Patents

Literature

165results about How to "Improve sewing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

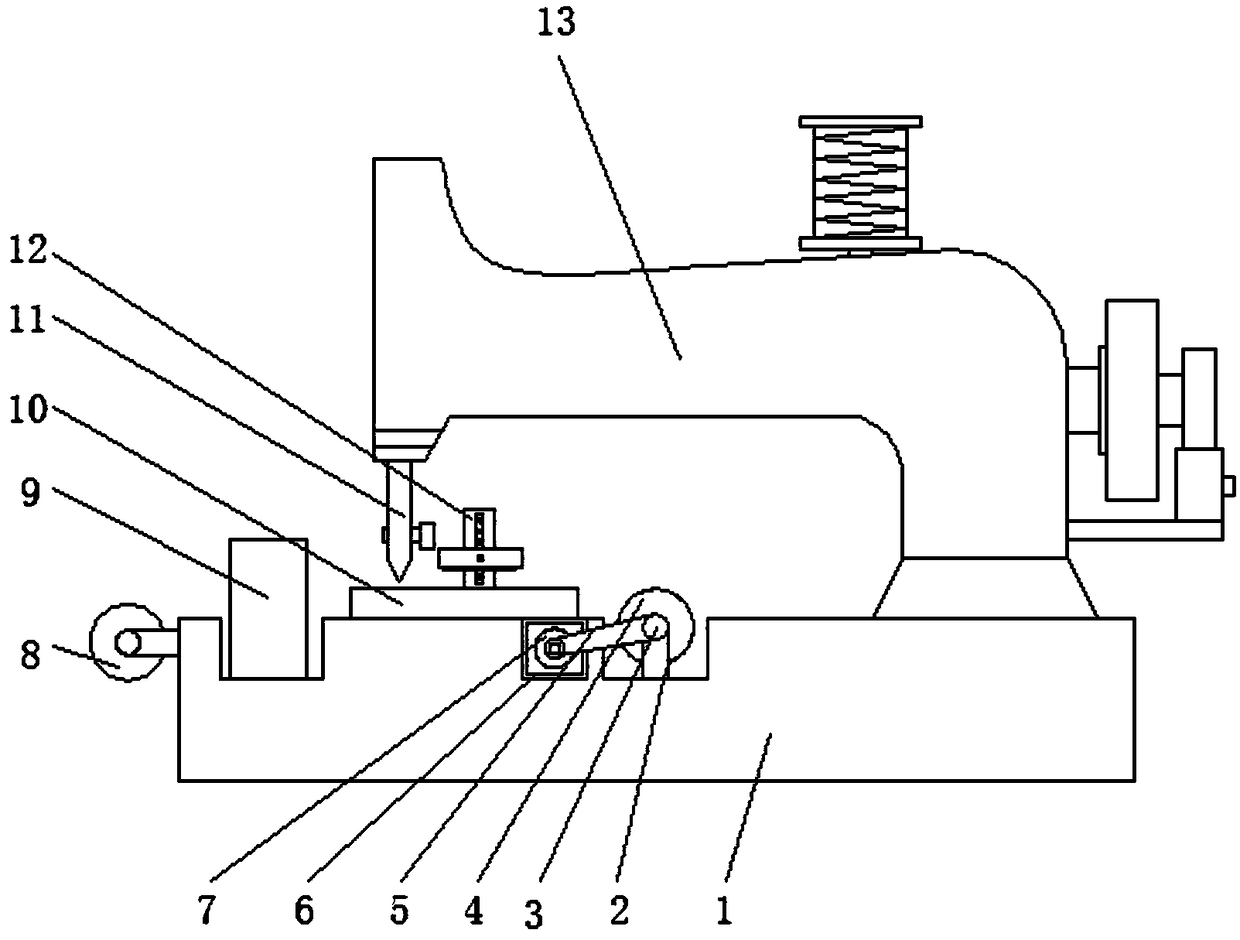

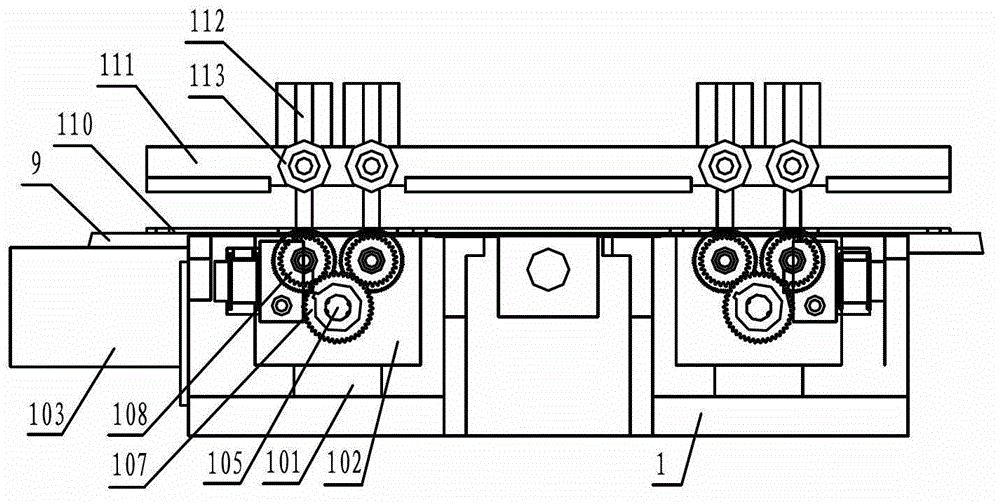

Sewing machine for up-down differential feeding

ActiveCN104233644ASimple structureCombined design is reasonableWork-feeding meansSewing-machine control devicesCrankControl engineering

The invention relates to a sewing machine for up-down differential feeding. The sewing machine comprises a secondary feeding adjusting mechanism, a feeding shaft and a feed lifting rock shaft, wherein the secondary feeding adjusting mechanism comprises a lower differential feeding adjusting crank and a first tooth frame seat which are fixed on the feeding shaft, a lower differential feeding crank which movably sleeves the feeding shaft and a lower differential transmission crank which movably sleeves the feed lifting rock shaft; the first tooth frame seat is connected with a feeding tooth; the lower differential feeding crank is connected with a lower differential feeding tooth; the lower differential feeding adjusting crank, a first lower differential feeding connecting rod, the lower differential transmission crank, a second lower differential feeding connecting rod and the lower differential feeding crank are hinged and linked in sequence; the hinging position between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is adjustable. The hinging position is adjusted so that a force arm relation between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is changed and a relation of swinging and transferring the feeding shaft to the feeding tooth and the lower differential feeding tooth is changed, namely the lower differential feeding adjustment is realized.

Owner:宁波新三合自动化有限公司

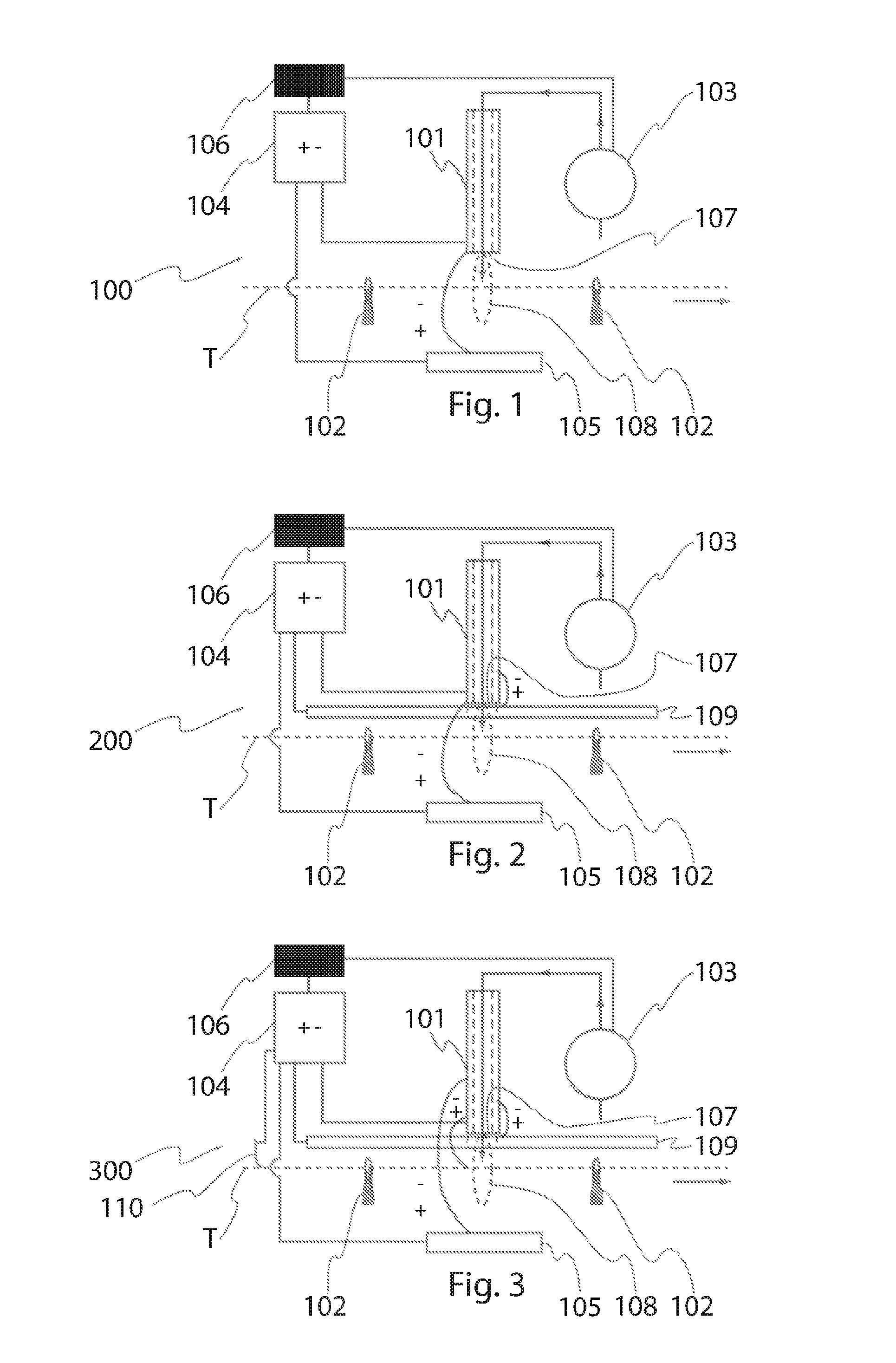

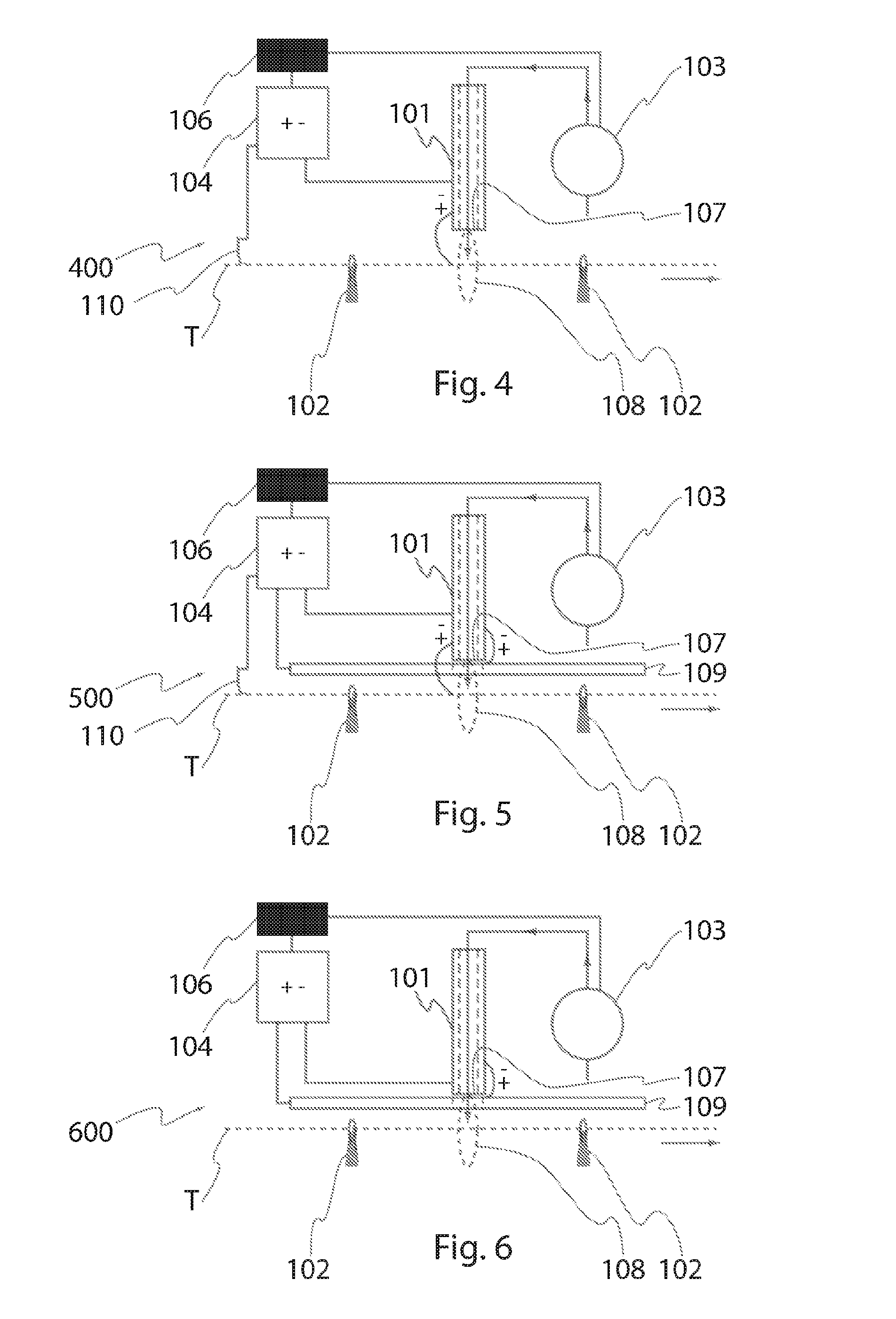

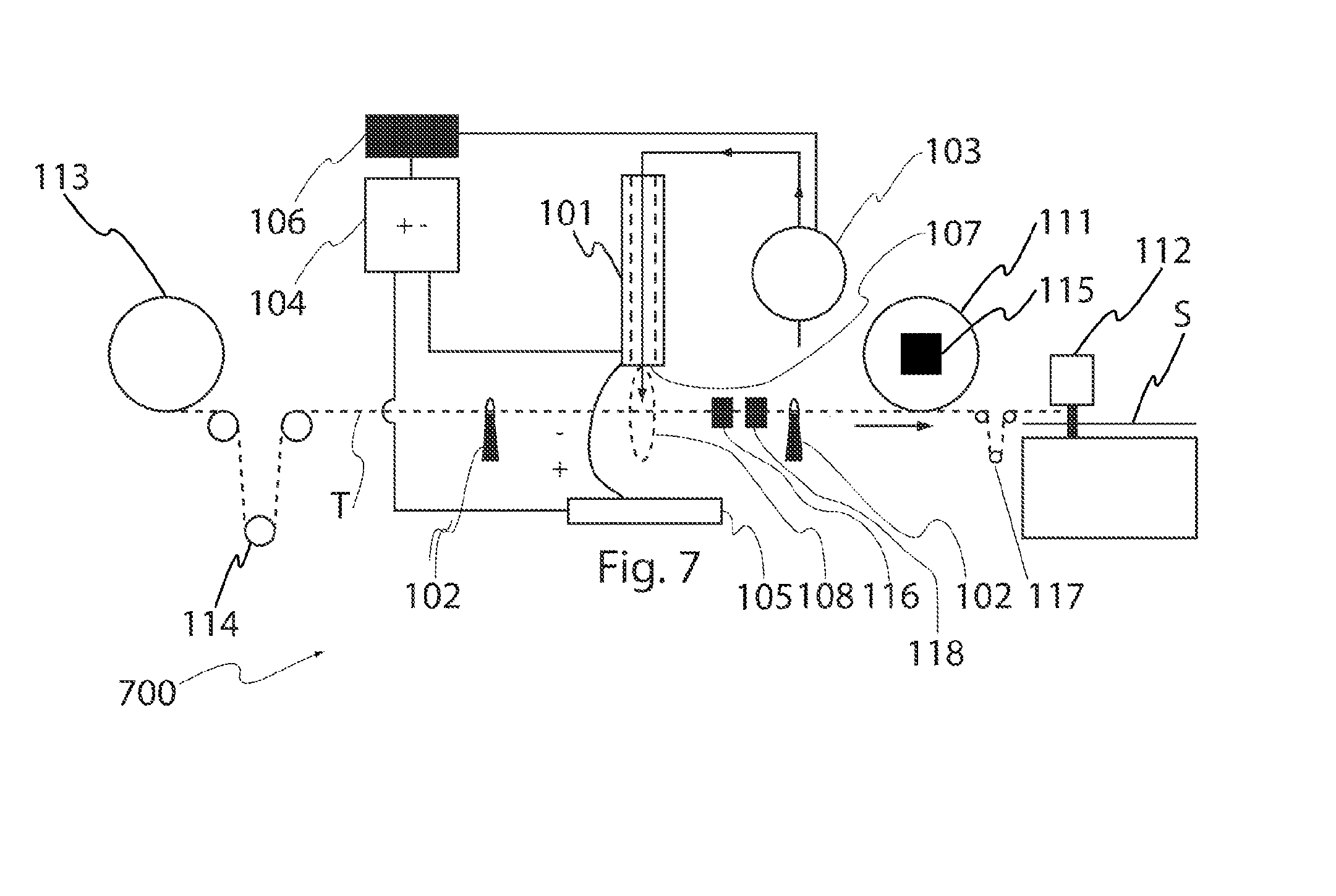

Coating Device for Coating an Elongated Substrate

InactiveUS20140349034A1Improve the lubrication effectImprove sewing effectLiquid spraying plantsLiquid surface applicatorsEngineering

A device and system for dynamically applying liquid to a single thread for a thread consuming device as said thread moves relative to the device along a path of movement. The device is configured to apply liquid to said thread by means of an electrospraying unit. A method for applying liquid to a single thread for a thread consuming device as said thread moves relative to the device along a path of movement is also provided.

Owner:COLOREEL GRP AB

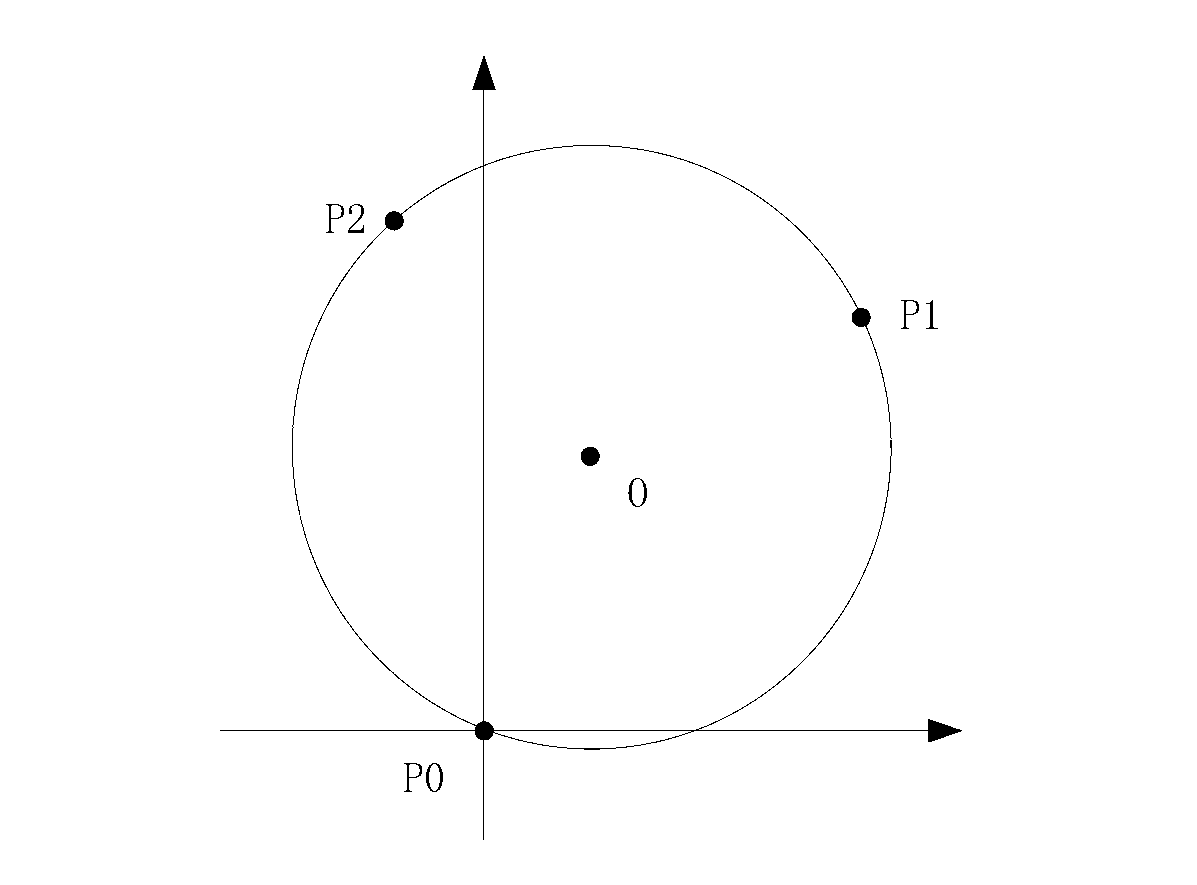

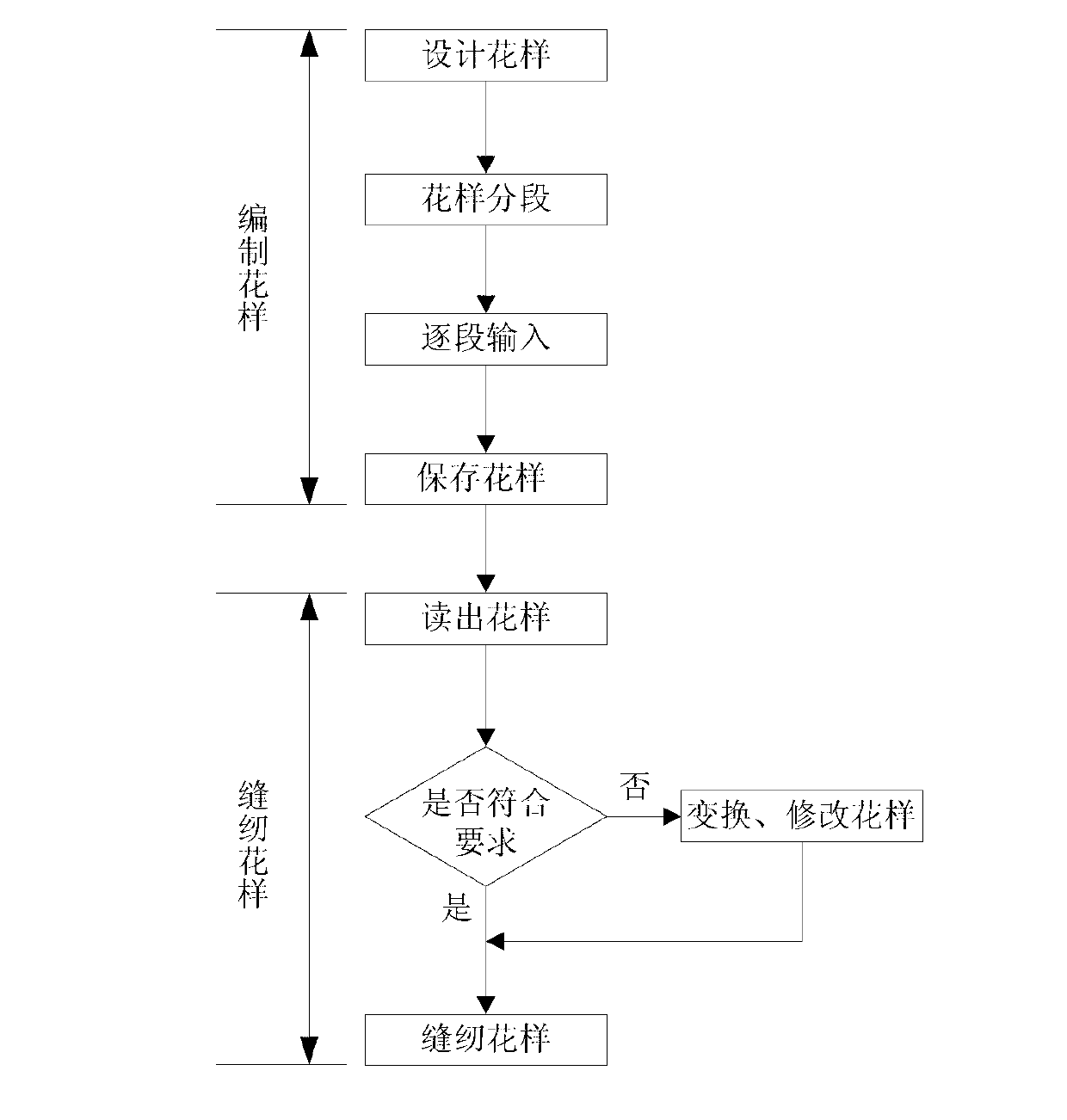

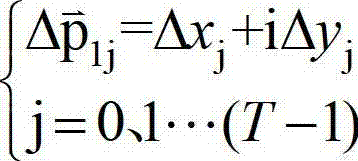

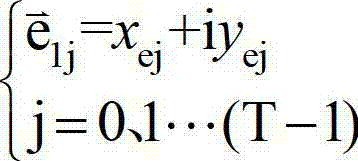

Method for controlling electronic pattern making machine for realizing uniform discretization of patterns

InactiveCN102995302AStitch smoothGuaranteed uptimeProgramme-controlled sewing machinesData fileInstability

The invention provides a method for controlling an electronic pattern making machine for realizing uniform discretization of patterns, aiming to solve the problems of running instability and pattern distortion caused by nonuniform discretization of patterns of the electronic pattern making machine in the prior art. According to the method, a plurality of straight line segments, circular arcs, circles and free curves for forming the patterns are discretized uniformly, the obtained relative coordinates of the pattern points indicate the relative running vector of a needle of a sewing machine on the frame of the sewing machine, the integrated pattern data files are stored in the electric control system of the electronic pattern making machine, the pattern data files selected by the user are read by the electric control system, and the pattern data are analyzed reversely to control an X-axis stepping motor and a Y-axis stepping motor to operate together with a servo motor.

Owner:西安海泰科技有限公司

High-grade noniron finishing method of deep dark pure cotton fabric

ActiveCN107938219AIncreased radial shrinkageImproves easy-care performanceTextile storage in superimposed formSingeingTextile printerMoisture absorption

The invention belongs to the technical field of textile printing and dyeing and particularly relates to a high-grade noniron finishing method of deep dark pure cotton fabric, comprising the sequentialsteps of spread-sewing, singeing, desizing, scouring, mercerizing, cold pad-batch dyeing, high temperature soaping, liquid ammonia finishing, pre-softening, primary pre-shrinking, noniron treating, curing, water washing, tentering and softening, and secondary pre-shrinking, wherein curing temperature is 120-130 DEG C, curing reaction time is controlled to 5-6 min, and the noniron step employs padding AP resin noniron aid. The high-grade noniron finishing method of deep dark pure cotton fabric has the advantages that radial stretch of the fabric can be improved, noniron state is retained afternoniron curing, and noniron property of the fabric can be improved accordingly; the deep dark pure cotton fabric is imparted good softness, breathability and moisture absorption and good washing fastness, never fades in long-term standing, has good ironing firmness, is suitable for batch production, and reaches grade 3.8 and above under AATCC-125 standard in terms of noniron property.

Owner:鲁丰织染有限公司

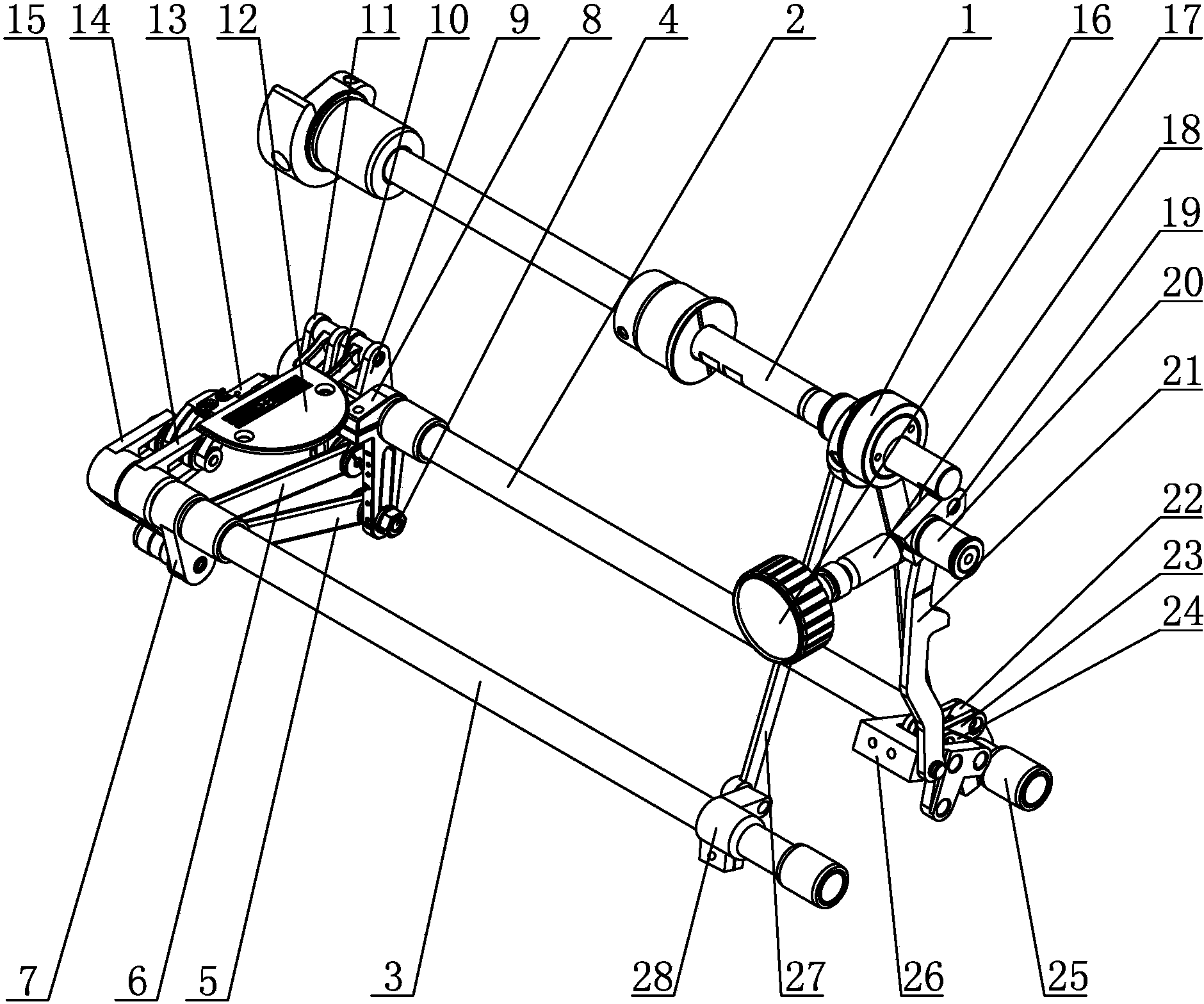

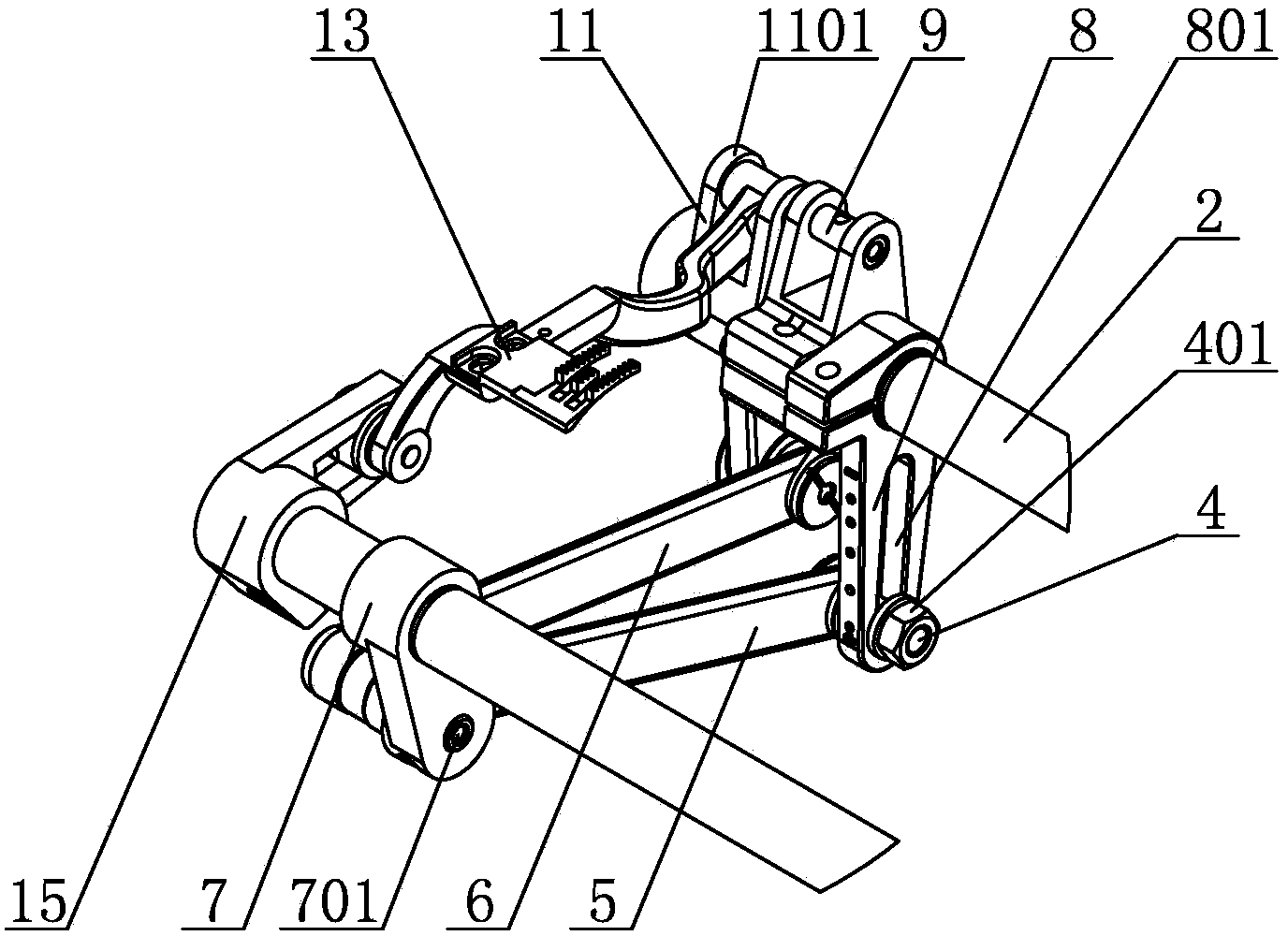

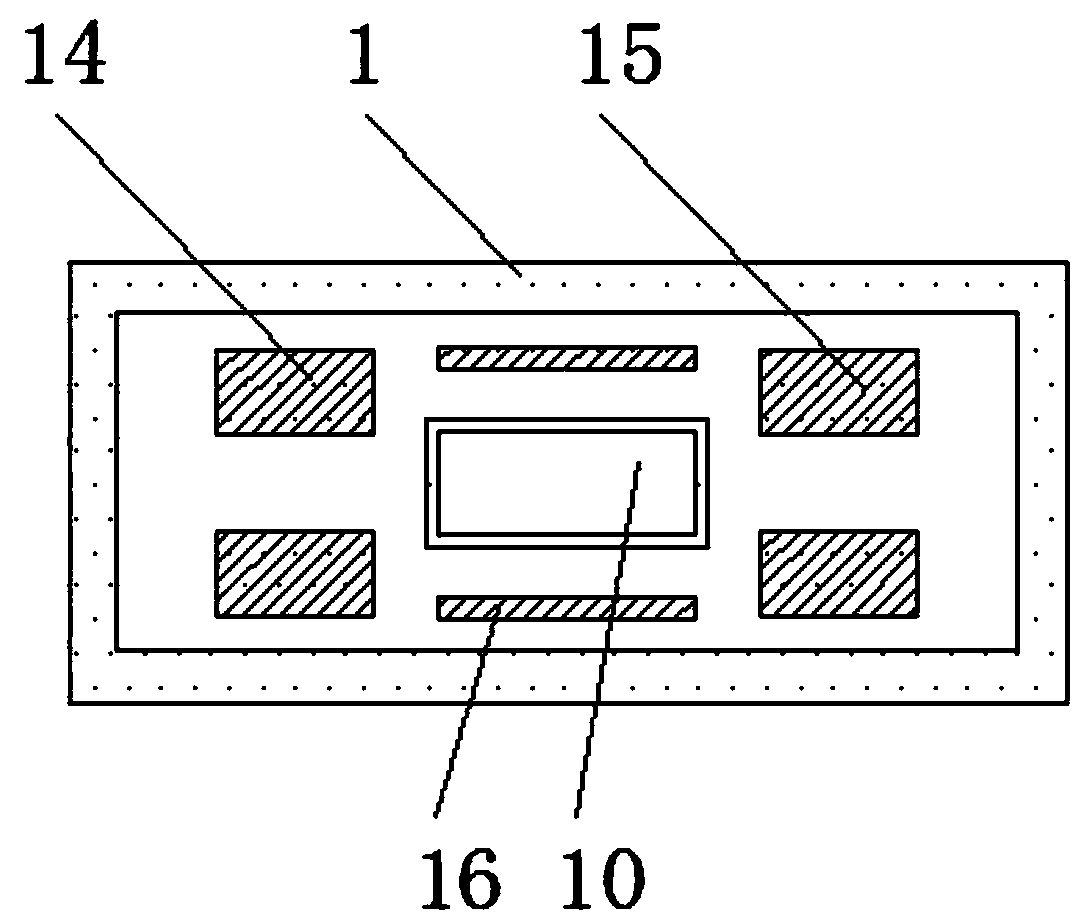

Sewing machine based on automatic template split synchronizing wheel apparatus

ActiveCN104963105AOutstanding and Beneficial Technical EffectsLifting height can be controlled at willWork-feeding meansSewing-machine control devicesElectromagnetSewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to a sewing machine based on an automatic template split synchronizing wheel apparatus. The sewing machine comprises a sewing machine body, the sewing machine body is provided with a drag wheel lifting and pressing mechanism and a lifting and pressing foot mechanism. A housing rear cover plate of the sewing machine body is provided with a lifting and pressing drag wheel electromagnet, a lifting and pressing foot electromagnet is disposed in the housing, and the lifting and pressing drag wheel electromagnet and the lifting and pressing foot electromagnet are used for respectively controlling the drag wheel lifting and pressing mechanism and the lifting and pressing foot mechanism to act. At the same time, a knee-operated lifting push rod is used for individually controlling the drag wheel lifting and pressing mechanism to act, so that the lifting height of a drag wheel can be adjusted at will, a cloth-dragging wheel can be lifted from a presser when a corner is sewed, and the presser can always pressed the cloth, the cloth can be normally sewed, the sewing performance can be raised, and the sewing effect can be ensured.

Owner:CHINA PRECIOUS SCI & TECH GRP CORP LTD

Sewing machine

ActiveCN106637733AFirmly connectedNot easy to fall offNeedle severing devicesSewing-machine control devicesState of artEngineering

The invention belongs to the technical field of sewing equipment and relates to a sewing machine. The sewing machine comprises a first driver and a first connection rod, the first connection rod is rotationally connected to a machine shell bottom plate, one end of the first connection rod is connected with a movable part of the first driver, the other end of the first connection rod is connected with a movable part of a second driver, the movable part of the second driver is also connected with a second connection rod, the second connection rod is driven by the first driver to rotate so that the other end of the first driver can drive the second connection rod to move to adjust to a corresponding stitch length for dense sewing, and the action of the first driver is controlled by a controller. The sewing machine can solve the problems that in the prior art, after thread cutting, thread ends are not attractive due to different lengths, and the thread ends are too long after thread cutting, and the stitch length during sewing can be adjusted through a mechanical structure. Before thread cutting, a small segment of dense sewing or variable-stitch-length sewing is conducted, so that the thread ends become short after thread cutting, the left thread ends are firmly connected and not likely to fall off after being torn, the sewing effect is improved, and attractiveness is improved.

Owner:JACK SEWING MASCH CO LTD

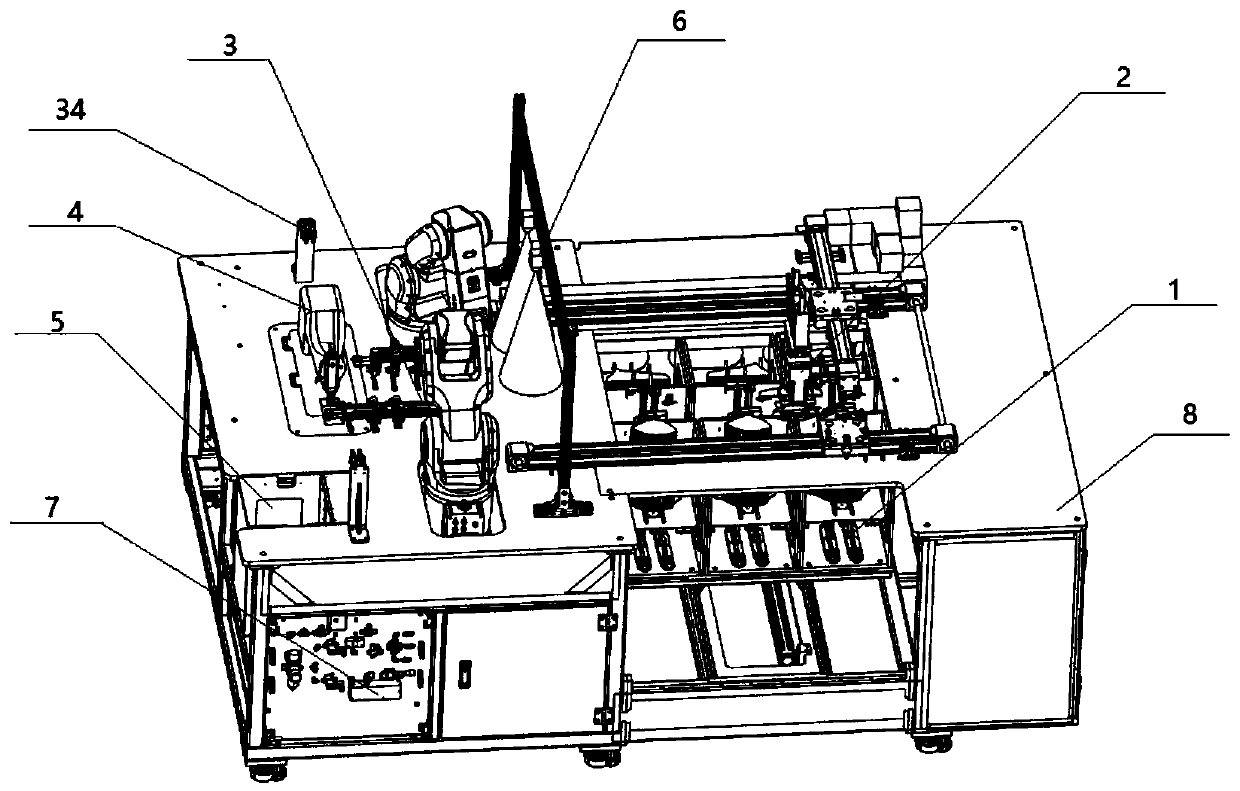

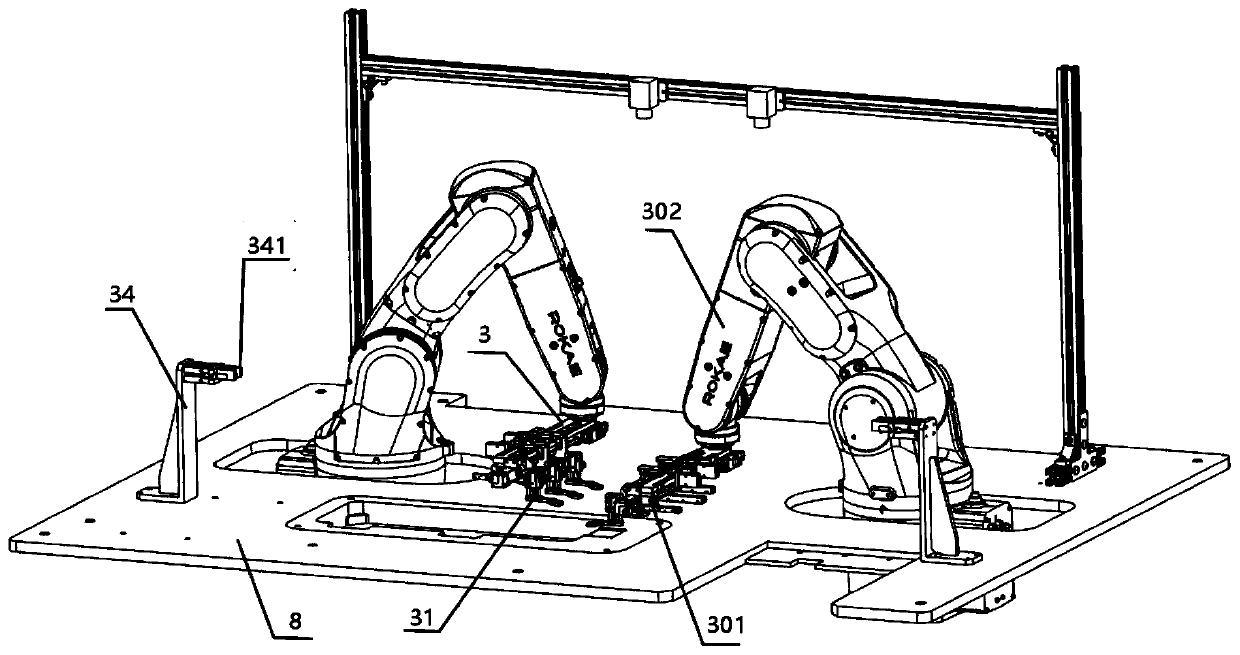

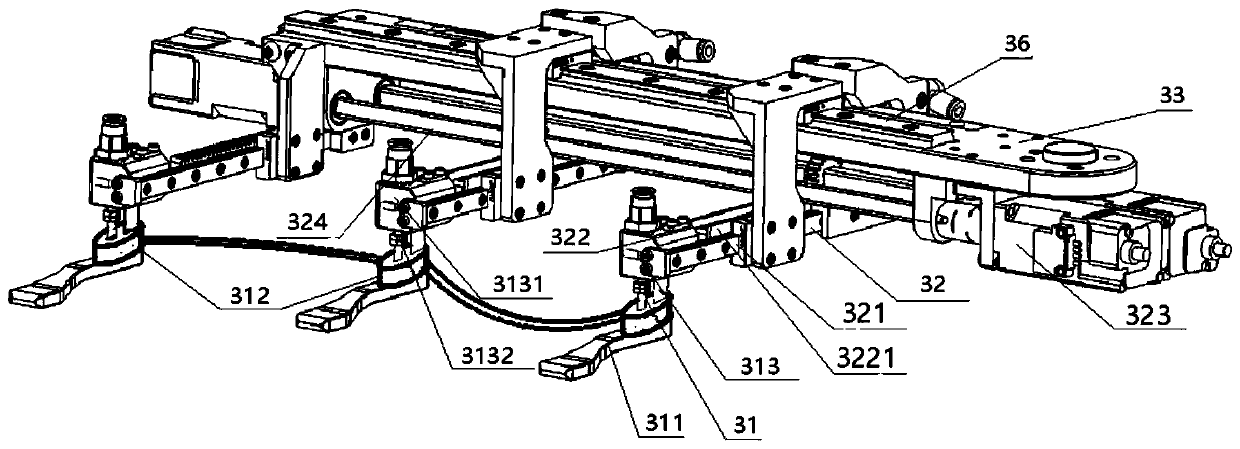

Sewing equipment and using method thereof

ActiveCN110820181ANot easy to wasteImprove work efficiencySewing-machine elementsControl systemVisual recognition

The invention relates to sewing equipment and a using method thereof. The sewing equipment comprise a workbench, two or more grabbing devices, sewing equipment, a visual recognition device and a control system, wherein the grabbing devices, the sewing equipment, the visual recognition device and the control system are respectively arranged on the workbench. The control system is respectively in signal connection with the grabbing devices, the sewing equipment and the visual recognition device and controls the operation of the grabbing devices, the sewing equipment and the visual recognition device; the visual recognition device recognizes the shape of cloth and feeds back the shape and size of the cloth to the control system; the control system controls the grabbing devices to adjust the grabbing angle and then convey the cloth to sewing equipment; the cloth is conveyed to the sewing equipment to be sewn; and the grabbing devices can keep pressing area on the cloth unchanged. By usingthe sewing equipment, the cloth can be fed, taken, grabbed, sewed and collected, the time and labor are saved, and the labor cost is reduced while the work efficiency is improved. Compared with manualsewing, the sewing equipment has the advantages that the finished product rate is high, and moreover, the smoothness of the cloth in the whole process can be guaranteed.

Owner:BEIJING HUAMEILI CLOTHING

Feeding device for sewing machine

InactiveCN108823823ASave time at workImprove work efficiencyWork-feeding meansPressersEngineeringSewing machine

The invention discloses a feeding device for a sewing machine. The device comprises a base, a feeding roller is arranged on the side wall of one side of the base, and two column grooves, two wind-up roller grooves and two bottom sliding grooves are formed in the upper surface of the base; each column groove is formed in one side of the corresponding wind-up roller groove, the two bottom sliding grooves are symmetrically formed, and the two bottom sliding grooves are formed between the two column grooves and the two wind-up roller grooves; a workbench and a main sewing machine body are fixedlyconnected to the upper surface of the base, the main sewing machine body is arranged at one side of the workbench, and the workbench is arranged between the two bottom sliding grooves; columns are fixedly connected to the interiors of the two column grooves. According to the feeding device, manual pulling for conveying is not needed, the working time is saved, the working efficiency is improved, cloth does not need to be manually supported by hand, the effect of sewing the cloth is better, the feeding device is reasonable in design and easy to operate, batting attached to the cloth can be removed, and the product quality is guaranteed.

Owner:邓瑞英

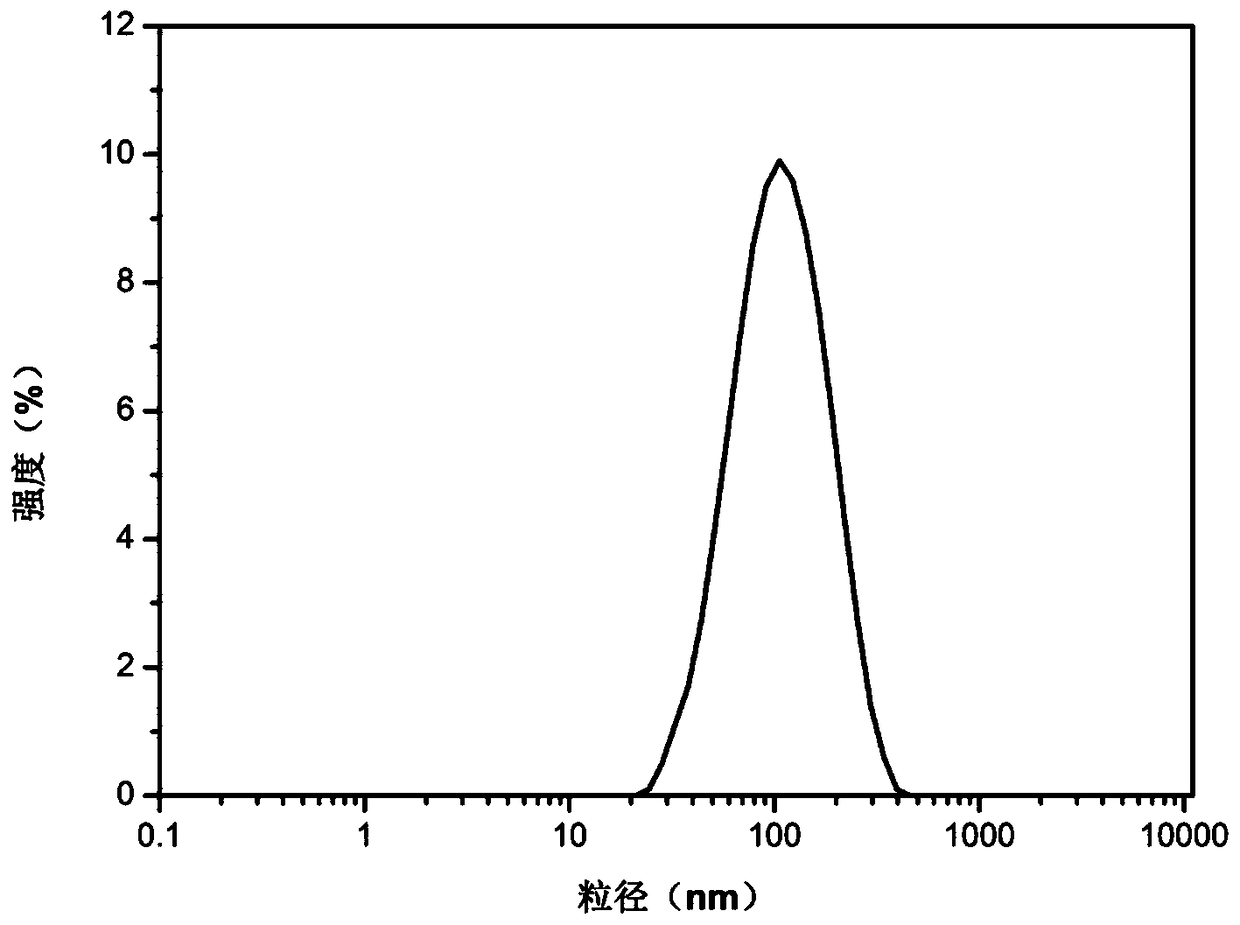

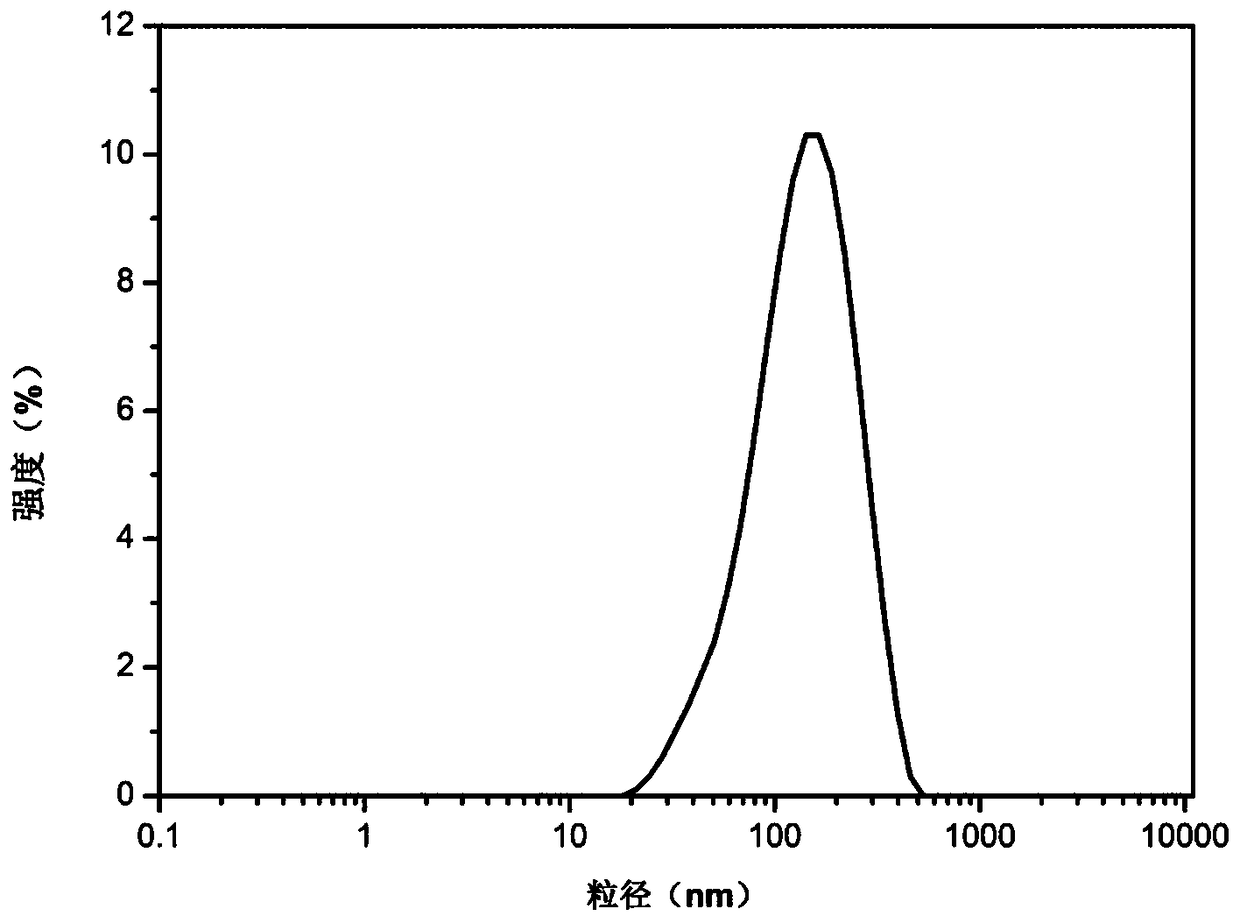

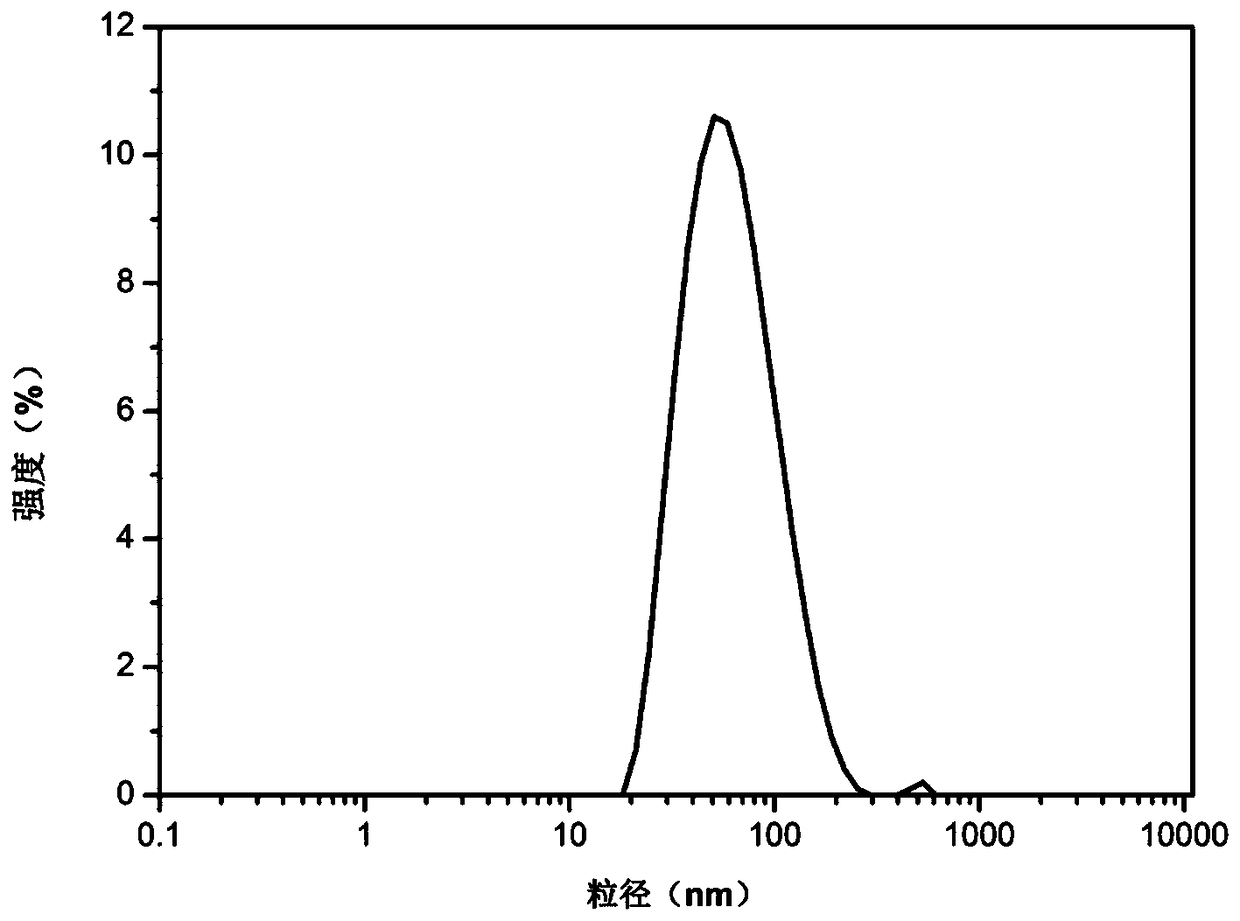

Compound wax microemulsion composition, and preparation method and application thereof

ActiveCN109487560AHigh Hydrophilic ContentHigh hardnessGrip property fibresVegetal fibresWater basedYarn

The invention discloses a compound wax microemulsion composition, and a preparation method and an application thereof. The compound wax microemulsion composition comprises the following components inpercent by weight: 8-28wt% of high melting point oxidized polyethlene wax, 4-14wt% of low melting point wax, 1-3wt% of a hyperbranched Gemini surfactant, 0.5-3wt% of a hyperbranched softener, 3-13wt%of an emulsifier, 0.1-1wt% of sodium hydroxide or potassium hydroxide and 50-80wt% of water based on the total weight of the compound wax microemulsion. The compound wax microemulsion can be preparedby a one-step high-temperature emulsification method which is simple in process. The prepared compound wax microemulsion is good in centrifugal stability and diluting stability. By trimming the microemulsion to a textile, the smooth performance of the textile can be improved obviously, the coefficient of kinetic friction of yarns can be reduced, the sewing performance and hydrophilia of a knittedfabric are improved, and yellowing is reduced.

Owner:TAICANG BAONI IND CO LTD

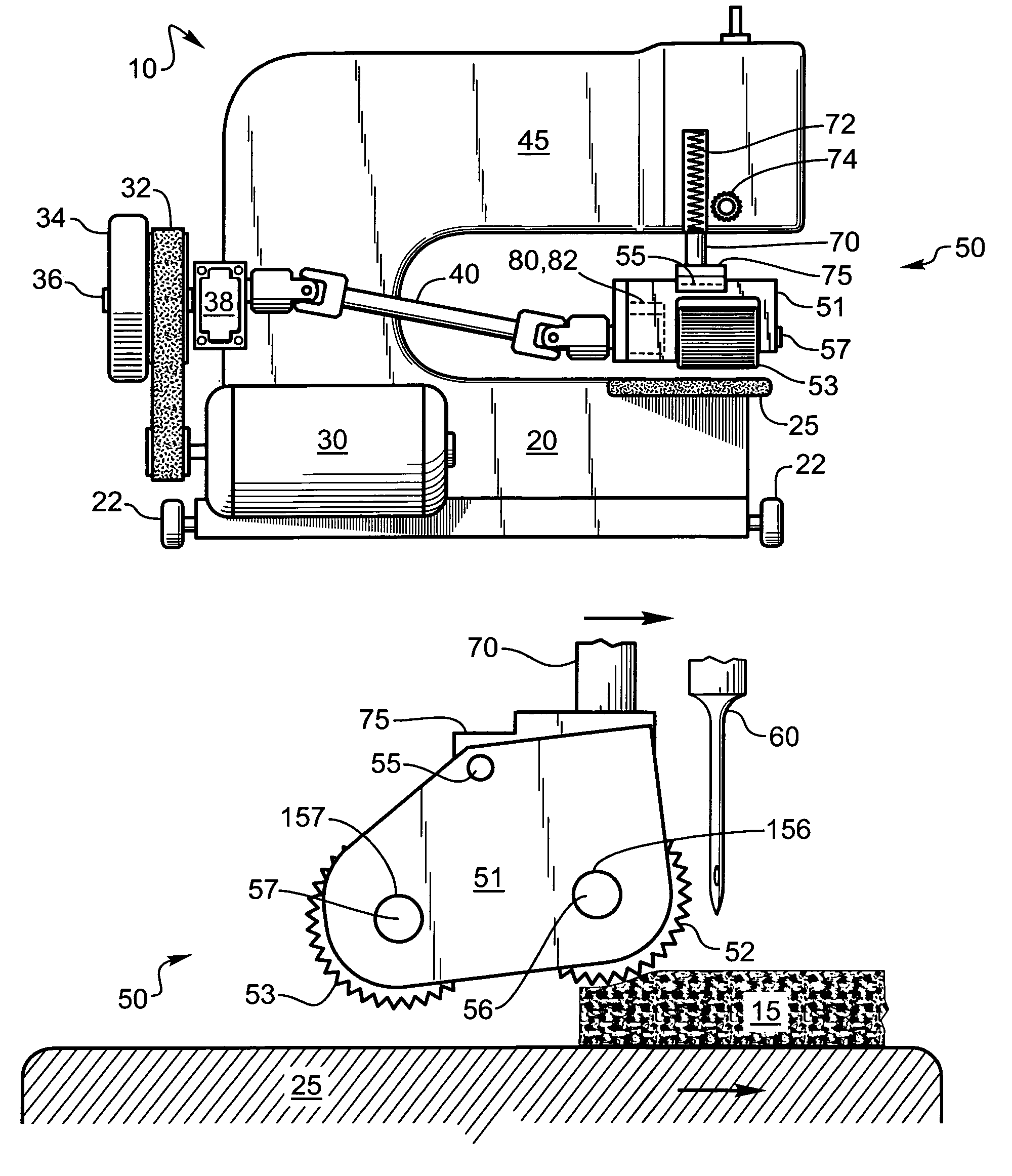

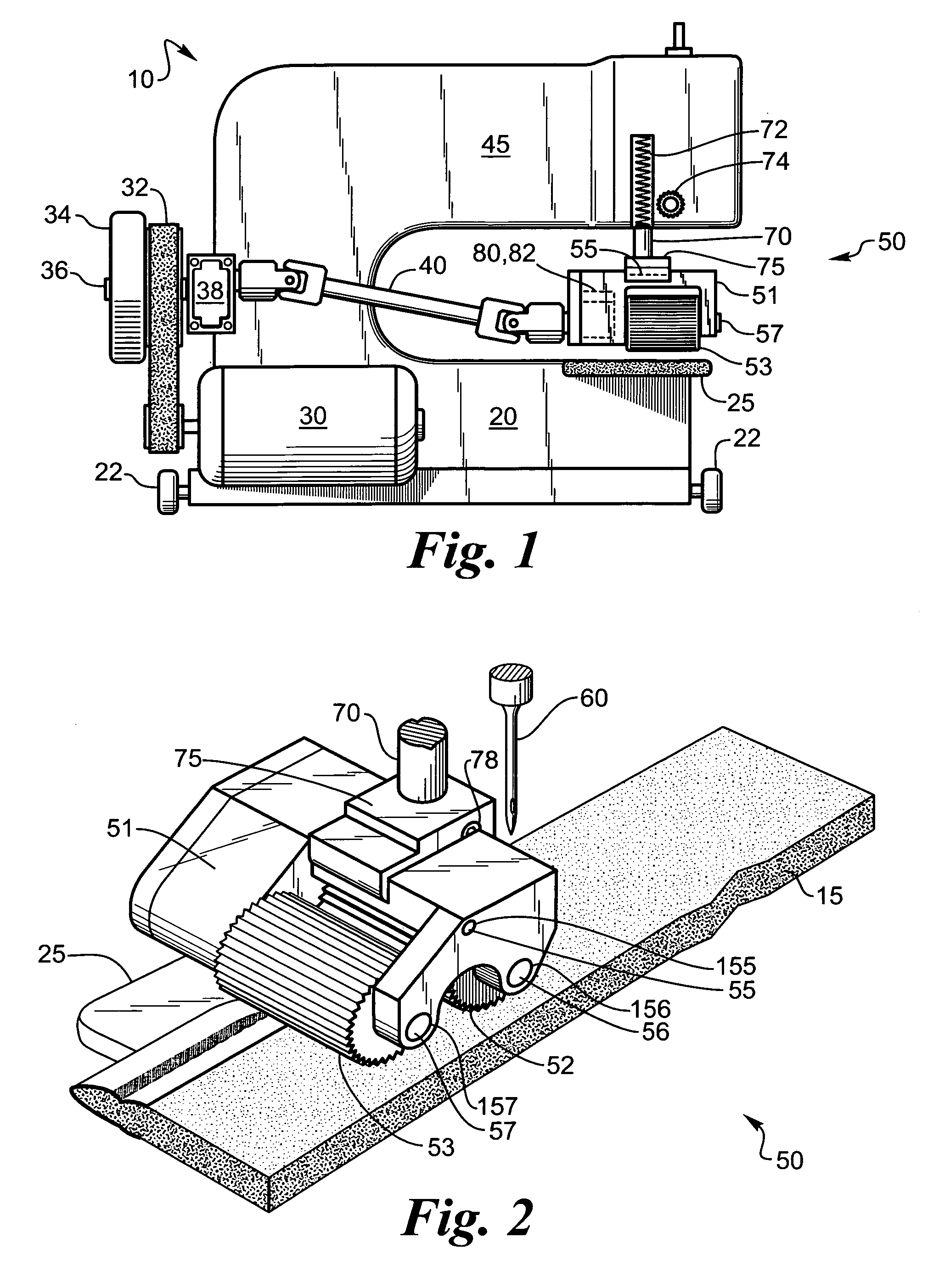

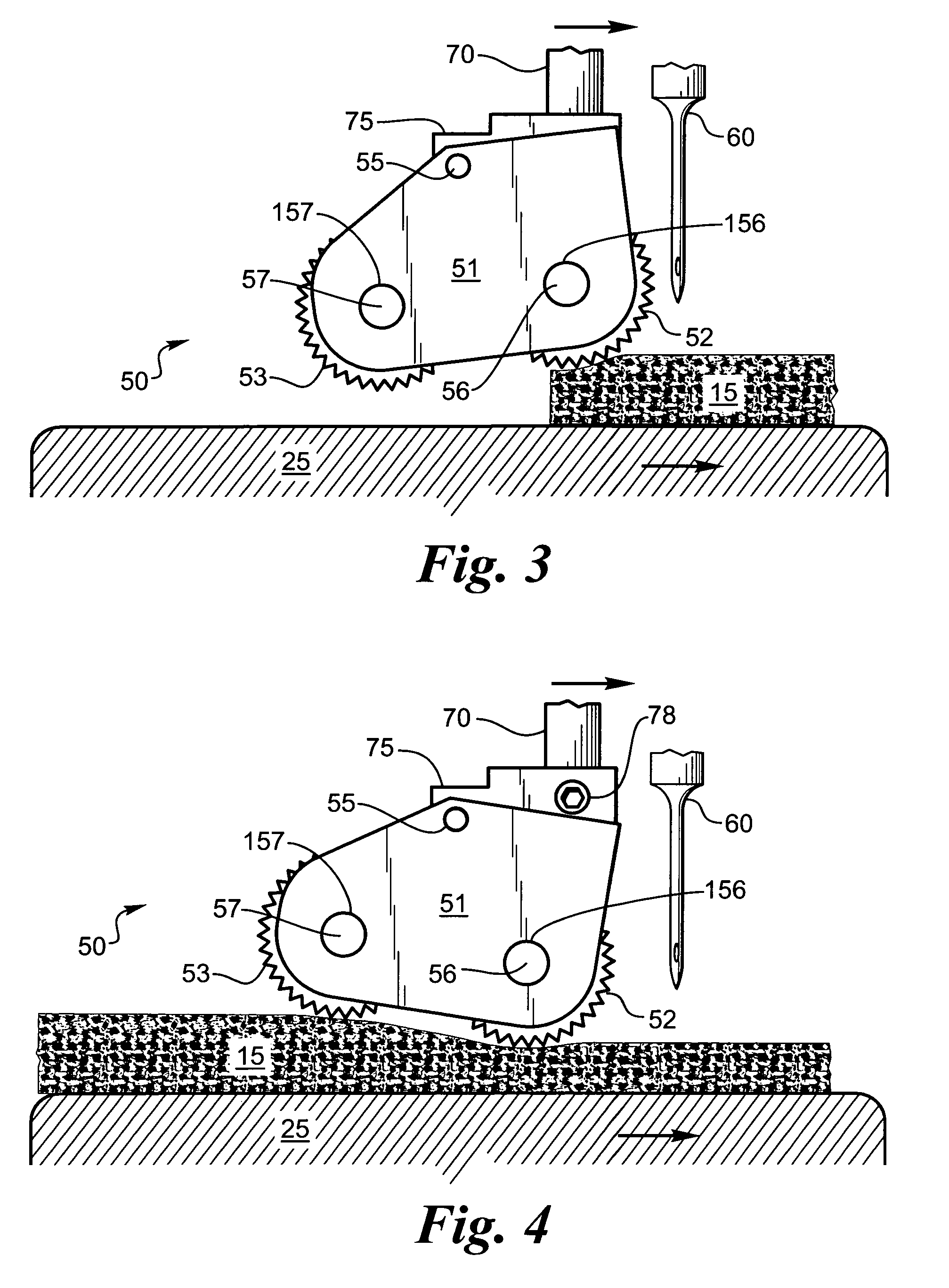

Pivoting feed roller

InactiveUS7080605B1Prevent floatingReduce maintenance costsWork-feeding meansCarpetsSewing machineEngineering

A pivoting twin roller for feeding a material to a sewing machine is disclosed. The twin rollers grip the material with serrated rollers, which rotate at the same rate for uniformly moving the material relative the sewing machine. The twin rollers press down on the material with equal force due to the central pivot point, which improves the feed of the material. The pivoting twin rollers also allow for automatic feeding of material to the sewing machine. A spring loading on the housing for the pivoting twin rollers applies downward pressure on the material being sewn for a sure grip thereon. The downward pressure also insures that the rollers will press down with equal force on uneven height materials since the pivot adjusts the height of the rollers to the height of the materials and thus prevents floating which can lead to jamming of the sewing machine.

Owner:NAT FLOORING EQUIP INC

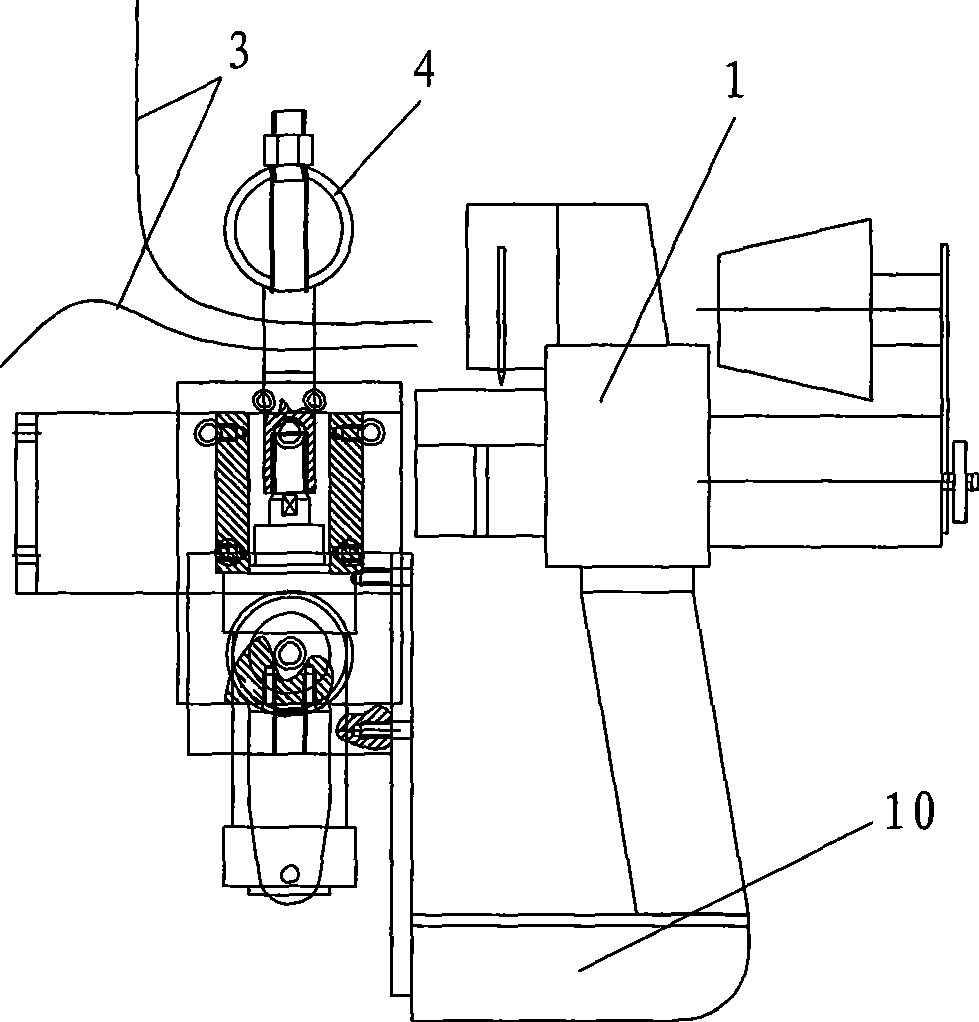

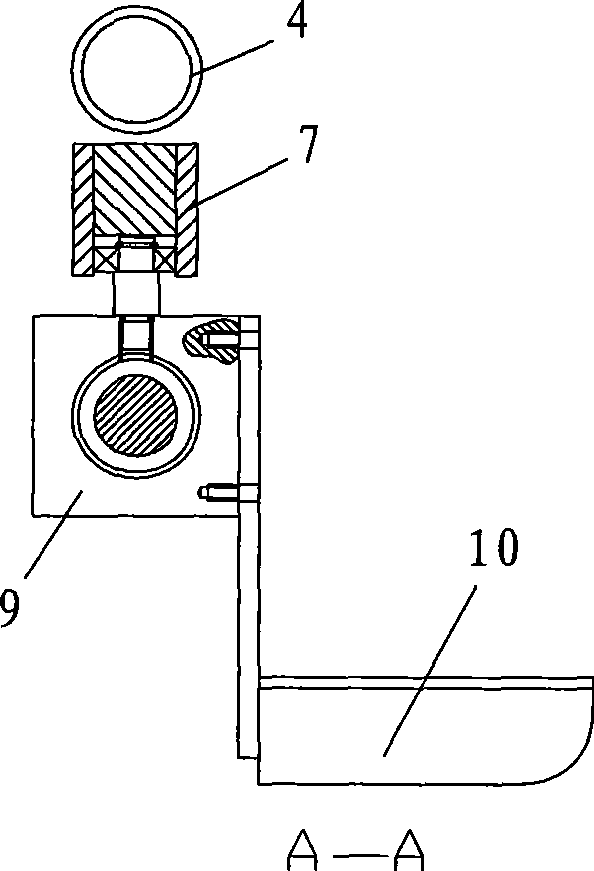

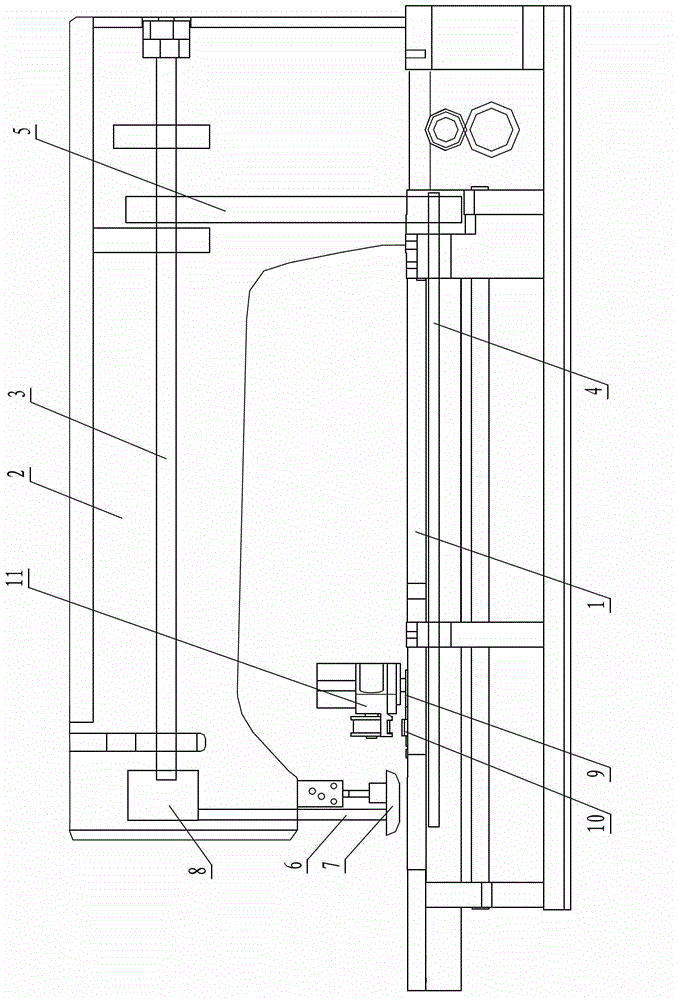

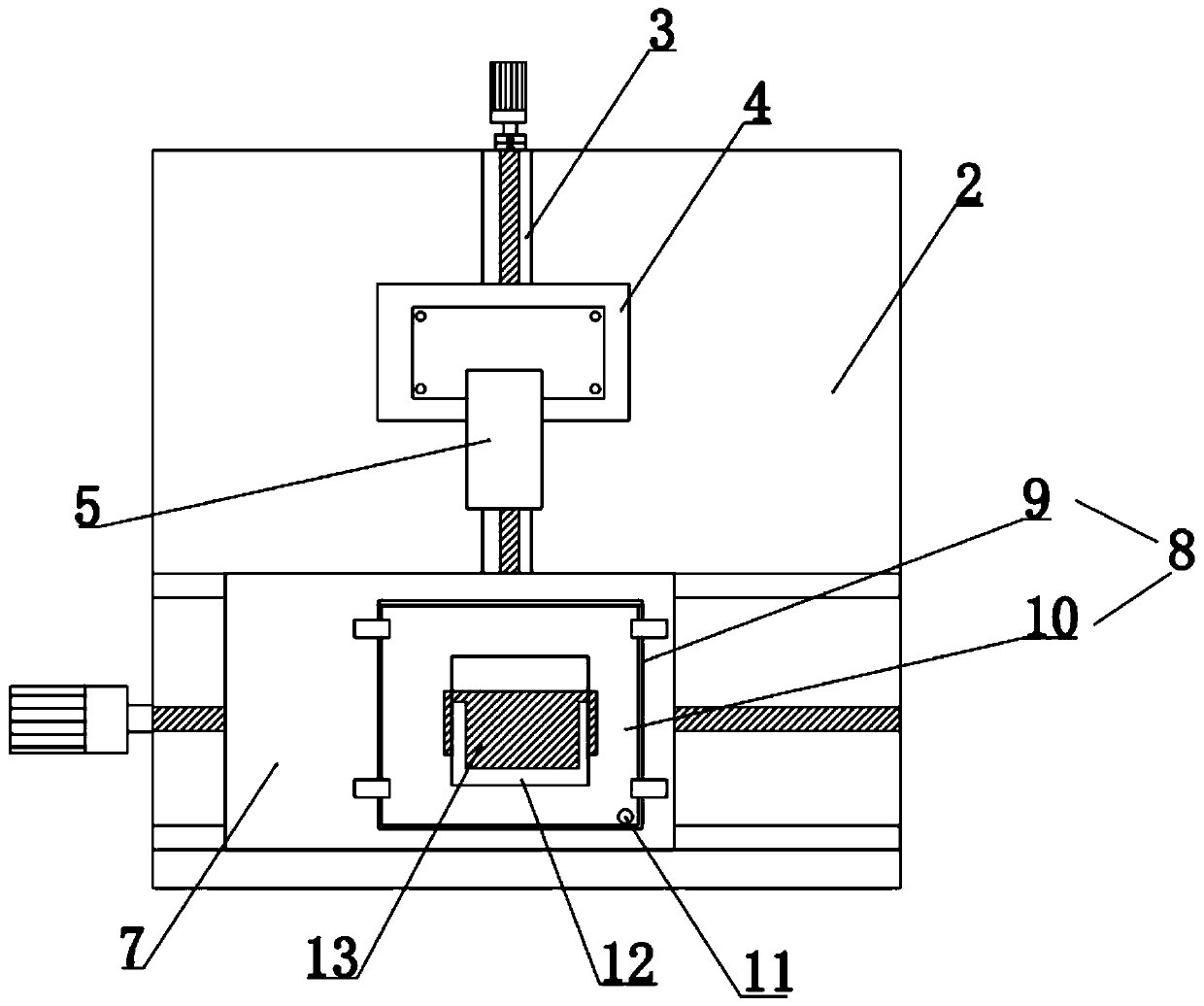

A plurality of cylindrical cutting piece opposite side machine sewing system

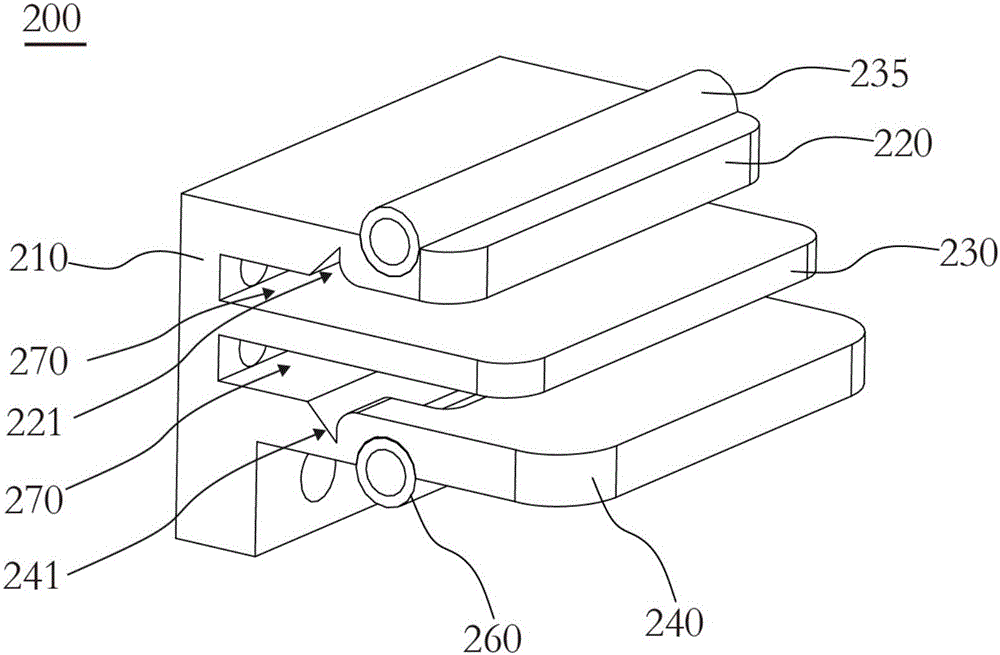

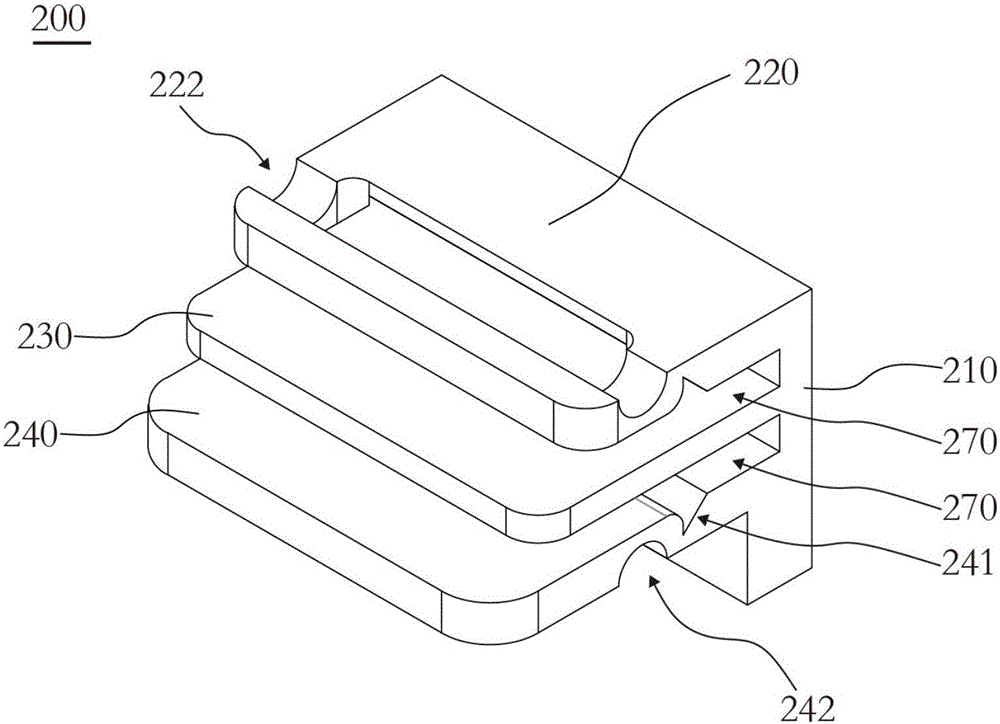

ActiveCN106702610AImprove sewing effectQuality assuranceWork-feeding meansEngineeringMechanical engineering

The invention provides a plurality of cylindrical cutting piece opposite side machine sewing system, which comprises: a machine, an opposite side device, a cylindrical automatic correction mechanism and a machine sewing device. The opposite device locates the edges of a plurality of cutting pieces. The cylindrical automatic correction mechanism comprises a base, a conical limit wheel, a conical driven wheel, a limit plate, a rotating shaft, a rotating drive part, and a moving drive part; the moving drive part is connected with the base to driving the base moving; the cylindrical automatic correction mechanism locates the cylindrical cutting piece. The machine sewing device is used to sew the cutting piece from the two material channels, the cylindrical cutting piece from the conical limit wheel and the body cutting piece from the working panel of the machine. The a plurality of cylindrical cutting piece opposite side machine sewing system saves time and labor and has high product efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

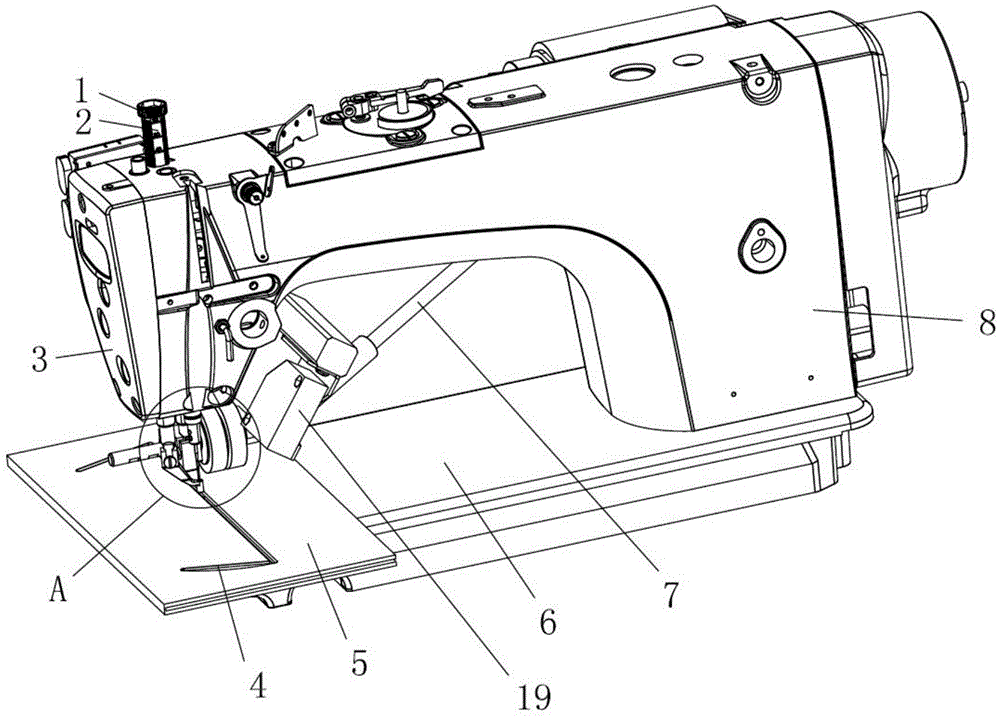

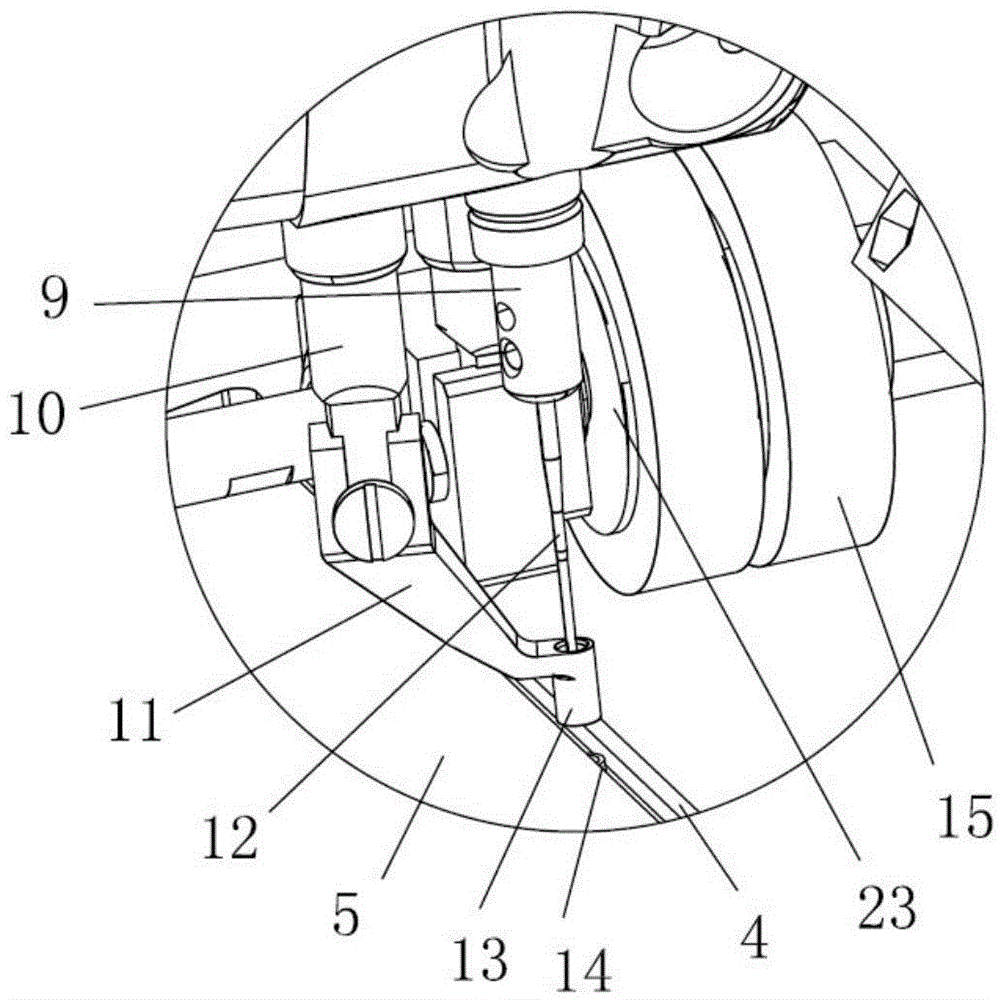

Method and device for shortening flat sewing machine trimmed thread

ActiveCN103088563AOutstanding and Beneficial Technical EffectsImprove sewing effectNeedle severing devicesNeedle barsEngineeringSlide plate

The invention belongs to the technical field of sewing machines and particularly relates to a method and a device for shortening a flat sewing machine trimmed thread that the needle pitch is adjusted close to zero when a thread is trimmed. The structure of the device is that an air cylinder is fixed on an air cylinder mounting plate, the outer end of an air cylinder piston rod and one end of a connecting rod are in hinge connection, the other end of the connecting rod and one side of a sliding plate are in hinge connection, the sliding plate is fixedly connected on a feeding swing plate seat, one end of a feeding-pouring connecting rod and a feeding regulator are in hinge connection, the other end of the feeding-pouring connecting rod and one side of the feeding swing plate seat are in hinge connection, the air cylinder piston rod drives the connecting rod in a retracting mode, the connecting rod pulls the sliding plate, the sliding plate is fixed on the feeding swing plate seat, the feeding regulator is driven through the feeding-pouring connecting rod, the needle pitch is adjusted between 0+1mm and 0-1mm, two thread ends remained after sewing is finished are nearly in the same needle hole and form a similar interlocking shape, neither one of the two thread ends is prone to falling off when any thread is pulled, and thus firmness and attractiveness are achieved.

Owner:JACK SEWING MASCH CO LTD

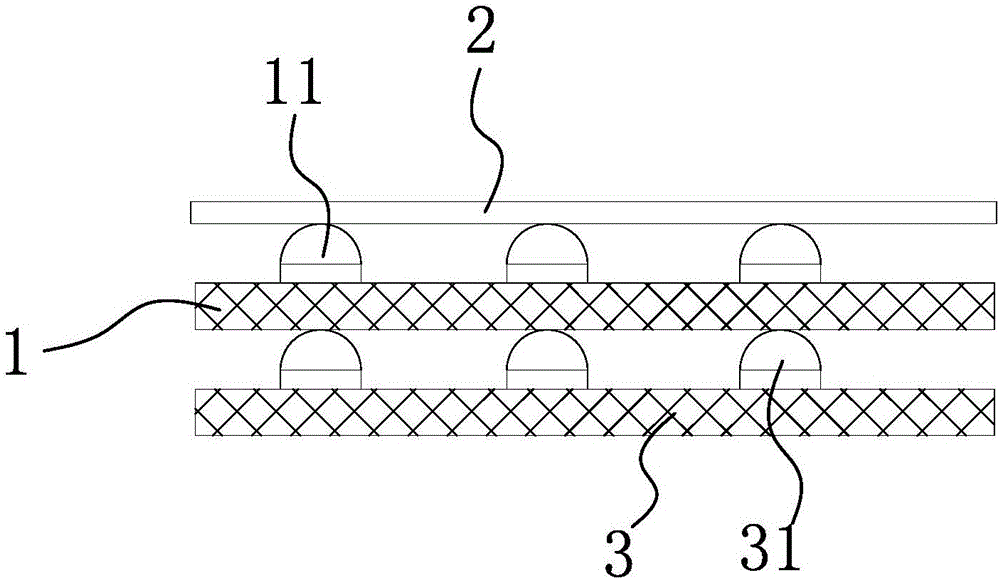

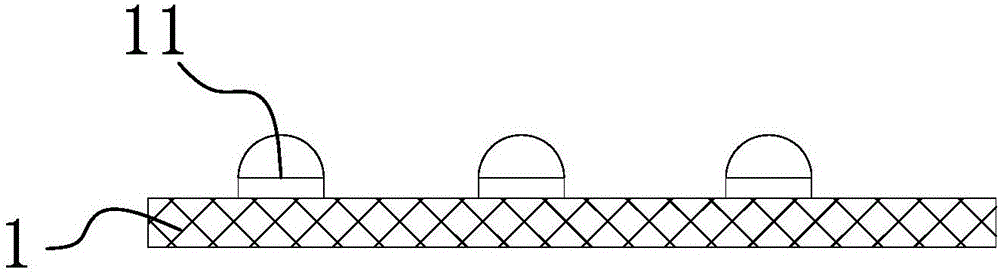

Three-layer knitted composite fabric and production technology thereof

ActiveCN106183119AImprove mechanical propertiesThick textureLaminationLamination apparatusEngineeringCoating

The invention belongs to the technical field of clothing materials, particularly relates to three-layer knitted composite fabric and a production technology thereof, and solves the technical problems of poor wearing comfort, poor shape maintenance performance, small application range and the like in the prior art. The three-layer knitted composite fabric comprises wrap-weft insertion warp knitted fabric, outer fabric and inner fabric, wherein a first double-dot coating is arranged on one surface of the wrap-weft insertion warp knitted fabric; the outer fabric is connected with one surface of the wrap-weft insertion warp knitted fabric through the first double-dot coating; a second double-dot coating is arranged on one surface of the inner fabric, and the other surface of the wrap-weft insertion warp knitted fabric is connected with the inner fabric through the second double-dot coating. The production technology of the three-layer knitted composite fabric comprises steps as follows: A, preparation of materials; B, compositing. The three-layer knitted composite fabric and the production technology thereof have the advantages that the technology is simple, good balance between the wearing comfort and the shape maintenance performance can be kept, and the application range can be enlarged.

Owner:CPL NEW MATERIAL TECH CO LTD

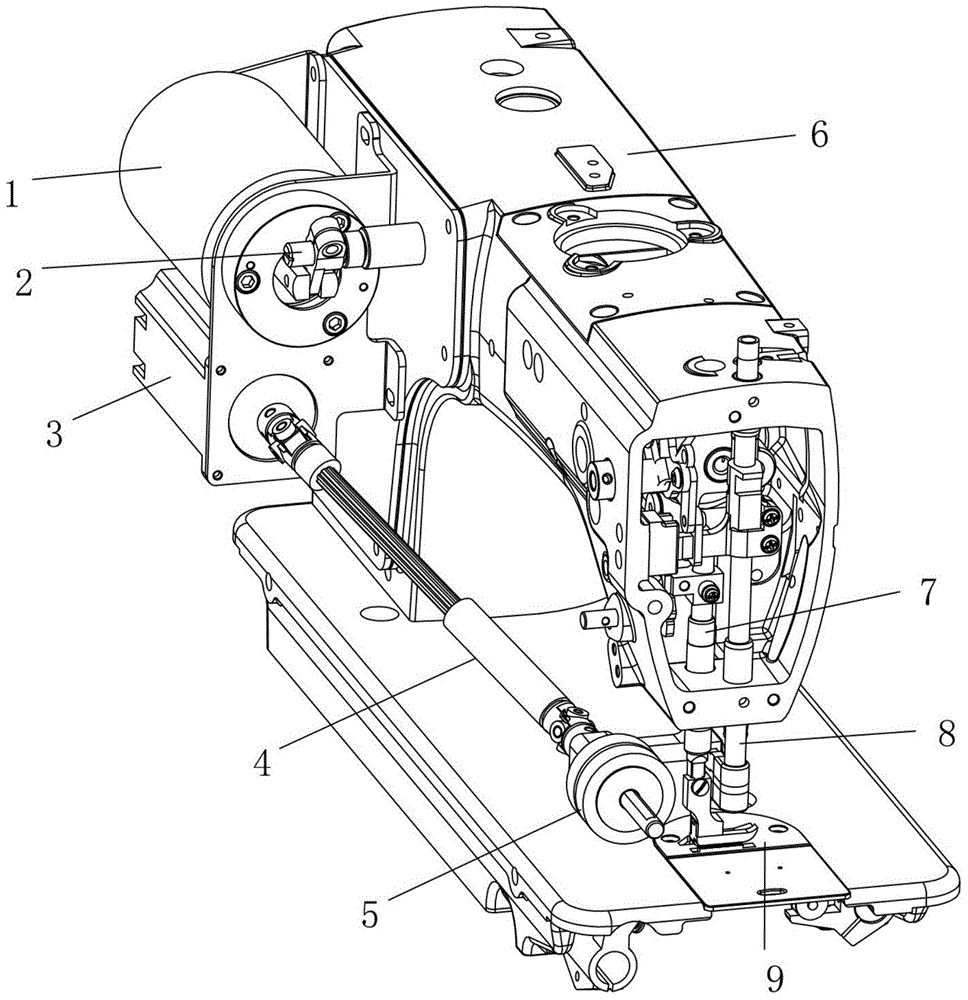

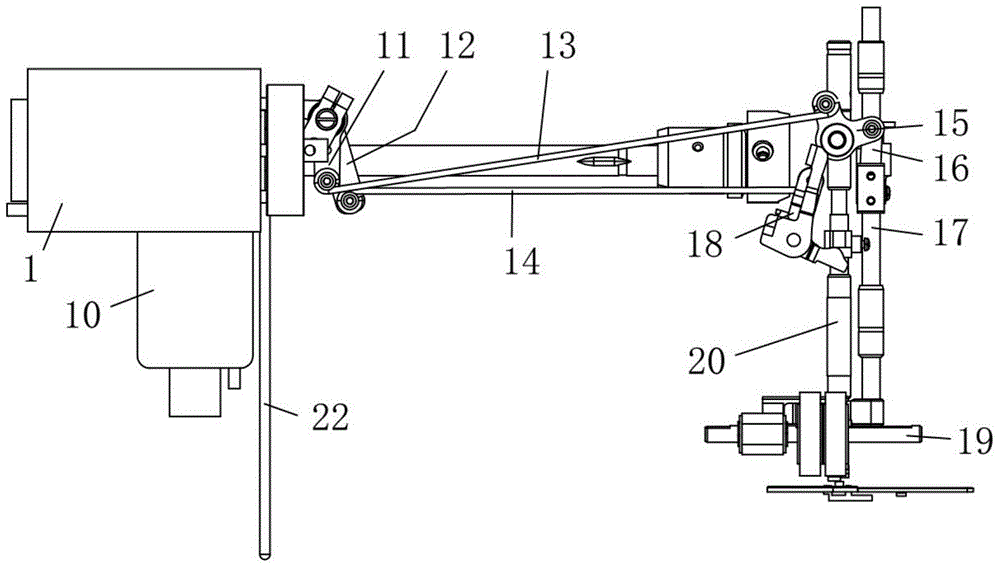

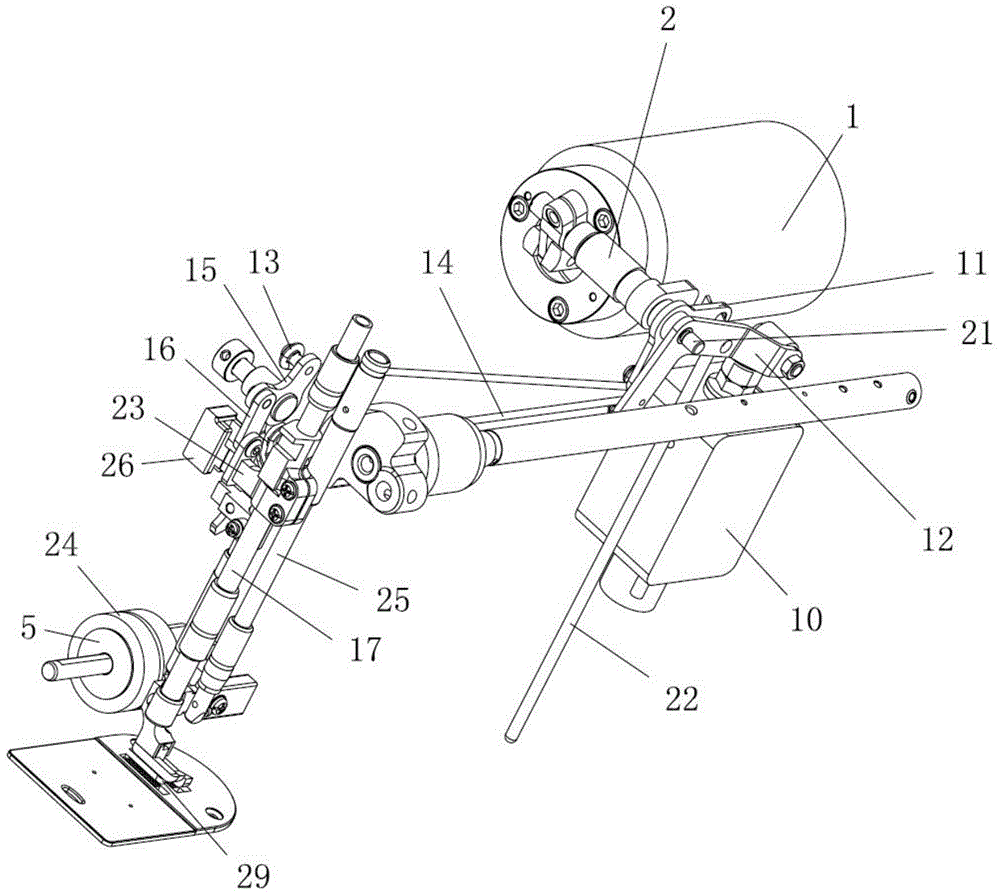

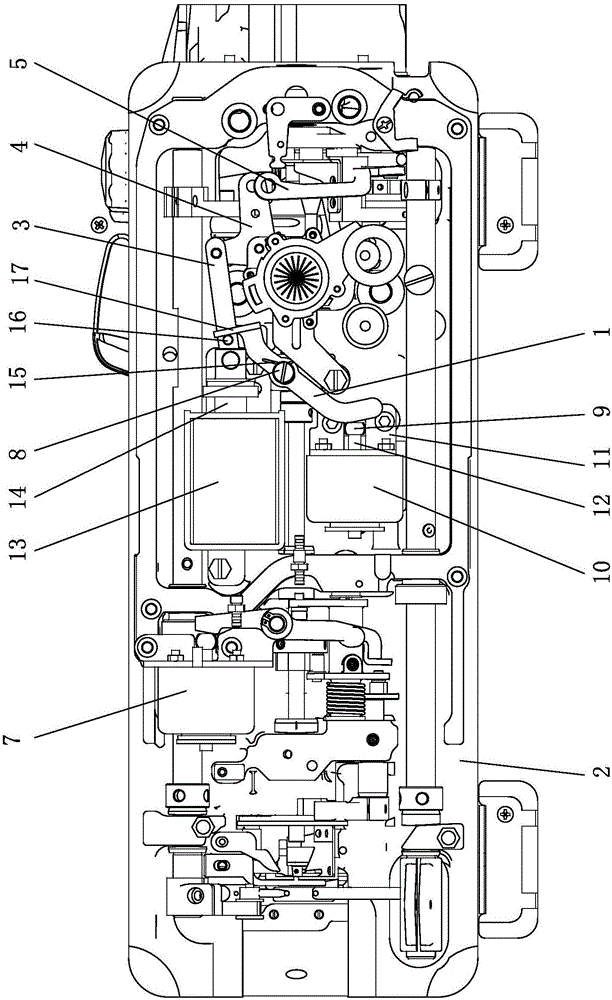

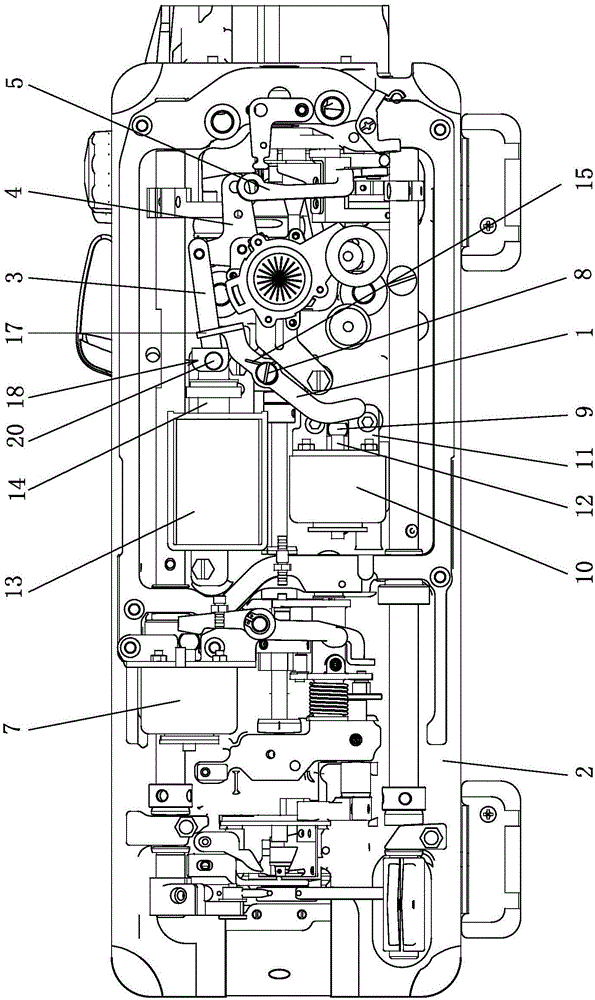

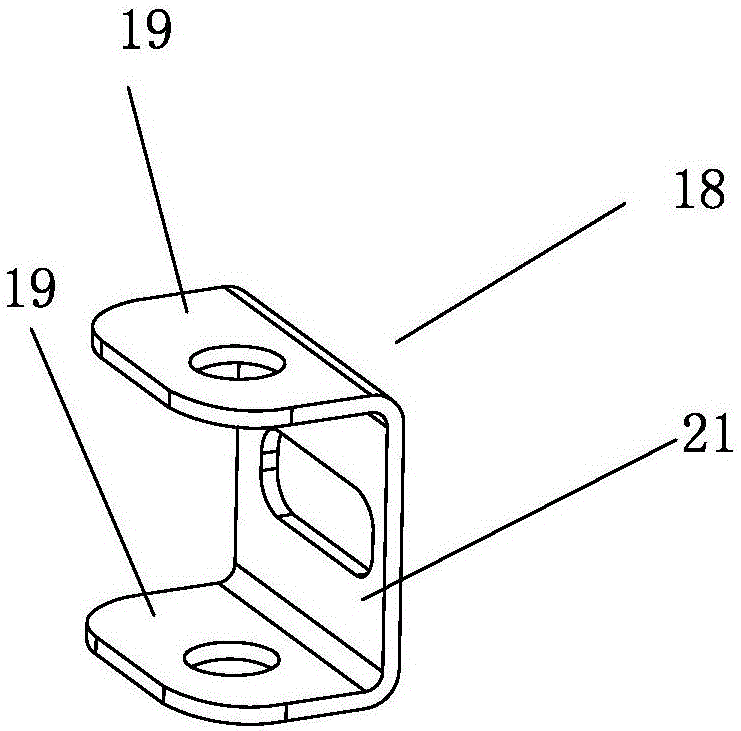

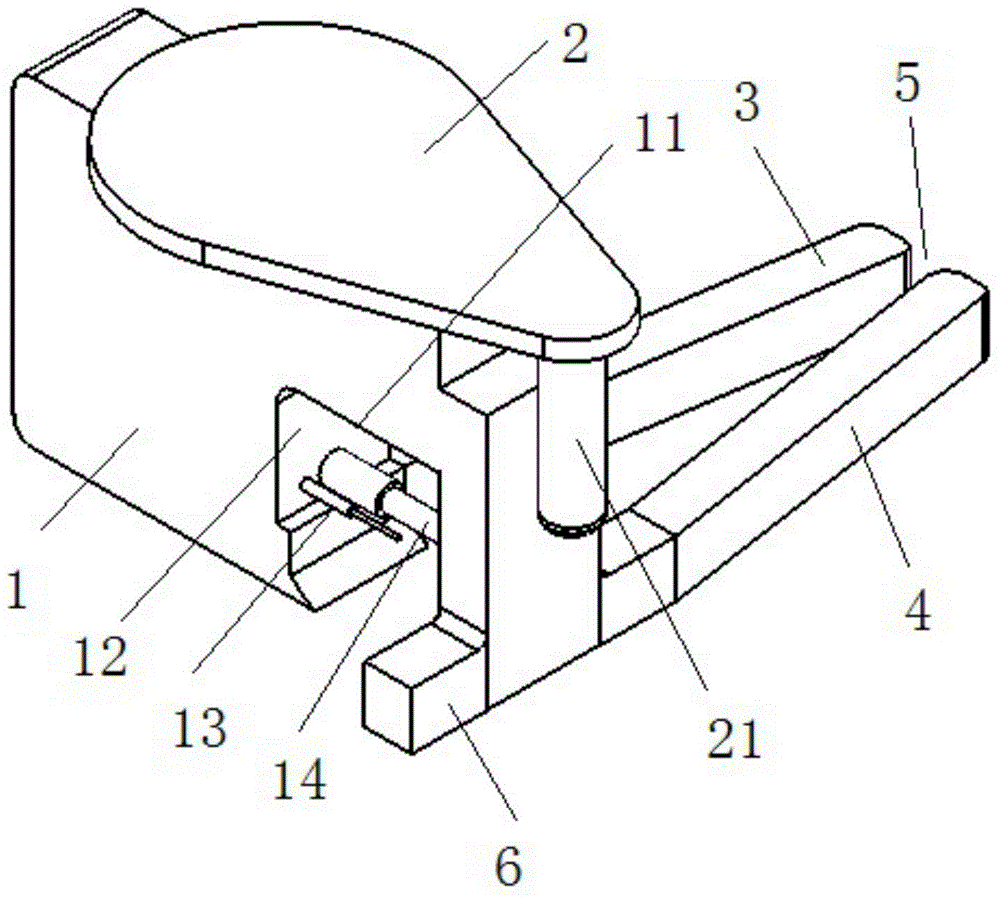

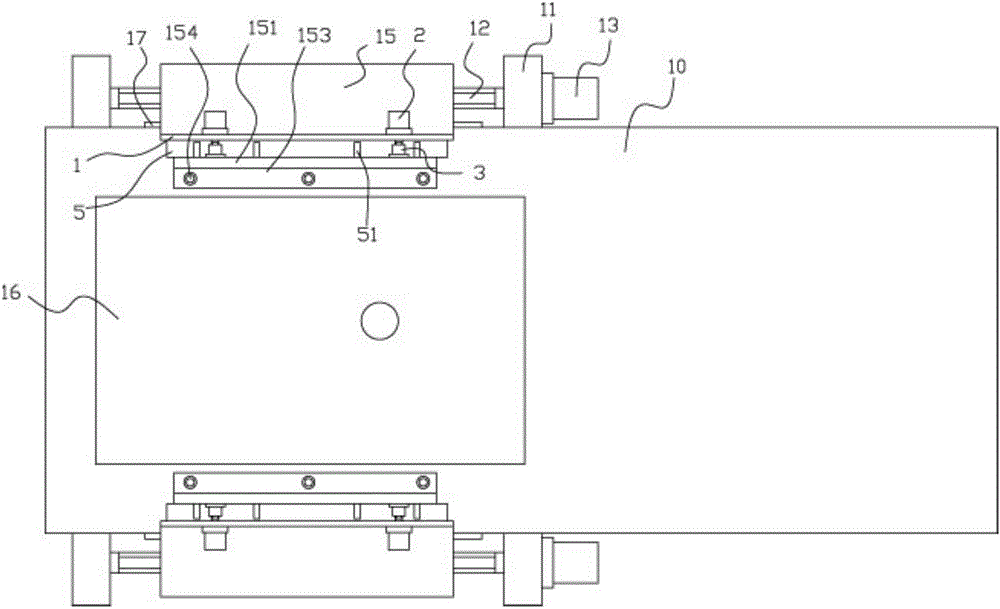

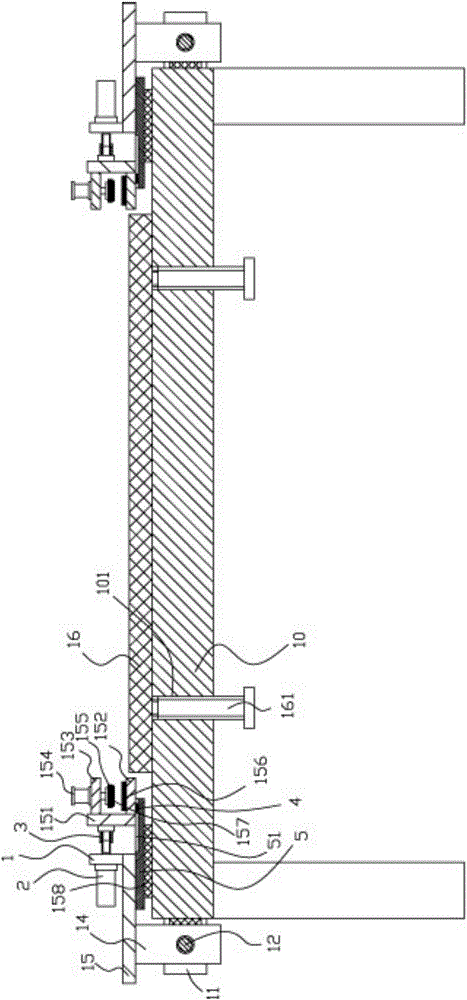

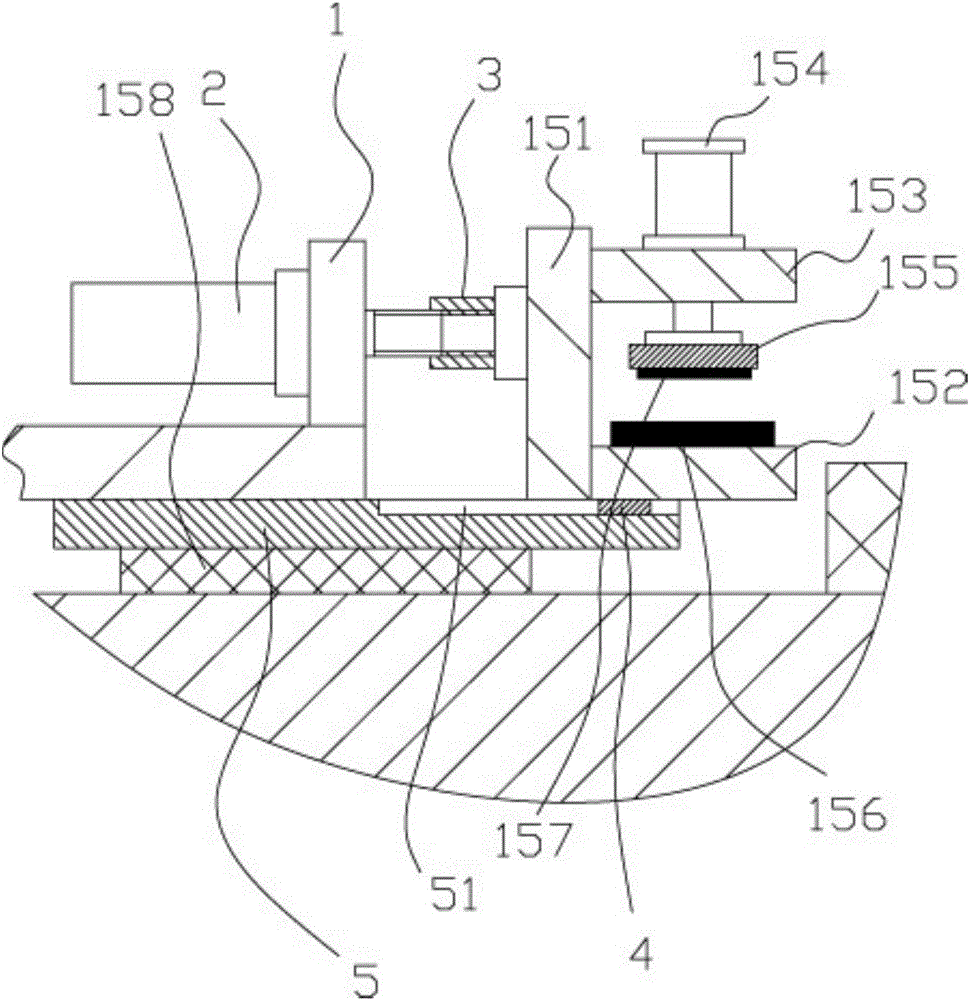

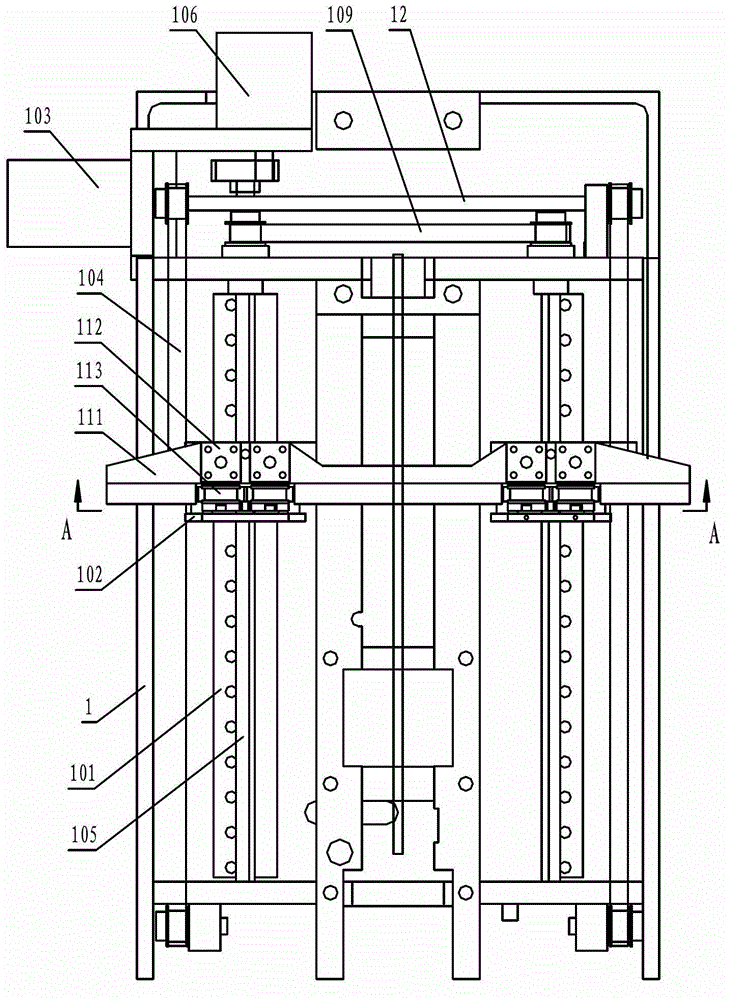

Sewing equipment head

ActiveCN104562453APrecise positioningGood sewing effectWork-feeding meansEngineeringMechanical engineering

Owner:吴江市宝鑫机械有限公司

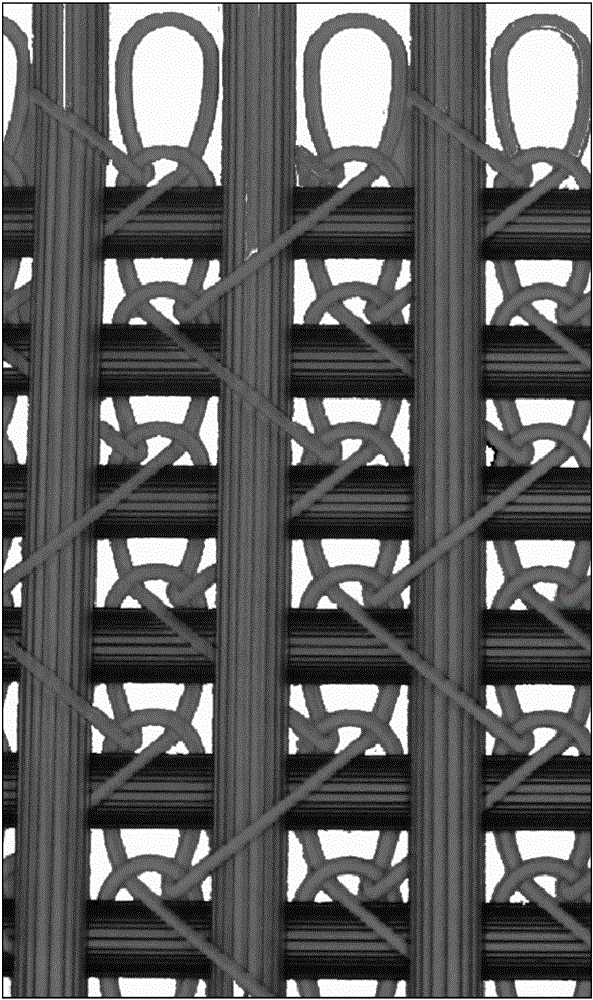

Woven fabric and process for producing same

ActiveCN104641029AReduce loose edgeExcellent uniform coatingLoomsPedestrian/occupant safety arrangementWoven fabricSynthetic fiber

Woven fabric most suitable as base fabric for airbags is provided in which selvage waving has been reduced by inhibiting the weaving sheds of the selvage edge parts from receding during high-density weaving and which is excellent in terms of smooth processability and even coatability in the steps of scouring, setting, and coating and is excellent also in terms of cuttability and sewability. Also provided is a process for producing the woven fabric. The woven fabric employs synthetic-fiber multifilament yarns as the ground yarns. This woven fabric includes in the selvage weave parts of the edge parts: a leno yarn constituted of a filament having a fineness of 33 dtex or less; an additional yarn constituted of a filament having a fineness of 33 dtex or less; and a selvage-tightening yarn constituted of a multifilament yarn having a total fineness that is 80% or more of the total fineness of the ground yarns. In a process for producing the woven fabric, filaments with a fineness of 33 dtex or less are used as a leno yarn and an additional yarn for forming selvage weave parts at edges parts of woven fabric to conduct weaving while a multifilament yarn having a total fineness that is 80% or more of the total fineness of the ground yarns is being inserted as a selvage-tightening yarn into each selvage weave part.

Owner:TORAY IND INC

Novel intelligent template sewing machine and automatic induction sewing method

ActiveCN104911826AAvoid wrinklesAvoid tearingProgramme-controlled sewing machinesPressersMotor driveControl signal

The invention belongs to the technical field of sewing machines and particularly relates to a novel template sewing machine. The novel template sewing machine comprises a machine shell, the machine shell is provided with a cloth drag mechanism, a template photoelectric sensor and a controller, a needle plate of the template sewing machine is provided with a lower guide sleeve, a sewing needle penetrates through the lower guide sleeve, a thread is hooked by the lower guide sleeve, and the lower guide sleeve can be embedded in a guide groove in a template to be adapted. The novel template sewing machine further comprises an induction device. The induction device is used for sending out a control signal to the controller when it is detected that the sewing needle penetrates out of cloth upwards, and the controller controls a stepping motor of the cloth drag mechanism to be started according to the signal; the induction device sends out a control signal to the controller when the sewing needle penetrates into the cloth downwards, the controller controls the stepping motor of the cloth drag mechanism to be suspended according to the signal, and a motor shaft of the stepping motor drives a drag wheel to rotate through a universal coupling. When the sewing needle penetrates into the cloth, the cloth drag mechanism can be controlled by the controller to be suspended, so that cloth tear caused by non-correspondence of the cloth drag mechanism and the sewing needle is avoided.

Owner:佛山市朗宸机械有限公司

Formula and process of organosilicone water repellent finish

InactiveCN104532591AExcellent water repellencyWashable Water RepellencyFibre treatmentEmulsionHydrogen

The invention discloses a formula and a process of organosilicone water repellent finish. The formula is characterized in that the padding liquid raw material composition is as follows: 8-12g / L of zinc acetate, 5.5-5.9g / L of zirconium oxychloride, 33-38g / L of methyl hydrogen-containing silane emulsion, 20-23g / L of epoxidized aminate cross-linker, 72-75g / L of hydroxyl silane emulsion and 5-6g / L of monoethanolamine. A fabric has a good and washable water-repellent performance, and moreover, the tearing strength, hand feeling and sewing performance of the fabric can be obviously improved.

Owner:赵立军

Mobile cloth-jointing sewing machine

The invention relates to a movable cloth-connecting sewing machine which is characterized by comprising a cloth clamp with a pressure-bearing rod and an upper pressure rod, wherein the pressure-bearing rod and the upper pressure rod are arranged in parallel on a production line in the width direction of cloth to be connected and can correspondingly move in the radial direction to form two position states, i.e., the upper pressure rod presses and abuts on the pressure-bearing rod to be in a cloth-clamping state, or the upper pressure rod and the pressure-bearing rod are separated to be in a cloth-loosening state; a linear rail parallel to the pressure-bearing rod is arranged, a movable block capable of sliding along with the linear rail is matched and arranged on the linear rail, and a sewing machine head facing the cloth clamp is fixedly arranged on the movable block by a cantilever-type machine base. The invention can satisfy the requirements of the synthetic leather industry to finish splicing two fabric piece goods.

Owner:ANHUI ANLI MATERIAL TECH

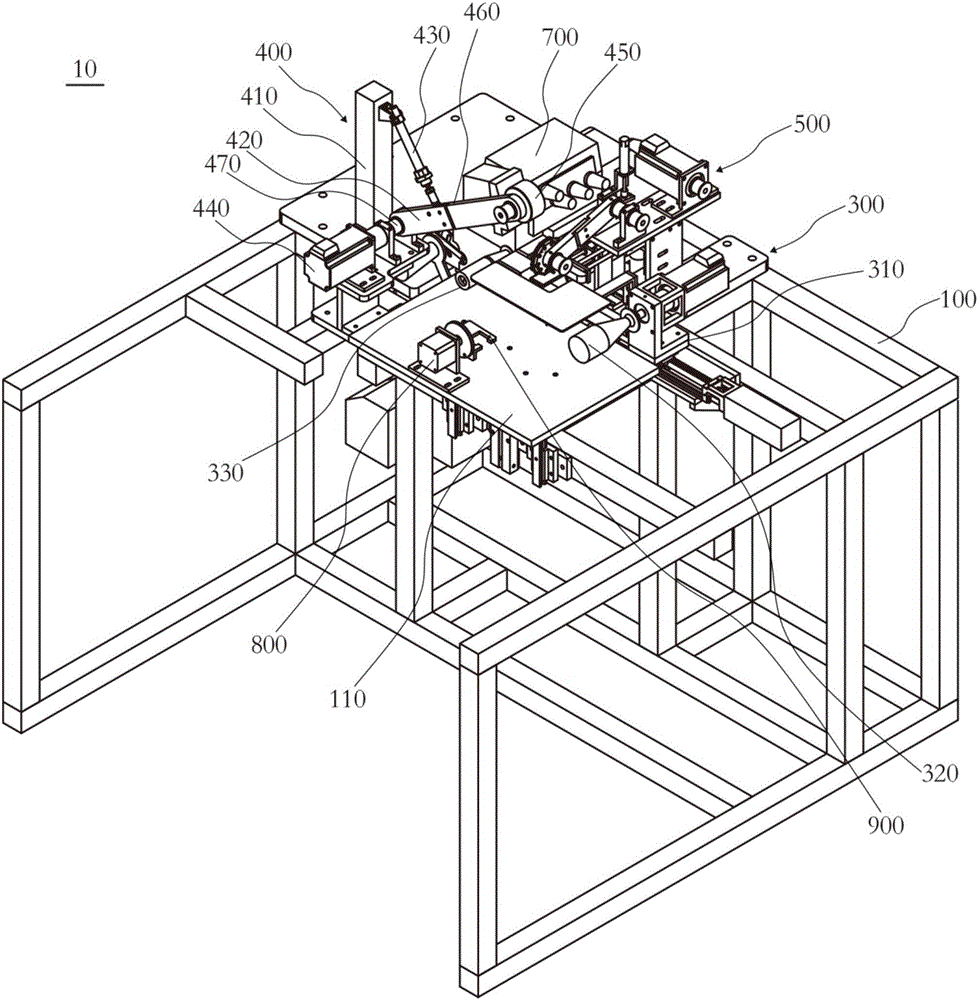

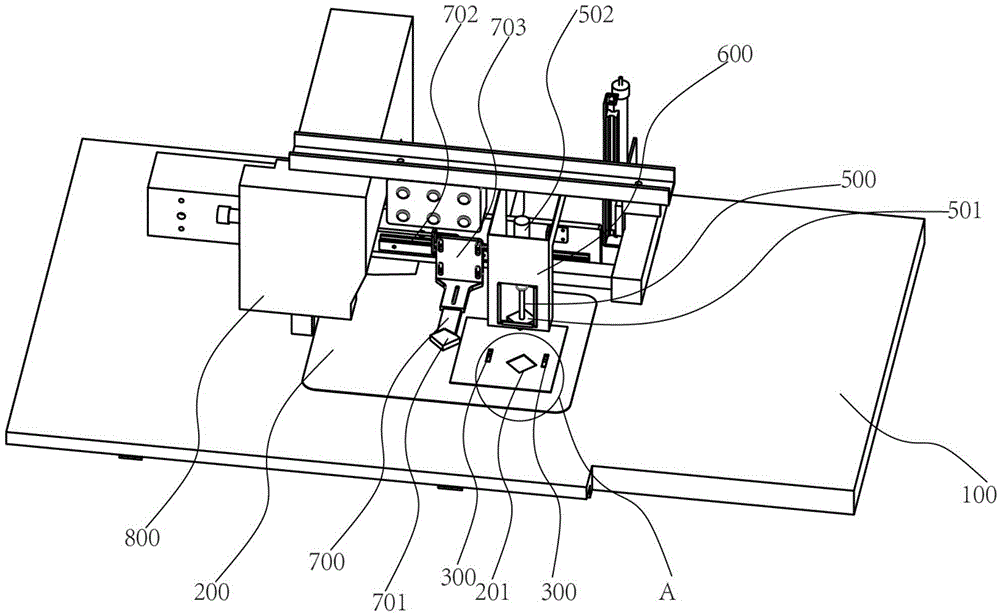

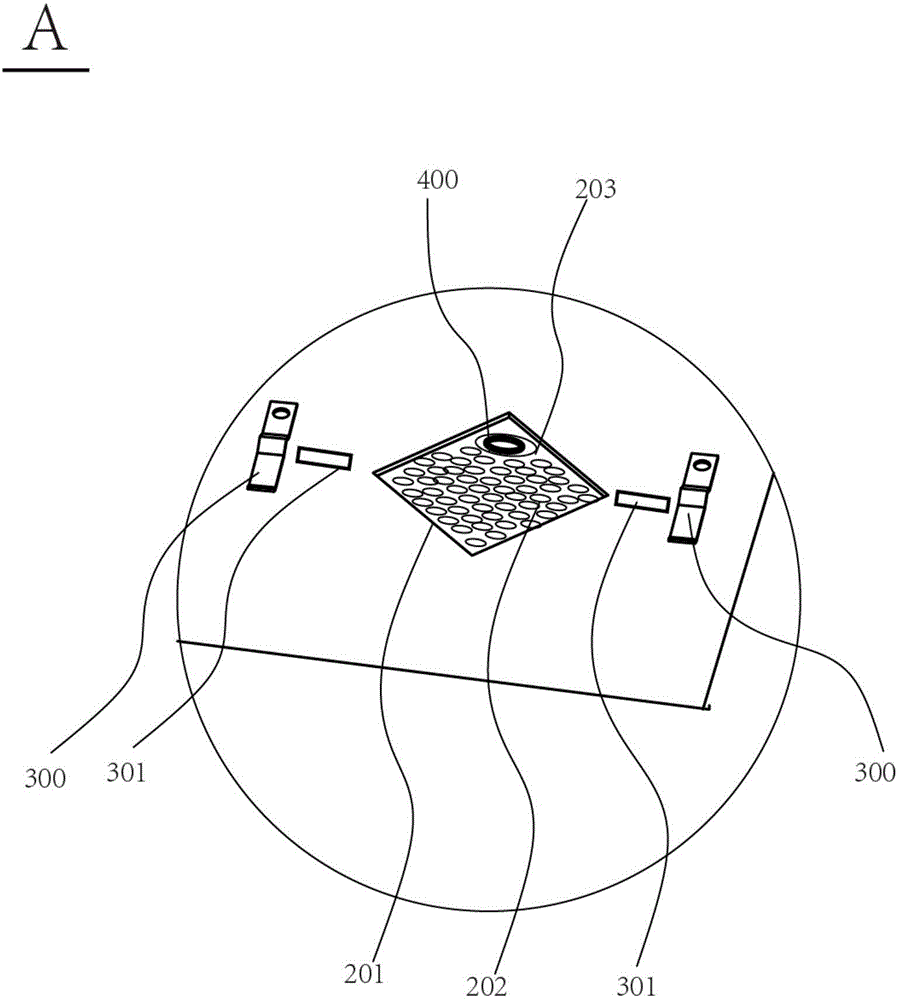

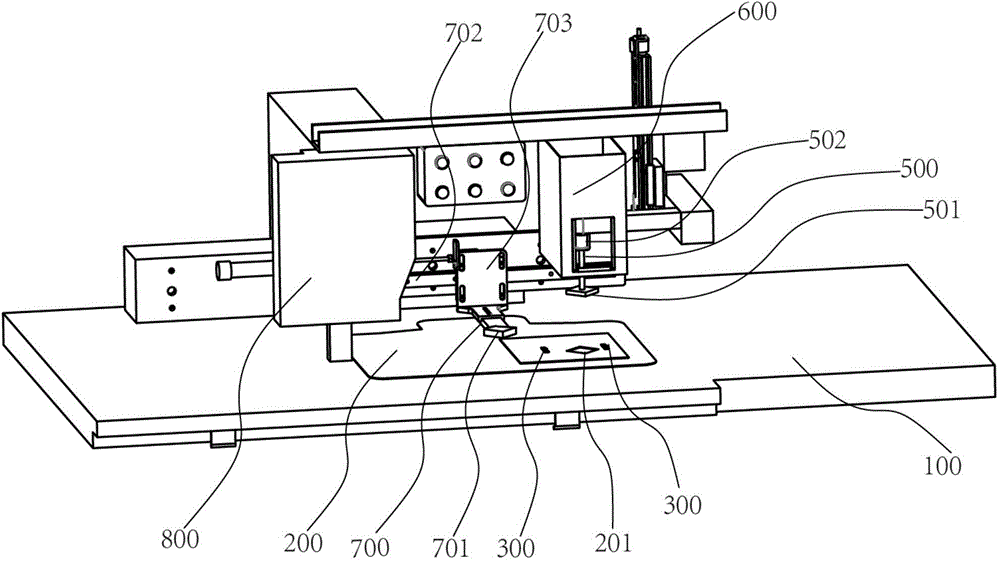

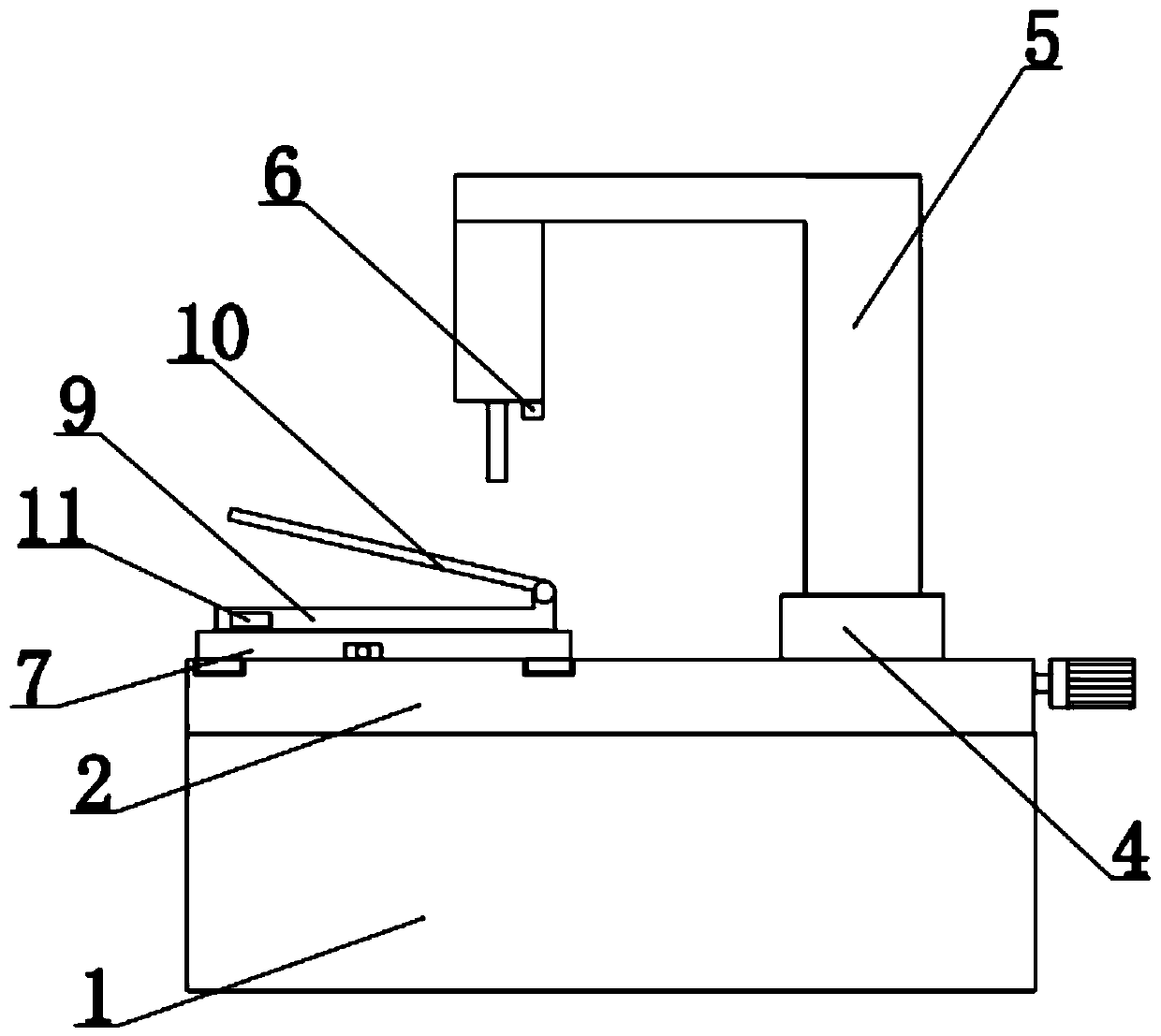

Multifunctional pressing and stitching system and application method thereof

ActiveCN104674468AQuality assuranceFully automatedWork-feeding meansSewing-machine control devicesEngineeringFace sheet

The invention discloses a multifunctional pressing and stitching system and an application method thereof. The multifunctional pressing and stitching system comprises a machine platform, a control device, a movable panel, a pressing device, a feeding device and a stitching device, wherein the movable panel is provided with a positioning groove and a plurality of air suction holes are formed in the positioning groove; the pressing device is provided with an ironing pressing sheet and an ironing driving part for driving the ironing pressing sheet to move; the ironing pressing sheet is embedded into and matched with the positioning groove; the movable panel, the pressing device, the feeding device and the stitching device are connected with the machine platform; the ironing driving part, the feeding device and the stitching device are electrically connected with the control device. According to the multifunctional pressing and stitching system, working procedures are saved and manpower and time are saved, the stitching effect is good and the quality of clothes is guaranteed.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

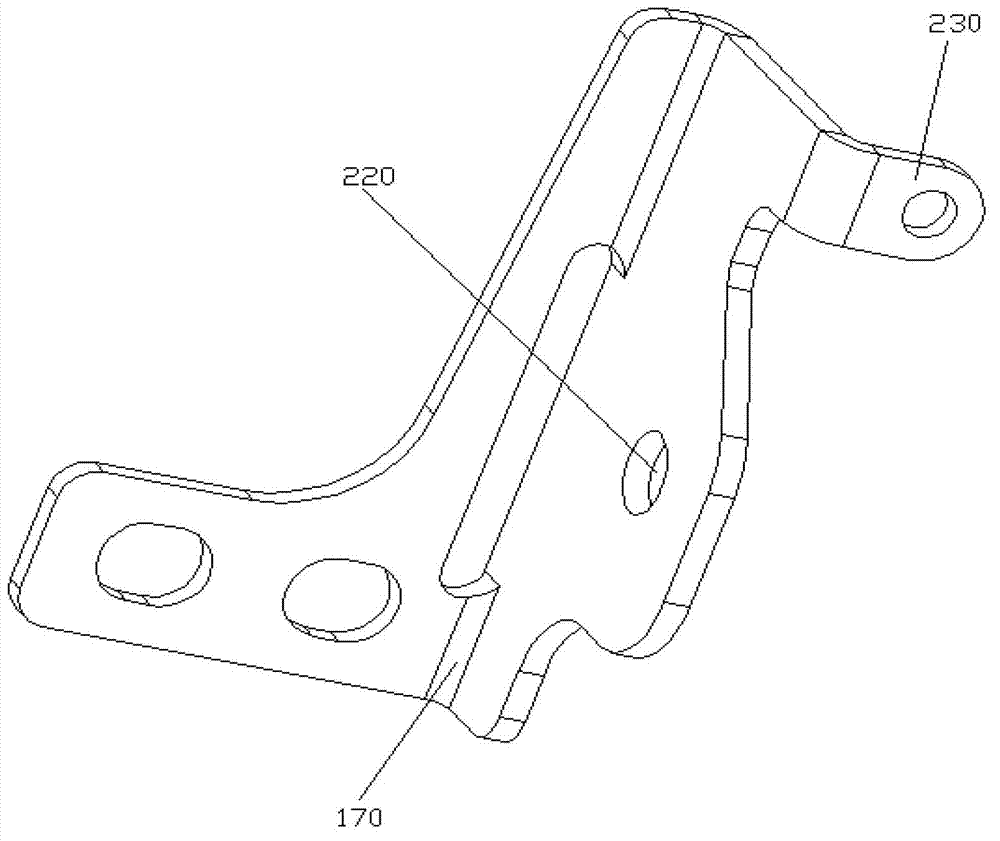

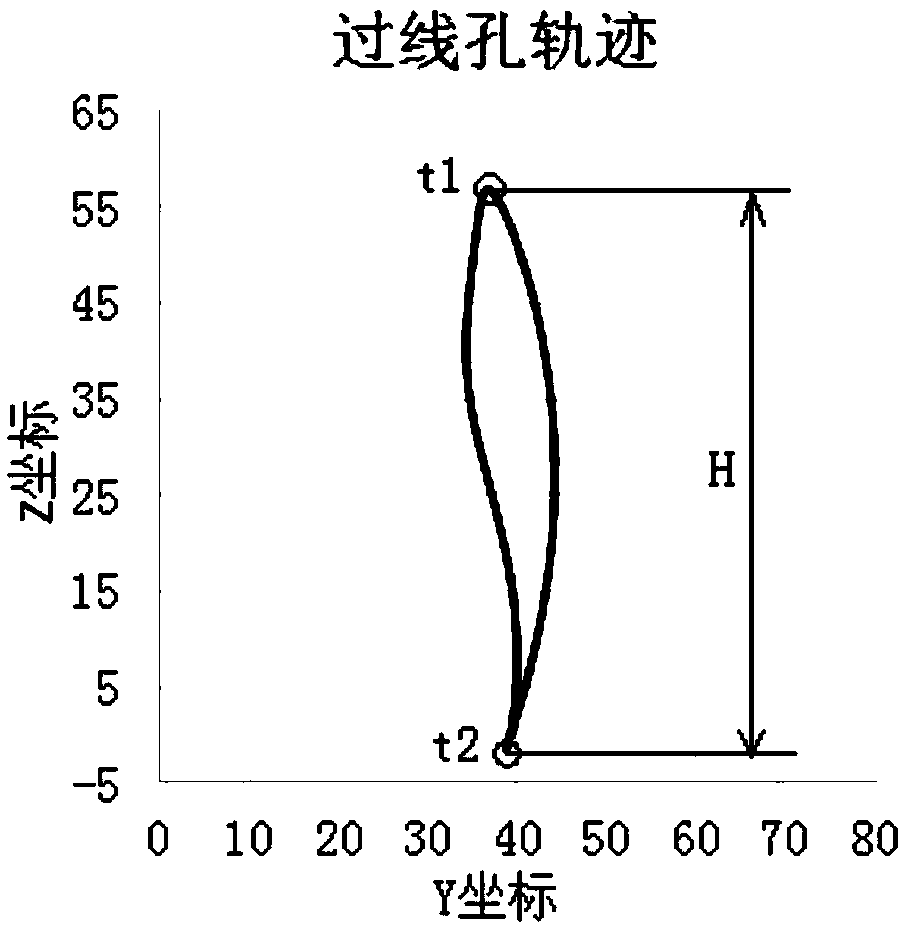

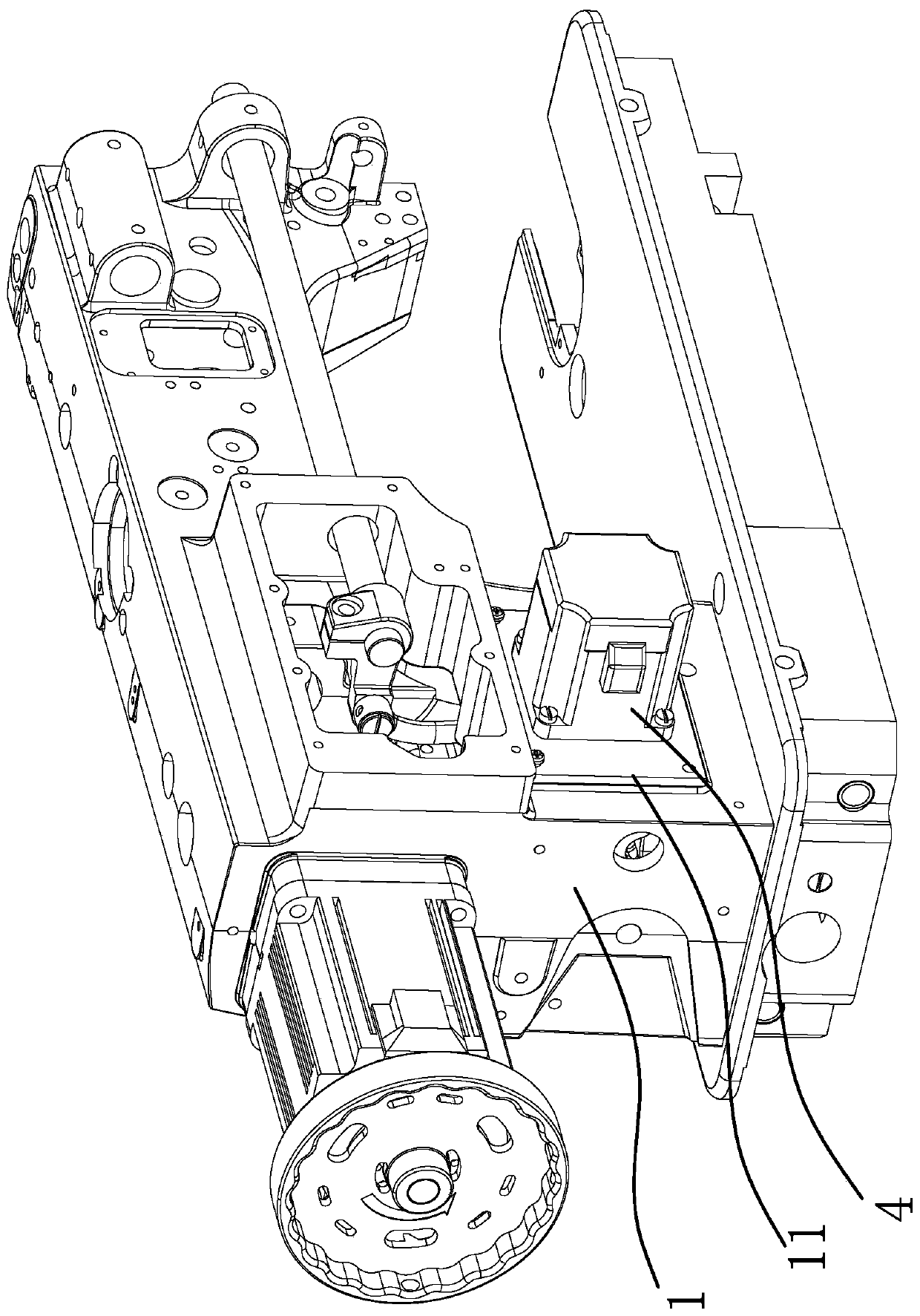

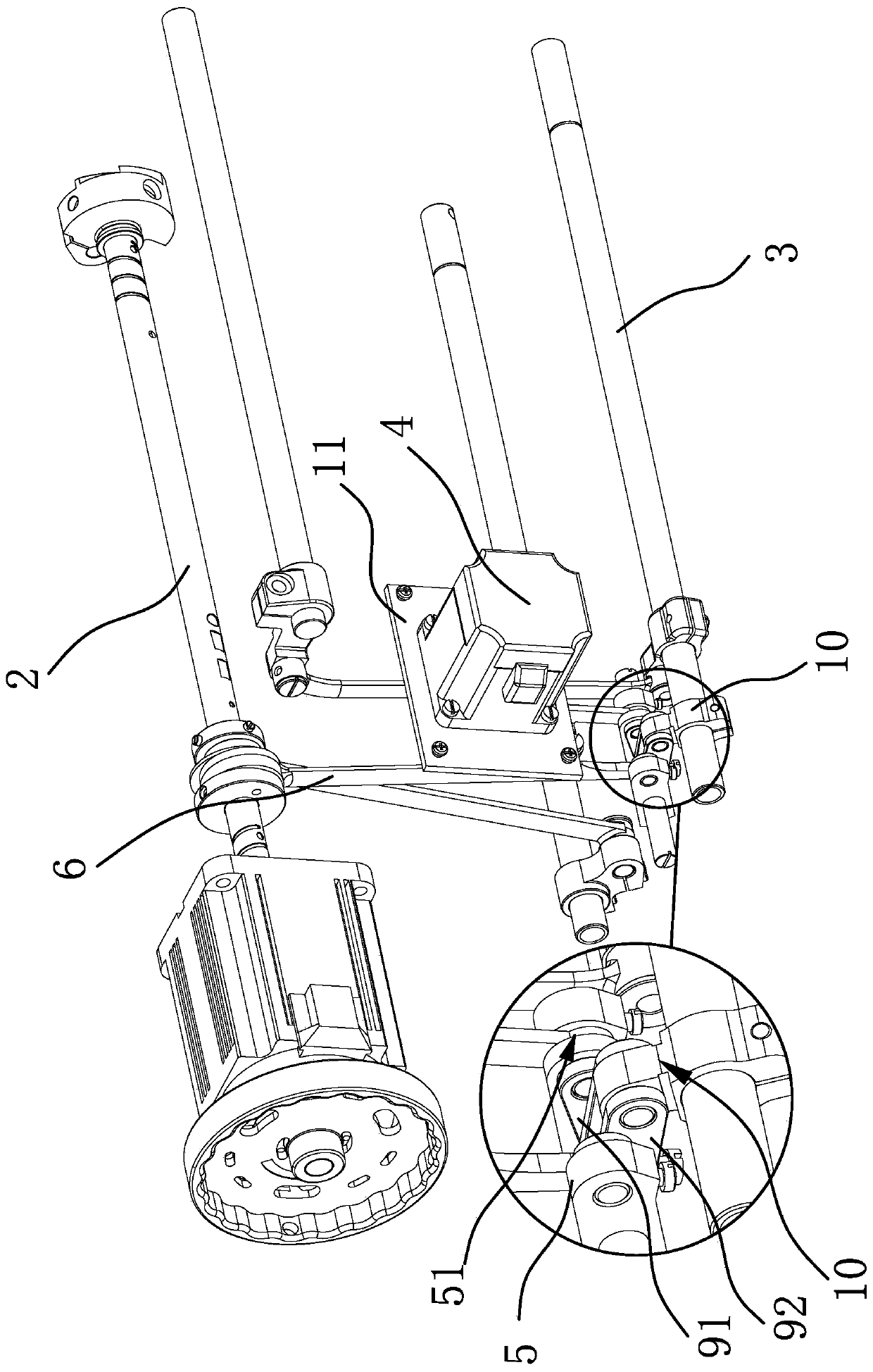

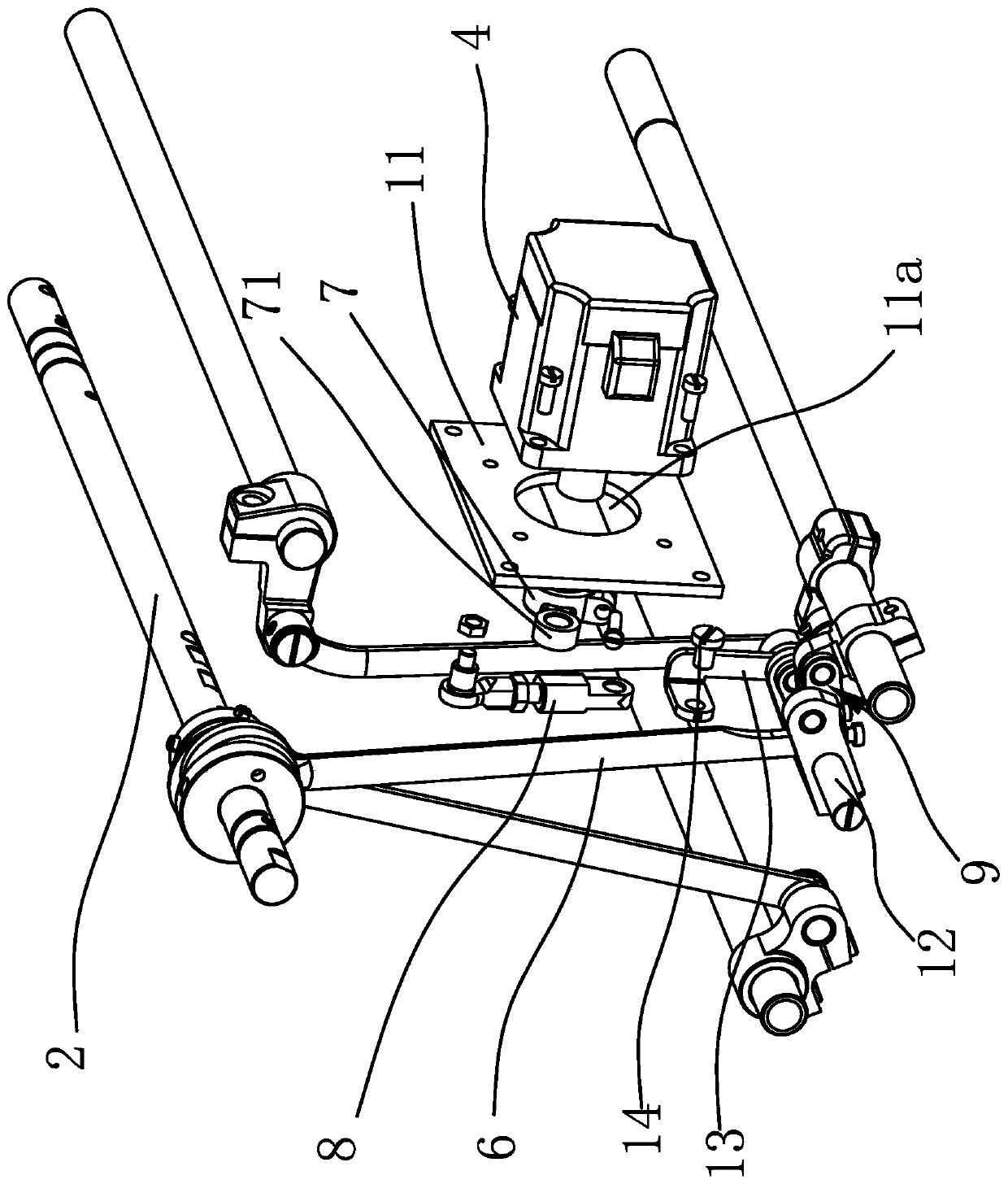

Sewing machine for automatically adjusting line taking for thickness of sewing material and line taking adjusting method thereof

The invention provides a sewing machine for automatically adjusting line taking for the thickness of a sewing material and a line taking adjusting method thereof. The machine comprises a sewing material thickness detecting assembly for detecting the thickness of the sewing material, a line take-up mechanism and a controller, and the sewing material thickness detecting assembly comprises a detecting sensor; the line take-up mechanism comprises a line take-up rod, a connecting rod assembly and a fixedly arranged driving member, the line take-up rod is a bent member, the bending part is rotatablyarranged, a threading hole is formed in one end of the line take-up rod, one end of the connecting rod assembly is connected with the driving member, the other end of the connecting rod assembly is connected with the other end of the line take-up rod, the driving member drives the connecting rod assembly to reciprocate and swing, and the threading hole of the line take-up rod is at the lowest point or at the highest point; the driving member and the detecting sensor are both connected to the controller. By controlling the action time of the driving member, the machine changes the line take-uptime when the stroke of the threading hole of the line take-up rod is constant, so that the line taking is adjusted in real time with the thickness of the sewing material.

Owner:JACK SEWING MASCH CO LTD

Sewing machine and stitch-length adjusting and backstitch control method for sewing machine

PendingCN109778437AHigh coincidenceSmall sizeWork-feeding meansNeedle severing devicesElectric machineryDrive motor

The invention provides a sewing machine and a stitch-length adjusting and backstitch control method for the sewing machine, and belongs to the technical field of garment manufacturing equipment. The technical problem that an existing stitch-length adjusting and backstitch control device is inaccurate, unreliable and the like is solved. The sewing machine comprises a machine shell, an upper shaft and a feeding shaft; a stitch-length adjusting crank capable of swinging is arranged between the upper shaft and the feeding shaft, and the upper shaft is connected with the stitch-length adjusting crank through a feeding connecting rod; a driving motor is fixedly arranged on the machine shell, a motor crank is fixedly arranged on an output shaft of the driving motor, a base groove is formed in theoutput shaft of the driving motor, and the motor crank is connected with the stitch-length adjusting crank through an adjusting connecting rod assembly; a shaft handle is fixedly arranged on the feeding shaft, and is connected with the stitch-length adjusting crank through a crank connecting rod assembly. According to the sewing machine and the stitch-length adjusting and backstitch control method for the sewing machine, stitch-length adjusting and front-stitch-and-backstitch conversion controlling are achieved through the driving motor, the automatic degree is high, operation is convenient,the stitch length can be frequently adjusted, the stitch length is accurate and stable, and the sewing effect is good.

Owner:JACK SEWING MASCH CO LTD

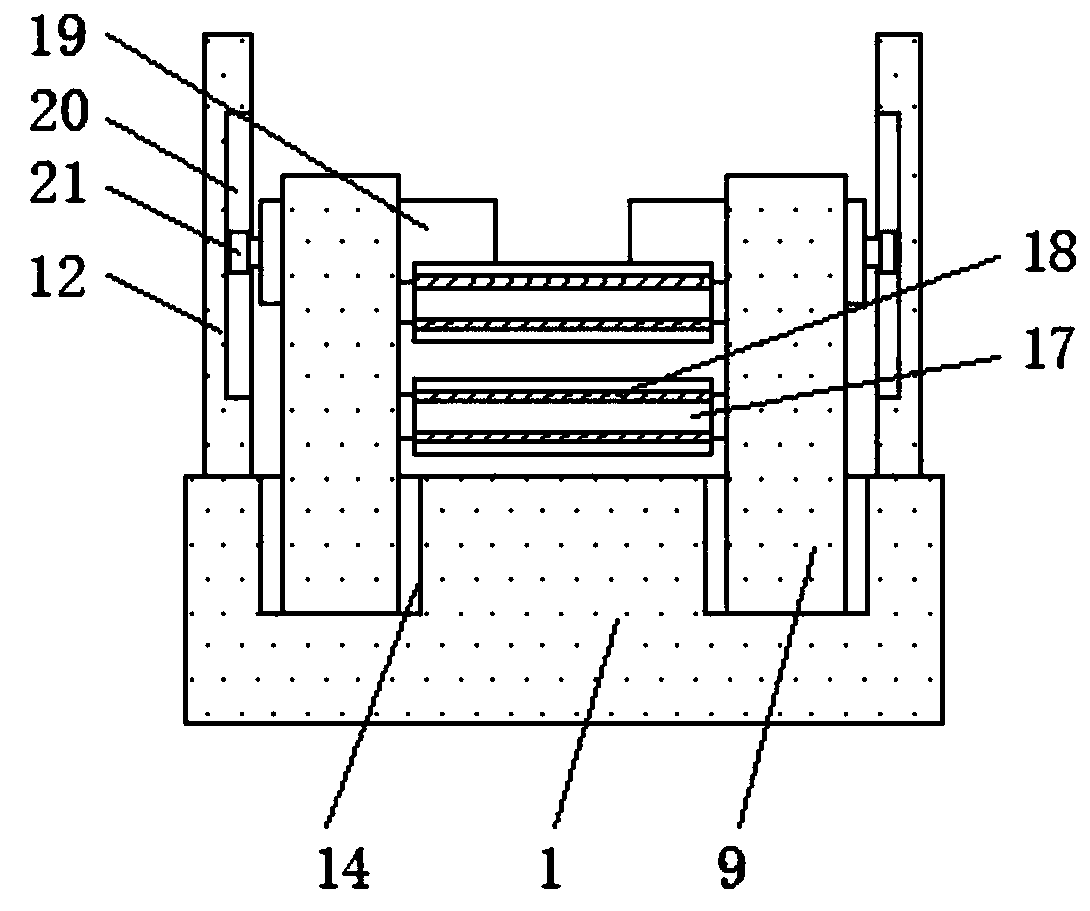

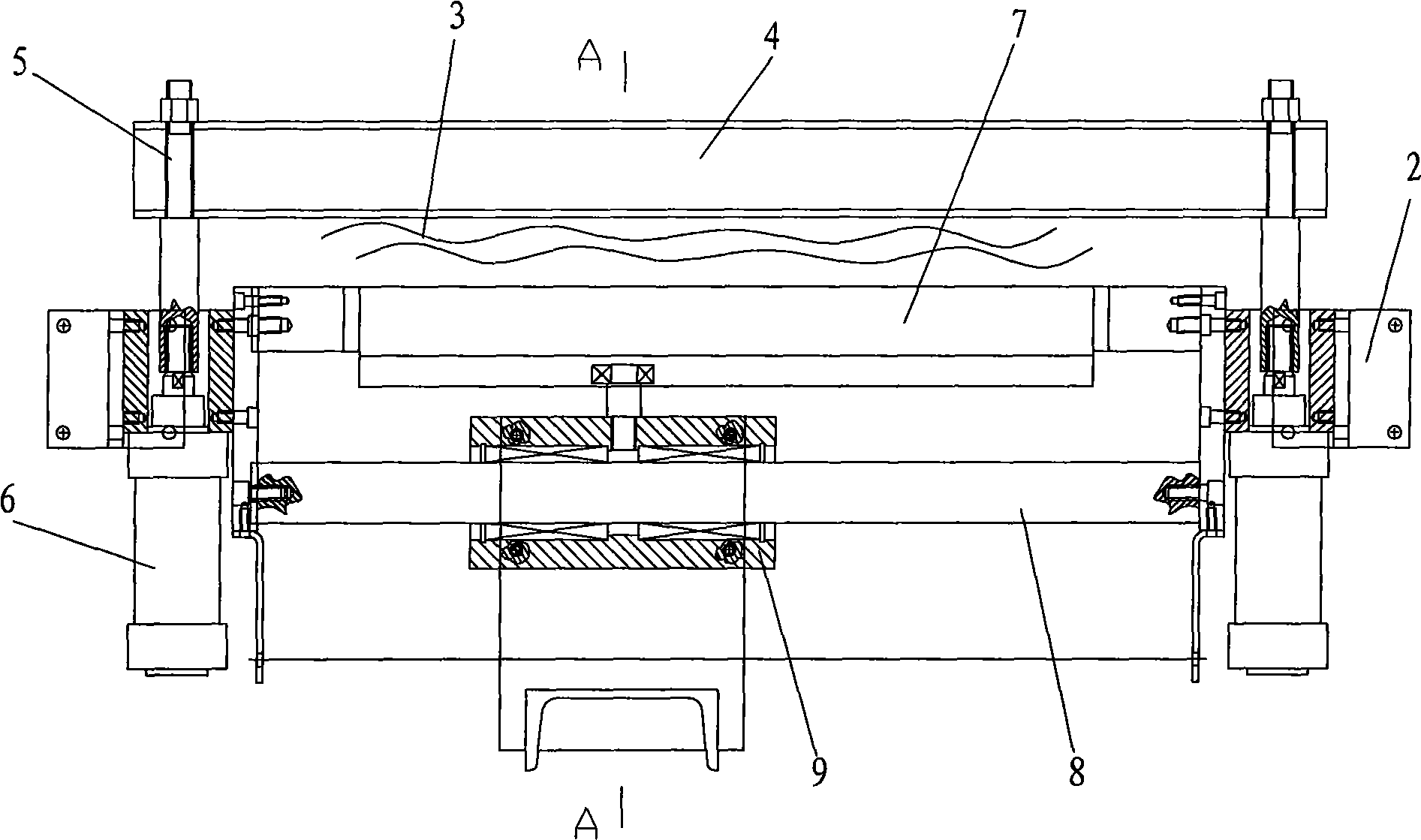

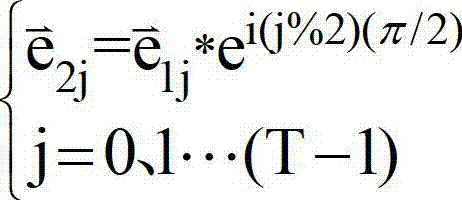

Sewing machine frame cloth tensioning, clamping and moving mechanism

InactiveCN106757834AImprove sewing effectImprove processing efficiencyWork-feeding meansElectric machineryDrive motor

The invention discloses a sewing machine frame cloth tensioning, clamping and moving mechanism, comprising a frame bench plate; the front and rear ends of each side of the frame bench plate are each provided with a support plate, two ends of a transmission screw are hinged to two support plates, a driving motor is fixed to the outer wall of one support plate, an output shaft of each driving motor is a splined shaft, each splined shaft is inserted into a splined hole arranged in one end of the corresponding transmission screw, a moving block is screwed to each transmission screw, the tops of two moving blocks are each fixedly provided with a main connection plate, the two main connection plates are arranged on two sides of the frame bench plate, opposing ends of the two main connection plates are fixedly provided with motor connection plates, the two main connection plates are arranged on two sides of the frame bench plate, motor connection plates are fixed to the opposing ends of the two main connection plates, tension motors are fixed to the outer walls of the two ends of the motor connection plates, output shafts of the tension motors are passed though the motor connection plates and are connected with main adjusting nuts in screwed manner, and the ends of the main adjusting nuts are fixed to vertical plates. Cloth is clamped and fixed by upper and lower clamp plate and is tensioned automatically and pushed automatically, so that sewing effect is improved.

Owner:FOSHAN ZHIDA SIJIA ELECTRICAL & MECHANICAL TECH CO LTD

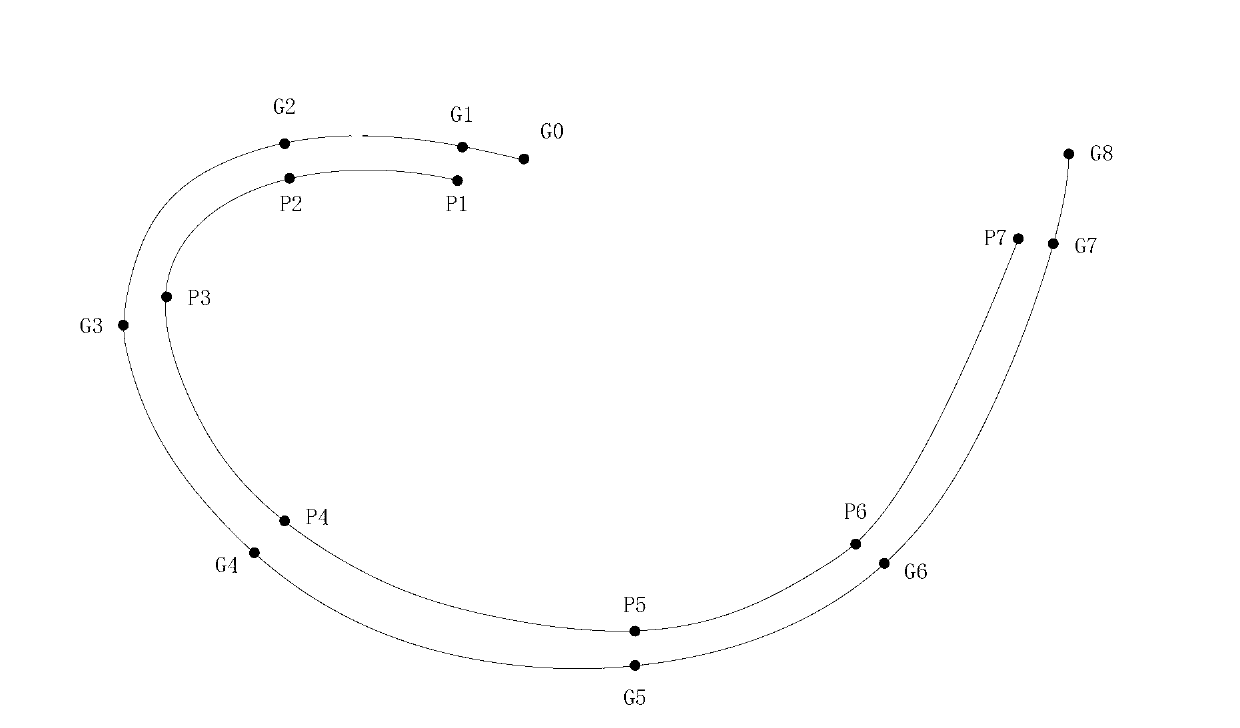

Method for controlling electronic pattern sewing machine to carry out herringbone sewing

The invention provides a method for controlling an electronic pattern sewing machine to carry out herringbone sewing. According to the method, firstly, a plurality of straight line sections, circular arcs, circles and free curves for forming patterns respectively generate herringbone sewing data; secondly, a herringbone sewing data file obtained through integration is stored into an electric control system of the electronic pattern sewing machine; and the pattern data file selected by the users is read out by the electric control system, and the pattern data is reversely analyzed for controlling an X-axis stepping motor and a Y-axis stepping motor to be matched with a main shaft servo motor for operation. The needle pitch of the generated pattern data is smooth, no particularly large or small needle pitches exist, the operation of the pattern sewing machine is stable, the noise and the vibration are greatly reduced, and the sewing effect is good. When the pattern file is read out, the increment in the XY axis direction can be obtained without carrying out complicated bit operation like the traditional pattern file, the pattern data is directly read out, and the movement vector of a pattern frame relative to a frame needle is indicated through pattern point relative coordinates.

Owner:中国船舶重工集团公司第七〇五研究所

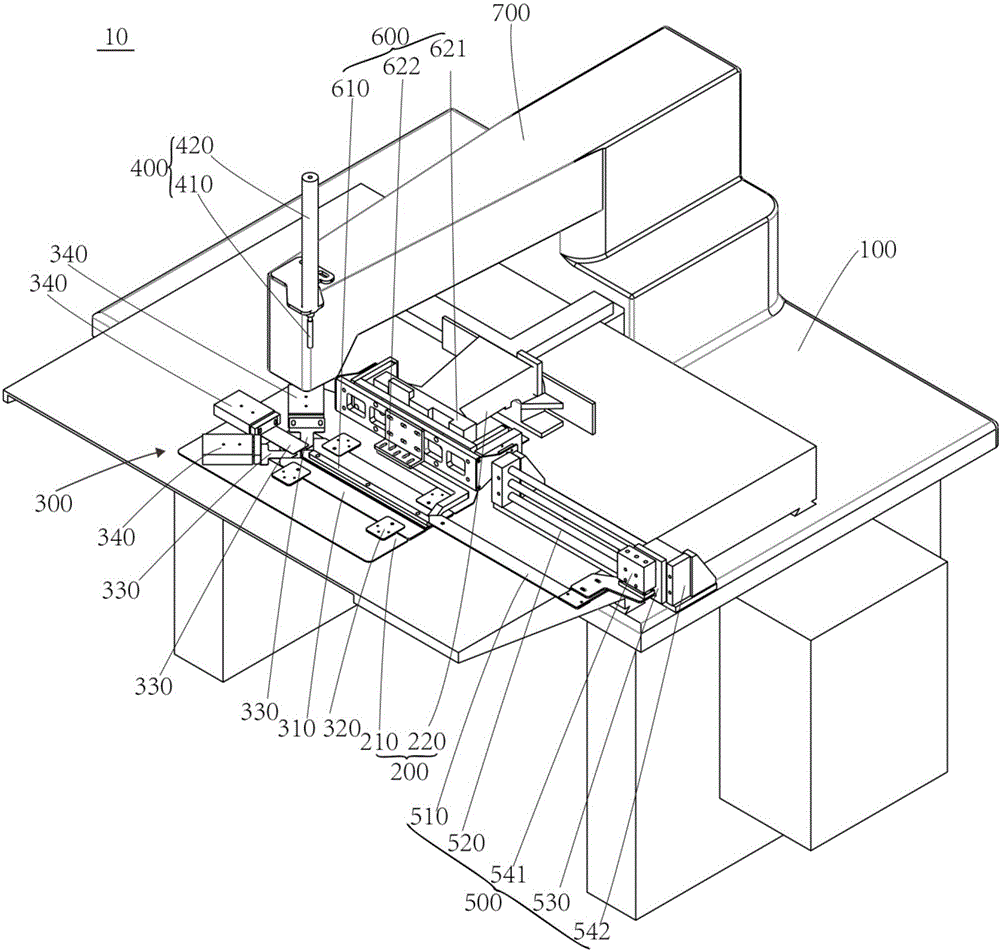

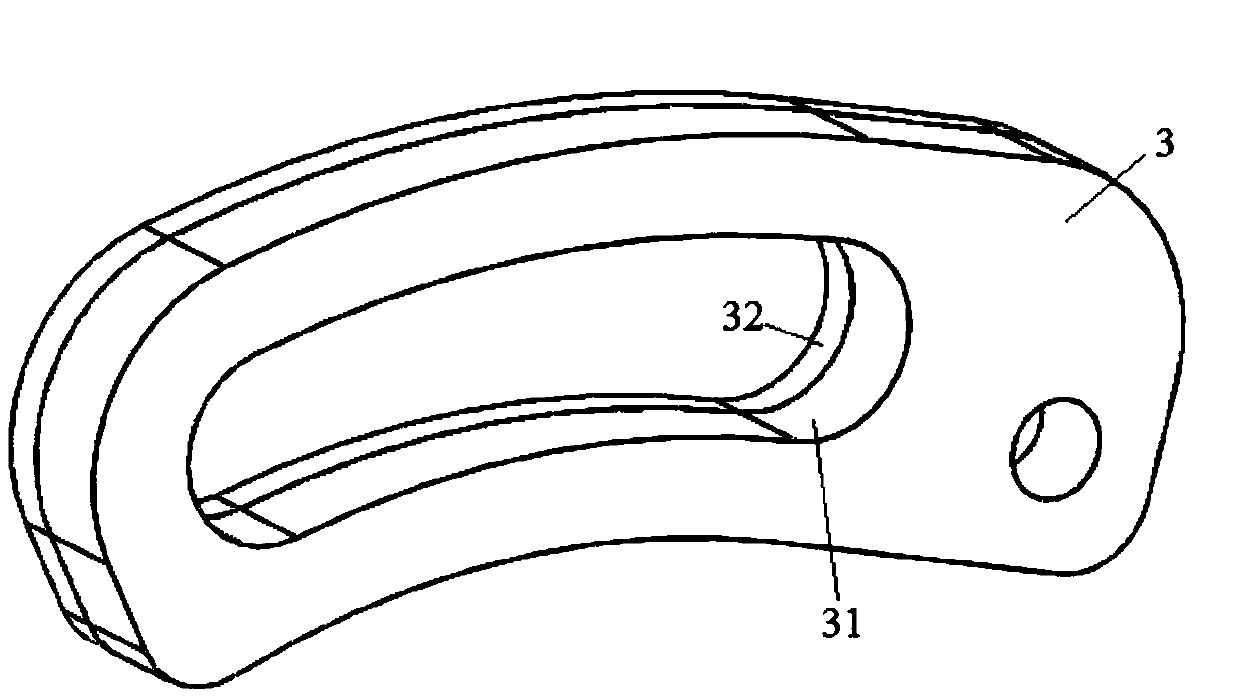

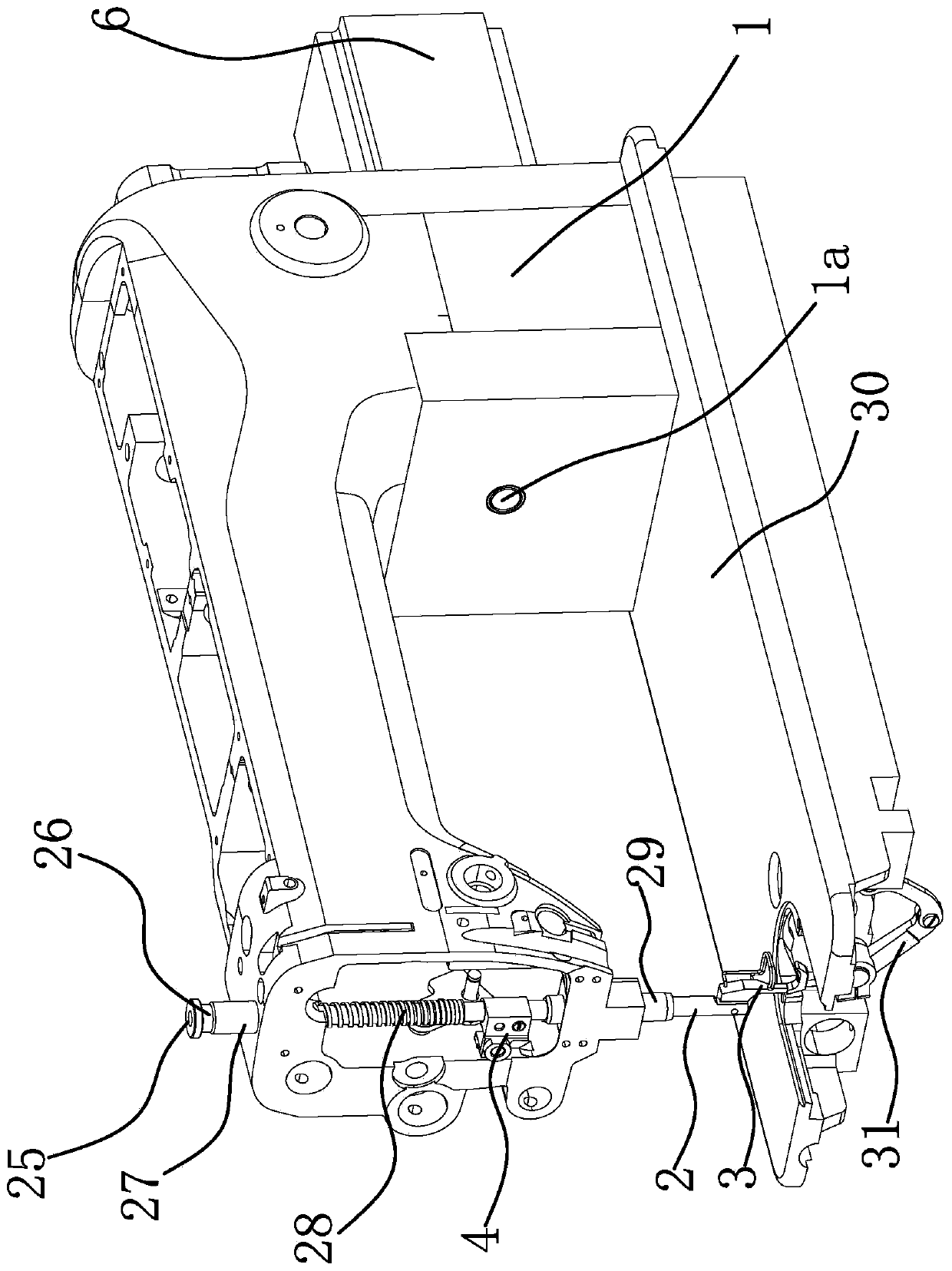

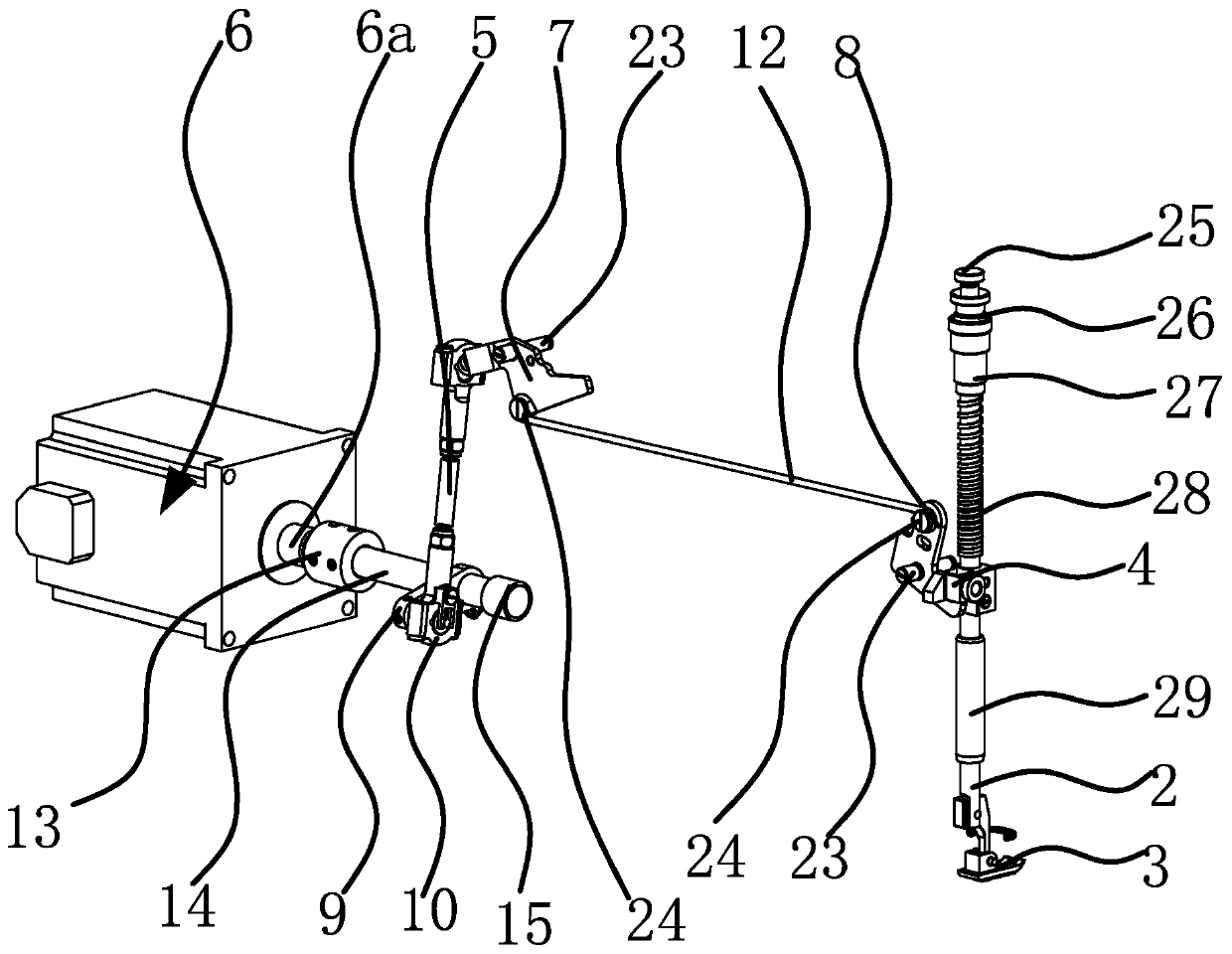

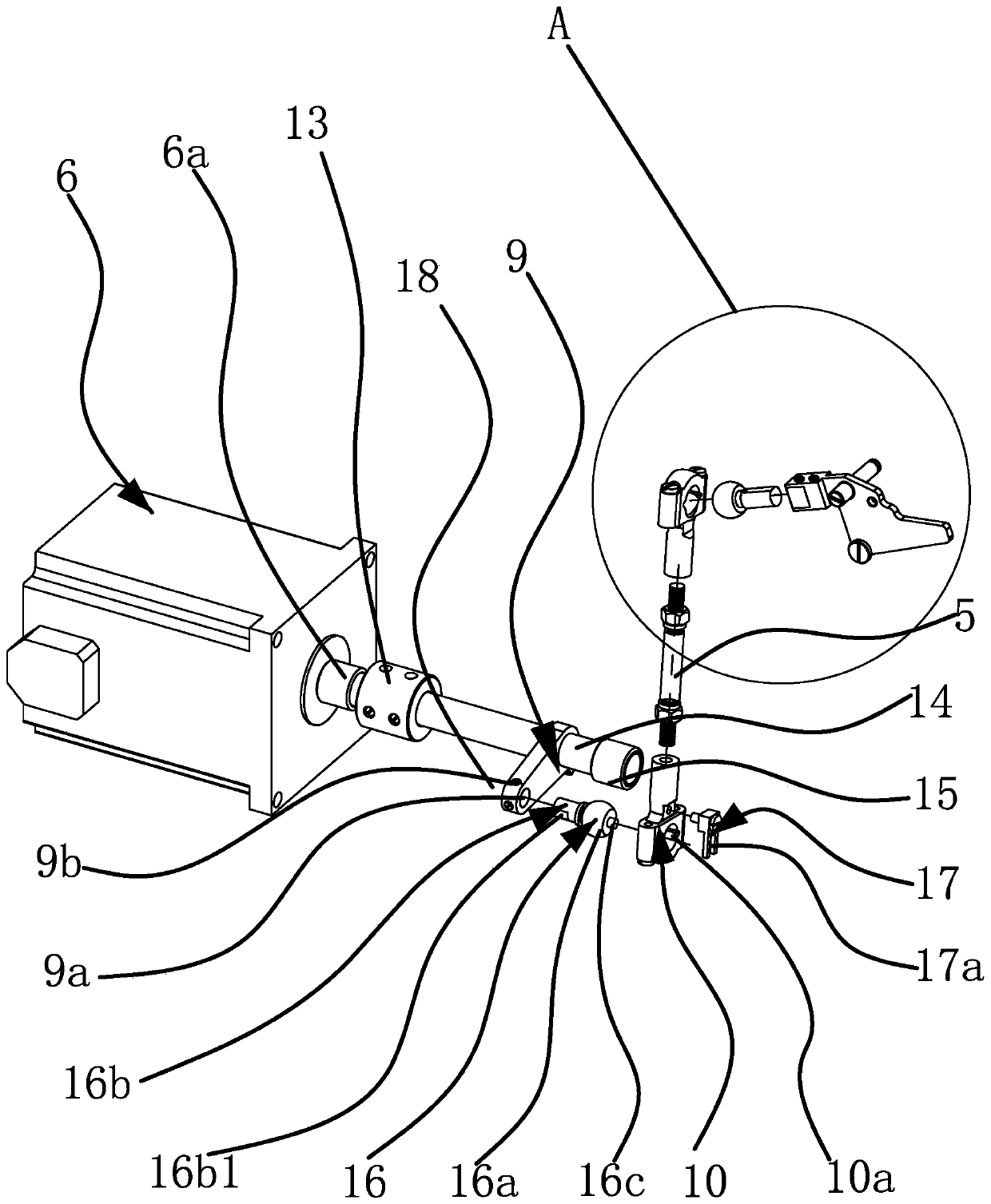

Multifunctional electronic pattern sewing machine

ActiveCN103334226ARealize constant pressure pressingPrevents fluctuation and wrinkling of sewing materialWork-feeding meansPressersRange of motionHooking

The invention discloses a multifunctional electronic pattern sewing machine. The multifunctional electronic pattern sewing machine comprises a machine base, a machine body, an upper shaft straight shaft mechanism, a rotating shuttle thread hooking hob thread trimming mechanism, a needle bar, a boat-shaped compressing device, a cloth dragging moving device and a pressing frame holding-down device. The cloth dragging moving device converts the X motion trail and the Y motion trail of an existing sewing machine from the lower portion of a working table of the sewing machine to the lower portion of the working table and the upper portion of the working table for moving respectively, the pressing frame holding-down device cooperates at the upper portion of the working table to move in the X direction and is matched with the cloth dragging moving device to move sewing materials in the X direction, and the boat-shaped compressing device massively compresses the sewing materials, and therefore a sewing needle is stably sewn on the sewing materials with proper tightness degrees. The multifunctional electronic pattern sewing machine has multiple functions, is novel in structure, and is capable of greatly improving production efficiency and quality of sewn products. Due to the fact that the sewing materials are moved in the X direction and do not limited by the track length of the sewing machine in the X direction, the moving range in the X direction for the sewing materials is unlimited, the using requirement of the traditional length of the sewing materials needed by a user can be met, and the perfect sewing effect is achieved.

Owner:CHANGZHOU INDAL SEWING MACHINE

Automatic folding mechanism for cutting sheet

PendingCN106436066AEasy to switchShorten the timeWork-feeding meansEngineeringMechanical engineering

The invention discloses an automatic folding mechanism for cutting sheet, which comprises a machine table, a feeding device, a material folding device and a sewing device. The feeding device is provided with a feeding plate and a feeding driving part. The feeding driving part drives the feeding plate to move. The material folding device comprises a core mold, fold shoveling plates and a driving part for fold shoveling plate. The core mold is detachably connected with the feeding plate, and the core mold is provided with a feed chute used to place the cutting sheet. Two of a plurality of fold shoveling plates cling to an end of the feed chute. The two fold shoveling plates are distributed in designed angle and there are also provided with a fold shoveling plate in the middle of the two fold shoveling plates. The driving part for fold shoveling plate drive the fold shoveling plates to move on the surface of the feeding plate towards the direction of the feed chute. The moving fold shoveling plate can fold the end edge of the cutting sheet which is out of the feed chute to achieve folding. The sewing device sew the folded cutting sheet which is sent by the sewing feeding device. The automatic folding mechanism for cutting sheet has the advantages of time saving, labor saving and high production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Sewing machine and thread break detection control device thereof

ActiveCN109554845ARealize automatic shutdownImprove sewing effectSewing-machine control devicesThread-break detectorsElectric machineryEngineering

The invention discloses a sewing machine and a thread break detection control device thereof. The thread break detection control device comprises a thread clamp, a thread break detection device and acontroller. The thread clamp is arranged on a shell of the sewing machine and provided with a thread picking spring; the thread picking spring is used for cooperating with a sewing thread in normal sewing of the sewing machine to continuously contact with and separate from the thread break detection device, and thread picking spring and the thread break detection device are in a normally contactedstate in breakage of the sewing thread; the thread break detection device is arranged on the shell and used for generating connection signals when contacting with the thread picking spring and generating disconnection signals when separating from the thread picking spring; the controller is connected with an output end of the thread break detection device and used for determining that the sewingmachine is not in thread break after receiving the disconnection signals and determining thread break of the sewing machine after only receiving the connection signals and controlling halting of a driving motor of the sewing machine, wherein connection and disconnection signals include cyclically generated connection signals and disconnection signals. Therefore, automatic halting of the sewing machine after thread break of the sewing machine is realized, and great sewing effects are achieved.

Owner:JACK SEWING MASCH CO LTD

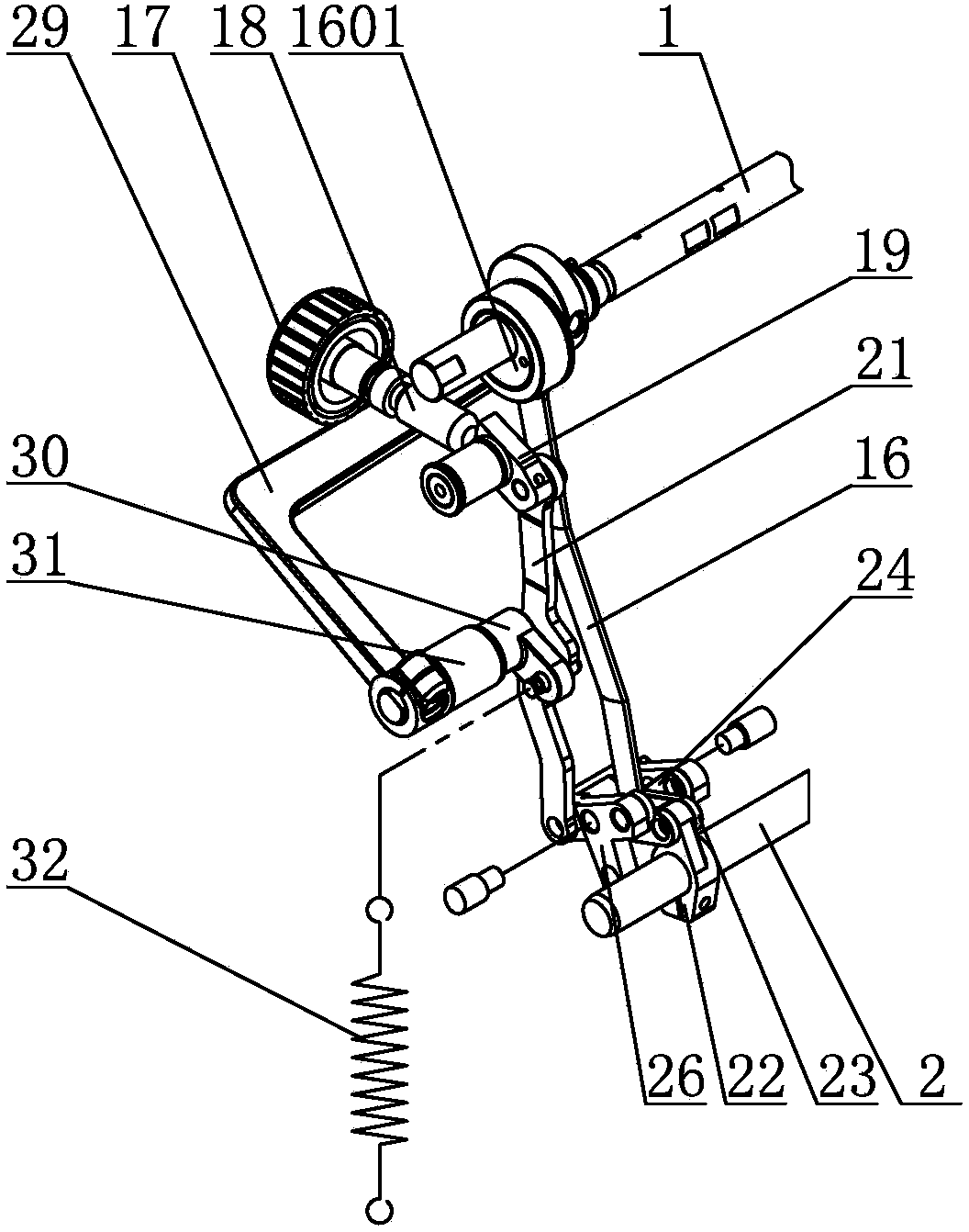

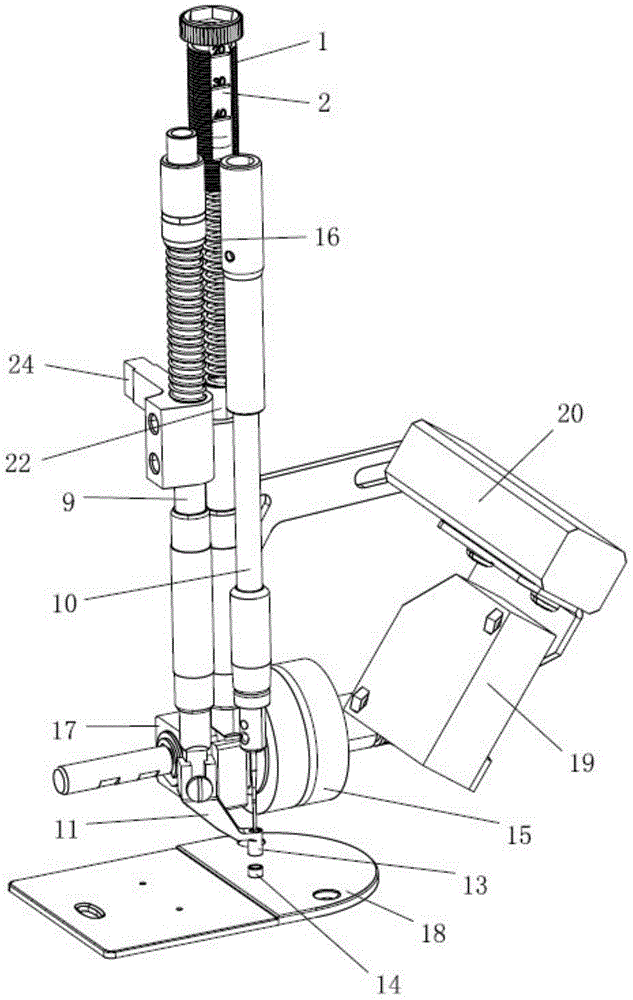

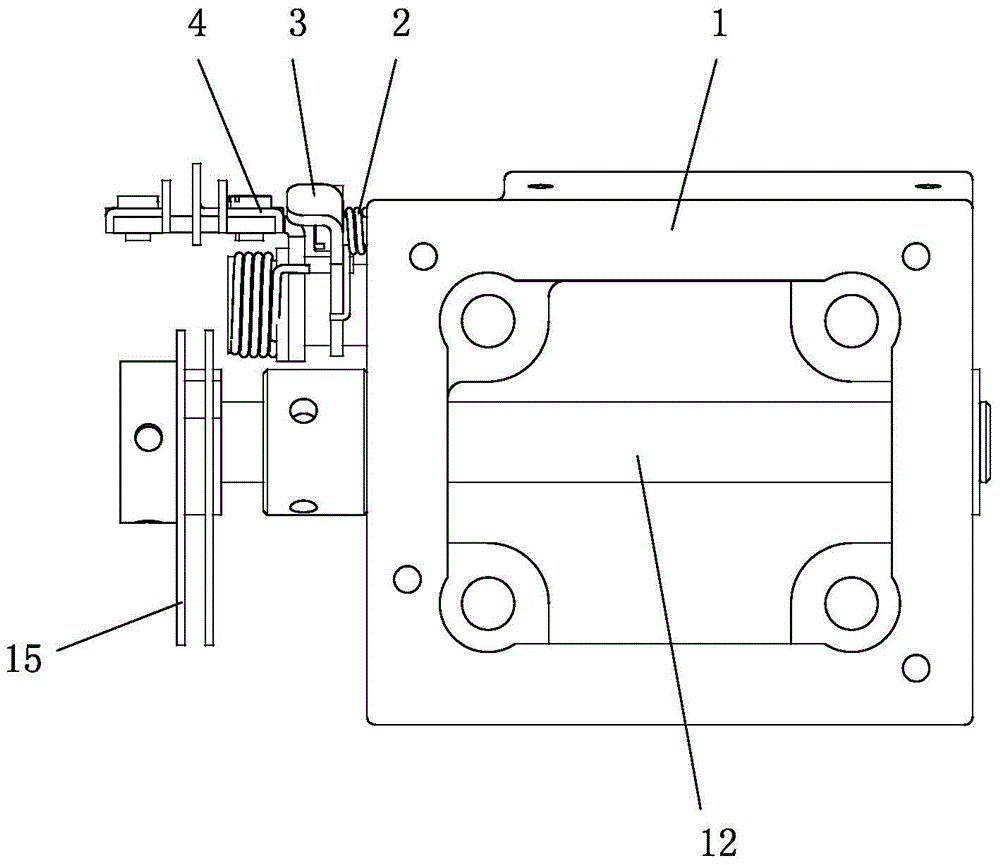

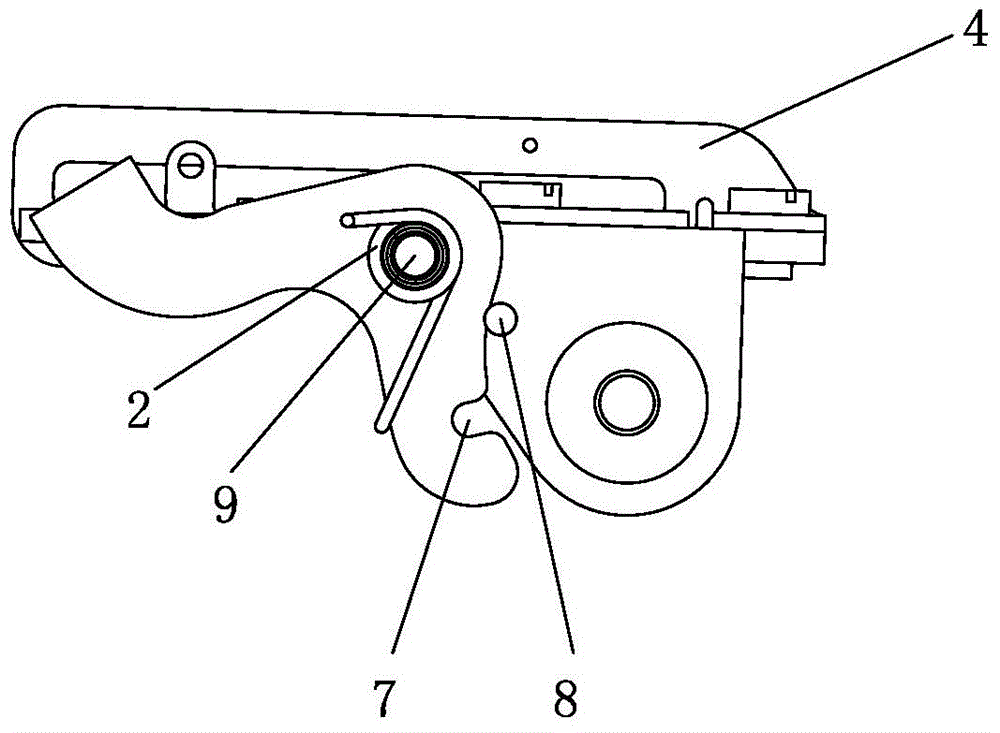

Driving device for automatically lifting presser foot and trimming thread in sewing machine

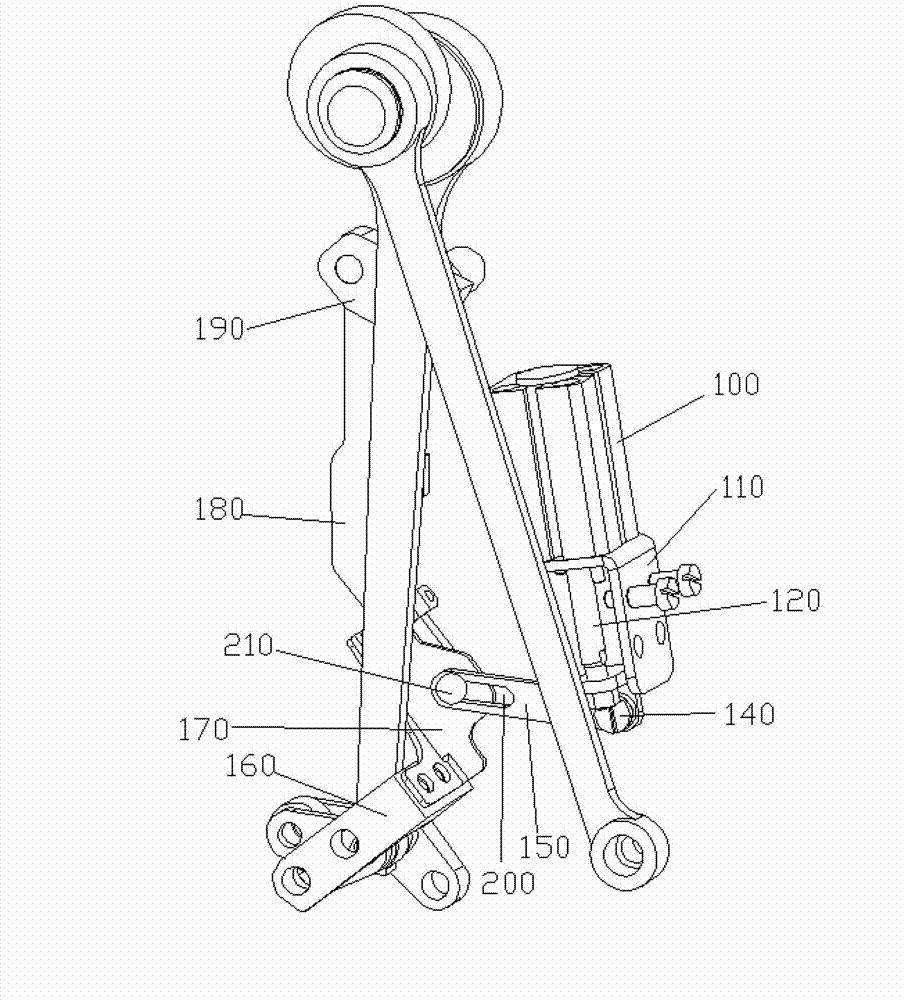

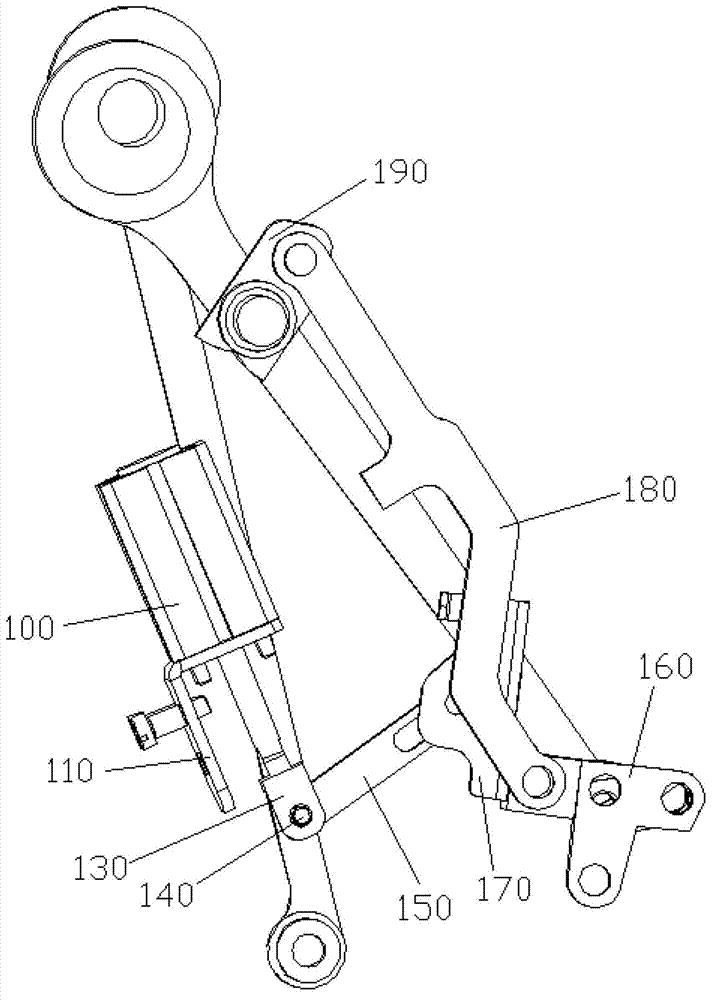

ActiveCN111534937AReduce machining accuracyReduced installation accuracyNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention provides a driving device for automatically lifting a presser foot and trimming a thread in a sewing machine, and belongs to the technical field of garment manufacturing equipment. The technical problem that an existing driving device for automatically lifting the presser foot and trimming the thread in the sewing machine is unstable in function is solved. The sewing machine comprises a bottom plate, a machine shell, a pressing rod and the presser foot, wherein a guide frame is fixedly arranged on the pressing rod, and a thread trimming assembly is arranged at the bottom of the bottom plate. The driving device comprises a lifting pull rod, a driving part, a left lever and a right lever, wherein a swing crank is connected to an output shaft of the driving part; the lower end of the lifting pull rod is in spherical hinge joint with the outer end of the swing crank through a lower spherical connecting rod; the upper end of the lifting pull rod is in spherical hinge joint with one end of the left lever through an upper spherical connecting rod; the other end of the left lever is connected with one end of the right lever through a lifting connecting rod; the other end of the right lever can abut against the lower side of the guide frame; and the outer end of the swing crank is connected with the thread trimming assembly. The driving device is stable in function, the lifting height of the presser foot can be accurately controlled, and meanwhile the thread trimming function is achieved.

Owner:浙江杰克智能缝制科技有限公司

Precise processing device for sewing

InactiveCN110093724AReduce work intensityImprove sewing effectWork-feeding meansEngineeringUltimate tensile strength

The invention discloses a precise processing device for sewing. The device comprises a rack, the rack is provided with a worktable surface, the worktable surface is provided with a sliding rail, the sliding rail is provided with a sewing machine seat, the sewing machine seat is provided with a sewing machine, and the front end of the sewing machine is provided with an optical fiber transmitter; the worktable surface is provided with a sliding table, a sewing mold is clamped to the sliding table and comprises a bottom plate and a pressing plate which are hinged to each other, the bottom plate is provided with an origin sensor, the pressing plate is provided with a through hole, and the through hole is internally provided with a cover plate. Cloth is placed on the bottom plate, the pressingplate and the bottom plate cooperate with each other to realize clamping and loading, the through hole is filled with cloth parts, and the cover plate is adopted for pressing; the sewing machine seatdrives the sewing machine to move back and forth along a guide rail, the sliding table drives the sewing mold to move left and right, and an origin locator and an optical fiber generator ensure that the sewing machine performs sewing work in a gap between the cover plate and the through hole. The working intensity is low, manual driving of the cloth for rotation and sewing is not needed, only thecloth needs to be clamped, the sewing effect is good, and the production efficiency is high.

Owner:文登华绮服装有限公司

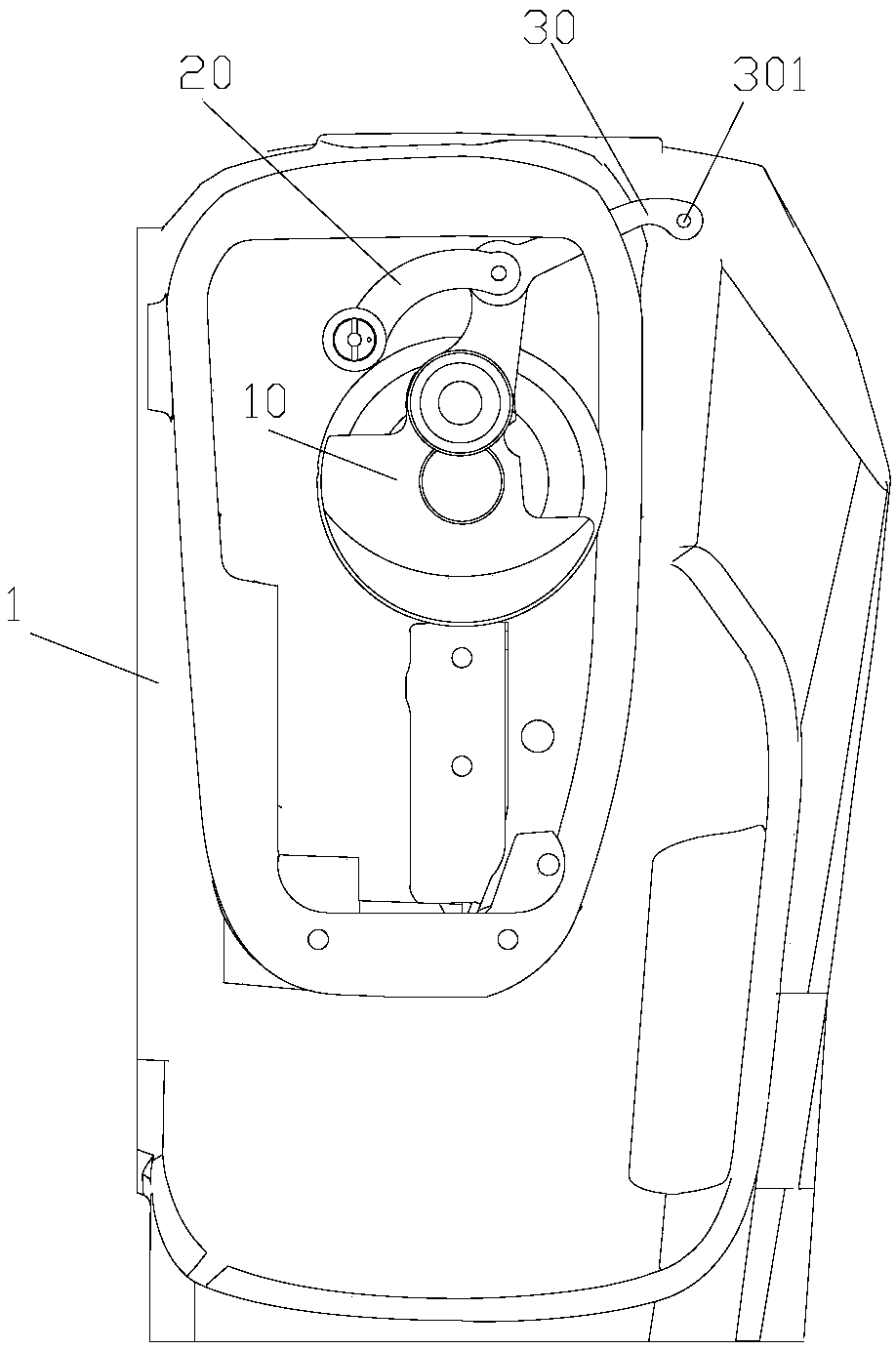

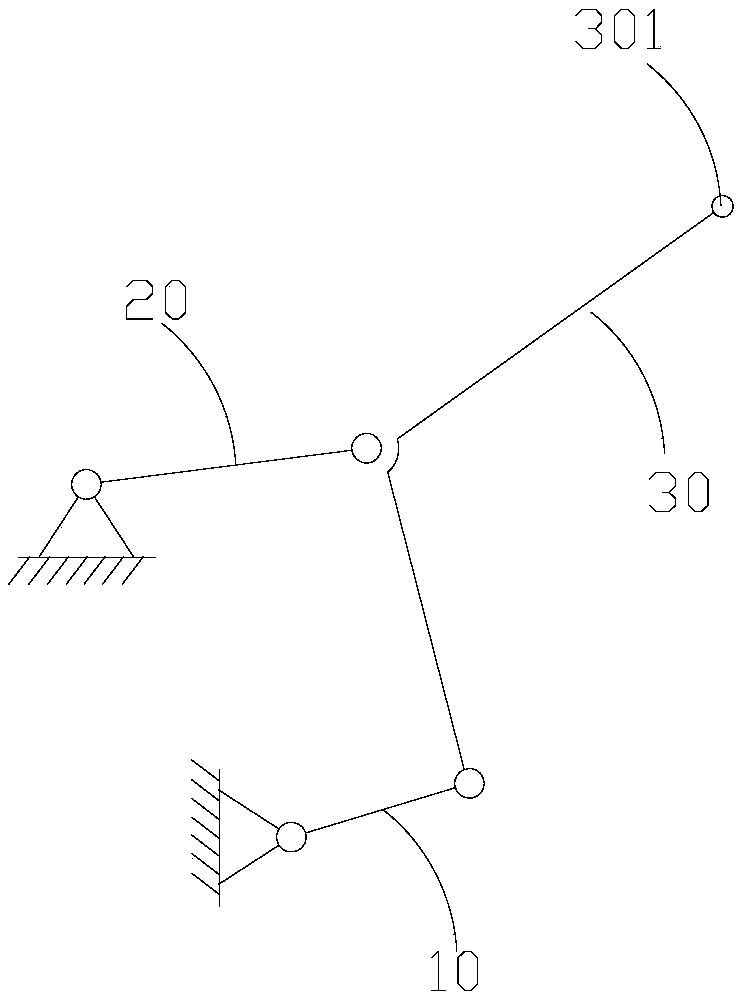

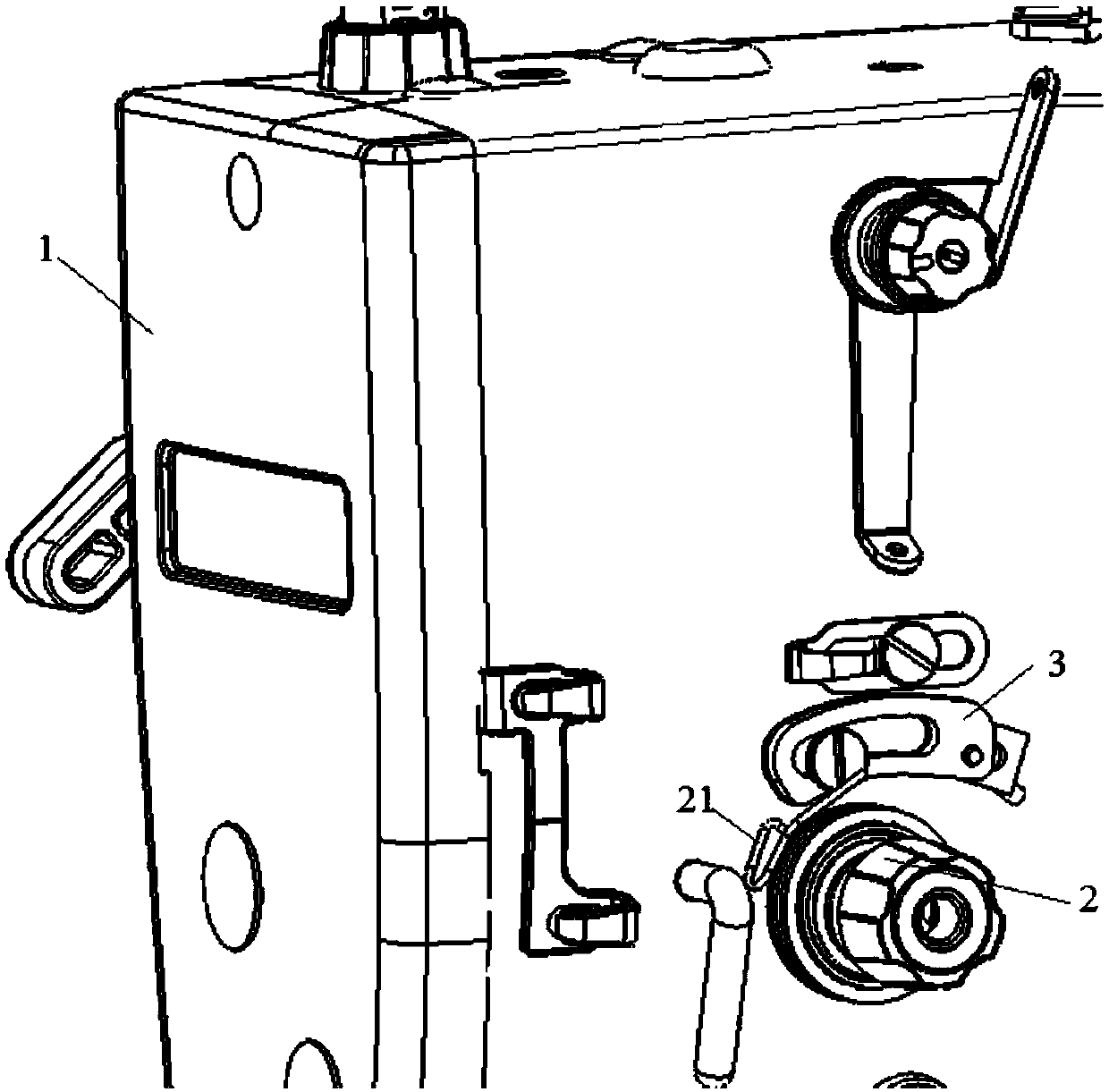

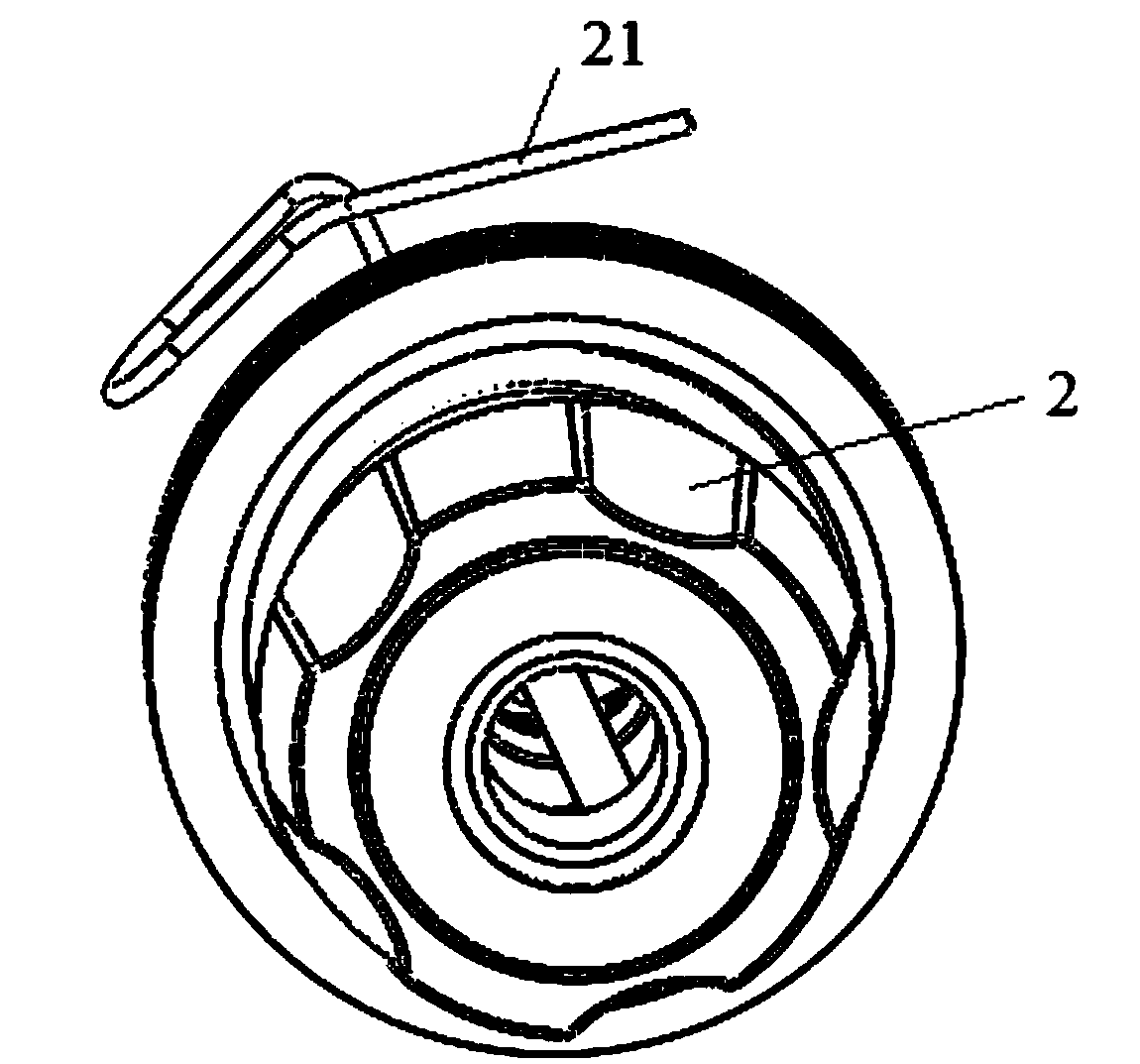

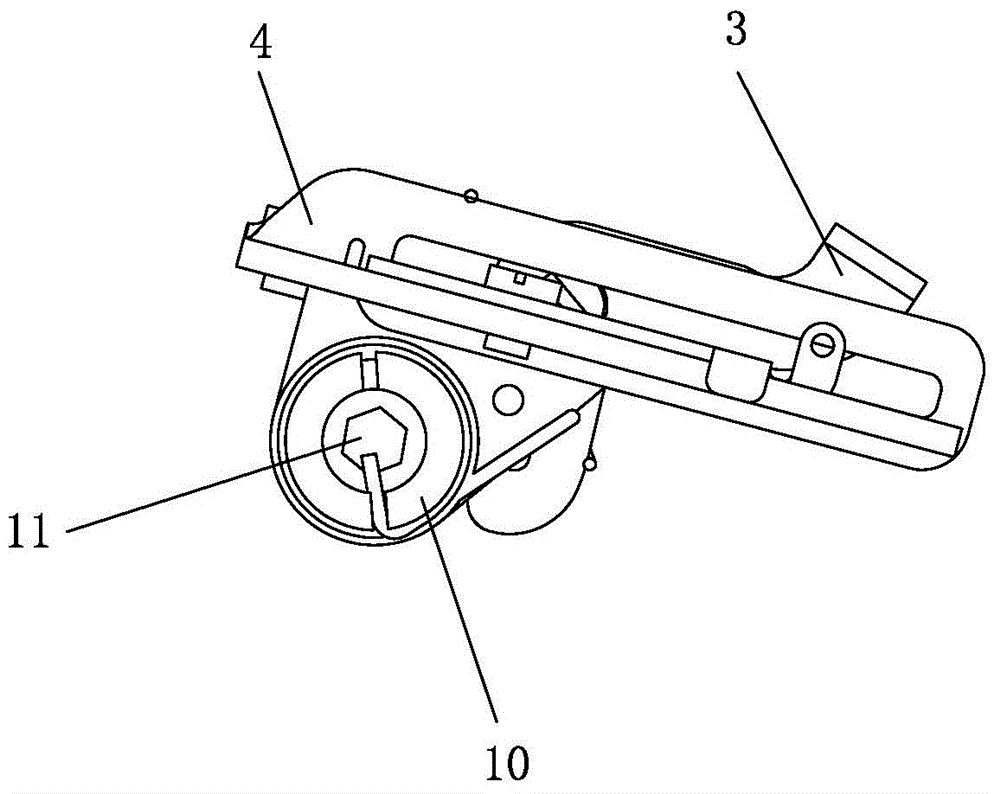

Bottom thread control mechanism for sewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to a bottom thread control mechanism for a sewing machine. The bottom thread control mechanism comprises a pin shaft with one end fixed on a casing, wherein a stitching frame spanner which rotates around the pin shaft and is driven by a first reset spring to perform automatic resetting is arranged on the pin shaft, a stitching frame is arranged on one side of the stitching frame spanner and connected with a stop block fixed on the casing, the stitching frame rotates around the stop block and is driven by a second reset torsional spring to perform automatic resetting, a clamping groove is formed in the stitching frame spanner, a limiting pin is arranged on the stitching frame, and the stitching frame is in a working state when the limiting pin is arranged in the clamping groove of the stitching frame spanner and is in a threading state after the limiting pin is separated from the clamping groove. Automatic resetting structures of two torsional springs are arranged, the threading state and the working state of the stitching frame can be conveniently switched by simply operating the stitching frame spanner, and when a stitching cam is wound with a thread, dismounting and maintaining are very convenient.

Owner:JACK SEWING MASCH CO LTD

Preparation method of anti-run smoothing agent for fabrics

ActiveCN103696262AImprove abrasion resistanceImproved tear strengthFibre treatmentPolymer scienceEmulsion

The invention discloses a preparation method of an anti-run smoothing agent for fabrics. The preparation method comprises the following steps: (1) emulsifying, stirring and reacting 25-35 parts by mass of polyethylene wax, 2-7 parts by mass of an emulsifier, 0.05-0.15 part by mass of potassium hydroxide, 0.05-0.15 part by mass of sodium sulfite and 65-75 parts by mass of deionized water for 0.5-2 hours at the pressure of 0.1-0.3Mpa and the temperature of 110-130 DEG C; and (2) after ending emulsification, rapidly cooling emulsion to 30-40 DEG C, and discharging, thus obtaining the anti-run smoothing agent for the fabrics, wherein the molecular weight of the polyethylene wax is 2,000-3,000. After the fabrics are treated by the anti-run smoothing agent prepared by the method, the wear resistance, the tear resistance and the sewability of the fabrics are improved, the hand feel softness of the fabrics is promoted, and the fabrics are prevented from being off from the needle in a manufacturing process.

Owner:南通鸿业纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com