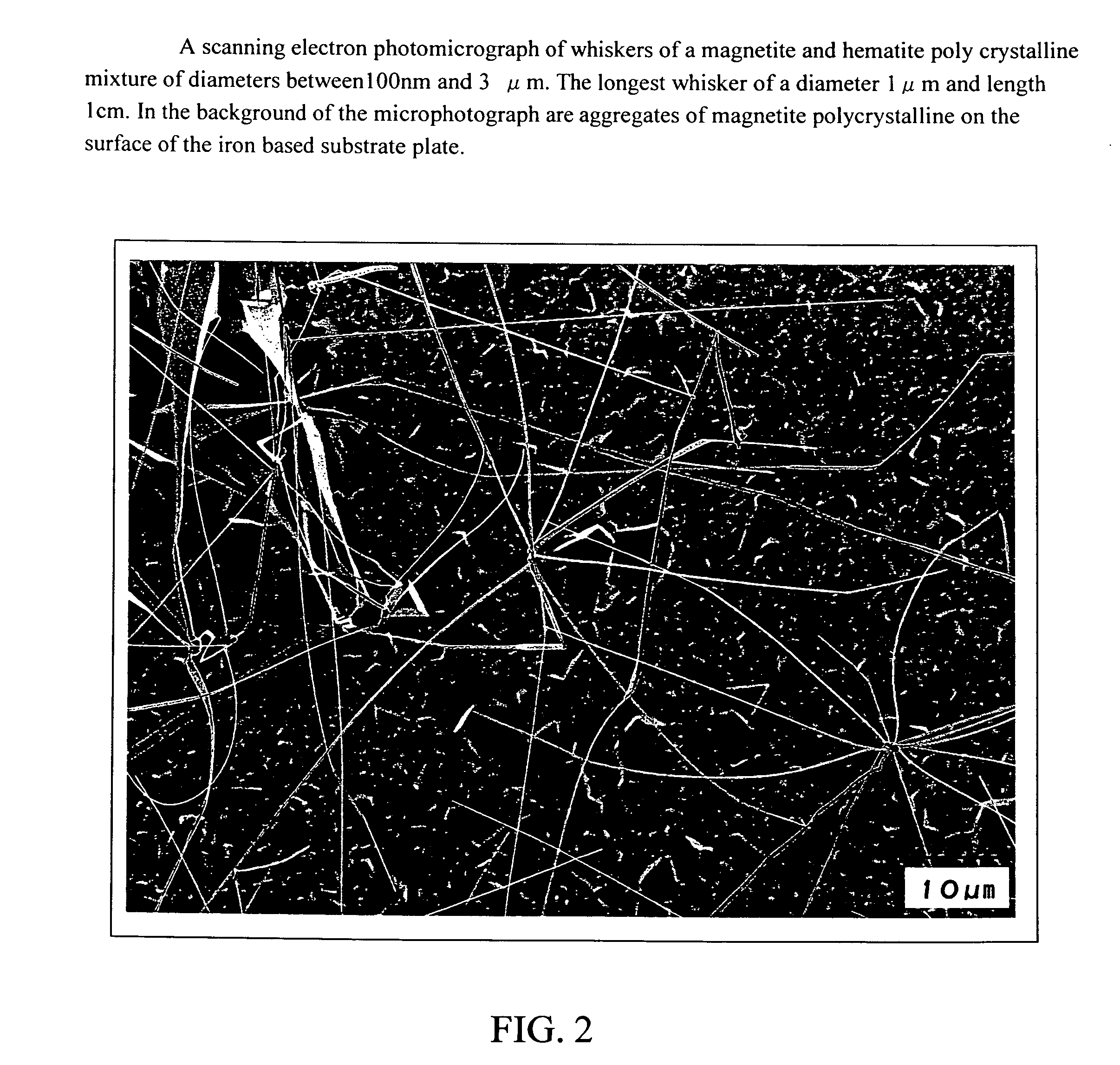

Iron Oxide Whisker of High Aspect Ratio, Titanium Oxide Whisker of High Aspect Ratio, Structure Containing These and Process for Producing Them

InactiveUS20070292339A1High aspect ratioImprove magnetic propertiesMaterial nanotechnologyPolycrystalline material growthTitanium metalWhiskers

An iron oxide whisker of high aspect ratio or titanium oxide whisker of high aspect ratio that is useful as a magnetic material for magnetic recording, a part of micromachine, etc.; and a structure having such a whisker erected on a basal plate that is useful as a catalyst, etc. There is provided an iron oxide whisker of 5 nm to 2 μm diameter and ≧20 aspect ratio wherein the content of non-iron metal atoms is ≦10 at %, and provided a titanium oxide whisker of 5 nm to 20 μm diameter and ≧5 aspect ratio wherein the content of non-titanium metal atoms is ≦10 at %. Further, there is provided a structure, such as a basal plate having these whiskers densely erected thereon. These whiskers excel in magnetic properties, etc., and the structures having these erected exert excellent characteristics, such as large contact area as a catalyst and freedom from clogging, and hence are useful. In the production of these oxide whiskers, an iron or titanium material is brought into contact with an oxidative atmosphere so as to react the surface iron or titanium atoms with oxygen brought into contact therewith at high temperature, thereby attaining growth as oxide whiskers.

Owner:KANAZAWA R & D

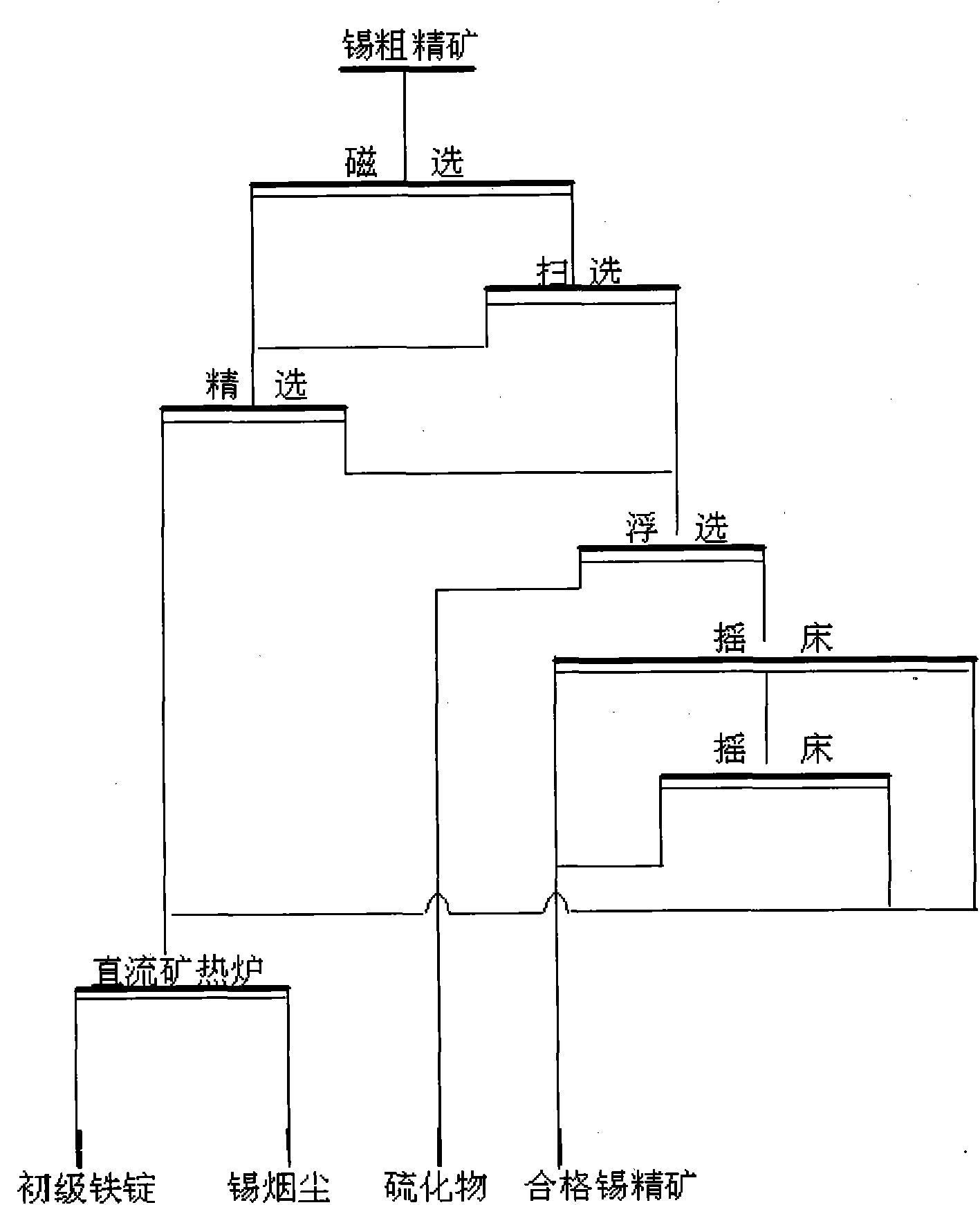

Combined flow treatment method of tin rough concentrate

ActiveCN101792867AHigh recovery rateImprove recovery indicatorsFlotationMagnetic separationTin dioxideResource utilization

The invention relates to a combined flow treatment method of tin rough concentrate, belonging to the technical field of non-ferrous metal ore-dressing and metallurgy. The process flow comprises the following steps: preparing pulp containing the tin rough concentrate; feeding the tin rough concentrate subjected to the pulp preparation into a magnetic separator for dressing magnetic minerals; making sulfide minerals float out of non magnetic ore by a floating operation; sorting by using a table concentrator to obtain qualified tin rough concentrate and a lean middling ore product; combining a magnetic mineral and lean middling ore obtained by magnetic separation; and treating a mixture by a direct current submerged arc furnace to obtain tin dioxide soot and primary iron ingot. By adopting an ore-dressing and metallurgy combined process flow, the method greatly simplifies the ore-dressing and concentrating process flow. Iron products are treated by the direct current submerged arc furnace, so that not only tin metals of the iron products can be recovered, but also the primary iron ingot can be obtained and iron metals can be recycled while improving the tin recovery rate; and the invention improves the resource utilization rate and has favorable application and popularization prospect.

Owner:YUNNAN TIN GROUP HLDG

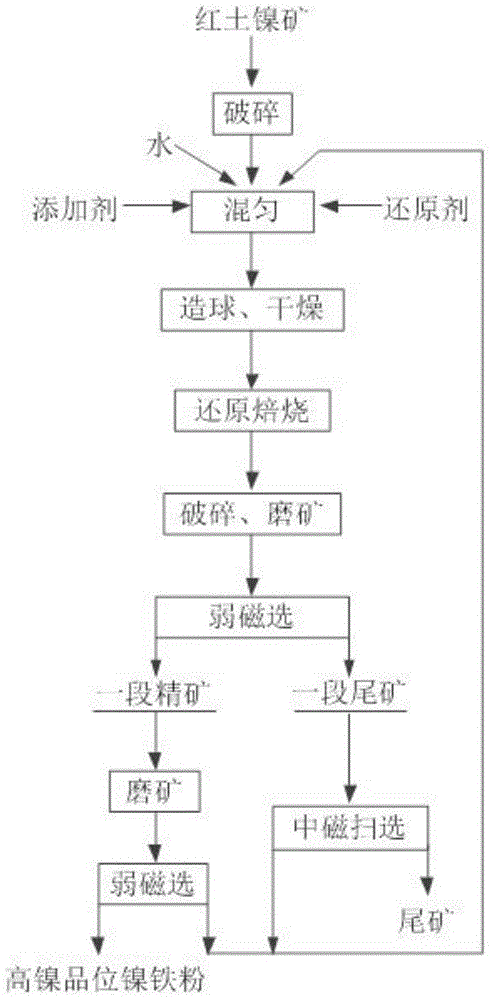

Method for producing high-nickel-grade nickel-iron powder by laterite-nickel ore autocatalytic reduction

The invention provides a method for producing high-nickel-grade nickel-iron powder by laterite-nickel ore autocatalytic reduction, belonging to the field of comprehensive utilization of mineral resources. The method comprises the following steps: proportionally mixing powdery laterite-nickel ores, a reducer and an adhesive, pelletizing, carrying out reduction roasting on the carbonous pellets at high temperature, cooling, carrying out multistage grinding, carrying out low-intensity magnetic separation, carrying out medium-intensity scavenging on the magnetic tailings, and returning the scavenger concentrate to the raw ores for pelletizing. The returned product has the characteristic of small particle size and contains a small amount of nickel-iron metal particles; and the returned product has the following functions: the fine particles are filled in the slits among the coarse particles, thereby enhancing the pellet strength in the pelletizing process; and in the roasting process, the metal iron promotes the reduction of nickel through the catalytic coal gasification, and is used as the nucleating agent of the newly generated metal nickel-iron particles to promote the accumulation and growth of the metal nickel-iron particles. Compared with the existing coal-base direct reduction-magnetic separation technique, the method provided by the invention has the advantage of obviously higher nickel recovery rate and nickel grade, wherein the nickel recovery rate is up to 90%, and the nickel grade can reach more than 10%.

Owner:UNIV OF SCI & TECH BEIJING

Three-step metal reducing method

The invention relates to a three-step metal reducing method. A metal oxide and a certain amount of carbon, adhesive, CaO and water are prepared into a shaped substance, and the shaped substance is placed into a reduction device. The method comprises the following steps: firstly, pre-reducing the shaped substance under the condition of isolating air and oxygen; secondly, collecting separated gas produced during reducing in a reduction furnace of the first step, and cooling, purifying and pressurizing the separated gas; and finally, mixing and burning the separated gas and the heat exchanged airor oxygen rich gas, or mixing and burning the separated gas and pure oxygen, and finally reducing and melting a reduction furnace product in a final reduction furnace and removing the slag to producemolten iron or directly reduce molten steel. The method has the advantages of reasonable process flow, strong adaptability, flexible operation, energy conservation and good product quality, can be used for producing iron metals, and also can be used for reducing other oxygen-containing substances.

Owner:贾会平

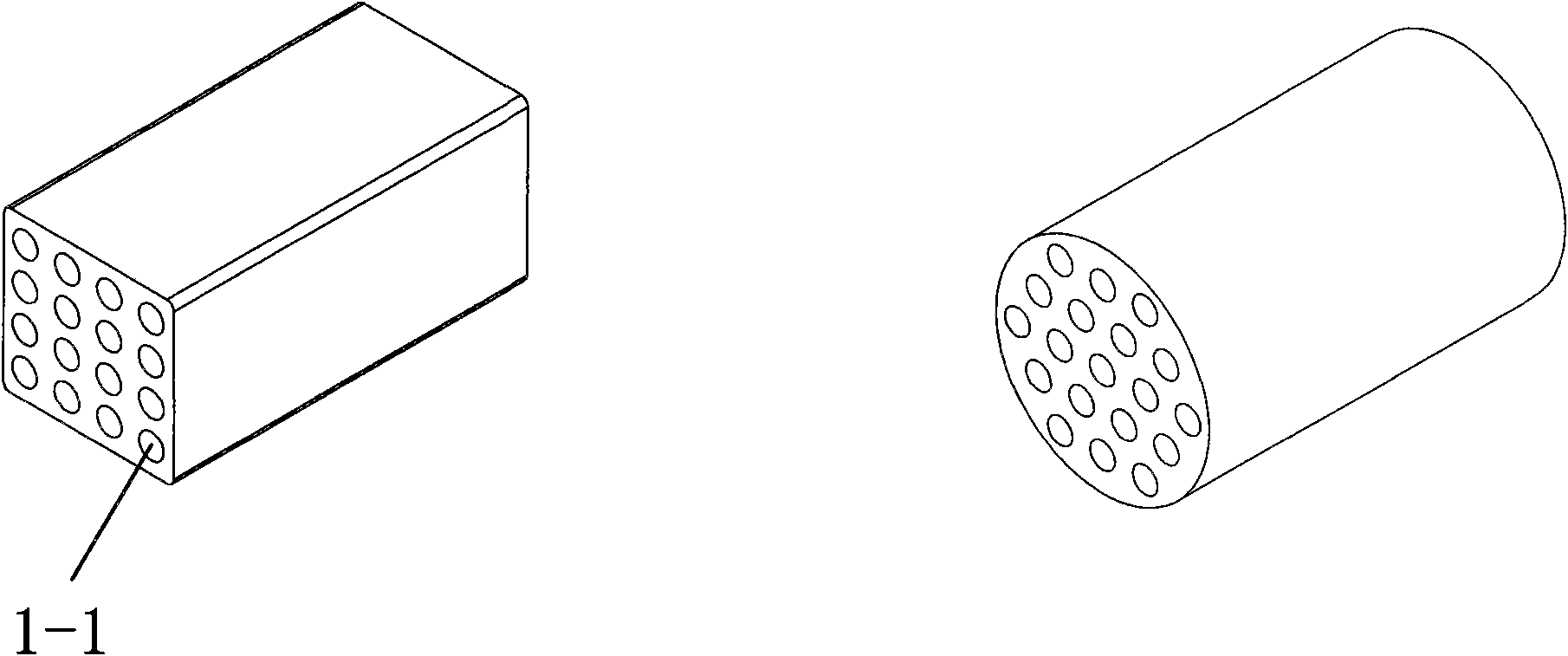

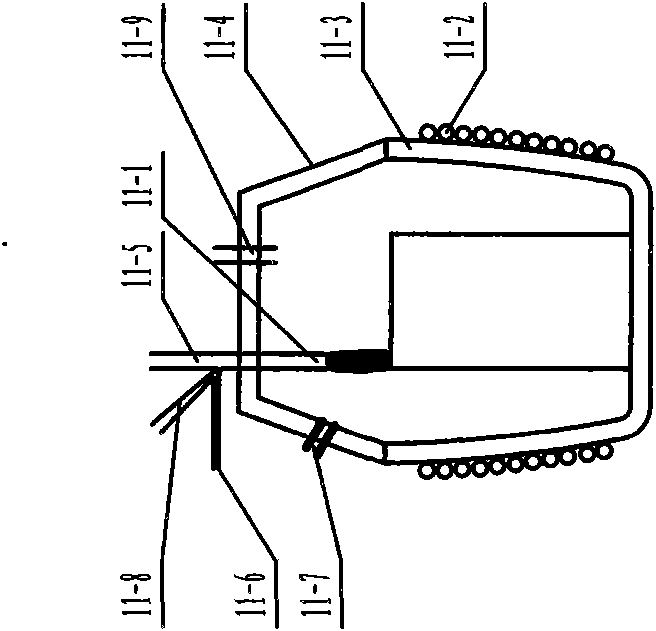

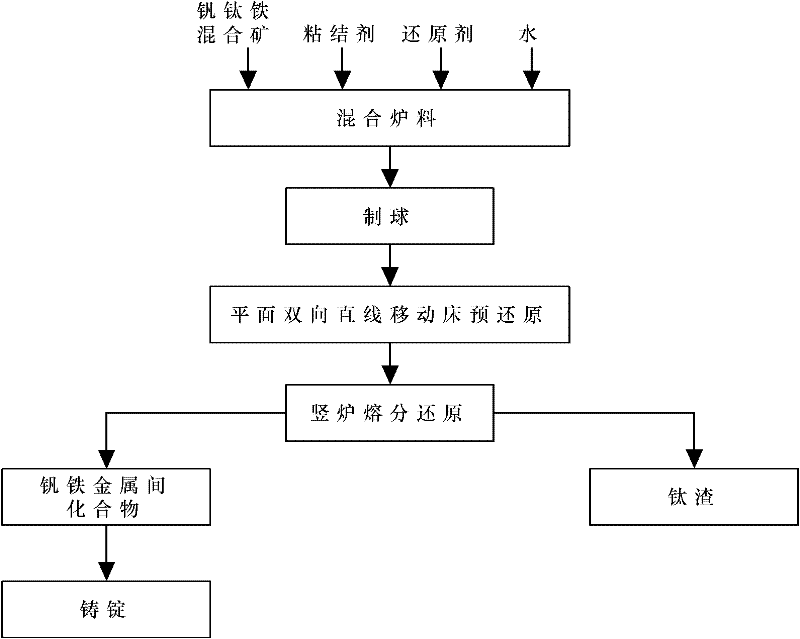

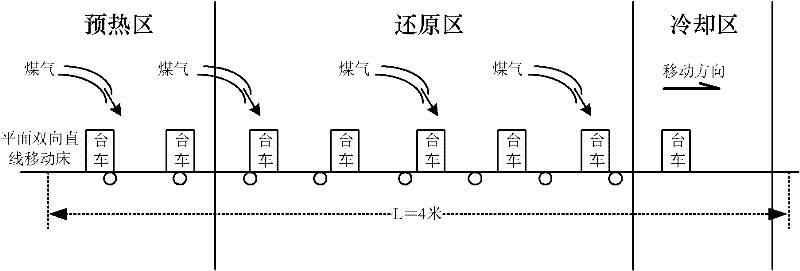

Method for preparing vanadium-iron intermetallic compound and titanium slag using linear moving bed pre-reduction-shaft furnace melting process

InactiveCN102296138AHigh recovery rateNo pollution in the processShaft furnaceReduction treatmentPowder mixture

The invention discloses a method for preparing a ferrovanadium intermetallic compound and titanium slags by a linear moving bed prereduction and shaft furnace melting process. The method comprises the following steps of: firstly, preparing the raw materials into a powder mixture; then pelletizing the powder mixture and carrying out drying processing on pellets; after carrying out prereduction processing on the dried pellets by a linear moving bed, feeding the pellets into a shaft furnace to carry out melting processing so as to obtain the ferrovanadium intermetallic compound and the titanium slags. The method disclosed by the invention has simple and controllable preparation process and low production cost.

Owner:陕西延长石油中陕金属矿业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com