Patents

Literature

169 results about "Openwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Openwork or open-work is a term in art history, architecture and related fields for any technique that produces decoration by creating holes, piercings, or gaps that go right through a solid material such as metal, wood, stone, pottery, cloth, leather, or ivory. Such techniques have been very widely used in a great number of cultures.

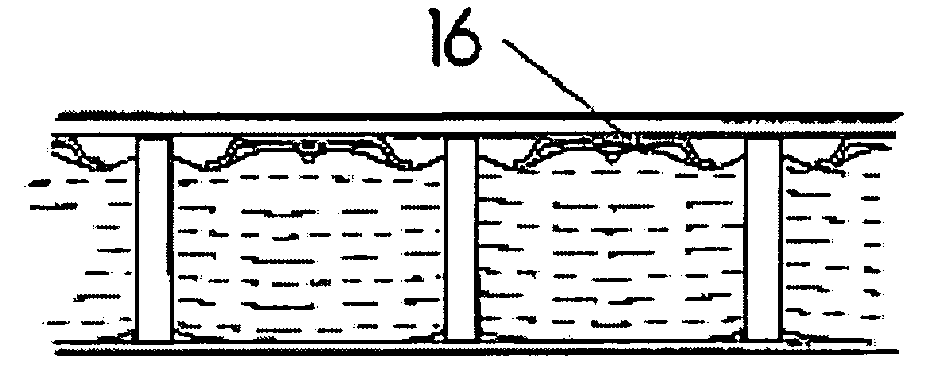

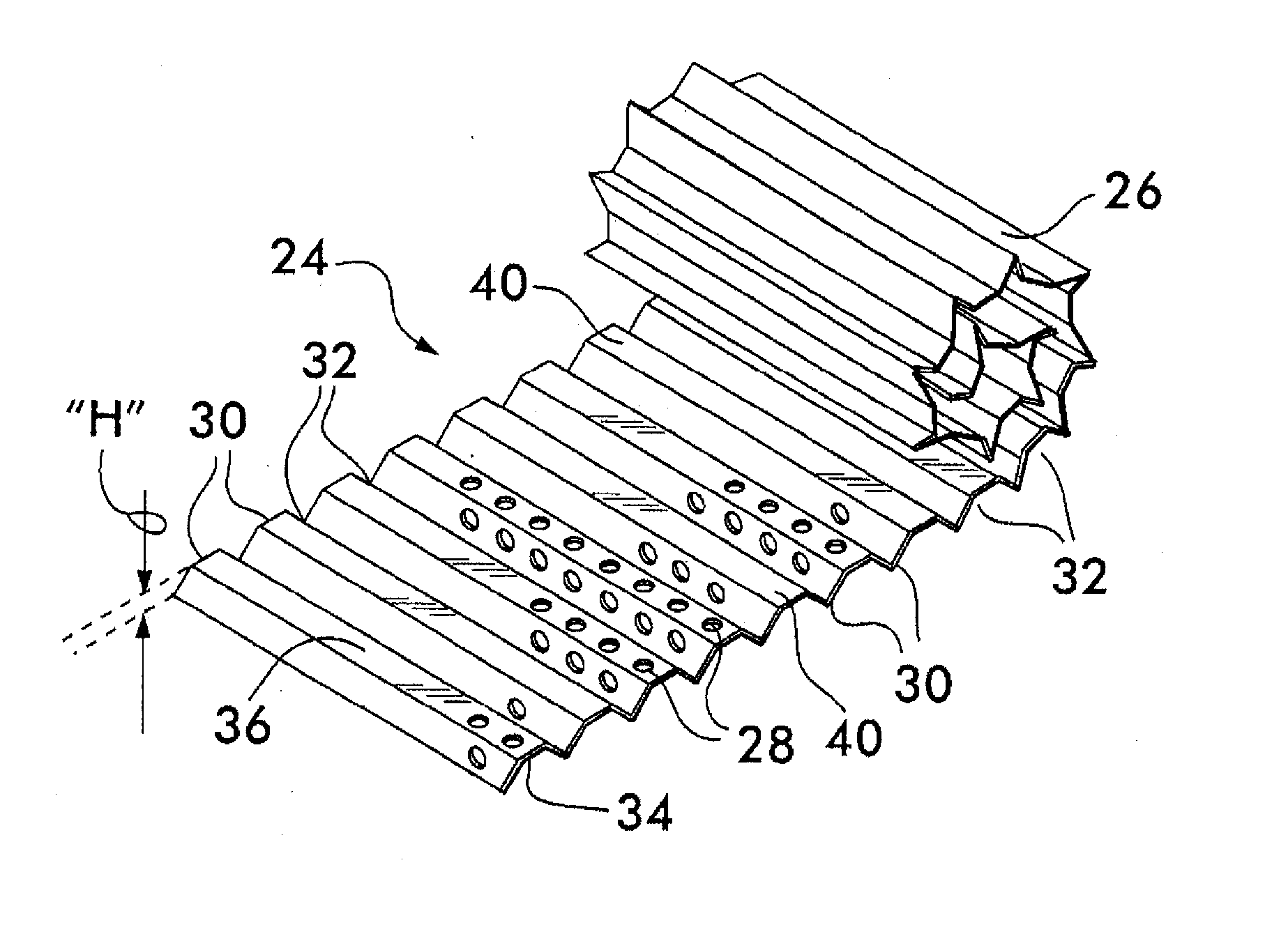

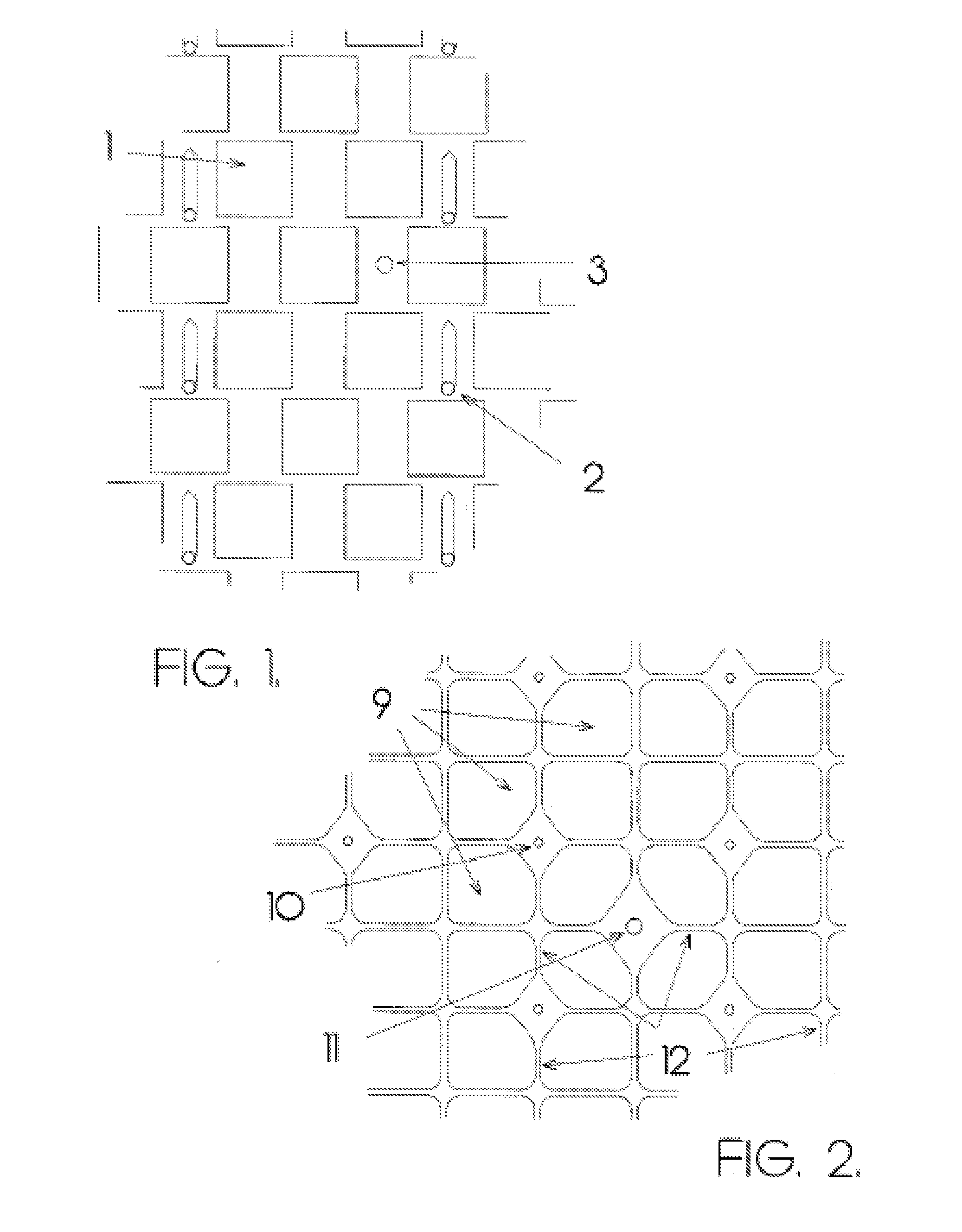

Spacer for providing drainage passageways within building structures

InactiveUS6594965B2Easy to installEfficient and economicalLighting and heating apparatusBuilding repairsEngineeringMoisture

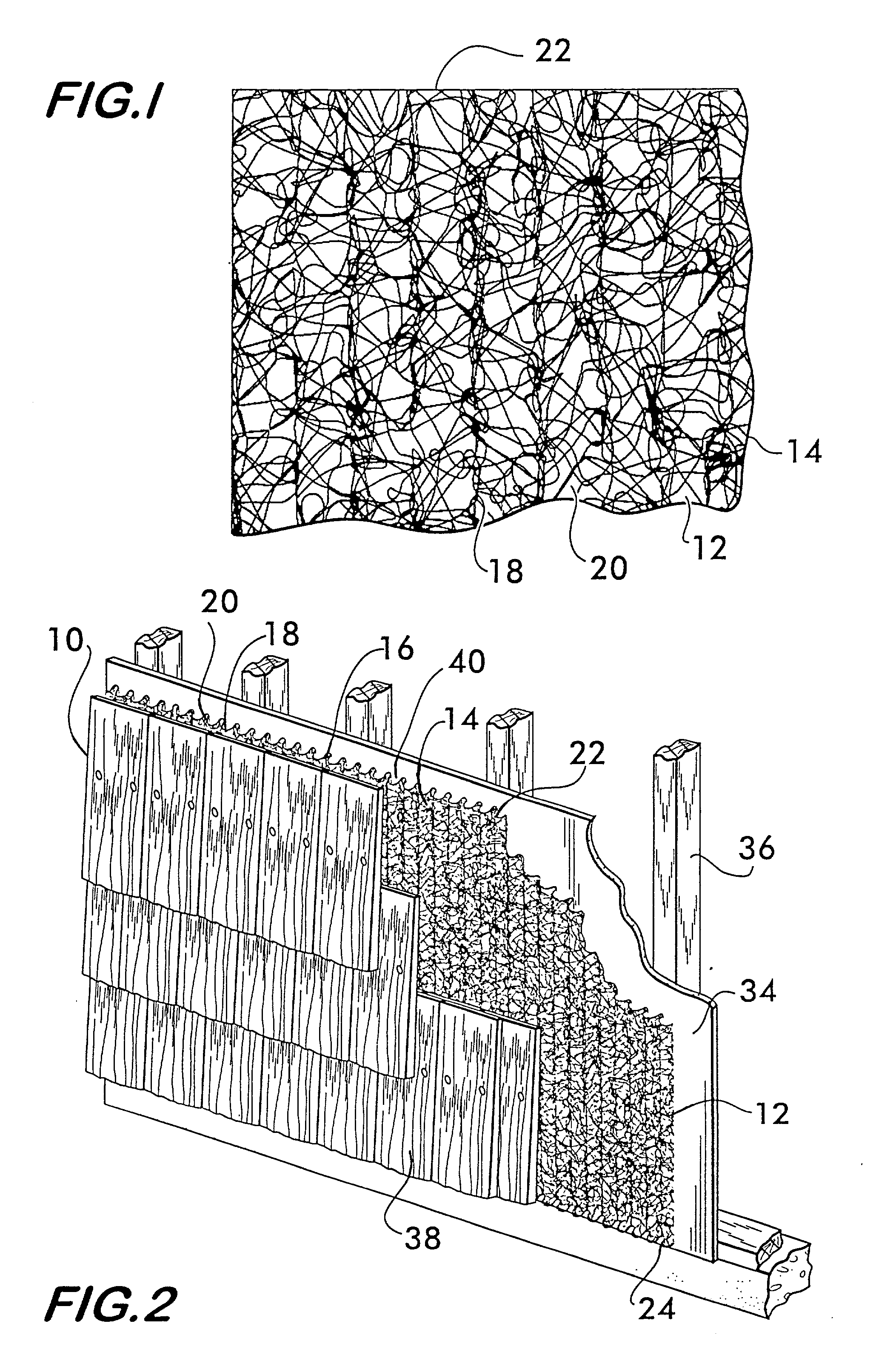

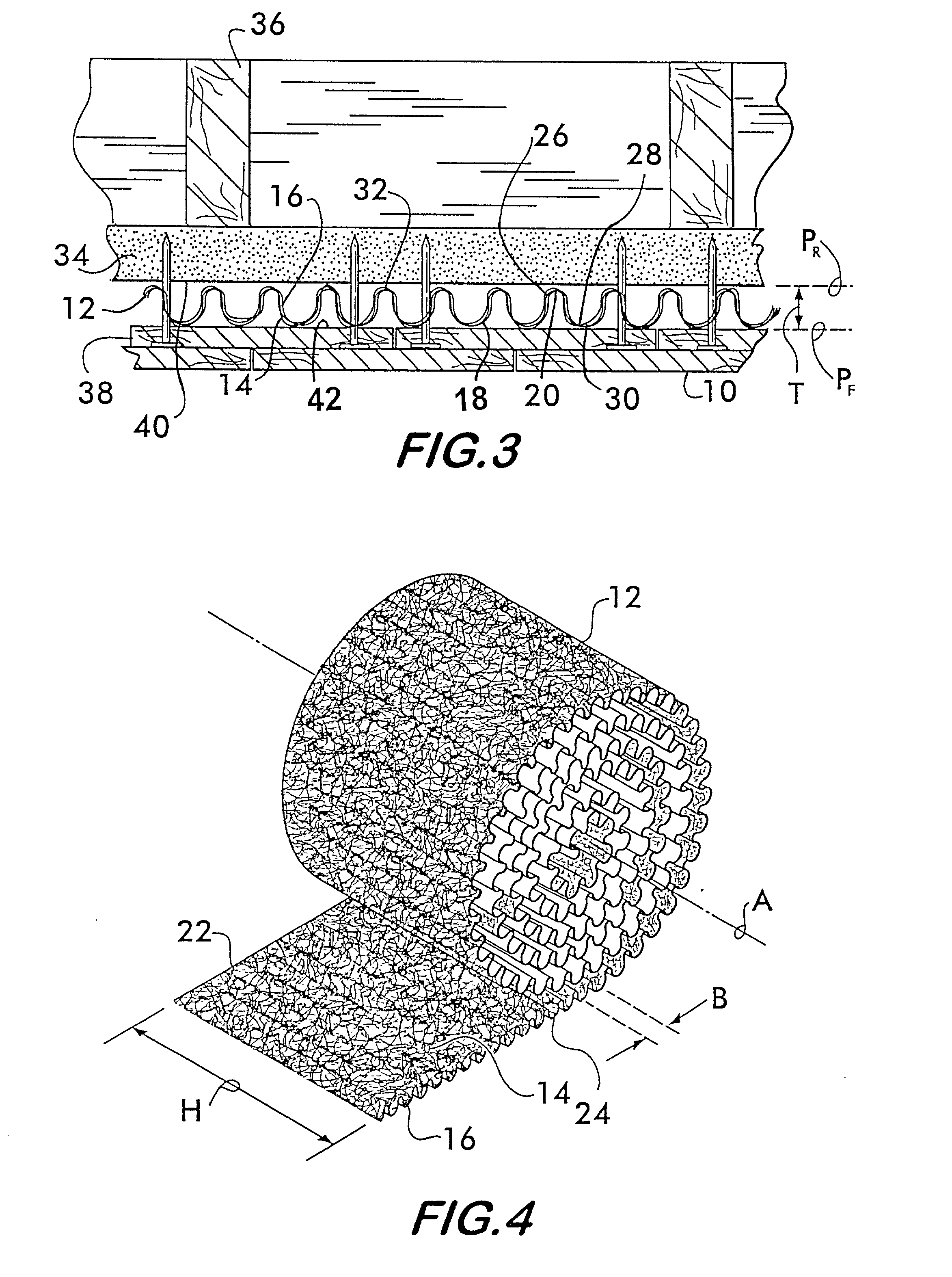

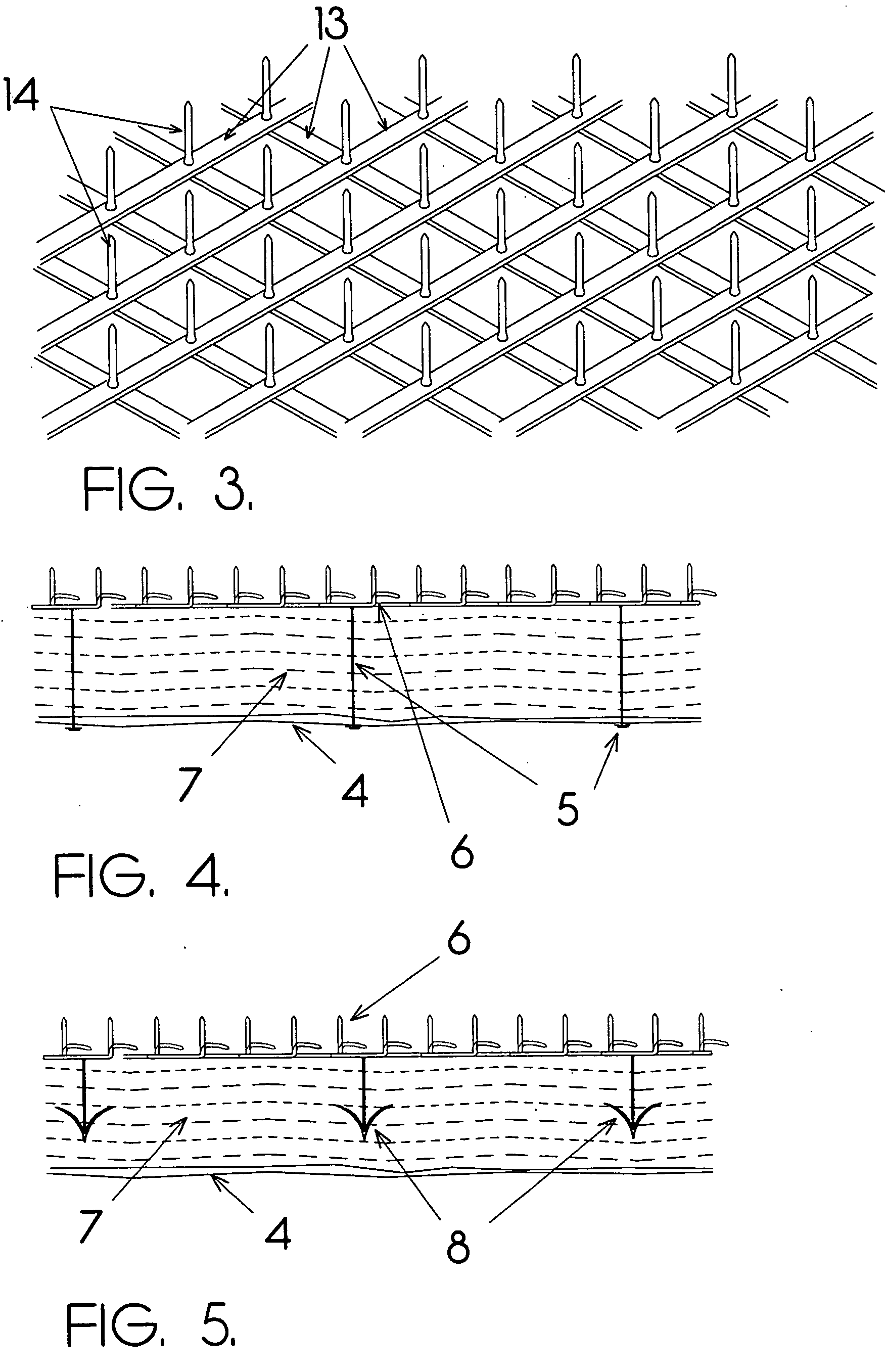

A roll-form spacer product providing air space and drainage passageways within a building structure. Preferably, the spacer product is a corrugated web of material having undulating front and rear faces and serpentine-shaped longitudinally extending edges. The faces include alternating arrays of grooves and ridges which extend perpendicular to the side edges and parallel to an axis of a spiral roll of the spacer. Thus, when the spacer is unrolled and applied to a building structure in a plurality of horizontally extending rows, the ridges and grooves are substantially vertically-disposed to form a plurality of unobstructed passageways for the drainage of moisture. Preferably, the web is made of an openwork mat of randomly convoluted polymeric filaments, and thus, enables ready circulation of air.

Owner:BENJAMIN OBDIKE

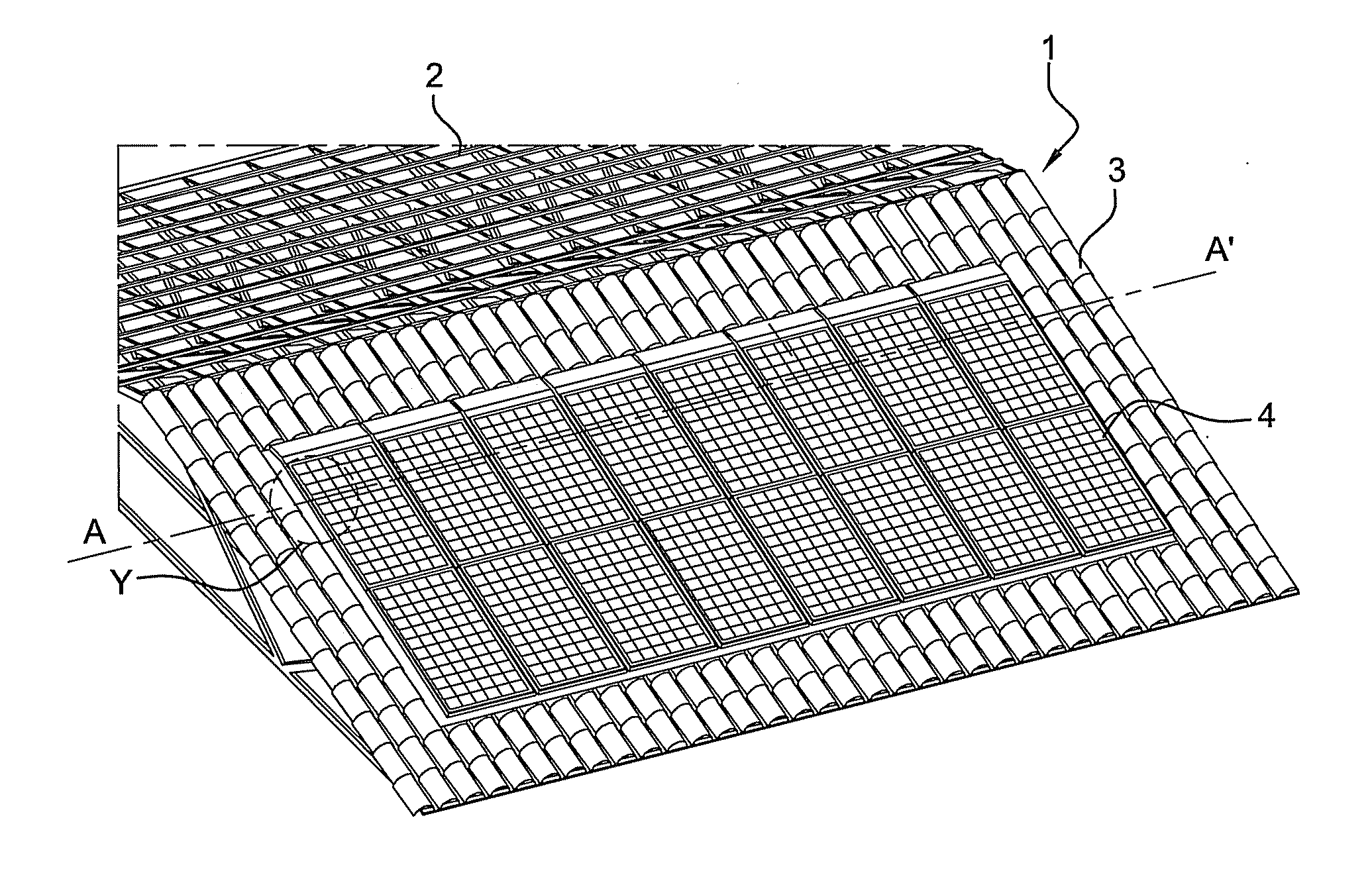

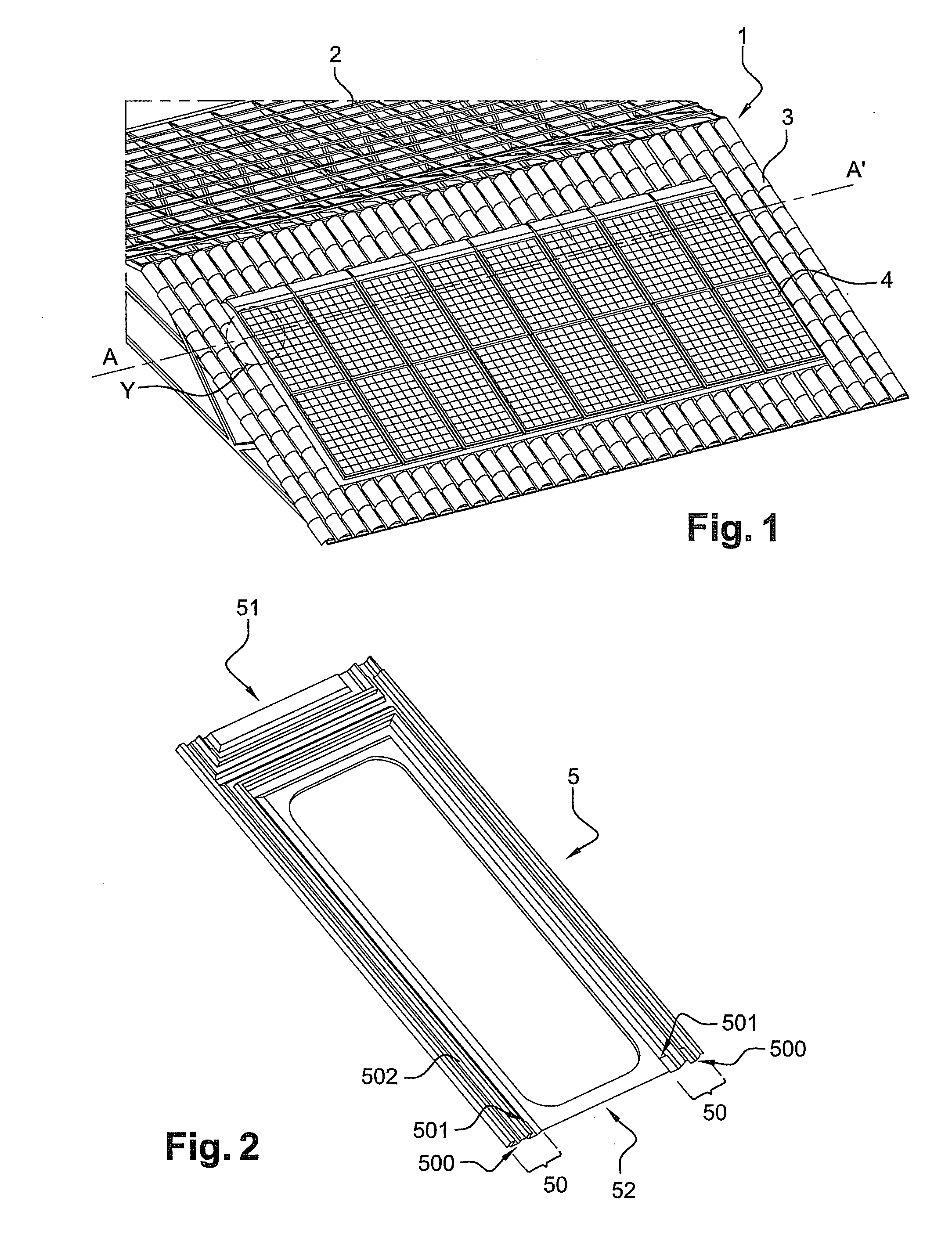

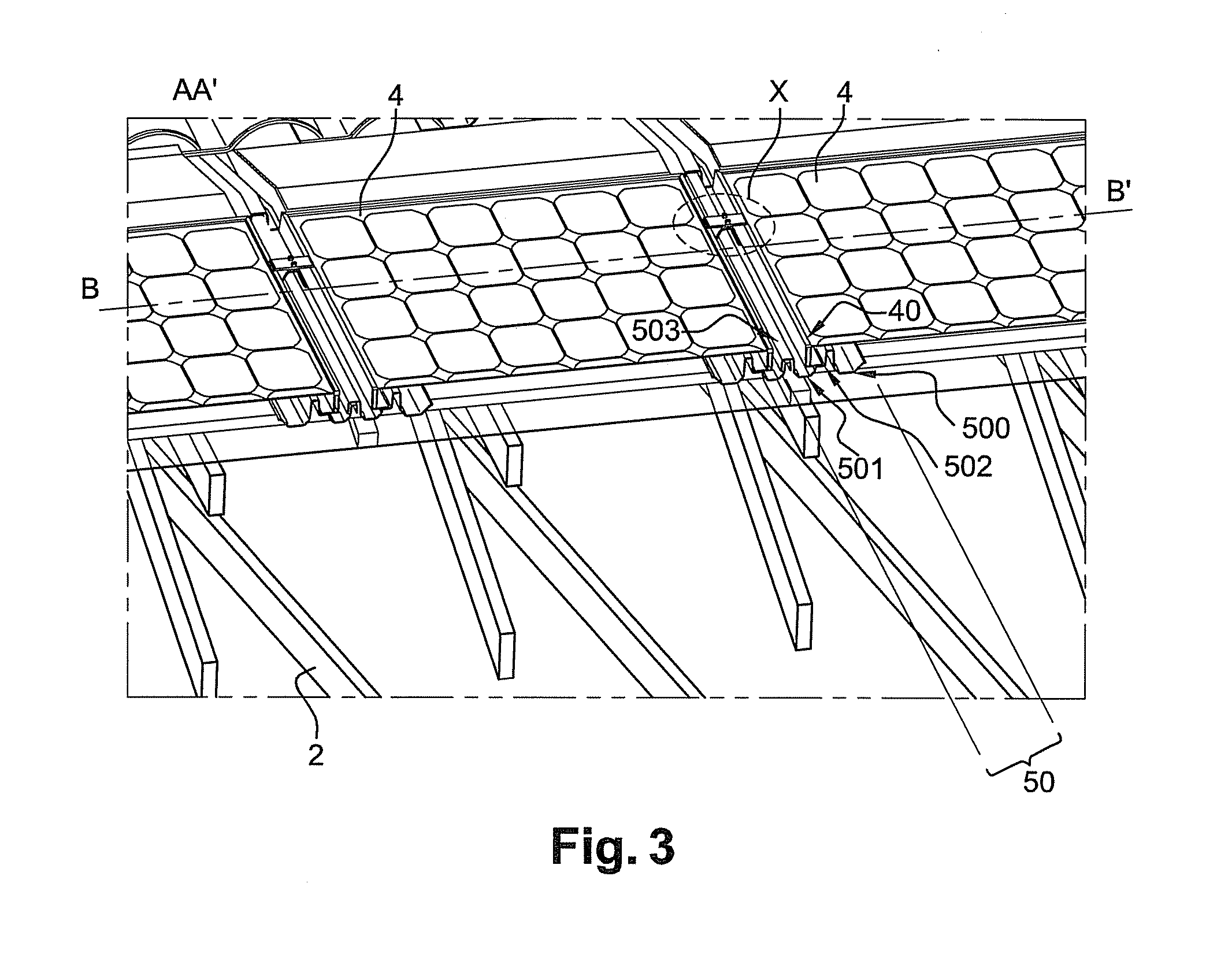

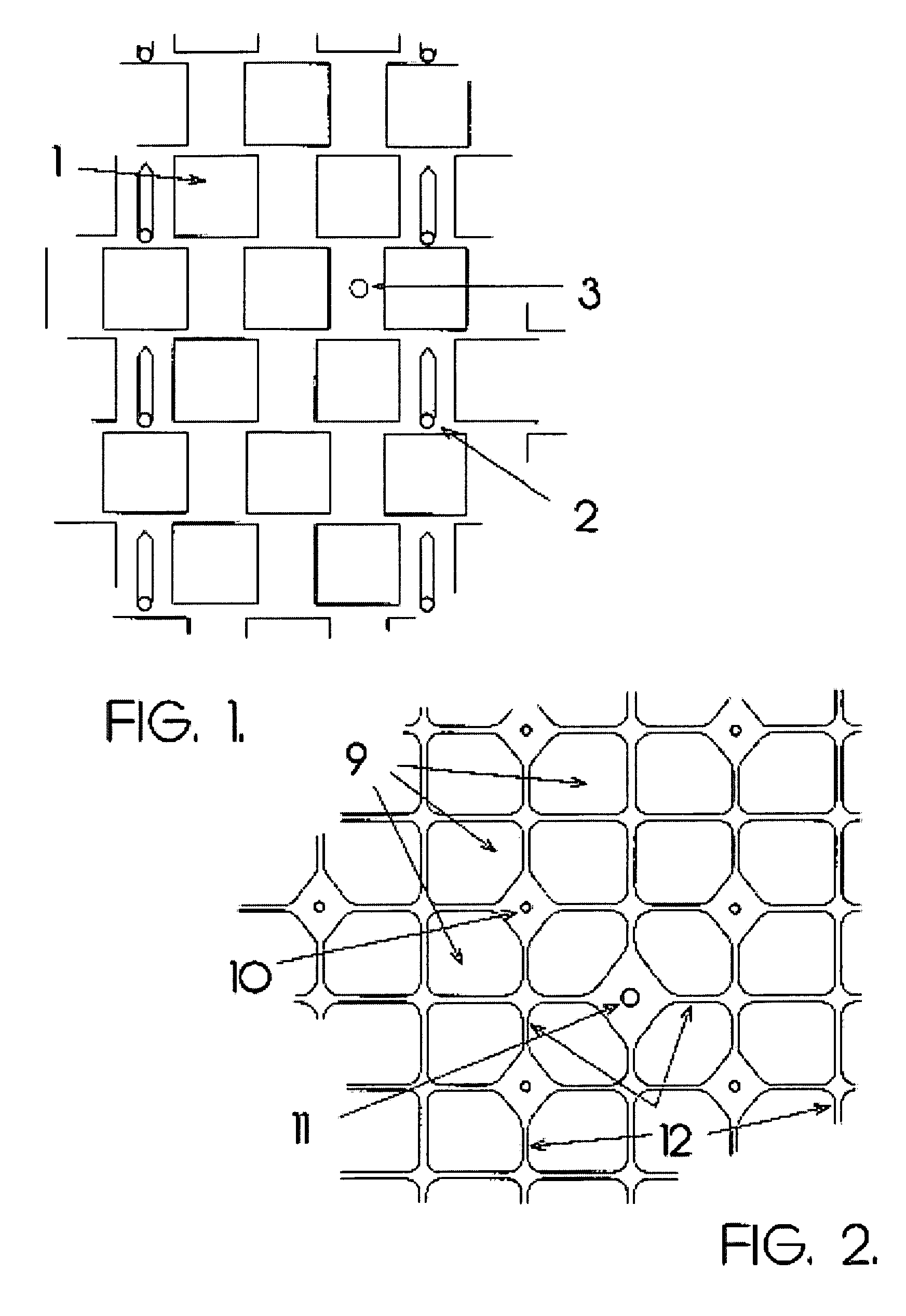

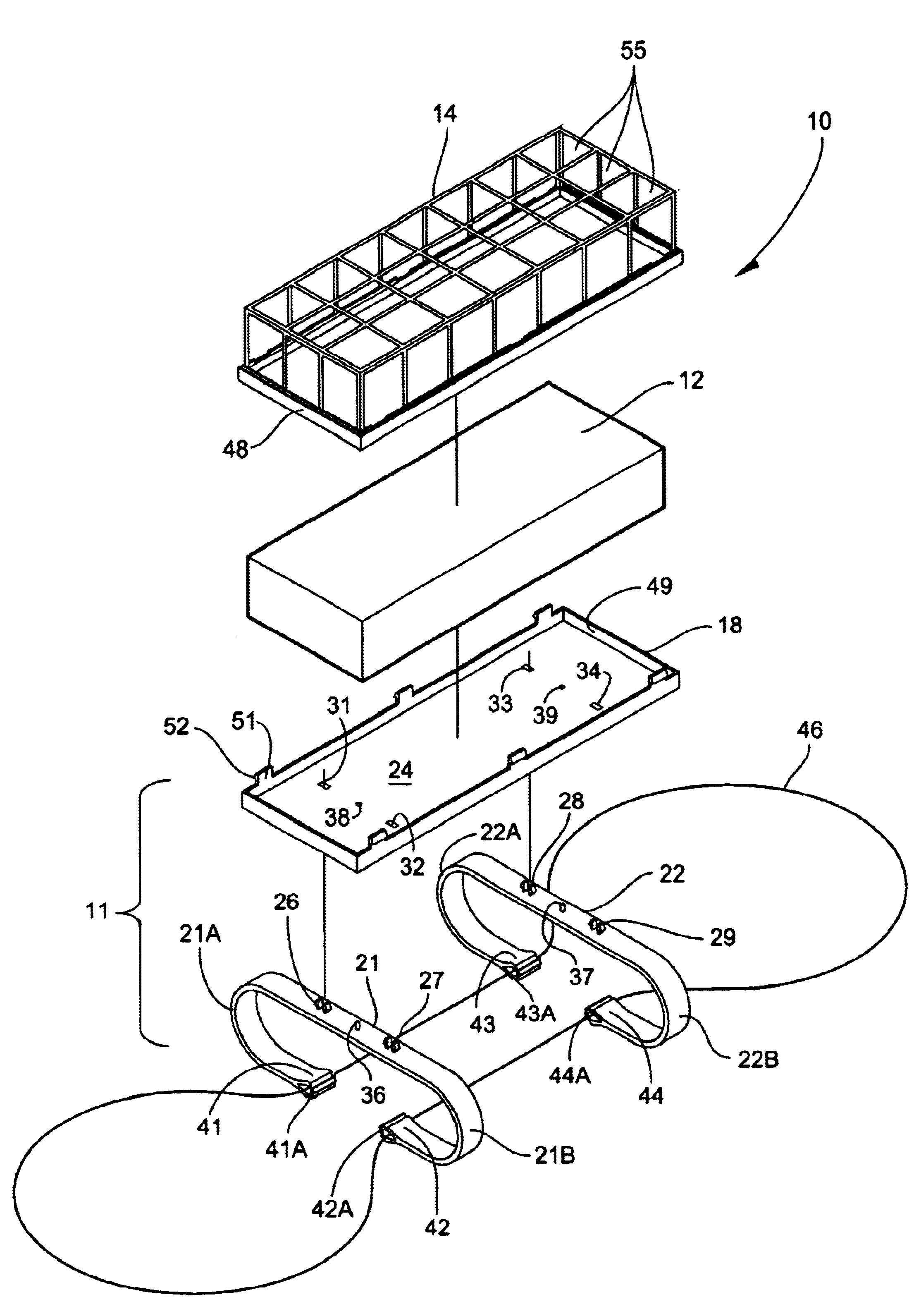

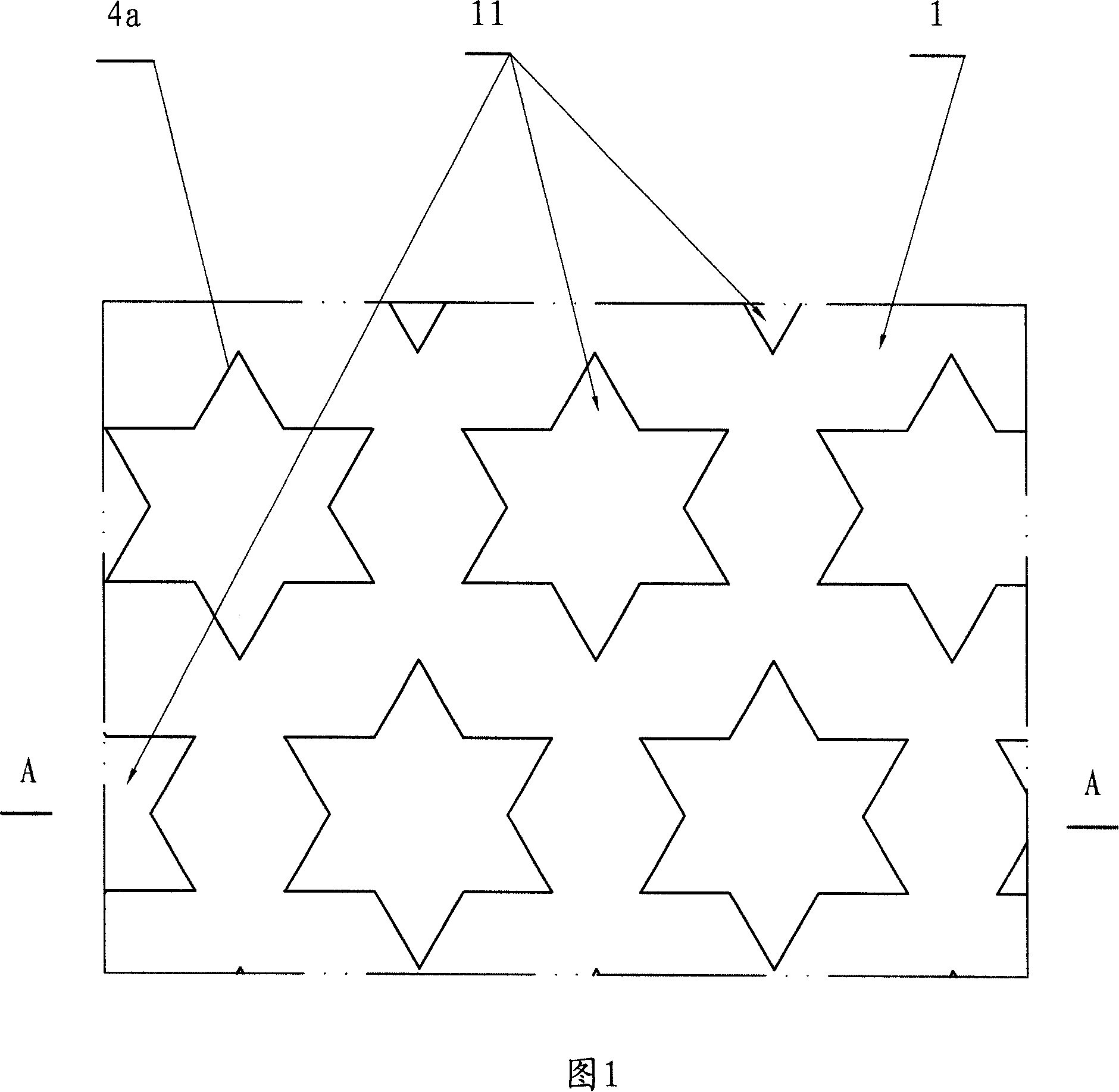

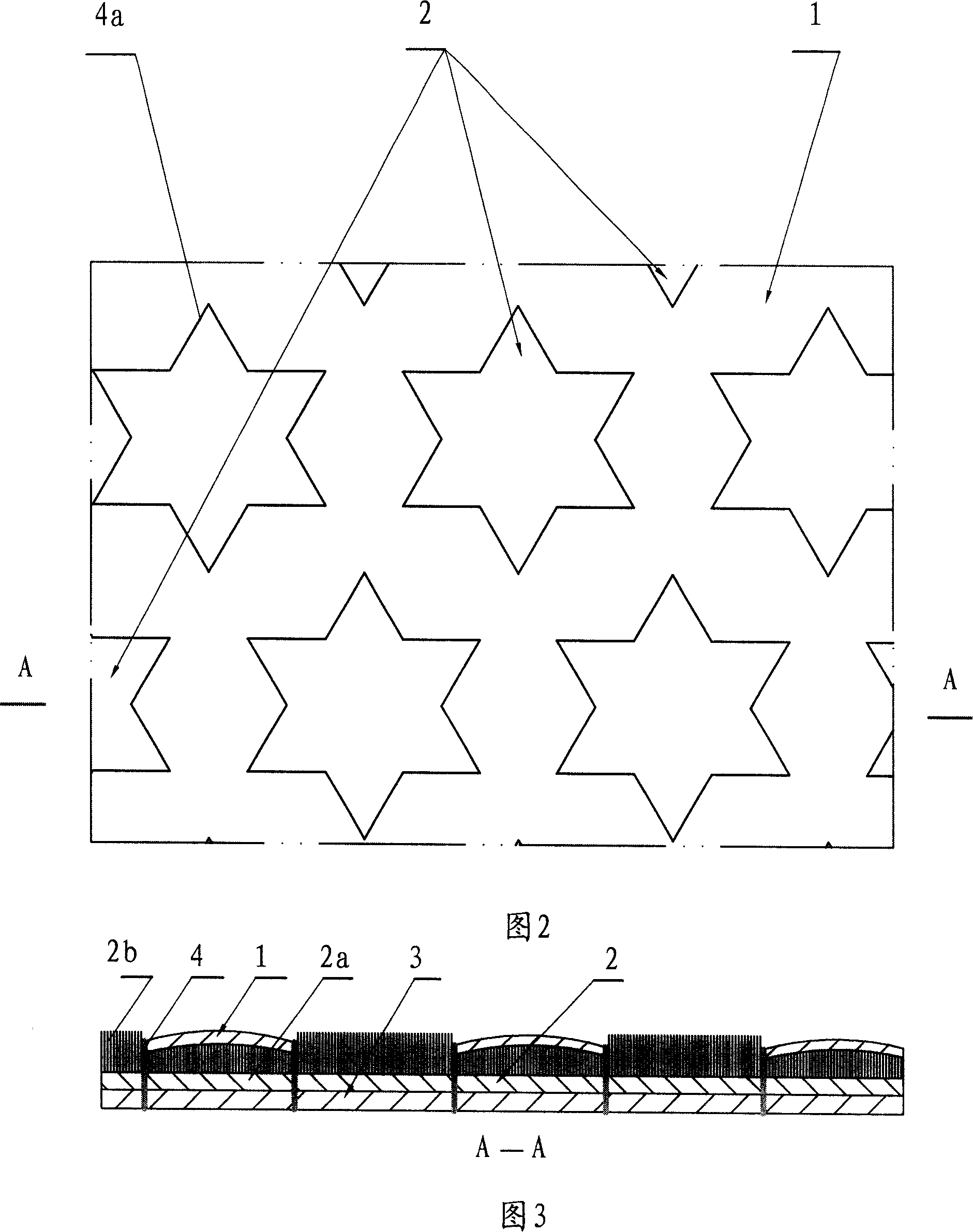

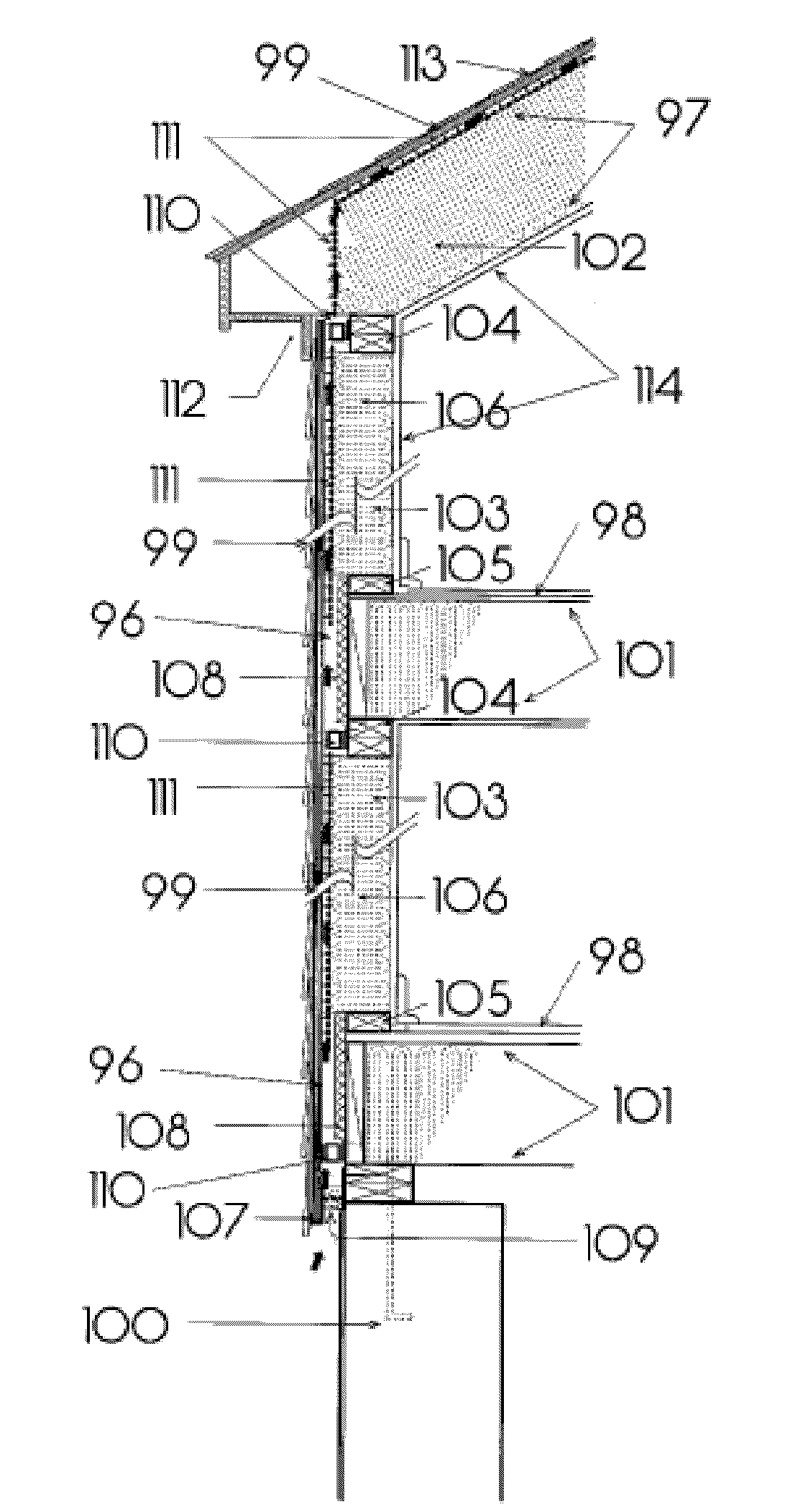

Structure for rigidly connecting solar panels to a fixture

InactiveUS20110302859A1Reduce water penetrationImprove sealingPhotovoltaic supportsSolar heating energyRoof pitchLinear element

A device for integrating solar panels on a fixture, in particular a roofing framework, that includes a plurality of frames intended to accommodate the solar panels, added to the fixture, said frames being defined by a peripheral edge fitted with linear elements that project relative to the plane in which the frames are set; tightening means for holding said panels on the frames; and means for securing the frames to the fixture. The frames are openwork and cover or partially overlap each other on the edges which define them, laterally on the one hand and in the direction of the roof pitch on the other hand, the projecting linear elements with which they are fitted cooperating with each other to form a barrier seal.

Owner:INSTITUT DE RECH FONDAMENTALE & TECH SOLAIRES - IRFTS

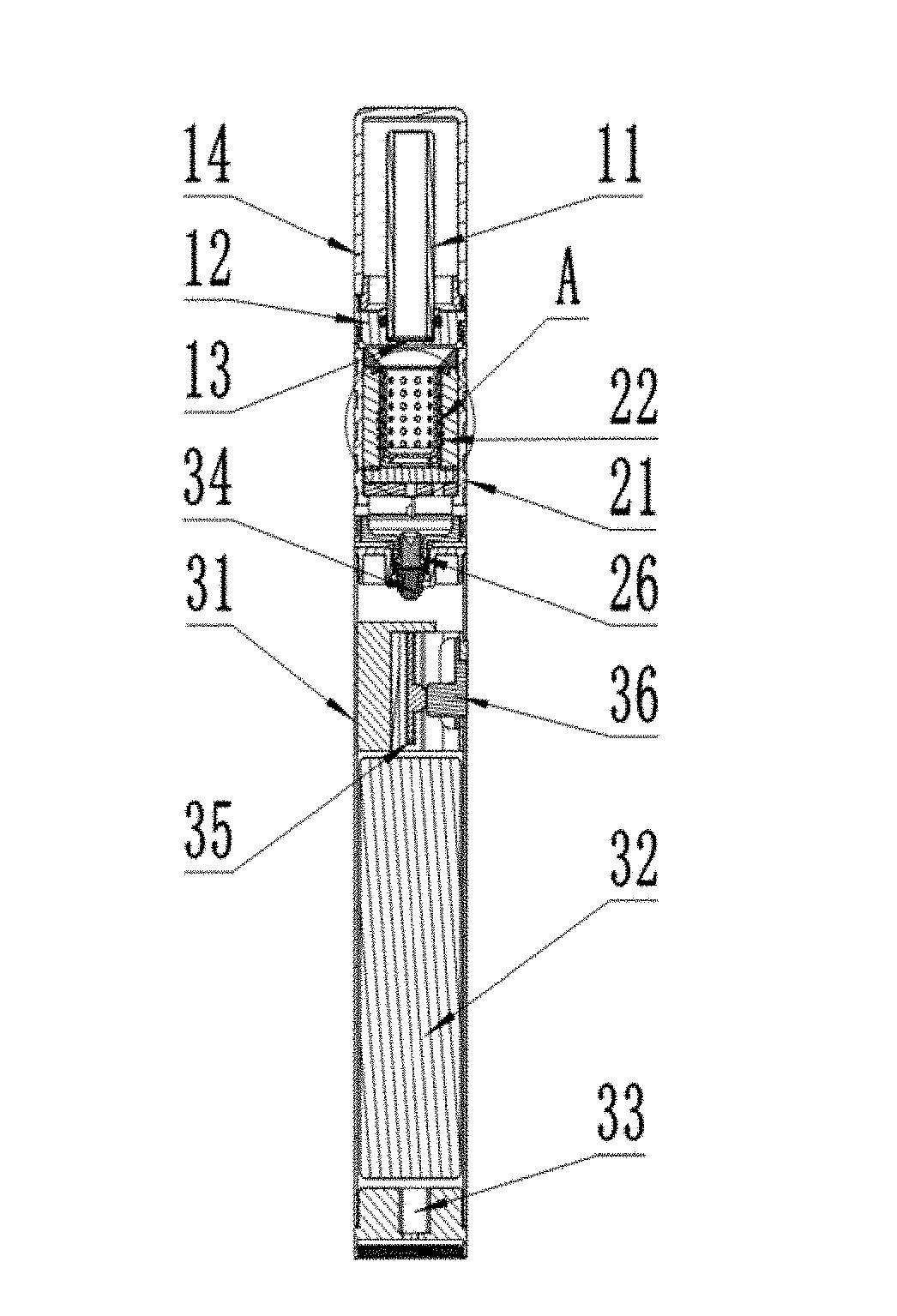

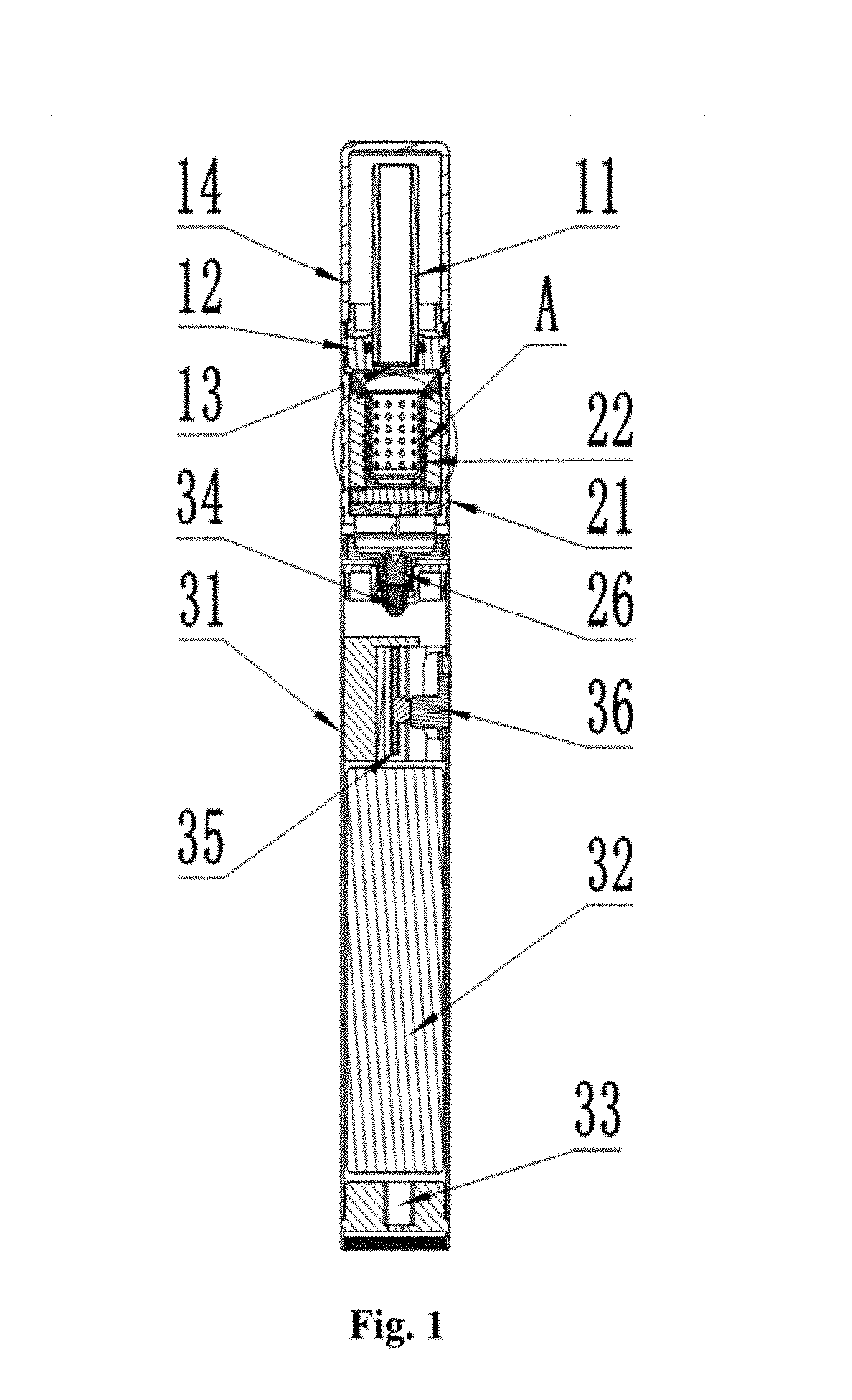

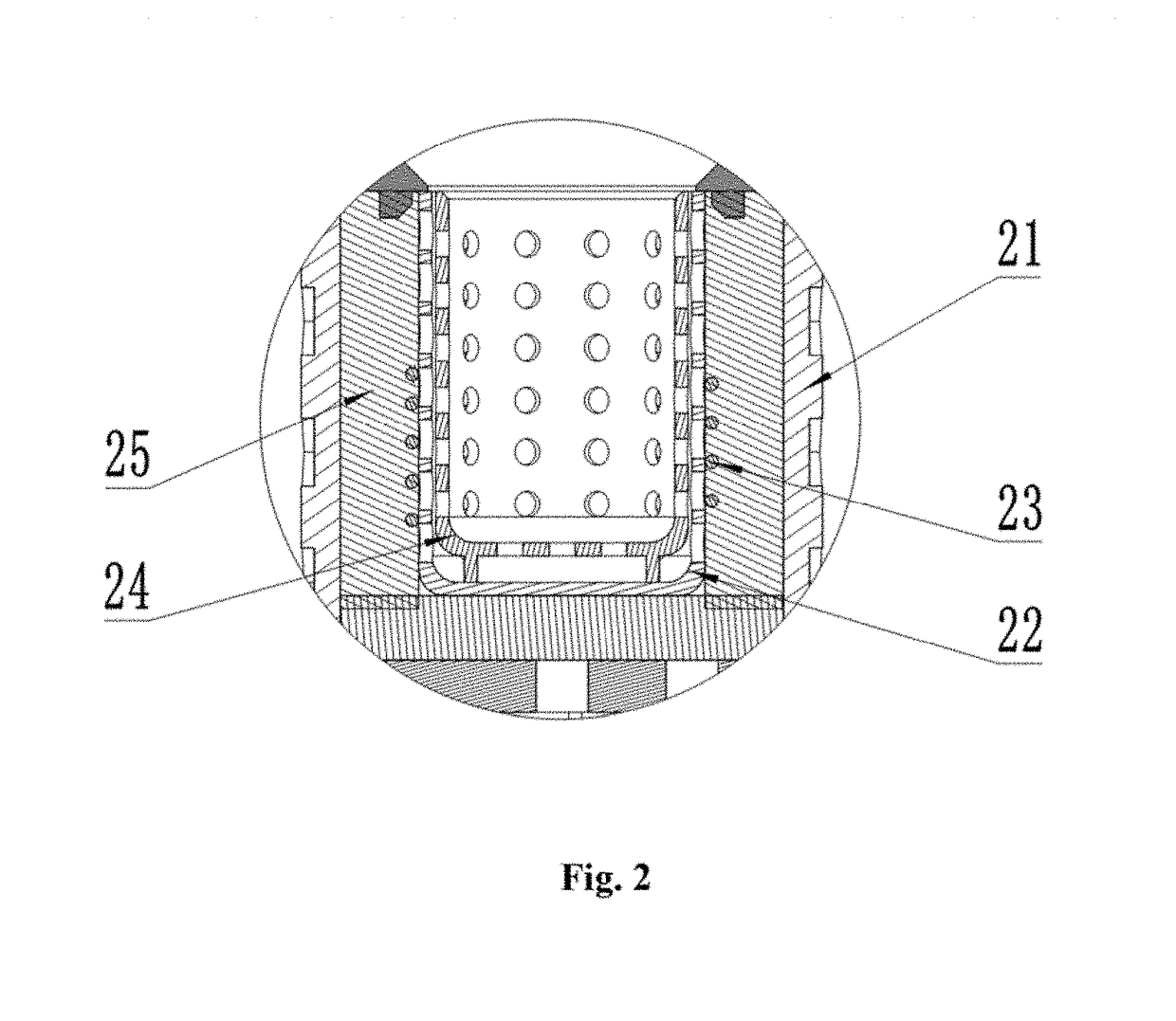

Annular stereoscopic-heating electronic cigarette with replaceable inner container

InactiveUS20170215474A1Evenly heatedProlonging smoking timeProgramme controlTobacco pipesNickel cadmiumEngineering

This invention provides an annular stereoscopic-heating electronic cigarette with replaceable inner container, comprising: a cylindrical electronic cigarette body; the electronic cigarette body comprises a smoke-filtering member, an annual stereoscopic-heating member and a heat-controlling member; wherein: the annual stereoscopic-heating member comprises an annual stereoscopic-heating casing, and an openwork member for conducting heat. A nickel cadmium (Ni-Cd) heating coil is spirally wind around and firmly contacts the exterior surface of the open member. A replaceable shredded tobacco inner container is sleeved within the openwork member. The exterior of the Ni-Cd heating coil and the bottom of the openwork member are respectively wrapped around by an asbestos heat-insulating layer. A short-circuit contactor is set at the bottom of the annular stereoscopic-heating casing and connects to the Ni-Cd beating coil.

Owner:LRIDER TECH CO LTD

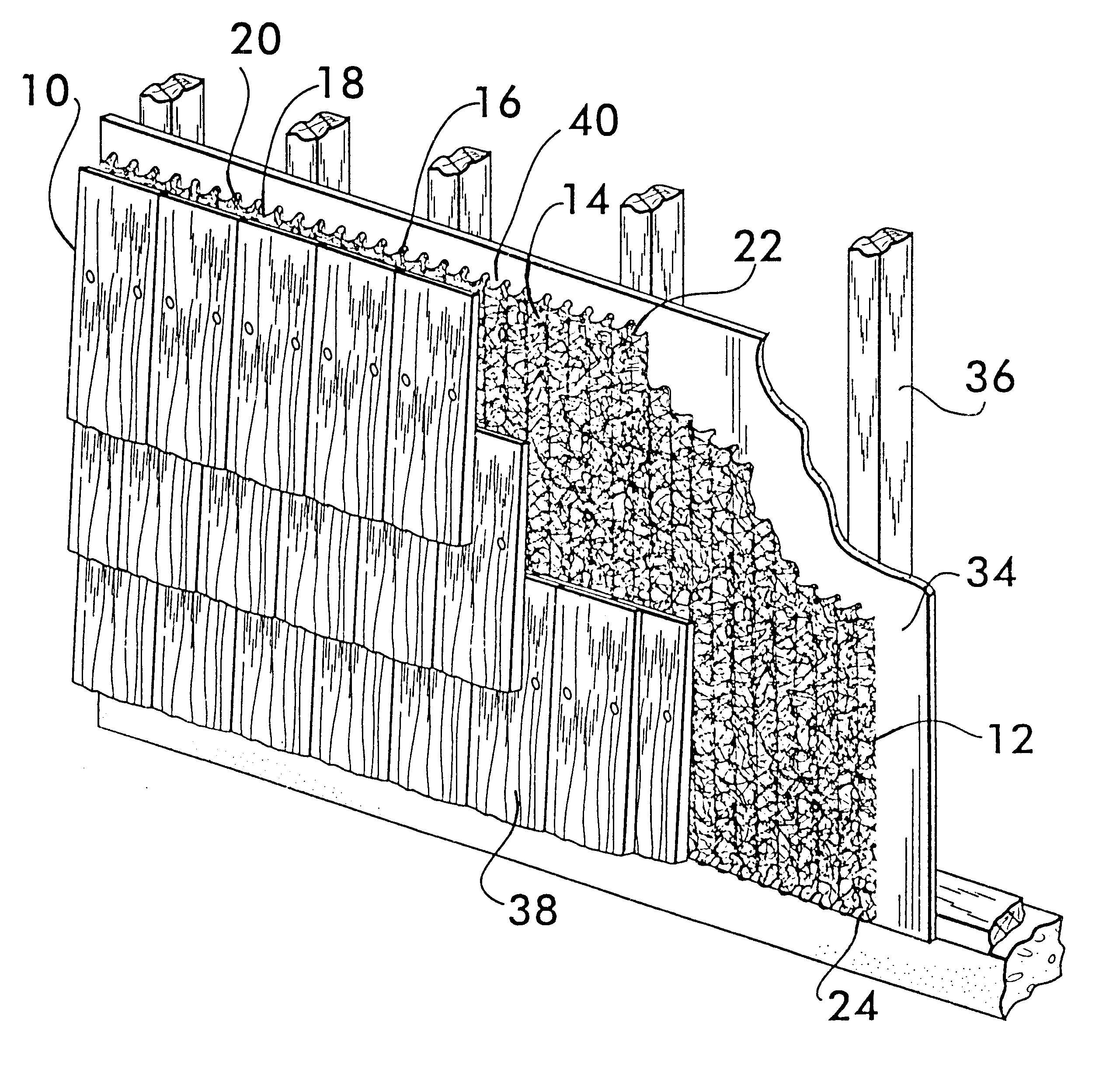

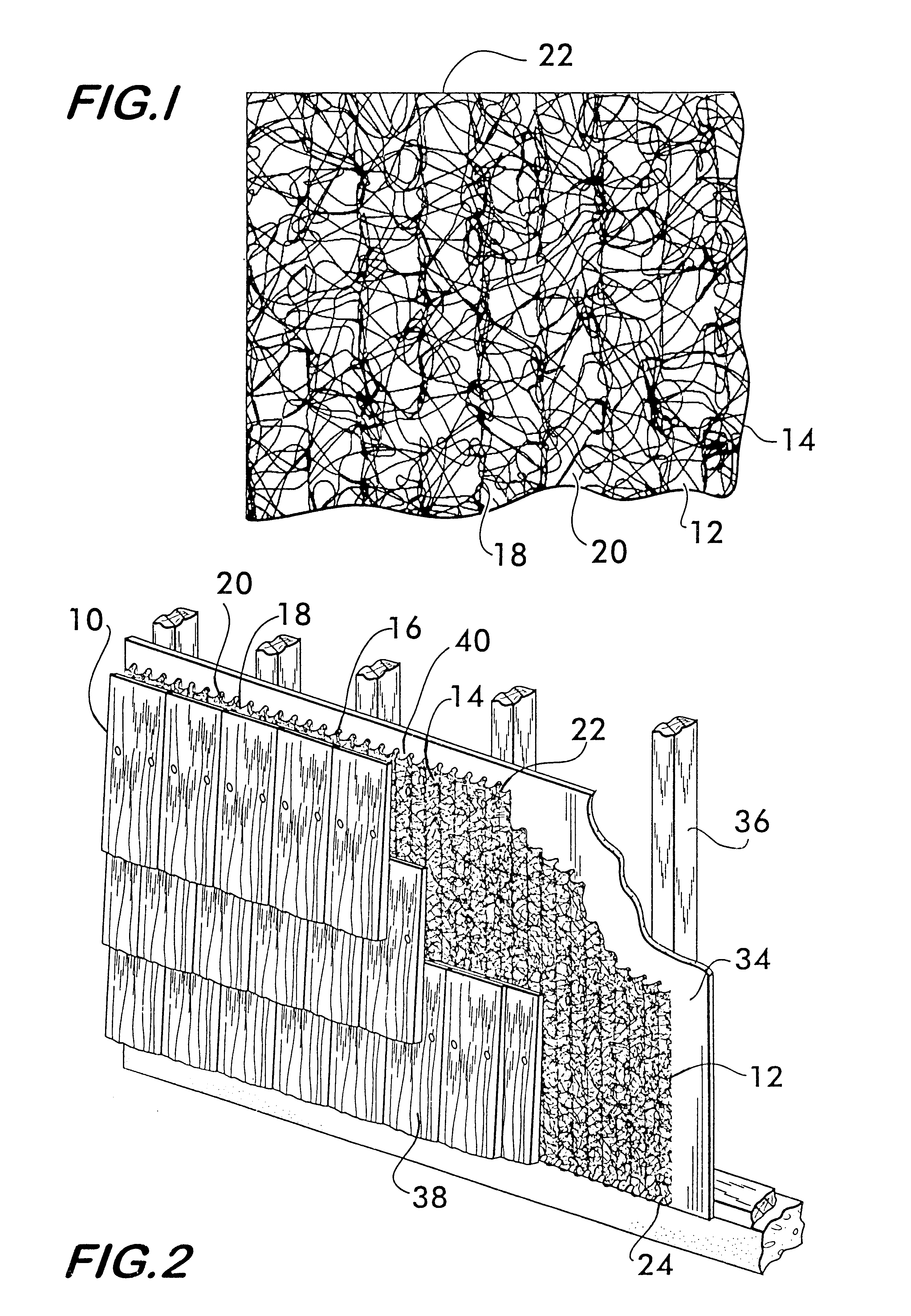

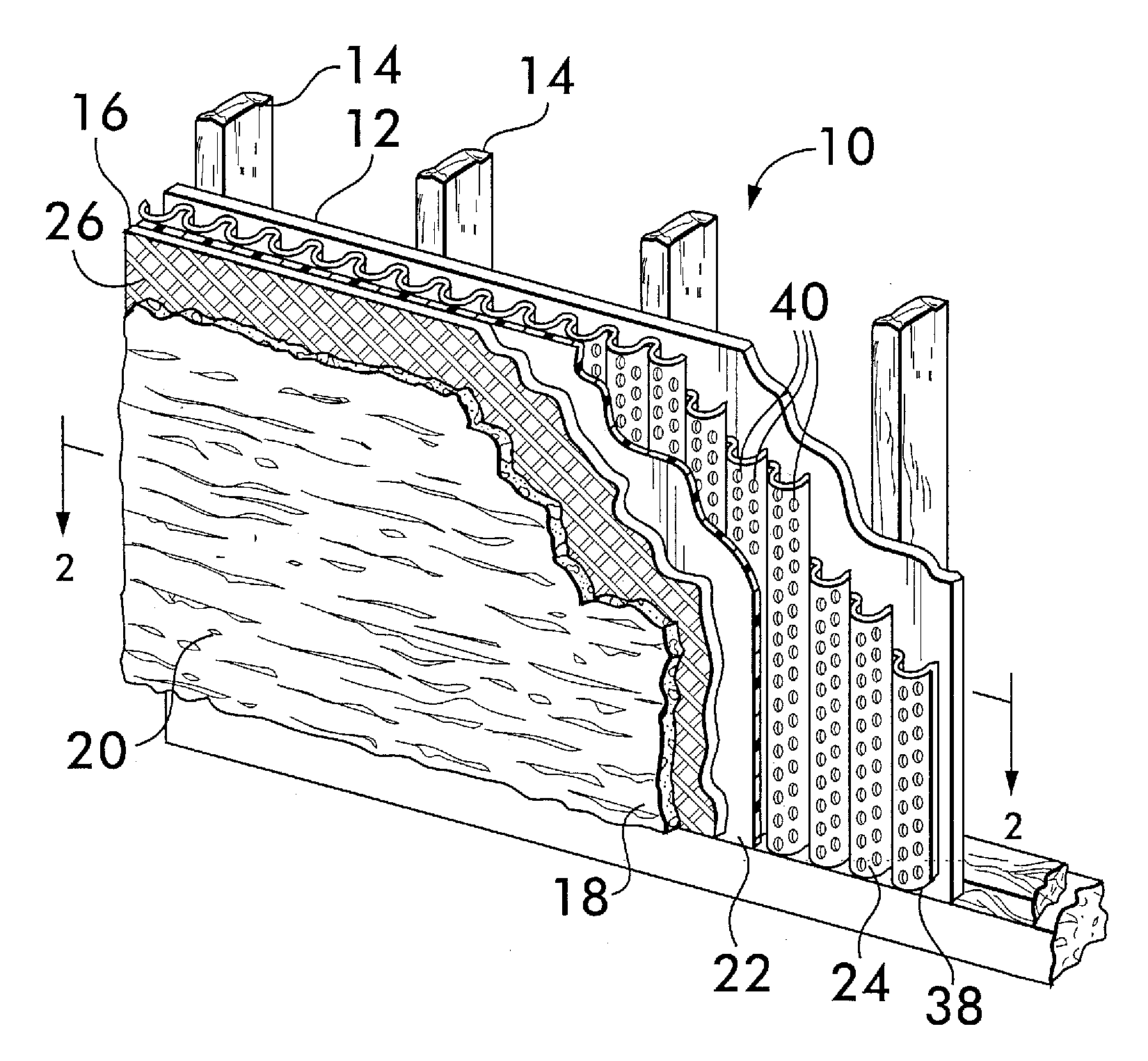

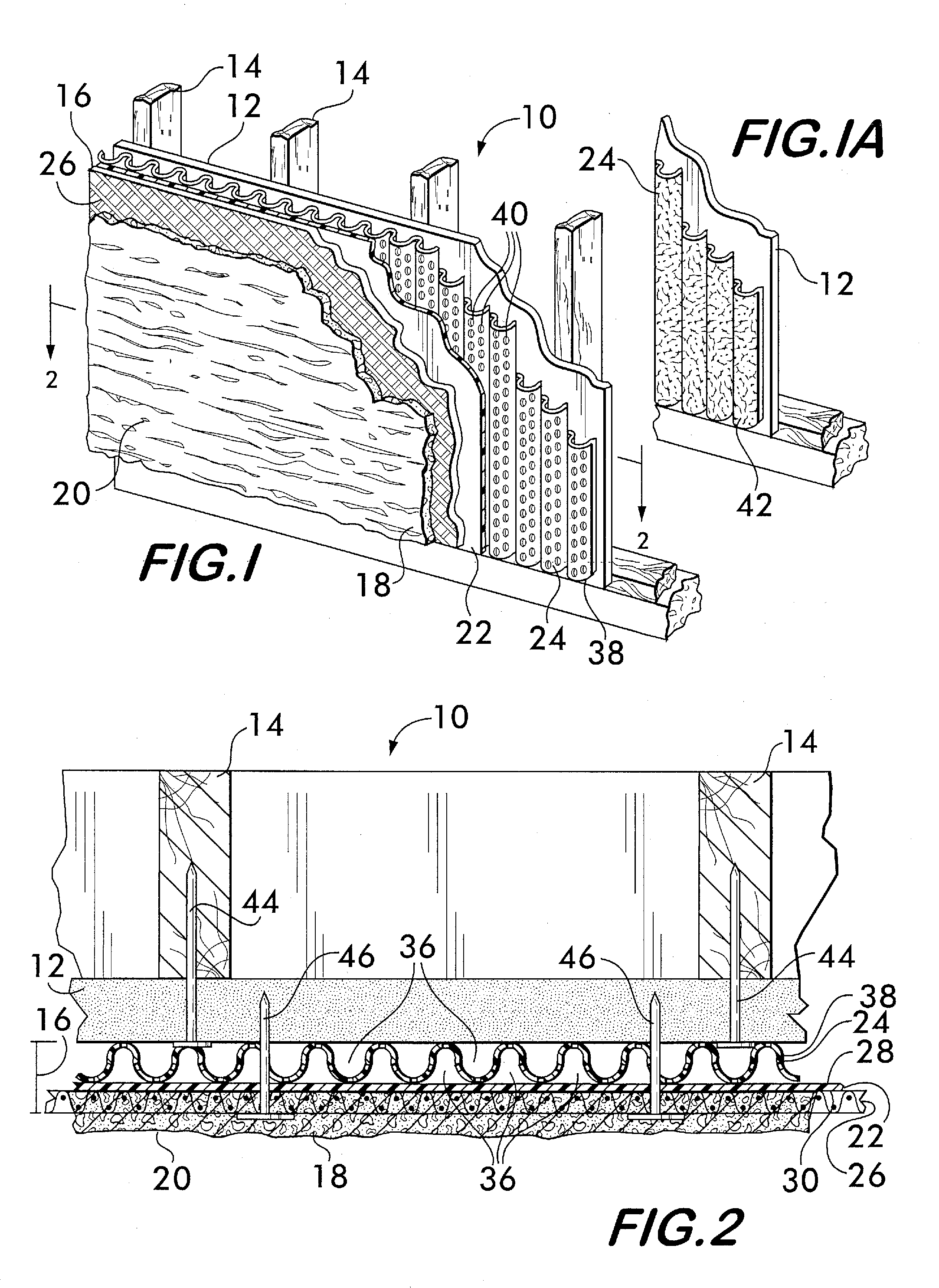

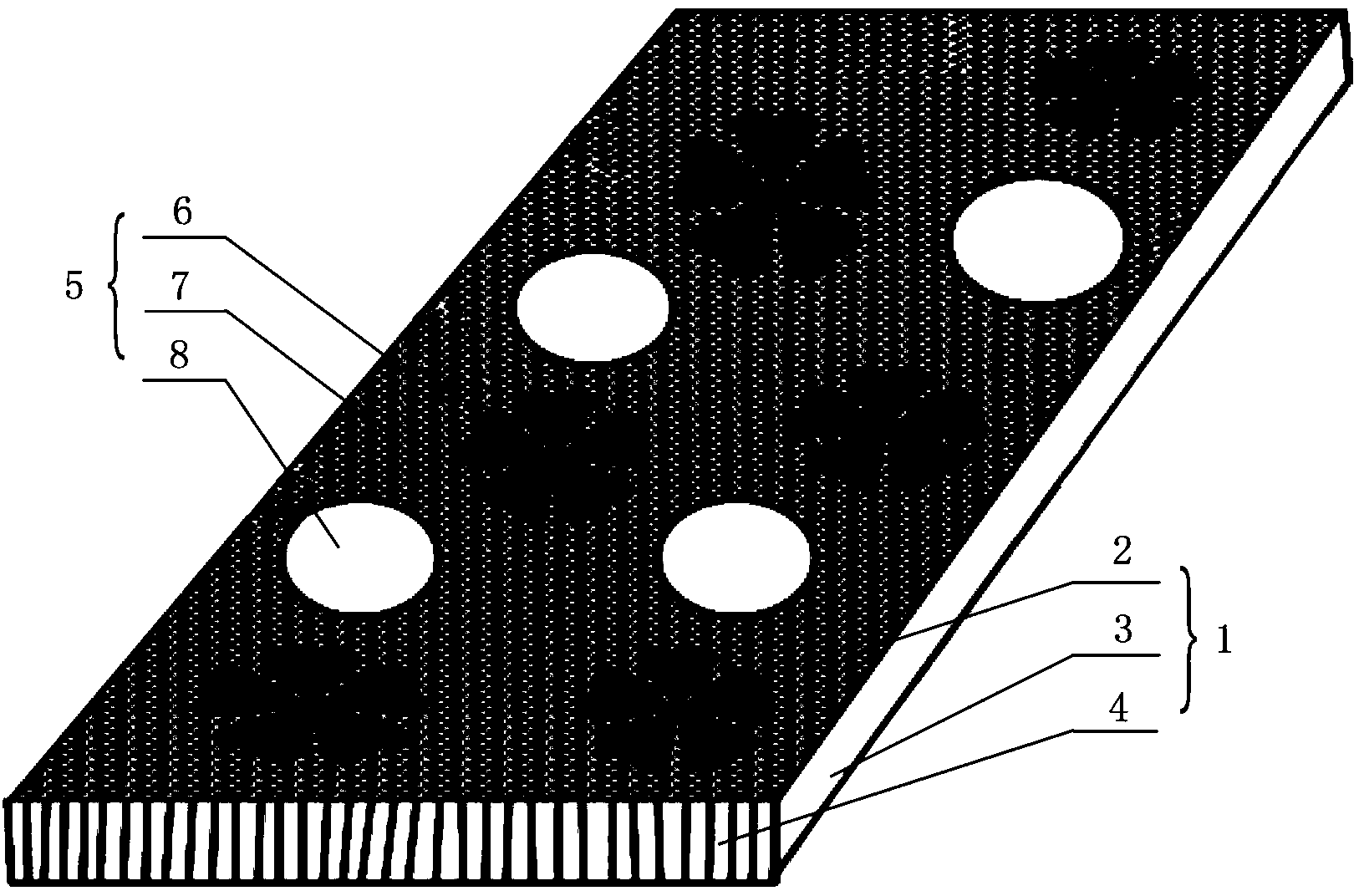

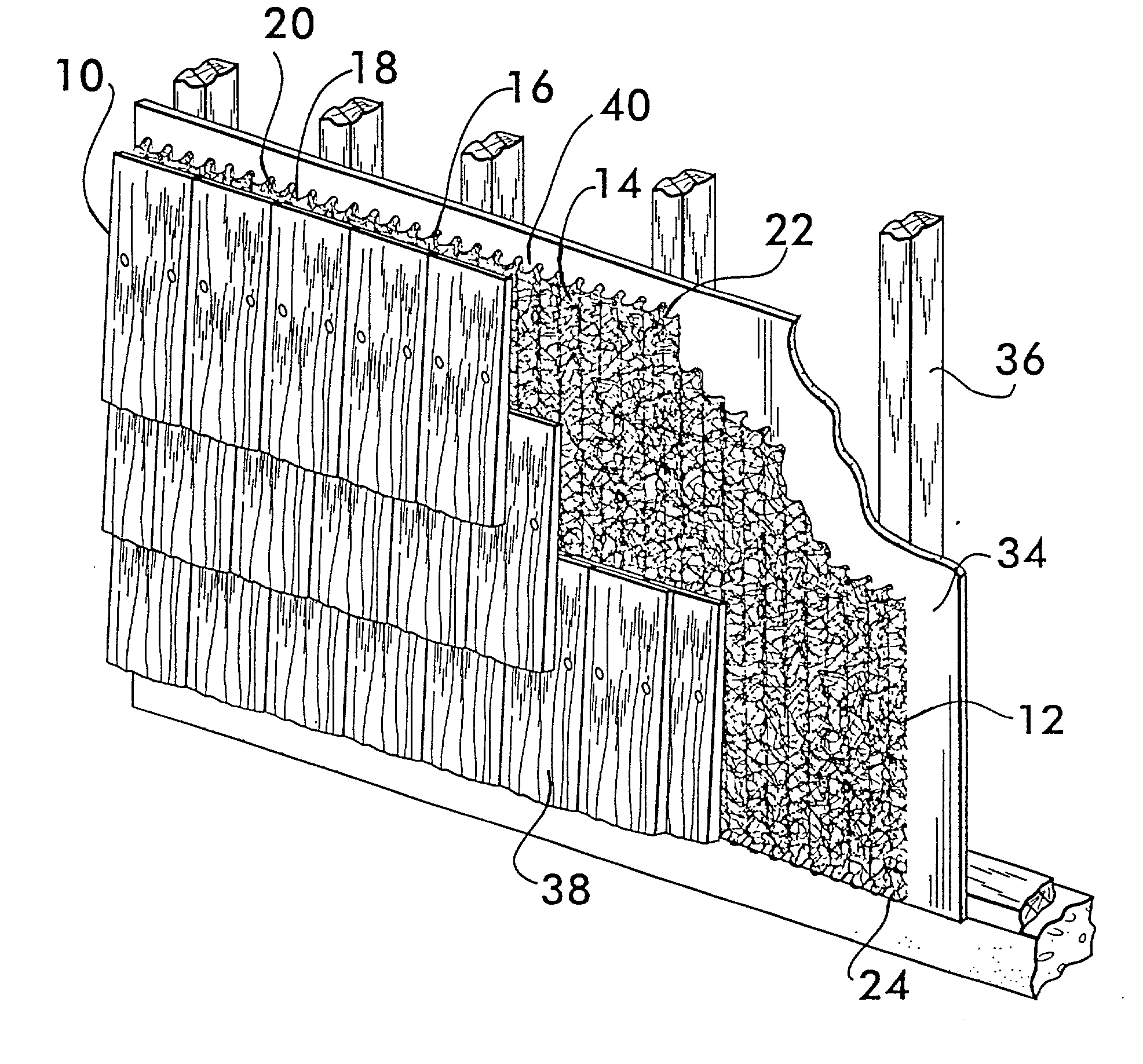

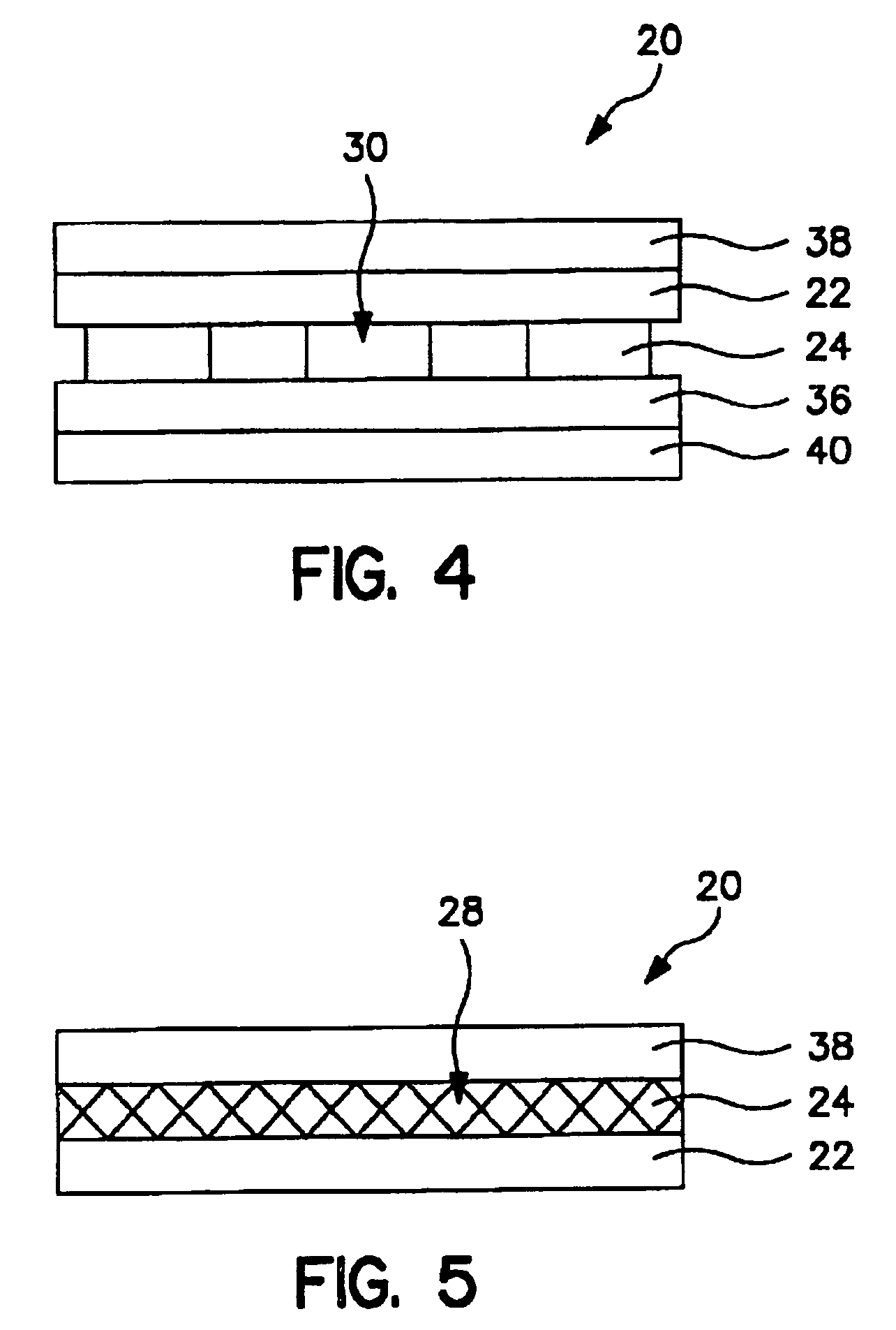

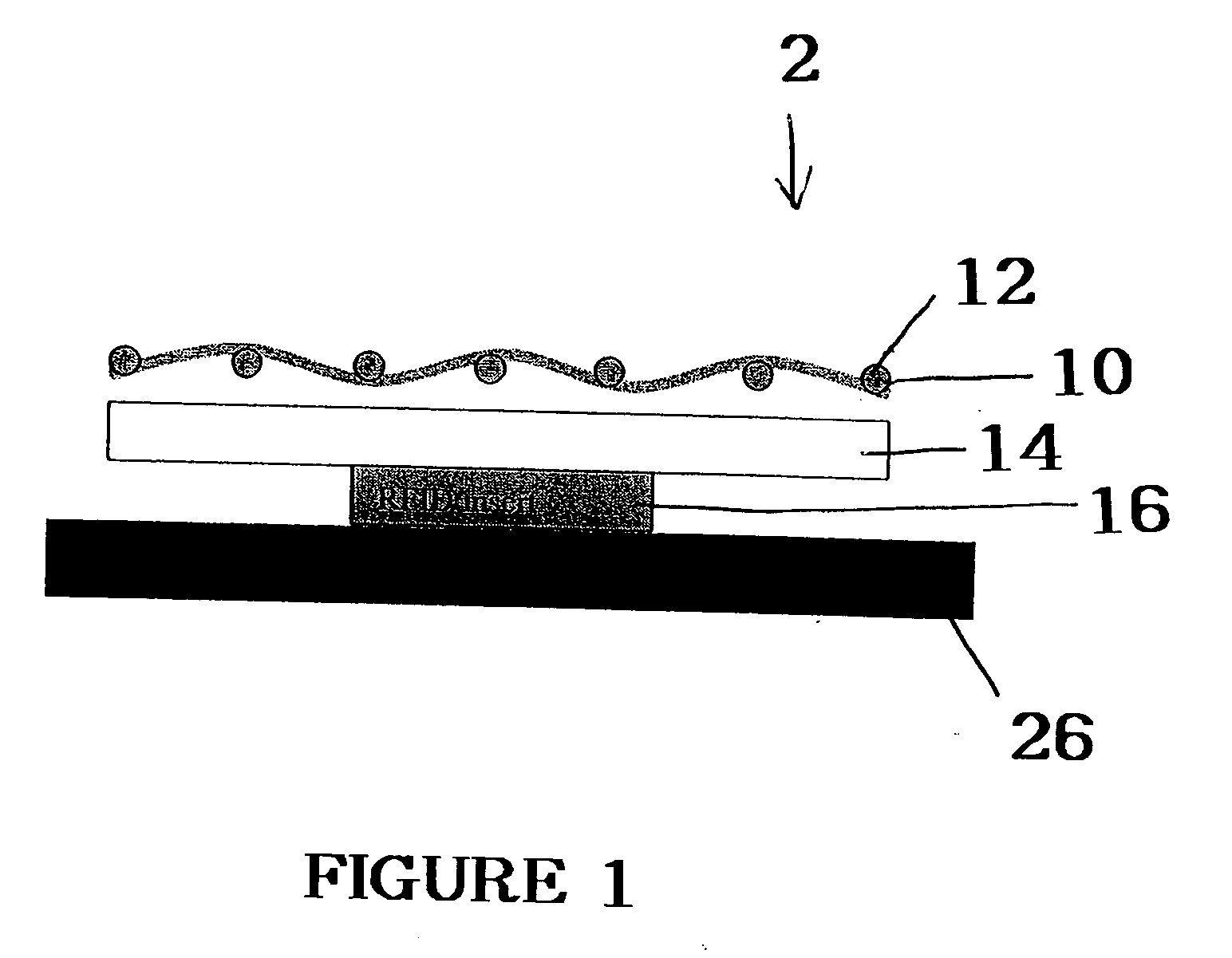

Composite Building Material for Cementitious Material Wall Assembly

A composite building material includes at least one membrane, a spacer material bonded to one face of the membrane, and a lath bonded to an opposite face of the membrane. The components of the composite building material are installed simultaneously as an integral unit within a wall, roof or like assembly. The lath is preferably made of plastic or metal and is used to support cementitious material such as stucco, mortar, plaster, concrete and the like. The spacer material provides ventilation and drainage passages and is preferably provided as separate or integrally-formed spacer elements, an openwork mat, a corrugated material, or the like. Preferably, the membrane is building paper, tar paper, roofing felt, house-wrap material or like weather-resistive material. A wall / roof assembly and a method of assembling a wall / roof structure are also disclosed.

Owner:BENJAMIN OBDIKE

Three-dimensional jacquard sandwich fabric

The invention discloses three-dimensional jacquard sandwich fabric. The fabric comprises an upper layer structure, a lower layer structure and a middle layer structure, wherein the upper layer structure and the lower layer structure form a transparent bottom cloth which is knitted by transparent micro-thin filaments; the middle layer structure adopts synthetic multi-filaments with certain elasticity as a woven material; the synthetic multi-filaments are combined according to certain patterns, so as to form various floral designs by adopting needle front and needle back migration of a jacquard needle; the fabric surface is exposed through the transparent upper layer bottom cloth and lower layer bottom cloth; the embossing jacquard effect is formed on the surface, thereby generating a good effect of hollow three-dimensional patterns in a three-dimensional structure. The fabric disclosed by the invention is strong in pattern stereo perception, and is mainly applied to the fields such as lady brassieres and shoe materials; the hand feeling, the comfort and the functionality of the fabric are obviously improved.

Owner:JIANGNAN UNIV

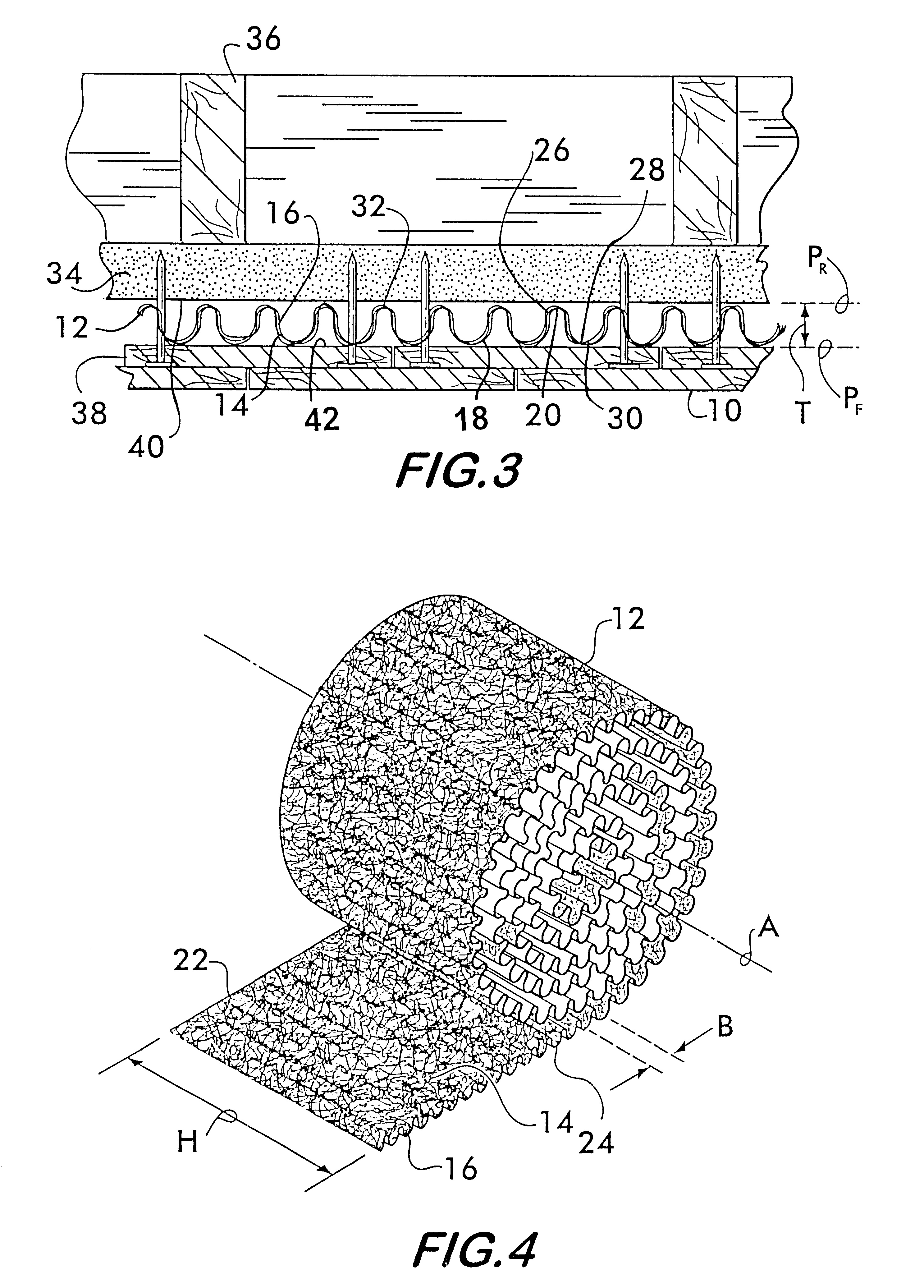

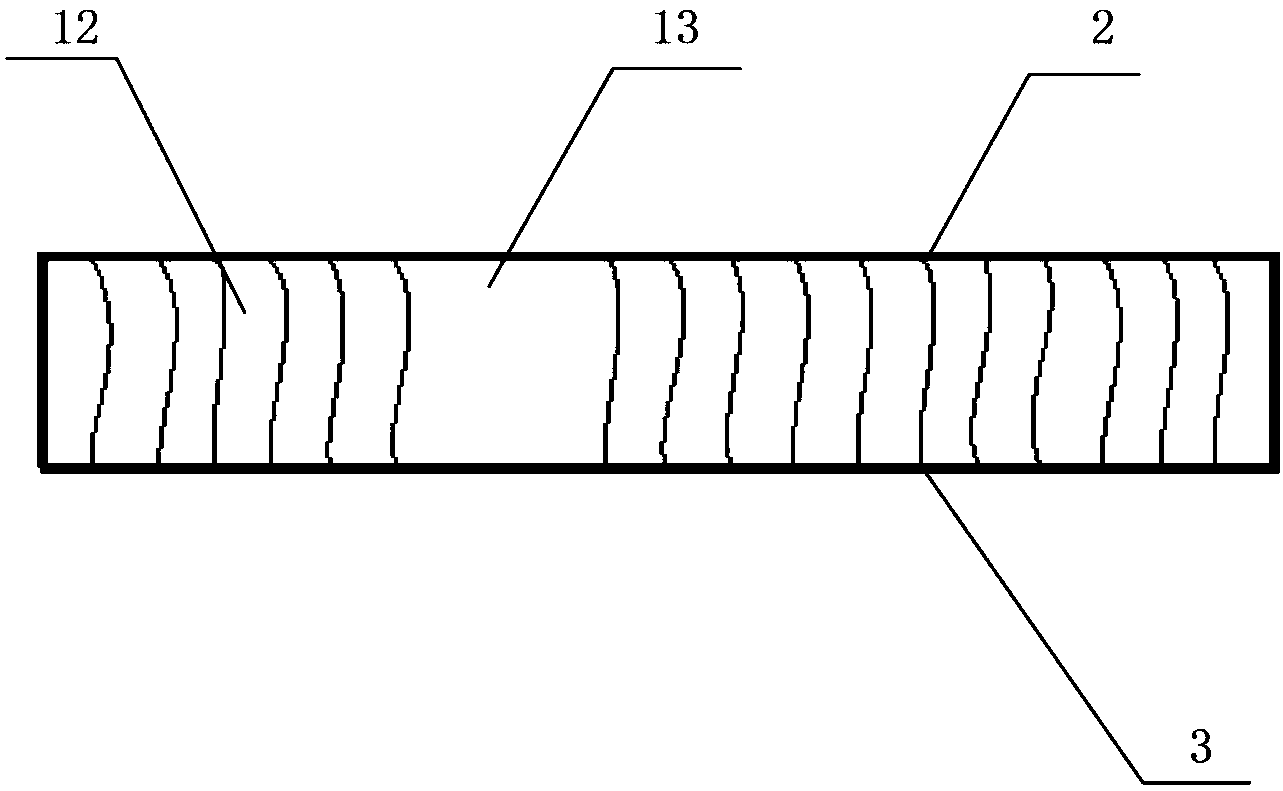

Spacer for providing drainage passageways within building structures

InactiveUS20030037499A1Easy to installEfficient and economicalLighting and heating apparatusBuilding repairsMoistureMechanical engineering

A roll-form spacer product providing air space and drainage passageways within a building structure. Preferably, the spacer product is a corrugated web of material having undulating front and rear faces and serpentine-shaped longitudinally extending edges. The faces include alternating arrays of grooves and ridges which extend perpendicular to the side edges and parallel to an axis of a spiral roll of the spacer. Thus, when the spacer is unrolled and applied to a building structure in a plurality of horizontally extending rows, the ridges and grooves are substantially vertically-disposed to form a plurality of unobstructed passageways for the drainage of moisture. Preferably, the web is made of an openwork mat of randomly convoluted polymeric filaments, and thus, enables ready circulation of air.

Owner:BENJAMIN OBDIKE

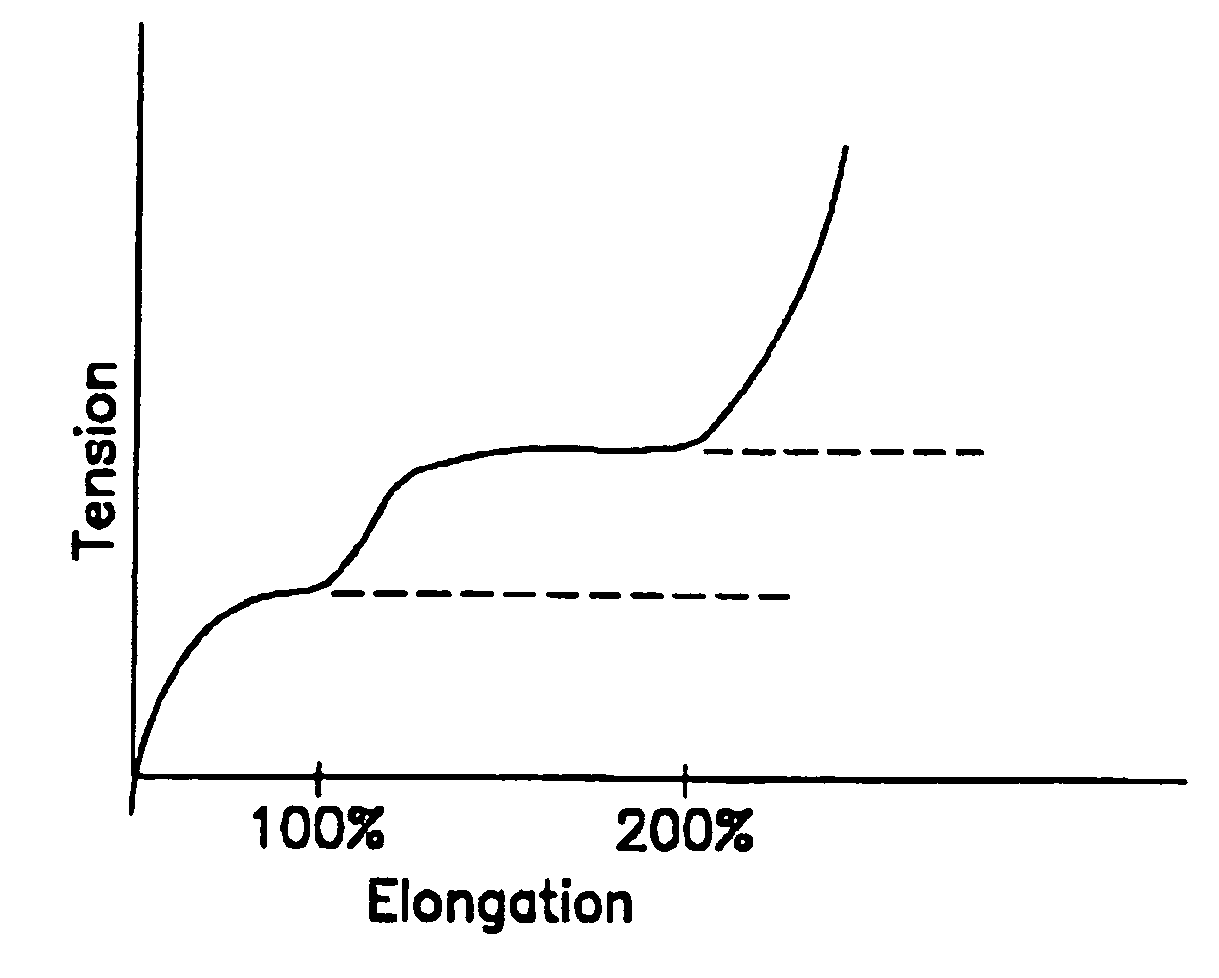

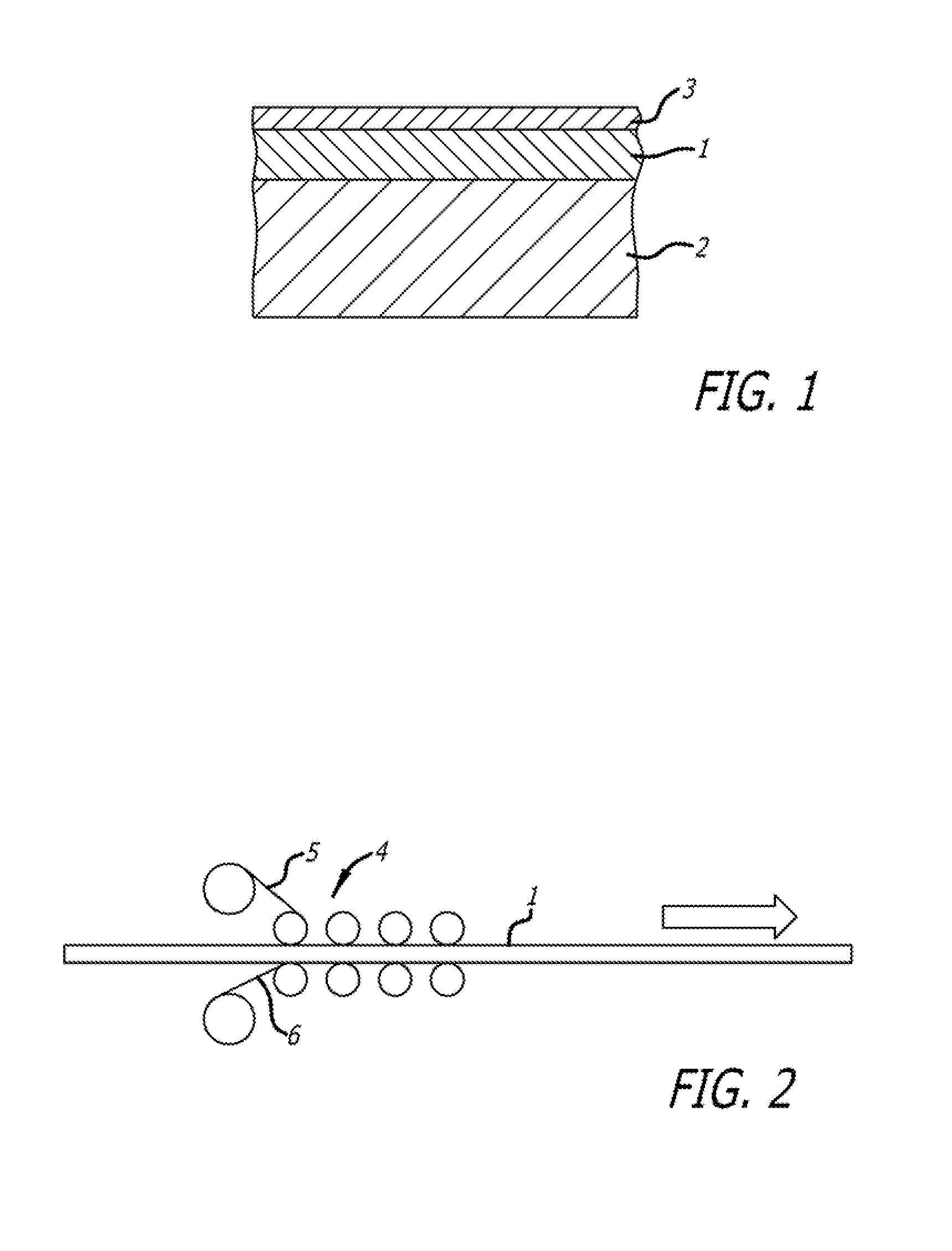

Stretchable film laminates and methods and apparatus for making stretchable film laminates

Stretchable film laminates including a layer of elastomeric openwork, such as a plurality of elastic strands or an elastomeric mesh structure. The stretchable film laminates may include a film layer bonded to the layer of elastomeric openwork, with the film layer having cross-directional stretch and the laminate having a multi-phase stretchability profile. The stretchable film laminates may be made by extruding a film from a die, stretching the film, forming and stretching a layer of elastomeric openwork, conveying the stretched elastomeric openwork onto the film while the film is stretched, and passing the film and the elastomeric openwork through a nip. The invention also includes a machine capable of producing machine-direction, cross-direction, and biaxial stretch materials. The machine includes at least one extruder, at least one filament die and at least one film die both attached to the extruder(s), and at least one nip downstream of the extruder(s).

Owner:KIMBERLY-CLARK WORLDWIDE INC

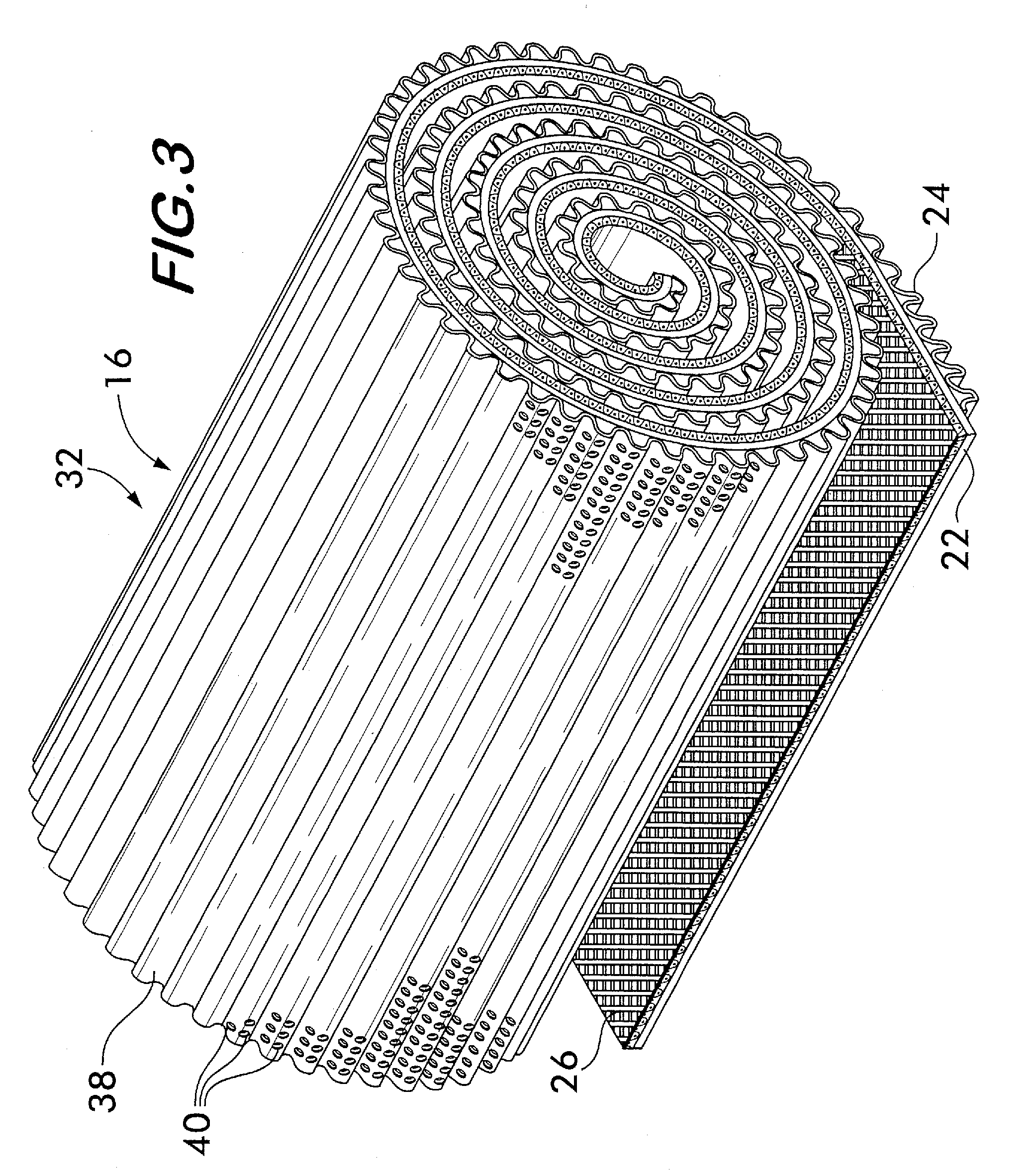

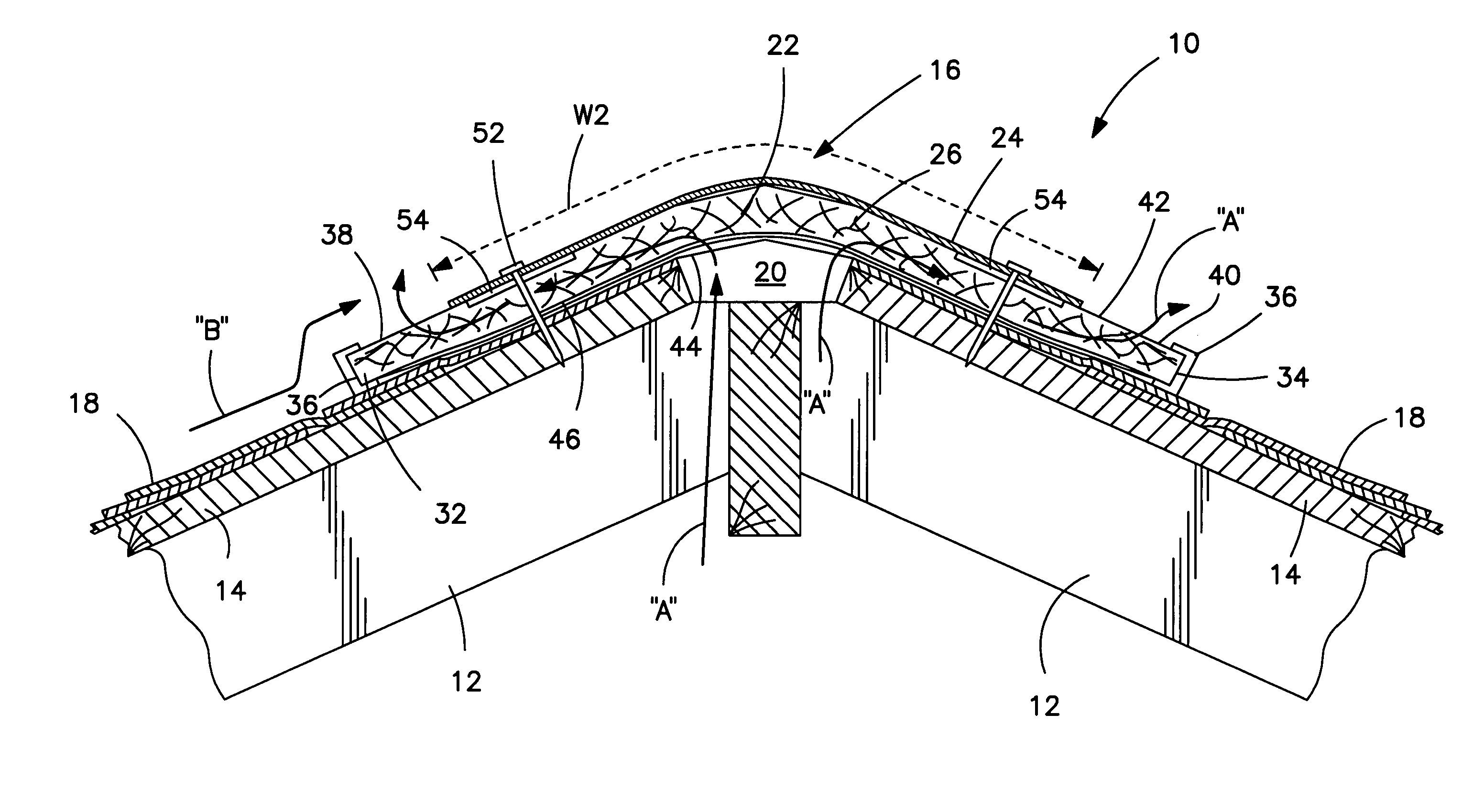

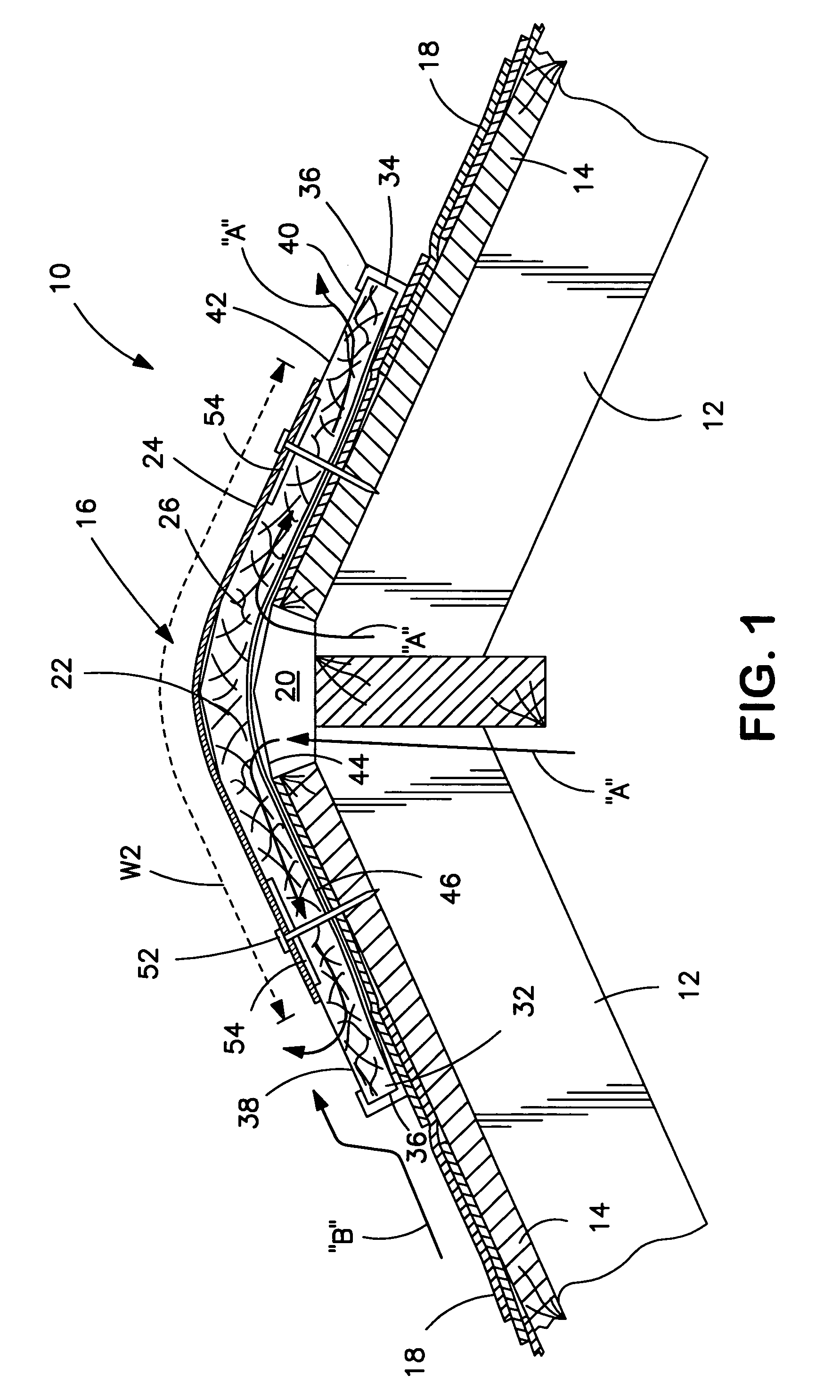

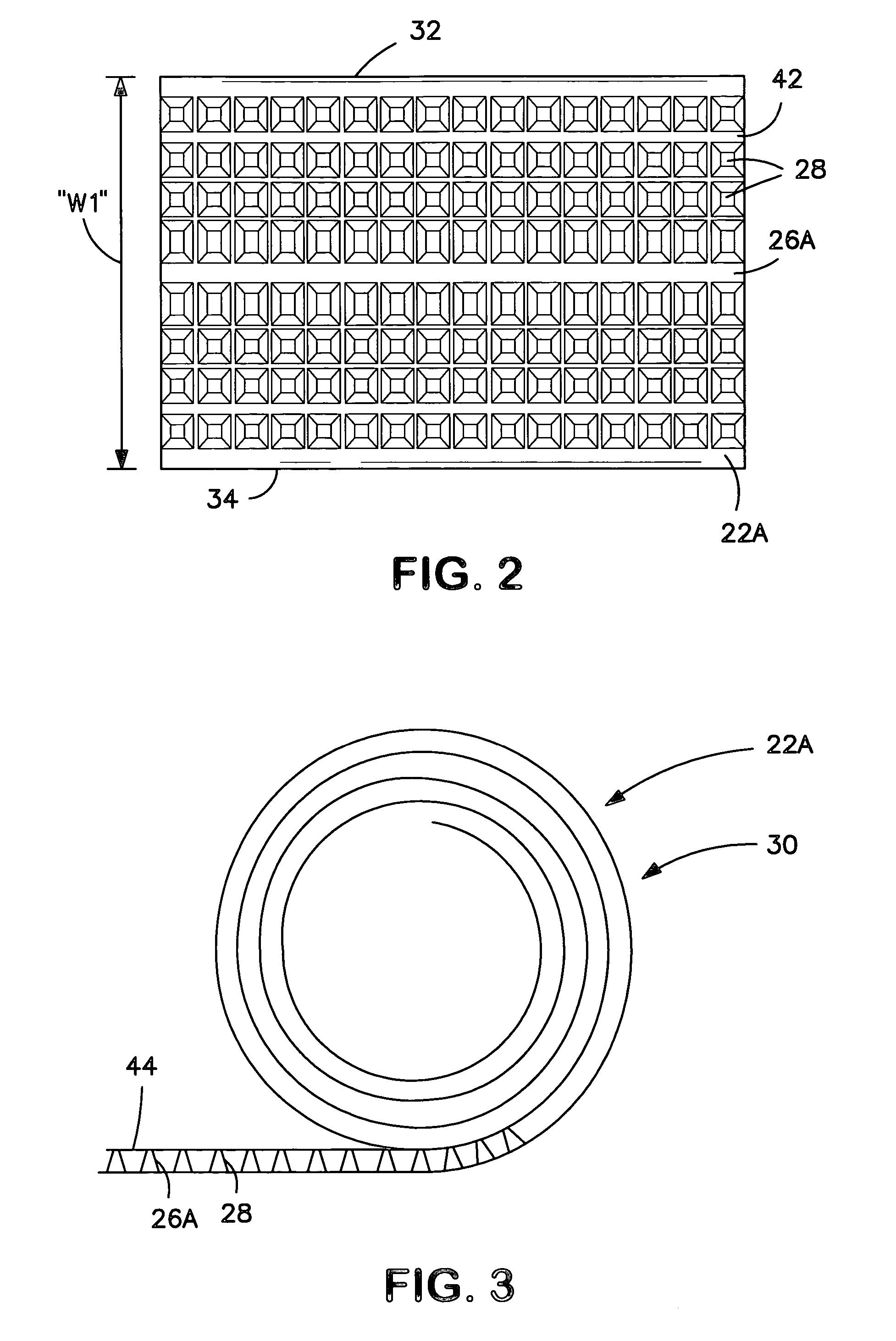

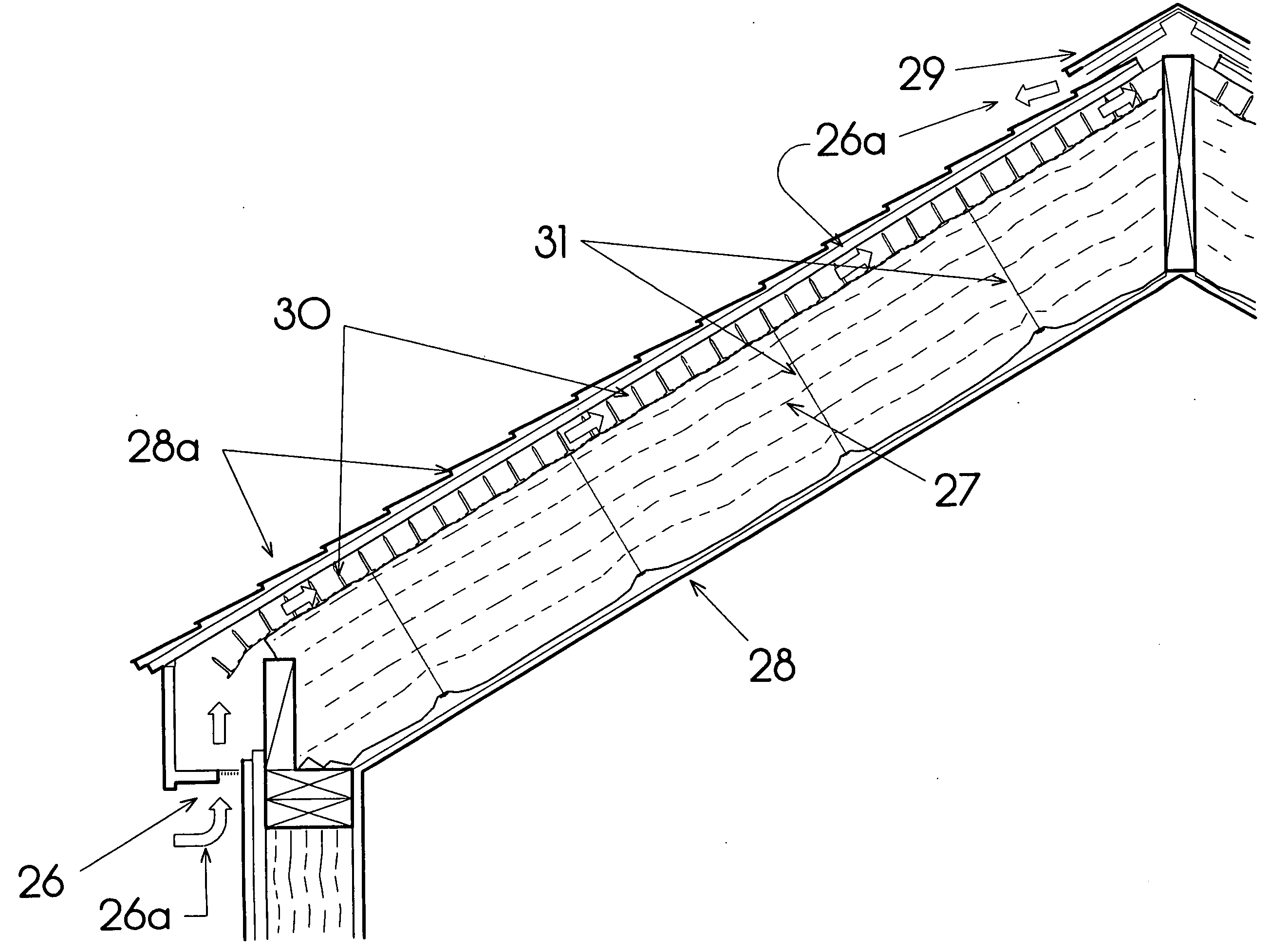

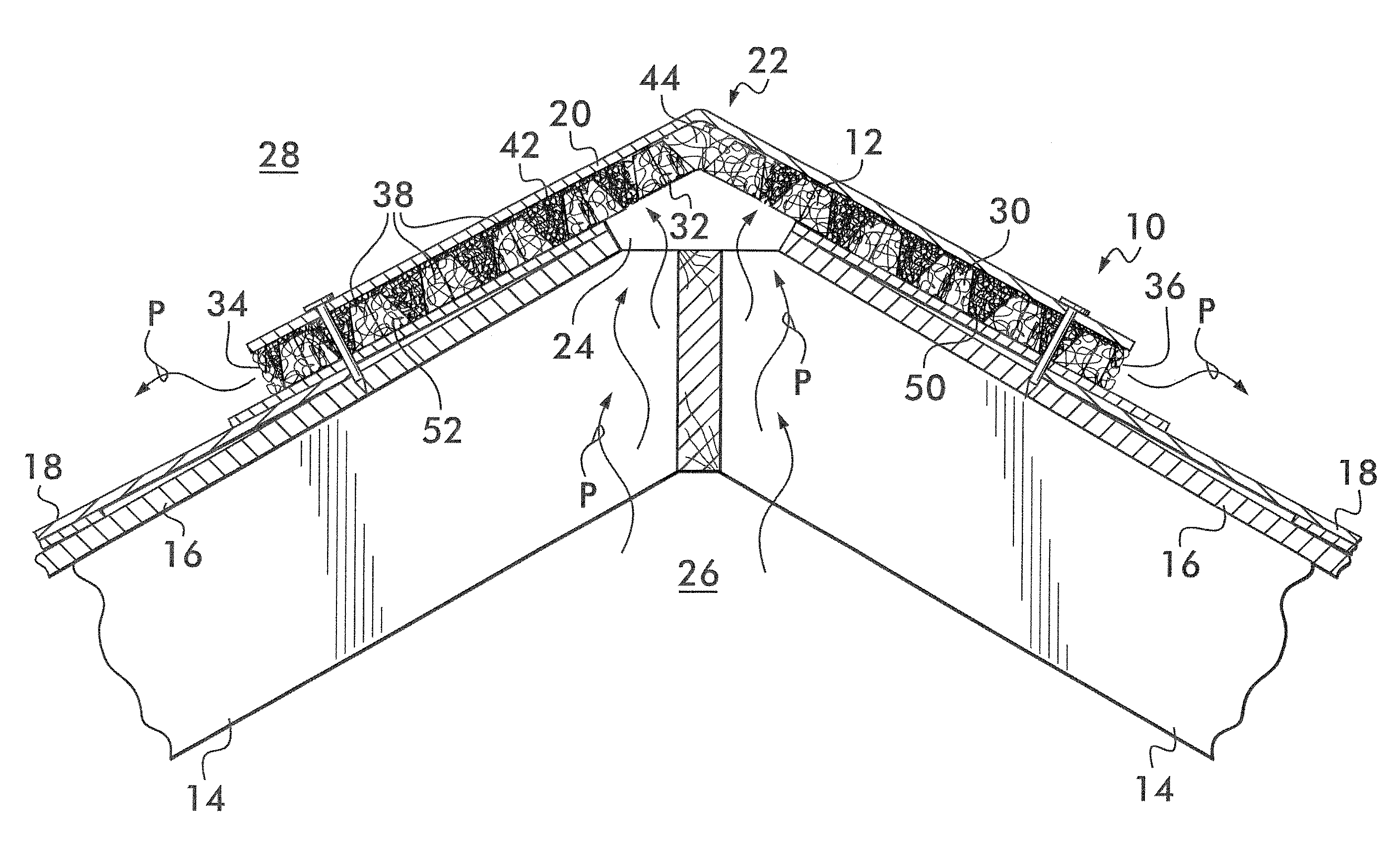

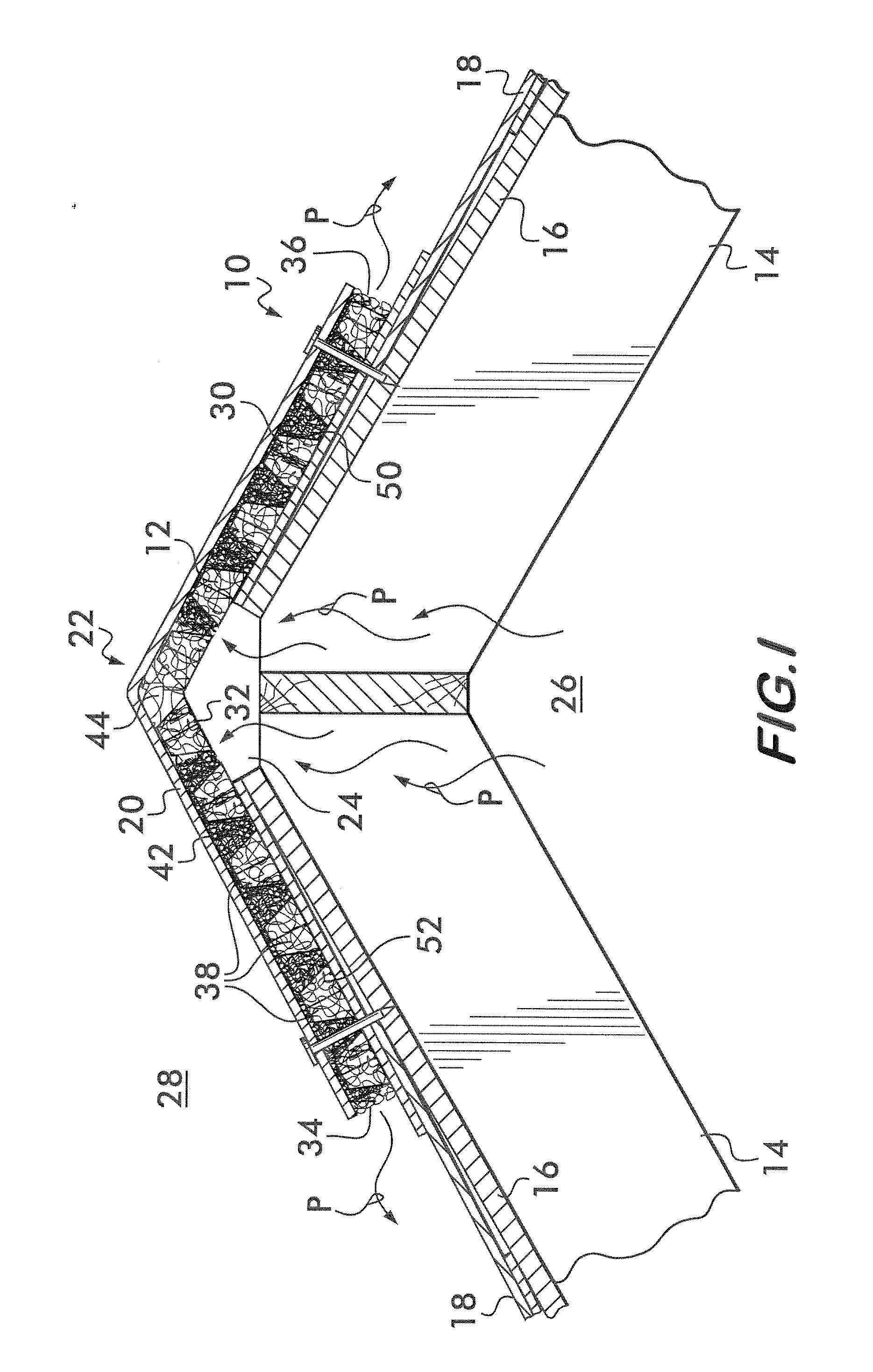

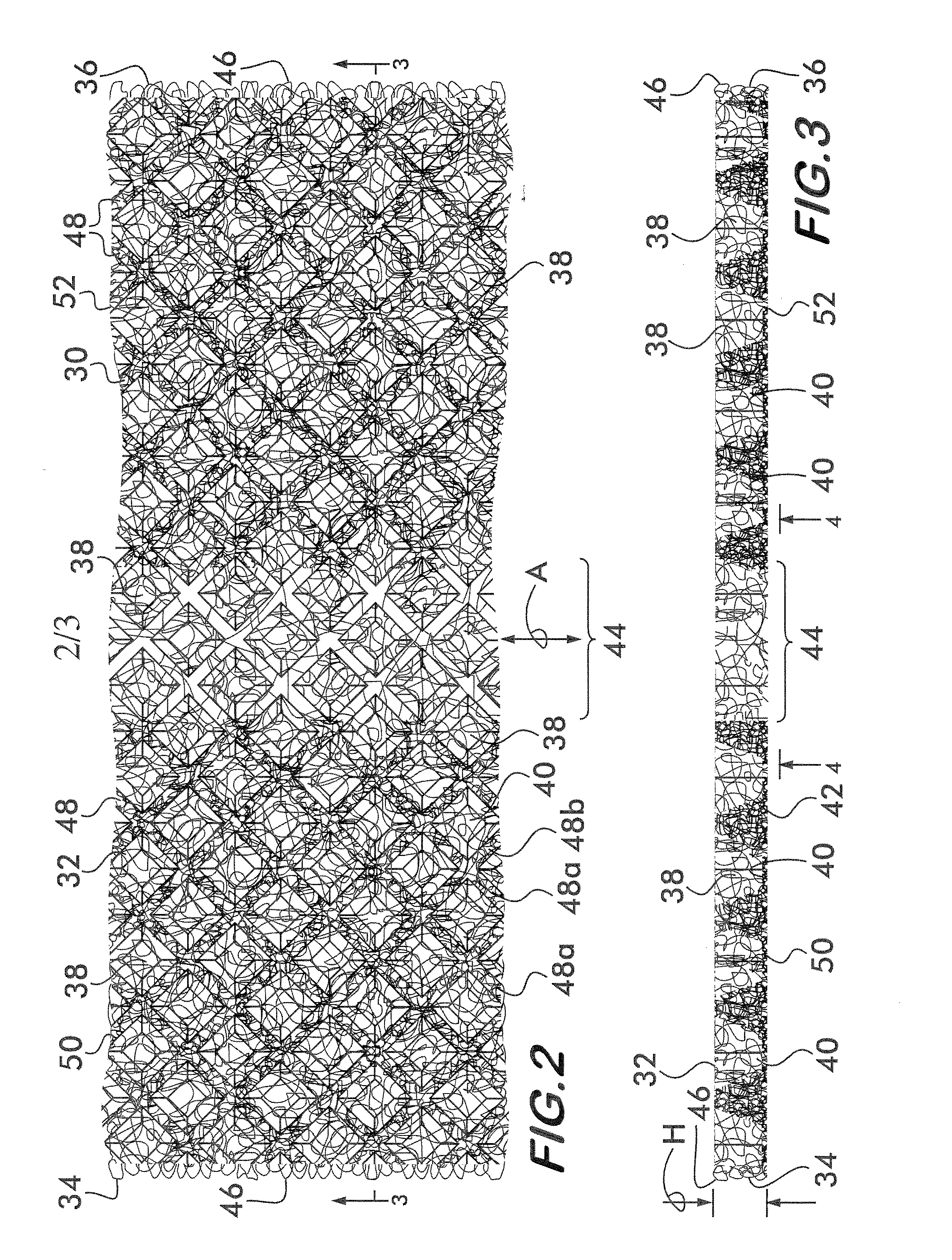

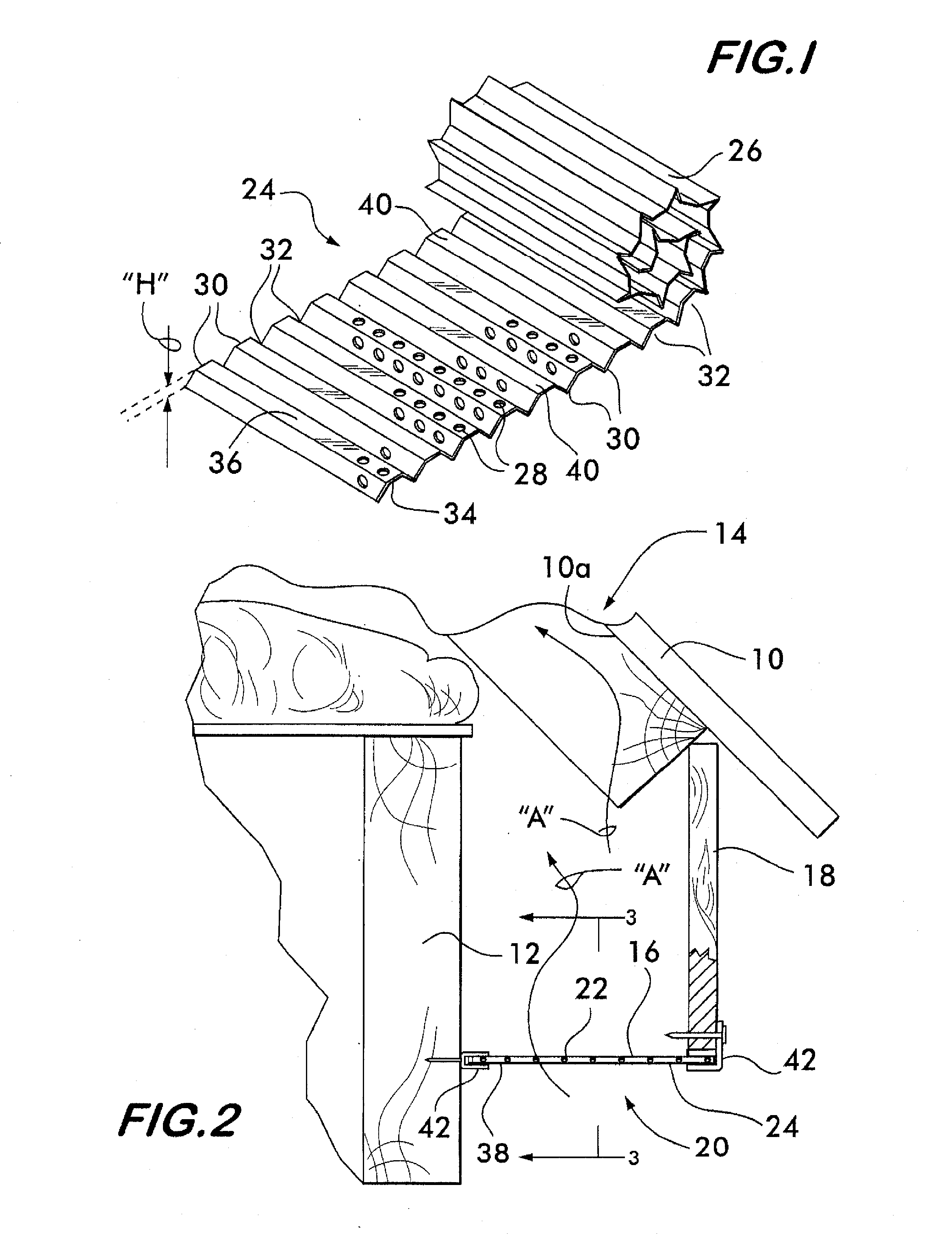

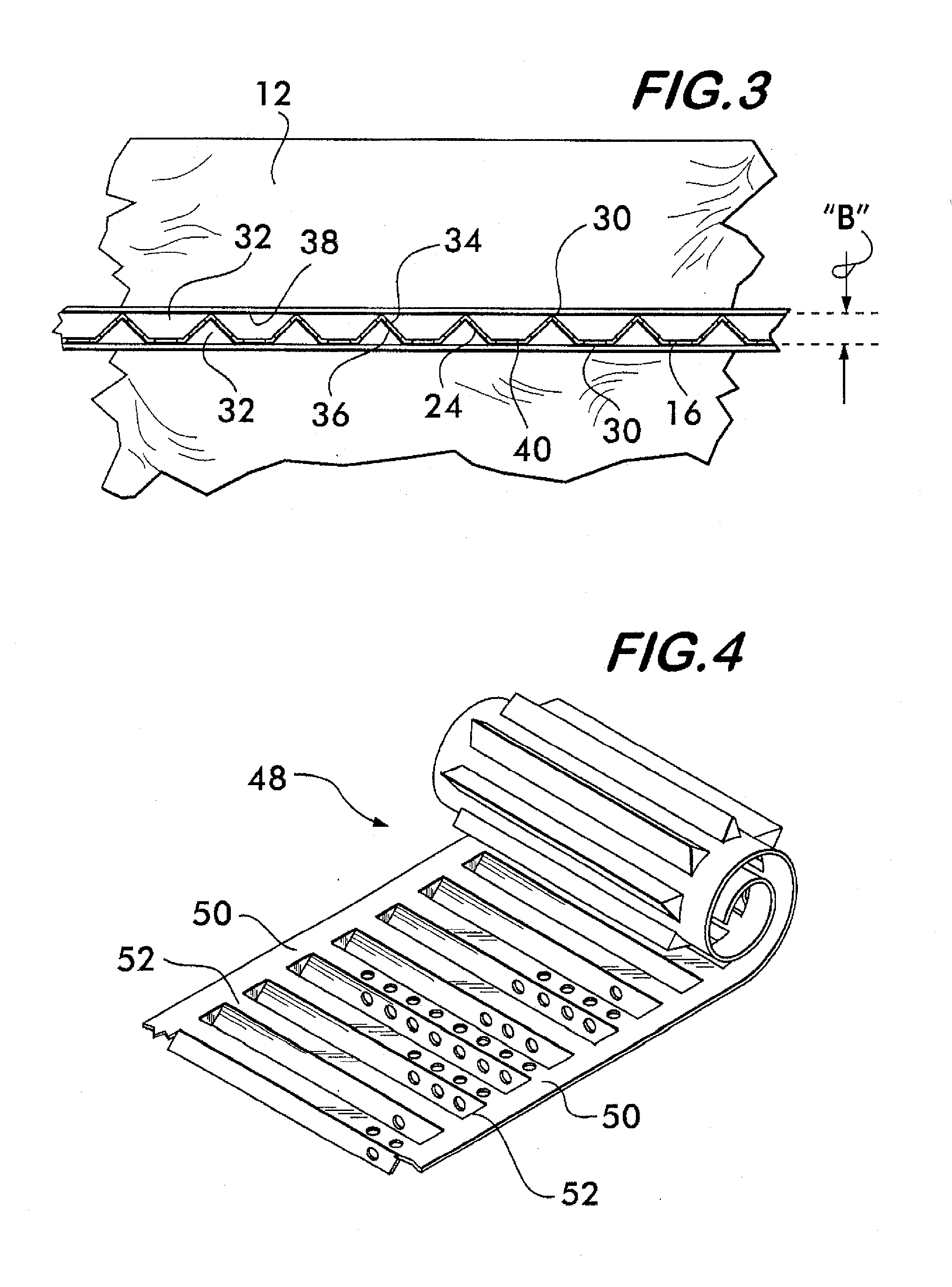

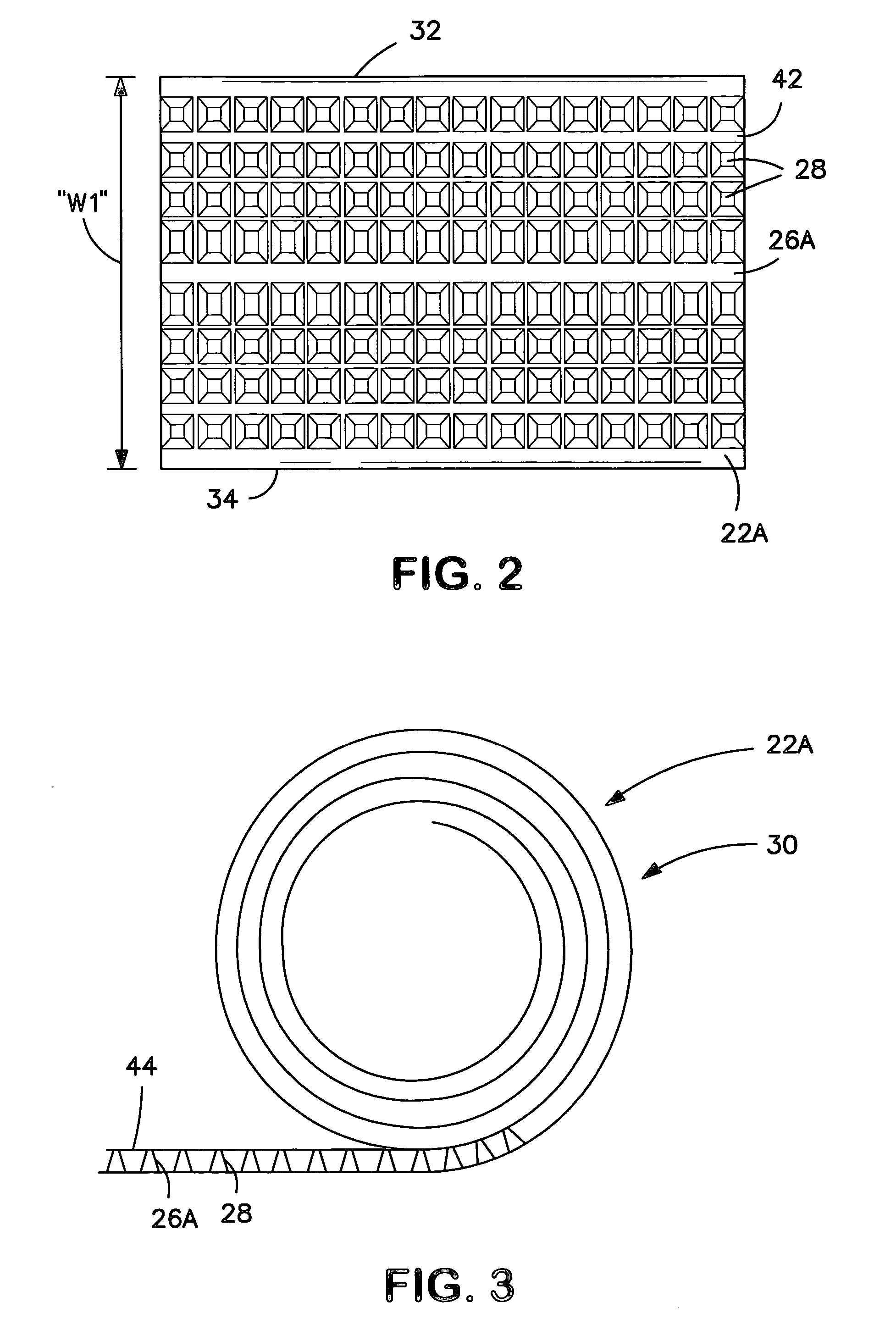

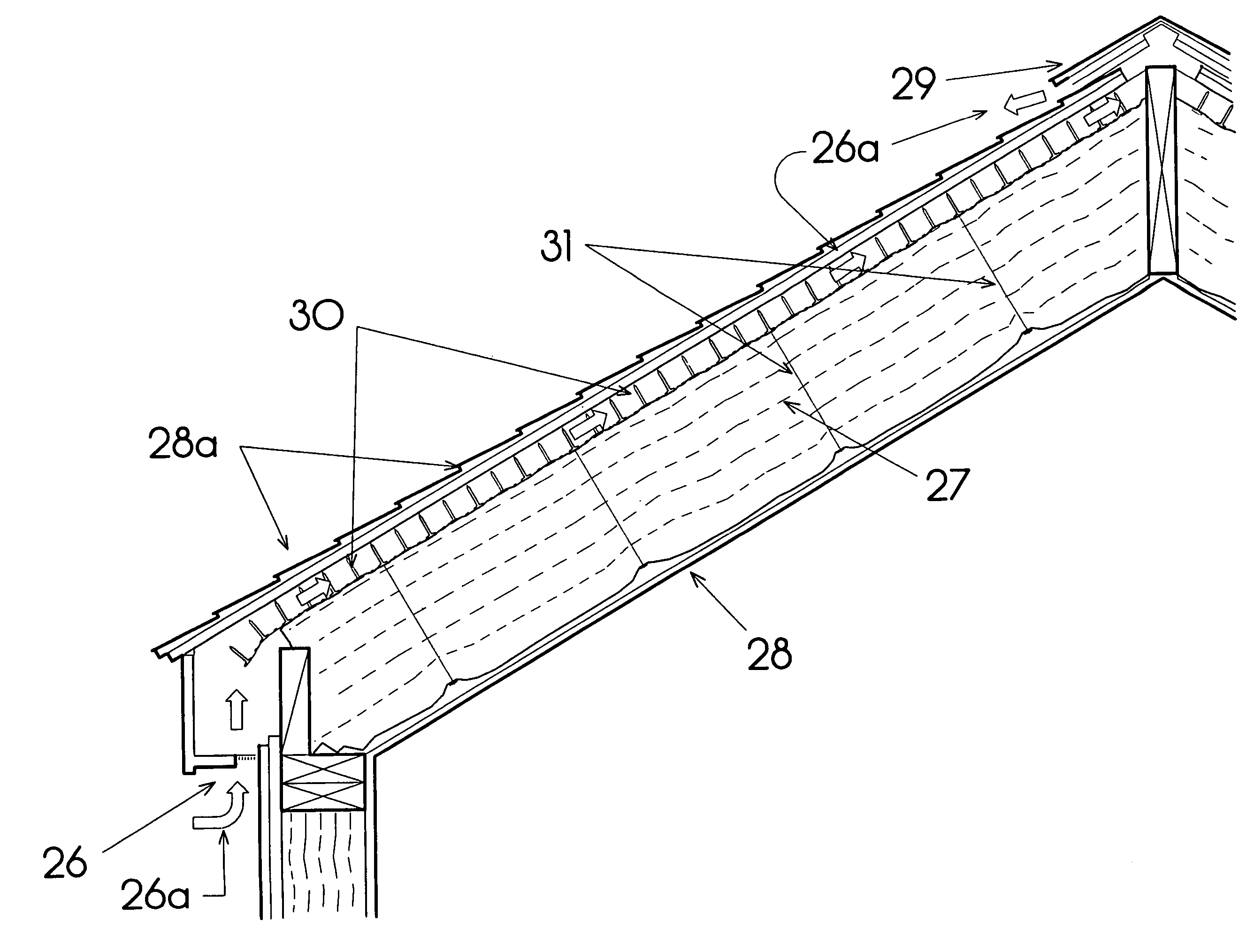

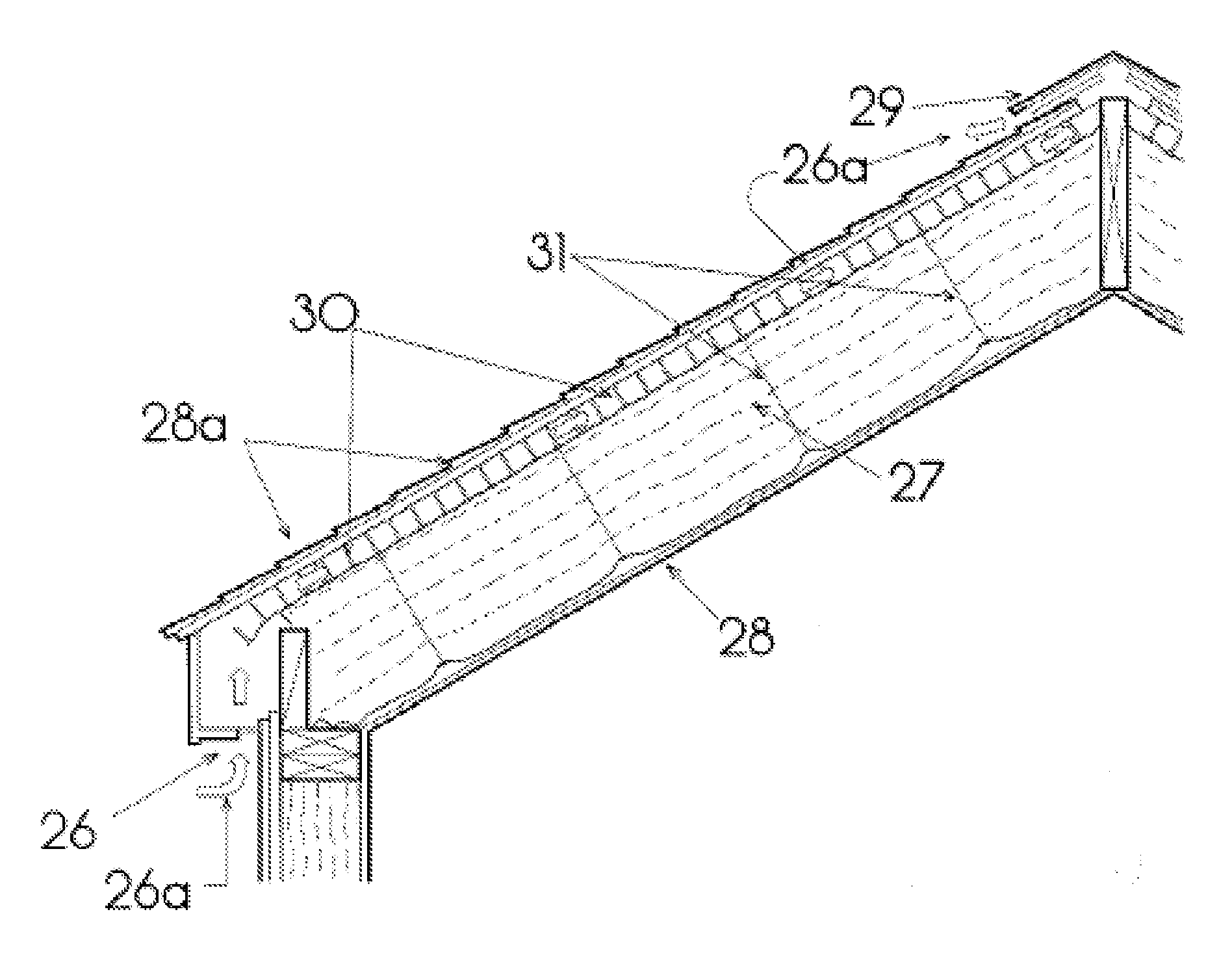

Rollable roof ridge vent having baffles

A roof ridge vent formed from a continuous, indeterminate-length, elongate strip of openwork material that has a pair of longitudinally-extending side edges each covered with a waterproof material. The edge coverings function as wind baffles and promote air circulation through the vent when wind blows over the roof ridge. The ridge vent is rollable lengthwise into a spiral roll for storage and shipment and is unrolled lengthwise during installation on a roof ridge.

Owner:BENJAMIN OBDIKE

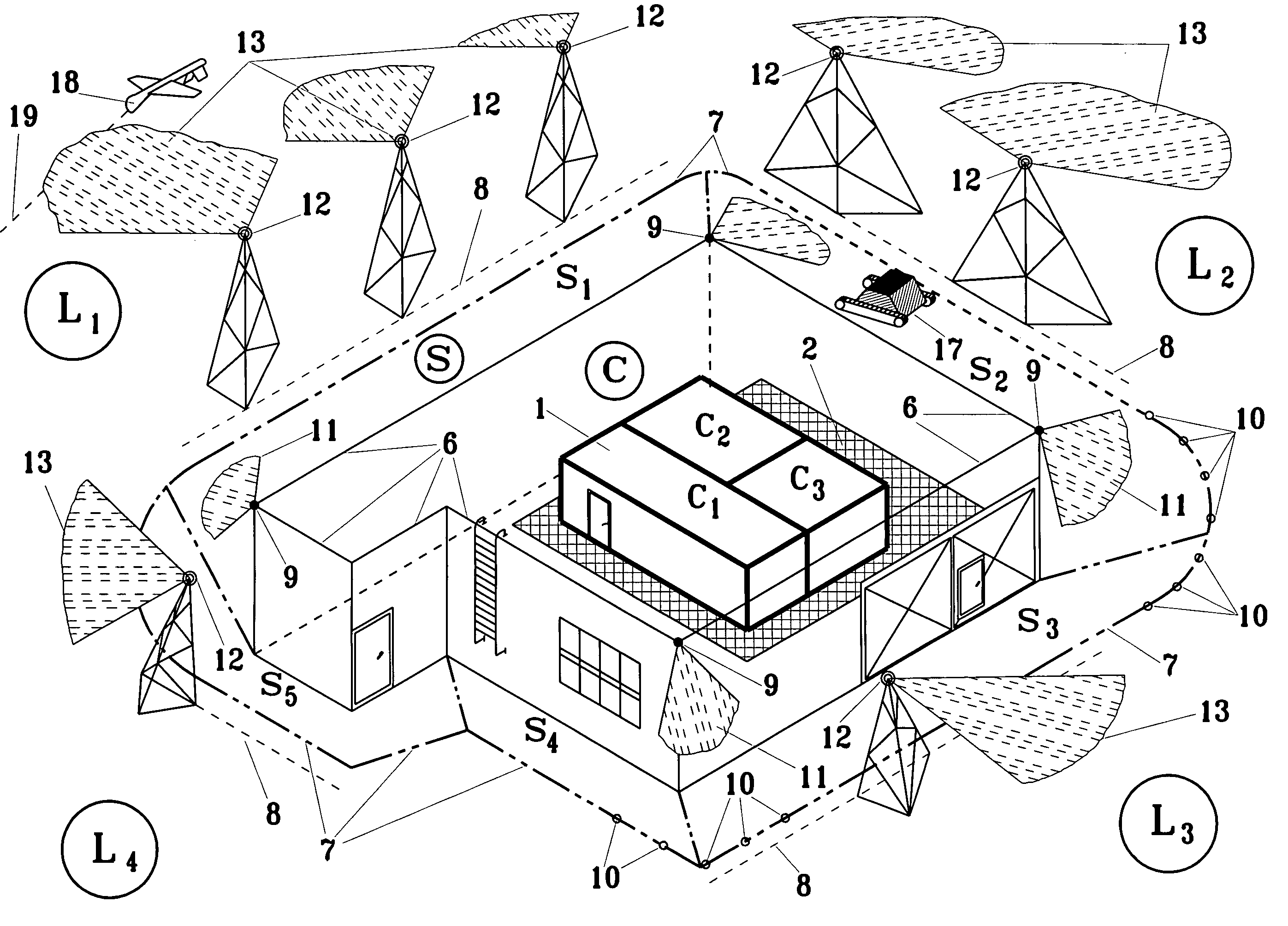

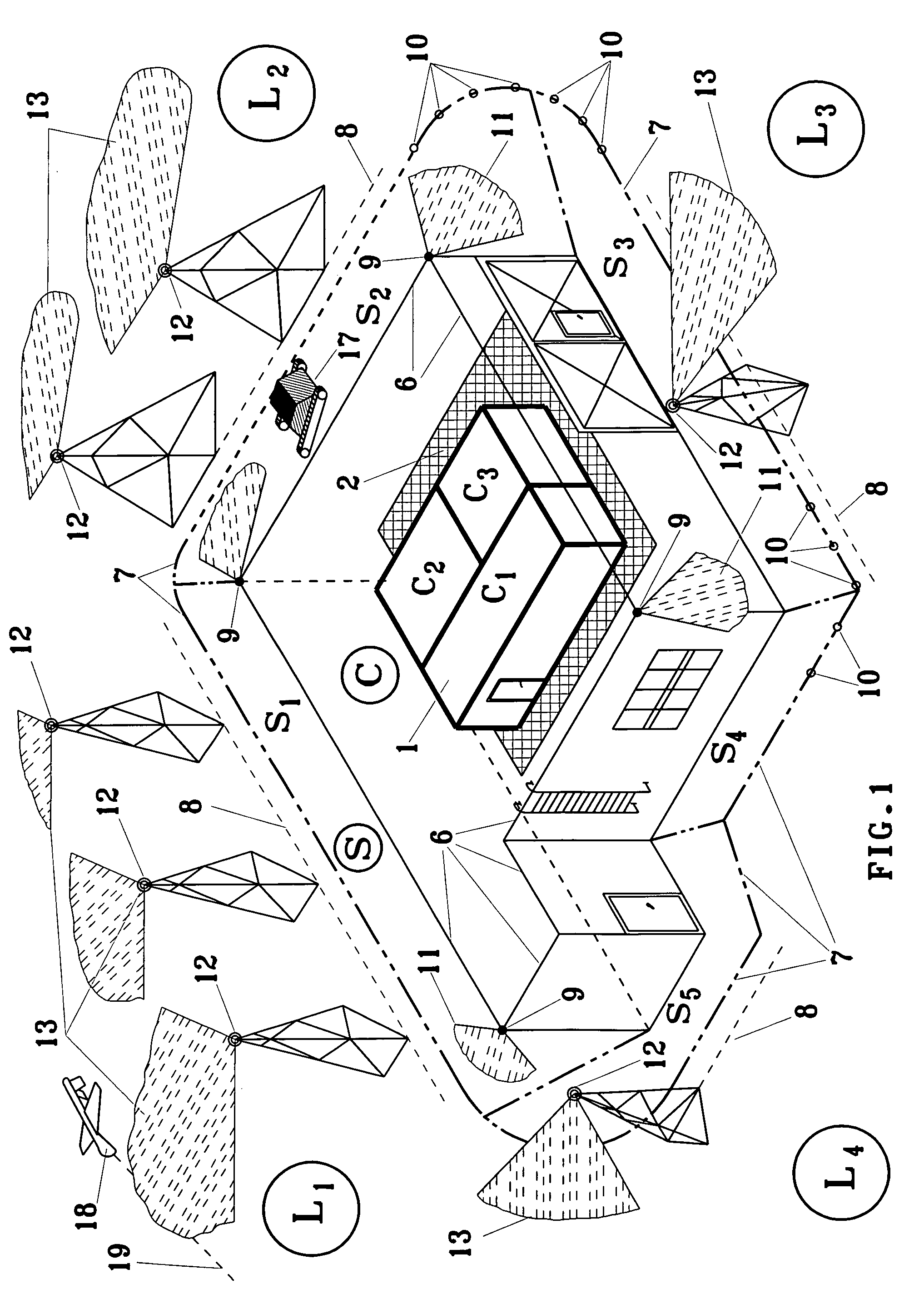

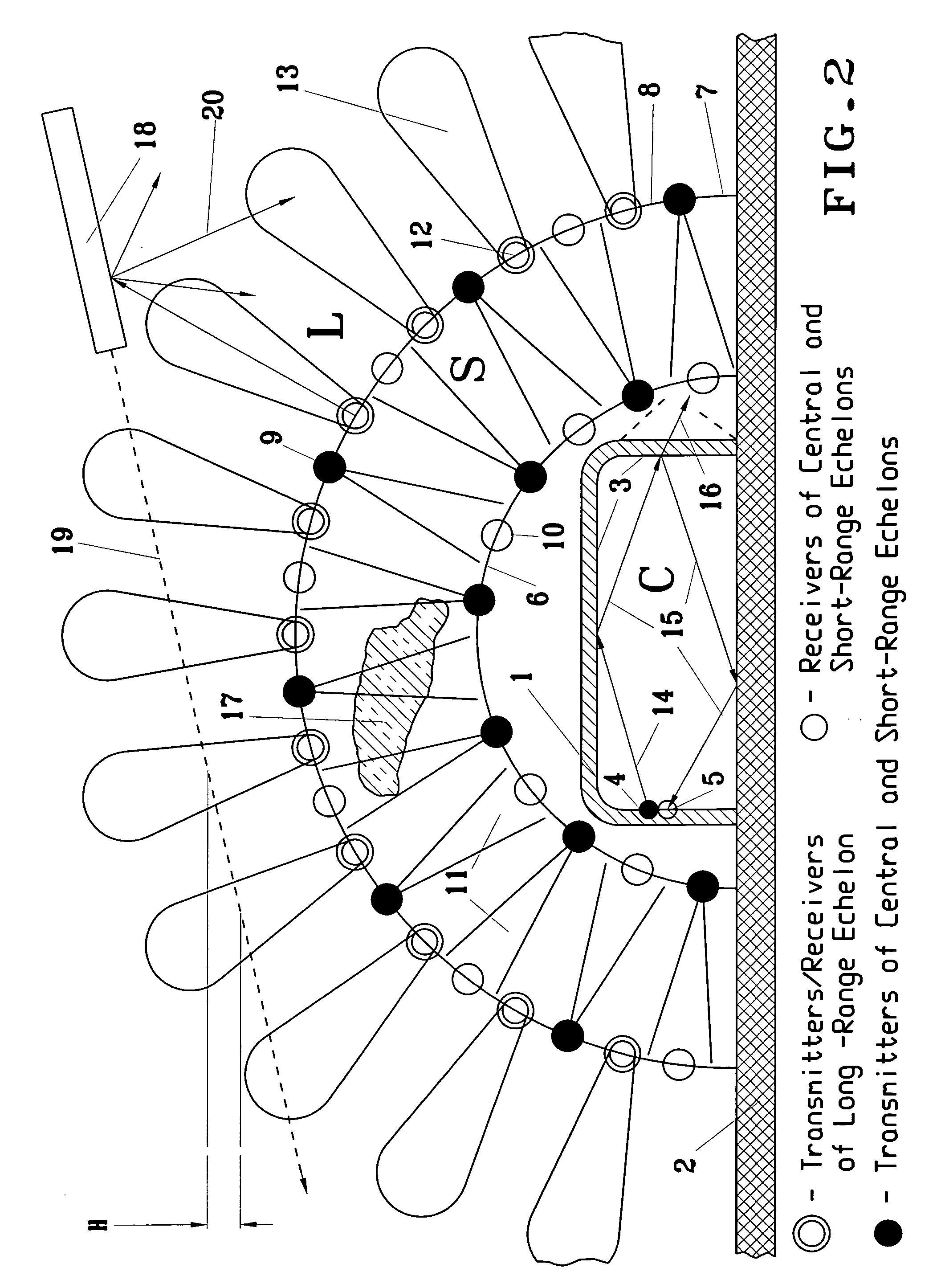

Method of defense-in-depth ultrasound intrusion detection

InactiveUS7233243B2Burglar alarm mechanical vibrations actuationBurglar alarm short radiation actuationSonificationUltrasonic beam

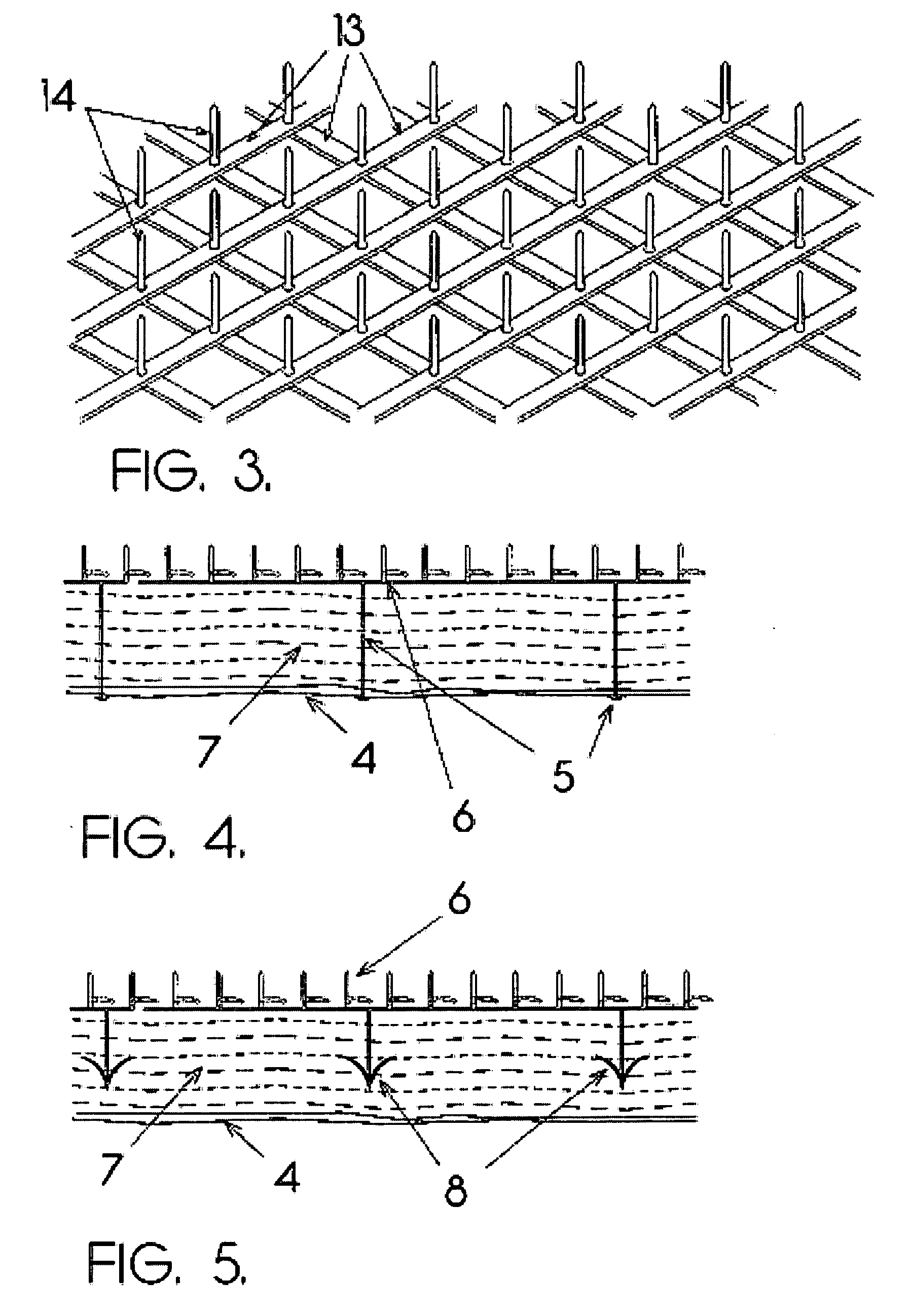

Method of ingress or egress intrusion detection by ultrasound surveillance throughout volumetric multi-area room around a protected object, where the surveyed room is arranged in juxtaposed volumetric closed or open areas that represent central, short-range and long-range echelons of defense-in-depth intrusion protection infrastructure. The used techniques of ultrasound intrusion detection are based on the phenomena of reflection, refraction by edge diffraction, and interference by shadowing of ultrasonic beams. The ultrasonic beam patterns are closely disposed in 2-D curvilinear or polygonal array, or in 3-D curved surface lattice over multilevel substantial openwork frames of different echelons. The informational and processing inter-echelon interrelation is being treated by control software algorithm that features situational logic transition driven by IF-THEN operator. The disclosed method shall enhance the distance of location, trustworthiness and cost-effectiveness of ultrasonic intrusion detection arrangements.

Owner:CTRL SYST

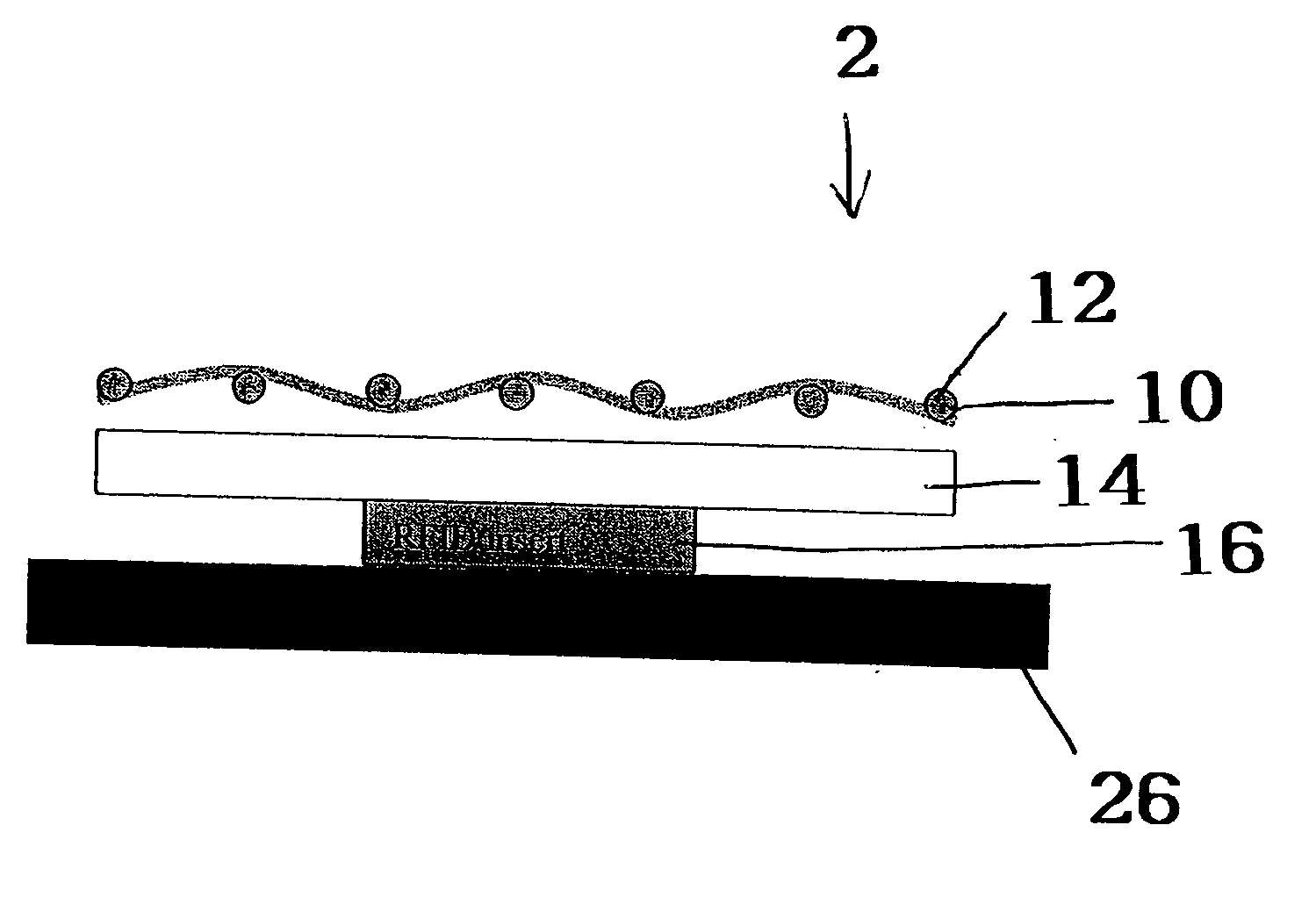

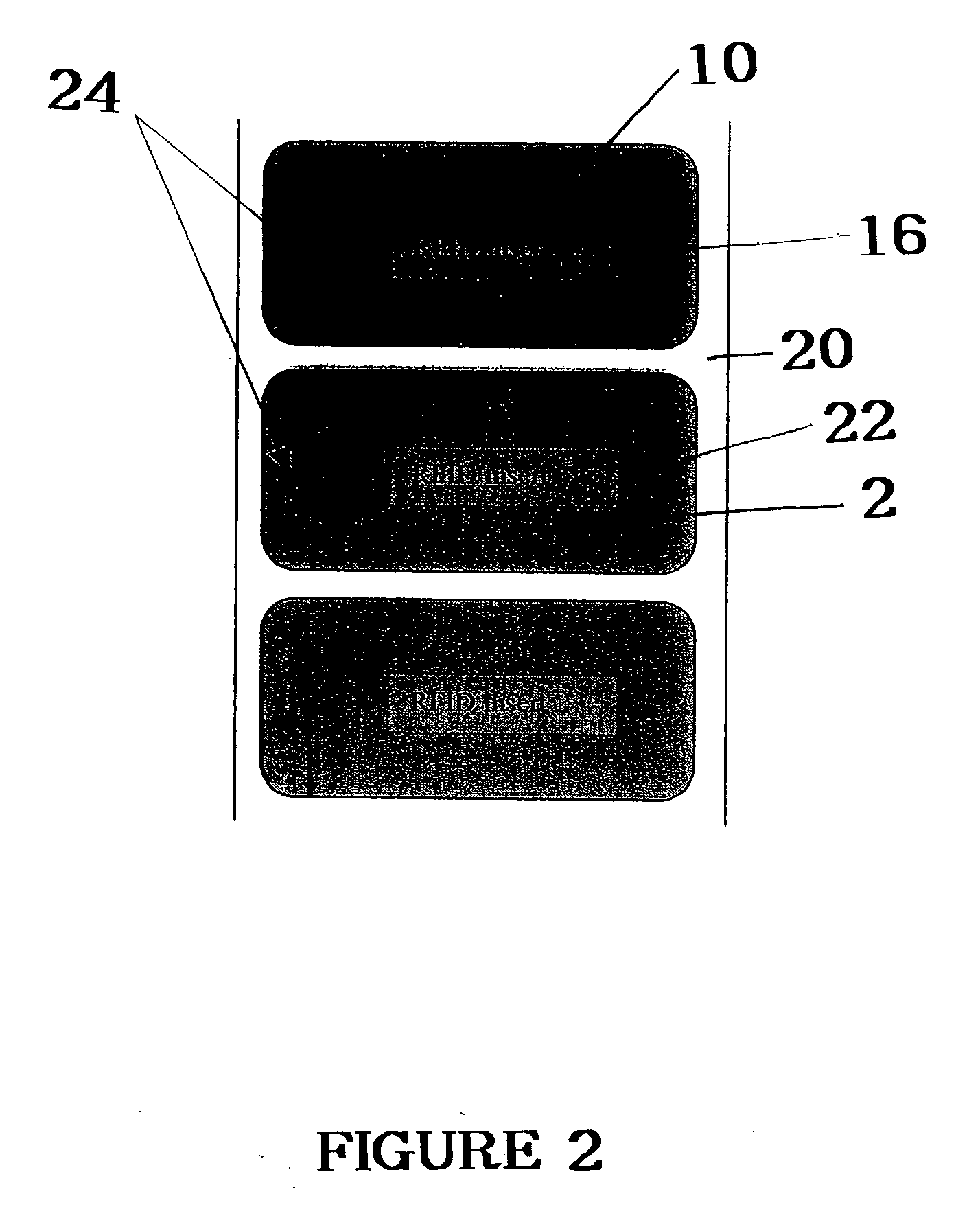

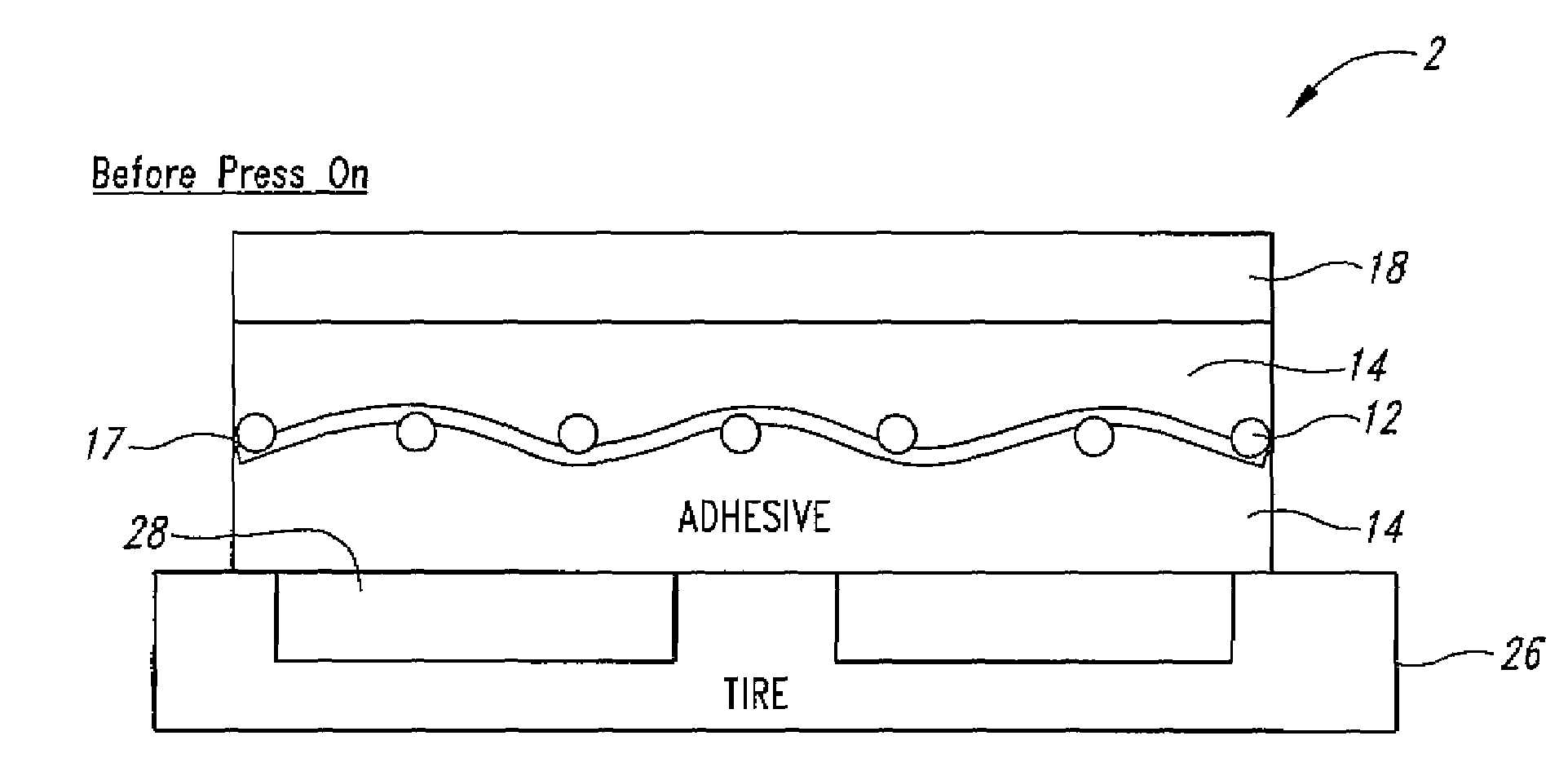

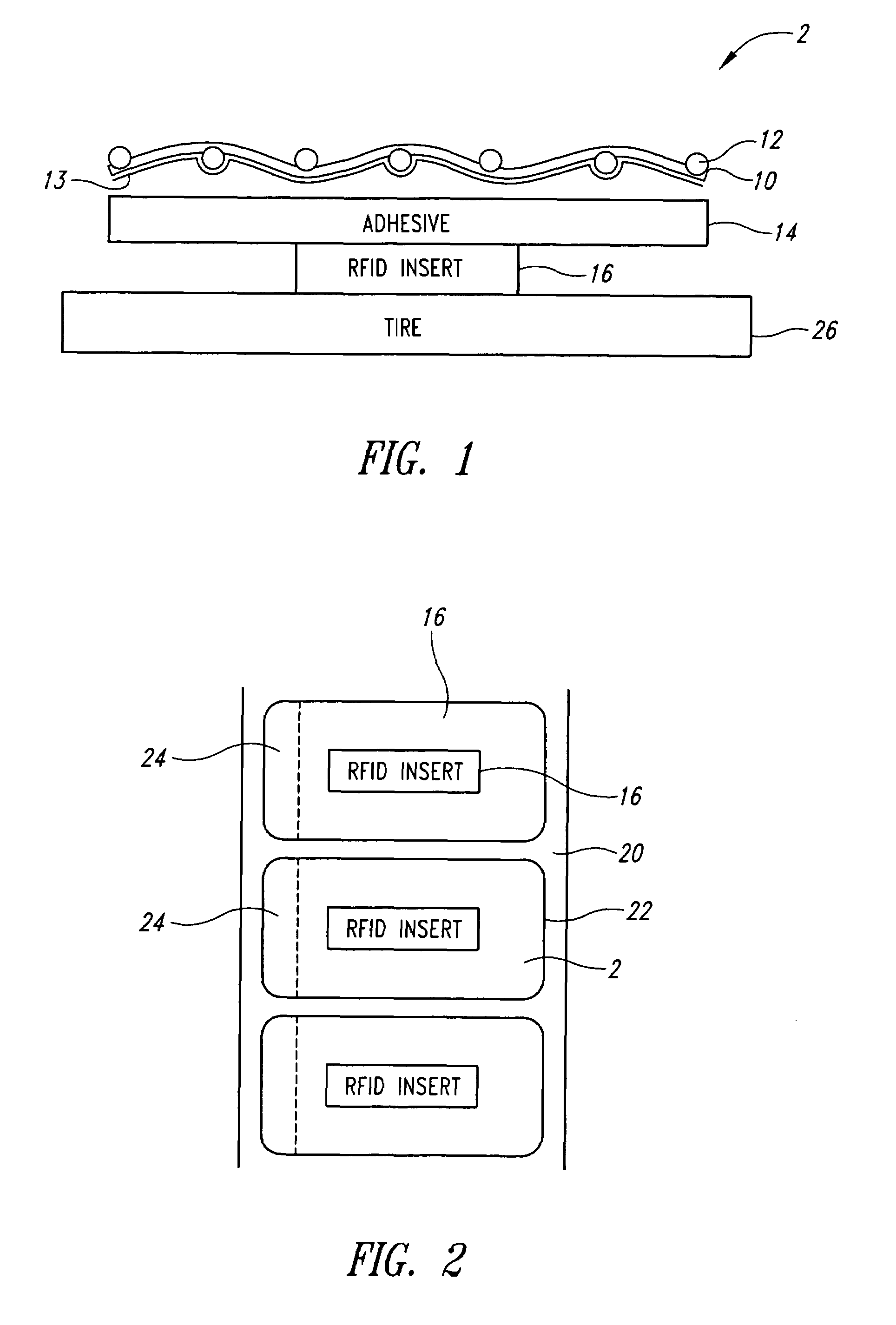

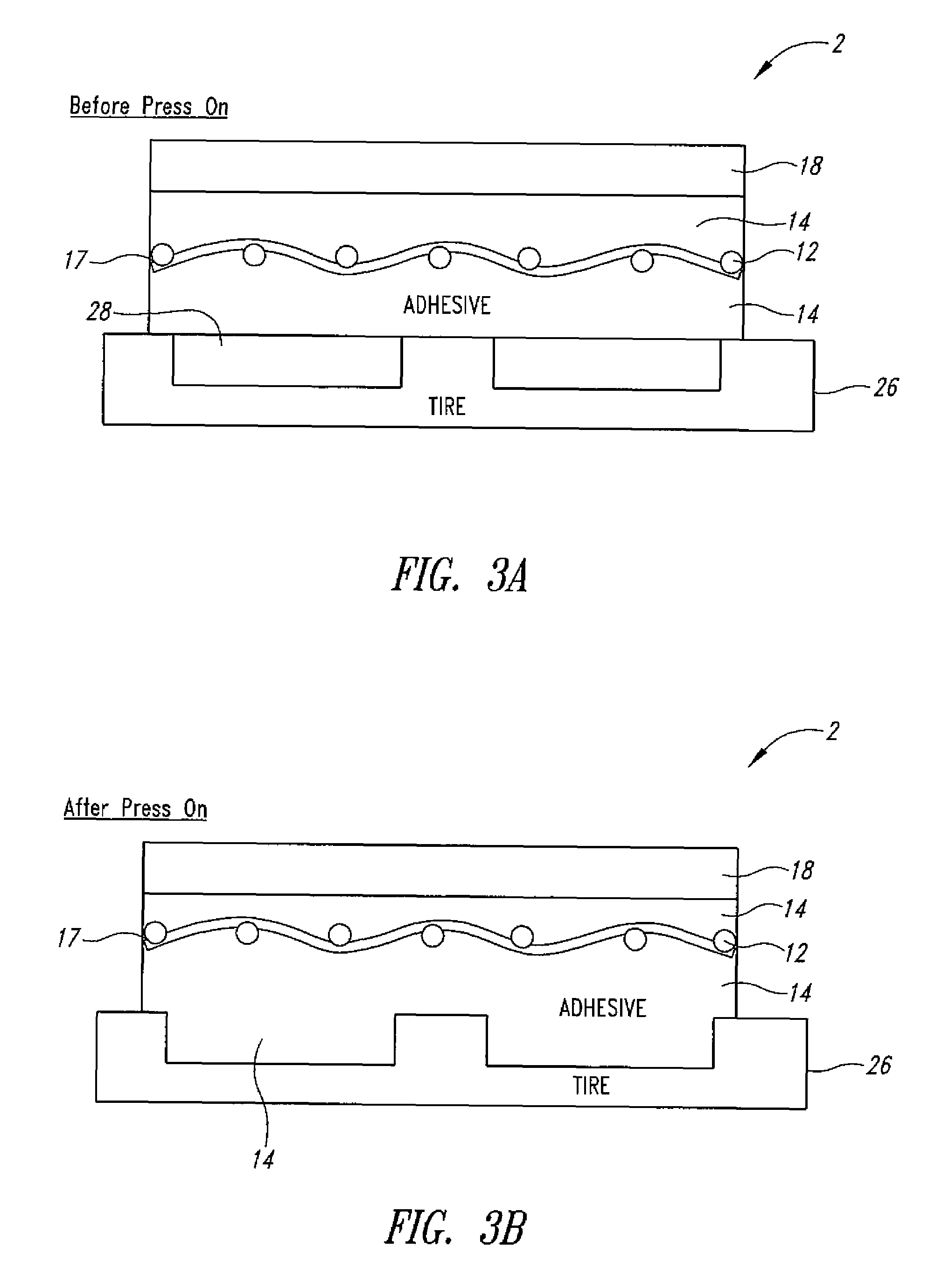

RFID tire label

ActiveUS20050221704A1Easy to disassembleLose tensile strengthStampsSynthetic resin layered productsEngineeringTyre label

Owner:INTERMEC IP

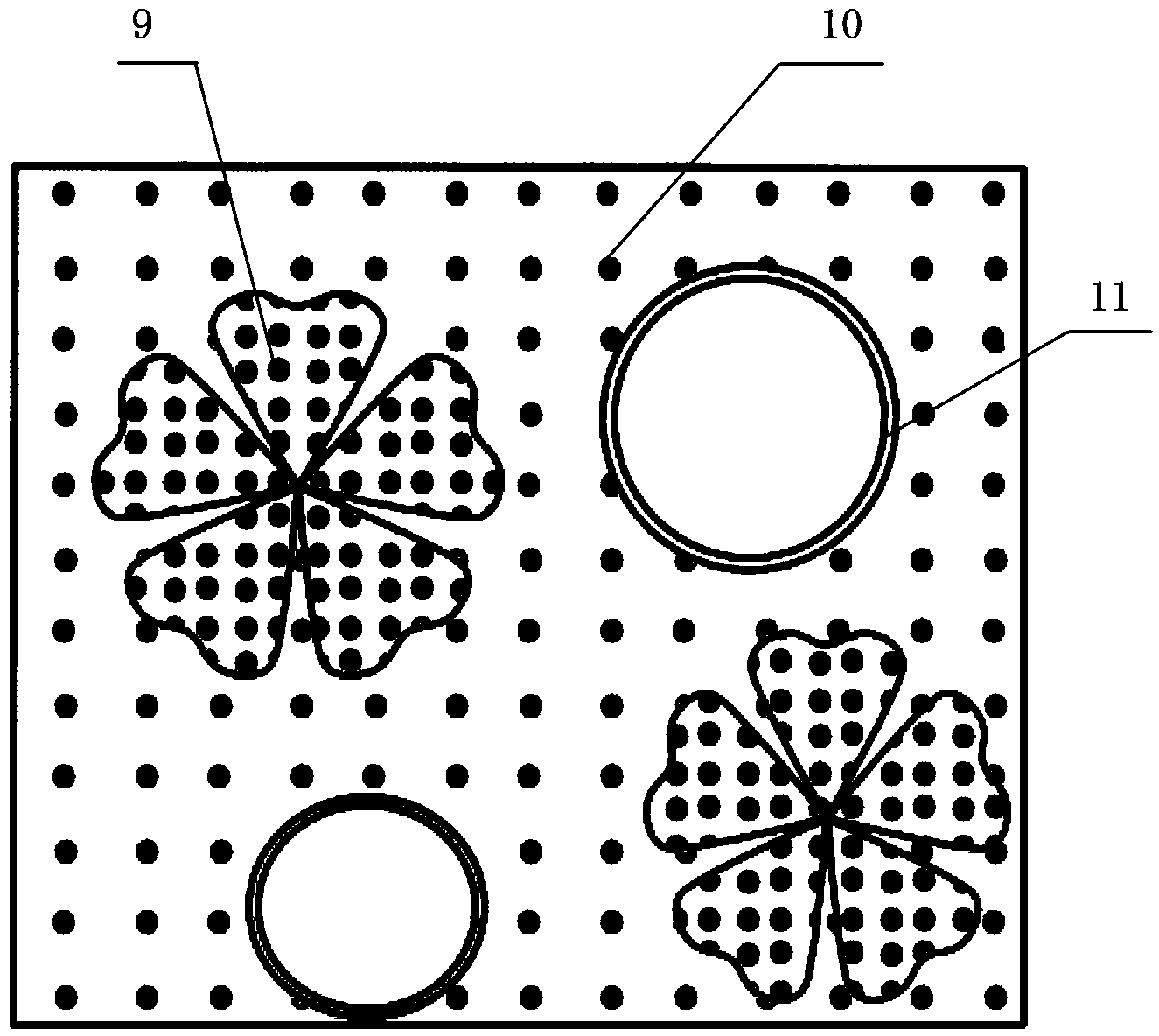

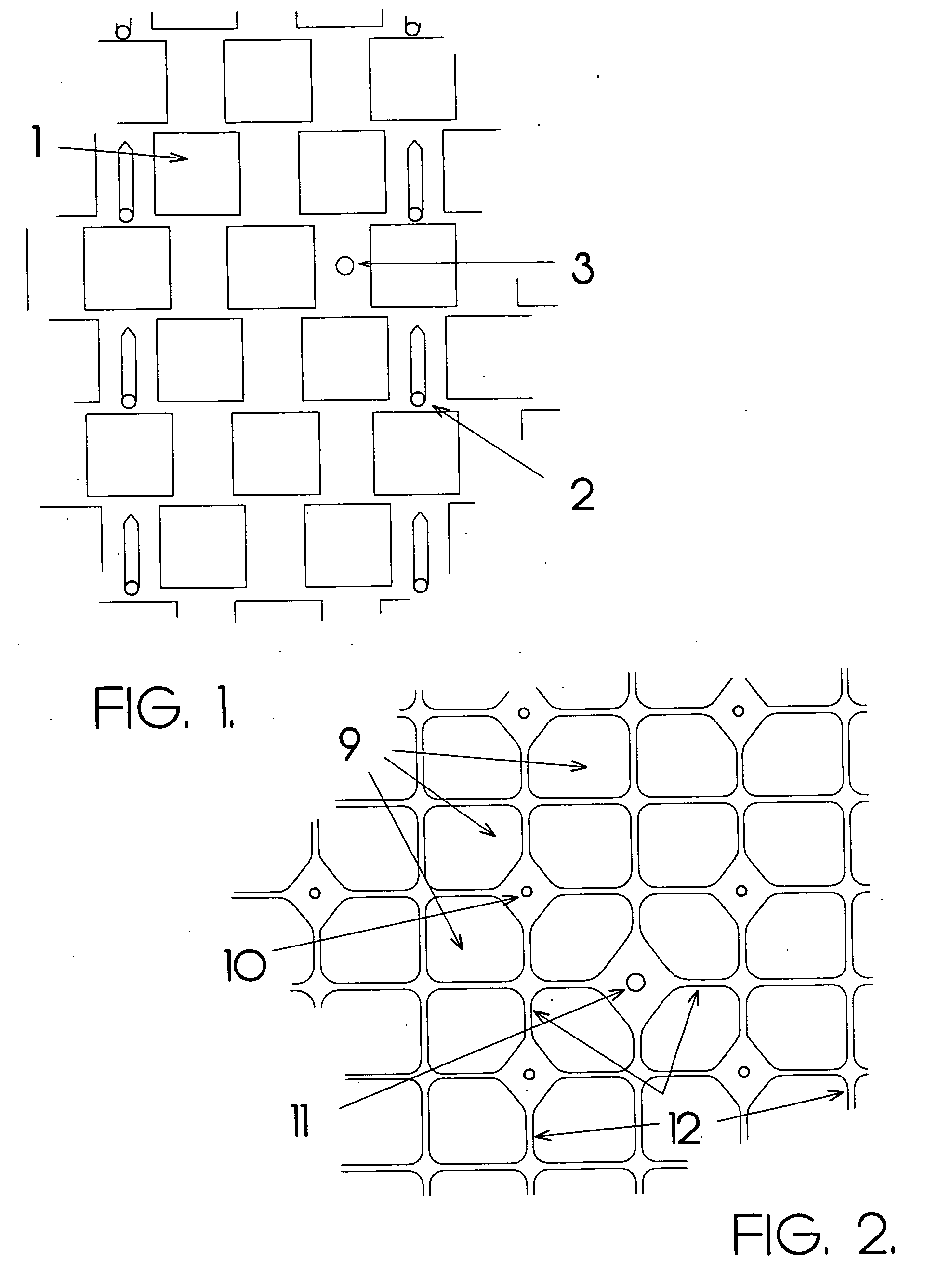

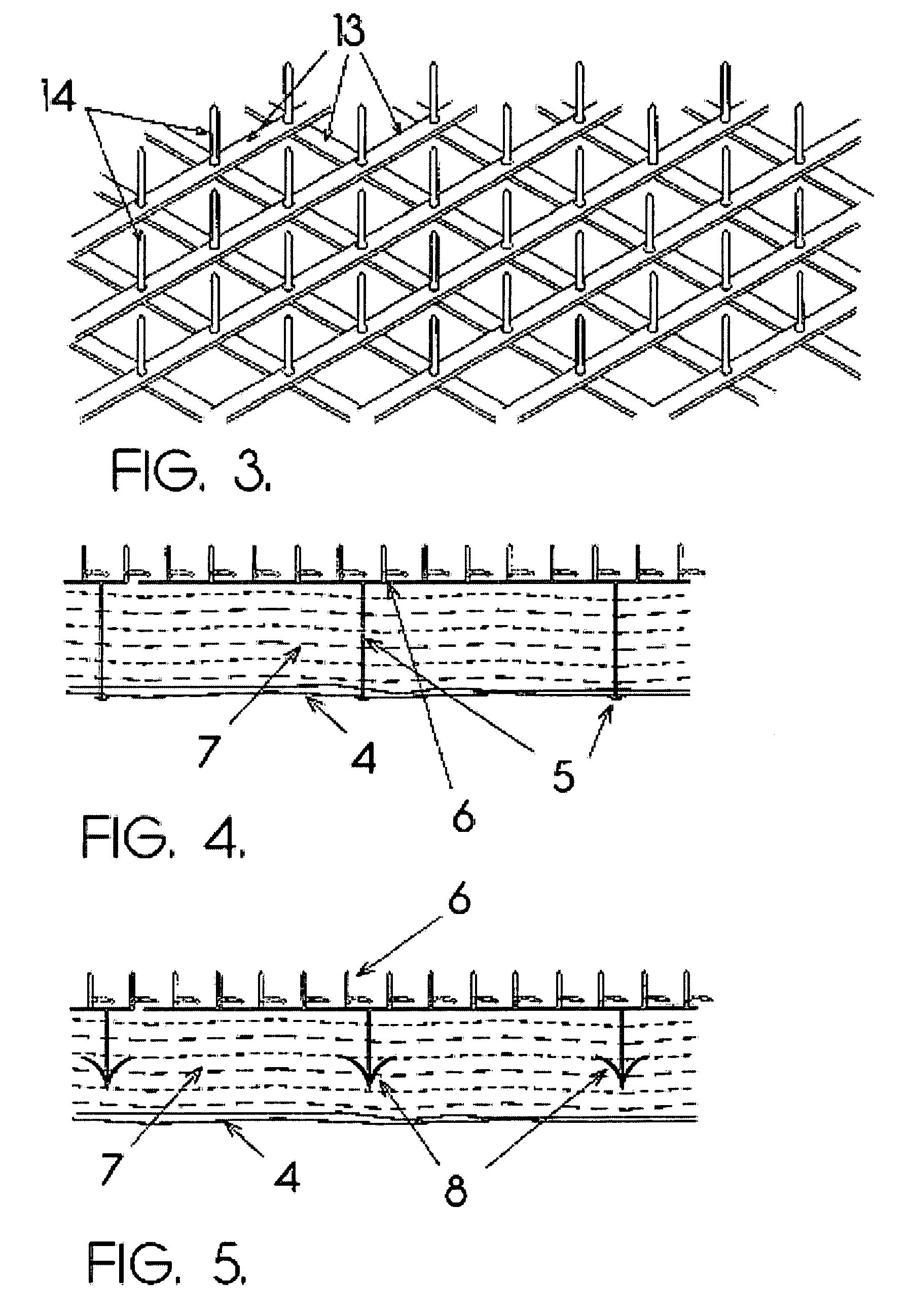

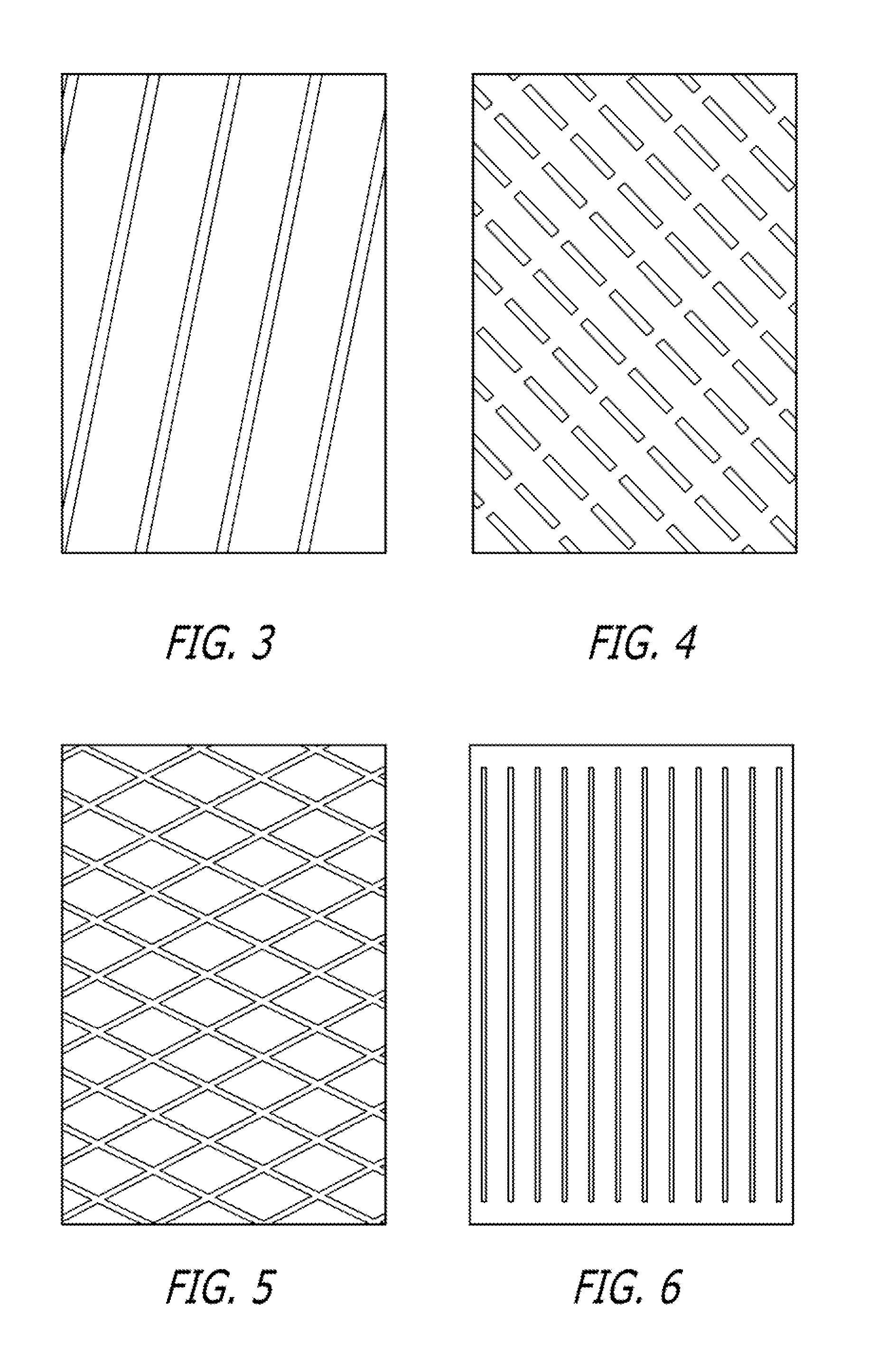

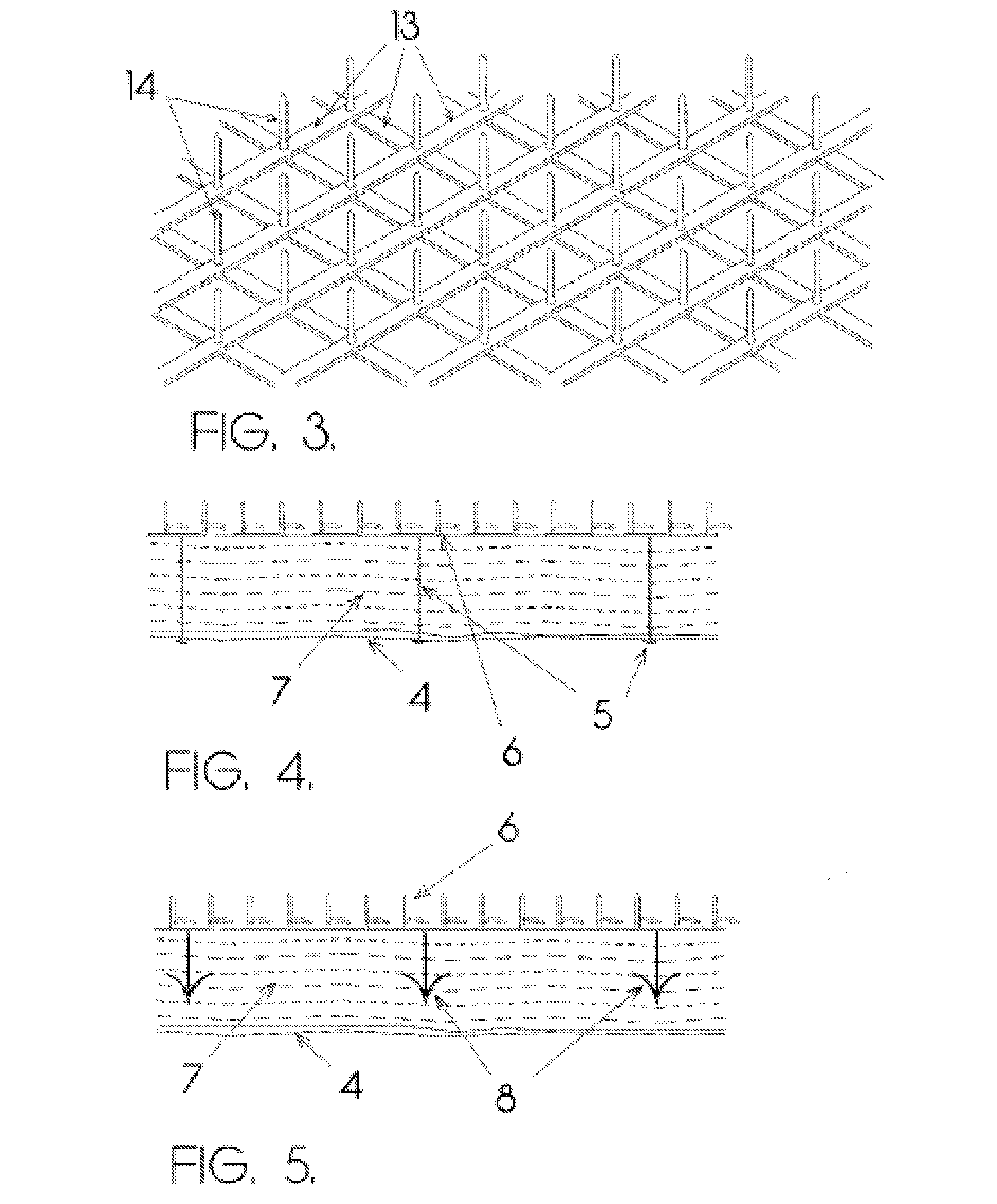

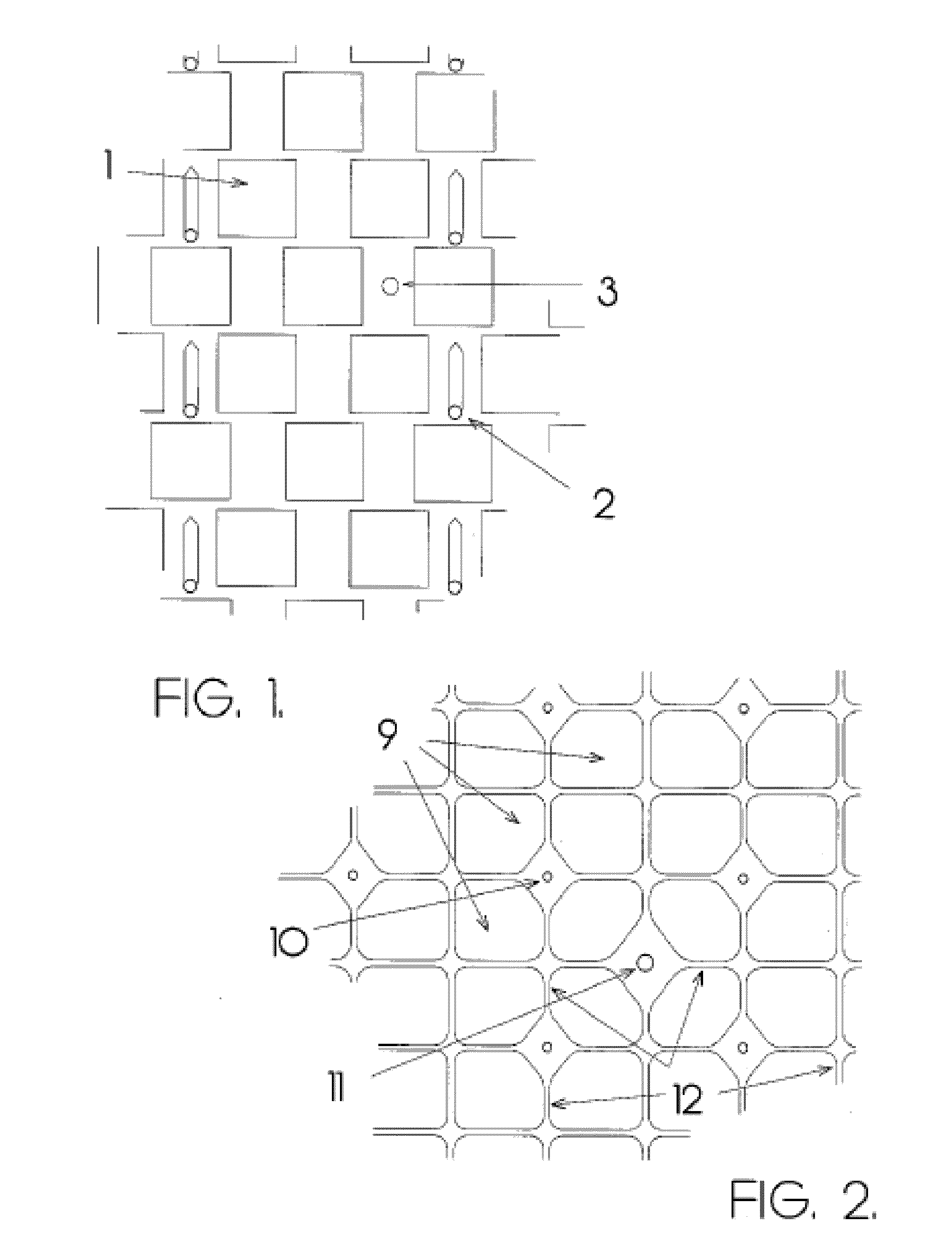

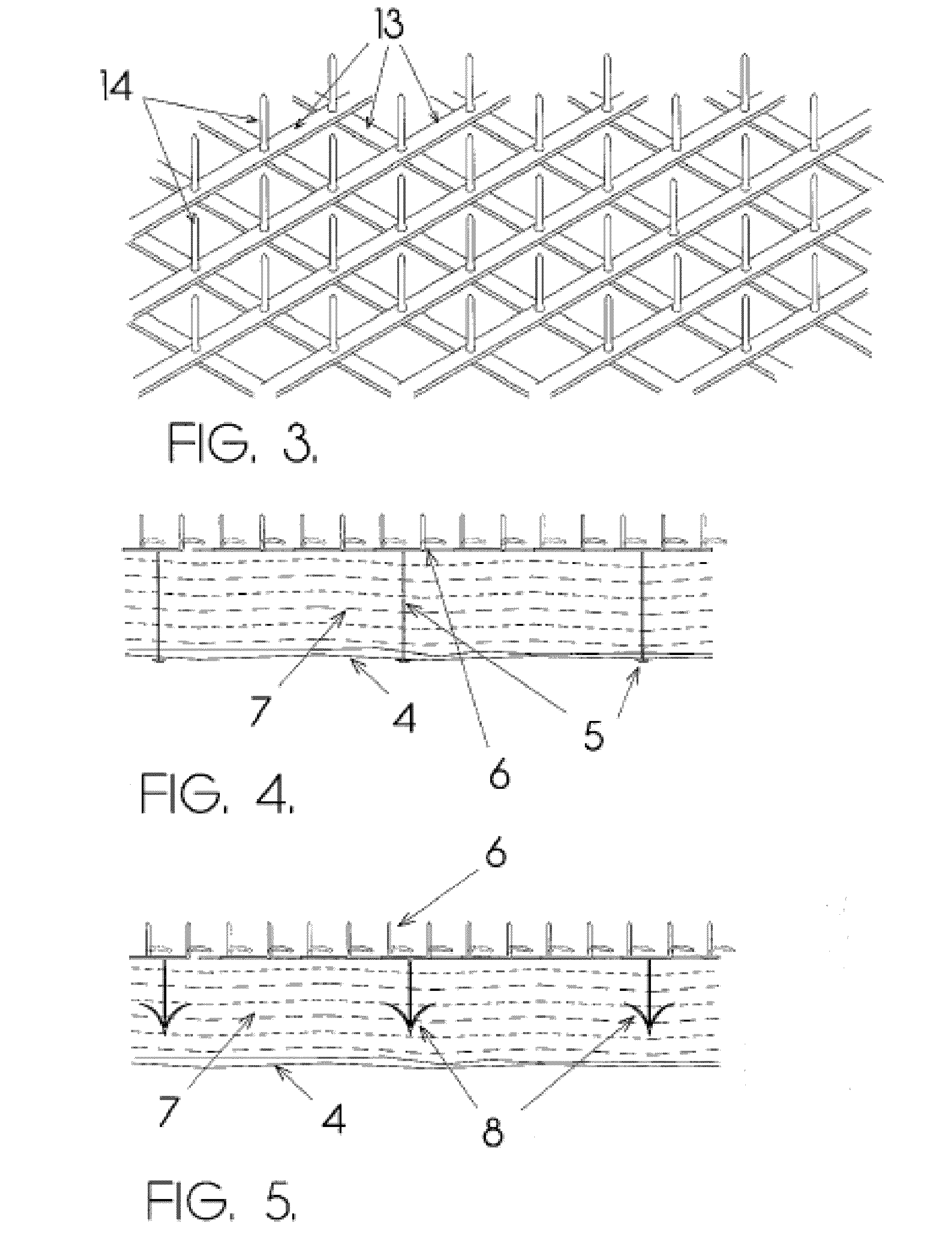

Device and method to provide air circulation space proximate to insulation material

A spacer device is provided including (1) a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material, and (2) a plurality of spacer struts fixedly attached to the body. The struts are configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of entangled net filaments.

Owner:HETTRICH HANSL

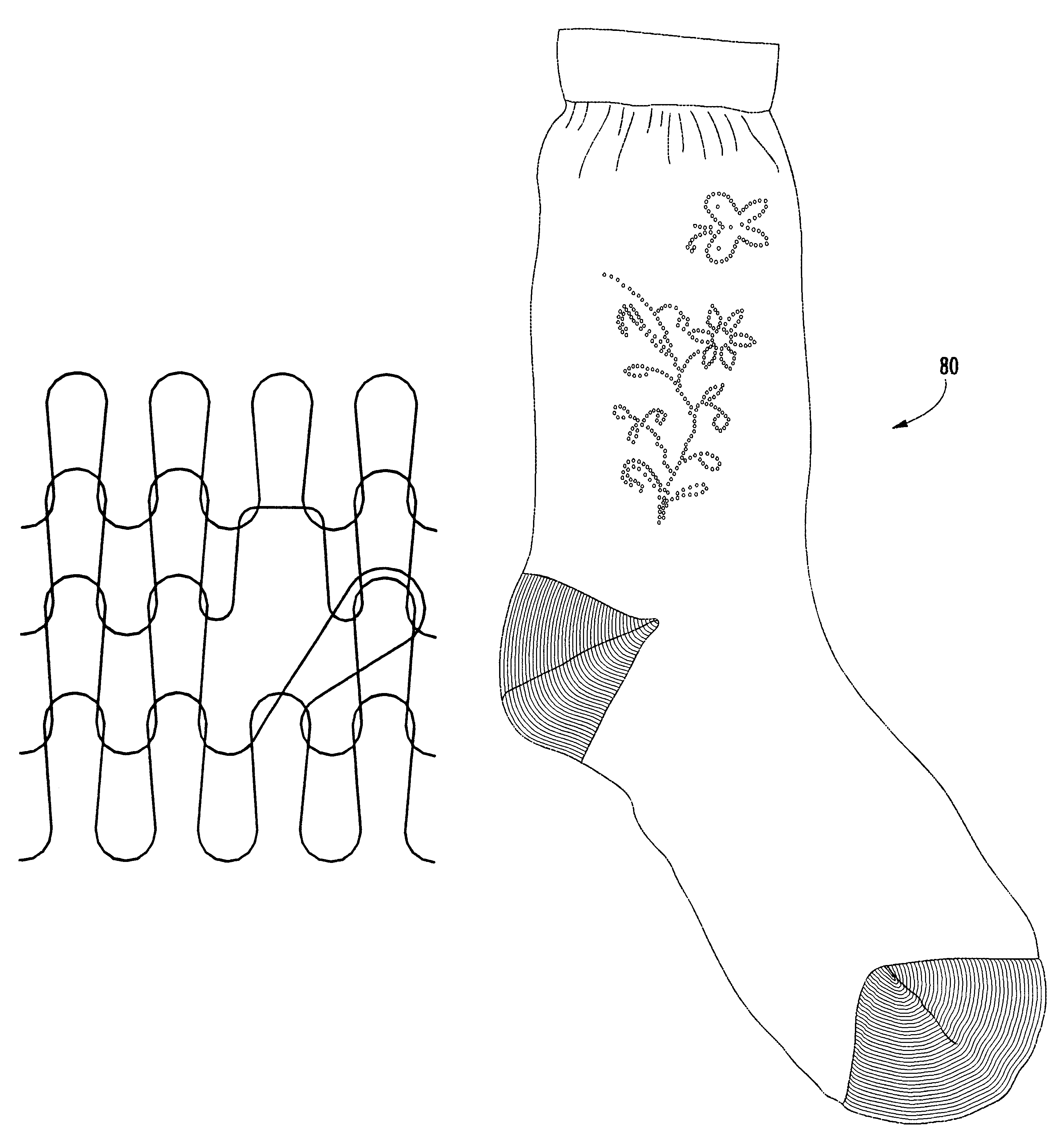

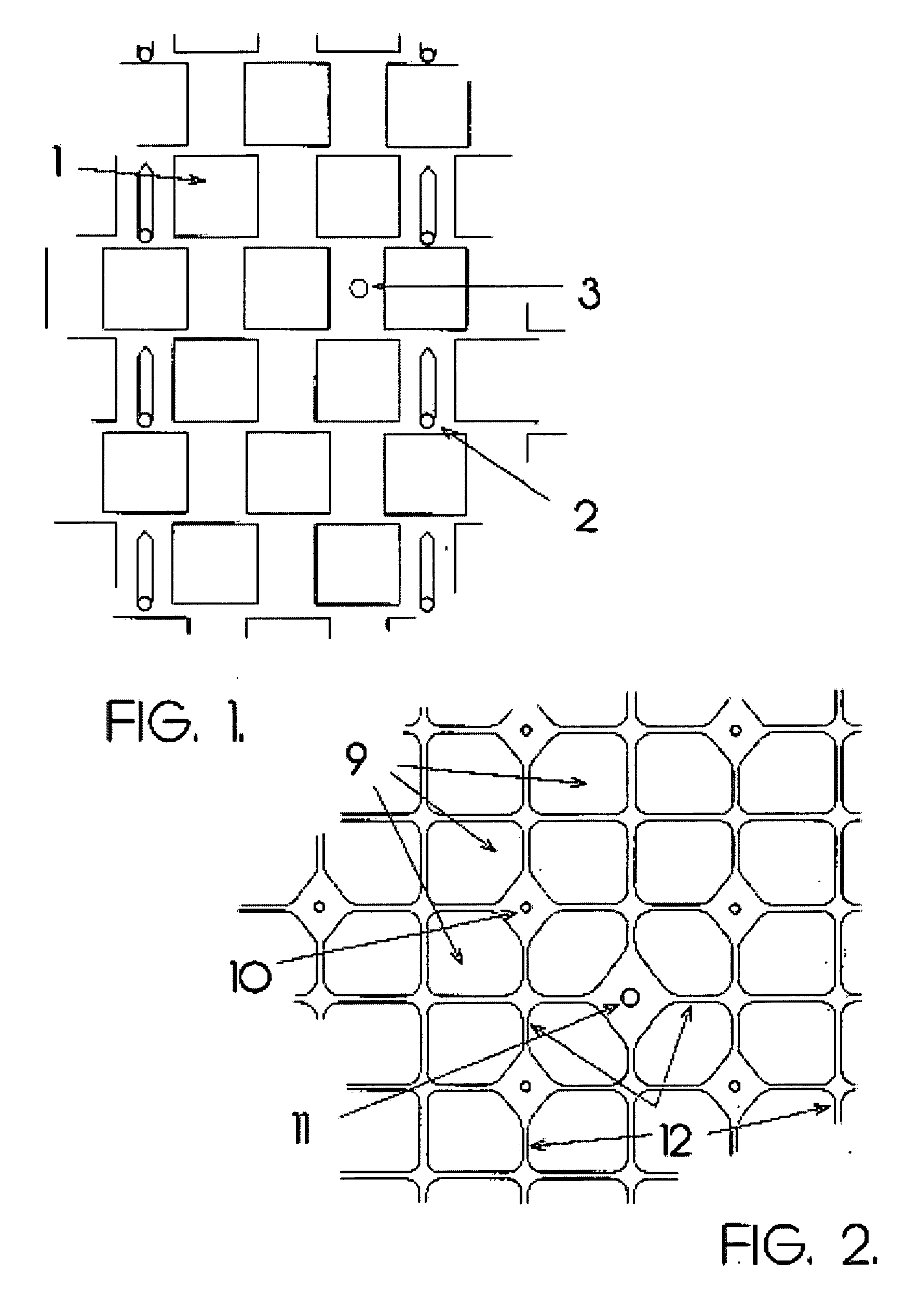

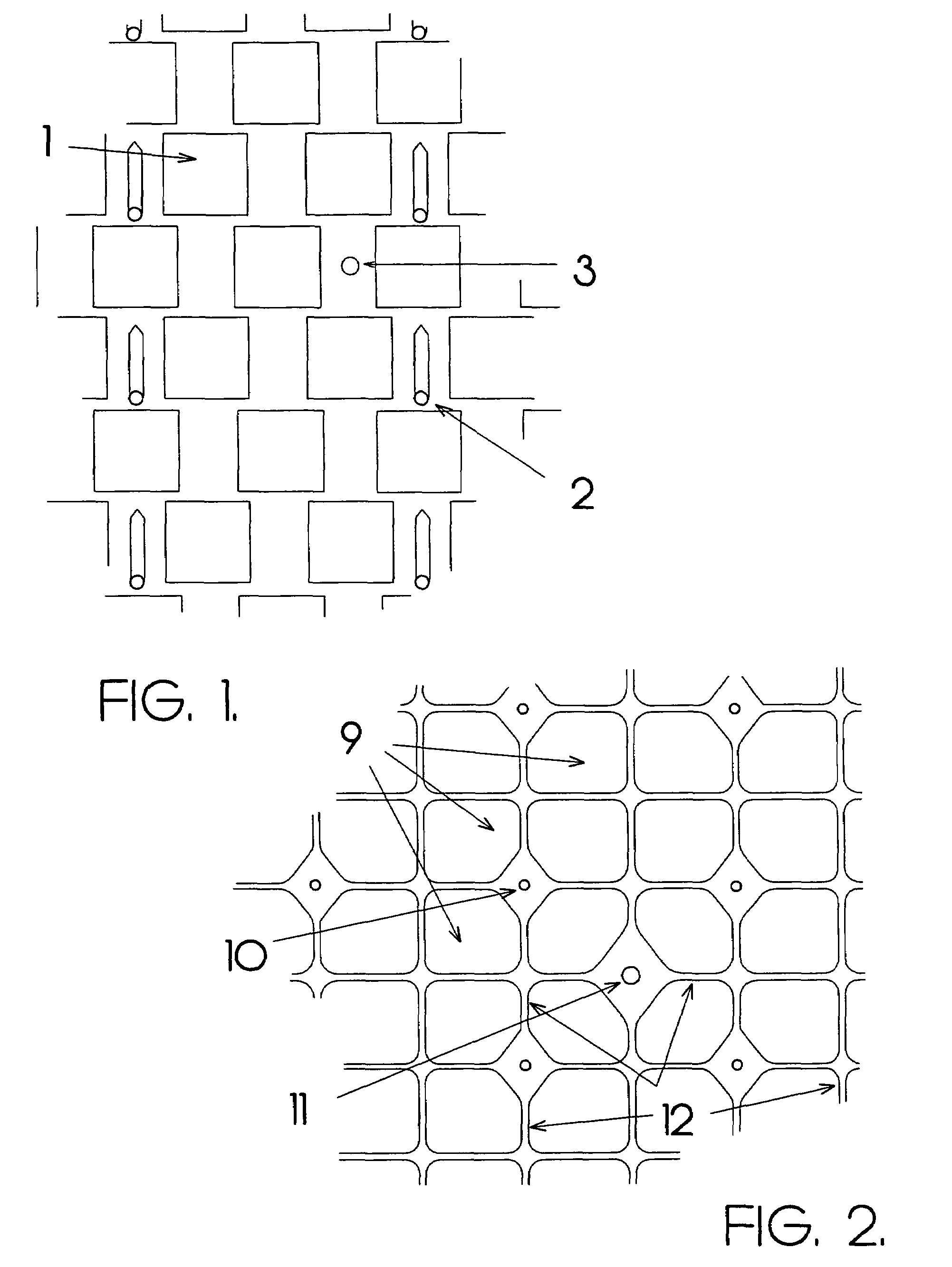

Fine gauge knitted fabric with open-work pattern

An openwork tubular knitted fabric formed of closely knitted, fine gauge yarns formed into knitted loops utilizing at least 11 needles per inch and having at least 25 courses per inch. The fabric is formed by using needles having a hook formed in a top end of a needle shank and a latch pivotally mounted on the needle shank below the hook for opening and closing the hook, and including a deflector for deflecting a loop of yarn being formed by a needle into the vertical plane of an adjacent needle, and a needle cam mounted for reciprocal movement between first and second vertically-spaced positions. The fabric is characterized by having a fine, dense background with small, closely-spaced holes which enable a highly-detailed pattern suitable for a wide range of undergarments and hosiery products. The density and fineness of the fabric provides both the comfort and lack of show through necessary for many garments of this type.

Owner:LONATI

Integrally formed 3D flyknitted vamp and making method thereof

The invention discloses an integrally formed 3D flyknitted vamp and a making method thereof.Low-melting yarn and dyed yarn are adopted as raw materials, an upper layer of double-faced jacquard vamp body and a lower layer of double-faced jacquard vamp body with the edges interwoven together are woven on a bidirectional jacquard double-faced loop transfer computer flat knitting machine, openwork figured texture weave is primary weave, different weave structures are adopted in functional zones of the vamp, and then the integrally formed 3D flyknitted vamp is made through hot pressing shaping.The temperature of hot pressing shaping ranges from 170 DEG C to 200 DEG C, and the time of hot pressing shaping ranges from 20 s to 80 s.Each double-faced jacquard vamp body comprises a dyed yarn layer and a low-smelting yarn layer which are interwoven together through yarn coils, and the integrally formed 3D flyknitted vamp is formed by bonding and combining the two layers of double-faced jacquard vamp bodies according to the wave structure of one dyed yarn layer, one low-melting yarn layer, the other low-melting yarn and the other dyed yarn layer through the upper low-melting yarn layer and the lower low-melting yarn layer in a hot pressing and melting mode.The integrally formed 3D flyknitted vamp has the advantages of being soft, comfortable, durable, colorful, attractive, low in cost and the like.

Owner:厦门翔鹭化纤股份有限公司

Device and method to provide air circulation space proximate to insulation material

Owner:HETTRICH HANSL

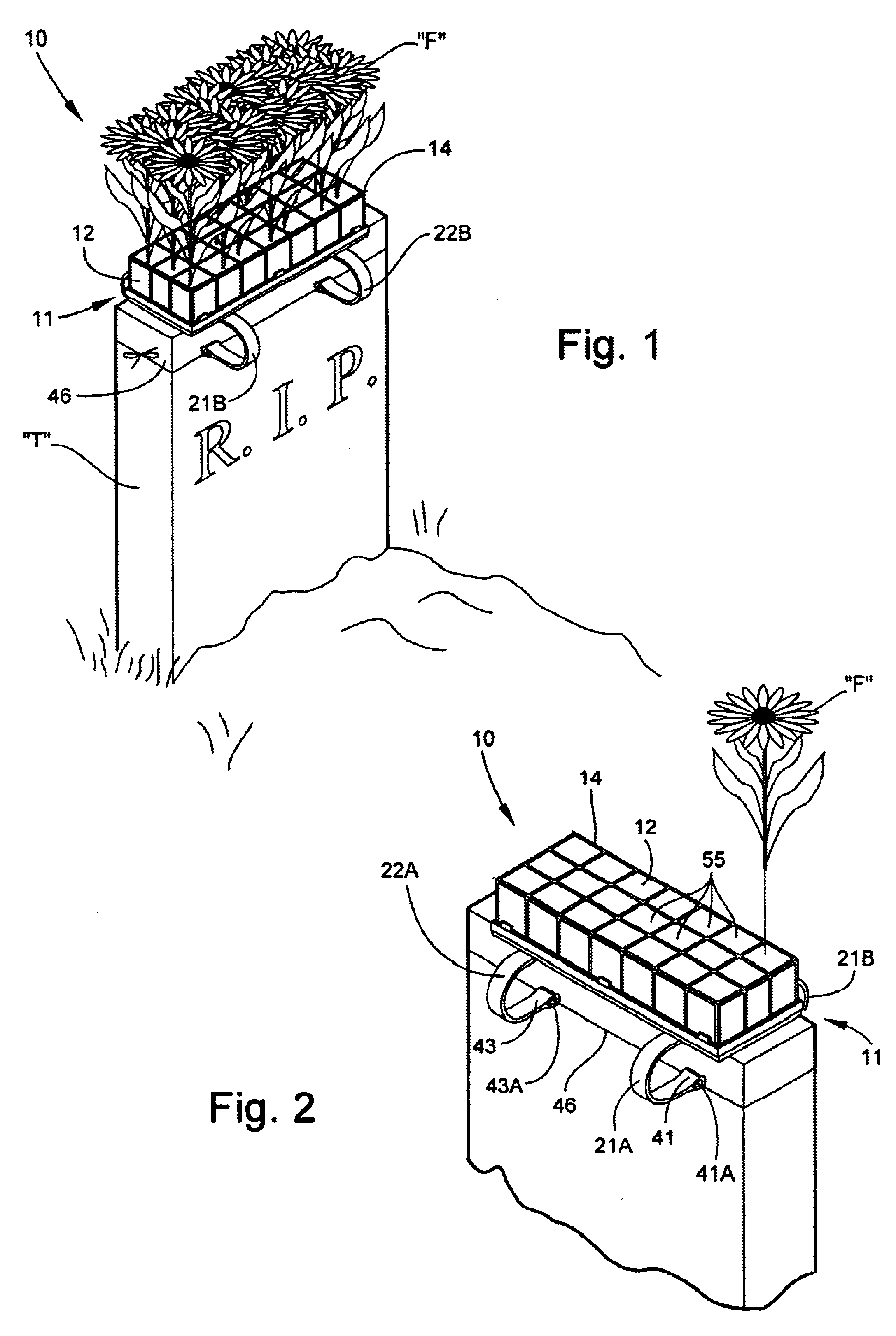

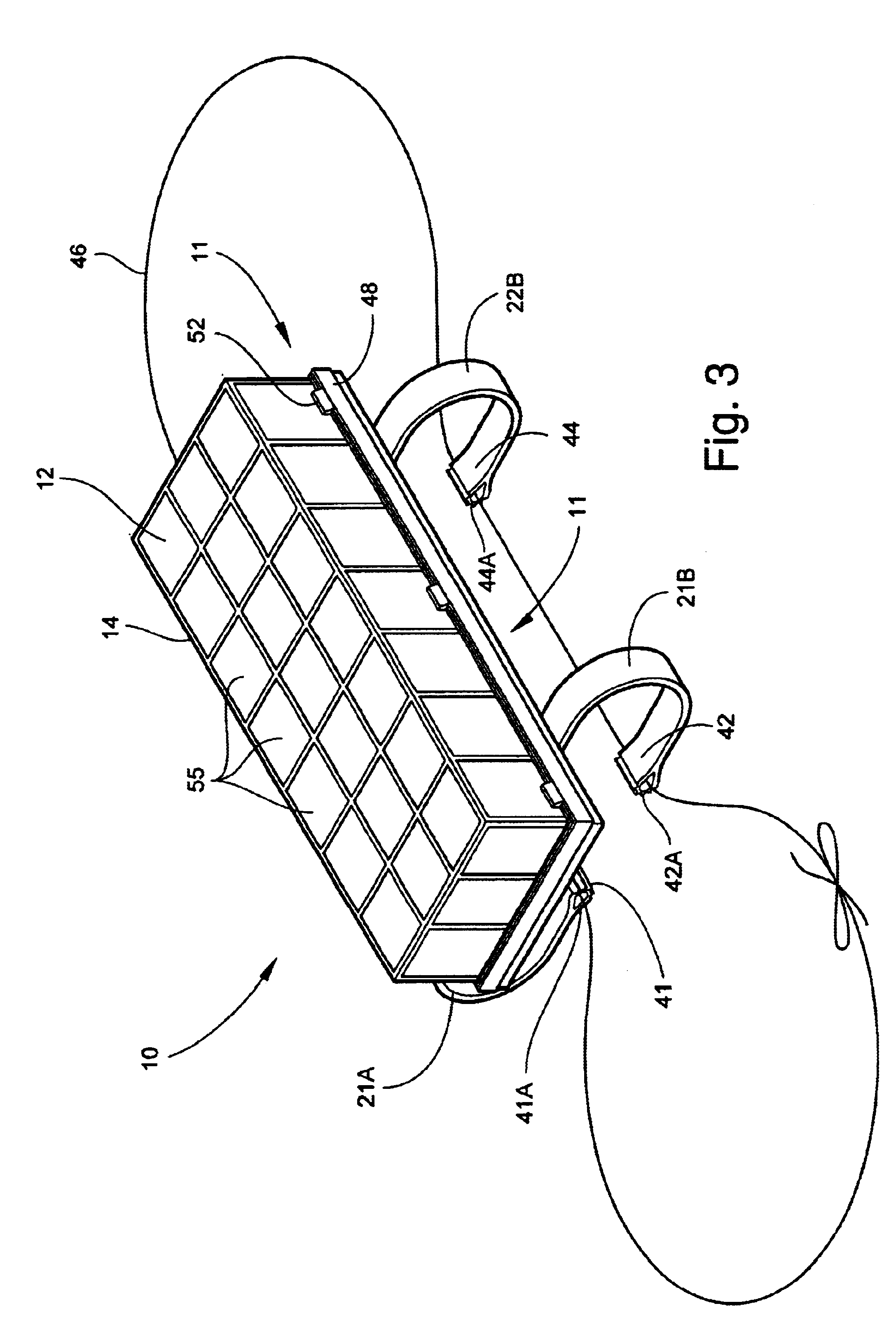

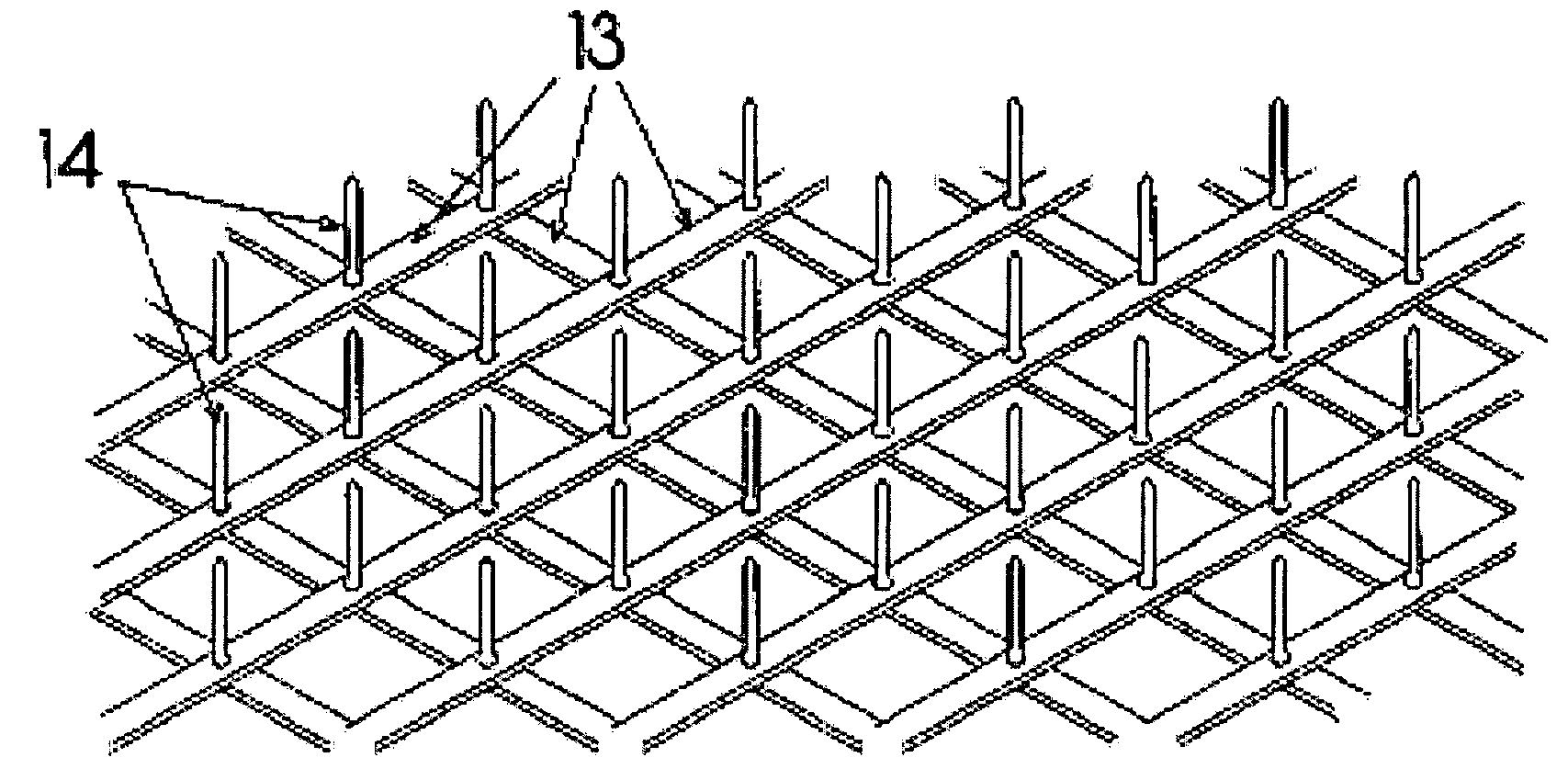

Tombstone flower saddle

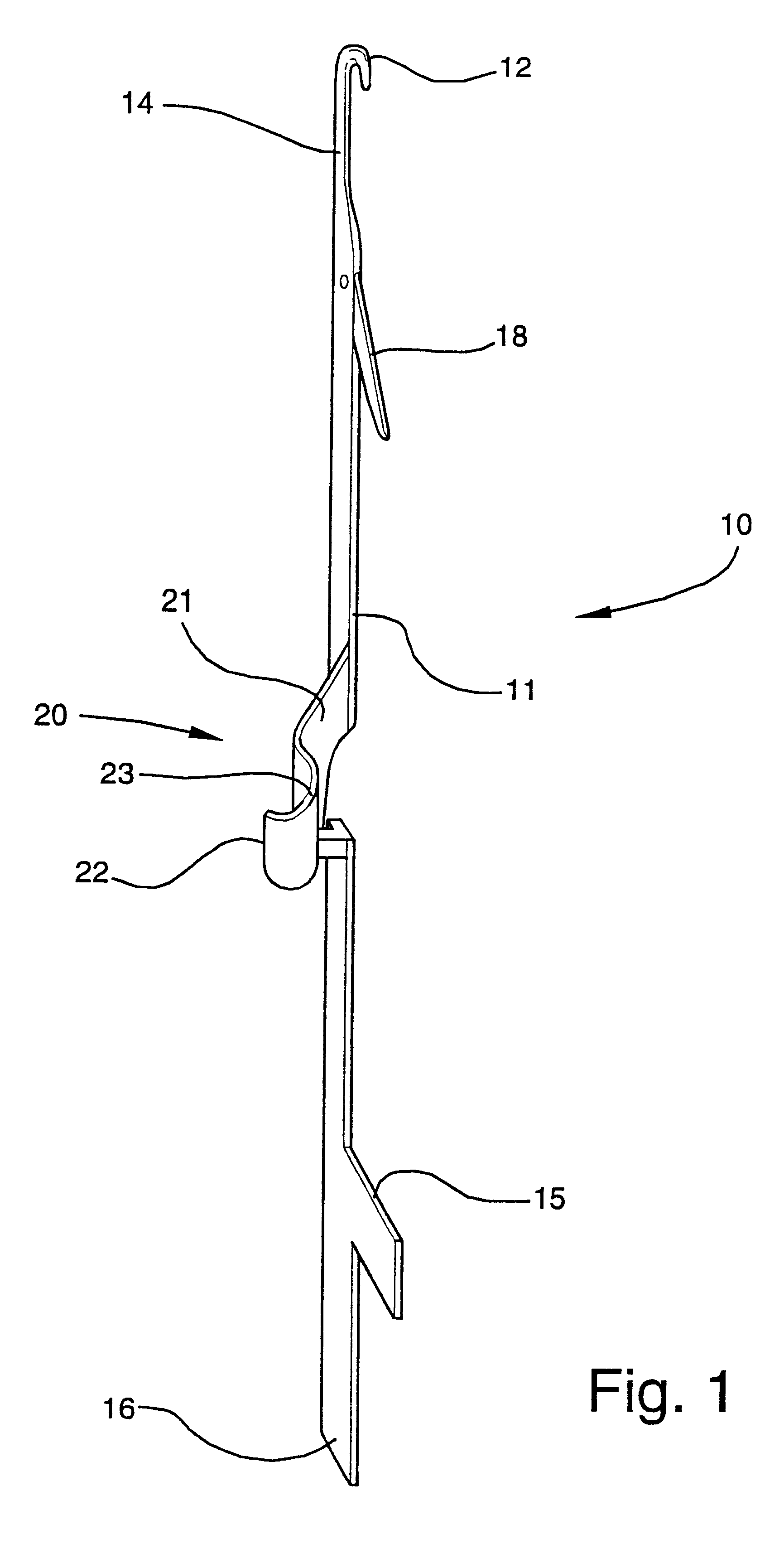

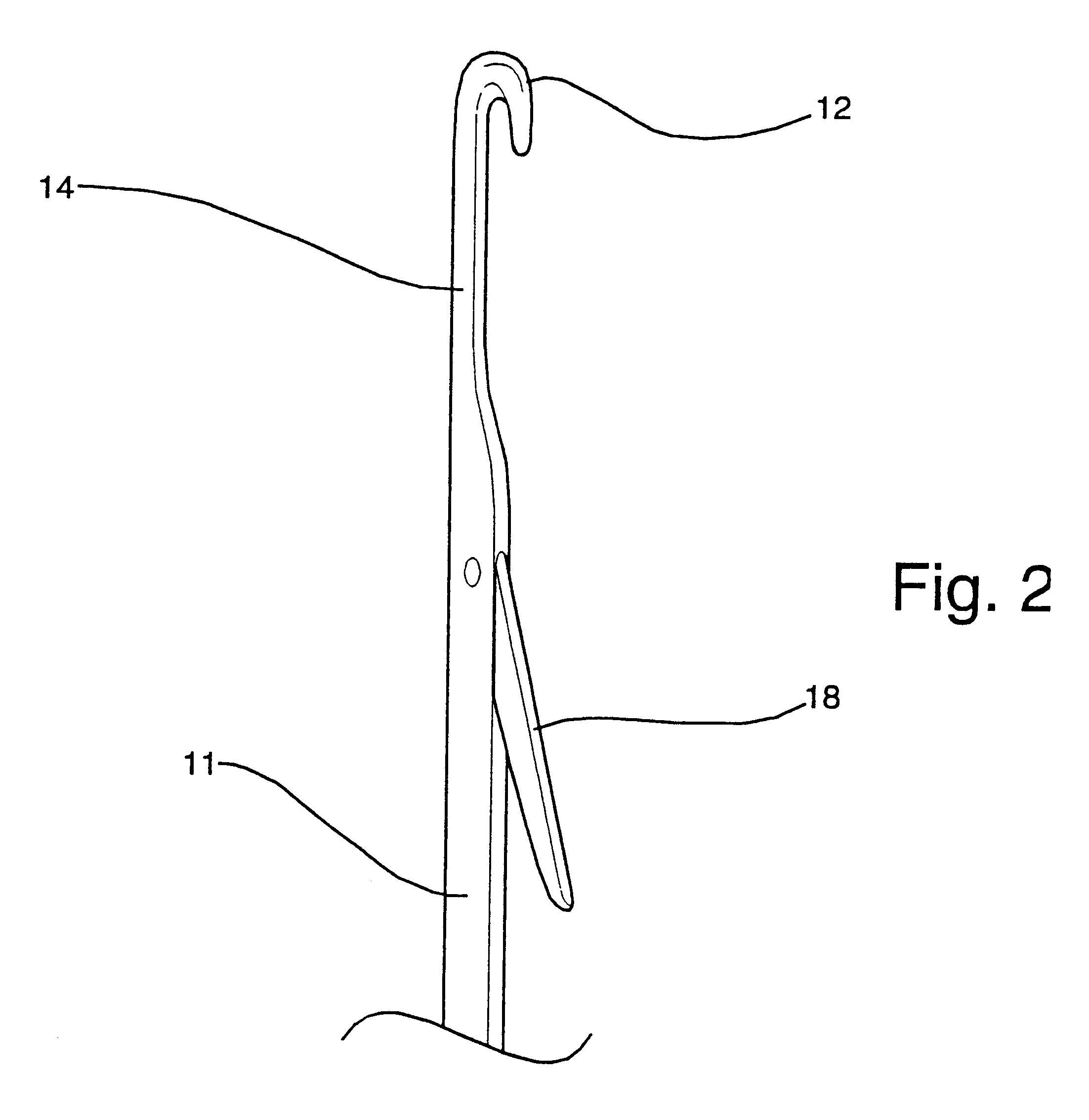

InactiveUS6688040B1For accurate placementConveniently disassembledFloral handlingFlower holdersEngineeringMechanical engineering

A flower saddle includes a base adapted for securing the flower saddle to a supporting structure. A foam block is located on the base, and is adapted for receiving stems of flowers and for holding the flowers in a desired position for display. A cage includes openwork covering the foam block. The openwork defines access points through which the stems of the flowers are received into the foam block.

Owner:YANG RONG TEAI

Device and method to provide air circulation space proximate to insulation material

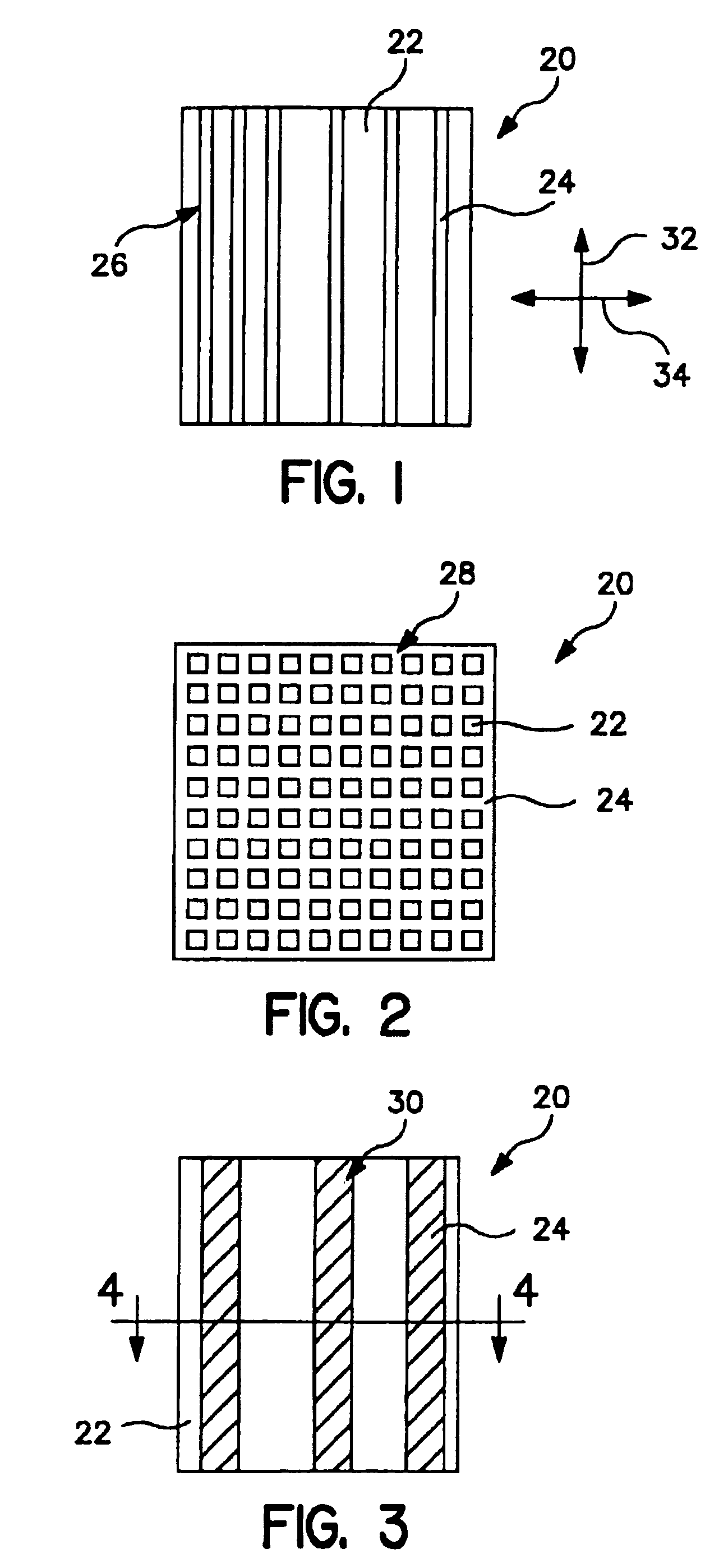

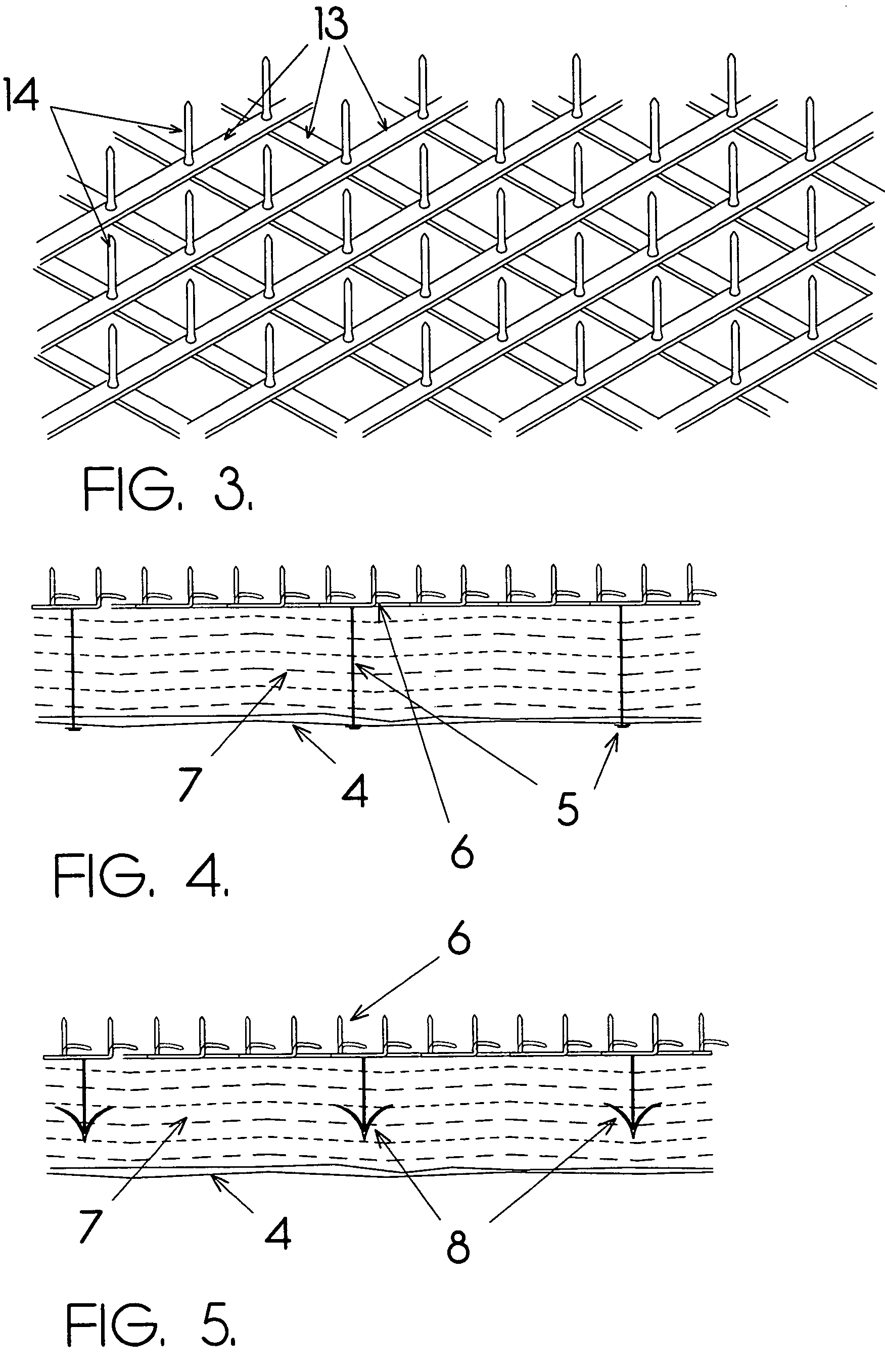

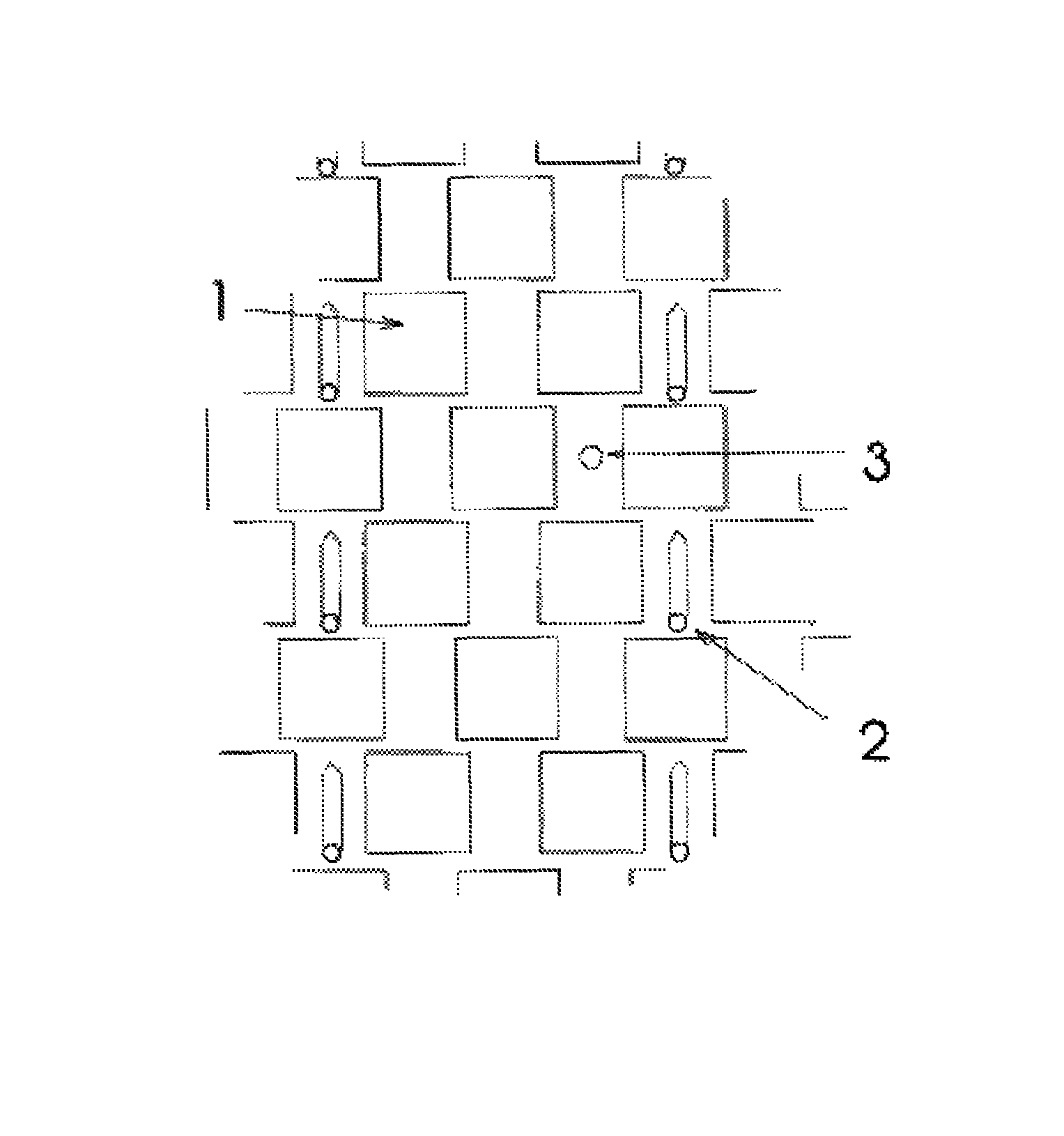

InactiveUS20080245010A1Easy to stackEasy to handleBuilding roofsCovering/liningsAir cycleEngineering

Insulation spacer devices, methods and related construction techniques are provided. An exemplary device may include a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material. The device may further include a plurality of spacer struts and / or spacing depressions fixedly attached to the body. The struts may be configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an insulated attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of Entangled net filaments or other similar material.

Owner:HETTRICH HANSL

RFID tire label

ActiveUS7338914B2Excellent label conformance and adhesionQuickly conform to tire surface irregularitiesStampsSynthetic resin layered productsEngineeringTyre label

Owner:INTERMEC IP

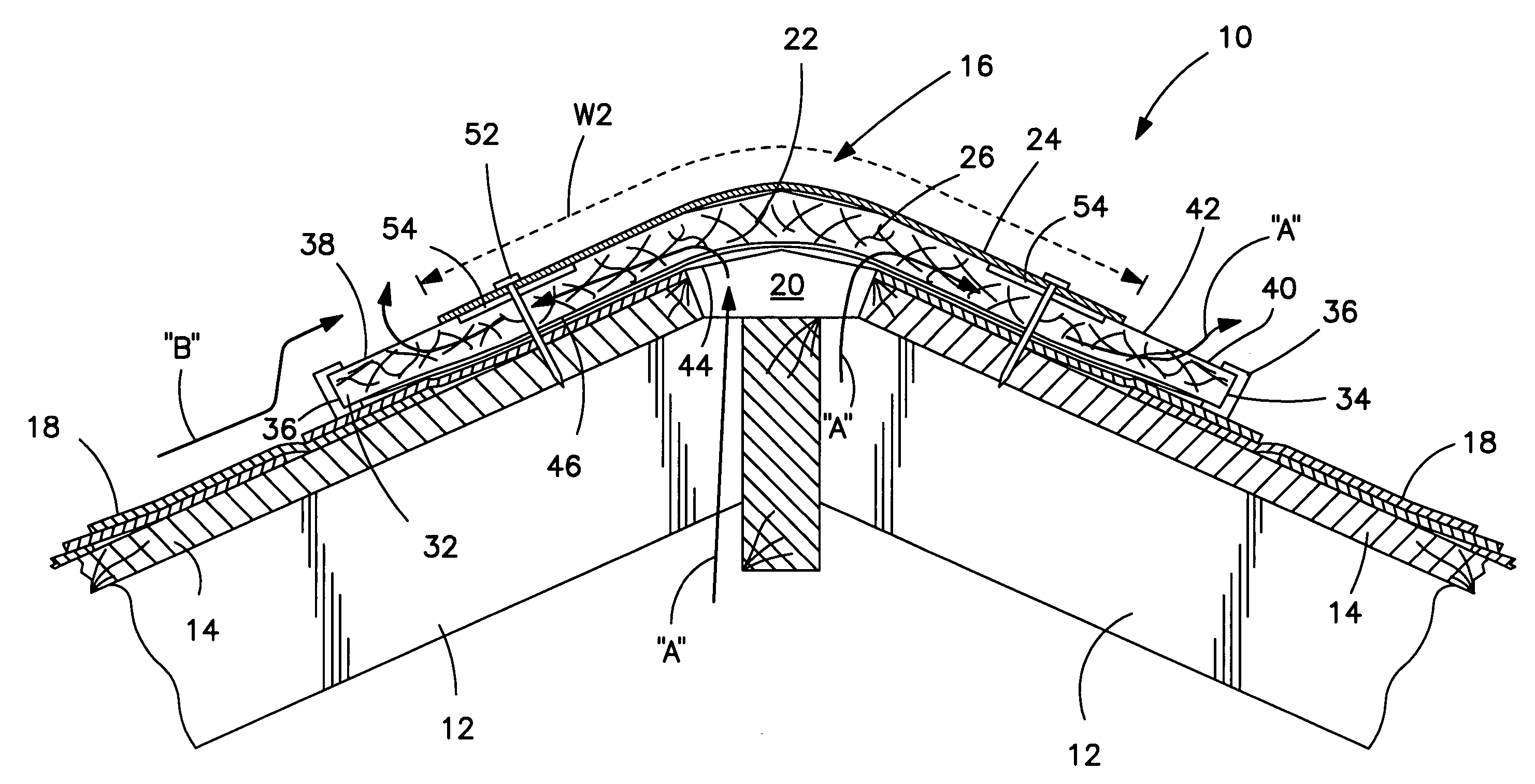

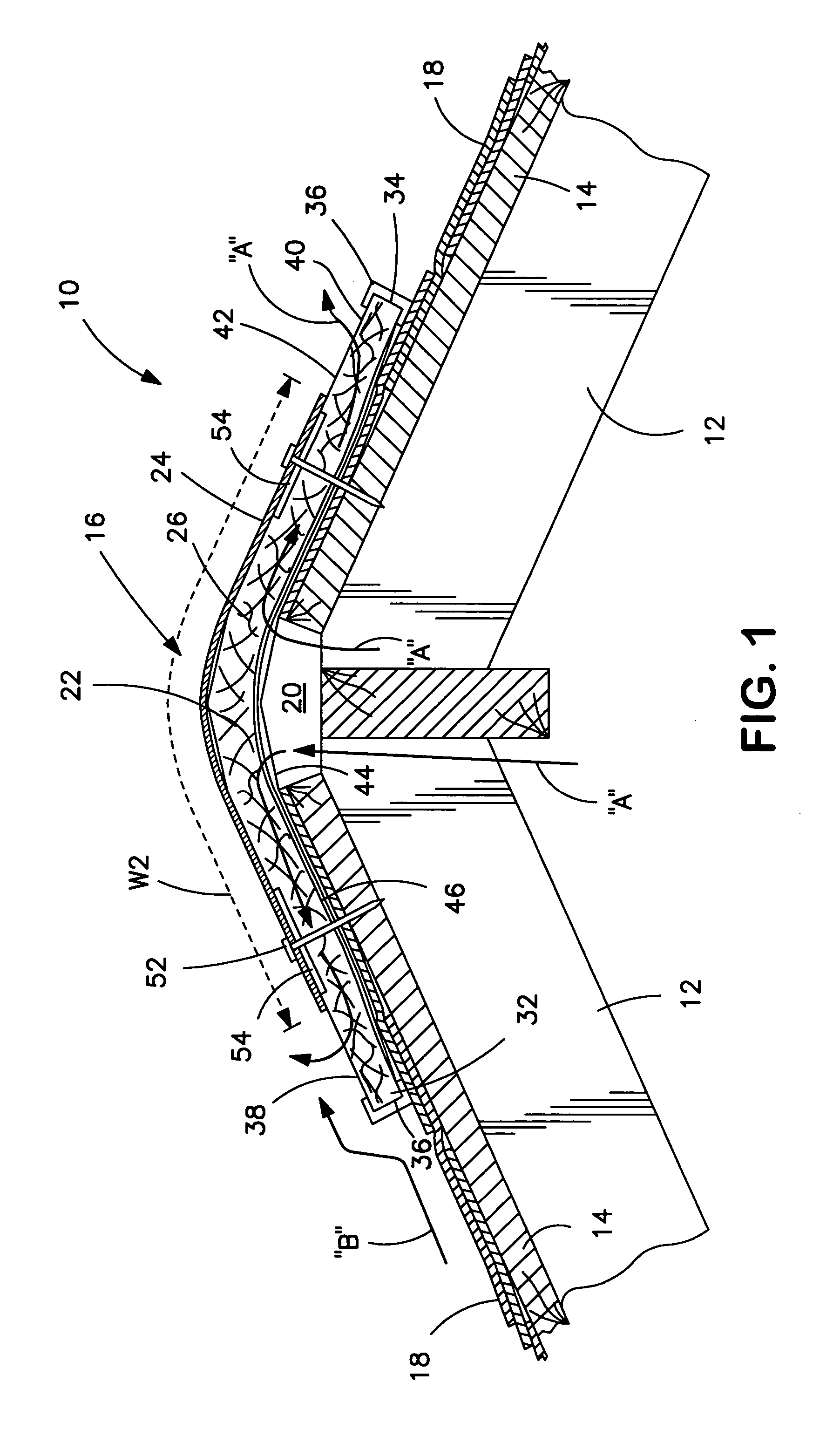

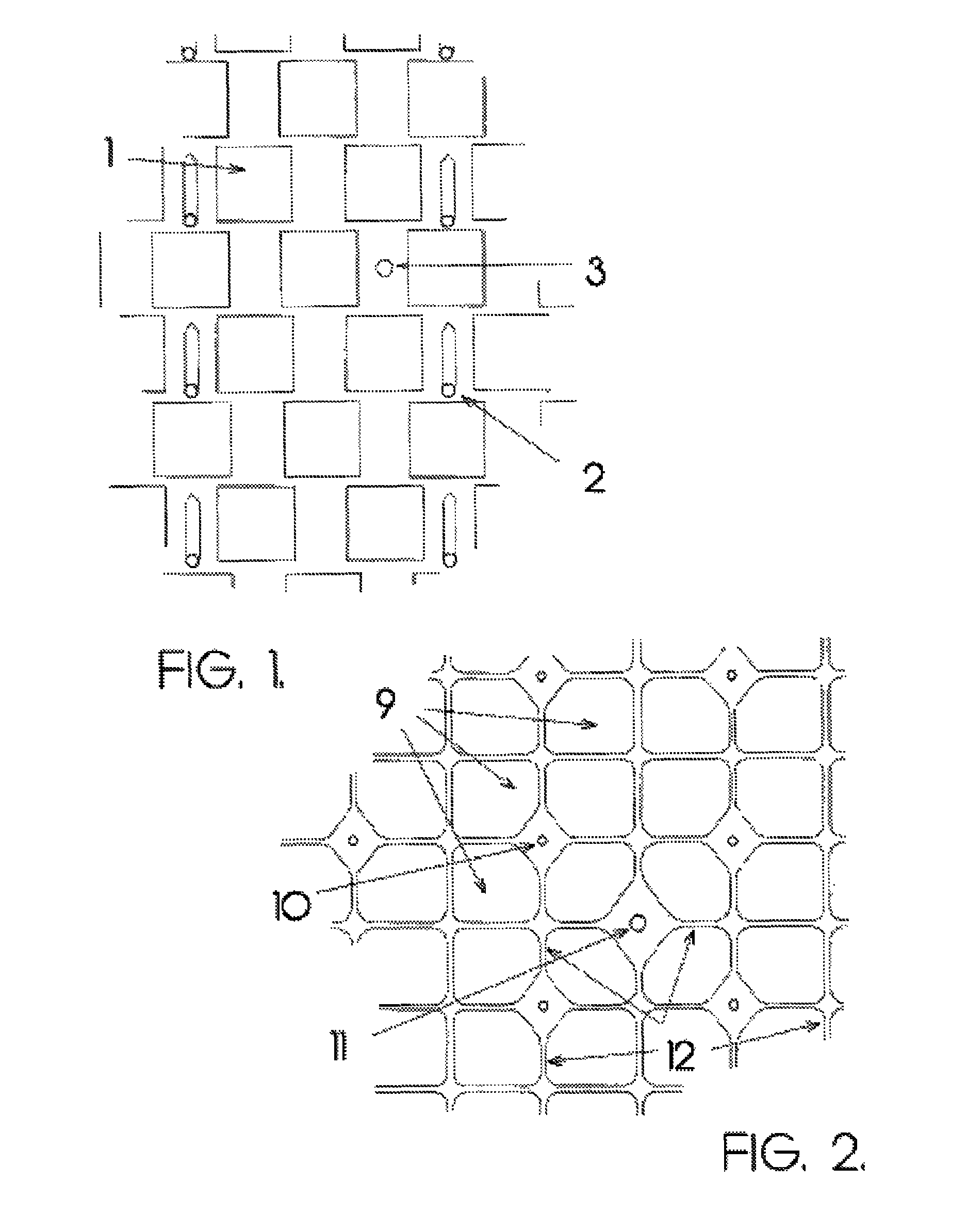

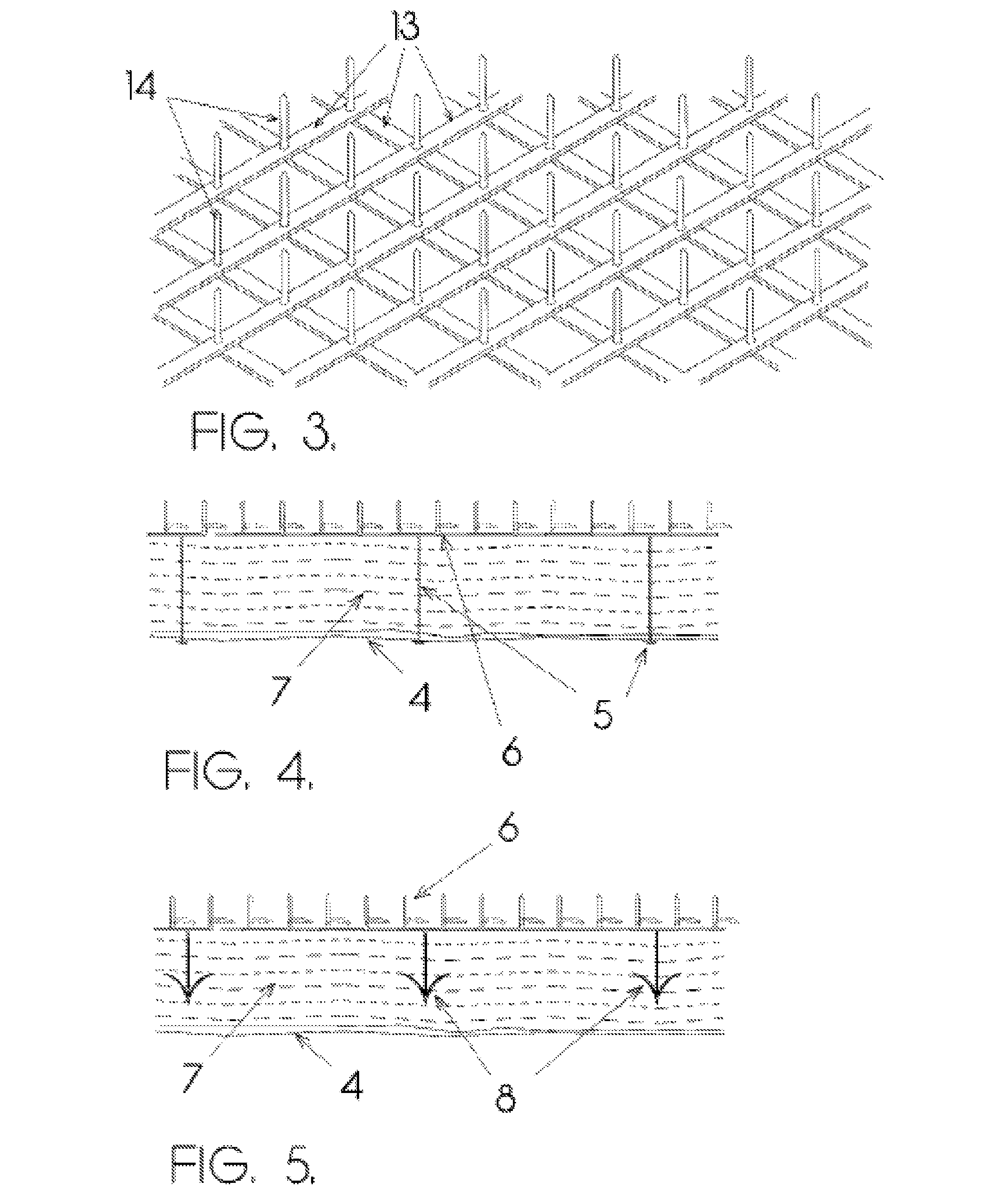

Ridge Vent and Roof Ridge Assembly

A roof ridge vent for installation overlying an open roof ridge to provide ventilation to a space beneath a roof is provided. The ridge vent is a continuous, elongate mat of randomly convoluted polymeric filaments having an openwork upper face, an openwork opposite lower face, a plurality of hollow recesses extending into the mat and opening into the lower face, and opposite longitudinally-extending openwork side edges. The openwork upper face is formed of randomly convoluted filaments formed to provide a relatively flat surface of sufficient density to catch heads of fasteners. The plurality of hollow recesses is defined by a plurality of upstanding openwork walls of convoluted filaments that extend from the upper face to the lower face of the mat. The upstanding openwork walls are arranged in a latticework structure such that no unobstructed passageways extend through the mat through which wind-blown rain and snow can freely pass into the side edges of the mat and laterally pass through the mat. A ventilated roof ridge assembly including the vent is provided.

Owner:BENJAMIN OBDIKE +1

Vented Soffit Assembly and Method of Installation

InactiveUS20070234650A1Roof covering using slabs/sheetsBuilding roofsEngineeringMechanical engineering

A continuous, elongate, strip of openwork ventilation material is provided in roll form and is unrolled and installed in a soffit as a one-piece, continuous vent along a length of the soffit. The opposite longitudinally-extending side edges of the ventilation material are inserted within opposed, spaced-apart channels lining the periphery of the soffit opening or are provided with laterally-extending fastening strips that are fastened to boards lining the soffit opening.

Owner:BENJAMIN OBDIKE

Rollable roof ridge vent having baffles

A roof ridge vent formed from a continuous, indeterminate-length, elongate strip of openwork material that has a pair of longitudinally-extending side edges each covered with a waterproof material. The edge coverings function as wind baffles and promote air circulation through the vent when wind blows over the roof ridge. The ridge vent is rollable lengthwise into a spiral roll for storage and shipment and is unrolled lengthwise during installation on a roof ridge

Owner:BENJAMIN OBDIKE

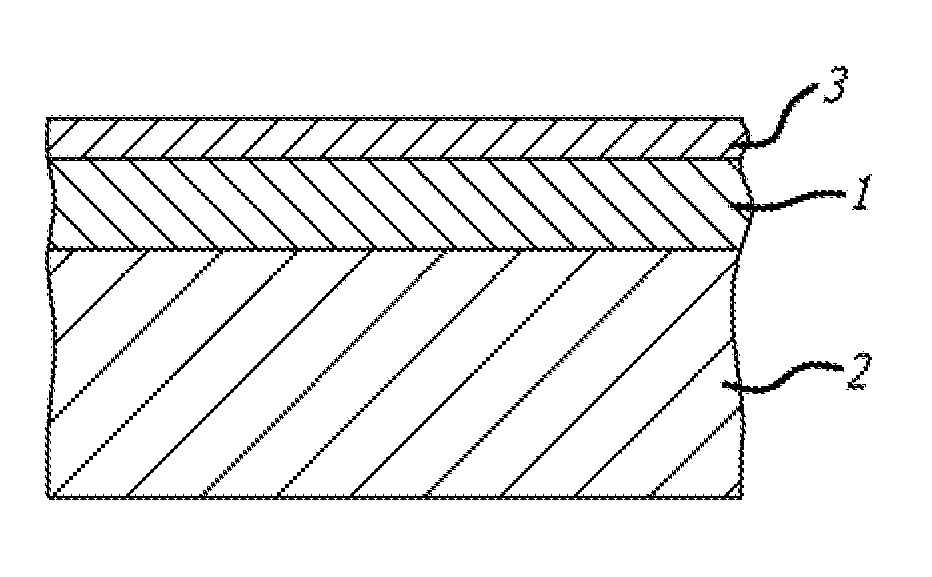

Moulding materials

InactiveUS7261930B2Good mechanical integrityPrecise positioningSynthetic resin layered productsCoatingsFibre reinforcementOpenwork

Moulding material that includes a layer of fibrous reinforcing material having one surface on which a first layer of a resin partially impregnates the fibrous material and a further resin layer located on the opposite surface which retains in position surface fibers of the fibrous material. The further resin layer is of lower weight than the first layer and is formed as an openwork structure with a solid part and spaces through which the fibrous material is exposed.

Owner:HEXCEL COMPOSITES LTD (GB)

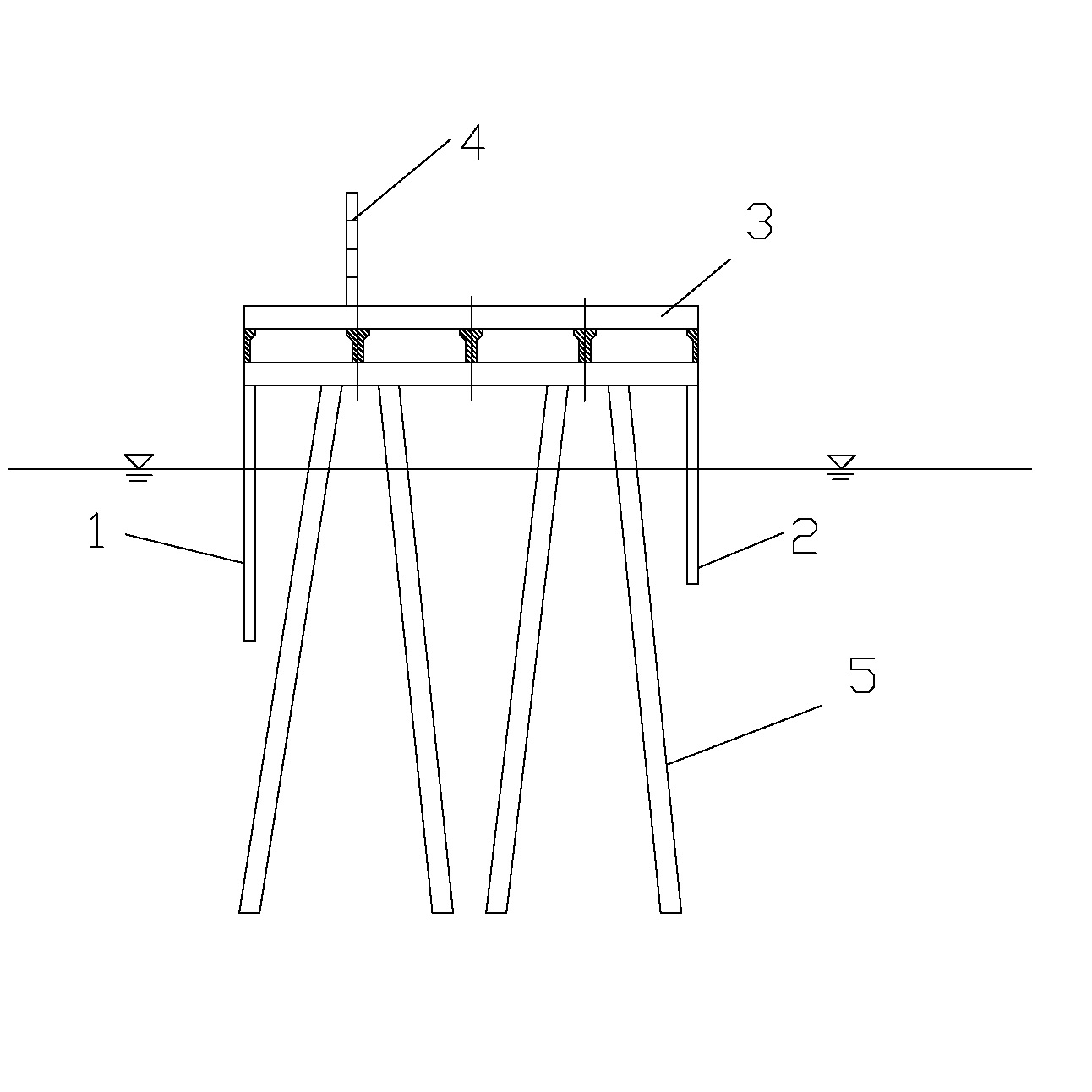

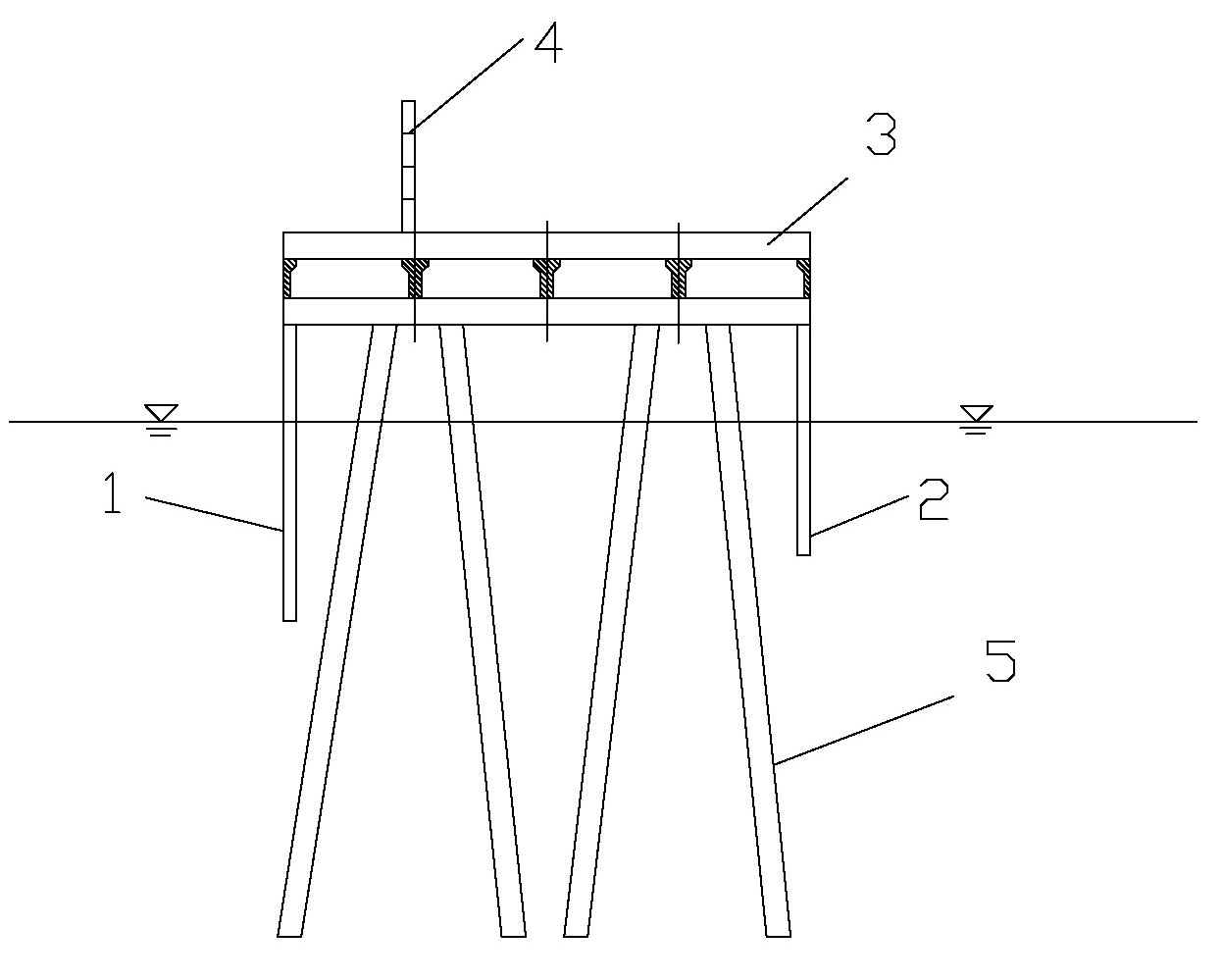

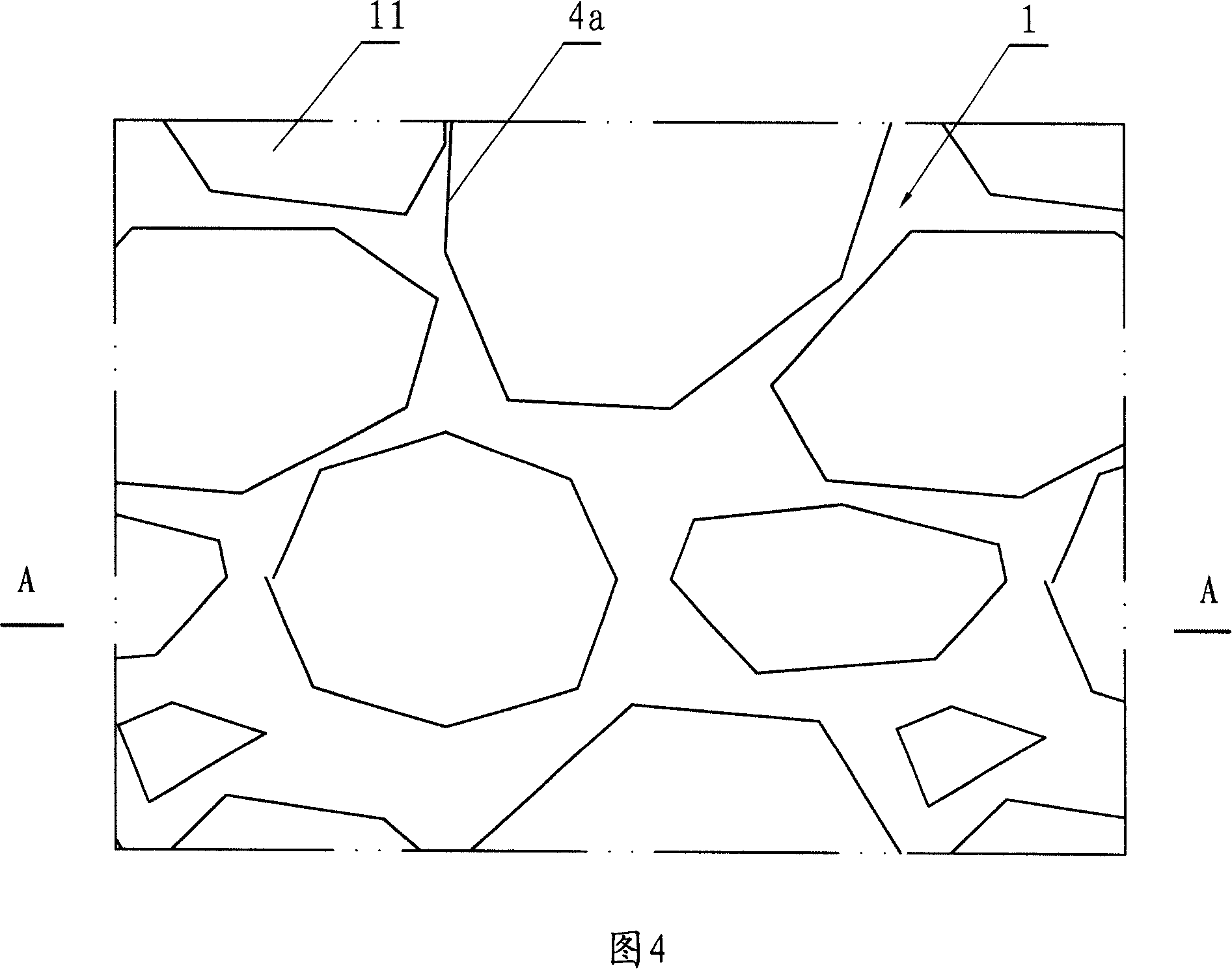

Openwork breakwater

The invention discloses an openwork breakwater which is characterized by comprising a pile foundations (5), wherein the pile foundations (5) are fixed under water; the upper end of each pile foundation is provided with an openwork breakwater horizontal plate (3); both the front and rear sides of the openwork breakwater horizontal plate (3) are provided with an outside manger board (1) and an inside manger board (2) which extend into water; and the openwork breakwater horizontal plate (3) is also provided with a wave wall. The openwork breakwater is simple in structure and low in cost, is specially applicable to sea areas with deep water depth and hostile environments, and is more consistent with the actual wave-breaking situation, thus playing a preferable wave-breaking effect and ensuring the stabilities of the sea areas in a harbor.

Owner:HOHAI UNIV

Device and method to provide air circulation space proximate to insulation material

Owner:HETTRICH HANSL

Devices and methods to provide air circulation space proximate to insulation material

Owner:HETTRICH HANSL

Devices and methods to provide air circulation space proximate to insulation material

Insulation spacer devices, methods and related construction techniques are provided. An exemplary device may include a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material. The device may further include a plurality of spacer struts and / or spacing depressions fixedly attached to the body. The struts may be configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an insulated attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of Entangled net filaments or other similar material.

Owner:HETTRICH HANSL

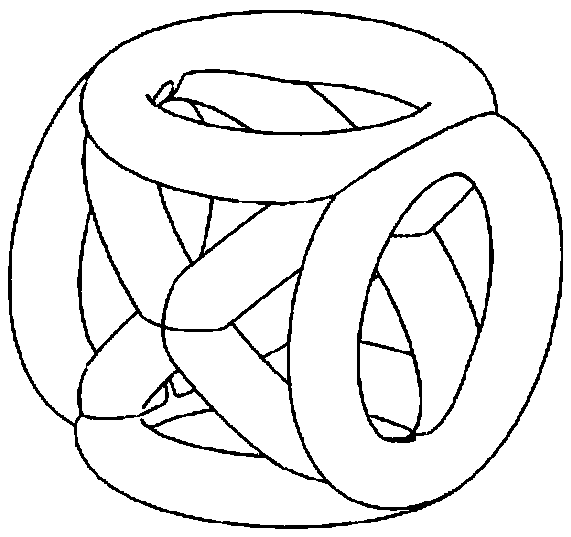

Porous implant filled with O-intersecting lines units

InactiveCN105496611AThe preparation method is reliable and feasibleGreat potentialJoint implantsTissue regenerationBone structureTissue fluid

A porous implant filled with O-intersecting lines units is mainly oriented to femoral stems and comprises a femoral stem end, a porous main body part and a screw positioning hole part, wherein the femoral stem end is used for positioning the porous implant, the screw positioning hole part is used for fixing the implant and a host, the porous main body part is a three-dimensional through porous network entity mainly formed by being filled with the O-intersecting lines units, the porous network entity comprises hollowed-out entities formed by scanning of O-intersecting lines unit cylinders penetrating through and crossing with one another in space, the hollowed-out entities are formed by pairwise perpendicular and linearly stacked O-intersecting lines unit cylinder surfaces, and the porous network entity has the pore diameter ranging from 400 mu m to 1,000 mu m, the unit wall thickness ranging from 80 mu m to 120 mu m and the porosity ranging from 55% to 85%. Thus, a porous network structure formed by stacking of the hollowed-out entities is close to a bone structure, has the high porosity, the high communication ratio and the larger surface contact area, is suitable for new bone ingrowth and circulation of nutrition tissue liquids and has the considerable clinical medical prospect.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Multilayer composite lining

InactiveCN101125470AIncreasing the thicknessImprove the ability to keep warmOrnamental structuresSpecial ornamental structuresSurface layerInter layer

The invention relates to a multi-layer compound capstock, which consists of a surface layer, a bottom layer and a central layer. A plurality of layers are super positioned and then oversewed together. Through dyeing and water washing operation, the partial sealed area formed by the oversewed line of the surface layer is cutout and peeled or cut into various shapes. Finally the capstock is well made after the sealed area is over turned to the upper surface of the surface layer and the central layer is the capstock of various velvets. Resulting from that the central layer selects the fluffy and extending velvet surface capstock, concave and convex parts are caused on the oversewed or water washed surface of the capstock. The sealed area formed by the print of the oversewed line is provided with a hollow, and then the velvet sewed article of the central layer is exposed. The exposed weaving material with various quality enables the clothing generally to form pictures with inscribed stereoscopic sensation. The capstock at the hollowed position is cut into various shapes and overturned and later is oversewed on the surface layer and reoversewed, in this way, the decorating stereoscopic sensation is greatly reinforced. Therefore, the invention not only improves the heat insulation and processing property of the capstock, but also has undesirable effect on beautifying and decoration.

Owner:季灵英

Devices and methodd to provide air circulation space proximate to insulation material

InactiveUS20110209426A1Easy to stackEasy to handleRoof coveringConstruction materialAir cycleEngineering

Insulation spacer devices, methods and related construction techniques are provided. An exemplary device may include a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material. The device may further include a plurality of spacer struts and / or spacing depressions fixedly attached to the body. The struts may be configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an insulated attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of Entangled net filaments or other similar material.

Owner:HETTRICH HANSL

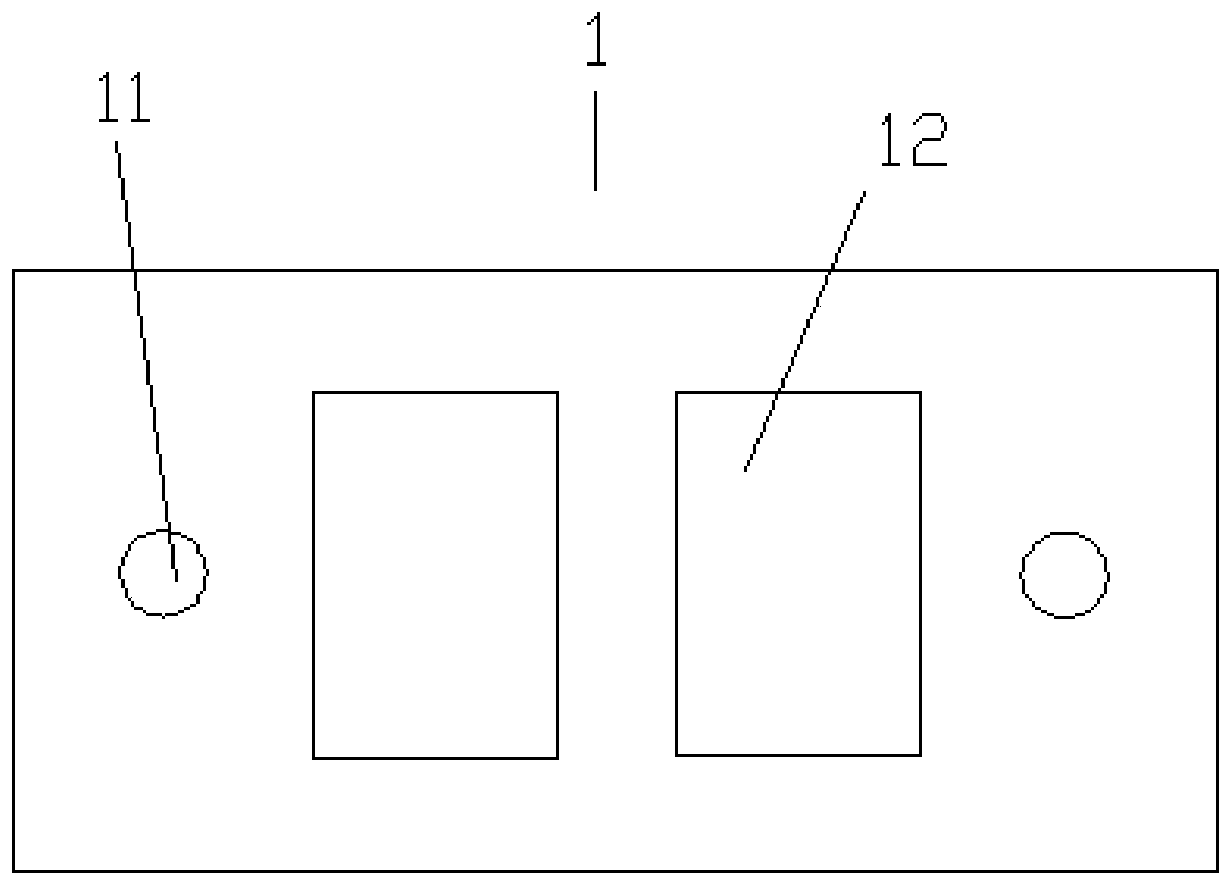

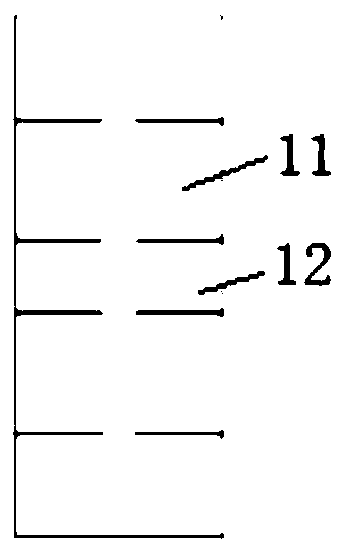

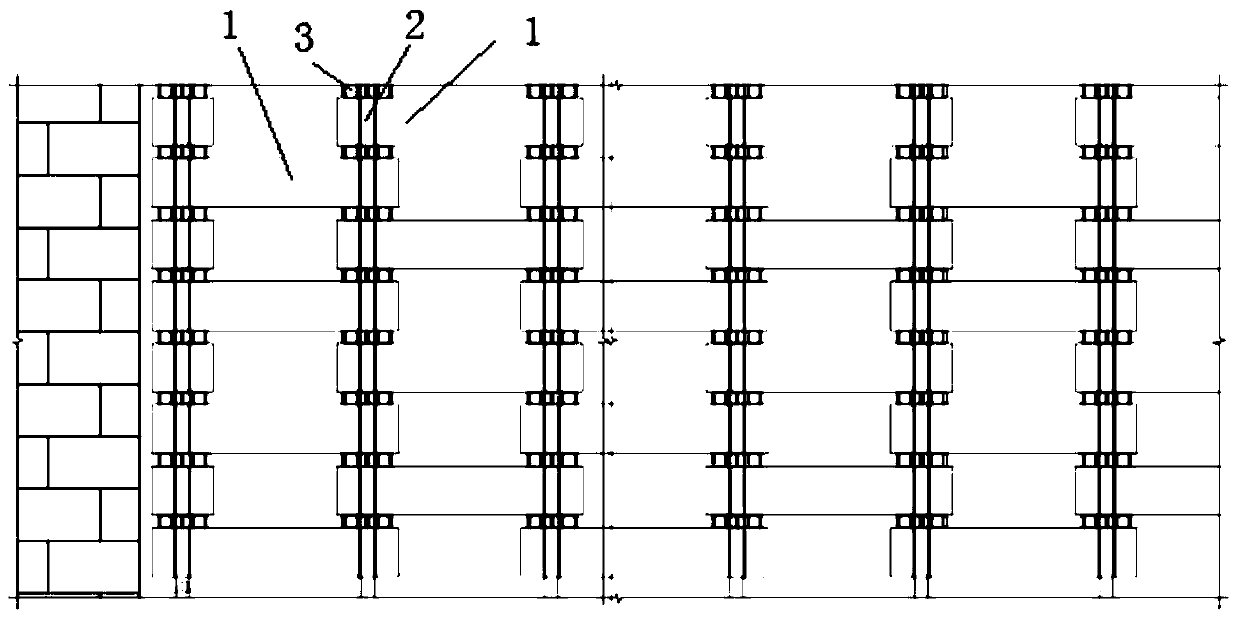

Dry hanging structure of fabricated hollow-out earthenware brick curtain wall and construction method of dry hanging structure of fabricated hollow-out earthenware brick curtain wall

The invention relates to a dry hanging structure of a fabricated hollow-out earthenware brick curtain wall and a construction method of the dry hanging structure of the fabricated hollow-out earthenware brick curtain wall. The dry hanging structure comprises a keel skeleton arranged on the side wall of a structure main body outer wall and a hooking-up assembly fixed to the keel skeleton, and a plurality of hollow-out earthenware bricks are connected through the hooking-up assembly; the hooking-up assembly comprises a plurality of vertically arranged connecting rods; and connecting holes enabling the connecting rods to penetrate through are formed in the hollow-out earthenware bricks, and the adjacent upper and lower hollow-out earthenware bricks are connected through a mode of the connecting rod penetrating through the corresponding connecting hole. The technical problems that a dry hanging structure of an existing hollow-out earthenware brick curtain wall is prone to causing crackingand breakage of side walls of the hollow-out earthenware bricks, the operation difficulty is large, the material waste is serious, and the construction cost is greatly increased are solved.

Owner:CHINA CONSTR DONGFANG DECORATION CO LTD

Decorative fair-faced concrete construction method

InactiveCN107956261AImprove protectionImprove waterproof performanceWallsForms/shuttering/falseworksEngravingWindow opening

The invention discloses a decorative fair-faced concrete construction method. The method comprises the steps of S1, engraving by adopting the combination of intaglio engraving and hollow engraving; S2, assembling a frame mold; S3, assembling a formwork and the frame mold; S4, forming holes on the formwork; S5, spreading salad oil after the surface of the formwork is wiped clean; S6, snapping a wall position line, installing a door and window opening formwork and correcting; S7, installing an inner side wall body formwork and an outer side wall body formwork; S8, correcting and reinforcing theformworks installed in step S7; S9, pouring cement between the inner side wall body formwork and the outer side wall body formwork which are reinforced in S8; S10, removing the formworks to acquire decorative fair-faced concrete. According to the construction method, the salad oil is spread as a demoulding agent, the salad oil is transparent and pollution-free and has good protective effect on theconcrete and protective waterproof effect on the formworks, and by adopting the combination of the intaglio engraving and the hollow engraving, the forming effect is good, formed patterns are plump and have three-dimensional senses, and membrane papers of other formworks are not damaged.

Owner:中匠华湄模板制造有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com