Patents

Literature

1001results about How to "Increase expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

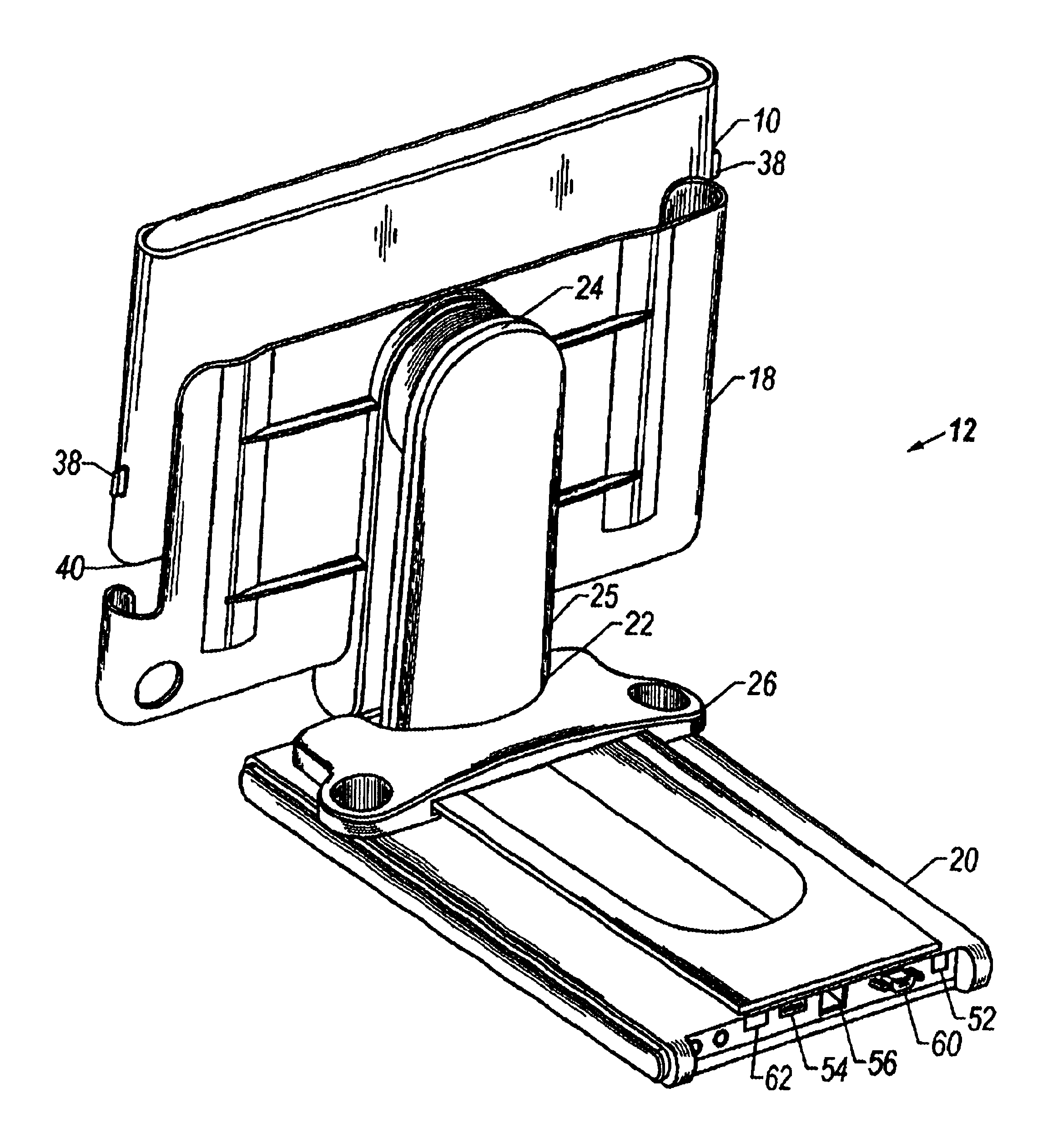

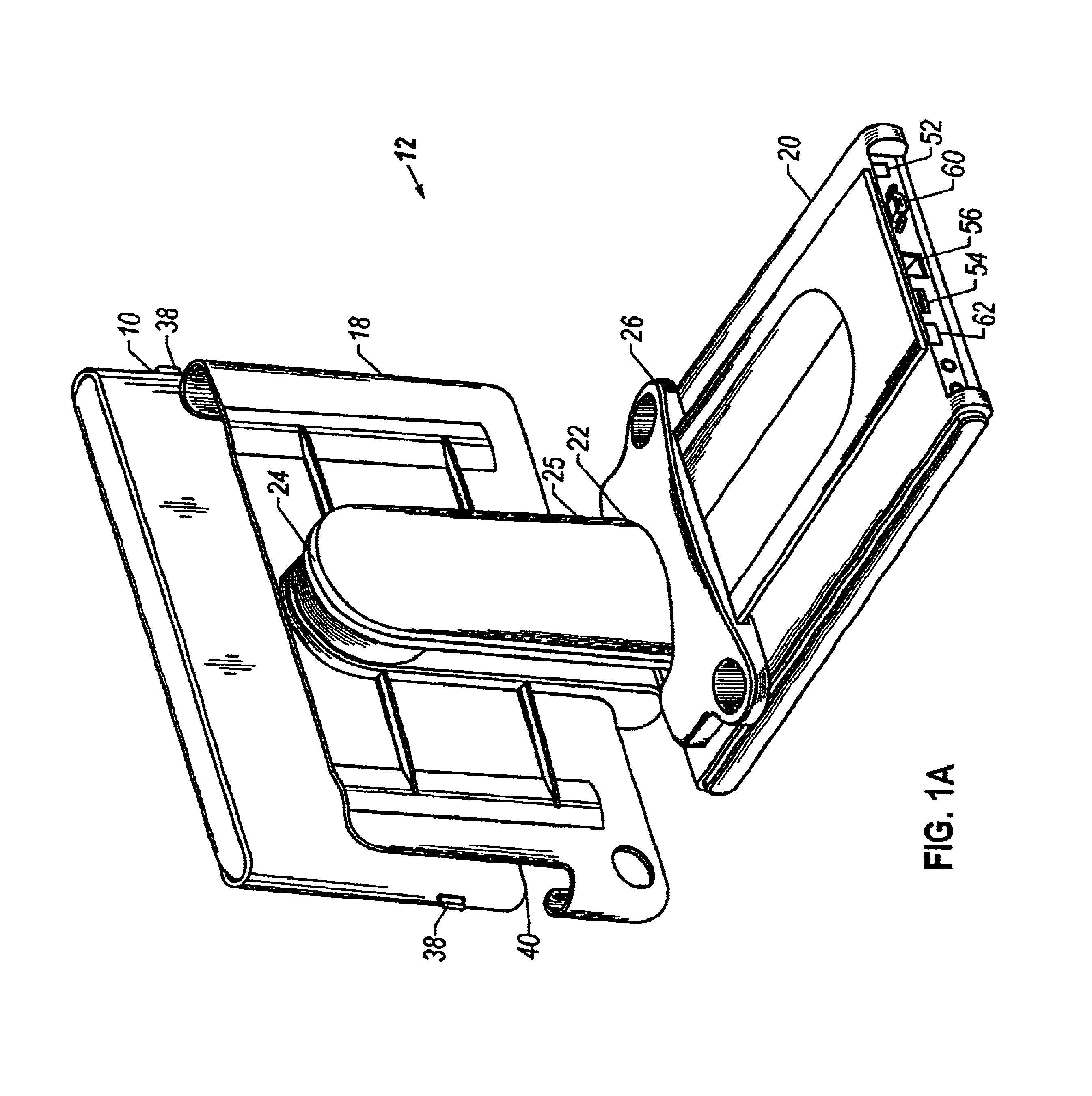

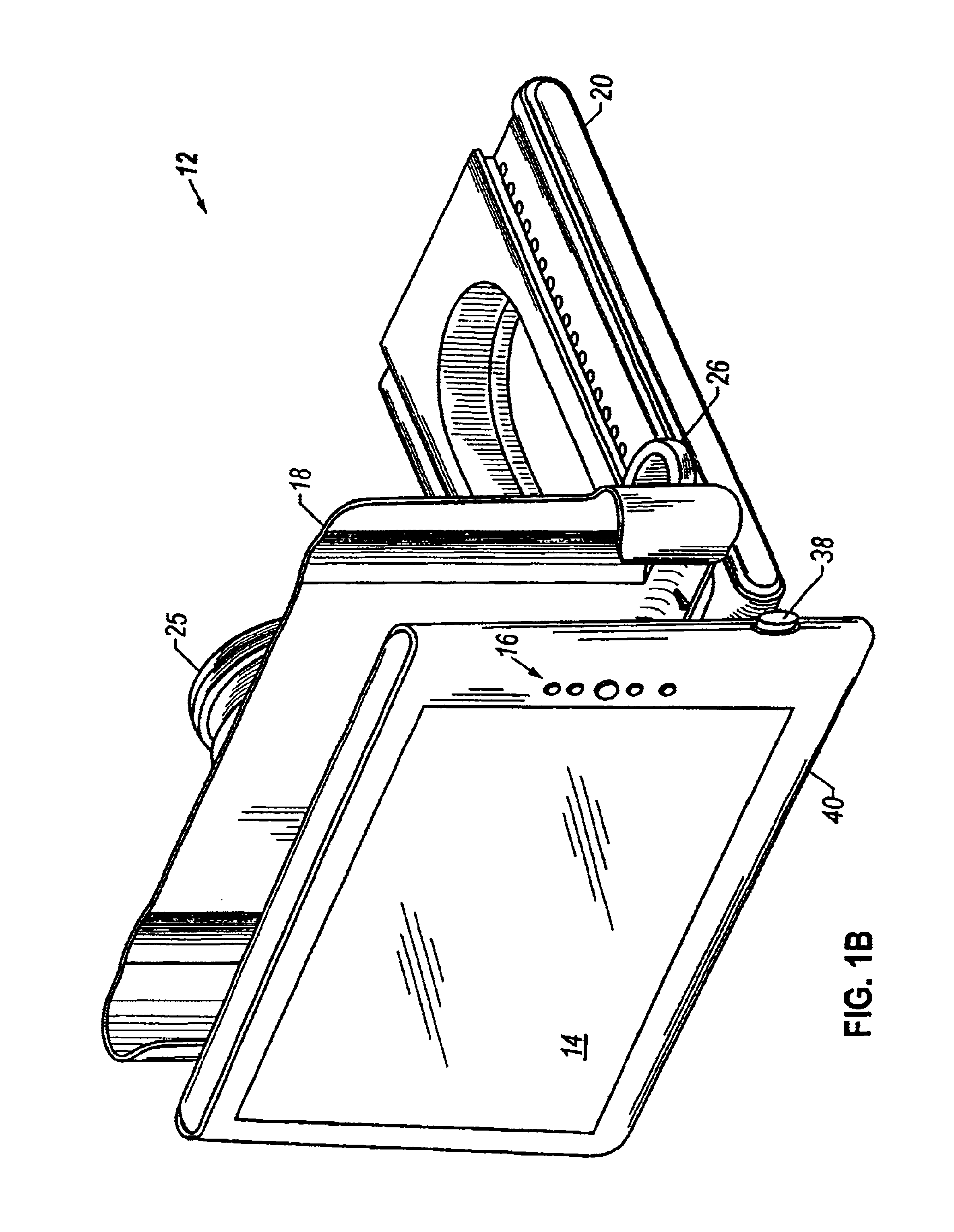

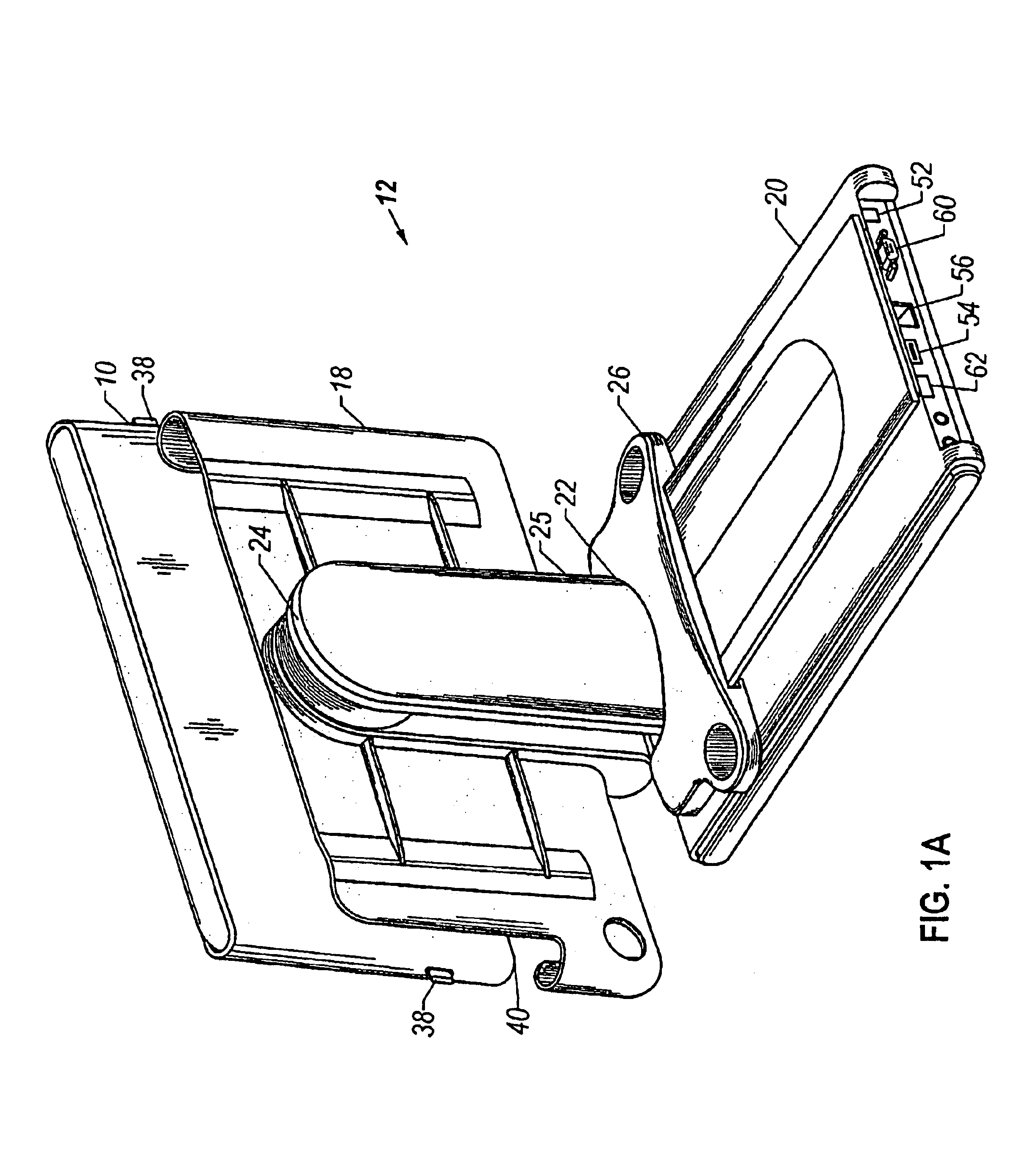

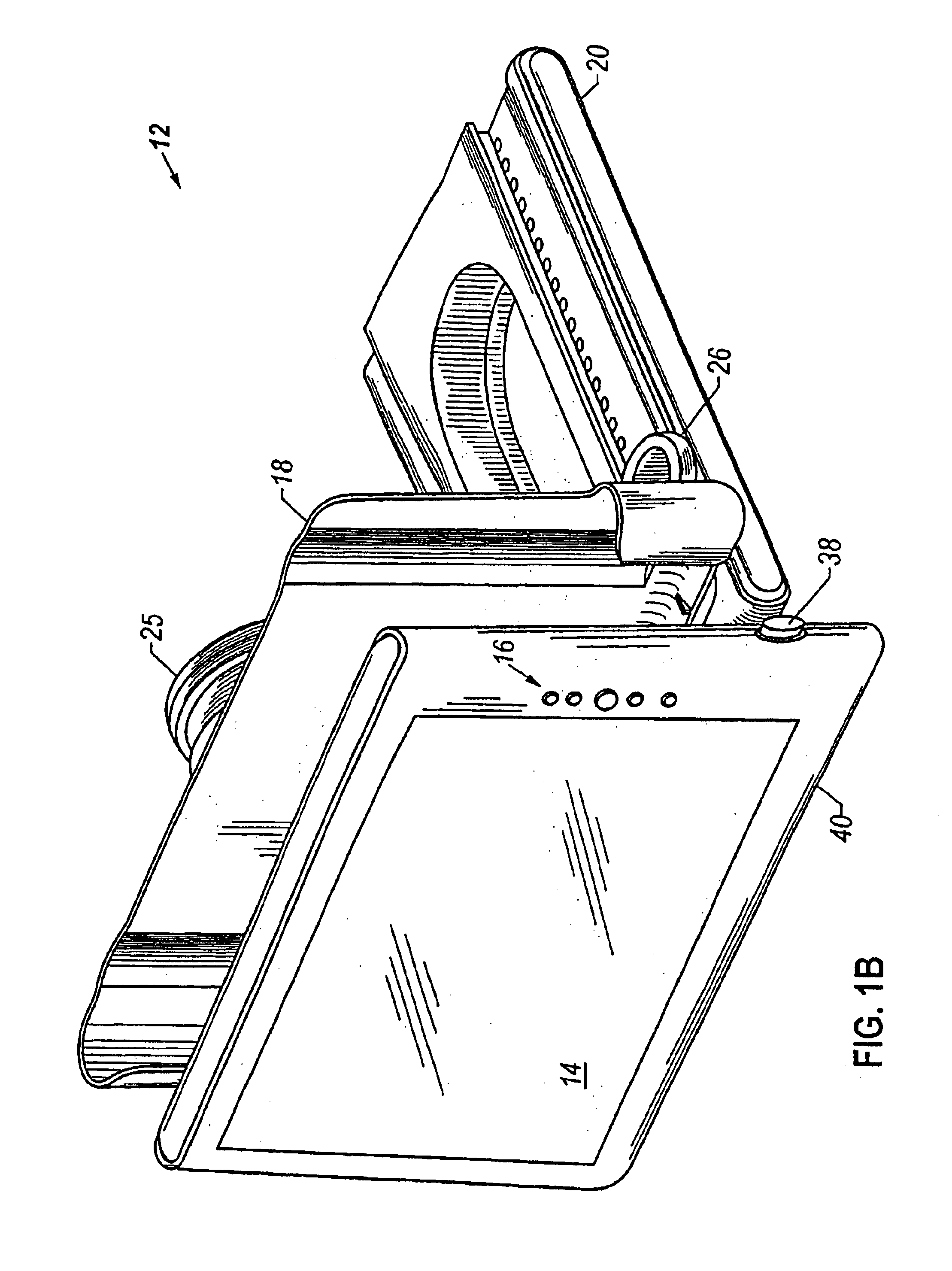

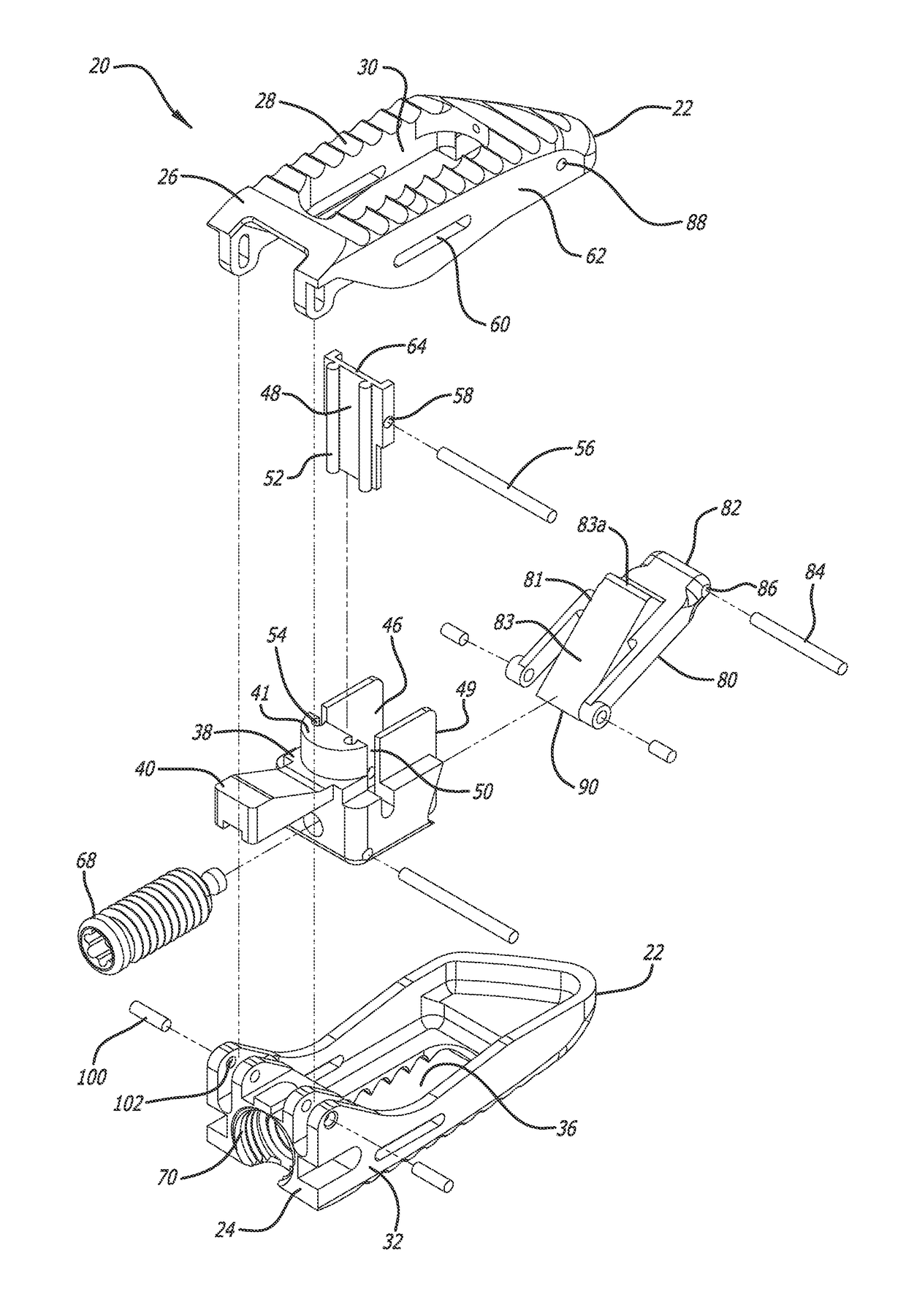

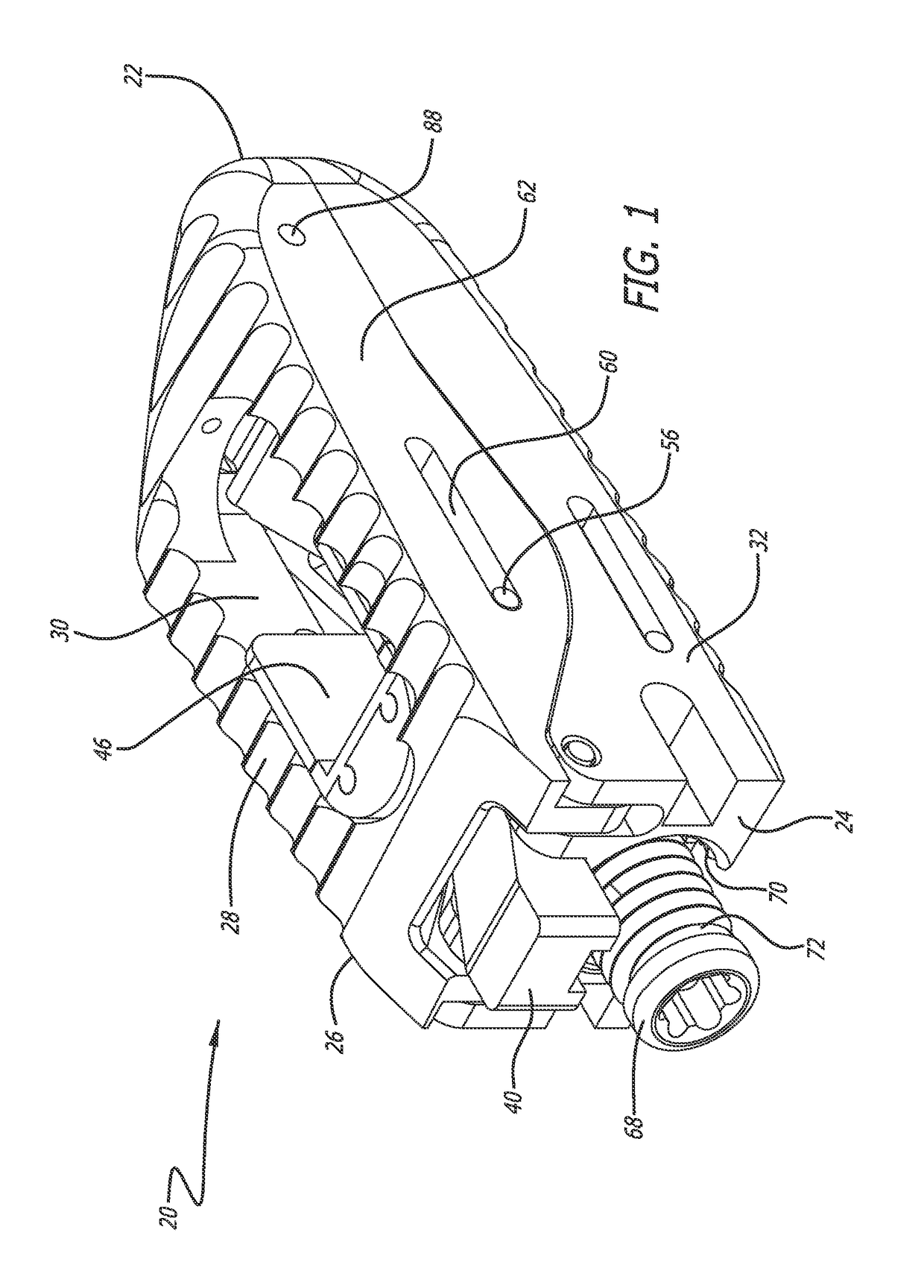

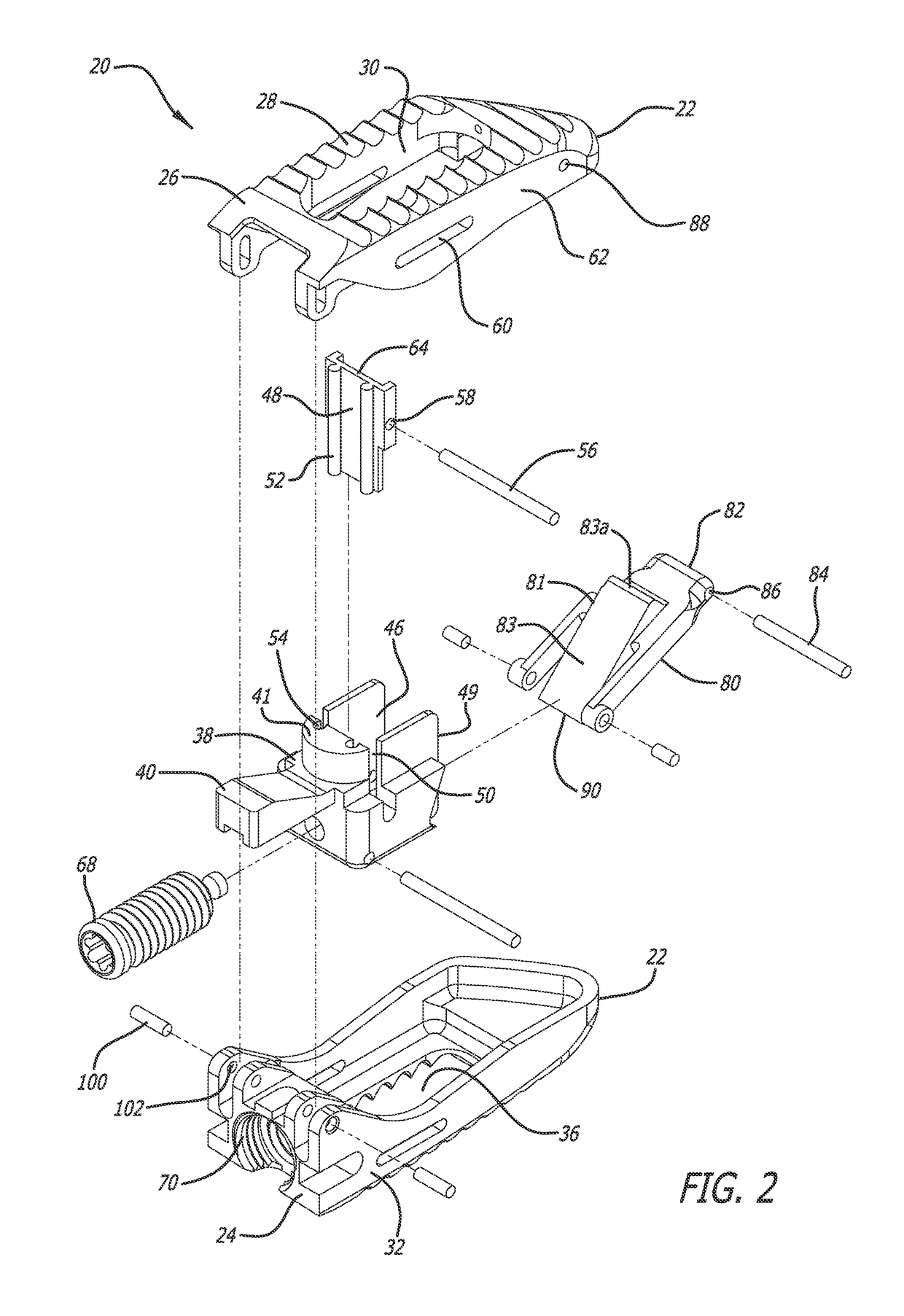

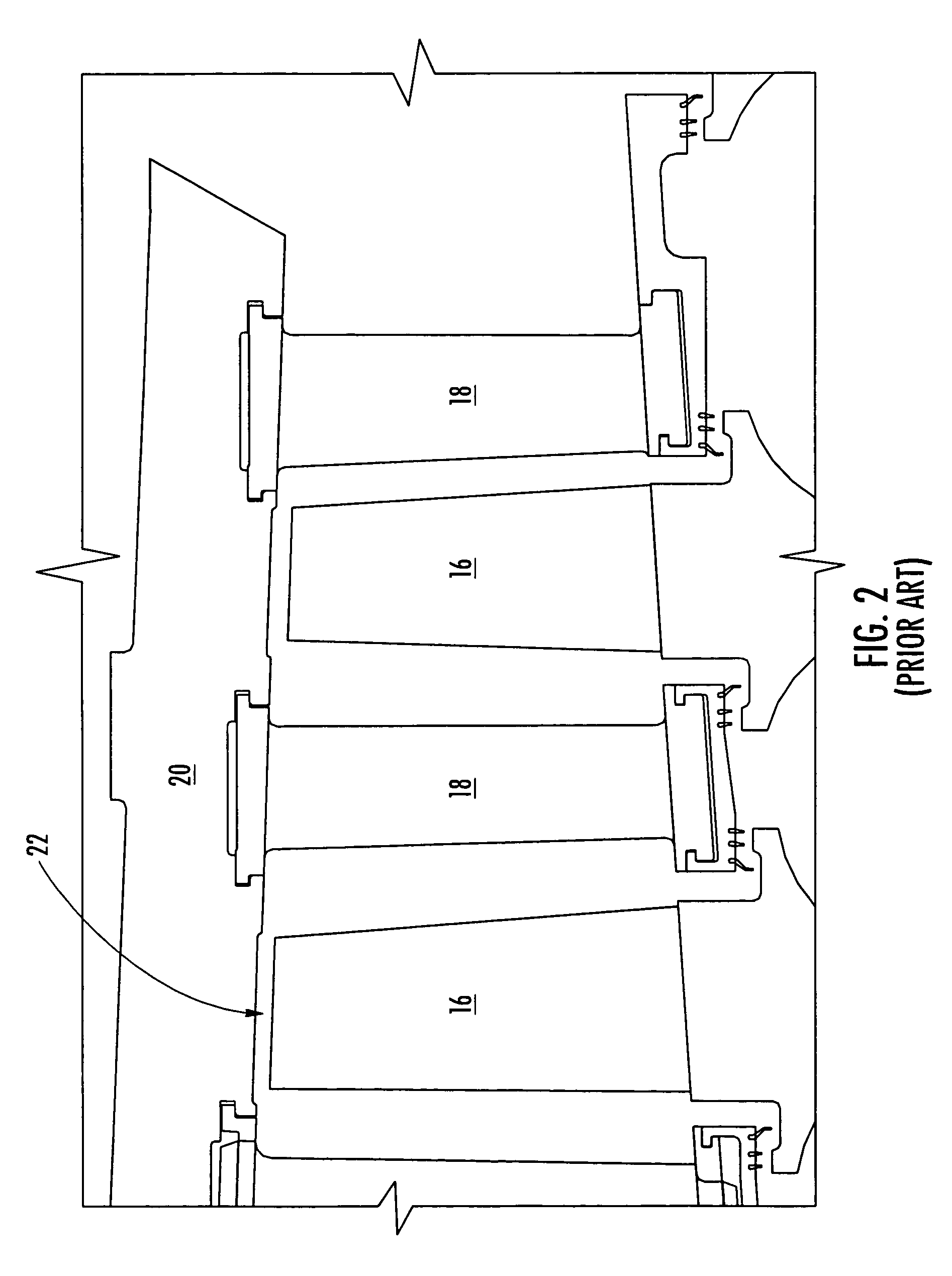

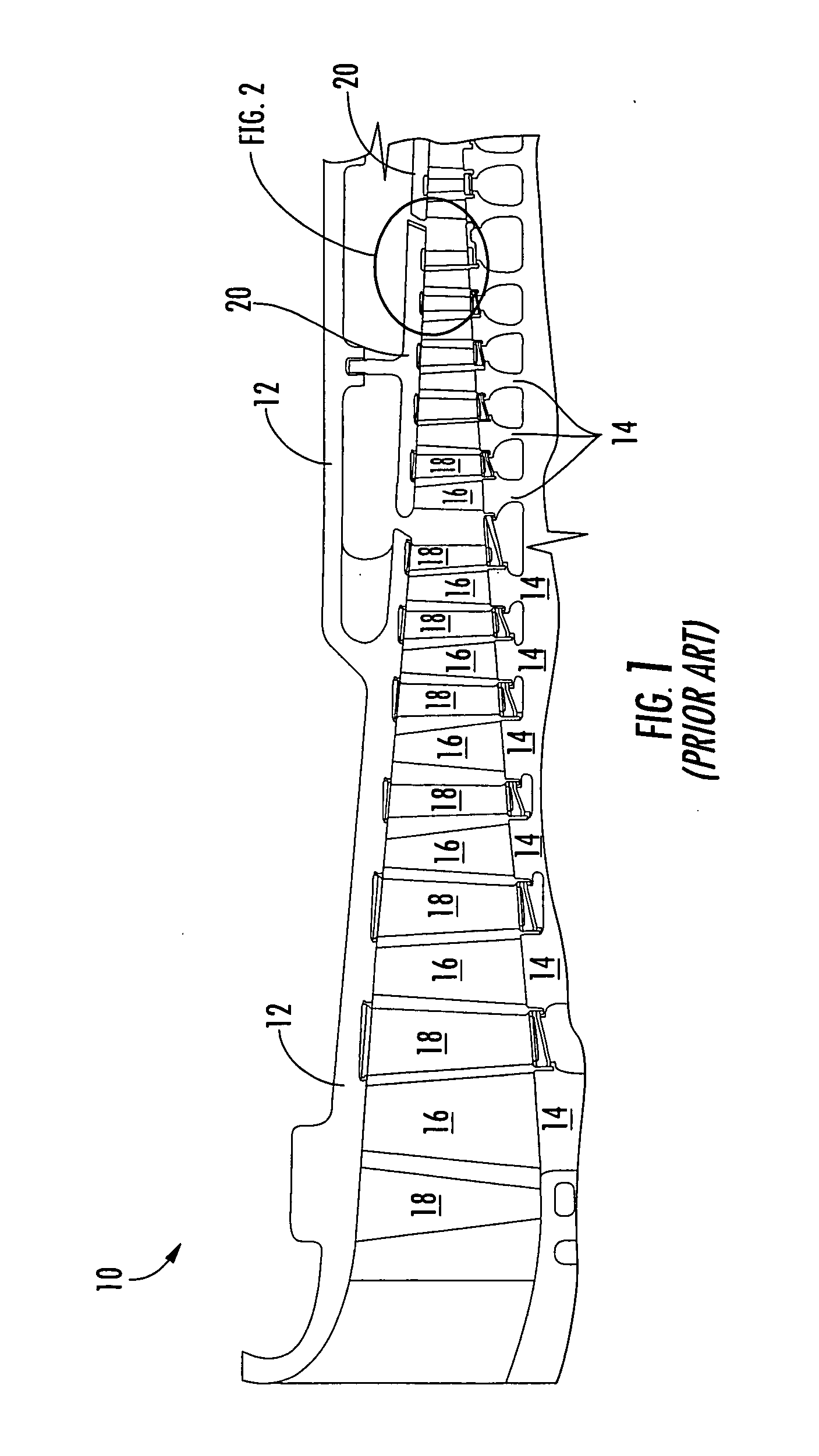

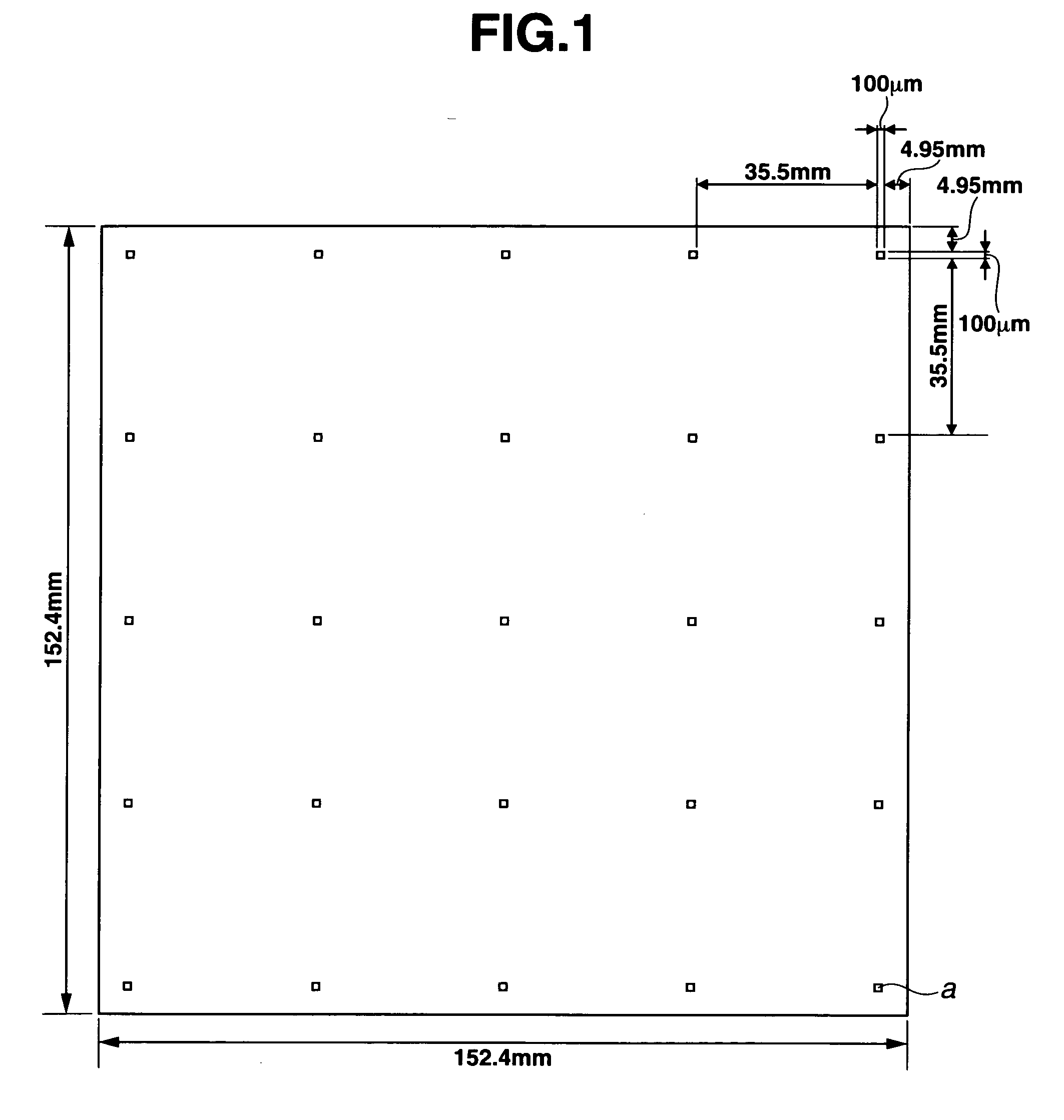

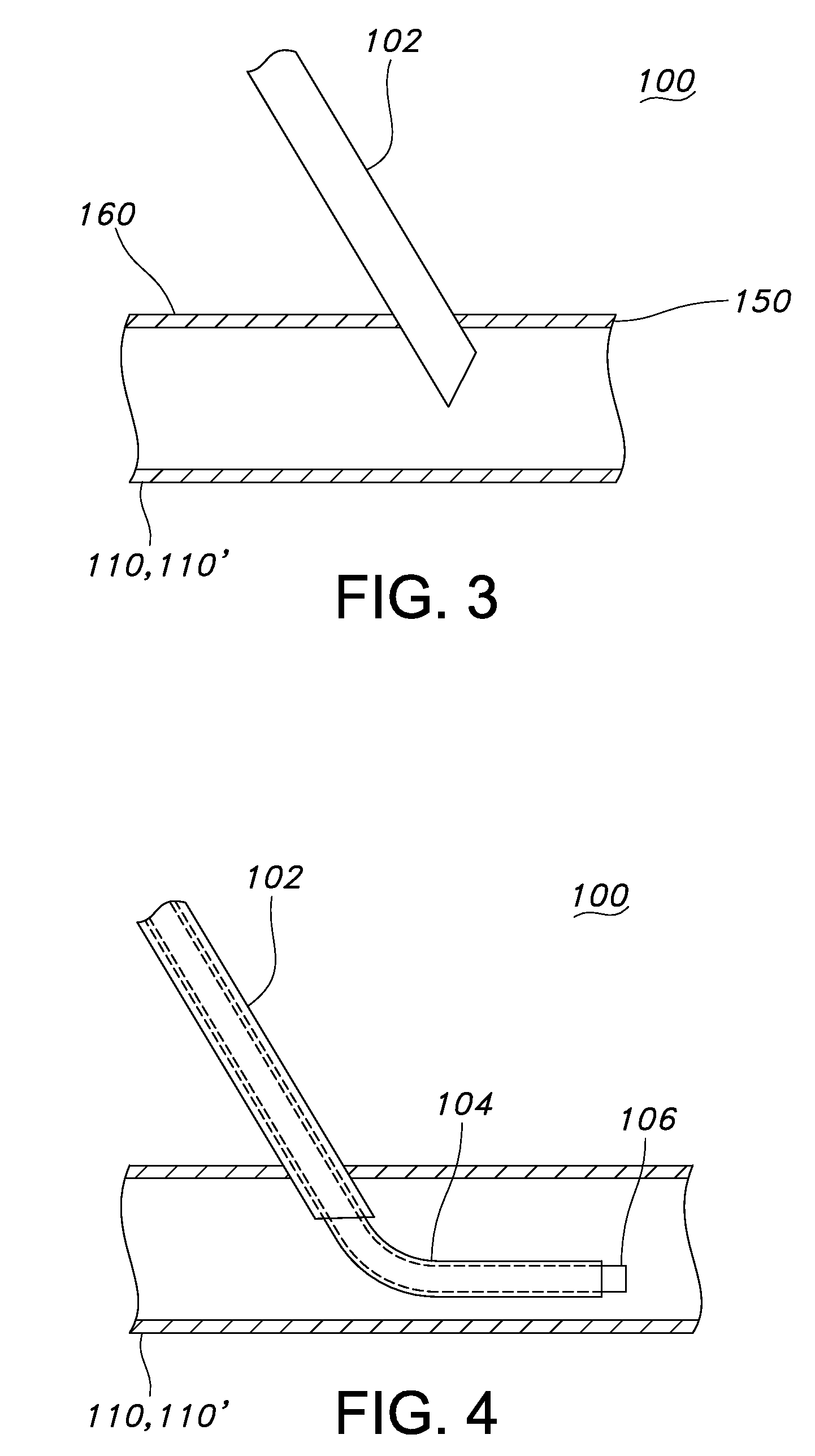

Tablet computing device with three-dimensional docking support

InactiveUS6856506B2Improved expansion baseImproved docking stationInput/output for user-computer interactionCoupling device connectionsTablet computerData connection

The present invention provides a tablet computer and a docking station assembly. This docking station comprises a docking assembly for positioning with three degrees of freedom and having a data connector for mechanically supporting and interfacing with the tablet computer. A support member couples the docking assembly to an expansion base. The base includes a number of ports for interfacing with a variety of peripheral devices or power supplies. These varieties of ports mount to a printed circuit board contained within the expansion base. A flexible printed circuit (FPC) combines the signal pathways for the variety of ports, allowing the signal pathways to travel from the printed circuit board and to the data connector. The tablet computing device has a plurality of contact or touch points positioned on the right and left edges of the tablet to facilitate aligning the tablet to the docking assembly in either a landscape or portrait mode.

Owner:ZEBRA TECH CORP

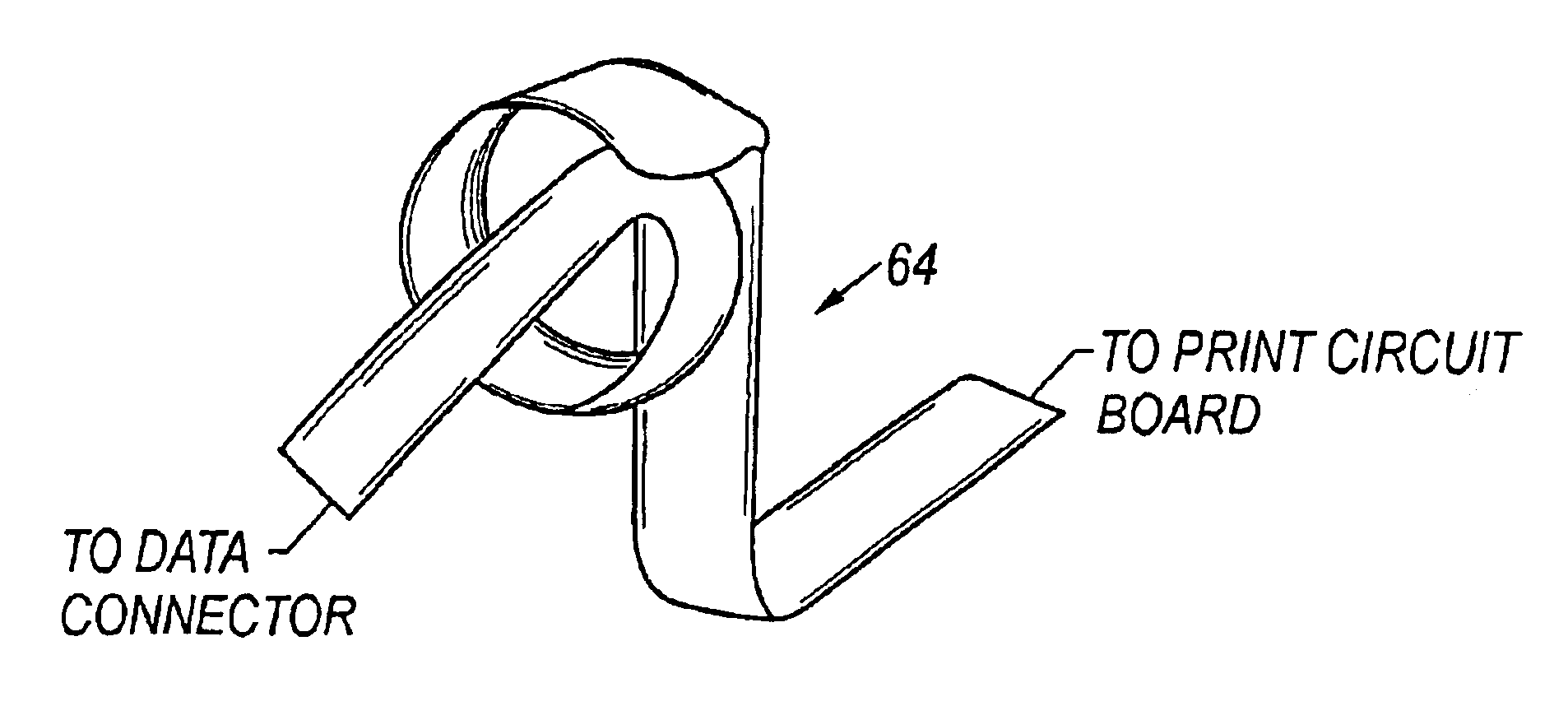

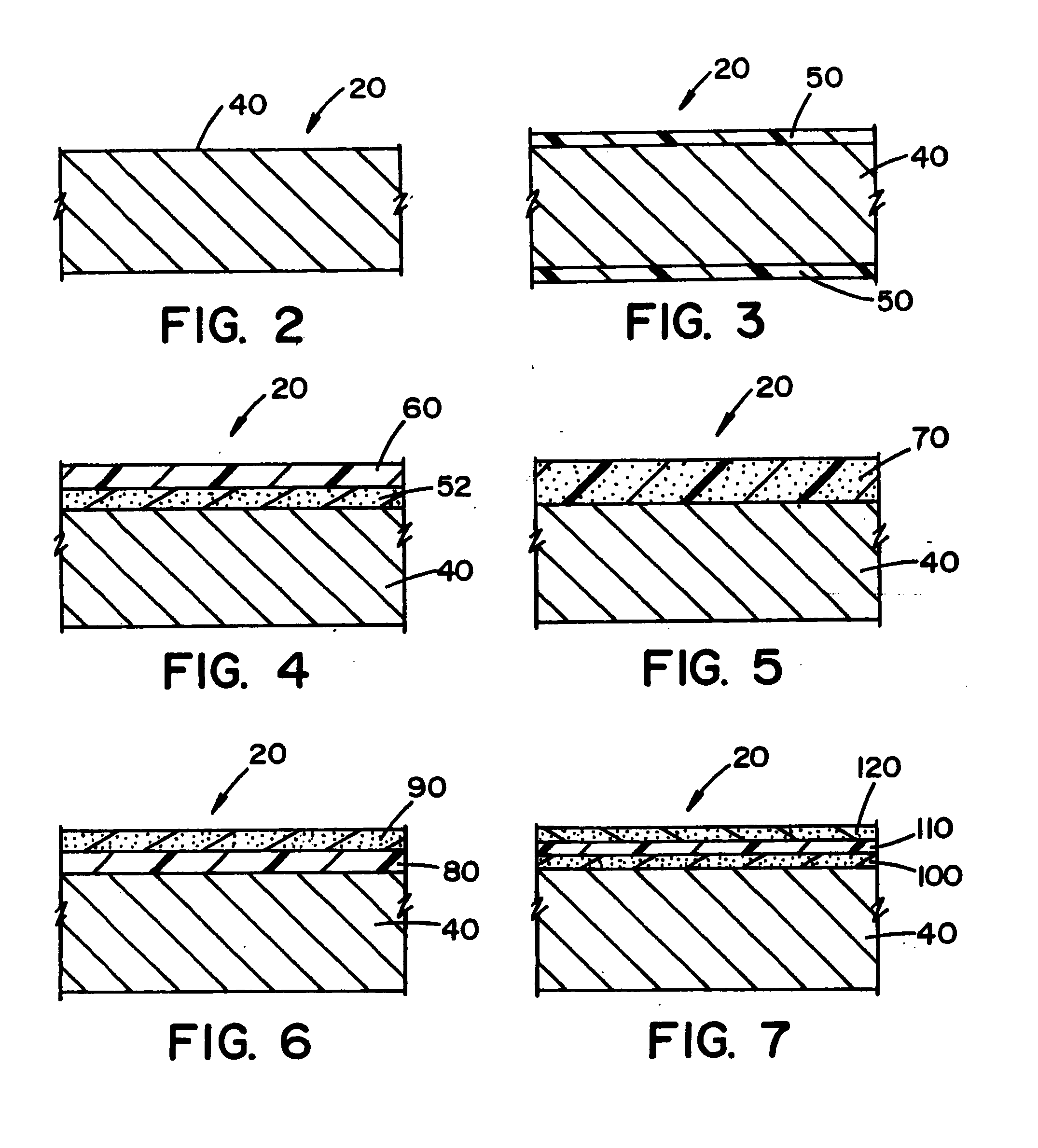

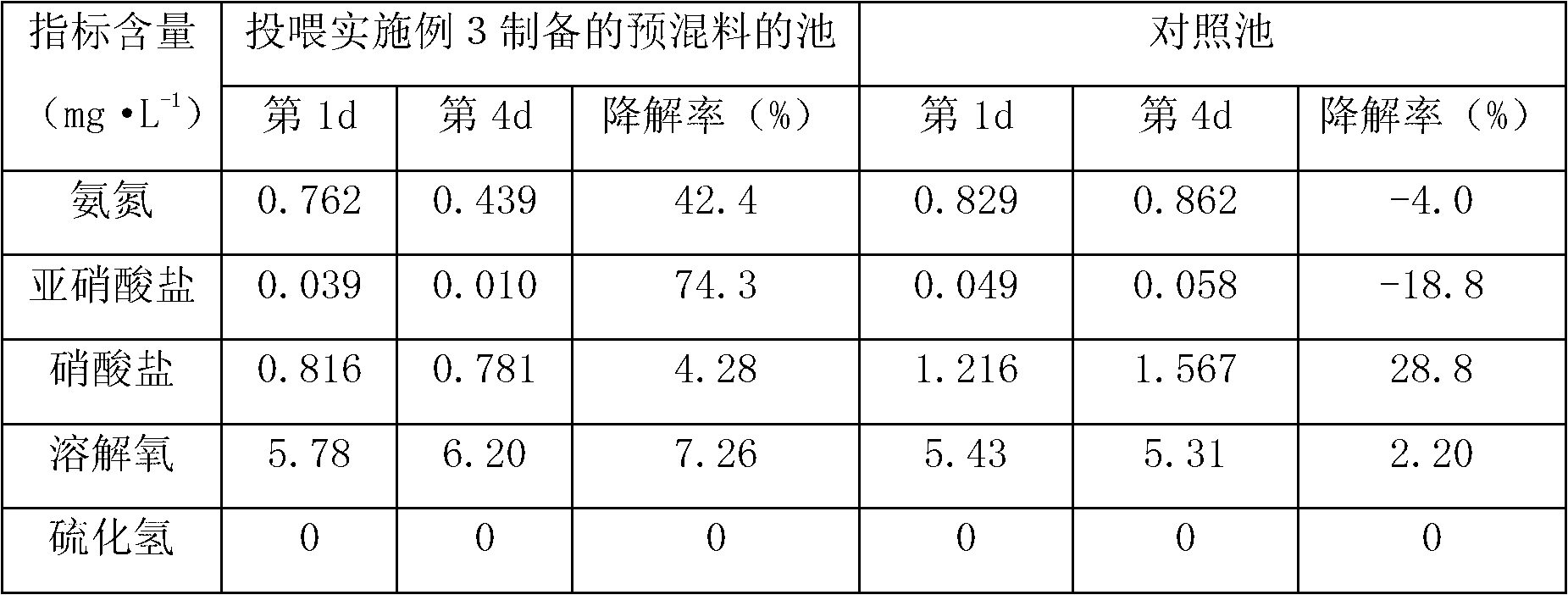

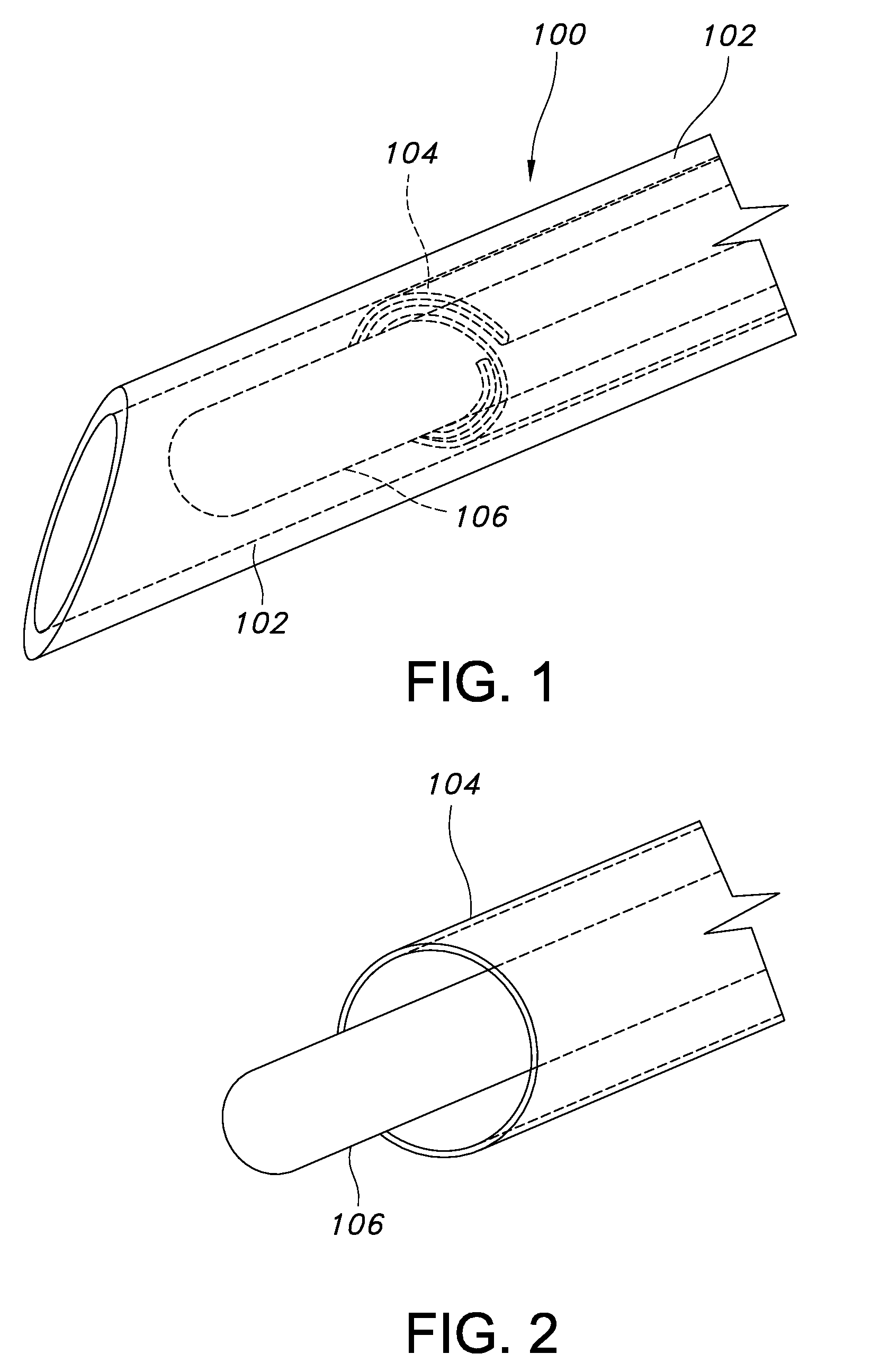

Flexible circuit board for tablet computing device

InactiveUS6914197B2Easy constructionReduce manufacturing costCoupling device connectionsDigital data processing detailsTablet computerDocking station

Owner:ZEBRA TECH CORP

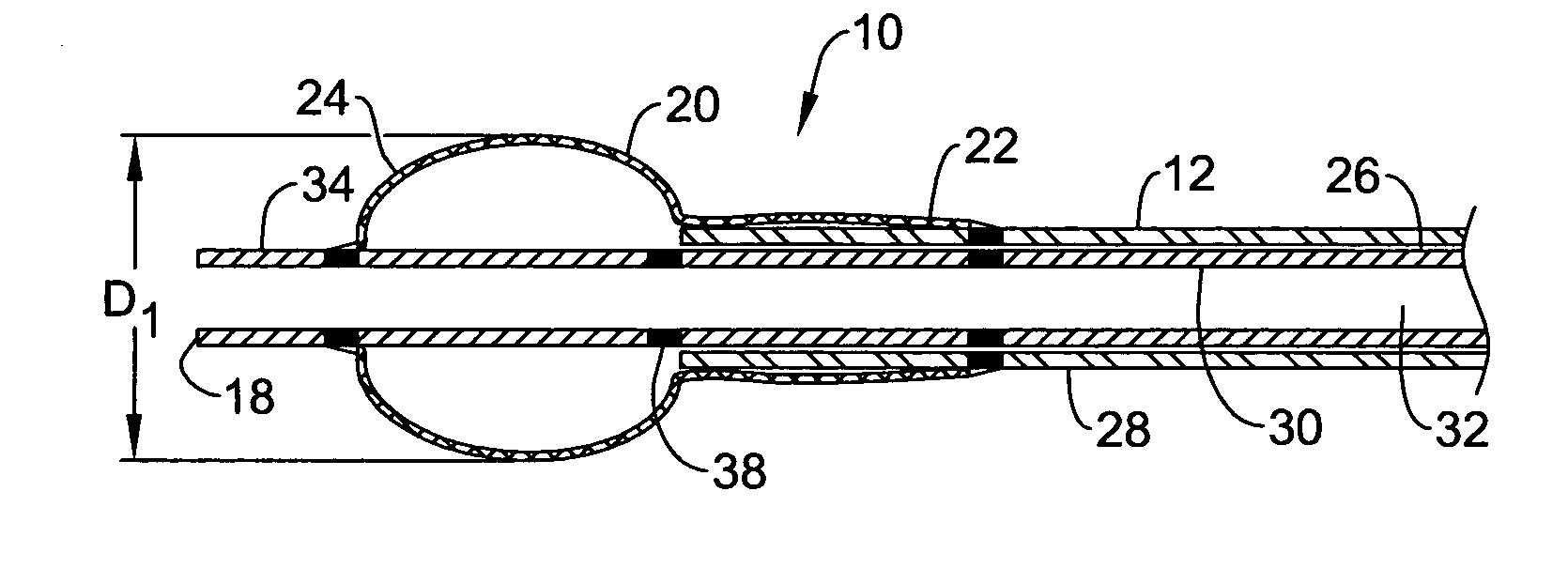

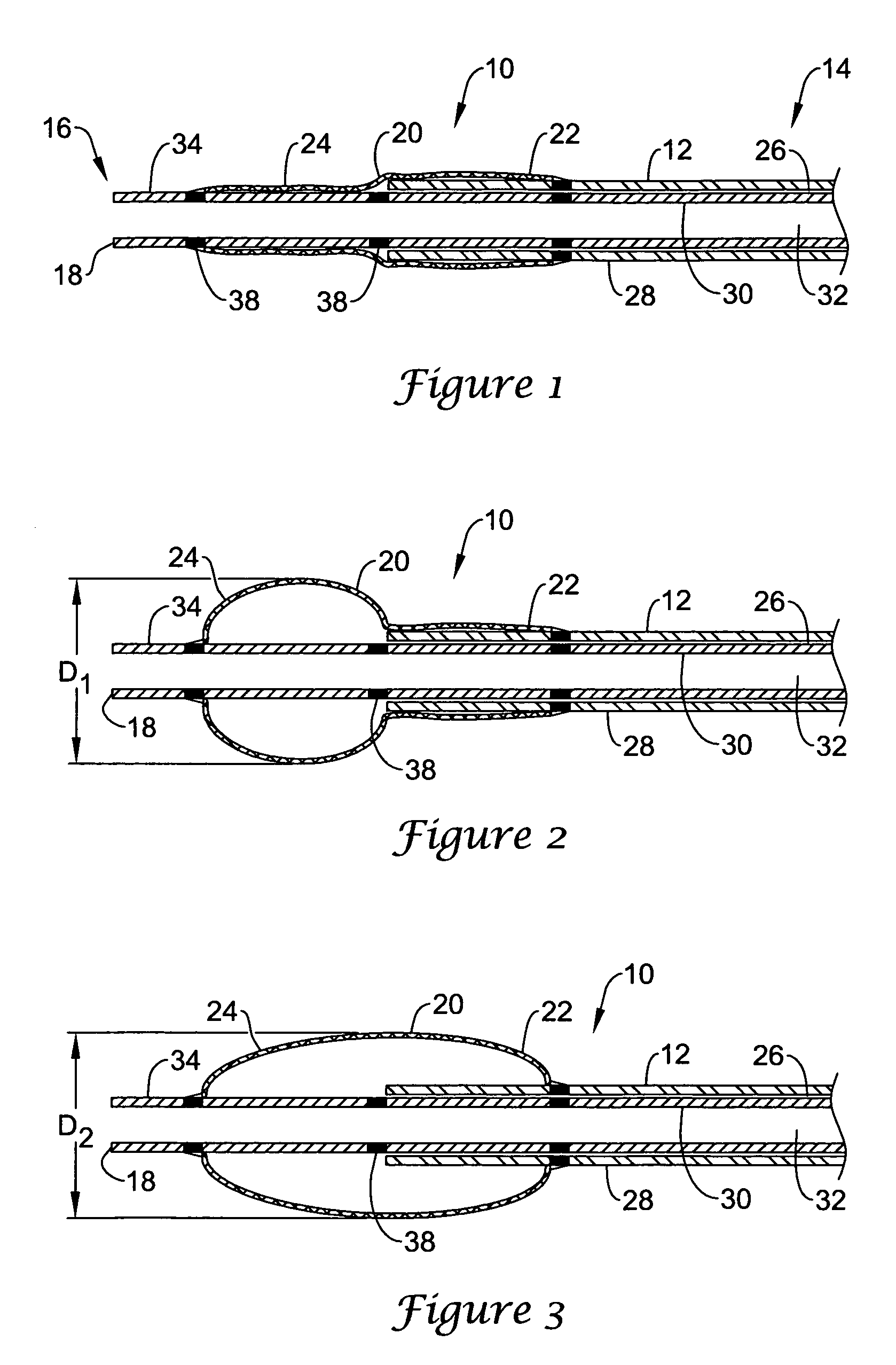

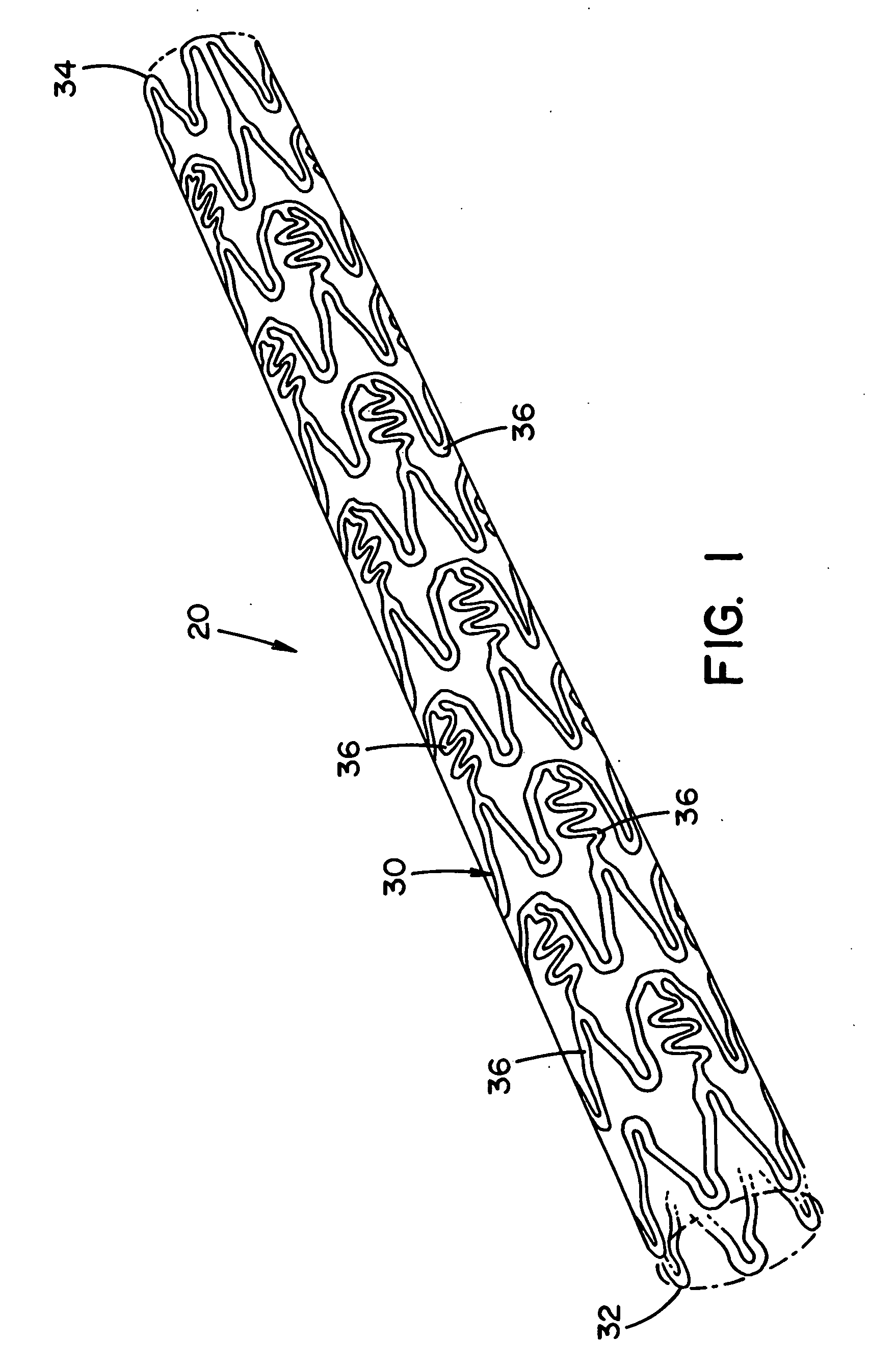

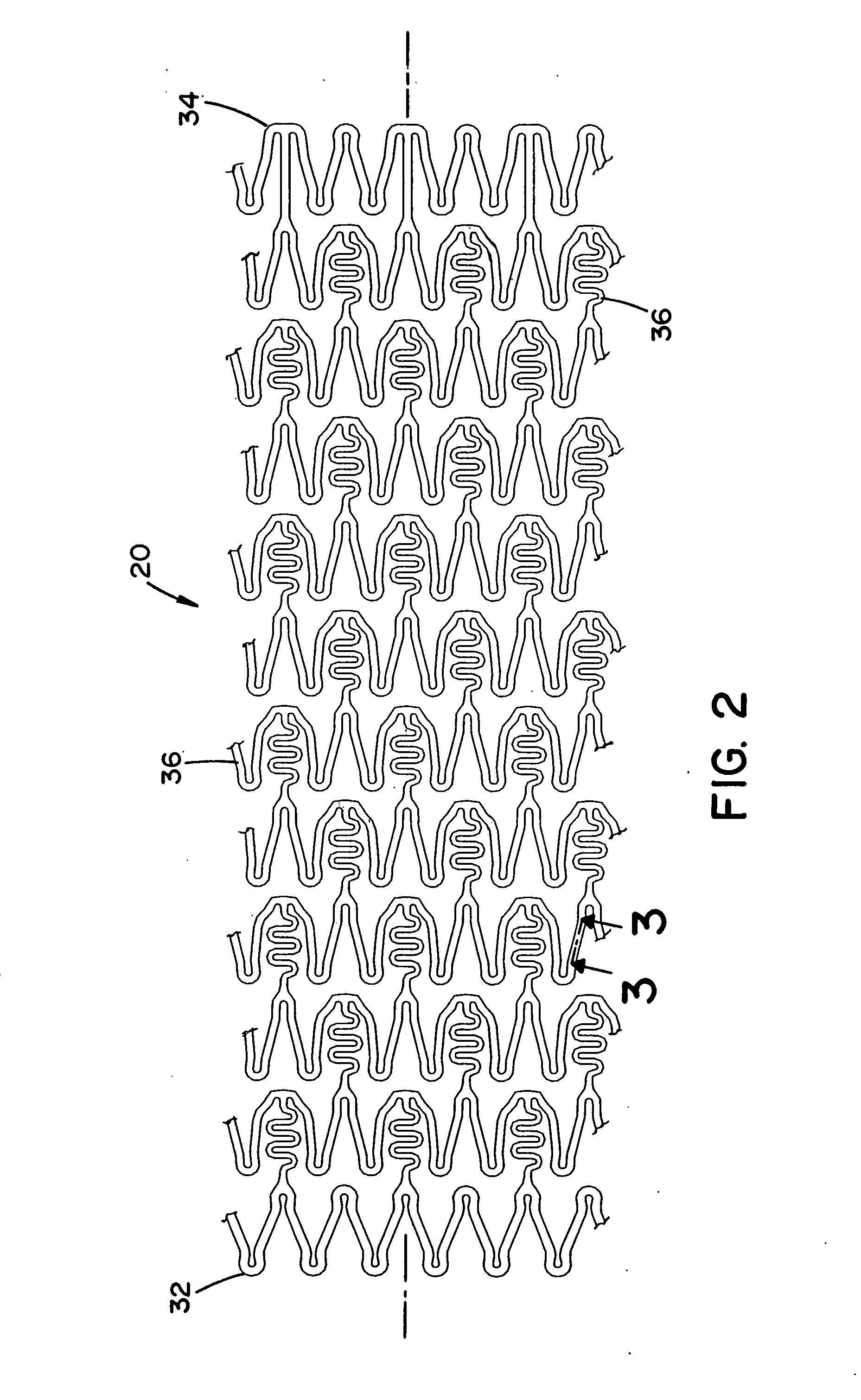

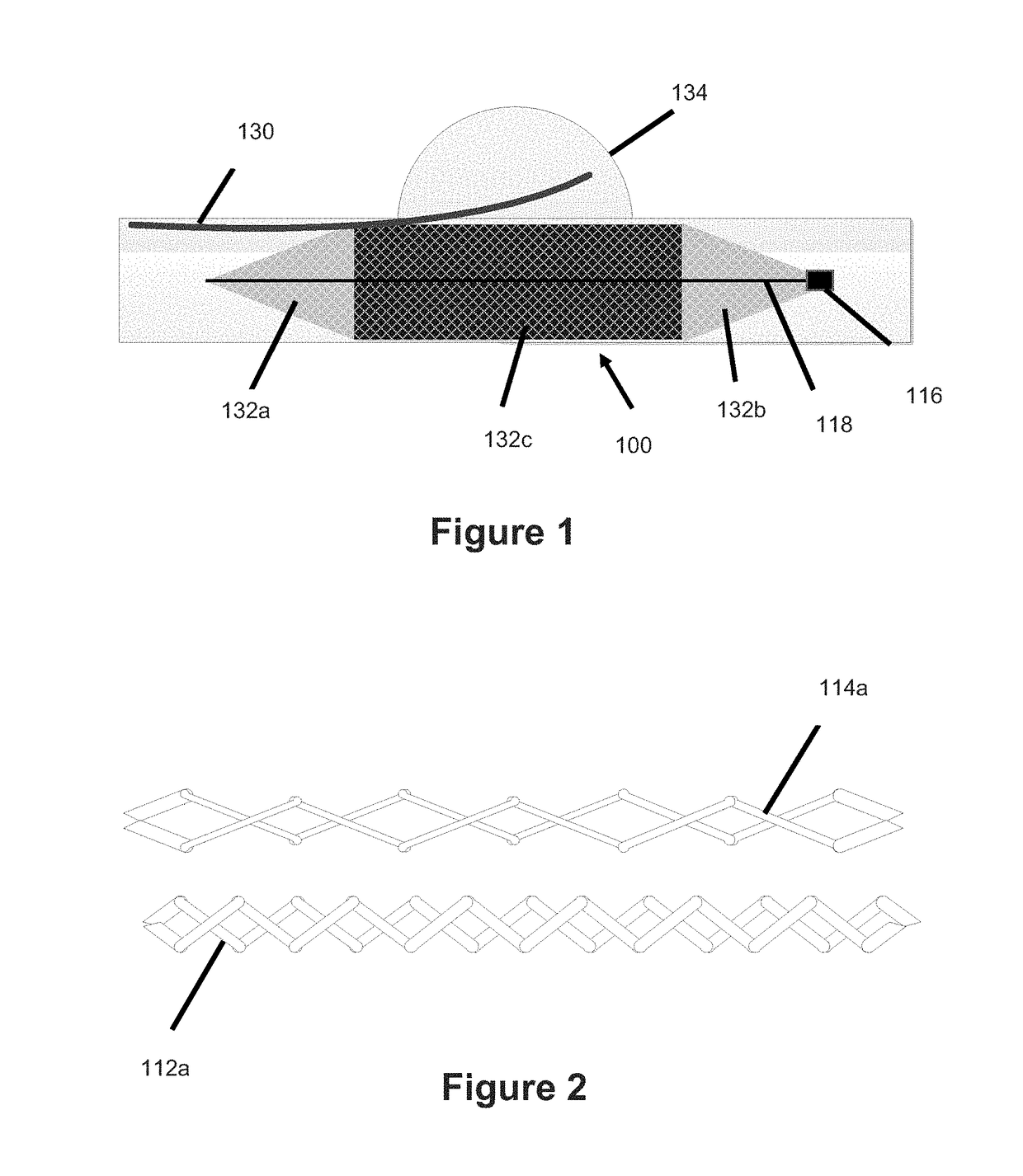

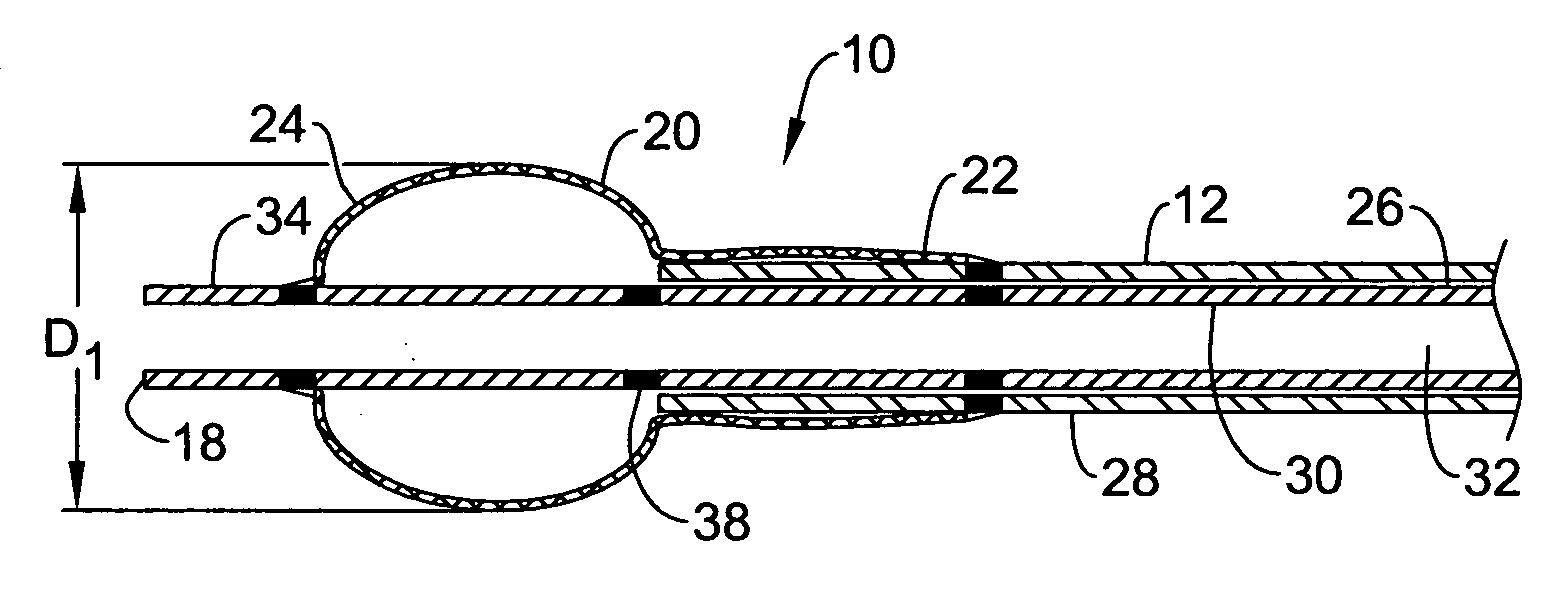

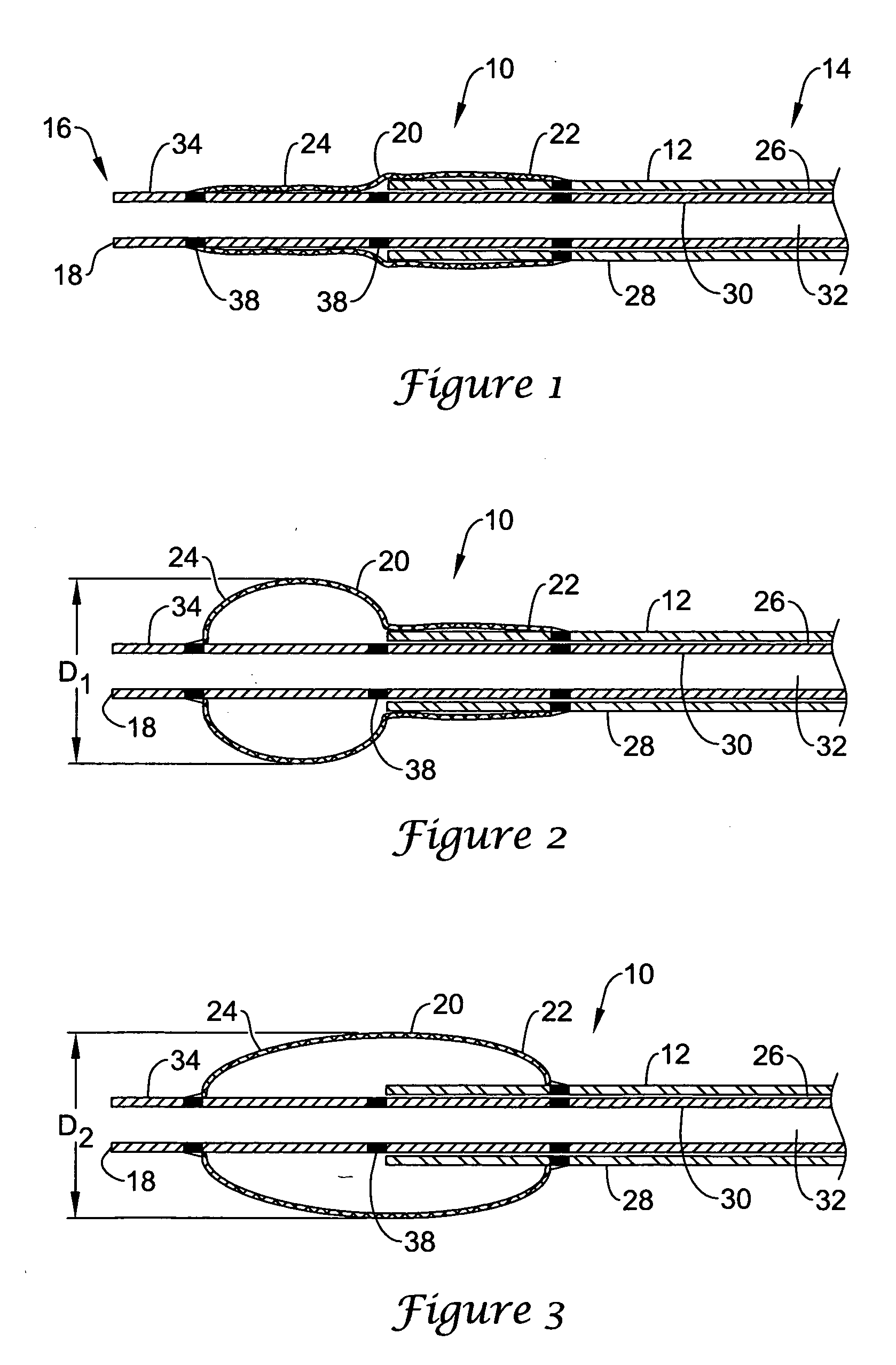

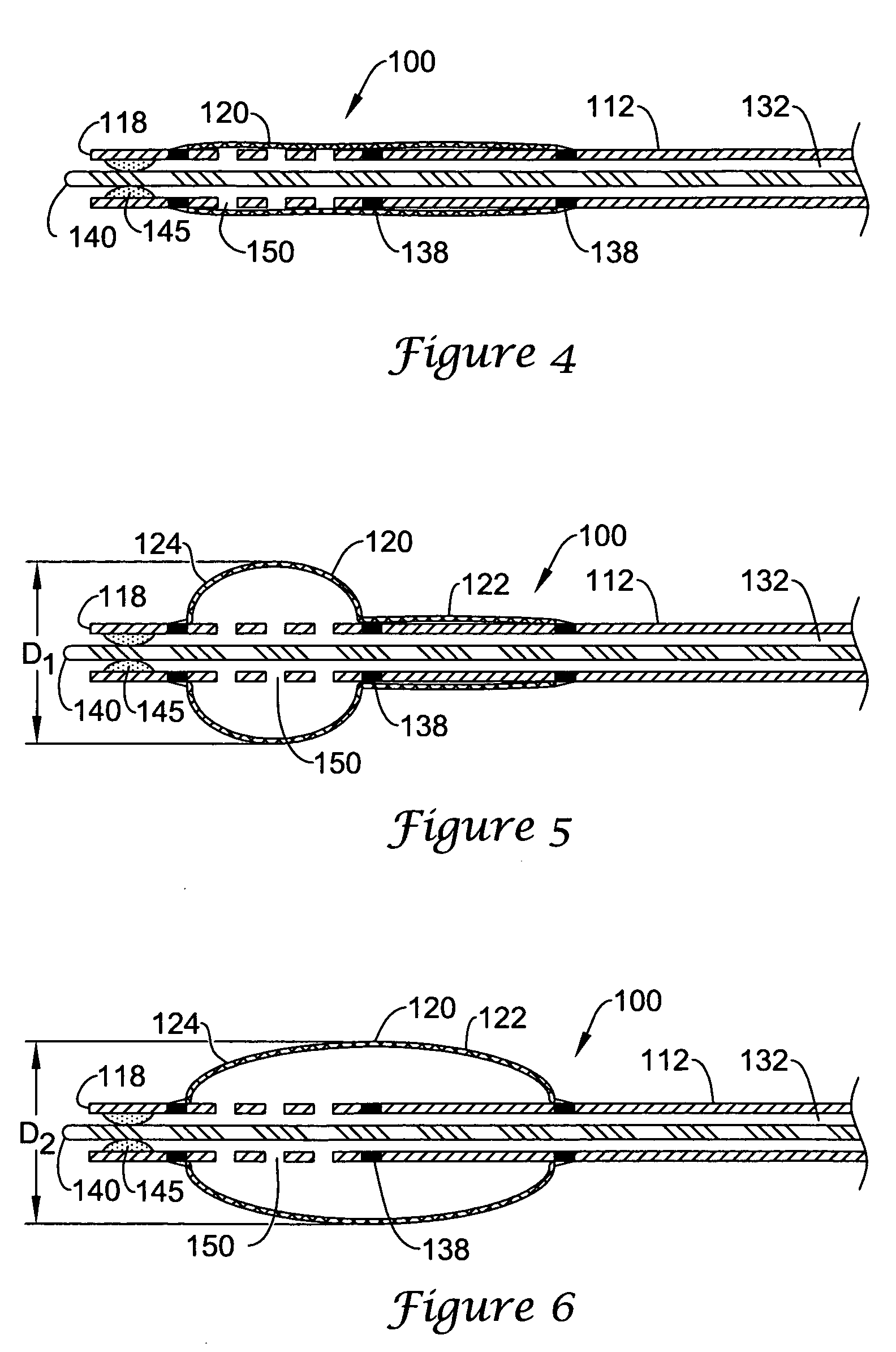

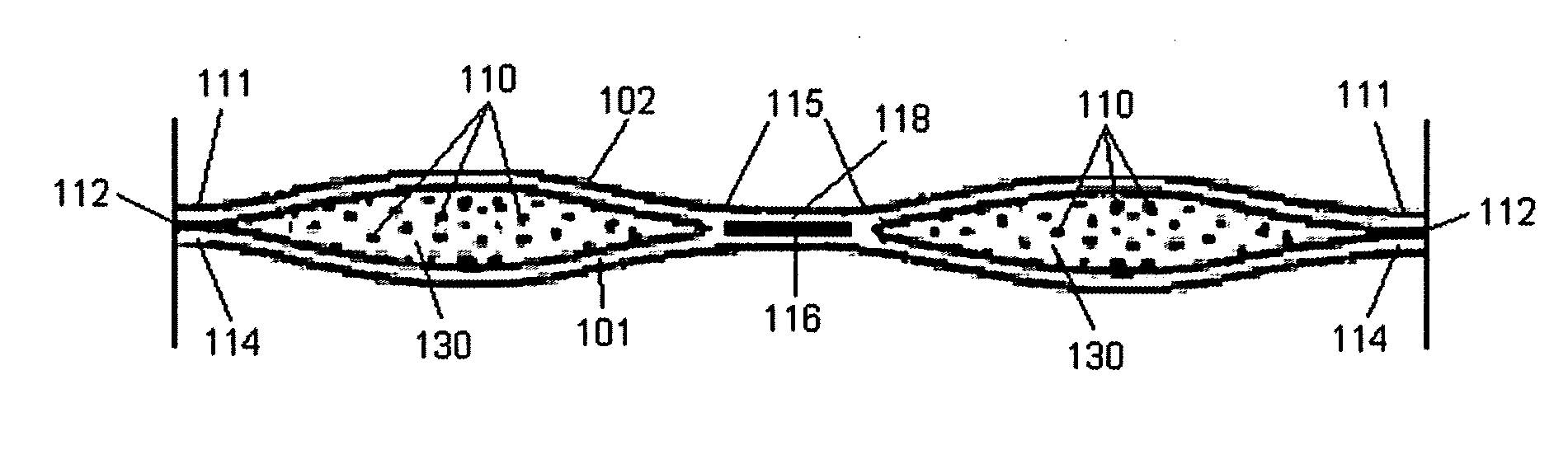

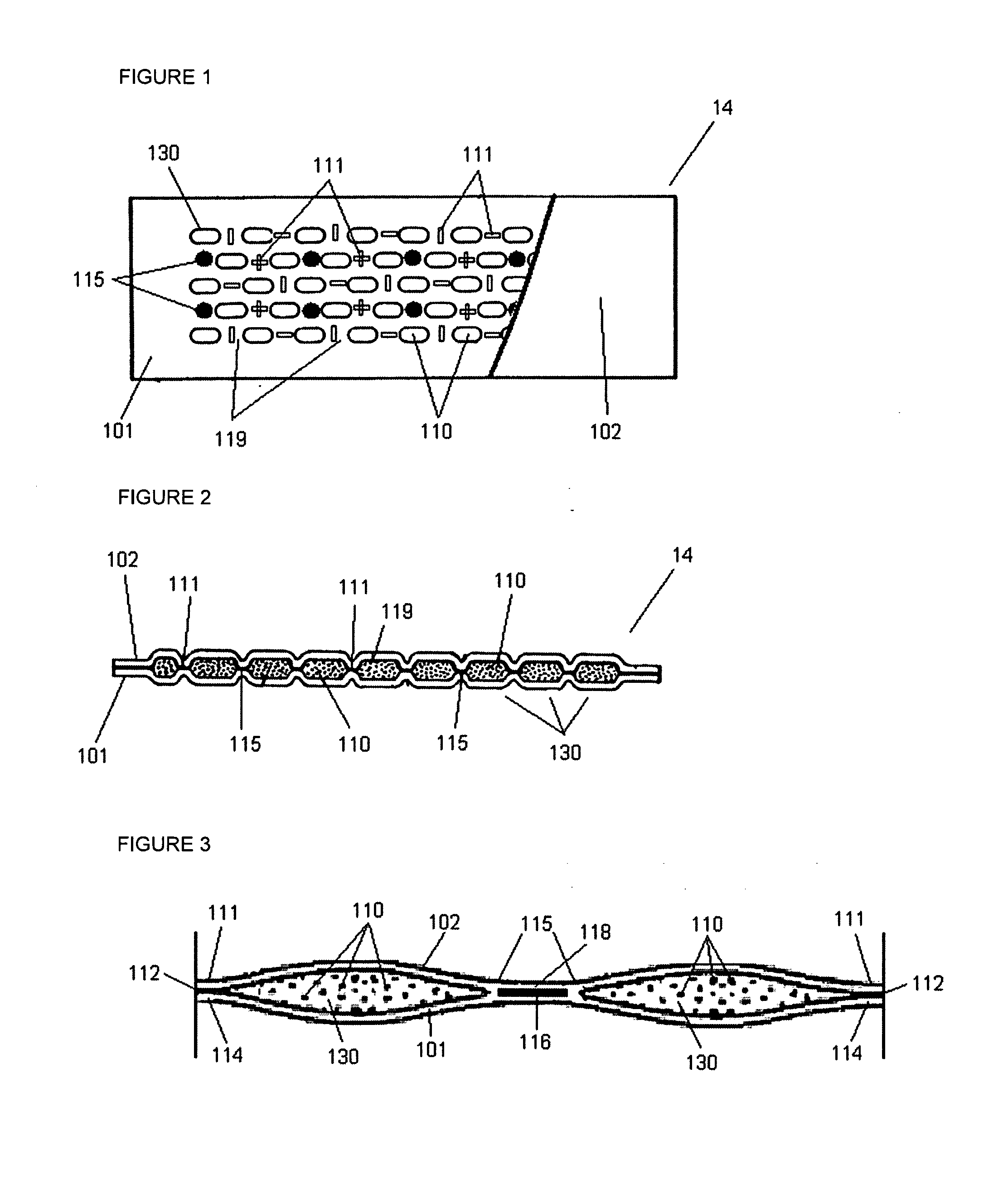

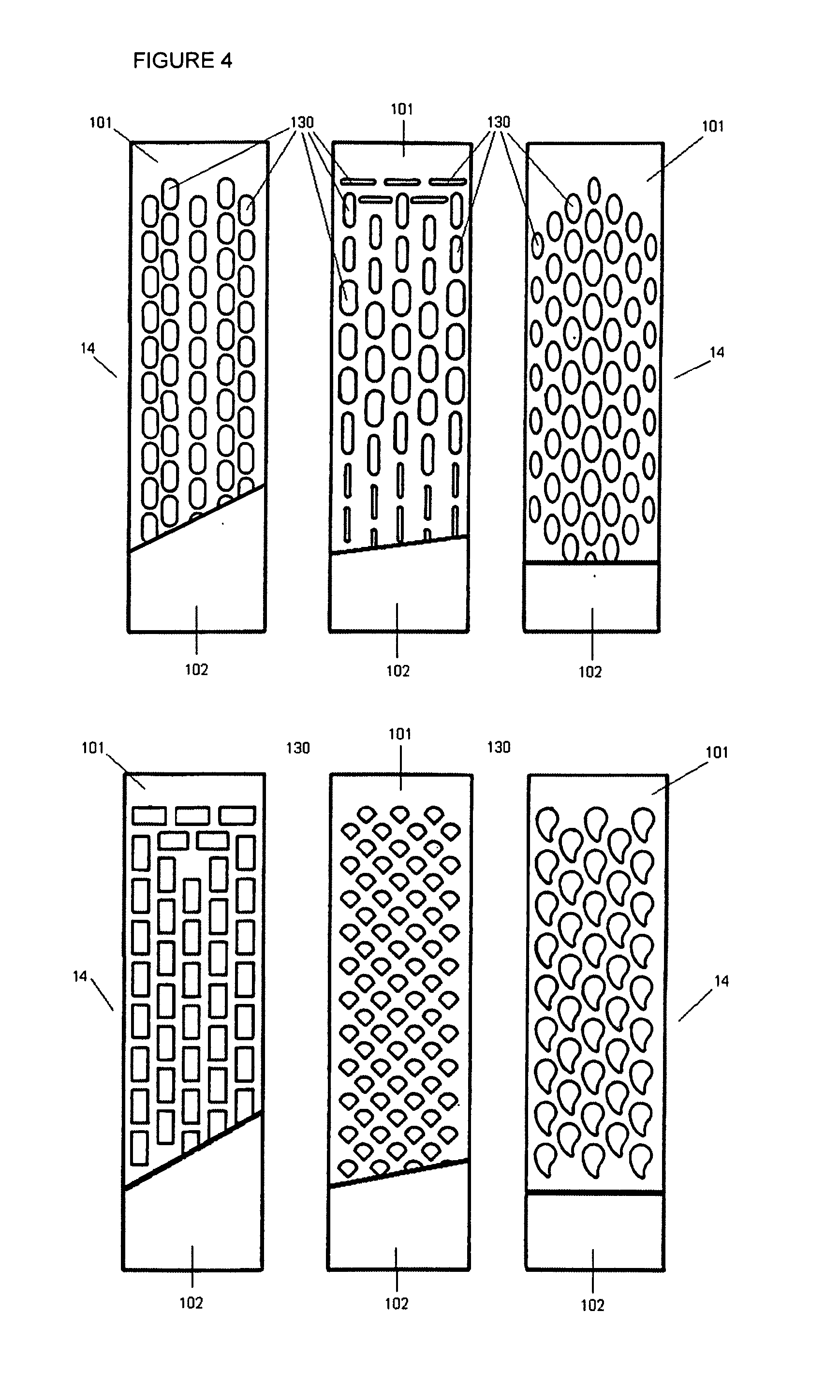

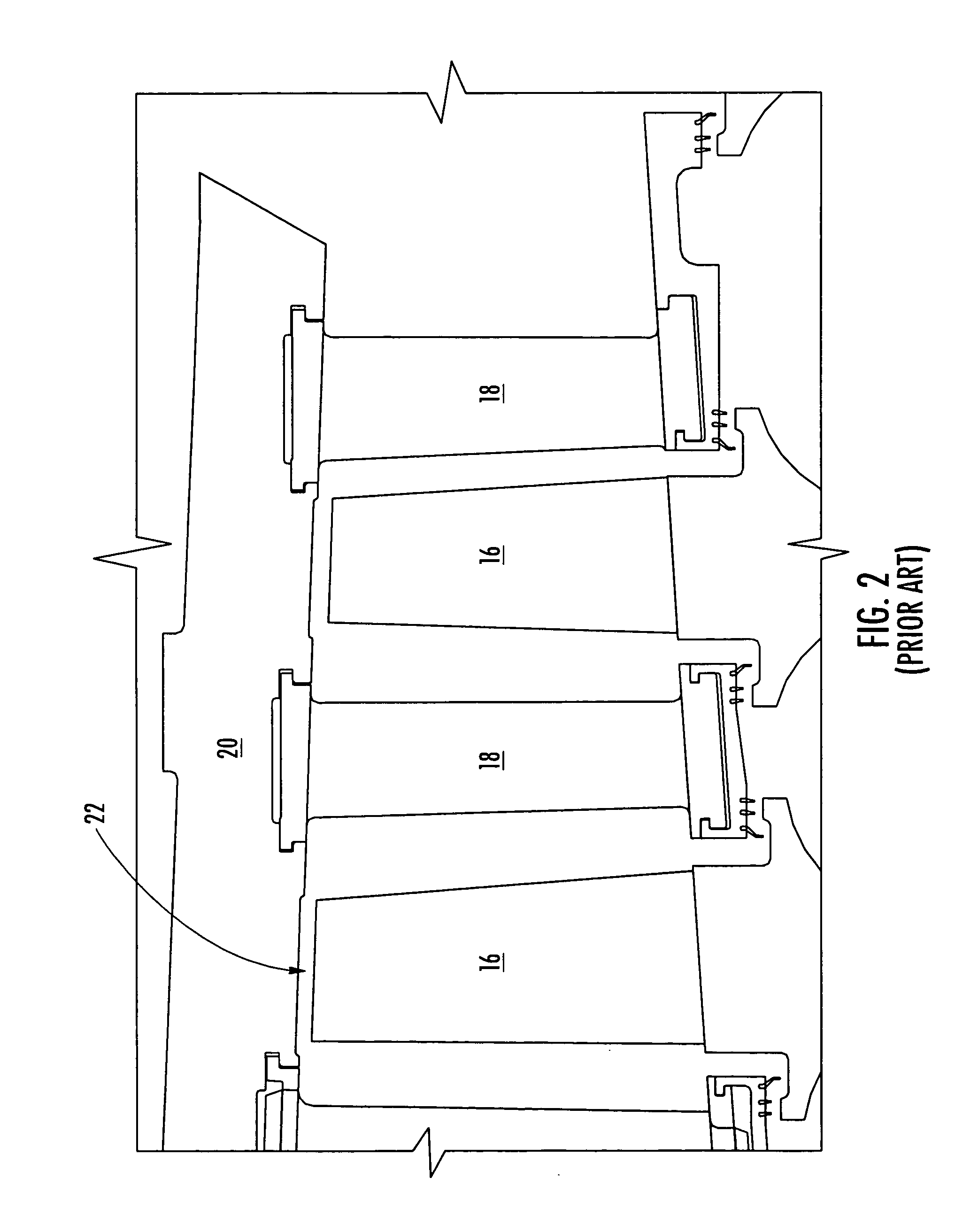

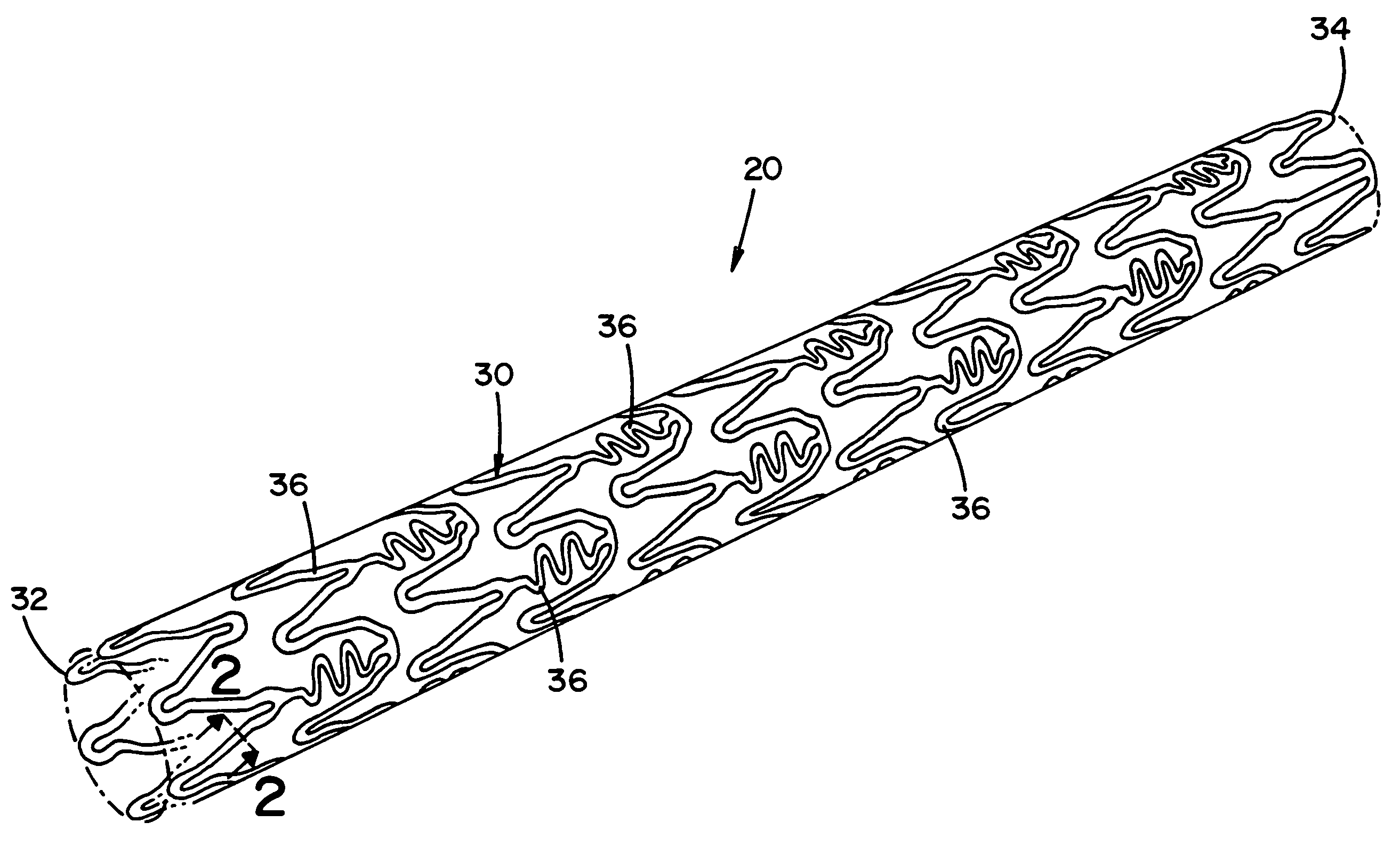

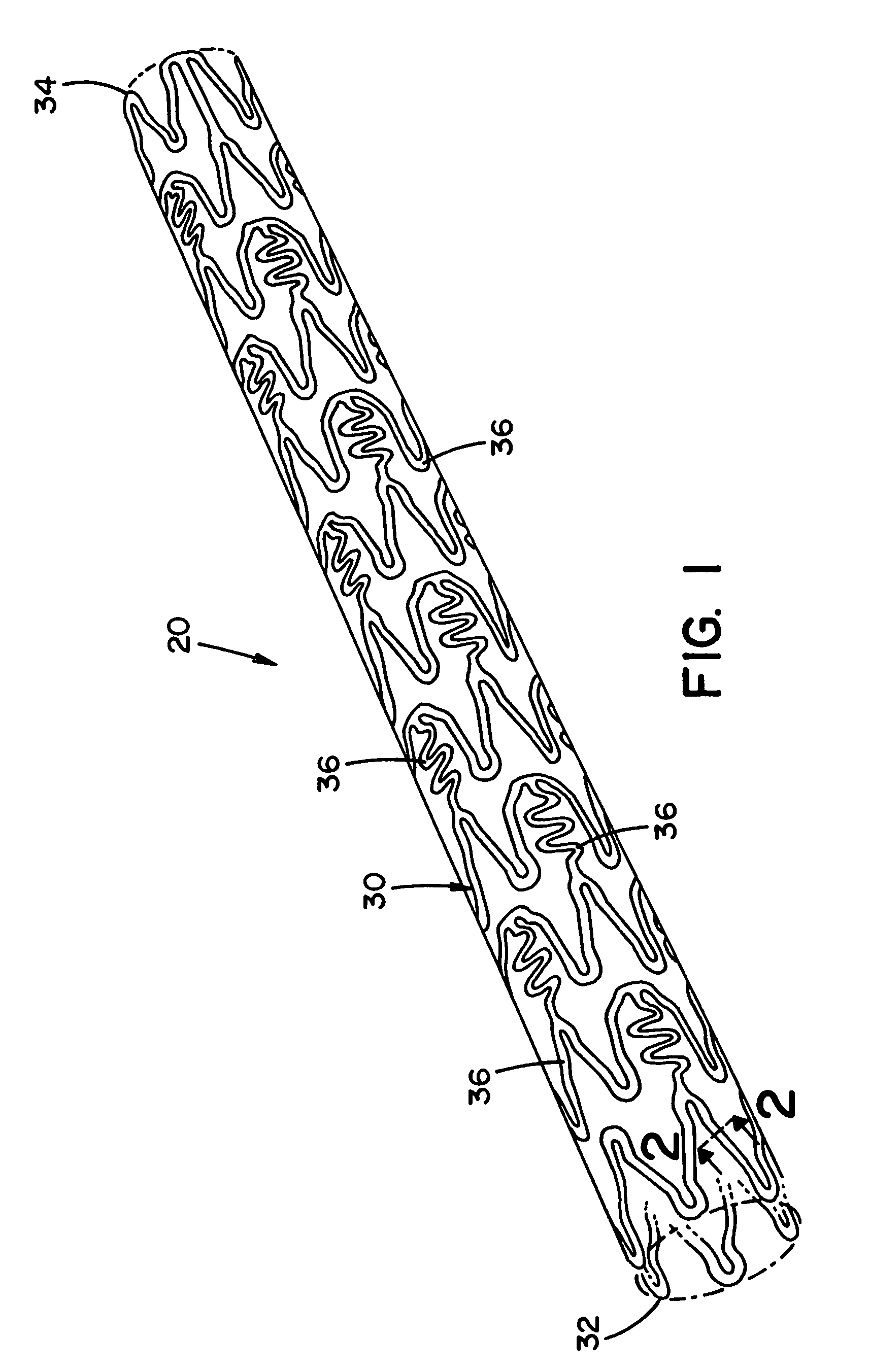

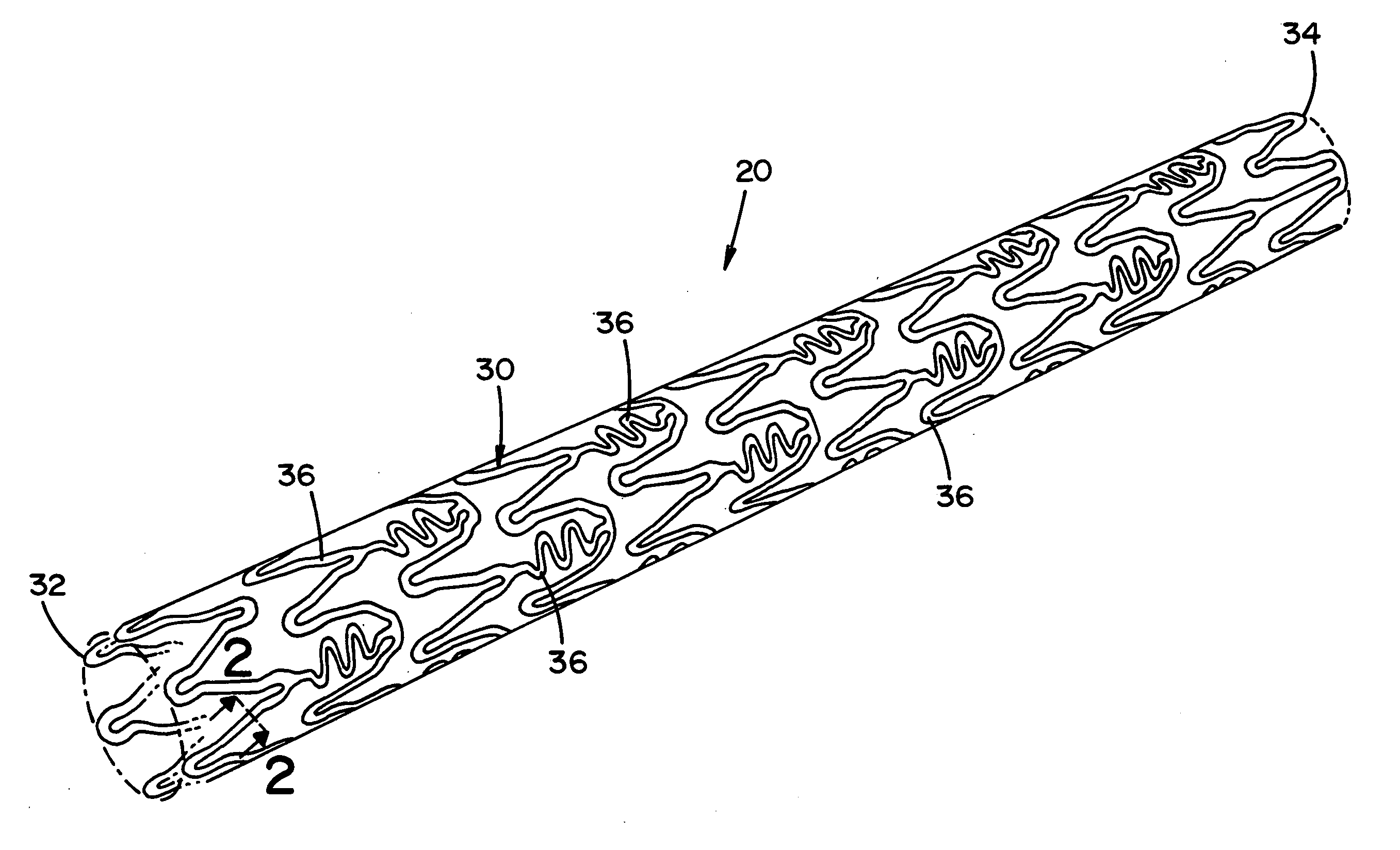

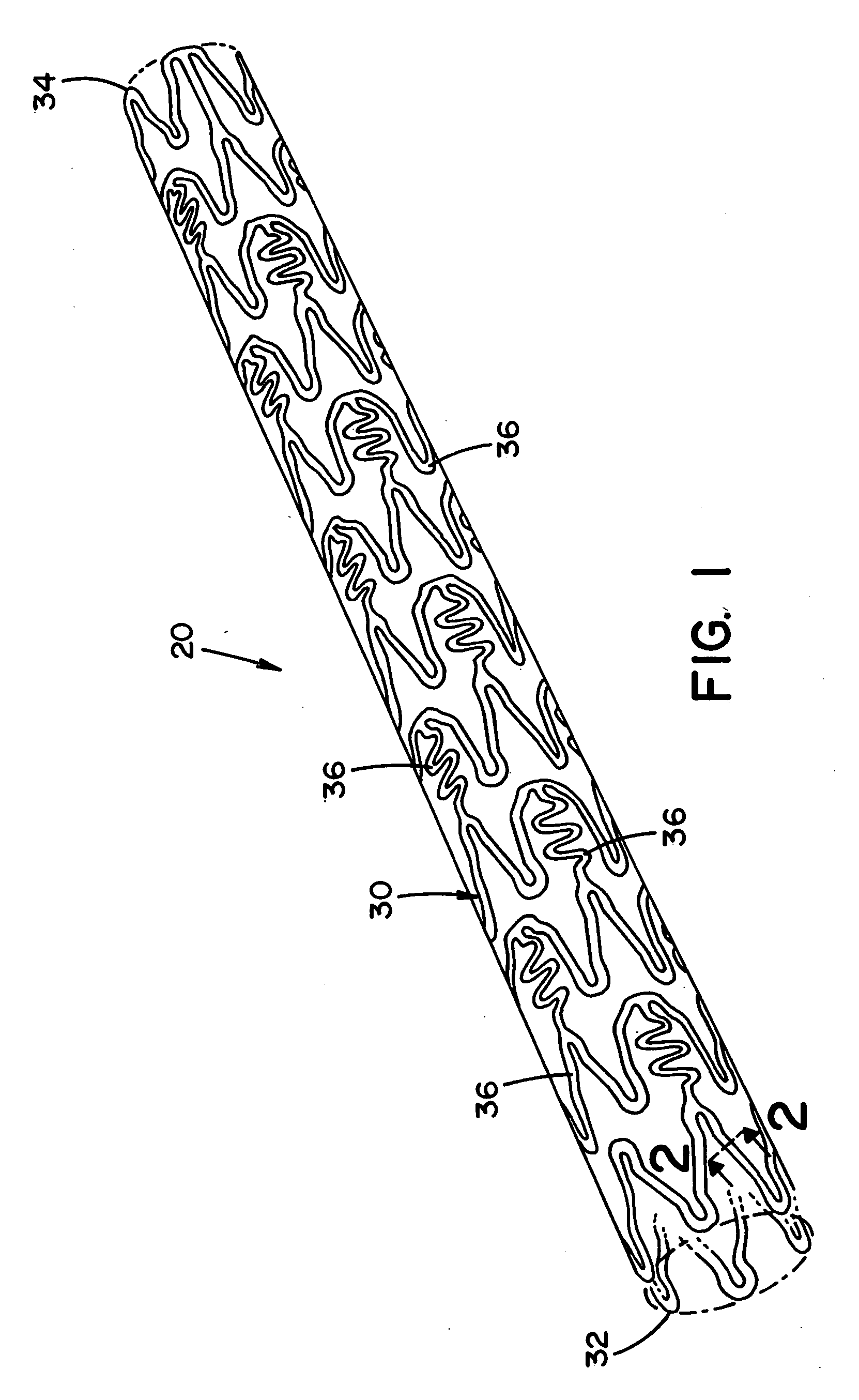

Occlusion balloon catheter with longitudinally expandable balloon

ActiveUS7198632B2Increase expansionConstant radial expansionStentsBalloon catheterBalloon catheterBalloon dilatation

Owner:BOSTON SCI SCIMED INC

Bioabsorable medical devices

InactiveUS20060198869A1Facilitate deploymentImprove physical propertiesStentsPeptide/protein ingredientsYttriumMagnesium

Owner:ICON MEDICAL CORP

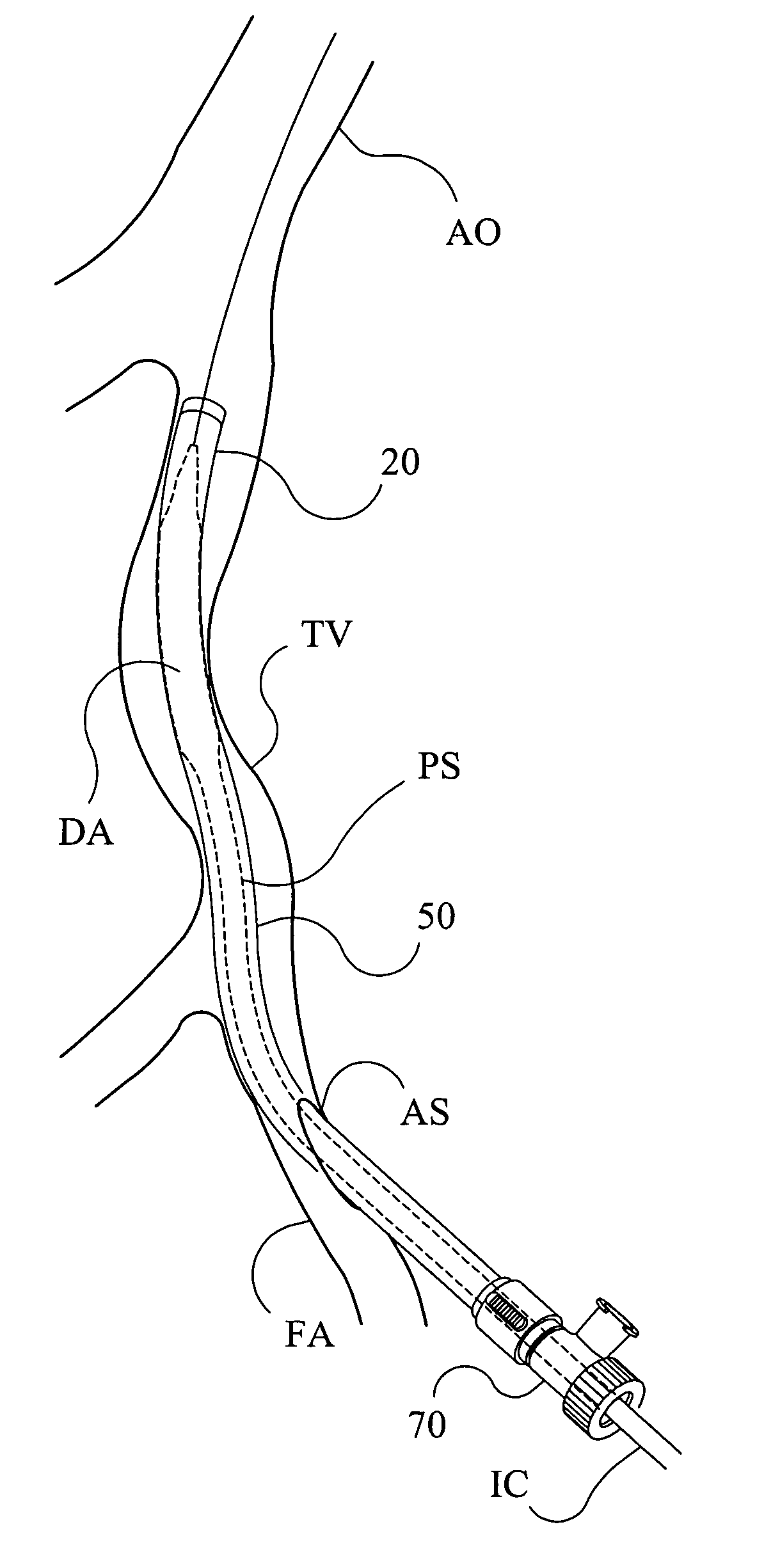

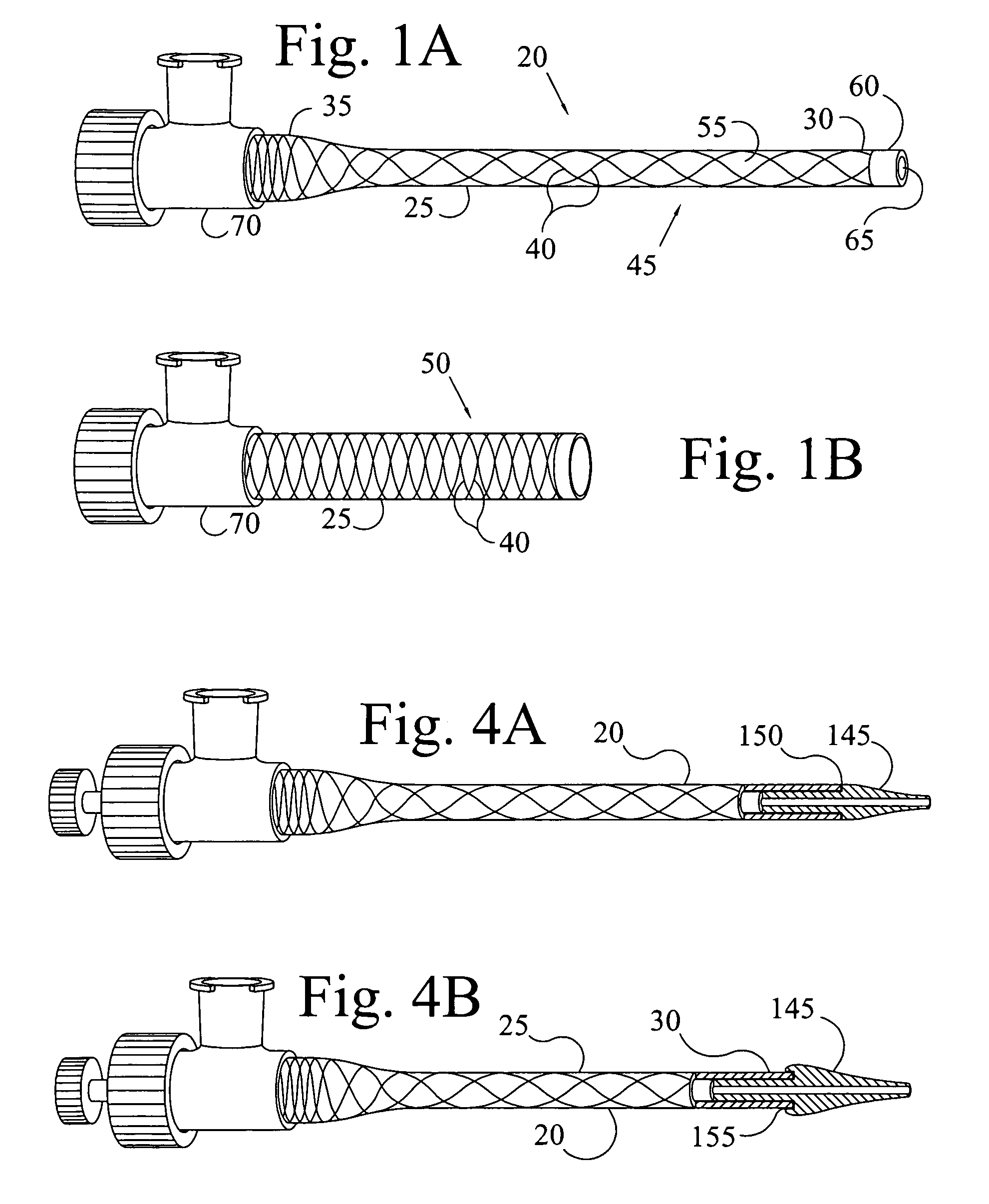

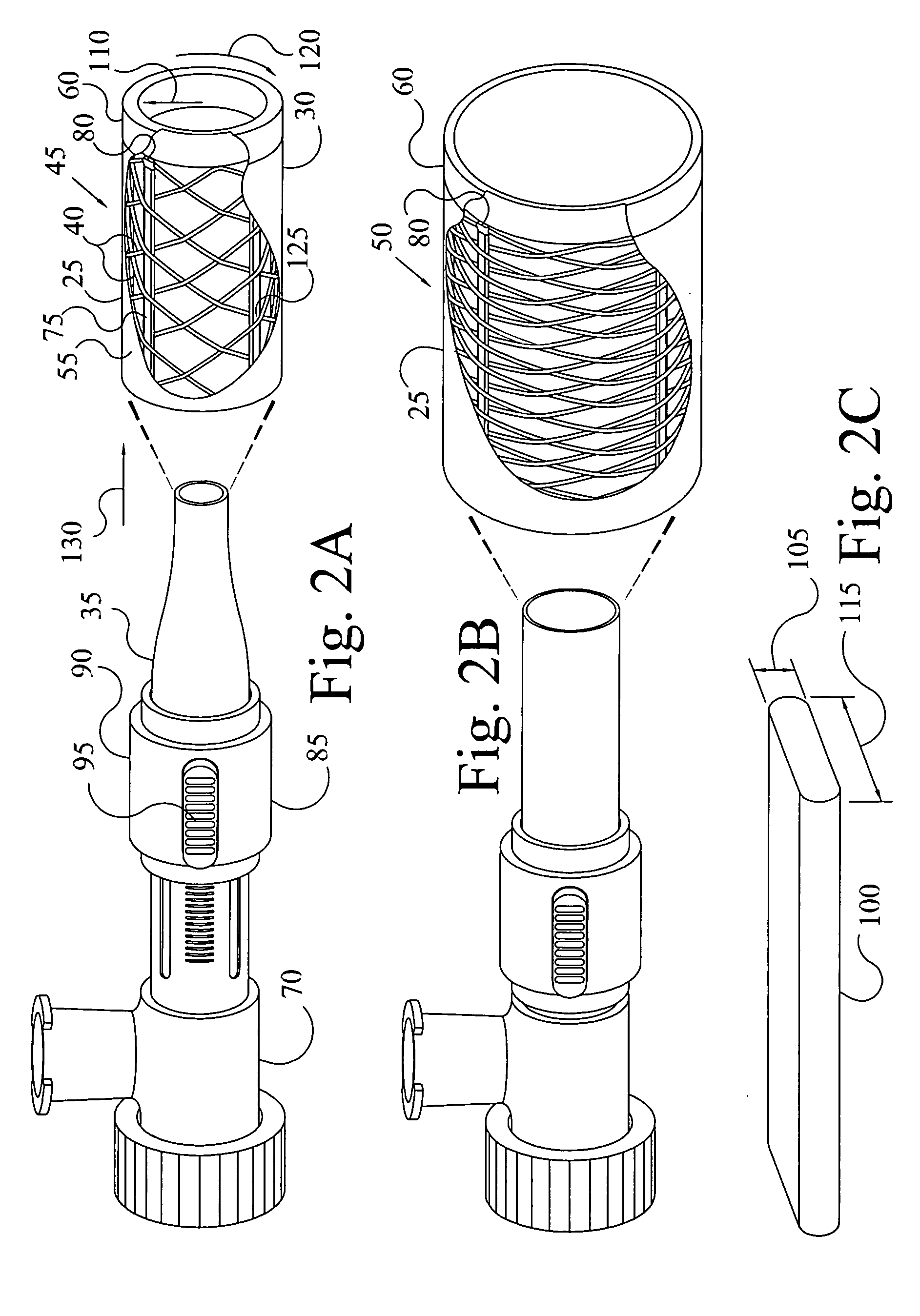

Expandable introducer sheath

InactiveUS20090240202A1Less traumaReduce the overall diameterInfusion syringesDilatorsGuide tubeIntroducer sheath

An expandable introducer sheath can actively be induced to reduce in diameter or enlarge in diameter due to a braided internal structure that has axial strands connected to its distal end. The introducer sheath is delivered to the blood vessel or other tubular member of the body in a smaller diameter configuration with the axial strands in compression. The catheter is flexible and can be delivered to eccentrically shaped and tortuous vessels. Once the catheter is in position, the axial strands are placed into tension to cause the introducer sheath to assume a larger diameter configuration that will help straighten out tortuous vessels. The access site into the blood vessel is expanded via a radial expansion that is less traumatic. Passage of a larger interventional catheter can proceed through the larger diameter sheath configuration. If the interventional catheter has a smaller shaft, the introducer sheath can be reduced in diameter to come into close approximation with the shaft to reduce the opening size at the access site. The sheath can be removed over time with incremental reductions in its diameter to allow the access site time to relax to a smaller size for improved vascular sealing.

Owner:DRASLER WILLIAM JOSEPH +1

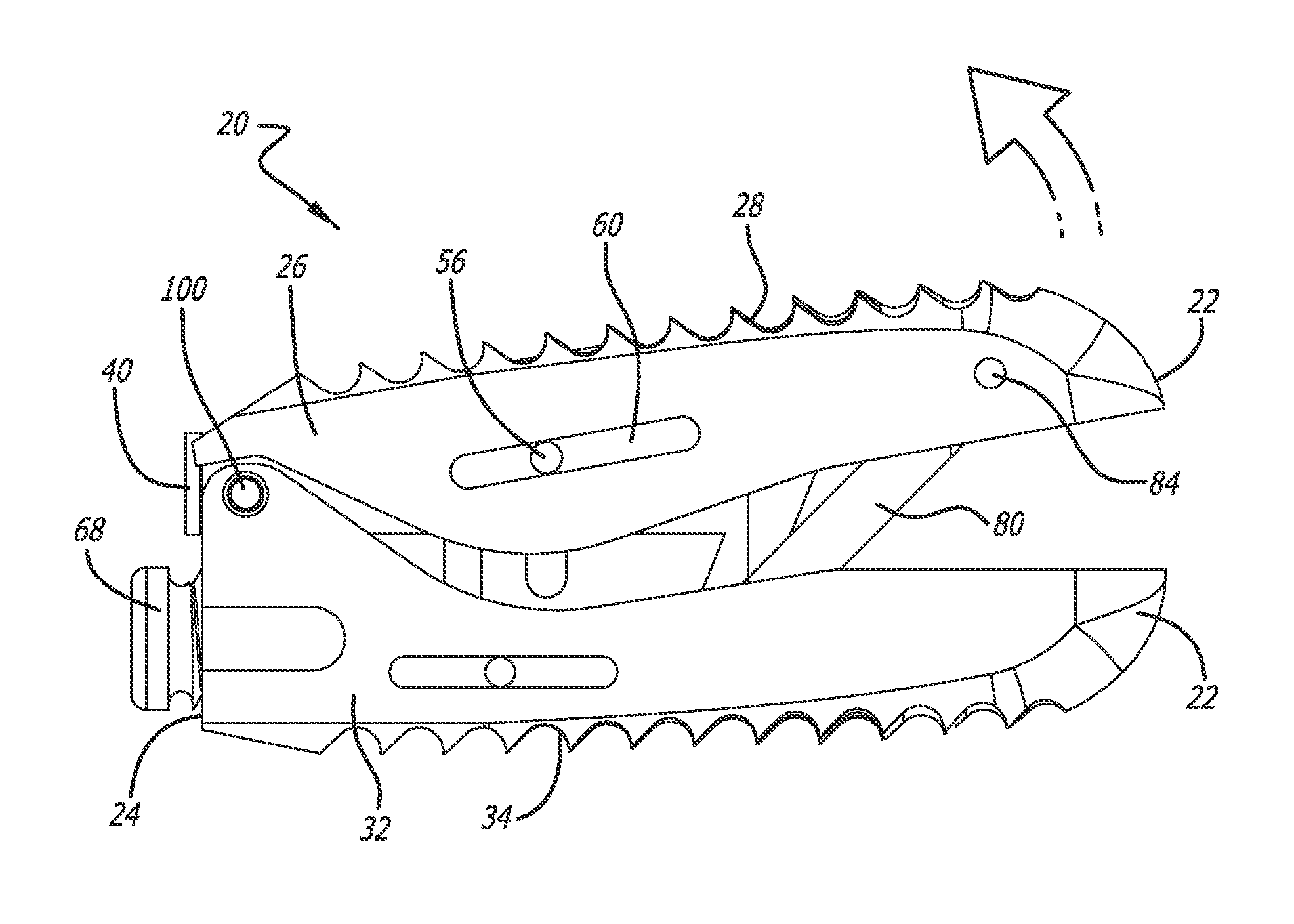

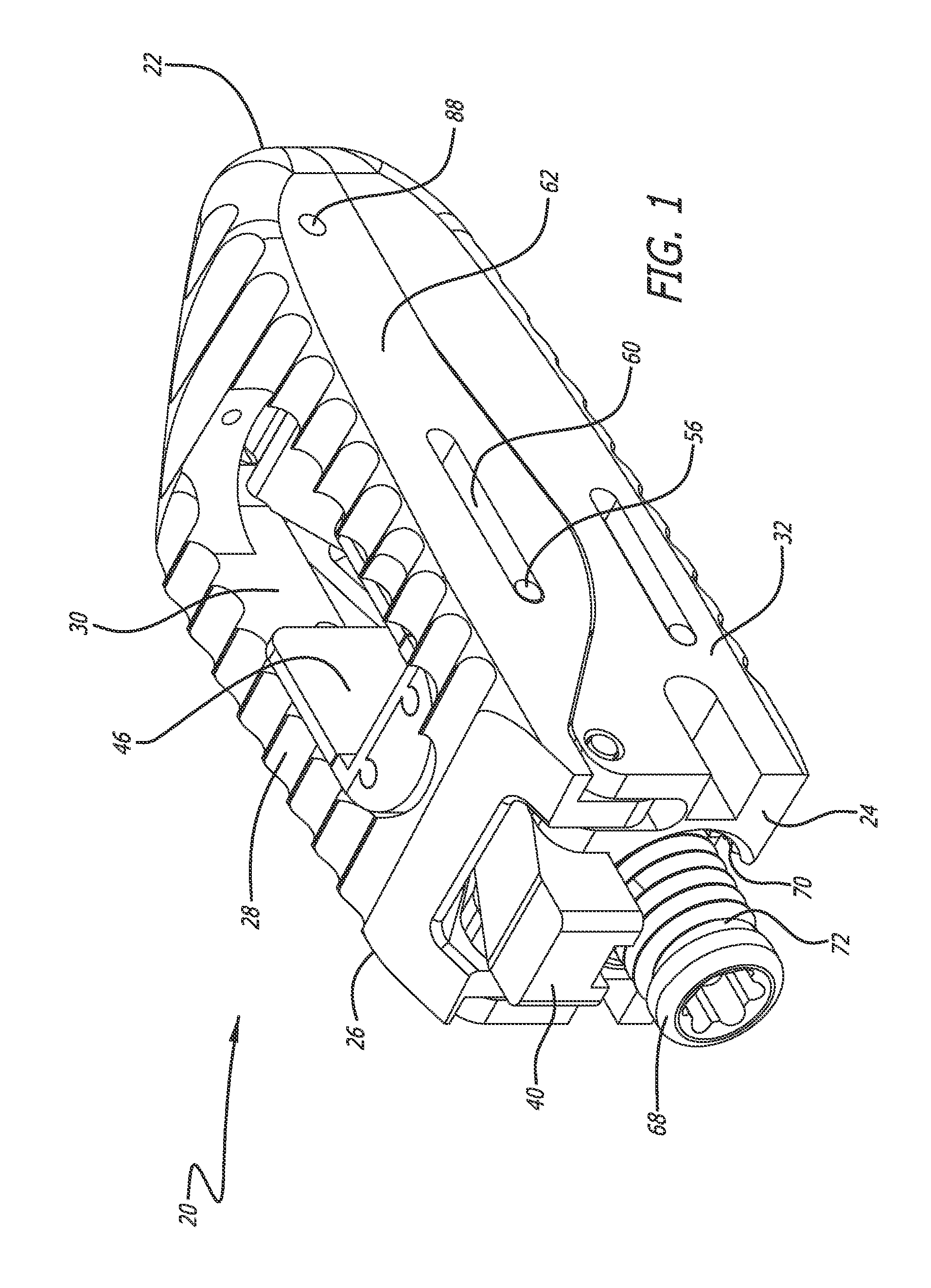

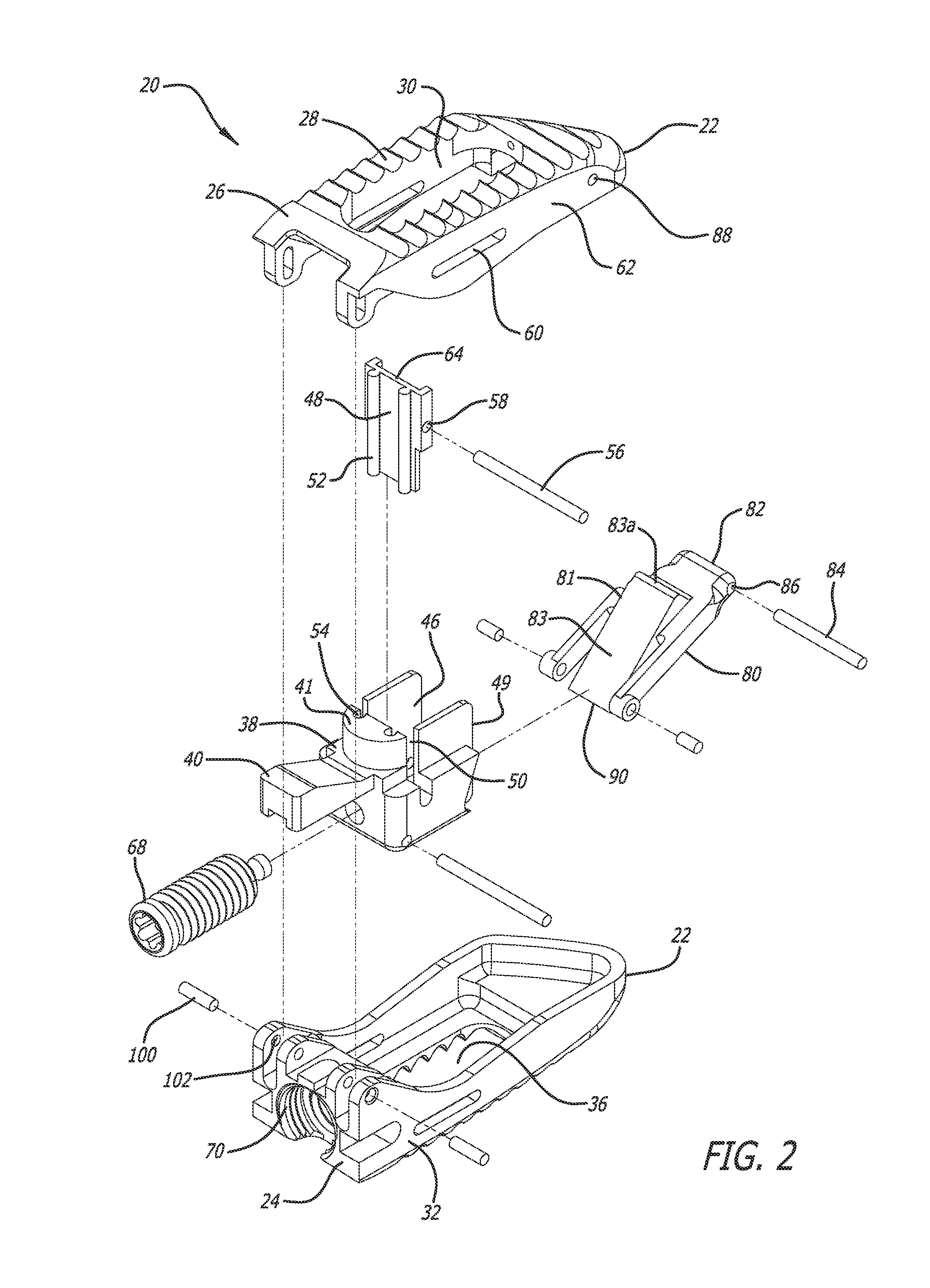

Expandable interbody implant

ActiveUS20160120660A1Improved driving linkSmoothly and reliably expandInternal osteosythesisSpinal implantsIntervertebral discBone growth

An expandable interbody implant adapted for insertion at least into a disc space, between two adjacent vertebrae of a spine. An upper member and a lower member are pivotally connected at least by a drive link. A bone graft storage portion packed with a selected volume of bone growth material. A translational wall is provided between the bone graft storage portion and a trailing end of the implant. An actuator engages the bone graft storage portion, pushing it forward into engagement with the drive link, which pivots upward, moving the upper member upward away from the lower member. Upward movement of the upper member raises the translational wall to a position to assist in retention of the selected volume bone graft material within the hollow portion of the bone graft storage portion. Upward rotation of the drive link brings a face thereof into contact with a front of the bone graft storage portion, thereby retaining near constant volume of the bone graft material.

Owner:WARSAW ORTHOPEDIC INC

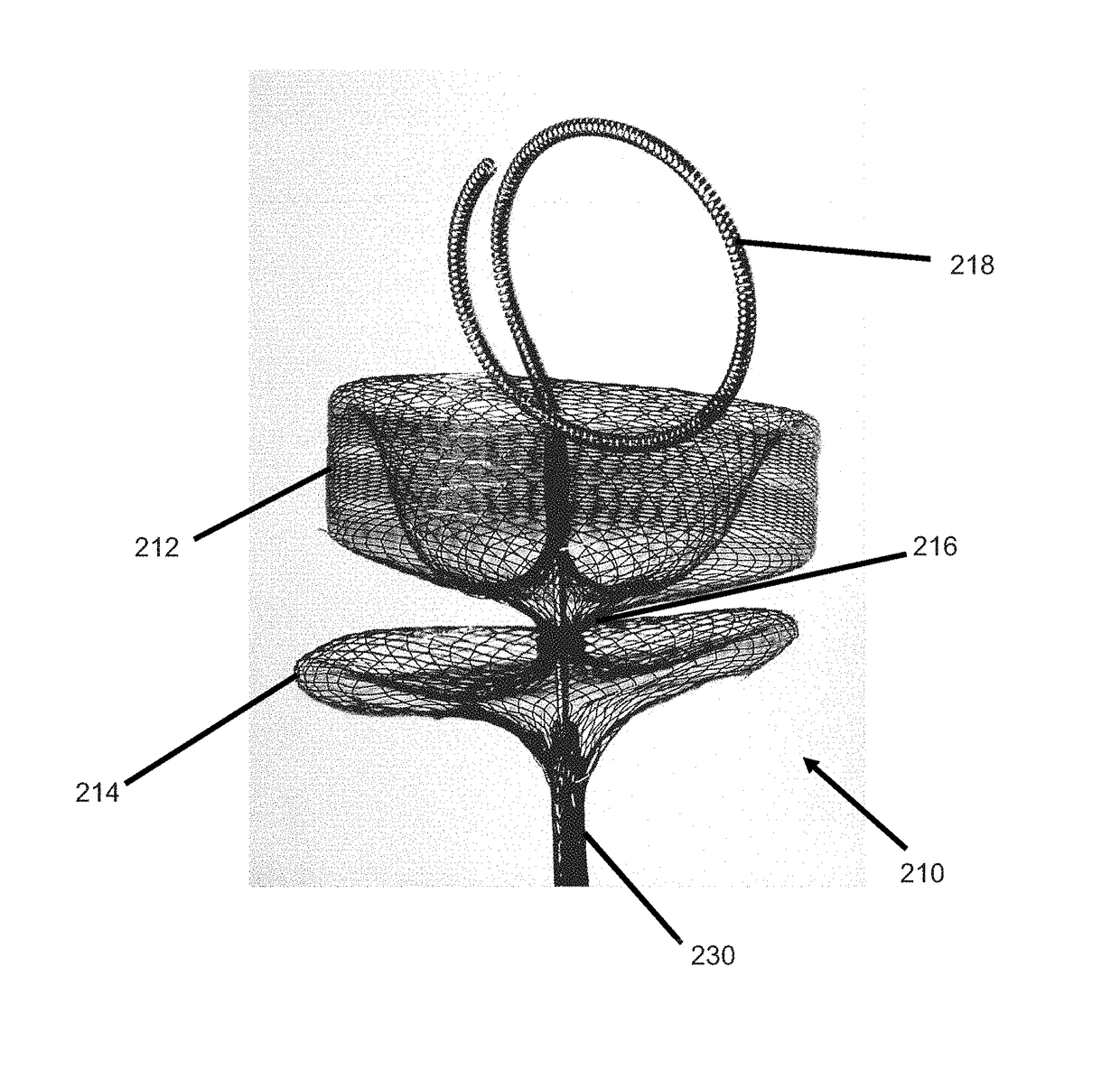

Embolic Containment

Owner:MICROVENTION INC

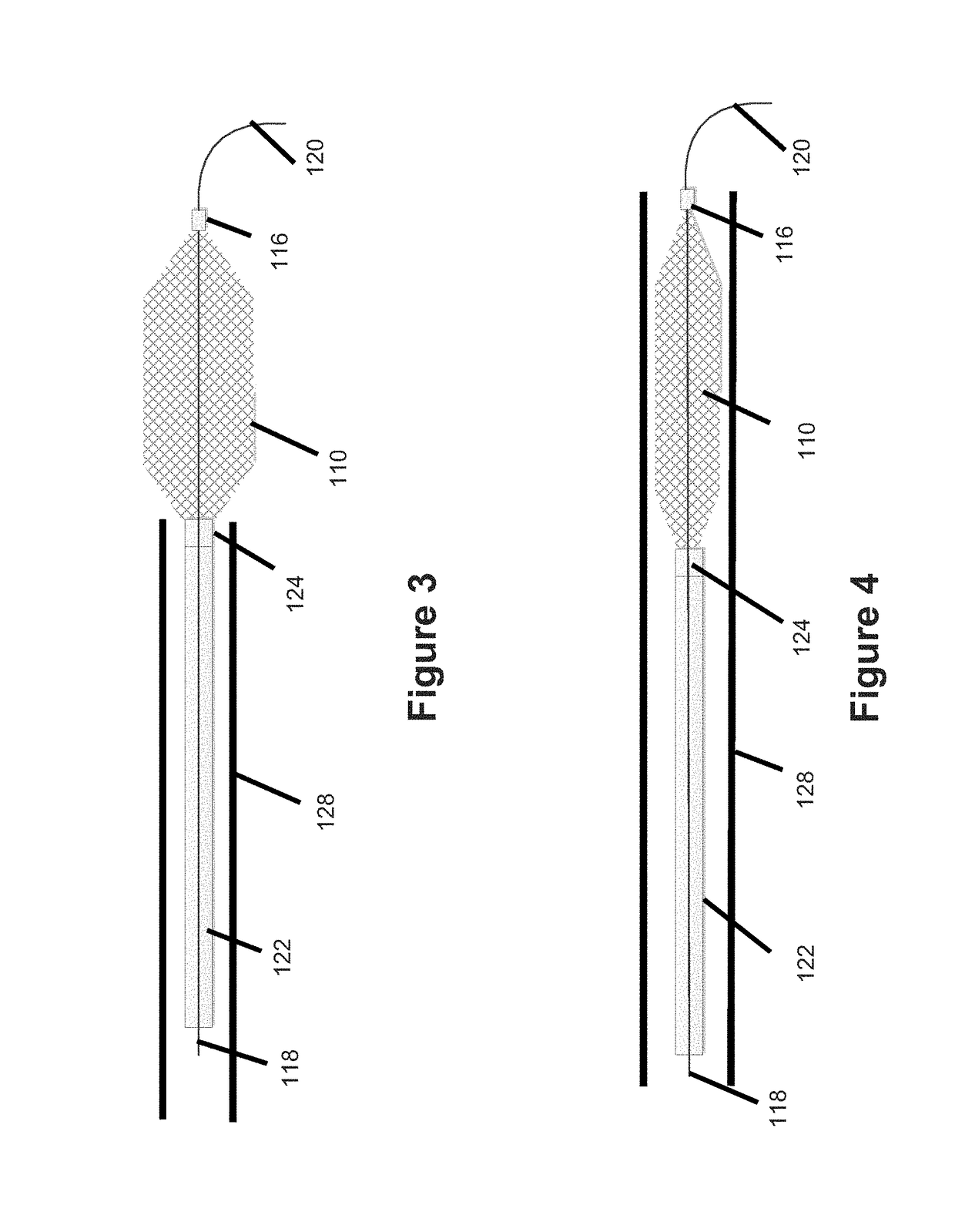

Occlusion balloon catheter with longitudinally expandable balloon

ActiveUS20050197668A1Increased longitudinal expansionConstant radial expansionStentsBalloon catheterBalloon dilatationBalloon catheter

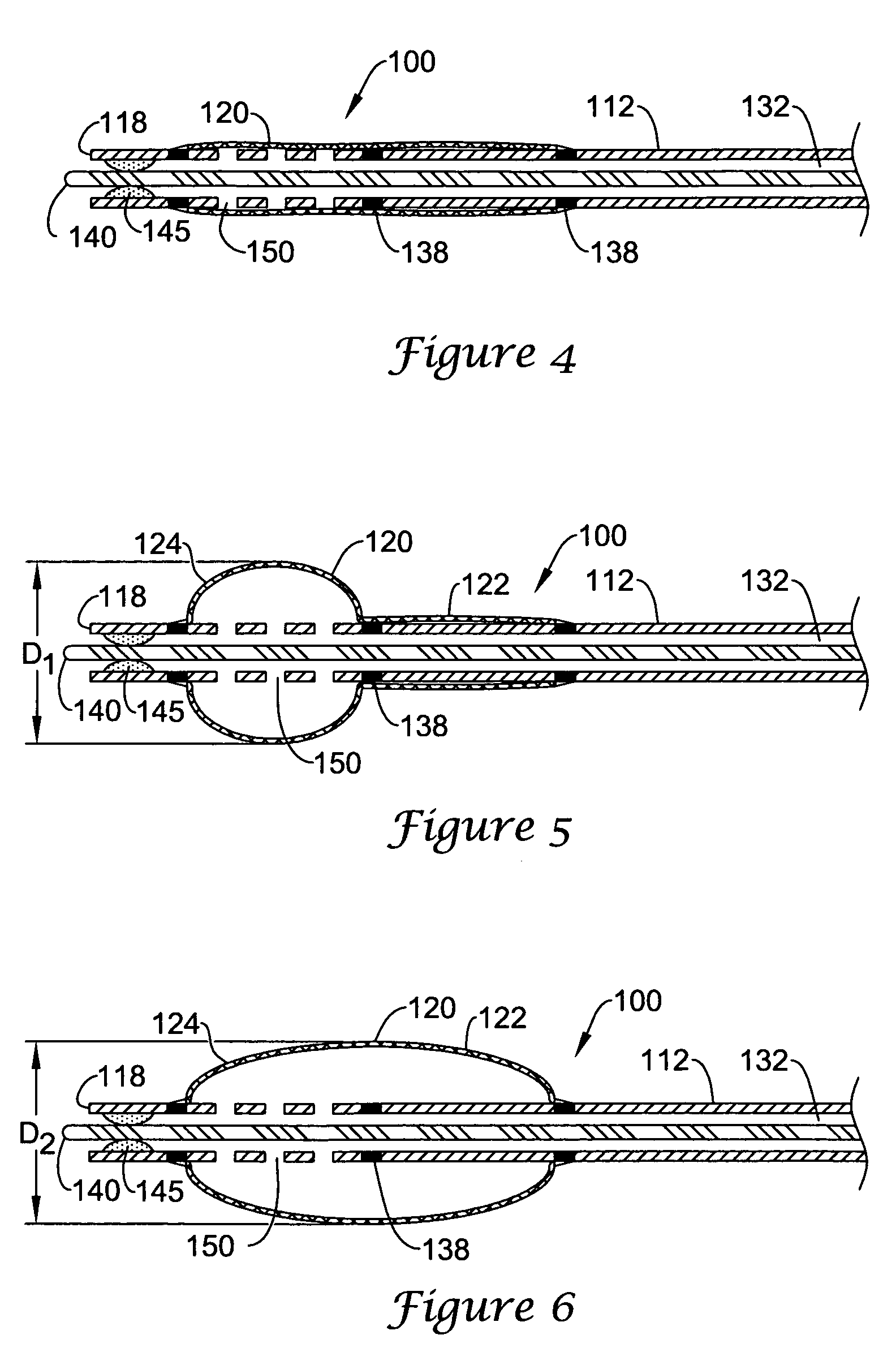

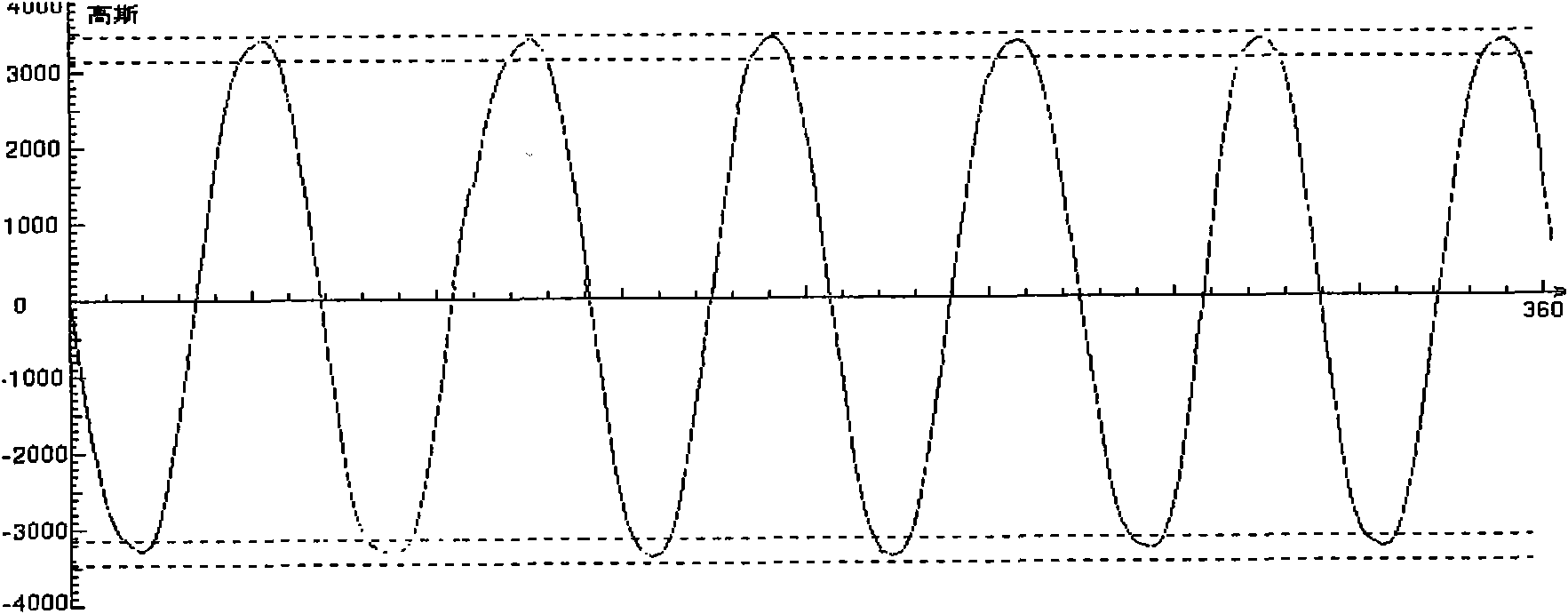

Balloon catheters such as guide catheters can be configured to provide distal occlusion, while still providing sufficient interior lumen space for device delivery. Such catheters can provide a desired level of balloon expansion, yet prevent vessel damage caused by balloon over-expansion. A catheter can include an elongate shaft having a distal region, a proximal region and a lumen extending therebetween. A balloon is inflated to a desired expansion configuration with a desired diameter. Over-inflation of the balloon causes longitudinal expansion instead of increased radial expansion, thus maintaining the diameter of the balloon.

Owner:BOSTON SCI SCIMED INC

Expandable interbody implant

ActiveUS9937053B2Improved driving linkSmoothly and reliably expandInternal osteosythesisJoint implantsIntervertebral discActuator

An expandable interbody implant adapted for insertion at least into a disc space, between two adjacent vertebrae of a spine. An upper member and a lower member are pivotally connected at least by a drive link. A bone graft storage portion packed with a selected volume of bone growth material. A translational wall is provided between the bone graft storage portion and a trailing end of the implant. An actuator engages the bone graft storage portion, pushing it forward into engagement with the drive link, which pivots upward, moving the upper member upward away from the lower member. Upward movement of the upper member raises the translational wall to a position to assist in retention of the selected volume bone graft material within the hollow portion of the bone graft storage portion. Upward rotation of the drive link brings a face thereof into contact with a front of the bone graft storage portion, thereby retaining near constant volume of the bone graft material.

Owner:WARSAW ORTHOPEDIC INC

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

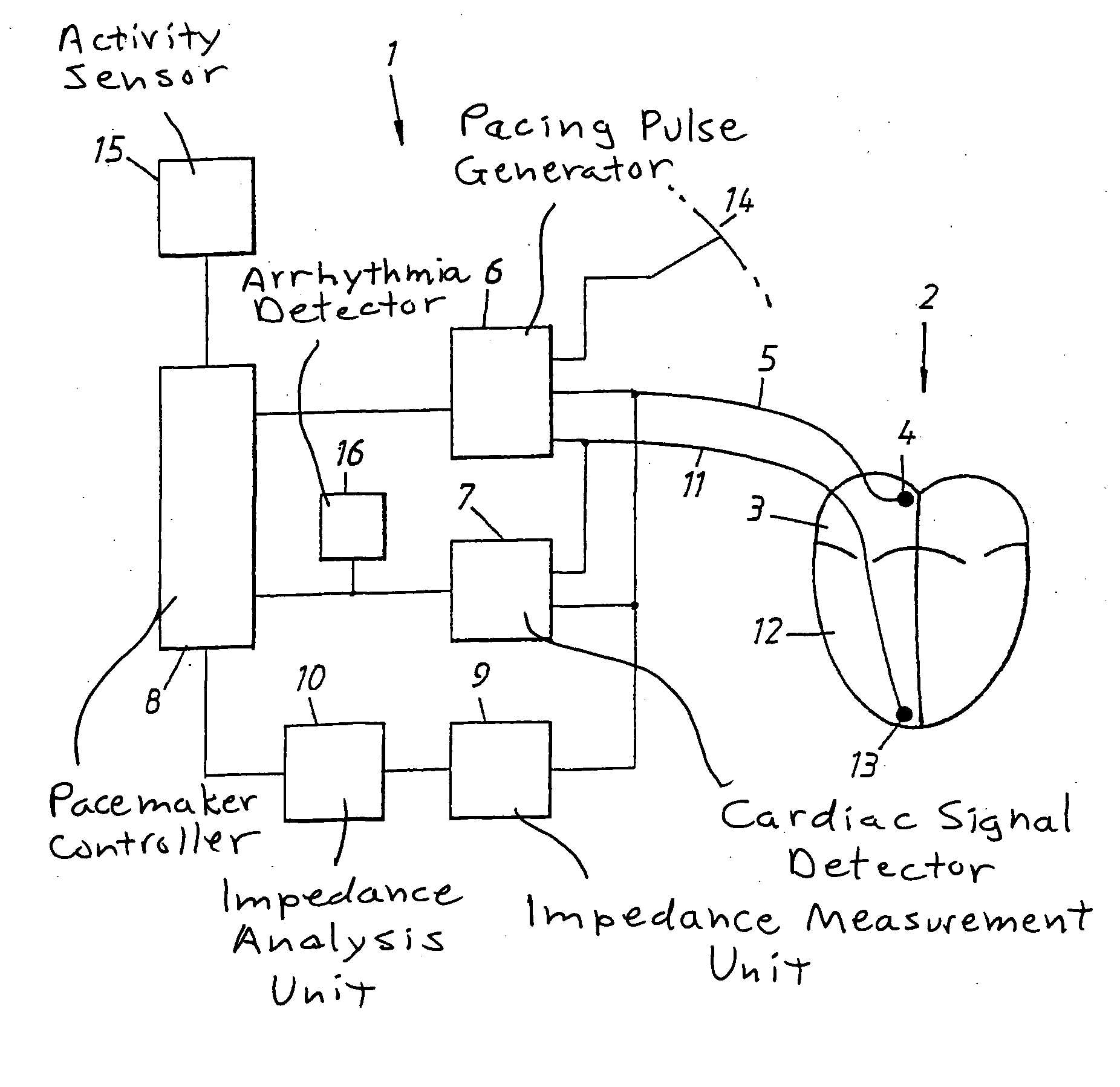

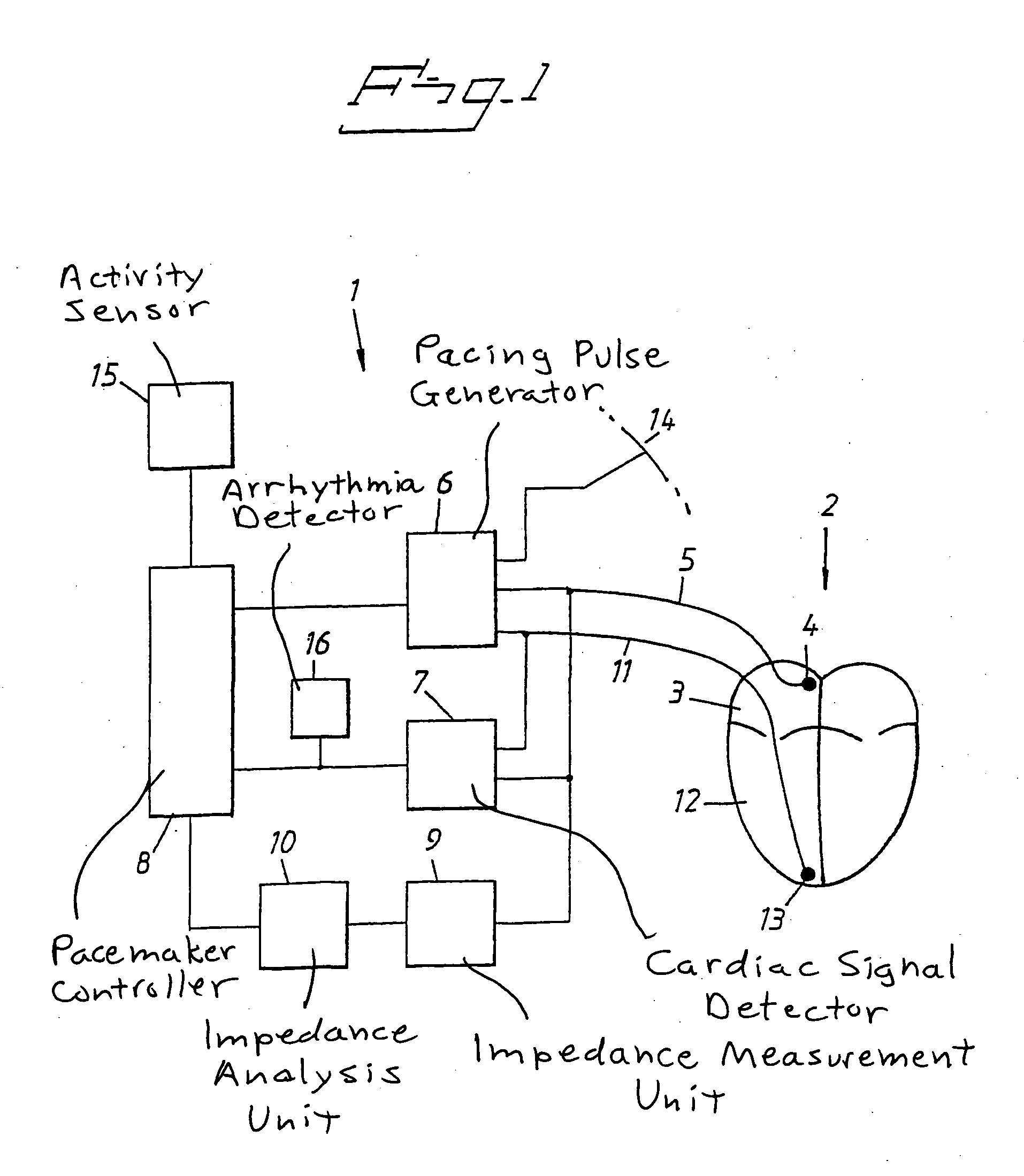

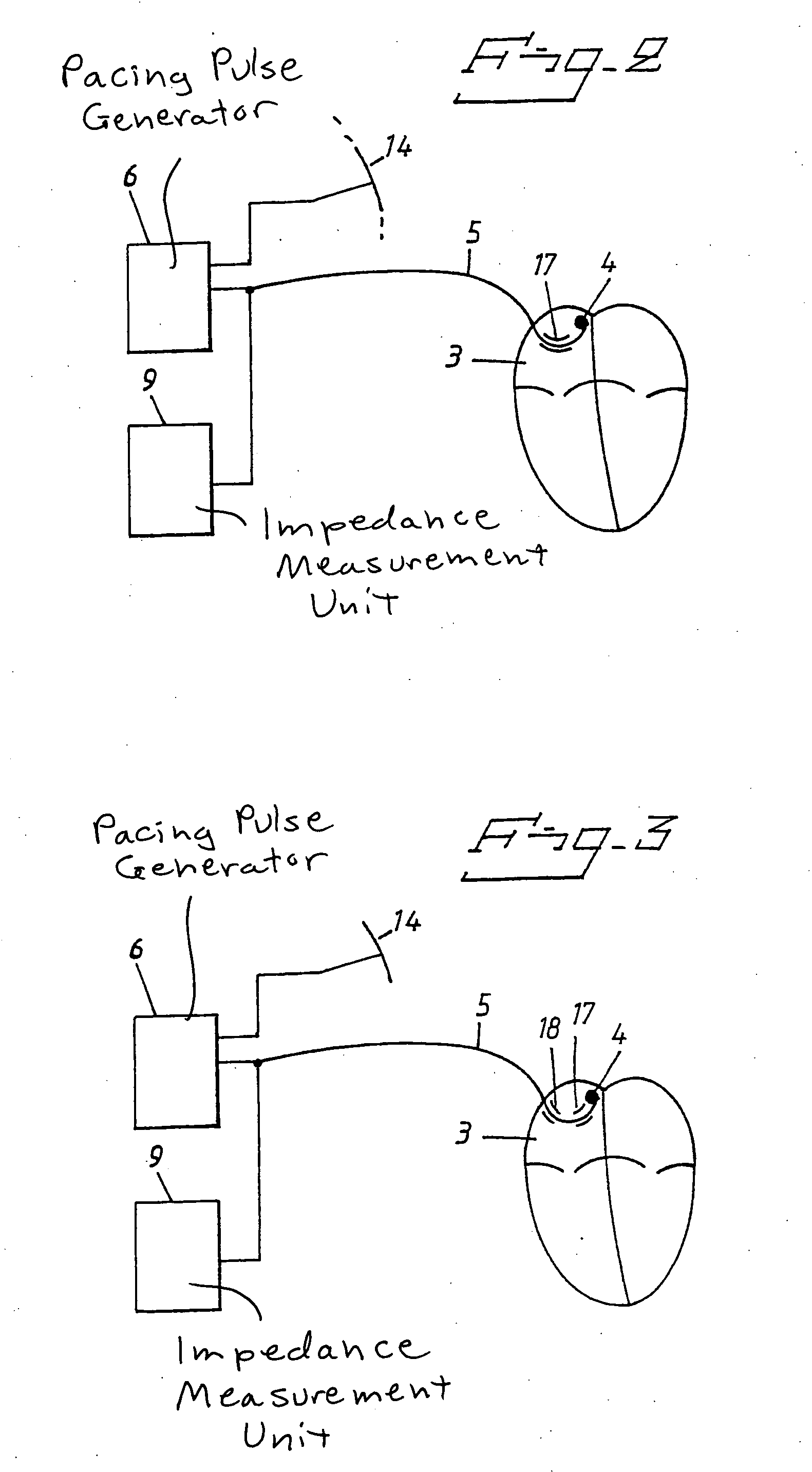

Heart stimulator detecting atrial arrhythmia by determing wall distension by impedance measuring

InactiveUS20060206157A1Limit atrial distensionEliminates atrial remodelingHeart stimulatorsAtrial cavityCardiac pacemaker electrode

In an implantable pacemaker, pacing pulses are delivered to a ventricle in a P-wave synchronous mode as long as no atrial arrhythmia is detected, pacing pulses and a mode switch is made to deliver pacing pulses to the ventricle in a non-P-wave synchronous mode if atrial arrhythmia is detected. From an impedance signal measured in the atrium, atrial distention is determined and, in the non-P-wave synchronous mode, the delivery rate of the pacing pulses is increased to decrease the atrial distention during atrial arrhythmia.

Owner:ST JUDE MEDICAL

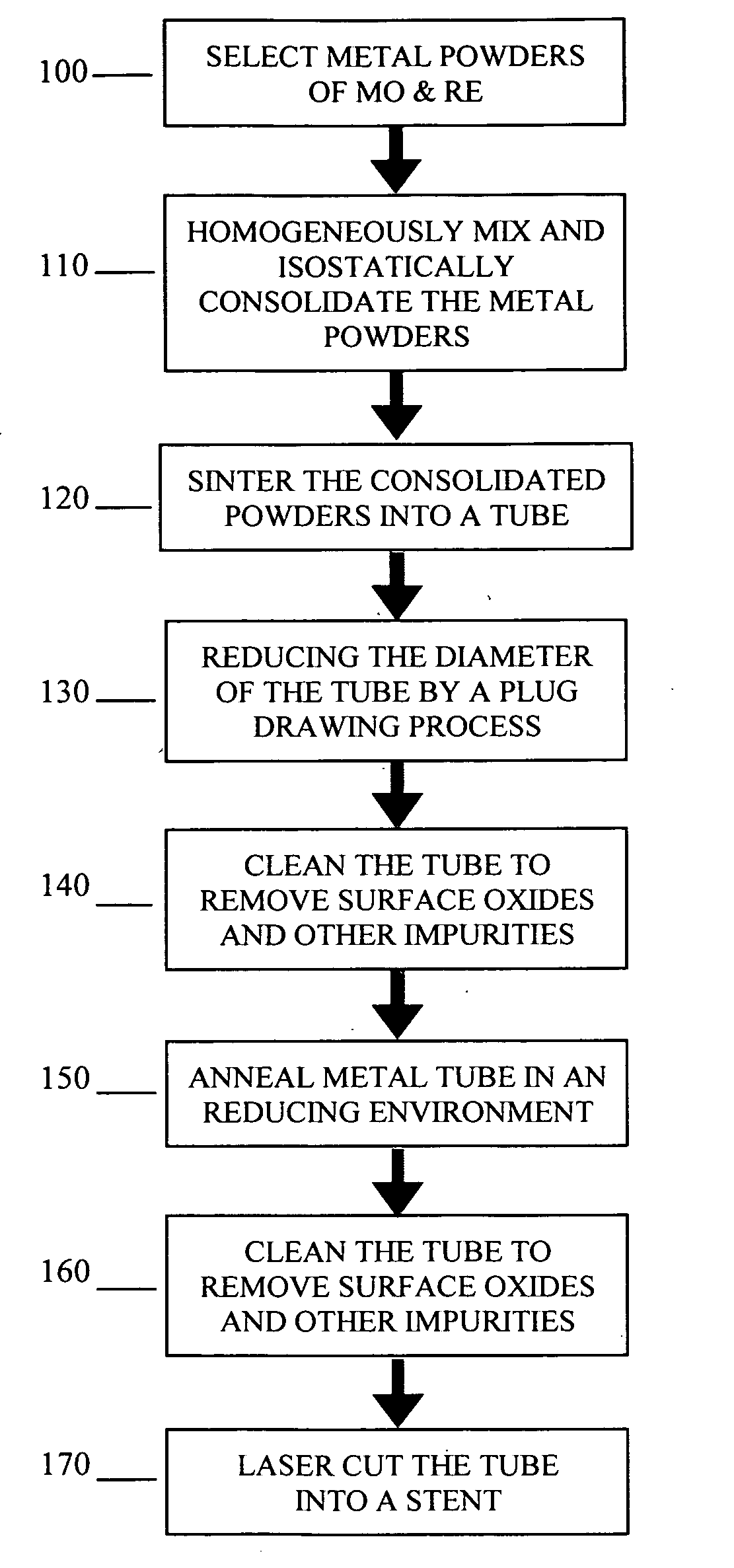

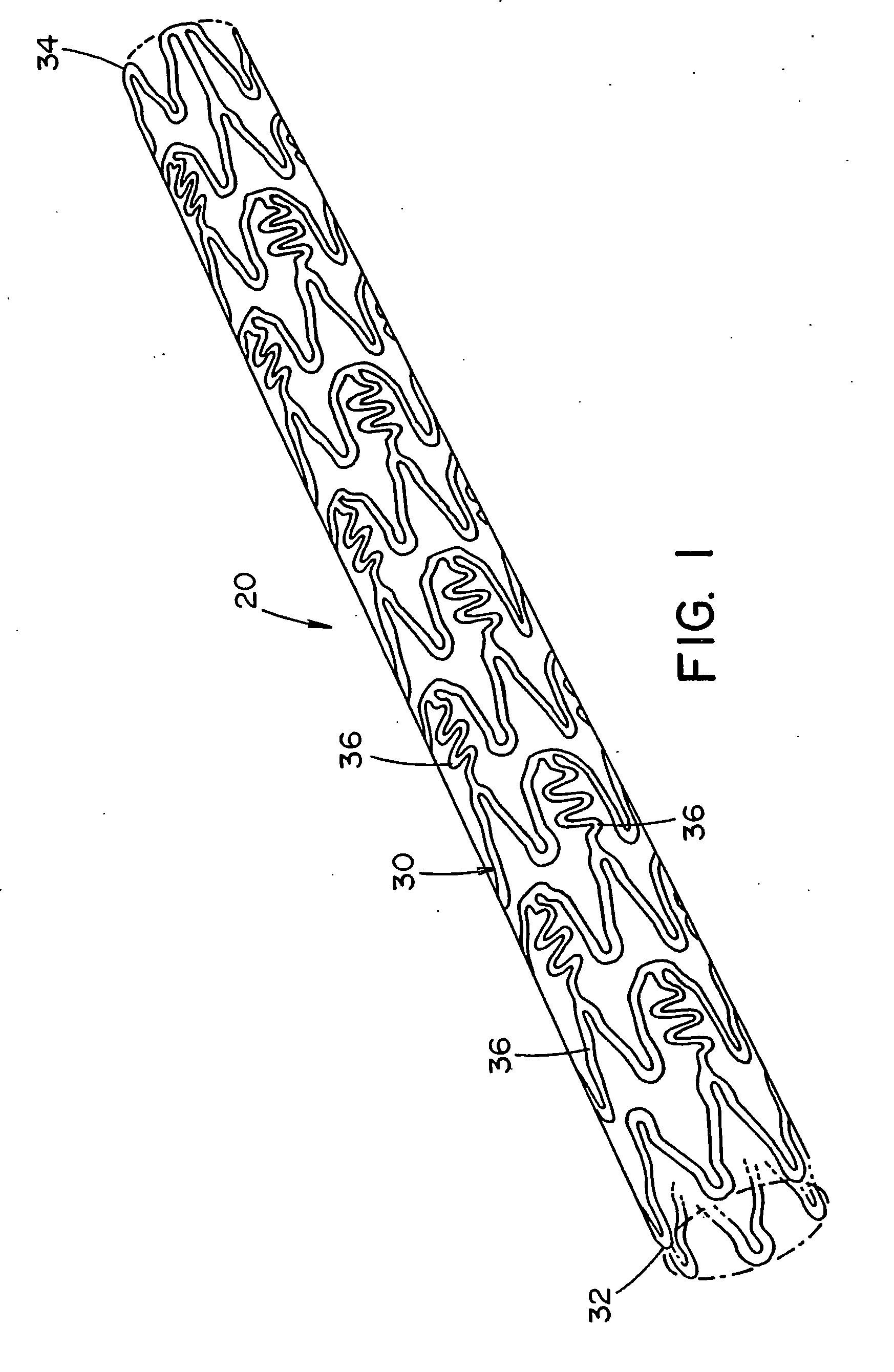

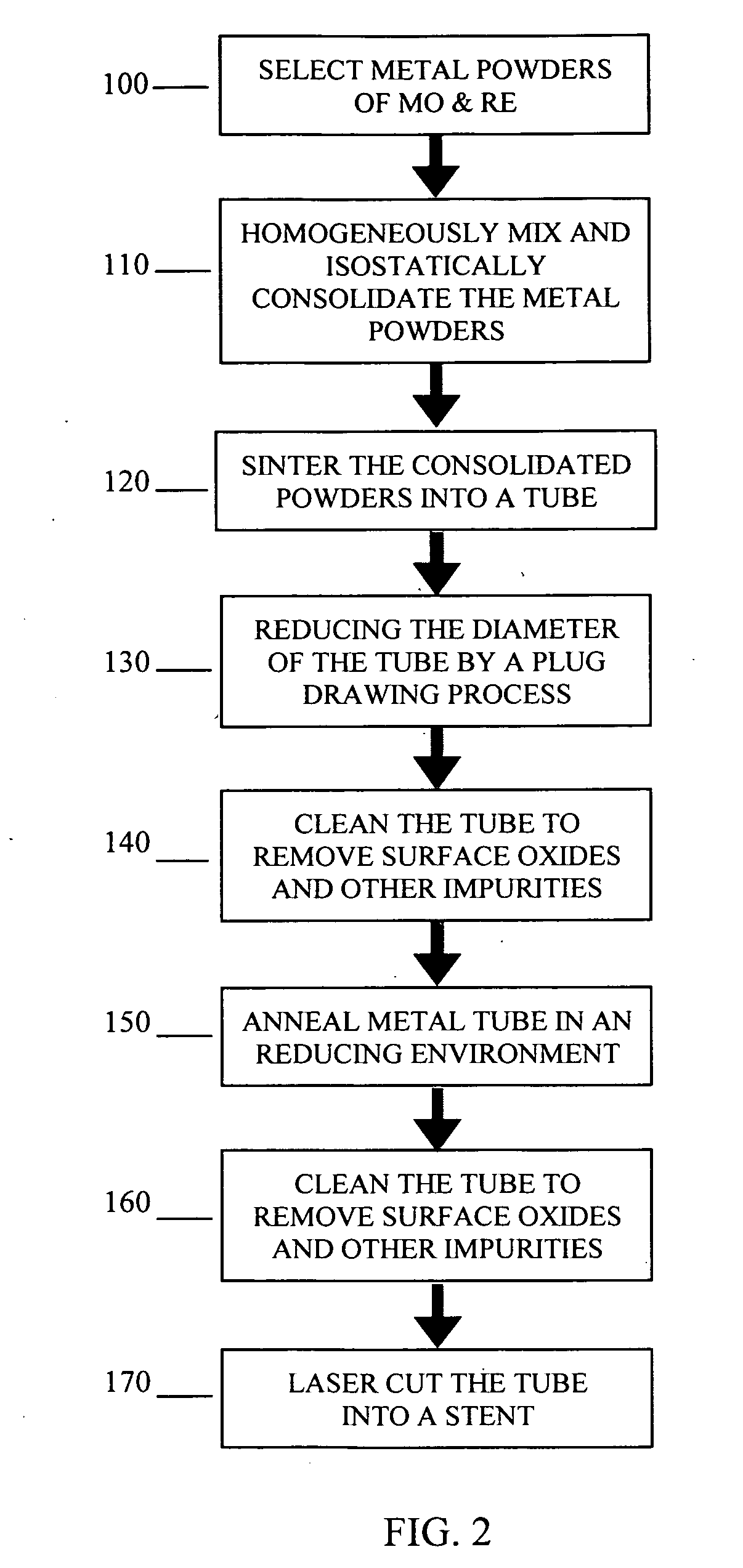

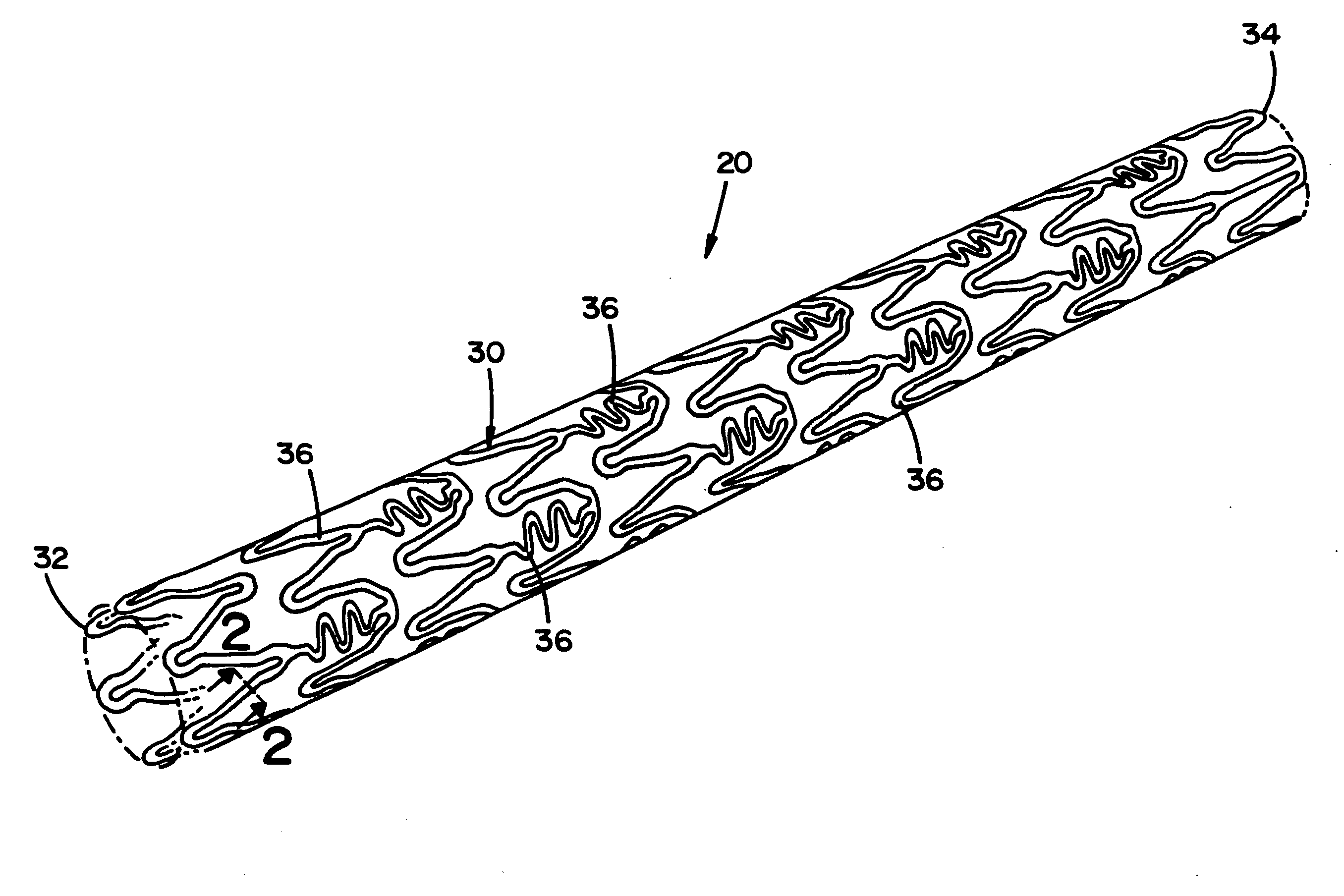

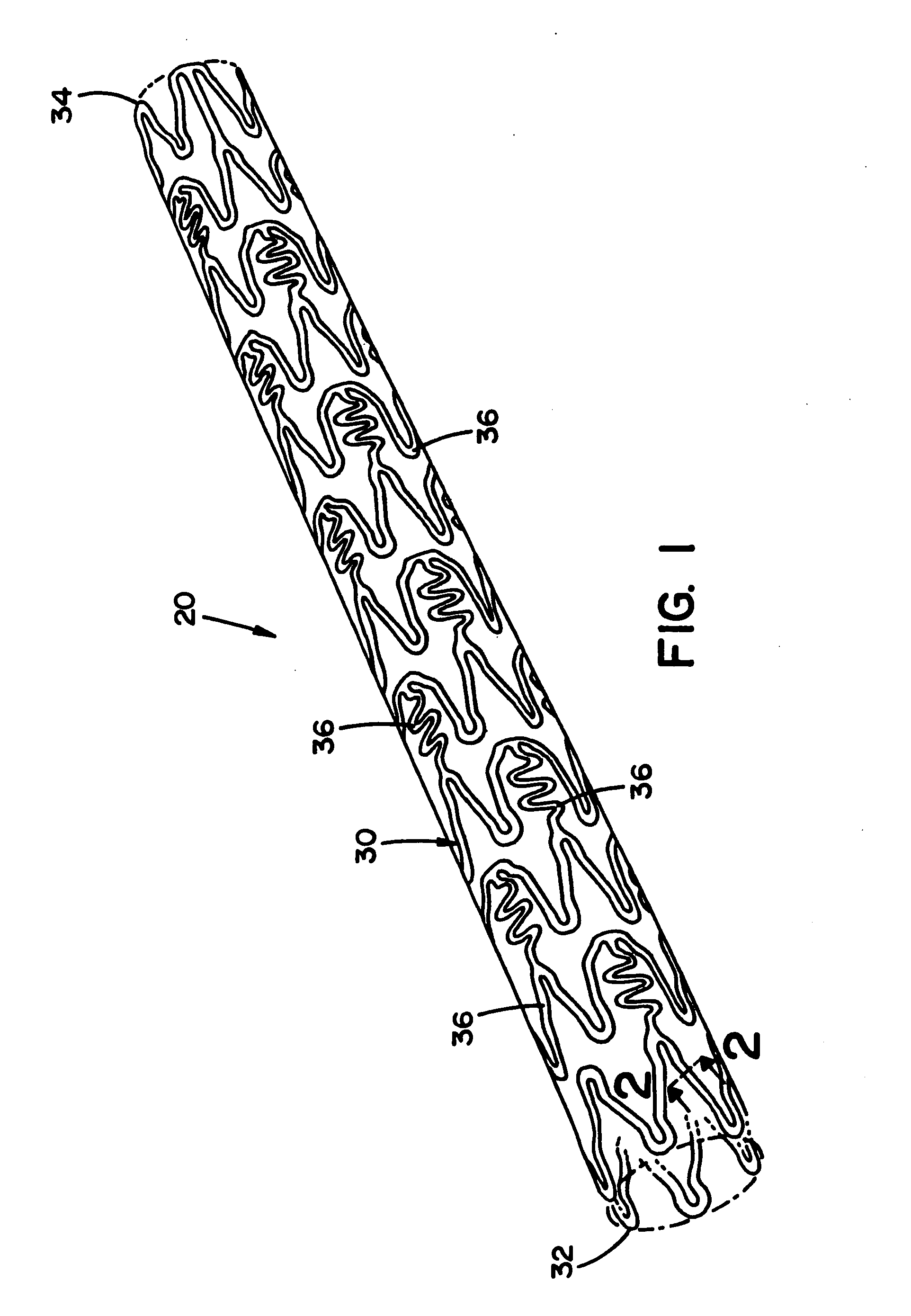

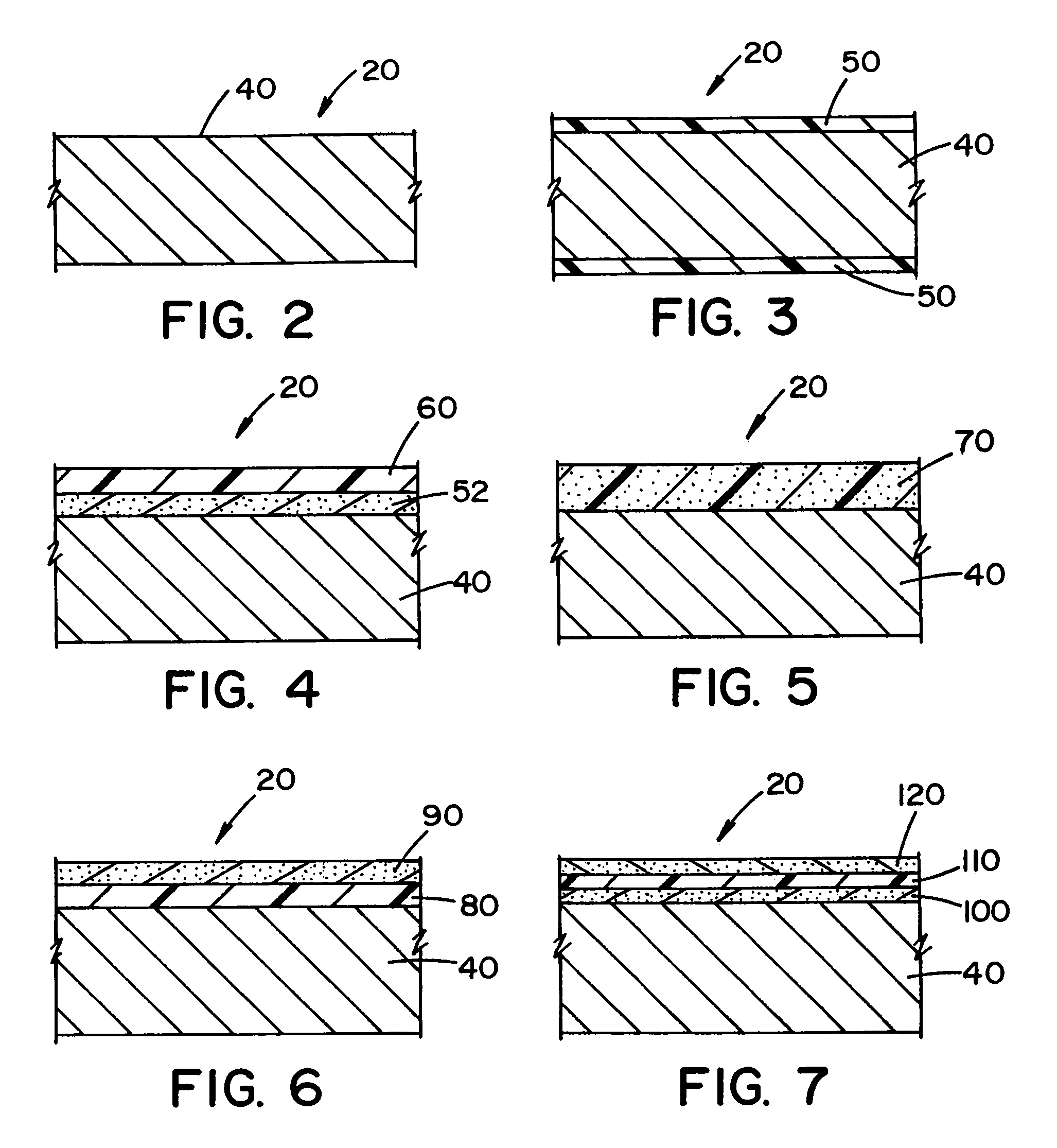

Process for forming an improved metal alloy stent

A method and process for at least partially forming a medical device that is at least partially formed of a novel metal alloy which improves the physical properties of the medical device.

Owner:MIRUS LLC

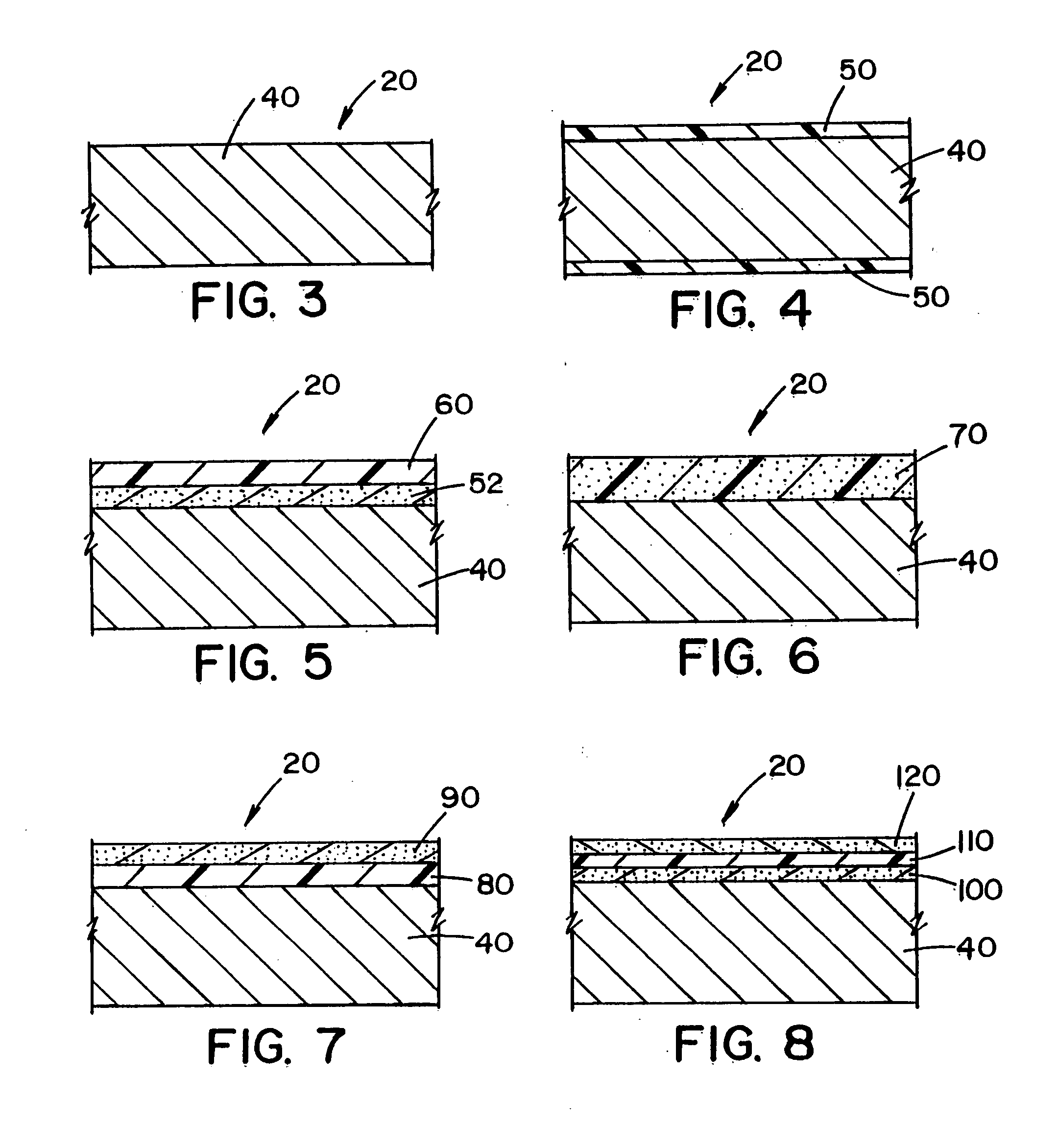

Environmentally friendly absorbent structure

ActiveUS20150038929A1Increase expansionPromote swellingBaby linensTamponsEnvironmentally friendlyPermanent primary

The present invention relates to an absorbent structure, preferably for use in absorbent articles as used in the personal hygiene industry such as feminine hygiene garments, baby diapers and pants or adult incontinence garments. The present invention also relates to an absorbent article comprising such absorbent structure and to a method of manufacturing the absorbent structure. The absorbent structures comprise a carrier layer, an auxiliary layer and an absorbent material there between wherein substantially permanent primary attachments and substantially temporary secondary attachments join the carrier layer and auxiliary layer at least partially together, whereby the substantially temporary secondary attachments are loosened as a result of exposing the absorbent structure to a liquid whereas the substantially permanent primary attachments remain substantially intact. The present invention foresees in the need for improved flexible, thin, lightweight absorbent structures for an absorbent article which overcomes the absorbency problems of the prior art during absorption, distribution and retention of liquids with optimal fit.

Owner:DRYLOCK TECHNILOGIES NV

Foaming type electromagnetic wave absorption composite material and preparation method thereof

InactiveCN101899221AReduce oxidationExtended service lifeOther chemical processesDielectric lossElectromagnetic interference

The invention discloses a foaming type electromagnetic wave absorption composite material and a preparation method thereof. The electromagnetic wave absorption composite material is prepared from 10 to 40 mass percent of an electromagnetic absorbent and 60 to 90 mass percent of a base material through a foaming process. Impedance matching between the base material and air is improved by uniform gaps formed by foaming, and a powder material with electromagnetic wave absorption function is uniformly diffused in the foaming process of the base and adsorbed on foam hole walls to form a dielectric loss and magnetic hysteresis loss electromagnetic wave absorption network, so that the electromagnetic waves entering the base are converted into heat energy and attenuated through motion such as reflection, refraction, vortex, resonance and the like. The foaming type electromagnetic wave absorption composite material is widely applied to the field of electromagnetic radiation, electromagnetic interference and electromagnetic information leakage prevention, suppression and absorption treatment.

Owner:李勇

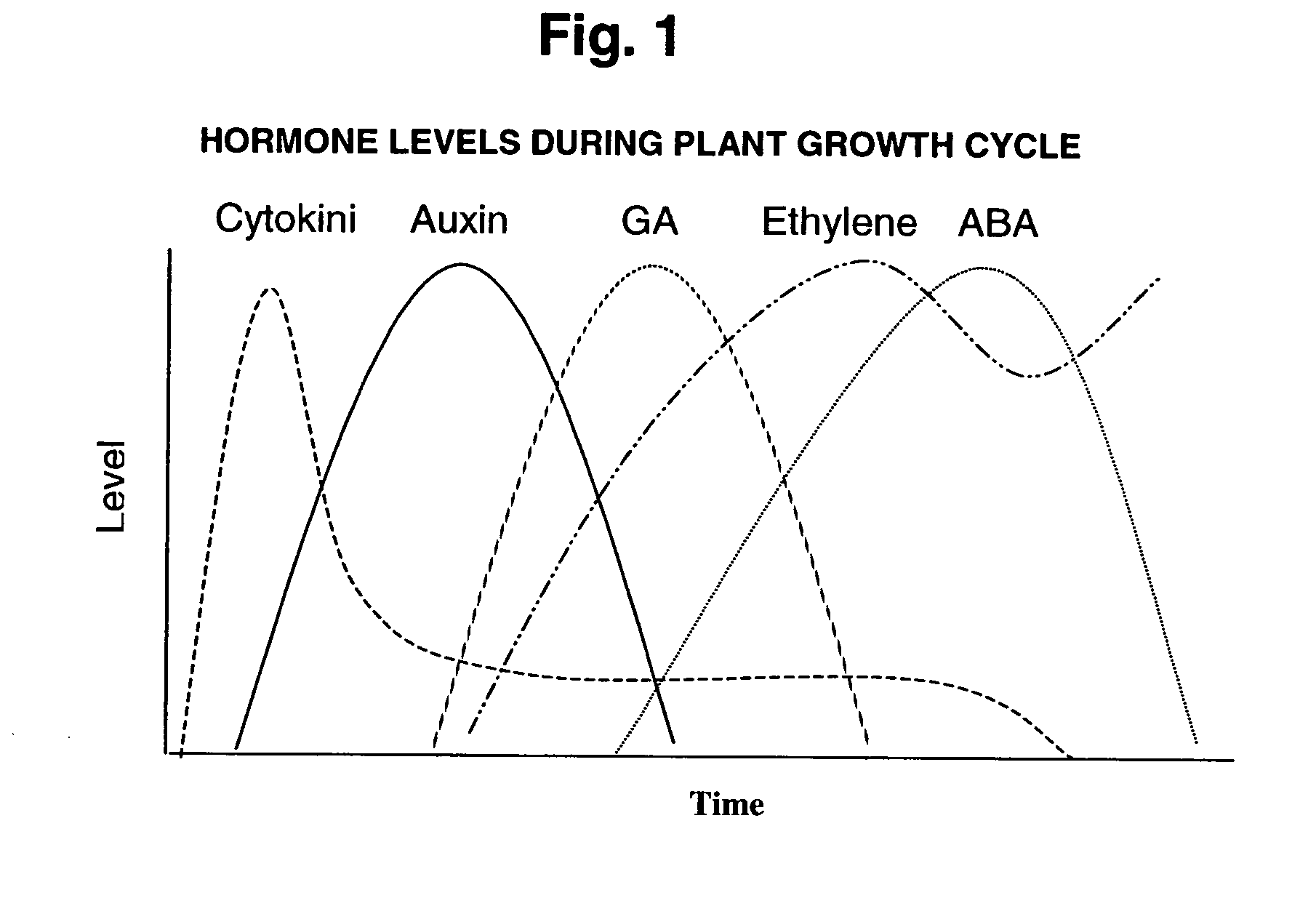

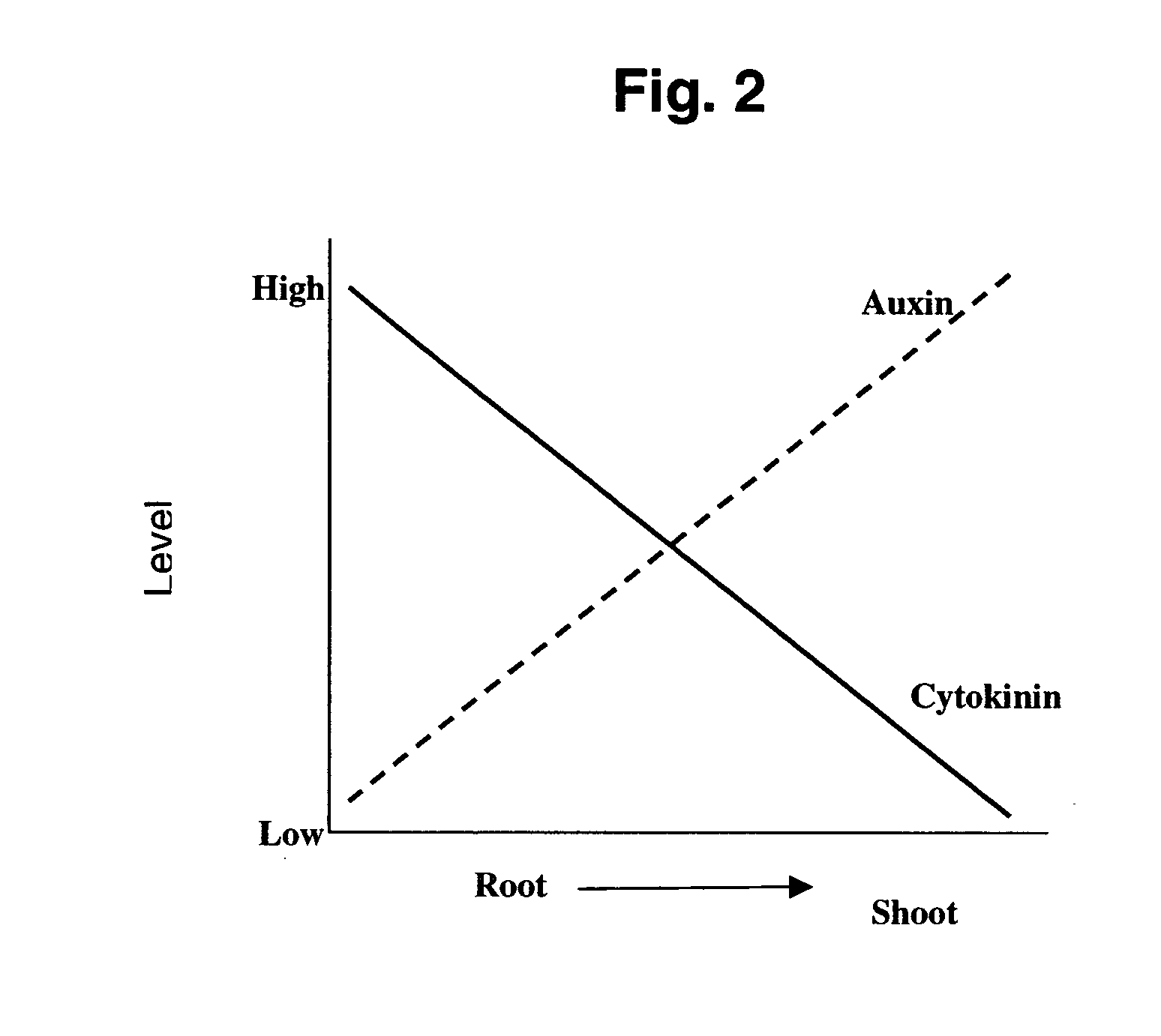

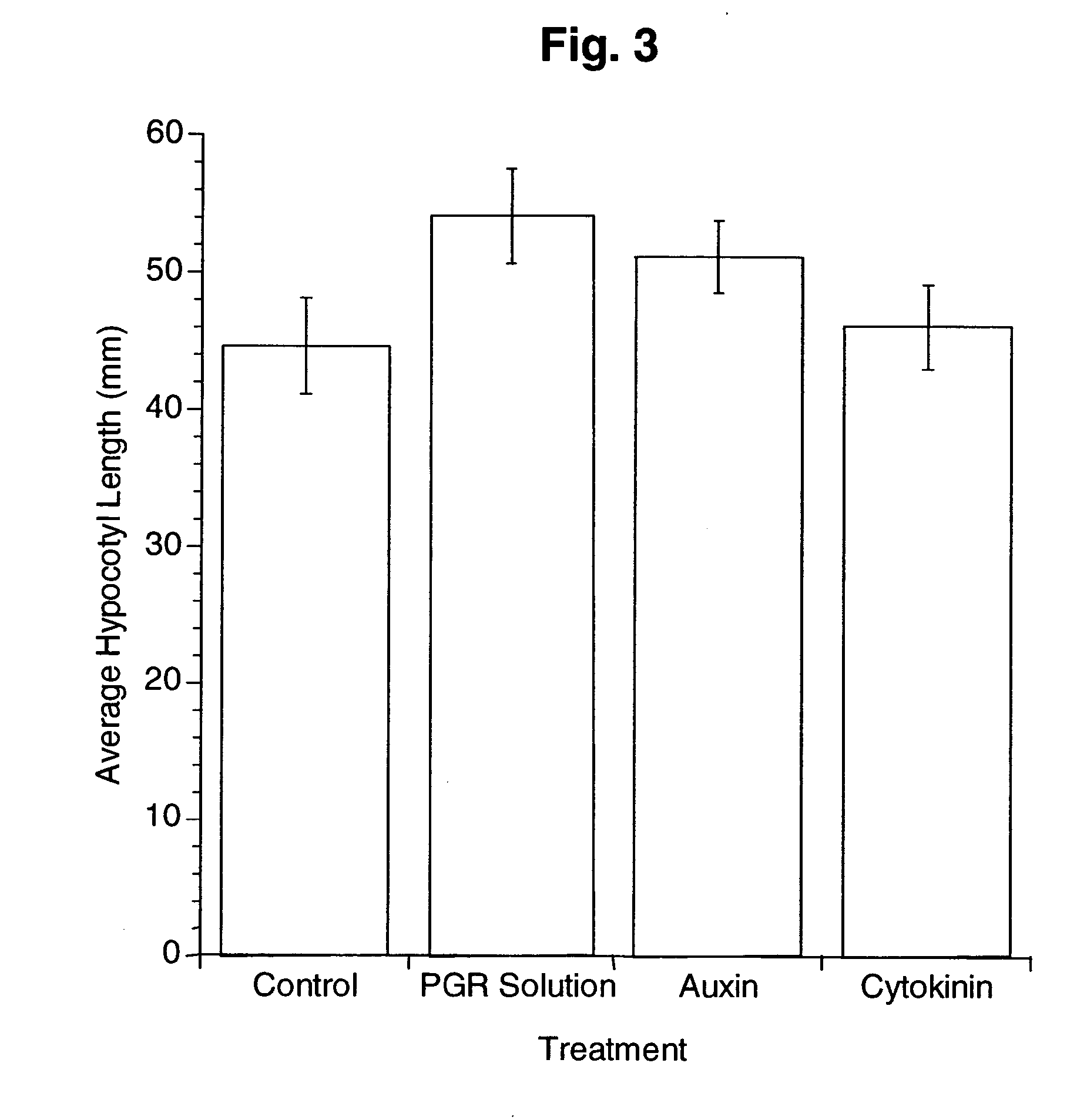

Methods for improving growth and crop productivity of plants by adjusting plant hormone levels, ratios and/or co-factors

ActiveUS20050197253A1Improve architectureIncrease crop yieldBiocideAnimal repellantsCytokininDisease

In agriculture when temperature and moisture deviate from the norm two things happen, plant growth suffers and disease flourishes. The Stoller model for plant growth states that proper hormone balance is necessary for optimum growth and performance. When growth conditions deviate from the norm, hormone balance is altered and plant growth suffers. This invention presents evidence to support this model and explain the relationship between hormone levels and plant growth. A clear understanding of this relationship will facilitate crop treatments aimed to eliminate these problems. Although we cannot control the climate, we can control the damage caused by environmental stresses by manipulating the levels and / or ratio of plant hormones in the different plant tissues. By adjusting the levels and / or ratios of hormones, particularly auxin and cytokinins in the root tissue, we can assist the plant in overcoming or compensating for this environmental stress.

Owner:STOLLER ENTERPRISES INC

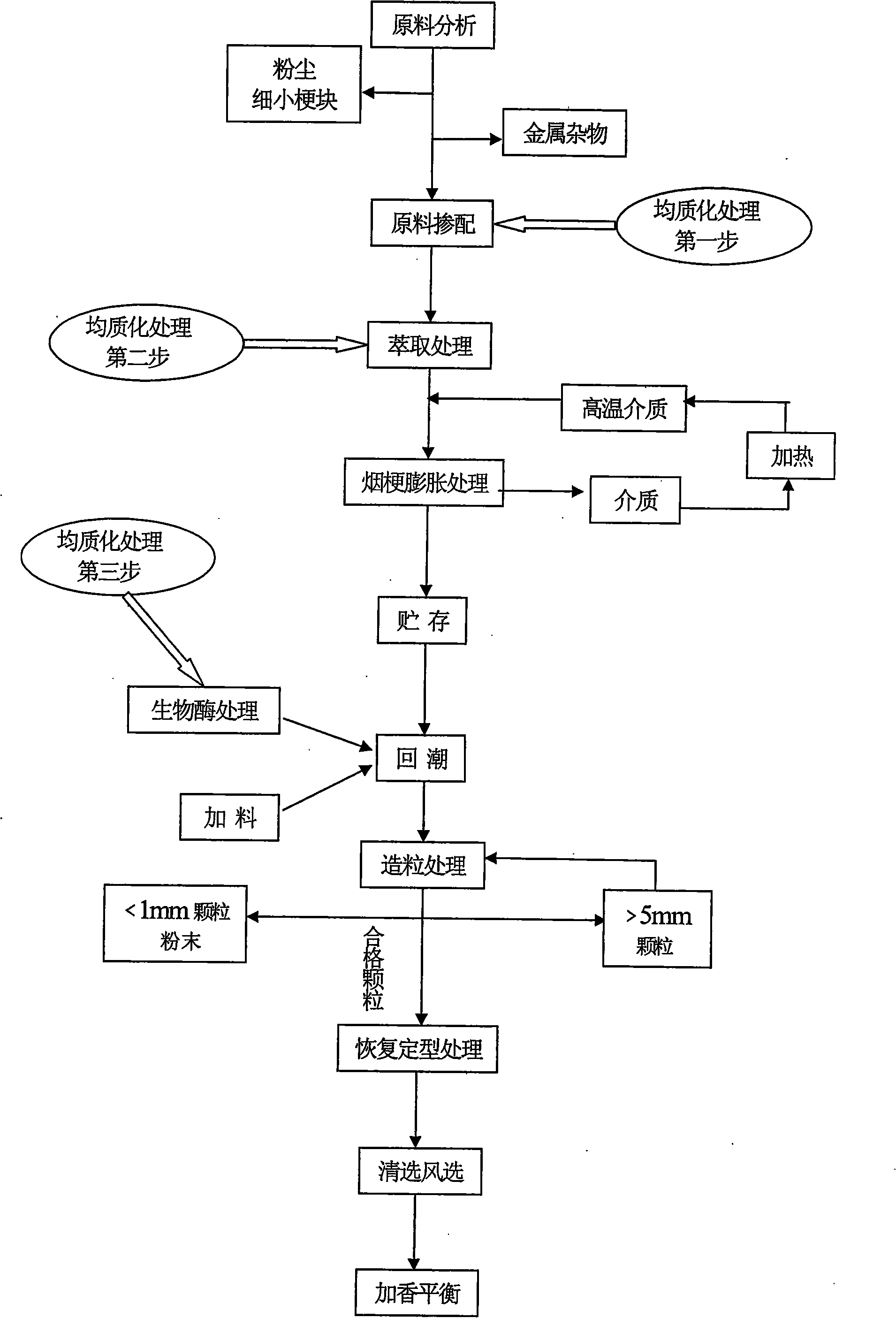

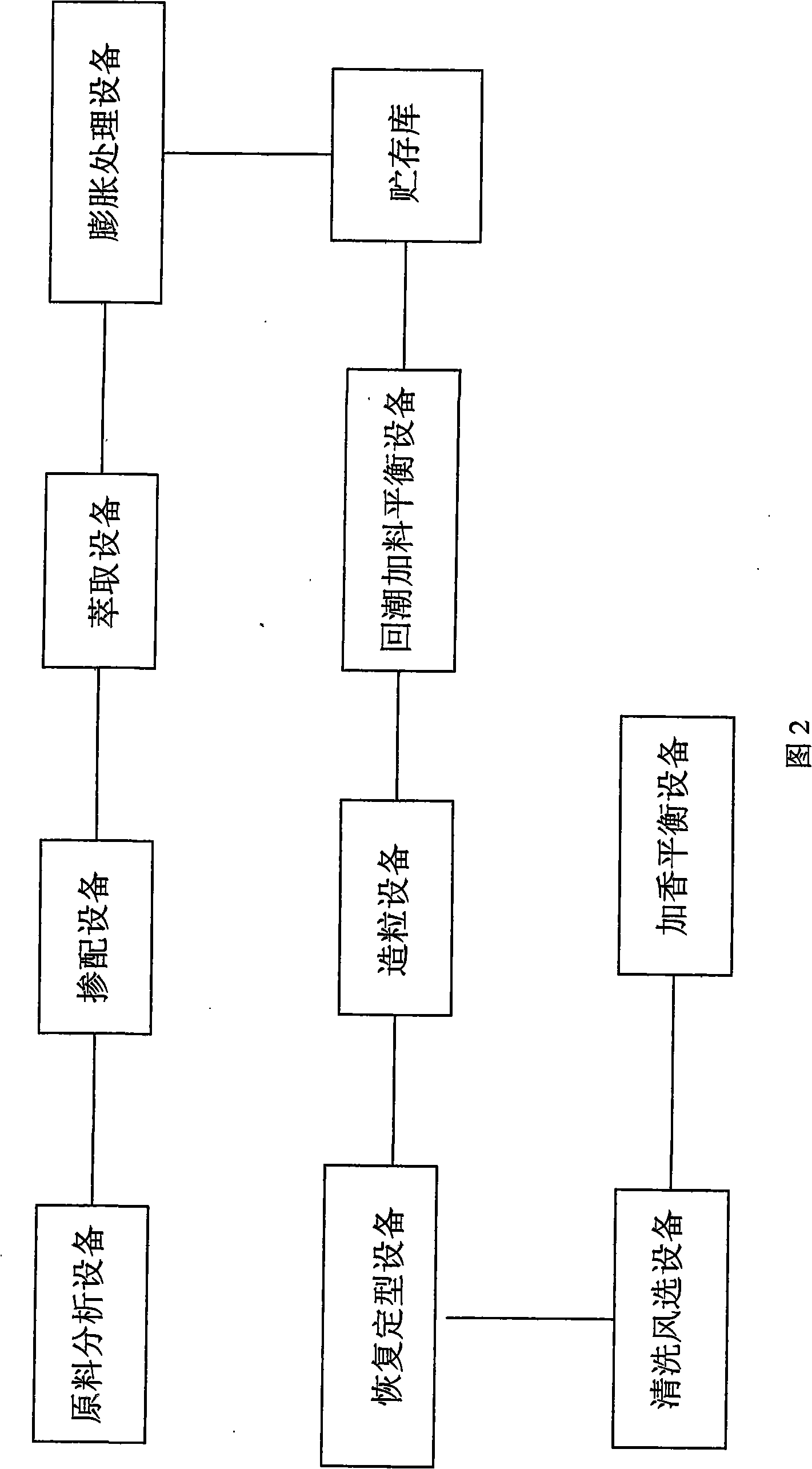

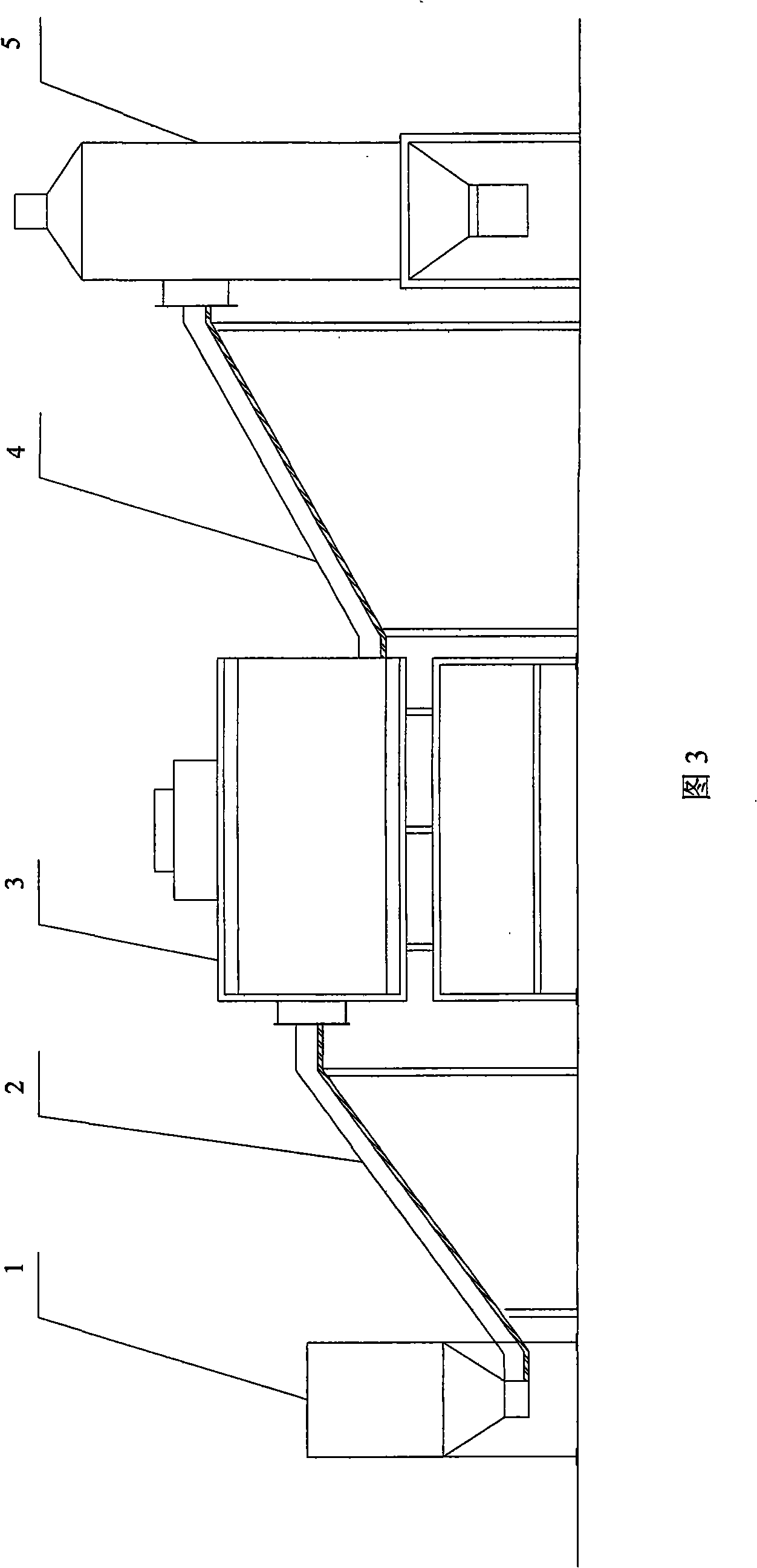

Method and device for preparing expanded stem granule

ActiveCN101305836AWide variety of sourcesAchieve expansionTobacco preparationTobacco treatmentTotal nitrogenSugar

The invention discloses a method for preparing expanded tobacco stem particles and the equipment thereof. The method is characterized in that the method can control the mixed ratio of tobacco stems on the basis of raw material analysis. The method comprises the following steps: mixing materials to obtain tobacco stem containing 10 to 18%of total sugar, 8 to 16% of reduced sugar, 0.3 to 1.5% of nicotine, and 1.0 to 2.0% of total nitrogen, extracting, expanding, storing, regaining moisture, granulating, recovering, shaping, cleaning and air-sorting, flavoring, and balancing to obtain the required expanded tobacco stem particles. The invention eliminates the influences of material difference on the quality of the expanded tobacco stem particles to ensure the stability and the uniformity of the product quality, thus improving the utilization rate of the tobacco stem and further improving the production process of the expanded tobacco stem particles. The method has the advantages of simple, reasonable and easy process flow, stable equipment operation, high efficiency, low energy loss, and good application prospect.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

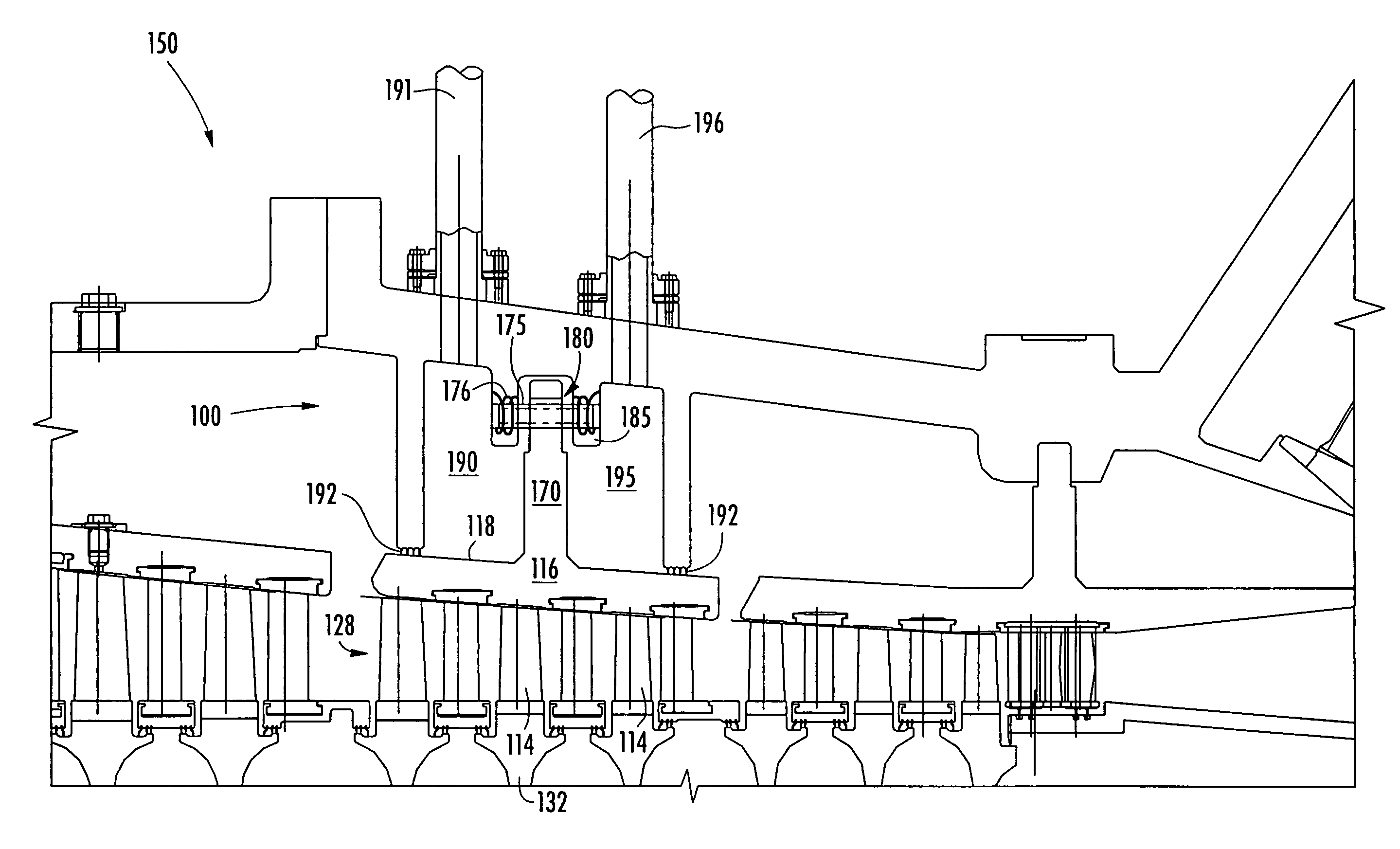

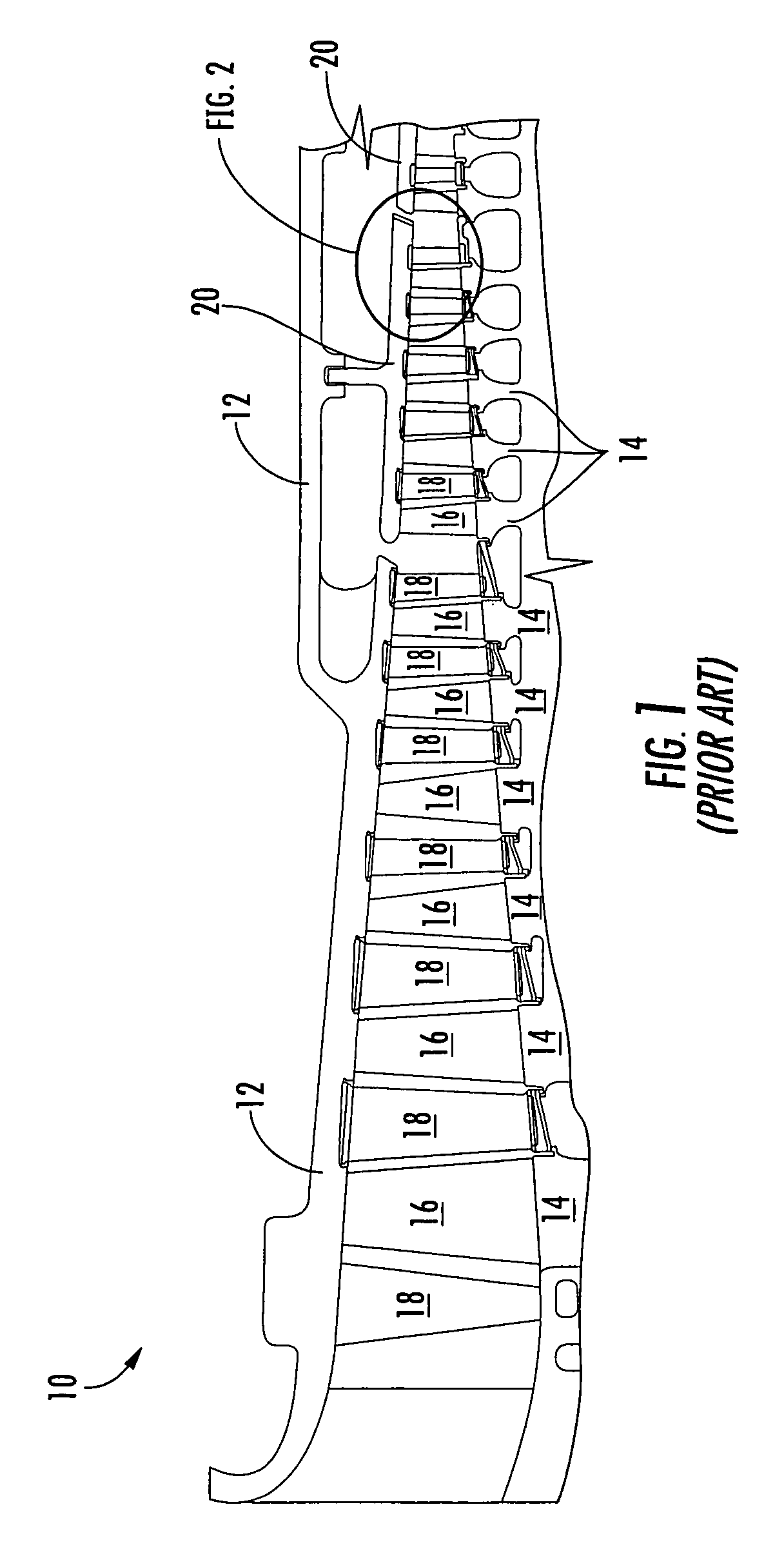

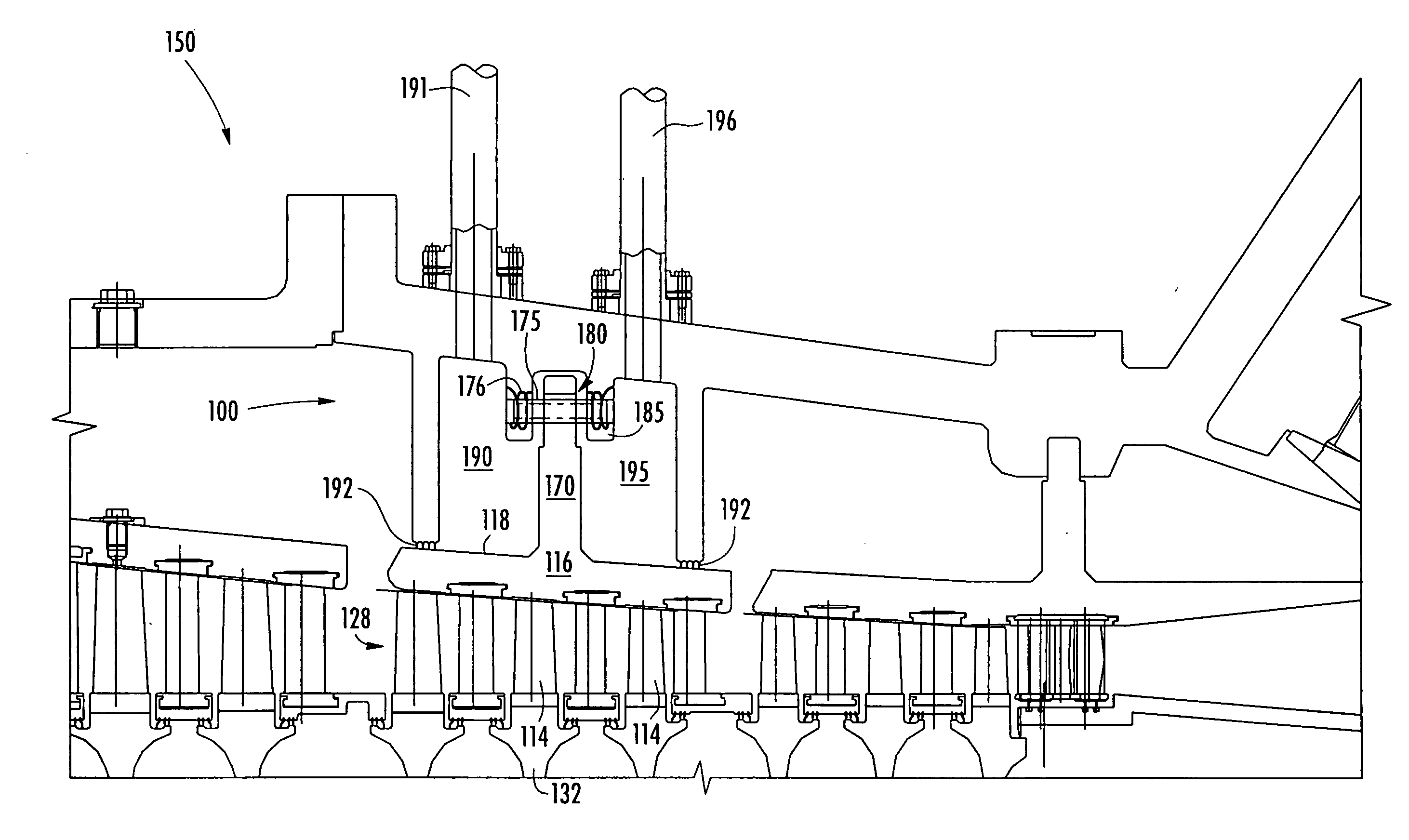

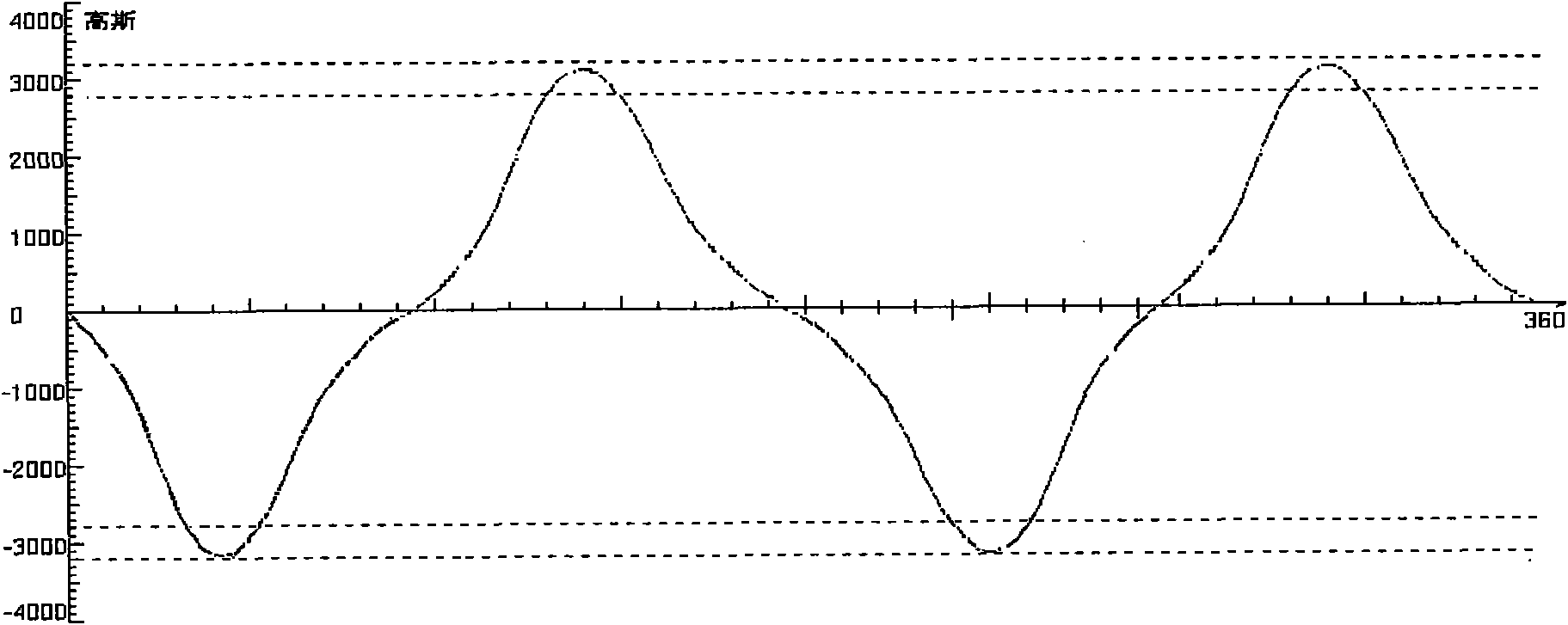

Blade clearance system for a turbine engine

InactiveUS7686569B2Improve efficiencySmall sizePump componentsBlade accessoriesRotational axisAcute angle

A blade gap control system configured to move a blade ring of a turbine engine relative to a blade assembly to reduce the gaps between the tips of the blades and the blade rings to increase the efficiency of the turbine engine is provided. The blade rings can be at an acute angle with respect to the rotational axis of the blade assembly. The axial movement of the blade ring can be done by a pressure differential supplied across the blade ring, the thermal expansion and / or contraction of a linkage or by a piston.

Owner:SIEMENS ENERGY INC

Metal alloys for medical devices

InactiveUS20100168841A1Good physical propertiesHigh yield strengthSuture equipmentsStentsMetal alloyMedical device

A medical device that is at least partially formed of a novel metal alloy, which novel metal alloy improves the physical properties of the medical device.

Owner:ICON MEDICAL CORP

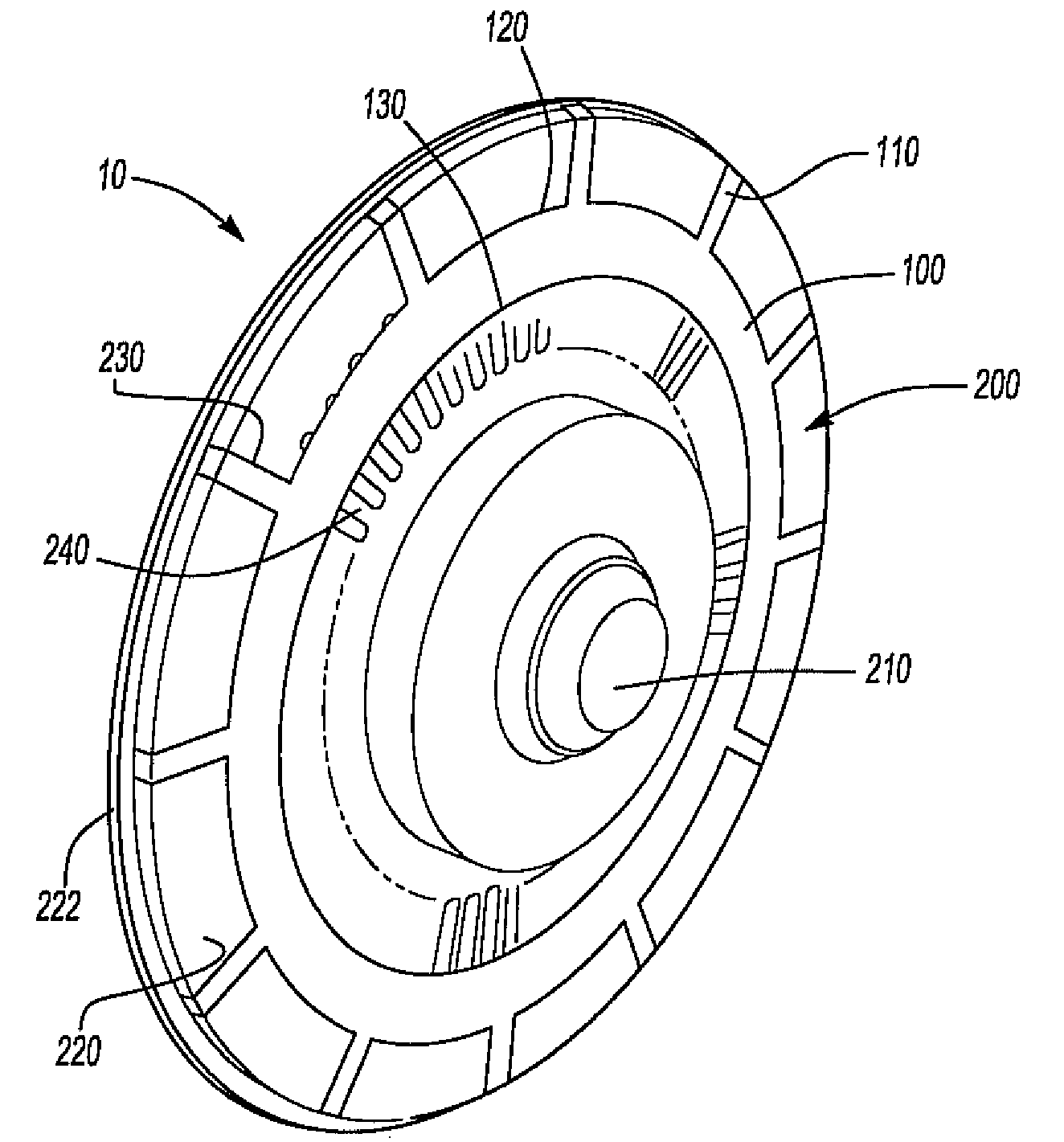

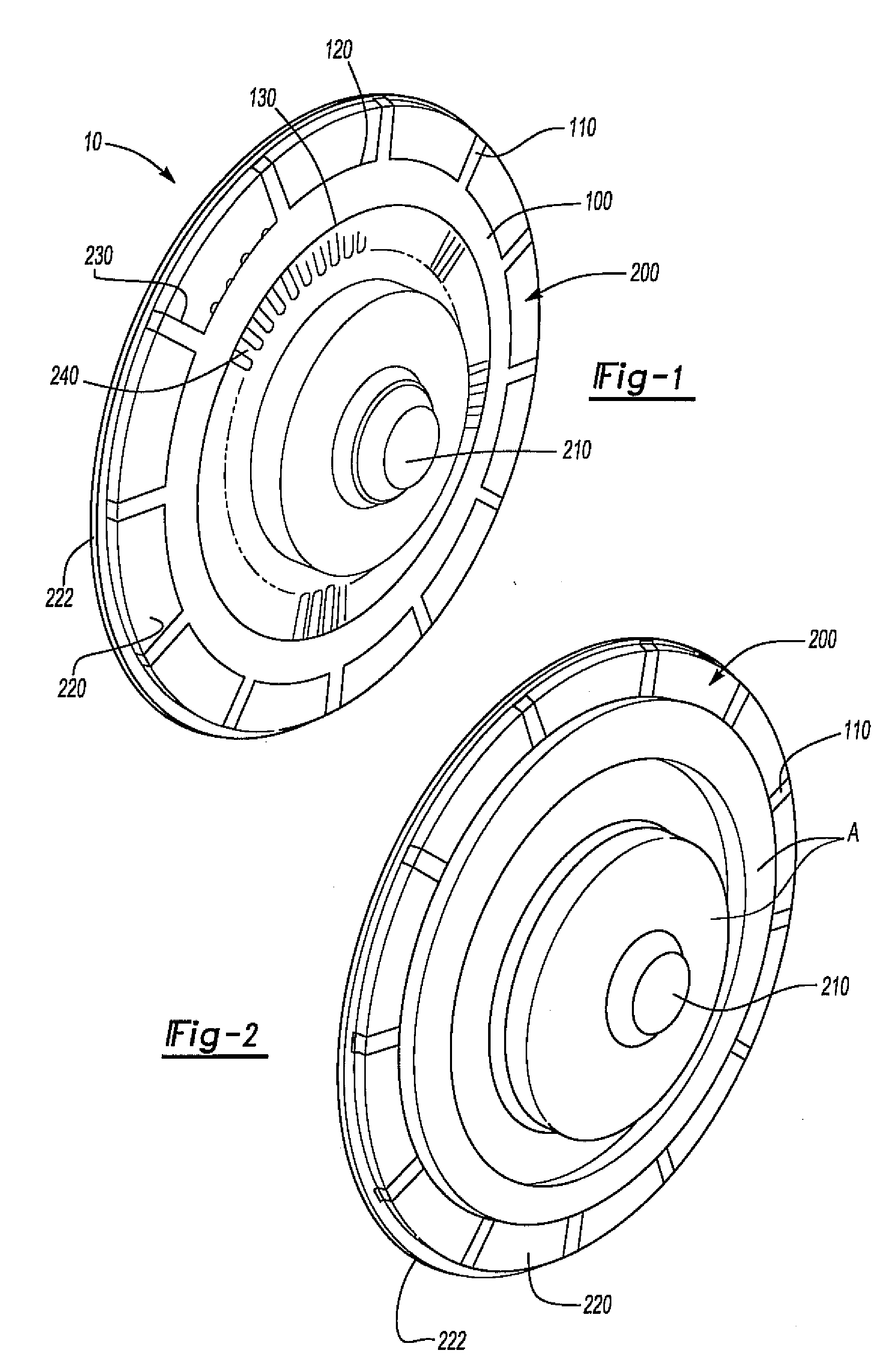

Insert for manufacture of an enhanced sound dampening composite rotor casting and method thereof

InactiveUS20070235270A1High melting pointIncrease expansionNoise/vibration controlBraking discsCasting moldCalipers

An insert for a casting mold used to produce a sound dampening rotor of a caliper disc brake is provided. The insert includes a ring having an inner diameter, an outer diameter and at least one tab. The insert also includes an inner core made from a refractory material, the inner core being adjacent to the ring. The tab of the ring is operable to position the ring relative to the inner core. Furthermore, the ring and the inner core together can be placed within the casting mold and afford for the desirable and accurate placement of the sound dampening ring within a cast sound dampening composite rotor of a caliper disc brake.

Owner:THYSSENKRUPP WAUPACA DIV

Roll sleeve of ultra-strong wear-resistant high alloy steel roll squeezer and manufacturing method roll sleeve

The invention relates to a roll sleeve of an ultra-strong wear-resistant high alloy steel roll squeezer and a manufacturing method of the roll sleeve, belonging to the technical field of casting in building material industry. The technical scheme is as follows: an outer layer adopts ultra-strong wear-resistant high alloy steel, an inner layer is formed by compounding low-carbon medium alloy steel, and the roll sleeve is manufactured through the process steps of melting the outer-layer ultra-strong wear-resistant high alloy steel, melting the inner-layer low-carbon medium alloy steel, centrifugally casting the compound roll sleeve and performing heat treatment on the compound roll sleeve. The roll sleeve and the manufacturing method thereof, disclosed by the invention, have the positive effects that: the preferential mixture ratio of the inner-layer material to the outer-layer material of the roll sleeve is adopted and a reasonable centrifugal compound casting process is adopted, thereby the inner layer and the outer layer are subjected to metallurgical bonding and a good bonding state is achieved. According to the characteristics of high alloy of the roll sleeve, the fracture toughness of the roll sleeve is enhanced by raising tempering temperature and performing multiple tempering processes. The outer layer of the roll sleeve disclosed by the invention has the hardness of 60-64HRC and the impact toughness of 12J / cm<2>, the inner layer has the hardness of 26-30HRC, the tensile strength of 800-900MPa and the yield strength of 730MPa, and the service life of the roll sleeve is prolonged by above 2 times in comparison with the traditional roll sleeve formed by forging and overlaying welding.

Owner:河北津西钢铁集团重工科技有限公司

Blade clearance system for a turbine engine

InactiveUS20080131270A1Improve efficiencySmall sizePump componentsBlade accessoriesRotational axisAcute angle

A blade gap control system configured to move a blade ring of a turbine engine relative to a blade assembly to reduce the gaps between the tips of the blades and the blade rings to increase the efficiency of the turbine engine is provided. The blade rings can be at an acute angle with respect to the rotational axis of the blade assembly. The axial movement of the blade ring can be done by a pressure differential supplied across the blade ring, the thermal expansion and / or contraction of a linkage or by a piston.

Owner:SIEMENS ENERGY INC

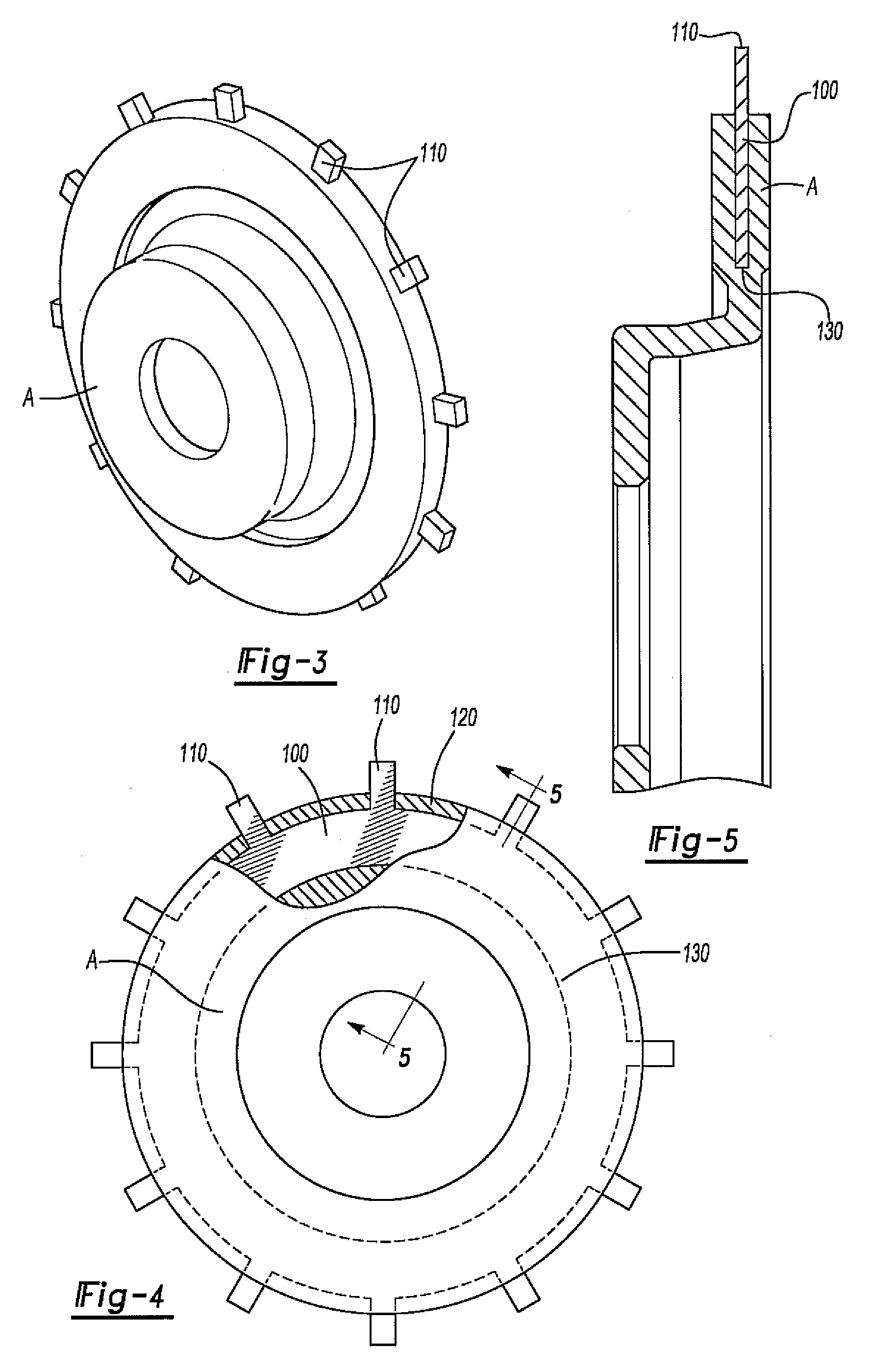

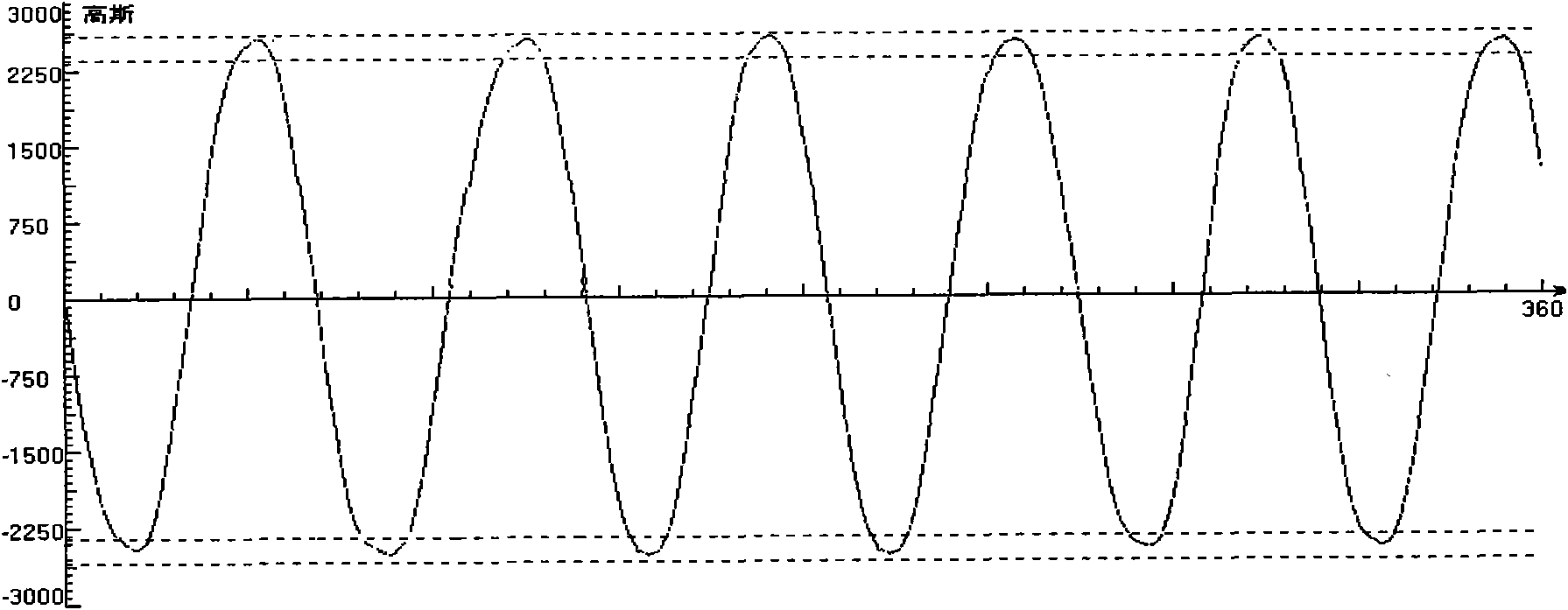

Method for manufacturing injection-molding rare-earth radial magnetic ring

InactiveCN101552132AIncrease the areaIncrease expansionInductances/transformers/magnets manufactureMagnetic materialsQuadrupoleMagnetic characteristic

A method for manufacturing injection-molding rare-earth radial magnetic ring belongs to the technical field of rare earth magnet preparing. The method of the invention comprises the following technical processes: mixing and drying the rare-earth magnetic powder which is coated by the coupling agent and antioxidant in negative pressure until the dissolvent and the absorbed gas is totally released, then placing the thermoplastic organic resin powder into a mixing machine for mixing to uniform in inert protective atmosphere, then placing a double-screw extruder with protective atmosphere, fully compounding the thermoplastic organic binding agent with magnetic powder, granulating for obtaining the granulate for rare-earth anisotropic bonded permanent magnet, placing the granulate into a magnetic field injector with magnetic field mold for preparing into the magnetic ring oriented along the radial direction, wherein the magnetic ring comprises radially oriented magnetic ring and multipole magnetic ring. The method of the invention has the advantage that the granulate manufactured by organic resin has excellent oxidation resistance, fluidity and magnetic characteristic. The radiating, quadrupole and multipole oriented magnetic field which is obtained by matching the permanent magnet repulsive permutation and combination and magnetic material is higher than the permanent magnetic field in which N and S are alternately permutated and combined. An energy saving effect is obtained.

Owner:BEIJING BEILILONG MAGNETIC MATERIALS TECH

Metal alloys for medical devices

A medical device that is at least partially formed of a novel metal alloy, which novel metal alloy improves the physical properties of the medical device.

Owner:MIRUS LLC

Metal alloys for medical devices

InactiveUS20060264914A1Good physical propertiesIncrease success rateStentsSurgeryMetal alloyMedical device

A medical device that is at least partially formed of a novel metal alloy which improves the physical properties of the medical device.

Owner:ICON MEDICAL CORP

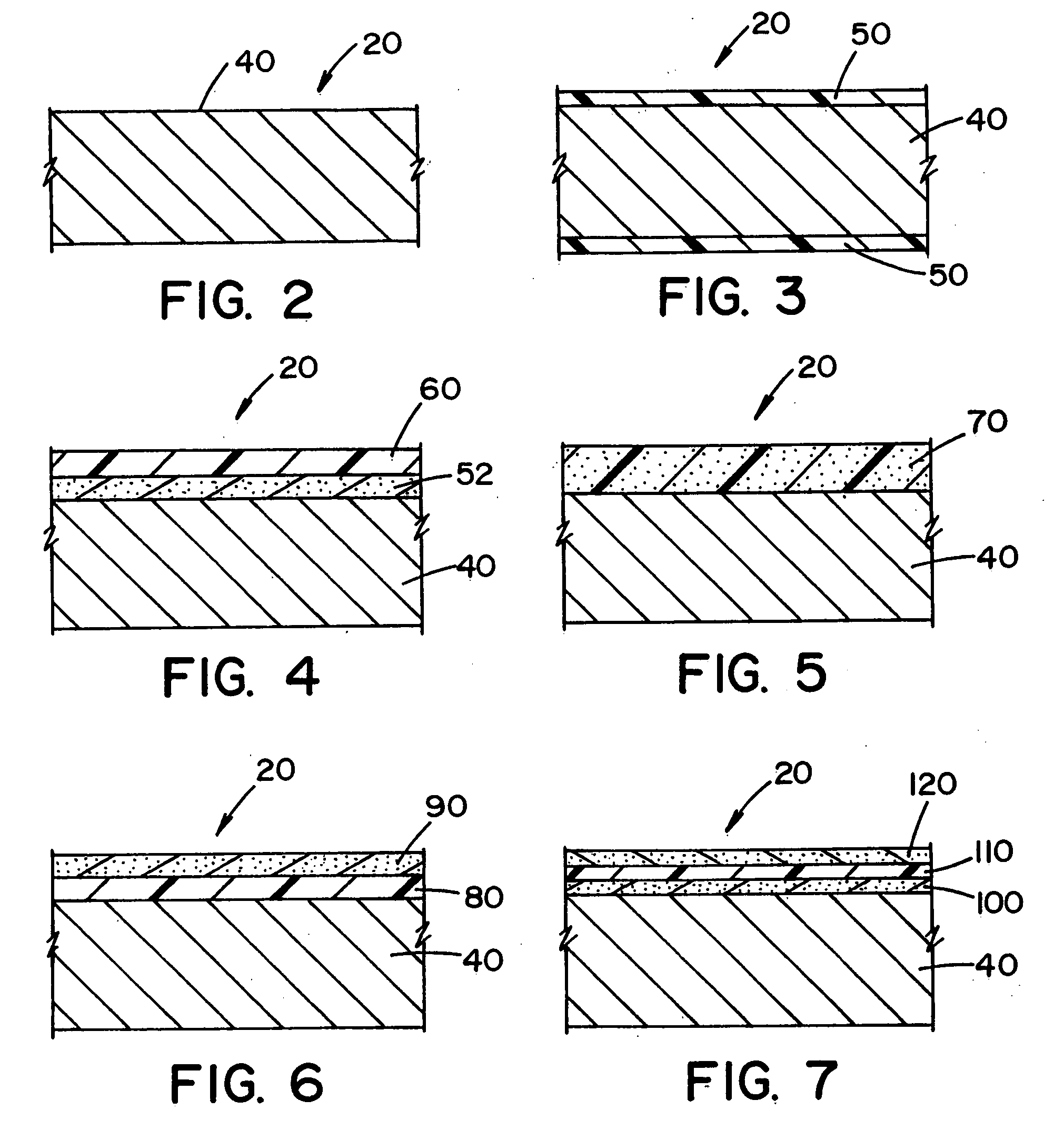

Titania-doped quartz glass and making method, EUV lithographic member and photomask substrate

ActiveUS20070134566A1Improve homogeneityImprove flatnessRadiation/particle handlingNanoinformaticsTransmittanceConcentration gradient

A titania-doped quartz glass containing 3-12 wt % of titania at a titania concentration gradient less than or equal to 0.01 wt % / μm and having an apparent transmittance to 440 nm wavelength light of at least 30% at a thickness of 6.35 mm is of such homogeneity that it provides a high surface accuracy as required for EUV lithographic members, typically EUV lithographic photomask substrates.

Owner:SHIN ETSU CHEM IND CO LTD

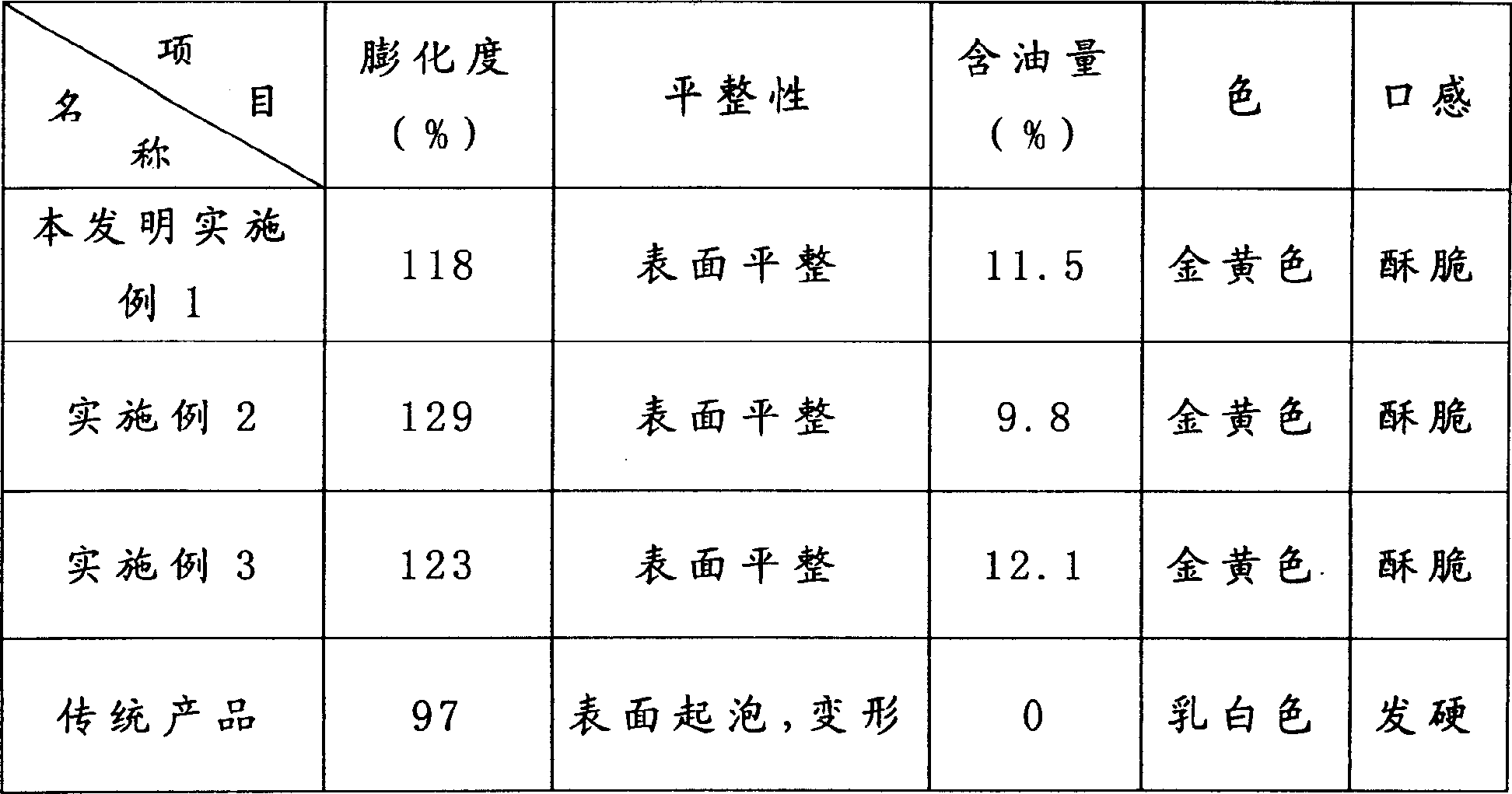

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

Fermented beverage of full cereal grains

The invention relates to fermented beverage of full cereal grains. The fermented beverage of full cereal grains is composed of the following ingredients by mass percent: 50-90% of fermentation broth of cereal grains, 8-14% of sucrose, 0.05-0.2% of citric acid, 0.05-0.1% of malic acid and the balance of pure water. The fermented beverage is prepared by mixing the ingredients, fine filtering the ingredients, homogenizing at the pressure of 18-25 Mpa, performing ultrahigh-temperature instant sterilization for 2-6 seconds at 135-137 DEG C, cooling to 80-85 DEG C and sterilely filling. The preparation process of the fermentation broth of cereal grains comprises the following steps of: adding alpha amylase in adjusted cereal grain pulp to perform enzymolysis at 50-65 DEG C, and inoculating specially domesticated lactic acid bacteria culture solution or powder to naturally ferment the zymolytic cereal grain pulp within 35-45 DEG C to obtain the fermentation broth of cereal grains. According to the invention, the development bottle neck of utilizing the cereal grains as food processing raw materials is solved through modern enzyme engineering and fermentation technology; and prebiotics are added in the beverage, and the dietary fiber content is within the range of 0.6-1.3mg / 100ml.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

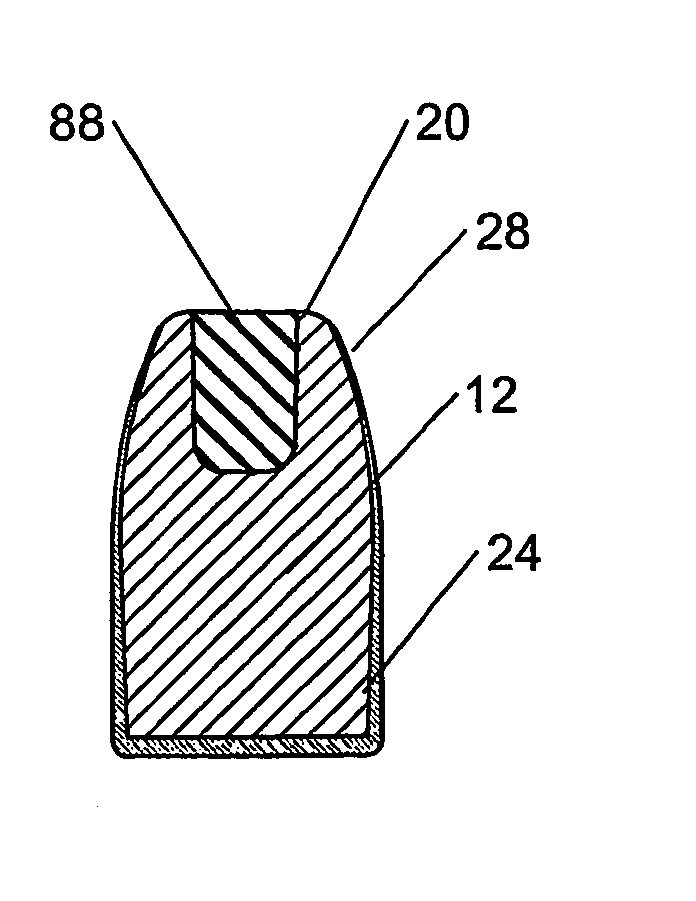

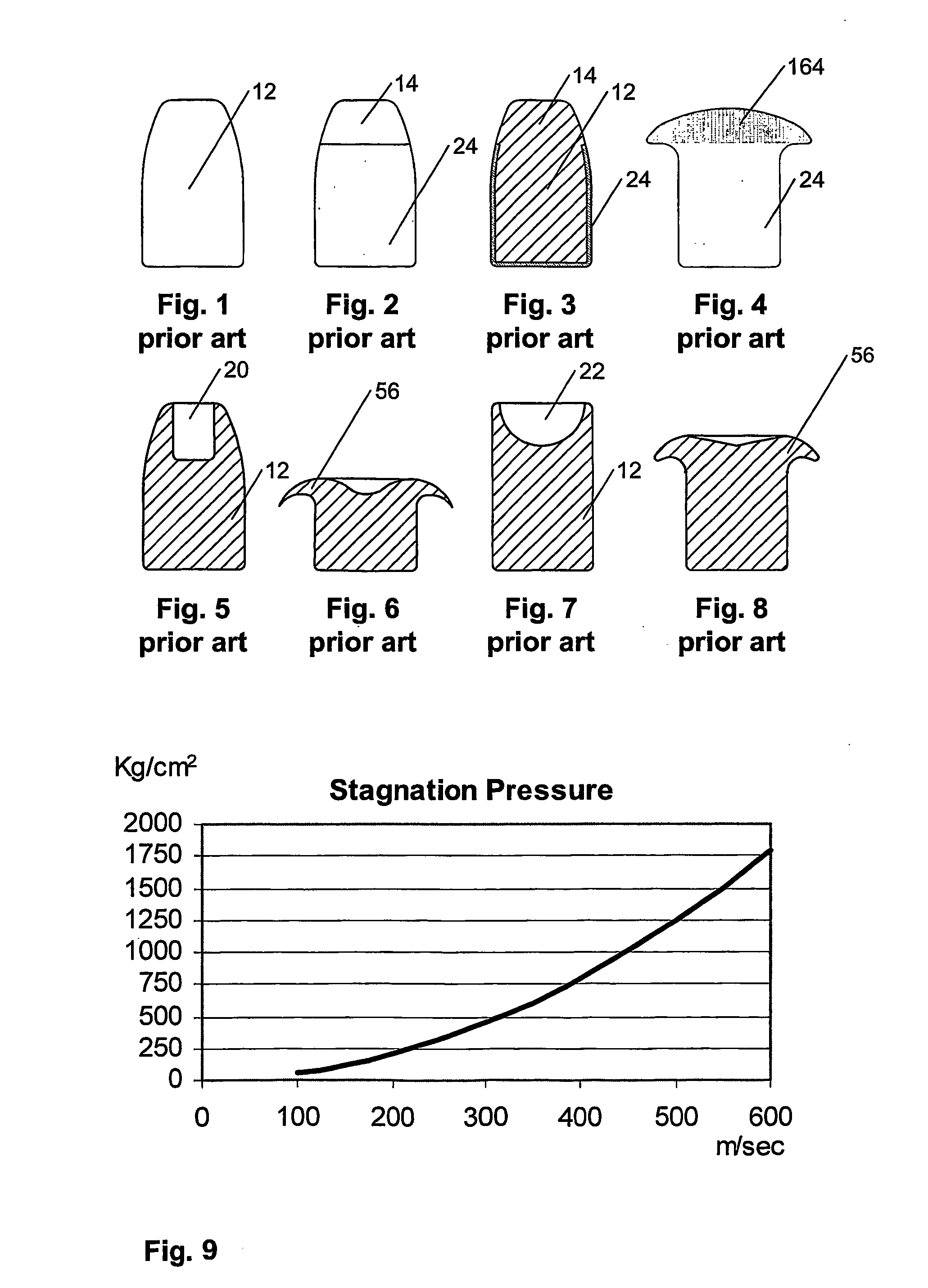

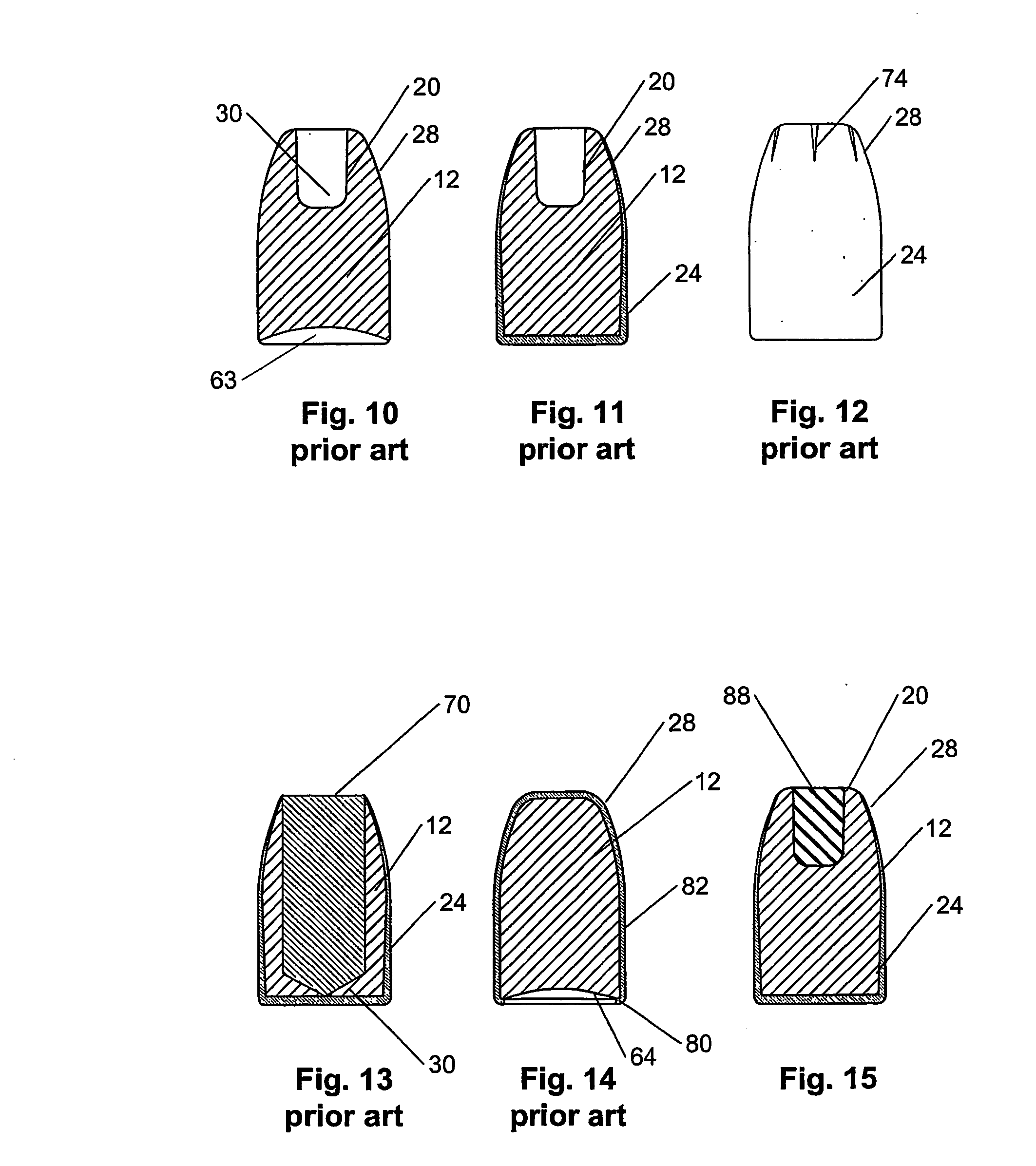

Bullet with booster filling and its manufacture

InactiveUS20050126422A1Preventing pointIncrease heightAmmunition projectilesTraining ammunitionElastomerEngineering

A bullet having a cavity in its forward end that is open at that end and a filling situated within said cavity. Preferably, the filling comprises an elastomer. Preferably, the elastomer filling is vulcanized. More preferably, the vulcanized elastomer filling has a Shore hardness in the range from about 6 to about 90. Alternatively, the filling is a colored rigid polymer filling, if a non-expanding training hollow point bullet is desired. In particular, the invention is a filling and its application to hollow point bullets for the purposes of: improving bullet expansion during the penetration of liquid targets; preventing clogging with debris from intermediate targets; increasing expansion during the perforation of hard materials; preventing the expansion of training bullets; and allowing users to identify different cartridge designs. The invention is also devices and methods for introducing the filling into the cavity.

Owner:LAMM CHARLES ROBERT EMILE

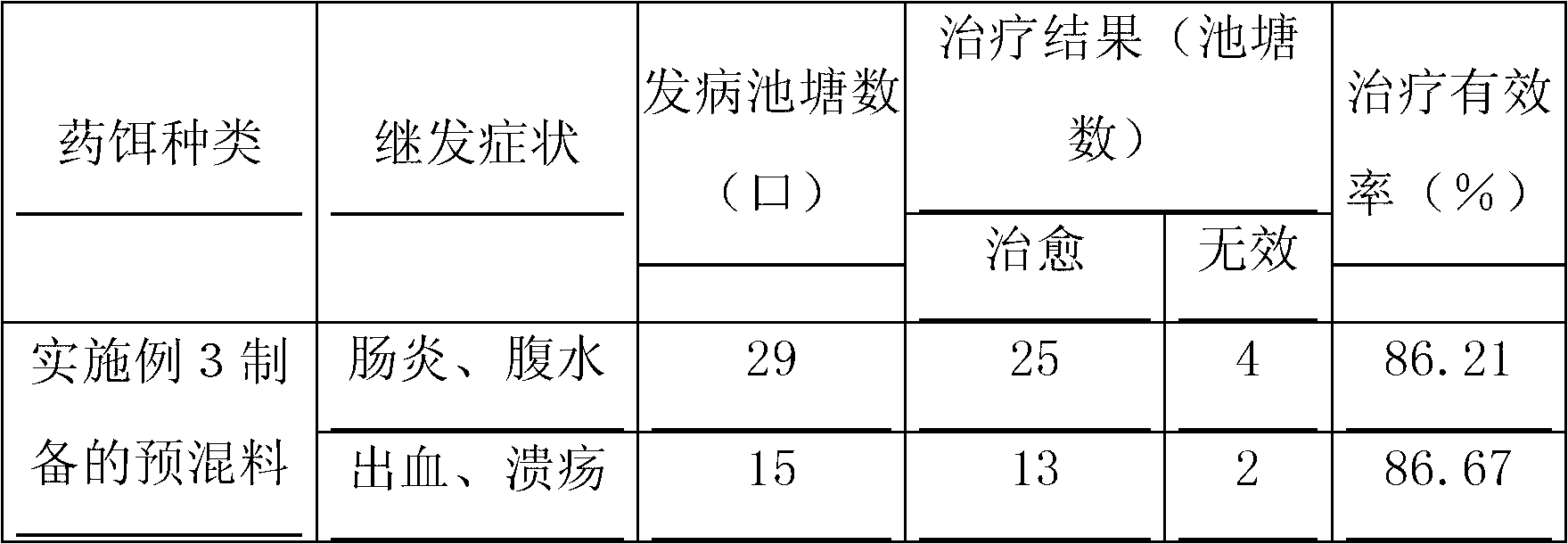

Premix compound for aquatic products, application thereof in feed additive, and batch thereof

InactiveCN102696923AHigh content of live bacteriaPromote growthAnimal feeding stuffFood additiveBacillus licheniformis

The invention discloses premix compound for aquatic products, the application thereof in feed additive and the batch thereof. In the premix compound per kilogram, vitamin B complex accounts for 80 to 140g, composite trace element accounts for 110 to 200g, taurine accounts for 100 to 300g, phytase accounts for 10 to 30g, glutamine accounts for 100 to 300g, DMPT accounts for 5 TO 20 g, composite microbial ecological agent accounts for 1 to 10g, composite traditional Chinese medicine composition accounts for 1 to 10g, and the margin is a carrier. The ingredients of the composite microbial ecological agent include fermented powder of bacillus subtilis CGMCC, No. 4628, fermented powder of bacillus licheniformis CGMCC, No. 5094 and fermented powder of enterococcus faecalis CGMCC, No. 5092. The main ingredients of the composite microbial ecological agent include three probiotics. Not only the probiotic function is achieved, but also the premix compound can be used for purification and conditioning to aquaculture water body, the environmental suitability is strong, the function is stable, and pollutants such as ammonia nitrogen, tric nitrogen, trite nitrogen, COD and the like in the water body are effectively degraded.

Owner:TIANJIN CHANGNONG TECH +1

Expandable dialysis apparatus and method

A venovenous expandable dialysis apparatus includes a blood feeding needle component configured to introduce blood at a position of a first peripheral vein and a blood withdrawal needle component configured to withdraw blood at another position from a second peripheral vein located, where the first position is located away from the second position. The expandable dialysis apparatus further includes a guide wire having a central axis, an expanding sheath configured circumferentially around the guide wire to form an annular lumen between a distal blood withdrawal position and a proximal extracorporeal position; and a needle disposed around the expandable sheath.

Owner:LIFESHIELD SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com