Multipolar magnetic shoe assembling device

An assembly device, multi-pole magnet technology, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of poor consistency of magnetic tile installation, small application range, low efficiency, etc., and achieve the effect of good consistency and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

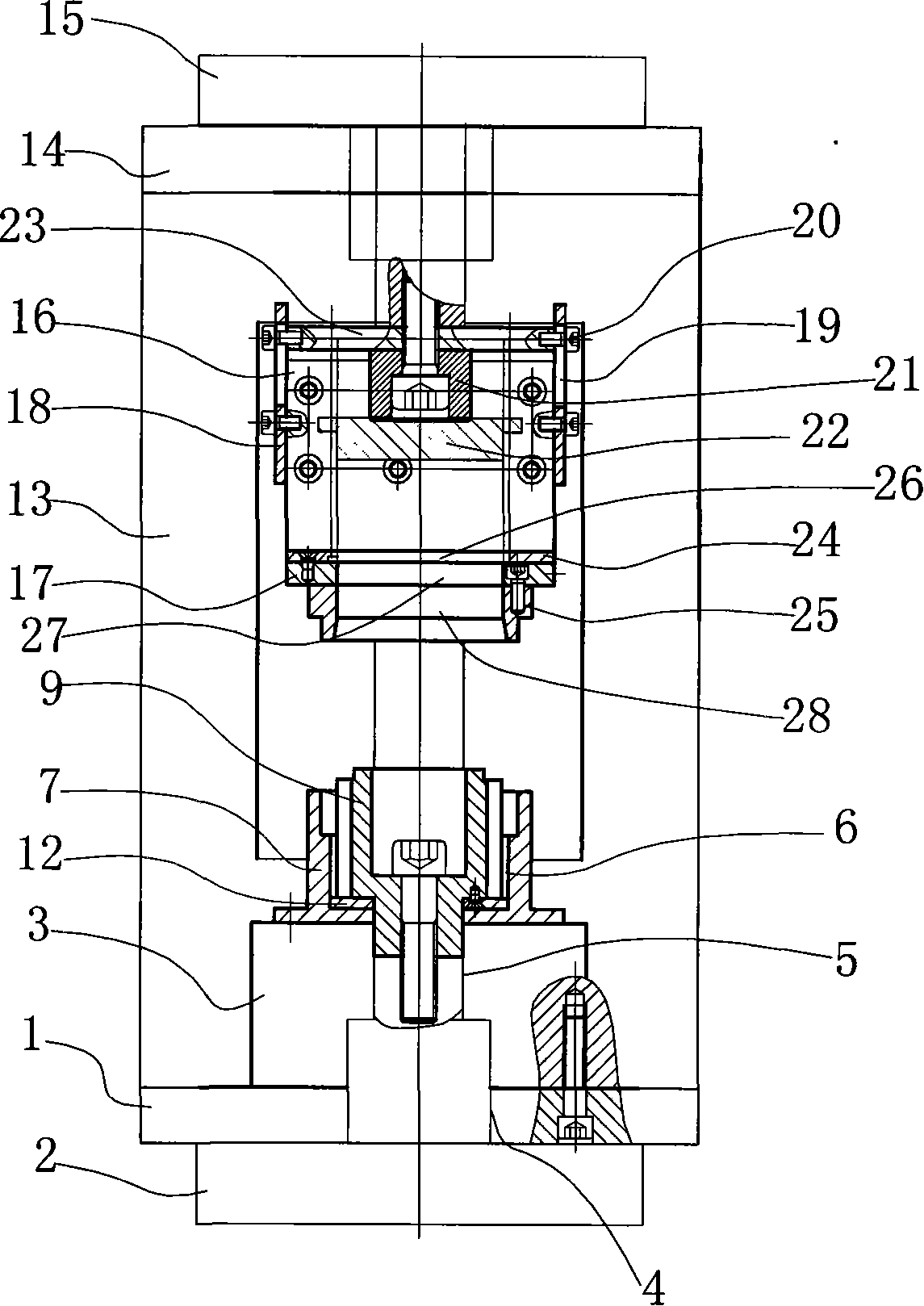

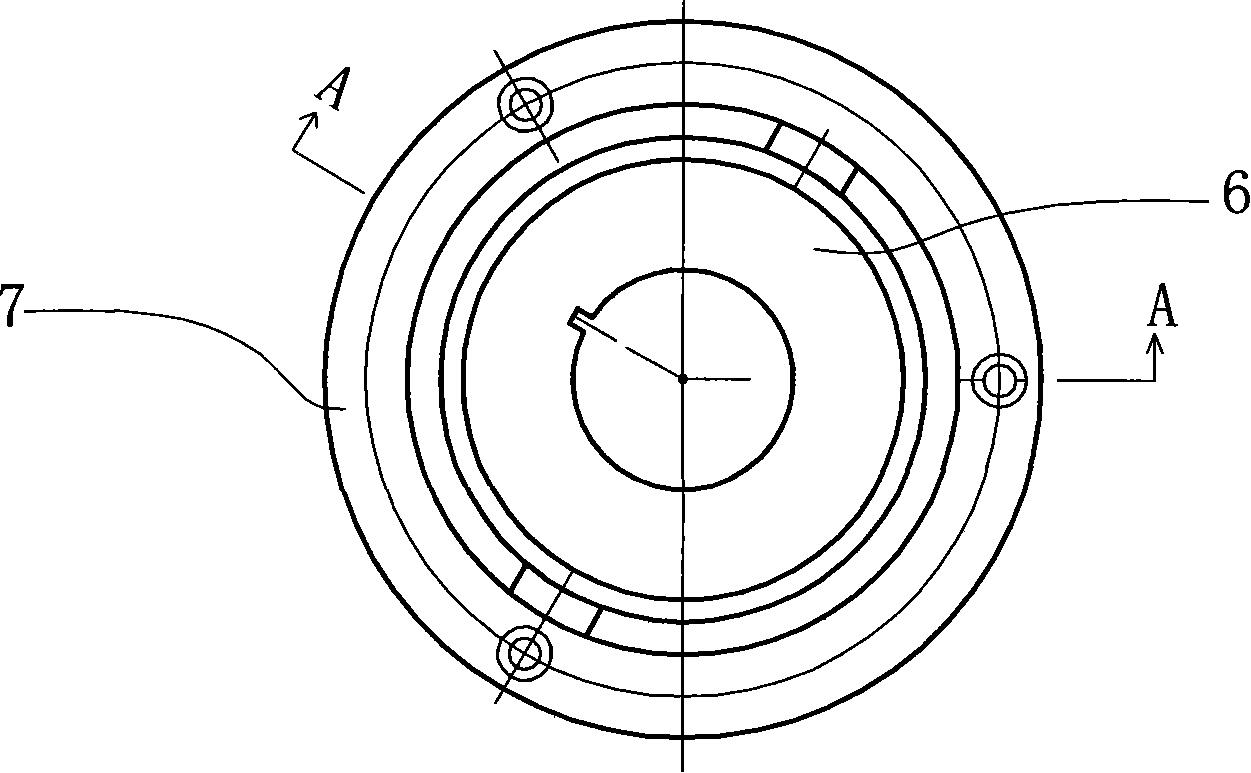

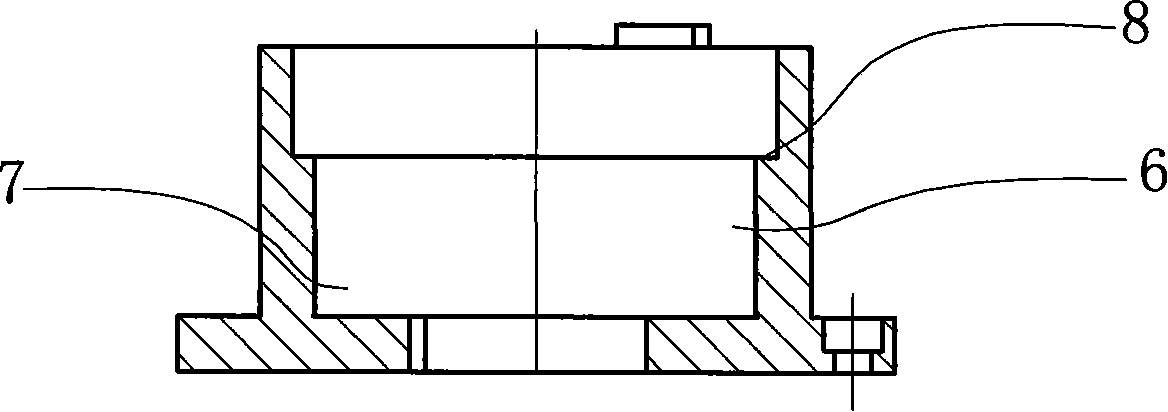

[0021] Embodiment 1: as figure 1 As shown, the lower side of the lower backing plate 1 is provided with a lower cylinder 2, and the center of the upper side of the lower backing plate is provided with a spacer 3, and the lower backing plate 1 and the spacer 3 are respectively provided with a coaxial shaft for the piston rod of the lower cylinder 2 to pass through. The center hole 4 and the center hole 5 passed through, and the positioning seat 7 with the center hole 6 is provided on the upper side of the pad 3, the center hole 6 of the positioning seat 7 is connected with the center hole 4 and the center hole 5 of the lower backing plate 1 and the pad 3 coaxial; as figure 2 and image 3 As shown, the inner wall of the center hole 6 of the positioning seat 7 is formed with an annular inner step 8 with a larger inner diameter at the upper end and a smaller inner diameter at the lower end.

[0022] The central hole 6 of the positioning seat 7 is provided with a positioning cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com