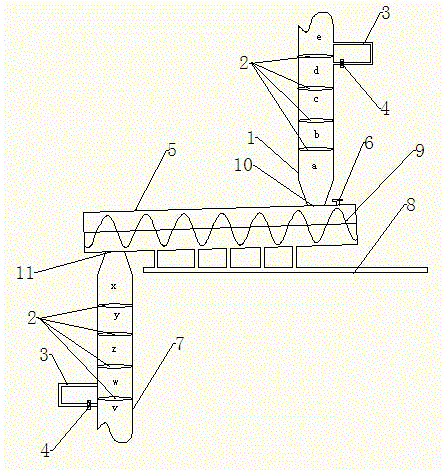

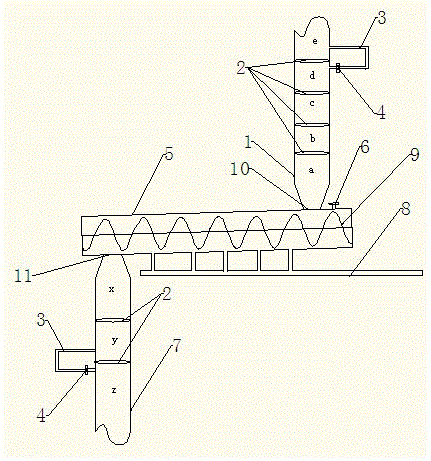

Alkaline soil conditioner and continuous steam-pressing device and method thereof

A soil conditioner and alkaline technology, applied in soil conditioning materials, chemical instruments and methods, fertilization equipment, etc., can solve the problems of non-continuous production, long pressure relief time, unsatisfactory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Alkaline soil conditioner comprises the following components in parts by weight:

[0113] Citric acid residue 14.13

[0114] Waste sulfur 4.56

[0115] Phosphogypsum / desulfurized gypsum 22.38

[0116] Superphosphate 16.05

[0117] Furfural residue 32.45

[0118] Magnesium sulfate 16.48

[0119] Aluminum sulfate 8.52

[0120] Sulfuric acid compound 2.16

[0121] Humic acid 23.84;

[0122] The sulfuric acid compound is a mixture of iron sulfate, zinc sulfate, and manganese sulfate, and the weight-number ratio of iron sulfate, zinc sulfate, and manganese sulfate is 1:1:1;

[0123] Waste sulfur is used for dust removal of waste sulfur by the sulfur coating system.

[0124] Choose three lands with the same soil quality and close proximity, and the common feature of the three lands is alkaline soil, with a pH value of about 8.7; these three lands are recorded as A, B, and C respectively, and the same fertilizer is applied, watered and weeded The conditions are exactl...

Embodiment 2

[0131] A kind of alkaline soil conditioning agent, this alkaline soil conditioning agent comprises the component of following parts by weight:

[0132] Citric acid residue 10

[0133] Waste sulfur 3

[0134] Phosphogypsum / desulfurization gypsum 15

[0135] ssp 12

[0136] Furfural residue 30

[0138] Aluminum sulfate 6

[0139] Sulfate compound 2

[0140] humic acid15.

[0141] The sulfuric acid compound is a mixture of iron sulfate, zinc sulfate, and manganese sulfate, and the weight-number ratio of iron sulfate, zinc sulfate, and manganese sulfate is 1:1:1;

[0142] Waste sulfur is used for dust removal of waste sulfur by the sulfur coating system.

Embodiment 3

[0144] A kind of alkaline soil conditioning agent, this alkaline soil conditioning agent comprises the component of following parts by weight:

[0145] Citric acid residue 20

[0146] Waste sulfur 10

[0147] Phosphogypsum / desulfurized gypsum 30

[0148] ssp 20

[0149] Furfural residue 35

[0151] Aluminum Sulfate 10

[0152] Sulfate compound 3

[0153] Humic Acid 30.

[0154] The sulfuric acid compound is a mixture of iron sulfate, zinc sulfate, and manganese sulfate, and the weight-number ratio of iron sulfate, zinc sulfate, and manganese sulfate is 1:1:1;

[0155] Waste sulfur is used for dust removal of waste sulfur by the sulfur coating system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com