Patents

Literature

655results about "Sewing-machine elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

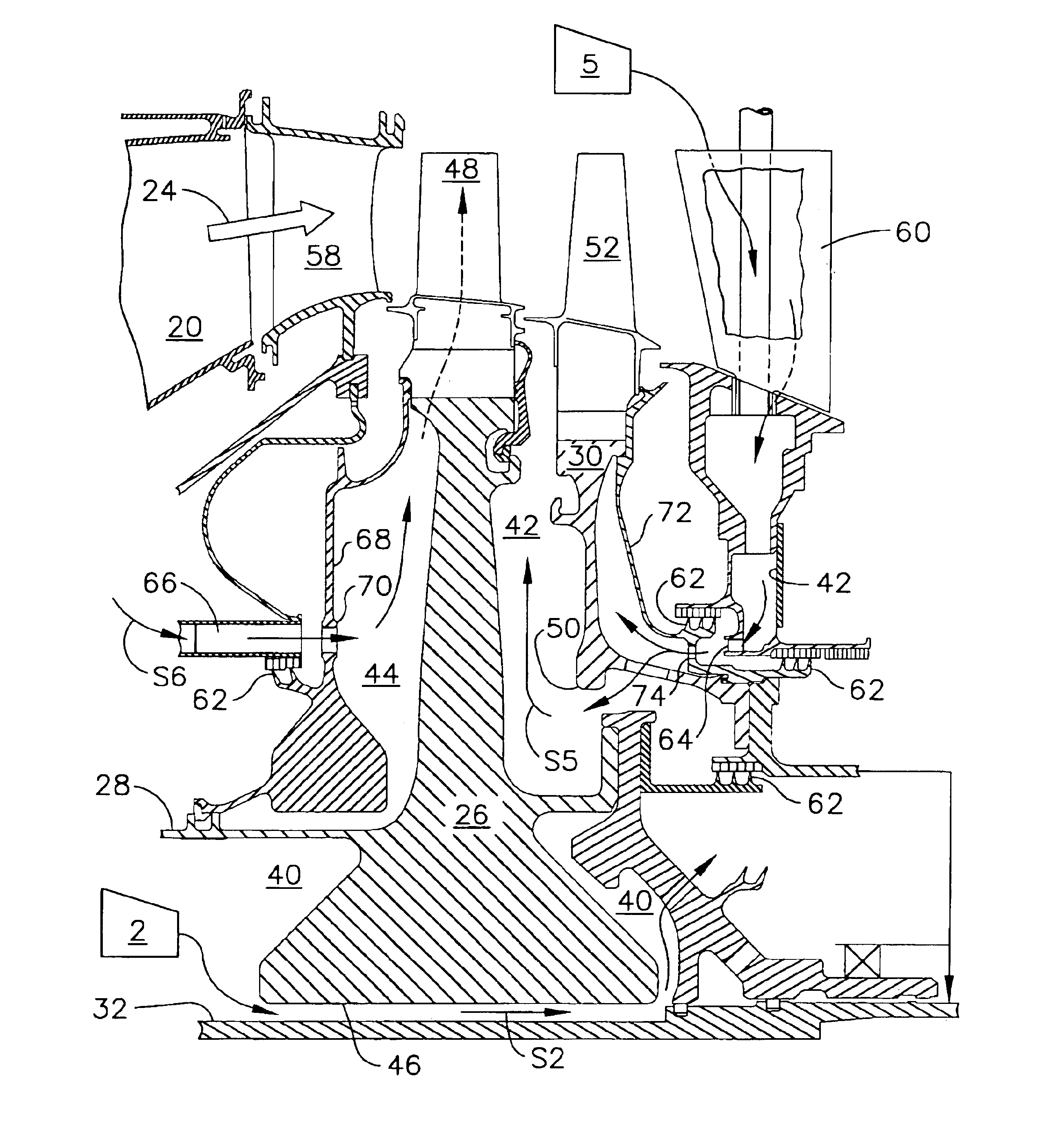

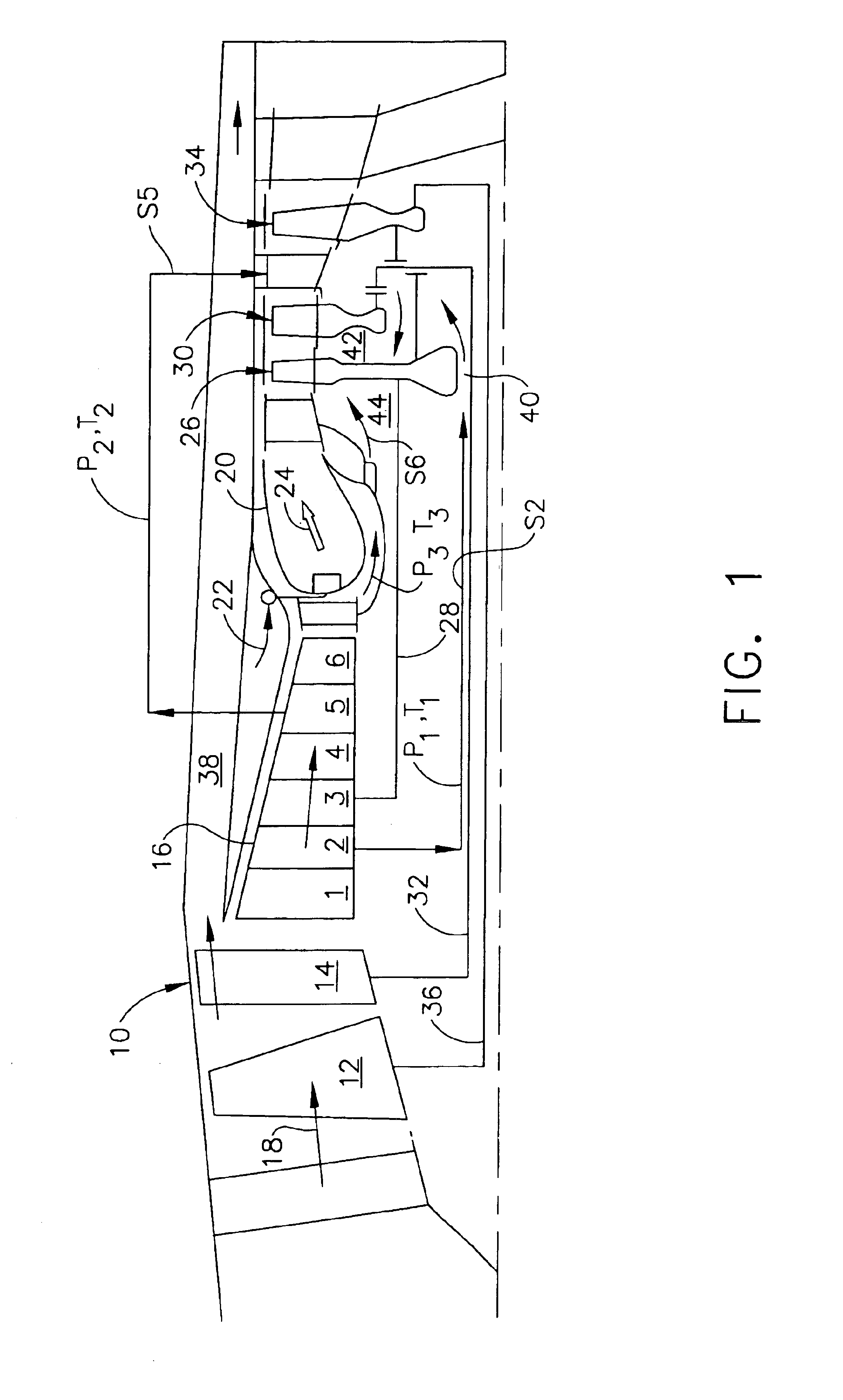

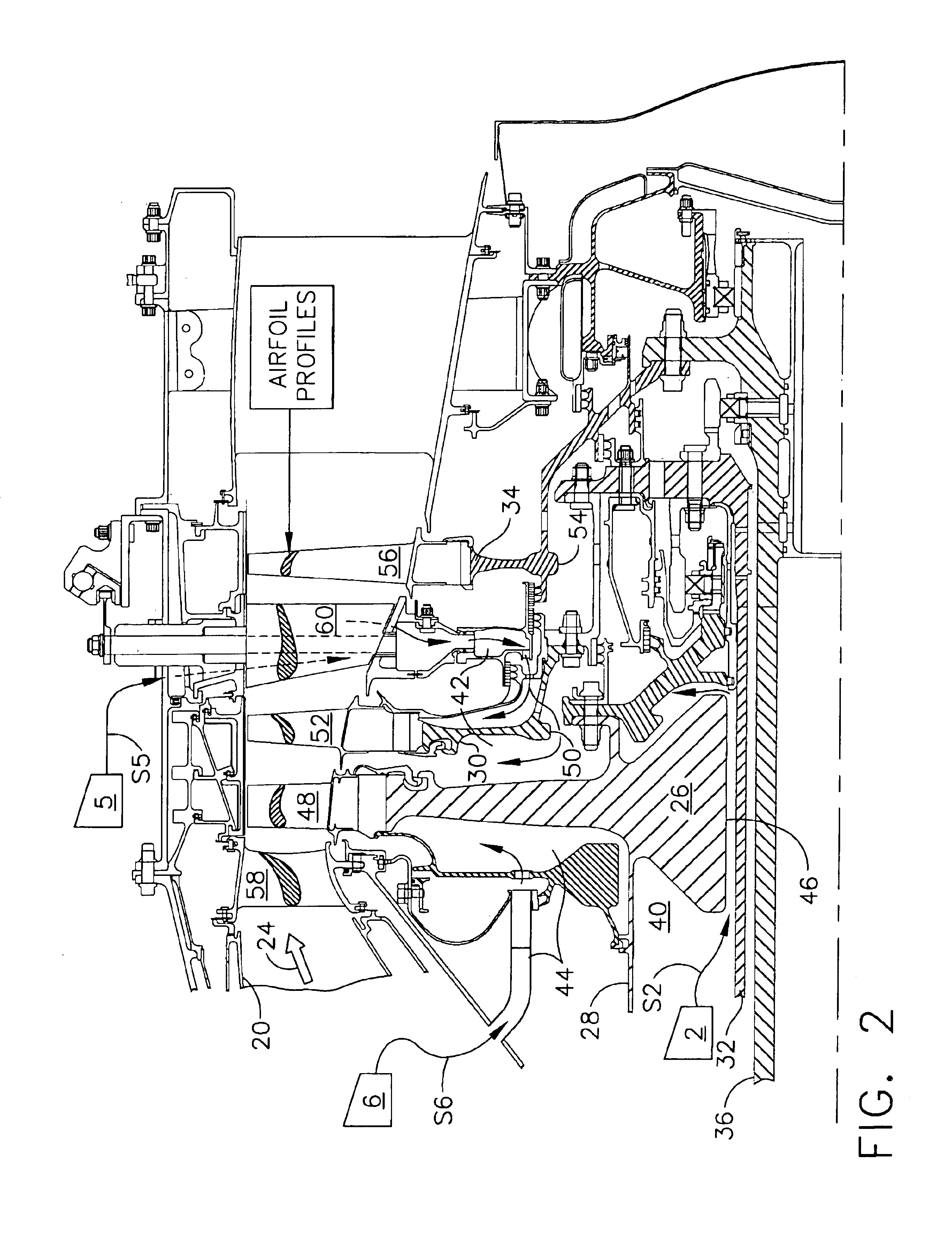

Triple circuit turbine cooling

A turbofan engine includes in serial flow communication a first fan, second fan, multistage compressor, combustor, first turbine, second turbine, and third turbine. The first turbine is joined to the compressor by a first shaft. The second turbine is joined to the second fan by a second shaft. And, the third turbine is joined to the first fan by a third shaft. First, second, and third cooling circuits are joined to different stages of the compressor for cooling the forward and aft sides and center bore of the first turbine with different pressure air.

Owner:GENERAL ELECTRIC CO

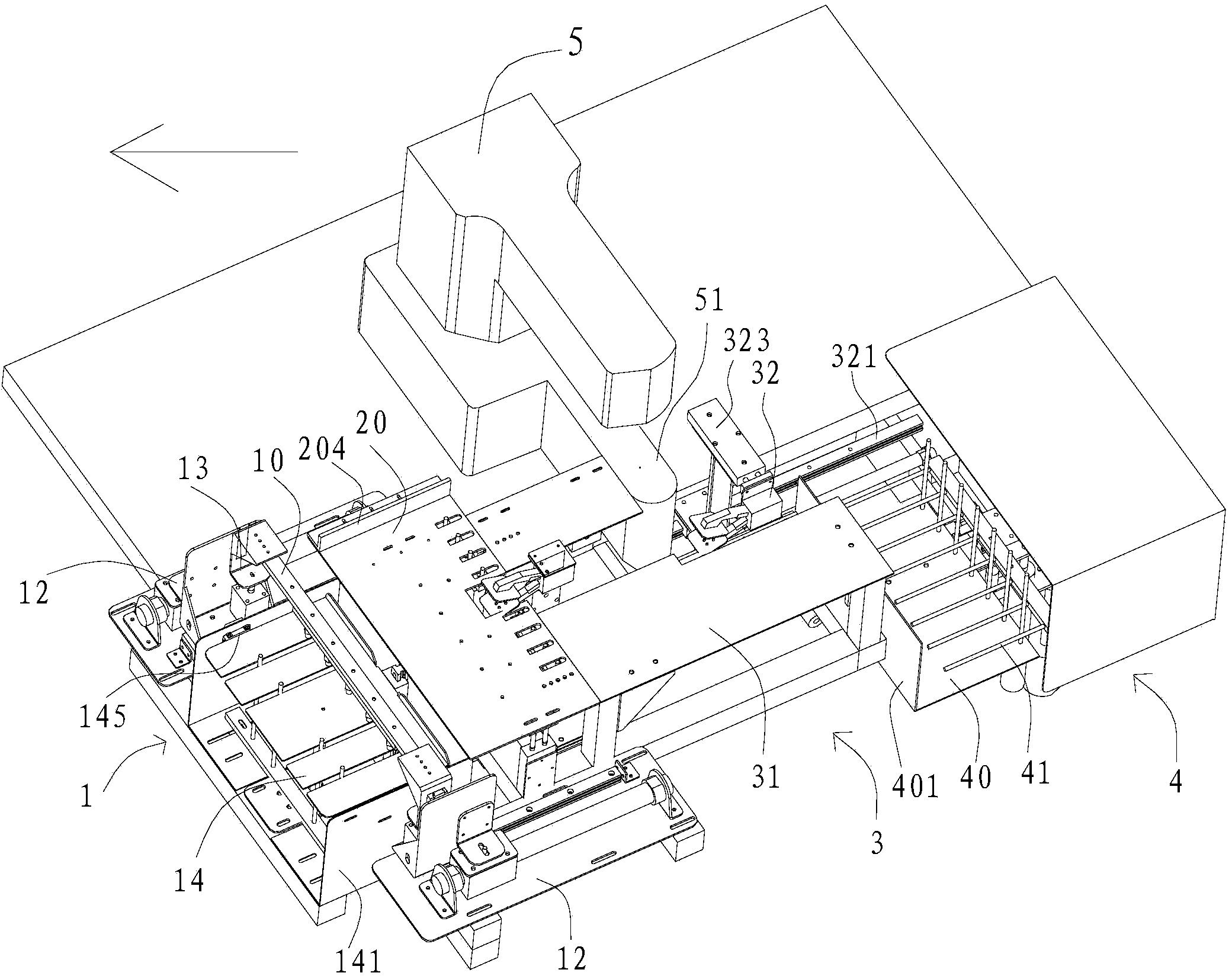

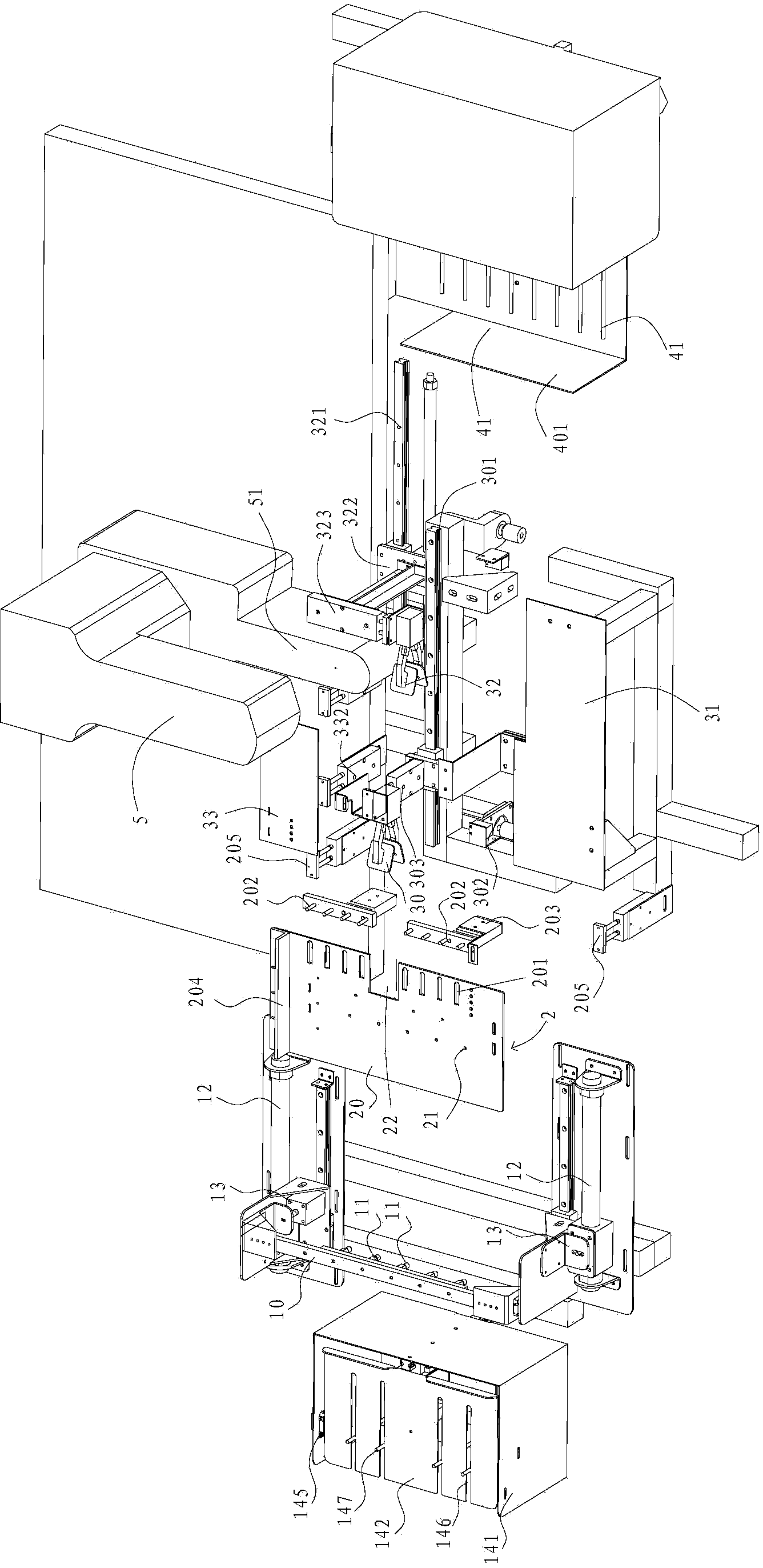

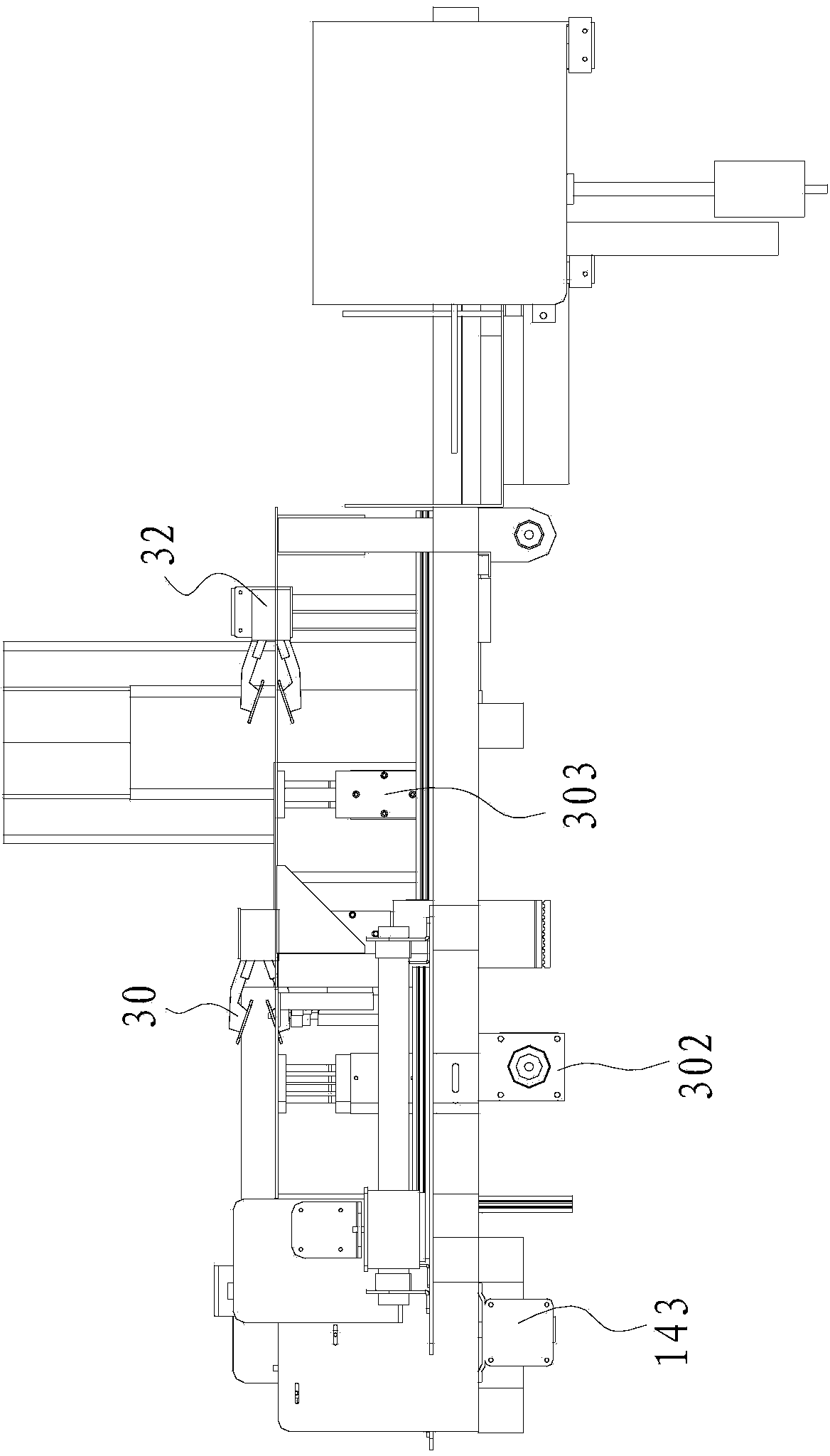

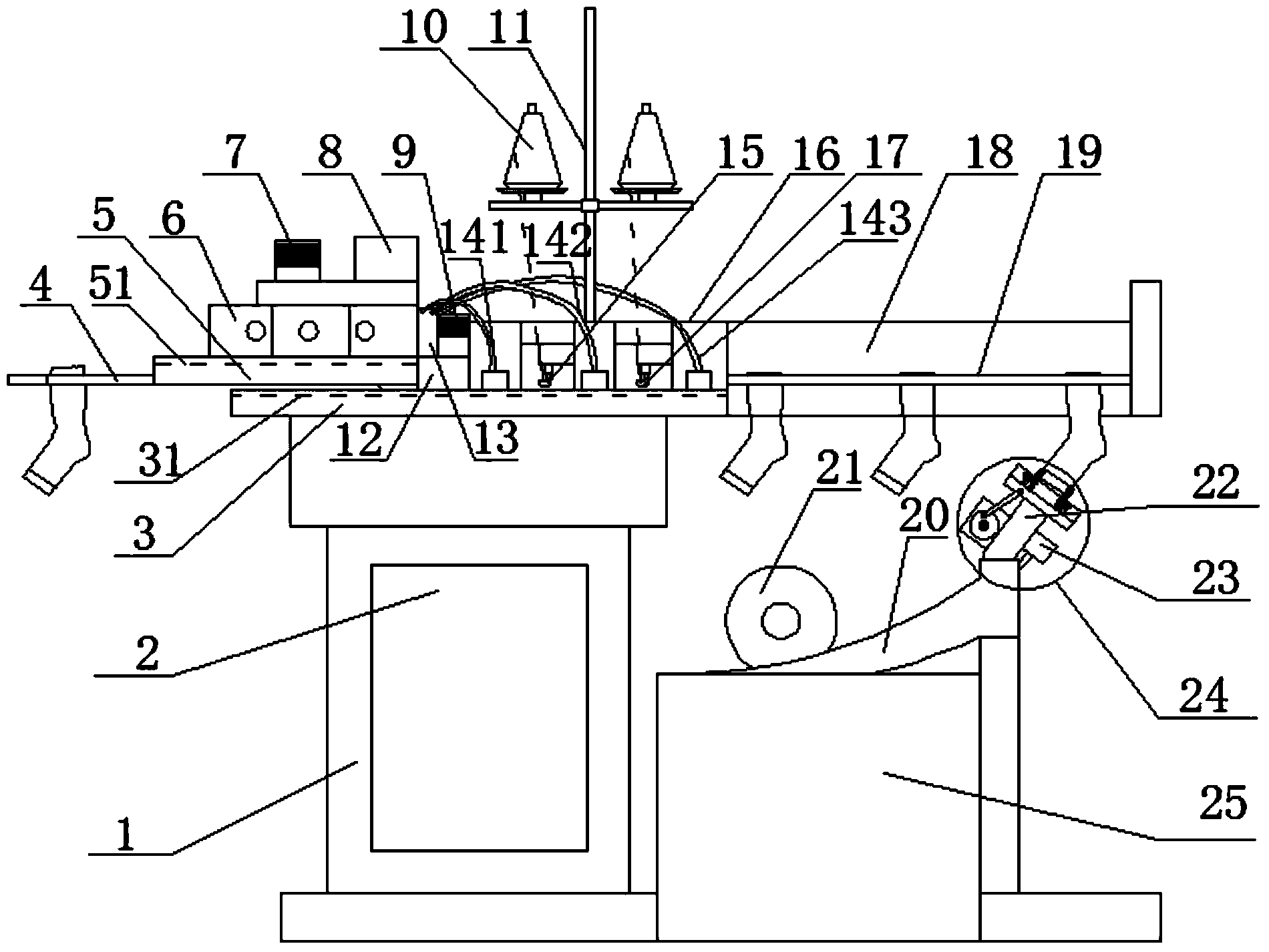

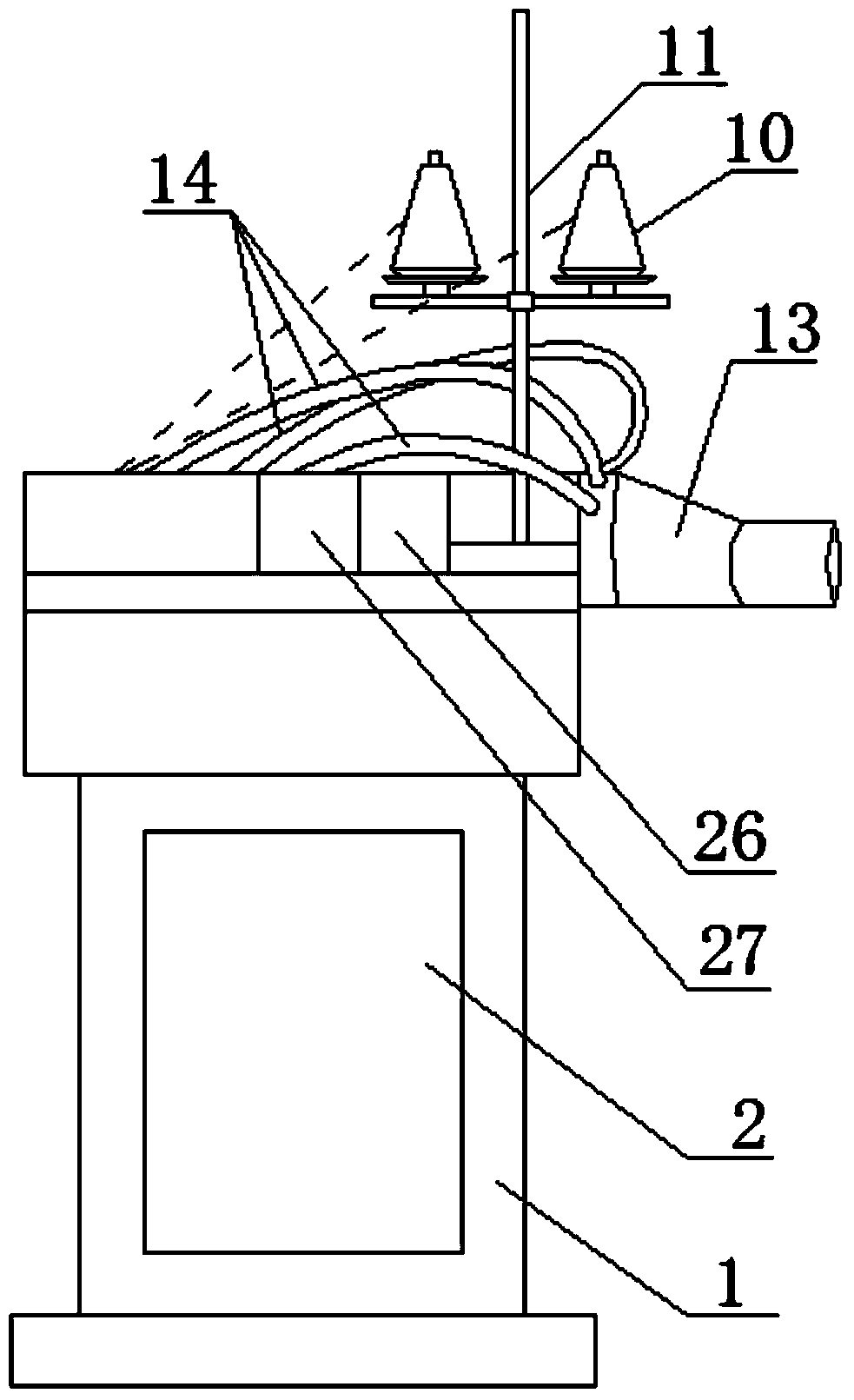

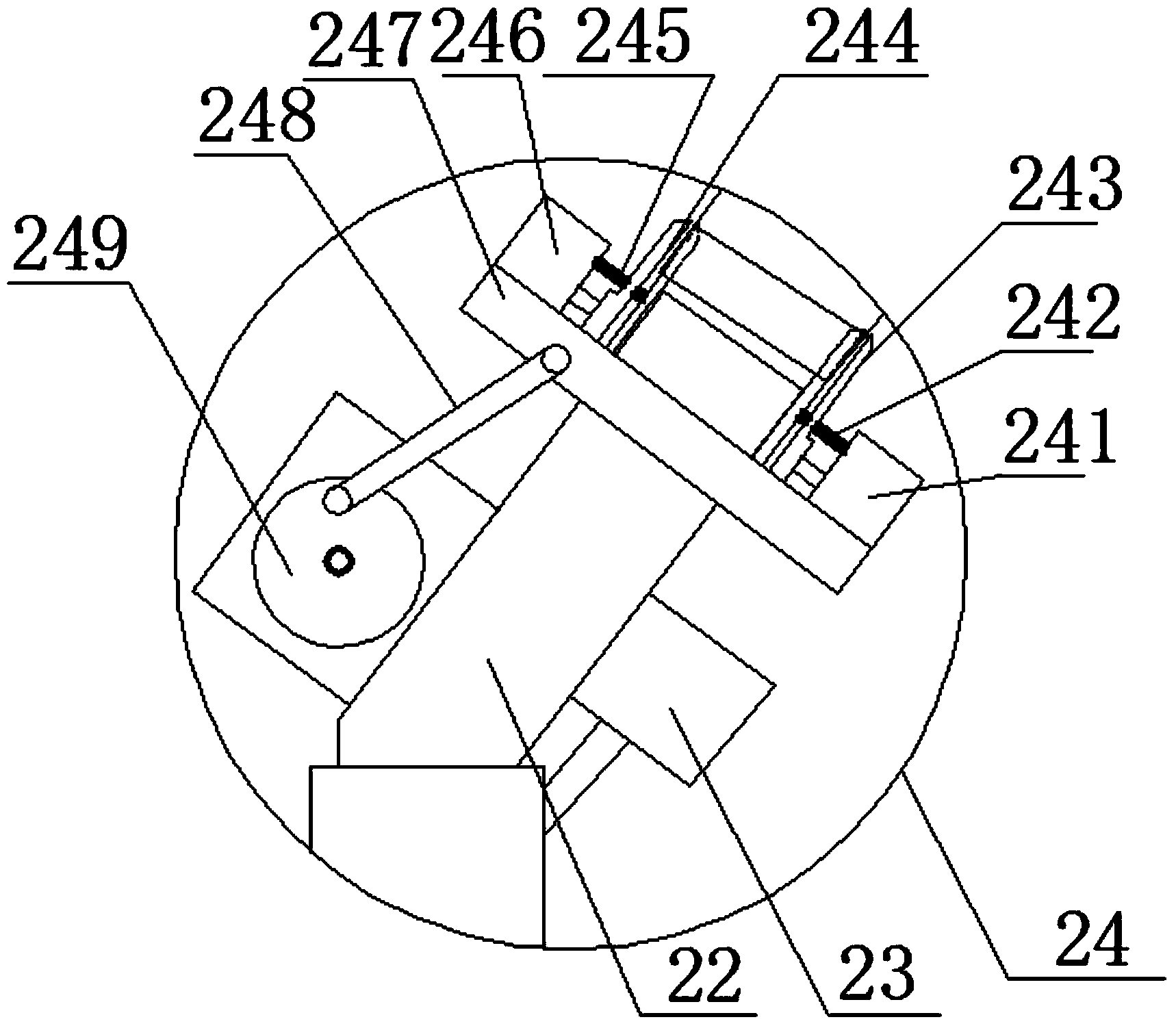

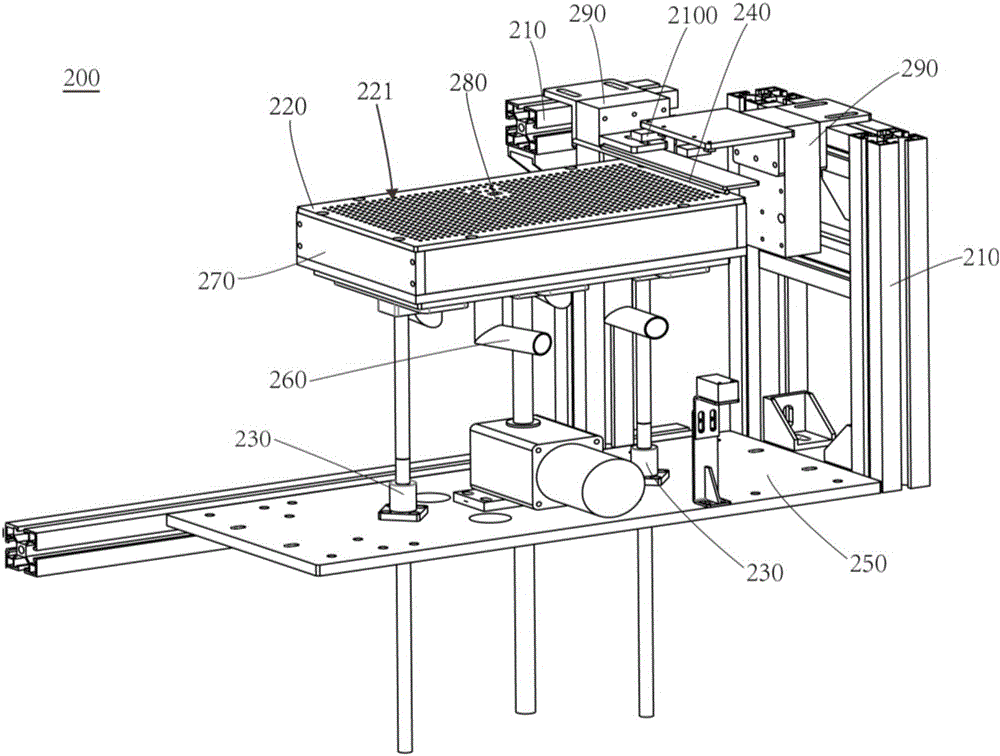

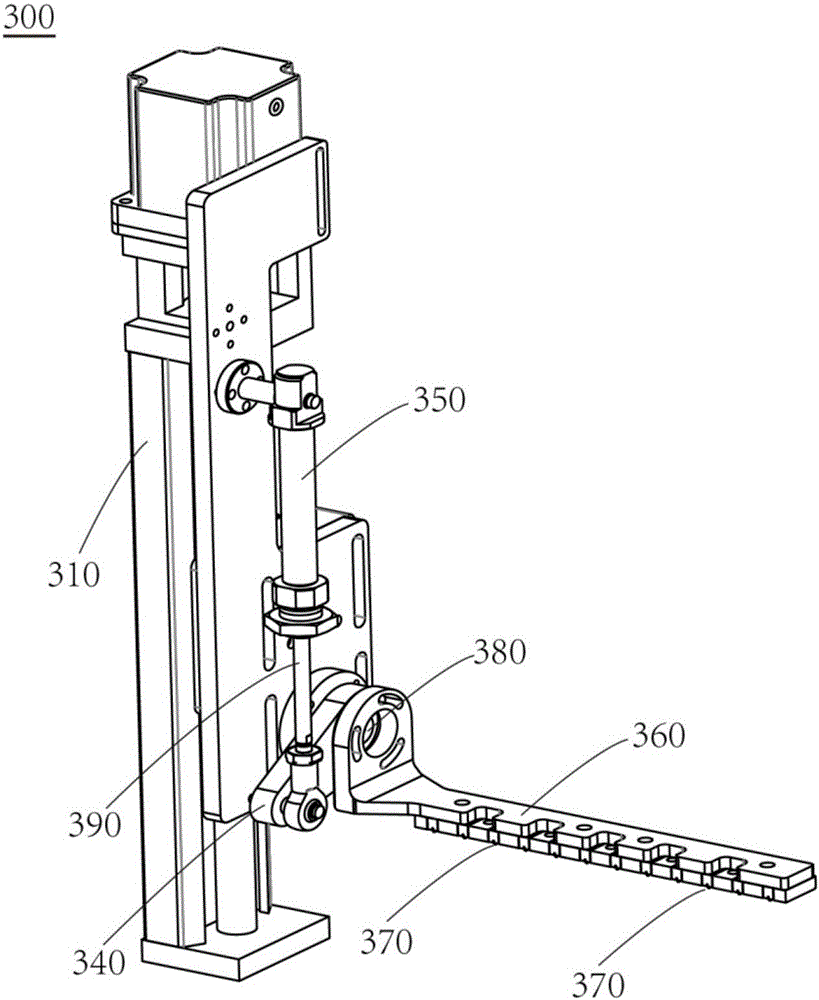

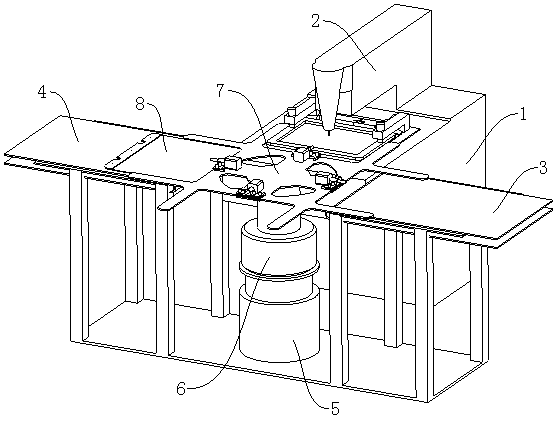

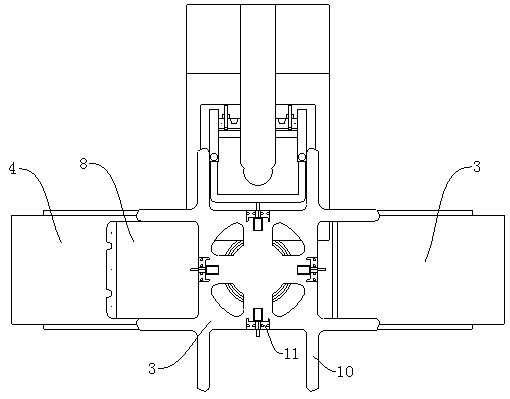

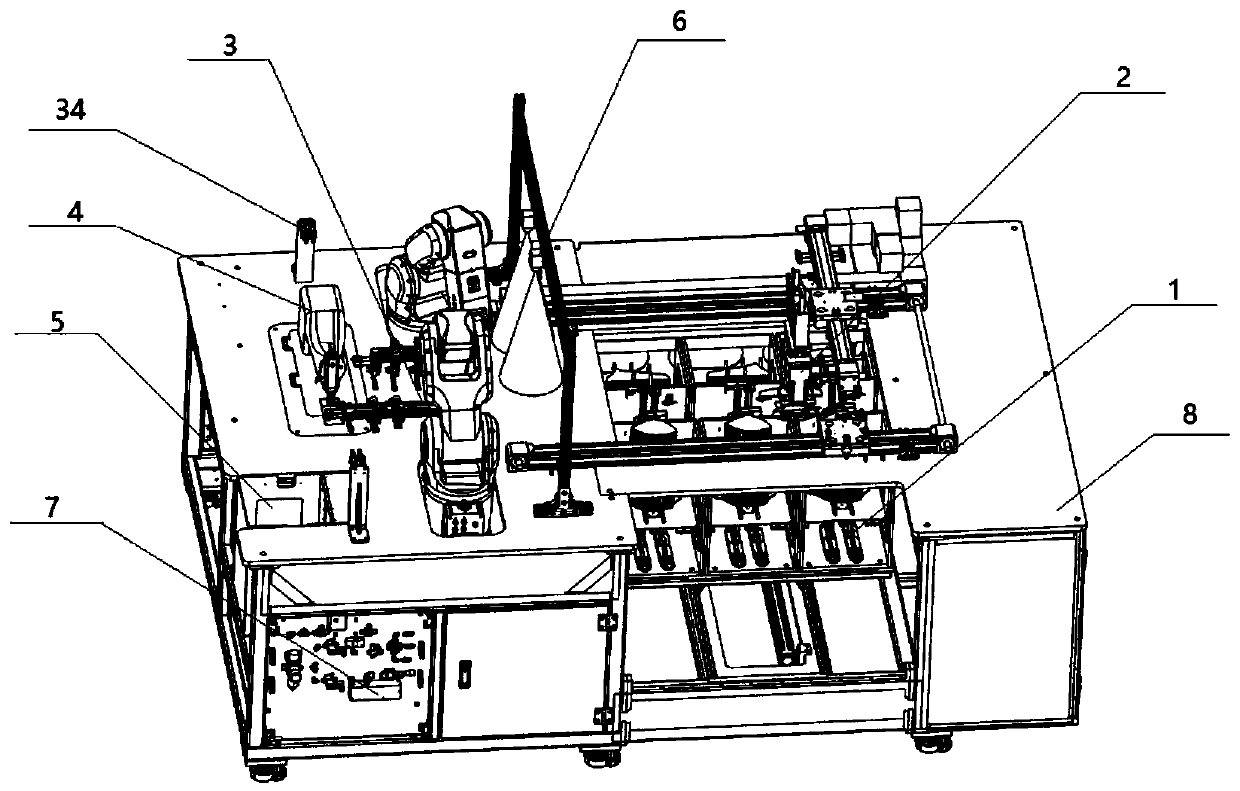

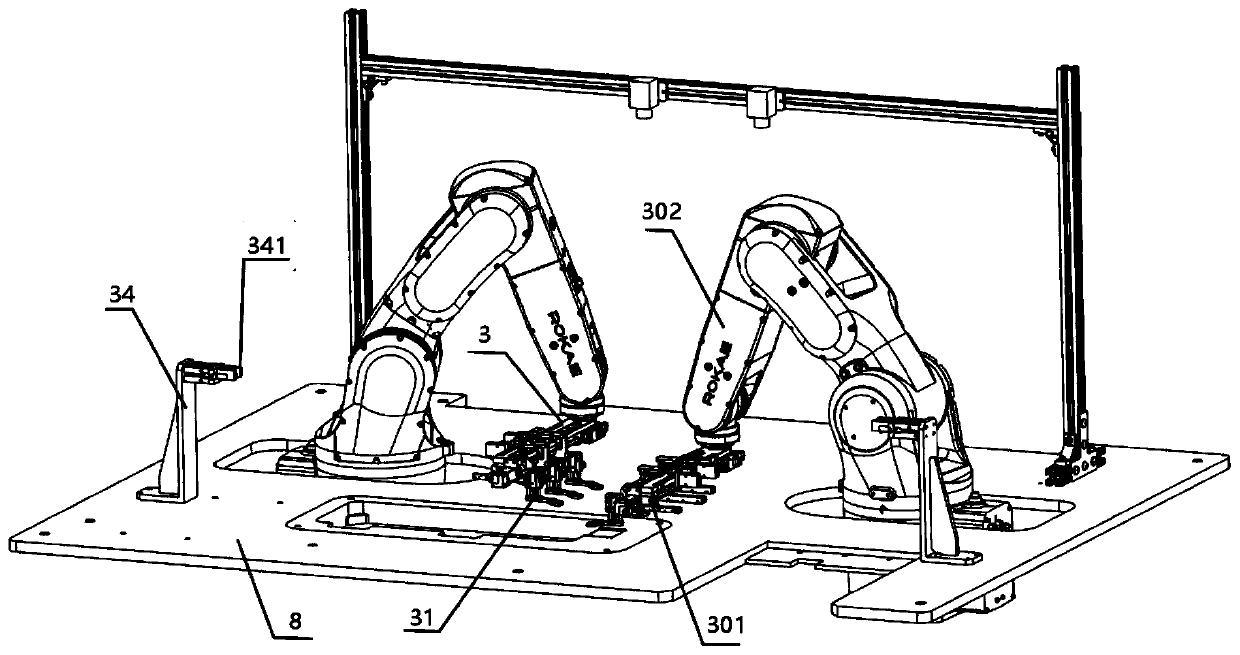

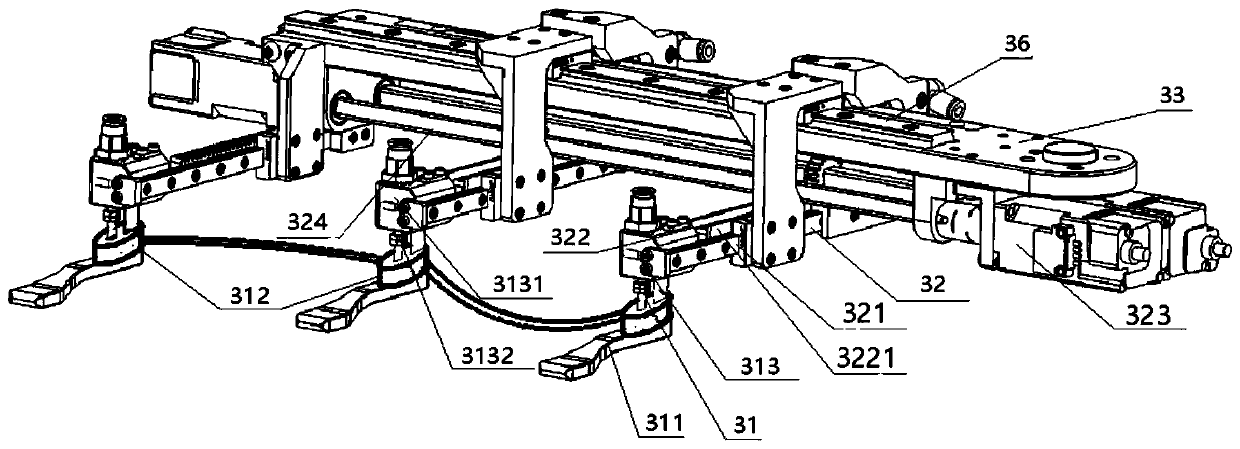

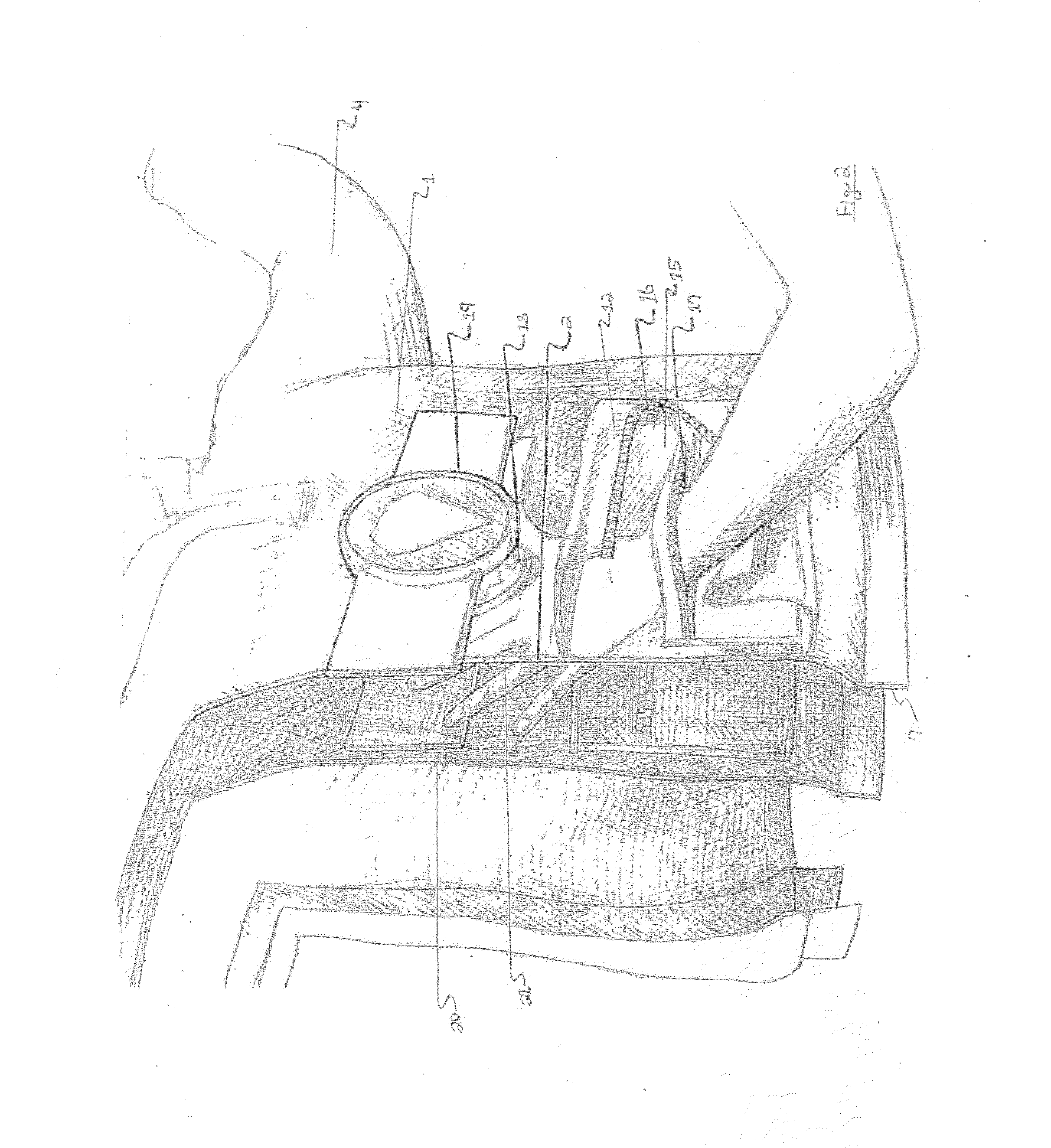

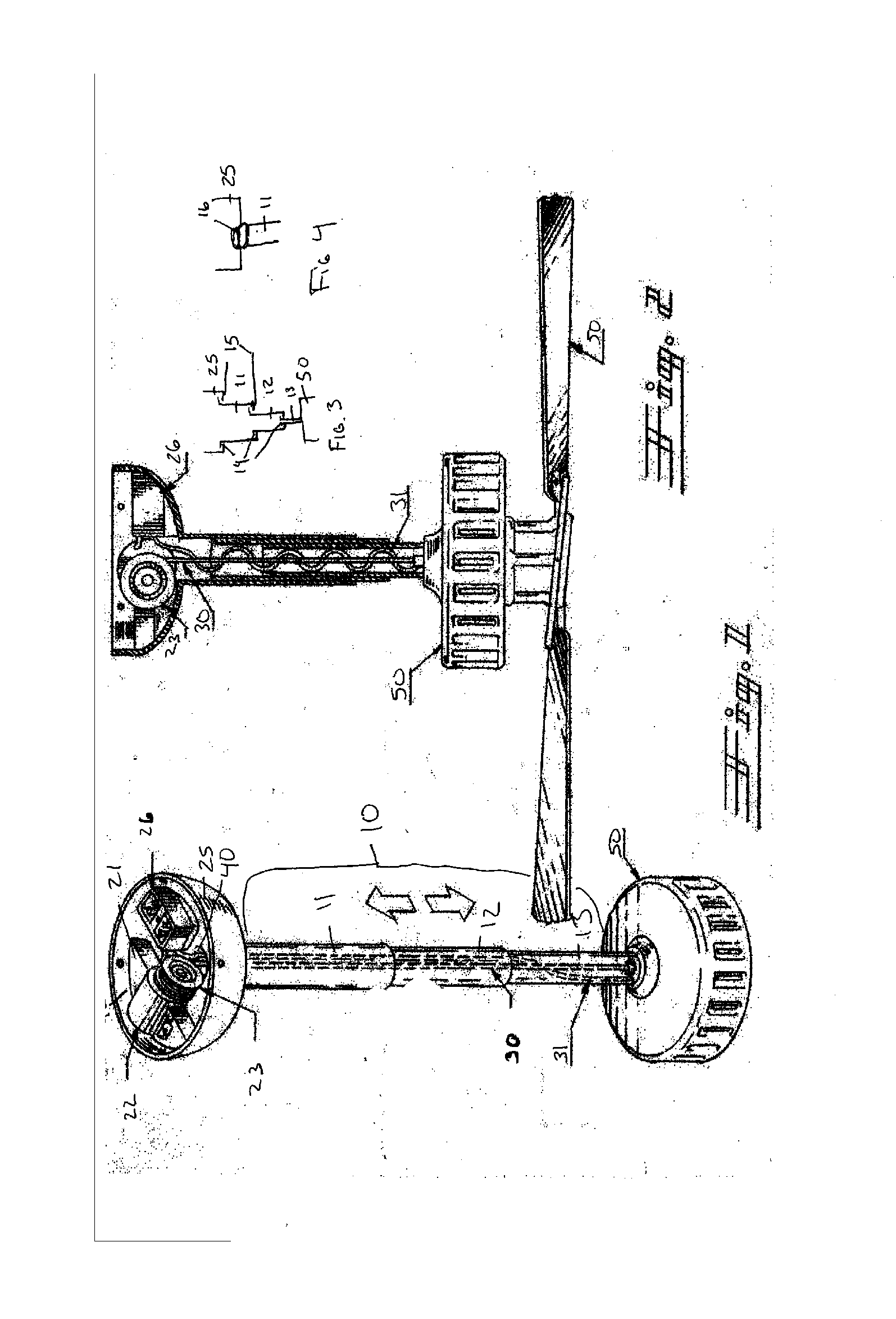

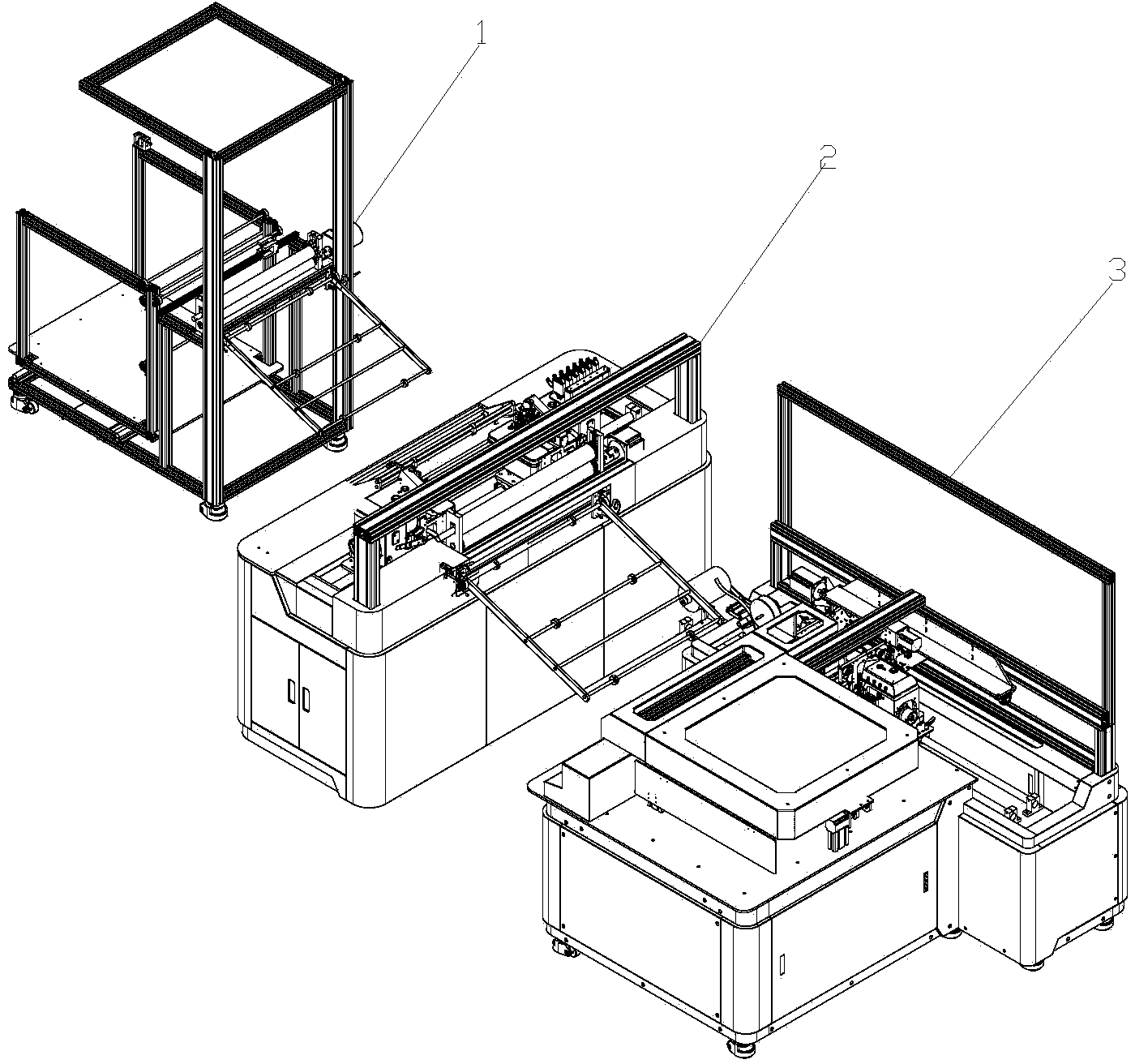

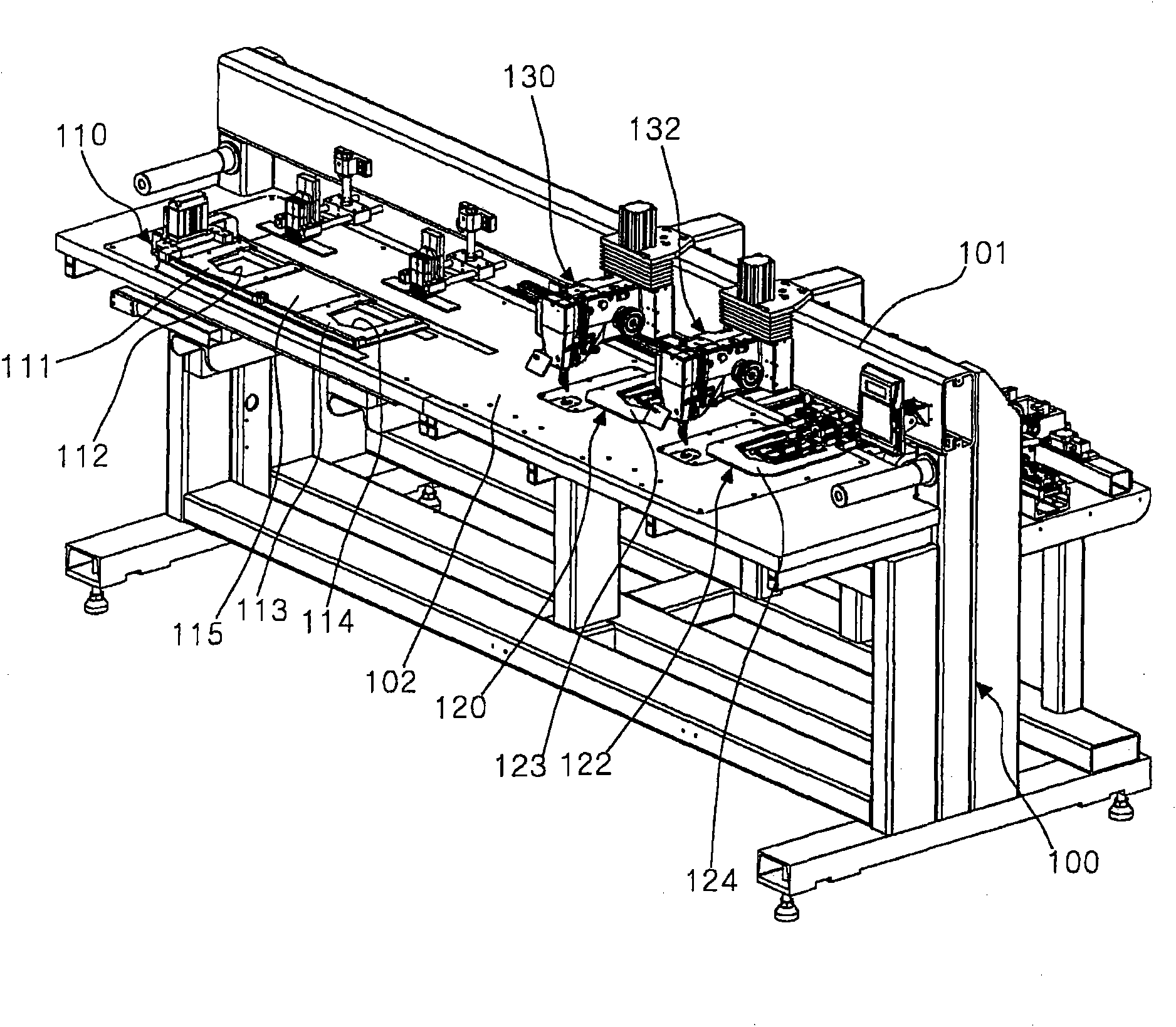

Sewing feeding and discharging assisting device

ActiveCN104047125AEasy maintenanceChange positionSewing-machine elementsArticle feedersEngineeringManipulator

The invention discloses a sewing feeding and discharging assisting device. The device is characterized by comprising a material taking device, a positioning device, a conveying assisting device and a receiving device. When the device works, a cut piece is placed on a cut piece position, a material taking shuttling mechanism and a material taking lifting mechanism cooperatively move a material taking mechanical arm to the upper side of the cut piece position, the cut piece is picked through a material taking piece by the material taking mechanical arm, the material feeding is carried out by the material taking shuttling mechanism along the feeding direction, and the cut piece is sent to a positioning panel; a plurality of positioning adjusting elements are used for positioning the cut piece; a first clamp is used for clamping the cut piece from a material taking opening to move between a first conveying platform and a second conveying platform; the cut piece can be moved to a sewing position under the dynamic effect of the first clamp; after the sewing is completed, the cut piece is clamped by a second clamp to be moved to the upper side of a material receiving mechanical arm; the second clamp releases the cut piece and the cut piece falls on the material receiving mechanical arm; after the material receiving mechanical arm is moved above a receiving tank, the cut piece is resealed to be contained in the receiving tank.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

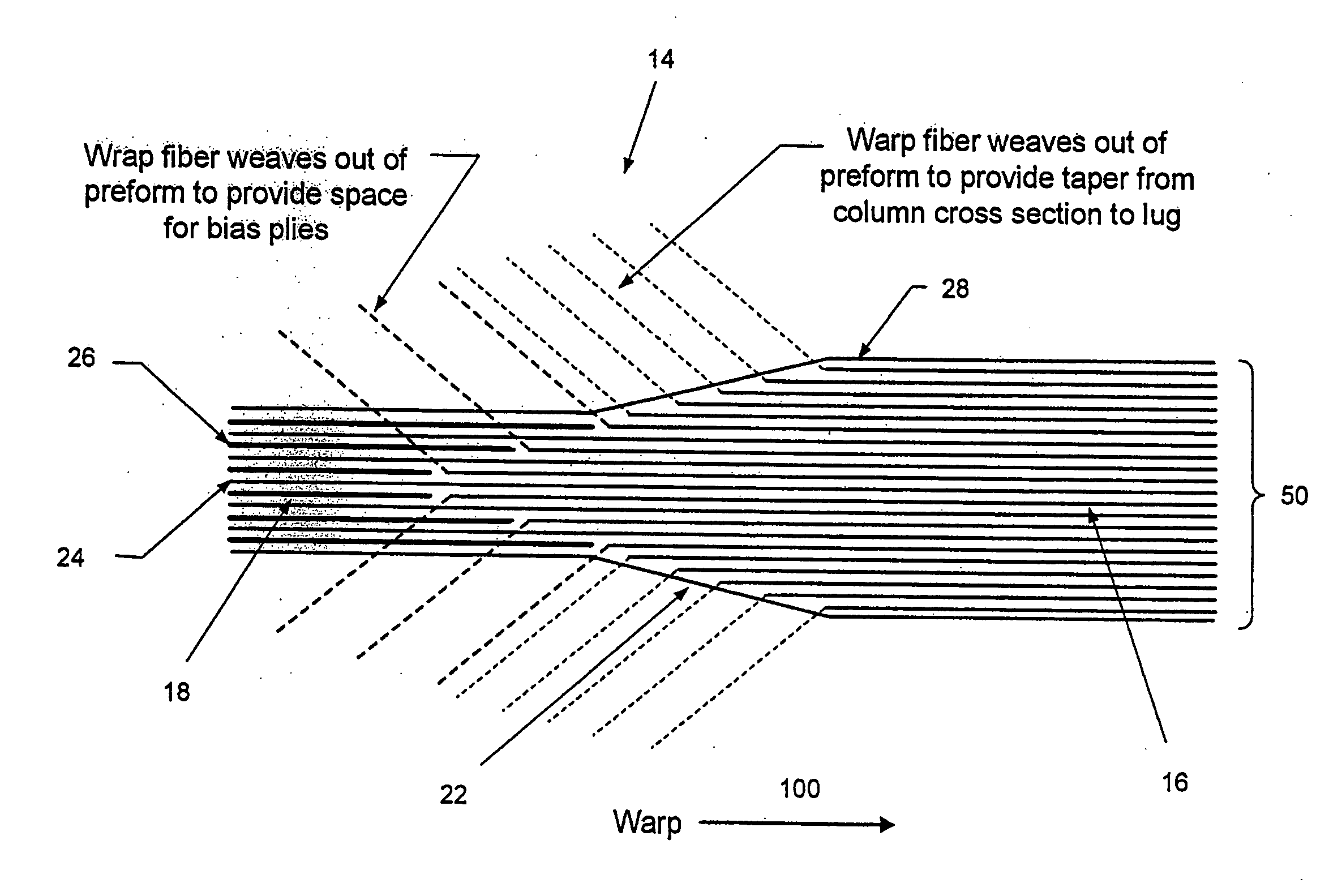

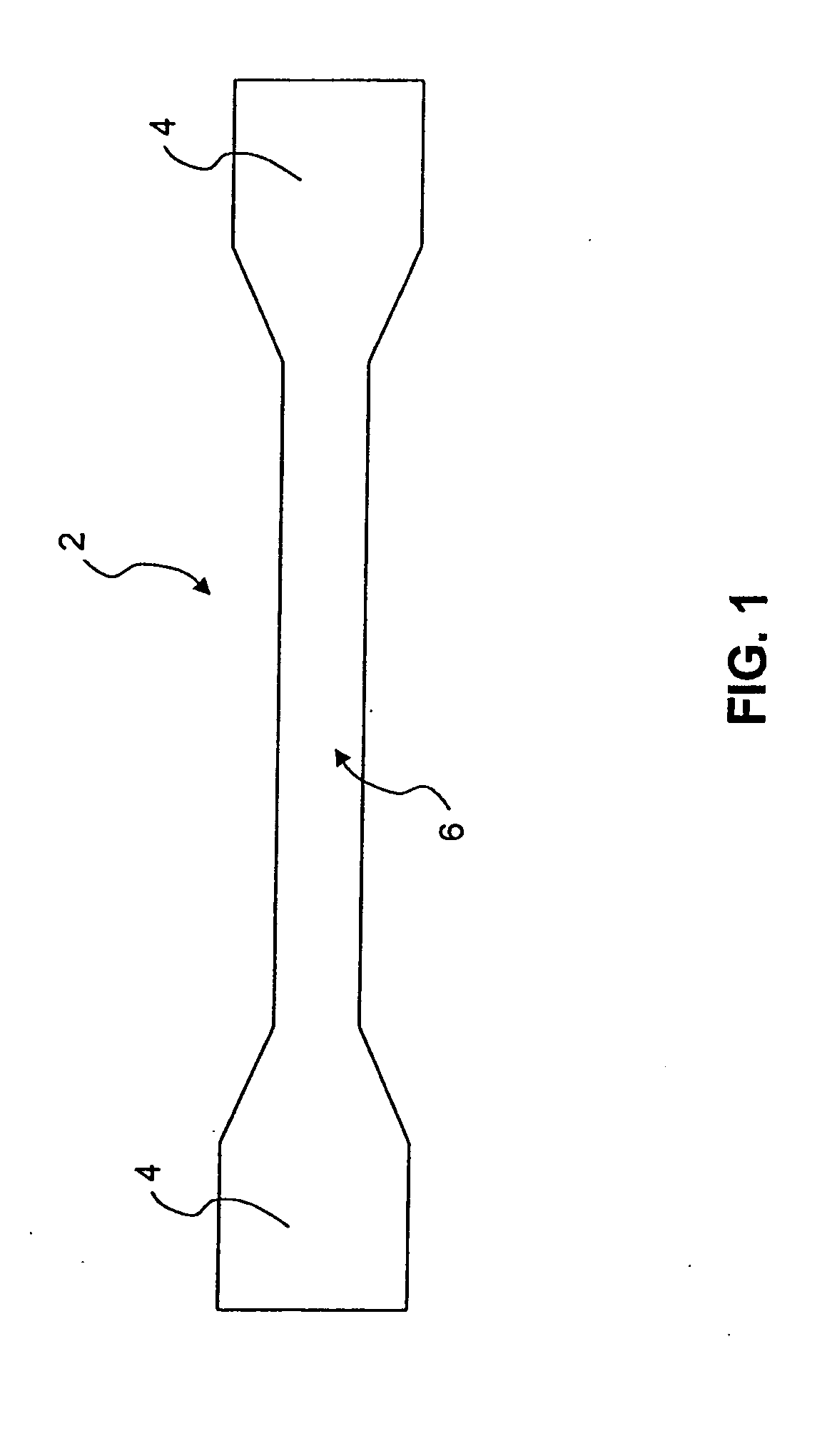

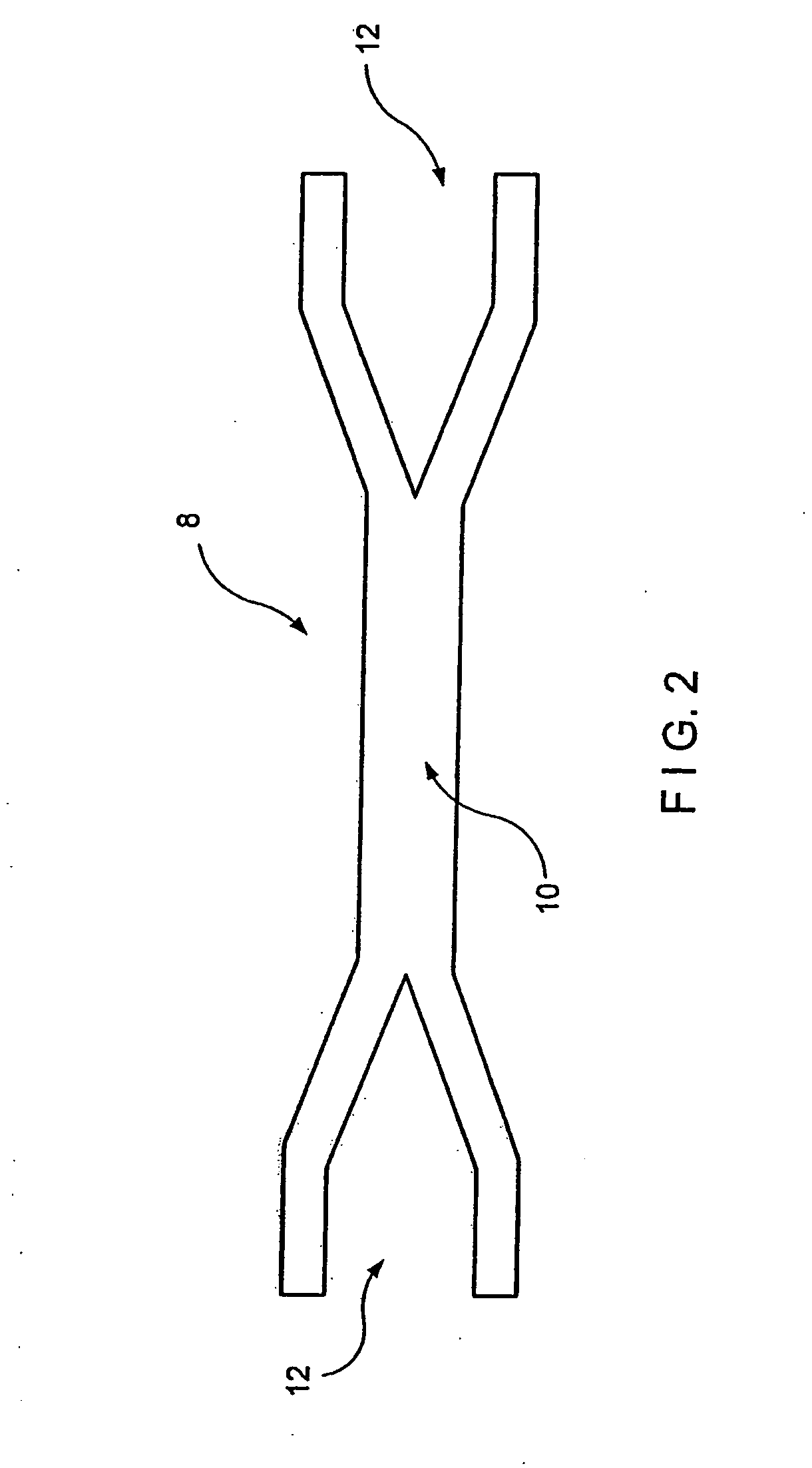

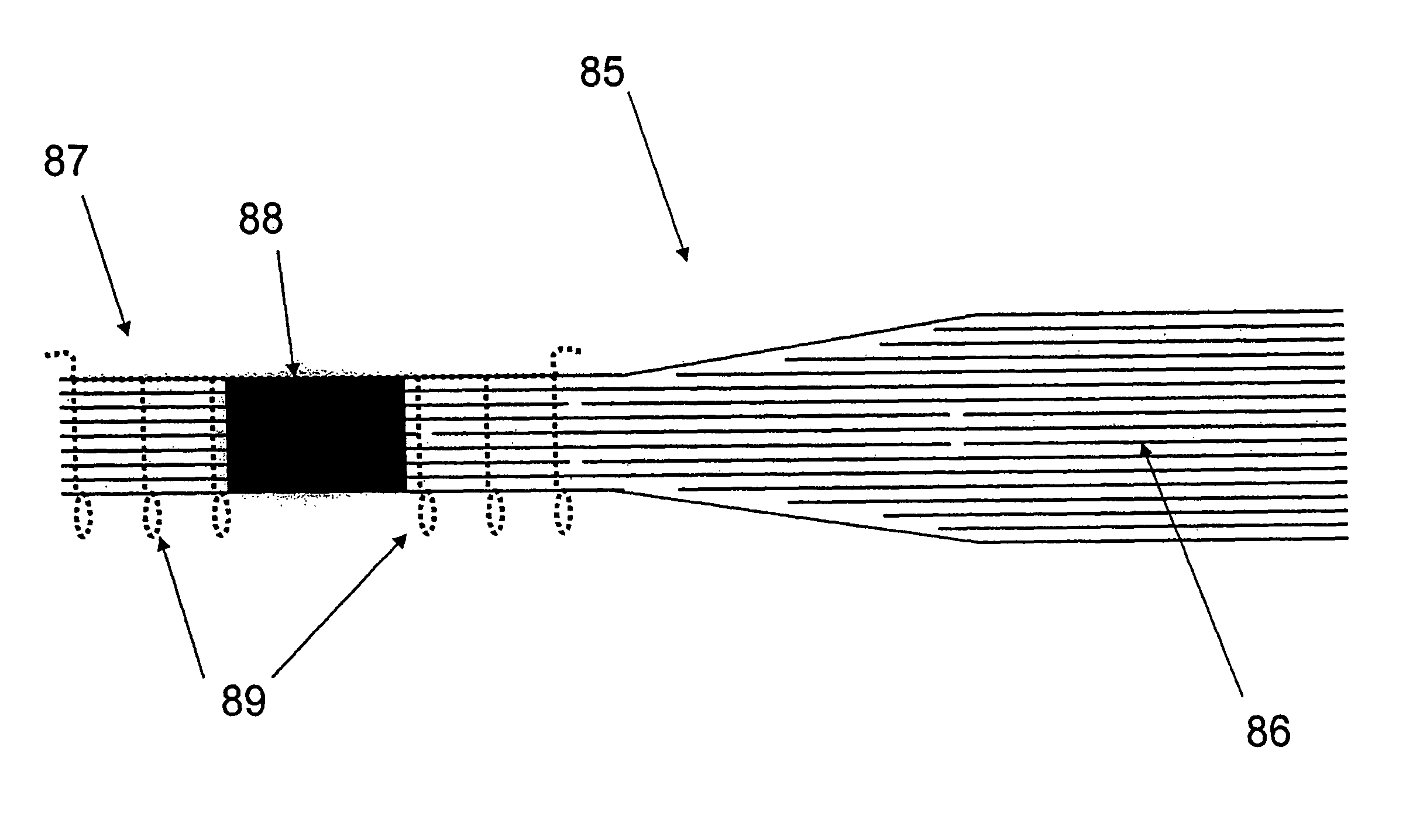

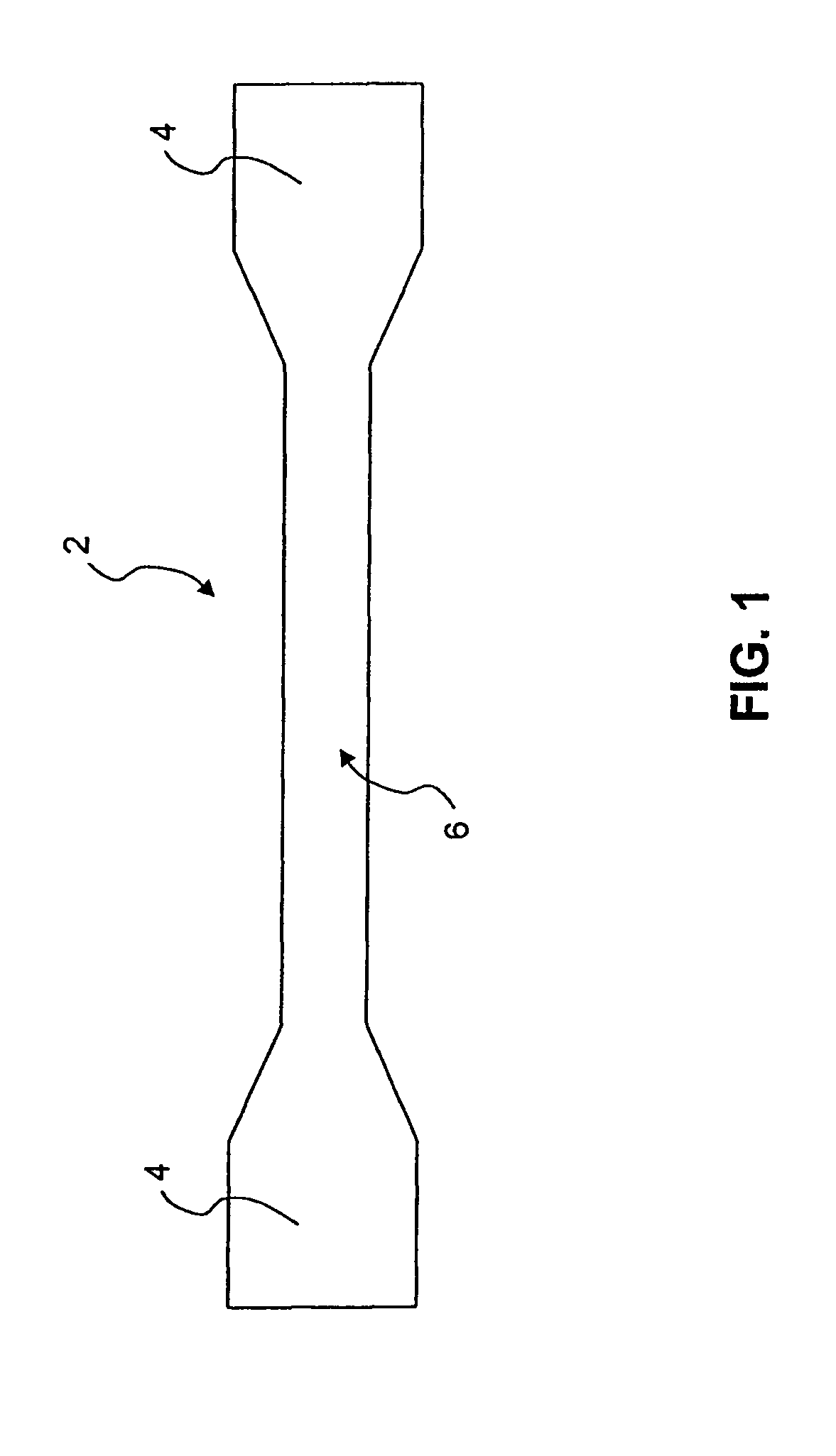

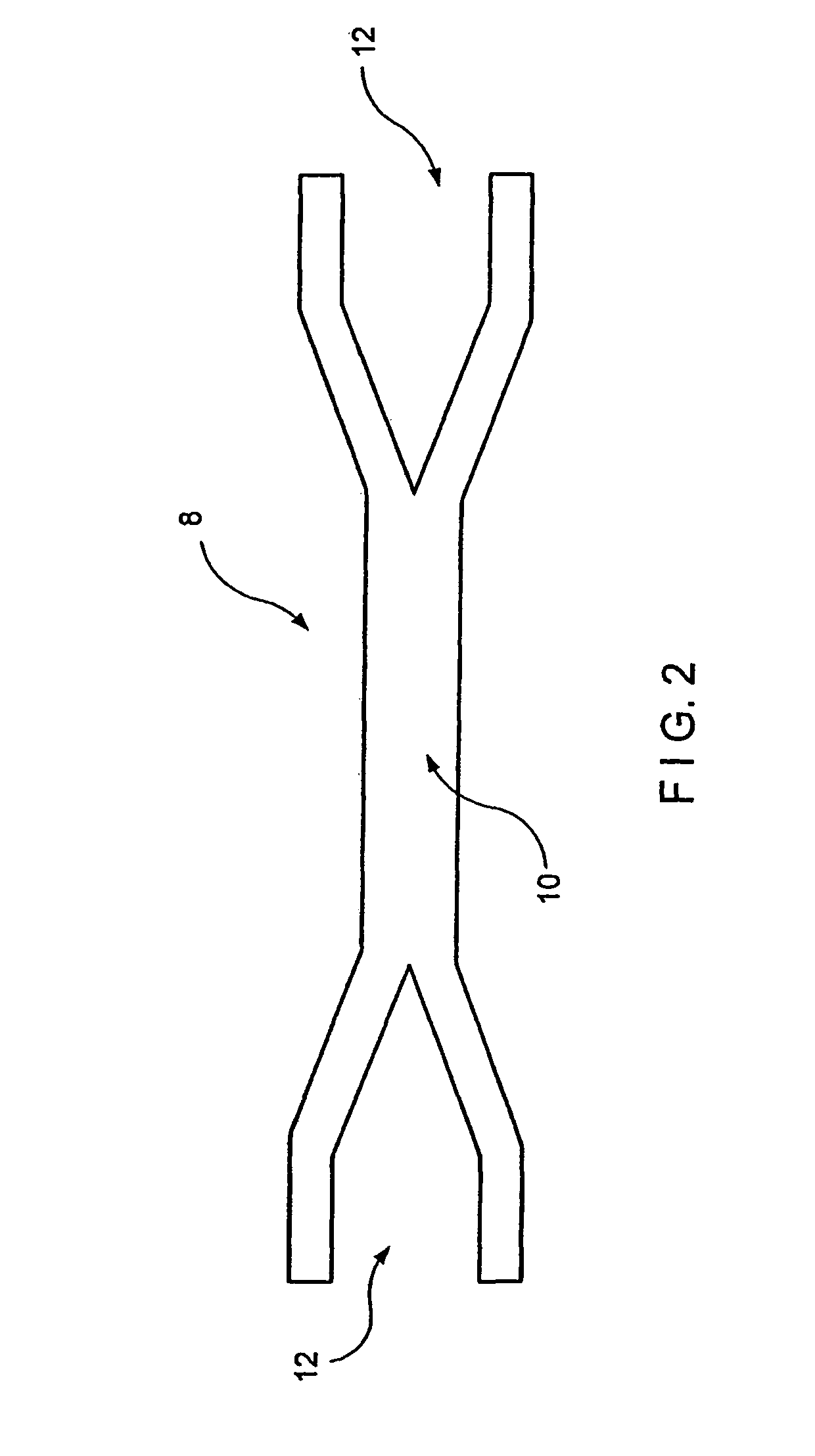

Hybrid Three-Dimensional Woven/Laminated Struts for Composite Structural Applications

ActiveUS20080261474A1High damage toleranceImprove through thickness propertySewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

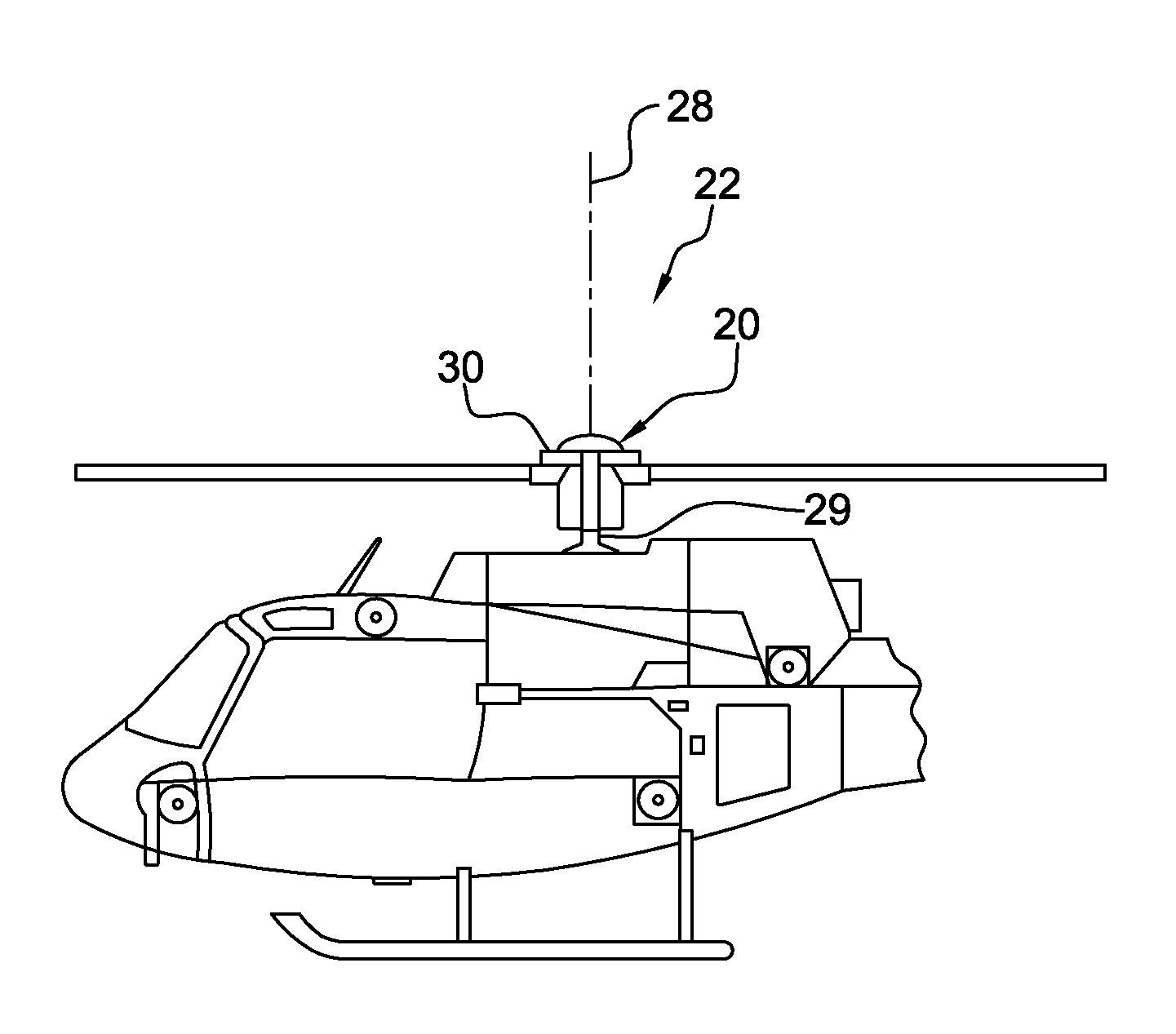

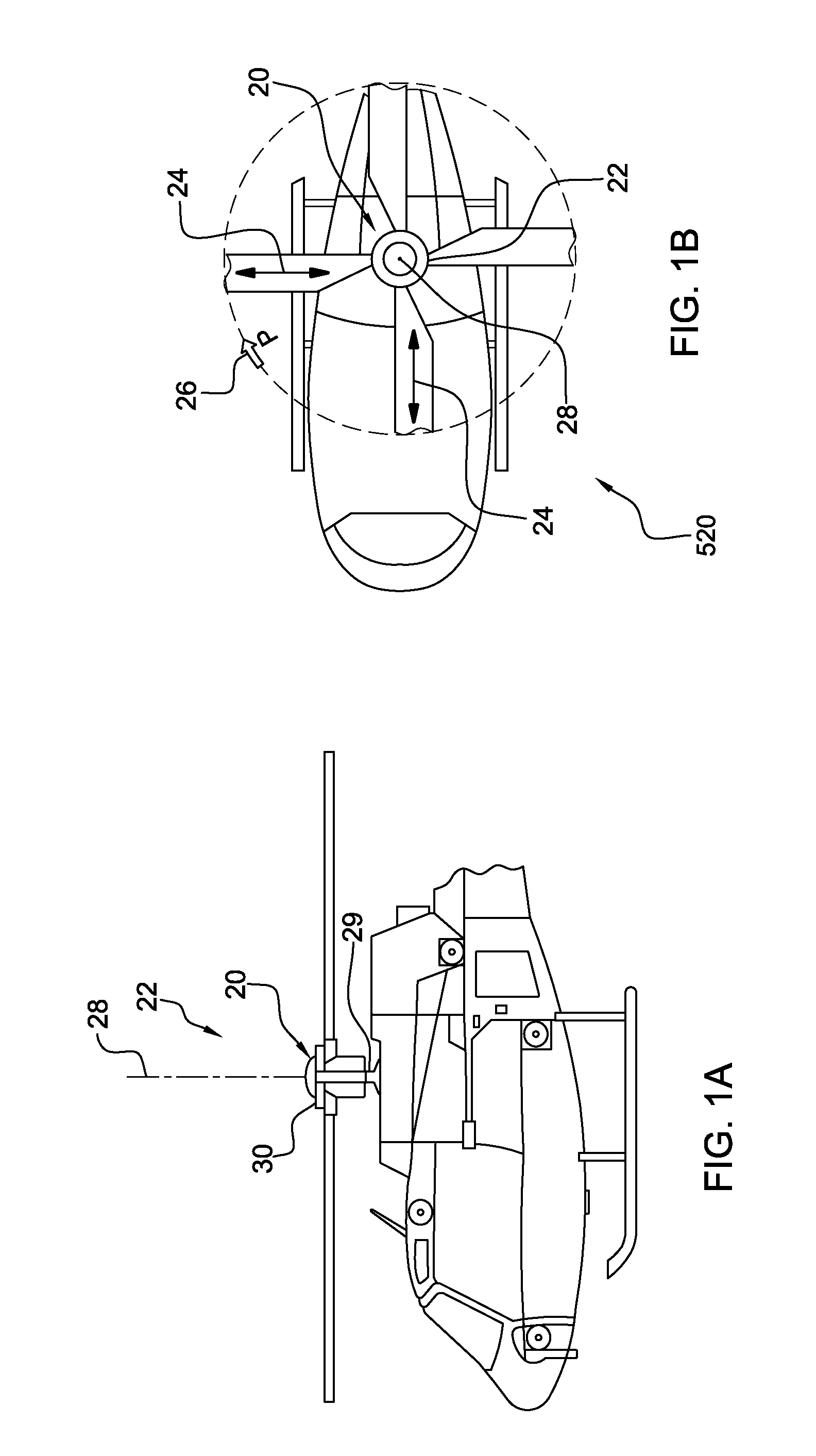

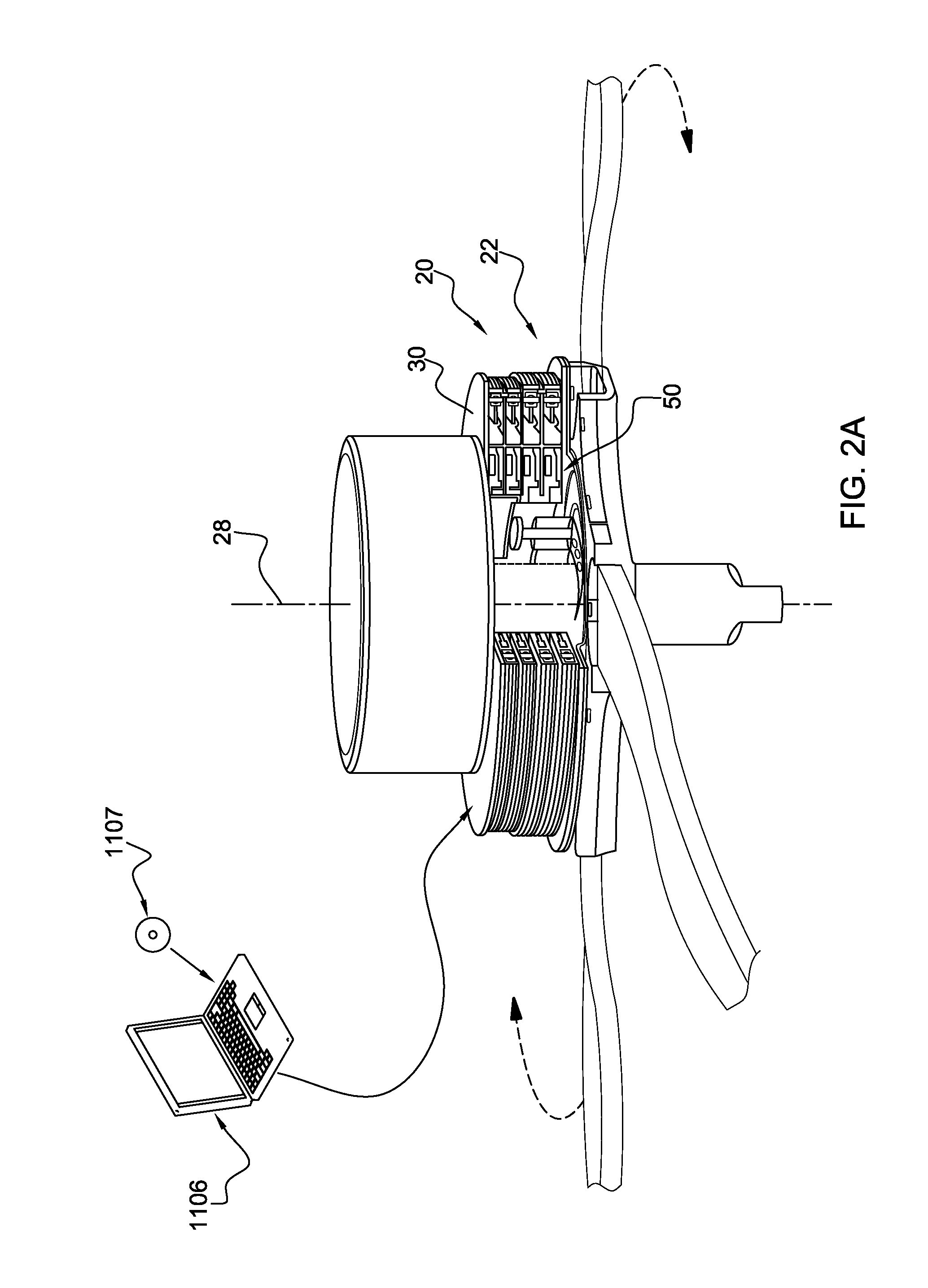

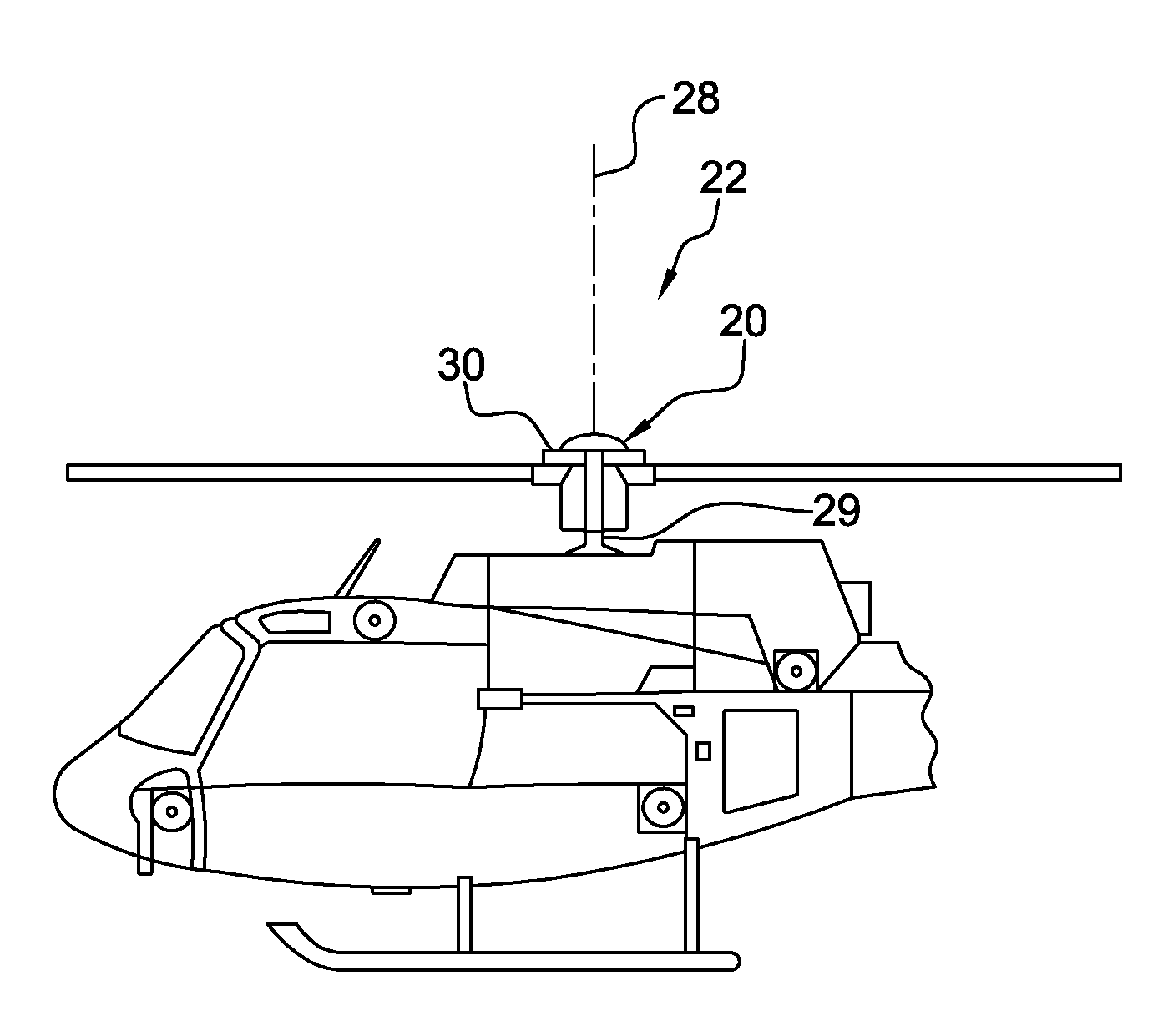

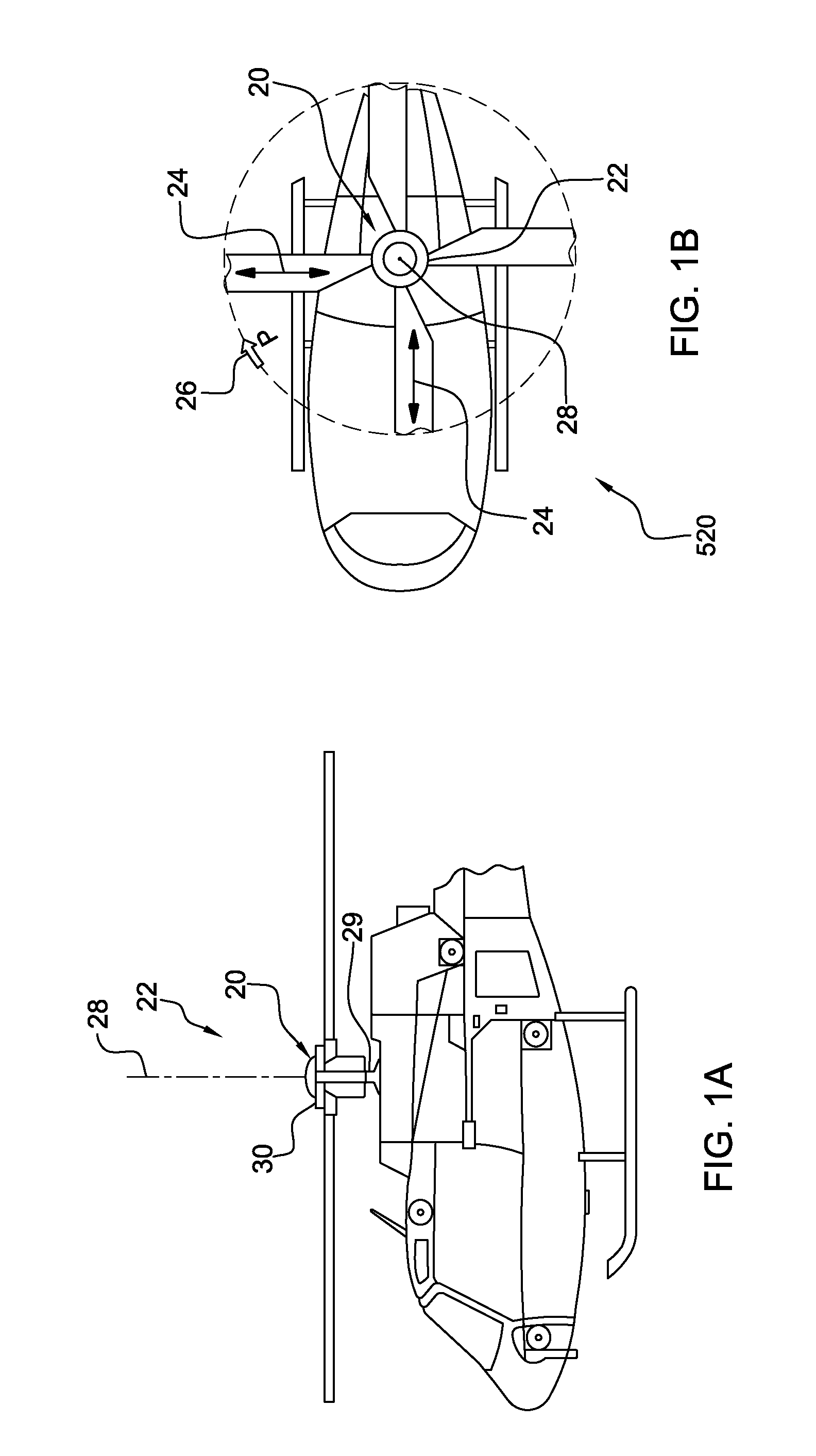

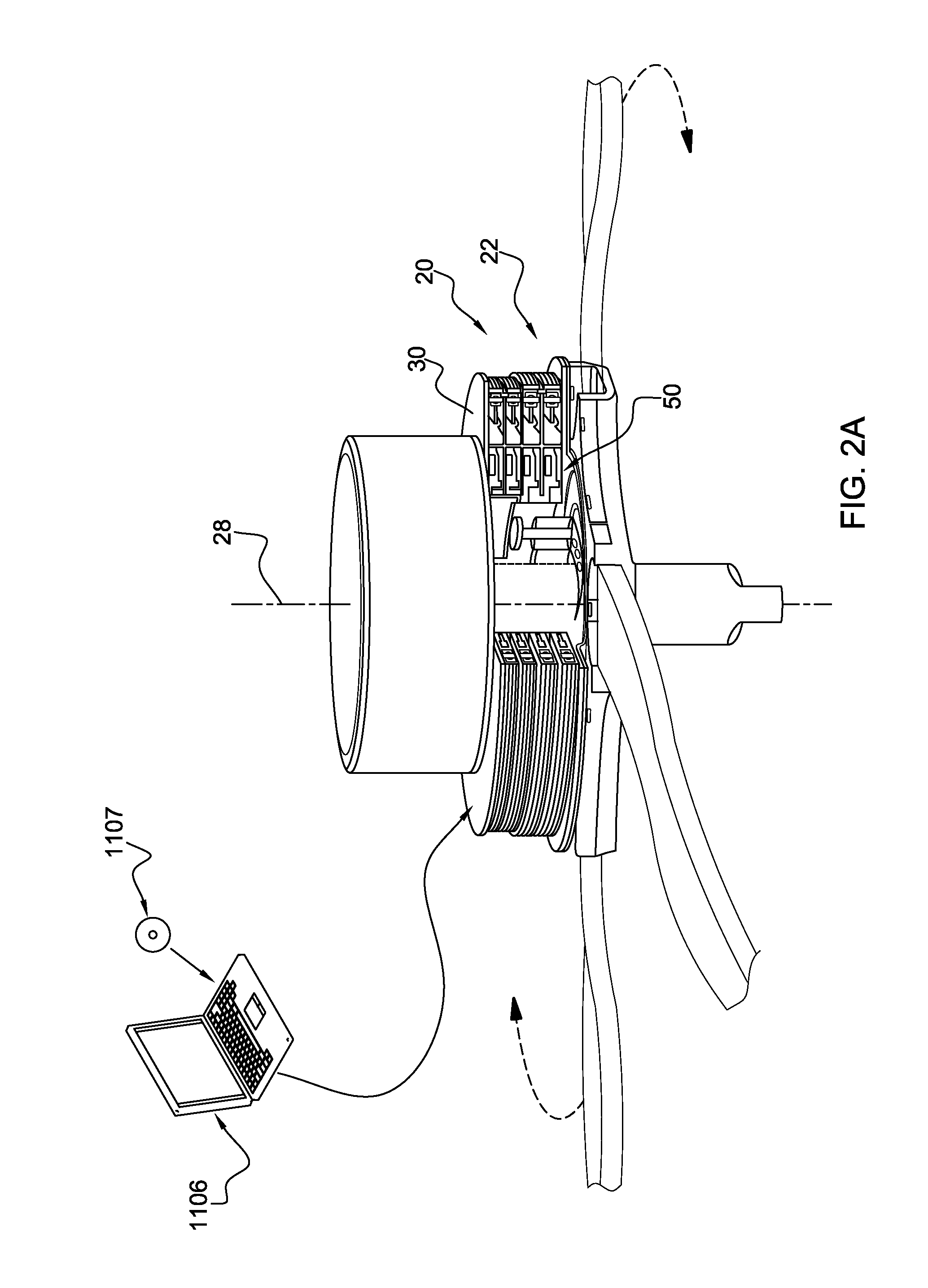

Helicopter vibration control system and rotating assembly rotary forces generators for canceling vibrations

A rotary blade rotating hub mounted rotating assembly vibration control system including a first imbalance mass concentration rotor, a second imbalance mass concentration rotor, a third imbalance mass concentration rotor, and a fourth imbalance mass concentration rotor. The first imbalance mass concentration rotor has a first imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The second imbalance mass concentration rotor has a second imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The third imbalance mass concentration rotor has a third imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The fourth imbalance mass concentration rotor has a fourth imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The first and second imbalance mass concentration rotors are driven at a first rotation speed greater than the rotating assembly operational rotation frequency while controlling the rotational position of the first imbalance mass concentration and the second imbalance mass concentration to produce a first rotating net force vector to inhibit a first vibration frequency. The third and fourth imbalance mass concentration rotors are driven at a second rotation speed greater than the rotating assembly operational rotation frequency while controlling the rotational position of the third imbalance mass concentration and the fourth imbalance mass concentration to produce a second rotating net force vector to inhibit a second vibration frequency.

Owner:LORD CORP

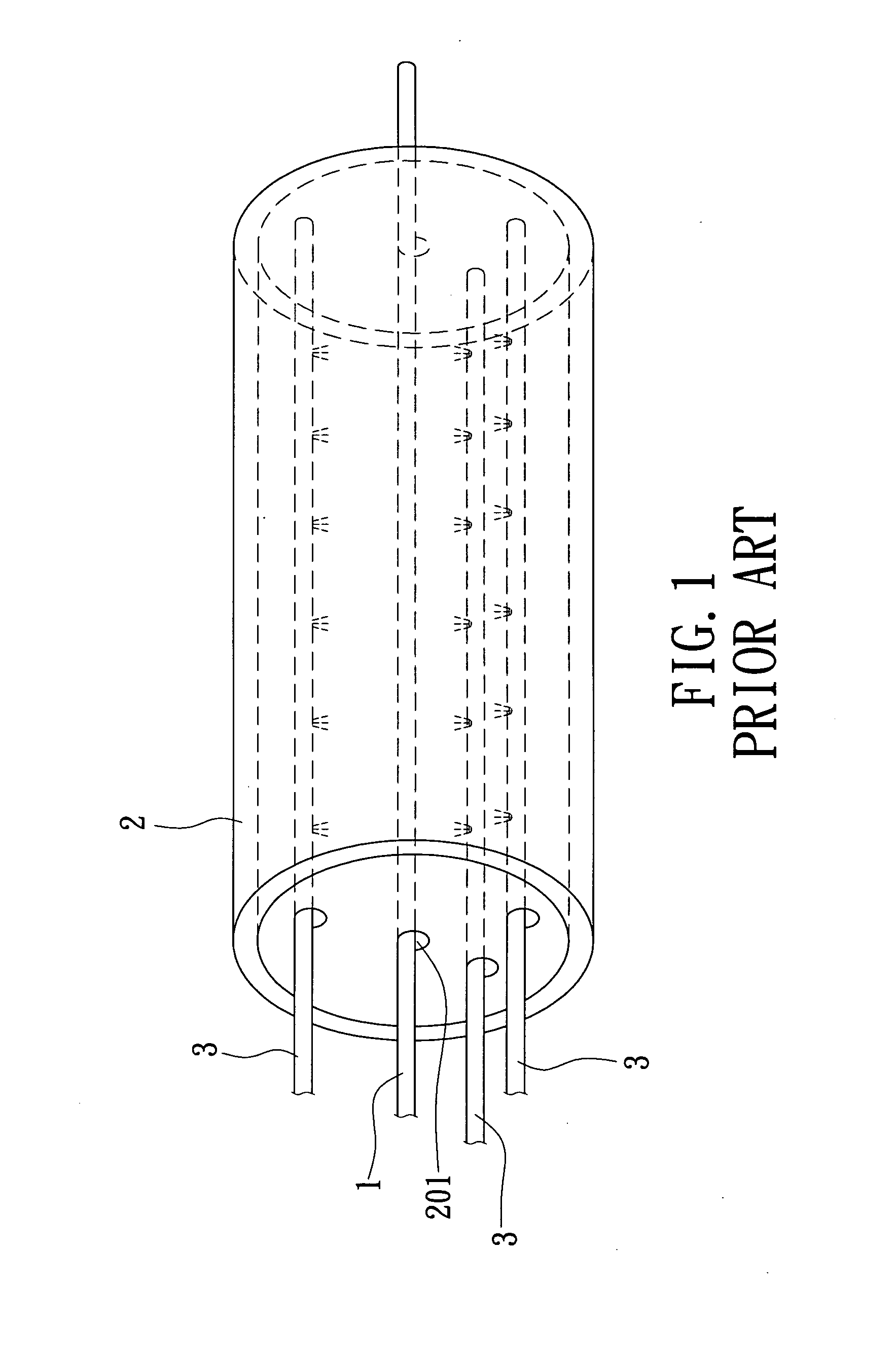

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

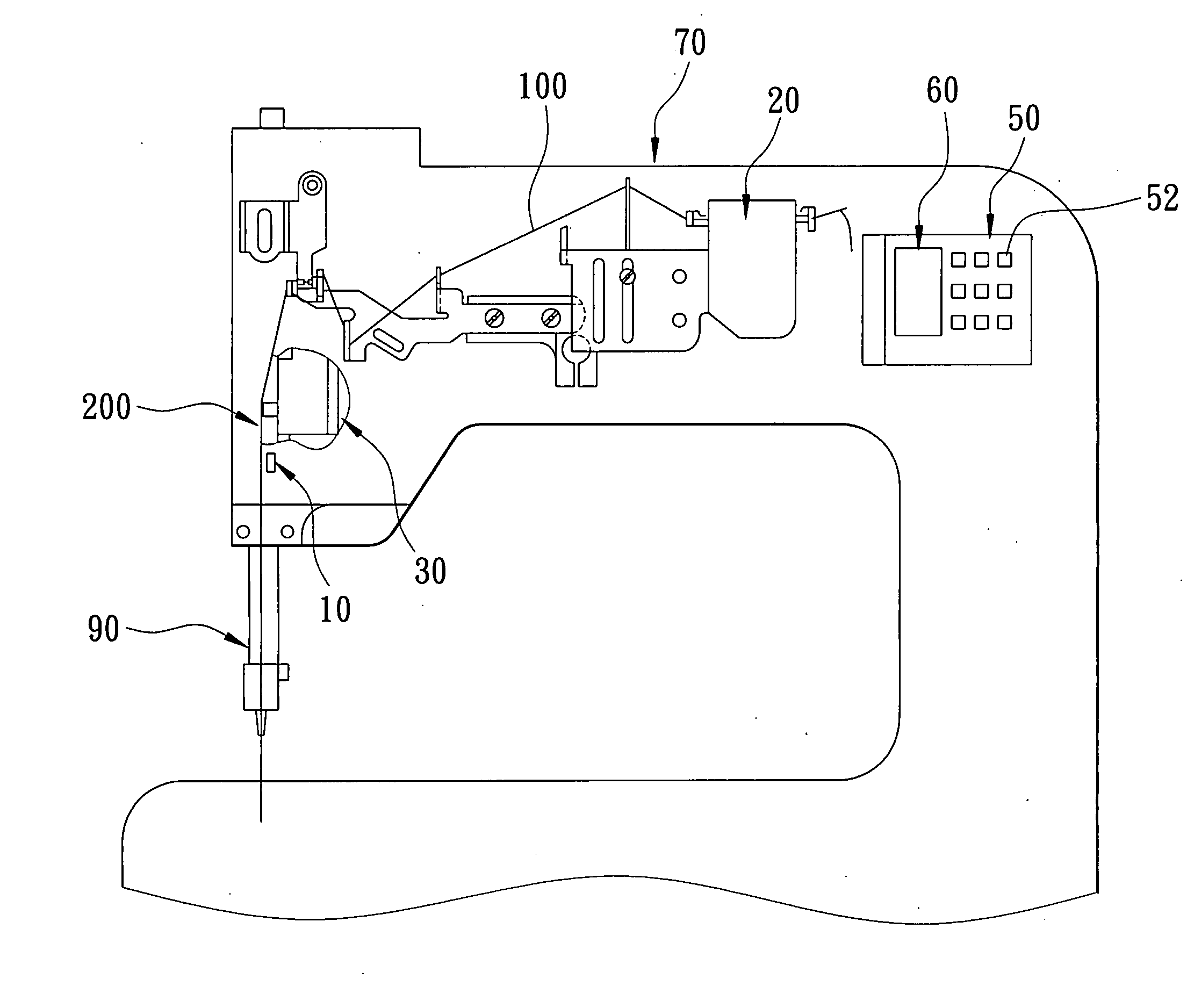

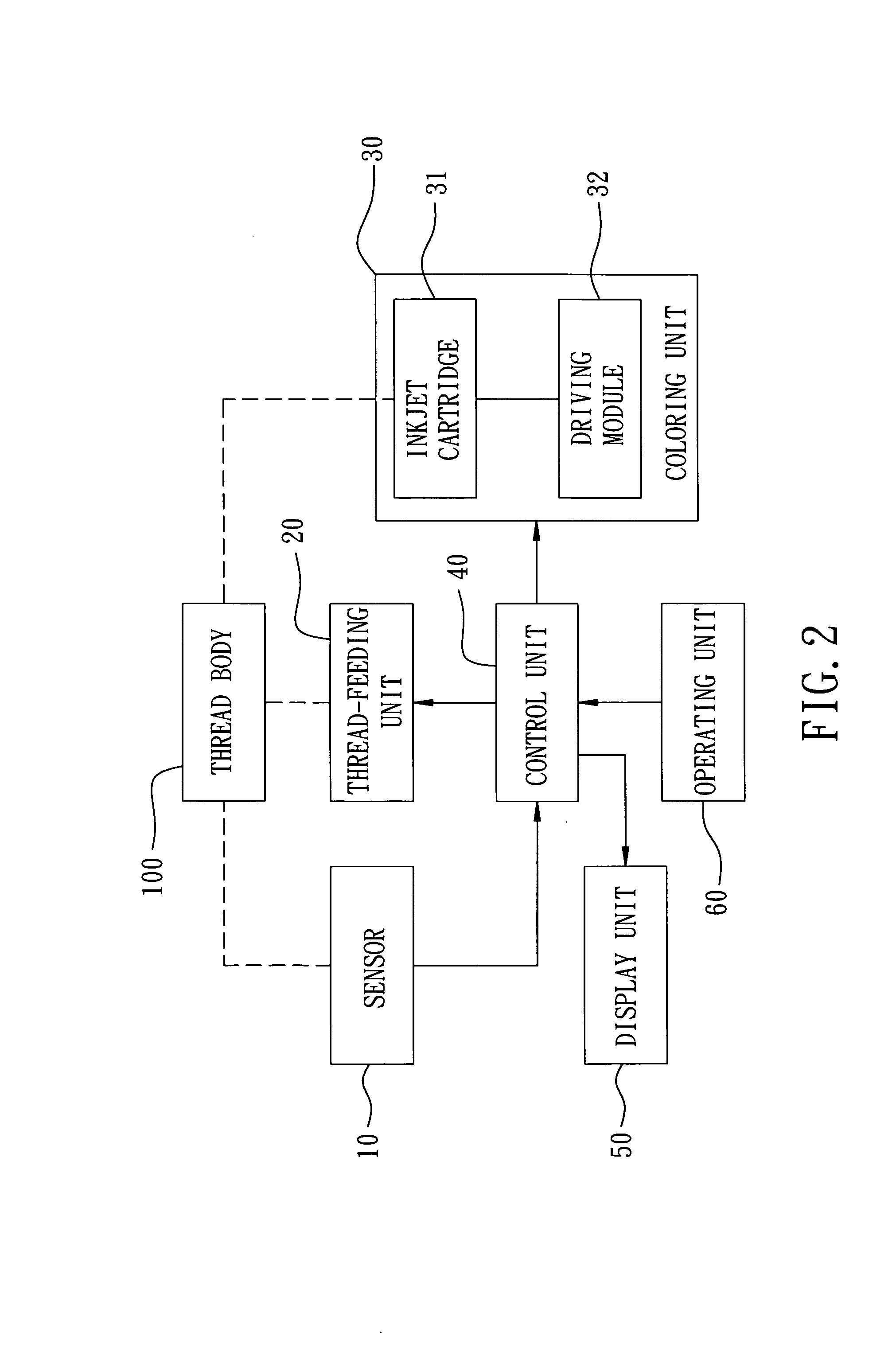

Device for coloring a thread body, and sewing machine having the same

InactiveUS20090241819A1Programme-controlled sewing machinesLiquid surface applicatorsEngineeringControl unit

A device for coloring a thread body includes a thread-feeding unit adapted for feeding the thread body at a predetermined speed such that the thread body is transported along a feeding path. A coloring unit is disposed fixedly adjacent to the feeding path, and is operable so as to spray a coloring material onto the thread body. A control unit is connected electrically to the coloring unit, and is operable so as to control the coloring unit to spray the coloring material, which has a desired one of a plurality of different colors.

Owner:ZENG HSING INDUSTRIAL CO LTD

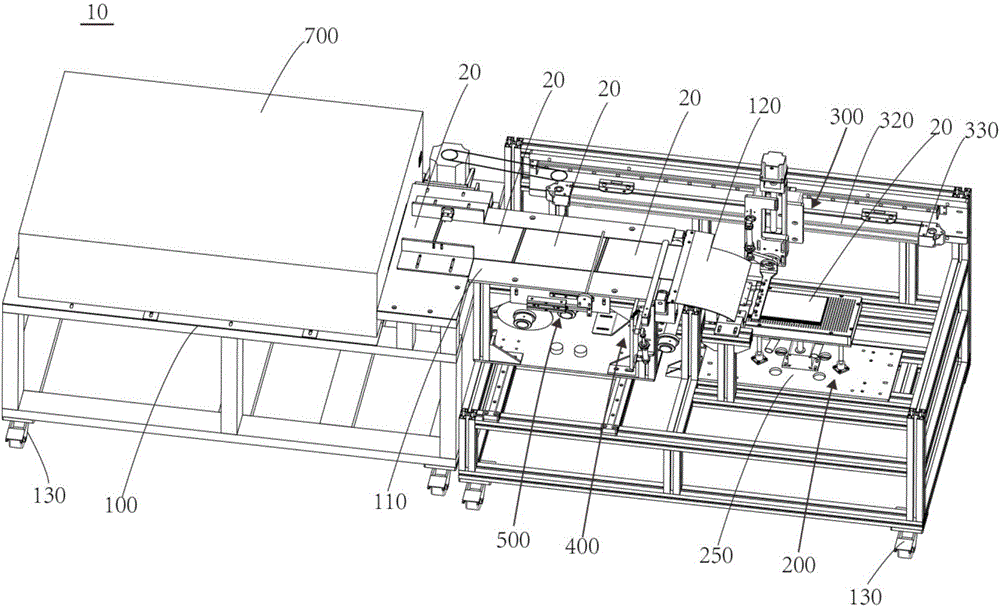

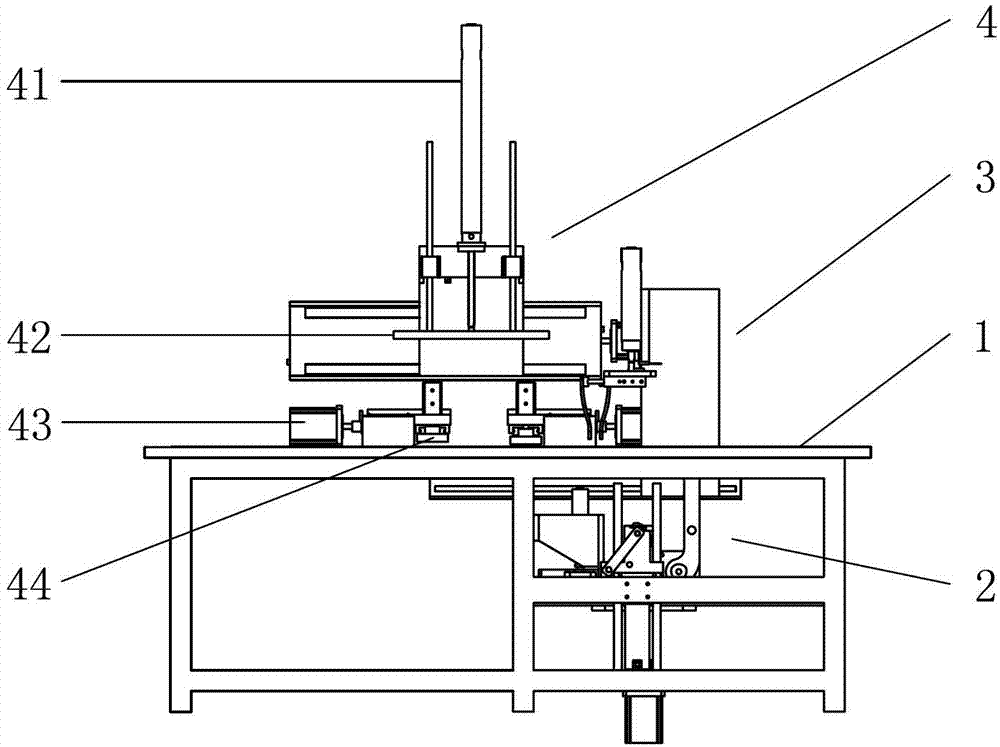

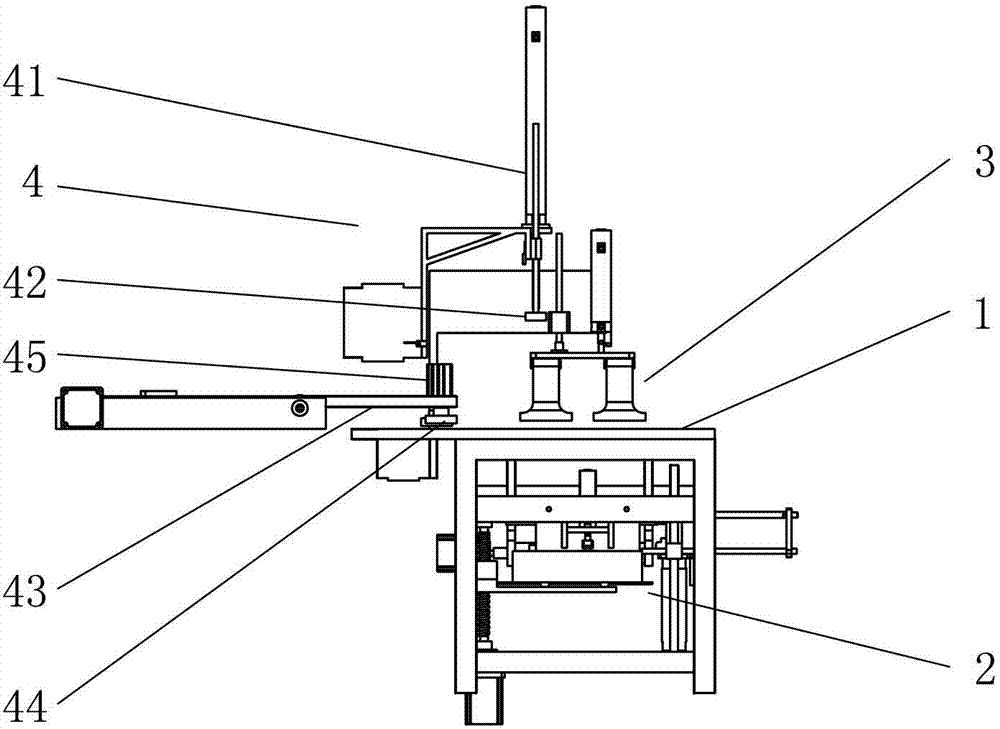

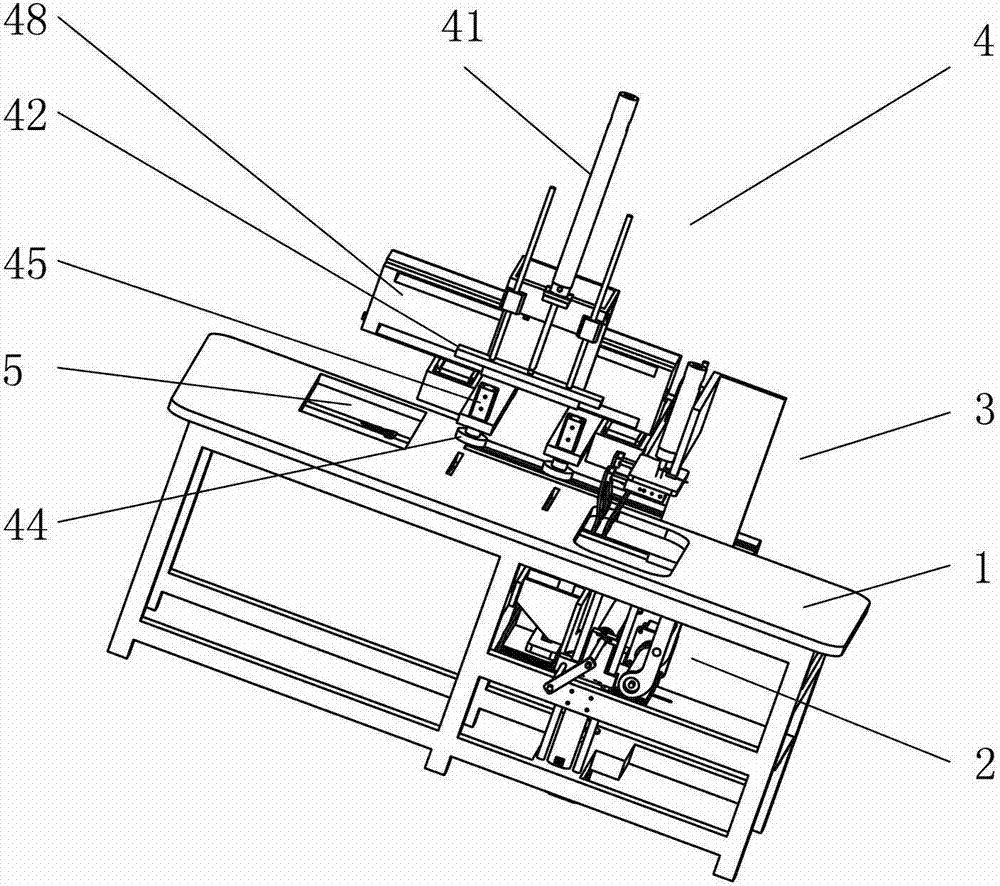

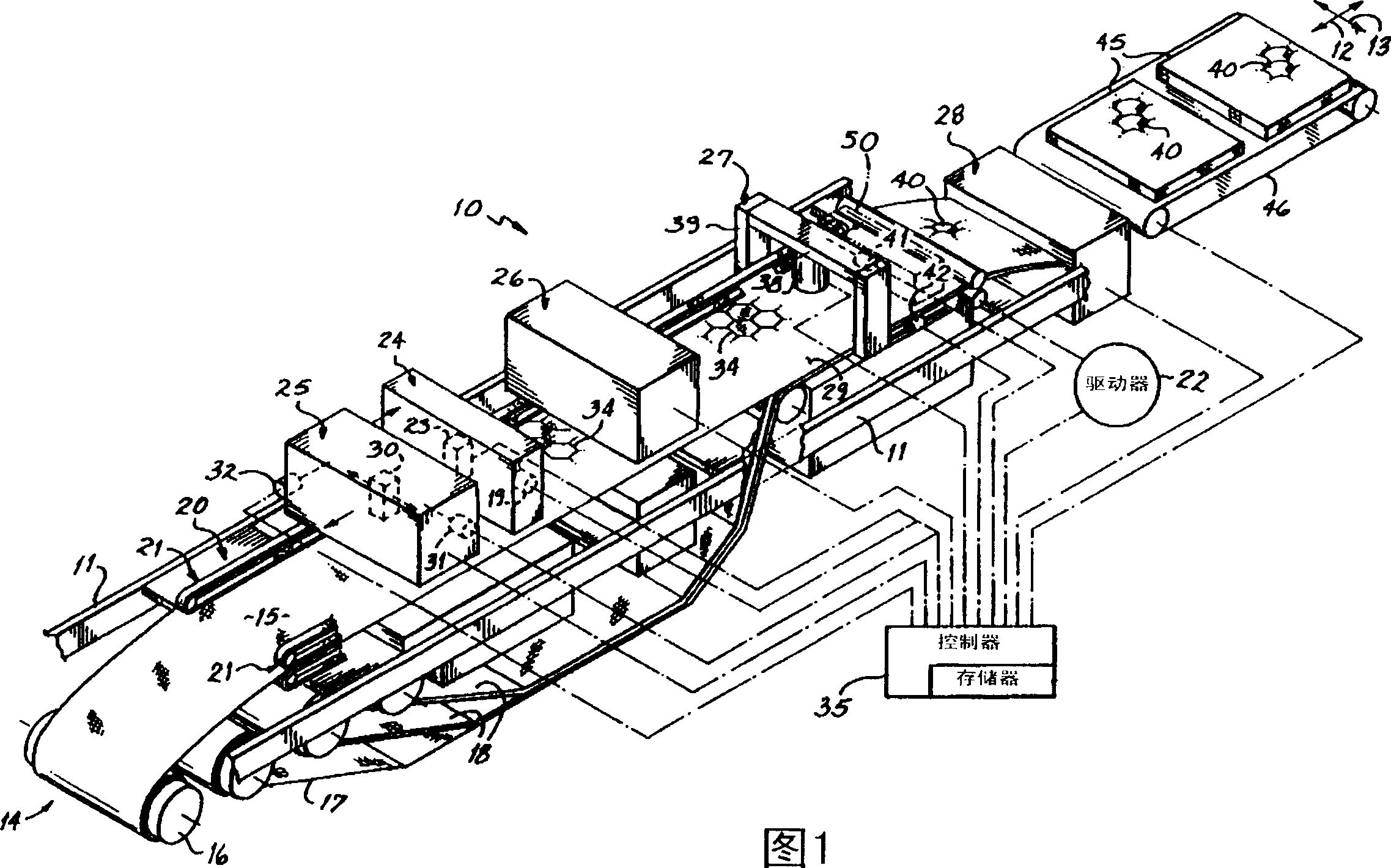

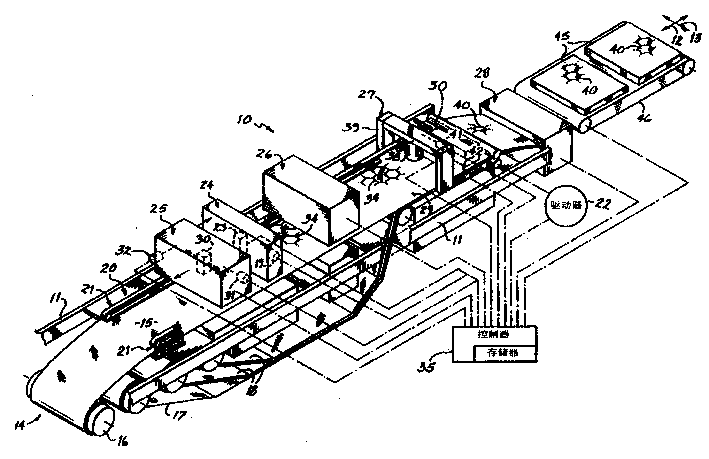

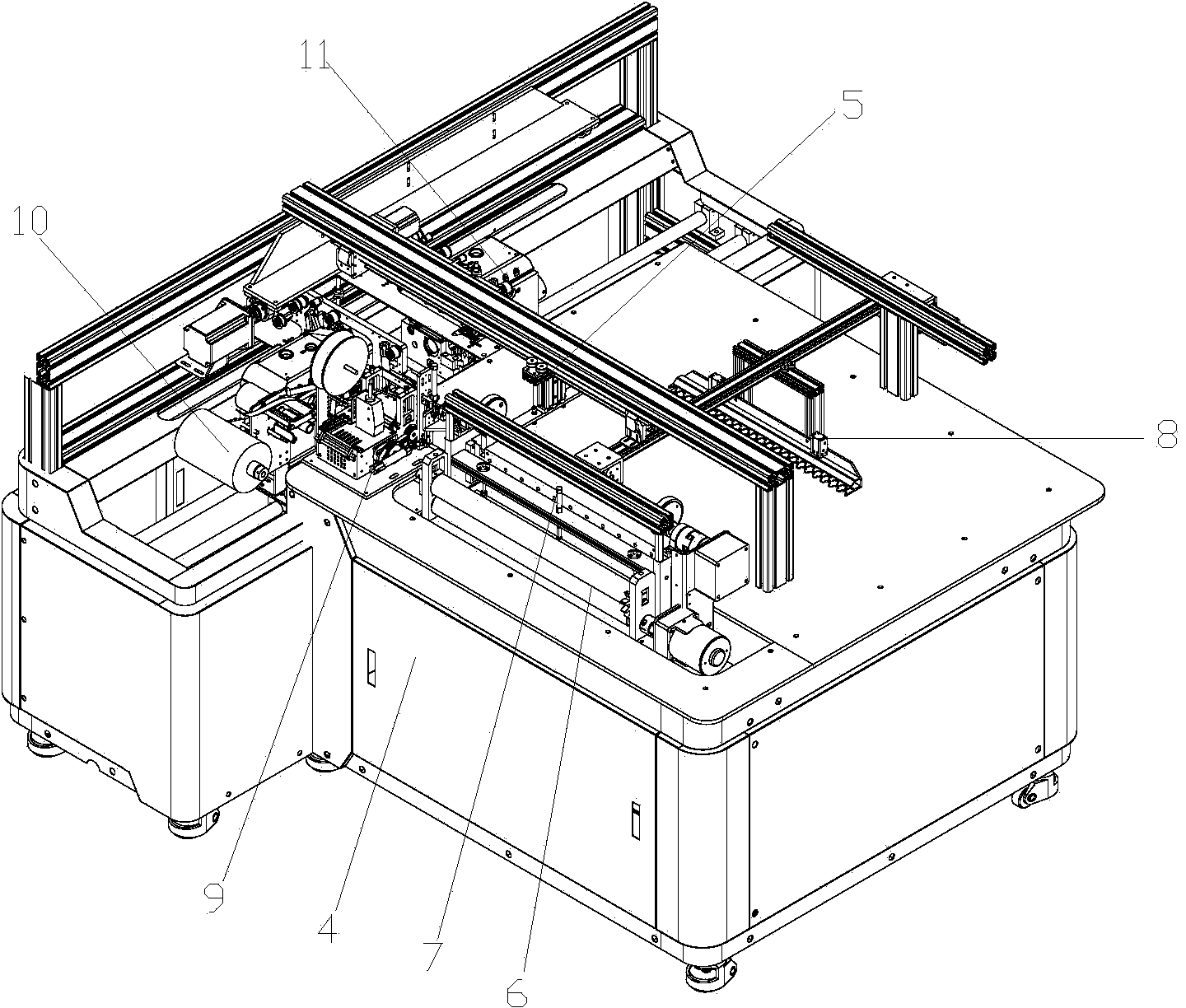

Ironing and interlining system

ActiveCN106087277ARealize automatic reclaimingRealize automatic feedingSewing-machine elementsClothes making applicancesInterliningFeed drive

The invention discloses an ironing and interlining system which comprises a machine, a feeding device, a taking device and an ironing and interlining device. A conveying surface is arranged on the machine, and can be used for holding interlining ribbons. The feeding device is provided with a support, a feeding plate, feeding drive components and a positioning blowpipe, the support is connected to the machine, the feeding drive component is arranged on the machine and connected to the feeding plate to drive the feeding plate to move, the feeding plate is used for overlap placement of multiple cut-parts, the feeding plate is provided with fixing air suction holes, and the positioning blowpipe is arranged on the support and located above the feeding plate. The taking device is arranged on the machine and used for getting the cut-parts from the feeding plate and moving the cut-parts to the interlining ribbons located on the conveying surface. The ironing and interlining device is arranged on the machine and used for ironing and interlining the interlining ribbons and the cut-parts. The ironing and interlining system is timesaving, laborsaving and high in ironing and interlining efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

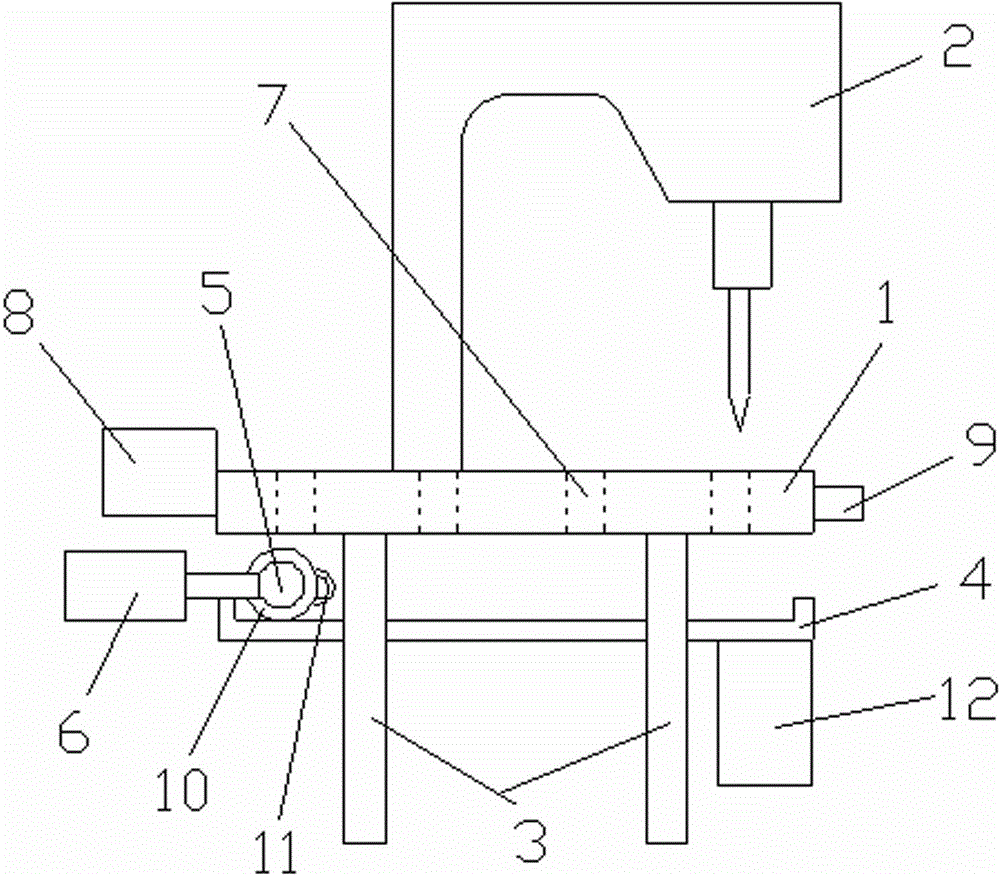

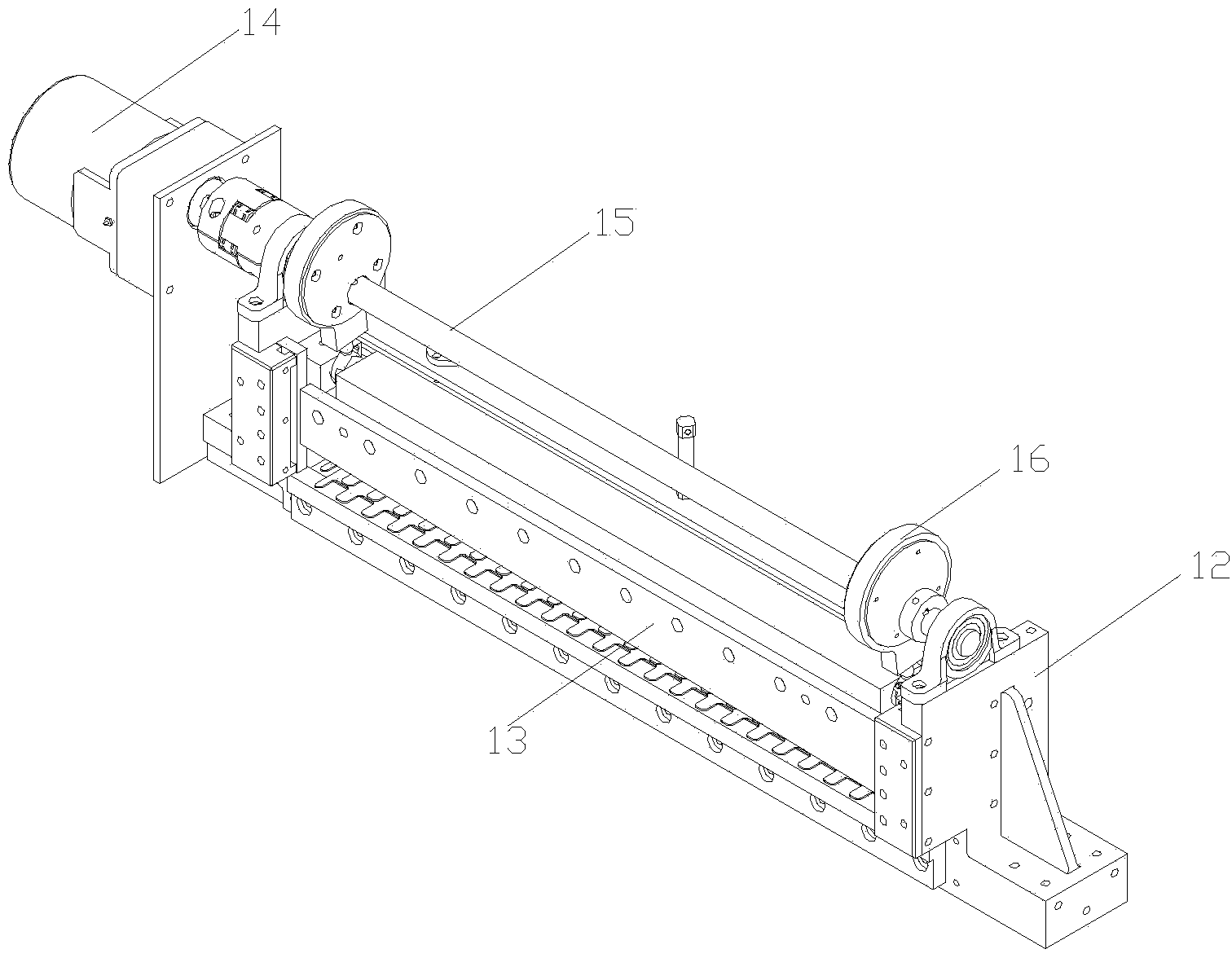

Full-automatic feeding device of sewing machine

ActiveCN102864586AOutstanding and Beneficial Technical EffectsFully automatedSewing-machine elementsPosition sensorAutomation

The invention belongs to the technical field of sewing machines, and relates to a full-automatic feeding device of a sewing machine. A separating mechanism, a clamping and lifting mechanism and a feeding mechanism are sequentially arranged on one side of a table plate of the sewing machine, wherein the separating mechanism gradually separates to-be-sewn cloth one by one; the clamping and lifting mechanism clamps and lifts the to-be-sewn cloth separated by the separating mechanism; the feeding mechanism transfers the to-be-sewn cloth lifted by the clamping and lifting mechanism to a position above a needle plate; a plurality of position sensors are arranged on a transfer track of the to-be-sewn cloth; and a controller receives position signals of all the position sensors and controls sequential actions of the mechanisms. The full-automatic feeding device has the advantages that labor intensity is low, laying speed is high, and positions of laid cloth are standard, so that work efficiency is high, standard degree of sewn products is high, production cost is low, automation of a cloth sewing process can be realized by the device, and the full-automatic feeding device is applicable to various types of sewing machines.

Owner:JACK SEWING MASCH CO LTD

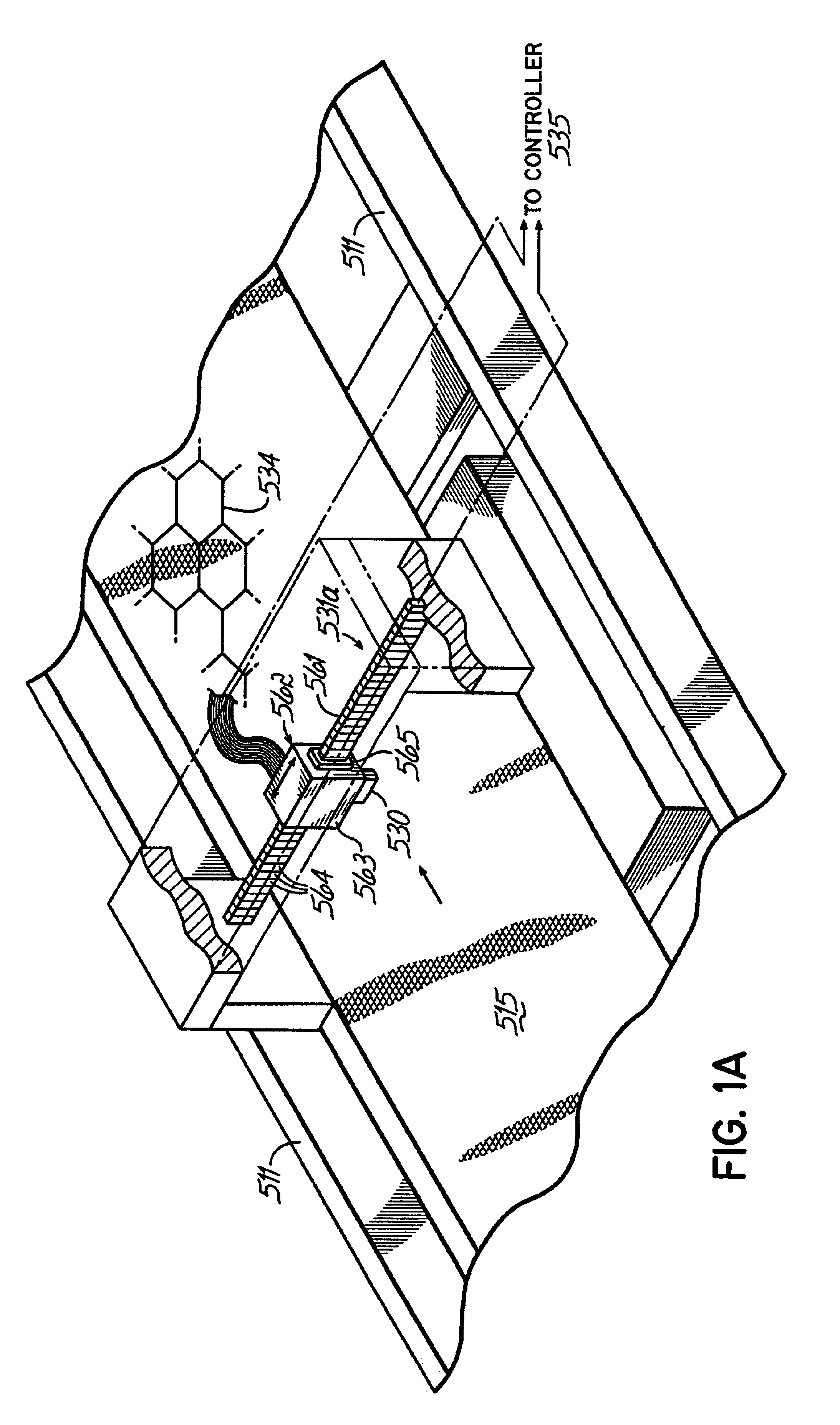

Method nad apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1377313AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsUV curingRadiant heater

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

Helicopter vibration control system and rotating assembly rotary forces generators for canceling vibrations

A rotary blade rotating hub mounted rotating assembly vibration control system including a first imbalance mass concentration rotor, a second imbalance mass concentration rotor, a third imbalance mass concentration rotor, and a fourth imbalance mass concentration rotor. The first imbalance mass concentration rotor has a first imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The second imbalance mass concentration rotor has a second imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The third imbalance mass concentration rotor has a third imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The fourth imbalance mass concentration rotor has a fourth imbalance mass concentration rotor center axis rotation centered on the rotating assembly center rotation axis. The first and second imbalance mass concentration rotors are driven at a first rotation speed greater than the rotating assembly operational rotation frequency while controlling the rotational position of the first imbalance mass concentration and the second imbalance mass concentration to produce a first rotating net force vector to inhibit a first vibration frequency. The third and fourth imbalance mass concentration rotors are driven at a second rotation speed greater than the rotating assembly operational rotation frequency while controlling the rotational position of the third imbalance mass concentration and the fourth imbalance mass concentration to produce a second rotating net force vector to inhibit a second vibration frequency.

Owner:LORD CORP

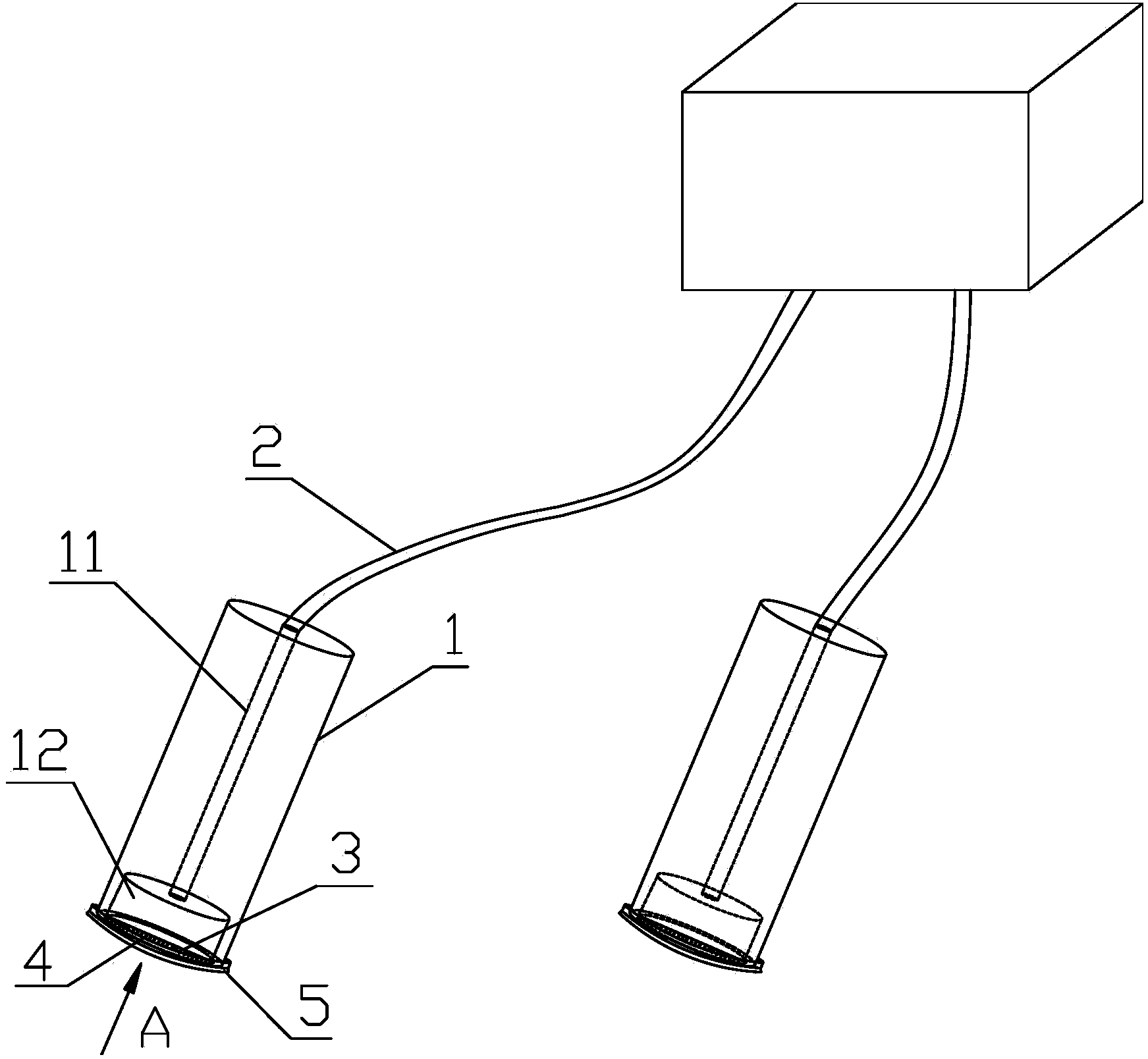

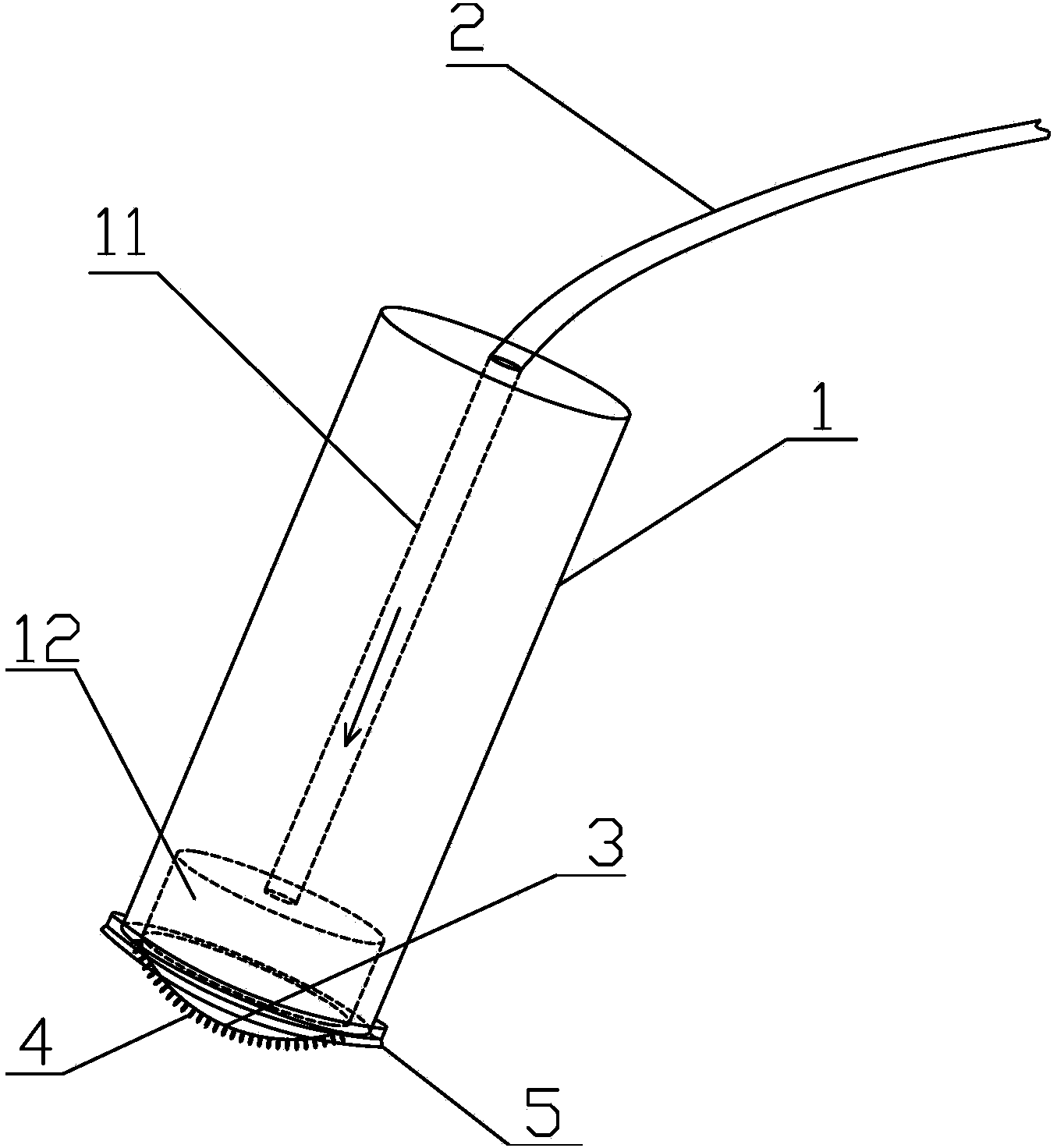

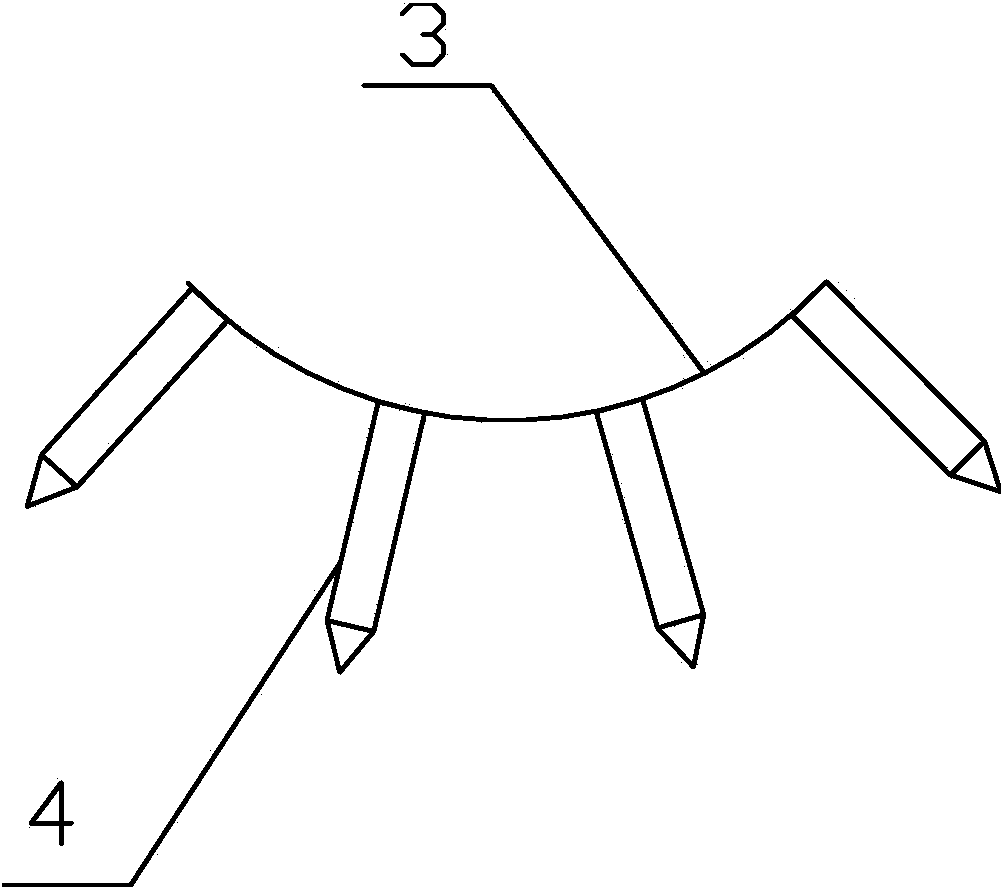

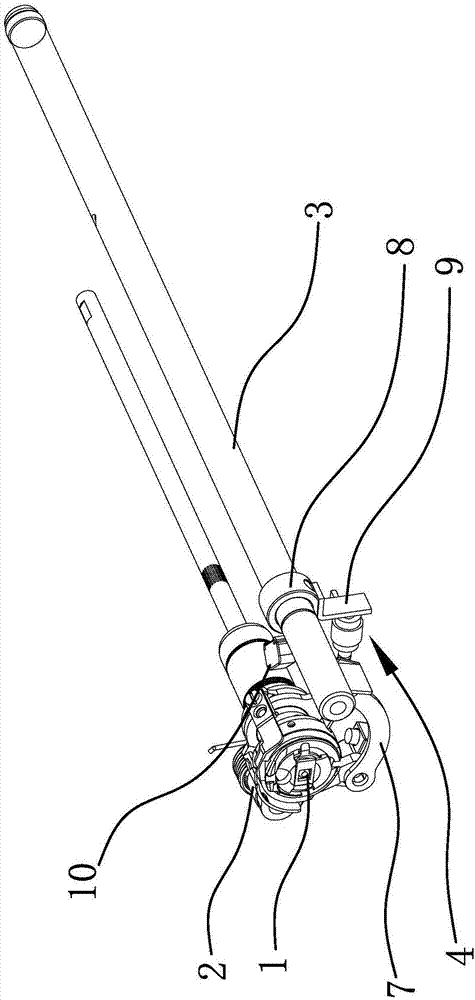

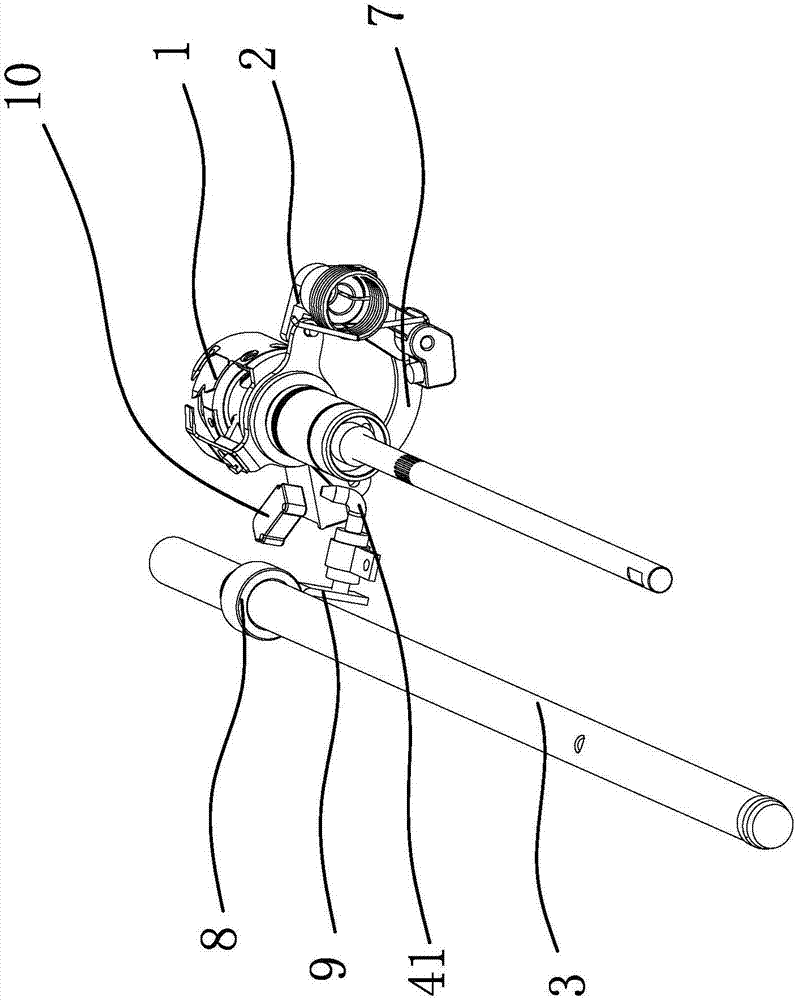

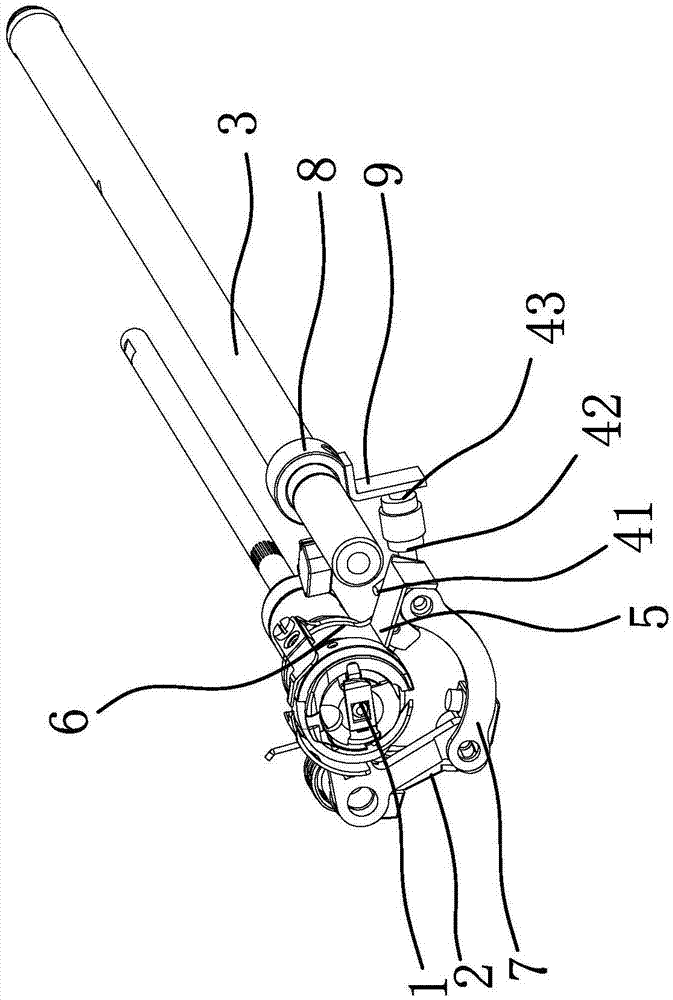

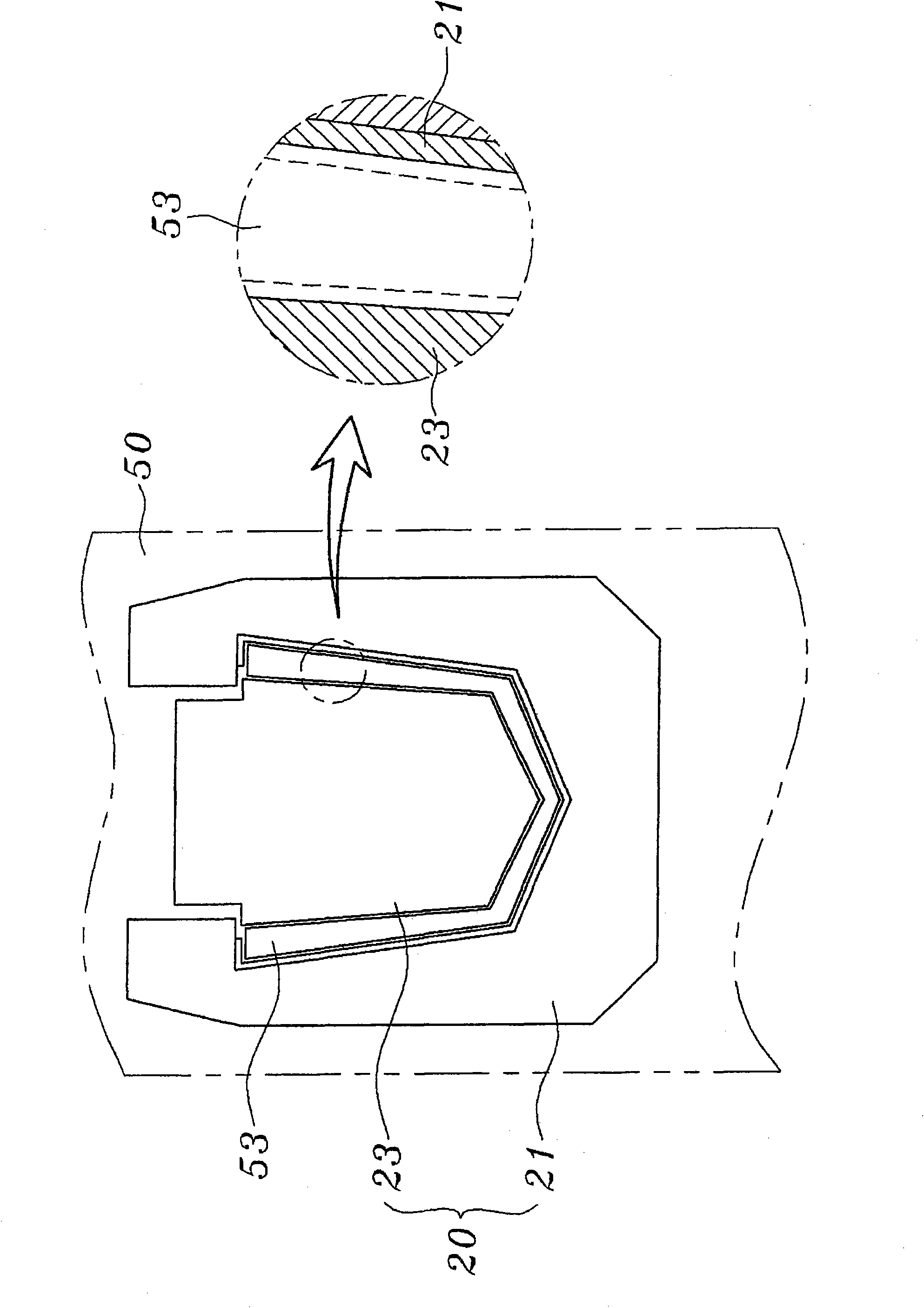

Cloth gripping device

ActiveCN103789935AReduce air leakageGuaranteed air pressureSewing-machine elementsEngineeringAtmospheric pressure

The invention provides a cloth gripping device which comprises a gripping arm body. One end of the gripping arm body is provided with a cavity. One end of the cavity is covered with an elastic film piece arranged on the gripping arm body. The elastic film piece is provided with a through hole. The other end of the cavity is connected with an air pipe. The outer side of the elastic film piece is provided with a plurality of rows of needle-shaped protrusions. According to the cloth gripping device, by means of the adsorption force of air pressure and the clamping force of the needle-shaped protrusions, automatic feeding of cloth is stable and reliable. Moreover, due to the clamping function of the needle-shaped protrusions, the applicable cloth range of the cloth gripping device is wide. In addition, due to the special structure, the energy consumption in the working process of the cloth gripping device is small and the noise is low.

Owner:JACK SEWING MASCH CO LTD

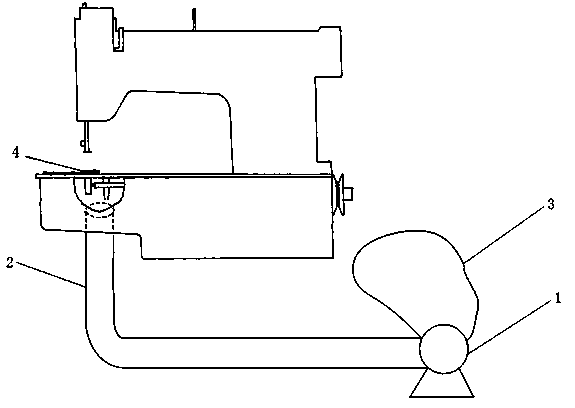

Sewing machine with dust collection device

InactiveCN103510303AReduce the possibility of failureAvoid accumulationSewing-machine elementsThermodynamicsEngineering

The invention relates to a sewing machine, in particular to a sewing machine with a dust collection device. The sewing machine comprises a fan, an air suction pipeline and a dust collecting bag. A suction opening of the air suction pipeline is formed below a needle plate, the other end of the air suction pipeline is connected with the fan, and an air outlet of the fan is connected with the dust collecting bag. Due to the fact that the air suction pipeline is arranged below a bottom plate of the sewing machine, dust generated in the sewing process can be effectively removed and prevented from accumulating on various movable parts, and the probability that the sewing machine breaks down is reduced. A dust blowing mode is changed into a dust suction mode, so that pollution caused by the dust to workshop environment is reduced, and air quality in a workshop is guaranteed.

Owner:中江县四海制衣有限责任公司

Method and apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1572492AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsPolymer scienceEngineering

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

Cleaning structure for sewing machine

ActiveCN107460659AEfficient and reliable cleaningSimple structureSewing-machine elementsForeign matterEngineering

The invention provides a cleaning structure for a sewing machine, and belongs to the technical field of sewing equipment. By the aid of the cleaning structure, the technical problems of poor effects of cleaning foreign matters at rotating shuttles of existing sewing machines and the like can be solved. The sewing machine comprises a rotating shuttle, a thread trimming crank and a feed lifting rock shaft. The cleaning structure comprises a blowing assembly and a scrap cleaning plate. The scrap cleaning plate can be driven by the thread trimming crank or the feed lifting rock shaft to swing and is positioned on the outer side of the rotating shuttle; the blowing assembly comprises a blowing nozzle, a check valve and a piston, the blowing nozzle is positioned below the scrap cleaning plate and is connected with the check valve, a driving plate capable of driving the piston to reciprocate is connected onto the feed lifting rock shaft, and air can be supplied into the check valve when the piston moves. The cleaning structure has the advantages that external air sources can be omitted, and accordingly the cleaning structure is simple and is high in universality and easy to detach and maintain; the scrap cleaning plate and the blowing assembly are combined with each other, accordingly, oil mist, lint and mixtures of the oil mist and the lint at the rotating shuttle can be cleaned, and the lint and the oil mist can be efficiently and reliably cleaned.

Owner:JACK SEWING MASCH CO LTD

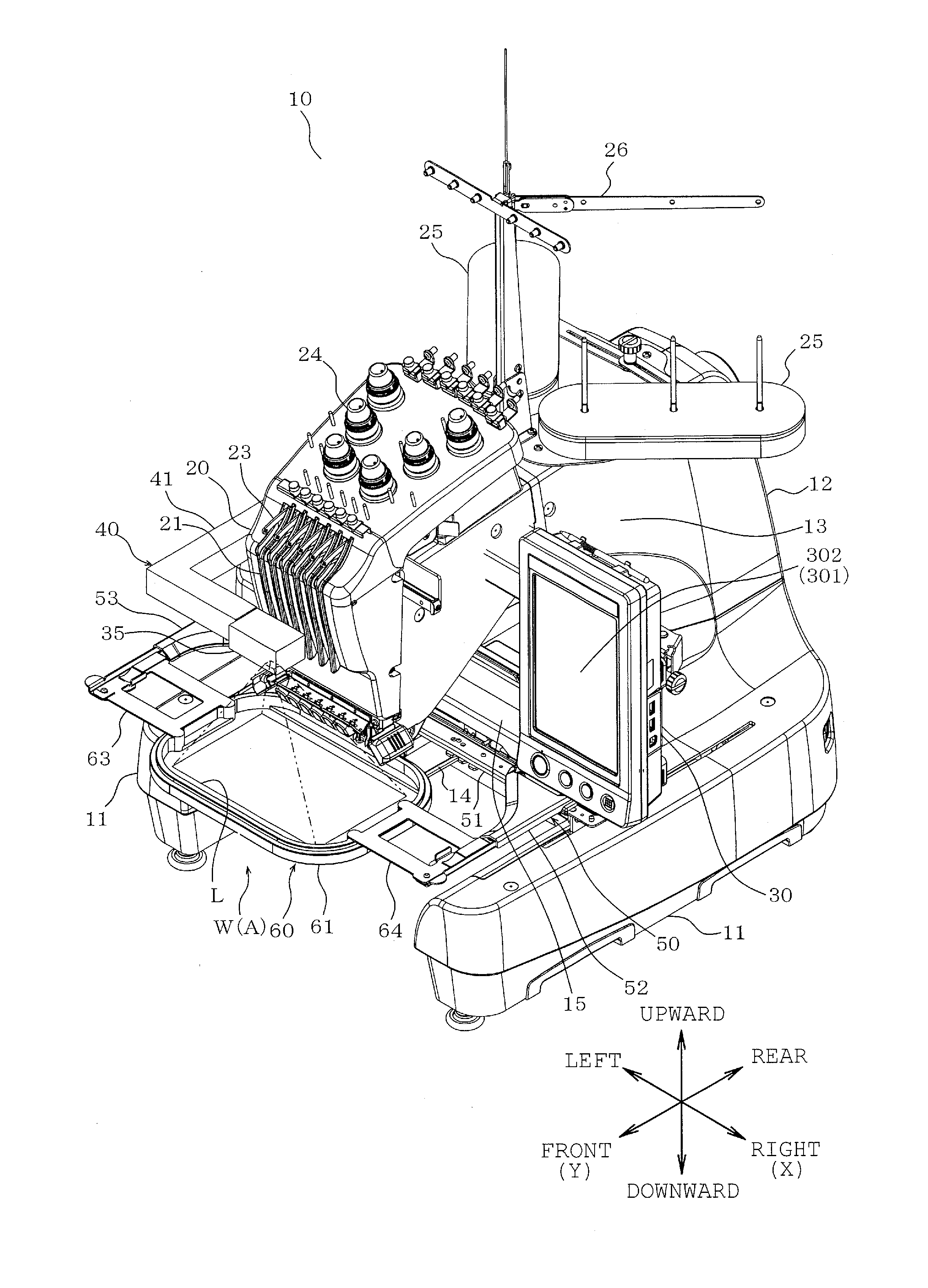

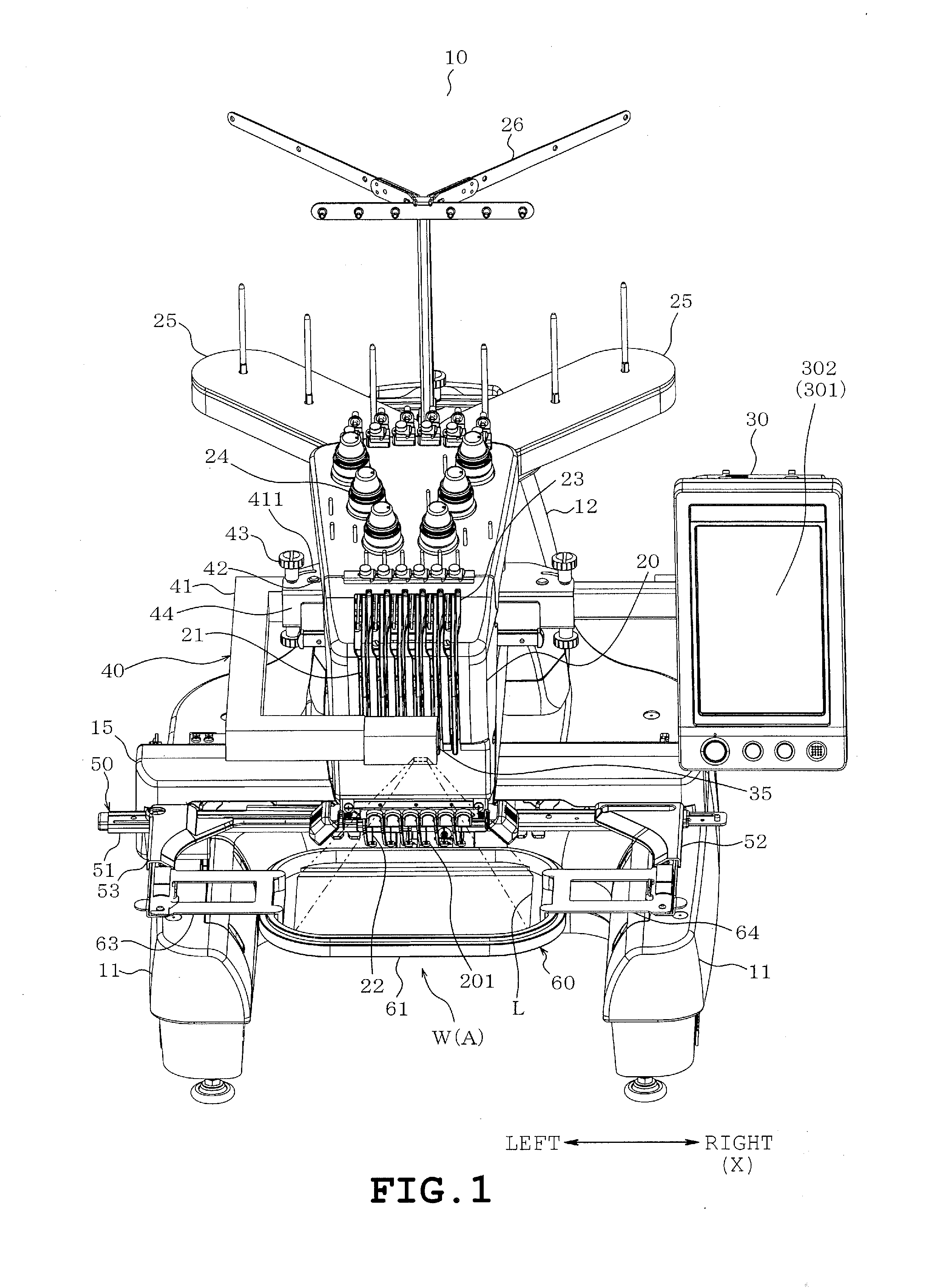

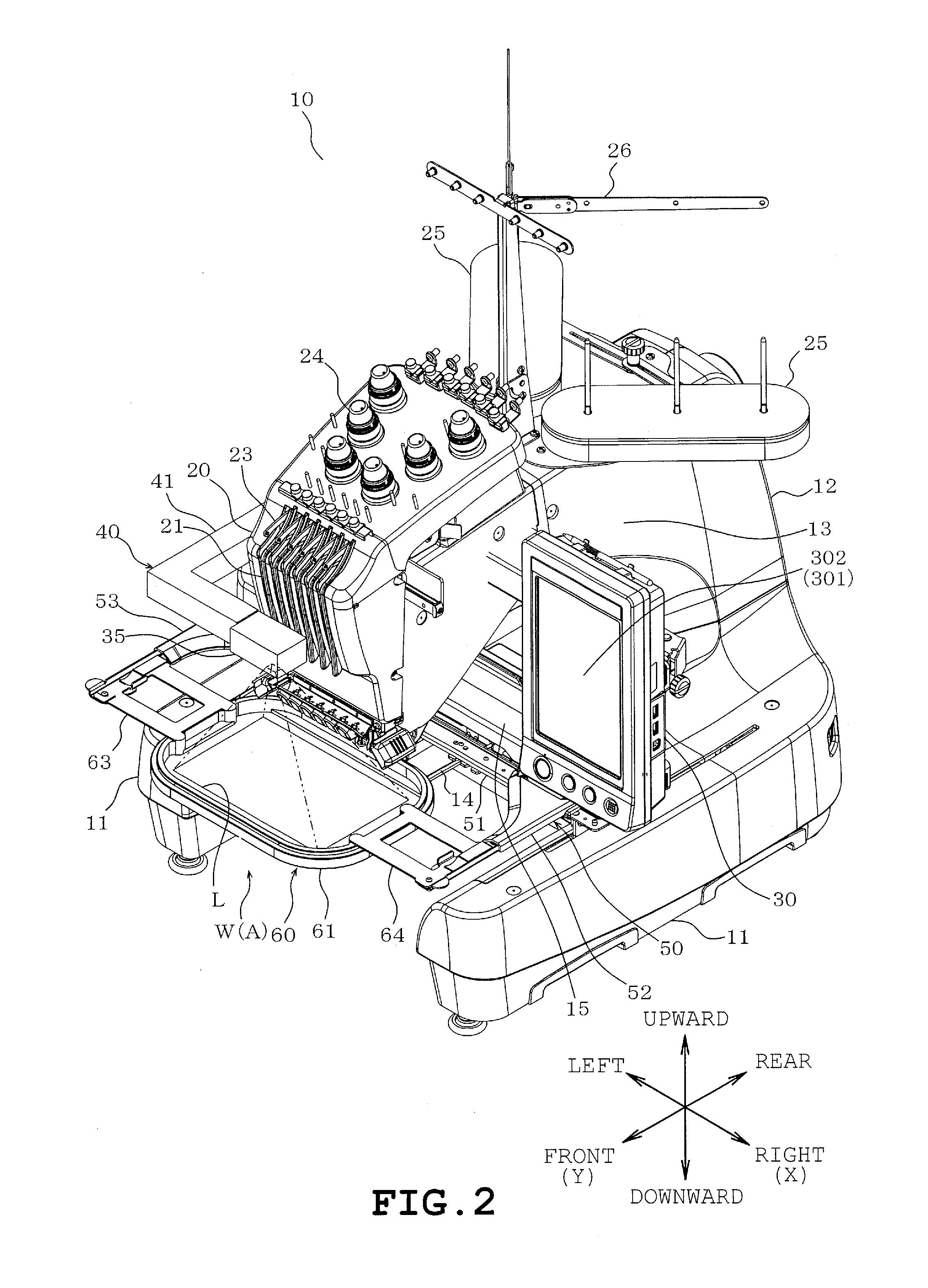

Sewing machine

InactiveUS20150259841A1Programme-controlled sewing machinesSewing-machine elementsEngineeringControl unit

A sewing machine includes a plurality of types of embroidery frames having respective holding parts holding workpiece cloth, the holding parts having forms differing from one type of embroidery frame to another, a carriage to which one of the embroidery frames is selectively attached, the carriage being configured to transfer the embroidery frame, a projector configured to project an image onto the workpiece cloth, a detector configured to detect a type of the embroidery frame attached to the carriage, a storage unit configured to store frame information set for every type of embroidery frame, a setting unit configured to read the frame information according to result of detection by the detector and to set a projection region for an image to be projected, based on the frame information, and a control unit configured to control the projector so that the projector projects the image onto the set projection region.

Owner:BROTHER KOGYO KK

Hybrid three-dimensional woven/laminated struts for composite structural applications

ActiveUS7943535B2High damage toleranceImprove propertiesSewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

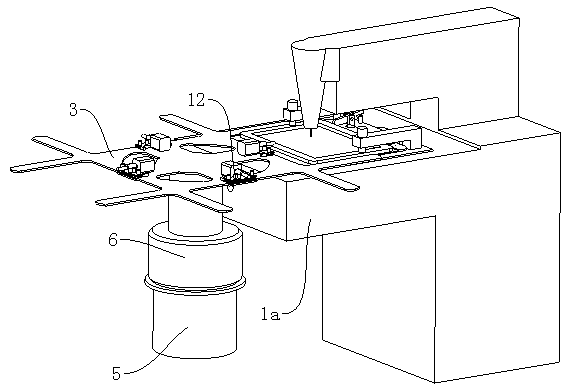

Rotary disc type automatic feeding, sewing and discharging tool

ActiveCN108708091AImprove work efficiencyReduce labor cost per personSewing-machine elementsEngineeringPer capita

The invention relates to the technical field of sewing equipment, in particular to a rotary disc type automatic feeding, sewing and discharging tool. The rotary disc type automatic feeding, sewing anddischarging tool comprises a sewing station, a feeding conveying belt, a discharging conveying belt, a material circulation station and a cloth jig and is characterized in that a sewing machine baseis provided with a sewing table which is located below a sewing machine and extend forwards, the material circulation station is arranged in front of the sewing table, the feeding conveying belt and the discharging conveying belt are respectively arranged on the left side and the right side of the material circulation station, and the conveying directions of the feeding conveying belt and the discharging conveying belt are identical. The rotary disc type automatic feeding, sewing and discharging tool has the advantages that automatic cloth jig material circulation between the feeding conveyingbelt and the sewing table and between the sewing table and the discharging conveying belt through the material circulation station, a jig positioning device and a jig clamping device are mounted on the sewing table, the jig positioning device is used for positioning the cloth jig moved to a support plate, the jig clamping device is used for clamping the positioned cloth jig to the support plate,high sewing efficiency is achieved, and the labor cost per capita of single equipment is reduced greatly.

Owner:浙江湖州物装综合体管理服务有限责任公司

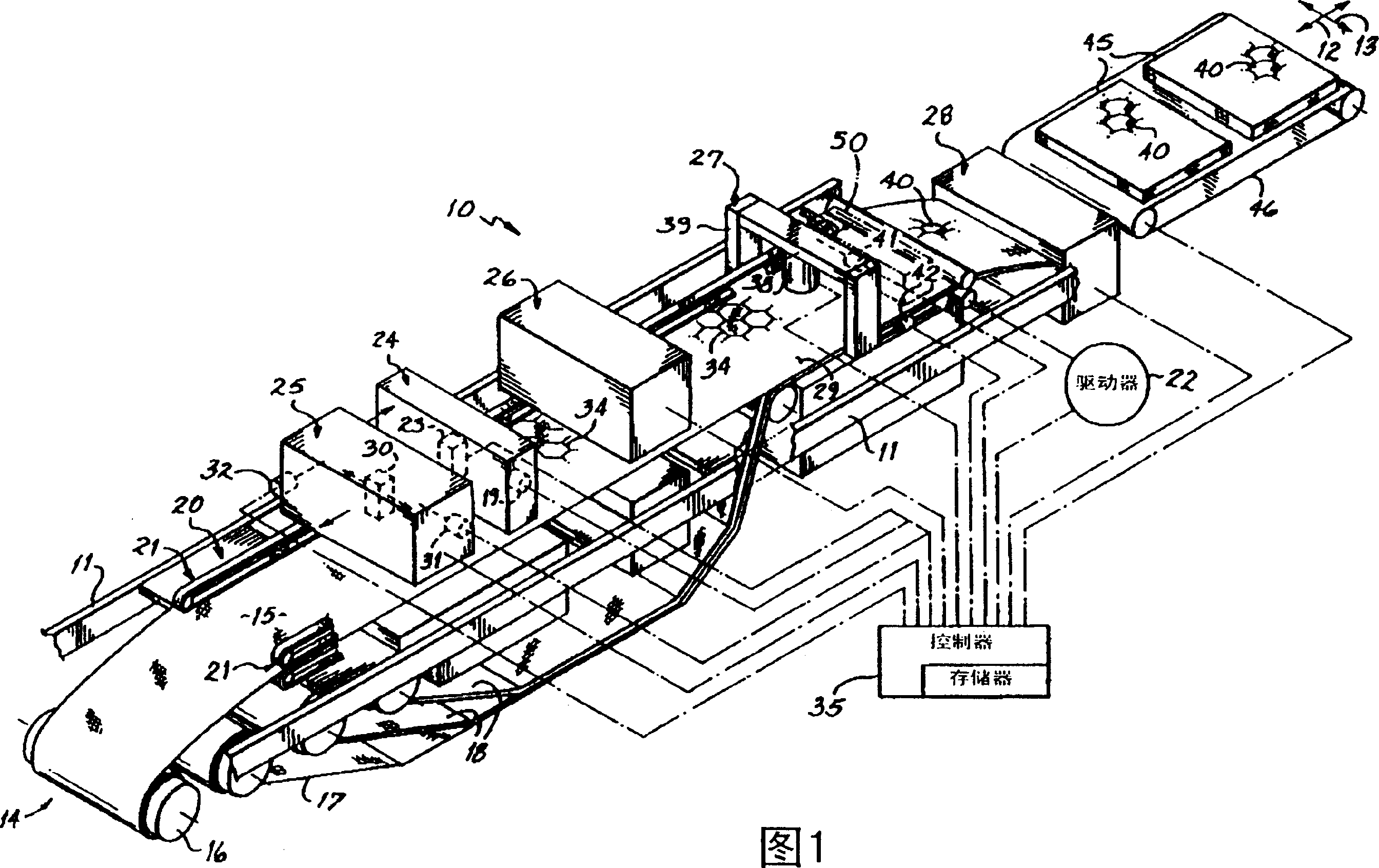

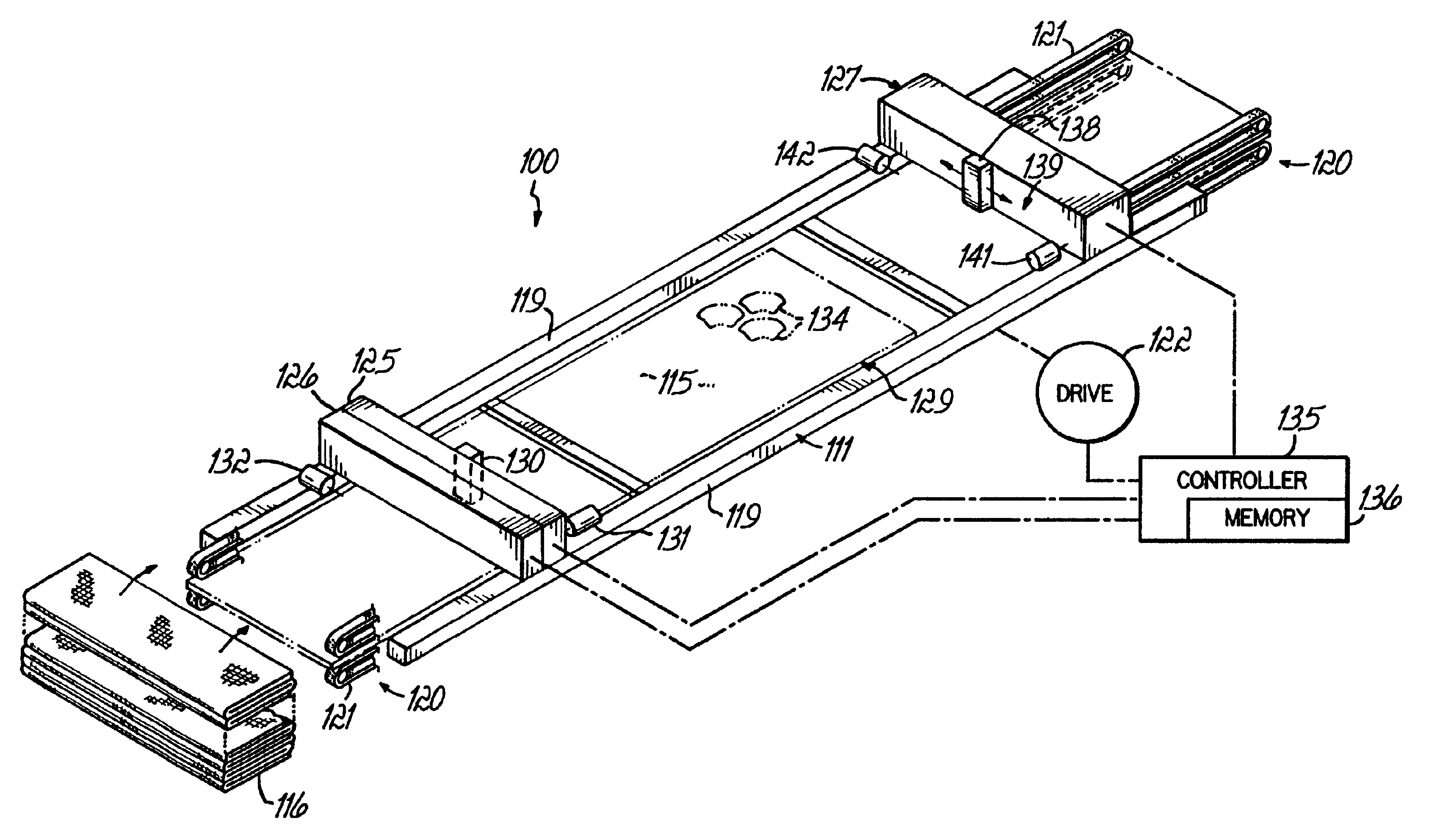

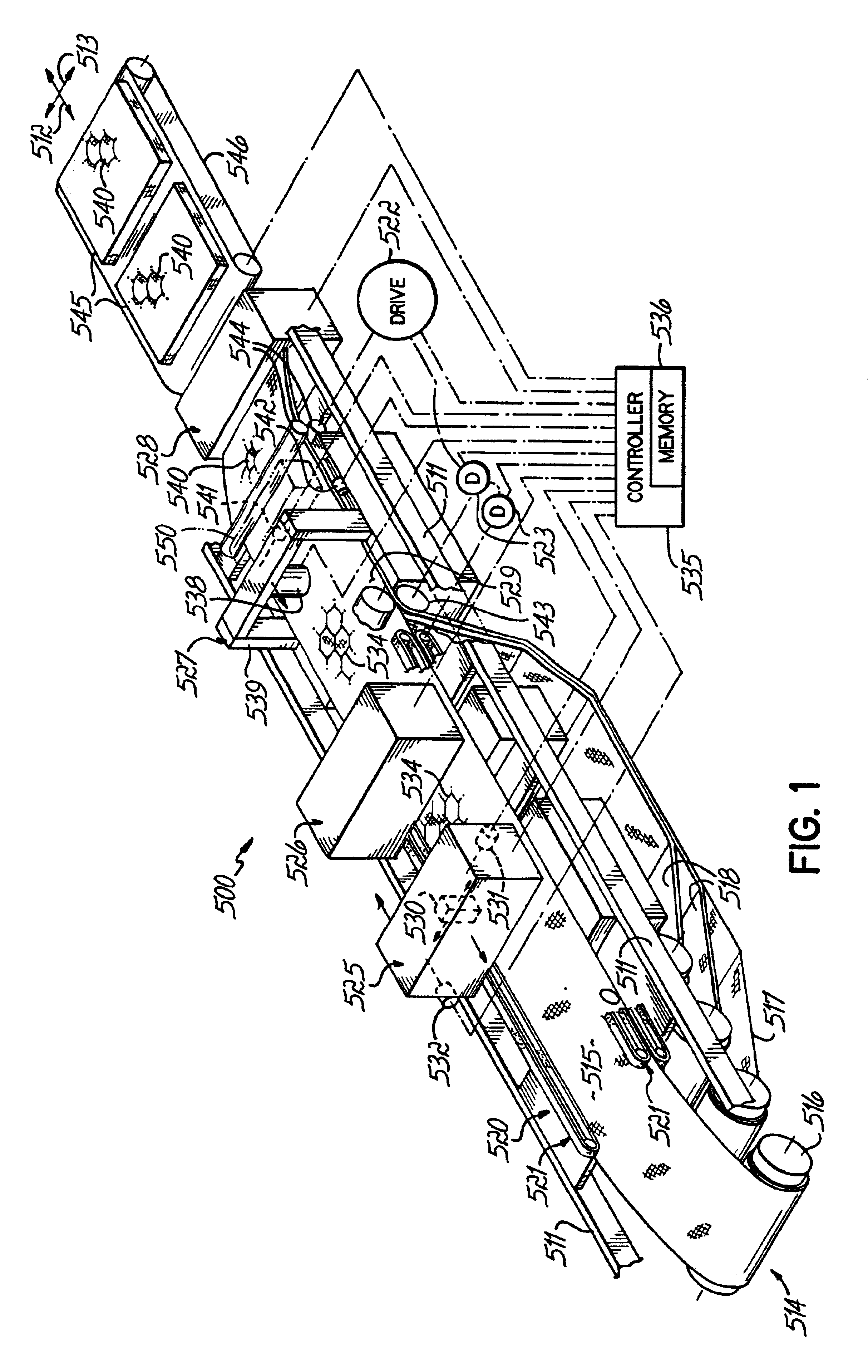

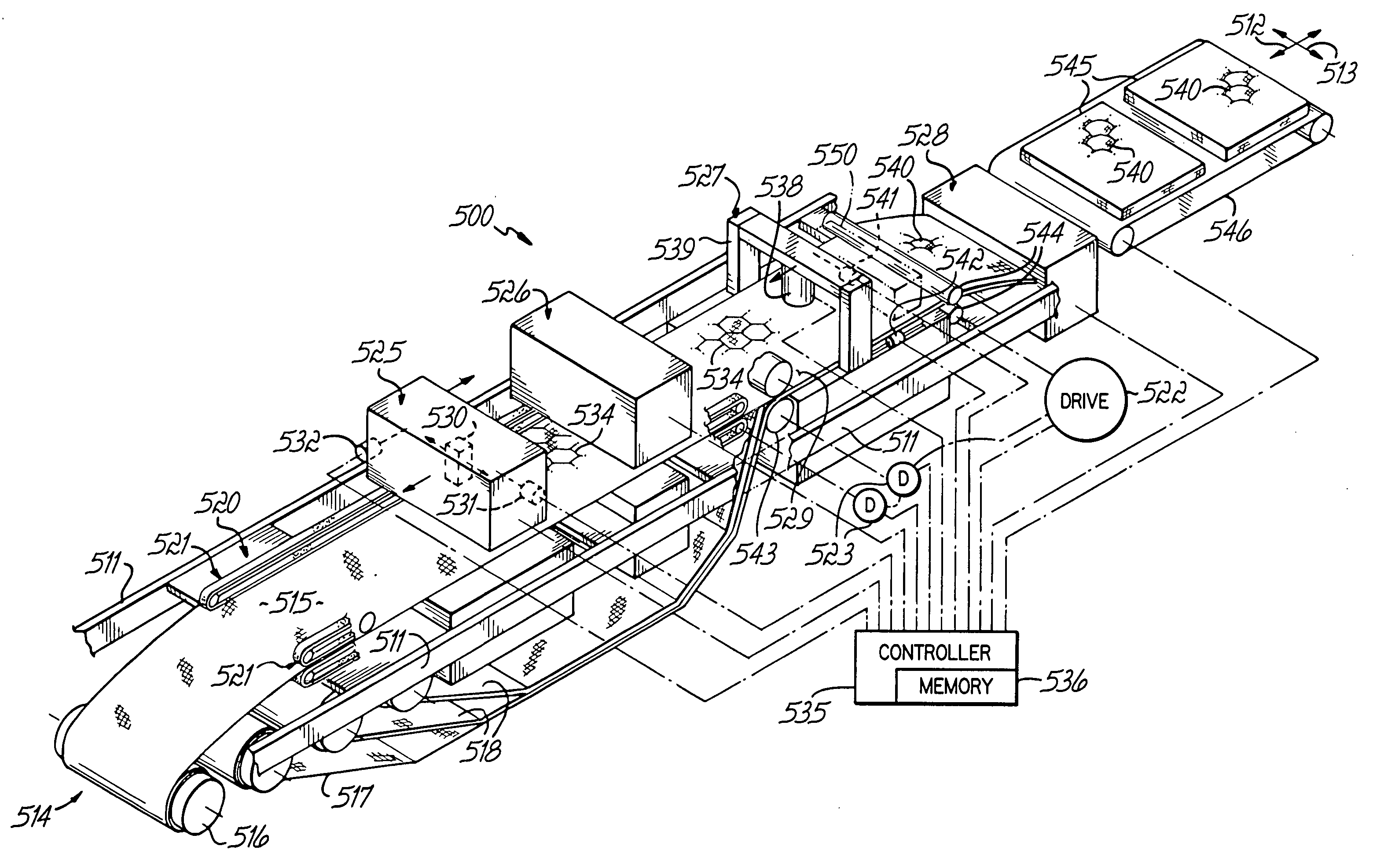

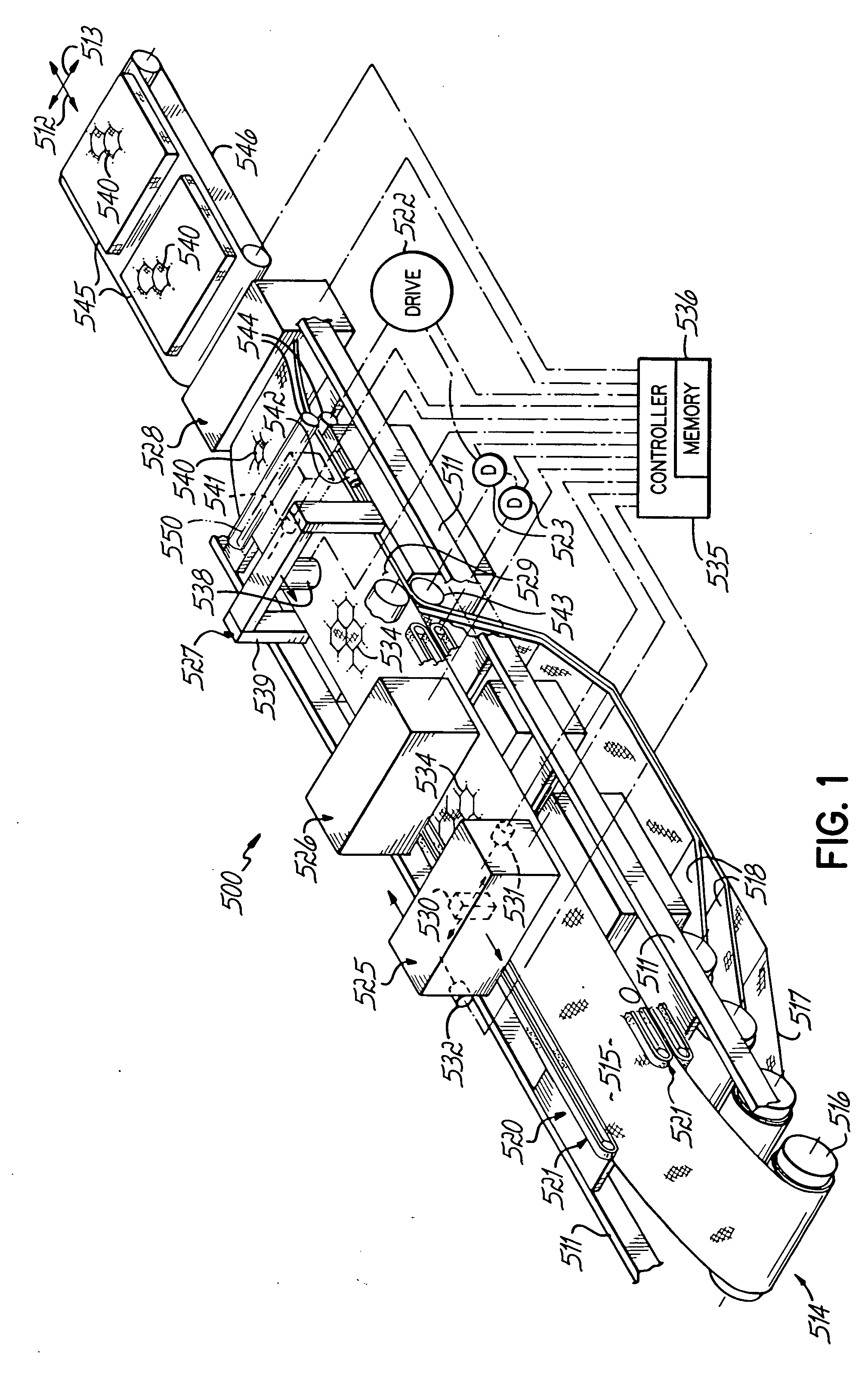

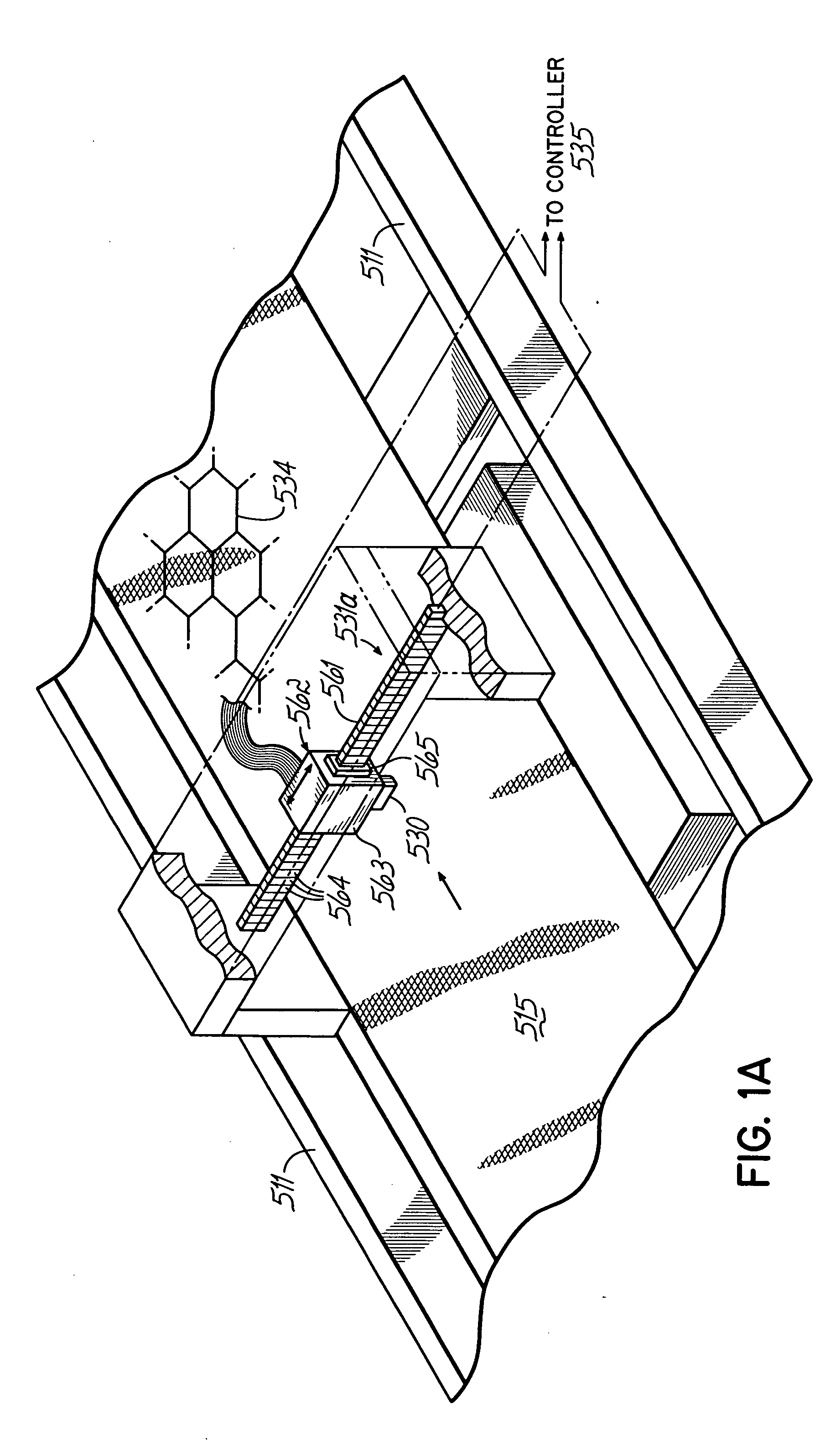

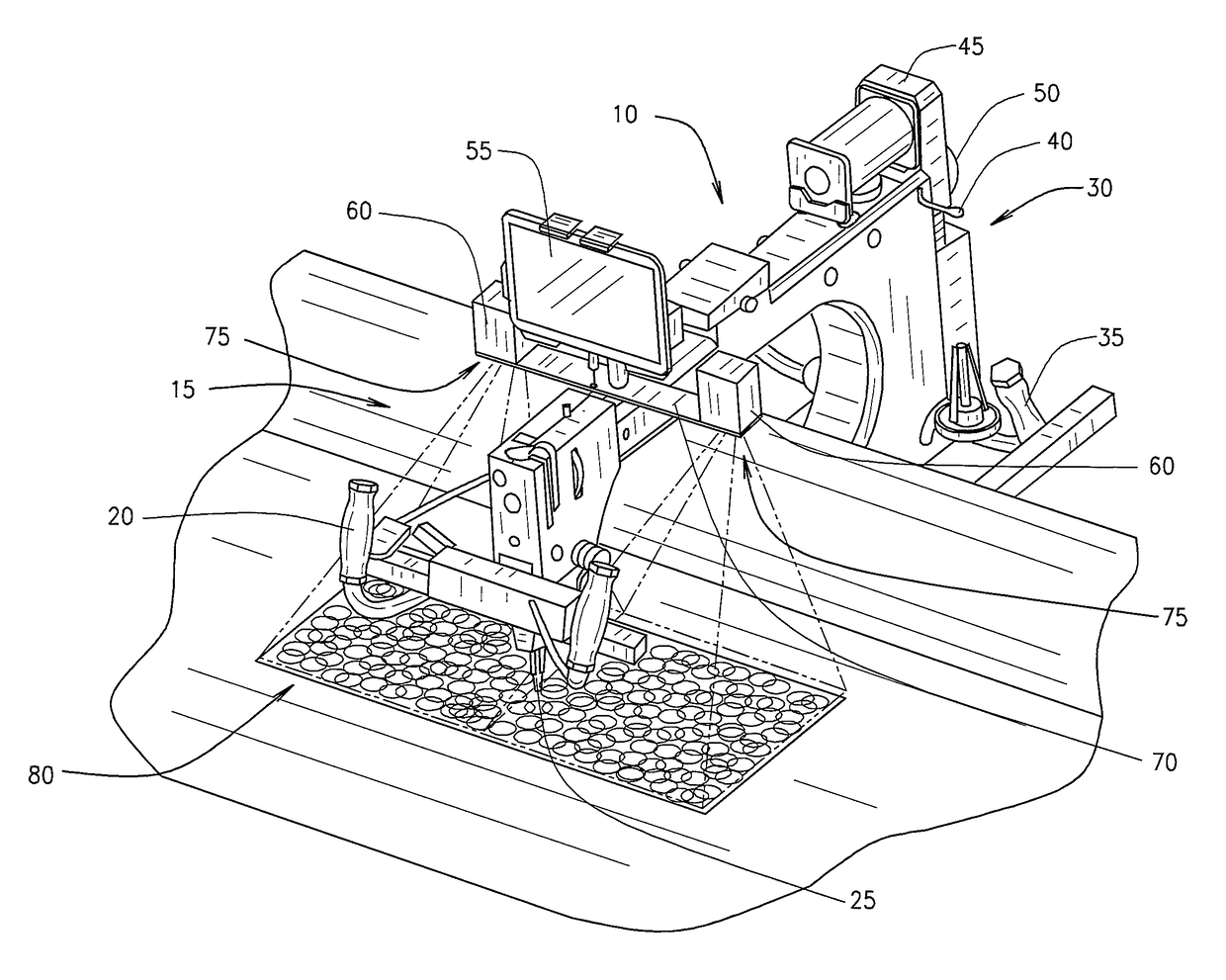

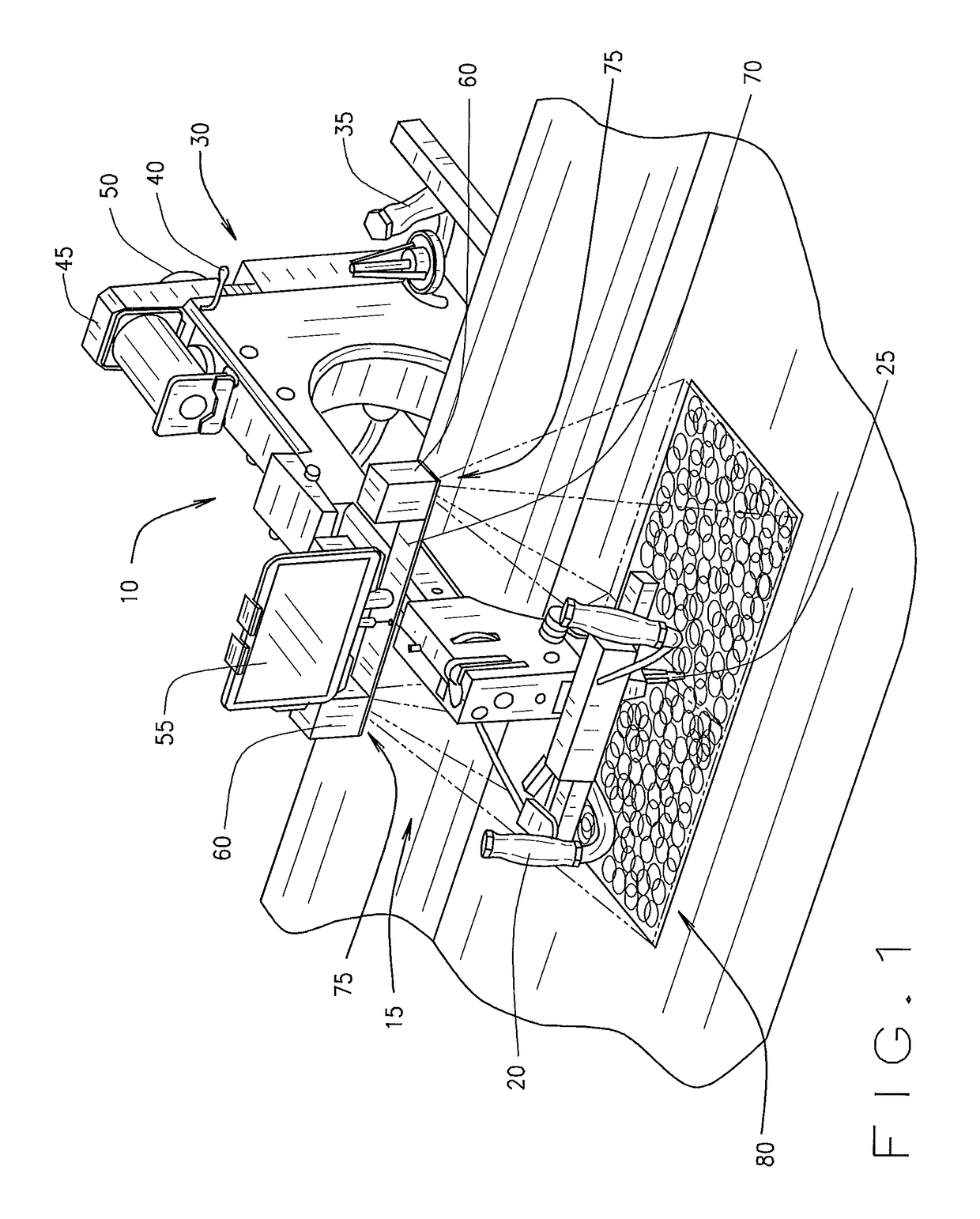

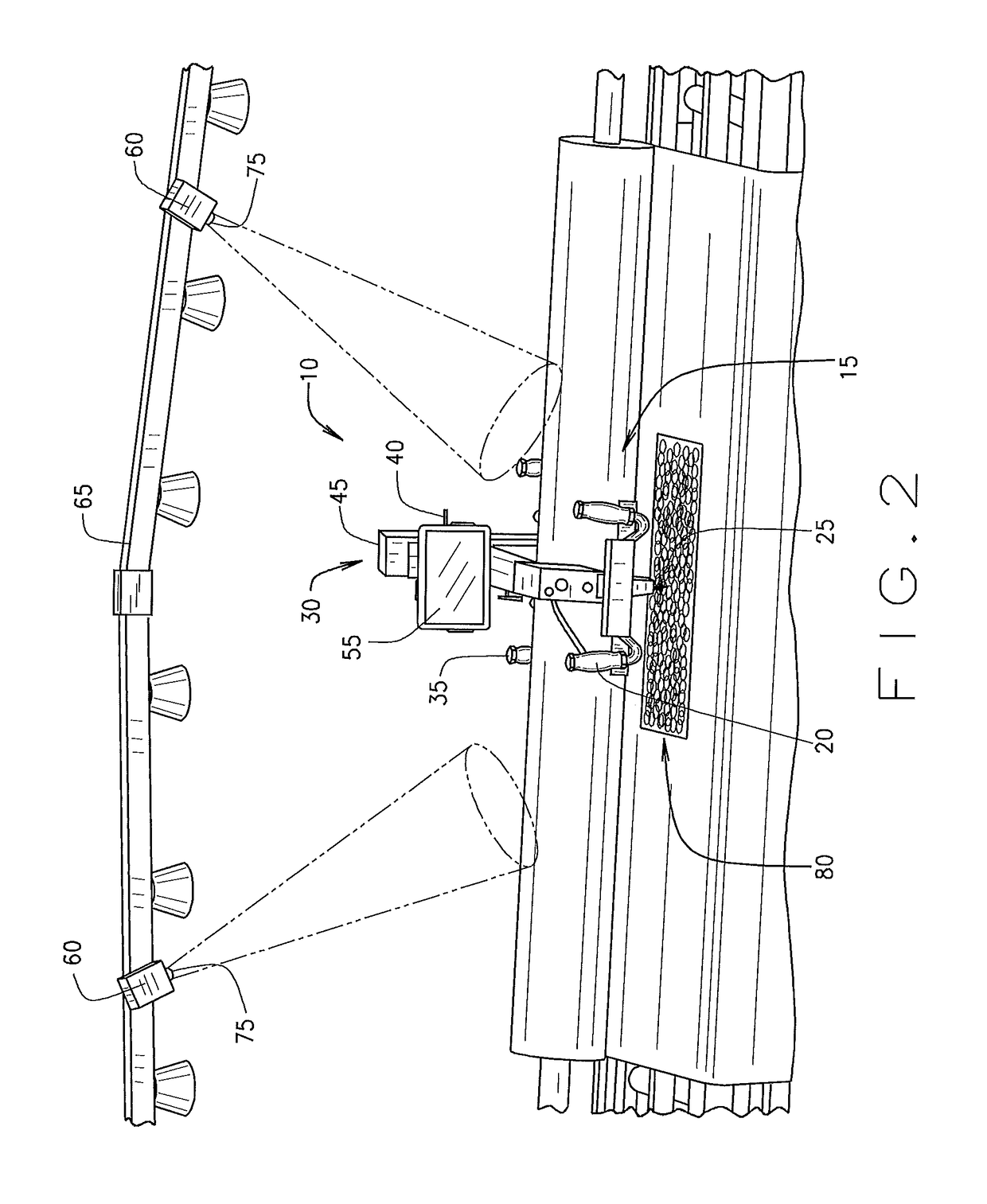

Printing and quilting method and apparatus

InactiveUS6848846B2Efficiently and economicallySave a lot of costRecording apparatusOrnamental textile articlesData fileEngineering

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632). The printing station is located either in line and preferably upstream of the quilting station, with a conveyor (520) extending through each of the stations to convey a web of quilting material through the machine, or is off of the quilting line such that the material with a pre-applied pattern thereon is transferred, preferably in web form, to the line of the second station for the application of a pattern in registration with the first applied pattern. At the quilting station, registration longitudinal and transverse registration is measured and skewing or rotation of the material is determined. Opposite transverse sides of the material are differently adjusted to orient and register the material. A master batch controller (90, 135, 235, 335, 435, 535) assures that the proper combinations of printed and quilted patterns are combined to allow small quantities of different quilted products to be produced automatically along a material web. Ticking is preprinted with a plurality of different patterns, organized and communicated by the computer so that a print head can scan the material and print different patterns of different panels (32) across the width of a web. Identifying data (40) for matching the panels of a mattress product can be provided in data files printed on the fabric. Cutting and slitting of the panels from each other and the quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

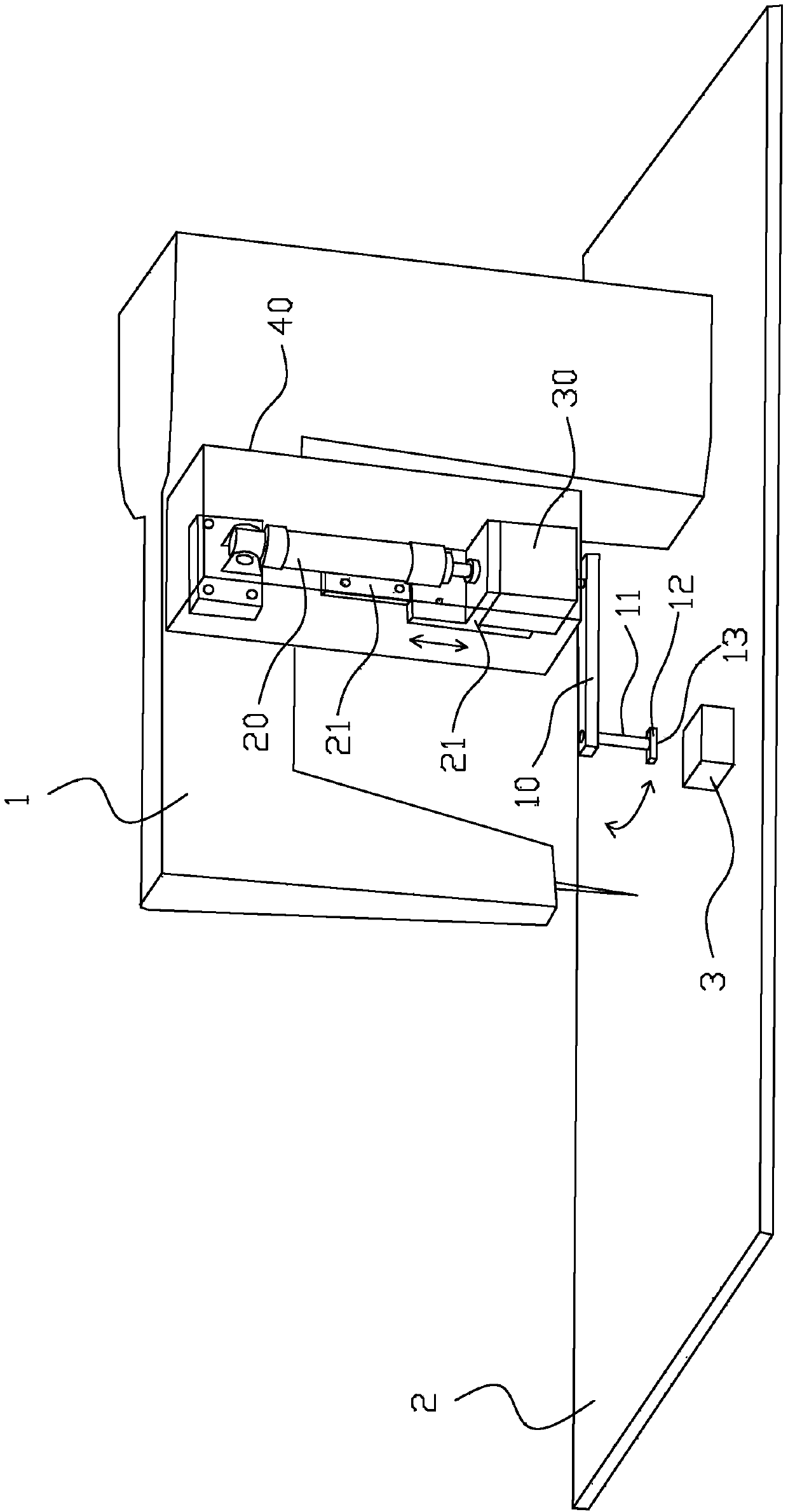

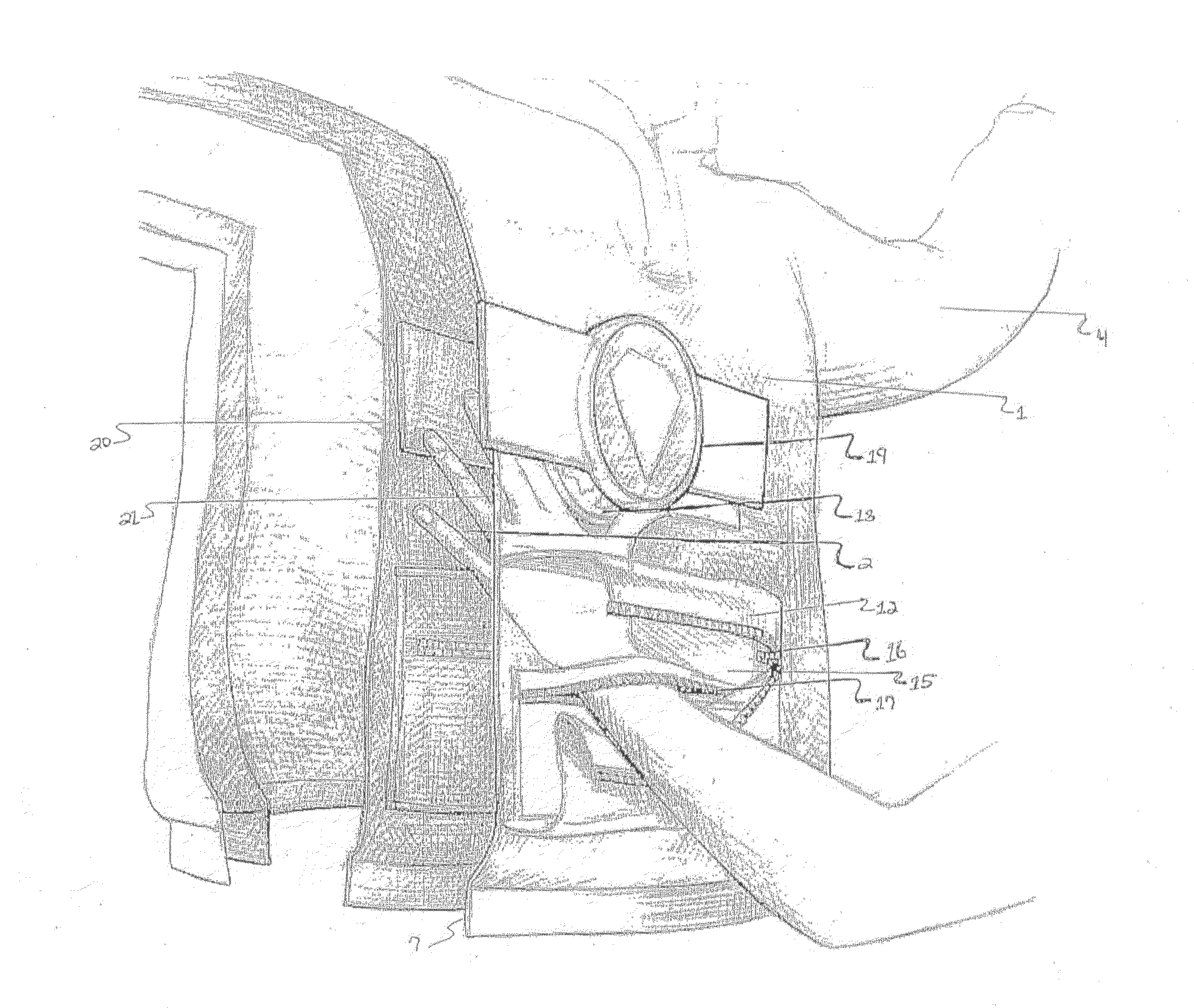

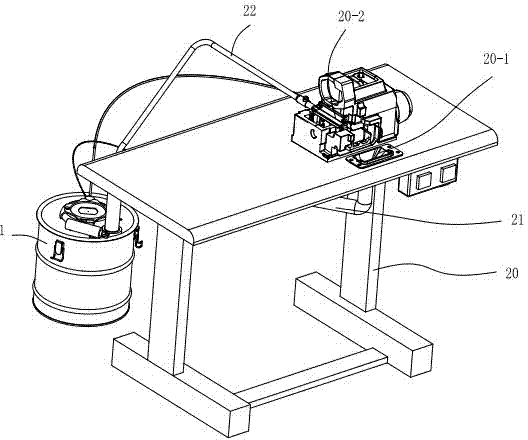

Sewing machine capable of automatically taking and feeding materials

ActiveCN103361895AOperating platform is tidyReduce labor intensitySewing-machine elementsEngineeringMaterial storage

The invention provides a sewing machine capable of automatically taking and feeding materials. The sewing machine comprises a sewing machine body and a platform on which the sewing machine body is arranged, the platform is provided with a material storage groove for containing cloth, the sewing machine body is provided with a material feeding swinging rod, a rotating mechanism which drives the material feeding swinging rod to swing, and a lifting mechanism which drives the rotating mechanism and the material feeding swinging rod to move vertically, the back part of the material feeding swinging rod is connected to the rotating mechanism, by taking the connecting part of the back part as a rotating axis, the front part of the material feeding swinging rod can swing back and forth between the material storage groove and the stitch of the sewing machine, the front part of the material feeding swinging rod is provided with a material taking part which extends downward for taking the cloth in a pasting mode. According to the sewing machine capable of automatically taking and feeding materials, the material feeding swinging rod is used for realizing the material taking and feeding, so the labor intensity of workers is reduced, the production efficiency is improved, and the operation platform of the sewing machine is neater in the cloth sewing process.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Dust removal device of sewing machine

InactiveCN103556410AGuarantee air qualitySimple structureSewing-machine elementsEngineeringElectrostatic generator

The invention relates to a dust removal device of a sewing machine. The dust removal device comprises two groups of stand columns which are symmetrically arranged at the front and the rear, a bed plate which is fixedly arranged on the two groups of stand columns and a machine head which is installed on the bed plate. Each group of stand columns consists of a left stand column and a right stand column which are symmetrically arranged. A guide rail is installed between the two stand columns. An adsorbing bar and an air cylinder which is connected with the adsorbing bar are arranged on the guide rail. A plurality of clipping discharge holes are formed in the bed plate. A static charge generator and a controller are respectively fixed at the two side ends of the bed plate. The adsorbing bar is connected with the static charge generator. The air cylinder and the static charge generator are connected with the controller. The dust removal device of the sewing machine has the advantages that the structure is simple, the device is convenient to use, the adsorbing bar is enabled to carry static charges through the static charge generator to adsorb thread residues, fabric clippings, dust and the like on the adsorbing bar, then the thread residues, the fabric clippings and the dust are scraped into a dust accumulation tank through a circular ring, the quality of air in a sewing workshop is guaranteed and the working efficiency is improved.

Owner:WUJIANG XILI MACHINERY FACTORY

Sewing equipment and using method thereof

ActiveCN110820181ANot easy to wasteImprove work efficiencySewing-machine elementsControl systemVisual recognition

The invention relates to sewing equipment and a using method thereof. The sewing equipment comprise a workbench, two or more grabbing devices, sewing equipment, a visual recognition device and a control system, wherein the grabbing devices, the sewing equipment, the visual recognition device and the control system are respectively arranged on the workbench. The control system is respectively in signal connection with the grabbing devices, the sewing equipment and the visual recognition device and controls the operation of the grabbing devices, the sewing equipment and the visual recognition device; the visual recognition device recognizes the shape of cloth and feeds back the shape and size of the cloth to the control system; the control system controls the grabbing devices to adjust the grabbing angle and then convey the cloth to sewing equipment; the cloth is conveyed to the sewing equipment to be sewn; and the grabbing devices can keep pressing area on the cloth unchanged. By usingthe sewing equipment, the cloth can be fed, taken, grabbed, sewed and collected, the time and labor are saved, and the labor cost is reduced while the work efficiency is improved. Compared with manualsewing, the sewing equipment has the advantages that the finished product rate is high, and moreover, the smoothness of the cloth in the whole process can be guaranteed.

Owner:BEIJING HUAMEILI CLOTHING

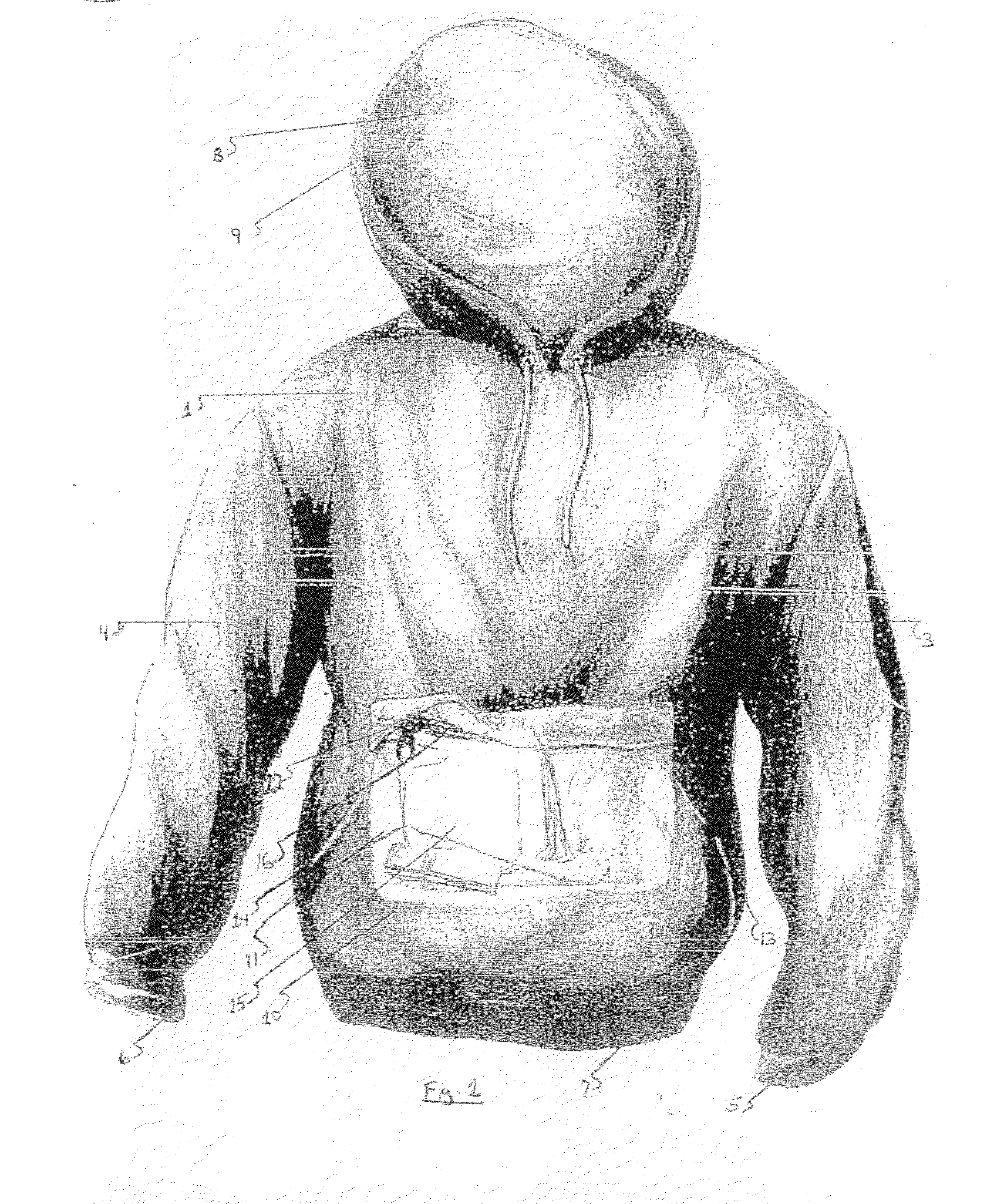

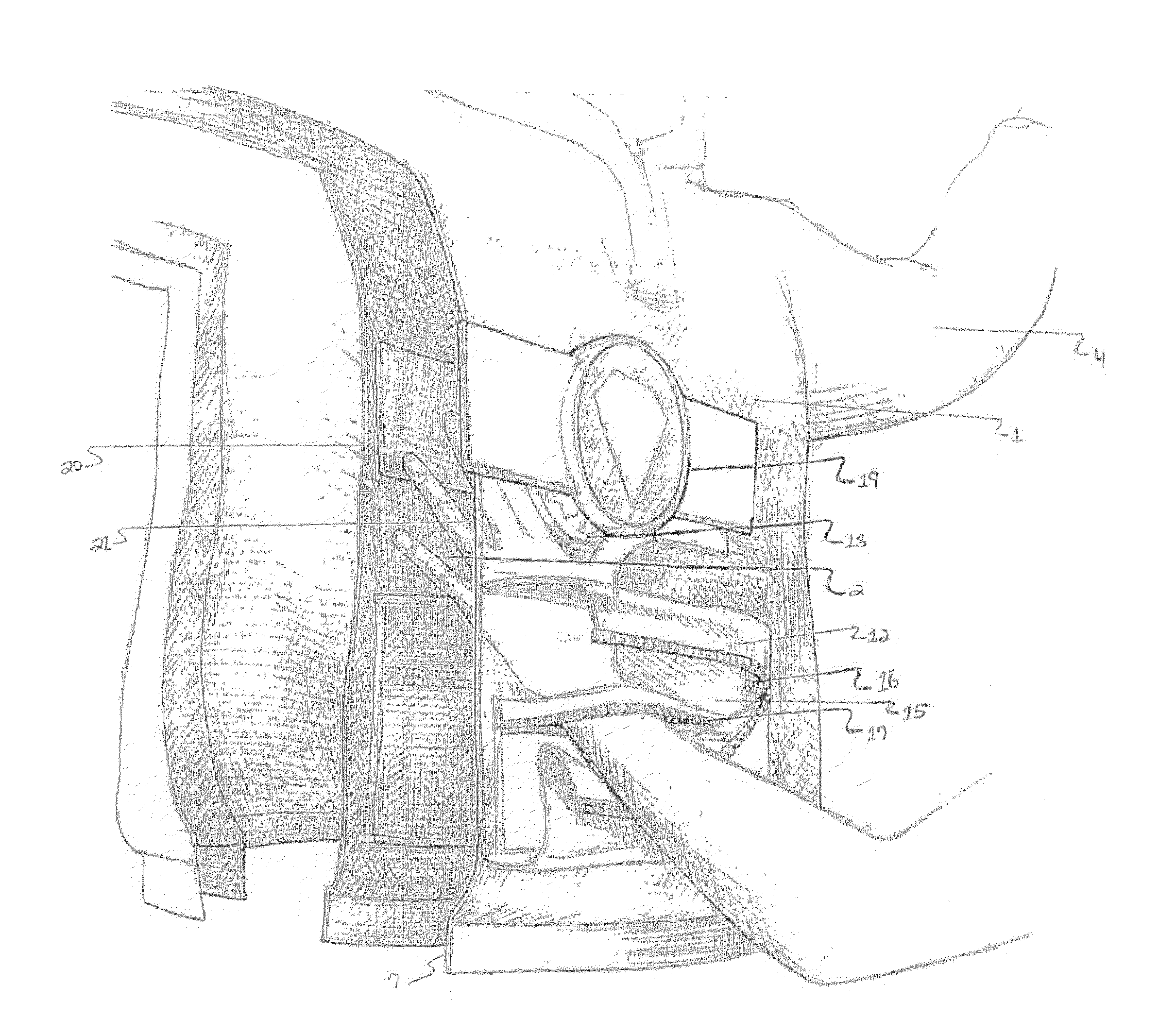

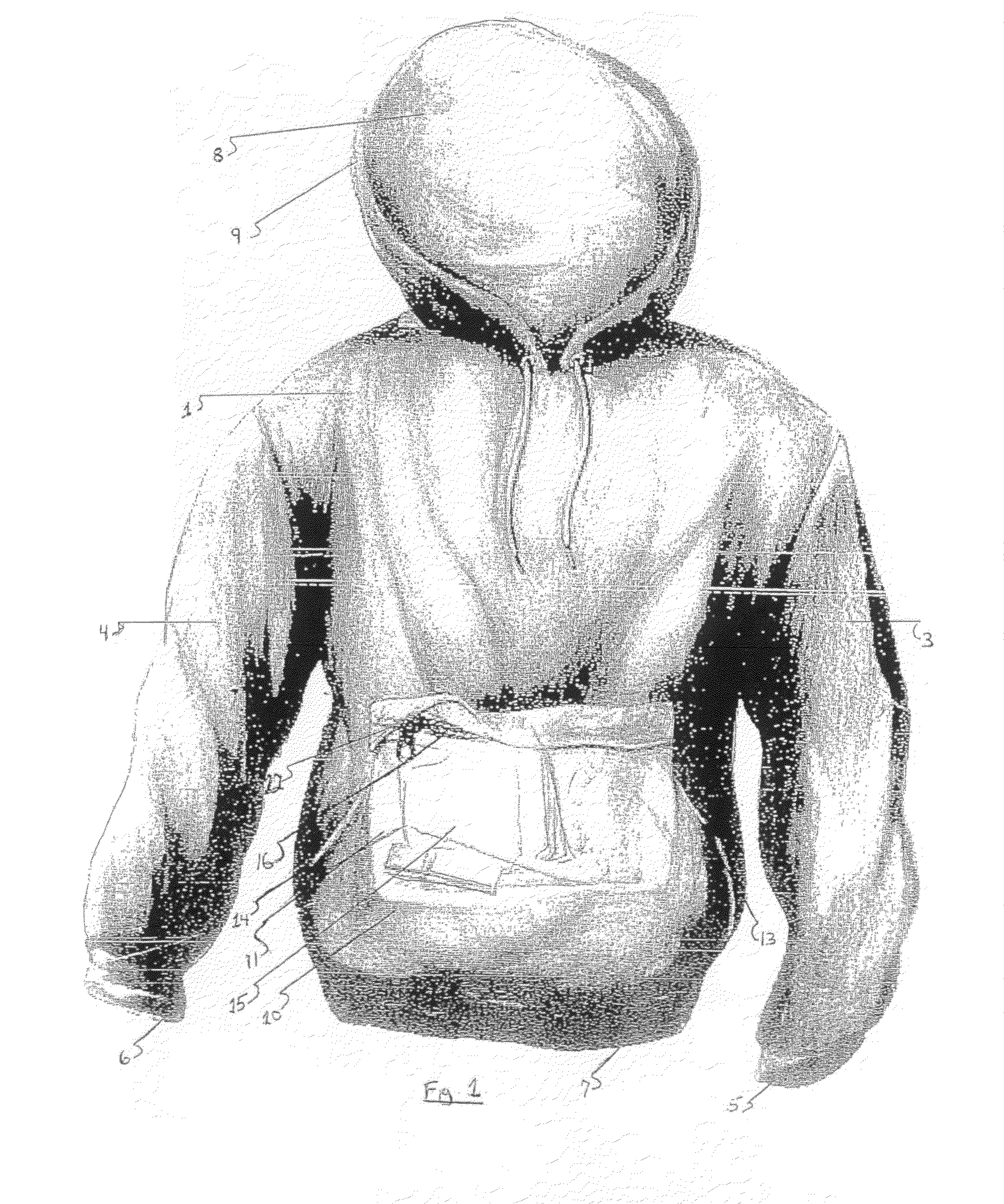

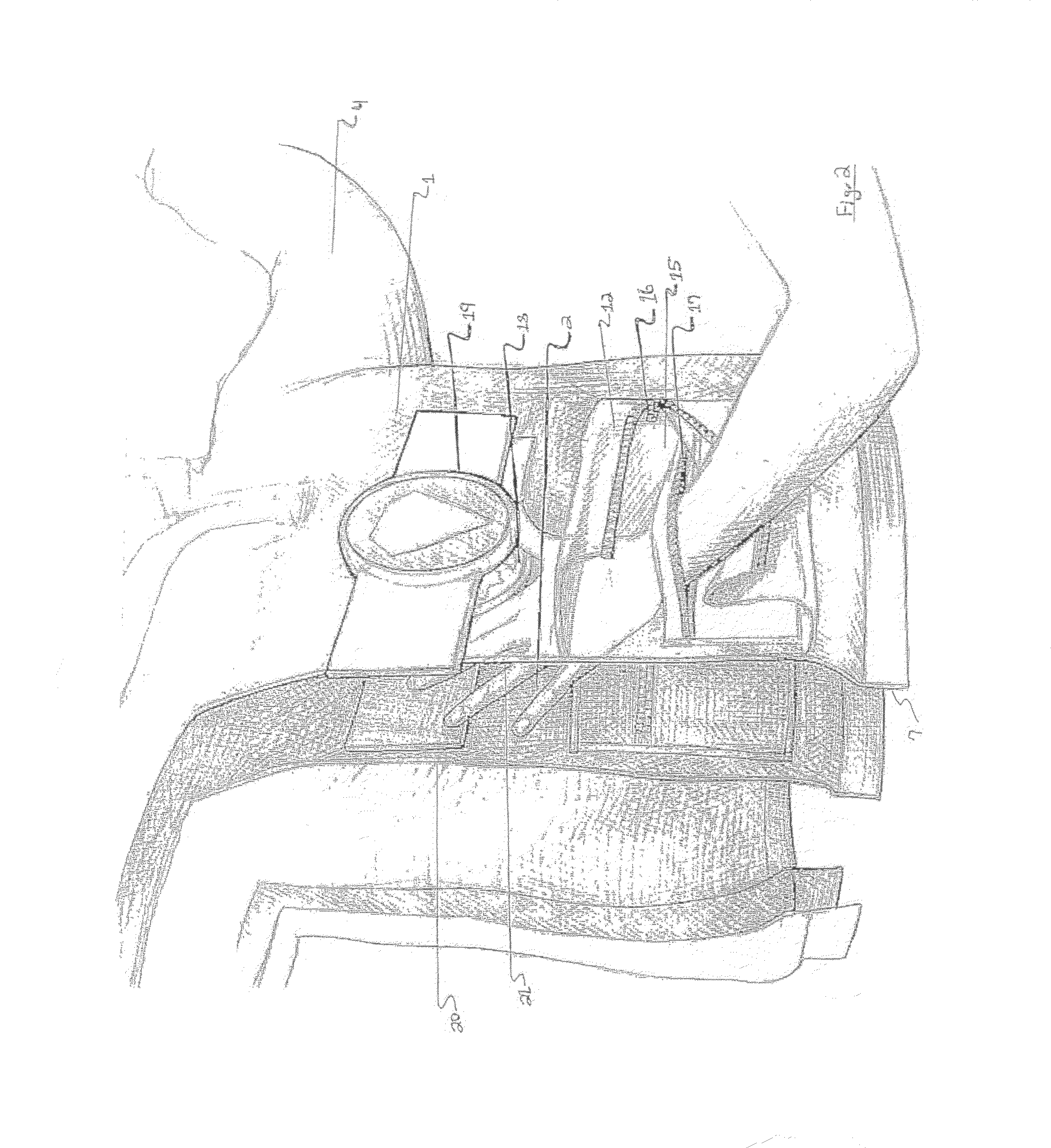

Reversible Sweatshirt with Secure Pocket Slot and Secure Interior Pocket Pouch and Method for Embroidering Same

ActiveUS20090031468A1Easy to customizeSafe storageConvertible garmentSewing-machine elementsEngineering

Reversible sweatshirt has a pair of contiguous configurations, each of which may have distinct coloration and distinct embroidery and a secure pocket slot, the application of such embroidery is facilitated through a secure pocket slot having a secure interior pocket pouch, accessible from one or more of the contiguous configurations, for safely securing items and for facilitating the embroidery process of both contiguous configurations. A wearer may select which side of the reversible sweatshirt to wars outside and / or inside, to expose the secure pocket slot and display the distinct coloration and distinct embroidery of the exposed configuration.

Owner:SANDOVAL LOUIS ALBERT

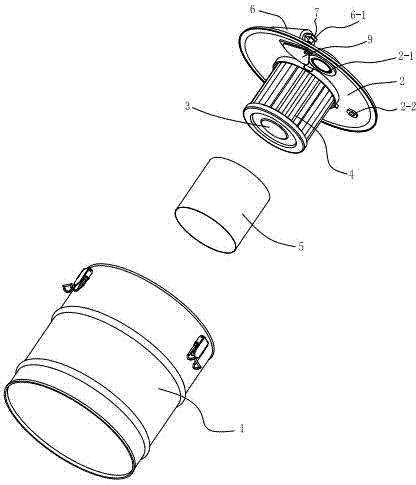

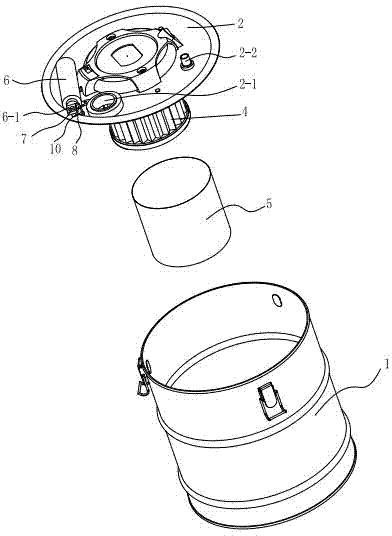

Sewing machine dust collection device

InactiveCN104846568AGreat suctionMake up for the lack of suctionSewing-machine elementsSuction forceEngineering

The invention discloses a sewing machine dust collection device which comprises a dust collection barrel. An upper cover plate is arranged on the dust collection barrel; a rear suction inlet and a thread suction pipe connector are formed in the upper cover plate; a motor is arranged in the inner cavity of the dust collection barrel, and the output shaft of the motor is connected with a fan; an electromagnet is arranged on the outer side or the inner cavity of the dust collection barrel, a clamping arm is formed at one end of the electromagnet and is fixedly connected with a connecting pin, the connecting pin is connected with the free end of a rotating piece, the fixing end of the rotating piece is provided with a fixed pin, and the connecting pin can rotate around the fixed pin; the connecting pin is fixedly connected with a partition; the electromagnet drives the clamping arm to eject out, the clamping arm drives the connecting pin to rotate around the fixed pin, and the connecting pin drives the partition to rotate with the same to have the rear suction inlet covered. During operation of a thread suction pipe, suction force generated from the thread suction pipe can be increased instantly, the defect about insufficient suction force of the thread suction pipe is made up, and the suction force of a suction pipe and the thread suction pipe can satisfy the requirements of use.

Owner:YUHUAN YI ELECTRONICS

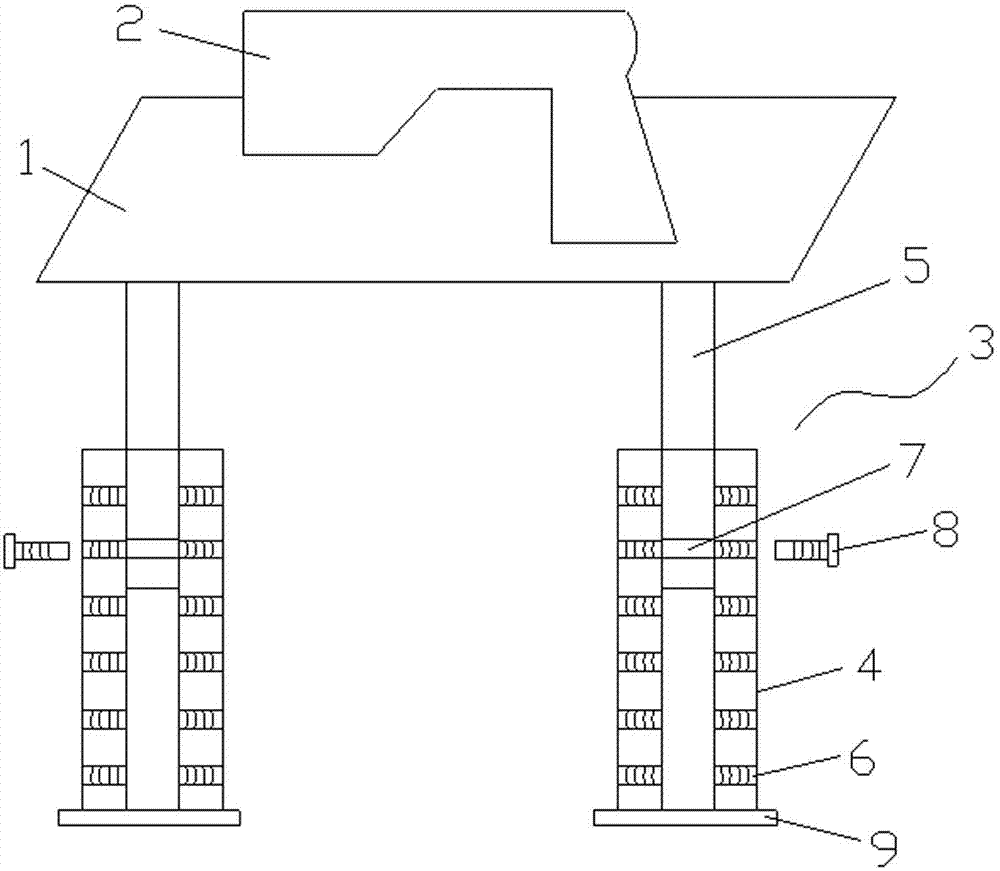

Adjustable frame of sewing machine

The invention relates to an adjustable frame of a sewing machine. The adjustable frame comprises a bedplate, a headpiece which is arranged on the bedplate, and supporting devices which are arranged on the lower end face of the bedplate, wherein the supporting devices comprise outer sleeves and supporting legs which are arranged in the outer sleeves; threaded holes are formed in two sides of the outer sleeves; positioning holes are formed in two sides of the lower ends of the supporting legs; and an adjusting bolt penetrates through one threaded hole and the positioning hole of each supporting leg to ensure that the outer sleeves are fixedly connected with the supporting legs. The adjustable frame is simple in structure, and can ensure that the relative height between the outer sleeves and the supporting legs can be increased or reduced, so that convenience is brought to people with different figures; and a rubber pad is arranged at the bottom of each outer sleeve to prevent the ground from being scratched, so that the adjustable frame has a great application value and a great promotion value.

Owner:WUJIANG XIAOYU JET WEAVING

Printing and quilting method and apparatus

InactiveUS20050051071A1Efficiently and economicallyHighly efficient and economical and high and mannerLeather sewingOrnamental textile articlesProduction lineData file

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632), either on the same or a different production line. Ticking is preprinted with a plurality of different patterns, organized and coordinated by the computer so that a print head can scan the material and print different patterns of different panels (32). Identifying data (40) for matching the panels of a mattress product can be provided in data files and codes can be printed on the fabric. Panels can be matched and assembled into products based on the codes, and quilting, cutting, slitting and other operations can be controlled by printed codes and other data. The quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

Pantograph projection

ActiveUS9650734B2Programme-controlled sewing machinesSewing-machine elementsHead movementsMeasurement device

The present invention relates to a sewing machine, specifically a long-armed stitcher. The present invention includes a computer device that may store pantograph patterns therein. The data including the pantograph patterns may be sent to projection units associated with the sewing machine head of the long-armed stitcher. The projection units use projection elements to project the pantograph patterns on the fabric to be stitched, allowing an operator of the stitcher to trace the projected pattern with a needle associated with the sewing machine head. Measurement devices associated with the sewing machine head determine head movement and alter the projected pattern accordingly such that the needle of the sewing head may continue to follow the pantograph pattern despite the head having moved in order to trace the pattern.

Owner:GAMMILL

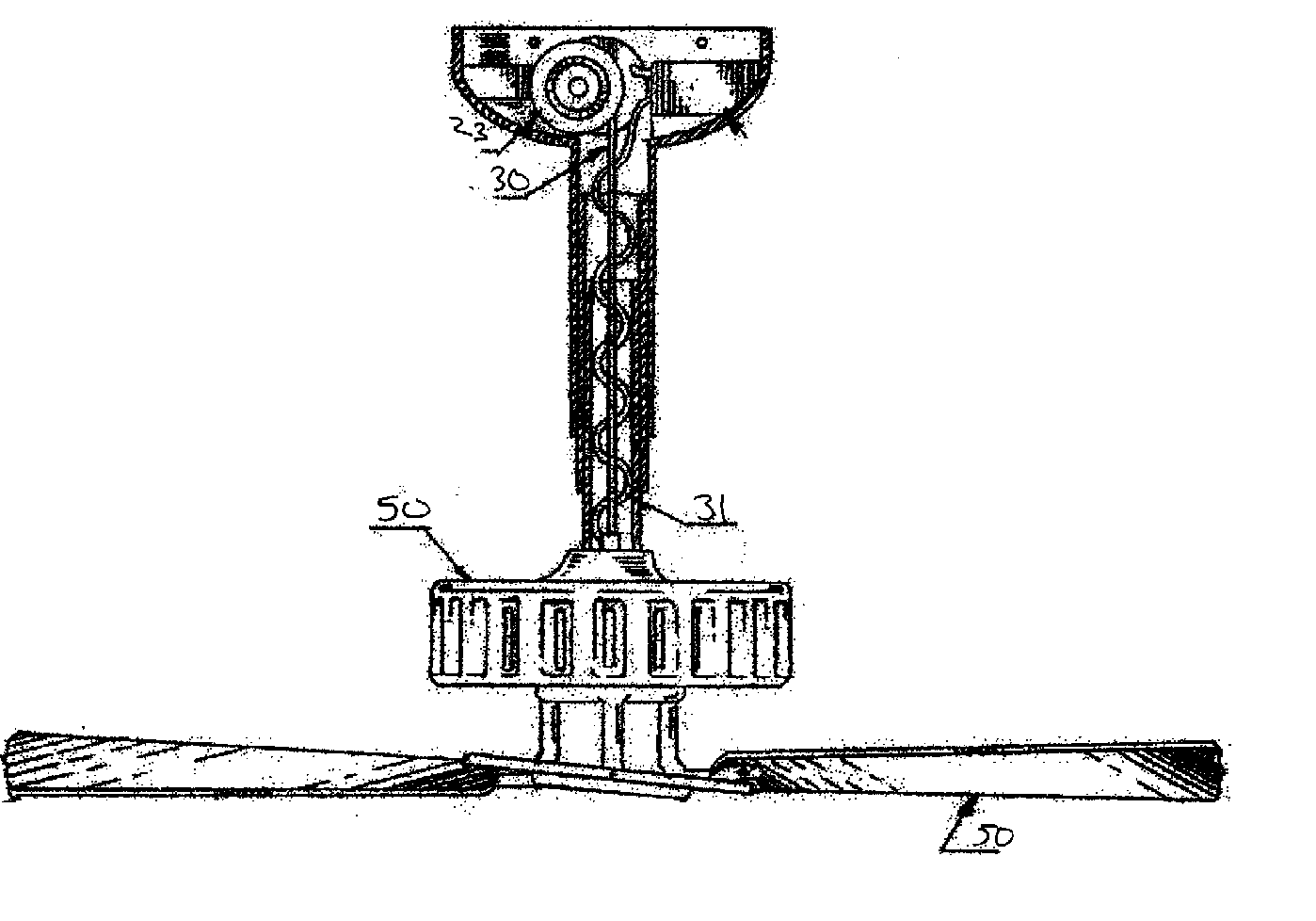

Device and method for raising and lowering ceiling fixtures

InactiveUS20070134093A1Lighting support devicesSewing-machine elementsEngineeringElectrical and Electronics engineering

Owner:WEILER THOMAS

Reversible sweatshirt with secure pocket slot and secure interior pocket pouch

Owner:SANDOVAL LOUIS ALBERT

High-efficiency towel machine

ActiveCN104250888AGood transmission effectHigh precisionProgramme-controlled sewing machinesCombination sewing machinesElectric machineryEngineering

The invention relates to a high-efficiency towel machine. The high-efficiency towel machine comprises a control center, a feed device, a first machining device and a second machining device. The feed device feeds cloth into the first machining device for first double-side binding, and the processed cloth of the first machining device is fed into the second machining device. The second machining device cuts off the cloth for second double-side binding. The second machining device comprises a second machine table, a sucker conveying mechanism, a second synchronous wheel, a cutting mechanism, a clamping mechanism, a label folding and sending mechanism, a belt loosening device and a second double-needle sewing machine, wherein the sucker conveying mechanism, the second synchronous wheel, the cutting mechanism, the clamping mechanism, the label folding and sending mechanism, the belt loosening device and the second double-needle sewing machine are fixed on the second machine table. The cutting mechanism comprises a first cutter rest, a first cutter, a first cutter motor, a spindle and an eccentric bearing, wherein the first cutter rest is provided with a vertical guide groove, the vertical side of the first cutter is matched in the guide groove, the spindle is horizontally fixed on the first cutter rest, the spindle is arranged above the guide groove, the eccentric bearing is sleeved with the spindle and is radially and movably connected with the first cutter, and one end of the spindle is connected with the first cutter motor. According to the above technical scheme of the high-efficiency tower machine provided, production efficiency and machining quality are greatly improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

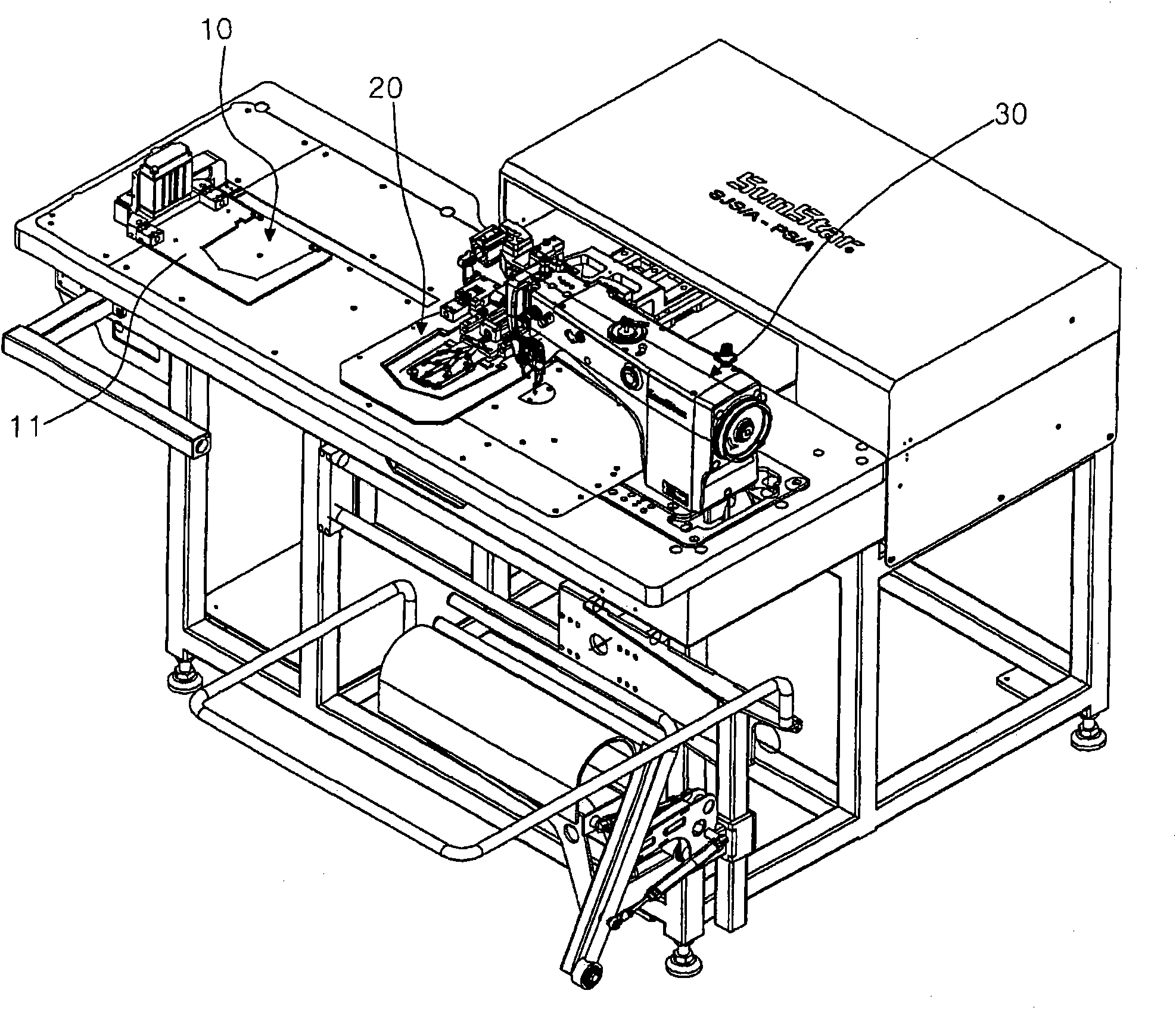

Duplex pocket sewing device capable of performing multicolour sewing operations and sewing method thereof

InactiveCN101768840AImprove work efficiencyHigh degree of completionSewing-machine elementsEngineeringMechanical engineering

The present invention relates to a duplex pocket sewing device capable of performing multicolour sewing operations and a sewing method thereof. The duplex pocket sewing device comprises a device body, a transferring unit installed at one side of the upper part of the device body and having a transferring board forming a plurality of pocket incision parts for transferring back an object to be sewed and being fixed on the transferring board to sewing units; a plurality of holding units, a plurality of sewing units for sewing the objects to be sewed and being pressed and fixed by the holding units, X-Y axis driving unit for driving the holding units along the X axis and the Y axis for forming seaming stitches on the objects to be sewed, and a control unit capable of controlling the X-Y axis driving unit and each device. According to the invention, two pocket operations can be performed by only one time driving of the duplex pocket sewing device, and the pocket sewing operations can be performed by using sewing threads of two kinds of color by one device, not only shortening operation time and preventing inconvenience of operations, but also improving the degree of completion of objects to be sewed.

Owner:SUNSTAR KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com