Internal force testing method for load test of pre-stress tubular pile

A technology of prestressed pipe piles and a testing method, which is applied in the test of foundation structure, construction, infrastructure engineering and other directions, can solve the problems of difficult installation and construction, difficulty in testing the internal force of prestressed pipe piles, and low test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

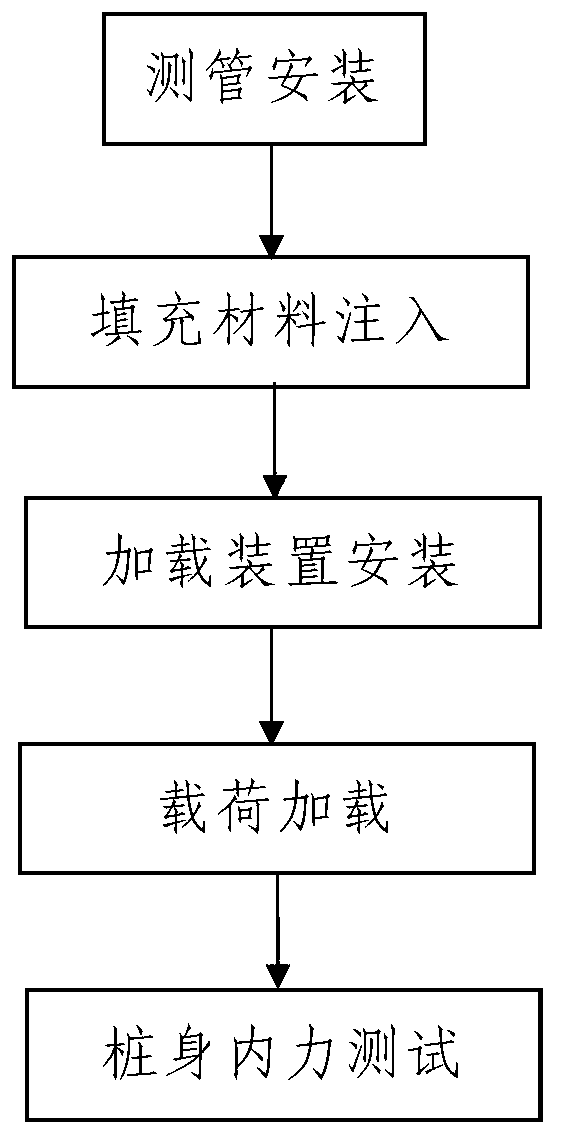

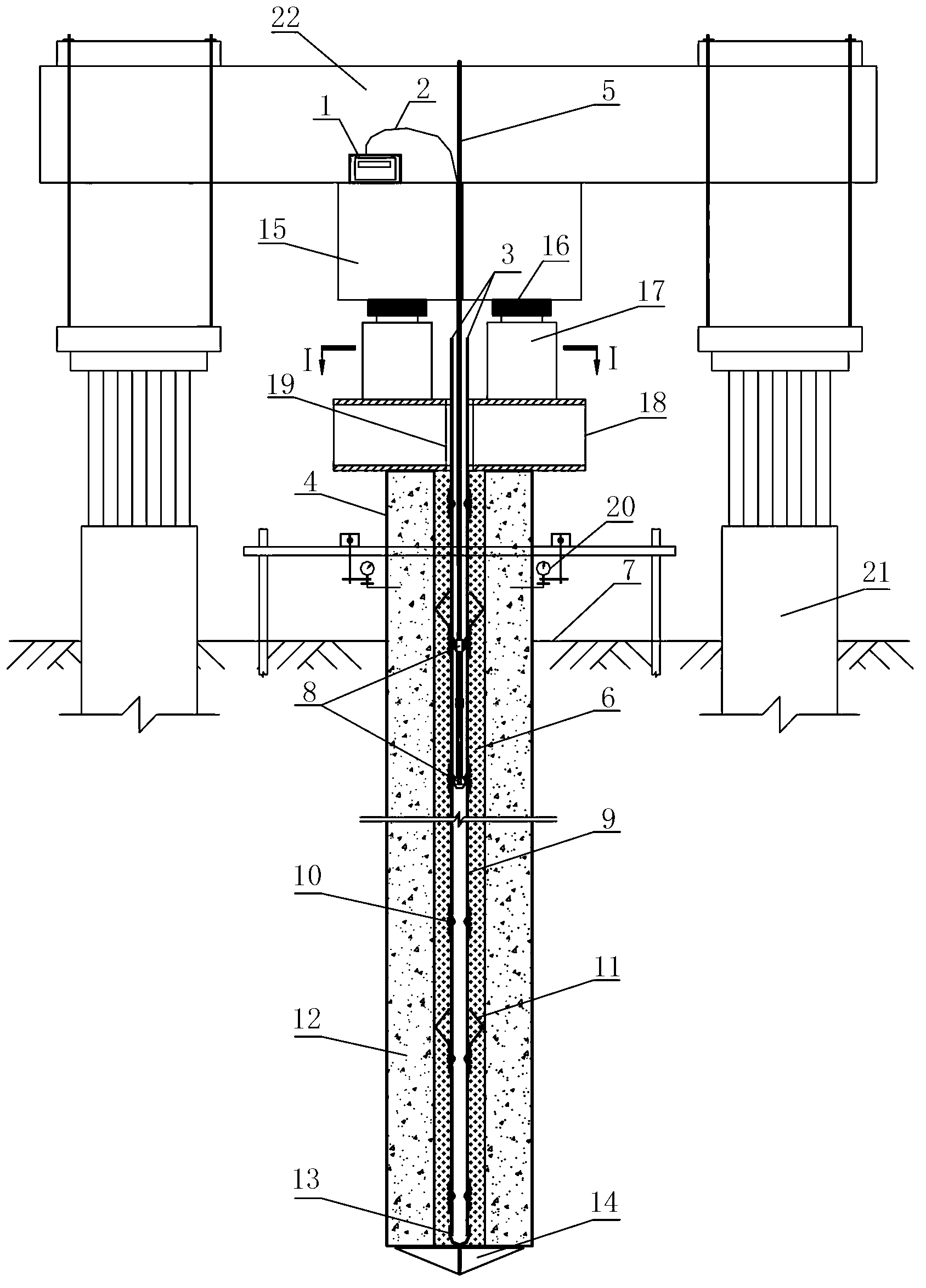

[0096] like figure 1 Shown a kind of prestressed pipe pile load test internal force testing method, comprises the following steps:

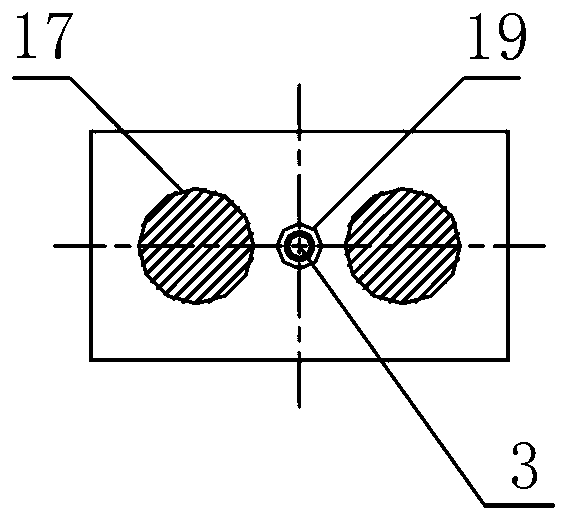

[0097] Step 1. Installing the measuring tube: install the measuring tube 3 of the sliding micrometer in the completed prestressed pipe pile 4 , and the measuring tube 3 is arranged vertically in the middle of the pipe pile core of the prestressed pipe pile 4 . The structure of the measuring tube 3 is detailed in figure 2 .

[0098] The measuring tube 3 is composed of a plastic sleeve 9 with openings at both ends and a plurality of measuring targets 10 installed on the plastic sleeve 9 from bottom to top; the bottom of the measuring tube 3 is sealed by a sealing cover 13, and the measuring Tube 3 is filled with water.

[0099] In this embodiment, when the measuring tube 3 is installed in step 1, the installation process is as follows:

[0100] Step 101, water injection into the prestressed pipe pile: after the construction of the prestressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com