Patents

Literature

207results about How to "Low ion content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

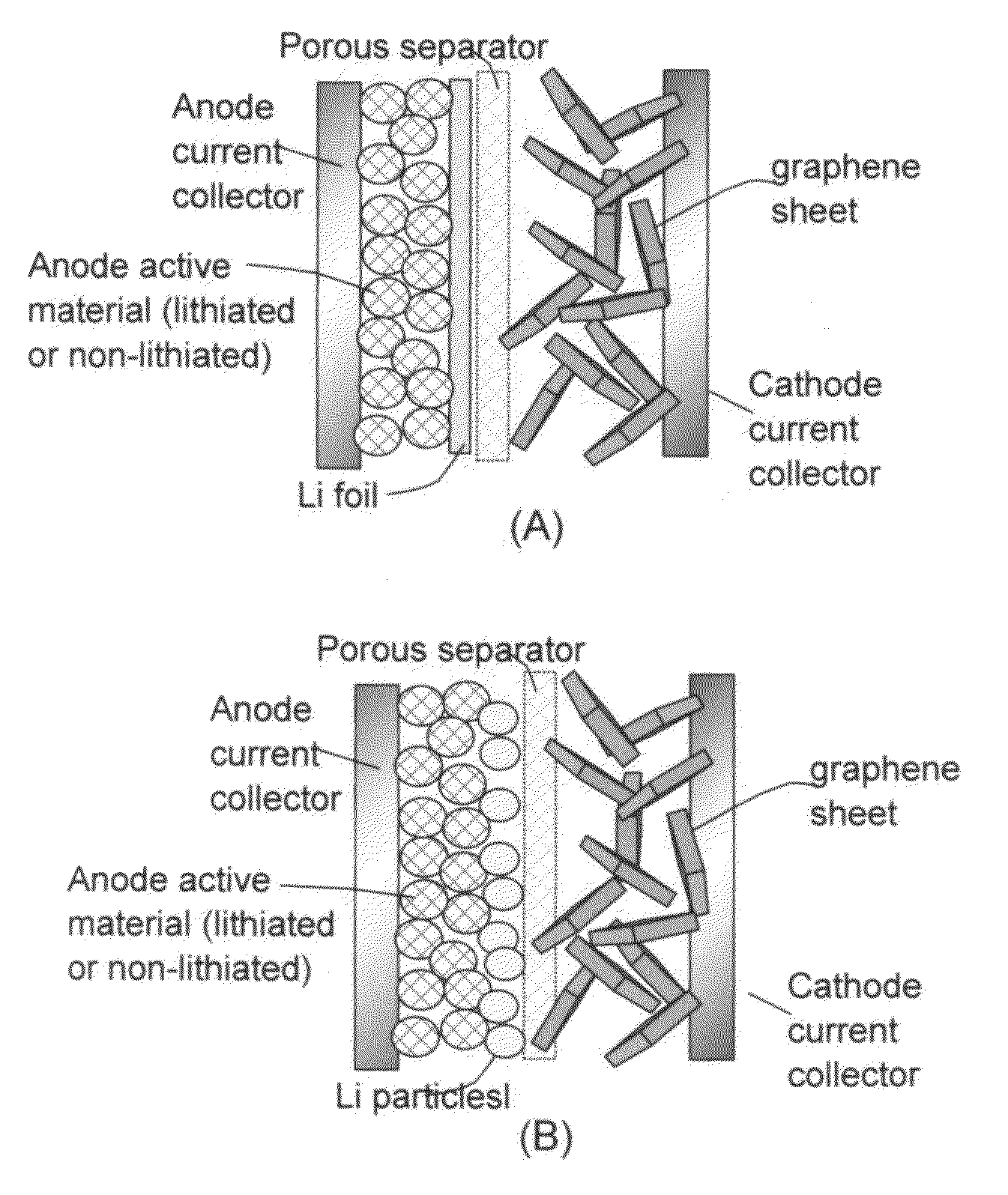

Lithium-ion cell having a high-capacity anode and a high-capacity cathode

ActiveUS20130224603A1Easy dischargeImprove power densityMaterial nanotechnologyHybrid capacitor electrodesLithiumHigh energy

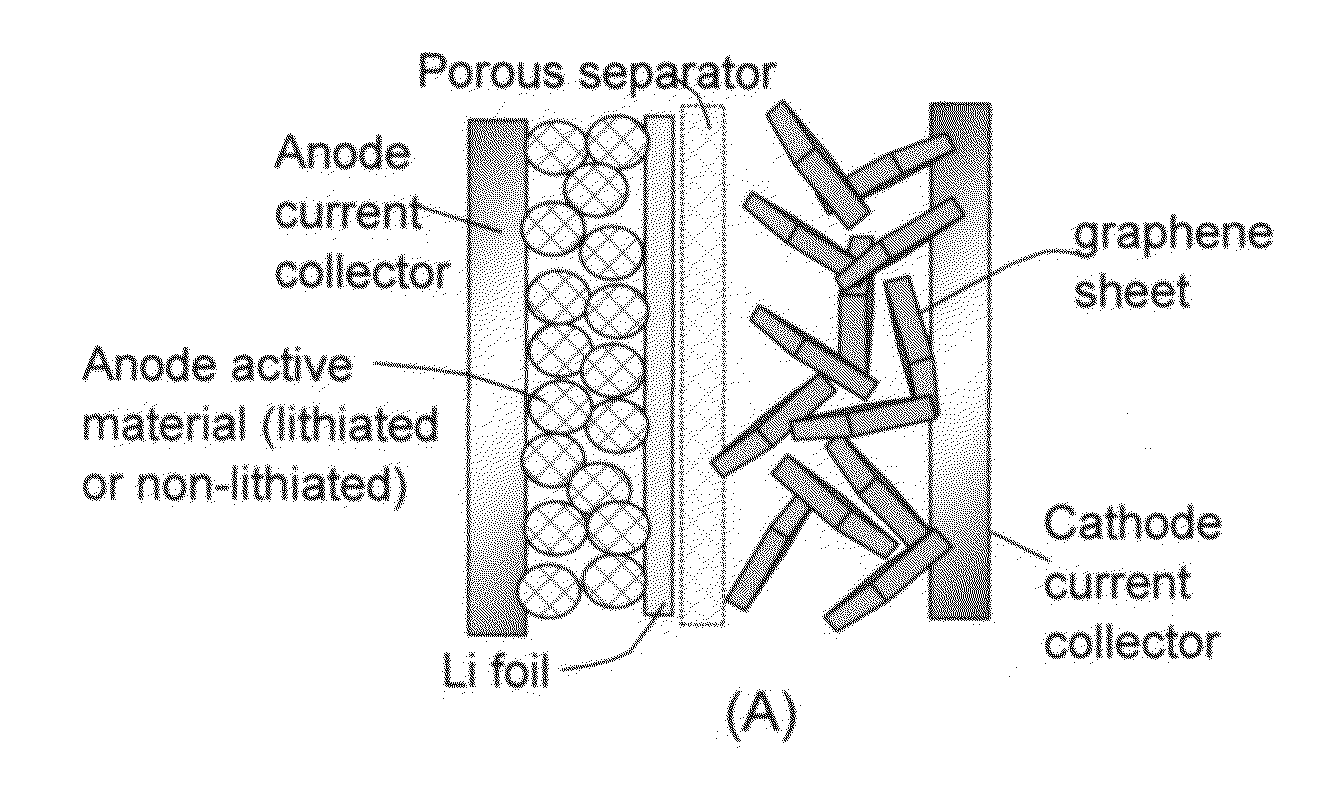

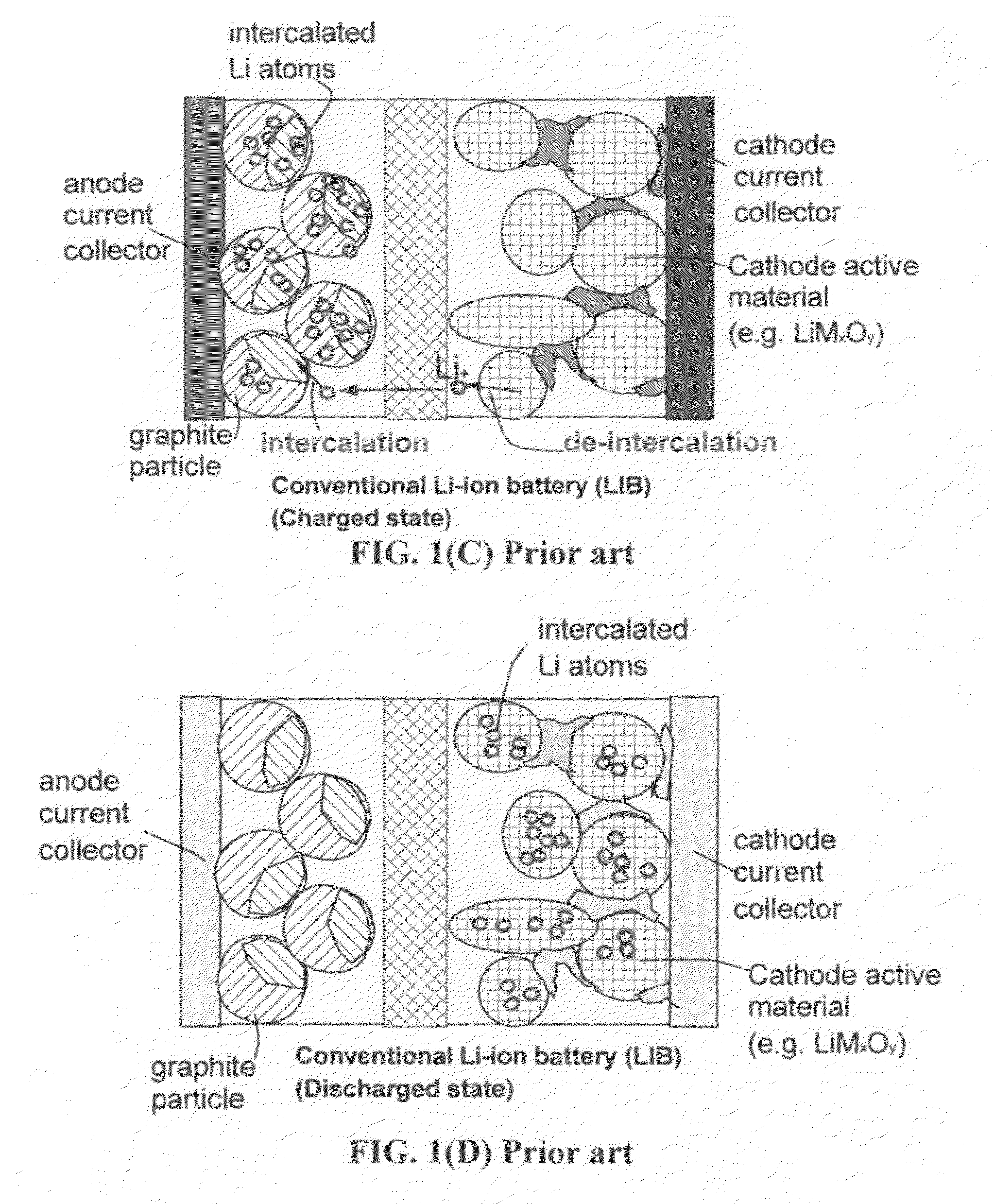

A lithium-ion cell comprising: (A) a cathode comprising graphene as the cathode active material having a surface area to capture and store lithium thereon and wherein said graphene cathode is meso-porous having a specific surface area greater than 100 m2 / g; (B) an anode comprising an anode active material for inserting and extracting lithium, wherein the anode active material is mixed with a conductive additive and / or a resin binder to form a porous electrode structure, or coated onto a current collector in a coating or thin film form; (C) a porous separator disposed between the anode and the cathode; (D) a lithium-containing electrolyte in physical contact with the two electrodes; and (E) a lithium source disposed in at least one of the two electrodes when the cell is made. This new Li-ion cell exhibits an unprecedentedly high energy density.

Owner:GLOBAL GRAPHENE GRP INC

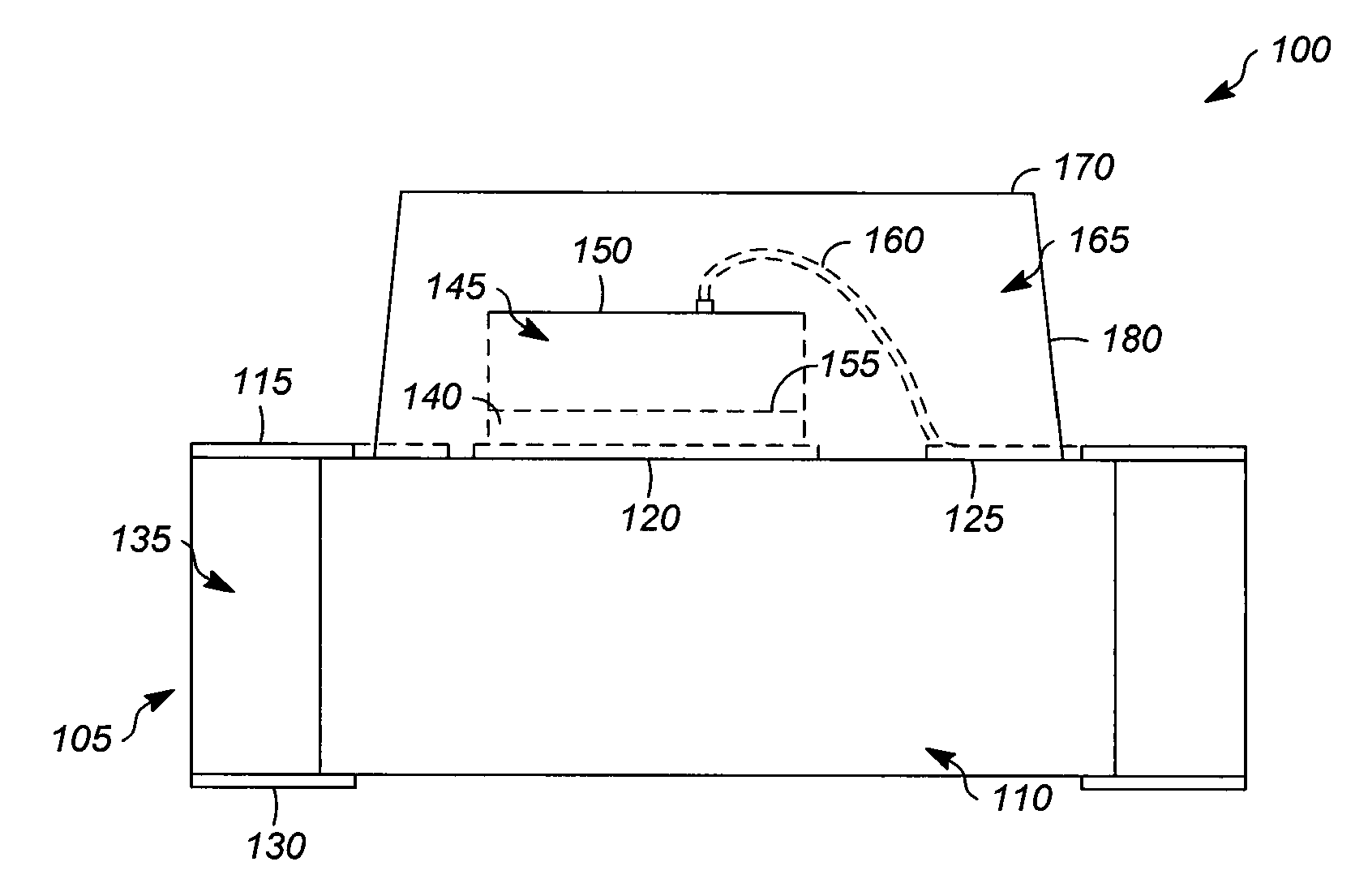

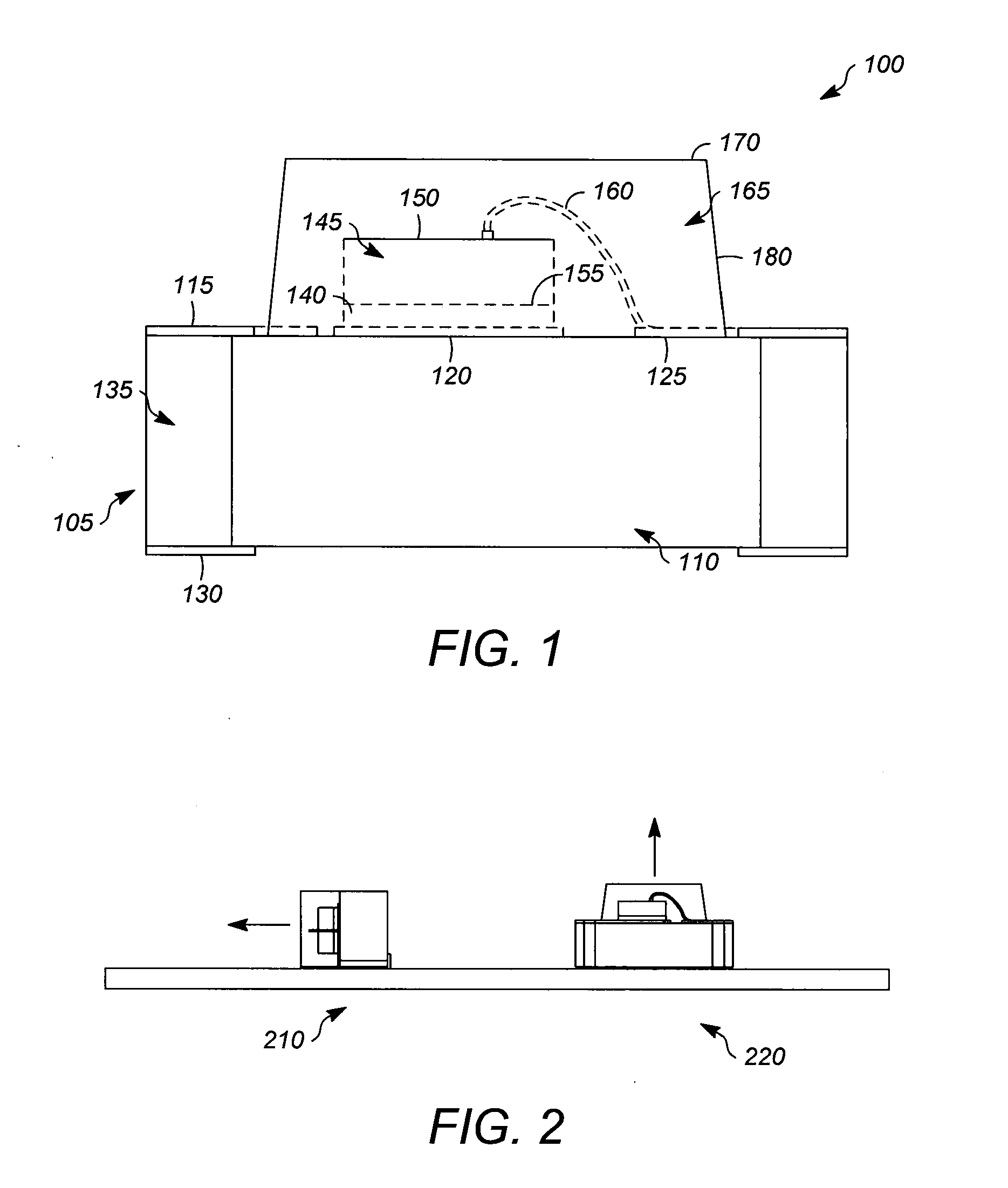

Optoelectronic devices with laminate leadless carrier packaging in side-looker or top-looker device orientation

ActiveUS20110079801A1Low ion contentImprove moisture resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLead bondingEngineering

A laminate leadless carrier package comprising an optoelectronic chip, a substrate supporting the chip, the substrate comprising a plurality of conductive and dielectric layers; a wire bond coupled to the optoelectronic chip and a wire bond pad positioned on the top surface of the substrate; an encapsulation covering the optoelectronic chip, the wire bond, and at least a portion of the top surface of the substrate, wherein the encapsulation is a molding compound; and wherein the package is arranged to be mounted as a side-looker. A process for manufacturing laminate leadless carrier packages, comprising preparing a substrate; applying epoxy adhesive to a die attach pad; mounting an optoelectronic chip on the die attach pad; wire-bonding the optoelectronic chip; molding a molding compound to form an encapsulation covering the optoelectronic chip, a wire bond, and the top surface of the substrate; and dicing the substrate into individual packages.

Owner:EXCELITAS CANADA

Functional fertilizer and repair agents for repairing soil heavy metal

ActiveCN103788960AReduce the content of high-priced heavy metal ionsLow ion contentAgriculture tools and machinesOrganic fertilisersSolubilitySoil heavy metals

The invention discloses functional fertilizer and repair agents for repairing soil heavy metal. Modified attapulgite, chitosan, biochar and sodium thiosulfate are compounded, and on one hand, the absorption performance of the attapulgite and the biochar and the chelation of the chitosan are used for fixing heavy metal ions in soil and preventing the heavy metal ions in the soil from migrating through leaching and runoff. On the other hand, the sodium thiosulfate is used for restoring the high-valence-state heavy metal ions (like hexavalent chromium ions) to low-valence-state ions (like trivalent chromic ions), and therefore virulence and solubleness of the ions are reduced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

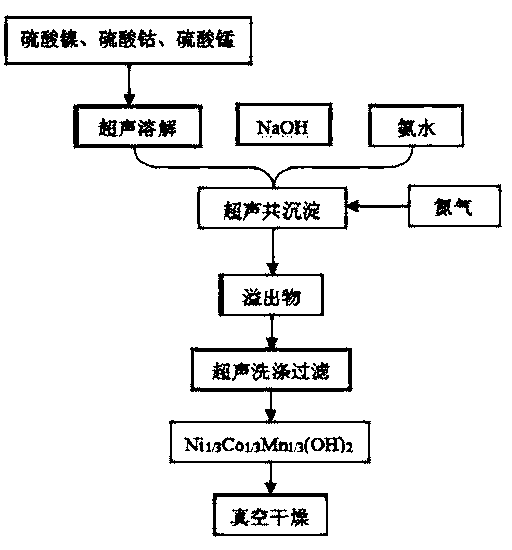

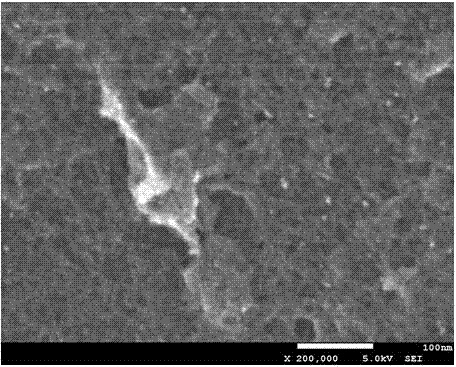

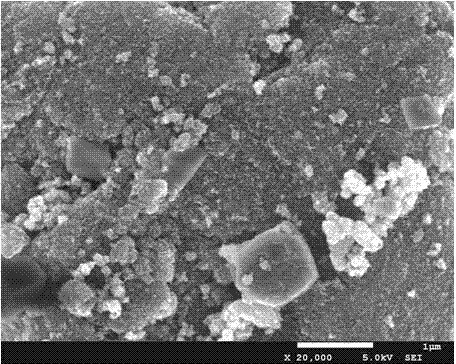

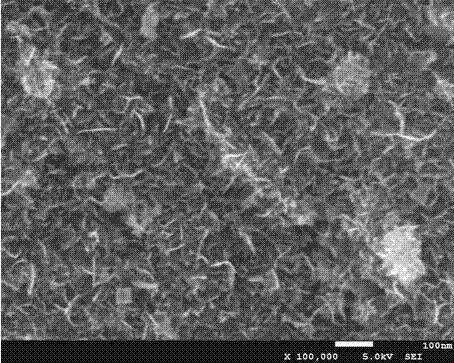

Ultrasonic assisted method for preparing precursor of ternary positive material of lithium ion battery

ActiveCN103482711AEasy to shapeNarrow particle size distributionCell electrodesManganese oxides/hydroxidesAluminium-ion batteryManganese

The invention discloses an ultrasonic assisted method for preparing the precursor of a ternary positive material of a lithium ion battery. The method disclosed by the invention comprises the following steps that under the protection of inert gas nitrogen, nickel, cobalt, and manganese in a metal mixed solution are continuously co-precipitated by using a sodium hydroxide and ammonium hydroxide mixed solution by means of mechanical stirring dispersion and ultrasonic wave assistance; the precipitated product grows and then overflows; the overflowed product is washed, and filtered to obtain fresh composite hydroxide precipitate of nickel, cobalt, and manganese; and the product is ultrasonically-assisted washed by using pure water, and dried in vacuum to obtain the precursor of the hydroxide of nickel, cobalt and manganese, which is good in degree of sphericity and high in purity. According to the method disclosed by the invention, the fresh hydroxide precipitate is treated by using the ultrasonic assisted method, the product is the composite hydroxide precursor, the content of the impurity ion is less, and the composite hydroxide precursor has the advantages of spherical shapes, narrow particle size distribution, high tap density and the like.

Owner:DALIAN RUIYUANPOWER CO LTD

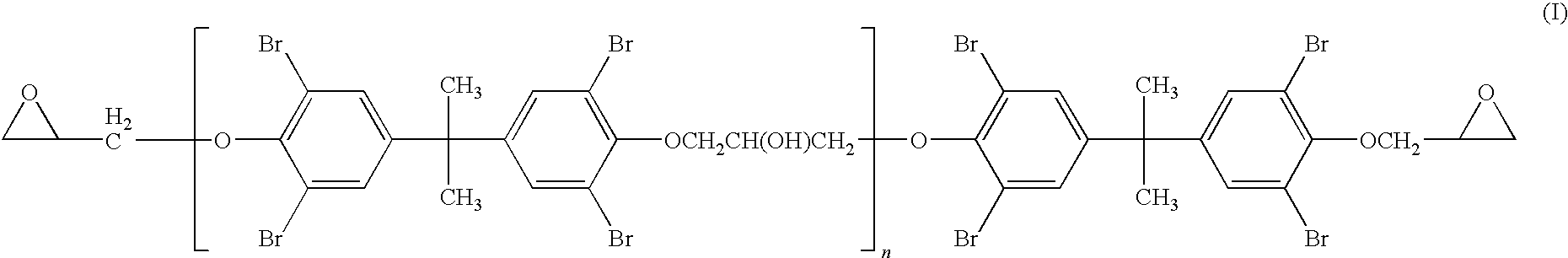

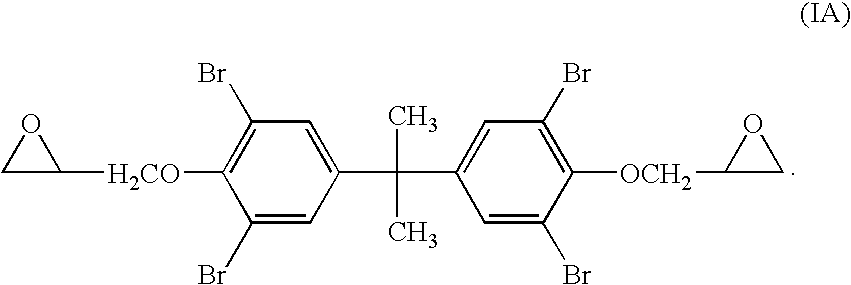

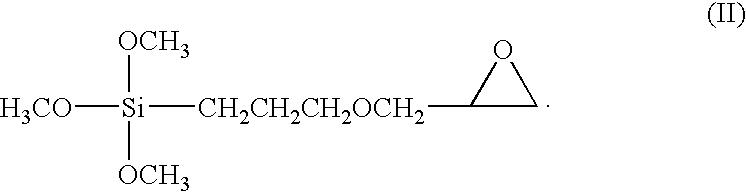

Epoxy resin varnishes, laminates and printed circuit boards

ActiveUS20100092764A1Increase contentLow ion contentSemiconductor/solid-state device detailsSolid-state devicesEpoxyCopper

Provided herein are, among other things, epoxy resin varnishes and methods of making and using the same. In some embodiments, the epoxy resin varnishes comprise at least a filler such as silica. In certain embodiments, the epoxy resin varnishes provided herein are used for making laminates such as copper clad laminates. In farther embodiments, the copper clad laminates provided herein are used for making printed circuit boards (PCBs).

Owner:VENTEC ELECTRONICS SUZHOU

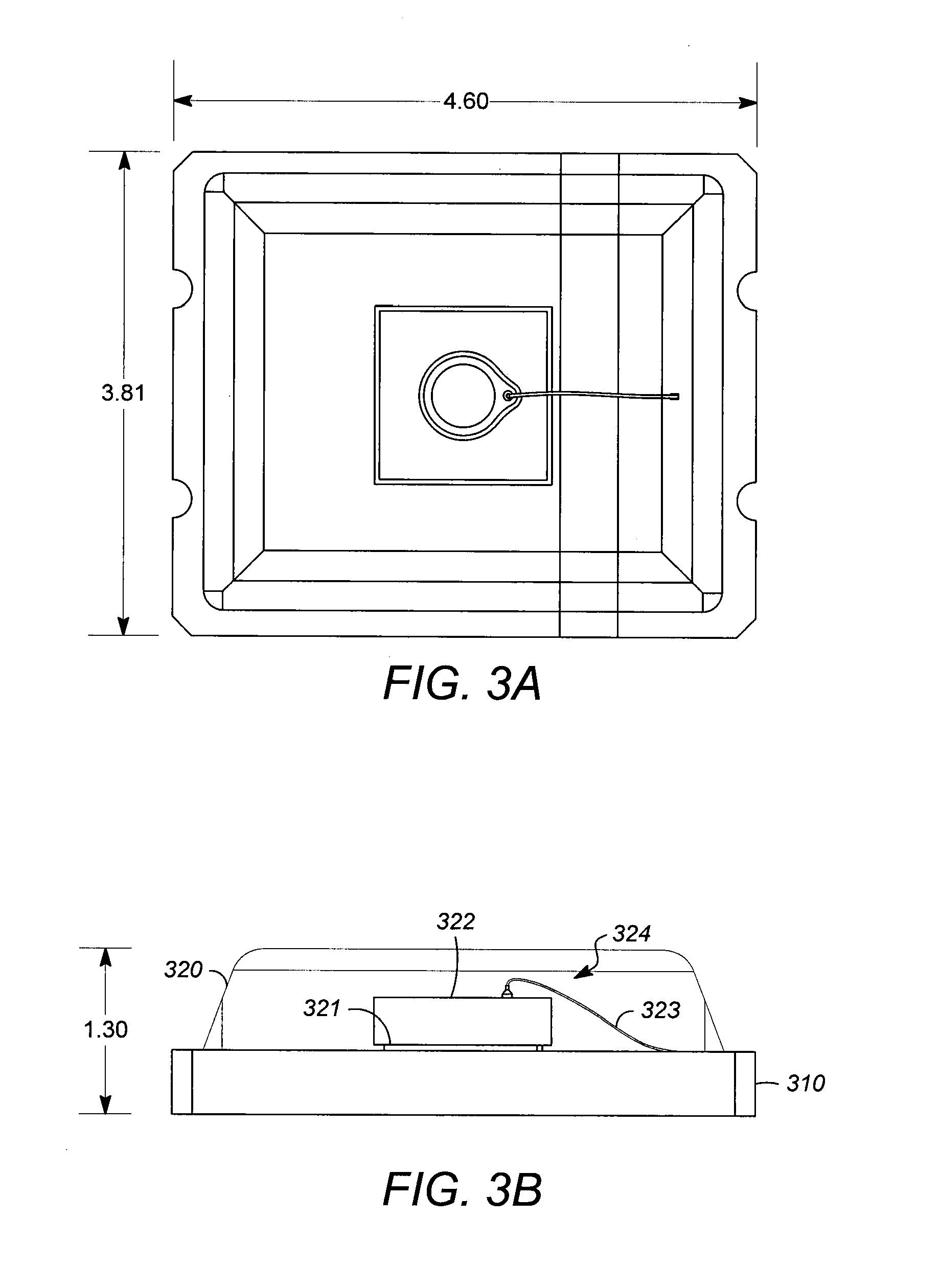

Lithium-ion cell having a high-capacity anode and a high-capacity cathode

ActiveUS9437370B2Improvement factorImprove diffusivityMaterial nanotechnologyHybrid capacitor electrodesLithiumHigh energy

A lithium-ion cell comprising: (A) a cathode comprising graphene as the cathode active material having a surface area to capture and store lithium thereon and wherein said graphene cathode is meso-porous having a specific surface area greater than 100 m2 / g; (B) an anode comprising an anode active material for inserting and extracting lithium, wherein the anode active material is mixed with a conductive additive and / or a resin binder to form a porous electrode structure, or coated onto a current collector in a coating or thin film form; (C) a porous separator disposed between the anode and the cathode; (D) a lithium-containing electrolyte in physical contact with the two electrodes; and (E) a lithium source disposed in at least one of the two electrodes when the cell is made. This new Li-ion cell exhibits an unprecedentedly high energy density.

Owner:GLOBAL GRAPHENE GRP INC

Glycolide production process, and glycolic acid composition

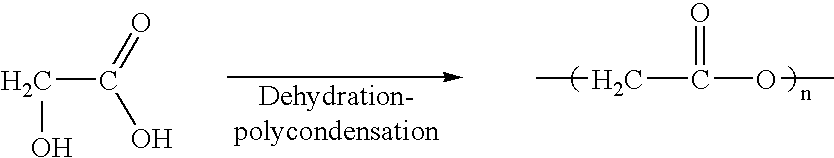

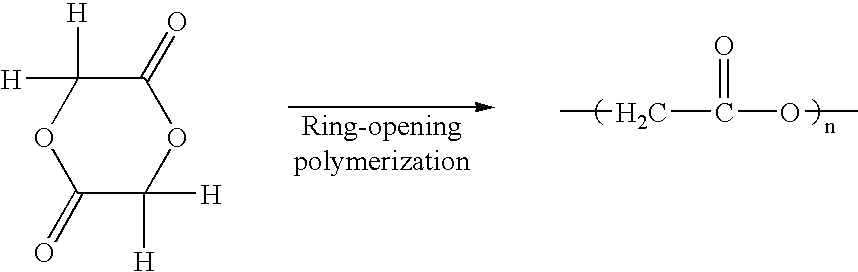

InactiveUS6891048B2Efficient productionLow ion contentOrganic chemistry methodsOrganic acidDepolymerization

The invention provides a process for producing glycolide by depolymerization by heating of a glycolic acid oligomer in the presence or absence of a solvent, which process ensures stable depolymerization. The depolymerization reaction is carried out while the content of alkaline metal ions in a glycolic acid oligomer-containing depolymerization reaction system is controlled to 0.001% by mass or lower; a sulfate or an organic acid salt, each in the form of di- or poly-valent cations, or a mixture thereof is allowed to be present as a stabilizer in the depolymerization reaction system; or the content of alkaline metal ions in the depolymerization reaction system is controlled to 0.001% by mass or lower, and a sulfate or an organic acid salt, each in the form of di- or poly-valent cations, or a mixture thereof is allowed to be present as a stabilizer in the depolymerization reaction system.

Owner:KUREHA KAGAKU KOGYO KK

Surface treatment method for environment-friendly chromium-free zirconium-containing electro-galvanized fingerprint resistant steel sheet

The present invention relates to surface treatment of steel plate, and is especially zinc electroplating process to form homogeneous fine zinc layer onto the surface of cold rolled steel plate and environment friendly zirconium-containing no-chromium fingerprint resisting paint for producing zinc electroplating fingerprint resisting steel plate. Cold rolled steel plate is first electroplated with zinc and then coated with fingerprint resisting paint. The production process of fingerprint resisting steel plate features the production process including the first production of zinc electroplated steel plate via vertical anode electroplating process, coating with water-base fingerprint resisting paint with zirconium to replace chromium, and curing through roasting at temperature lower than 125 deg.c to form composite resin film. The electroplated zinc layer has stable and reliable quality and the organic composite resin film has no environmental pollution.

Owner:JIANGYIN CHANGFA FINGERPRINT RESISTANT STEEL PLATE

Surfactant biocatalyst for remediation of recalcitrant organics and heavy metals

ActiveUS20050106702A1Resistance to degradationHigh molecular weightBacteriaUnicellular algaeMicrobiologyOrganism

Novel strains of isolated and purified bacteria have been identified which have the ability to degrade petroleum hydrocarbons including a variety of PAHs. Several isolates also exhibit the ability to produce a biosurfactant. The combination of the biosurfactant-producing ability along with the ability to degrade PAHs enhances the efficiency with which PAHs may be degraded. Additionally, the biosurfactant also provides an additional ability to bind heavy metal ions for removal from a soil or aquatic environment.

Owner:BATTELLE SAVANNAH RIVER ALLIANCE LLC

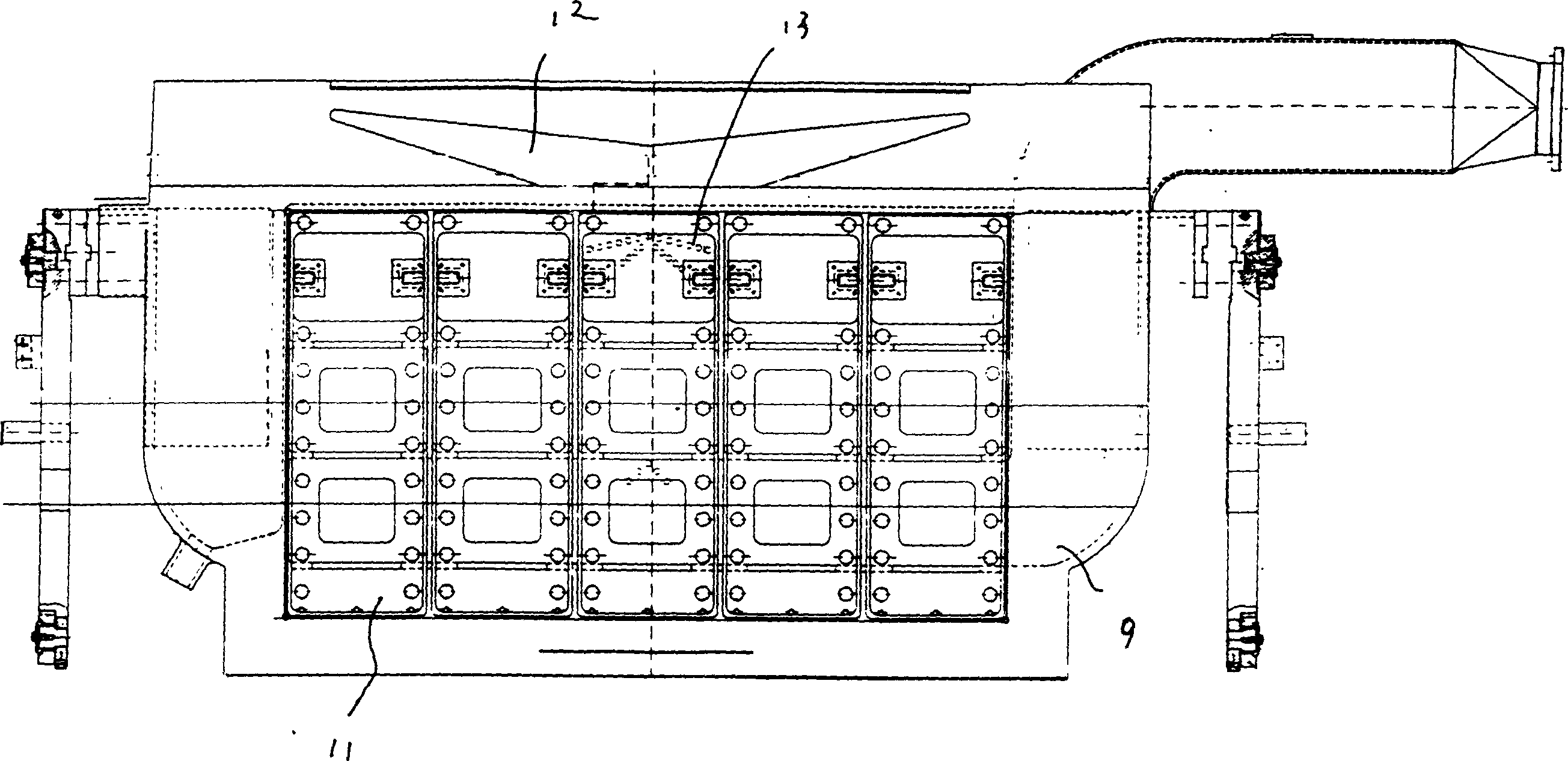

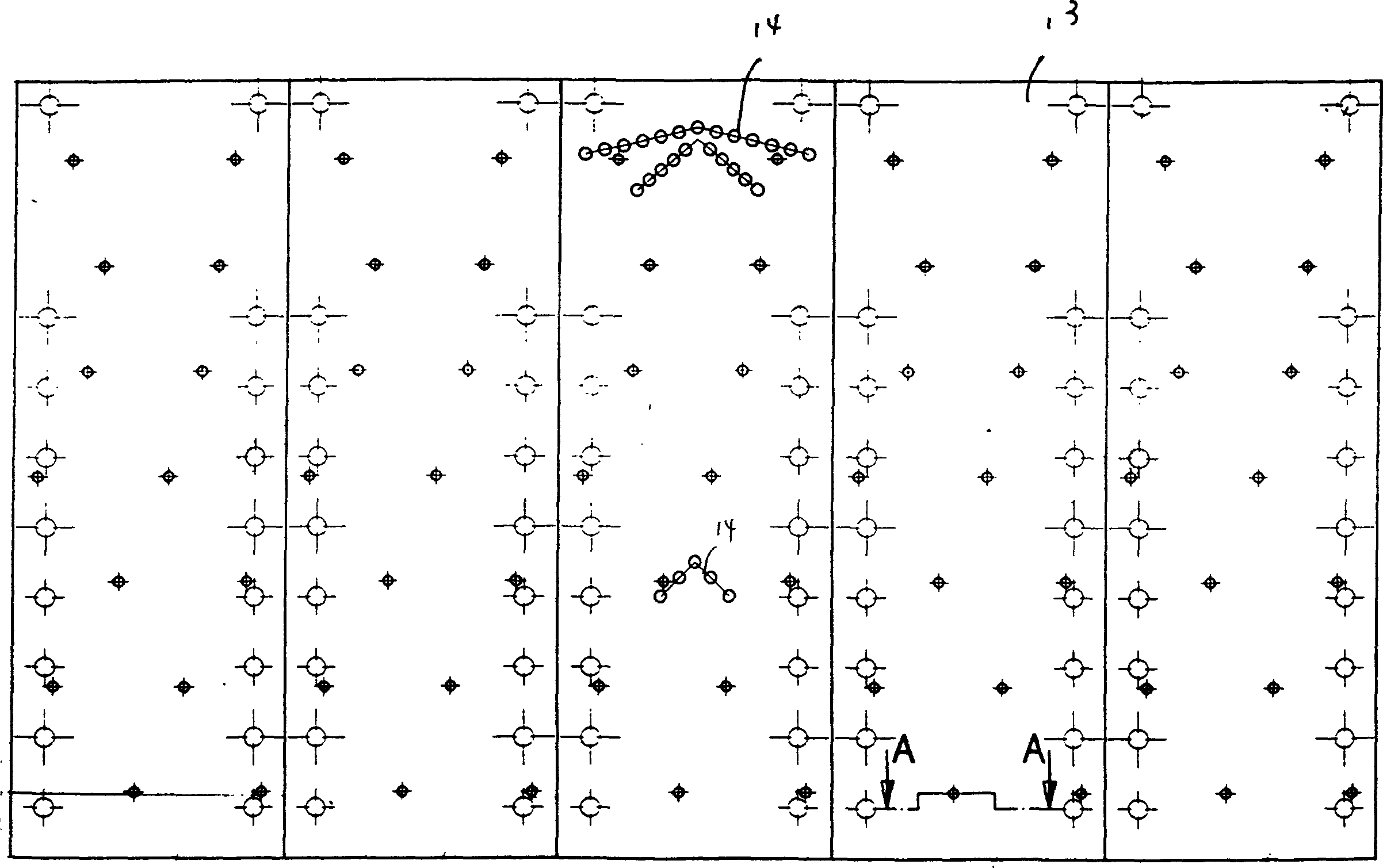

Alkaline soil conditioner and continuous steam-pressing device and method thereof

ActiveCN105131968ARealize isobaric transmissionIncrease exchangeable calcium and magnesium contentAgriculture tools and machinesOther chemical processesIon contentEcological environment

The invention belongs to the technical field of soil conditioning and repairing and particularly relates to alkaline soil conditioner and a continuous steam-pressing device and method thereof. The alkaline soil conditioner comprises, by weight, 15-30 parts of ardealite / desulfurized gypsum, 10-20 parts of citric acid residues, 3-10 parts of waste sulphur, 12-20 parts of superphosphate, 30-35 parts of furfural residues, 14-18 parts of magnesium sulfate, 6-10 parts of aluminum sulfate, 2-3 parts of sulfuric acid compounds and 15-30 parts of humic acid. According to the alkaline soil conditioner, surface soil alkaline substances can be neutralized, the Na+ and Cl-ion content of a soil plough layer can be reduced, the soil exchangeable calcium and magnesium content can be increased, and the soil structure can be improved. A compound microorganism microbial agent is adopted, alkalified soil can be effectively improved, the soil micro-ecological environment can be improved, and soil disease microorganisms can be killed. The alkaline soil conditioner can achieve the large-scale purpose, is free of the three-waste problem and suitable for being widely applied and popularized, and can generate great economic benefits.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

Zinc-containing dentifrice compositions having improved taste

InactiveUS20060099152A1Low ion contentGood flexibilityCosmetic preparationsToilet preparationsWater solubleSURFACTANT BLEND

The present invention relates to antimicrobial oral compositions comprising a water-soluble zinc salt wherein a surfactant selected from alkali metal or ammonium salts of alkyl sulfoacetate, dialkyl sulfosuccinate, dialkyl sulfosuccinamate; and mixtures thereof; is used in an amount effective to reduce the astringency of the zinc salt.

Owner:THE PROCTER & GAMBLE COMPANY

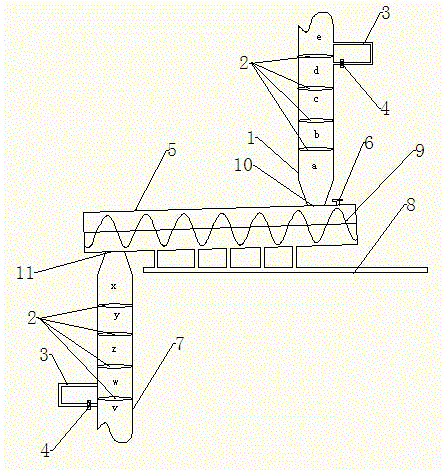

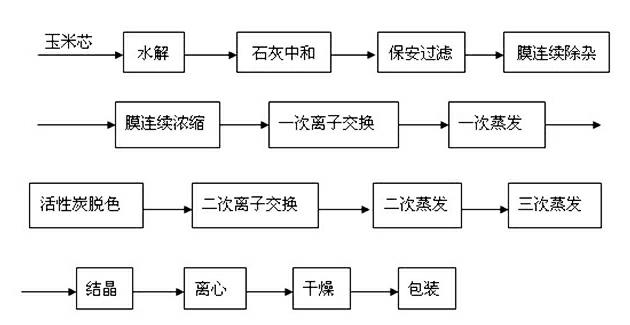

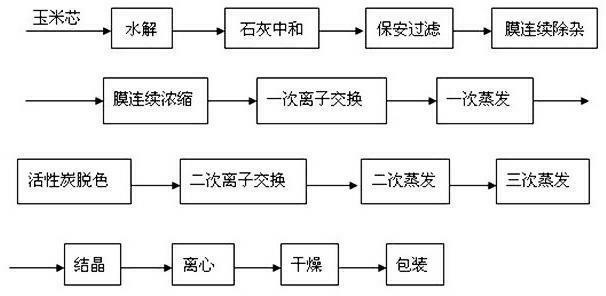

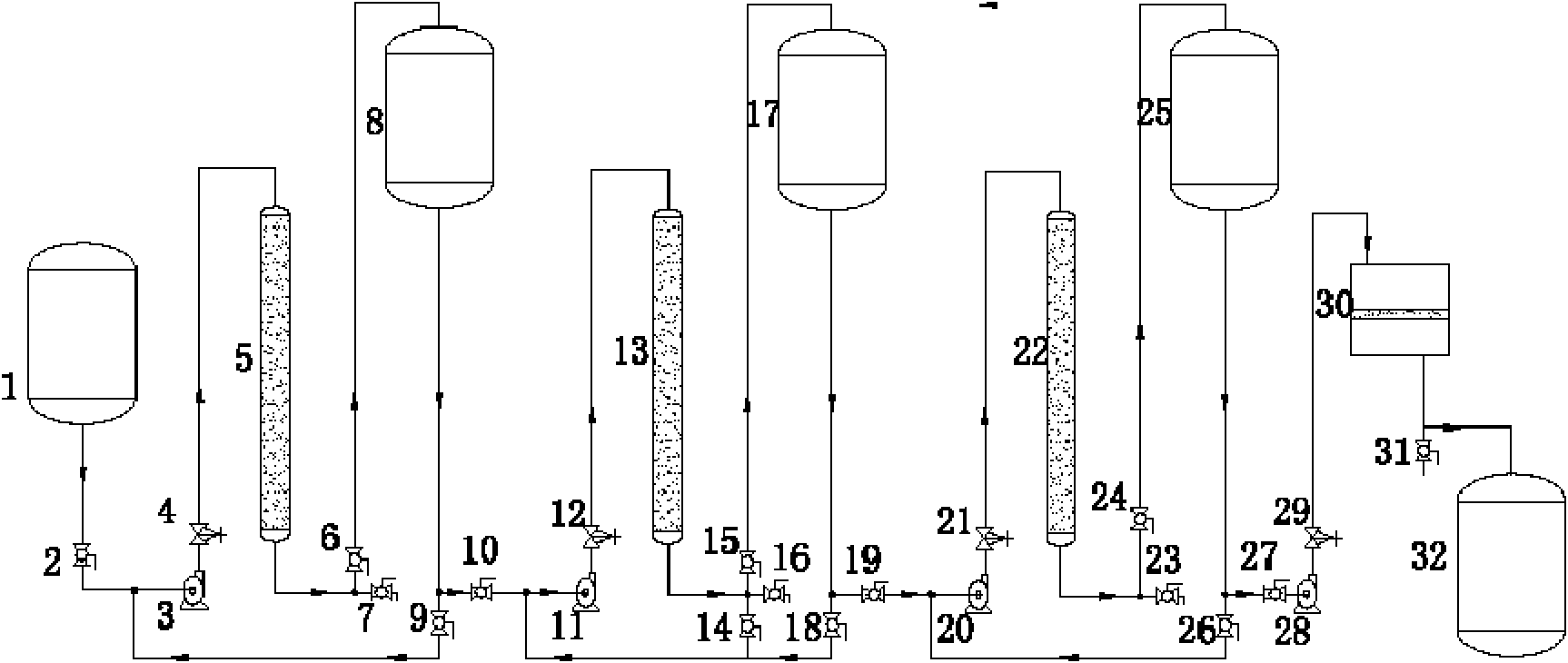

Efficient and energy-saving xylose producing process

The invention discloses an efficient and energy-saving xylose producing process, which comprises the following steps of: A, corncob hydrolysis; B, lime neutralization; C, cartridge filtration; D, continuous membrane decontamination; E, continuous membrane concentration; F, primary ion exchange; G, primary evaporation; H, activated carbon decoloration; I, secondary ion exchange; J, secondary evaporation; K, third-time evaporation; L, crystallization; M, centrifugation; N, drying; and O, finished product packaging. The process disclosed by the invention has the beneficial effects that impurities and pigment are removed by membrane separation and concentration, the usage amount of activated carbon is reduced, steam consumption is reduced, the pollution load of ion exchange resin is reduced, the regeneration period of the ion exchange resin is prolonged, the discharge of waste water of the producing process is reduced, the production efficiency is improved, and the production cost is reduced, so that the sustainable development ability of an enterprise is promoted.

Owner:上海诚洲科技中心(有限合伙)

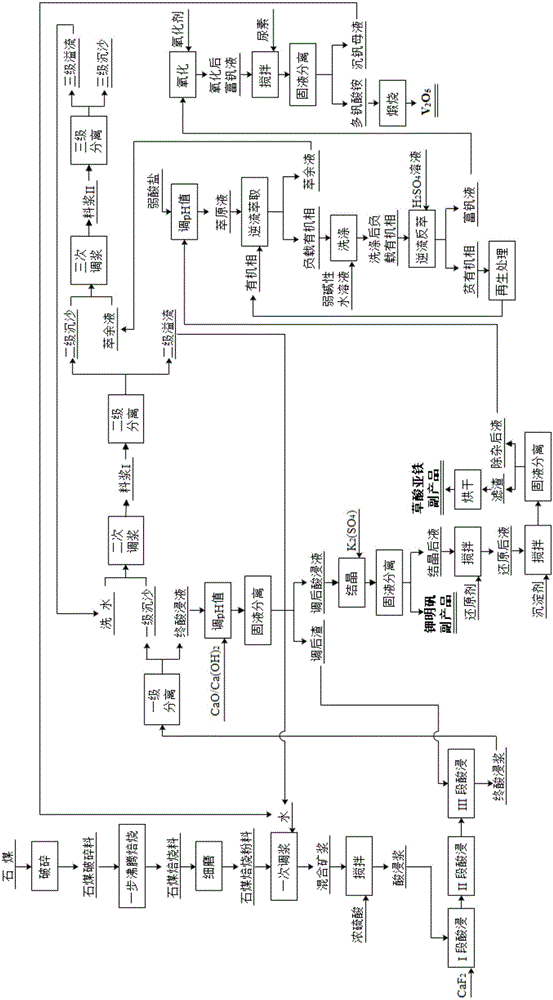

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

The invention relates to a method for preparing high-purity vanadium pentoxide by use of a stone coal one-step method. The technical solution is as follows: a fluidized bed furnace for one-step roasting of stone coal is adopted to perform one-step fluidized bed roasting on the stone coal; roasted materials are leached in three segments, final pickling slurry is subjected to primary separation so as to obtain final pickle liquor, secondary overflow is returned to be subjected to primary size mixing, and tertiary overflow is returned to be subjected to secondary size mixing; the pH value of the final pickle liquor is regulated, and slags obtained after regulation are returned to a segment III so as to be leached; the regulated pickle liquor is crystallized to obtain a potassium alum byproduct; after crystallization, the liquid is subjected to reduction and precipitation-based impurity removal, and filter residues are dried to obtained a ferrous oxalate byproduct; after impurity removal, pH value regulation is performed on the liquid by use of weak acid salt, then counter-current extraction is performed on the liquid, and extraction raffinate is returned to be subjected to tertiary size mixing; after being washed, the loaded organic phase is subjected to countercurrent reverse extraction; a lean organic phase is regenerated and then is returned to be extracted; after a vanadium-rich solution is oxidized, urea is added, stirring is performed, the obtained molybdenum precipitation mother solution is returned to be subjected to primary size mixing, and ammonium polyorthovanadate is calcinated to prepare vanadium pentoxide. The method has the characteristics of short process flow, less pollution, low energy consumption, less chemical usage, high vanadium recovery rate and high product purity.

Owner:WUHAN UNIV OF SCI & TECH

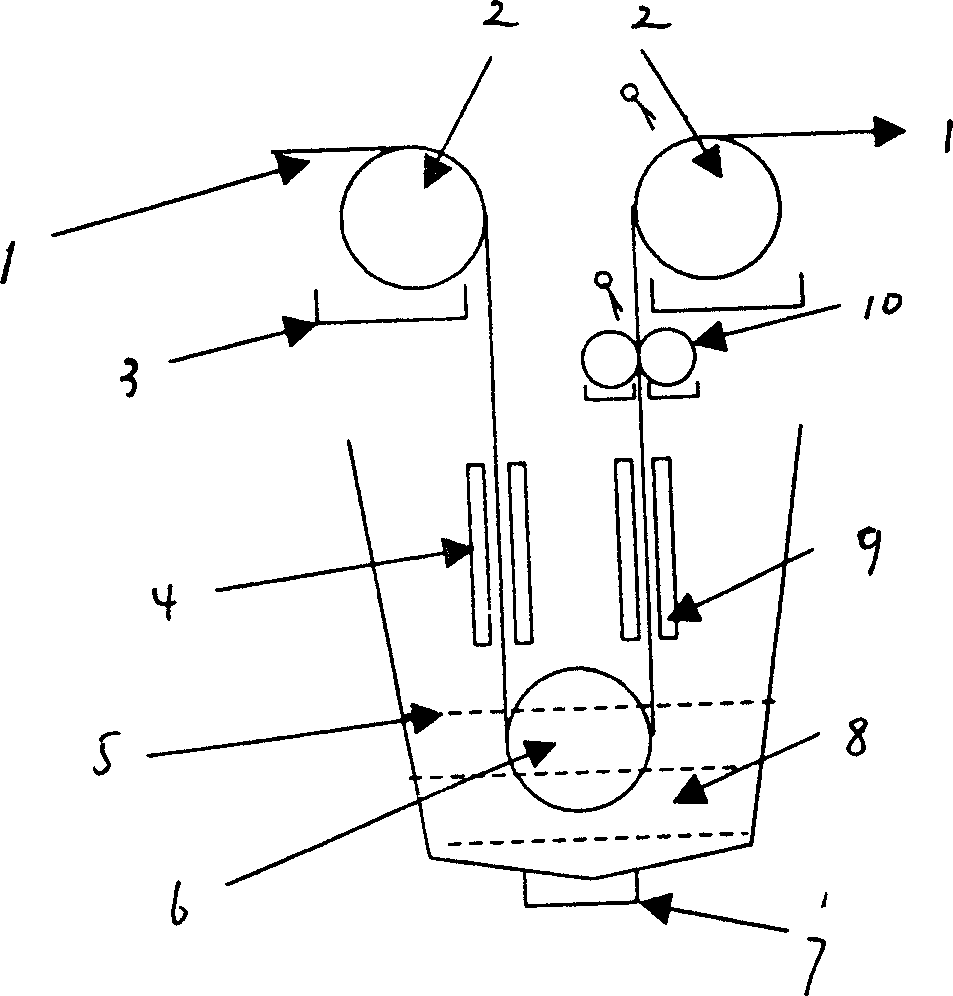

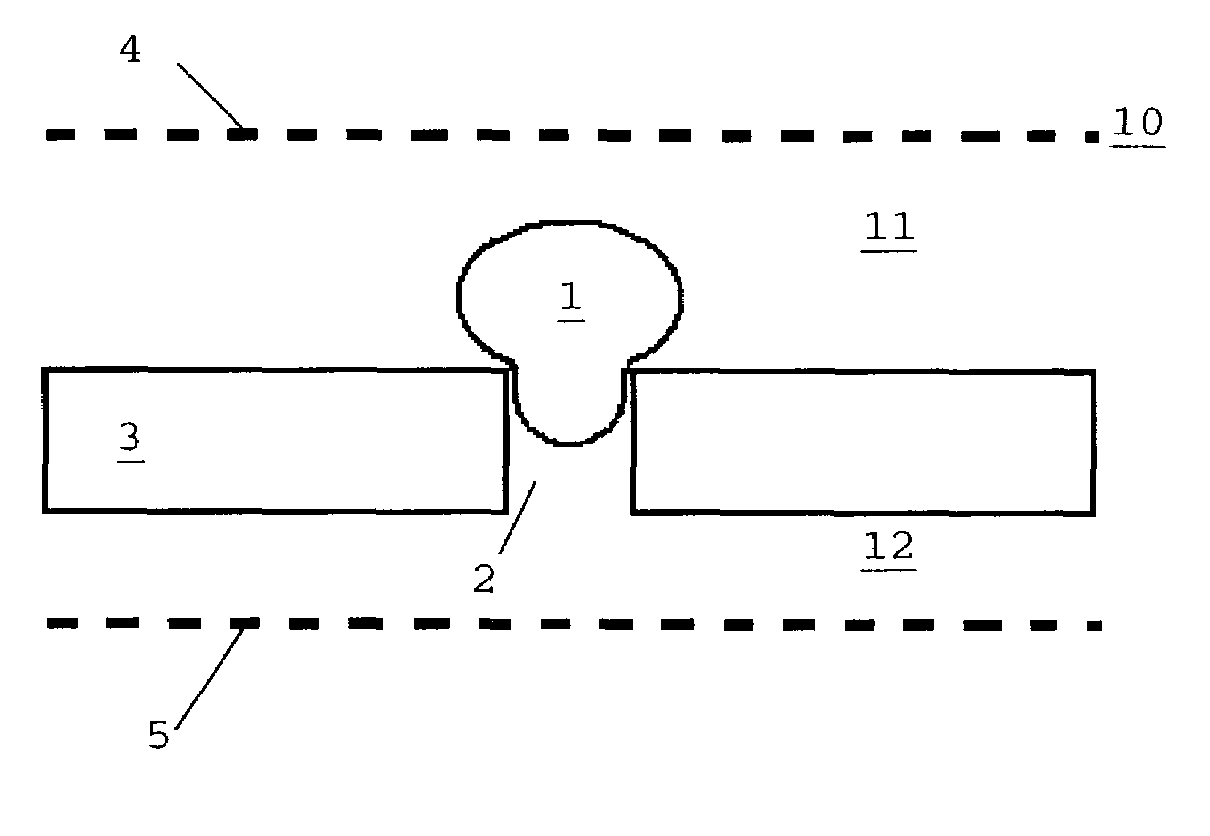

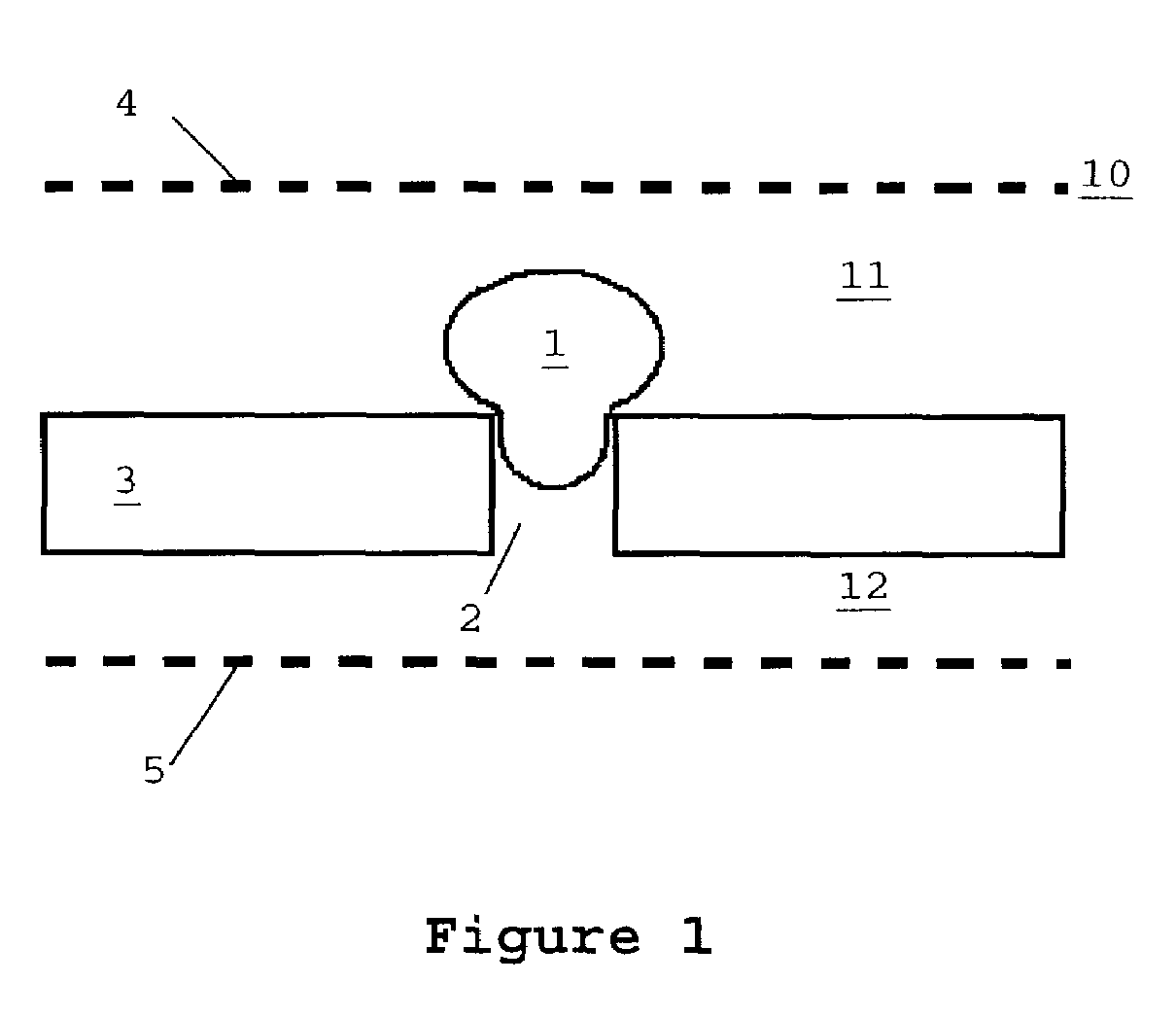

Method and device for electroporation of biological cells

InactiveUS7358077B2Encourages charging and break-throughImprove survivabilityBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityBiological cell

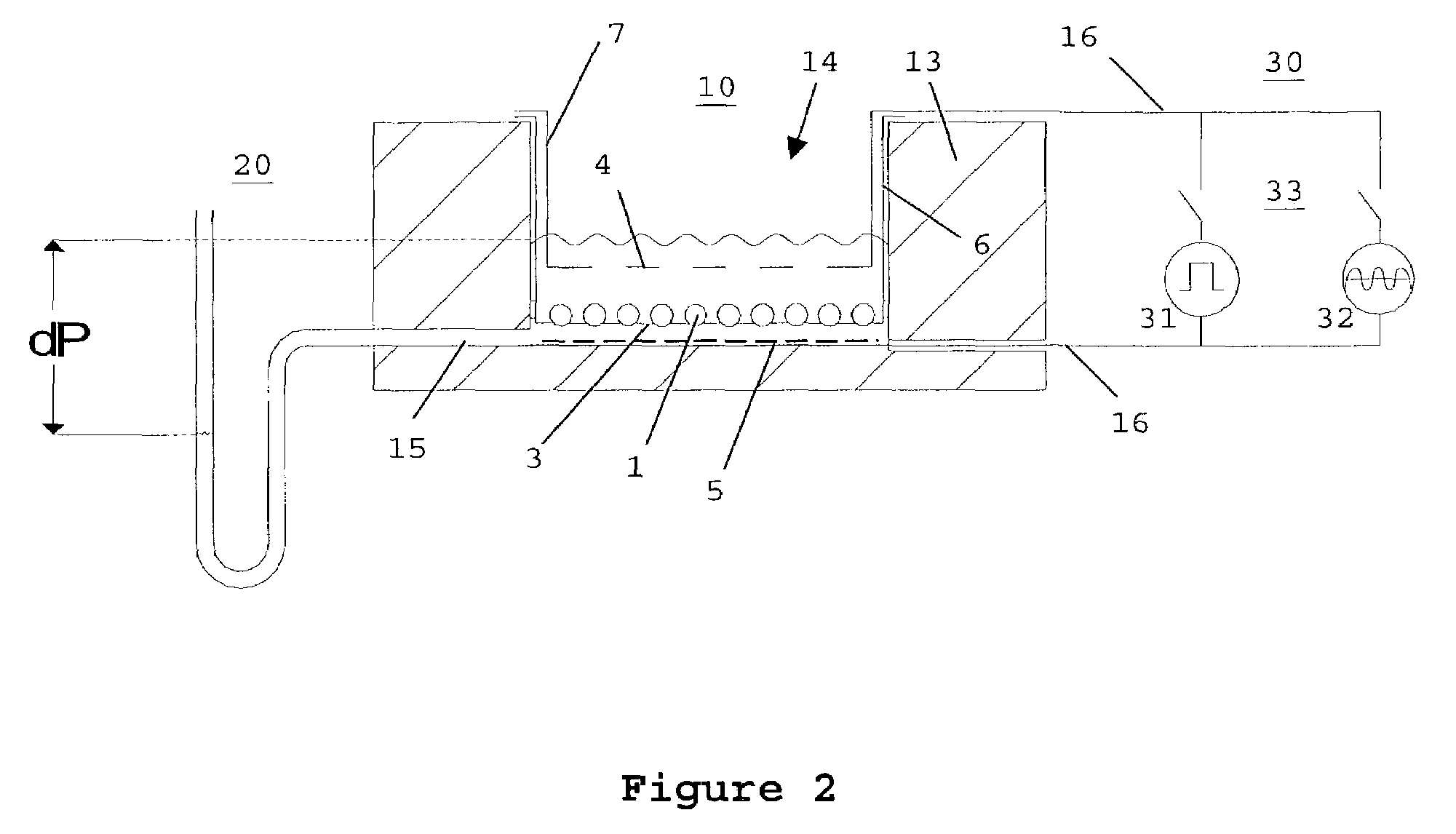

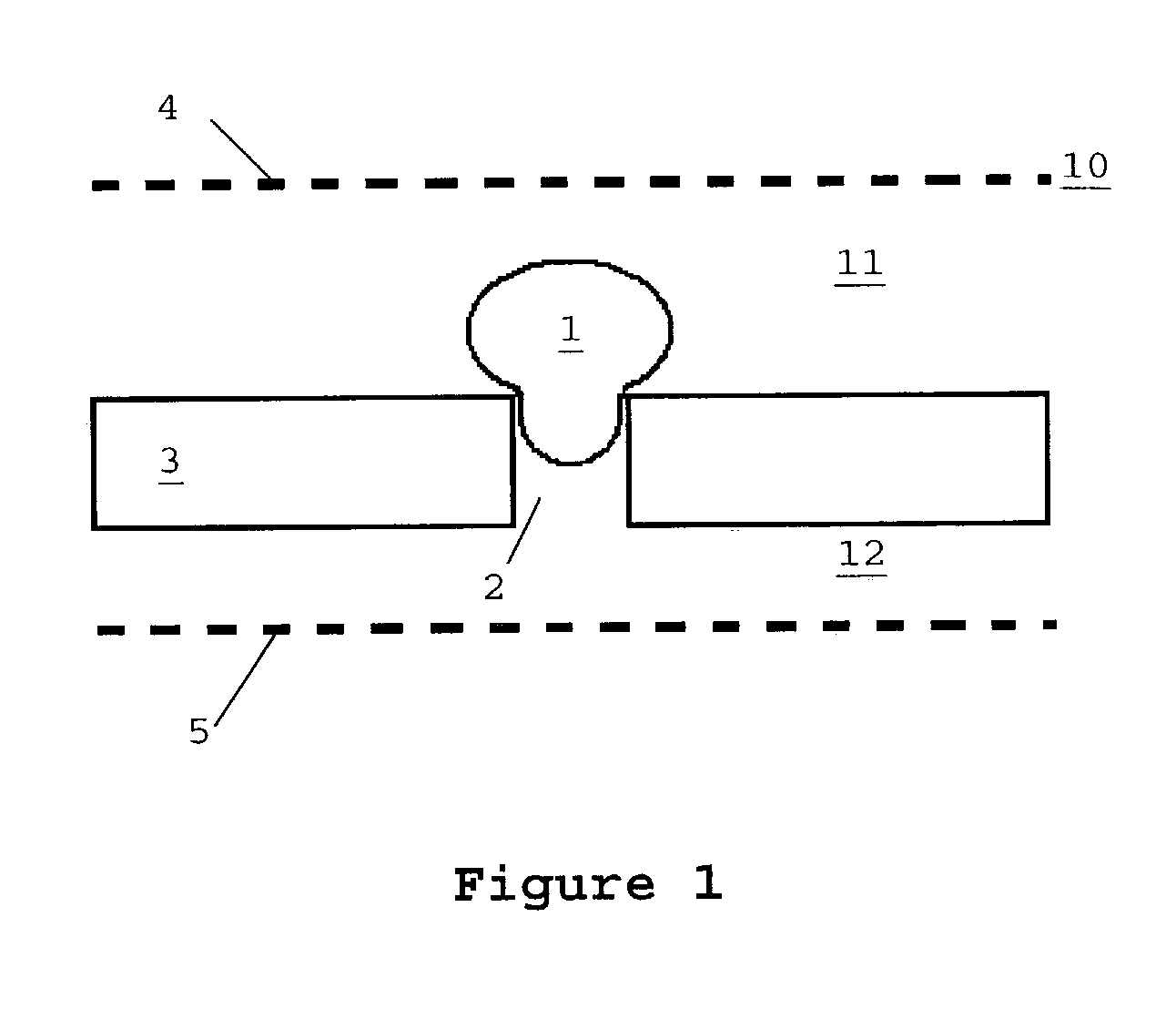

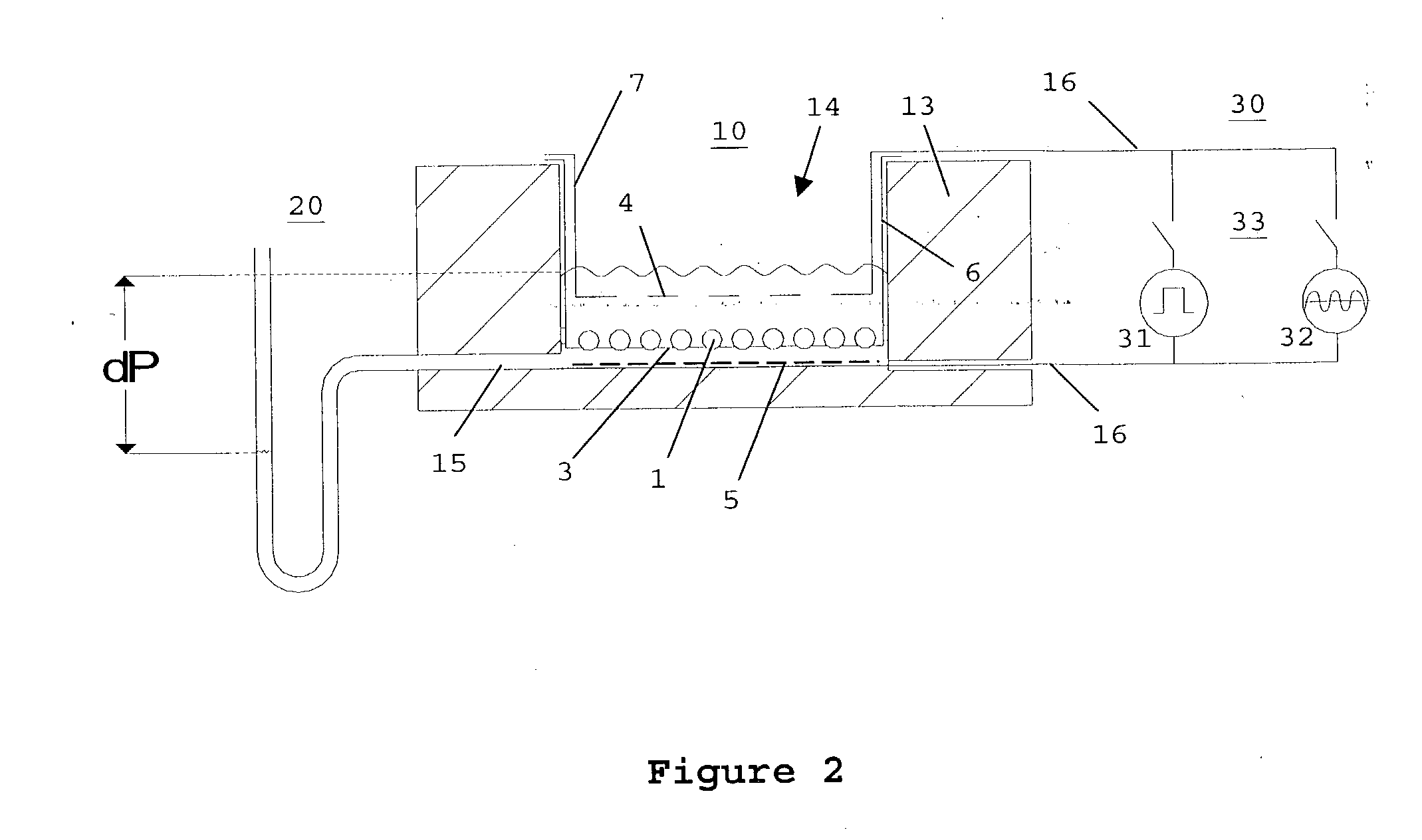

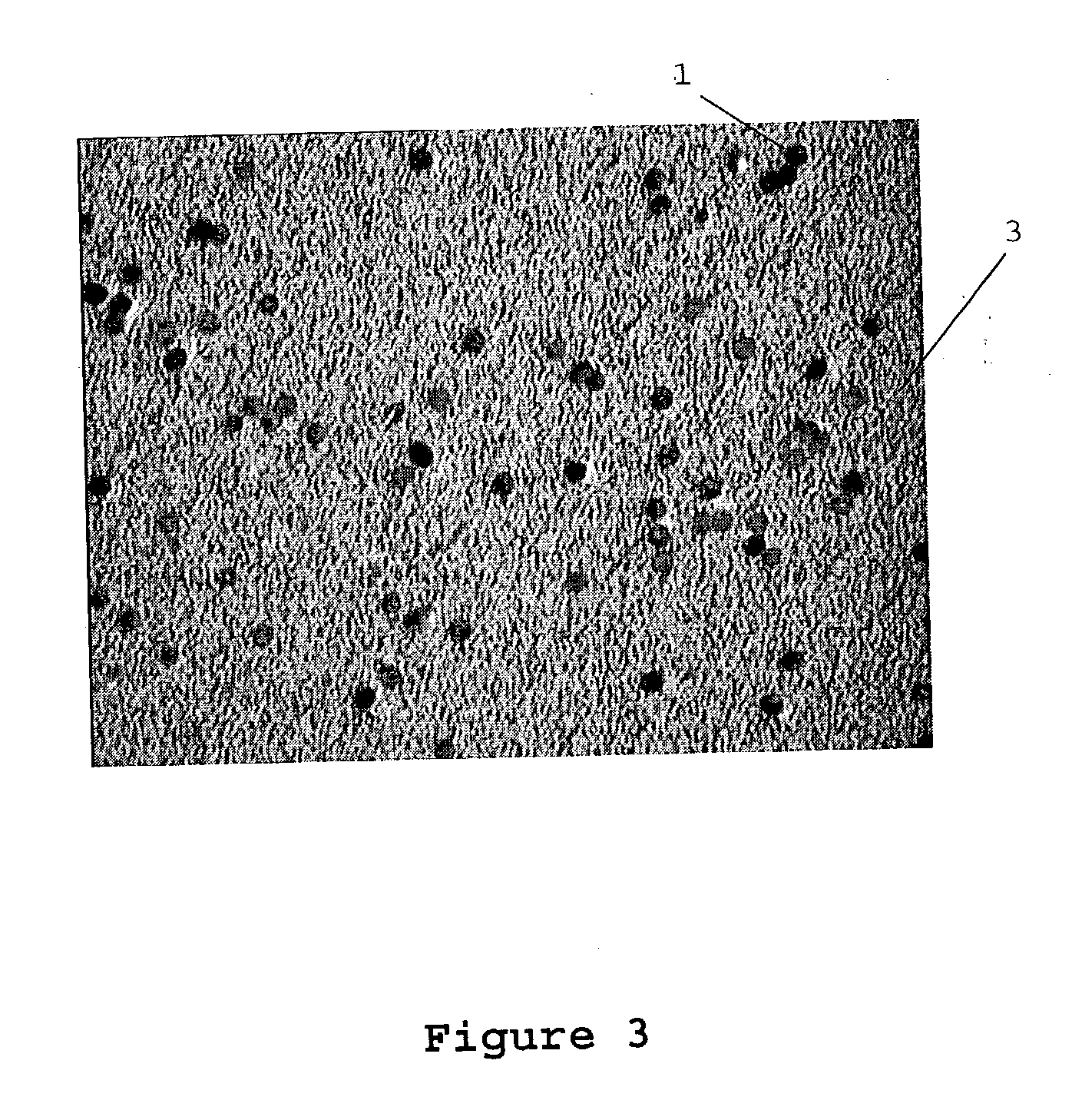

Described are methods for electrical treatment of biological cells, in particular using electrical field pulses, involving the steps: arrangement of the cells (1) on apertures (2) of a solid planar carrier element (3) which divides a measuring chamber (10) into two compartments (11, 12); and temporary formation of an electrical treatment field which permeates the cells, wherein an alternating-current impedance measurement takes place on the carrier element (3), and from the result of the alternating-current impedance measurement, a degree of coverage of the carrier element and / or healing of the cells after electrical treatment are / is acquired. Also described are devices for implementing the methods.

Owner:EPPENDORF AG

Method and device for electroporation of biological cells

InactiveUS20030148524A1Encourages charging and break-throughImprove survivabilityBioreactor/fermenter combinationsBiological substance pretreatmentsBiological cellElectricity

Described are methods for electrical treatment of biological cells, in particular using electrical field pulses, involving the steps: arrangement of the cells (1) on apertures (2) of a solid planar carrier element (3) which divides a measuring chamber (10) into two compartments (11, 12) ; and temporary formation of an electrical treatment field which permeates the cells, wherein an alternating-current impedance measurement takes place on the carrier element (3), and from the result of the alternating-current impedance measurement, a degree of coverage of the carrier element and / or healing of the cells after electrical treatment are / is acquired. Also described are devices for implementing the methods.

Owner:EPPENDORF AG

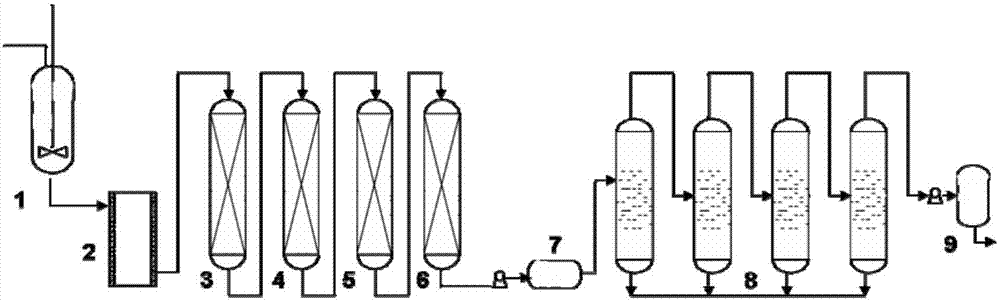

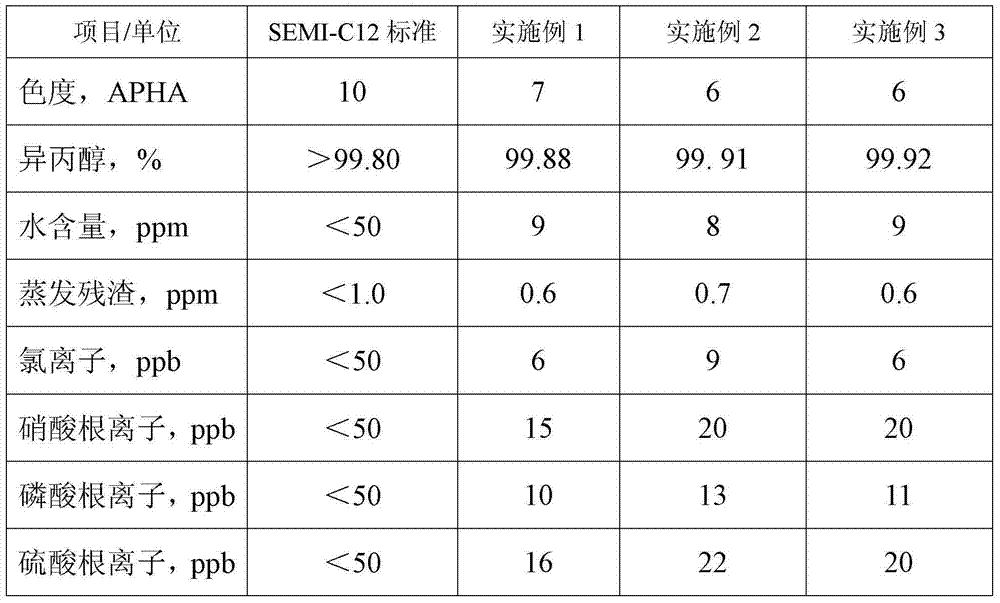

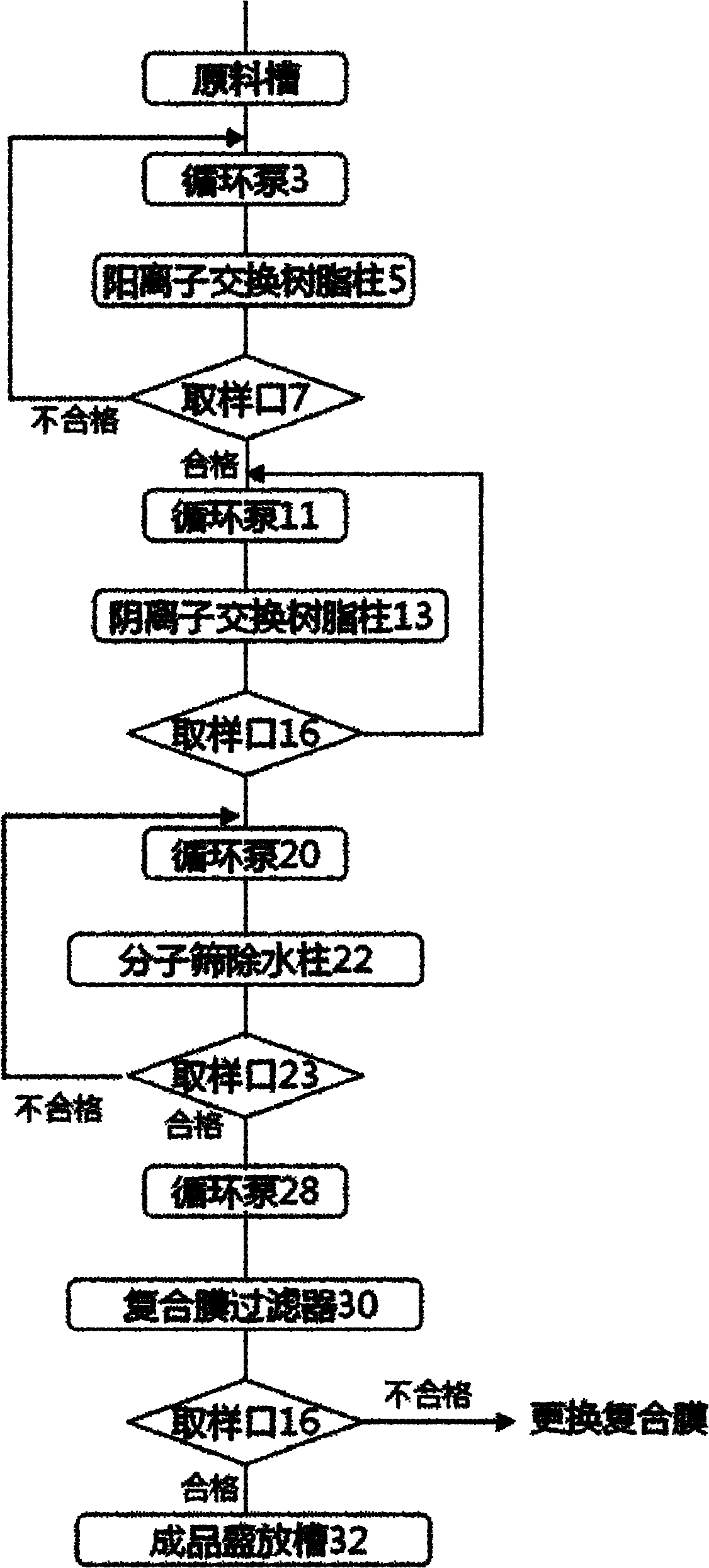

Preparation method of ultrapure isopropanol

ActiveCN103613486AImprove membrane efficiencyRelieve stressOrganic compound preparationElectrophoretic processesWater contentMolecular sieve

The invention discloses a preparation method of ultrapure isopropanol, which comprises the following steps: by using industrial isopropanol as a raw material, adding a metal ion complexing agent ethylene diamine tetraacetic acid disodium salt to form a charged chelate, moving charged corpuscles to positive and negative poles through an electrophoresis tank, removing impurity ions in the isopropanol respectively by anion and cation exchange resin exchange, dehydrating through a molecular sieve and a superstrong water-absorbing resin, filtering with a microfilter, carrying out multistage continuous rectification, and filtering with a nanofilter to obtain the target product ultrapure isopropanol. The main body content of the ultrapure isopropanol is higher than 99.80, the water content is lower than 10 ppm, the cation content is lower than 0.1 ppb, and the anion content is lower than 50 ppb. The product has the advantages of high purity, low content of metal impurities and stable quality; and the method has high operation continuity and is suitable for industrial production.

Owner:SHANGHAI CHEM REAGENT RES INST

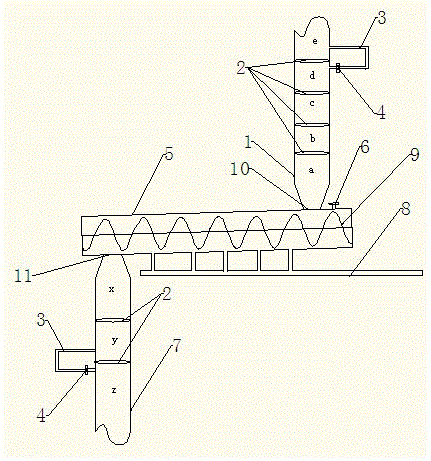

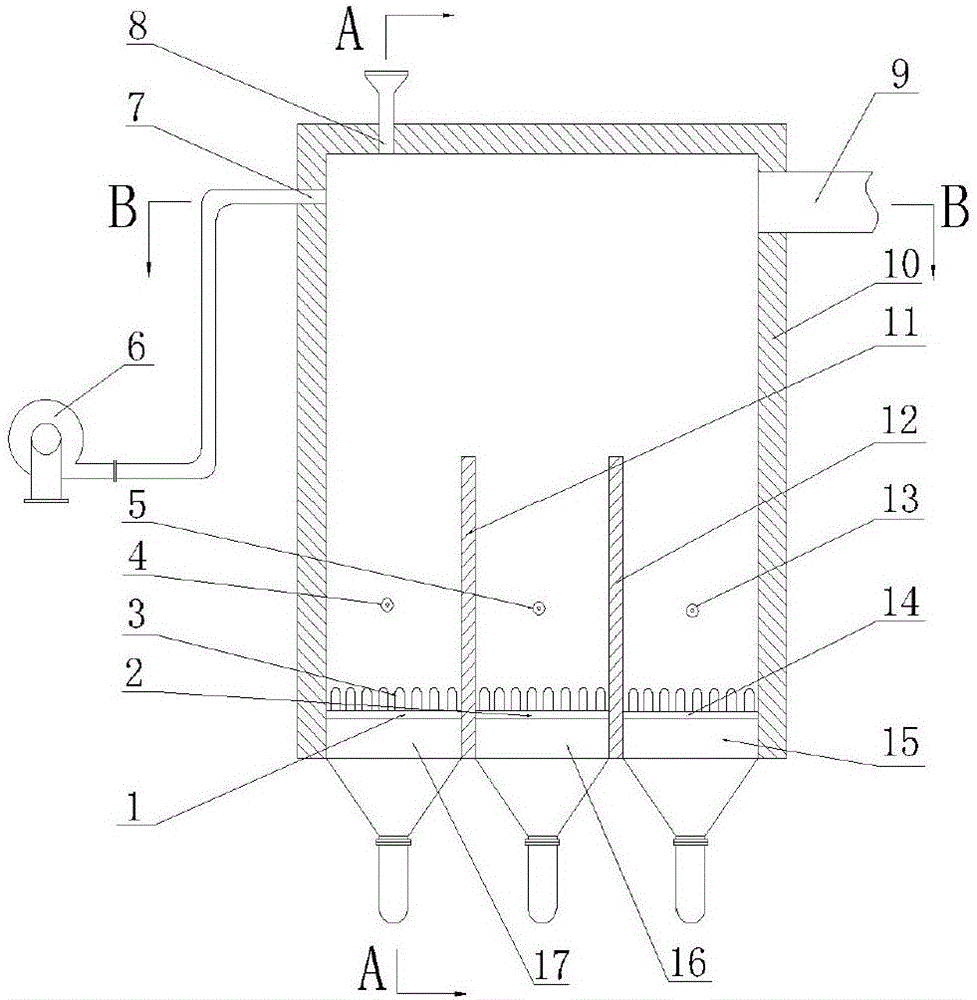

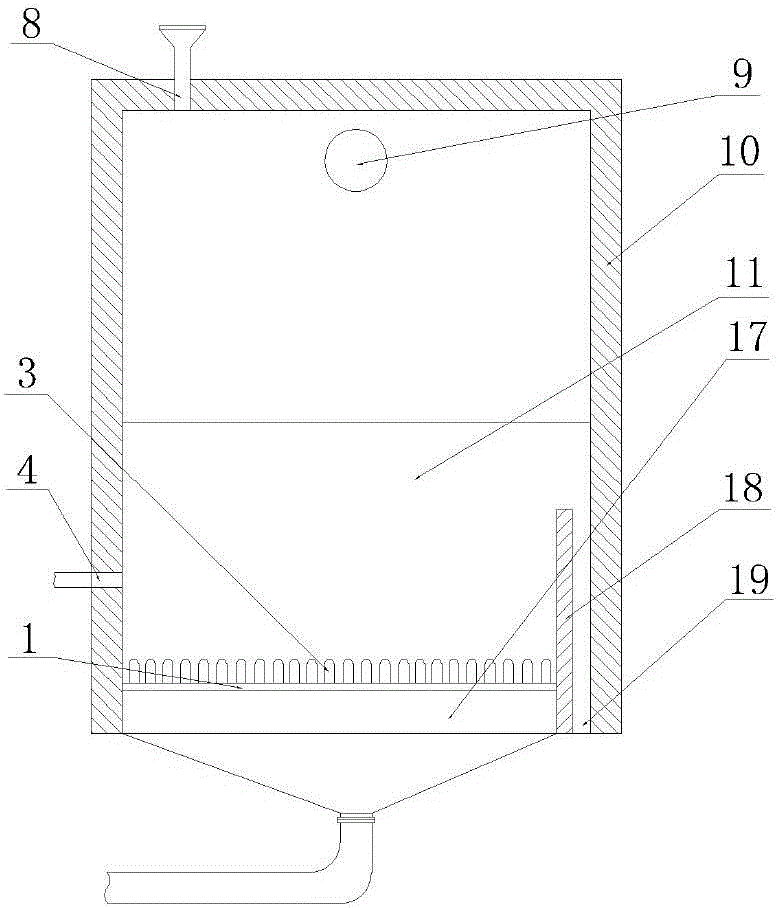

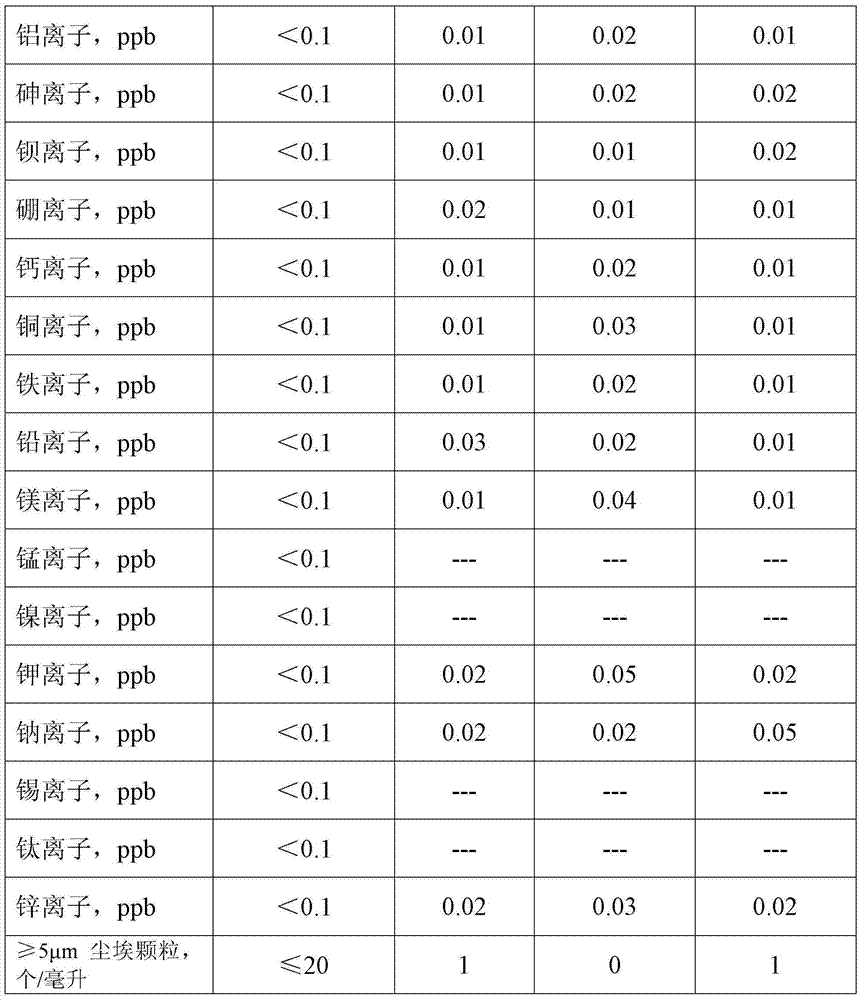

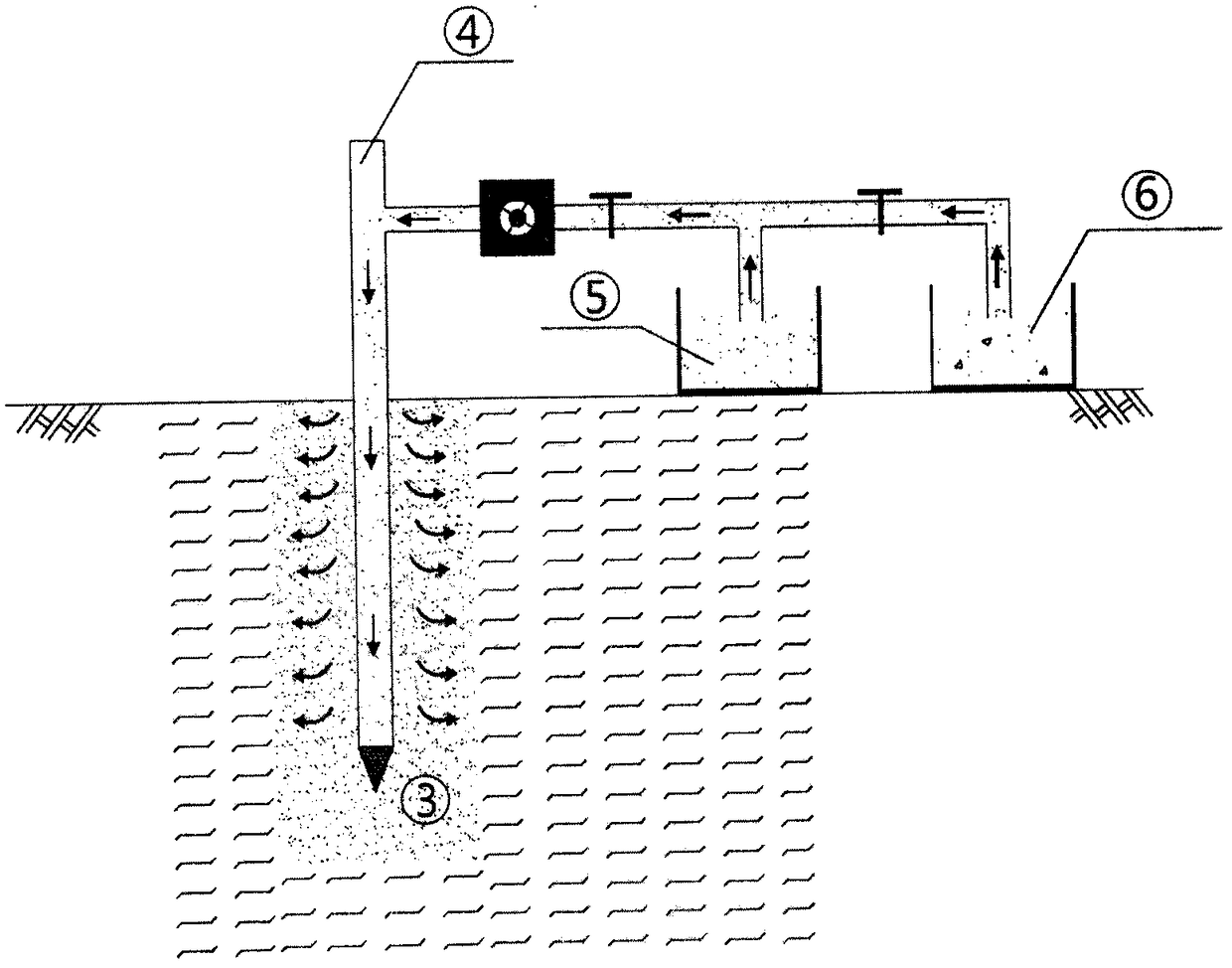

Method of treating petroleum-polluted clay foundation by using multiple microflora

ActiveCN108220196AReduce energy consumptionReduce noiseBacteriaContaminated soil reclamationMicrobial agentBiology

A method of treating petroleum-polluted clay foundation by using multiple microflora is capable of achieving integration of soil recovery and soil reinforcing construction. The method includes the steps of: (a) preparing a microbial agent (1); (b) uniformly stirring the microbial agent (1) with soil (3) in to-be-processed stratum with a deep stirring machine (2) according to the mass ratio of 1:100, and then leveling the field; (c) arranging injection pipes (4) in a row in the field according to hole distance of 0.8 m; (d) injecting a nutrient solution (5) into the to-be-processed stratum through the injection pipes (4) every three days; (e) arranging detection holes in the field according to density of one hole per 200 m<2>, and withdrawing soil pore liquid from the detection holes everysix days and performing oil content measurement, when the oil content of the soil reduces by more than 80%, alternately injecting the nutrient solution (5) and a cementing solution (6) into the to-be-processed stratum through the injection pipes (4); and (f) when preset injection times is reached, detecting foundation strength and heavy metal concentration of the soil, if the indices satisfy requirements, removing the injection pipes (4), or if not, repeating the step (e) until the requirements are satisfied.

Owner:NANJING FORESTRY UNIV

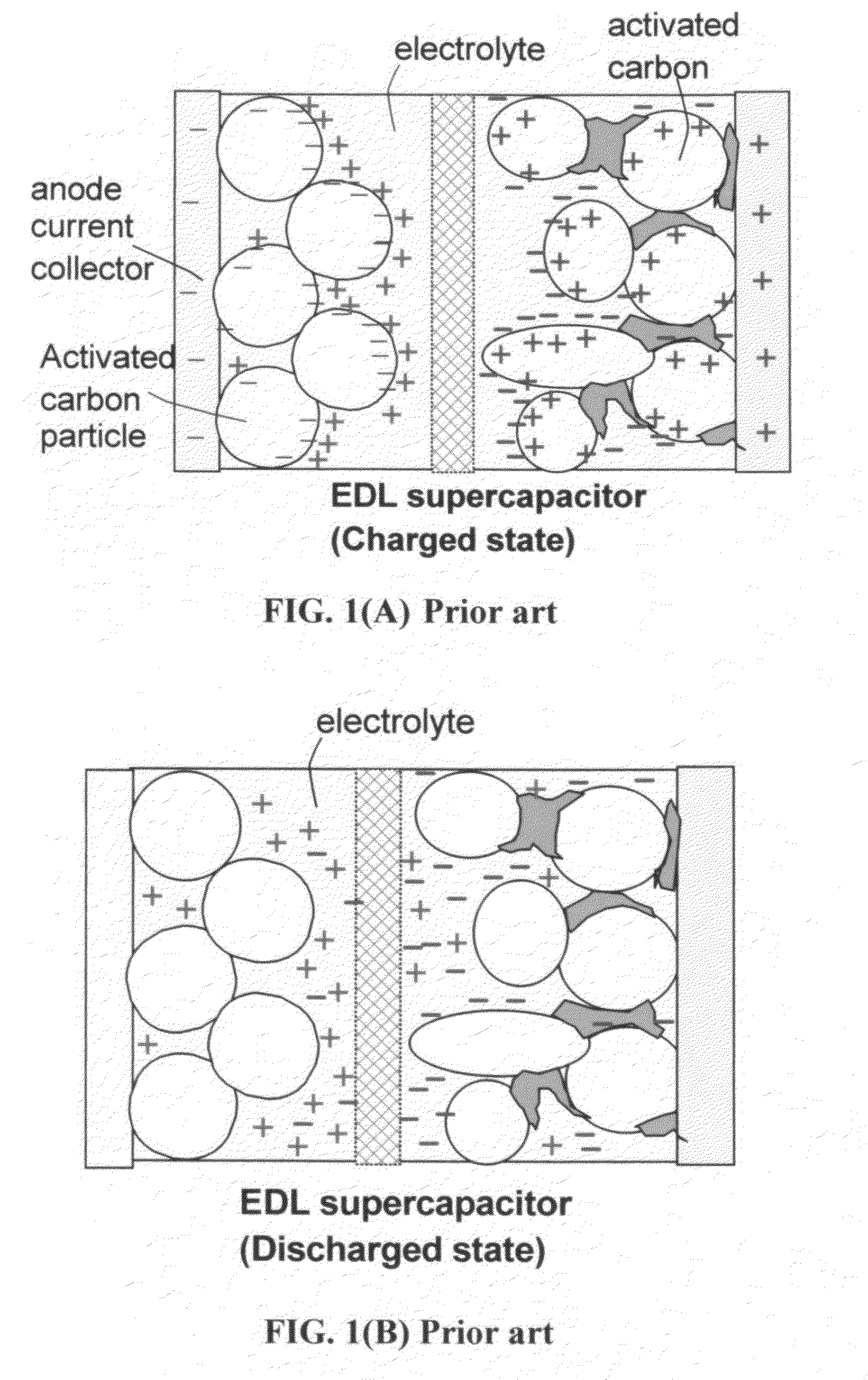

High-specific surface area functional active carbon material and electrode slurry preparation method

ActiveCN104124069ALarge particle sizeProportionally largeHybrid capacitor electrodesCell electrodesActivated carbonDiffusion

The invention relates to a high-specific surface area functional active carbon material and electrode slurry preparation method and solves the problems of small specific gravity, difficulty in diffusion and the like of high-specific surface area active carbon material. The preparation method includes steps that (1) acid pickling; (2) surface treatment; (3) loading of oxygenic metal compound; (4) high-temperature oxidizing; (5) secondary loading of oxygenic metal compound; (6) slurry preparation. According to the high-specific surface area functional active carbon material and electrode slurry preparation method, the oxygenic metal compound is loaded to the surface of the active carbon material so that the specific gravity of the high-specific surface area functional active carbon material is improved, and the high-specific surface area functional active carbon material with high pore volume and aperture is obtained; the high-specific surface area functional active carbon material is easy to adsorb electrolytic solution, the infiltration effect is obviously improved, the preparation technique is simple, and the large scale production can be realized.

Owner:DAYING JUNENG TECH & DEV

Method for extracting starch from jack fruit seed

The invention relates to the field of food industries, and discloses a method for extracting starch from a jack fruit seed, which comprises the following steps: washing off outer pectin of a fresh jack fruit seed; adding water, mashing and grinding; adding serrapeptass into ground size mixture to perform enzymolysis for 3-5h; filtering enzymolysis liquid; centrifuging filtering liquid; cleaning the obtained sediments after the filtering liquid is centrifuged with water and 50-80% of edible alcohol sequentially; centrifuging after cleaning to obtain white sediments; drying and smashing the white sediments to obtain the starch. According to the invention, the jack fruit seed is adopted as raw material to extract starch resource in the jack fruit seed, a single enzyme enzymolysis method is used in the extraction method rather than strong base and strong acid; compared with the compound enzymic method, based on the saved extraction cost, the single enzyme enzymolysis cannot break starch structure, doesn't pollute the environment, is simple to operate, and low in cost; the edible alcohol used for cleaning starch can remove residual ions to the greatest extent, so as to improve the purity of the starch, and the method is suitable for starch large-scale production.

Owner:海南兴科热带作物工程技术有限公司

Calcium-poor and silicon-rich ecological cement and application thereof

ActiveCN105502973ALow costAchieving processing powerCement productionPortland cementUltimate tensile strength

The invention discloses a calcium-poor and silicon-rich ecological cement and application thereof. The cement is prepared from a silicon-rich body and a calcium-rich body in a mixing mode. The silicon-rich body is obtained by adding a small amount of alkali metal salt into a wide-source silicon-aluminum material and then carrying out low-temperature calcination, and the calcium-rich body is composed of a raw material releasing Ca(OH)2 when hydrated and a raw material containing CaSO4. Compared with portland cement, the calcium-poor and silicon-rich ecological cement is good in early strength property, and the long-term strength can meet most use requirements; the raw materials of the calcium-poor and silicon-rich ecological cement are easy to obtain, and carbon emission, energy consumption, pollution and the like are substantially reduced; furthermore, a large quantity of solid industrial residues can be consumed, and the calcium-poor and silicon-rich ecological cement has important economic and social value.

Owner:HUNAN UNIV OF SCI & TECH

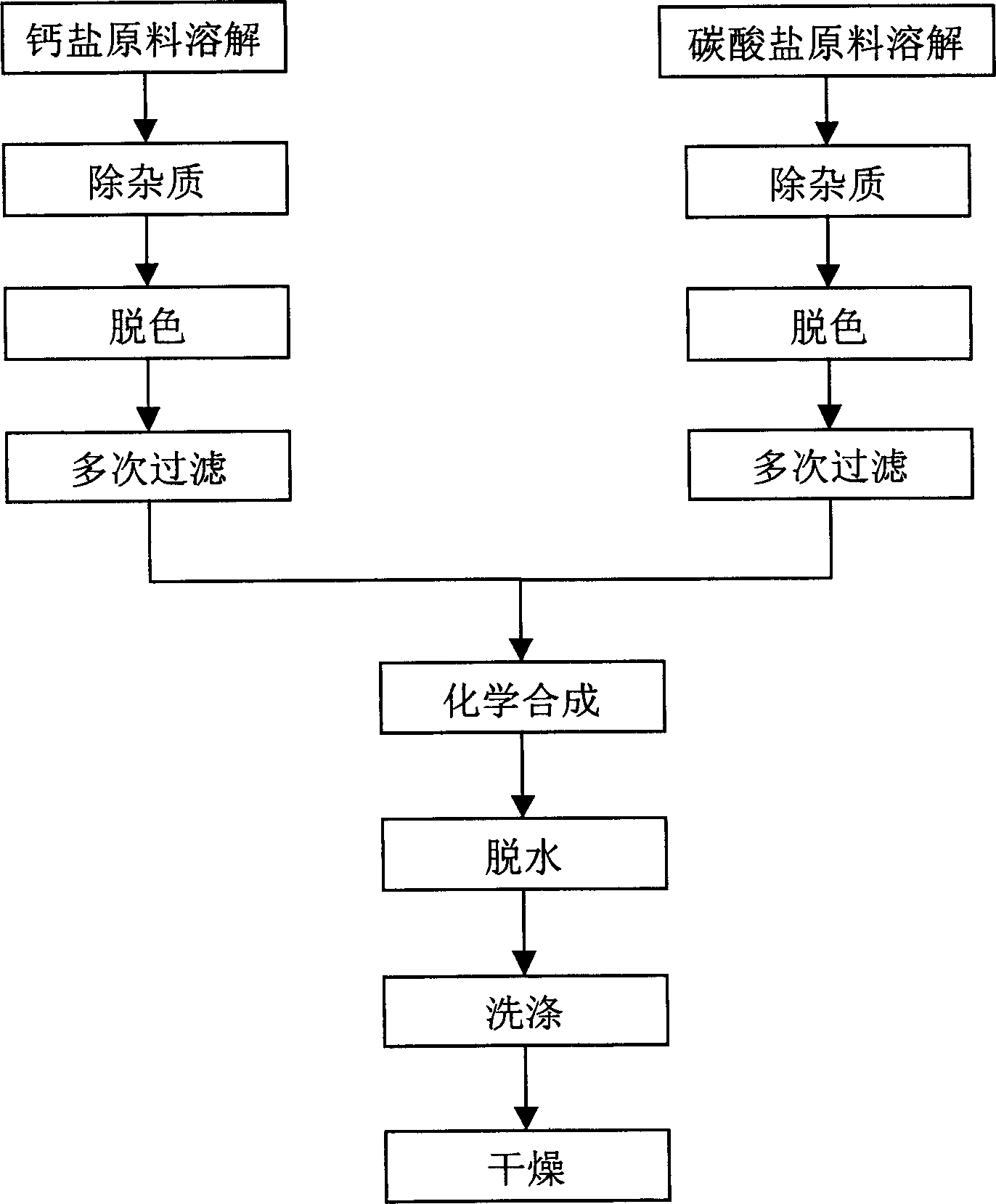

Manufacturing method of high purity calcium carbonate for electron industry

A process for preparing high-purity calcium carbonate used as insulating filler and crystal grain fining agent in electronic industry includes such steps as providing Ca-contained compound and SO4 radical contained compound, multi-step depositing for removing impurities, synthesizing reaction to generate deposit, washing and drying.

Owner:胡志彤

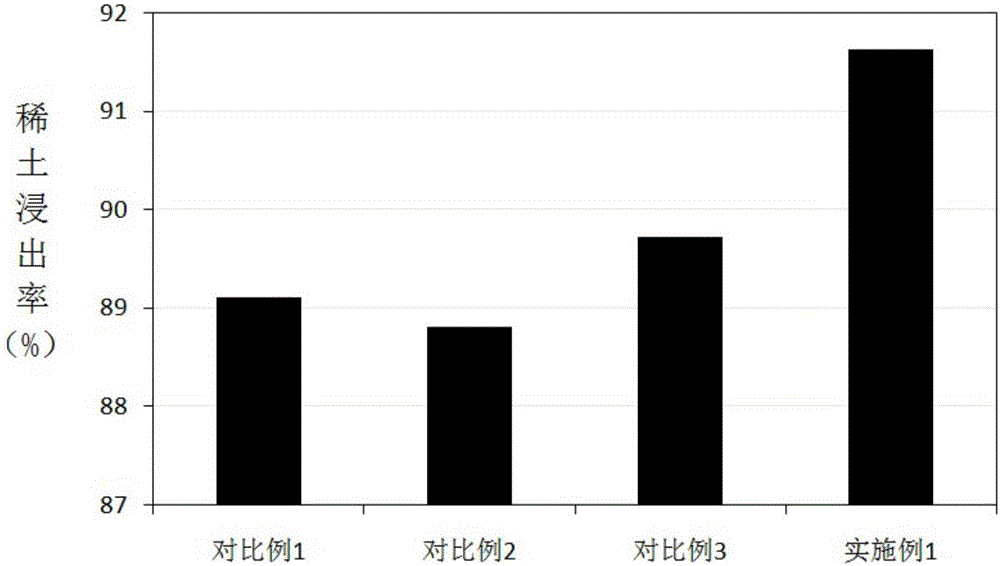

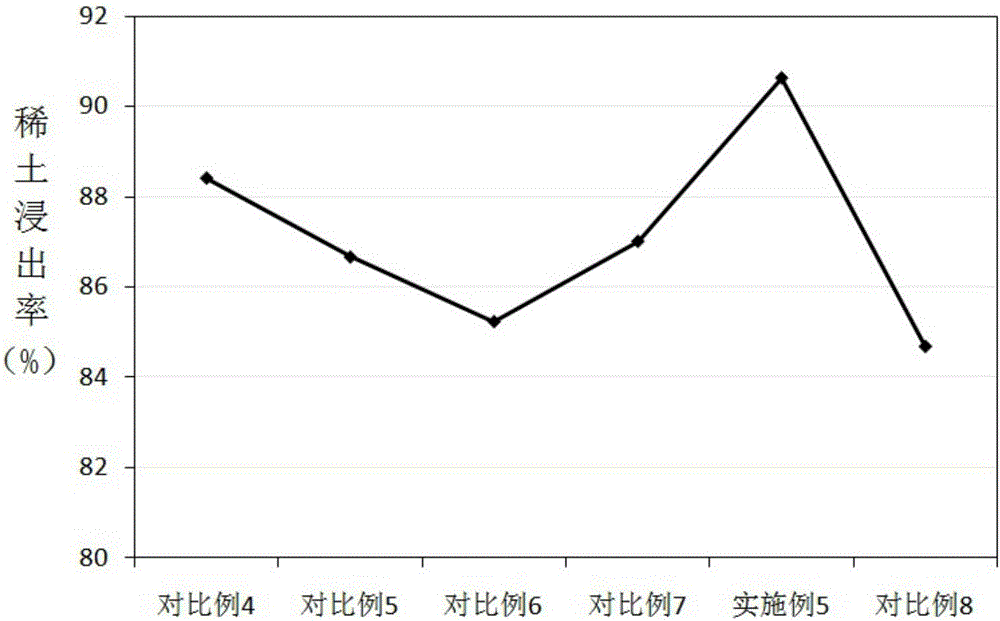

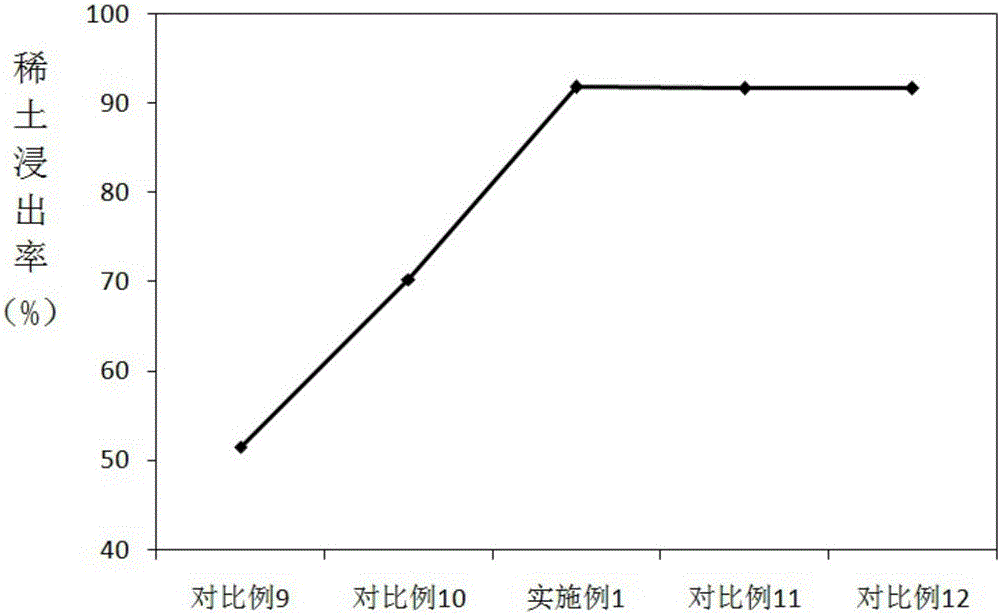

Rare earth ore leaching agent and leaching process

InactiveCN105821207AImprove leaching rateLow costProcess efficiency improvementSelective leachingRare earth ions

The embodiment of the invention relates to a rare earth ore leaching agent. The rare earth ore leaching agent comprises ammonium thiosulfate, ammonium sulfate and ammonium chloride. Rare earth ions are exchanged and desorbed through NH4+ in the three kinds of ammonium salt; through the positive synergistic effect of the ammonium thiosulfate, the ammonium sulfate and the ammonium chloride, the rare earth ore leaching agent in the embodiment can improve the rare earth ion leaching efficiency and reduce the content of aluminum and iron impurity ions in leaching liquid; and in addition, the agent cost is low, and the rare earth ore leaching agent can be used for the development and utilization of semi-weathering ionic adsorption type rare earth ore. A rare earth leaching process in the embodiment is simple, the high leaching rate and the high selective leaching of the rare earth ions can be achieved, and the rare earth ore leaching agent and leaching process are suitable for industrial large-scale use.

Owner:JIANGXI UNIV OF SCI & TECH +2

Relay liquid state epoxy resin pouring sealant and preparation method thereof

InactiveCN103087664AWide range of applicationsHigh bonding strengthNon-macromolecular adhesive additivesOther chemical processesChemistryCoupling reagent

The invention discloses a relay liquid state epoxy resin pouring sealant which comprises the following components: 15-25 parts of bisphenol A epoxy resin, 30-45 parts of bisphenol F epoxy resin, 0.5 part of pigment, 70-100 parts of spheroidal filler, 4-6 parts of curing agent, 0.5-2 parts of curing accelerator, and 1-3 parts of coupling reagent. The invention also discloses a preparation method of the relay liquid state epoxy resin pouring sealant. The relay liquid state epoxy resin pouring sealant has lower curing temperature, the curing temperature is around 110 DEG C, the curing speed is faster, the bonding strength is stronger, the percentage of concentration is lower, the ion content is lower, and the heat conducting property is good; the storage performance is more stable, and the storage life in a refrigerator at 2-8 DEG C is above six months; and the preparation technology is simple and environment-friendly, the cost is low and the application range is wide.

Owner:深圳市宝力科技有限公司

Surfactant biocatalyst for remediation of recalcitrant organics and heavy metals

ActiveUS20070249034A1Improve bioremediation efficiencyImprove solubilityBacteriaBiochemical fibre treatmentMicrobiologySurface-active agents

Novel strains of isolated and purified bacteria have been identified which have the ability to degrade petroleum hydrocarbons including a variety of PAHs. Several isolates also exhibit the ability to produce a biosurfactant. The combination of the biosurfactant-producing ability along with the ability to degrade PAHs enhances the efficiency with which PAHs may be degraded. Additionally, the biosurfactant also provides an additional ability to bind heavy metal ions for removal from a soil or aquatic environment.

Owner:BATTELLE SAVANNAH RIVER ALLIANCE LLC

A kind of method that uses zinc-containing waste liquid as raw material to prepare zinc oxide

InactiveCN102295308AHigh puritySmall specific surface areaZinc oxides/hydroxidesOXALIC ACID DIHYDRATEPotassium hydroxide

The present invention relates to a method for preparing zinc oxide by using zinc-containing waste liquid as a raw material, which includes (1) taking zinc-containing waste liquid, adding a precipitant to precipitate zinc particles in the waste liquid in the form of precipitation, and filtering to obtain zinc-containing material , the precipitating agent is one or more of potassium hydroxide, sodium hydroxide, bicarbonate, carbonate and ammonia water; (2), using a mixed aqueous solution of ammonium nitrate and oxalic acid to wash the zinc-containing material, Then wash with deionized water, dry, roast, and pulverize to obtain zinc oxide powder with a purity of more than 99.5%. The drying is carried out at a temperature of 100°C to 300°C, and the roasting is carried out at a temperature of 600°C to 800°C. The purity of the zinc oxide obtained by the method of the invention is as high as 99.5%. In addition, the process of the invention is simple, the production cost is low, and it is suitable for industrial production.

Owner:昆山德阳新材料科技有限公司

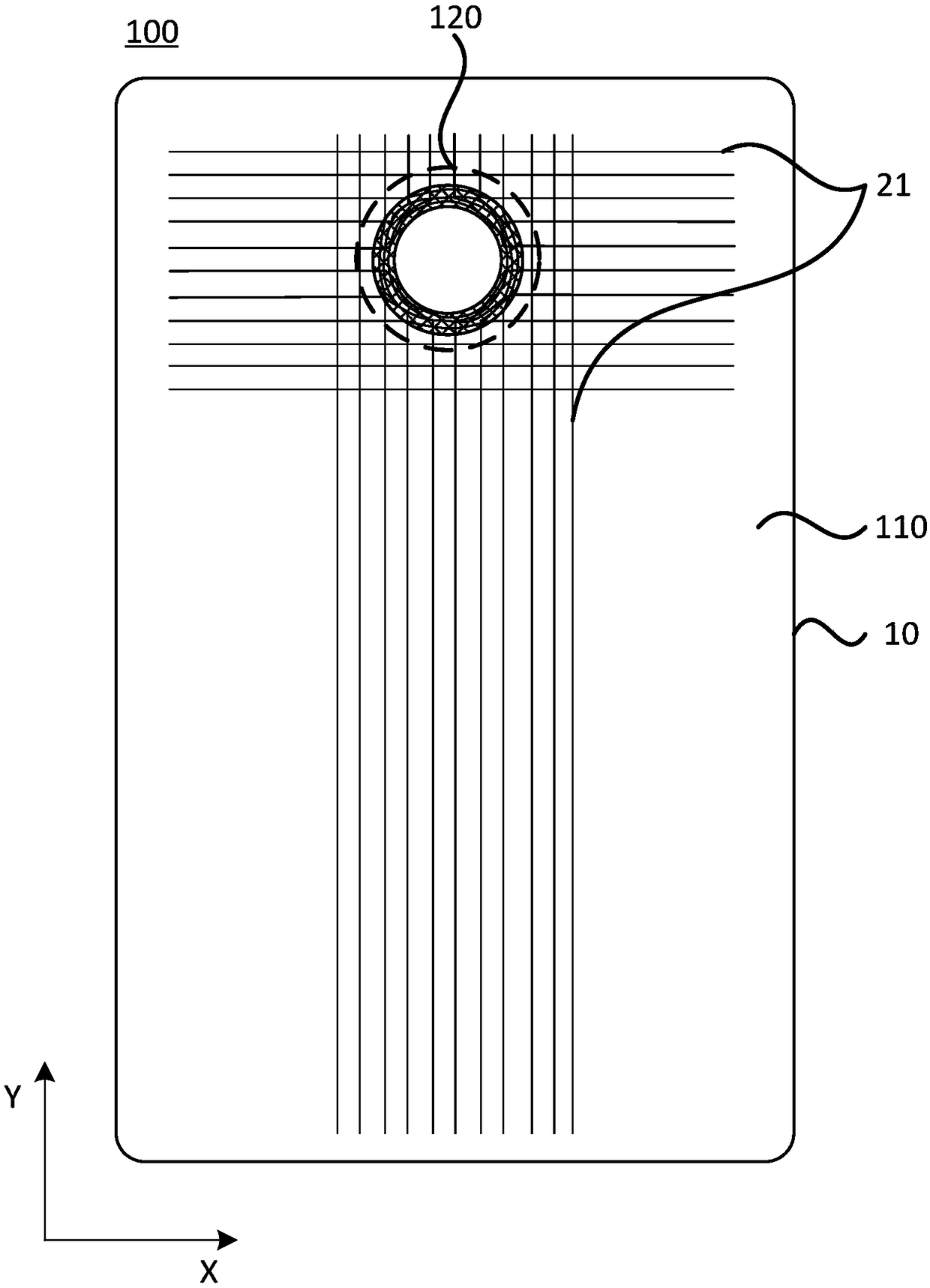

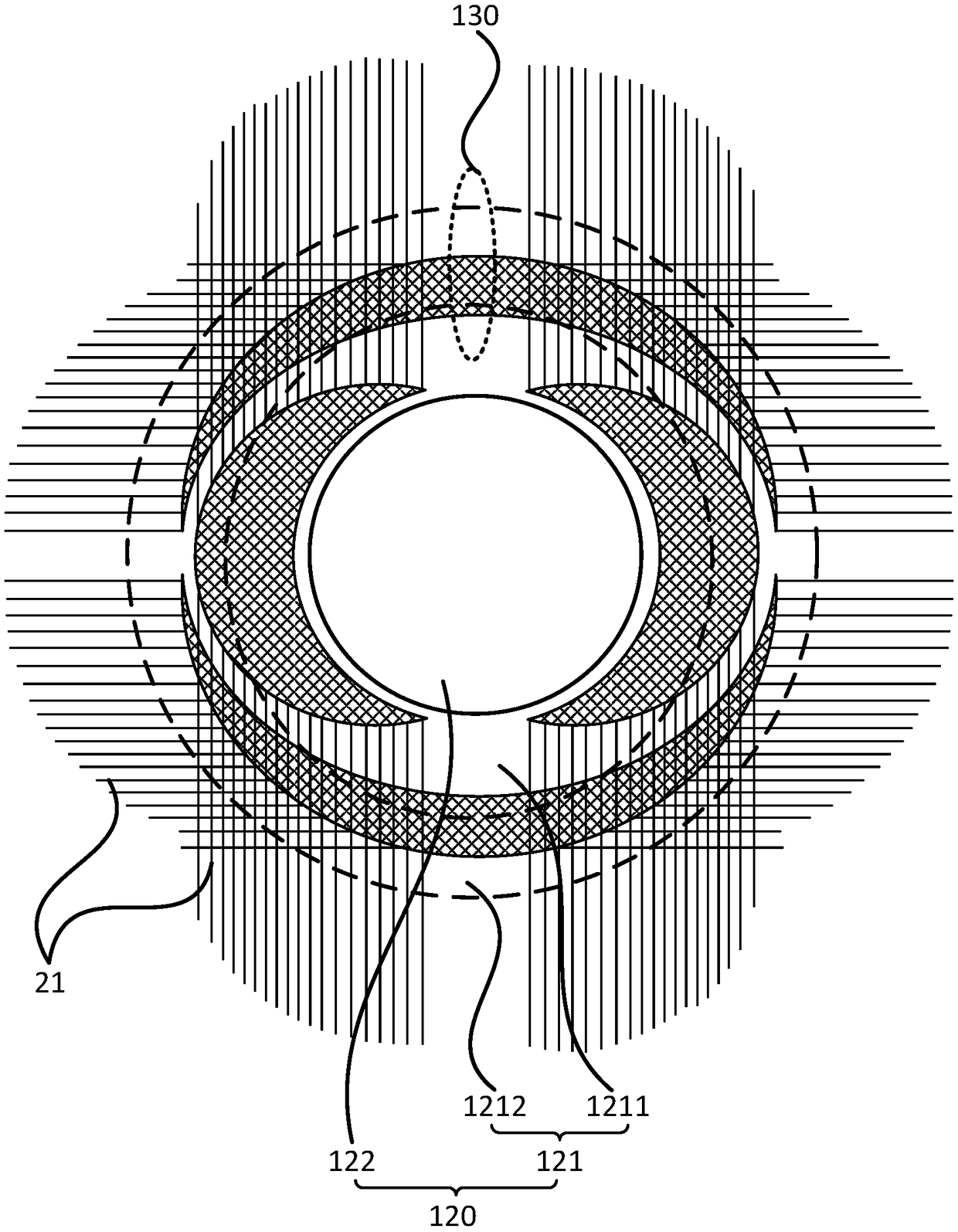

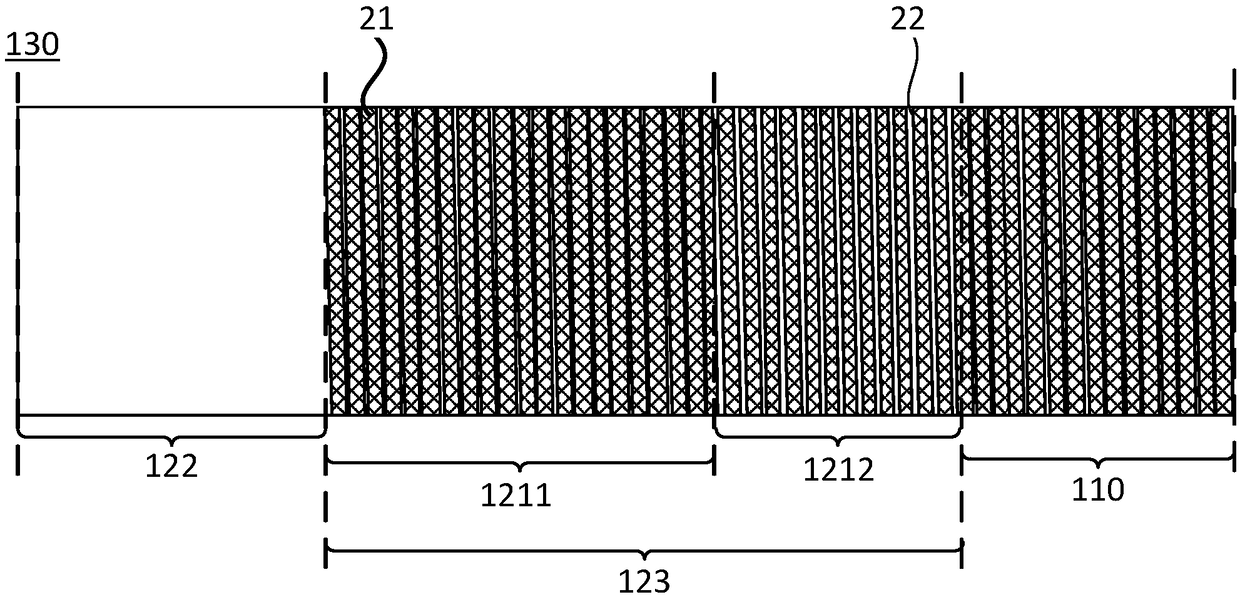

Array substrate, display panel and display device

The present invention discloses an array substrate, a display panel and a display device. The array substrate comprises a display area and at least one non-display area, and the display area surroundsthe non-display area. The non-display area comprises a wiring area and a module arranging area. The array substrate comprises a substrate base plate and multiple signal lines, and the multiple signallines extend to the wiring area and surround the module arranging area. The multiple signal lines on the wiring area are also provided with frame glue. The wiring area comprises a first wiring area and a second wiring area, the inner edge of the first wiring area is contacted with the module arranging area, the second wiring area surrounds the first wiring area, the upright projection, on the substrate base plate, of the first wiring area and the second wiring area is located in the upright projection, on the substrate base plate, of the frame glue, and the outer edge of the second wiring area is contacted with the outer edge of the frame glue. The light transmittance of the first wiring area is less than the light transmittance of the second wiring area. The array substrate can improve the curing efficiency of the frame glue, so that the ion content is reduced, and the image display effect is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Method and device for preparing ultrapure acetone

ActiveCN101973859AReduce adverse effectsLow-carbon and environmentally friendlyIon-exchange column/bed processesCarbonyl compound separation/purificationWater contentIon exchange

The invention discloses a method and a device for preparing ultrapure acetone. A target product, namely, the ultrapure acetone is obtained by treating industrial acetone with ion exchange resin, removing impurity ions, dehydrating and performing membrane filtration. The purity of the ultrapure acetone is 99.8 percent or higher, the water content is less than 0.1 percent, the impurity ion content of the target product is lower than an index value by detection, the number of particle impurities which are larger than 1.0 mu m is less than 10 / ml and each index value is accordant with SEMI C1.2-96 standard. Compared with the prior art, the method of the invention has the advantages of low carbon, environmental protection and low cost; feed liquor is treated circularly, so that negative influence on the environment can be reduced; the used ion exchange resin and a molecular sieve can be recycled; and a cation exchange unit, an anion exchange unit, and a water content unit and a particle impurity unit, which are independent of and related to one another, are combined into an integrated device, so that the operation process is convenient, the product quality is stable and the device has industrialized production prospect.

Owner:SHANGHAI CHEM REAGENT RES INST

Non-woven fabric for manufacturing dust-free wiping paper and manufacturing method thereof

The invention provides a non-woven fabric for manufacturing dust-free wiping paper. The non-woven fabric for manufacturing the dust-free wiping paper comprises a non-woven fabric containing cellulosic fibers, wherein the non-woven fabric is prepared by treating a treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent. The provided non-woven fabric is firm, high in cleanliness and soft. The invention also provides a method for manufacturing the non-woven fabric. The manufacturing method comprises the following steps: preparing the treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent; padding the non-woven fabric containing cellulosic fibers by adopting the treatment solution, and baking. The method is simple and low in cost.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

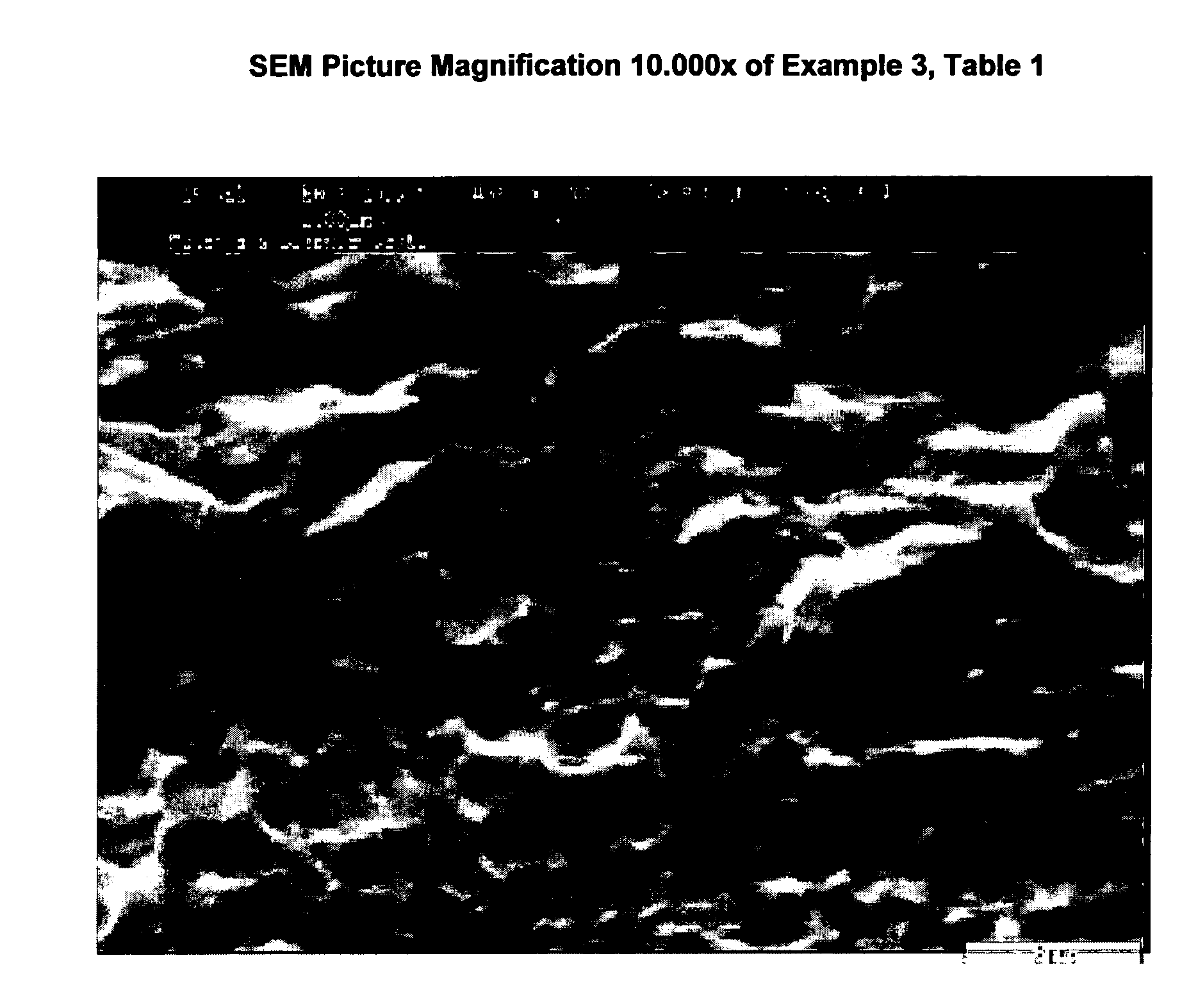

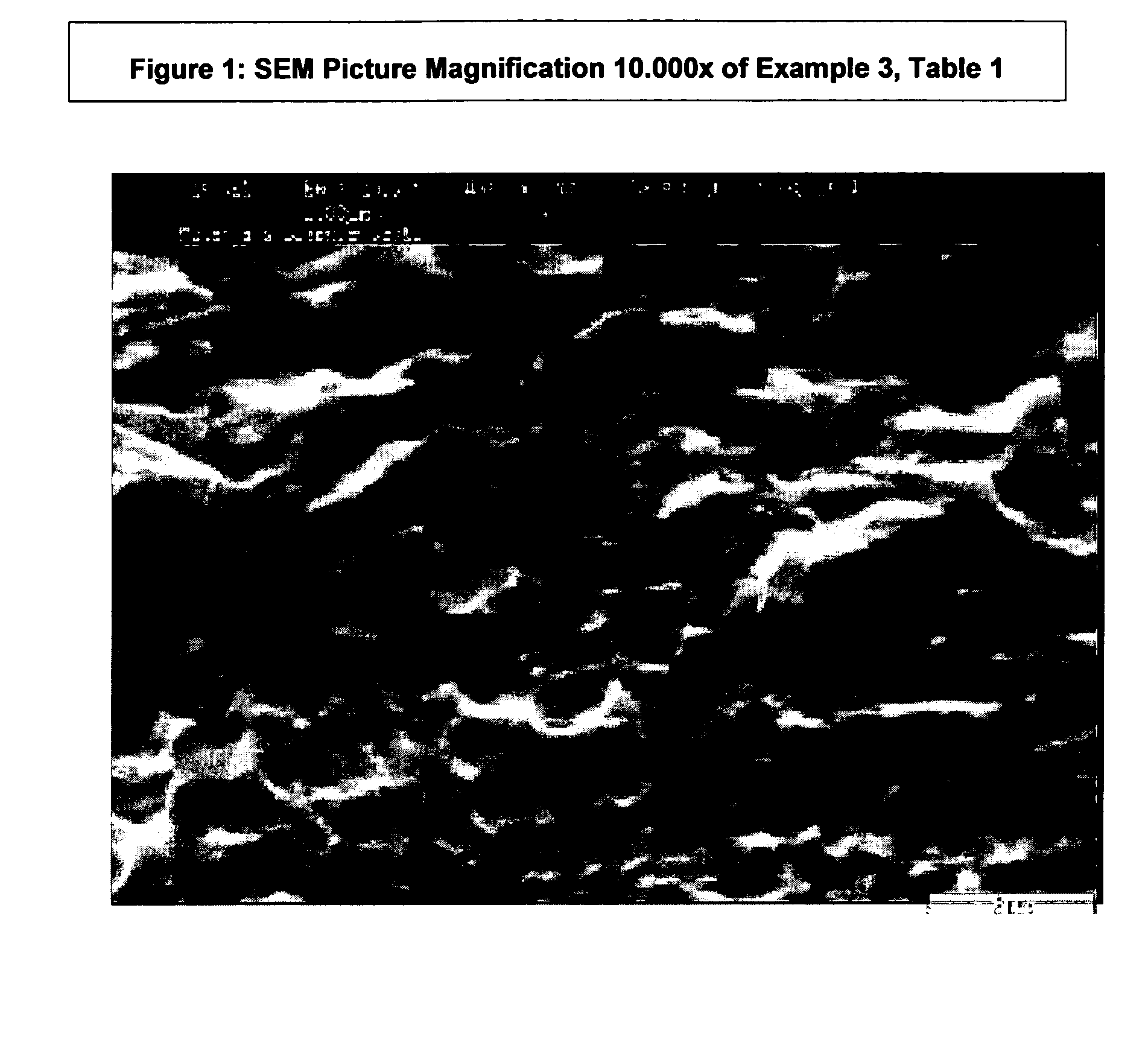

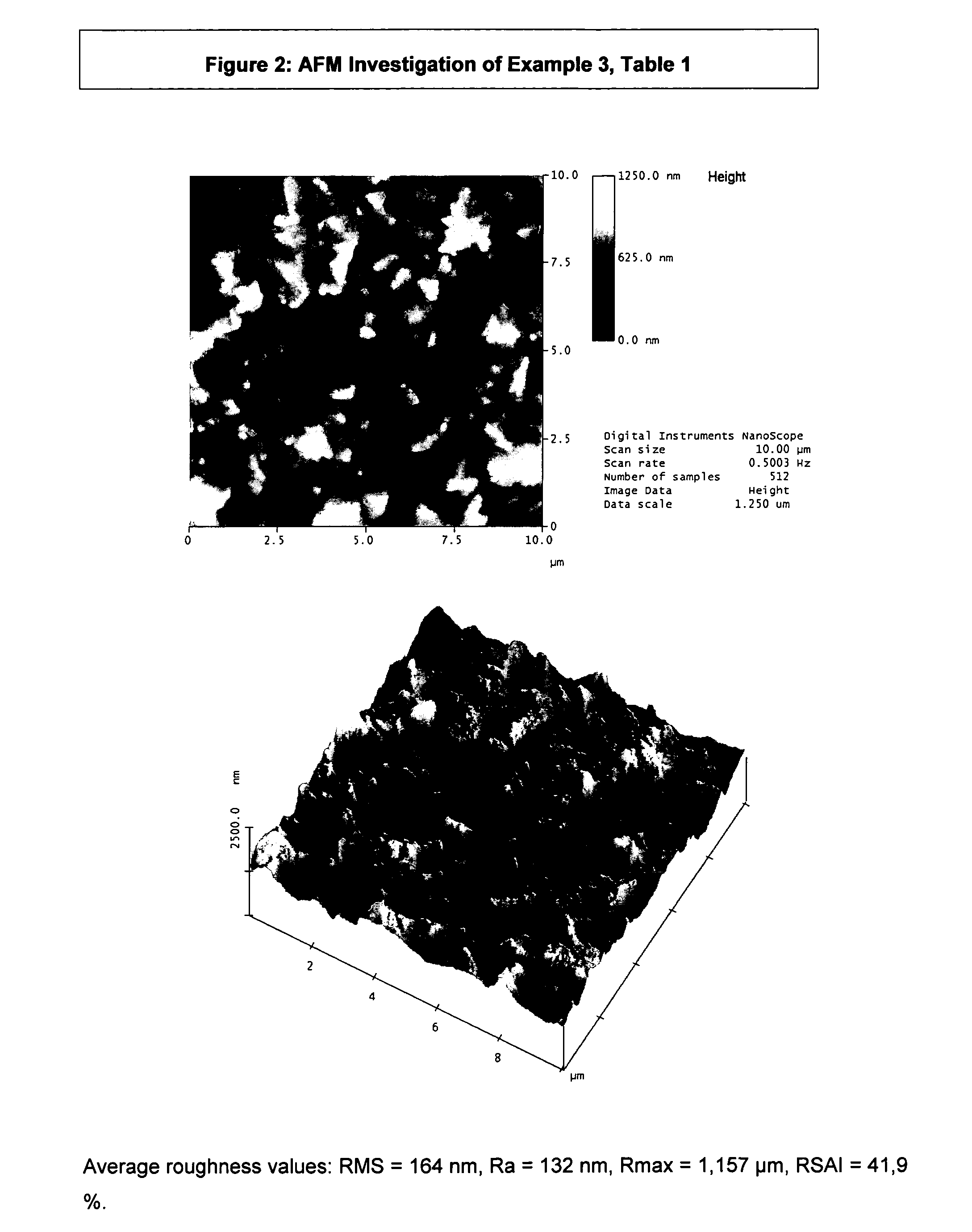

Composition and Method for Improved Adhesion of Polymeric Materials to Copper or Copper Alloy Surfaces

InactiveUS20100035435A1Easy to useIncrease etch rateLiquid surface applicatorsDecorative surface effectsSolder maskPolymer substrate

The present invention relates to a method for treating copper or copper alloy surfaces for tight bonding to polymeric substrates, for example solder masks found in multilayer printed circuit boards. The substrate generally is a semiconductor-device, a lead frame or a printed circuit board.

Owner:ATOTECH DEUT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com