Full-automatic feeding device of sewing machine

A feeding device and sewing machine technology, which is applied in the field of sewing machines, can solve the problems of low product standardization, manual laying of fabrics requires a lot of labor, and high production costs, and achieves the effects of low production costs, less labor, and high standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

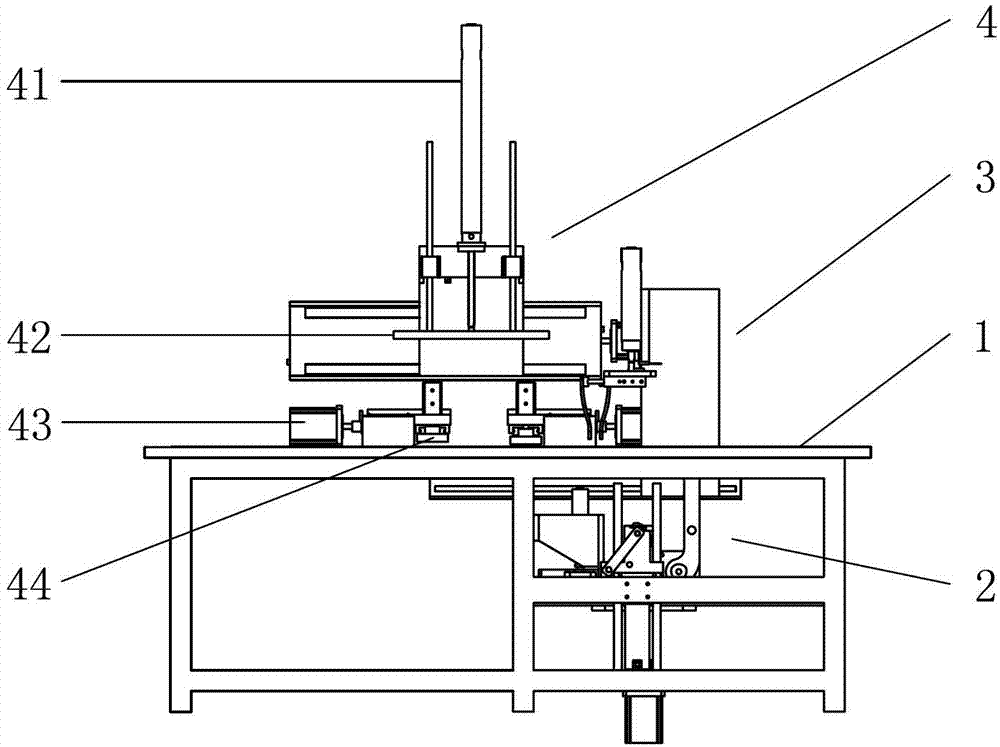

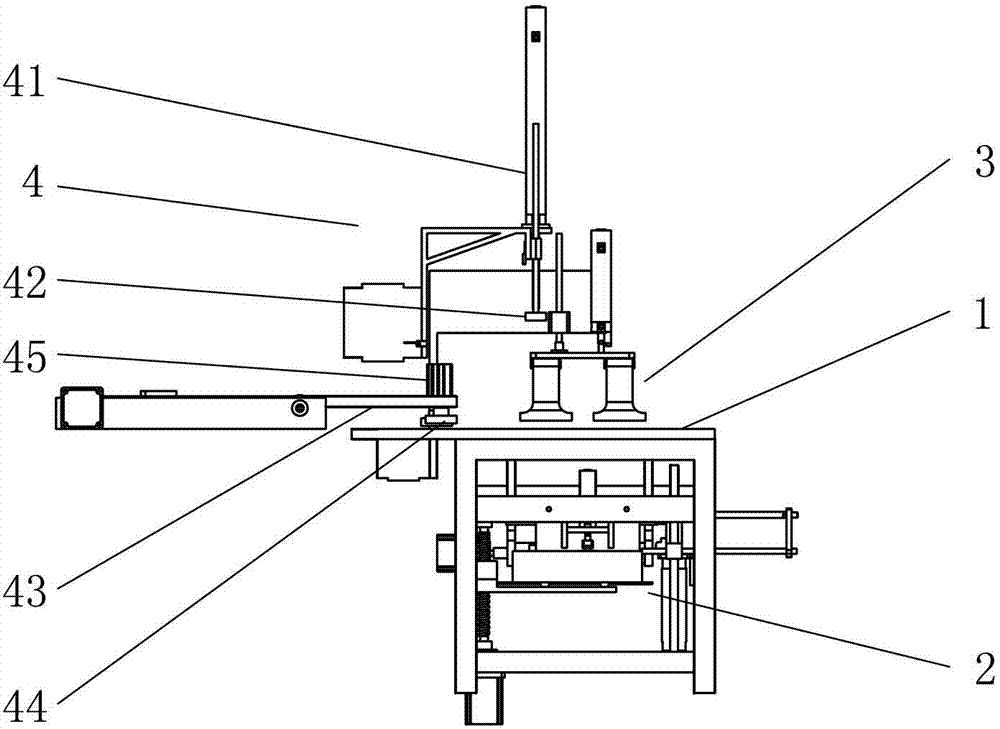

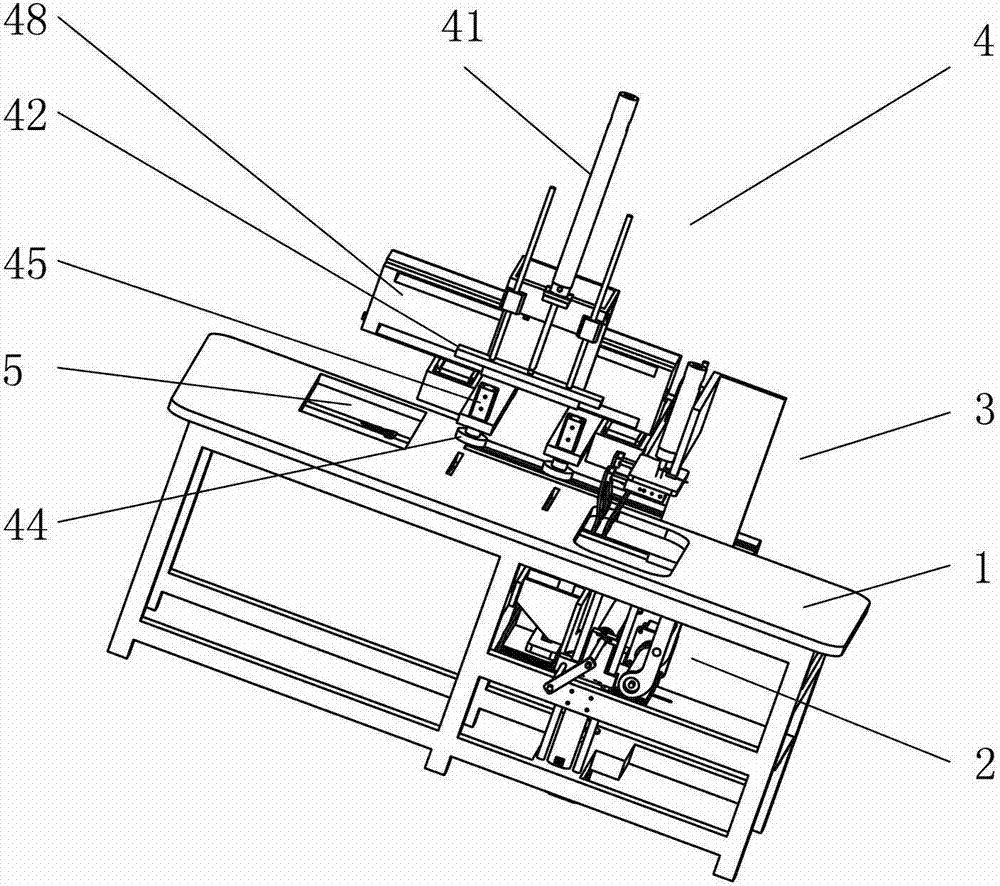

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -7:

[0024] The fully automatic feeding device of the sewing machine, on one side of the sewing machine table 1, is sequentially provided with a material distribution mechanism 2 that separates the materials 22 to be sewn one by one, and a gripper that clamps and lifts the materials 22 to be sewn separated by the material distribution mechanism 2. Material mechanism 3. Transfers the material to be sewn by the clamping and lifting mechanism 3 to the feeding mechanism 4 above the needle plate 5. Several position sensors are arranged on the transfer track of the material to be sewn 22, and the controller receives position signals from all position sensors. And control the sequence action of each mechanism.

[0025] The specific structure of the above-mentioned clip lifting mechanism 3 is: a lifting cylinder 33 is installed on the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com