Conveying roller mounting precision control method of roller bottom heat treatment furnace

A heat treatment furnace and installation accuracy technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large installation errors and rework of conveyor rollers, achieve precise positioning, improve installation efficiency, and ensure installation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

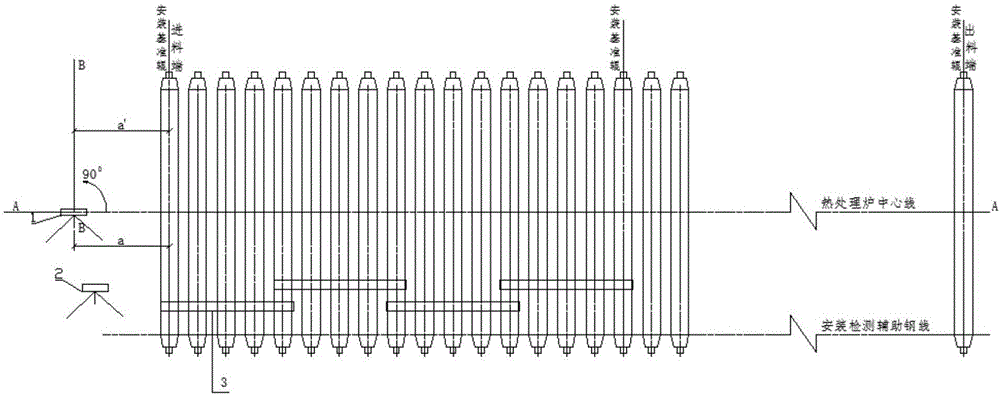

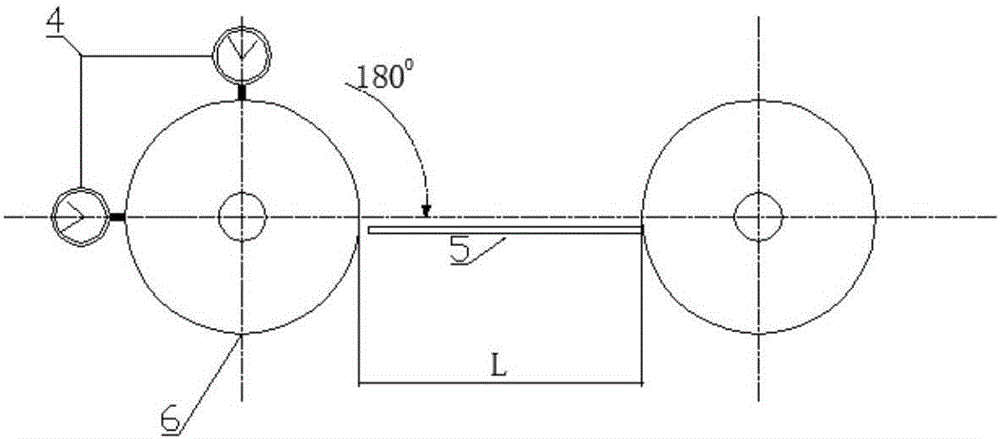

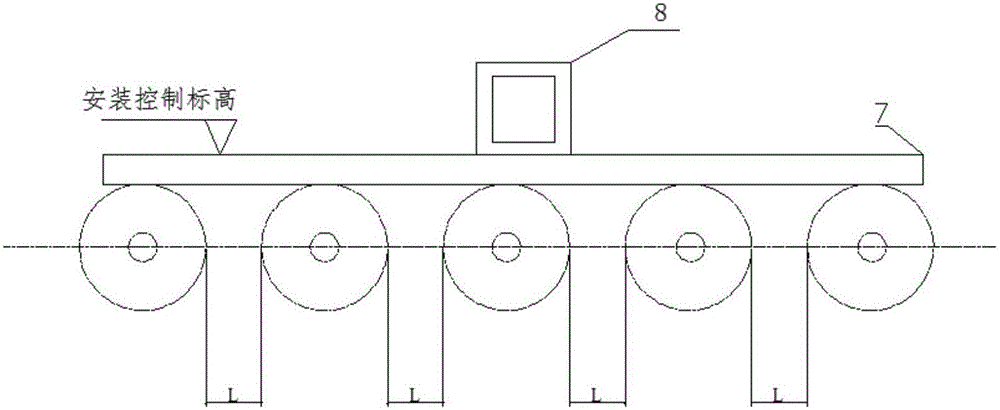

[0022] The furnace roller system used in the roller hearth heating furnace is roughly composed of furnace rollers, roller conveyor motors (with reducers), furnace roller bearing housings, couplings, water-cooled furnace roller rotary joints and other components. According to the installation reference line and the appearance size of the furnace roller bearing seat, adjust the furnace roller bearing seat in place, fix the base after leveling; and then carry out the furnace roller seat. According to the length of the furnace and the number of rollers in the furnace, the installation reference roller table should be reasonably determined. Generally, three groups of roller tables at the inlet and outlet end and the middle position are selected as the reference rollers for installation (refer to the attached figure 1 ). Adjust the accuracy of ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com