Patents

Literature

998results about How to "Guaranteed installation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

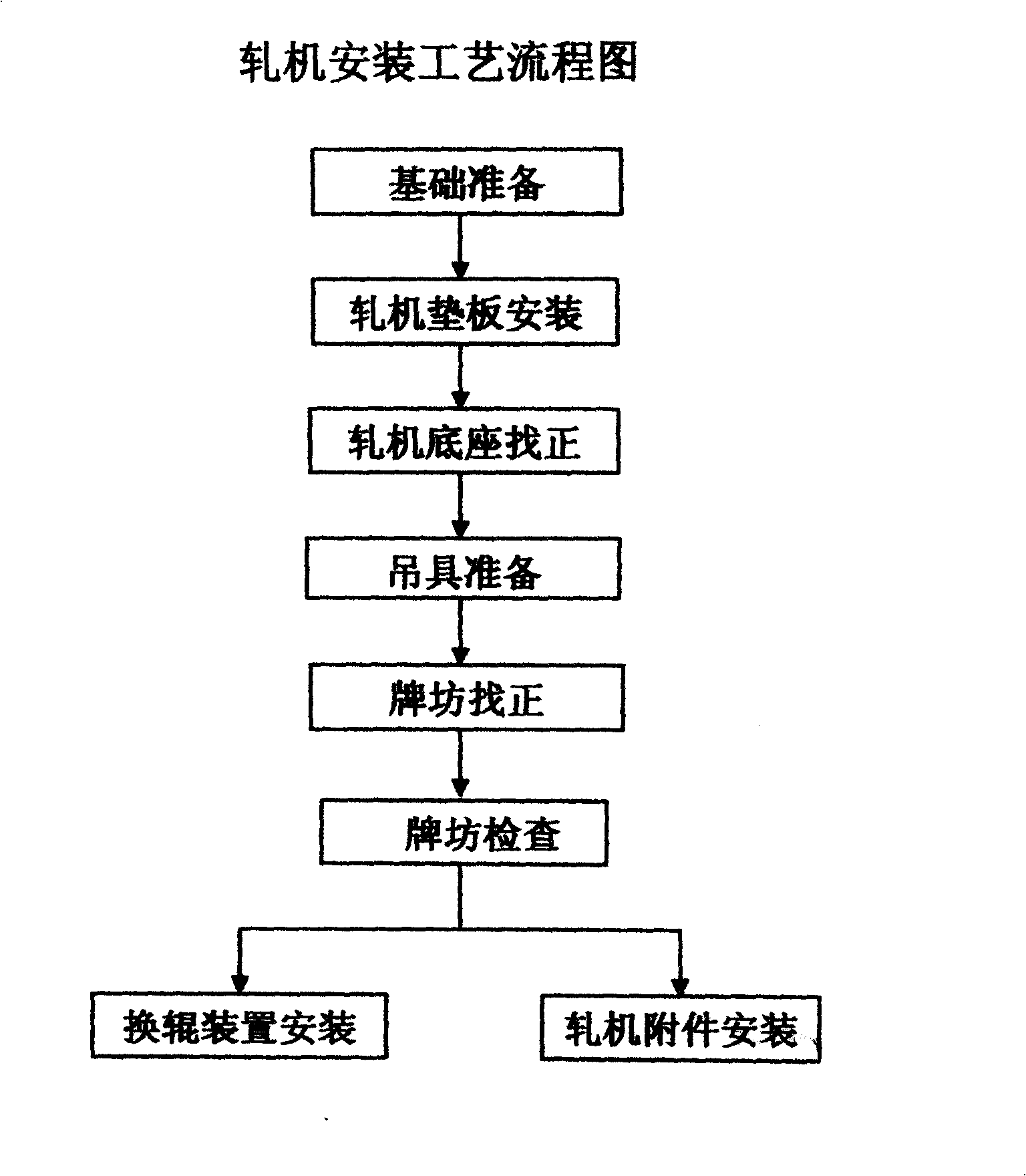

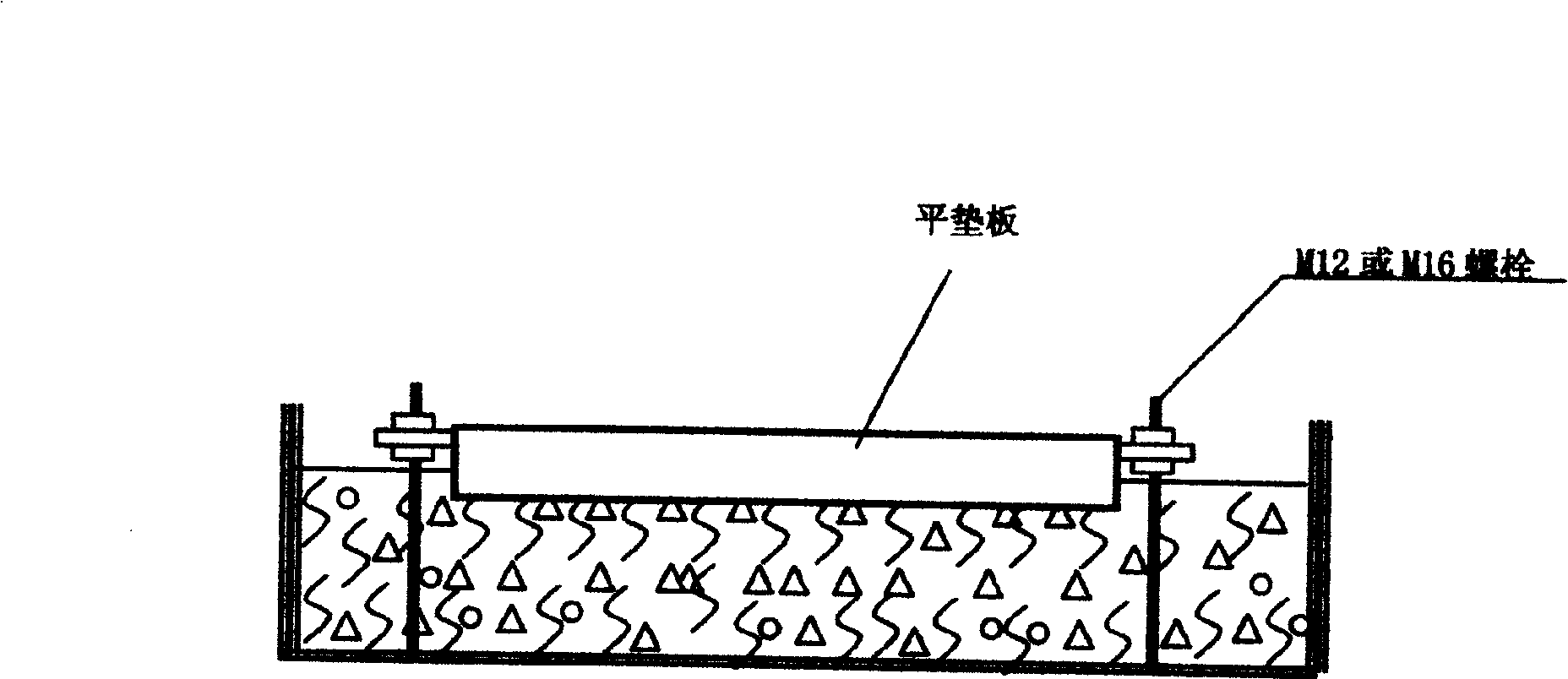

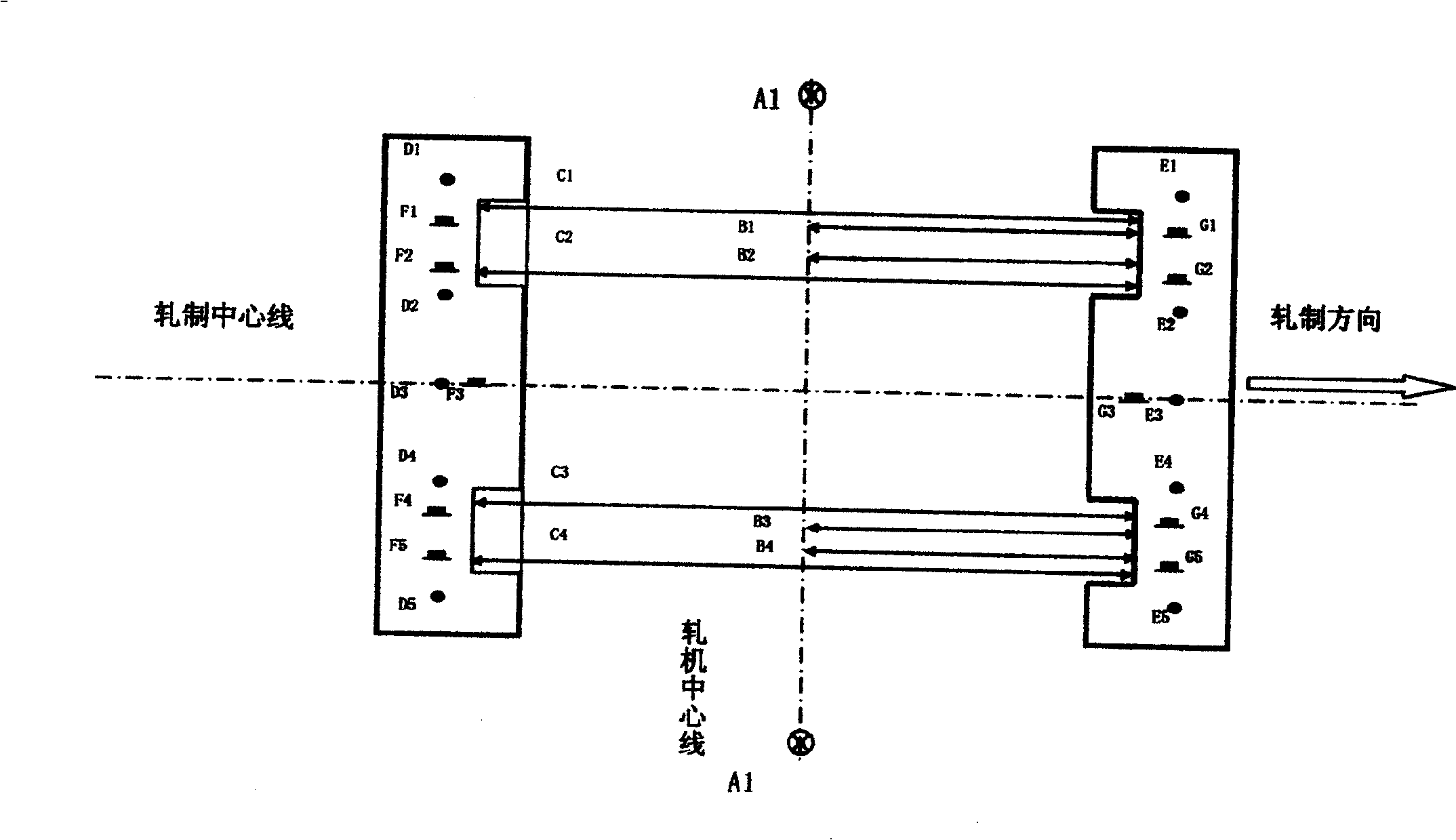

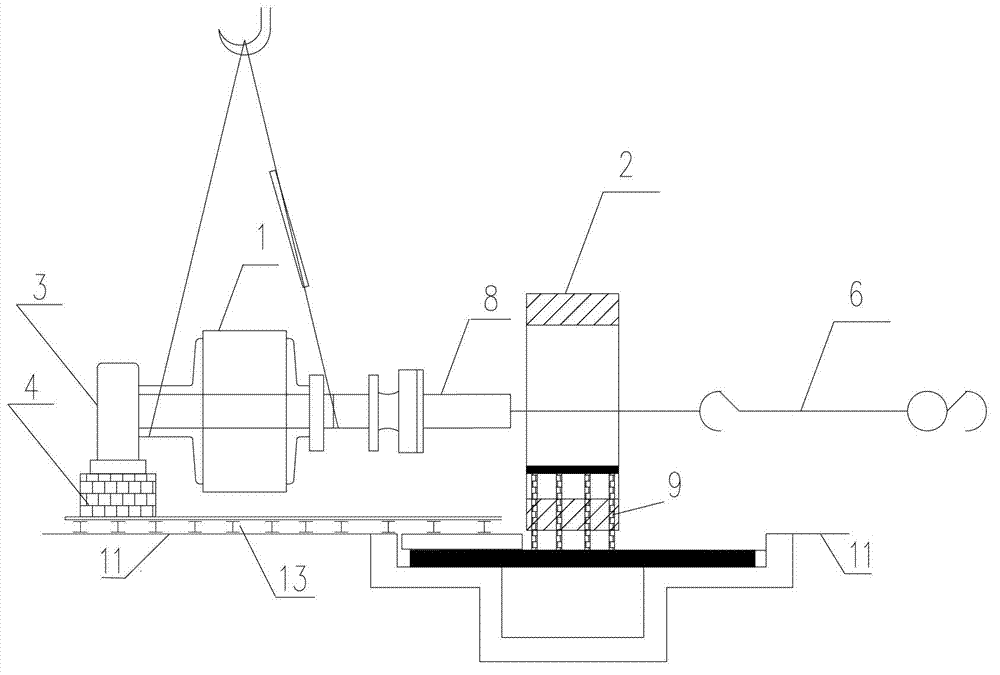

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

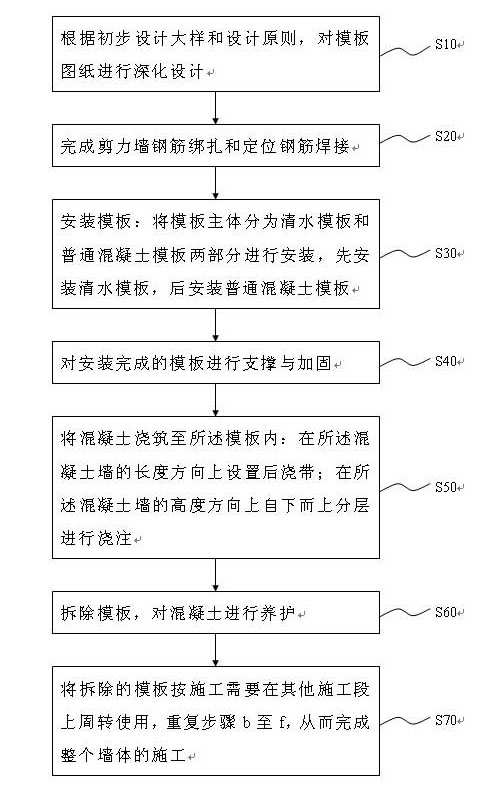

Construction method of overlong and superhigh single-side fair-faced concrete wall

ActiveCN101956458AGuaranteed installation qualityReduce construction costsForms/shuttering/falseworksBuilding material handlingRebarShear wall

The invention relates to a construction method of an overlong and superhigh single-side fair-faced concrete wall. The method comprises the following steps of: (a) carrying out deepening design on a template drawing; (b) finishing binding shear wall reinforcing bars and welding positioning reinforcing bars; (c) mounting a template: mounting the template by dividing the template into a fair-faced template and an ordinary concrete template, mounting the fair-faced template firstly and then mounting the ordinary concrete template; (d) supporting and reinforcing the mounted templates; (e) pouring concrete into the templates: arranging a rear pouring band along the length direction of the concrete wall, and pouring by layers from top to bottom along the height direction of the concrete wall; (f) dismantling the templates to maintain the concrete; and (g) circularly using the dismantled templates on other construction sections according to construction requirements and repeating the steps from (b) to (f) to finish the construction of the whole wall body. The invention is suitable for the construction of the overlong and superhigh single-side fair-faced concrete wall, and not only guarantees the mounting quality of the fair-faced concrete template, but also reduces the construction cost.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

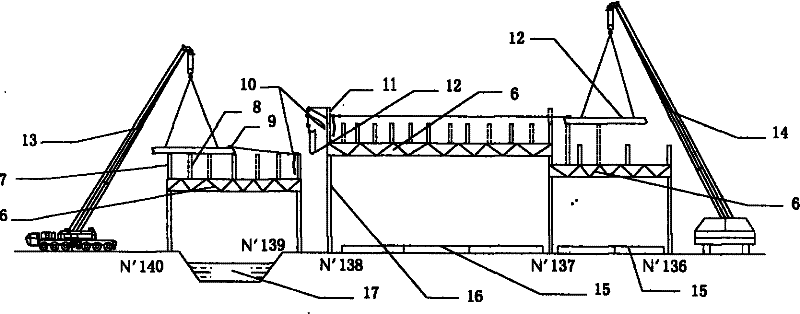

Split high-altitude butt-joint installation method of offshore wind generating set

ActiveCN102425530ASuitable for installationGuaranteed installation qualityWind energy generationWind motor componentsWind drivenWind force

Owner:CHINA MCC17 GRP

Large-span overhead pipeline sliding installation method

ActiveCN102192368AHoisting in place smoothlyEnsure safety and qualityPipe laying and repairEngineeringBuilding construction

Owner:MCC5 GROUP CORP SHANGHAI

Assembly ship building unit element, modularization designing method

InactiveCN1948081AImprove build qualityGuaranteed Build QualityVessel partsModular designComputer module

A modular design method for building all units and assembling them together includes such steps as 3D modeling of ship body, 3D arrangement modeling for assembling, dividing it into functional or regional units or modules, providing the interfaces between units or modules, designing and drawing them, and integrating them together in frame mode while preserving the interfaces between them.

Owner:DALIAN SHIPBUILDING IND

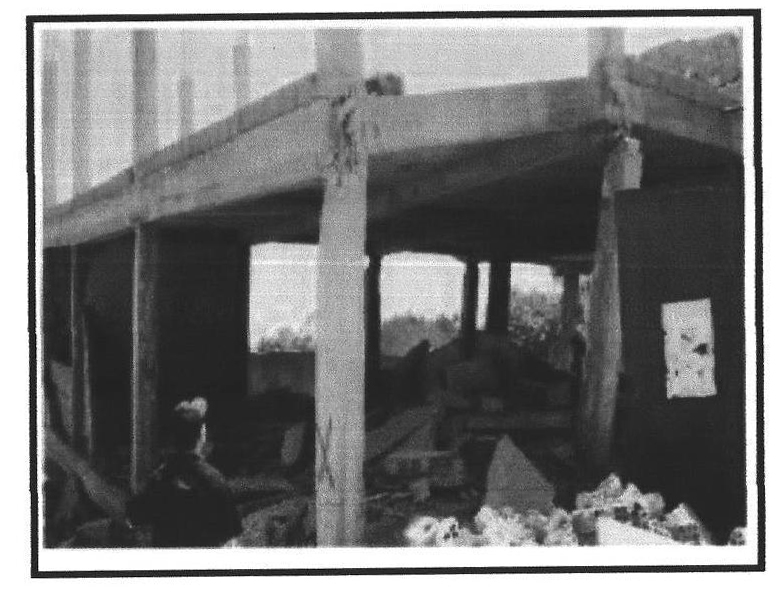

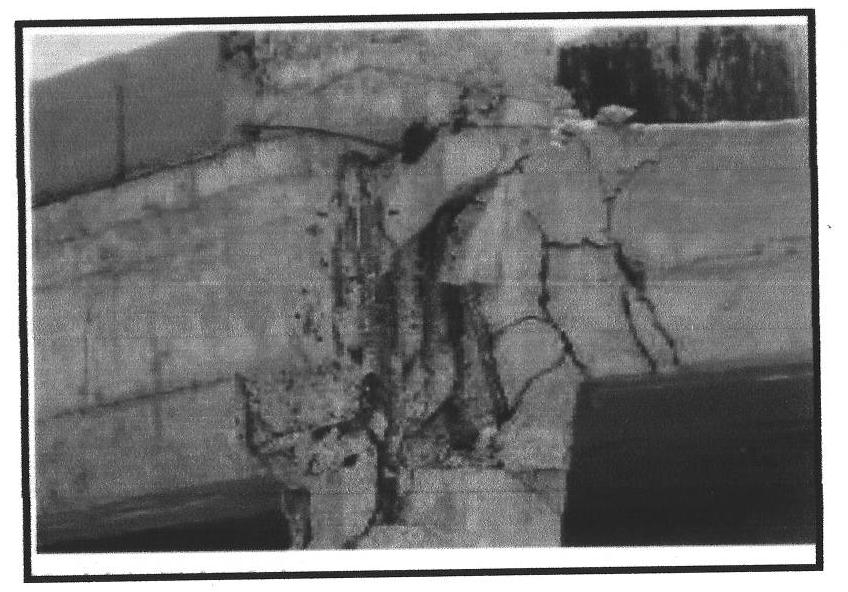

Improved method for installing reinforcement cage in beam column joint zone of reinforced concrete frame structure

ActiveCN102359279AGuaranteed installation qualityReduce labor intensityBuilding material handlingReinforced concreteEngineering

The invention discloses an improved method for installing a reinforcement cage in the beam column joint zone of a reinforced concrete frame structure, which belongs to the building and the structure of the reinforced concrete frame structure in the civil engineering field. The method aims to overcome the problems brought by the traditional installing method, can guarantee the installing quality of the reinforcement cage at the positions of the nodes of beams and columns and creates great convenience for operation. In the detail drawing 3, erecting a bracket above a beam template groove; the longitudinal reinforcements of the beams are interspersed in the longitudinal tendons of the columns and are arranged on the bracket; core zone column stirrups are arranged at the positions of the longitudinal tendons of the columns and between the upper longitudinal tendons and the lower longitudinal tendons of the beams; the longitudinal reinforcements of the beams are fixed by being bonded with the stirrups of the beams; the stirrups of the columns are fixed by bonded with stirrup spacing tringles (B in the drawing 4) to form a reinforcement cage in the beam column joint zone, which is temporarily arranged exactly above the beam column joint zone and the beam template groove and is not bonded with the longitudinal tendons of the columns; finally, the beam reinforcement cage and a column stirrup cage integrally slide into the beam template groove and the beam column joint core zone along the longitudinal tendons of the columns; and therefore, the final position of the reinforcement cage in the beam column joint zone is realized.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

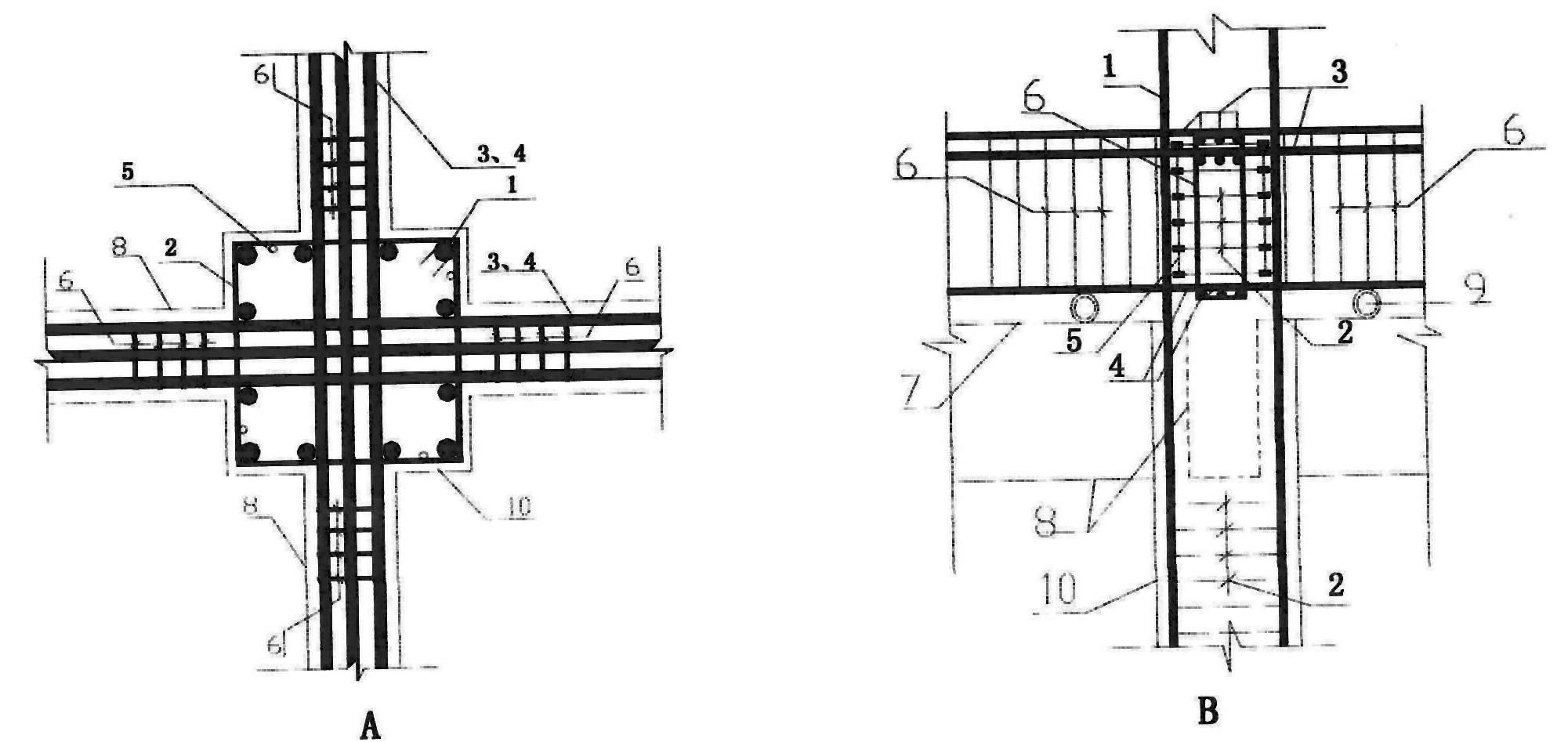

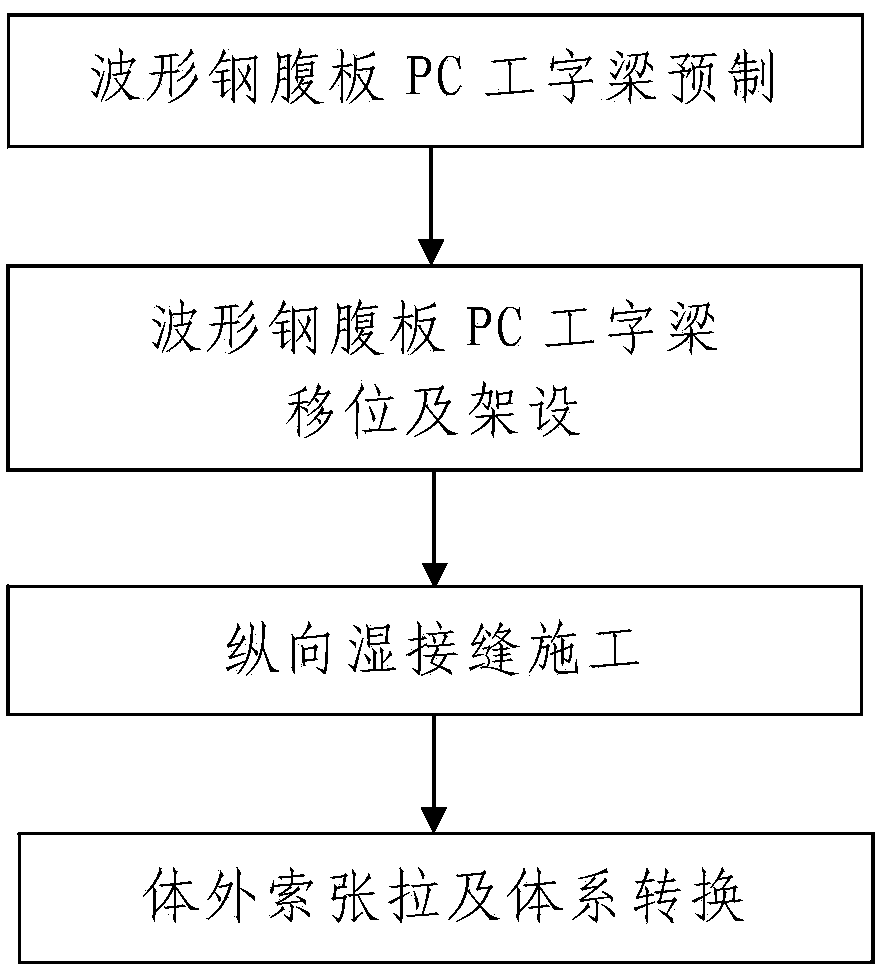

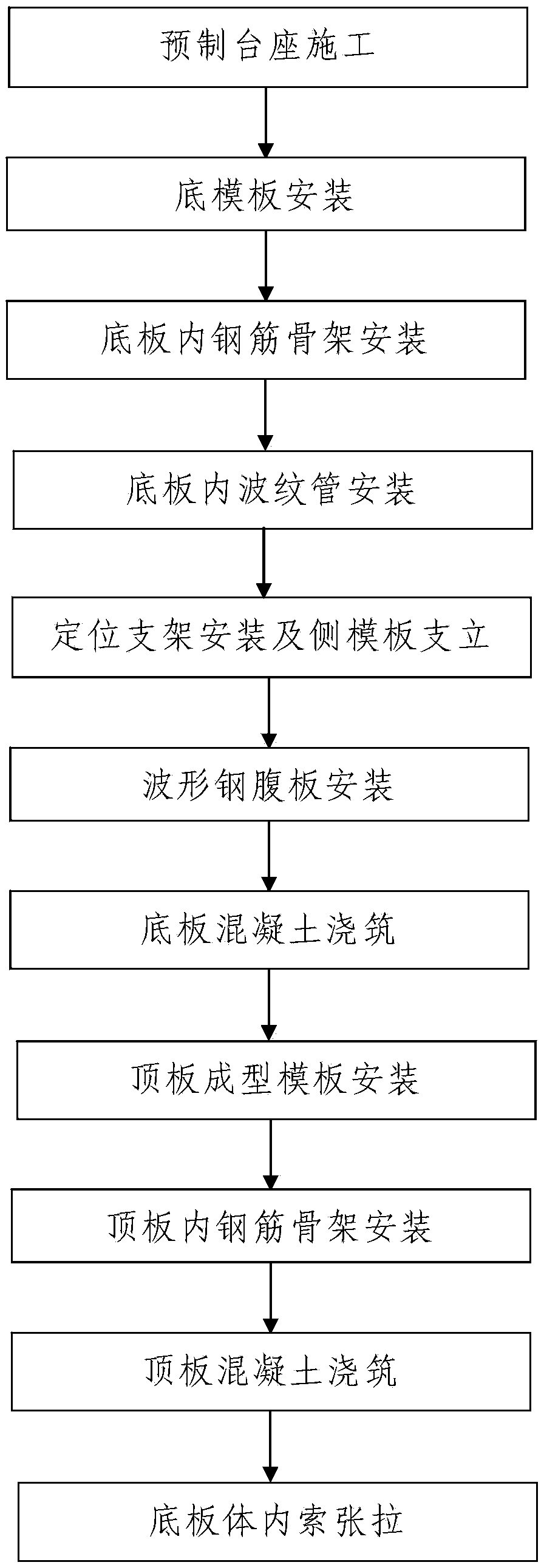

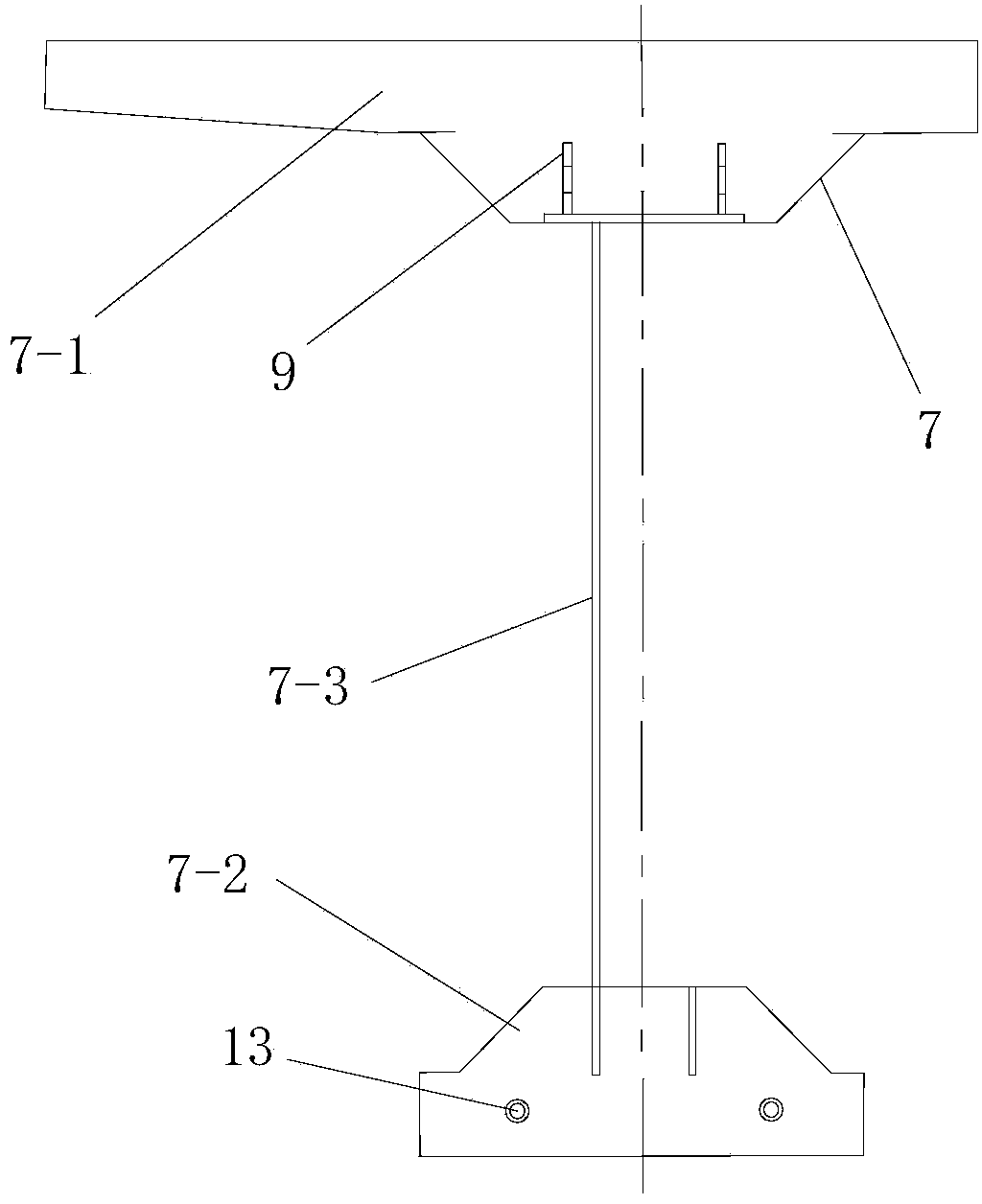

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

Method for installing blast furnace single-tube downcomer

InactiveCN102851421AEasy to controlGuaranteed installation qualityBlast furnace componentsBlast furnace detailsHigh energyEngineering

The invention discloses a method for installing a blast furnace single-tube downcomer, characterized by using single machine and double shackles to lift each lifting unit. The method comprises the following steps: 1, conducting lifting preparation: 1) dividing lifting units; 2) determining the barycenter of each lifting unit; 3) determining the lifting point and shackle position of each lifting unit and completing the welding of the shackles; 4) determining the position lines of a riser tube and an upper shaking head, and determining the position lines of a gravity deduster shell and a lower T-joint; and 5) building a joint temporary operation platform the inner side and the outer side of the joint of each lifting unit; and 2, conducting lifting operation. According to the invention, by using single machine to lift, the amount of large-scale machines is reduced, the limitation of narrow and small construction place can be overcome, the construction cost and energy consumption can be reduced, the construction safety is raised, the target of realizing safety, high quality, high efficiency, energy saving, and low carbon is realized, and the situation of high energy consumption, high cost and high pollution existing in traditional double-machine lifting is thoroughly changed.

Owner:TIANJIN 20 CONSTR

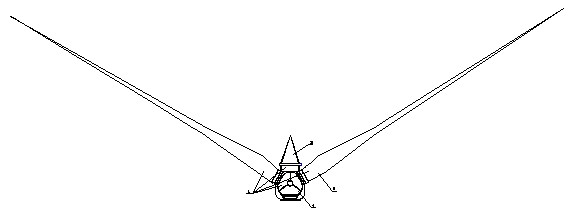

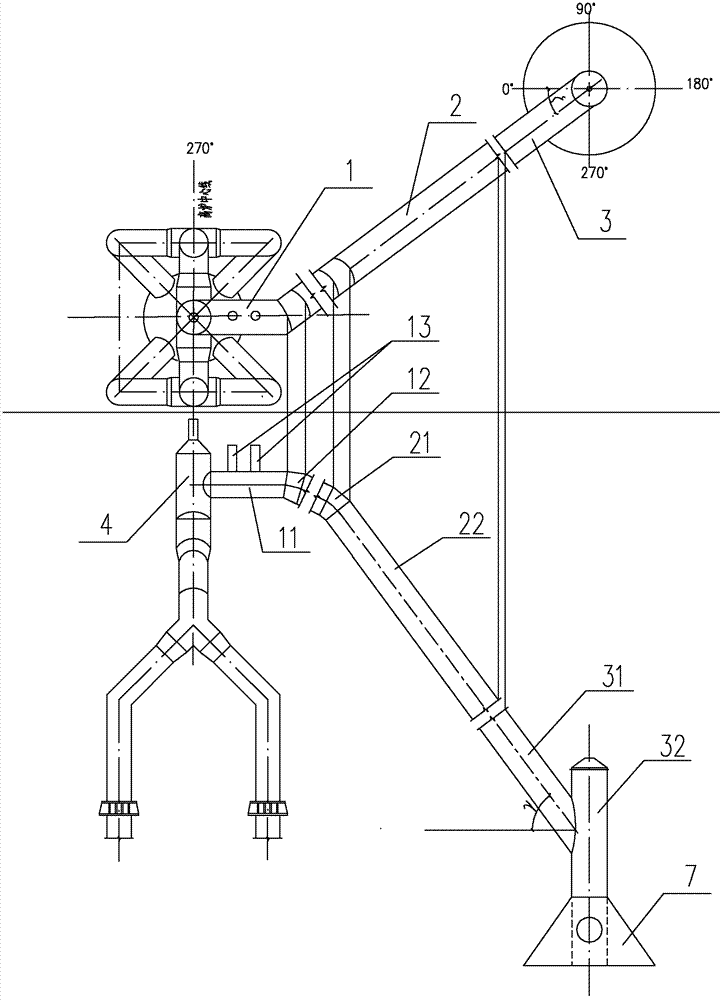

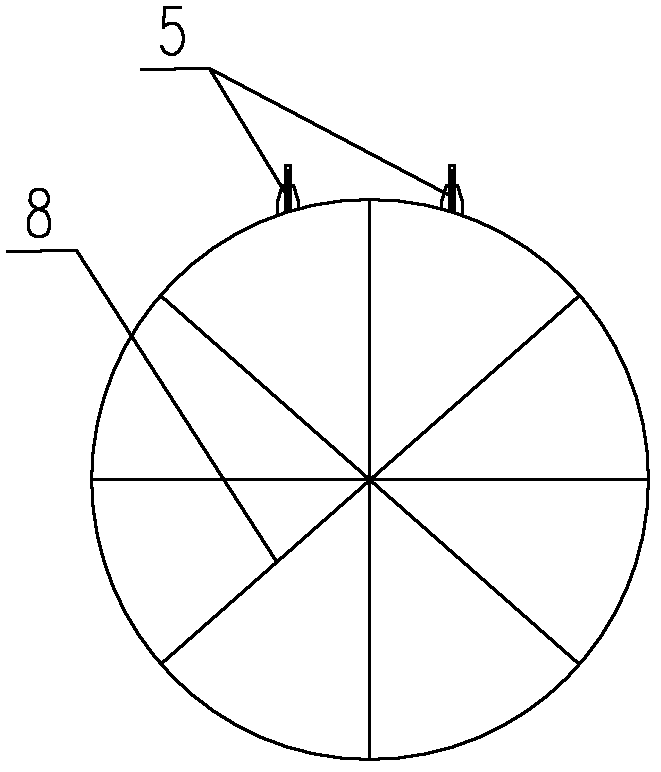

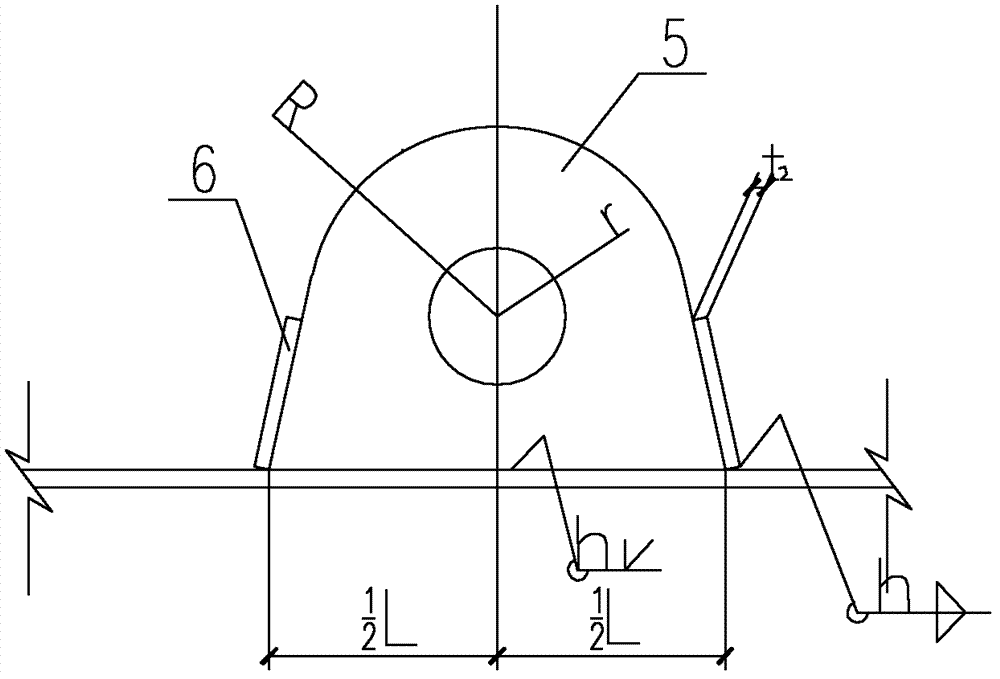

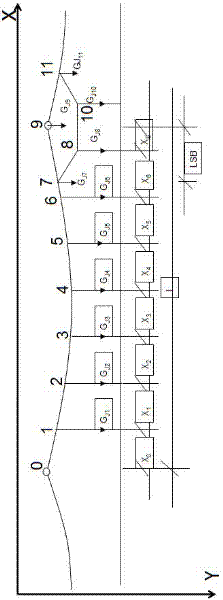

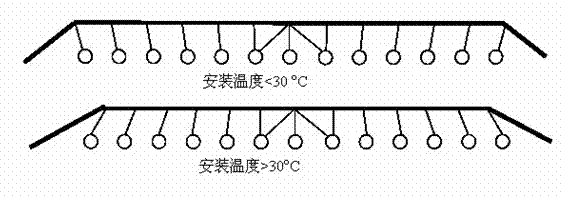

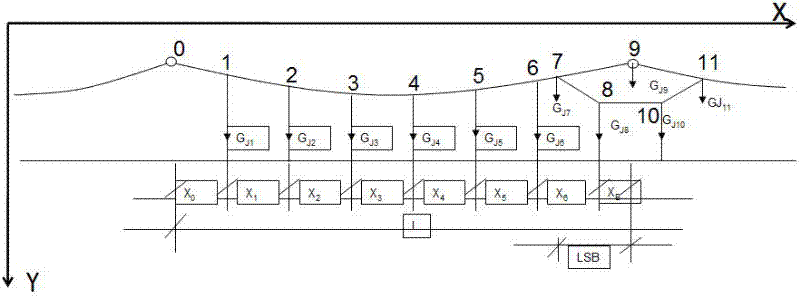

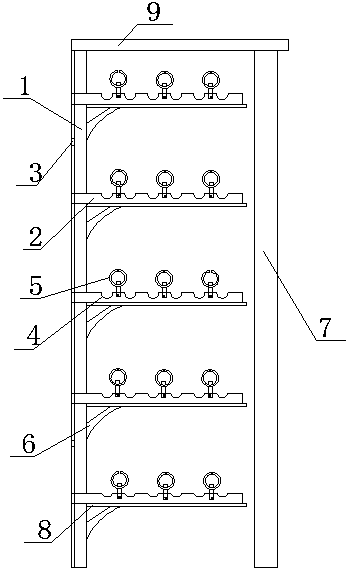

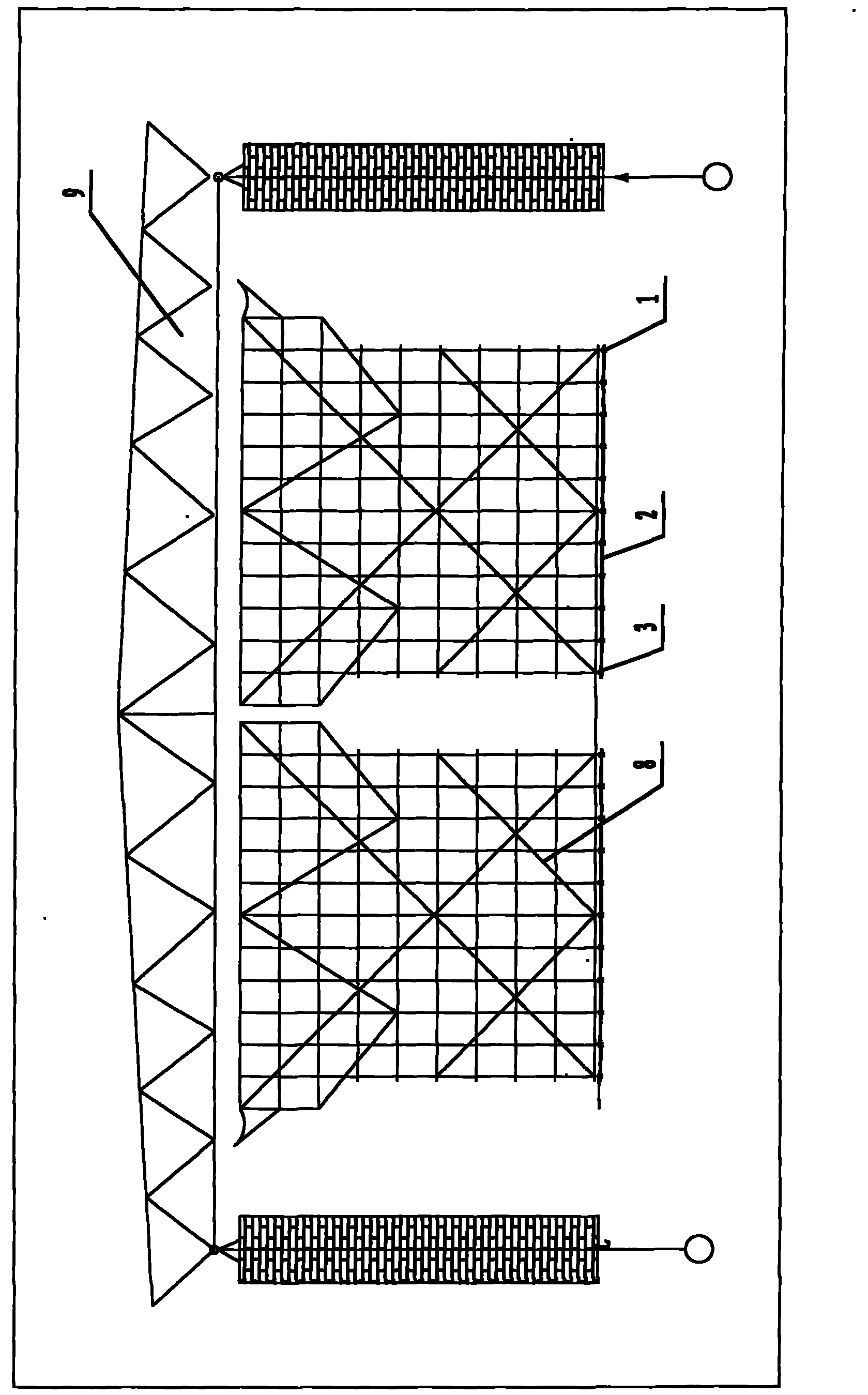

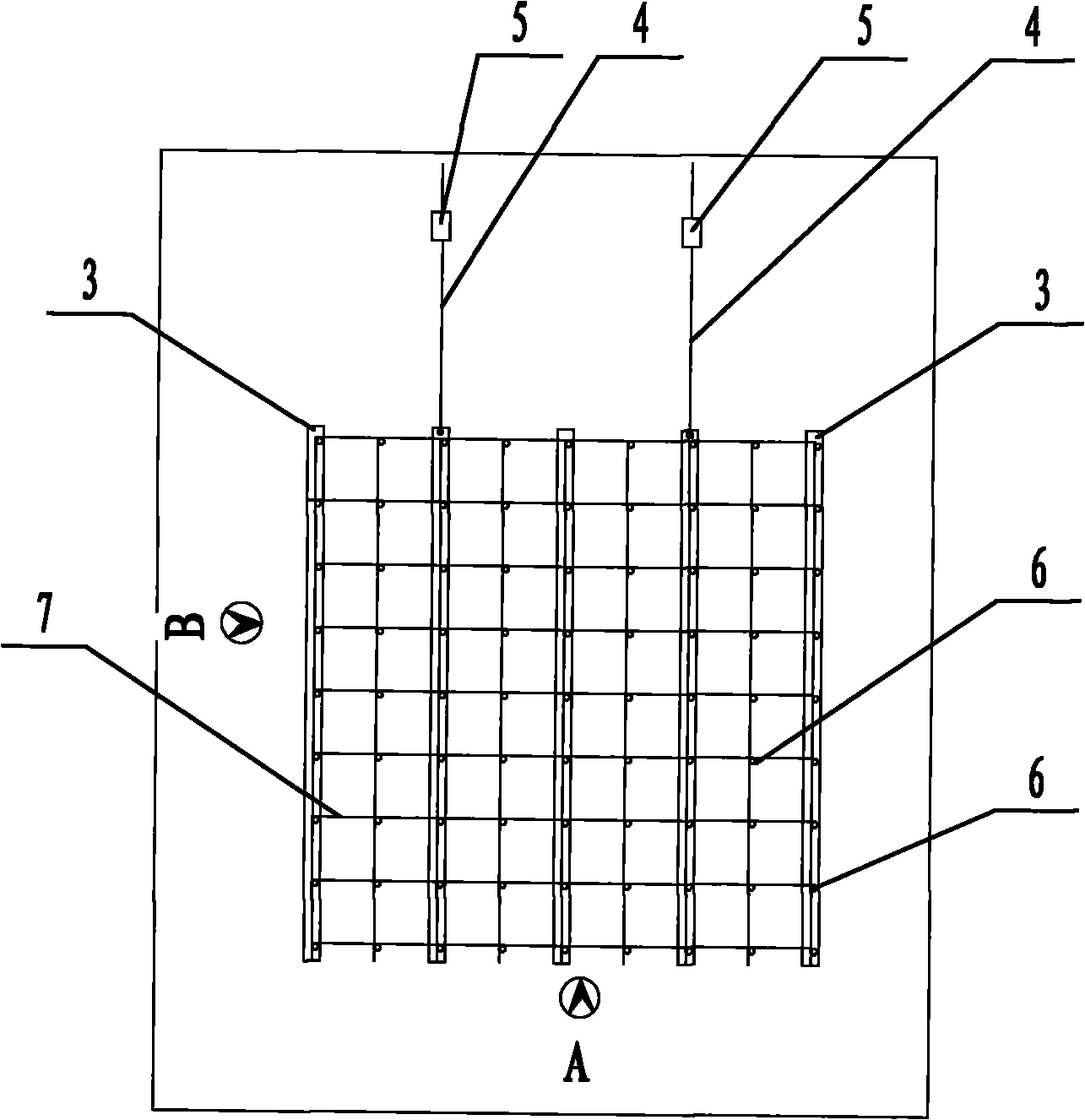

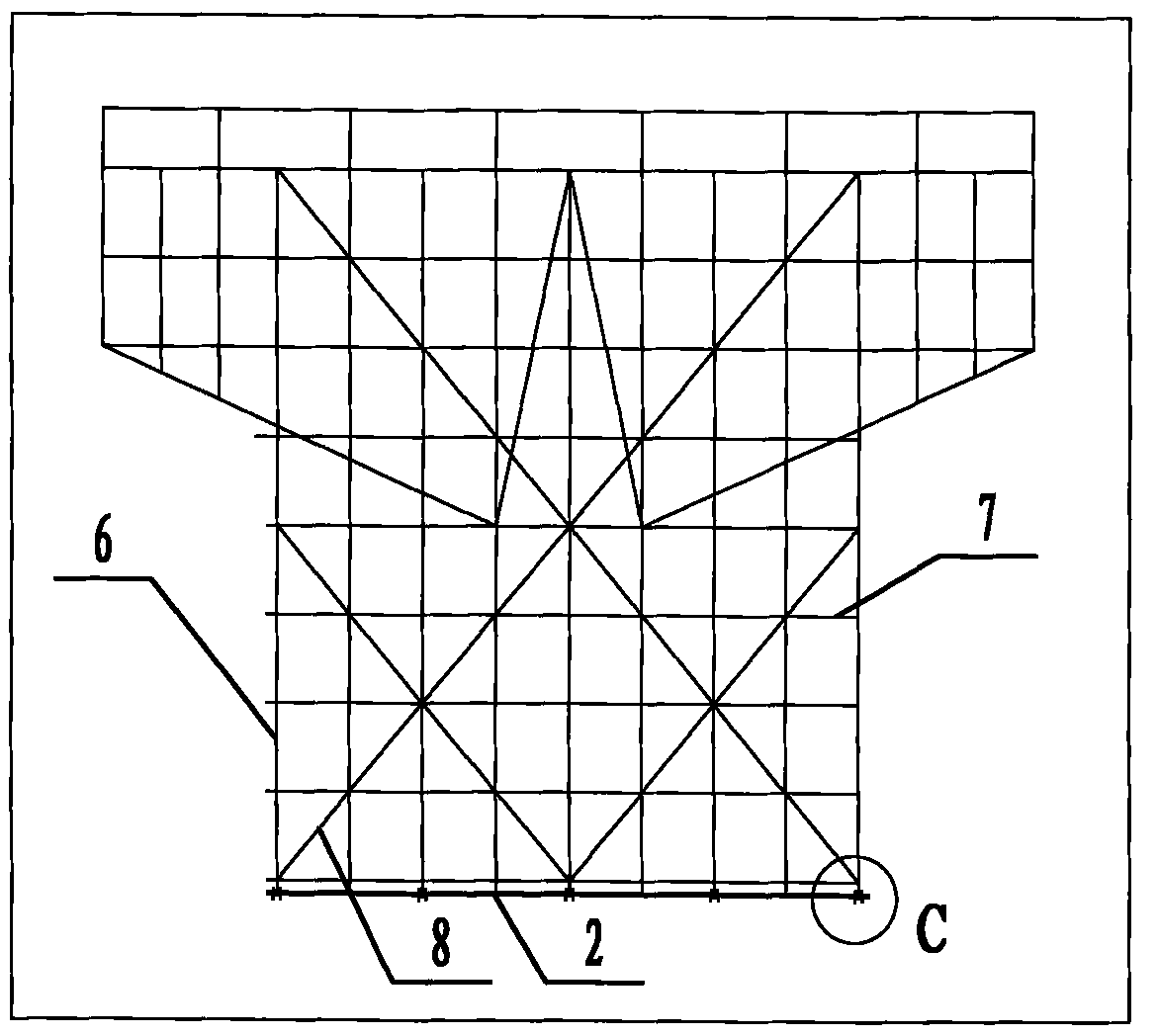

Full-compensation elastic chain hanging construction method for high-speed rail contact network

InactiveCN102381212AGuaranteed accuracyGuaranteed installation qualityTrolley linesContact networkArchitectural engineering

A full-compensation elastic chain hanging construction method for high-speed rail contact network, which comprises a construction preparing process, a construction measuring process, a software calculating process, a precasting process for sling and dropper, a mounting adjusting process for sling and dropper, and an ending process; each process is equipped with uniform and high-quality construction standards, and is assisted by modern construction meanses for satisfying with technical requirements for construction of high-speed rail contact network of 350 km / h; the software calculating process especially can obtain more accurate pre-stowage data of dropper length via a brand new calculating method finding form based on sling net, and then improve elastic chain hanging construction accuracy for high-speed rail contact net of 350 km / h. So the construction method does not only benefit for improving accuracy of sling and droppser calculation, and the construction method but also has high-quality construction standards and modern construction meanses, and is capable of improving quality and speed of construction of high-speed rail contact net of 350 km / h.

Owner:中铁建电气化局集团南方工程有限公司

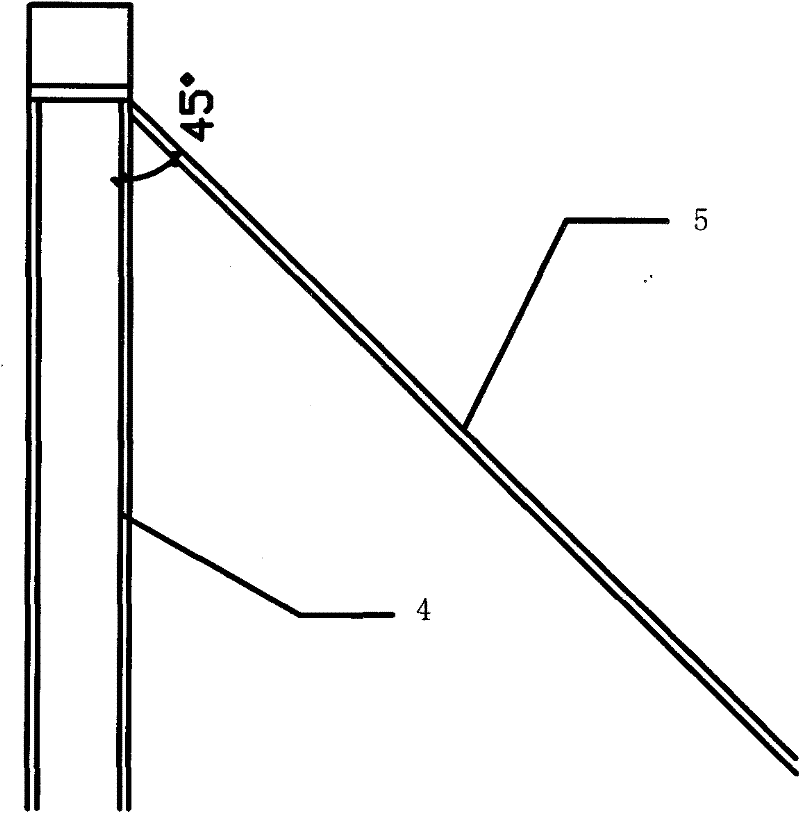

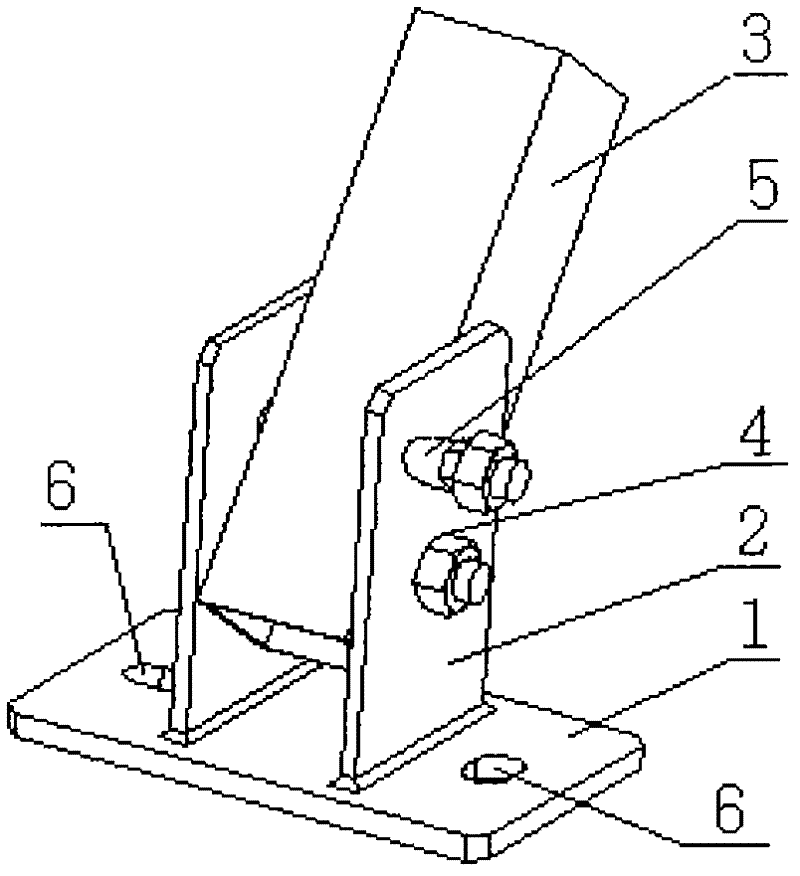

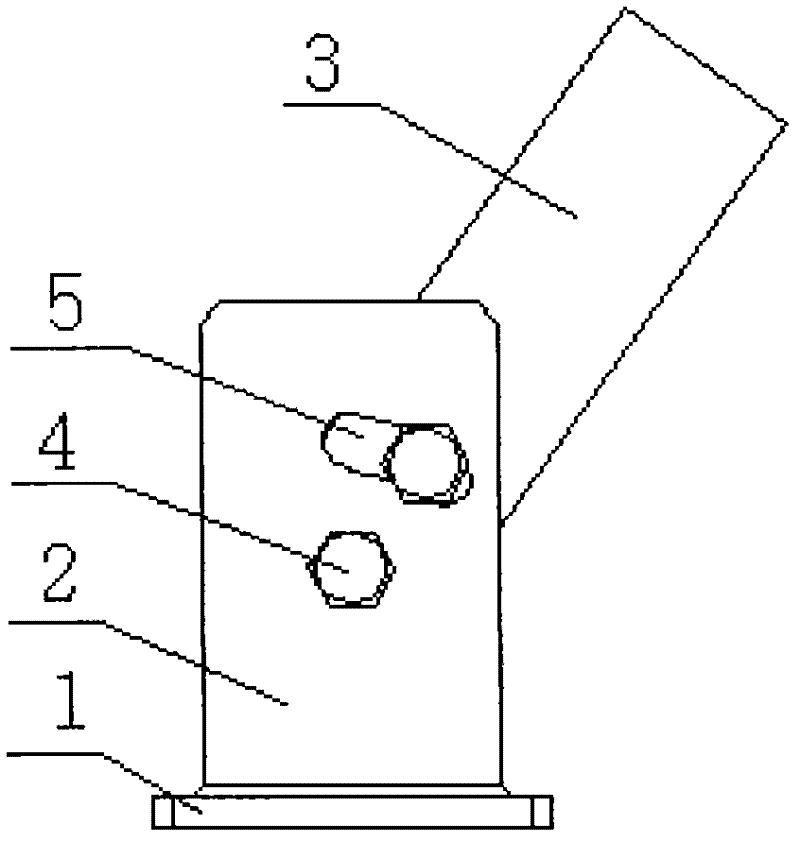

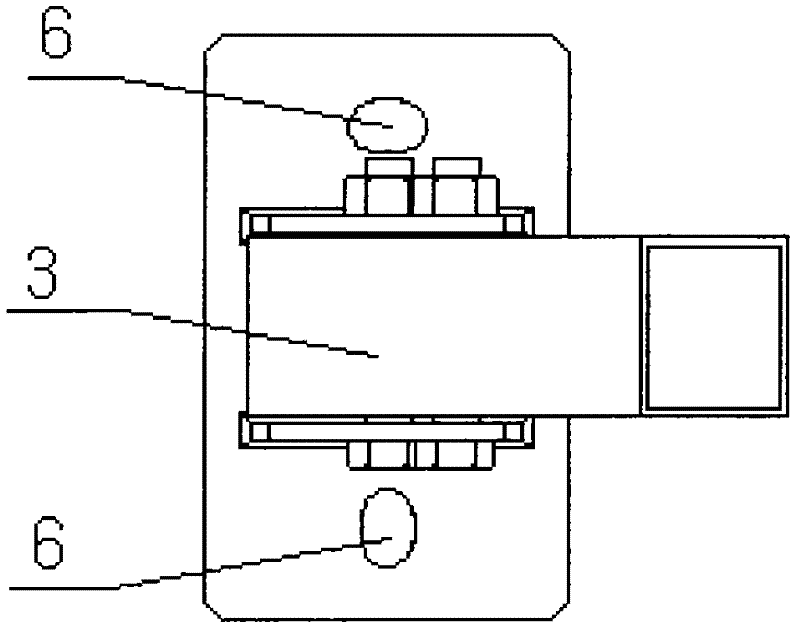

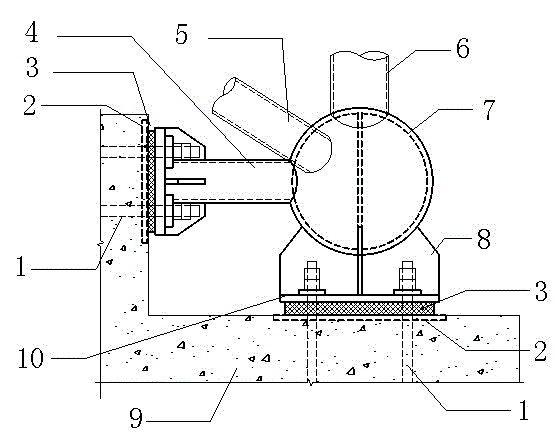

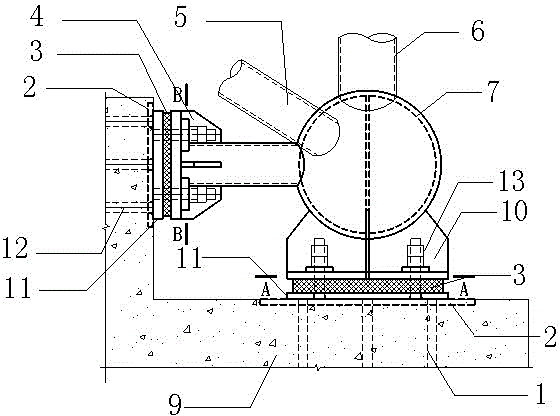

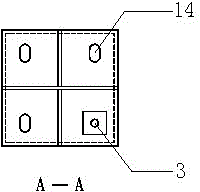

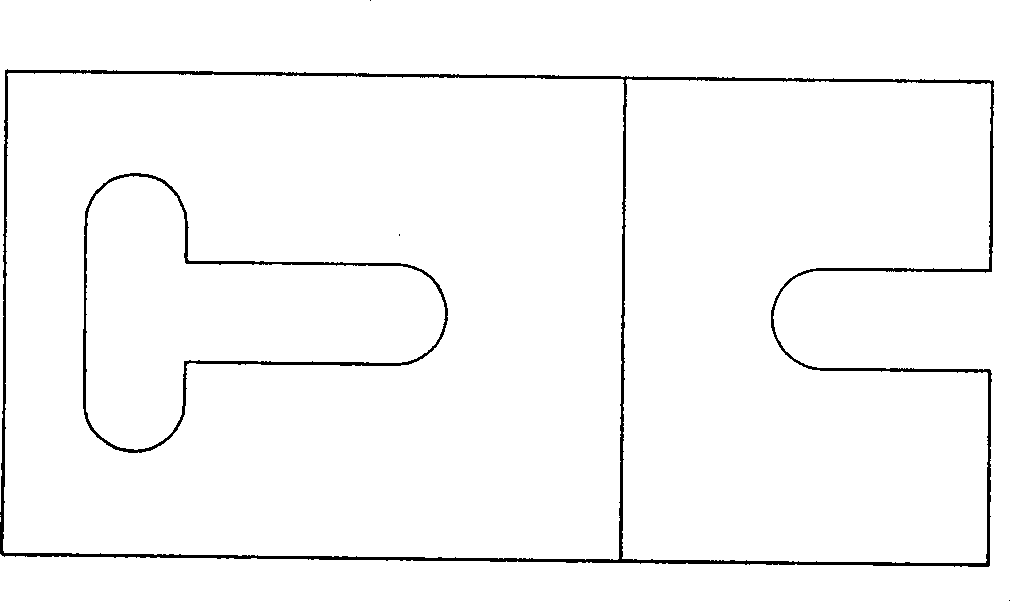

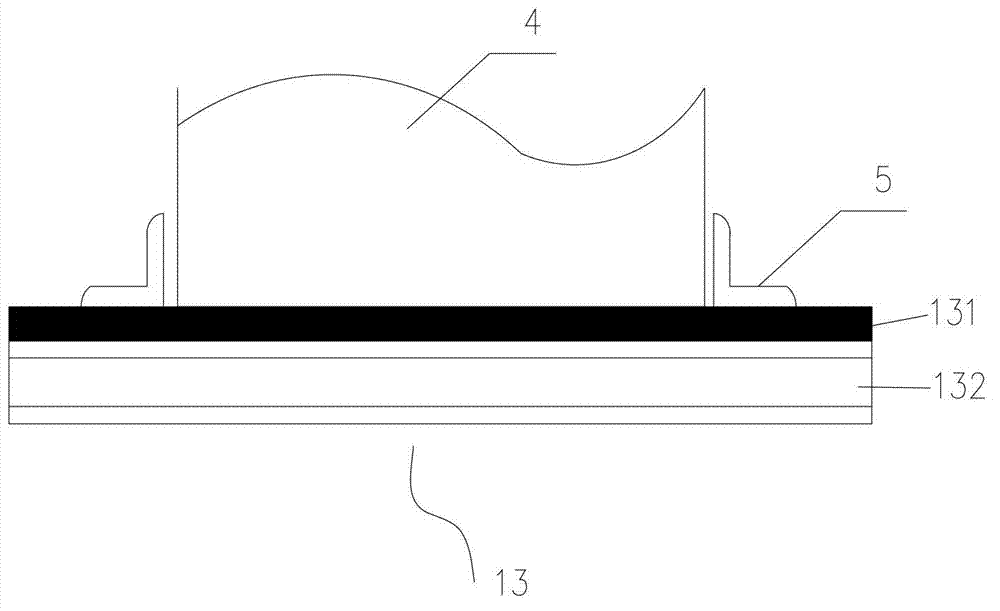

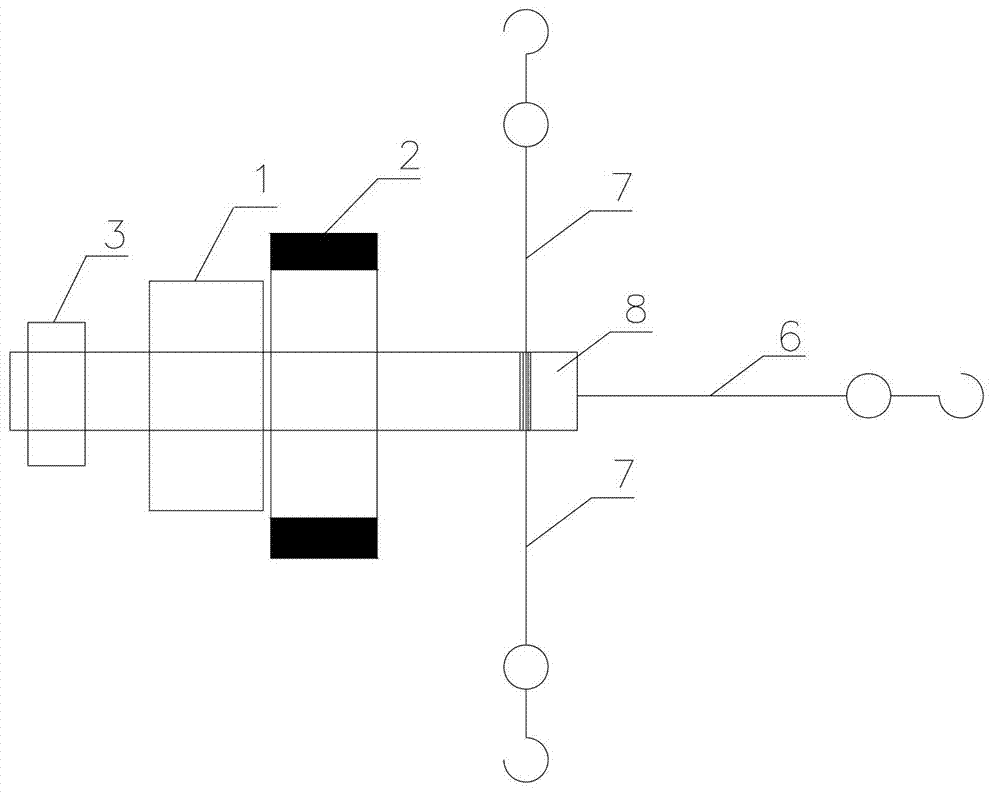

Adjustable adaptor

InactiveCN102305338AGuaranteed installation qualityEasy to installStands/trestlesEngineeringSolar energy

The invention discloses an adjustable adaptor, which comprises a bottom plate (1), two parallel ear plates (2) and a connecting sleeve (3), wherein the two parallel ear plates (2) are vertical to the bottom plate (1); the connecting sleeve (3) is pivoted between the two ear plates (2), and an inclination angle of the connecting sleeve (3) can be adjusted; a long waist hole (6) is arranged outside each of the two ear plates (2) on the bottom plate (1); a circular bolt hole (4) and an arc-shaped bolt hole (5) are arranged in the middle of each ear plate; a bolt, which passes through the circular bolt hole (4), of the connecting sleeve (3) serves as a pivot shaft; the bolt, which passes through the arc-shaped bolt hole (5), of the connecting sleeve (3) serves as an adjustment shaft; and an adjustable angle of the connecting sleeve (3) is 0 to 45 DEG. The adjustable adaptor can be arranged on a roof, a wall surface, a ground surface and the like, and vertical columns of a solar member bracket or other member equipment brackets are inserted into the connecting sleeve, so the whole member is supported. The invention has the advantages that: the adjustable adaptor is simple in structure, convenient for installation, firm and reliable; field installation efficiency is greatly improved; the angle can be adjusted; and the installation quality of a product is ensured.

Owner:POWERWAY RENEWABLE ENERGY

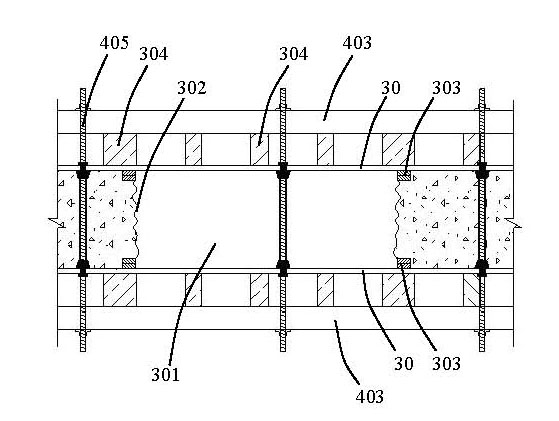

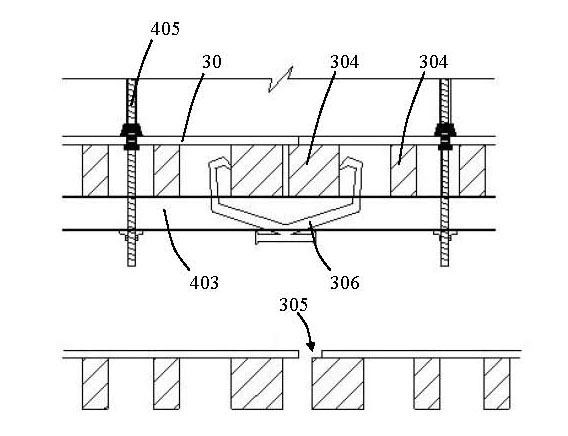

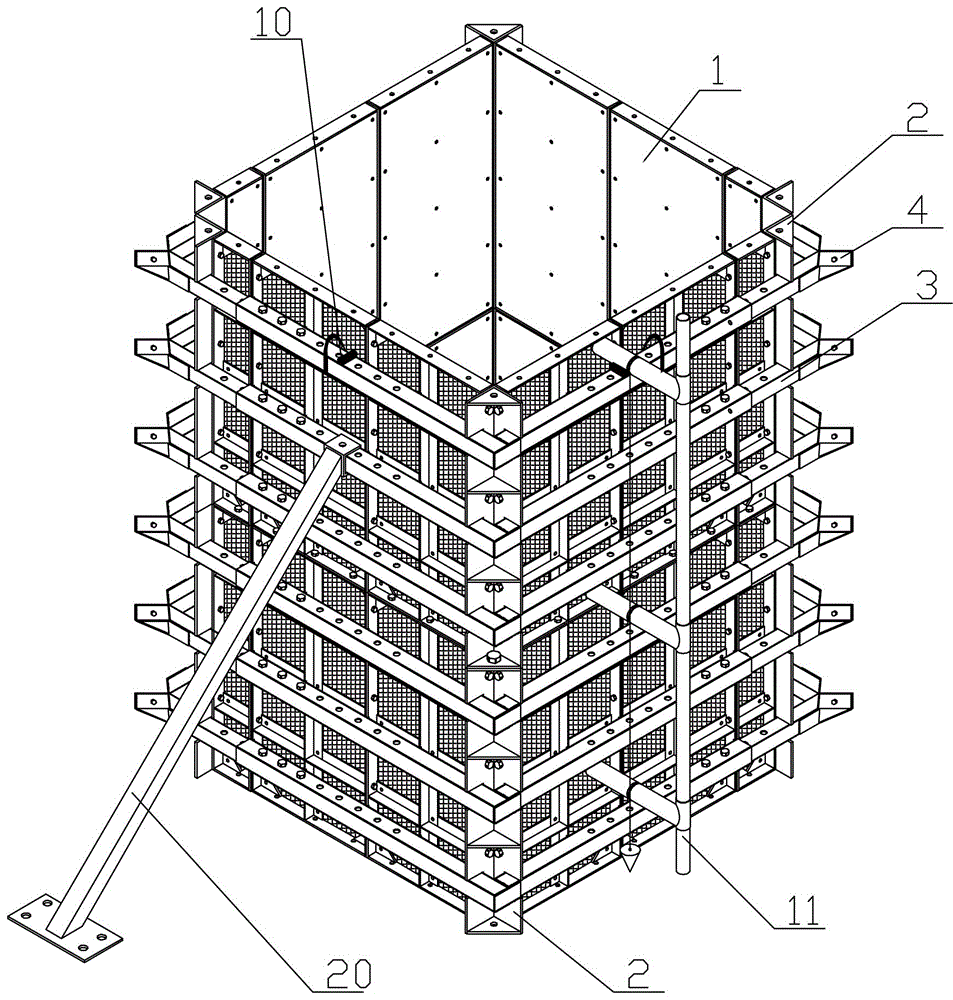

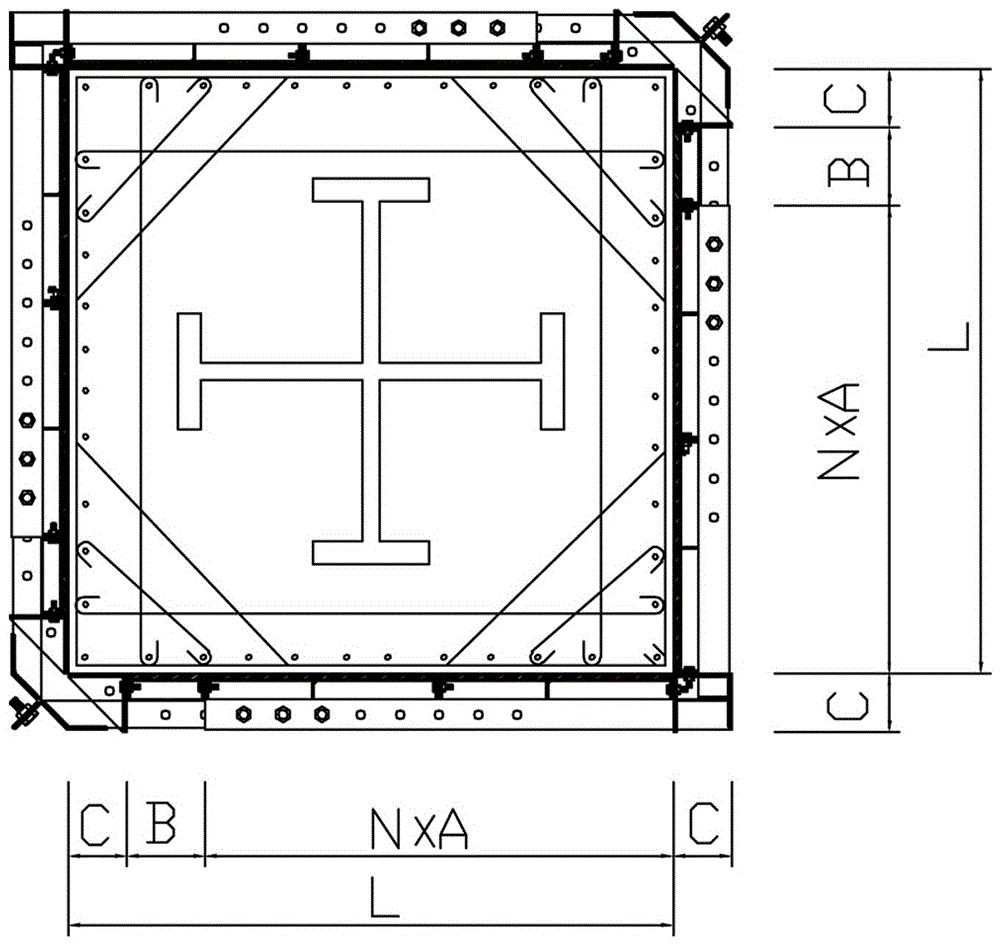

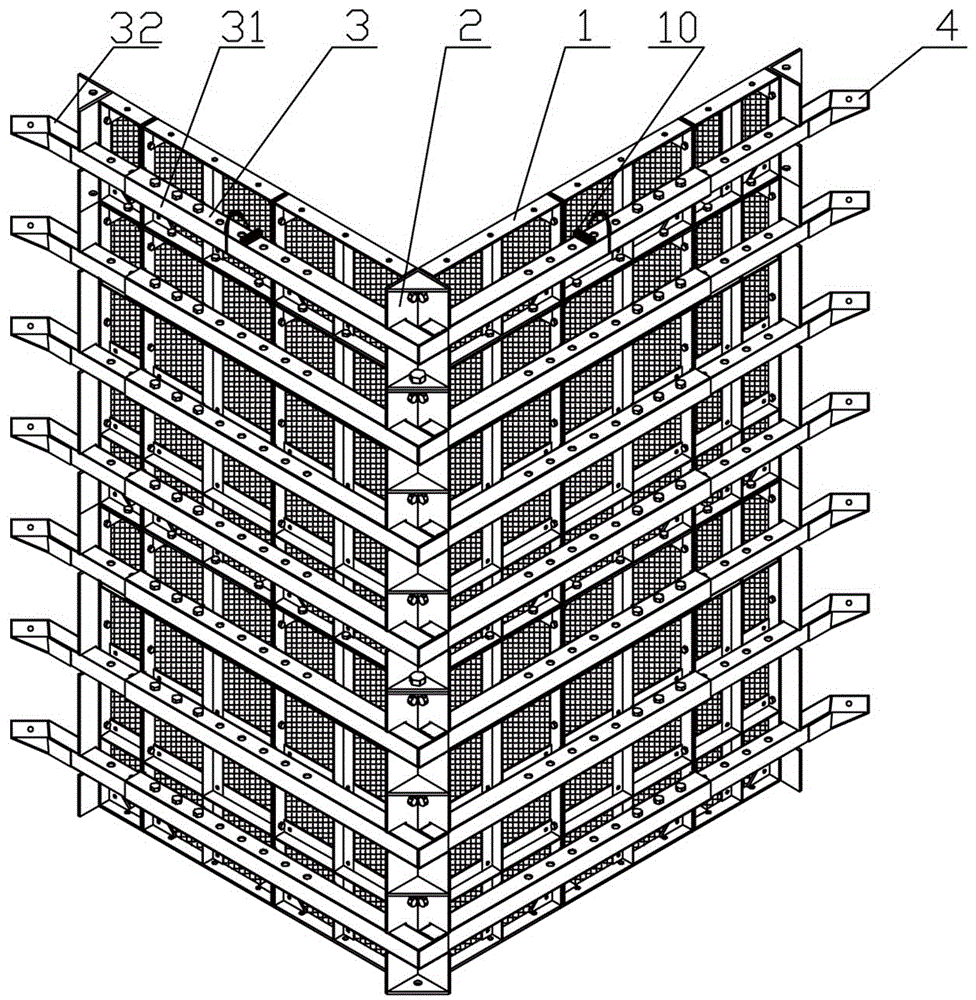

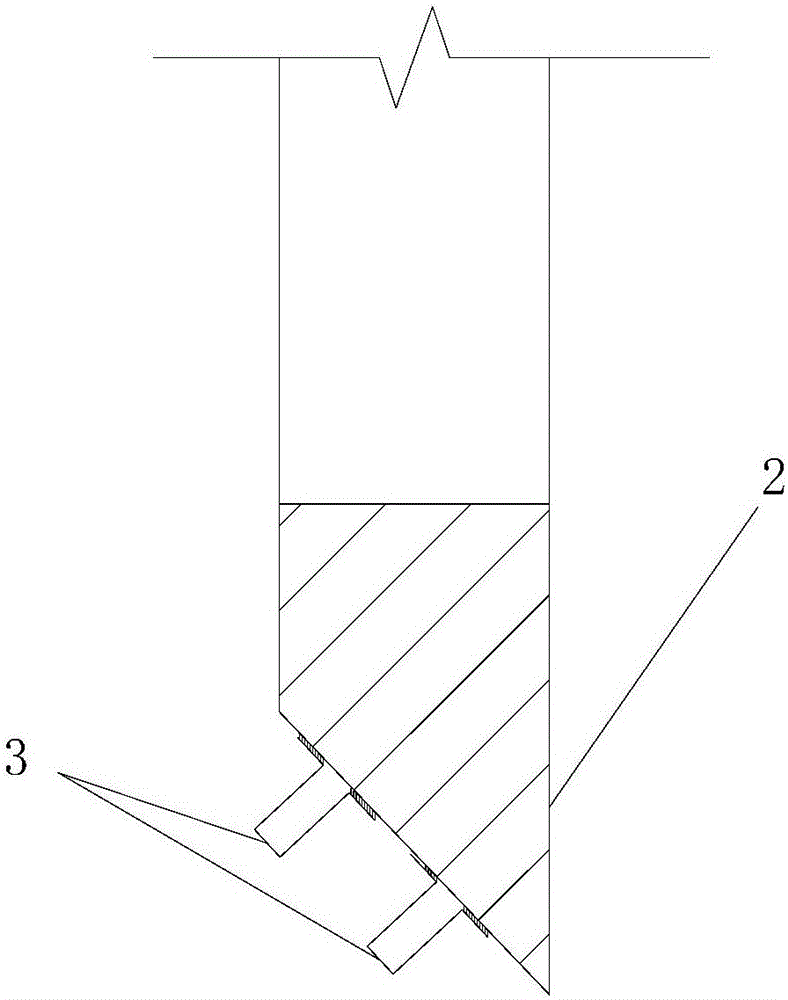

Fabricated section-adjustable formwork system for square stiff pillars and construction method of fabricated section-adjustable formwork system

ActiveCN105926936AReduce damageSolve the disadvantagesForms/shuttering/falseworksSocial benefitsBuilding construction

The invention relates to a fabricated section-adjustable formwork system for square stiff pillars. The fabricated section-adjustable formwork system is of a rectangular structure formed by four surface formworks. Every two surface formworks are connected with each other through angle-steel positioning members. A plurality of evenly distributed rectangular grooves are formed in each angle-steel positioning member vertically. A plurality of limiting cross beams are arranged on the outer surfaces of the surface formworks. Two ends of each limiting cross beam are located in the corresponding rectangular grooves, and are vertically connected with the corresponding limiting cross beams on the adjacent surface formwork. Each surface formwork is formed by connection of a plurality of standard unit formworks and a non-standard unit formwork. Each limiting cross beam is formed by inserted connection of outer square steel and inner square steel, and the length of each limiting cross beam is adjusted according to the width of the corresponding surface formwork. The formwork system has the advantages that during turnover, damage degree is low, construction speed is high, auxiliary measures are few, and requirements on operation levels of operators are low; the formwork system is applicable to construction requirements of section changes of the square stiff pillars, is environment friendly and has high economic and social benefits.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Boiling heat-exchange reinforced wall-attached orifice plate assembly shell component

InactiveCN102969033AHigh densityEnhanced boiling heat transferNuclear energy generationCooling arrangementVena contracta diameterReactor pressure vessel

A boiling heat-exchange reinforced wall-attached orifice plate assembly shell component relates to the technical field of reinforced heat exchange. A wall-attached orifice plate assembly is mounted on an outer wall of a reactor pressure vessel and is supported and fixed by a fixing assembly, and is composed of a plurality of wall-attached orifice plate units mutually connected with each other as one. The wall-attached orifice plate units are orifice plate structure and are provided with a plurality of plate holes in an array arrangement. A plurality of wall-attached supporting members in the array arrangement are arranged at the inner side of the wall-attached orifice plate units, so that a gap is formed between part of the inner wall of the wall-attached orifice plate units except the supporting members and the outer wall of the reactor pressure vessel. The wall-attached orifice plate units are composed of orifice plates and connecting and strengthening side plates, and the connecting and strengthening side plates are arranged at edges of the orifice plates. The component can substantially reinforce boiling heat-exchange process, improve critical hot-fluid density, and thus substantially improve security; and strengthens heat exchange and improve performance stability of critical hot-fluid density.

Owner:TSINGHUA UNIV

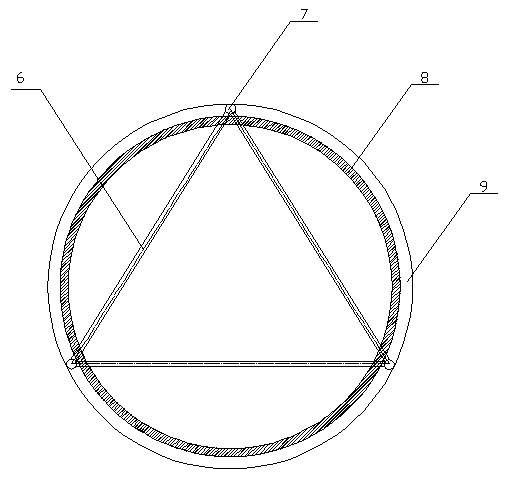

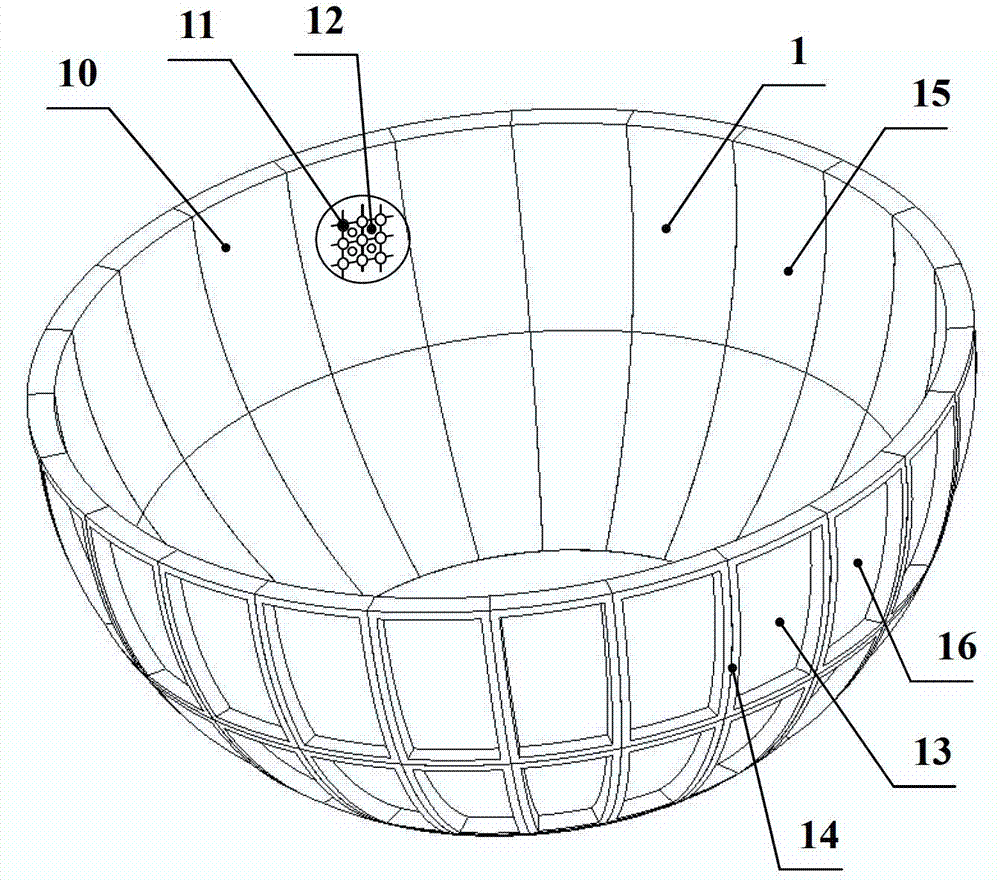

Bearer for gliding reticulated shell

ActiveCN105625581AShorten construction timeImprove efficiencyBuilding constructionsWeld seamBearing surface

The invention discloses a bearer for gliding a reticulated shell. The bearer has a lateral bearer (4) and a vertical bearer (10) which are adjacently arranged to support a bearer ball (7) together. The bearer ball is connected to a reticulated shell web member (5) and a reticulated shell chord member (6). The bearer includes a pre-embedded bearer bearing surface roof plate and a transition plate. The bearer is characterized in: the pre-embedded bearer bearing surface roof plate is a normal pre-embedded steel plate. The steel plate is welded to an anchor rib of which the diameter, the position, and the length are determined based on calculation and meet configuration requirements. The transition plate (11) includes a vertical transition plate and a lateral transition plate. The thickness and size of the transition plate are the same as those of a bearer base plate or are determined based on calculation. The transition plate is perforated at a place corresponding to an eyelet of the supporting base plate. A bearer bolt is inserted to the perforated place of the transition plate and is fastened through plug welding to the perforated place of the transition plate, and the welding seam is ground and flattened. The bearer of the invention has the advantages of reducing height of gliding and unloading, reducing difficulty in gliding and unloading and implementation fees, shortening construction time, and guaranteeing construction safety and quality.

Owner:MCC5 GROUP CORP SHANGHAI

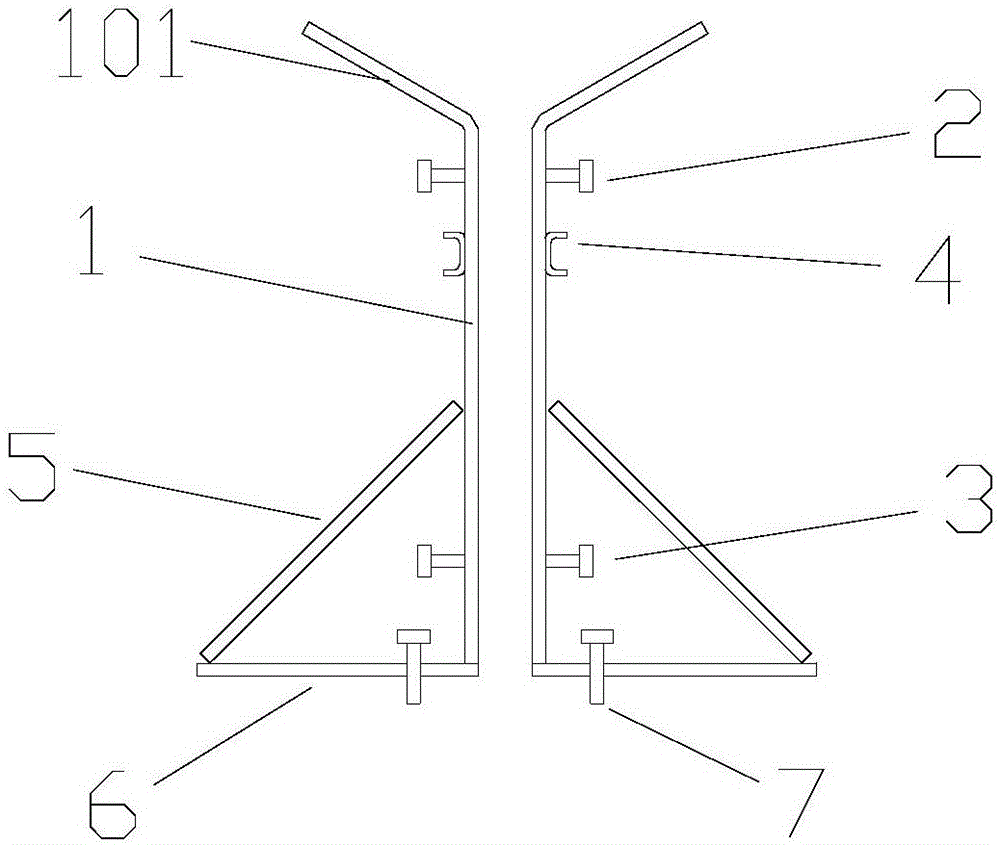

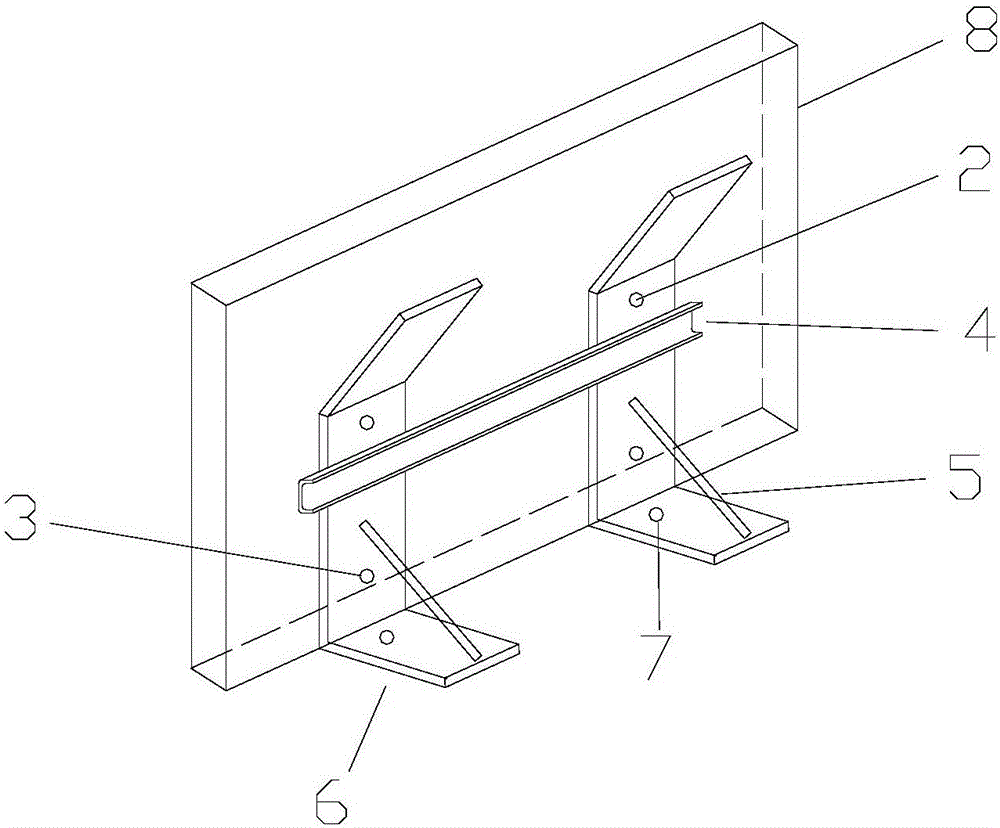

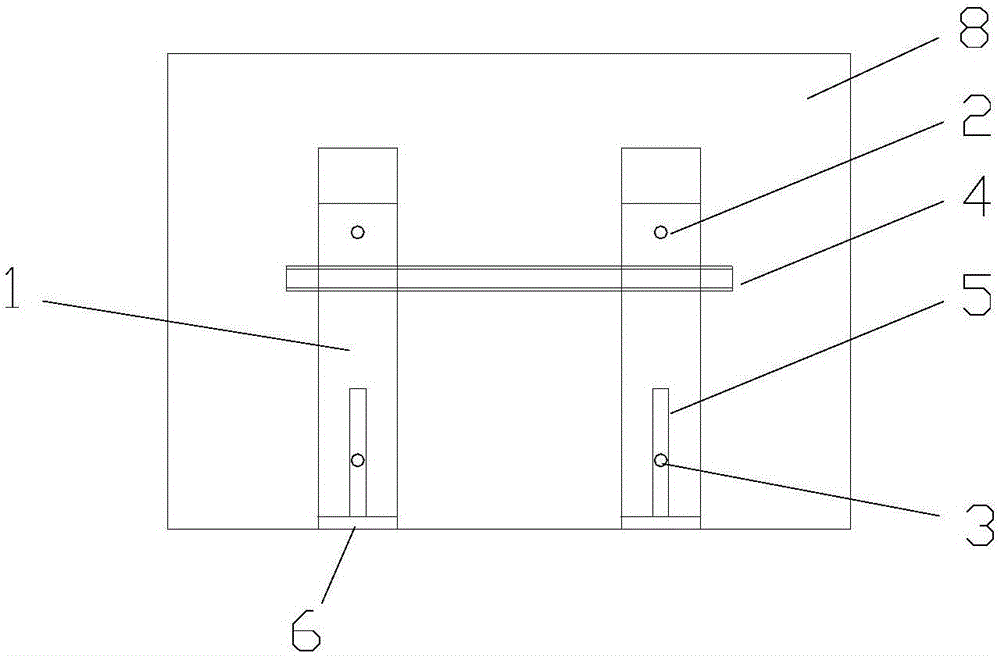

Prefabricated concrete wall panel installation and emplacement orientation adjustment device and construction method thereof

InactiveCN106639336APrevent structural integrityGuaranteed installation qualityBuilding material handlingEngineeringPrecast concrete

The invention provides a prefabricated concrete wall panel installation and emplacement orientation adjustment device and a construction method thereof, and belongs to the technical field of prefabrication and assembly, in order to solve the problems that the existing prefabricated concrete wall panel construction and installation efficiency is low, the process is complicated, and the installation quality can not be ensured. The adjustment device includes a funnel-shaped structure formed by vertical plates and a base, each vertical plate includes an upper bent portion and a lower vertical portion, the bottom end of each vertical plate is vertically and fixedly connected with the base, the base is fixedly connected with a floorboard through embedded bolts, and the two vertical plates located at the same side of a prefabricated concrete wall panel are fixed through a connection rod to form a cavity which can contain the prefabricated concrete wall panel. The invention further provides the construction method of the prefabricated concrete wall panel installation and emplacement orientation adjustment device, the problem that the prefabricated concrete wall panel is difficult to rapidly and accurately emplace and adjust is solved, and the prefabricated wall panel installation efficiency is improved.

Owner:SHANGHAI CONSTRUCTION GROUP +1

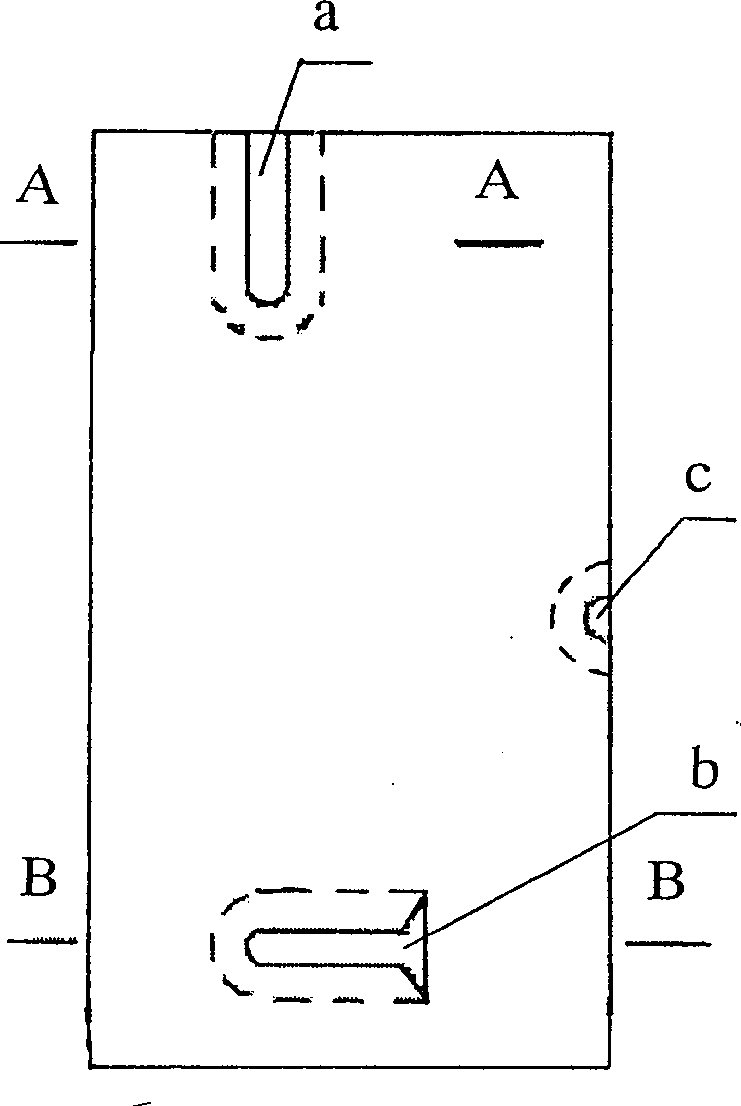

Implanted pottery-stone connector for building decorative plates, and dry-hanging installation technique thereof

The invention provides an implanted pottery-stone connector for building decorative plates, and a dry-hanging installation technique thereof, which relates to a dry-hanging technique for building decorative materials. The dry-hanging technique adopts specific components and tools, and is characterized in that a plate is cut into finished-product material to be dryly hung according to construction requirements; the side or the back of the finished-product material is provided a T-shaped groove; a T-shaped bolt is placed in the T-shaped groove and then is directly connected with a building, or is combined with a washer and a nut to form a hanging piece for installation, wherein the T-shaped groove is or is not filled with cement gum; a mounting hole is drilled on a metal bracket before the metal bracket is installed; and after the installation of the metal bracket is finished, the hanging piece is arranged according to the position of the mounting hole. The invention has the advantages of realizing line production and factory construction, improving engineering quality, ensuring construction safety and simultaneously solving the technical problem that ceramic tiles, stones and plates usually fall off after installation.

Owner:沈阳嘉美科技有限公司

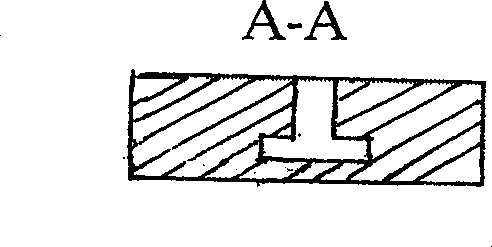

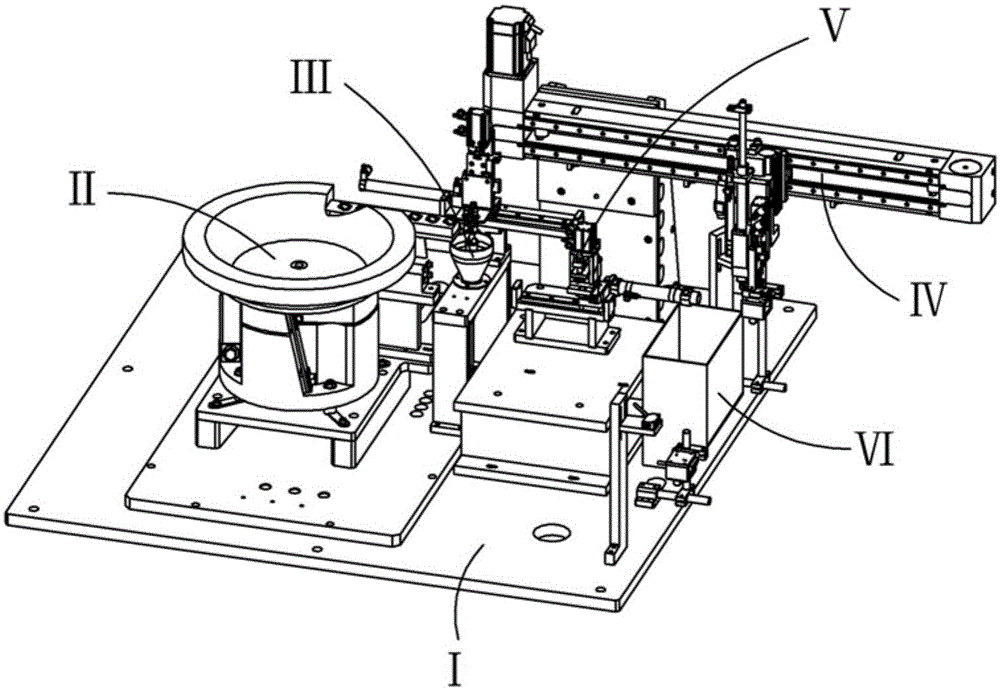

Automatic installing mechanism of wave washer

ActiveCN105033631AEasy to operateImprove installation efficiencyMetal working apparatusEngineeringUltimate tensile strength

The invention relates to an automatic installing mechanism of a wave washer. A bottom plate is provided with a vibrator feeding mechanism. The vibrator feeding mechanism conveys the wave washer to a vibration disc end. A material taking mechanism is arranged at the position, located on the right rear portion of the vibrator feeding mechanism, of the bottom plate. The material taking mechanism can suck the wave washer out of the vibration disc end and place the wave washer in a hopper, and positioning and ejecting of the wave washer are facilitated. A conveying mechanism is arranged above the right rear portion of the bottom plate. The conveying mechanism can convey the positioned and ejected wave washer to a detecting mechanism or an installing position. The detecting mechanism is arranged at the position, located on the right side of the material taking mechanism, of the bottom plate, and can detect whether the thickness of the wave washer is qualified or not. A waste box is arranged at the position, located on the right side of the detecting mechanism, of the bottom plate and contains waste. By means of the mechanism, automatic adsorbing, conveying and installing of the wave washer can be achieved; and the installing efficiency is improved, the installing quality is guaranteed, the labor intensity of workers is relieved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

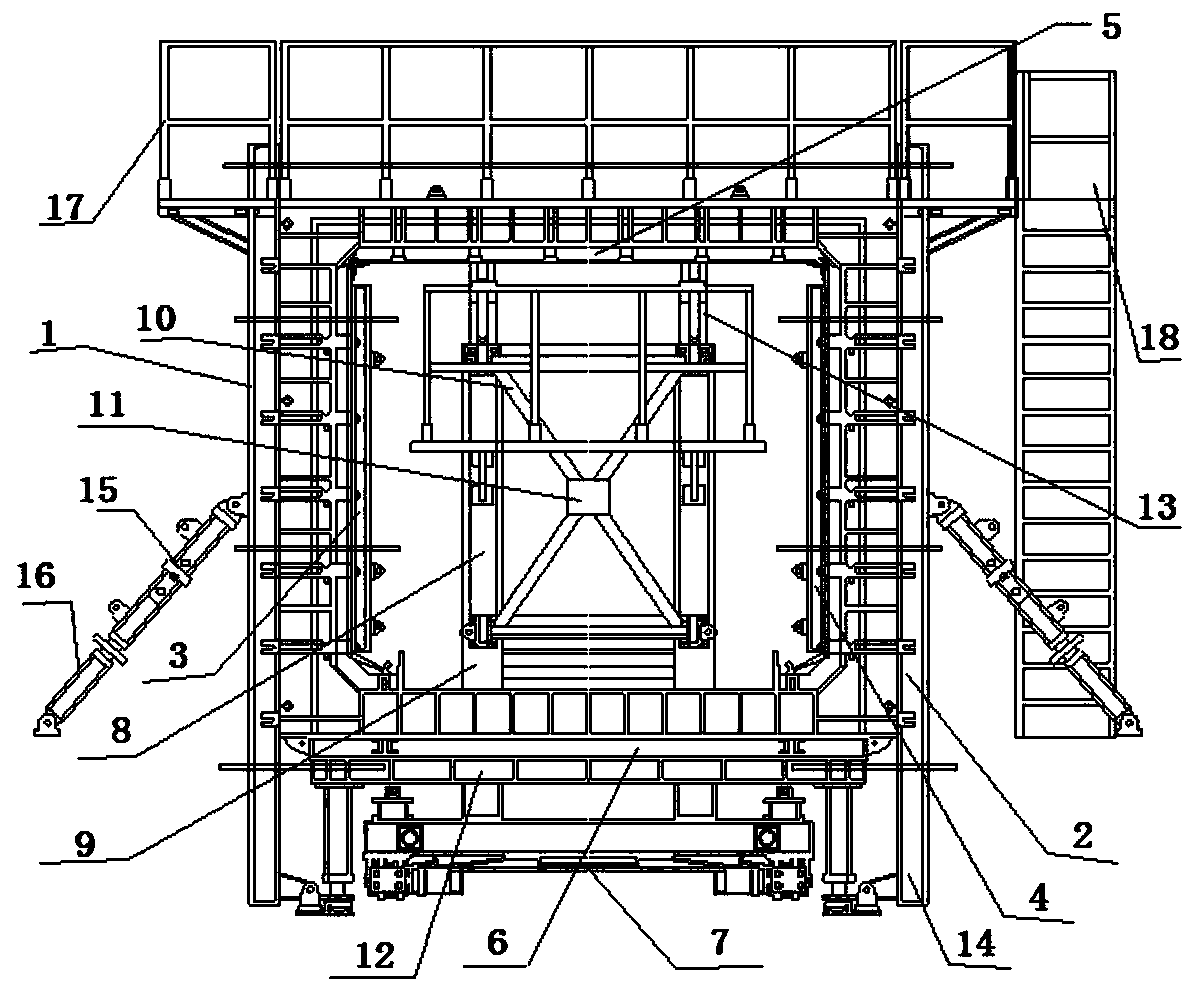

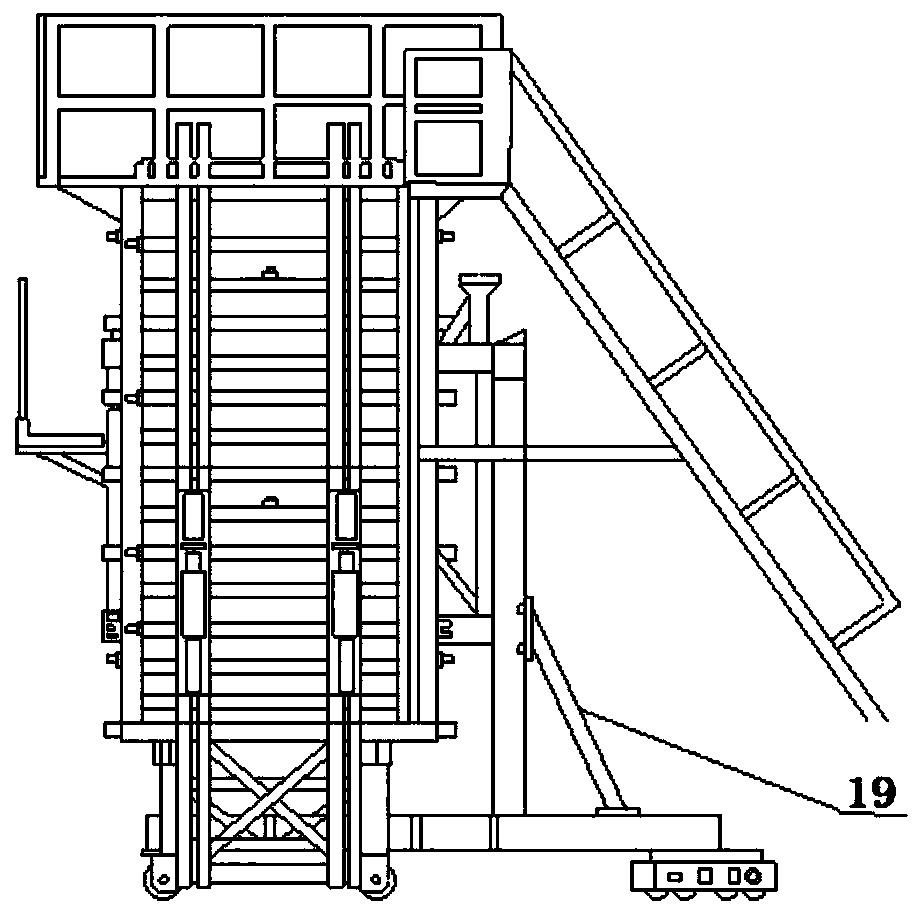

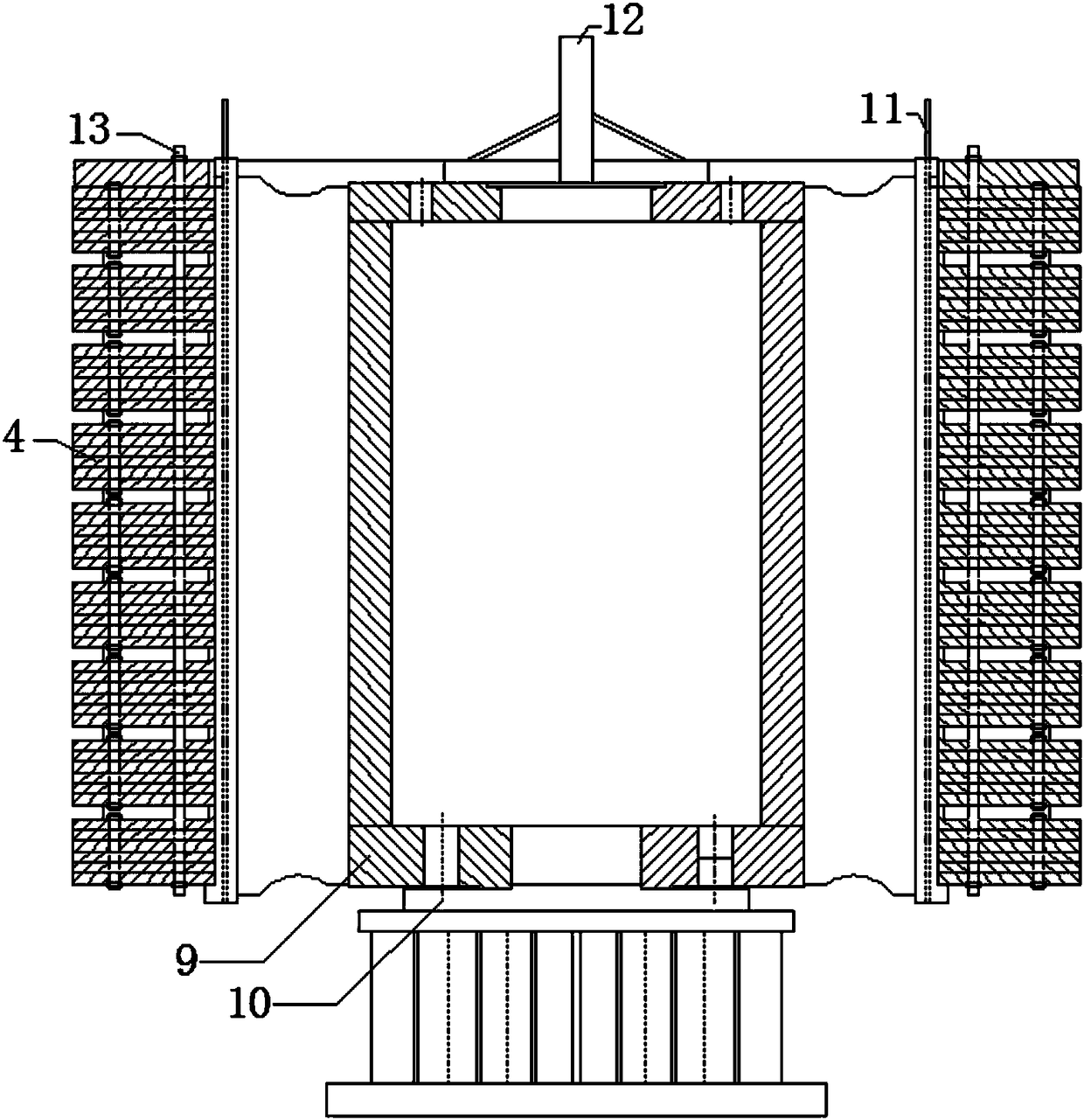

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

Novel manufacturing and installing method for cable holder

InactiveCN103996998AImprove installation efficiencyQuick and easy replacementElectrical apparatusEngineeringMaterial selection

The invention provides a novel manufacturing and installing method for a cable holder. Holes are formed in the cable holder according to a certain technological standard, cable grooves, hoops, reinforcing ribs, fireproof division plates and the like can be arranged on supporting arms of the holder as needed, reserved holes are formed in the two walls of a cable trench, and then the cable holder and the walls can be assembled and disassembled fast through expansion bolts. Through material selection, premachining, accessory addition and preliminary combination of the cable holder, the installation procedure can be achieved at one step, so that the labor and the time are saved, the cost is saved, the problem that installation, maintenance, fixation, rust prevention, fire prevention and the like of an existing cable holder are difficult is solved, and the whole cable holder is stable, scientific in design, convenient to manufacture and install, safe and practical. Thus, the novel manufacturing and installing method is worthy of popularization and application.

Owner:XICHUAN COUNTY POWER BUREAU

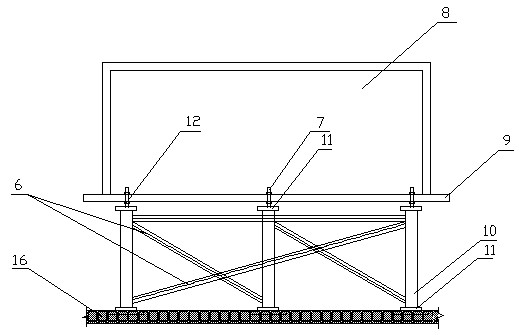

Building method of integral slip type scaffold used for steel grid construction

The invention relates to a device for steel grid construction, in particular to a building method of an integral slip type scaffold used for steel grid construction, which solves the problem that the existing various construction methods for grid construction have respective shortcomings. The method comprises the steps of fixing channel steel guide rails; arranging steel tube guide wheels vertical to the guide rails at intervals on each channel steel guide rail; paving channel steel slip bases coincident with each channel steel guide rail on the steel tube guide wheel, and arranging a drawing head connected with a drawing device via wire ropes on the channel steel slip base; erecting a standing bar; longitudinally and transversely erecting horizontal cross bars; erecting a scissors brace; and paving an operating platform. The invention has the advantages of simple erection, stable integral structure, greatly increased slip efficiency, easy operation and high slip safety, has small influence on periphery construction and production environment, has construction continuity, can fully guarantee the quality of grid installation and the construction of other types of work, saves time and labor, ensures the construction safety, and increases the construction efficiency.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +2

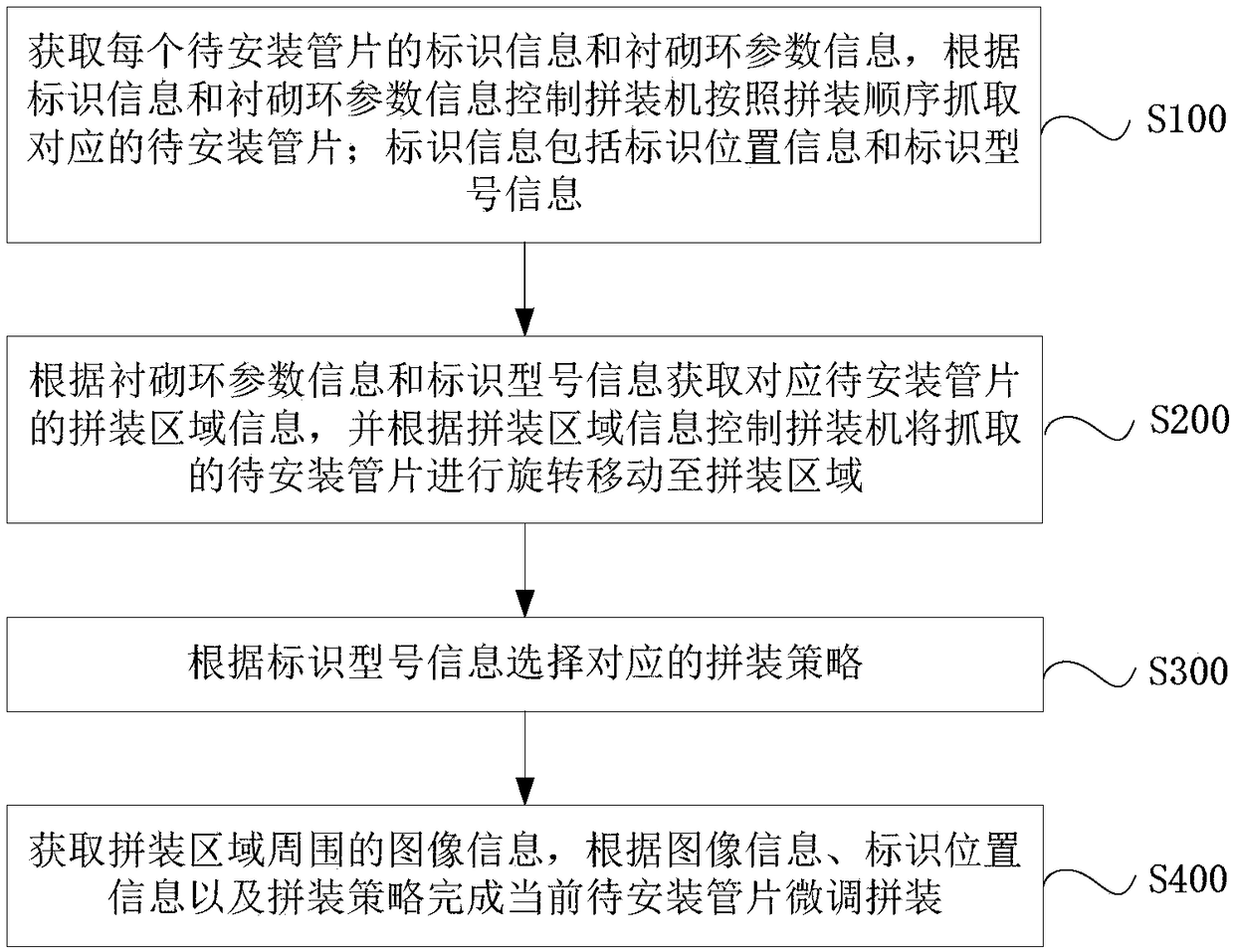

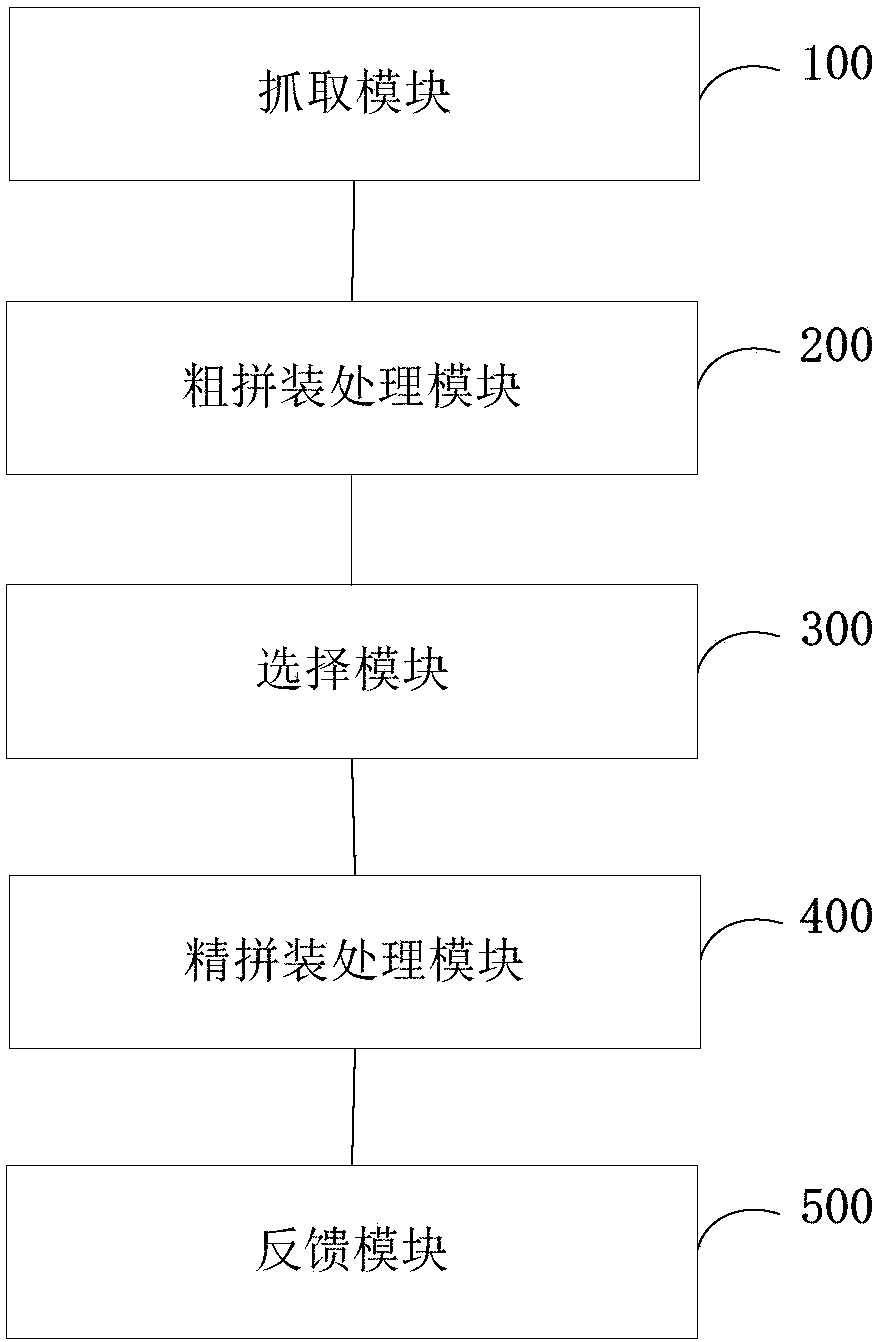

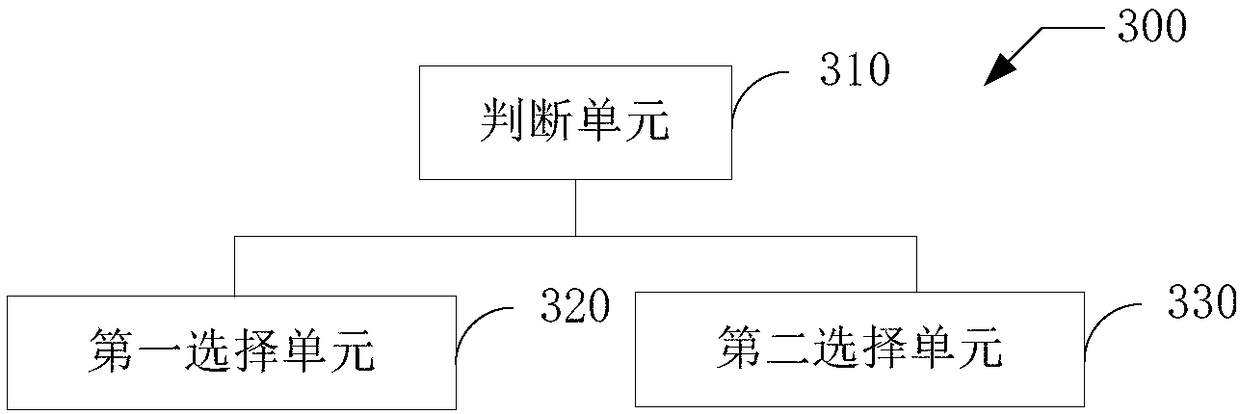

Shield segment automatic assembly method and system

ActiveCN108104834AFast and automatic assembly workGuaranteed installation qualityMining devicesUnderground chambersEngineeringFine-tuning

The invention discloses a shield segment automatic assembly method and system. The shield segment automatic assembly method comprises the steps that according to obtained identification information and lining ring parameter information of each pipe piece to be installed to control an erector to grab corresponding pipe pieces to be installed according to assembly sequence; the identification information includes identifying location information and identifying model information; the erector is controlled to rotate and move the grabbed pipe pieces to be installed to an assembly area according tothe obtained results obtained by the lining ring parameter information and the identifying model information; corresponding assembly strategy is selected according to the identification model information; and image information around the assembly area is obtained, fine-tuning and assembly of the current pipe pieces to be installed is completed according to the image information, the identifying location information and the assembly strategy. According to the shield segment automatic assembly method and system, a splicing method depending on artificial experience is abandoned, not only is thelabor cost reduced, thereby improving the safety guarantee of operating personnel, but also man-made assembling errors can be eliminated, so that the stability of the assembly quality of the pipe pieces is enhanced, and the assembly efficiency of the pipe pieces is improved.

Owner:SUZHOU MAICHUANG INFORMATION TECH

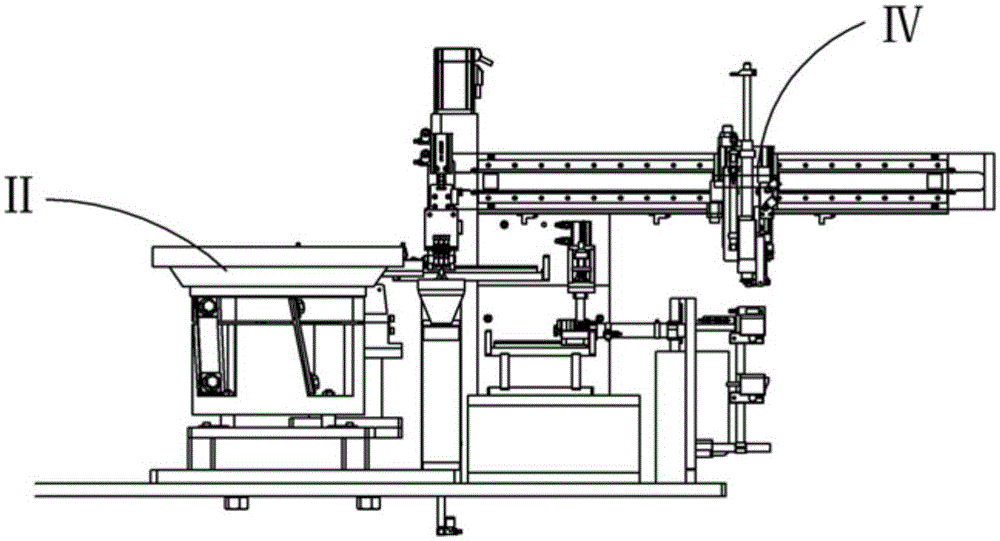

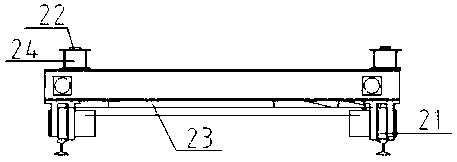

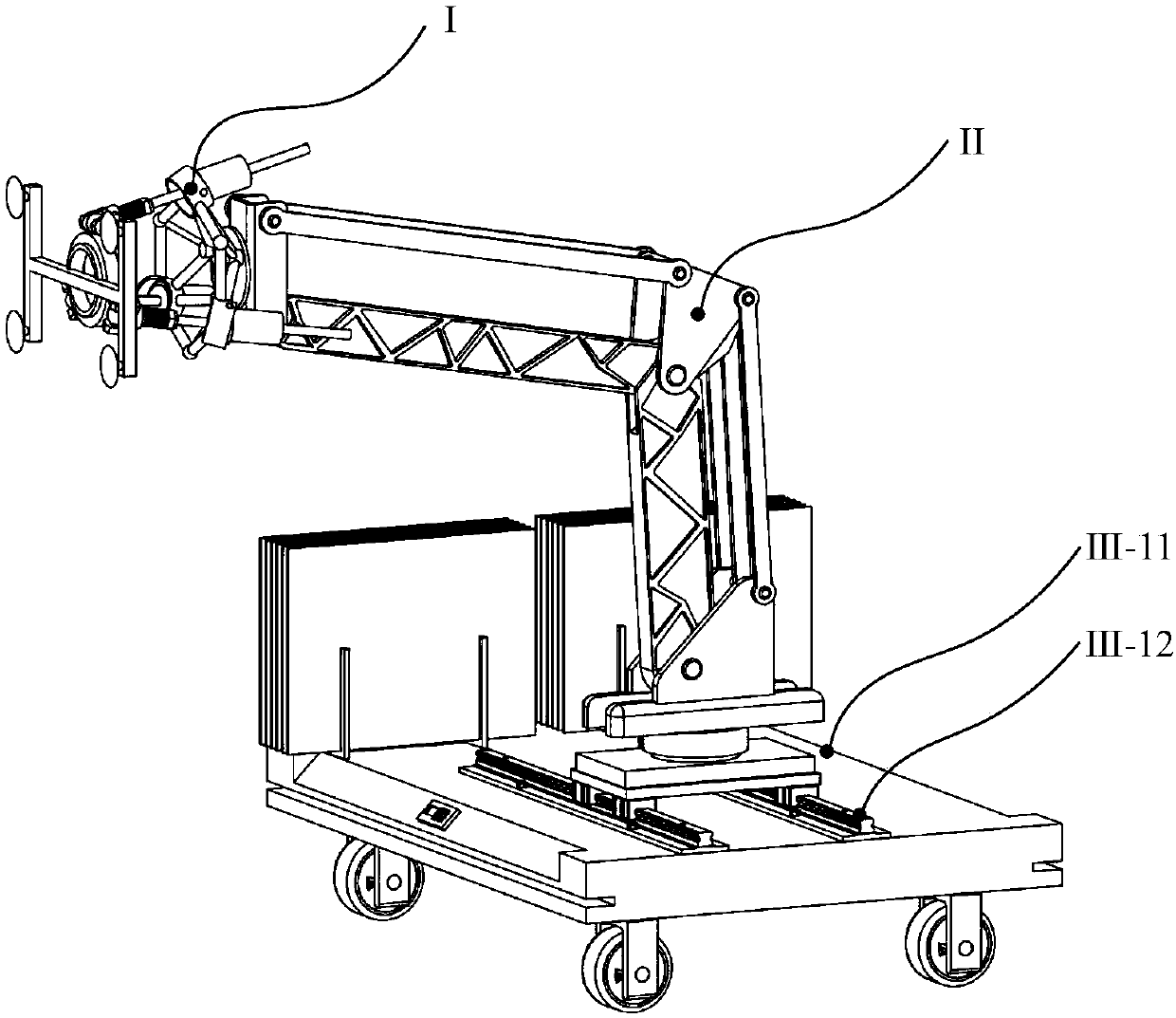

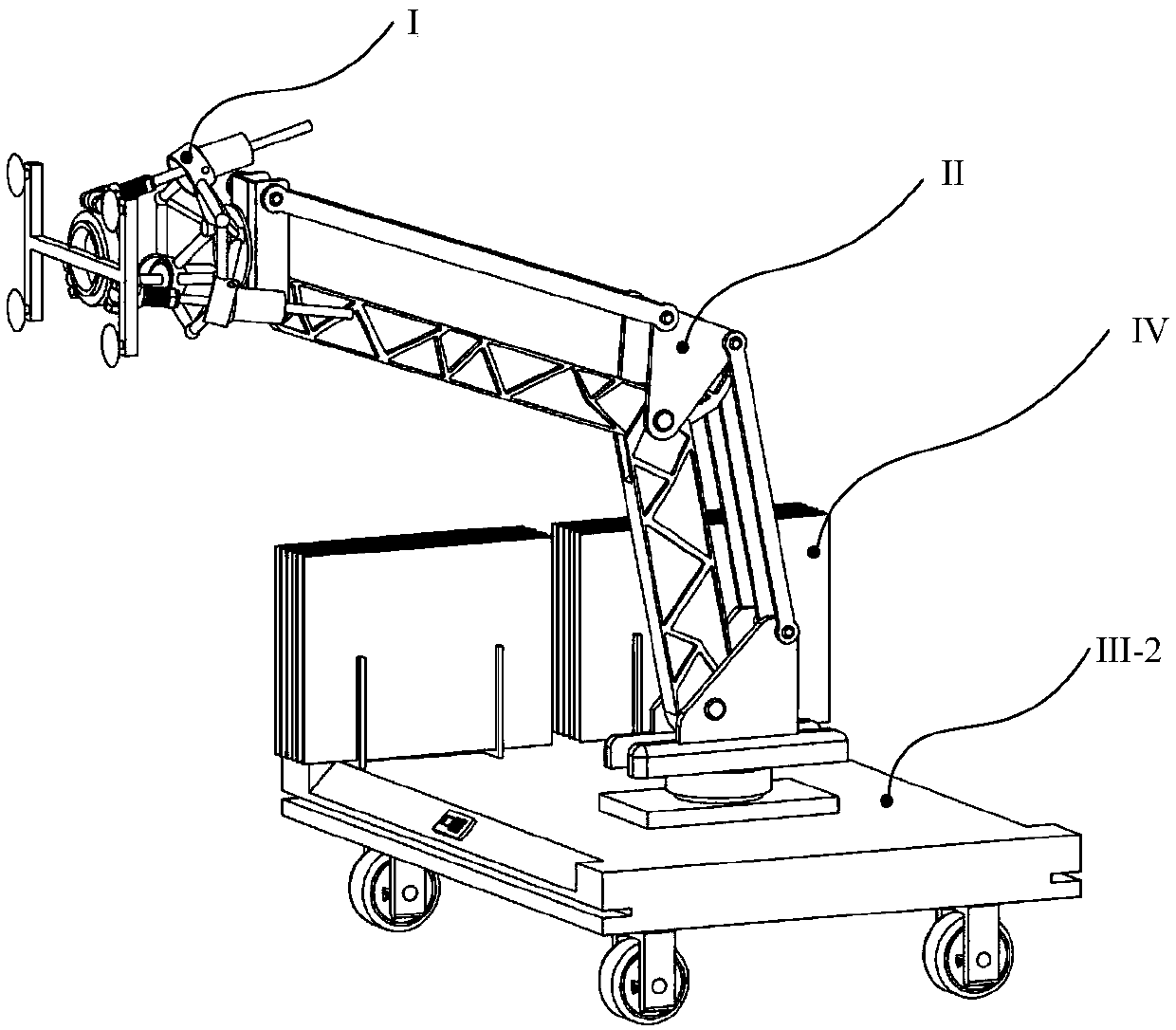

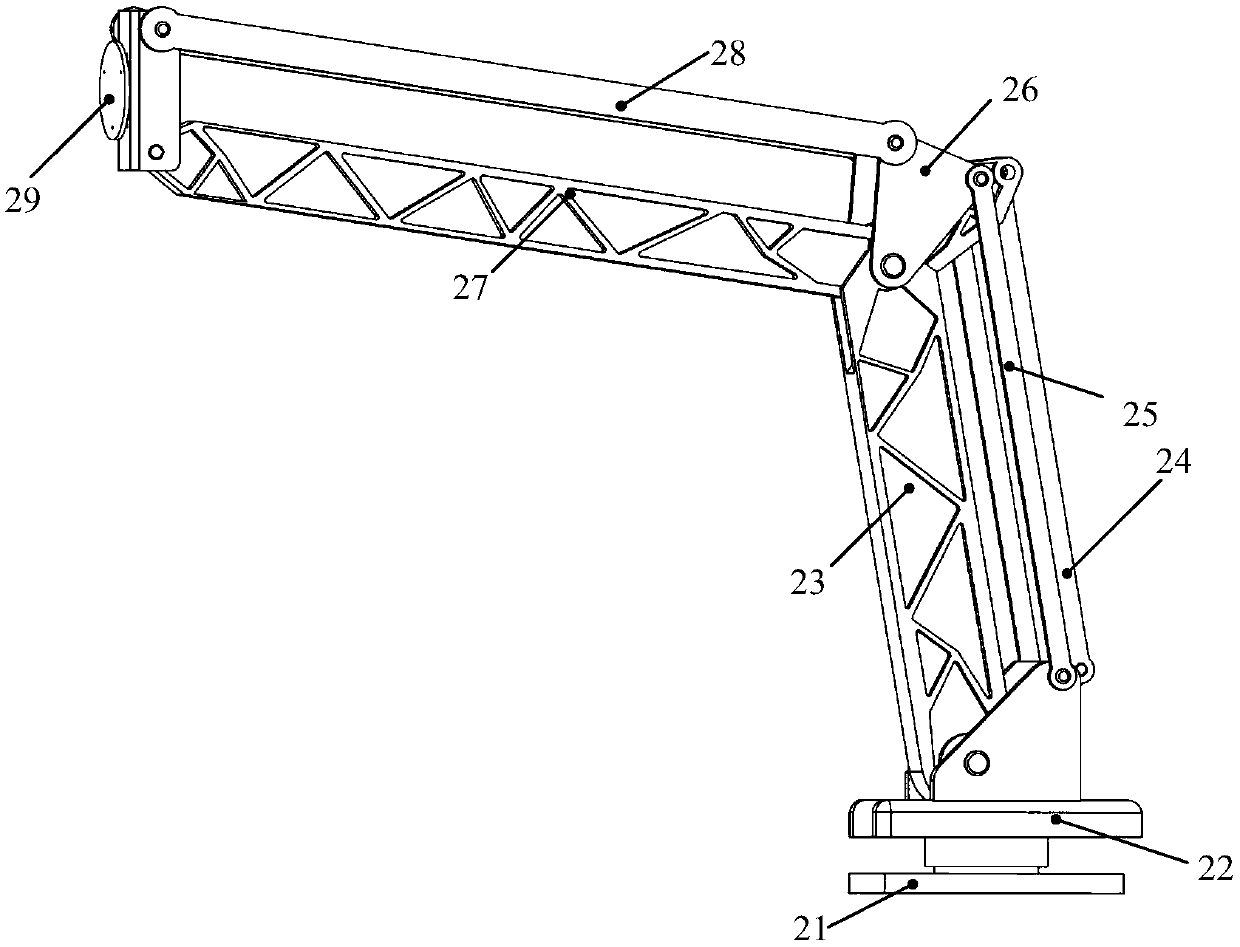

Force control building installation robot based on hybrid mechanism

InactiveCN109623770AGuaranteed installation qualityProgramme-controlled manipulatorGripping headsTerrainManipulator

The invention discloses a force control building installation robot based on a hybrid mechanism. The force control building installation robot includes a rubber wheel omni-directional mobile platform,a linear guideway, a three-freedom-degree hybrid manipulator, a four-freedom-degree force control hybrid operation module and a ceramic tile glass mobile raw material warehouse, wherein the rubber wheel omni-directional mobile platform realizes large stroke movement of the robot and adapts to the complex terrain of a construction site, the linear guideway increases the operating range of the force control building installation robot when the omni-directional mobile platform stops, and the three-freedom-degree hybrid manipulator is used for controlling three-freedom-degree motion of the manipulator in the space and ensuring the tail end attitude unchanged; the four-freedom-degree force control hybrid operation module is used for controlling one freedom degree of movement and three freedomdegrees of rotation, ensuring that a sucker type ceramic tile glass installation actuator completes taking and installation and other operation of ceramic tile glass, and controlling external force acting on the ceramic tile glass; and the ceramic tile glass mobile raw material warehouse realizes on-board movement of the ceramic tile glass and other raw materials. According to the force control building installation robot based on the hybrid mechanism, the four-freedom-degree force control hybrid operation module is installed at the tail end of the three-freedom-degree hybrid manipulator and combined with the linear guideway and the rubber wheel omni-directional mobile platform, and large stroke installation operation of the ceramic tile glass can be realized.

Owner:TSINGHUA UNIV

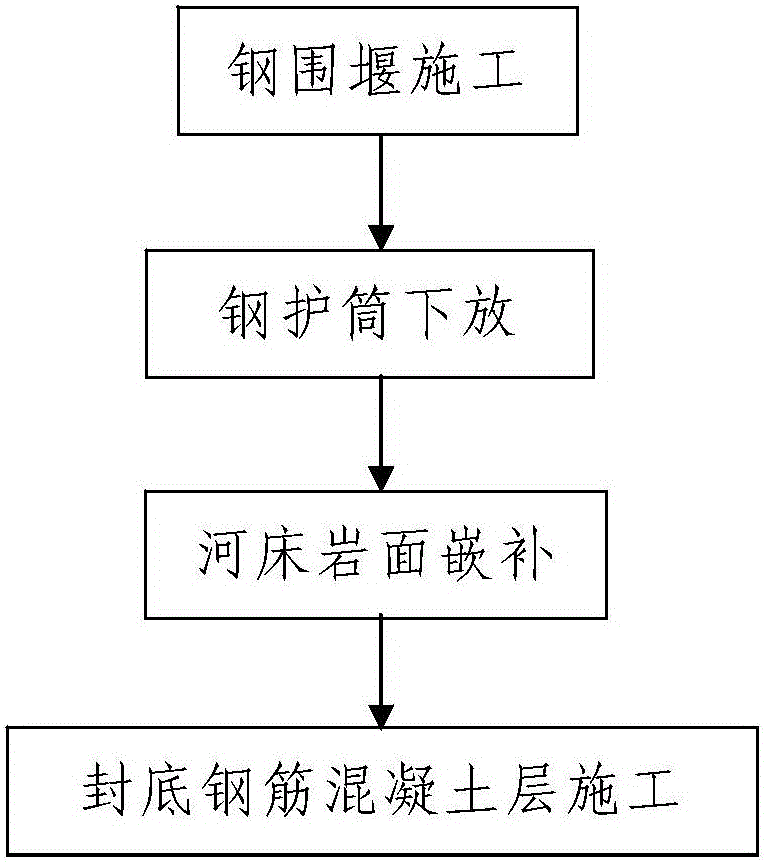

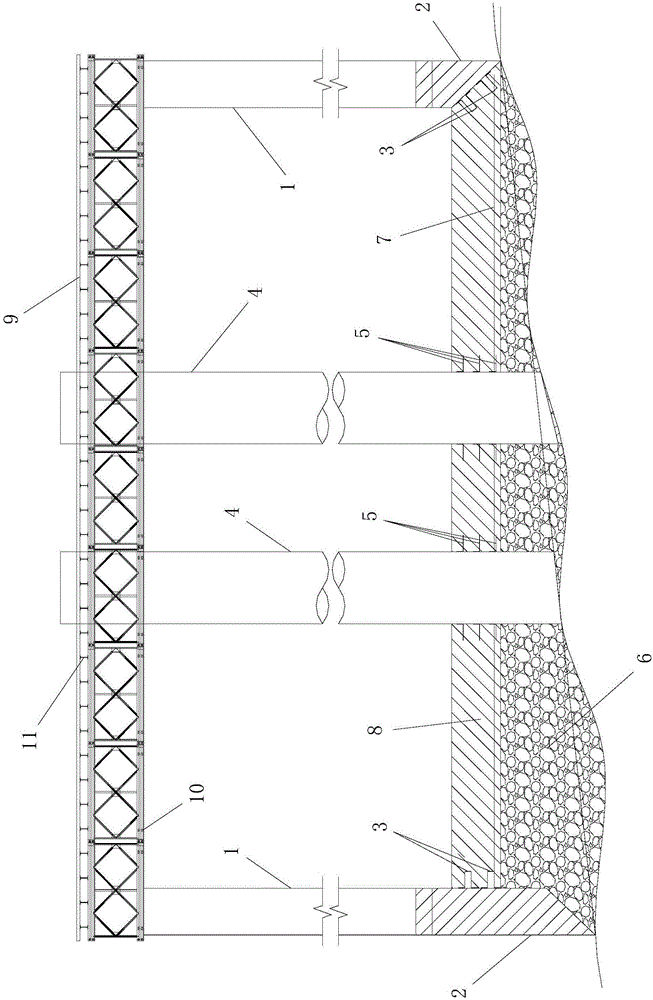

High-low cutting edge double-wall steel cofferdam reinforced concrete once bottom sealing construction method

ActiveCN105064381AThe method steps are simpleReasonable designFoundation testingCaissonsReinforced concreteCofferdam

The invention discloses a high-low cutting edge double-wall steel cofferdam reinforced concrete once bottom sealing construction method which comprises the steps that Step one, steel cofferdam construction is performed: double-wall steel cofferdam sinks to a pre-designed construction position, high-low cutting edges are arranged at the bottom of the double-wall steel cofferdam, inclined surfaces are designed as the bottom surfaces of the cutting edges, and are supported on an inclined bare rock surface, and a plurality of groups of first anchor steel bars are arranged on the cutting edges; Step two, steel casing laying is performed: a steel bar anchor structure is arranged on the outer side wall of the bottom of each steel casing, and comprises a plurality of rows of second anchor steel bars distributed from the top down; Step three, riverbed rock surface patching is performed: a riverbed rock surface is backfilled with a mixture to form a backfilled layer; and Step four, bottom sealing reinforced concrete layer construction is performed: a horizontal steel bar mesh is mounted on the backfilled layer, and concrete is poured into the double-wall steel cofferdam to form a concrete bottom sealing layer. The method is simple in step, reasonable in design, low in construction difficulty, short in construction period and good in using effect, and can effectively solve the various problems in the conventional plain concrete bottom sealing method.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

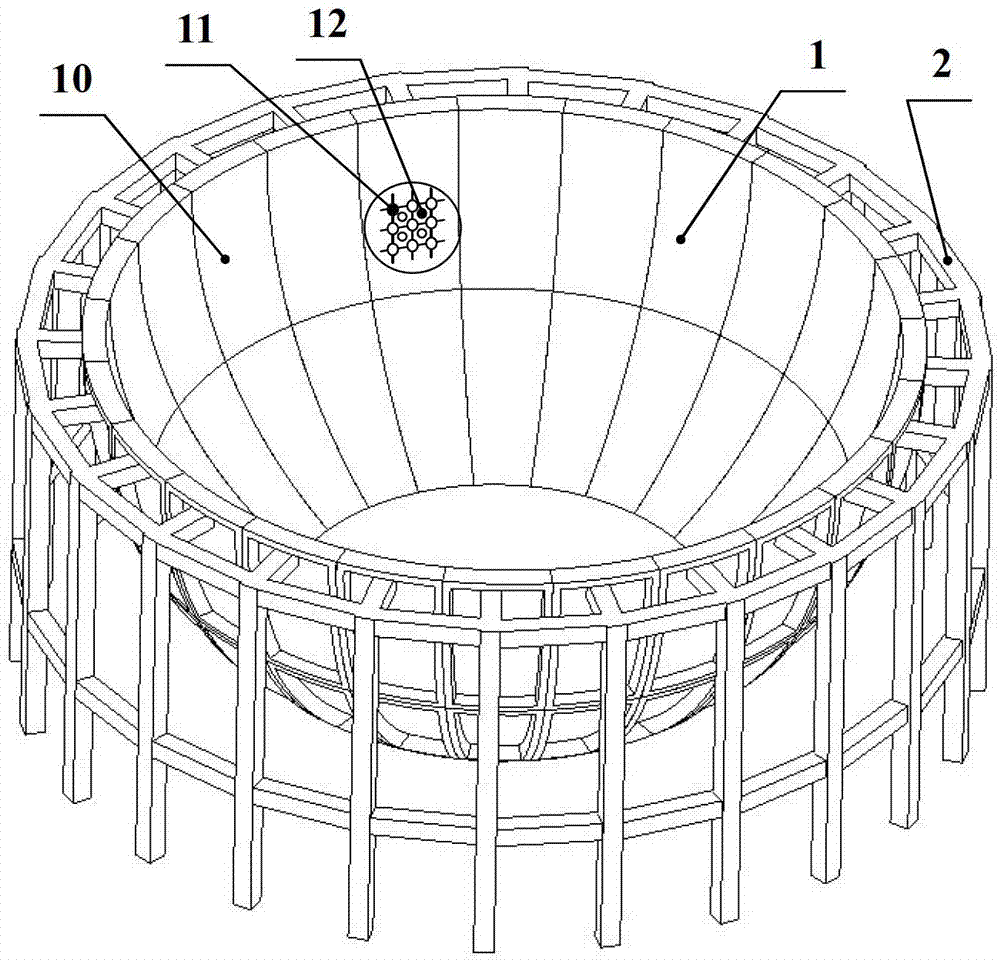

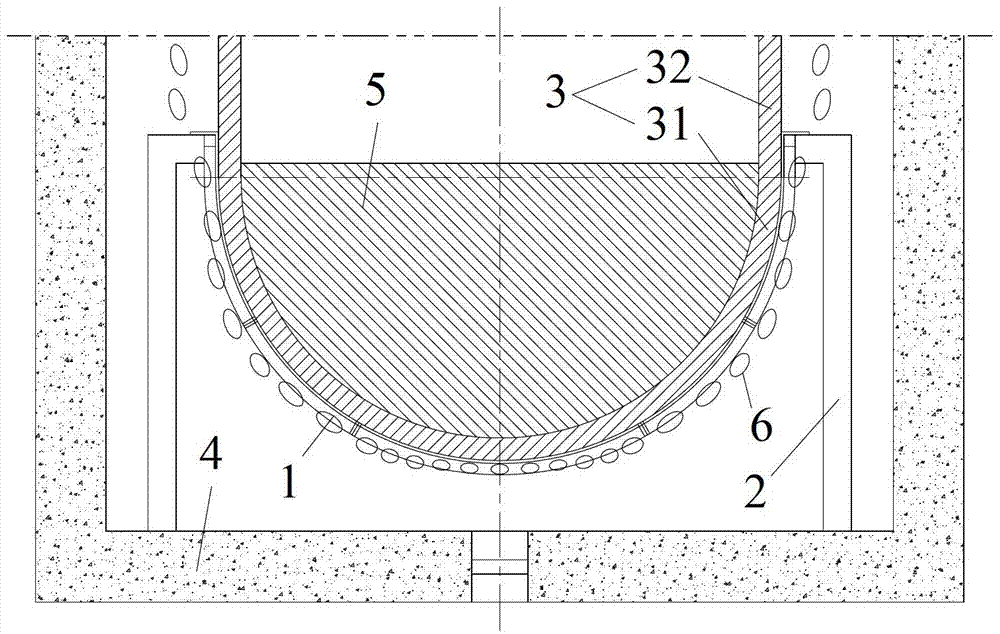

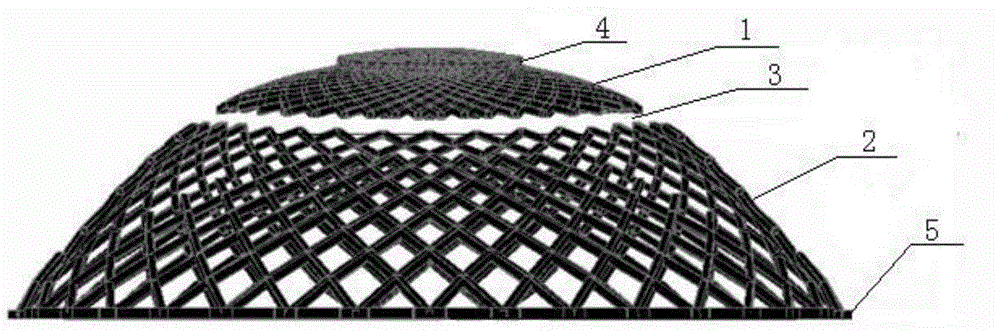

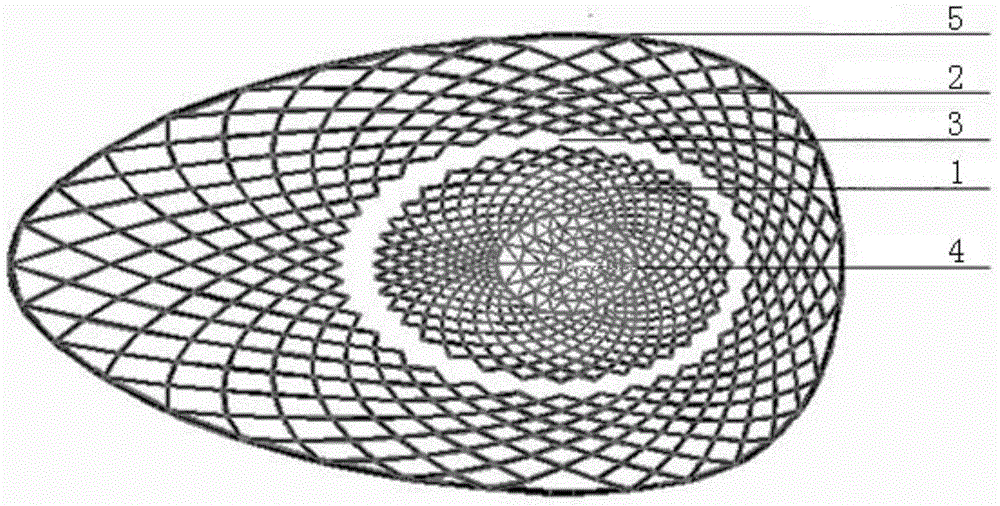

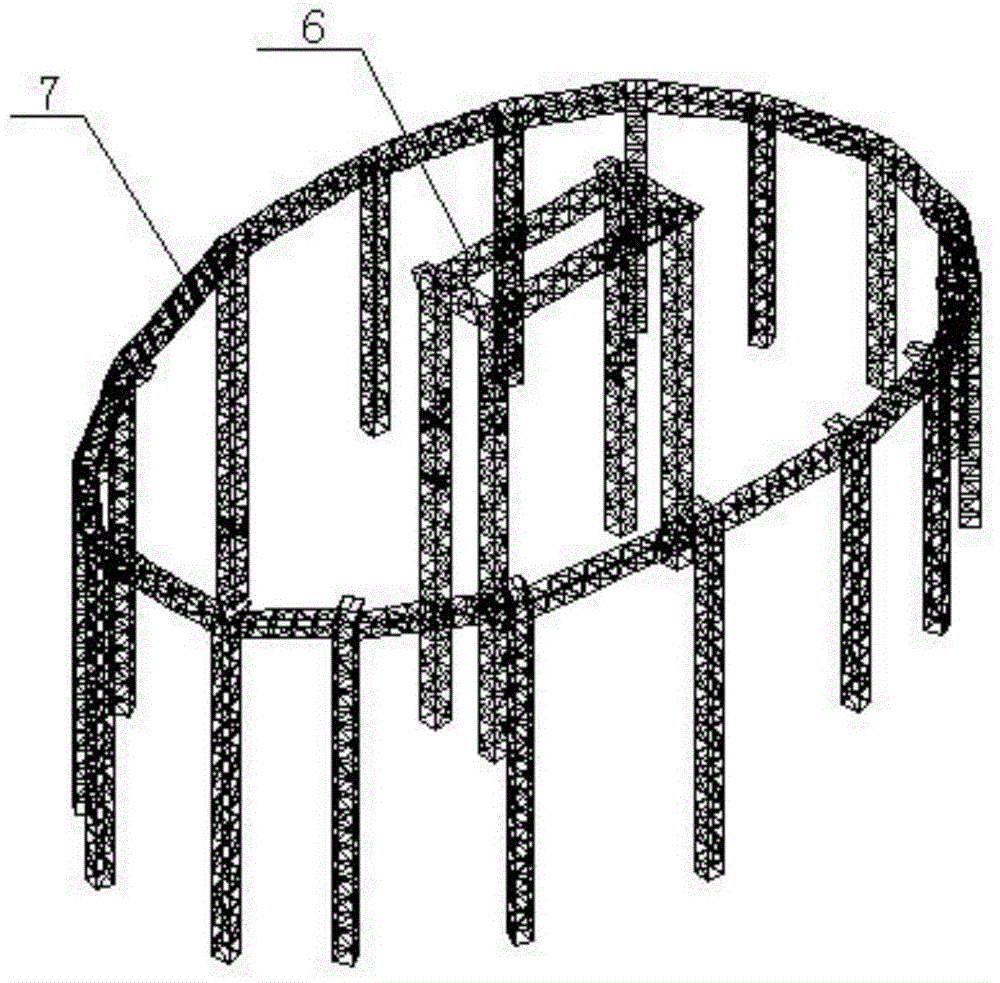

Construction method of large-scan single-layer latticed shell steel structure

InactiveCN104652831AReduce deformationEnsure stability and securityBuilding material handlingMono layerLifting equipment

The invention provides a construction method of a large-scan single-layer latticed shell steel structure. According to the construction method, during construction, the single-layer latticed shell steel structure is sequentially divided into three areas, namely a lifting area, an inlaying area and a splicing area from top to bottom, wherein rod pieces in the lifting area are installed on a bed-jig group of the lifting area lower than a design height, and are entirely lifted after installation. Therefore, the installation precision and quality can be ensured, and the construction security is improved. The construction method avoids the problems in the traditional bed-jig support method that a mass of bed-jig need to be erected and large-tonnage hoisting equipment needs to be used, and the stability of the bed-jigs is difficult to ensure. The invention provides the safe and reliable construction method with lower cost.

Owner:CHINA RAILWAY CONSTR ENG GROUP

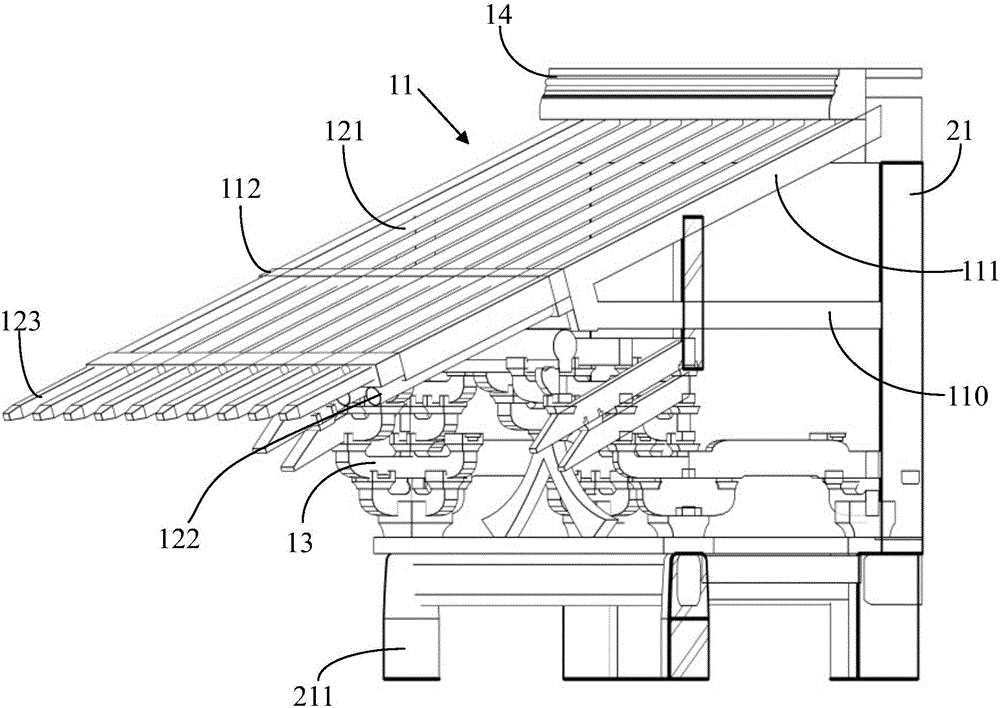

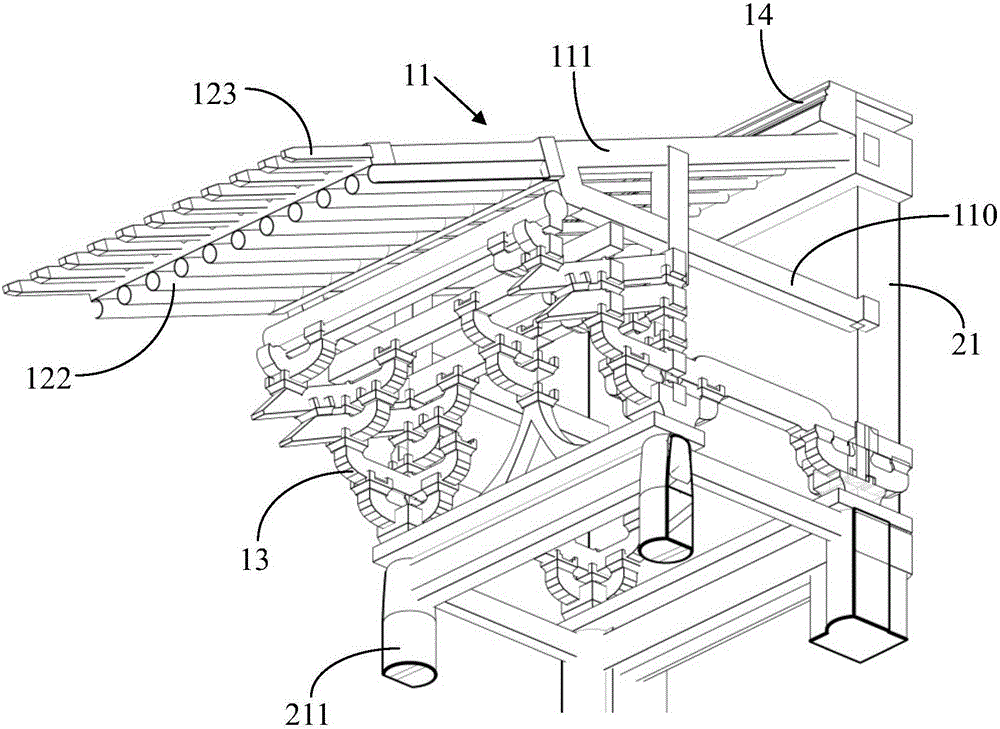

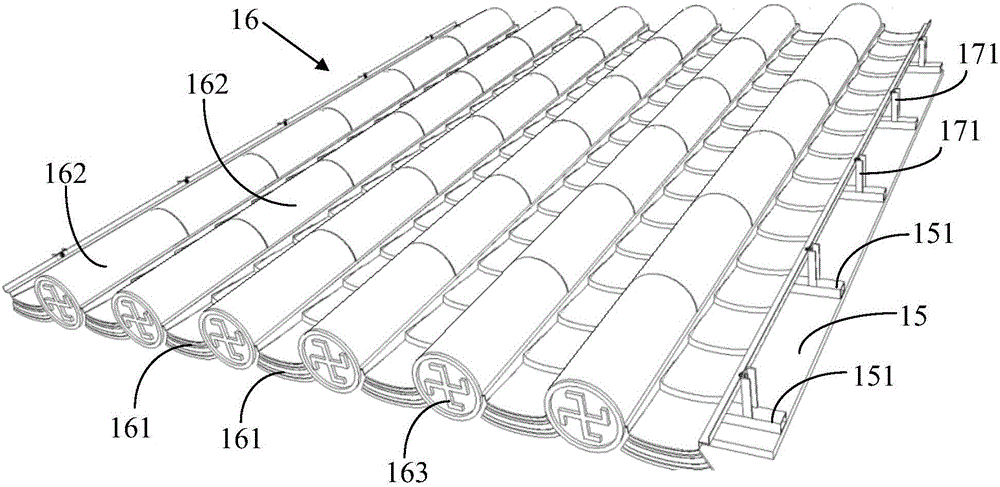

Combined eave system with large-span steel structure and bracket system wood structure and construction method of combined eave structure

ActiveCN106049766ARealize factory mass productionImprove ergonomicsBuilding roofsRoof covering using tiles/slatesEavesSteel frame

The invention discloses a combined eave system with a large-span steel structure and a bracket system wood structure and a construction method of the combined eave structure. The combined eave system comprises a main structure steel frame, a secondary steel structure, the bracket system wood structure, a ridge structure, an eave panel and a roof tile structure. According to the combined eave system, a wood component and the steel structure are assembled and connected through screw connecting pieces, the installation process is standard, the speed is high, and the construction efficiency is greatly improved; the properties and advantages of steel and wood are utilized fully to form a reasonable and firm structure framework, and the seepage resistance of a roof system is improved while the artistic effect of a historic building is accurately and completely mastered; by the adoption of the technologies that punched brasses are adopted, a plate tile and an embedded piece are fixed with a U-shaped connection plate, and hooks and an n-shaped support are connected, simpleness and high speed are achieved, the component mounting speed is increased, and the mounting quality is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

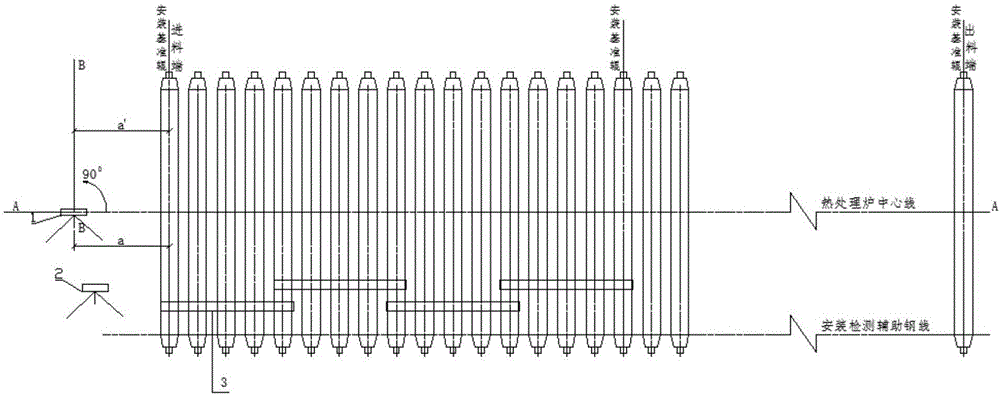

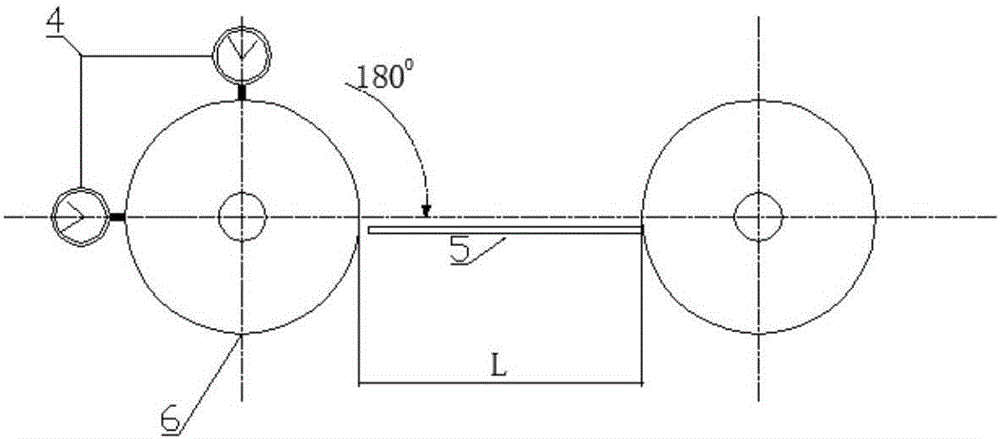

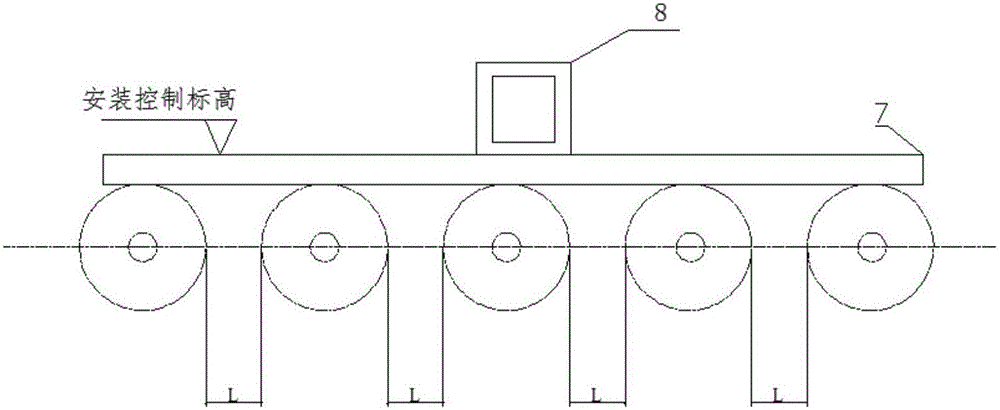

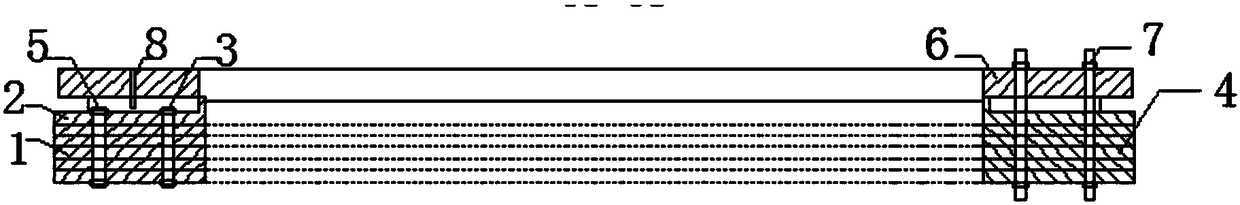

Conveying roller mounting precision control method of roller bottom heat treatment furnace

ActiveCN106834643AImprove installation efficiencyFast installationFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a conveying roller mounting precision control method of a roller bottom heat treatment furnace. The method comprises the steps of roller way assembly, lifting, finish adjustment of a standard roller way, finish adjustment of a nonstandard roller way, installation of a roller way driving device and overall adjustment of the roller ways. The method reasonably sets a standard roller, divides different mounting working surfaces, adjusts the precision of working rollers mounted on the working surfaces with all mounting control precision indexes of the standard roller way as basis, improves the mounting efficiency, accelerates the mounting speed, guarantees the mounting quality, is clear in mounting sequence, is precise in positioning, and prevents the problems of rework and work delaying. The method reasonably uses such auxiliary mounting tools as 5 m steel flat rulers, can realize overall adjustment of one set of several roller ways, accelerates the mounting progress, and meanwhile, can adopt a superposition progressive mode to guarantee non-overproof mounting errors.

Owner:TIANJIN 20 CONSTR

Manufacturing technique of rigid magnetic yoke of motor rotor of large pumped storage generator

ActiveCN108436394AEasy to operateImprove machining accuracyManufacturing stator/rotor bodiesMagnetic polesEngineering

The invention discloses a manufacturing technique of a rigid magnetic yoke of a motor rotor of a large pumped storage generator. According to the manufacturing technique, preassembling is conducted firstly through single disc bolt fixing holes, and rod fixing holes are drilled and reamed at the same time after a magnetic yoke section is fixed, so that the machining precision is improved; and an inner circular key groove is machined through a single section of a milling mold, and an outer circular T-shaped tail groove of the magnetic yoke section is machined integrally. By adoption of the manufacturing technique, the problems that scrap iron cannot be discharged through bolt holes which are reamed at the same time, and an inner circular key groove and an outer circular T-shaped tail grooveof a magnetic yoke section are staggered are solved, and successful hanging assembly of a magnetic pole in the subsequent stage is effectively ensured; and meanwhile, the manufacturing technique has the advantages of being easy and convenient to implement, high in machining precision, capable of shortening the machining cycle, and the like. The manufacturing technique is suitable for manufacturingrigid magnetic yokes of motors of all large pumped storage generators and has high application and popularization value.

Owner:HARBIN ELECTRIC MASCH CO LTD

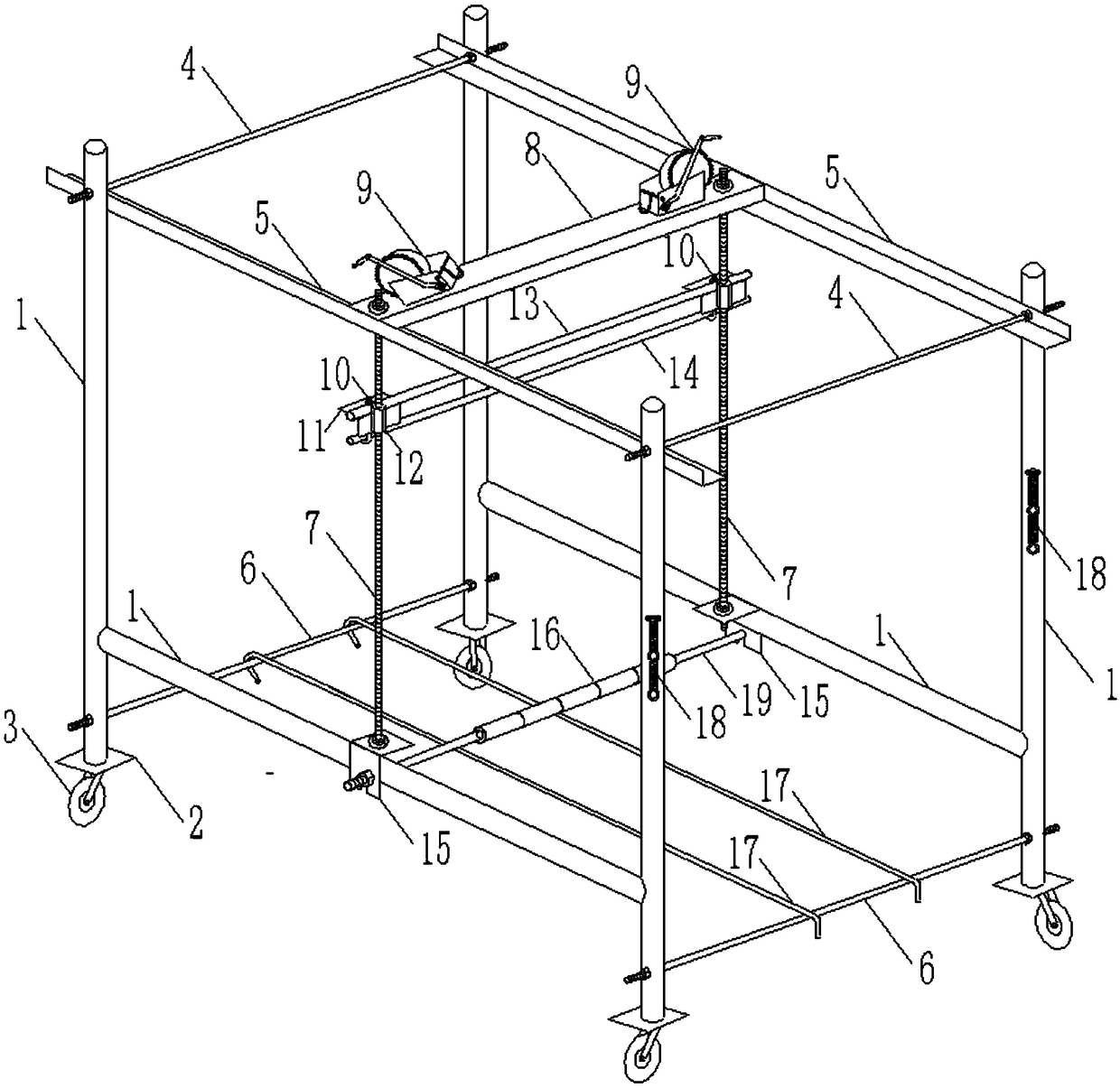

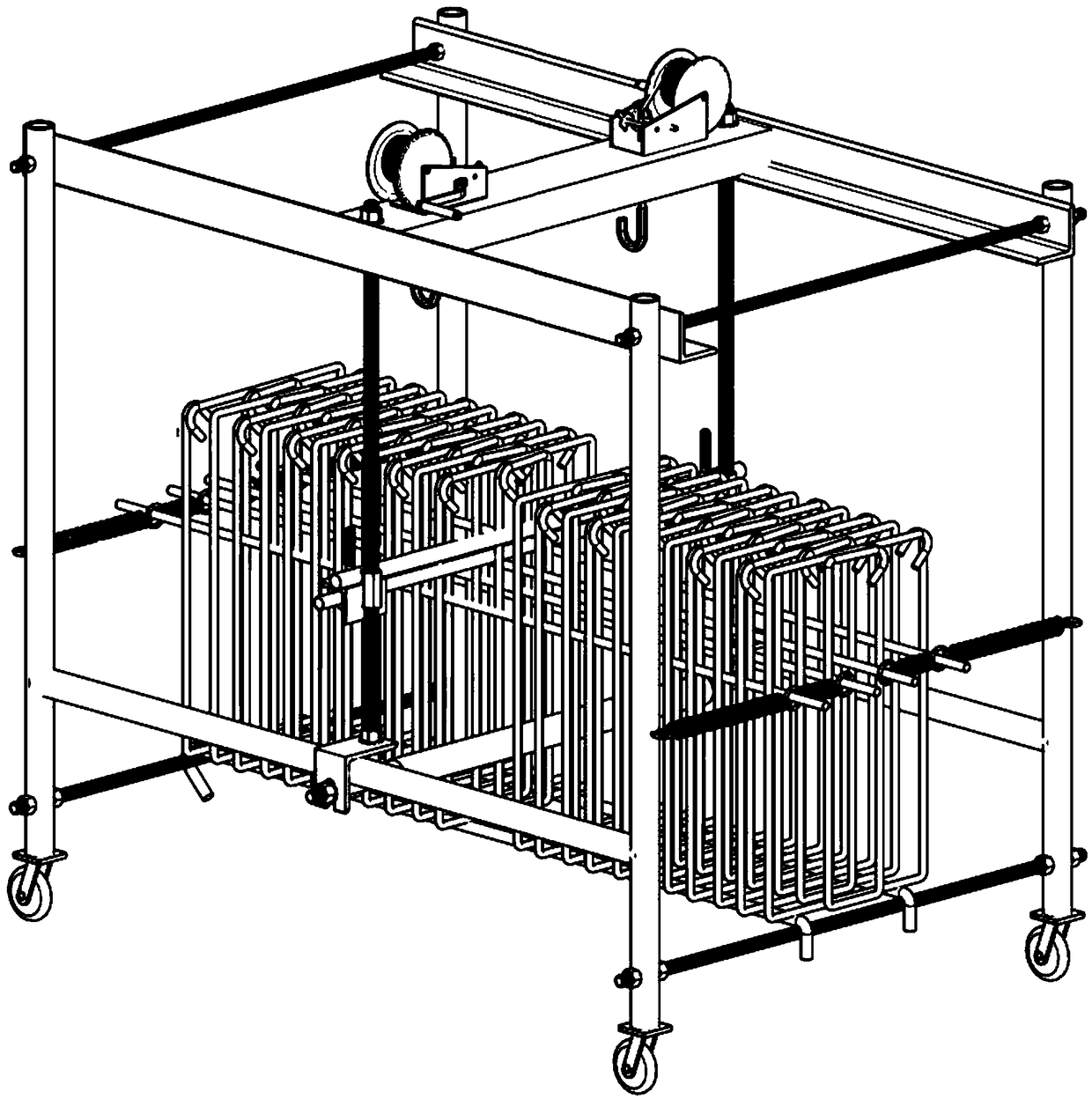

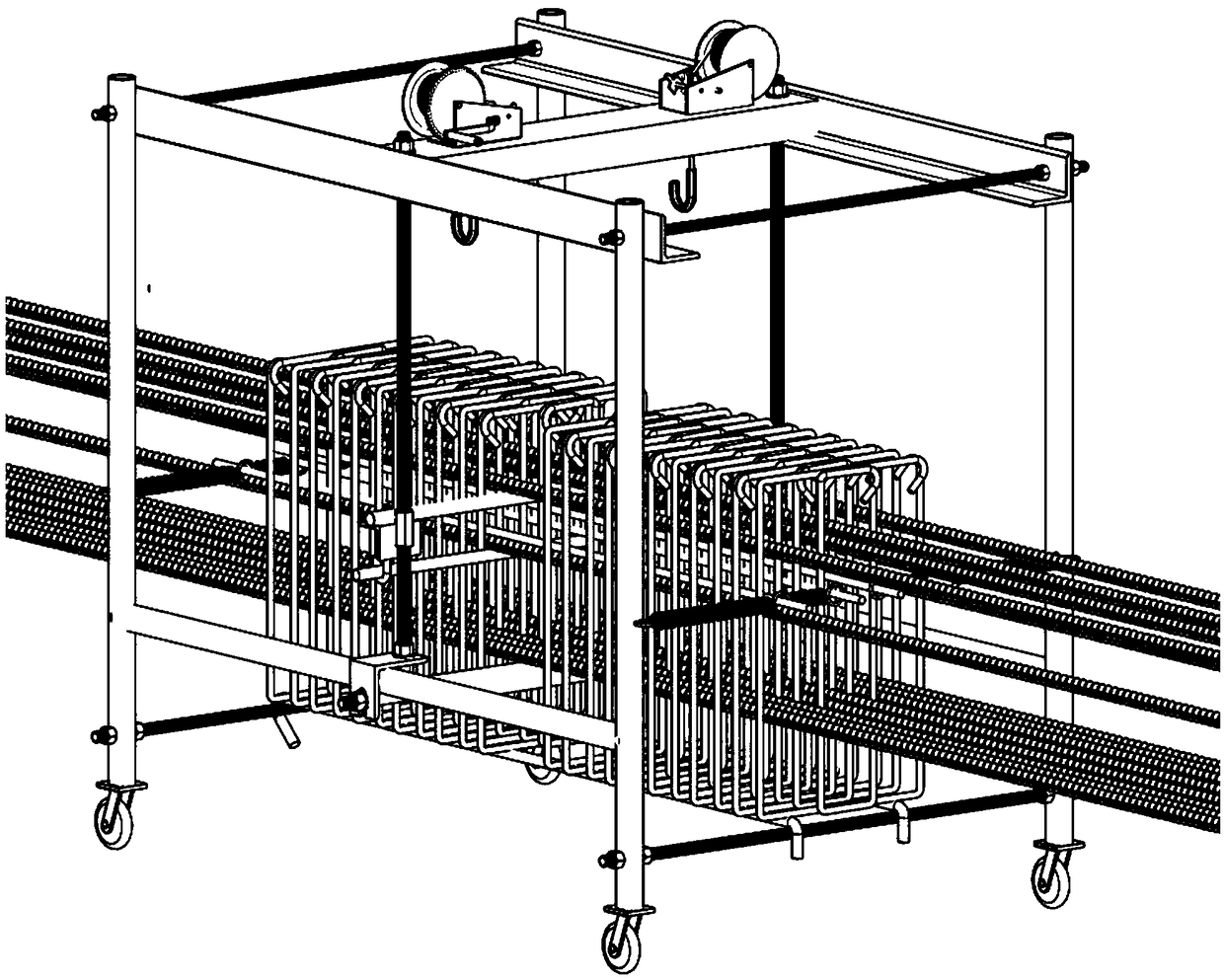

Cast-in-place beam reinforcement cage binding installation multi-function trolley

PendingCN109339458AGuaranteed installation qualityReduce labor intensityBuilding material handlingEngineeringRebar

The invention discloses a cast-in-place beam reinforcement cage binding installation multi-function trolley. The cast-in-place beam reinforcement cage binding installation multi-function trolley comprises a rectangular tubular trolley body frame extending in the front-rear direction, and openings at the front and rear ends of the trolley body frame correspond to reinforcement cage stirrups. A first transverse support, a second transverse support and a third transverse support are detachably arranged in the trolley body frame from top to bottom. The first transverse support, the second transverse support and the third transverse support separately extend in the left and right direction, and the first transverse support and the second transverse support can slide up and down synchronously. The trolley body frame is further internally provided with limiting screws corresponding to the reinforcement cage stirrups in a penetrating mode, and the limiting screws extend in the front-rear direction. A plurality of tension springs are arranged at the front and the rear ends of the trolley body frame, and the limiting screws and the tension springs are detachably connected. The cast-in-placebeam reinforcement cage binding installation multi-function trolley has the characteristics and functions of loading and transporting, stirrup pre-penetrating, skeleton binding, vertical lifting and lowering, adjustable size, flexible movement and the like and replaces traditional cumbersome processes of temporary bracket building, on-site secondary transportation, multiple times of replacing andsupporting, manual or mechanical lifting of the reinforcement cage into a mold.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

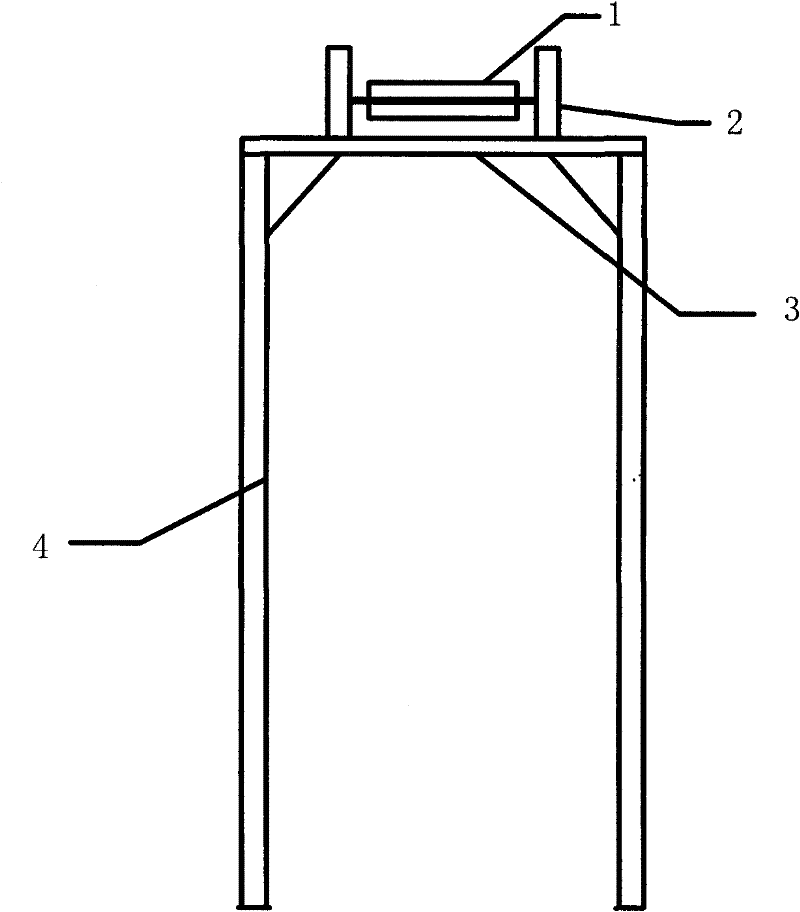

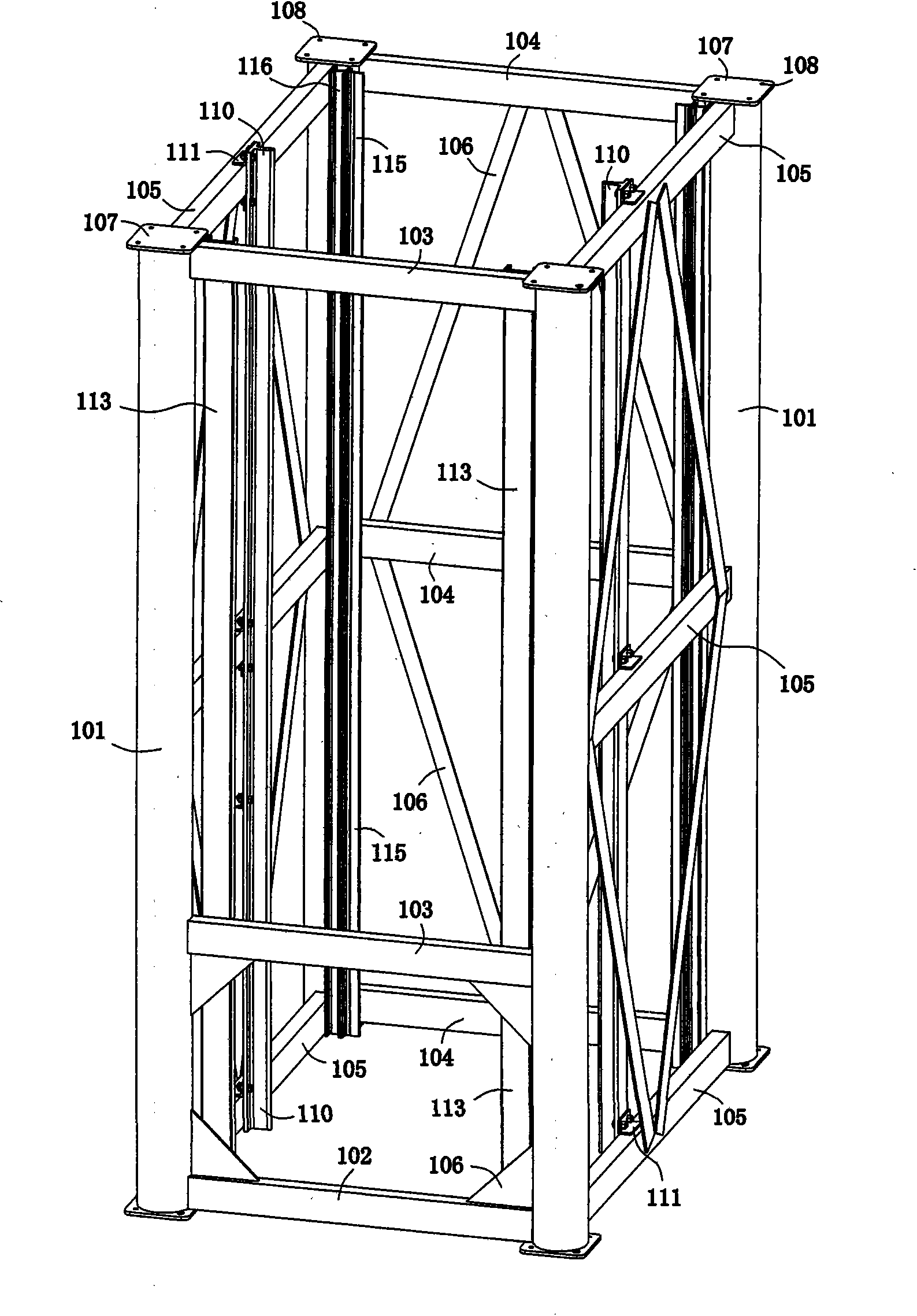

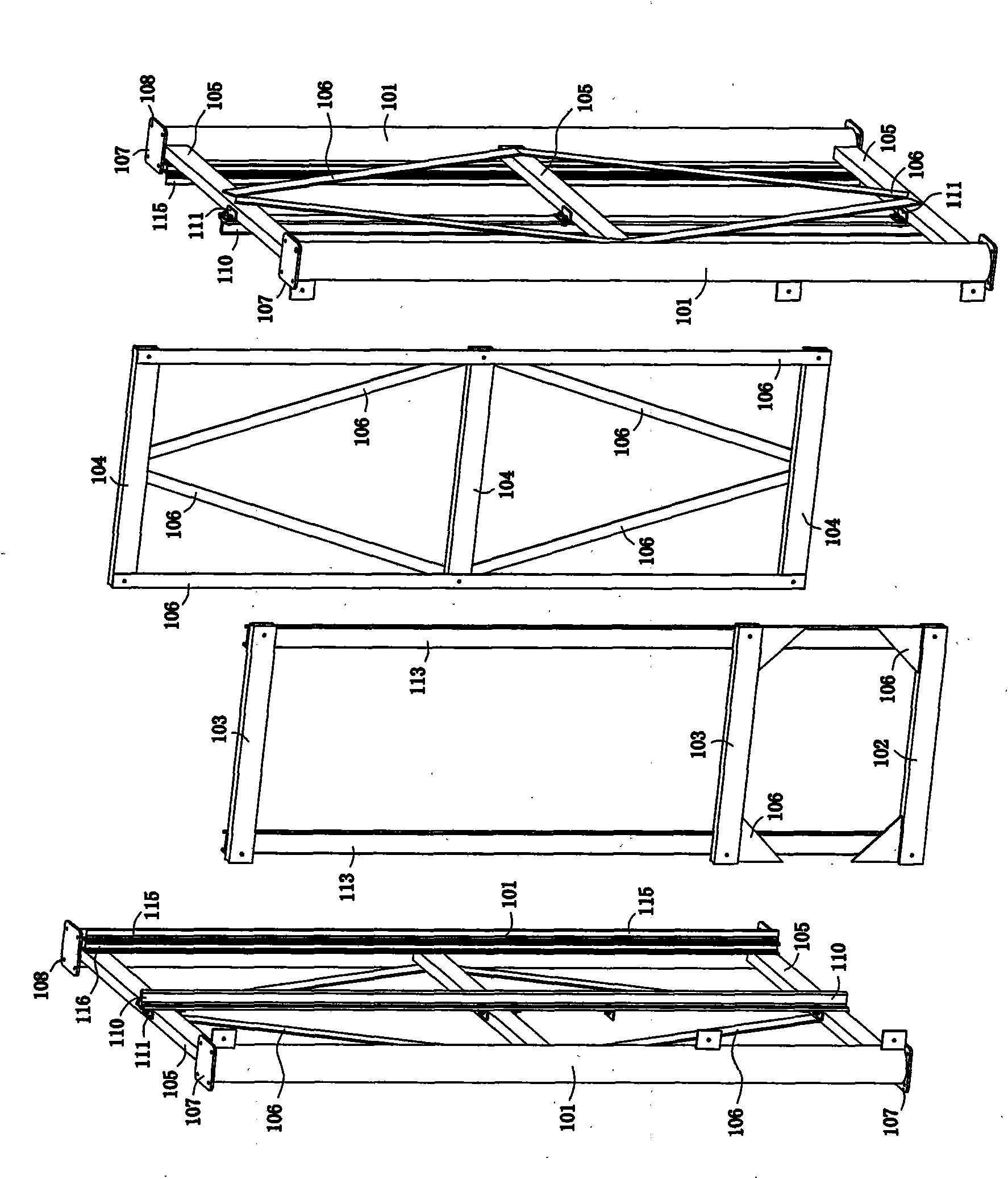

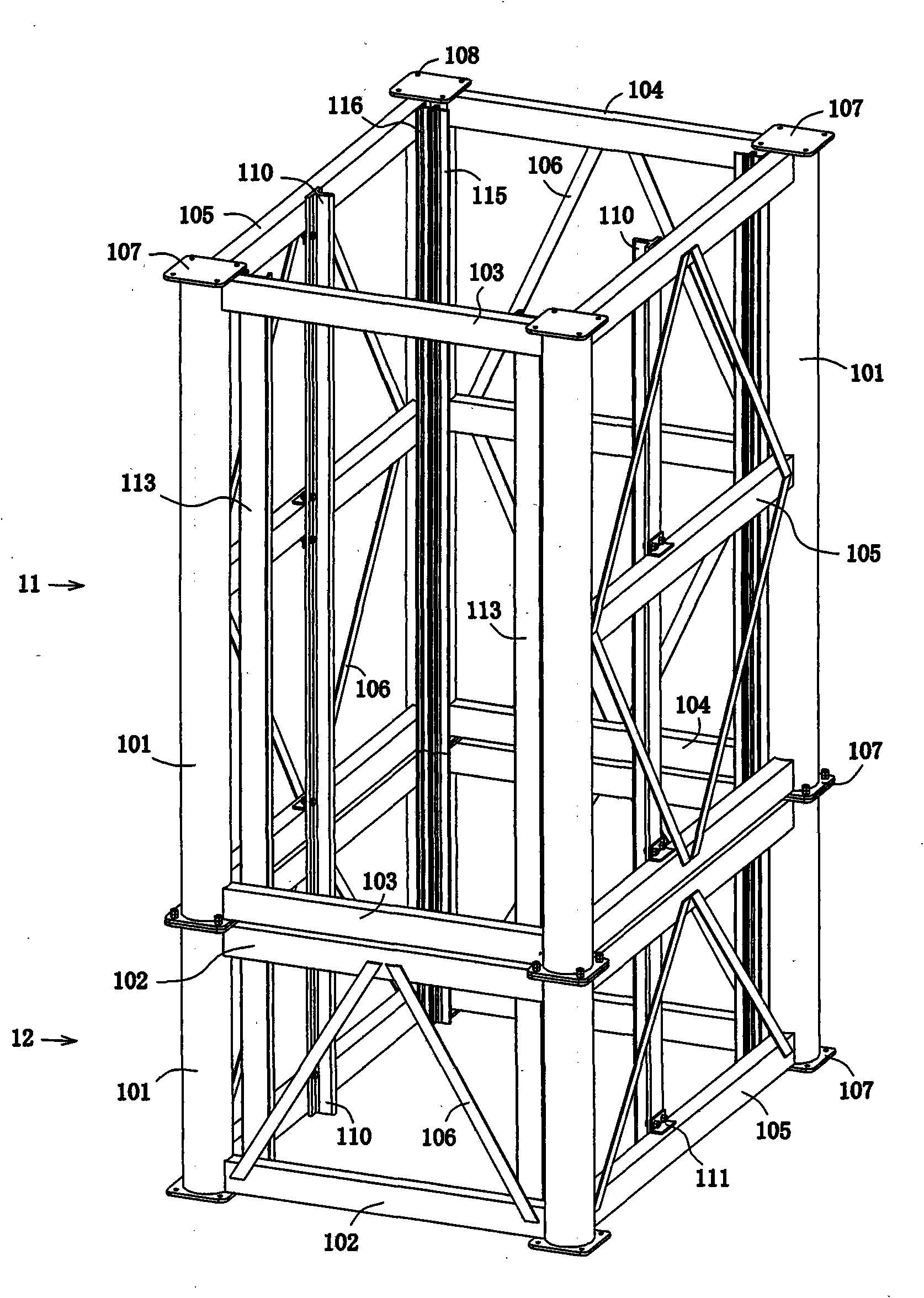

Elevator assembled by utilizing combination type derrick

InactiveCN102060222ASave the trouble of civil constructionFlexible assemblyElevatorsBuilding liftsEngineeringWork time

The invention discloses an elevator assembled by utilizing combination type derricks, relating to hoisting equipment. A hoistway wall of the elevator is formed by assembling more than two derricks, wherein each derrick comprises stand columns, a door beam, a front beam, a back beam, a left beam, a right beam, a cage guide rail and a counter-weight guide rail, wherein the four stand columns are distributed at four corners of the derrick, and connection seats are horizontally and fixedly arranged at the top end and the bottom end of each stand column and provided with connection holes; two ends of the door beam, the front beam, the back beam, the left beam and the right beam are transversely and respectively connected with the stand columns; and the cage guide rail and the counter-weight guide rail are respectively installed in the middle parts and the inner sides of the back ends of the left beam and the right beam. Because the derricks can be produced in a standardized way in a factory and assembled on site, the working time limit can be shortened, the cost can be lowered, the manufacturing cost can be reduced, and the installation efficiency and quality can be improved; and because the derricks are matched with an up-down door-opening and closing mechanism, the influence of the installed elevator on ventilation and daylighting of a household can be reduced. The elevator assembled by utilizing the combination type derricks is mainly used for places of low storey dwelling houses, in particular to the old style low storey dwelling houses of less than 9 storeys.

Owner:张向阳

Method and device for mounting rotor of large-sized synchronous motor

InactiveCN102820744AGuaranteed installation qualityNot easy to bumpManufacturing stator/rotor bodiesInsulation layerSynchronous motor

The method for mounting a rotor of a large-sized synchronous motor includes steps of heightening a stator, laying a rail used for the rotor to penetrate through, mounting a guide limiting device of a rotor front bearing seat support on the rail, mounting limiting chain blocks and the like. The device for mounting the rotor of the large-sized synchronous motor comprises the rail, the rotor front bearing seat support, the guide limiting device of the rotor front bearing seat support, a positioning device and a drawing device. When a rotor of a roughing main motor is mounted according to the method and by the device, the motor rotor and the stator are less prone to collide with each other under the action of the guide limiting device and the positioning device, insulation loss caused by damages of coil insulation layers can be avoided, and mounting process is safe and reliable, so that motor mounting quality is guaranteed.

Owner:CHINA HUAYE GROUP

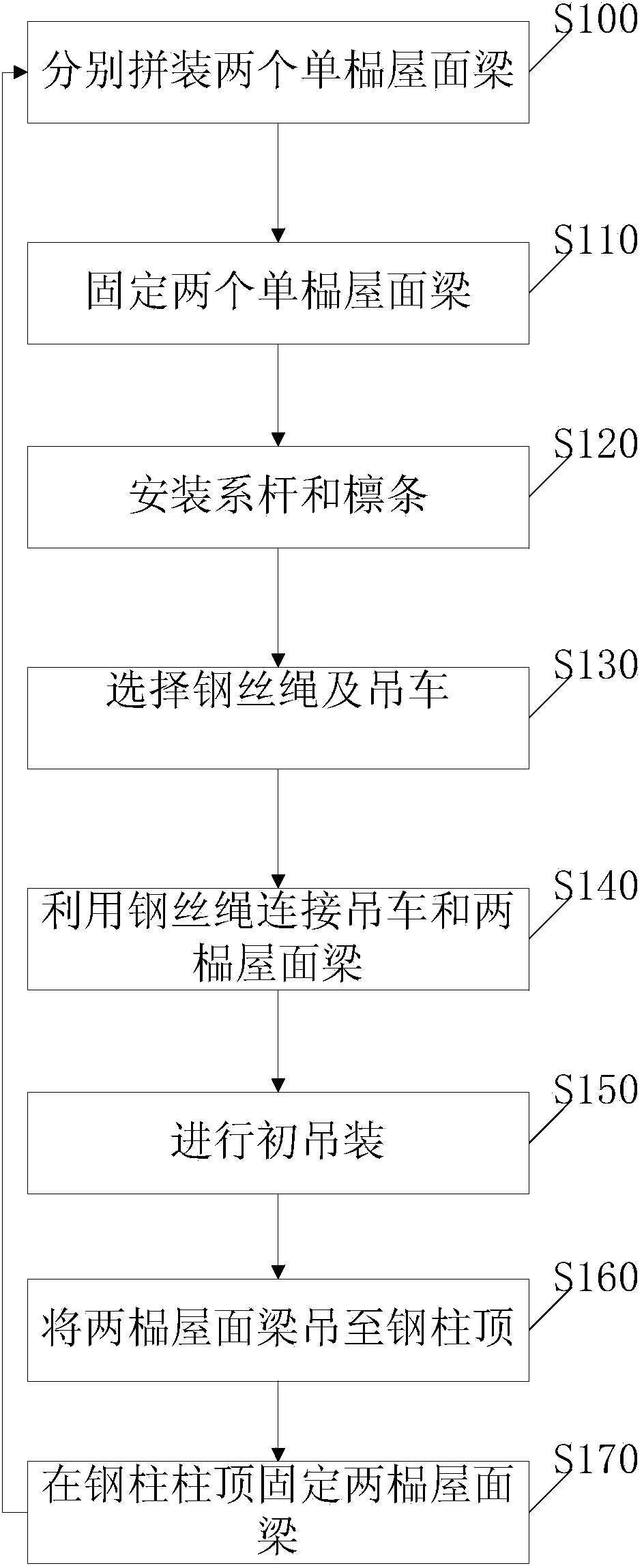

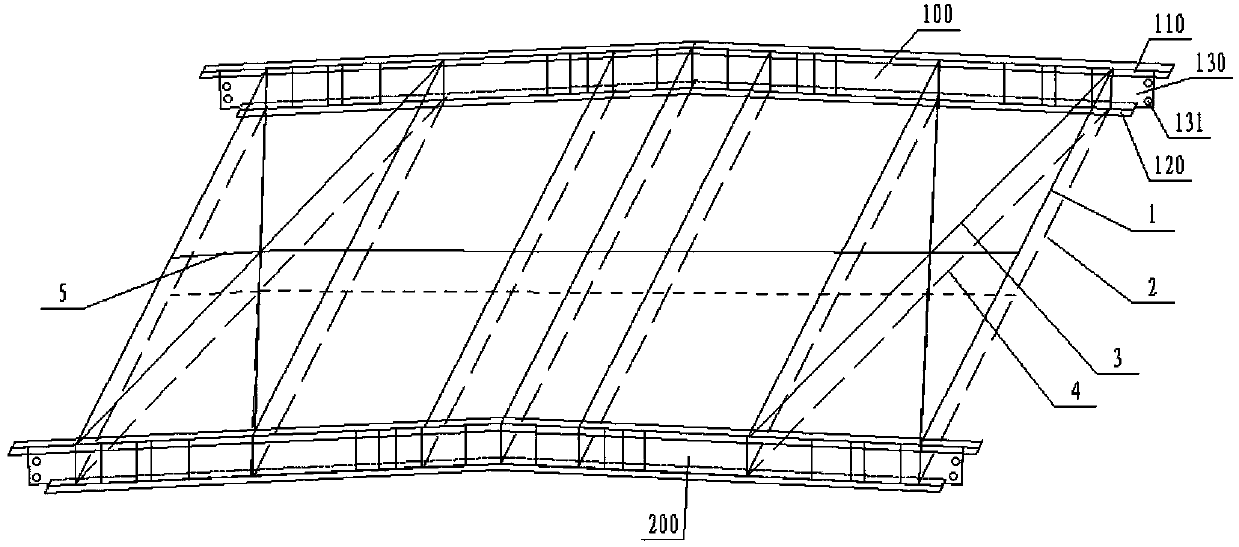

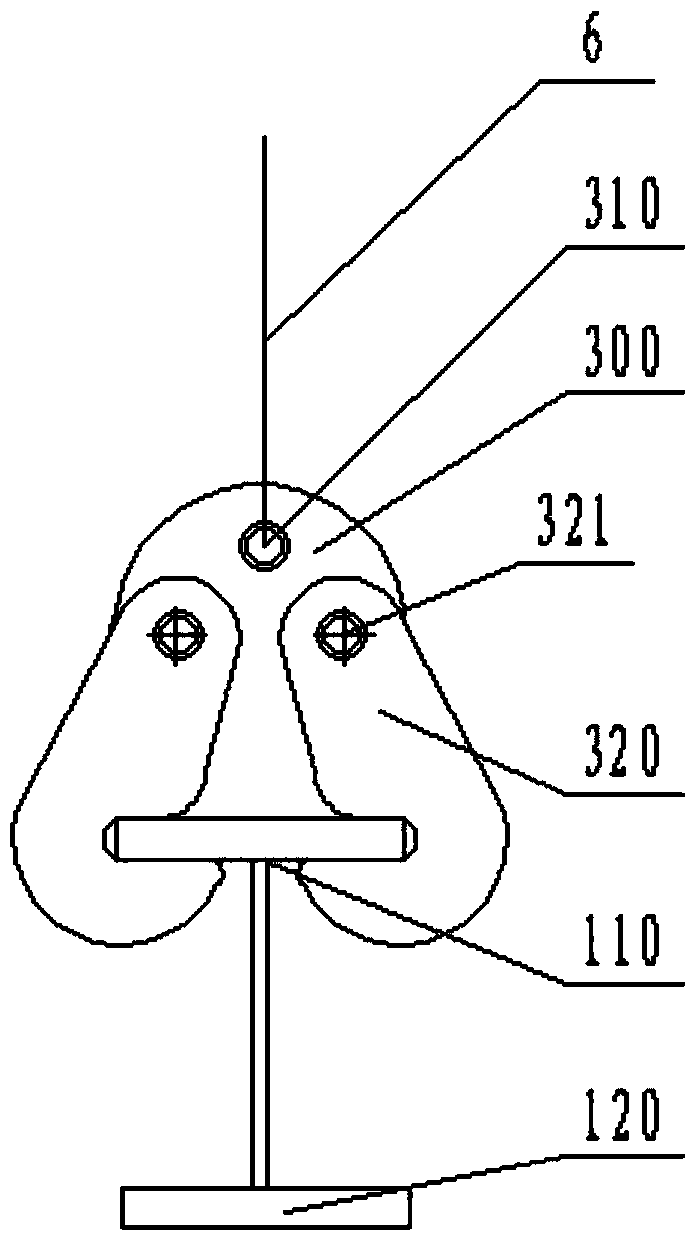

Method for installing steel structure roof beams

The invention provides a method for installing steel structure roof beams. The method includes the steps of respectively assembling two single-frame roof beams, fixing the two single-frame roof beams on a steel platform, installing tie bars and a purline on the steel platform, selecting steel wire ropes and a crane, connecting the crane with the two single-frame roof beams through the steel wire ropes, carrying out initial hoisting, after the initial hoisting is qualified, hoisting the two single-frame roof beams to the tops of steel columns, fixing the two single-frame roof beams to the tops of the steel columns, and sequentially repeating the hoisting process to complete hoisting of all the roof beams. According to the method for installing the steel structure roof beams, the tie bars and the purlines are installed on the bottom face, and the safety is high; every two single-frame roof beams are hoisted at a time, and the installation efficiency is improved.

Owner:CHINA HUAYE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com