Bolt connection structure and damper structure

A technology for connecting structures and bolts, used in building structures, building components, friction dampers, etc., can solve the problems of friction coefficient change, electrical corrosion, rust on contact surfaces, etc., and achieve increased friction coefficient and long-term performance. , The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

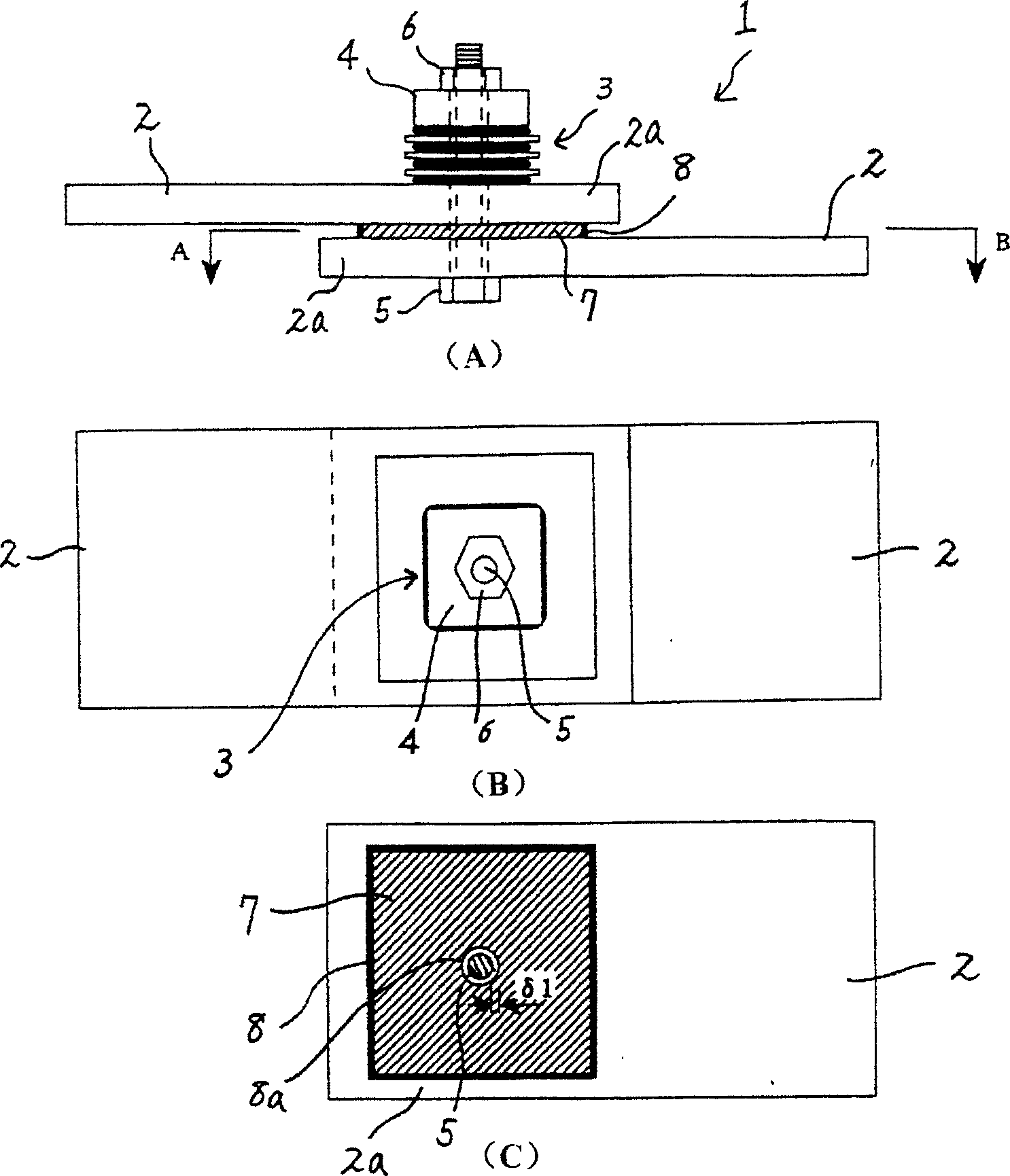

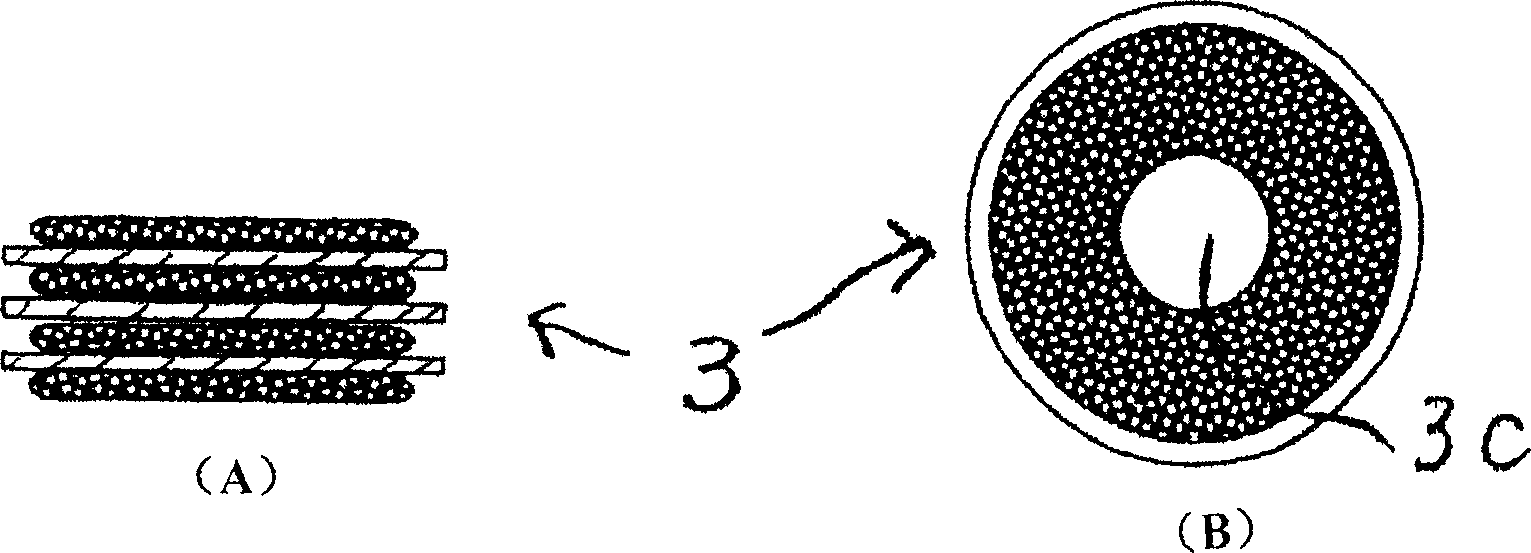

[0044] Such as Picture 1-1 (A), (B), shown in (C), in the outside of the overlapping portion 2a of the two structural steel plates 2 of the required size of the structure, a non-metallic elastic material made of rubber or synthetic leather, etc., or made of the non-metallic elastic material A multi-layer structure formed by alternate lamination of metal elastic materials and metal plates (thin steel plates) ( Figure 1-2 Refer to) the elastic material 3 and the metal pressing plate 4, and then the high-strength bolt 5 passing through these materials is introduced with a predetermined tensile force by the nut 6.

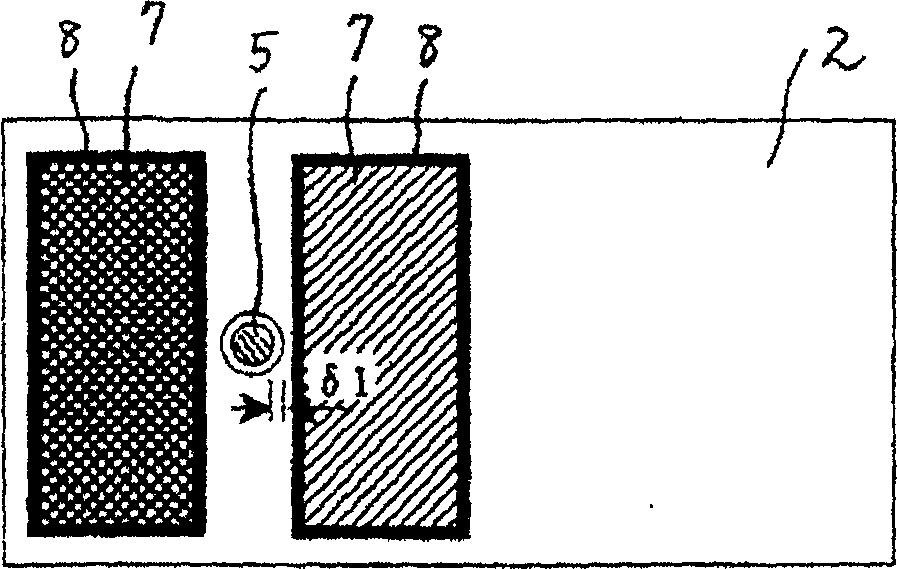

[0045] Insert at least one of the following non-ferrous metal plates 7 or composite ceramic plates 7 between the plurality of structural steel plates 2 to be connected, aluminum plate, copper plate, lead plate, brass plate, titanium plate, zinc plate, nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com