Patents

Literature

151results about How to "Stable friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

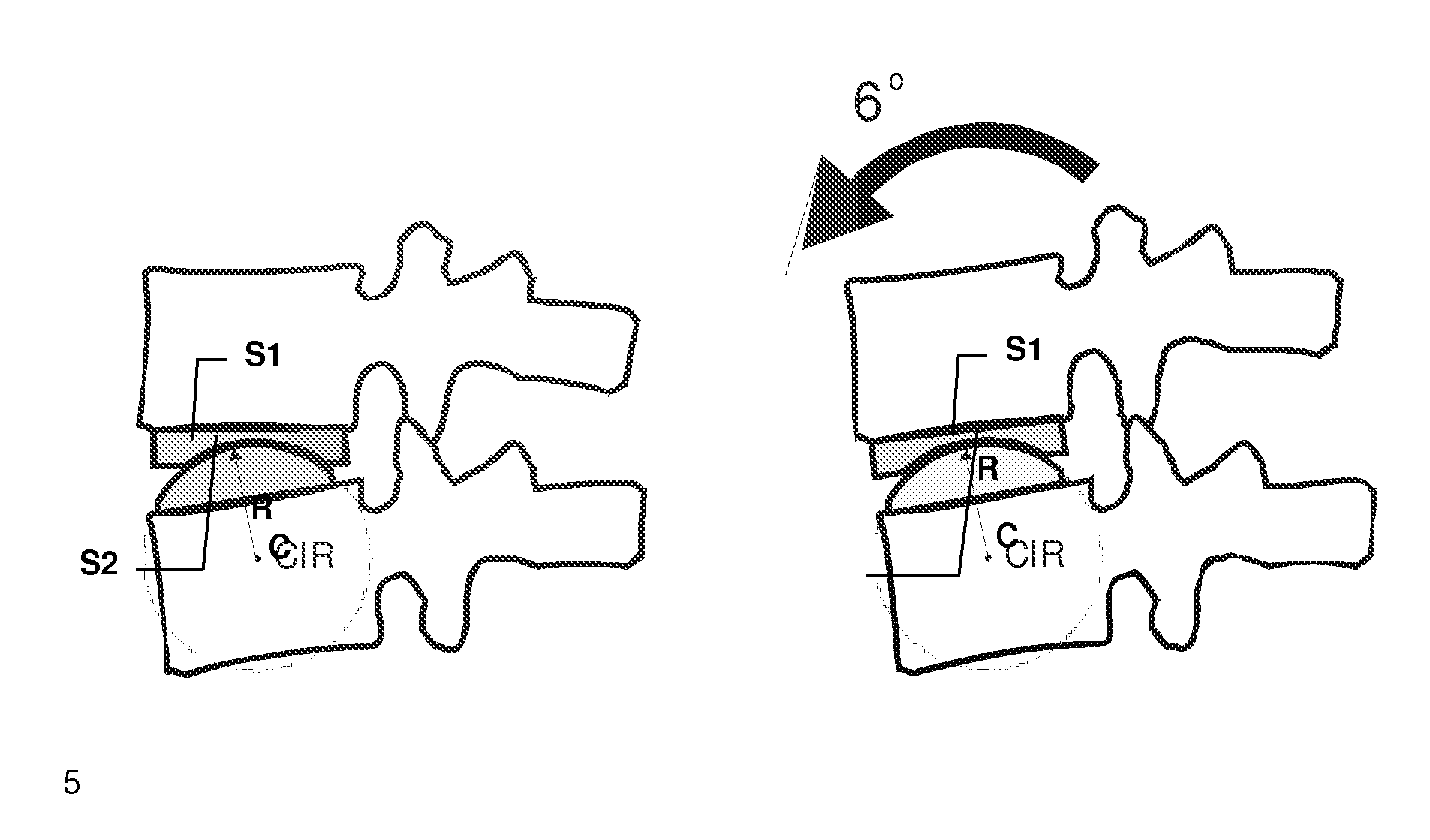

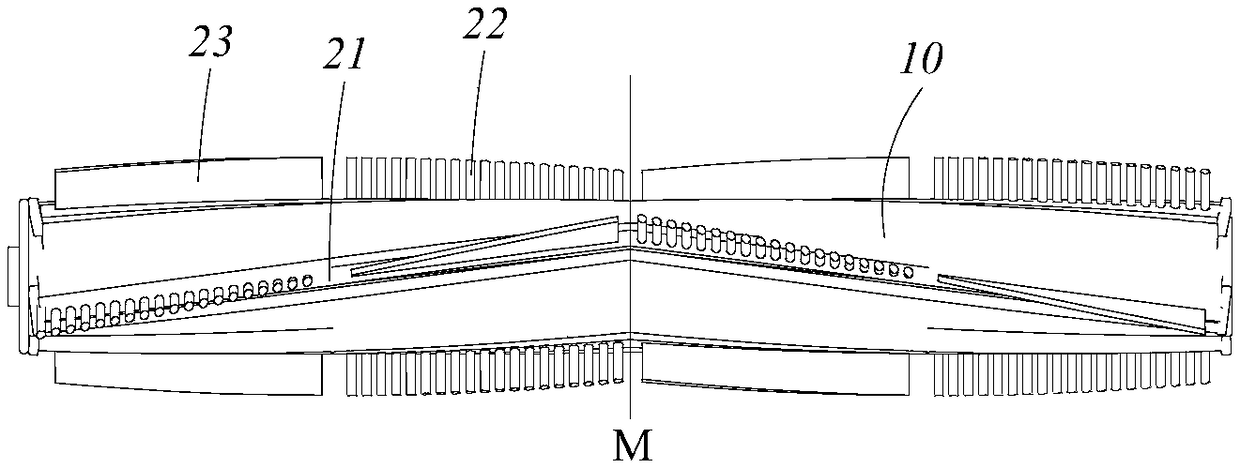

Intervertebral disc prosthesis for universal application

InactiveUS20090082867A1Improve wear resistanceStable frictionSpinal implantsInstabilityBiocompatibility Testing

An Invertebral Disc Model Prosthesis, of the type denominated of double articulation, to substitute the function and the movement of intervertebral discs, for universal application due to its principal characteristic of being able to be used as a constrained, semi-constrained or non-constrained prosthesis, specially indicated for treatment of pathological degenerative of the intervertebral discs, discal hernias, by anterior approach, transition syndromes of supra-adjacent disc, chronic lumbagos resistant to conserver treatment, chronic adjacent vertebral instability, made from materials of proved biocompatibility, endowed with a low profile that makes it optimum for its implant in the human being and which consists of three pieces, two plates, upper and lower, and am intermediate piece , which serves for the substitution of the discs of the lumbar and cervical column, capable of being placed by the anterior or lateral approach.

Owner:DEPUY SYNTHES PROD INC

Fluid compositions for dual clutch transmissions

InactiveUS20060264340A1Increase frictionStable frictionGear lubrication/coolingLiquid carbonaceous fuelsBase oilFluid composition

An additive composition and lubricating fluid are disclosed that provide high steel-on-paper friction durability, good metal-metal extreme pressure performance characteristics and synchronizer performance. The lubricating fluid includes a base oil, a succinimide dispersant, a succinimide friction modifier, and a phosphonate. Also disclosed is a method for lubricating a dual clutch transmission employing a plurality of wet clutches, with the lubricating fluid of the disclosure.

Owner:IYER RAMNATH N +2

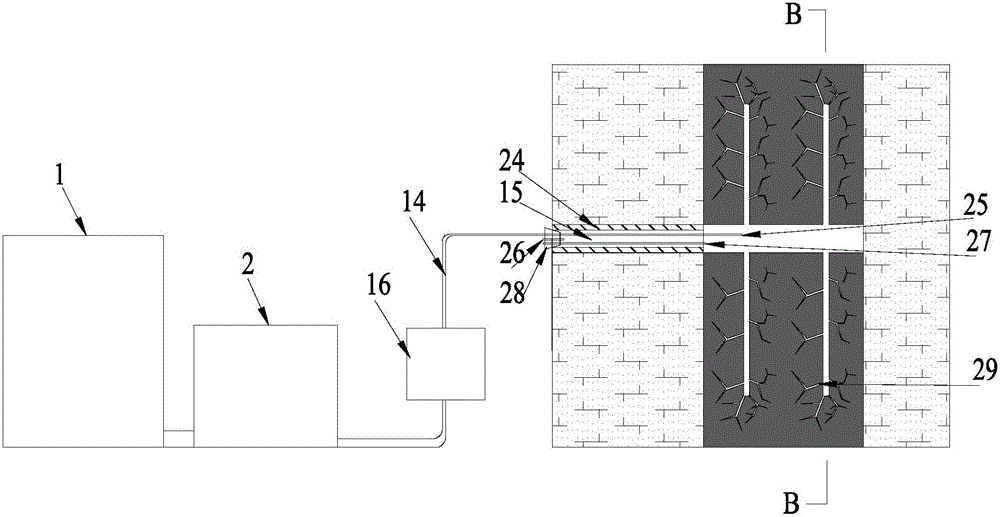

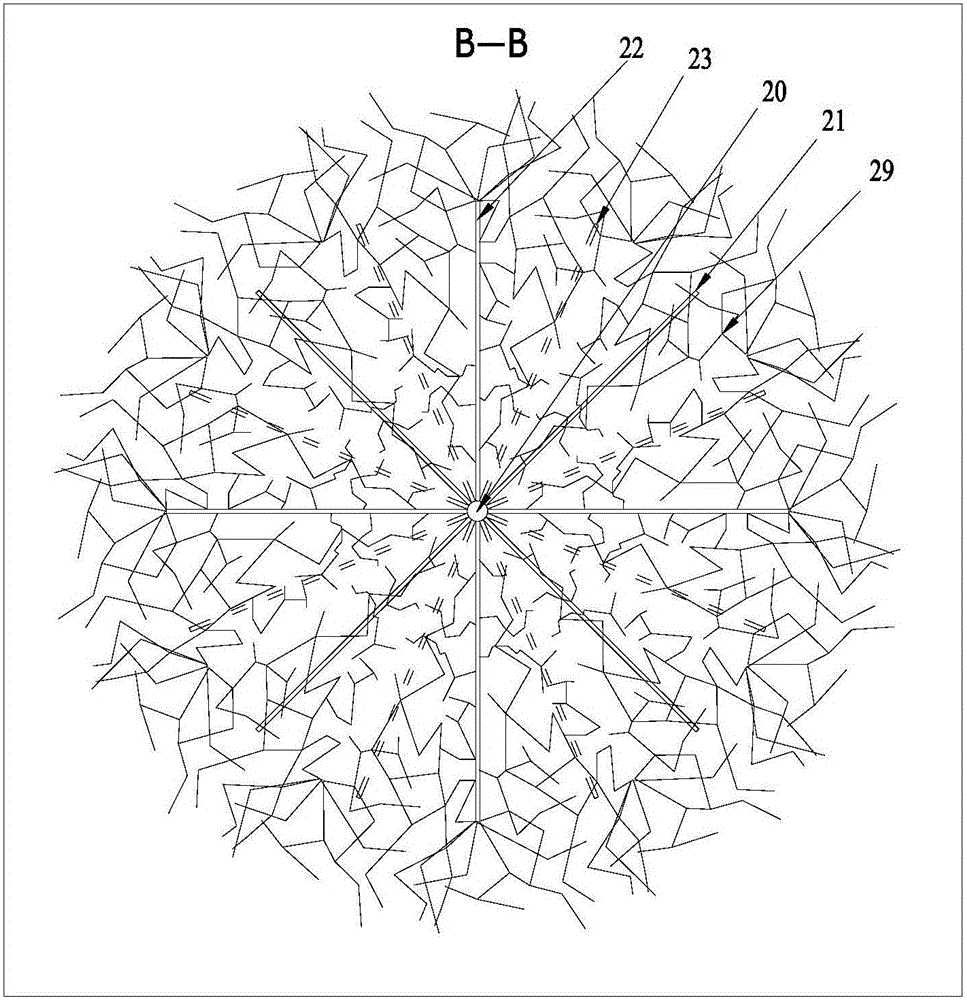

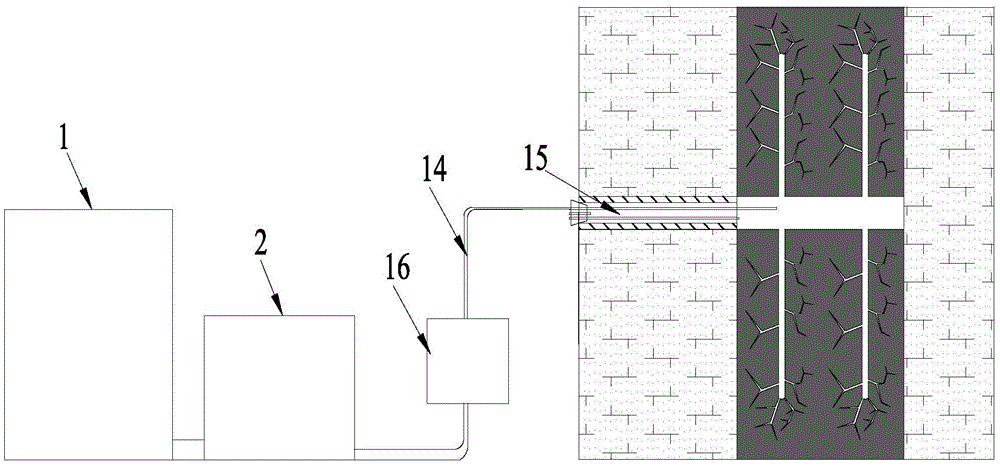

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

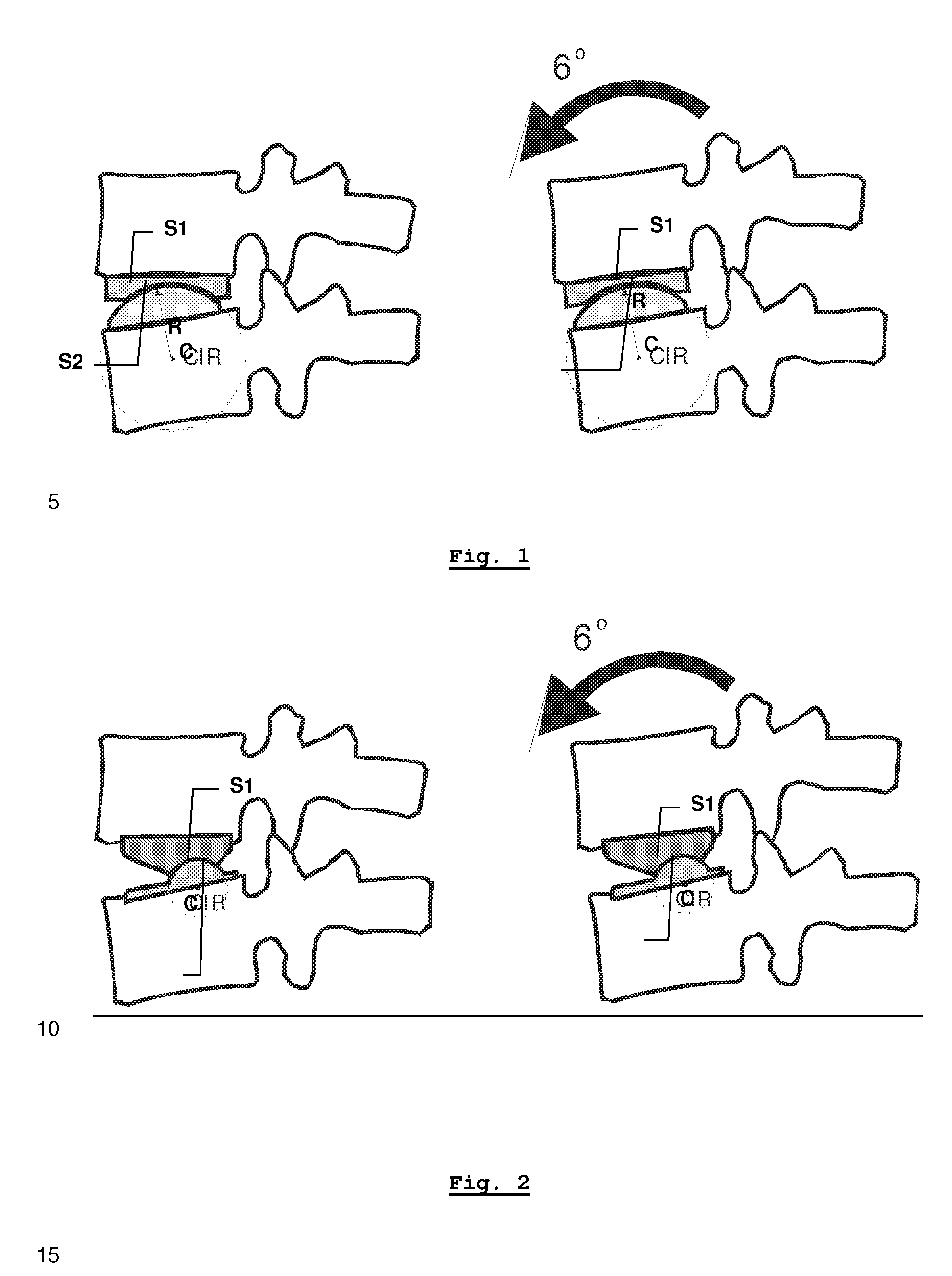

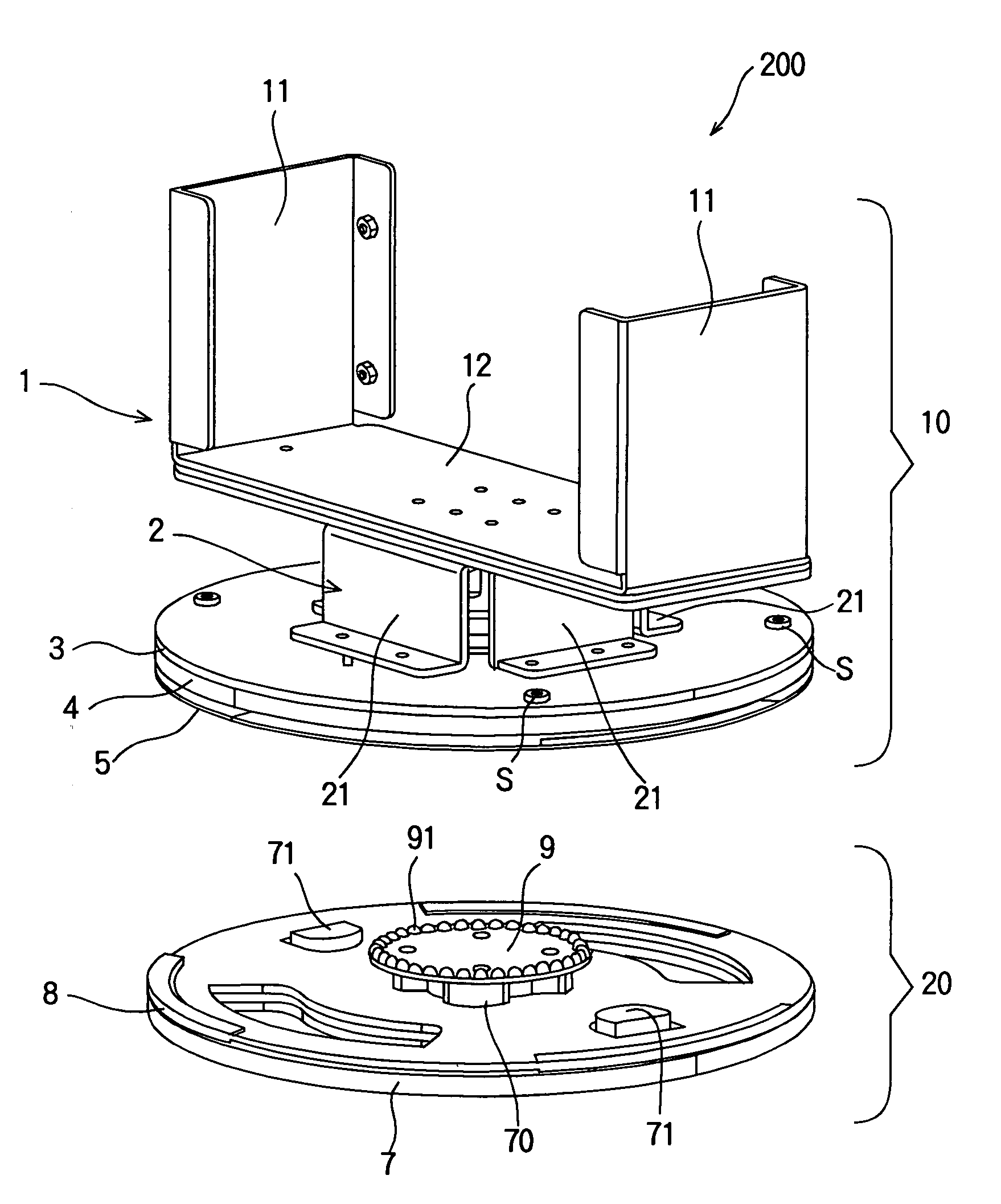

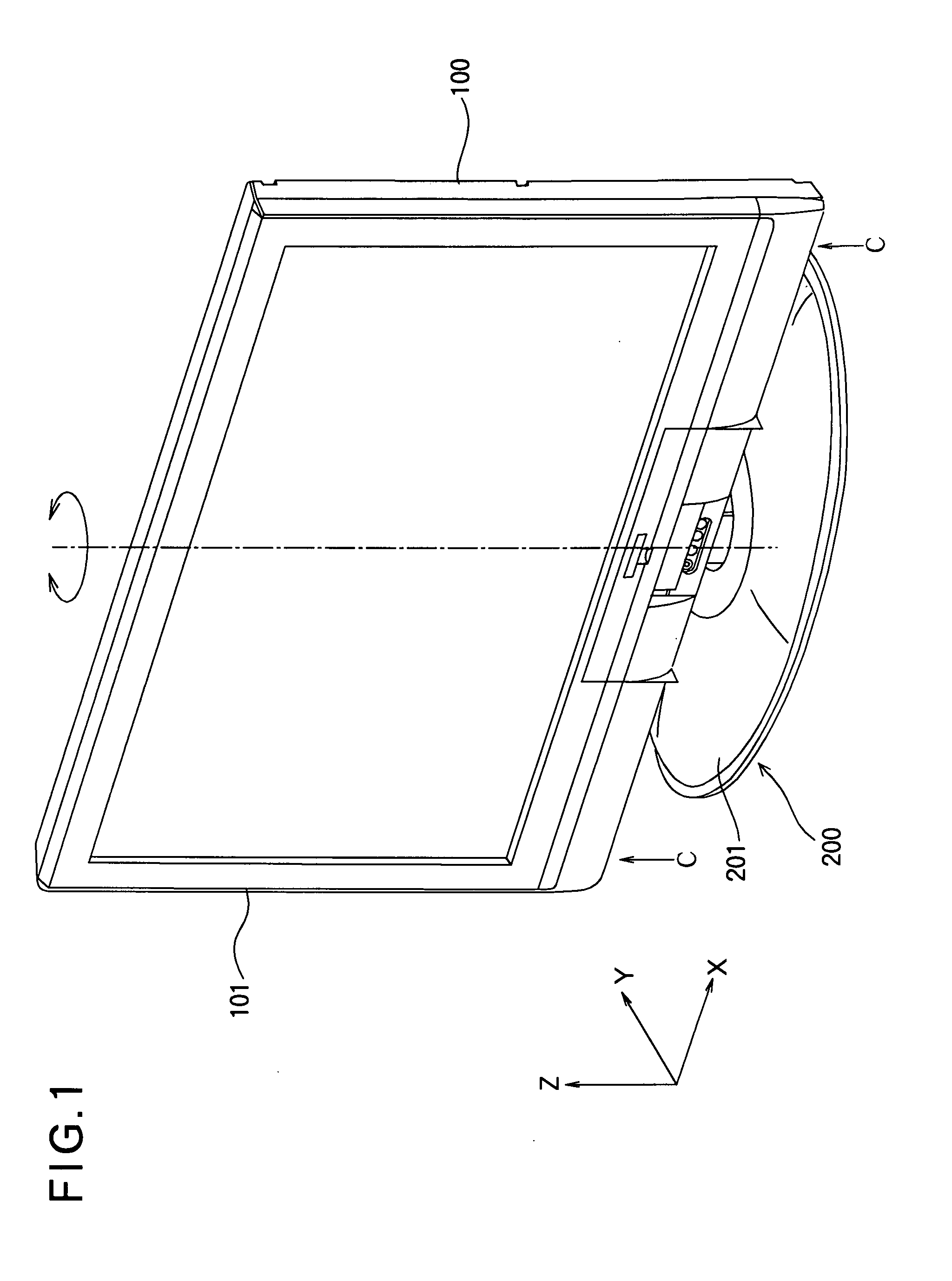

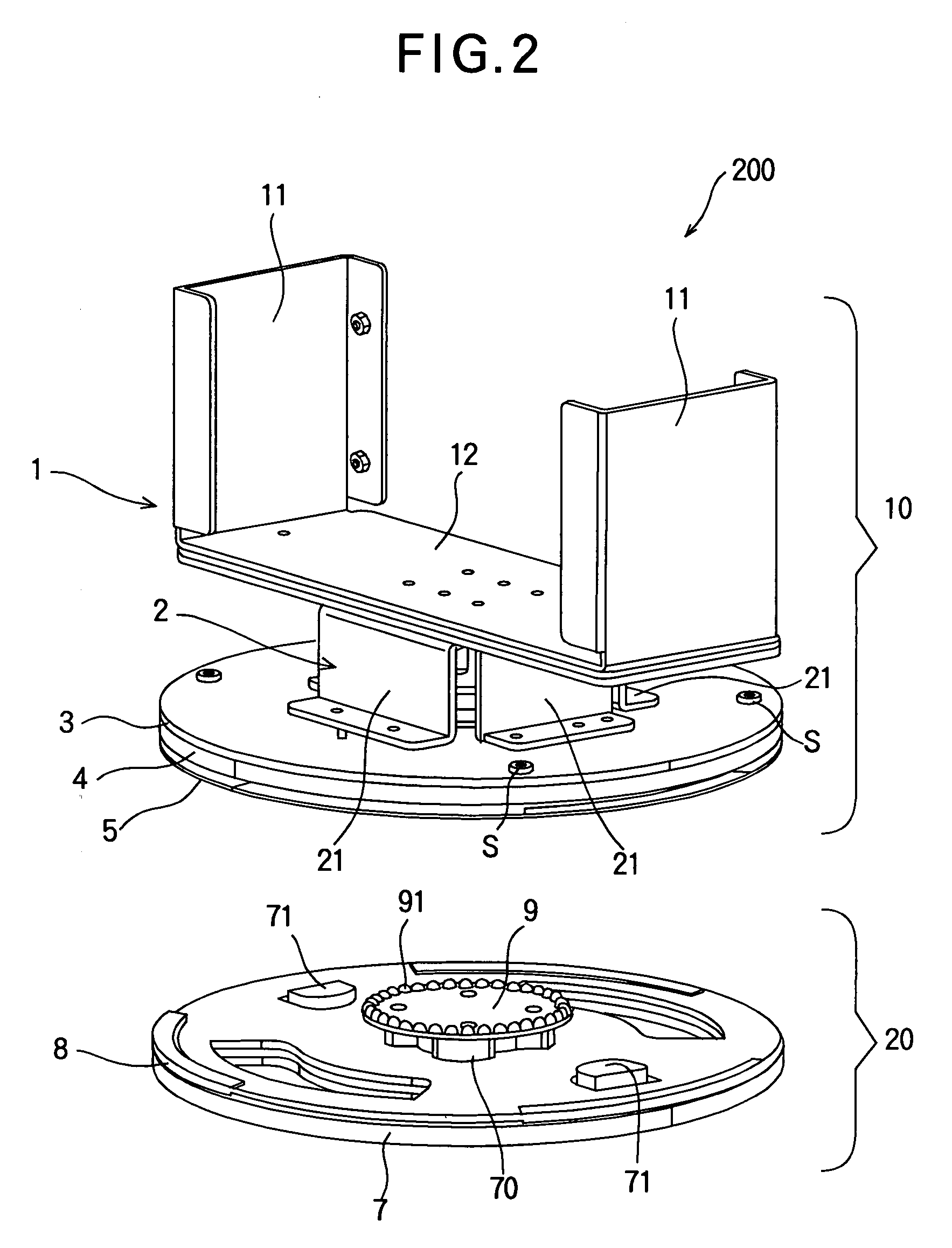

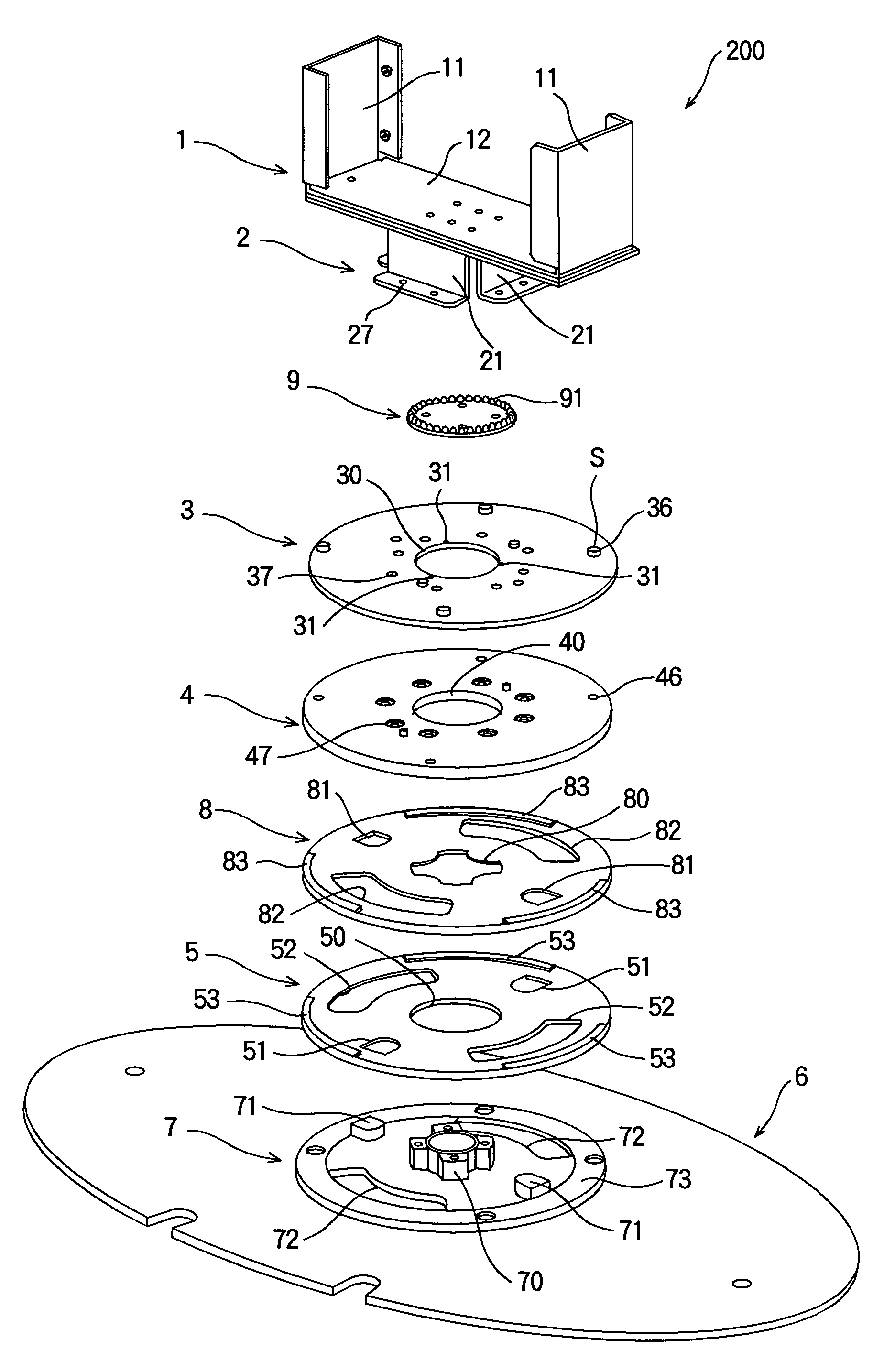

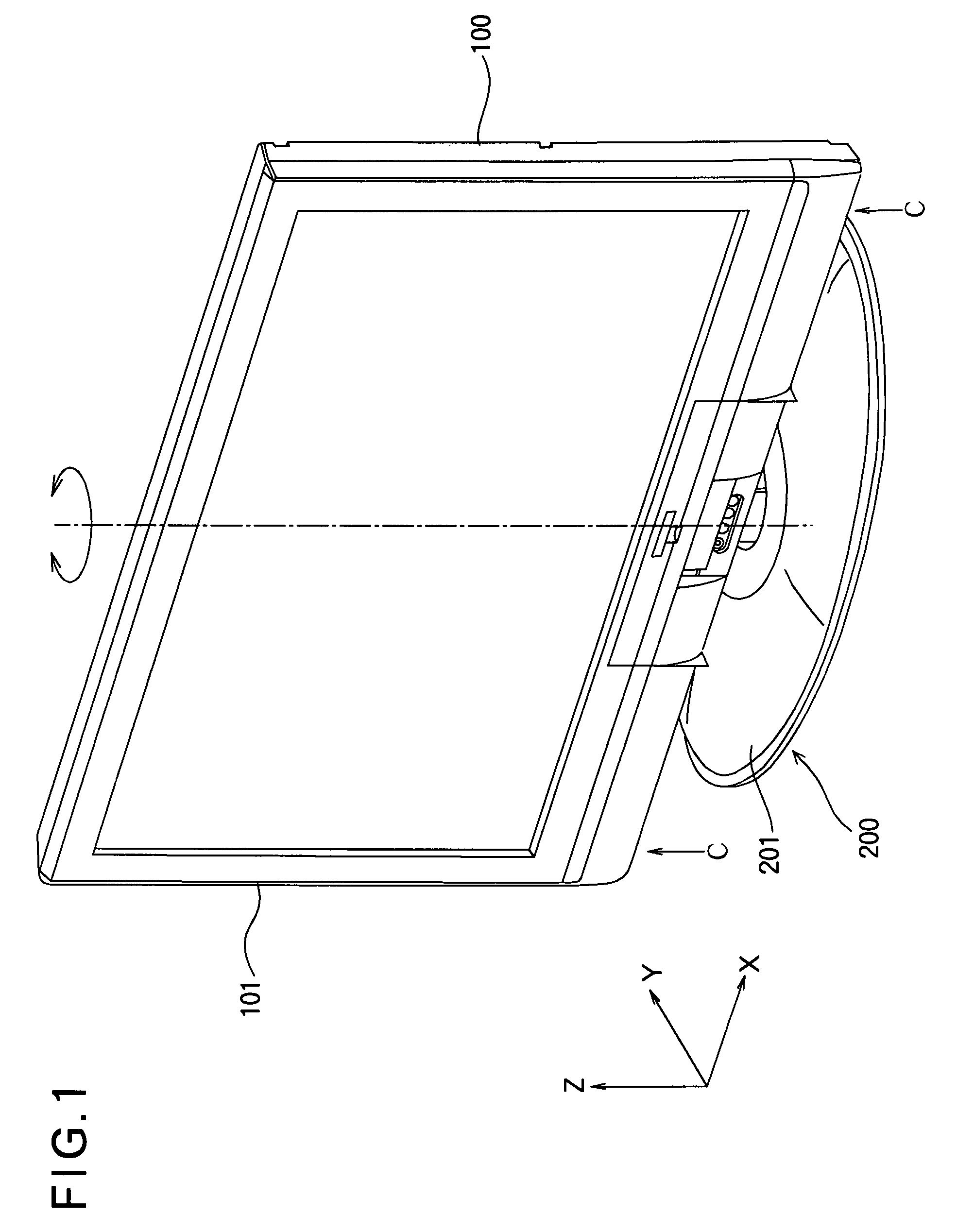

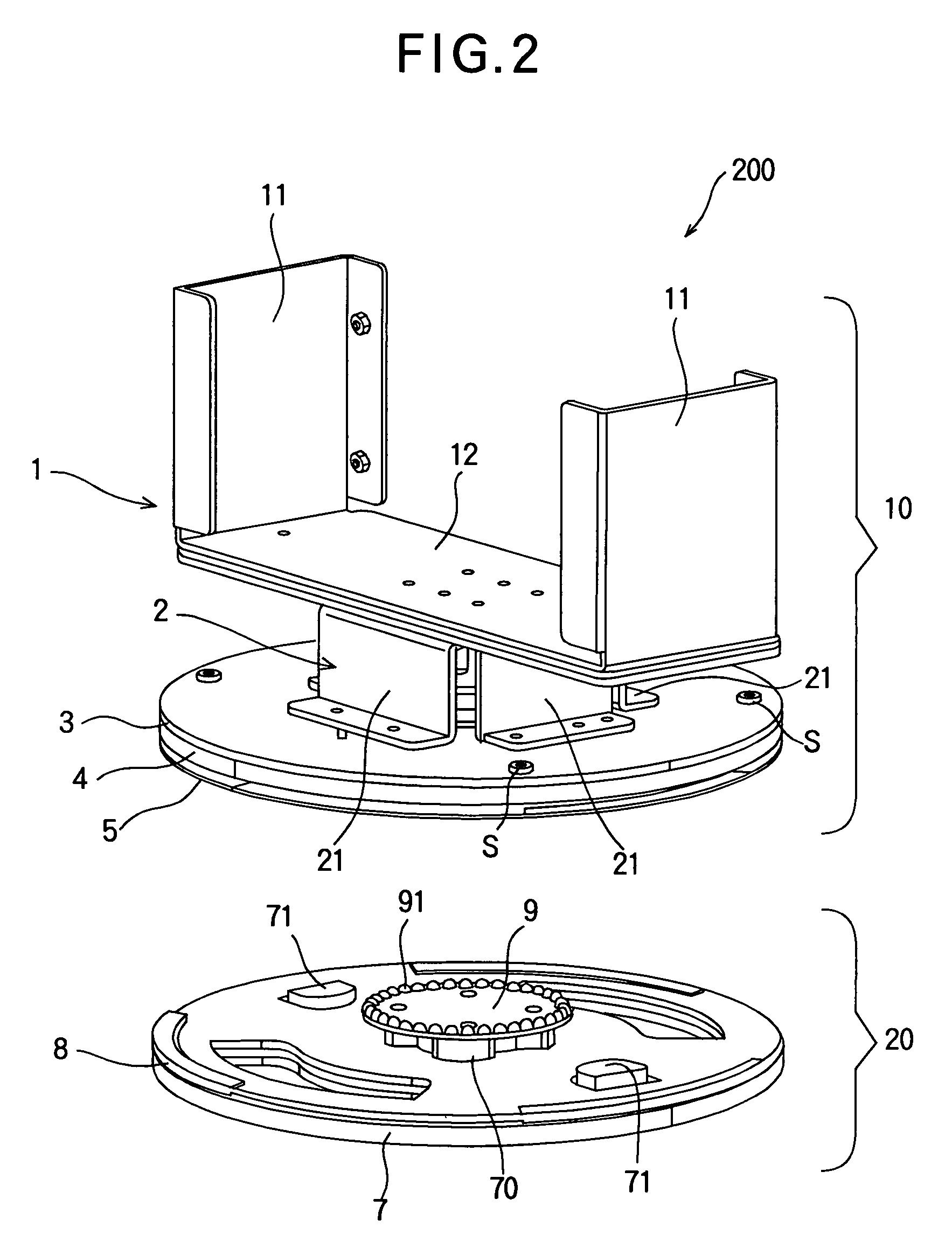

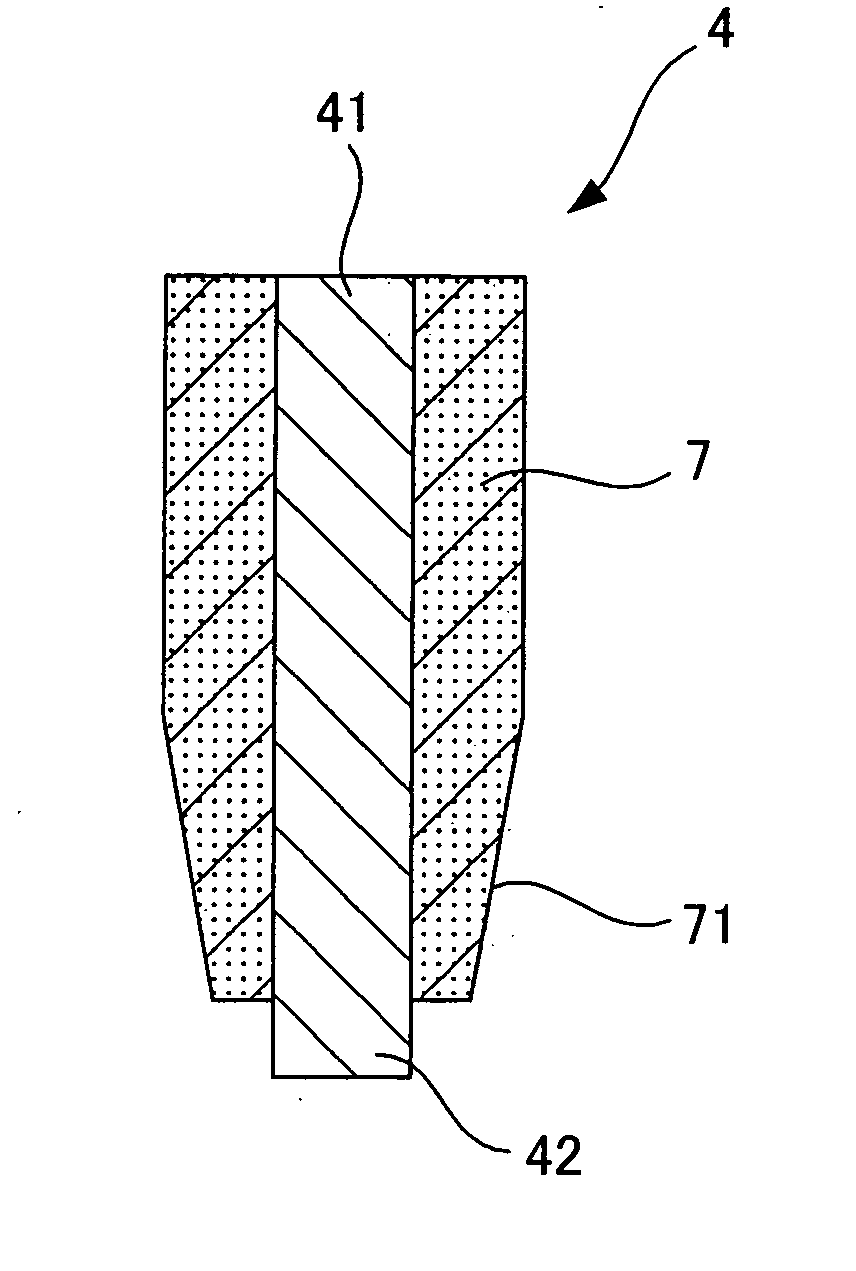

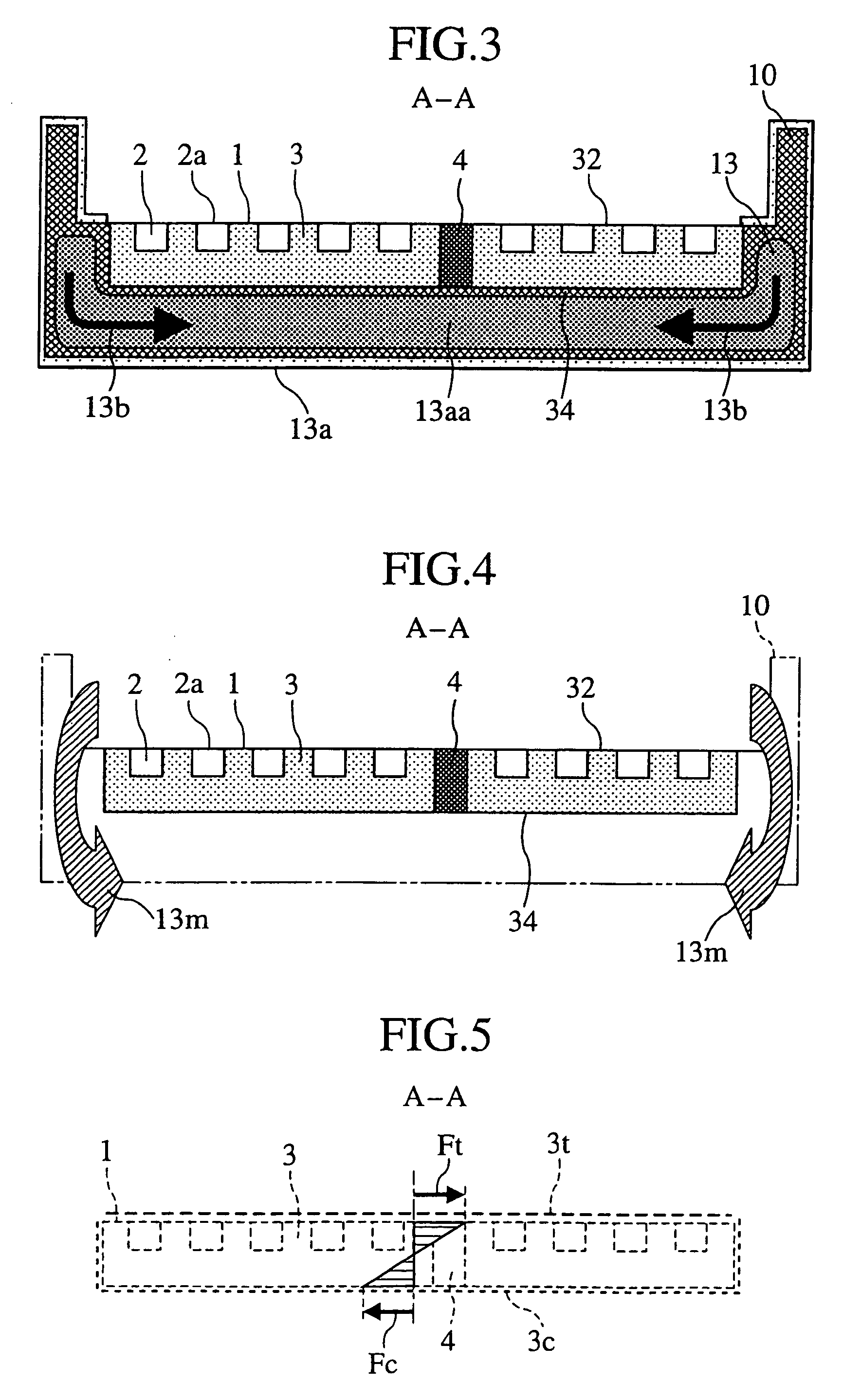

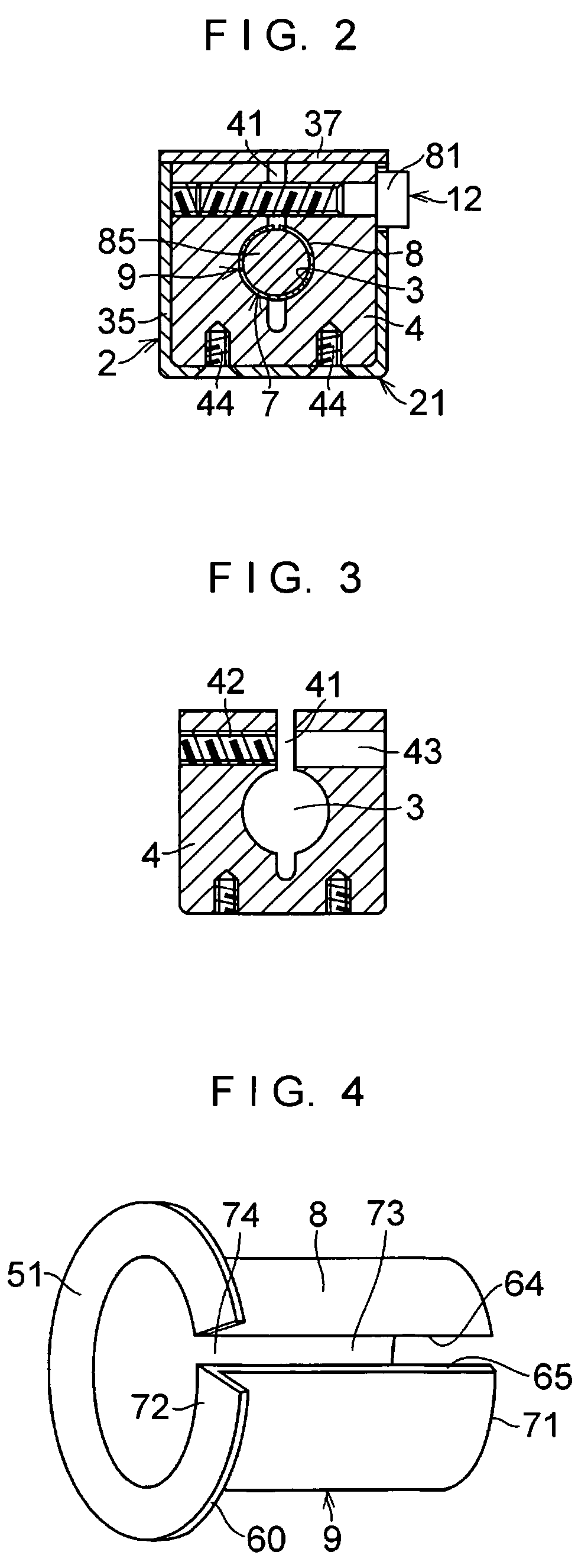

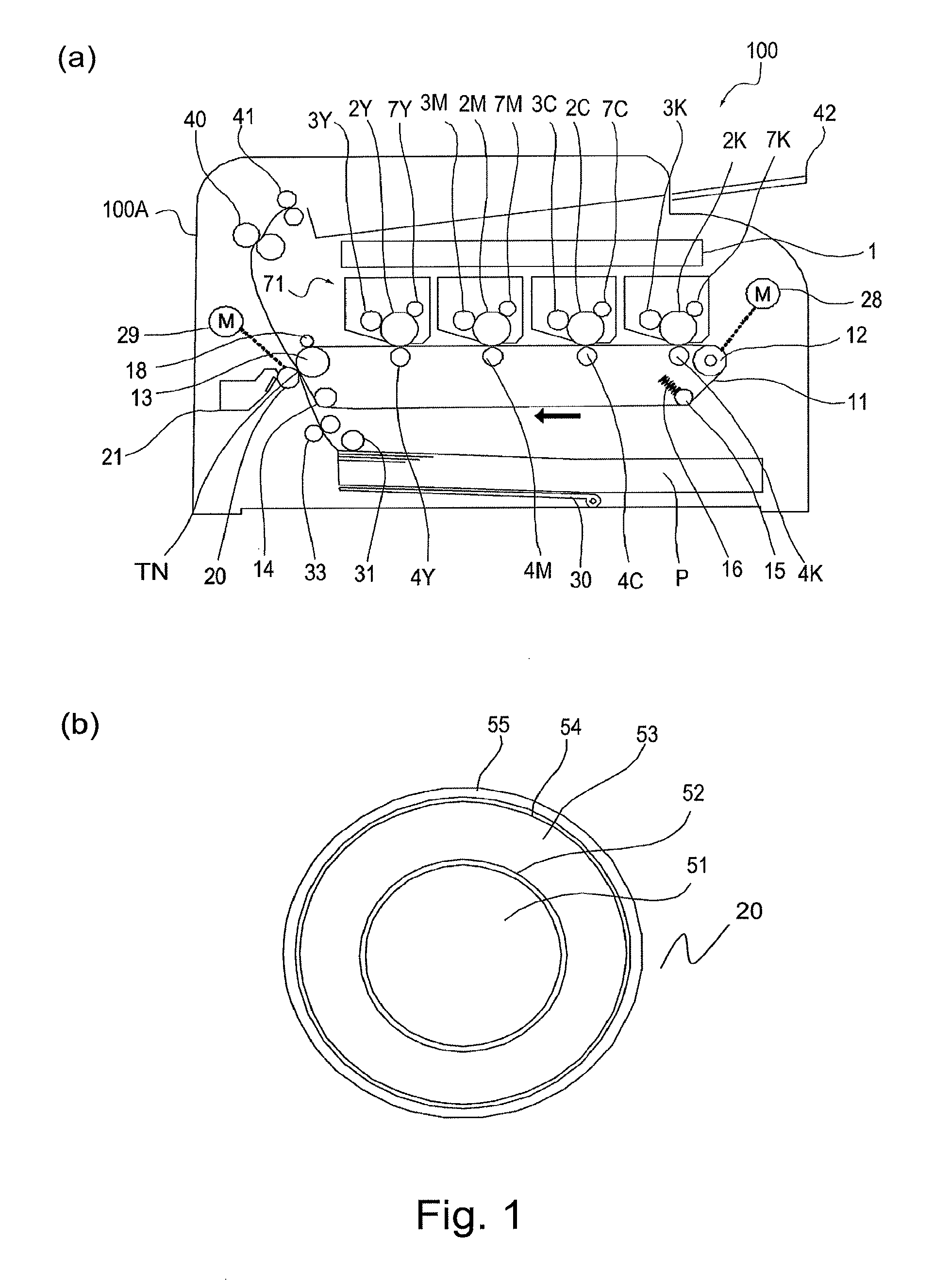

Turntable and display apparatus

InactiveUS20080006748A1Stable frictionReduce variationStands/trestlesKitchen equipmentEngineeringSliding contact

A turntable includes a rotatable member rotatable together with a display portion about a predetermined axis line, a fixed member disposed on one side of the rotatable member in a direction of the axis line, a first friction plate whose rotation about the axis line is restricted by the rotatable member (and movable relative to the rotatable member in a direction of the axis line), and a second friction plate whose rotation about the axis line is restricted by the fixed member (and movable relative to the fixed member in a direction of the axis line). The first friction plate and the second friction plate are disposed between the fixed member and the rotatable member in a direction of the axis line. At least, a sliding contact portion between the fixed member and the first friction plate, a sliding contact portion between the first friction plate and the second friction plate, and a sliding contact portion between the second friction plate and the rotatable member are provided.

Owner:MITSUBISHI ELECTRIC CORP

Turntable and display apparatus

InactiveUS7708239B2Smooth rotationReduce variationStands/trestlesKitchen equipmentSliding contactEngineering

A turntable includes a rotatable member rotatable together with a display portion about a predetermined axis line, a fixed member disposed on one side of the rotatable member in a direction of the axis line, a first friction plate whose rotation about the axis line is restricted by the rotatable member (and movable relative to the rotatable member in a direction of the axis line), and a second friction plate whose rotation about the axis line is restricted by the fixed member (and movable relative to the fixed member in a direction of the axis line). The first friction plate and the second friction plate are disposed between the fixed member and the rotatable member in a direction of the axis line. At least, a sliding contact portion between the fixed member and the first friction plate, a sliding contact portion between the first friction plate and the second friction plate, and a sliding contact portion between the second friction plate and the rotatable member are provided.

Owner:MITSUBISHI ELECTRIC CORP

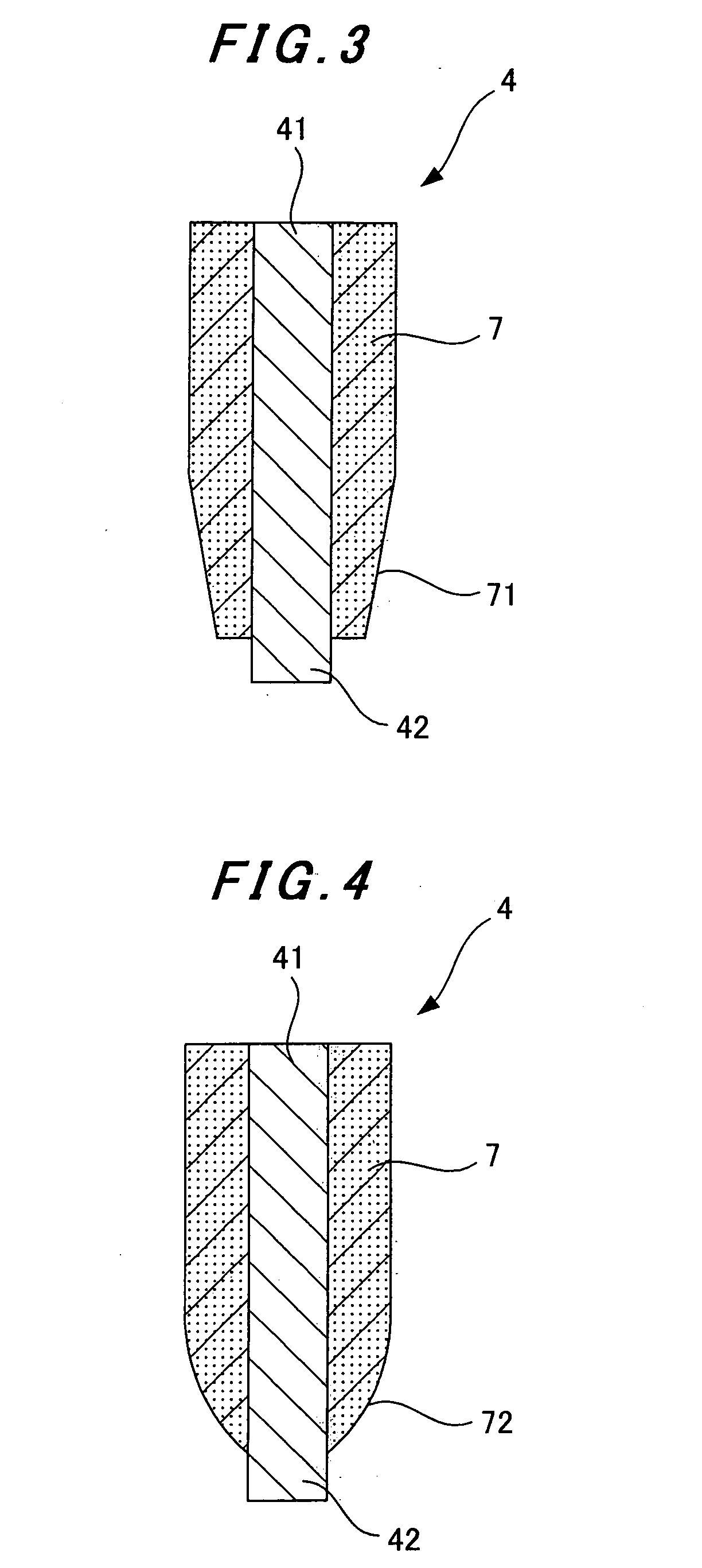

Friction plate for wet-type multiplate clutch

ActiveUS20060102443A1Stable frictionReduction in a drag upon idlingFluid actuated clutchesFriction clutchesEngineeringClutch

A friction plate for a wet-type multiplate clutch provided with a core plate and friction linings fixed on opposite sides of the core plate, respectively. Each of the friction linings is formed such that at a section thereof located on a side radially inner than a radial center line thereof, the friction lining has a thickness that gradually increases from an inner circumferential portion of the section toward an outer circumferential portion of the section.

Owner:NSK WARNER

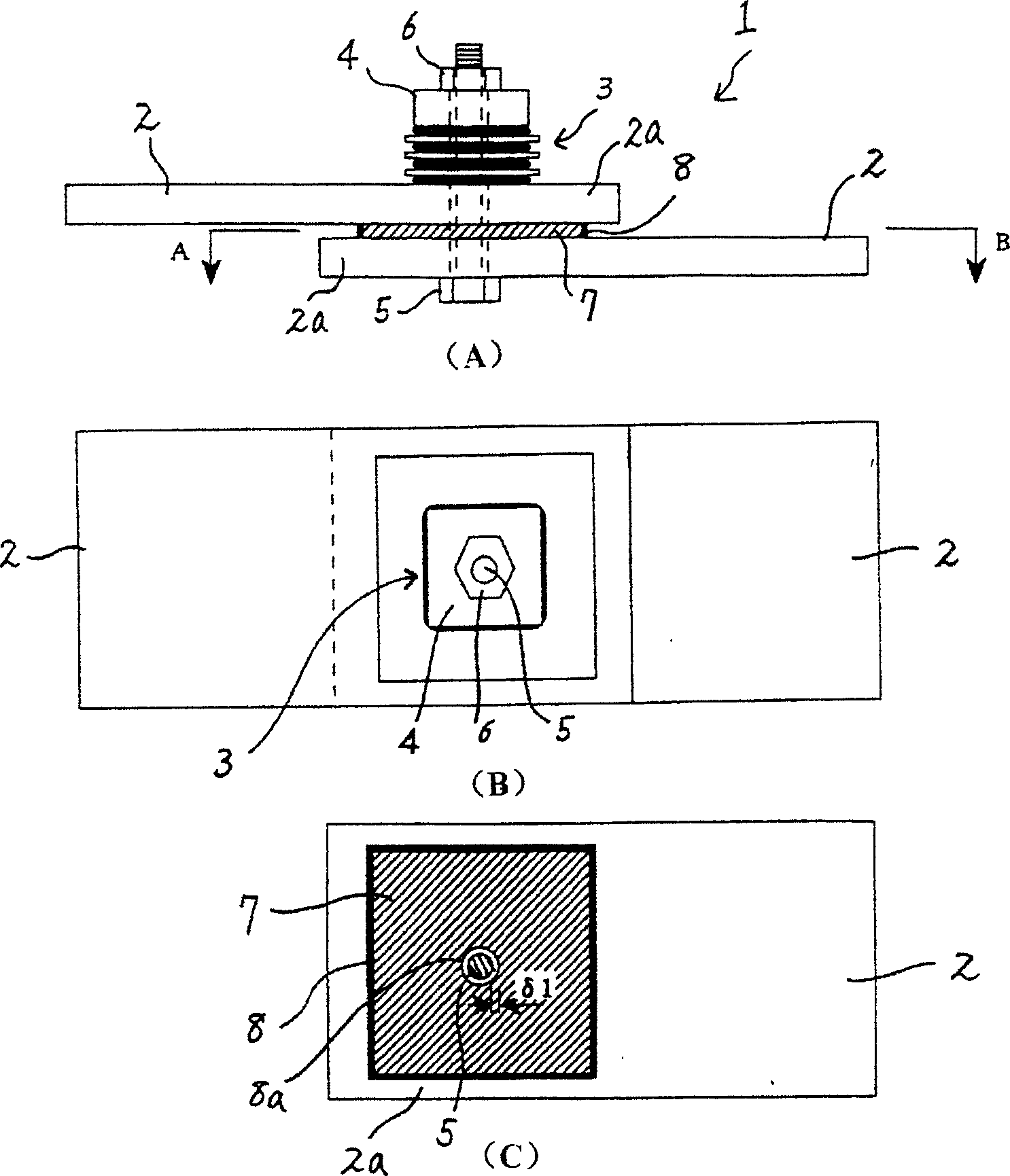

Bolt connection structure and damper structure

InactiveCN1641243AIncrease coefficient of frictionAvoid corrosionWallsProtective buildings/sheltersPull forceEngineering

The invention relates to a screw connection structure and a damper structure. In the invention, elastic materials and pressure plates are arranged on the outside of the overlap section of plates for building structure, a pulling force is inducted into screws which run through the elastic materials, at least one nonferrous metal plate or composite ceramic plate is inserted into the plates for building structure, and at least the peripheral surface of the surface of the nonferrous metal plate or the composite ceramic plate caught between the steels is carried on waterproof processing. The invention also applies the screw connection structure in the damper structure. The invention can keep a friction coefficient stable by increasing the friction coefficient to save screws, and lower cost and simple structure are realized.

Owner:佐藤 孝典

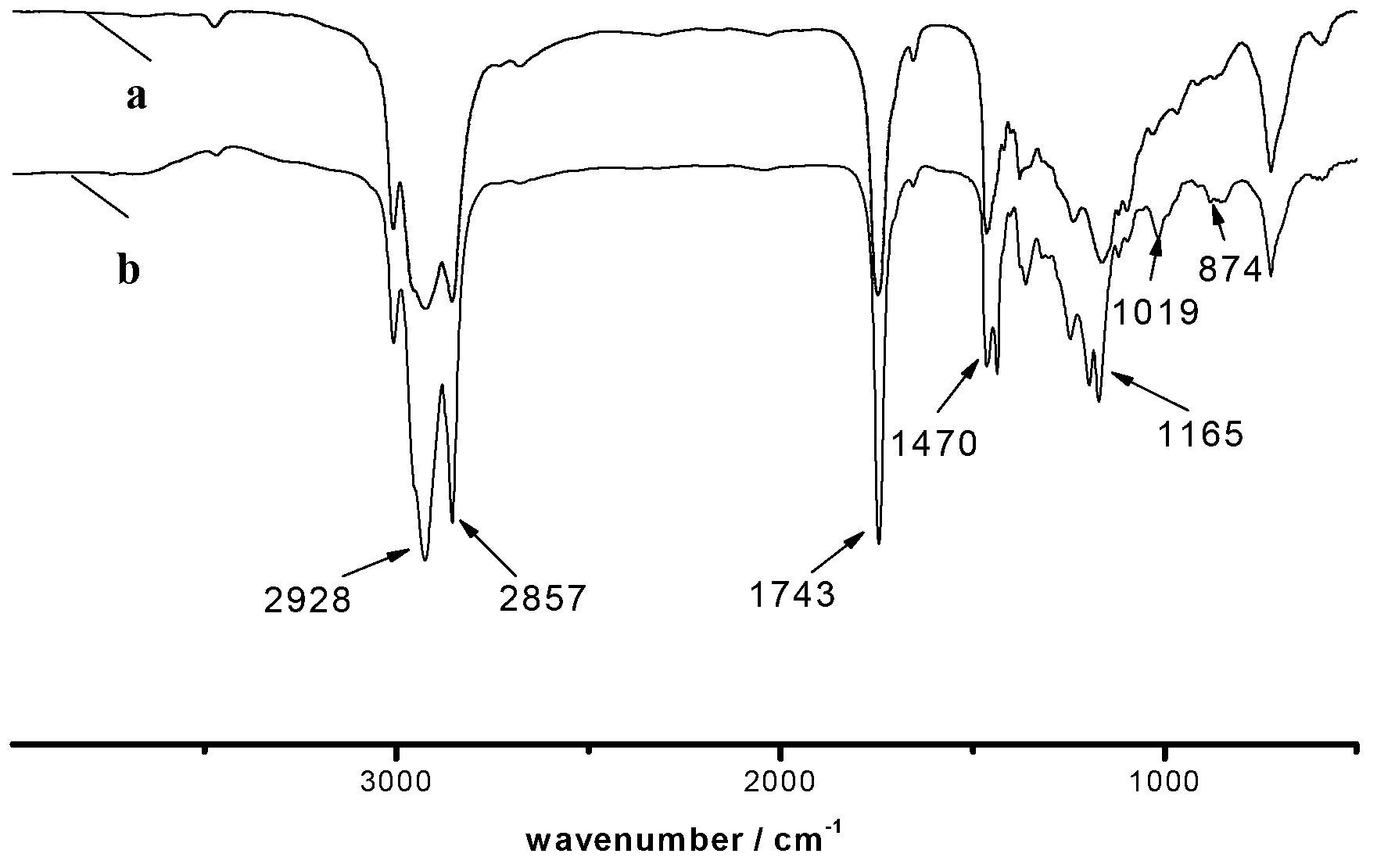

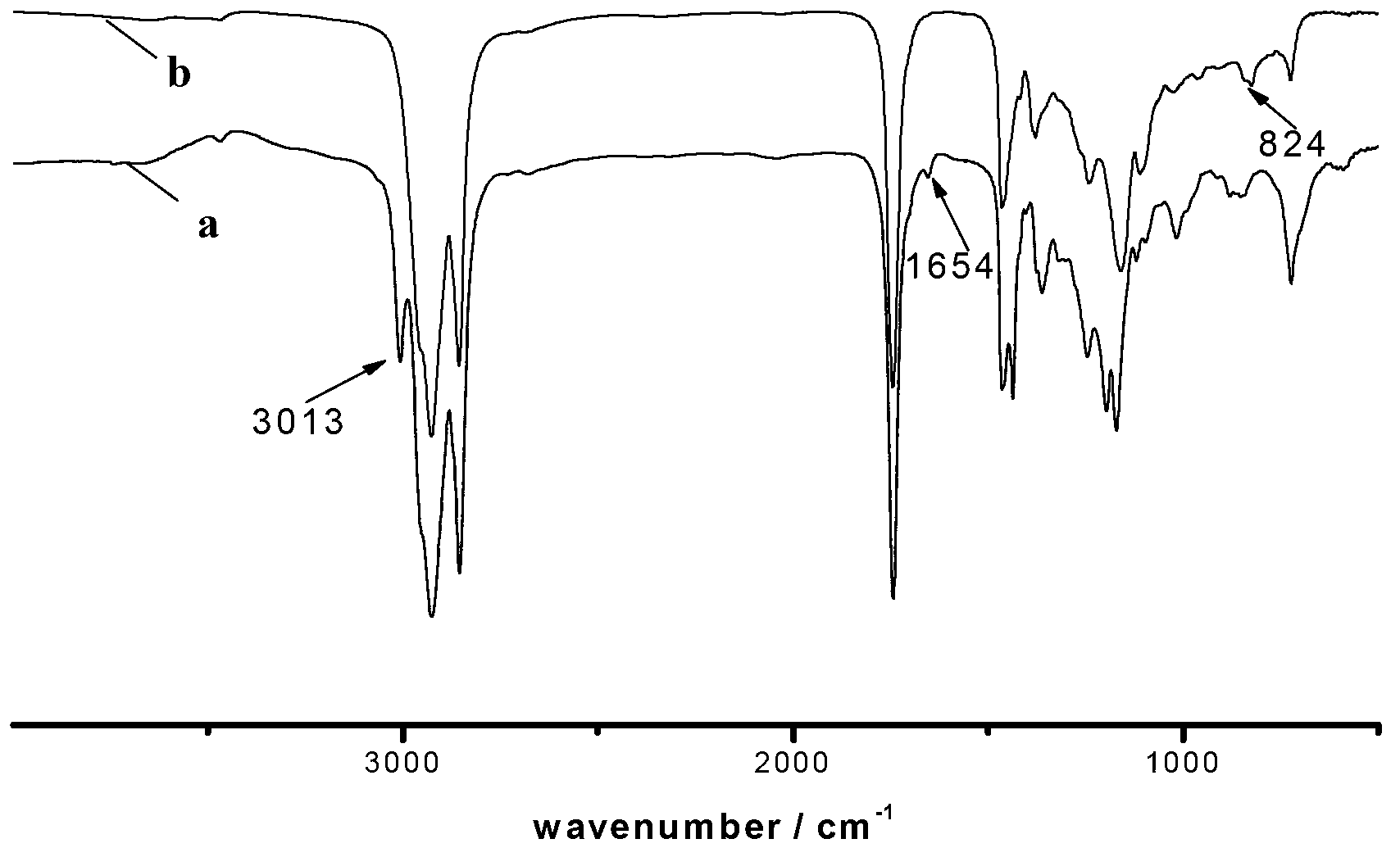

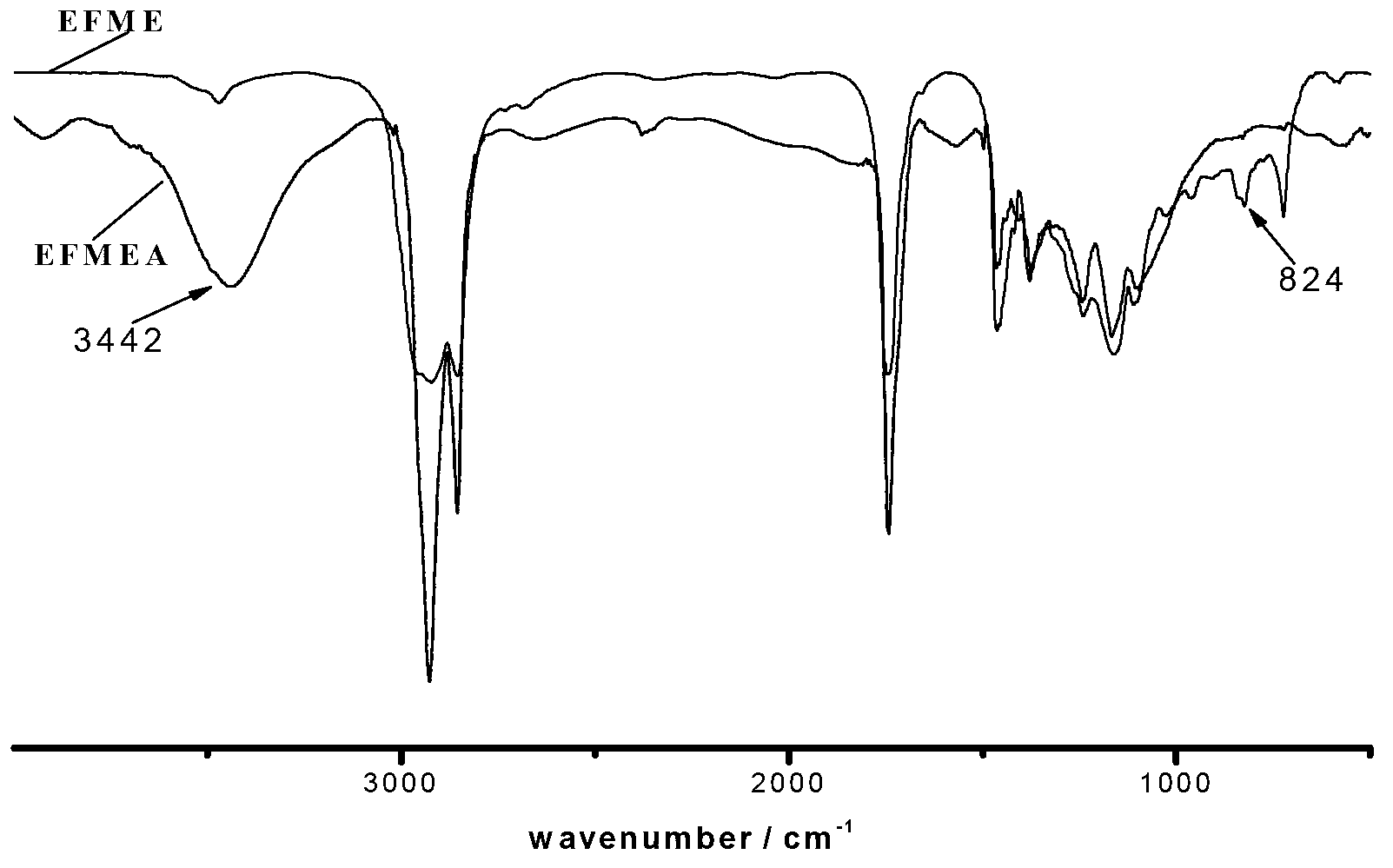

Method for preparing organic silicon modified plant oil

InactiveCN103266016AGood lubricityGood stabilityFatty acid chemical modificationBase-materialsOrganosiliconOxidation stability

The invention discloses a method for preparing organic silicon modified plant oil. The method comprises the following steps of: by taking colza oil as a raw material, preparing a colza oil alcohol orderly through methanol ester exchange, peracetic acid epoxidation and acetic acid ring opening; and then reacting organic silicon with the hydroxyl in the colza oil alcohol, thereby obtaining the organic silicon modified plant oil. The organic silicon modified plant oil produced by the method has good lubrication effect; and in addition, the oxidation stability of the organic silicon modified plant oil is also greatly improved.

Owner:HEFEI UNIV OF TECH

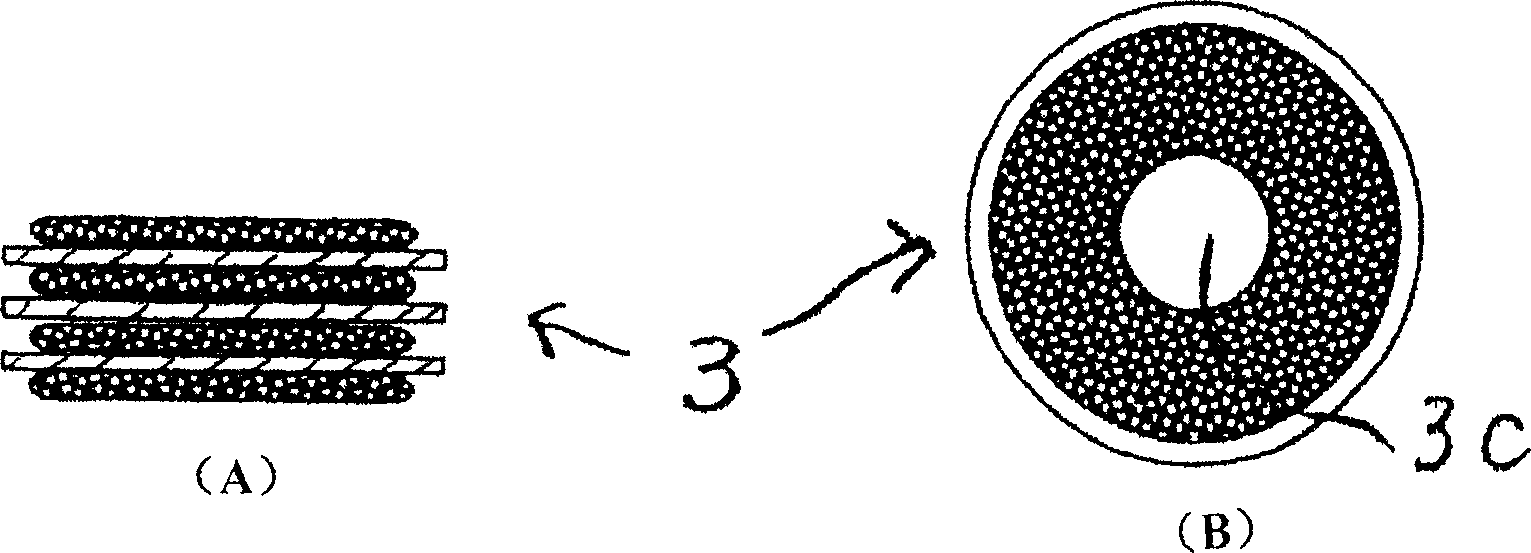

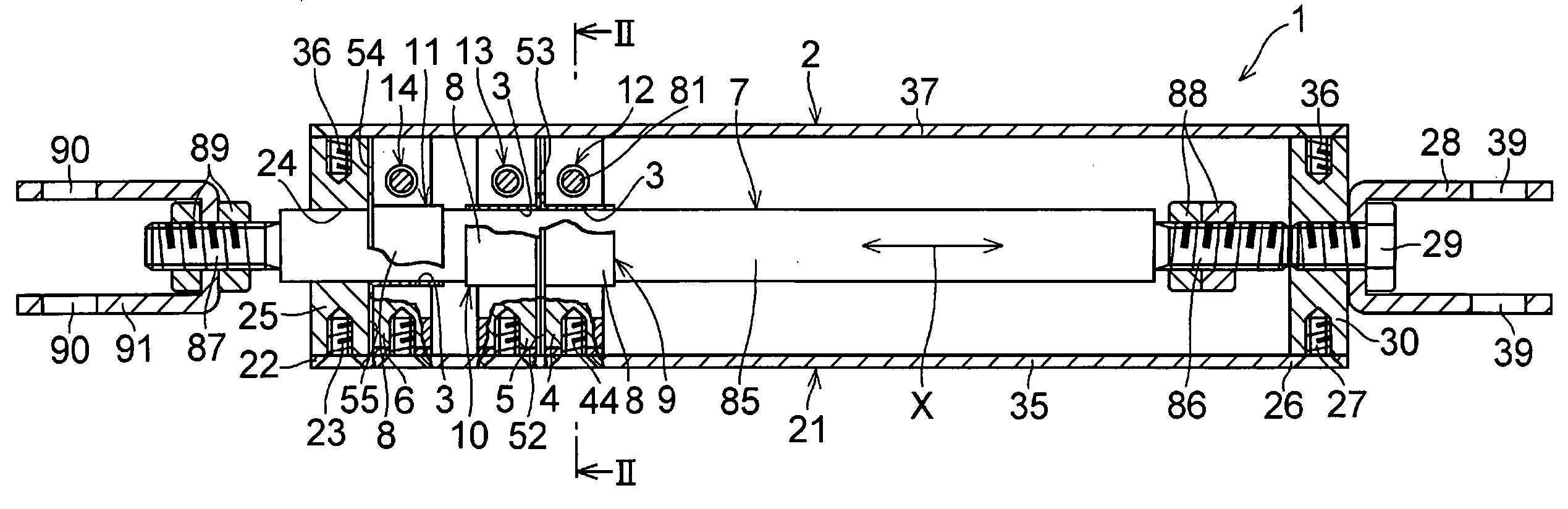

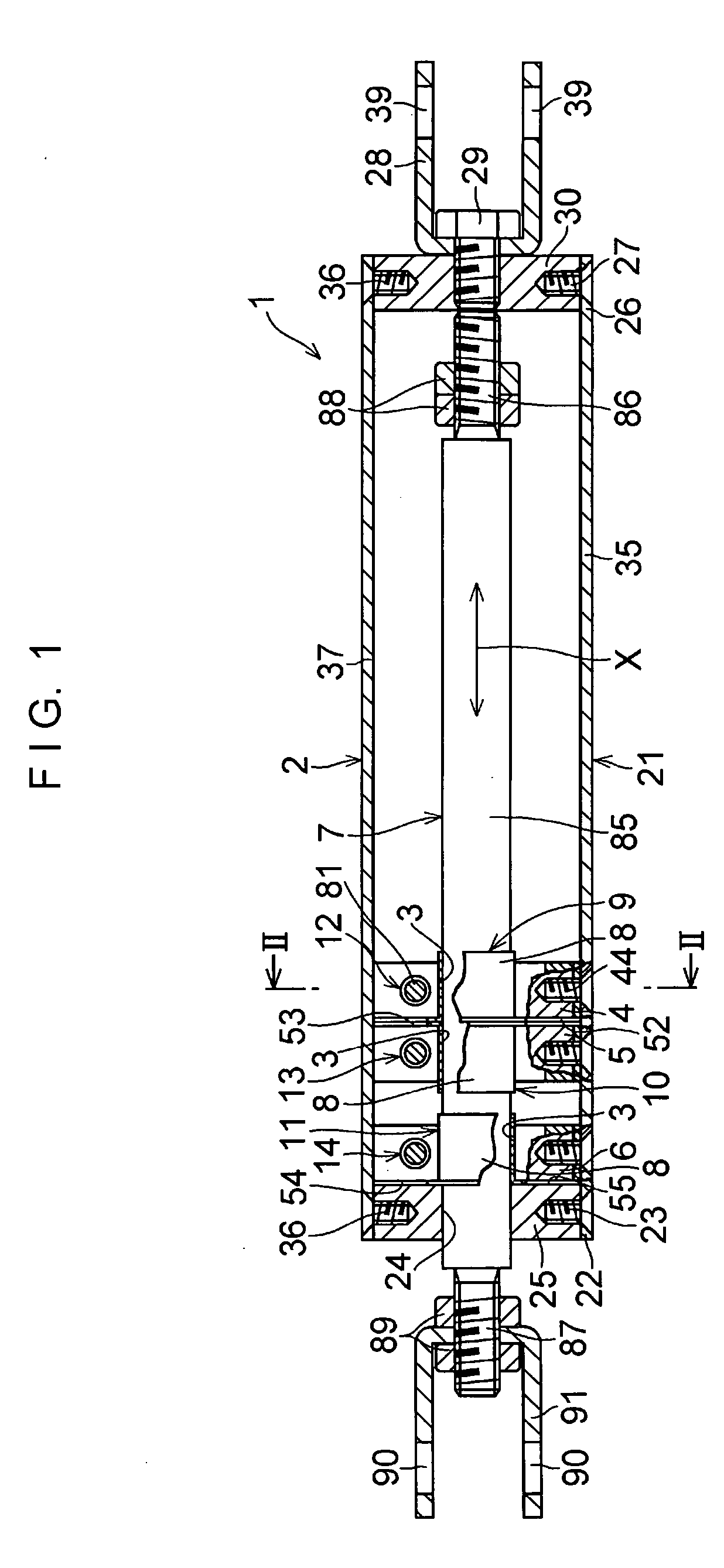

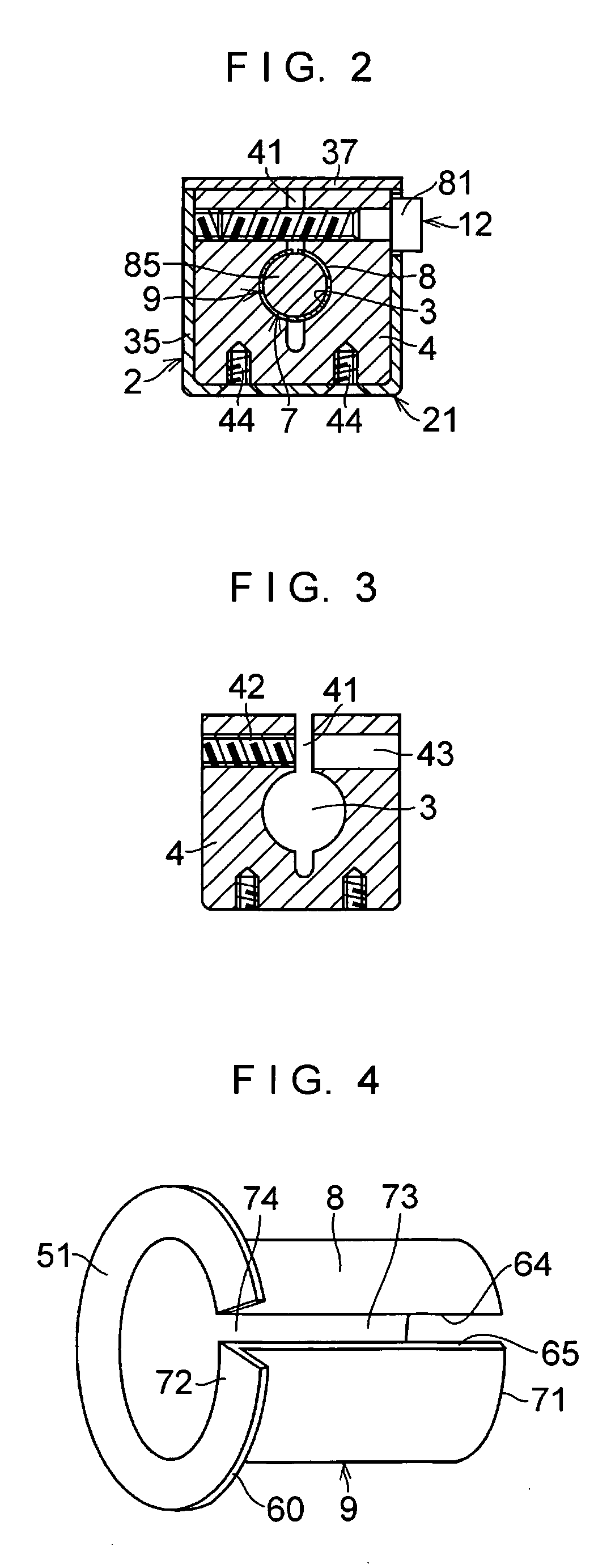

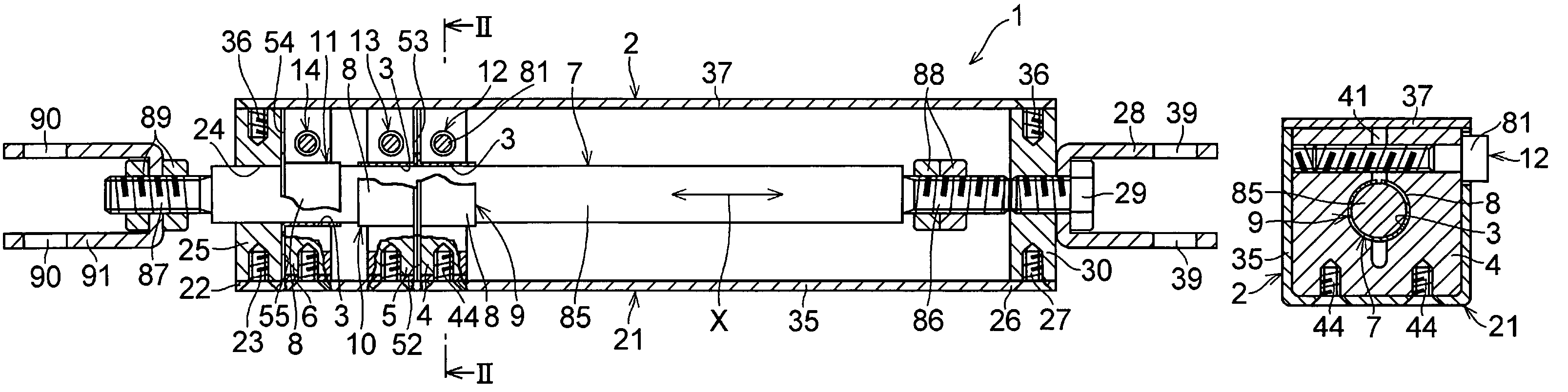

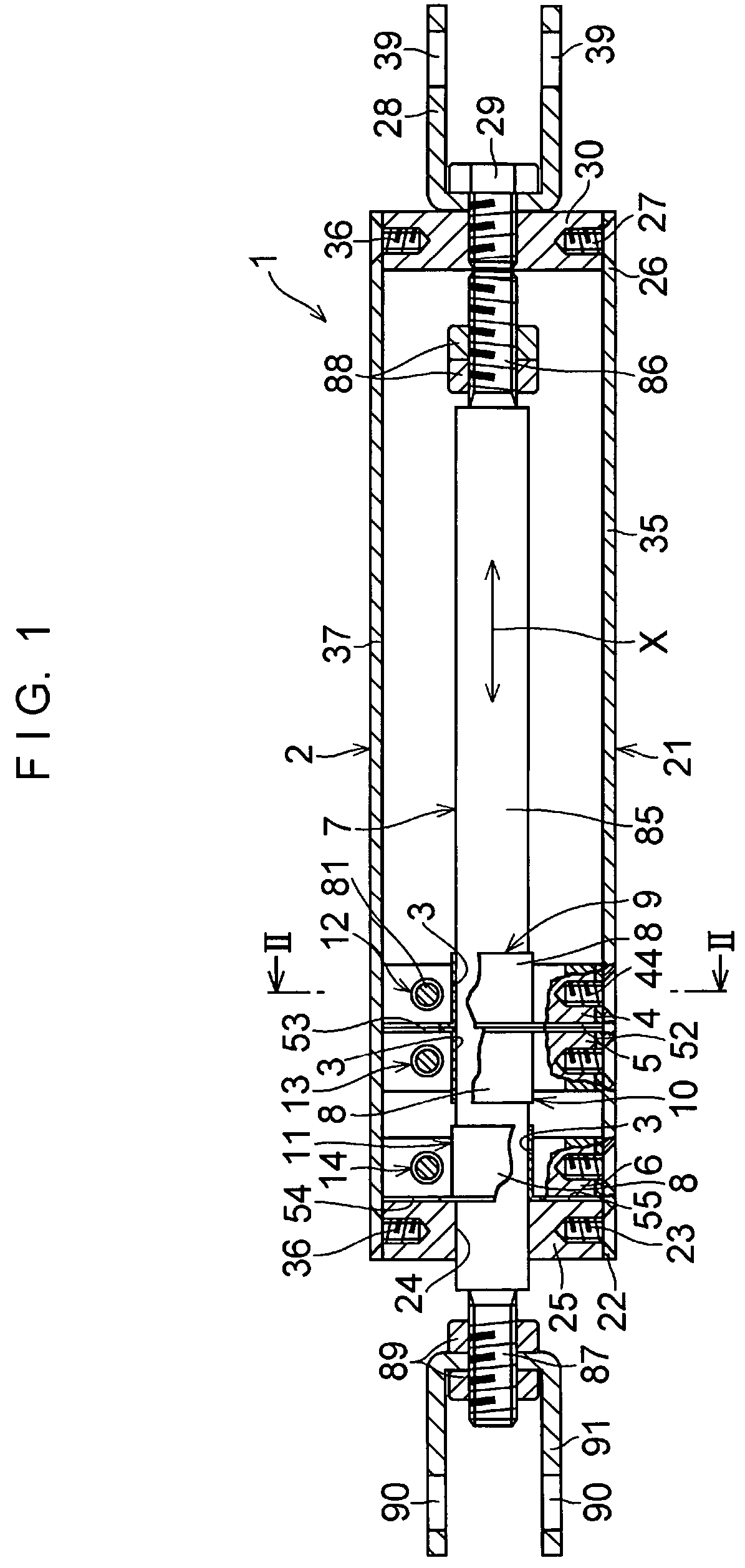

Friction damper

InactiveUS20050087414A1Inhibit wearPrevent peelingNon-rotating vibration suppressionFilament handlingEngineeringRelative motion

A friction damper includes a base body; a support secured to an elongated member of the base body and having a through hole; a rod which extends in such a manner as to pass through the through hole of the support and is movable in an axial direction with respect to the support; a friction member which has a hollow cylindrical portion interposed between the support and a main body portion of the rod in the through hole of the support, and which is fixed immovably with respect to the relative movement of the rod in the axial direction with respect to the base body; and a tightening structure provided for the support so as to tighten the hollow cylindrical portion of the friction member onto the main body portion of the rod.

Owner:OILES CORP

Specific crystallizer casting powder for sulphur free-cutting steel and production method thereof

The invention discloses a specific crystallizer casting powder for sulphur free-cutting steel and production method thereof, mass percents of chemical components thereof are as follows: 29-35% of CaO, 25-30% of Sio2, 2-5% of MgO, 3-5% of Al2O3, 2-6% of Fe2O3, 5-11% of NaO?, 0-2% of Li2O, 5-9% of CaF2?, 0-5% of MnO, 0.5-2.0% of Al grey, 0-2% of B2O3, 5-11% of solid carbon, and allowance is building material adhesive and water. The sulphur free-cutting steel has low high-temperature strength and high crack sensitivity, and the casting powder should have properly high basicity. Basicity of a slag is improved, so that diffusion velocity is accelerated, and absorption of impurities in molten steel is benefited. So, improvement of basicity is an effective means for improving absorption of the impurities and control of surface longitudinal crack.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

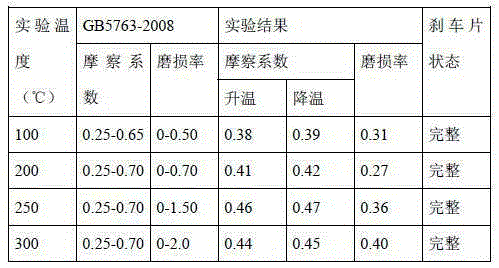

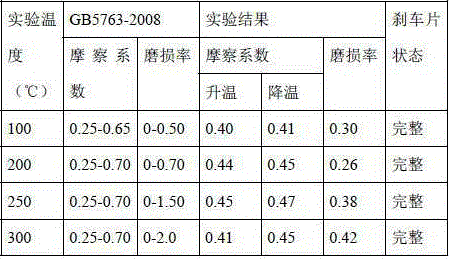

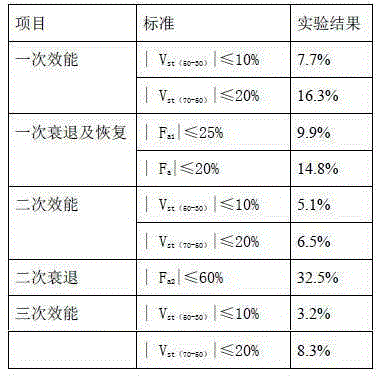

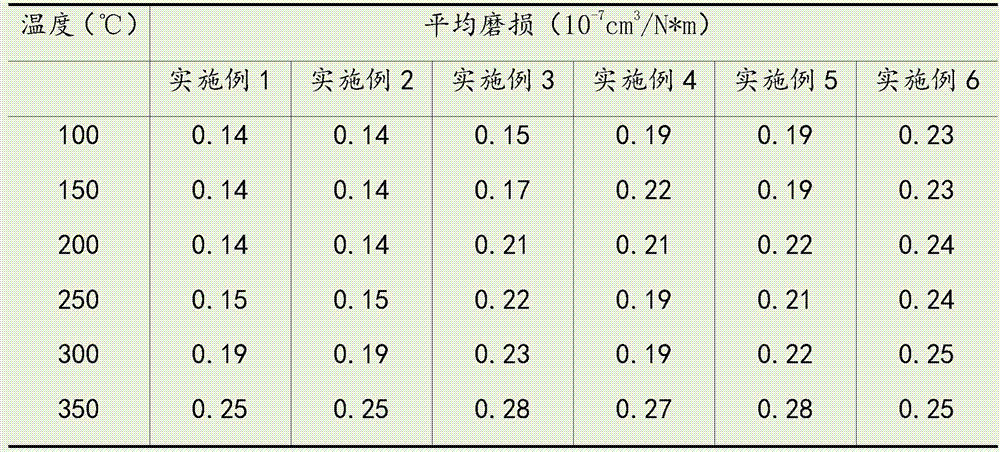

Vanadium-contained semimetallic brake block

ActiveCN105240429ANot easy to produceReduce wear rateOther chemical processesFriction liningAluminum silicateCellulose fiber

The invention discloses a vanadium-contained semimetallic brake block. The vanadium-contained semimetallic brake block includes, by weight, 5-7 parts of red copper fibers, 3-6 parts of potassium hexatitanate whiskers, 4-5 parts of barium sulfate, 15-25 parts of ferrovanadium powder, 4-6 parts of frictional powder, 13-15 parts of short stainless steel fibers, 6-10 parts of graphite, 2-4 parts of cellulosic fibers, 7-9 parts of coke blacking, 1-5 parts of modified resin nitrile fibers, 3-7 parts of chromite ore fine, 1-5 parts of nitrile rubber, 5-9 parts of ceramic adhesive agents and 8-10 parts of spray-bounded aluminum silicate fibers. The brake block obtained by material mixing, steel backing treatment, press molding, heat treatment, packaging and storage is low in wear rate, not prone to being dusty, high in density, good in heat dissipation, small in vibration, low in noise and high in corrosion resistance. The whole manufacturing process is simple, stability is good, cost is low and the cost-performance ratio is high.

Owner:盐城加能汽车部件有限公司

Function protecting material for special ASP ultra-low carbon continuous casting crystallizer

The invention discloses a function protecting material for a special ASP ultra-low carbon continuous casting crystallizer, comprising the following components by weight percent: 1.5 percent of carbon black, 4.5 percent of bentonite, 15 percent of fluorite, 4.0 percent of manganese dioxide, 7.0 percent of white alkali, 4.0 percent of sodium fluoride, 2.0 percent of alum clay, 3.0 percent of magnesia, 1.0 percent of lithium carbonate, 9.5 percent of glass and 48.5 percent of wollastonite. Field test results show that when the function protecting material is used, the continuous casting crystallizer has better internal spreading property, thermal insulating performance and melting property, no slag, and normal flame; and the periphery in the crystallizer has stable and even heat transfer quantity, stable thermocouple heat flow, stable friction force and no occurrence of viscosity alarm, thereby meeting the requirement of high casting speed. A casting billet has no fire slag and slag sticking on the surface and no carburization, thereby meeting the requirements of a steel plant.

Owner:乌兰察布市西蒙鼎新技术开发有限公司

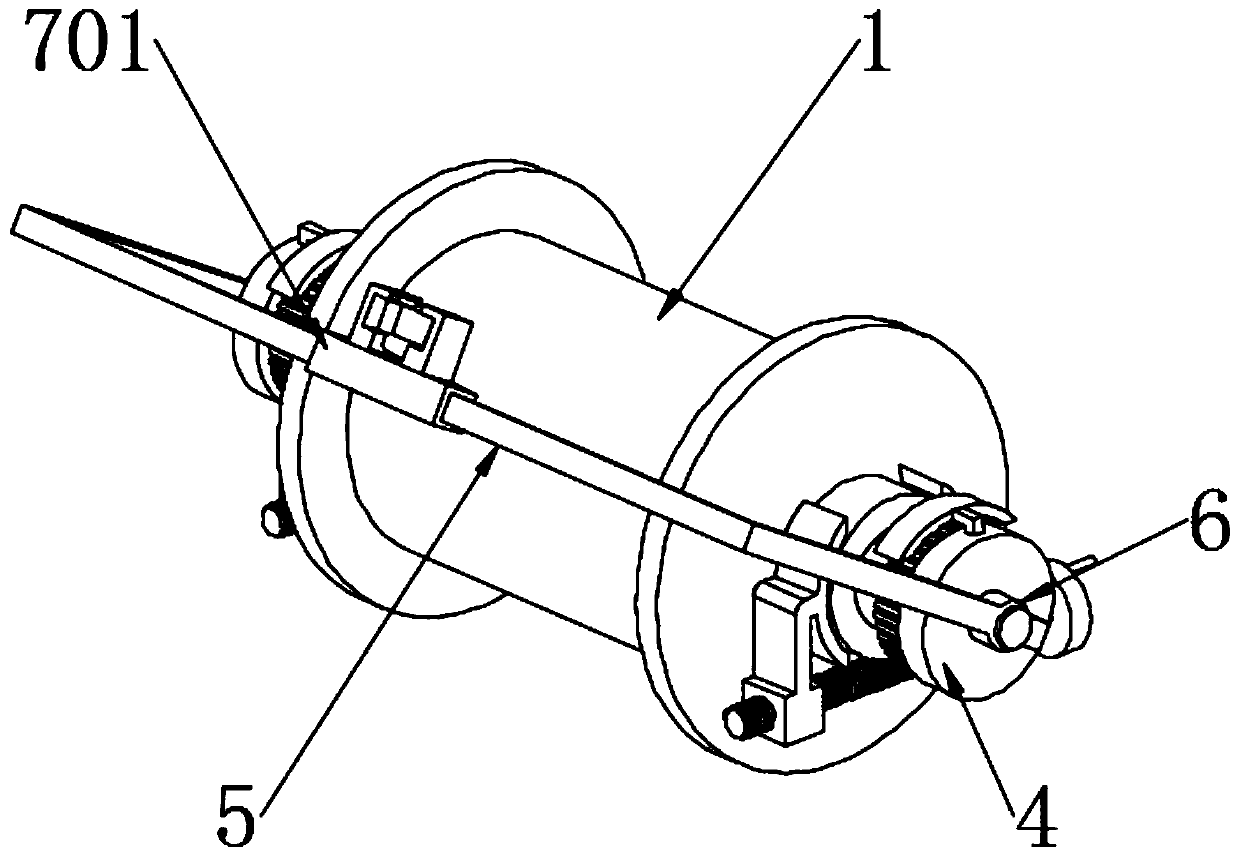

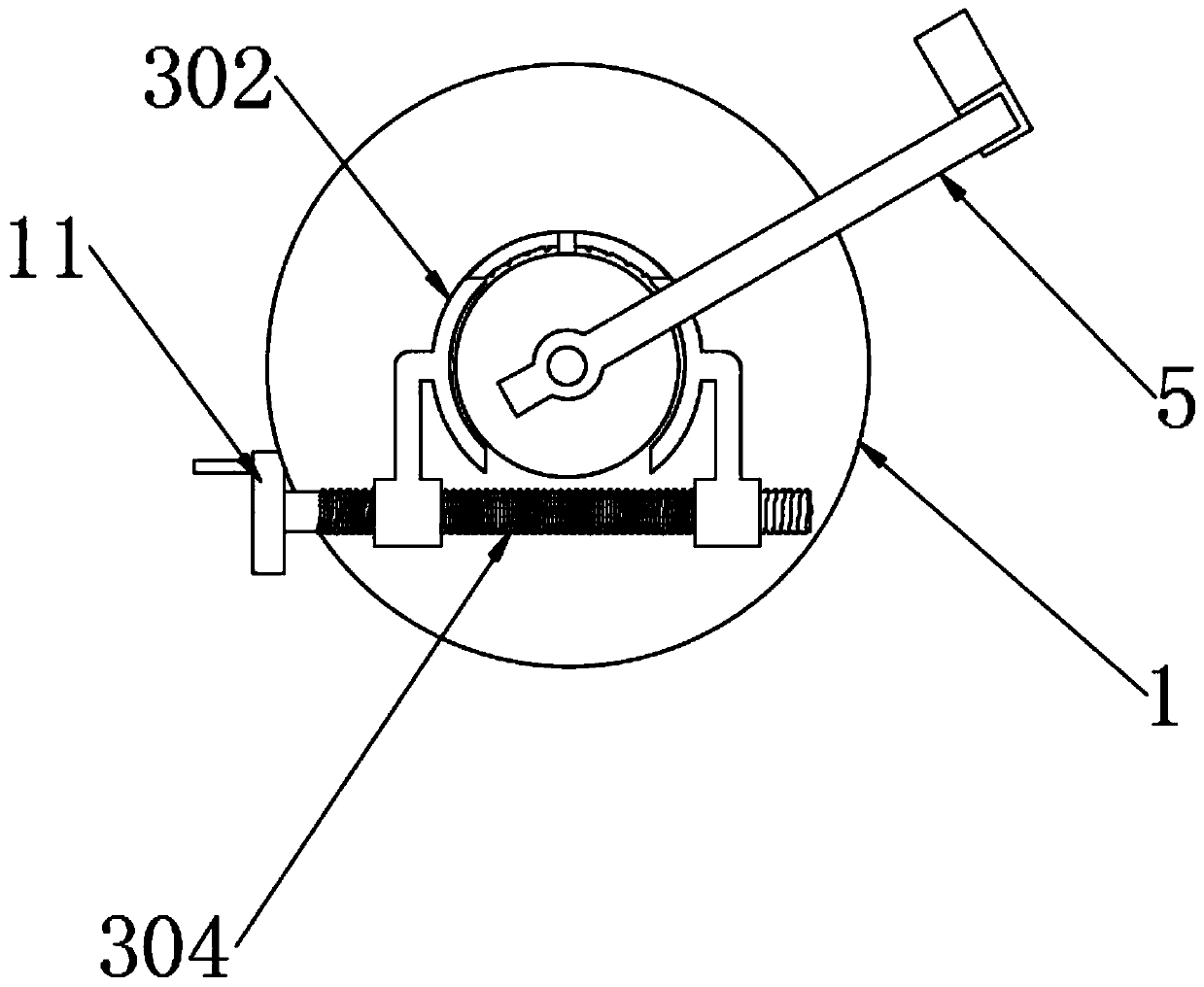

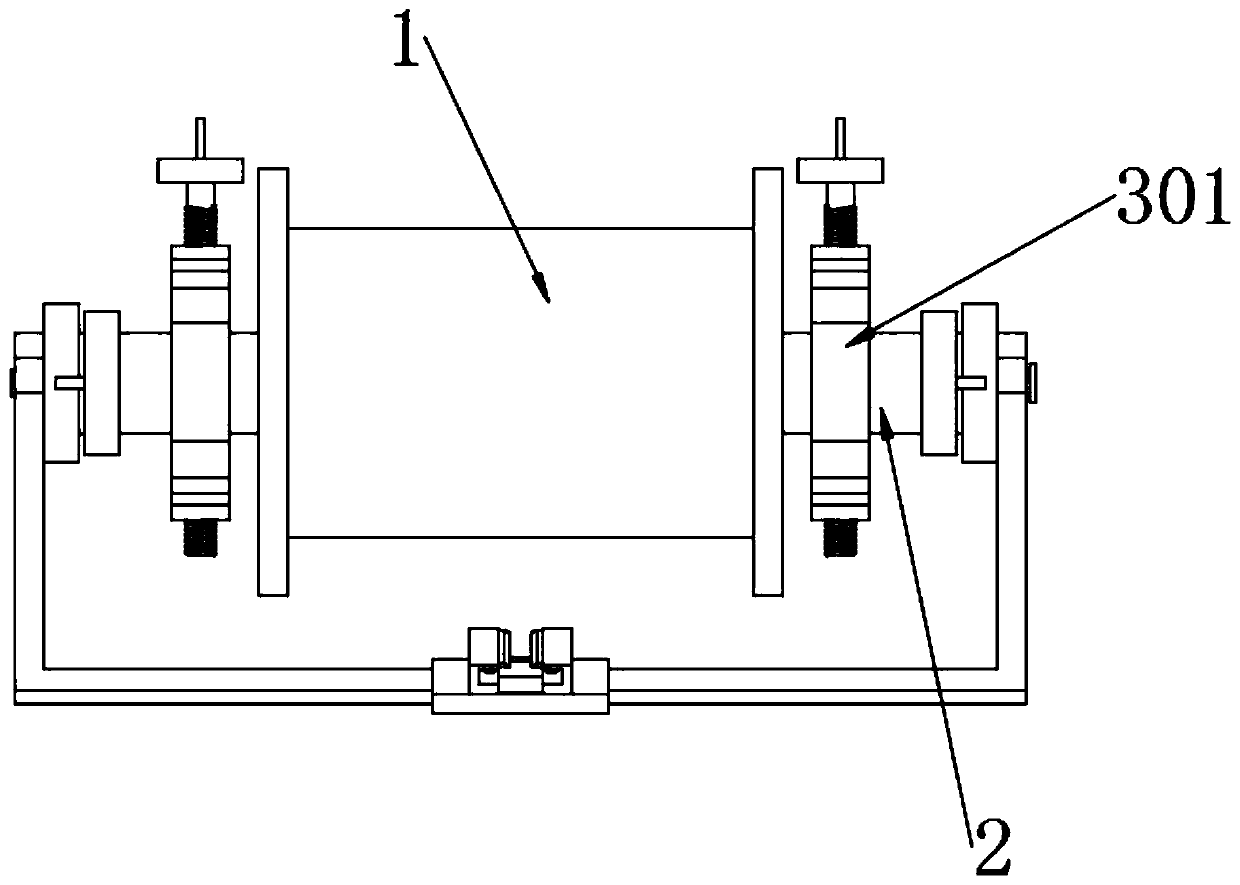

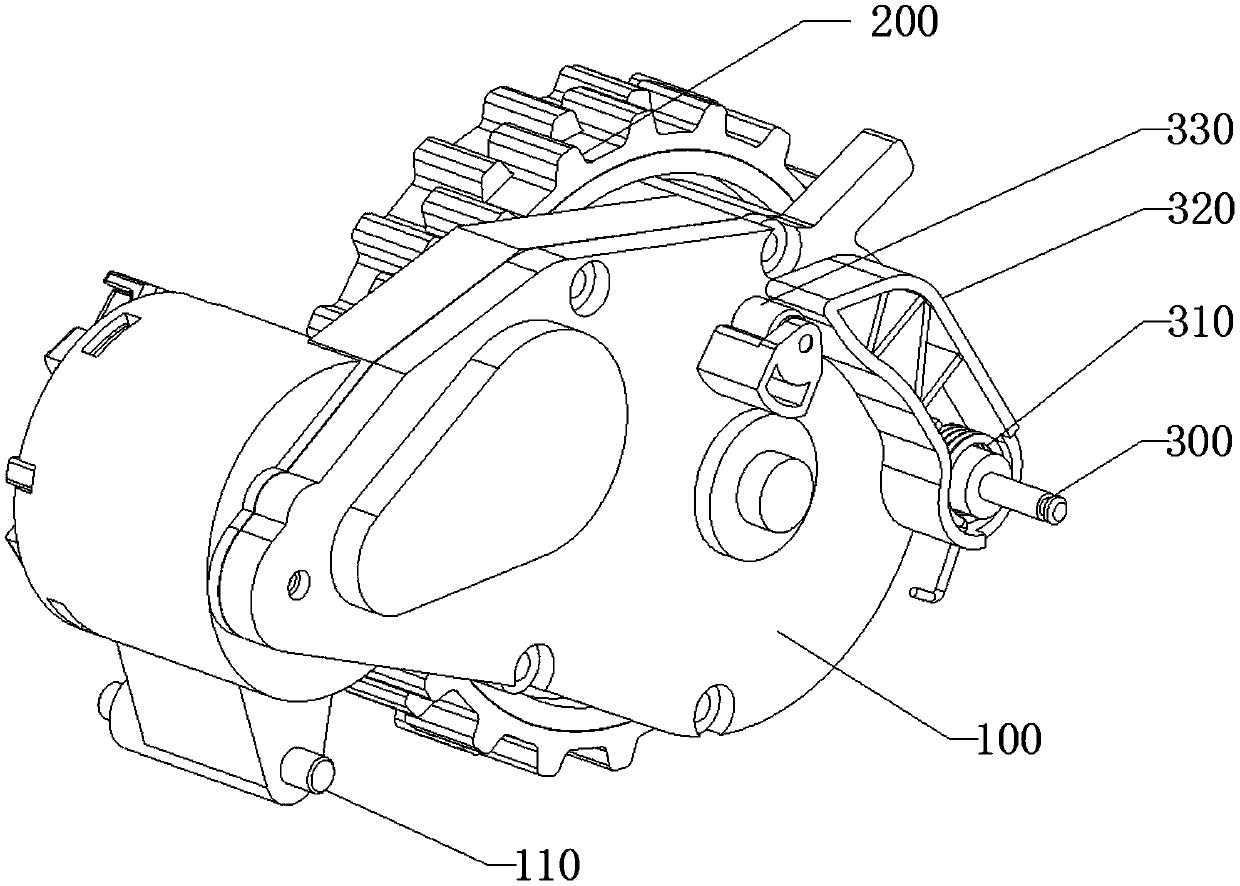

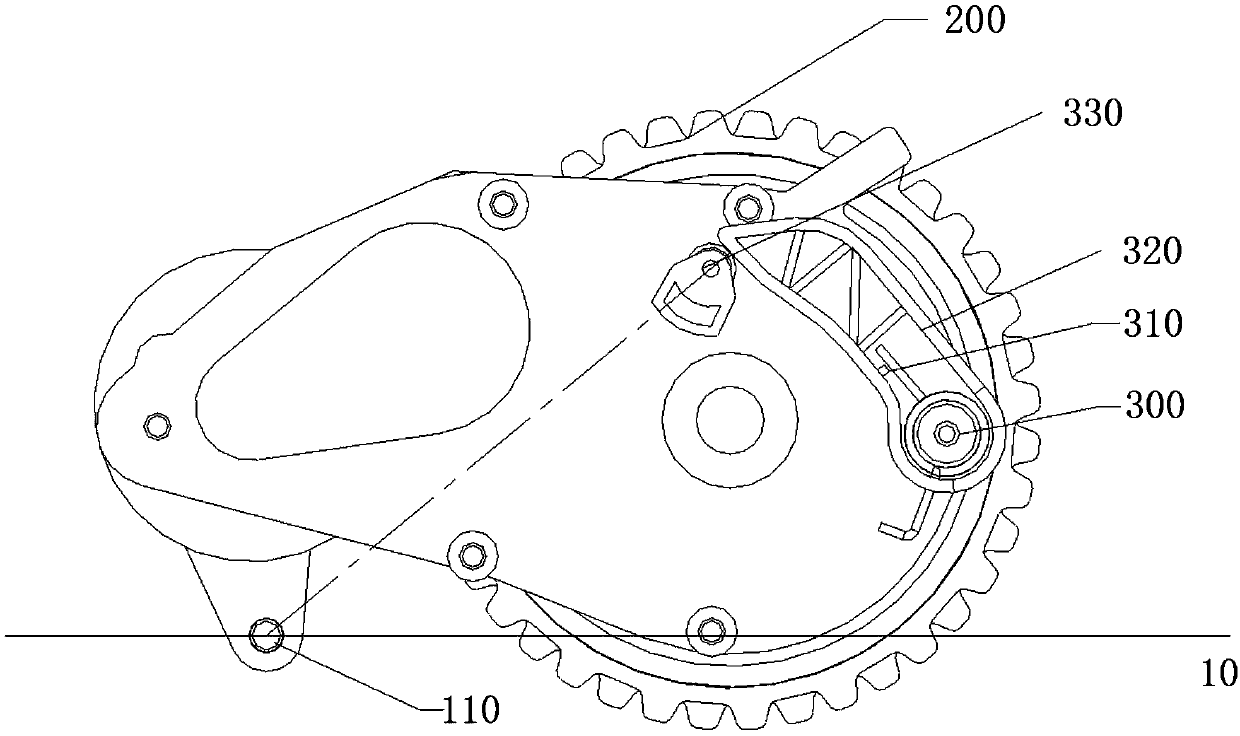

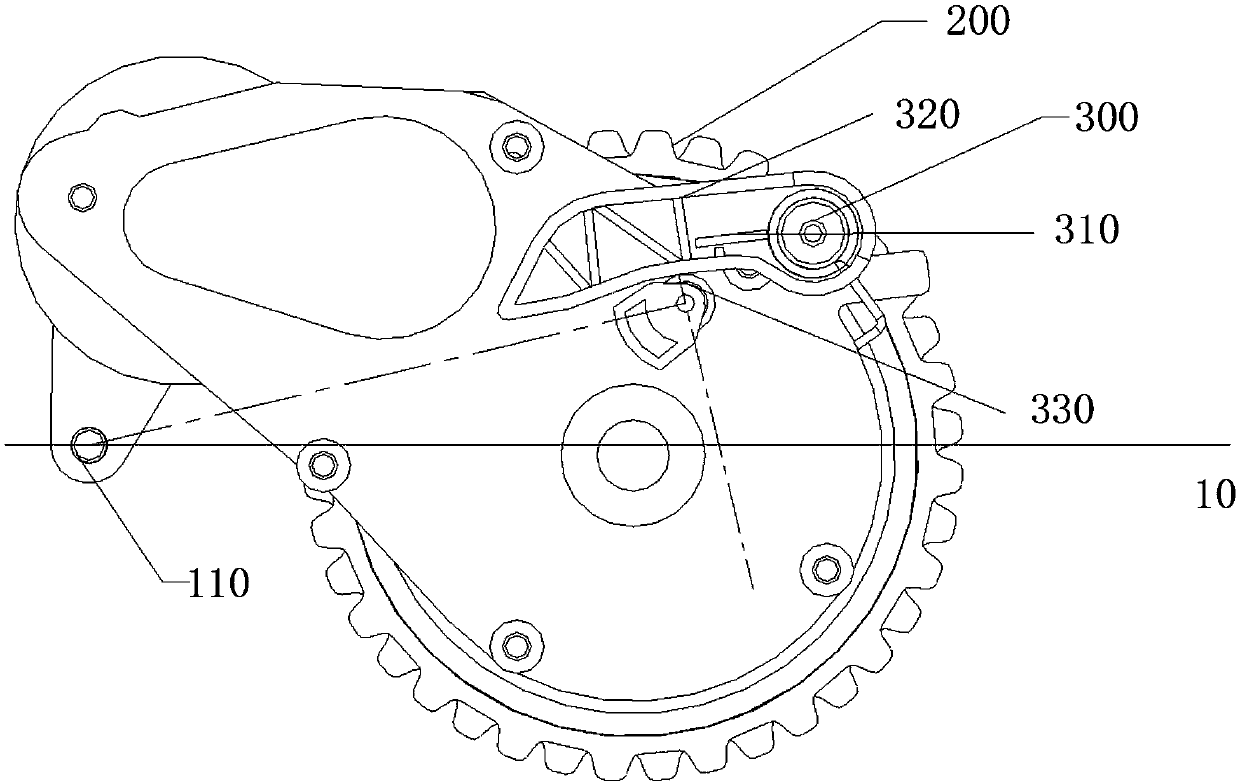

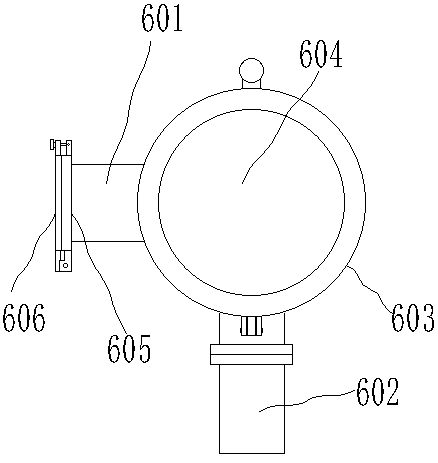

Mechanical damping passive pay-off unit

ActiveCN110642092AScientific and reasonable structureEasy to useFilament handlingGear wheelThreaded rod

The invention discloses a mechanical damping passive pay-off unit. The mechanical damping passive pay-off unit comprises a pay-off wheel and a center shaft, wherein the center shaft is located in thecenter of the pay-off wheel and penetrates through the pay-off wheel. Damping mechanisms are arranged on the two sides of the center shaft respectively. The mechanical damping passive pay-off unit isscientific and reasonable in structure, and safe and convenient to use; because of the damping mechanisms, friction is generated through contact between each damping fin and the corresponding rotary plate, the pay-off speed of the pay-off wheel can be controlled, and the pay-off wheel can carry out pay-off work stably; because of connecting rods, lead screws, threaded rods and nuts, the separationdistance between each threaded rod and the corresponding nut is adjusted by turning the corresponding lead screw to adjust the gluing force between the corresponding damping fin and the correspondingrotary plate, then friction is changed to achieve the effect of having control over the rotating speed of the pay-off wheel, pay-off is smooth and steady, and the tension of cables is kept as well; and because adjusting gears are driven by rotary shafts to rotate, then racks are driven to move upwards or downwards to enable each positioning toothed plate and the corresponding gear to be separatedor be in engagement connection, the gears can rotate freely when each positioning toothed plate and the corresponding gear are separated, and when each positioning toothed plate and the correspondinggear are separated, the gears are locked, the pay-off wheel is locked as well, and the mechanical damping passive pay-off unit is more convenient to use.

Owner:NANJING INST OF RAILWAY TECH

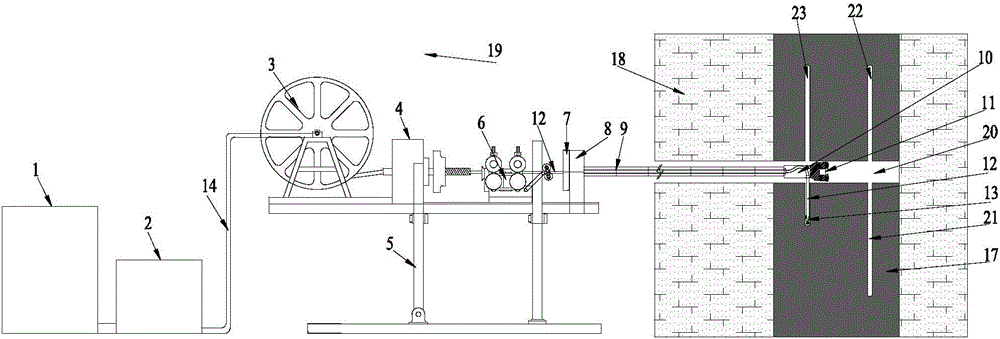

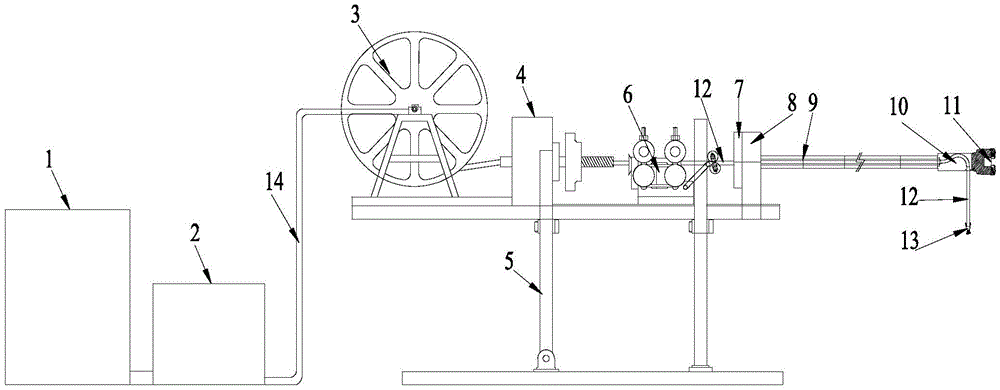

Composite fracturing and uniform permeability increasing equipment for treelike drilling in coal seam of underground coal mine

The invention discloses composite fracturing and uniform permeability increasing equipment for treelike drilling in a coal seam of an underground coal mine. The whole equipment can be divided into a hole forming system and a fracturing system. The hole forming system comprises a drilling machine, a drill stem, a drill bit, a support, a water tank, a high-pressure pump, a winch, a propelling mechanism, a chuck, a high-pressure hose, a self-propelled drill bit and the like. The fracturing system comprises the water tank, the high-pressure pump, a pressure meter, a high-pressure rubber pipe, a hole sealing device and the like. The composite fracturing and uniform permeability increasing equipment is suitable for carrying out volume fracturing on the coal seam of the underground coal mine, can reach the effects of carrying out uniform permeability increasing on the coal seam and increasing the gas extraction rate, and is easy to operate and good in economic performance.

Owner:CHONGQING UNIV

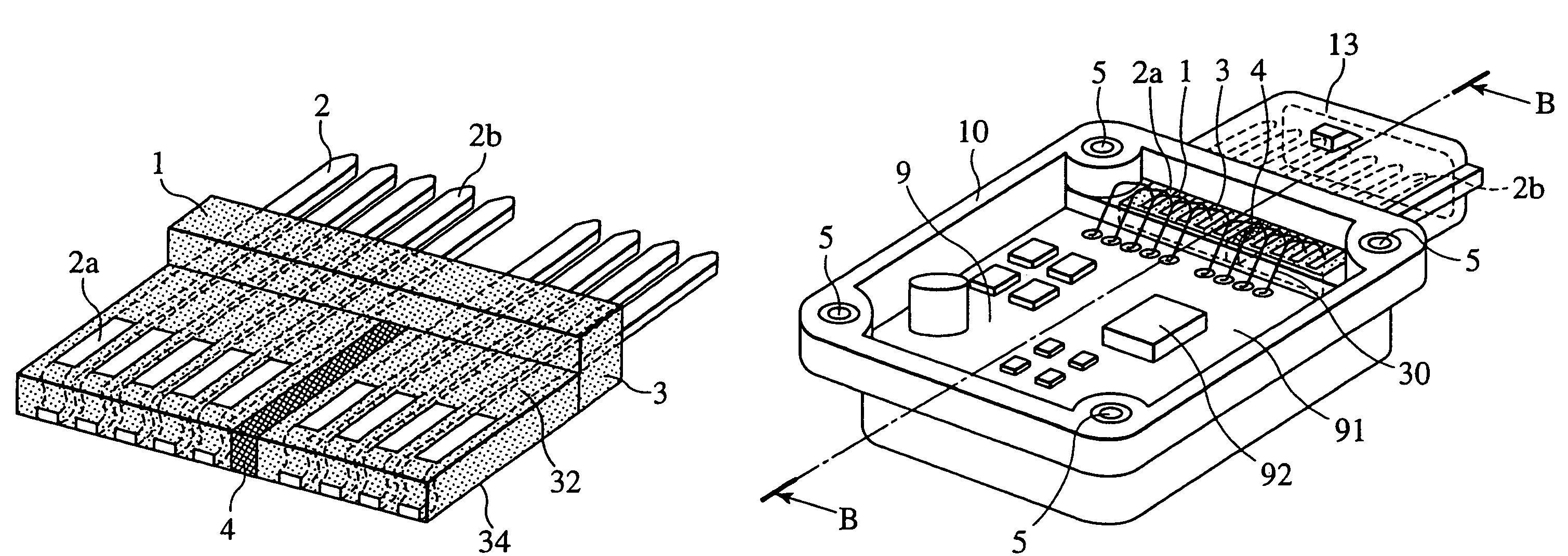

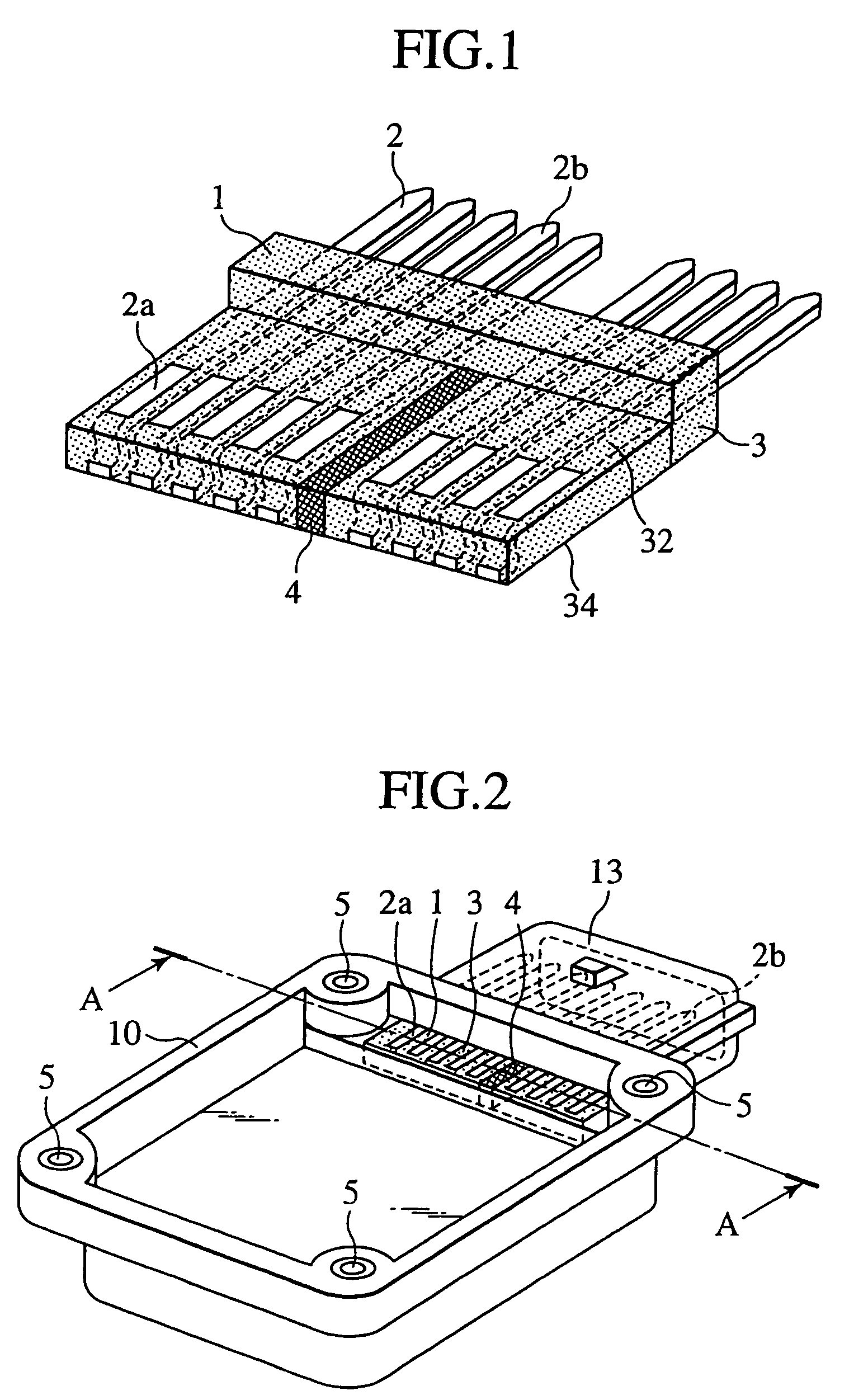

Molded part and electronic device using the same

ActiveUS7255610B2Relieve pressureSuppressing any actionContact member assembly/disassemblySemiconductor/solid-state device detailsShell moldingElectrical connection

An integrally multiple-molded part for electronic devices is provided capable of absorbing and relieving the internal stresses of a multiple-molded part, preventing the occurrence of clearances between the bonding side face of each electrical connection terminal and a resin, obtaining stable frictional force at the contact region between the bonding surface of the electrical connection terminal and an aluminum wire, obtaining the energy required for bonding, and achieving high bondability. The surface of the molded electrical connection terminal section formed as a primary-molded article becomes exposed after secondary molding, and a stress-absorbing structure is formed in the primary molding resin section of the primary-molded article that serves as a transmission path for stresses associated with the resin shrinkage occurring when the secondary molding resin is cured.

Owner:HITACHI ASTEMO LTD

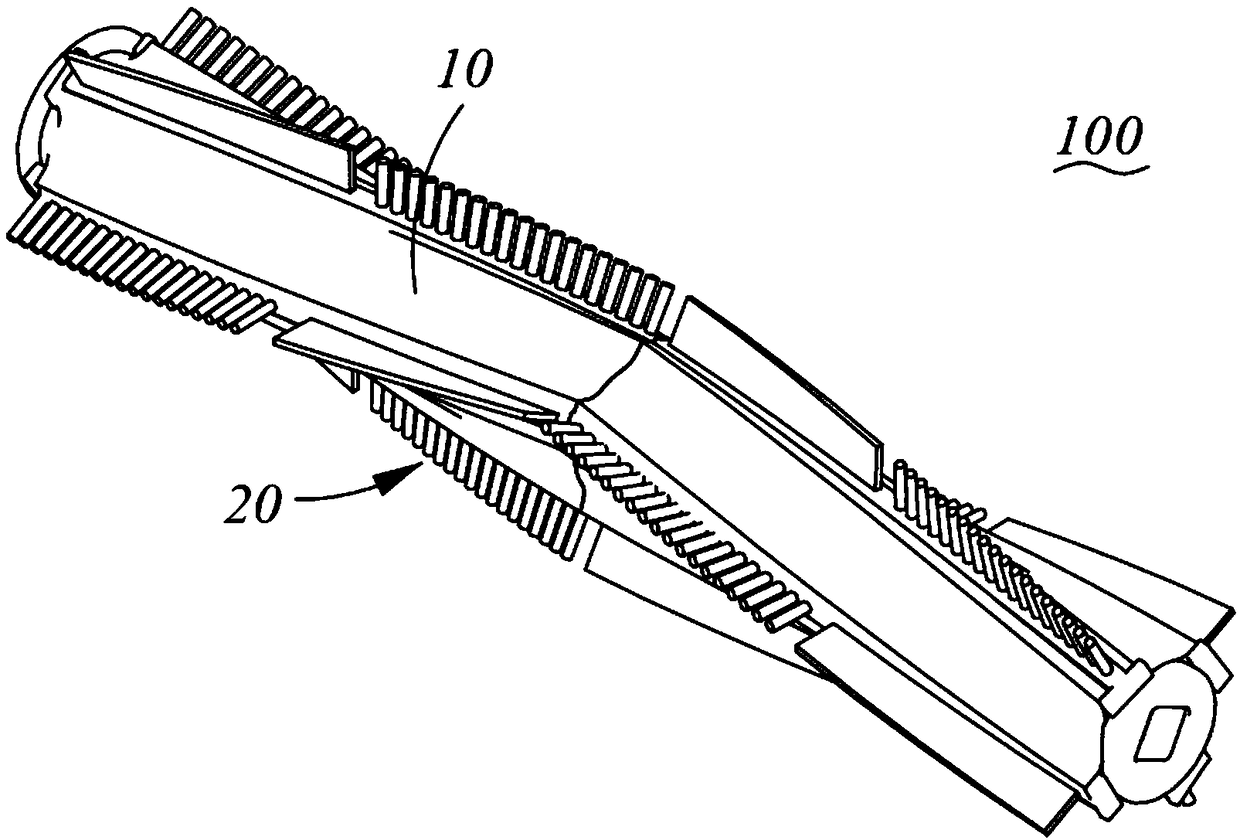

Rolling brush, manufacturing method of rolling brush and sweeper with rolling brush

PendingCN108903823ASimple manufacturing processEasy to replaceCarpet cleanersFloor cleanersBristleMechanical engineering

The invention provides a rolling brush. The rolling brush comprises a lengthwise rolling brush roller and a plurality of brushing strips, wherein the brushing strips longitudinally extend along the rolling brush roller and are arranged at intervals in the circumference direction of the rolling brush roller, each brushing strip comprises a main body portion, bristles and a scraping strip, wherein the bristles and the scraping strip are fixed to the main body portion, and the bristles and the scraping strips are arranged alternately in the lengthwise direction of the main body portion. The bristles and the scraping strips are arranged at intervals on the same main body portion, dusts collected by the scraping strips are raised by the brushing hair, then the dusts are taken away through an air inlet opening, and working pressure of a hair brushing segment is reduced.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

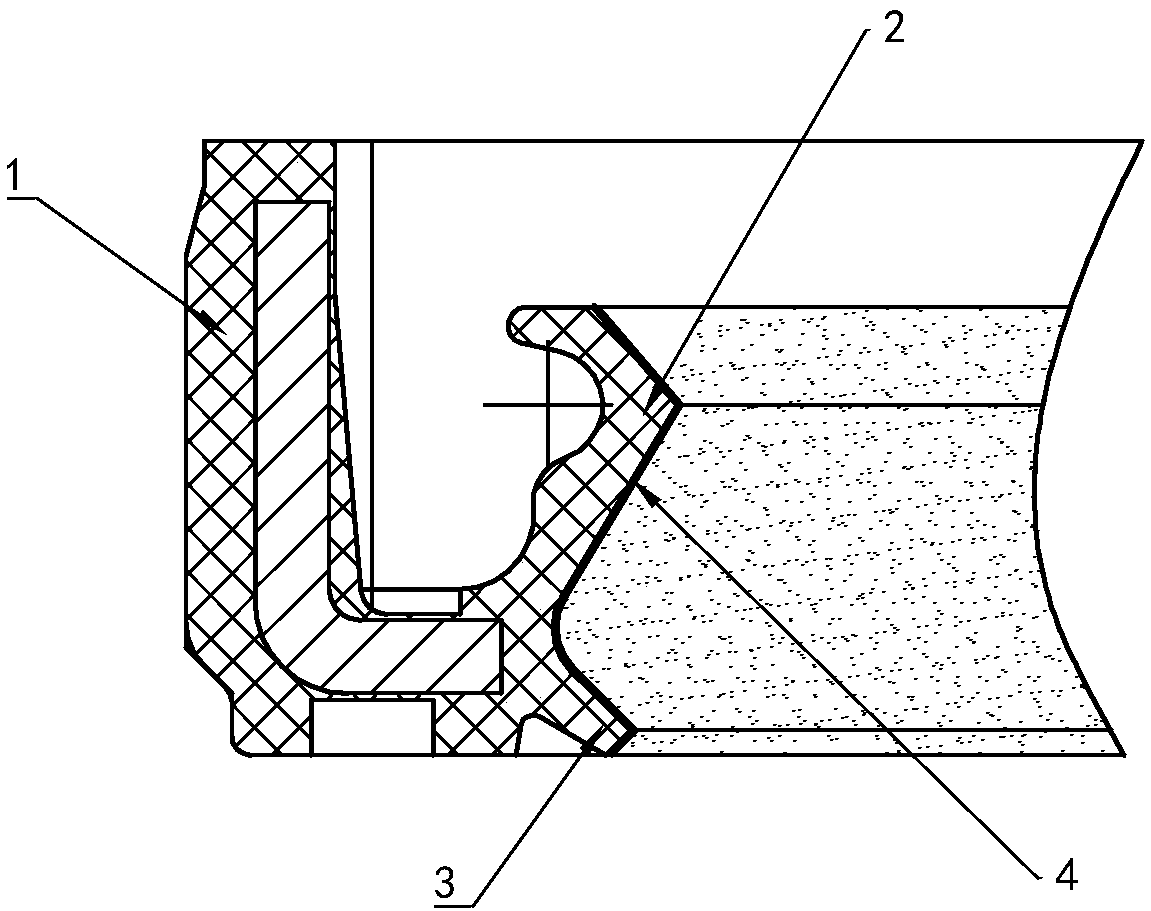

Oil seal coating agent, spraying method thereof and oil seal prepared therefrom

InactiveCN108587404APrecise control of injection volumeReduce coefficient of frictionEngine sealsPretreated surfacesGraphiteFriction force

The invention relates to an oil seal coating agent, a spraying method thereof and an oil seal prepared therefrom. The oil seal coating agent is composed of a component A, a component B and a componentC according to a mass proportion of 100:7-8:100, wherein the component A is composed of graphite powder, molybdenum disulfide and polytef, the component B is waterborne curing agent and is composed of homopolymer of polyethylene glycol monomethyl ether terminated 1, 6-diisocyanate hexane and 1, 6-diisocyanyl hexane, and the component C is composed of polyacrylate salt and waterborne epoxy resin.The coating agent is used for being coated in oil seal main lip and dustproof lip areas, and coating thickness is about 30um. When the oil seal works, part of the coating agent is transferred from theoil seal to the surface of a shaft, a coating film is promoted to closely cover the surface of the shaft under action of contact force between an oil seal lip opening and the shaft at the same time to enable the shaft to be smoother so as to play a role in lowering friction coefficient, and low and stable friction force and friction torque are provided in the whole life cycle of the oil seal.

Owner:广东天诚密封件股份有限公司

Boron-steel-containing mold flux dedicated for continuous casting

The invention discloses boron-steel-containing mold flux dedicated for continuous casting, comprising the following chemical ingredients by mass: 34-40% of CaO, 23-27% of SiO2, 2-4% of Al2O3, 6-8% of F, 1-2% of MgO, 2-4% of MnO, 7-9% of Na2O, 5-8% of C and 0.1-1.5% of Li2O. Experiments on site prove that boron-steel-containing 15MnVB and S400B are cast in a slab casting machine with specification of 200*900-1200mm <2> in a steel mill under the condition that the stable casting speed is 1.60m / min, the flux consumption is 0.38Kg / steel T; and no caking occurs in the process of melting the mold flux, no flux strip exists at molten steel meniscus, the thickness of a melt cinder layer on a molten steel surface is 10-15mm, the stable and even heat flux around a crystallizer is observed by a heat flow curve to be stable and uniform, and the frictional force of the crystallizer is stable. Therefore, the experiments show that heat transmission and lubrication performances of the mold flux are good.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

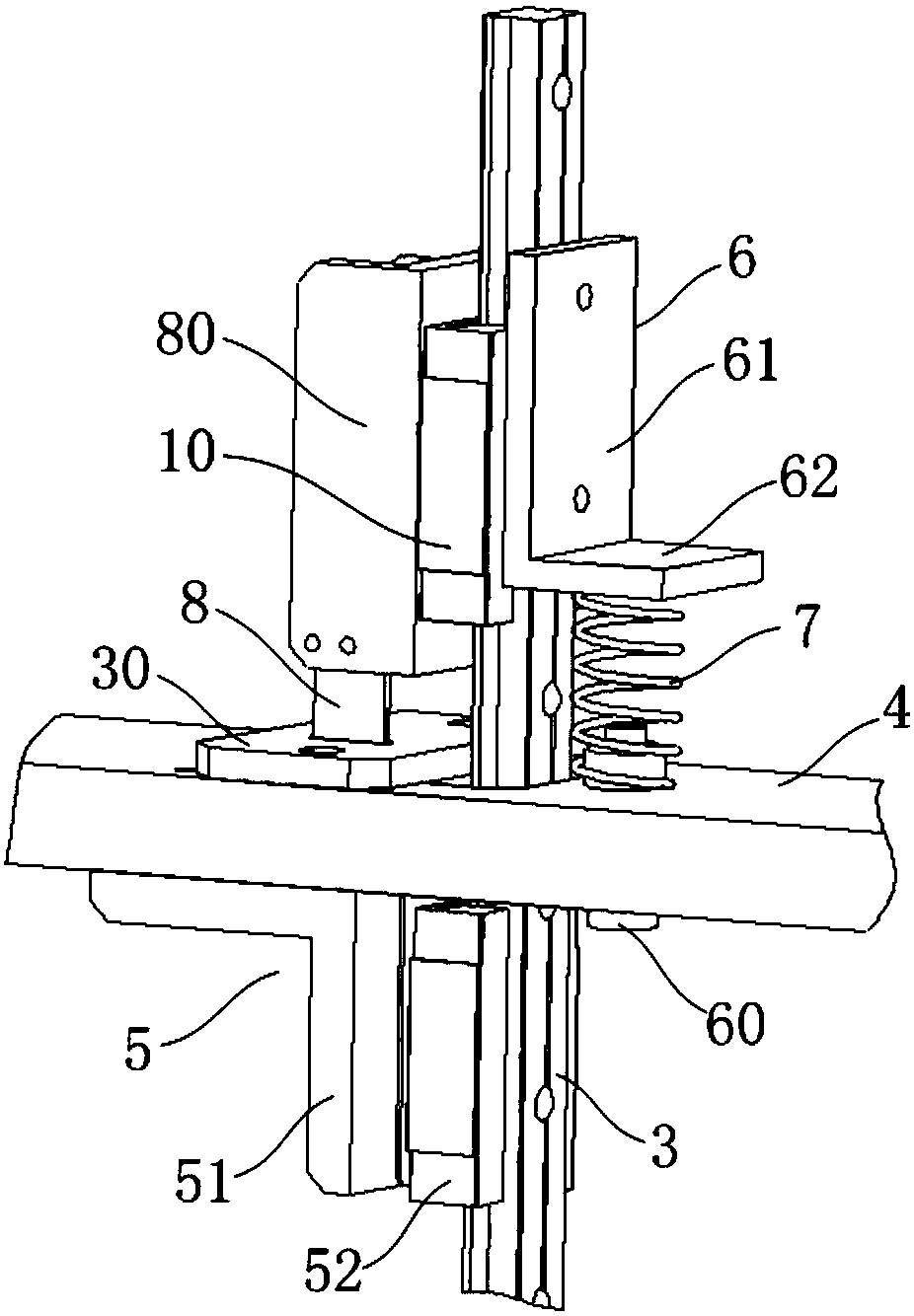

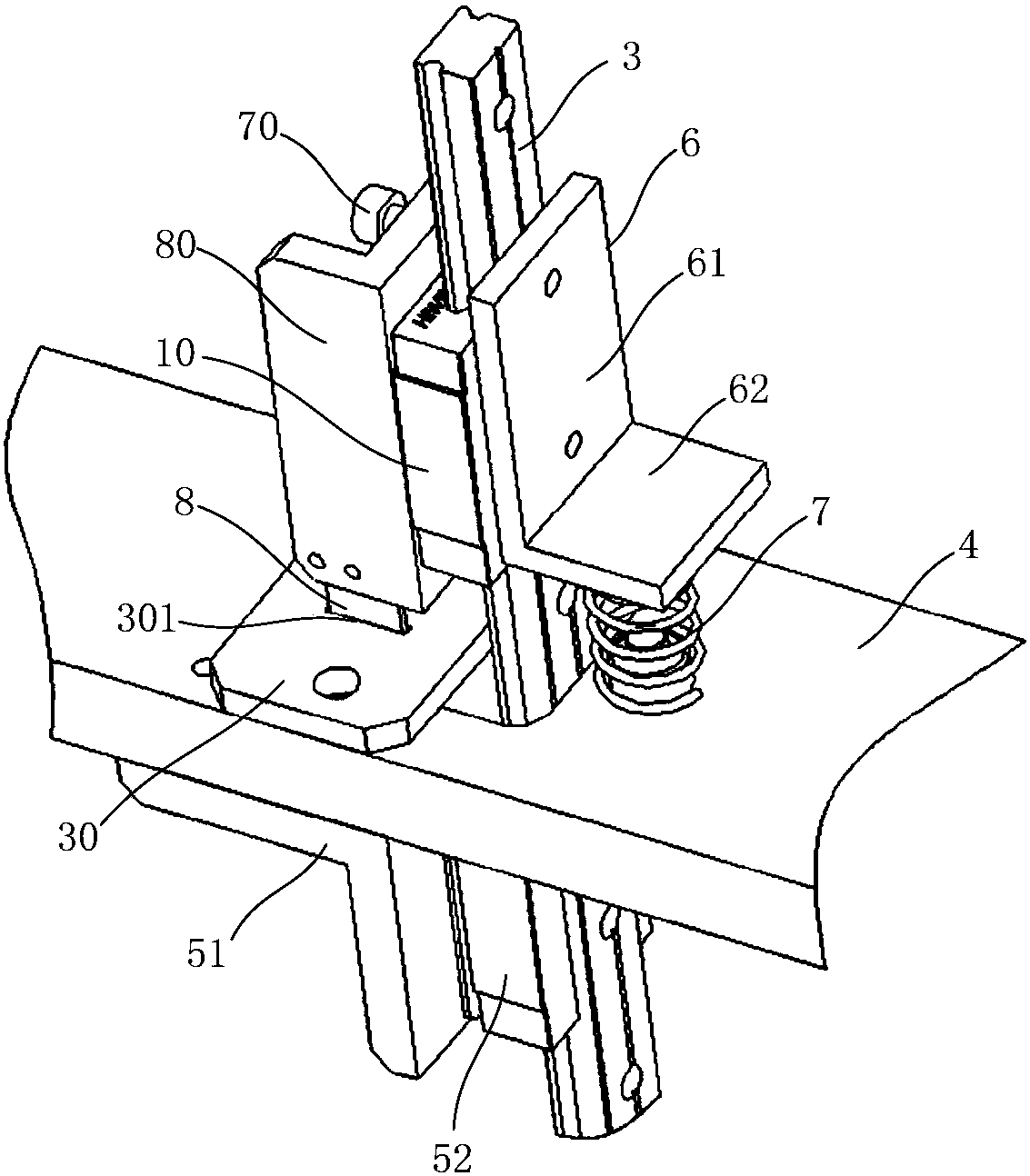

Pressure control based cloth separation device

ActiveCN105951315AFriction remains constantThe effect is stable and reliableSewing-machine elementsEngineeringPressure control

The invention provides a pressure control based cloth separation device which comprises a lifting plate capable of going up and down, wherein a roller capable of rotating around an axis is suspended above the lifting plate; the roller is arranged on a suspension rod; the suspension rod passes through a transverse cross beam; a guide member for enabling the suspension rod to move along the axis direction of the suspension rod is fixed on the cross beam; a spring catch is fixed on the part of the suspension rod above the cross beam; a compression spring is arranged between the spring catch and the cross beam; a sensor catch is also fixed on the suspension rod; and a sensor for measuring the position of the sensor catch is fixed on the cross beam. In the pressure control based cloth separation device, the pressure of the roller on the cloth surface can be effectively controlled for separating single layers of a stack of cloth, so that the friction between the roller and the cloth can be kept stable, and the cloth separation effect is more stable and reliable.

Owner:JACK SEWING MASCH CO LTD

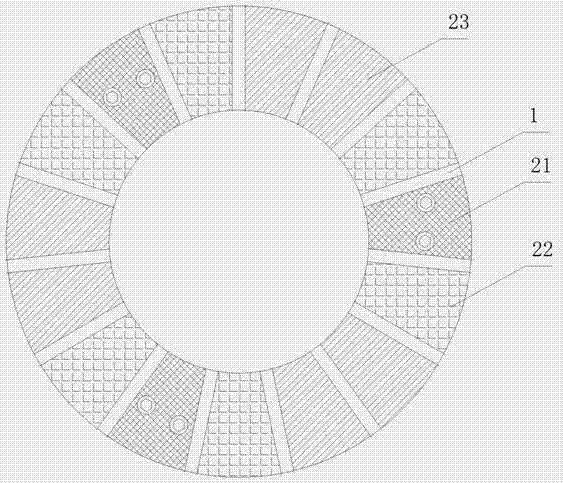

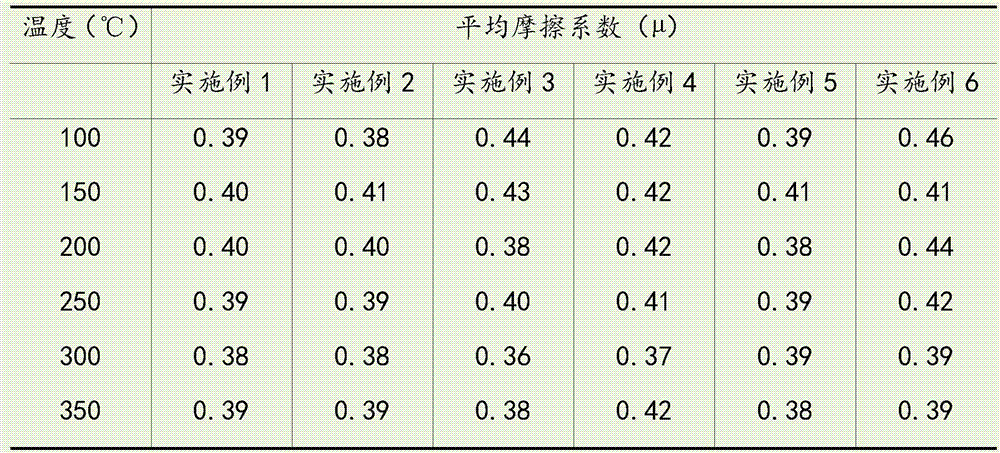

High-performance clutch plate for heavy truck

The invention provides a high-performance clutch plate for a heavy truck. The high-performance clutch plate for the heavy truck achieves the technical purposes of being novel in structure, reasonable in material formula and balanced and excellent in performance index, cost and application effect. The high-performance clutch plate for the heavy truck is divided into a friction working layer and a structural layer. The friction working layer comprises at least three friction linings made of different materials. The three friction linings made of the different materials comprise the rubber-based friction linings, the substitute rubber FA friction linings and the ceramic fiber friction linings, all of which are of the same thickness. The high-performance clutch plate has the following beneficial effects that due to the fact that the rubber-based friction linings, the ceramic fiber friction linings and the substitute rubber FA friction linings are arranged on the surface of the structural layer in a mixed manner, in clutch operation of the clutch plate, the characteristics of the three different materials can be brought into play, when the clutch plate is applied to a clutch mechanism of the heavy truck, friction force resistant to attenuation and stable at high temperature is effectively reduced, and the high-performance clutch plate is particularly suitable for being applied to the heavy truck.

Owner:浙江科马摩擦材料股份有限公司

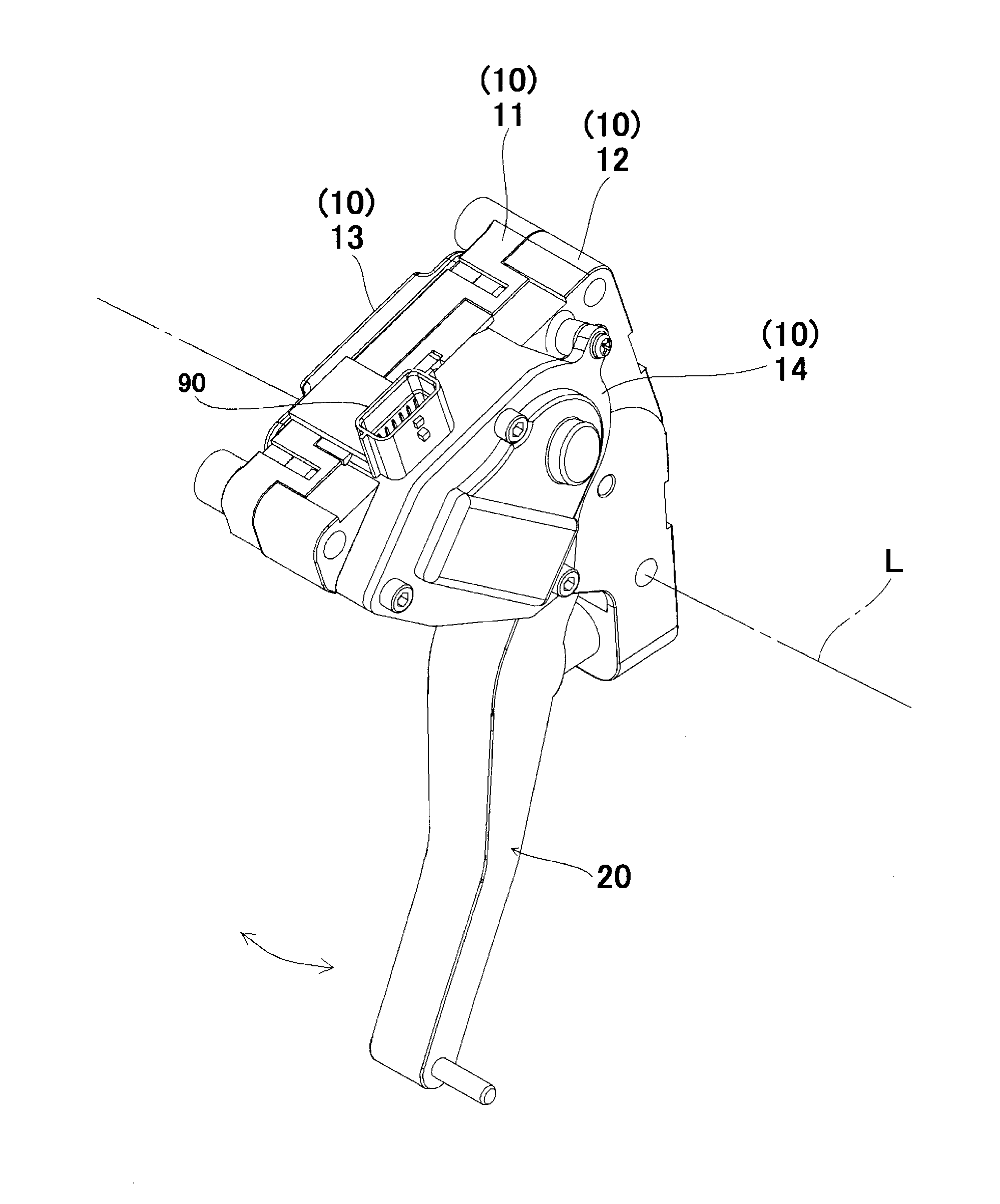

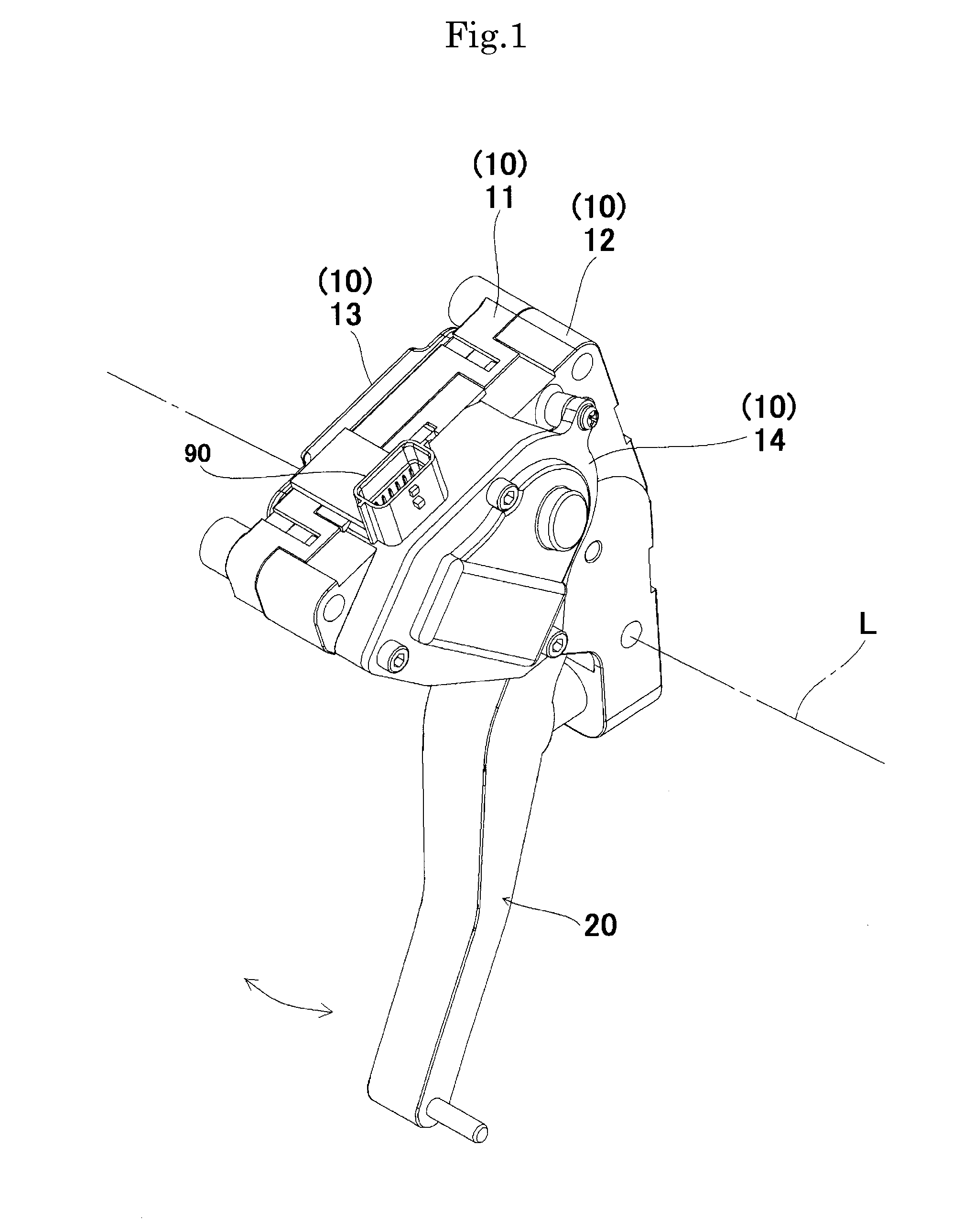

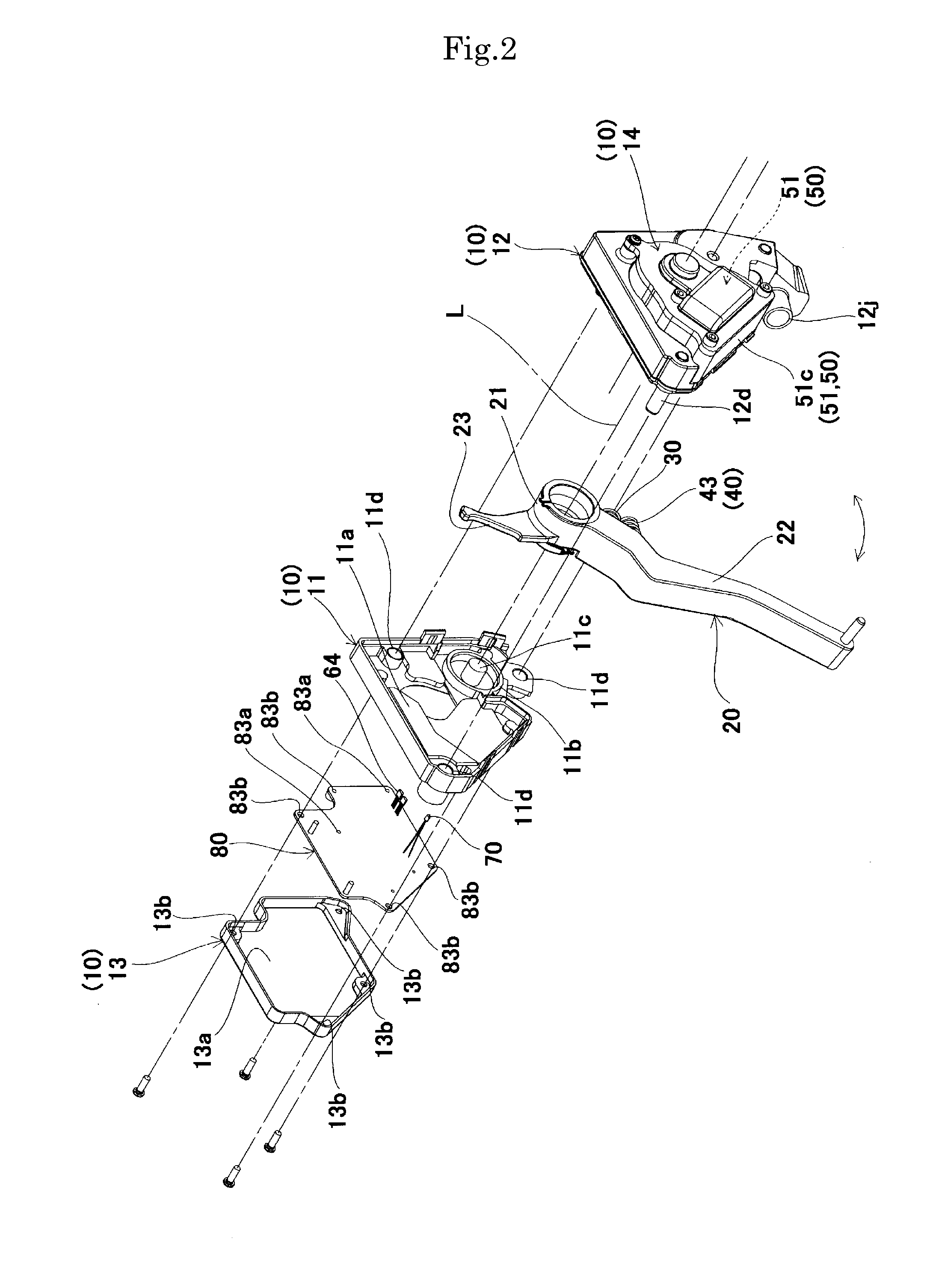

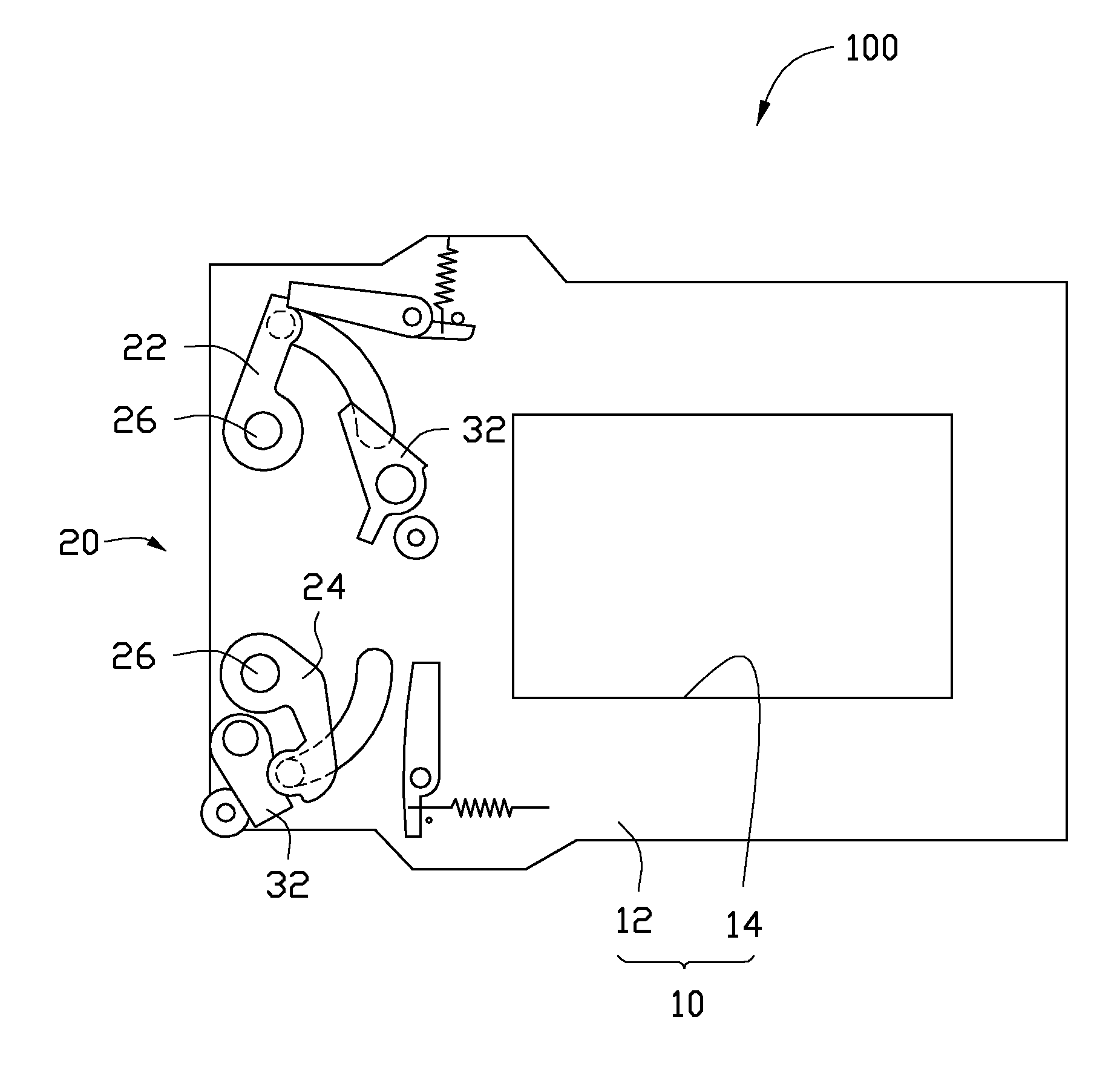

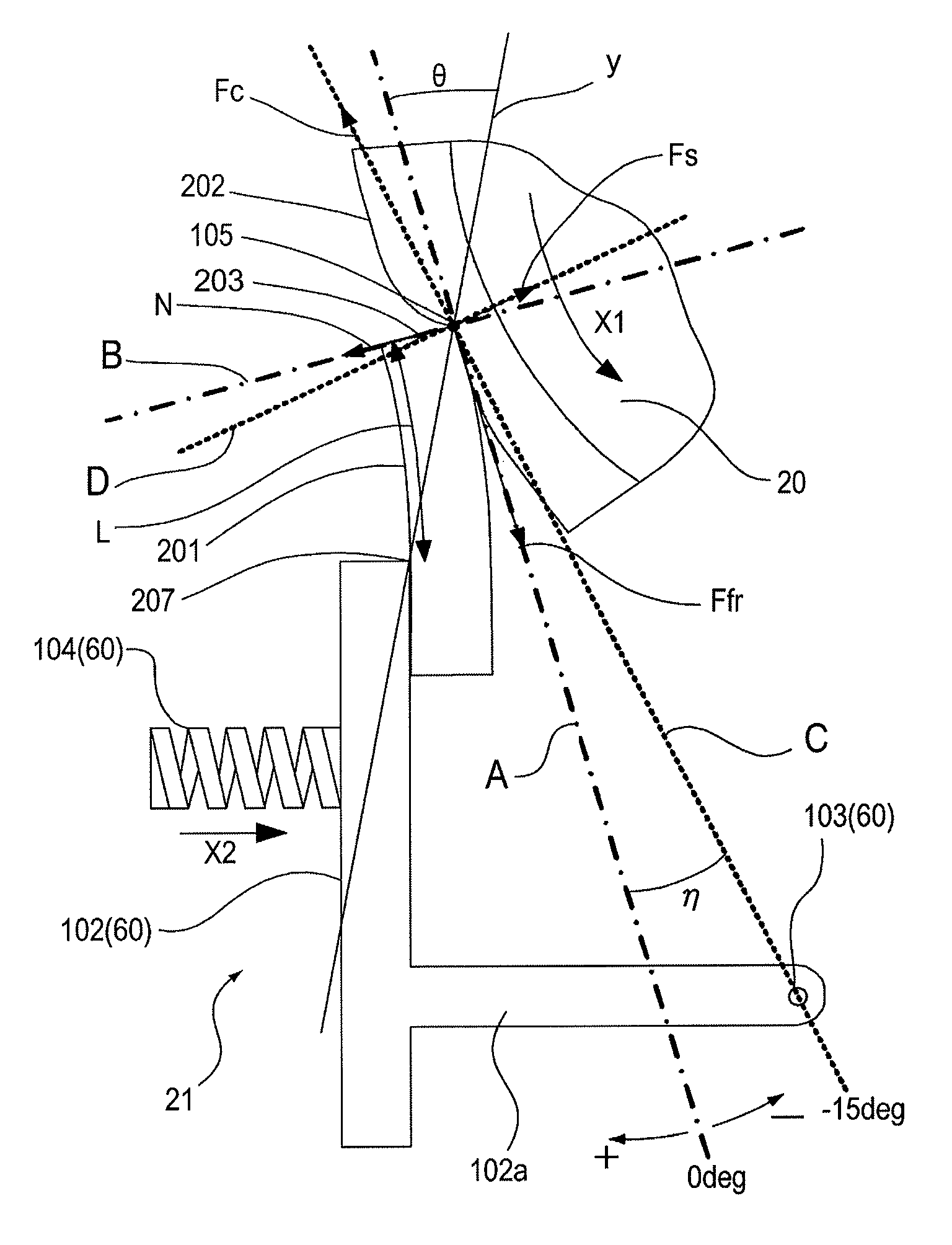

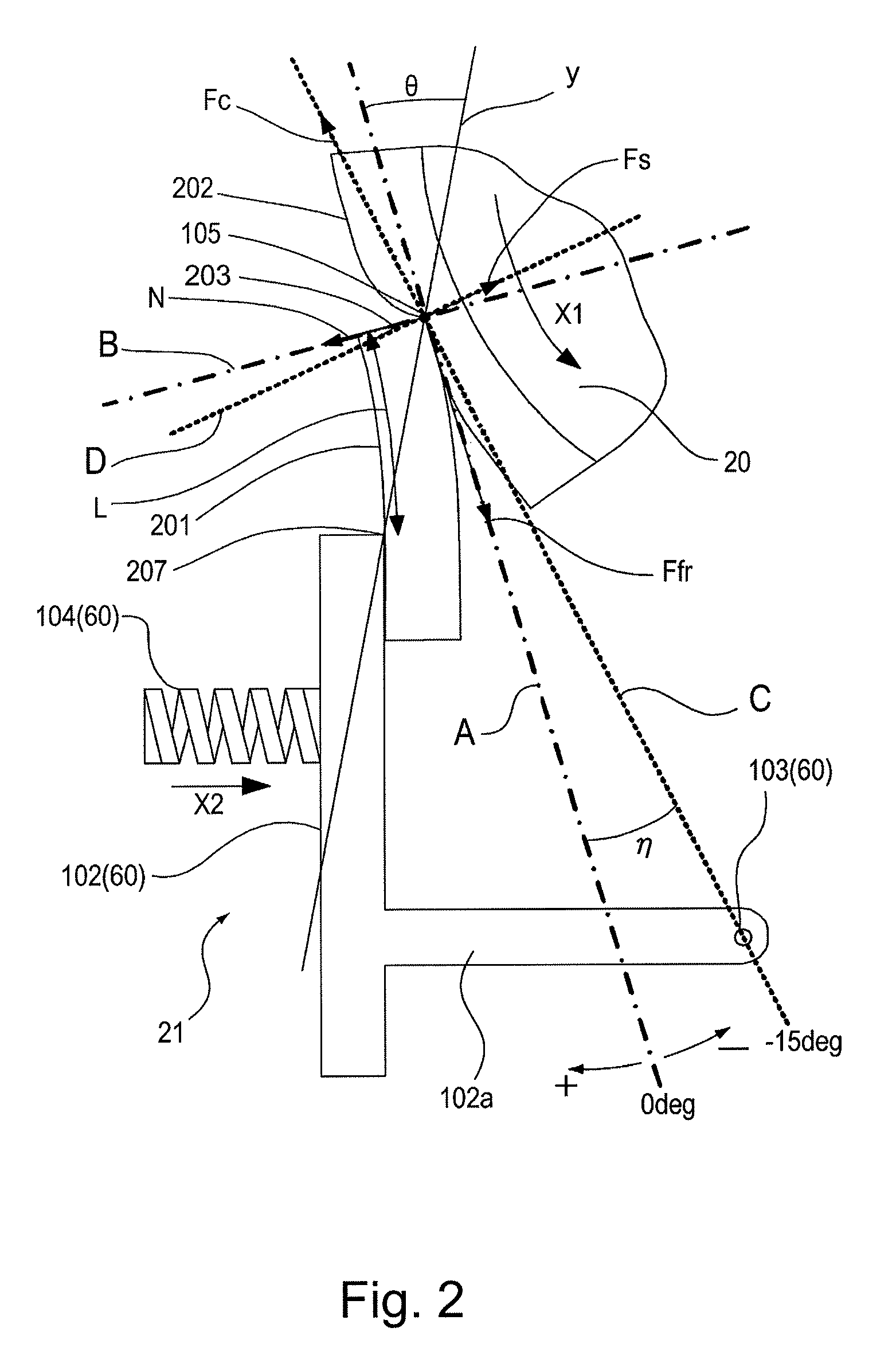

Accelerator pedal device

InactiveUS20140238181A1Cost reductionHysteresis characteristicControlling membersEngine controllersEngineeringMechanical engineering

An accelerator pedal device includes a slide guide path which is formed in a housing, a first slider which is engaged with the pedal arm for receiving pedaling force as being slidably arranged in the slide guide path and which includes a first inclined face inclined against a movement direction of the first slider, a second slider which is slidably arranged in the slide guide path and which includes a second inclined face contacted to the first inclined face, and an urging spring which exerts urging force in a direction opposing to the pedaling force as being engaged with the second slider, wherein the slide guide path is formed as being tapered in a direction of movement of the first slider and the second slider which are moved in association with depression of the accelerator pedal. Accordingly, desired hysteresis can be obtained on the pedaling force while achieving downsizing.

Owner:MIKUNI CORP

Friction damper

InactiveUS7322451B2Inhibit wearPrevent peelingNon-rotating vibration suppressionFilament handlingRelative motionEngineering

A friction damper includes a base body; a support secured to an elongated member of the base body and having a through hole; a rod which extends in such a manner as to pass through the through hole of the support and is movable in an axial direction with respect to the support; a friction member which has a hollow cylindrical portion interposed between the support and a main body portion of the rod in the through hole of the support, and which is fixed immovably with respect to the relative movement of the rod in the axial direction with respect to the base body; and a tightening structure provided for the support so as to tighten the hollow cylindrical portion of the friction member onto the main body portion of the rod.

Owner:OILES CORP

Friction member for brake mechanism and camera shutter using the same

ActiveUS20120141109A1Stable frictionHigh strengthMaterial nanotechnologyLayered productsShutterCarbon nanotube

A friction member for a brake mechanism in a camera shutter is provided. The friction member includes at least two carbon nanotube composite layers stacked on each other, each carbon nanotube composite layer includes a polymer and a carbon nanotube structure including a number of carbon nanotubes substantially oriented along a same direction. An angle defined by the carbon nanotubes oriented along the same direction in adjacent carbon nanotube composite layers ranges from greater than 0 degrees, and less than or equal to 90 degrees. The camera shutter using the friction member is also provided. The camera shutter includes a brake mechanism and a drive mechanism including a blade driving lever having a moving path. The brake mechanism includes two abovementioned friction members and a brake lever clamped between the two friction members. The brake lever is located at a termination of the moving path to brake the blade driving lever.

Owner:BEIJING FUNATE INNOVATION TECH

Self-moving robot and traveling method thereof

PendingCN110115549AImprove obstacle performanceIncrease frictionAutomatic obstacle detectionSpeed controllerDrive wheelPositive pressure

An embodiment of the invention provides a self-moving robot and a traveling method thereof. The self-moving robot comprises a body, a driving wheel component and an obstacle surmounting component. Thedriving wheel component is rotationally arranged on the body through a first rotating shaft and comprises a driving wheel; in a process that the driving wheel moves from a first position to a secondposition relative to the body, the obstacle surmounting component applies force to the driving wheel component, and the positive pressure variation amplitude between the driving wheel and an advancingsurface is smaller than or equal to a set threshold. In the technical scheme, when the body of the self-moving robot encountering an obstacle is jacked up or travels to a pit position, the driving wheel component is subjected to the acting force applied by the obstacle surmounting component besides own gravity; under the joint action of the forces, the positive pressure variation amplitude between the driving wheel and the advancing surface is smaller than or equal to the set threshold, so that friction between the driving wheel and the advancing surface is increased, and an obstacle surmounting performance of the self-moving robot is improved.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

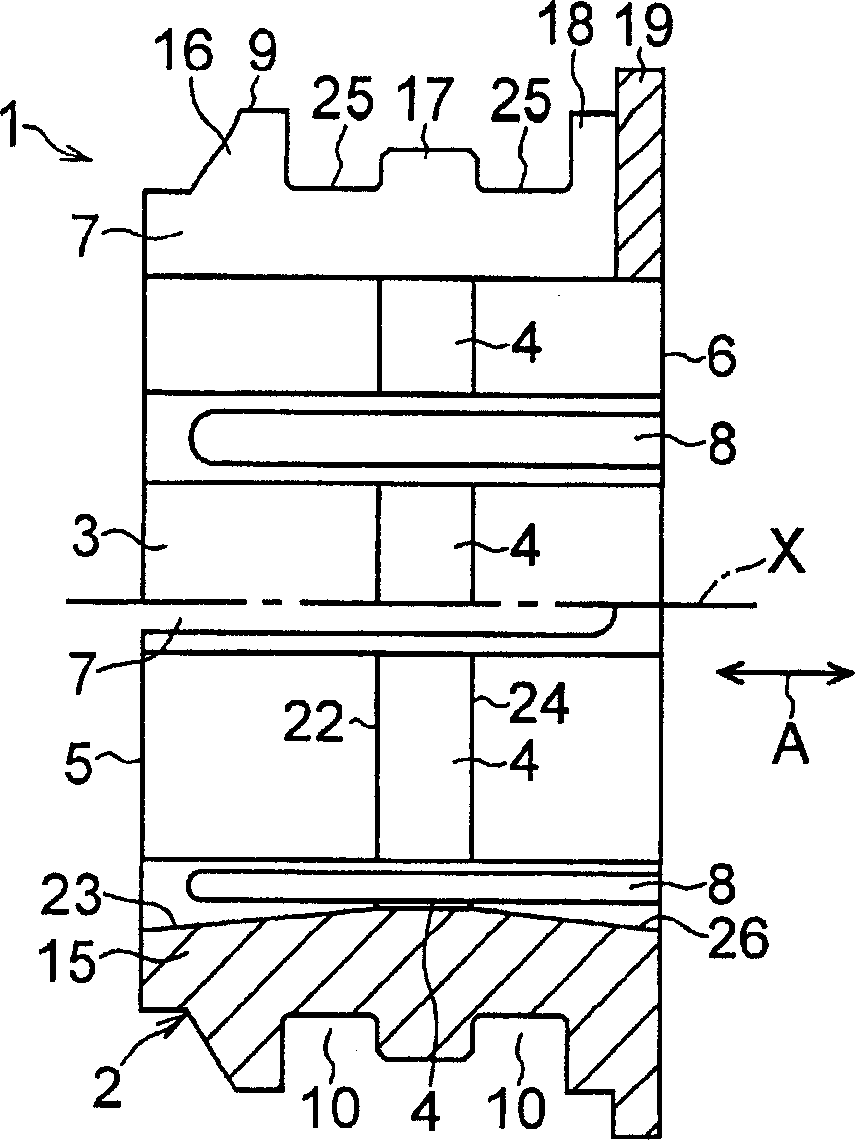

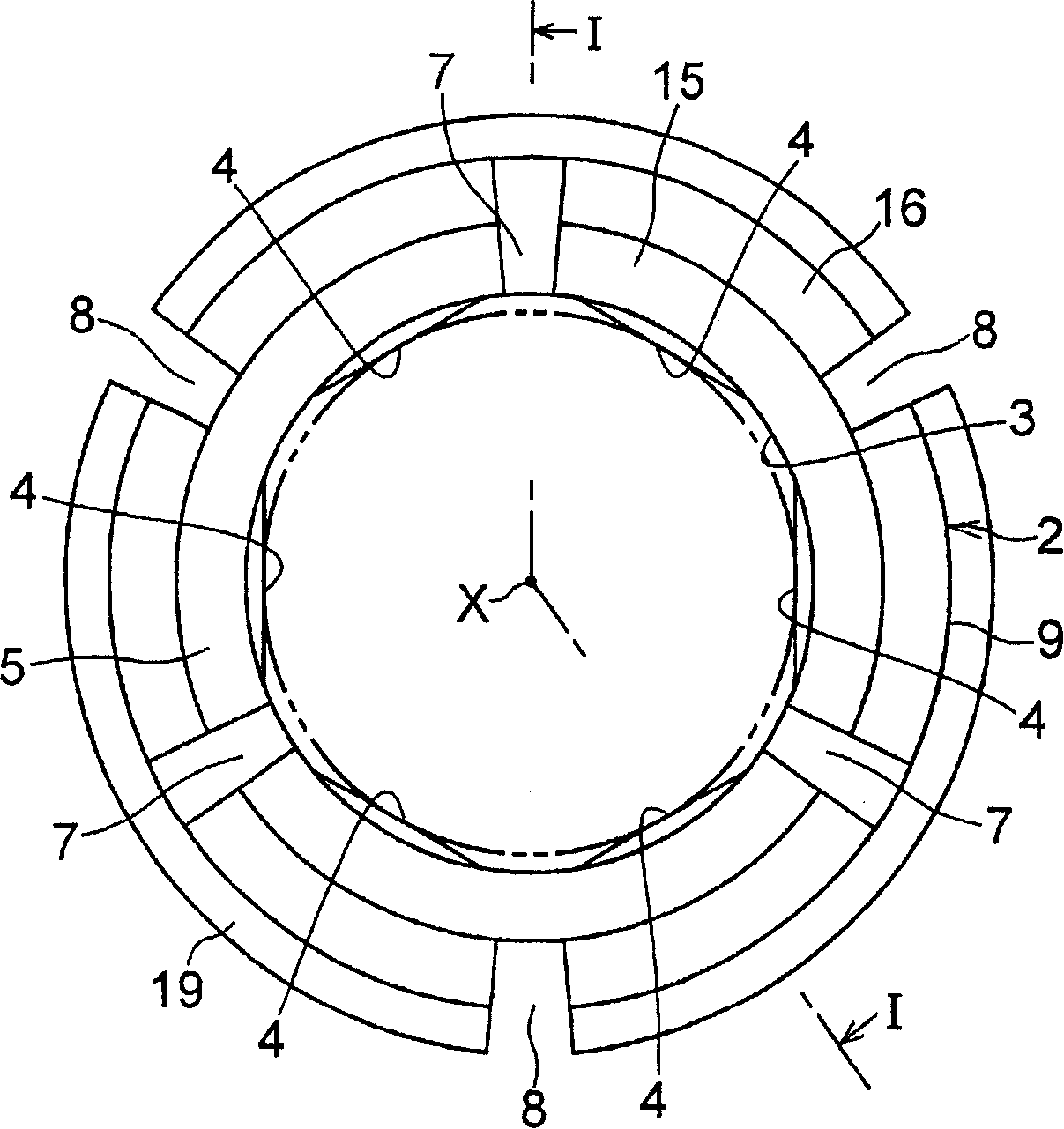

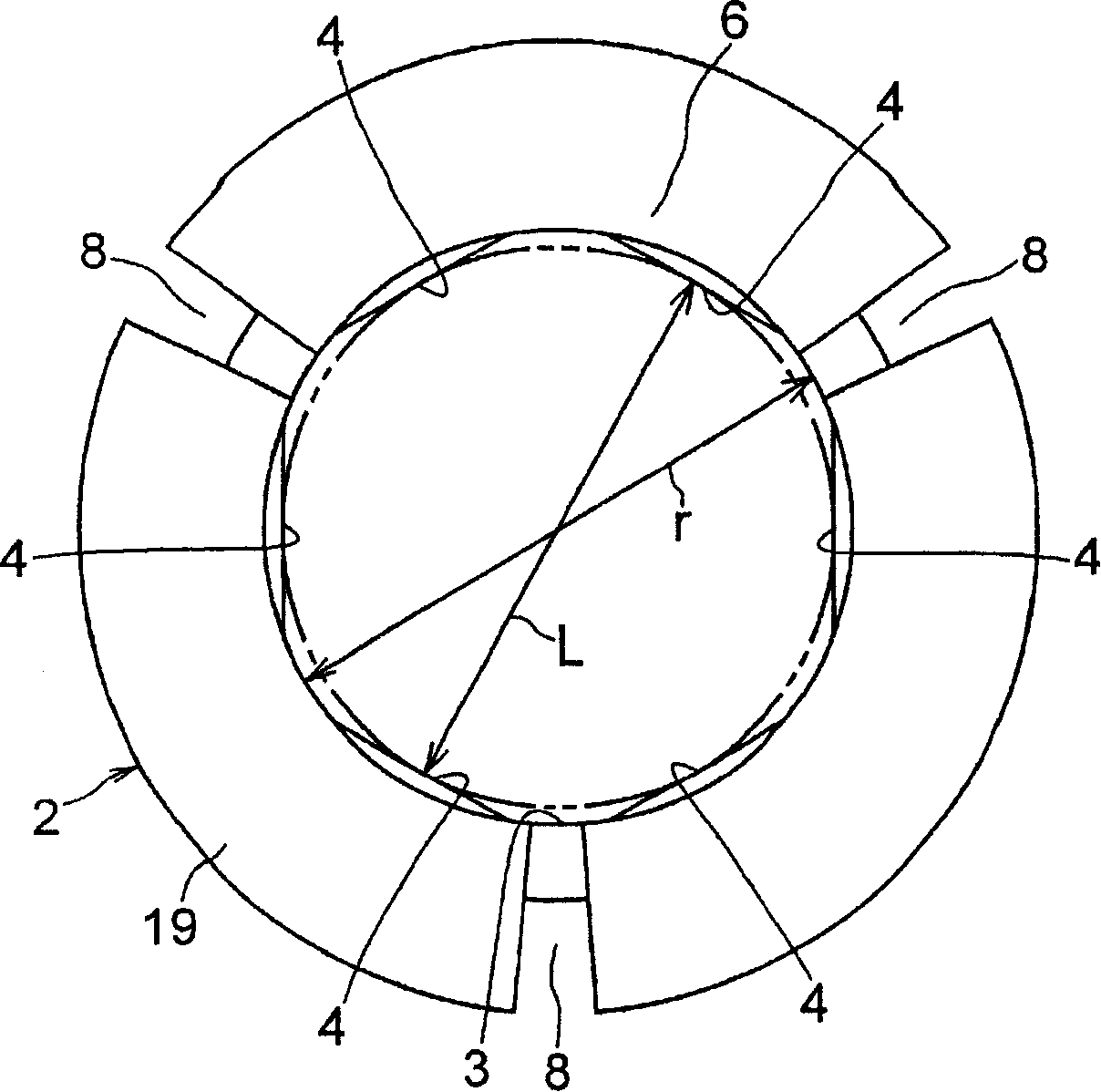

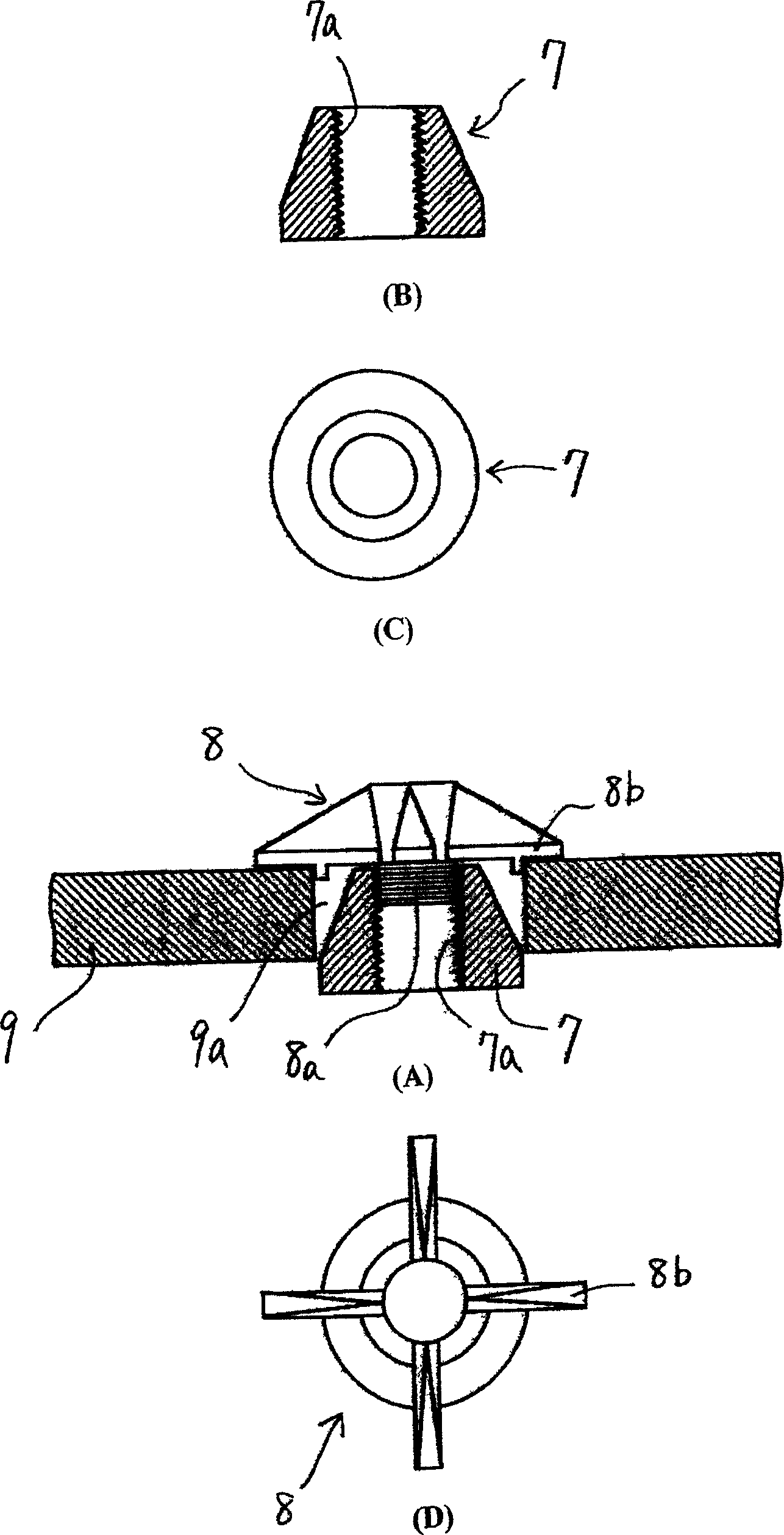

Sliding bearing and bearing mechanism having the same

A sliding bearing for a steering column includes: a cylindrical bearing body (2); flat surfaces (4) formed integrally on an inner peripheral surface of the bearing body; first slits (7) extending from one end face (5) of the bearing body to this side of the other end face (6) of the bearing body; second slits (8) extending from this side of the other end face (6) of the bearing body to the one end face (5) of the bearing body; grooves (10) formed in an outer peripheral surface of the bearing body (2); and elastic rings which are respectively fitted in the grooves in such a manner as to project from the outer peripheral surface of the bearing body (2) and to reduce the diameter of the bearing body.

Owner:OILES CORP

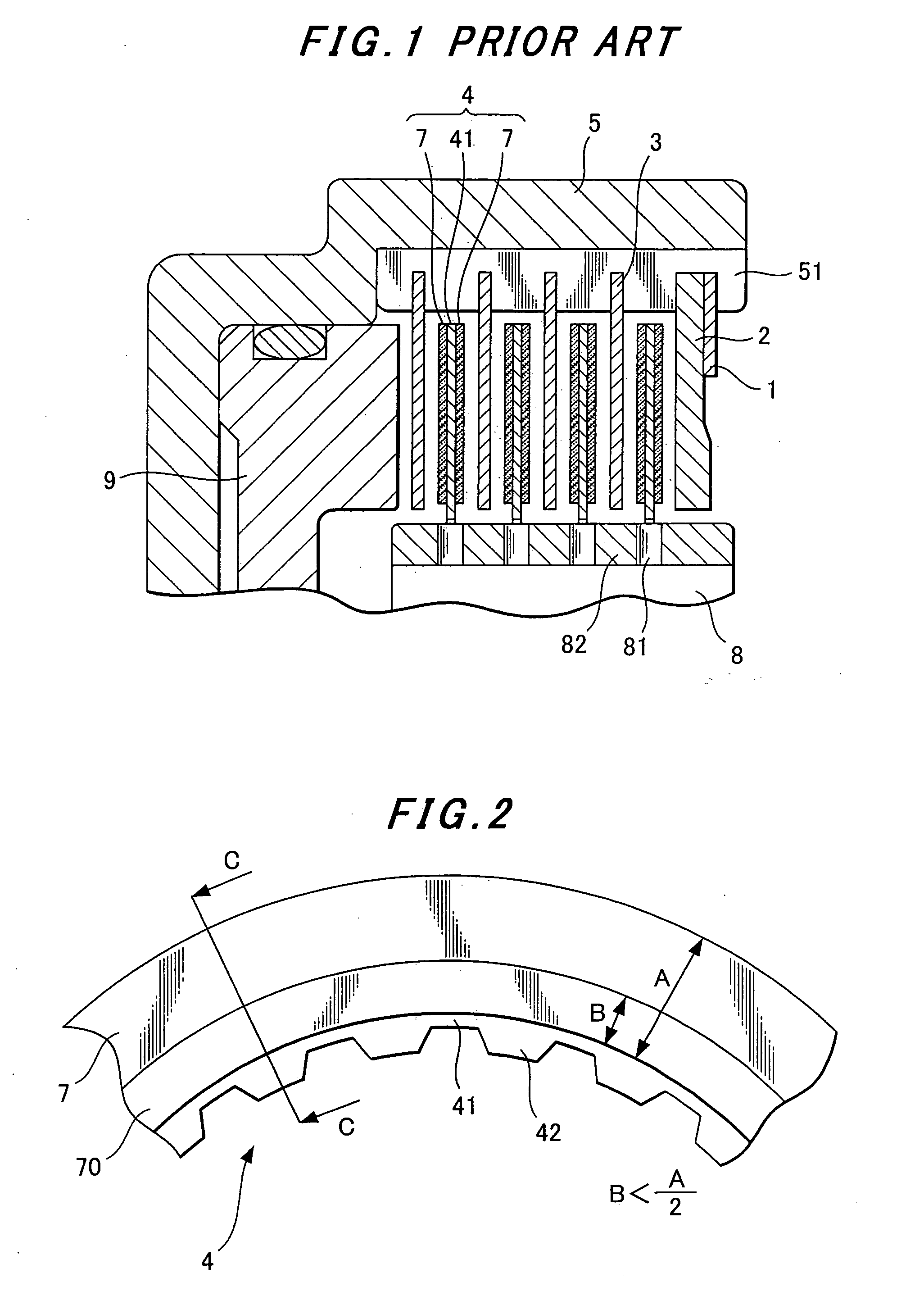

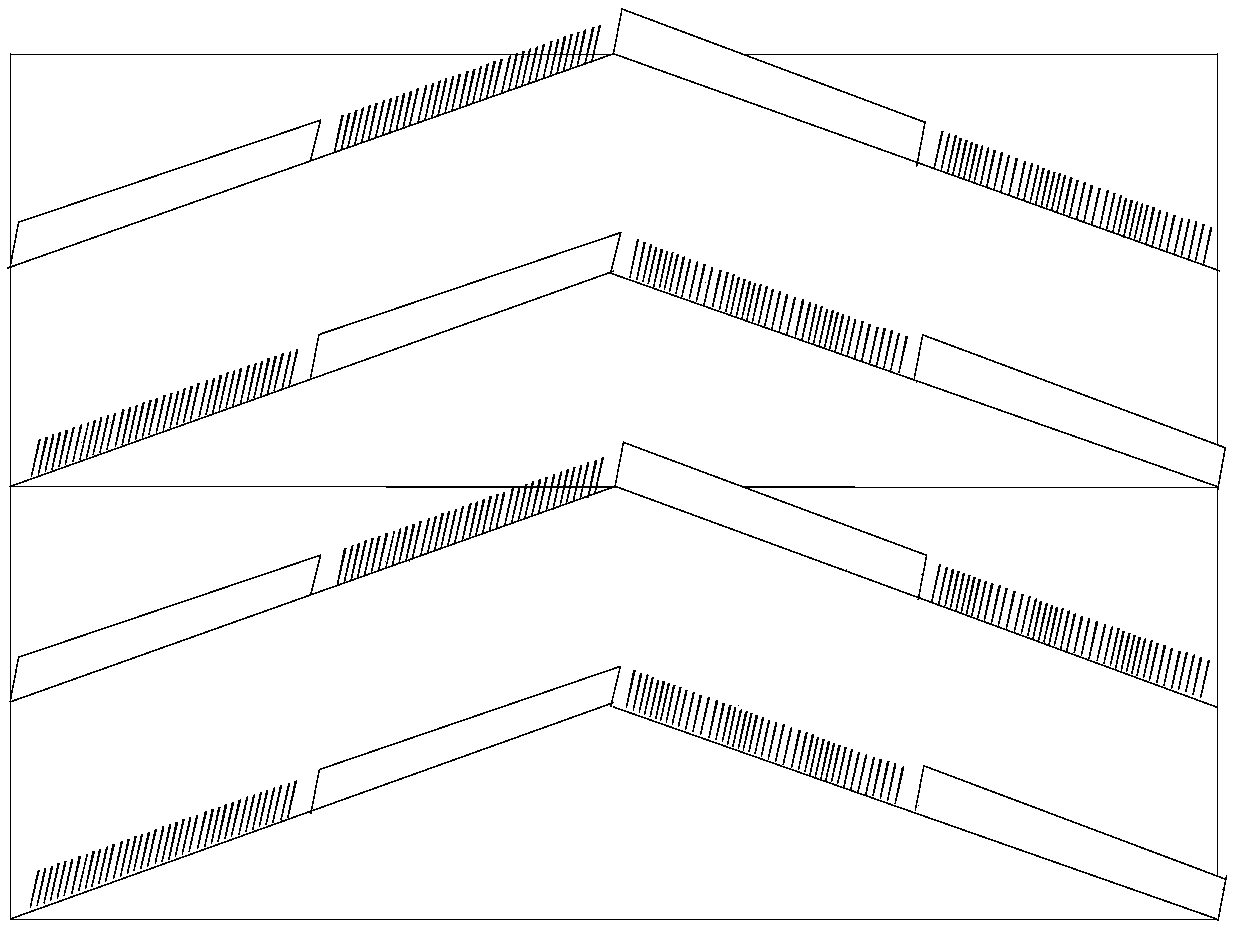

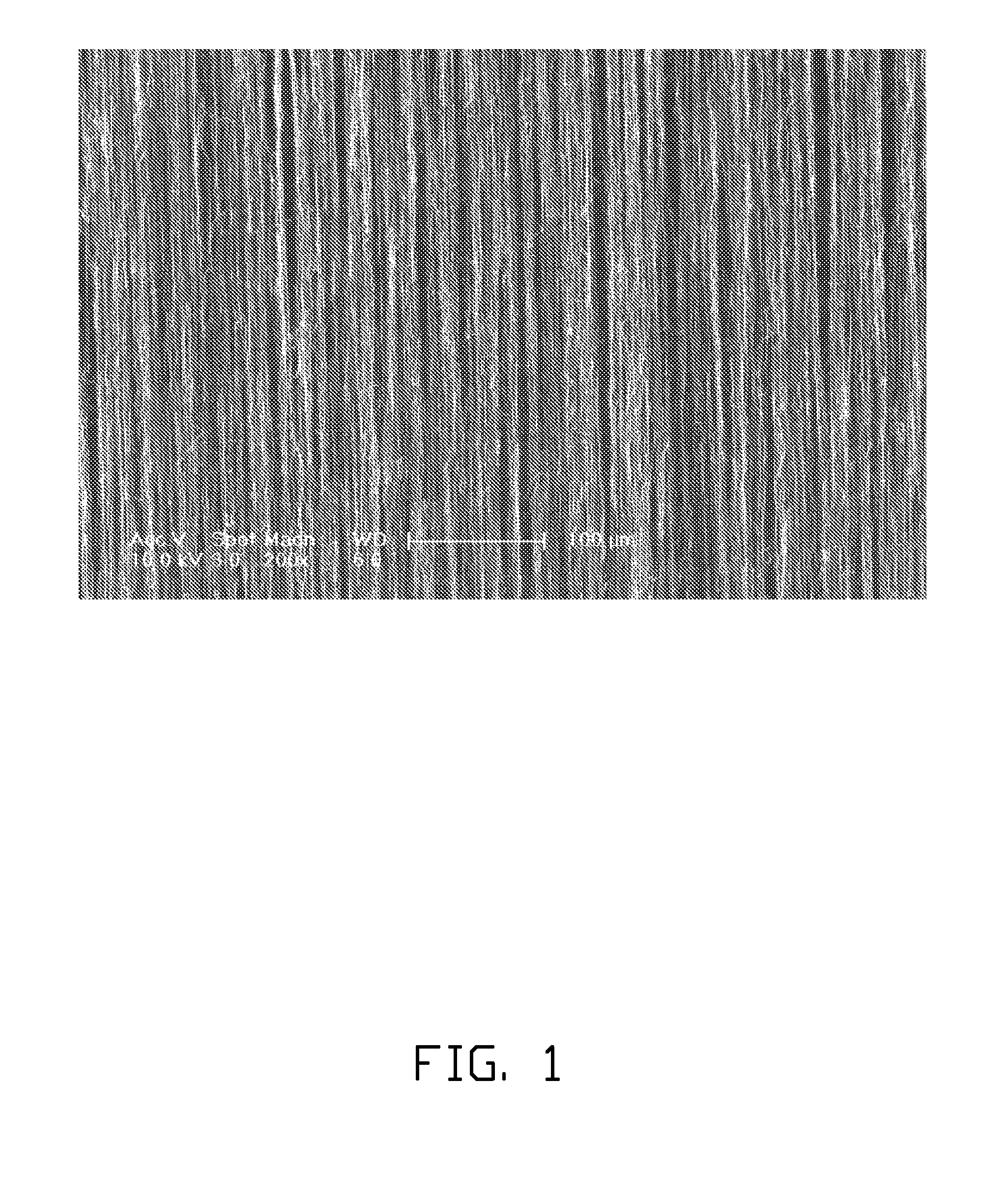

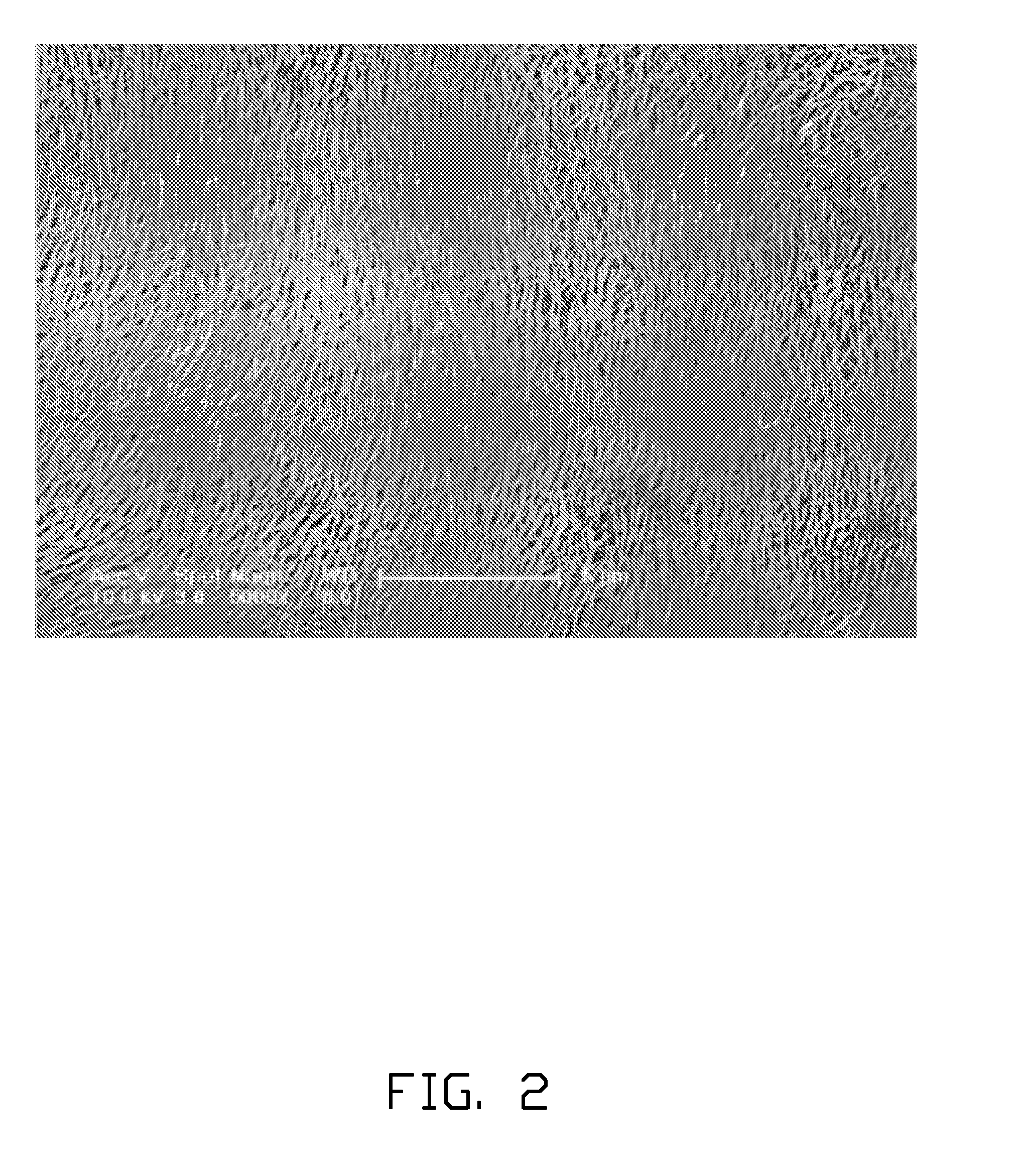

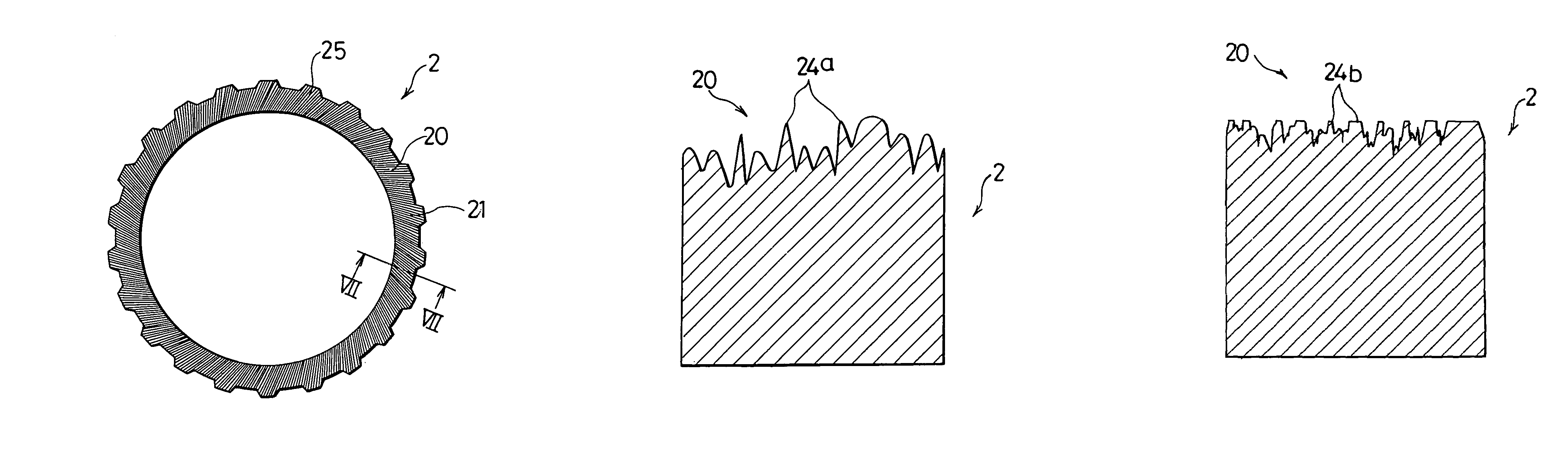

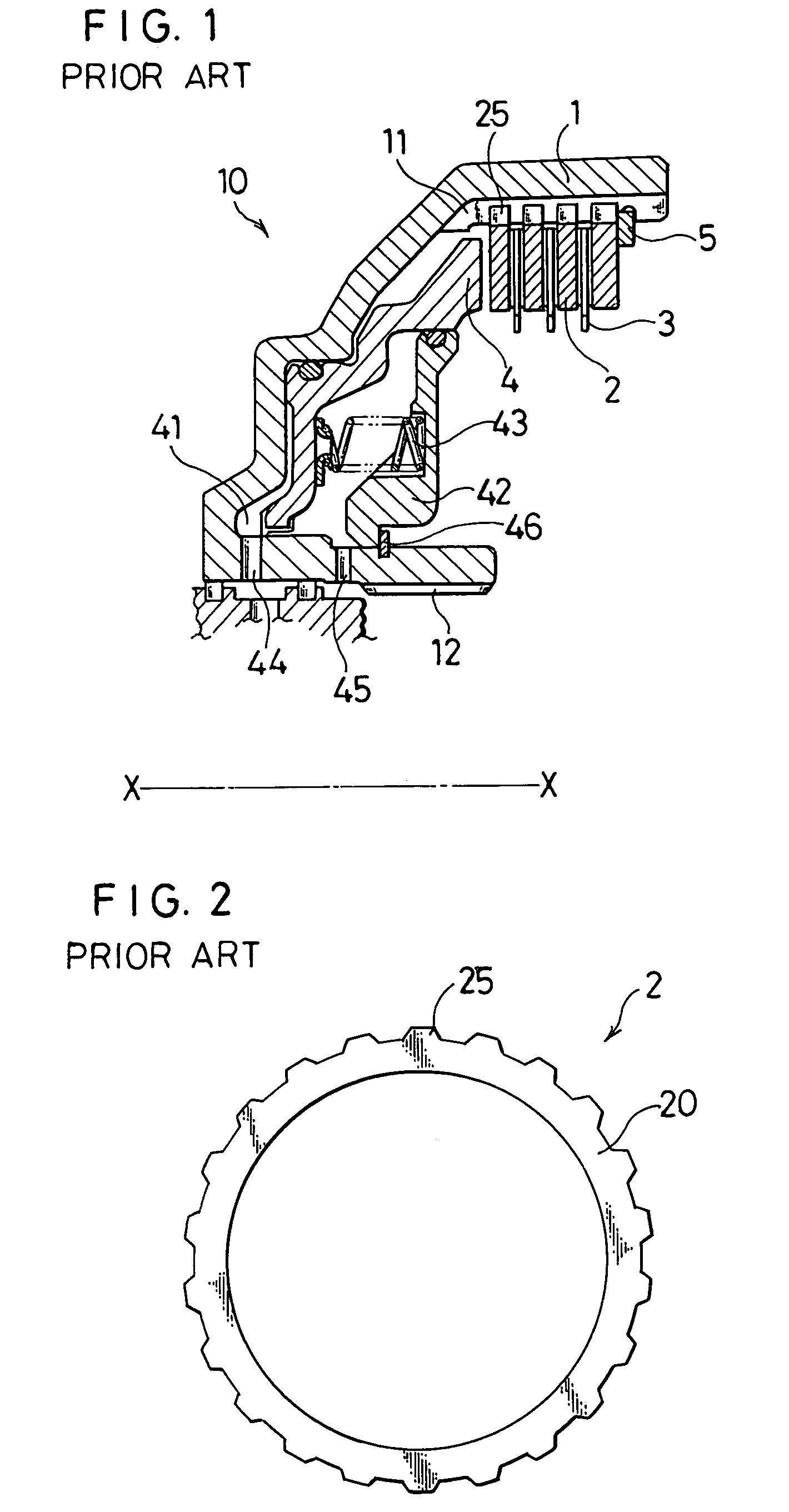

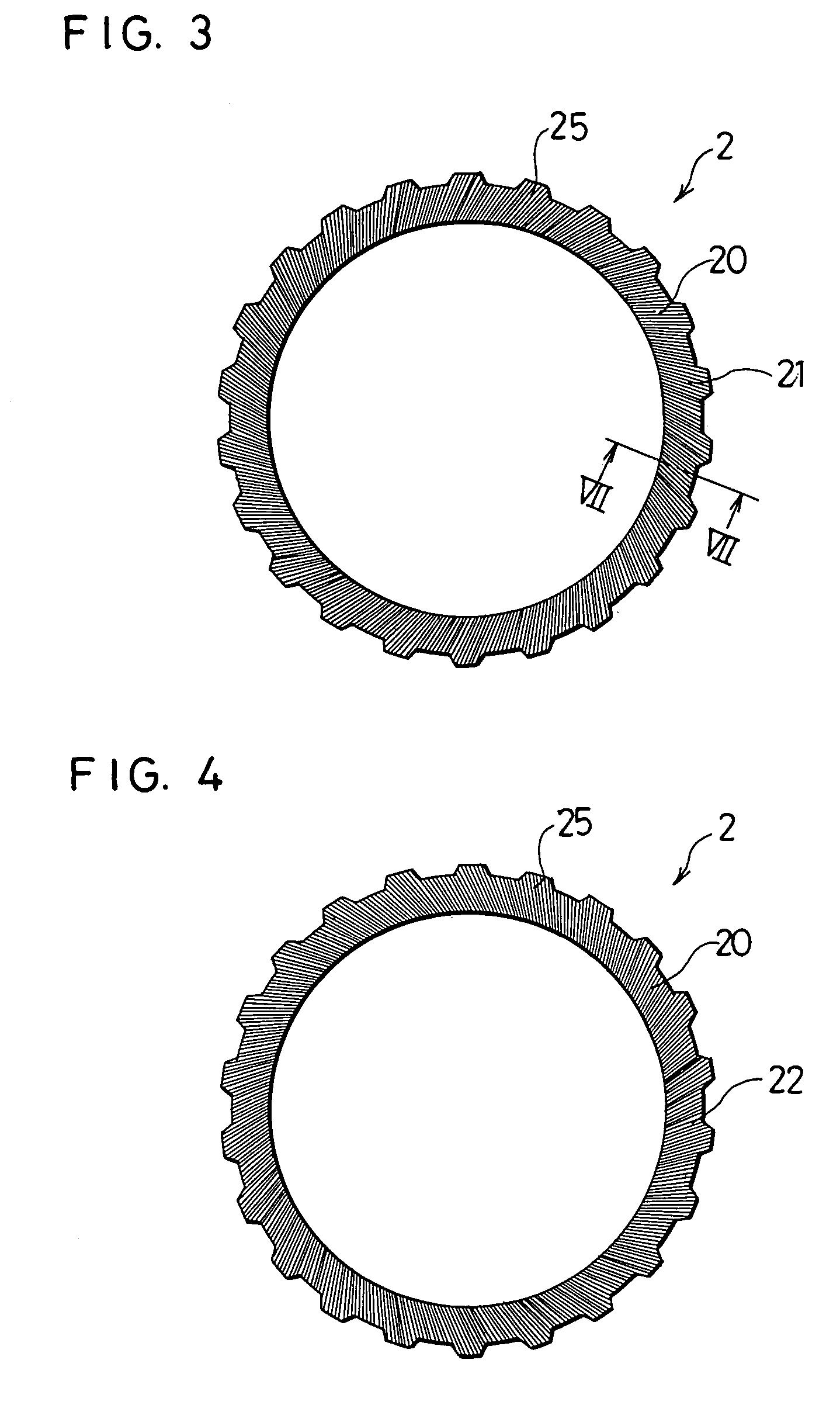

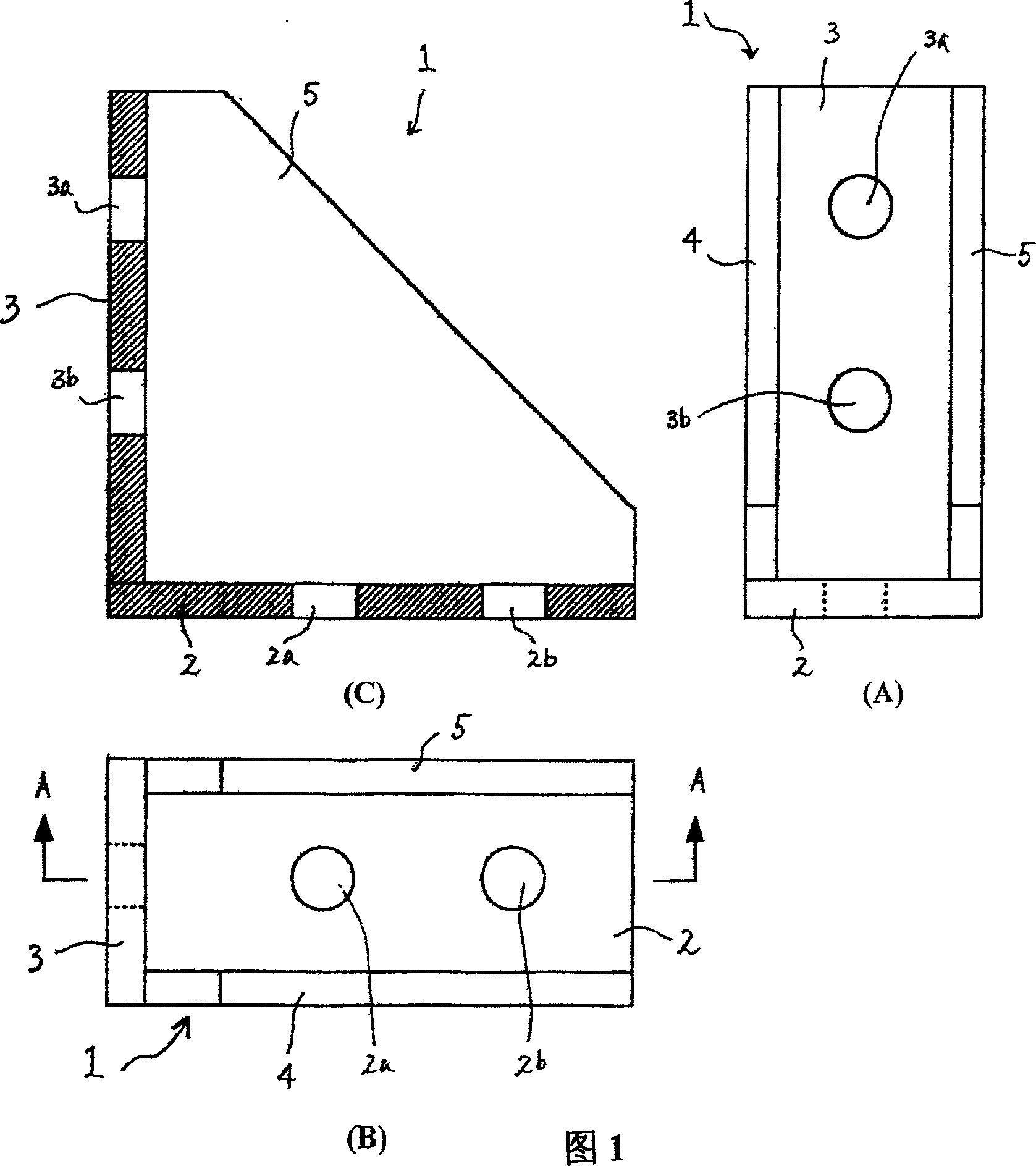

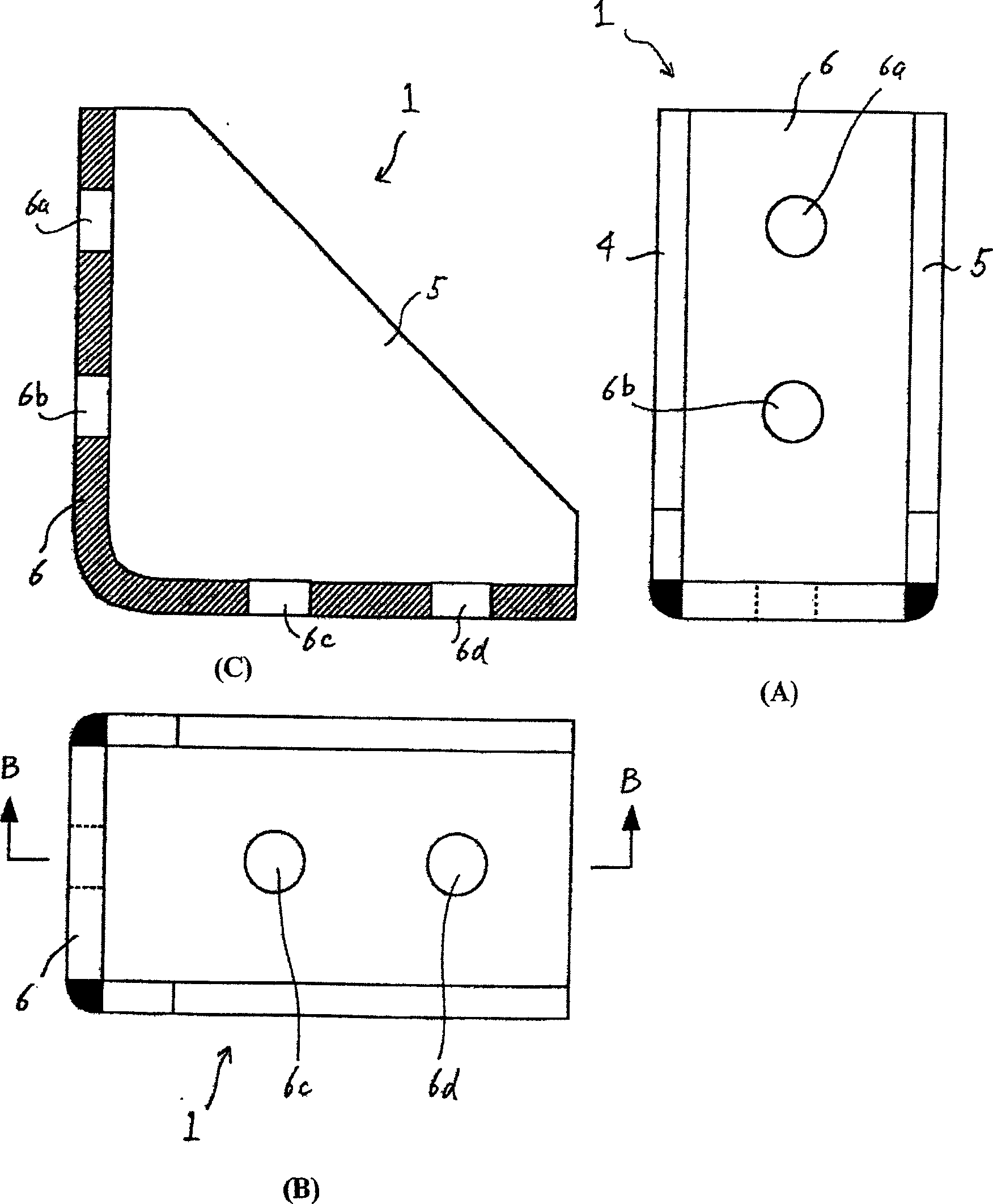

Separator plate for wet-type multiplate clutch and wet-type multiplate clutch provided with such separator plates

ActiveUS7096561B2Inhibit wearReadily and efficiently manufactureMetal rolling stand detailsFluid actuated clutchesEngineeringGrinding wheel

A separator plate useful in a wet-type multiplate clutch is provided on a friction surface thereof with elongated asperities extending with regularity in a predetermined direction. Peak portions of the elongated asperities, said peak portions being to project toward a counterpart member when the separator plate is assembled in the wet-type multiplate clutch, have been removed to form elongated plateaus. The separator plate can be manufactured by fixedly mounting a blank for the separator plate on a work support, forming elongated asperities with regularity in a predetermined direction on one of opposite surfaces of the blank by a grinding wheel, and then removing peak portions of the elongated asperities, said peak portions being to project toward a counterpart member when the separator plate is assembled in the wet-type multiplate clutch, to form elongated plateaus.

Owner:NSK WARNER

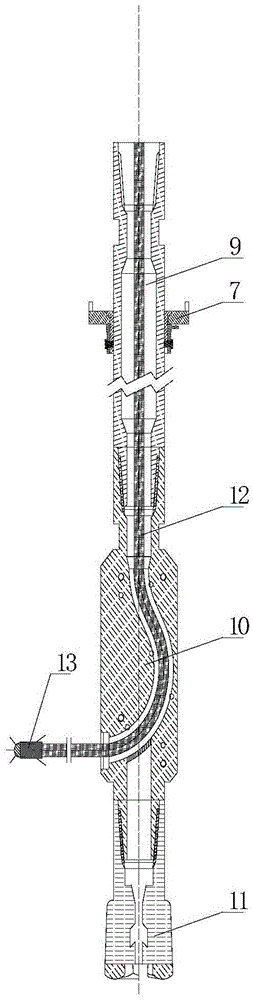

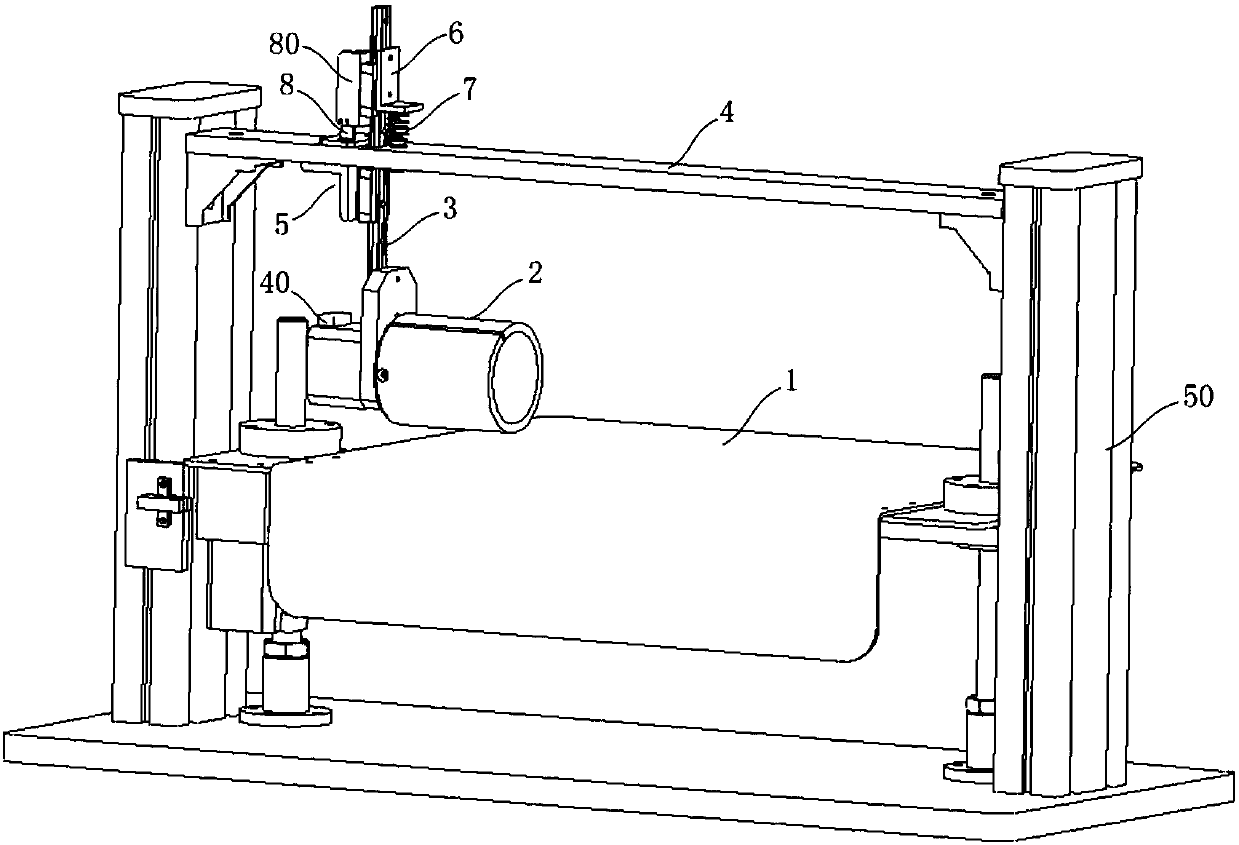

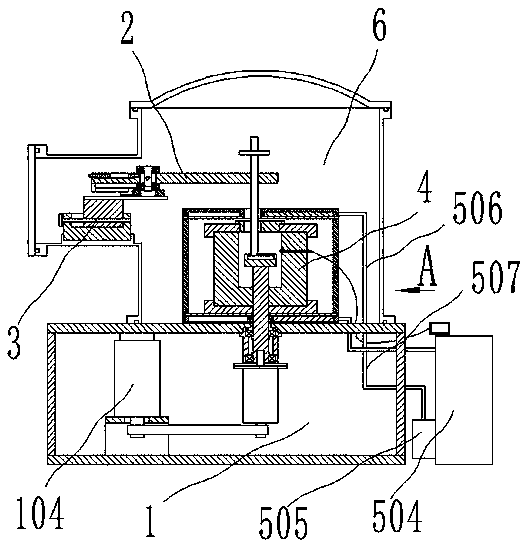

Vacuum high-temperature friction-wear tester

PendingCN111380766AImprove accuracyEasy to operateInvestigating abrasion/wear resistanceEngineeringMachine

The invention relates to material surface performance test equipment, and particularly relates to a vacuum high-temperature friction-wear tester. The tester is characterized in that a vacuum cover isarranged above a machine base, a force measuring assembly, an adjusting support, a heating furnace assembly and a cooling circulation system are arranged in the vacuum cover, the cooling circulation system is connected above the machine base, the heating furnace assembly is arranged in the cooling circulation system, a supporting connecting pipe is arranged at the left end of the vacuum cover, theadjusting support is connected in the supporting connecting pipe, the left end of the force measuring assembly is connected to the adjusting support, the right end of the force measuring assembly isconnected with a loading rod, the loading rod penetrates through the force measuring assembly, the heating furnace assembly comprises a furnace body, a heating cavity is formed in the furnace body, the loading rod is inserted into the heating cavity, a friction disc is arranged in the heating cavity, a detection piece is clamped between the loading rod and the friction disc, the lower end of the friction disc is connected with a rotating shaft, the rotating shaft penetrates through the heating furnace assembly and the cooling circulation system, the lower end of the rotating shaft is rotationally connected into the machine base, and the side wall of the vacuum cover is further connected with a molecular pump unit.

Owner:兰州华汇仪器科技有限公司

Cross-connection method for steel pipe and H-shape steel

InactiveCN1641126ALess welding workReduce quality accidentsStrutsGirdersCross connectionWelding defect

The invention relates to a cross-linking method for connecting a steel pipe with an H-type steel. The invention is to drill holes on the pipe wall of the steel pipe at the cross-contact where the steel pipe connects with the H-type steel of steel building, to arrange internal threads in the hole or to outstretch bolts from the holes which pass through angle steels strengthened by ribbed slabs, and to fix H-type steel onto the outside of the steel pipe. The invention has the advantages that welding operations in construction site are avoided and welding defects, quality accidents caused by welding and fire disaster caused by welding sparks are all reduced because internal threads are preformed on the wall of the steel, ribbed slabs are arranged on the two side of the angle steel so that the angle steel can transmit shearing force, the web plate of the H-type steel needs not to connect with the steel, angle steel can resists horizontal pull and stress greater force in vertical direction compared with the current L-type angle steel, and the usage amount of the bolts and the cost can be reduced after a board used for increasing friction coefficient is inserted between the steels mutually connected.

Owner:佐藤 孝典

Cleaning unit and image forming apparatus

Owner:CANON KK

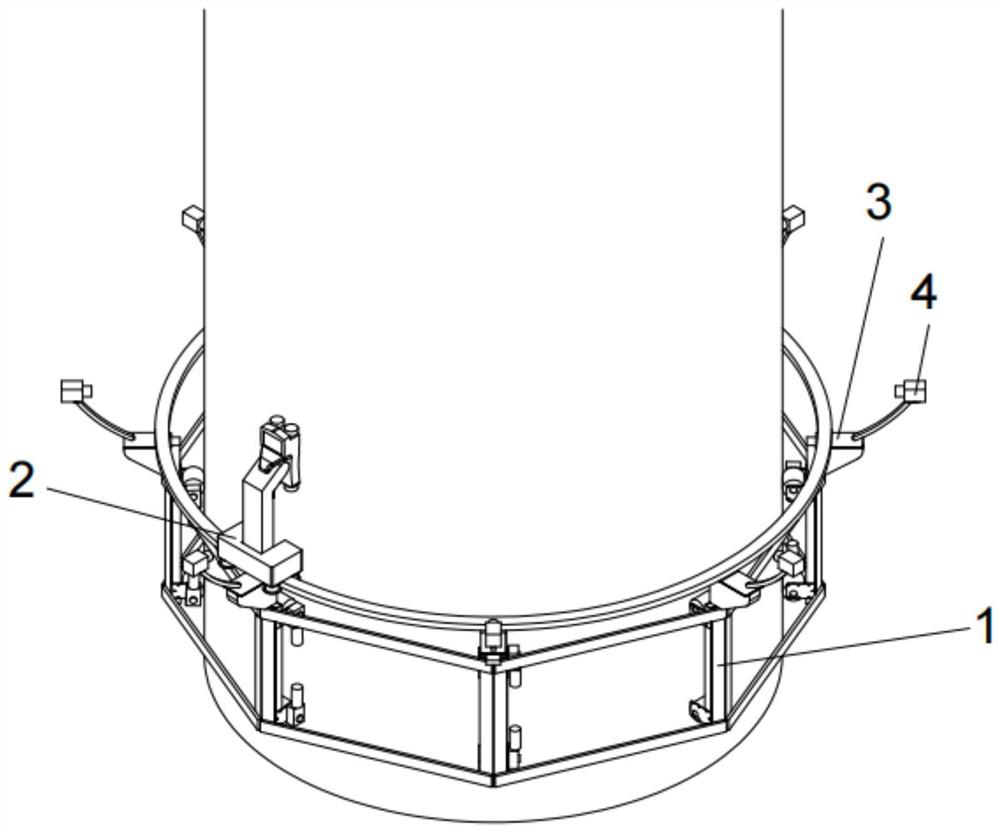

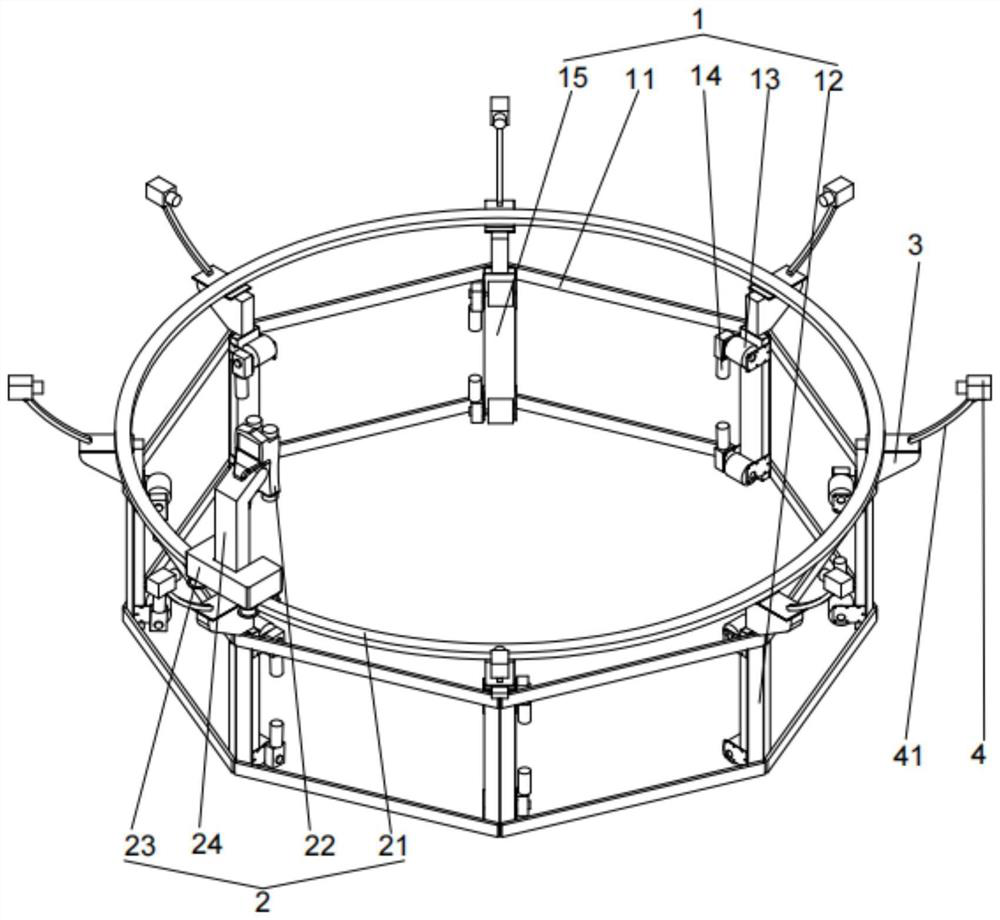

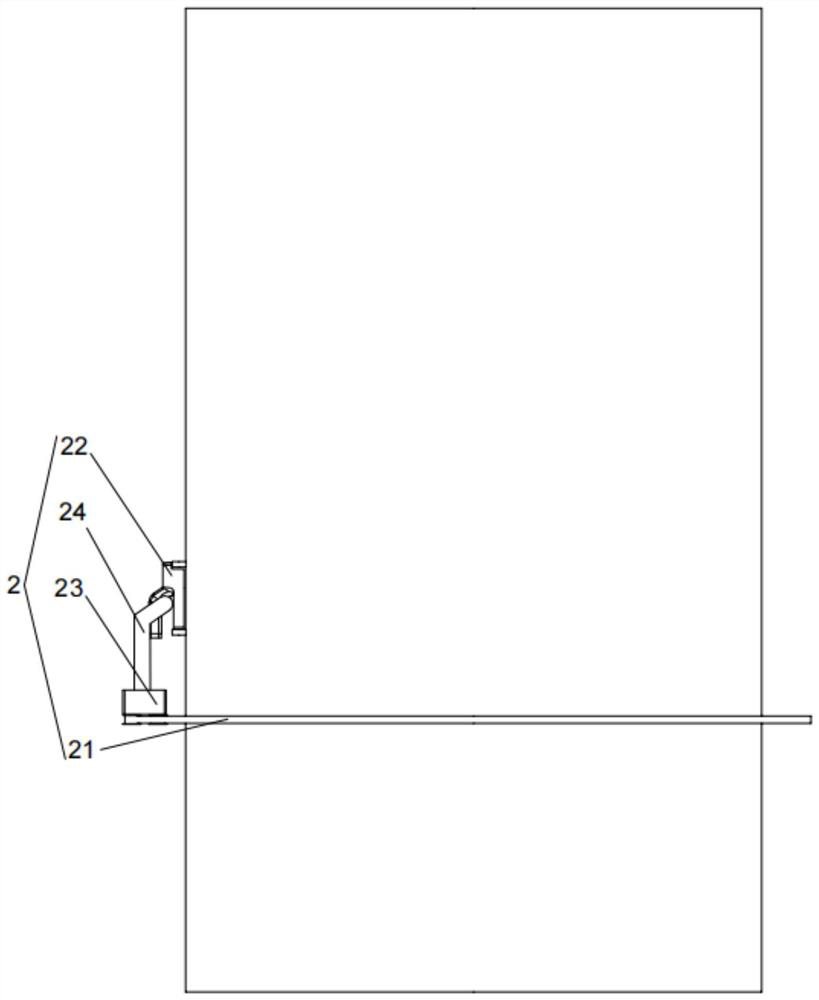

Bridge pier column detection device and method

PendingCN113587828AEasy to carryEasy to assemble and disassembleBridge structural detailsUsing optical meansModular constructionMovement control

The invention provides a bridge pier column detection device and method, and the device comprises: a climbing device which surrounds and is detachably disposed at the periphery of a pier column, and is used for moving up and down along the pier column; and a surrounding detection device which is arranged at the upper part of the climbing device and is used for carrying out surrounding detection on the pier column, wherein the climbing device is uniformly connected with a plurality of brackets, and the surrounding detection device is connected with the climbing device through the brackets. The brackets are connected with a plurality of cameras which are uniformly distributed, and the plurality of cameras jointly capture full-angle images of the pier stud; the climbing device is of a modular structure and comprises a plurality of climbing assemblies which are assembled in a matched mode according to the diameter of a pier column; and the climbing device, the surrounding detection device and the camera are all electrically connected with the comprehensive control equipment, so that movement control over the climbing device is achieved, and data detected and captured by the surrounding detection device and the camera are processed and displayed.

Owner:JIANGXI PROVINCE TIANCHI HIGHWAY TECH DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com