Patents

Literature

2138results about How to "Fast installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

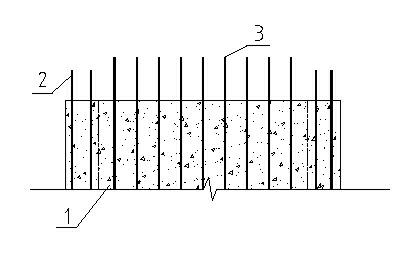

Assembly-type residential shear wall structural wall body vertical connection construction method

ActiveCN102425310AReduce the number of connectionsReduce construction costsBuilding material handlingHigh pressureRebar

The invention relates to a prefabricated shear wall body vertical connection construction method, in particular to an assembly-type residential shear wall structural wall body vertical connection construction method, which is characterized in that: when a prefabricated lower layer wall body is connected with a prefabricated upper layer wall body, supporting leg parts on two ends of the bottom part of a shear wall body are connected with each other through a reinforced bushing anchoring grouting method, and preformed steel reinforced parts on the middle part of the shear wall are connected with each other through a binding and overlapping method. When an upper layer wall body is prefabricated, anchoring connection bushings are respectively embedded on the supporting leg parts on two ends of the shear wall, the middle part of the shear wall is produced into a feeding passage for pouring concrete at a later period by embedding a steel bushing, self-compacting concrete is poured towards the middle part of the shear wall from a feeding port on the top part of the feeding passage, and high-strength grouting materials are fulfilled into the anchoring connection bushing at high pressure through a high-pressure grouting machine. Due to the adoption of the method, the quantity of the connection bushing can be reduced, the cost can be saved, and the connection quality and the connection speed can be improved. The weaknesses of the traditional shear wall vertical connection installation process that the cost is high, the construction speed is slow, the quality is difficult to control, and the like can be overcome.

Owner:CHINA 22MCC GROUP CORP +1

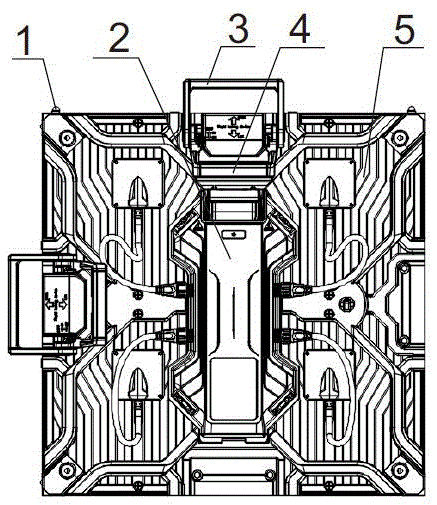

Waste metal treatment equipment

ActiveCN106945334ARealize automatic controlImprove work efficiencySolid waste disposalPressesCompression deviceEngineering

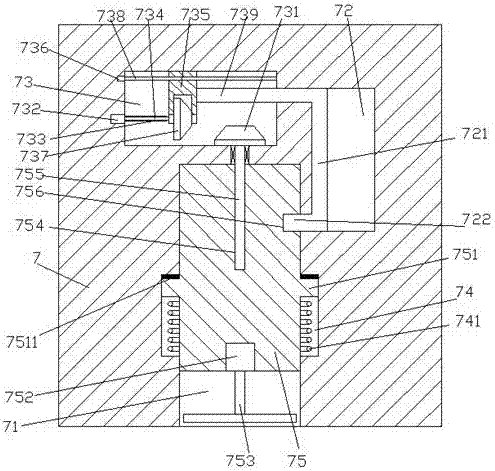

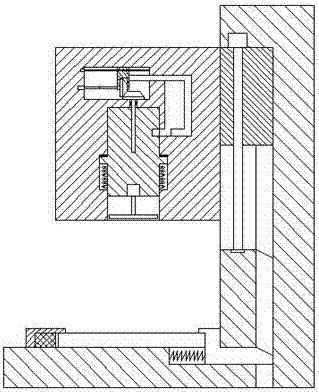

The invention discloses waste metal treatment equipment. The waste metal treatment equipment comprises a frame body composed of a working platform and a pillar body and a compression device arranged in the frame body; the end face of the bottom of the compression device is internally provided with a compression sliding transport slot, the position, above the compression sliding transport slot, of the compression device is internally provided with a transmission cavity, the position, on the right side of the top of the compression sliding transport slot, of the compression device is internally provided with a locking cavity extending upwards, and the extending portion segment at the top of the locking cavity is located on the right side of the transmission cavity; the inner side wall of the compression sliding transport slot is provided with a guide slot, the compression sliding transport slot is internally connected with a compression sliding transport block in a sliding transport fit manner, the end face of the top of the compression sliding transport block is internally provided with a spiral hole, and the spiral hole is internally in fit connection with a spiral rod; and the guide slot is internally provided with a protruded block, the side, close to the compression sliding transport block, of the protruded block is fixedly connected with the compression sliding transport block, and the right side end face of the compression sliding transport block above the protruded block is internally provided with a locking slot. The waste metal treatment equipment is simple in structure, convenient to operate and high in work efficiency and safety, and quality is improved.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

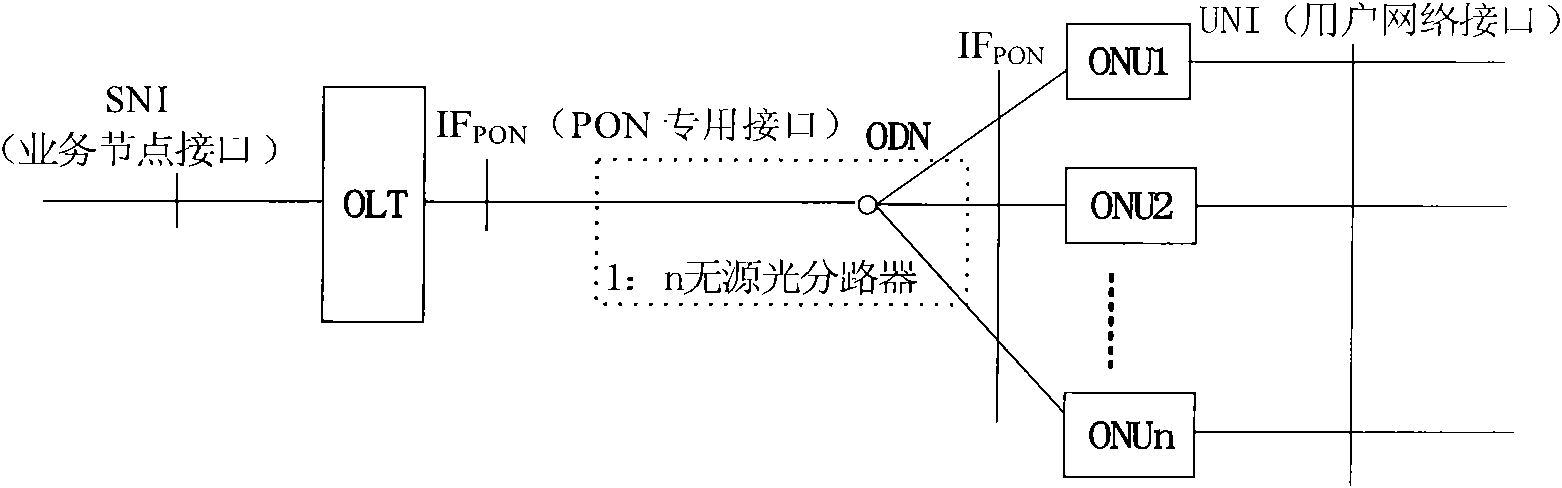

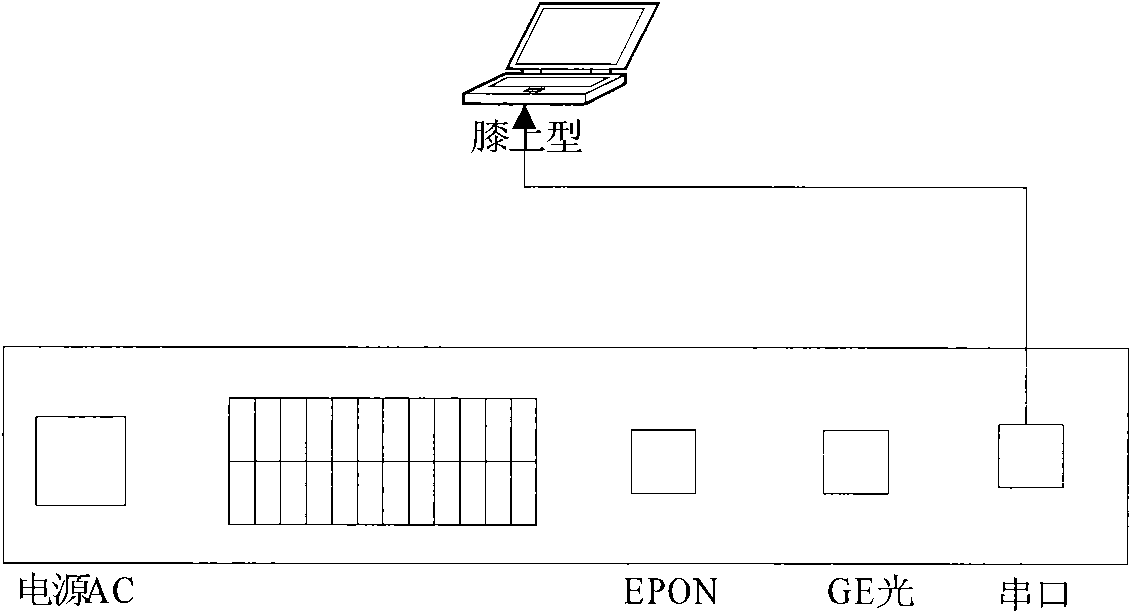

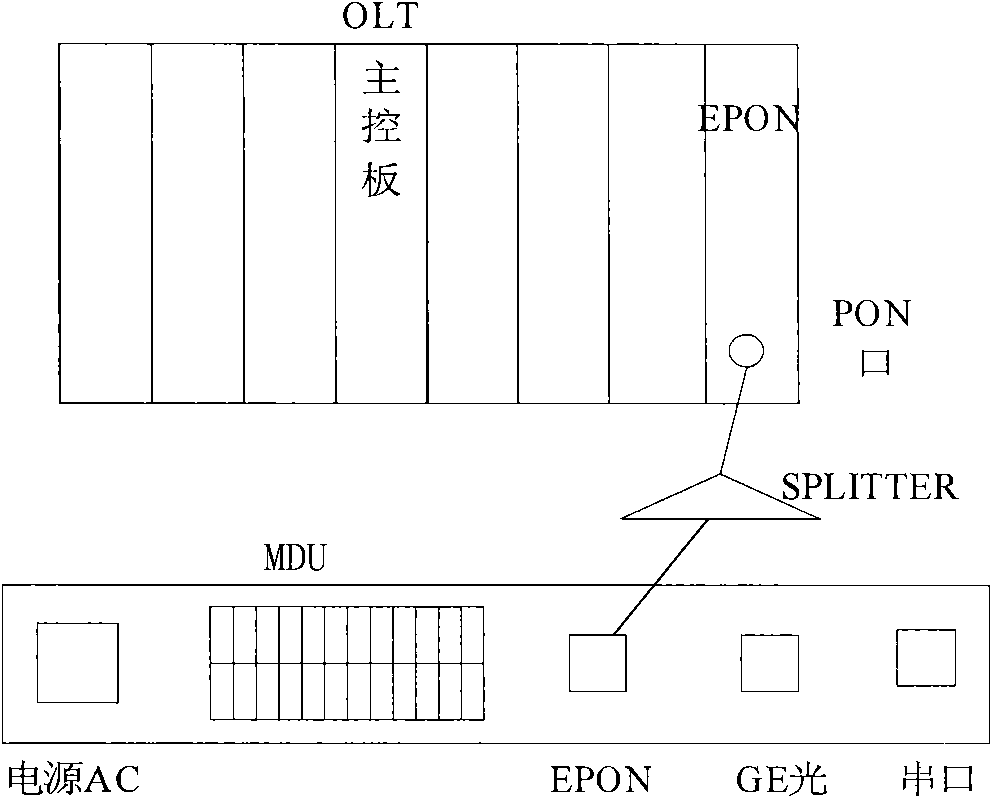

Method, device and system for building management and maintenance channel in passive optical network system

InactiveCN101594250ASolve the shortcomings of not being able to open the maintenance channelImprove satisfactionTime-division multiplexData switching by path configurationNetwork managementData error

The invention discloses a method, a device and a system for building a management and maintenance channel in a passive optical network system. The method of the invention comprises the following steps: configuration information transmitted by a network management equipment is received, and the configuration information comprises a first configuration information and a second configuration information; according to the first configuration information, a management and maintenance channel between an optical line terminal and the network management equipment is built; the second configuration information is transmitted to a customer premises equipment; and the second configuration information is used for building a management and maintenance channel between the optical line terminal and the customer premises equipment. The method lowers soft cost for installing equipment, lowers complexity of installing new equipment, improves customer satisfaction, needs no on-site data configuration, reduces the probability of configuration data errors and improves equipment installation speed; in addition, the method is simple to replace equipment, needs no on-site re-configuration of data, and reduces maintenance cost.

Owner:HUAWEI TECH CO LTD

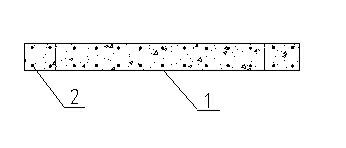

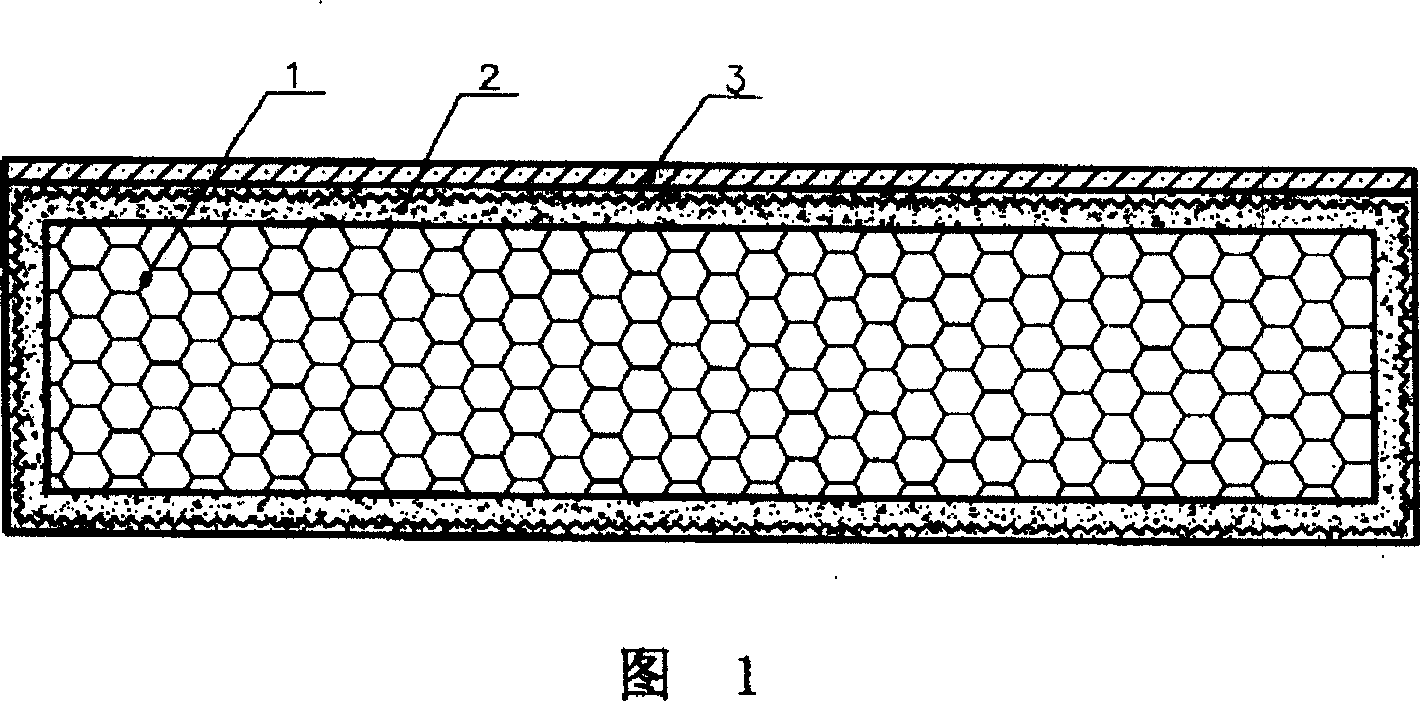

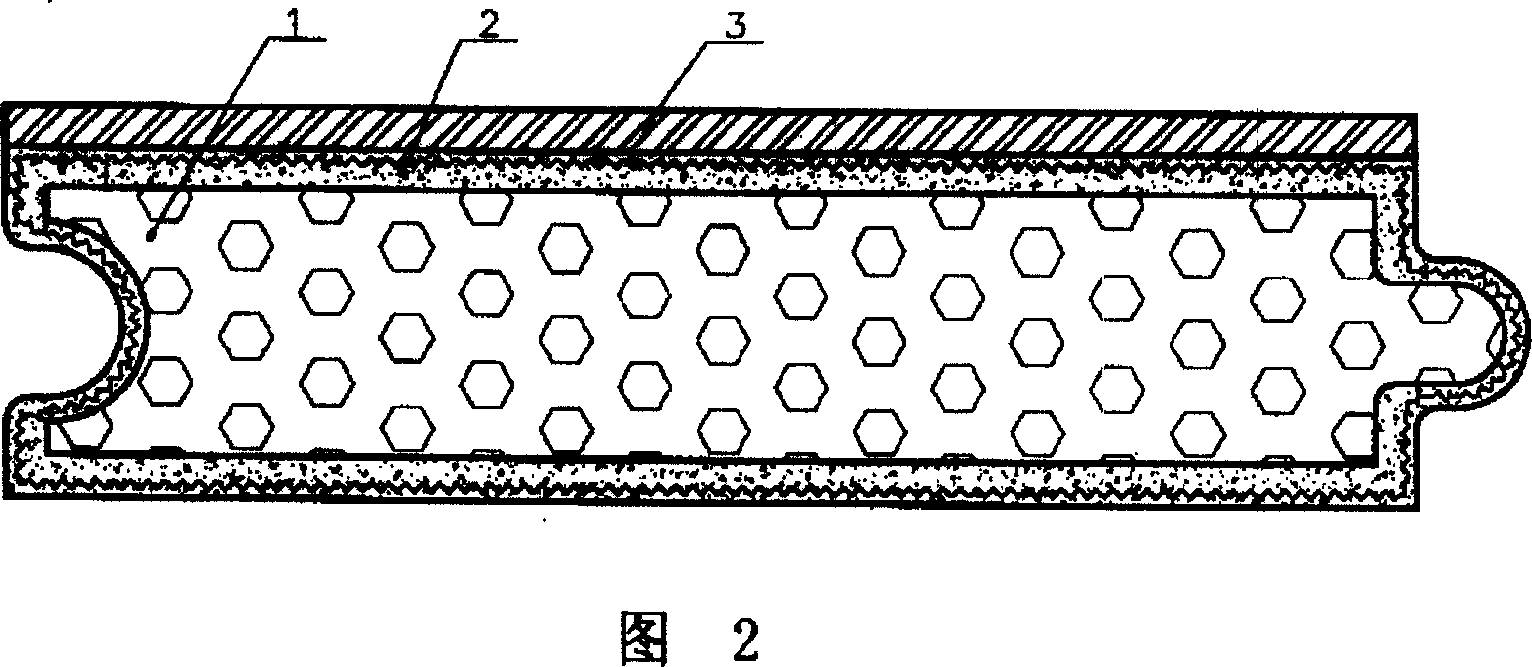

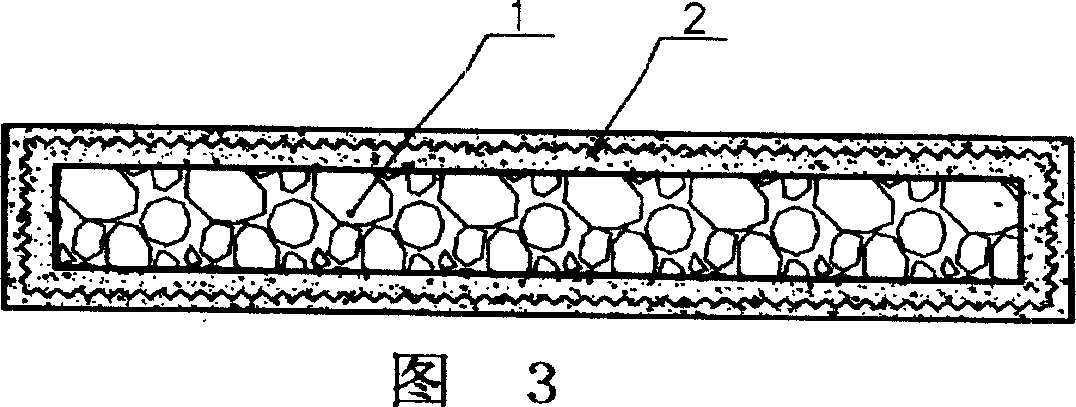

Composite heat insulation plate

InactiveCN101050644AHigh strengthImprove insulation effectCovering/liningsHeat proofingEngineeringUltimate tensile strength

The present invention relates to a composite heat-insulating plate. It is mainly formed from heat-insulating layer and reinforced protection layer. It is mainly characterized by that said reinforced protection layer is set on the outer side of heat-insulating layer. Said reinforced protection layer can at least cover upper and lower two surfaces and left and right two side surfaces of said heat-insulating layer, said reinforced protection layer and heat-insulating layer are connected into one body, and on the reinforced protection layer a finishing coat can be made up.

Owner:戴长虹

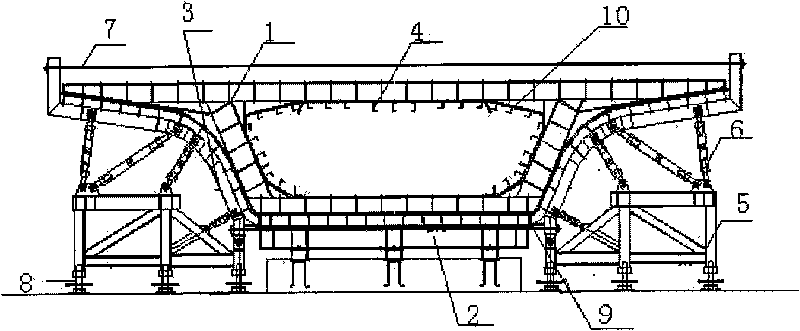

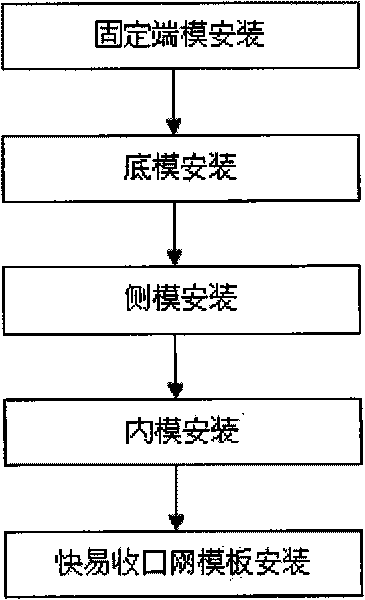

Process for mounting template for manufacturing sectional box girders

ActiveCN101713168AStreamlined productionReduce mistakesForms/shuttering/falseworksBridge erection/assemblyAgricultural engineeringBox girder

The invention discloses a process for mounting a template for manufacturing sectional box girders. The mounting process comprises the following steps: (1) mounting a fixed end die; (2) mounting a bottom die; (3) mounting a side die; (4) mounting an inner die; and (5) mounting a fast-easy closing-up net template. The mounting process obtained according to the technical scheme can quickly mount the template precast by matching long lines and short lines so as to streamline the production of the sectional box girders, facilitates the control of the measurement in the whole mounting process, ensures that the mounting speed is high, shortens the construction period, greatly reduces the error of the sectional box girder manufacturing process, and improves the yield of the whole sectional box girder manufacture so as to improve the quality of manufacturing the sectional box girders.

Owner:CCCC THIRD HARBOR ENG

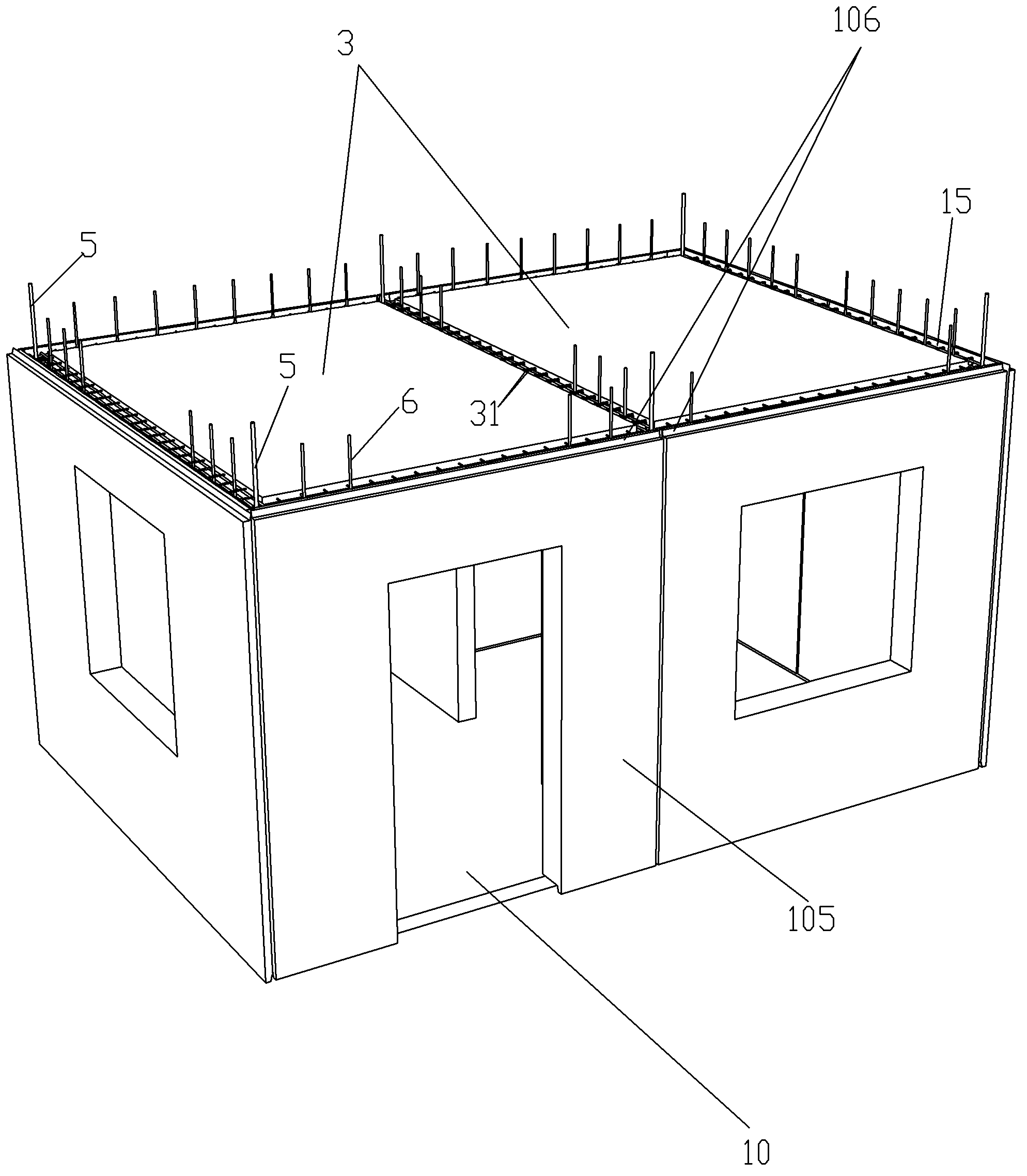

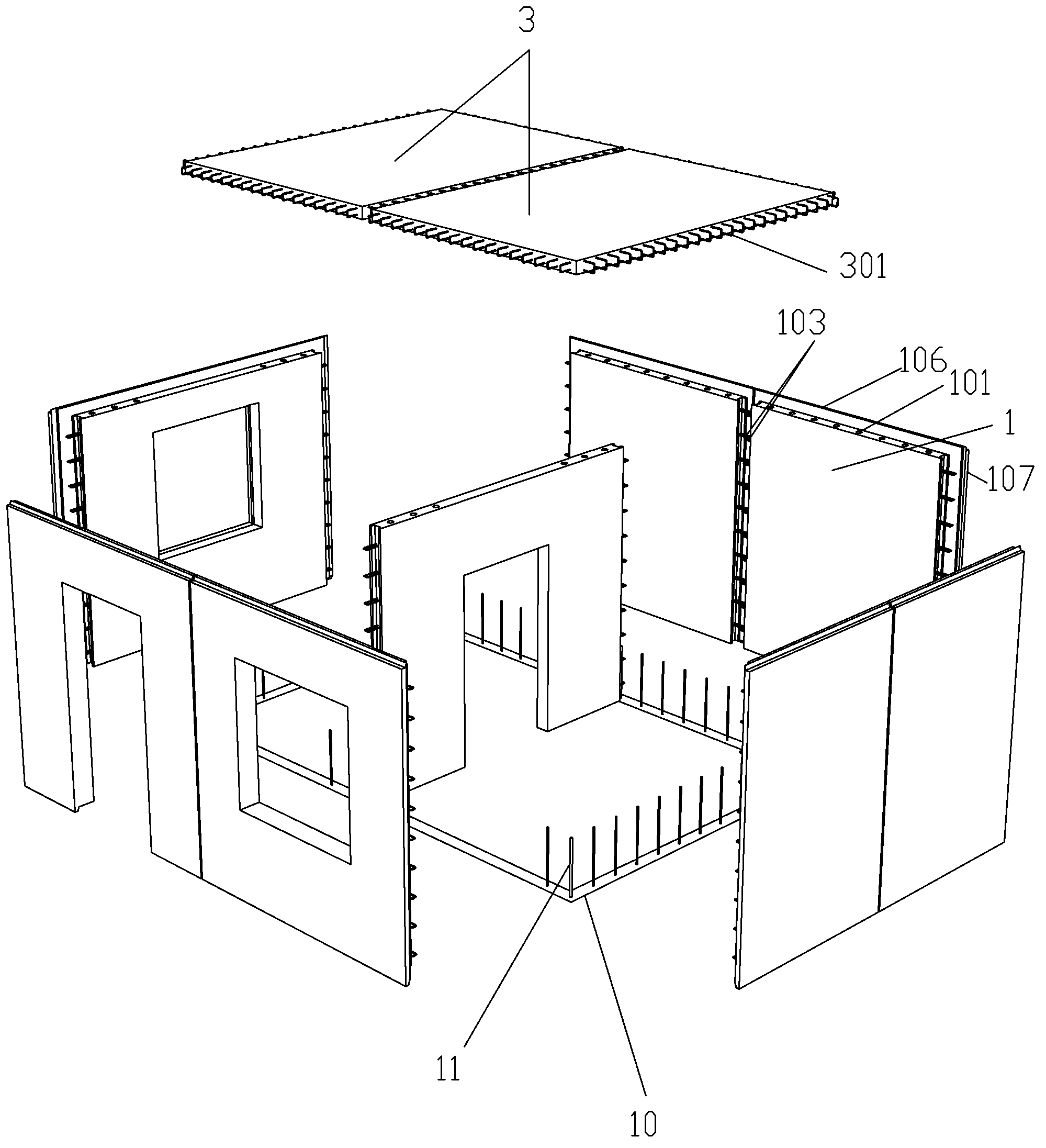

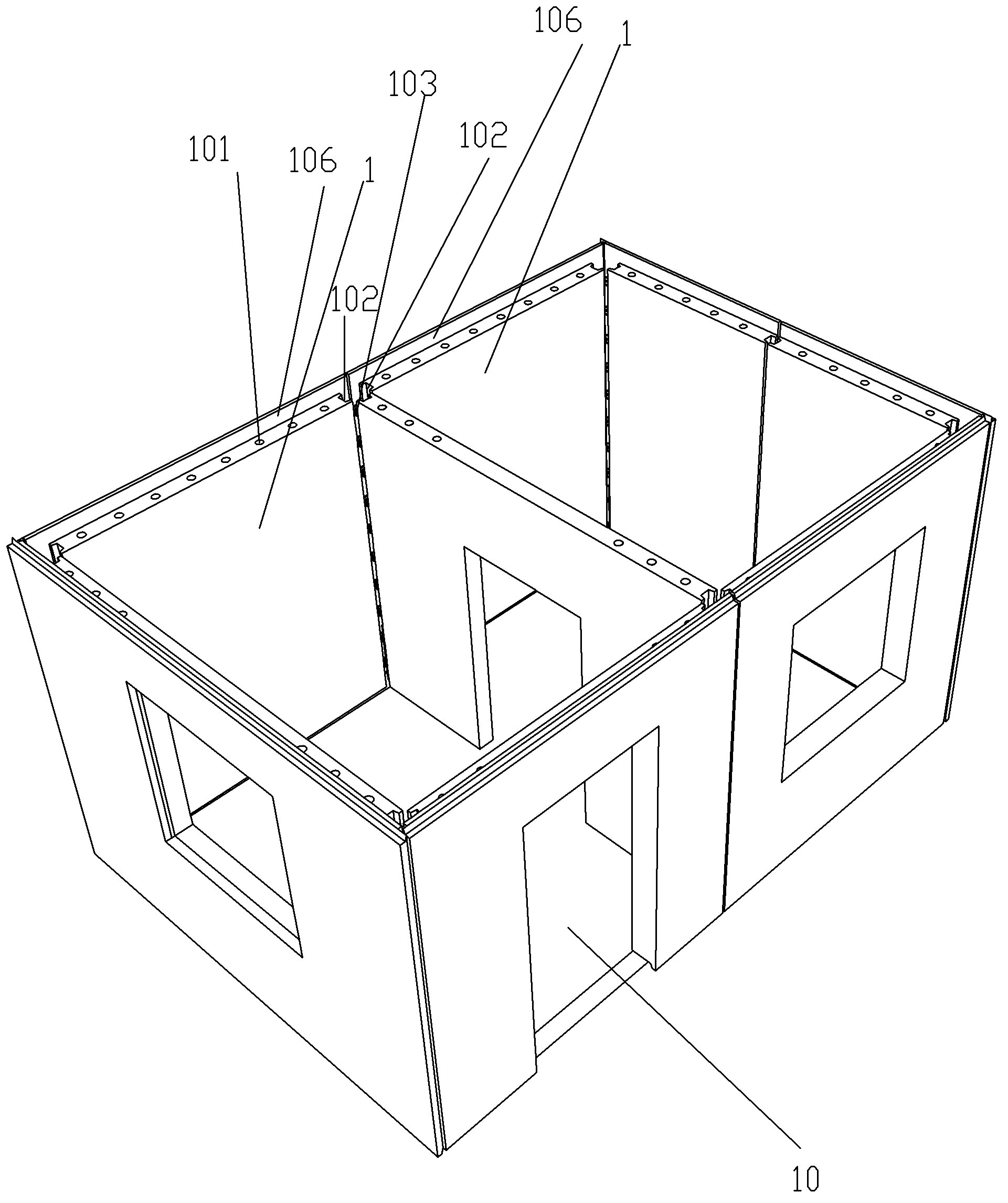

Prefabricated house wallboards, fully prefabricated house using wallboards, and installation method for fully prefabricated house

InactiveCN102535738AImprove connection strengthFast installationWallsBuilding material handlingAgricultural engineeringWall plate

Owner:广东乐而居建筑科技有限公司

Mounting method for steel anchor beam of cable-stayed bridge and assembly jig and cable bent tower mounting platform used in method

ActiveCN103243654AImprove installation accuracyFast installationBridge erection/assemblyAssembly lineCable stayed

The invention discloses a mounting method for a steel anchor beam of a cable-stayed bridge and an assembly jig and a cable bent tower mounting platform used in the method. The steel anchor beam and steel corbels are preassembled on the steel anchor beam assembly jig, a hoist is used for replacing the steel anchor beam to hoist the steel corbels and the assembly jig integrally, the steel corbels are positioned and mounted through the steel anchor beam cable bent tower mounting platform on a cable bent tower, and the steel anchor beam is assembled. According to the mounting method for the steel anchor beam of the cable-stayed bridge and the assembly jig and the cable bent tower mounting platform used in the method, construction costs are saved, construction processes are simple and convenient, and accurate adjustment and positioning is facilitated.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Volatile flux measuring device and method for volatile organic compounds of pollution site

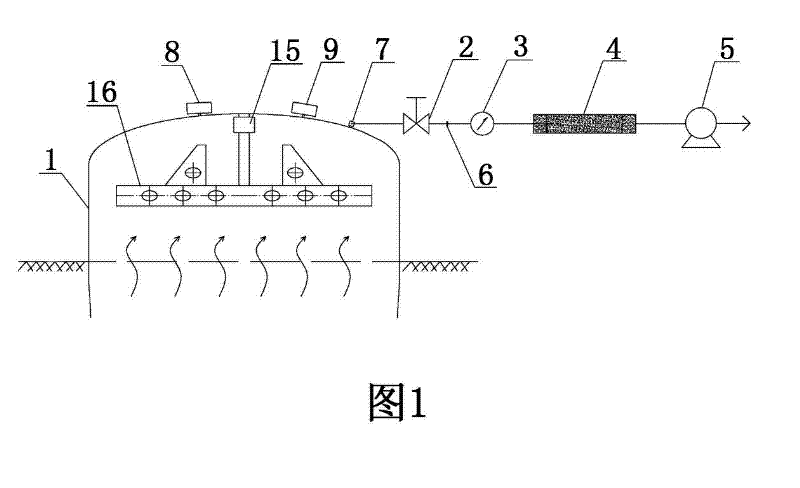

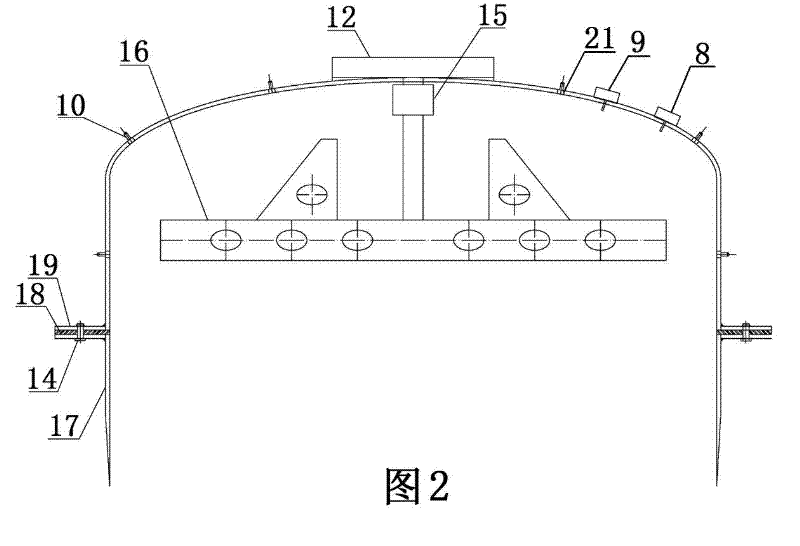

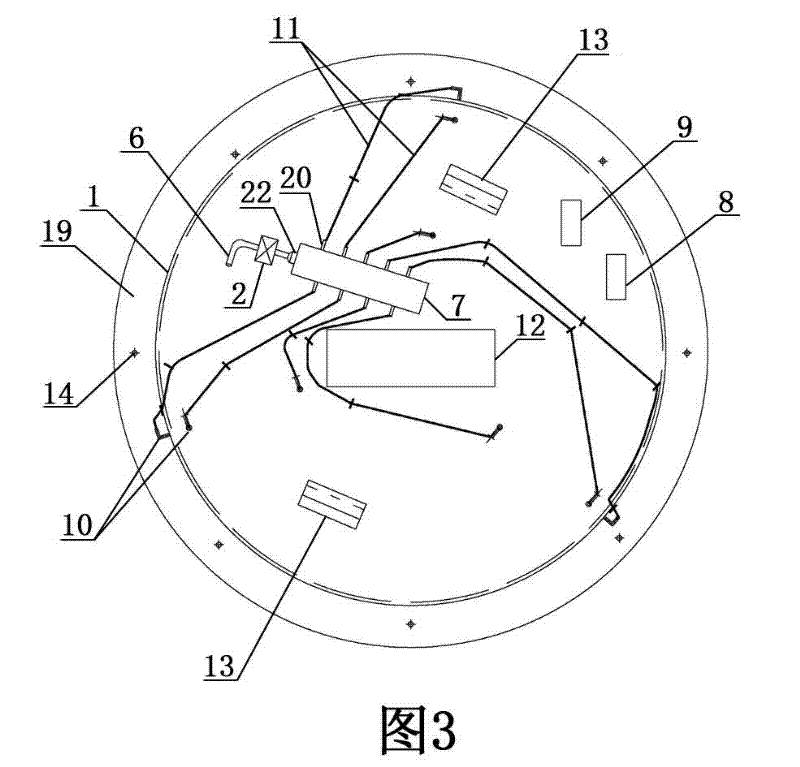

ActiveCN102243225AWell mixedThe test result is accuratePreparing sample for investigationEarth material testingPollutionVolatile organic compound

The invention provides a volatile flux measuring device and method for volatile organic compounds of a pollution site. The device comprises a flux test cavity, wherein the flux test cavity is in a cylindrical structure with a closed top and an open bottom; a gas mixer, a power supply box, a pressure meter and a thermometer are connected with the external part of the flux test cavity; a plurality of air inlets are formed on the gas mixer, and the air inlets are connected with sampling holes, which are distributed all over the flux test cavity, through sampling tubes; an air outlet of the gas mixer is sequentially connected with an adjusting valve, a flowmeter, a sample collecting tube and a sampling pump through pipelines; and the measurement end of the pressure meter and the measurement end of the thermometer extend to the inside of the flux test cavity. The device and method can directly measure the volatile flux of volatile organic compounds in the site on site, and has the advantages of simple structure, accurate detection result and low cost, and is convenient to mount.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

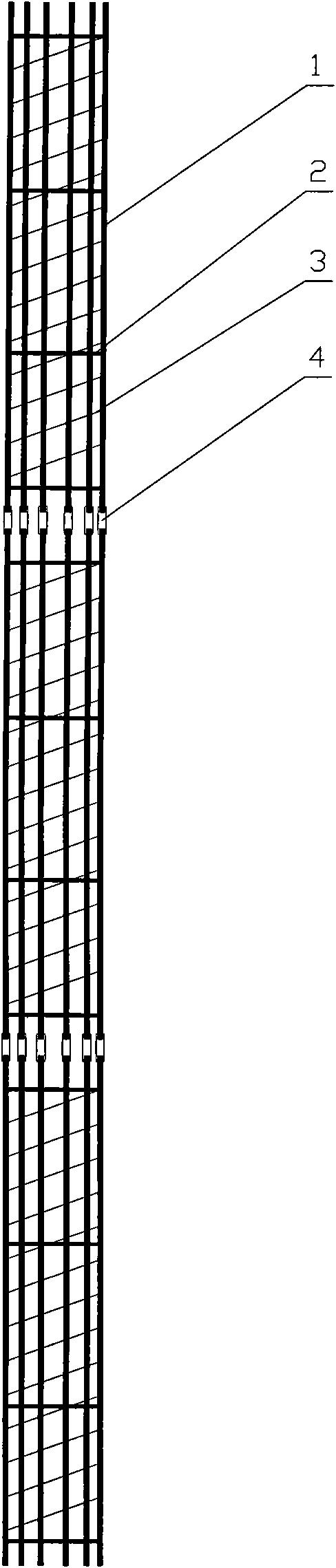

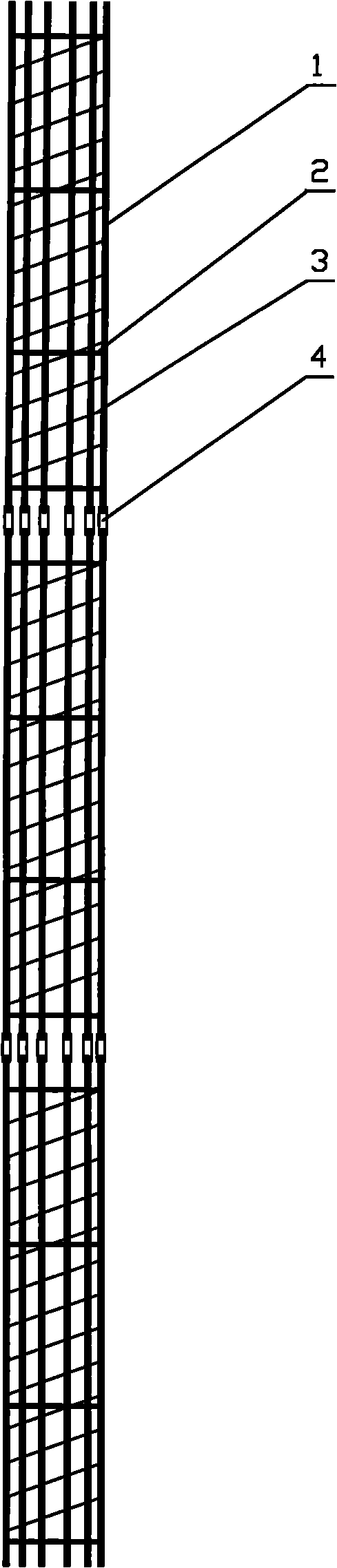

Reinforcement cage and manufacturing method thereof

InactiveCN101967825AQuality improvementImprove machining accuracyBuilding reinforcementsBulkheads/pilesEngineeringRebar

The invention relates to a reinforcement cage and a manufacturing method thereof. The reinforcement cage comprises main reinforcements; the reinforcement cage is divided into a plurality of sections; the main reinforcements, an inner locating stirrup and an outer locating stirrup are arranged in each section of reinforcement cage; the length of the main reinforcements is the same; one ends of the main reinforcements are half wires, and one ends of the reinforcements are full wires; a main reinforcement joint between each section of reinforcement cage is provided with straight thread connectors; and the main reinforcements in each section of reinforcement cage are connected in one-to-one correspondence. The manufacturing method comprises the following steps of: blanking the reinforcements; performing thread rolling on the reinforcement cages; processing the reinforcement cages; storing and delivering the reinforcement cages; splicing the reinforcement cages, preassembling on a spot, putting the processed reinforcement cages end to end according to the sequence of the divided sections into a straight line, sequentially splicing from one end to another end, screwing the connectors one by one, and sequentially arranging the rest reinforcement cages; splicing orifices; and detecting. The invention solves the problem that the reinforcement cage needs to be divided into a plurality of sections for processing and splicing due to the limitation of construction condition. The invention has the characteristics that: the manufacturing method is simple to operate, and the reinforcement cage has high precision and installation rate.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

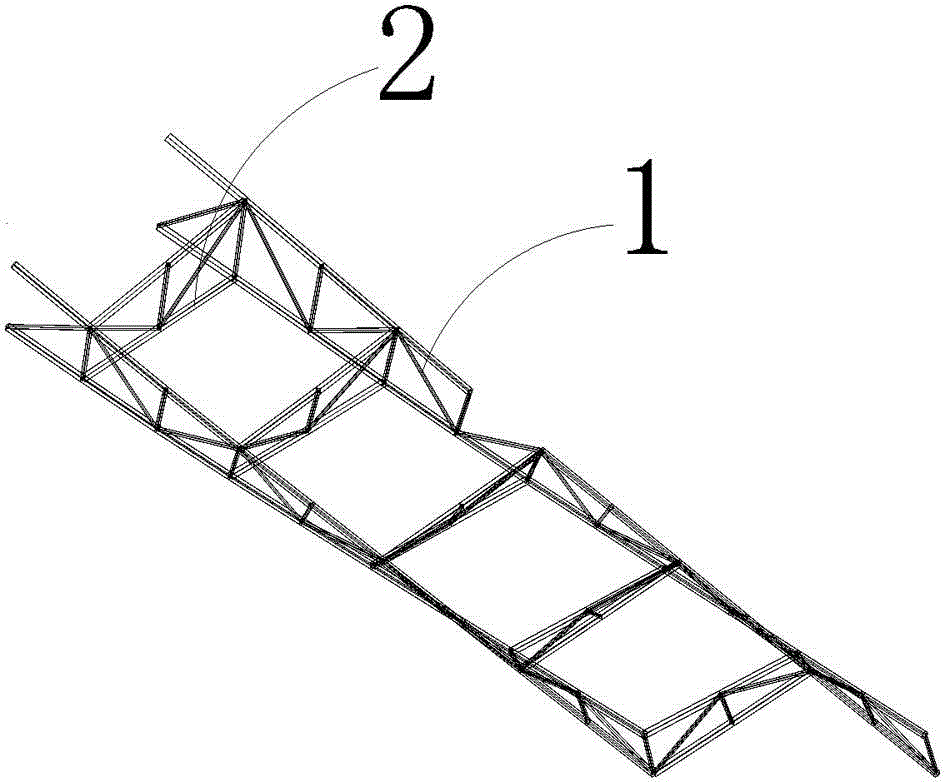

Multi-node integral installation method for steel truss beam

The invention discloses a multi-node integral installation method for a steel truss beam, comprising the following steps: firstly, integral manufacturing is carried out in a factory, then the product is installed to form standard segments, the standard segments are temporarily fixed and pre-jointed in the factory, then the segments are transported to bridge location by large transportation equipment, integral lifting is carried out by a large lifting appliance and the segments are installed; the installation sequence is that firstly, a lower chord and an oblique web plate are installed, then a middle chord, an upper chord and a side upper chord are installed, at last, a lower lateral bracing, a lateral plate and a bridge deck in a welding way. The invention has the advantages that the linetype is easily controlled, the steel truss beam can be used as the operation platform, the installation speed is high, construction period is shortened and construction security is guaranteed.

Owner:THE 5TH ENG MBEC

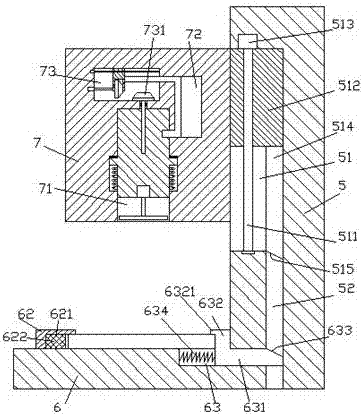

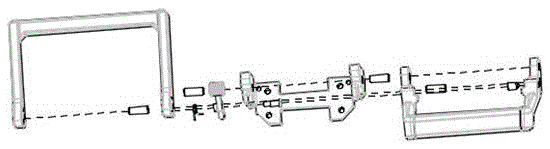

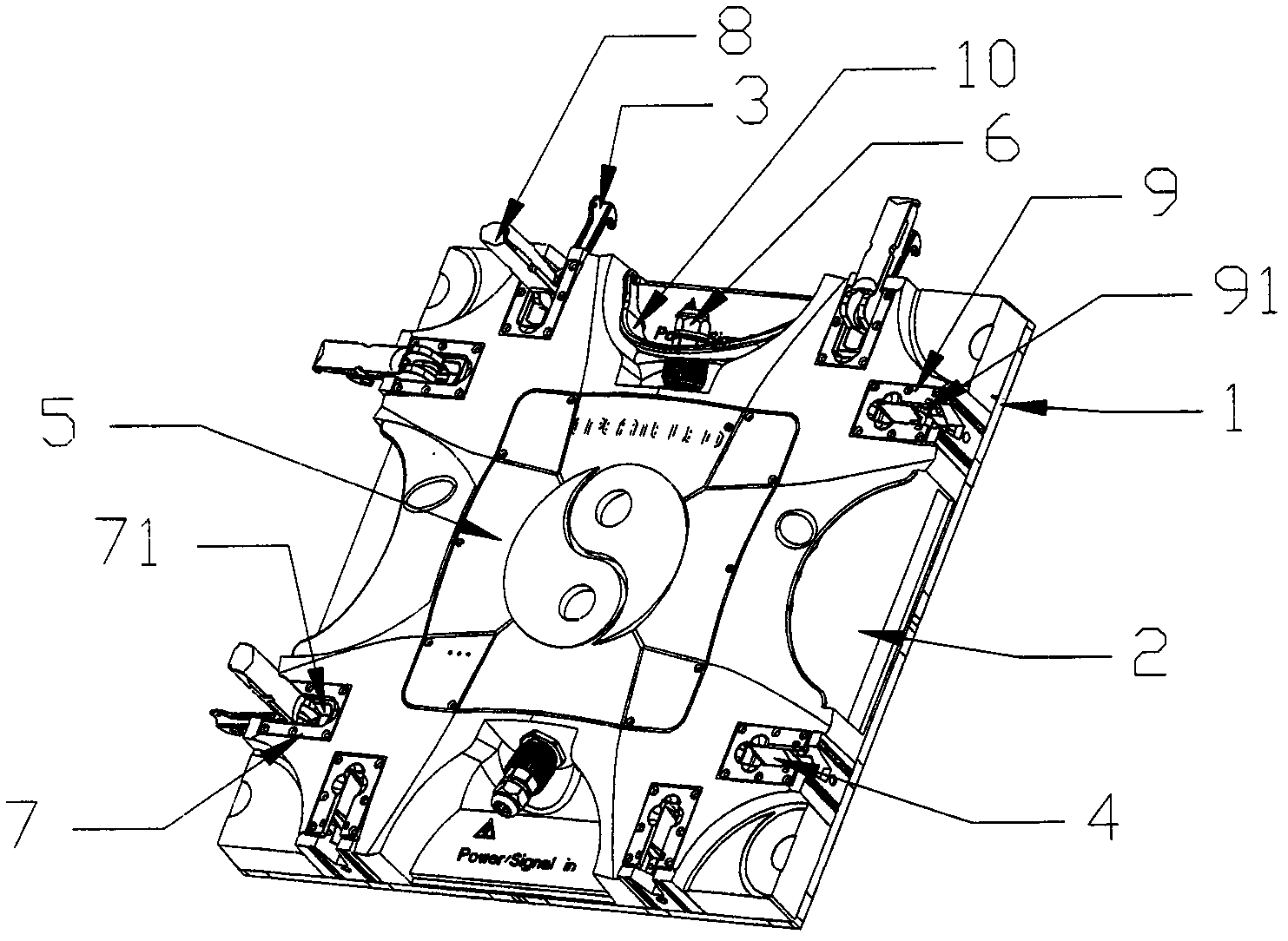

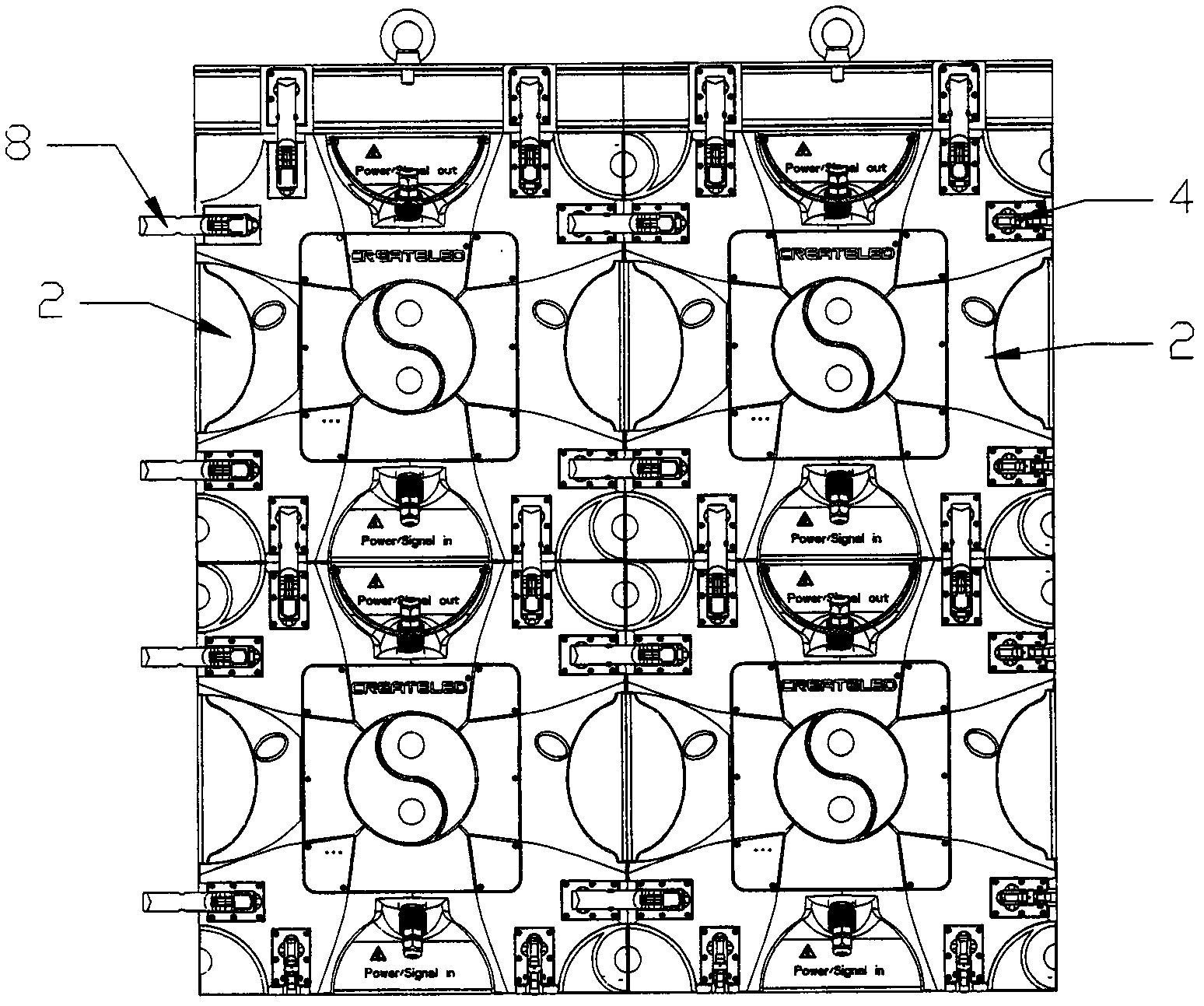

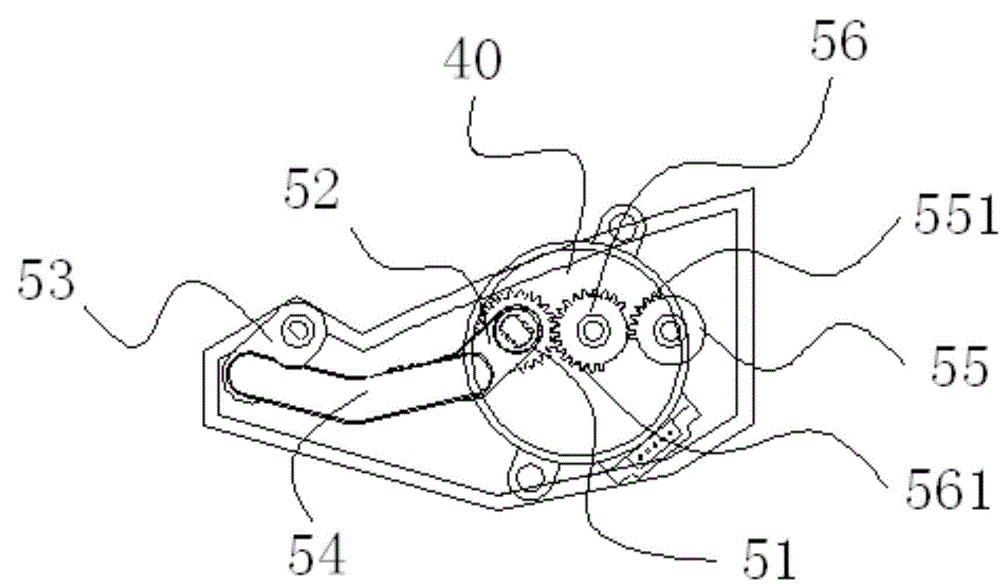

Pre-maintenance LED display screen and maintaining method thereof

The invention discloses a pre-maintenance LED display screen and a maintaining method thereof. The pre-maintenance LED display screen comprises at least two LED display boxes and a splicing device. Each LED display box comprises a frame and at least two LED display modules. A power pack is fixedly arranged on the back of the frame. Connecting portions are arranged on the first side edge and the second side edge of the frame. Fixing portions are arranged on the third side edge and the fourth side edge. The splicing device comprises a rapid lock and a rapid lock fixing base. The rapid lock is installed on the connecting portion. The rapid lock fixing base is installed on the fixing portion. The rapid lock comprises a lock catch and a spanner. The rapid lock fixing base comprises a base, a connecting plate, a first clamping tongue and a second clamping tongue, wherein the first clamping tongue and the second clamping tongue are arranged on the two sides of the connecting plate and symmetric with each other. By adopting the scheme, the pre-maintenance LED display screen is simple in structure and easy to install and maintain, the LED module assembling and disassembling speed is high, the pre-maintenance LED display screen particularly meets the requirement for narrow installation environment or rapid installation, workloads of front-line workers are greatly reduced, and the good market application value is achieved.

Owner:SHENZHEN MARY PHOTOELECTRICITY

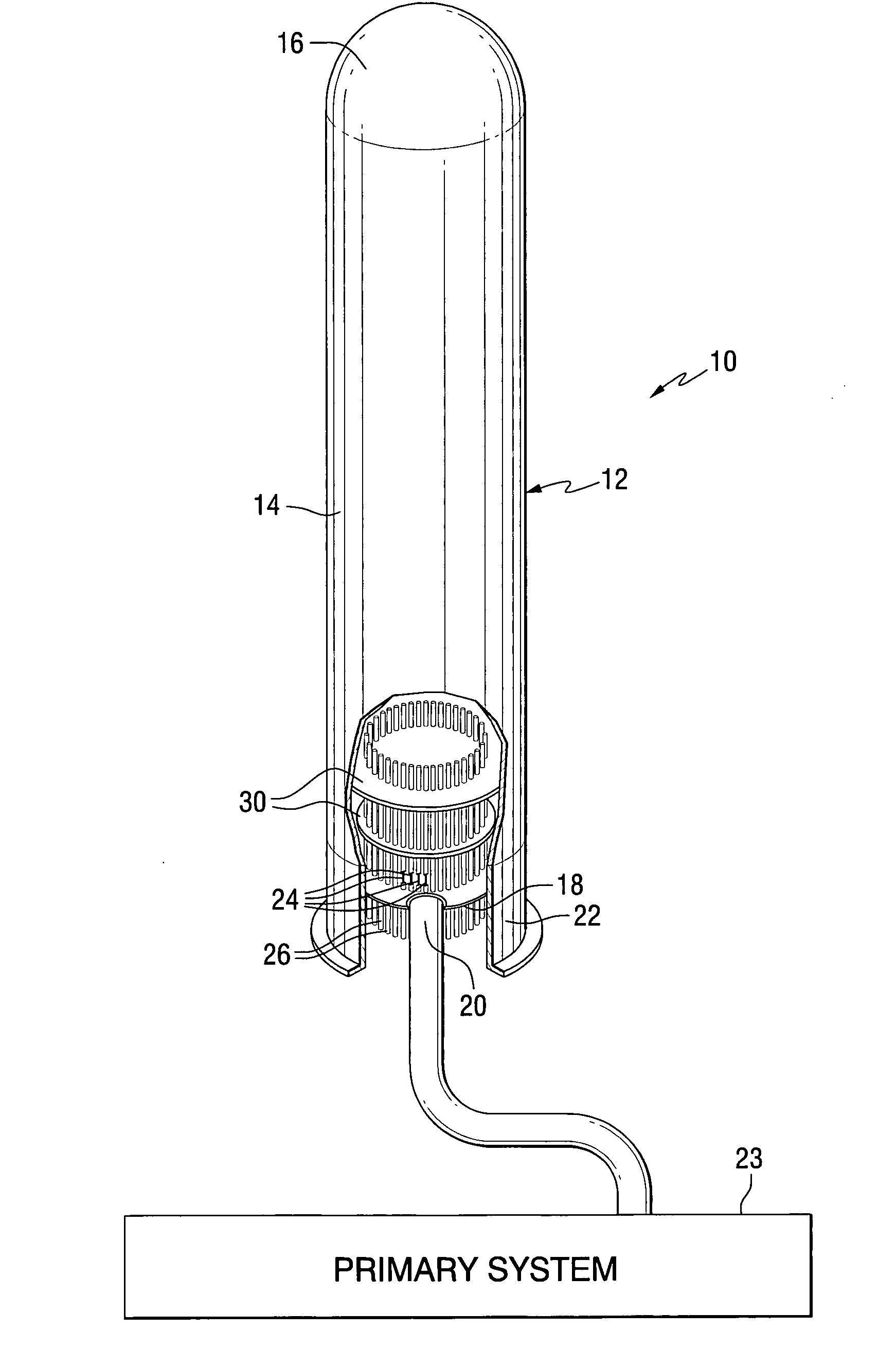

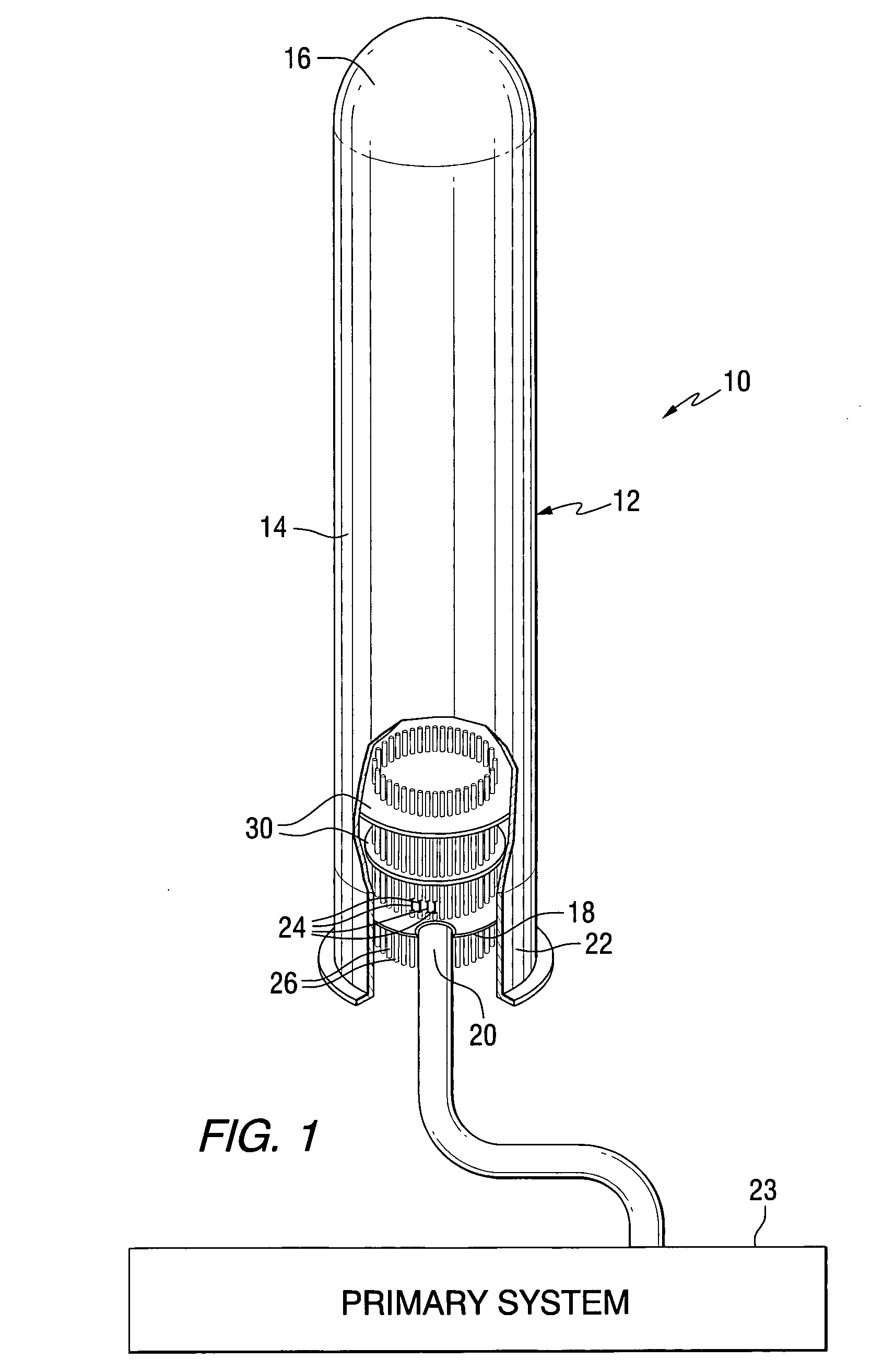

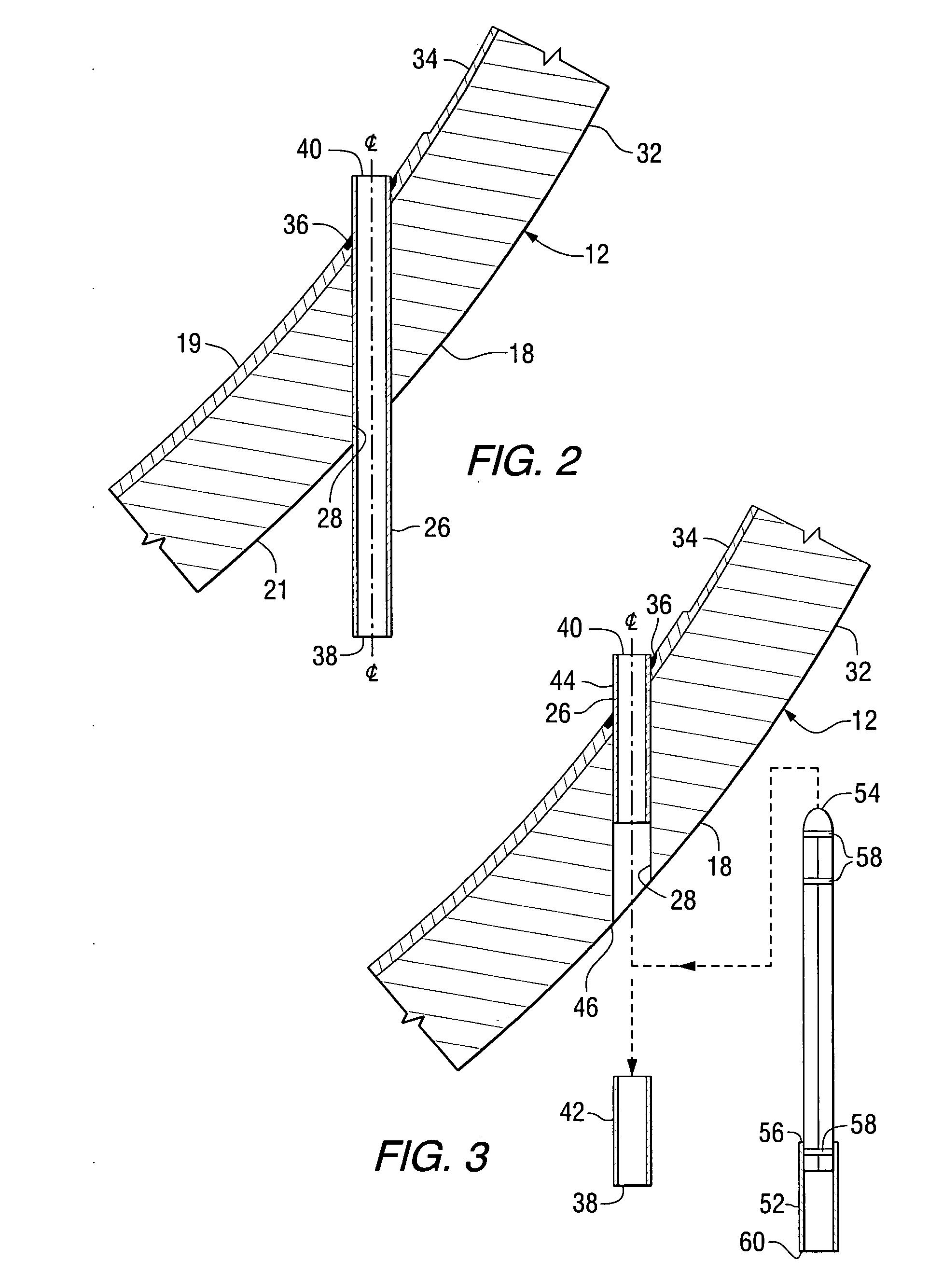

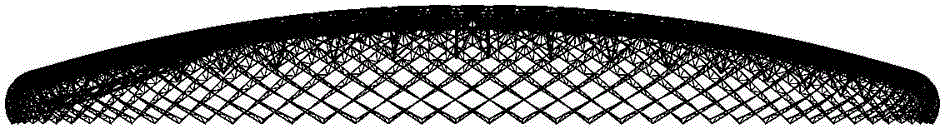

Method of forming a weld pad

InactiveUS20050199591A1Fast installationQuick installationArc welding apparatusWelding/soldering/cutting articlesBiomedical engineeringPressure vessel

Owner:WESTINGHOSE ELECTRIC CORP

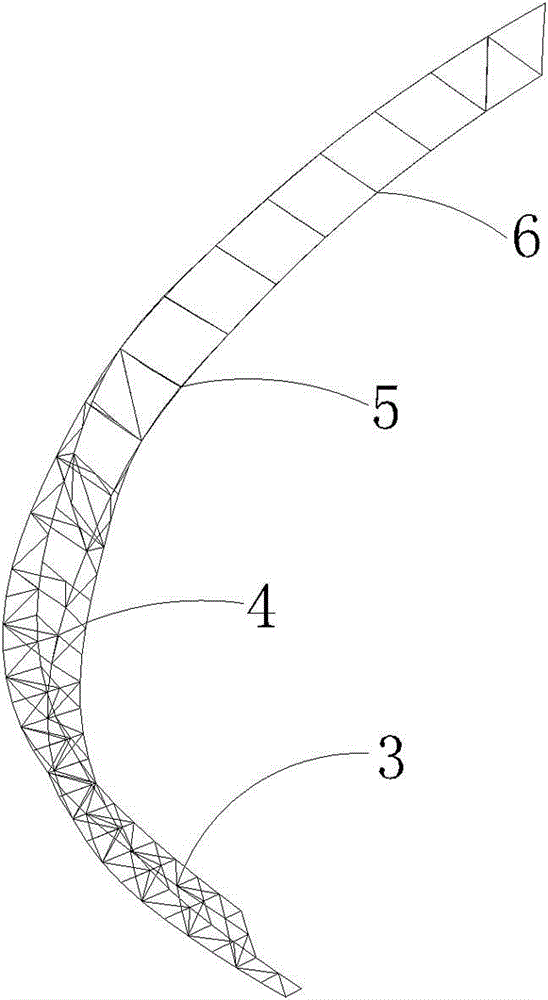

Mounting positioning method of two-way skew curved combined truss

ActiveCN104060837ACompact structureFast installationBuilding material handlingEngineeringSteel structures

The invention relates to a two-way skew curved combined truss, in particular to a mounting positioning method of a two-way skew curved combined truss, and is applied to a steel structure. The mounting positioning method comprises the following steps: a combination and segmentation method of the two-way skew curved combined truss and a mounting positioning method of combined truss hoisting units. Through the adoption of the mounting positioning method of the two-way skew curved combined truss, the structure is compact, the mounting speed is high, the stability is high, and the mounting precision is high.

Owner:浙江东南网架股份有限公司

Construction method for light steel keel partition wall

InactiveCN106168067AReduce wasteSimple and fast operationBuilding material handlingSocial benefitsFalsework

The invention discloses a construction method for a light steel keel partition wall. The technological process of the construction method comprises the steps of construction preparation, scaffold erection, surveying and lining, welding and fixation of galvanized steel components, sleeper wall construction, fixation of an uppermost keel, a bottommost keel and frame keels, staging of vertical keels, keel installation, gypsum face plate installation, joint treatment, wall decoration and acceptance check. The construction method is easy and convenient to implement, the installation speed is high, and the labor efficiency is improved; meanwhile, the stability of the partition wall and the shock resistance of the integral structure are enhanced, the sound insulation effect and the fireproof grade between every two rooms are better improved, the common quality problem of cracking of light steel keel partition wall bodies is solved, and remarkable economic benefits and social benefits are achieved.

Owner:上海闵轩钢结构工程有限公司

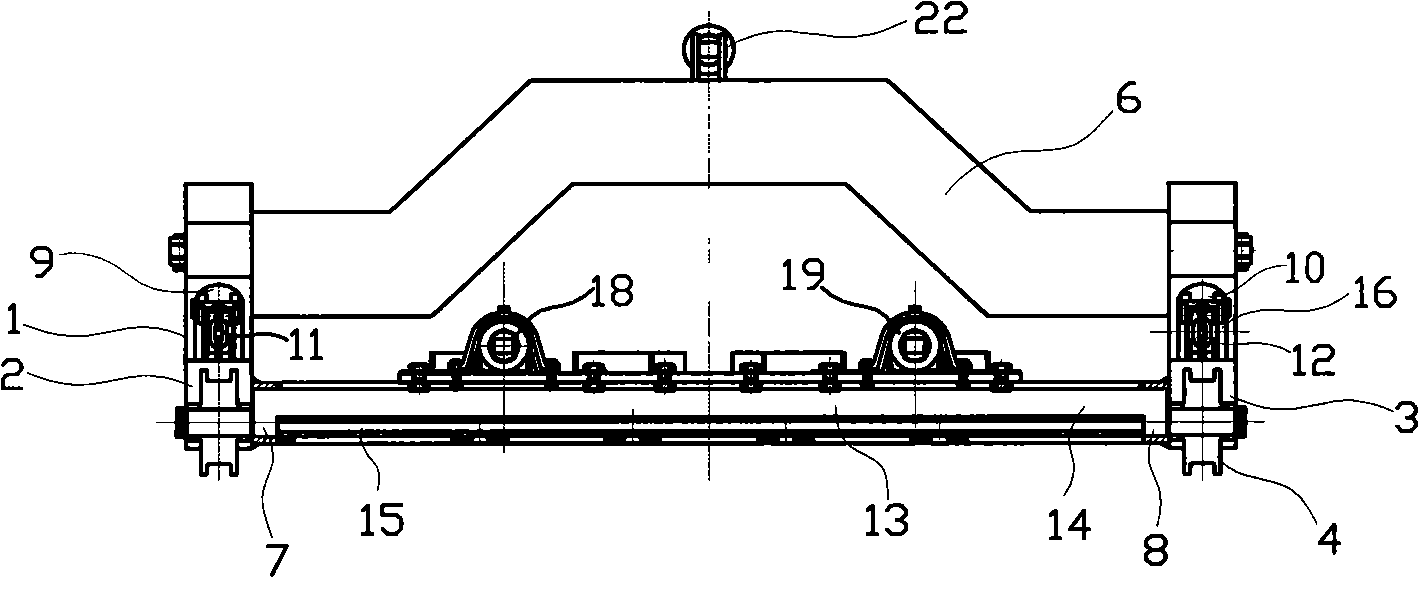

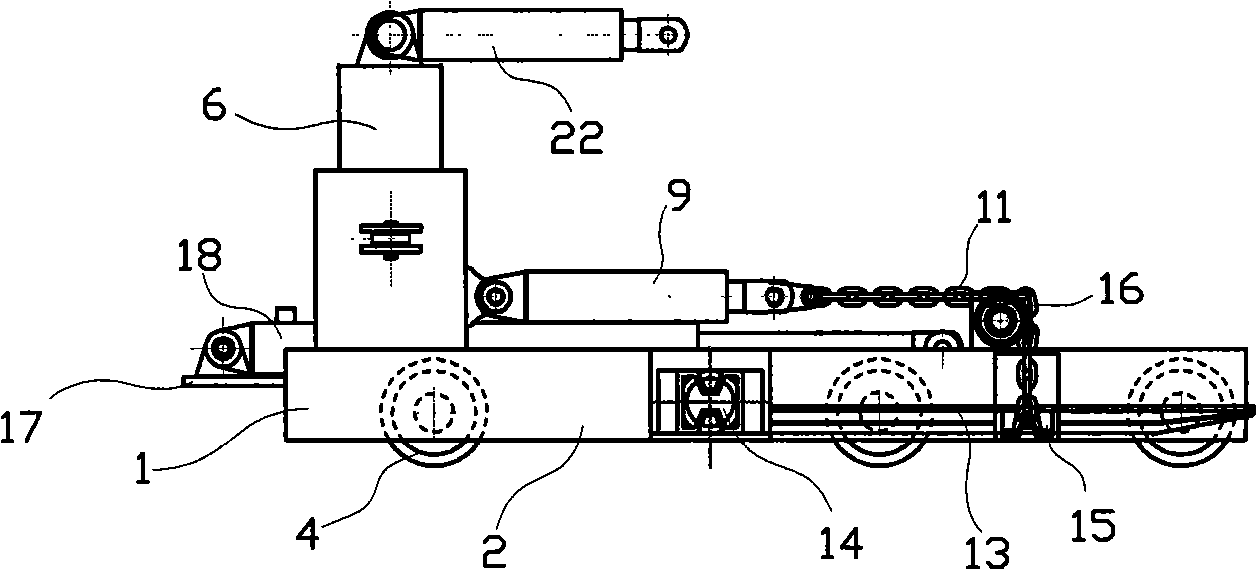

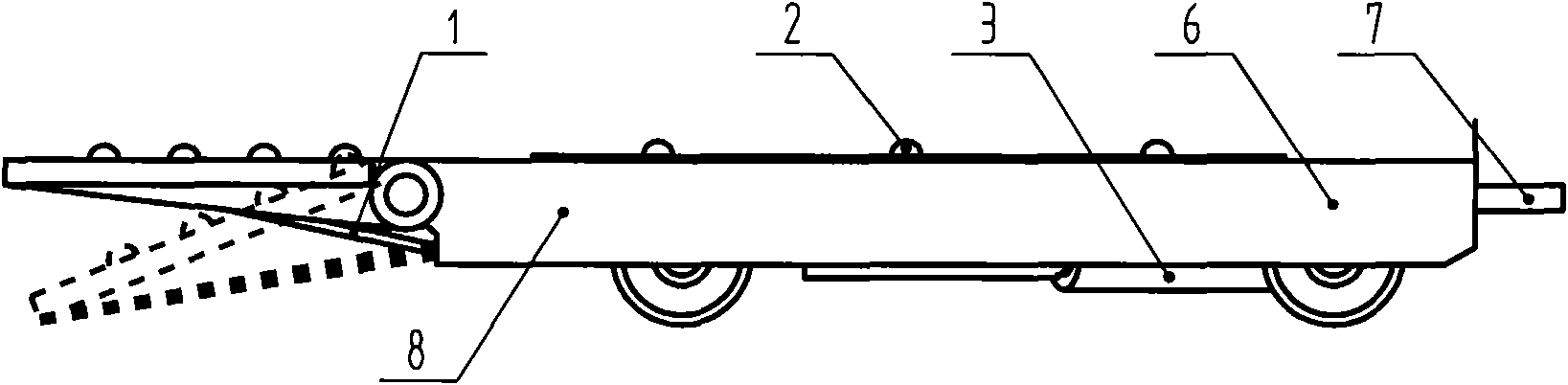

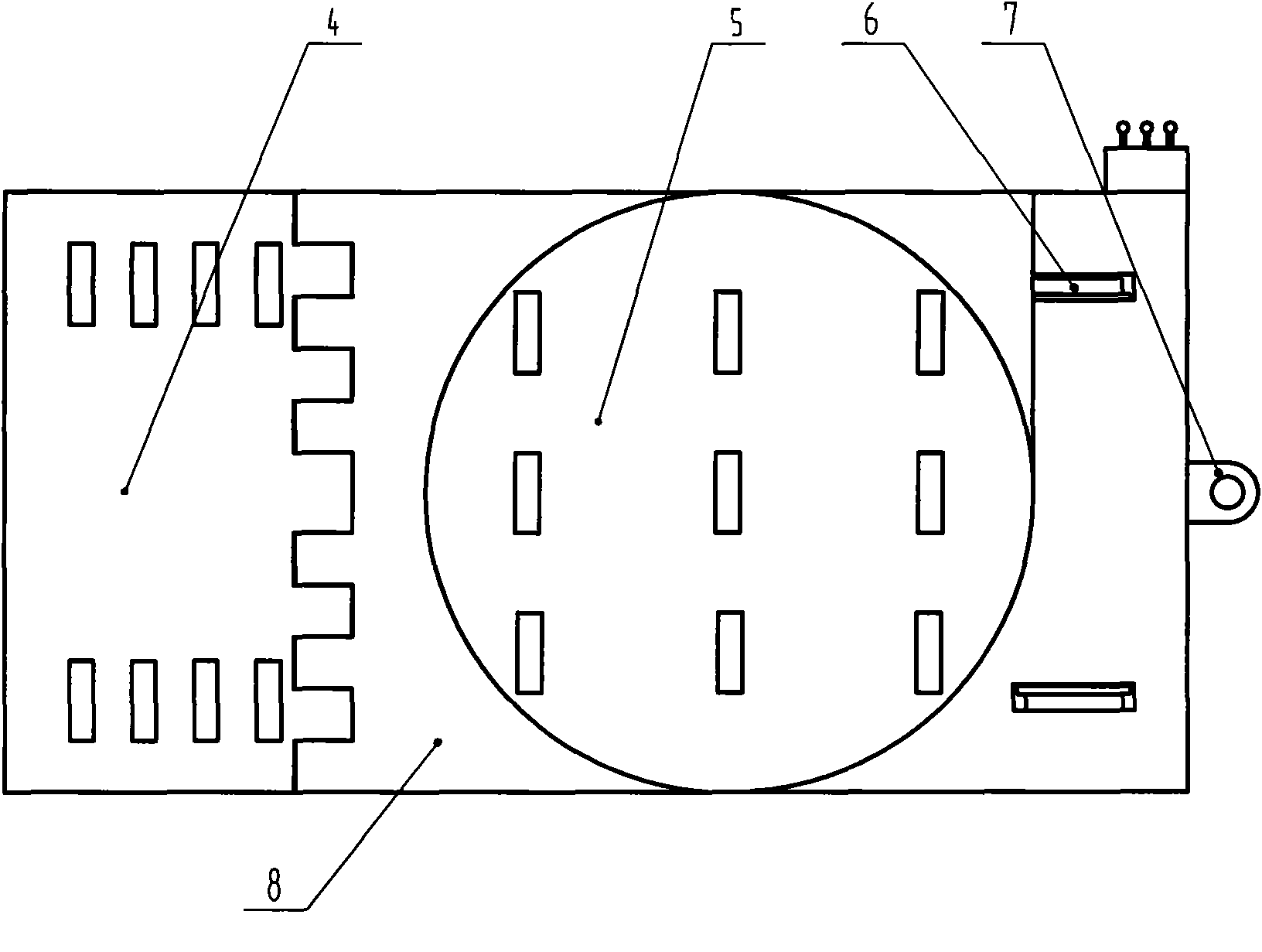

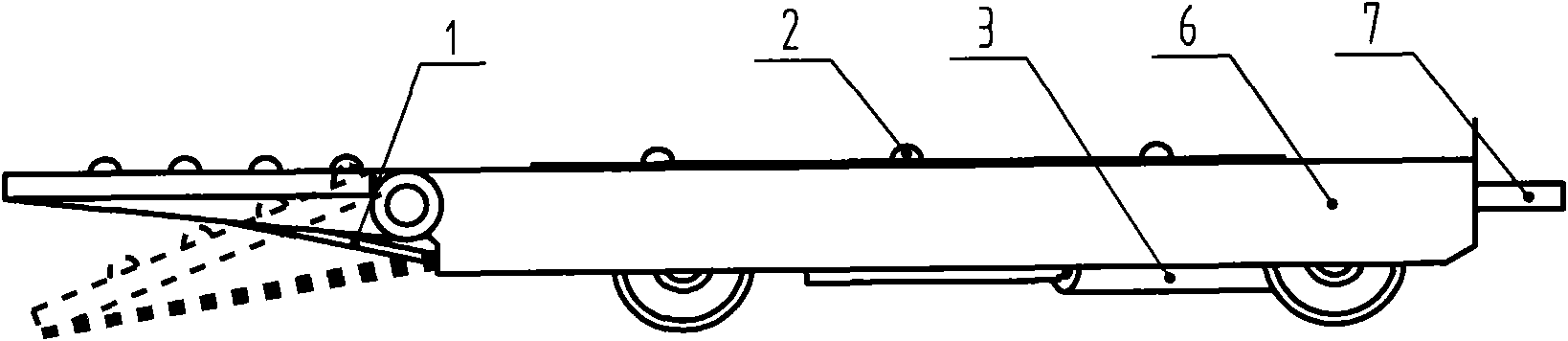

Comprehensive mining hydraulic support mounting transport vehicle

ActiveCN101532388AEasy to shipReduce labor intensityProps/chocksHydraulic cylinderControl engineering

The invention relates to a comprehensive mining hydraulic support mounting transport vehicle, which is provided with a left horizontal longitudinal beam and a right horizontal longitudinal beam which are mutually parallel. The rear part of the longitudinal beam is connected with a cross beam by using a hydraulic cylinder, the insides of the middle parts of the longitudinal beams are provided with a left axle hole seat and a right axle hole seat which are opposite, the upsides of the left longitudinal beam and the right longitudinal beam are provided with a left lifting hydraulic cylinder and a right lifting hydraulic cylinder connected to the rear part and in parallel to the longitudinal beams, a piston rod of the lifting hydraulic cylinder is connected with a supporting chain, the front part of the vehicle is provided with a loading plate, the back side of the loading plate is provided with a back plate shaft, the underside of the front part of the loading plate is provided with a bottom beam, the back plate shaft is positioned in the axle hole seat, the bottom beam is connected with a left supporting chain and a right supporting chain through steering sprocket wheels, the back side plate of the loading plate is connected with a platform plate on which a left loading hydraulic cylinder and a right loading hydraulic cylinder are arranged, the piston rod is connected with a chain, a pushing rod is connected between the piston rods, and the upside of the rear cross beam is provided with a fastened hydraulic cylinder parallel to the longitudinal beams. In the mounting of a coalmine comprehensive mining working surface hydraulic support, the comprehensive mining hydraulic support mounting transport vehicle is used for mounting the hydraulic support, and has the advantages of low labor intensity, high mounting speed, high working efficiency and good safety during the mounting of the hydraulic support.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

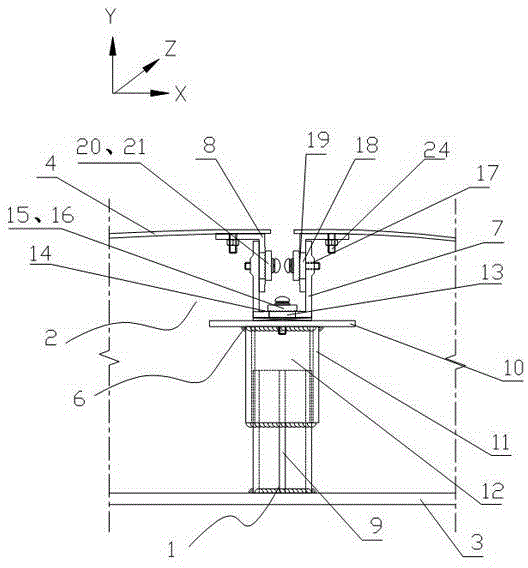

Double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure and double-curved-surface metal plate curtain wall three-dimensional adjustment installing method

ActiveCN104975666AGood effectNice appearanceWallsBuilding material handlingEngineeringSurface structure

The invention discloses a double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure, which comprises a fixed connecting element and a three-dimensional adjustment element, wherein the fixed connecting element is fixedly connected with a main body structure; the three-dimensional adjustment element is adjustably connected with the fixed connecting element in the three-dimensional direction; the three-dimensional installation adjustment of a double-curved-surface metal plate is realized; and a double-curved-arc-surface structure matched with the double-curved-surface metal plate through curved surfaces is arranged on the three-dimensional adjustment element. The double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure has the advantages that the adjustment of the double-curved-surface metal plate in the three-dimensional direction position in the installing process is realized, so that the field installation is more convenient and faster; safety and firmness are realized; the integral effect of the double-curved-surface metal plate after the installation is enabled to be good; the appearance is attractive; and the installation requirements of double-curved-surface metal plates with different curvatures can be met. The invention also discloses a double-curved-surface metal plate curtain wall three-dimensional adjustment installing method, which has the advantages that the installation is fast; the operation is convenient; the installing method is suitable for field construction; and the installing speed of the double-curved-surface metal plate curtain wall is greatly accelerated.

Owner:ZHEJIANG YASHA CURTAIN WALL

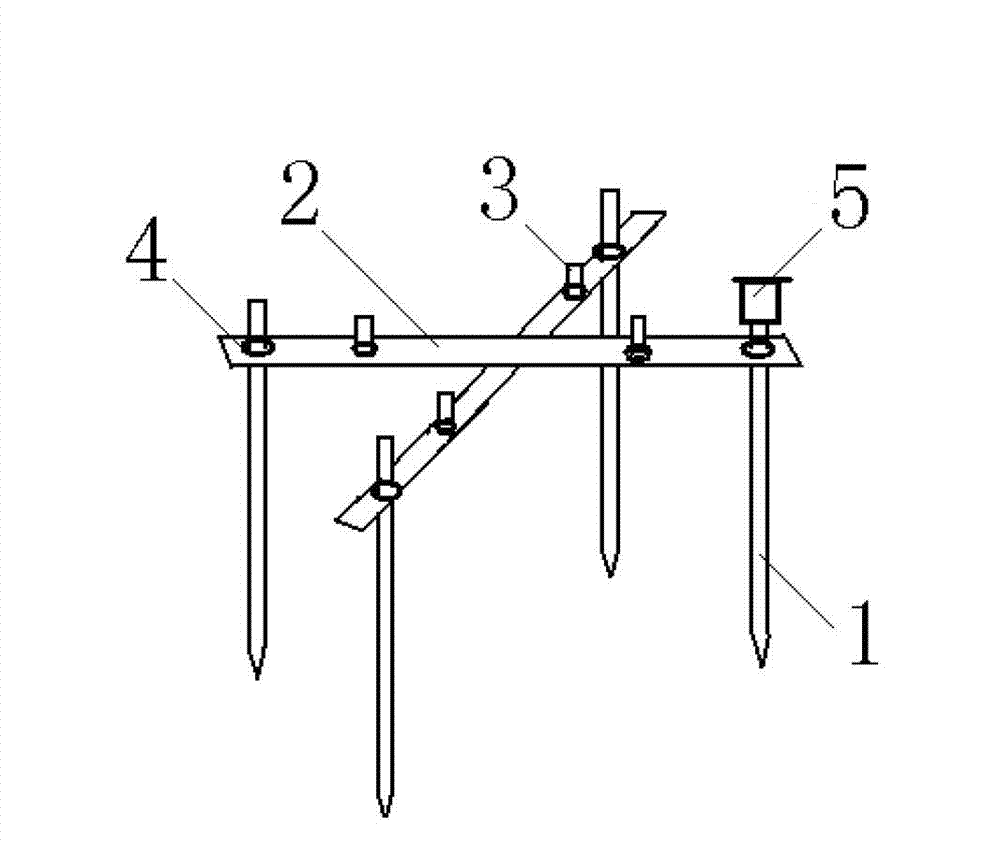

Base used for fixedly installing light pole, telegraph pole and high-tension wire tower and installation method thereof

The invention discloses a base used for fixedly installing a light pole, a telegraph pole and a high-tension wire tower. The base comprises a base steel plate and a column pile, wherein the base steel plate is connected with the upper end of the column pile through a nut, and the base steel plate is provided with a fixing bolt. The base disclosed by the invention has the advantages that the cost is low, and the installing speed of a pole frame is increased to a large extent; and when the pole frame needs to be disassembled, the nut on the base can be loosed and taken down, the column pile and the base steel plate can be separately separated, the column pile can be conveniently taken out and can be repeatedly used, thus the resource saving can be realized, and the environment cannot be affected.

Owner:芜湖国群新能源有限公司

LED (light-emitting diode) spliced screen module box

InactiveCN103000088AFast installationImprove implementation efficiencyCasings/cabinets/drawers detailsIdentification meansEngineeringLight-emitting diode

The invention relates to an LED (light-emitting diode) spliced screen, in particular to an LED spliced screen module box which is easy to splice and combine. The LED spliced screen module box comprises a rectangular or square panel and a main box body. The main box body is arranged behind the panel. Lock hooks and / or lock grooves for fastening the lock hooks are arranged on each side of the main box body. The lock hooks and the lock grooves on opposite two sides are oppositely arranged. By adopting a matched installation structure with the lock hooks and the lock grooves instead of the traditional matched installation structure with screws and nuts, during installation, the lock hooks are only required to be placed and fastened in the lock grooves, then the combination and the splicing of LED spliced screen module boxes can be realized, the LED spliced screen module box is convenient to install, tools such as screw drivers are not required, the implementation efficiency of splicing operation is improved, the installation speed of the entire spliced screen is accelerated, and the labor cost and the time cost are saved.

Owner:成卓

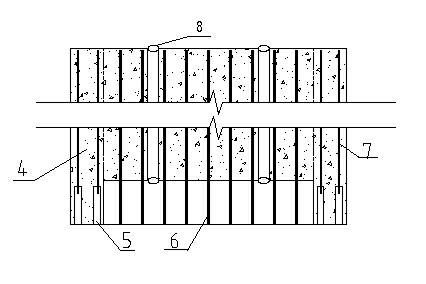

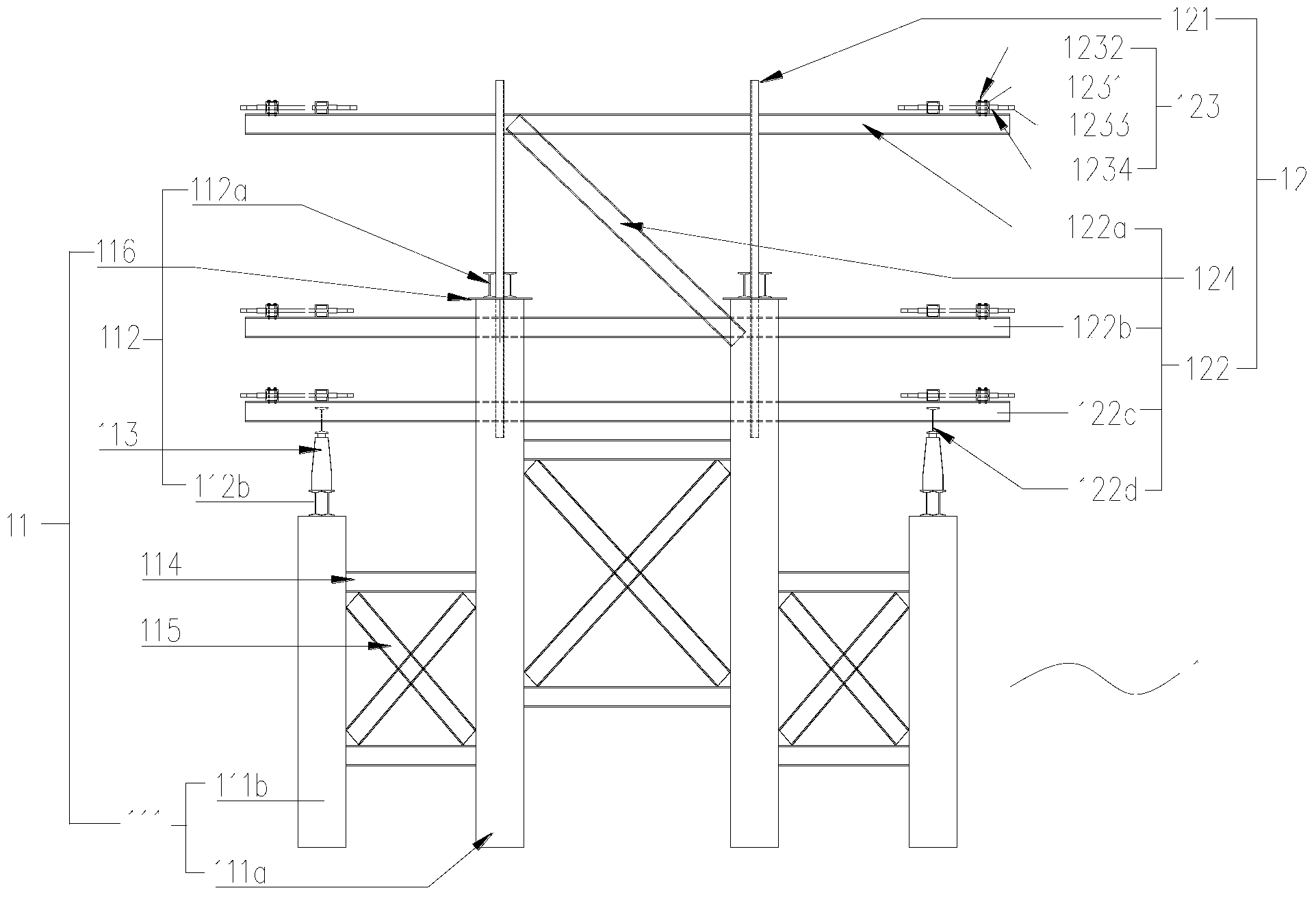

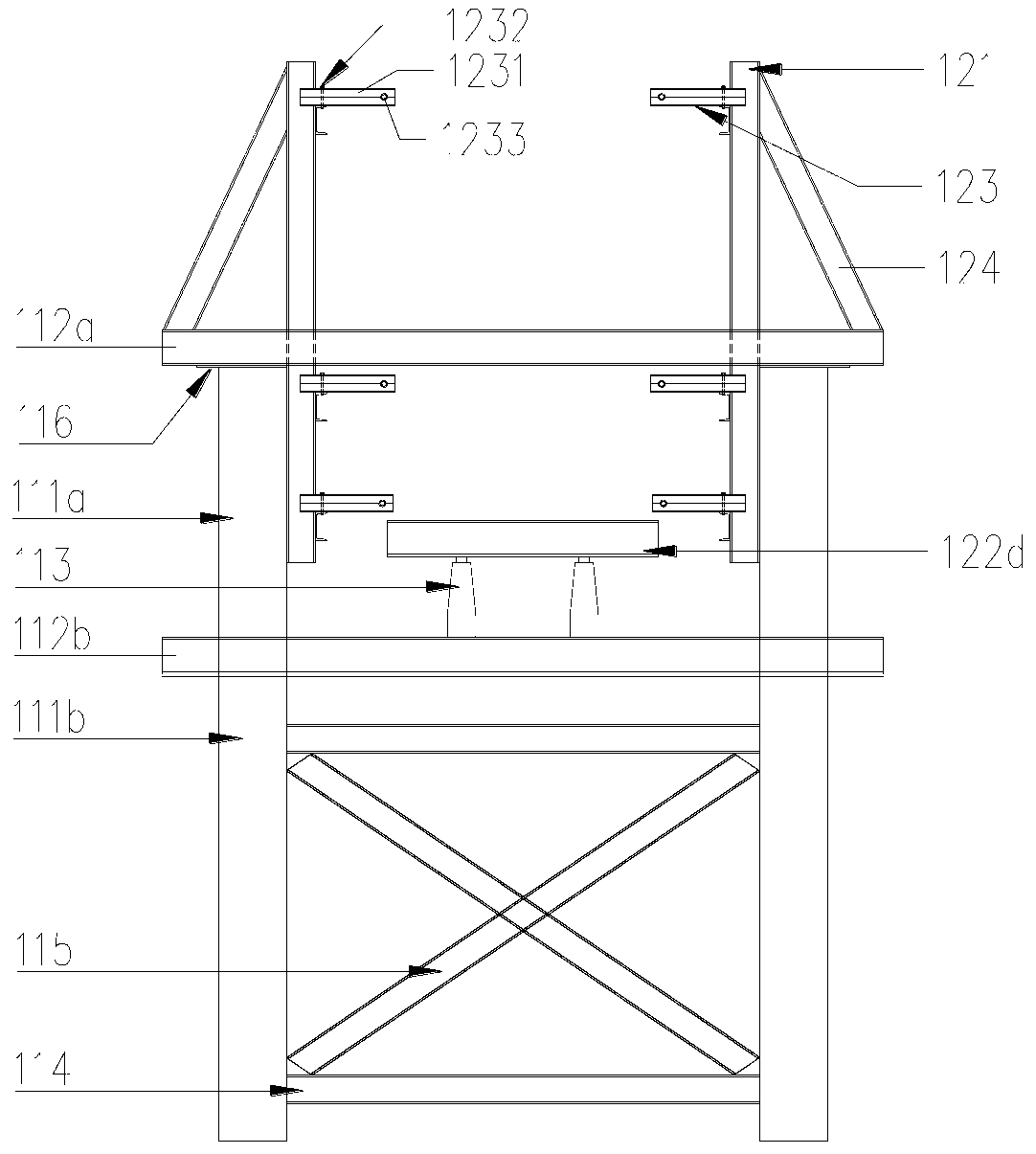

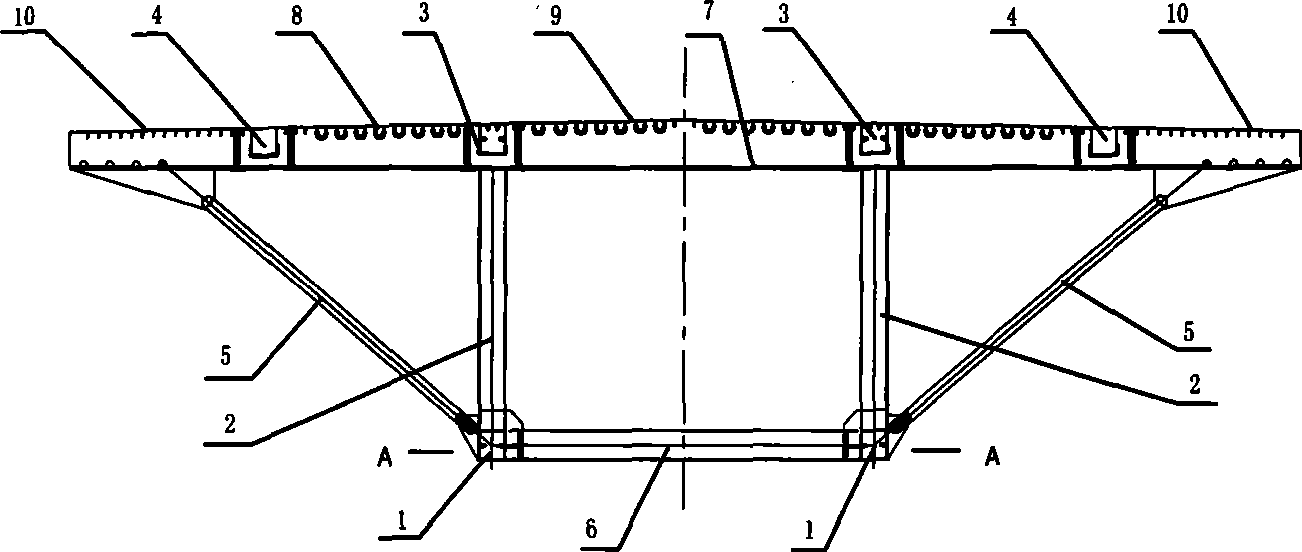

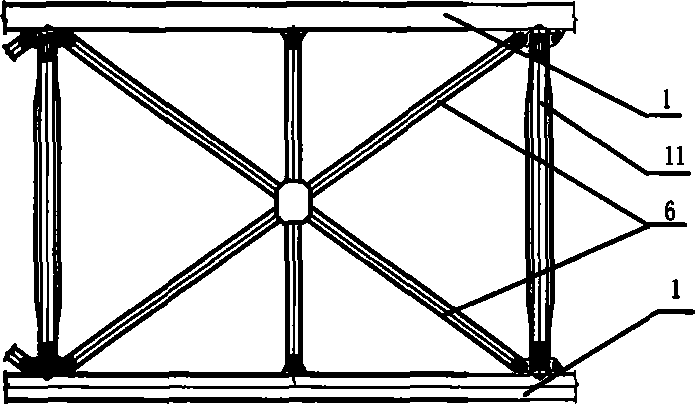

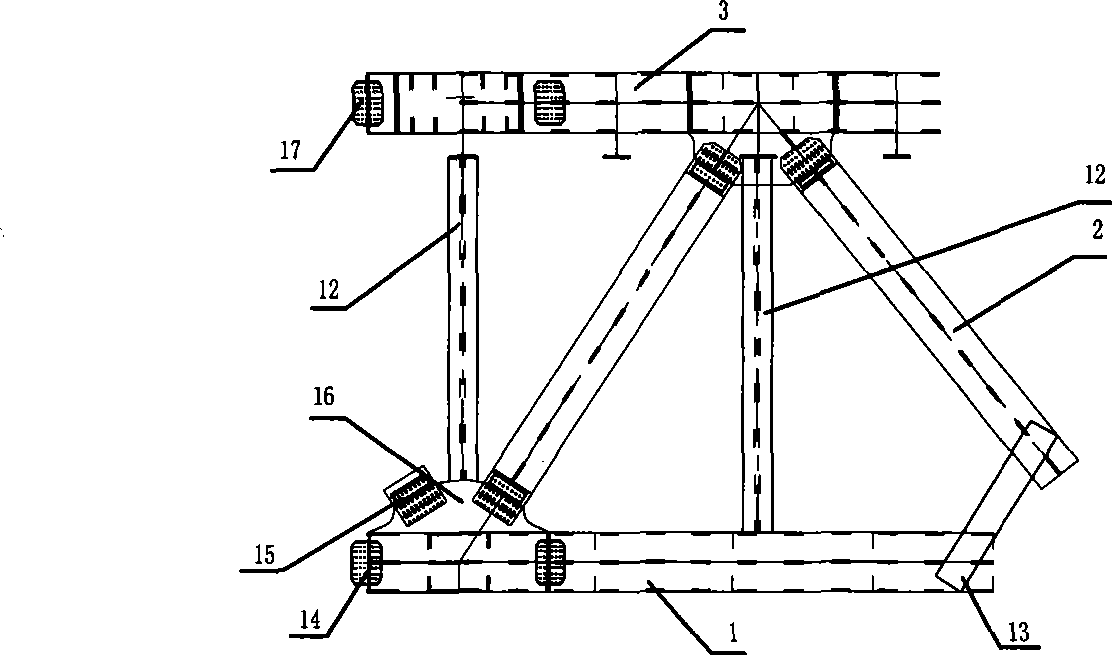

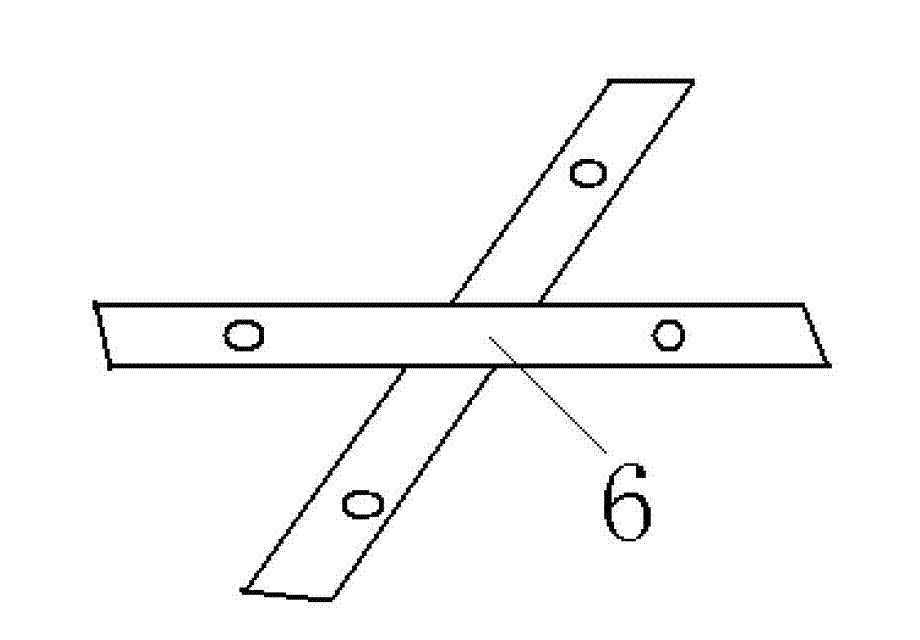

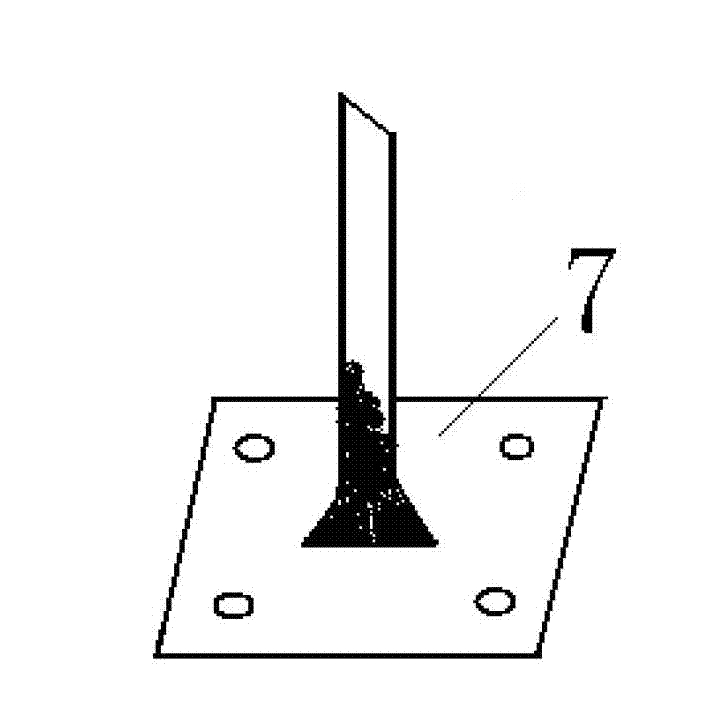

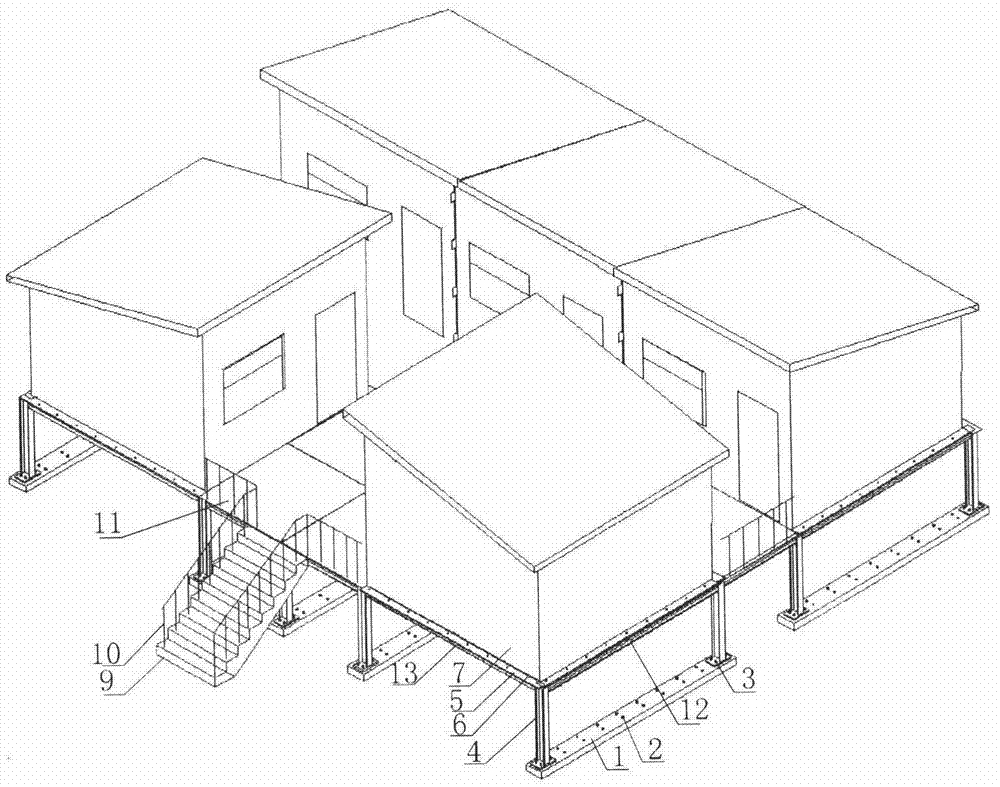

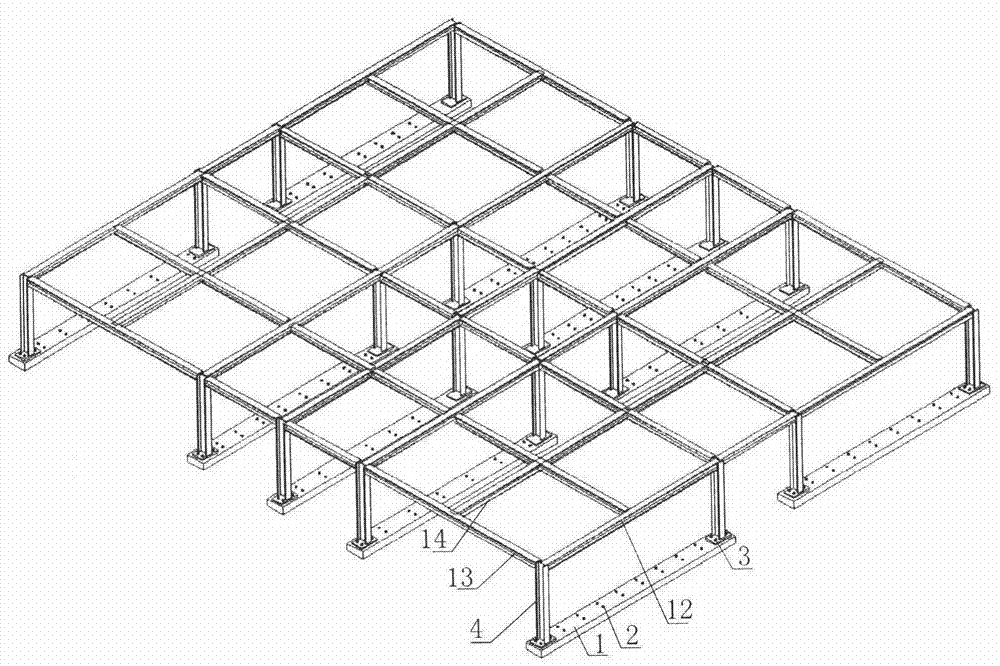

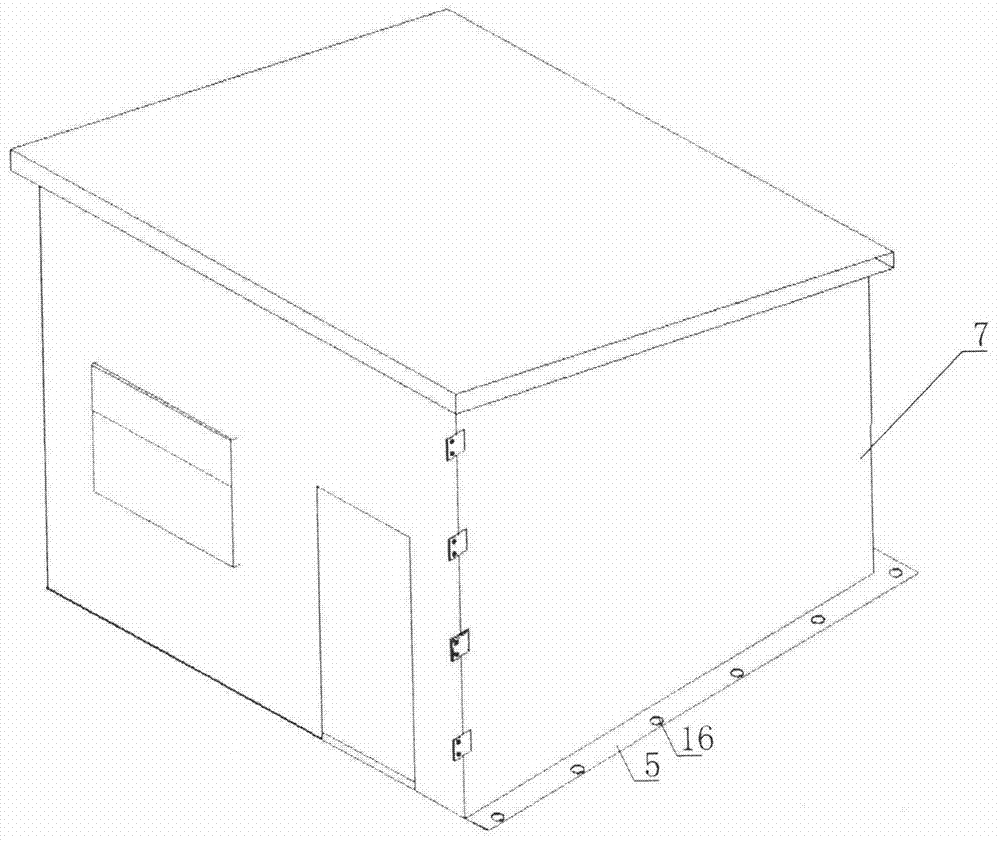

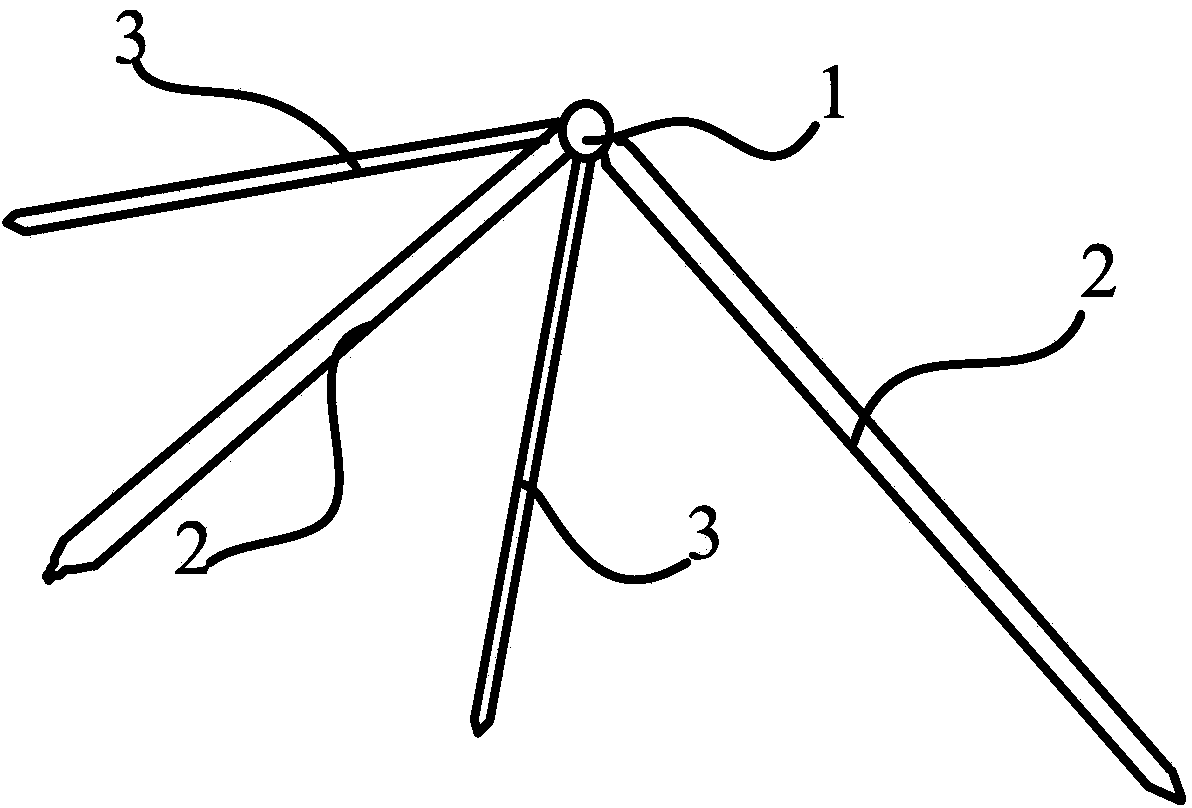

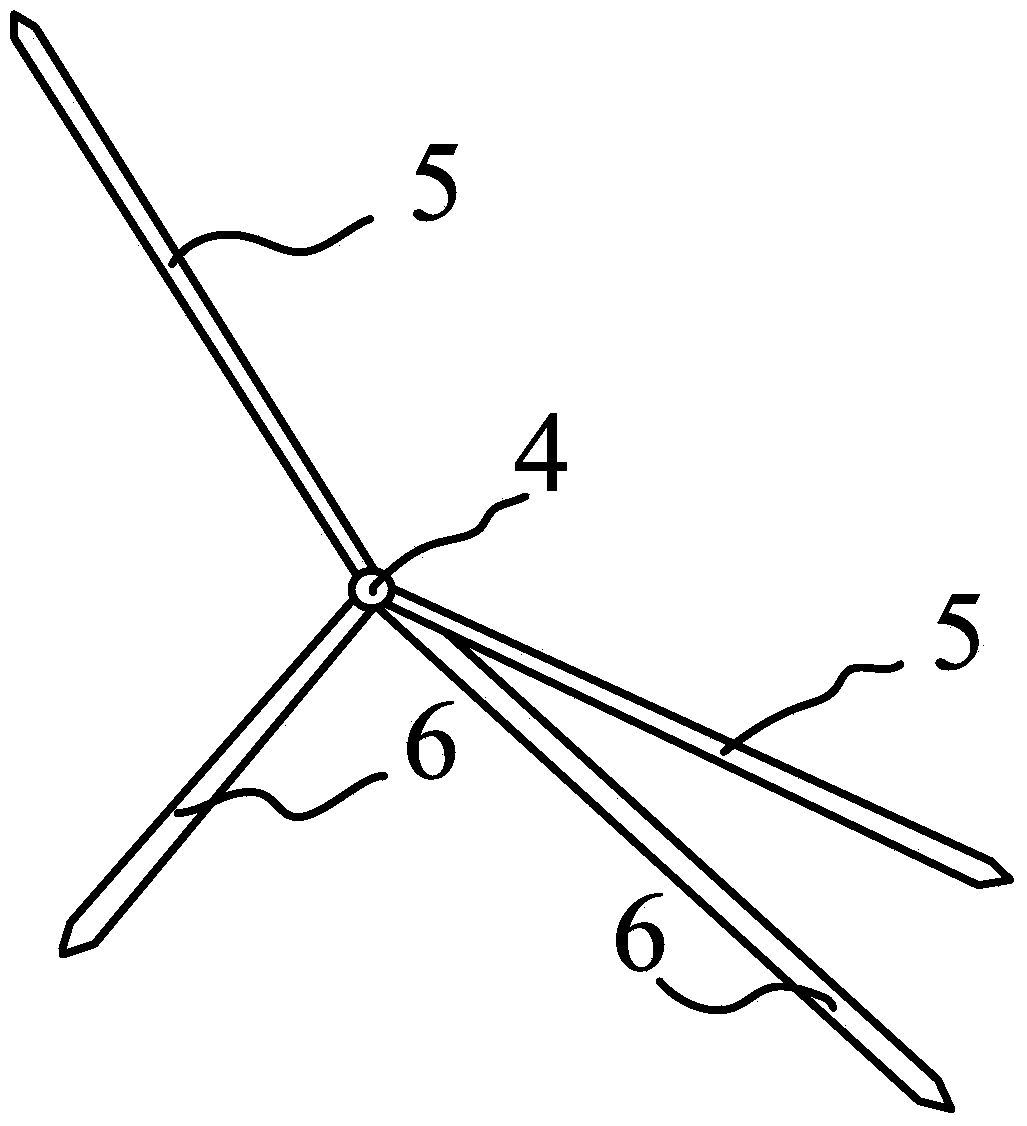

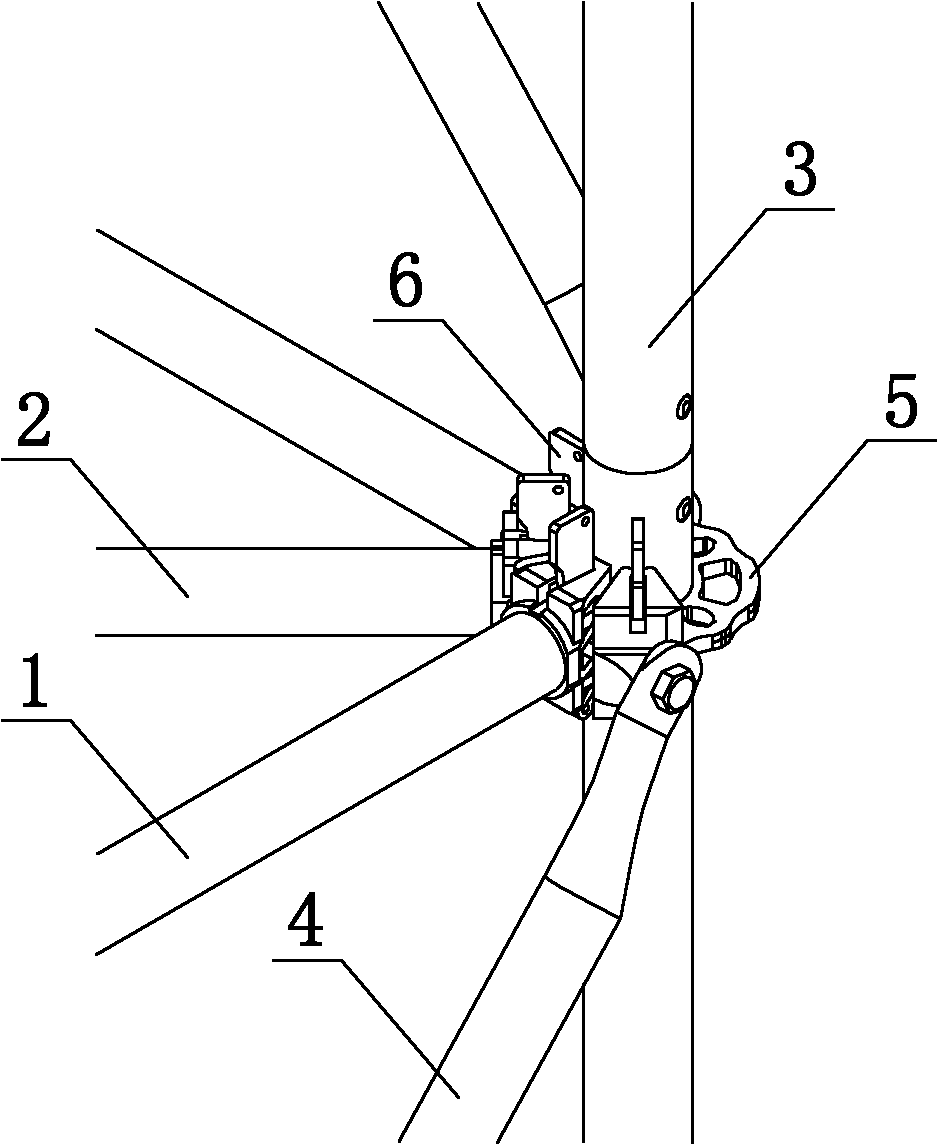

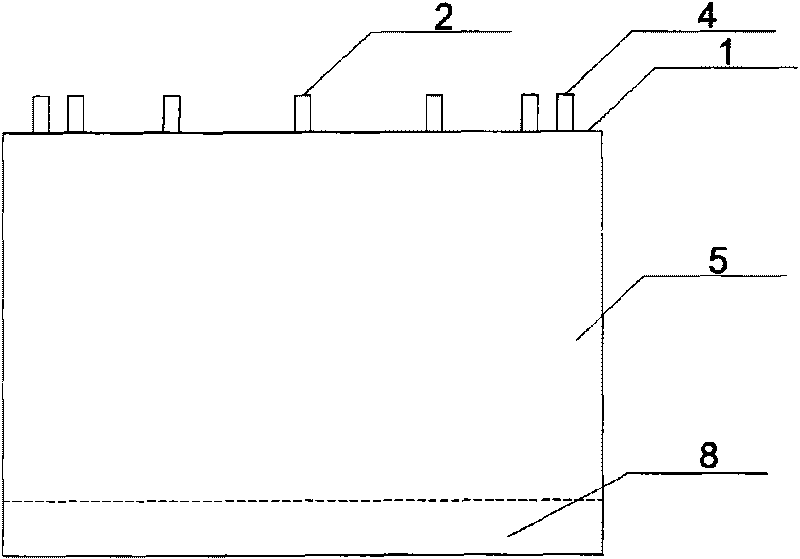

Construction method for assembly type light-steel integrated house in pasturing area

InactiveCN103046755AEasy to assemble and disassembleMeet storage needsBuilding material handlingReinforced concreteSteel frame

A construction method for assembly type light-steel integrated house in a pasturing area is characterized by including: preparing sufficient prefabricated reinforced concrete ground beams (1), foundation long anchor rods (2), a layer of frame columns (4), bolts (6), nuts, single houses (7), top plates (11), a layer of frame crossbeams (12), a layer of frame longitudinal beams (13) and combination stairs (9); peripherally compacting the prefabricated reinforced concrete ground beams (1); adjusting the prefabricated reinforced concrete ground beams (1) to be horizontal and fixing to selected positions; fixing the frame crossbeams (12) and the frame longitudinal beams (13); forming a layer of beam column rod assembly type light steel frame structure; lifting the single houses (7) above the beam column rod assembly type light steel frame structure and fixing, and laying the top plates (11) on the rest portion; mounting the combination stairs (9) between the ground and the top plates (11); and completing construction of the assembly type light-steel integrated house in the pasturing area.

Owner:SOUTHWEAT UNIV OF SCI & TECH

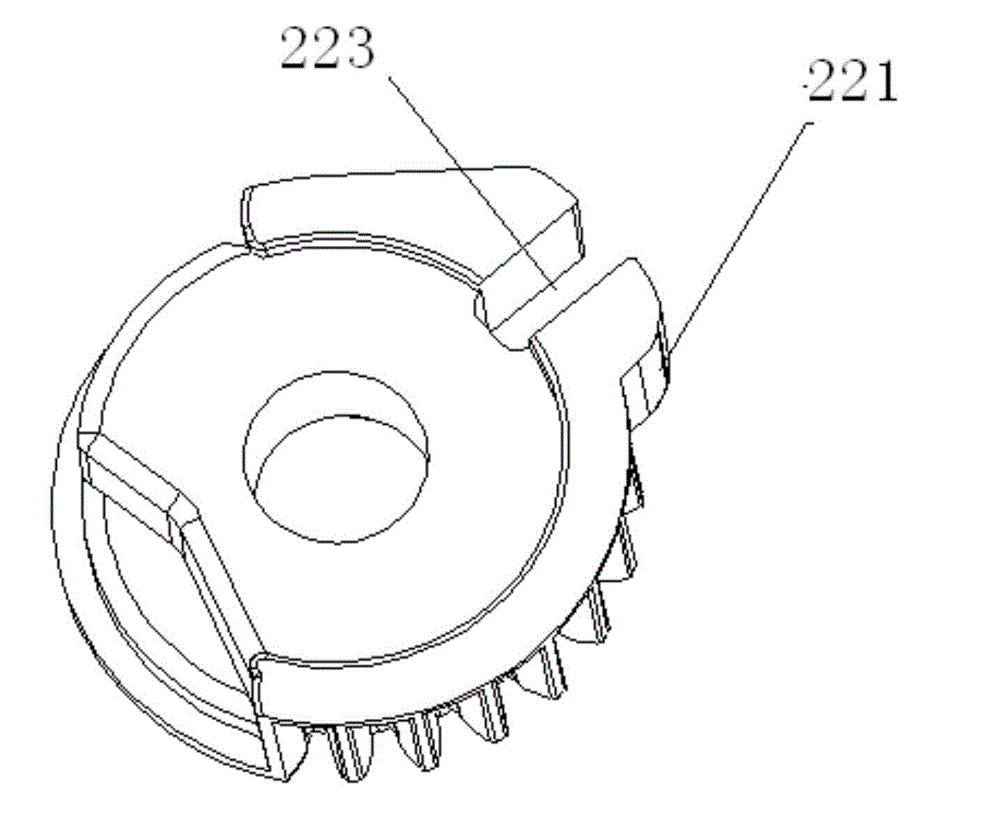

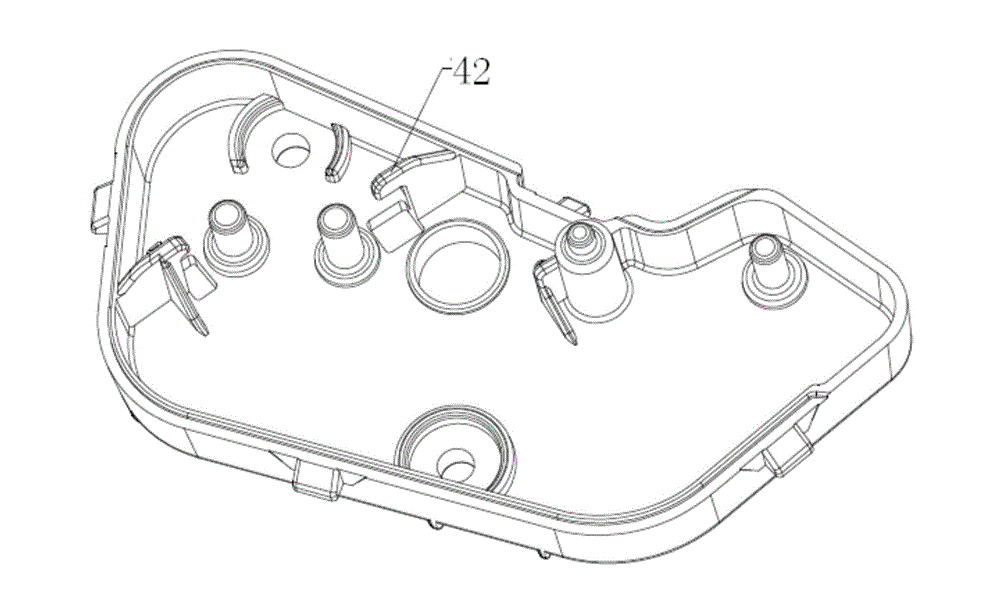

Air conditioner

ActiveCN104456897ASimplify installation and positioningFast installationLighting and heating apparatusAir conditioning systemsMotor driveAerospace engineering

Owner:GREE ELECTRIC APPLIANCES INC

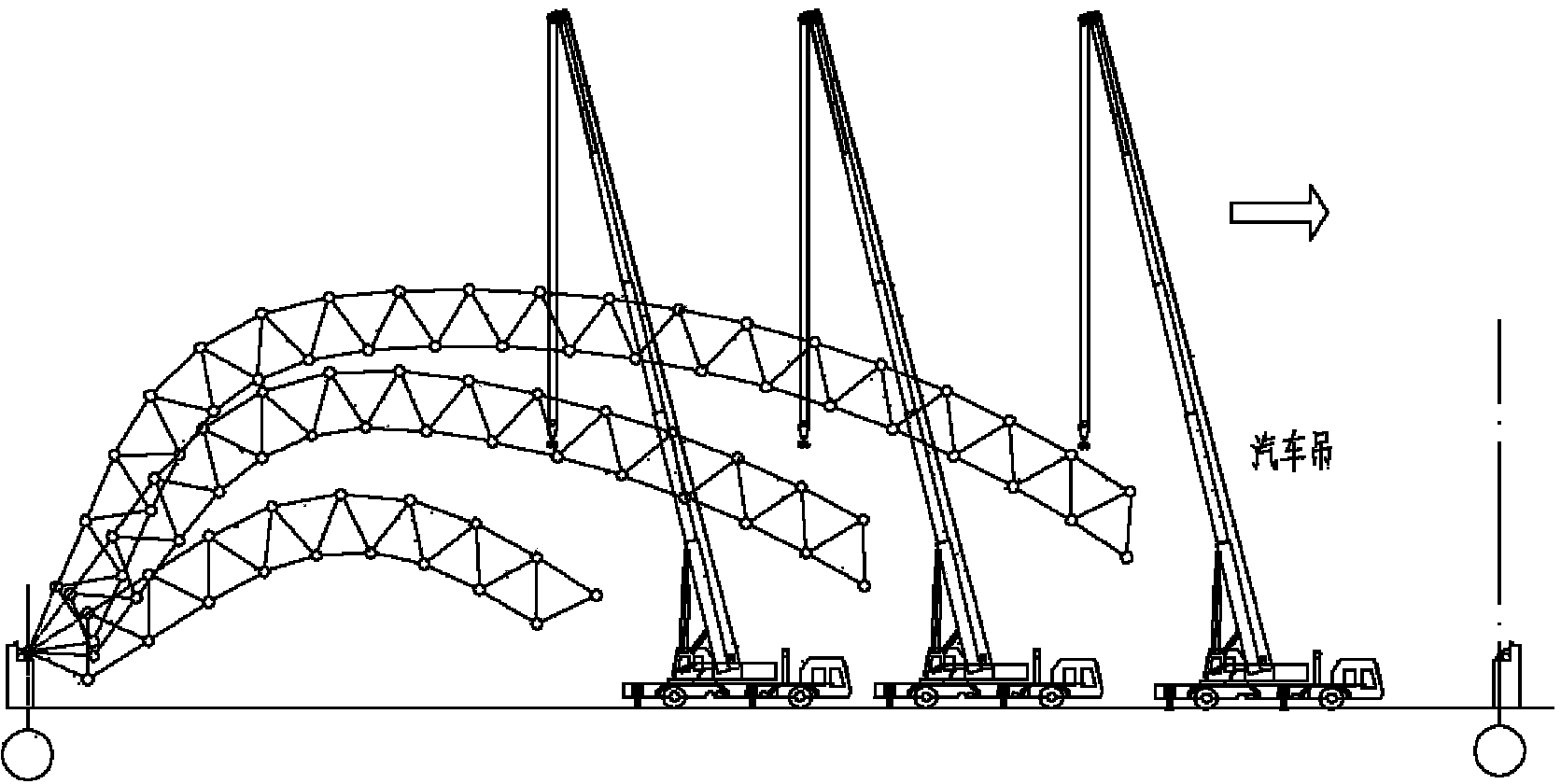

Installation construction method of roof lattice shell structure without supports and cantilevers

ActiveCN103982045ADoes not affect parallel operationsShorten the construction periodBuilding material handlingFalseworkTruck

The invention provides an installation construction method of a roof lattice shell structure without supports and cantilevers. An existing installation method needs a plurality of installation tools and scaffolds, and is high in working cost and low in speed. The method provided by the invention comprises the following steps of installing built-in fittings on the ground, permanently fixing the built-in fittings, then assembling lattice shells on the ground, lifting the lattice shells by using a truck crane for the installation of a first block lattice shell, completely installing the first block, installing the left blocks in sequence. The method has the following advantages that the lattice shells are spliced on the ground according to a design; the truck crane lifts the cantilevers to install all the lattice shells without the need of using large lifting equipment and the scaffolds; the internal parallel work is not influenced; in construction, the work at multiple aspects is implemented, and multiple types of work are simultaneously and crossly constructed; therefore the construction period is shortened greatly, and the installation speed is high.

Owner:浙江国盛钢结构有限公司

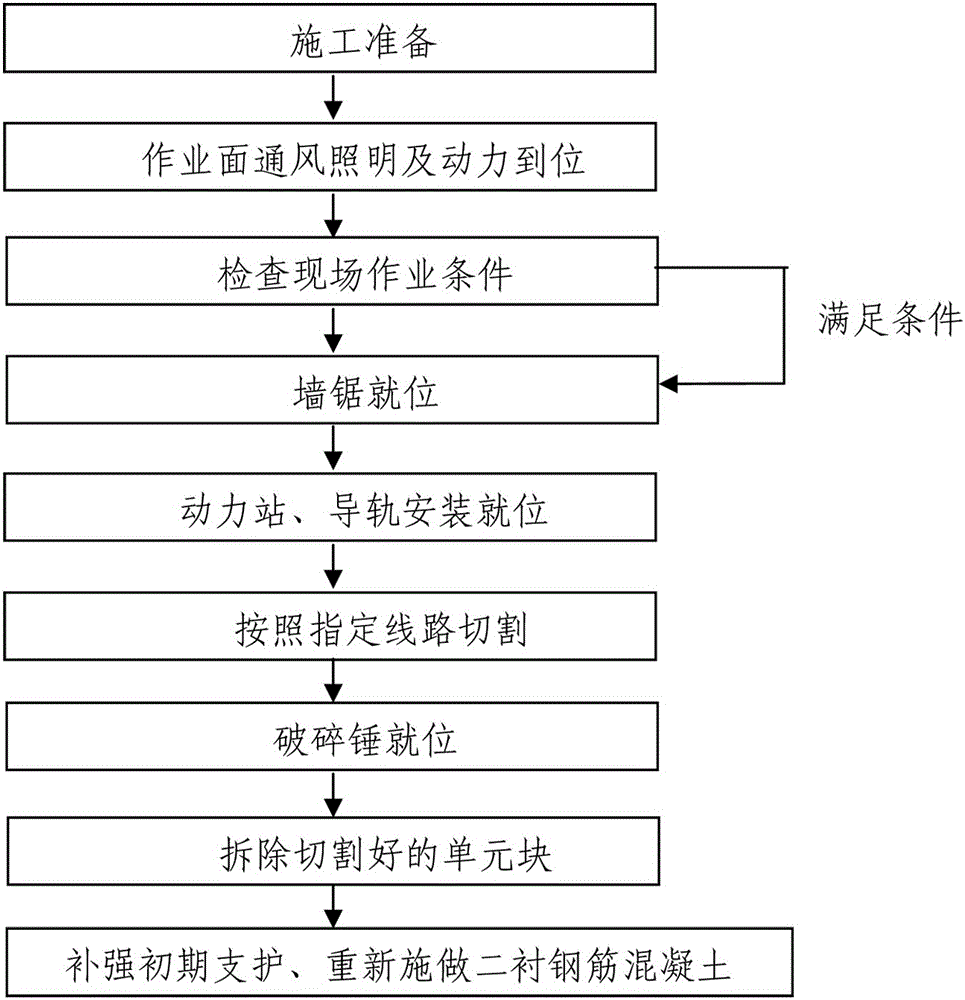

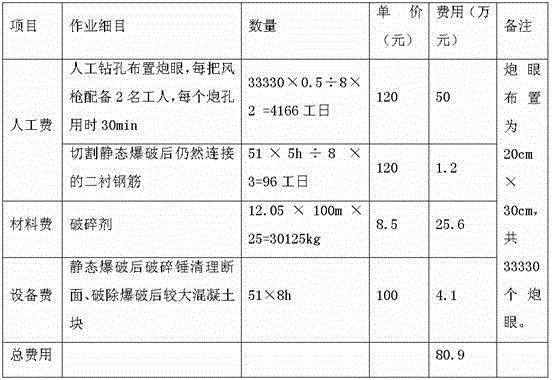

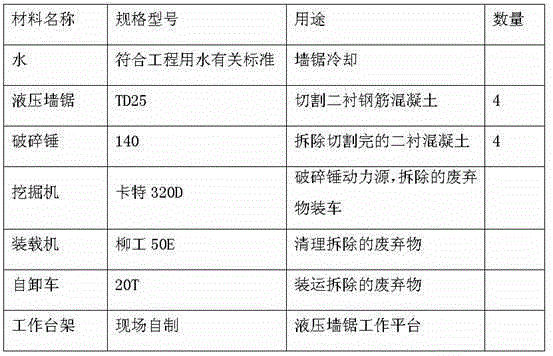

Method for dismounting second-lined reinforced concrete in tunnel

InactiveCN105019942AFast installationEasy to operateMining devicesUnderground chambersRebarReinforced concrete

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

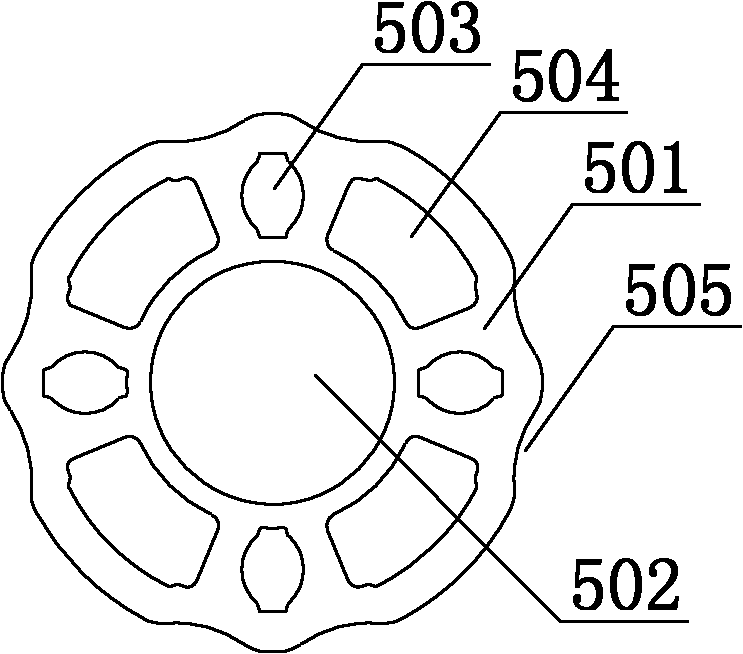

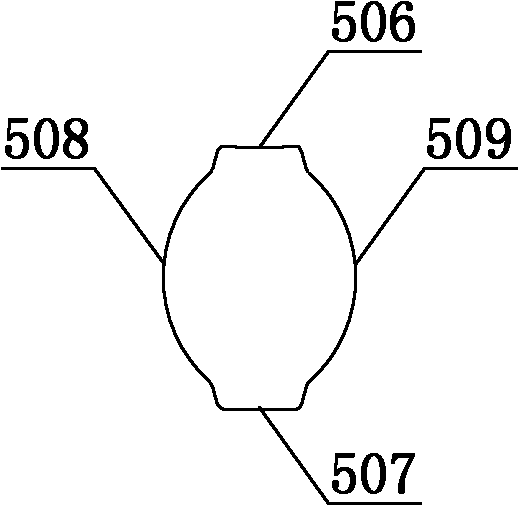

Support frame or scaffold and construction method thereof

InactiveCN101942901AChange the point of view that the thicker the wall, the greater the load-bearingWeight controlScaffold connectionsBuilding material handlingBearing capacityClassical mechanics

The invention provides a support frame or a scaffold and a construction method thereof. The support frame or the scaffold comprises a transverse rod, a horizontal inclined rod, an upright rod and an inclined rod, and is characterized in that: a disk chuck is arranged on the upright rod; the transverse rod, and the horizontal inclined rod and the inclined rod are clamped on the disk chuck through joints thereon and are fixed through pins. The support frame or the scaffold has the advantages of simple structure, standard members, high bearing capacity, steel conservation, rapid assembly and disassembly and easy transportation.

Owner:刘辉

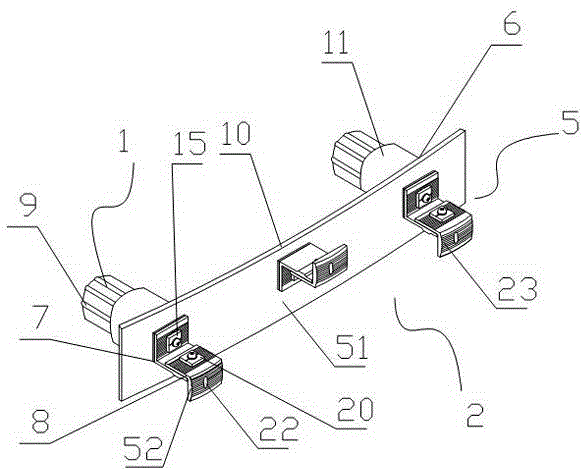

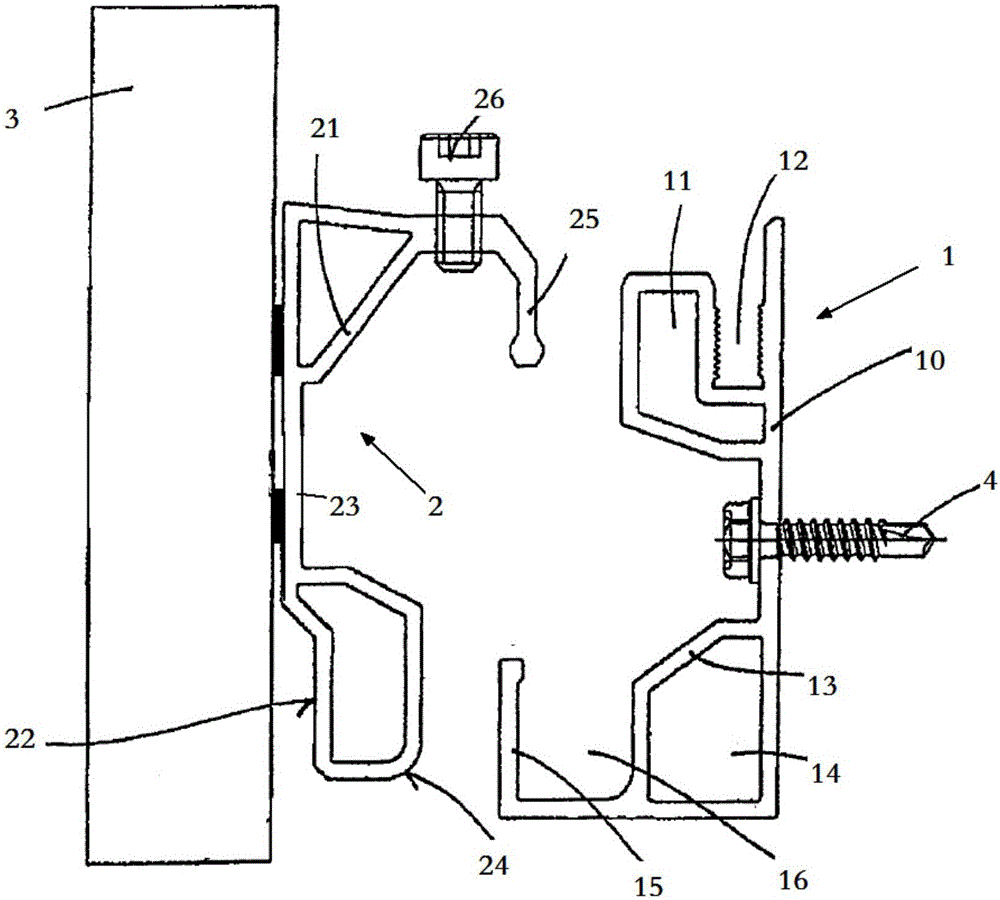

Mounting structure of concave keel wall space wood veneer

The invention provides a mounting structure of a concave keel wall space wood veneer. The mounting structure comprises a wood veneer and a concave keel, wherein the concave keel is composed of two parts, namely a male keel and a female keel; the female keel is fixed on a wall space beam or a purline by virtue of a tapping screw; the male keel is adhered to the back of the wood veneer by virtue of a structural adhesive; the male keel is provided with an upper connecting part and a lower connecting part; the female keel comprises a top connecting part and a bottom connecting part; an insertion groove is formed in the top connecting part; a clamping groove is formed in the bottom connecting part; according to insertion between the upper connecting part and the insertion groove and clamping between the lower connecting part and the clamping groove, the male keel is fixedly connected with the female keel, and the wood veneer is mounted on the wall space beam or the purline. The mounting structure has the advantages of being fast in mounting, convenient in removal, fixed, stable, nondestructive in mounting and the like.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

Installation method for thermal insulation and decoration integrated facade panels

The invention relates to an installation method for thermal insulation and decoration integrated facade panels in the field of construction methods of the construction industry. The method includes the following steps: (Step 1) main wall surface treatment; (Step 2) datum line making; (Step 3) framing installation; (Step 4) thermal insulation and decoration integrated facade panel installation; (Step 5) gap filling; (Step 6) sealant filling; (Step 7) panel surface cleaning. When the method disclosed by the invention is adopted, integral installation is convenient, cost is reduced, the construction period is short, the load of facade panels is reduced greatly, the utilizability of space and land is enhanced, the application range is wide, temperature is kept, heat is insulated, energy consumption is reduced, structural destruction caused by the circulation of rain, snow, freezing, thawing, dryness and wetness is prevented, the worry about the water seepage of wall surfaces is eased after installation, the phenomenon that indoor wall surfaces go moldy is effectively prevented, and the thermal insulation and decoration integrated facade panels are environment-friendly and durable.

Owner:杭锦旗亿利朗新材料科技有限公司

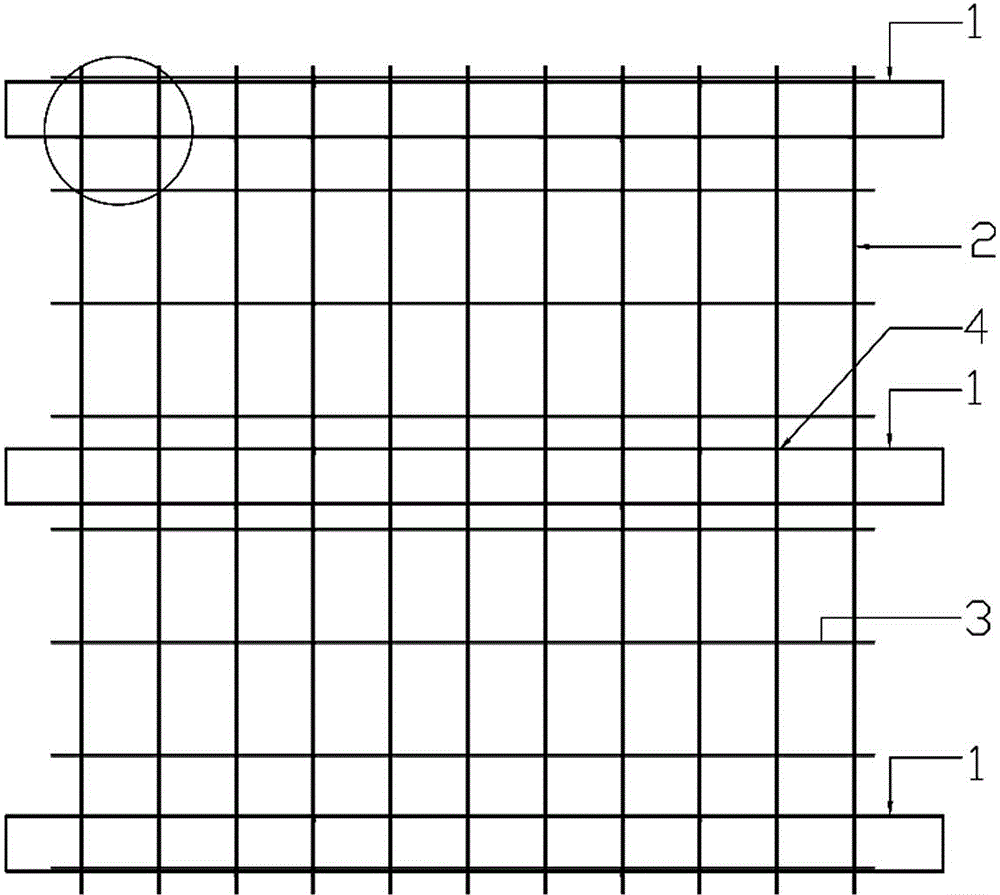

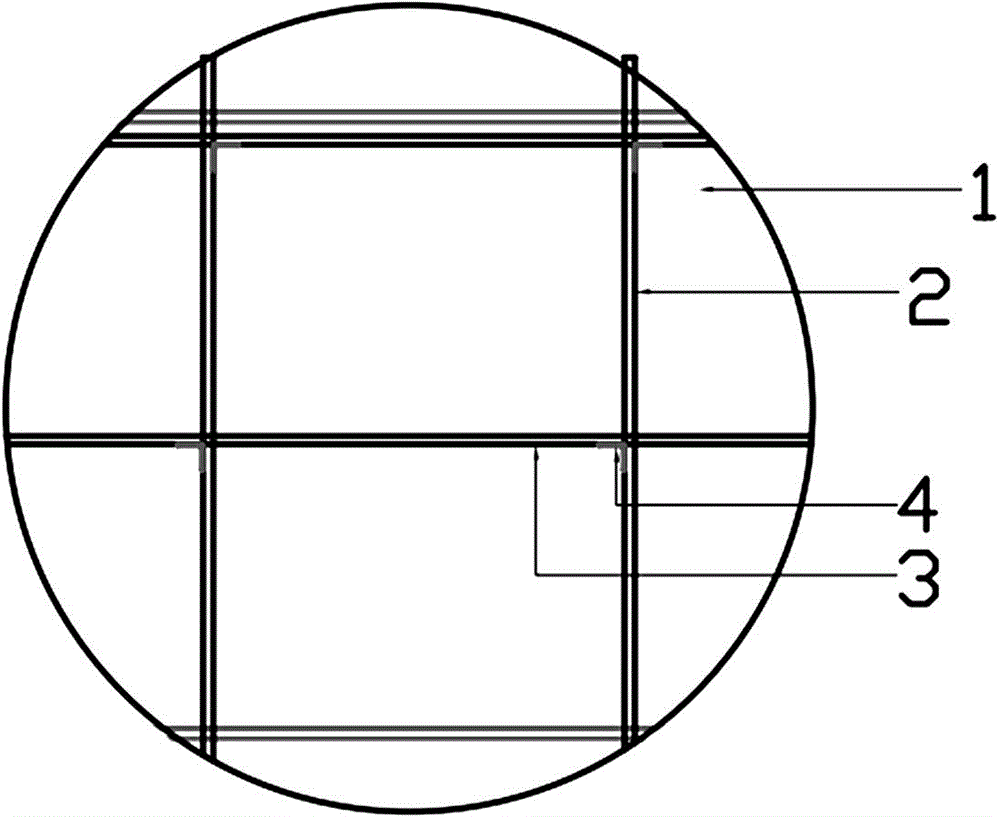

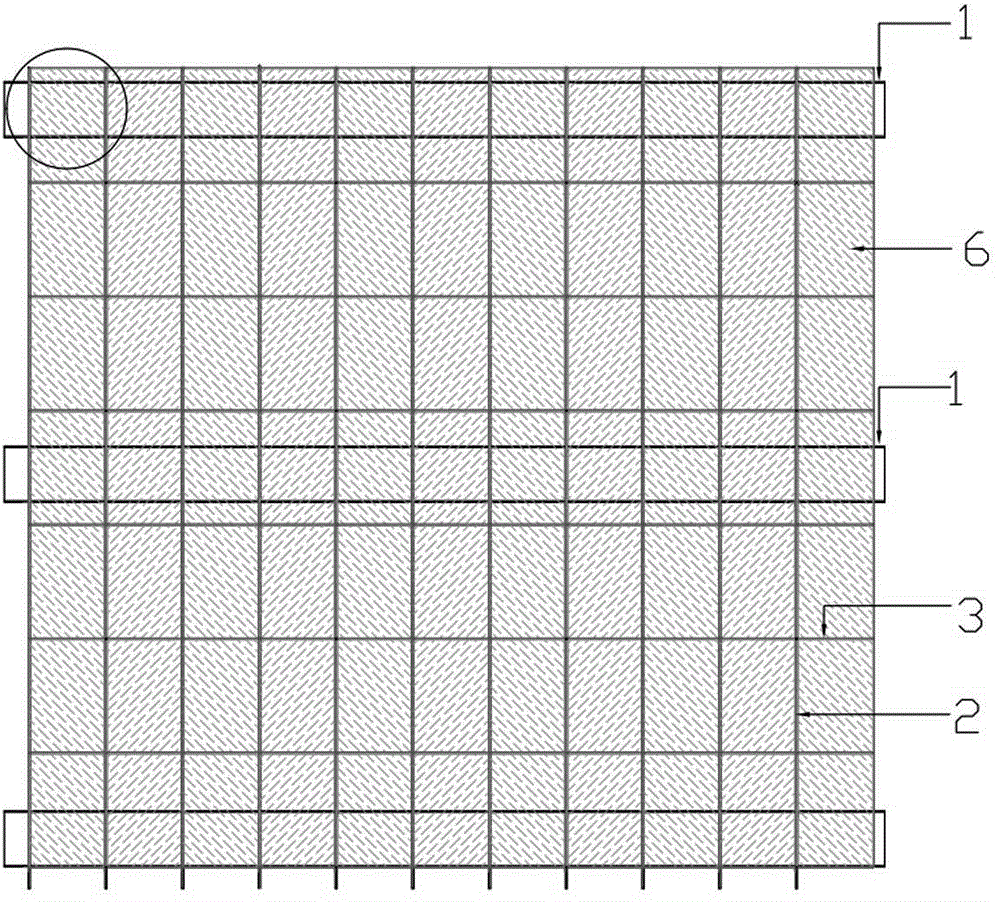

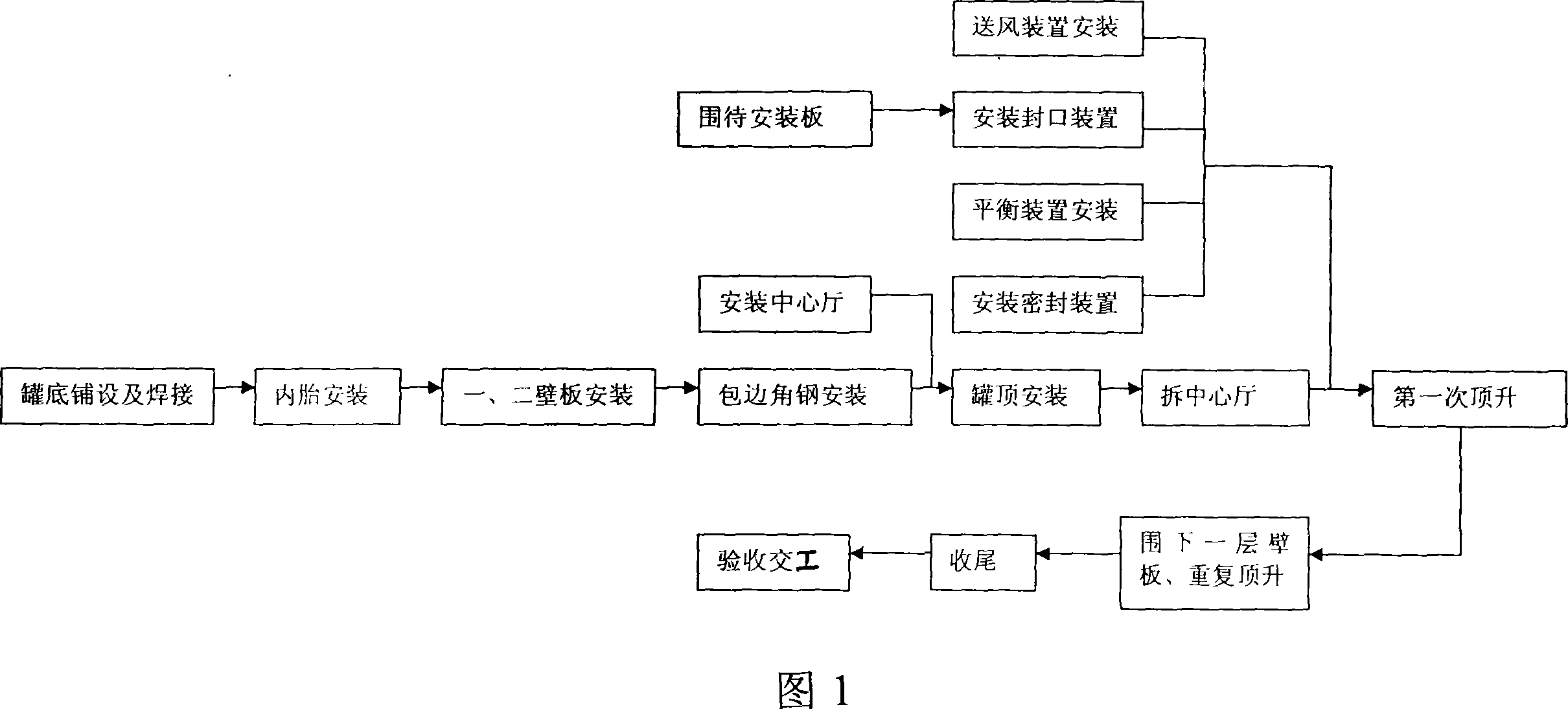

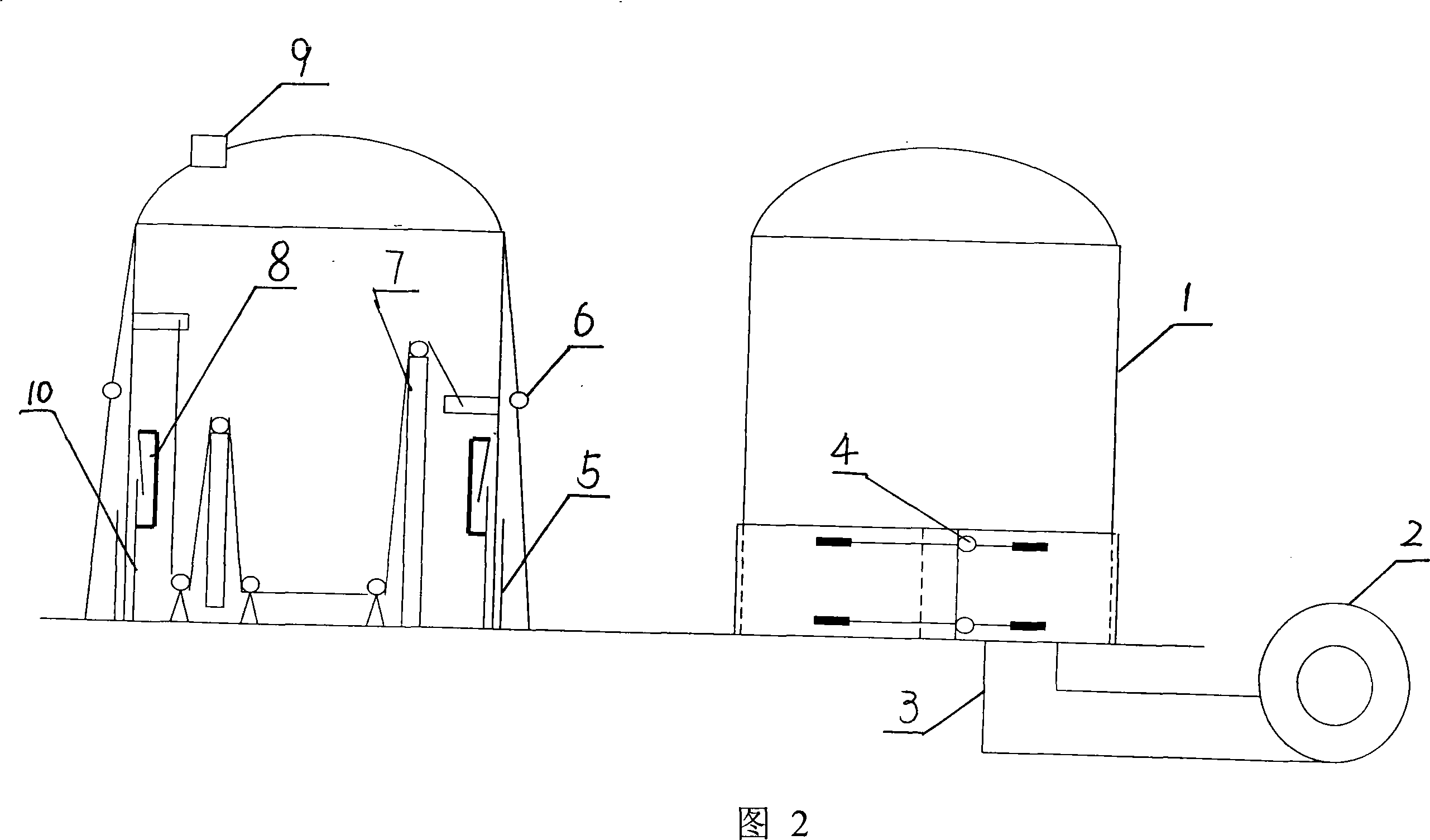

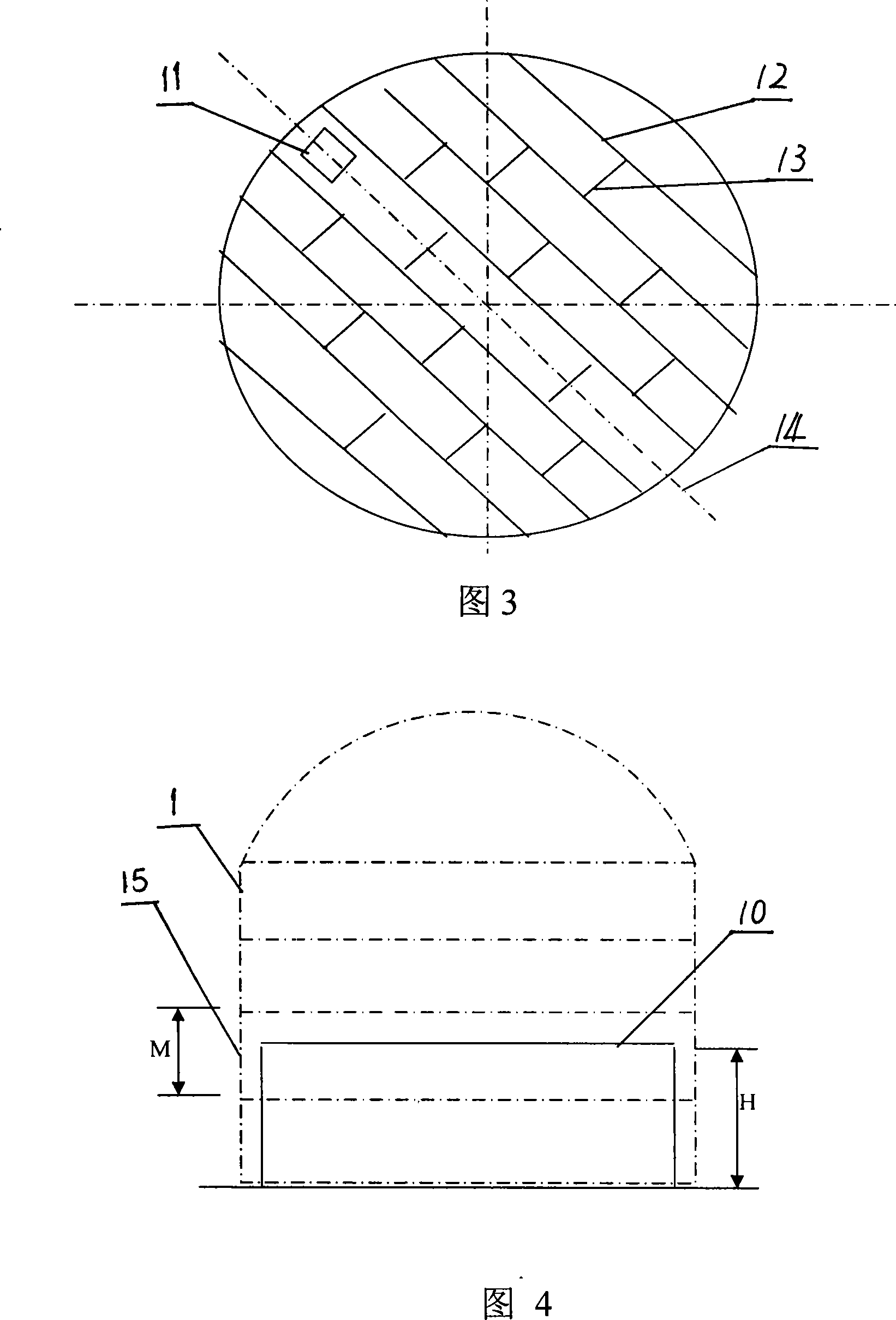

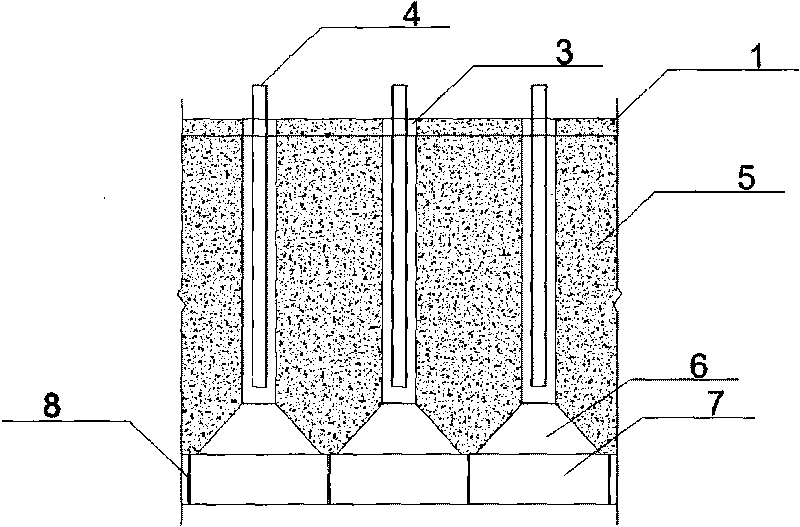

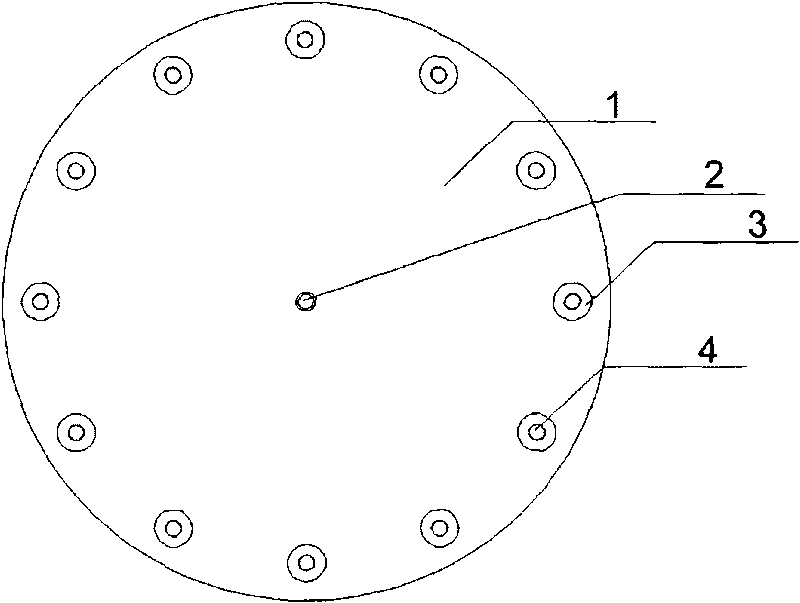

Silo high-altitude pressure-swing gas-cap mounting process

ActiveCN101200982AEasy to masterLarge working surfaceBulk storage containerSUSPENDING VEHICLEEngineering

The invention provides a high altitude mounting method of pressure transformative gas cap of silo, belonging to the high altitude machine mounting method technical field, and comprising a storage tank body. The mounting method includes the following steps: the mounting and welding of the bottom plate of the tank; the mounting of the inner tube; the mounting of first and the second wainscot and the angle steel for wrapping the edge; the mounting of a central space; the mounting of the tank roof; the removing of the central space; wrapping of the plates to be mounted; mounting of the mouth closing device; mounting of the balancing device; mounting of the sealing device. The invention is a mounting method of storage tank, which adopts the gas cap technology. The method is simple and easily grasped, the working space is wide, the construction period is short, few types of equipment are used, the structure is simple and nonbreakable, and the maintenance is convenient. As the invention is an inverted mounting method of gas cap, large-scale crane and high altitude operations are unnecessary, thereby large amount of falsework is saved, and the operations are safe.

Owner:CHINA 22MCC GROUP CORP

Large wall thickness foundation sinking method by combining diversion and negative pressure technology

The invention discloses a large wall thickness foundation sinking method by combining diversion and negative pressure technology. A diversion system of a wall of a foundation and a negative pressure system of a top cover of the foundation are combined; the diversion system of the wall of the foundation comprises vertical holes reserved at equal intervals along the circumference of the supporting wall; dredging pipes are arranged in the vertical holes; the middles of the dredging pipes are provided with diversion pipes; the bottom of the dredging pipes are provided with a trumpet-shaped conical cavity and a ripping cavity which is divided by clapboards arranged at the bottom of the vertical holes; in the negative pressure system of the top cover of the foundation, a negative pressure extracting hole is reserved on the sealed top cover; and the dredging pipes and the diversion pipes all penetrate the sealed top cover. The large wall thickness foundation sinking method has the advantages that: in a foundation sinking system by combining the diversion and negative pressure technology, by guiding seawater and applying negative pressure, the large wall thickness bucket foundation is sunk into various foundation soil bodies in economic expenditure; the sinking process is more simple; the installation speed is greatly improved; the interference of the environmental conditions can be avoided; and full automatic monitoring operation in the sinking process can be realized and the construction quality and safety are guaranteed.

Owner:JLANGSU DAODA OFFSHORE WIND CONSTR TECH CO LTD

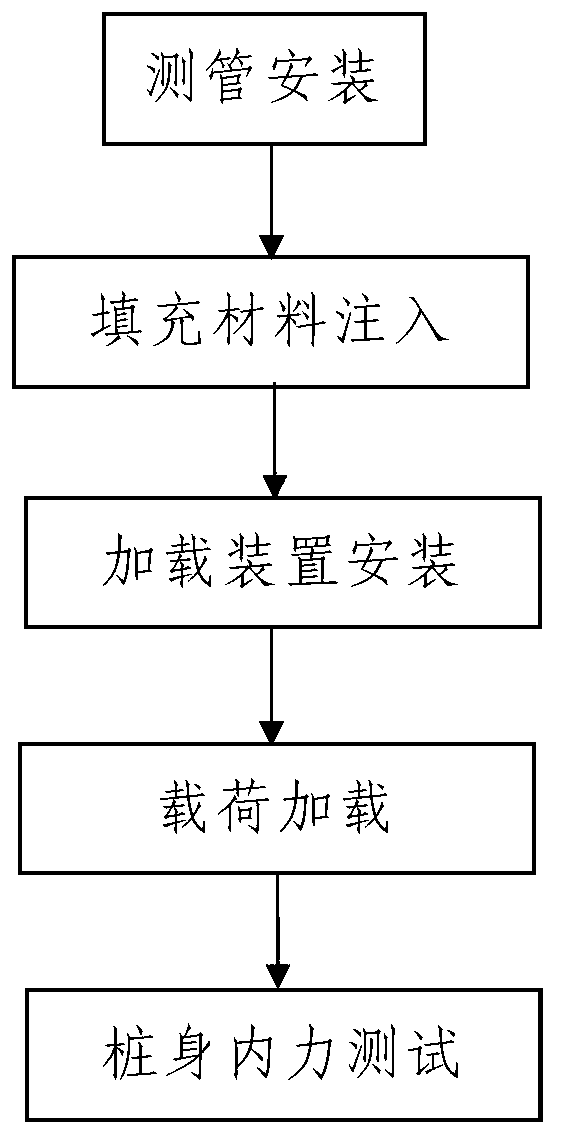

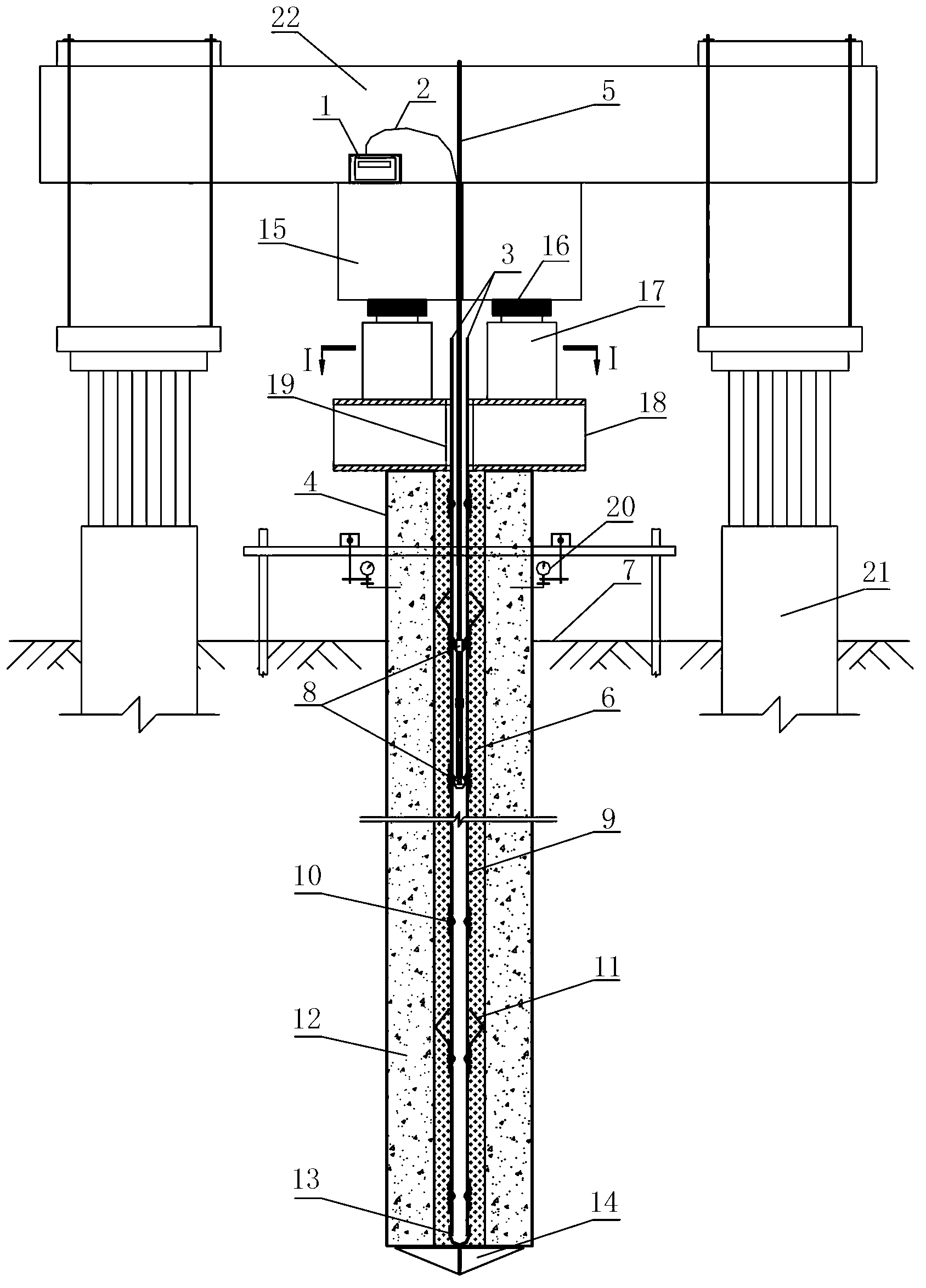

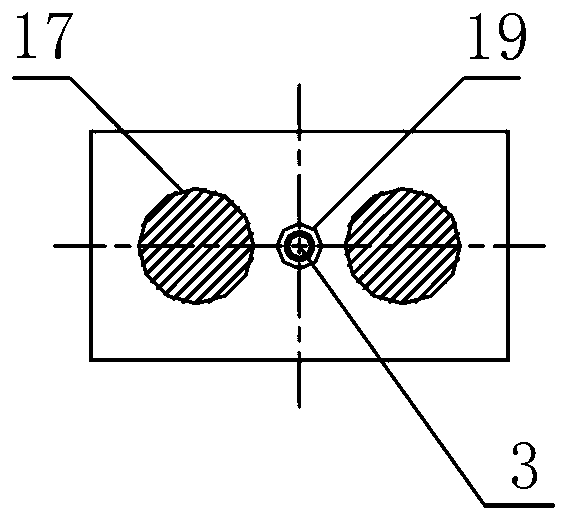

Internal force testing method for load test of pre-stress tubular pile

ActiveCN102797269AReasonable designSimple and fast operationFoundation testingMicrometerFilling materials

The invention discloses an internal force testing method for a load test of a pre-stress tubular pile. The method comprises the following steps: 1, installing a testing tube: the testing tube of a slide micrometer is installed in a constructed pre-stress tubular pile, and the testing tube is arranged in the middle of the pile core of the pre-stress tubular pile in the vertical direction; the bottom of the testing tube is sealed through a sealing cap and the testing tube is full of water; 2, injecting a filling material: the filling material is injected into the cavity between the tubular pile core of the pre-stress tubular pile and the testing tube from bottom to top by adopting grout injecting equipment, and comprises water, cement and bentonite; 3, loading an installation device; 4, loading a load; and 5, testing the internal force of a pile body: after the load is loaded and the pre-stress pile is settled and stabilized, the internal force of the pile body of the pre-stress tubular pile is tested by adopting the slide micrometer. According to the invention, the measuring method has simple steps and is convenient to implement while having high test precision and low investment, so as to obtain the internal force test result of the pre-stress tubular pile simply, conveniently, rapidly and accurately.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

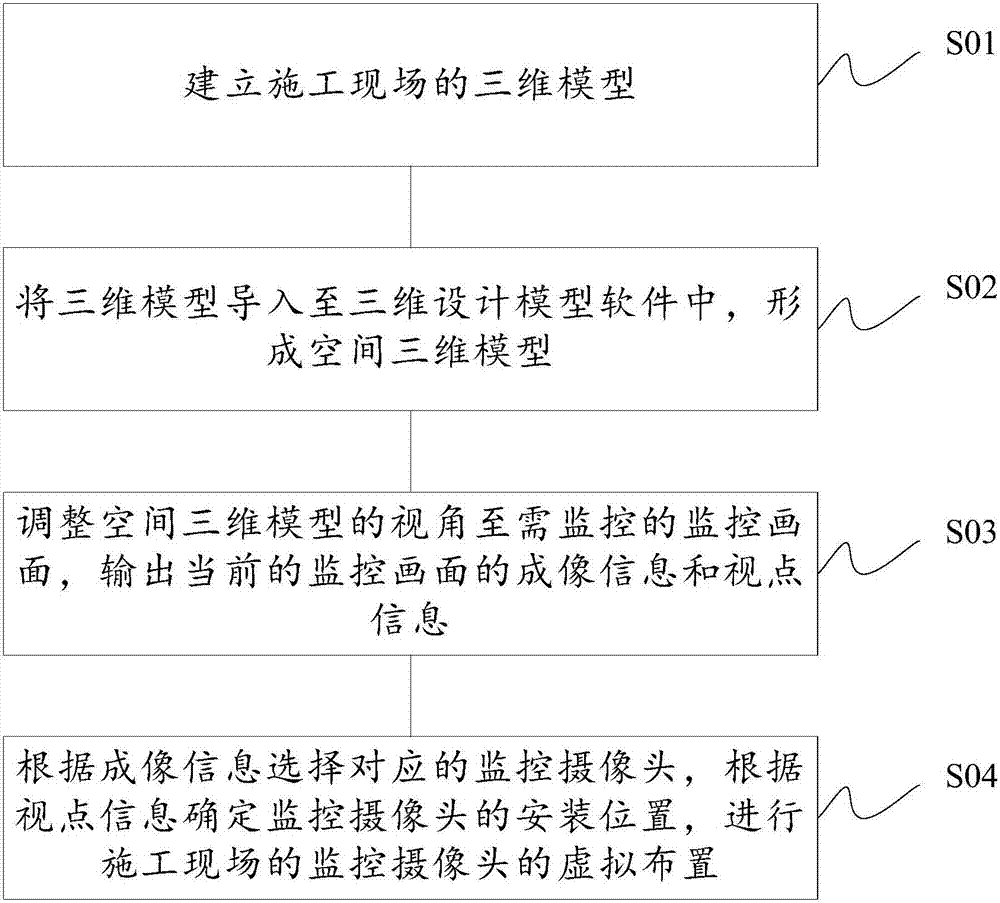

Method for virtually arranging monitoring camera of construction site based on BIM technology

ActiveCN106951583AReduce unnecessary wasteFast installationGeometric CADSpecial data processing applicationsThree dimensional modelSurveillance camera

The invention discloses a method for virtually arranging a monitoring camera of a construction site based on a BIM technology. The method comprises the steps of building a three-dimensional model of the construction site; importing the three-dimensional model to three-dimensional design model software, thereby forming a spatial three-dimensional model; adjusting a view angle of the spatial three-dimensional model to a monitoring image needed to be monitored, and outputting imaging information and viewpoint information of the current monitoring image; and selecting a corresponding monitoring camera according to the imaging information, determining a mounting position of the monitoring camera according to the viewpoint information, and performing virtual arrangement of the monitoring camera of the construction site. According to the method, reasonable arrangement can be performed through the BIM technology; and the monitoring camera of the construction site is subjected to virtual and reasonable arrangement by utilizing a visualization characteristic and a simulation characteristic of the BIM technology, so that unnecessary waste of materials in a real mounting process is reduced, the mounting speed is increased, and the management cost is reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

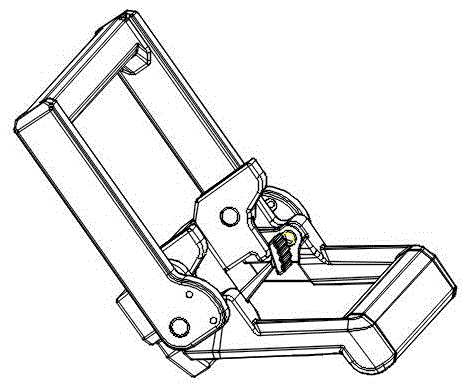

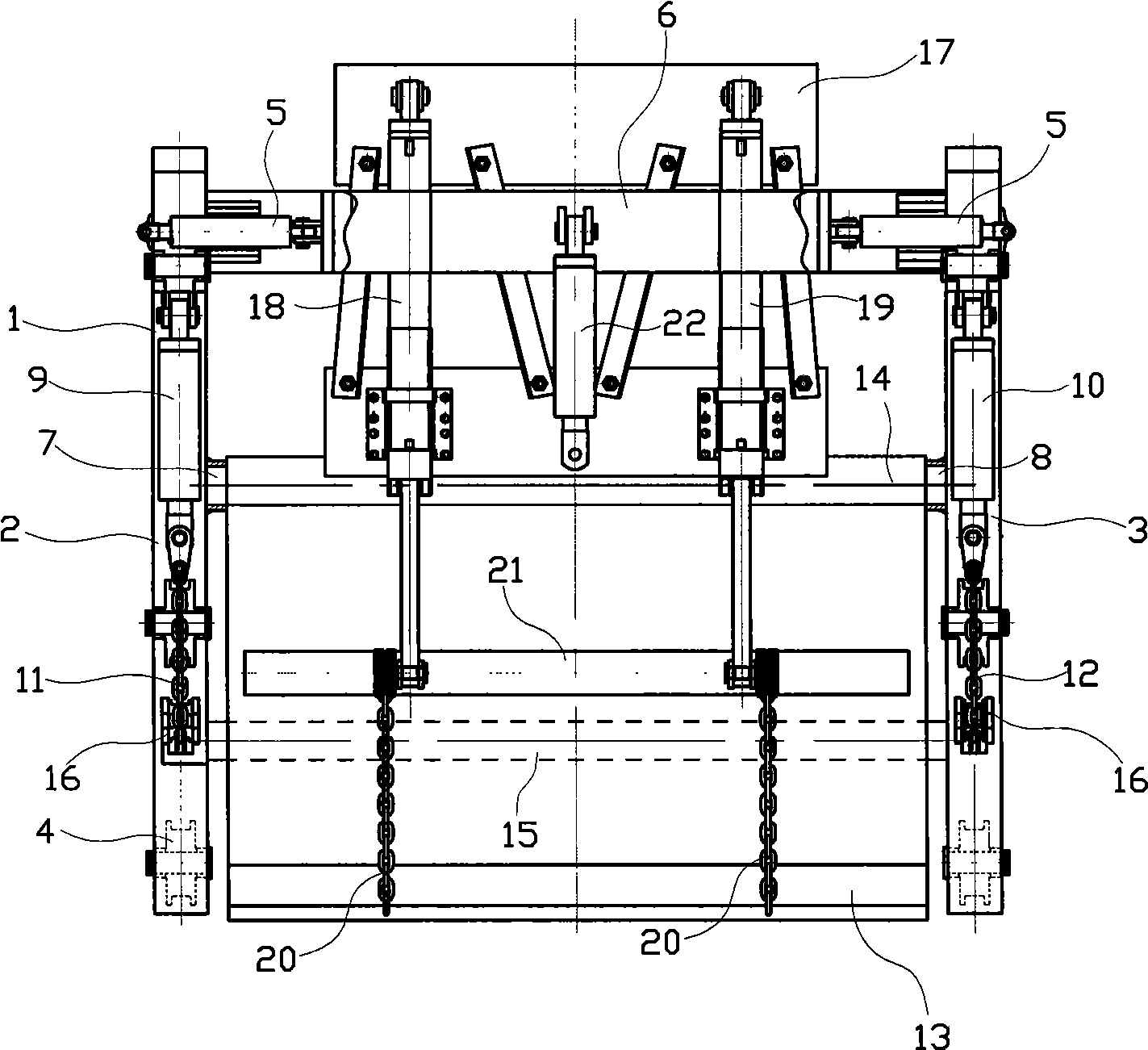

Hydraulic bracket assembling machine

InactiveCN101936176AFast installationReduce labor intensityMine roof supportsProps/chocksPiston rodPulley

The invention discloses a hydraulic bracket assembling machine, which belongs to the technical field of equipment for assembling a hydraulic bracket in a coal mine. The invention adopts the scheme that: a pull ring is fixed at one end of a vehicle body; the other end of the vehicle body is hinged with a lifting plate; the lower part of the lifting plate is provided with an angle regulating oil cylinder, the cylinder body of the angle regulating oil cylinder is arranged on the vehicle body below the lifting plate, and a piston rod is connected with the lower part of the lifting plate; and a turntable is positioned on the middle part of the vehicle body, the cylinder body of a rotary oil cylinder is arranged on the lower part of the vehicle body, the end of a piston rod of the rotary oil cylinder is connected with the bottom of the turntable through a crank, a plurality of rollers are arranged on the turntable, and a pulley is arranged on the lower part of the vehicle body. The hydraulic bracket assembling machine greatly accelerates the assembly of the hydraulic bracket, saves the assembling time and reduces the labor intensity of workers.

Owner:SHANXI DONGHUA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com