Surface treatment method for environment-friendly chromium-free zirconium-containing electro-galvanized fingerprint resistant steel sheet

A technology of surface treatment and electro-galvanized sheet, which is applied in the direction of coating, etc., can solve the problems of zinc mist generation, affecting the life of welding parts, and harmful to human body, so as to reduce the voltage of the tank, reduce the chance of strip steel scratching the anode, and reduce power consumption Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1. Prepare materials

[0041] 1. Substrate: cold rolled plate

[0042] 2. Plating solution: zinc sulfate

[0043] 3. Coating composition: Take 750kg of acrylic resin, 40kg of silicon dioxide, 90kg of silane bonding agent, 80kg of polytetrafluoroethylene, 5kg of metal zirconium ion and 35kg of polyethylene wax, put them in a mixer, stir and mix evenly to make chromium-free Zirconium anti-fingerprint paint.

[0044] Step 2, using an acidic vertical insoluble anodic electro-galvanizing process to produce an electro-galvanized sheet, forming a uniform and delicate zinc layer on the surface of the cold-rolled sheet.

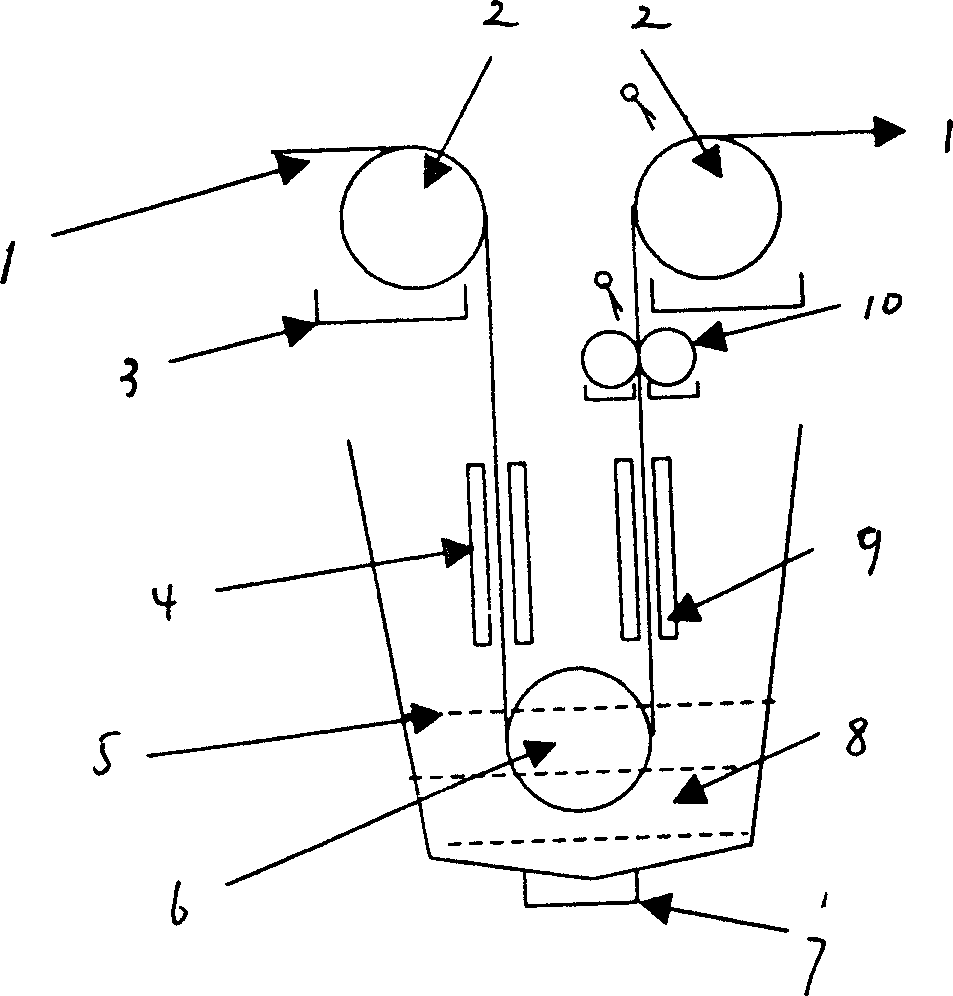

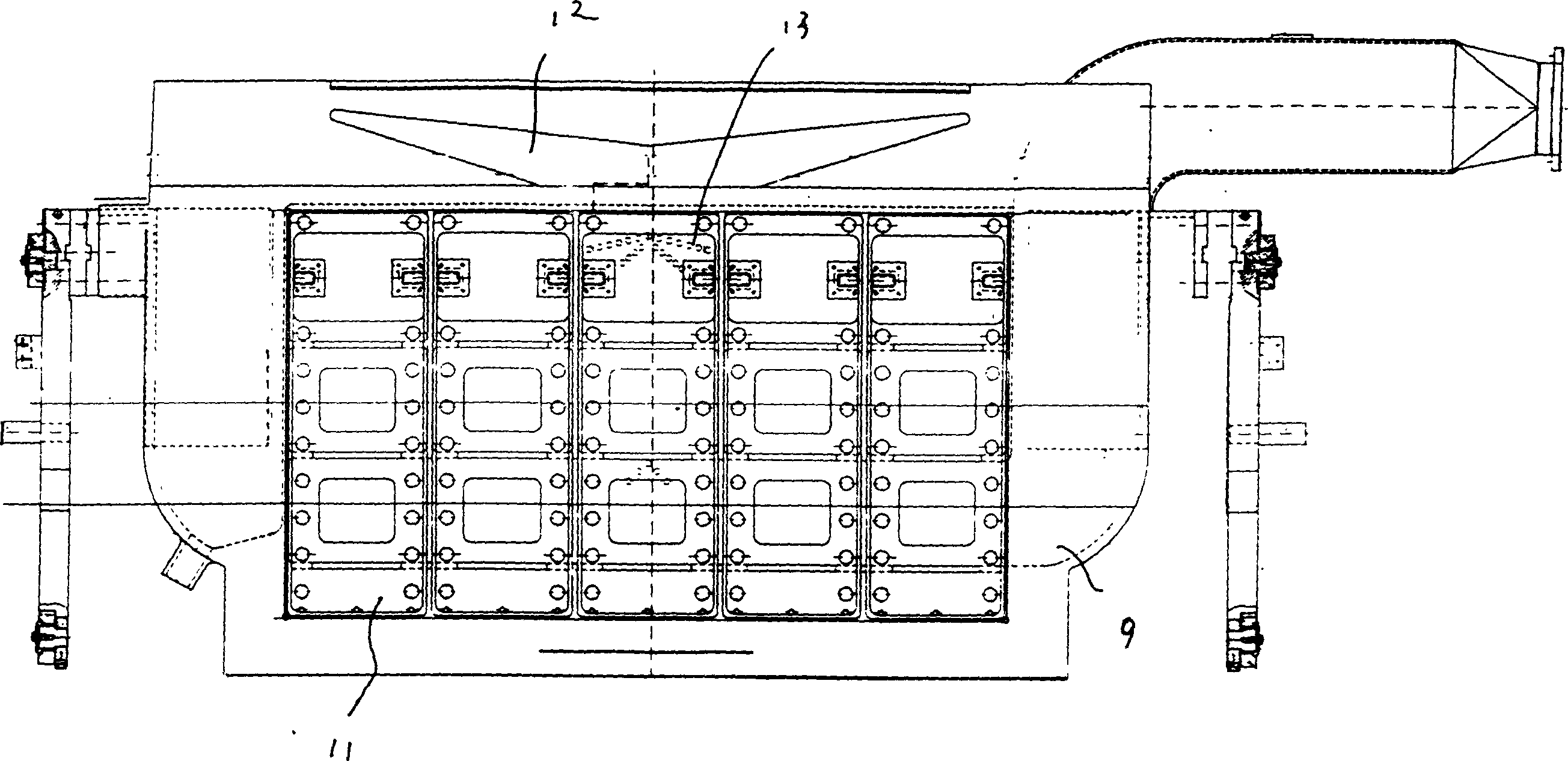

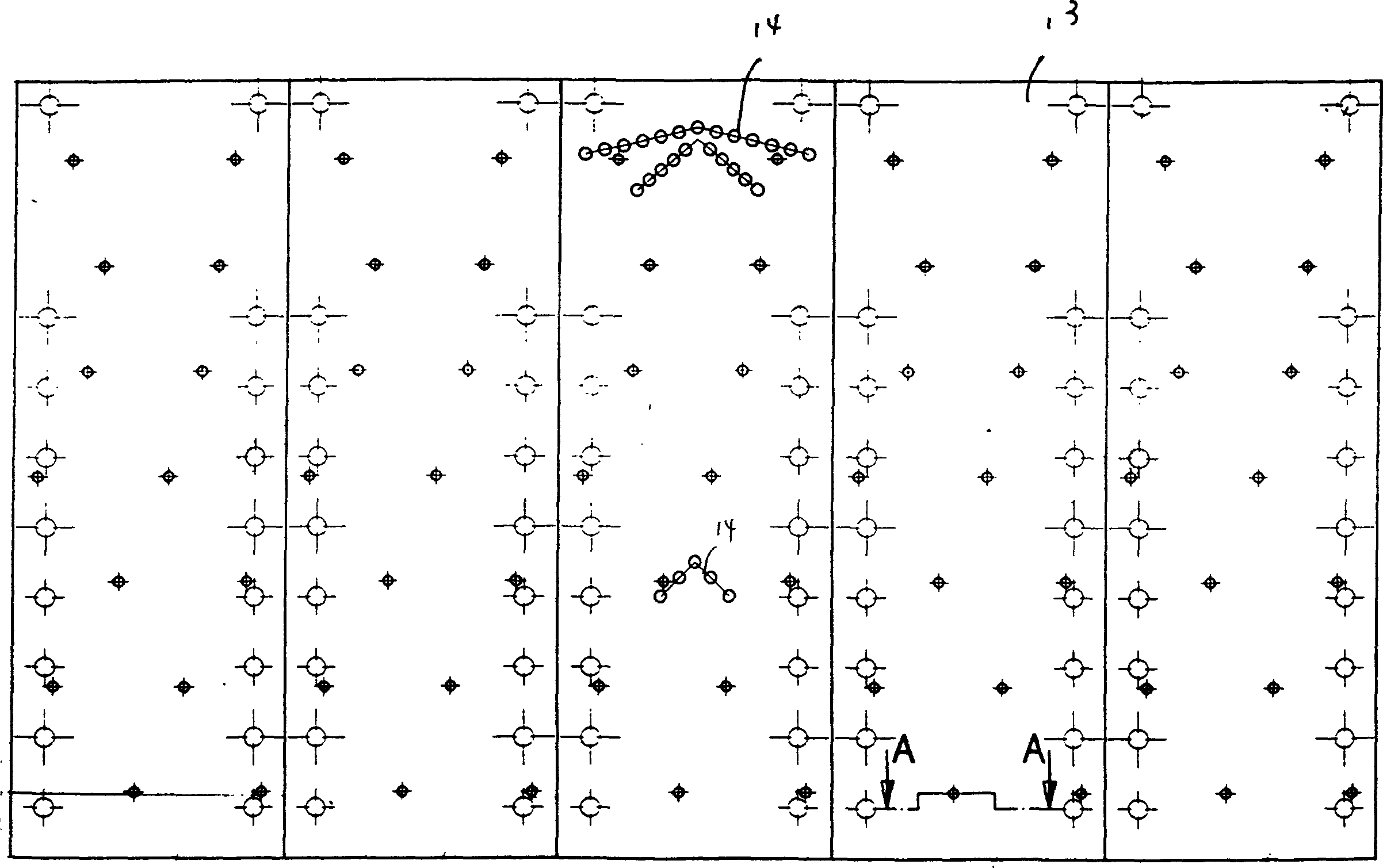

[0045] Plating tank structure see figure 1 , the present invention adopts 4 identical plating tanks altogether, and each plating tank 5 contains two pairs of anode boxes 4 altogether, and totally 40 fritters are coated with IrO 2 Anode plate.

[0046] The anode box 4 in the plating tank 5 is vertically arranged, and the strip steel 1 is also vertical....

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 lies in the coating composition: get acrylic resin 500kg, silicon dioxide 100kg, silane bonding agent 200kg, polytetrafluoroethylene 100kg, metal zirconium ion 15kg, polyethylene wax 85kg and place in a stirring In the container, stir and mix evenly to make chrome-free zirconium-containing anti-fingerprint paint. The rest are the same as example 1.

Embodiment 3

[0060] The difference between embodiment 3 and embodiment 1 lies in the coating composition: get acrylic resin 600kg, silicon dioxide 100kg, silane bonding agent 90kg, polytetrafluoroethylene 100kg, metal zirconium ion 10kg, polyethylene wax 100kg and place in a stirring In the container, stir and mix evenly to make chrome-free zirconium-containing anti-fingerprint paint. The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com