Novel rare-earth electrolytic bath

An electrolytic cell and rare earth technology, applied in the electrolytic process, electrolytic components, electrodes, etc., can solve problems such as inability to adjust, constant change of pole distance, heat loss in open electrolytic cells, etc., to achieve automatic feeding control and lower cell voltage , to solve the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

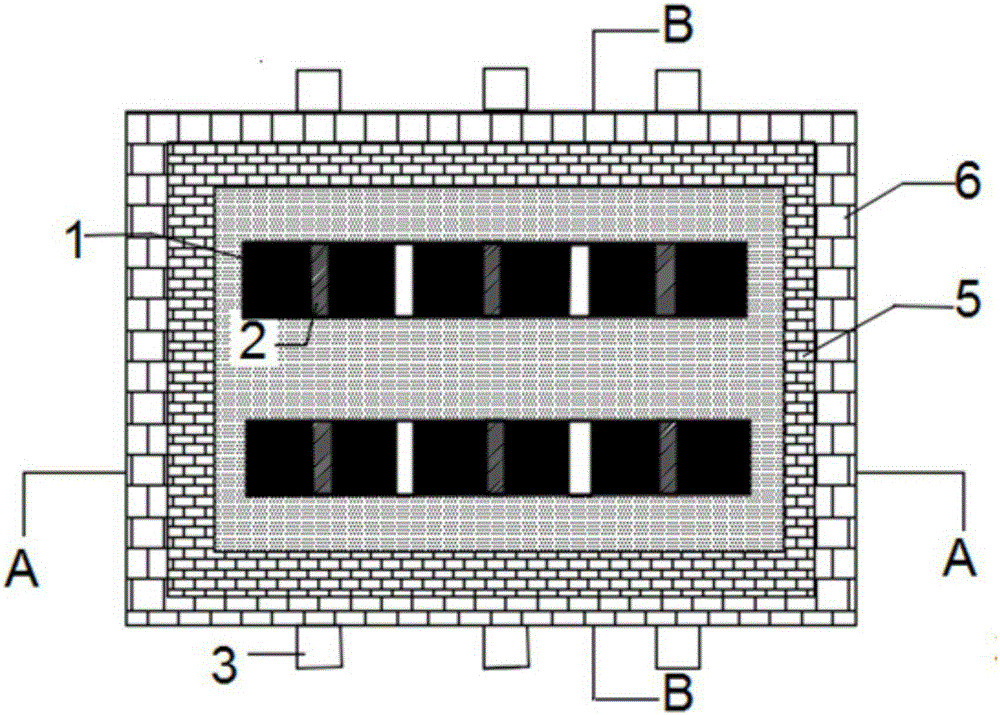

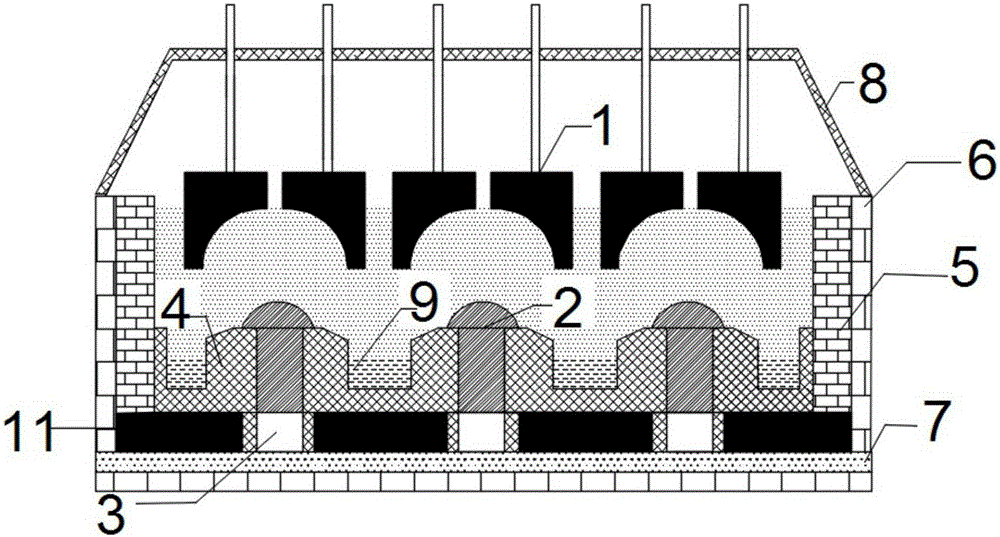

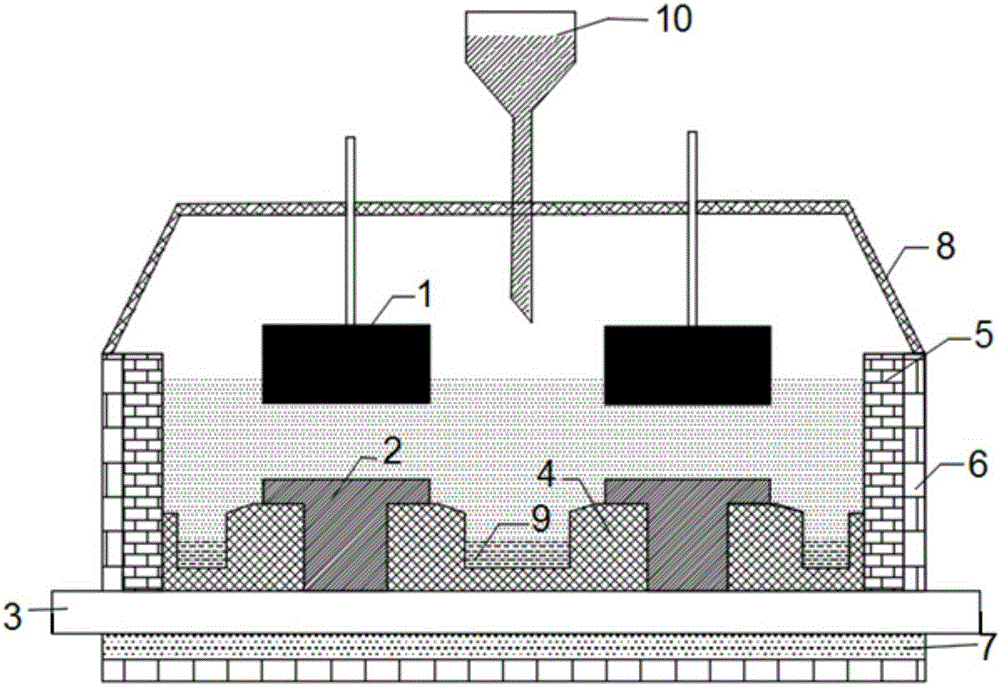

[0027] see figure 1 , figure 2 , image 3 In this embodiment, the cathode is placed under the anode, the bottom of the anode is an arc-shaped concave surface, and the top of the cathode is an arc-shaped convex surface. An anode in this embodiment is composed of two anode blocks, and a gap is left between the two anode blocks , Through the combination of the concave surface and the gap, the air bubbles can be discharged more quickly without staying at the bottom of the anode. In this embodiment, 6 anodes and corresponding 6 cathodes are arranged in the electrolytic cell. The anode is graphite and the cathode is tungsten. The cathode is buried in the raised high-temperature insulating material, and criss-cross metal grooves made of high-temperature insulating material are formed between the cathodes to collect liquid metal. The bottom of the cathode is connected with the cathode steel rod. Each cathode steel rod in this embodiment The rod connects the two cathodes of the sa...

Embodiment 2

[0029] see Figure 4 In this embodiment, the cathode is placed under the anode, the bottom of the anode is an arc-shaped concave surface, and the top of the cathode is an arc-shaped convex surface. In this embodiment, 6 anodes and 6 cathodes are arranged on the upper part of the electrolytic cell, which are divided into two rows. Each row has corresponding 3 anodes and 3 cathodes. In this embodiment, the 3 anodes in a row are composed of 4 anode blocks. The two anode blocks in the middle are T-shaped, and the two anode blocks on both sides are inverted L-shaped. , The assembled anode leaves a gap above the cathode, through the combination of the concave surface and the gap, the air bubbles are discharged more quickly without staying at the bottom of the anode. The anode is graphite and the cathode is molybdenum. The cathode is embedded in the protruding metal material, criss-cross metal grooves made of metal material are formed between the cathodes to collect liquid metal, an...

Embodiment 3

[0031] In this embodiment, the cathode is placed under the anode, the bottom of the anode is an arc-shaped concave surface, and the top of the cathode is an arc-shaped convex surface. An anode in this embodiment is composed of two anode blocks, and a gap is left between the two anode blocks. Through the combination of the concave surface and the slit, the air bubbles can be discharged more quickly without staying at the bottom of the anode. In this embodiment, 6 anodes and corresponding 6 cathodes are arranged in the electrolytic cell. The anode is graphite and the cathode is carbon. The cathode is buried in the raised high-temperature insulating material, and criss-cross metal grooves made of high-temperature insulating material are formed between the cathodes to collect liquid metal. The bottom of the cathode is connected with the cathode steel rod. Each cathode steel rod in this embodiment The rod connects the two cathodes of the same column. Graphite blocks are filled be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com