Patents

Literature

5003 results about "Acoustic insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

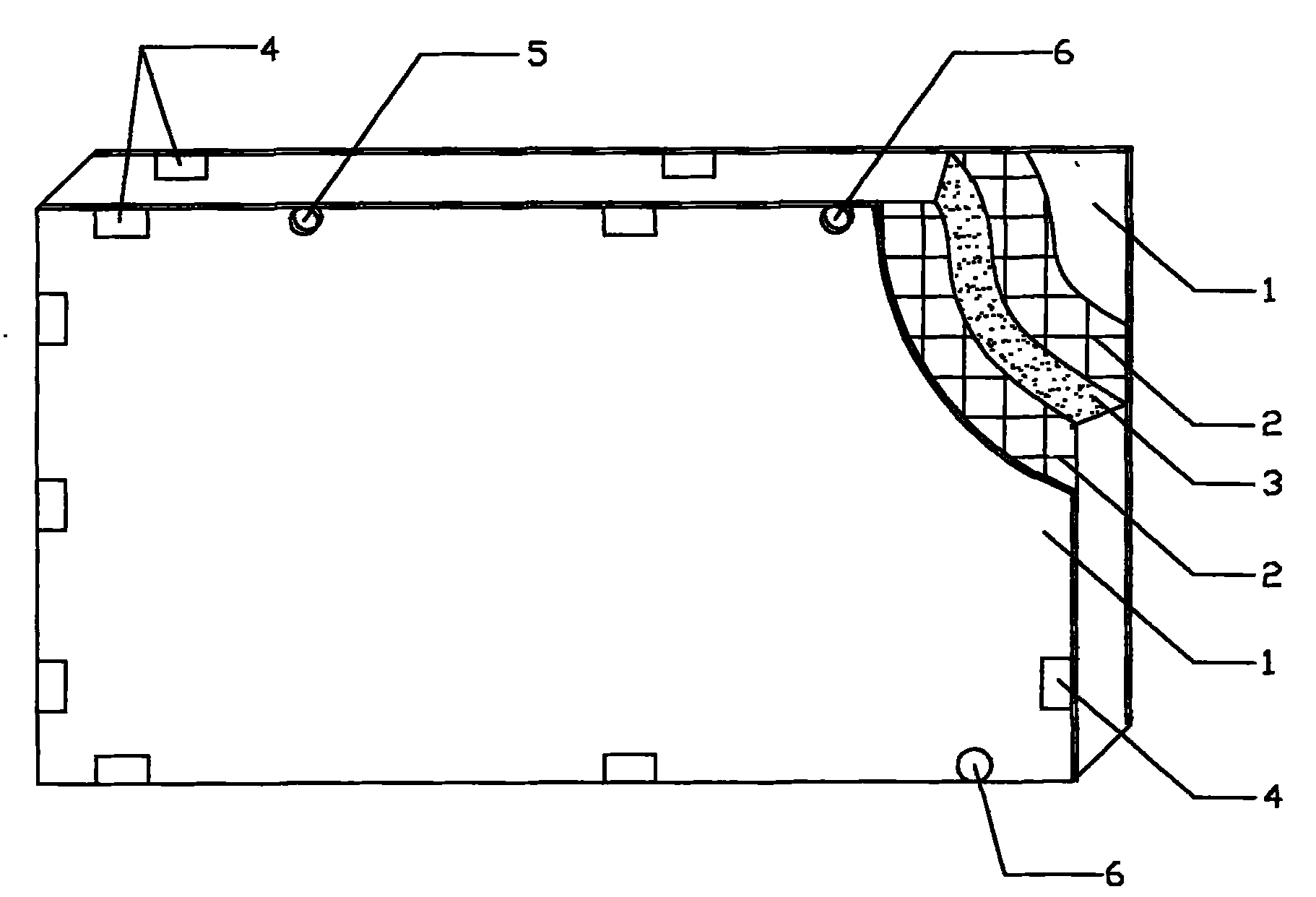

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

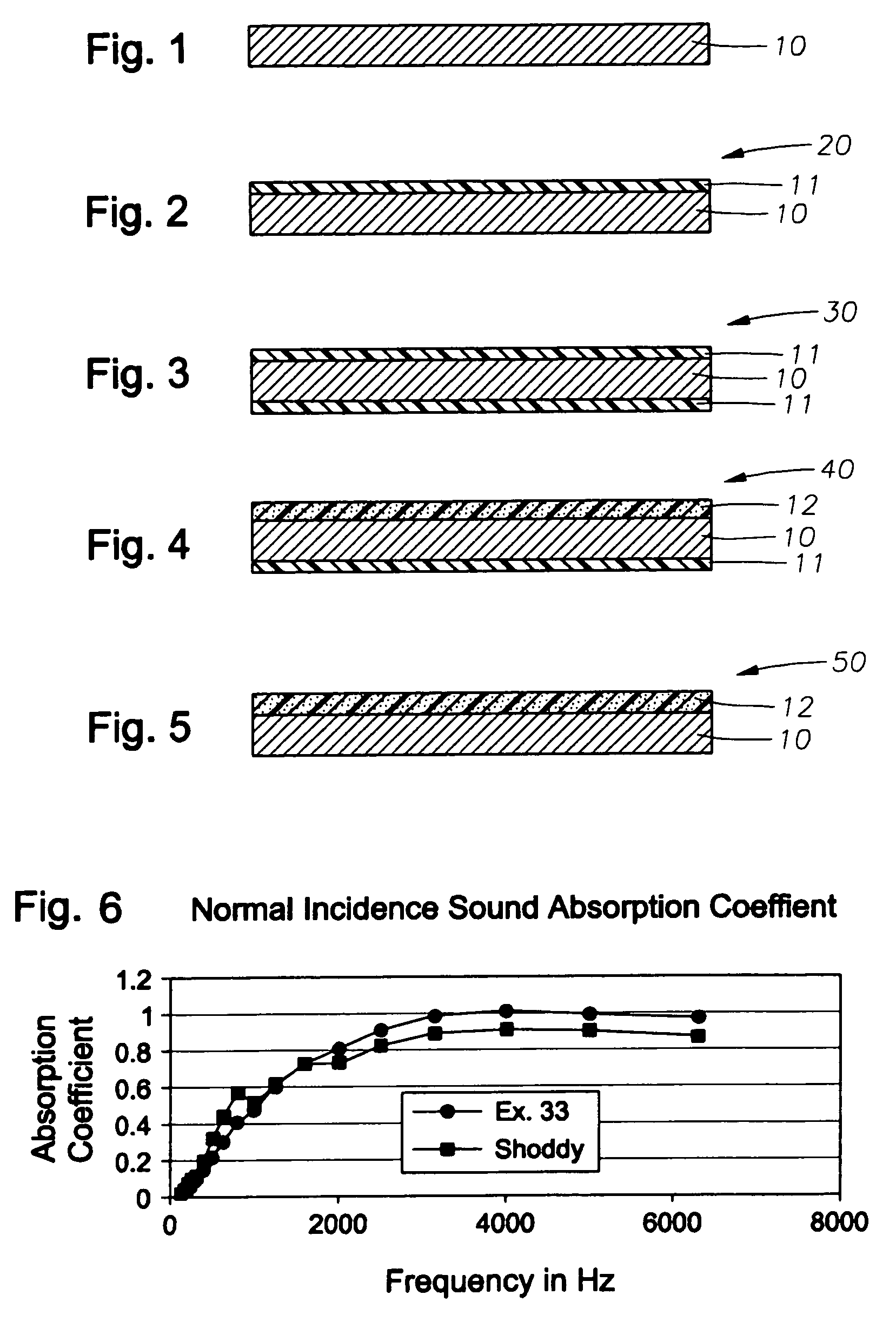

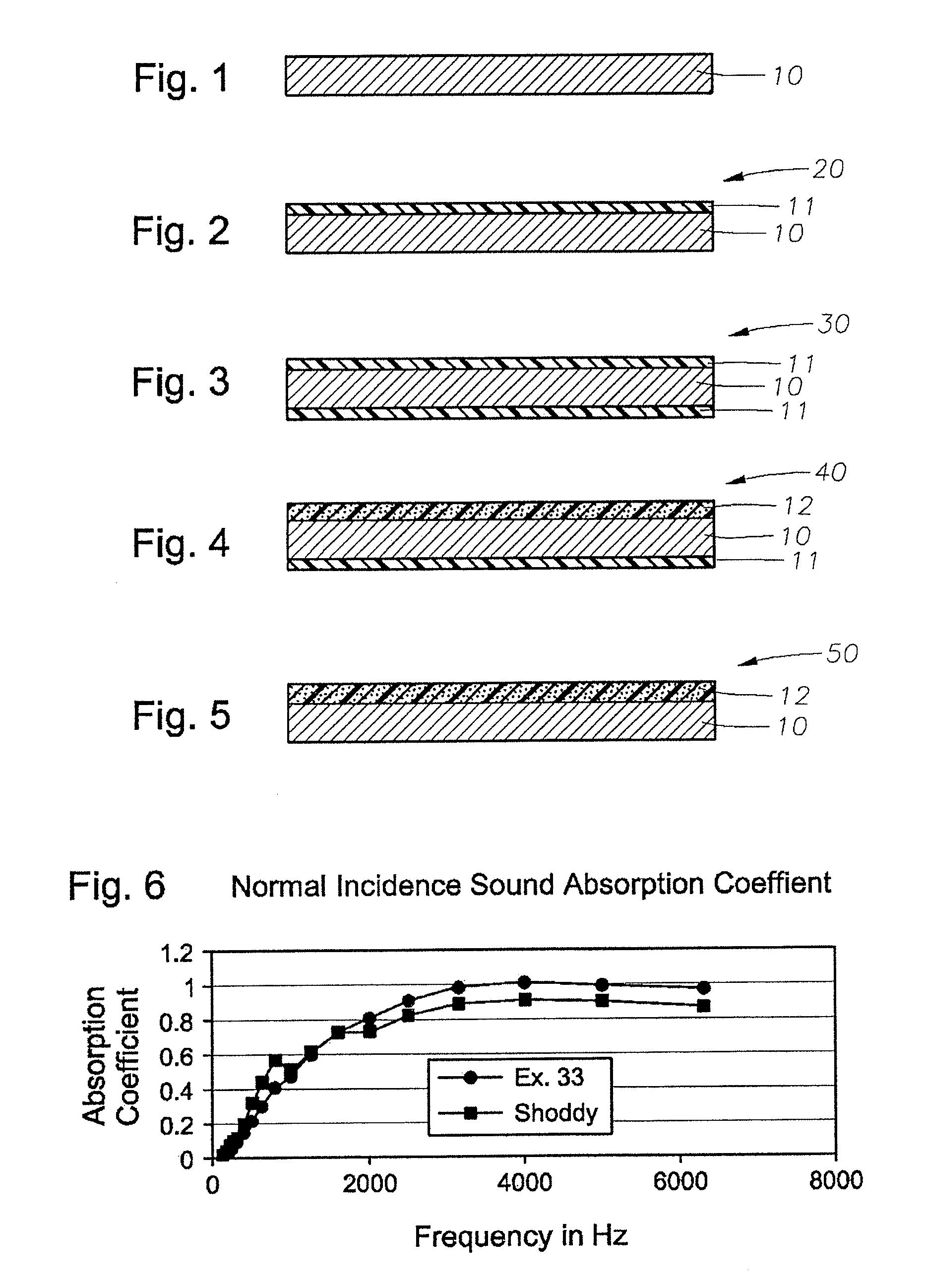

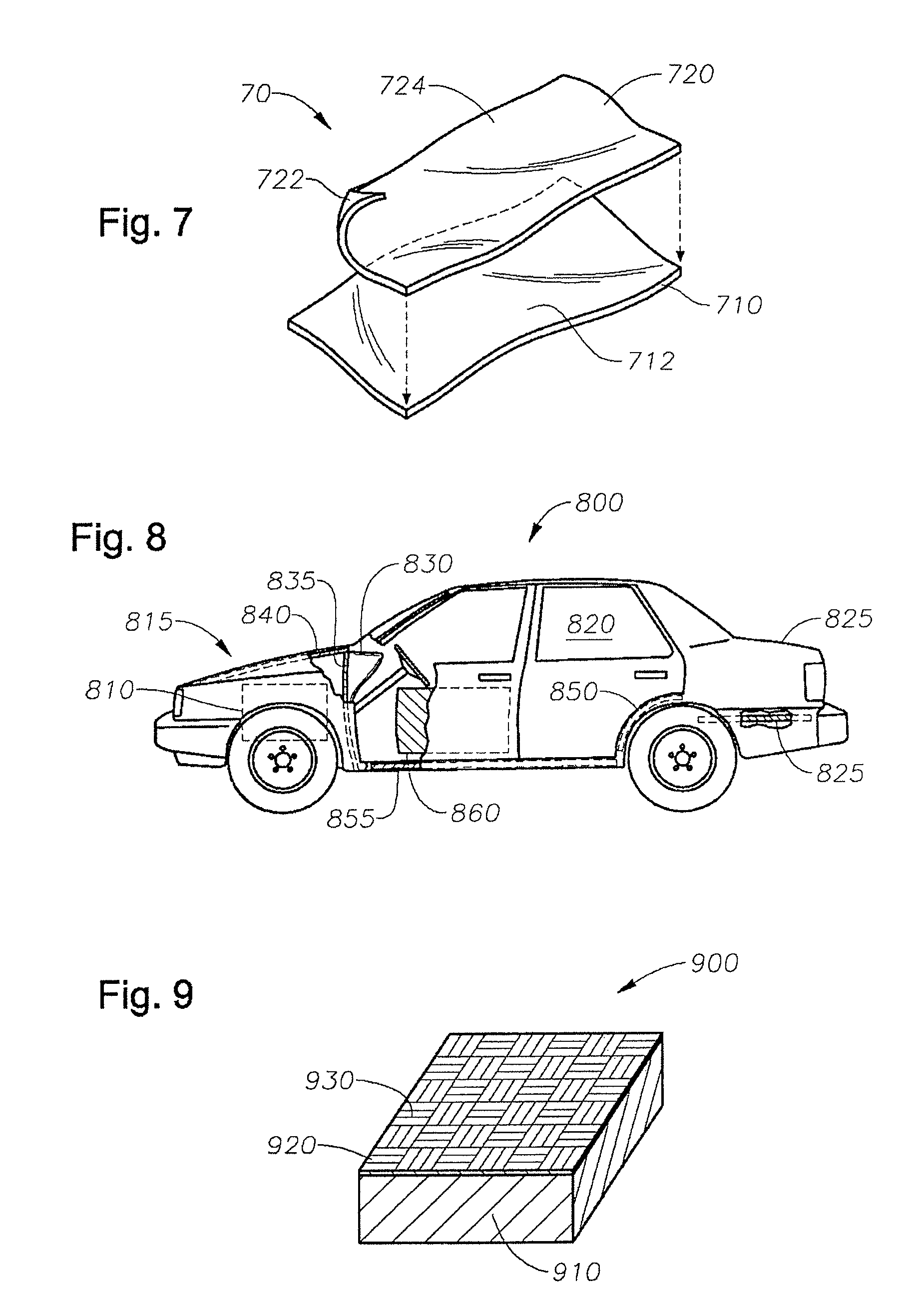

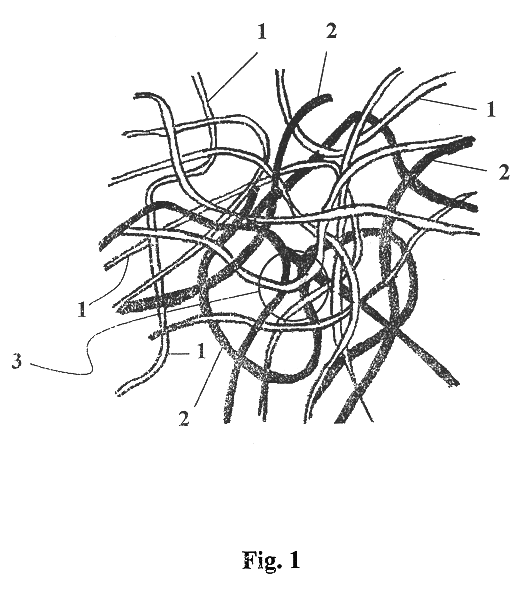

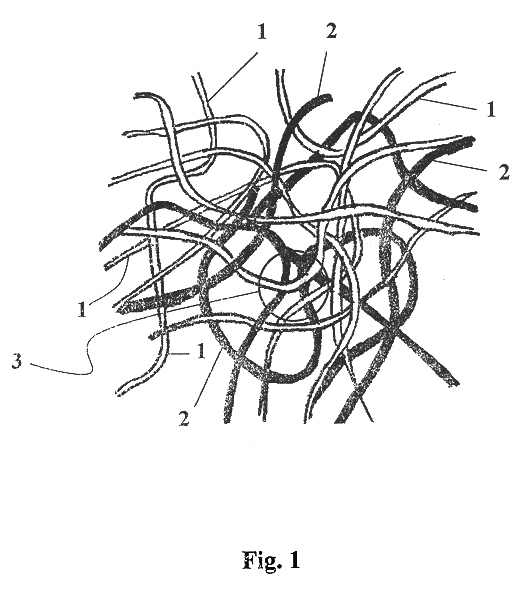

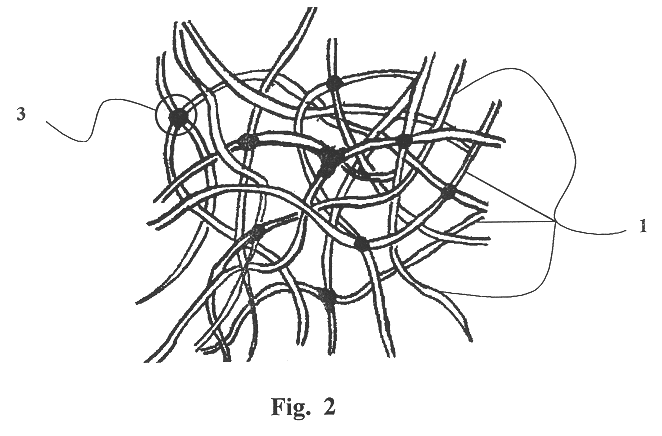

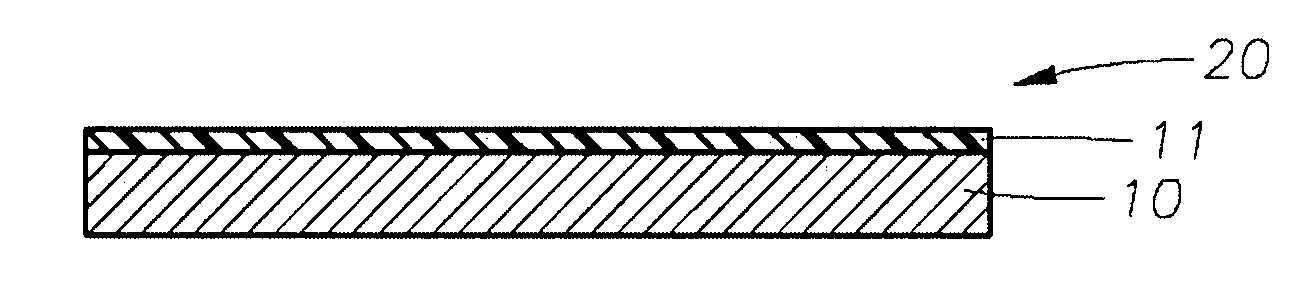

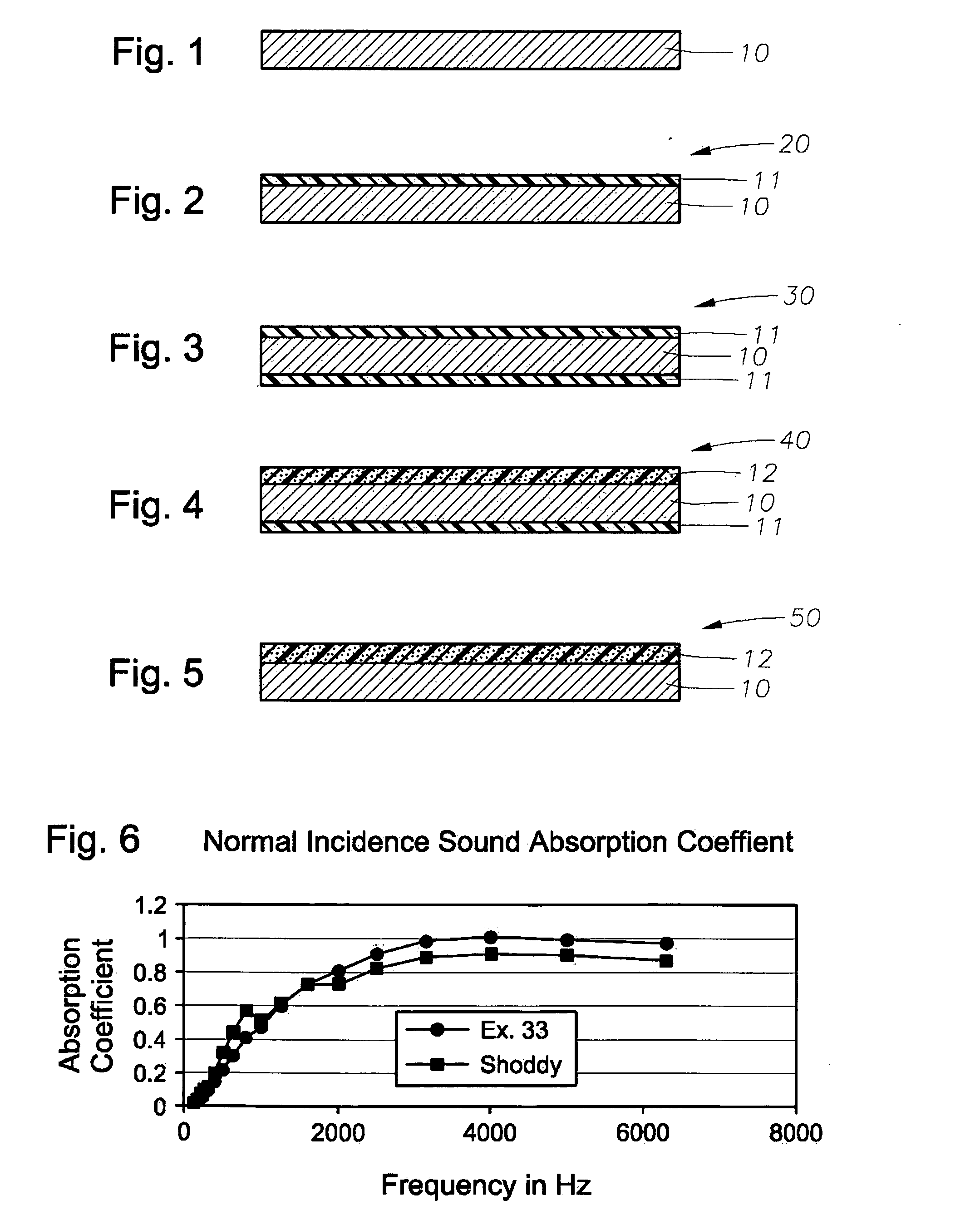

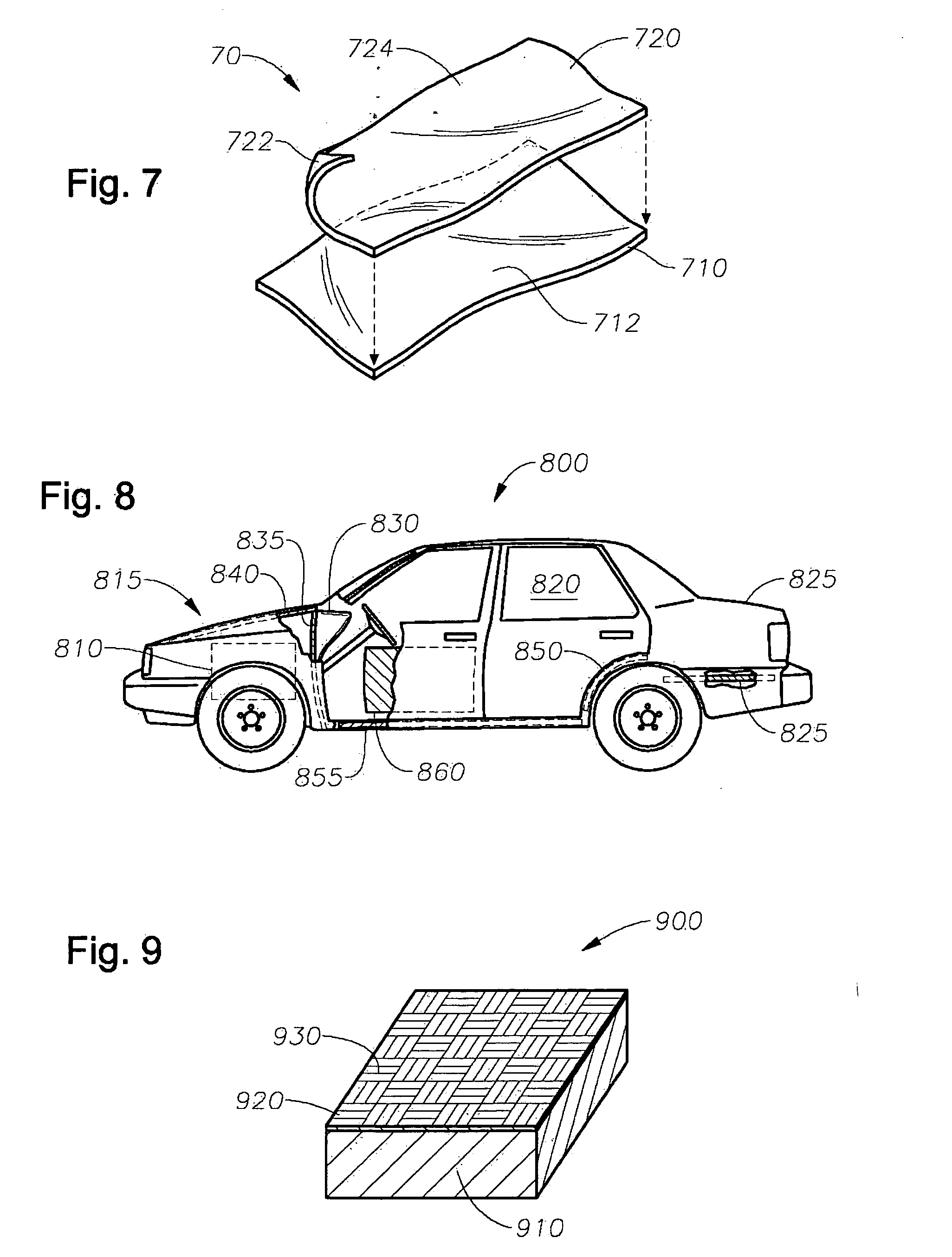

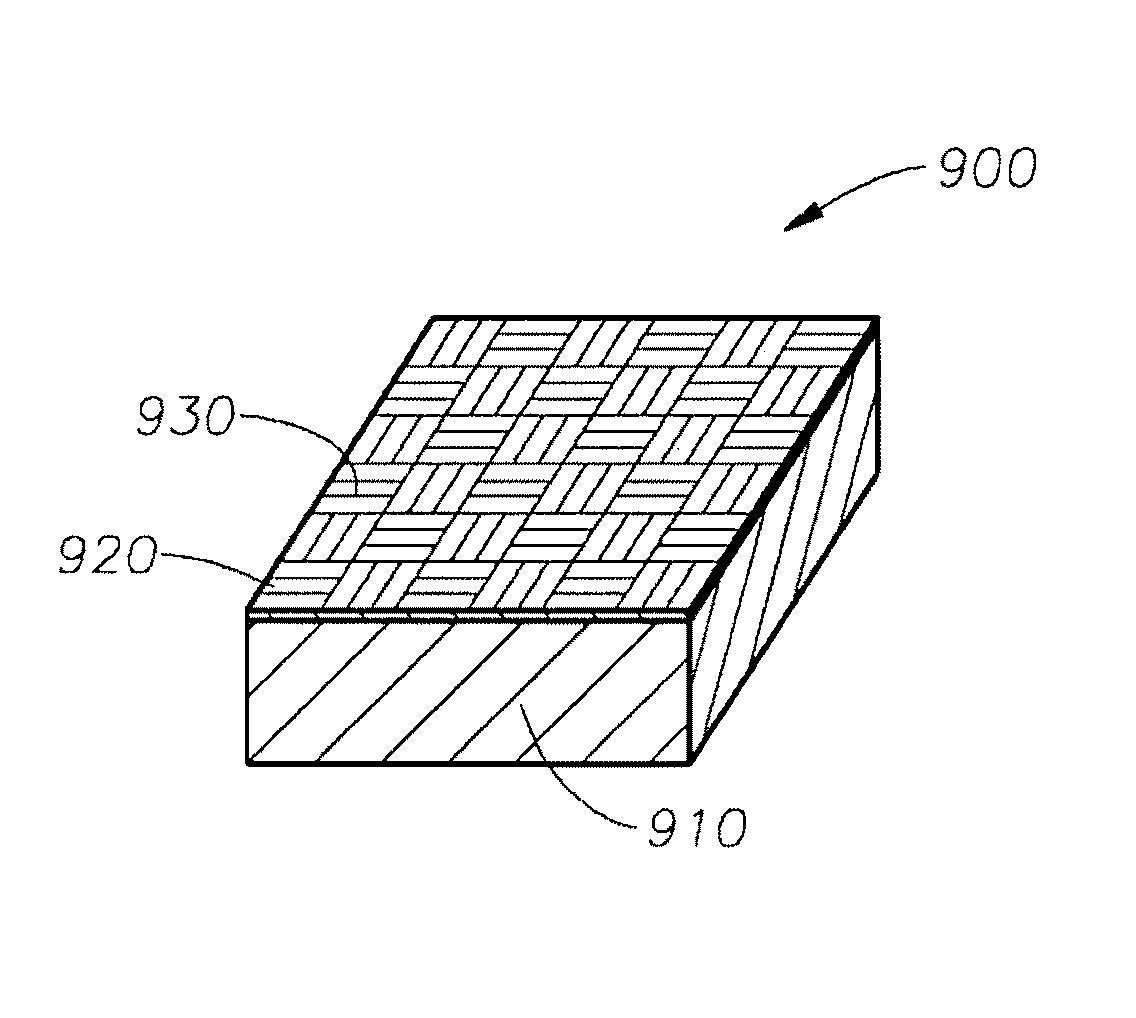

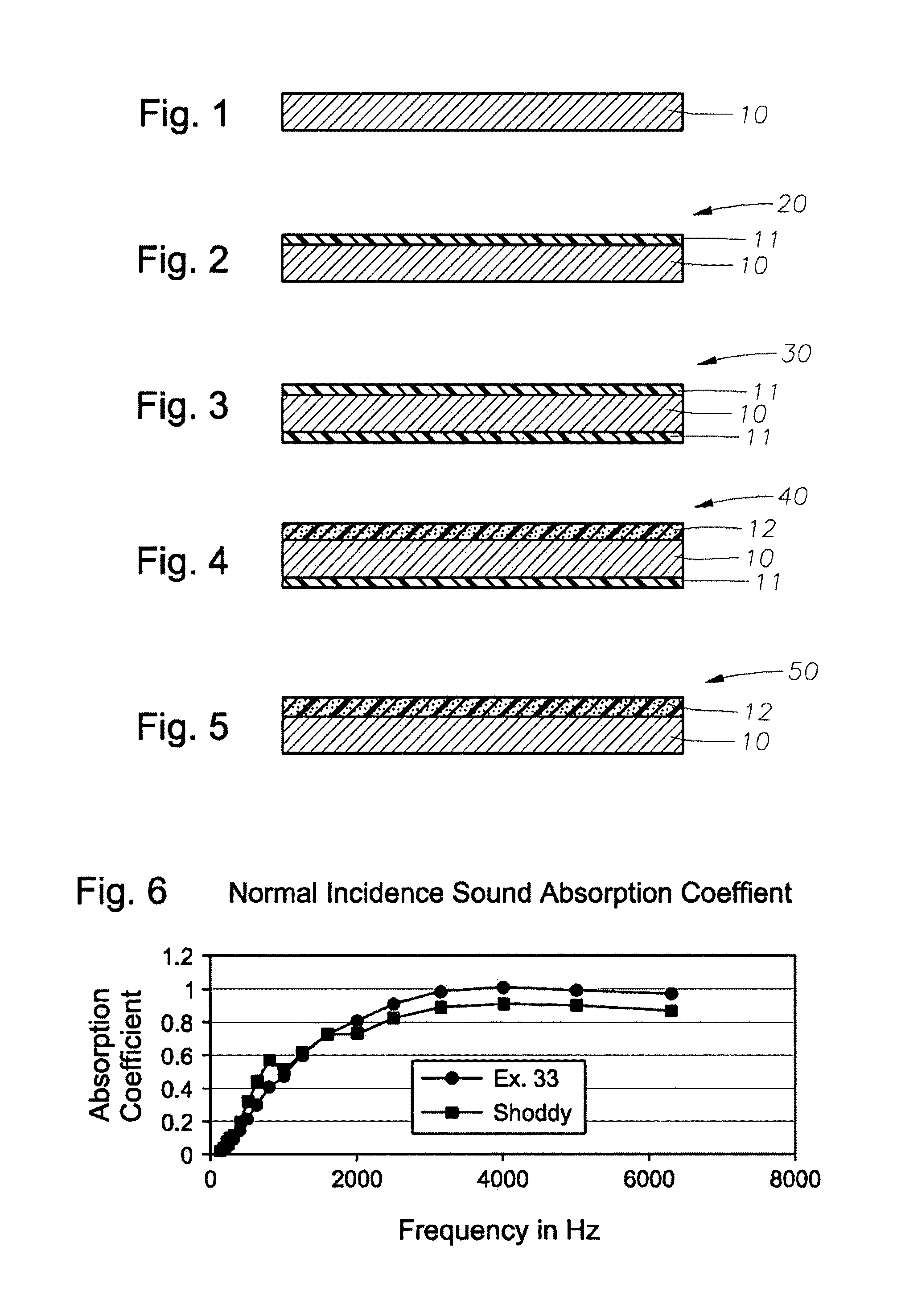

Nonwoven material for acoustic insulation, and process for manufacture

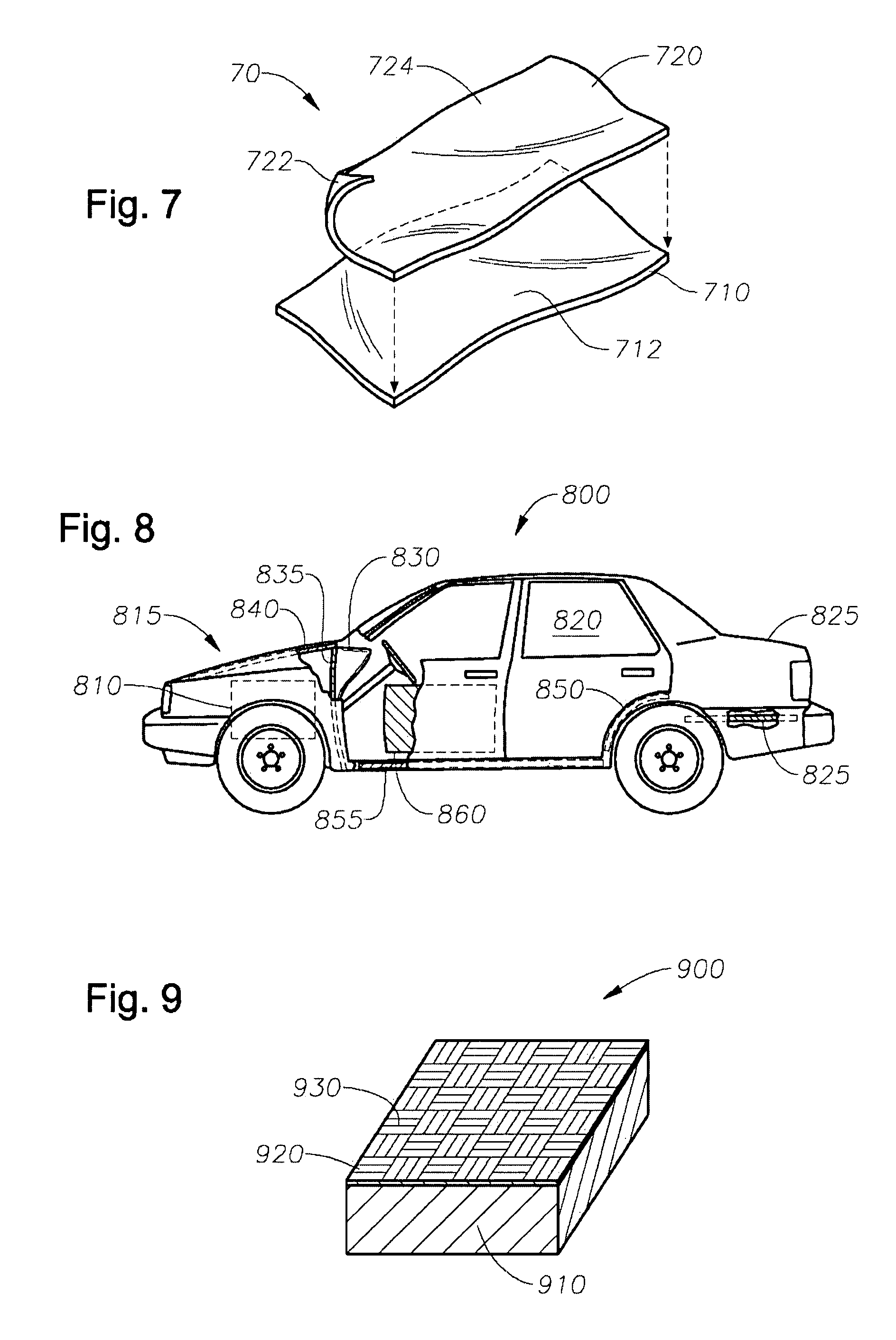

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

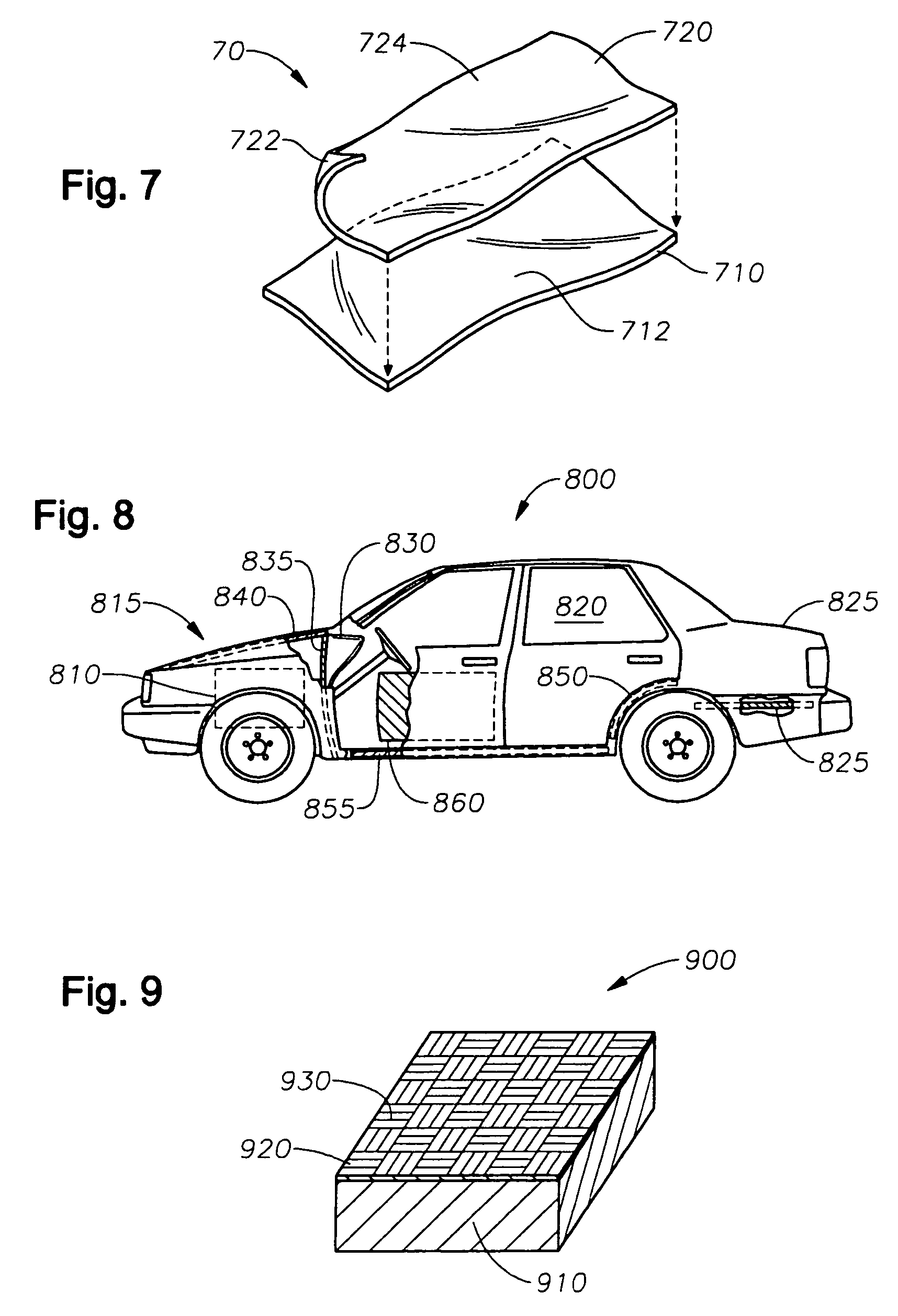

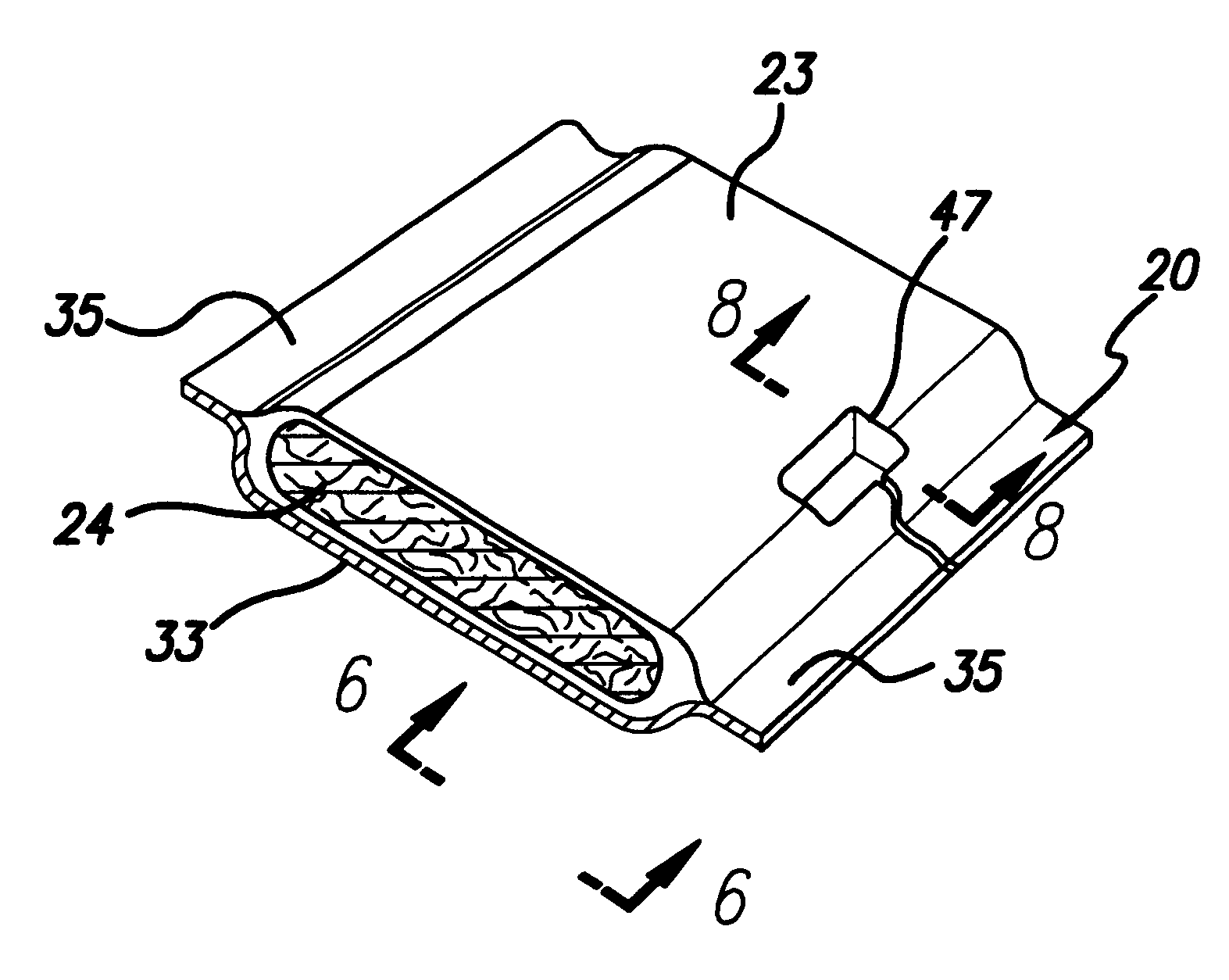

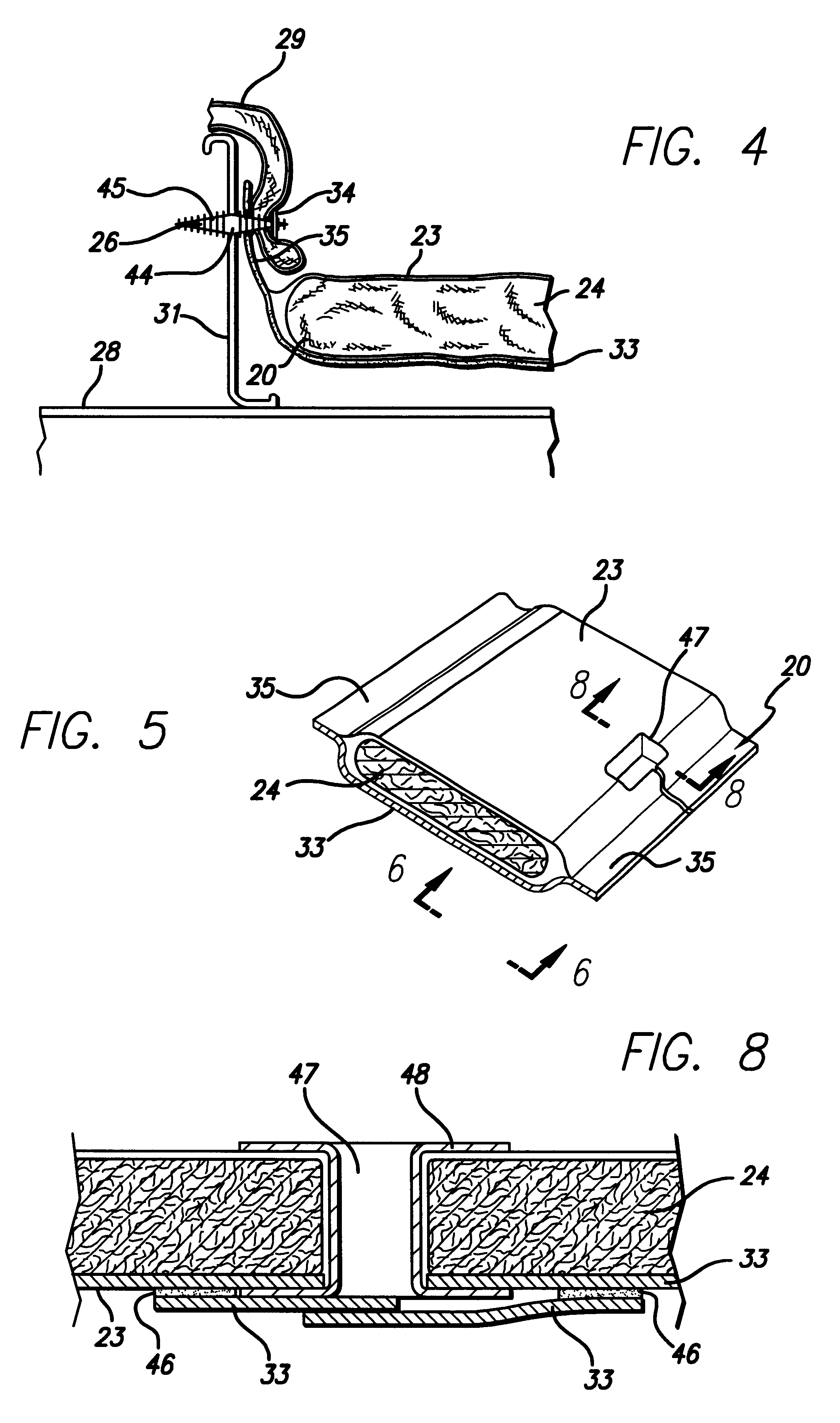

Fire-blocking insulation blanket

InactiveUS6358591B1Improve protectionLow costSynthetic resin layered productsCellulosic plastic layered productsGlass fiberFuselage

An insulation blanket is disclosed that contains fire-blocking materials for preventing rapid penetration of fire into an aircraft fuselage in case of a fire outside the aircraft. The insulation blanket contains at least one layer of fiberglass or other thermal-acoustic insulation material without fire-blocking properties, and one or more layers of fire-blocking material. The fire blocking material is wider than the thermal-acoustic insulation so that it may be folded against and attached to adjacent structural frame members of the fuselage. In the alternative, a thermal-acoustic insulation material is used that has fire-blocking properties instead of the separate layers of fire-blocking and thermal-acoustic insulation materials. A method for installing insulation blankets according to the present invention is disclosed, whereby a fire-blocking insulation portion of the blanket is folded against and attached to frame members of the aircraft using attachment posts or spring clips.

Owner:ORCON CORP

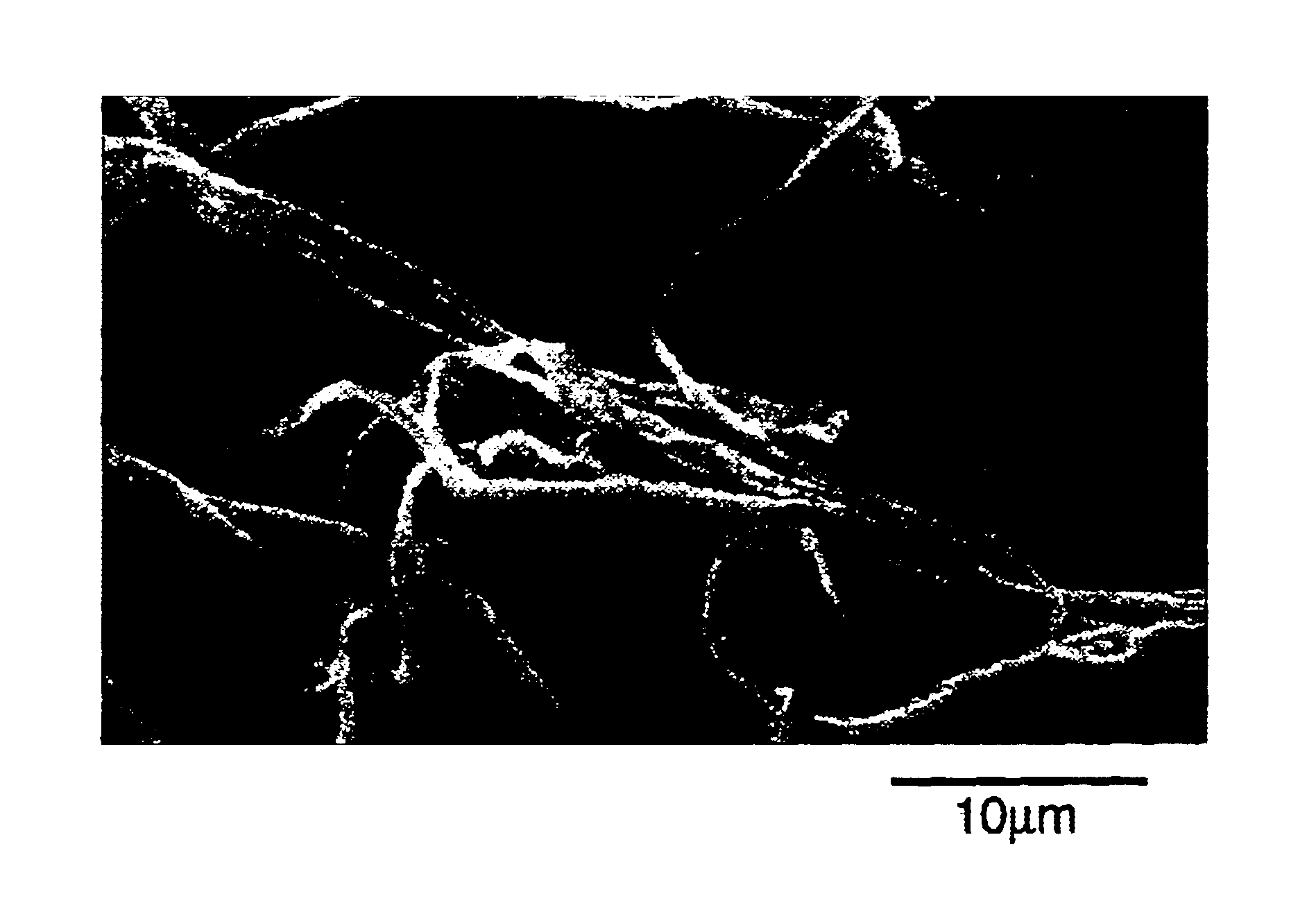

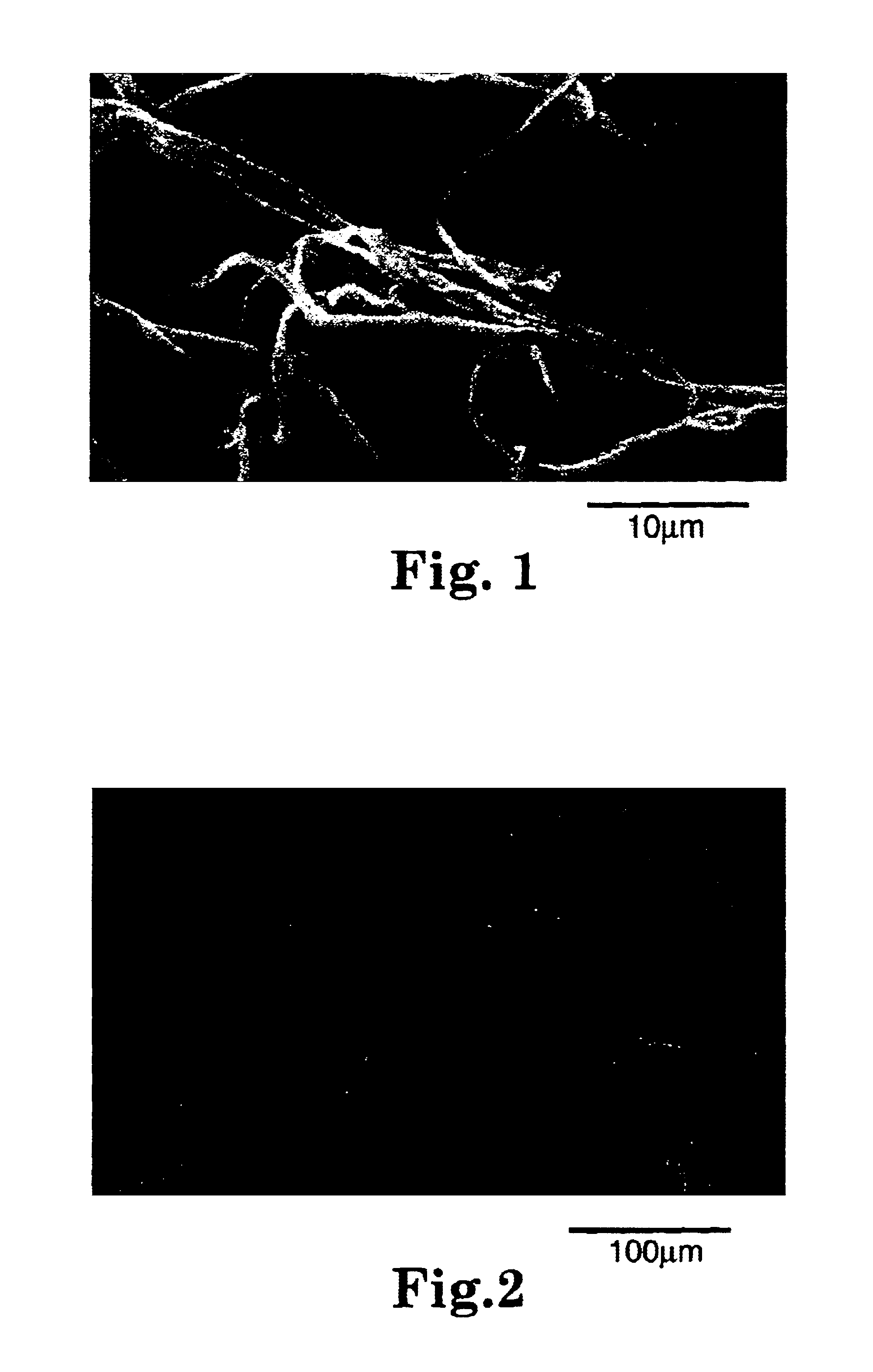

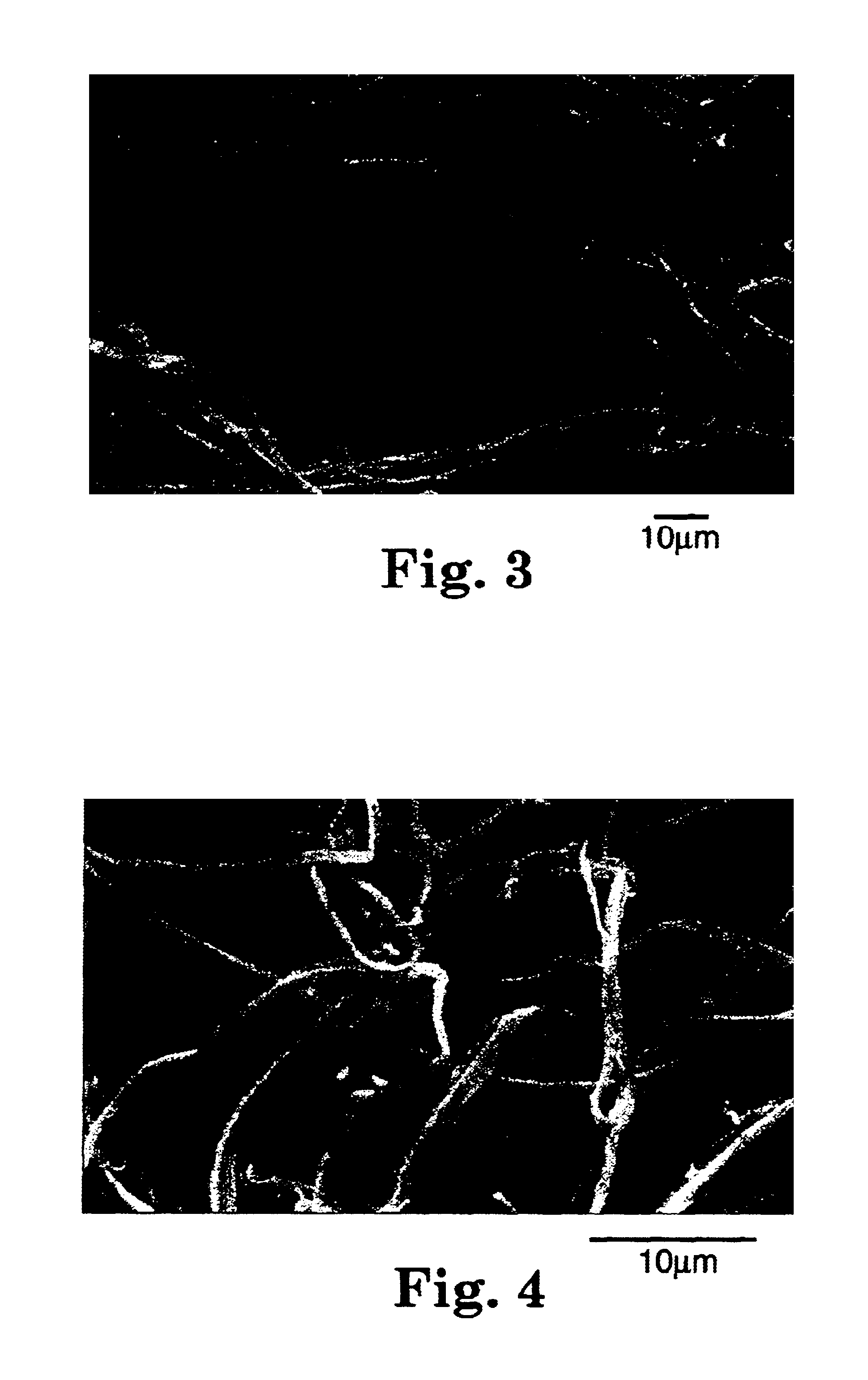

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

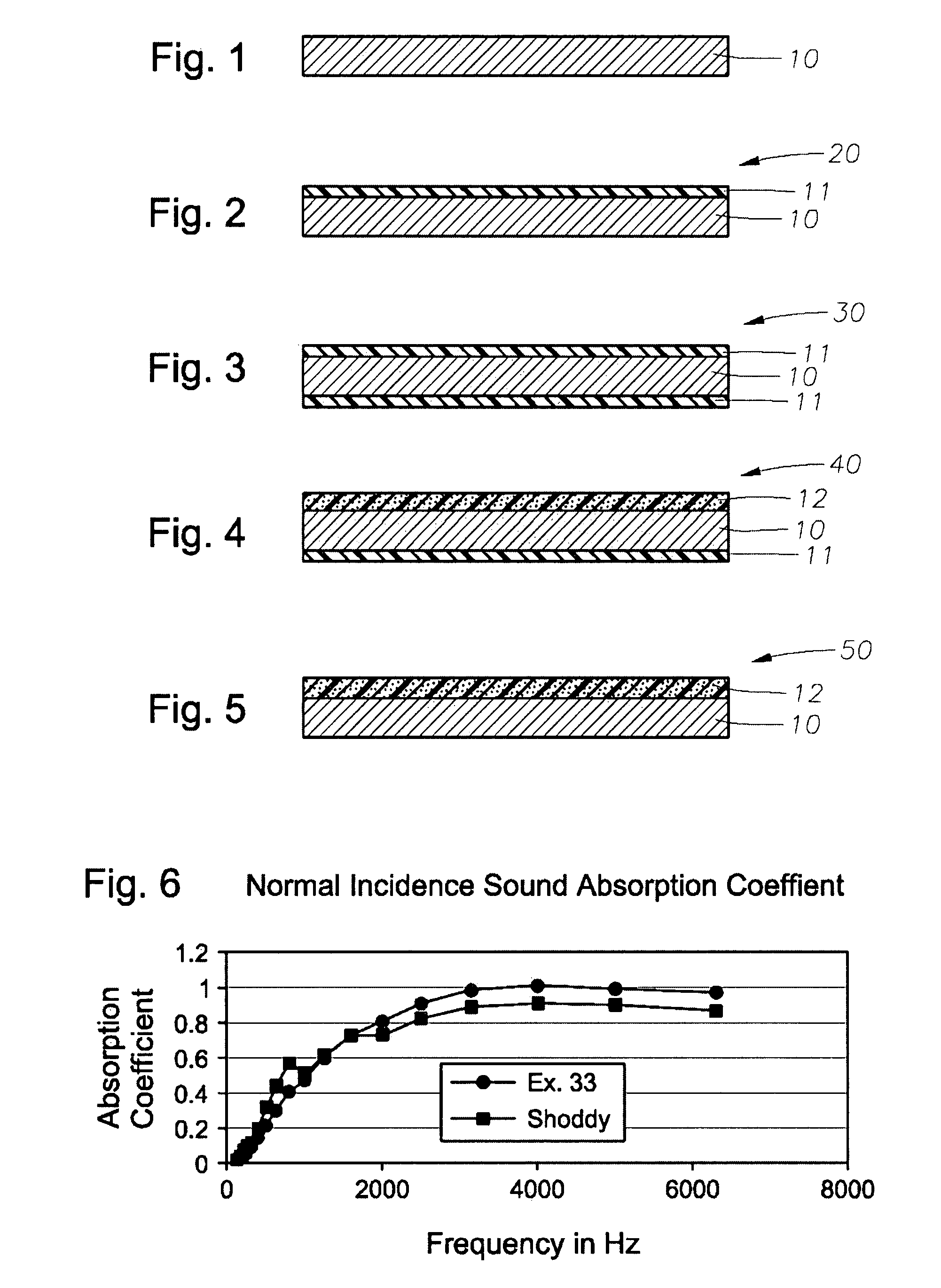

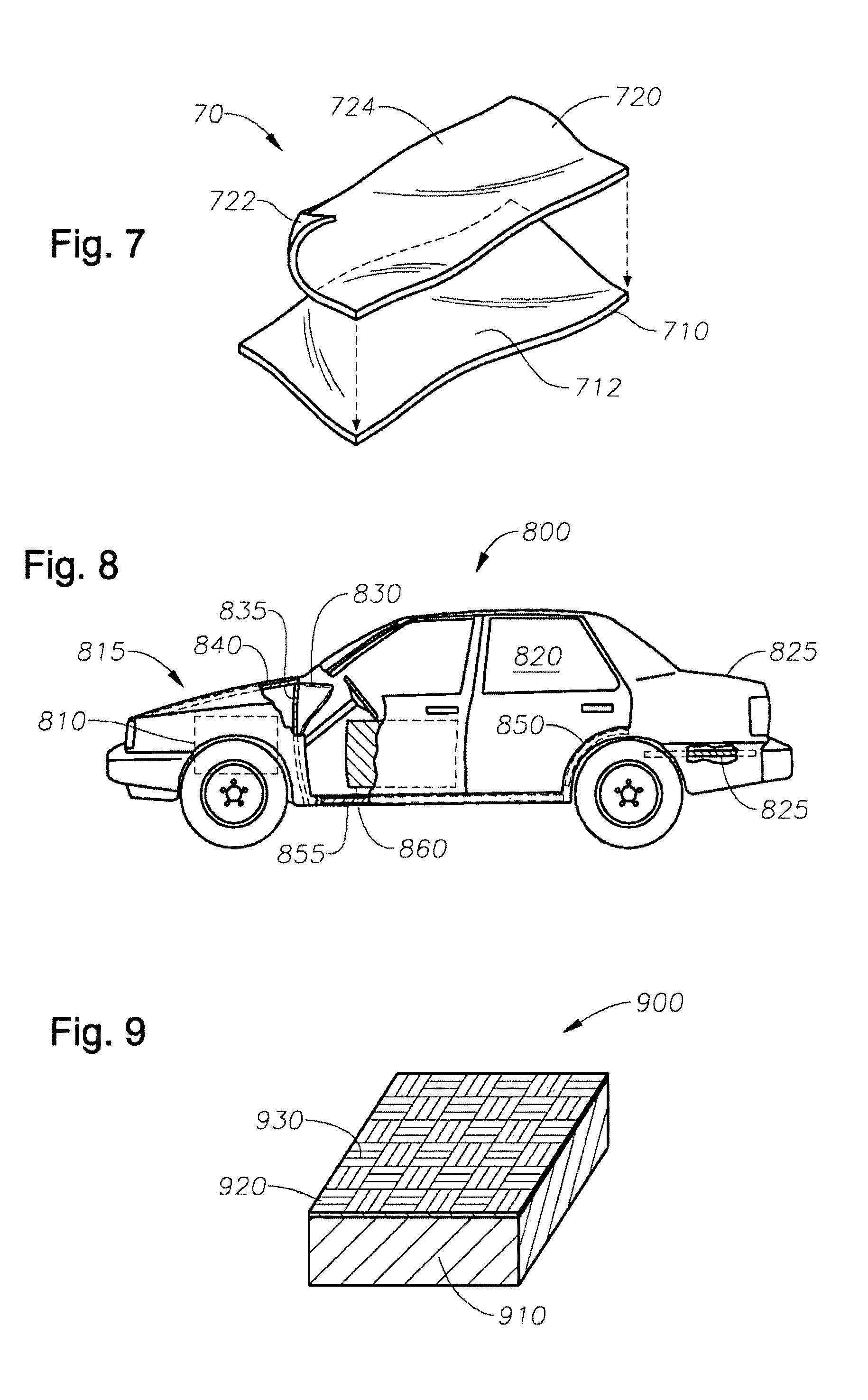

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS7837009B2Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsMildewEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

High performance insulations

A durable, low-density, high performance insulating material is suitable for use as a high temperature thermal and acoustic insulation. The insulation includes fiber batting made with non-thermoplastic fibers or blends of fibers such as aramid fibers and ceramic fibers, which are bound within at least some interstices by high temperature non-flammable thermoplastic binder such as polyphenylene sulfide. In addition, a fireblocking layer can be provided on at least one surface of the insulation to further improve fire ablation or flame retardance.

Owner:TEX TECH INDS INC

Fire retardant nonwoven material and process for manufacture

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GLATFELTER CORP

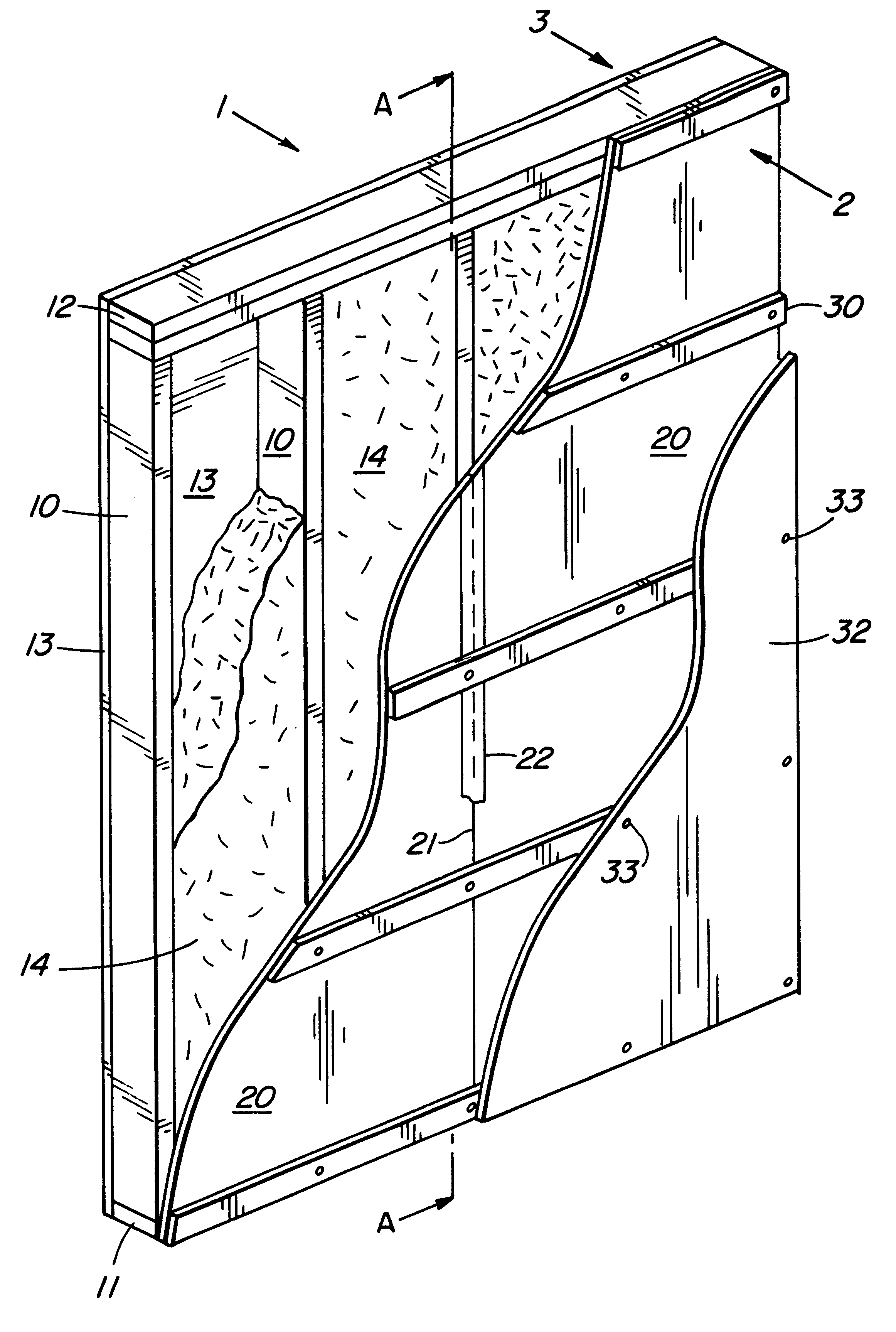

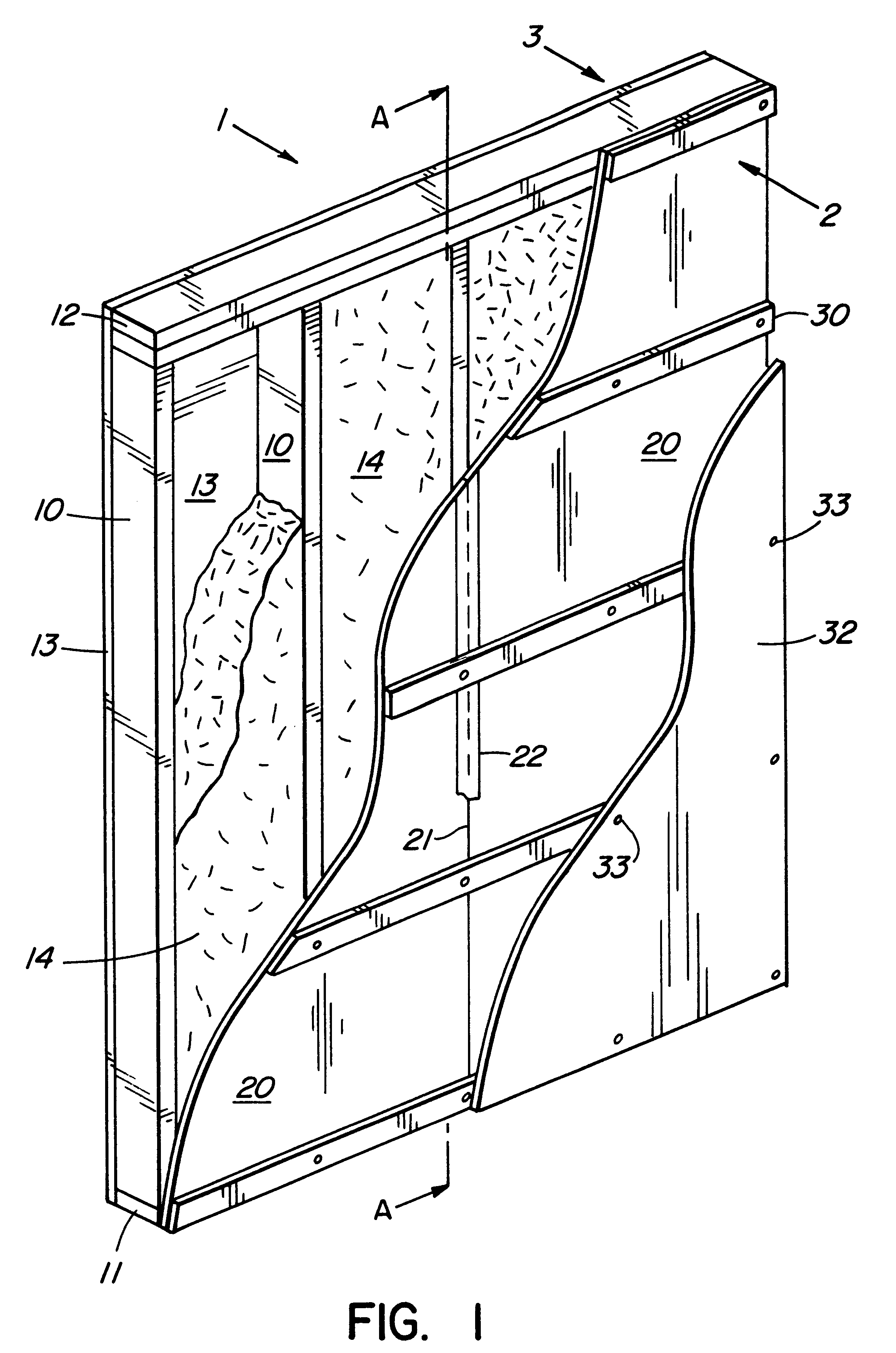

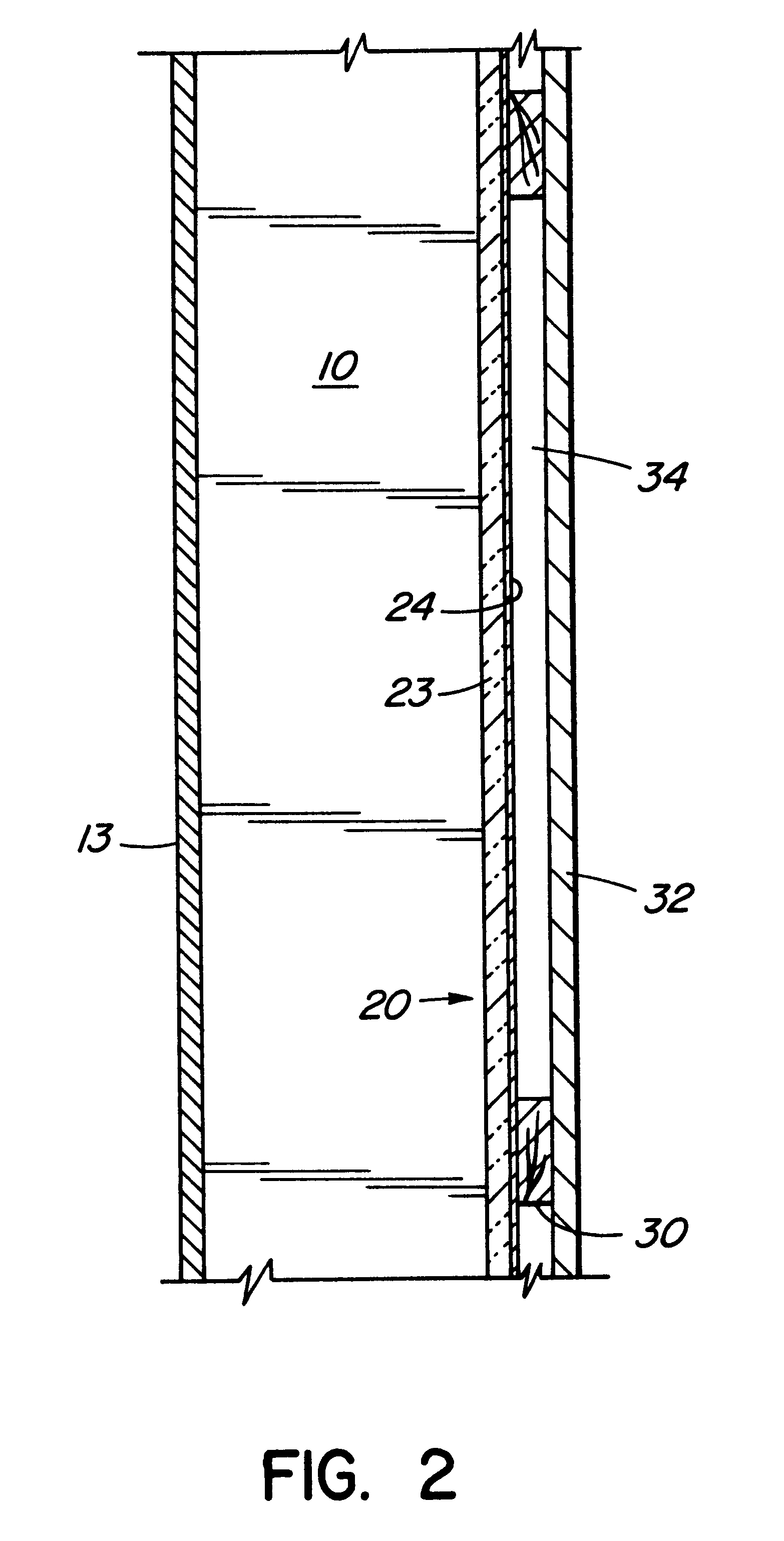

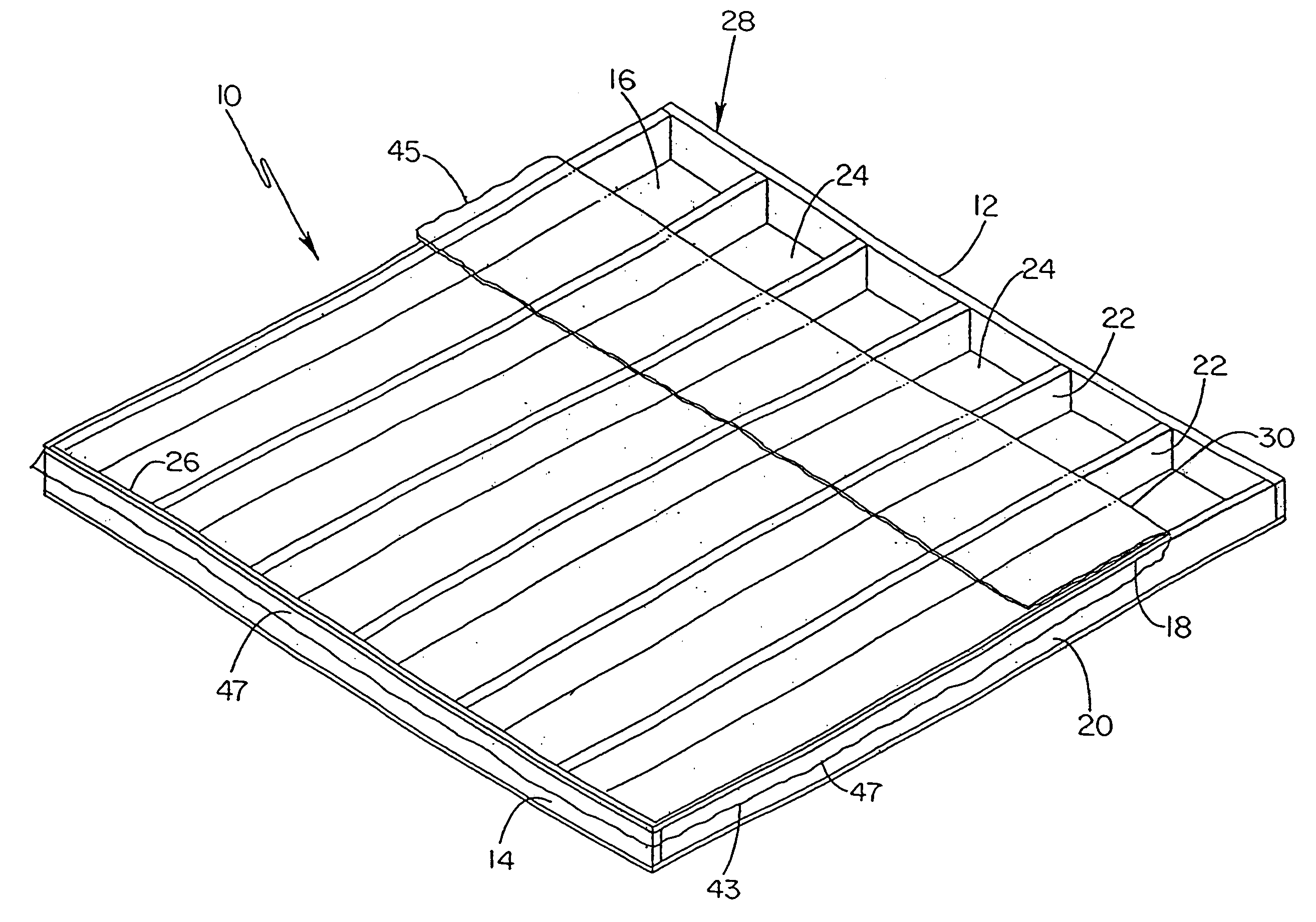

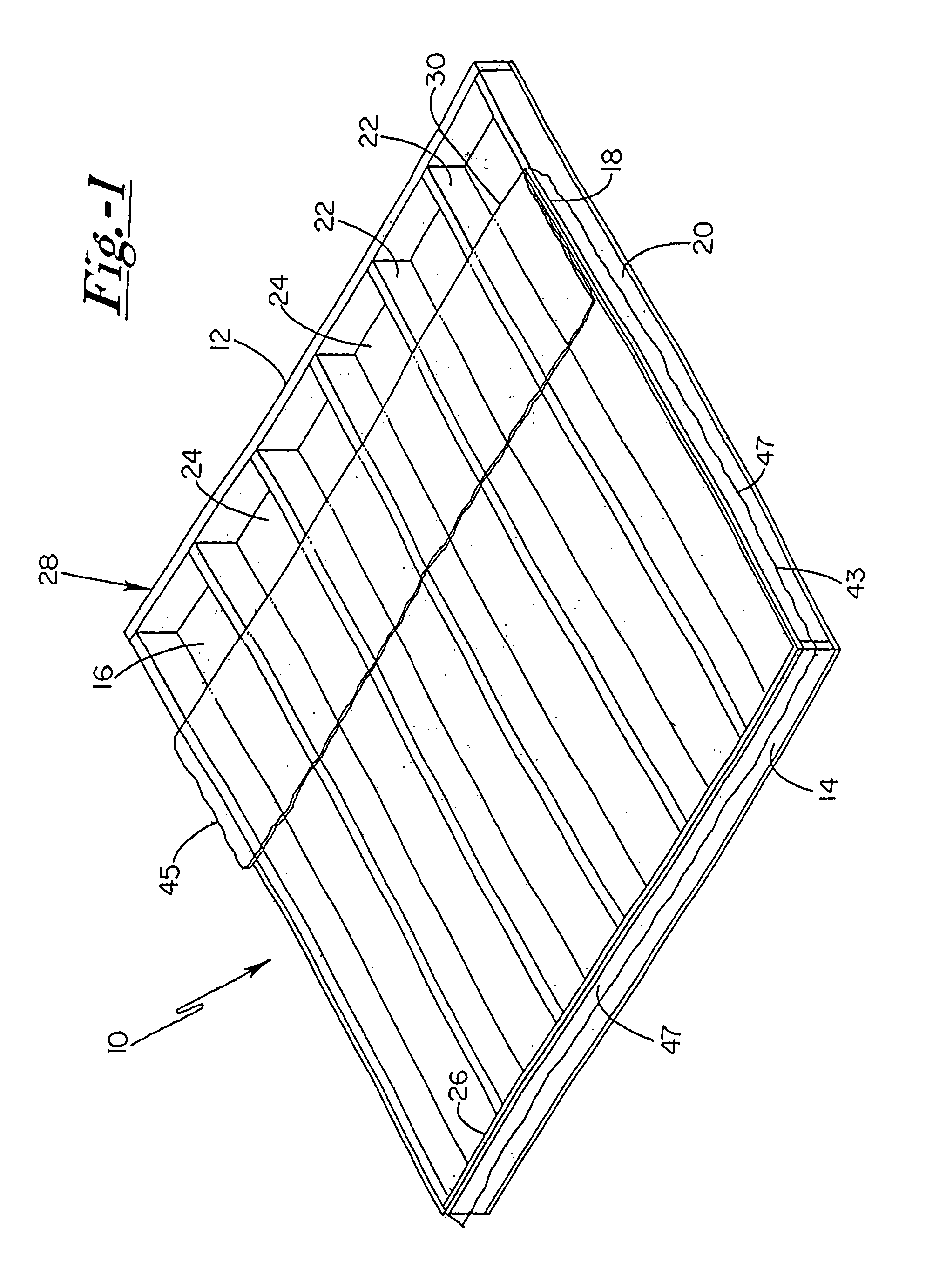

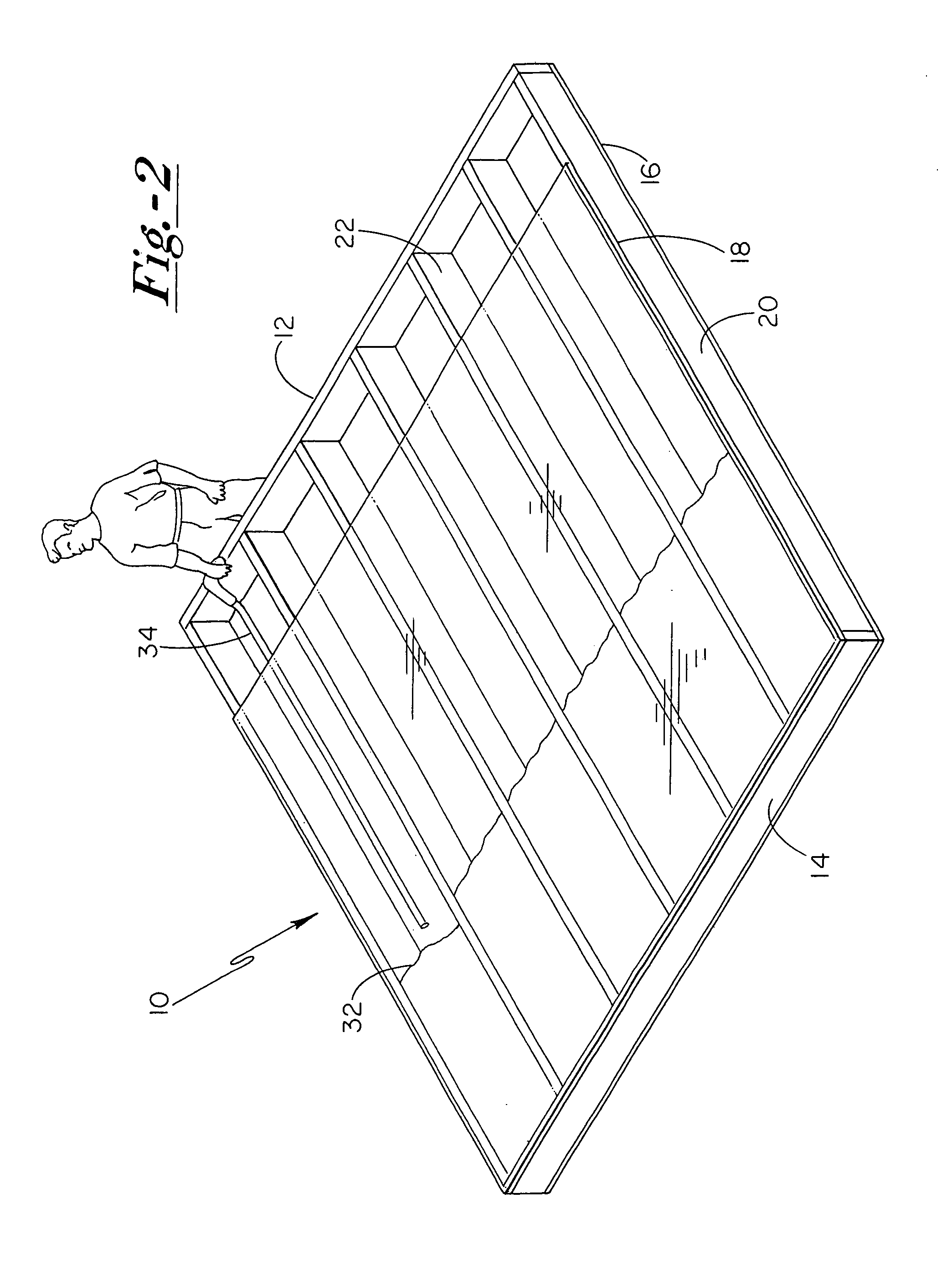

Insulated stud panel and method of making such

A stud panel and method of making a stud panel where interior sheathing may be a temporary piece of transparent plastic or a permanent panel of sheet rock so as to retain insulation in place and minimize scarfing. The stud panel may include studs having through holes extending in a length direction of the stud panel such that insulation in adjacent inner regions separated by such studs interlock with each other and contribute to a structural integrity of the stud panel. The stud panel may include a space between inner studs and one of the exterior and interior sheathing so as to provide a thermal and sound break between the exterior and inner sheathing so as to minimize heat, air and sound transfer between the exterior and interior sheathing. A method of making the stud panel is further disclosed, where such a method may include the step of incrementally introducing insulation from a closed end of an inner region to an open end of an inner region and may further include the step of automatically introducing insulation into the inner regions of the stud panel.

Owner:HAGEN HANS T JR +1

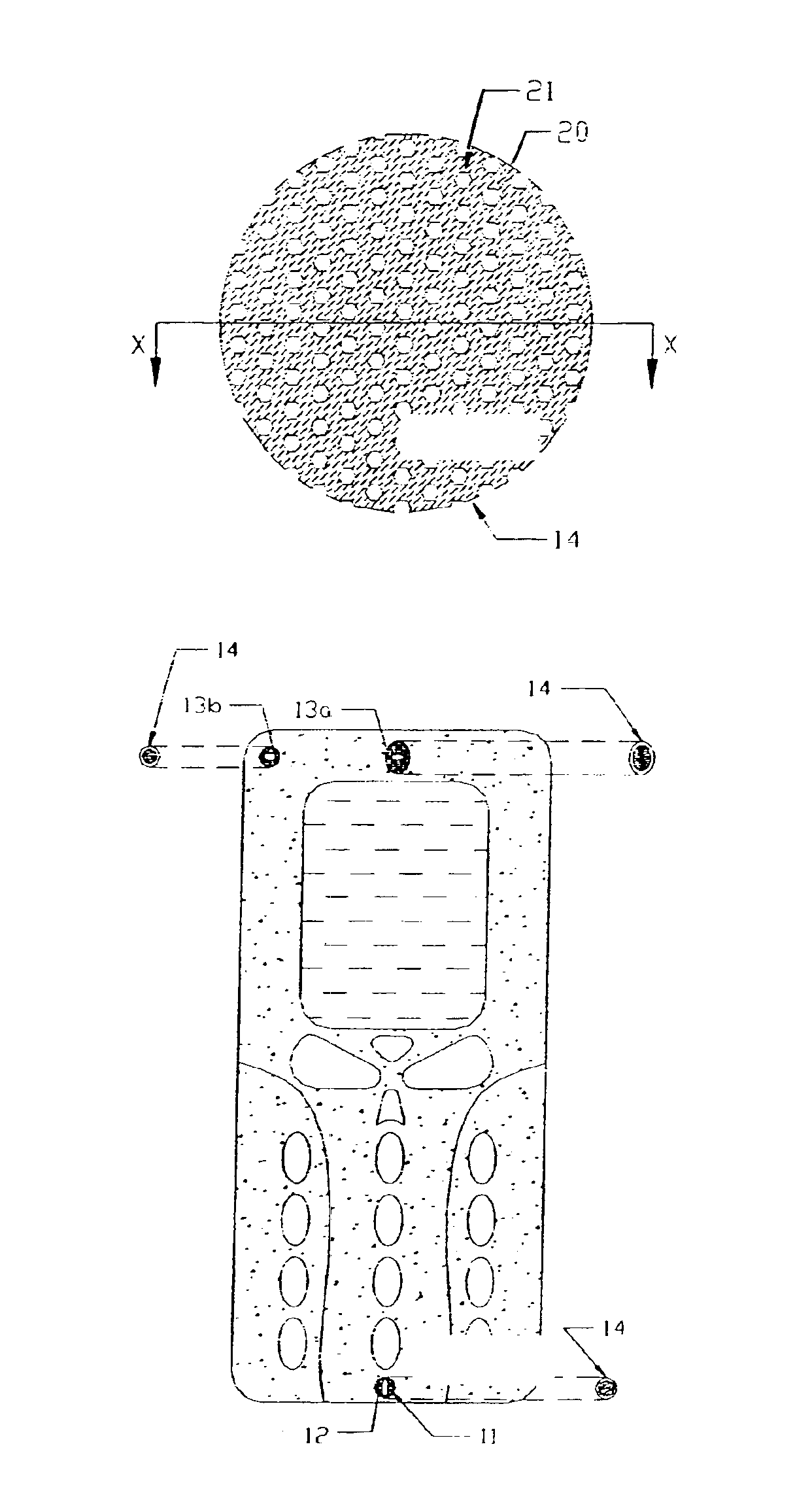

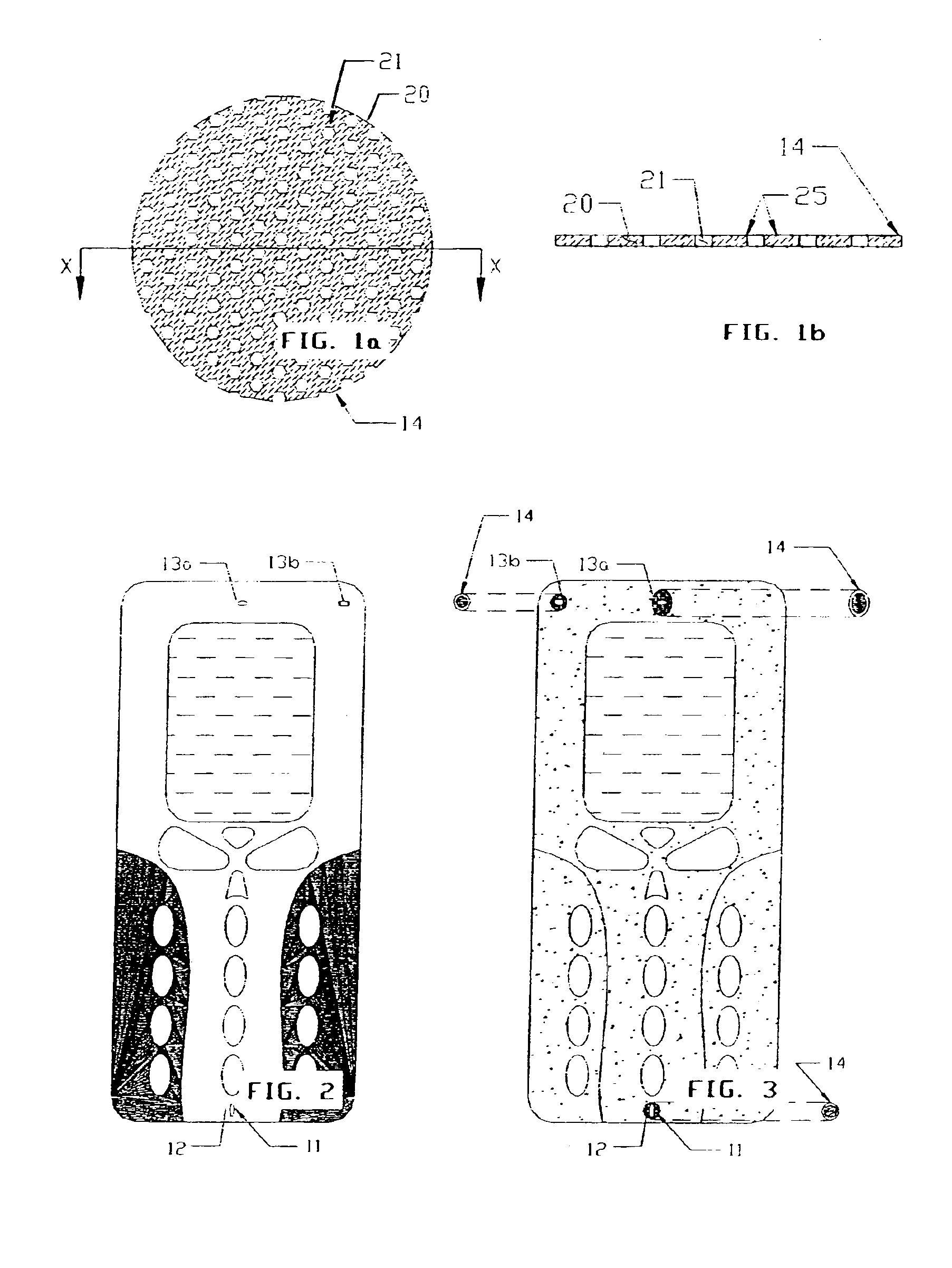

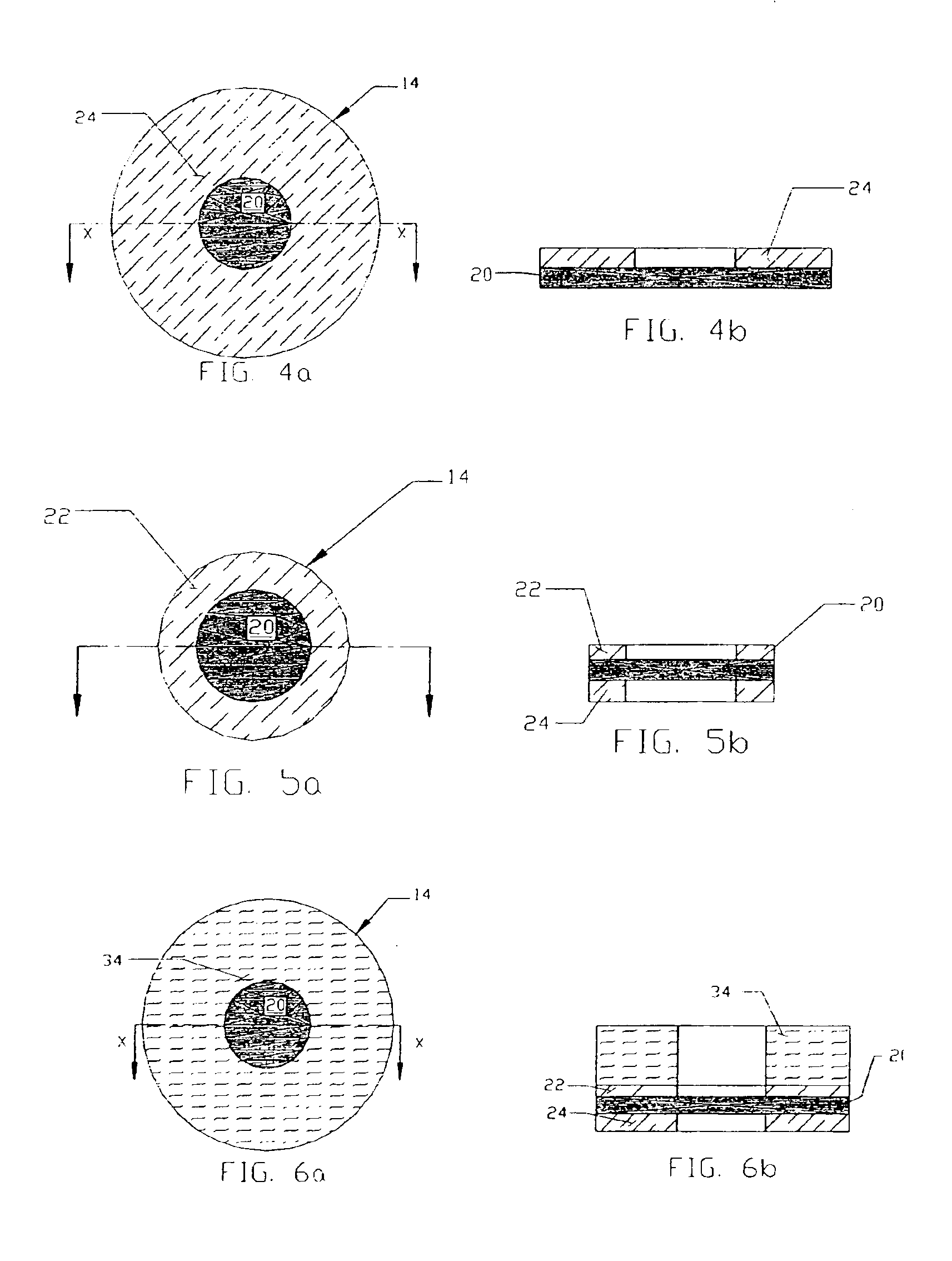

Protective acoustic cover assembly

A protective acoustic cover assembly including a metal foil with perforations, and a treatment on one or more surfaces of said metal foil. The treatment is a hydrophobic or oleophobic treatment, or both. The protective acoustic cover assembly has an average specific acoustic resistance of less than about 11 Rayls MKS from 250-300 Hz, an average specific acoustic reactance magnitude of less than about 1 Rayls MKS from 250-300 Hz, and an instantaneous water entry pressure value of greater than about 11 cm. The perforations of the metal foil preferably have an average maximum pore size of less than about 150 micrometers. The protective acoustic cover assembly further includes an adhesive mounting system, and the preferred metal foil is nickel.

Owner:WL GORE & ASSOC INC

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS20080121461A1Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsVolumetric Mass DensityEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

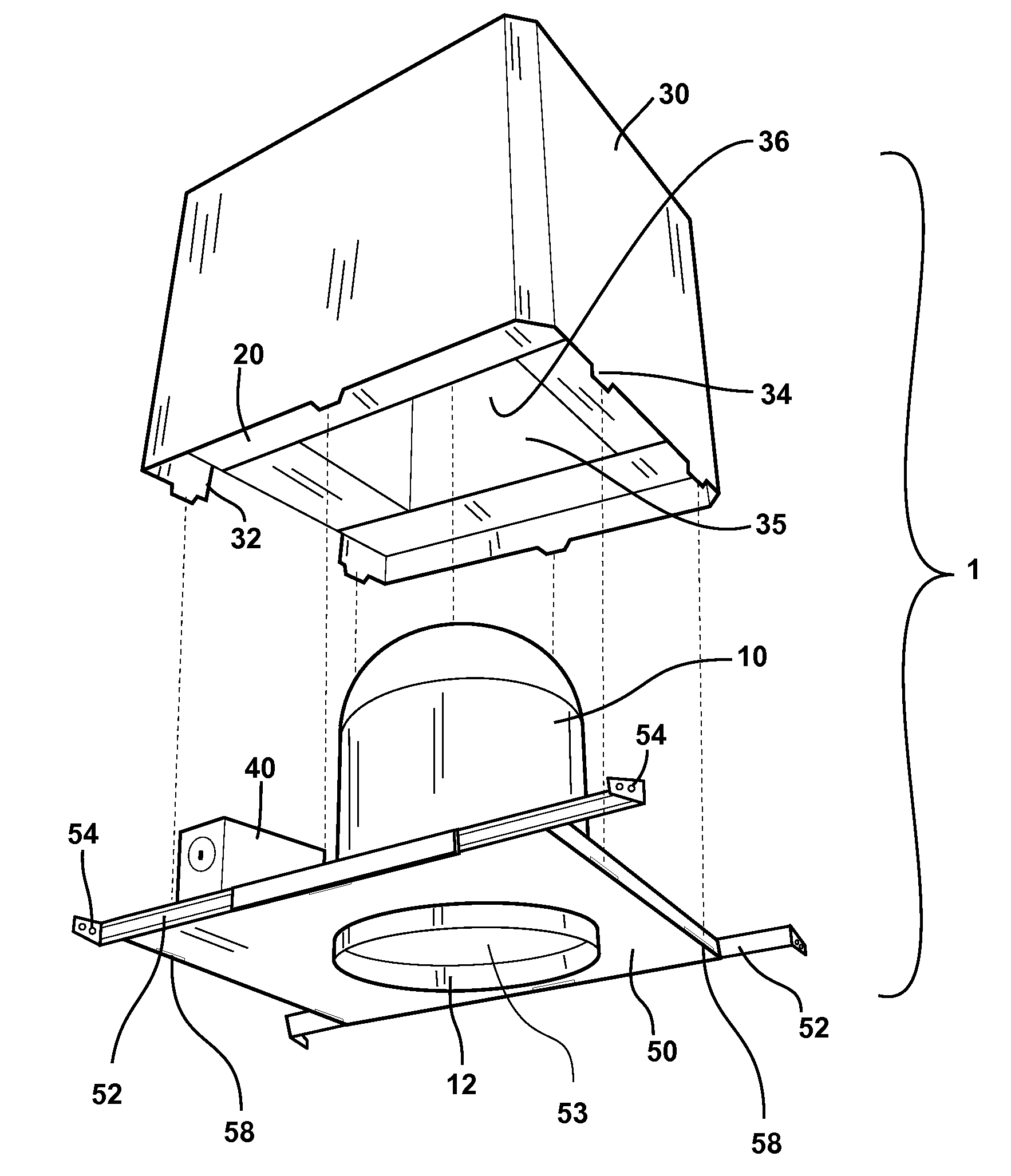

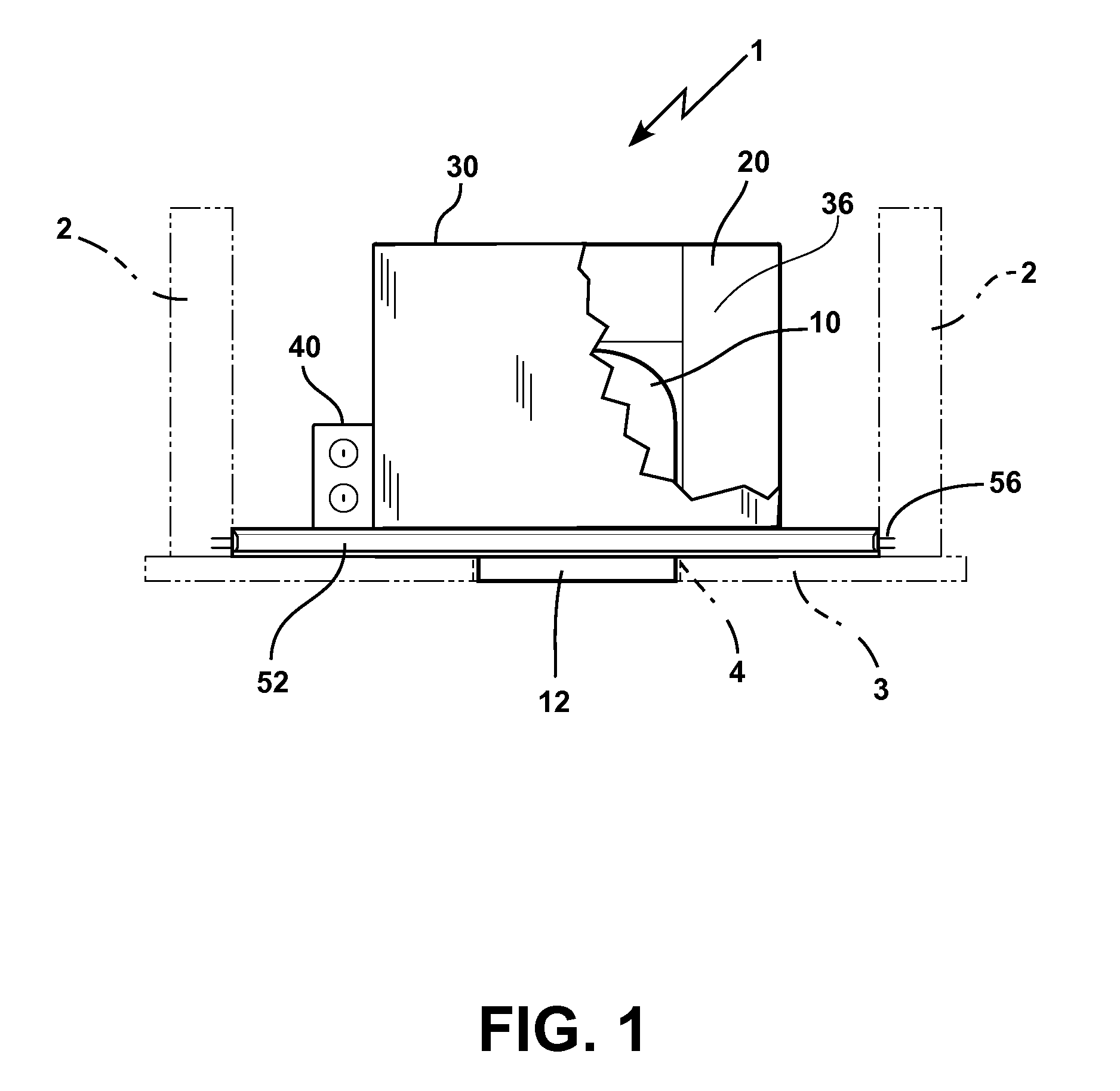

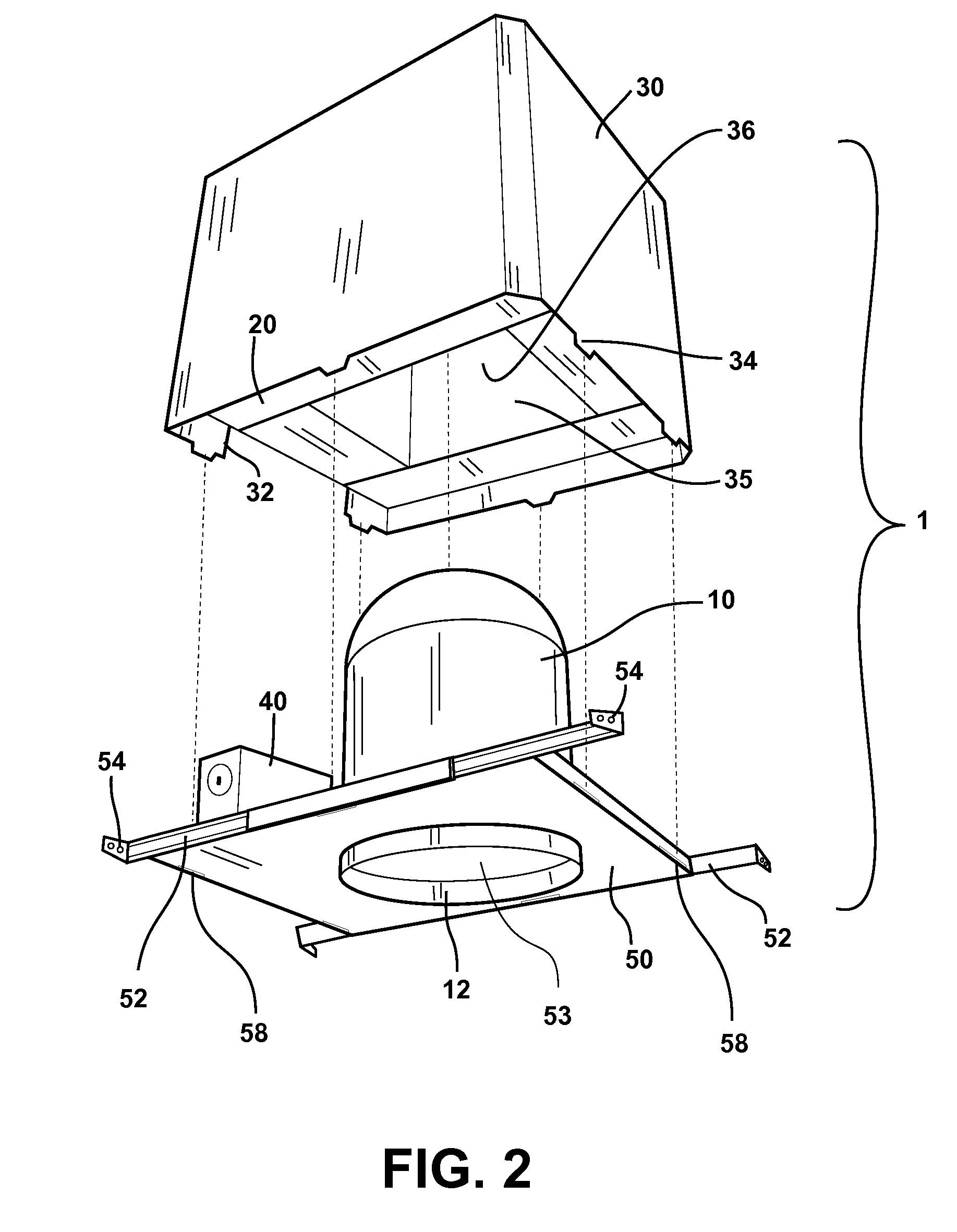

Fire-resistant and noise attenuating recessed lighting assembly

A fire resistant and sound-attenuating lighting assembly adapted to be recessed or mounted behind a ceiling or other surface comprising a light fixture mounted on a plaster frame and adapted to emit light through an opening in the plaster frame and an insulating blanket deployed around the light fixture except for an opening in the light fixture through which light is emitted. In one embodiment, a shell attached to the plaster frame substantially surrounds the insulating blanket. Among other things, the fire-resistant lighting assembly is capable of sustaining fire barrier standards for a ceiling or other surface and maintains the acoustic insulation of the ceiling or other surface thereby reducing noise transmission.

Owner:FAHRENHEIT LIGHTING

Fire retardant nonwoven material and process for manufacture

Owner:GLATFELTER CORP

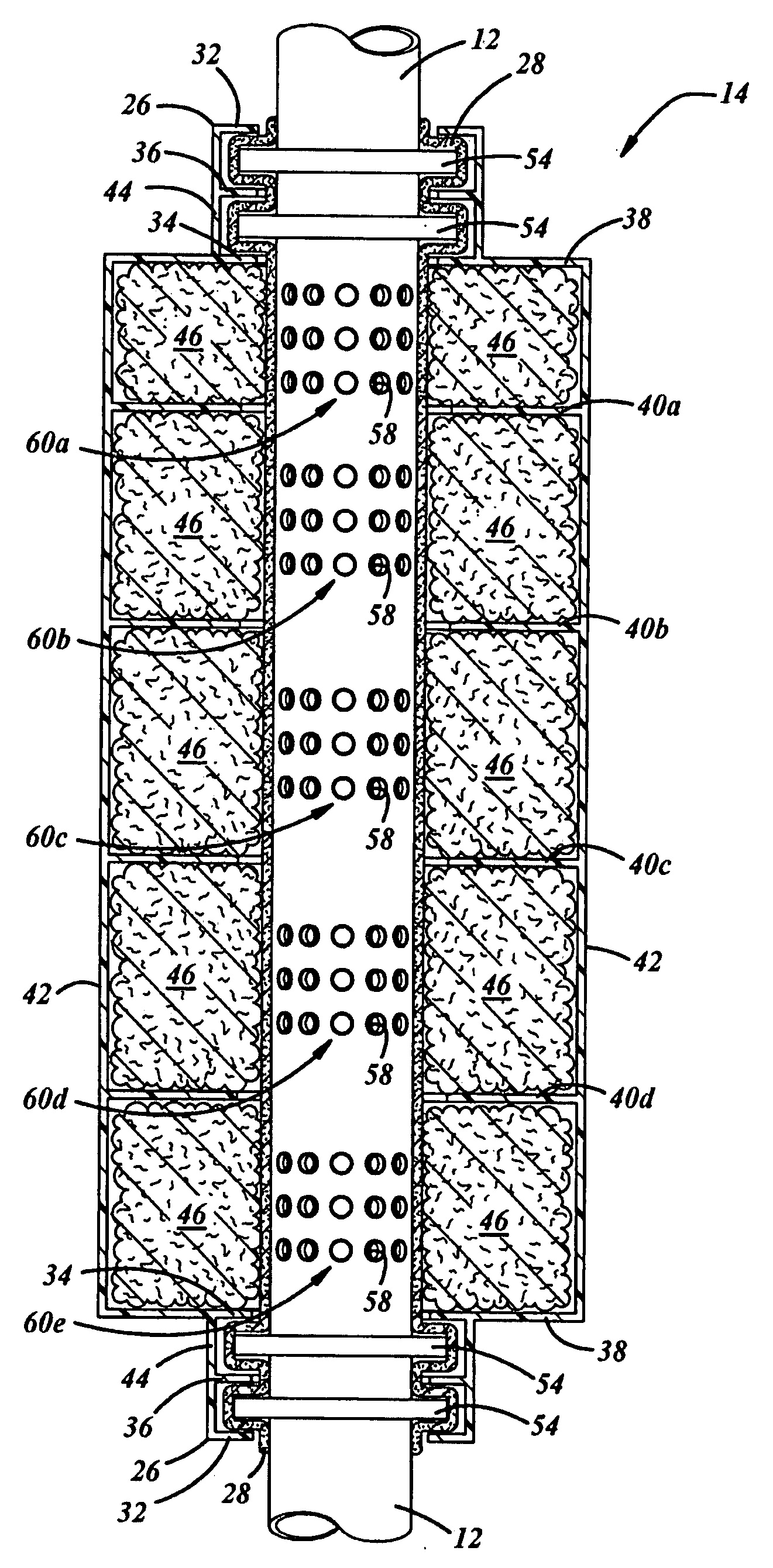

Power generating system

ActiveUS20070158946A1Reduce lateral movementControl moreCombustion enginesGaseous engine fuelsCircular discEngineering

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generator employs a miniature internal combustion engine / generator (MICE) having a piston moving within a cylinder arranged for two-cycle operation, and an interconnected, axially arranged piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is opposed by a strong, multiple-helix spring. The cylinder head, in which the piston operates, is cooled by moving (electrically pumped) fluid in a cooling head, or by another heat-transfer mechanism. The MICE generator's intake arrangement includes a preheater heated by a heated fluid flow thereon. The MICE generator is vibration-isolated using a base that supports the MICE on a plurality of soft coil springs. The MICE generator is encased in an acoustic enclosure having a shell composed of sheet metal or another stiff material extending from the base plate and being covered by a top side. Holes in the enclosure top are covered by porous discs that allow exhaust gasses from the internal muffler to pass therethrough. The acoustic enclosure resides in a large, typically portable, external package enclosure.

Owner:AERODYNE RES

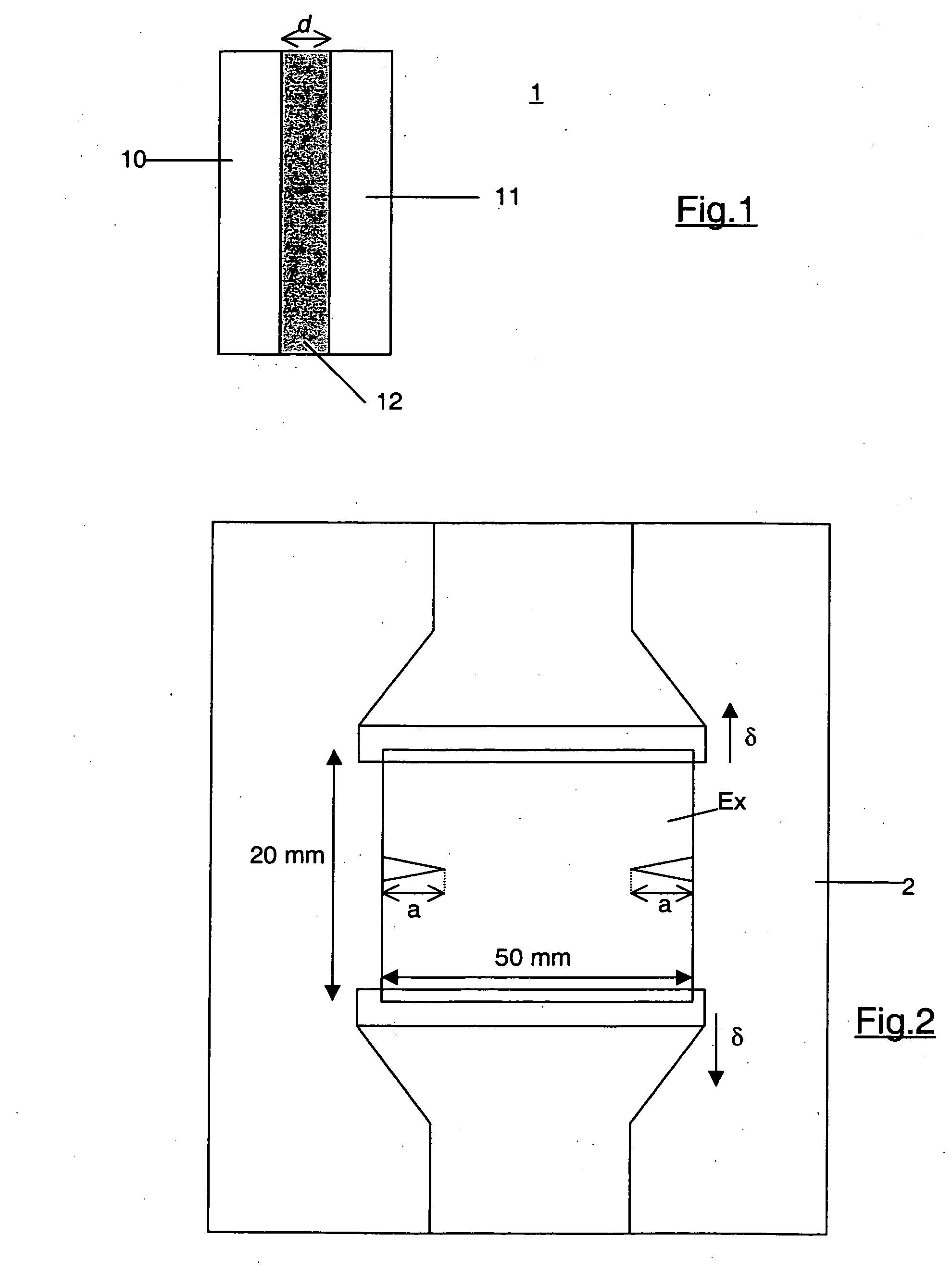

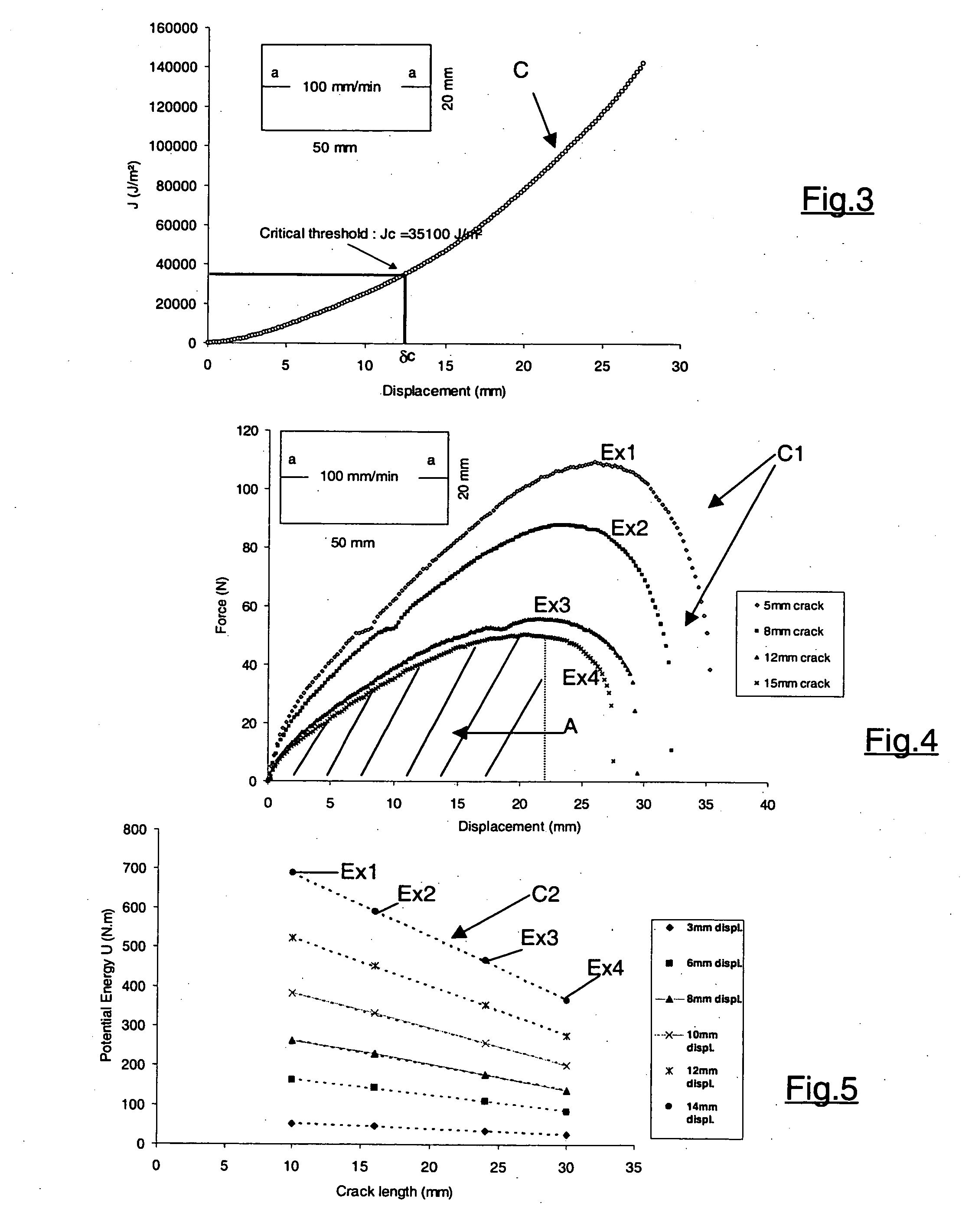

Laminated glazing material

ActiveUS20060070694A1Lamination ancillary operationsSynthetic resin layered productsCritical energyGlass sheet

A laminated glazing material with properties of acoustic insulation and mechanical strength. The laminated glazing material including two glass sheets and a single-ply intermediate layer of a thickness having the form of a polymer film. The thickness of the intermediate layer being defined as a function of a variable which is specific to the material, and which defines the critical energy value of the intermediate layer and is representative of the energy necessary for propagation of a crack initiated in the intermediate layer.

Owner:SAINT-GOBAIN GLASS FRANCE

All-in-one water-borne inorganic-organic hybrid architectural coating and preparation method thereof

ActiveCN102408220AWaterproof and breathableIncrease viscosityEmulsion paintsThermal insulationOragene

The invention relates to an all-in-one water-borne inorganic-organic hybrid architectural coating and a preparation method thereof, wherein the all-in-one water-borne inorganic-organic hybrid architectural coating is prepared by taking a compounded product of a water-borne inorganic film-forming matter and an organic polymer emulsion as a base material through the steps of adding various pigments / fillers and auxiliaries into the base material, then carrying out beating, grinding and paint mixing on the obtained mixture. In the invention, through a Si-O-Si polymer net structure which can be formed by compounding alkali metal silicates and small-particle-size silica sols in the process of film forming, the early water resistance of a paint film is greatly increased, and the eventual hardness, scraping resistance and stain resistance of the paint film are greatly increased; and through adding the organic polymer emulsion, the film-forming performance of the coating can be improved, and the defects that the traditional two-component inorganic coating is easy to crack, bad in decorative properties, poor in storage stability, and the like are overcome. The coating prepared by using the method disclosed by the invention has various functions of environmental friendliness, non-toxicity, thermal insulation, ultra scrubbing resistance, abrasion resistance, yellowing resistance, ageing resistance, fouling resistance, good air permeability, sound insulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Five-layer sound absorbing pad: improved acoustical absorber

ActiveUS20040065507A1The process is simple and convenientDecreasing flexibilityWallsLayered productsEngineeringNatural fiber

An acoustical absorber, having the structure: scrim / film / batt / film / scrim. Preferably, the batt is made from about 60% to about 90% by weight natural fiber and about 10% to about 40% synthetic fiber. Also, a method of making the acoustical absorber is provided. Additionally, a method for acoustically insulating a structure with the acoustical absorber is provided. The method for acoustically insulating may include the steps of compressing the acoustical absorber to less than its original volume prior to installing the absorber and releasing the absorber from compression following the installing step, allowing the material to recover and to fill the void of the structure in which the absorber was placed.

Owner:ACOUSTEK NONWOVENS

Resin composition for vibration-damping material, vibration-damping material, and sound-insulating member

InactiveUS7041377B2Reduce nipping temperatureGood release effectOther chemical processesFibre treatmentPolymer scienceChlorinated paraffins

The object of the invention is to provide sound insulating members exhibiting both high vibration damping performance and high sound insulation performance, a vibration damping material for affording such members and a resin composition for forming the vibration damping material. The invention provides a first resin composition for vibration damping materials which contains 100 parts by weight of a chlorine-containing thermoplastic resin, and 20 to 200 parts by weight of a chlorinated paraffin having 12 to 16 carbon atoms on average. The thermoplastic resin contains preferably 20 to 70 wt. %, more preferably 30 to 70 wt. %, of chlorine. The chlorinated paraffin is preferably 30 to 70 wt. %, more preferably 35 to 65 wt. %, in chlorination degree.

Owner:SEKISUI CHEM CO LTD

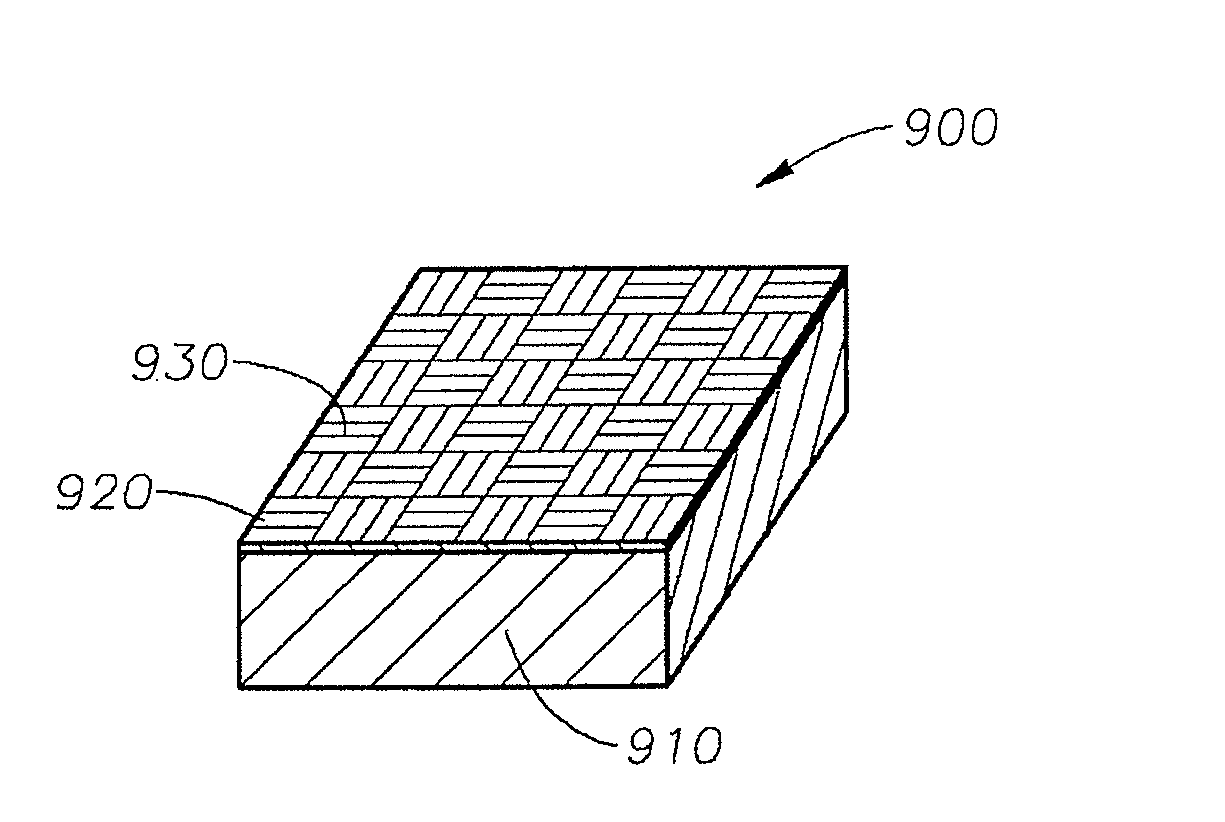

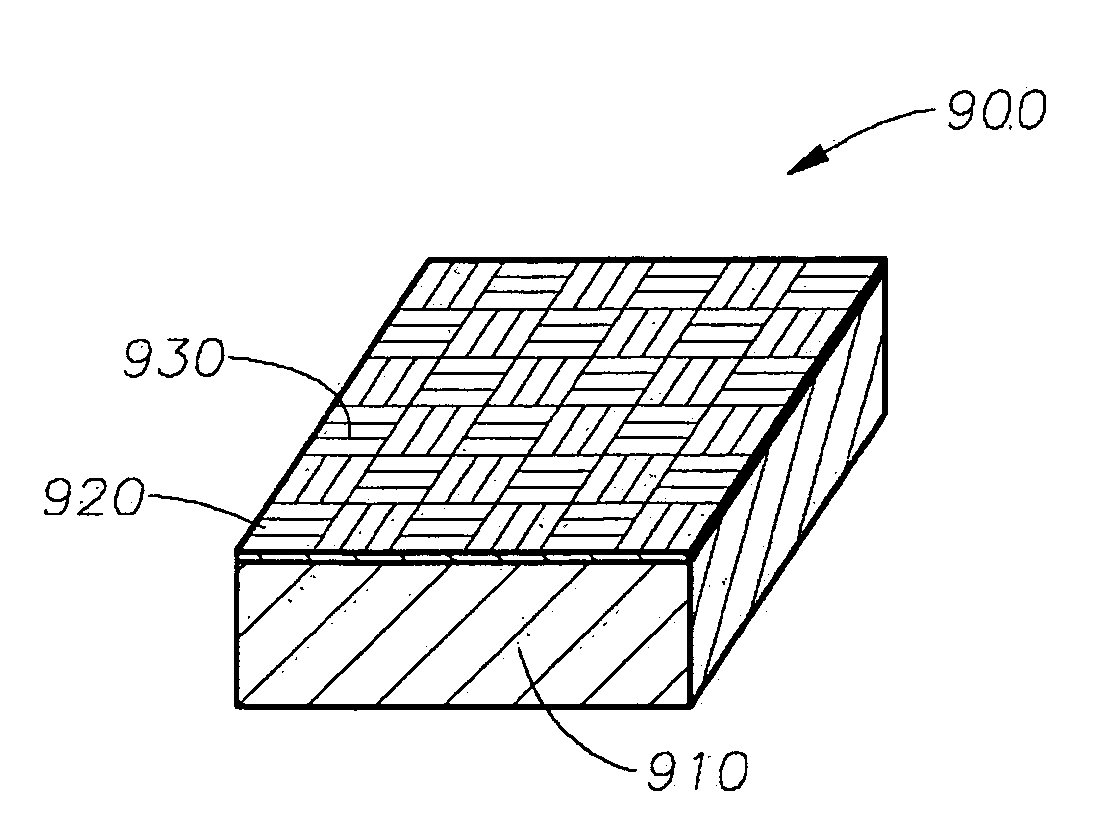

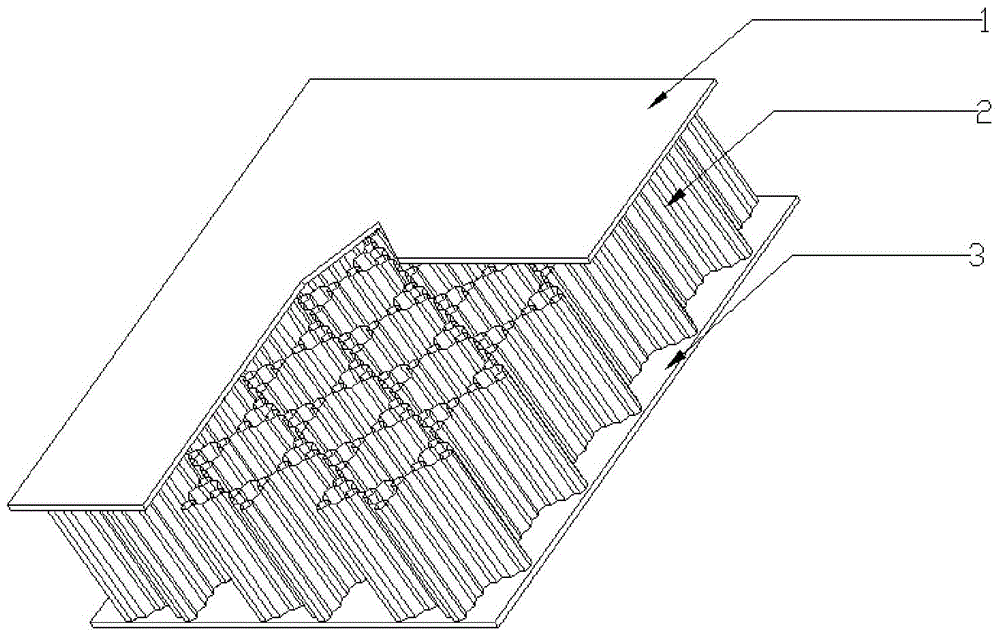

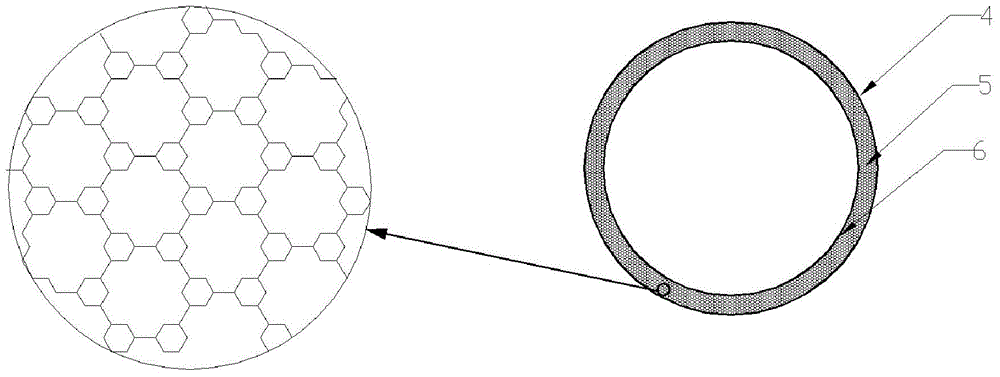

Sandwich structure and honeycomb structure core

The invention provides a sandwich structure, comprising a first interlayer, a second interlayer and a core located between the first interlayer and the second interlayer. The core is in a multilevel honeycomb structure. In the multilevel honeycomb structure, intersections of every two or three sides of a current-level honeycomb structure having cell-element side length L<0> are replaced with polygons with side length L<1> to form a next-level honeycomb structure, wherein L<1> is less than L<0>. The sandwich structure is light in weight, high in specific strength, high in energy absorption efficiency, good in thermal insulation and acoustic insulation, and high in multifunctional comprehensive performance; compared with the traditional honeycomb structures in in-plane (X-Y) and out-plane (Z) directions, the sandwich structure is evidently higher in various performances such as mechanical properties, mechanical strength, energy absorption efficiency and impact resistance; the higher the honeycomb level, the better the performances; thus, the honeycomb structure is of greater advantages in the engineering field than the traditional honeycomb structures.

Owner:HUNAN UNIV

Acoustical tile

The present invention relates to an acoustical tile that includes a core and a surface treatment. The surface treatment comprises a formaldehyde-free latex binder, the binder including at least one formaldehyde-free biocide. The present invention also provides a process of manufacturing an acoustical tile.

Owner:USG INTERIORS LLC

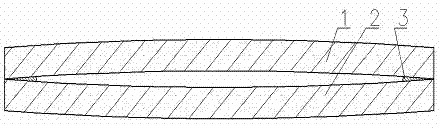

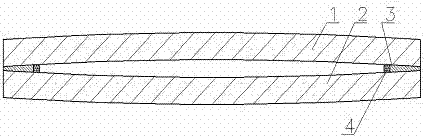

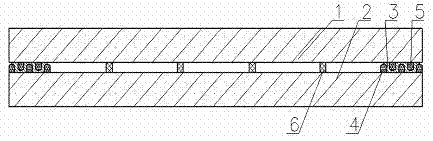

Convex-sided vacuum heat-insulating board, flattened vacuum heat-insulating board and preparation methods thereof

InactiveCN102953441AHigh compressive strengthSimple manufacturing processClimate change adaptationInsulation improvementConvex sideEngineering

The invention provides a vacuum heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed vacuum layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the vacuum heat-insulating board provided by the invention is simple in process, and the prepared vacuum heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a vacuum layer of the vacuum heat-insulating board can be effectively guaranteed, the service life of the vacuum heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the vacuum heat-insulating board can be increased.

Owner:戴长虹

Low-density composite foaming cement and preparation method thereof

The invention discloses low-density composite foaming cement and a preparation method thereof, relating to a light building material. The foaming cement is prepared by adopting a normal-temperature foaming technology, and comprises the following components in parts by weight: 100 parts of cement, 10-50 parts of active admixture, 1-5 parts of redispersible emulsion powder, 1-4 parts of water repellent, 0.5-1.5 parts of cellulose ether, 0.3-0.7 parts of reinforced fiber, 0.2-0.5 parts of foam stabilizer, 3-8 parts of foaming agent and 50-80 parts of water. The method comprises the following preparation steps of: proportionally mixing and stirring the cement, active admixture, redispersible emulsion powder, water repellent, cellulose ether, reinforced fiber, foam stabilizer, and water into cement slurry; adding the foaming agent; and stirring, molding by casting and naturally curing. The foaming cement disclosed by the invention has the advantages of low volume weight, small heat conducting coefficient, small shrinkage ratio, high intensity, integration of heat preservation, sound insulation, fire prevention and low carbon, simple and convenient production preparation process and easiness in controlling.

Owner:JIANGSU JINMAO TECH DEV

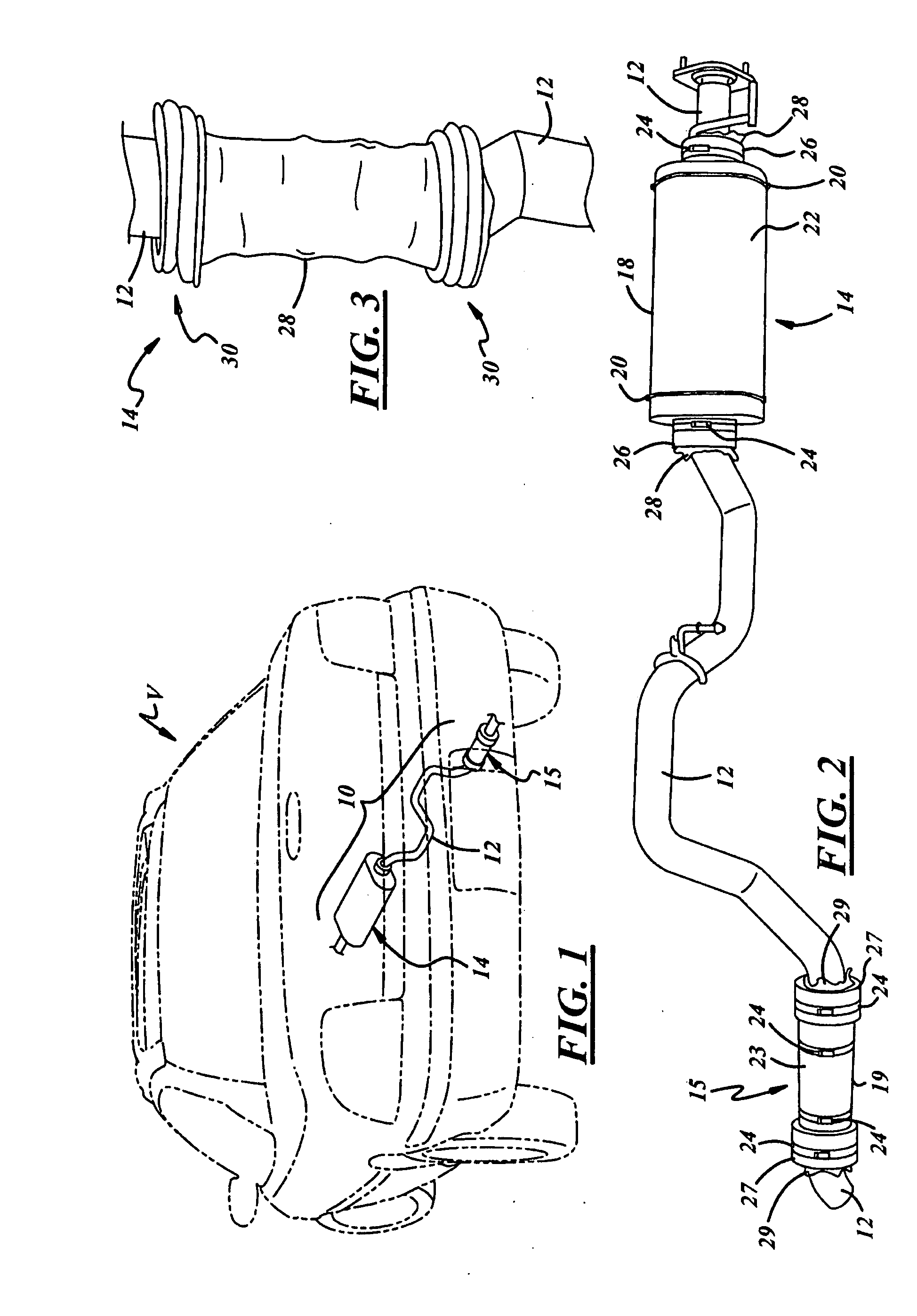

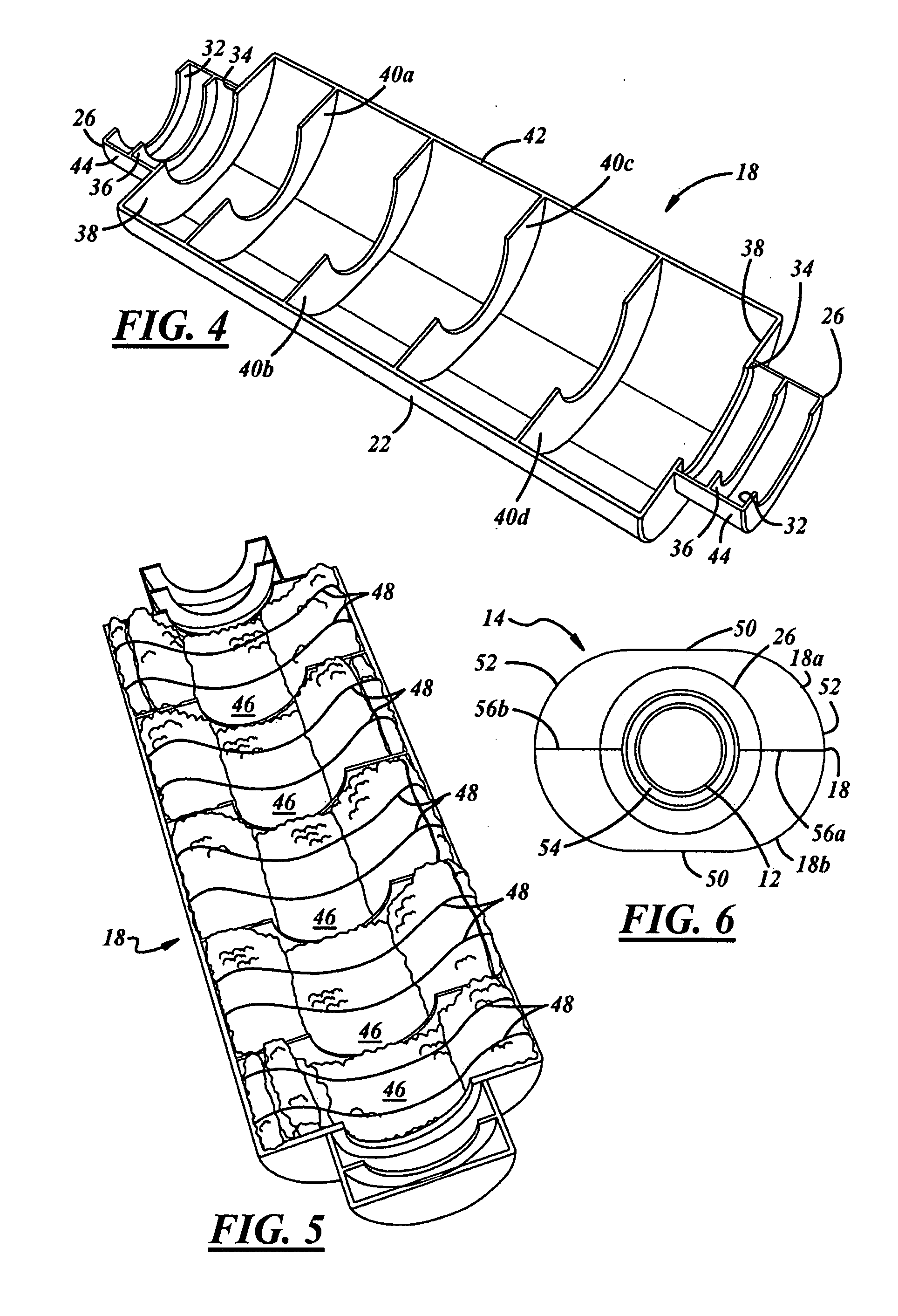

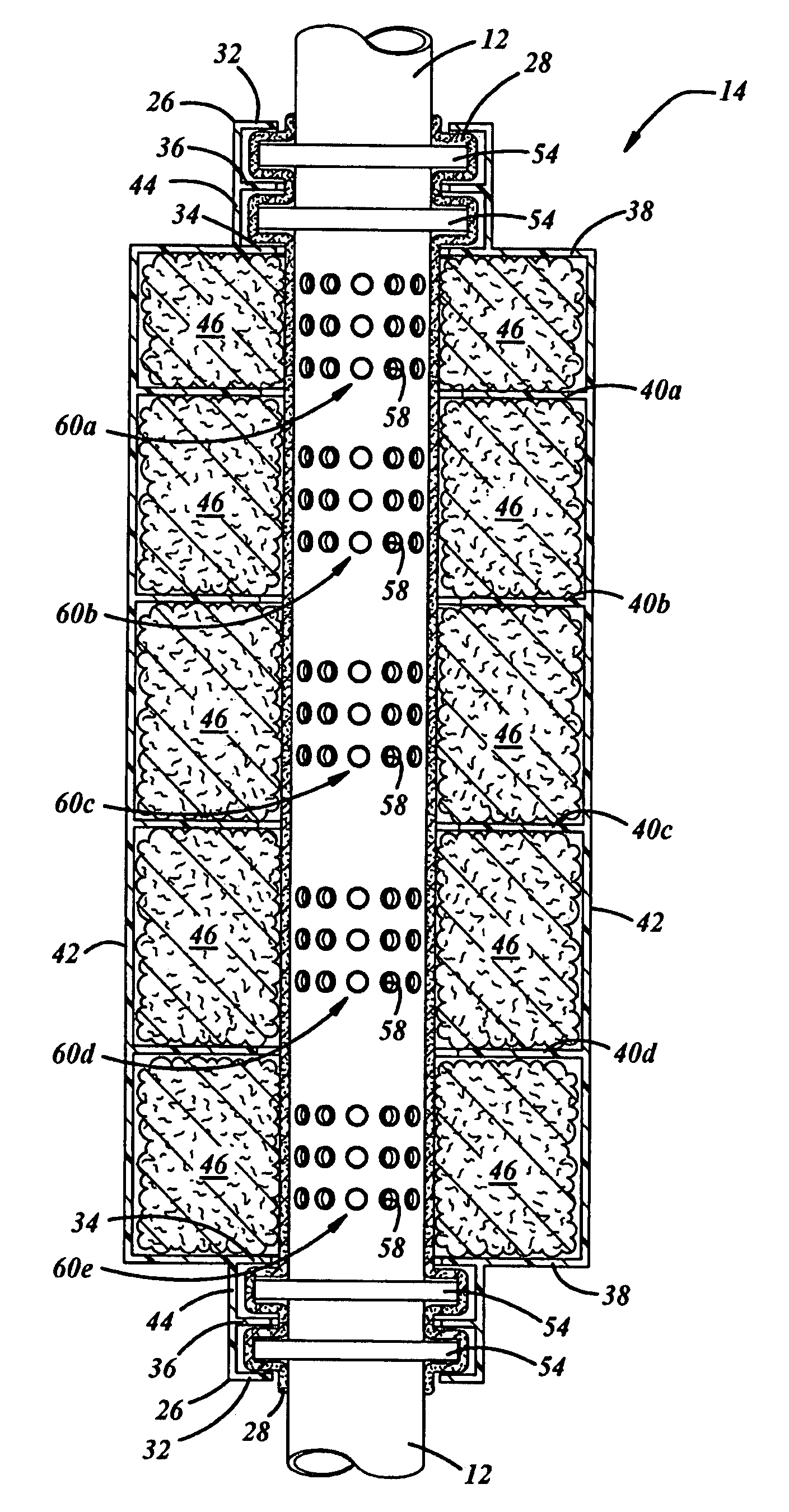

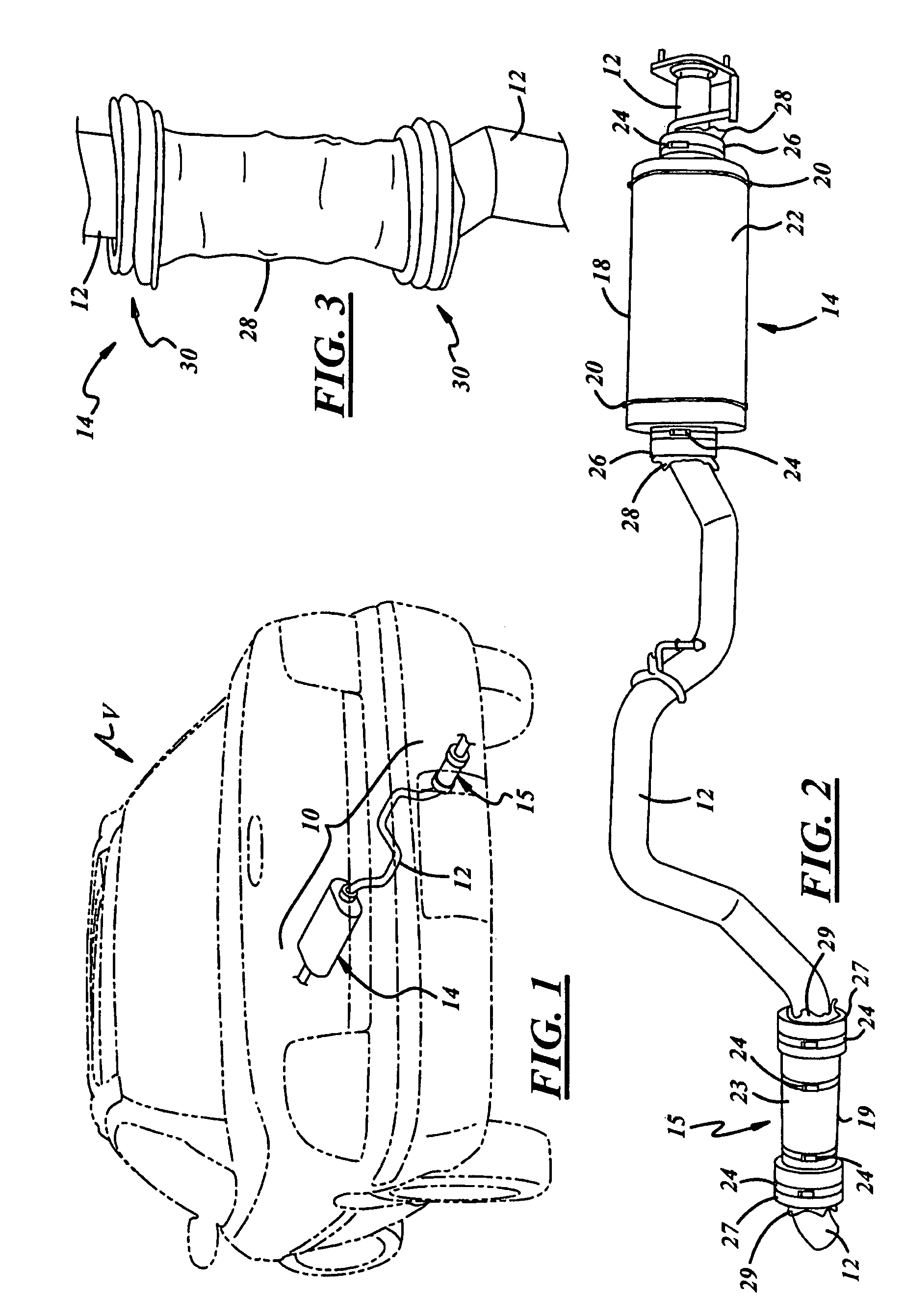

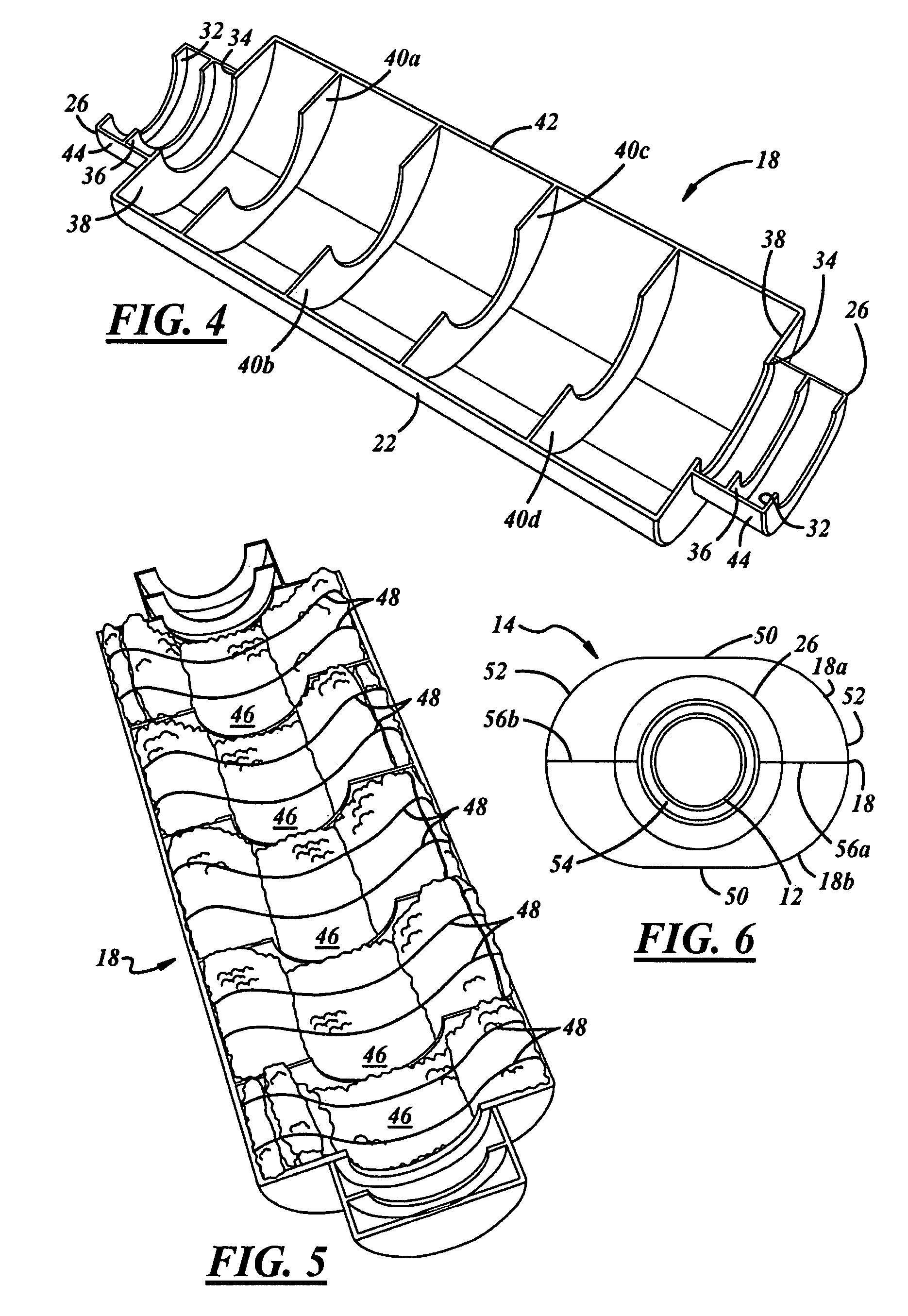

Muffler

An absorption muffler includes a metallic exhaust pipe including a plurality of perforations, a polymeric housing carried by the exhaust pipe and enclosing the plurality of perforations, and including axially opposed ends. Thermal insulation is carried radially between the exhaust pipe and the polymeric housing and axially between the axially opposed ends inclusive thereof. Acoustic insulation is carried between the thermal insulation and the polymeric housing.

Owner:FCA US +1

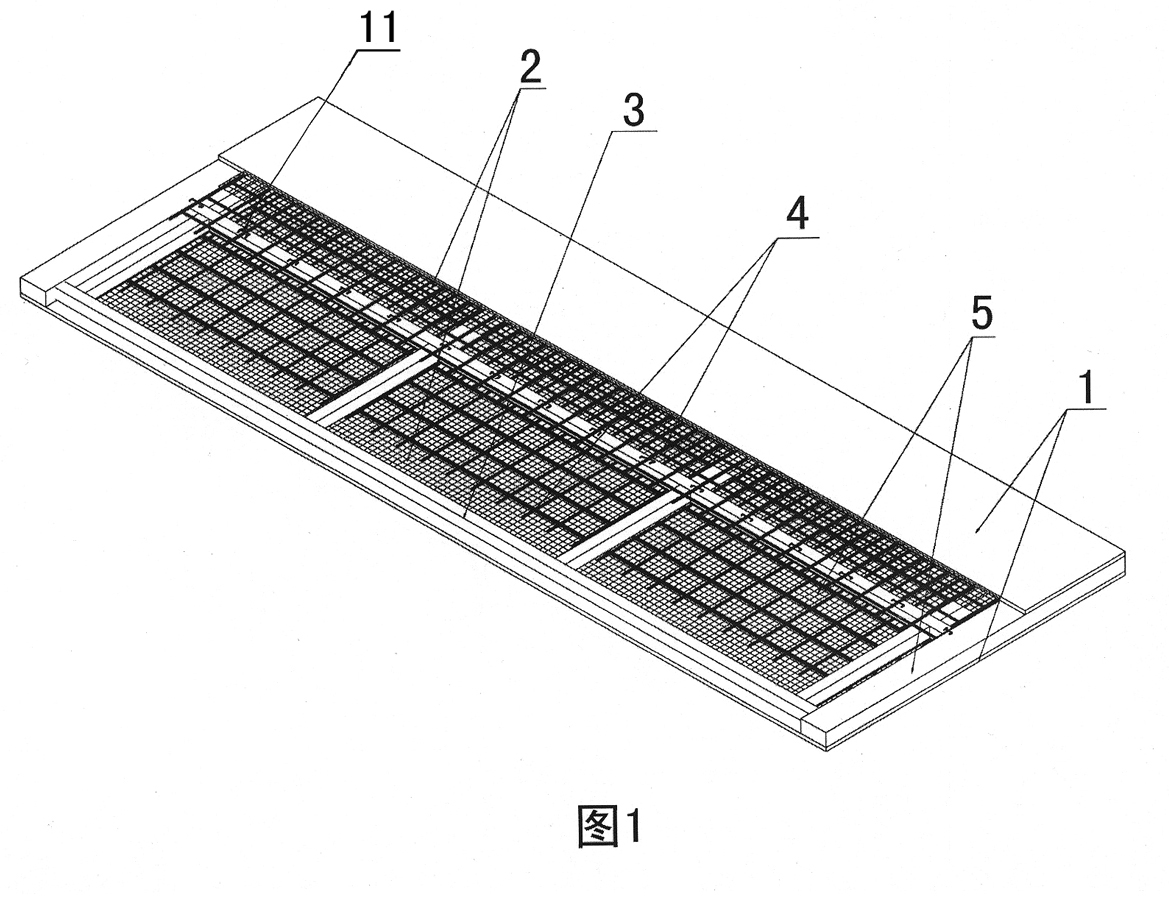

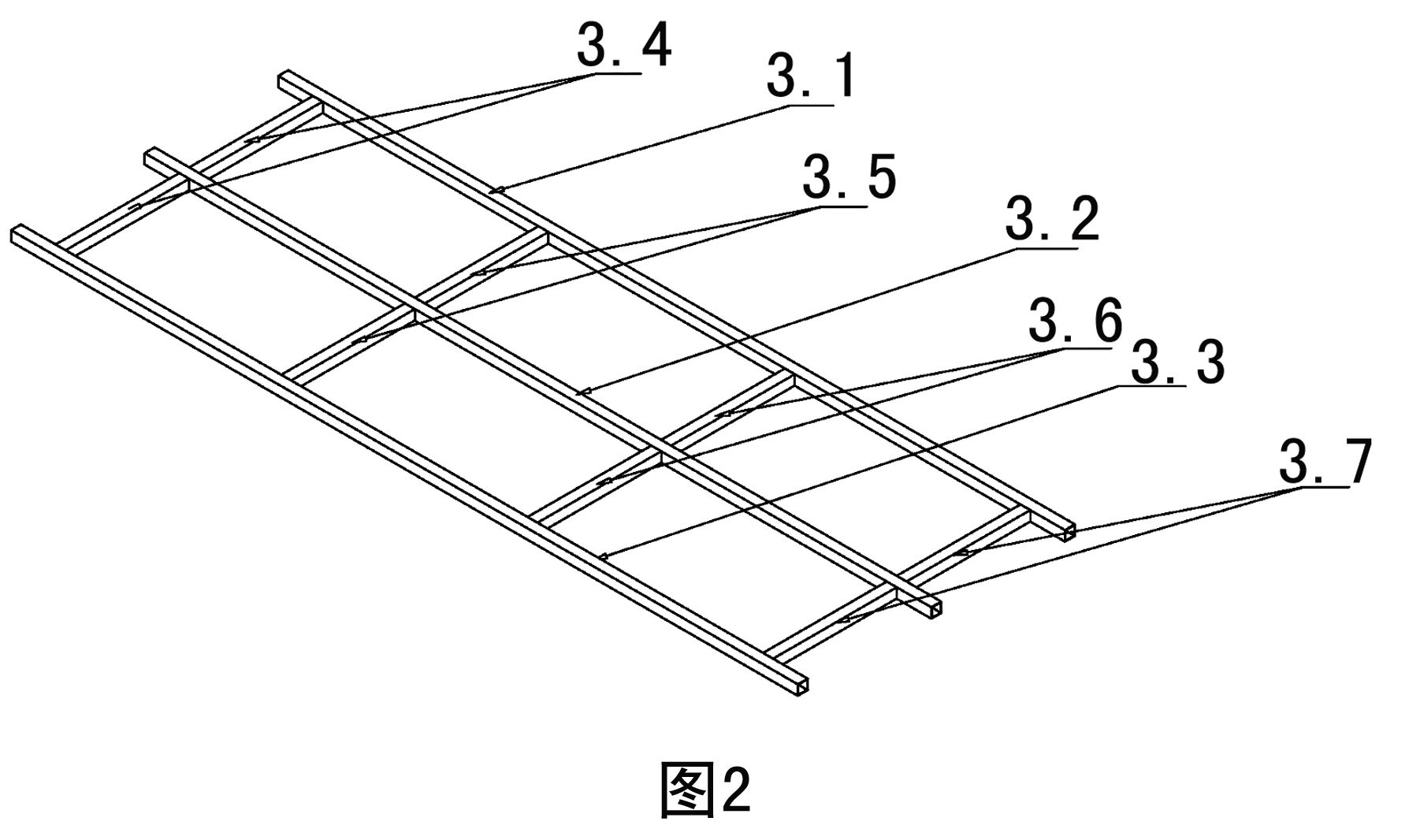

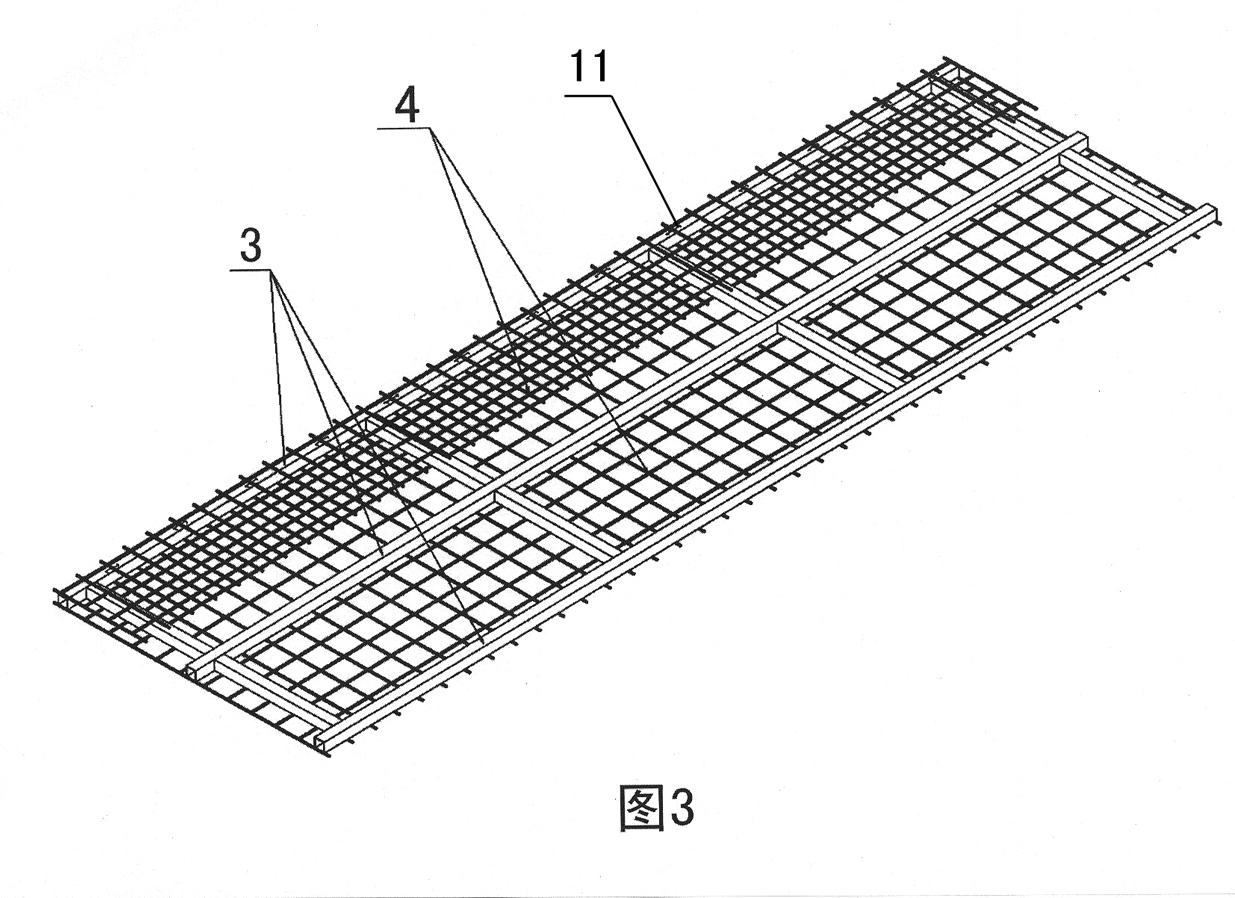

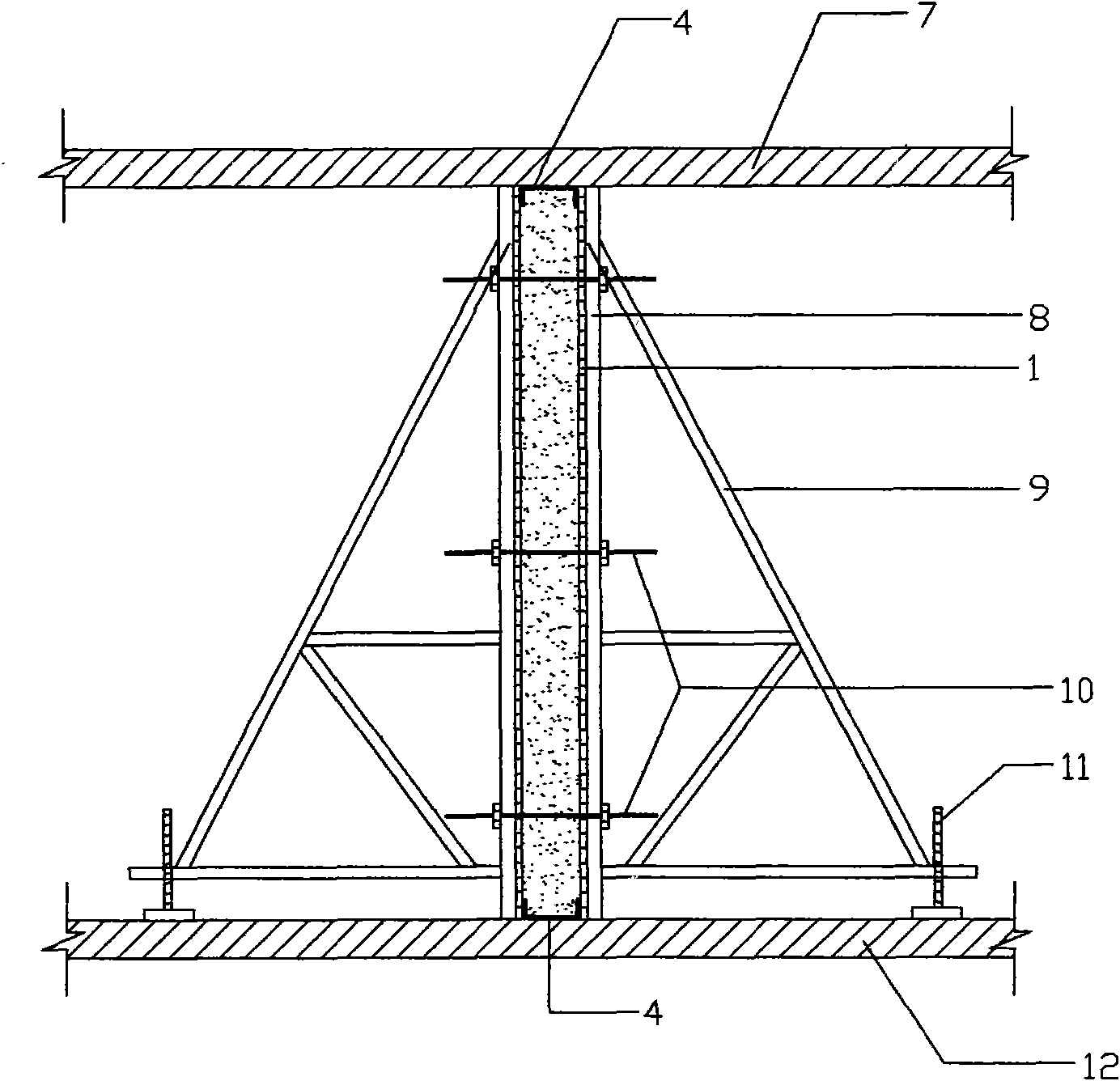

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

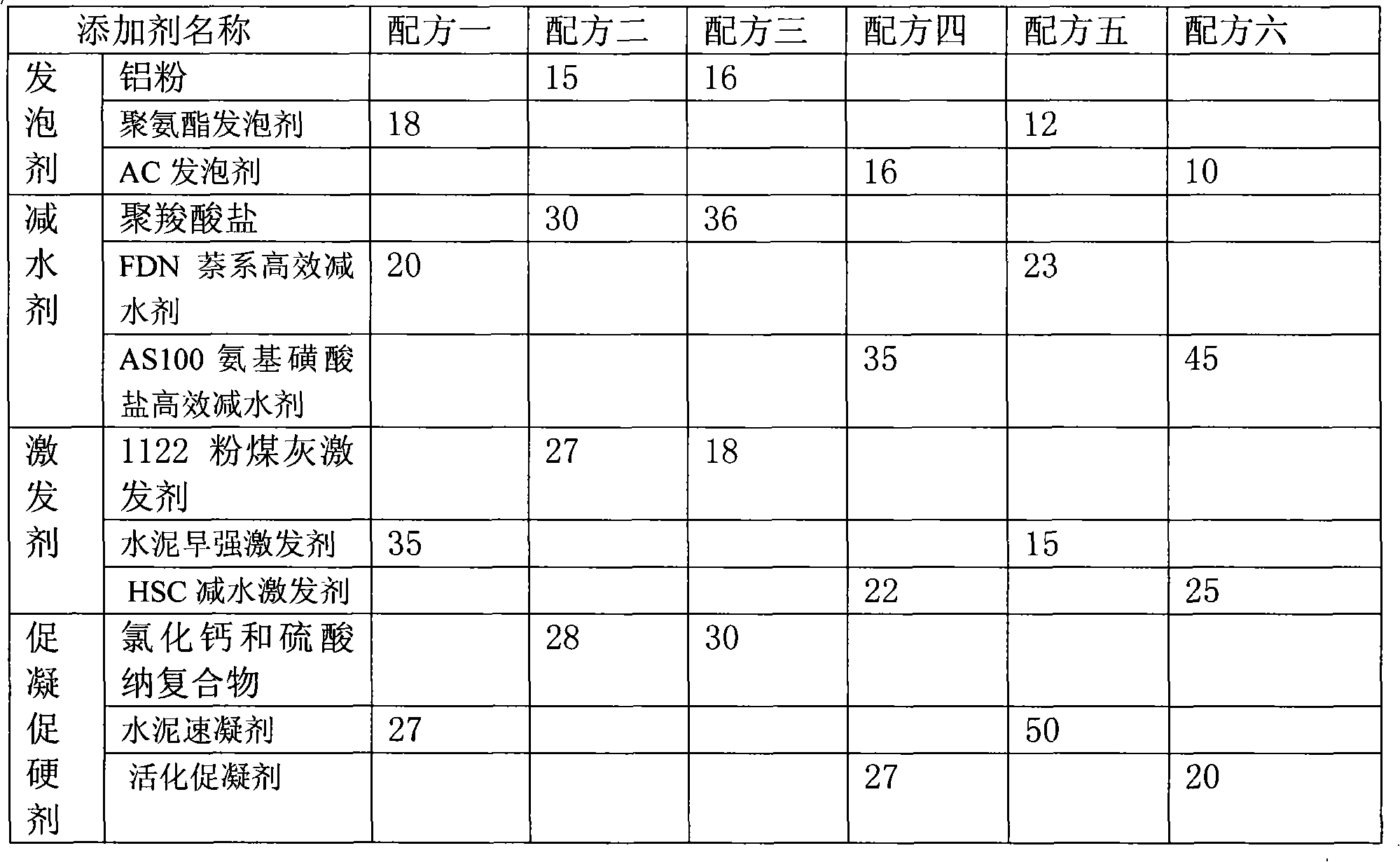

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

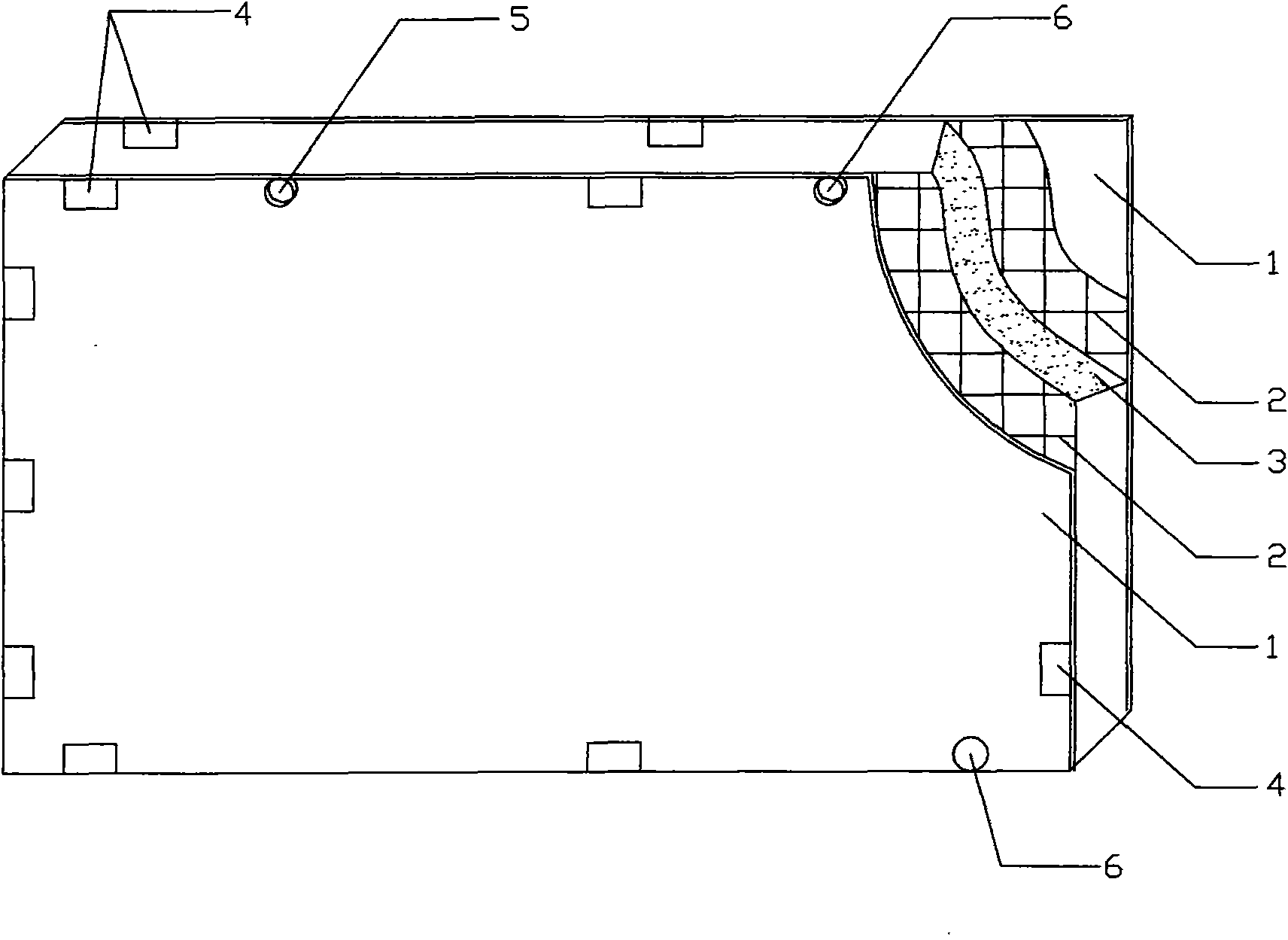

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

Muffler

Owner:FCA US +1

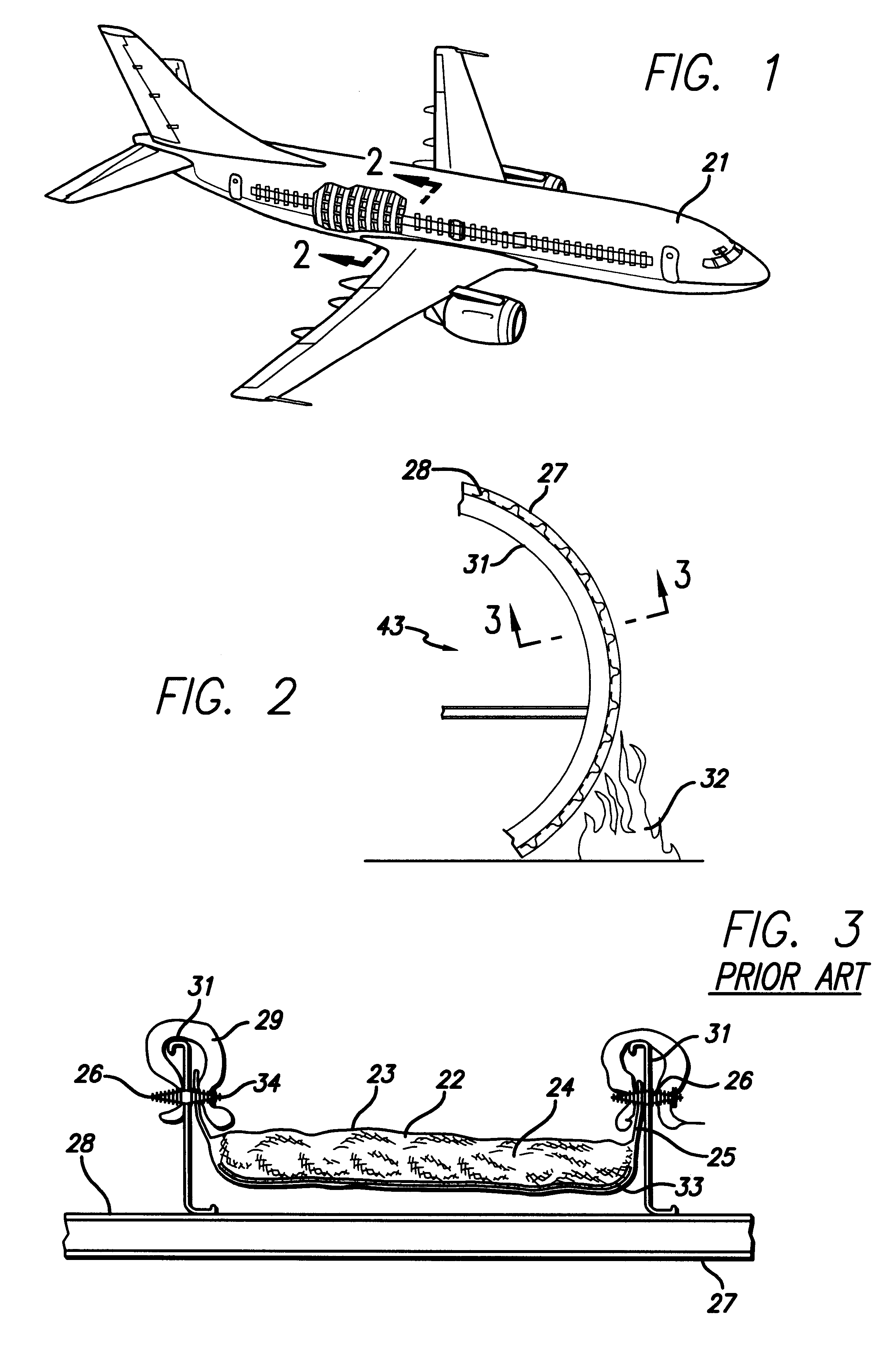

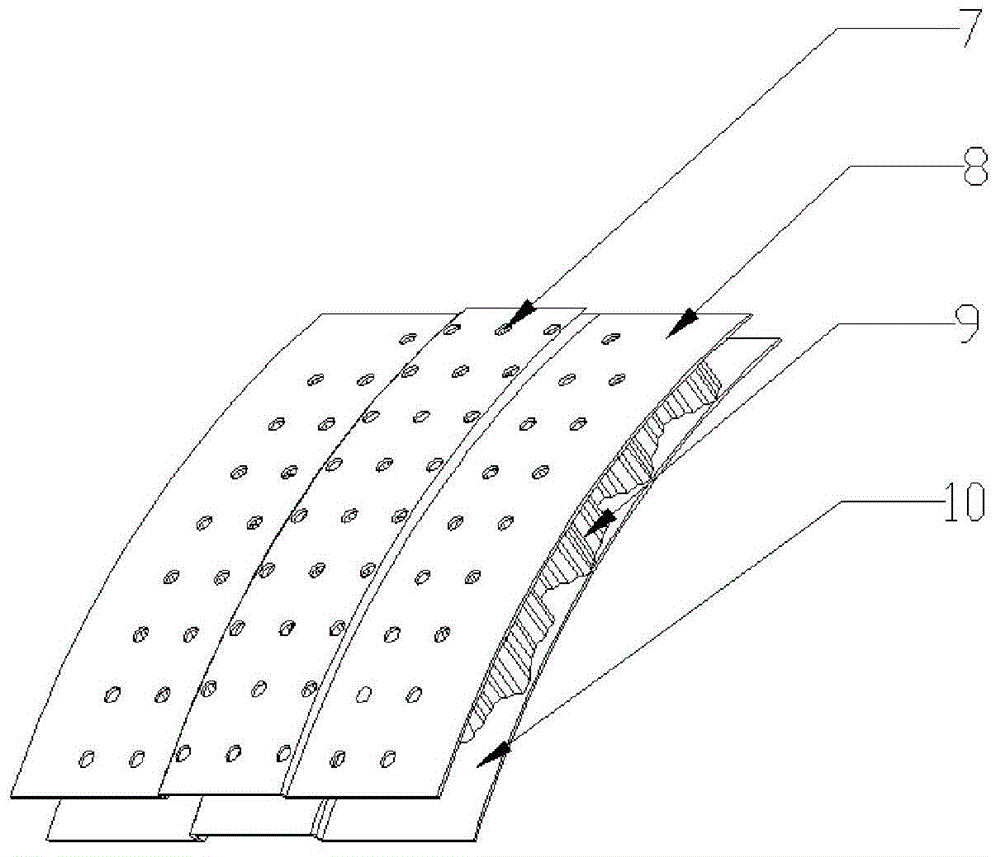

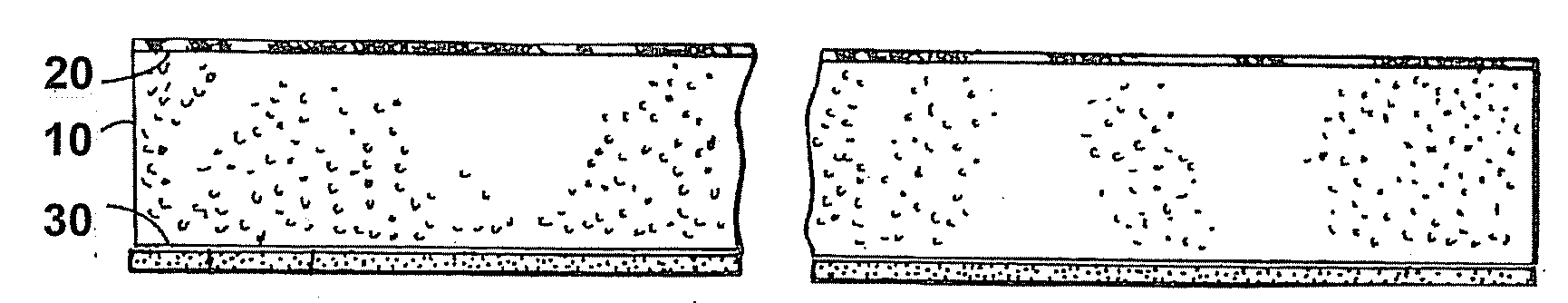

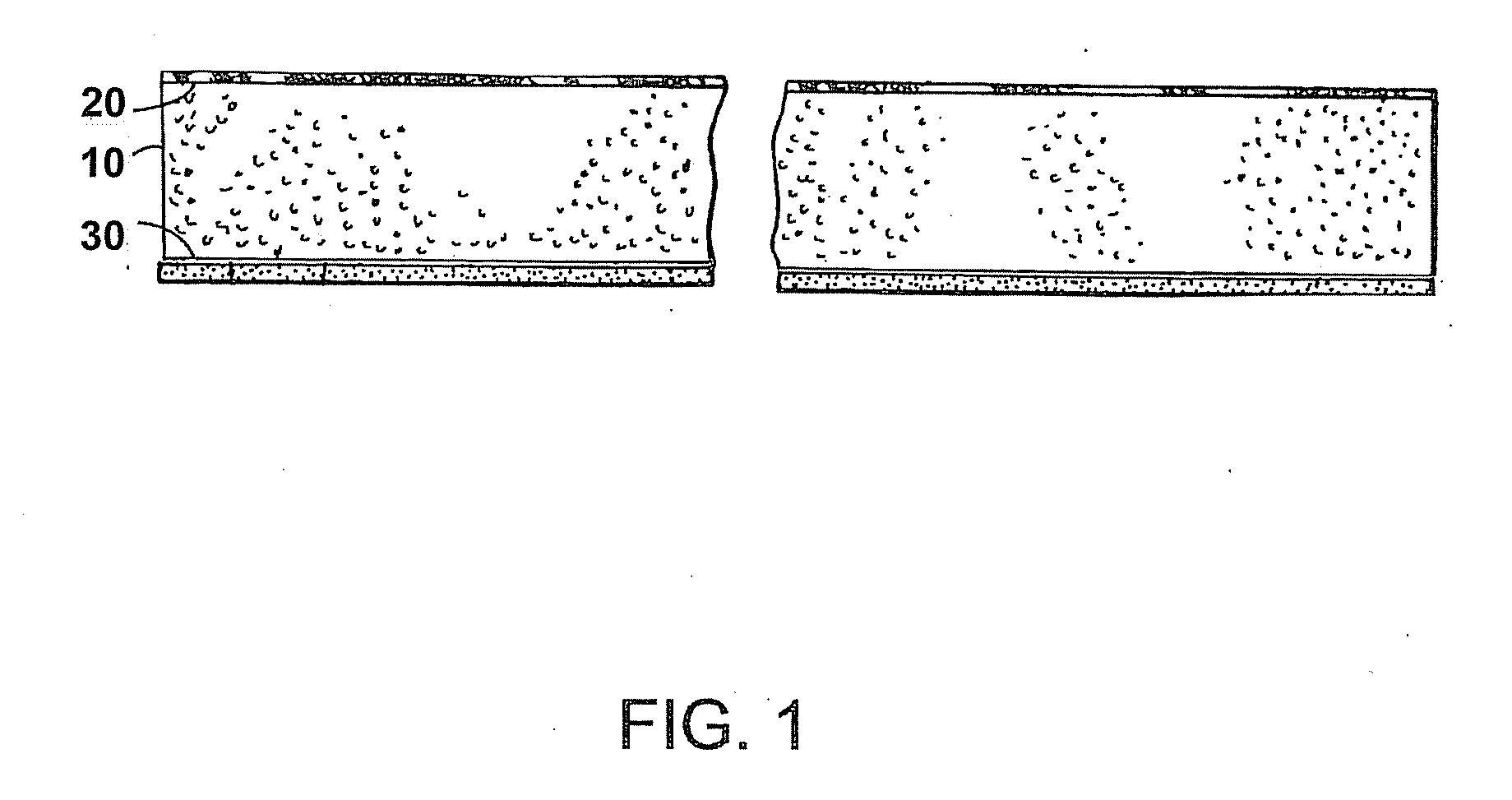

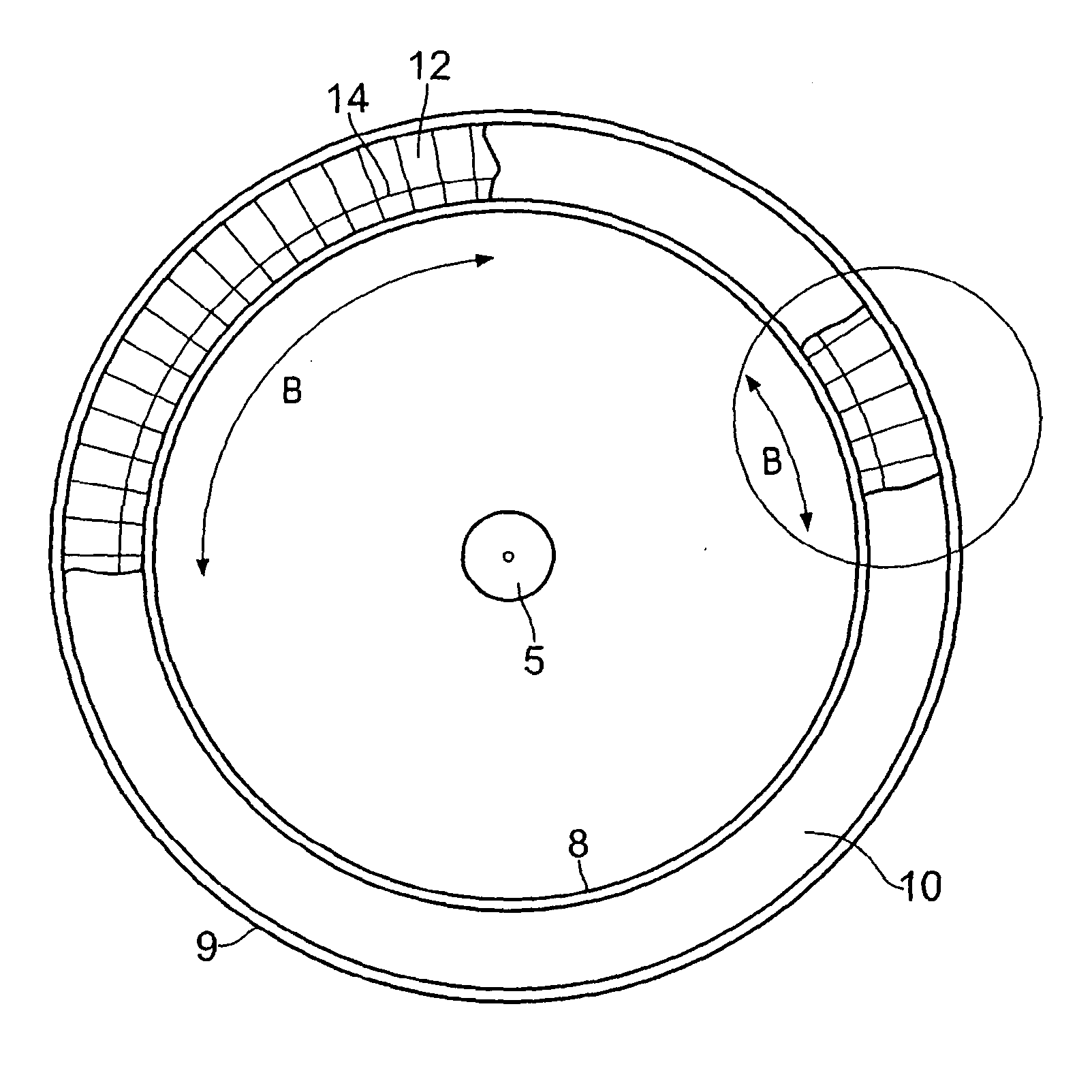

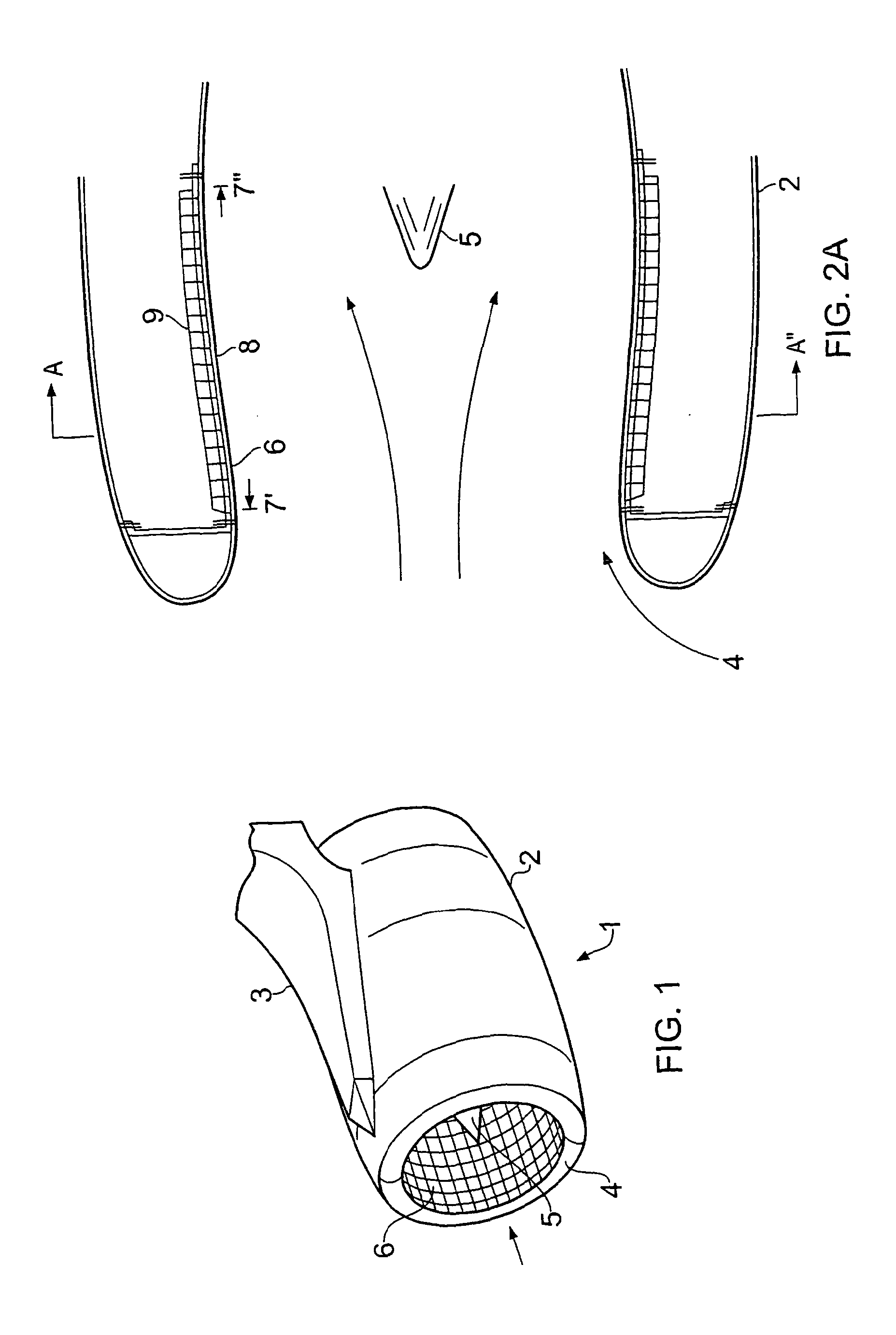

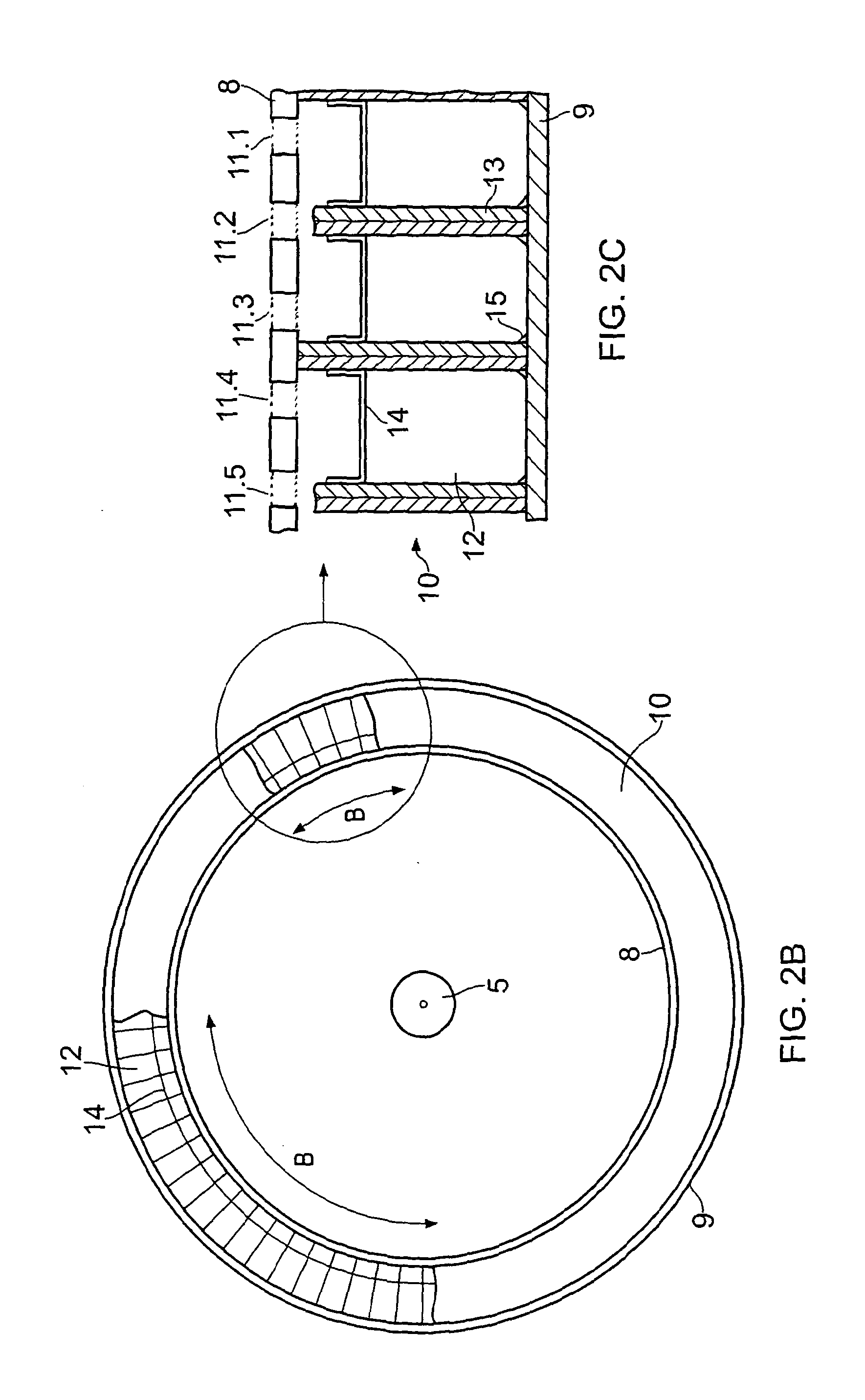

Seamless acoustic liner

ActiveUS20130075193A1Add partsAvoid introducingCeilingsTurning machine accessoriesEngineeringTurbine

The invention relates to a method of manufacturing a composite acoustic panel employed in an inlet passage of a gas turbine engine (1). The acoustic panel comprises a permeable face-layer (8), an impermeable backing sheet (9) and a sound absorbing layer (10) disposed therebetween. The method comprises a double polymerisation process for the face-layer and the remainder of the acoustic panel and finally a perforation step to perforate the face-layer according to a pre-determined perforation distribution (11.1, 11.2, 11.3, 11.4, 11.5).

Owner:GKN AEROSPACE SERVICES LTD

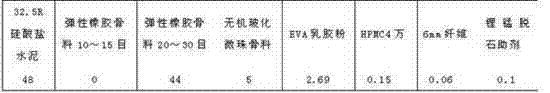

Light thermal insulation soundproof damping floor mortar

ActiveCN102249614AFully hydrated and hardenedBatch scratch smoothSolid waste managementCelluloseFiber

The invention discloses light thermal insulation soundproof damping floor mortar, which is prepared by mixing the following components in percentage by mass: 30 to 40 percent of cement, 0 to 28 percent of coarse elastic rubber aggregate, 5 to 50 percent of fine elastic rubber aggregate, 5 to 15 percent of inorganic vitrified microsphere aggregate, 0.5 to 3 percent of redispersible emulsion powder, 0.05 to 0.15 percent of cellulose ether, 0.02 to 0.06 percent of 6mm fiber and 0.05 to 0.1 percent of hectorite aid. Inorganic silicate is taken as a binding material, so the light thermal insulation soundproof damping floor mortar has good compatibility with cement mortar and a concrete base, is firmly bound, avoids a hollowing phenomenon, is suitable for various base conditions, has a leveling function under the condition of poor evenness, is easy and convenient to construct, and can be scraped after being added with water and uniformly stirred; the whole soundproof layer is a whole, sound bridges are greatly reduced, the compression strength is moderate, the deformation hardly occurs, and the load of a building cannot be increased greatly; and the light thermal insulation soundproof damping floor mortar has low coefficient of heat conductivity, makes floors soundproof, and has the thermal insulation effect.

Owner:上海曹杨建筑粘合剂厂

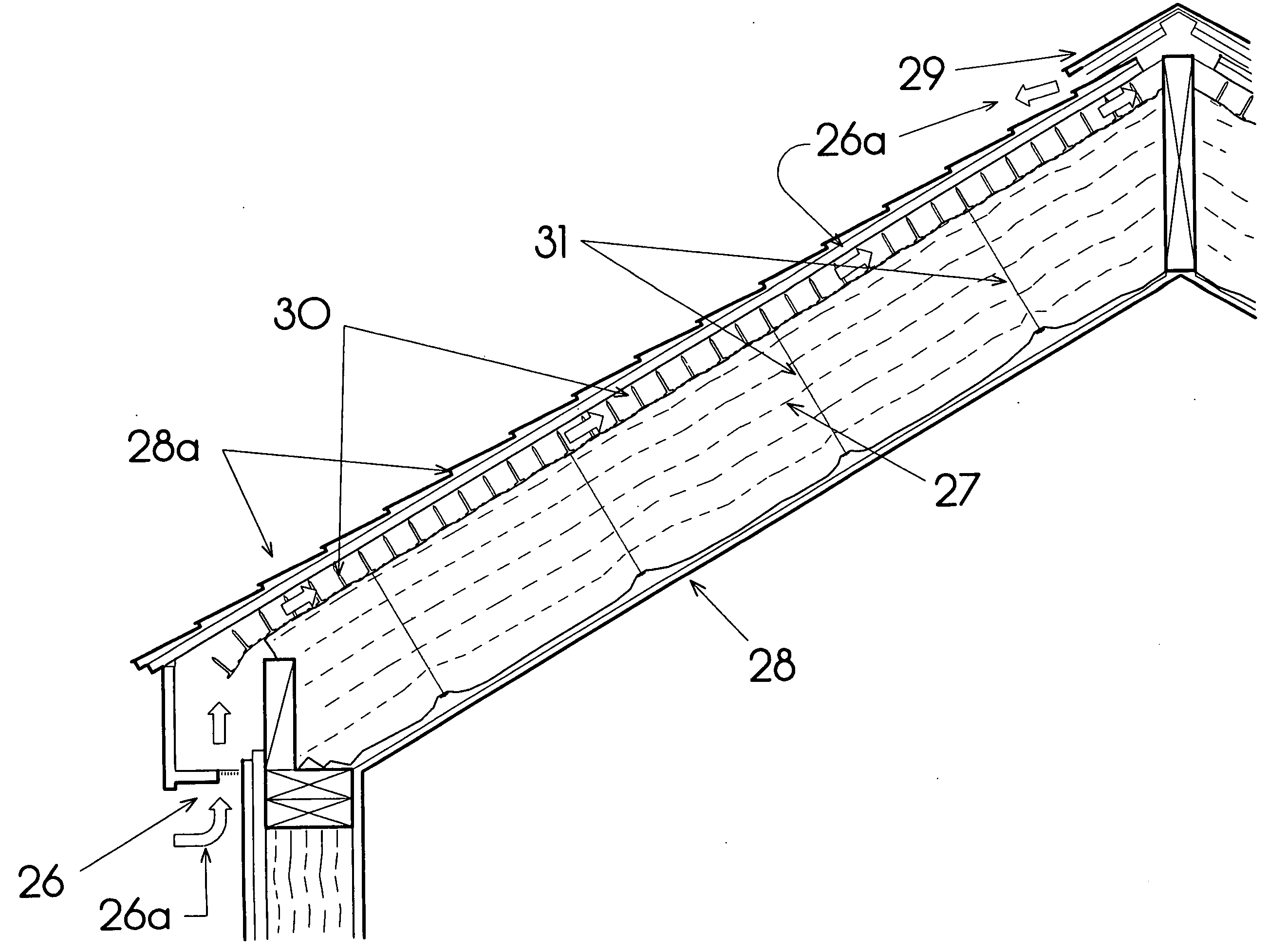

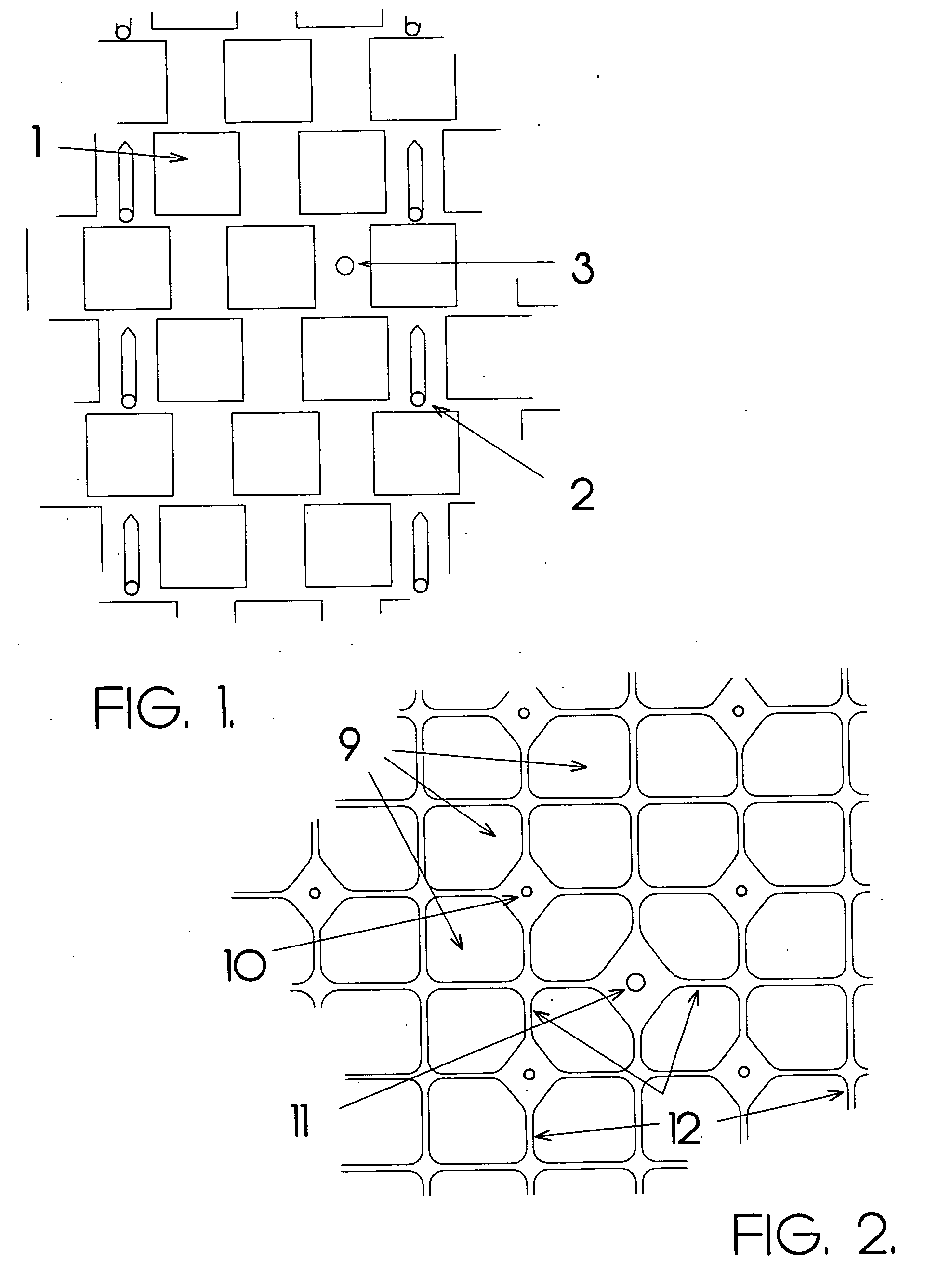

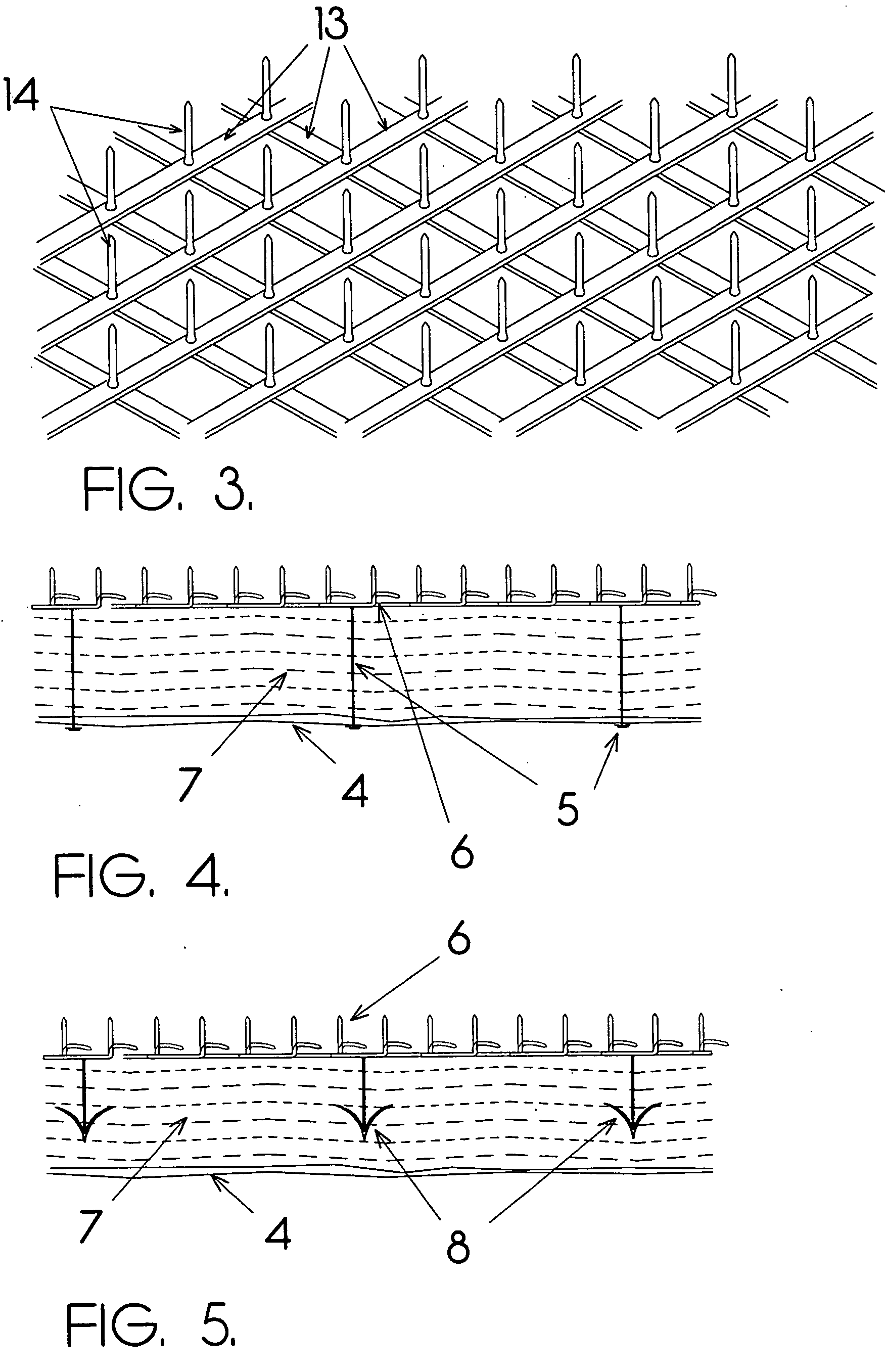

Device and method to provide air circulation space proximate to insulation material

A spacer device is provided including (1) a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material, and (2) a plurality of spacer struts fixedly attached to the body. The struts are configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of entangled net filaments.

Owner:HETTRICH HANSL

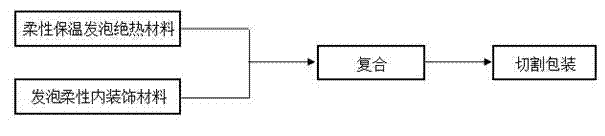

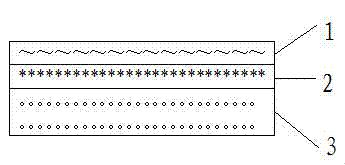

Flexible thermal-insulating decorative material for internal wall and method for producing flexible thermal-insulating decorative material

ActiveCN102505820ALow densityImprove the decorative effectCovering/liningsSynthetic resin layered productsAdhesive cementThermal insulation

The invention discloses a flexible thermal-insulating decorative material for an internal wall and a producing method for the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material is composed of a flexible inner decorative layer, an adhesive layer and a flexible foamed heat-insulating layer. The invention also provides a method for producing the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material for the internal wall has the advantages of low energy consumption, good benefit, simple construction and large market, and integrates thermal insulation, damp prevention, mold prevention, sound insulation and decoration; the combination of a flexible foamed heat-insulating material and a flexible decorative material for the internal wall to form the unique decorative material for the internal wall is a great breakthrough for emission reduction and energy conservation of a wall body; and the flexible thermal-insulating decorative material for the internal wall is particularly applicable to energy-saving reconstruction of old buildings.

Owner:四川金路高新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com