Silo high-altitude pressure-swing gas-cap mounting process

An installation method and silo technology, applied in the field of silo high-altitude variable pressure air cap installation, can solve the problems of slow lifting speed, high labor intensity, and high construction cost of high-altitude installation machinery, and achieve saving of wrench, low labor intensity, and high construction cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

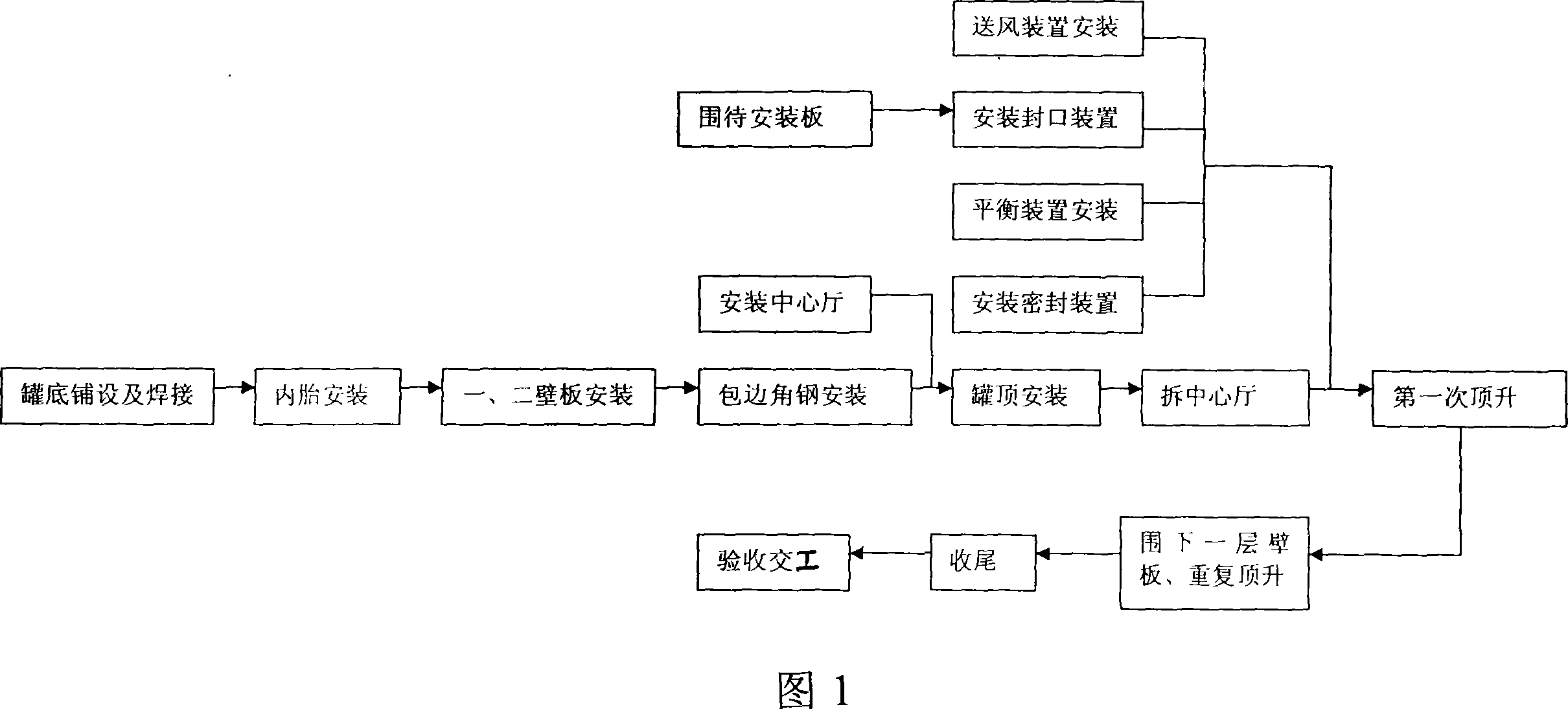

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

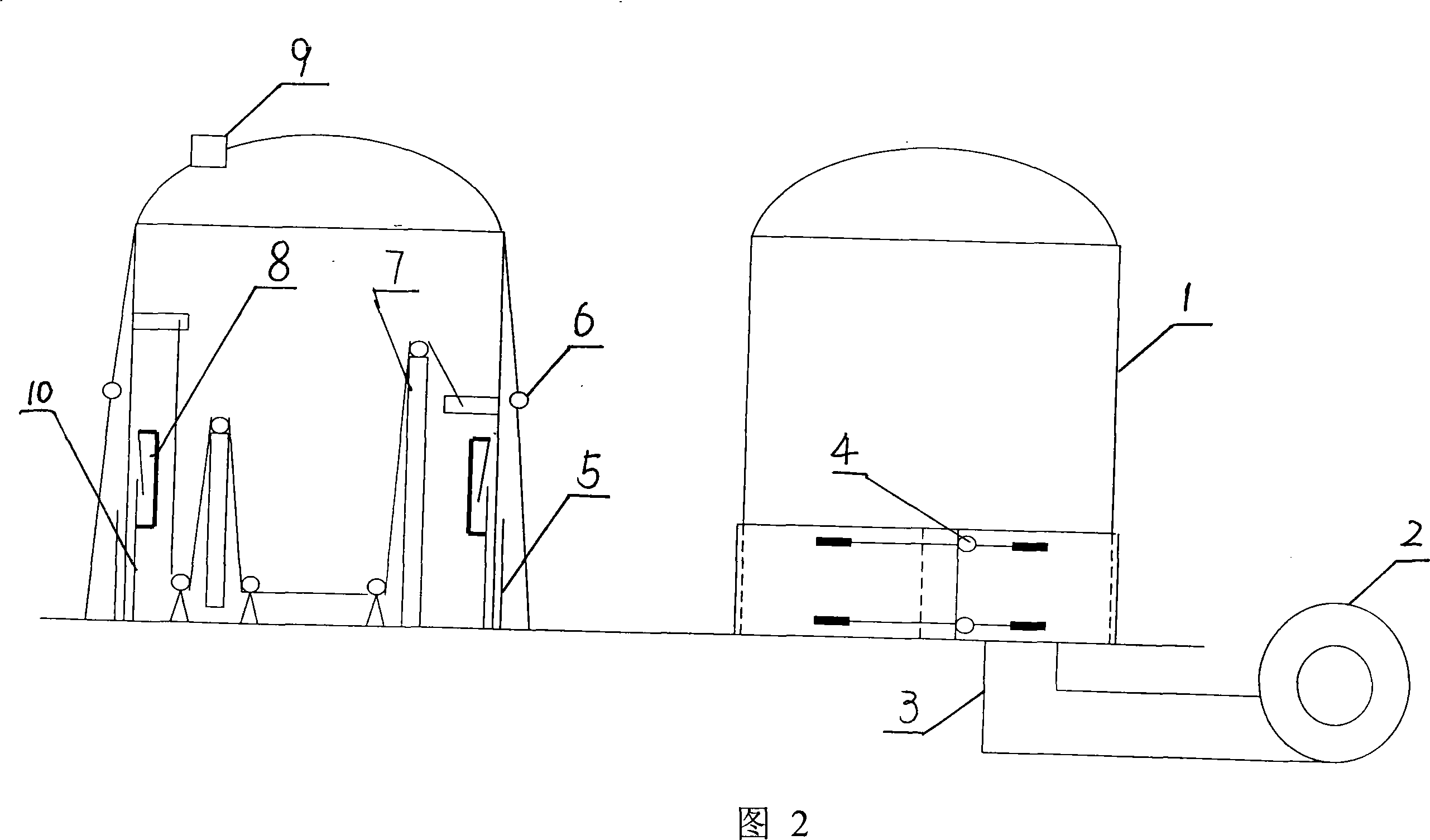

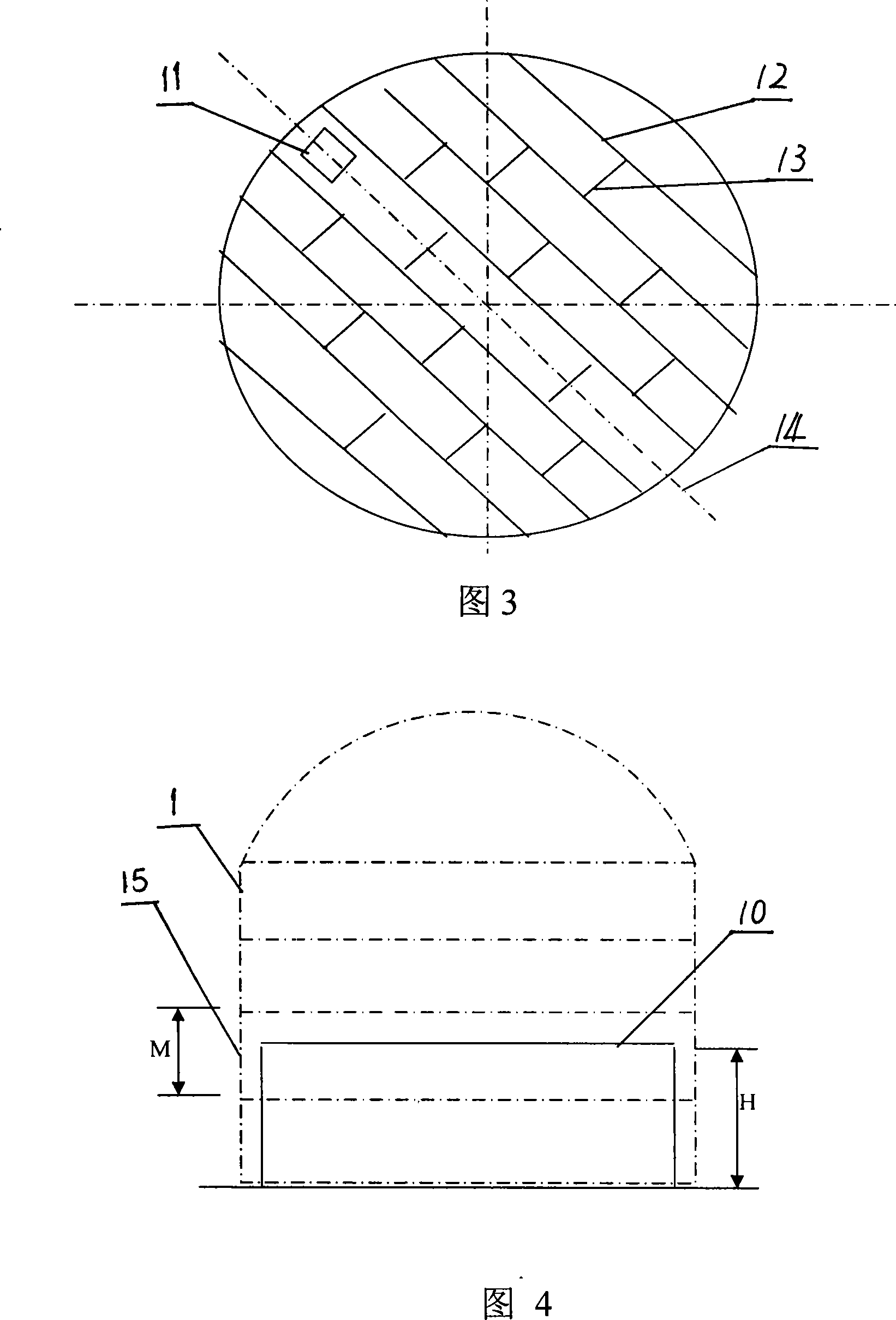

[0049] According to the structural characteristics of the tank body, the present invention assembles part of the tank body 1 in the order of inversion, and seals it, and uses a high-flow low-pressure blower to send air into the tank body 1. Since the cross-sectional size of the tank body 1 is uniform Larger, a small pressure difference can generate a huge buoyancy. When the buoyancy generated by the gas in the tank 1 exceeds the mass and friction of the tank 1 to be lifted, the tank 1 will float. When the tank 1 floats When the predetermined height is reached, control the air volume and cooperate with the balance limit device to stop it at the predetermined height, quickly carry out the combination of the upper and lower wall panels, after the spot welding is fixed, stop the wind for formal welding, and the board and so on until complete.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com