Method for testing fluid-producing section of horizontal pump well

A liquid production profile and testing method technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of low production, high oil well production, low implementation success rate, etc., and achieve short operation time and reduce The effect of less logging cost and producing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

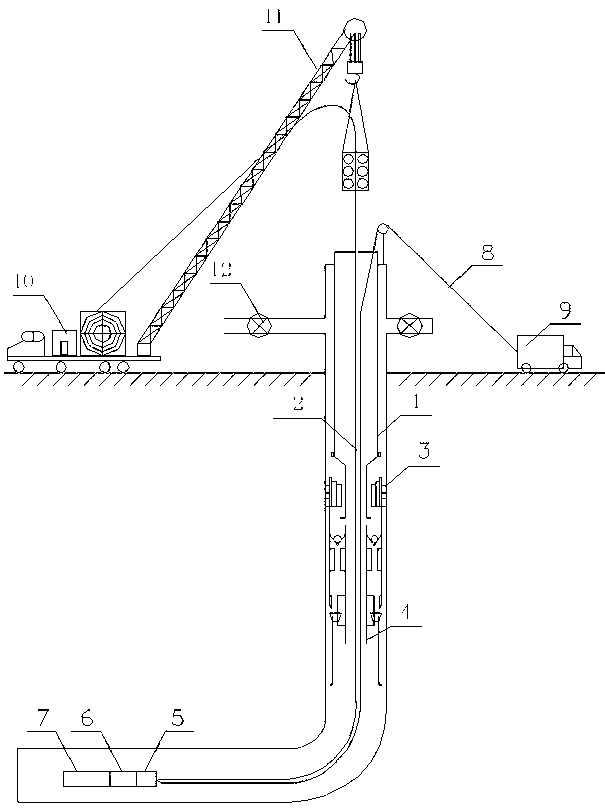

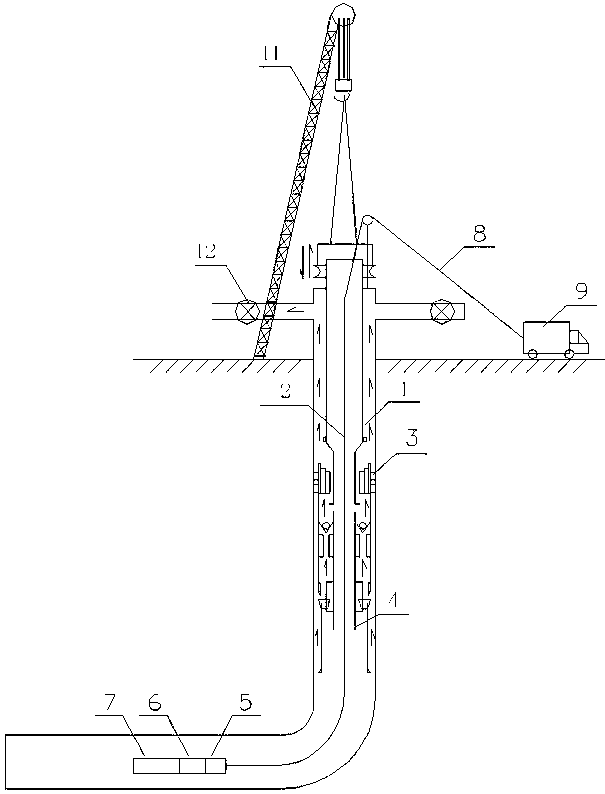

[0018] Such as figure 1 , 2 As shown, the operation steps of testing the liquid production profile of a horizontal well:

[0019] 1. Stop the production of the well to be tested, pull out the original production string, run down the well cleaning string to perform circular flushing, and then run the well gauge to the bottom of the artificial well. The outer diameter of the well gauge should be less than the inner diameter of the casing by 6mm~ 8mm, the length is not less than 0.8m, and the large end must have a 60° conical surface.

[0020] 2. Connect the long plunger hollow well pump 4 with the anchored packer 3 to the 2 The bottom of the tubing 1 is lowered into the horizontal well to the designed pump depth through the surface lifting device 11, so that the packer 3 is anchored, sealed, and separated. At this time, the tubing 1 is connected to the plunger through the upper part of the tubing.

[0021] 3. One end of the tool nipple string 6 is connected with the release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com