Patents

Literature

360 results about "Position line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A position line is a line that can be identified both on a nautical chart or aeronautical chart and by observation out on the surface of the earth. The intersection of two position lines is a fix that is used in position fixing to identify the navigator's location.

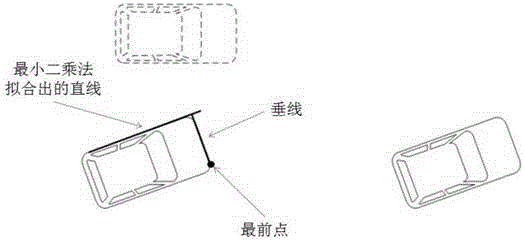

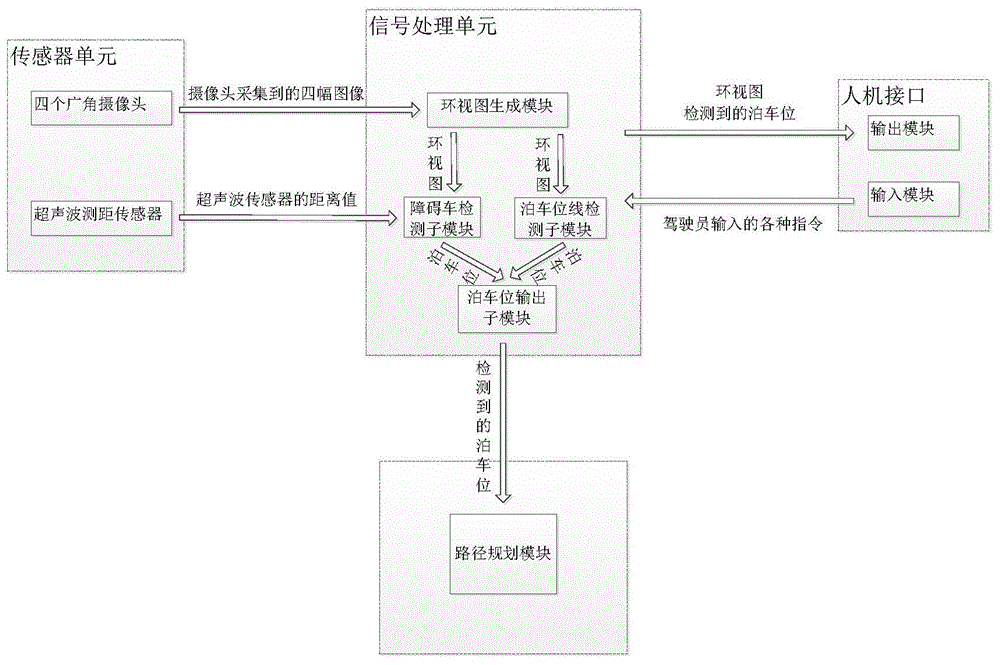

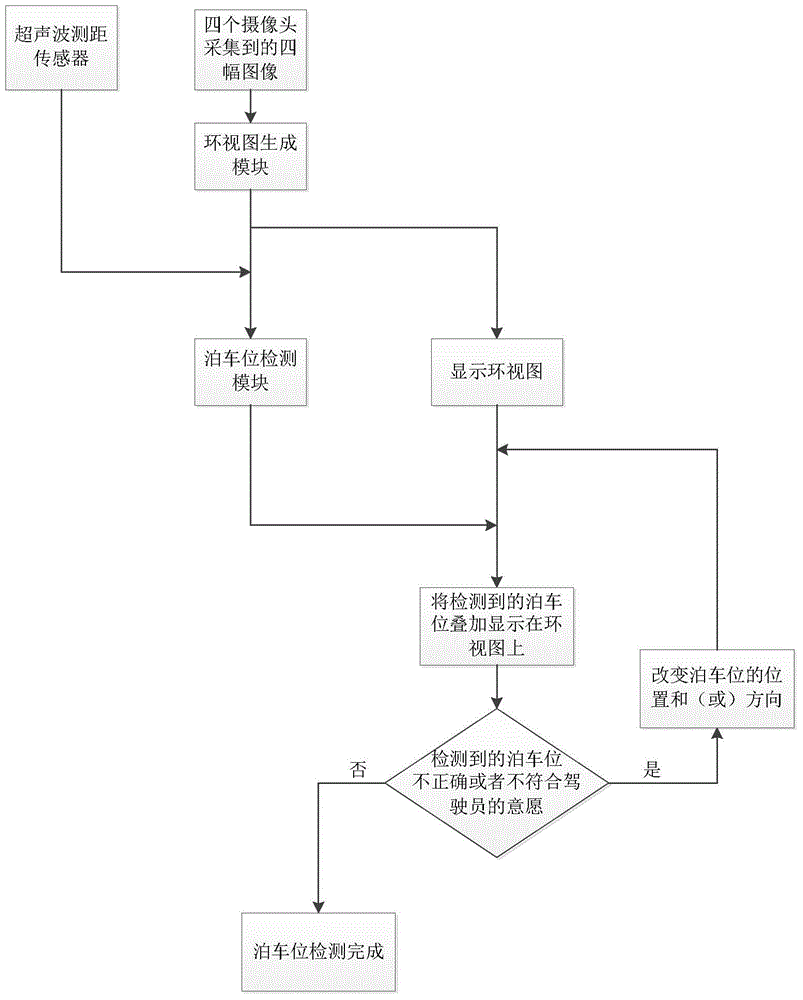

Parking position detecting device and method of intelligent parking system

The invention discloses a parking position detecting device of an intelligent parking system. The parking position detecting device comprises a sensor unit, a signal processing unit, and a man-machine interface unit. The sensor unit comprises four wide-angle cameras and an ultrasonic ranging sensor. The signal processing unit comprises an annular view generation module and a parking position detecting module. The man-machine interface unit comprises an output module used for displaying an annular view and detected garage positions, and an input module used for receiving various commands inputted by a driver. The parking position detecting module comprises a garage position line detection submodule, an obstacle vehicle detection submodule and a parking position output submodule. The invention further discloses a parking position detecting method of the intelligent parking system. A low-cost sensor scheme is adopted, accuracy and precision of parking position detection are improved by mixing distance value obtained by the ultrasonic ranging sensor with image information collected by the cameras, and parking positions can be effectively detected under multiple conditions that garage lines and obstacle vehicles exist on a ground.

Owner:TONGJI UNIV

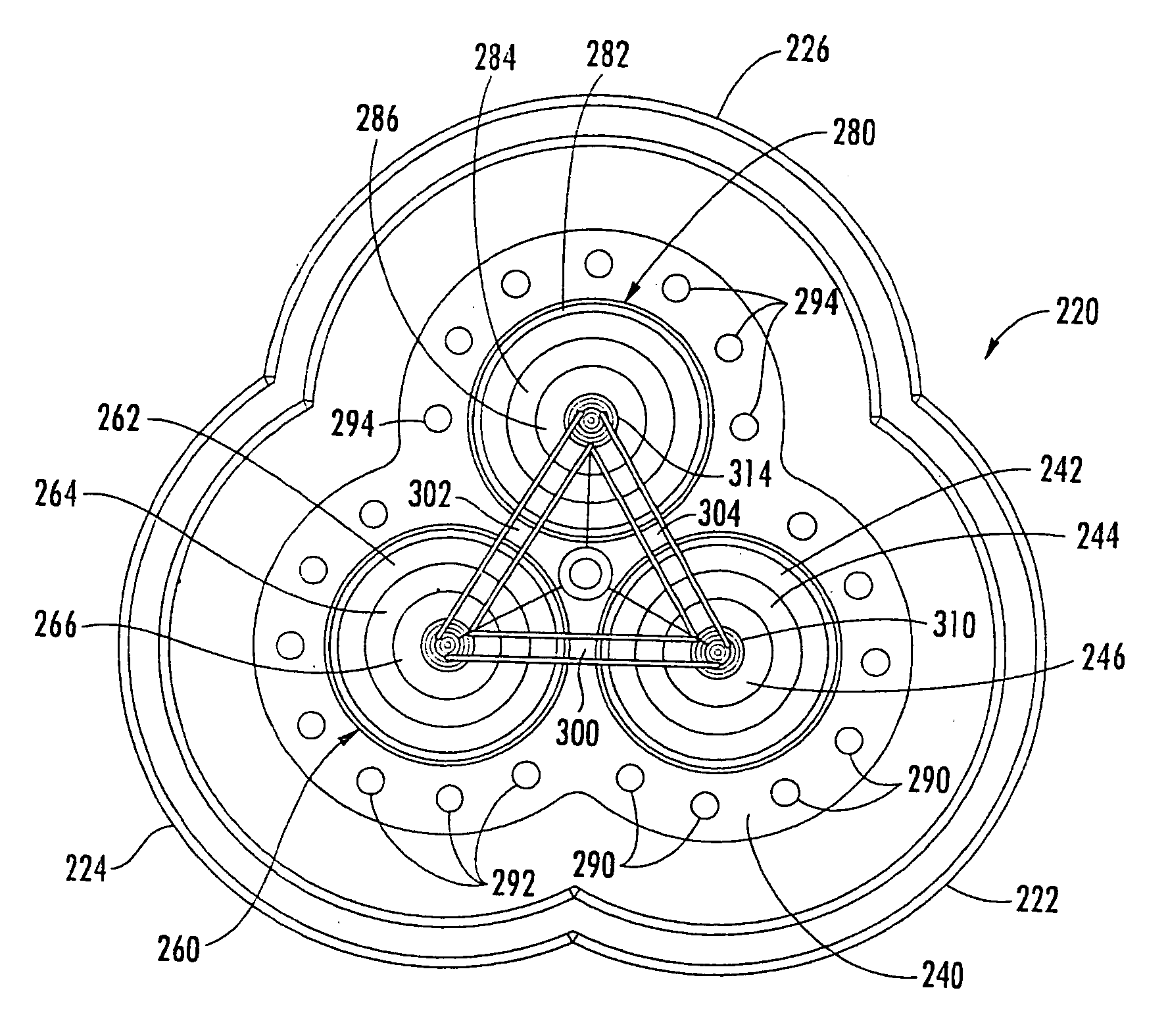

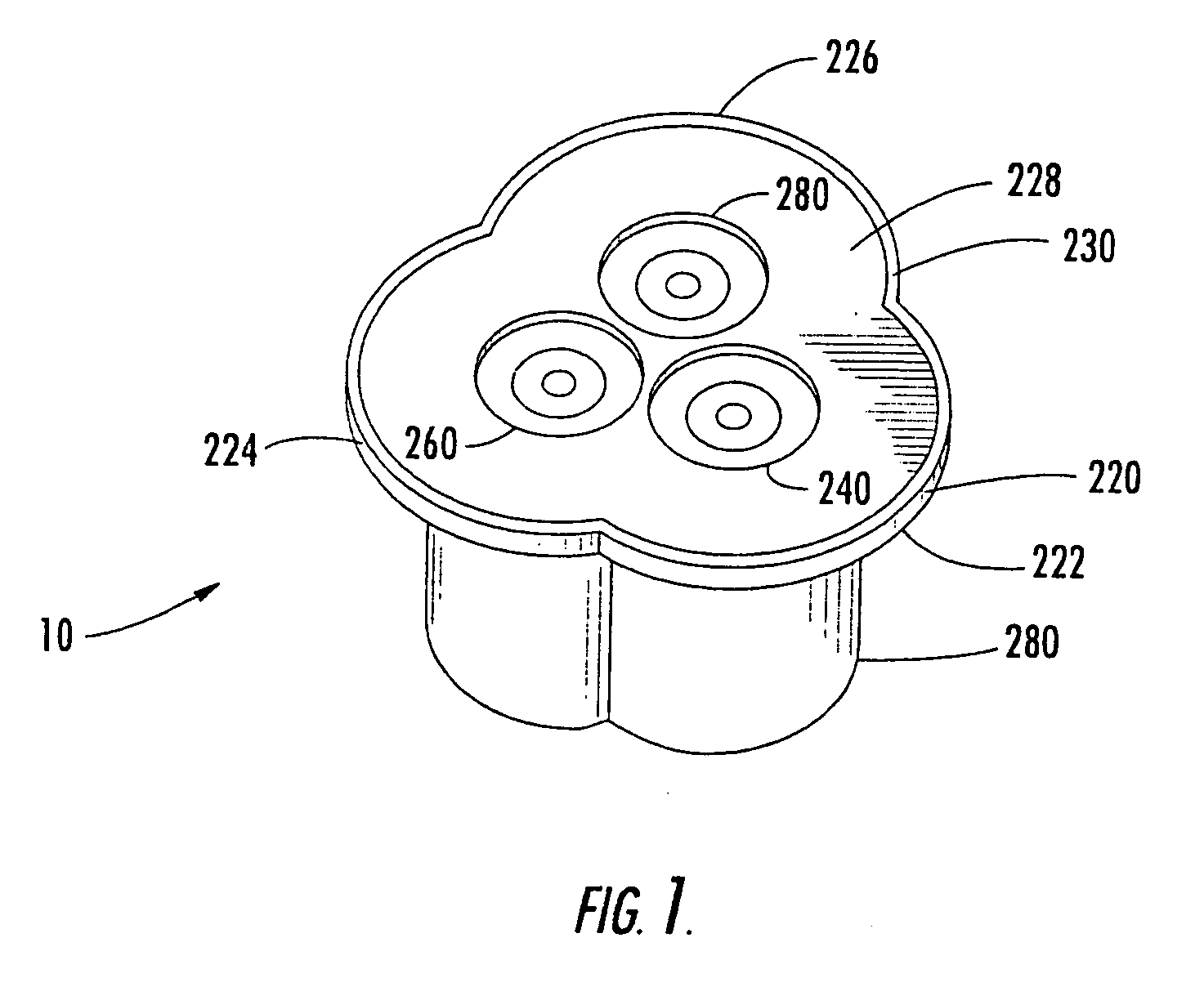

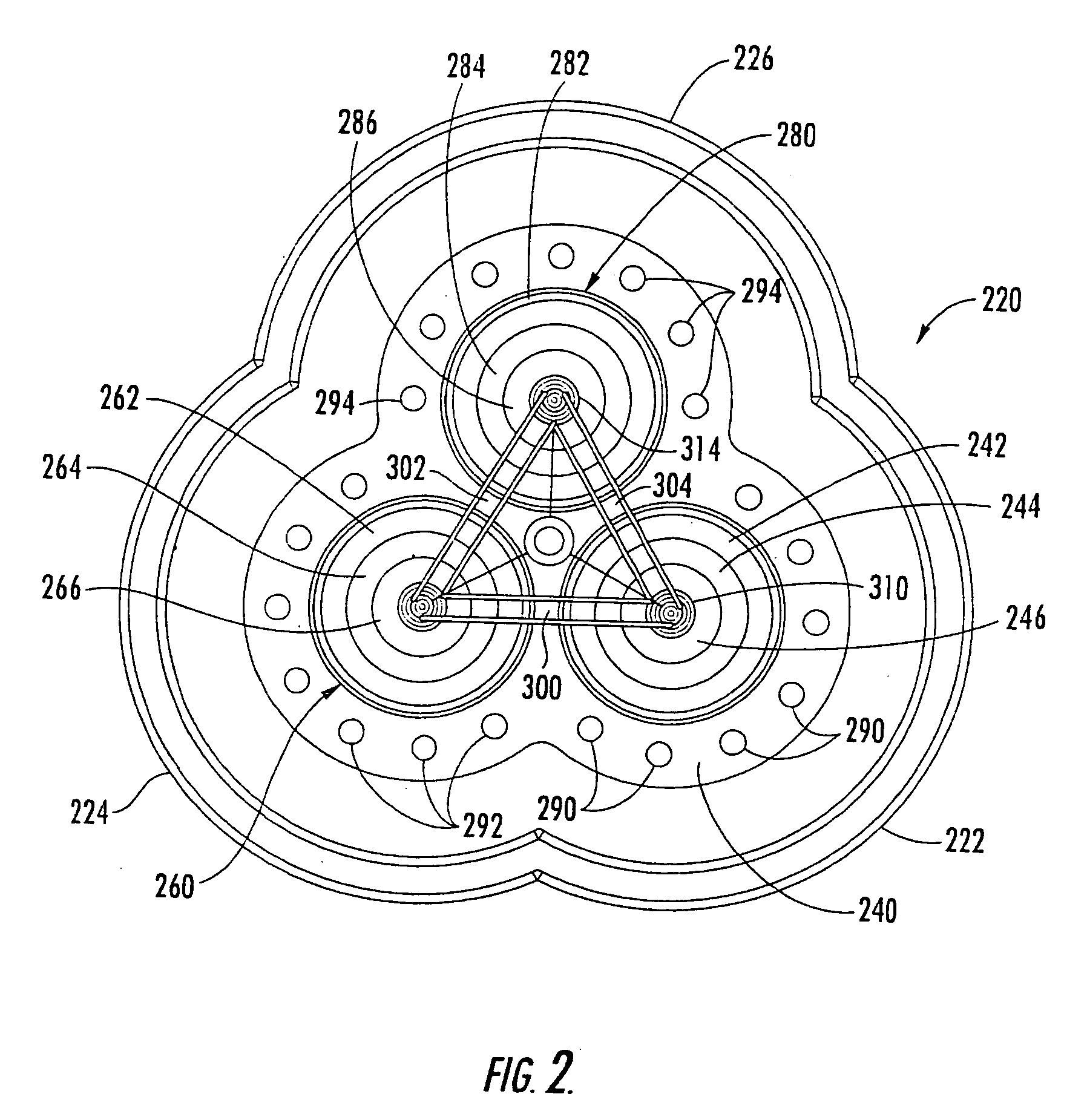

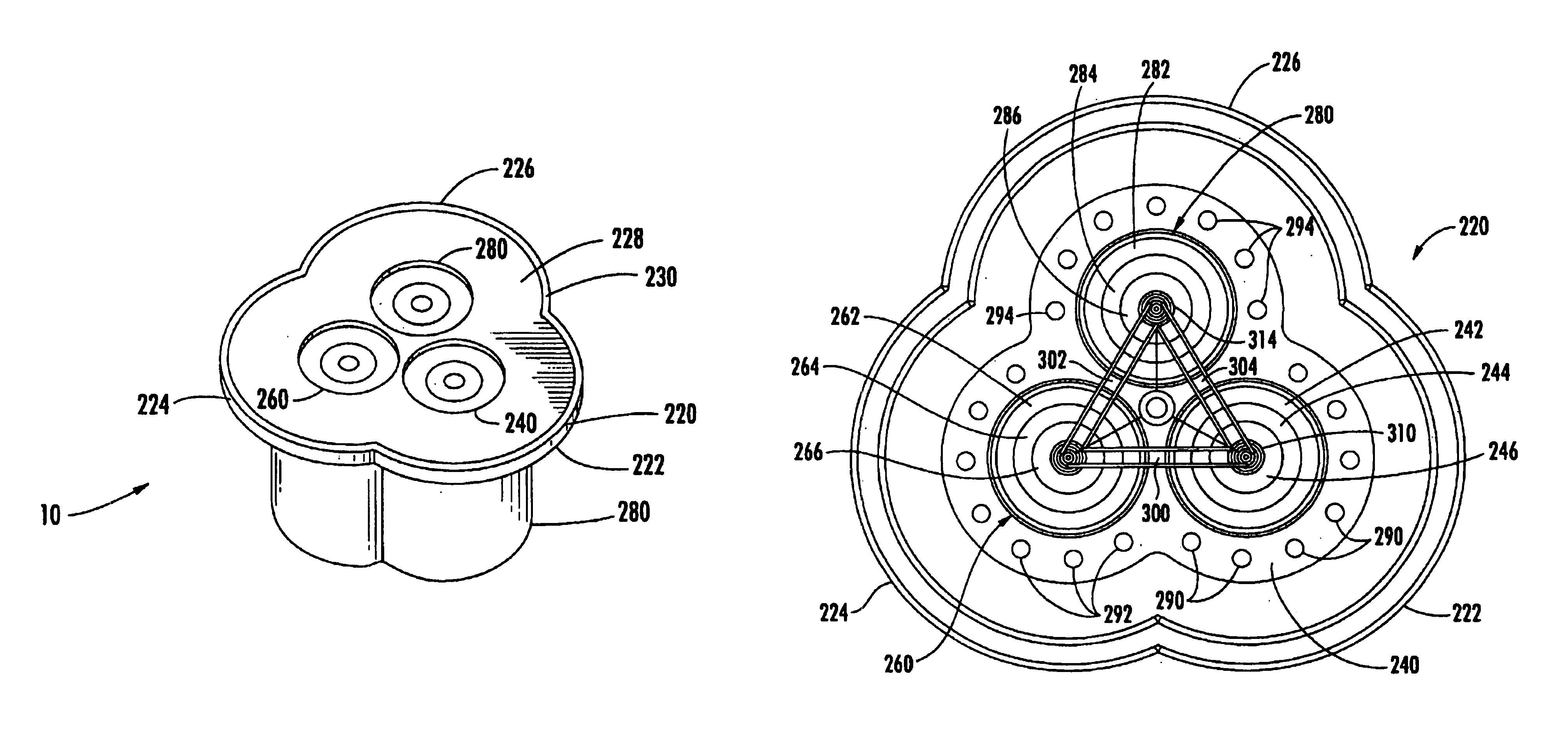

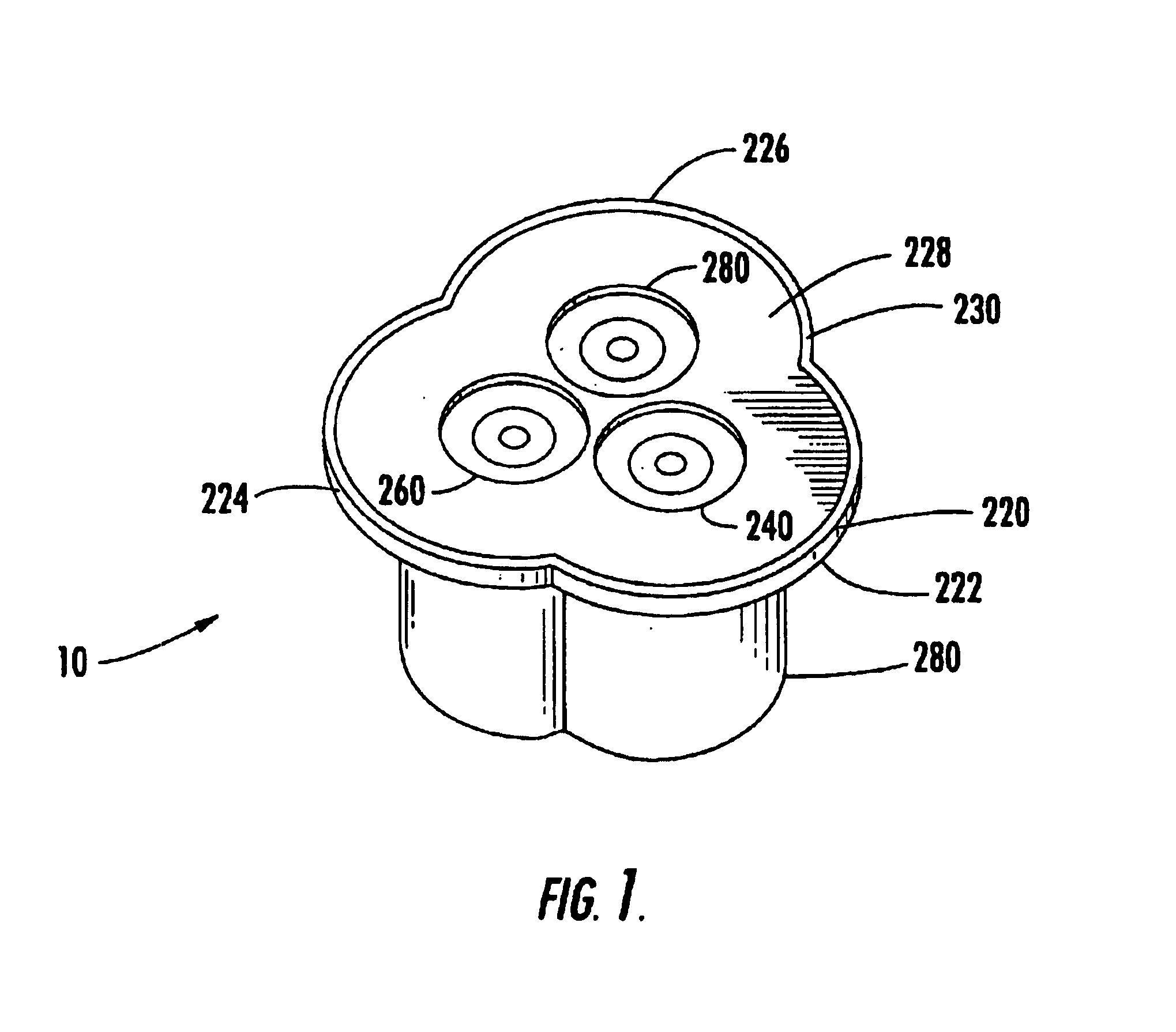

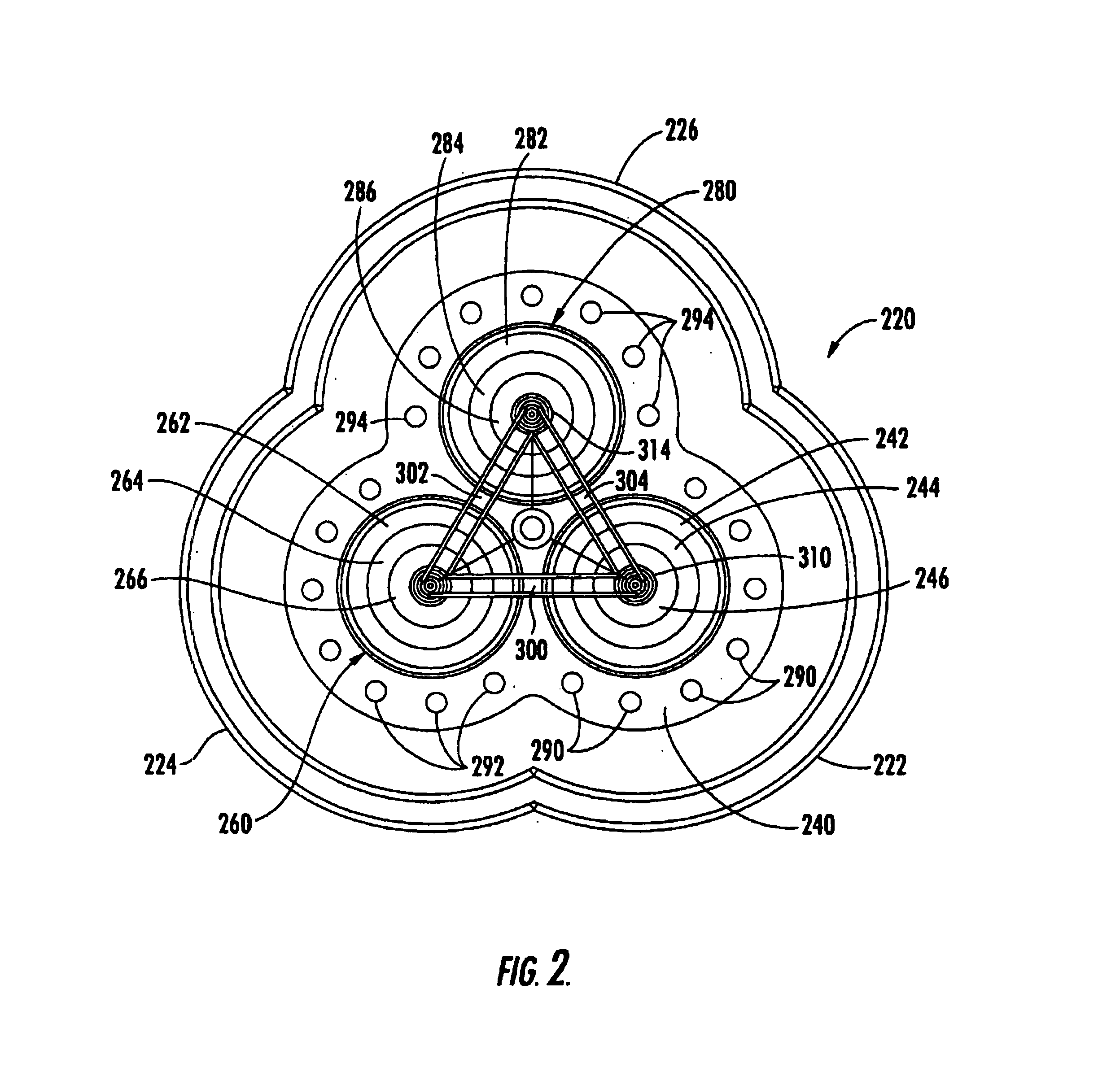

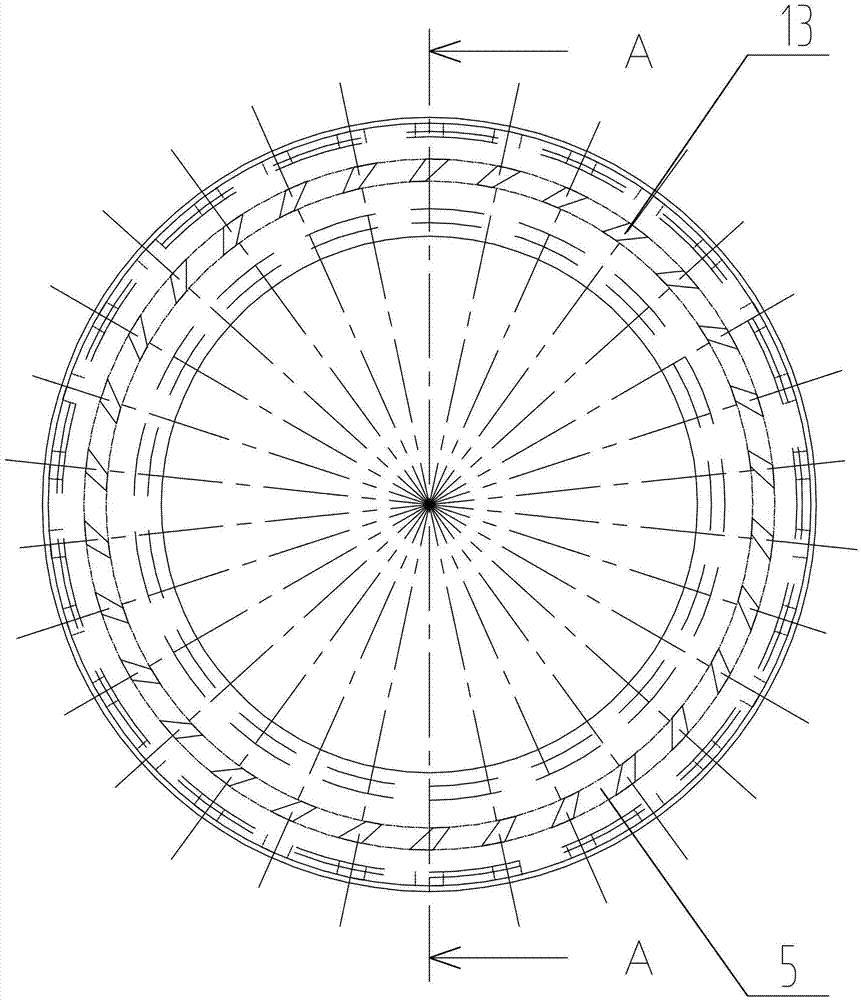

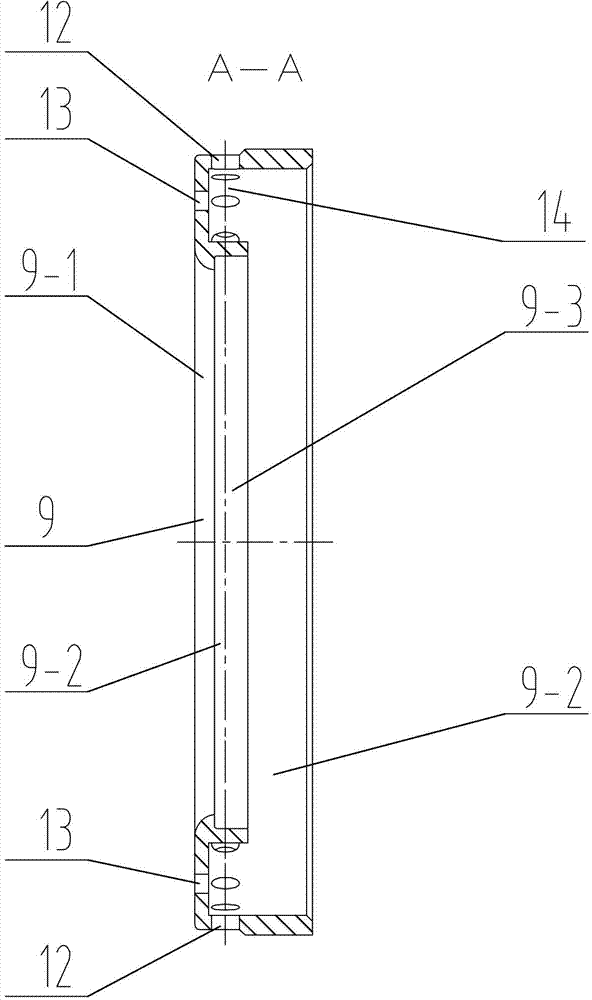

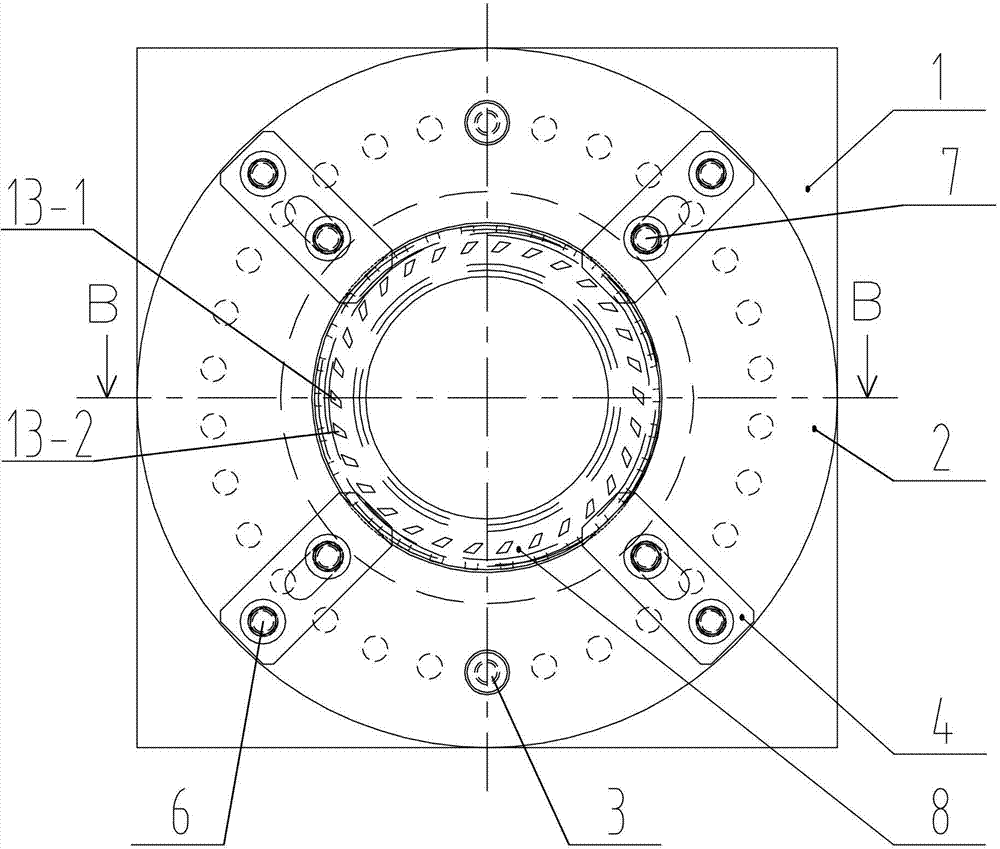

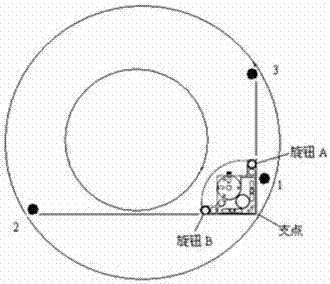

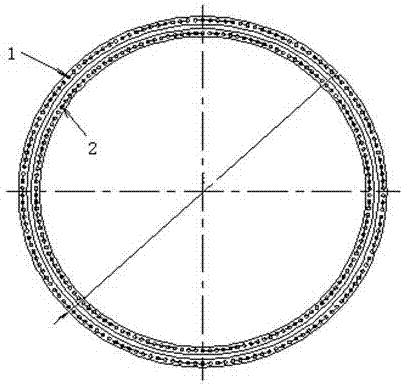

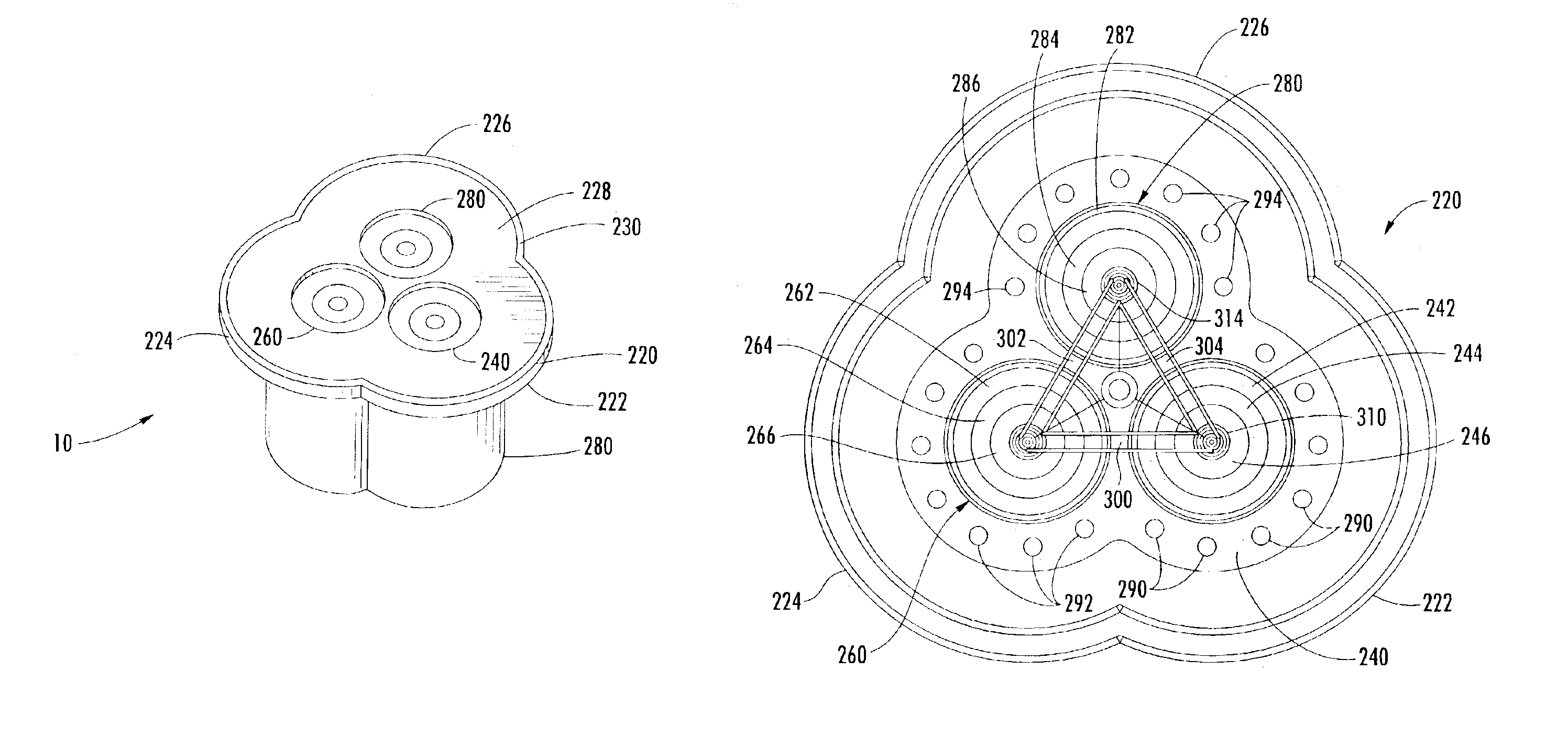

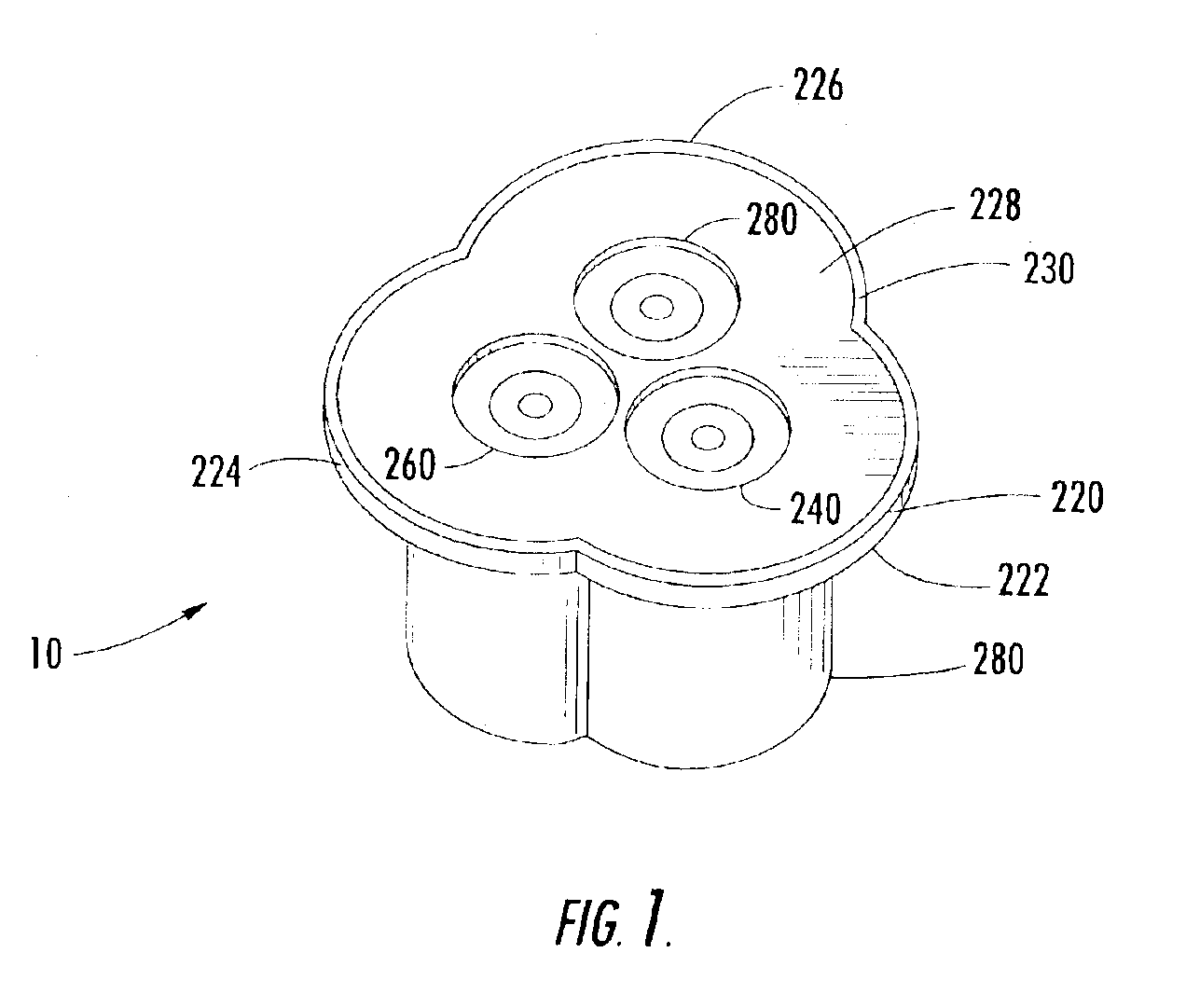

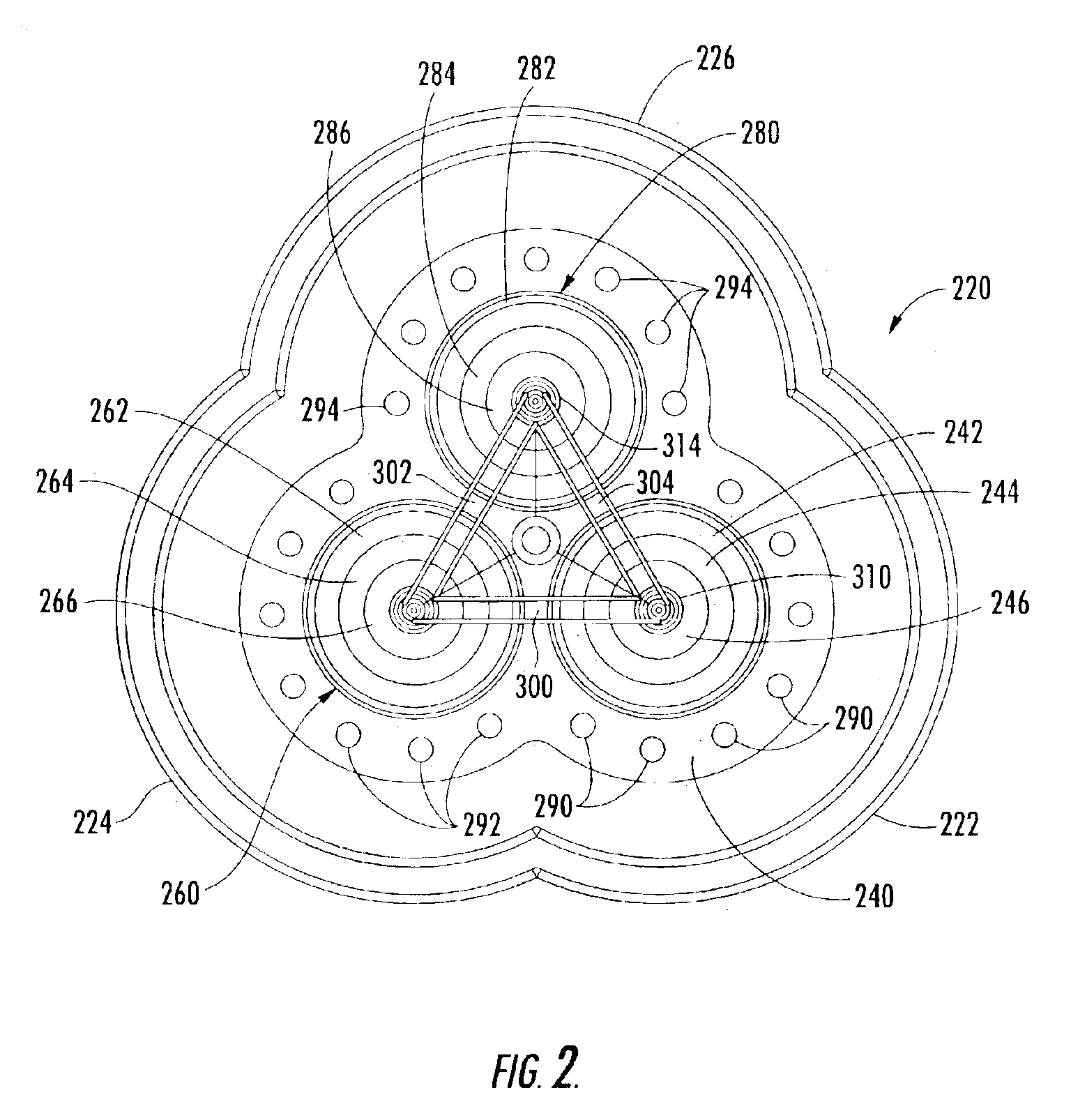

Gaming device with multiple spinning wheels and method

InactiveUS7216867B1More revenueCard gamesApparatus for meter-controlled dispensingEngineeringMechanical engineering

The specification discloses a multi-wheel game-of-chance having at least two groups of spinning wheels, wherein each group includes at least two concentric spinning wheels having a viewable surface face thereon. A plurality of indicia are positioned on the peripherals of the viewable surface face of each wheel such that all indicia on each wheel is viewable to the user. Bet areas are positioned at various locations around at least a portion of each group of wheels; along a line joining the center of any two groups of wheels; and / or a junction between various radially positioned lines extending from the center of two or more groups of wheels. Each bet area represents a possible payline with various pay ratios depending on the probability of various predetermined combinations. For instance, a one-group combination payline has the lowest pay ratio; a two-group payline requires the combination from two groups of wheels and thus, has a higher pay ratio than a one-group payline; and as additional group combination paylines are added, the higher the pay ratio can become.

Owner:BALLY GAMING INC

Gaming device with multiple spinning wheels and method

The specification discloses a multi-wheel game-of-chance having at least two groups of spinning wheels, wherein each group includes at least two concentric spinning wheels having a viewable surface face thereon. A plurality of indicia are positioned on the peripheral of the viewable surface face of each wheel such that all indicia on each wheel is viewable to the user. Bet areas are positioned at various locations around at least a portion of each group of wheels; along a line joining the center of any two groups of wheels; and / or a junction between various radially positioned lines extending from the center of two or more groups of wheels. Each bet area represents a possible payline with various pay ratios depending on the probability of various predetermined combinations. For instance, a one-group combination payline has the lowest pay ratio; a two-group payline requires the combination from two groups of wheels and thus, has a higher pay ratio than a one-group payline; and as additional group combination paylines are added, the higher the pay ratio can become.

Owner:BALLY GAMING INC

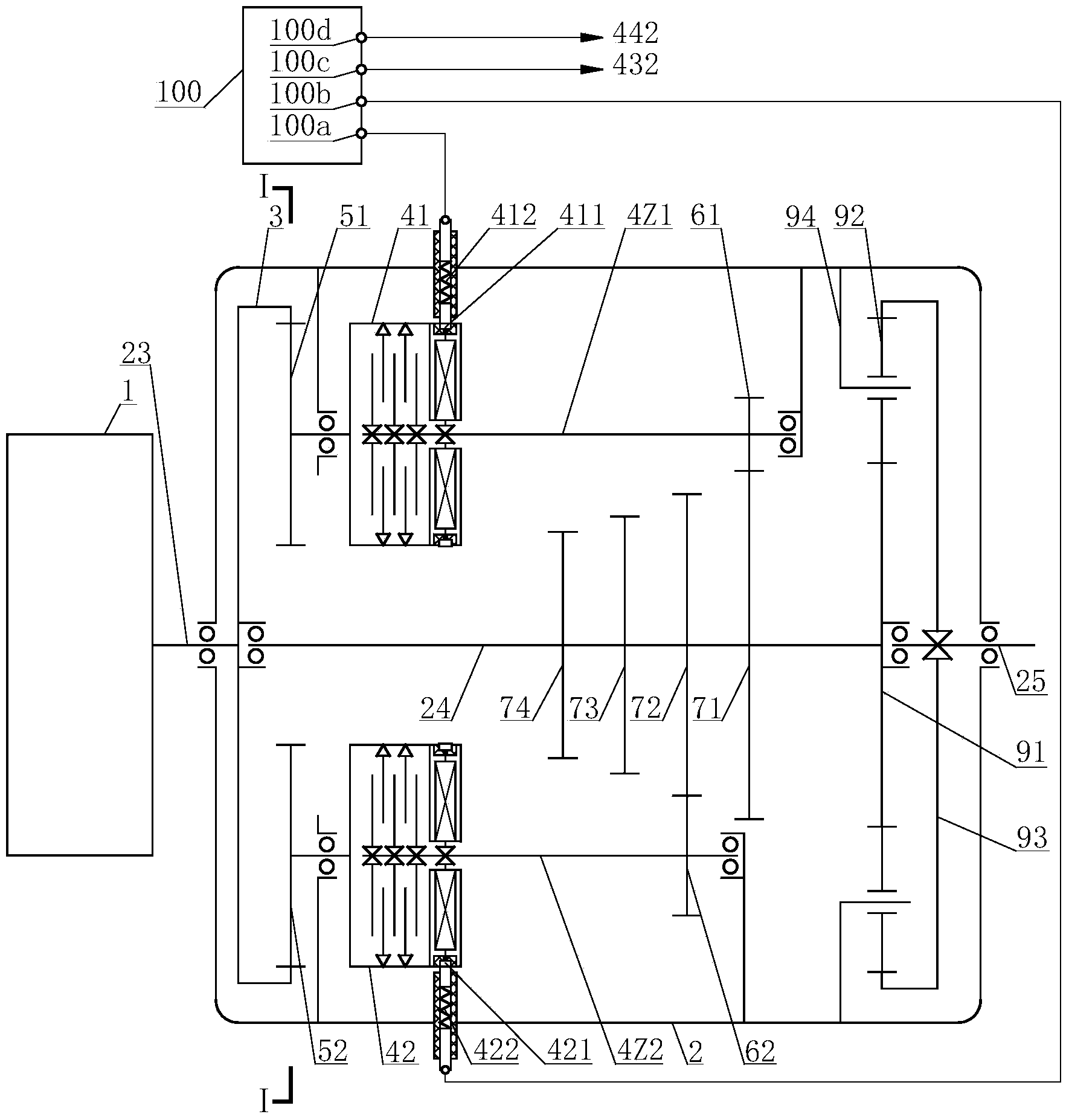

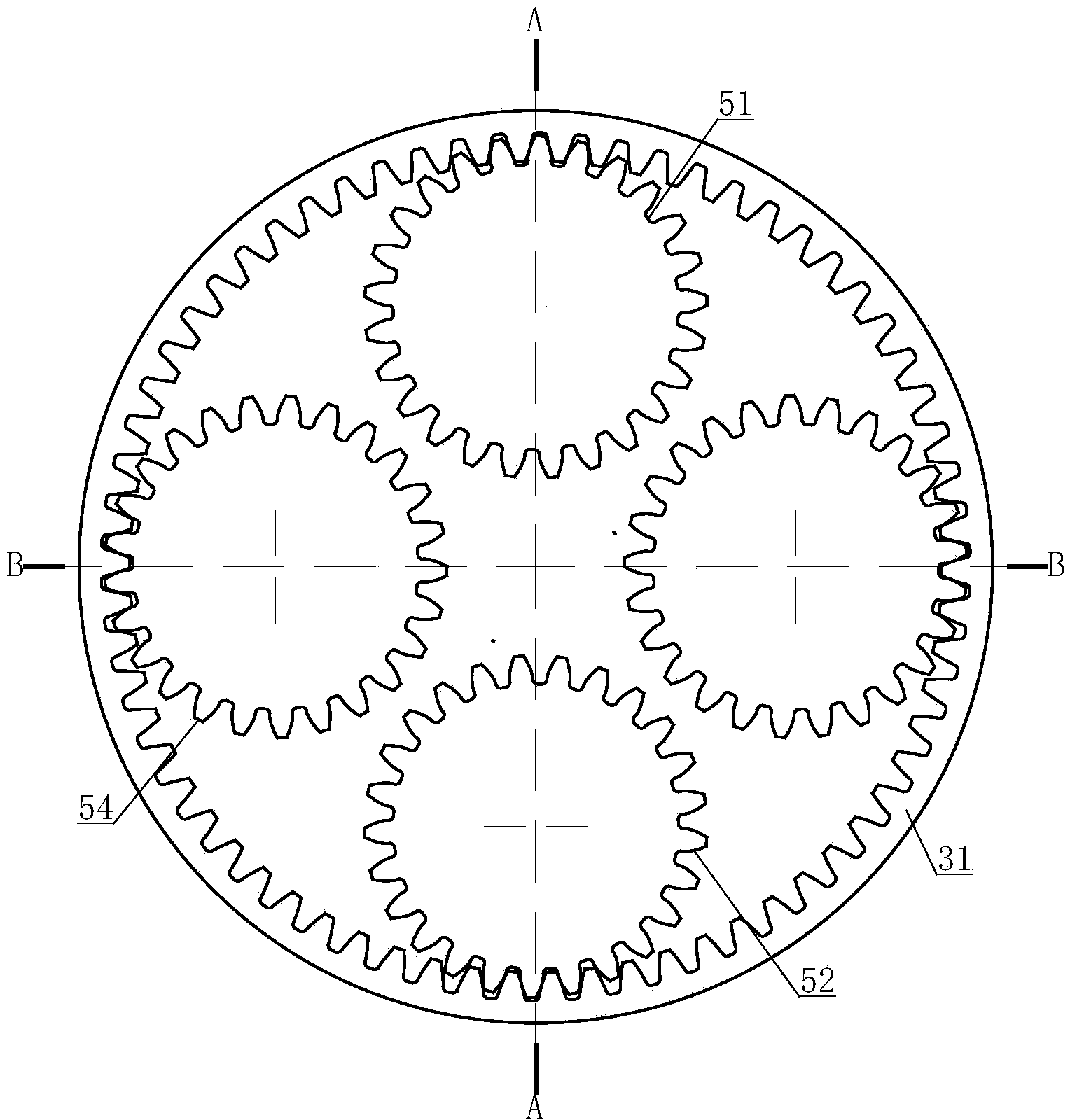

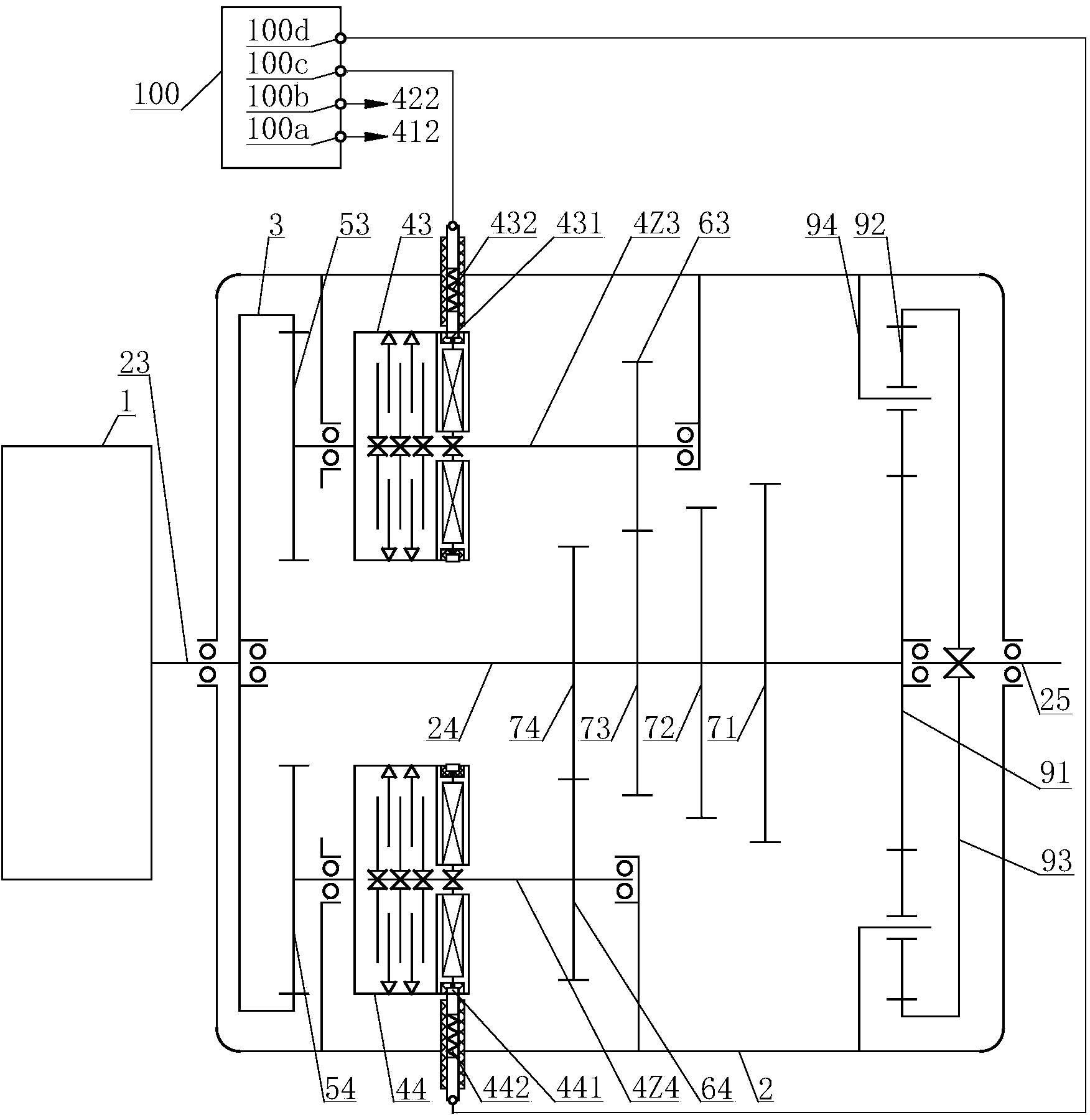

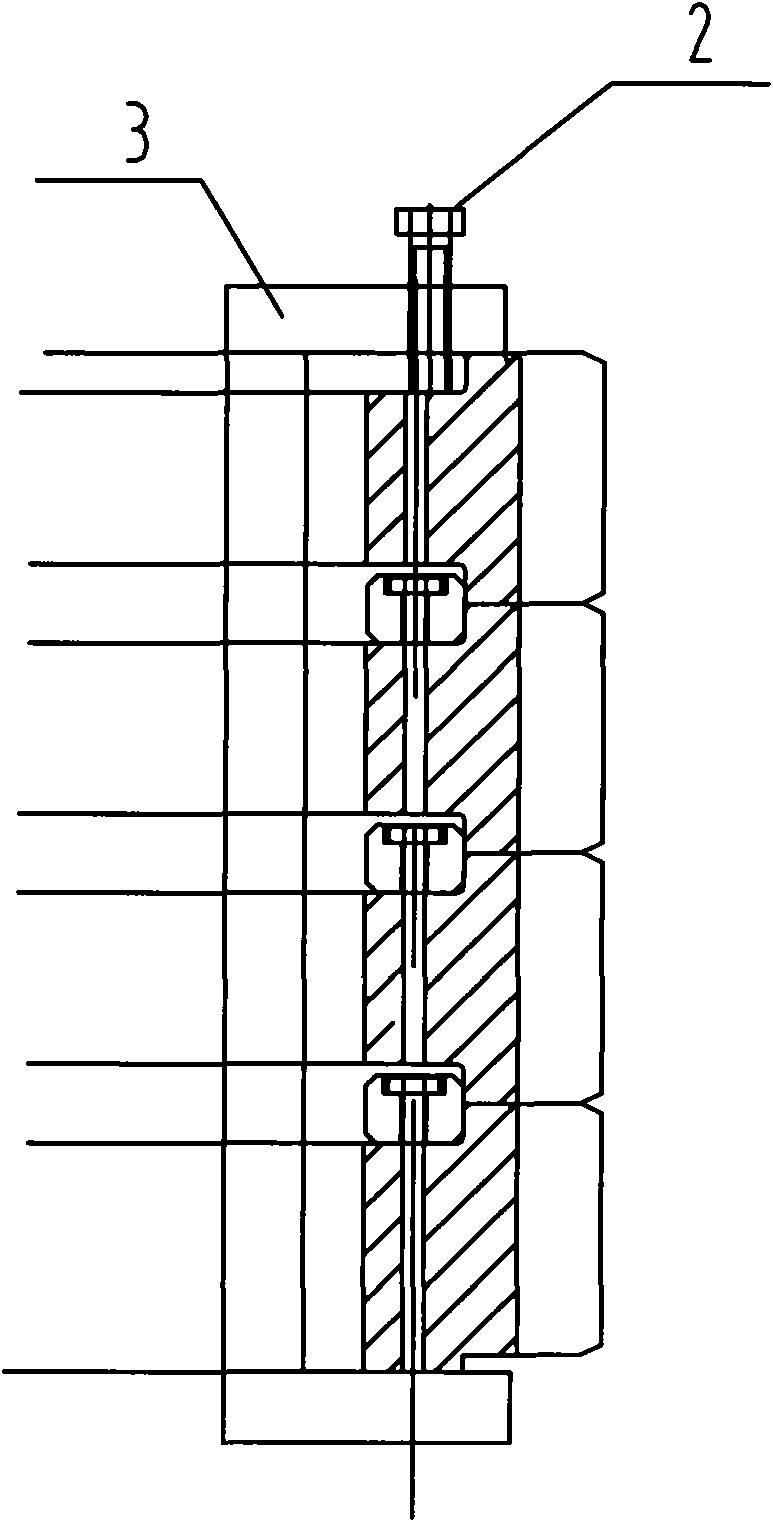

Multi-position line-control automatic transmission for electric automobile

ActiveCN104389958ASmall sizeReduce power consumptionToothed gearingsGearing controlAutomatic transmissionElectromagnetic clutch

The invention discloses a multi-position line-control automatic transmission for an electric automobile. One end of an internal ring gear of an input shaft is connected with an input shaft of the transmission, and the other end of the internal ring gear of the input shaft is sequentially engaged with a first-position high-speed gear, a second-position high-speed gear, a third-position high-speed gear and a fourth-position high-speed gear along the inner side of the periphery of a gear. The first-position high-speed gear, the second-position high-speed gear, the third-position high-speed gear and the fourth-position high-speed gear are respectively connected with a first-position main shaft, a second-position main shaft, a third-position main shaft and a fourth-position main shaft through a first-position electromagnetic clutch, a second-position electromagnetic clutch, a third-position electromagnetic clutch, and a fourth-position electromagnetic clutch. The first-position main shaft, the second-position main shaft, the third-position main shaft and the fourth-position main shaft are distributed at the periphery of a central shaft of the transmission. The engagement and separation of all high-speed gears of all electromagnetic clutches with driving gears is controlled by an electric control unit, thereby achieving line-control gear shift of the transmission. The transmission is compact in structure, employs line-control gear shift, and has no machines or hydraulic gear shift parts.

Owner:SHANDONG UNIV OF TECH

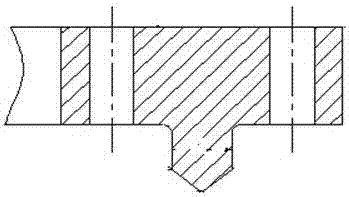

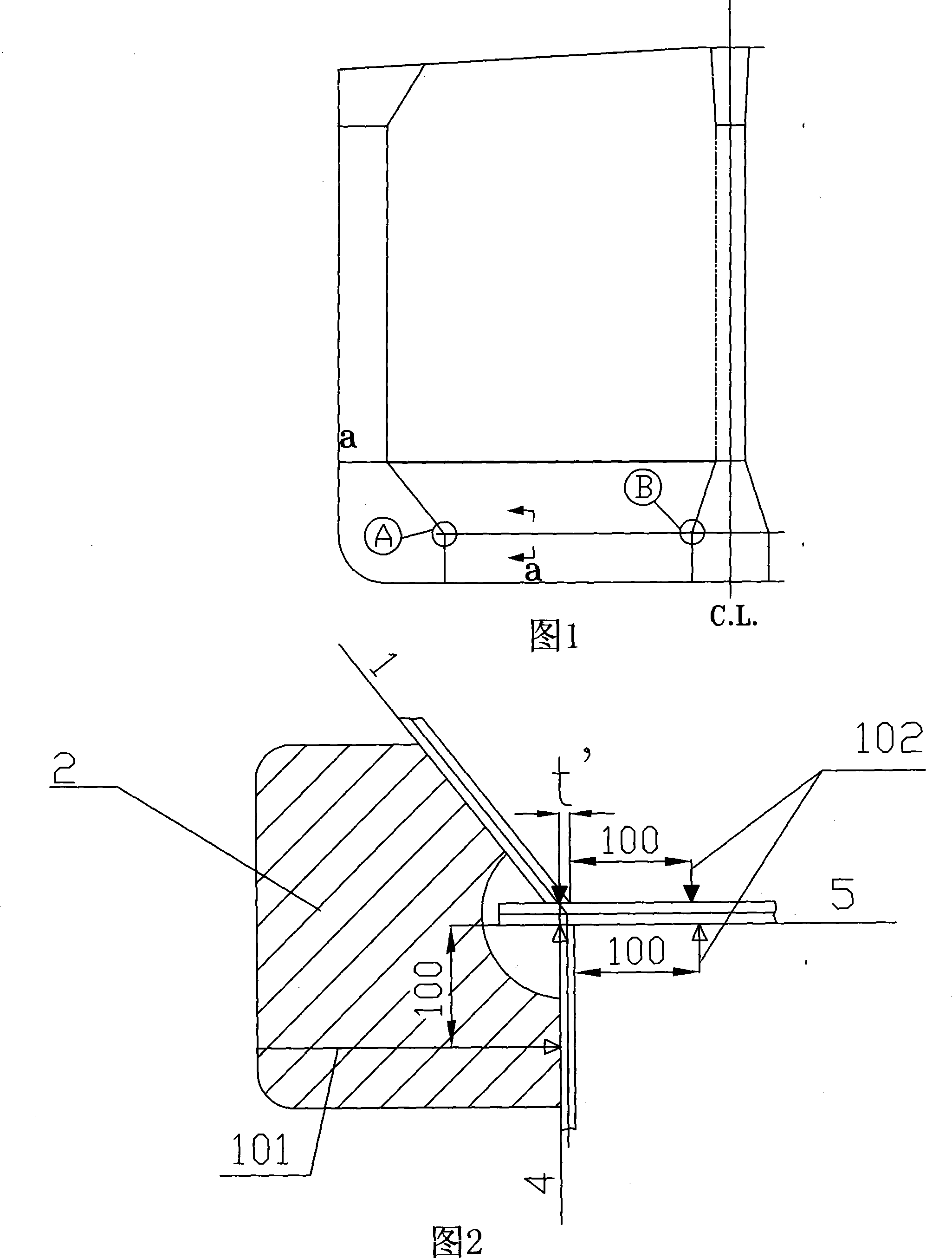

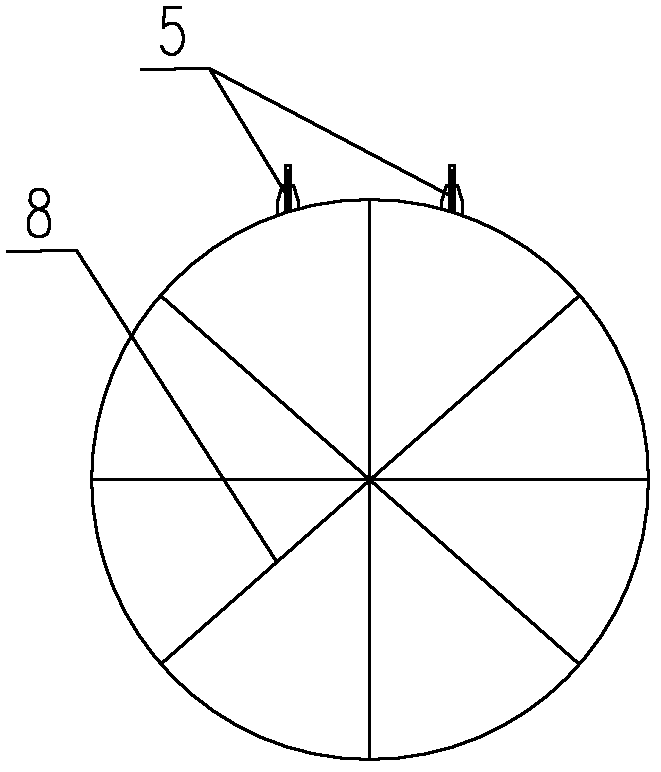

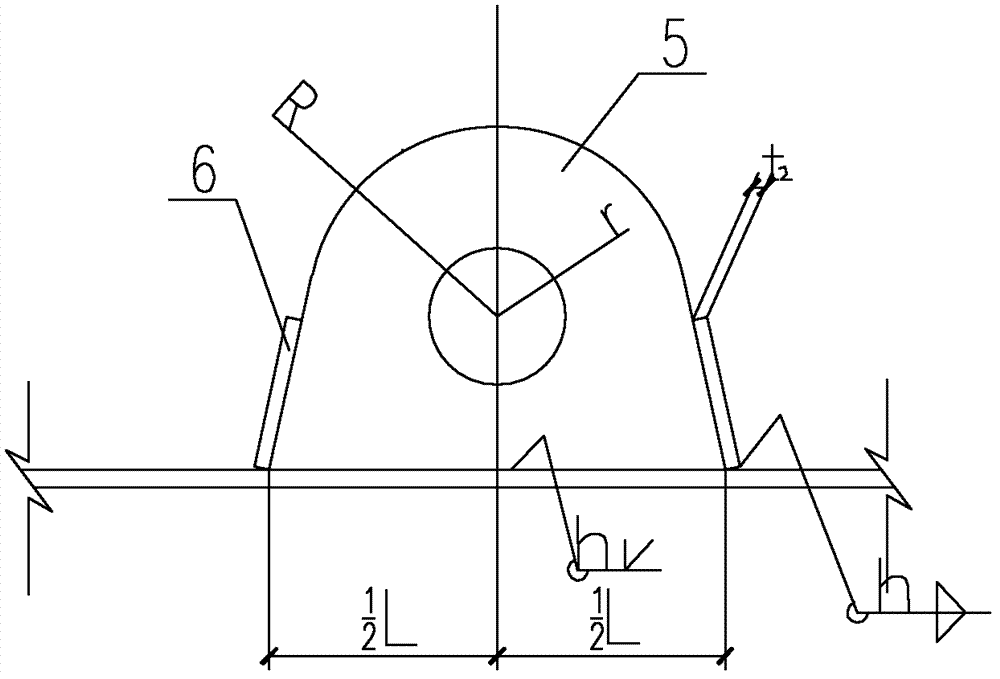

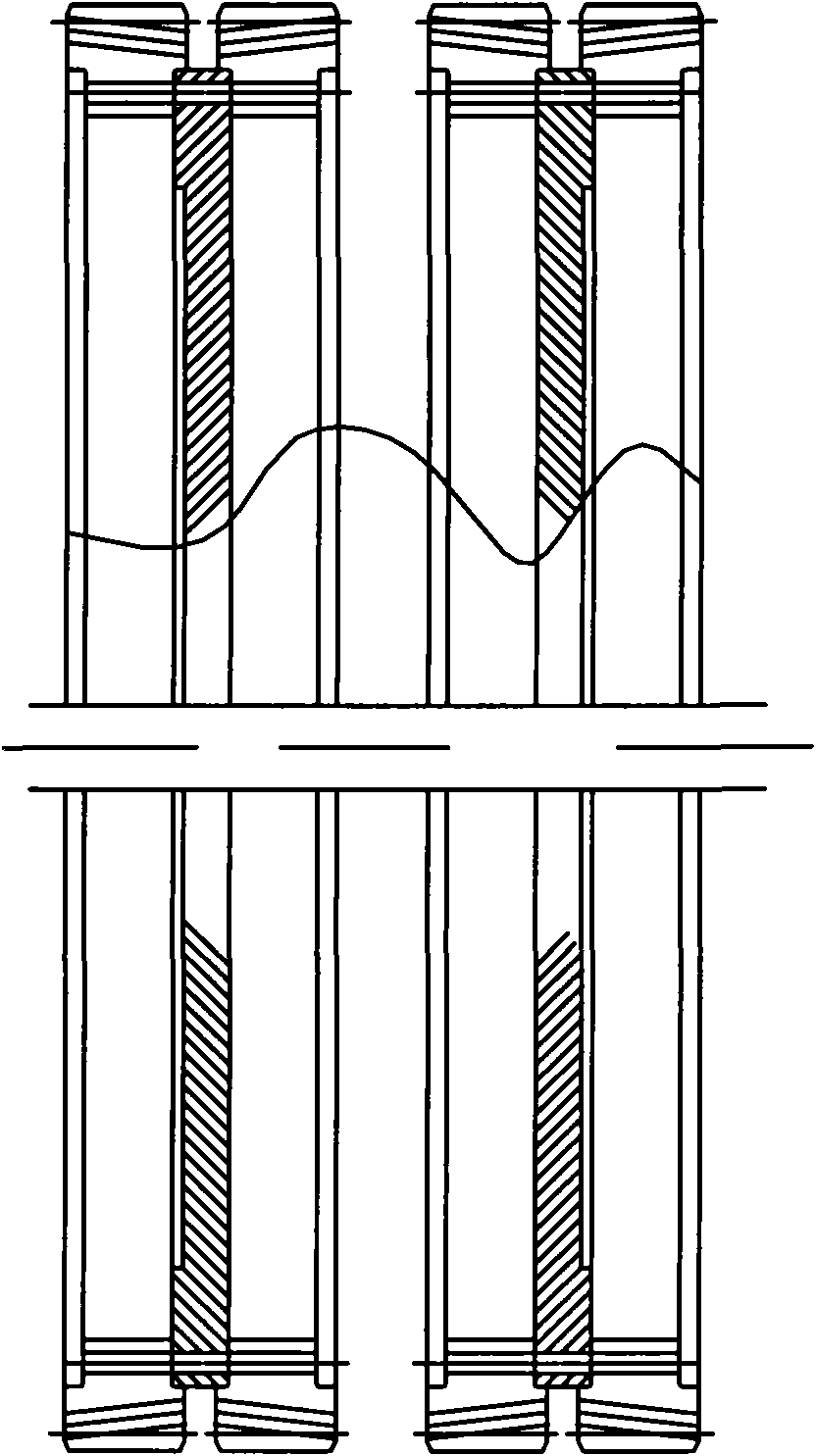

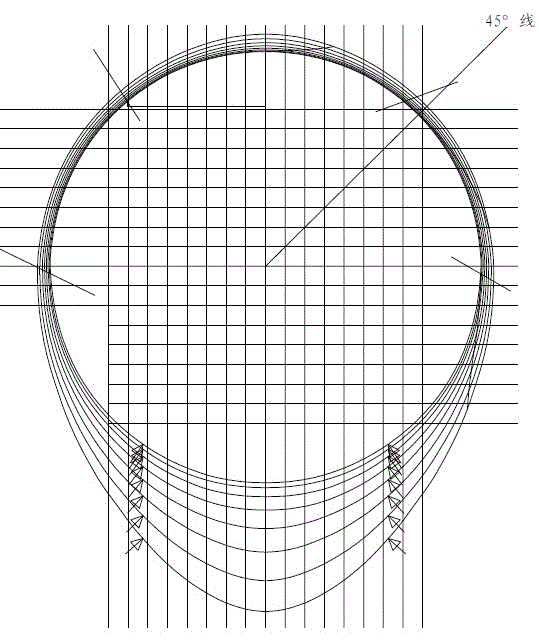

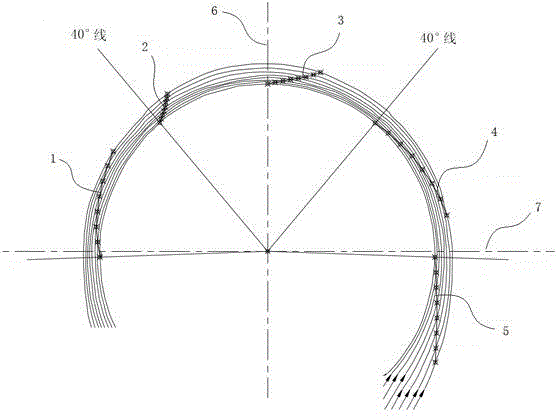

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

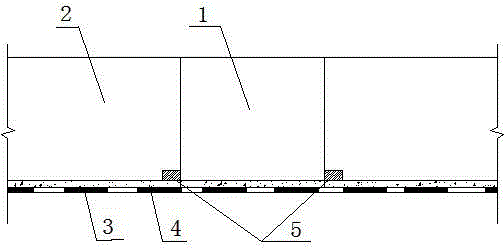

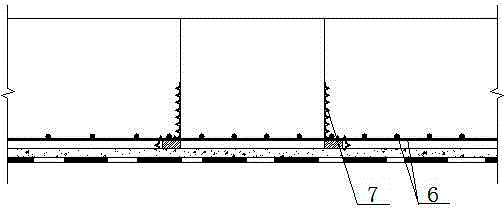

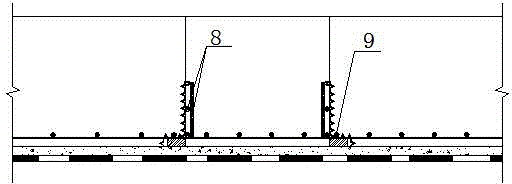

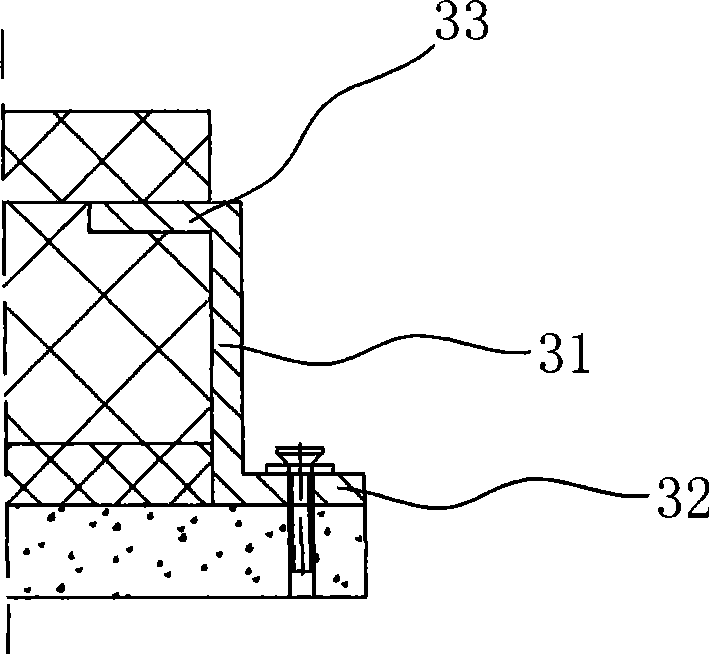

Foundation post-pouring belt template constructing method

InactiveCN102720216AReduce labor intensityReduce engineering costsArtificial islandsUnderwater structuresEngineeringConstruction management

The invention relates to building construction methods, particularly to a foundation post-pouring belt template constructing method, which includes the following steps: a) pouring concrete stripes on the two sides of the post-pouring belt along the position line of the post-pouring belt after the completion of the foundation waterproof protective layer construction; b) supporting a waterstop steel plate quick and easy closing-up mesh along the side line of the post-pouring belt after the lower layer reinforcing bars of the foundation base plate are bound; c) fixing the reinforcing bar mesh pieces at the lower part of the waterstop steel plate; d) mounting the waterstop steel plate; e) welding the upper part reinforcing bar mesh pieces on the waterstop steel plate and placing the waterstop steel plate upper part quick and easy closing-up mesh; f) binding the upper layer reinforcing bars of the foundation base plate, fixing the waterstop steel plate upper part quick and easy closing-up mesh and mounting the upper part guard of the post-pouring belt; and g) pouring foundation concrete. By adopting the quick and easy closing-up meshes for the post-pouring belt construction joint, the surface poured with the concrete is uneven, so that the complicated conventional procedures for dismounting template and surface dabbing are avoided, the project quality and the construction progress are ensured, the construction wastes are reduced, and the civilized construction management is facilitated.

Owner:NANTONG DAXIN ENG

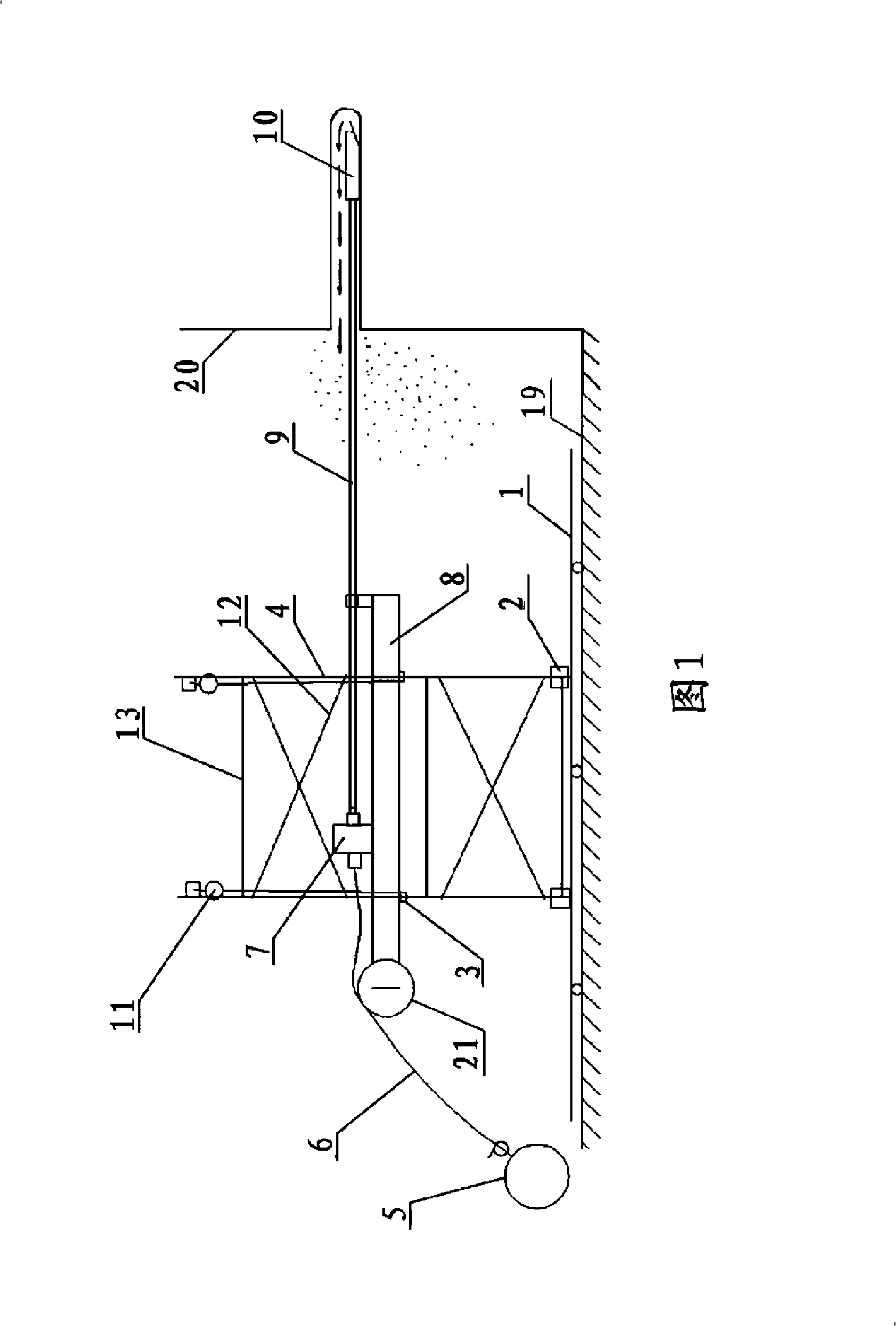

Construction process of wind power tower tube

InactiveCN107876943AGuaranteed accuracyReduce reworkFinal product manufactureWelding accessoriesNumerical controlElectricity

The invention relates to a construction process of a wind power tower tube. The construction process comprises the procedures of sectioned tube section manufacturing, tower tube flange installation, and tower tube assembly; sectioned tube section manufacturing comprises the procedures of factory inspection of raw materials, material reinspection, pretreatment of a steel plate, numerical control cutting blanking, dimensional inspection, groove machining, circle rolling, group-welding of longitudinal joints, circle rectifying, measuring of tube section ovality, 100%UT detection and T-shaped seam100%MT detection; tower tube flange installation is achieved through the procedures of flange detection, tower tube detection, flange fixing, tube body installation, welding measuring, bottom flangeassembly, tube body connection, bolt connection, tube body positioning welding and detection after welding jointly; and tower tube assembly comprises the procedures of grouping of tube sections and flange nipples, inspection, welding, 100% UT detection, inspection, drawing of position lines of inner parts, inspection, group-welding of the inner parts, anticorrosion treatment, assembly of the innerparts, packing and forwarding. The construction process has the advantage of being high in precision.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

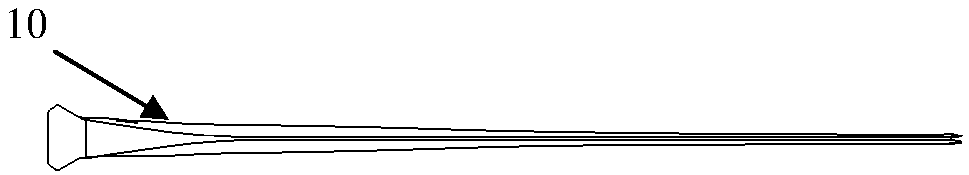

Tunnel advanced support air circulated drilling construction method and drilling tool

InactiveCN101260784AAvoid disturbanceEnsure construction safetyEarth drilling toolsUnderground chambersPosition angleAir compressor

The invention provides a tunnel forepoling air circulating drilling construction method. The construction steps are as follows: a driller is firstly installed and is moved to the appointed hole position along a track, according to the tunnel position line, the position angle of the driller is adjusted to ensure that the driller is parallel with the tunnel position line, the driller is fastened with a frame; an air compressor is turned on, the wind pressure is controlled above 0.4MPa, and then the driller is turned on to ensure that a drill pipe drills towards the earth at a constant speed, the compressed air is sent to an aiguille part through an internal cavity of the drill pipe and air-cools the aiguille, drilling cuttings are blown out of the drill hole from the gap between the drill pipe and the earth; the inner part of the aiguille is provided with a guide drilling device; finally, the hole drilling is finished and the grout is cast, the grout is cast into the inner cavity of the drill pipe by a casting pipe, the grout is filled into the inner cavity of the drill pipe and the ring-shaped gap out of the drill pipe, and the next hole position is turned to construct. The tunnel forepoling air circulating drilling construction method solves the problems of low security and slow drilling of the earth layer, especially the fourth new loess area pipe roofing timbering construction, can avoid the landslide and minimize the potential safety hazard.

Owner:BEIJING SHOUER ENG TECH

Method for rapidly detecting accuracy of position seaming in shipbuilding process

The invention discloses a method of rapid detection of precision of the position and closure in the process of ship building, which is mainly used to detect the structure and the closure precision of block assembly, and the steps include: before the closure, presetting an assembly position line which is used for ensuring the position of closure on to-be-assembled plates or a truss; before position closure, arranging an another reference line parallel to the assembly position line on one side of the assembly position line on assembled plates or the truss via equidistance; when positioning to assemble, detecting the location precision of the reference line. The invention increases the precision and speed of the block assembly and position closure through the arrangement and application of the reference line (check line), thereby reducing the workload of trimming. Experiments have proved the invention, such as that in the sectioned position closure of vertical wall and horizontal wall of each ship body, the hoisting time of the method is saved by nearly one hour, and the trimming rate of 60% in the existing implementing method is reduced to 20%.

Owner:DALIAN SHIPBUILDING IND

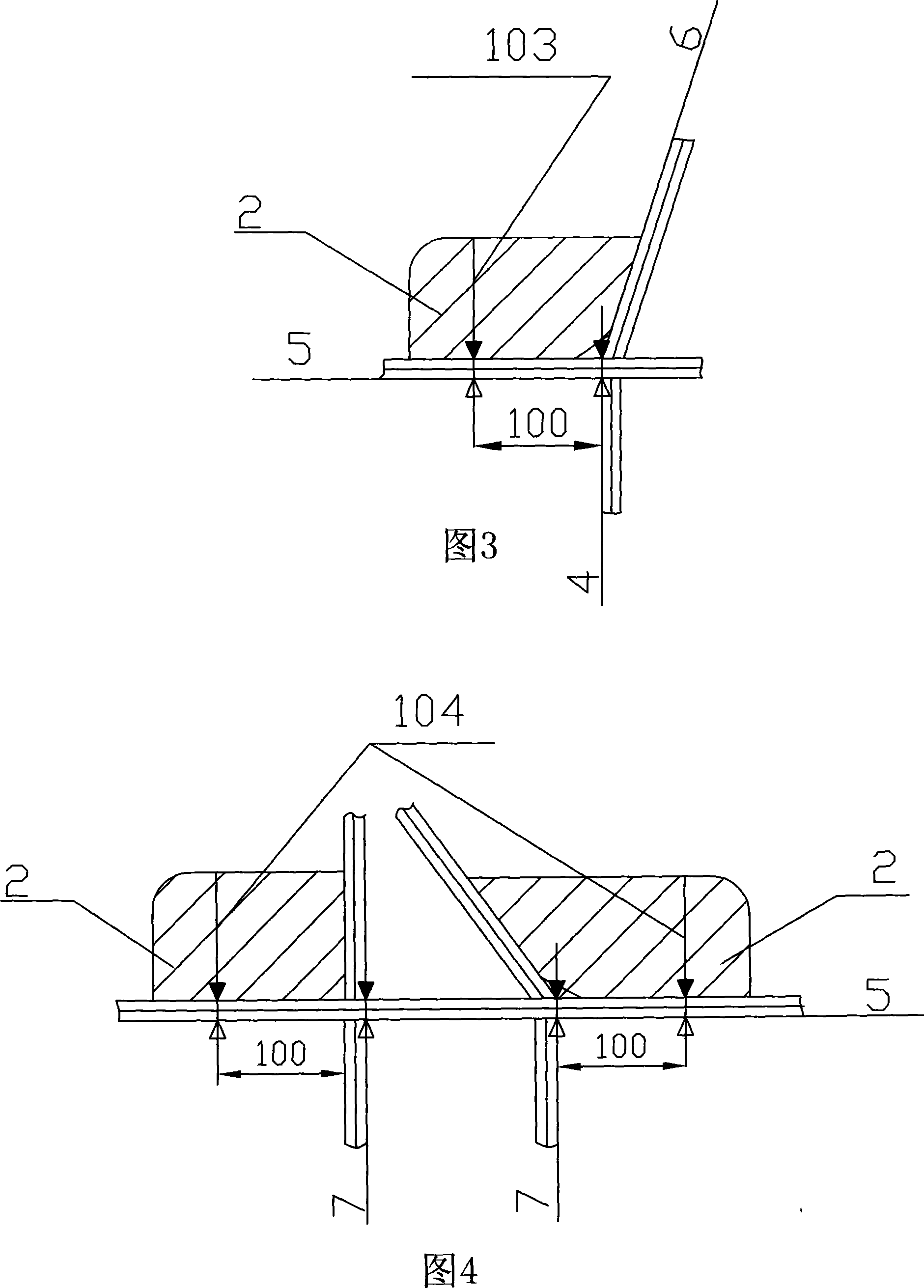

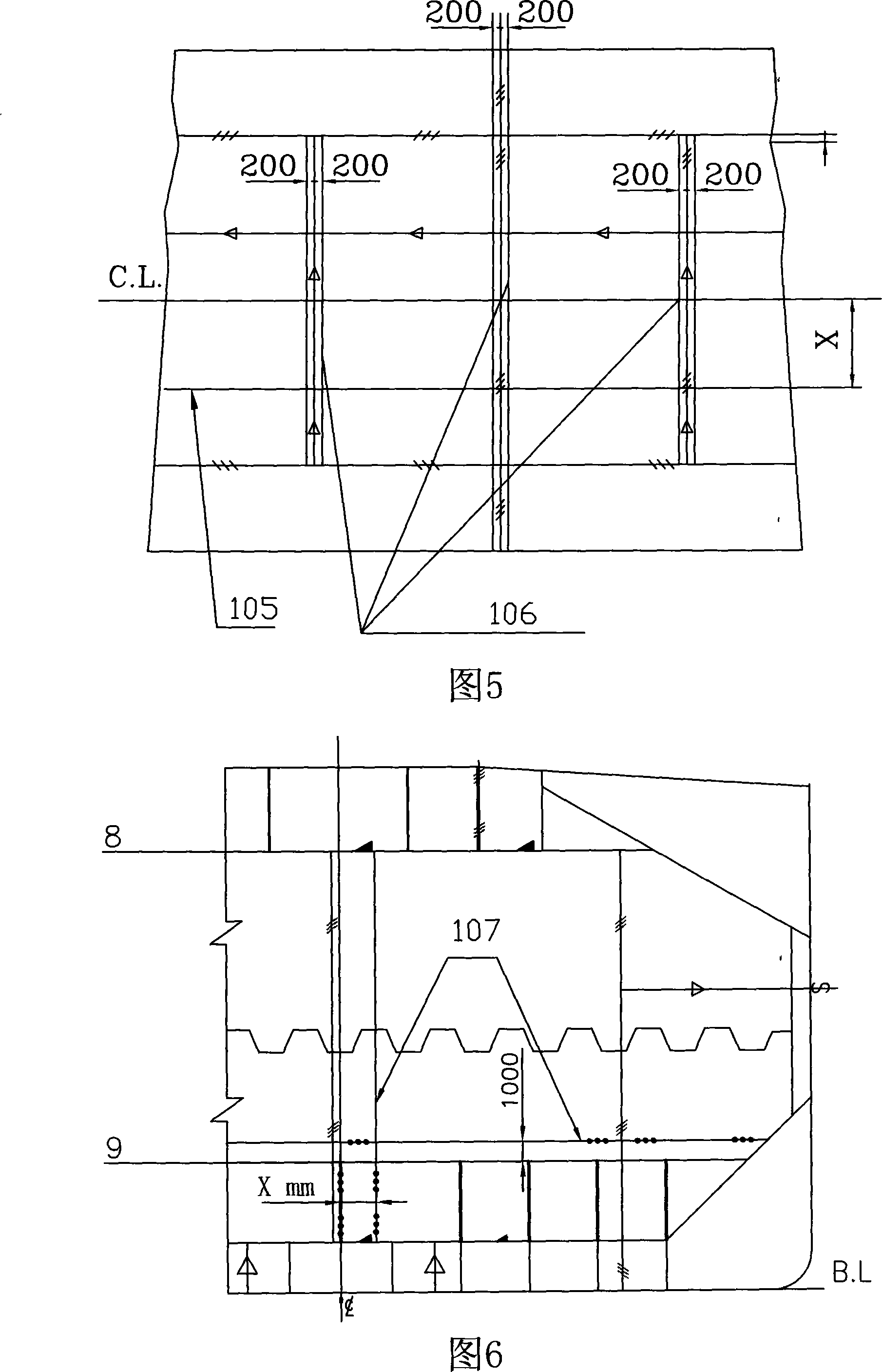

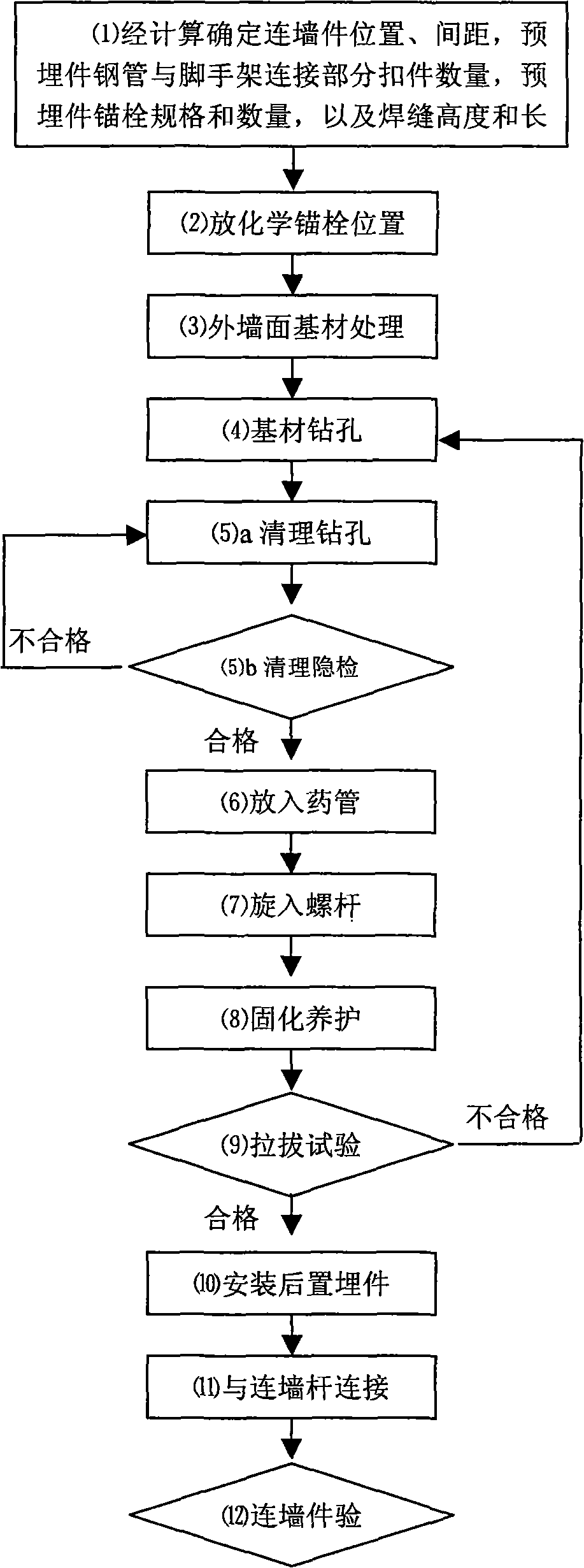

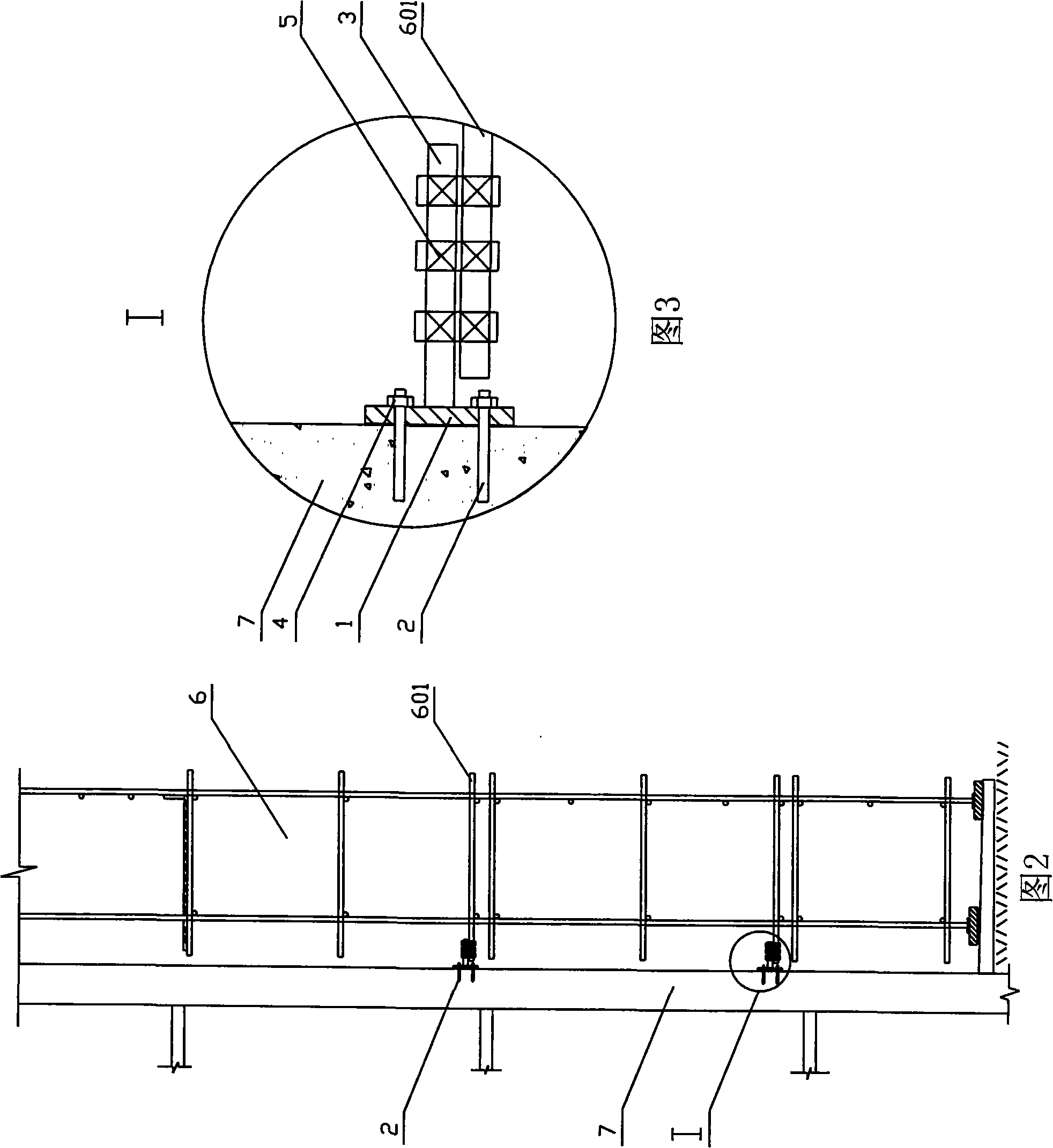

Construction method for building postposition pre-buried wall connecting parts

InactiveCN101275432AReliable anchoring forceLow priceScaffold accessoriesSheet steelCompound (substance)

The invention relates to an erection construction method for a rearmounted pre-embedded type fastener to wall, wherein a chemical anchor widely applied to steel structure and concrete is anchored on the wall or post of a building, a steel plate embedded part with a short steel pipe is fixed on the chemical anchor, and the short steel pipe on the steel plate embedded part is connected with the a scaffold wall rod. The method comprises the following steps: (1) determining the chemical anchor; (2) placing a chemical anchor position line; (3) processing outer wall surface base material; (4) drilling holes the base material; (5) cleaning the holes; (6) putting a drug tube in; (7) screwing in a screw; (8) curing; (9) pull-out testing; (10) installing a rearmounted embedded part; (11) connecting with a wall rod and (12) acceptance checking the wall rod. The method is easy to operate, the anchoring force is reliable, the construction cost is low, the efficiency is high, convenient for detaching and turnover for many times, the safe use of a scaffold and the normal use and security of the inside of a building are effectively ensured; the damage to the original building structure is little, and the method can be widely applied to a floor type scaffold higher than 24 meters in rebuilding or refitting engineering, and the anchoring of steel structure and concrete having a concrete strength less than C20.

Owner:北京城建建设工程有限公司

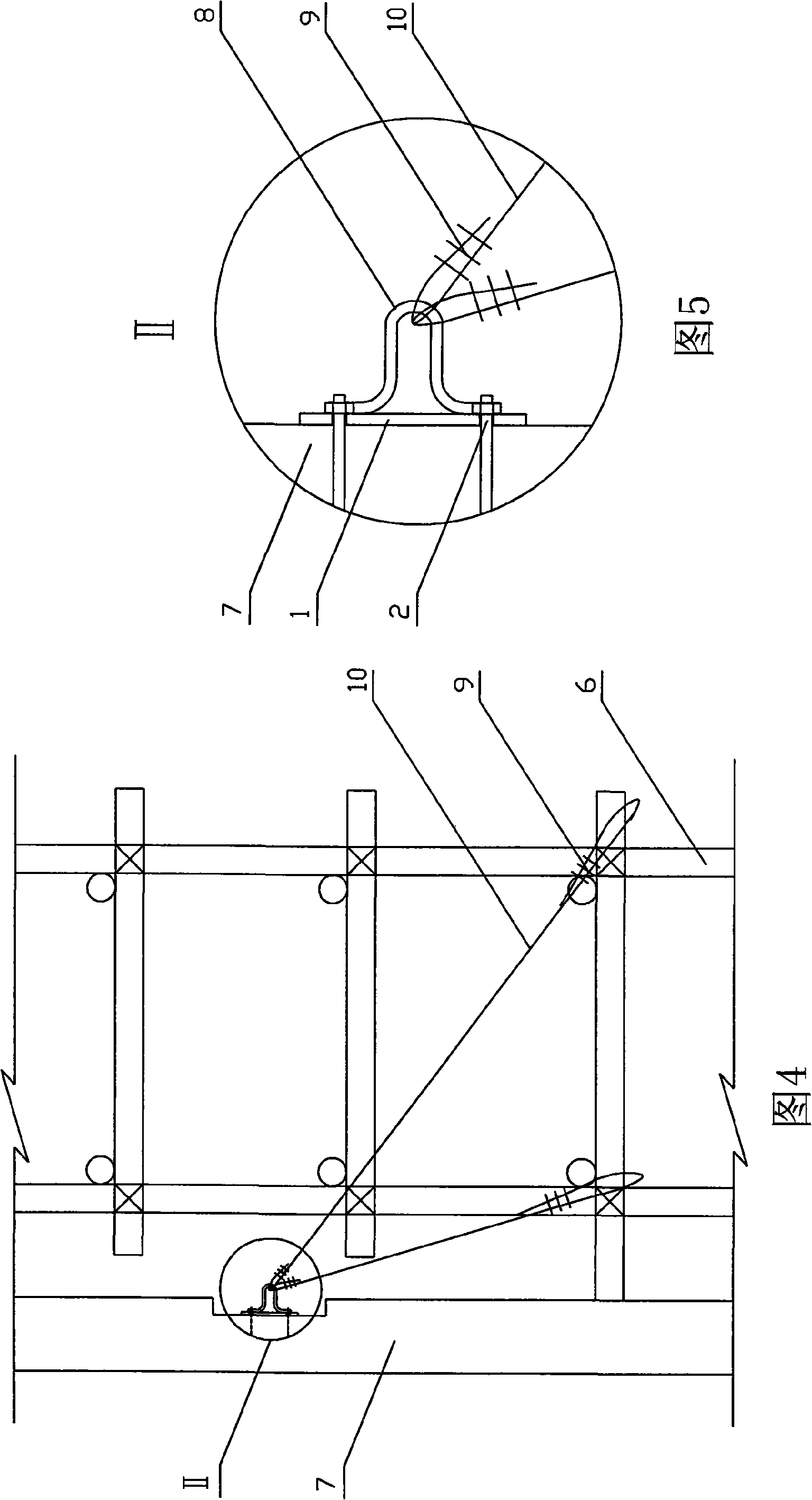

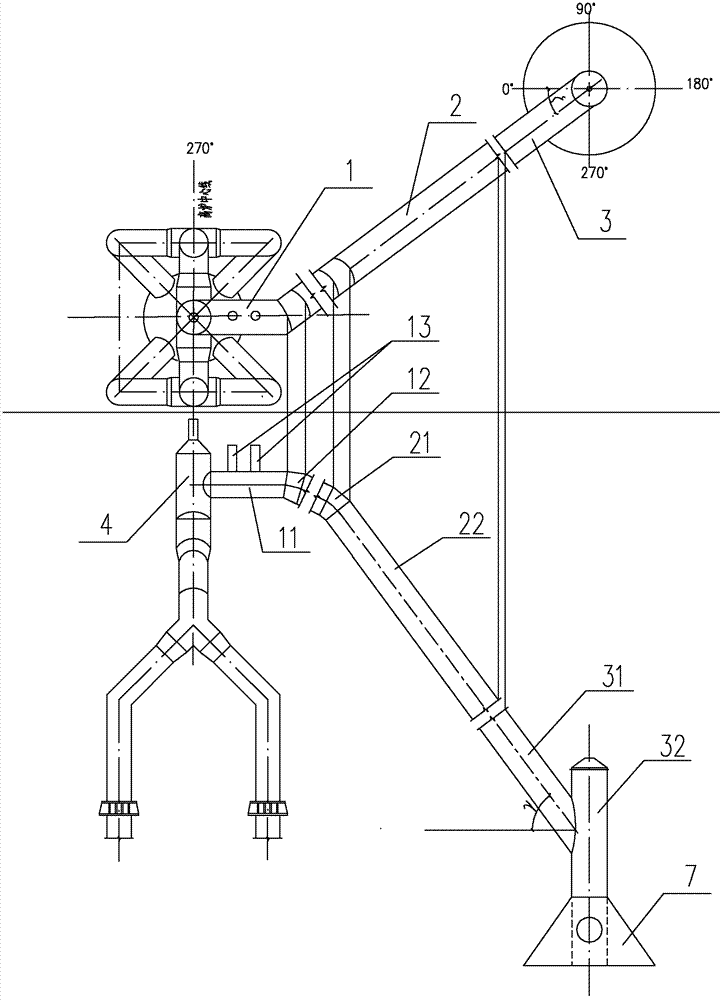

Method for installing blast furnace single-tube downcomer

InactiveCN102851421AEasy to controlGuaranteed installation qualityBlast furnace componentsBlast furnace detailsHigh energyEngineering

The invention discloses a method for installing a blast furnace single-tube downcomer, characterized by using single machine and double shackles to lift each lifting unit. The method comprises the following steps: 1, conducting lifting preparation: 1) dividing lifting units; 2) determining the barycenter of each lifting unit; 3) determining the lifting point and shackle position of each lifting unit and completing the welding of the shackles; 4) determining the position lines of a riser tube and an upper shaking head, and determining the position lines of a gravity deduster shell and a lower T-joint; and 5) building a joint temporary operation platform the inner side and the outer side of the joint of each lifting unit; and 2, conducting lifting operation. According to the invention, by using single machine to lift, the amount of large-scale machines is reduced, the limitation of narrow and small construction place can be overcome, the construction cost and energy consumption can be reduced, the construction safety is raised, the target of realizing safety, high quality, high efficiency, energy saving, and low carbon is realized, and the situation of high energy consumption, high cost and high pollution existing in traditional double-machine lifting is thoroughly changed.

Owner:TIANJIN 20 CONSTR

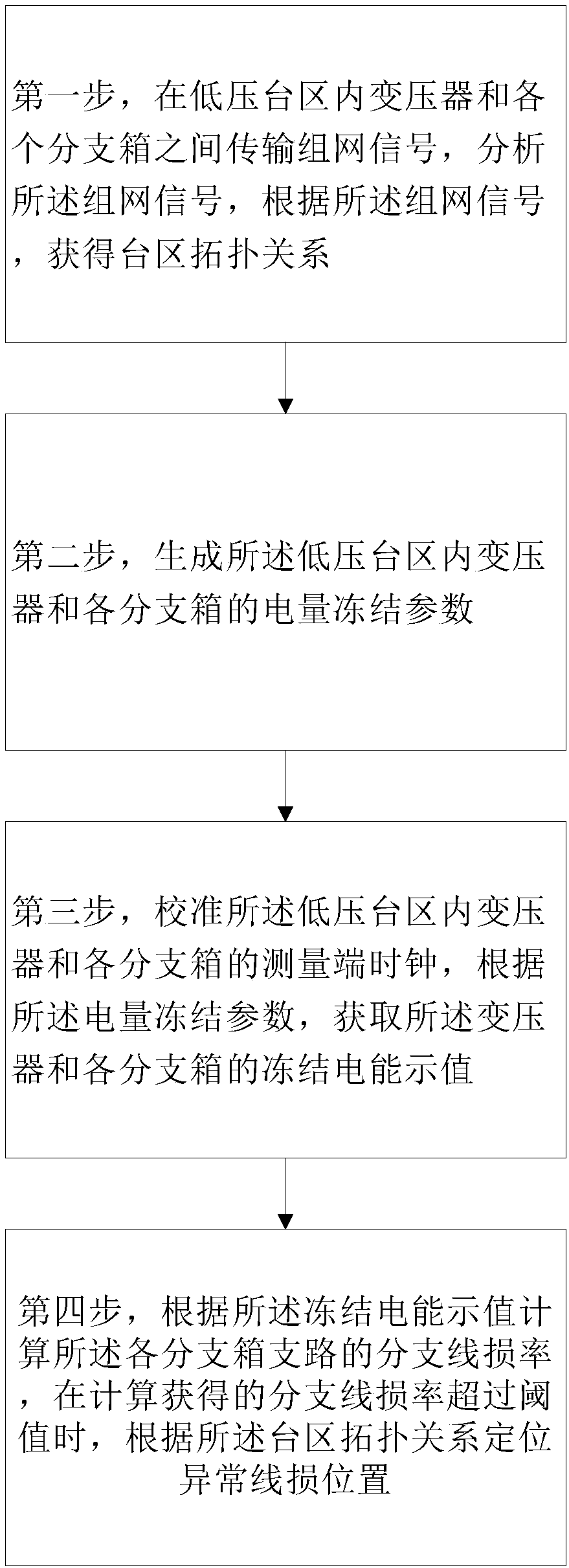

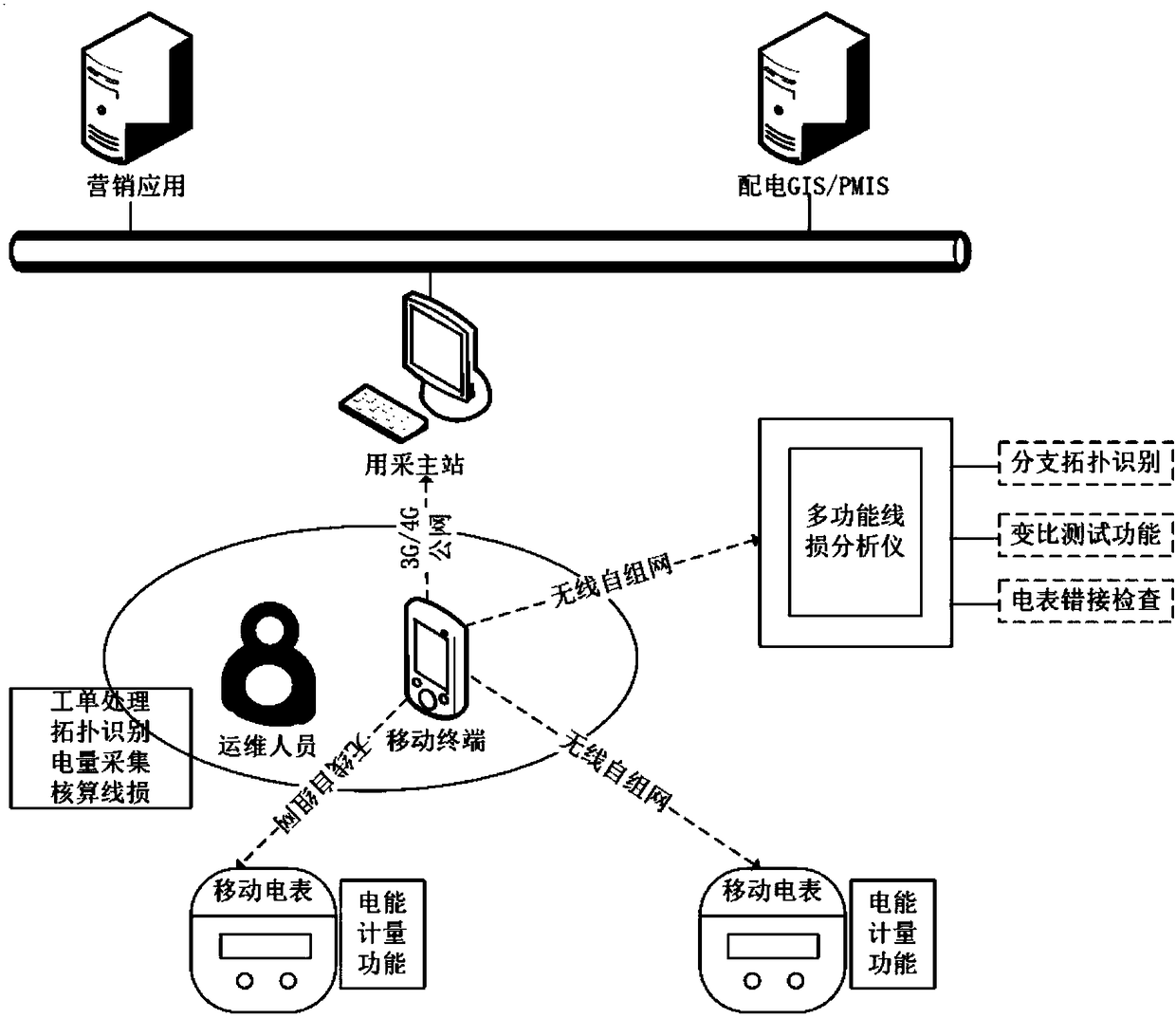

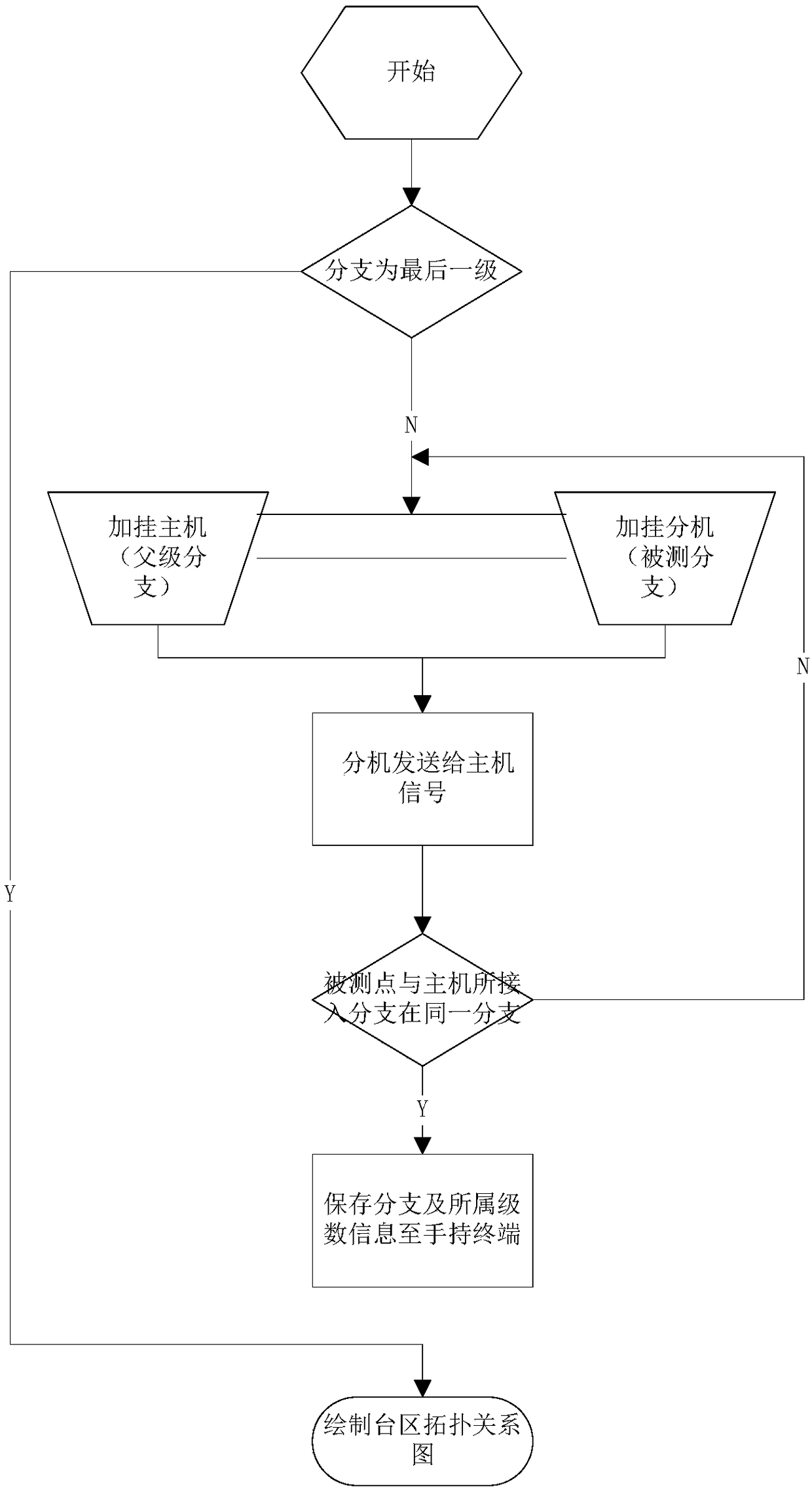

Method and system for quickly positioning line loss of low-voltage transformer region

InactiveCN108063493AImprove management efficiencyRealize entryCircuit arrangementsElectrical measurementsLoss rateLow voltage

The invention provides a method and a system for quickly positioning line loss of a low-voltage transformer region. The system comprises a mobile electric energy meter, a line loss analyzer and a mobile terminal. The method comprises the steps of acquiring a transformer region topological relation between a transformer in the low-voltage transformer region and each branched box by the lien loss analyzer; acquiring power consumption data of a plurality of transformer regions and users through the mobile electric energy meter; and finally integrating the data by the mobile terminal, performing calculation for obtaining the branch line loss rate of each branched box branch line, and realizing accurate positioning of the abnormal line loss branch of the low-voltage transformer region. According to the method and the system, a remote transmission mode is utilized; the mobile terminal realizes closed-loop management on a whole process which comprises work order task starting, field diagnosispositioning and reporting to a service department, thereby realizing higher management efficiency. Different from existing technology in which only integral line loss management can be performed on the integral transformer region, the method and the system have advantages of calculating each branch line loss in the transformer region, realizing quick positioning of the abnormal line loss of the high-loss transformer region, supplying each branch power consumption distribution condition, and effectively improving transformer region line loss treatment level by an electric power management department.

Owner:ELEFIRST SCI & TECH

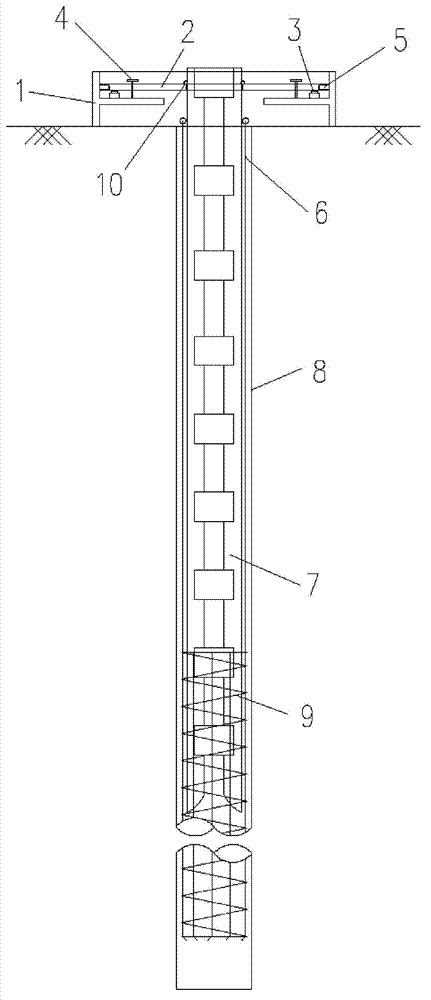

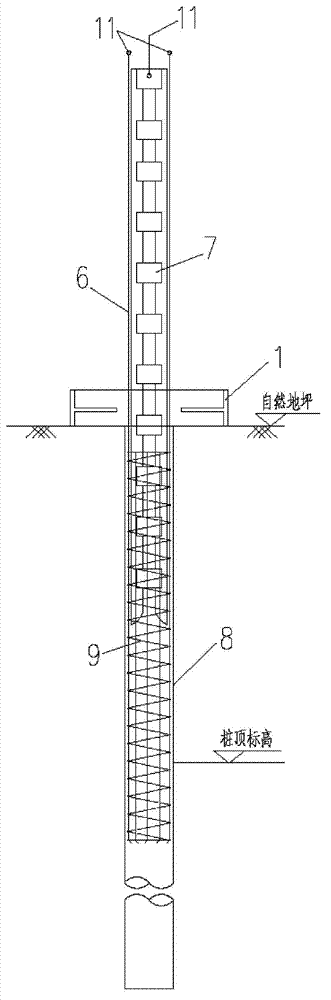

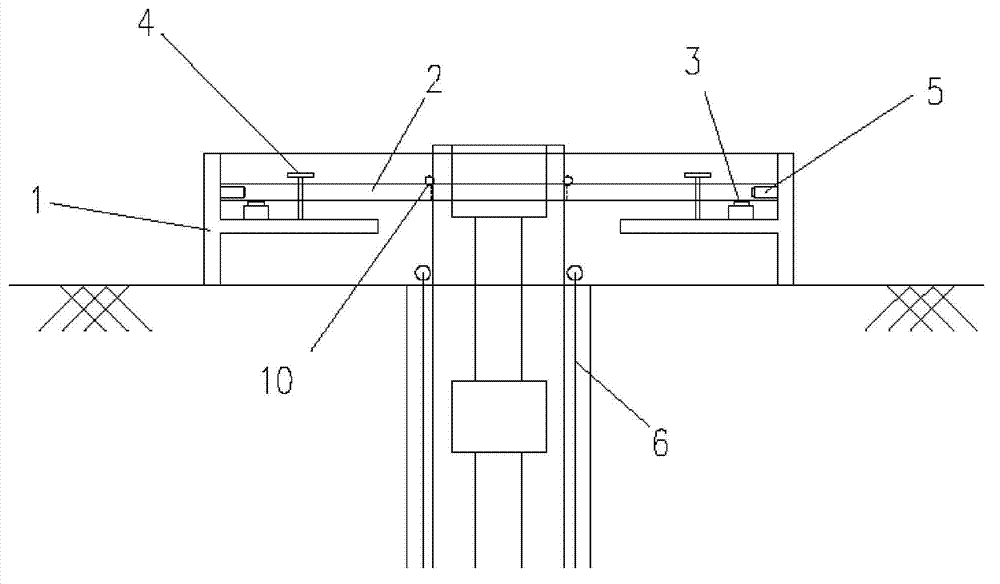

Verticality adjustment system for lattice column correcting mount and construction method thereof

ActiveCN102767182AImprove verticalityHigh precisionArtificial islandsUnderwater structuresSpecial designStructural engineering

The invention relates to the technical field of constructional engineering, in particular to a verticality adjustment system for a lattice column correcting mount and a construction method thereof. In the method, the verticality adjustment system for the correcting mount, a spacer, a correcting mount placement method and a correcting method for lower placement of the lattice column are adopted. The verticality adjustment system is characterized in that the lattice column is positioned for free hanging; the placement method for the spacer and the correcting mount is as follows: through the natural terrace position line, the X direction and the Y direction are aligned and leveled to the water level; and the correcting method for lower placement of the lattice column is as follows: when the lattice column is hanged to a marked elevation, the lattice column is free hanging by utilizing the correcting system, and the purpose for controlling the lattice column verticality is achieved. Through the special innovation for the construction method of the verticality adjustment of the lattice column with ultra-deep foundation and the special design for the verticality adjustment system for the lattice column correcting mount, only the construction technology of a normal column pile is adjusted, so that the lattice column can satisfy the verticality control requirement in ultra-deep foundation, necessary construction conditions are provided for the subsequent construction, and the resource expenditure and construction cost of the column pile and the subsequent construction are greatly reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

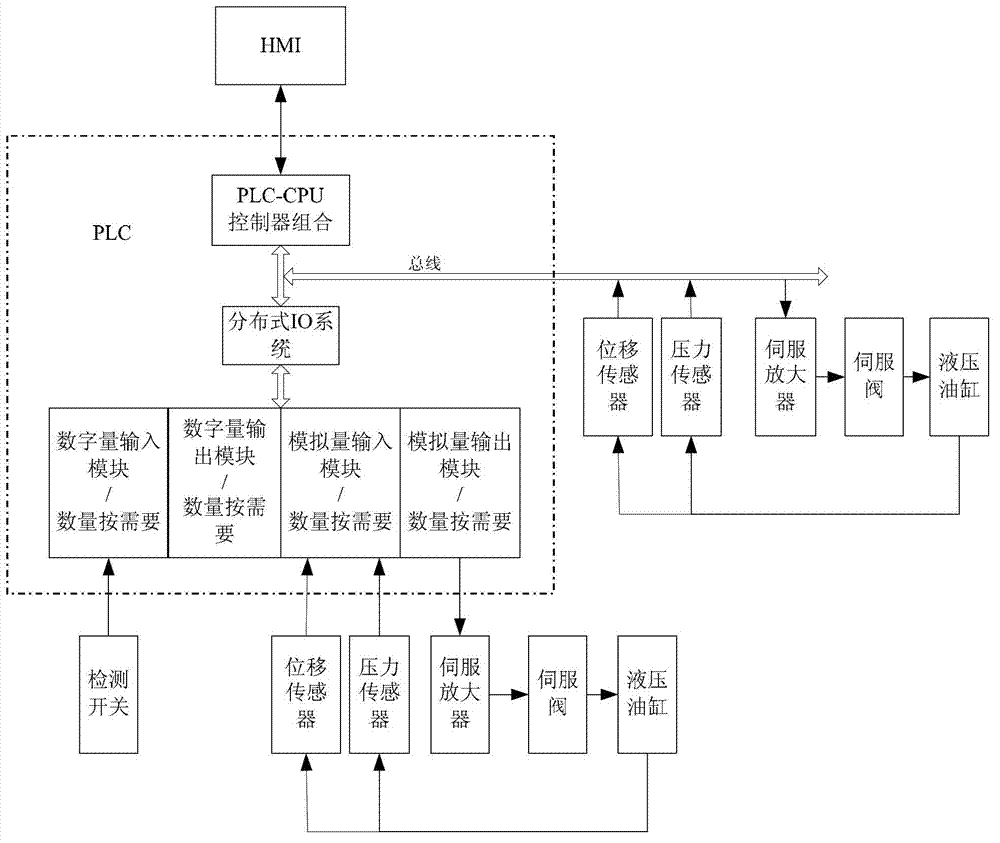

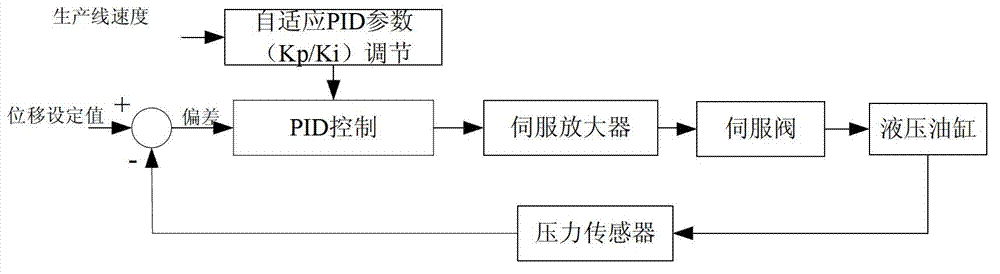

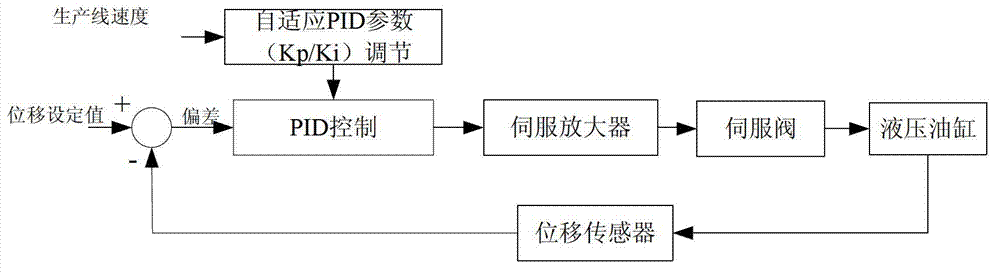

Control system and method of continuous artificial plate hot press

InactiveCN102773902AEasy to debug and maintainImprove reliabilityWood working apparatusDomestic articlesHuman–machine interfaceValve amplifier

The invention discloses a control system and method of a continuous artificial plate hot press. The control system comprises a PLC (Programmable Logic Controller), a hydraulic cylinder, a displacement sensor, a pressure sensor, an amplifier, a control valve, and a computer or a touch screen which is connected with the PLC and provides a man-machine interface, wherein the PLC comprises a CPU (Central Processing Unit), a distributed type I / O (Input / Output) system, an analog quantity input module and an analog quantity output module; the analog quantity input module and the analog quantity output module are respectively connected with the CPU through the distributed type I / O system; the displacement sensor and the pressure sensor are respectively connected with the PLC; and the servo valve amplifier is respectively connected with a servo valve and the PLC. The control method disclosed by the invention adopts a correction program in the PLC to correct pressure and displacement deviation signals generated in a correction system; and hydraulic pressure and a position line of oil in the hydraulic cylinder in the system are controlled through the servo valve. The control system disclosed by the invention has the advantages of high reliability, strong interference resistance, easiness for programming, and high precision in thickness setting of an artificial plate.

Owner:GUANGZHOU MECHANICAL ENG RES INST +2

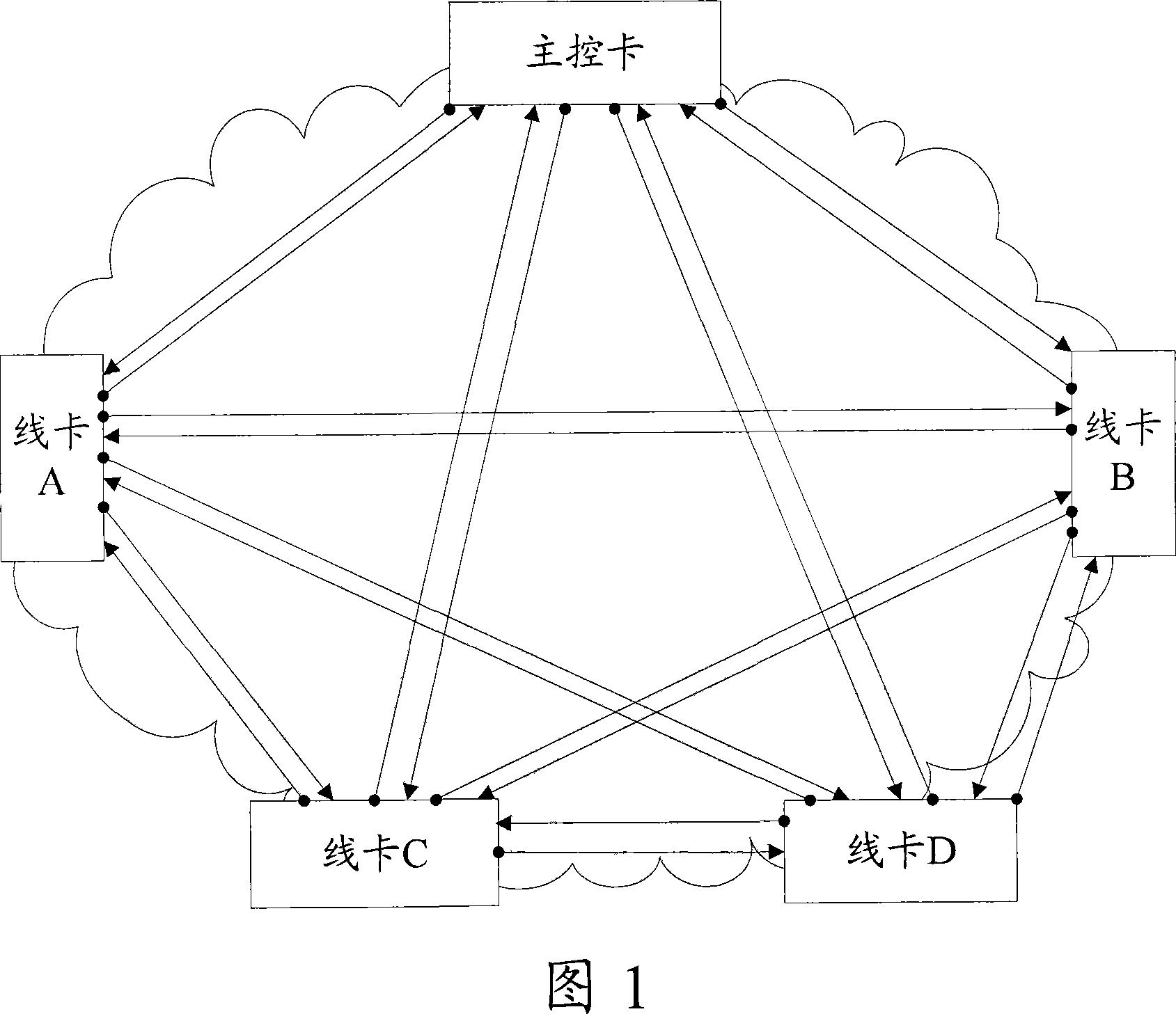

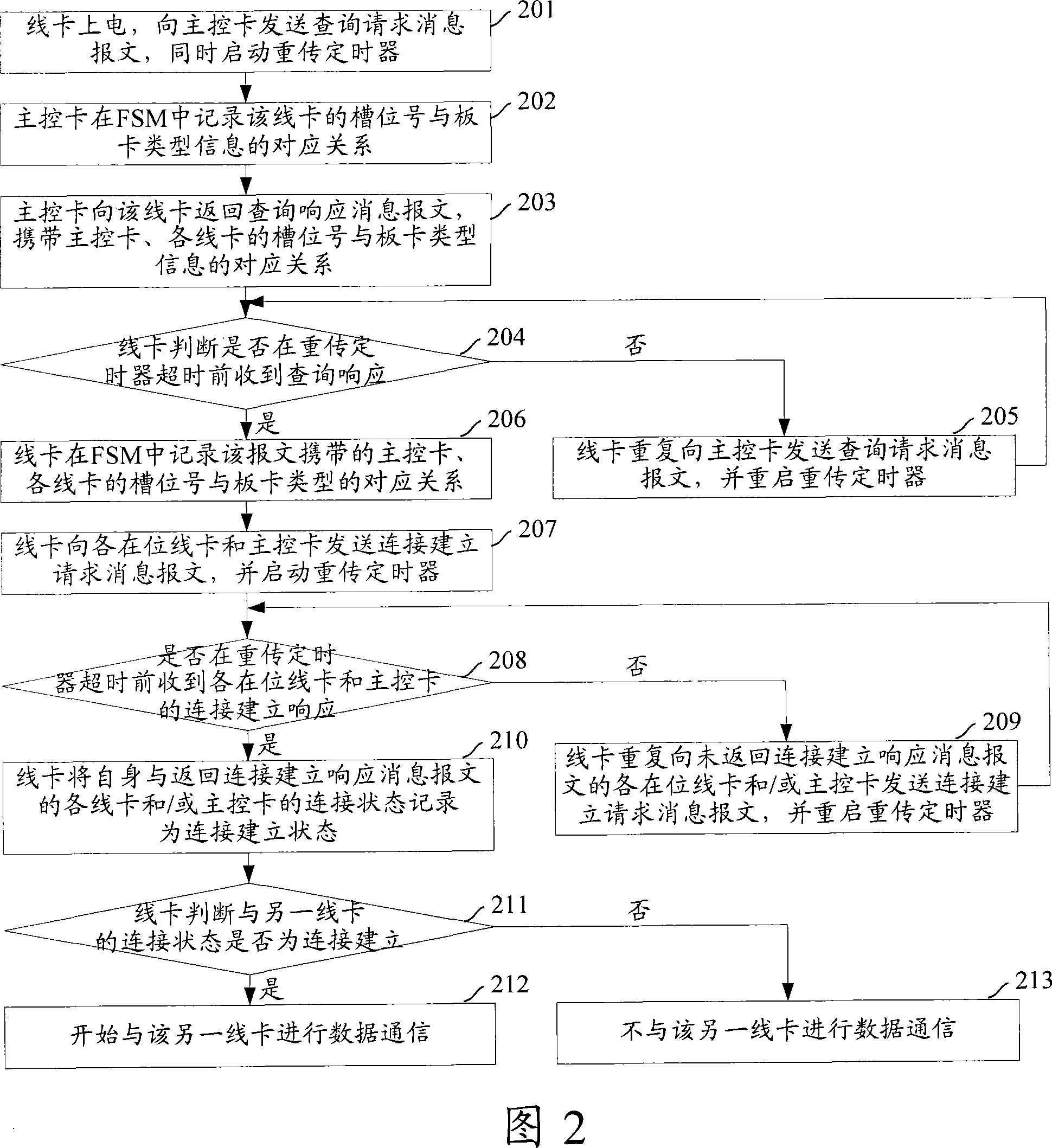

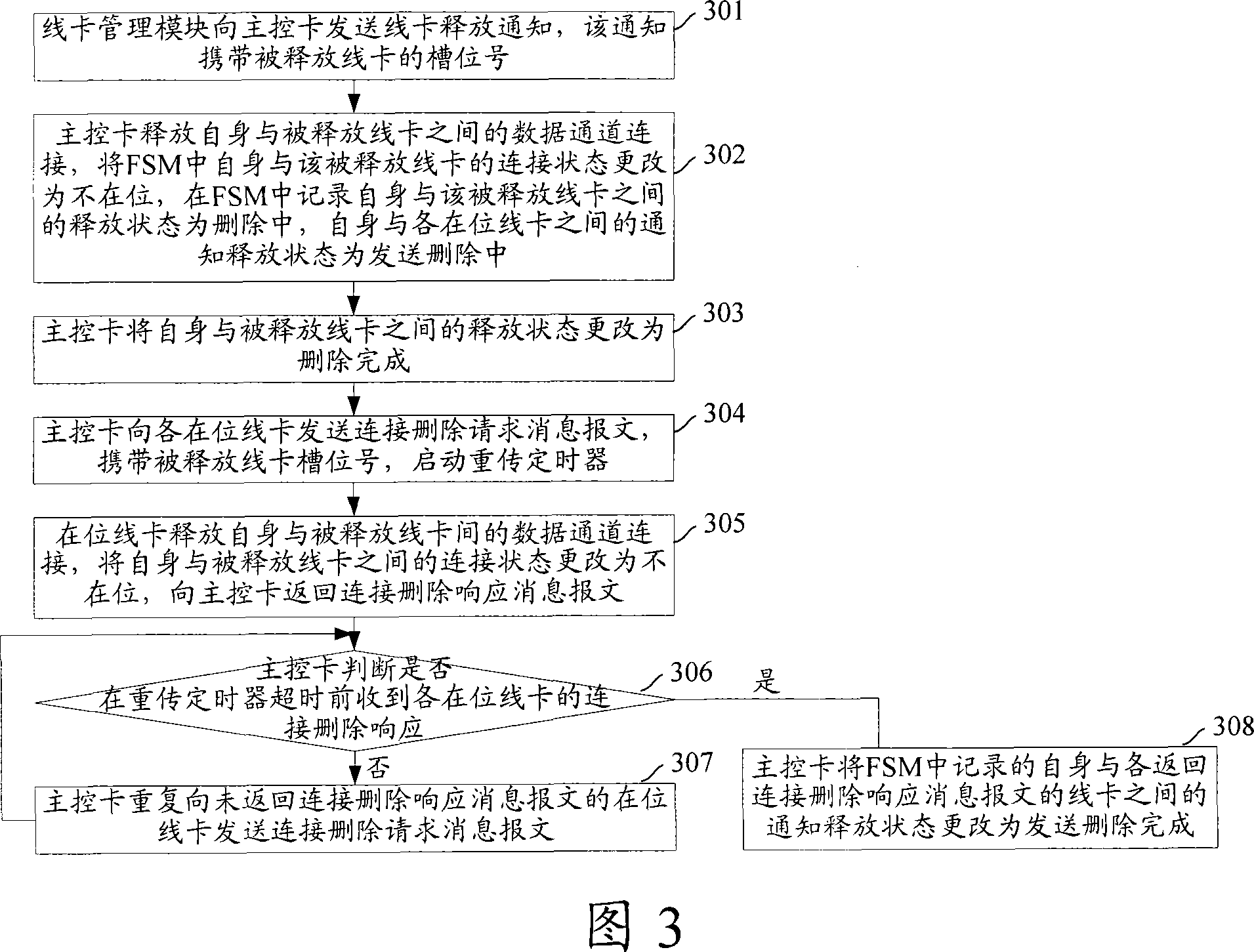

Data communication method, system, master control card and cable fastener

ActiveCN101110768ARealize data communicationImprove stabilityData switching detailsLine cardFastener

The present invention discloses a method, a system and a main control card and line cards for data communication, which comprise that the main control card receives the communication attribute information sent from the on-position line card, and notices the on-position line card with the communication attribute information of all the on-position line cards; the on-position line card establishes a data channel connection with other on-position line cards according to the communication attribute information sent from the main control card, and operates the data communication with other n-position line cards through the data channel connection. The present invention realizes the data communication based on a non-switched network environment.

Owner:XINHUASAN INFORMATION TECH CO LTD

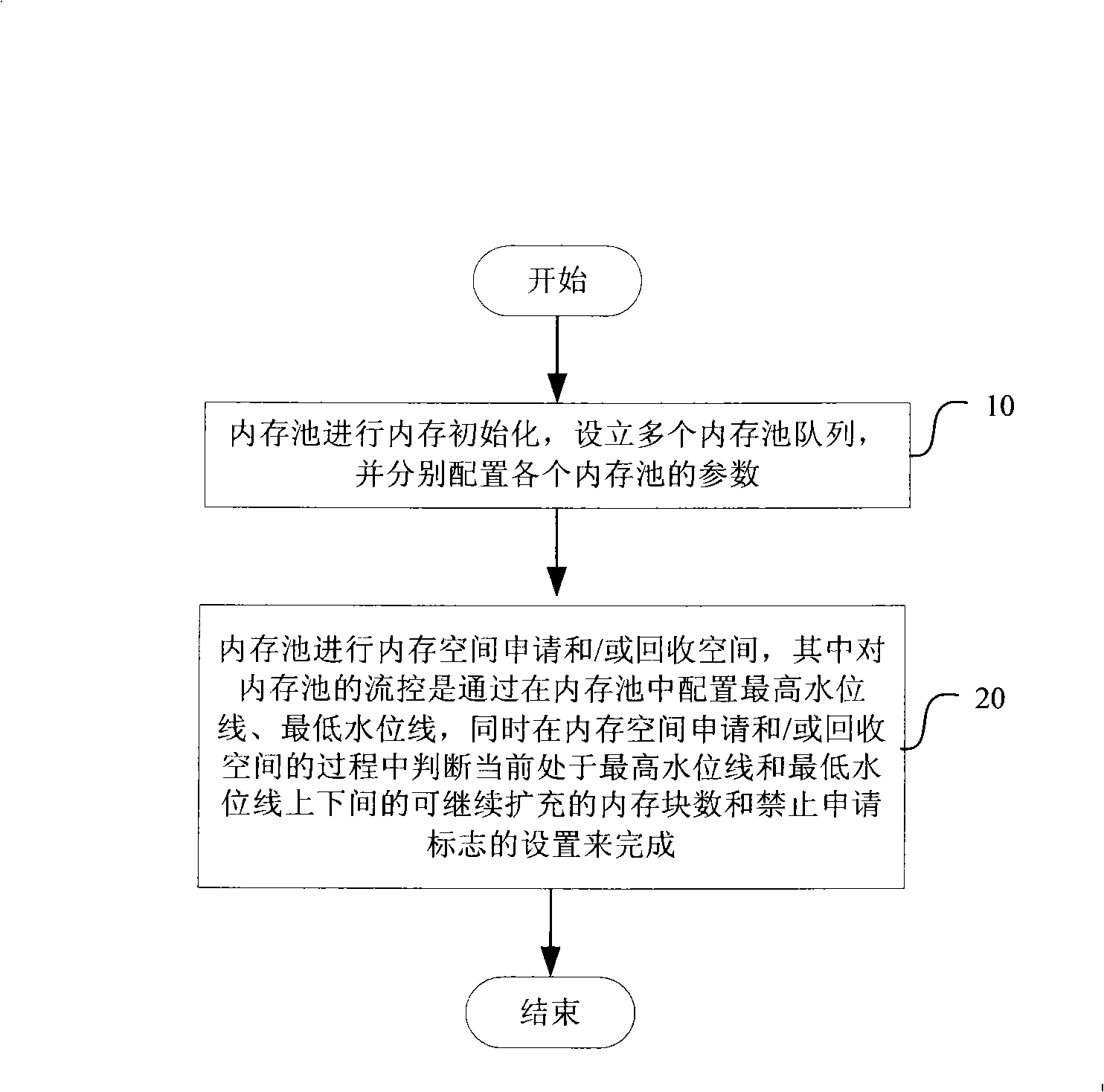

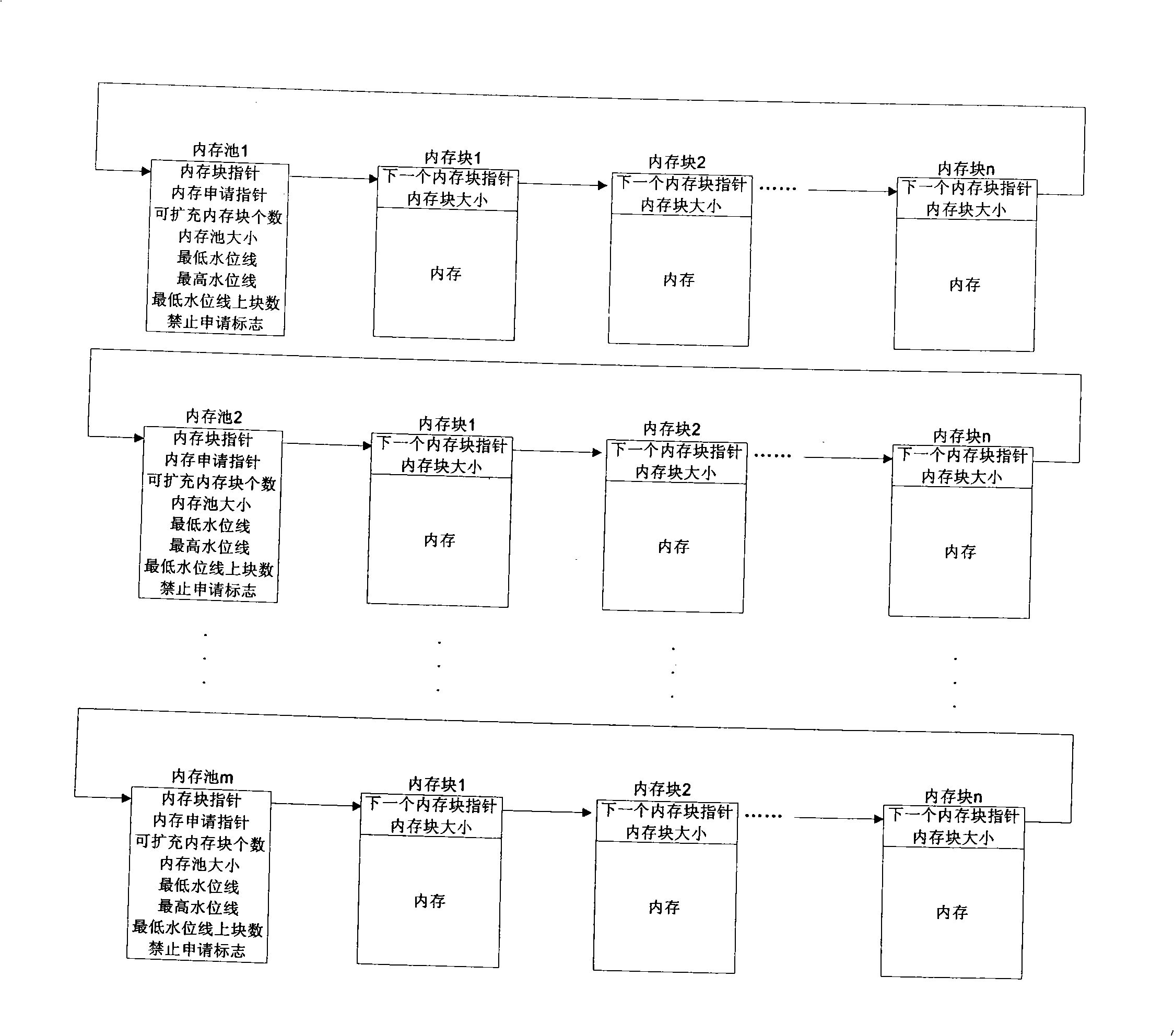

Management method of memory pool for terminal

InactiveCN101286878AImprove distribution efficiencyInput/output to record carriersMemory adressing/allocation/relocationParallel computingComputer terminal

The invention discloses a method for managing memory pools of a terminal, which comprises the steps that: the memory pools are first initialized; a plurality of memory pool arrays are established and parameters of each memory pool are respectively configured; after the memory pools are initialized, flow control of the memory pools is completed by configuring the highest water level and lowest water level, judging the number of memory modules that can be extended continuously and presently positioned between the highest water level and the lowest level in the process of applying for and / or reclaiming the spaces in memory spaces and setting signs for forbidding the applying, wherein, the highest water level and the lowest level are two position lines that show the number of the memory modules that can be expanded continuously in the memory pools. By applying the method of the invention, the number of memory pages in the memory pools can be dynamically expanded by a system, and the distribution efficiency of the memory spaces can be enhanced and memory fragments can be reduced in a certain degree; meanwhile, the corresponding state information and flow control signs can be added to assist the control of the flow control.

Owner:ZTE CORP

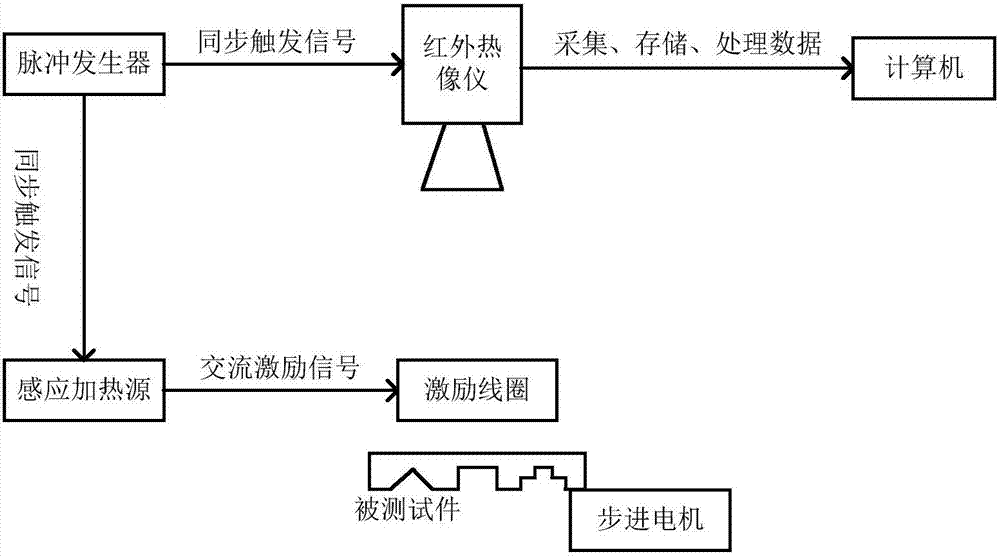

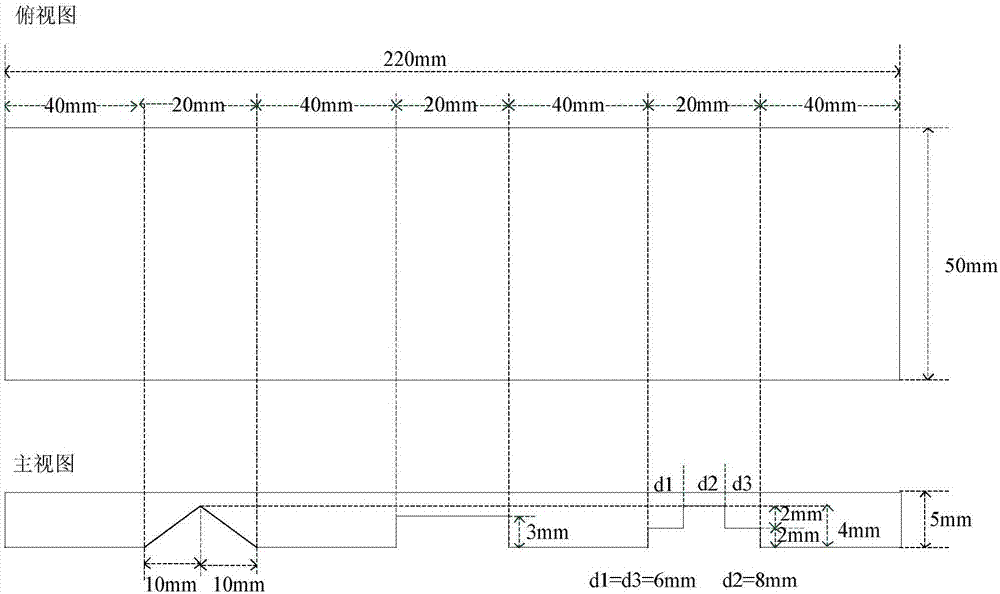

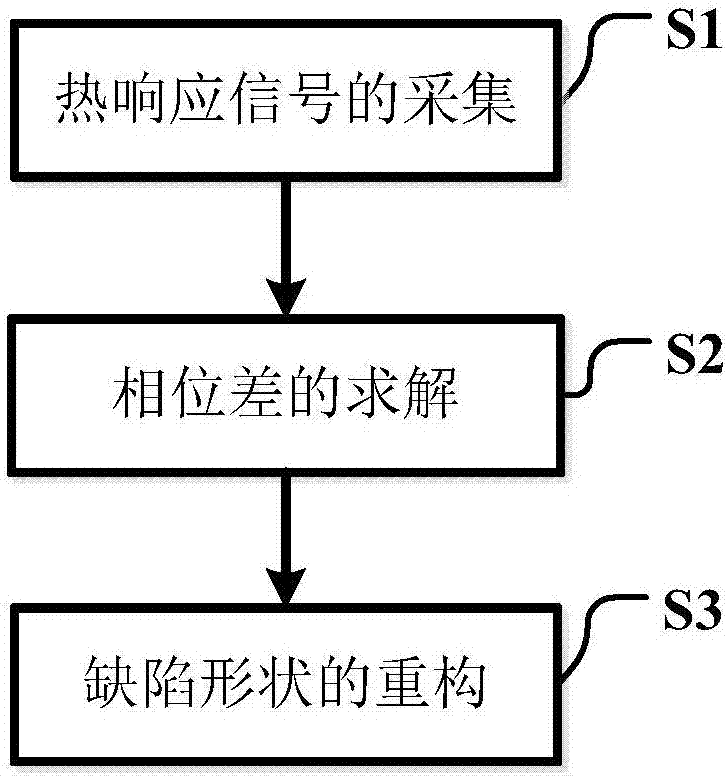

Sub-surface defect shape reconstruction method for thermal imaging detection

ActiveCN106996944AConducive to quantitative evaluationSolving Quantitative Analysis ProblemsMaterial flaws investigationPhase differenceFourier analysis

The invention discloses a sub-surface defect shape reconstruction method for thermal imaging detection. The sub-surface defect shape reconstruction method consists of a thermal response signal acquisition process, a process of solving a phase difference between a defective region and a non-defective region, and a process of reconstructing a defect shape by adopting an envelope line. The method comprises the following steps: performing linear scanning on a test piece by adopting a linear thermal source; then performing Fourier analysis on data at a collected heating source position; solving corresponding phase differences between other position and non-defective positions; reversing the depths of defects according to the phase differences; then, making an envelope line according to scanning results of position lines, namely, solved depths; finally, estimating the shapes of the defects according to the envelope line. By adopting the sub-surface defect shape reconstruction method, the shapes of irregular defects can be estimated and reconstructed, quantitative assessment can be performed on the defects, and the problem on the aspect of quantitative analysis of the defects of the type during surface excitation is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

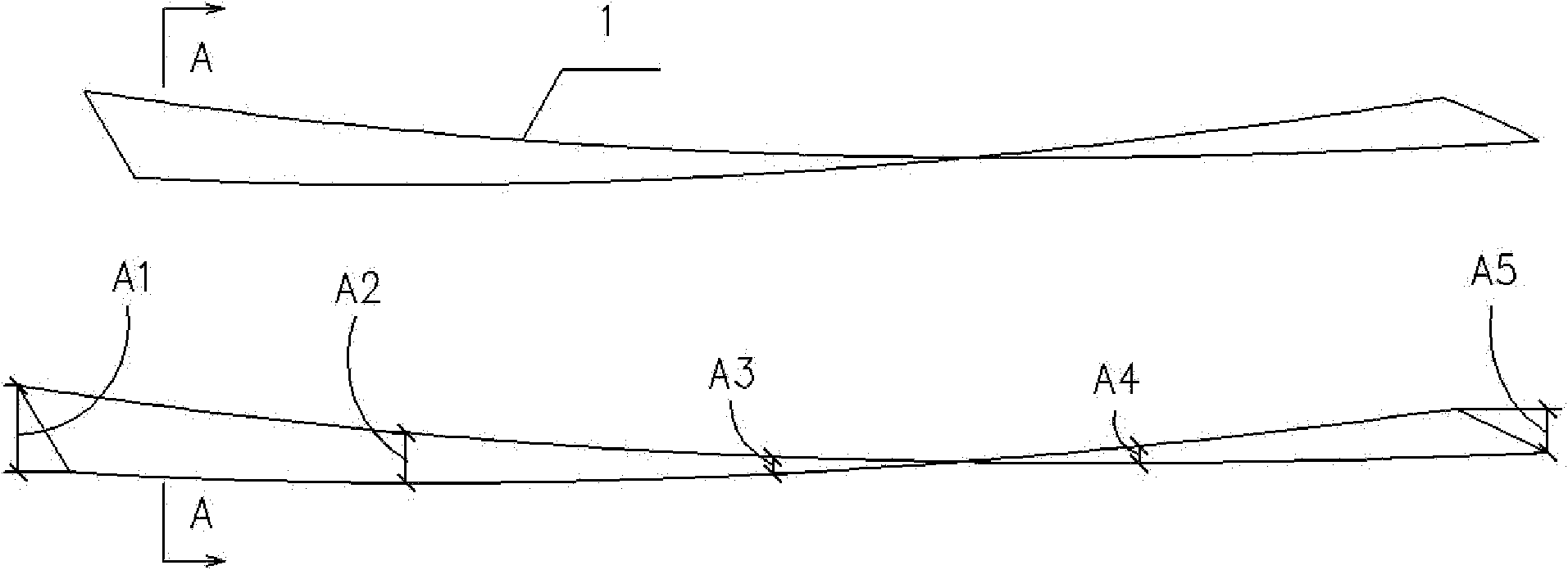

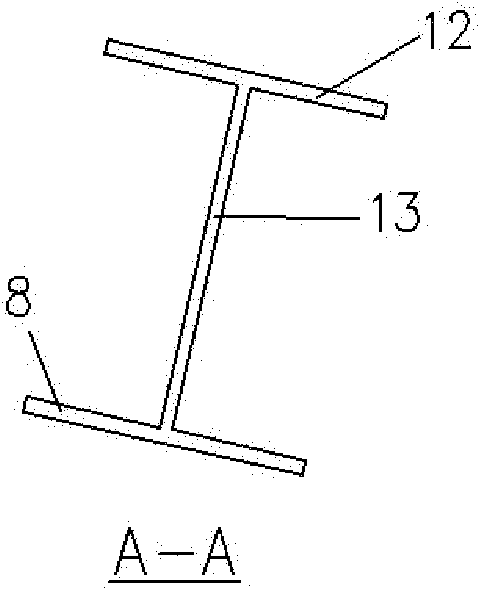

Method for processing H-shaped crankle beam

The invention discloses a method for processing an H-shaped crankle beam, which is characterized by comprising the following steps of: firstly, respectively obtaining a vertical face jig frame chart and a plane drawing chart of the H-shaped crankle beam according to a deepening model; drawing a top flange contour line and a bottom flange contour line of the H-shaped crankle beam on a steel platform; building each grade of jig frame on the steel platform; marking a bottom flange center line and a flame distortion correction position line on a spread bottom flange subjected to digital control cutting, baking by flame according to the flame distortion correction position; pot-welding firmly the qualified bottom flange with each grade of jig frame, installing a triangle support on the bottom flange, and processing a top flange by using the same method; rigidly fixing a web plate with the triangle support and the bottom flange by using auxiliary outside force, and pot-welding firmly; positioning and assembling the top flange on the web plate and pot-welding and fixing the top flange and the web plate; and integrally asymmetrically welding and forming on the jig frame. The invention has the advantages of simple and rapid method and high processing quality.

Owner:ANHUI FUHUANG STEEL STRUCTURE

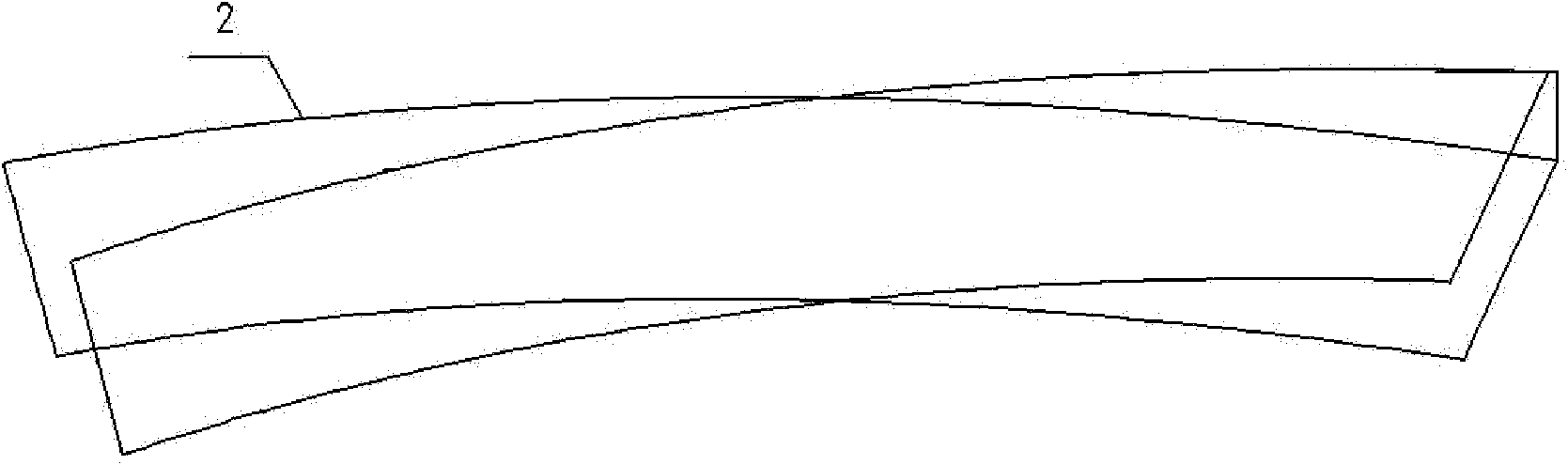

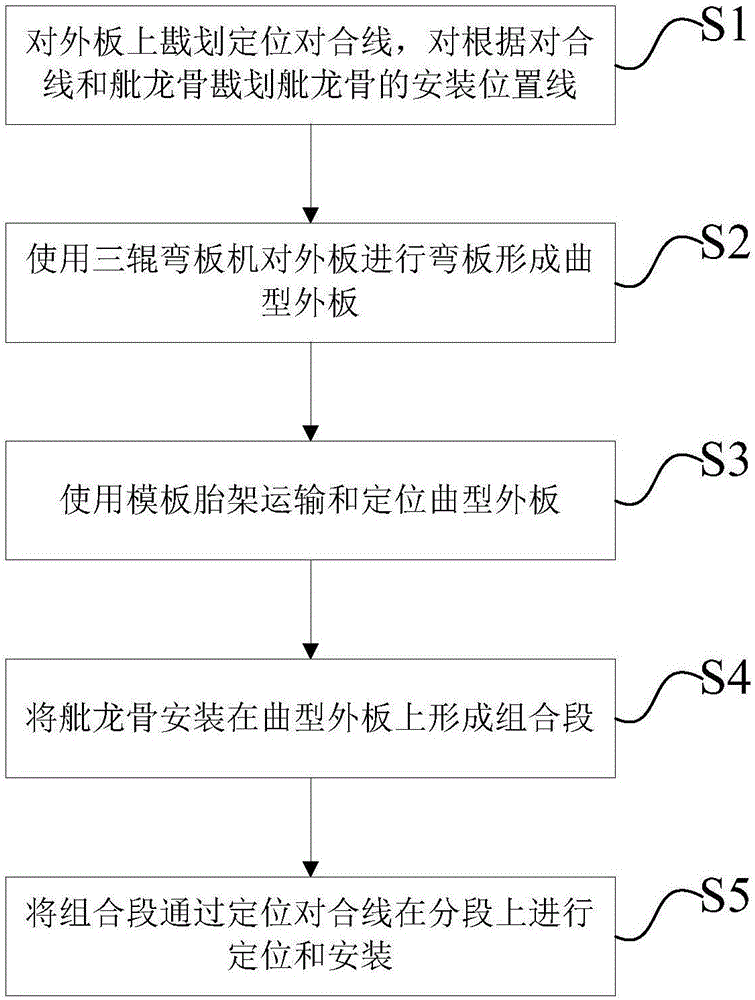

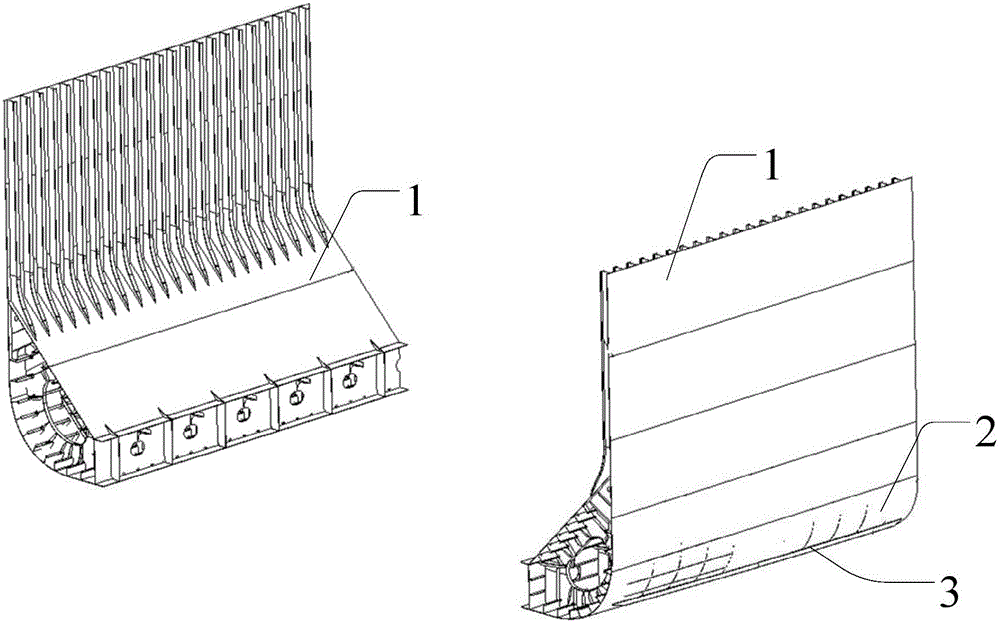

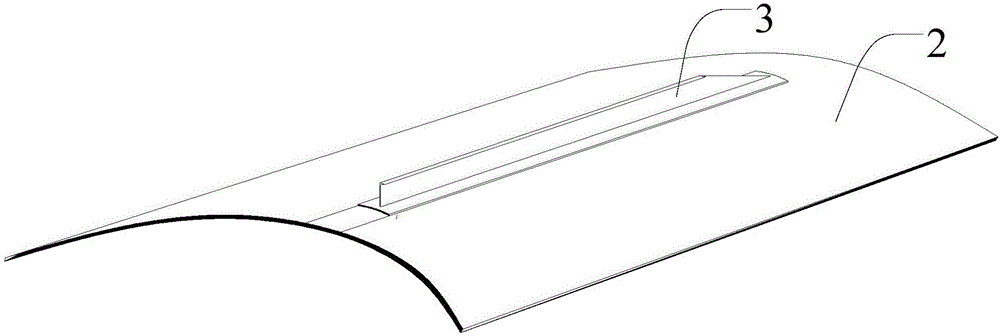

Ship bilge keel positioning and mounting method

ActiveCN106516001AOptimize the segmented construction processReduce installation difficultyVessel designingBilgeKeel

The invention provides a ship bilge keel positioning and mounting method. A bilge keel is mounted on an outer curved plate which is positioned in a bilge section. The method includes steps: S1, marking a positioning joining line on the outer plate, and marking a bilge keel mounting position line according to the positioning joining line and the bilge keel; S2, adopting a three-roll plate bending machine for linear curvature processing of the outer plate to form the outer curved plate; S3, using a moulding bed for transporting and positioning the outer curved plate; S4, mounting the bilge keel on the outer curved plate to form a combined section; S5, positioning and mounting the combined section on the bilge section according to the positioning joining line. At a bilge keel mounting stage, after completion of a large section group, curvature processing of the outer plate of the bilge section is performed before mounting of the bilge keel. A normal-posture faceup installation way of the bilge keel is optimized into a horizontal faceup installation way to lower installation difficulty. Bilge keel installation precision is optimized from rough installation to accuracy control, subsequent reworking is avoided due to angle control of the bilge keel, and the moulding bed guarantees linear precision of the outer curved plate in a placement and transport process to avoid subsequent reworking.

Owner:JIANGNAN SHIPYARD GRP CO LTD

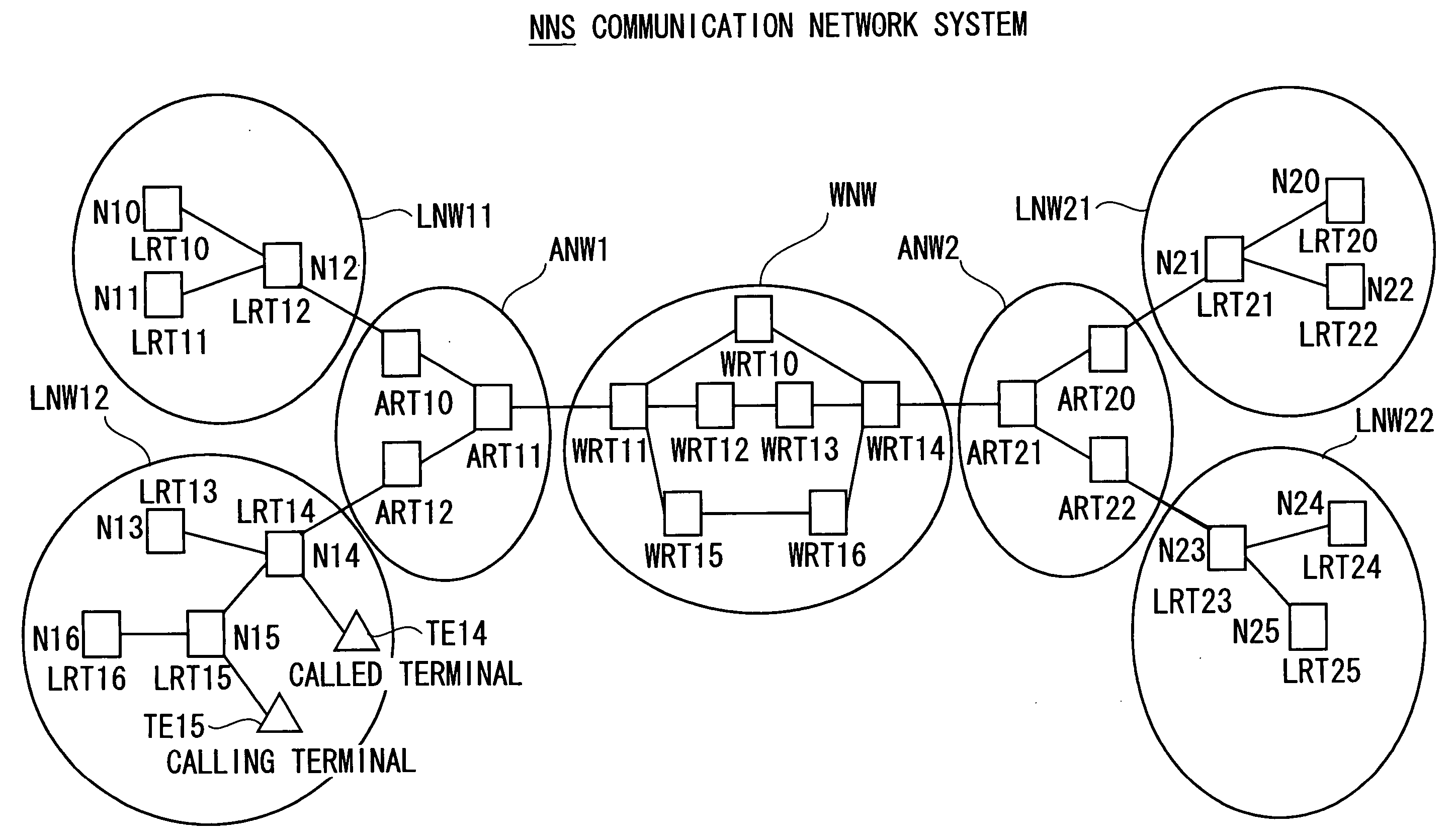

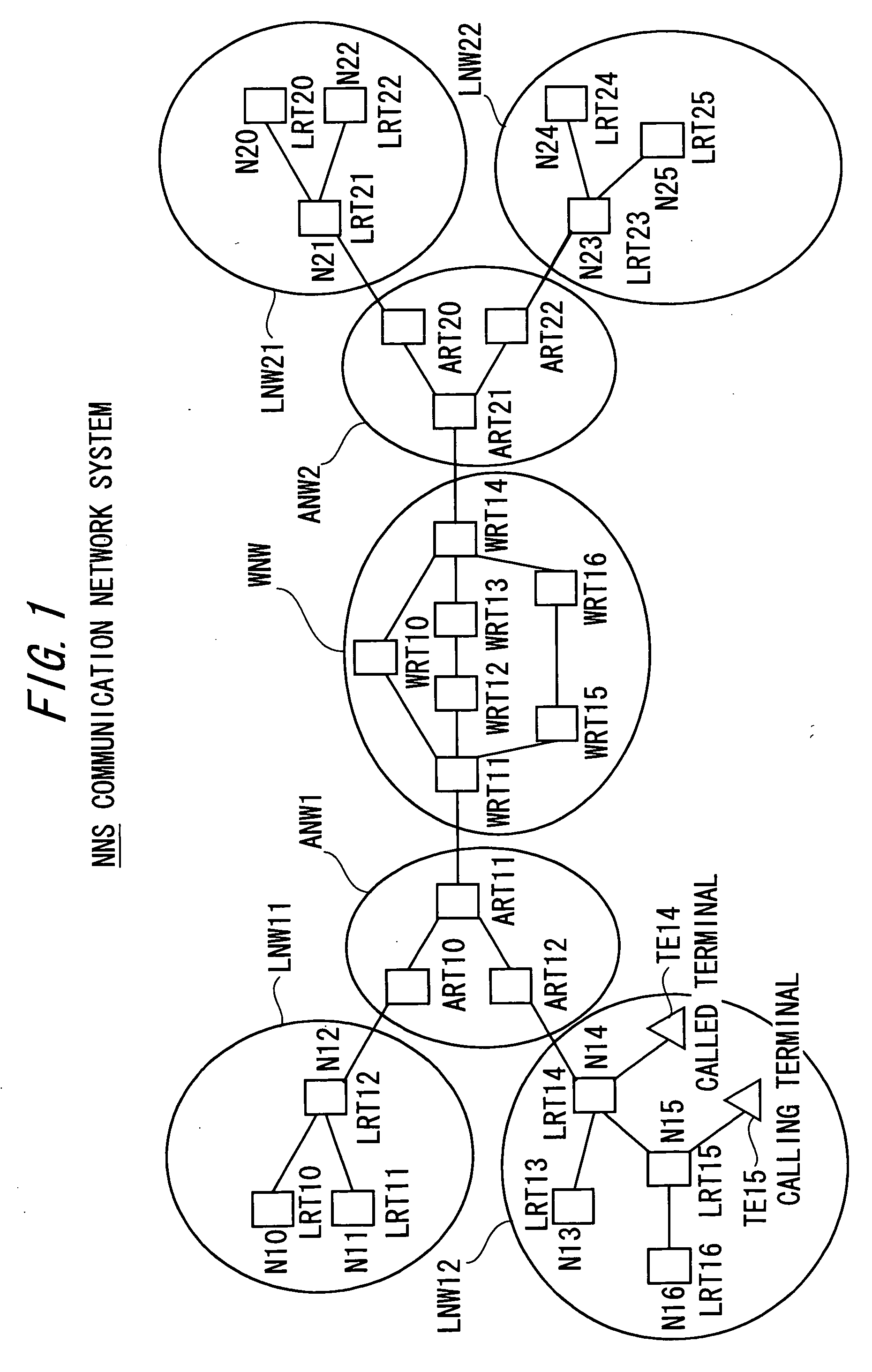

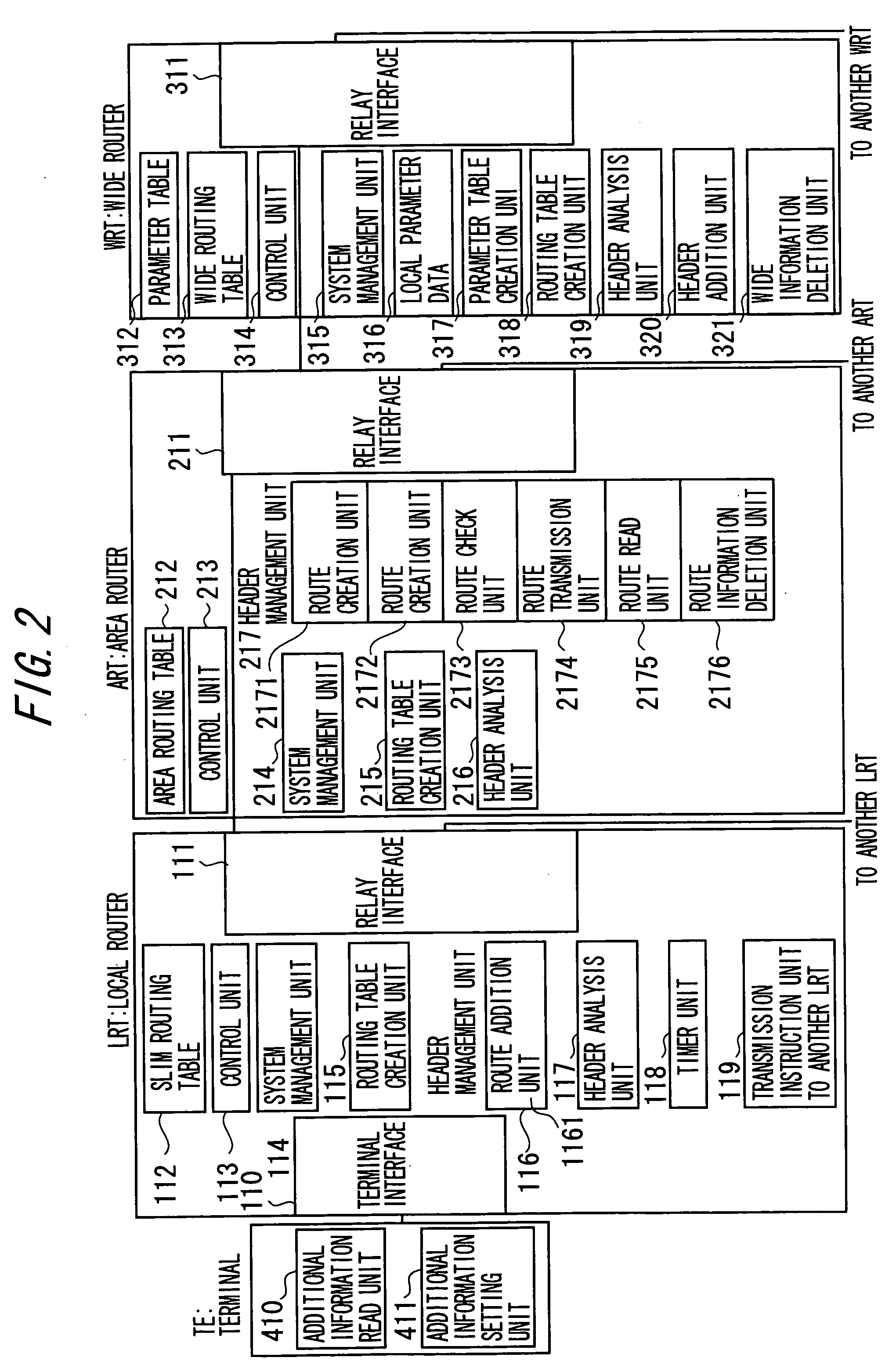

Communication network system

InactiveUS20050122981A1Reduce processing loadMinimize the numberData switching by path configurationRouting tableNetworked system

A communication network system includes: a plurality of lower hierarchy networks, each having a plurality of first relay apparatuses; and an intermediate hierarchy network having a plurality of second relay apparatuses for connecting the plurality of lower hierarchy networks via the second relay apparatuses at the edge position line-connected to the first relay apparatuses at the edge position. Each of the first relay apparatuses has a first routing table that holds information limited to routing information corresponding to the first relay apparatus and routing information on at least one of the first relay apparatuses and the second relay apparatuses in the edge positions that come into an adjacent state. Each of the second relay apparatuses has a second routing table that holds information including routing information on at least one of the second relay apparatuses and the first relay apparatuses in the edge positions that come into an adjacent state.

Owner:FUJITSU LTD

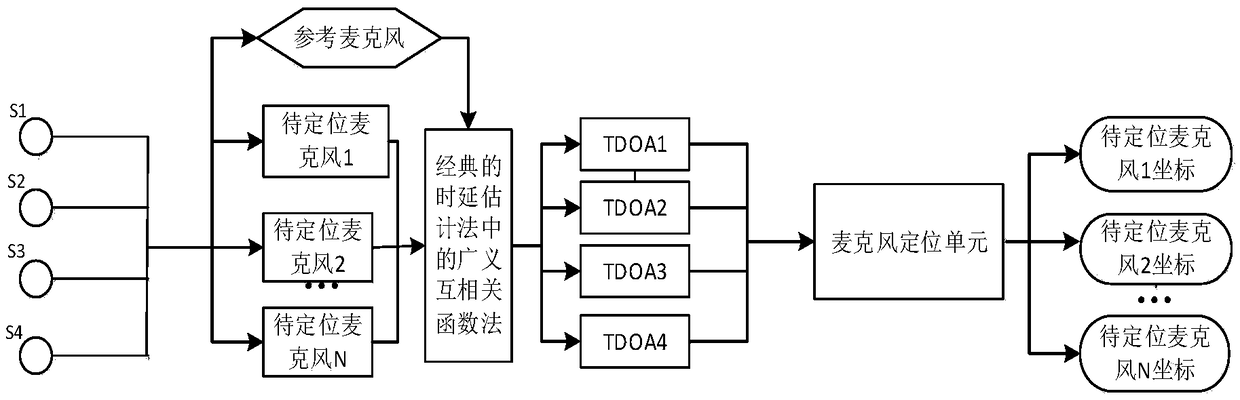

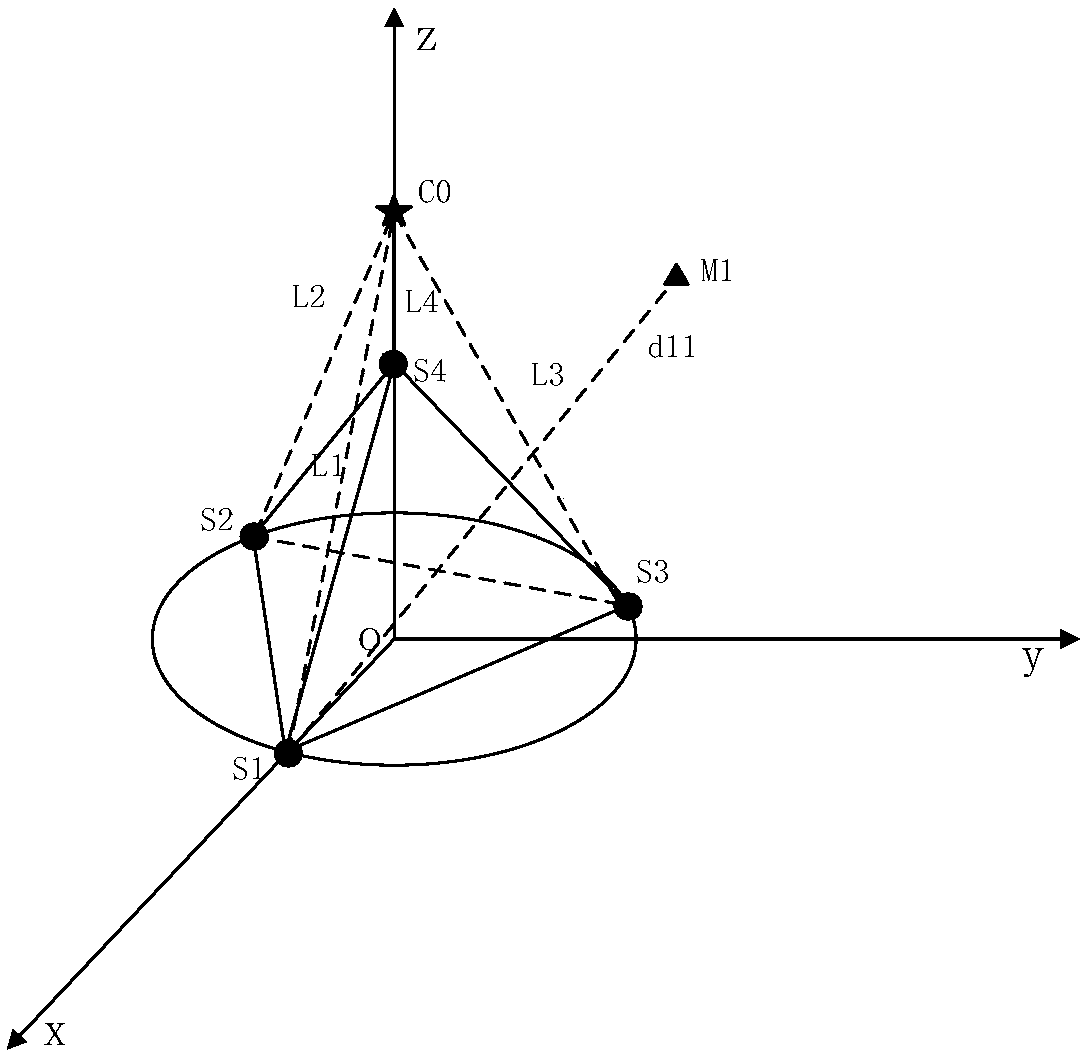

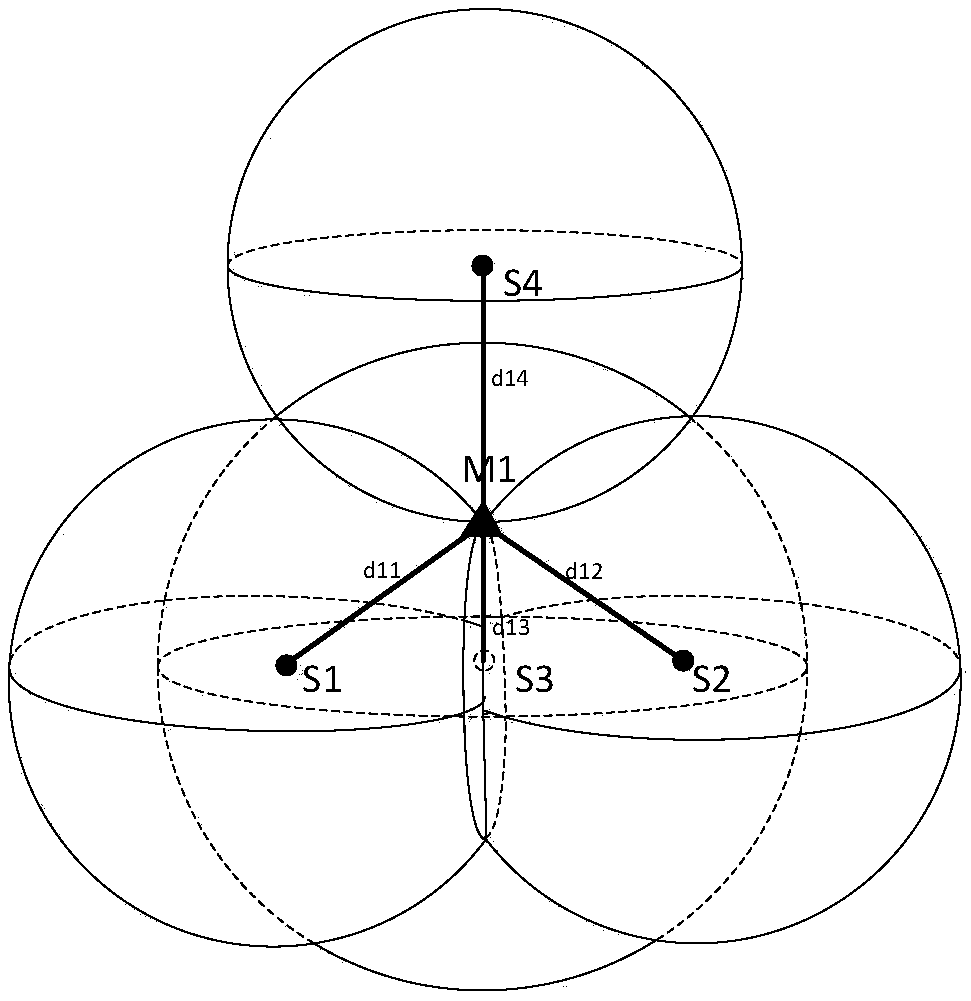

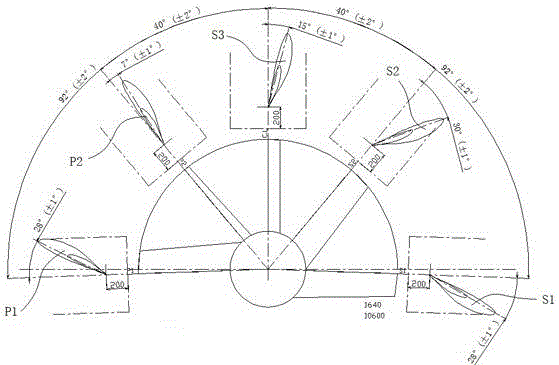

Space microphone positioning method based on sound source array

ActiveCN108802689AOutstanding FeaturesHighlight significant progressPosition fixationSound sourcesThree-dimensional space

The invention discloses a space microphone positioning method based on a sound source array and relates to sound wave application. Cooperation of multiple position lines determined by path differencemeasuring is utilized to determine position of a signal source, and online positioning of a microphone in three-dimensional space is realized by utilizing sound signals of four sound sources and fixeddistance between a reference microphone and each sound source. The method includes steps: subjecting the sound sources to quaternary three-dimensional array distribution; arranging the reference microphone; marking a to-be-positioned microphone; using a microphone positioning unit to position spatial position of the to-be-positioned microphone. By the method, the defects that signal collection istroublesome in operation and low in efficiency, only offline calculation is supported, online estimation of microphone position cannot be realized and position estimation of spatially distributed microphones cannot be realized due to the fact that position estimation is performed only on planar microphone arrays are overcome.

Owner:HEBEI UNIV OF TECH

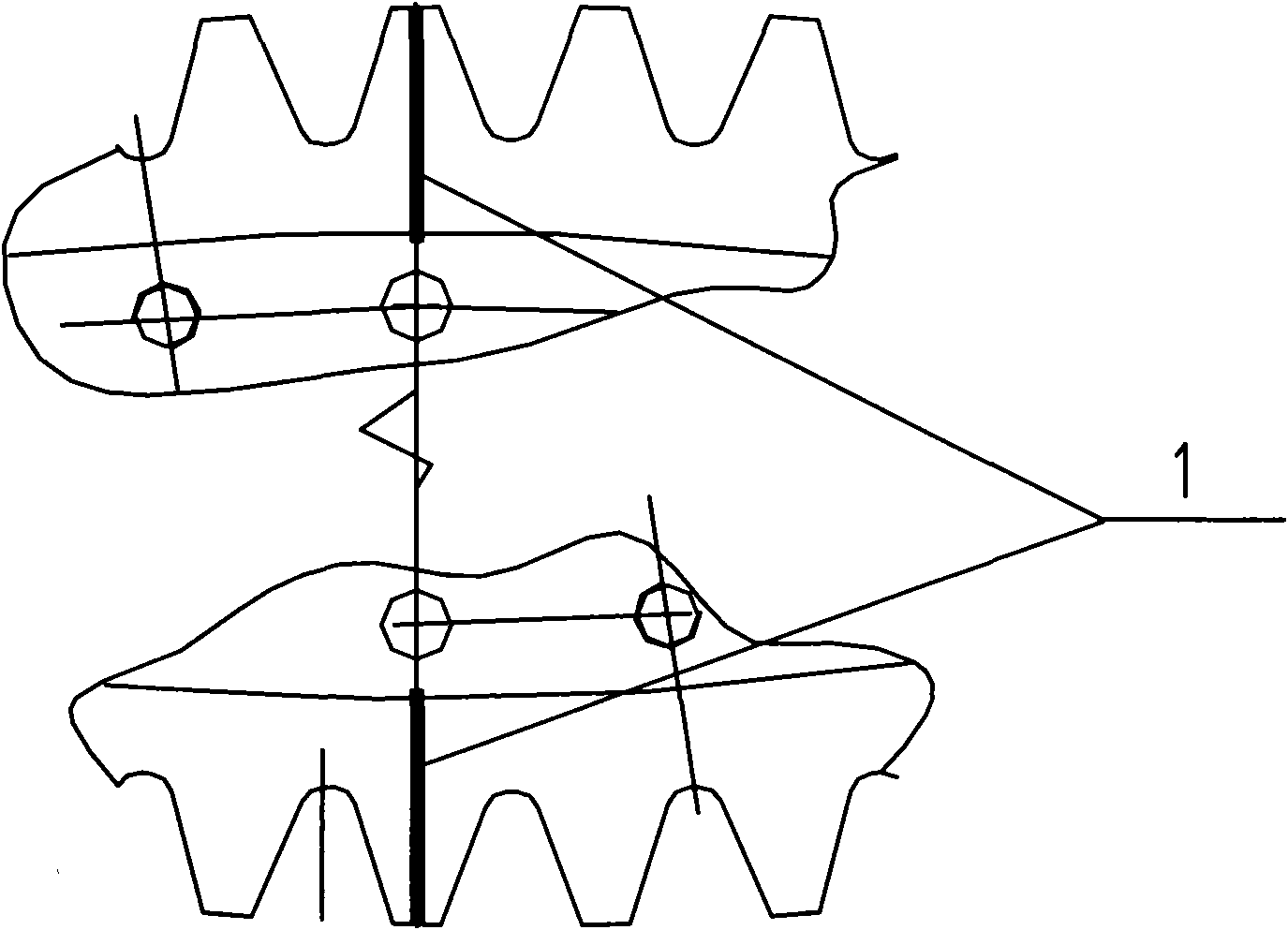

Method for processing large combination type herringbone gear

ActiveCN101862945ASave materialShorten the timeTransportation and packagingTrepanning drillsGear grindingHobbing

The invention discloses a method for processing a large combination type herringbone gear, which comprises the following steps of: forging; carrying out rough processing of the end surface, an incircle and an excircle on a processed workpiece by utilizing a lathe; drilling a hoisting hole; carrying out rough gear hobbing on the workpiece by utilizing a gear hobbing machine; carrying out tempering processing on a gear; semifinishing an inner hole, the end surface and an addendum circle by utilizing the lathe; drawing any pair of end surface gear central lines based on the end surface of one side of a reference groove, making a reference groove mark on an addendum and drawing a position line of each hole; drawing and drilling each hole by using a drilling machine; finishing and lathing the inner hole and both end surfaces of the lathe to a preset size; positioning based on a reference surface, carrying out correcting gear grinding on the addendum circle ; chambering, drilling and articulating each hole on a gear ring; and screwing a bolt and hinging the bolt and combining two gears into a pair. The invention has the advantages of material saving, cost reduction and mechanical performance improvement of products.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

Installation method for energy-saving fin keel of ship

The invention discloses an installation method for an energy-saving fin keel of a ship. The installation method comprises following steps: actually measuring the contour line of an outer plate of a stern tube shaft in an installation region of an energy-saving fin, utilizing the actually measured line shape and an installation angle of the fin keel to find a primary installation position line of the fin keel on the stern contour of a tube shaft, utilizing the line shape to cut off the remaining amount of the fin keel in advance, compiling control program of deviation of the fin plate, correlating three-dimensional coordinates of a fin keel point measured by a total-station instrument to the positioning deviation of the fin keel for real-time tracking and positional guiding of the fin keel, reinforcing the fin keel prior to welding and formulating reasonable program of welding process, utilizing positioning deviation of the fin plate to control program so that welding influence upon installation of the fin keel is adjusted within the controllable range. The installation method for the energy-saving fin keel of the ship is capable of shortening time spent on positioning and installing the energy-saving fin keel in the dock phase and effectively reducing period of newly constructing a dock of the ship and dock-repair period of repairing the ship so that construction or cost of the ship or dock repair can be effectively saved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

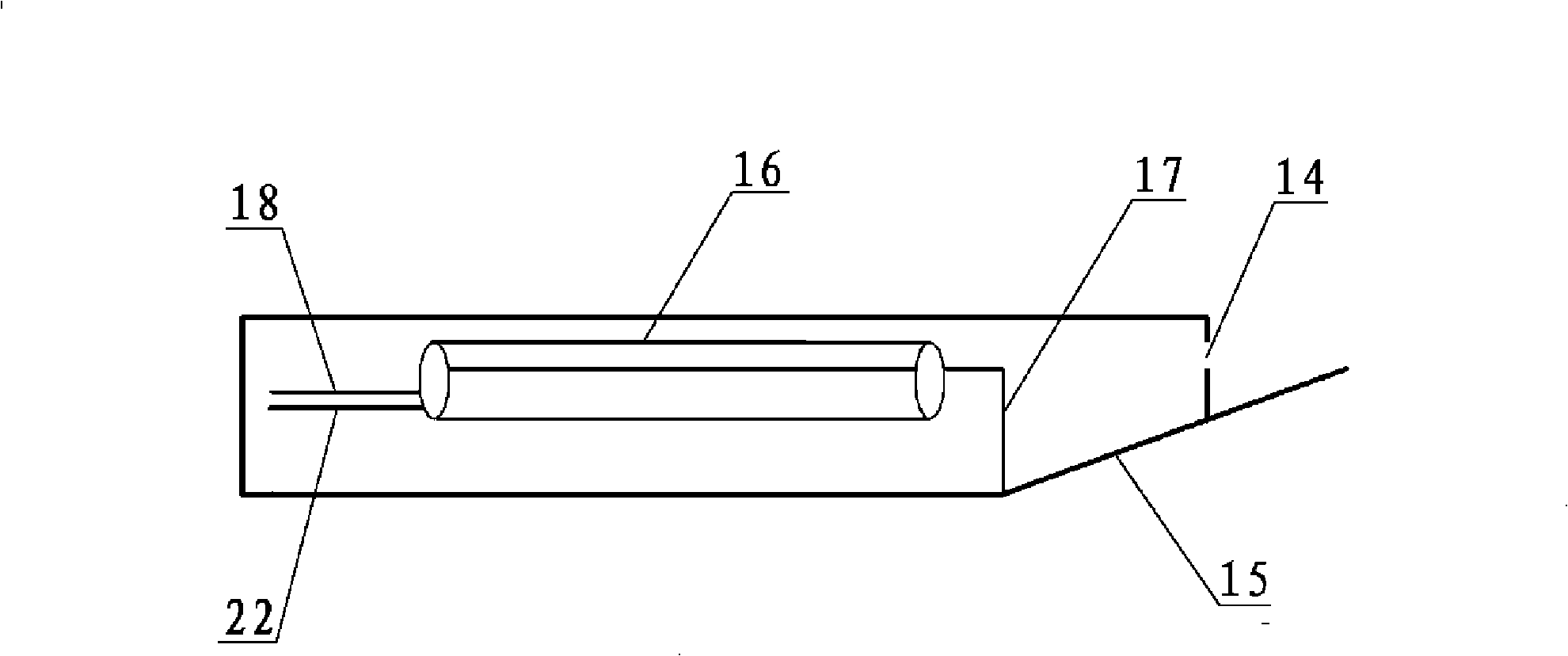

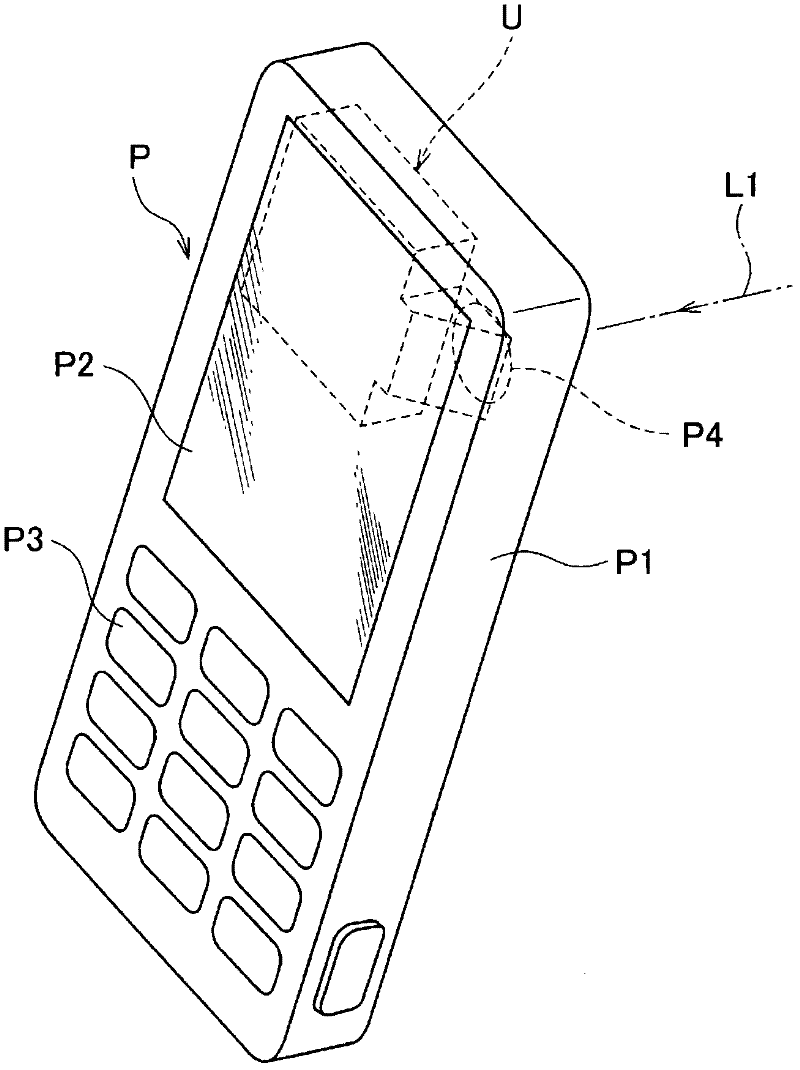

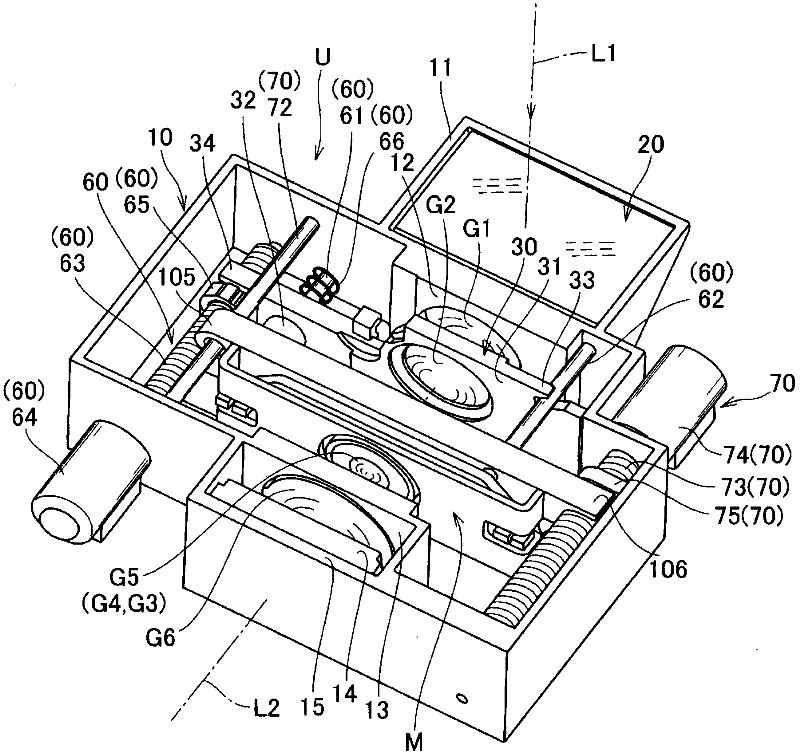

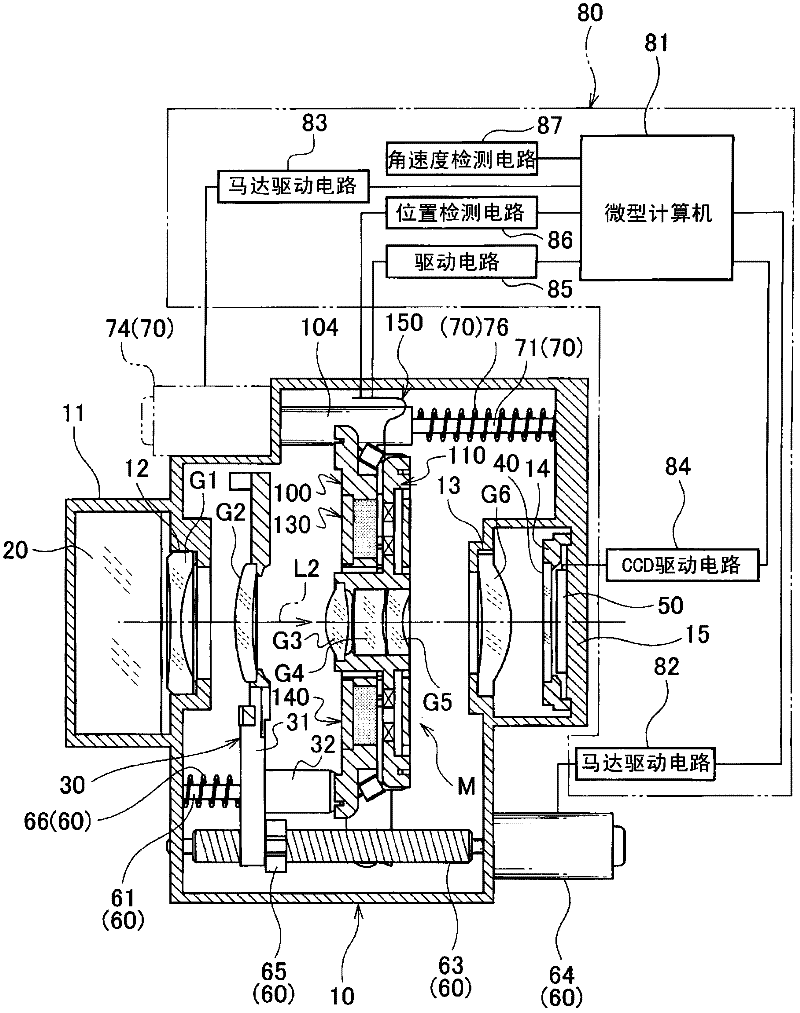

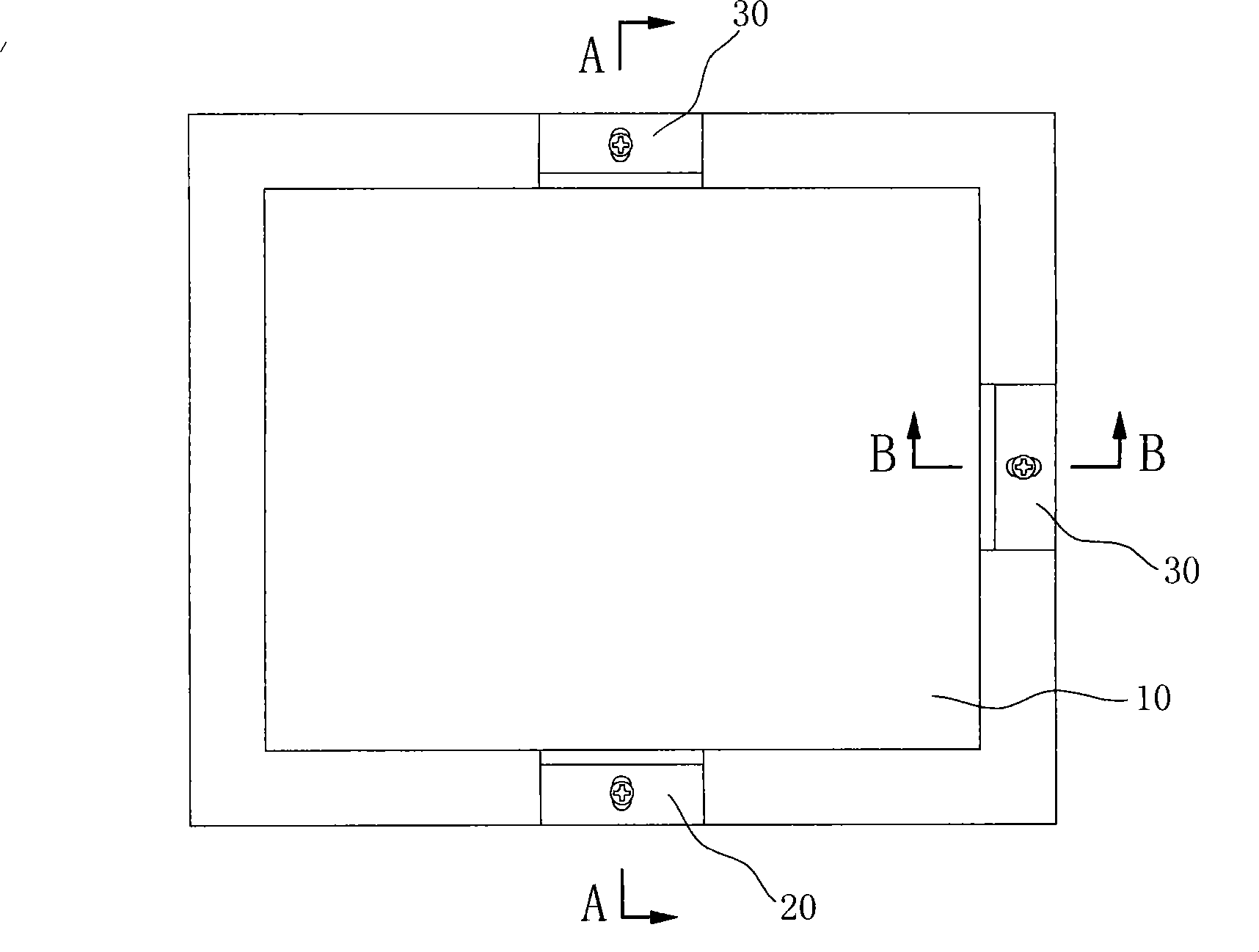

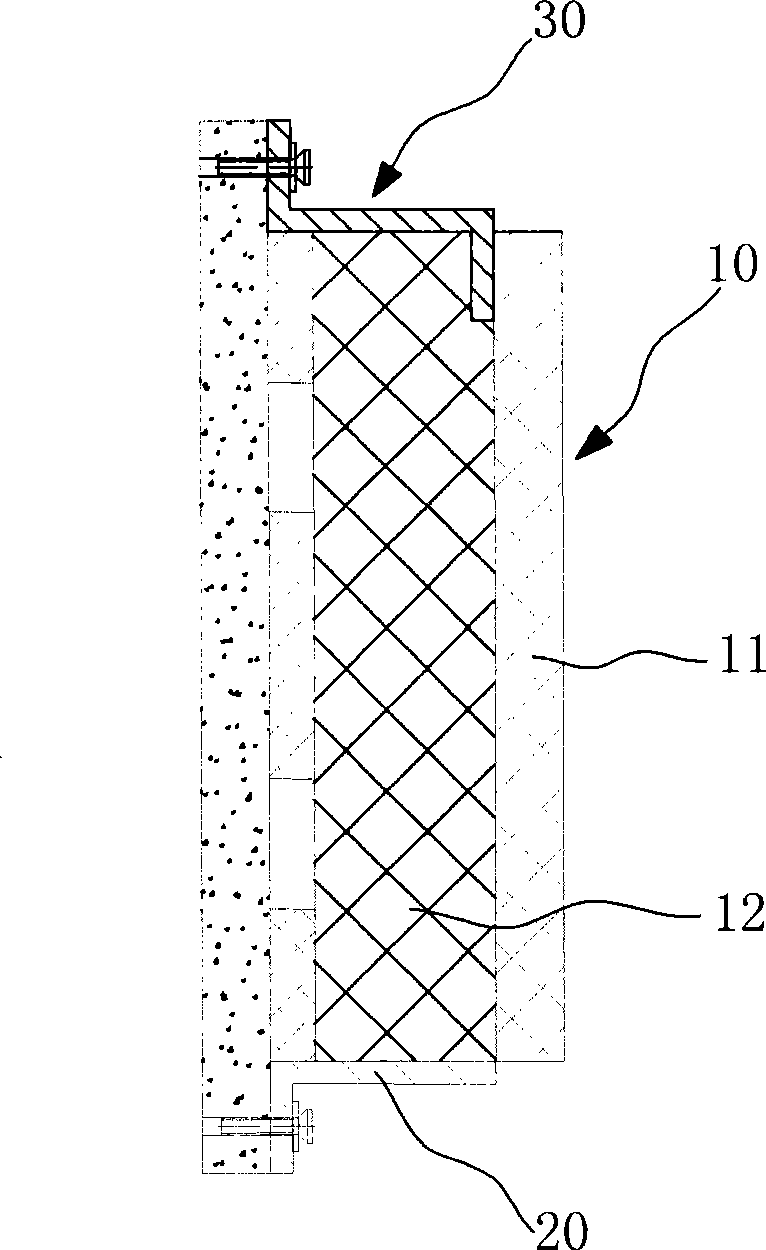

Image blur correction device, imaging lens unit, and camera unit

InactiveCN102165367ASimple structureEasy welding workTelevision system detailsPrintersOptical axisEngineering

An image blur correction device comprises: a flat plate-like base (100) having an opening section (101) open in an optical axis direction; a flat plate-like movable holding member (110) for holding a lens and supported so as to be movable within a plane perpendicular to the optical axis of the lens; a first drive mechanism (130) including a first magnet and a first coil to drive the movable holding member in a first direction perpendicular to the optical axis; a second drive mechanism (140) including a second magnet and a second coil to drive the movable holding member in a second direction perpendicular to the optical axis; and detecting means (170, 180) for detecting the position of the movable holding member. The movable holding member is movably supported located adjacent to a base. The first drive mechanism and the second drive mechanism are arranged at positions line-symmetrical with respect to a first straight line (S1) perpendicular to the optical axis of the lens. The configuration allows the device to be reduced in size and thickness and can highly accurately correct a shift of the optical axis of the lens due to hand shaking.

Owner:COPAL CO LTD

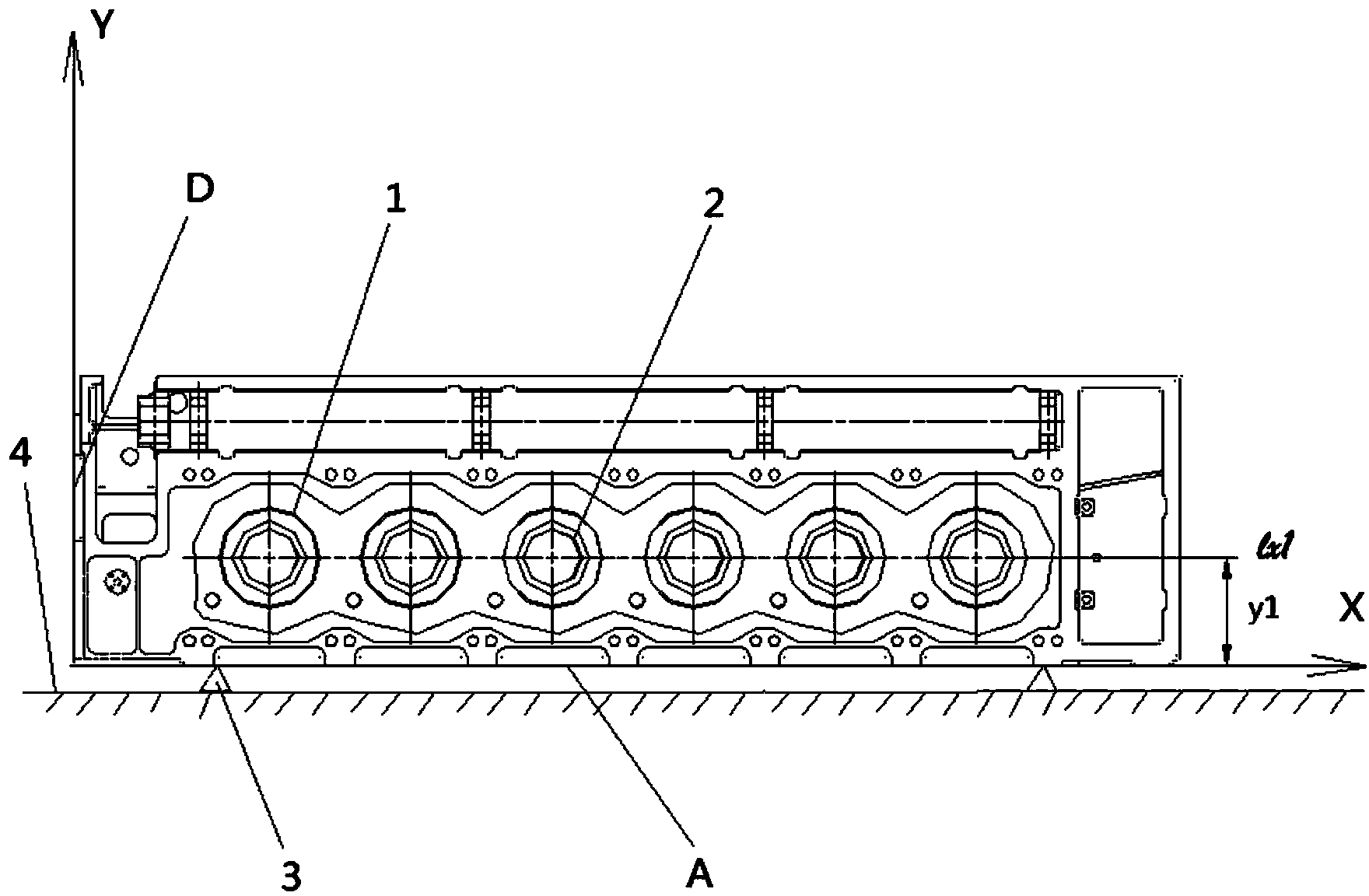

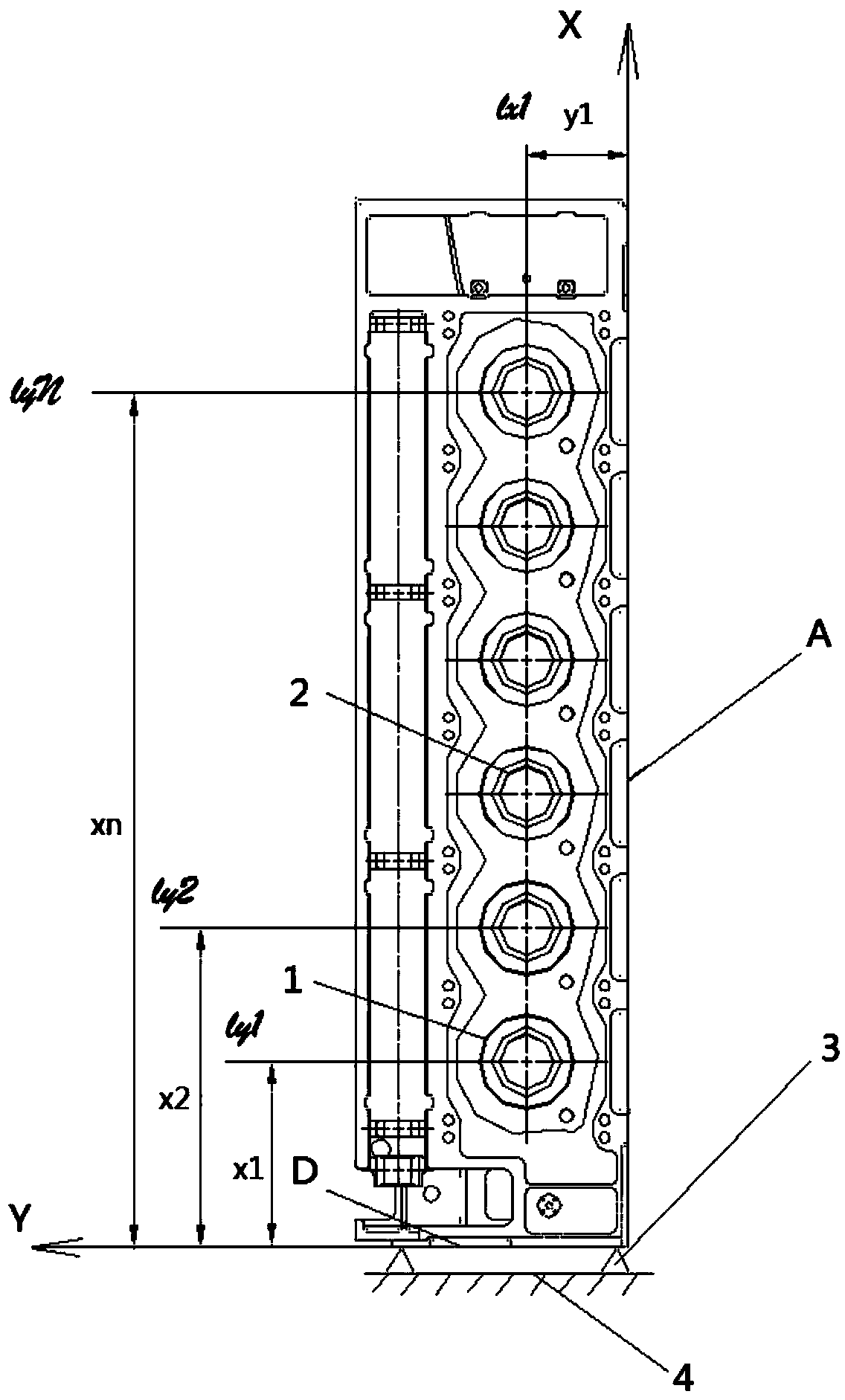

Method for scribing integral cylinder block blanks of large diesel engines

ActiveCN103909297AReduce boardingReduce the number of calibrationsDrilling/boring measurement devicesOther workshop equipmentThree-dimensional spaceEngineering

The invention discloses a method for scribing integral cylinder block blanks of large diesel engines. A plurality of groups of coaxial cylinder liner blank holes and gland blank holes are formed in each cylinder block blank. The method is characterized in that three-dimensional space scribing tasks are completed in a two-dimensional scribing mode on the premise that machining allowance is guaranteed, and center lines of various cylinder liner holes and gland holes and position lines of reference end surfaces of the various cylinder liner holes and the gland holes can be scribed by the aid of two scribing positions of each cylinder block blank on a scribing platform, and meet dimensional requirements. The method is combined with an existing scribing technology, so that stereoscopic scribing operation can be implemented on each cylinder block at the two corresponding scribing positions by the aid of conventional scribing tools, effects of reducing the production cost and preventing safety and quality accidents can be realized, and the method has the advantages of simplicity and convenience in operation and high scribing precision, and is applicable to scribing operation on optional integral cylinder blocks and similar large castings.

Owner:HUDONG HEAVY MACHINERY

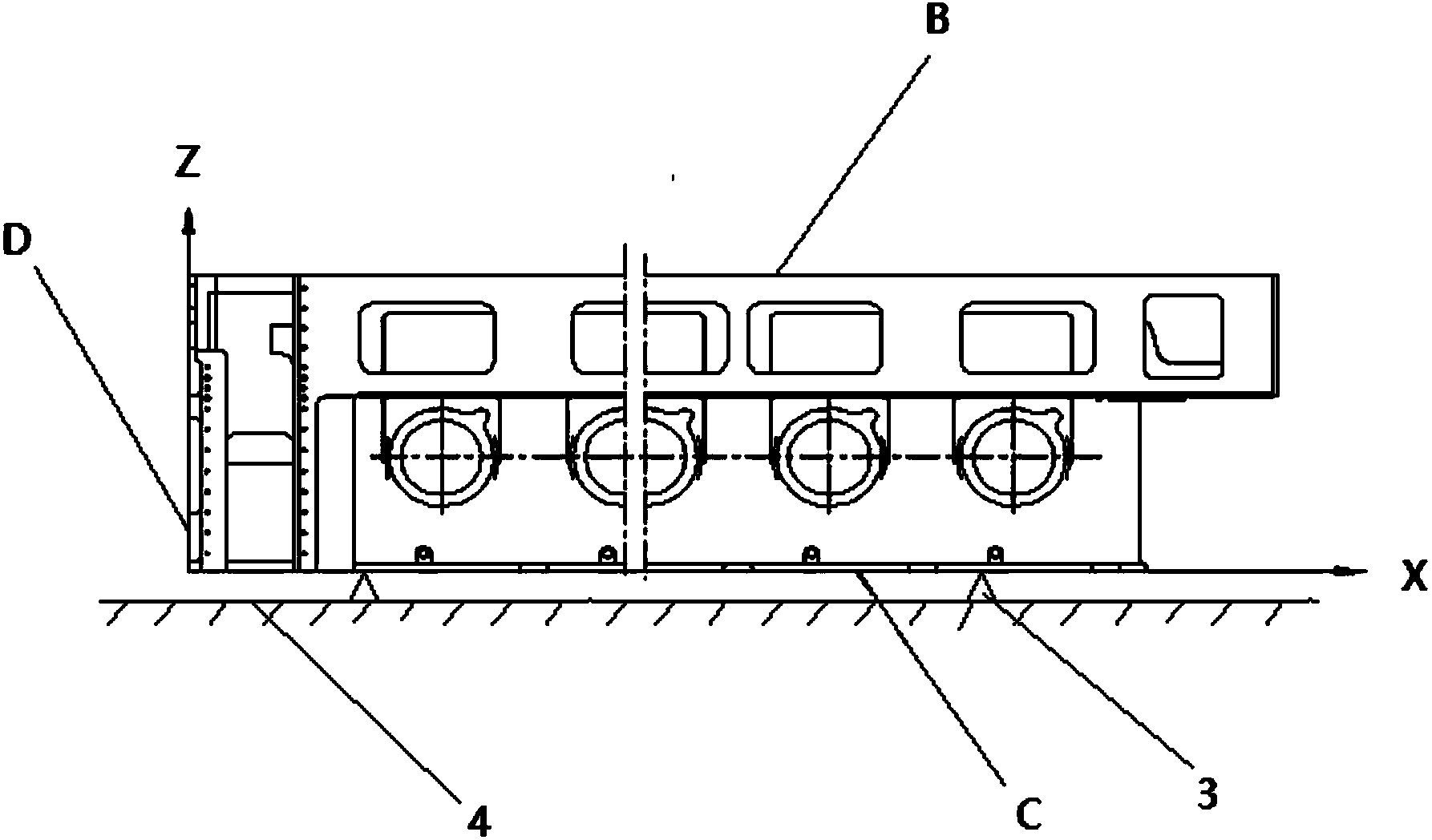

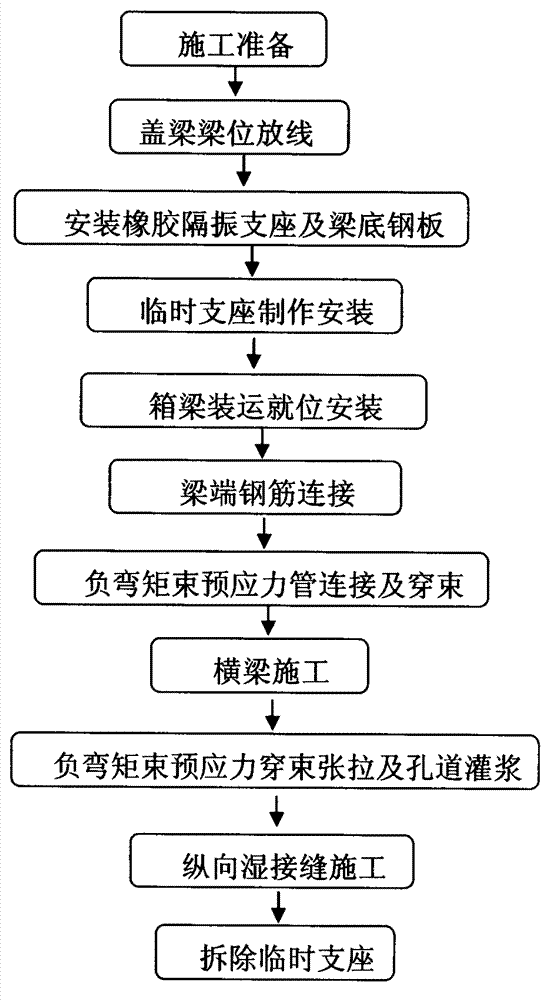

Construction method of simply supported-continuous switching system of negative moment beam prestressed precast box beam

The invention discloses a construction method of a simply supported-continuous switching system of a negative moment beam prestressed precast box beam, sequentially comprising the following procedures of construction preparation, cap beam position line putting, installation of a rubber vibration isolating support and a beam bottom steel plate, manufacture and installation of a temporary support, box beam shipping emplacement installation, beam end reinforcement connection, negative moment beam prestressed pipe connection and penetration, construction of a cross beam, negative moment beam prestress penetration tensioning and hole grouting, longitudinal wet joint construction and disassembly of the temporary support. According to the construction method disclosed by the invention, by adopting negative moment beam prestressed pipe connection, negative moment beam prestressed pipes have high compression strength and smooth surfaces, can bear pressure of the box beam and transfer the pressure to a cap beam, is beneficial to ensuring the engineering quality and increases the safety coefficients; with the adoption of the construction method, standard technical operation is beneficial to implementing, a construction period is shortened, a box beam continuous system has large rigidity, less expansion joints, is small in deformation and is comfortable in car driving, the safety and reliability of system switching are improved, and beam body quality control and safe and civilized construction management are convenient; and the construction method is economic and applicable.

Owner:YONGSHENG CONSTR GRP

Method for installing external wall heat insulation decoration board

The invention relates to a method for installing an external wall heat preservation decorated board, comprising the following steps: first, a metope is placed with wires for position; the positioned part under a warming plate is provided with a strutting piece with supporting function; at least the left side, the right side or the upper side of the warming plate adopts a fixing piece to be connected with a wall body, and colloid is used for splicing the warming plate and the metope; by adopting the connecting mode, when in connection, enough space can be ensured for convenient operation ; the left side or the right side is connected with the metope by adopting the fixing piece; after one piece of warming plate is installed, another two pieces of warming plates which are adjacent to the left and the right sides of the installed warming plate are mounted; therefore, the installation of each plate body does not interfere with the installation of another adjacent plate body, and all the warming plates take a position line as standard and orderly installed on the metope.

Owner:安徽根源光大高深新材料有限公司

Gaming device with multiple spinning wheels and method

The specification discloses a multi-wheel game-of-chance having at least two groups of spinning wheels, wherein each group includes at least two concentric spinning wheels having a viewable surface face thereon. A plurality of indicia are positioned on the peripheral of the viewable surface face of each wheel such that all indicia on each wheel is viewable to the user. Bet areas are positioned at various locations around at least a portion of each group of wheels; along a line joining the center of any two groups of wheels; and / or a junction between various radially positioned lines extending from the center of two or more groups of wheels. Each bet area represents a possible payline with various pay ratios depending on the probability of various predetermined combinations. For instance, a one-group combination payline has the lowest pay ratio; a two-group payline requires the combination from two groups of wheels and thus, has a higher pay ratio than a one-group payline; and as additional group combination paylines are added, the higher the pay ratio can become.

Owner:BALLY GAMING INC

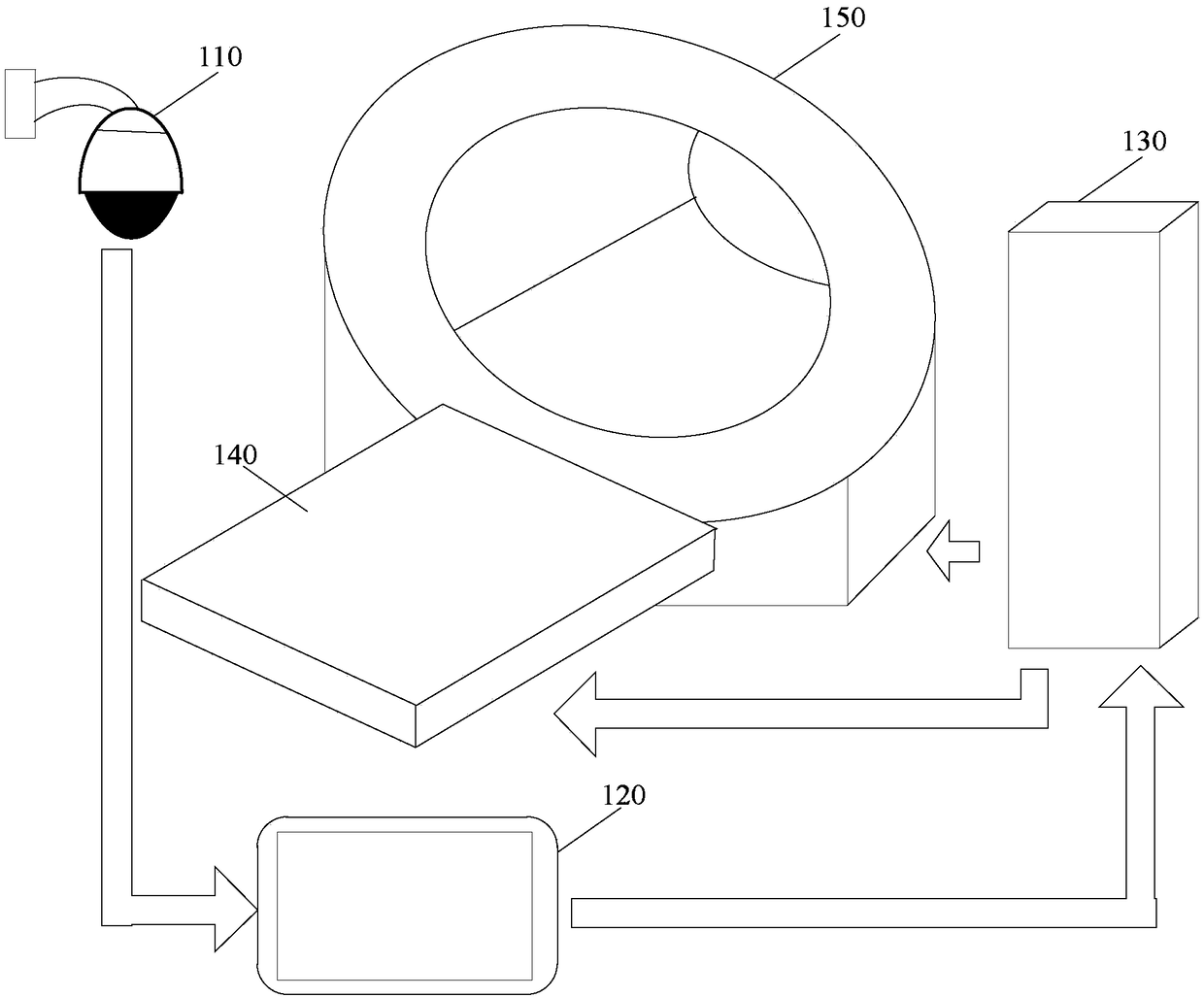

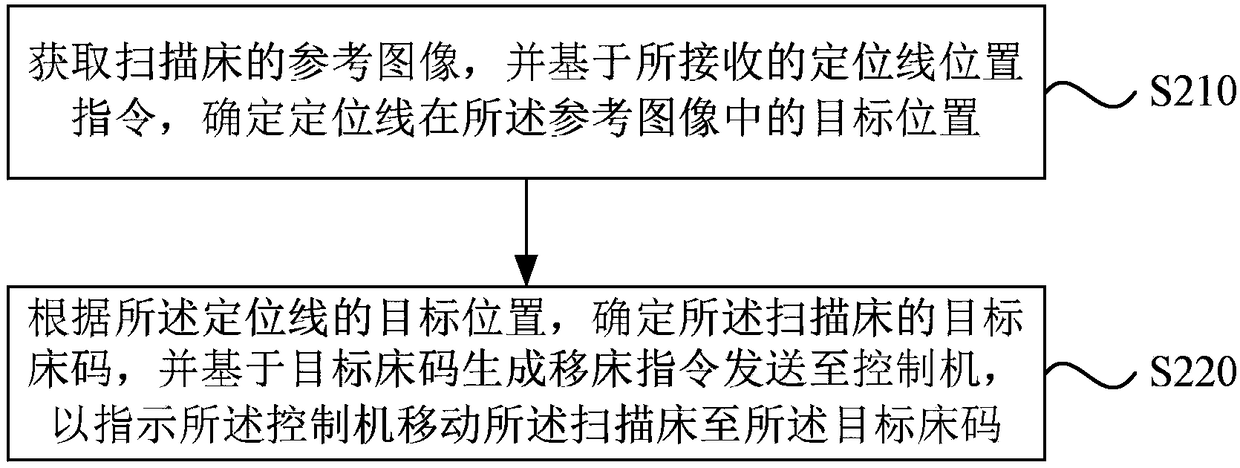

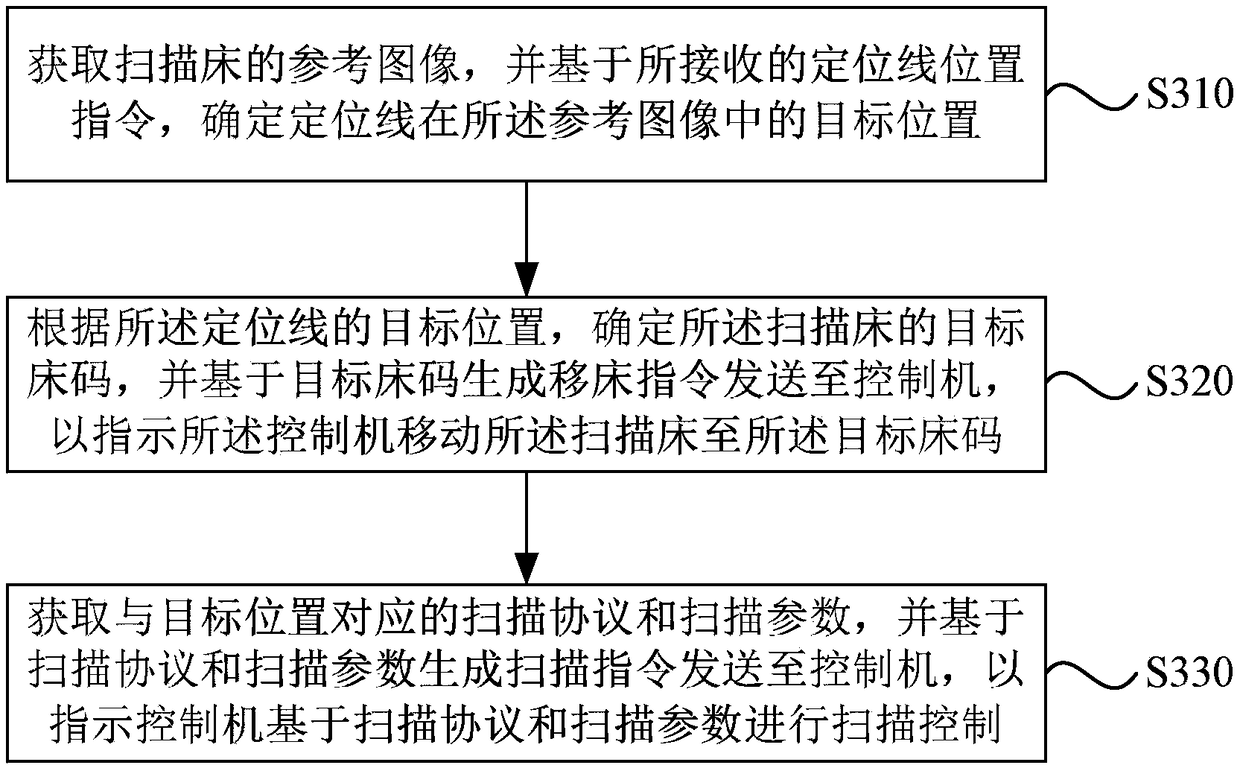

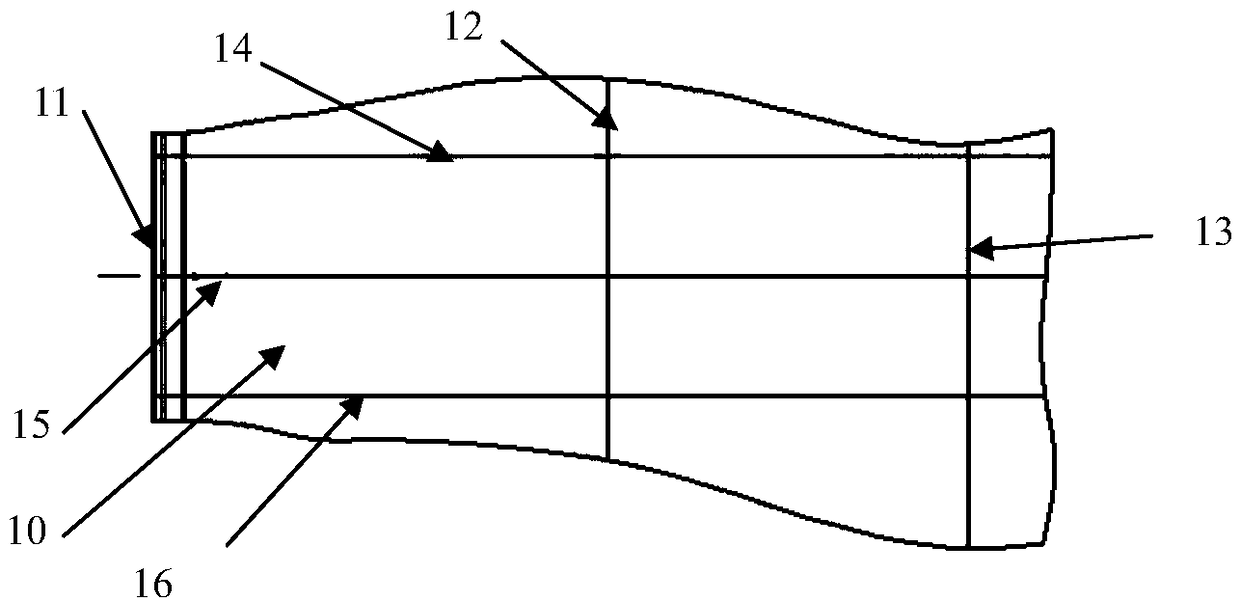

Medical imaging system, scanning table control method and device and storage medium

PendingCN109363872AReduce preparation timeImproving Imaging EfficiencyOperating tablesAmbulance serviceCommand and controlImaging quality

The embodiment of the invention discloses a medical imaging system, a scanning table control method and device and a storage medium. The medical imaging system includes a scanning table and a controlmachine and further includes a camera and a control terminal; the camera is used for collecting reference images of the scanning table; the control terminal is connected with the camera and is used for acquiring the reference images and determining the target positions of positioning lines in the reference images after positioning line position commands are received; the control terminal is in communication connection with the control machine and is further used for determining a target table number of the scanning table according to the target positions of the positioning lines, generating atable movement command on the basis of the target table number and sending the table movement command to the control machine; the control machine is in communication connection with scanning table andis used for receiving the table movement command and controlling the scanning table to move to the position corresponding to the target table number. By adopting the technical scheme, early-stage preparation time for image scanning is shortened, thus, the imaging efficiency is improved, the positioning accuracy of scanning positions is also improved, and therefore the imaging quality is improved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

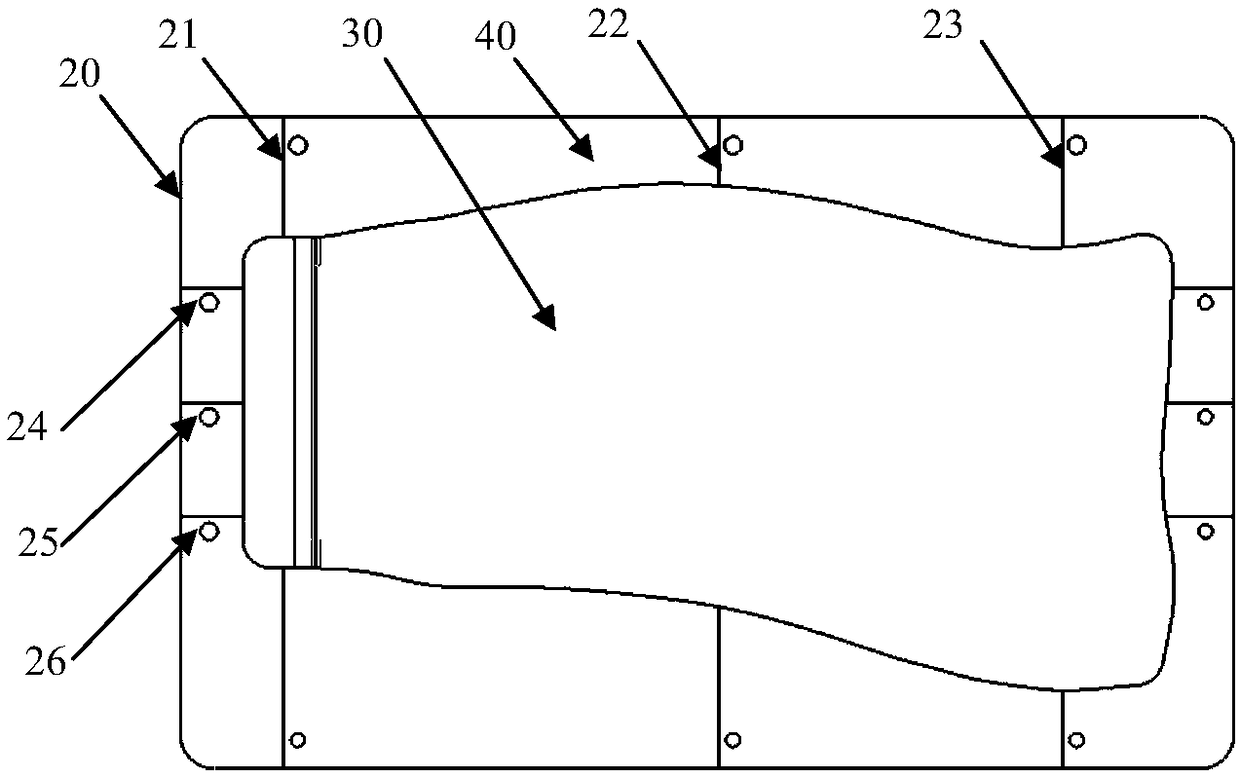

Device and method for positioning variable-thickness preform and detecting thickness of preform

The invention belongs to a liquid molding technology of the resin-based composite material, and relates to a device and method for positioning a variable-thickness preform and detecting the thicknessof the preform. The device comprises a molded surface tool, transverse clamping plates and longitudinal clamping plates, wherein the molded surface tool is a flat plate and is divided into a molded surface area and a positioning area, machining is carried out on the molded surface area by taking the lower surface of the preform as a benchmark, transverse scribed lines are machined on the positioning area based on the transverse positioning lines on the preform, and longitudinal scribed lines are machined on the positioning area based on the longitudinal positioning lines on the preform; and machining is carried out by taking the upper surface of the preform as the detection surfaces of the transverse clamping plates and the longitudinal clamping plates, the transverse clamping plates and the longitudinal clamping plates are positioned on the positioning area of the molded surface area through pin holes, and after positioning, the center lines of the transverse clamping plates are aligned with the transverse scribed lines on the positioning area, and the center lines of the longitudinal clamping plates are aligned with the longitudinal scribed lines on the positioning area. According to the device, the molded surface state of the complex-structured preform can be pre-judged and processed before mold closing, and the yield of the composite material workpieces is remarkably improved.

Owner:AVIC COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com