Patents

Literature

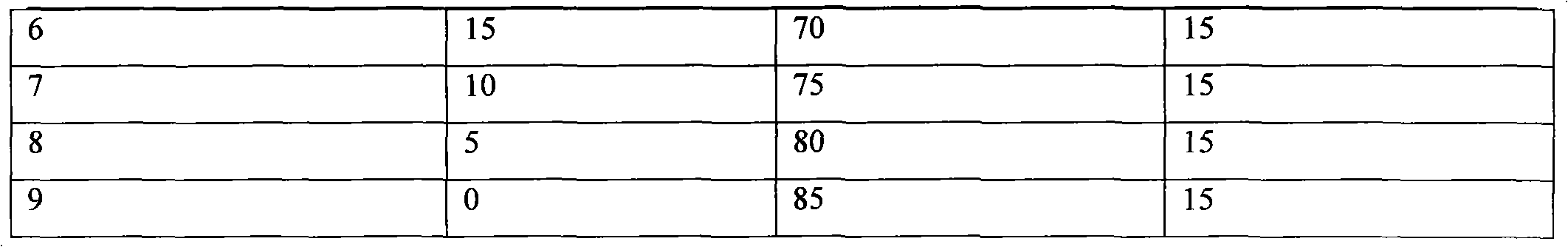

304results about How to "Lower cell voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

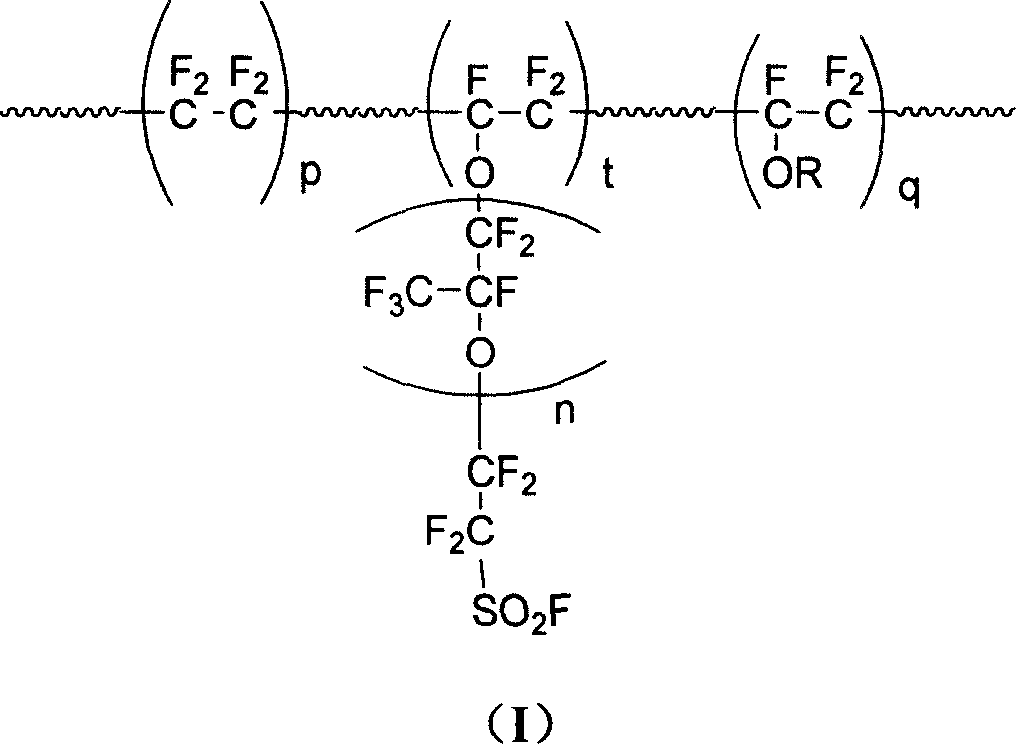

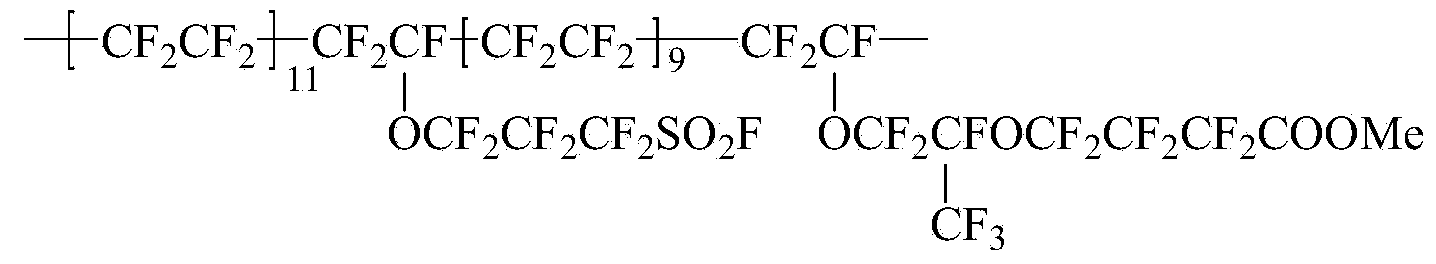

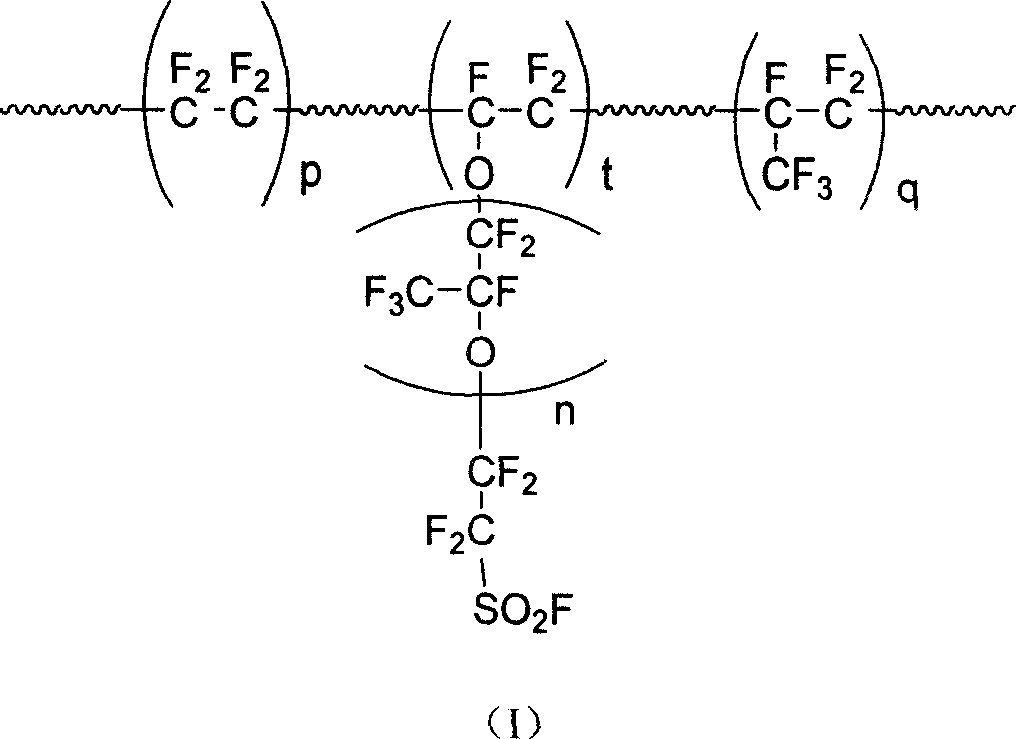

Polymer of containing fluorin, and application as material of ion exchange fiber

InactiveCN101003588AIncrease the effective areaLower resistanceMelt spinning methodsVinyl etherAlkali ions

This invention discloses a fluorine-containing polymer and its application as ion exchange fiber material. The fluorine-containing polymer is a perfluoro resin containing sulfonylfluoride groups, and is shown in formula 1. The fluorine-containing polymer has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and hexafluoropropylene in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

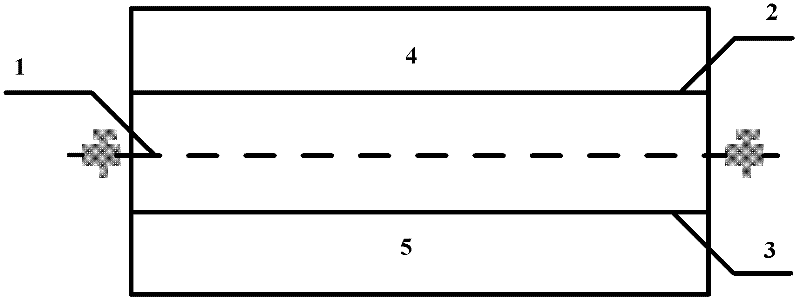

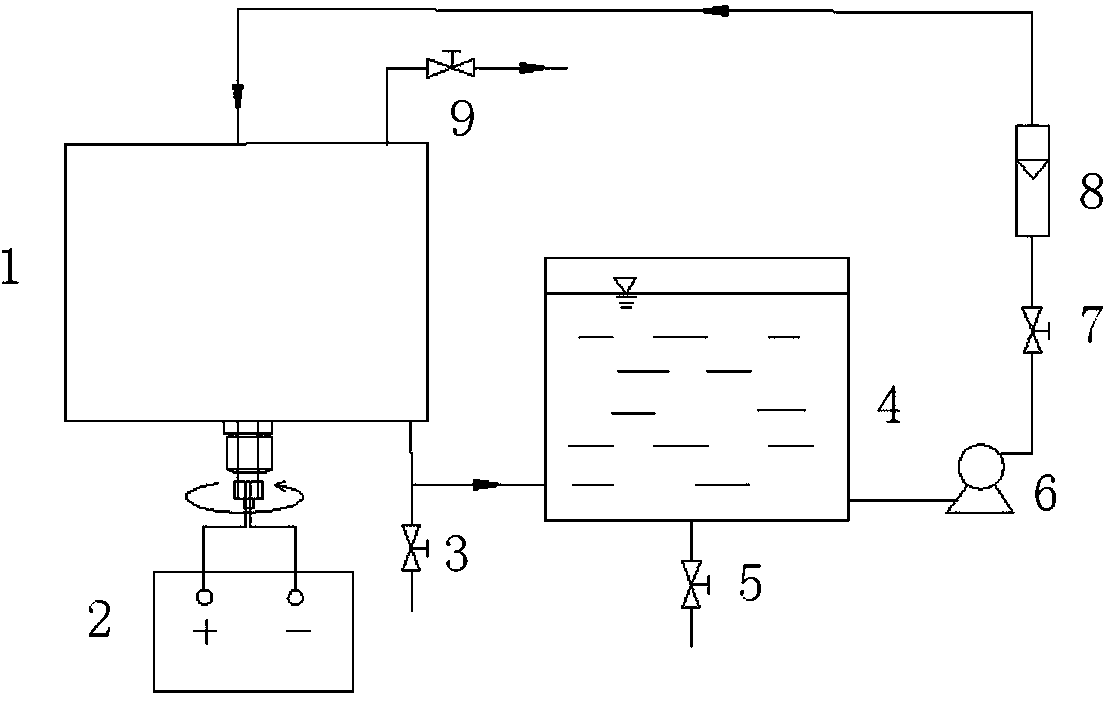

Method and device for separating magnesium and lithium and enriching lithium from salt lake brine

ActiveCN102382984AGood choiceImprove stabilityProcess efficiency improvementSupporting electrolyteIon-exchange membranes

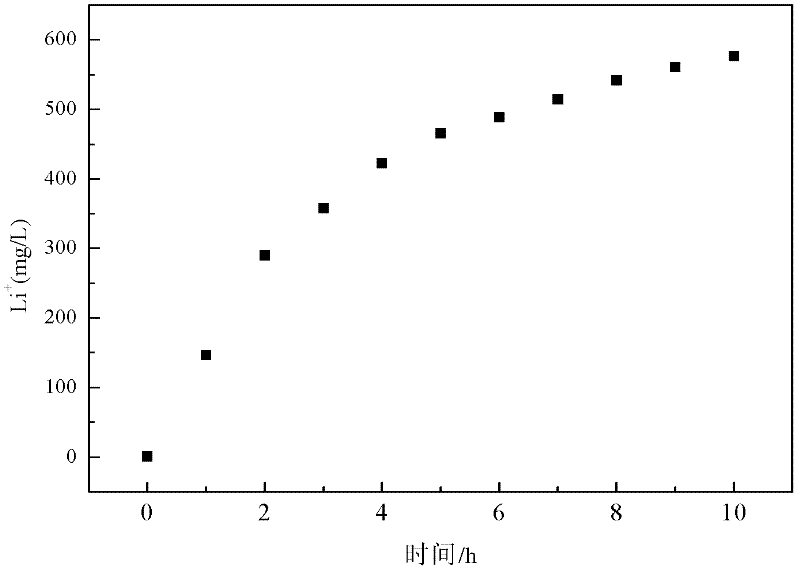

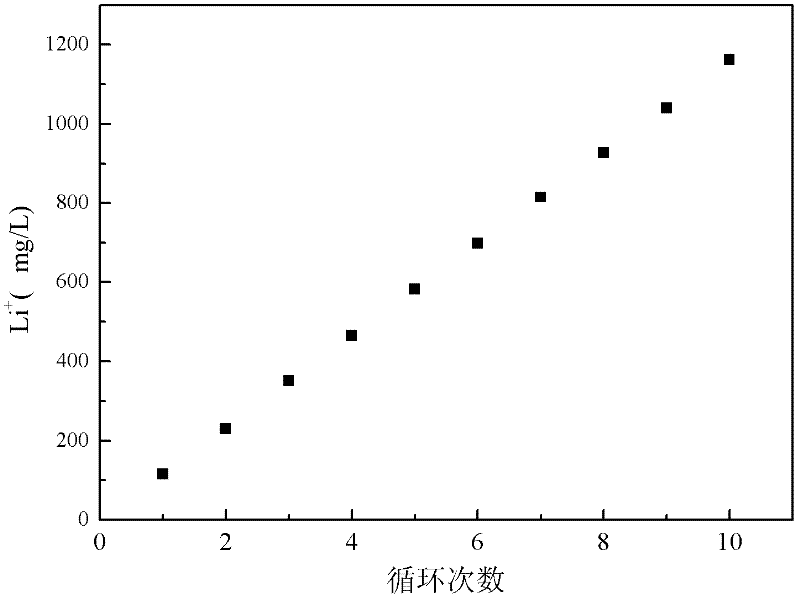

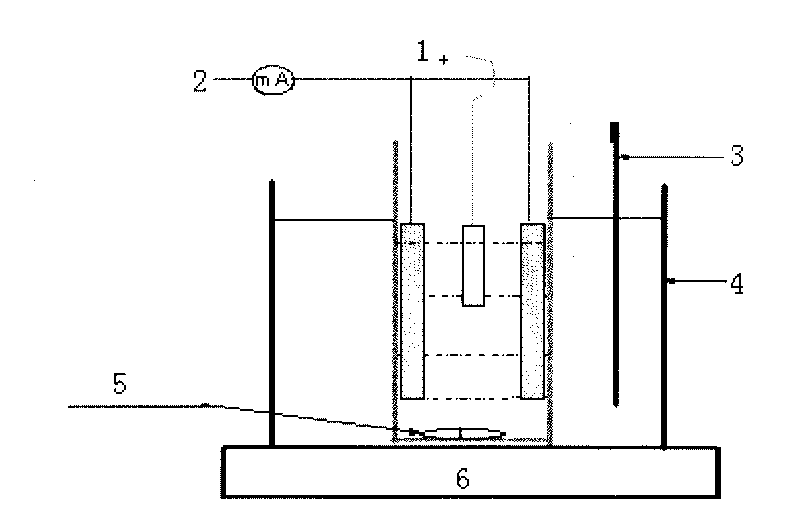

The invention relates to a method and a device for separating magnesium and lithium and enriching the lithium from salt lake brine. The method comprises the following steps of: separating an electrodialyzing device into two areas by using an anion exchange membrane, namely a lithium salt chamber and a brine chamber, filling the salt lake brine in the brine chamber, and filling a supporting electrolyte solution which does not contain Mg<2+> in the lithium salt chamber; placing a conducting matrix coated by an ionic sieve in the brine chamber as a cathode; placing the conducting matrix coated by a lithium-embedded ionic sieve in the lithium salt chamber as an anode; under the driving of an external electric potential, embedding Li <1+> in the brine in the brine chamber into the ionic sieve to form the lithium-embedded ionic sieve, and recovering the lithium-embedded ionic sieve into the ionic sieve after the lithium-embedded ionic sieve in the lithium salt chamber releases the Li <1+> into a conducting solution; and discharging a liquid in the brine chamber after the lithium is embedded, adding the salt lake brine again, alternatively placing electrodes in the two chambers, and repeating and circulating operations. Through the method and the device for separating magnesium and lithium and enriching lithium in the salt lake brine, the separation of the lithium and other ions is effectively realized, and a lithium-enriched solution is synchronously obtained. The method has a short flow and low production cost, is simple to operate, can be operated continuously, and is easy to industrially apply.

Owner:CENT SOUTH UNIV

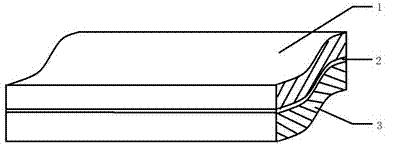

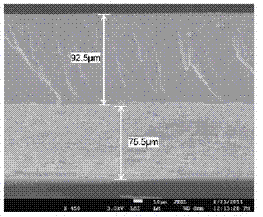

Low-resistance and high-strength ion exchange membrane for chlor-alkali industry and preparation method of low-resistance and high-strength ion exchange membrane

ActiveCN102978654AHigh mechanical strengthAvoid formingOrganic diaphragmsPhysical chemistryIon-exchange membranes

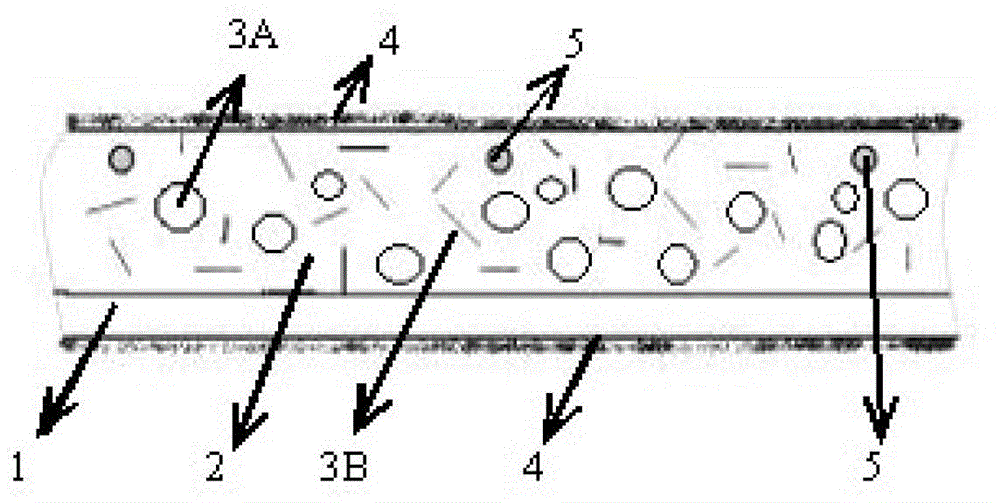

The invention relates to a low-resistance and high-strength ion exchange membrane for the chlor-alkali industry and a preparation method of the low-resistance and high-strength ion exchange membrane. The low-resistance and high-strength ion exchange membrane is a multi-layer composite membrane comprising a perfluorosulfonic ion exchange resin layer, a perfluoropropionate ion exchange resin layer, reinforced screen cloth and gas release coatings, wherein the perfluorosulfonic ion exchange resin layer with the thickness of 80-150 micrometers and the perfluoropropionate ion exchange resin layer with the thickness of 8-12 micrometers form a perfluorosulfonic ion exchange resin base membrane, the gas release coatings with 3-12 micrometers are arranged on two outer side surfaces of the base membrane, the reinforced screen cloth is arranged in the perfluorosulfonic ion exchange resin layer, and the perfluorosulfonic ion exchange resin layer is also internally provided with a nano pore and a nano cavity. The low-resistance and high-strength ion exchange membrane can be prepared through a melt co-extruding or multi-layer hot-pressing compounding process, can be used in an ion exchange membrane in the chlor-alkali industry, and has good mechanical property and electrochemical performance.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

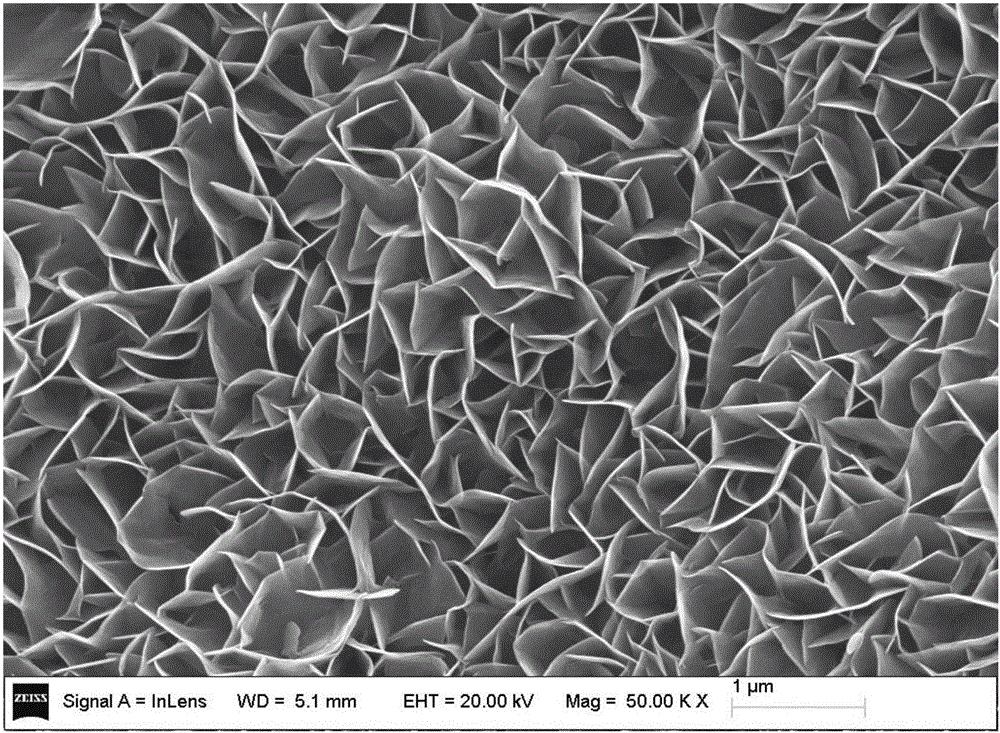

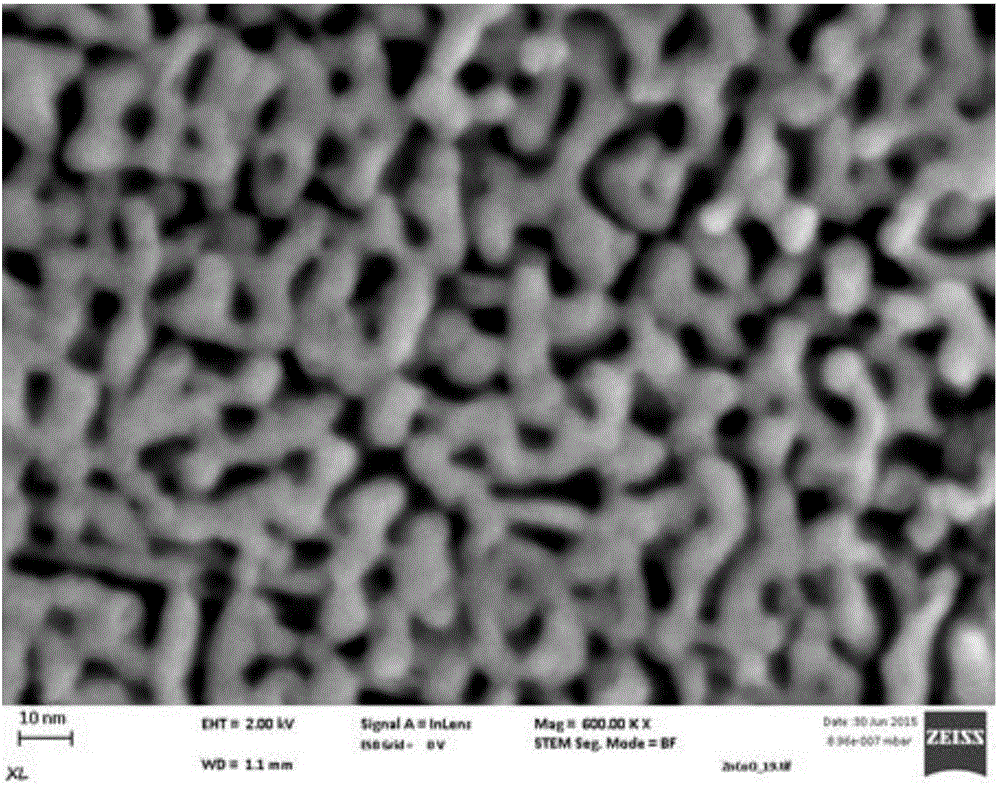

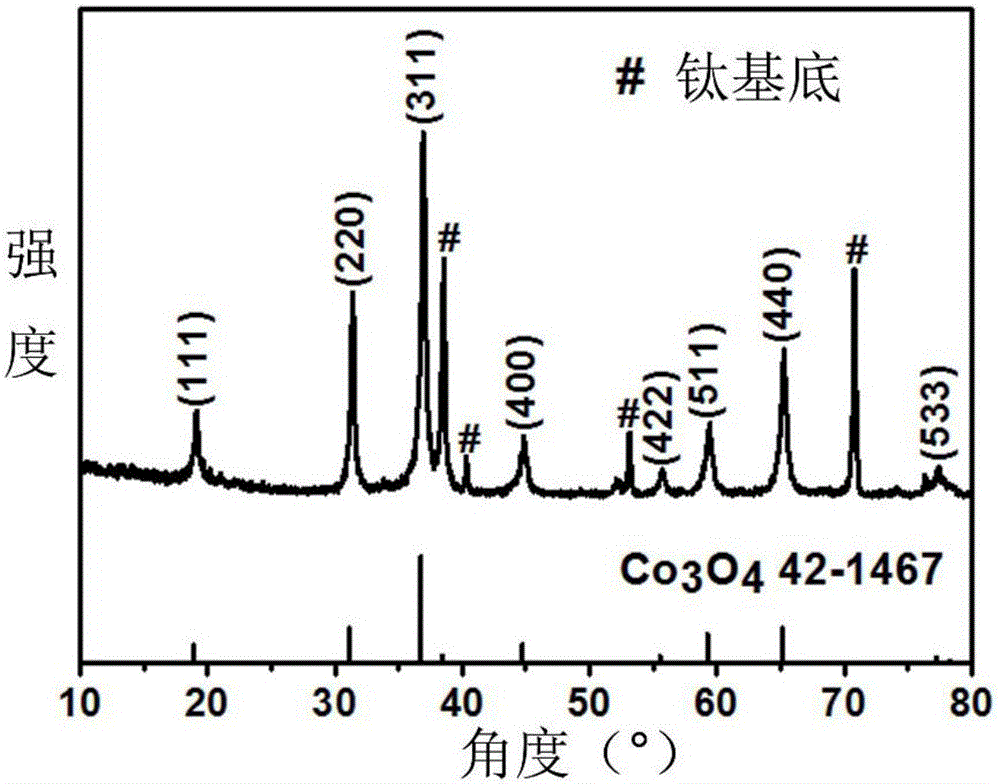

Single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material

InactiveCN106025302AEnsure continuous and stable workExcellent hydrogen evolution reaction performanceMaterial nanotechnologySpecific nanostructure formationDecompositionOxygen

A single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material is characterized in that a metal-doped cobalt oxide primary nanosheet array is perpendicularly grown on a conductive substrate, a porous nanosheet is obtained from each primary nanosheet, and the nanosheets are of porous structure; the material is used as an electrocatalyst for oxygen evolution reaction; the material also has excellent hydrogen evolution performance and may function as a bifunctional catalyst for an alkaline full-decomposition water system. The invention has the advantages that the material can effectively reduce overpotential and peaking potential of oxygen evolution reaction, increase conversion rate of single cobalt atoms and operate stably and continuously in a strong alkali environment; the material has excellent oxygen evolution reaction performance and can be applied as an anode and cathode of a full-decomposition water system, effectively reducing trough voltage; the material is simple to prepare, convenient to operate, low in cost and environment-friendly, and new idea and strategy are provided for the guide design and performance optimization of the bifunctional catalyst for the full-decomposition water system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Low-temperature molten salt system for aluminum electrolysis and method for carrying out aluminum electrolysis by same

The invention relates to the field of molten salt electrolysis of nonferrous metal metallurgy and provides a novel molten salt electrolyte system which can be applied to the aluminum electrolysis industry. The molten salt as an electrolyte system of aluminum electrolysis can greatly reduce the electrolysis temperature, and the electrolyte system also presents a favorable dissolving performance onAl2O3 in the process of electrolysis. The novel molten salt electrolyte system comprises ternary or multivariant salt, such as KF, KCl, NaF, NaCl, AlF3, MgF2, CaF2, LiF, BaF2, Al2O3, and the like. Theelectrolyte system has a lower primary crystal temperature and the favorable dissolving performance on the Al2O3. The problems of low Al2O3 solubility and low dissolving speed brought by reducing theelectrolyte primary crystal temperature through reducing the NaF / AlF3 ratio in a sodium cryolite system are solved. In addition, the low-temperature electrolyte system is particularly suitable for adopting an inert anode of metal ceramics or metal alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

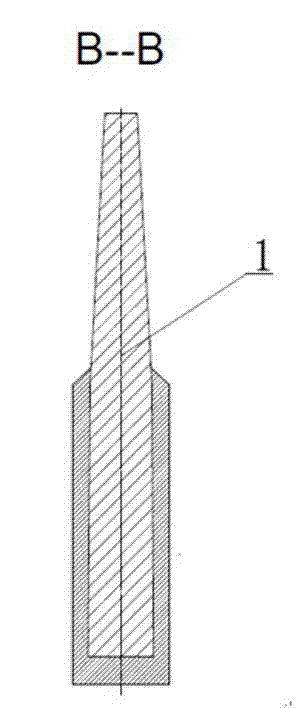

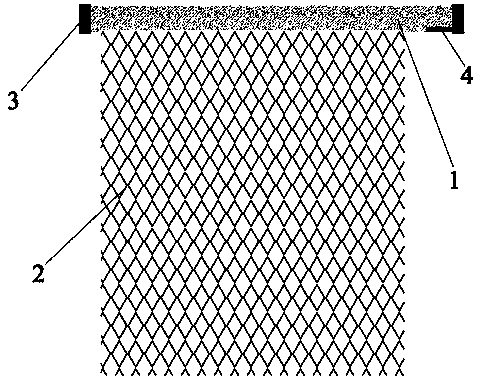

Fiber-reinforced perfluorinated ion exchange membrane containing non-continuous nano-pore canal and preparation method thereof

ActiveCN103031566AImprove electrochemical performanceImprove mechanical propertiesOrganic diaphragmsFiberPhysical chemistry

The invention relates to a fiber-reinforced perfluorinated ion exchange membrane containing a non-continuous nano-pore canal and a preparation method thereof. A basic membrane of the membrane comprises a perfluorosulfonic acid ion exchange resin layer and a perfluorocarboxylic acid ion exchange resin layer, reinforcing fiber mesh cloth is arranged in the perfluorosulfonic acid resin layer, and gas release coatings are sprayed on the surfaces on the two outer sides of the basic membrane; and the fiber-reinforced perfluorinated ion exchange membrane is characterized in that the non-continuous nano-pore canal is further contained in the perfluorosulfonic acid resin layer. The membrane is prepared through a melting co-extrusion or multi-layer hot-pressing compounding process. The membrane is used for the ion exchange membrane in the chlor-alkali industry and has better mechanical properties and electrochemical properties.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Ionic conductive membrane for chlorine-alkali industry and preparation method thereof

The invention relates to the technical field of ionic membranes, and particularly relates to an ionic conductive membrane for a chlorine-alkali industry and a preparation method thereof. The ionic conductive membrane comprises a perfluorinated ion exchange resin base membrane, a micro-porous reinforcing material and a surface layer of a perfluorinated ion exchange resin microparticle. The perfluorinated ion exchange resin microparticle is a mixture of one or two of a perfluorinated carboxylic acid resin microparticle or perfluorinated sulfonic acid-carboxylic acid copolymer resin microparticle and a perfluorinated sulfonic acid resin microparticle, wherein the perfluorinated sulfonic acid resin microparticle accounts for 95%-50% of the percentage by mass of the mixture. The surface layer of the ionic conductive membrane has good compatibility and adhesion and maintains a good degassing effect in the whole service life of the ionic conductive membrane. An alkali metal chloride solution of which the range of concentration is wide can be efficiently and stably treated by the ionic conductive membrane in the chlorine-alkali industry, and the ionic conductive membrane is applicable for running in a zero-pole electrolytic cell under a novel high current density condition and a very excellent product purity index is achieved. The invention also provides a preparation method of the ionic conductive membrane, the process is simple and reasonable and industrial production is easily achieved.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Grate type titanium-based PbO2 electrode for nonferrous metal electrodeposition and preparation method of grate type titanium-based PbO2 electrode

The invention discloses a grate type titanium-based PbO2 electrode for nonferrous metal electrodeposition and a preparation method of the grate type titanium-based PbO2 electrode. The PbO2 electrode comprises an anode consisting of a lead-coated copper conducting bar (1) an a group of titanium rods (2) connected below the lead-coated copper conducting bar, wherein the titanium rods are successively formed by a titanium substrate, a lead silver alloy bottom layer, an alpha-PbO2 composite middle layer and a beta-PbO2 activation surface layer form inside to outside. The preparation method comprises the following steps: carrying out quenching, tapping, sand blasting, deoiling and activating, connecting the titanium substrate with the lead-coated copper conducting bar, electrically depositing a Pb-Ag-TiO2 composite layer on the titanium substrate, plating an alpha-PbO2 composite layer in an alkaline way and plating a beta-PbO2 composite layer in an acidic way to obtain the grate type titanium-based PbO2 electrode for nonferrous metal electrodeposition. The electrode prepared according to the invention has the advantages of good electrocatalytic activity, strong electrode electrical conductivity, low slot voltage in electrodeposition, long service life and low energy consumption.

Owner:KUNMING HENDERA SCI & TECH

Surface treatment method for environment-friendly chromium-free zirconium-containing electro-galvanized fingerprint resistant steel sheet

The present invention relates to surface treatment of steel plate, and is especially zinc electroplating process to form homogeneous fine zinc layer onto the surface of cold rolled steel plate and environment friendly zirconium-containing no-chromium fingerprint resisting paint for producing zinc electroplating fingerprint resisting steel plate. Cold rolled steel plate is first electroplated with zinc and then coated with fingerprint resisting paint. The production process of fingerprint resisting steel plate features the production process including the first production of zinc electroplated steel plate via vertical anode electroplating process, coating with water-base fingerprint resisting paint with zirconium to replace chromium, and curing through roasting at temperature lower than 125 deg.c to form composite resin film. The electroplated zinc layer has stable and reliable quality and the organic composite resin film has no environmental pollution.

Owner:JIANGYIN CHANGFA FINGERPRINT RESISTANT STEEL PLATE

Processing method of effluent brine produced in MDI production process

ActiveCN101665302ARemove completelyReduce pollutionMultistage water/sewage treatmentNature of treatment waterDiphenylmethaneSaline water

The invention discloses a processing method of effluent brine produced in MDI production process, comprising the following steps: (1) effluent brine containing phenylamine, diphenylmethane toluene diamine and polyamine, which is produced in MDI production process, carries out super-gravity extraction, and then tower-type extraction is carried out; (2) effluent brine discharged by the step (1) is fed to a stripping tower to carry out steam stripping; (3) effluent brine discharged from the stripping tower in step (2) and chemical oxidants are conveyed to an oxidation reactor, and air is vented to carry out aeration; (4) the effluent brine processed by the step (3) is transported to an adsorption tower to carry out adsorption. The effluent brine processed by the method of the invention has less than 8ppm of TOC, less than 2.5 ppm of TN (total nitrogen); sodium chloride and water and the other resources in effluent brine are realized, so as to carry out circulating utilization.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Electrolyte and method for electrolyzing and refining crude lead

InactiveCN104746098AAvoid serious harmAvoid heavy pollutionPhotography auxillary processesHydrometallurgyMethanesulfonic acid

The invention relates to electrolyte and a method for electrolyzing and refining crude lead, and belongs to the technical field of wet-process metallurgy. The electrolyte electrolyzing and refining crude lead is of a methylsulphonic acid solution system comprising methyl lead sulfonate and free methyl sulfonic acid, wherein the concentration of Pb<2+> is 50-200g / L, and the concentration of the free methyl sulfonic acid is 50-160g / L. The method comprises the following steps: placing a solution system electrolyte comprising the methyl lead sulfonate and free methyl sulfonic acid, a to-be-refined crude lead anode plate and a cathode plate into an electrolytic cell, then, applying direct-current power, adding an additive comprising one or a mixture of animal glue, lignosulfonate, aloin and beta-naphthol into the electrolyte to electrolyze for 2-7 days so as to generate cathode lead and anode mud, obtaining national-standard 1# lead ingot after melting and casting cathode lead, performing washing and filter pressing on the anode mud, and then feeding the anode mud to a noble metal extracting process. According to the method, a brand-new methanesulfonic acid solution system is adopted as an electrolyte for electrolysis, so that the method has the characteristic of being remarkable in environment-friendly advantage.

Owner:KUNMING UNIV OF SCI & TECH

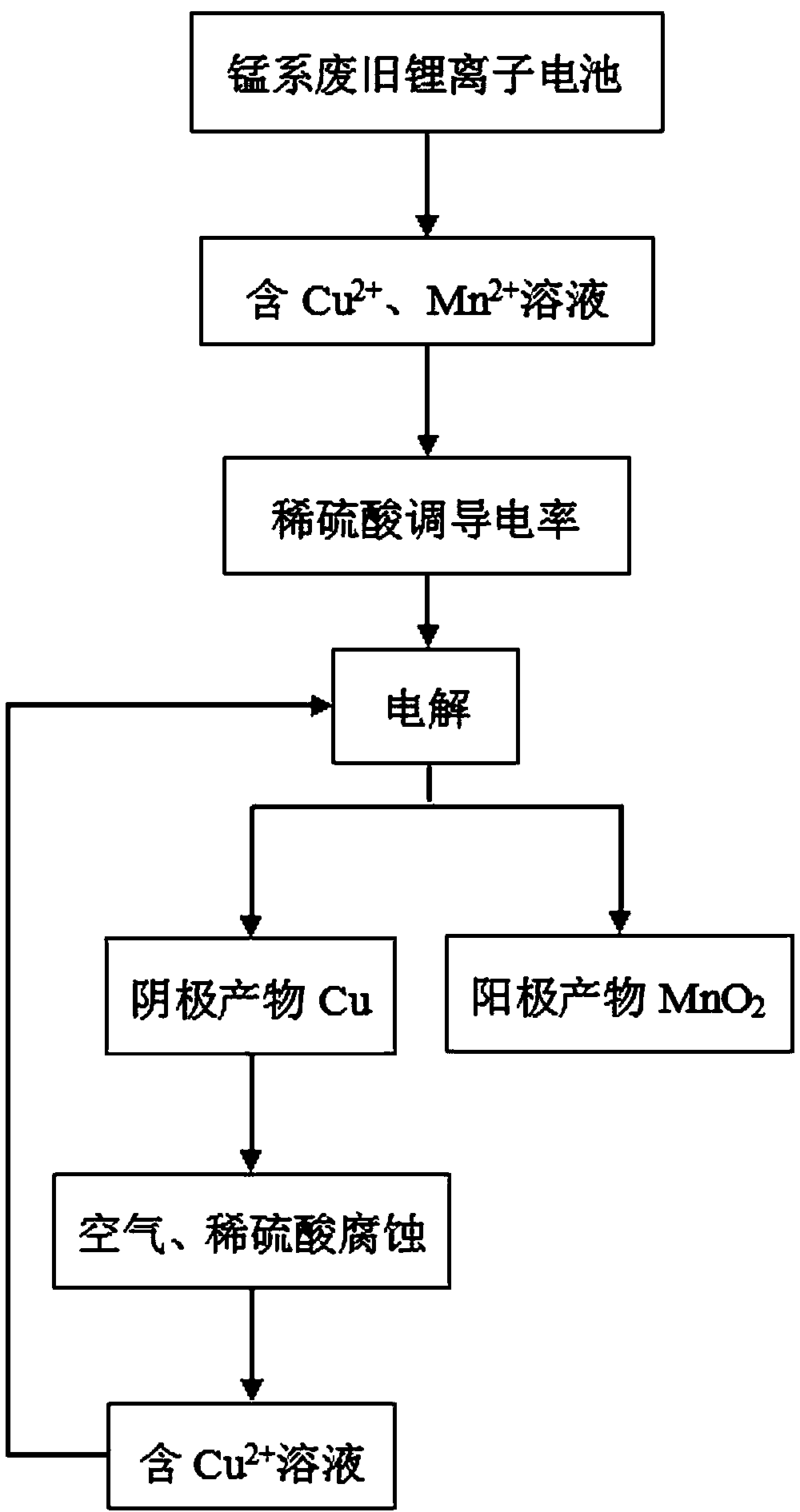

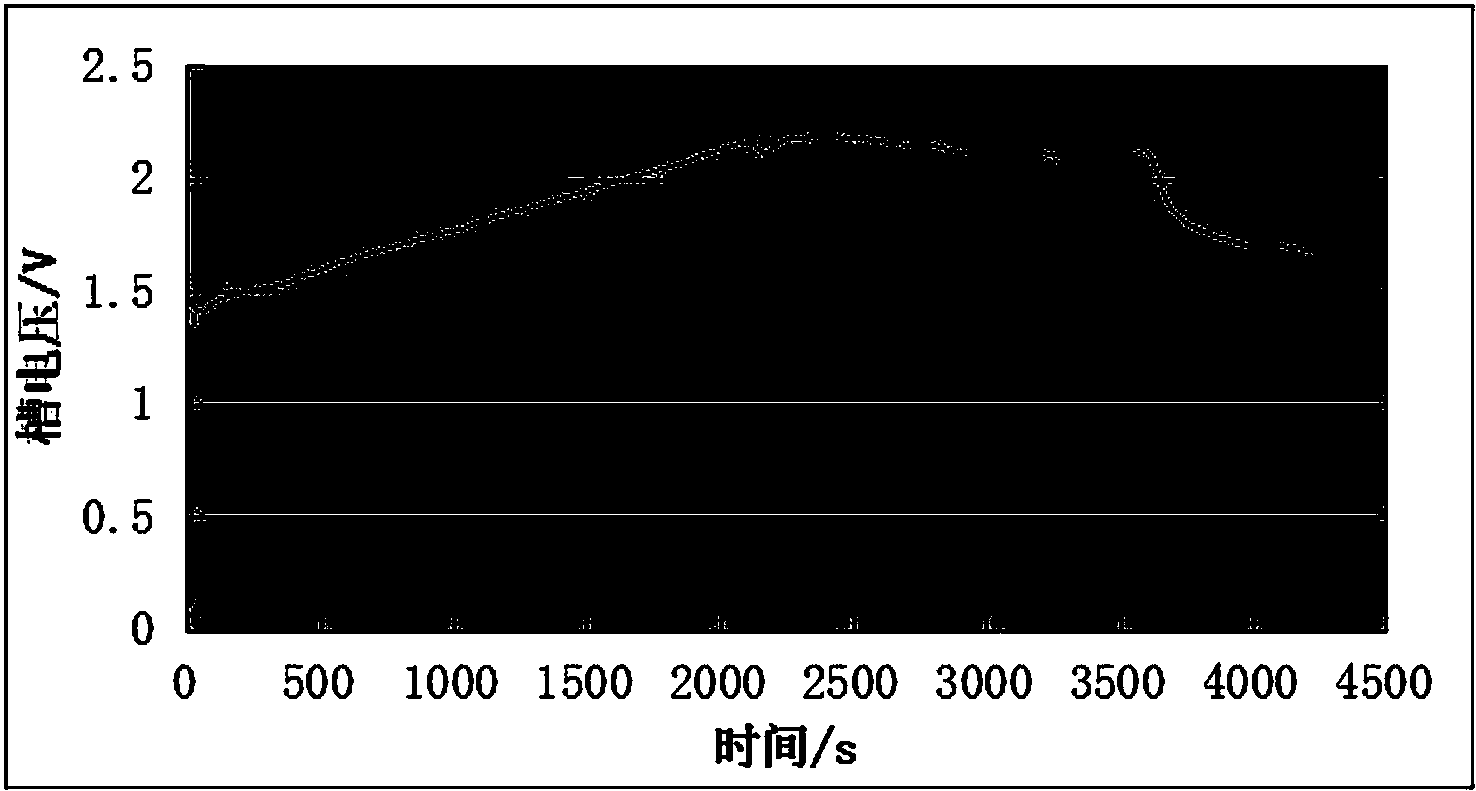

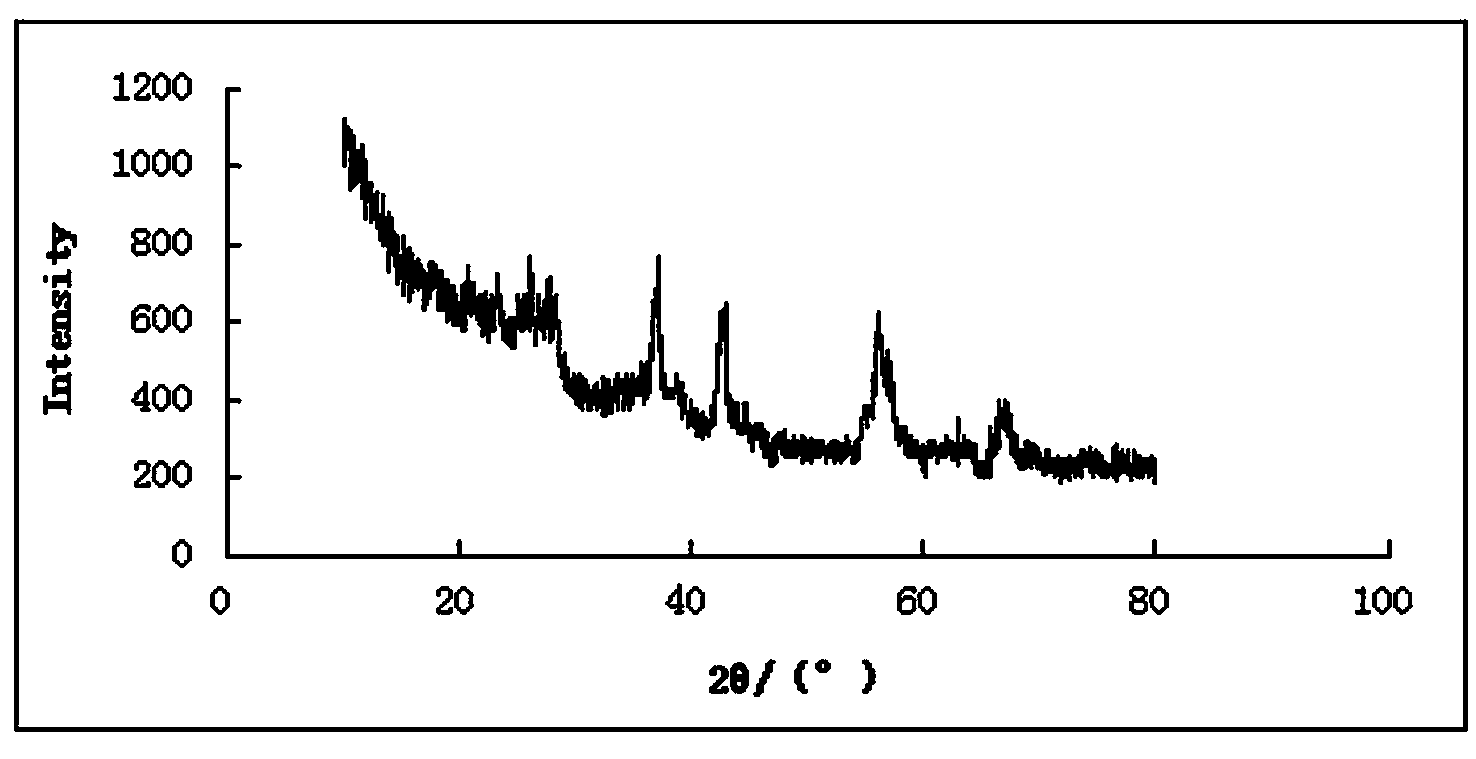

Method for recycling manganese and copper resources from waste lithium ion batteries

ActiveCN104037468ALower cell voltageReduce energy consumptionWaste accumulators reclaimingProcess efficiency improvementManganeseLithium-ion battery

The invention relates to a method for recycling manganese and copper resources from waste lithium ion batteries. The method comprises the following steps: (1) recycling Co, Ni, Li, Al and other elements from the waste lithium ion batteries and separating to obtain a solution mainly containing Cu<2+> and Mn<2+>, and adding appropriate amount of dilute sulphuric acid into the solution to adjust the pH value and the electric conductivity of the dilute sulphuric acid, wherein the concentration of the dilute sulphuric acid of the solution after adjustment is 0.1-5mol / L. (2) performing electrolysis, with a copper sheet or a titanium sheet as a cathode, graphite flake or titanium-based manganese dioxide as an anode, and the solution adjusted in the step (1) as electrolyte solution under the condition that the anodic current density is adjusted to be 0.5-50mA / cm<2>; and (3) separating MnO2 out from the anode and separating Cu out from the cathode after electrolysis, recycling the MnO2 separated out from the anode as products, spraying the dilute sulphuric acid on Cu separated out from the cathode in the air for corroding, recycling a Cu<2+> containing solution into an electrolytic cell after corrosion, and recycling metal copper after electrolysis, thus recycling all Cu resources. The method can greatly reduce the voltage of the electrolytic cell during electrolysis and greatly reduce the energy consumption.

Owner:ZHEJIANG UNIV OF TECH

Method for controlling stability and uniformity of aluminum oxide concentration in aluminum electrolysis cell

The invention discloses a method for controlling stability and uniformity of aluminum oxide concentration in an aluminum electrolysis cell. The method comprises the following steps of: firstly, setting the aluminum oxide concentration control target at a low resistance concentration area, and performing two main control processes, namely long-term 'blanking as required' and short-term 'concentration check', to realize feeding as required in time in the aluminum electrolysis cell and stable operation in the low resistance concentration area; secondly, performing online measurement of current distribution on each anode of the electrolysis cell, and adjusting the blanking proportion of each blanking point according to the consumption rate of aluminum oxide of the anode around each blanking point to realize uniform distribution of the aluminum oxide concentration in the space; and thirdly, improving a blanking device and a blanking manner to reduce aluminum oxide sediment generated by accumulation at the blanking port. The method is favorable for stable, efficient, low-voltage, low-power consumption and low-discharge production operation of the aluminum electrolysis cell.

Owner:包头铝业有限公司 +1

Zero-polar-distance ion exchange membrane and preparation method thereof

ActiveCN104018180AWith ion exchange functionReduce accumulationMembranesSemi-permeable membranesHigh current densityMicroparticle

The invention belongs to the technical field of ion membranes, which particularly relates to a zero-polar-distance ion exchange membrane. The ion exchange membrane is converted from a polymer membrane which is prepared by compounding a perfluorinated ion exchange resin and a reinforcement material, wherein a non-electrode porous gas releasing layer is arranged on at least one side of the ion exchange membrane and is formed by bonding a dispersion liquid on the surface of an ion exchange membrane layer and then drying; the dispersion liquid is formed by dispersing the broken microparticles of a perfluorinated sulfonic acid resin in an aqueous alcohol solution of the sulfonic acid resin. The prepared zero-polar-distance ion exchange membrane which is applied to the chlor-alkali industry can be used for stably and efficiently treating an alkali metal chloride solution with high impurity content and is more suitable for being applied in a zero-polar-distance electrolytic bath under a high current density condition as well as has an extremely low surface resistance. The invention further provides a preparation method of the zero-polar-distance ion exchange membrane. The method is reasonable in process and easy for industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Novel ionic conduction membrane and preparation method thereof

ActiveCN104018179AGood compatibilityGood adhesionOrganic diaphragmsHigh current densityInorganic compound

The invention belongs to the technical field of ionic membranes, and particularly relates to a novel ionic conduction membrane. The novel ionic conduction membrane comprises a perfluoro ion exchange resin basal membrane, a porous reinforcing material and a surface layer made of a mixture of perfluoro ion exchange resin microparticle and inorganic compound particle, wherein the inorganic compound particle is one of or a mixture of oxides, hydroxides and nitrides of IV-A groups, IV-B groups, V-B groups, iron, cobalt, nickel, chromium, manganese or boron elements; and the perfluoro ion exchange resin microparticle is a mixture of one or two of perfluoro carboxylic acid resin microparticle or perfluoro sulfonic acid carboxylic acid copolymerization resin microparticle and perfluoro sulfonic acid resin microparticle. The novel ionic conduction membrane is used for the chlorine-alkali industry and is capable of stably and efficiently treating an alkali chloride solution wide in concentration range and suitable for operation in a novel zero-polar-distance electrolytic bath under the condition of high electric current density, and the product is high in purity. The invention also provides a preparation method of the novel ionic conduction membrane, which is simple and reasonable in process and facilitates industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing energy-saving metal-based ceramic inert anode material for nonferrous metal electrowinning

ActiveCN101538724ALarge specific surface areaExtended service lifeElectrodesAlloy substrateManganese

The invention relates to a method for preparing an energy-saving metal-based ceramic inert anode material for nonferrous metal electrowinning, and the method is characterized in that: a serrated pattern is compressed on the surface of a polar plate with a lead-based multinary alloy substrate, and a PbO2 and MnO2 conductive ceramics is prepared on the surface of the serrated pattern. The method adopts the physical and the electro-chemical methods for preparing the metal-based ceramic inert anode material which takes lead-based multinary alloy as the substrate. When the metal-based ceramic inert anode material is used in electrowinning, as the surface of an anode is the conductive ceramic material, the surface of the anode is in the insoluble state, thereby being capable of reducing the pollution of lead dissolution of the anode to a cathode product, improving the quality of the cathode product and ensuring the qualified rate of a cathode zinc No. 0 product to achieve 99 percent. The use of the compound electrode can significantly reduce the bath voltage during the electrowinning process and further reduce the power consumption. When in electrowinning of zinc, copper, nickel, cobalt, manganese and the like, the bath voltage can be reduced by 0.3-0.5V, and the current efficiency can be improved by 2-3 percent.

Owner:晋宁理工恒达科技有限公司

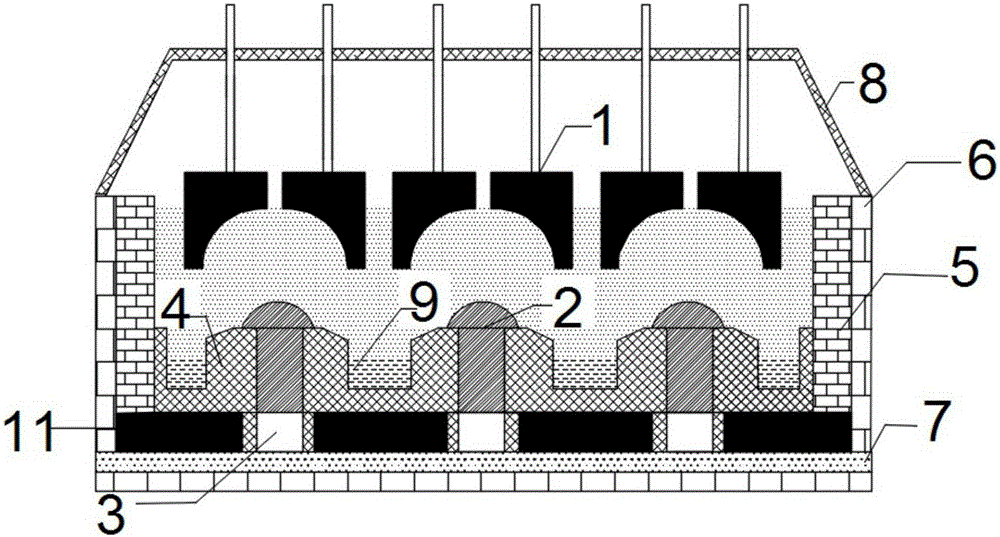

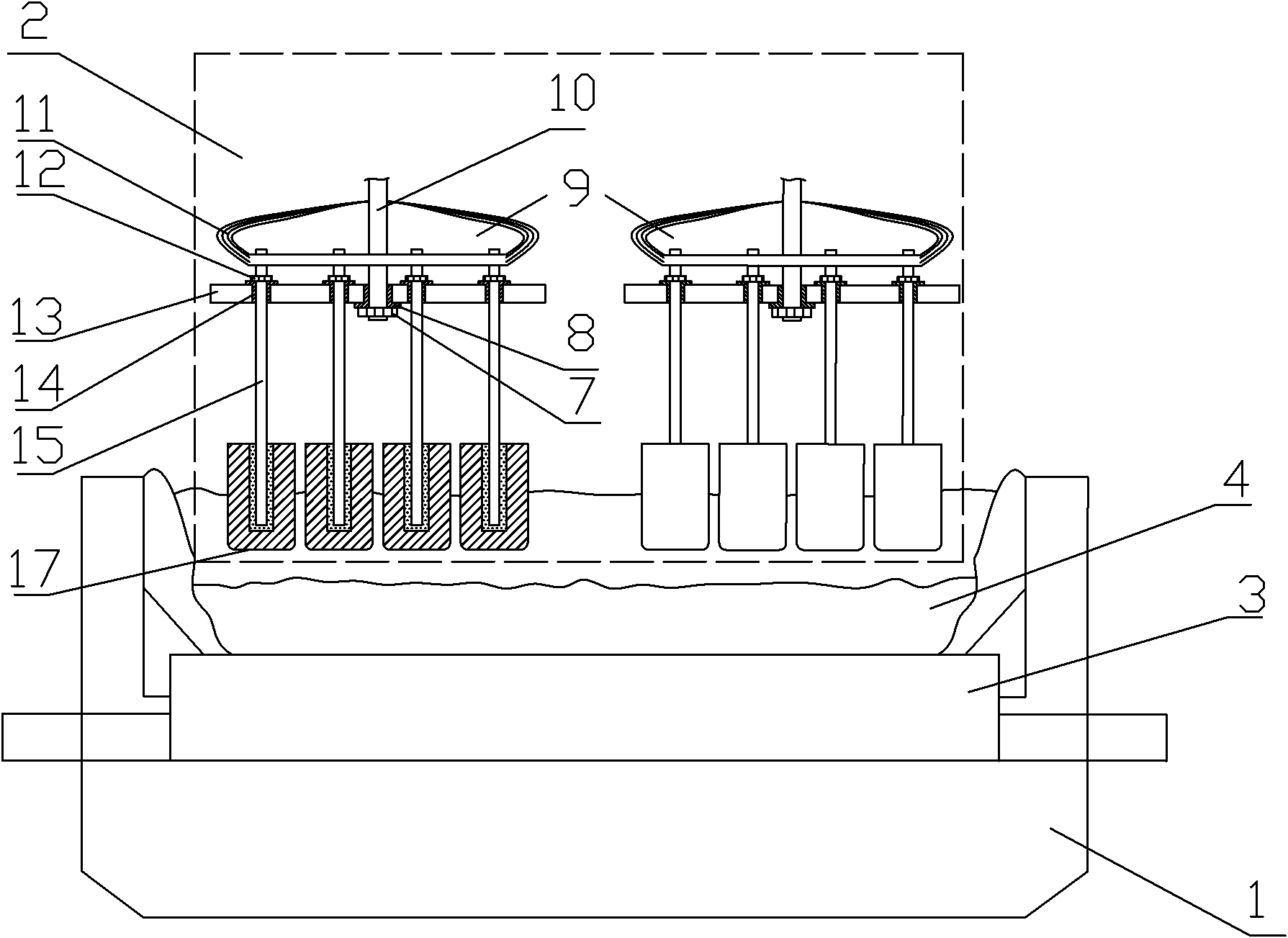

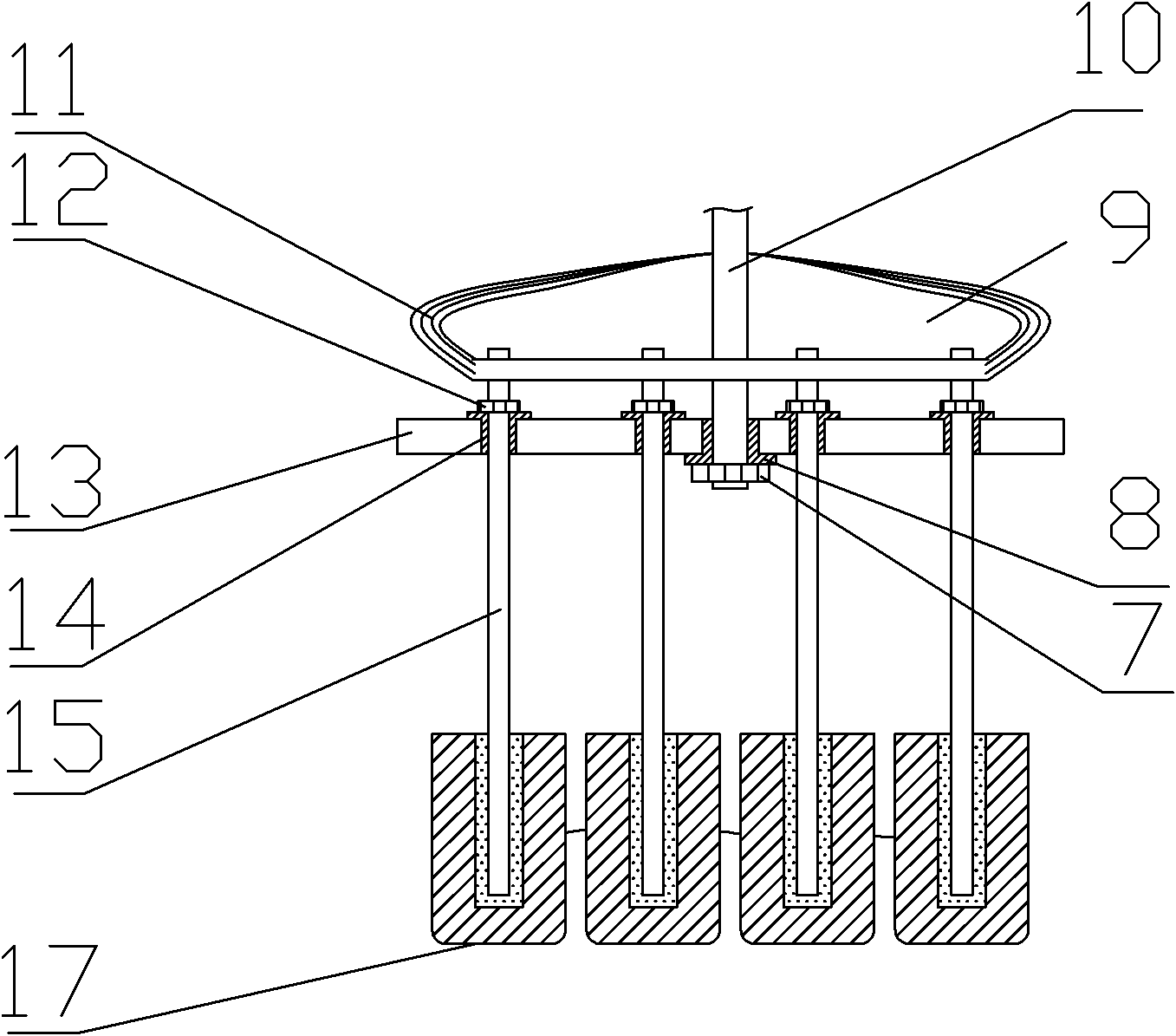

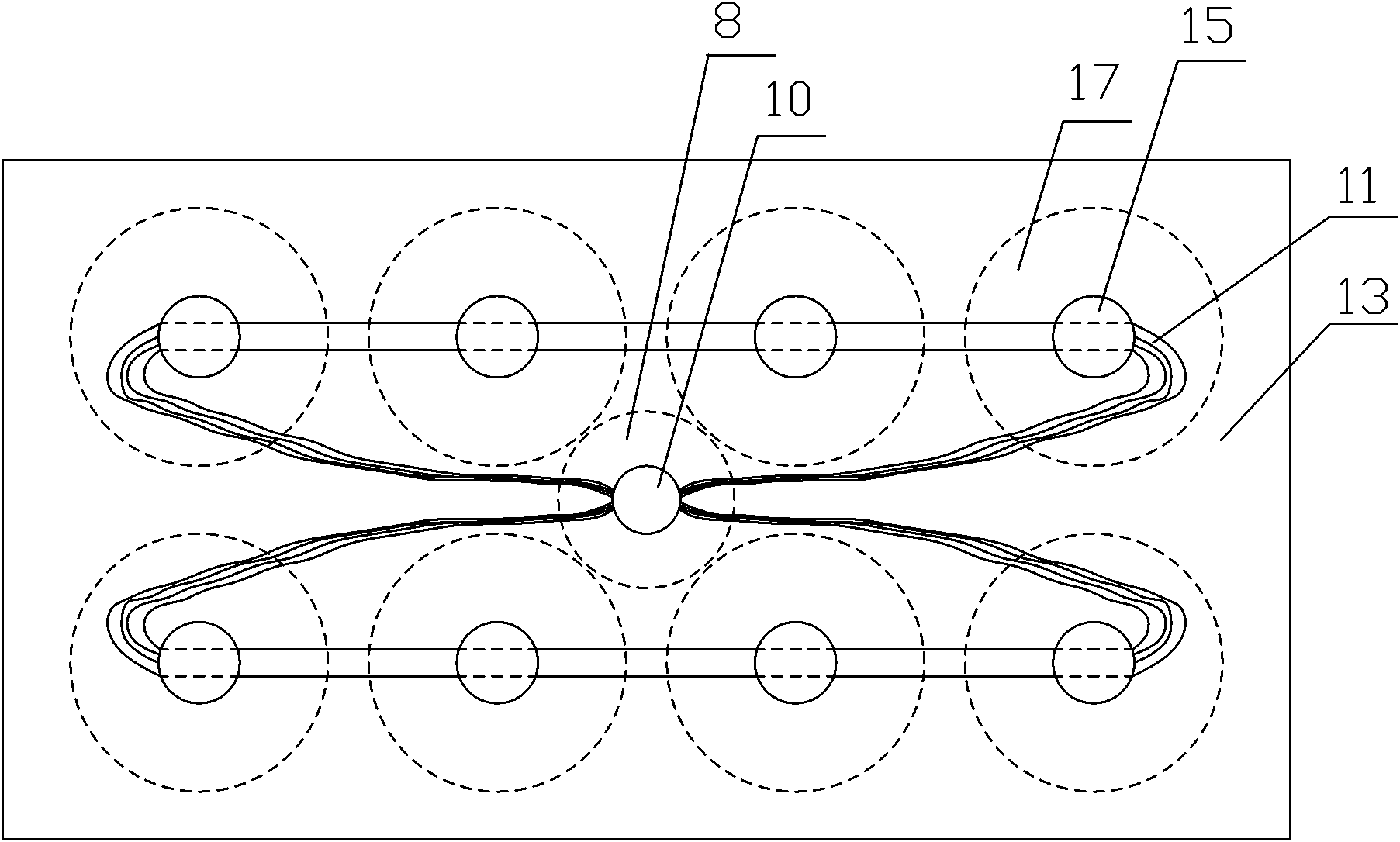

Novel rare-earth electrolytic bath

The invention relates to a novel rare-earth electrolytic bath. A gap is reserved in the center of each anode, and the bottom surface of each anode is a concave surface being concave from the periphery towards the center. A cathode is correspondingly arranged below each anode. The cathodes are buried in a protruding high-temperature-resisting material. The top of each cathode is an arc convex surface and protrudes out of the high-temperature insulating material. An electrical insulating layer is arranged between the high-temperature-resisting material and each cathode. A metal groove is formed between every two cathodes, and the high-temperature-resisting material is concave downwards to form the metal grooves. A cathode steel bar is located at the bottom of each cathode and connected with the cathode. The space between every two adjacent cathode steel bars is filled with a graphite block. An electrical insulating layer is arranged between each graphite block and the corresponding cathode steel bar. A feeder is arranged on the top of a bath body. According to the novel rare-earth electrolytic bath, the convex surfaces of the cathodes are higher than the high-temperature insulating layers, so that a high-temperature zone of the electrolytic bath is moved upwards. Through the metal grooves designed for the electrolytic bath, the contact area of metal and an electrolyte is reduced, re-dissolution of the metal is restrained, and the current efficiency is improved. The shapes of the anodes of the electrolytic bath are beneficial for discharging of anode bubbles.

Owner:CENT SOUTH UNIV

Composite alloy inert anode for aluminum electrolysis and aluminum electrolysis method utilizing same

ActiveCN101824631AChange performanceImprove physical and chemical propertiesTectorial membraneRare-earth element

The invention relates to a composite alloy inert anode for aluminum electrolysis. The composition of the matrix of the composite alloy inert anode for aluminum electrolysis is (x)A(y)B, wherein X is the content of A in percentage by weight, y is the content of B in percentage by weight, X is 40-100%, and y is 0-60%; A consists of one or multiple elements of Cu, Ni, Fe, Co, Al, Mn, W, Cr, Ti, Sn and Zn; and B consists of one or multiple elements of Mo, Pd, Ag, Cd, Au, Pt, Sb, Mg, Ir, Bi, Pb, Si, N, C and rare-earth. A compact protective film is coated on the matrix, and is an oxide film and or a permeator. The composite alloy inert anode is adopted in the process of electrolysis, thus solving the problems of poor conductivity and thermal shock stability of ceramic anodes; the composite alloy inert anode has better corrosion resistance as compared with a single alloy anode; and in addition, the composite alloy inert anode is especially suitable for being applied in a low-temperature aluminum electrolysis system and can also be applied in the field of fusion-electrolysis metallurgy of rare earth, Mg and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

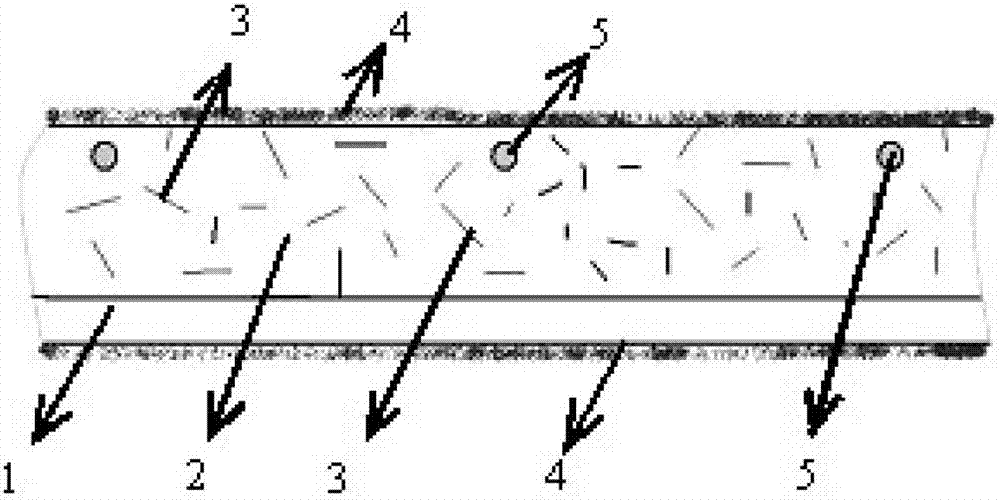

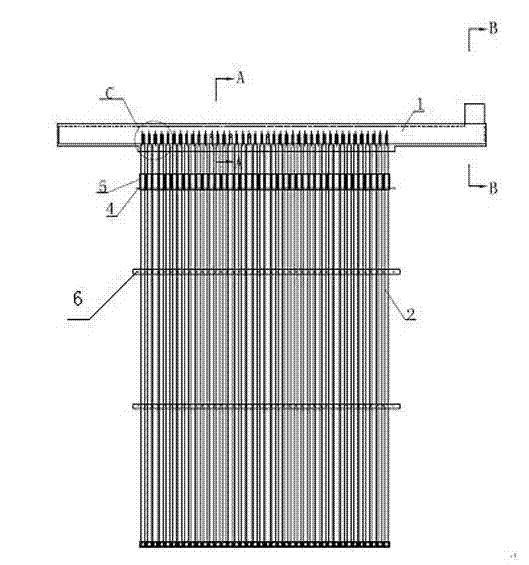

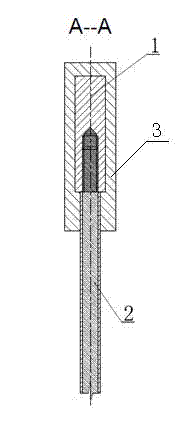

Titanium-based beta-MnO2-RuO2 composite coating anode plate and preparation method and application thereof

ActiveCN109023436AHigh catalytic activityExtended service lifeLiquid/solution decomposition chemical coatingElectrodesSilica gelOxygen

The invention relates to a titanium-based beta-MnO2-RuO2 composite coating anode plate and a preparation method and application thereof, and belongs to the technical field of anode plates in wet metallurgy. The titanium-based beta-MnO2-RuO2 composite coating anode plate comprises a titanium clad copper conducting beam, a titanium net matrix, silica gel cases and a conducting head. The left end andthe right end of the titanium clad copper conducting beam are sleeved with the silica gel cases, the conducting head is fixedly arranged at the bottom end of the titanium clad copper conducting beamand externally connected with a power source, the titanium net matrix is fixedly arranged at the lower end of the titanium clad copper conducting beam, and the titanium net matrix is sequentially coated with a gradient Ir-Ta-Sn-SbOx interlayer and a beta-MnO2-RuO2 composite surface active layer. The titanium-based beta-MnO2-RuO2 composite coating anode plate has excellent catalytic performance andlong service life, the cell voltage is low in the electrolytic process, it is effectively avoided that in the using process of a titanium matrix, oxygen is generated, so that a TiO2 film is generated, and titanium-based metal oxide anode passivation fails, environmental friendliness is achieved, and the defect that the cost of a precious metal oxide coating is too high is overcome.

Owner:KUNMING HENDERA SCI & TECH

Method for preparing carbon nano tube modified bipolar membrane with anion groups

InactiveCN102580549AGood compatibilityHigh water dissociation efficiencySemi-permeable membranesCell component detailsCelluloseAcetic acid

The invention relates to a method for preparing a carbon nano tube modified bipolar membrane with anion groups. The method comprises the following steps of: preparing a sodium carboxymethylcellulose (CMC) aqueous solution or a sodium alginate (SA) aqueous solution by using sodium carboxymethylcellulose or sodium alginate, adding a carbon nano tube with the anion groups, stirring and defoaming under reduced pressure to obtain viscous membrane liquid; casting the viscous membrane liquid in a smooth culture dish to prepare a cation exchange membrane; stirring and dissolving chitosan in 1 to 10 mass percent of acetic acid aqueous solution to prepare 1 to 10 mass percent of chitosan acetic acid aqueous solution, dripping 2.5 volume percent of glutaraldehyde solution slowly with stirring, and defoaming under the reduced pressure to obtain a chitosan (CS) anion membrane liquid; and forming a membrane of the CS anion membrane liquid, fixing the membrane to a prepared cation membrane layer, and airing at room temperature to obtain the bipolar membrane. Due to the adoption of the carbon nano tube modified cation membrane layer with the anion groups, the bipolar membrane has the characteristics of high water dissociation efficiency, small membrane impedance, low tank voltage, high compatibility of two membrane layers and the like.

Owner:FUJIAN NORMAL UNIV

Method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution

InactiveCN102181886AImprove current efficiencyIncrease current densityNanotechnologyElectrolysisHigh energy

The invention provides a method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution, relating to the production technology of flake zinc powder. The method is characterized by firstly preparing zinc-containing strong alkaline solution, wherein the solution contains 1-100g / L of Zn, 10-200g / L of OH<->, 5-70mg / L of additive A and 10-110mg / L ofadditive B; secondly taking a stainless steel plate as an anode and a magnesium plate as a cathode to electrolyze the solution for 1-180min under the following conditions: the distance between the two plates is 0.5-5cm; the current density is 100-2500A / m2; and the solution temperature is 10-100 DEG C, then stopping electrolysis, rapidly taking out the electrodeposit and washing the electrodepositwith water until the pH value of the water is lower than 8; and finally, rapidly vacuum-drying the washed electrodeposit, thus obtaining the one-dimensional nanometer flake zinc powder, wherein the electrolysis waste liquor is returned to be used for preparing the zinc-containing strong alkaline solution. The method has the following advantages and effects: the produced zinc powder has high activity, is flaky and is 10-100nm thick; the method is low in production cost and energy consumption, is simple to operate and is convenient for mass production; and the defects of high cost, high energy consumption, low capacity, difficulty in controlling quality and the like in the traditional production methods are thoroughly overcome.

Owner:TONGJI UNIV

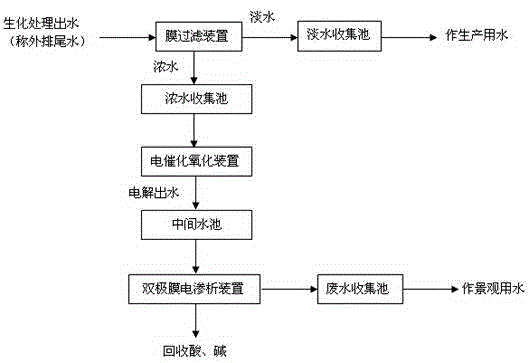

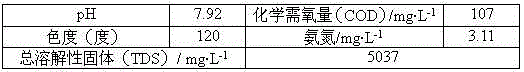

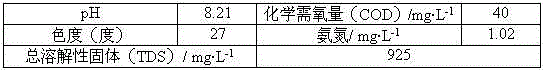

Wastewater advanced treatment method coupling membrane and electricity

ActiveCN104944646AImprove conductivityEmission reductionMultistage water/sewage treatmentWater useFiltration

A wastewater advanced treatment method coupling membrane and electricity belongs to the technical field of wastewater treatment. The treatment method comprises the following steps: discharged wastewater is filtered through a membrane filtration device to obtain fresh water and concentrated water; the fresh water is recycled, the concentrated water is conveyed into an electrocatalysis and electrooxidation device, and the organic pollutants and organisms in the concentrated water are treated and decomposed by electrocatalysis and electrooxidation; the obtained reclaimed water is conveyed into a bipolar membrane electrodialysis device, and the inorganic salt in the reclaimed water is transformed into acid and alkali, so that resource utilization is achieved; the wastewater with the inorganic salt separated by the bipolar membrane electrodialysis device is adopted as scenic environmental water. According to the treatment method, membrane and electricity are coupled, so that advanced treatment of wastewater, material recycling and emission reduction of pollutants are achieved; all water quality indexes of the fresh water and the concentrated water treated through the treatment method respectively meet the standards of GB / T 19923-2005 The Reuse of Urban Recycling Water-Water Quality Standard for Industrial Uses and GB / T 18921-2002 The Reuse of Urban Recycling Water-Water Quality Standard for Scenic Environment Use.

Owner:ZHEJIANG UNIV OF TECH

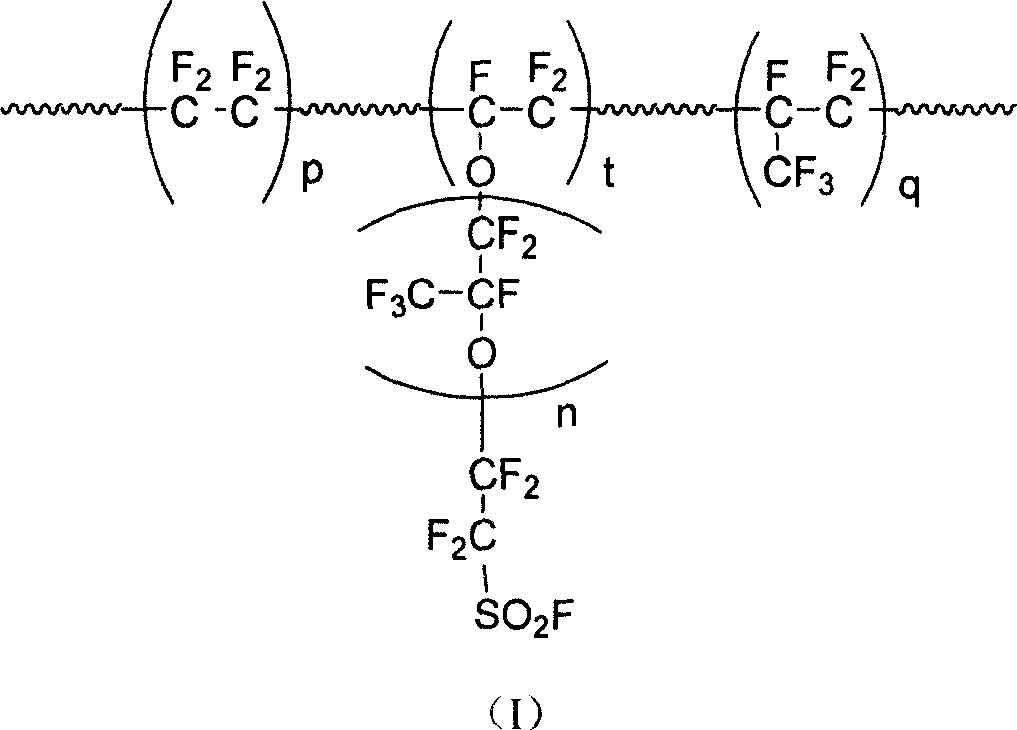

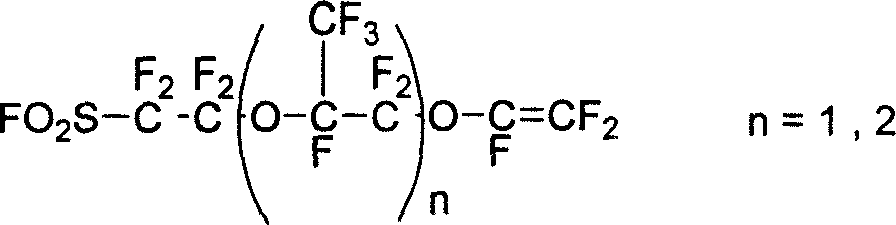

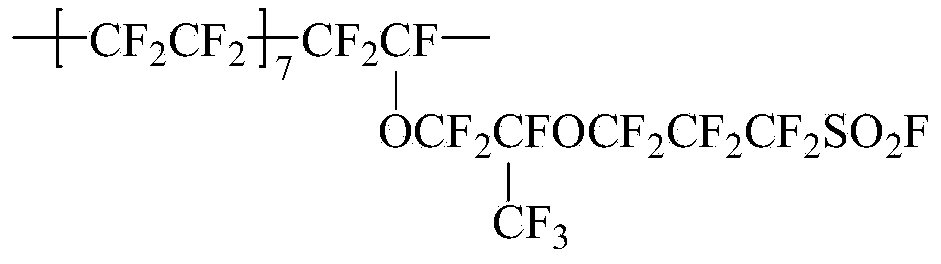

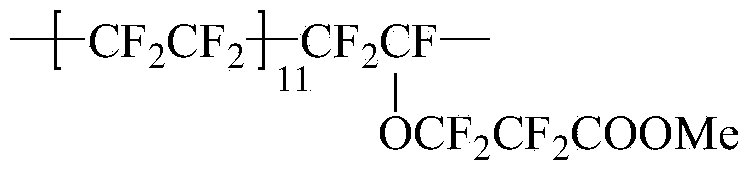

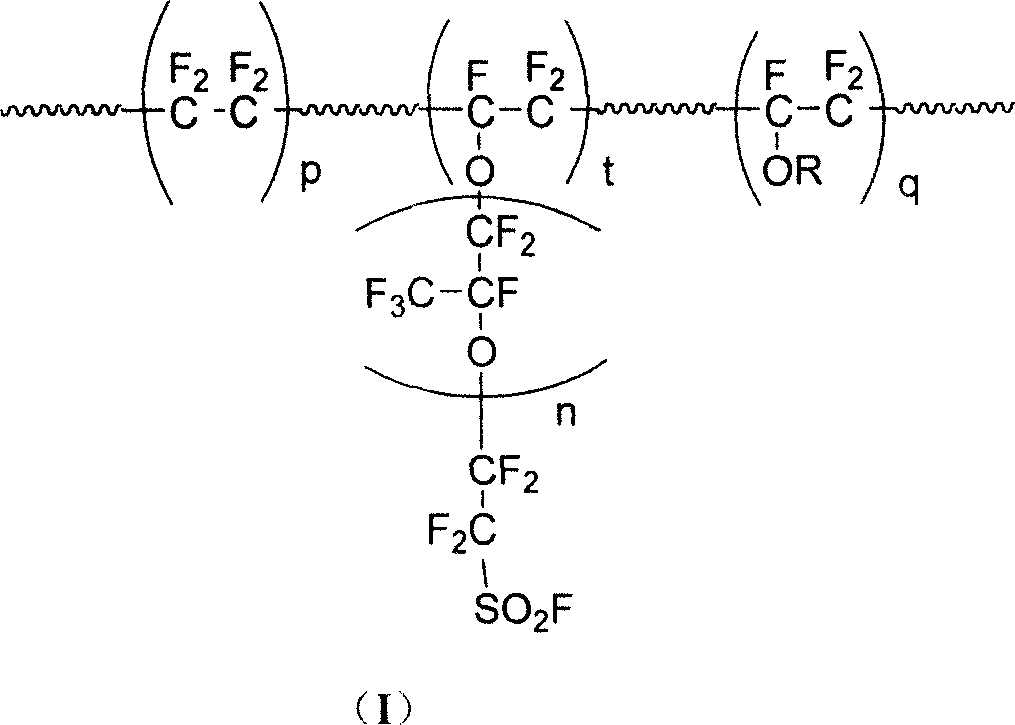

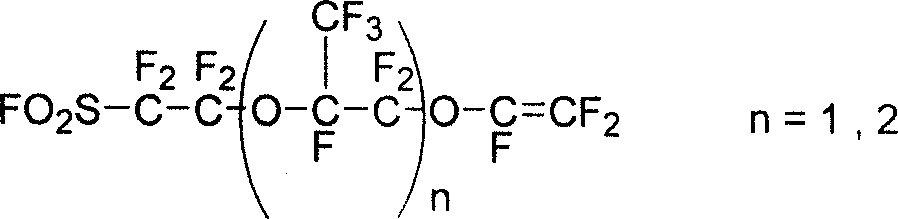

Perfluoro - resin with ion exchange, and application

InactiveCN101003596AIncrease the effective areaLower membrane resistance and cell voltageMelt spinning methodsIon-exchange membranesSolvent

This invention discloses a perfluoro resin containing sulfonylfluoride groups, which is shown in formula 1. The perfluoro resin has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and alkyl vinyl ether in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

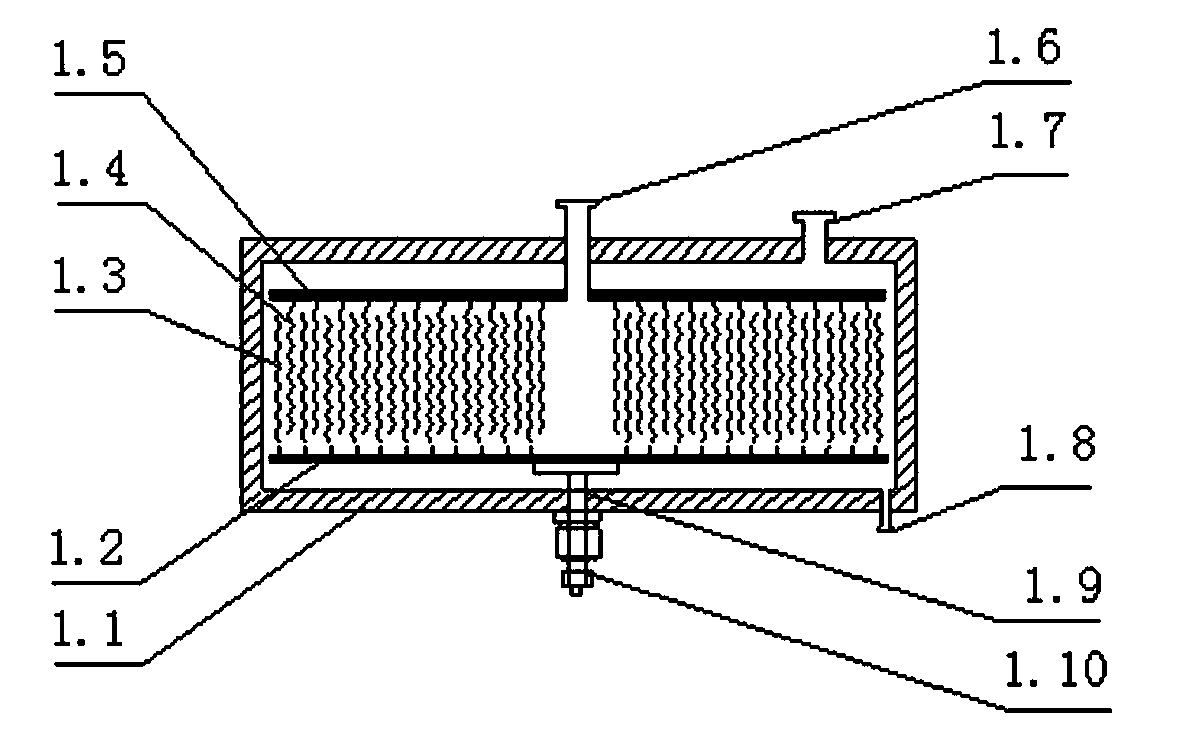

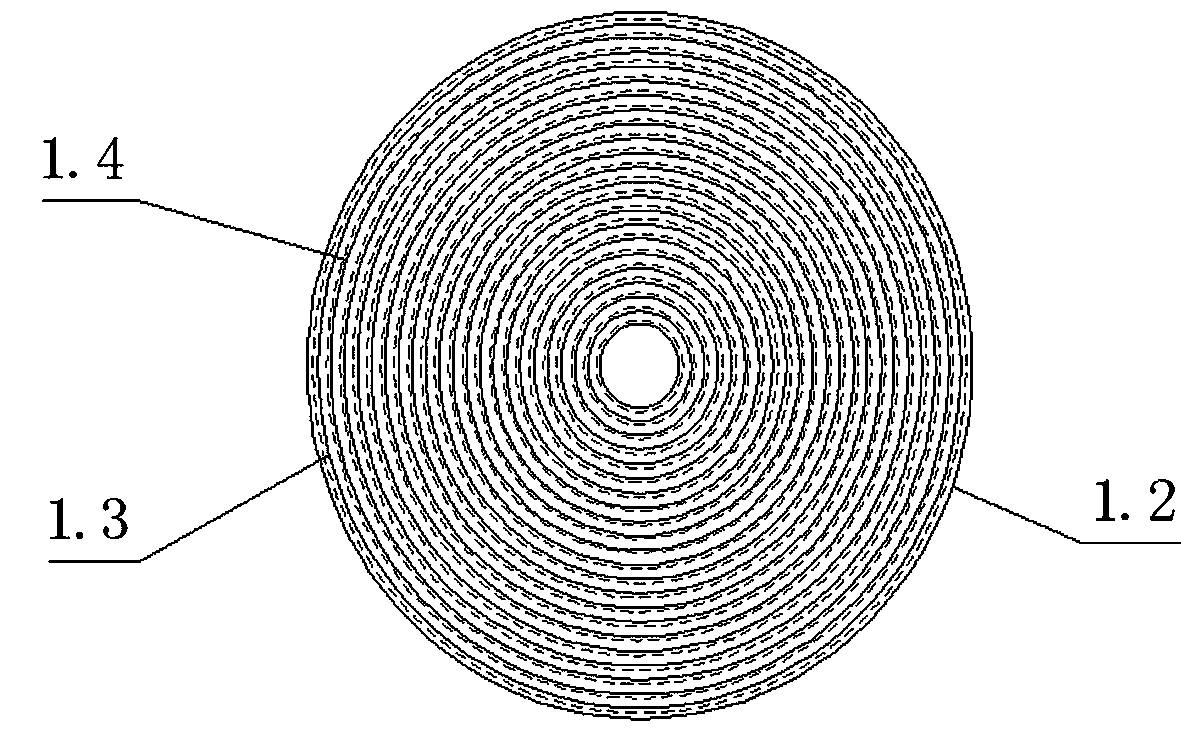

Device and technology for processing degradation-resistant waste water through hypergravity multistage sacrificial anode electro-Fenton method

ActiveCN103613169AImprove processing efficiencyIncrease electrode areaWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationOxygen utilization rateWastewater

The invention belongs to the water processing technology field, concretely provides a device and a technology for processing degradation-resistant waste water through a hypergravity multistage sacrificial anode electro-Fenton method, and solves the problem of mass transfer limitation in processing degradation-resistant waste water through a sacrificial anode electro-Fenton method. The device comprises a plurality of corrugated cylindrical anodes and anode connection disks and a plurality of corrugated cylindrical cathodes and cathode connection disks. The corrugated cylindrical cathodes and the cathode connection disks are stationary relative to a shell. The centers of the anode connection disks are connected with a rotating shaft. In the technology, the rotary corrugated cylindrical anodes and anode connection disks, the stationary corrugated cylindrical cathodes and cathode connection disks and a H2O2 solution form a hypergravity multistage sacrificial anode electro-Fenton reaction system. The device and the technology can reinforce the mass transfer process of the electro-Fenton reaction. The electrode area utilization rate, the oxygen utilization rate, the H2O2 production rate and the processing efficiency are all raised. The device has advantages of small size, low load and low energy consumption, and is suitable for continuous operation and scale processing.

Owner:ZHONGBEI UNIV

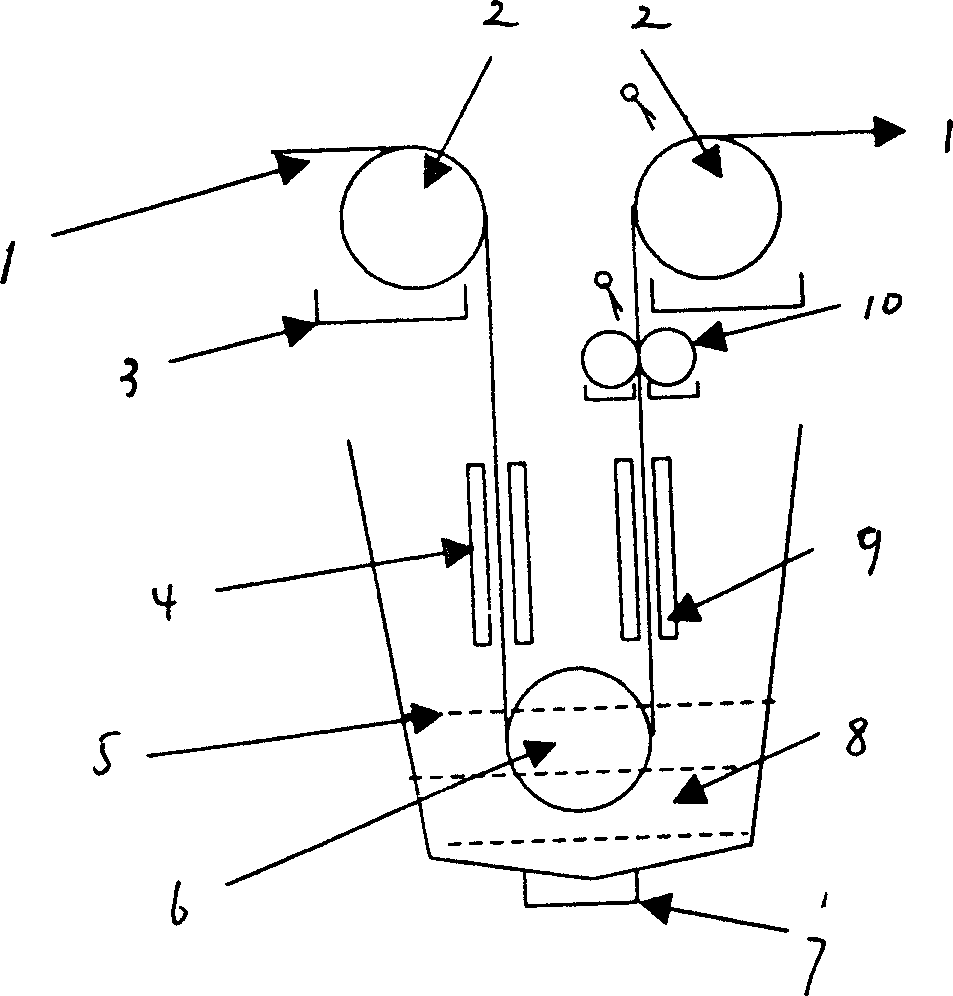

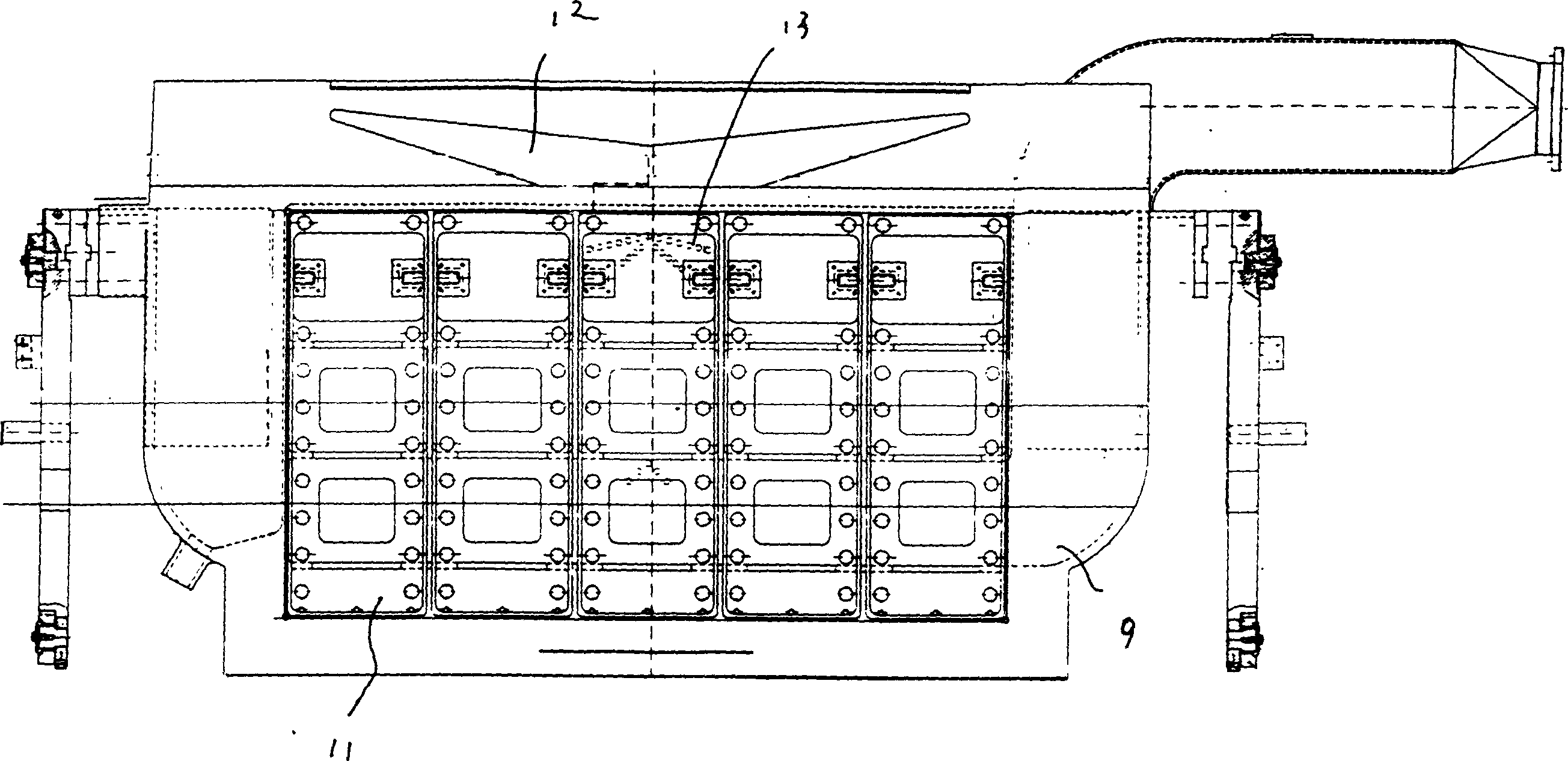

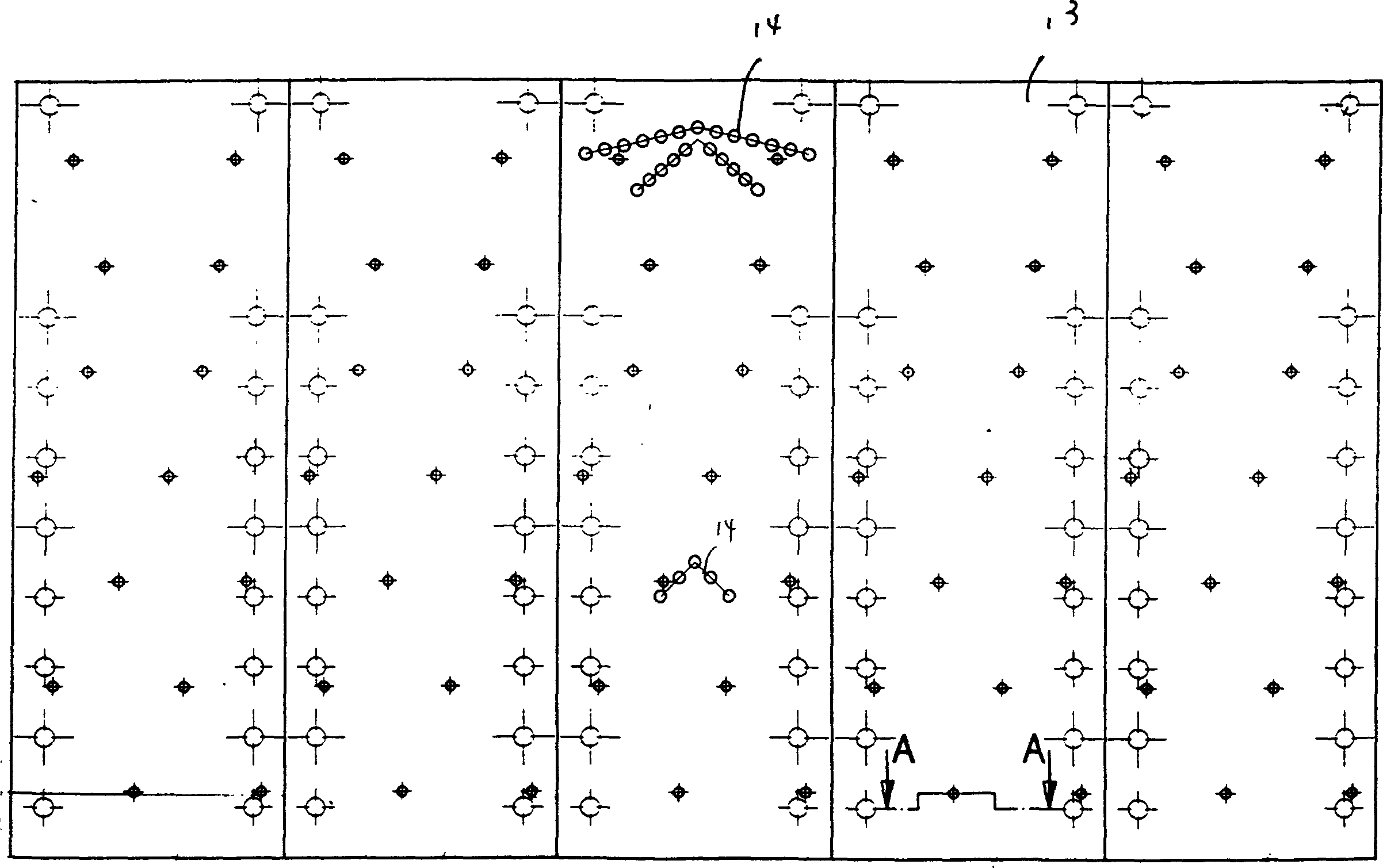

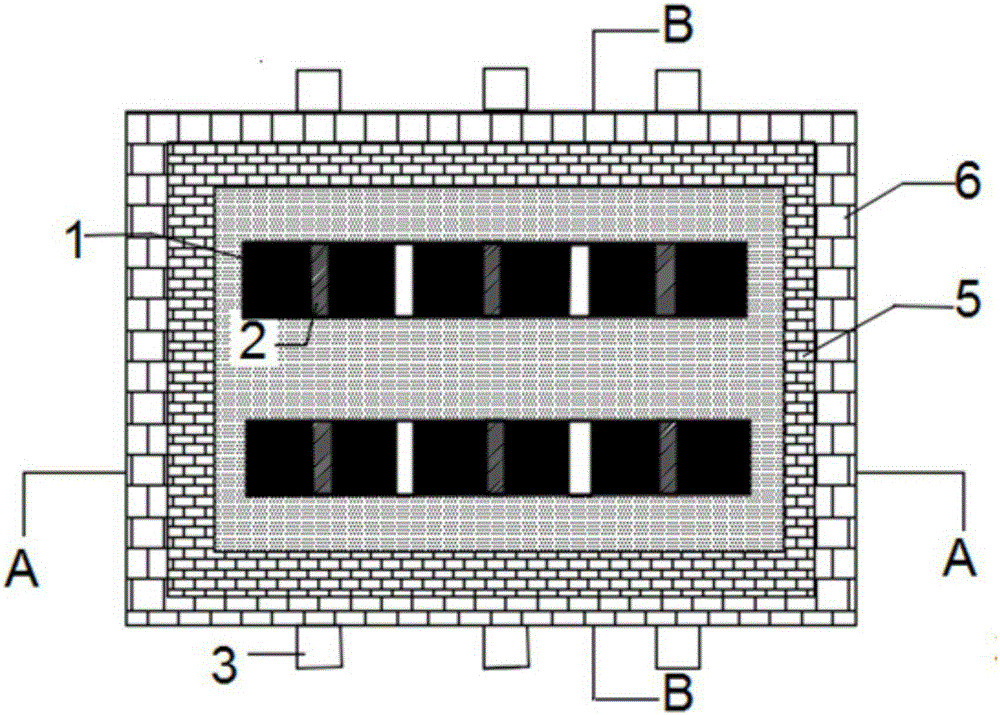

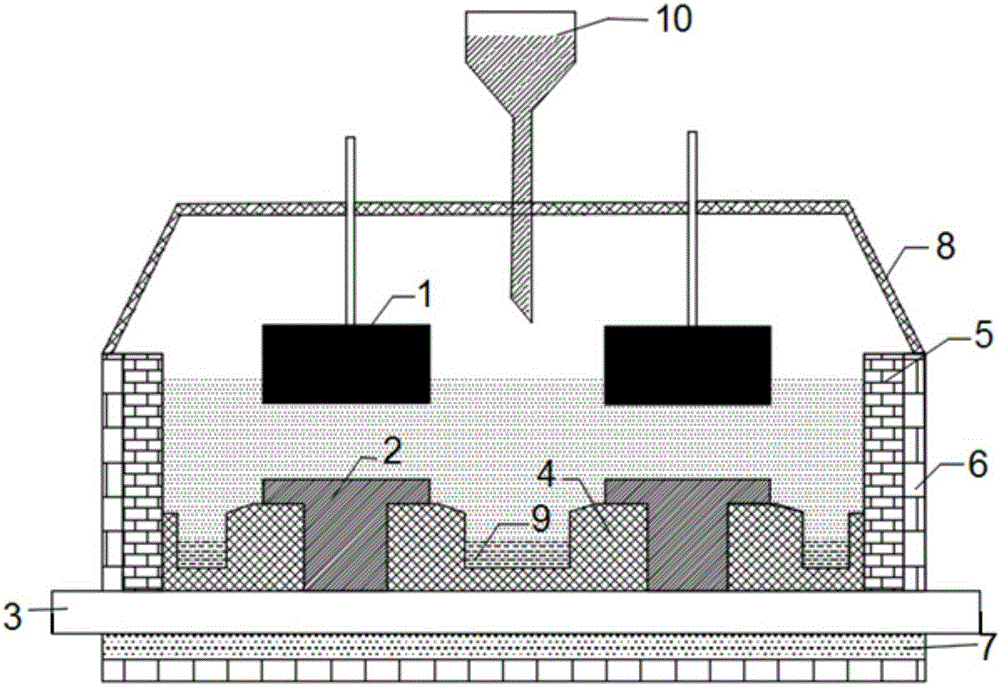

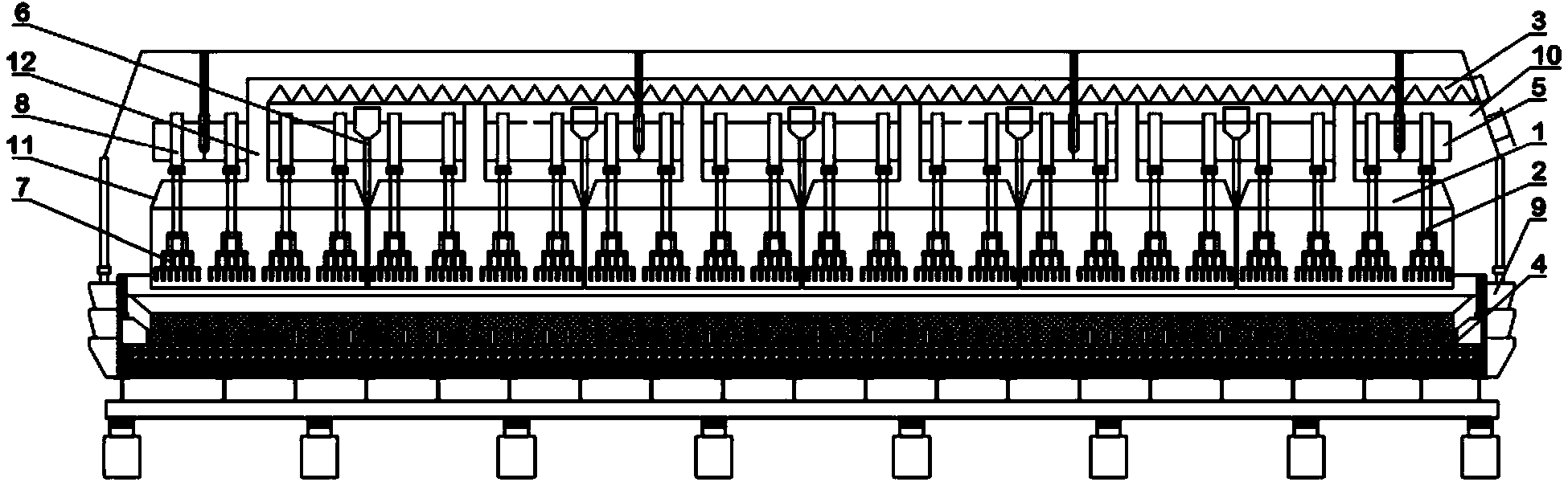

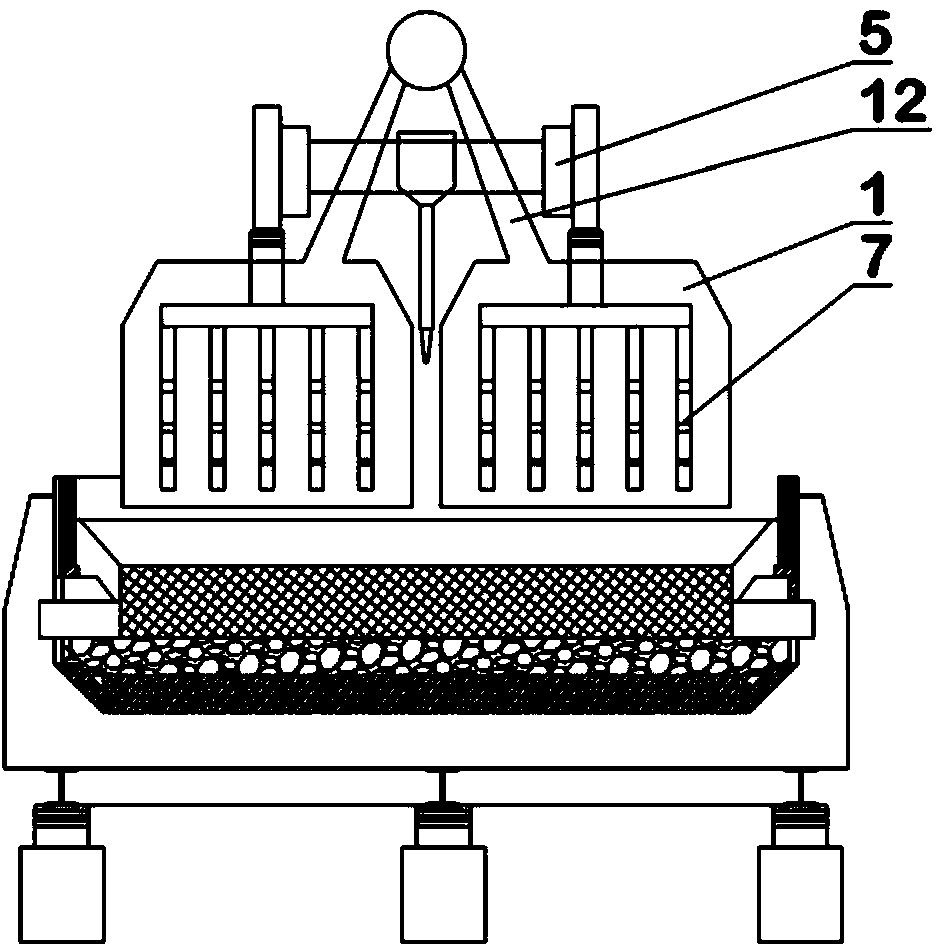

Oversize continuous-production energy-saving environment-friendly aluminum electrolysis cell

The invention discloses an oversize continuous-production energy-saving environment-friendly aluminum electrolysis cell, particularly an electrolysis cell with the current intensity of greater than 400kA. The electrolysis cell is mainly composed of a cell shell, (9), a cell lining (4) and an upper structure (10), wherein the upper structure (10) is provided with a novel continuous automatic baked anode (1); an anode network conductive system (2) is arranged in the (1); and the upper structure (10) is also provided with a conventional aluminum oxide blanking system (6), an anode cross beam bus (5) and an anode paste automatic blanking and sealing device (3). The oversize aluminum electrolysis cell can implement continuous energy-saving production. The number of anodes can be set and the anode conductive network can be configured according to the actual cell type, thereby implementing the optimized current configuration in the anode and also implementing continuous energy-saving production of the oversize aluminum electrolysis cell. Besides, the automatic baked anode and blanking pipeline are sealed to implement clean production. The cell lining, bus structure and the like do not need to be changed, and thus, the electrolysis cell is easy to implement.

Owner:国网电力科学研究院武汉能效测评有限公司 +1

Annular radial-flow negative-pressure suction internal loop photoelectric catalytic reactor

ActiveCN104445533ADoes not reduce treatment effectIncrease expansionWater/sewage treatment by irradiationWater contaminantsAir pumpEngineering

The invention provides an annular radial-flow negative-pressure suction internal loop photoelectric catalytic reactor, comprising a photoelectric catalysis oxidation reaction system and an annular radial-flow negative-pressure suction internal loop water inlet system, wherein the photoelectric catalysis oxidation reaction system comprises a plate-type tubular DSA anode and a mesh-type tubular titanium cathode; a granular photoelectric catalyst is filled between the anode and the cathode; an ultraviolet generator is arranged in the mesh-type tubular titanium cathode; the annular radial-flow negative-pressure suction internal loop water inlet system is arranged at the lower part of the photoelectric catalysis oxidation reaction system; a liquid injection pipe is arranged at the center of the water inlet system; a plurality of pipelines with adjustable lengths are arranged at a bottleneck of the liquid injection pipe; the liquid injection pipe is communicated with an annular radial-flow water feeder which is densely distributed with constant-diameter round holes in a bottom region of the reactor; a gas injection pipe is arranged at the top of the reactor; an air inlet of the gas injection pipe is connected with a compressed air pump; an air outlet is connected with the atmosphere; the bottleneck is connected with an exhaust pipe at the top of the reactor; and hydrogen generated in the reactor is diluted and discharged.

Owner:CHINA NAT OFFSHORE OIL CORP +2

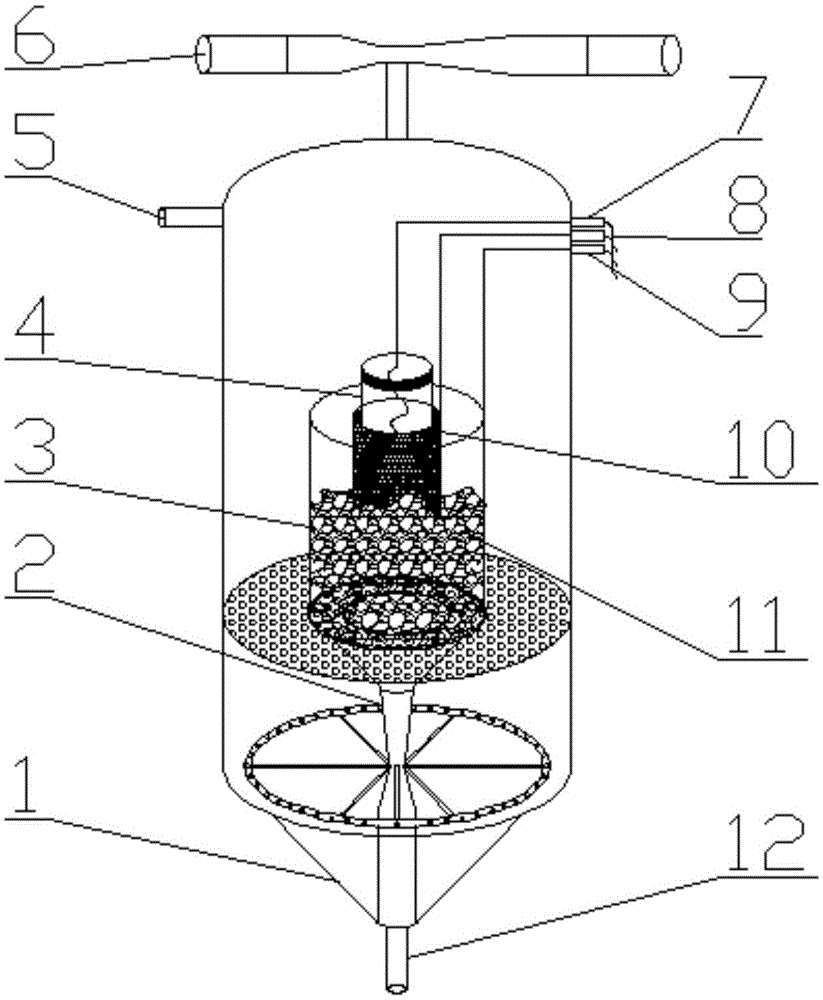

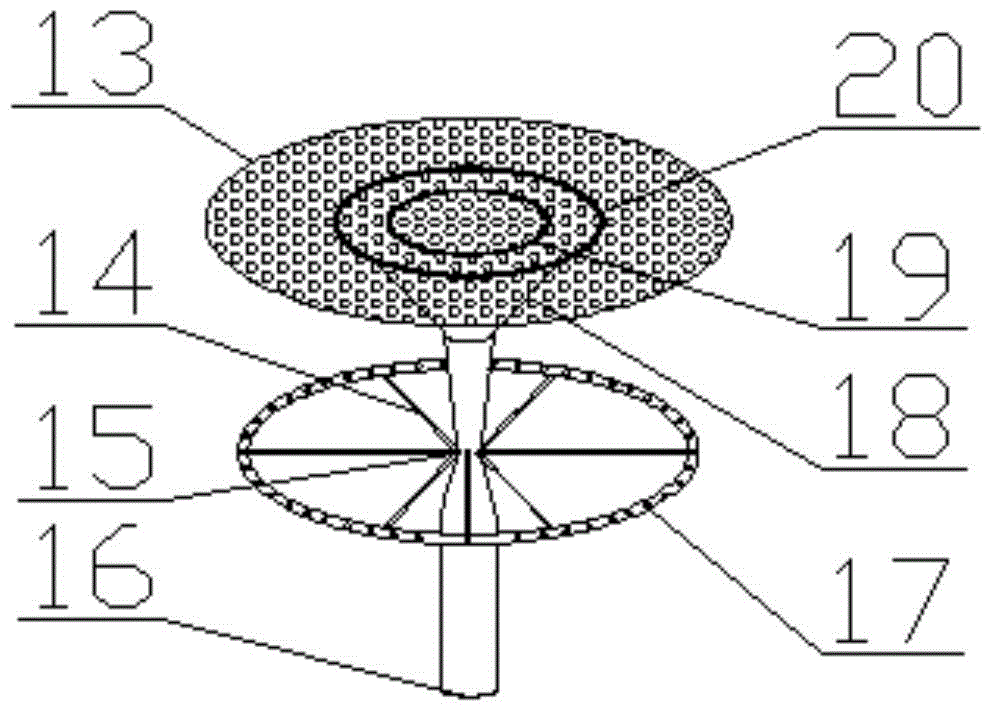

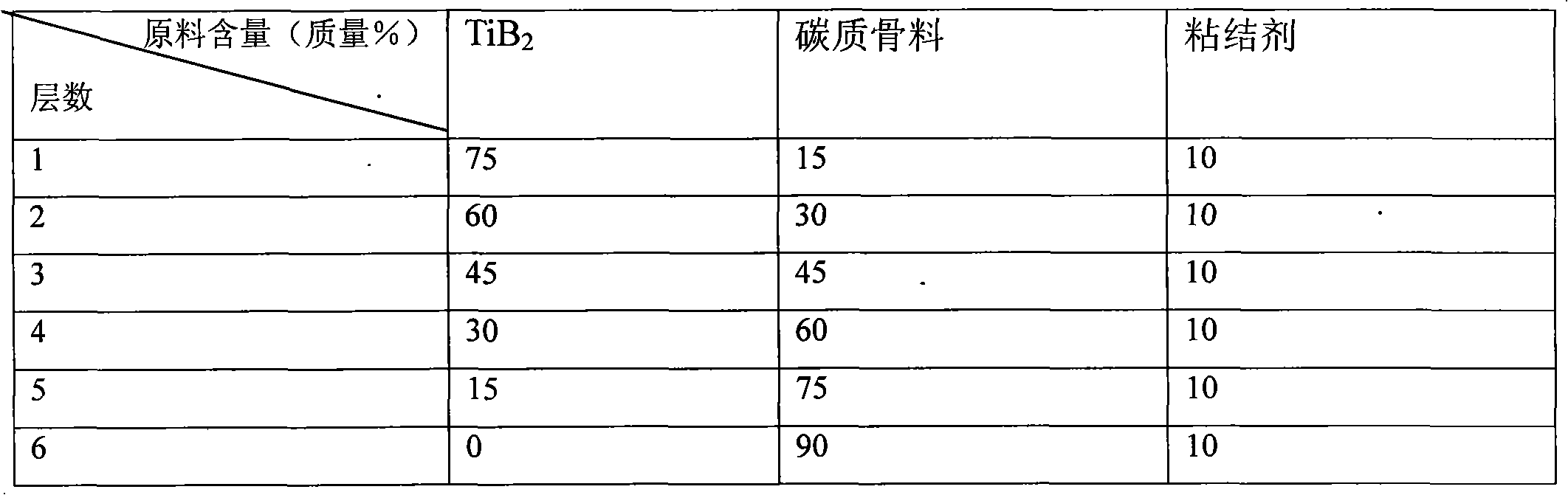

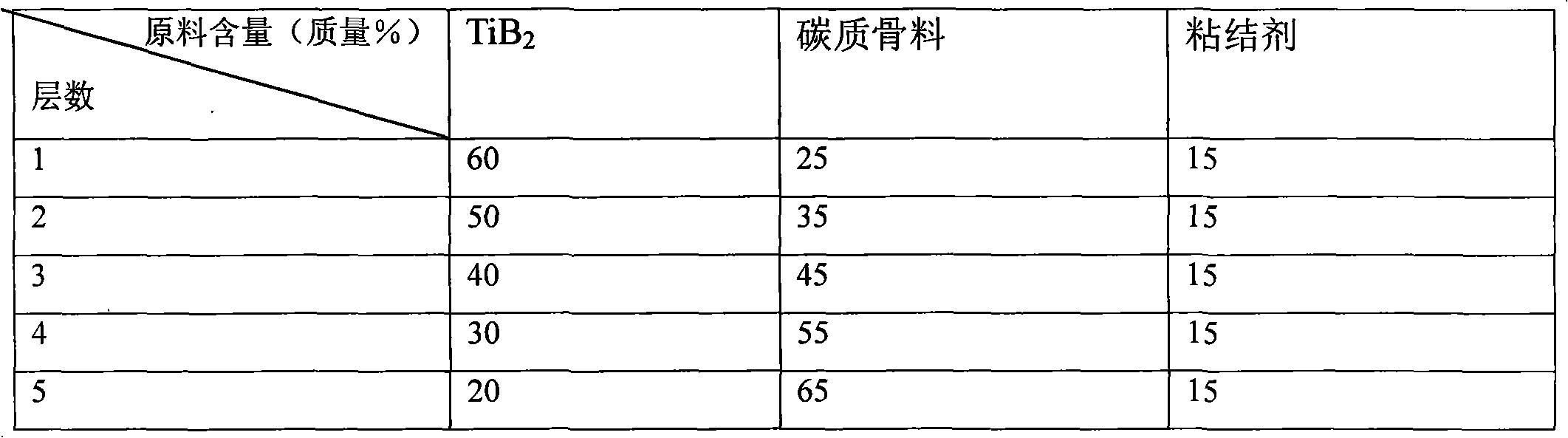

Preparation method of TiB2/C gradient cathode material for aluminum electrolytic bath

InactiveCN101608321AImproved working characteristics of the working faceImprove working characteristicsContinuous mixingMaterials science

The invention relates to a preparation method of TiB2 / C gradient cathode material for an aluminum electrolytic bath, which belongs to the technical field of electrolytic aluminum. The adopted raw materials comprise TiB2, carbon aggregate and cementing agent. The procedure is continuous dosing, continuous mixing and paving and adopts the sequence as follows: the content of the TiB2 in each layer sequentially increases and changes from a bottom layer to a surface layer, and the content of the carbon aggregate sequentially reduces and changes; or the content of the TiB2 sequentially reduces and changes, and the content of the carbon aggregate sequentially increases and changes; the materials paved layer by layer are hot-pressed and sintered, and then are naturally cooled to the room temperature so as to obtain the product. Because micro components of the materials prepared by the invention sequentially change, the invention can better solve the problems of easy coating shedding and the like caused by thermal mismatching of carbon and TiB2; meanwhile, the cathode material has strong sodium corrosion resistance, can remarkably improve the current efficiency of the electrolytic bath, and prolongs the service life of the electrolytic bath.

Owner:NORTHEASTERN UNIV

Inertial electrode low-temperature aluminium electrolytic cell

The invention discloses an inertial electrode low-temperature aluminium electrolytic cell comprising a electrolytic cell body, a metallic ceramic inertial anode, a wettable cathode and a low-temperature electrolyte, wherein, the wettable cathode is arranged at the bottom of the electrolytic cell body; the low-temperature electrolyte is arranged in the electrolytic cell body; the metallic ceramic inertial anode is arranged at the upper part of the electrolytic cell body, and end part of the metallic ceramic inertial anode extends into the low-temperature electrolyte; the metallic ceramic inertial anode is composed of at least two groups of metal ceramic inertial anode sets; each metallic ceramic inertial anode set is composed of at least two metallic ceramic inertial anode monomers; the metallic ceramic inertial anode sets and the metal ceramic inertial anode monomers in the same metal ceramic inertial anode sets are both in electrical parallel connection. The inertial electrode low-temperature aluminium electrolytic cell has reasonable structure, simple and convenient operation, stable operation, less oxygen discharge and small aluminium liquid fluctuation, low electrolytic cell voltage, low operation temperature and less energy consumption, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

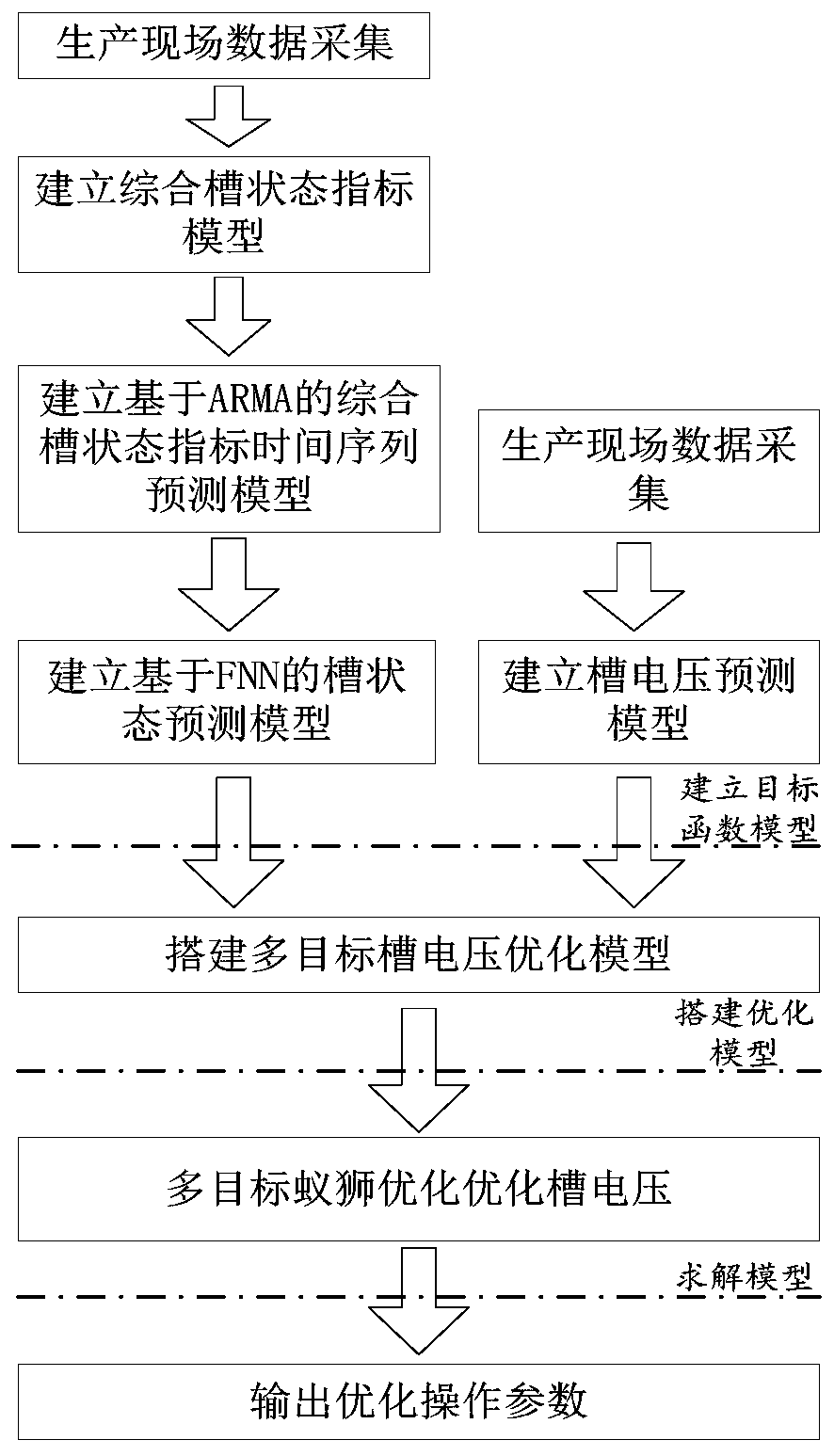

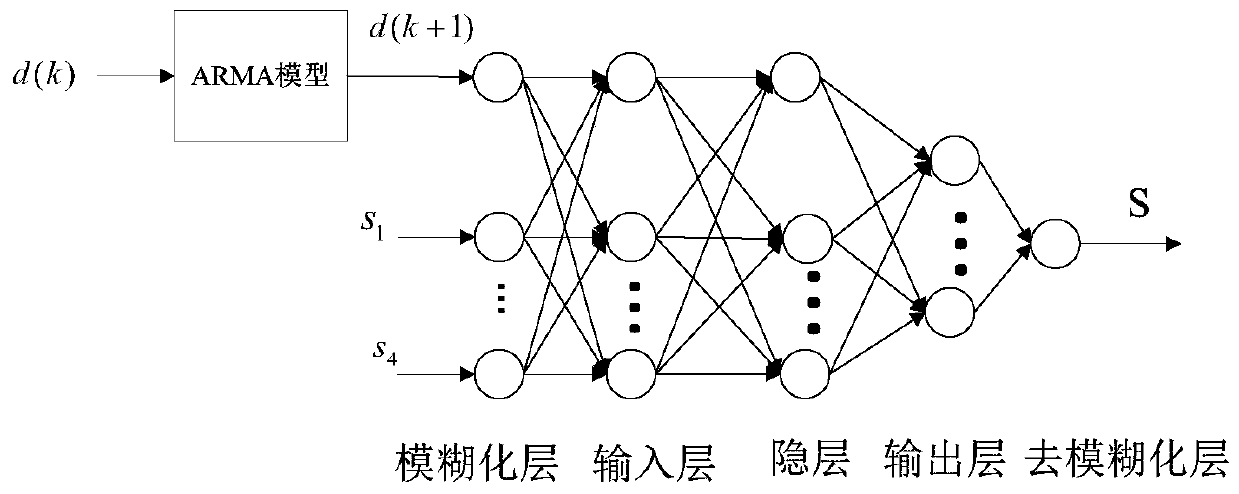

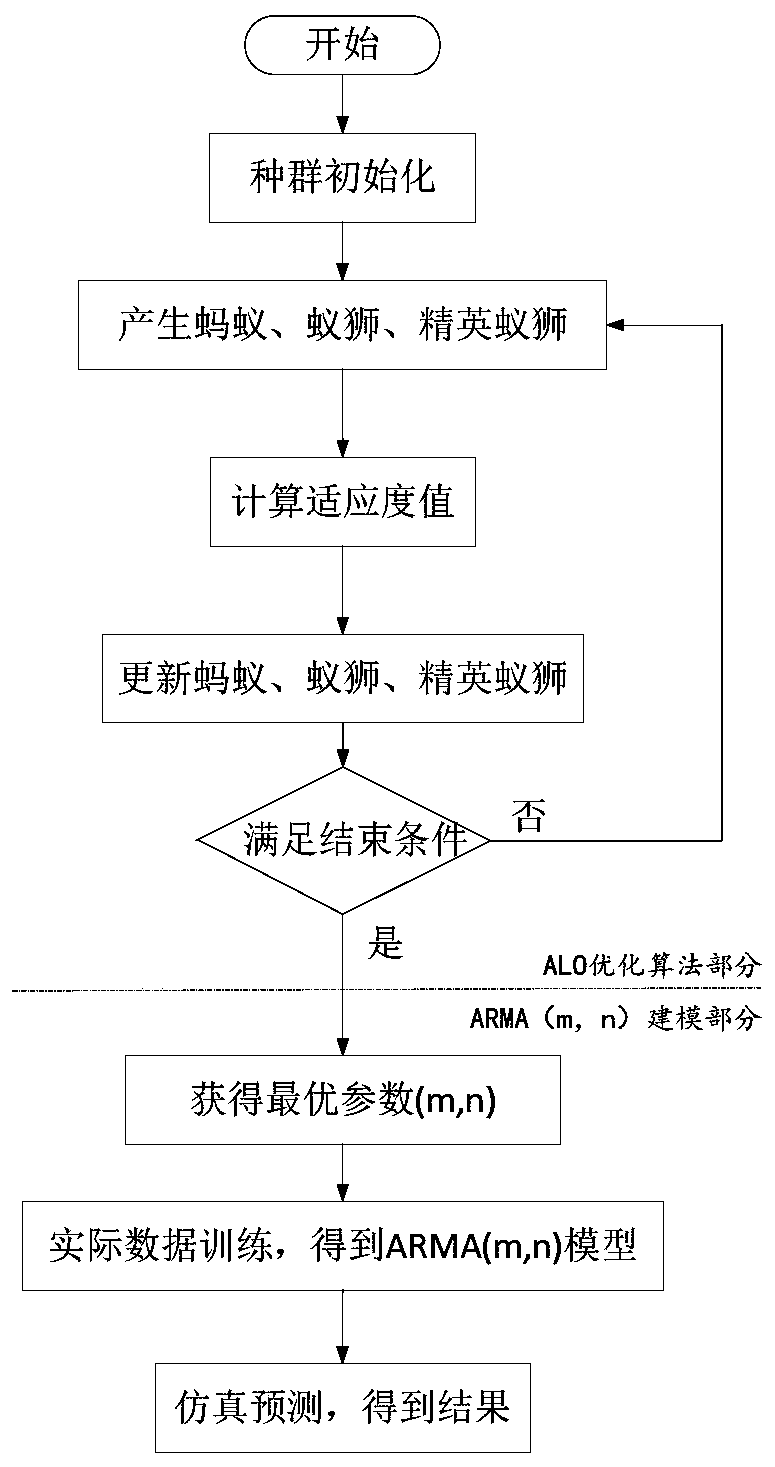

Multi-target optimization method for bath voltage in aluminum electrolysis process

ActiveCN110129832AGood conditionLower cell voltageComposite indicatorLeast squares support vector machine

The invention discloses a multi-target optimization method for bath voltage in an aluminum electrolysis process. The multi-target optimization method comprises the following steps: step 1, collectingand washing data of an aluminum electrolysis production site; step 2, establishing a bath state comprehensive index model related to stability, material balance and energy balance; step 3, establishing an autoregression moving average model for predicating a time sequence of a comprehensive index; step 4, taking a state time sequence solved in step 3 as input and establishing a fuzzy neural network for predicating the bath state; step 5, establishing a bath voltage predication model by adopting an ant lion optimized LSSVM (Least Squares Support Vector Machine); step 6, taking minimum difference between the bath voltage and a target value and a good bath state as targets and taking production operation requirements as constraint conditions to establish a multi-target optimization model forthe bath voltage; and step 7, solving the model by adopting a multi-target ant lion optimization algorithm, so as to solve one group of optimized setting values. The group of optimized setting value can provide guidance for operating workers; and the bath voltage is reduced while the good bath state is ensured and the aims of energy saving and consumption reduction are realized.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com