Patents

Literature

1644 results about "Aluminum sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium sulfate is a chemical compound with the formula Al2(SO4)3. It is soluble in water and is mainly used as a coagulating agent (promoting particle collision by neutralizing charge) in the purification of drinking water and waste water treatment plants, and also in paper manufacturing.

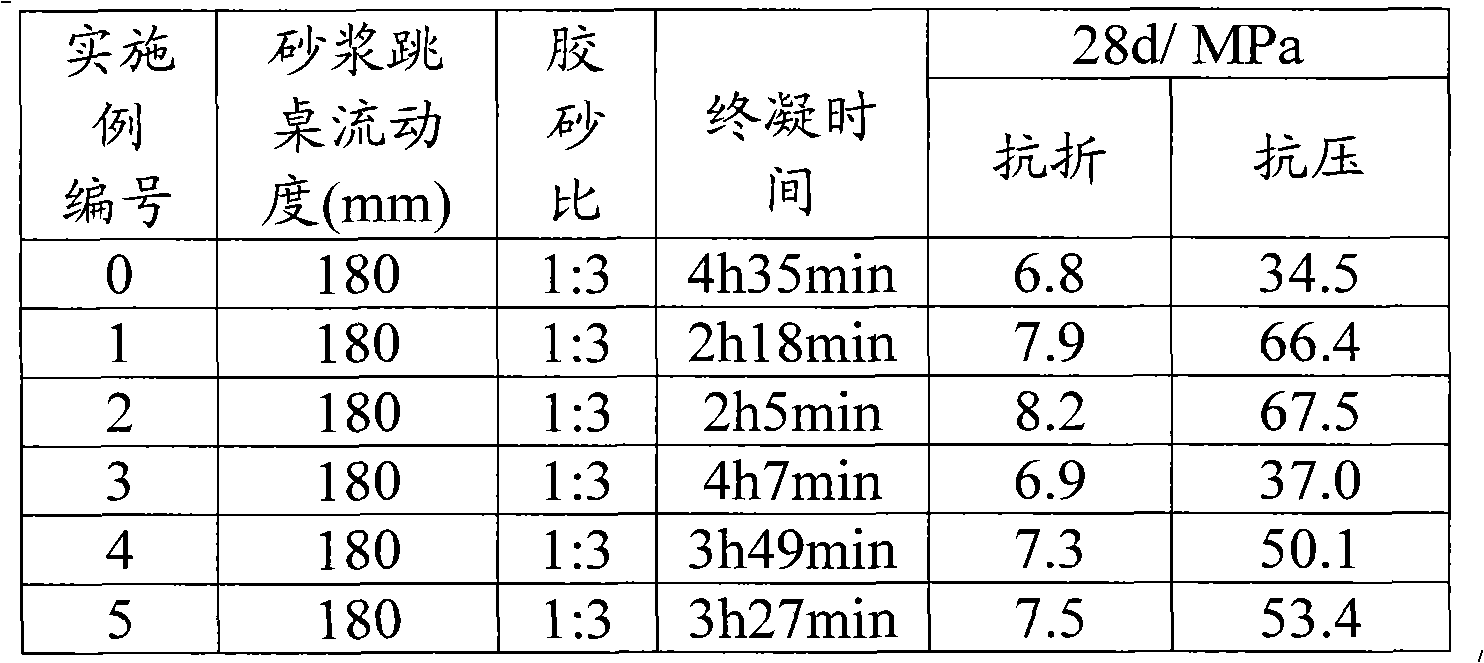

Environment-friendly type alkali-free liquid accelerator for sprayed concrete and preparation method thereof

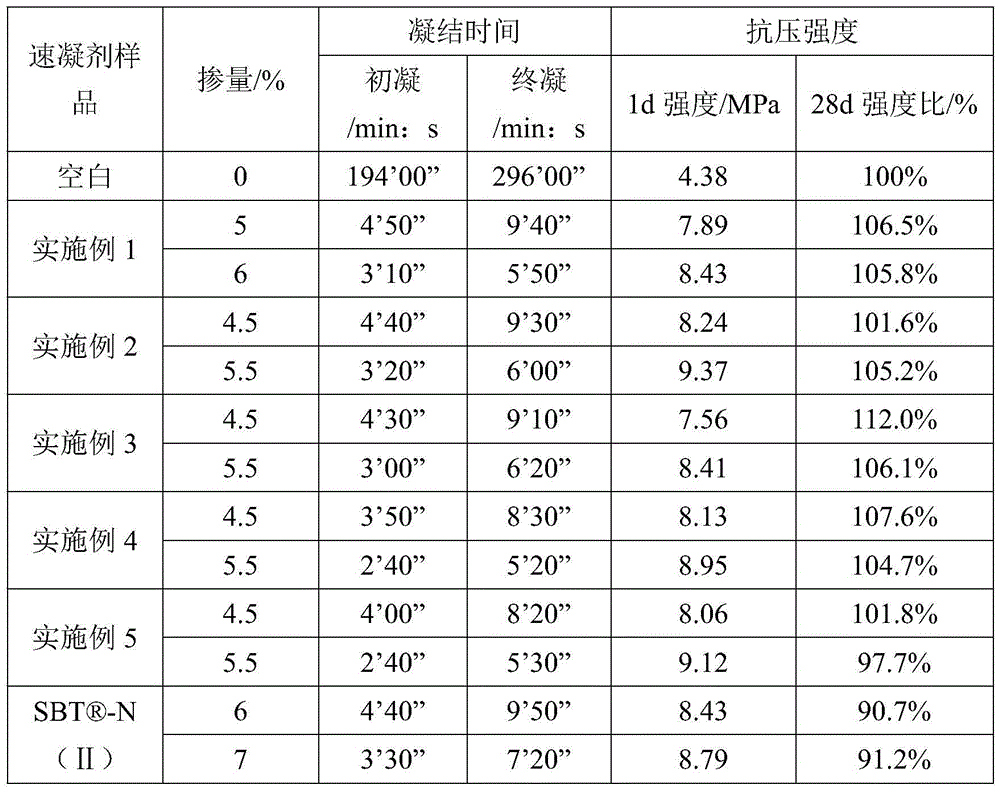

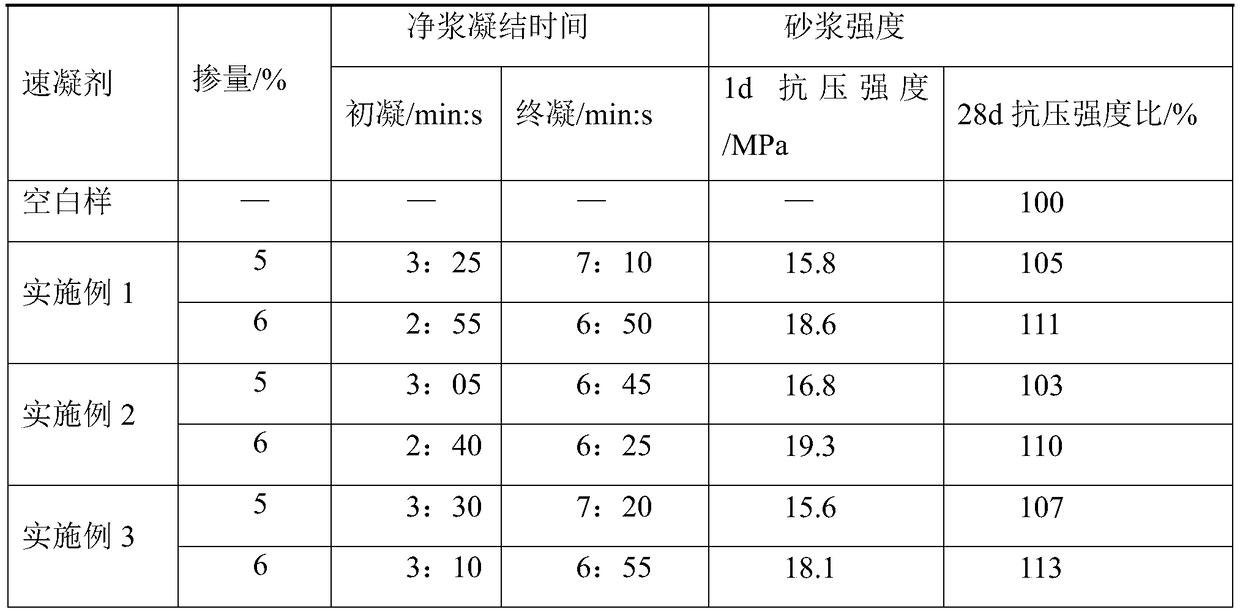

The invention belongs to the technical field of building materials, and in particular relates to an environment-friendly alkali-free liquid quick-setting agent used for shotcrete and a method for preparing the same. The alkali-free liquid quick-setting agent is a light green viscous liquid prepared from aluminum sulfate, sodium fluoride, triethanolamine and polyacrylamide, wherein the aluminum sulfate and the sodium fluoride are main quick-setting components, the aluminum sulfate can significantly reduce the initial setting time of cement, while the sodium fluoride can significantly shorten the final setting time of the cement, promote the formation of a hydrate structure, and improve the shear strength of the concrete and the binding power of a reinforcing steel bar. The triethanolamine shortens the setting time of the concrete to csertain extent and greatly improves the 1d compressive strength of mortar, and the polyacrylamide is an organic tackifying component to improve the thickness of a primarily sprayed layer, improve the bond strength between the concrete and a substrate, reduce the rebound loss in the spraying process, and save materials. The environment-friendly alkali-free liquid quick-setting agent has the advantages of wide source of raw materials, low cost, simple production method, and high production efficiency, and is suitable for industrial mass production.

Owner:TONGJI UNIV

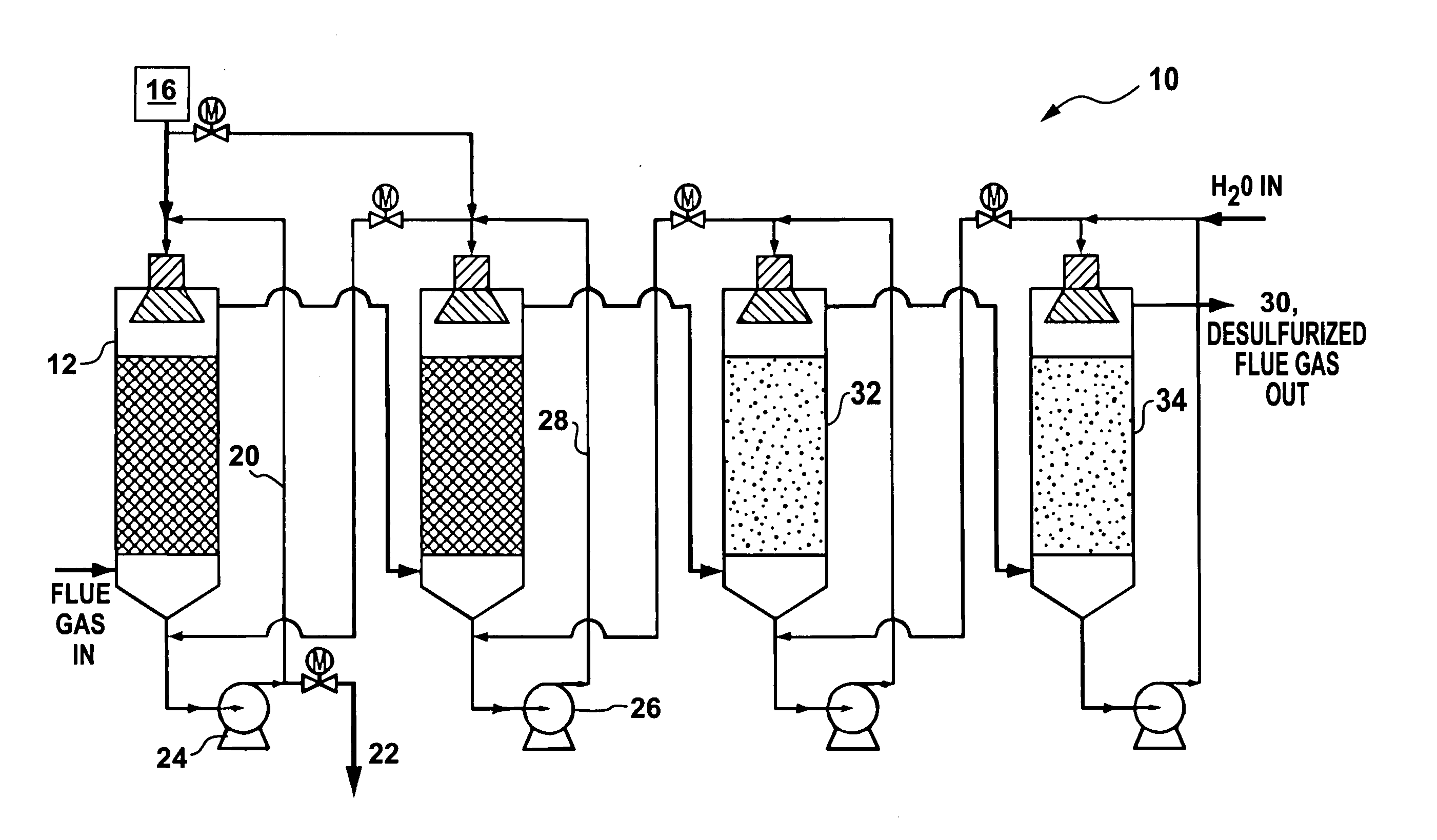

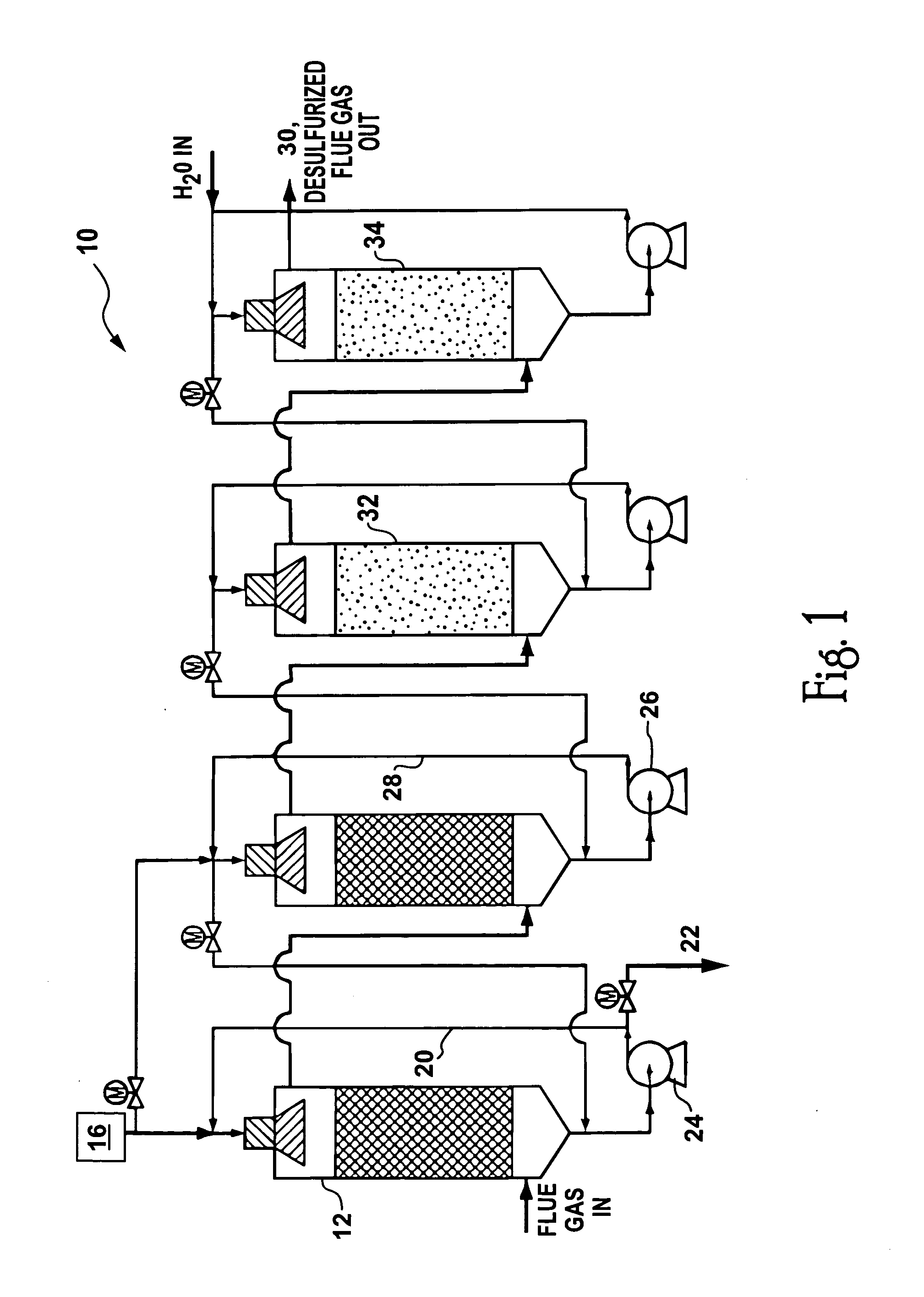

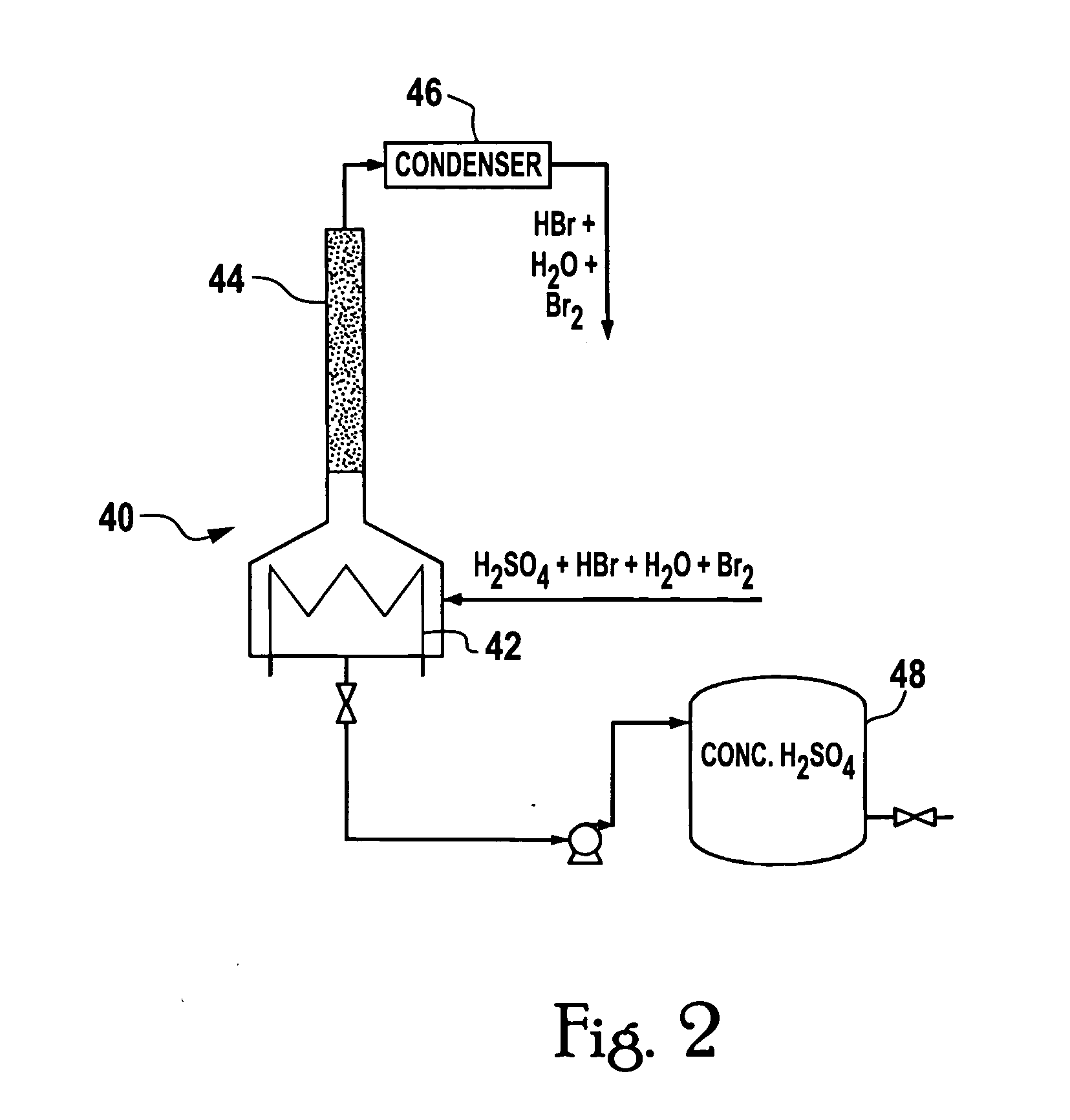

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:SOLAR REACTOR TECH

Alumina supporter and preparation method thereof

ActiveCN101322949AHigh activityGood stabilityCatalyst carriersPreparation by hydrogenationAluminium saltsCarbon black

The invention provides an aluminum oxide carrier and a preparation method thereof. The aluminum oxide carrier takes a mixture prepared by mixing pseudo-boehmite powder prepared by the carbonization method and pseudo-boehmite powder prepared by the aluminum sulfate method according to a weight proportion of 1:0.1 to 5 as a precursor and a complex acid as a peptizing agent; substances such as zirconium, titanium, silicon, alkali metals, alkaline-earth metals, rare-earth metals, carbon black, and the like, are added during kneading process; then the aluminum oxide carrier is obtained after forming, drying and roasting. The physical properties of the carrier are as follows: pore volume is 0.4 to 1.2ml / g; specific surface area is 180 to 370m<2> / g; pores with the diameter being more than 100nm accounts for more than 90 percent of total pore volume; the amount of B acid is 0.1 to 0.3mmol / g; the amount of L acid is 0.2 to 0.5mmol / g. The carrier is especially applicable to the preparation of 1, 4-butanediol catalysts in the two-stage hydrogenation catalytic synthesis of 1, 4-butynediol.

Owner:SHANXI UNIV

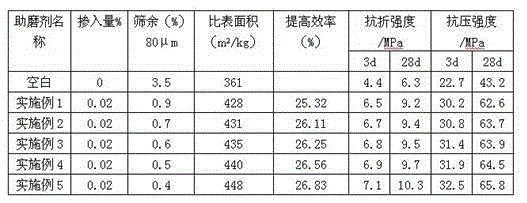

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

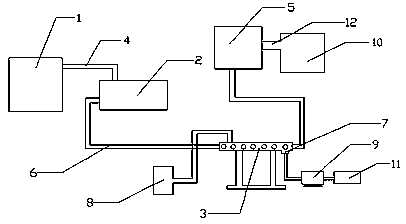

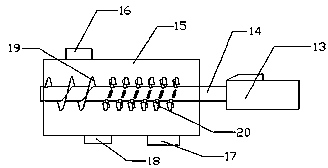

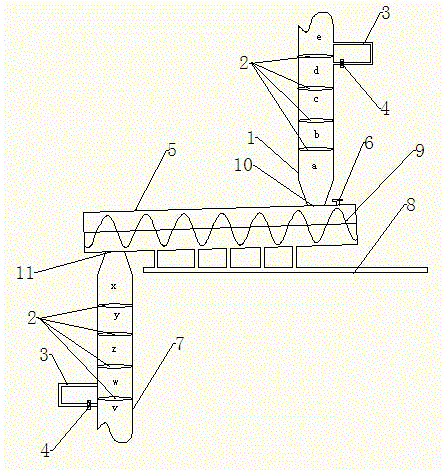

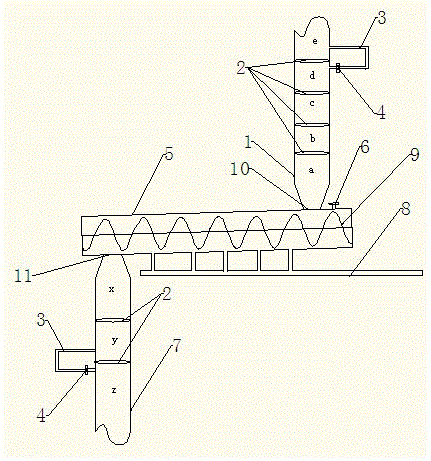

Sludge dehydrating and drying process method and device

InactiveCN101823825AGood effectLow costSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentAutomatic controlSlag

The invention belongs to the technical field of environmental engineering, in particular to a sludge dehydrating and drying process method and a device. The technical essential points of the invention are that: firstly, adding one or several of fly ash, fine manganese slag, calcined lime, ferric chloride solution and aluminum sulfate solution into sludge and dehydrating and conditioning the sludge; secondly, feeding the sludge into a pre-drying area and simultaneously adding a certain amount of calcined lime, potassium permanganate and finished product of dry sludge and uniformly mixing; feeding the sludge treated in the pre-drying area into a hollow paddle spiral indirect dryer; returning one part of finished product of dry sludge to the pre-drying area and carrying out drier back-mixing with wet sludge; supplying saturated heated steam to a drier by an electric boiler; and introducing steam tail gas from the drier to the pre-drying area for heating the wet sludge. The device is automatically controlled by a control center through a control bus. The process has the advantages of energy saving, environmental protection and high efficiency.

Owner:HUNAN UNIV OF SCI & TECH

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Preparation method of special foamed ceramic filter for magnesium alloy

InactiveCN1410393ALow priceGood chemical stabilityProcess efficiency improvementFiltration separationAluminum sulphateFoam polyurethanes

Owner:SHANGHAI HAOHUA MOLD

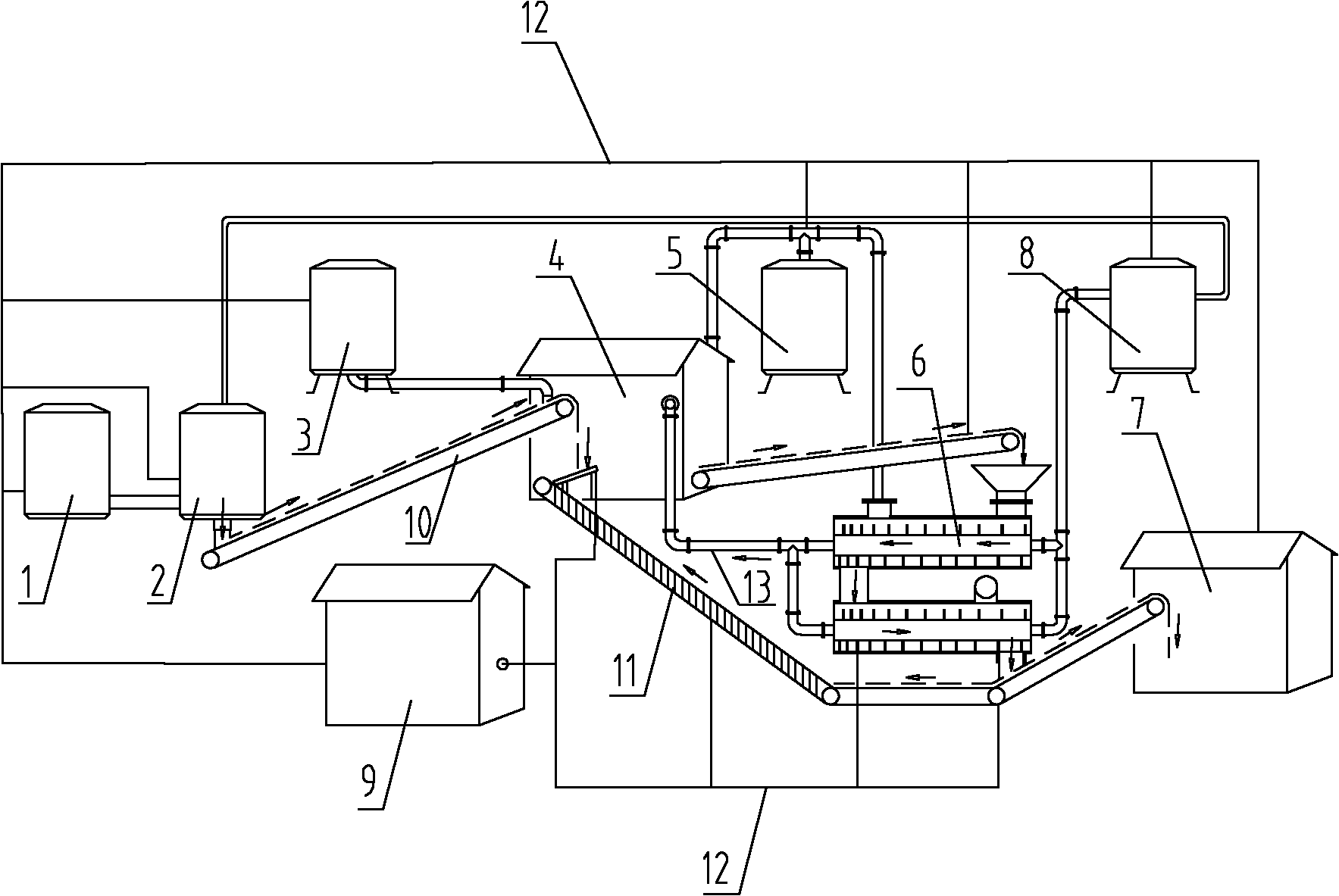

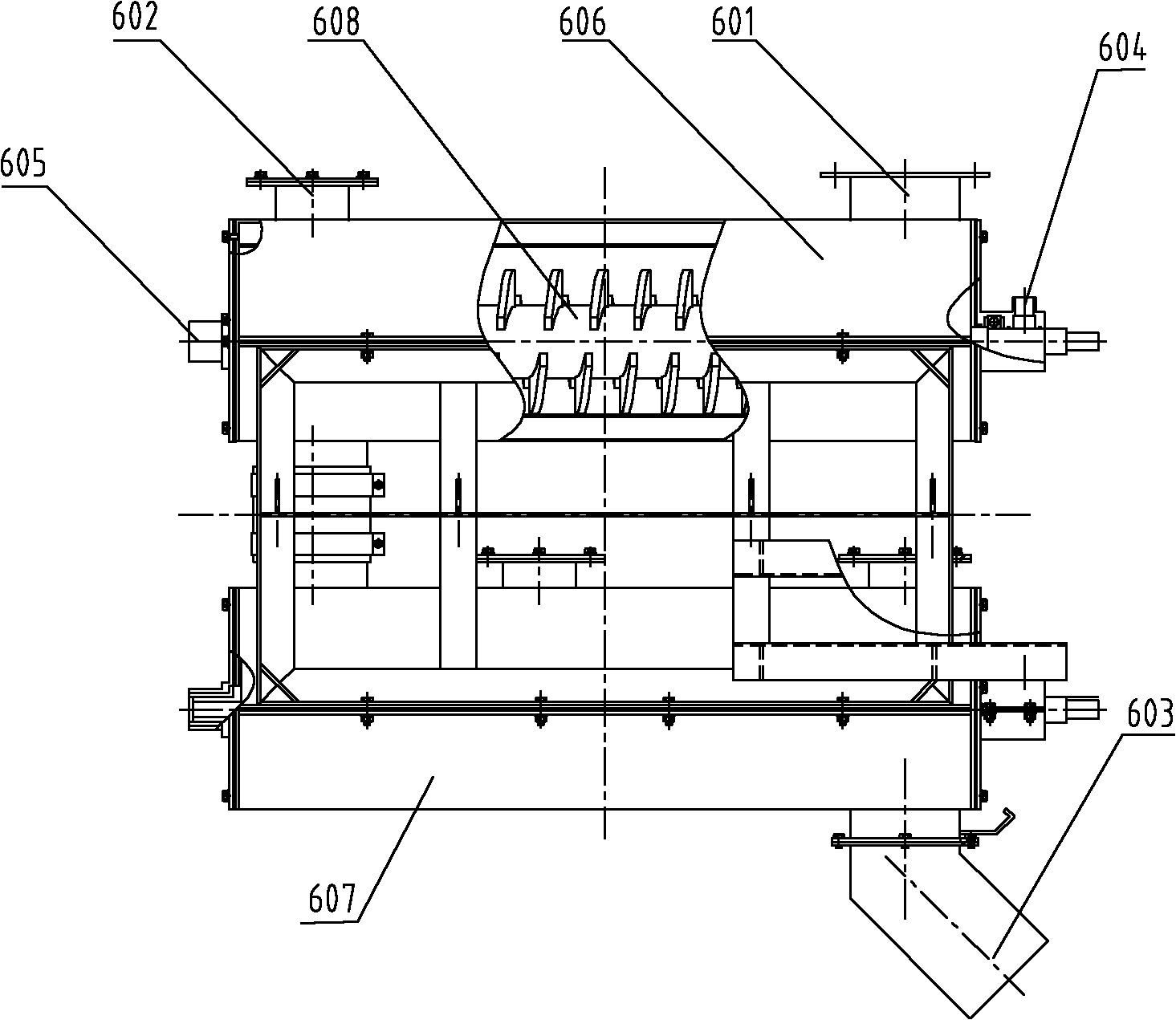

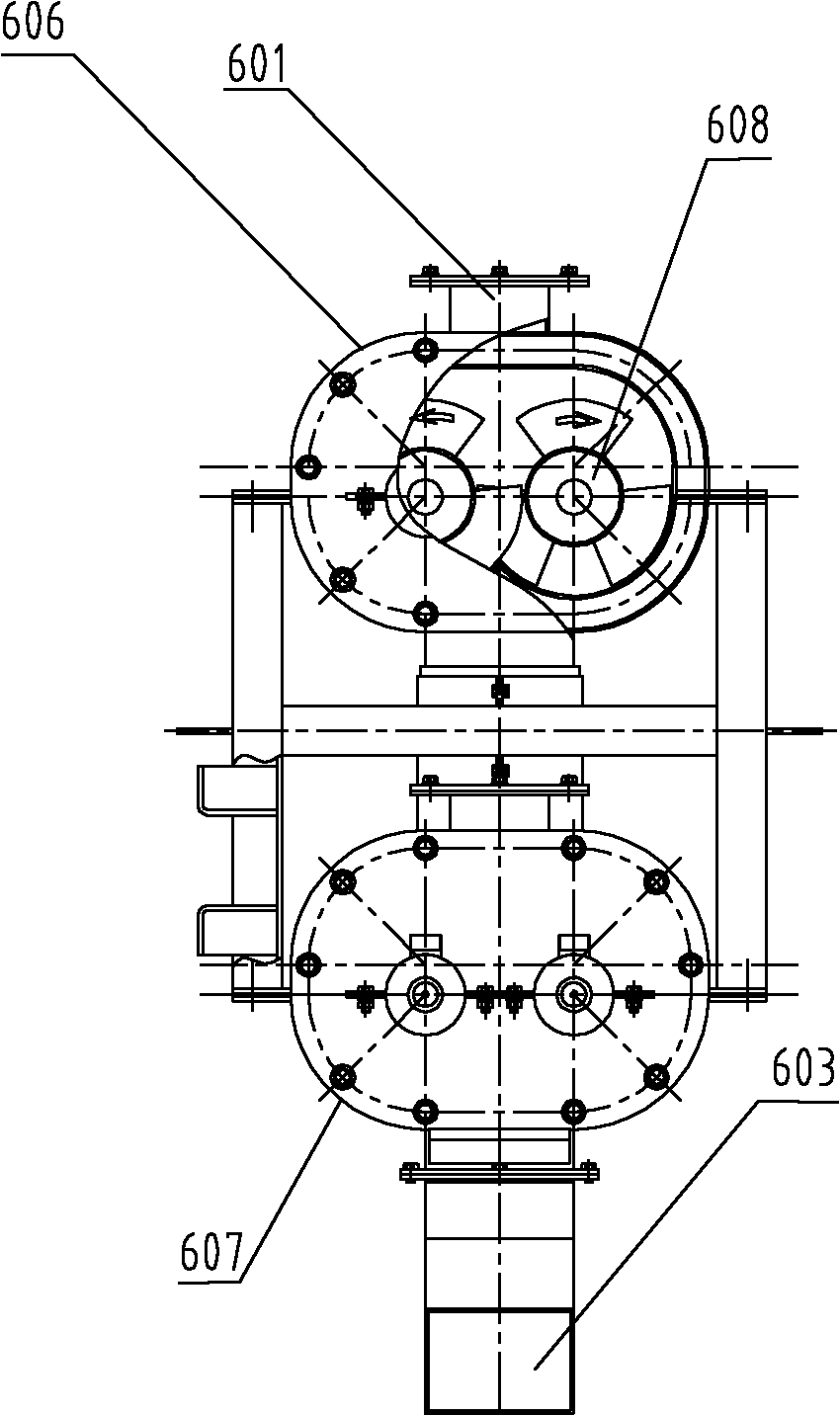

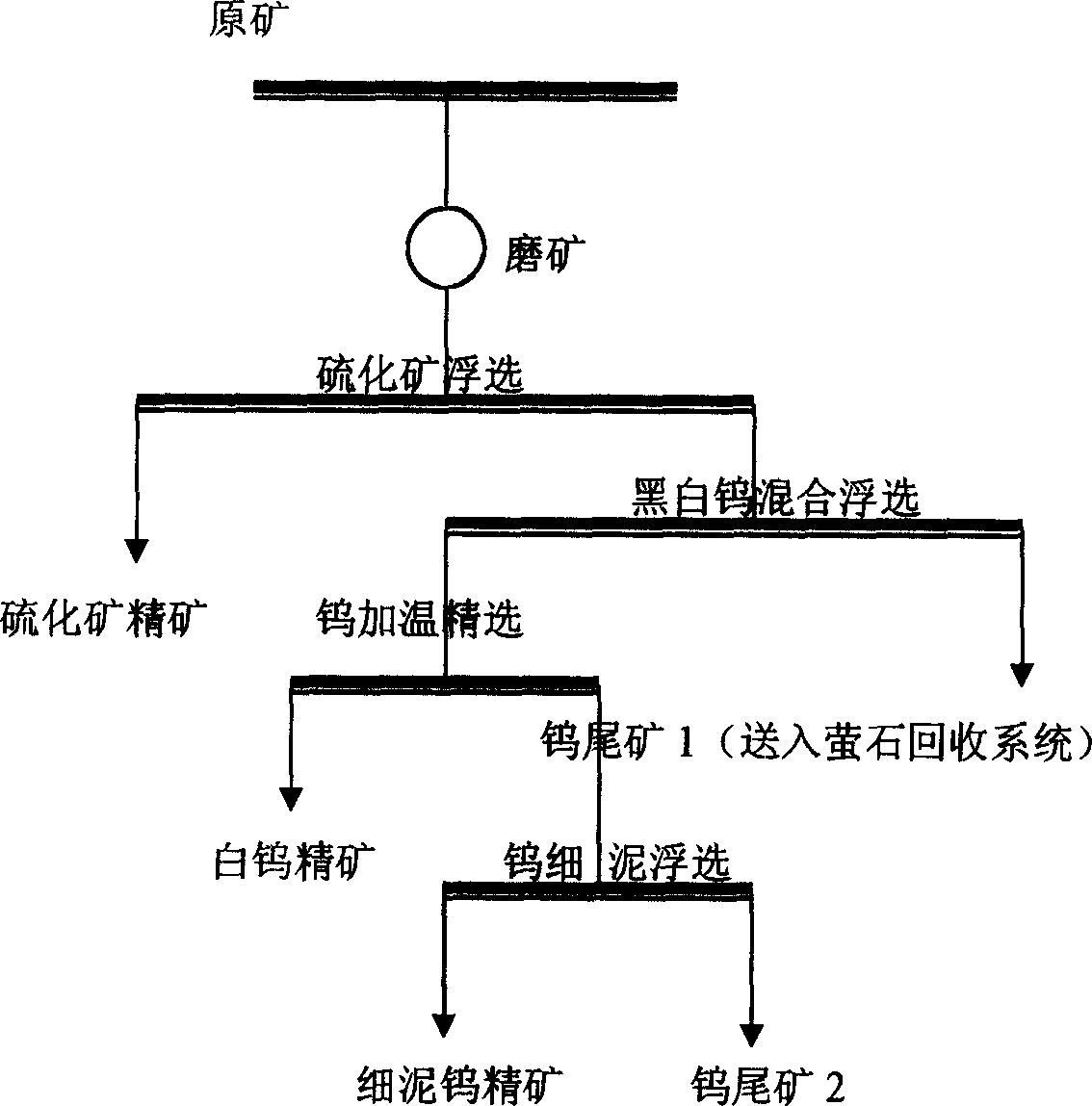

Mineral dressing method for black and white tungsten minerals

A technology for dressing the mixture of wolframite and scheelite incldues magnetic separation to remove iron, floatation for removing sulfide ore, adding water glass, aluminium sulfate and lead nitrate for regulating sludge, adding benzhdroxyoximic acid, sulfated oleic soap and kerosene, and combined floatation.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Sludge curing agent and sludge curing process employing sludge curing agent

ActiveCN104016626AImprove delivery efficiencyHigh degree of automationSludge treatment by de-watering/drying/thickeningSolid waste managementSludgePolyacrylamide

The invention relates to a sludge curing agent and an application thereof in sludge curing treatment, and belongs to the field of sludge treatment. In order to overcome the technical defect of poor curing effect of the existing sludge curing agent in the prior art, the sludge curing agent which is low in cost and good in curing effect is provided by the invention. The sludge curing agent comprises the following components in parts by weight: 25 to 45 parts of coal ash, 20 to 30 parts of swollen resin, 15 to 20 parts of cement, 7 to 9 parts of water glass, 10 to 12 parts of kieselguhr, 10 to 12 parts of quick lime, 6 to 9 parts of sodium hydroxide, 3 to 8 parts of aluminum sulfate, 8 to 10 parts of polyacrylamide, 6 to 8 parts of magnesium perchlorate and 5 to 15 parts of quartz sand. The sludge curing agent has the advantages of high curing efficiency and large hardness when being applied to the sludge curing treatment. Thus, the sludge curing agent is very suitable for the sludge curing treatment for water conservancy.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

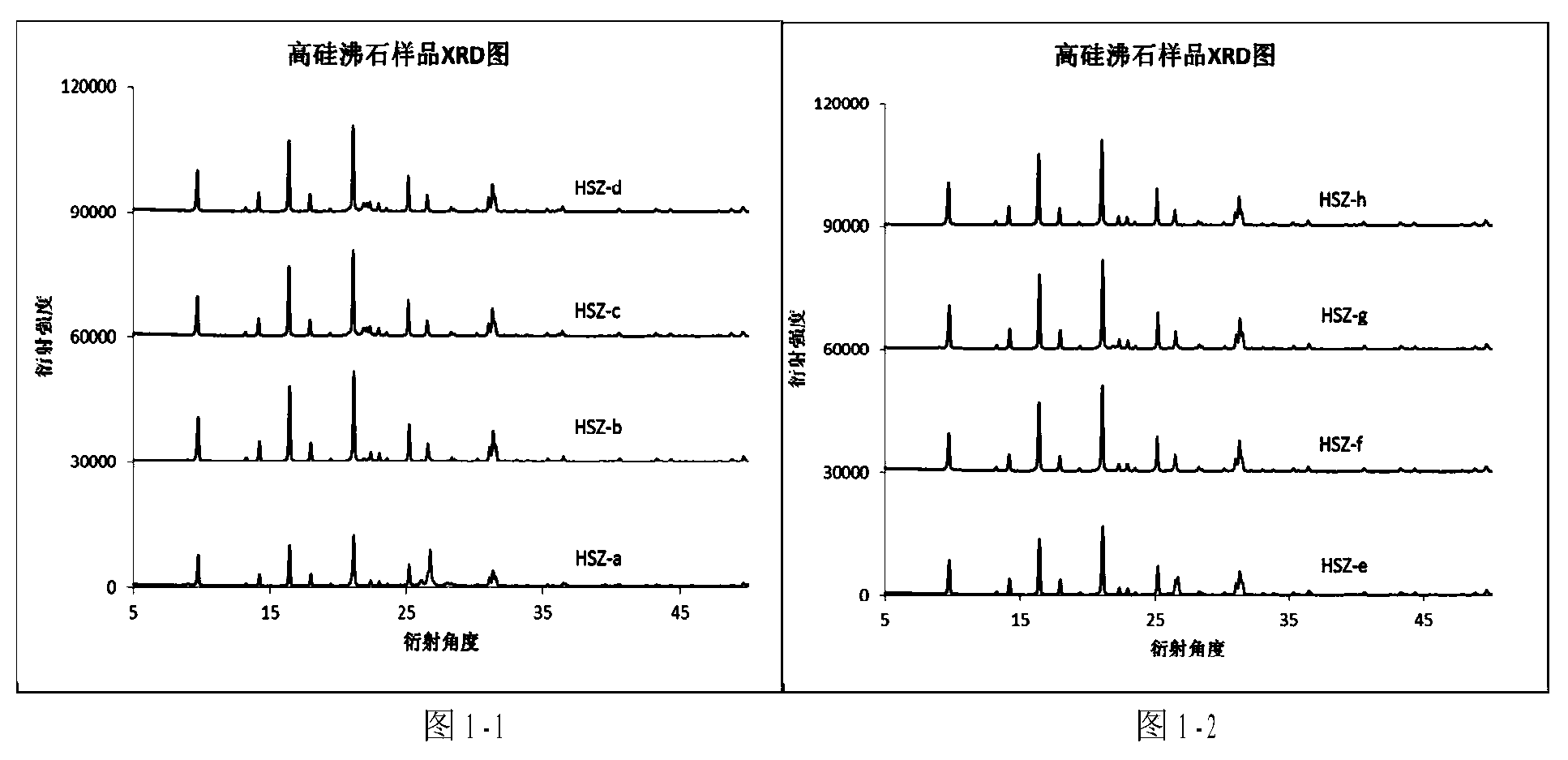

Seeding method for synthesizing chabasite type molecular sieve with high silica/alumina ratio and application of the molecular sieve

ActiveCN104163434AReduce dosageHigh specific surface areaMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDistillationPotassium hydroxide

The invention discloses a seeding method for synthesizing chabasite type molecular sieve. The seeding method comprises the following steps: evenly mixing alkaline silica sol and a template agent, slowly adding potassium hydroxide into the mixture, then adding sodium hydroxide, keeping on stirring, then slowing adding an aluminum sulphate water solution, adding a crystal seed in a chabasite crystalline phase, carrying out distillation to remove excess water, sealing, maintaining the temperature, stirring, shearing in a high speed so as to obtain uniform gel; and finally subjecting the gel to steps of crystallization, burning, and ammonium-exchange so as to obtain the finished product. The molecular sieve has the advantages of high silica / alumina ratio, high specific surface area, high MTO diolefin selectivity, and no pollution during the whole preparation process.

Owner:天津众智科技有限公司

Conditioner and conditioning method for dewatering of domestic sludge

ActiveCN101985386AEnvironmental protection dehydration treatmentAdd lessSludge treatment by de-watering/drying/thickeningAluminum sulphatePulp and paper industry

The invention discloses a conditioner for dewatering of a domestic sludge, a formula of the conditioner includes a polyacrylamide being 0.3%-0.9% of the sludge to be processed, a bamboo charcoal being 5%-20% of dry weight of the sludge to be processed, a quaternary ammonium salt being 2%-1% of dry weight of the sludge to be processed, a quick lime being 2%-5% of dry weight of the sludge to be processed, and a polymeric aluminum sulfate being 5%-20% of dry weight of the sludge to be processed; and the method comprises the following steps of: at normal temperature and normal pressure, orderly adding the polymeric aluminum sulfate, the quick lime and the bamboo charcoal into the sludge to be processed, stirring the sludge for reaction for at least 5 minutes, further orderly adding the polyacrylamide and the quaternary ammonium salt, stirring the sludge for at least 3 minutes, finally, performing a filter pressing step. The conditioner and the conditioning method for dewatering of the domestic sludge have the advantages of being short in conditioning reaction time, fast in sludge depositing speed, good in dewatering effect and protective for environment without pollution.

Owner:湖南多普生环境能源有限公司

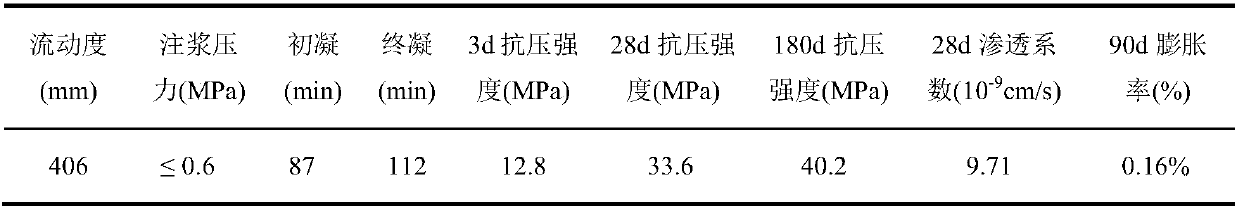

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

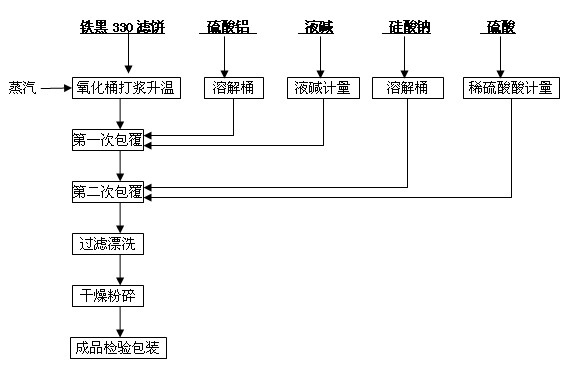

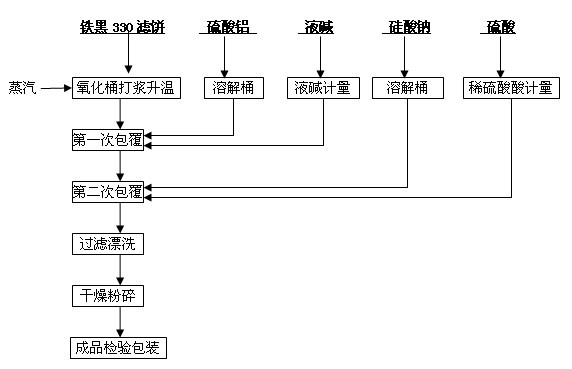

Preparation method of coated iron oxide black with medium temperature resistance

The invention relates to a preparation method of temperature resistant iron oxide black, and discloses coated iron oxide black with medium temperature resistance. According to the preparation method, a plurality of layers of compact films are coated on the surfaces of iron oxide molecules, so that the heat resistance of iron oxide black is improved. The method mainly comprises the steps of firstly stirring iron oxide black filter cake into pulpous state, then adding aluminum ions and silicon ions, ensuring that ion precipitate is gradually coated on the surface of the iron oxide black molecules by adjusting pH value, so as to form a plurality of protecting films to ensure that the heated temperature of coated iron oxide black reaches 200 DEG C. According to the method, coating treatment process is performed on the surface of iron oxide pigment to passivate the surface, the treatment method is advanced, and coated pigment ions are uniform, and have high strength and superior dispersion property. Accessory ingredients such as aluminum sulfate and sodium silicate for coating are easily accessible, and have low costs. The oxide black filter cake is provided by oxide black plants, the coating treatment is performed in middle stage test workshop, the treatment process is short, the energy consumption is low, the technology of the project is mature, samples are approved by customers, and performance indexes of products meet the demands of the customers.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Modifying agent for soda-alkalized paddy field soil

InactiveCN102517027AImprove efficiencyLower unit costOrganic fertilisersSoil-working methodsIron sulfateBiology

The invention discloses a modifying agent for soda-alkalized paddy field soil. The modifying agent is prepared by mixing polyferric sulfate with polyaluminum sulfate according to the weight ratio of 1:(0.6-1.4) and is suitable for modifying severe soda-alkalized soil into a paddy field; and the modifying method comprises the following steps of: applying the modifying agent to the paddy field soil of the field prior to soil preparation, wherein the application rate is 5.6-18 tons per hectare of soil; carrying out normal soil preparation; and soaking and leaching the soil after the modifying agent is sufficiently mixed with the soil. Compared with the polyferric sulfate, the unit cost of the modifying agent for the soda-alkalized paddy field soil disclosed by the invention is reduced by 9.4-15% under the condition that the same effect is maintained; and compared with the aluminum sulfate soil modifying agent, the macromolecular polymer of the modifying agent has a better flocculation effect and higher modifying efficiency, and meanwhile, the concentration of activated aluminum of soil is controlled to be in a low-concentration level, which is harmless to crops.

Owner:JINAN UNIVERSITY

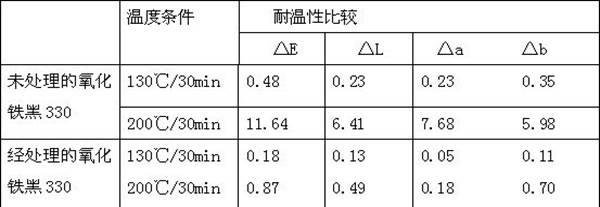

Extraction method of soil microbe genome DNA and total RNA

The invention provides a method for effectively extracting crop rhizosphere soil microbe genome DNA and total RNA, which comprises the following steps: firstly, removing humus and other impurities which severely disturb nucleic acid extraction in soil samples by aluminum sulfate; further crushing soil microbe cells by glass beads; adding sodium dodecyl sulfonate (SDS) and LiCl solutions for cracking cells and dissociating nucleic acids; adding the mixture of phenol, chloroform and isoamylol for extracting; and then, depositing the extraction solution by isopropanol and sodium acetate to finally acquire the soil microbe metagenome DNA and total RNA. The method is suitable for extraction of the DNA and total RNA of soil in different regions. The invention establishes an extraction technology which has the advantages of simple and easy operation processes and higher purity of the prepared sample, and can provide an important basis for the research of soil metagenomics.

Owner:FUJIAN AGRI & FORESTRY UNIV

Slag vertical mill grinding assisting activating agent and its compounding method

ActiveCN102745917APlay a grinding roleReduce manufacturing costSolid waste managementCement productionMetallurgyAluminum sulphate

The invention provides a slag vertical mill grinding assisting activating agent and its compounding method. The slag vertical mill grinding assisting activating agent is composed of, by weight percent: 10-12% of industrial salt, 3-6% of urea, 8-12% of triethanolamine, 10-15% of glycerol, 8-12% of an aluminum sulfate solution, 3-6% of beet molasses, 5-8% of polycarboxylic acid, and the balance a solvent. The method consists of: adding the industrial salt, the urea, the triethanolamine, the glycerol, the aluminum sulfate solution, the beet molasses, and the polycarboxylic acid into the solvent in order, fully dissolving each raw material when it is added, and conducting uniform stirring, then adding another raw material till all the raw materials are added into the solvent for dissolving, and mixing the mixture uniformly, thus obtaining the slag vertical mill grinding assisting activating agent, which can play a grinding assisting role and an activating role. By employing a compatible mode of chemical excitation and slag powder particle size distribution improvement, the slag vertical mill grinding assisting activating agent provided in the invention has an advantage complementary effect, not only adapts to low activity acidic slag, but also adapts to neutral and alkaline slag, and is applicable to both vertical mills and ball mills.

Owner:酒钢(集团)宏达建材有限责任公司

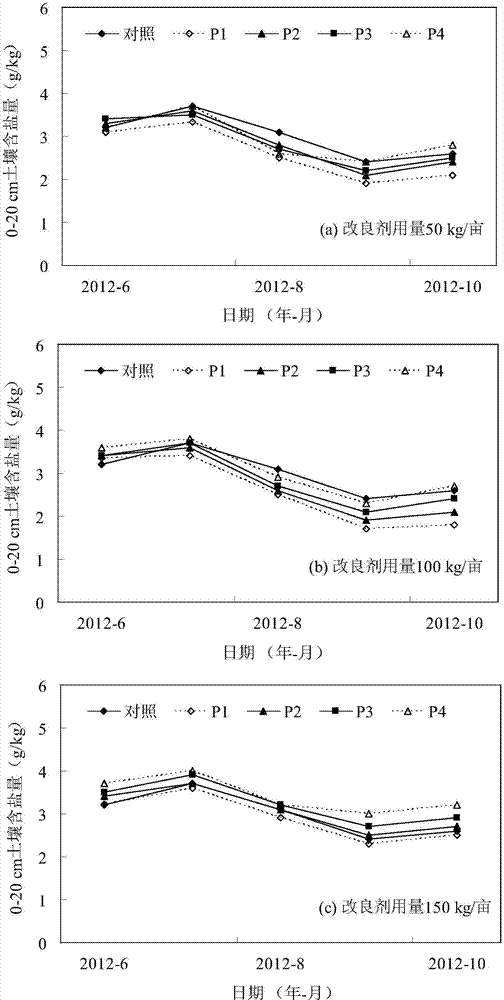

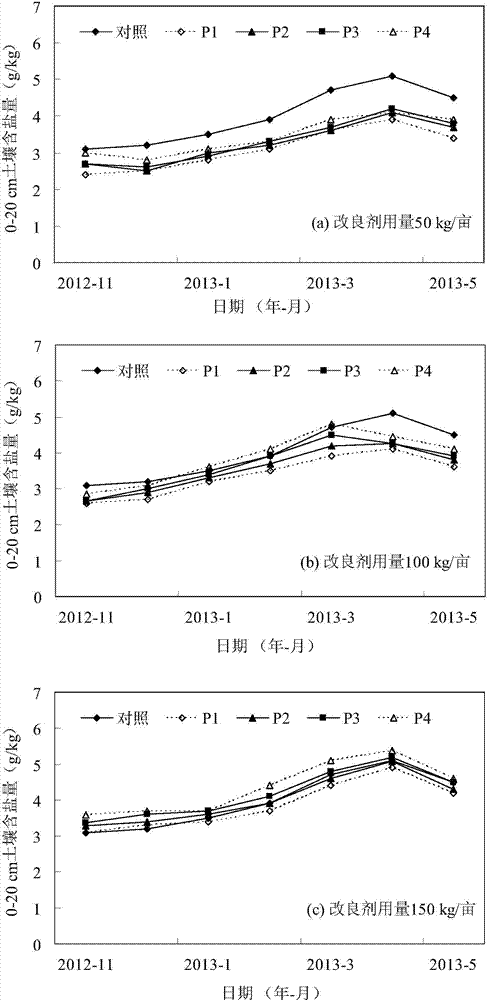

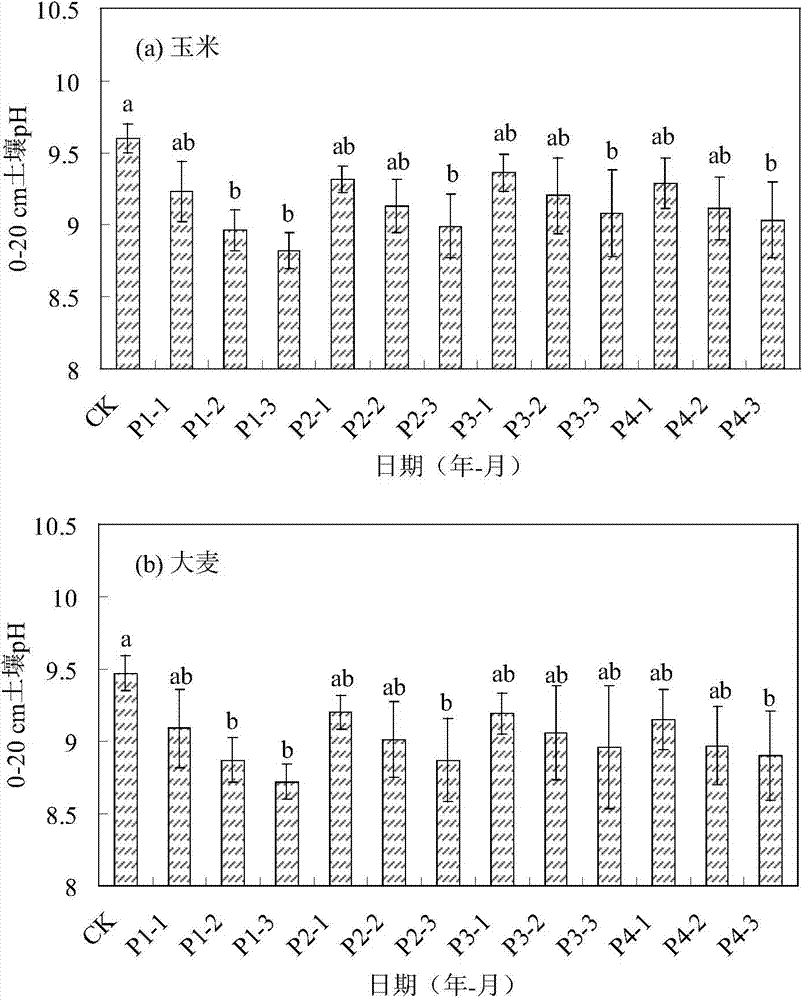

Chemical improvement conditioner suitable for coastal beach and strongly saline-alkaline land and application method thereof

InactiveCN104276903AShorten the governance cycleIncreased rinse volumeOther chemical processesClimate change adaptationAlkali soilDry season

The invention relates to a chemical improvement conditioner suitable for a coastal beach and a strongly saline-alkaline land and an application method thereof. The chemical improvement conditioner comprises the following components in parts by weight: 50-70 parts of ardealite, 20-30 parts of humic acid, 5-10 parts of aluminum sulfate and 3-5 parts of potassium dihydrogen phosphate. The chemical improvement conditioner disclosed by the invention has the advantages of simple improver component and preparation process, clarity in principle, low cost and quick effect. The application method of the chemical improvement conditioner aiming at different planting modes and soil salinity conditions provides an optimized application mode of 'less use for dry farming, more use for water farming, less use for a dry season, more use for a rainy season, more use for double salt and less use for light salt' by comprehensively considering the plant modes, soil salt contents and the rainfall difference of different seasons, thereby improving the desalting and alkali-improving efficiency, farthest decreasing the residues of an improver in soil and realizing multiple purposes of salt leaching, soil improvement and fertility improvement of the coastal beach and the saline-alkaline land.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

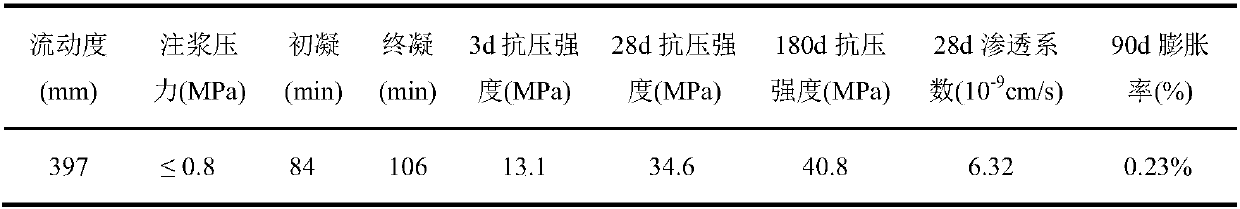

Low-addition-amount environment-friendly alkali-free chlorine liquid accelerator and preparation method thereof

The invention discloses a low-addition-amount environment-friendly alkali-free chlorine liquid accelerator. The low-addition-amount environment-friendly alkali-free chlorine liquid accelerator is prepared from, by mass, 45-55% of aluminum sulphate, 5-10% of magnesium sulfate, 5-10% of alcohol amine, 1-5% of organic acid, 1-5% of high-molecular polymer, 0-3% of a stabilizing agent and the balance water. The aluminum sulphate is at the industrial level, and the mass fraction percent of alumina is larger than or equal to 16.00. The magnesium sulfate is at the industrial level, and the alcohol amine is diethanolamine or triethanolamine. The organic acid is oxalic acid, formic acid or benzoic acid. The high-molecular polymer is polyacrylic acid or polyacrylamide. The stabilizing agent contains citric acid. The organic acid is used as a coagulation accelerating component and a pH adjusting agent, and on the basis that no alkali exists, the accelerator is stable and free of strength loss within 28 days, and concrete resilience is small, the addition amount is remarkably reduced; polyacrylic acid is used, not only is later-stage strength not affected, but also the stability of a solution is improved, and the stable time of the accelerator is longer than half a year.

Owner:WUHAN UNIV OF TECH

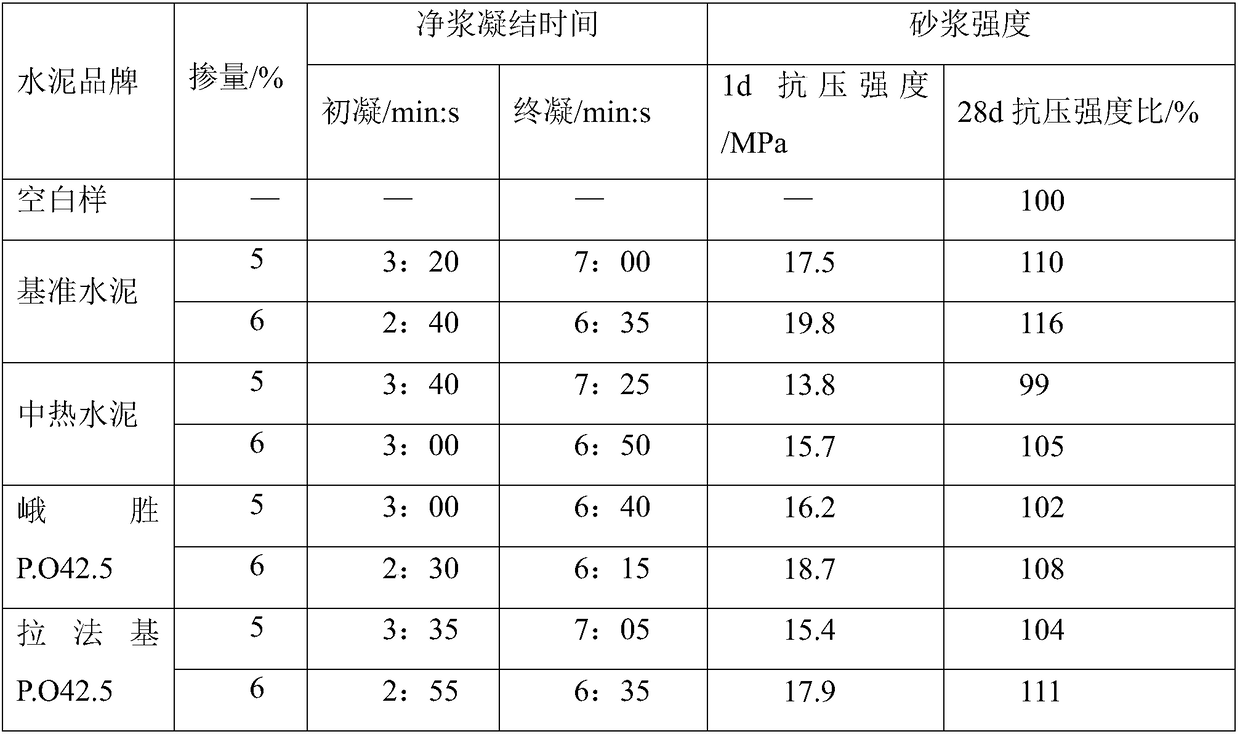

Impervious high-strength alkali-free liquid accelerator and preparation method thereof

The invention discloses an impervious high-strength alkali-free liquid accelerator. The impervious high-strength alkali-free liquid accelerator consists of the following components in percentage by weight: 40-60% of aluminum sulfate, 3-16% of an inorganic salt, 0.1-0.5% of an inorganic acid, 0.3-0.9% of a stabilizer, 3-8% of an organic modifier, and water. The invention further discloses a preparation method of the impervious high-strength alkali-free liquid accelerator. The beneficial effects are as the follows that a high rebound rate and a high dust concentration in a construction process are reduced, product performance stability is improved, good adaptability to different cement is achieved, the mixing amount is low, early strength is high, and later strength is basically not lost oreven increased.

Owner:四川恒泽建材有限公司

Fireproof heat insulation wet felt and production process thereof

The invention relates to a fireproof heat insulation wet felt, which comprises an inorganic fiber blanket and an inorganic adhesive, wherein the weight ratio of the inorganic fiber blanket to the inorganic adhesive is 1:3-6. The inorganic fiber blanket is one or mixture of more of 1260 ceramic fiber blanket, high-aluminum ceramic fiber blanket, zirconium-containing ceramic fiber blanket, chromium-containing ceramic fiber blanket, polycrystalline mullite fiber blanket, glass fiber blanket and high-silica fiber blanket; and the inorganic adhesive is one or composite solution of more of water glass, silicon sol, aluminum sol, aluminum phosphate, aluminum sulfate and aluminum potassium sulfate. The wet felt can be randomly folded and bent in any direction, is wrapped, wound and stick togetherwith the shapes of equipment and parts during construction, and particularly can remarkably improve the construction efficiency during construction of a special-shaped part or a pipeline part or the like. The wet felt is formed by soaking the inorganic fiber blanket into the inorganic adhesive, so the wet felt is very easily bent, has good wet strength, and can be cut into various shapes and sizes or subjected to compression molding.

Owner:上海伊索热能技术股份有限公司

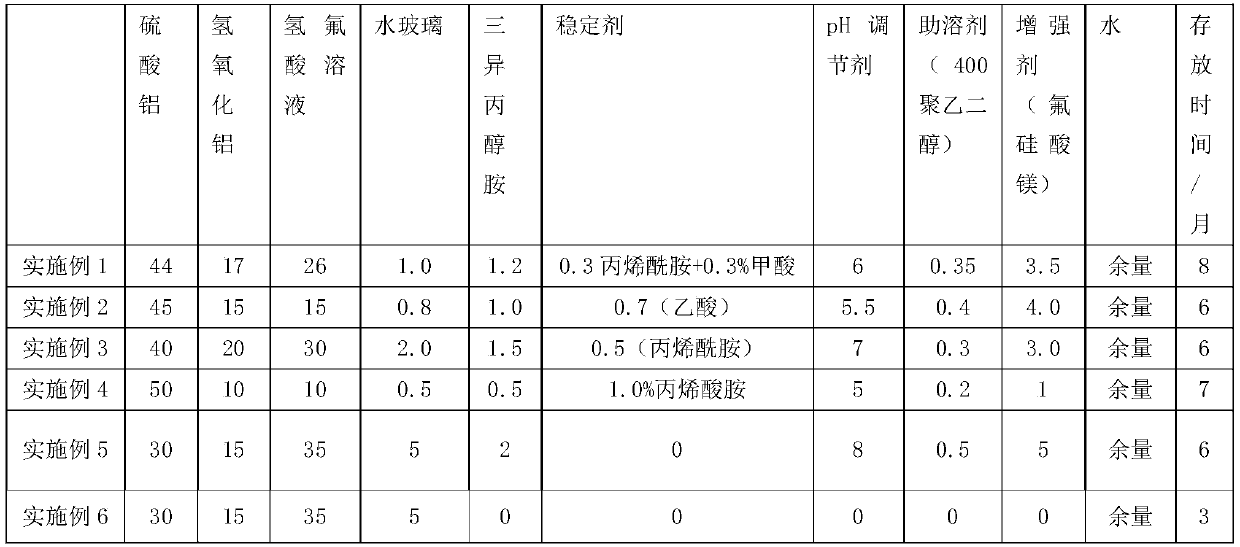

Liquid alkali-free accelerator and preparation and application thereof

The invention brings forward a liquid alkali-free accelerator and preparation and application thereof. The liquid alkali-free accelerator comprises the following ingredients (by weight): 20-45% of aluminum sulfate, 15-25% of aluminium hydroxide, 10-35% of hydrofluoric acid, 0.5-2% of triisopropanolamine, 0.5-5% of water glass, 0-1% of a stabilizing agent, 1-5% of a reinforcing agent, 5-8% of a pHregulator, 0.2-0.5% of a cosolvent, and the balance water. The liquid alkali-free accelerator has the following advantages: the production process is simple, heating is not required, and ''three wastes (waste gas, waste water and industrial residue)'' are not generated; alkali etch of concrete structures is reduced, strength is enhanced, and durability of sprayed concrete is increased. With low dosage, Portland cement grout can be initially coagulated within 2 min and finally coagulated within 4 min; 1d strength of cement mortar can reach 15 MPa and above, and ratio of 28d compressive strengthis greater than 100%; and the liquid alkali-free accelerator has good adaptation to different kinds of cement.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Preparation method of polysilicate aluminium ferric flocculant

ActiveCN102120623AOxidationLow costIron sulfatesWater/sewage treatment by flocculation/precipitationLiquid productPolymerization

The invention discloses a preparation method of a polysilicate aluminium ferric flocculant, which comprises the steps of: dissolving ferrous sulfate heptahydrate, which is a by-product of a titanium white industry and used as a main raw material, in water, regulating the pH value of the dissolved ferrous sulfate heptahydrate to be 0.6-1.0, and then adding titanium white for oxidation; adding aluminum sulfate for polymerization reaction for 30-50min at the water bath temperature of 50-100 DEG C to obtain the polysilicate aluminium ferric flocculant; adding H3PO3 to be used as a stabilizer in the polymerization reaction process; adding a small amount of Na2CO3 when the liquid is even to regulate the alkalization degree of the mixed liquid to be 0.05-0.6; and finally, obtaining a dark-brown polymerized liquid product, i.e. the silicate aluminium ferric flocculant. The preparation method provided by the invention has the advantages of simple process, low cost, and no waste liquid, waste gas, and waste residues in a production process. The product has high content of active flocculation components, is superior to the traditional industrial product in full-ferric content and the flocculation property, and can be widely applied to feed water treatment and sewage and wastewater treatment.

Owner:善水(南通)工业技术有限公司

Process for preparing modified ardealite by water-free calcining

The invention relates to a method for preparing modified phosphogypsum through calcination without water scrubbing. The method is as follows: firstly, composite excitant and modifier are added into phosphogypsum and uniformly mixed, wherein, the weight percent of the phosphogypsum is between 85 and 95 percent; the weight percent of the composite excitant is between 2 and 5 percent; the weight percent of the modifier is between 3 and 10 percent; the composite excitant is green vitriol and aluminum sulphate, and the modifier is calcium oxide and cement; secondly, after uniform mixing, the mixture is dried at a drying temperature of between 100 and 110 DEG C, and the moisture of the phosphogypsum is lower than 8 percent; thirdly, the mixture enters into a calciner, is calcined for 0.5 to 1 hour at a temperature of between 150 and 300 DEG C, and is naturally cooled to prepare the modified phosphogypsum. The method decomposes and volatilizes harmful substances such as phosphor, fluorine, organic substances and so on contained in the phosphogypsum or converts the harmful substances into inert substance calcium pyrophosphate which is harmless to products, thereby not only avoiding secondary pollution but also reducing or avoiding influence of harmful chemical microconstituents contained in the phosphogypsum on the quality and the performance of the products. Moreover, the method shortens the processing time by 15 to 20 percent, saves the investment by 3 to 8 percent and reduces the energy consumption by 10 to 20 percent.

Owner:KUNMING UNIV OF SCI & TECH

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

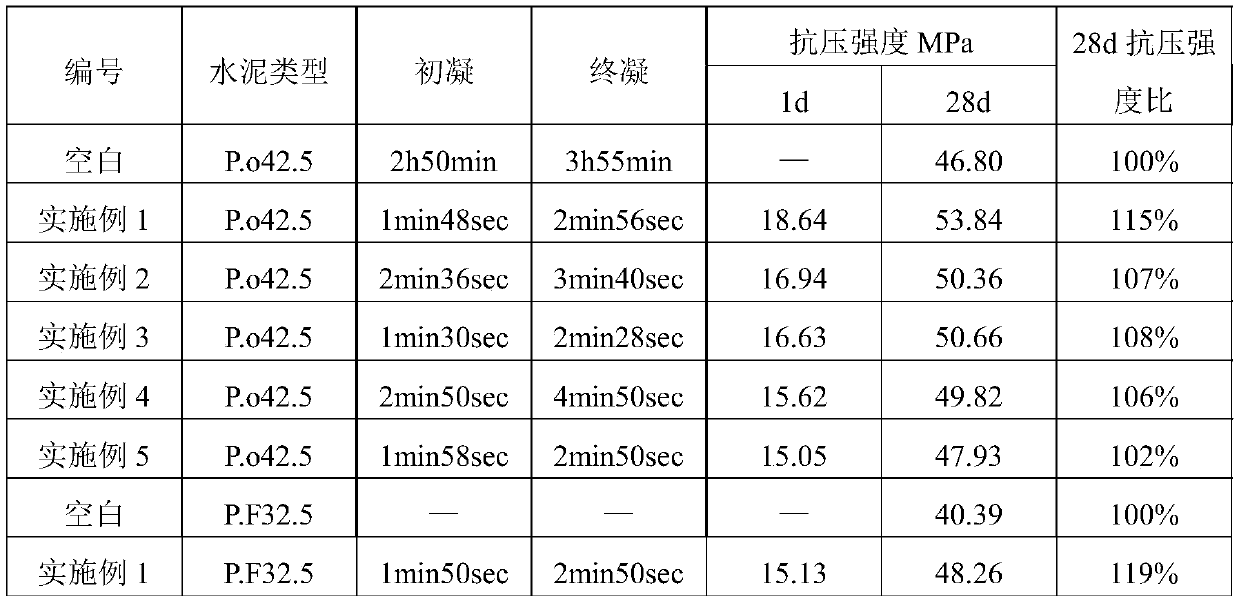

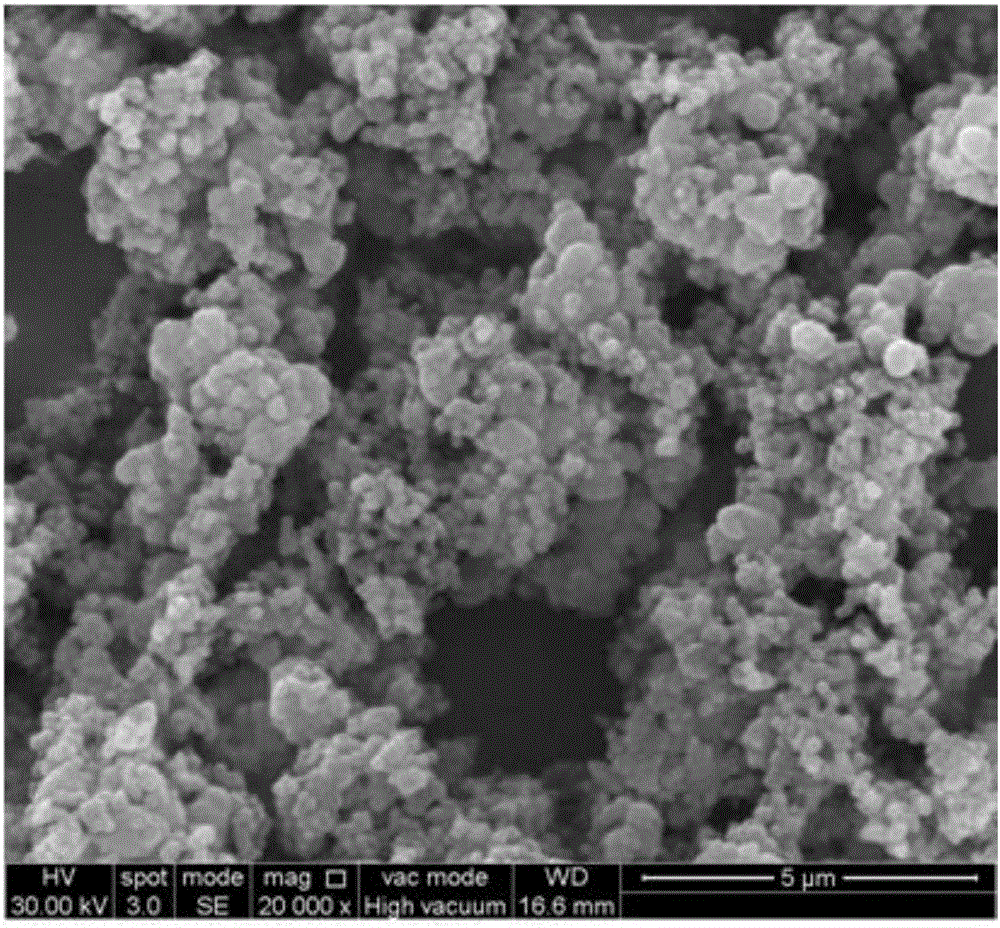

Preparation method of anhydrous aluminum chloride

ActiveCN103936047AReduce consumptionReduce manufacturing costAluminium chloridesSolid carbonElectrolysis

The invention discloses a preparation method of anhydrous aluminum chloride; and the method is as follows: using fly ash or aluminum ore with more than 25% of alumina as a raw material for leaching with sulfuric acid to obtain an aluminum sulfate solution, then concentrating for crystallization to obtain an aluminum sulfate crystal, and preheating at above 80 DEG C for more than 30 minutes to remove crystal water to obtain aluminum sulfate; mixing the aluminum sulfate and solid carbon, then adding into a chlorination furnace with the temperature above 600 DEG C and the pressure of normal pressure or slightly negative pressure, letting in chlorine gas to produce an anhydrous aluminum chloride mixed gas with the mass percent content of more than 30%, and then refining and purifying to obtain the anhydrous aluminum chloride with a purity above 99%. Chlorination tail gas is washed with water, absorbed by use of an alkaline solution, and then discharged. The preparation method has the characteristics cheap and easily-available raw materials, less energy consumption, simple process, easiness in industrial large-scale production and the like. Because of the characteristics, the preparation method is especially suitable for the anhydrous aluminum chloride preparation in the production of metal aluminum by aluminum chloride molten salt electrolysis method.

Owner:GUIYANG AL-MG DESIGN & RES INST

New material with air cleaning function and preparation method thereof

InactiveCN105478003ARealize "Deep Oxygenation"Promote absorptionOrnamental structuresDispersed particle separationFiberDisease

The invention relates to a new material with air cleaning function and a preparation method thereof. The artware material comprises the following compositions in percent by weight: 10-50% of a plant active raw material, 0.4-4% of an antiseptic, 0.1-5% of water-soluble essence, 0.1-5% of a fixative, 0.3%-2% of sodium sulfite, 0.5%-3% of sodium sulfite, 1%-10% of aluminium sulfate, 0.15%-1% of sodium hypochlorite, 0.2%-1% of a pigment, 20%-60% of a solid porous adsorbent, 10%-30% of an active catalyst, 5%-15% of flocculent fiber, and 10%-35% of a binder. A prepared artware possesses unique artistry, natural plant delicate fragrance and strong effects of removing formaldehyde and other harmful gases, performing sterilization and disinfection and purifying air, long-acting infrared ray can guarantee health of family members, and prevention and treatment of diseases are integrated. Also, the manufacture cost is low, operation is simple, and the material and the preparation method are suitable for industrialized production, and are beneficial for the nation and the people. The additive and the chemical reagents added during preparation do not contain harmful substances, and environment pollution is not caused during usage of the new material.

Owner:韦力

Industrial wastewater treating agent and preparation method thereof

InactiveCN106630181AWide variety of sourcesThorough treatmentWater treatment parameter controlWater contaminantsIron sulfateIndustrial waste water

The invention discloses an industrial wastewater treating agent which comprises the following components in parts by weight: 15-30 parts of polymeric aluminum silicate-sulfate, 15-30 parts of ferric sulfate, 1-5 parts of polyacrylamide, 1-5 parts of microorganisms, 15-30 parts of potato starch, 3-13 parts of chitosan, 7-17 parts of attapulgite powder, 5-10 parts of tannin, 4-11 parts of kaolin, 20-40 parts of modified vesuvianite, 10-20 parts of calcium hydroxide, 10-20 parts of activated carbon, 5-15 parts of sodium diphosphate, 1-5 parts of sodium hypochlorite and 5-20 parts of lignin. The raw materials of the industrial wastewater treating agent are wide in source, pollutants in the water can be effectively removed, the sewage treatment is thorough, the treatment cost is low, the treating agent does not has toxicity and does not cause pollution, and the treated wastewater meets the national sewage comprehensive emission standard requirements. The preparation method is simple and convenient to produce.

Owner:广西新六合环保有限责任公司

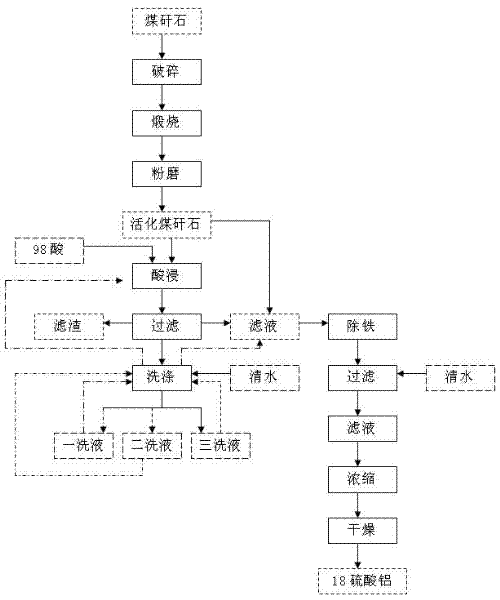

Method for producing low iron aluminum sulfate by utilization of coal gangue

InactiveCN102311136AGood slag activityUnderburn noneWaste processingSolid waste disposalSlagAluminum sulphate

The invention relates to a method for producing low iron aluminum sulfate by the utilization of coal gangue and belongs to the technical field of coal solid waste resource utilization. The method provided by the invention comprises the following steps of: carrying out calcination activation on coal gangue at the temperature of 785-850 DEG C, adjusting the pH of an aluminum sulfate solution by directly using the activated coal gangue, oxidizing divalent iron ions into trivalent ions, removing iron precipitate and a few gel in the aluminum sulfate solution by the utilization of the adsorption property of the coal gangue, producing low iron aluminum sulfate, recycling the removed iron slag, and terminating the recycling operation when the removed iron slag amount is greater than 120% of the acid-leach residue amount or the mass ratio of aluminium to iron in an iron-removing liquid is less than 160. The temperature of the calcinated coal gangue satisfies the operation condition for the boiling of a circulating fluidized bed. No addition of an auxiliary agent helps heat recovery. The activity of the coal gangue cinder is good, the grinding requirement is not high and the energy consumption is low. Hydrogen peroxide or ozone, air and variable valence element-containing hypervalent compounds KMnO4, MnO2 oxidizing agents are adopted to remove iron with less loss of aluminium. The ratio of Al2O3 to Fe in the product is greater than 160 and the quality of the product is high. The acid leaching reaction is carried out at normal pressure. And the production is easy to operate at low cost.

Owner:KUNMING UNIV OF SCI & TECH

Alkaline soil conditioner and continuous steam-pressing device and method thereof

ActiveCN105131968ARealize isobaric transmissionIncrease exchangeable calcium and magnesium contentAgriculture tools and machinesOther chemical processesIon contentEcological environment

The invention belongs to the technical field of soil conditioning and repairing and particularly relates to alkaline soil conditioner and a continuous steam-pressing device and method thereof. The alkaline soil conditioner comprises, by weight, 15-30 parts of ardealite / desulfurized gypsum, 10-20 parts of citric acid residues, 3-10 parts of waste sulphur, 12-20 parts of superphosphate, 30-35 parts of furfural residues, 14-18 parts of magnesium sulfate, 6-10 parts of aluminum sulfate, 2-3 parts of sulfuric acid compounds and 15-30 parts of humic acid. According to the alkaline soil conditioner, surface soil alkaline substances can be neutralized, the Na+ and Cl-ion content of a soil plough layer can be reduced, the soil exchangeable calcium and magnesium content can be increased, and the soil structure can be improved. A compound microorganism microbial agent is adopted, alkalified soil can be effectively improved, the soil micro-ecological environment can be improved, and soil disease microorganisms can be killed. The alkaline soil conditioner can achieve the large-scale purpose, is free of the three-waste problem and suitable for being widely applied and popularized, and can generate great economic benefits.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

Wet fly ash gelled material and preparation method thereof

InactiveCN101786821AHigh value-added utilizationImprove governance efficiencySolid waste managementSlagMetakaolin

The invention aims to provide a wet fly ash gelled material with high intensity and low cost and a preparation method thereof. According to the method, wet fly ash is used as a main raw material and the preparation method solves the problem of recovering an industrial solid waste of the wet fly ash. The wet fly ash gelled material is prepared from the following raw materials in percentage by mass: 45 to 66 percent of dried wet fly ash, 28 to 49 percent of active mineral material and 1.5 to 8 percent of chemical curing agent, wherein the active mineral material is prepared from the following raw materials in percentage by mass: 10 to 60 percent of blast furnace slag, 10 to 50 percent of cement clinker, 10 to 40 percent of metakaolin and 5 to 10 percent of gypsum; and the chemical curing agent is prepared from the following raw materials in percentage by mass: 3 to 30 percent of aluminum sulphate, 5 to 30 percent of potassium carbonate, 5 to 30 percent of sodium silicate, 5 to 40 percent of sodium carbonate, 5 to 30 percent of sodium sulphate and 10 to 60 percent of water reducing agent.

Owner:重庆市建筑科学研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com