Coating Device for Coating an Elongated Substrate

a coating device and substrate technology, applied in the field of coating of threads, can solve the problems of affecting the quality of textile parts, and requiring a large amount of time and work to embroider in different colors using this technique, so as to improve the quality of textile parts, and improve the effect of ink coverag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

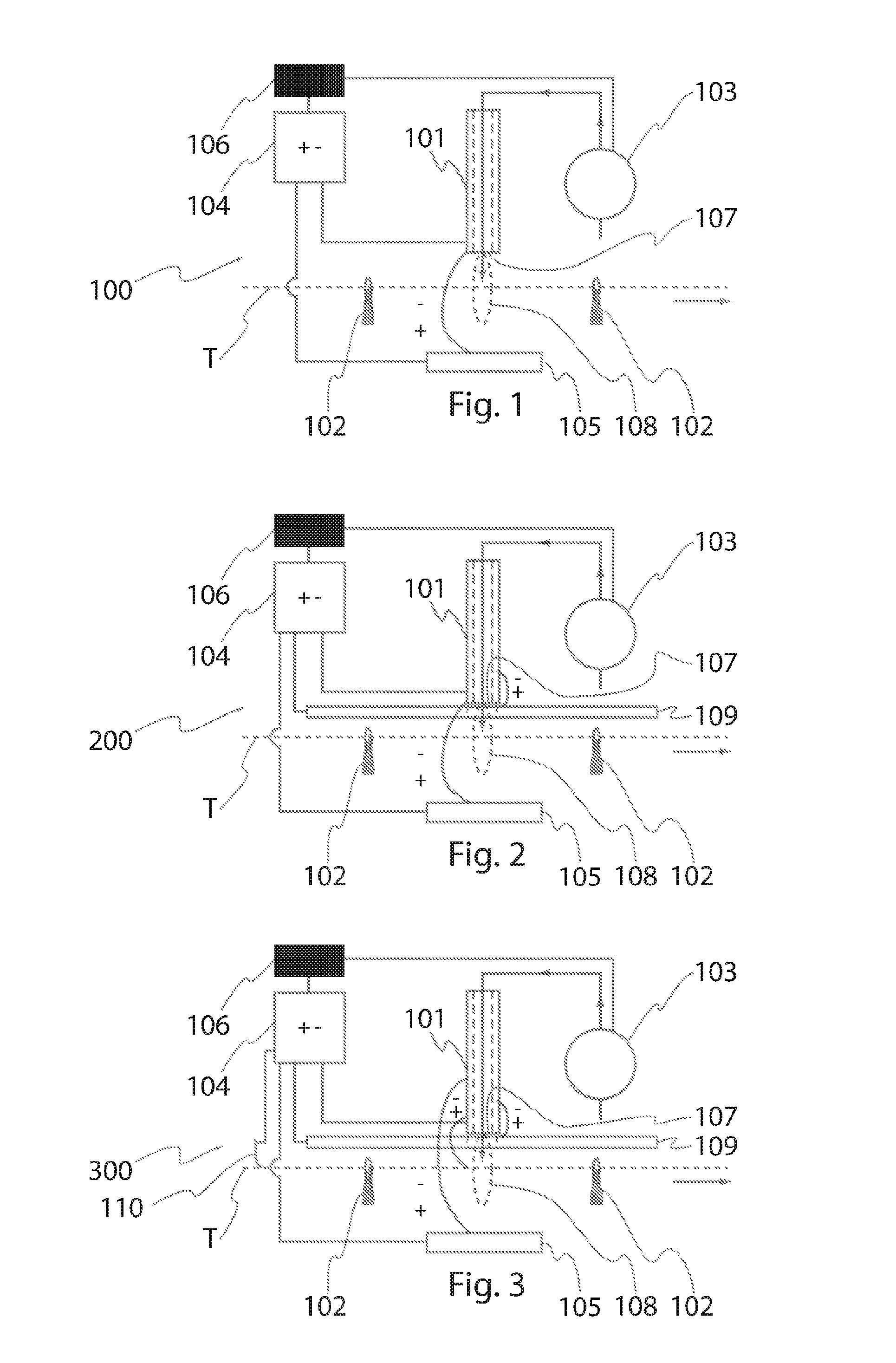

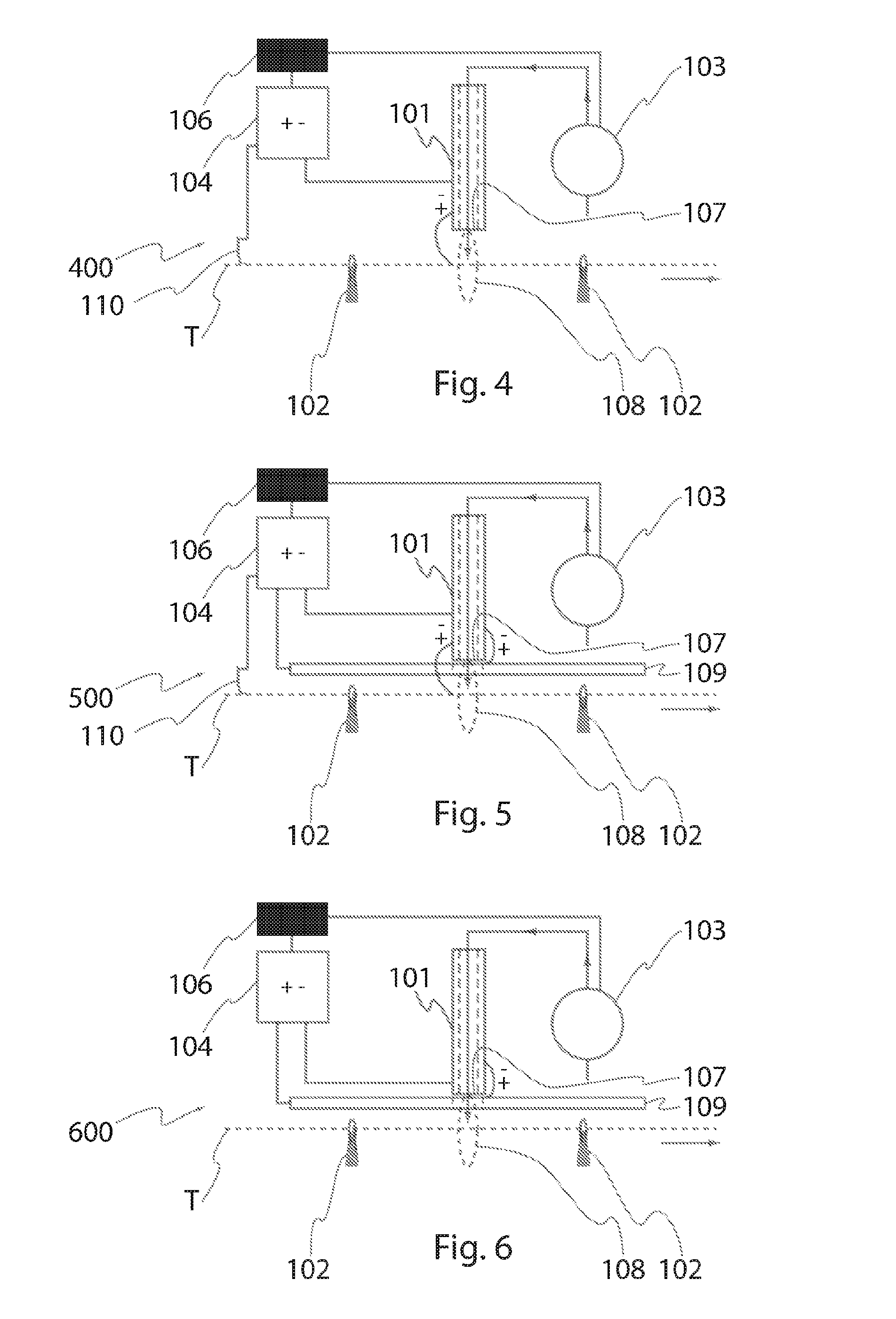

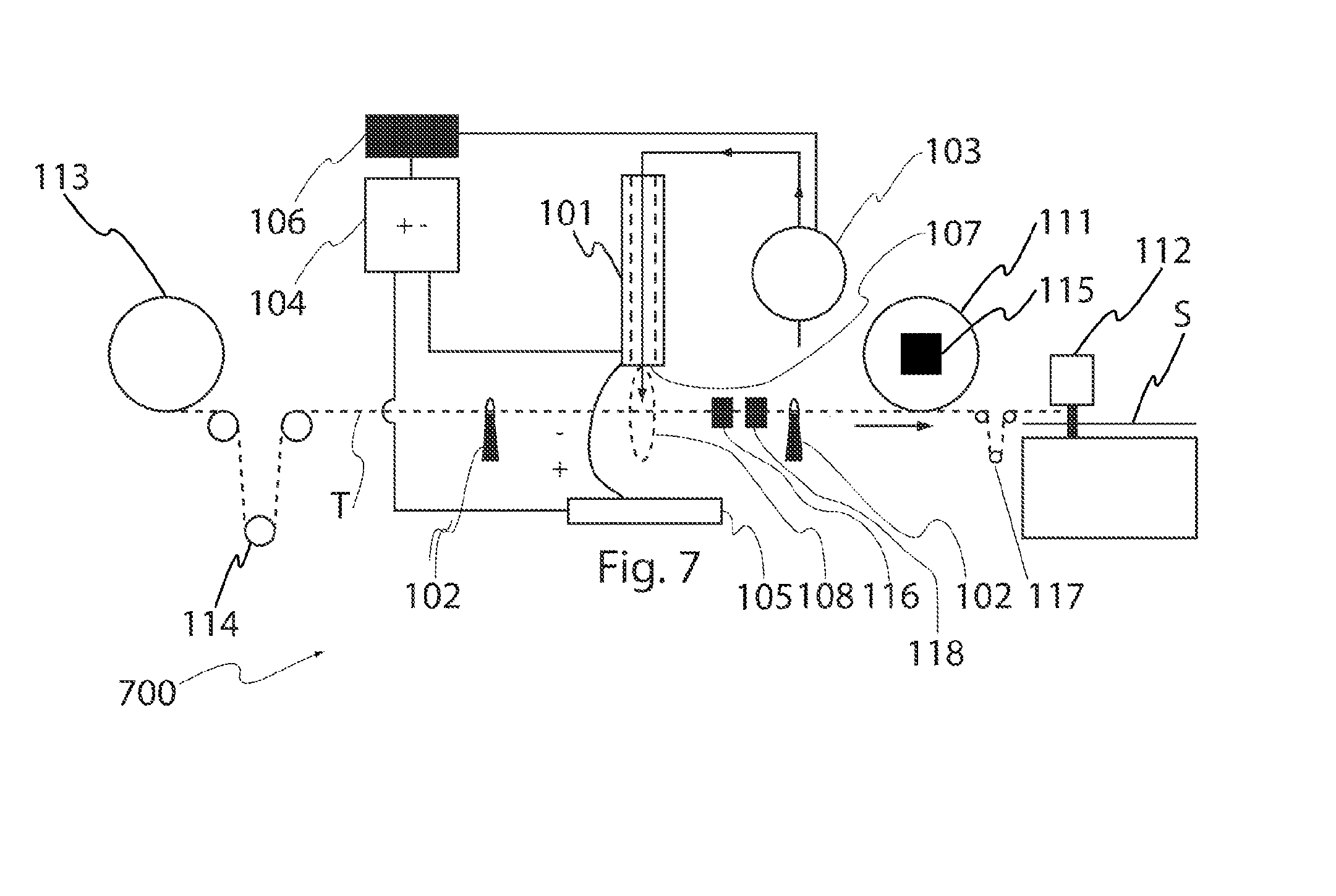

[0054]As previously mentioned, an aspect of the invention relates to a device for dynamically applying liquid, such as ink, to a single thread as said thread moves relative to the device along a path of movement. In this way, a thread may be coated or soaked with a liquid, such as an ink. The device is configured to apply liquid to the thread by means of an electrospraying unit. More specifically, the device is a thread consuming device, such as an embroidery machine, for applying ink to a single thread, such that the thread may be coated with said liquid, such as ink. When the device is a thread consuming device, such as an embroidery machine, for applying ink to a single thread, the device may be said to be a coating device. A thread may be glass fiber thread; a thread of wool; a thread of cotton; a synthetic thread; a metallic thread; a thread being a mixture of wool, cotton, polymer, or metal; a yarn; filament; or any elongated substrate that is intended and / or being suitable fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential | aaaaa | aaaaa |

| electric field | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com