Patents

Literature

2244results about "Embroidering machines apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

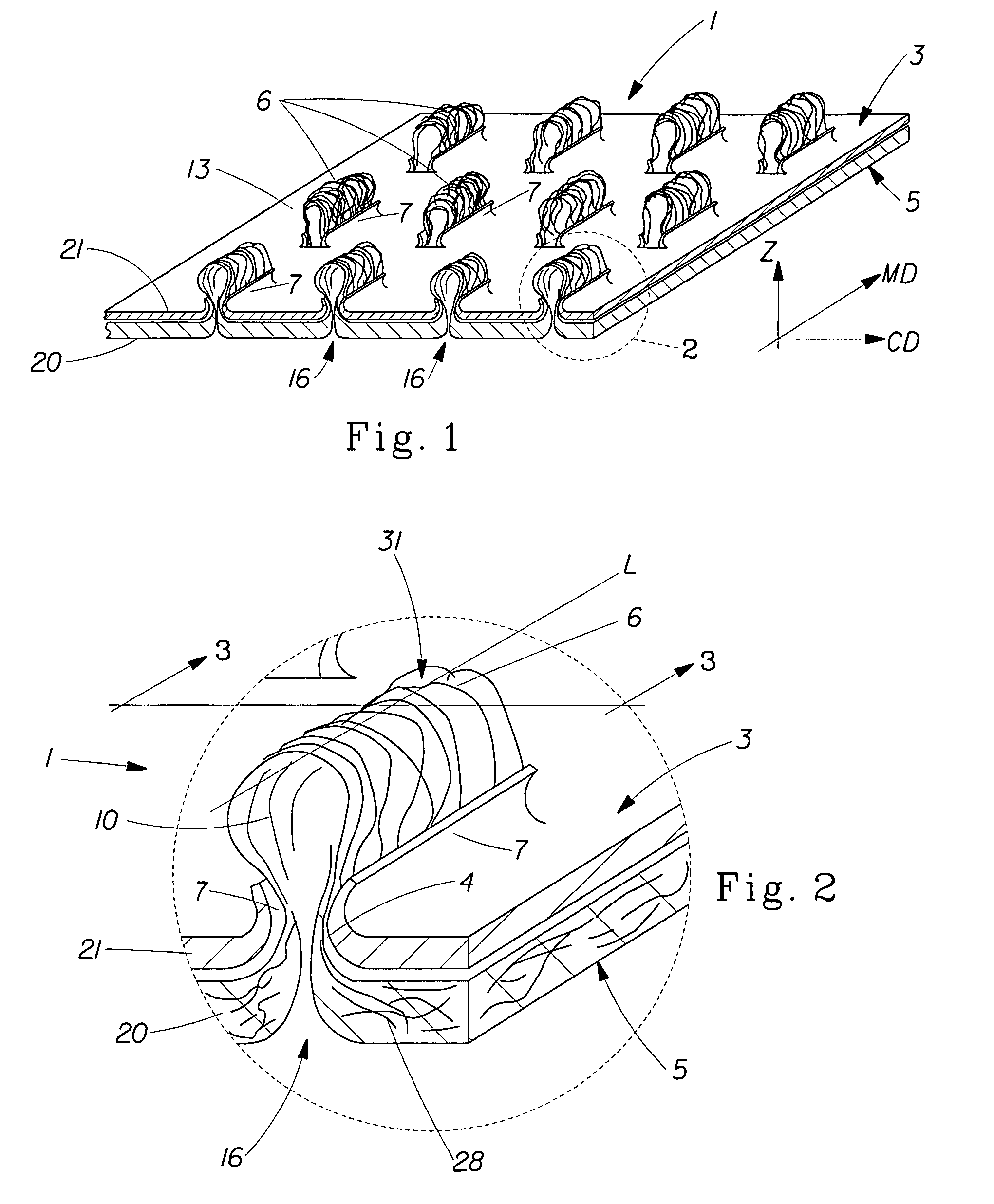

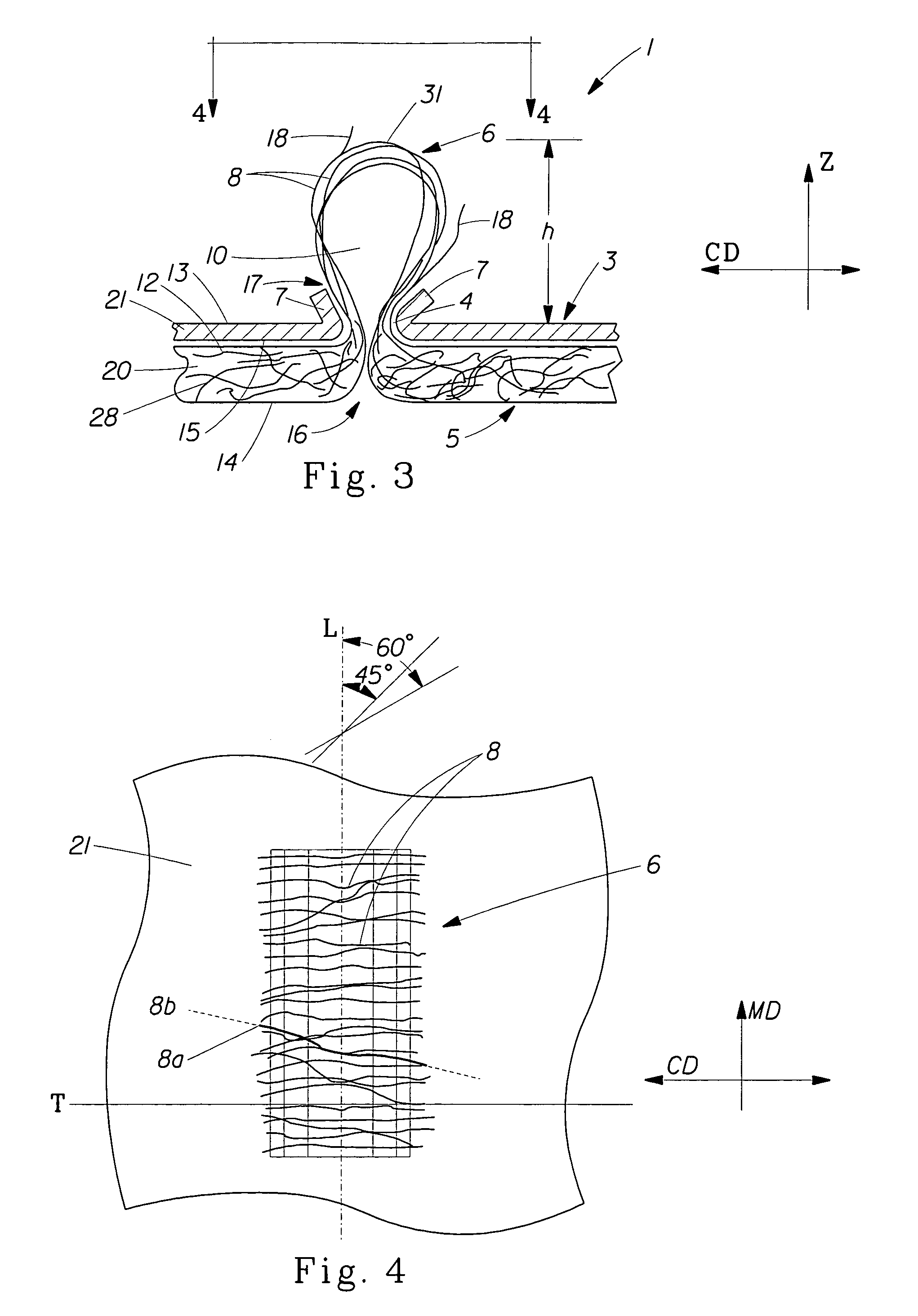

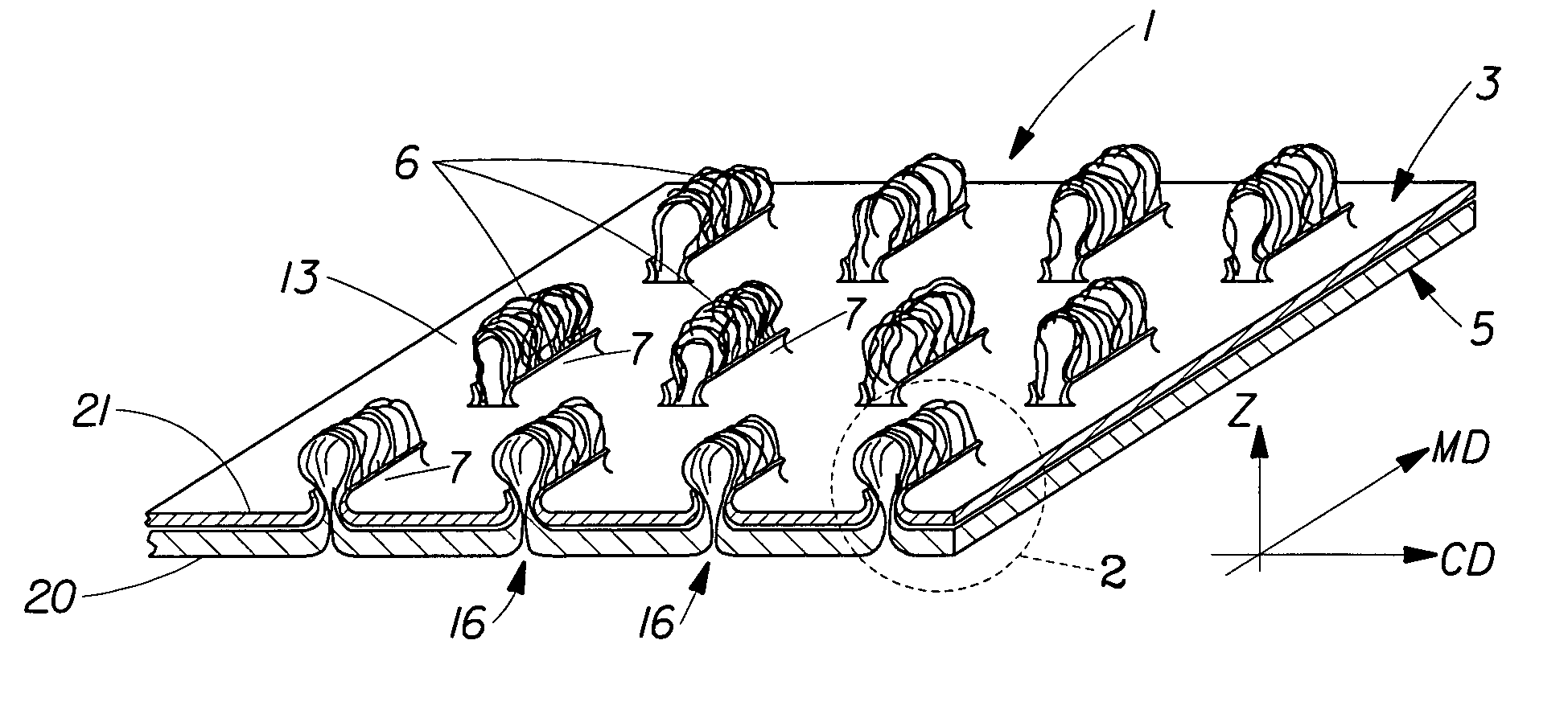

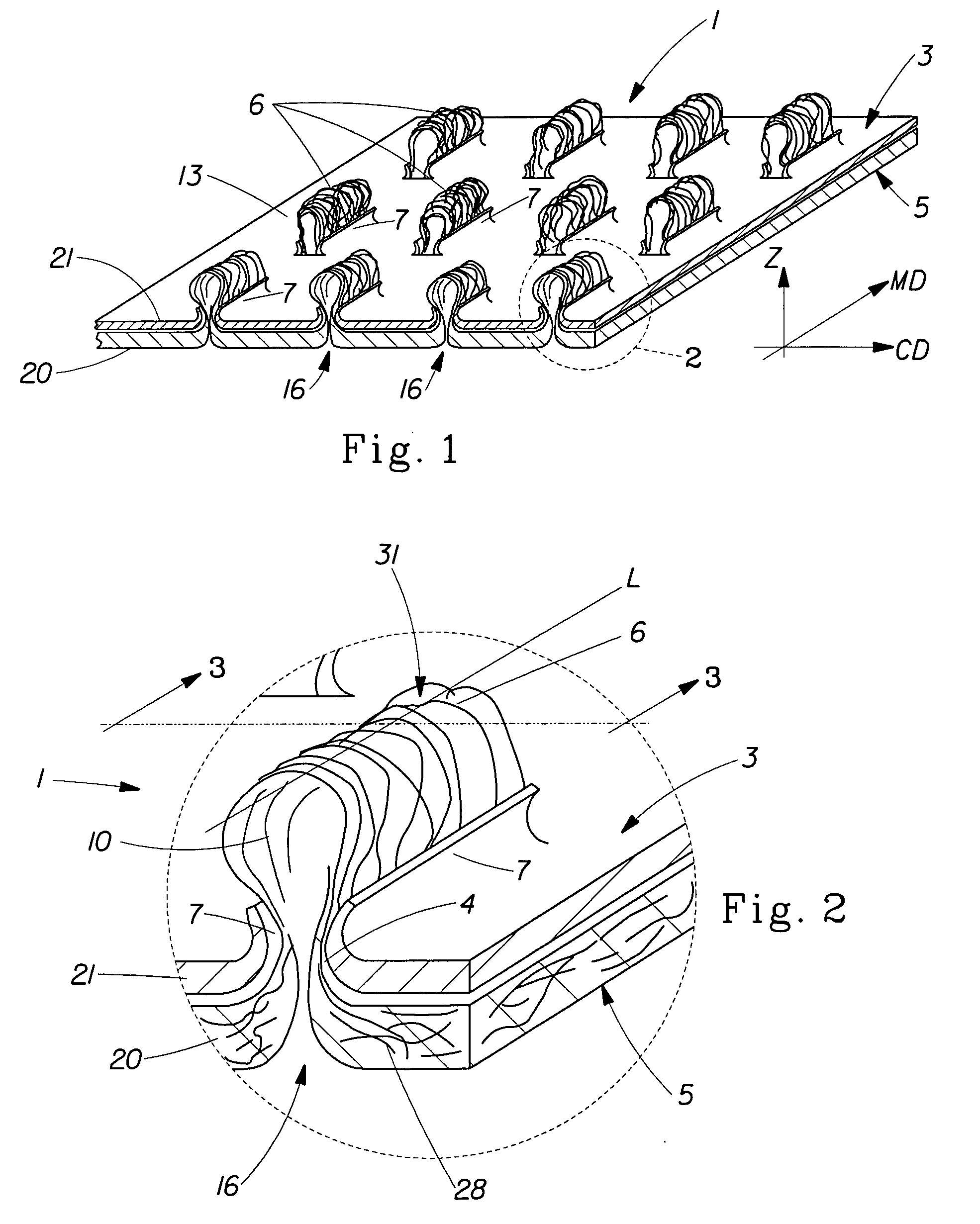

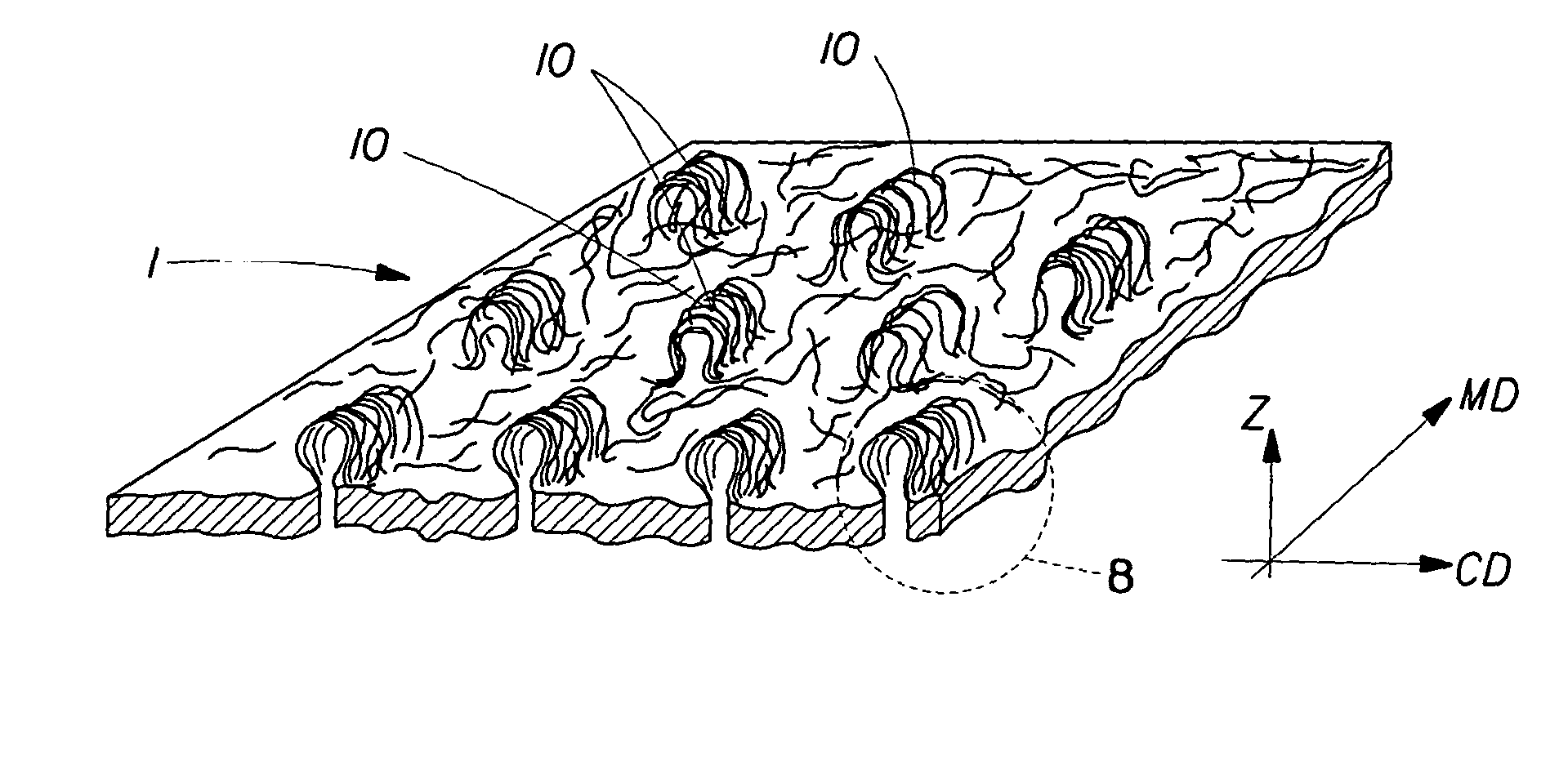

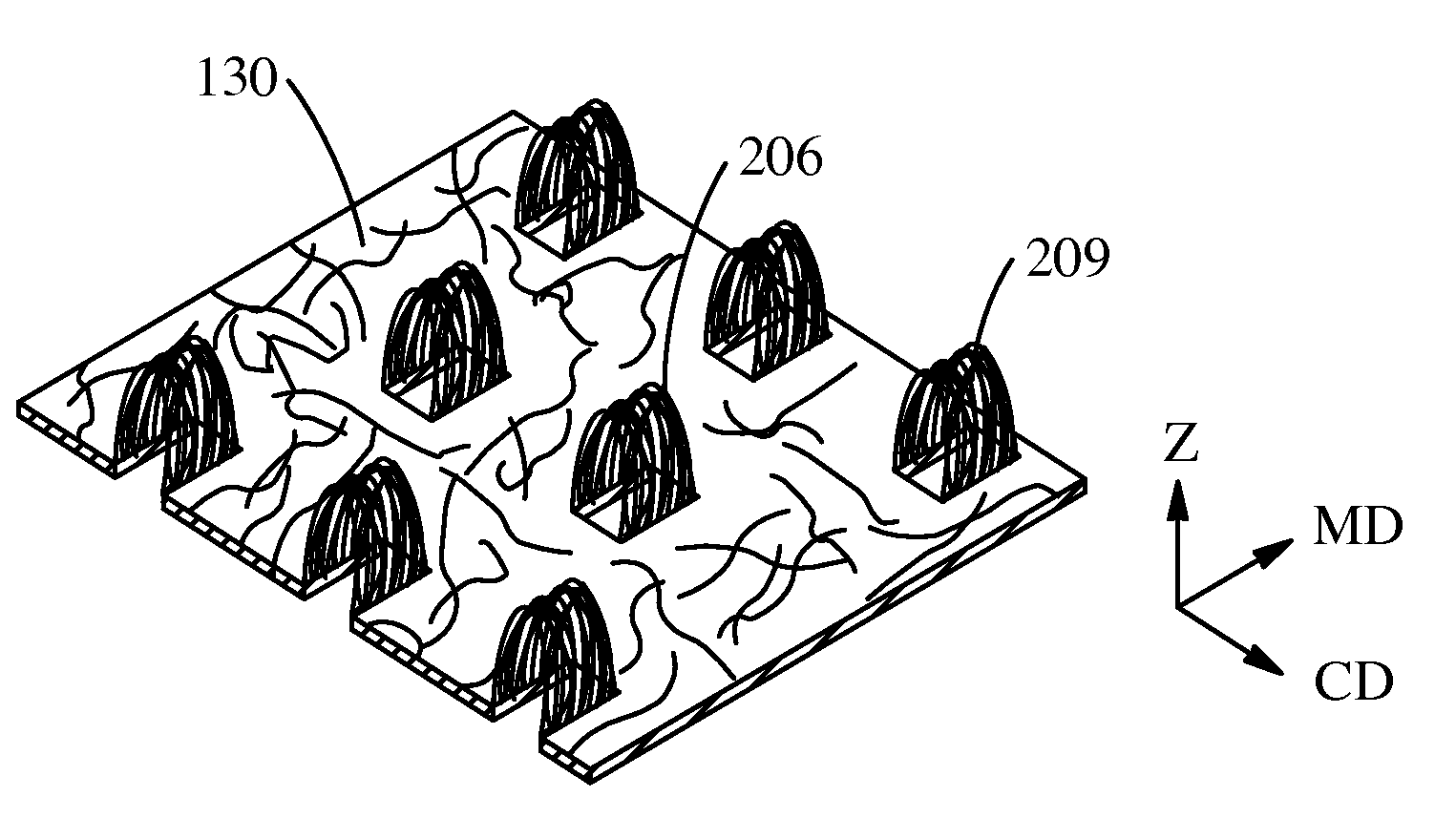

Tufted fibrous web

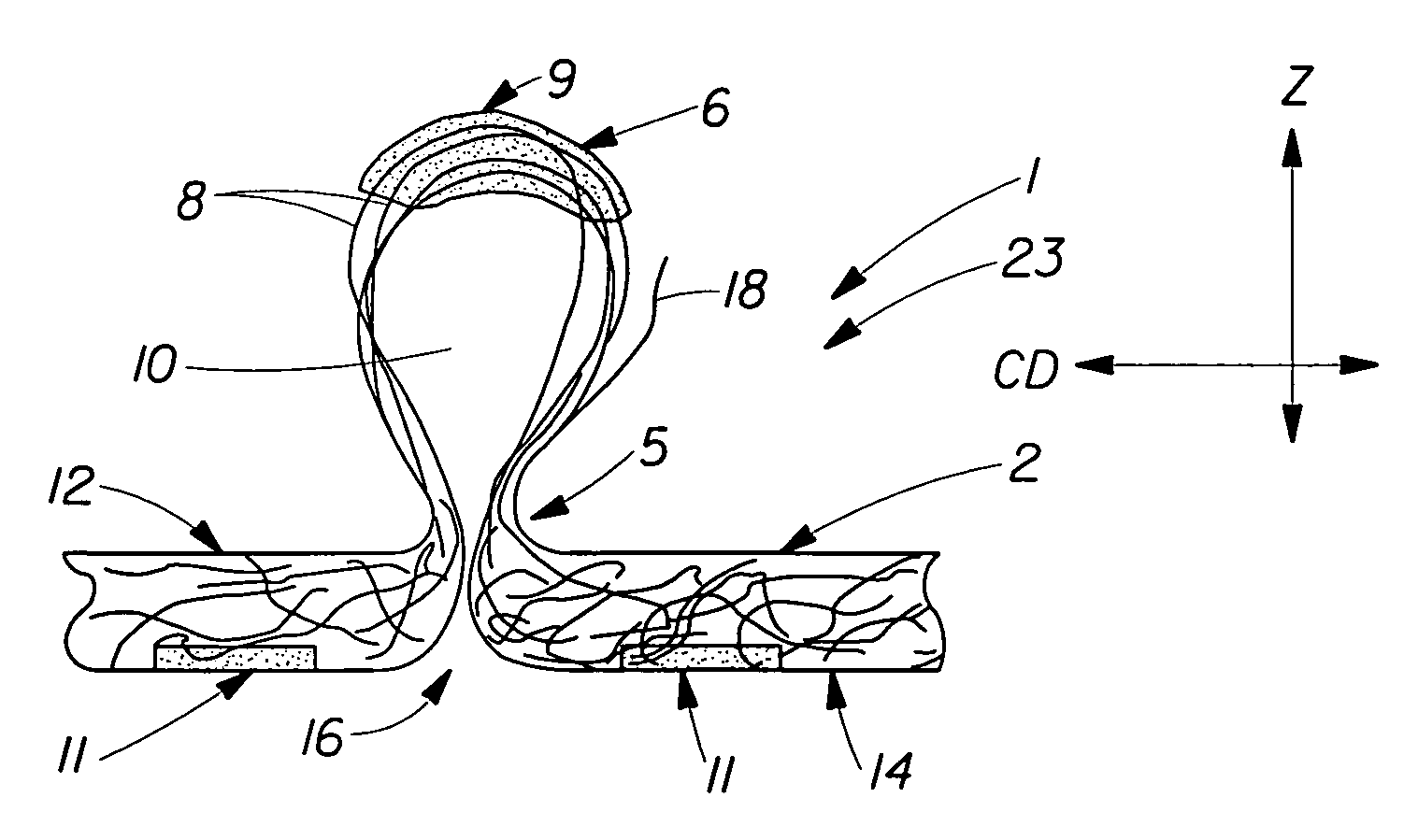

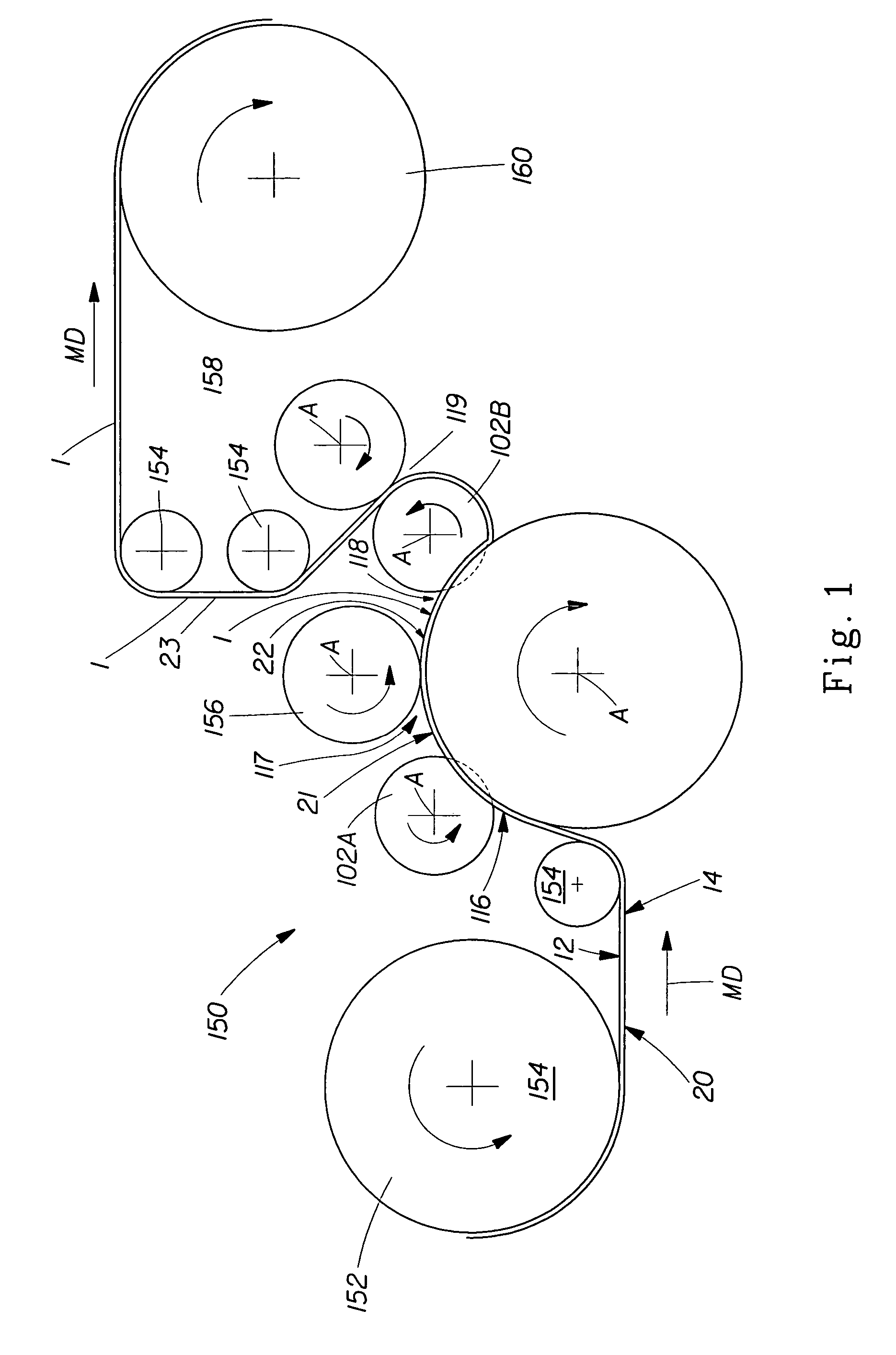

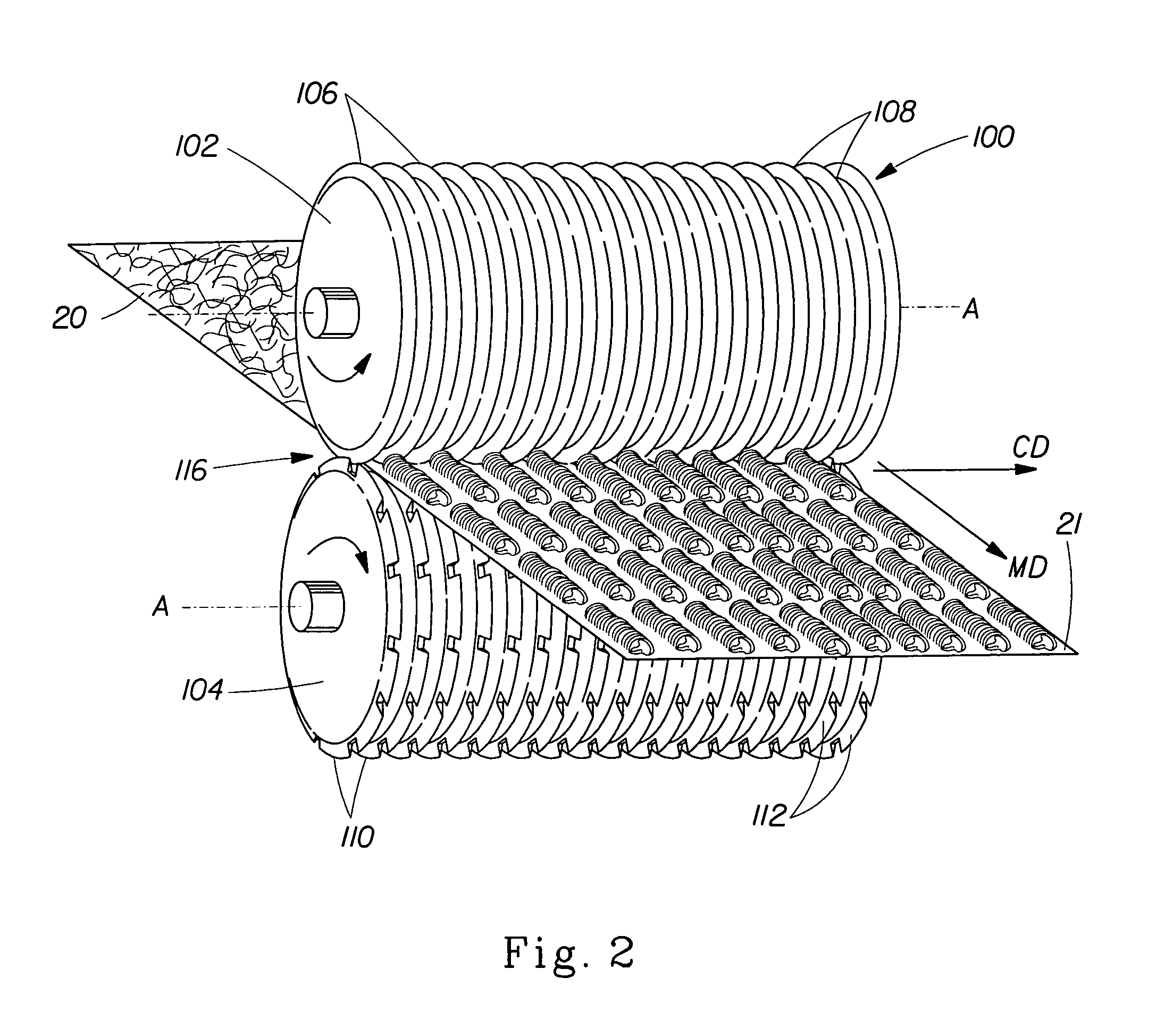

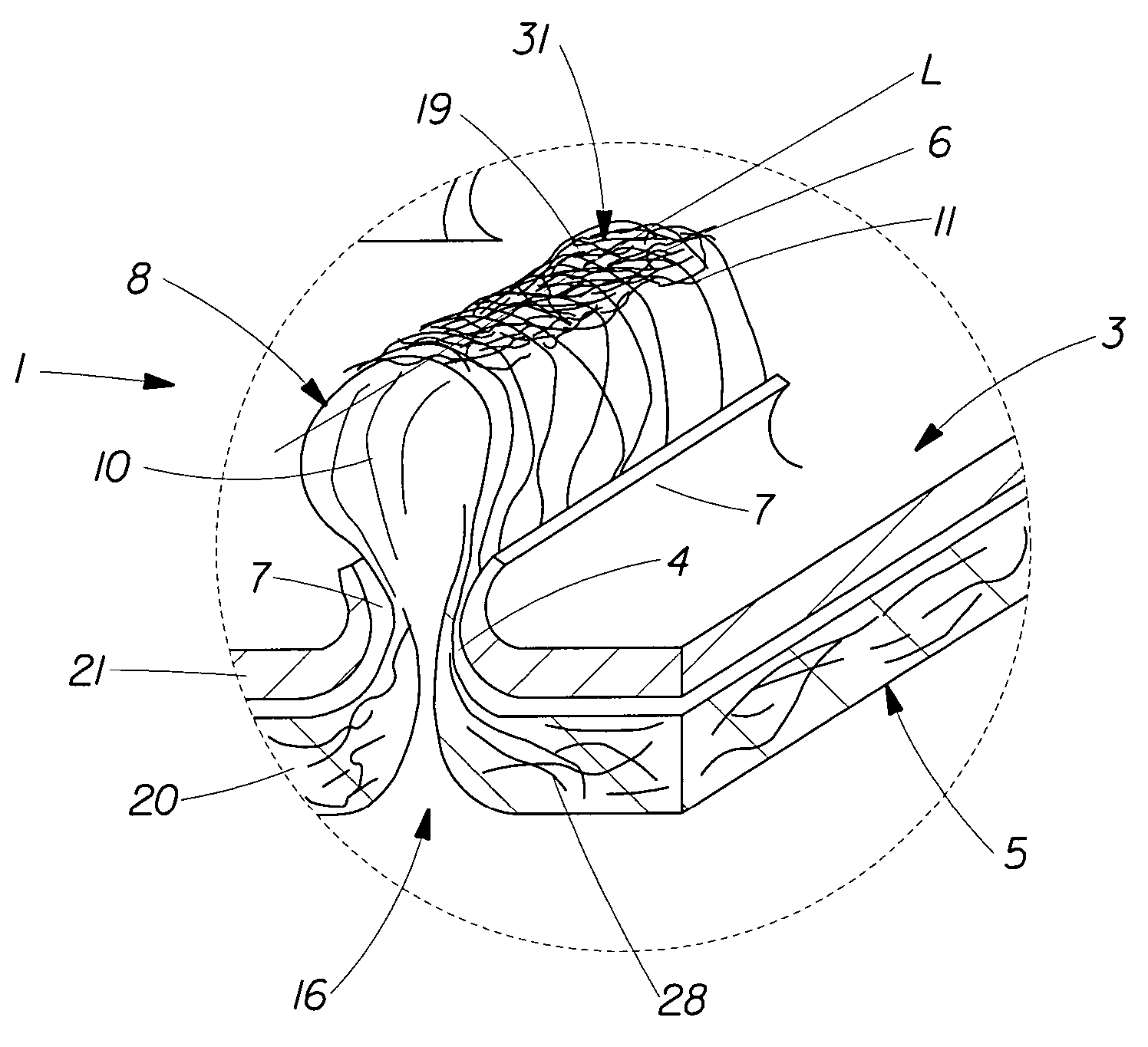

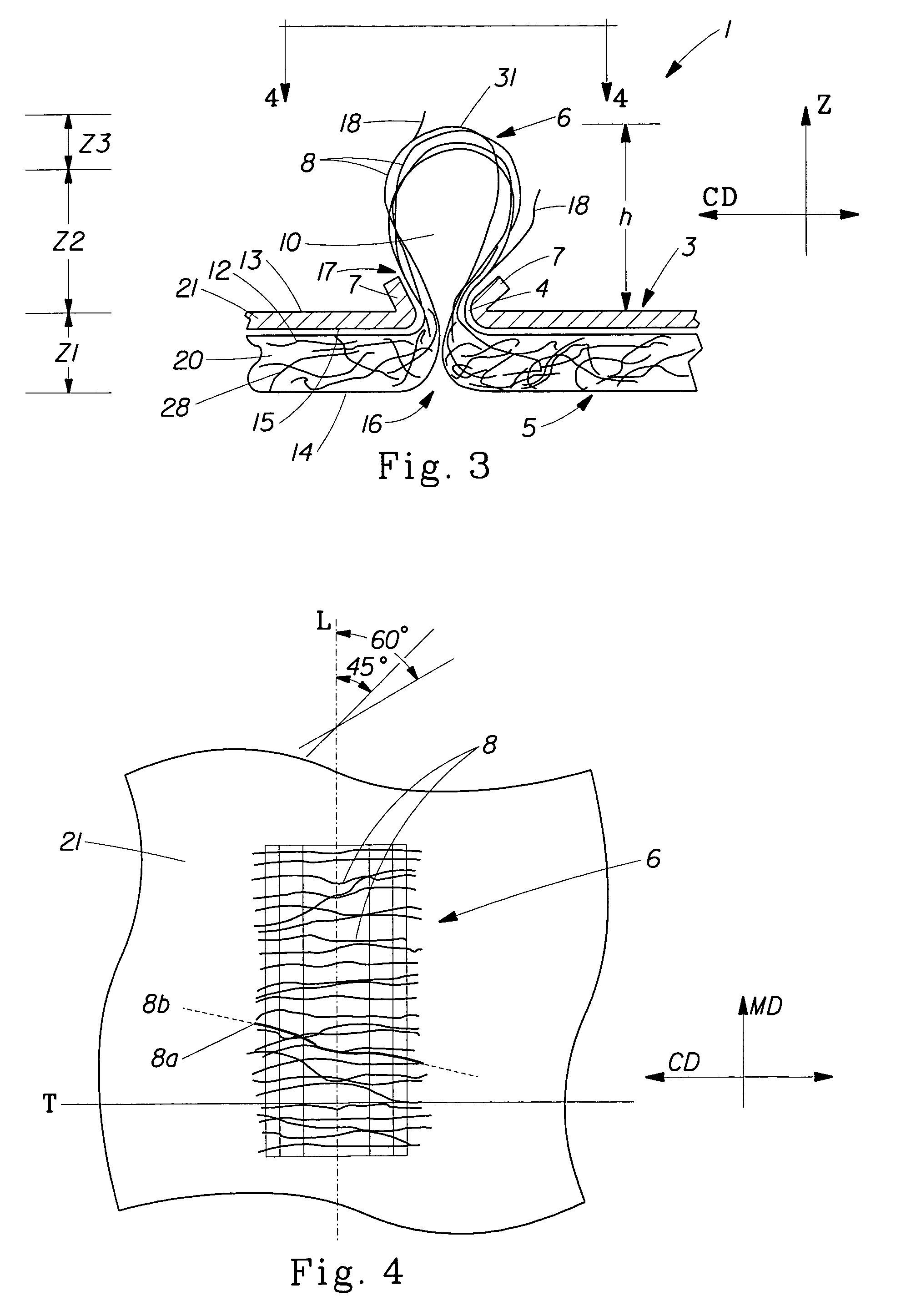

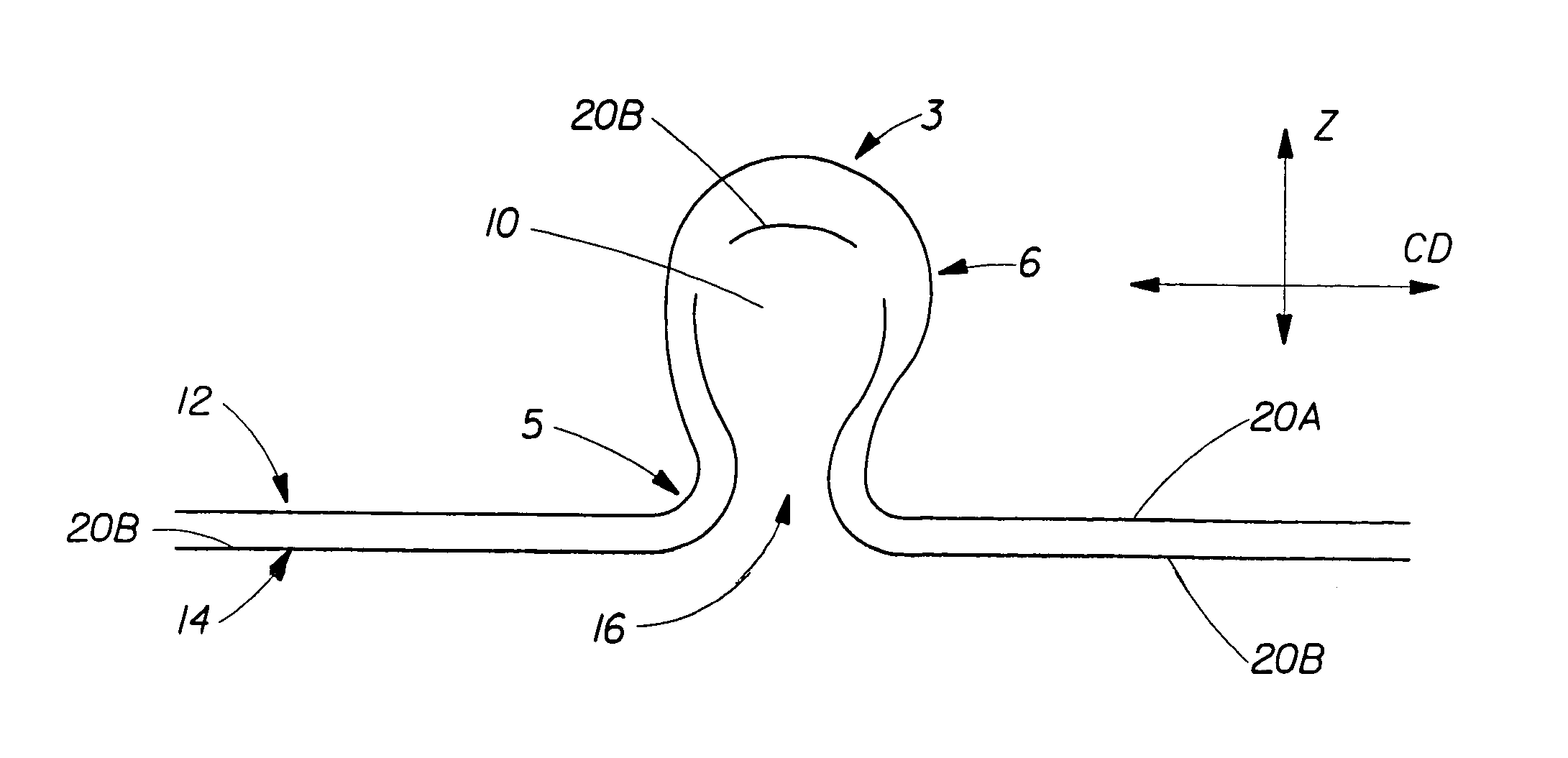

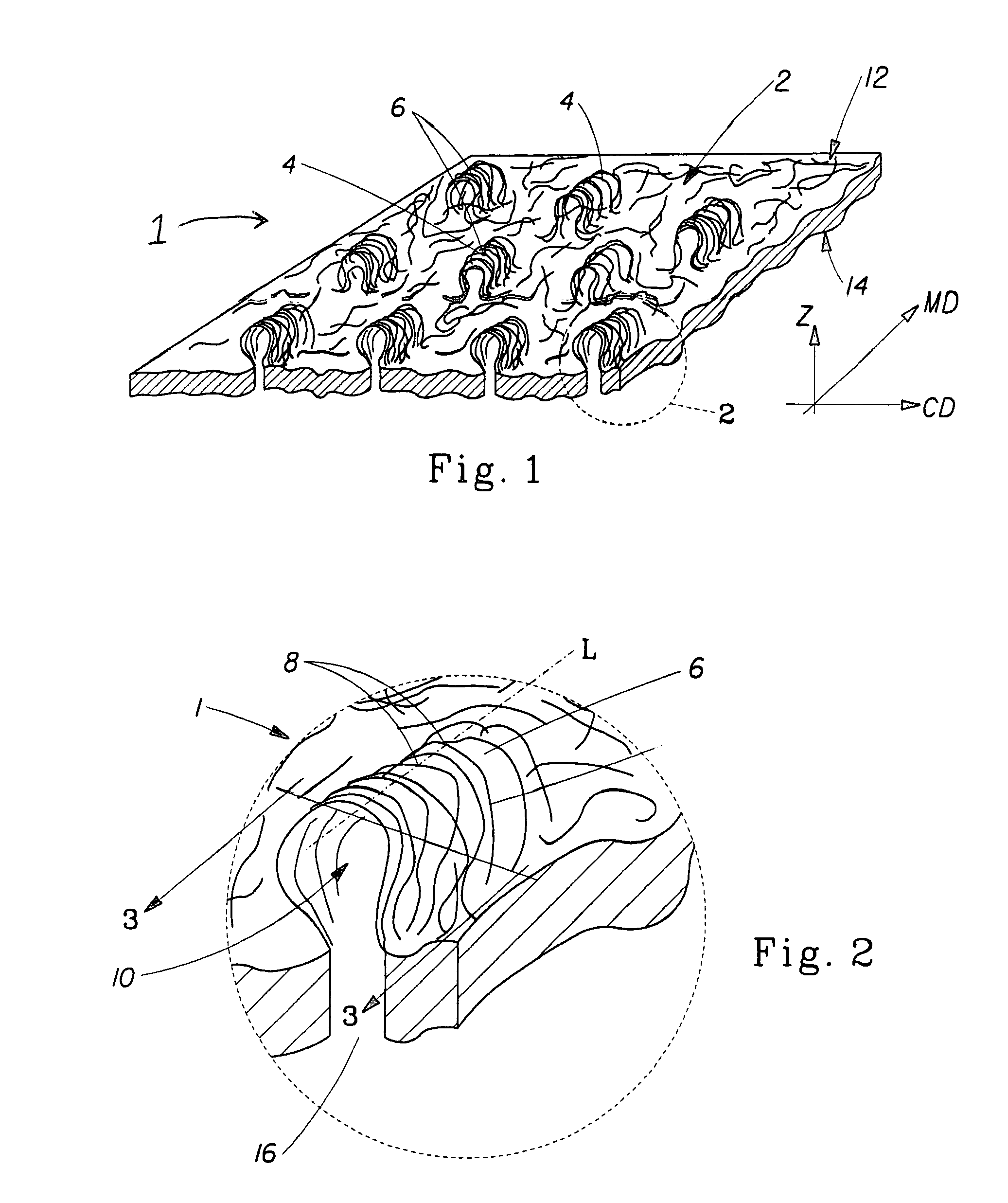

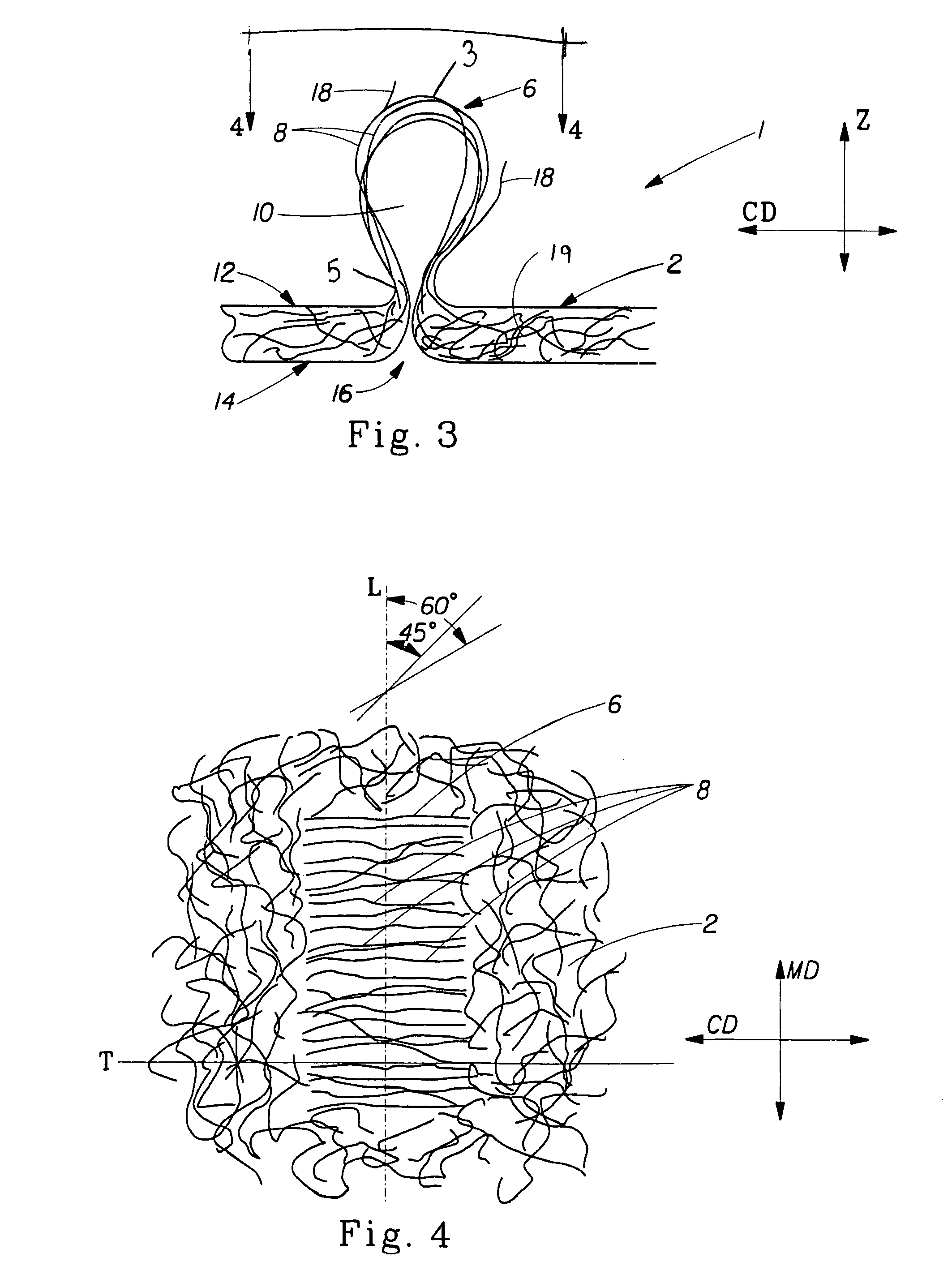

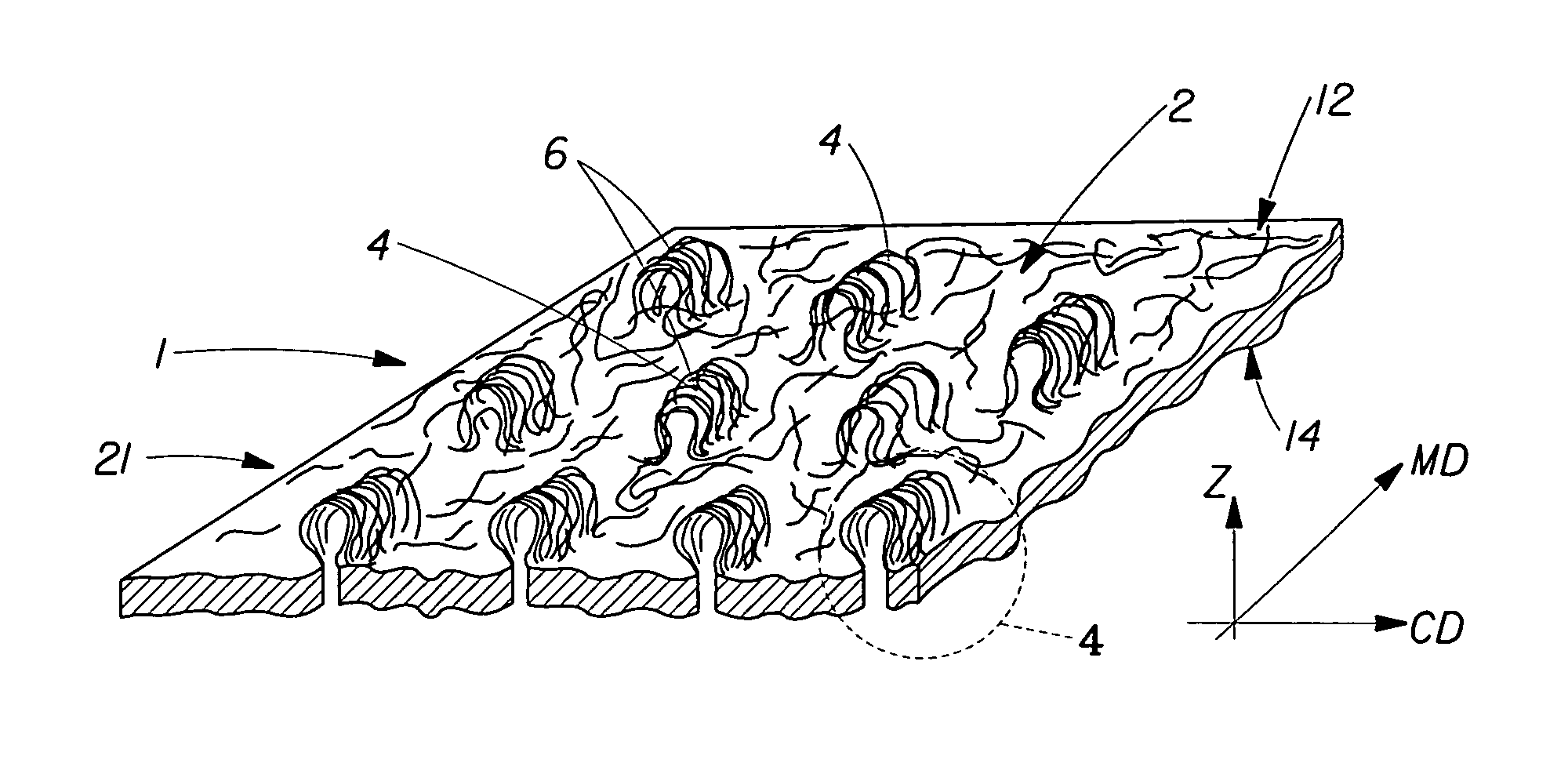

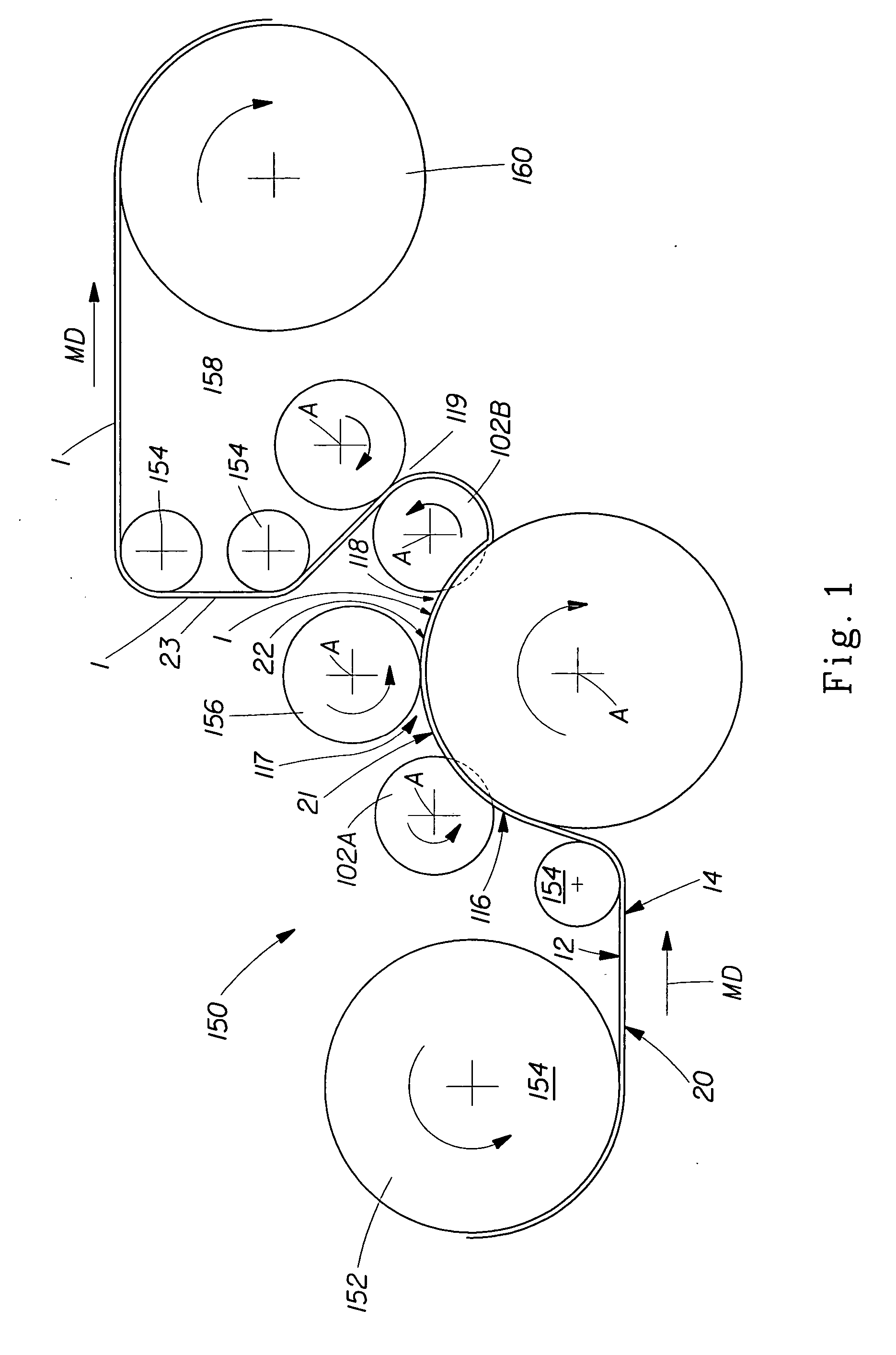

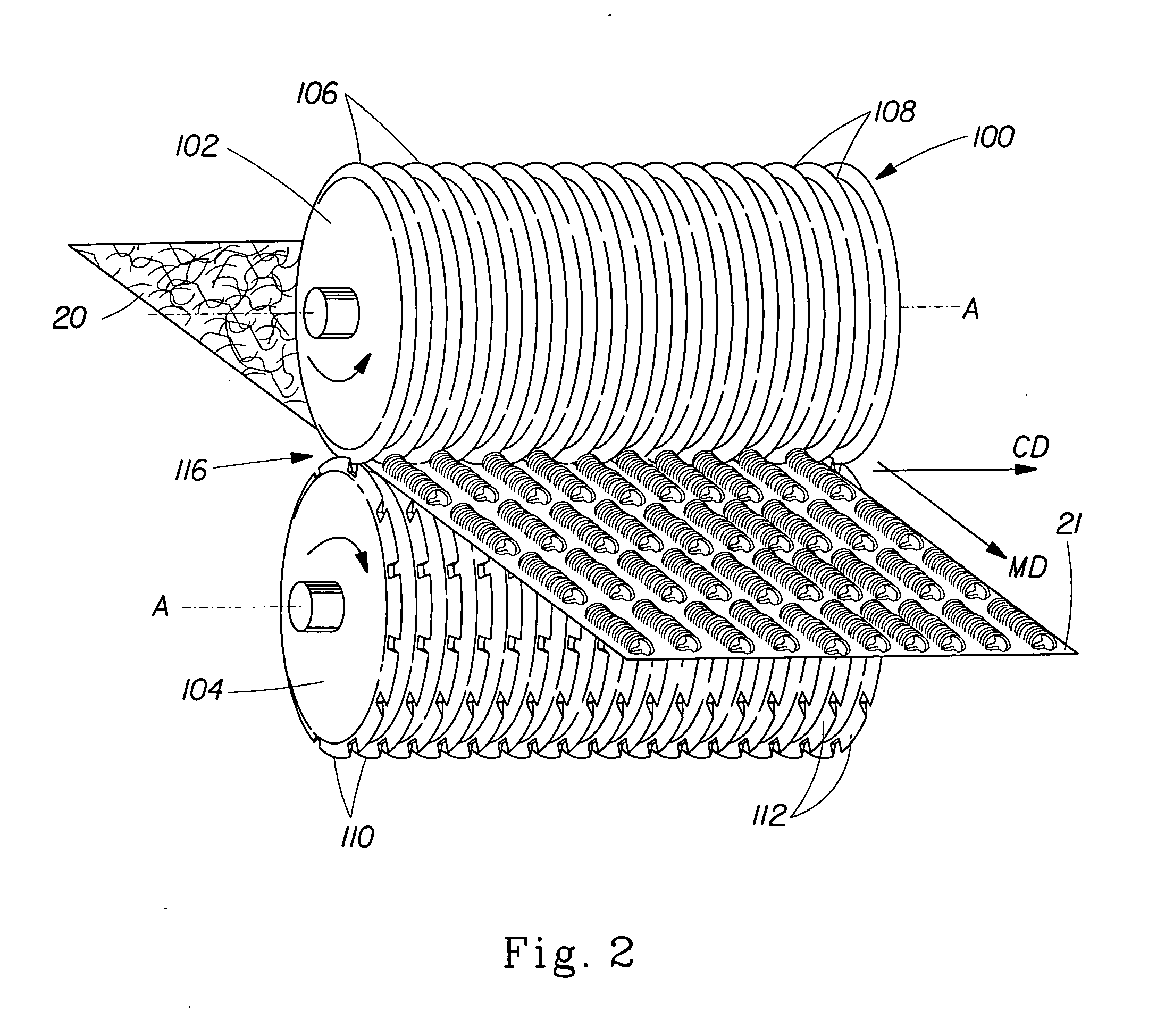

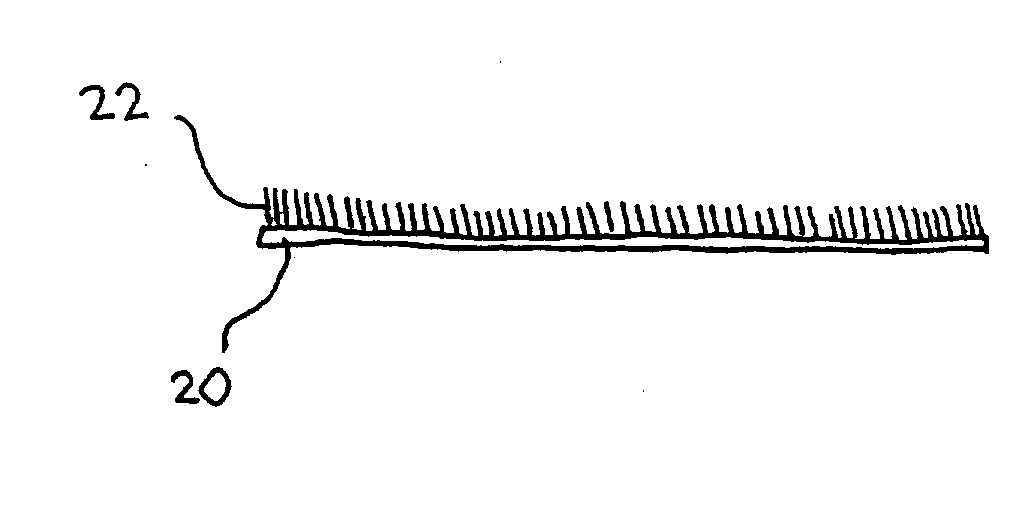

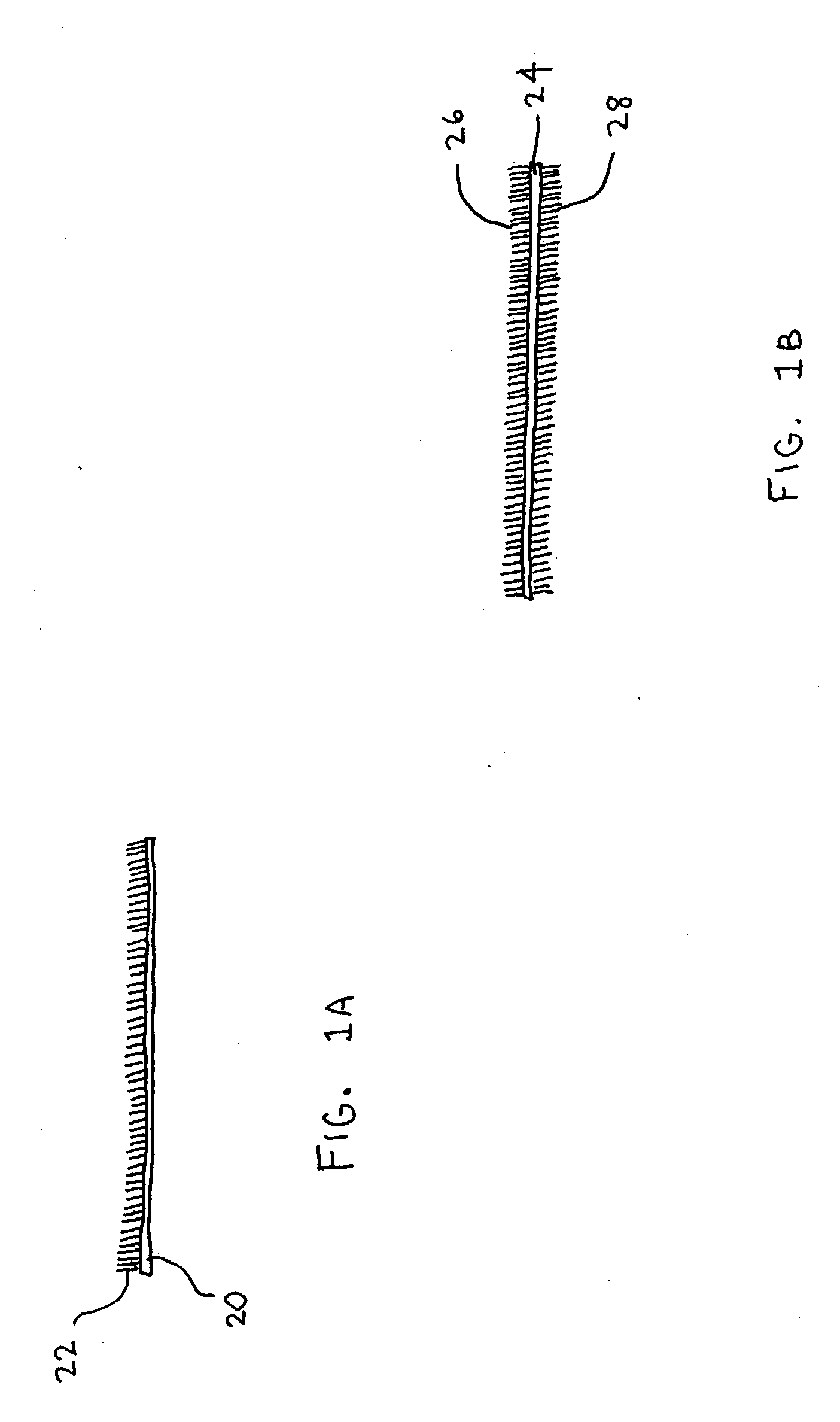

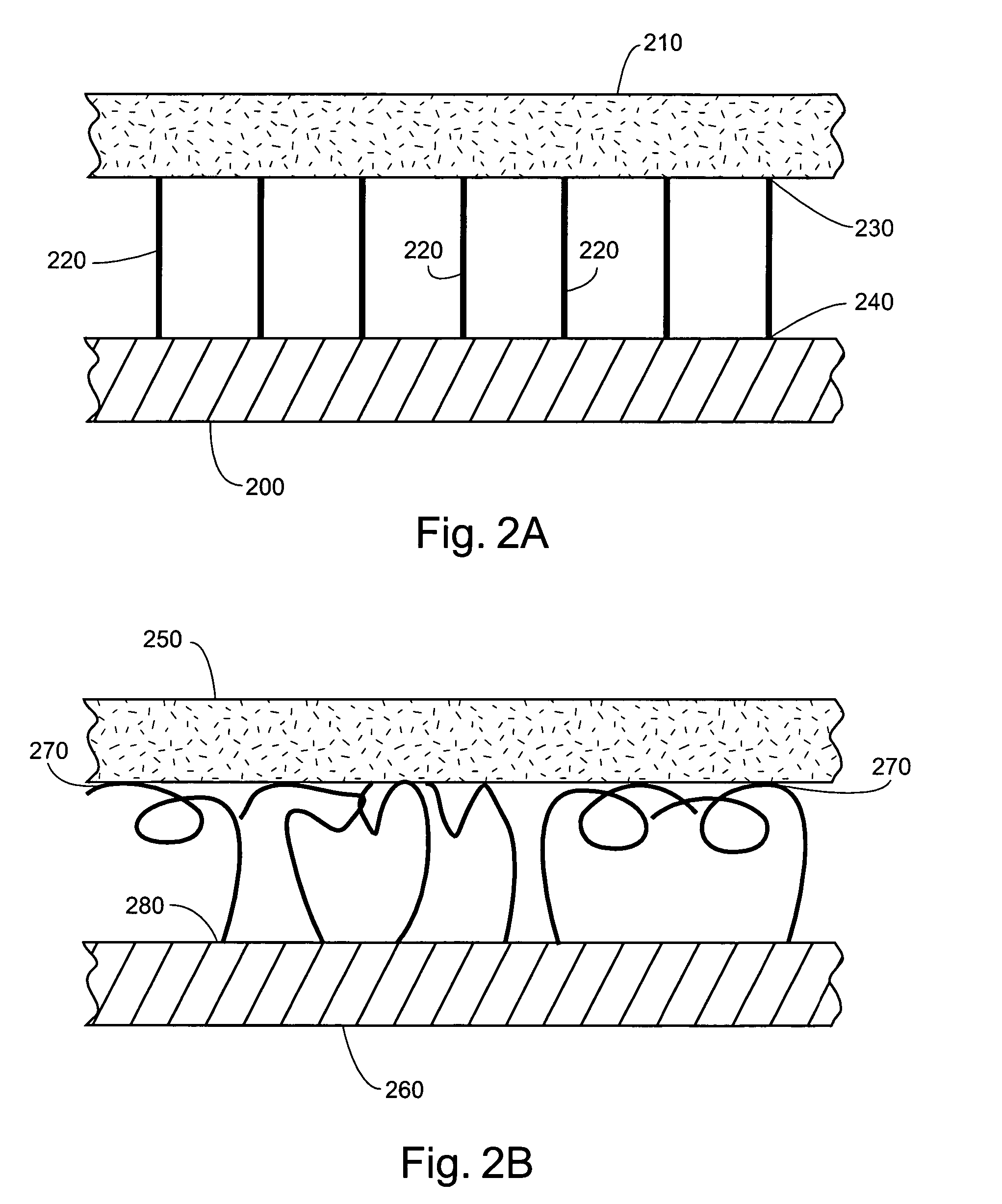

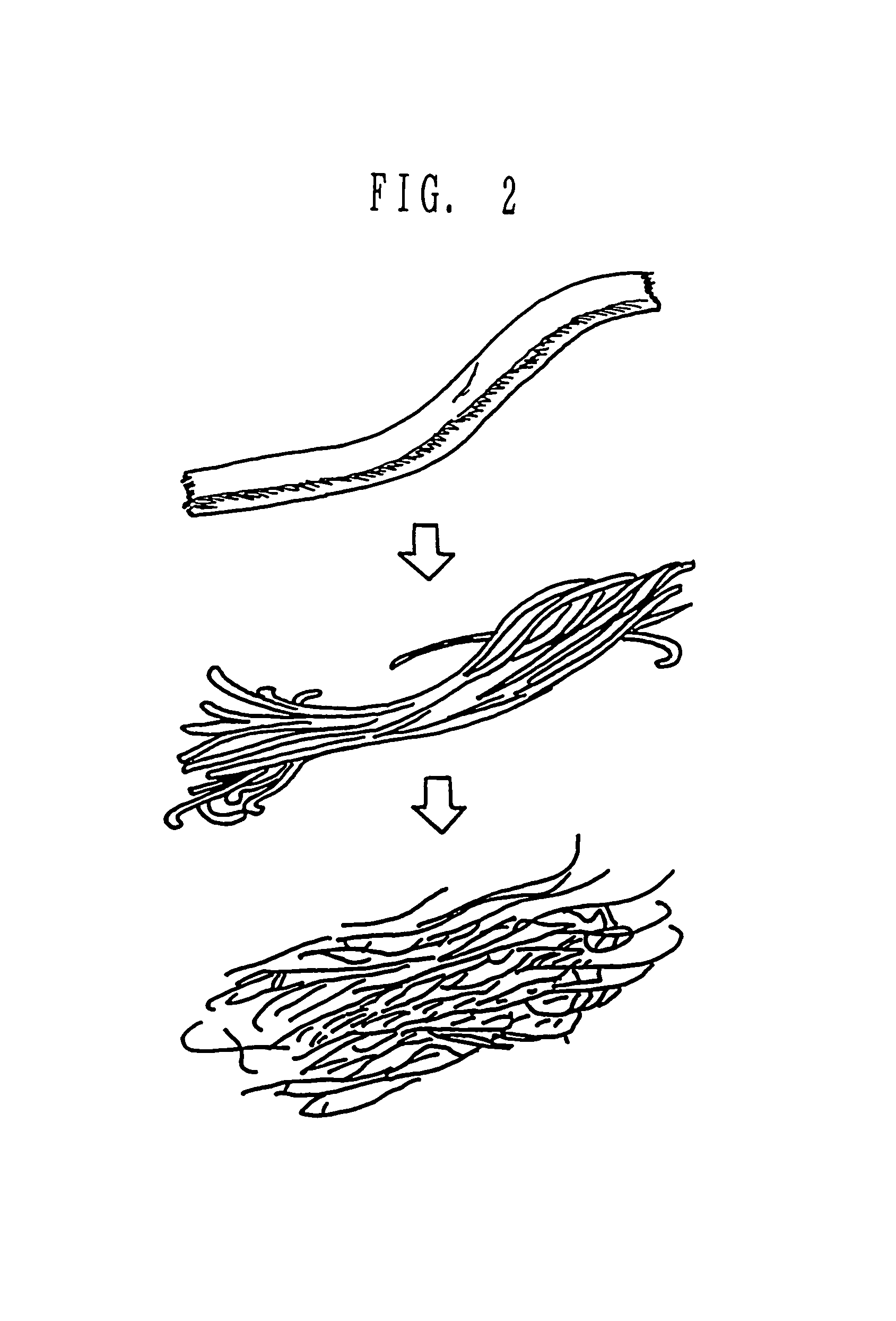

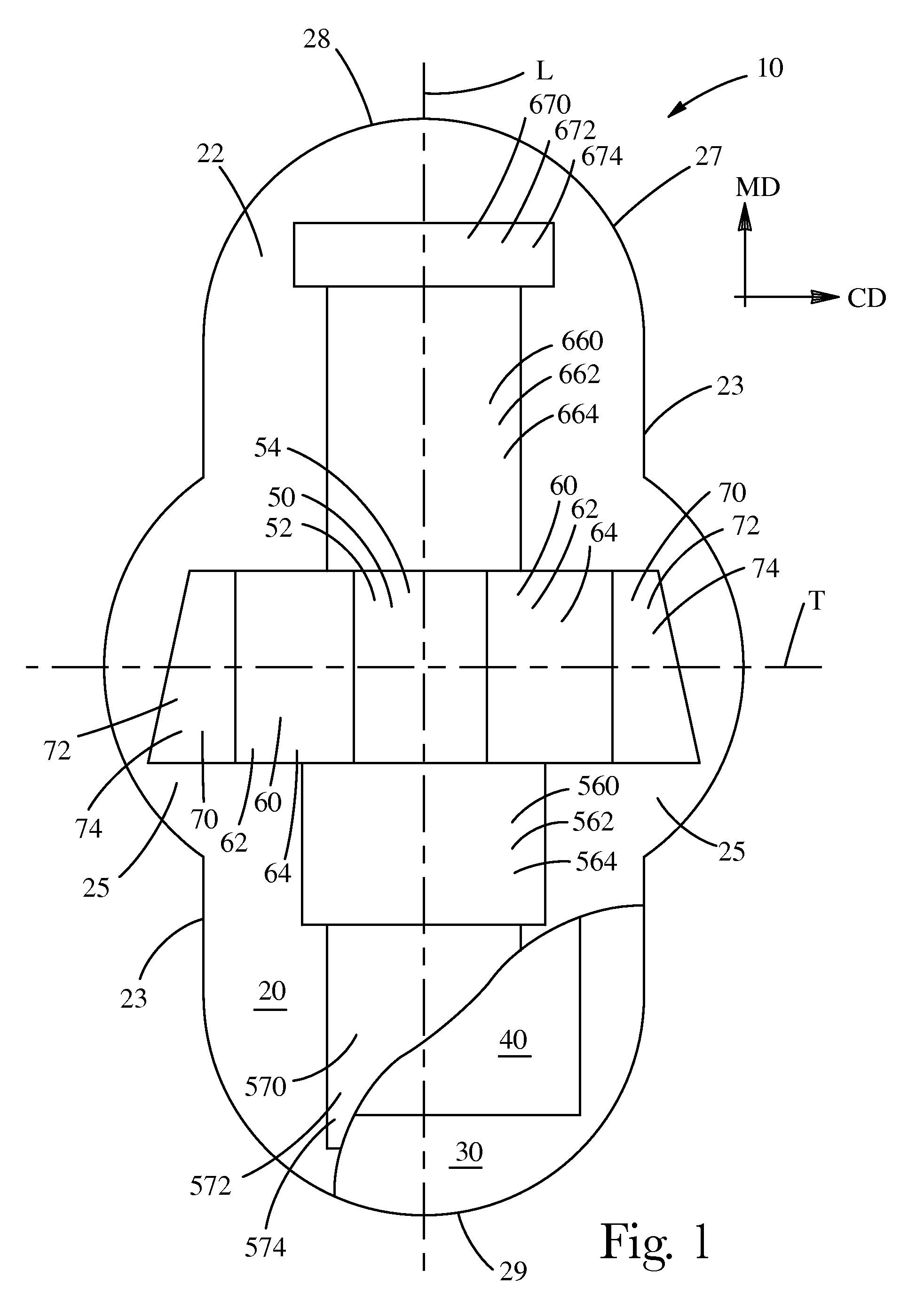

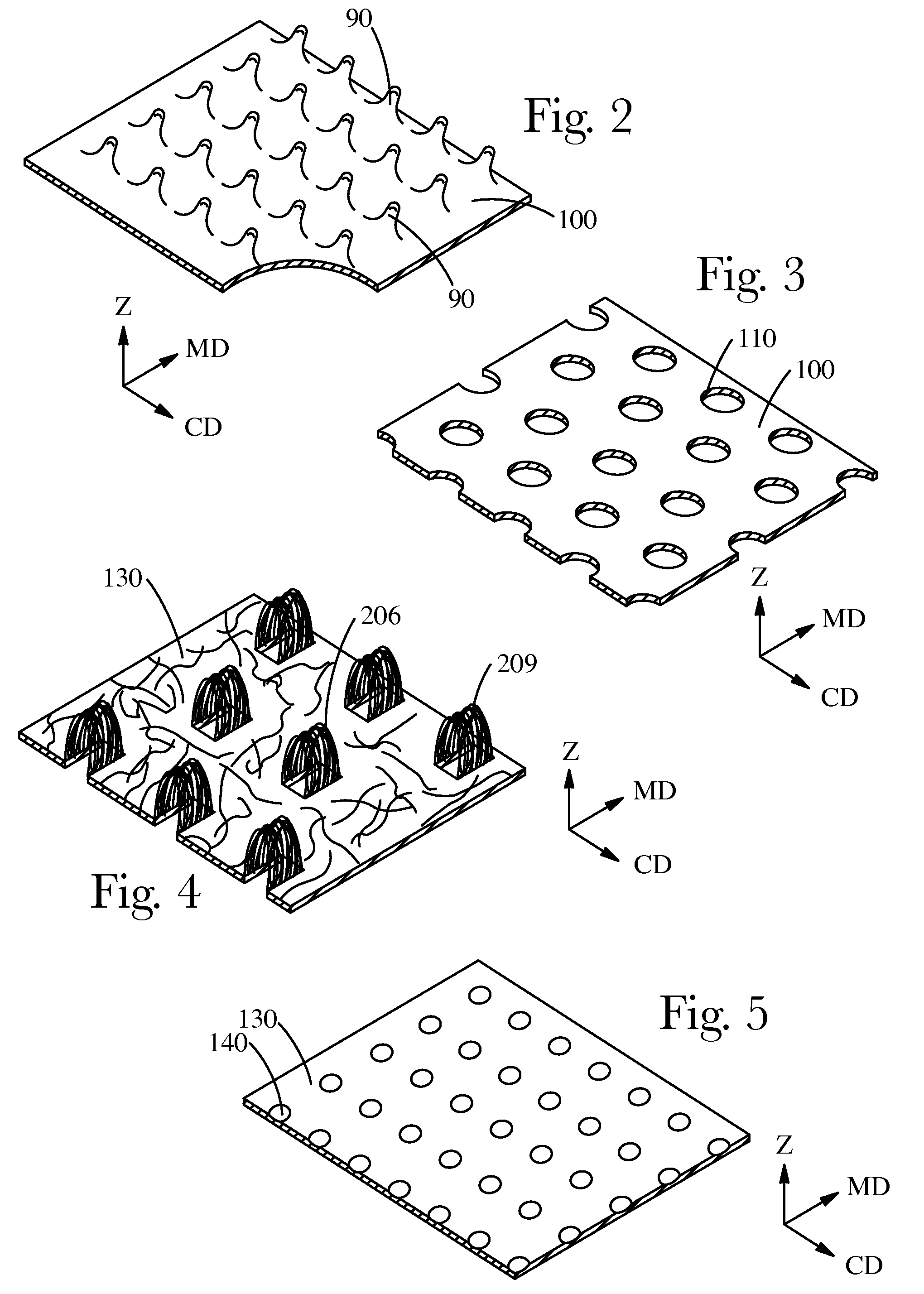

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:PROCTER & GAMBLE CO

Tufted laminate web

Owner:PROCTER & GAMBLE CO

Tufted laminate web

An absorbent article comprising a topsheet, a backsheet, and an absorbent core disposed between the topsheet and the backsheet is disclosed. The topsheet has a first side and a second side, the first side being a body-facing side and the second side being in fluid communication with the absorbent core. The topsheet also has a first relatively hydrophobic component and a second relatively hydrophilic component, the relatively hydrophilic component extending through the relatively hydrophobic component and being disposed on both of the sides of the topsheet. The absorbent article exhibits a rewet value of less than about 94 mg, and a fluid acquisition rate of at least about 0.10 ml / sec when tested by the Gush Acquisition and Rewet Test Method.

Owner:THE PROCTER & GAMBLE COMPANY

Tufted fibrous web

Owner:THE PROCTER & GAMBLE COMPANY

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:THE PROCTER & GAMBLE COMPANY

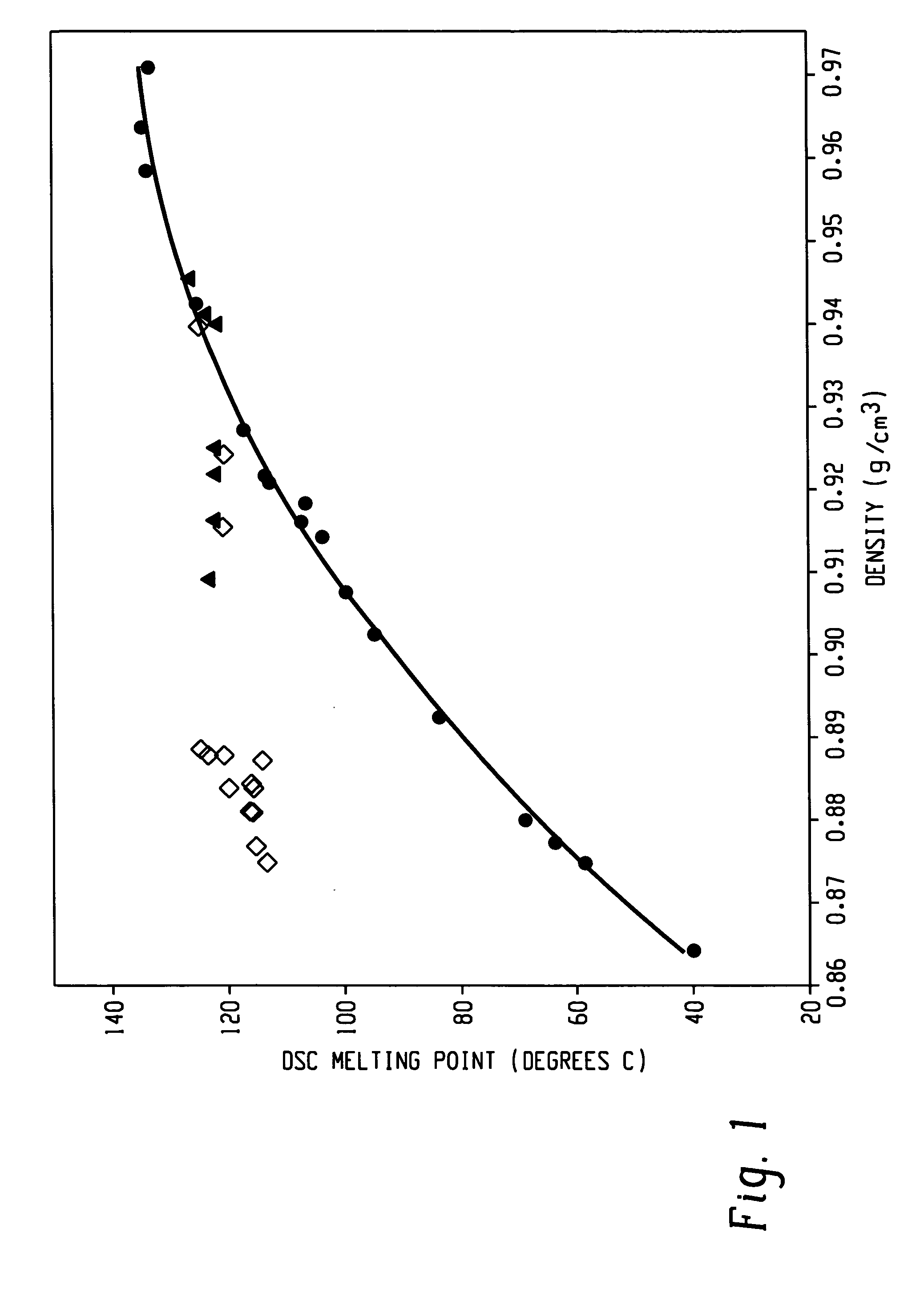

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

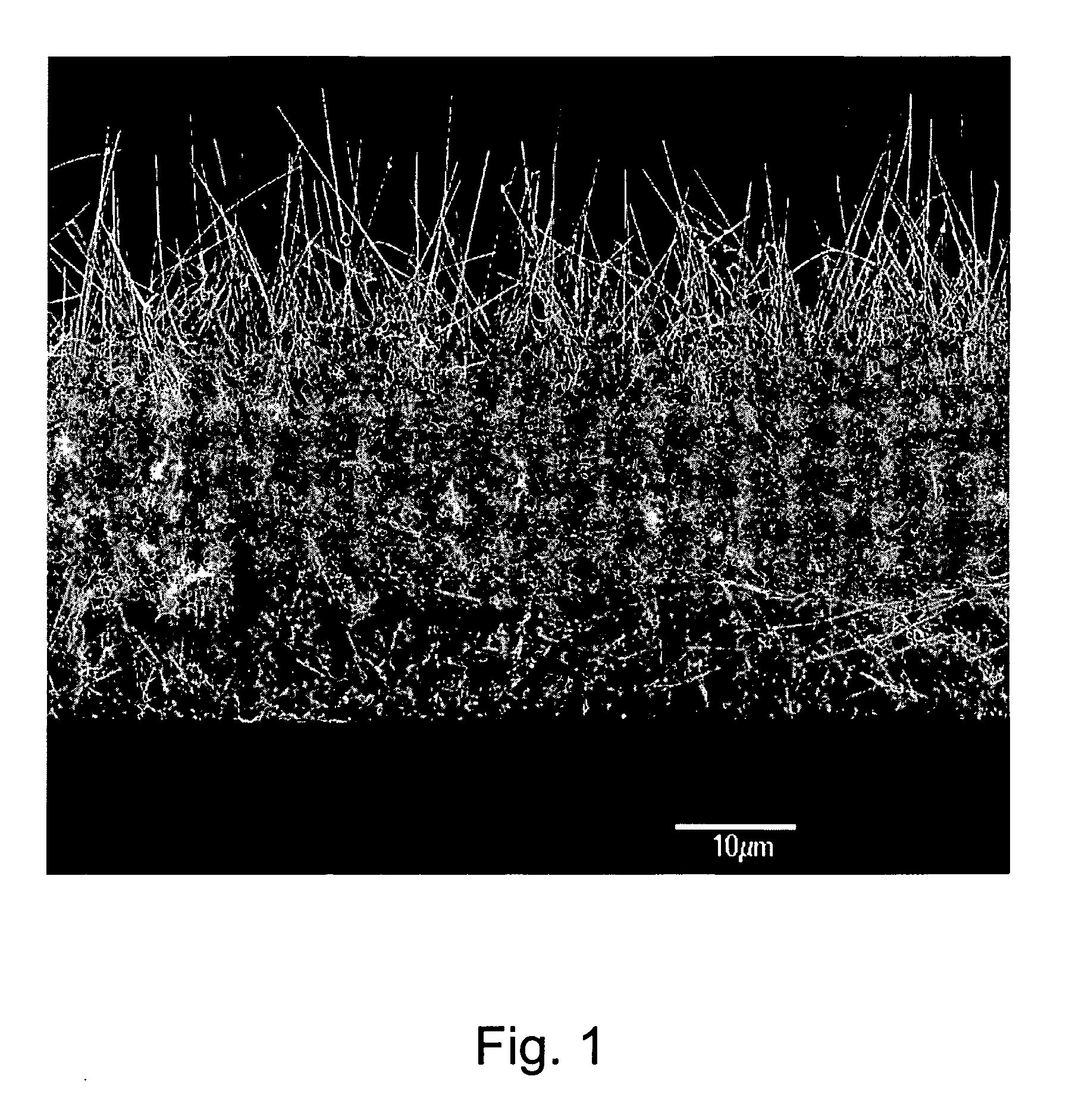

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

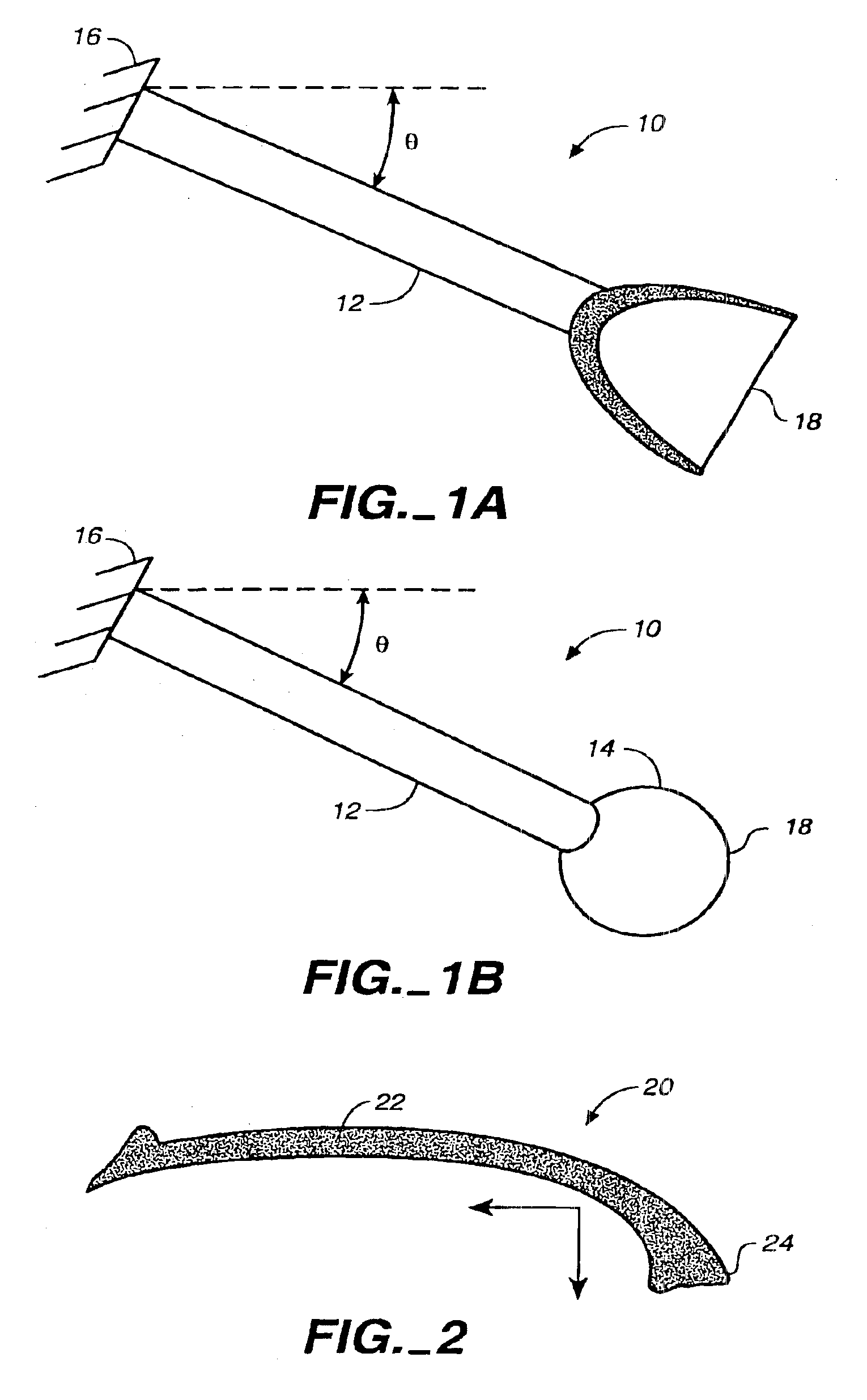

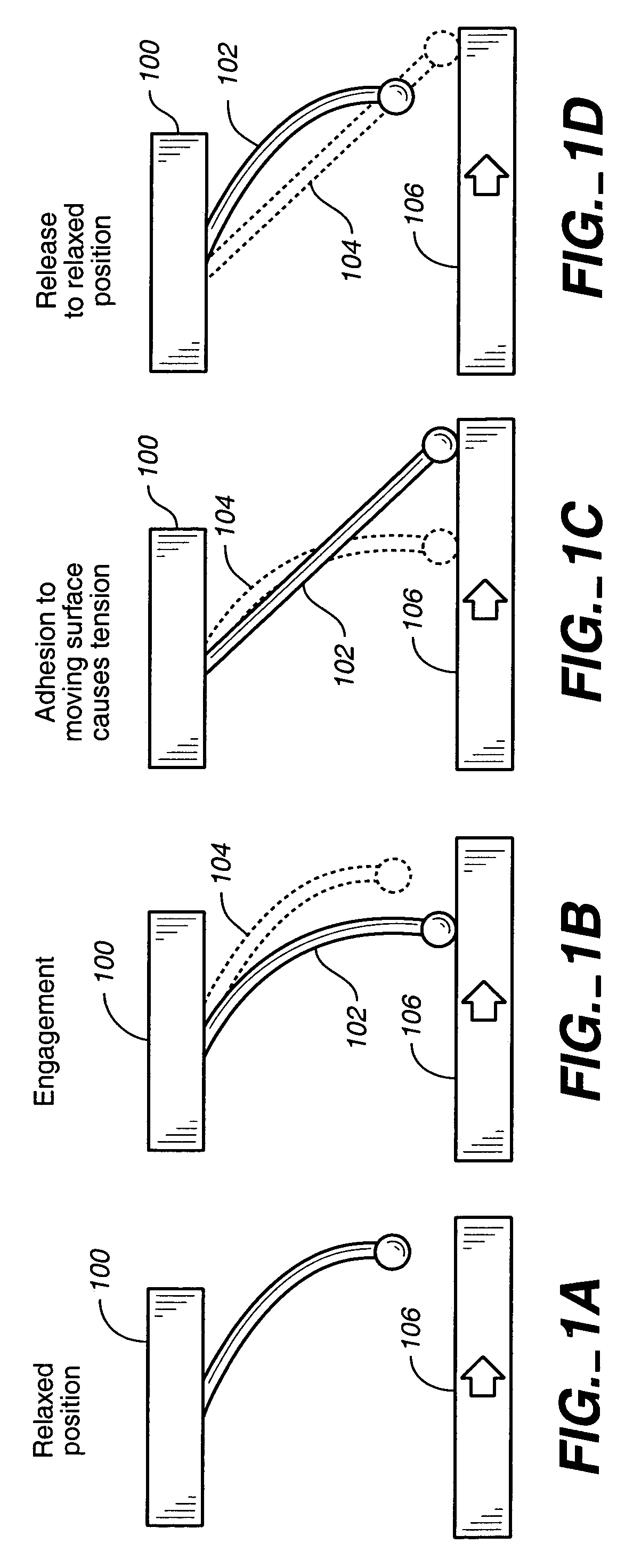

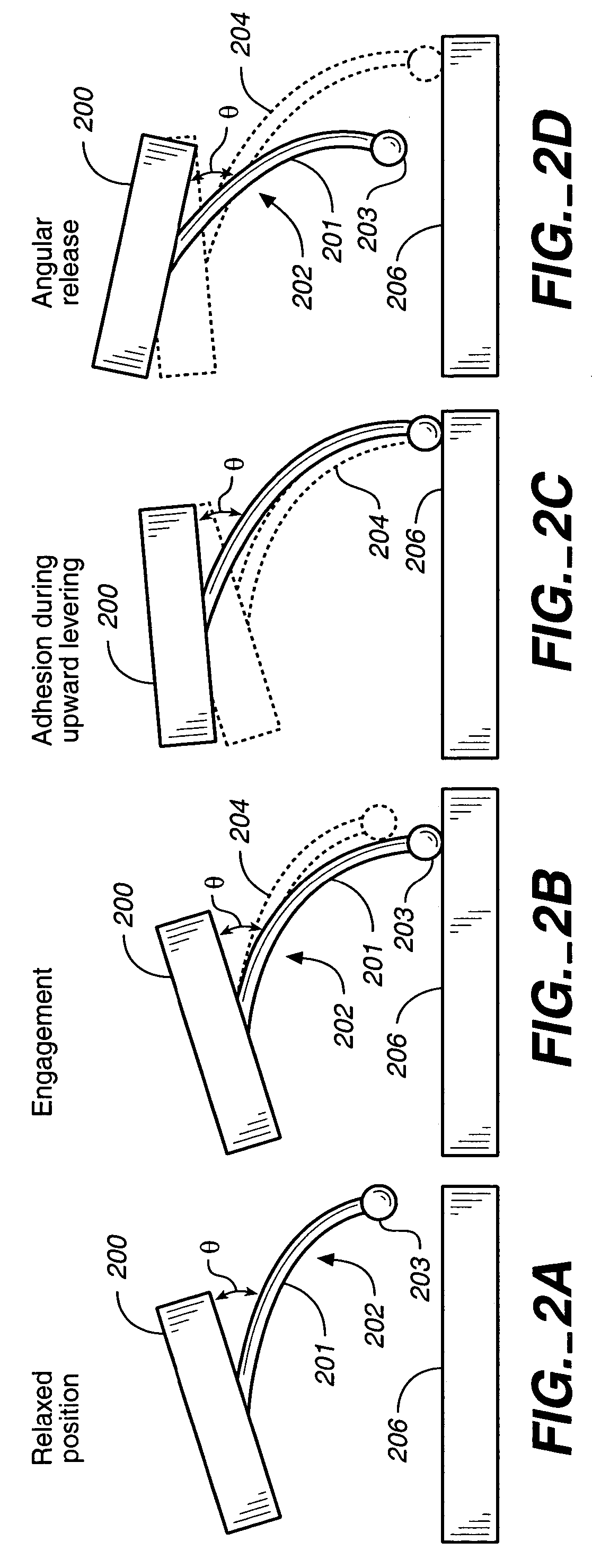

Adhesive microstructure and method of forming same

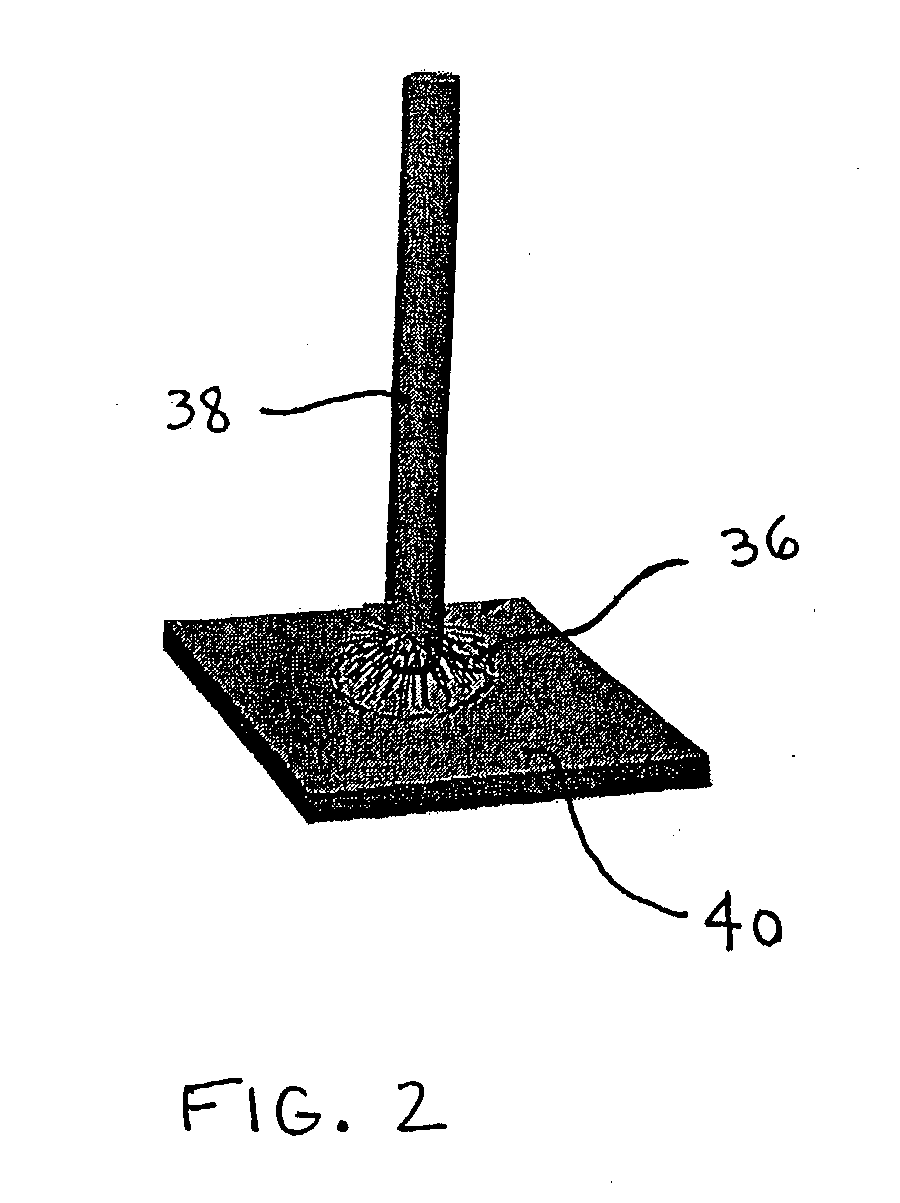

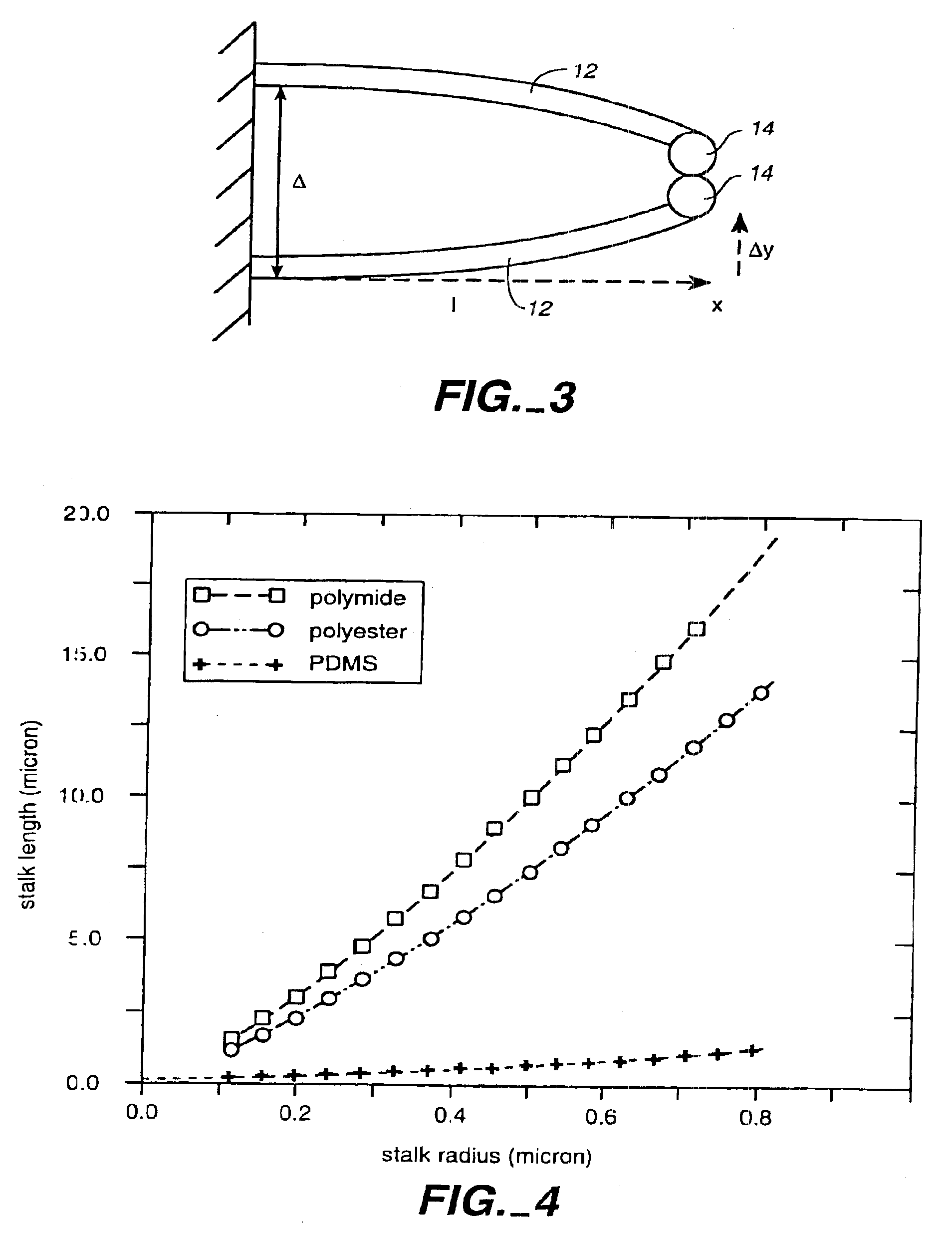

InactiveUS6872439B2Improve adhesionEasy to disengageSnap fastenersMaterial nanotechnologyMicroscopic scaleOblique angle

A fabricated microstructure comprising at least one protrusion capable of providing an adhesive force at a surface of between about 60 and 2,000 nano-Newtons. A stalk supports the protrusion at an oblique angle relative to a supporting surface. The microstructure can adhere to different surfaces.

Owner:RGT UNIV OF CALIFORNIA

Looped nonwoven web

Owner:PROCTER & GAMBLE CO

Carpet Construction and Carpet Backings for Same

Owner:PROPEX OPERATING

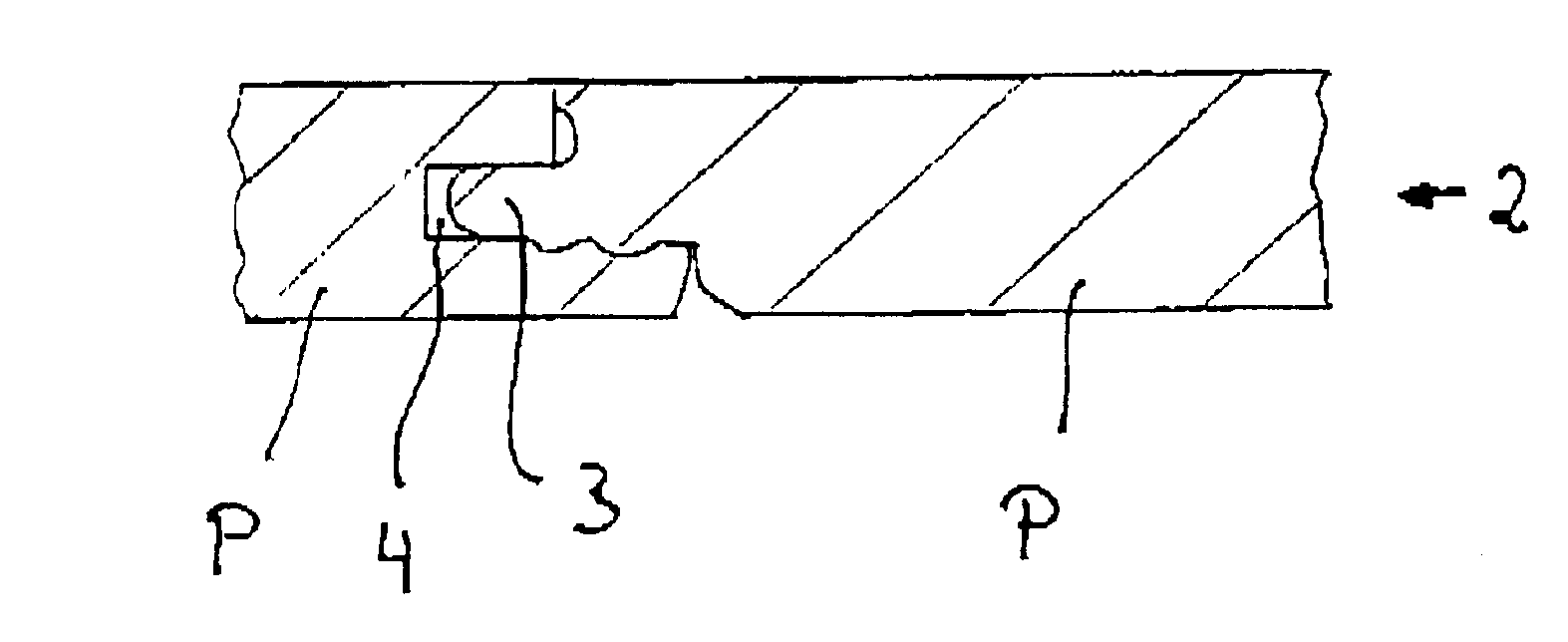

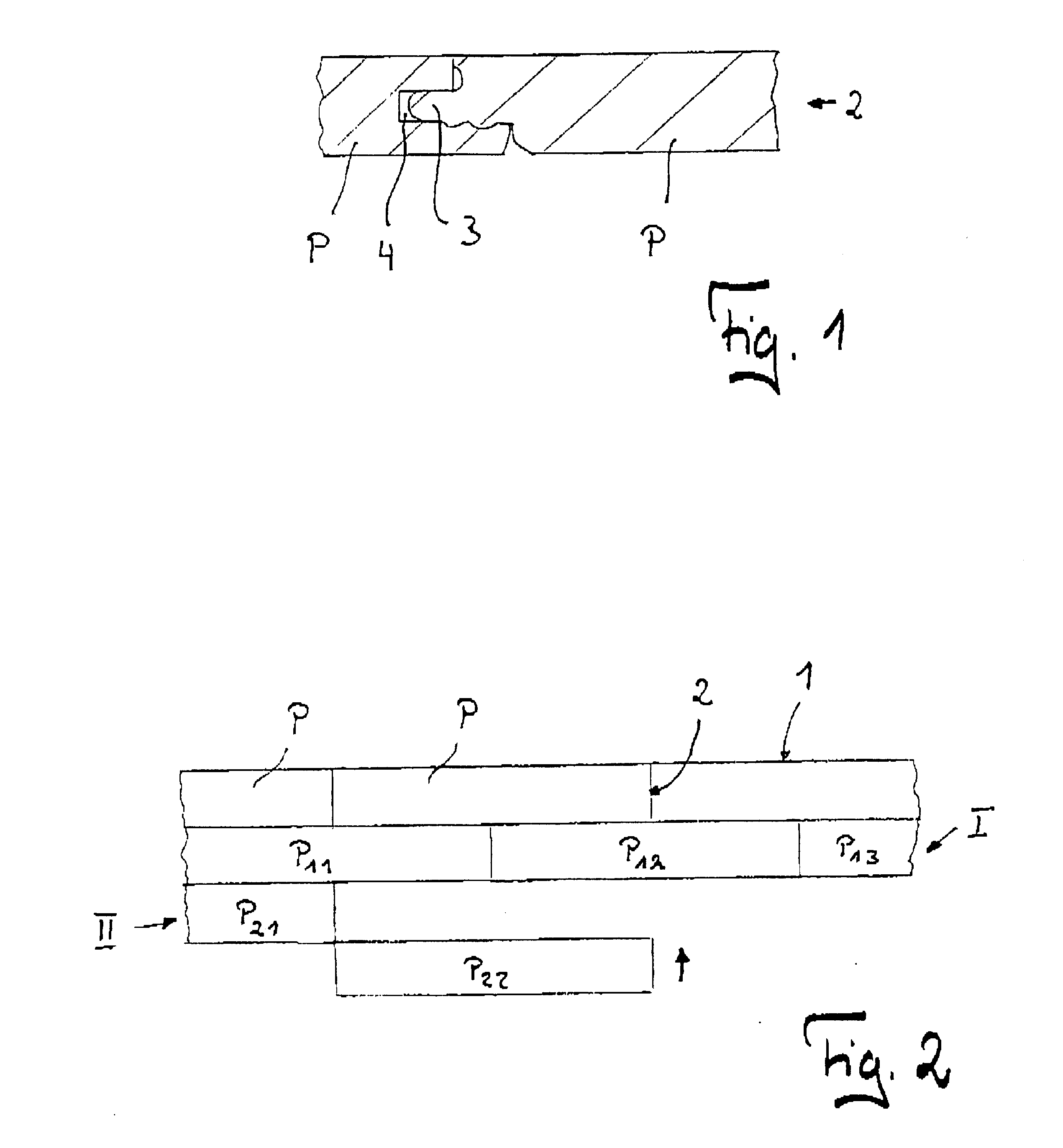

Process of laying floorboards

InactiveUS6711869B2Reduce frictionIncrease frictionCovering/liningsWallsTongue and grooveEngineering

A process is proposed for laying and mechanically jointing floorboards provided with tongue and groove engagements on all sides for horizontal attachment. The process involves a) jointing of a number of boards and making them engage on their transverse sides n order to lay a first row on the floor of a room, b) jointing of a first board for a second row and making it engage with one or two boards in the first row using the tongue and groove joint on the longitudinal side for the purpose of starting a second row, c) pushing the tongue (or groove) of a second board into the groove (or tongue) on the transverse side of the first board in the second row, with movement from the longitudinal side towards the boards in the first row, and d) making the second board engage with one or two boards in the first row.

Owner:KRONOTEX USA

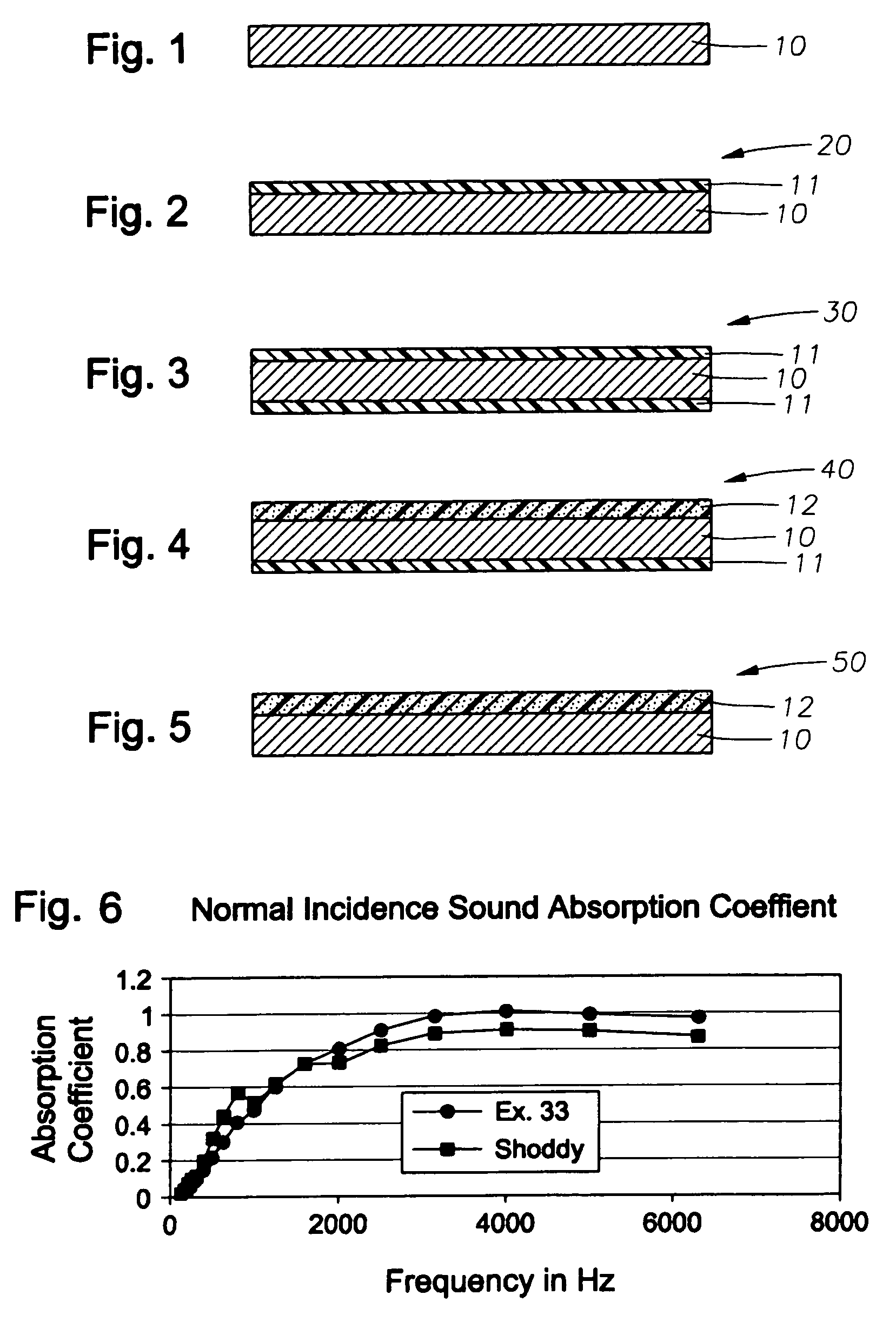

Nonwoven material for acoustic insulation, and process for manufacture

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

Carpet tile and related methods

InactiveUS20070275207A1Increase lateral gripReduce creepLamination ancillary operationsBristleBrickEngineering

Carpet tile, carpet tiles, or modular flooring include a carpet face or show surface in overlying relation to a backing of or including adjoined particle elements. In particular, but not exclusively, the carpet tiles incorporate a carpet surface or carpet face, having, for example, a pile or non-pile surface. In one embodiment, the carpet of the carpet tile has a tuft bind or precoat layer, such as a urethane precoat, disposed in overlying relation to a resilient backing formed from a mass, mixture, or slurry, for example, of particles or crumbs, bonded together in adjoined relation by a binder. One or more optional stabilizing and / or backing layers may be included. Methods of making such carpet tiles are also provided.

Owner:HIGGINS KENNETH B +1

Structures, systems and methods for joining articles and materials and uses therefor

Owner:NANOSYS INC

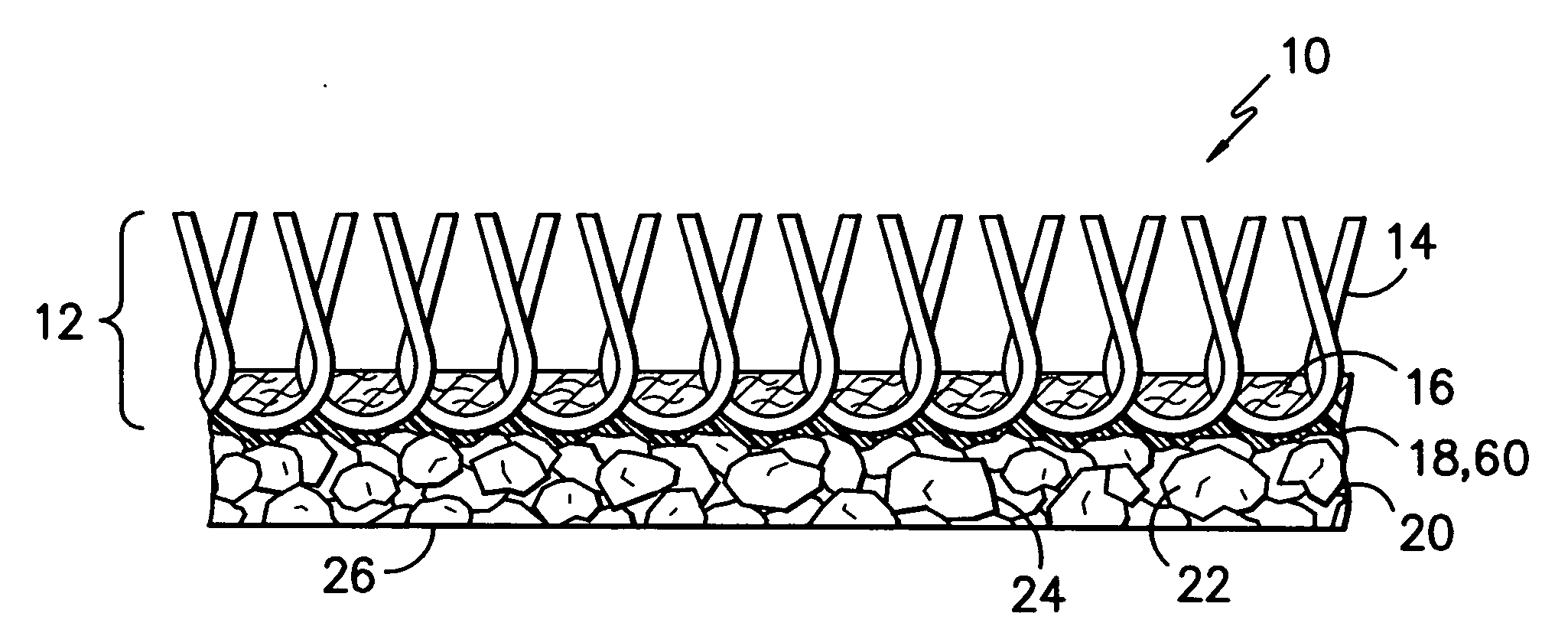

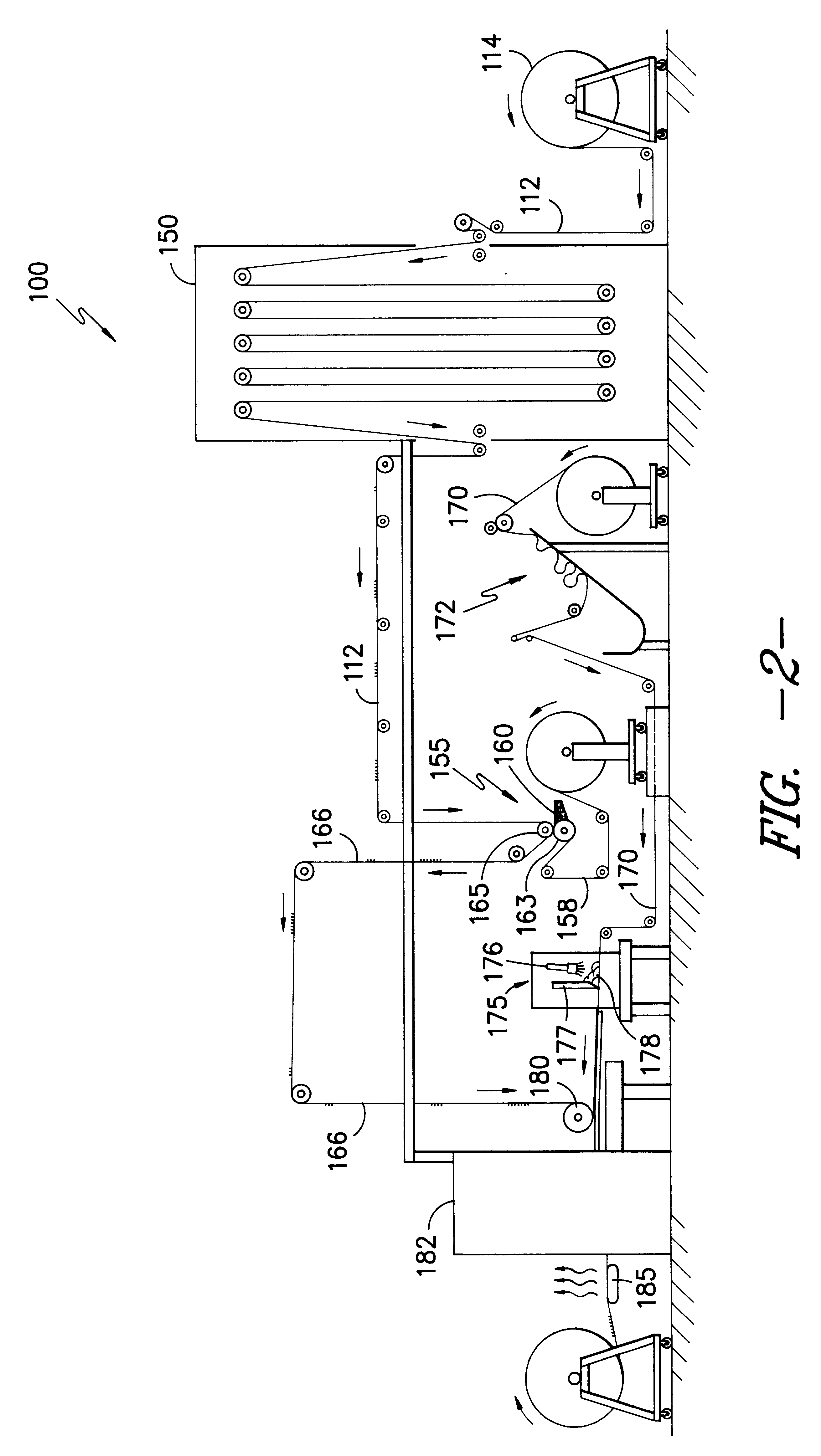

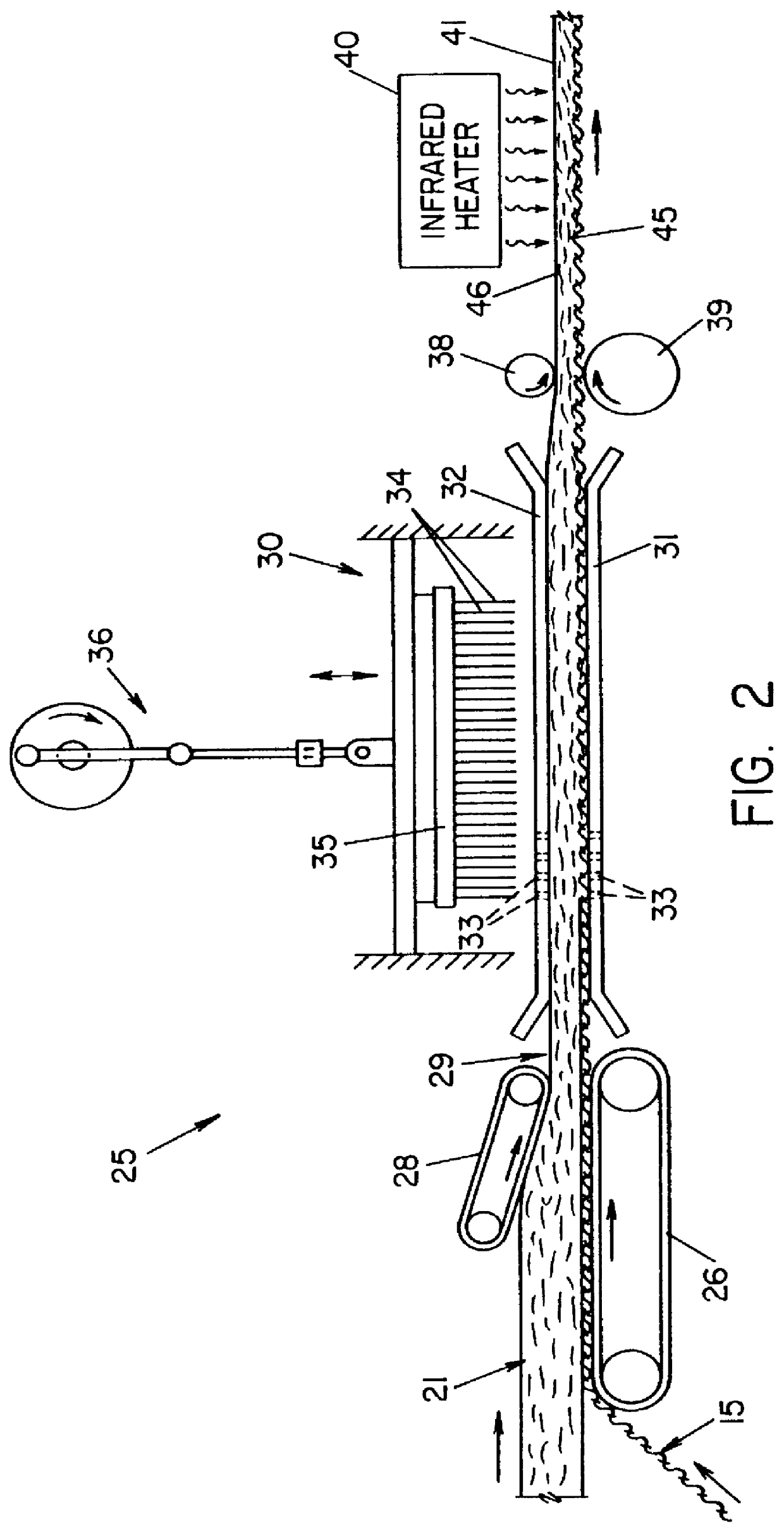

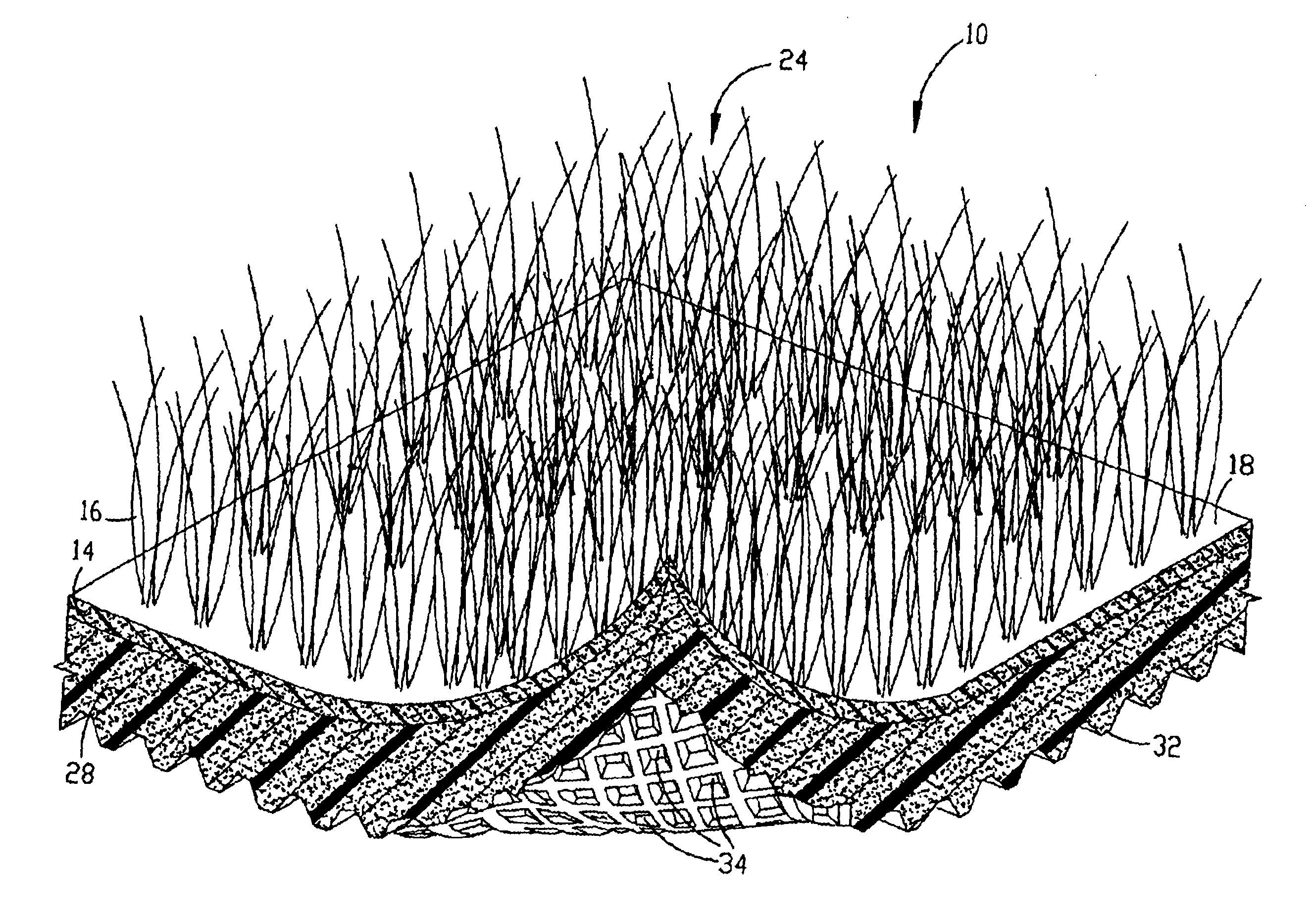

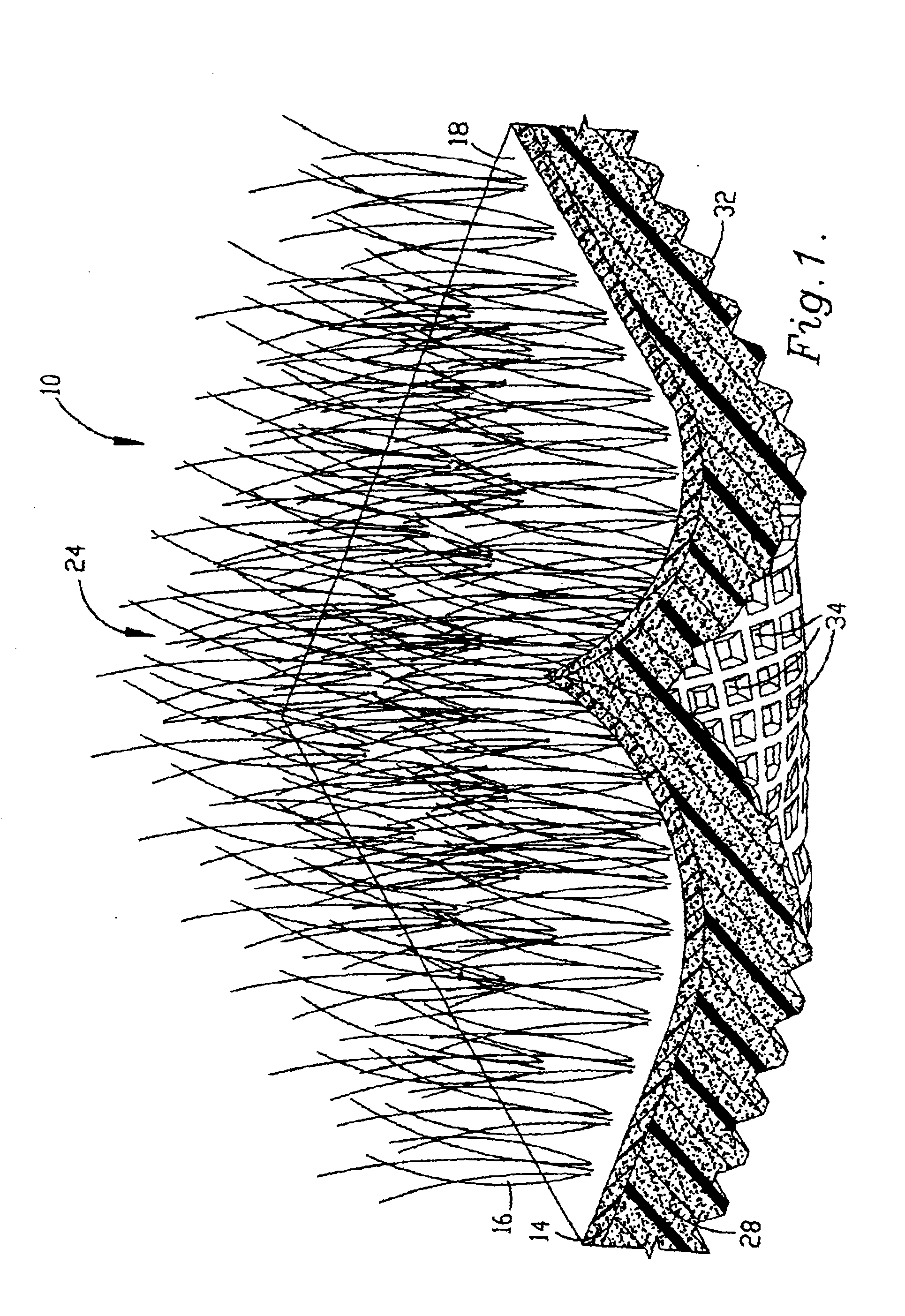

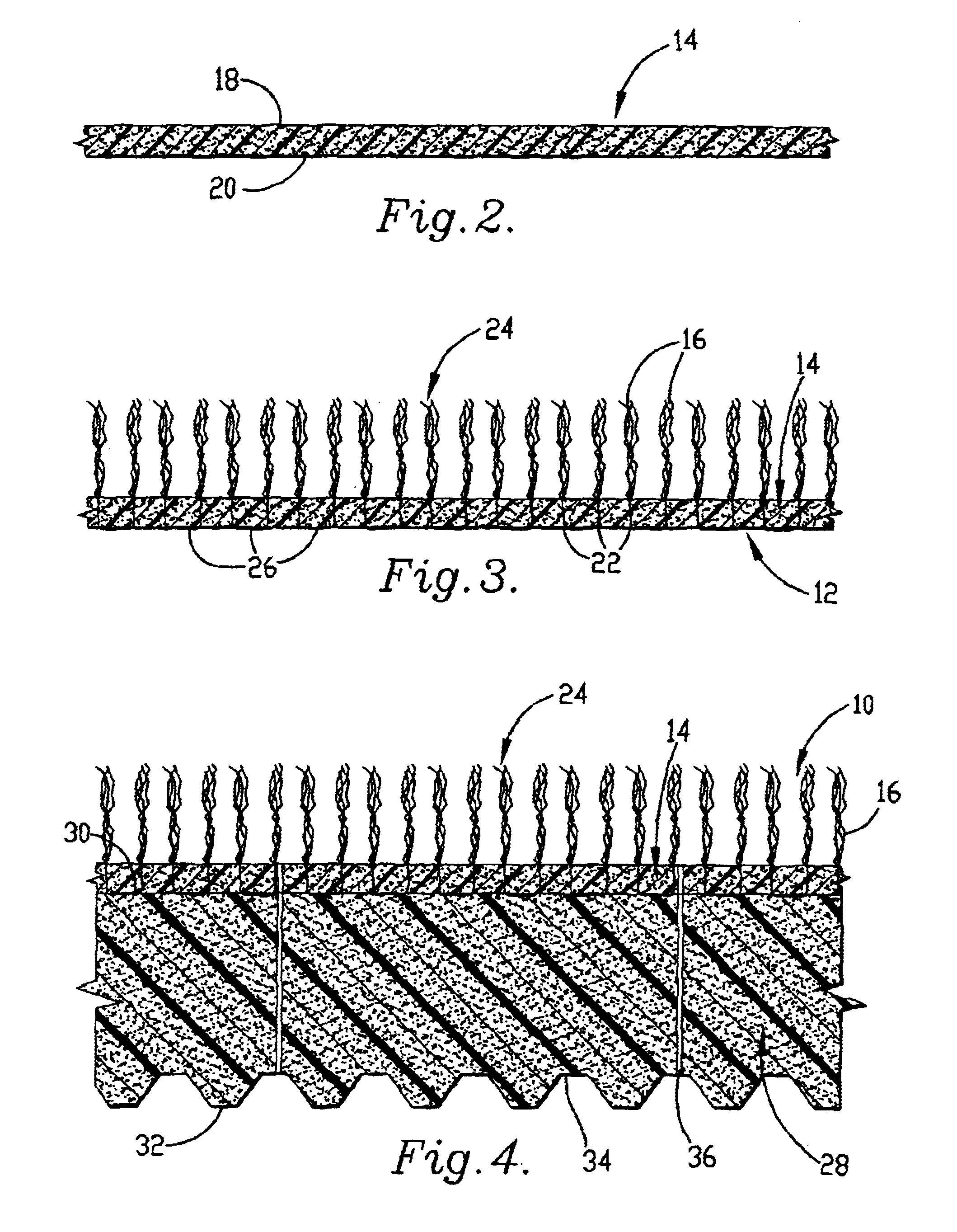

Cushion backed carpet

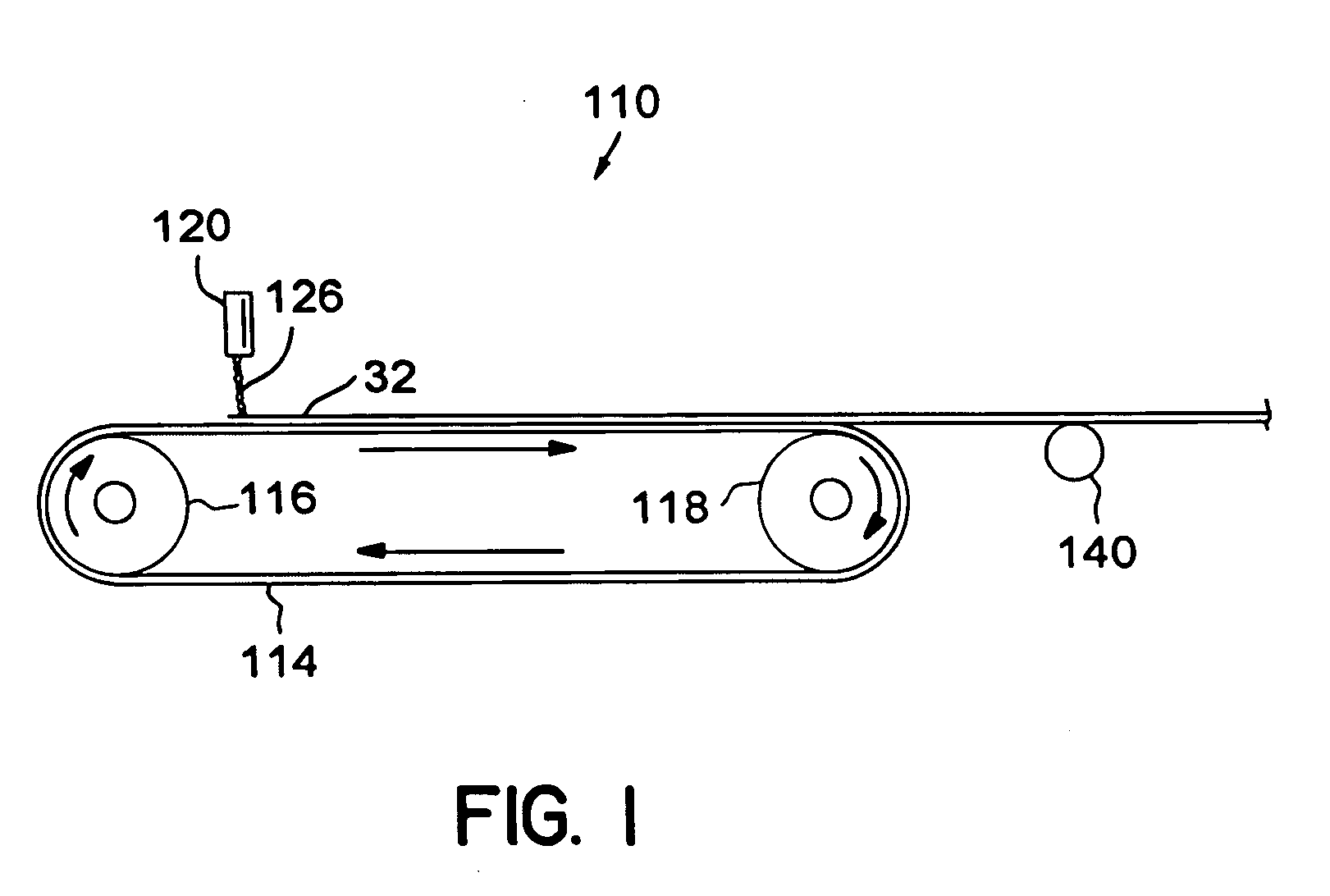

InactiveUS6203881B1Relieve pressureEasy to operateFibre treatmentSynthetic resin layered productsYarnAdhesive

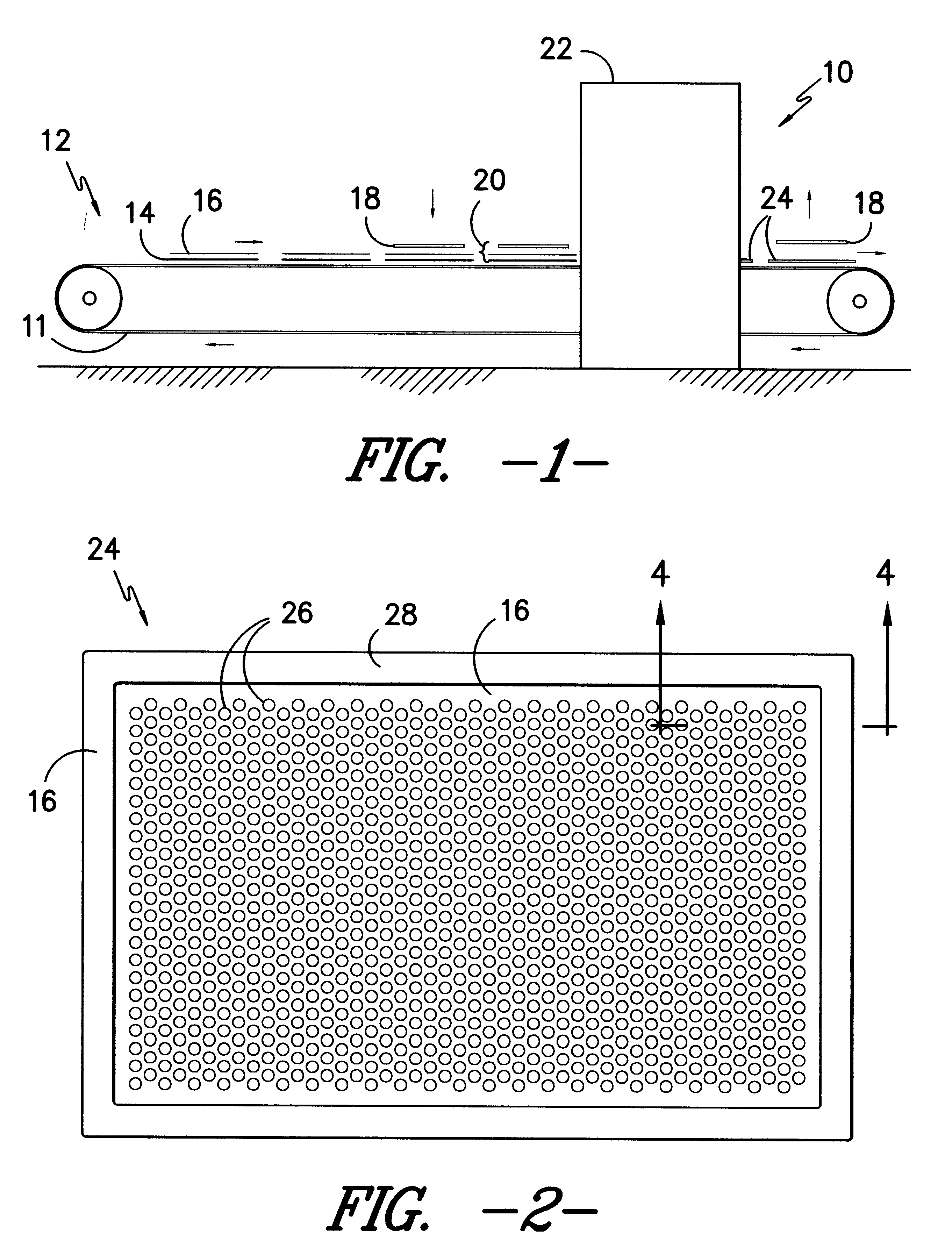

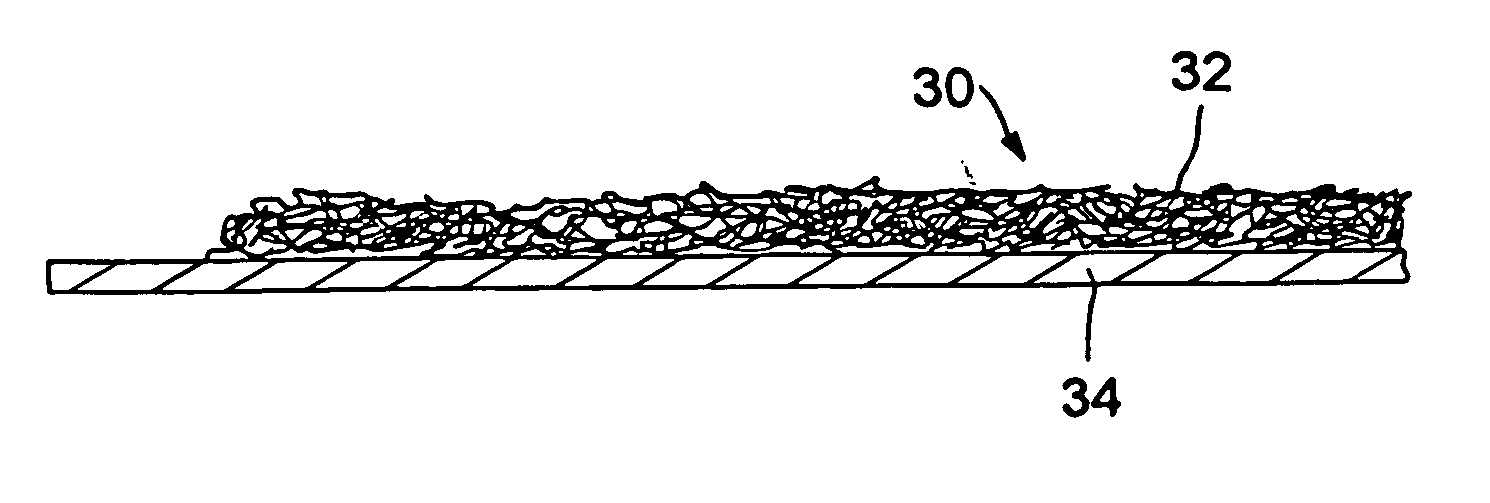

An improved cushioned carpet fabric is provided. The cushioned carpet comprises a primary carpet having a primary base and a plurality of pile-forming yarns projecting outwardly from one side. A layer of reinforcement material is bonded to the primary base on the side opposite the pile forming yarns. The reinforcement layer is adjacent to and embedded in, a cushion layer of a polymer such as a polyurethane. There is preferably no additional adhesive between the cushion layer and the layer of reinforcement material since the primary carpet fabric is mated in-situ to the polyurethane-forming composition without preheating the polyurethane-forming composition. An apparatus and process for forming the cushioned carpet fabric of the present invention are also provided.

Owner:MILLIKEN & CO

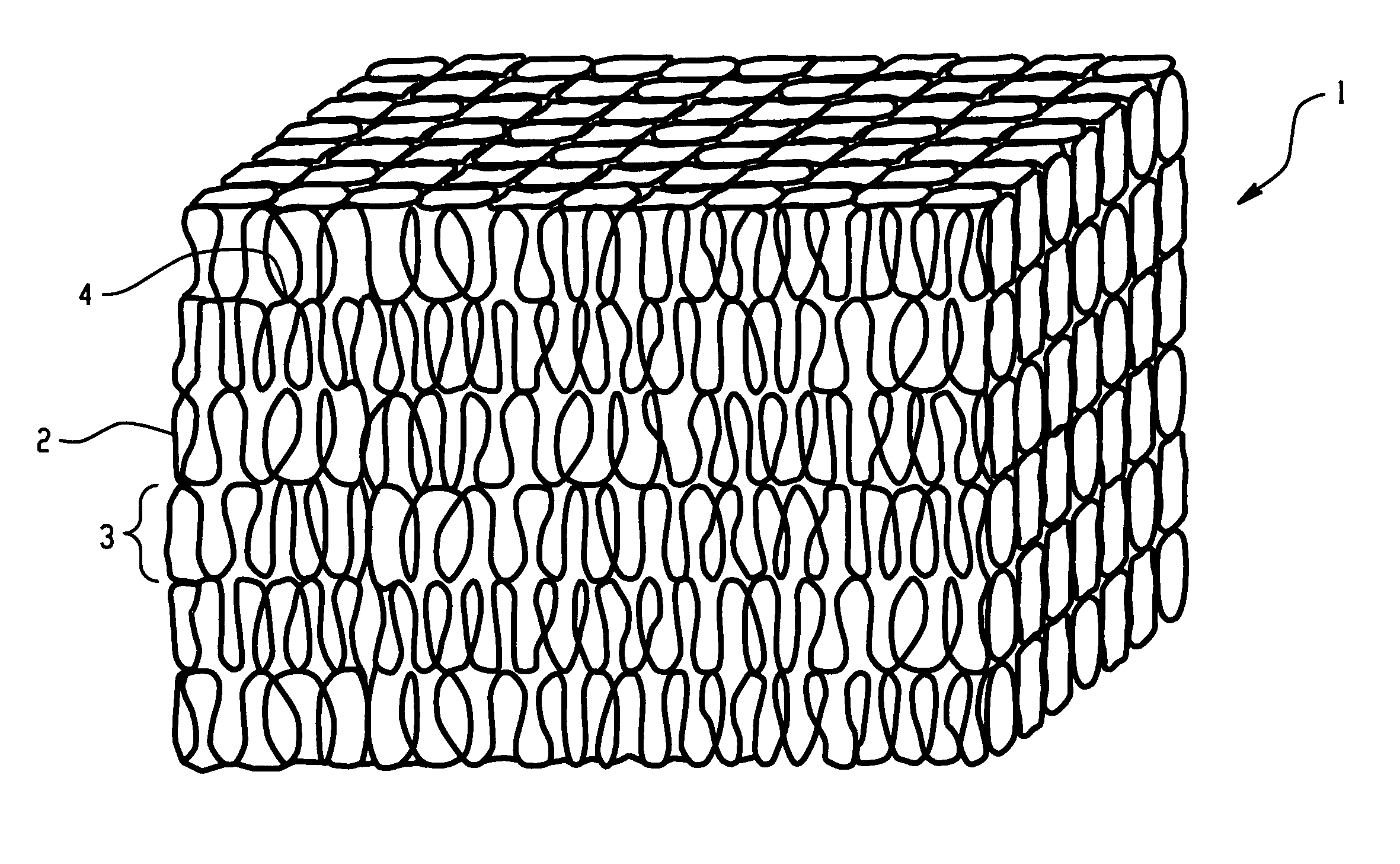

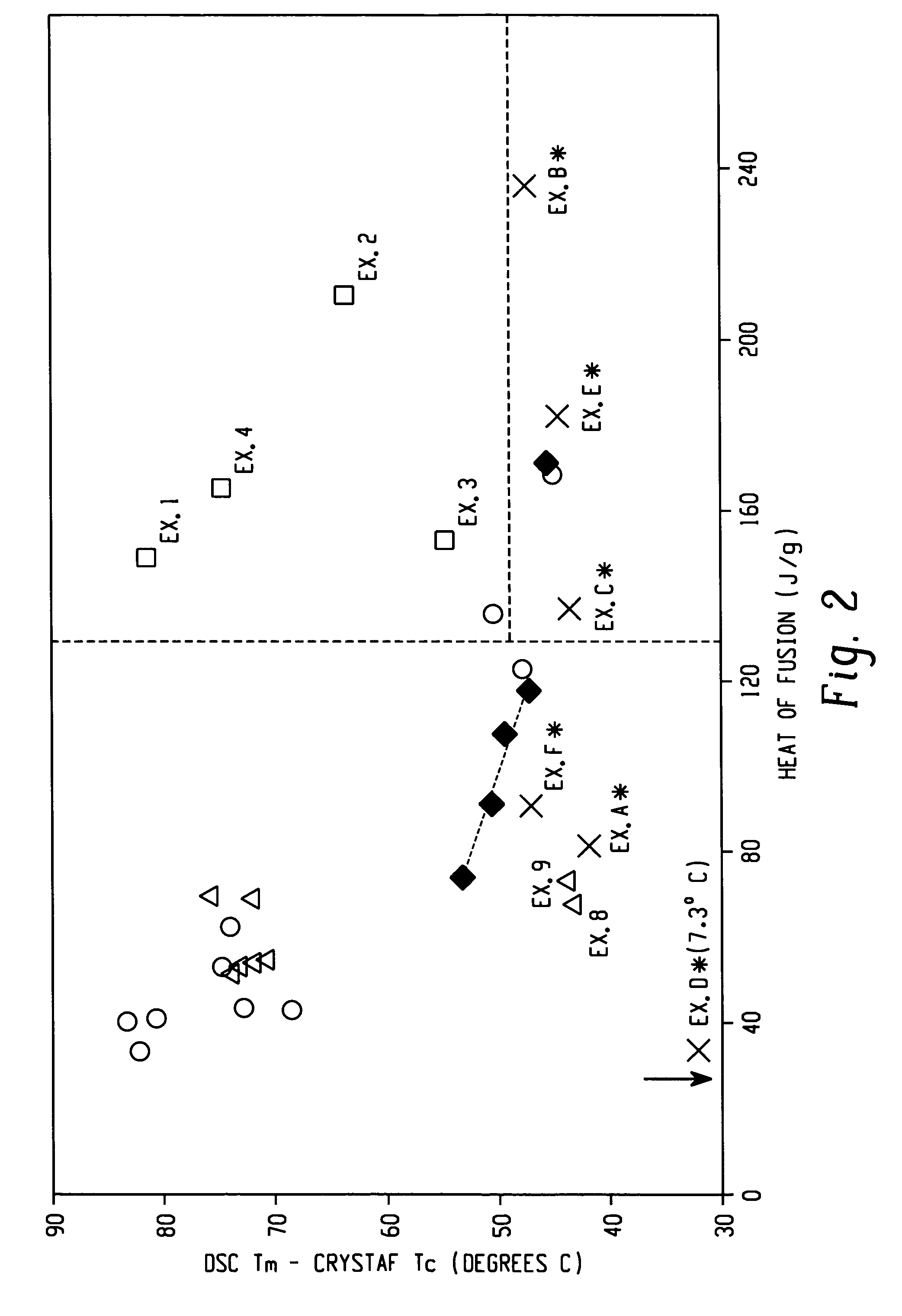

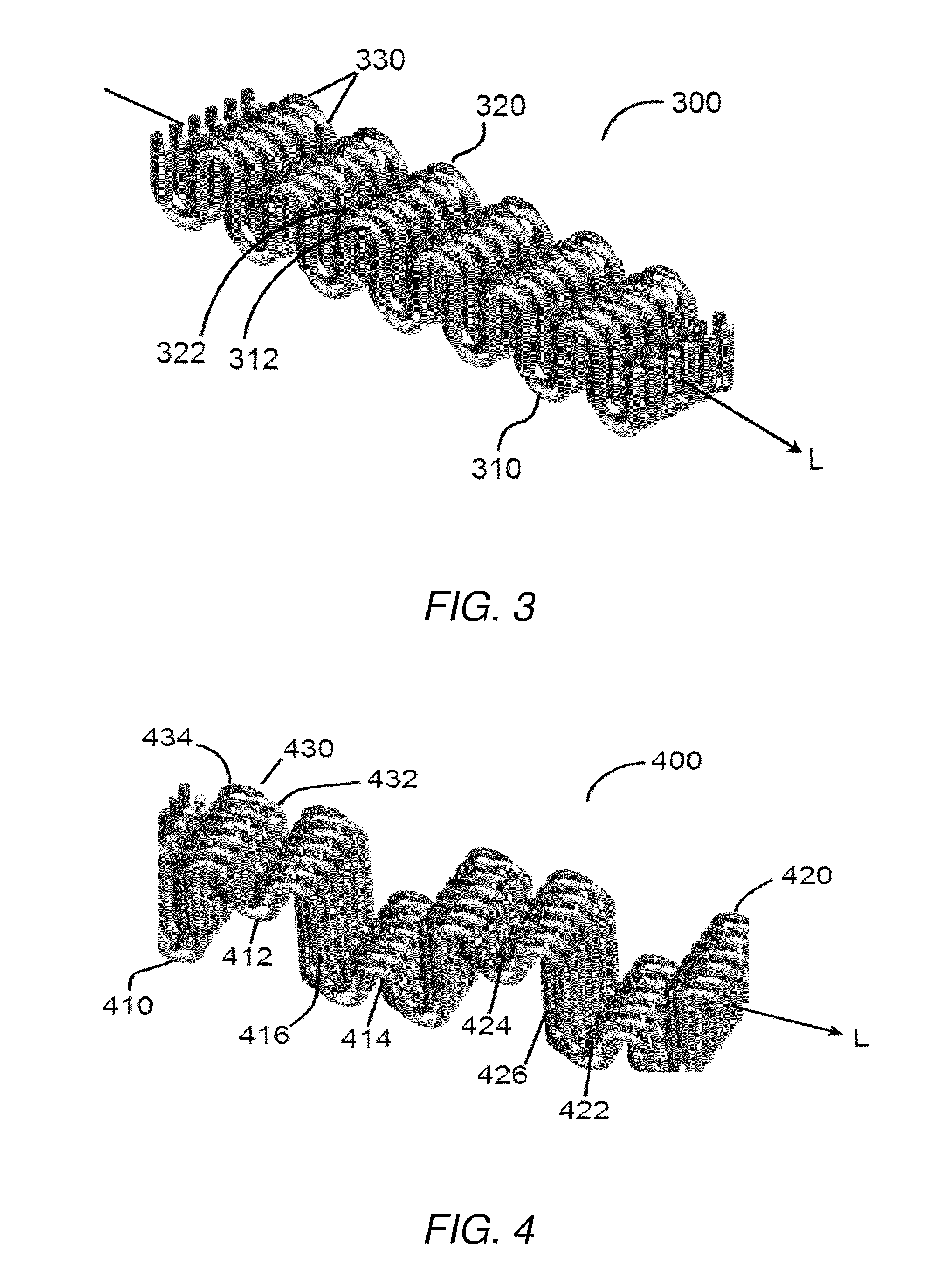

Three dimensional random looped structures made from interpolymers of ethylene/alpha-olefins and uses thereof

Cushioning net structures comprise random loops, such as three-dimensional random loops, bonded with one another, wherein the loops are formed by allowing continuous fibers, made of ethylene / α-olefin interpolymers, to bend to come in contact with one another in a molten state and to be heat-bonded at most contact points. The structures provided herein have desirable heat resistance, durability and cushioning property. The cushioning structures are used in furniture, vehicle seats etc.

Owner:DOW GLOBAL TECH LLC

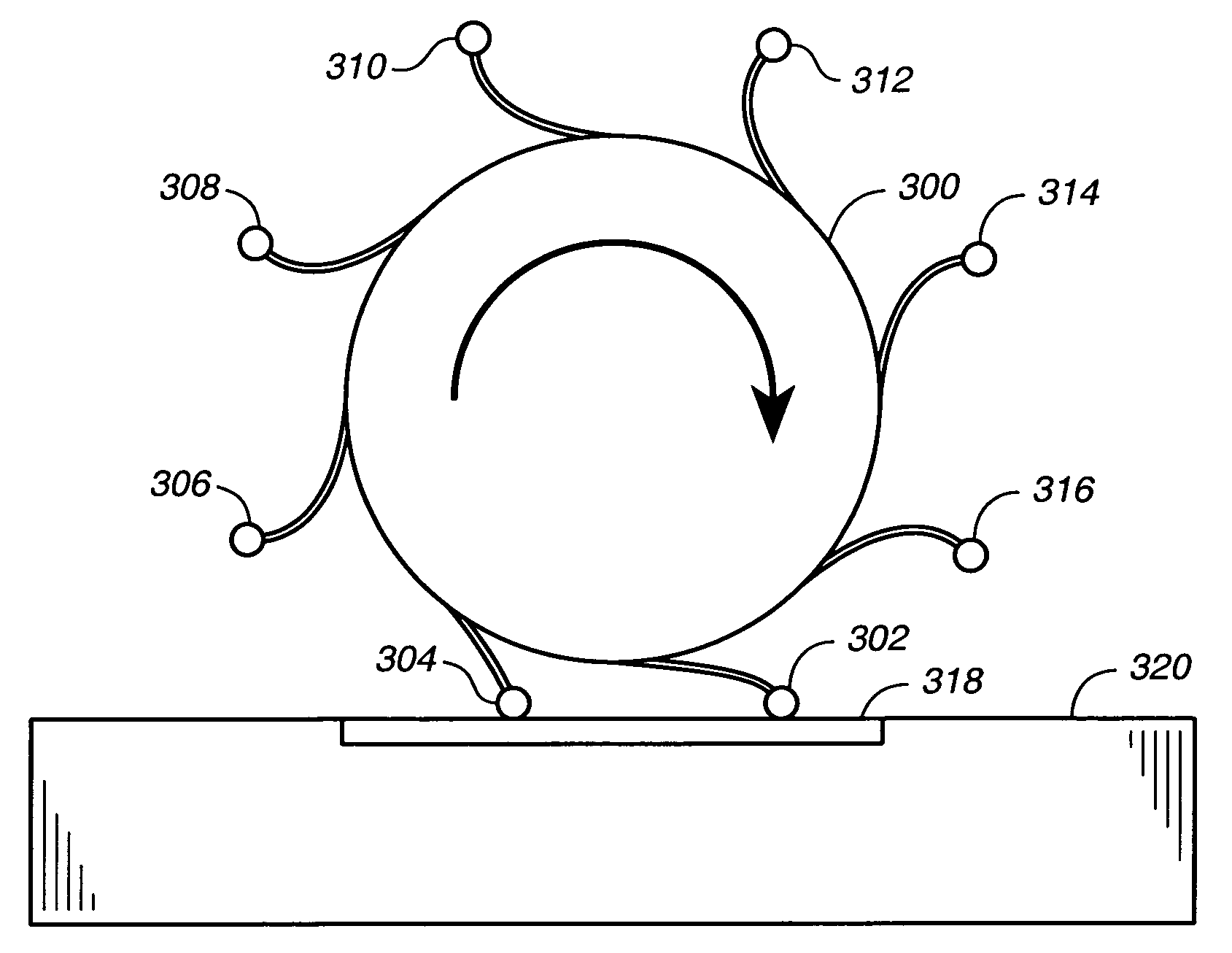

Structure having nano-fibers on annular curved surface, method of making same and method of using same to adhere to a surface

Owner:RGT UNIV OF CALIFORNIA

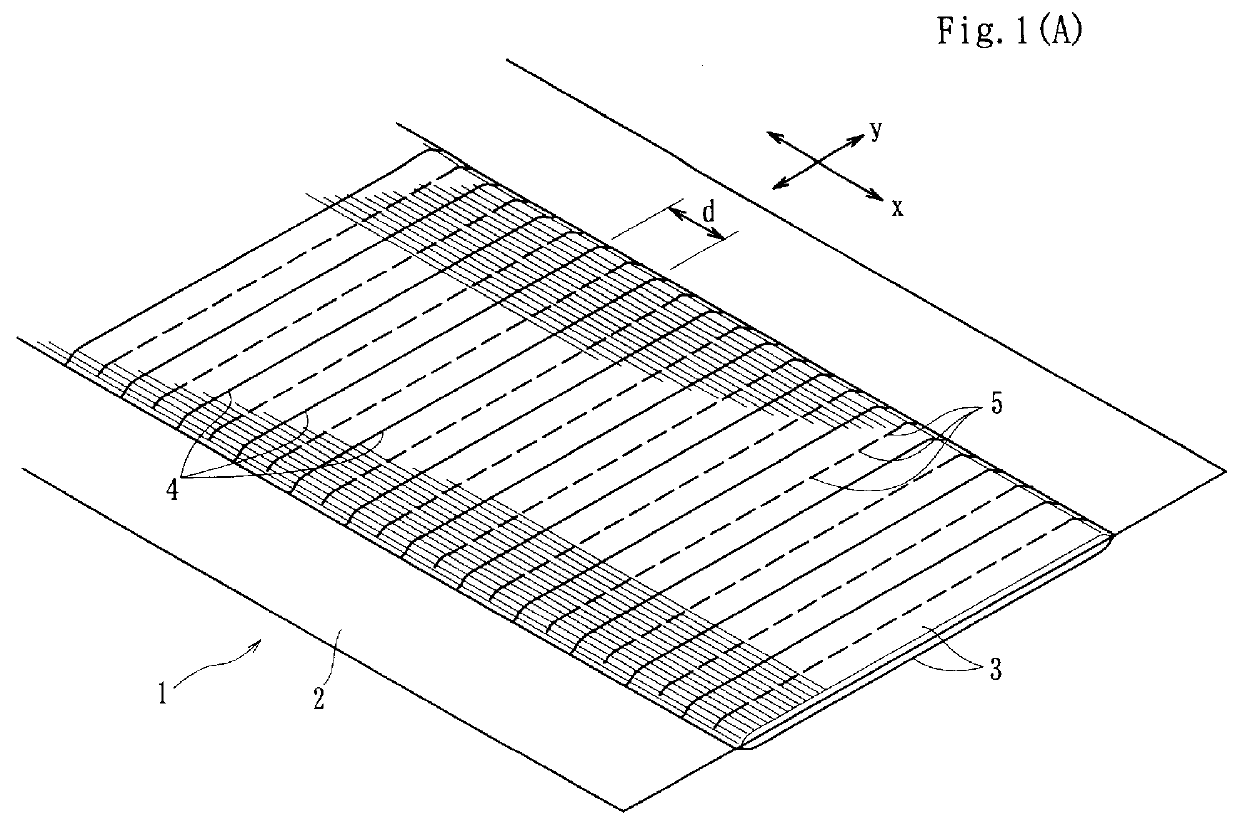

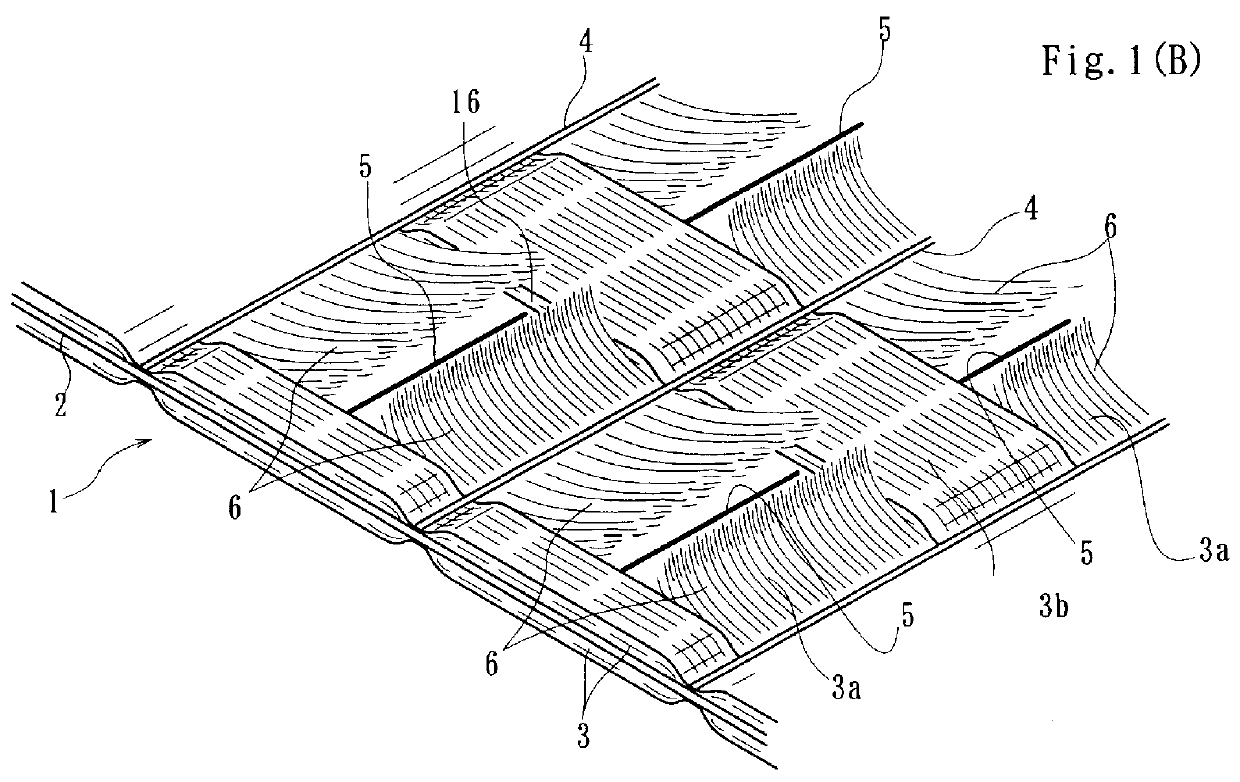

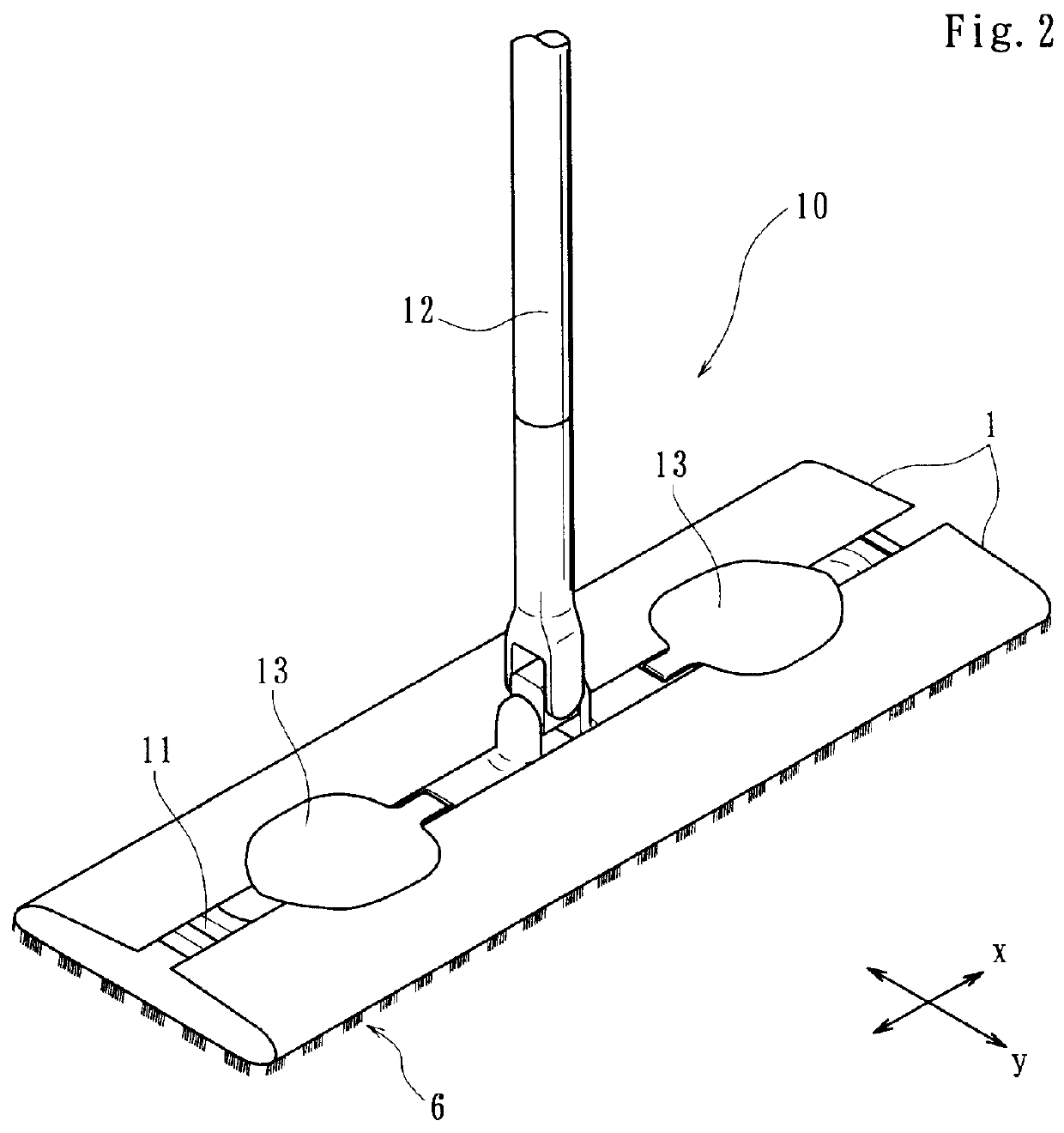

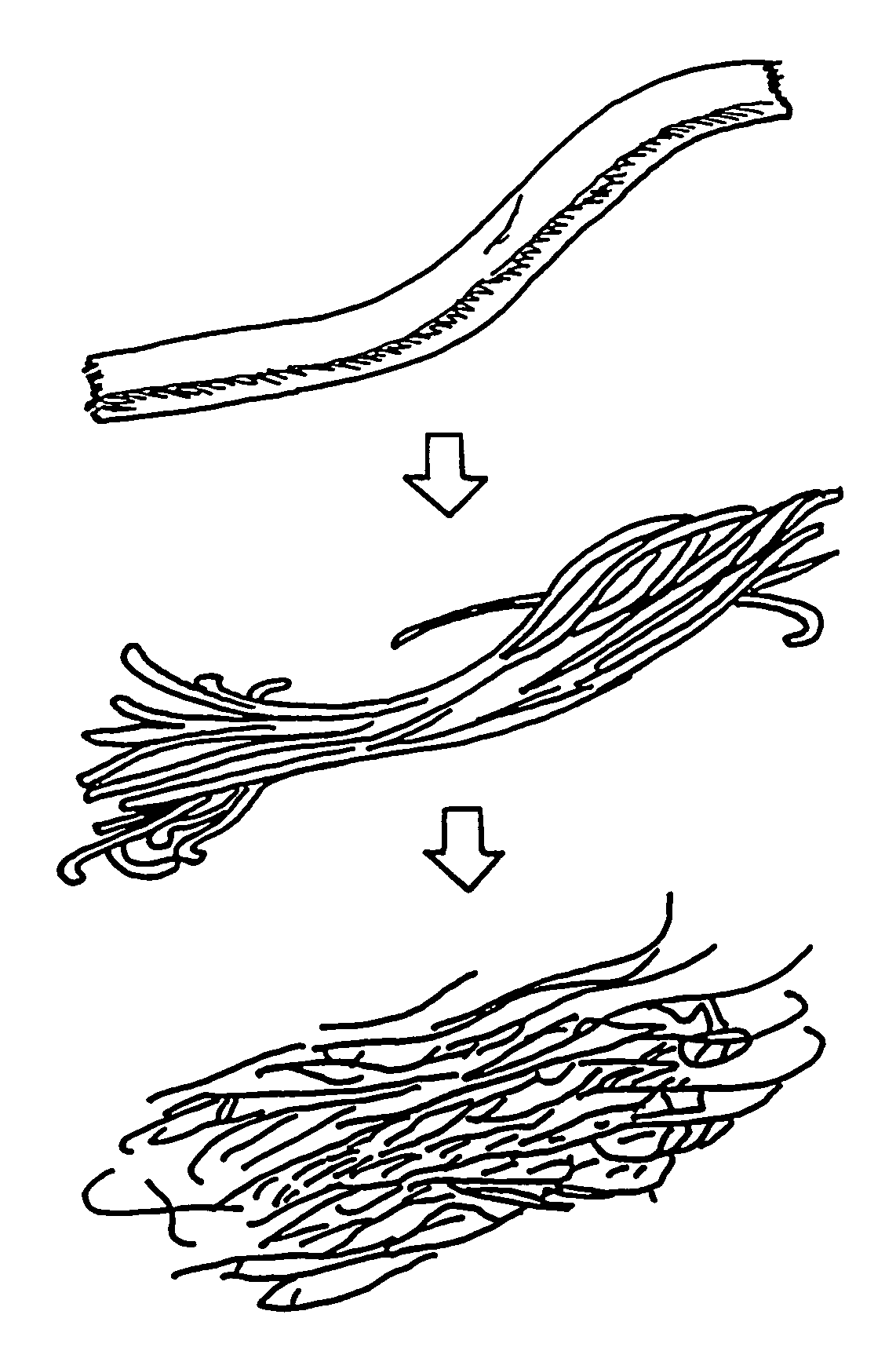

Cleaning product and production process therefor

A cleaning product comprises a base sheet and at least one layer of filaments or split yarns oriented in one direction, the base sheet and the layer are stacked and bonded together at a plurality of bonding lines extending in a direction intersecting with the one direction, and the base sheet is cut together with the layer intermittently in the intersecting direction between adjacent bonding lines to form cutting portions, thereby forming brushing portions with the layer. The cleaning product can be produced simply and conveniently at small cost. Further, it also has an excellent dust collecting effect.

Owner:UNI CHARM CORP

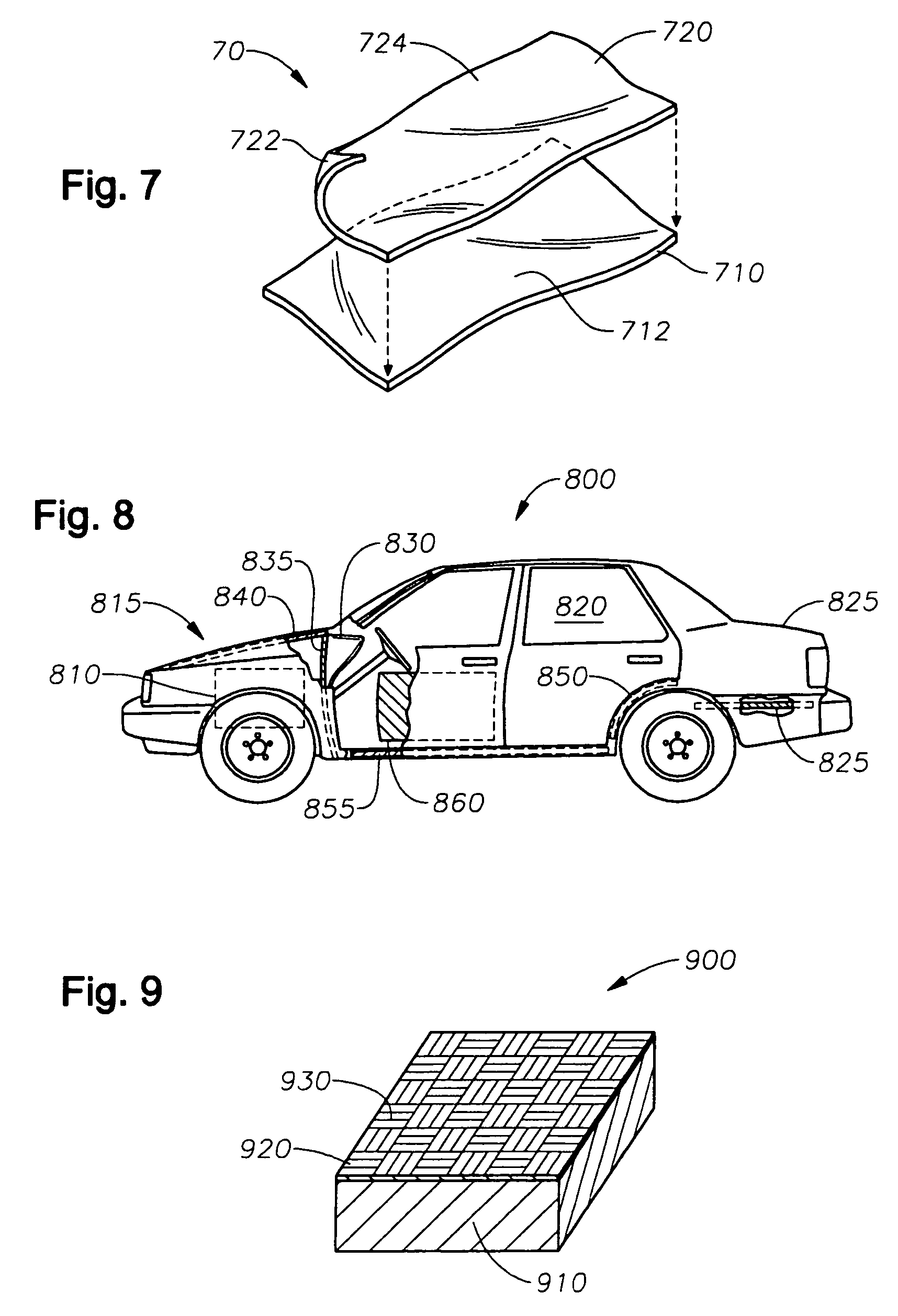

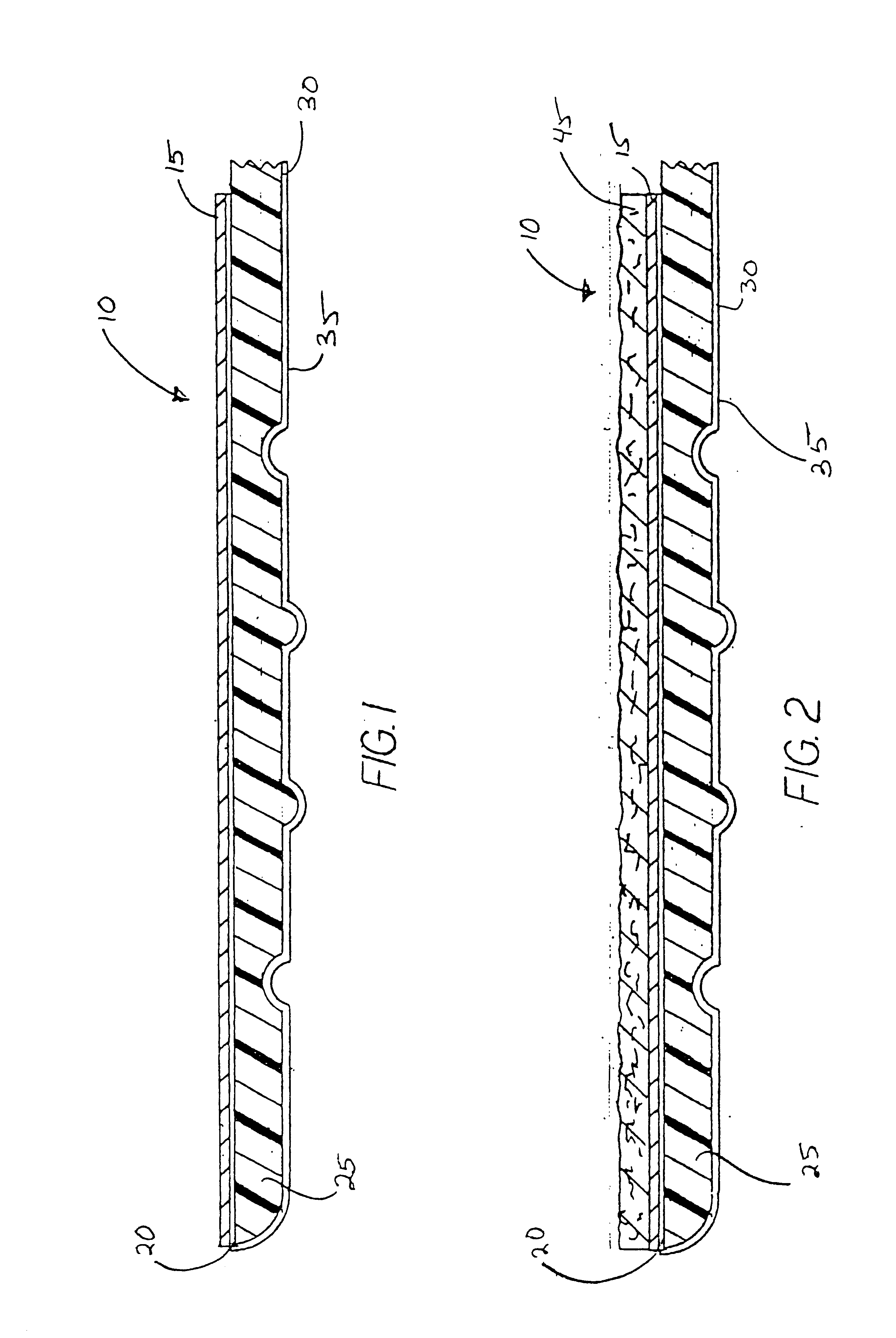

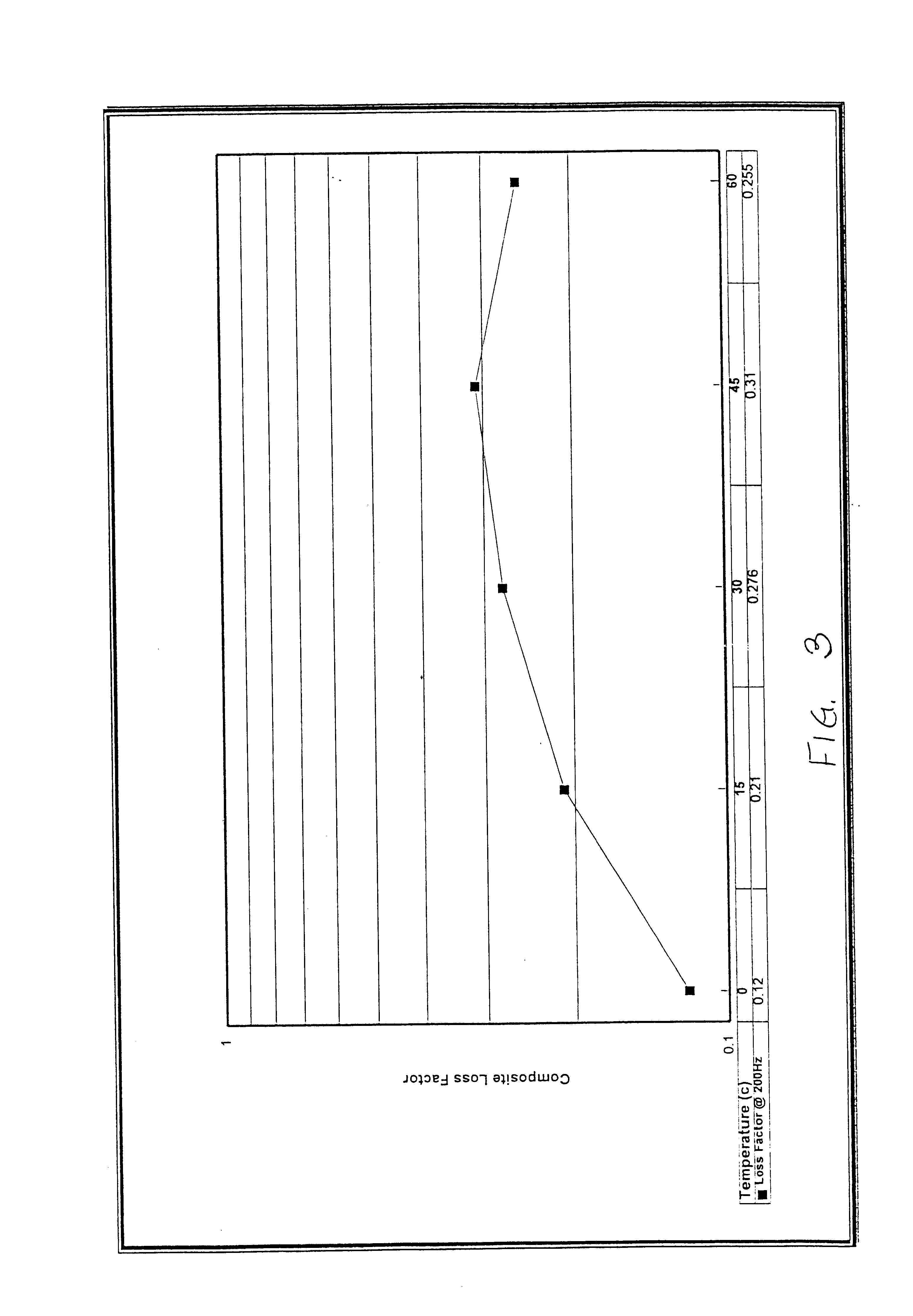

Vibration dampening laminate

The present invention provides a vibration dampening laminate that is lightweight and has superior sound insulation and vibration dampening properties. The vibration dampening laminate comprises a constraining layer, a viscoelastic adhesive layer, a foam spacing layer and a pressure sensitive adhesive layer including a release layer. The pressure sensitive adhesive layer and release layer are contoured to fit a profile of the article being soundproofed and vibration dampened.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

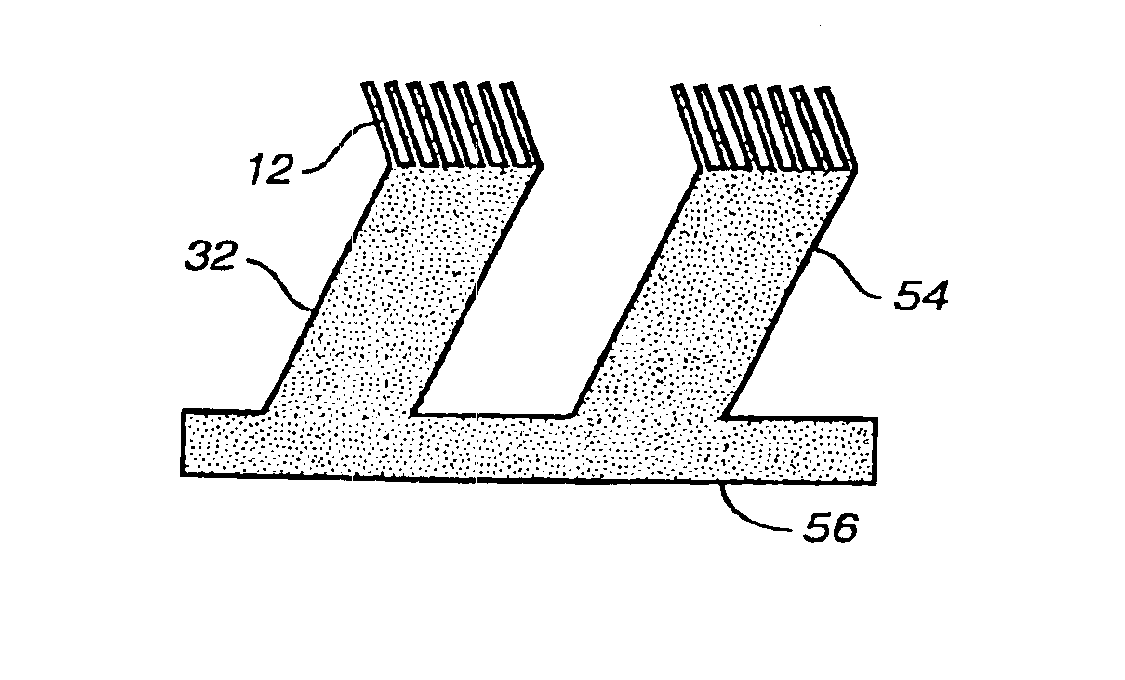

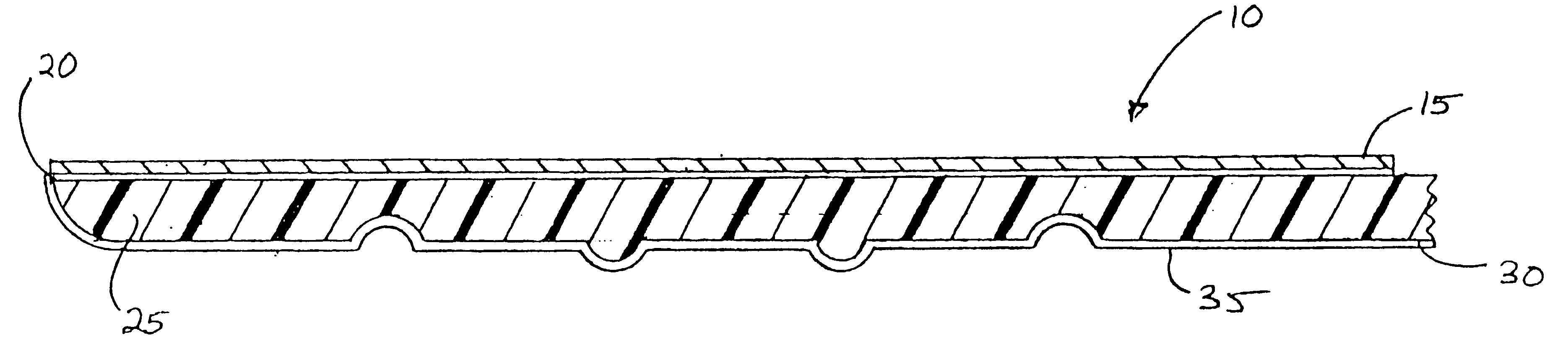

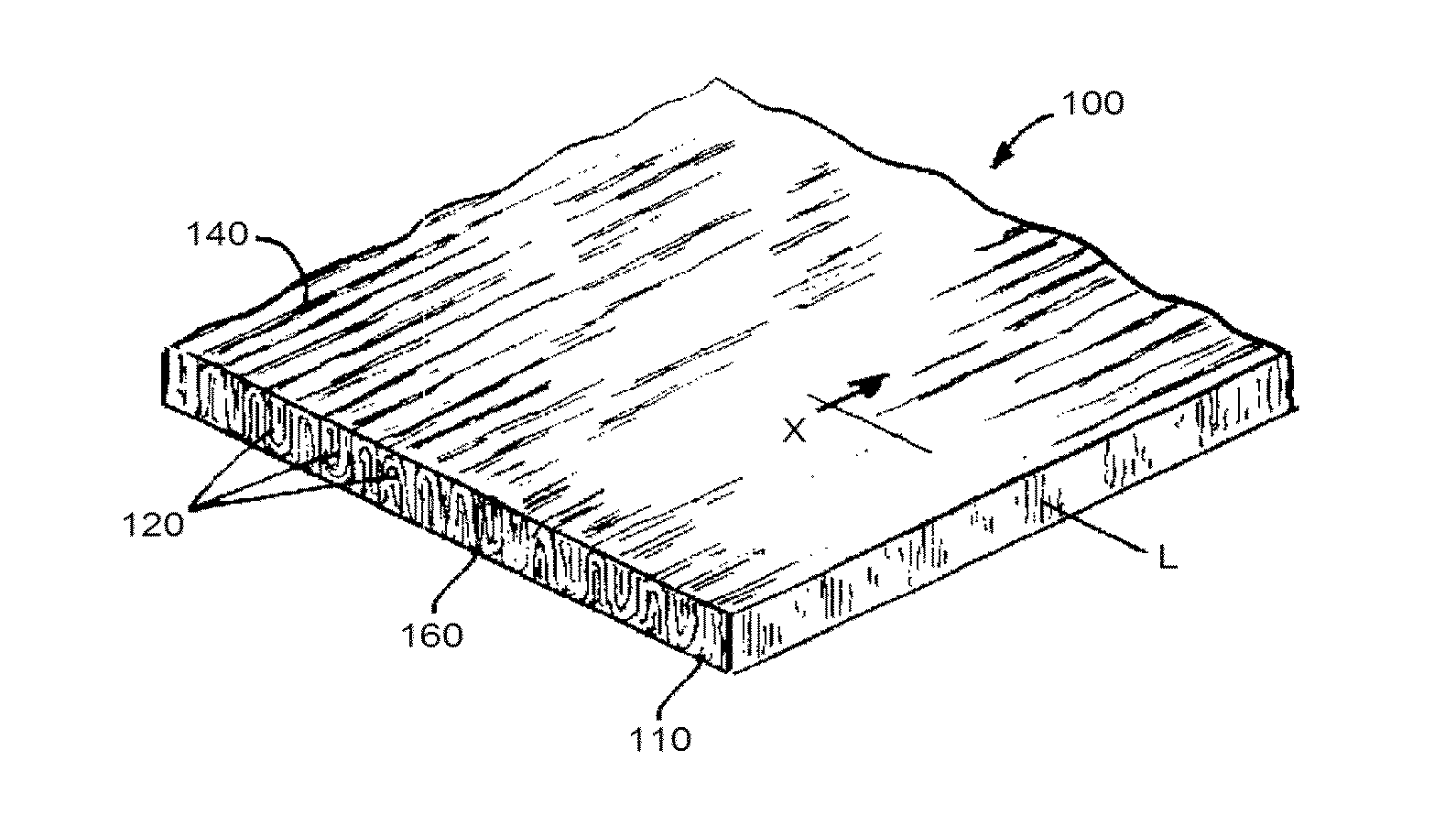

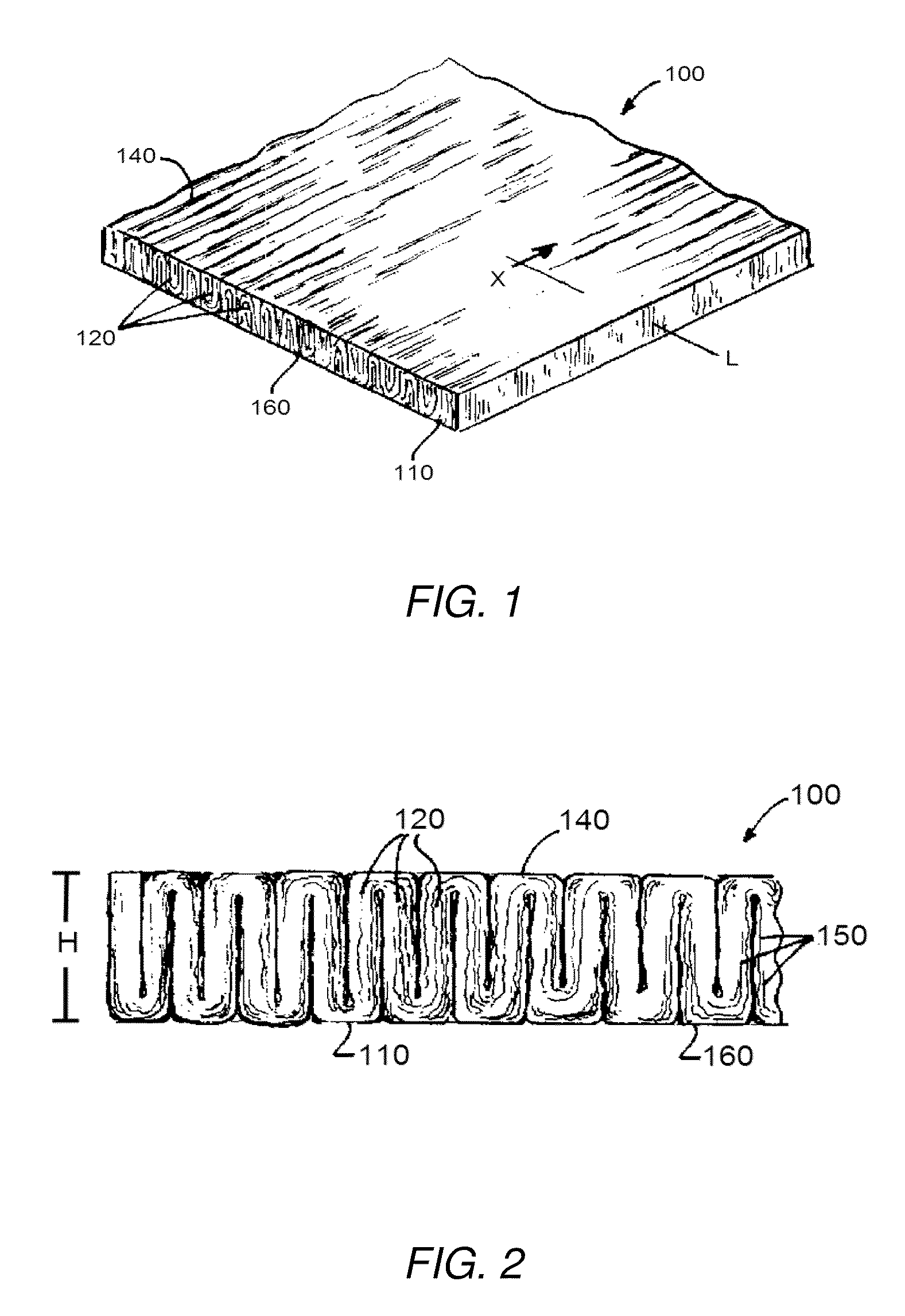

Fiber-based carpet cushion with added resilience from vertically oriented fiber construction

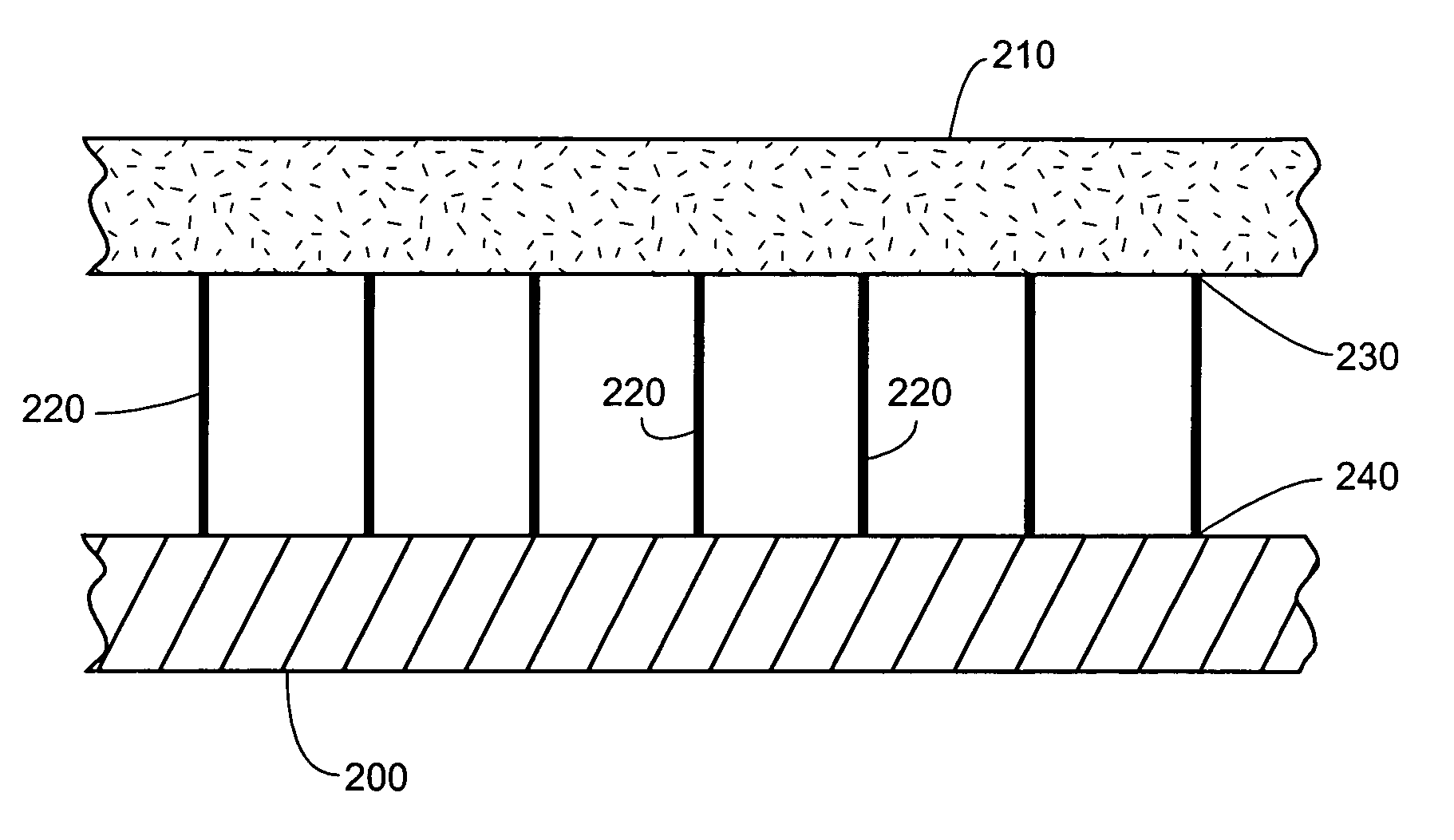

ActiveUS20110311758A1Increase elasticityImprove the immunityLayered productsWoven fabricsParallel fiberEngineering

A fiber pad having a core non-woven layer is disclosed. The core layer can have an upper surface and a lower surface. The core layer can comprise at least one fiber layer. The at least one fiber layer can comprise a plurality of parallel fibers. Selected groups of the parallel fibers can be folded into desired pleated configurations. Optionally, the core layer can comprise post-consumer carpet materials.

Owner:COLUMBIA INSURANCE CO

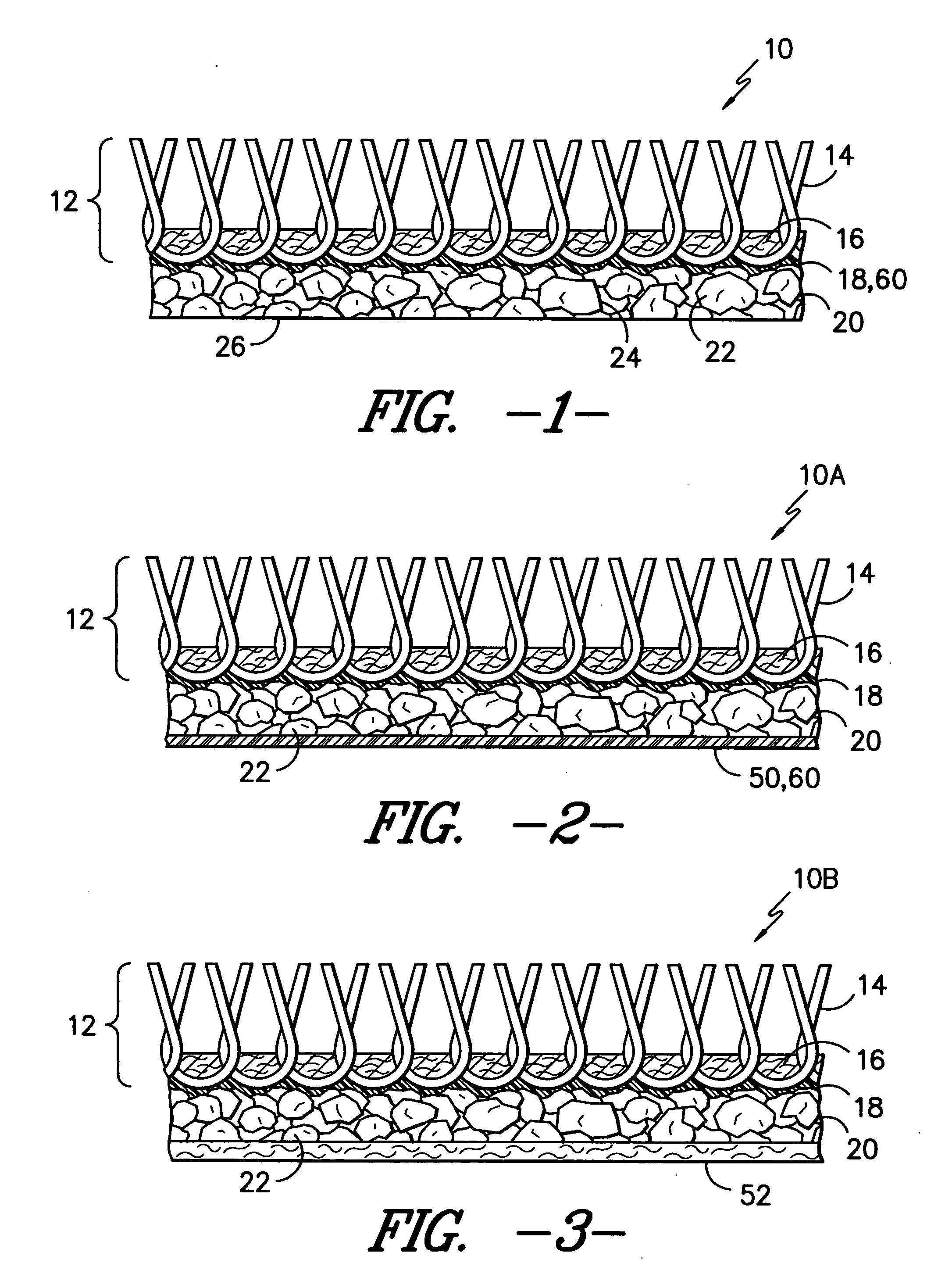

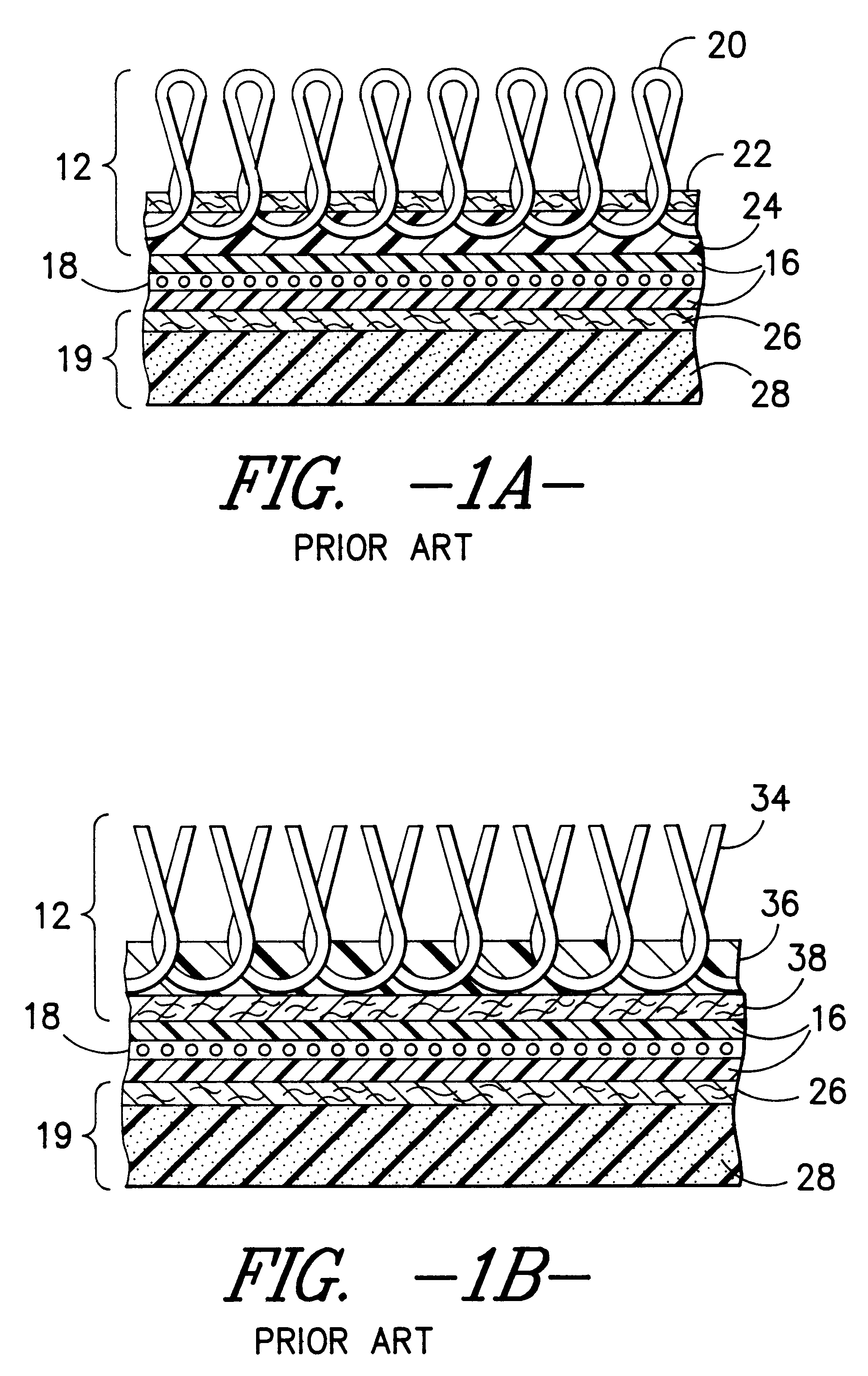

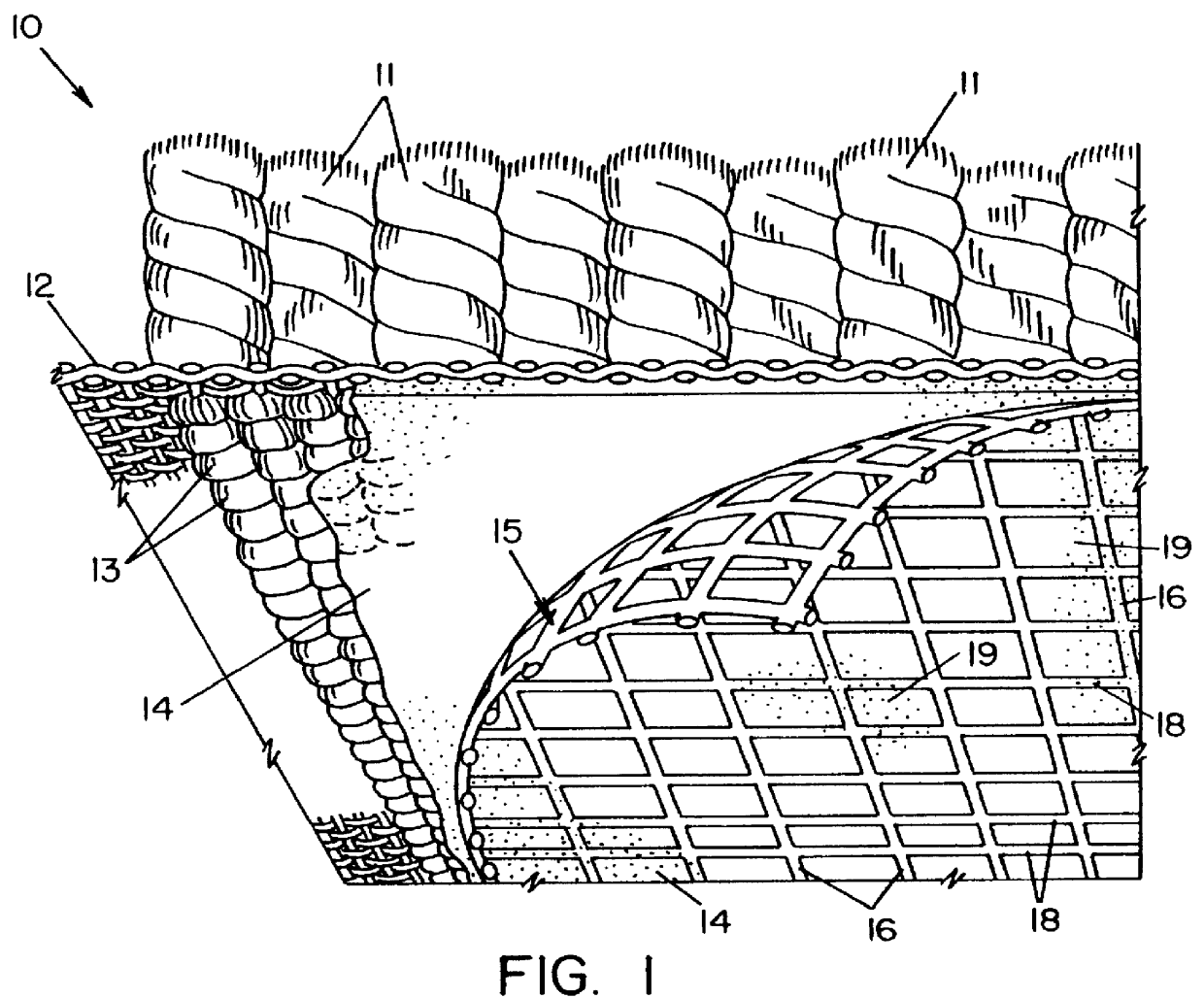

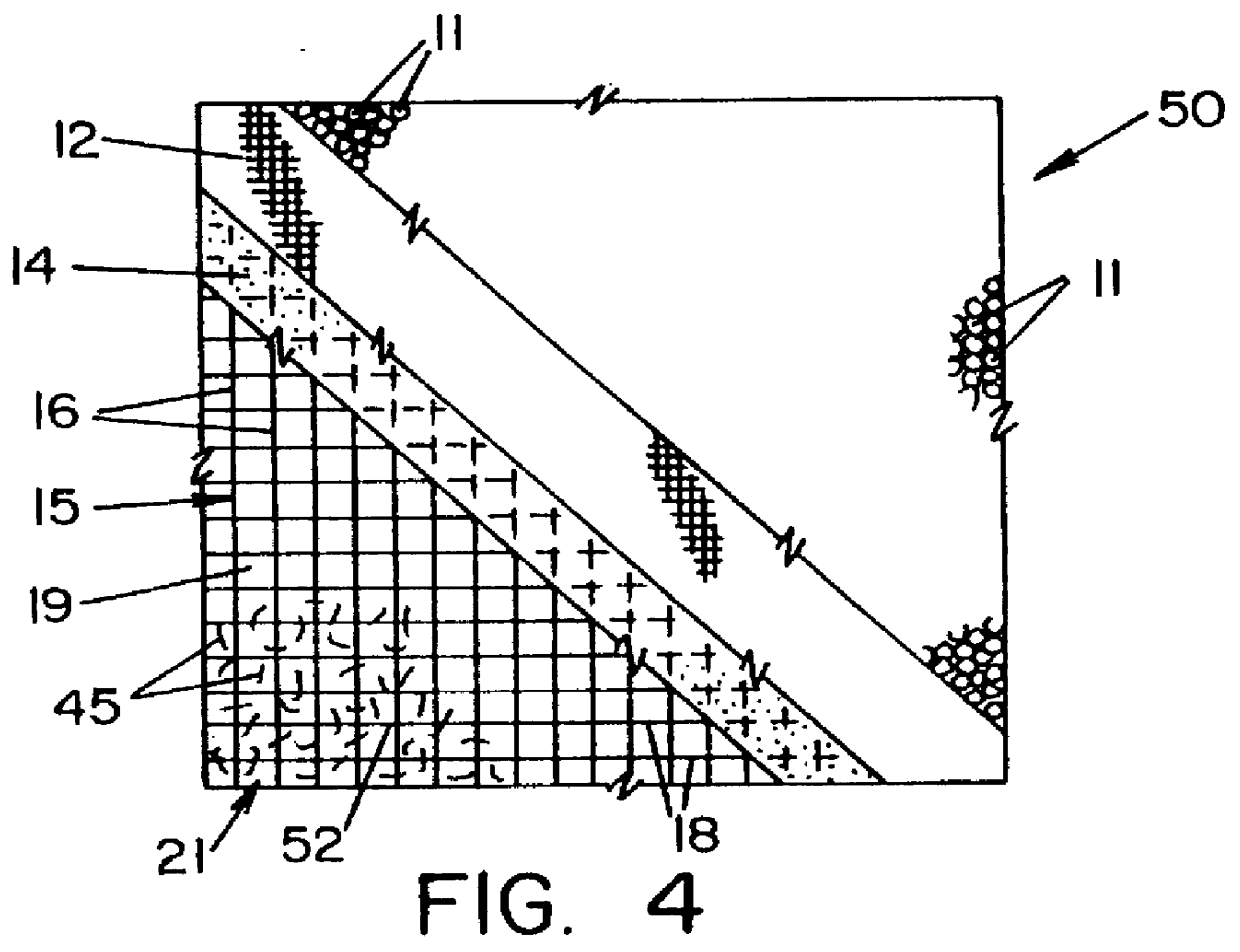

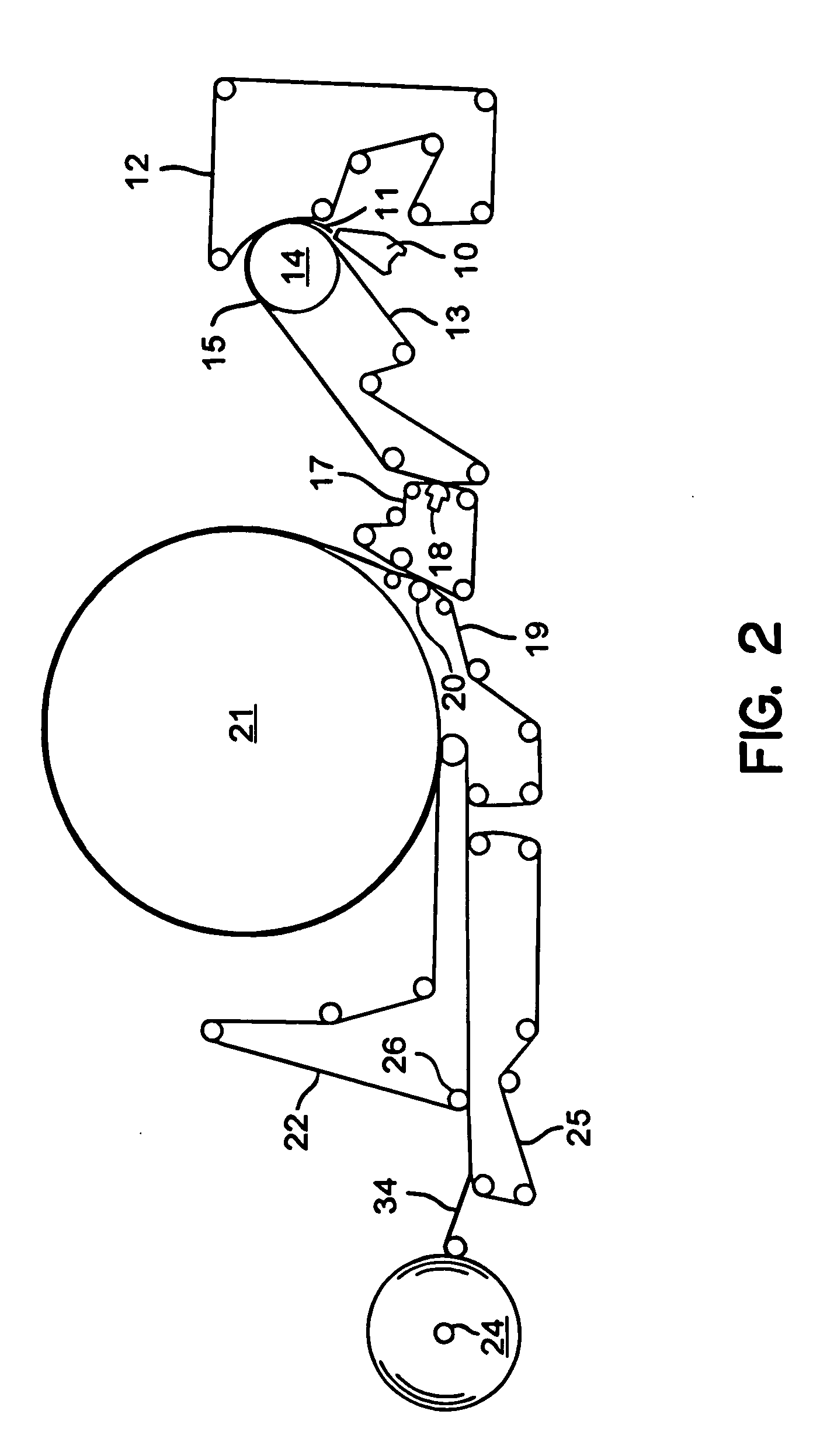

Modified secondary backing fabric, method for the manufacture thereof and carpet containing the same

InactiveUS6060145AIncrease delamination strengthGood dimensional stabilityLayered productsWoven fabricsFiberYarn

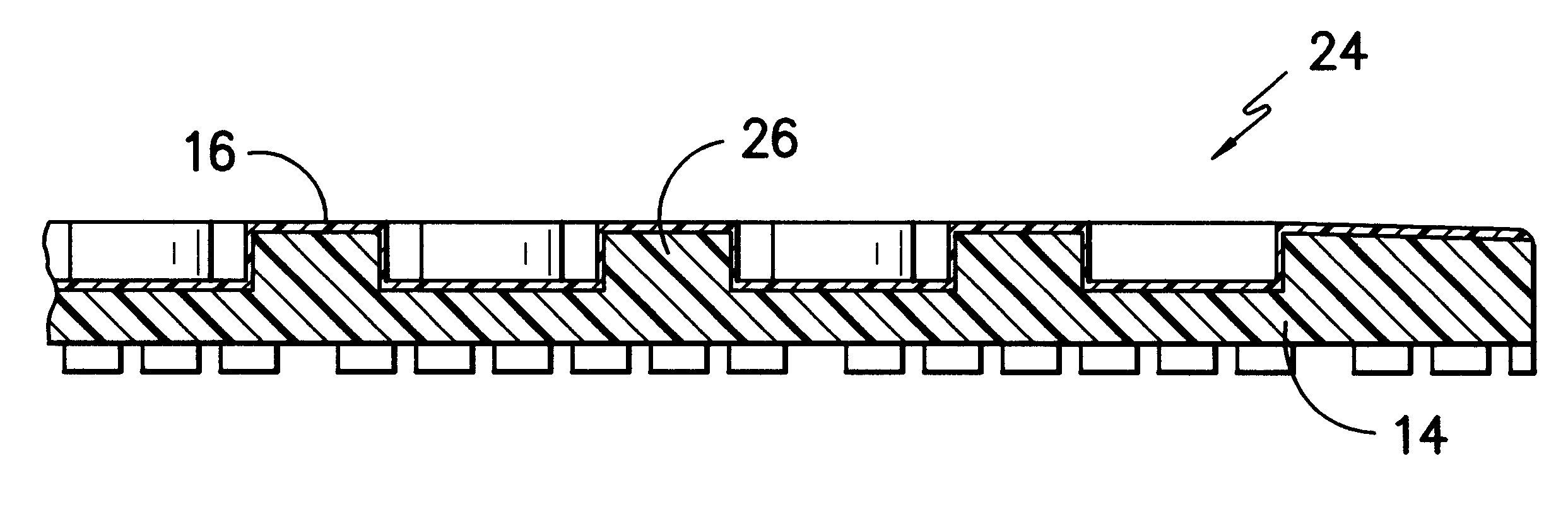

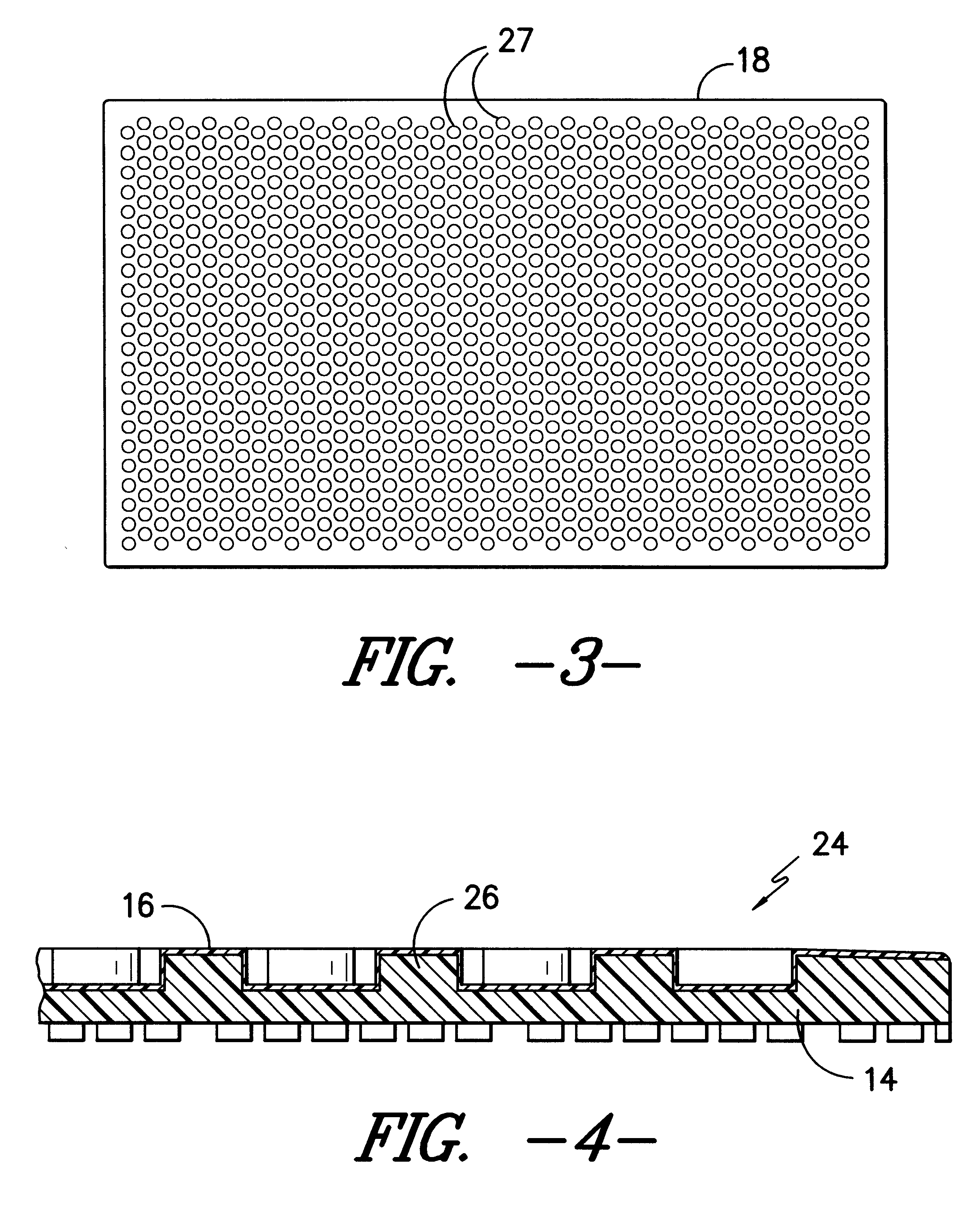

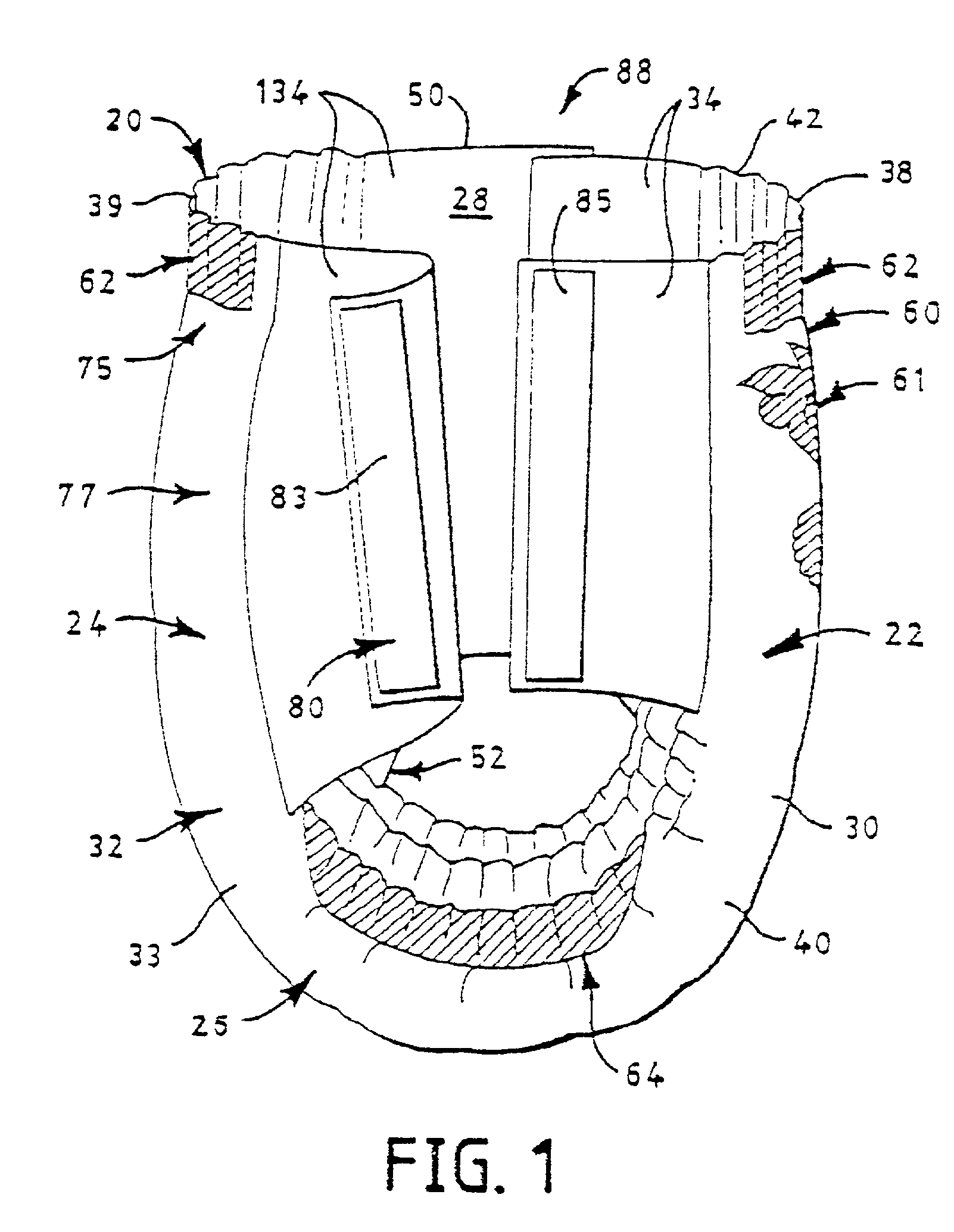

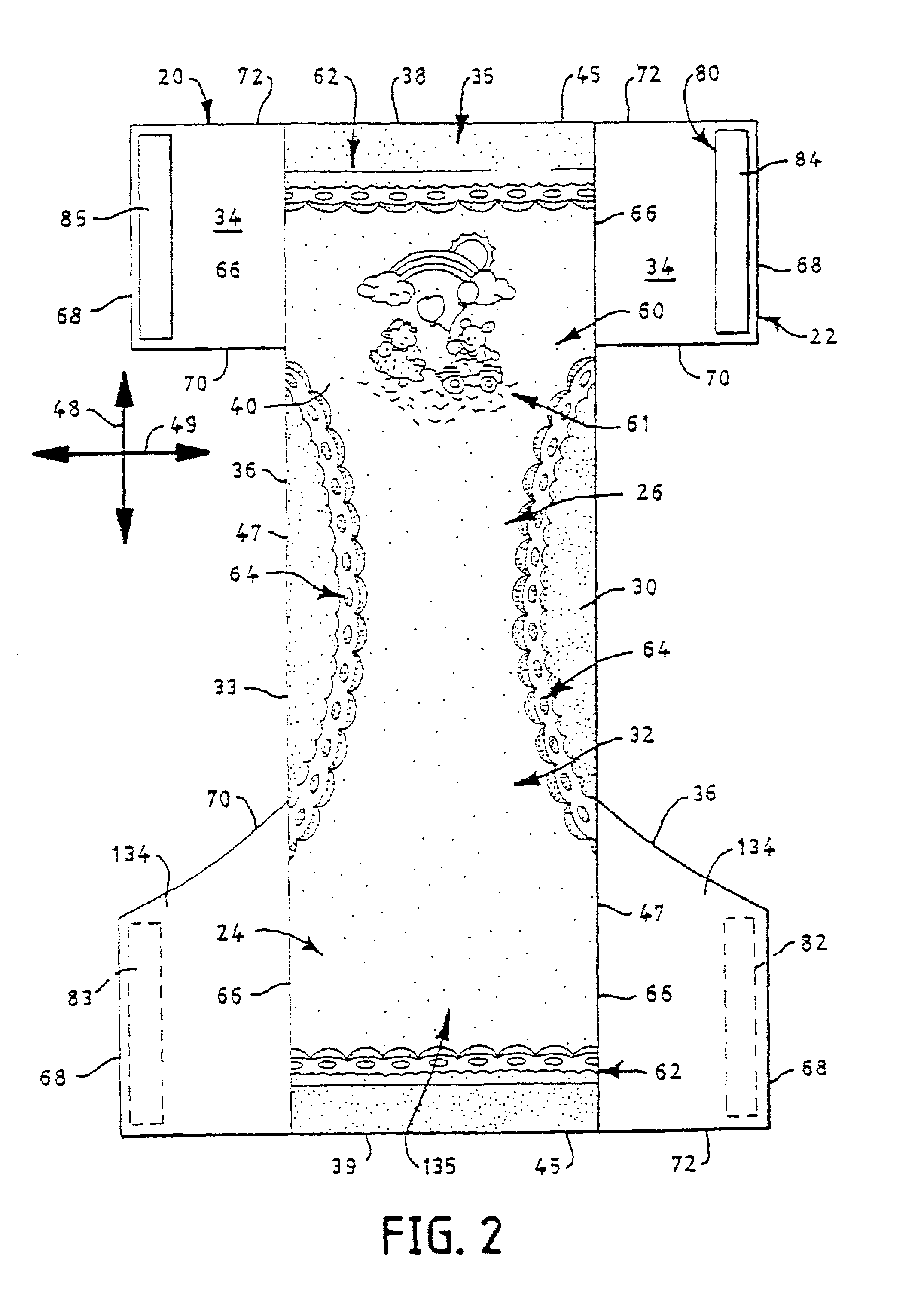

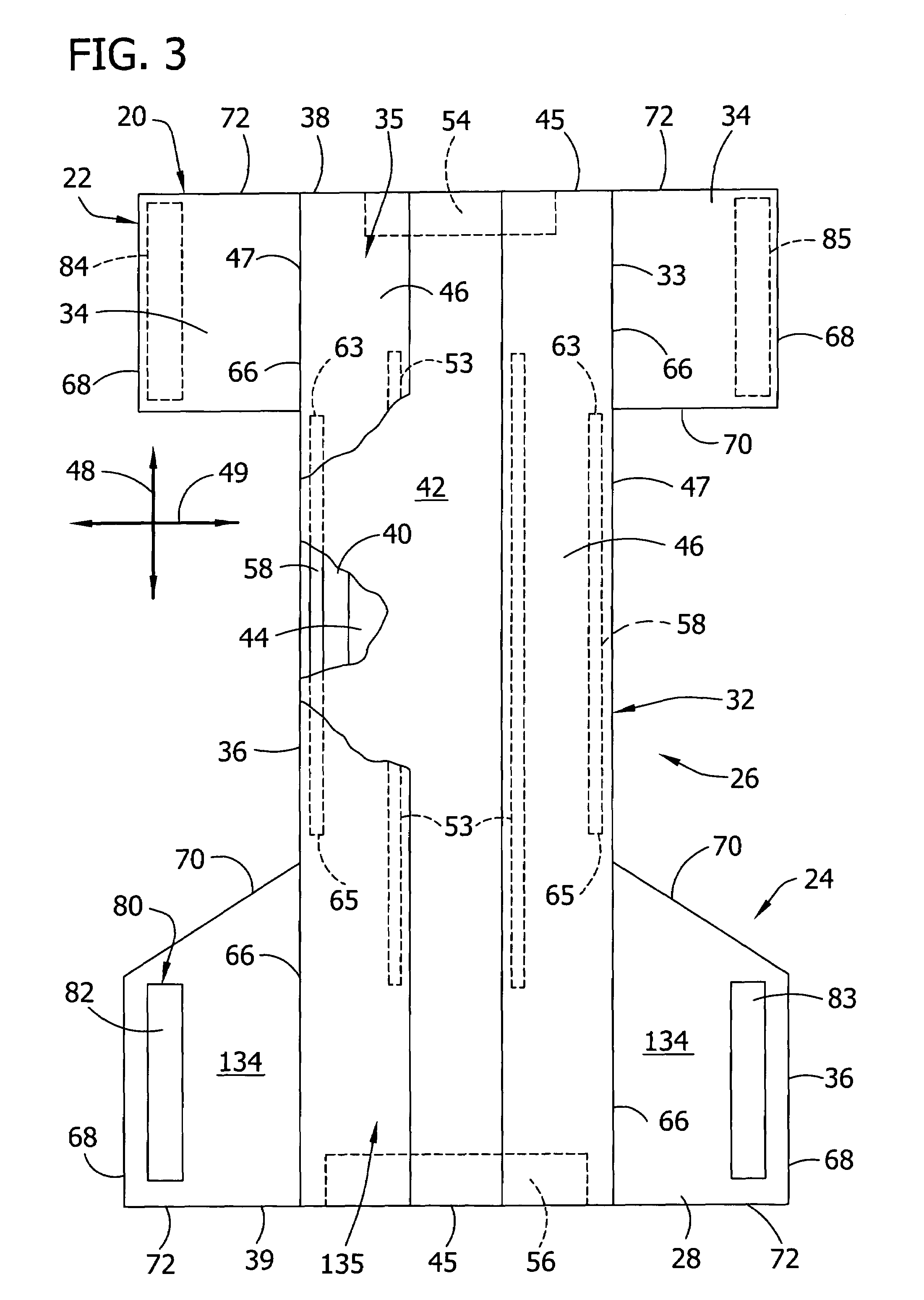

A modified secondary backing fabric (20) for carpet (50) comprises a secondary backing scrim fabric (15) and a fiber batt (21) integrated with the secondary backing fabric forming the modified fabric, providing a soft face (51) opposite the face (52) presented by the scrim fabric, uninterrupted by the scrim fabric. A carpet (50) comprises a face yarn (11); a primary backing fabric (12), the face yarn being tufted into the primary backing fabric; a modified secondary backing fabric (20) attached to the primary backing fabric; and an adhesive material (14) binding the face yarn to the primary backing fabric and the primary backing fabric to the secondary backing fabric. The modified secondary backing fabric (20) comprises a secondary backing scrim fabric (15) and a fiber batt (12) integrated as a unitary scrim, providing a soft face (51) forming the underside of the carpet, the soft face forming a barrier uninterrupted by the scrim fabric and blocking exudation of any of the adhesive material from the underside of the carpet. A method for the manufacture of a modified secondary carpet backing (20) comprises selecting a secondary backing scrim fabric (15) and a fiber batt (21); joining the two fabrics to form the modified secondary carpet backing (20), providing a soft face (51) opposite the face (52) presented by the scrim fabric, uninterrupted by the scrim fabric; and subjecting the modified fabric to heat sufficient to remove substantially all loose fibers (45) projecting from the soft surface. The present invention also provides a method for the manufacture of carpet.

Owner:COLUMBIA INSURANCE CO +1

High strength nonwoven fabric and process for making

InactiveUS6537935B1High strengthLow costSynthetic resin layered productsBaby linensEngineeringNonwoven fabric

A nonwoven fabric sheet comprising a multiplicity of generally parallel elongate strands of inelastic thermoplastic material extending in a first direction in spaced relationship, each of said strands having opposite elongate side surface portions that are spaced from and are adjacent elongate side surface portions of adjacent strands, and each of said strands also having corresponding opposite first and second elongate surface portions extending between said opposite elongate side surface portions, and a first sheet of flexible nonwoven material having spaced anchor portions bonded at first bond sites of the strands along said first elongate surface portions wherein the elongate strands thermoplastic material is oriented at least between adjacent bond sites along the length of the strands.

Owner:3M INNOVATIVE PROPERTIES CO

Flashless rubber floor mat and method

InactiveUS6589631B1Provide stabilityPermit cleaningLiquid surface applicatorsKitchenware cleanersCushioningDust control

A flashless floor mat or product and method are provided. At least one embodiment of this invention relates to a flashless cushioned dust control mat article wherein the mat comprises at least two distinct layers of rubber, one comprising foam rubber, the other comprising solid rubber. The solid rubber layer is present over the foam rubber layer on the side of the mat in which at least one integrated rubber protrusion is present to provide cushioning characteristics. The solid rubber layer acts as a cap or barrier for the foam rubber layer, particularly over the integrated protrusion or protrusions, in order to provide a mat which is resilient, will not easily degrade in its modulus strength after appreciable use and / or washing within industrial cleaning processes, and will not exhibit appreciable cracking or breaking, particularly within the integrated protrusion(s), after standard use for pedestrian traffic. A method of producing such an inventive cushioned floor mat article is also provided.

Owner:MILLIKEN & CO

Disposable scrubbing product

InactiveUS20050129897A1Resists effect of waterMaintain stiffnessStampsWrappersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, multiple layers of an abrasive structure are releasably attached together. In this manner, the top or outermost layer may be removed after being used in order to expose an unused abrasive structure located below the discarded layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

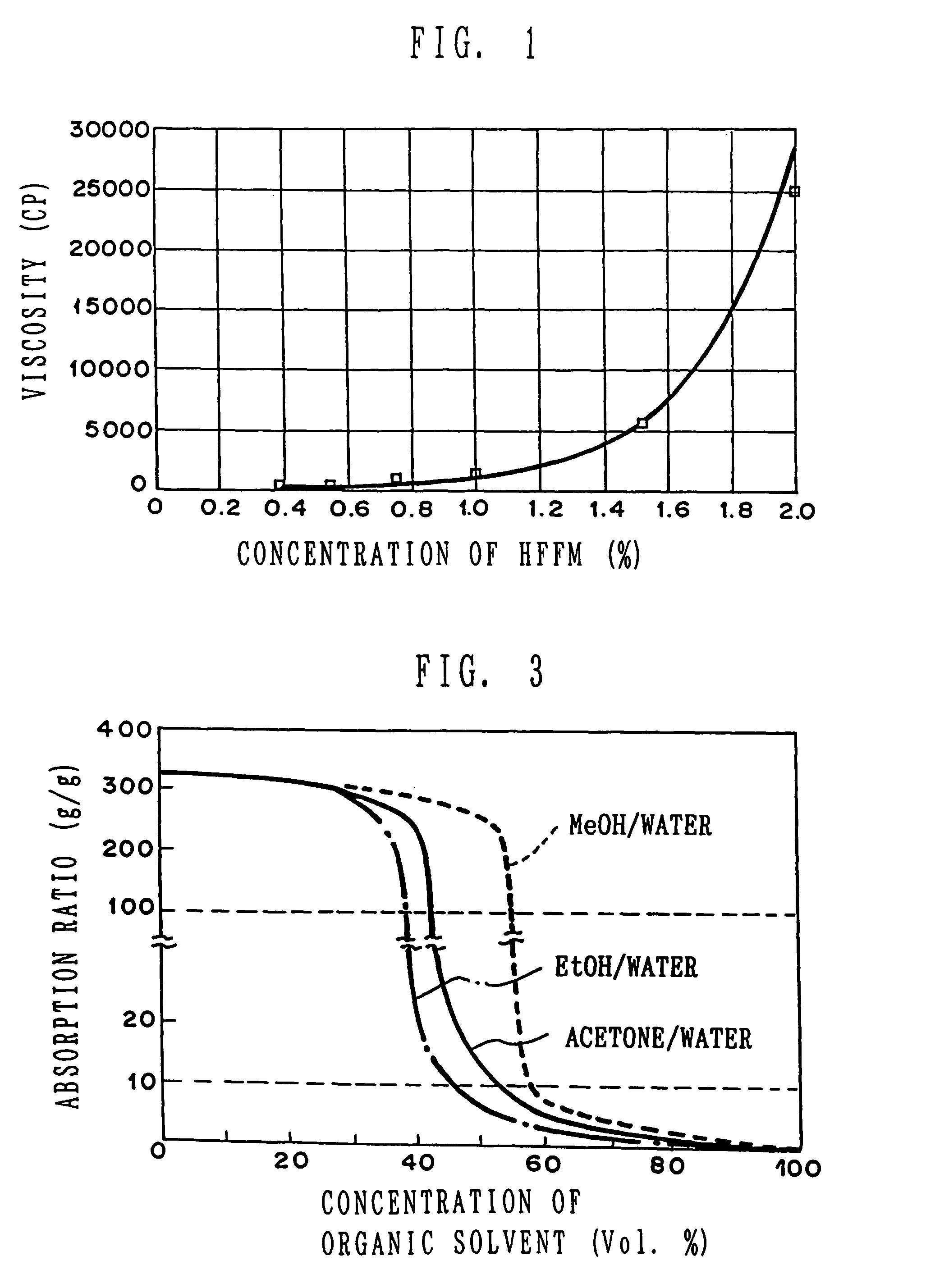

Highly absorbent composite compositions, absorbent sheets provided with the compositions, and process for producing the same

InactiveUS8268424B1Good dimensional stabilityEfficient designNon-fibrous pulp additionPreformed elementsFiberPolymer chemistry

A composite structure mainly composed of hydratable fine fibers in the form of microfibril and a water swellable solid body, the fine fibers being obtained from cellulose or a derivative thereof, and at least part of the surface of the solid body is covered with the fine fibers. The absorbent composite can be formed in various form of, for example, particle, pellet, sheet and the like, especially of a sheet type with a supporting sheet of a non-woven fabric. The present invention further provides a method of making the composite structure.

Owner:DSG INT LTD

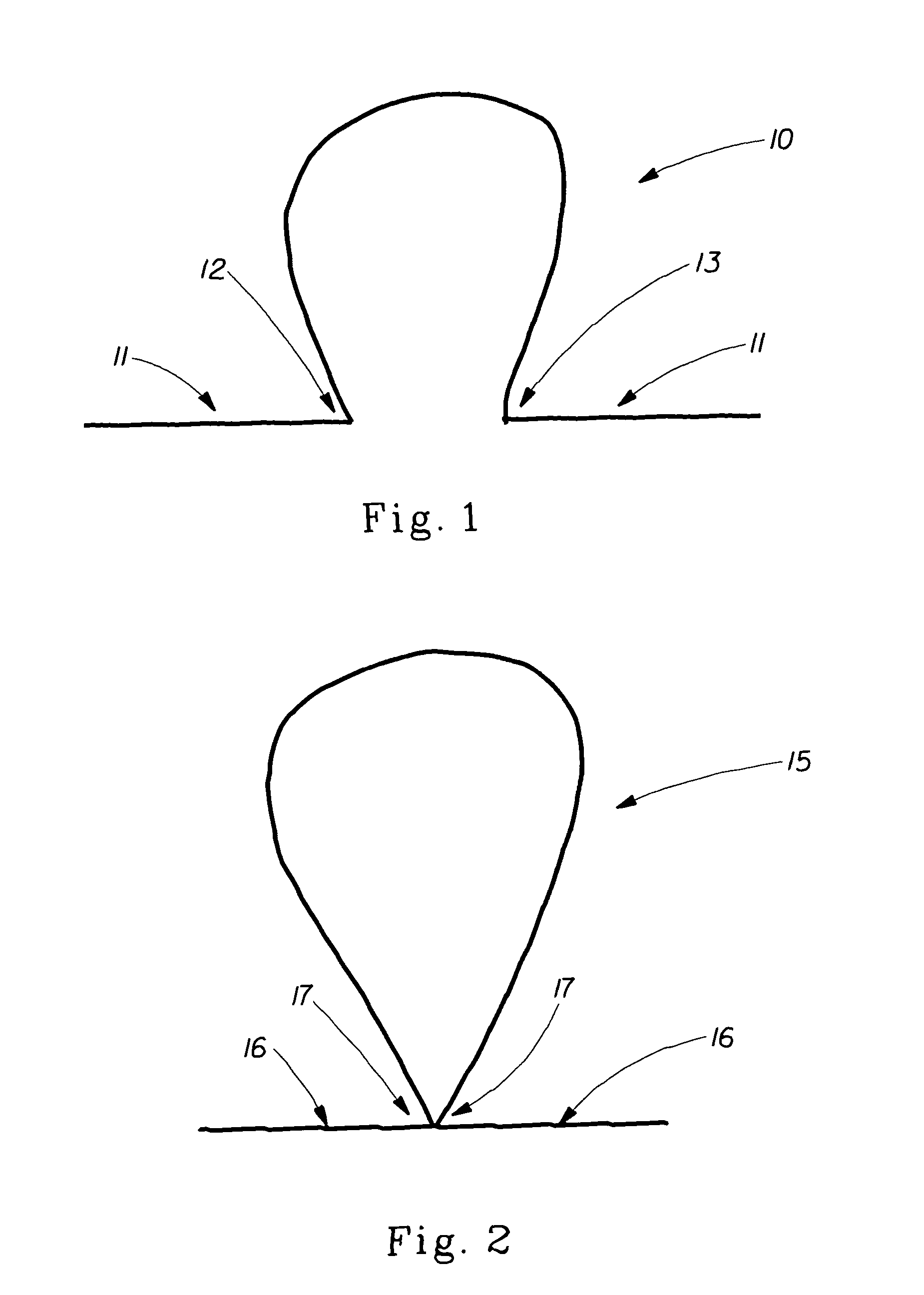

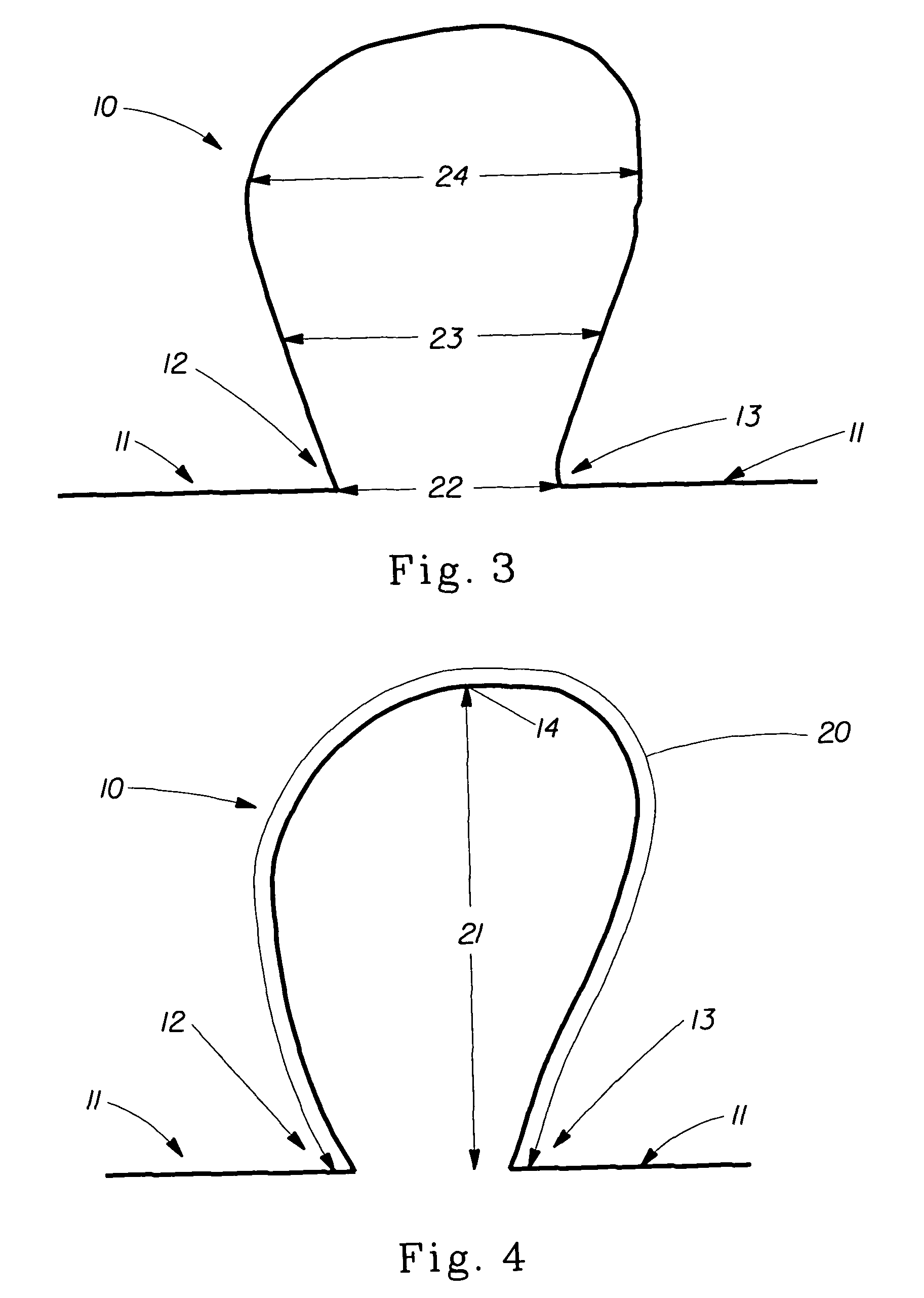

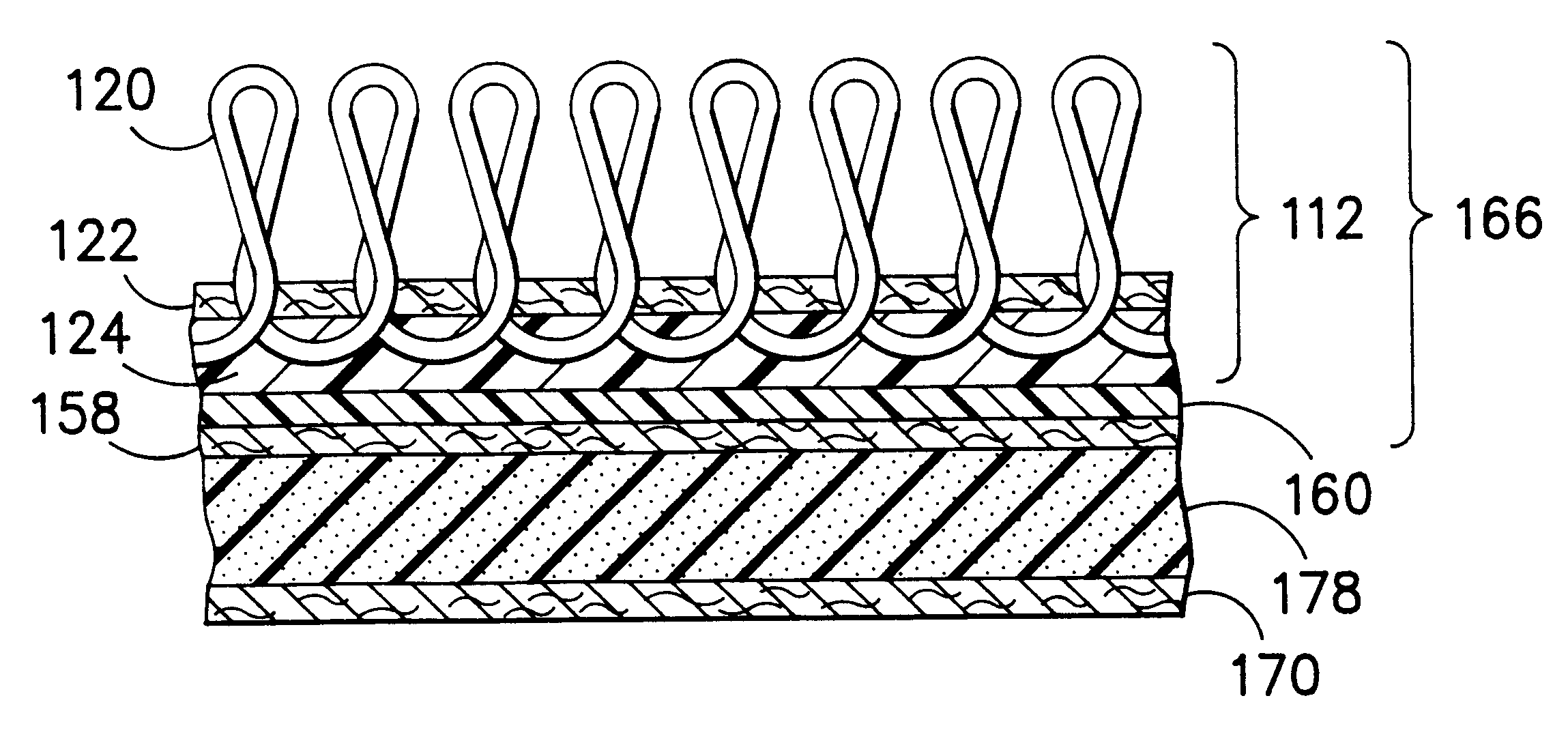

Mechanical fastening system for an absorbent article

An absorbent article such as infant training pants is provided with a mechanical hook-and-loop type fastening system in which at least the loop material is made of a laminate with a facing having a bond density of greater than 225 points per square inch.

Owner:KIMBERLY-CLARK WORLDWIDE INC

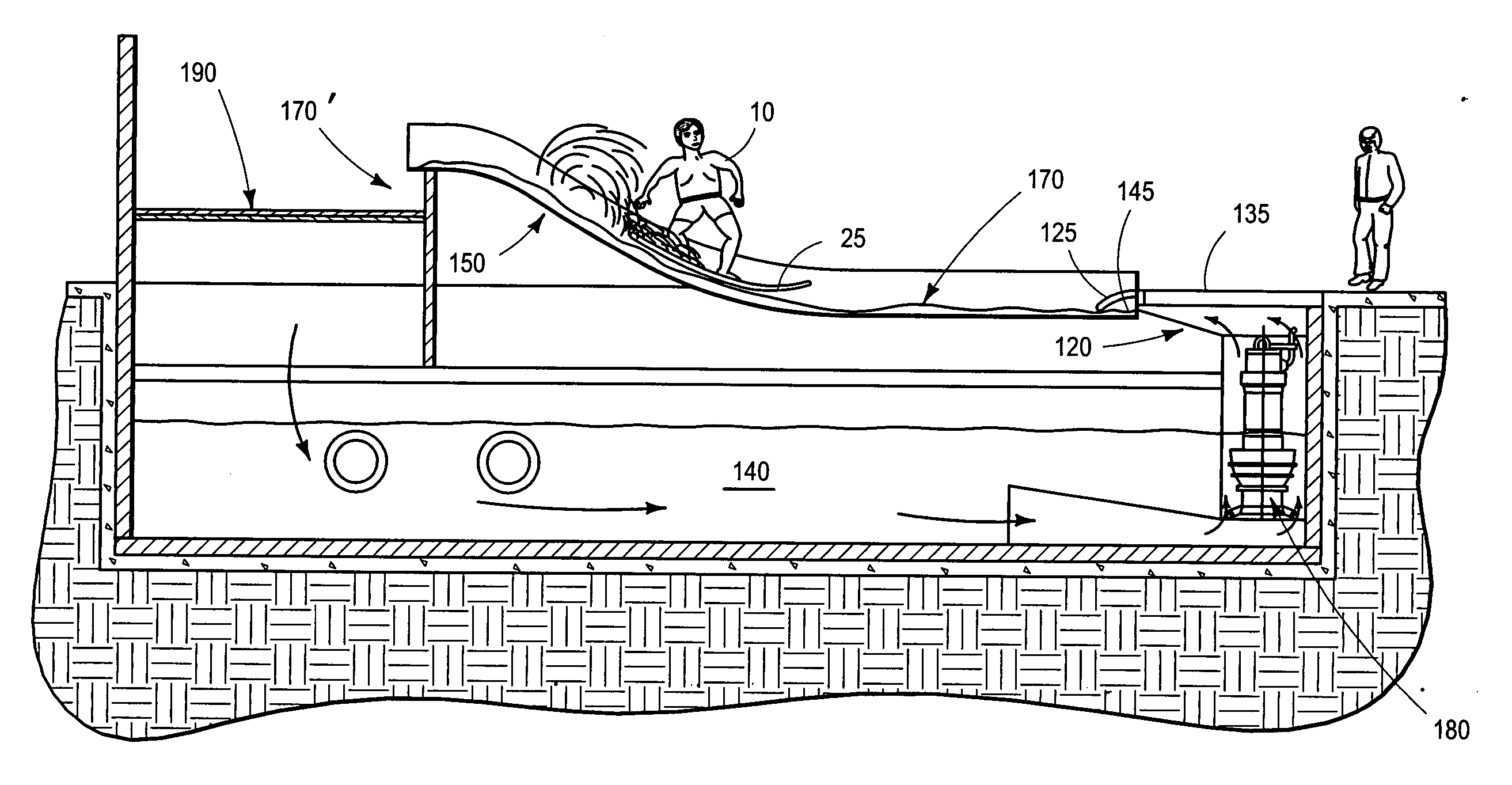

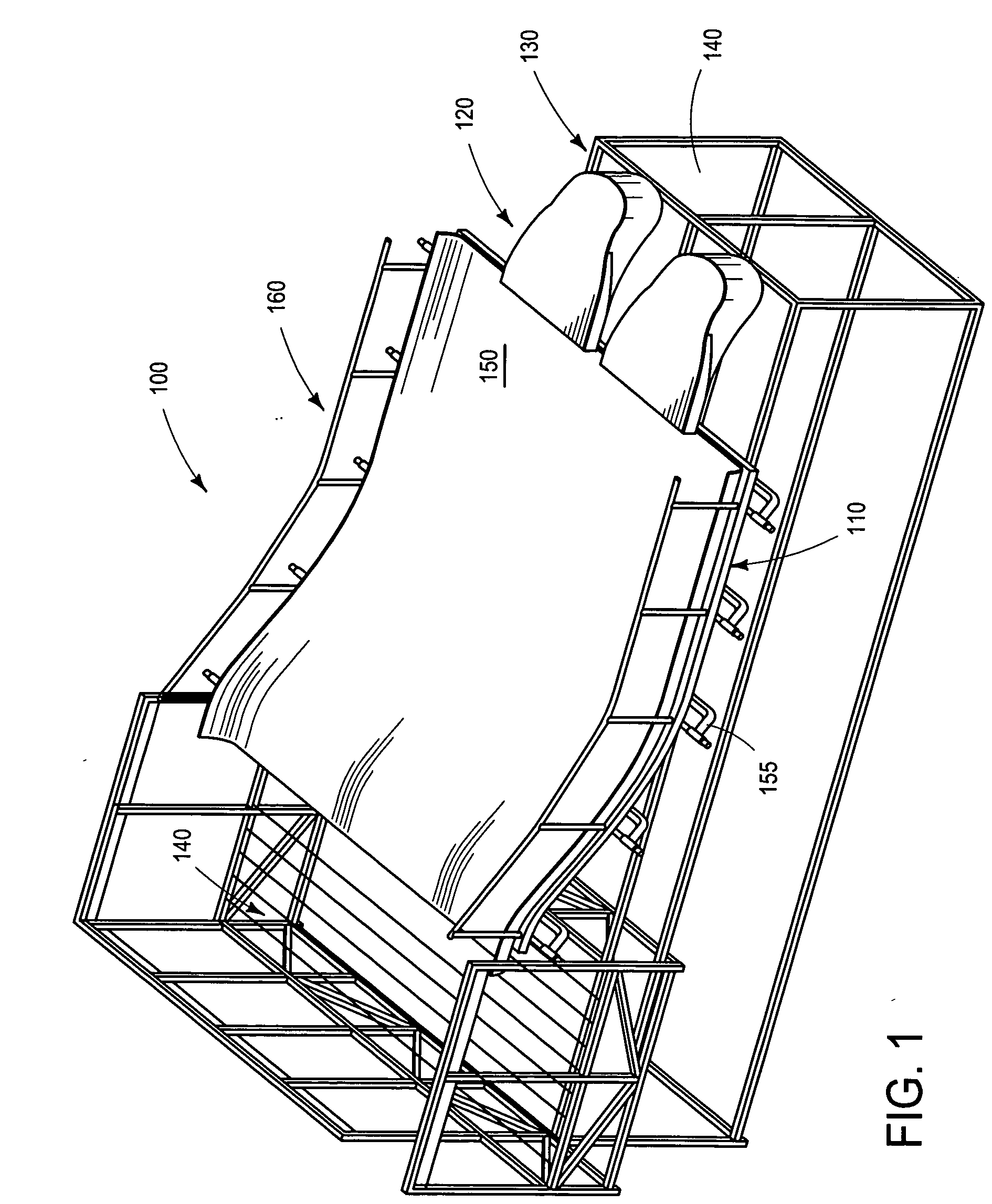

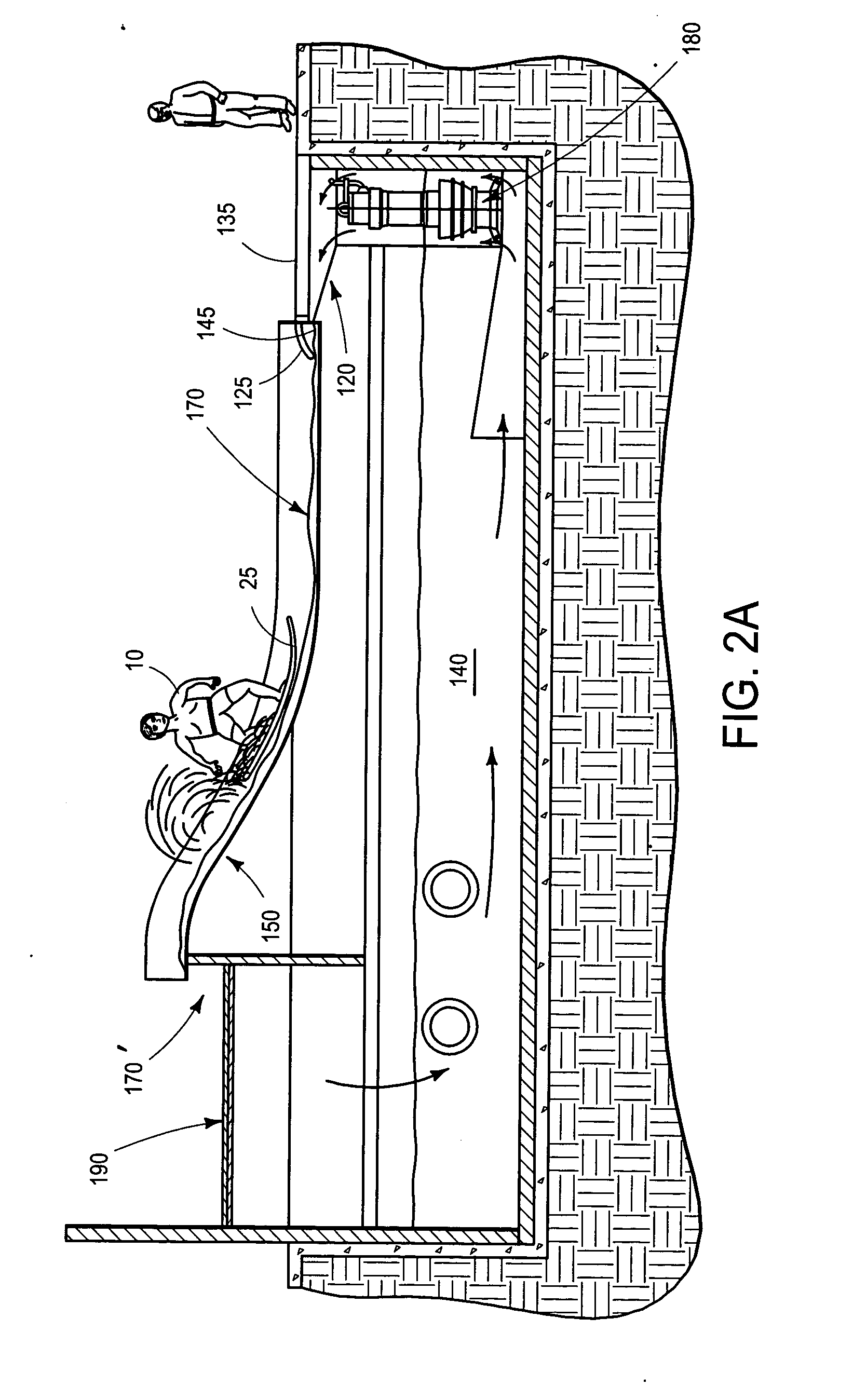

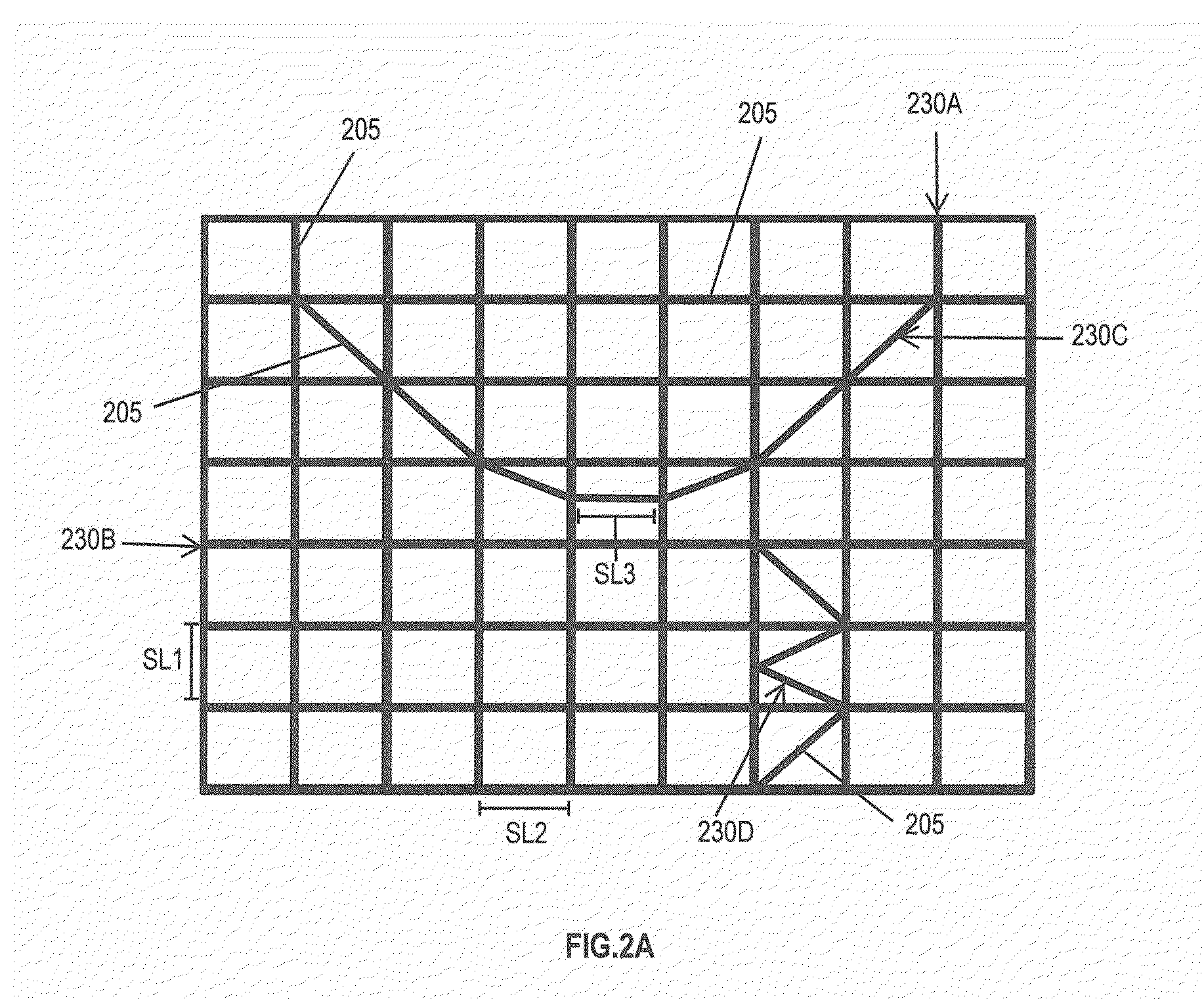

Contoured variably tensionable soft membrane ride surface for ride attraction

InactiveUS20050148398A1SaferRaise security concernsSki bindingsLayered productsBraced frameWater flow

A ride surface for water ride attractions and the like is provided. The ride surface is fabricated from a reinforced membrane material tensioned over a supporting framework. The tensioned membrane ride surface serves the dual role of providing structural support for water flow and riders thereon while at the same time providing an impact safe surface that is non-injurious to riders who may fall thereon. The tensioned membrane can be adjusted actively and / or passively in order to accommodate different and varied ride experiences. Optionally, the shape of the membrane ride surface can be changed either dynamically or passively by special tensioning techniques and / or by using auxiliary support structures such as air bladders, pressure / suction, foam supports or / or the like.

Owner:WHITEWATER WEST INDS

Zoned Topsheet

InactiveUS20100035014A1Cellulosic plastic layered productsSanitary towelsEngineeringMechanical engineering

An absorbent article having a topsheet, a backsheet, and an absorbent core between the topsheet and backsheet. The topsheet has a central region, a first end intermediate region, a first end region, a second end intermediate region, a second end region, an edge region, and an intermediate edge region. The central region, first end intermediate region, first end region, second end intermediate region, and second end region are disposed on a line generally parallel to the longitudinal centerline. The central region, intermediate edge region, and edge region are disposed on a line generally parallel to the transverse centerline. The central region texture, first end intermediate region texture, first end region texture, second end intermediate region texture, and second end region texture differ from one another. The central region texture, intermediate edge region texture, and edge region texture differ from one another.

Owner:THE PROCTER & GAMBLE COMPANY

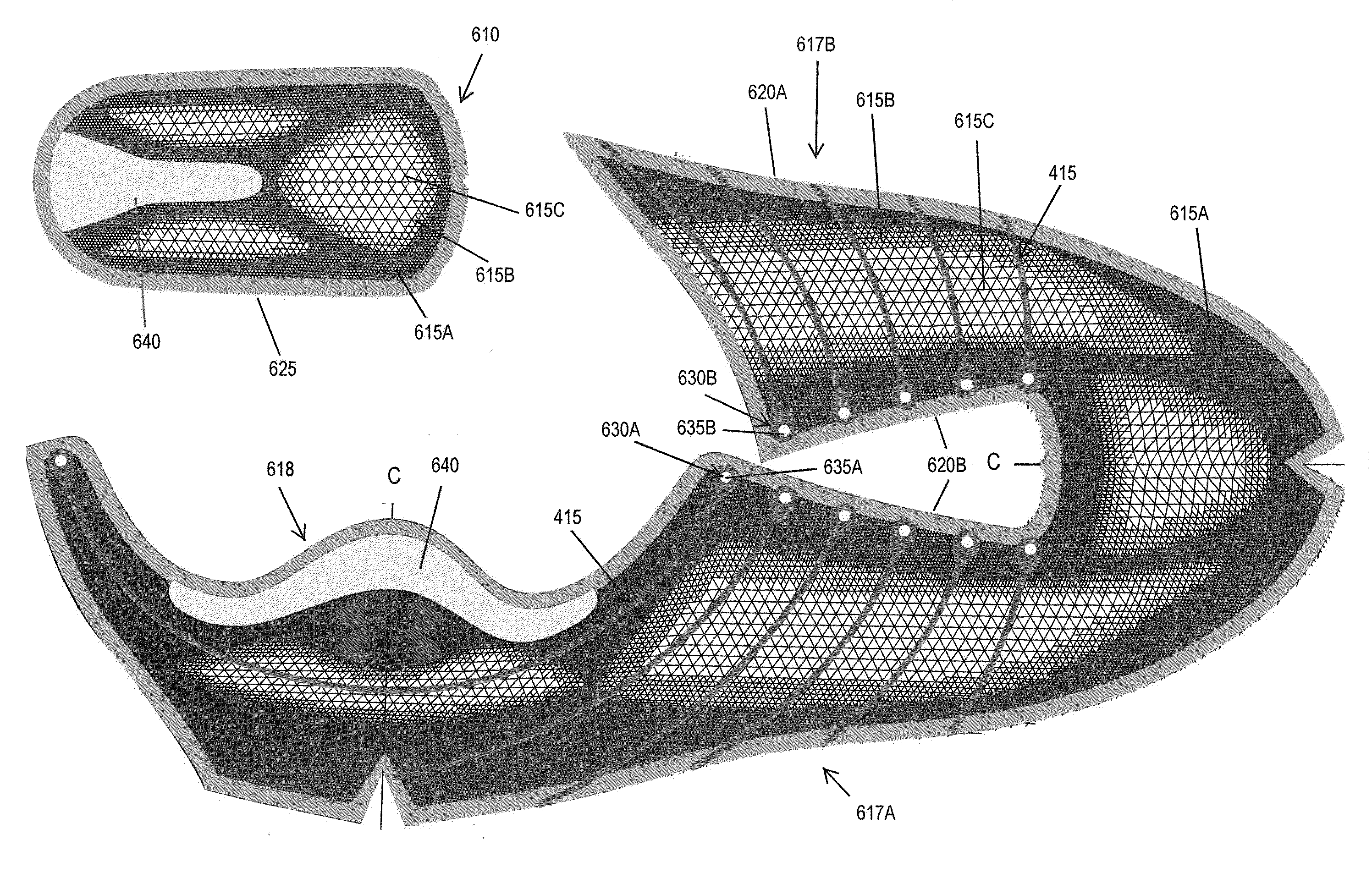

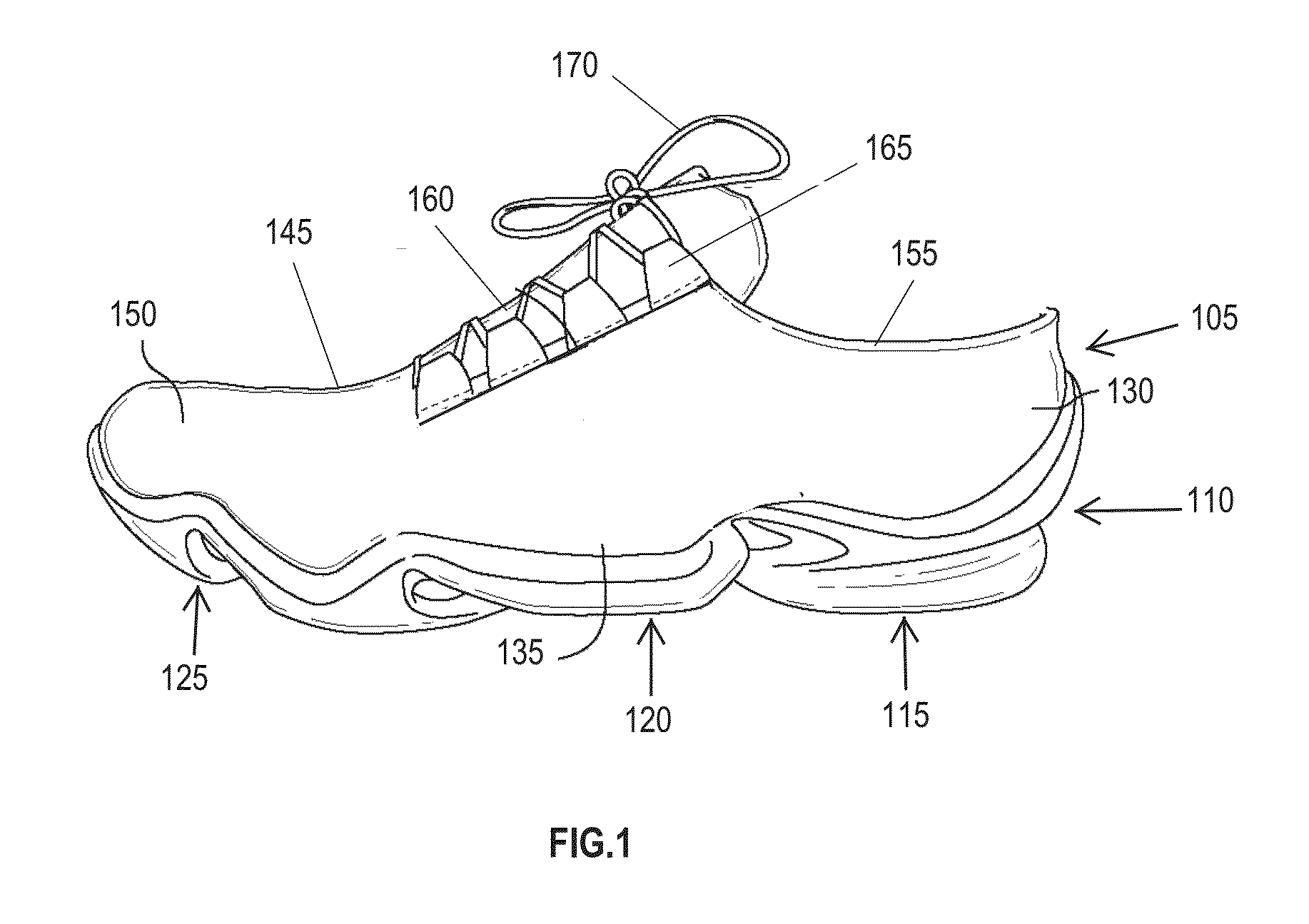

Footwear including textile element

An article of footwear includes a sole and an upper at least partially formed of an textile element. The textile element includes a yarn matrix having a plurality of interlocked strands oriented in predetermined directions. A structural element may be captured within the matrix at selected locations. In operation, the matrix is stitched onto a temporary substrate. The substrate is removed and the article coupled to a sole structure to form the article of footwear.

Owner:UNDER ARMOUR

Tufted surface covering and method

The tufted surface covering includes a base formed from particles of a thermosetting polymer compound mixed with a particle binding agent causing a portion of the particles to bind together to form a self supporting web. The base is tufted with a tufting material. Thermosetting vulcanized natural and / or synthetic rubber compounds are employed. The polymer layer is tufted with a tufting material and heated to a temperature of from about 110° C. to about 220° C. at an elevated pressure of up to two tons per square inch, to cause the particles to bind together at elevated temperature and pressure to anchor and seal the tufts in place. Cross-linking agents and polar polymer containing compounds may be employed as particle binding agents. In another aspect of the invention, a second layer of particles of a thermosetting polymer mixed with a particle binding agent may be joined together with the particles of the first layer at elevated temperature and pressure. A series of spaced apertures extends through the first and second layers to enable free draining of the surface covering. The lower surface of the covering includes spaced indentations to reduce the weight of the covering.

Owner:WALTERS IAN D

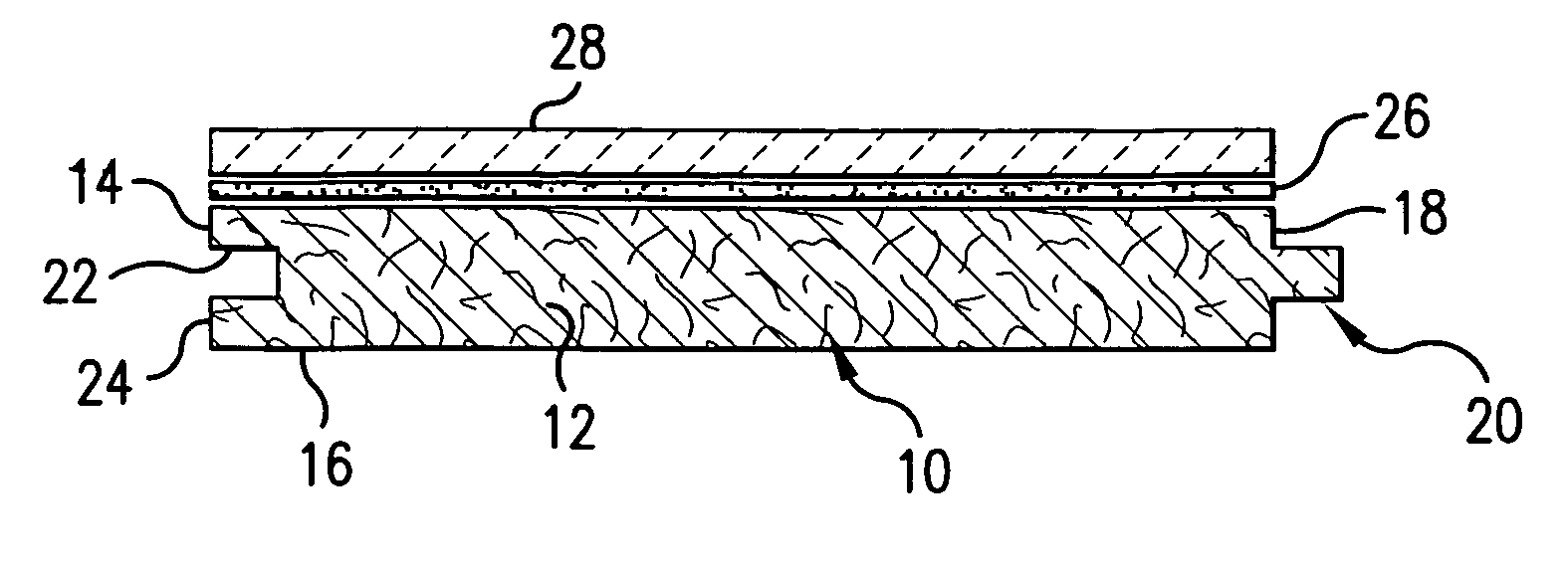

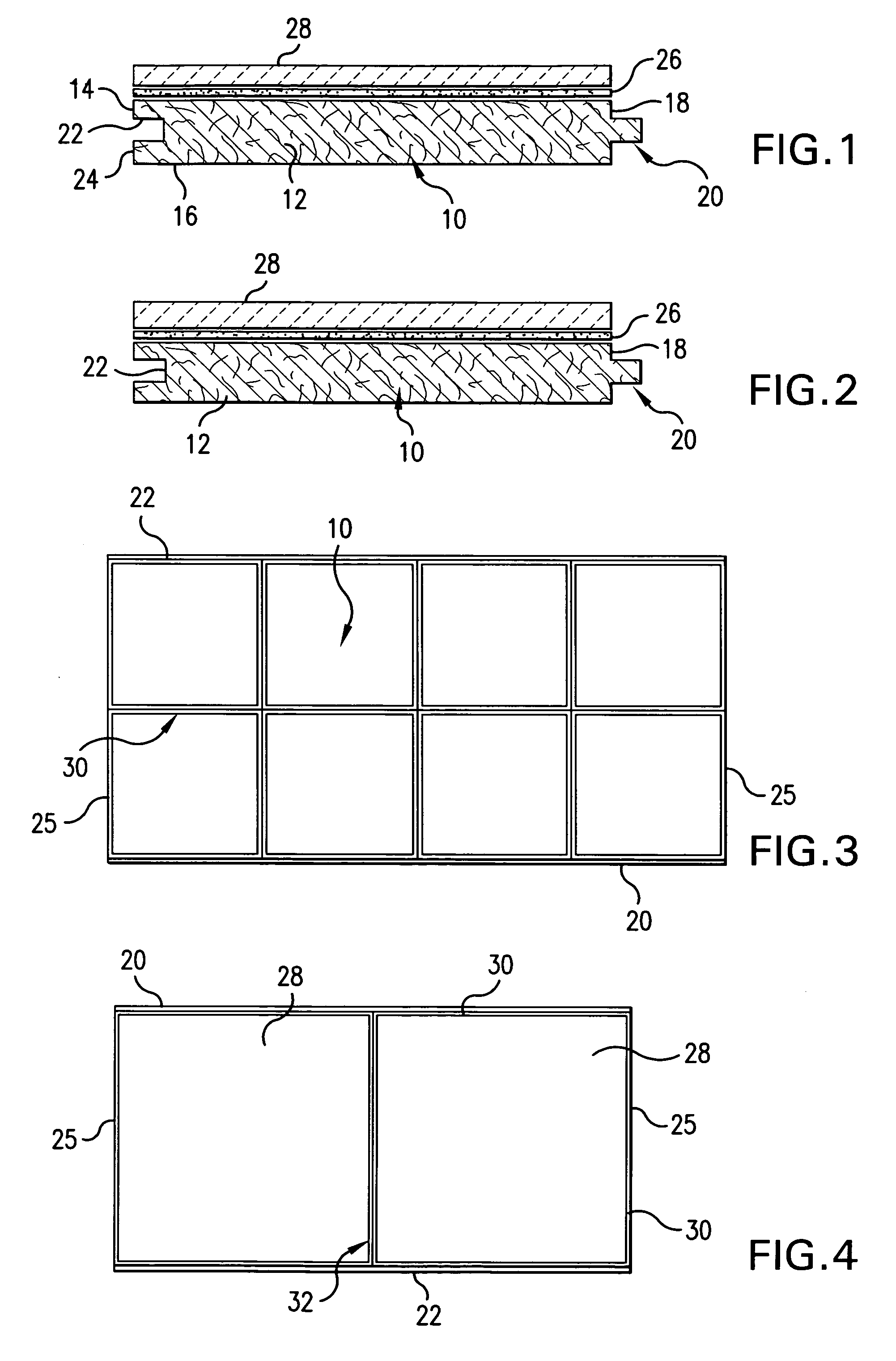

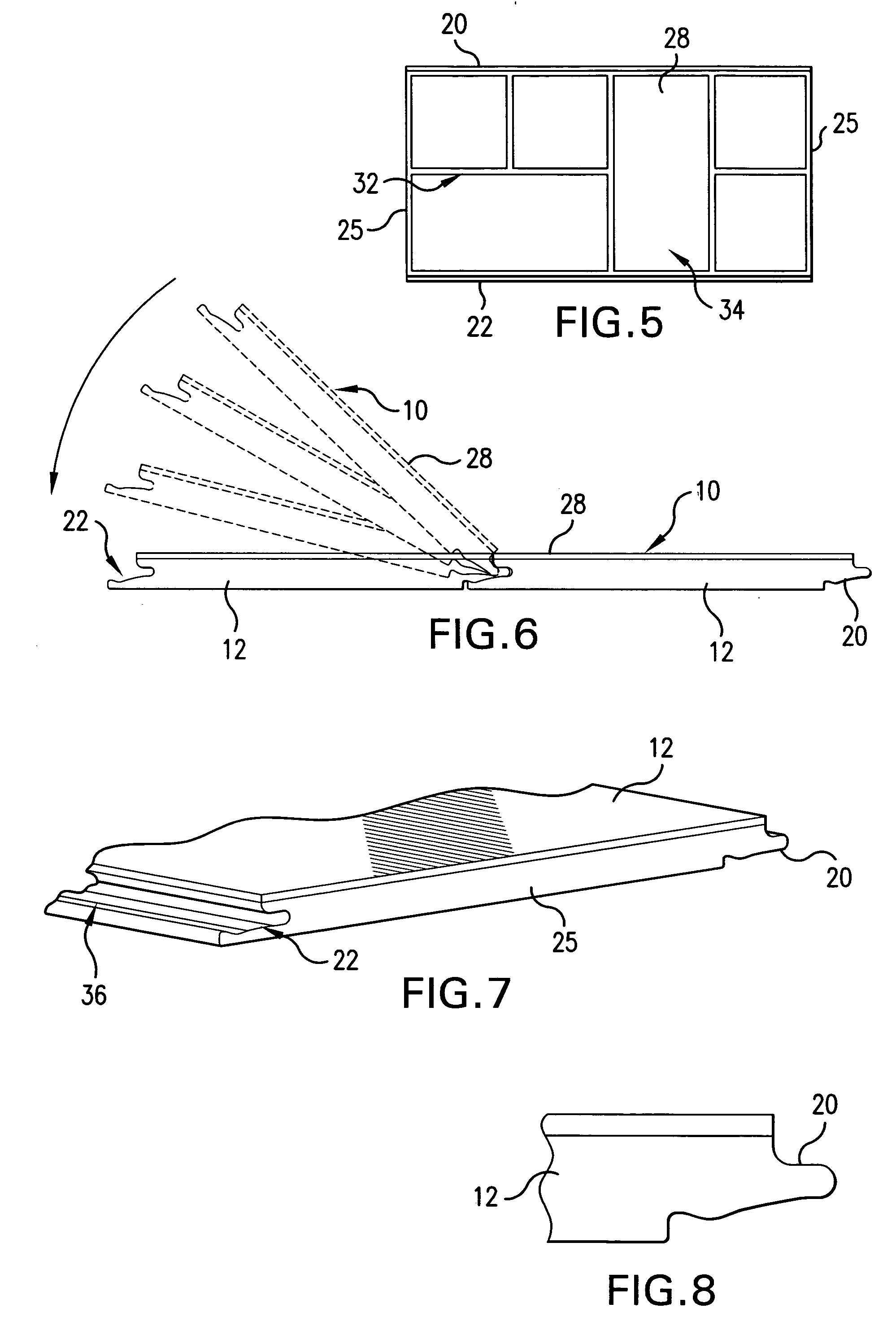

Hard surface-veneer engineered surfacing tiles and methods

A modular tile assembly having a substantially rigid substrate, at least one sealant layer, and at least one stone, ceramic, or porcelain tile. A bottom surface of a first sealant layer being bonded to an upper surface of the substrate and a top surface of a second sealant layer being bonded to a lower surface of the substrate. The tile being bonded to at least a portion of the top surface of the first sealant layer. In one example, the substrate is provided with a tongue or a groove defined in any one, combination, or each of the respective side edges of the substrate, as desired.

Owner:SHAW INDS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com