Patents

Literature

302results about How to "Use less equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

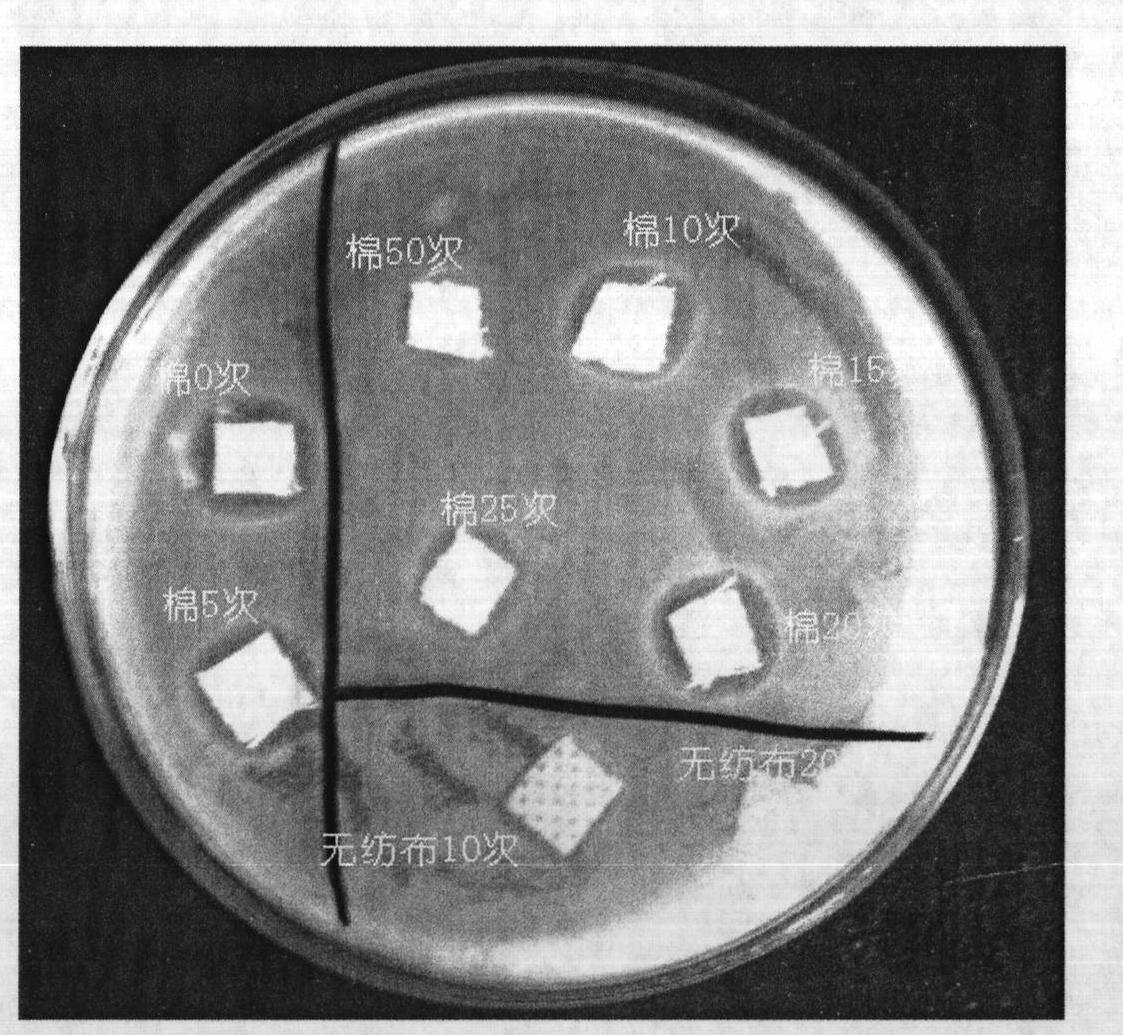

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

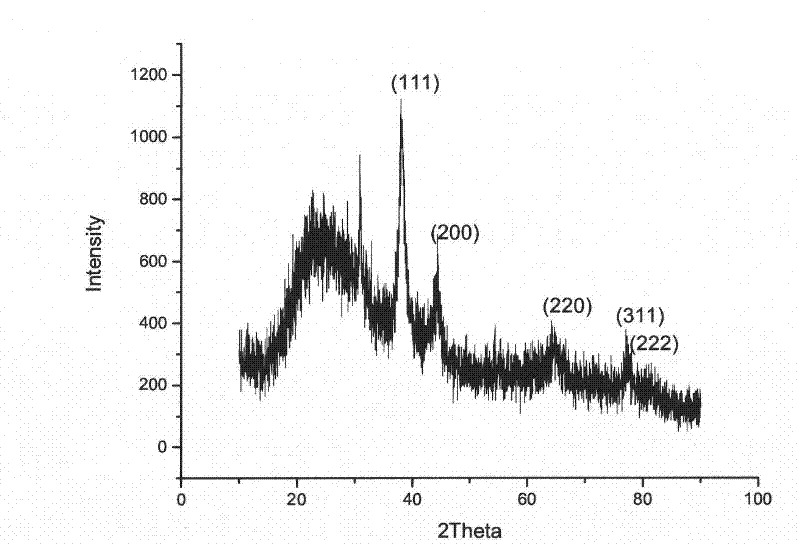

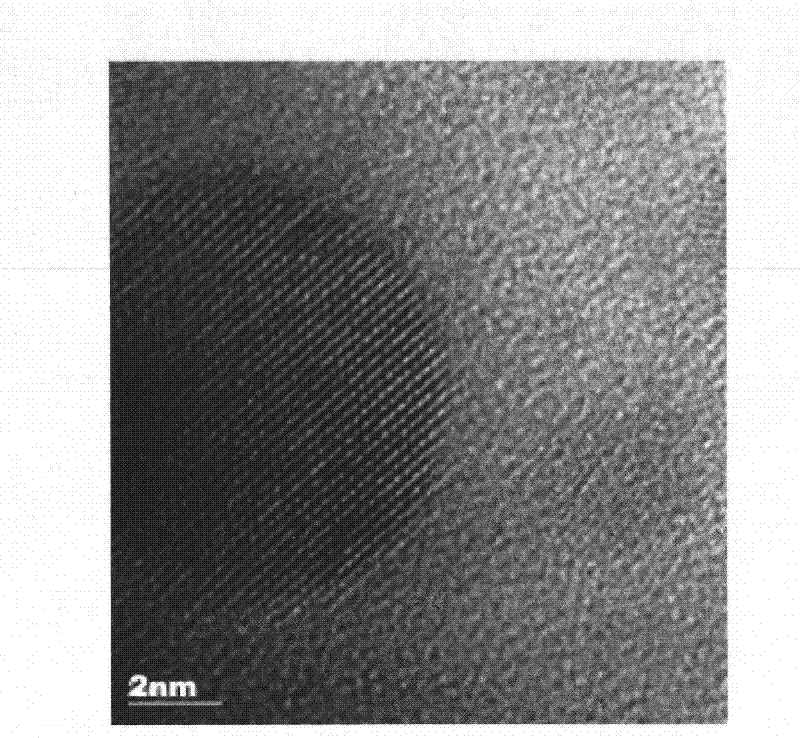

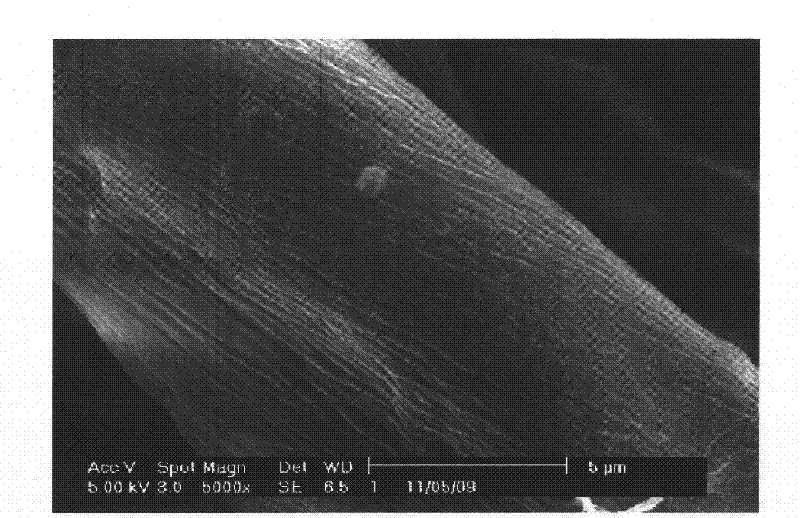

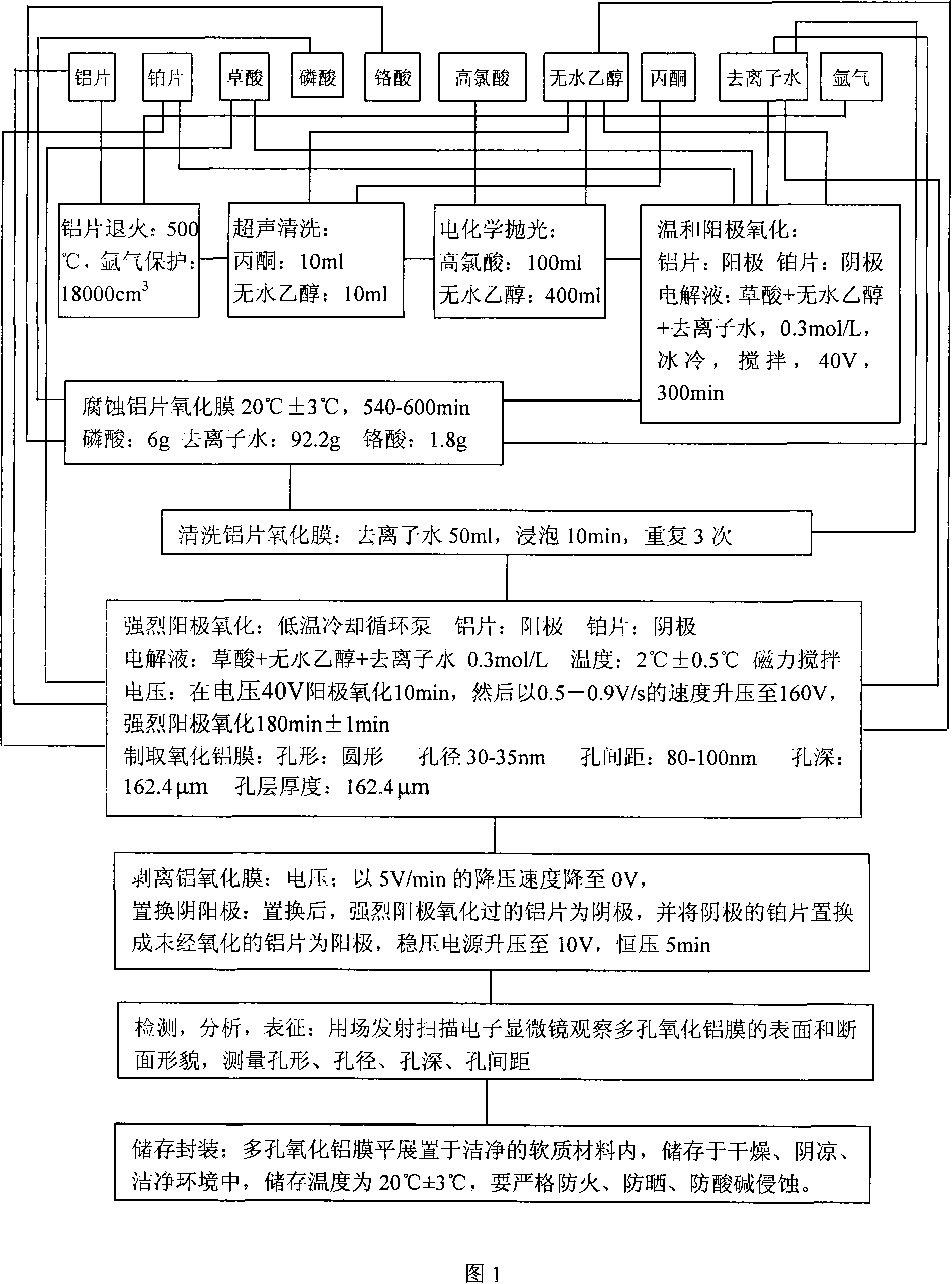

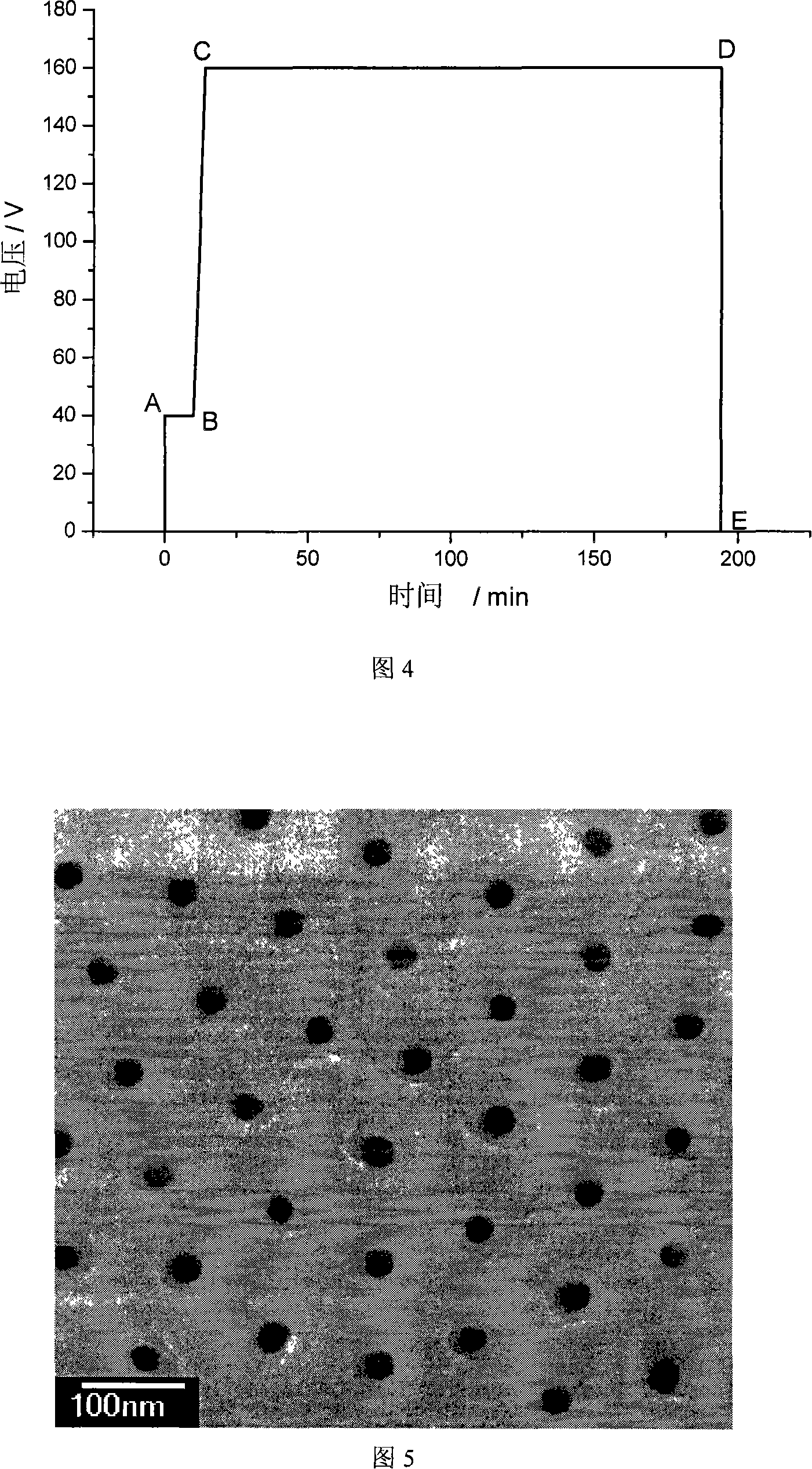

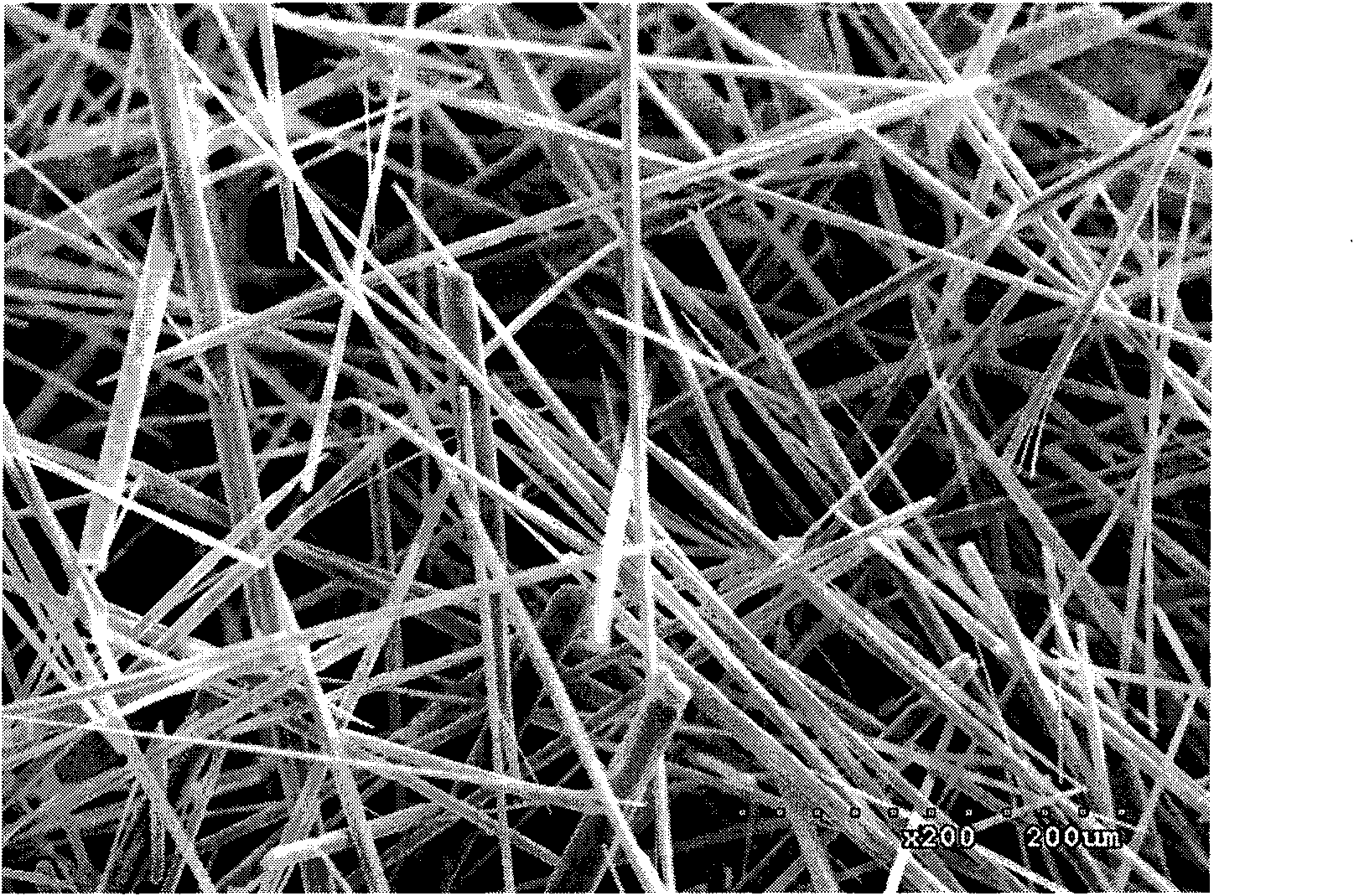

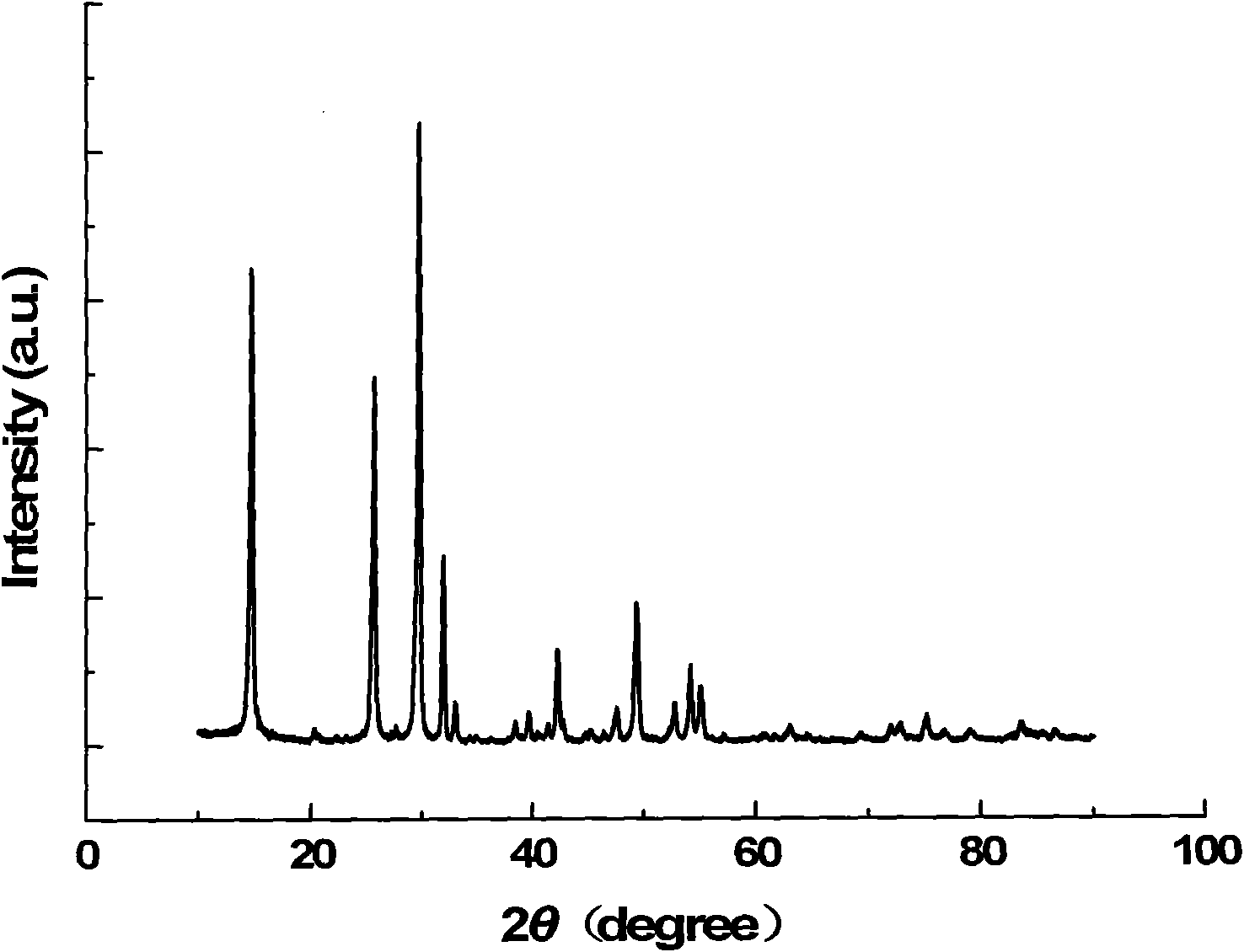

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

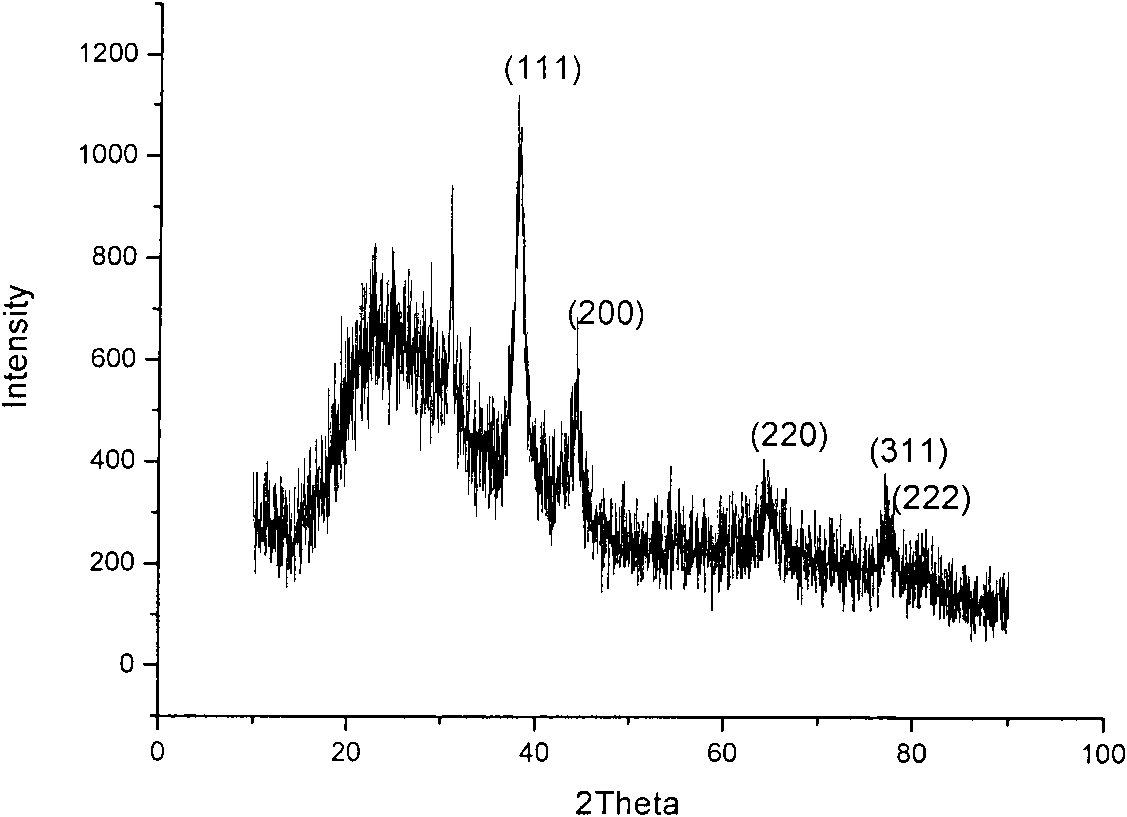

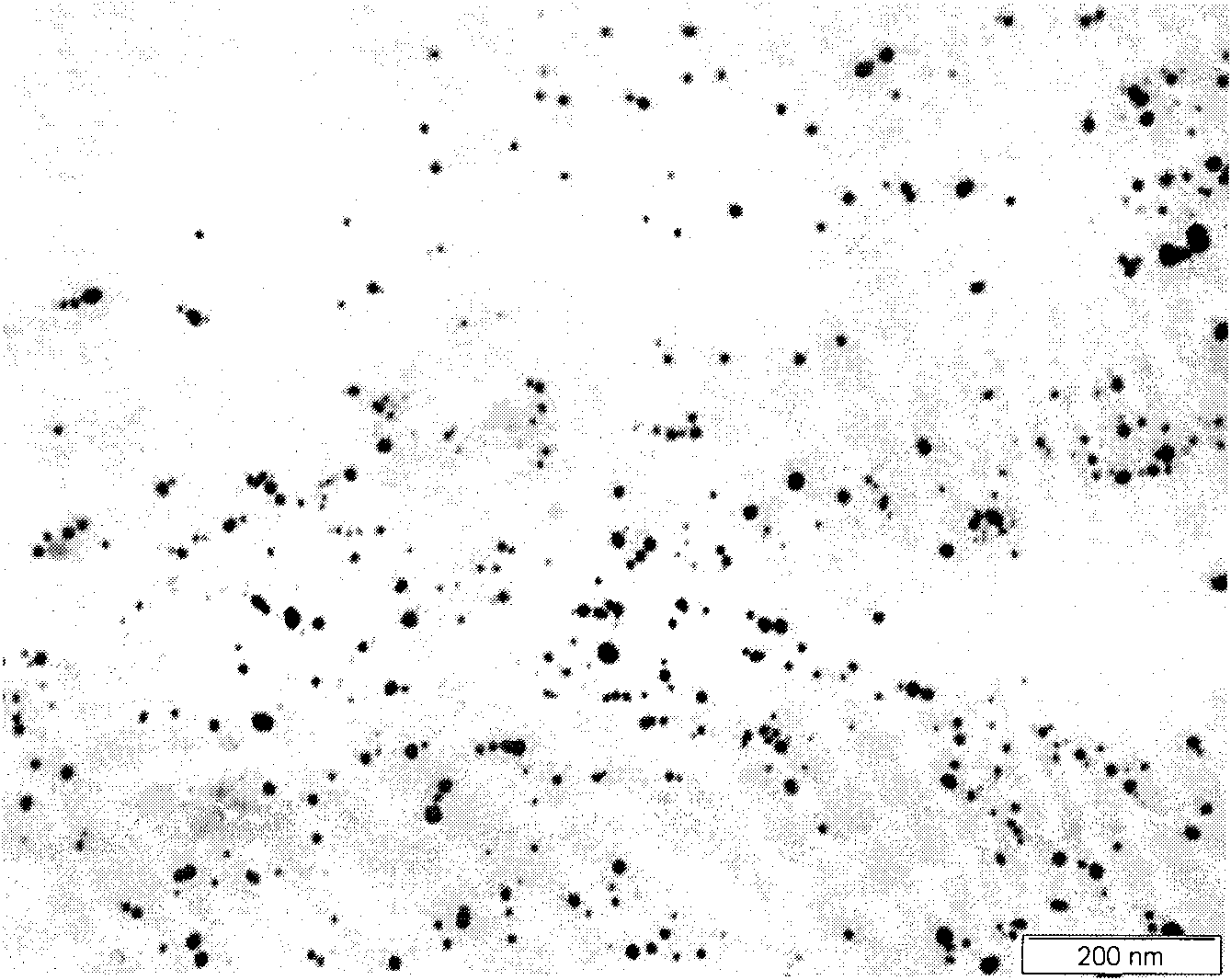

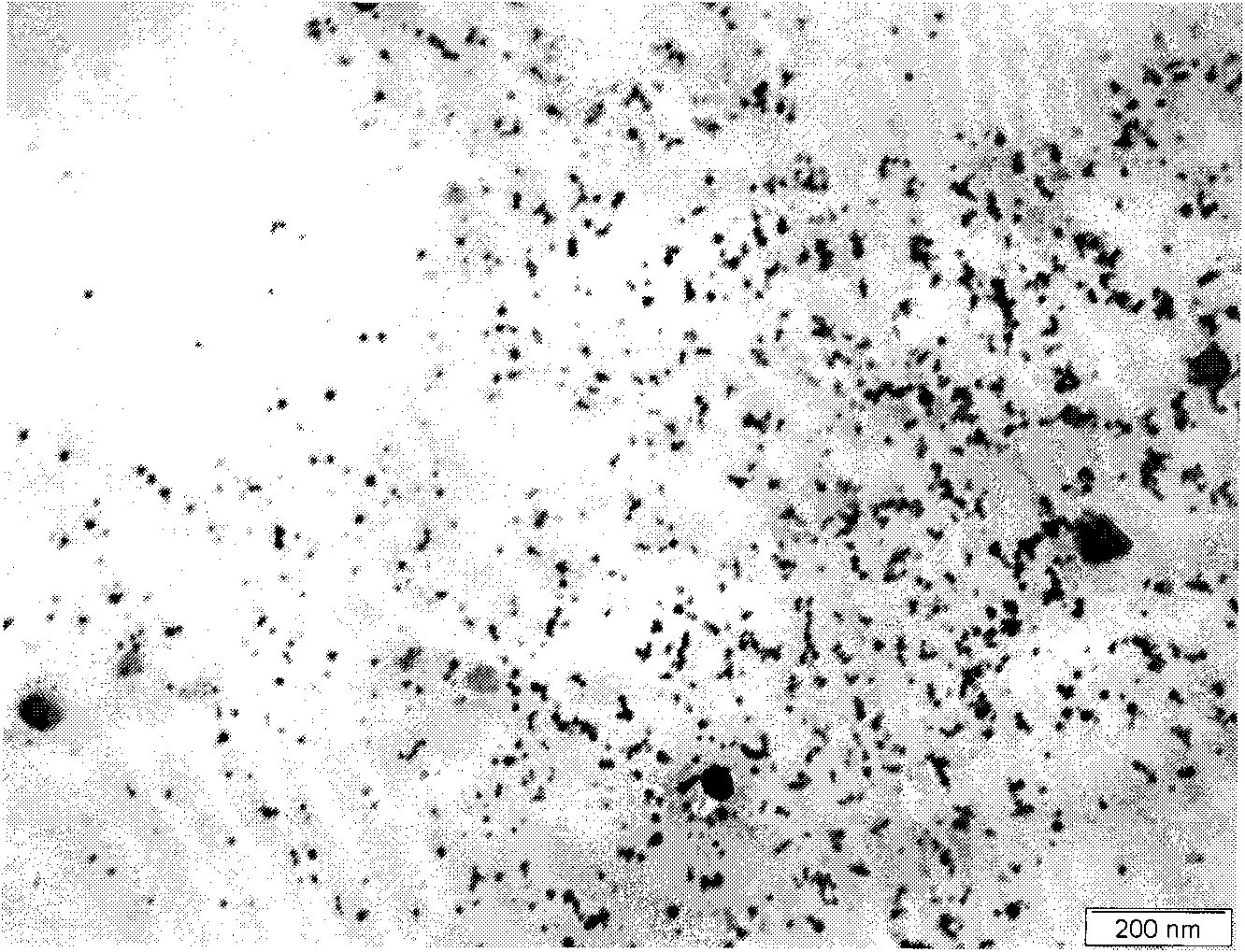

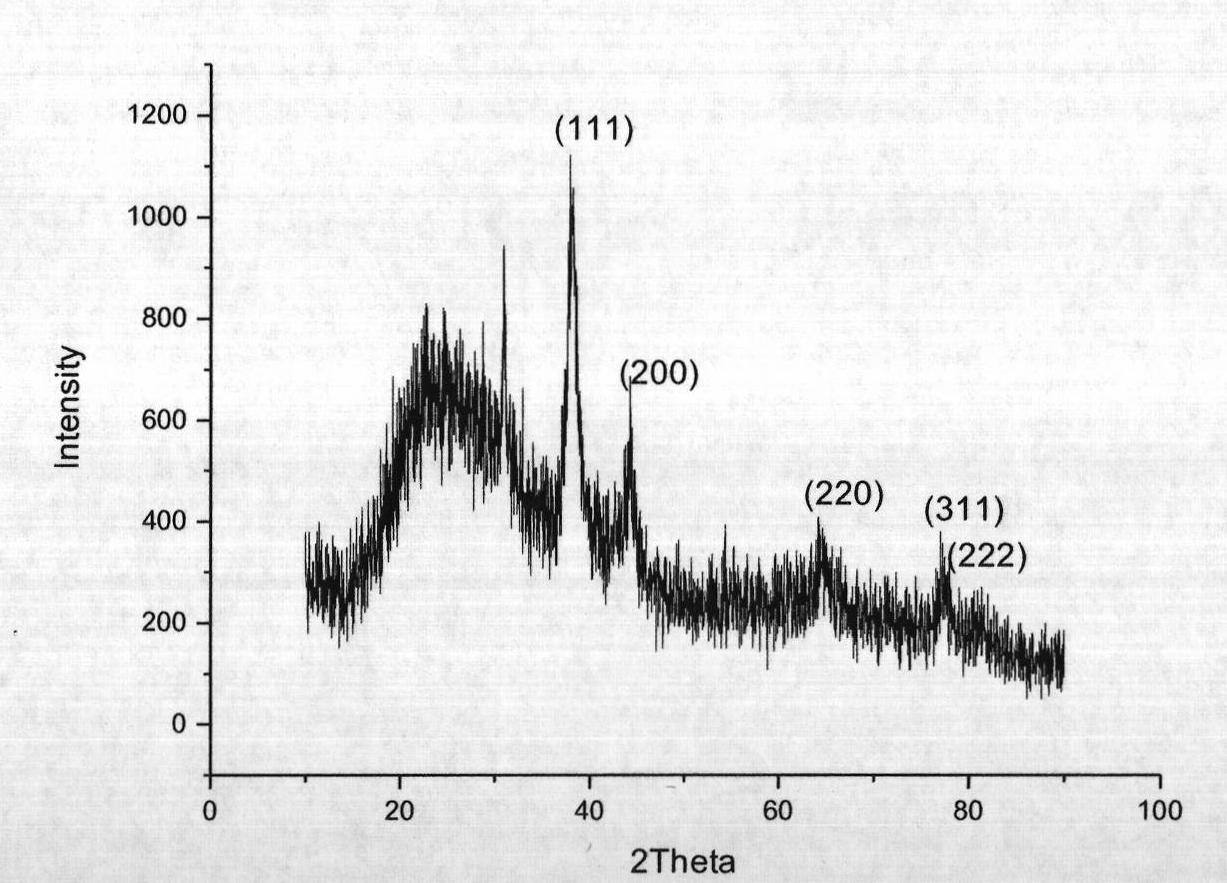

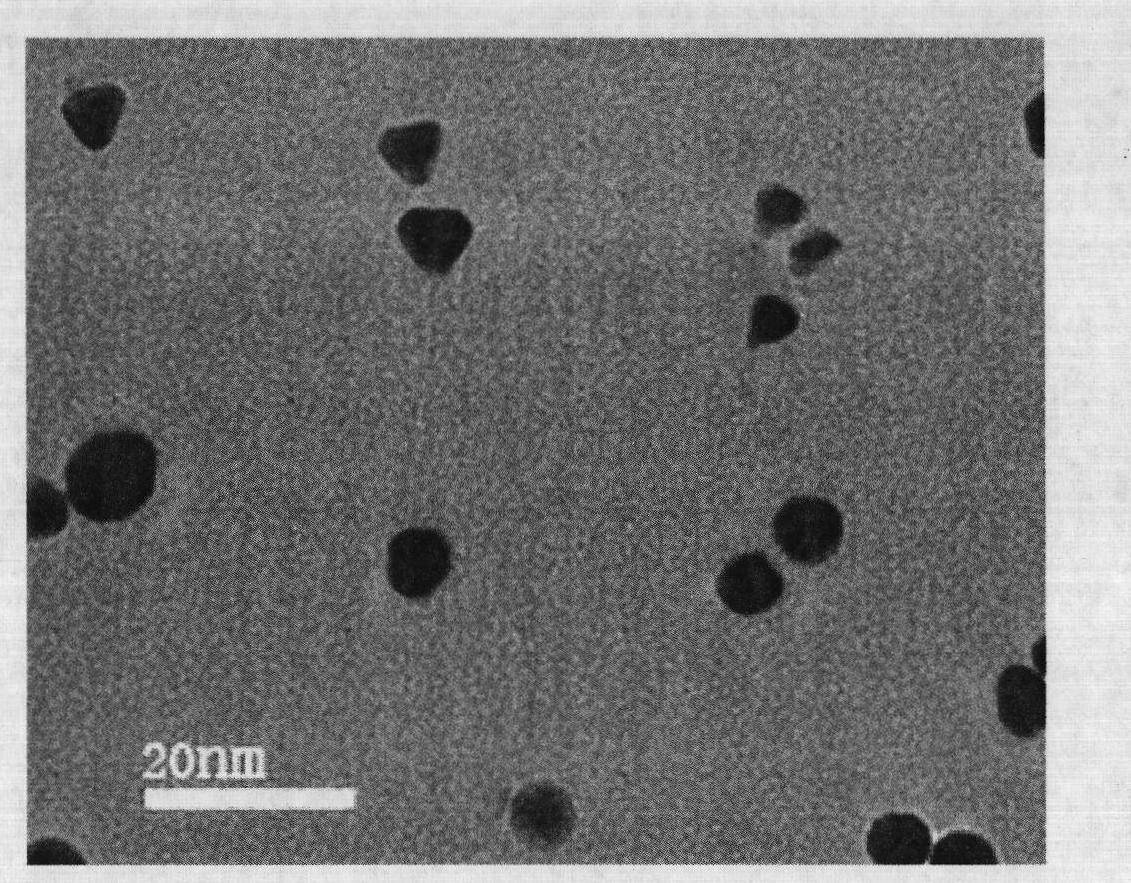

Nanometer silver collosol, preparation method and application thereof

ActiveCN101633045AImprove the safety of useImprove antibacterial propertiesFibre treatmentLavatory sanitoryAlcoholFatty alcohol

The invention relates to a nanometer silver collosol, a preparation method and an application thereof. The preparation method comprising the following steps: dissolving reductor, alcohol and fatty alcohol in a closed reactor to prepare a mixed dispersion reductor solution; and then carrying out reaction between a silver salt alcohol solution and the mixed dispersion reductor solution for 6-72 hours under the temperature of 35-70 DEG C to obtain the nanometer silver collosol. The nanometer silver collosol has good antibacterial property and is very stable, safe in use and low in production cost, thereby being extensively used for the antibacterial processing of textiles and the antibacterial and deodorizing processing of shoes and having strong market competitiveness.

Owner:CHANGZHOU CHAMGO NANO MATERIALS

Air purifying composition and preparation method and use thereof

InactiveCN102057961AGood antibacterial and mildew resistanceEasy to useBiocideDispersed particle separationPublic placeRoom temperature

The invention relates to an air purifying composition, and a preparation method and use thereof. The method comprises: adding 0.1 to 40 parts of mixed fatty alcohol, 0.01 to 10 parts of dispersing aid, 106 parts of water and 0.01 to 5 parts of synergistic components into a reaction kettle under normal temperature and at room temperature, and fully stirring; adding 0.01 to 10 parts of nano silver solution and 0.05 to 10 parts of plant extract in turn, and uniformly stirring; and performing ultrasonic dispersion treatment on the mixture in the reaction kettle to obtain the air purifying composition. The air purifying composition prepared by the method has high antibacterial performance, can effectively remove harmful volatile organic matters and improve air quality in rooms, carriages, public places and the like, is safe and low in production cost and has high market competitive power.

Owner:赵正坤 +1

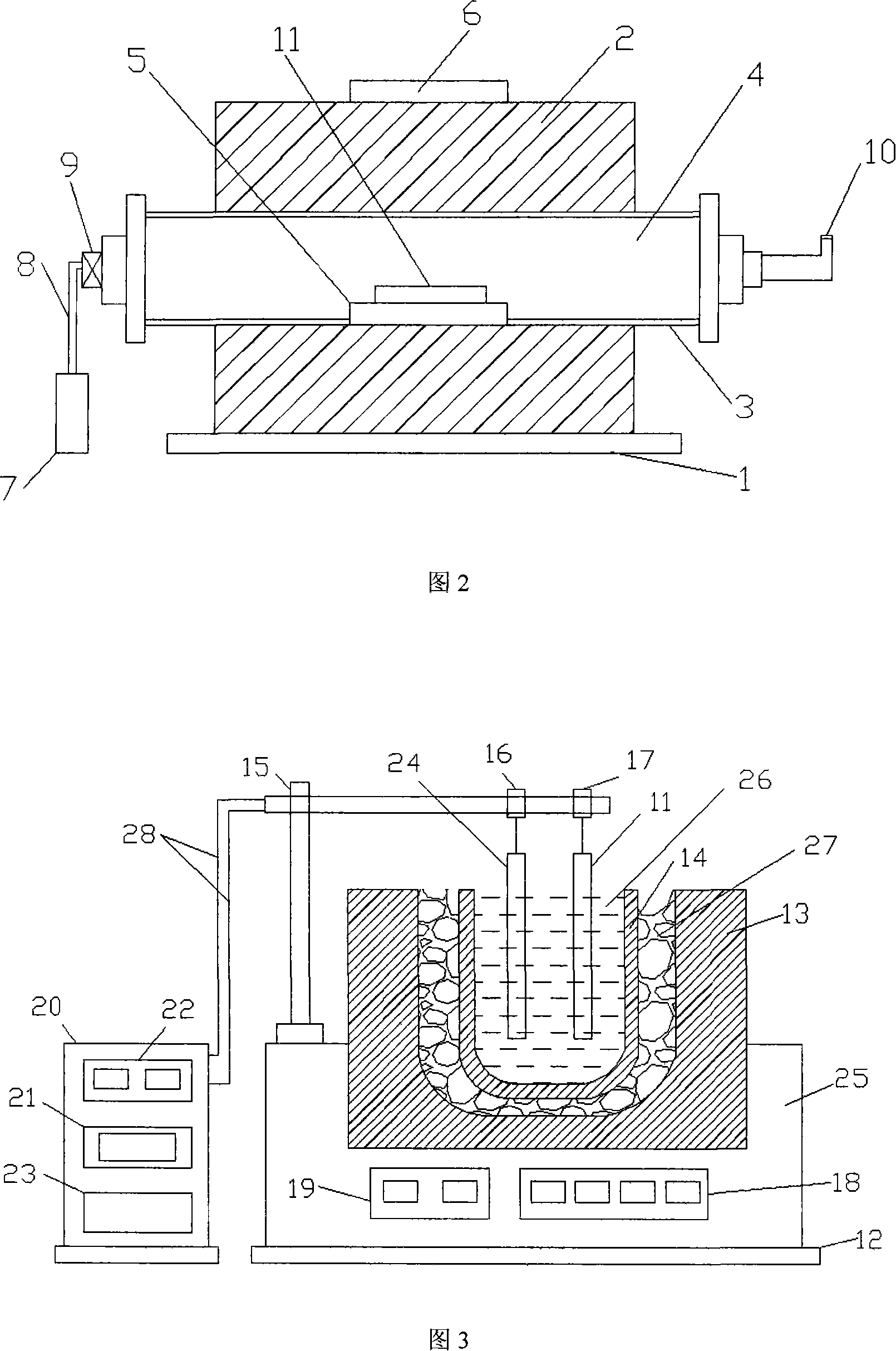

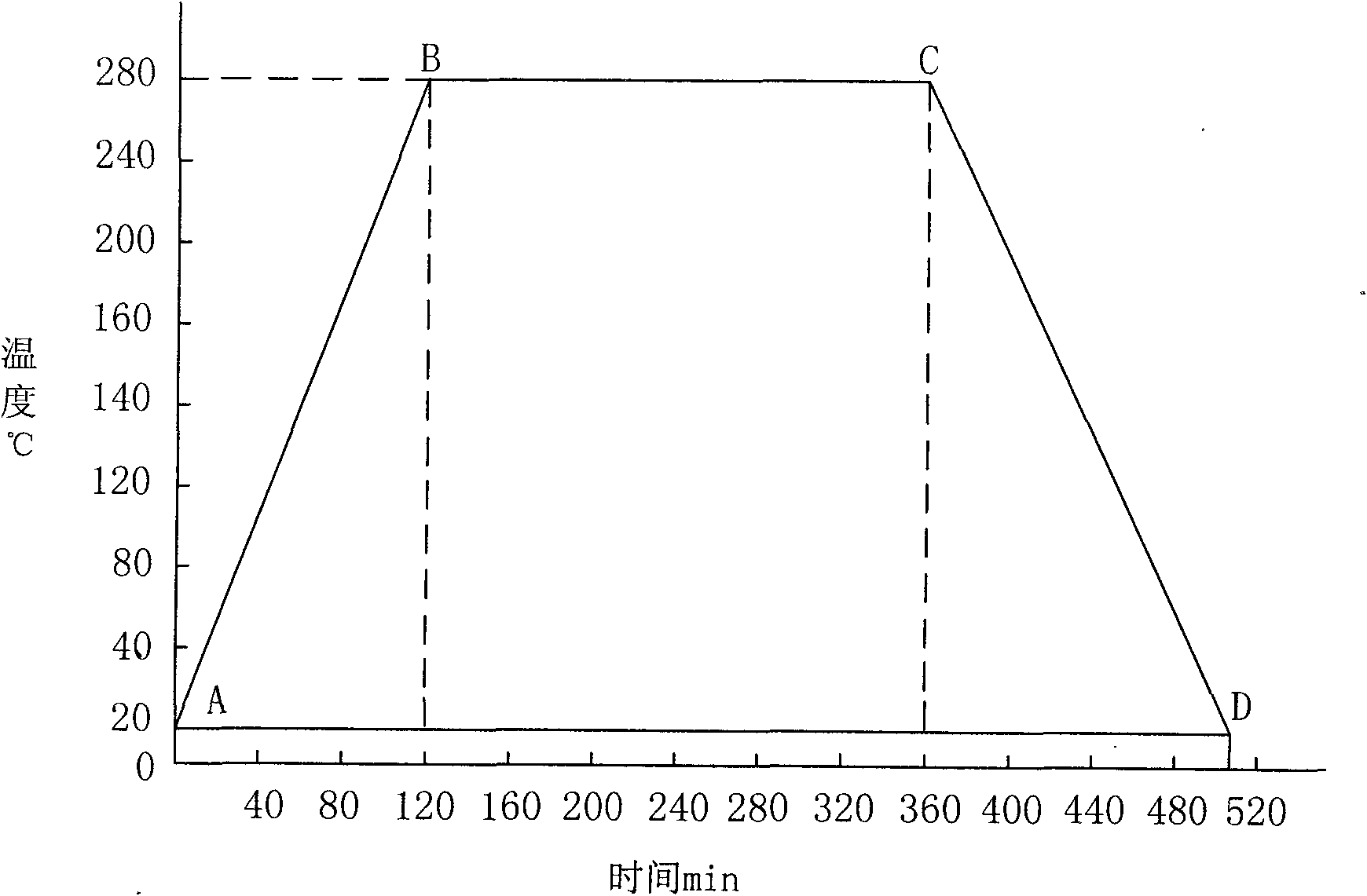

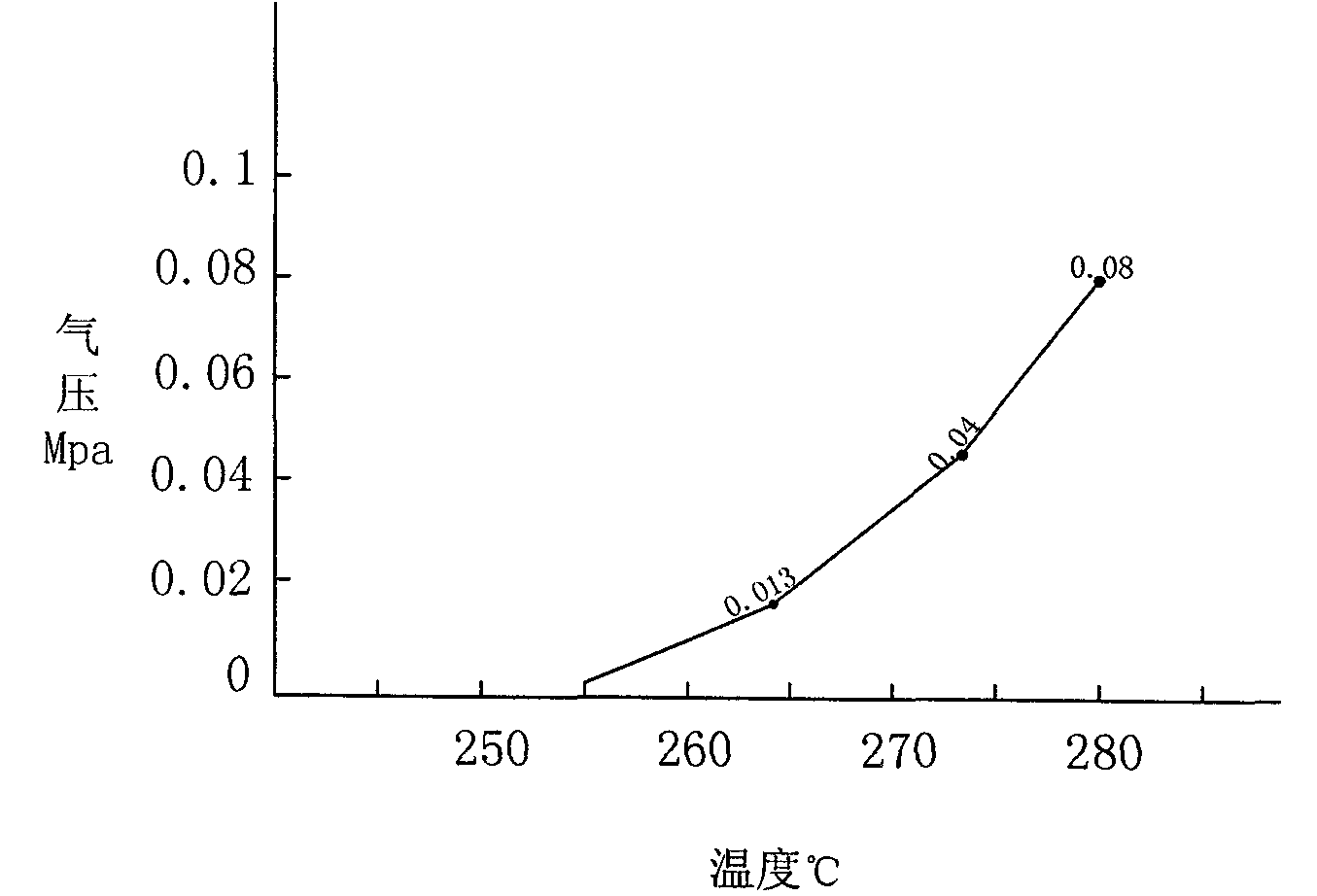

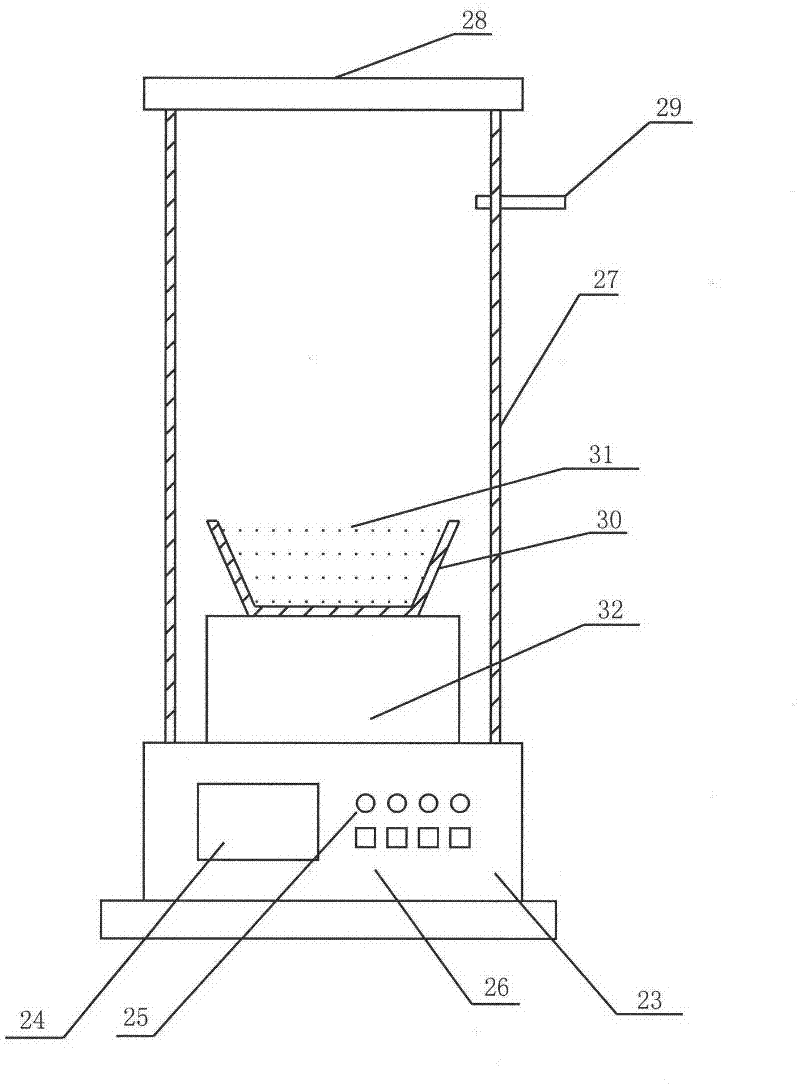

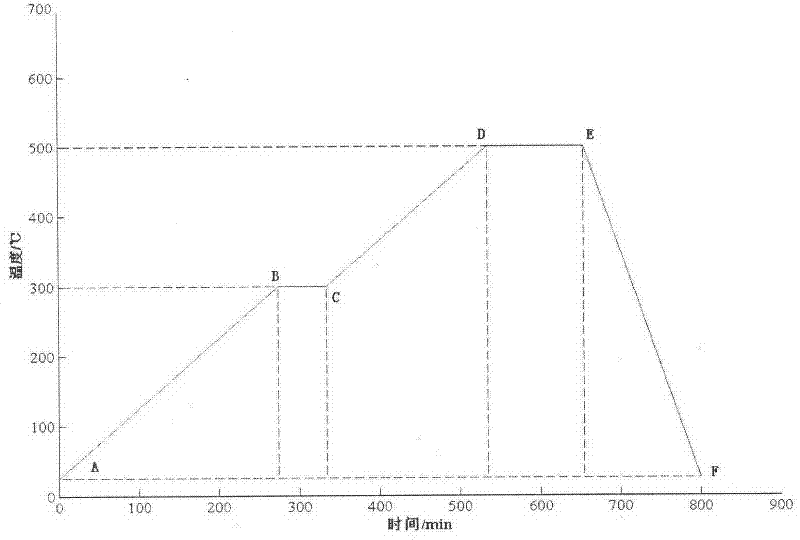

Method for cleaning polyphenylene sulfide melt spinning spinneret

The invention relates to a method for cleaning a polyphenylene sulfide melt spinning spinneret. Regarding that high polymer has the characteristics of high decomposition temperature, organic and inorganic solvent insolubility, based on the actual condition that the polyphenylene sulfide is firmly attached on the spinneret and is hard to clean, according to the principle that structural components of chemical substances are similar and compatible, the method adopts biphenyl-biphenyl ether served as cleaning agent to complete cleaning of the spinneret in a cleaning kettle at 280 DEG C and 0.08MPa under cleaning agent out-kettle circular flowing, and finally completes cleaning of the spinneret through calcining of a calcinator, ultrasonic cleaning and compressed air drying. The cleaning method has short technical process, few used equipment, good cleaning effect and cleaning rate of spinneret attachment reaching 99.999 percent, ensures that the spinneret has no phenomena of deformation, corrosion or decarburization, and is a perfect cleaning method for the polyphenylene sulfide melt spinning spinneret. Components and parts of other spinning machines attached with polyphenylene sulfide high polymer also can be cleaned by using the method.

Owner:TAIYUAN UNIV OF TECH

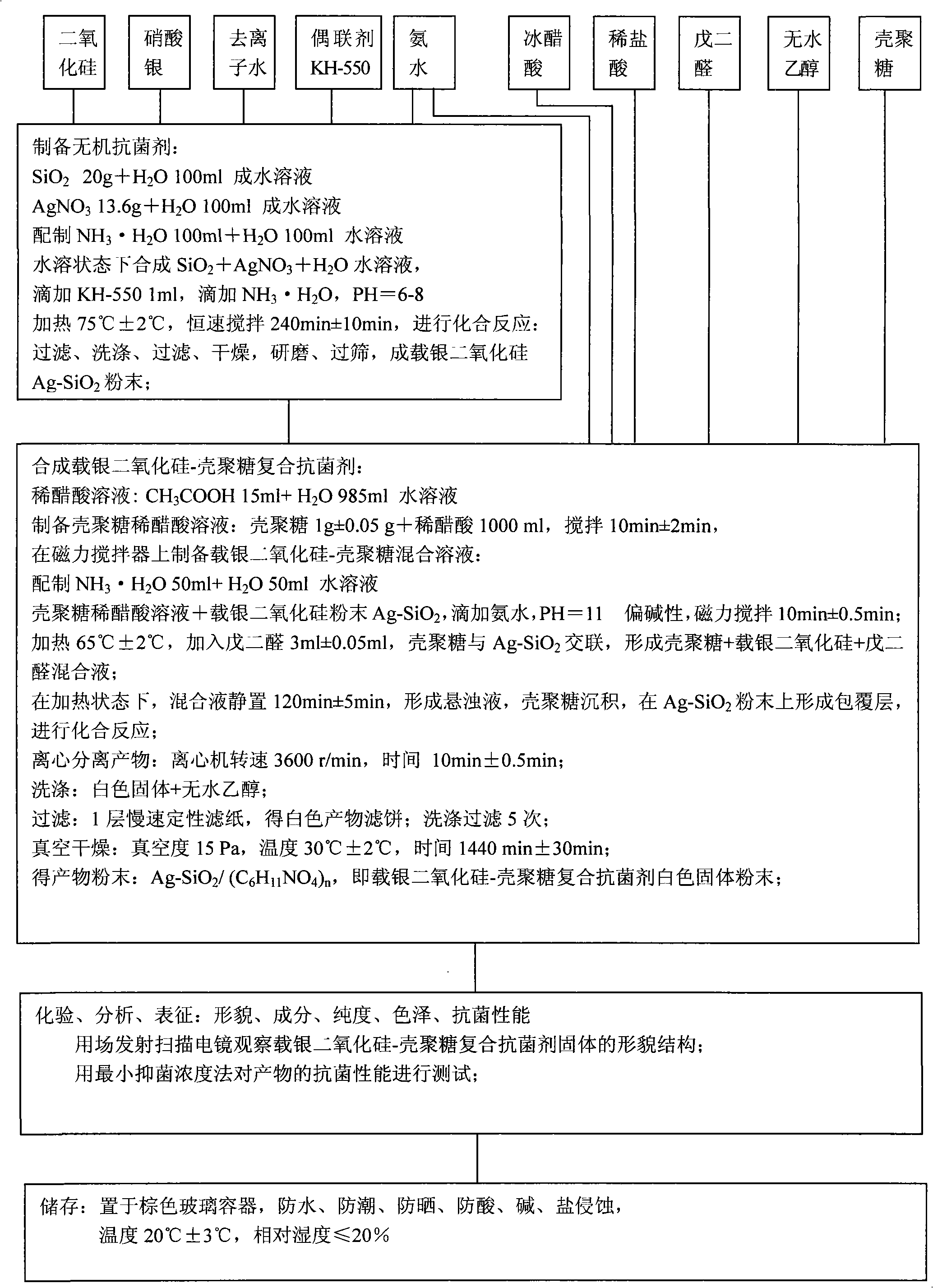

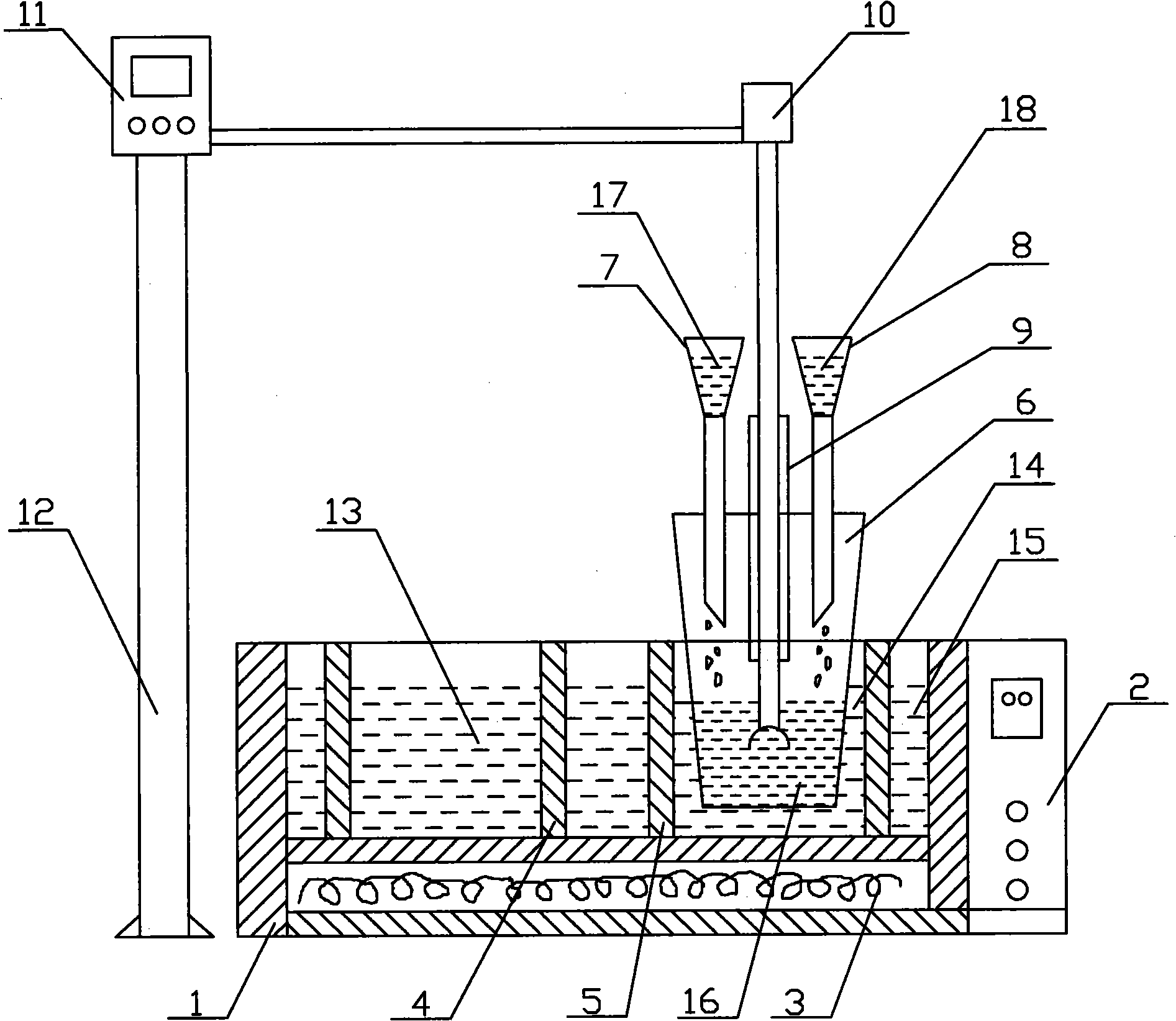

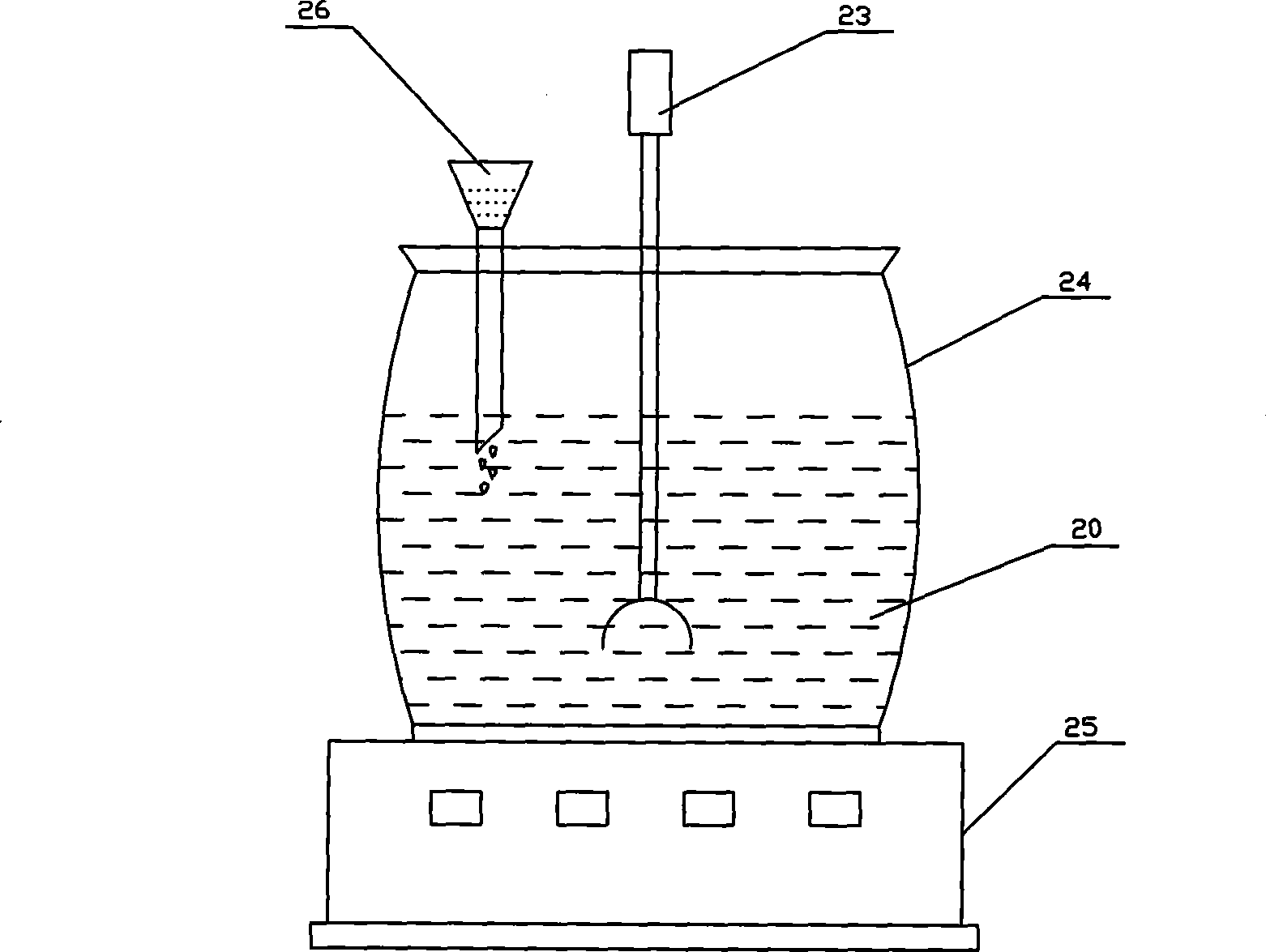

Preparation of silver-loaded silica-chitosan compound anti-bacteria agent

The invention relates to a preparing method for a silver-loaded silicon dioxide-chitosan compound antibacterial agent; the preparing method comprises the following steps: silver-loaded silicon of inorganic antibacterial agent is firstly prepared according to the antibacterial and bacteriostatic characteristics of the antibacterial agent; Ag-SiO2 is used as a carrier to prepare inorganic-organic compound antibacterial agent, namely, the silver-loaded silicon dioxide-chitosan compound antibacterial agent uses silicon dioxide as inorganic material, uses polymer chitosan as organic material, uses deionized water, silver nitrate, ammonia water, KH-550, glacial acetic acid, diluted hydrochloric acid, glutaric dialdehyde and absolute ethyl alcohol as agents, carries out chemical reaction by water bath synthesis, adjusts the pH value, carries out centrifugal separation, is washed, filtered and dried in vacuum, and finally the powdered product which is white, has laminated form, layered shape and crosslink structure is prepared. The preparing method has short technique process, little used equipment, rich material source and low cost; the purity of the product can be up to 97 percent, the yield of the product can be up to 98 percent, and compared with the product with single ingredient in the prior art, the antibacterial and bacteriostatic characteristics of the product can be improved by 90 percent; therefore, the preparing method of the invention is an ideal preparing method for the inorganic-organic compound antibacterial agent.

Owner:TAIYUAN UNIV OF TECH

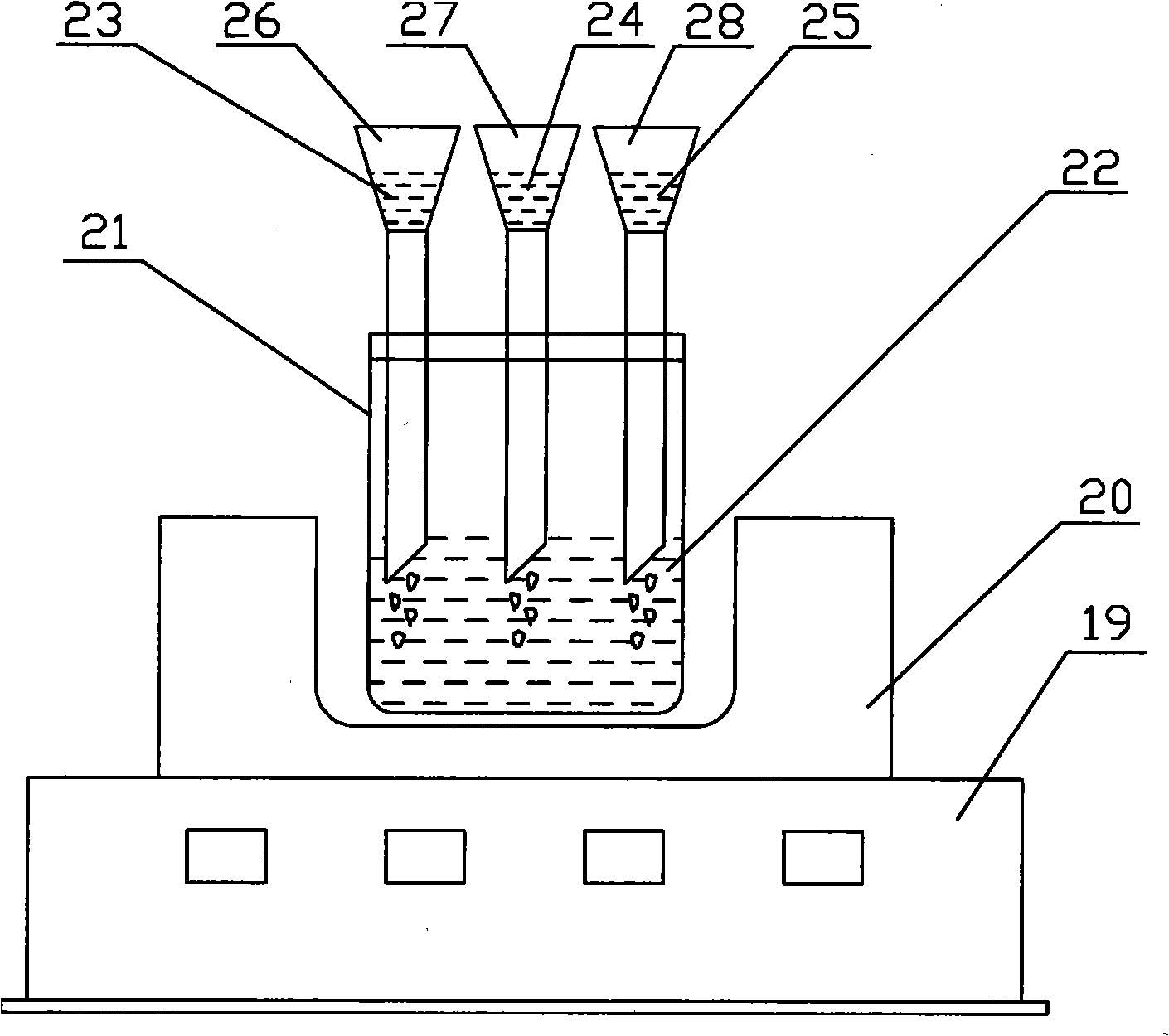

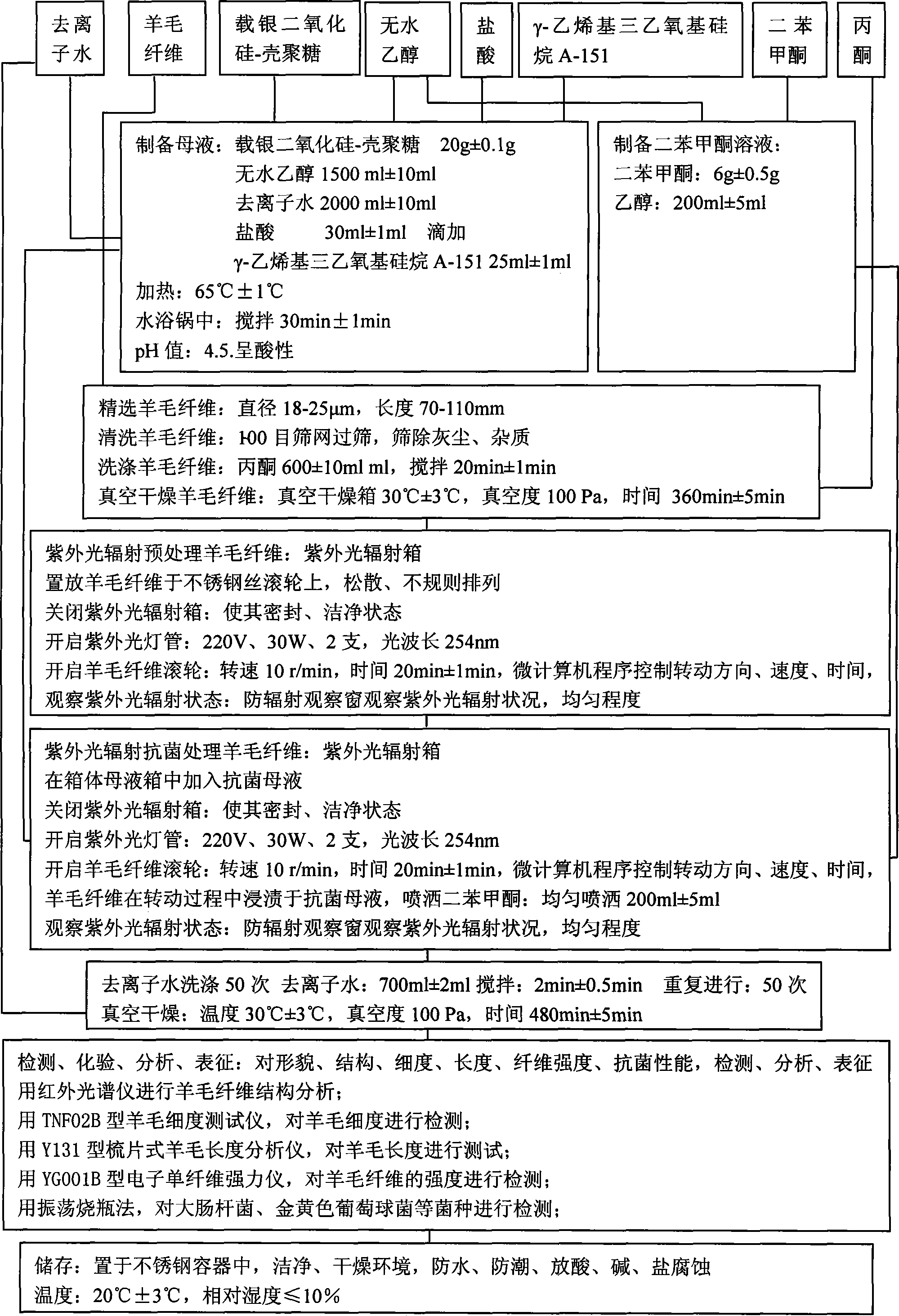

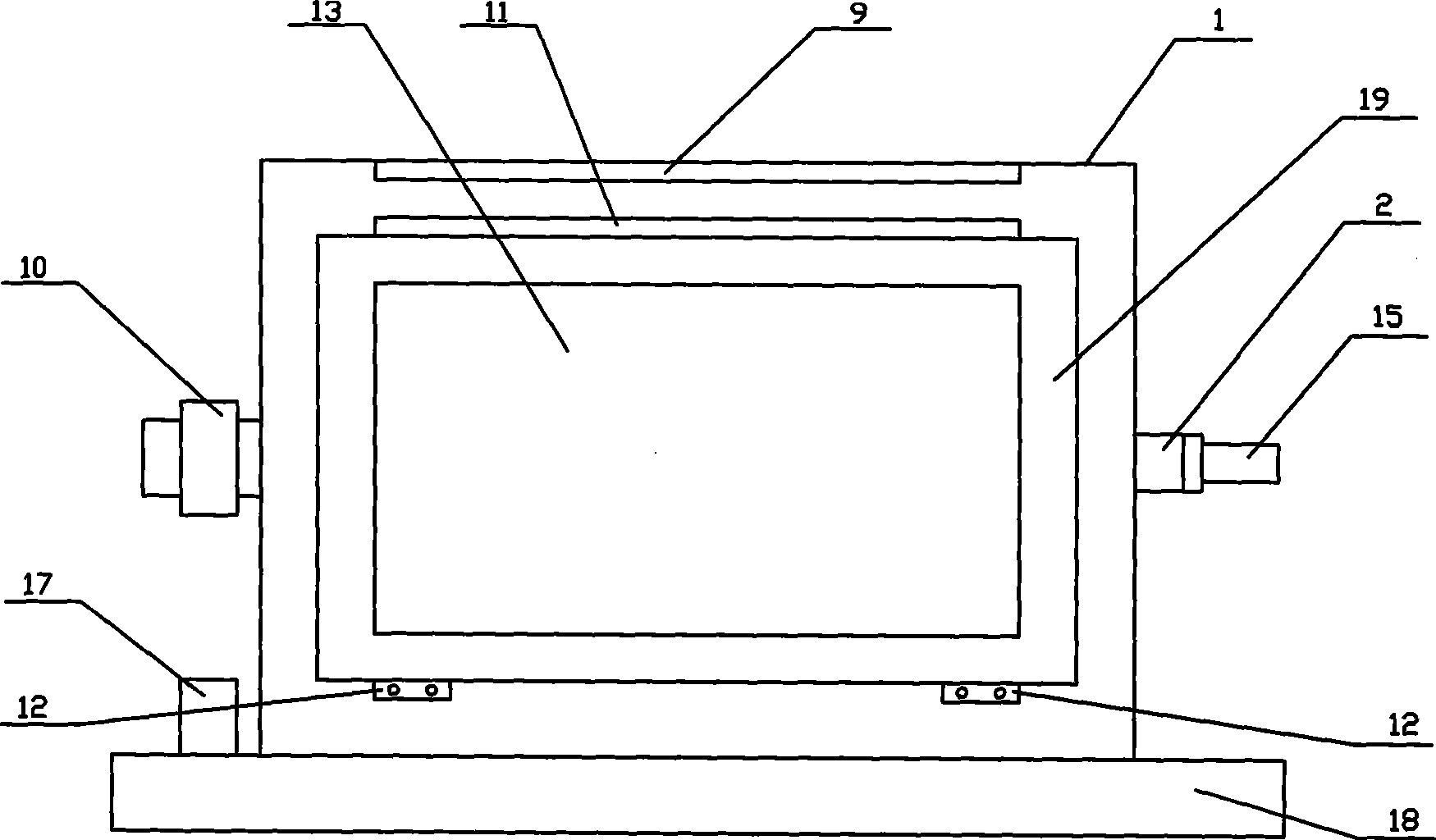

Antibacterial processing method for wool fiber

InactiveCN101413208AImprove durabilityEasy to manufacturePhysical treatmentAnimal fibresPre irradiationChemical reaction

The invention relates to an antibacterial treatment method for wool fiber, which comprises the following steps: an organic-inorganic composite antibacterial agent, namely silver-bearing silicon dioxide-chitosan is taken as an antibacterial agent and prepared into a pentabasic antibacterial mother liquor with anhydrous alcohol, deionized water, a diluted hydrochloric acid, a dispering / coupling agent and gamma-vinyltriethoxysilane A-151; the wool fiber is subjected to pre-irradiation of the ultraviolet light, and then immersed into the antibacterial mother liquor for secondary irradiation; and the wool fiber and the silver-bearing silicon dioxide-chitosan composite antibacterial agent generate chemical reaction under the action of a light trigger benzophenone and are combined by means of valence linkage to form an antibacterial film with the thickness of 200 nanometers. The antibacterial treatment method improves the persistence of antibacterial functions of the wool fiber, and the antibacterial rate of the wool fiber is still 98.6 percent after being washed for 50 times. Moreover, the antibacterial treatment method has short process flow, small number of equipment used, quick antibacterial speed, high efficiency and good effect, is easy to prepare the mother liquor, is particularly suitable for performing antibacterial treatment on the wool fiber and pashm fiber, and improves the efficiency by 90 percent compared with the prior antibacterial technology.

Owner:TAIYUAN UNIV OF TECH

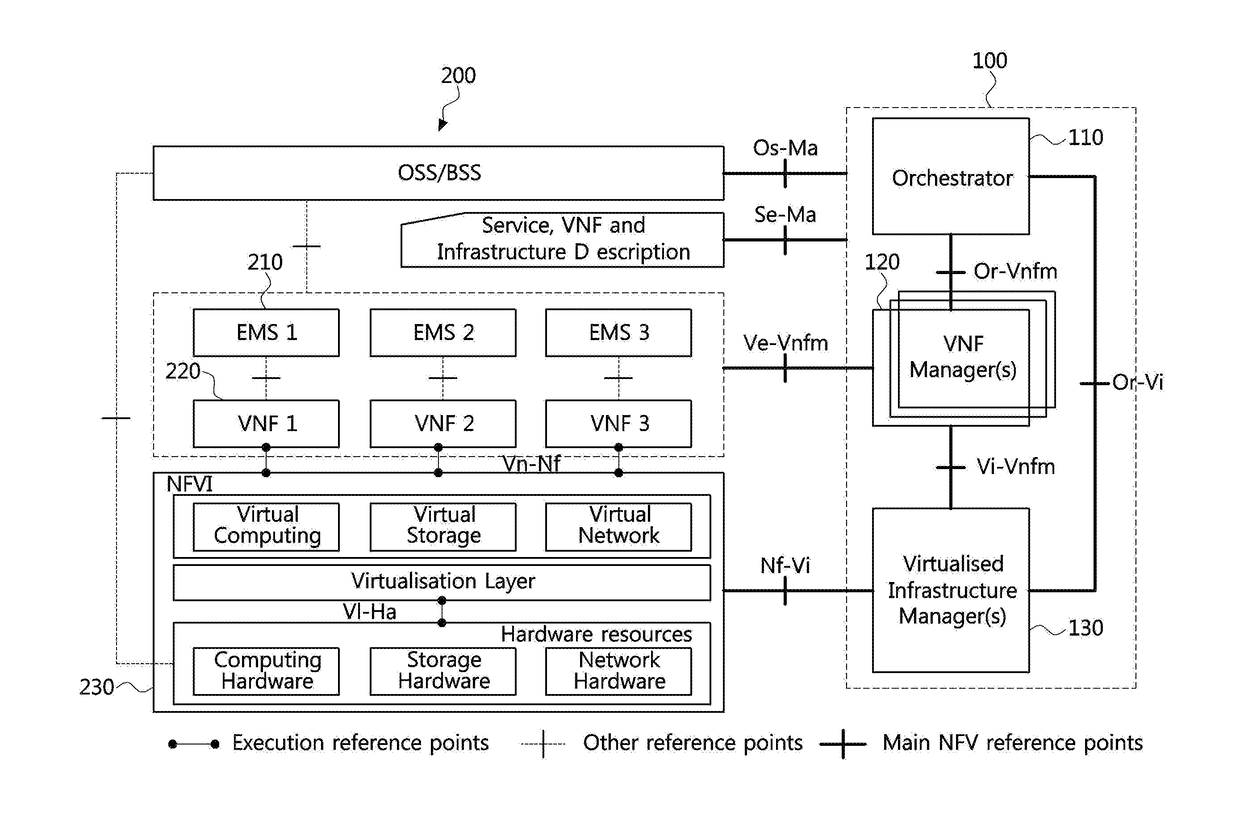

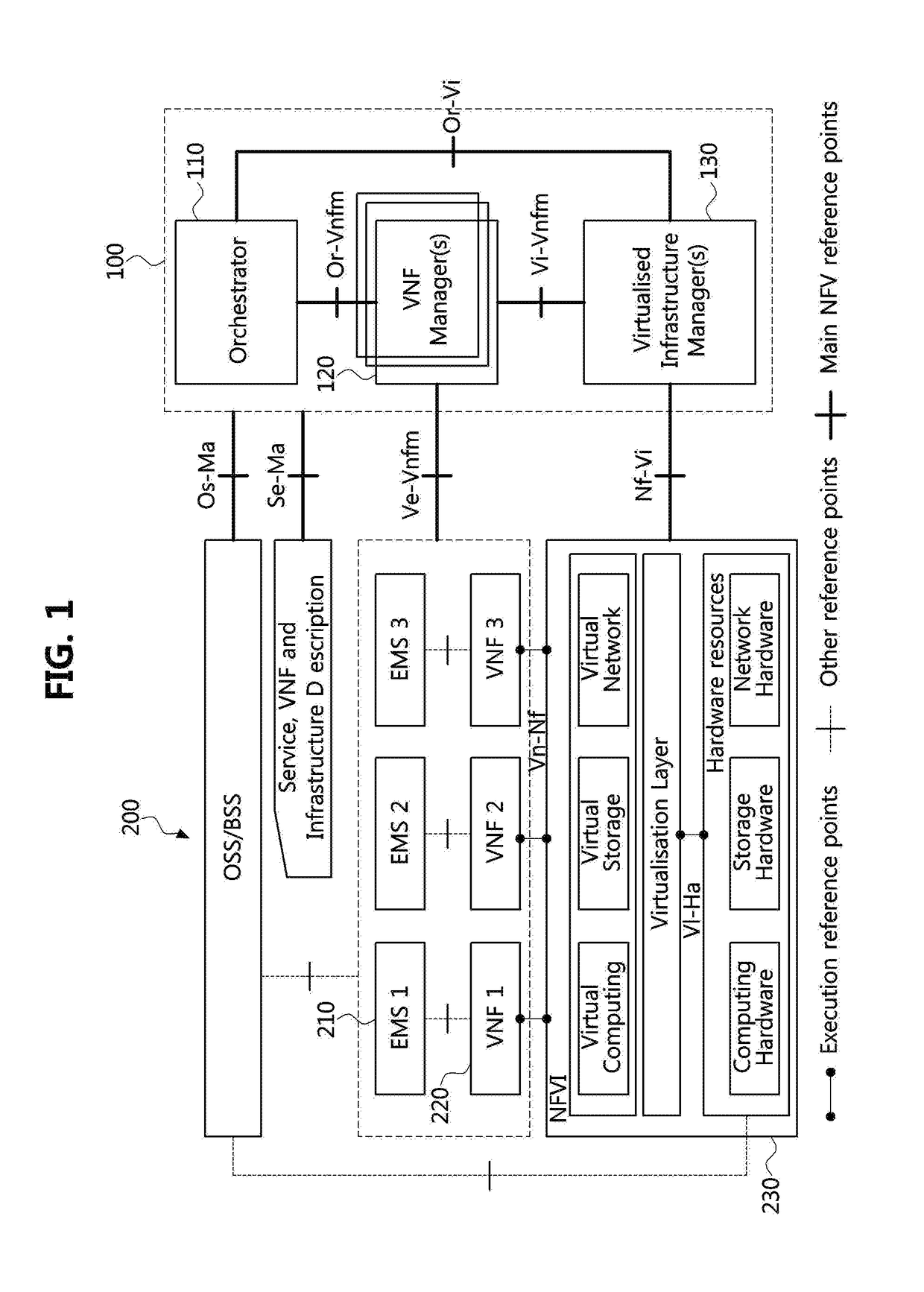

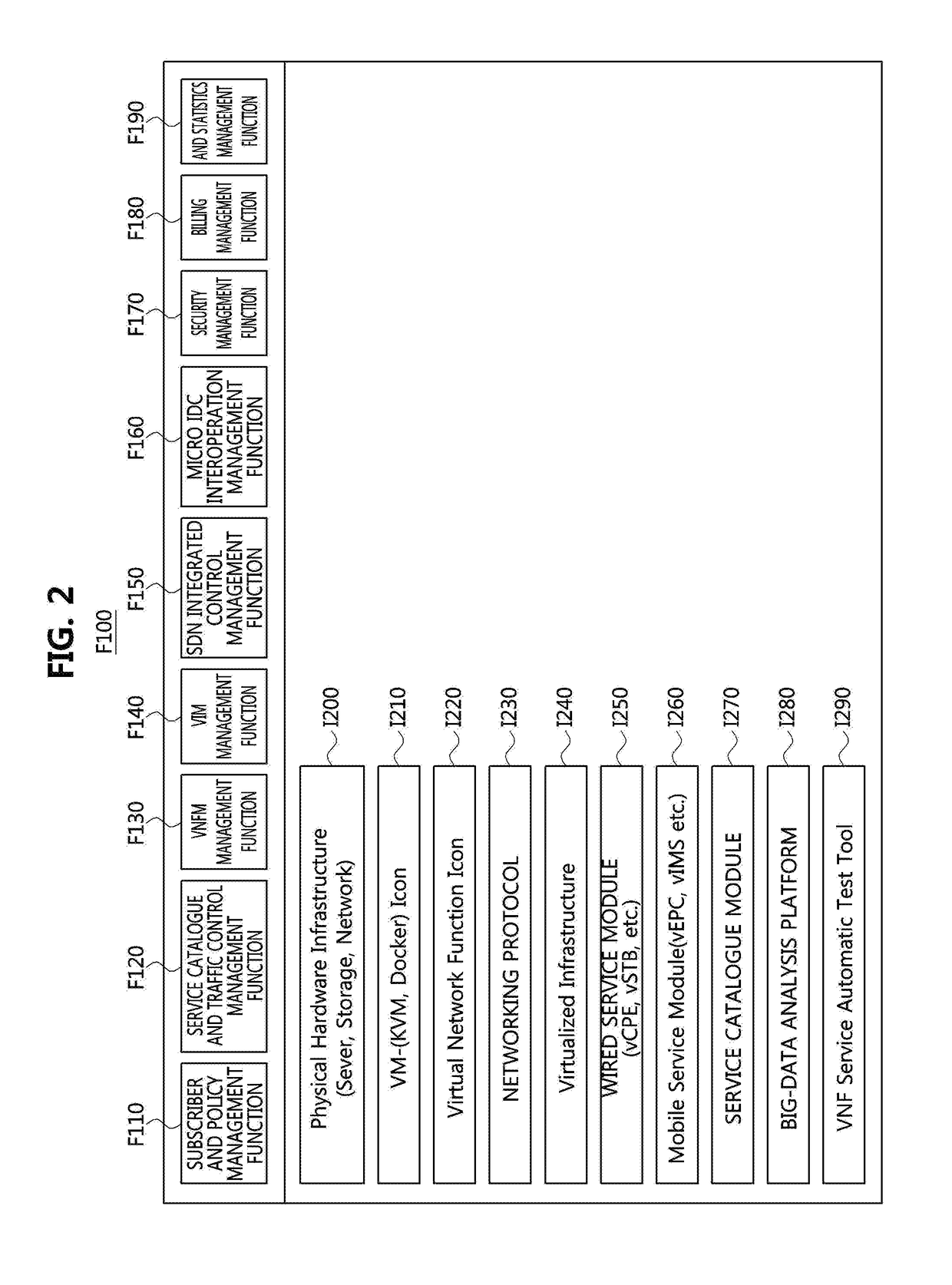

Apparatus and method for managing integrated platform of wired and mobile communication services

InactiveUS20180316543A1Providing serviceLow investment costBilling/invoicingData switching networksVirtualizationComputer network

An integrated platform management apparatus to which SDN and NFV technologies are applied includes a VIM controlling and managing virtualized computing, storage, and network resources of a NFVI and interaction of the resources of the NFVI; a VNFM controlling at least one network function and virtualization of the at least one the network function so that a part of the at least one network function and the NFVI is implemented in software; and a NFV orchestrator displaying appliance functions of a plurality of VNFs in form of icons on a UI screen, and provides integrated wired, mobile, and hyper-connection communication services by connecting functions corresponding to icons selected by an OSS or a BSS among the icons displayed on the UI screen in form of a forwarding graph.

Owner:ELECTRONICS & TELECOMM RES INST

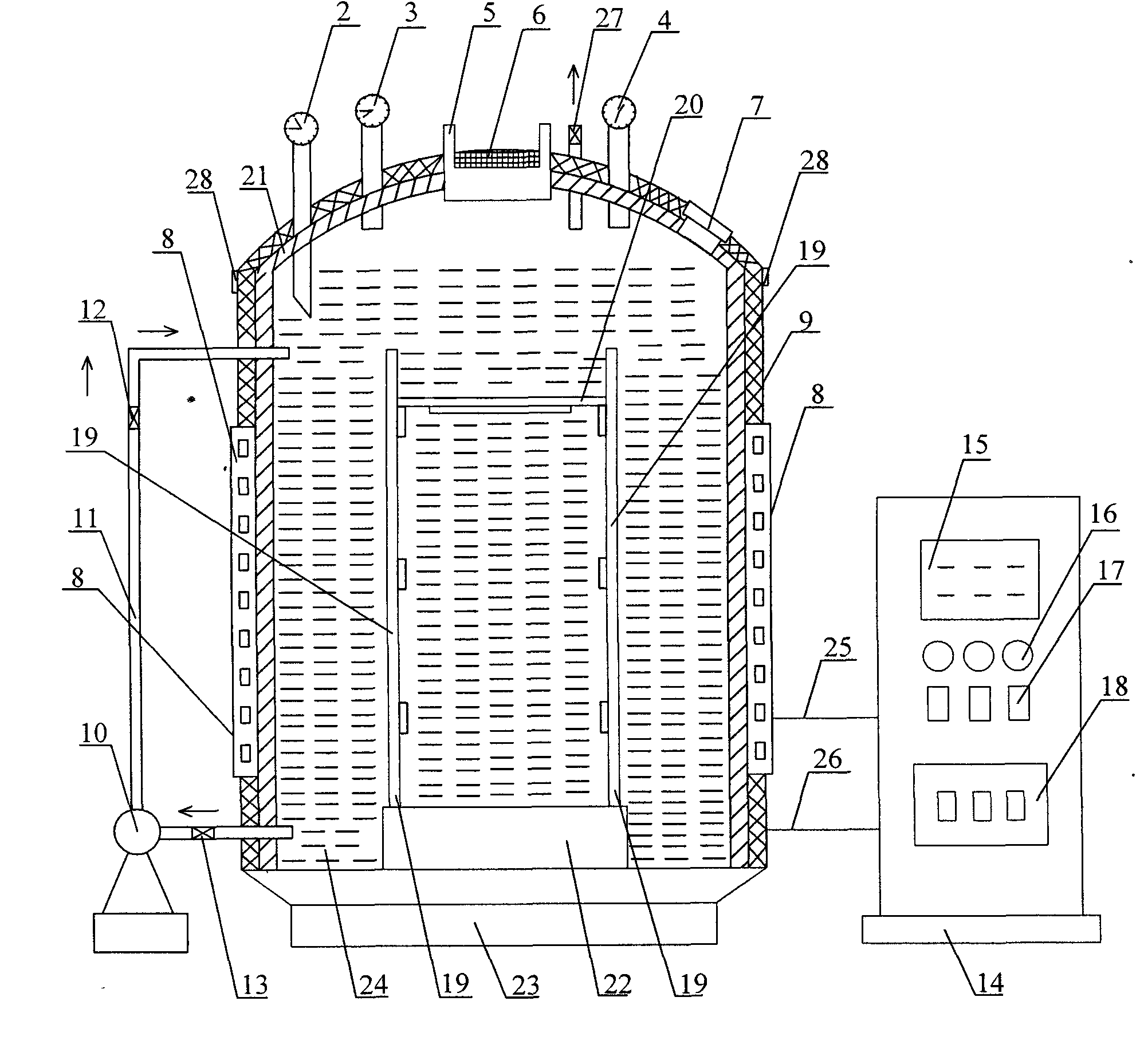

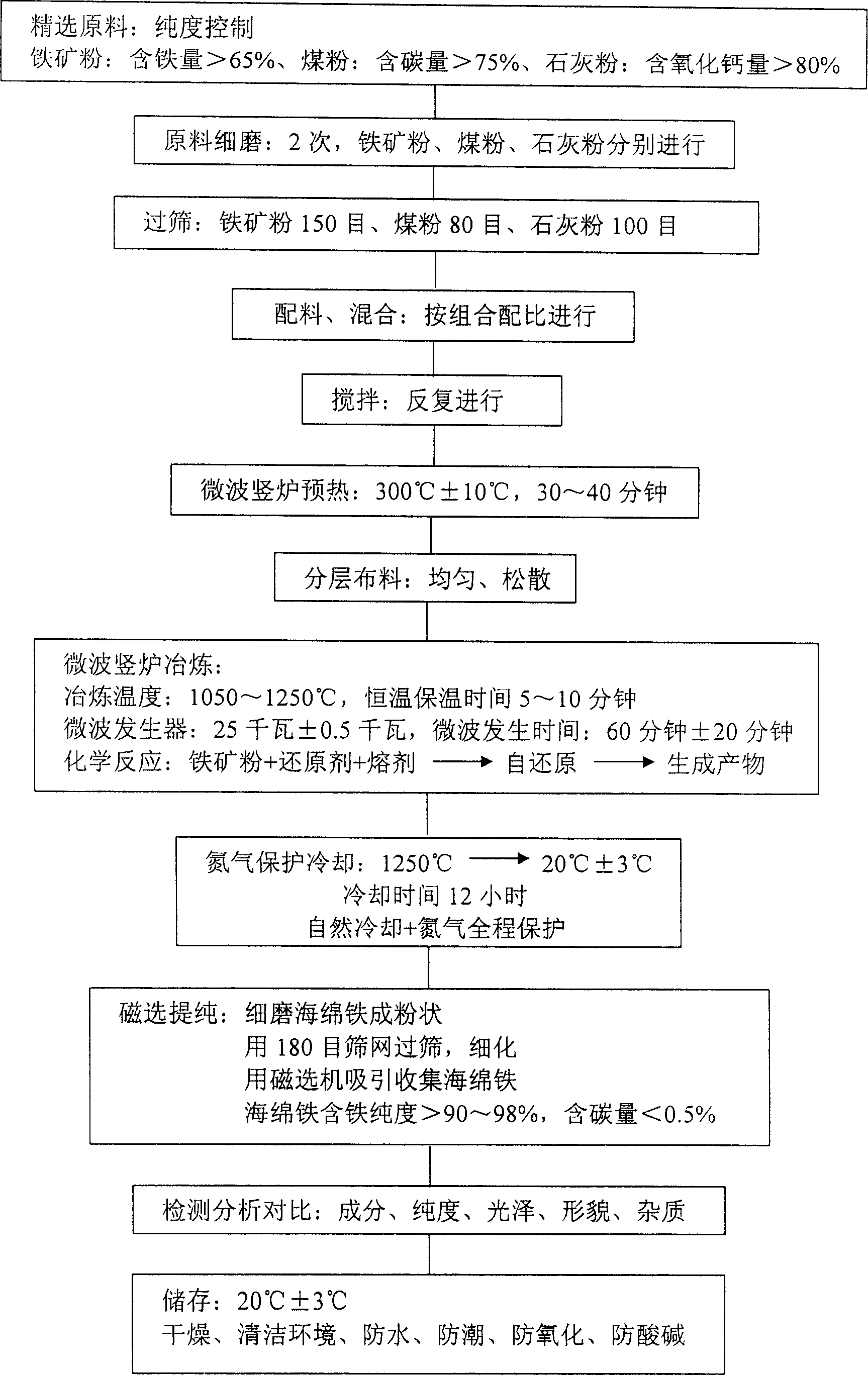

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

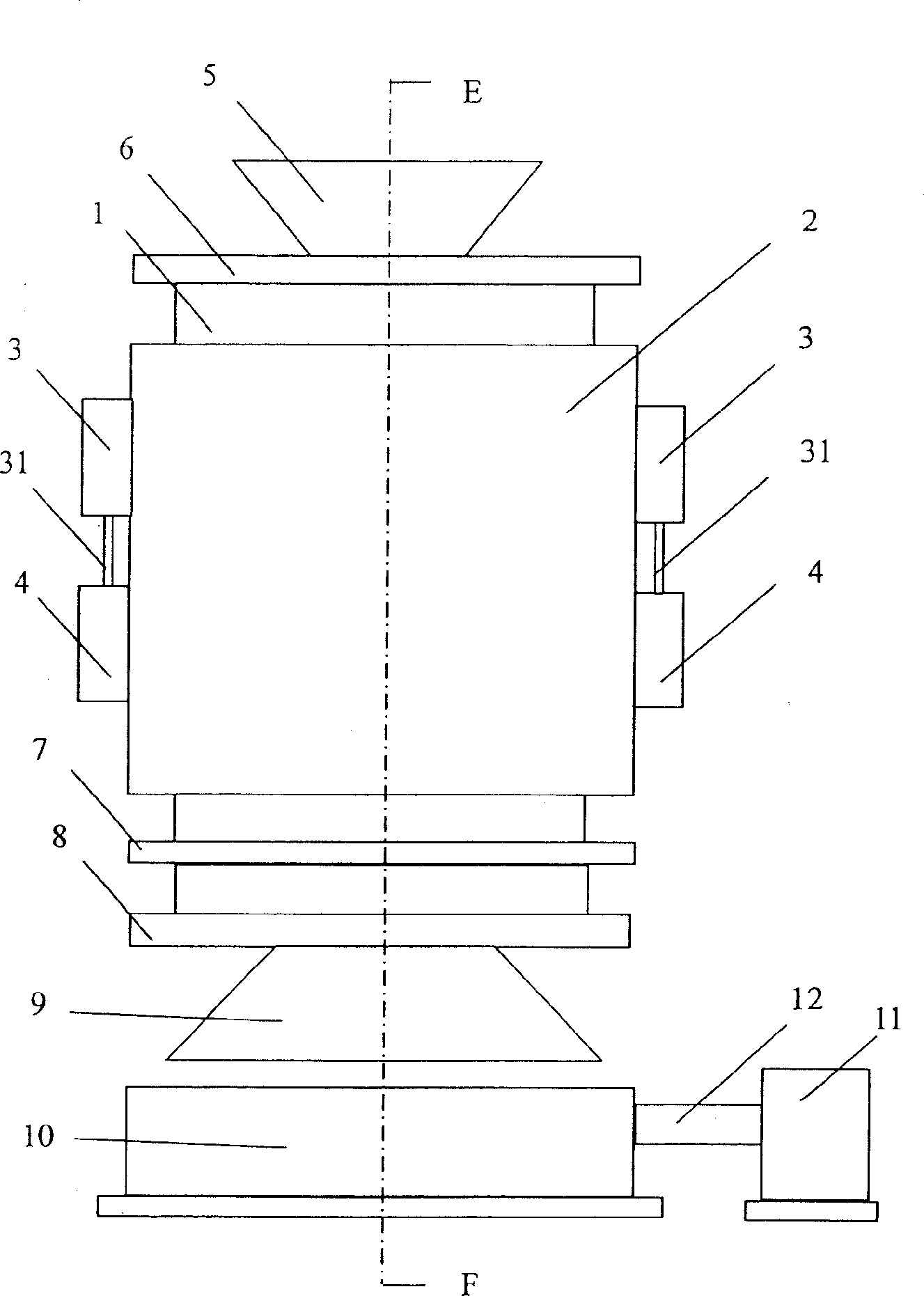

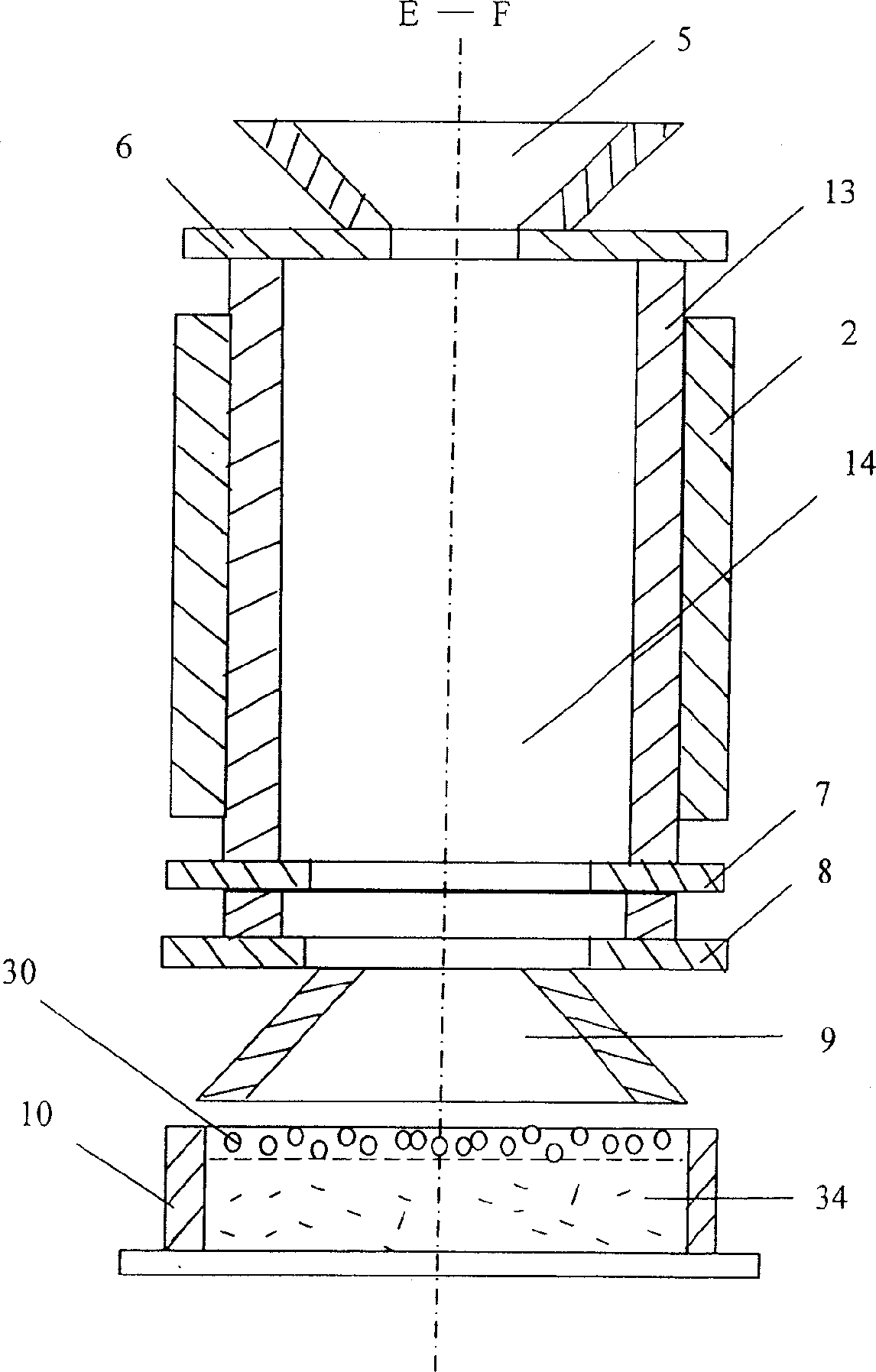

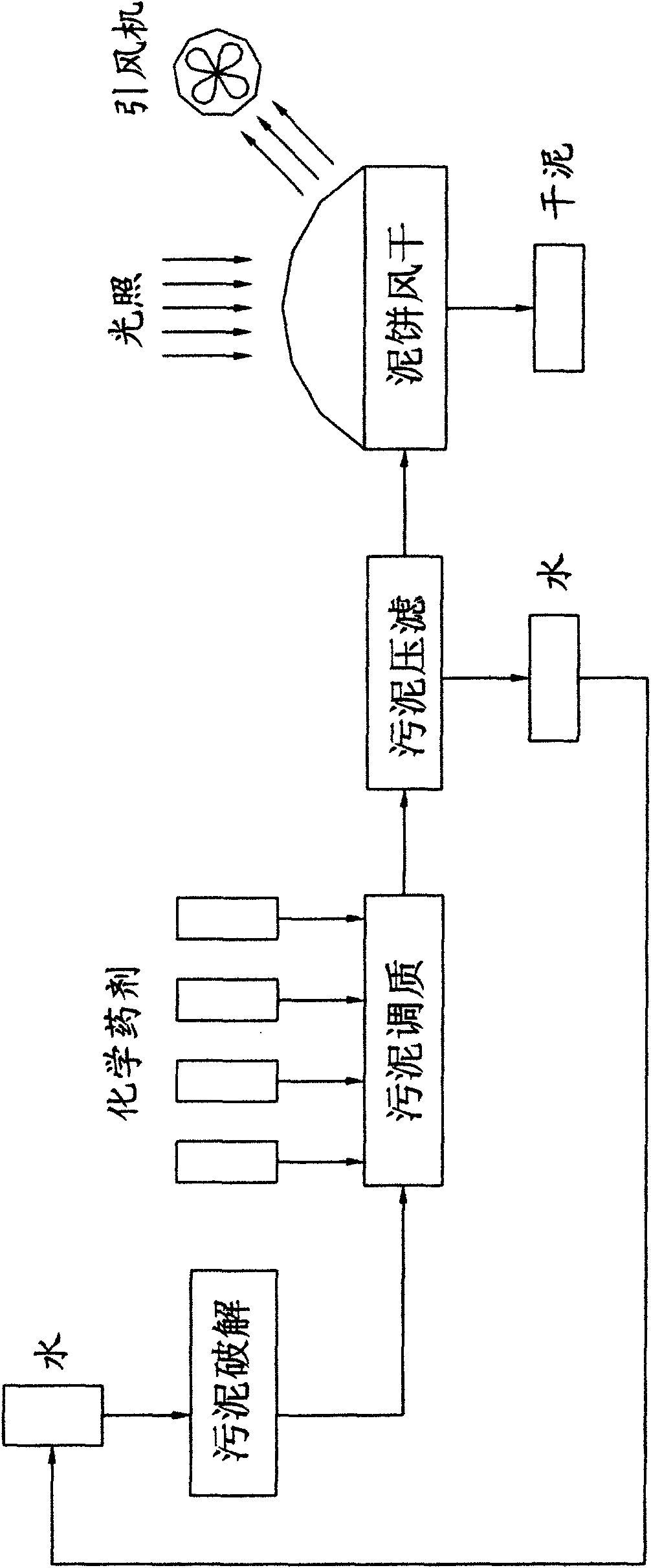

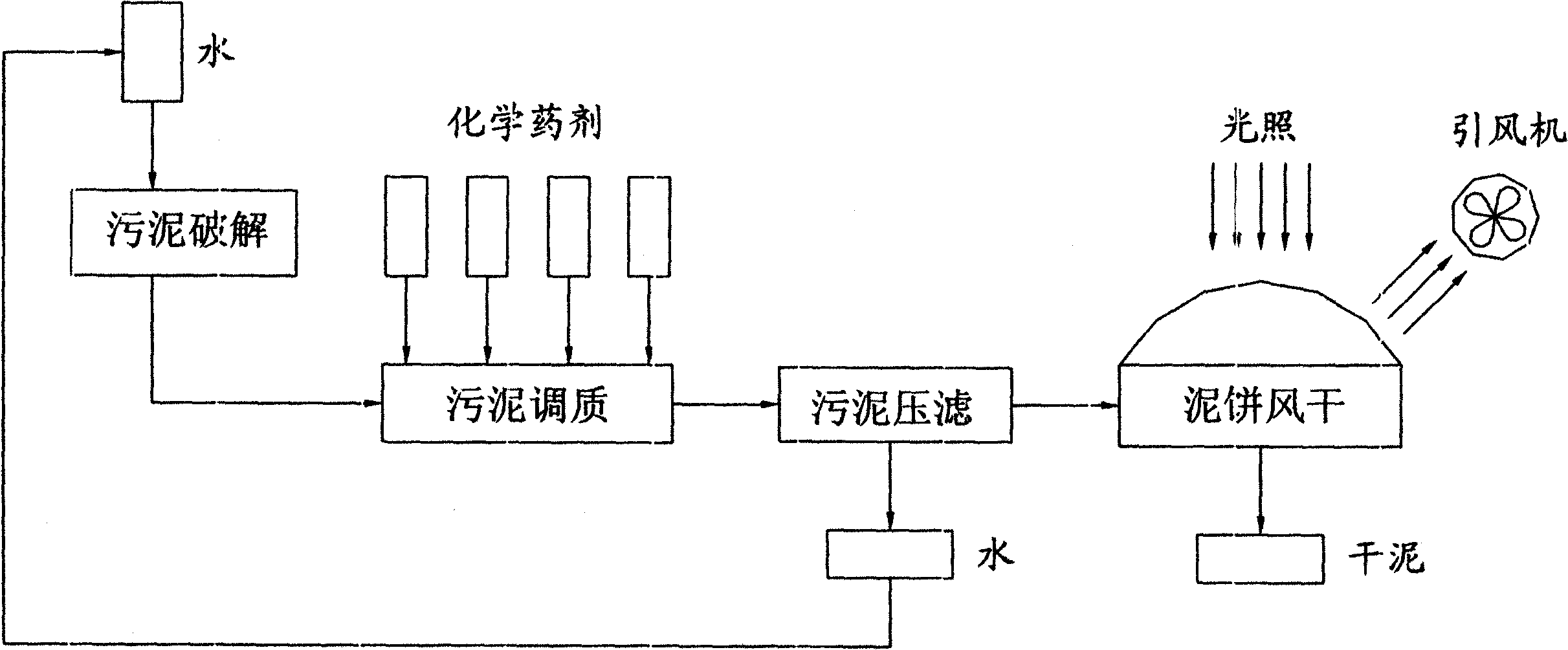

Low-energy drying treatment method for discharged sludge

InactiveCN102249514ALow running costSmall volumeSludge treatment by de-watering/drying/thickeningReduction treatmentLand resources

The invention discloses a low-energy drying treatment method for discharged sludge. The method comprises the following steps: after adding water into discharged sludge in a first reaction tank so as to carry out physical degradation on the discharged sludge and then uniformly stirring the obtained mixture completely, conveying the obtained discharged sludge with water content of 80% to a second reaction tank; adding a chemical reagent into the second reaction tank so as to carry out chemical conditioning and modification on the discharged sludge, then carrying out mechanical filter pressing on the sludge so as to reduce the water content of the sludge to 40-45%, and preparing the sludge into mud cakes; and ventilating and drying the mud cakes in a greenhouse shed so as to reduce the content content of the sludge to 20-30%. The method disclosed by the invention is suitable to be applied to the reclamation and reduction treatment of discharged sludge of municipal wastewater treatment plants, and the volume of the treated sludge is reduced by more than 70%, thereby effectively saving landfill land resources; the sludge treatment method is simple in operation, low in cost and low in energy consumption; by using the method disclosed by the invention, harmful substances in the sludge can be degraded completely, thereby avoiding the secondary pollution to the environment; meanwhile, the mud cakes can be directly used as boiler fuel so as to recycle heat energy.

Owner:唐菊香 +1

High strength and low density oil well cement

ActiveCN1721353AImprove early strengthImprove stabilitySolid waste managementLow densityUltimate tensile strength

The high strength and low density oil well reinforcing cement has cement mortar density of 1.60 g / cu cm, and consists of oil well cement, weight reducing material, cement mortar stabilizer and admixture. It has optimized material composition, high early stage strength, improved rheologic performance and controllable thickening time, and meets the requirement for reinforcing low stratum pressure oil well.

Owner:JIAHUA SPECIAL CEMENT

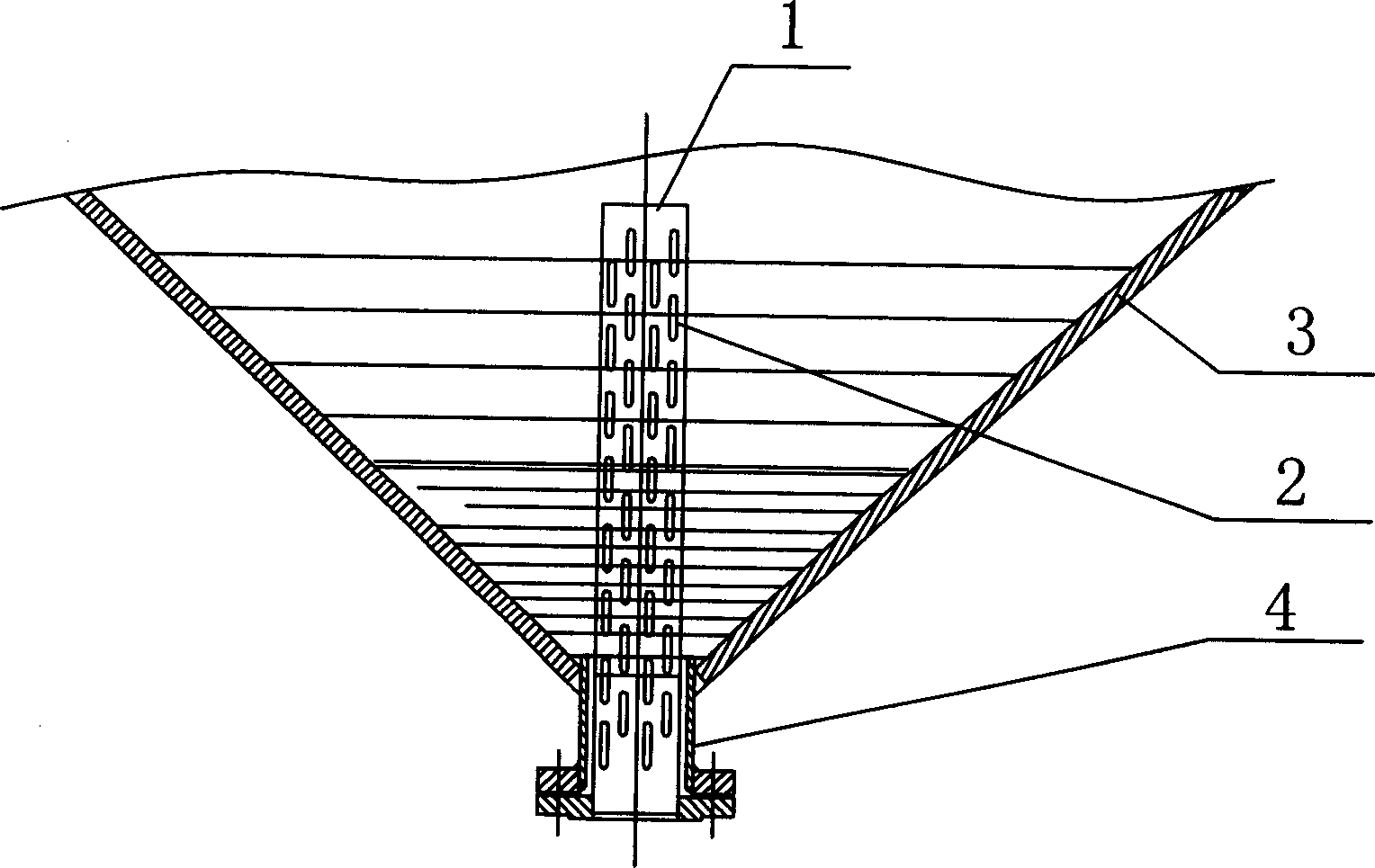

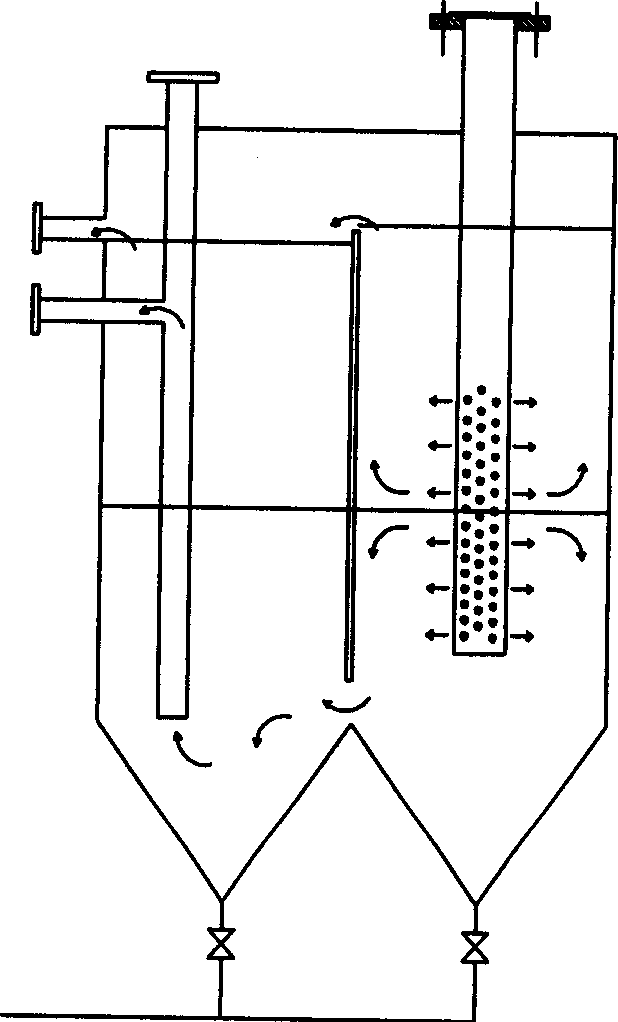

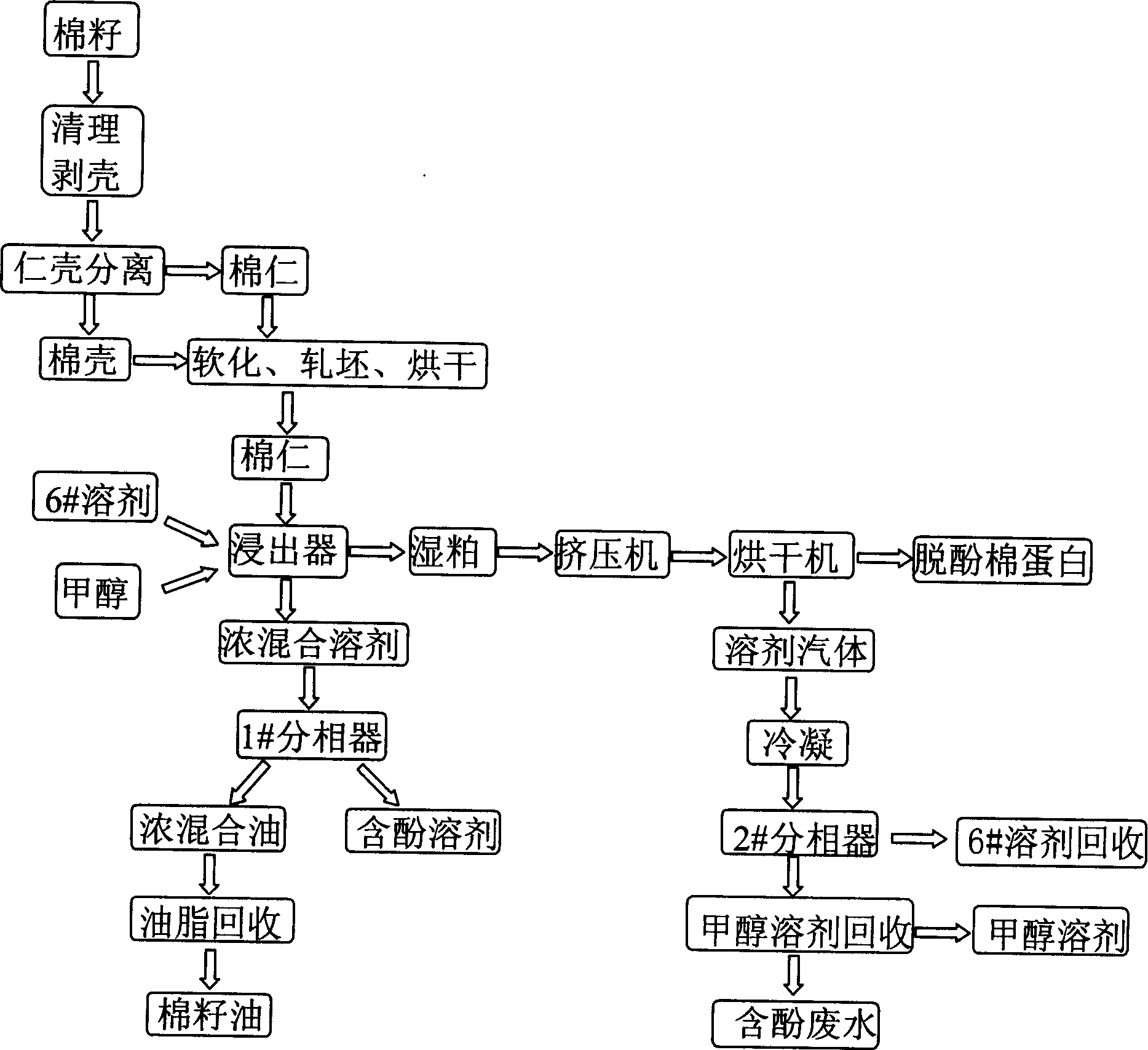

One-step method for producing dephenolized cotton protein

InactiveCN1775061AShort process routeUse less equipmentFatty-oils/fats refiningVegetable proteins working-upOil processingAlcohol

The present invention relates to the field of feed and oil processing technology, in particular, it relates to an one-step method for producing dephenolized cotton protein. It is characterized by that said invention fully utilizes the characteristics of 6# solvent and methyl alcohol mixed solvent, and utilizes the mutual incompatibility of polar solvent and non-polar solvent and simultaneously uses two solvents in one equipment so as to attain the goal of simultaneously extracting gossypol and oil, and can recover 6# solvent, methyl alcohol and oil.

Owner:陕西中恒粮油工程技术有限公司

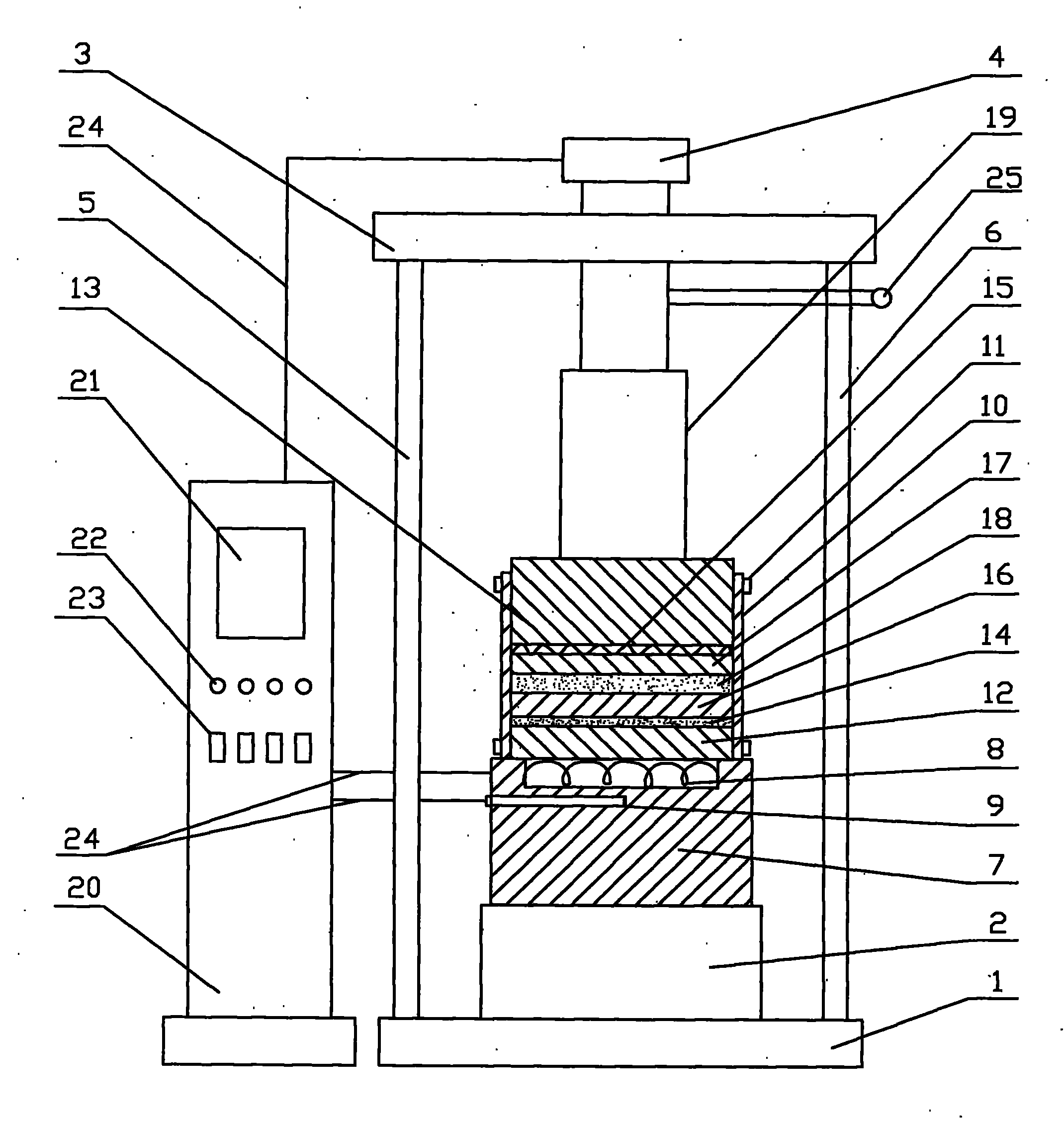

Preparation method of magnesium-aluminum layered composite plate

InactiveCN102166846AStable mechanical propertiesImprove corrosion resistanceLaminationLamination apparatusAlloyComposite plate

The invention relates to a preparation method of a magnesium-aluminum layered composite plate, aiming at solving the problems that the magnesium-aluminum alloy plate is light in weight, low in strength and poor in corrosion resistance. The method comprises the steps of: pressing and labeling a layer of aluminum plate on the magnesium-aluminum alloy plate; taking magnesium-aluminum eutectic alloy powder as a pressing and labeling material; pressing and labeling the magnesium-aluminum alloy plate+the magnesium-aluminum eutectic alloy powder+the aluminum plate into a magnesium-aluminum layered composite plate in an open-close through groove mould on a press machine under the temperature of 480 DEG C and the pressure of 30M Pa for 60s; and performing the low-temperature thermal treatment, so that an internal metallographic phase tissue of the magnesium-aluminum layered composite plate is more compact and stable. The method is advanced and reasonable, small in use equipment, short in technological process, and fast in speed. The mechanical property tensile strength of the magnesium-aluminum layered composite plate can reach 24MPa. Compared with the prior art, the mechanical property tensile strength can be improved by 95%, and the corrosion resistant performance can be improved by 94%, therefore, the preparation method of the magnesium-aluminum layered composite plate is very ideal.

Owner:TAIYUAN UNIV OF TECH

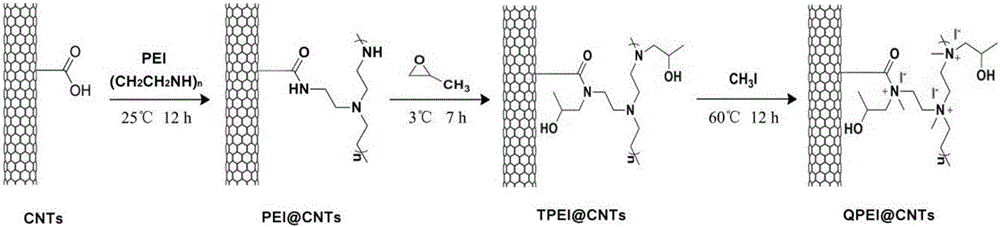

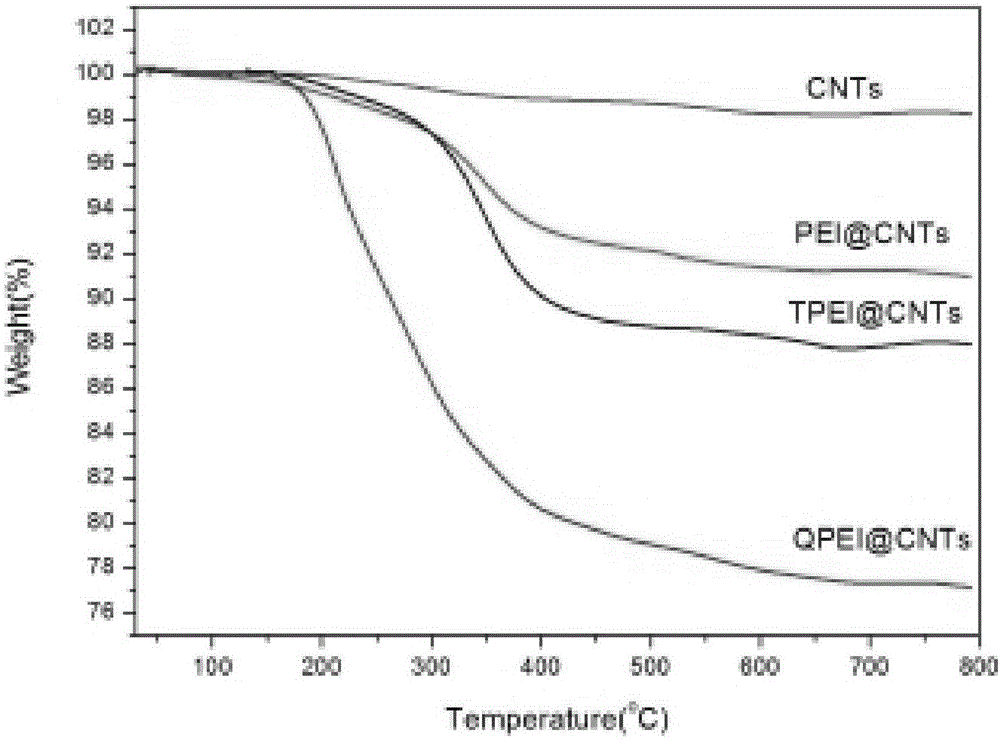

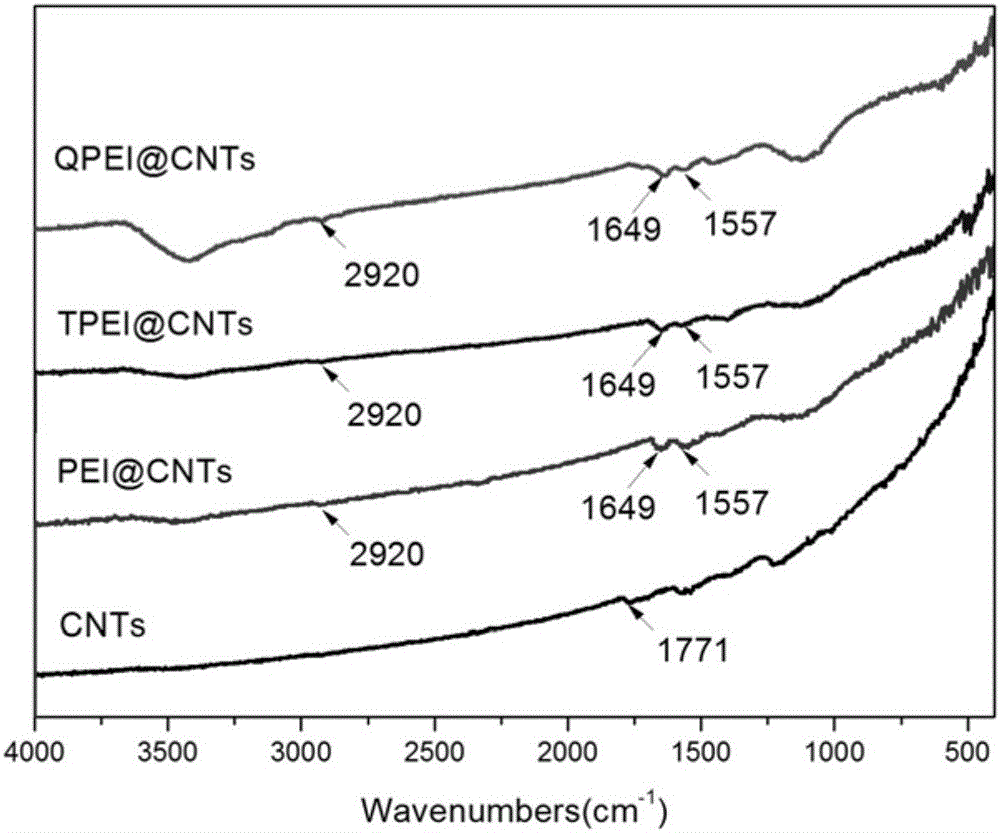

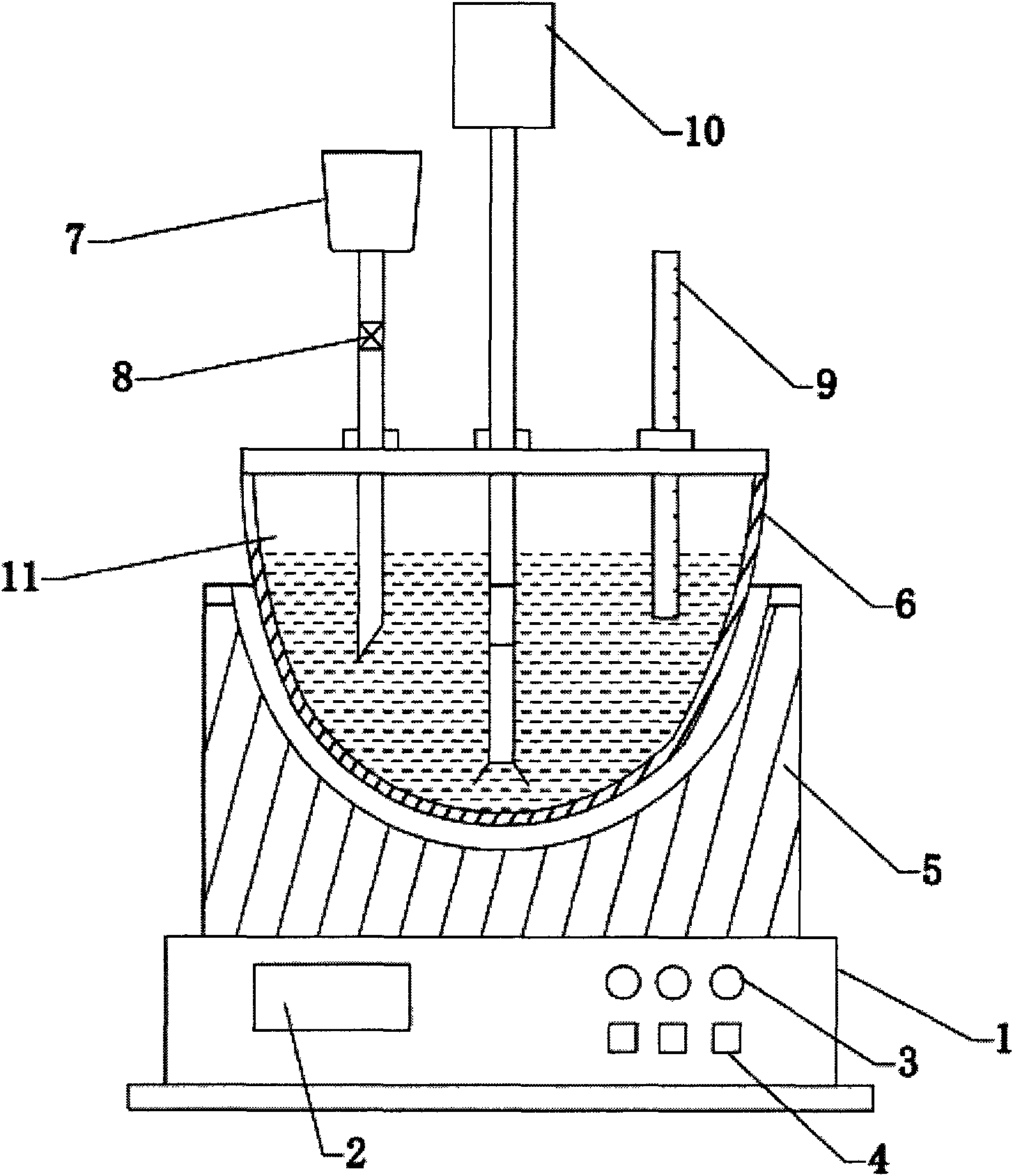

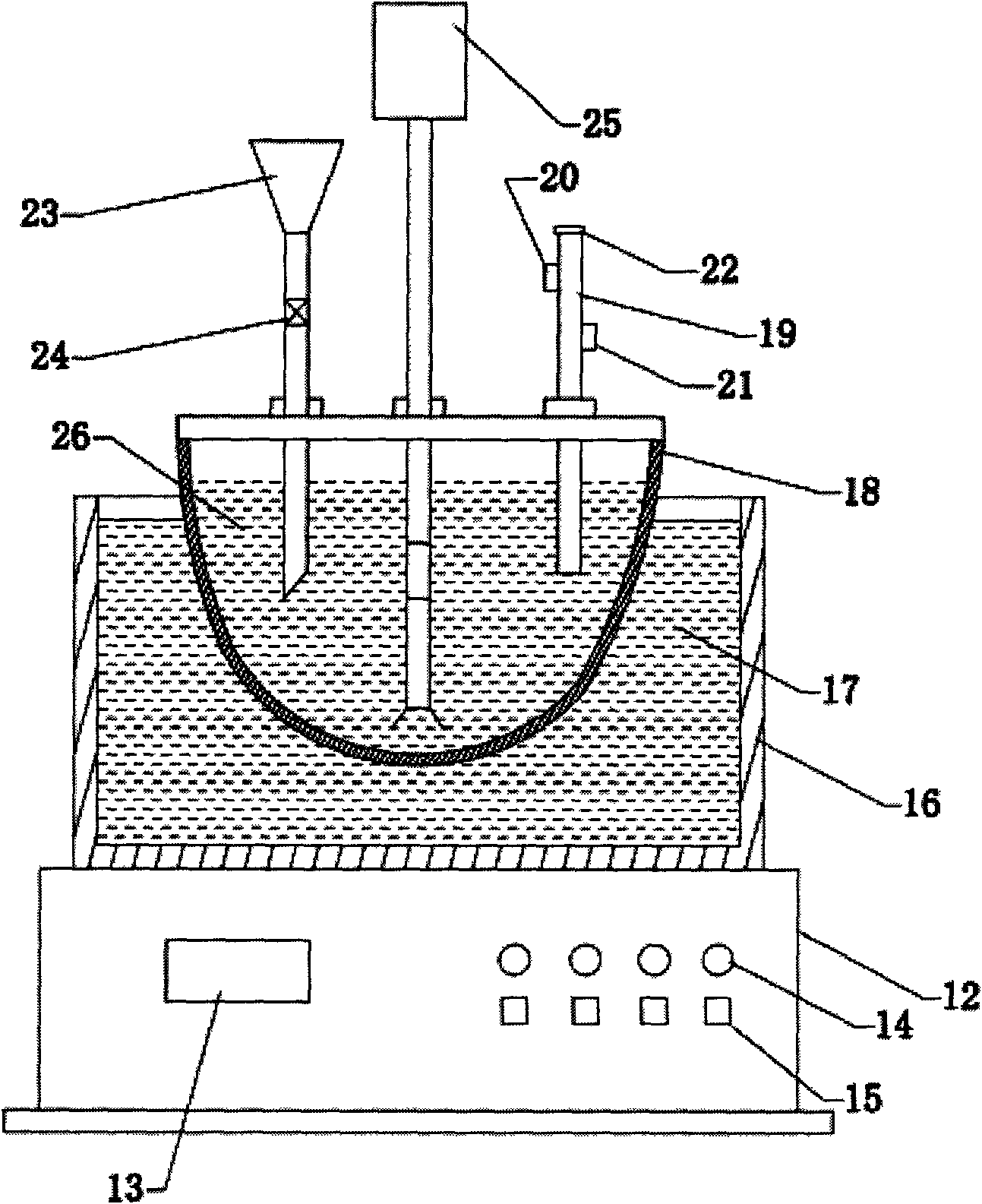

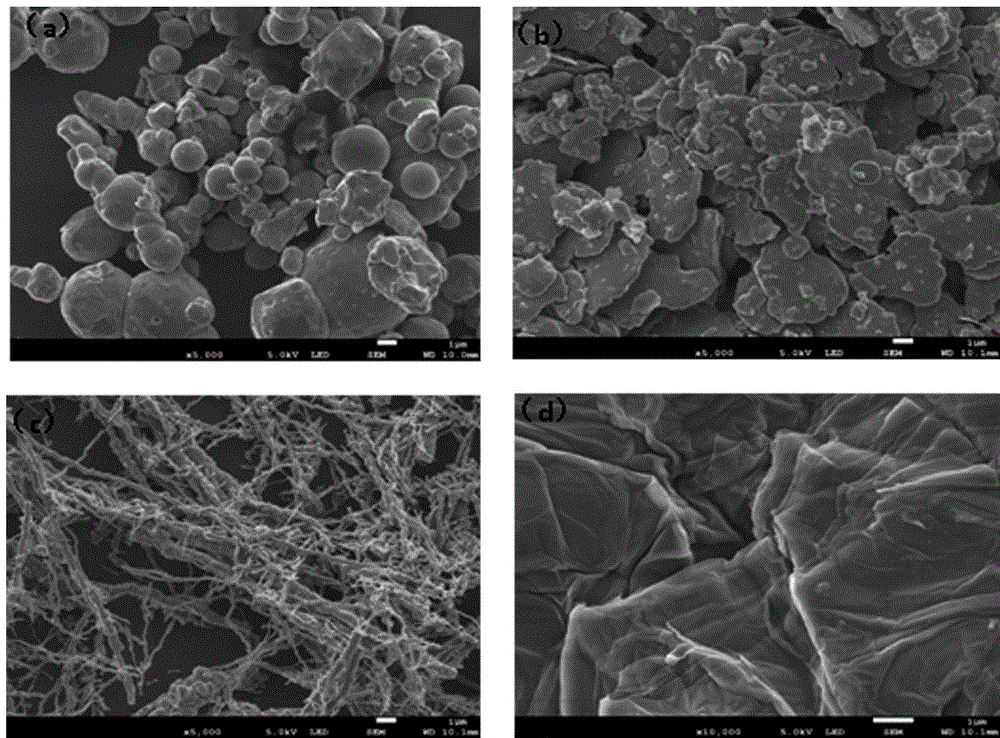

Preparation method of in-situ quaternized antibacterial agent on surface of carbon nano tube

ActiveCN106118198AImprove antibacterial propertiesHigh densityAntifouling/underwater paintsPaints with biocidesEscherichia coliFiber

The invention discloses a preparation method of an in-situ quaternized antibacterial agent on the surface of a carbon nano tube. The preparation method comprises the following steps: taking an acidulated carbon nano tube as a carrier, firstly grafting polyethylenimine to the surface of the carrier, and sequentially carrying out a tertiary amination reaction and a quaternization reaction on the grafted polyethylenimine so as to form an in-situ quaternized quaternary ammonium salt long-acting antibacterial agent of the carbon nano tube. The preparation method disclosed by the invention is simple and safe and is more environment-friendly, a synthetic method of the antibacterial agent is simple, less devices are used, the antibacterial effect is excellent, the using safety is high, a wide application value is obtained, and the agent can be applied to base materials such as coating, plastics, rubber, fiber and the like and material preparation and device system for water treatment, air purification and the like. The minimum antibacterial dosages of a target product of the invention on staphylococcus aureus and typical bacteria of Escherichia coli are respectively as low as 50 mg / L and 20 mg / L.

Owner:SOUTHWEST JIAOTONG UNIV

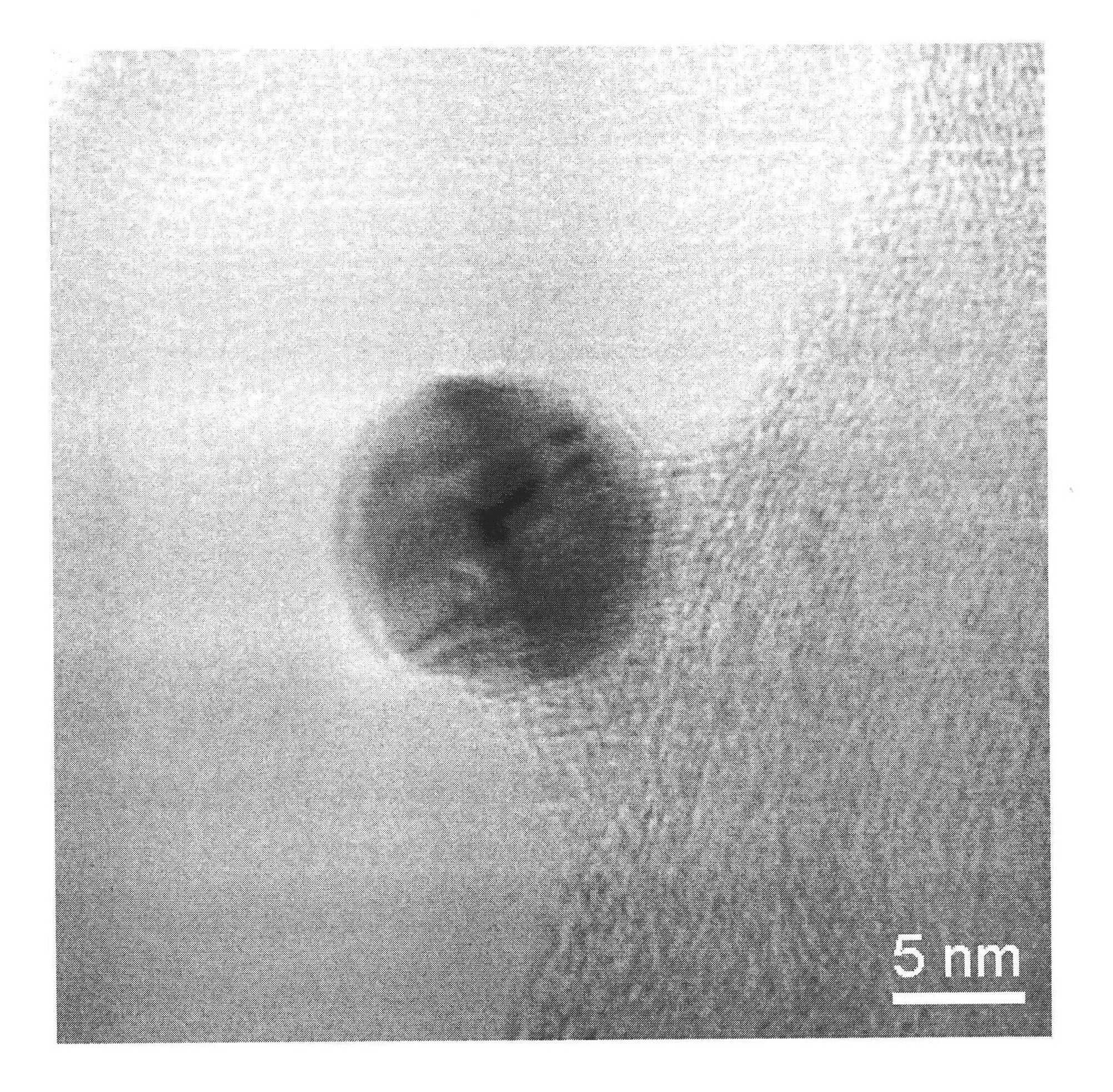

Method for preparing Ag-carrying carbon nano tube antibacterial agent

The invention relates to a method for preparing an Ag-carrying carbon nano tube antibacterial agent. In the method, a carbon nano tube is taken as a raw material, silver ion is taken as an antibacterial material, gamma-aminopropyl triethoxy silane is used as a coupling modifier, deionized water is used as a solvent, absolute ethyl alcohol and deionized water are used as detergents, and sodium hydroxide is used as a pH value regulator. The method comprises the following steps: acidizing the carbon nano tube; then carrying out coupling modification; finally performing heating, water bath, stirring, water cycle and condensation in a three-neck flask to finally prepare the Ag-carrying carbon nano tube antibacterial agent. The method has short technical process, and less equipment is used; andthe product has high purity up to 98% and good antibacterial performance up to 96%, can be used as an antibacterial agent in various products with high added value; and the method is an ideal method for preparing the Ag-carrying carbon nano tube antibacterial agent.

Owner:TAIYUAN UNIV OF TECH

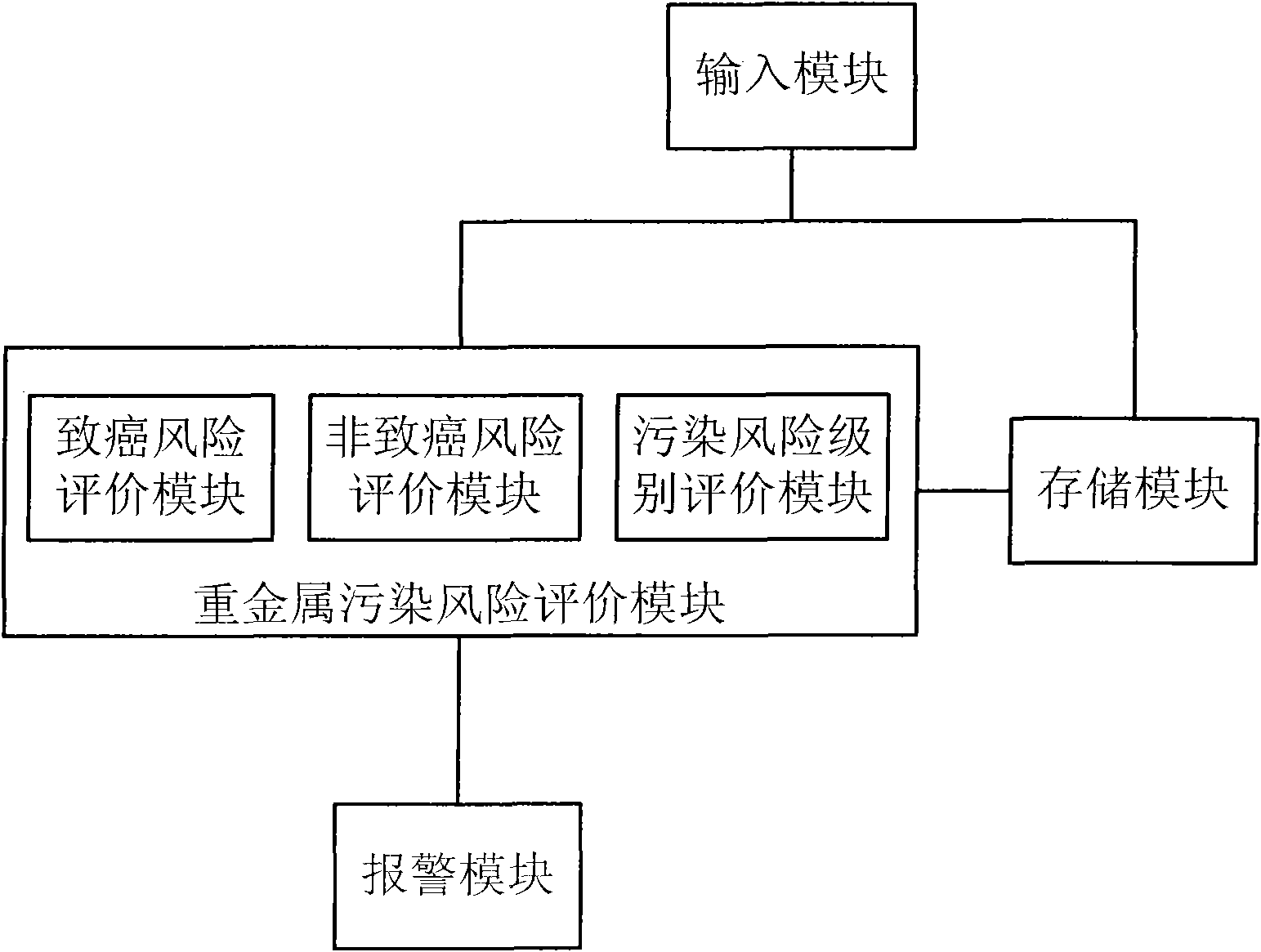

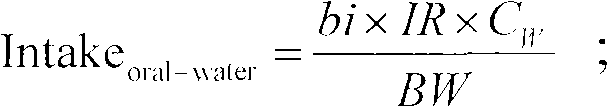

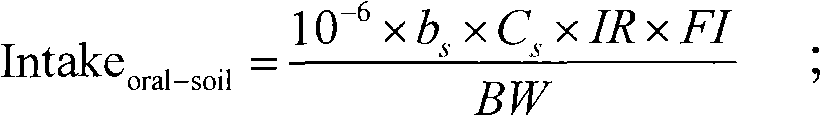

Risk assessment system of soil heavy metal pollution on human health

InactiveCN101982823AReduce laborUse less equipmentSpecial data processing applicationsRisk levelEnvironmental health

The invention relates to the technical field of environmental pollution evaluation, in particular to a risk assessment system of soil heavy metal pollution on human health, which can automatically assess the risk of the soil heavy metal pollution on the human health, save assessment time and improve assessment precision, and comprises a storage module, an input module and a heavy metal pollution risk evaluation module, wherein the storage module is used for storing parameters of physical and chemical properties and toxicological information of various soil heavy metal pollutants; the input module is used for inputting the types of the soil heavy metal pollutants of a region to be assessed, the ambient concentration and human health risk assessment parameters; and the heavy metal pollution risk evaluation module comprises a carcinogenic risk evaluation module, a non-carcinogenic risk evaluation module and a pollution risk level evaluation module, and is used for evaluating carcinogenic risk, non-carcinogenic risk and pollution risk level according to the types of the soil heavy metal pollutants, the ambient concentration and the human health risk assessment parameters.

Owner:CHONGQING UNIV

Preparation method of three-dimensional ordered macroporous ferric oxide desulfurizer

InactiveCN102260542AImprove desulfurization effectHigh purityGas purification with selectively adsorptive solidsNitratePore distribution

The invention relates to a preparation method of a three-dimensional ordered macroporous ferric oxide desulfurizer, which comprises the following steps: in view of the influence of the pore distribution of the desulfurizer on the desulfurization effect, preparing polystyrene microspheres by using ferric nitrate as the raw material, assembling an adhesive crystal template, and preparing the three-dimensional ordered macroporous ferric oxide desulfurizer. The preparation method has the advantages of short technological process, less equipment, full and accurate technological parameter data and high product purity (up to 96.9%). The pore size of the three-dimensional ordered macroporous ferric oxide desulfurizer is 90nm, the pores are orderly arranged, and the three-dimensional ordered macroporous ferric oxide desulfurizer has the advantages of favorable desulfurization effect and high desulfurization precision. The desulfurization effect of the three-dimensional ordered macroporous ferric oxide desulfurizer is enhanced by 91% as compared with the existing desulfurizer, thus, the preparation method is a very ideal method for preparing a ferric oxide desulfurizer.

Owner:TAIYUAN UNIV OF TECH

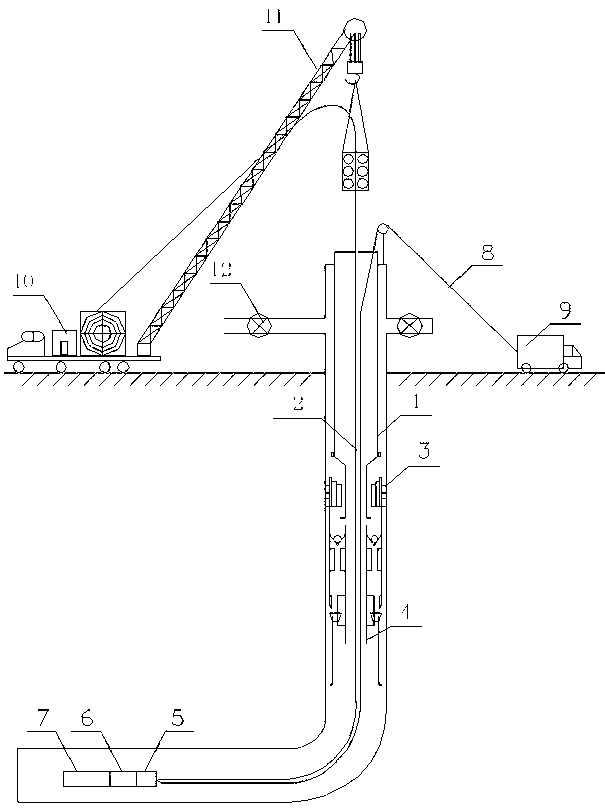

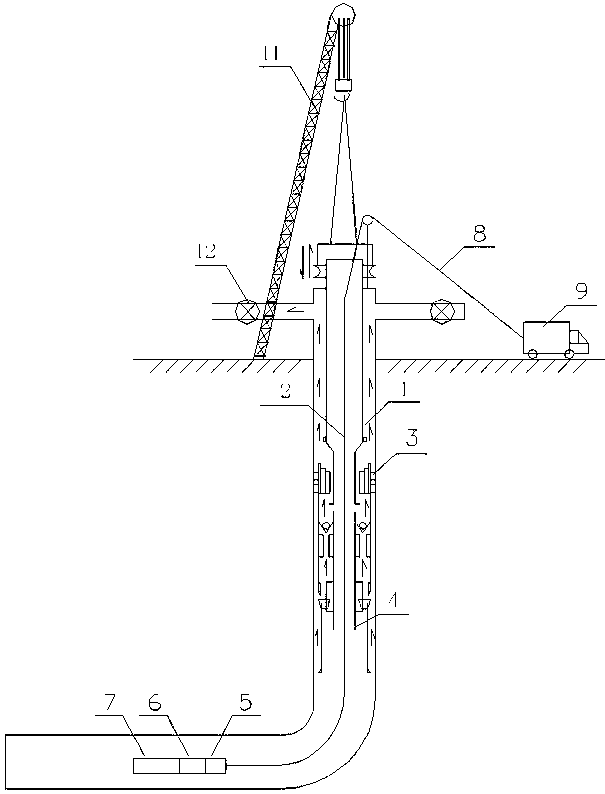

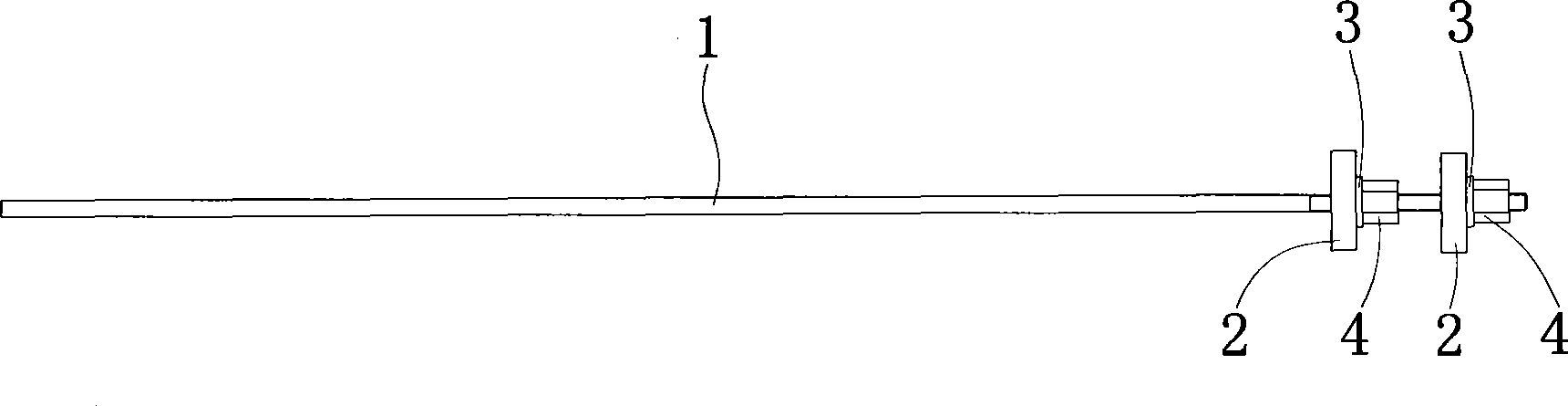

Method for testing fluid-producing section of horizontal pump well

The invention discloses a method for testing the fluid-production section of a horizontal pump well, which relates to the field of testing of fluid-producing sections of horizontal oil field wells. The method comprises the following steps of: connecting a long plunger hollow oil pump to the bottom of an oil pipe, feeding deep into the horizontal well by a design pump depth, and setting the long plunger hollow oil pump in a casing; synchronously feeding a continuous oil pipe and a logging cable deep into the lower part of a segment to be tested on the fluid-producing section of the horizontal well, pressing the ground where the continuous oil pipe is positioned to separate a releasing pipe nipple from the continuous oil pipe, and pulling the continuous oil pipe out; and connecting the upper end of the oil pipe with a reciprocating ground lifting device to perform reciprocating pumping actions, starting a fluid-producing section tester, pulling the logging cable slowly, and moving the fluid-producing section tester upwards for testing during production. According to the method, oil field No.5 casing well completion and fluid-producing section testing of the horizontal well by lifting with an oil sucking machine are realized; and meanwhile, the quantity of used equipment is small, the operation time is short, and the well testing cost is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reinforcing filler used for rubber latex product, preparation method thereof and application thereof

ActiveCN101696282APrevent each other from approachingClose to each other to preventPigment treatment with macromolecular organic compoundsPigment physical treatmentParaffin waxCellulose

The invention relates to reinforcing filler used for a rubber latex product, a preparation method thereof and application thereof. The reinforcing filler consists of the following components in part by weight: 50 to 80 parts of base material, 0.01 to 0.4 part of dispersant, 0.001 to 0.5 part of surface treating agent, 0.01 to 1 part of emulsion and 20 to 50 parts of water, wherein the base material is any one of heavy calcium carbonate powder, kaolin powder and argil powder; the dispersant is any one of casein, methylene dinaphthalene sodium sulfonate, sodium polyacrylate, potassium hydroxide and ammonia water; the surface treating agent is any one of bentonite, cellulose, swelling soil and attapulgite; and the emulsion is any one of mineral oil, vaseline, liquid paraffin and polyoxychloroethylene wax. The reinforcing filler has economic formulation and good reinforcing effect. The preparation method is a conventional stirring and grinding method. The process is simple, and little equipment is used. The application comprises the following steps: adding the reinforcing filler into rubber latex, blending the mixture evenly, forming a layer of film on a die by adopting a soaking and casting method, and then drying the film for 15 to 30 minutes at a temperature of between 110 and 130 DEG C to obtain the reinforced filled rubber latex product. The reinforcing filler is favorable for improving the tensile strength of the rubber latex product and reducing the usage amount of the latex.

Owner:BENGBU RUIJIE TECH

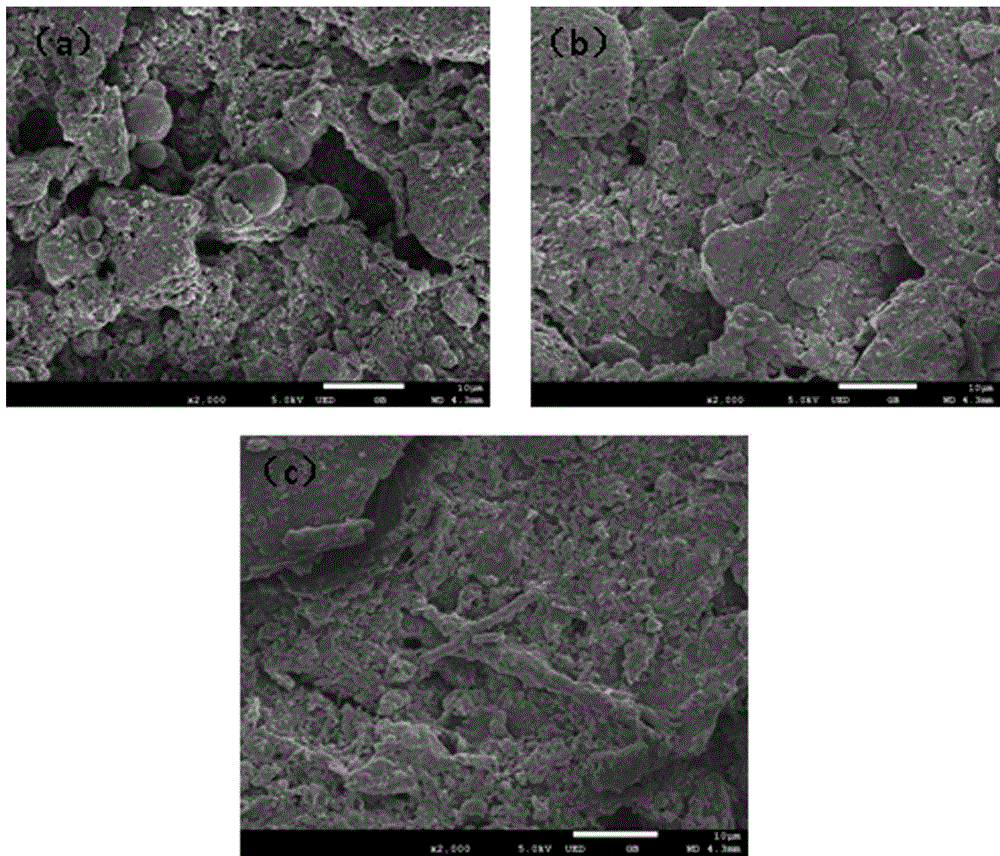

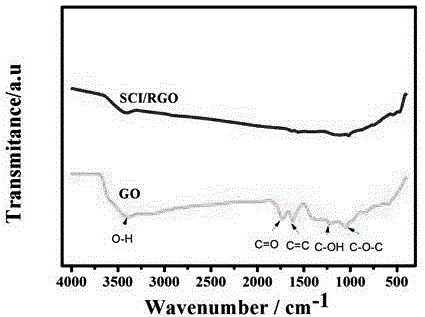

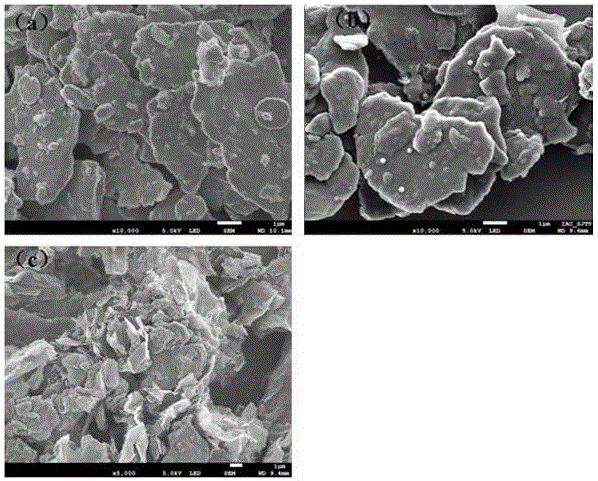

Graphene compounded wave absorbing material and preparation method thereof

InactiveCN106479433AHigh purityImprove absorbing performanceOther chemical processesHigh absorptionMicrowave

The invention relates to the technical field of microwave absorption and particularly relates to a graphene compounded wave absorbing material and a preparation method thereof. The graphene compounded wave absorbing material is prepared through uniformly compounding carbonyl iron and graphene. The preparation method comprises the steps: firstly, preparing graphite oxide by using an improved Hummers method, and then, uniformly dispersing the graphite oxide into a carbonyl iron dispersion solution; then, reducing the graphite oxide to graphene by using an ultrasonic reduction method, thereby preparing the graphene compounded wave absorbing material. Compared with the pure carbonyl iron and the pure graphene, the compounded wave absorbing material provided by the invention has the advantages that the wave absorbing performance is superior, the wave absorbing strength is high, the frequency band of wave absorbing is wide, and the density is relatively low; the compounded wave absorbing material has adjustability, high absorption at different frequencies is achieved through adjusting the mass ratio of the graphene to the carbonyl iron and the thickness of the compounded material.

Owner:INST OF DONGGUAN TONGJI UNIV +1

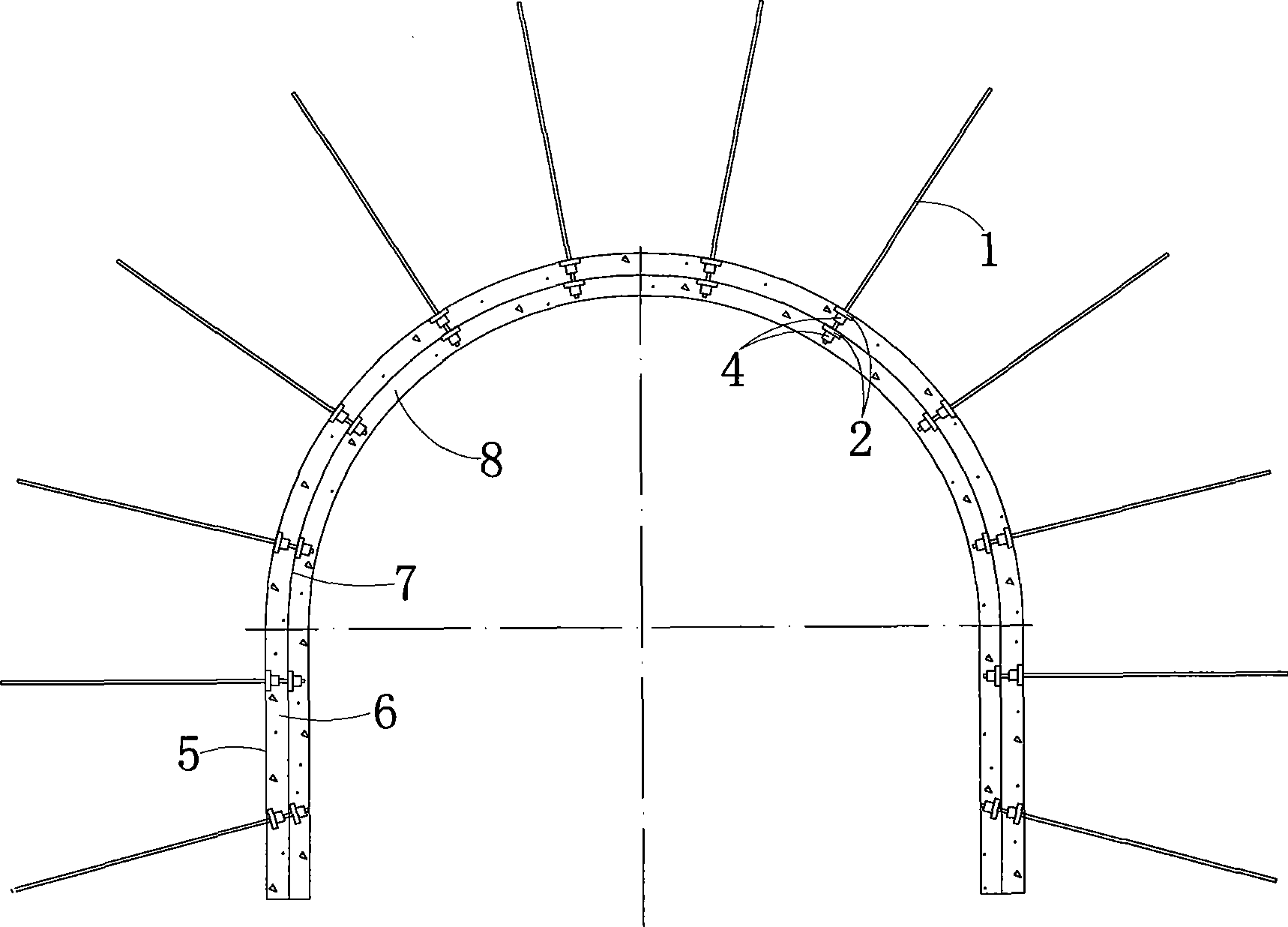

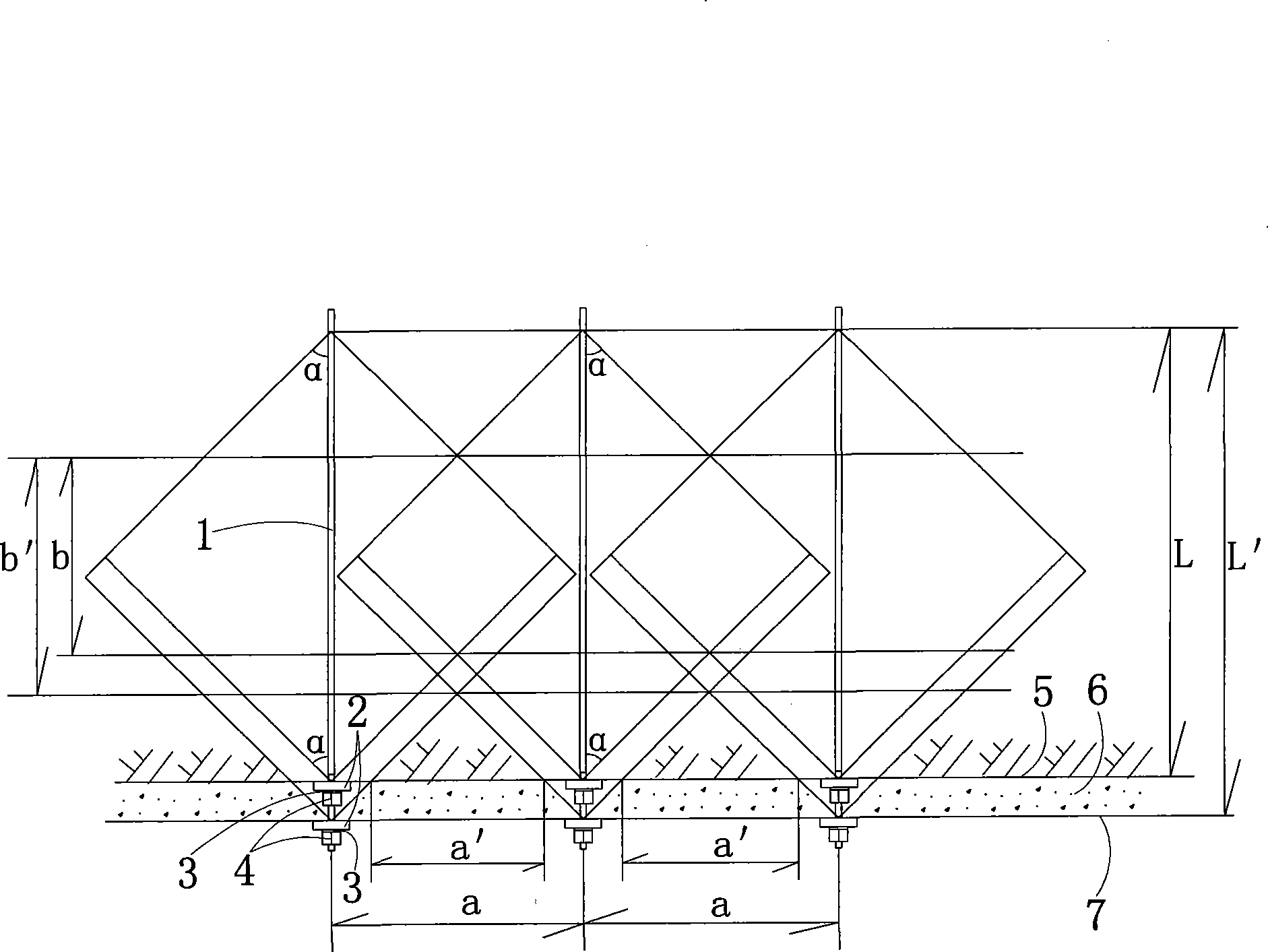

Composite support anchor rod and construction method thereof

The invention relates to a composite supporting anchor rod, comprising a rod body with an outside thread arranged at one side and at least two compressing pieces arranged on the rod body, wherein, each compressing piece comprises a tray sheathed with the rod body and a screw nut which is connected with the rod body in a revolving way and is close to the outer end of the outside thread. On the rod body, a washer is sheathed with the part which is corresponding to the part between the tray and the screw nut of each compressing piece. The construction method of the anchor rod is as follows: breaking rock; anchor eye positioning and pore-forming; first net hanging, anchor rod placing, compressing and cement mortar blowing; second net hanging, compressing and cement mortar blowing; according to actual needs of construction, the processes of net hanging, compressing and cement mortar blowing can be repeated, so as to finish plural times of supporting. The anchor rod of the invention features good supporting function, easy manufacturing, convenient installation, low cost and wide application, which is especially applicable to anchor net blowing and supporting of soft rock lanes and solves the problem of premature cracking and damage of concrete spray layer. The construction method of the invention features simple technique, safety and reliability, cost-effectiveness and high efficiency and few employed devices.

Owner:于守东

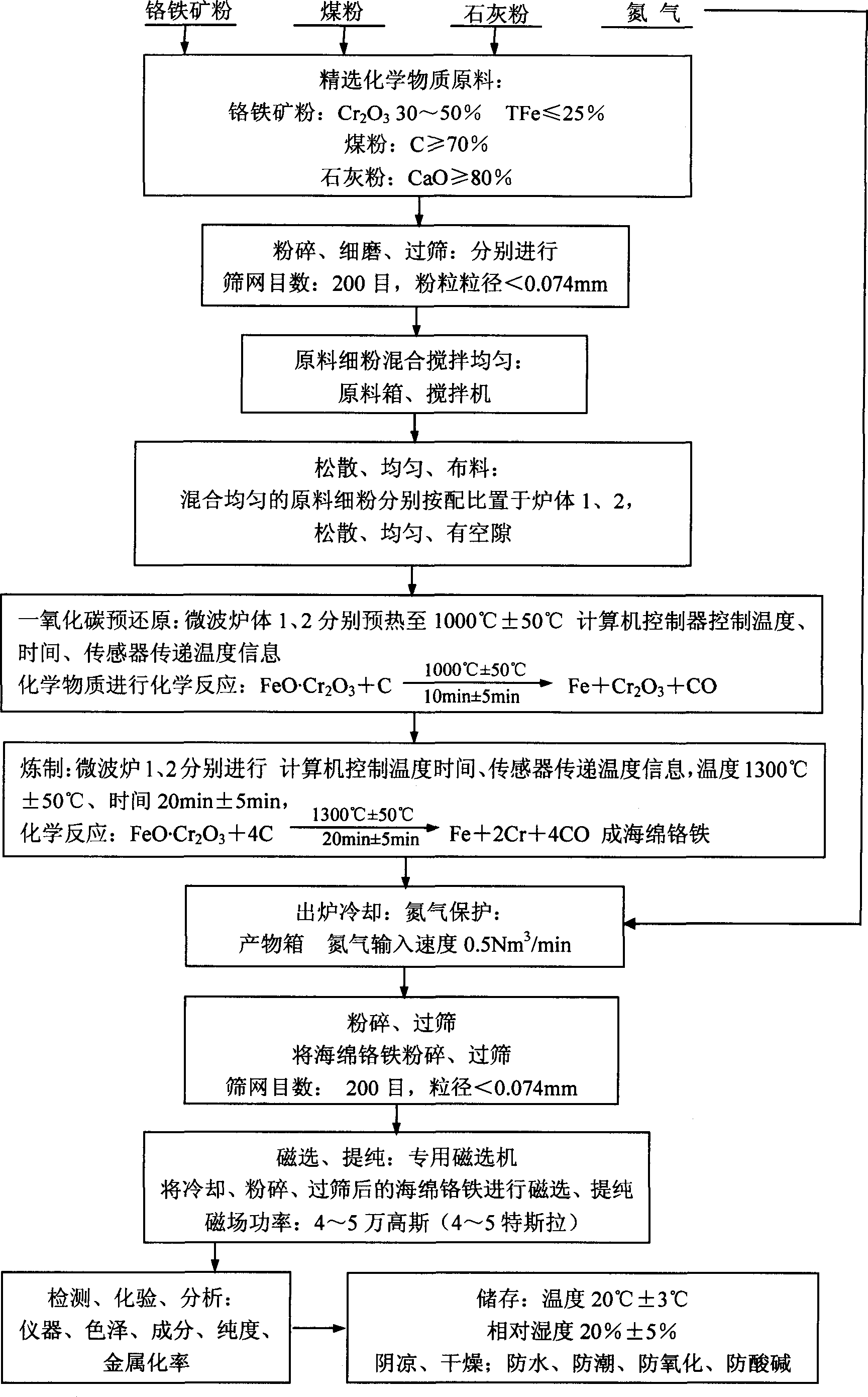

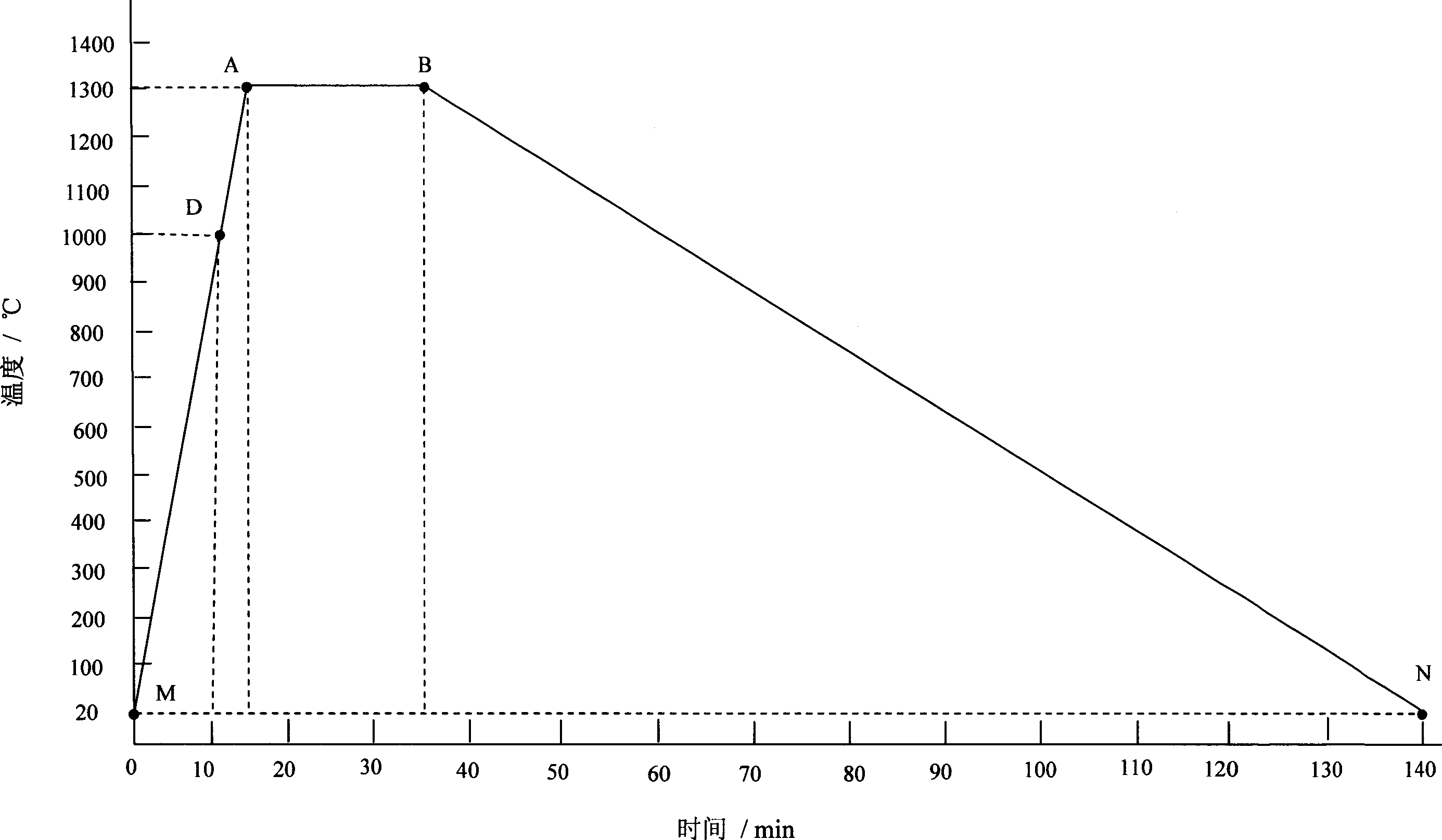

Metal ferrochromium preparing method by computer-controlled double microwave ovens

InactiveCN1827786AFast heatingPrevent oxidationMagnetic separationGrain treatmentsMicrowave ovenShielding gas

The invention relates the method for preparing chrome metal with microwave double wave controlled by computer. The method comprises the following steps: controlling purity of raw material, disintegrating, fine grinding, screening, mixing material, stirring, distributing, preheating furnace body, high temperature refining, nitrogen protection, cooling, purifying, and getting the high purity chrome metal whose purity is 95%, the chromium content being 63-75%, nitrogen content being 24-36%, using chromite powder as raw material, using common as reducing agent, using lime powder as fusing agent, using nitrogen as protective gas, adopting computer to control microwave double wave, using temperature probe to intake furnace body temperature information, using computer to control double furnace body smelting conversion, using microwave to heat, using LCD to display, fault alarming, and realizing the information, procedure and automation. The method has the advantages of high efficiency, short process flow and non environmental pollution.

Owner:TAIYUAN UNIV OF TECH

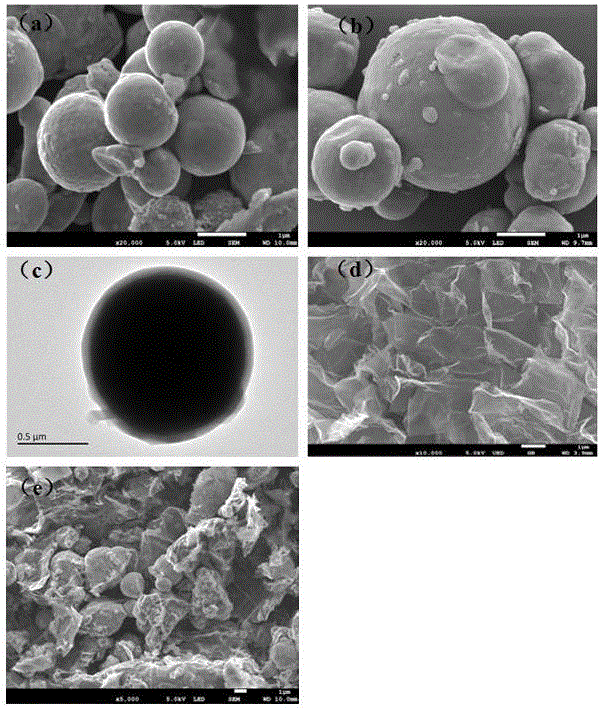

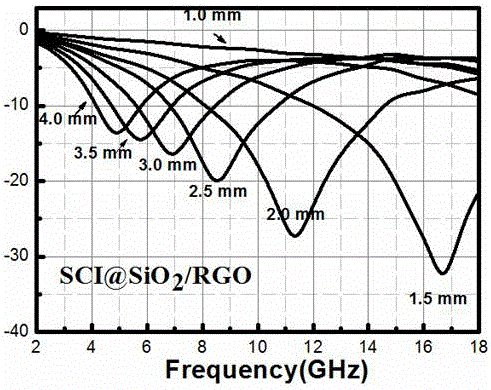

Graphene-based ternary composite wave-absorbing material and preparation method thereof

InactiveCN106800916ALow dielectric constantImproved Impedance Matching CharacteristicsOther chemical processesMicrowaveSilicon dioxide

The invention relates to the technical field of microwave absorption, in particular to a graphene-based ternary composite wave-absorbing material and a preparation method thereof. The preparation method comprises the steps of firstly, preparing silicon dioxide-coated carbonyl iron core-shell composite particles by using a sol-gel method, then preparing graphite oxide by using an improved Hummers method, evenly dispersing the graphite oxide into dispersion liquid of the silicon dioxide-coated carbonyl iron core-shell composite particles, and finally, using an ultrasonic reduction method to enable graphite oxide to be reduced into graphene so as to prepare the graphene-based ternary composite wave-absorbing material. The preparation method provided by the invention is simple and efficient; the prepared composite wave-absorbing material is more excellent in wave absorbing performance, high in wave absorbing strength, wide in wave absorbing bandwidth and smaller in density compared with a pure carbonyl iron binary composite wave-absorbing material and a pure graphene and carbonyl iron or graphene binary composite wave-absorbing material; the graphene-based ternary composite wave-absorbing material also has regulation performance, and can realize strong wave absorption under different frequencies by adjusting the thickness of a coating layer SiO2, the mass ratio of graphene to the coated core-shell composite particles and the thickness of the ternary composite material.

Owner:INST OF DONGGUAN TONGJI UNIV +1

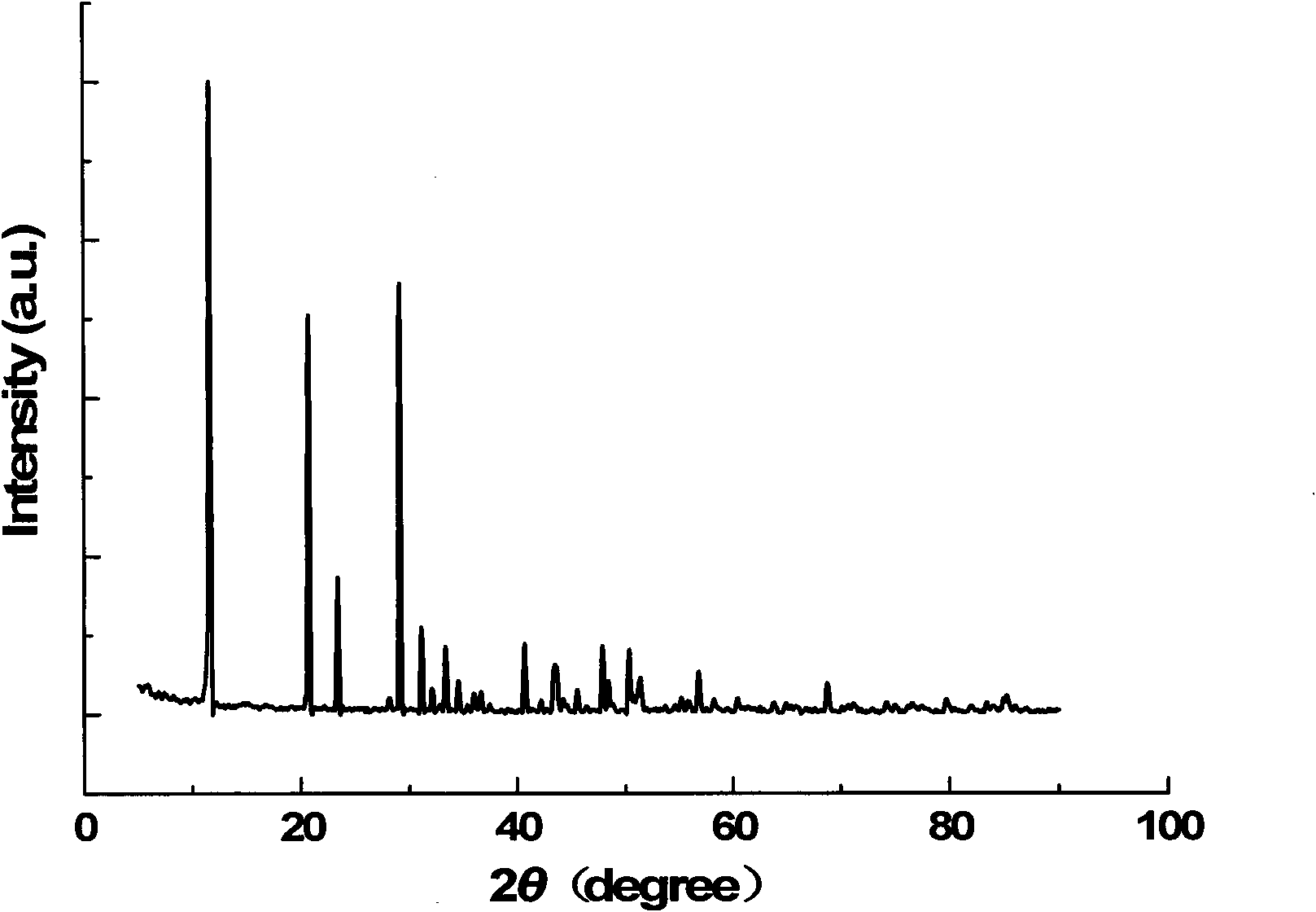

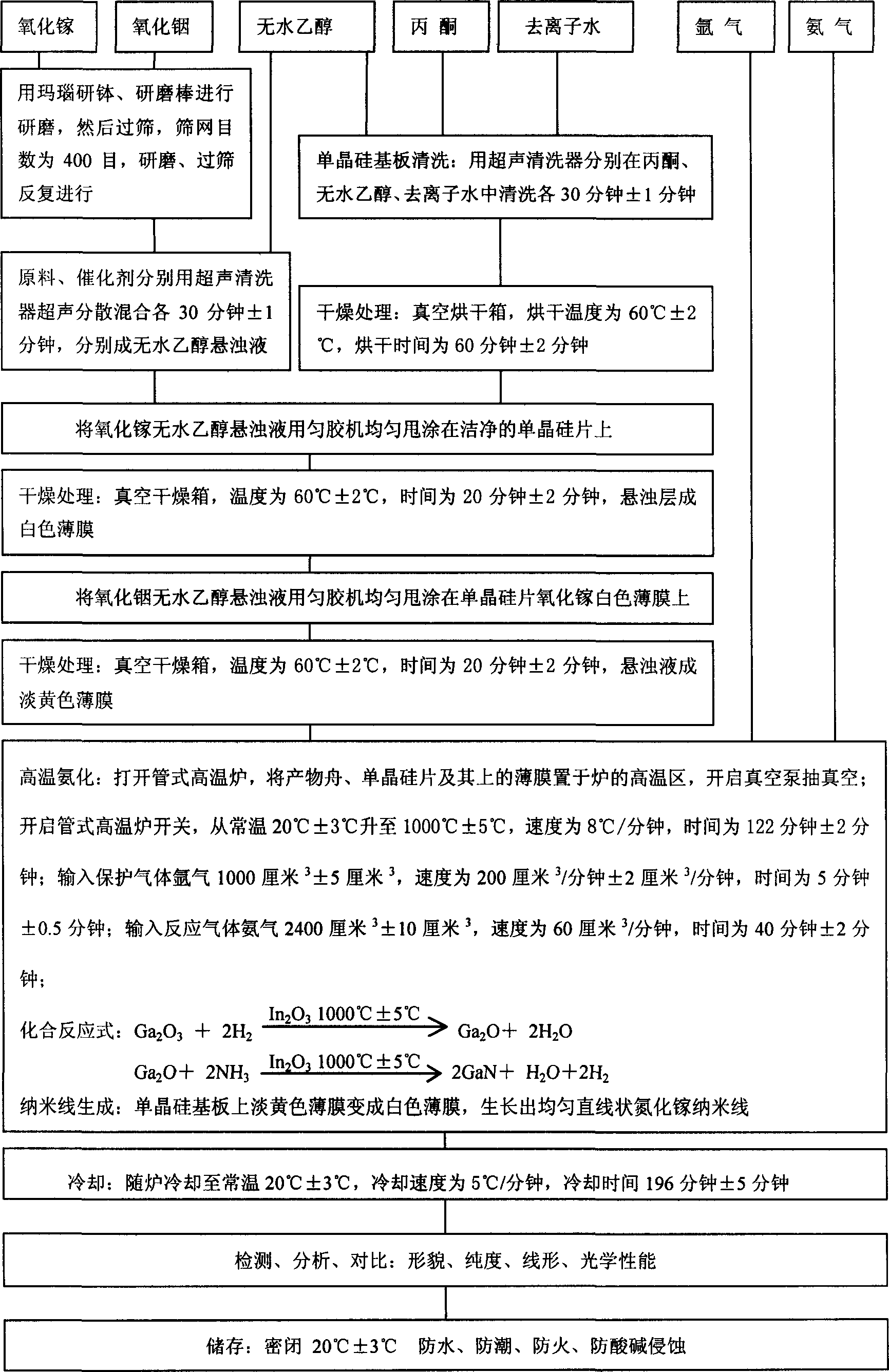

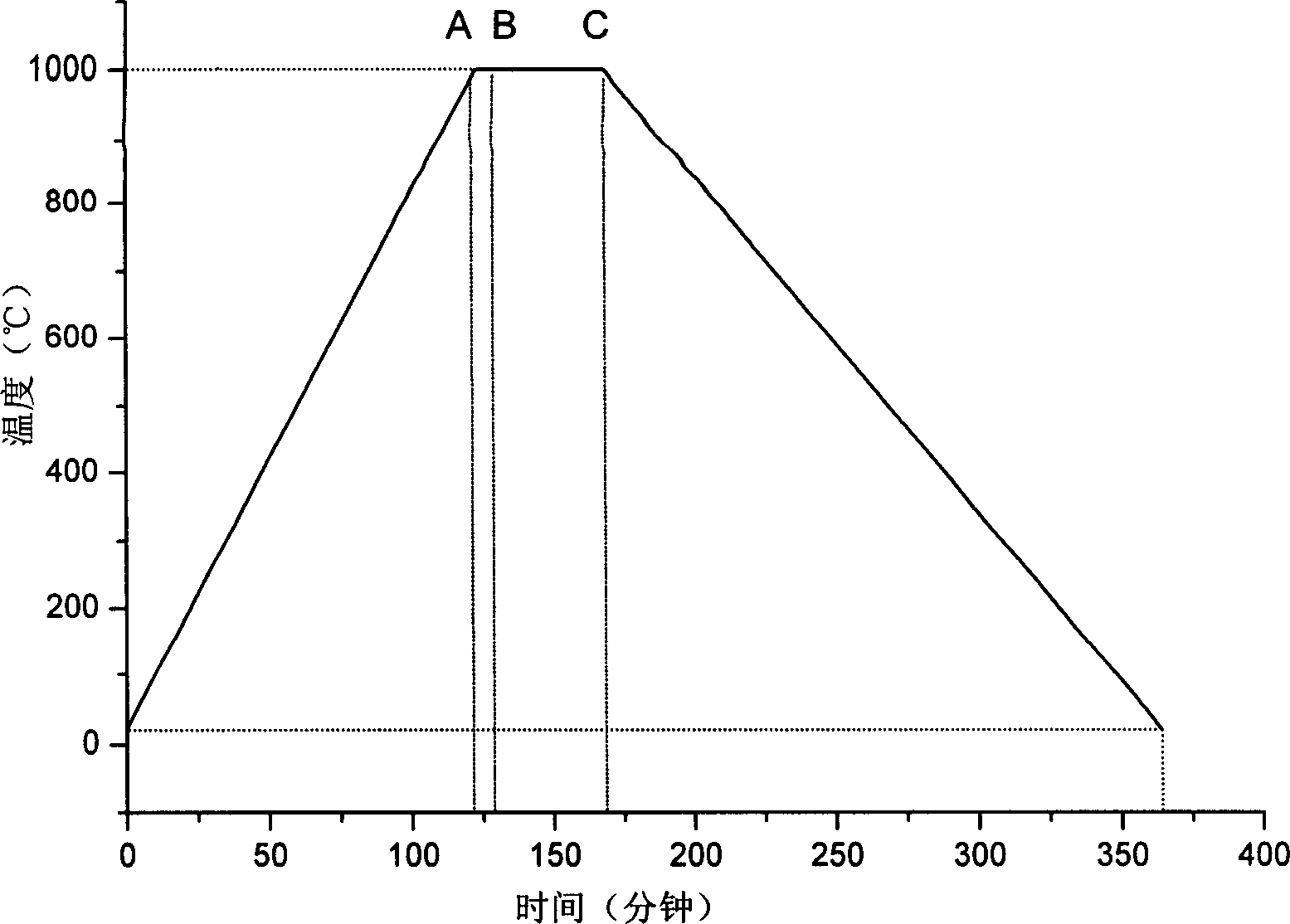

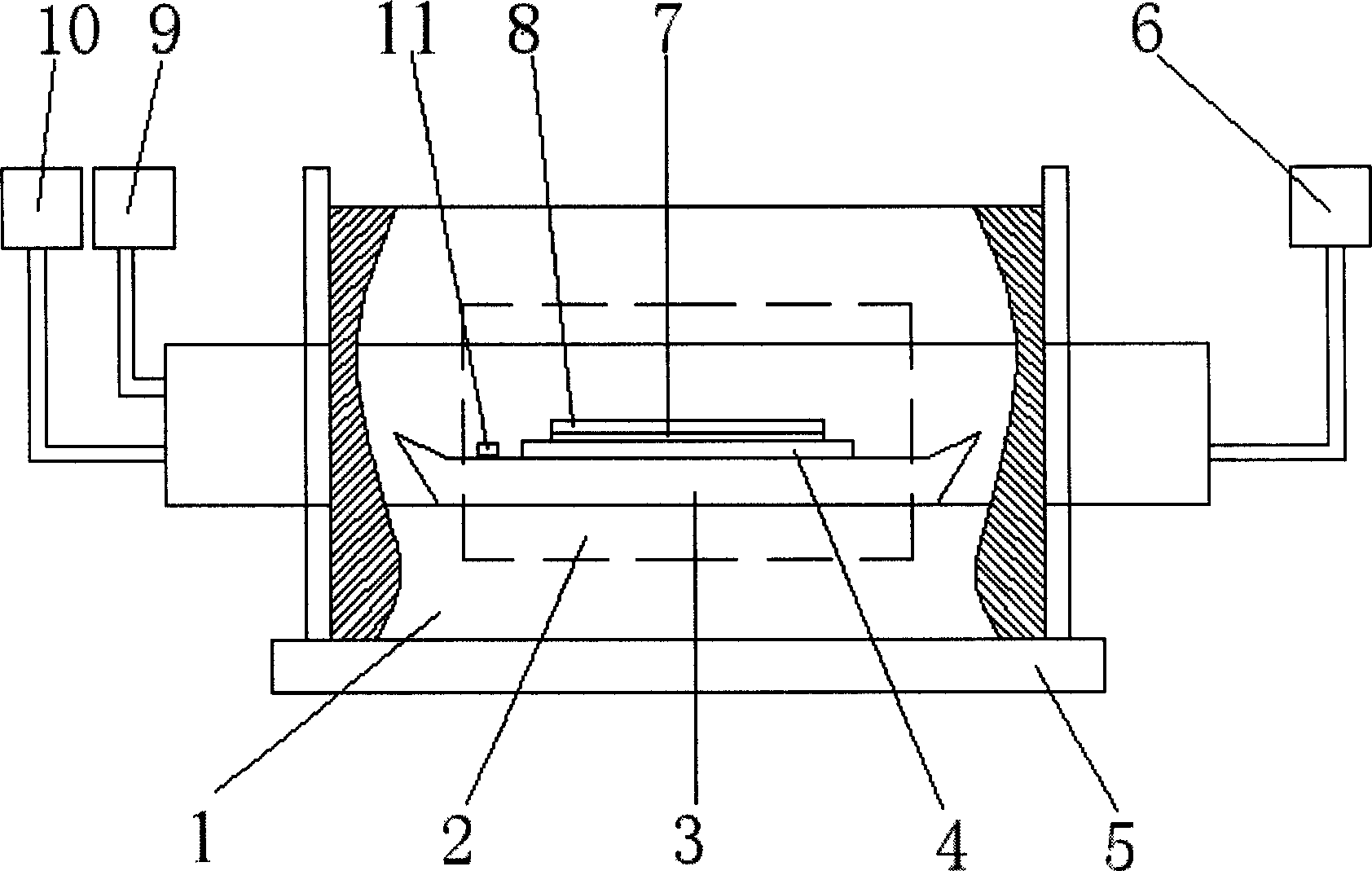

Method for preparing inorganic compound gallium nitride nanowire

InactiveCN1803627AThe morphology is evenly arrangedAdvancedNitrogen-metal/silicon/boron binary compoundsGallium/indium/thallium compoundsNanowireIndium

The disclosed preparation method for gallium nitride nano line comprises: using gallium oxide as material, indium oxide as catalyst, ammonia gas as reaction gas, argon gas as protective atmosphere, anhydrous alcohol as mixture, and all of acetone, anhydrous alcohol and deionized water as abluent for single-crystal silicon substrate; refining the material, controlling proportion and purity; optimizing the usage for catalyst, reaction gas, protective gas and other auxiliary agents; grinding and screening the material, supersonic cleaning the substrate; forming suspension to coat on the substrate; drying, vacuumizing, forcing ammonia gas, ammonifying at high temperature, growing the nano line; cooling, detecting, analyzing, and obtaining the objective product with diameter of 50nm-70nm and average length 90mum and well performance. This invention has short process, high yield of 95%, well purity of 98%, and belongs to ideal method for gallium nitride nano line.

Owner:TAIYUAN UNIV OF TECH

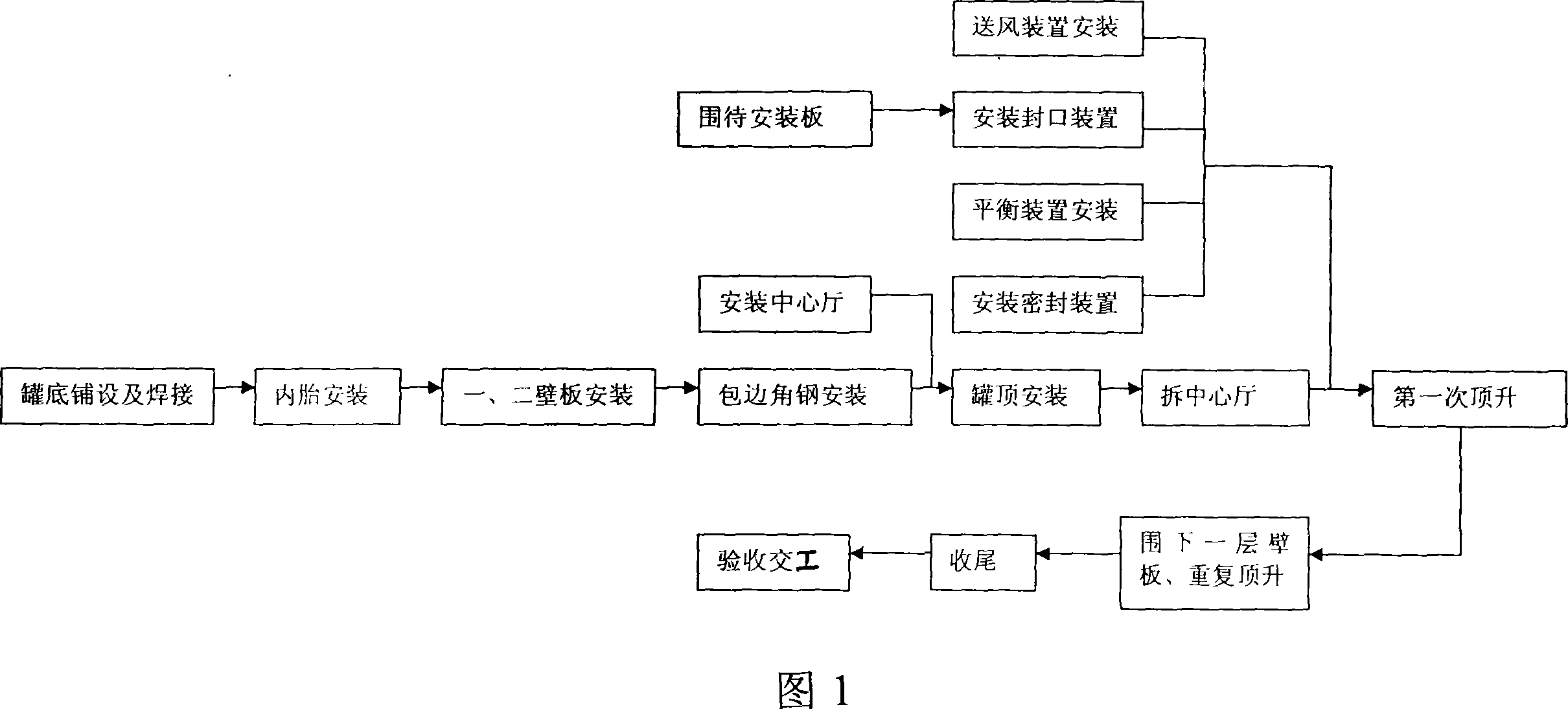

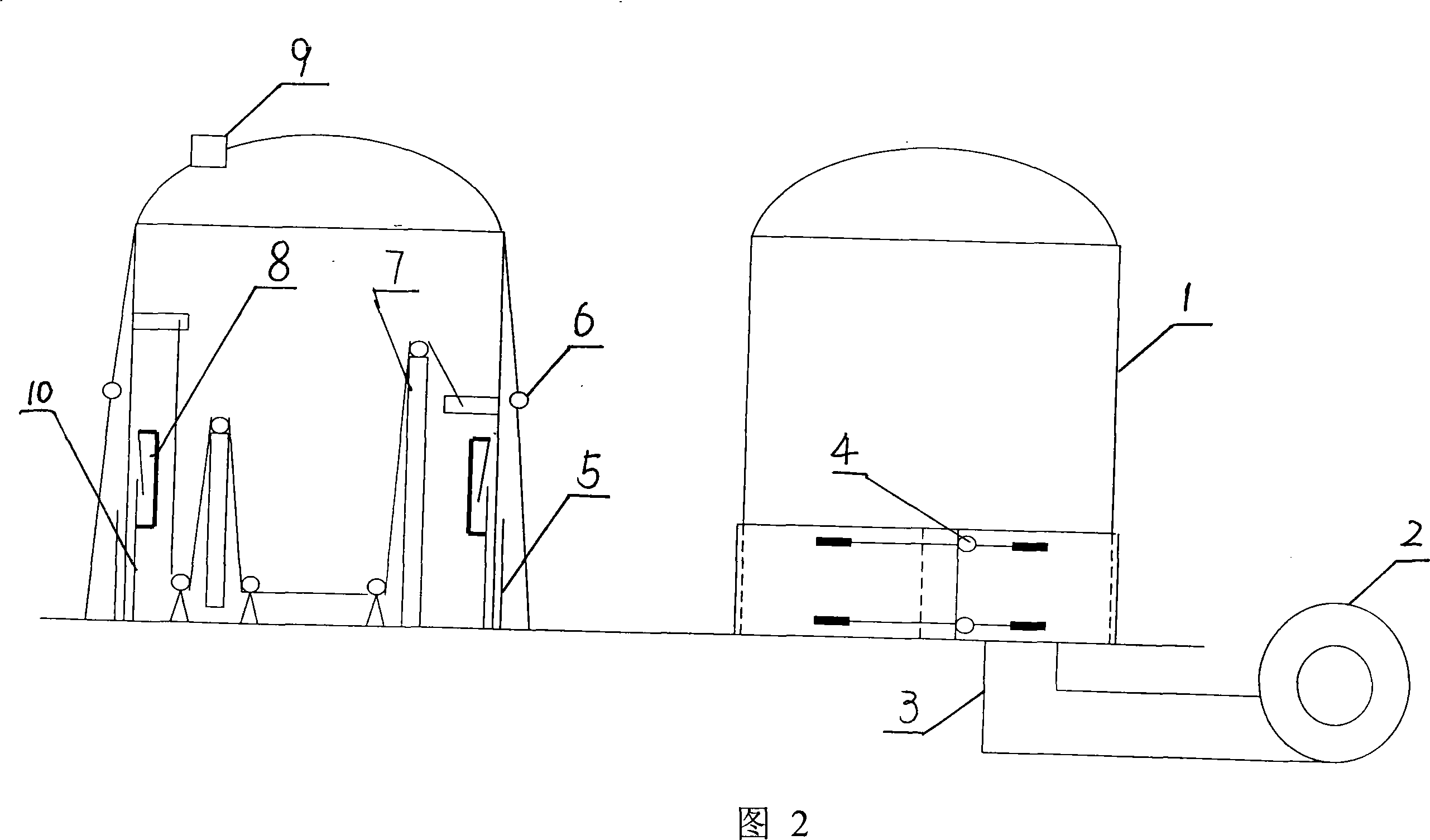

Silo high-altitude pressure-swing gas-cap mounting process

ActiveCN101200982AEasy to masterLarge working surfaceBulk storage containerSUSPENDING VEHICLEEngineering

The invention provides a high altitude mounting method of pressure transformative gas cap of silo, belonging to the high altitude machine mounting method technical field, and comprising a storage tank body. The mounting method includes the following steps: the mounting and welding of the bottom plate of the tank; the mounting of the inner tube; the mounting of first and the second wainscot and the angle steel for wrapping the edge; the mounting of a central space; the mounting of the tank roof; the removing of the central space; wrapping of the plates to be mounted; mounting of the mouth closing device; mounting of the balancing device; mounting of the sealing device. The invention is a mounting method of storage tank, which adopts the gas cap technology. The method is simple and easily grasped, the working space is wide, the construction period is short, few types of equipment are used, the structure is simple and nonbreakable, and the maintenance is convenient. As the invention is an inverted mounting method of gas cap, large-scale crane and high altitude operations are unnecessary, thereby large amount of falsework is saved, and the operations are safe.

Owner:CHINA 22MCC GROUP CORP

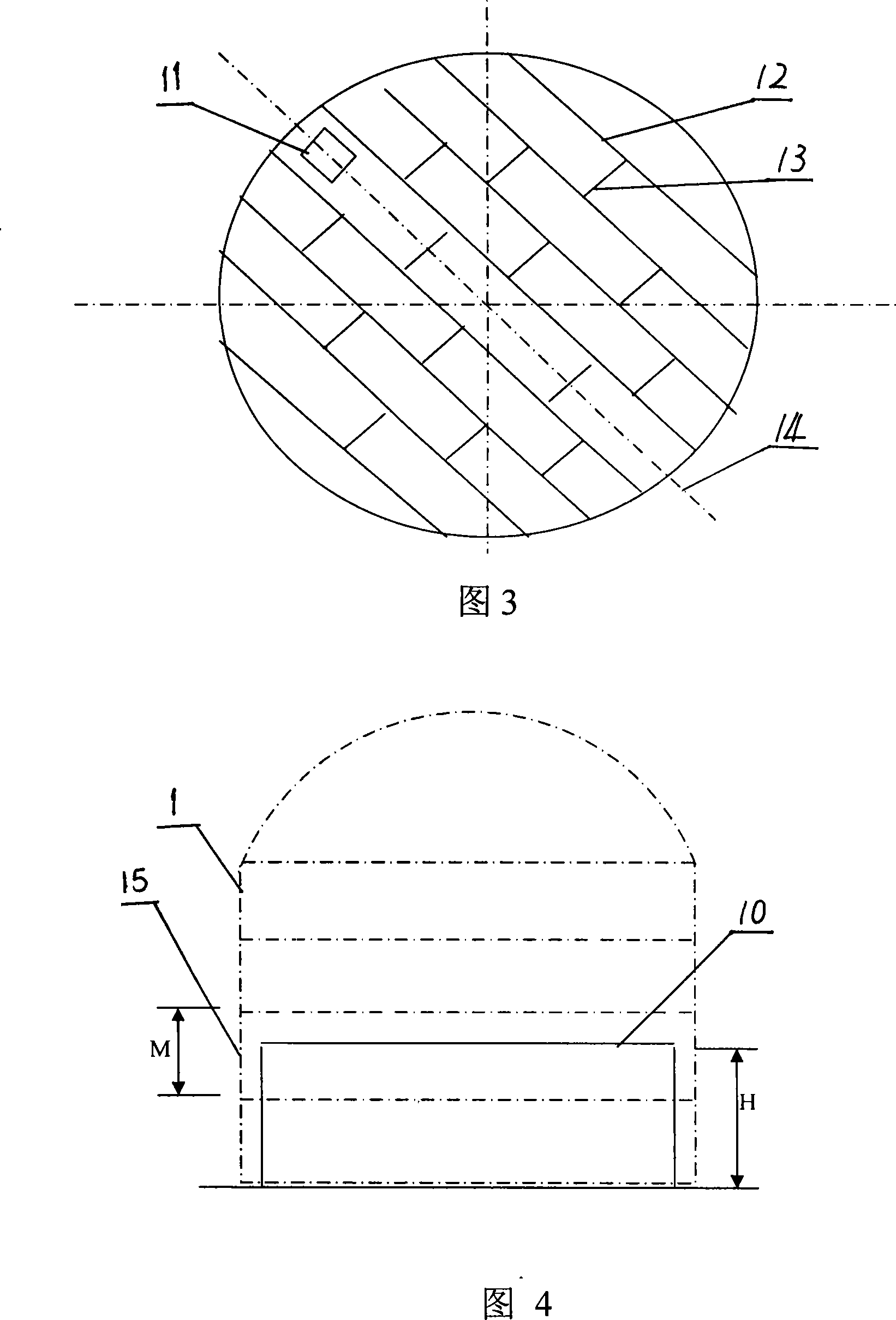

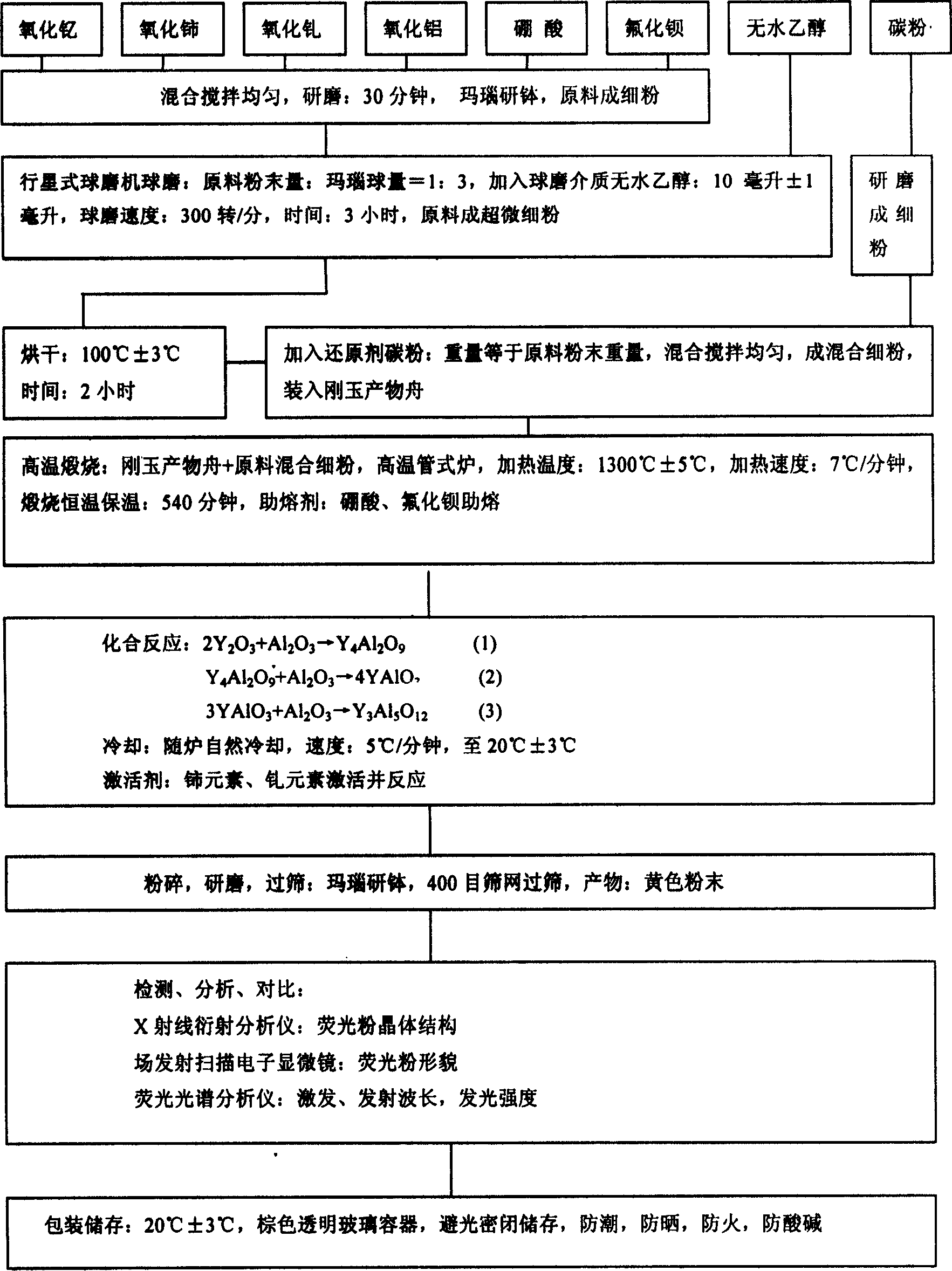

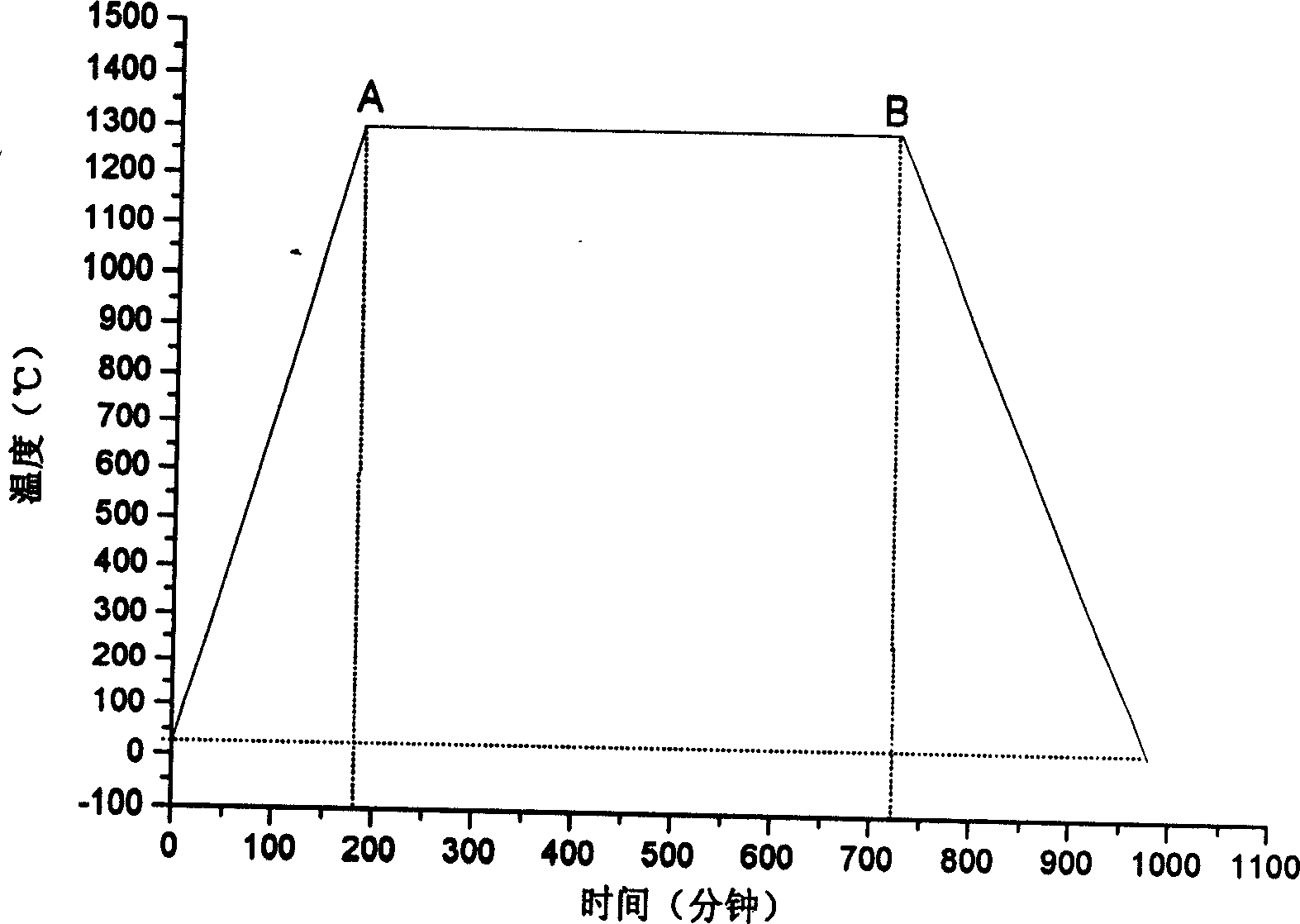

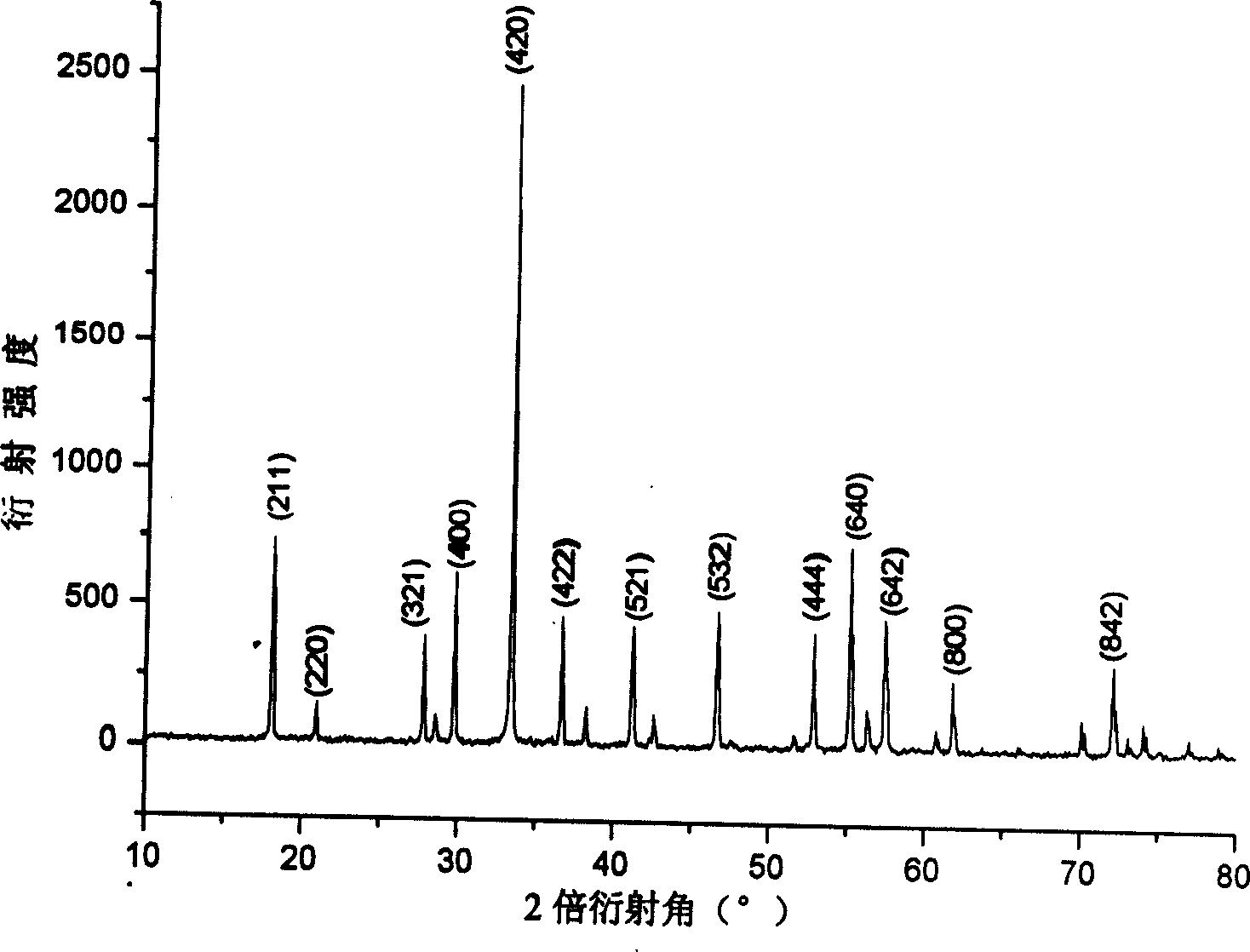

Cerium, gadolinium activated yttrium aluminium garnet fluorescent powder and preparation method

InactiveCN1730607AUniform particle distributionHigh yieldLuminescent compositionsGadolinium oxideCerium

The invention relates to a cerium, gadolinium activated yttrium aluminium garnet fluorescent powder and preparation method, wherein the fluorescent powder is prepared from yttrium oxide, aluminium oxide, cerium oxide, gadolinium oxide, boric acid, barium fluoride, carbon powder, anhydrous alcohol as raw material, cerium oxide, gadolinium oxide and water as activating agent, boric acid and barium fluoride as fluxing agent, anhydrous alcohol as ball grinding medium, carbon powder as reducing agent through raw material mixing, grinding, ball grinding, calcining in high temperature pipe heater, cooling down, grinding, sieving, detecting, packaging and storing.

Owner:TAIYUAN UNIV OF TECH +1

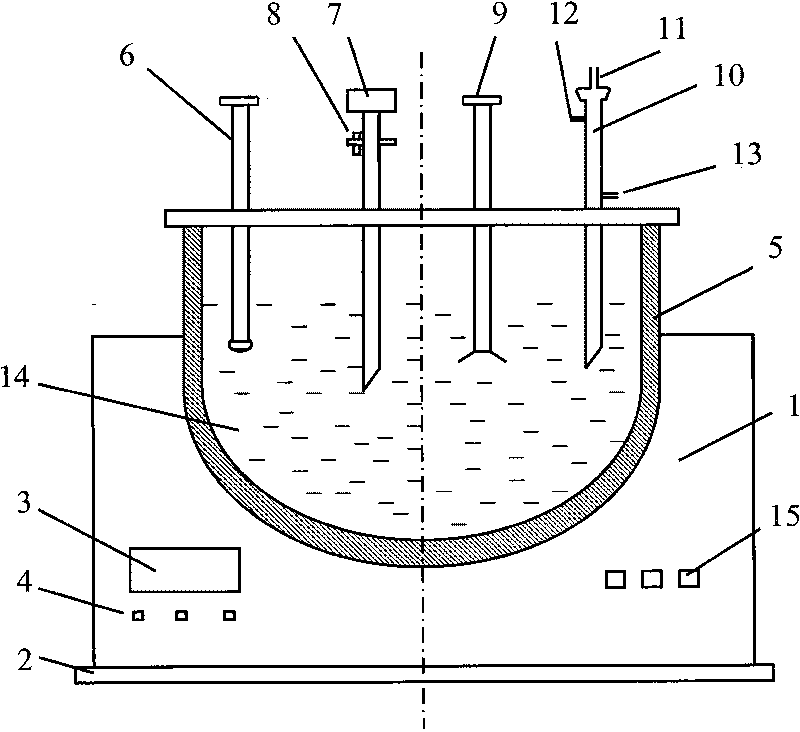

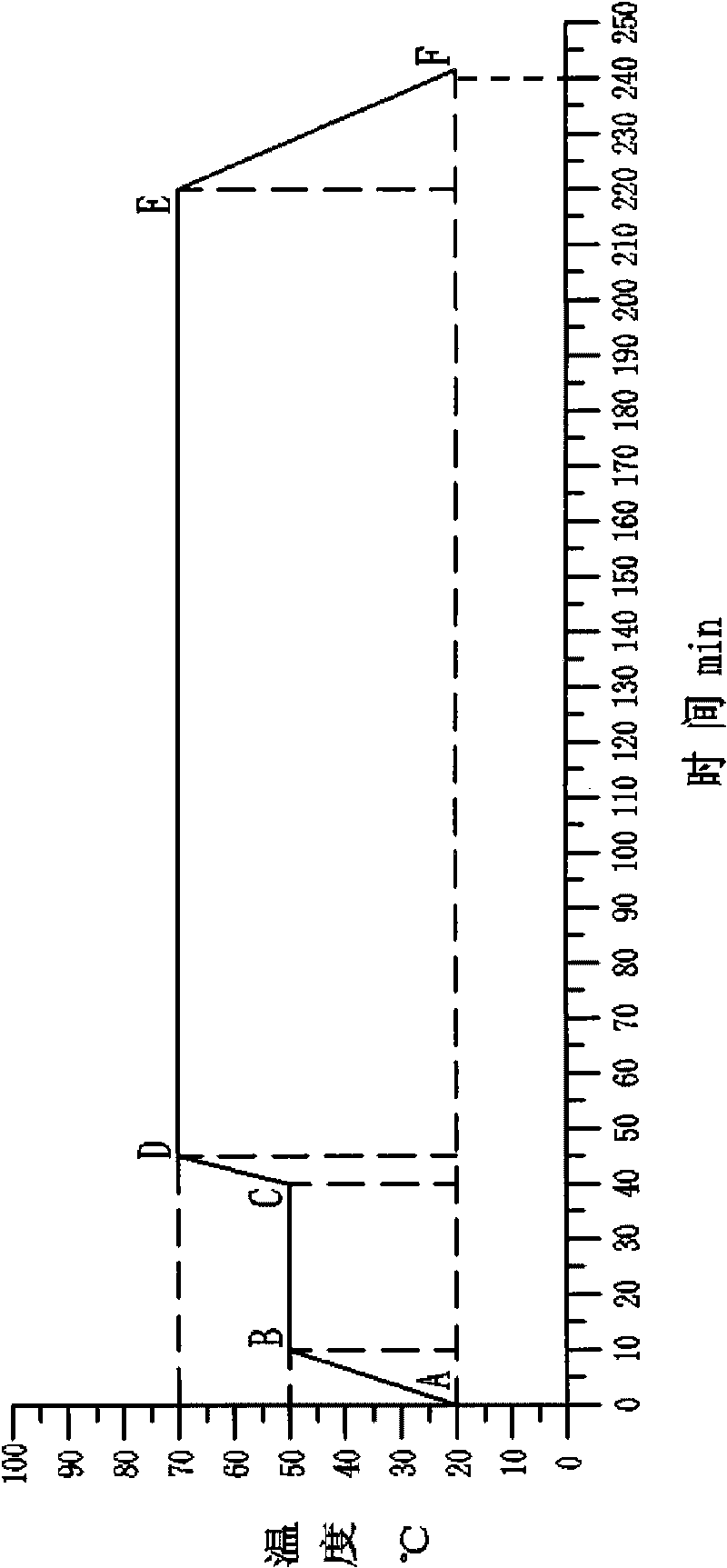

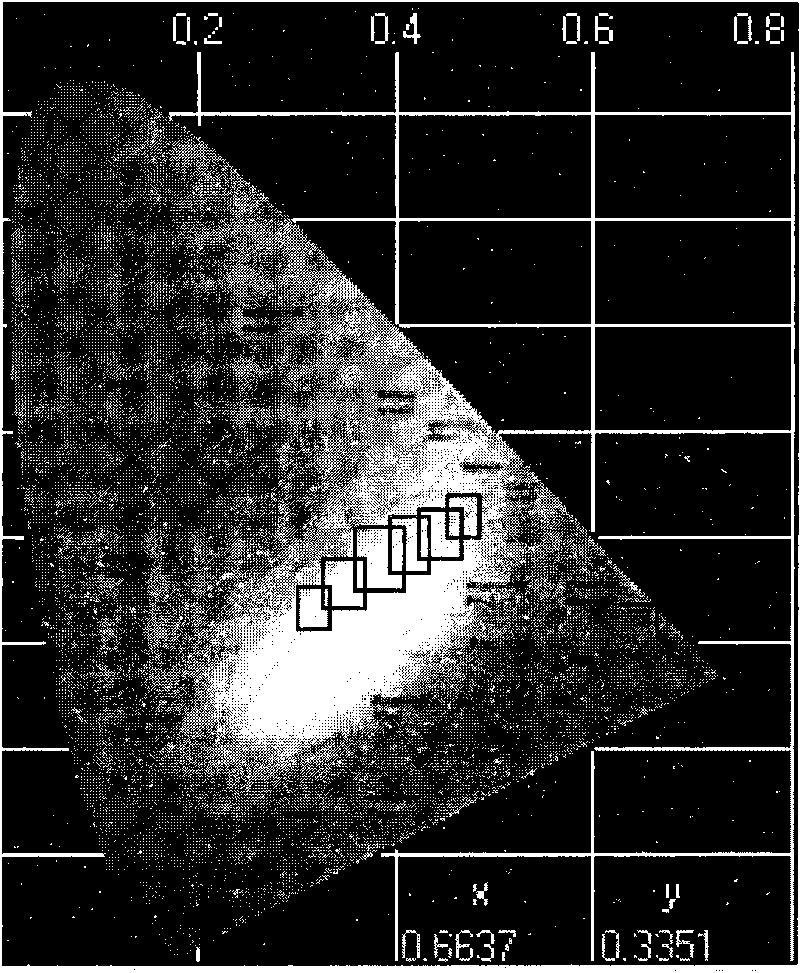

Method for preparing rare earth europium ternary complex

InactiveCN101704829AImprove luminosityHigh color purityGroup 3/13 element organic compoundsChemical reactionFiltration

The invention relates to a method for preparing a rare earth europium ternary complex, which comprises the following steps of: using europium chloride hexahydrate, benzoyl acetone and triphenylphosphine oxide as raw materials, using absolute ethyl alcohol as a solvent and a detergent, using deionized water as a solvent and a cleaning agent, and using sodium hydrate as an acidity-basicity pH value conditioning agent; preparing a solution added with the benzoyl acetone, the triphenylphosphine oxide and ethanol first, and then preparing an europium chloride hexahydrate ethanol solution and a sodium hydrate aqueous solution; dropping the europium chloride hexahydrate ethanol solution and the sodium hydrate aqueous solution into a four-hole boiling flask under a condition with heating, stirring and water circulation condensation to perform chemical reactions so as to prepare a ternary mixed solution; performing vacuum suction filtration, washing, recrystallization purification and vacuum drying on the ternary mixed solution to prepare white powder of the rare earth europium ternary complex, wherein the chromaticity coordinates are that X is equal to 0.6637 and Y is equal to 0.3351, and the rare earth europium ternary complex glows. The preparation method has the advantages of short process flow, fewer used devices, high yield up to 90 percent, good product purity up to 98 percent, good luminous performance and high luminous efficiency.

Owner:TAIYUAN UNIV OF TECH

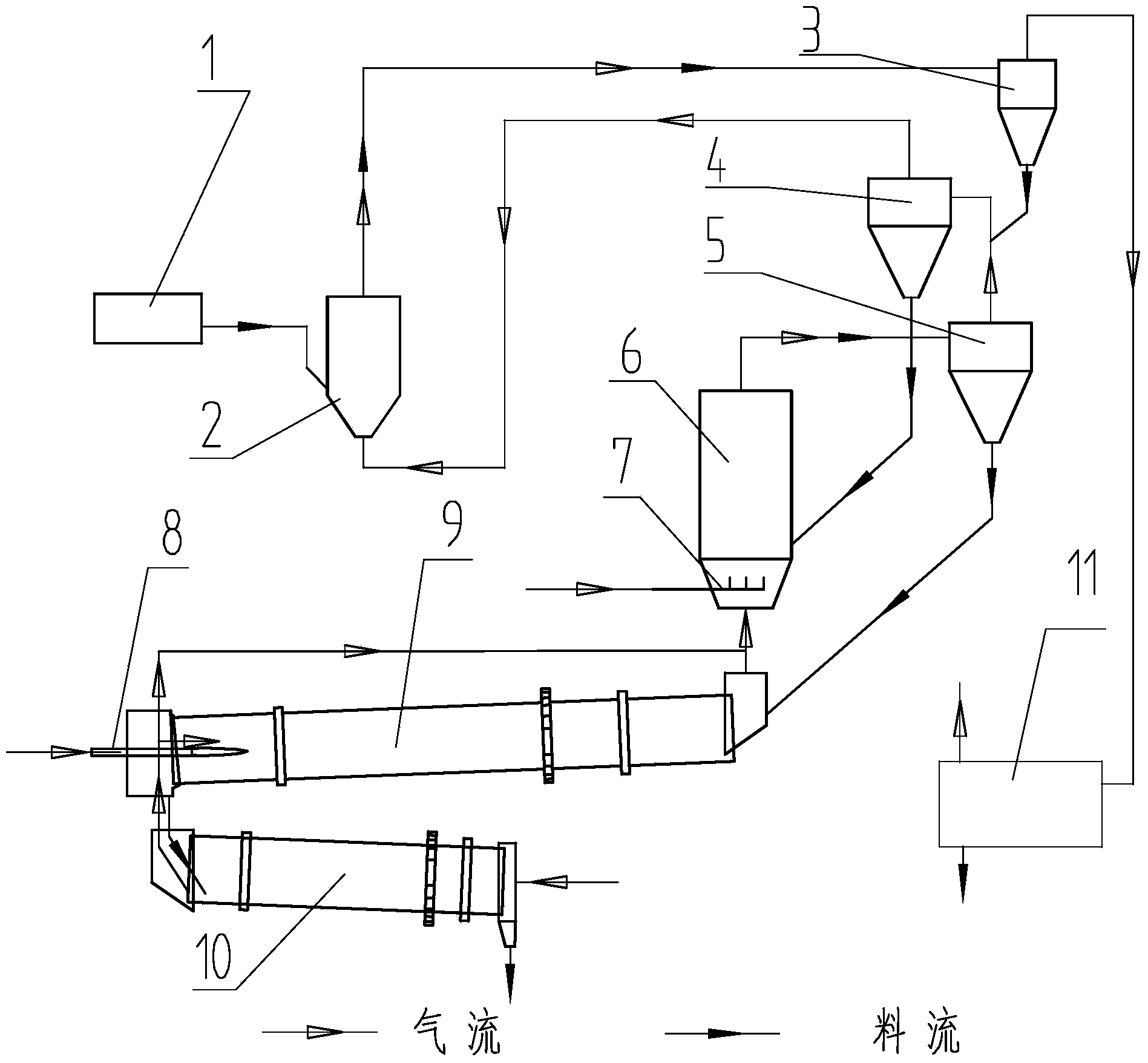

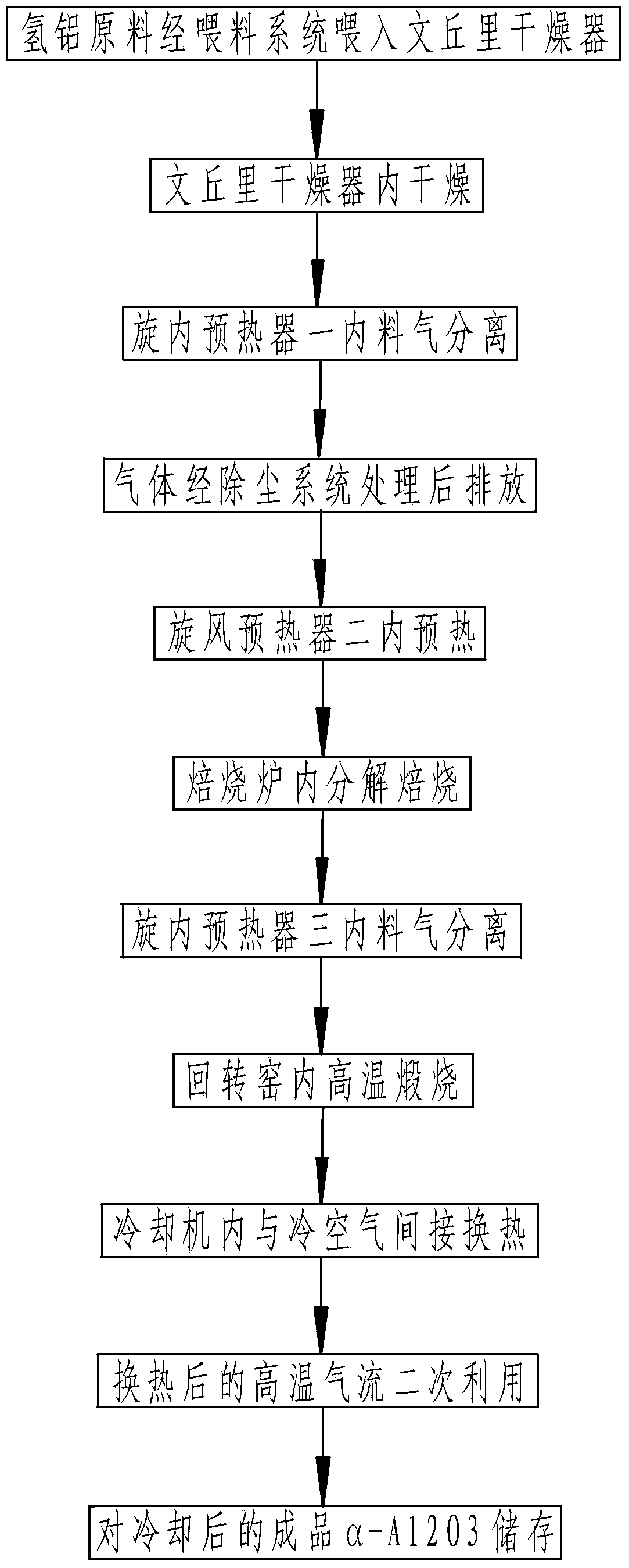

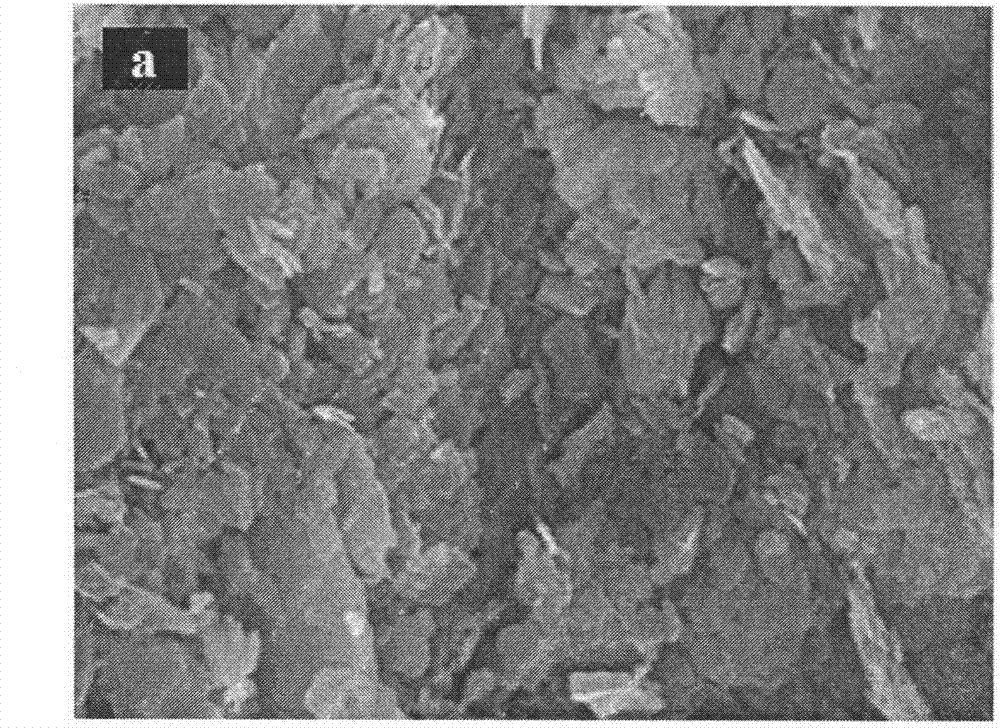

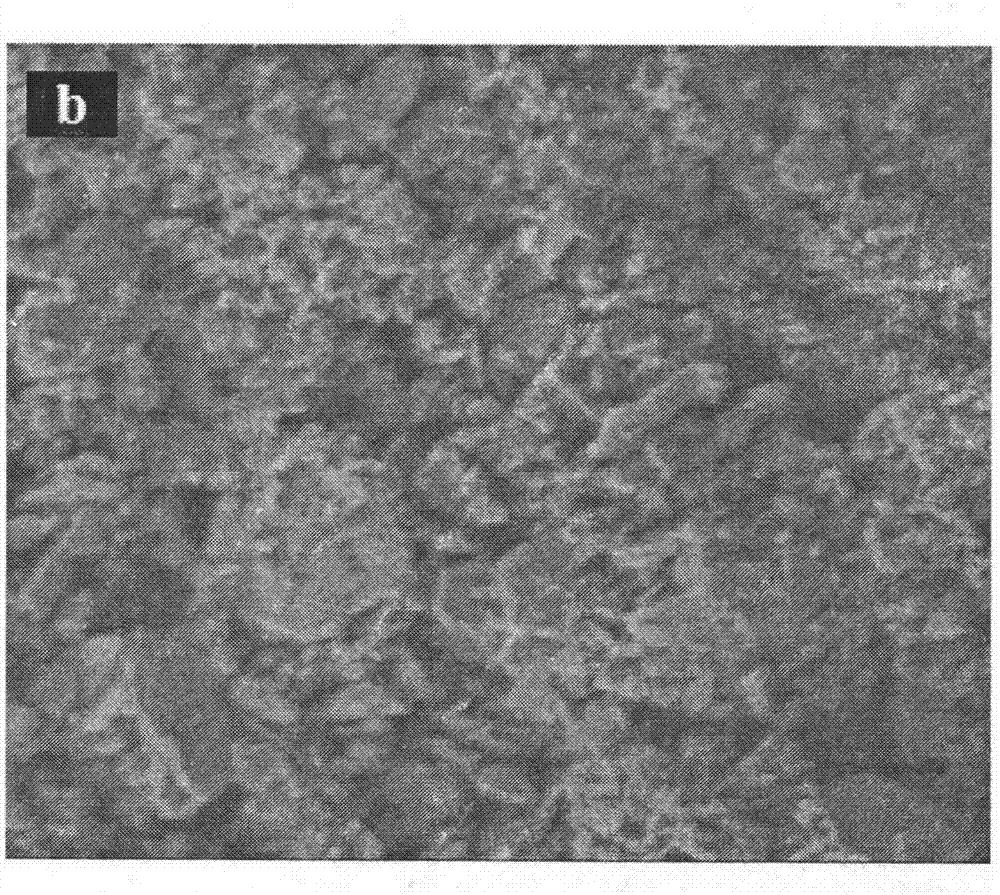

Method for producing alpha-Al2O3 by employing predecomposition technology and taking aluminium hydrogen as raw material

ActiveCN103708515ARealize large-scale productionReduce energy consumptionAluminium oxide/hydroxide preparationCycloneHydrogen

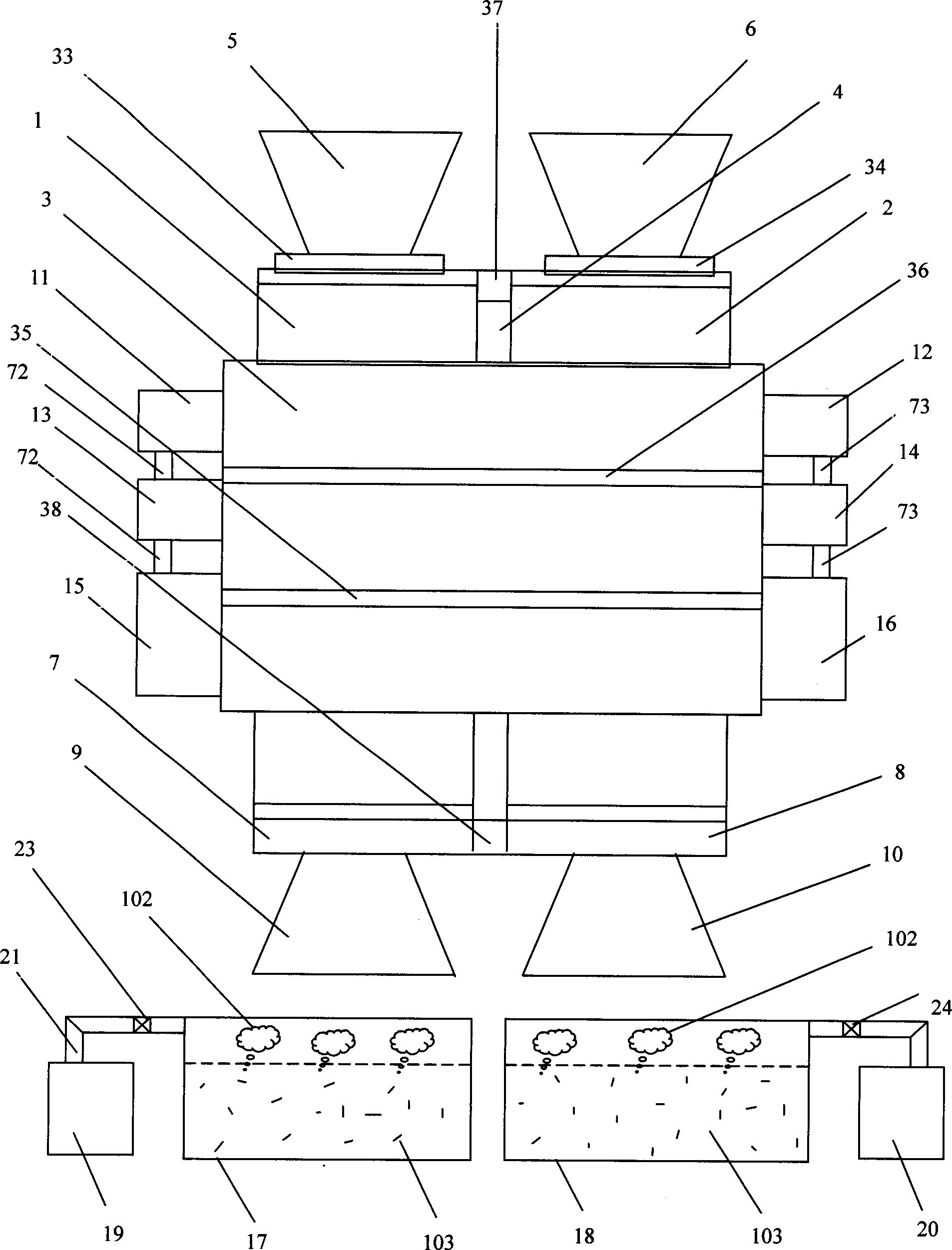

The invention discloses a method for producing alpha-Al2O3 by employing a predecomposition technology and taking aluminium hydrogen as a raw material. The method adopts a feeding system, a Venturi dyer, a first cyclone preheater, a second cyclone preheater, a third cyclone preheater, a roasting furnace, a natural gas burner, a kiln natural gas burner, a rotary kiln, a cooler and a dust removal system. Special aluminum oxide alpha-Al2O3 is produced by adopting a predecomposition technology. Large-scale production, low energy consumption (950*4.18kj / kg) and stable quality can be achieved, and achievement of automatic production control is achieved. The method is fewer in used equipments, small in floor area, simple in operation, high in quality of produced alpha-Al2O3, high in production efficiency, and simple and convenient in operation process, reduction of the production cost is facilitated, the operation flow is greatly simplified, the production time is shortened, and improvement of economic benefits of enterprises is facilitated.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

Method for whitening kaolin by using surface cladding method

InactiveCN102786818APlay a shielding roleHigh whitenessPigment physical treatmentMineral SourcesAluminum sulphate

The invention relates to a method for whitening kaolin by using a surface cladding method. The method comprises adding water and a dispersant into the kaolin to prepare slurry with a concentration of 40 to 60 %, adjusting a pH value to 7 to 8, and ball milling for 60 to 120 minutes with a high speed so as to fully activate the surface of the kaolin particles; and then adding an aluminum sulfate or aluminum nitrate solution into the kaolin slurry, fully mixing with stirring, slowly adding ammonia water, continuing to stir and react, standing, filtering and drying to obtain the highly whitened kaolin product. Through detection, the surface of the kaolin product is coated with an Al(OH)3 deposited layer which can shield dyeing substances in the kaolin and significantly improve whiteness of the product. The whitened kaolin through cladding can be used as papermaking paint, and especially as high-quality filling materials in the fields of plastic, rubber, etc. The implementation of the method can greatly increase added value of the low-quality kaolin, enlarge application scope of the low-quality kaolin and improve utilization efficiency of mineral resources.

Owner:赵曰浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com