Patents

Literature

1146 results about "Magnetic characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Characteristics of Magnets. The basic characteristics of magnets are known by any child who has come across a fridge magnet. Magnets snap to objects made out of iron and they either snap to each other or repel.

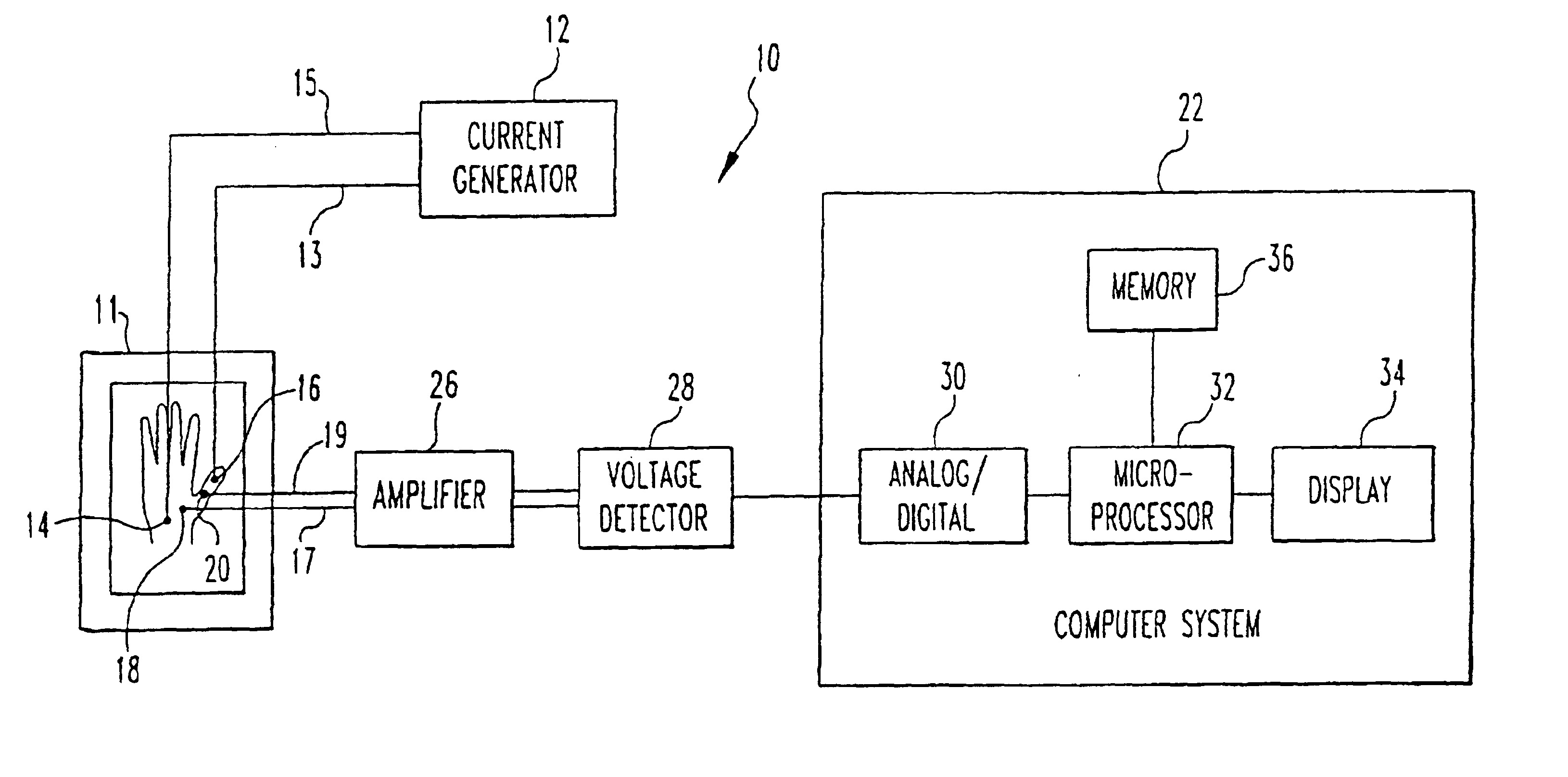

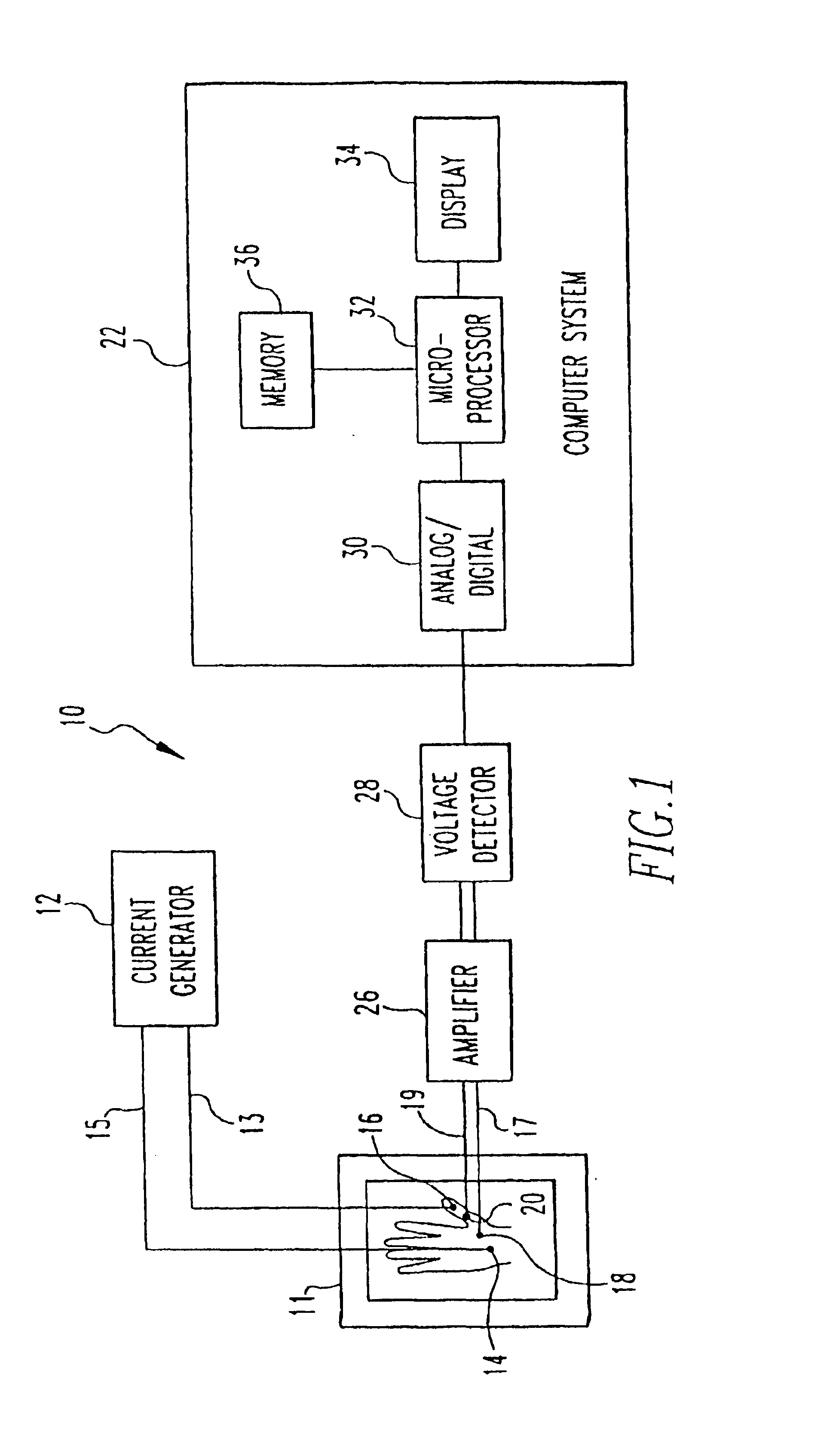

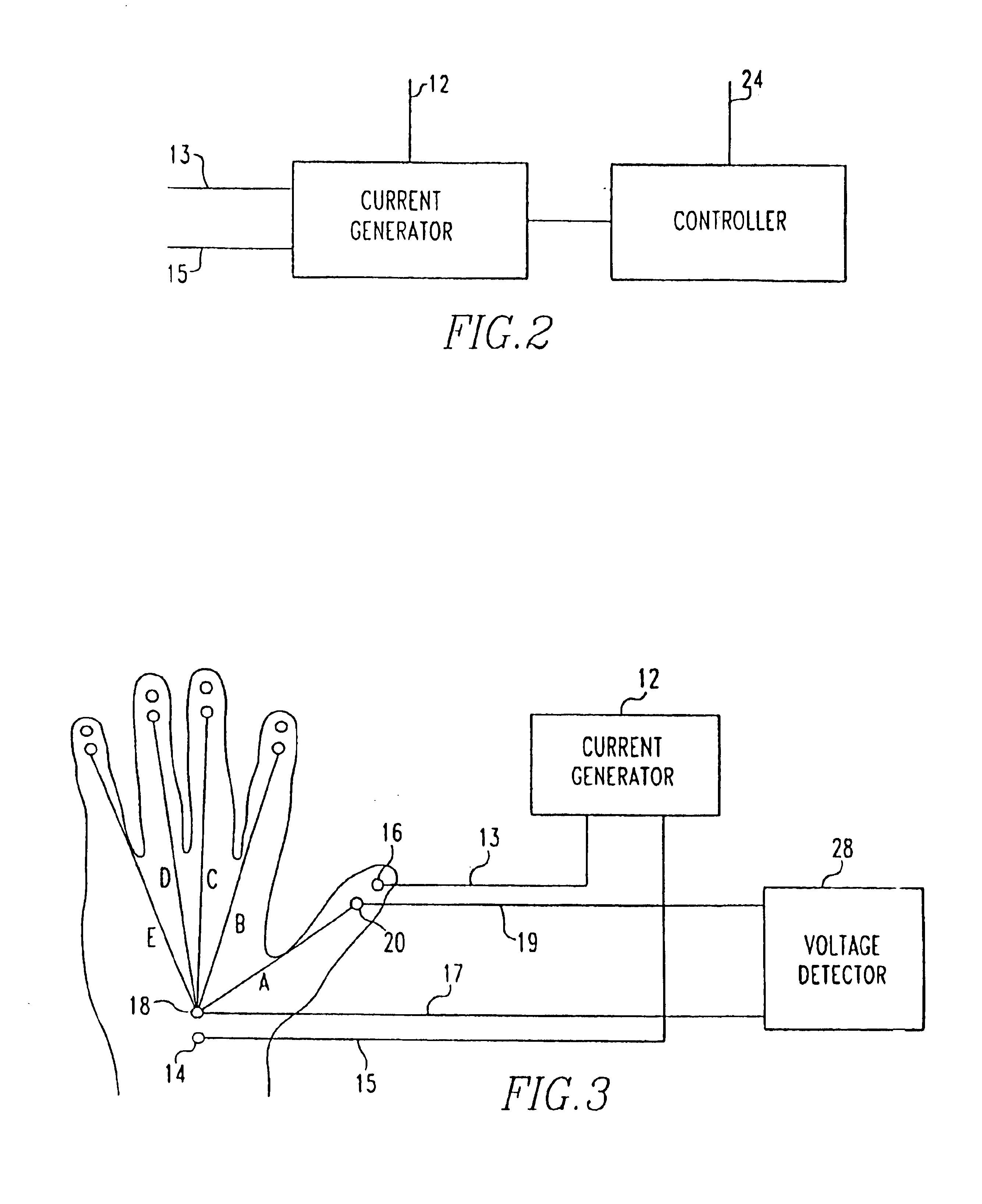

Method and system for biometric recognition based on electric and/or magnetic characteristics

InactiveUS6898299B1Electric signal transmission systemsDigital data processing detailsElectricityBiological body

A method and apparatus for authenticating an individual living organism by recognizing a unique internal electric and / or magnetic and / or acoustic characteristic, which comprises a biometric signature, involve presenting a body part to a sensing device that senses the signature. The sensed presented biometric signature is compared to a known biometric signature to authenticate the individual. This authentication can then be used to authorize any of a wide variety of actions by the individual, such as accessing equipment or an area, or to perform actions, such as conducting financial transactions. A card having sensors is used to sense the biometric signature which is read by a card reader and sent to a local or remote reader for biometric signature comparison.

Owner:GR INTELLECTUAL RESERVE LLC

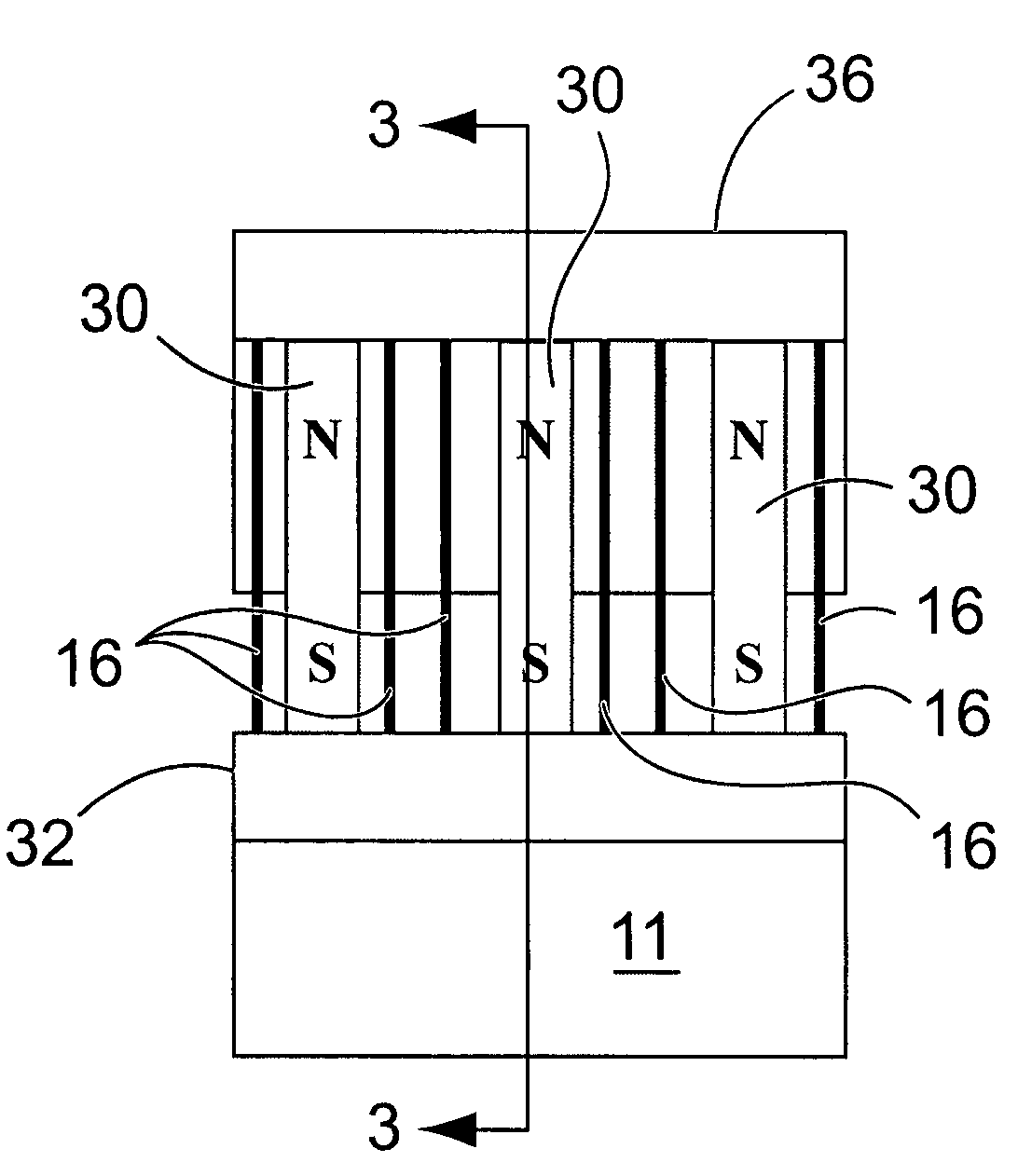

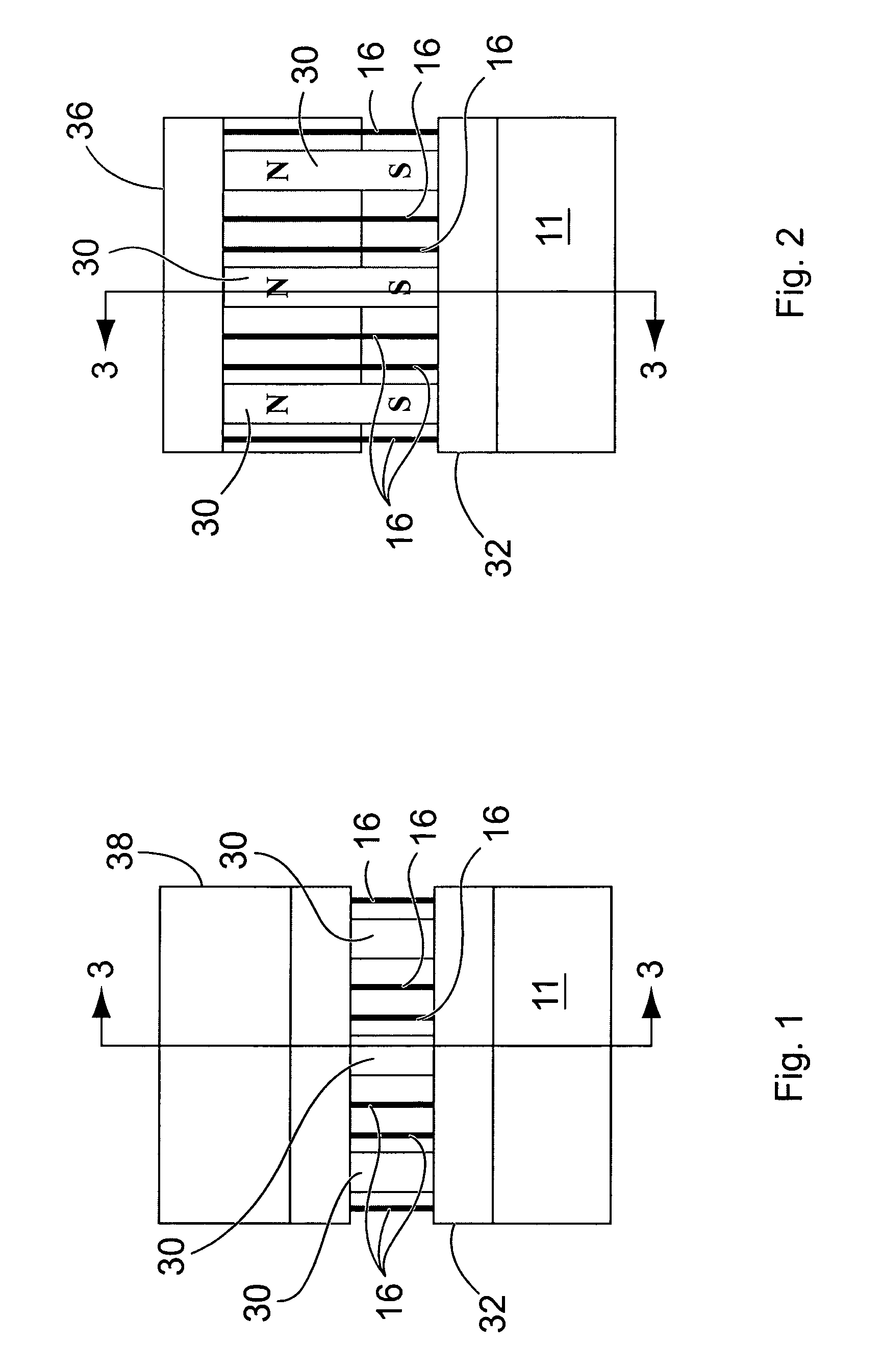

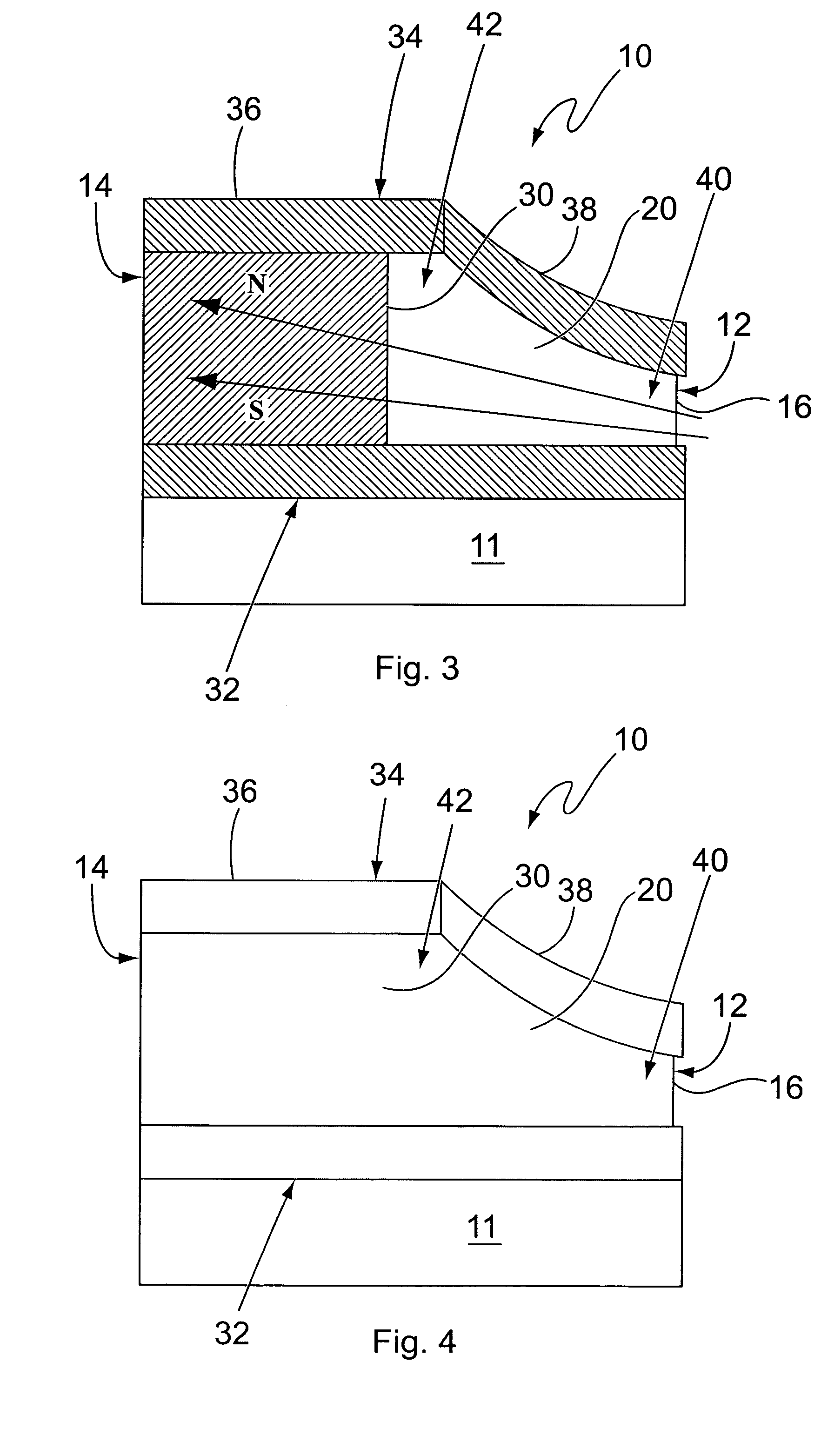

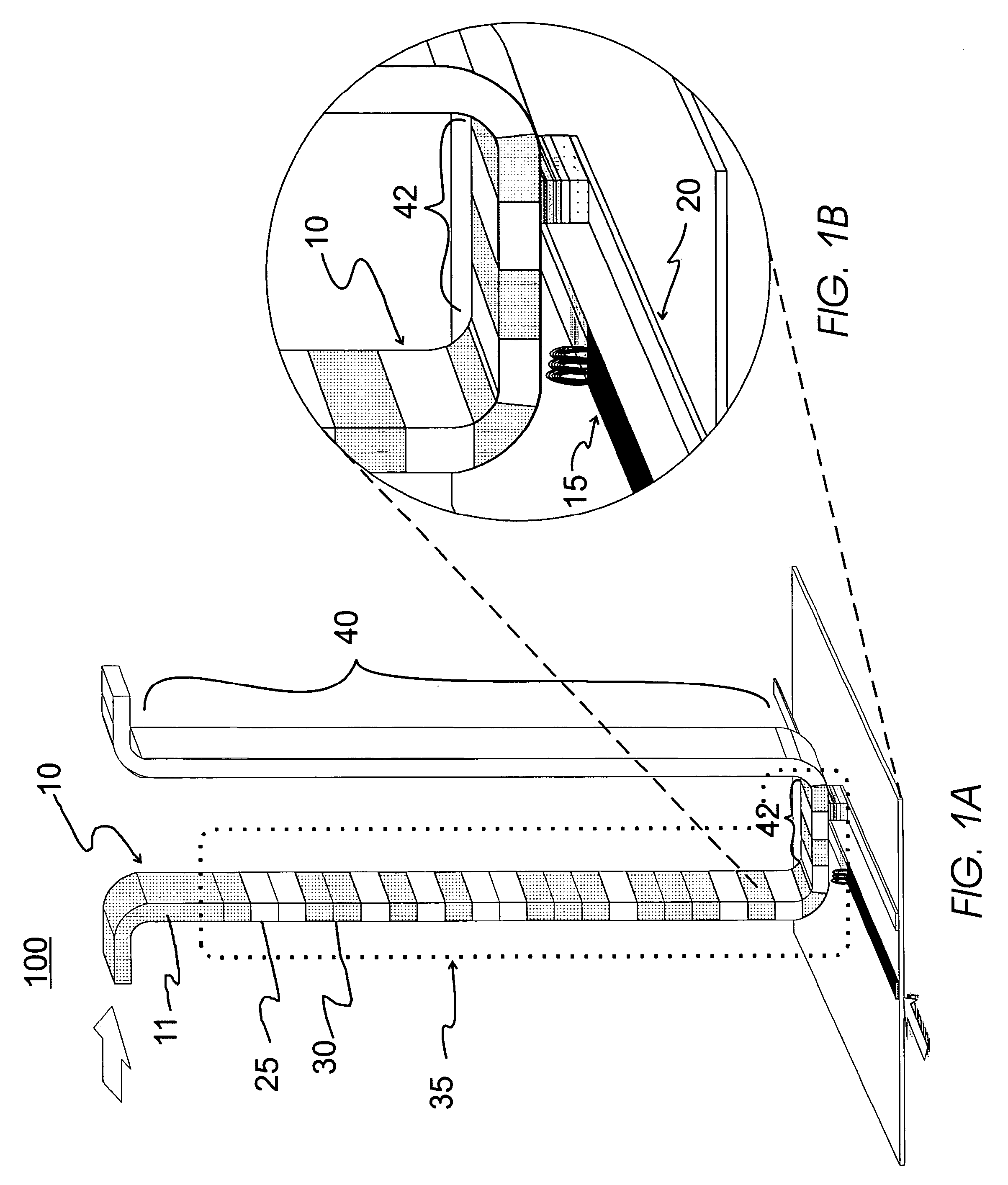

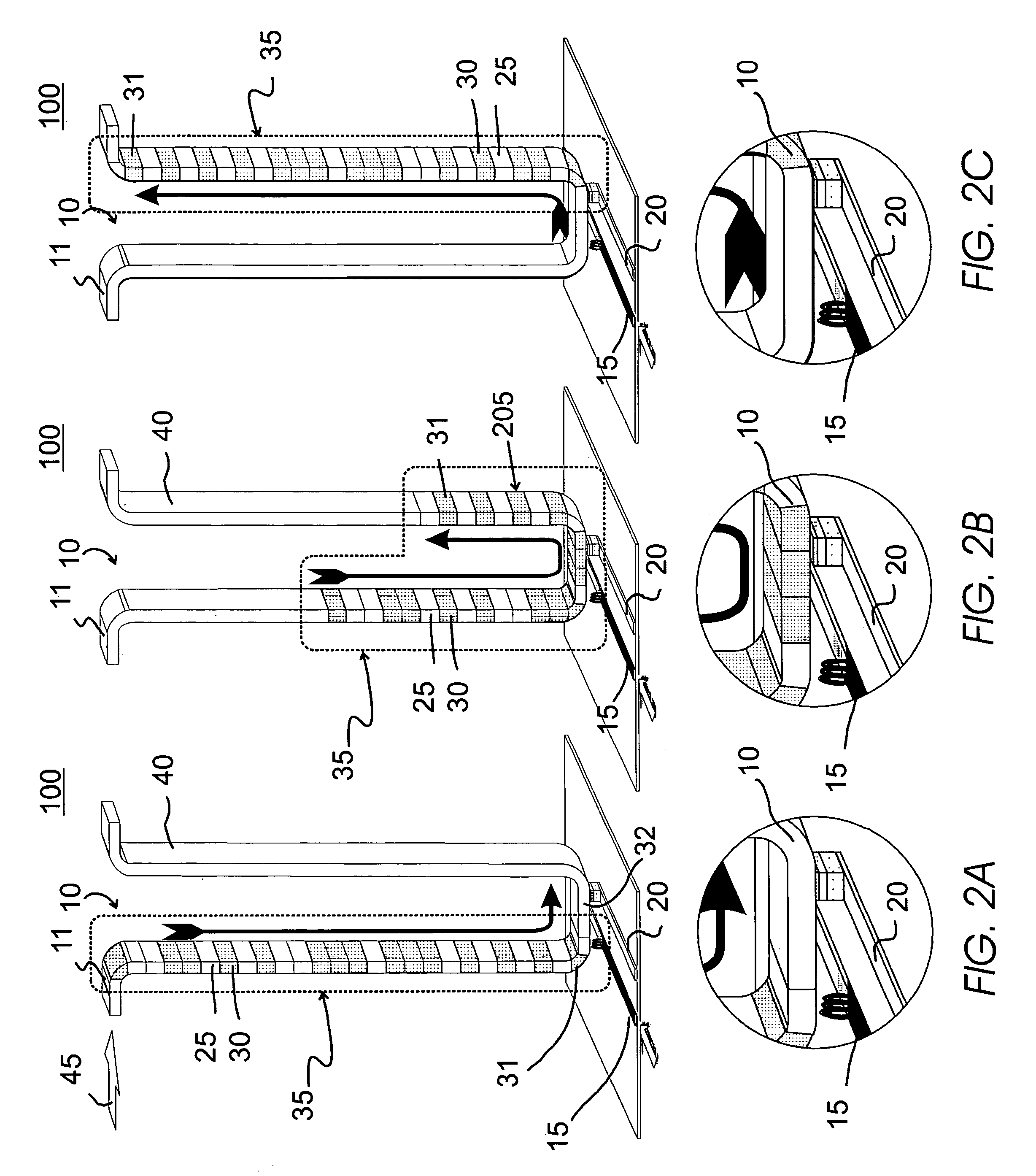

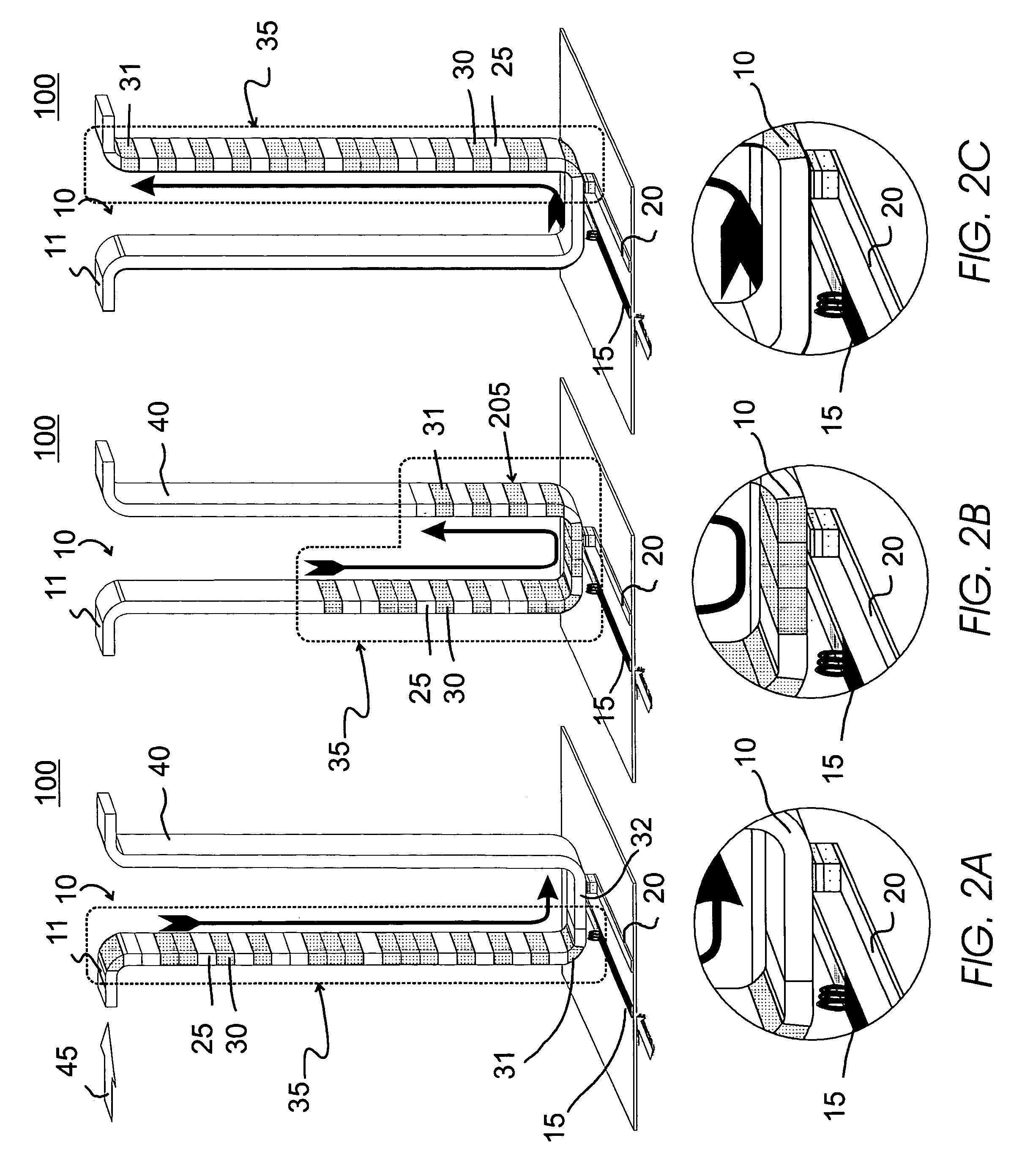

Magnetically enhanced convection heat sink

InactiveUS7031160B2Increased convection coolingHigh trafficElectromagnets without armaturesSemiconductor/solid-state device detailsMagnetic sourceConvection heat

A magnetically enhanced convection heat sink comprises a heat sink member for dissipating heat from a heat source. A magnetic source creates a magnetic field concentrated at a first location, the intensity of the magnetic field decreasing from the first location to a second location. The heat sink member is positioned within the magnetic field and in a gas flow path between the first and second locations. Gas, having paramagnetic properties, entering the heat sink at the first location is heated by the heat sink member, and as the gas becomes warmer is displaced by cooler gas causing the warmer gas to move toward the second location as it is further heated by the heat sink.

Owner:THE BOEING CO

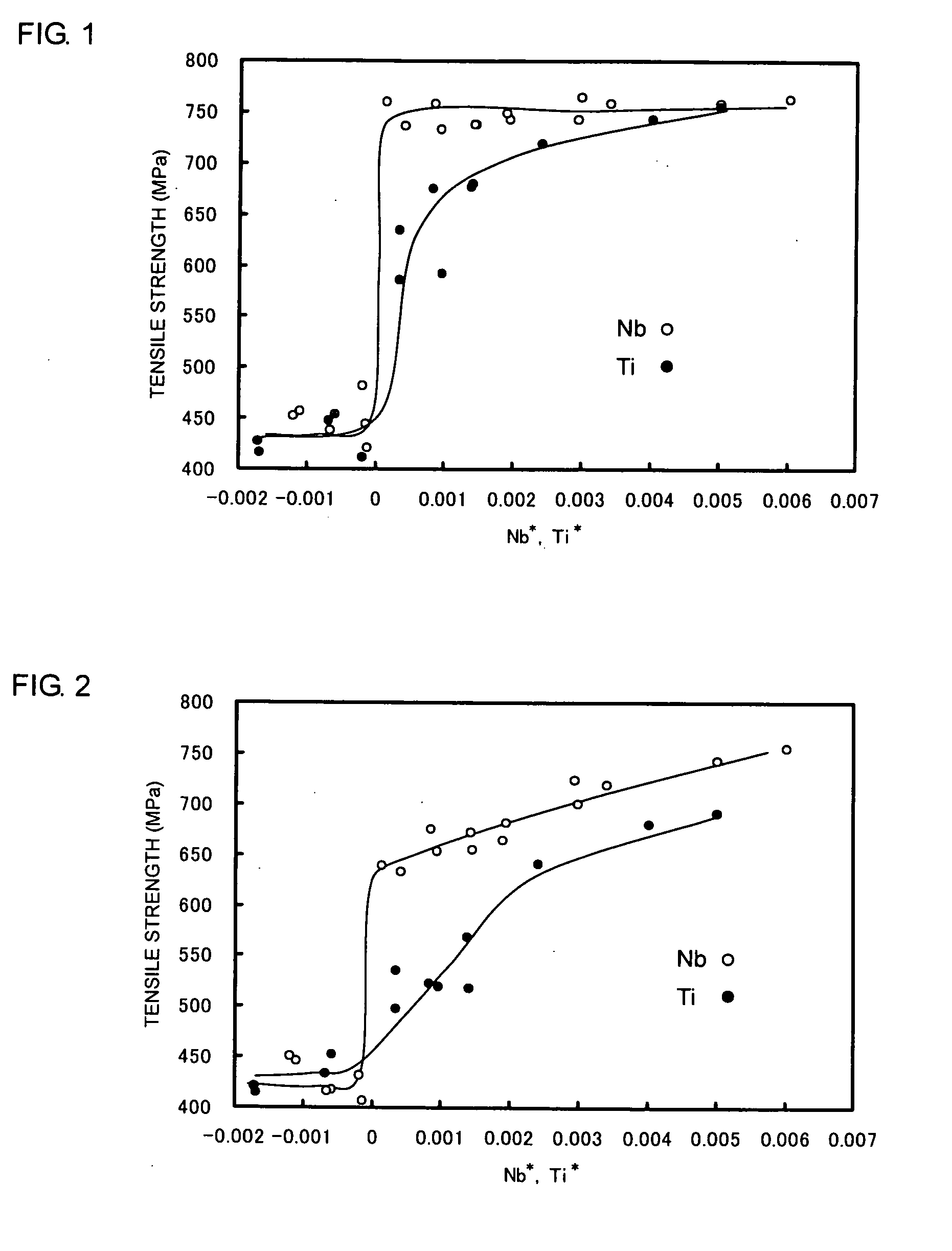

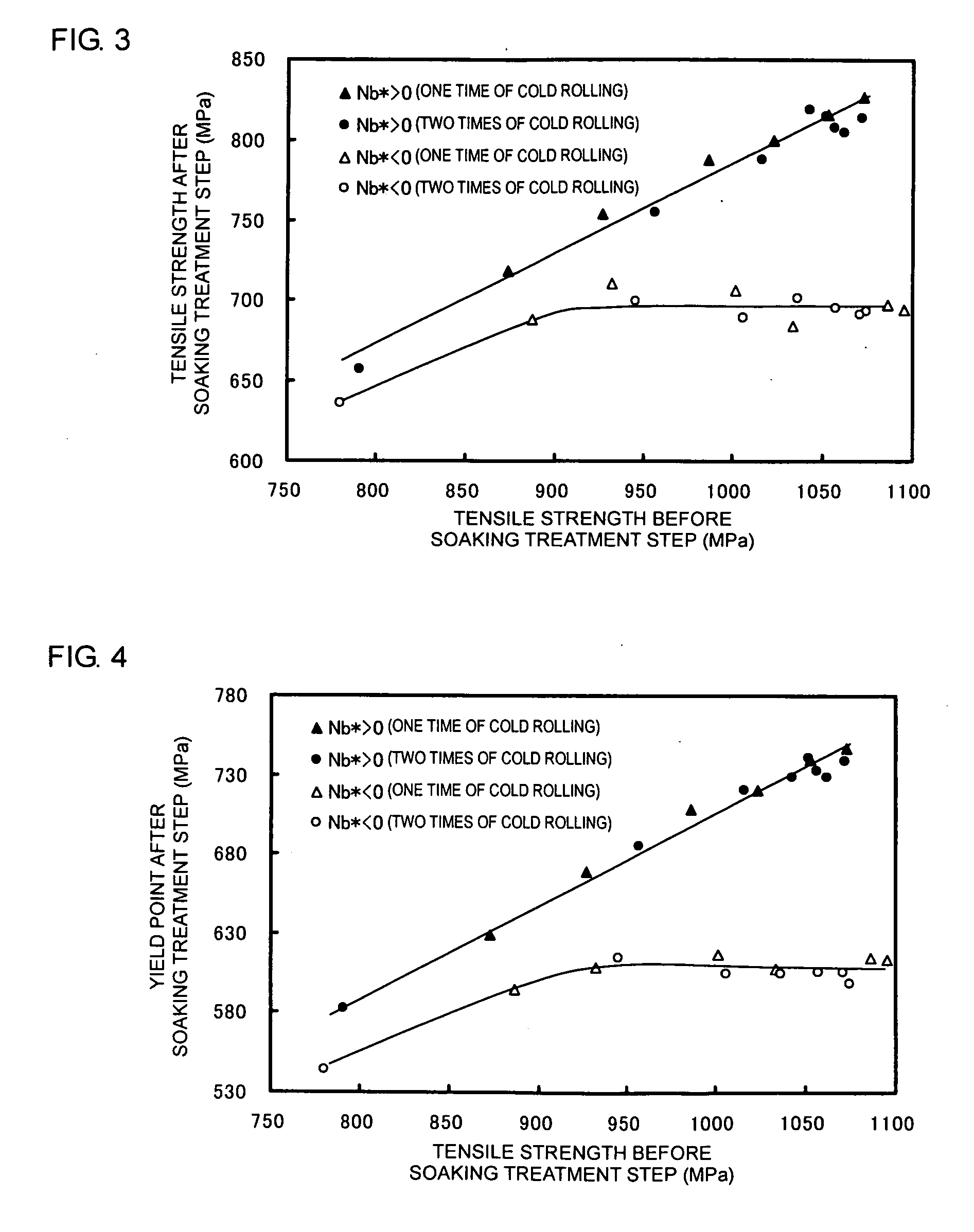

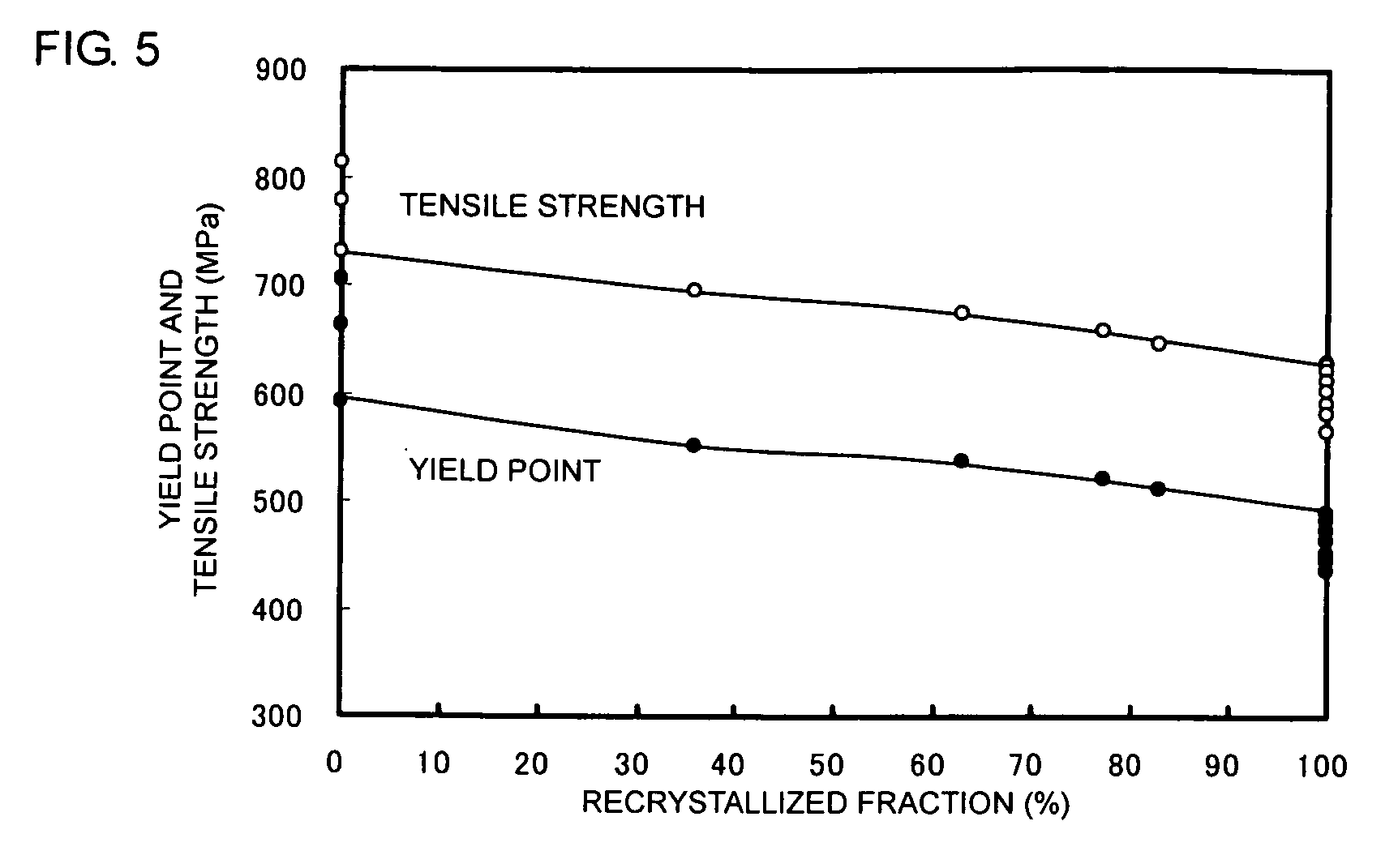

Non-Oriented Electrical Steel Sheet and Production Process Thereof

ActiveUS20090202383A1Excellent mechanical characteristicImprove surface propertiesInorganic material magnetismTransformers/inductances detailsElectrical steelMagnetic characteristic

A main object thereof is to provide a non-oriented electrical steel sheet being excellent in surface characteristics and having both excellent mechanical characteristics and magnetic characteristics necessary for a rotor of rotating machines such as motors and generators which rotate at a high speed, and a method for producing the same. To achieve the object, the present invention provides a non-oriented electrical steel sheet comprising in % by mass: 0.06% or less of C; 3.5% or less of Si; from 0.05% or more to 3.0% or less of Mn; 2.5% or less of Al; 0.30% or less of P; 0.04% or less of S; 0.02% or less of N; at least one element selected from the group consisting of Nb, Ti, Zr and Vin the predetermined range; and a balance consisting of Fe and impurities; and having a recrystallized fraction being less than 90%.

Owner:NIPPON STEEL CORP

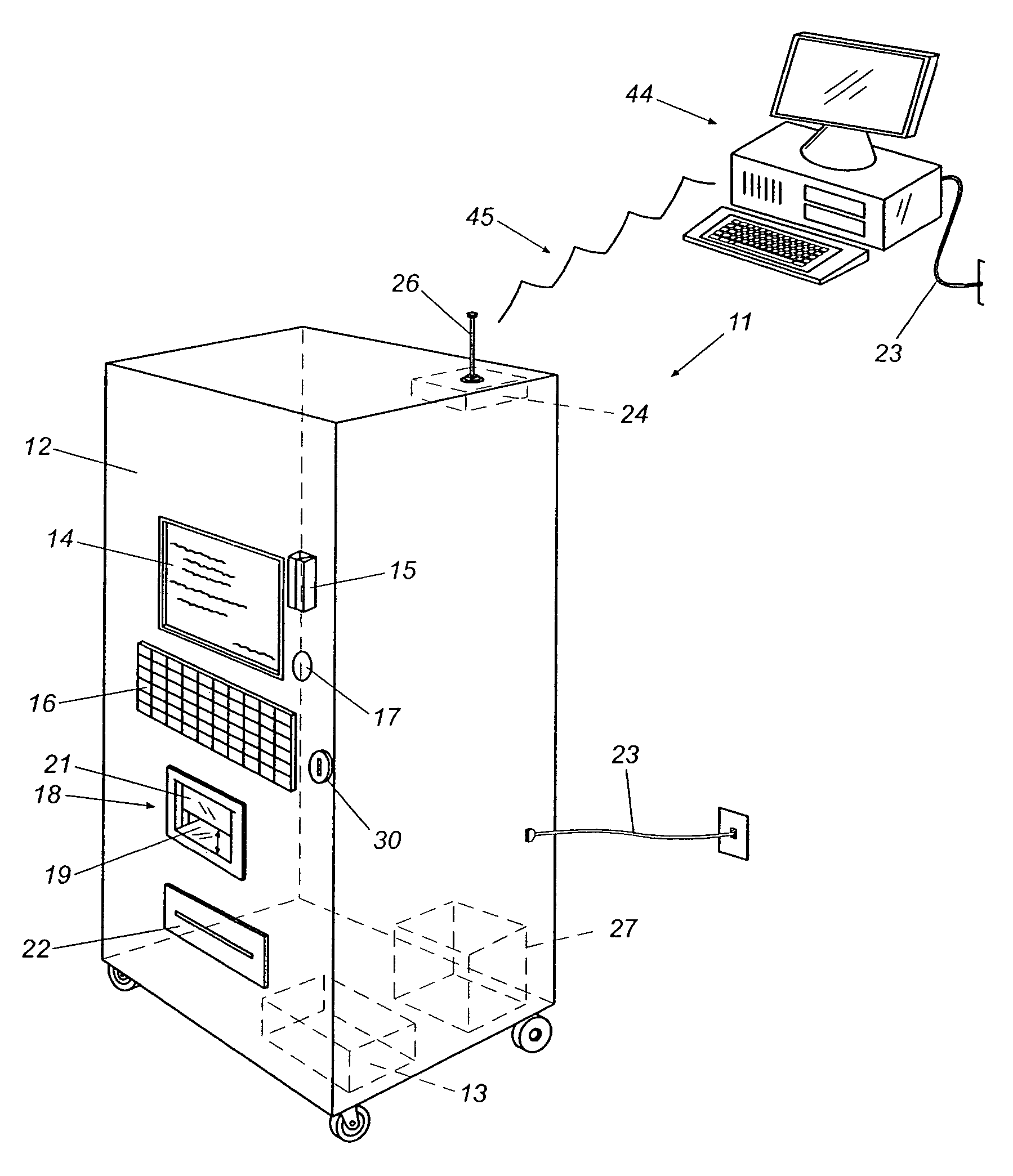

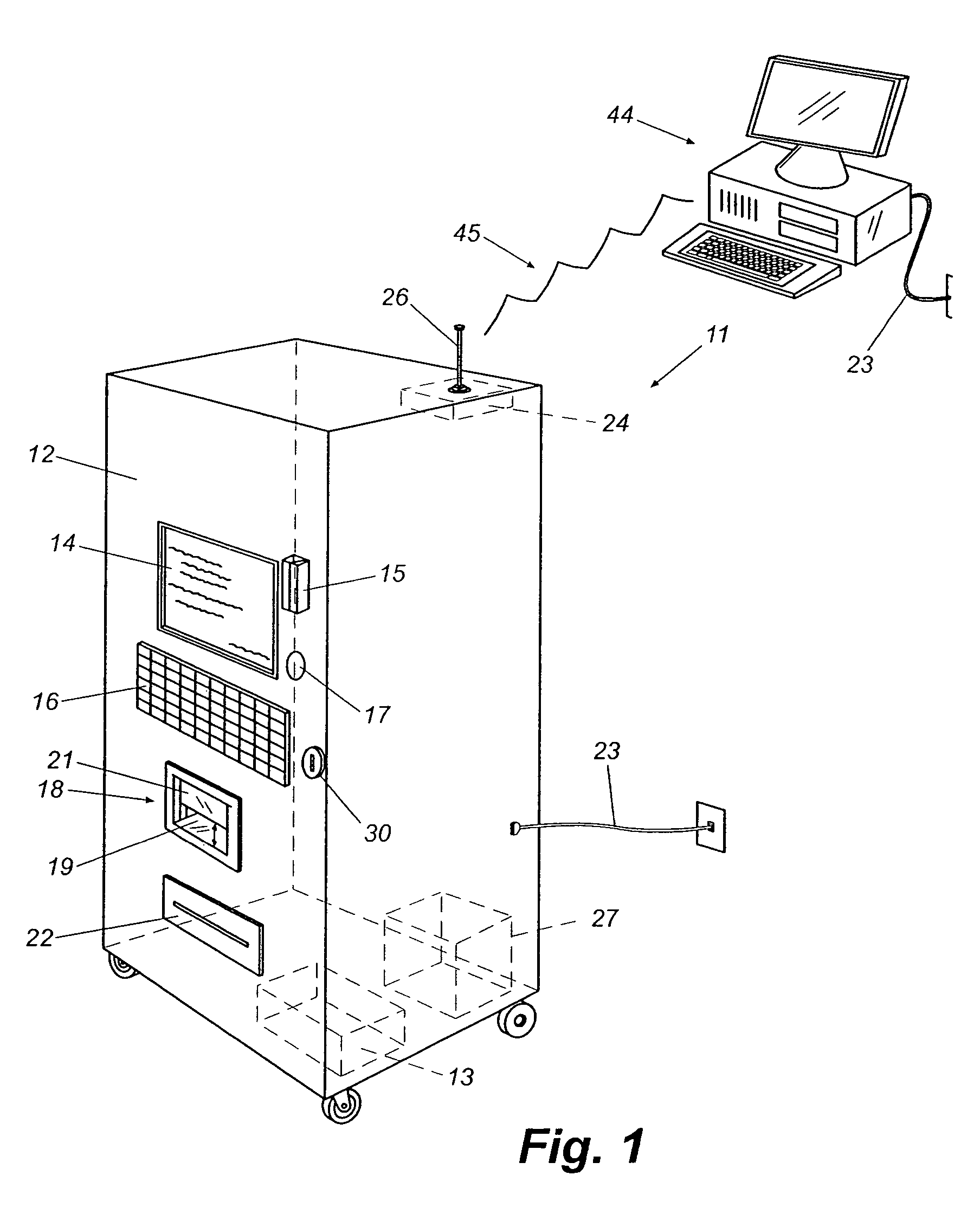

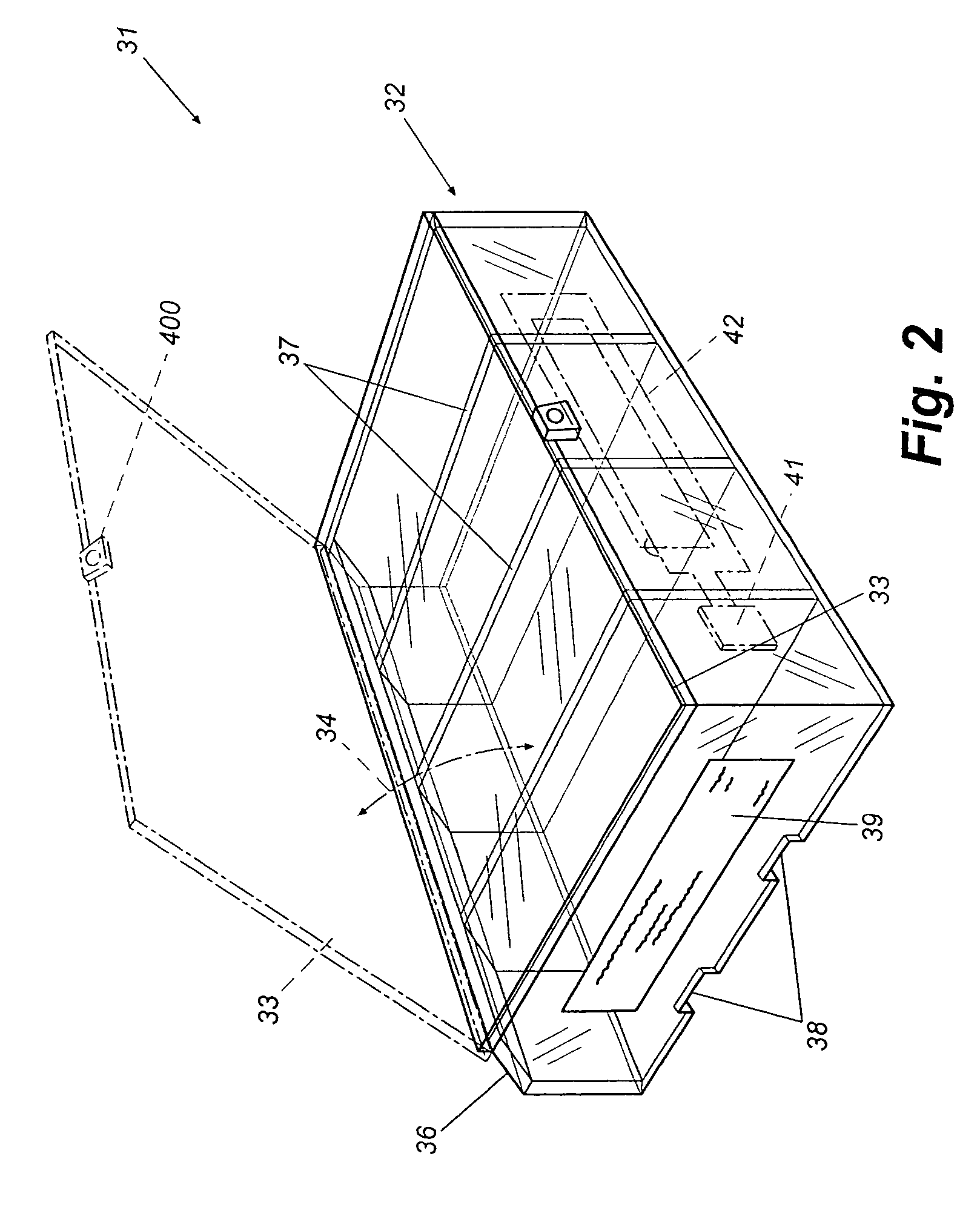

Object tracking method and system with object identification and verification

A system and method for tracking and controlling access to objects such as keys includes a lockable storage cabinet adapted to receive, store, and dispense objects within transparent security containers. A control computer is operably coupled to the cabinet. Information about objects, such as their weight, an image, or magnetic characteristics, is extracted by sensors when the objects within their containers are dispensed to a user or checked in by a user. This information is compared to a data base of the same information previously extracted for these objects. From the comparison, the connected control computer verifies that the objects present in the security container are the objects expected to be in the security container. If they are not, then theft or tampering is indicated and the computer takes remedial actions such as setting alarms or notifying security personnel.

Owner:KEY CONTROL HLDG

Amorphous and nanocrystalline glass-covered wires

InactiveUS6270591B2Prevent oxidationAvoid fragmentationInorganic material magnetismYarnGlass coverMetalloid

The invention refers to amorphous and nanocrystalline magnetic glass-covered wires. The wires consist of a metallic amorphous or nanocrystalline core with diameters by the order of 10-6 m, having compositions based on transition metal-metalloids and other additional metals and a glass cover, having a thickness of the wall by the same order of magnitude. The wires present high or medium saturation inducation, positive, negative or nearly zero magnetostriction and values of the coercive field and of the magnetic permeability in function of the requested applications in a field of electronics and electrotechnics to achieve sensors, transducers, inductive coils, trnasformers, magnetic shields, devices working on the basis of the correlation between the magnetic properties of the metallic core and the optical properties of the glass cover.

Owner:INSTL DE FIZICA TEHNICA IASI

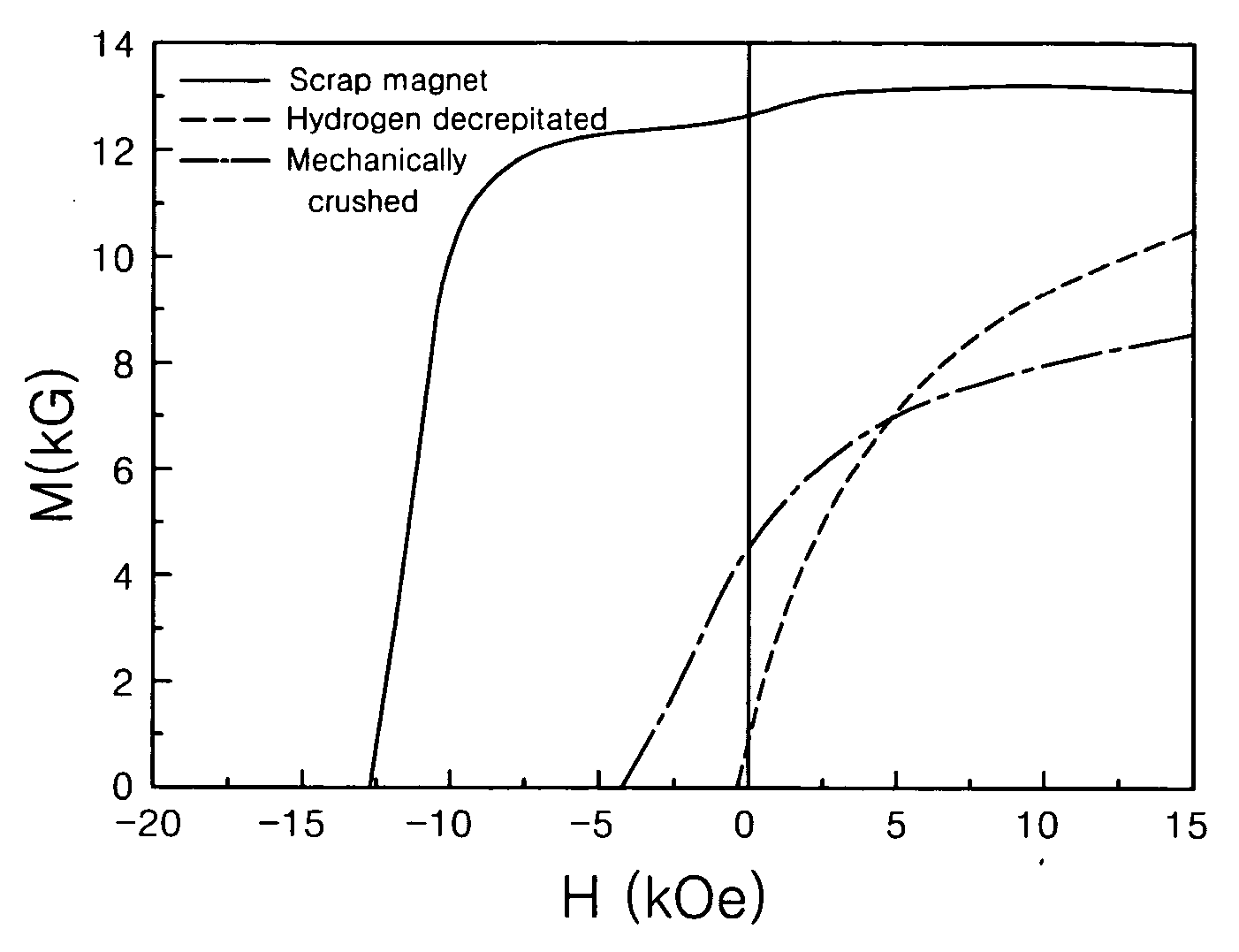

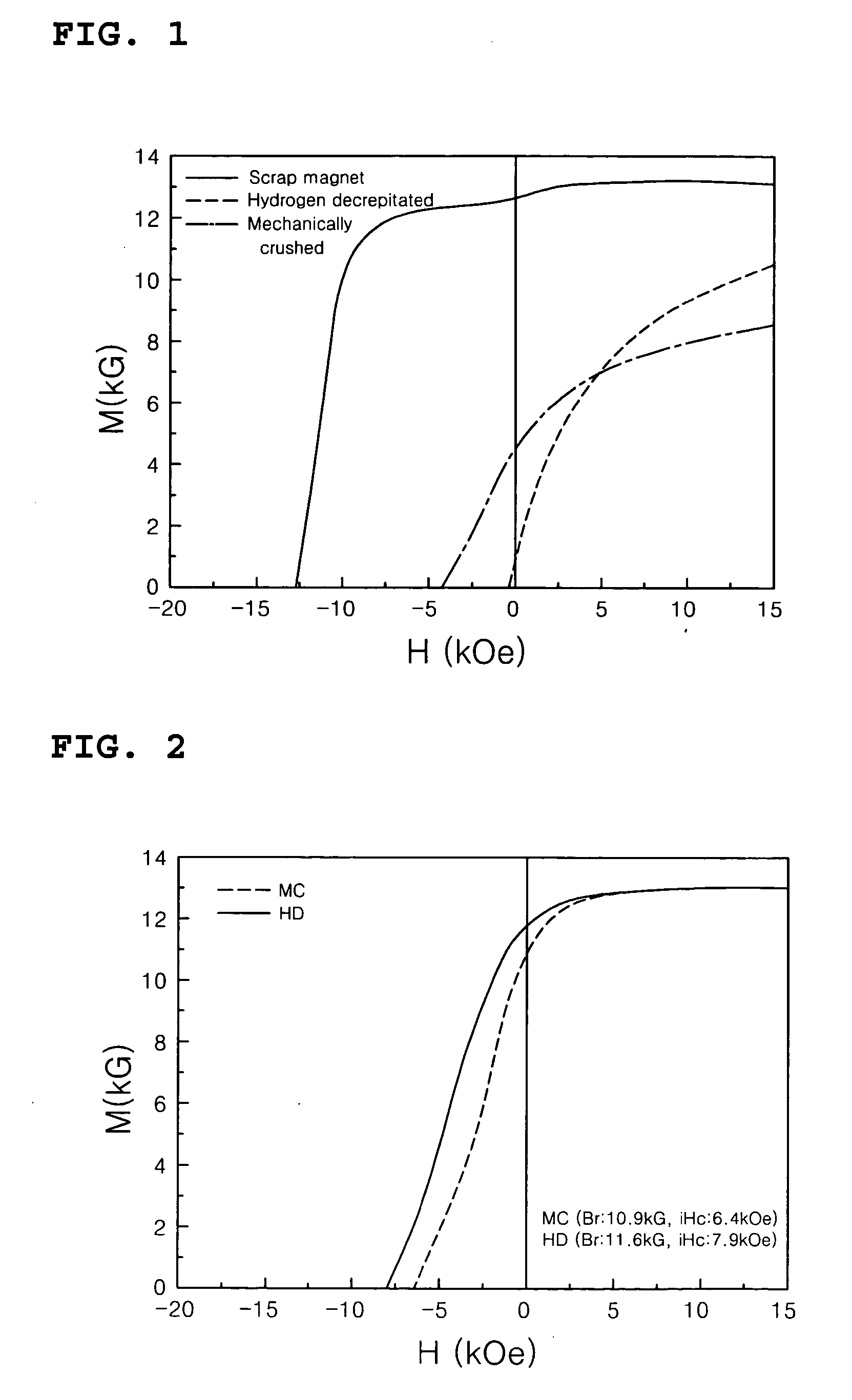

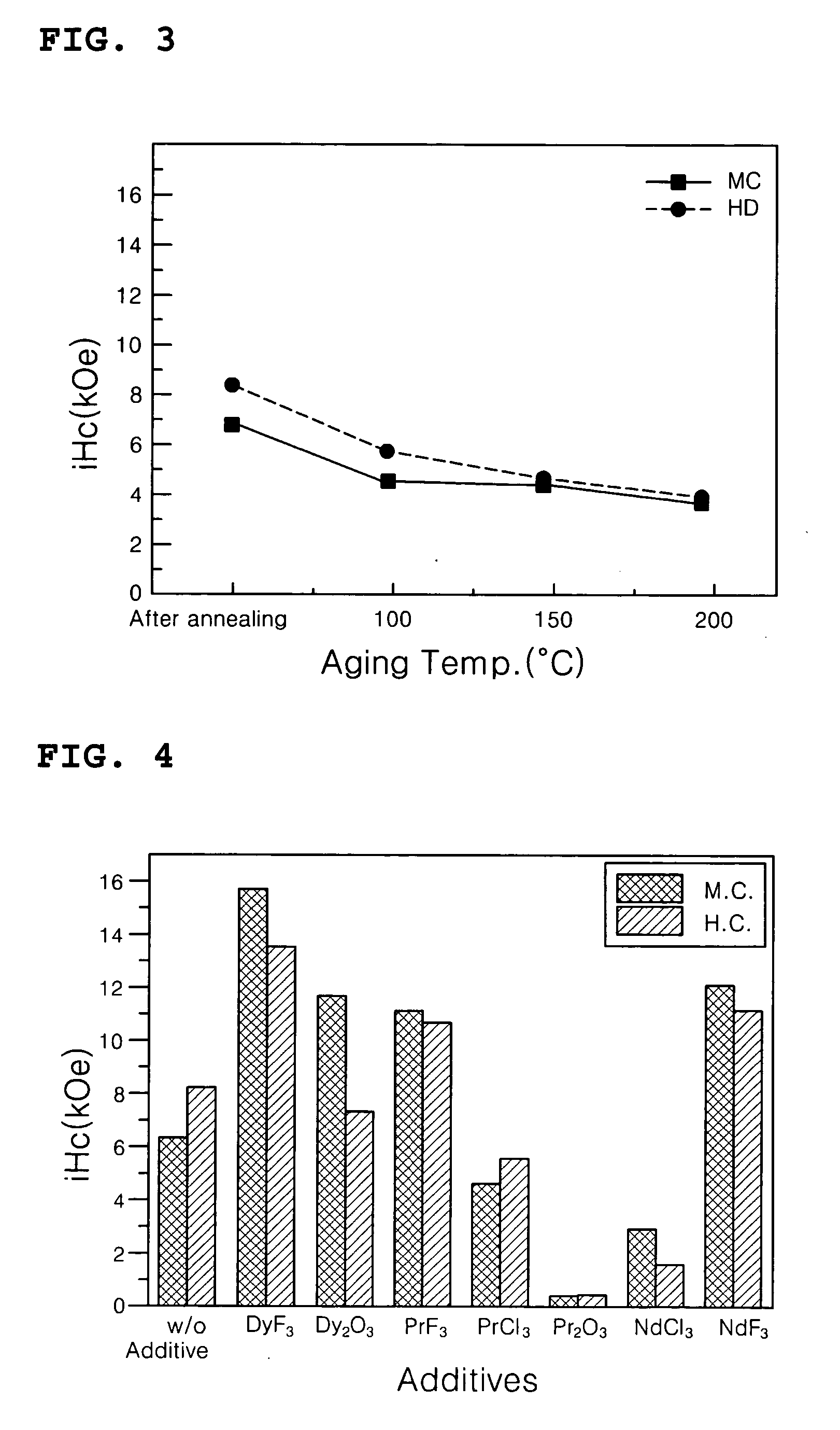

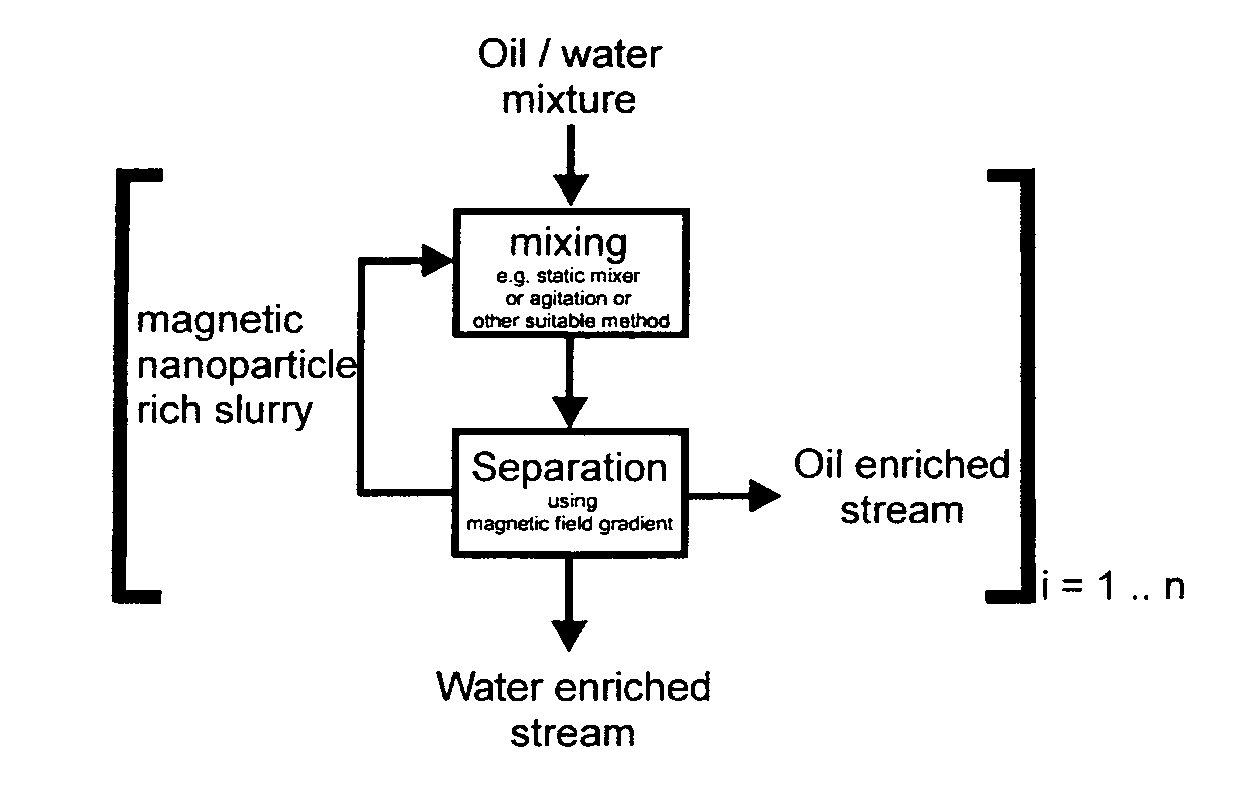

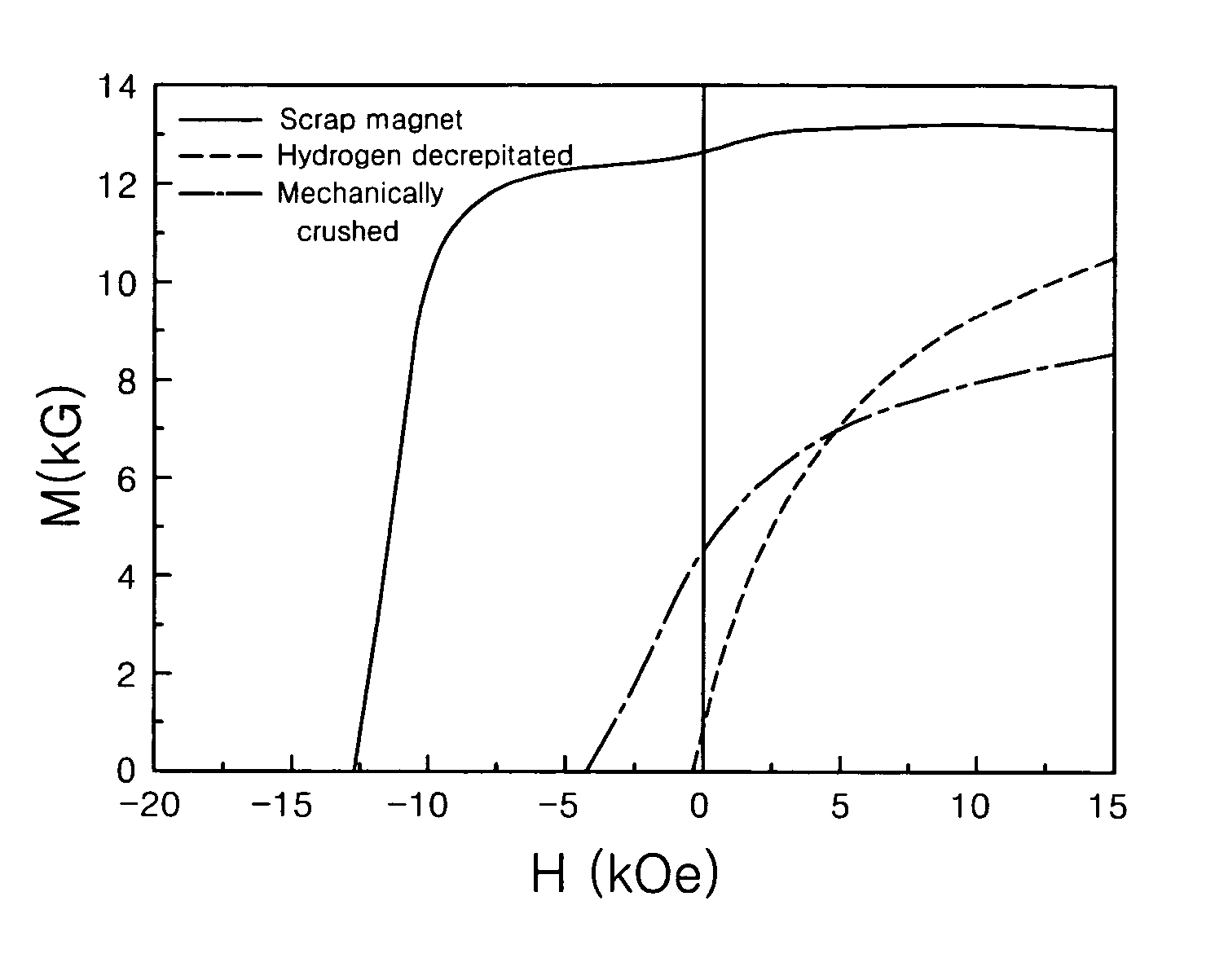

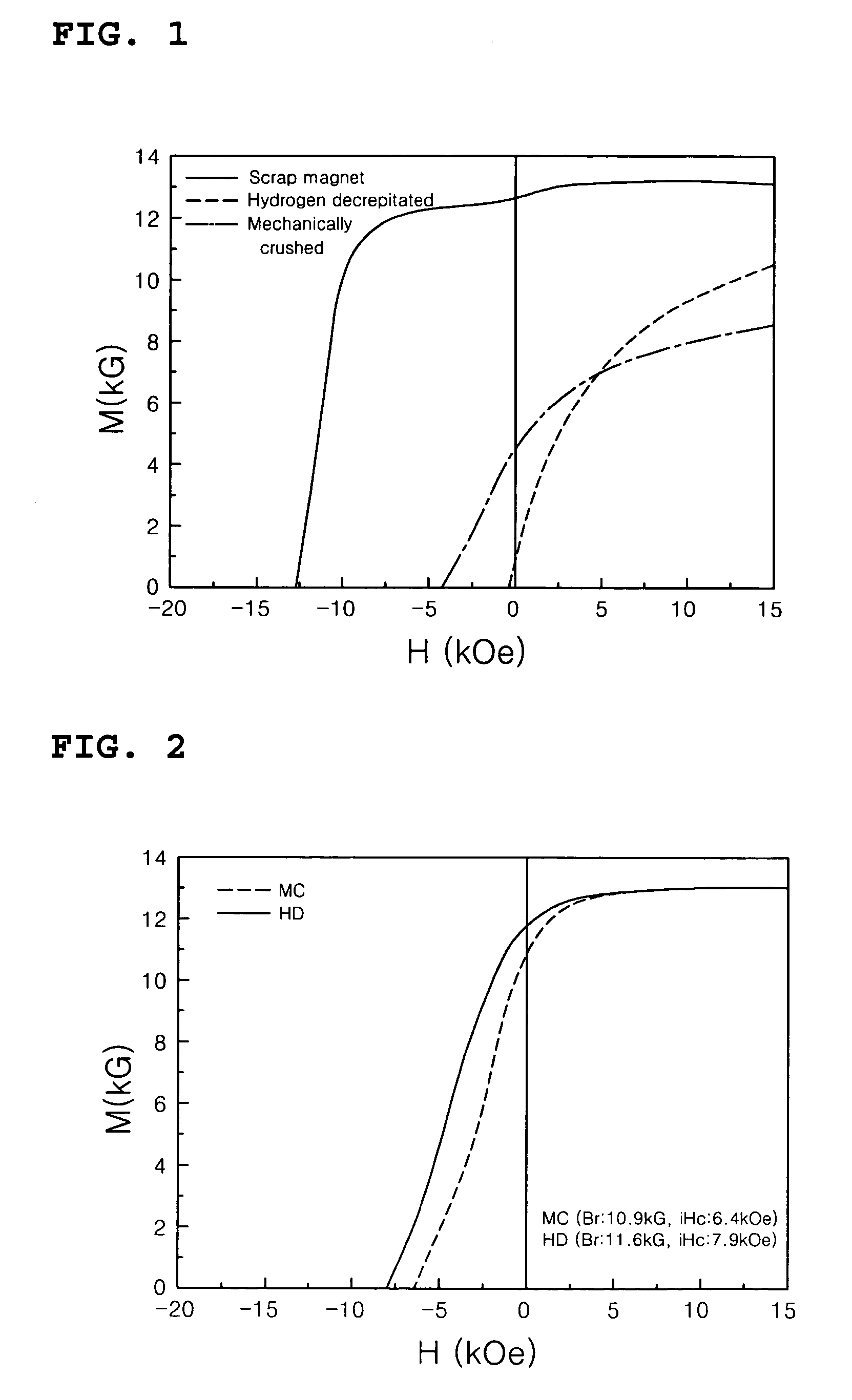

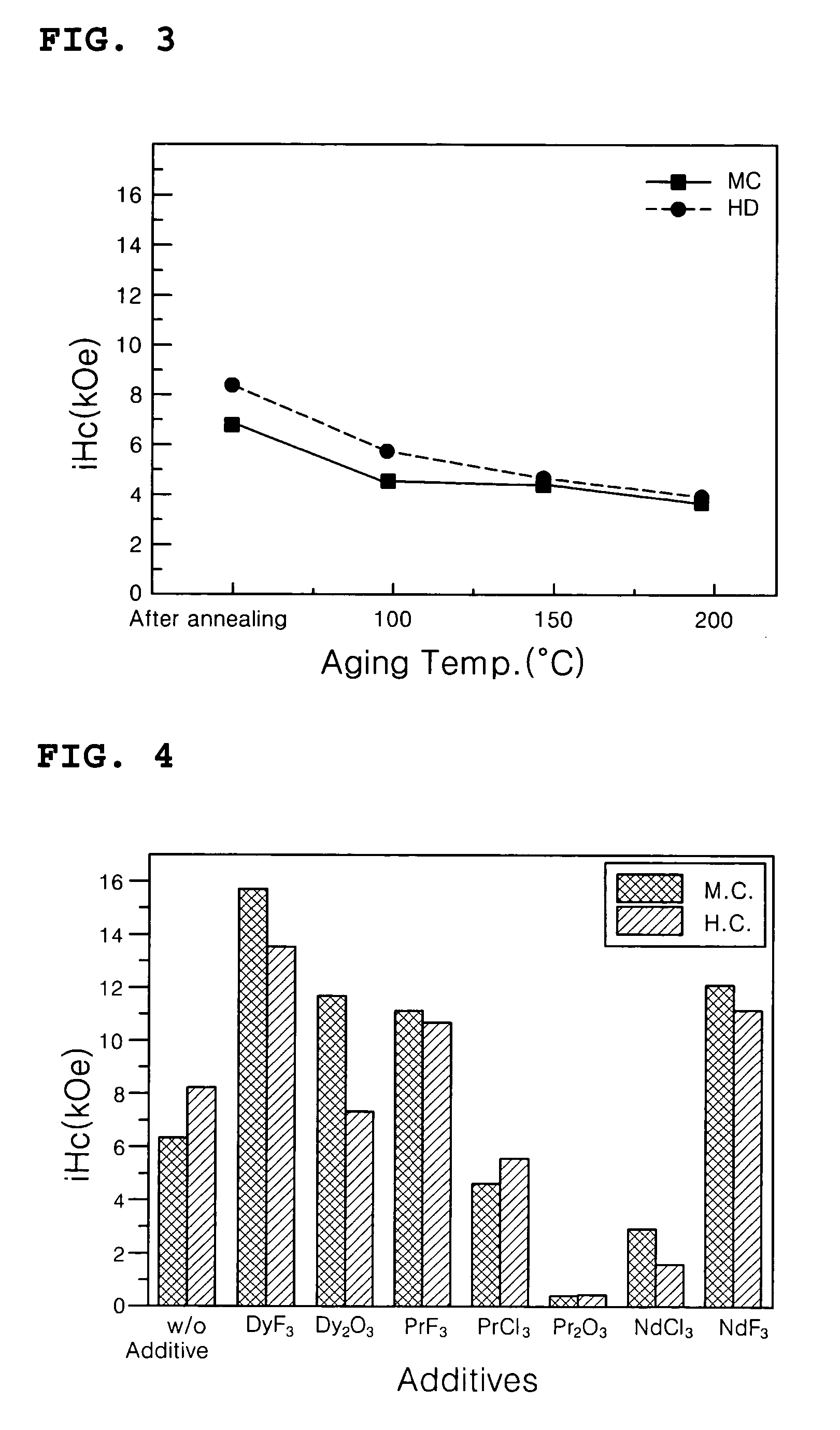

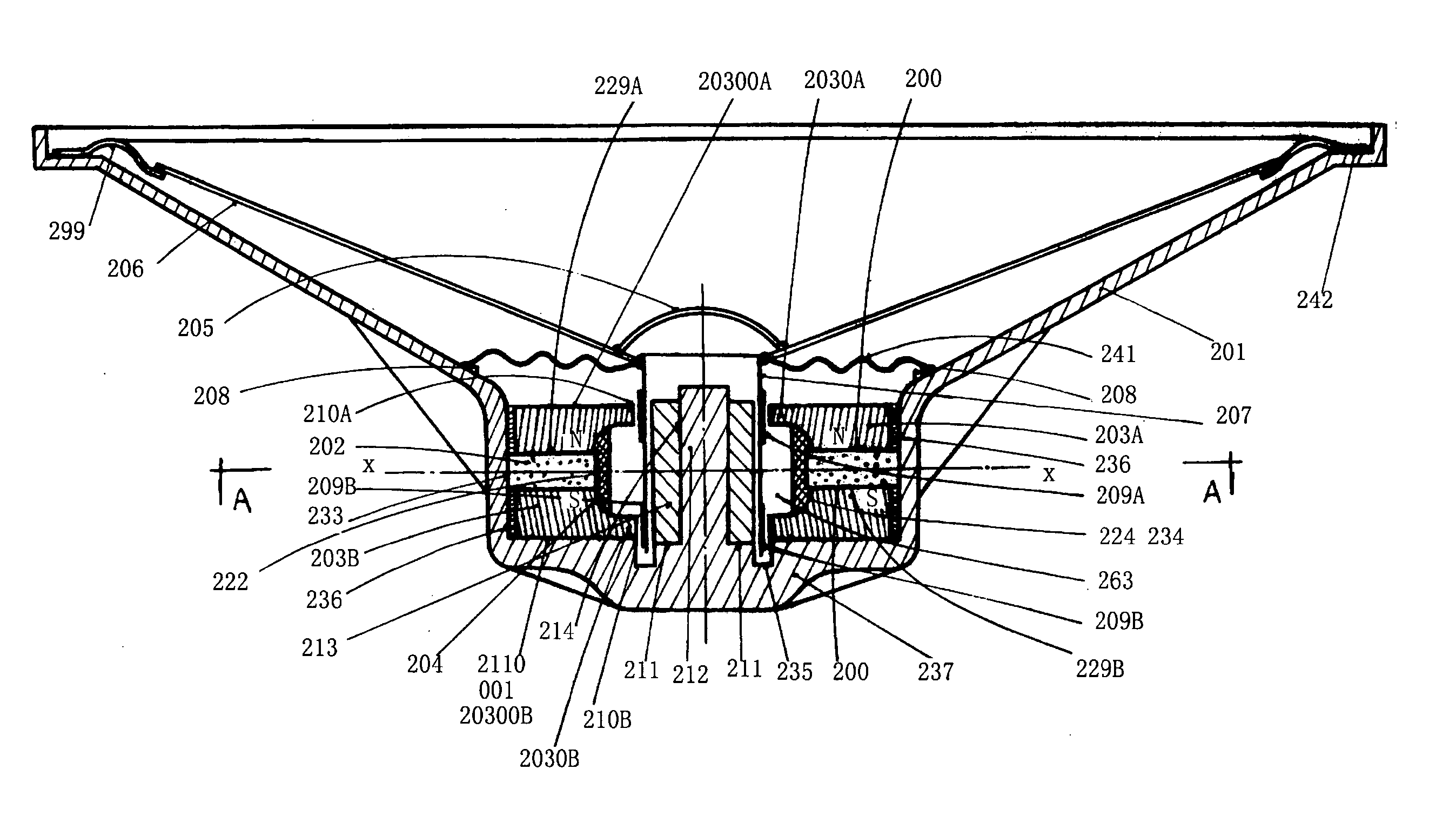

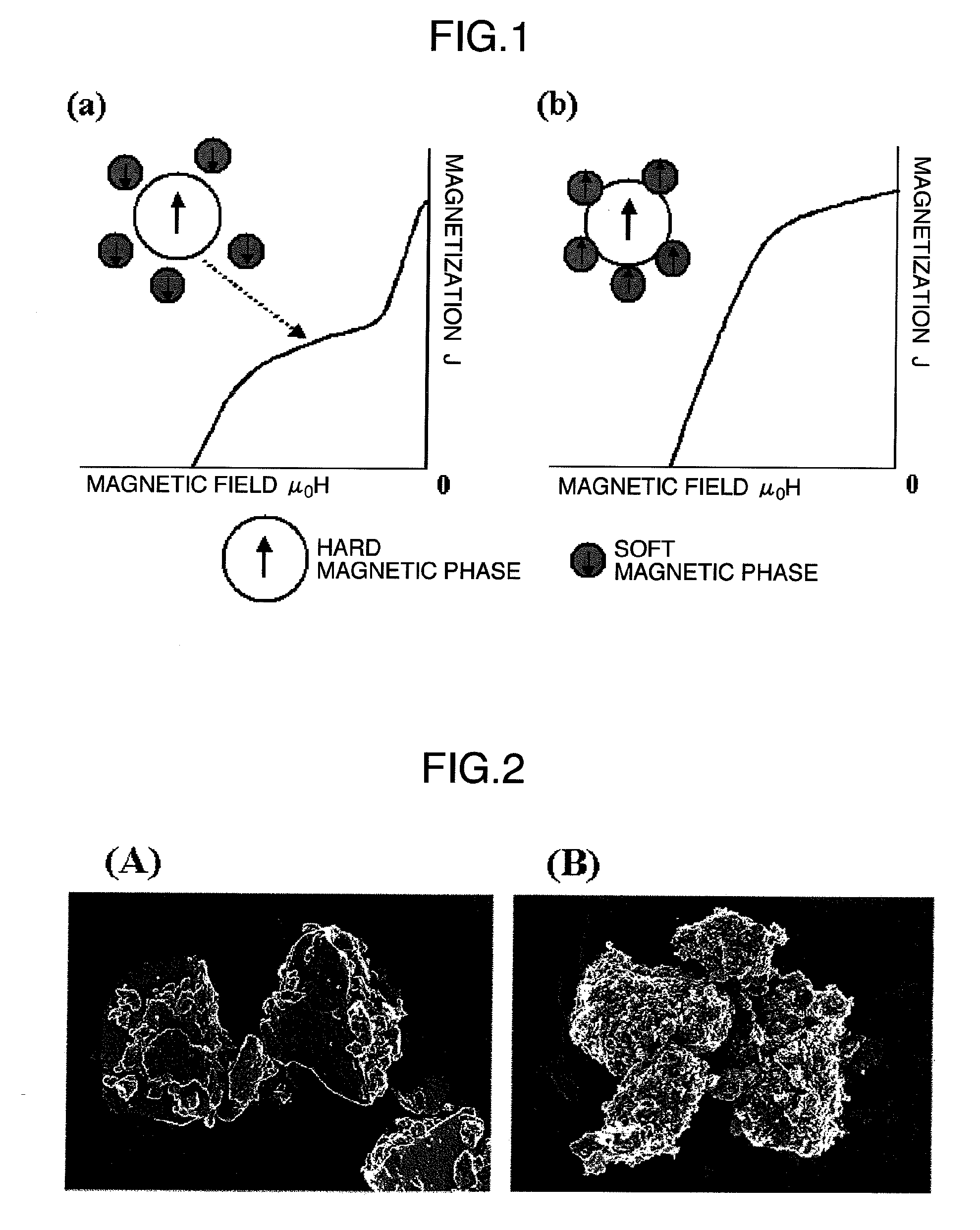

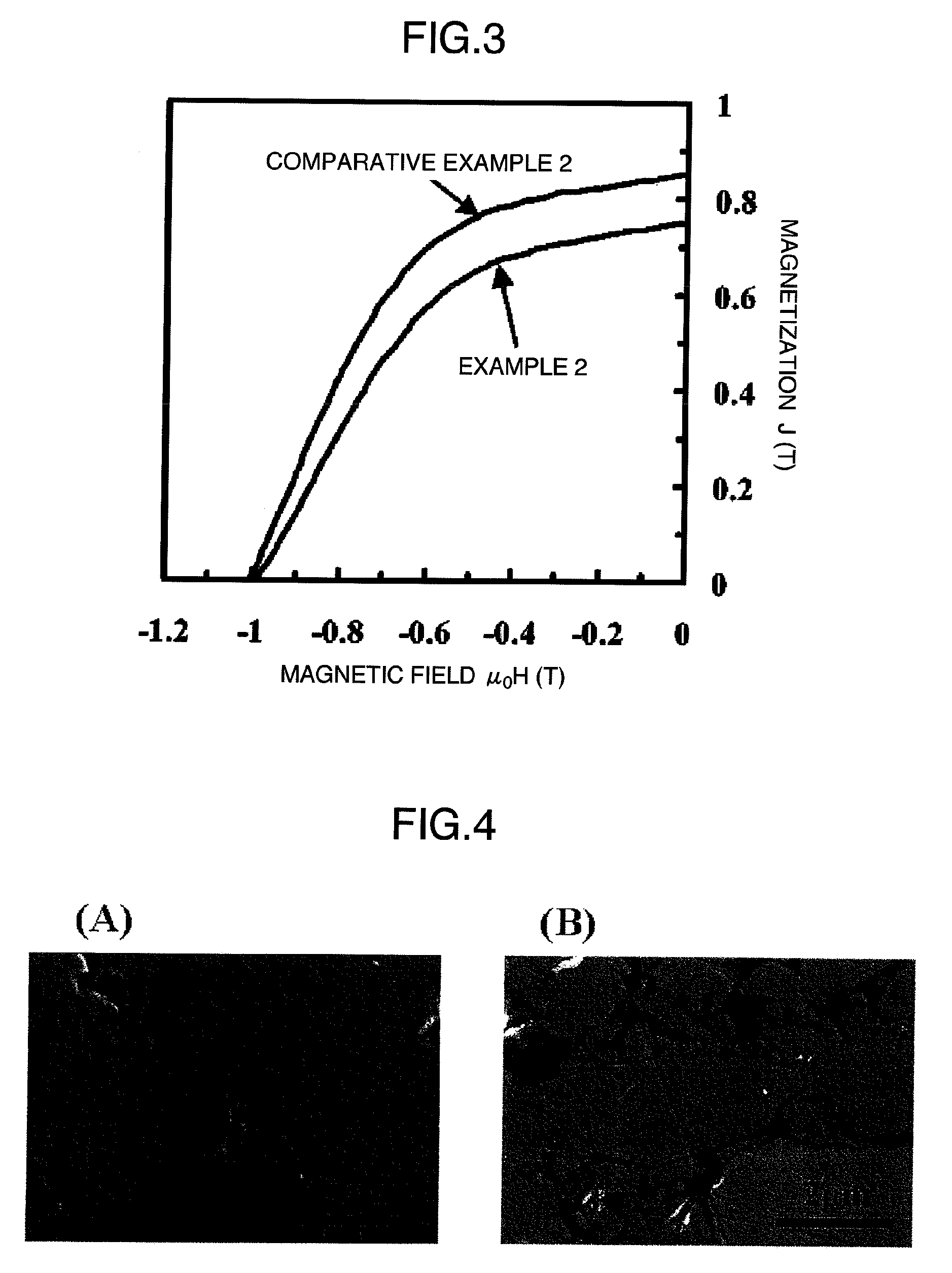

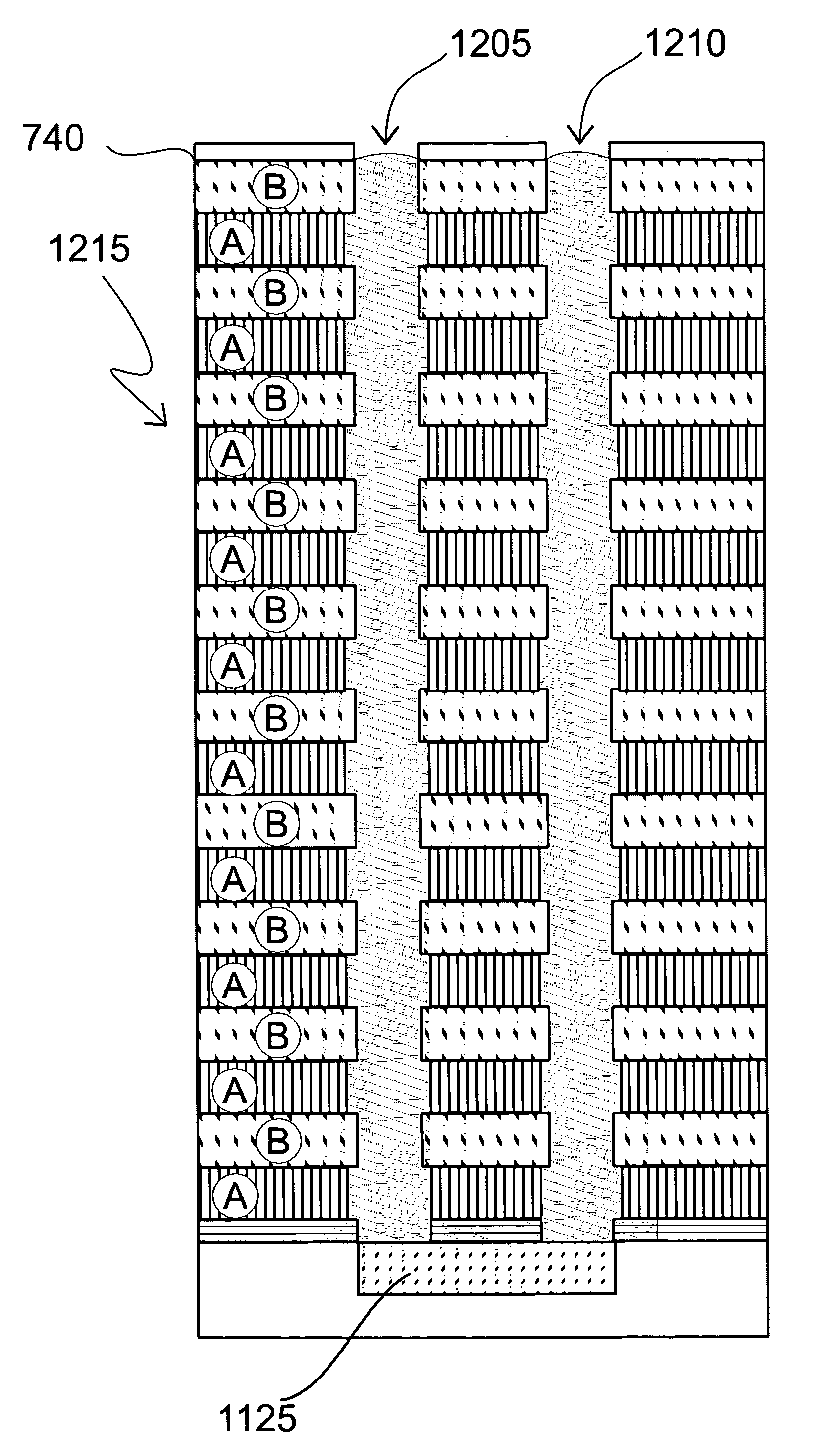

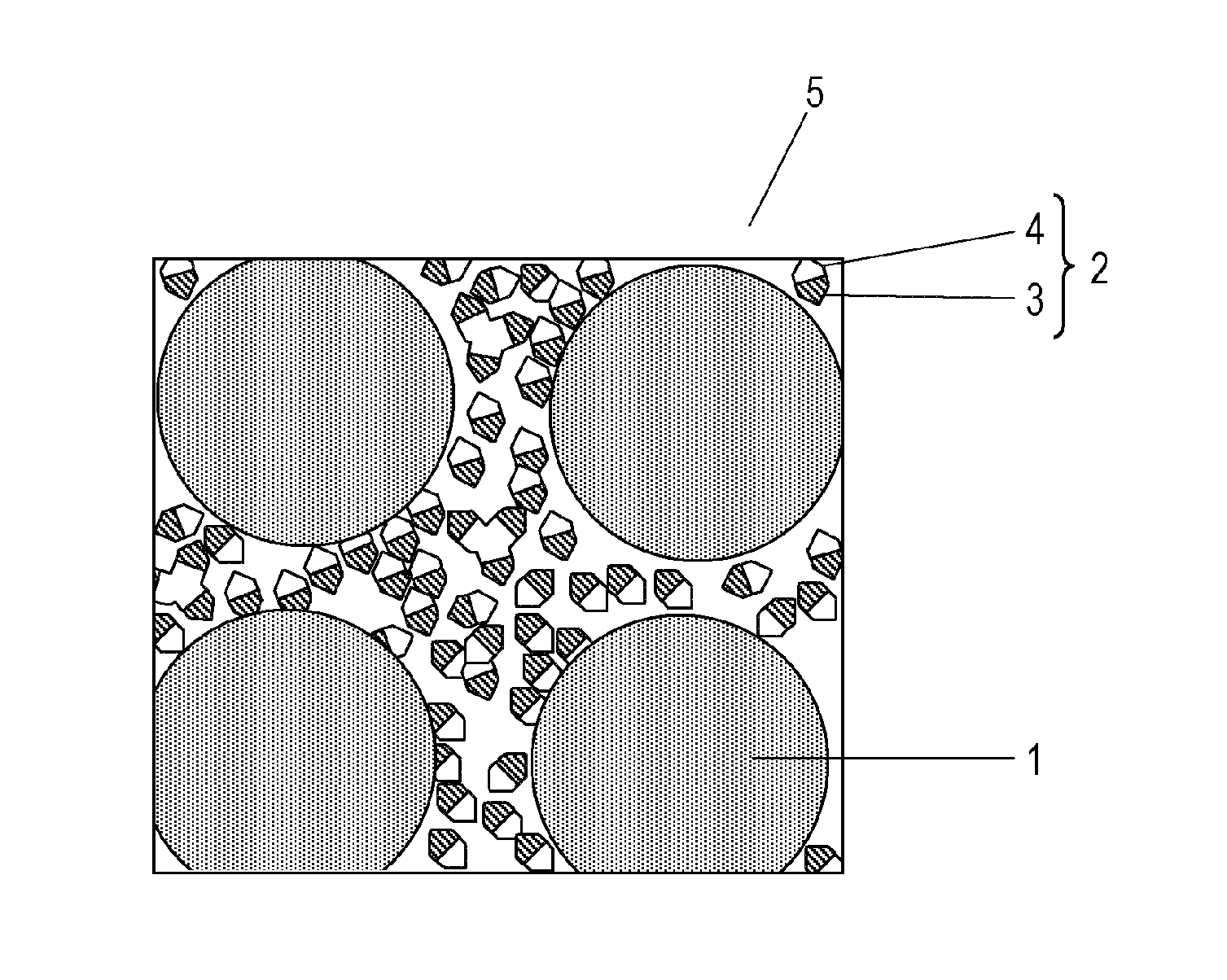

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS20050081959A1Reduce manufacturing costSimplified mass productionInorganic material magnetismRare earthGrain boundary

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50-500 μm sized magnet powders, which are then mixed with 1-10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500-1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1-20 μm, and the powders have an average size of 50-500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

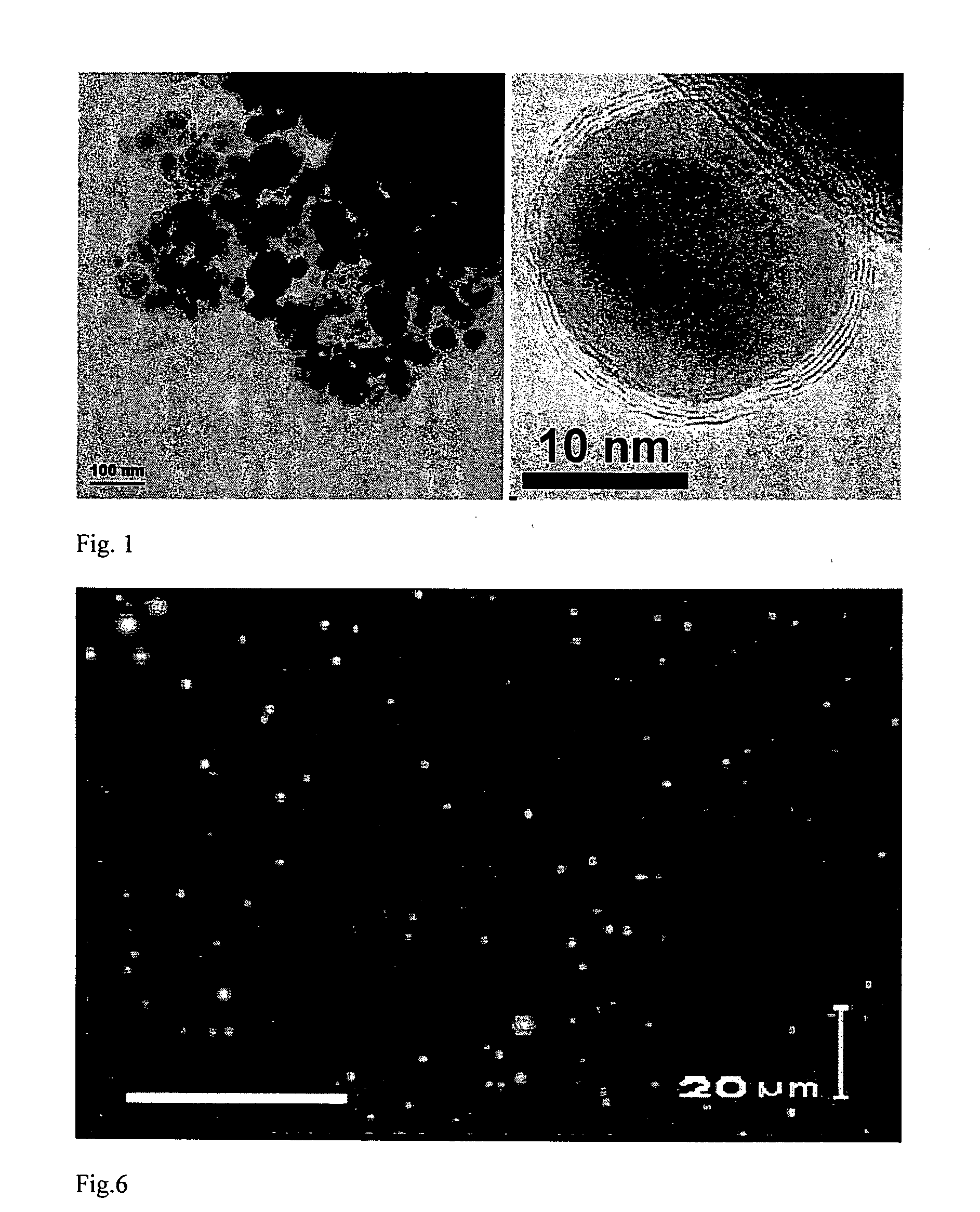

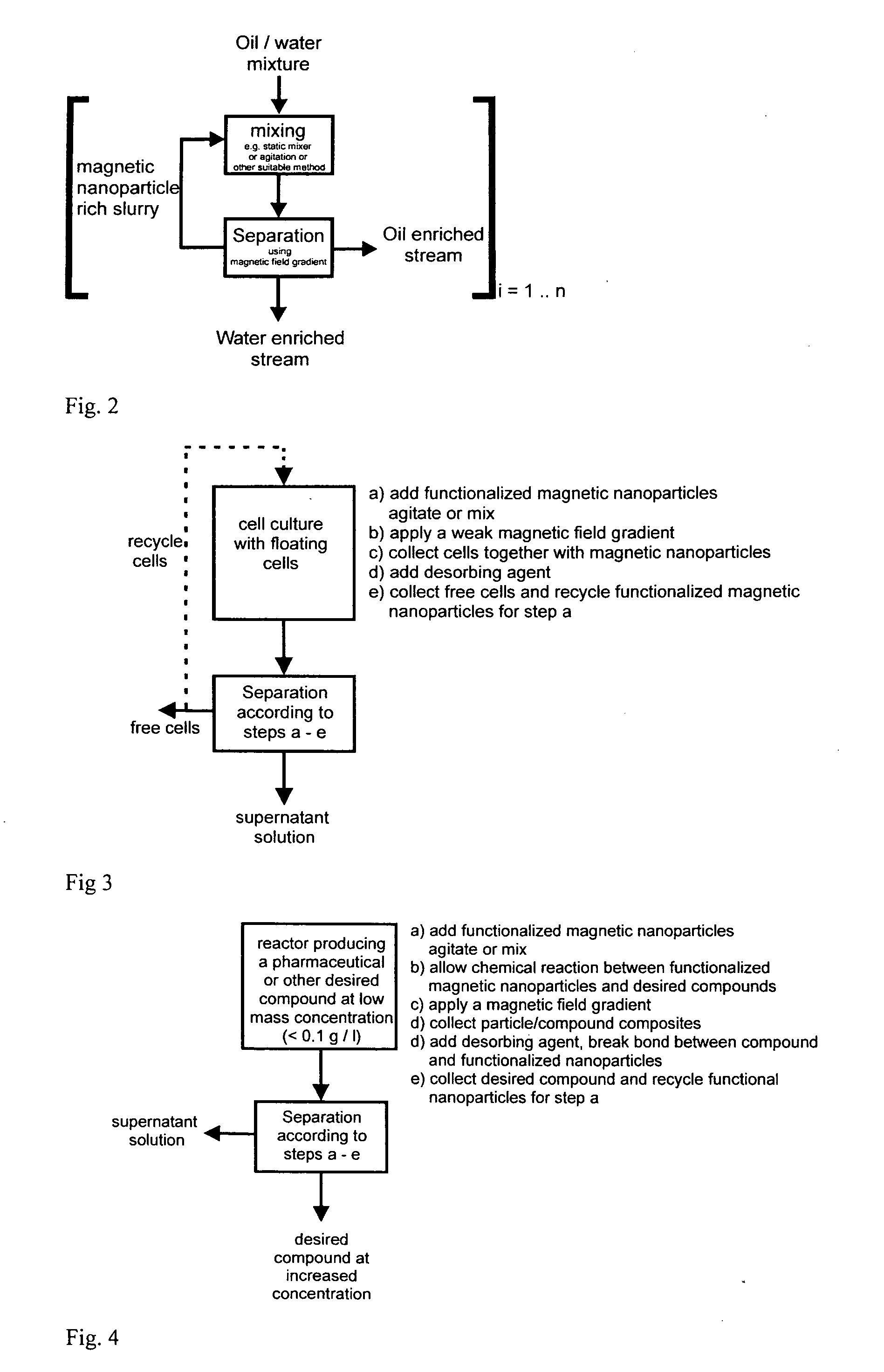

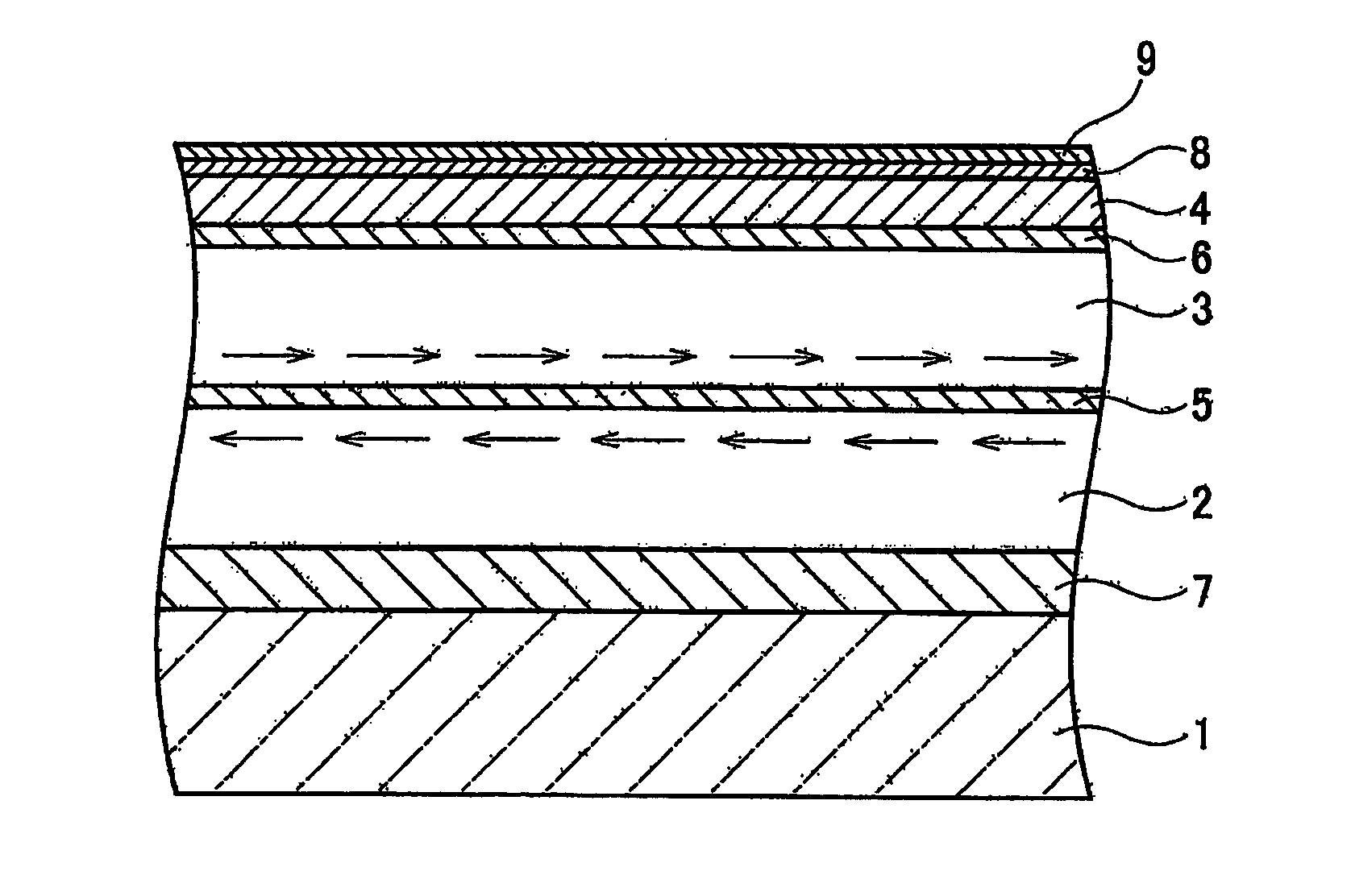

Carbon Coated Magnetic Nanoparticles and Their Use in Separation Processes

ActiveUS20100059449A1Improve mobilityRapidity and efficiencyNanomagnetismLiquid separation by electricityMagnetic field gradientMagnetite Nanoparticles

The invention relates to a process for separating a dispersed phase from a continuous phase comprising the steps of i) contacting said phases with an effective amount of nanoparticles; ii) applying a magnetic field gradient to the obtained system; iii) separating the obtained phases wherein said nanoparticles are of the core shell type, said core consists of a metal or alloy having soft magnetic properties and said shell contains a graphene layers which are optionally functionalized; to new nanoparticles and method of manufacturing such nanoparticles.

Owner:ETH ZZURICH

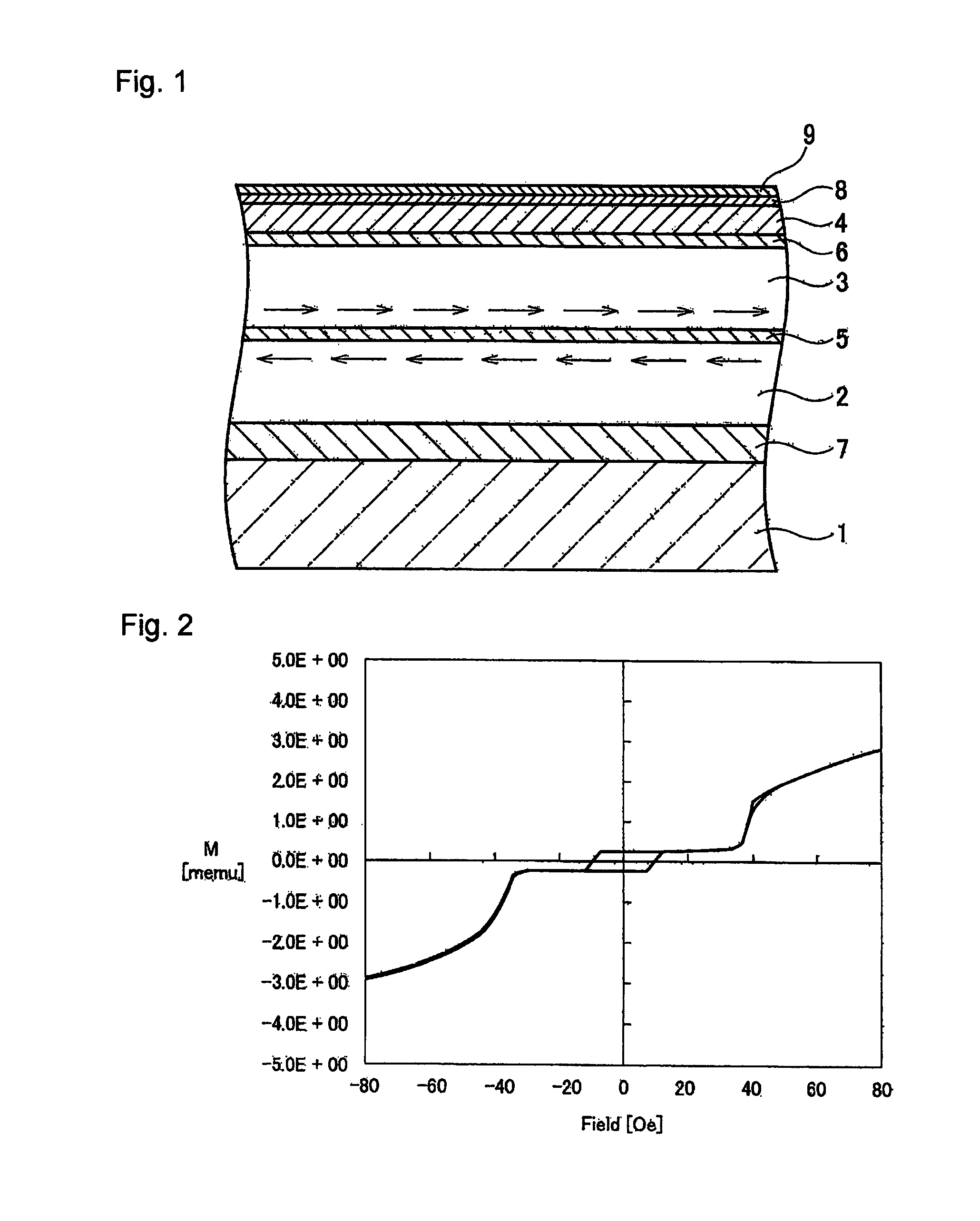

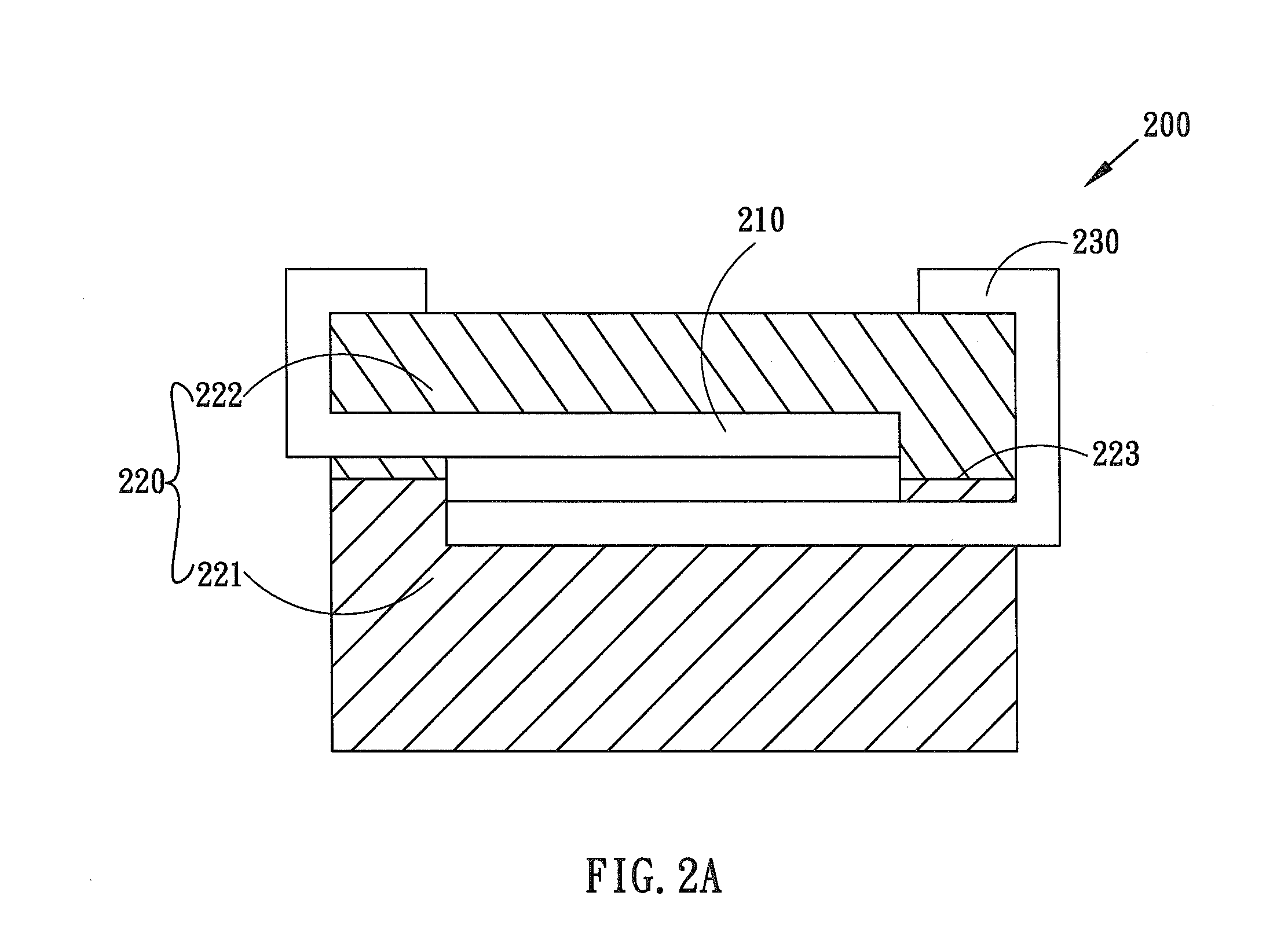

Magnetic recording medium substrate and perpendicular magnetic recording medium

InactiveUS7955723B2Inhibition formationSuppress generation of medium noiseLayered productsRecord information storageNon magneticMagnetic characteristic

A perpendicular magnetic recording medium comprising a pair of soft magnetic layers that are laminated via a non-magnetic layer and antiparallel-coupled to each other and that are provided between a non-magnetic substrate and a magnetic recording layer, wherein spike noise and medium noise can be positively suppressed when information recording and reproduction are carried out at high recording surface density. At least one pair of soft magnetic layers are laid and formed via a non-magnetic layer on a substrate of a non-magnetic material so that magnetic characteristics obtained by integrating the pair of soft magnetic layers have a magnetic hysteresis to thereby prevent the formation of a magnetic domain wall.

Owner:WESTERN DIGITAL TECH INC

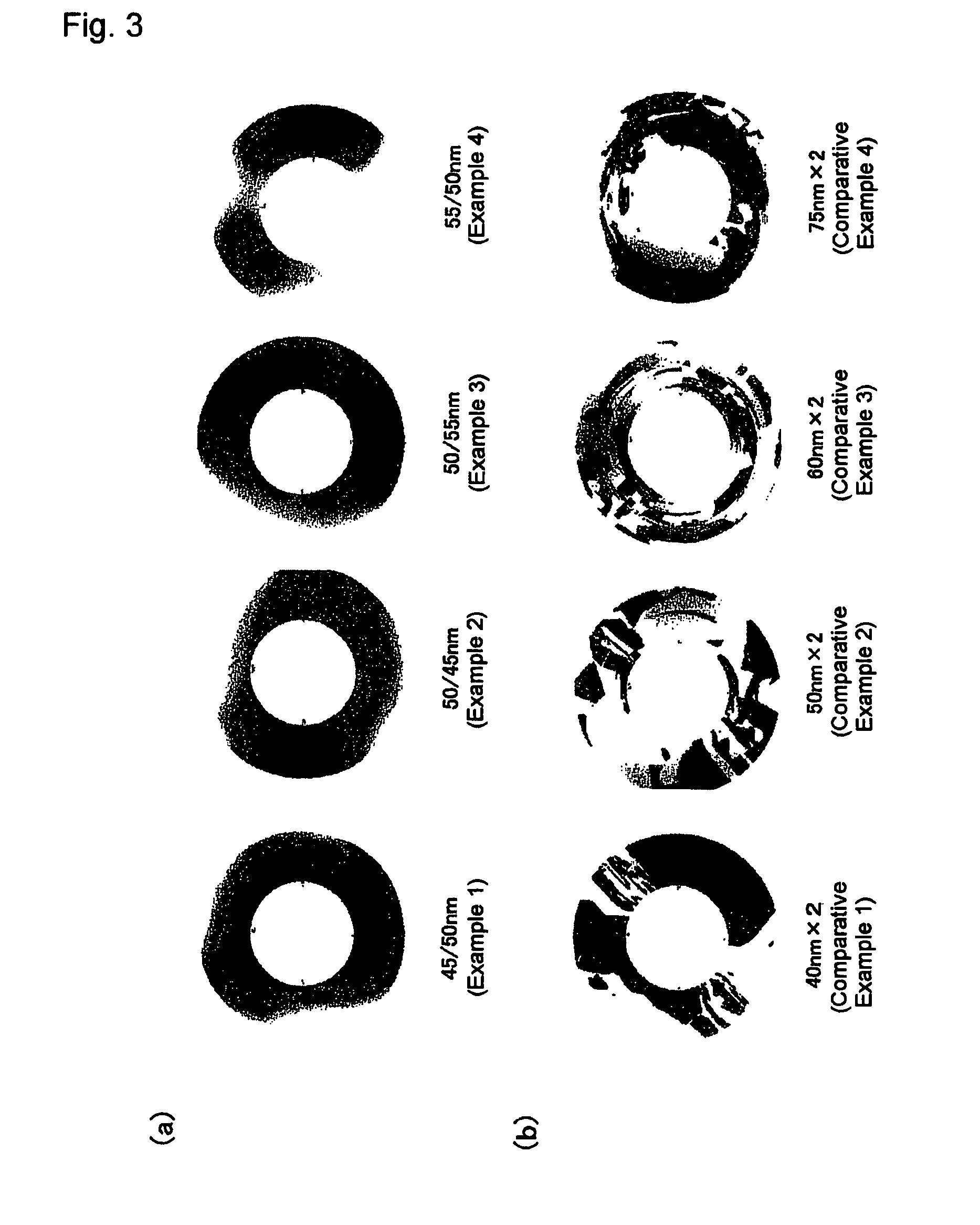

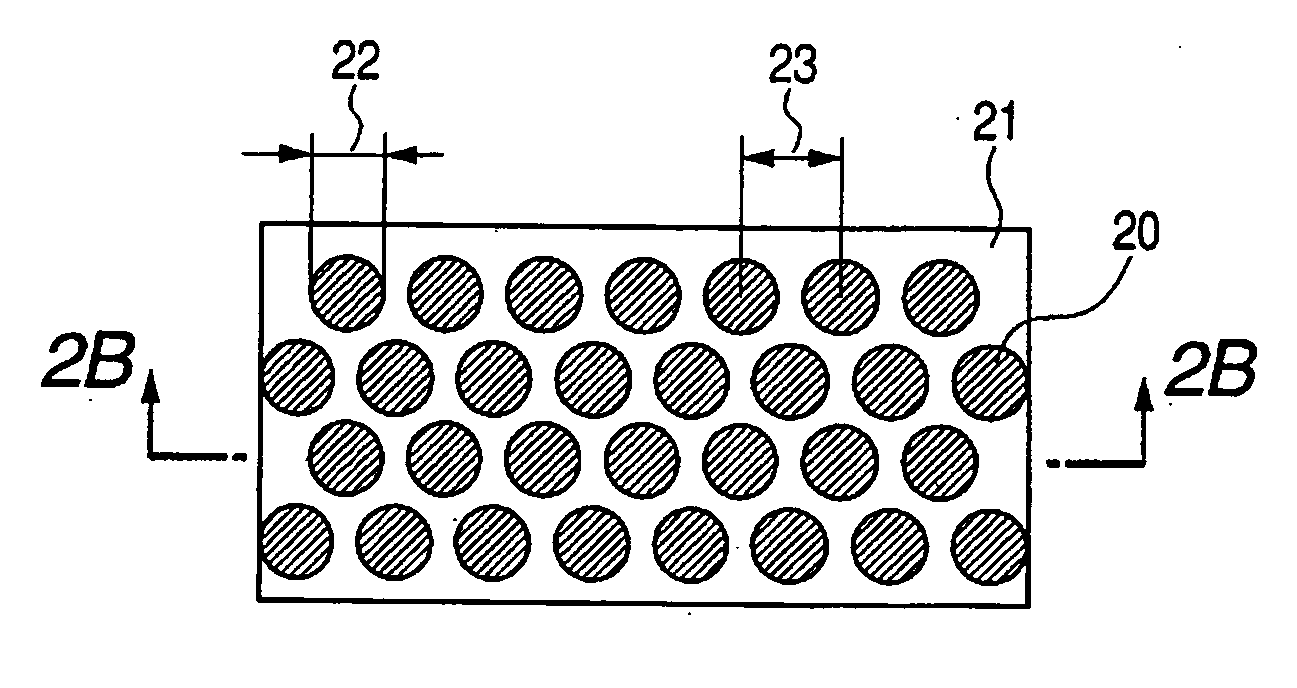

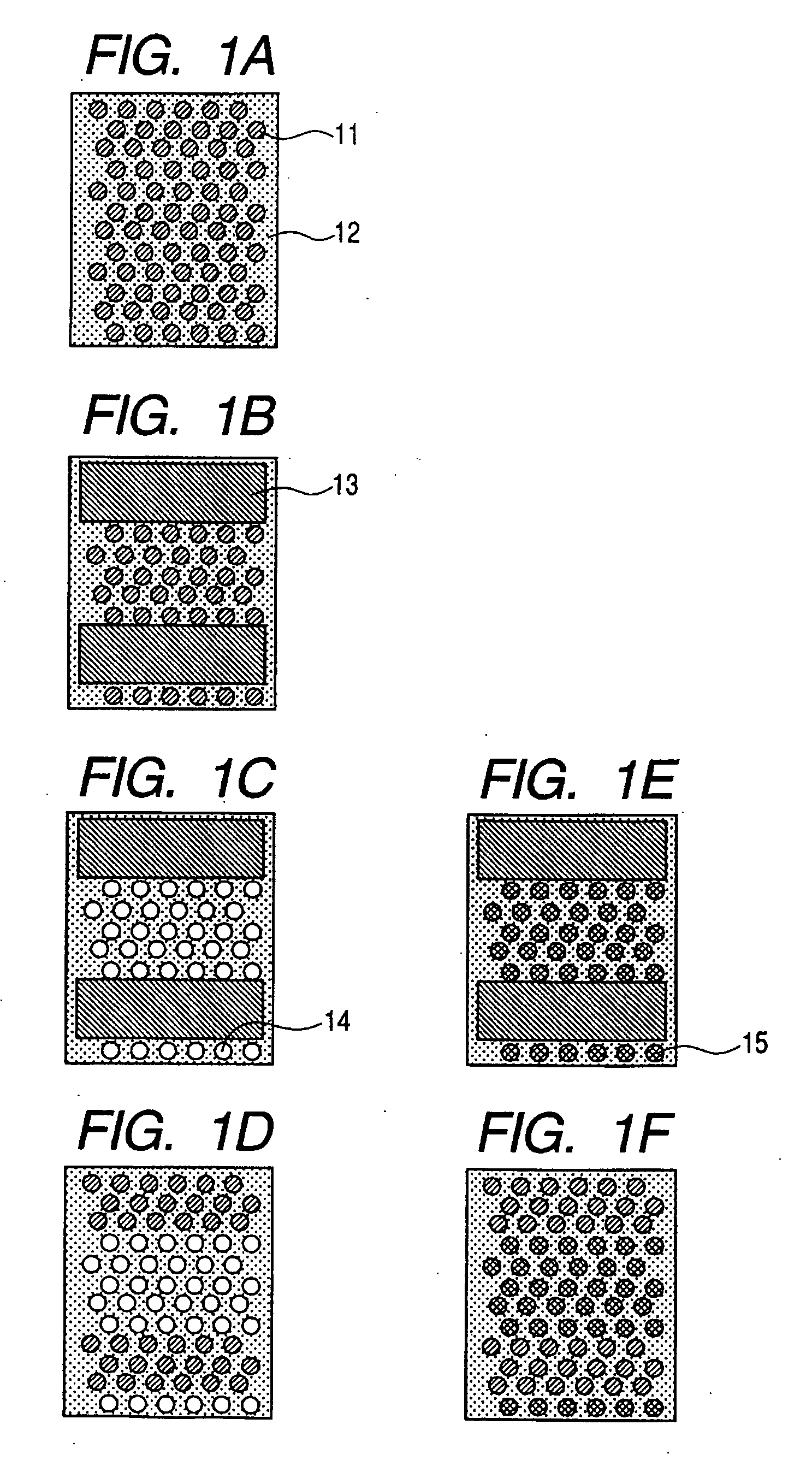

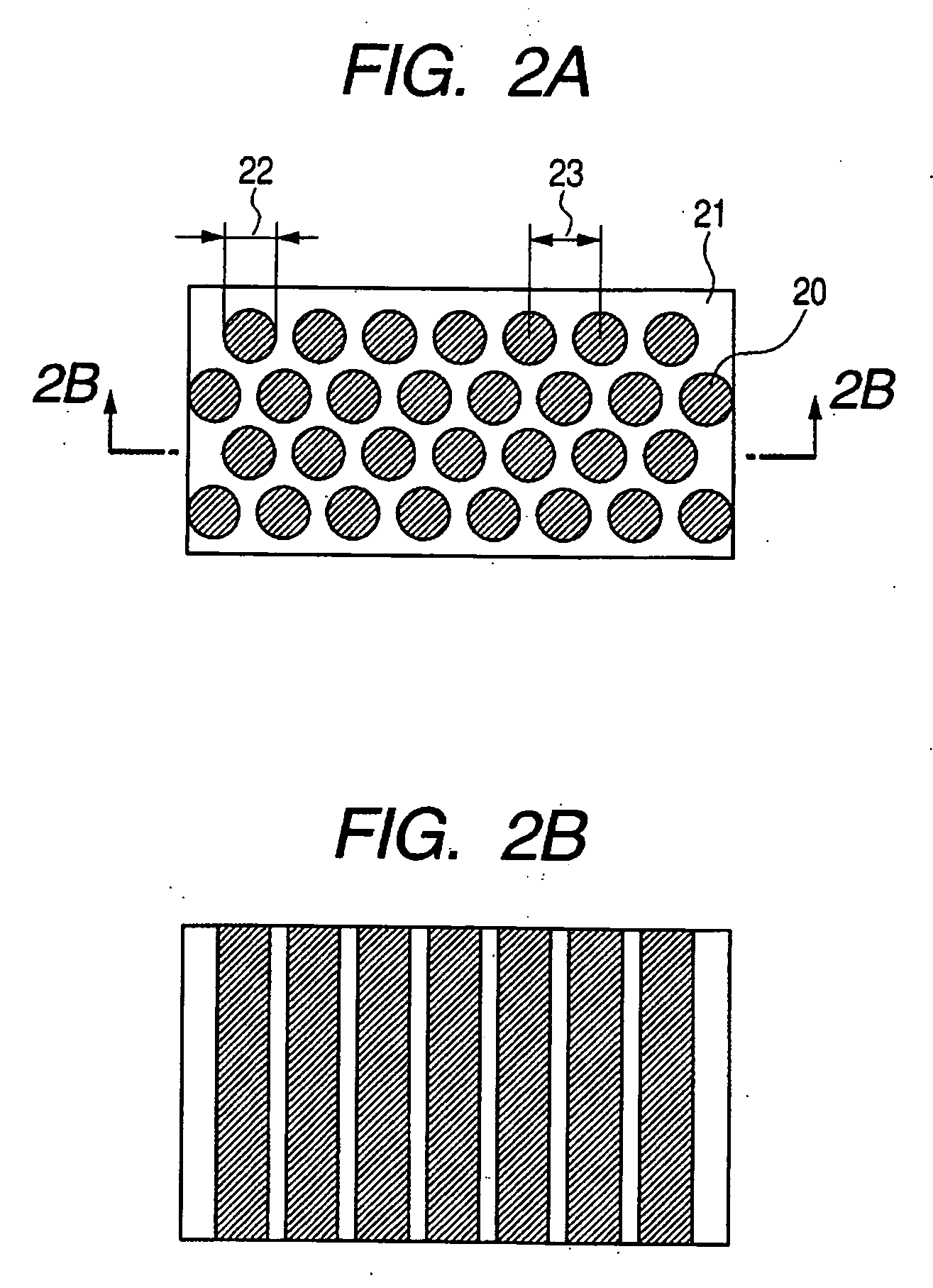

Magnetic recording medium and production method therefor

InactiveUS20060222898A1Reduced side cross talkEasy to trackRecord information storageCoatingsNon magneticMagnetic characteristic

An object is to provide a magnetic recording medium with a recording region having little magnetic property degradation, and to provide a production method therefor. This method for producing the magnetic recording medium comprises the steps of preparing a structure having a plurality of magnetic material regions 11 with a columnar structure made of a magnetic material separated by non-magnetic material regions 12 made of a non-magnetic material; forming a mask pattern 13 on a portion to be a recording region in the structure; and removing the magnetic material in a plurality of the magnetic material regions 11 in the regions on which the mask pattern 13 is not formed, in the structure, or transforming magnetic properties of the magnetic material, to arrange separation regions which magnetically separate adjacent recording regions.

Owner:CANON KK

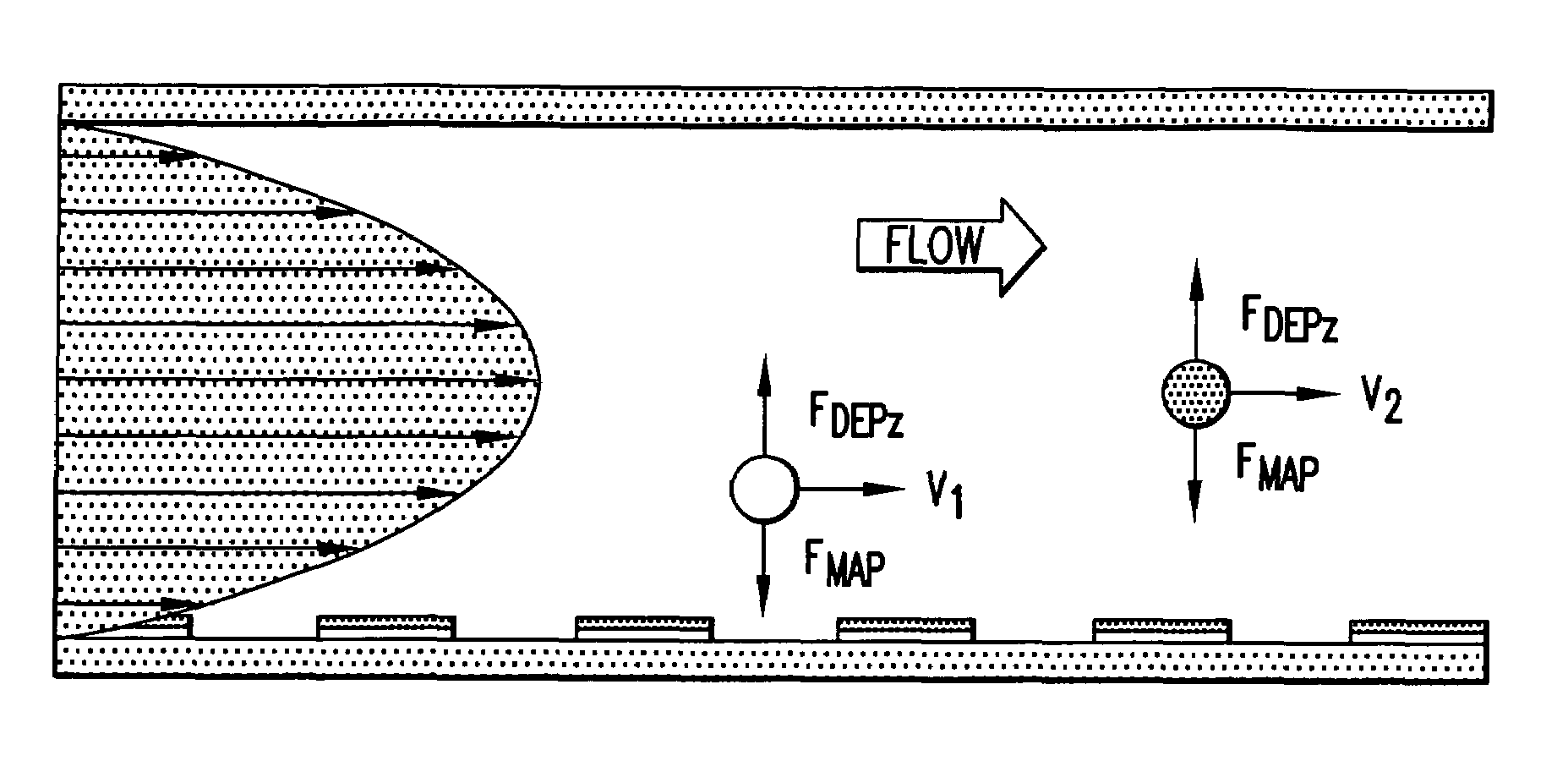

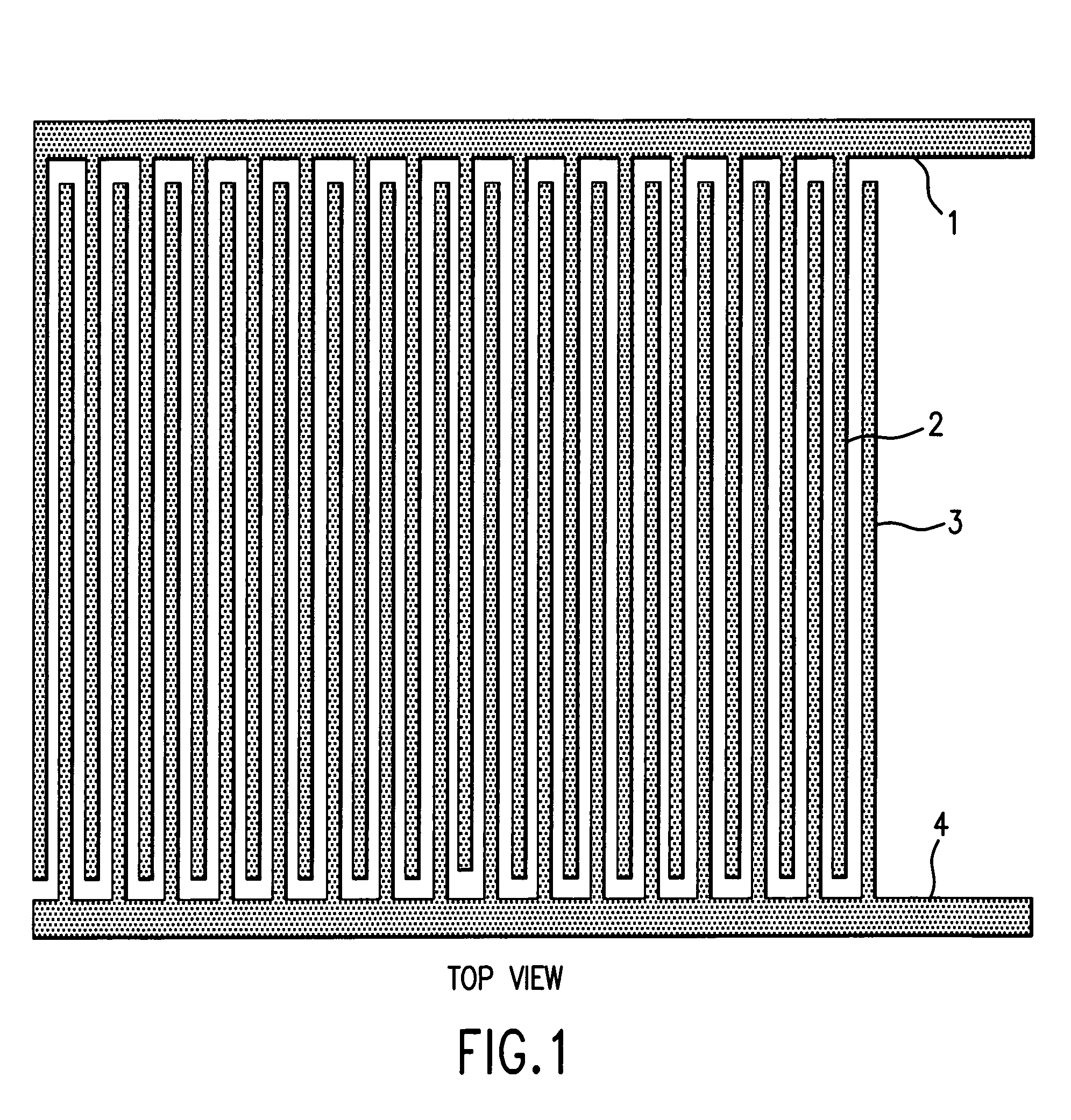

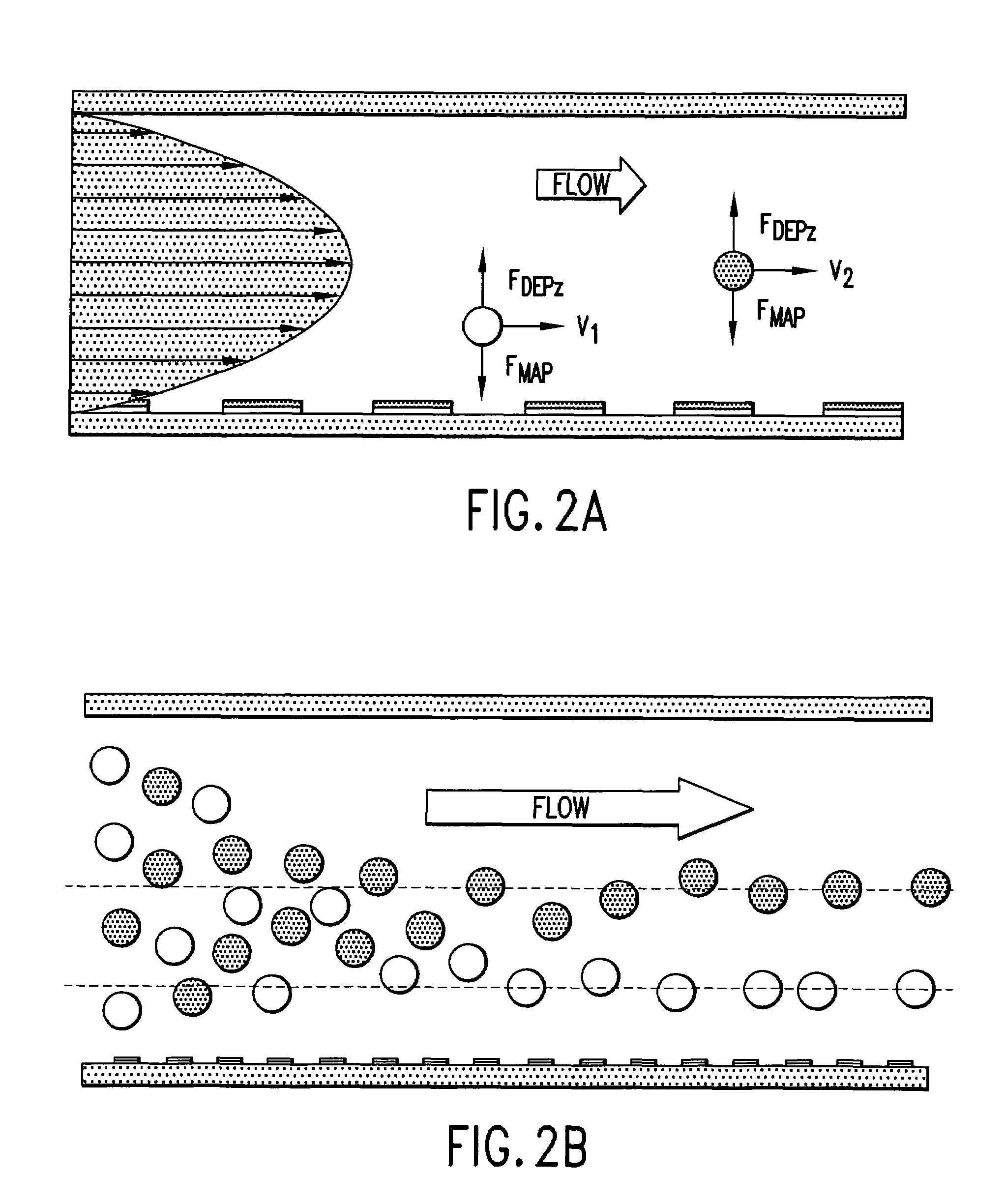

Method and apparatus for combined magnetophoretic and dielectrophoretic manipulation of analyte mixtures

InactiveUS7033473B2Improves analyte recovery efficiencyReduces and eliminates “ relaxation time ”Sludge treatmentElectrostatic separatorsElectricityAnalyte

Methods and apparatuses for discriminating matter utilizing dielectrophoresis combined with magnetophoresis. A sample having one or more constituents is injected into an inlet port of a chamber. A carrier medium flow is initiated at the inlet port to establish a flow within the chamber. A dielectrophoretic force is generated to act on the constituents of the sample. A magnetophoretic force is generated to act on the constituents of the sample. The dielectrophoretic force and magnetophoretic forces are balanced to position the constituents within the chamber. The constituents are then collected at one or more outlet ports of the chamber according to the dielectric and magnetic characteristics of the constituents. The constituents may be collected as a function of time-of-exit from the chamber and / or position within the chamber.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

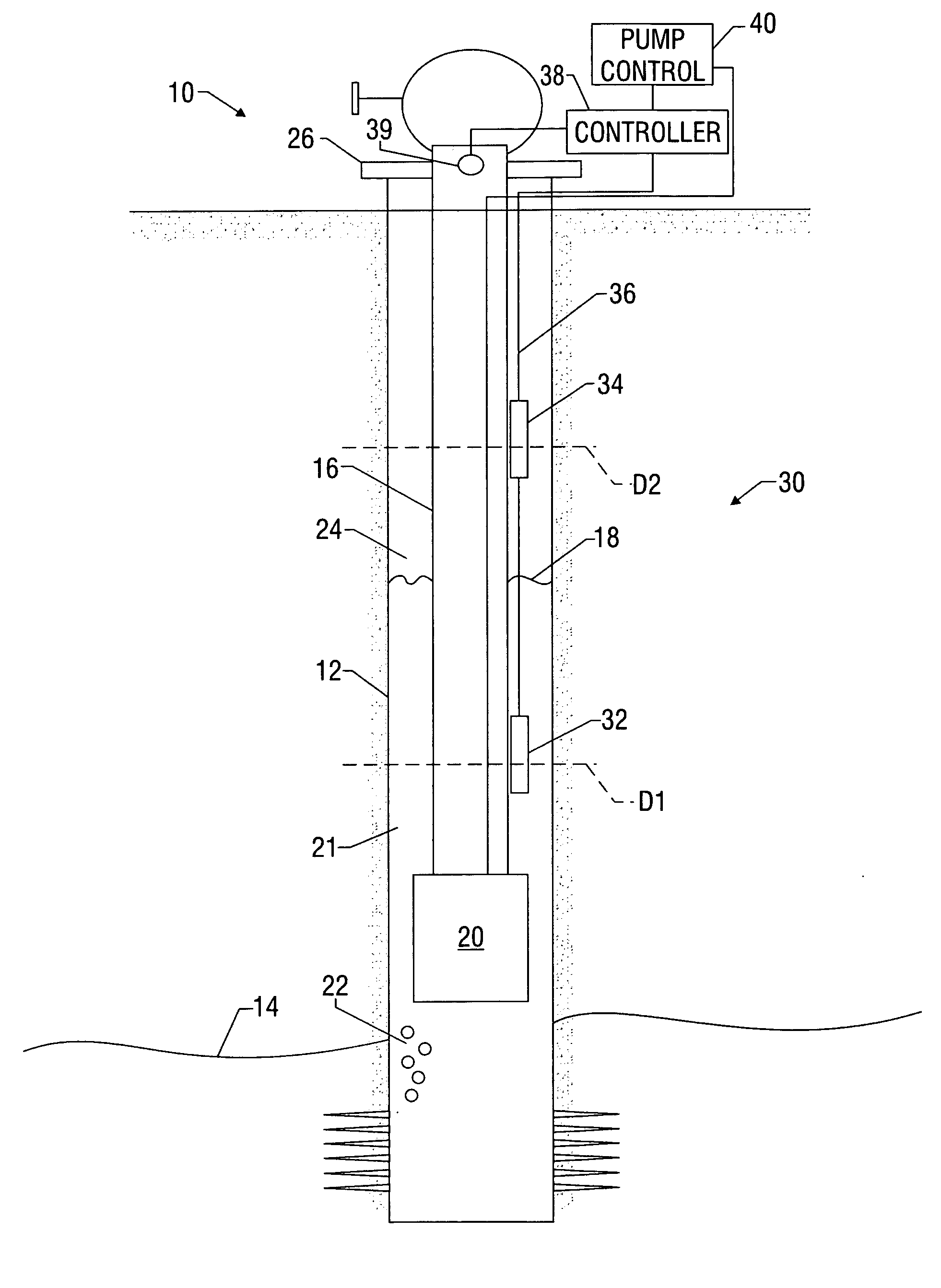

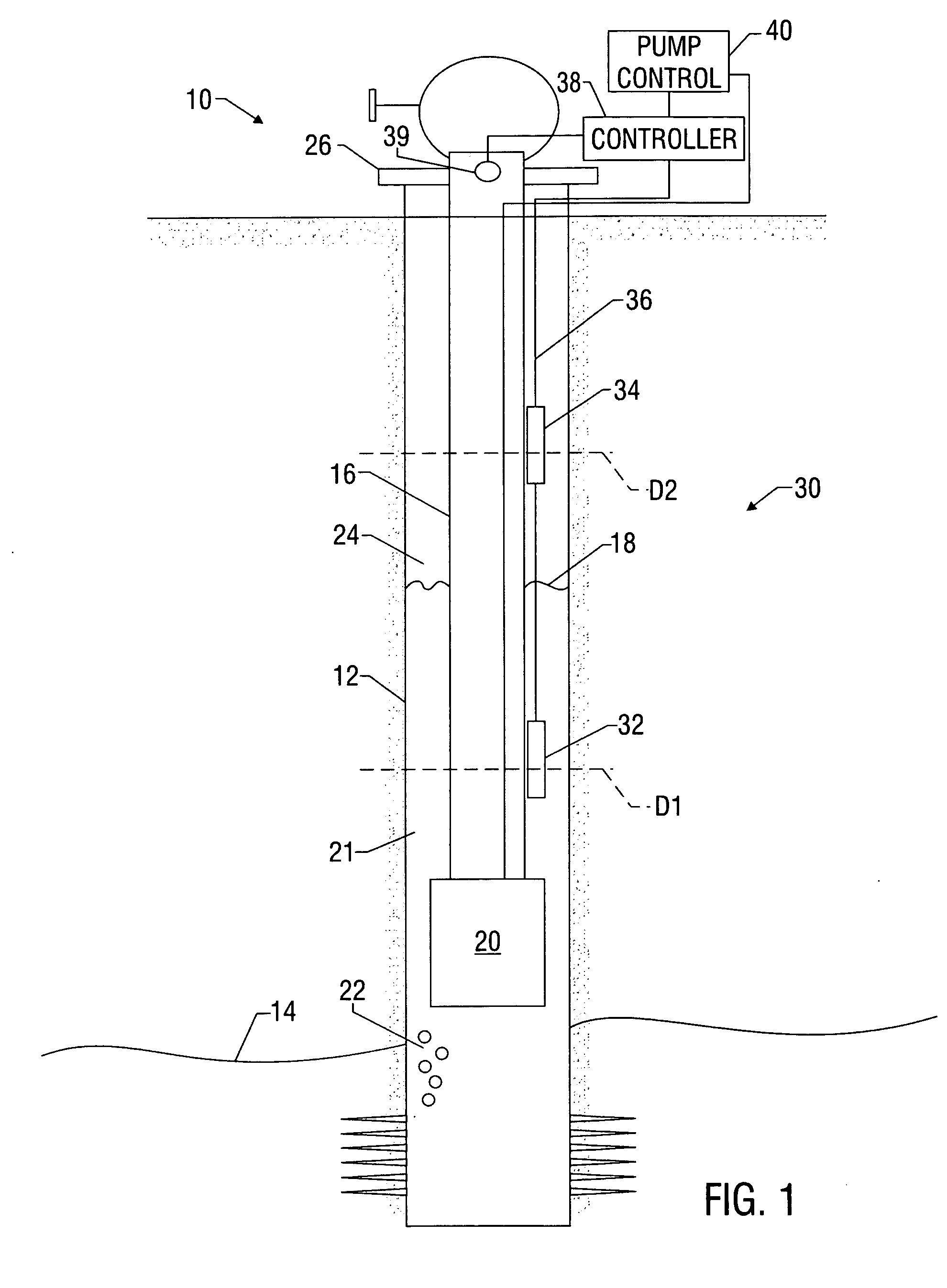

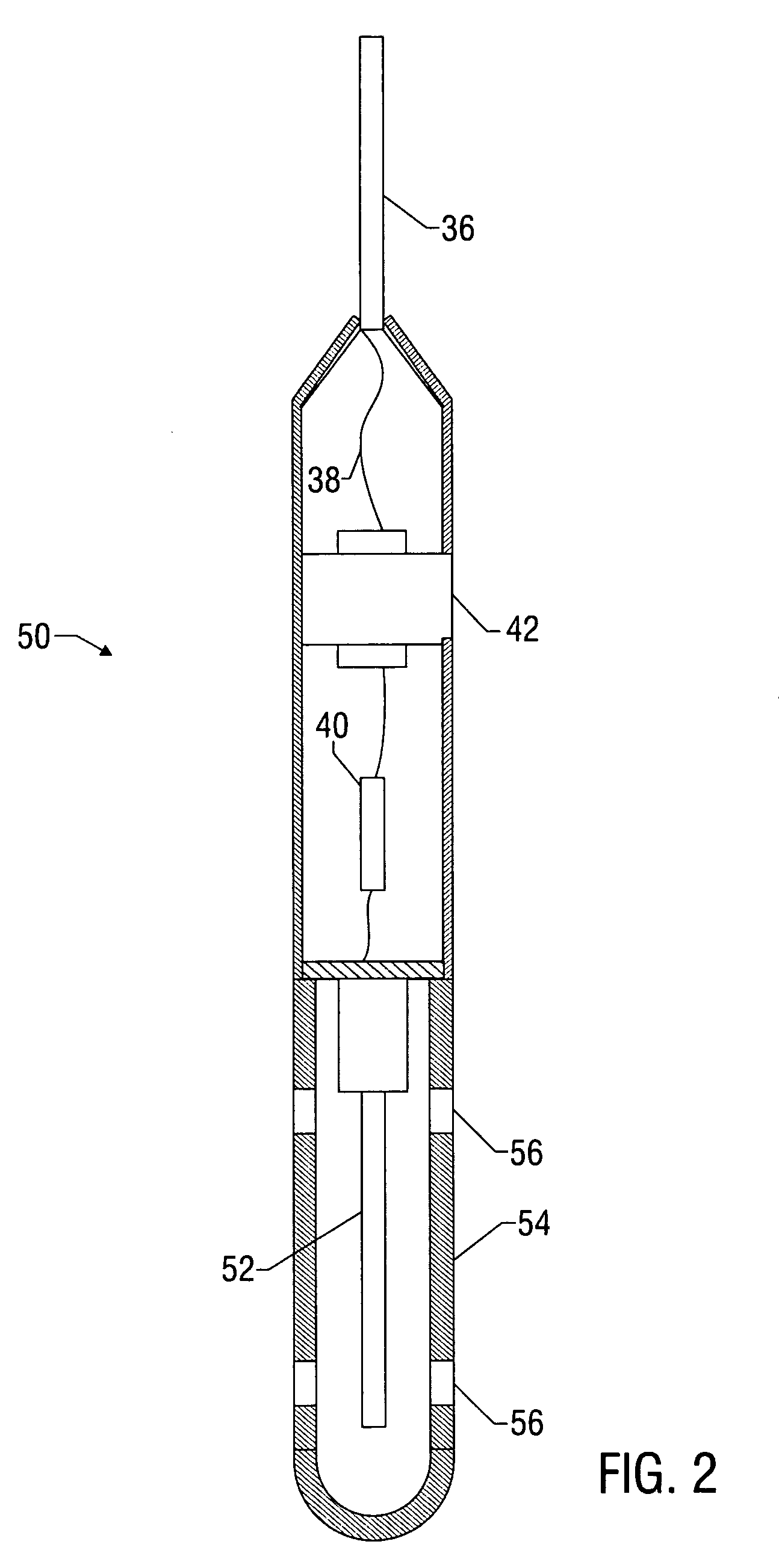

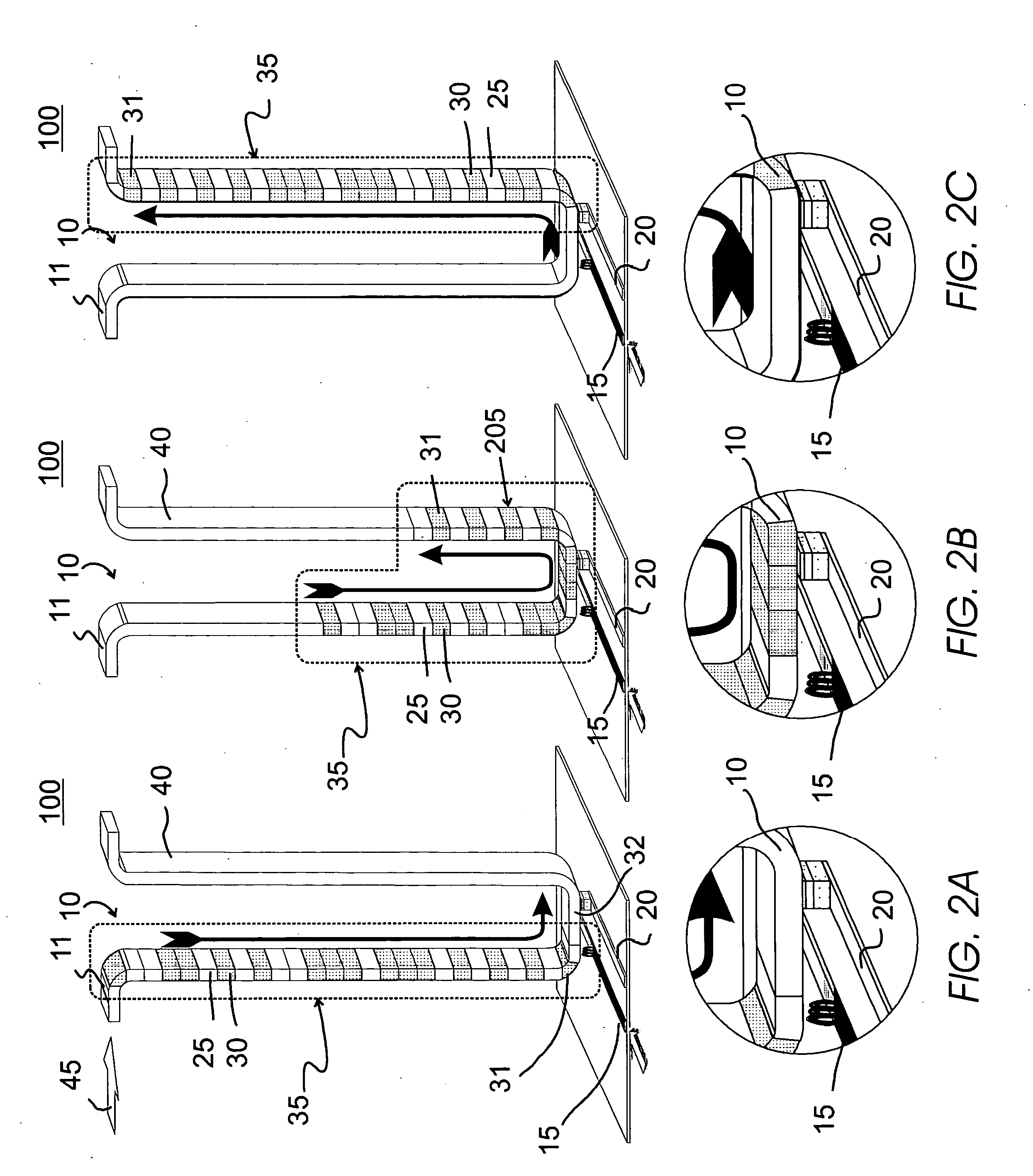

Systems and methods for controlling flow control devices

A device for determining a location of an interface between a first fluid and second fluid includes a non-mechanical sensor that measures a selected parameter of interest relating to the fluid surrounding the sensor (“the surrounding fluid”) and a processor for processing the sensor measurements. The non-mechanical sensor measures a parameter relating to the surround fluid without physically co-acting with the surrounding fluid. Exemplary parameters such as thermal properties, electrical properties, fluid properties, and magnetic properties can be measured. The processor is programmed to process the sensor measurements to identify one or more characteristics in the measurements that can indicate the nature of the fluid being measured and thereby determine the location of the interface. The determined location can be used to operate a downhole device such as a pump, to provide real-time monitoring of well conditions, to record data for long-term reservoir characterization, or to actuate an alarm.

Owner:CORE LAB CANADA

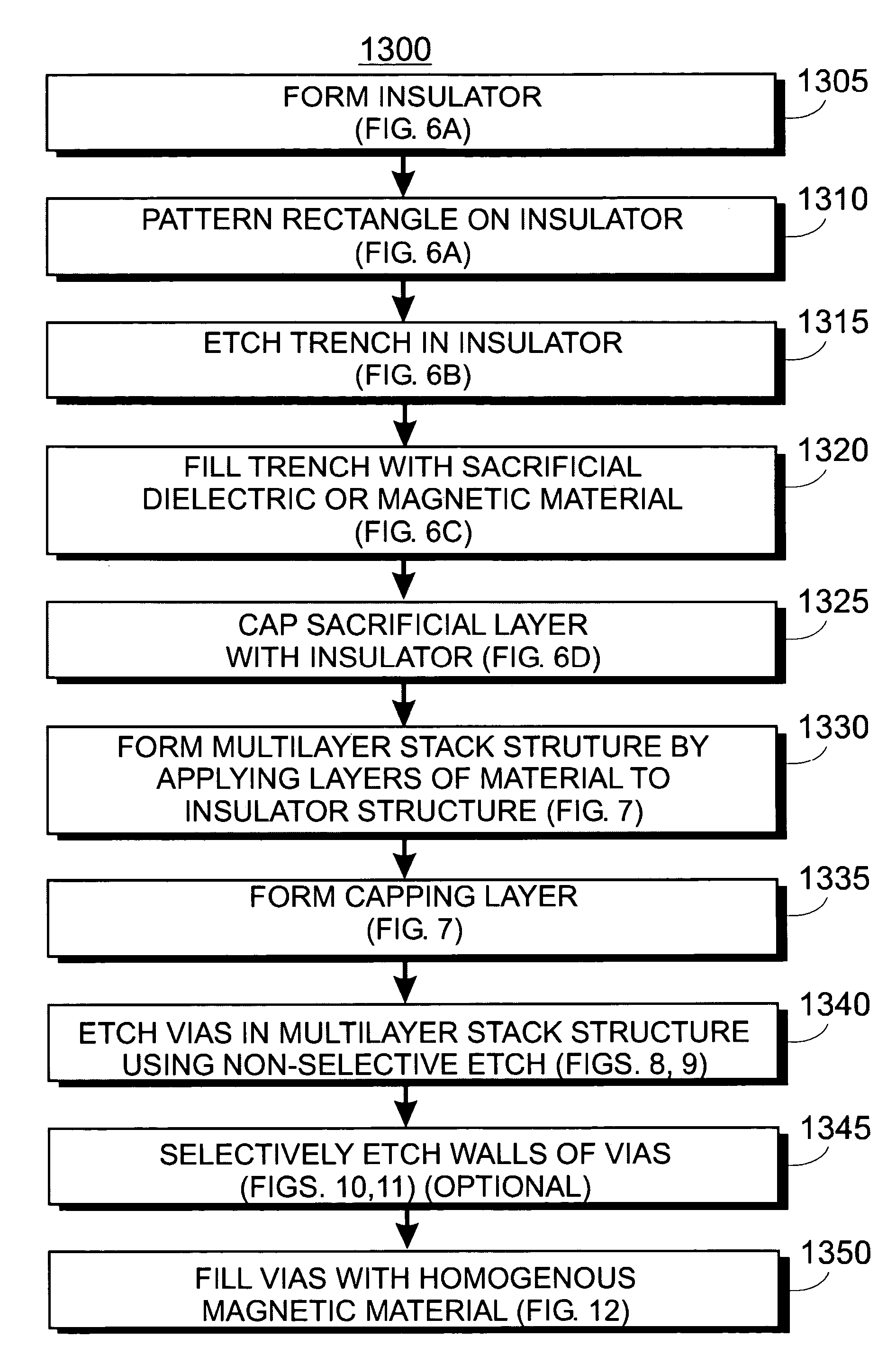

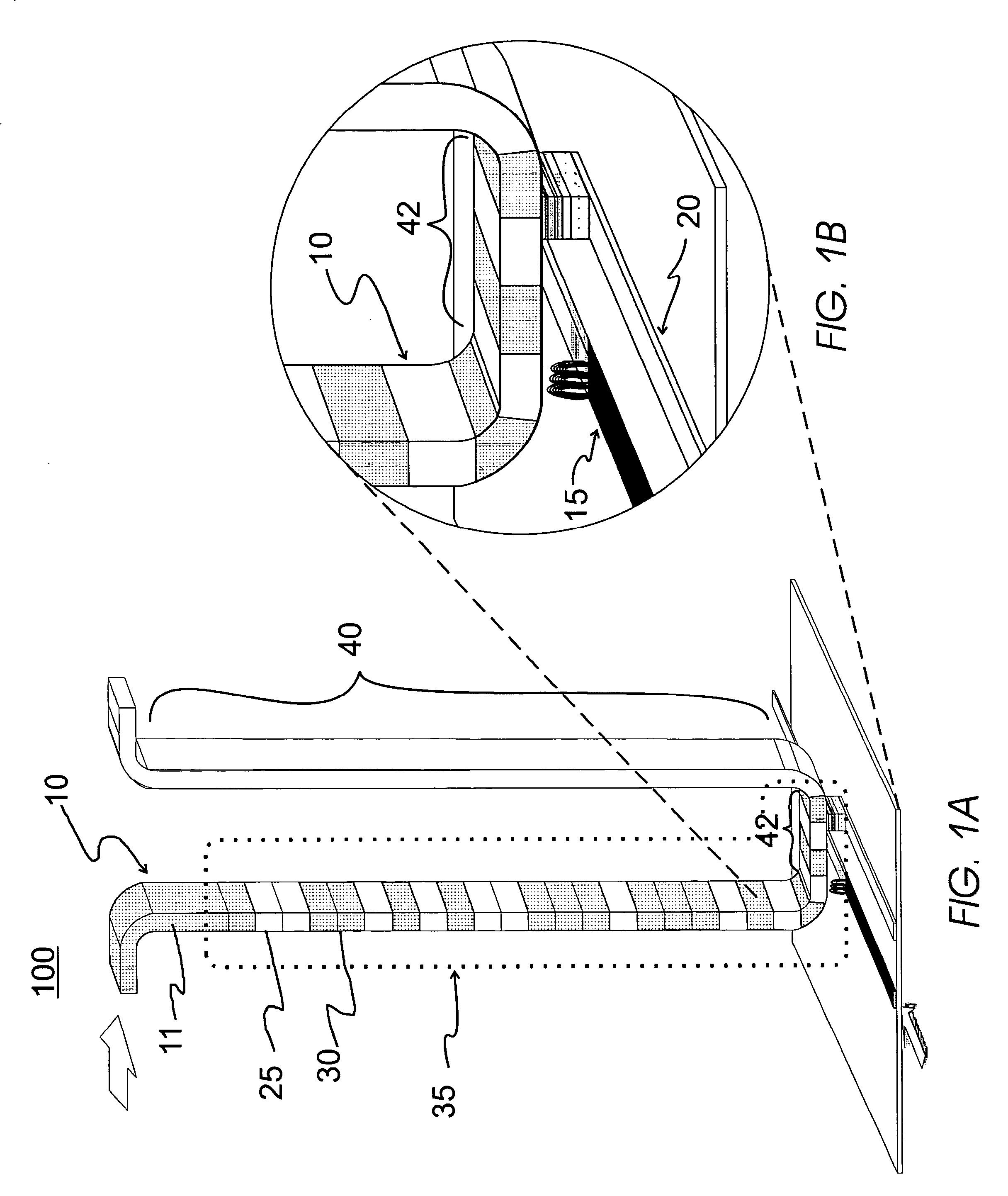

Method of fabricating data tracks for use in a magnetic shift register memory device

InactiveUS20050186686A1Solid-state devicesSemiconductor/solid-state device manufacturingShift registerDielectric

A magnetic data track used in a magnetic shift register memory system may be fabricated by forming a multilayered stack of alternating dielectric and / or silicon layers. Vias of approximately 10 microns tall with a cross-section on the order of 100 nm×100 nm are etched in this multilayered stack of alternating layers. Vias may be etched form smooth or notched walls. Vias are filled by electroplating layers of alternating types of ferromagnetic or ferrimagnetic metals. The alternating ferromagnetic or ferrimagnetic layers are comprised of magnetic materials with different magnetization or magnetic exchange or magnetic anisotropies. These different magnetic characteristics allow the pinning of magnetic domain walls at the boundaries between these layers. Alternatively, vias are filled with a homogeneous ferromagnetic material. Magnetic domain walls are formed by the discontinuity in the ferromagnetic or ferromagnetic material that occurs at the notches or at the protuberances along the via walls.

Owner:GLOBALFOUNDRIES INC

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

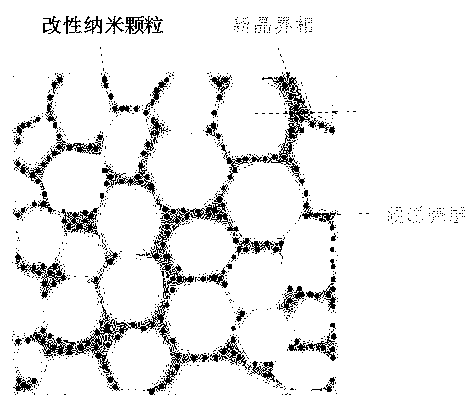

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

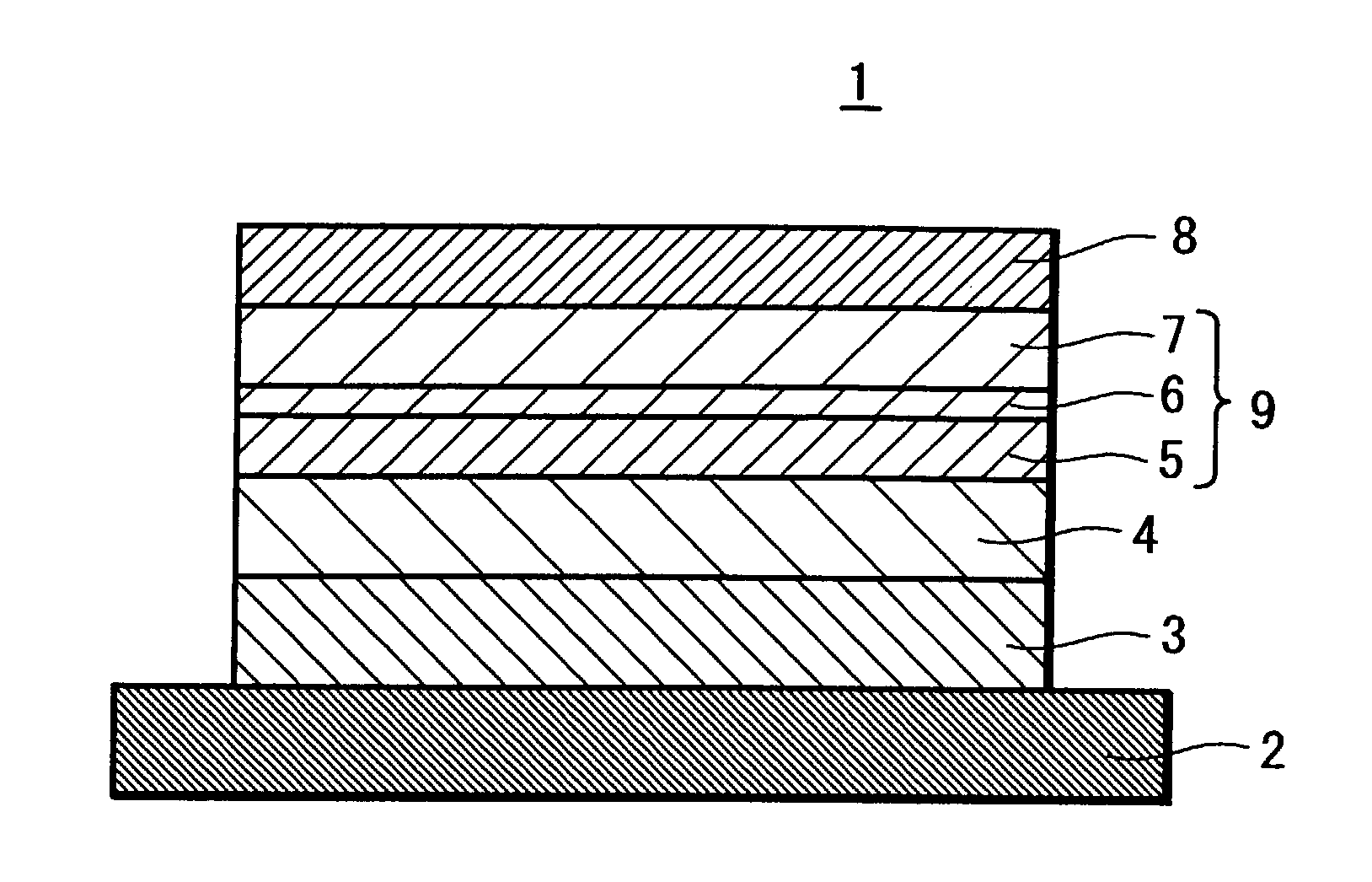

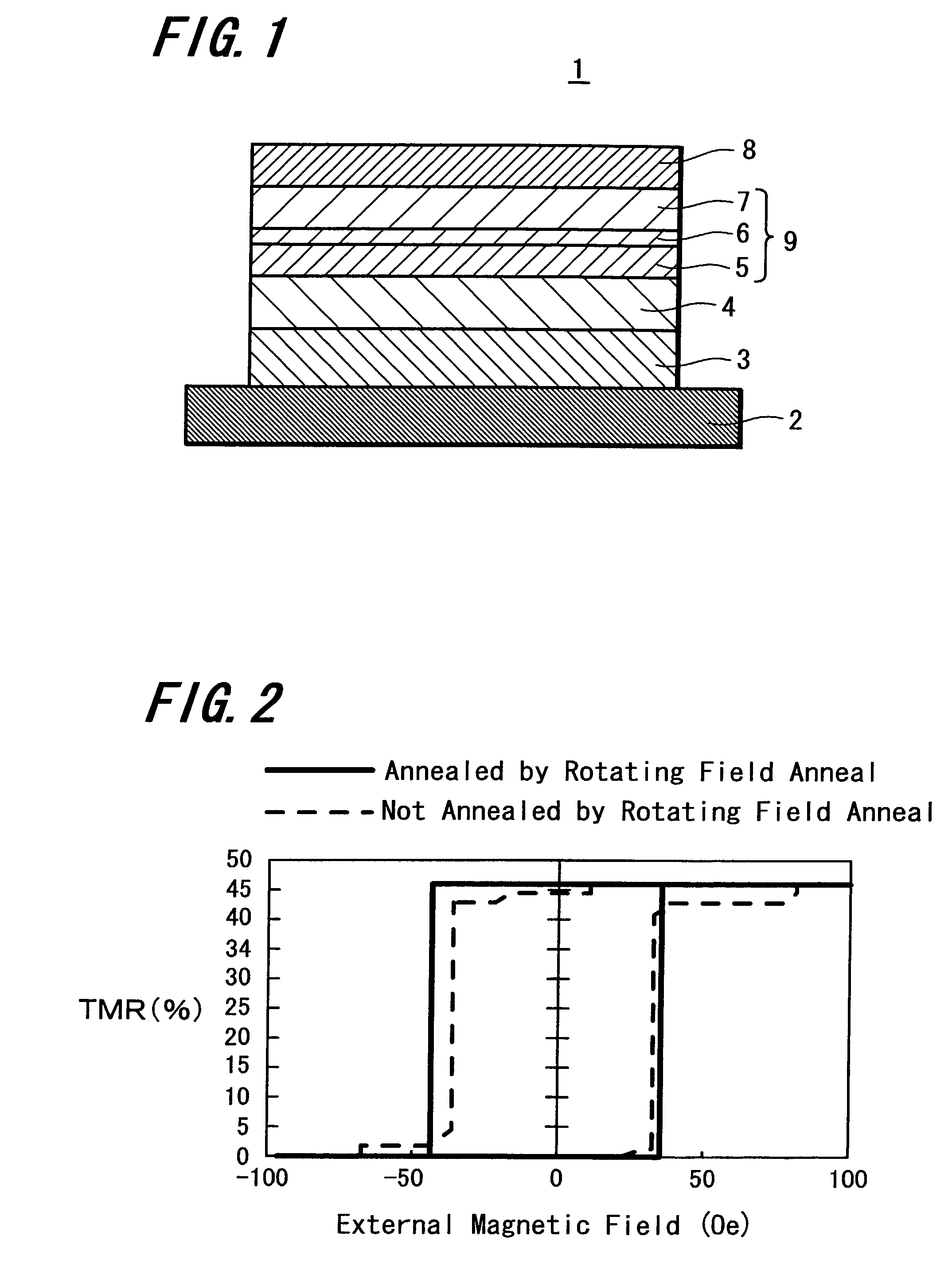

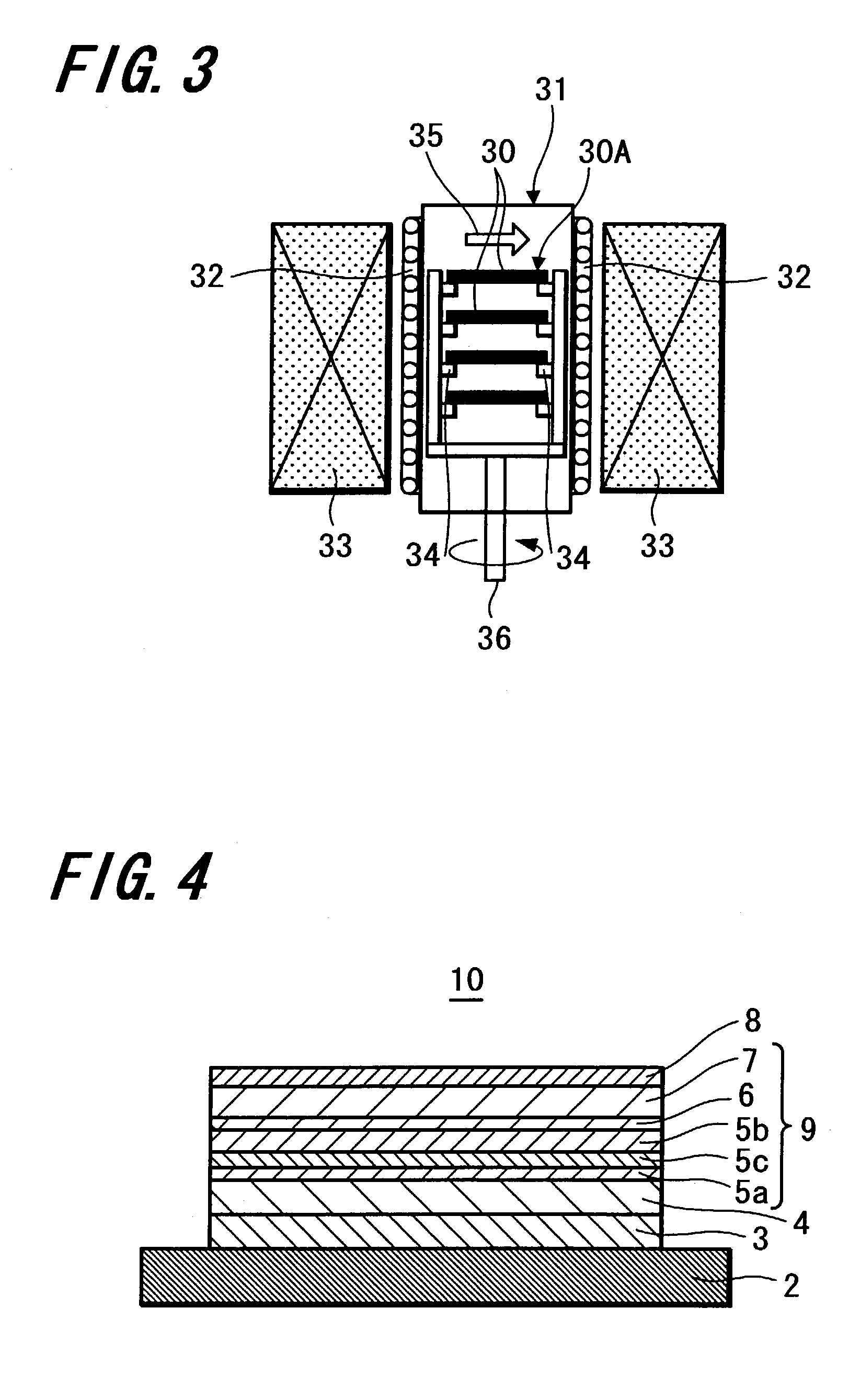

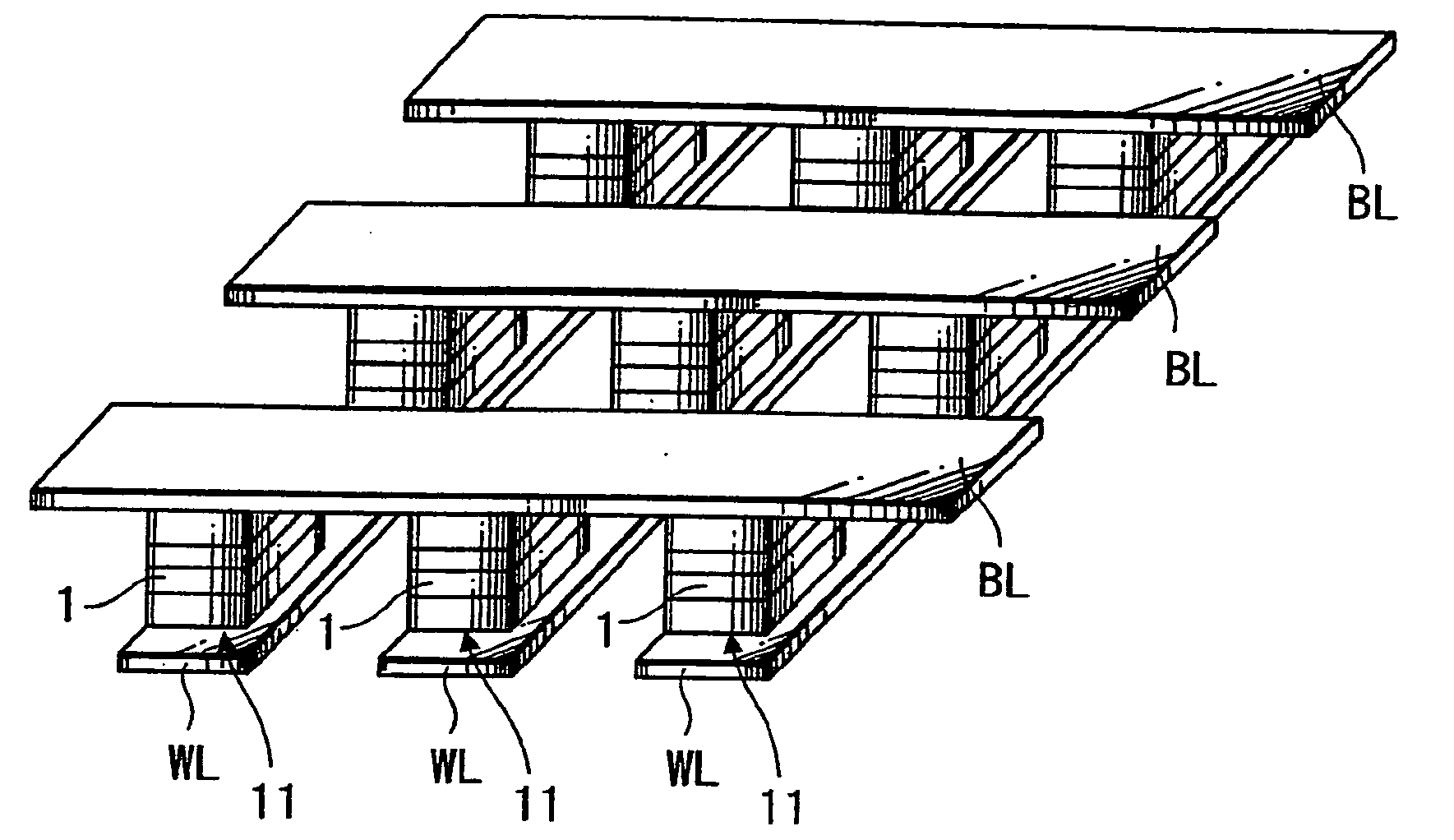

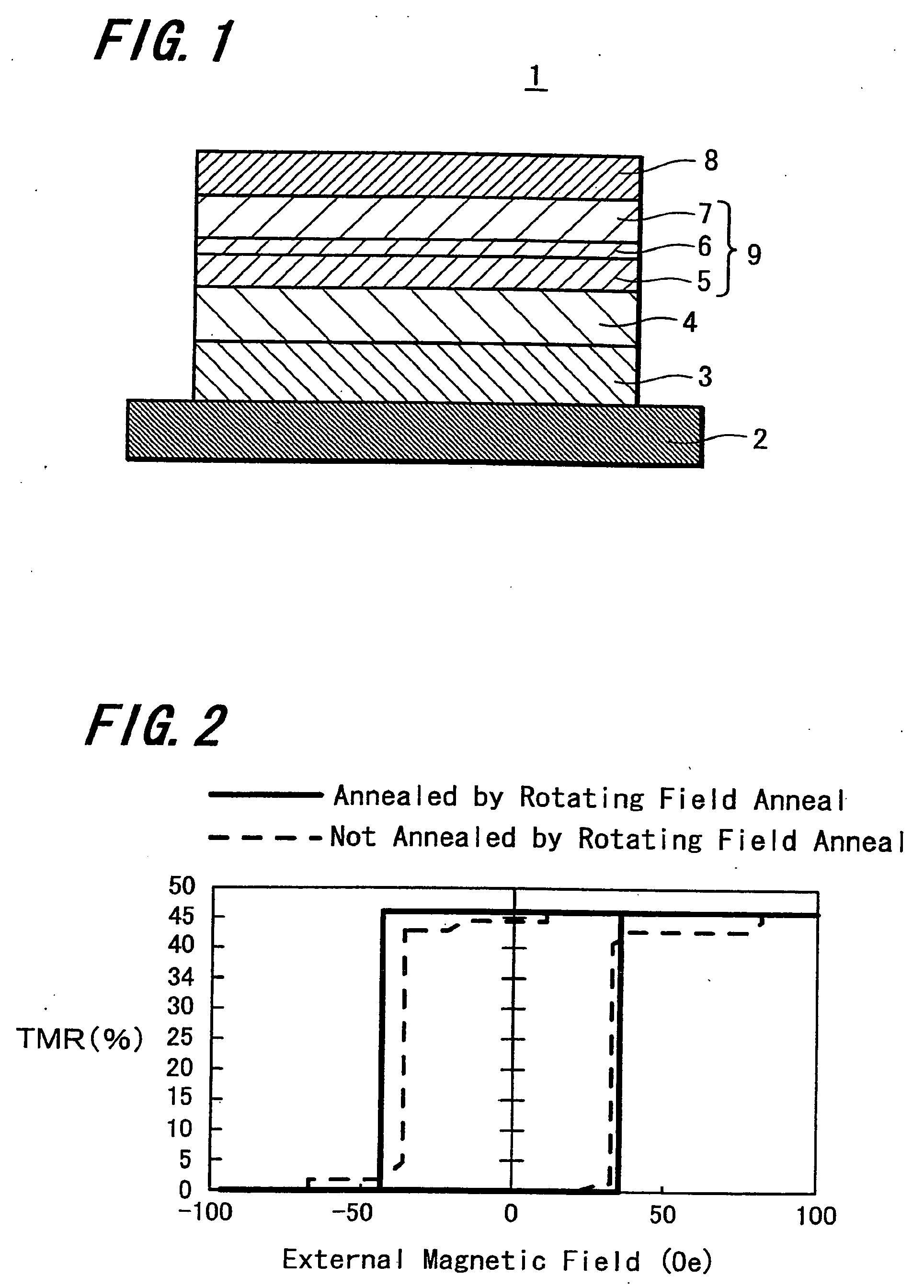

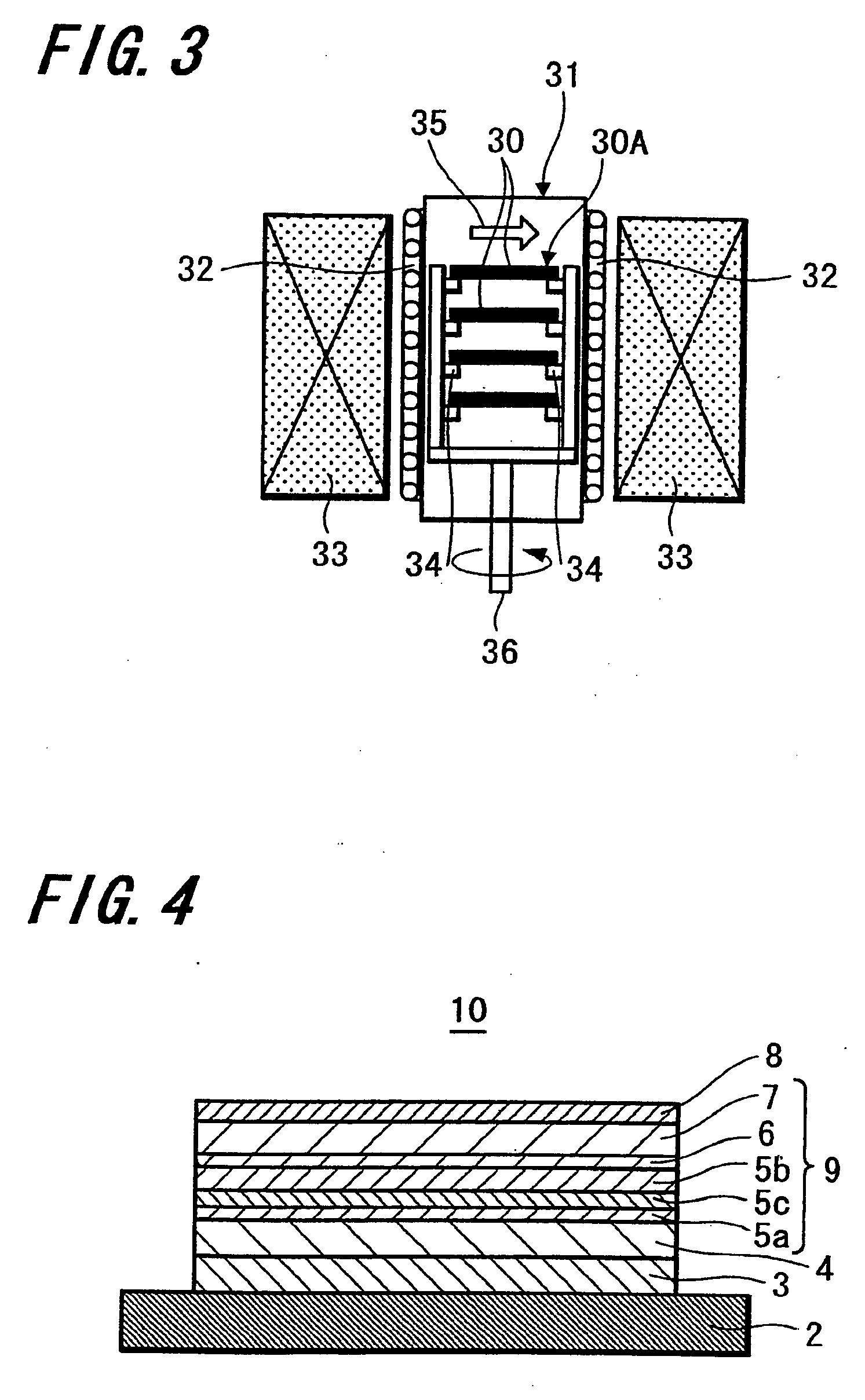

Magnetoresistive effect element, magnetic memory device and manufacturing method of magnetoresistive effect element and magnetic memory device

ActiveUS7026671B2Improve rectangle propertyImprove coercive forceNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

A magnetoresistive effect element (1) has an arrangement in which a pair of ferromagnetic material layers (magnetization fixed layer (5) and magnetization free layer (7)) is opposed to each other through an intermediate layer (6) to obtain a magnetoresistive change by causing a current to flow in the direction perpendicular to the layer surface and in which the ferromagnetic material layers are annealed by anneal including rotating field anneal and the following static field anneal. A magnetic memory device comprises this magnetoresistive effect element (1) and bit lines and word lines sandwiching the magnetoresistive effect element (1) in the thickness direction. When the magnetoresistive effect element (1) and the magnetic memory device are manufactured, the ferromagnetic material layers (5, 7) are annealed by rotating field anneal and the following static field anneal. There are provided the magnetoresistive effect element that can obtain excellent magnetic characteristics by controlling magnetic anisotropies of the ferromagnetic material layers, the magnetic memory device including this magnetoresistive effect element and which may have excellent write characteristics, and methods for manufacturing these magnetoresistive effect element and magnetic memory device.

Owner:DEXERIALS CORP

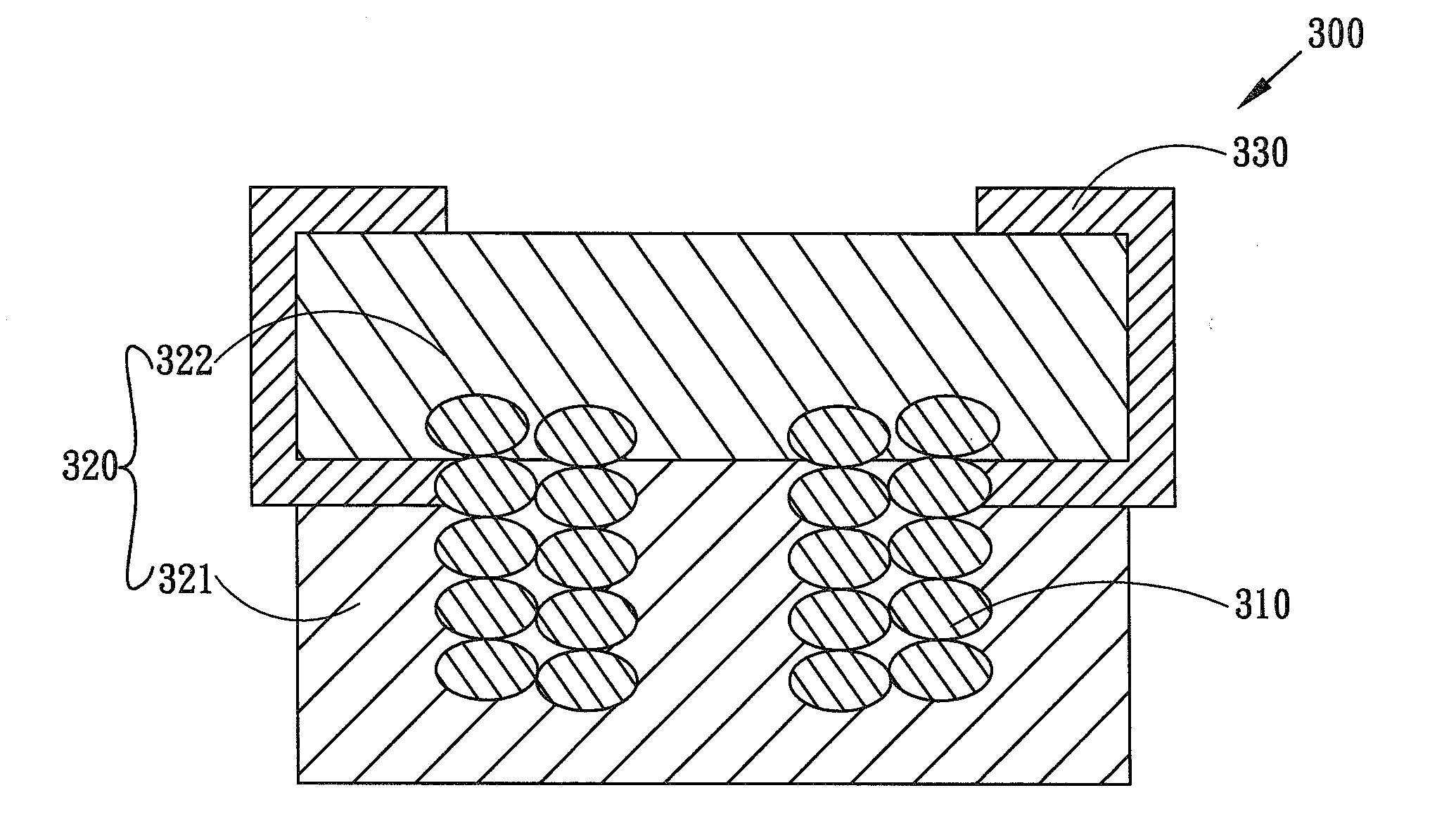

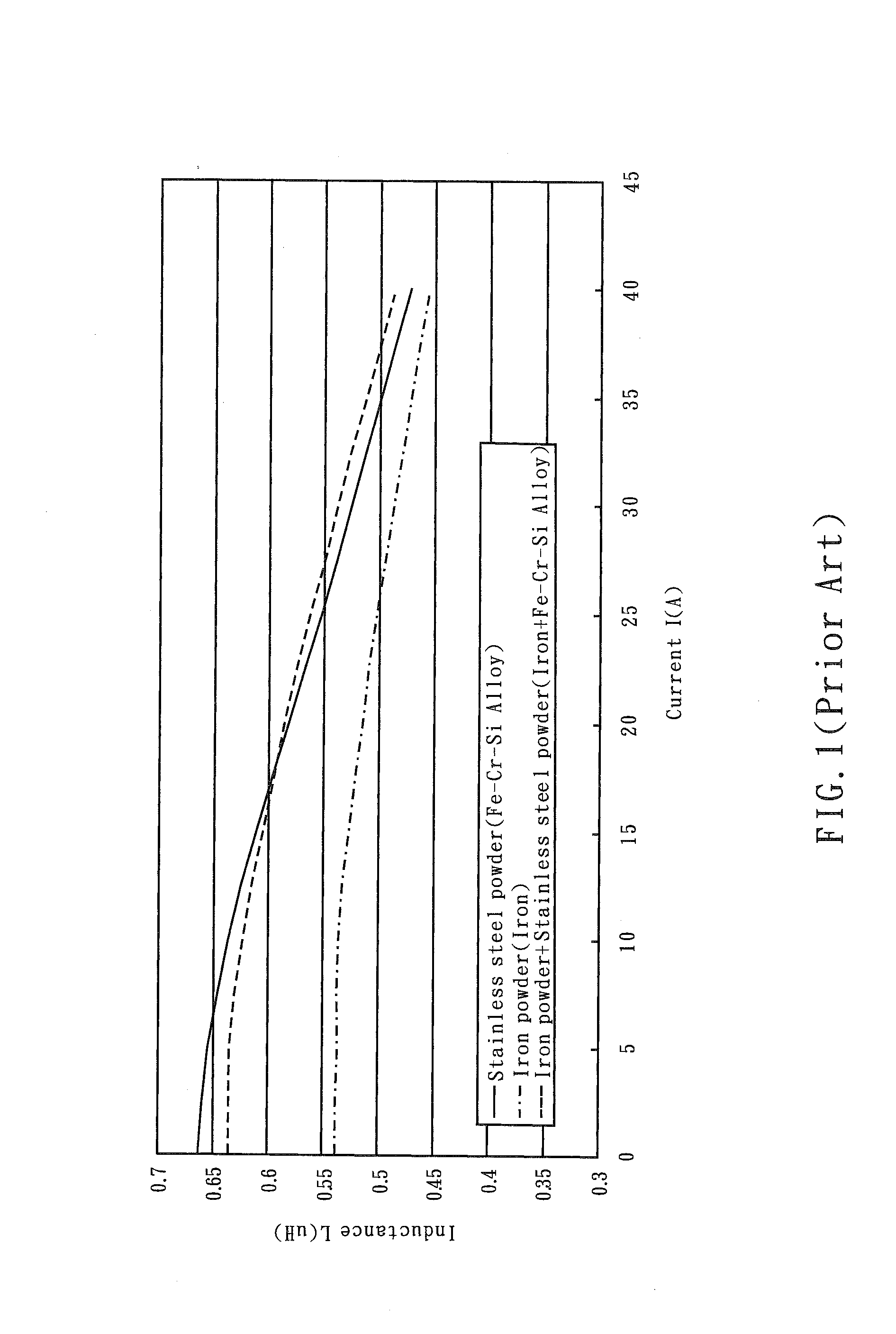

Inductor

InactiveUS20090231077A1Easy to adjustIncrease the number ofElectromagnetsCores/yokesInductorMagnetic characteristic

An inductor including a coil and an integrated magnetic body is provided. The integrated magnetic body includes a first magnetic body and a second magnetic body. The coil is disposed within the integrated magnetic body. The first magnetic body has a first magnetic property. The second magnetic body has a second magnetic property. The first magnetic property is different from the second magnetic property.

Owner:CYNTEC

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS7163591B2Improve coercive forceReduce manufacturing costInorganic material magnetismRare earthContamination

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50–500 μm sized magnet powders, which are then mixed with 1–10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500–1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1–20 μm, and the powders have an average size of 50–500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

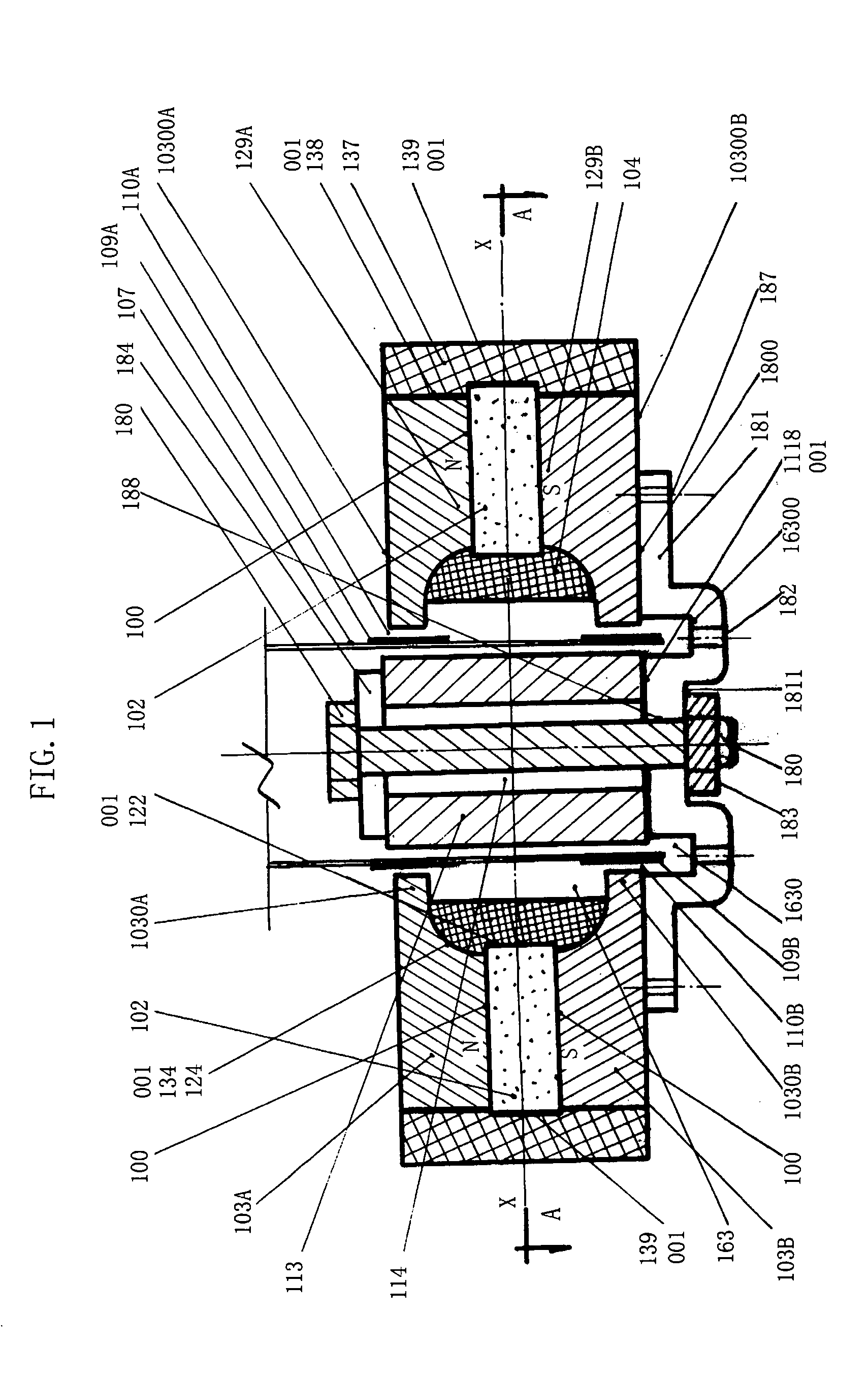

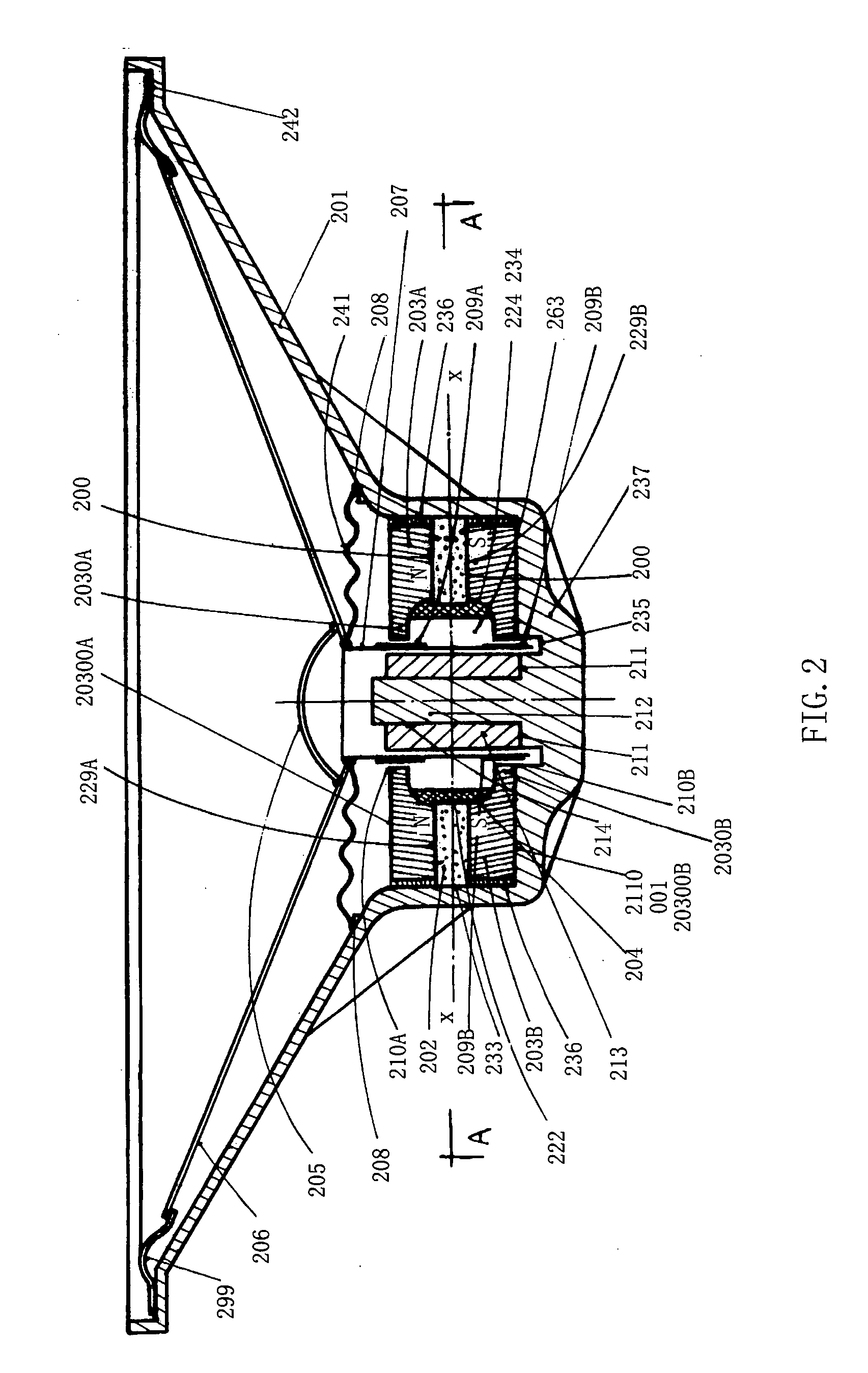

Transducer with dual coil and dual magnetic gap

InactiveUS20050099255A1Improve fidelitySmall volumeElectrical transducersDynamo-electric machinesDual coilTransducer

A transducer with dual coil and dual magnetic gap of which the upper and lower pole plates of are two inwardly concave plates or round plates. A set or more than1 a piece sets of axially magnetized permanent magnets are provided. Said permanent magnets are engaged with pole faces of said plates. Dual magnetic gap are formed between the vertical faces of said plates and the vertical faces of a coaxial mounted annular or cylindrical magnetic body. Coils are inserted into said magnetic gap, while wound direction of dual coil and the direction of current are decided to produce an electrodynamic force in the coils to the same direction. Said transducer possesses resistance load characteristics by setting the values of the inductance of the dual coil equal to each other in case that said transducer are provided with two magnetic paths and coil circuits completely symmetric in their magnetic characteristics.

Owner:ZHANG FAN

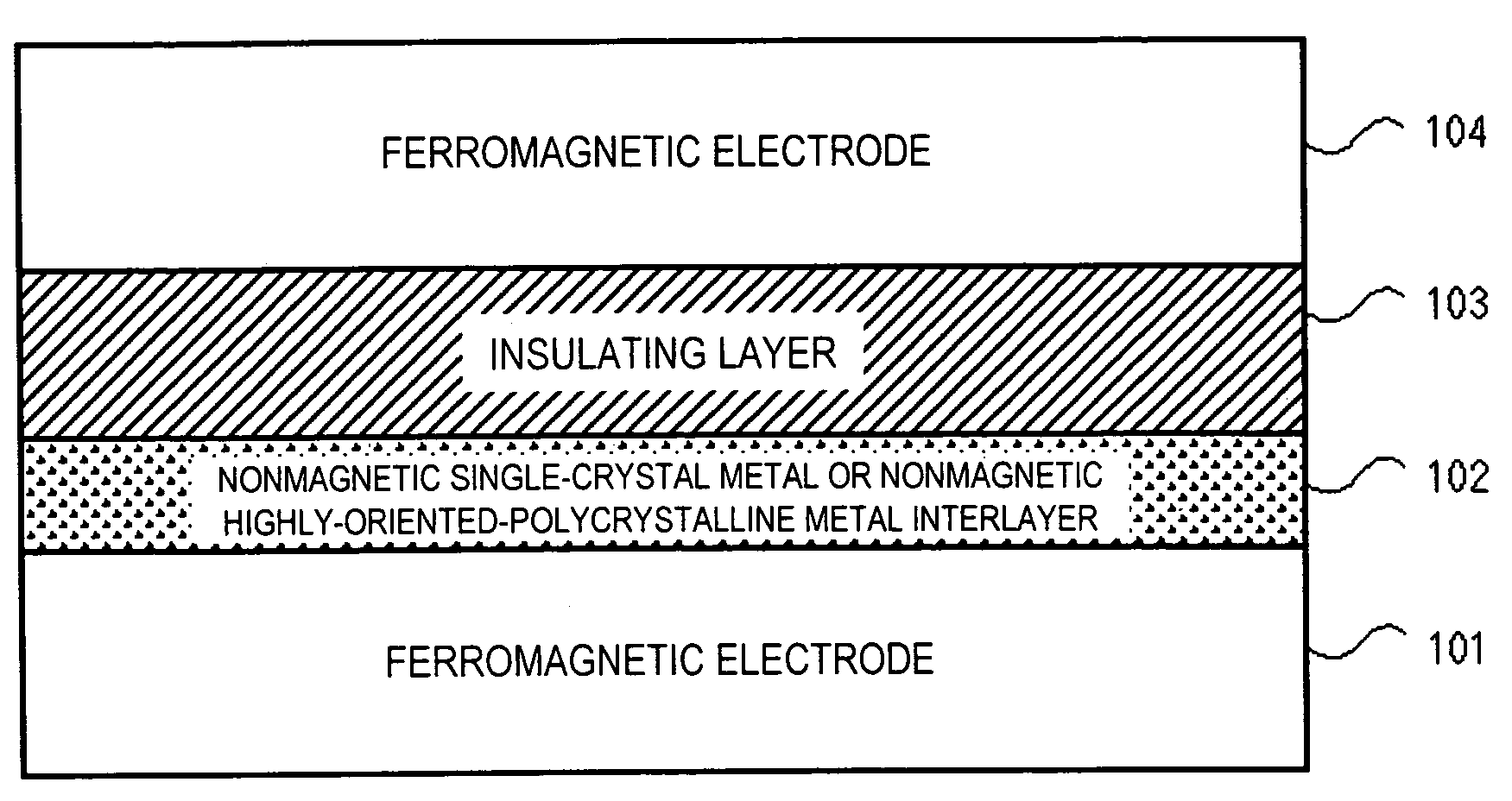

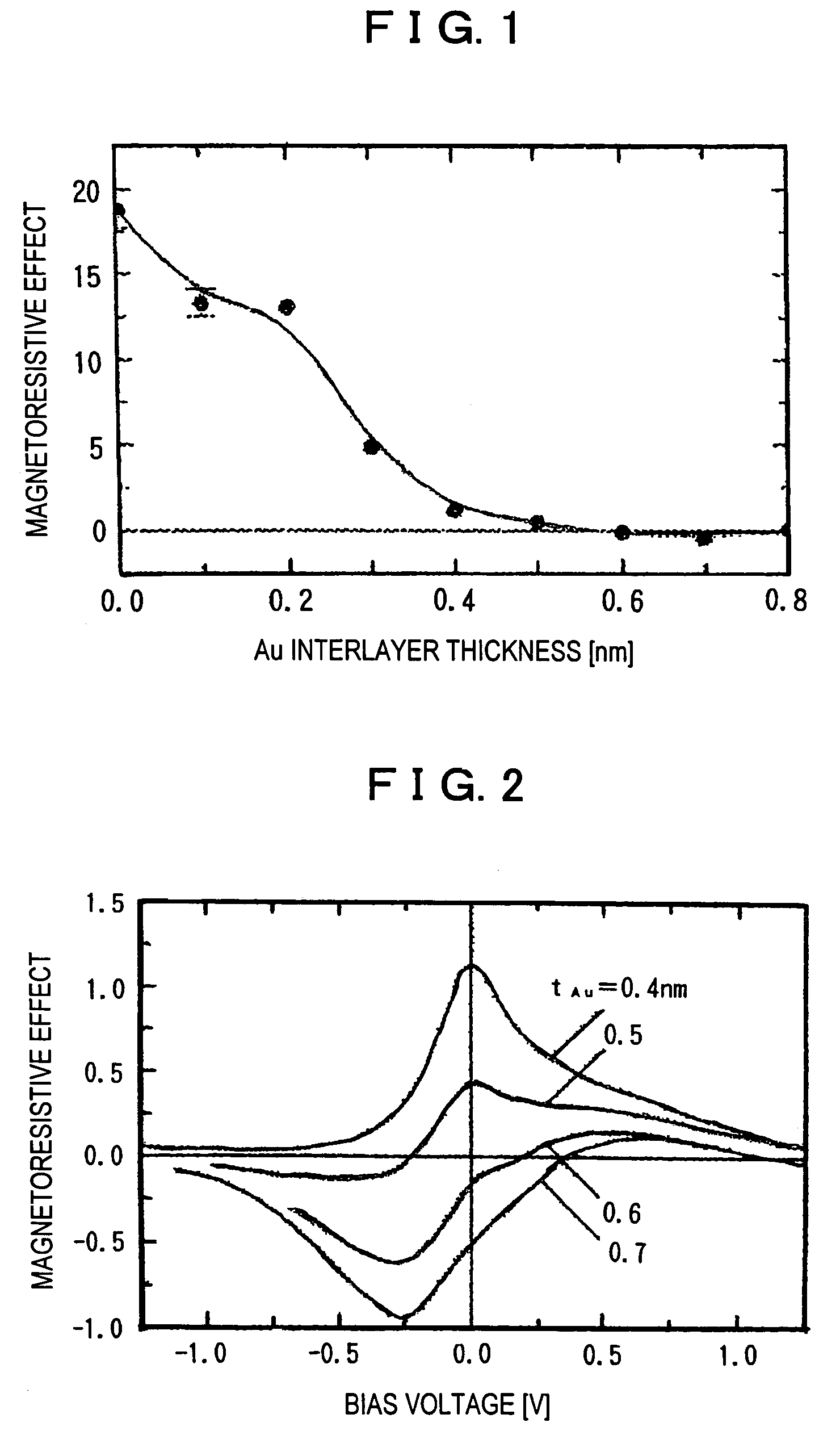

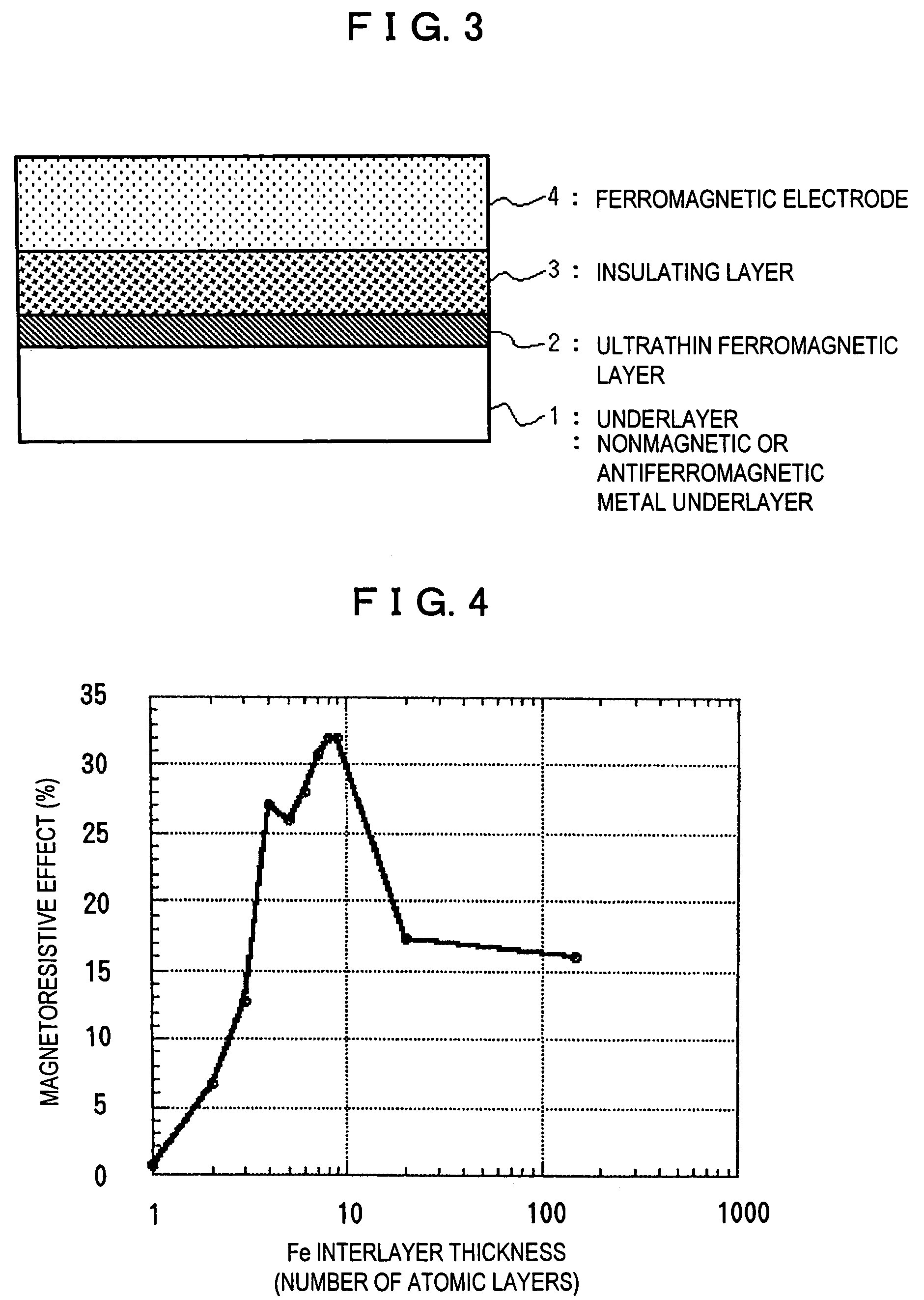

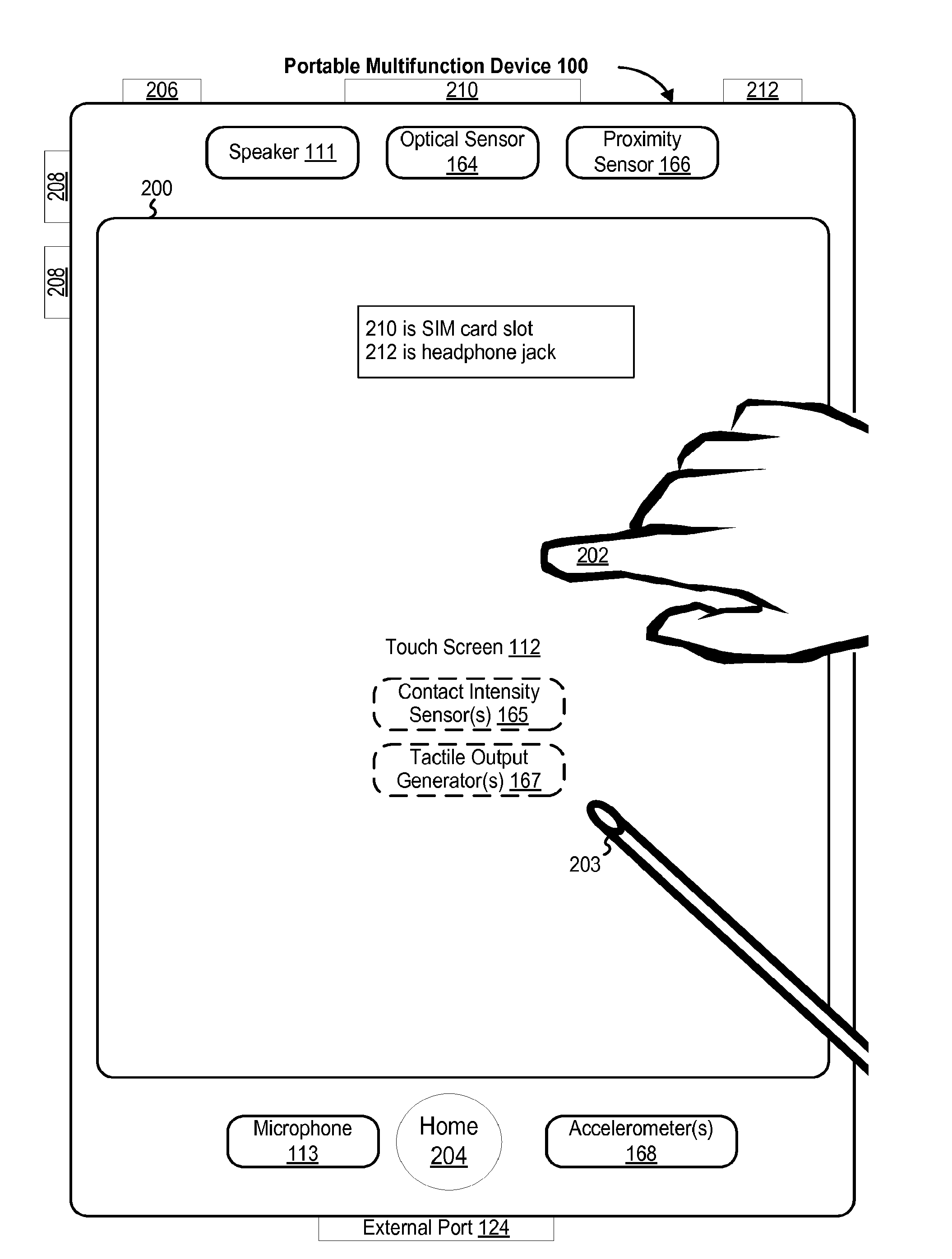

Tunnel magnetoresistance element

InactiveUS7220498B2Electron scattering of a nonmagnetic interlayer is preventedGood effectNanomagnetismNanoinformaticsChemical compositionMagnetic reluctance

By varying only the thickness of a known material having superior magnetic characteristics to increase spin polarization without changing the chemical composition, a tunnel magnetoresistive element capable of producing a larger magnetoresistive effect is provided. The tunnel magnetoresistive element includes an underlayer (nonmagnetic or antiferromagnetic metal film); an ultrathin ferromagnetic layer disposed on the underlayer; an insulating layer disposed on the ultrathin ferromagnetic layer; and a ferromagnetic electrode disposed on the insulating layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

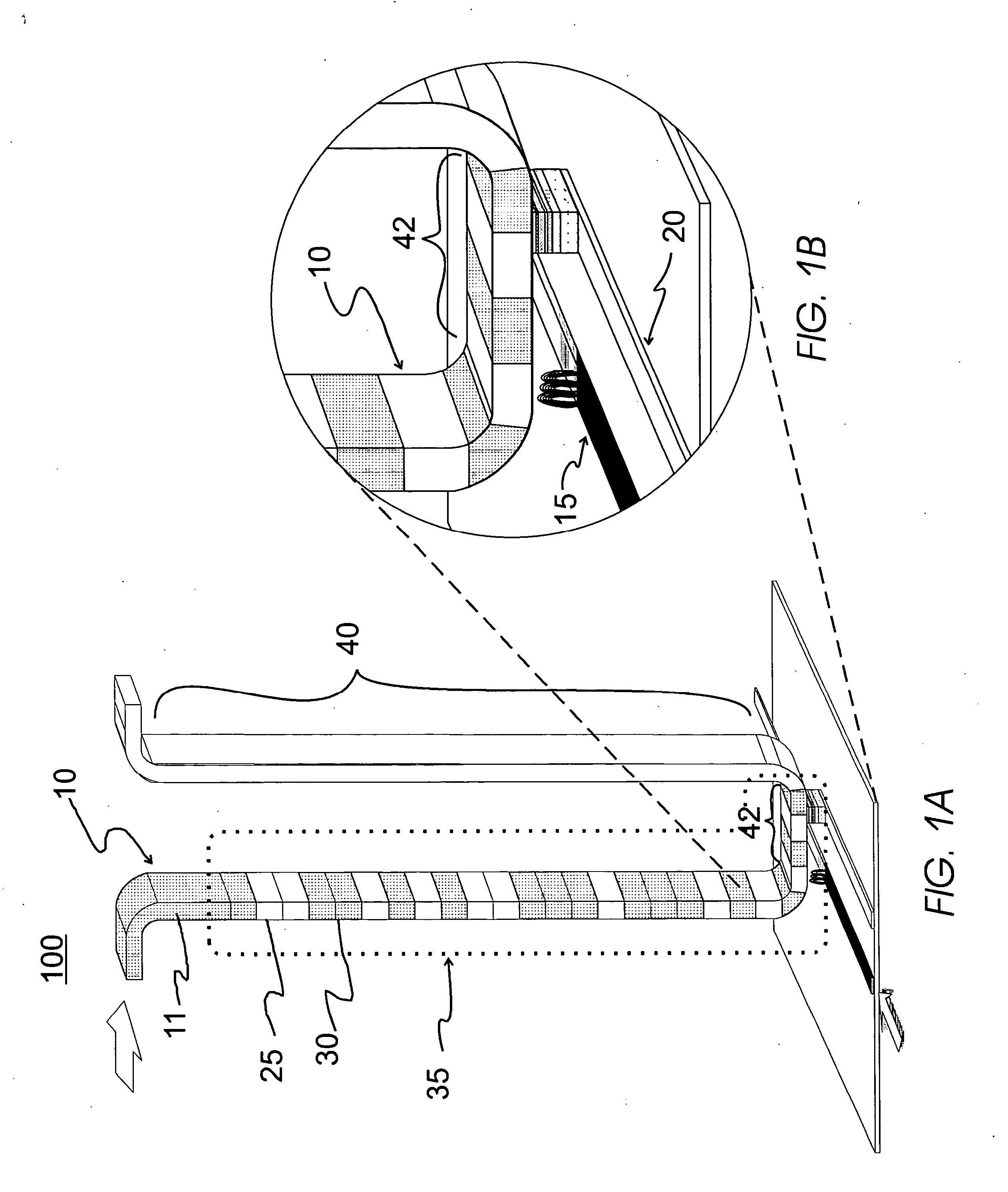

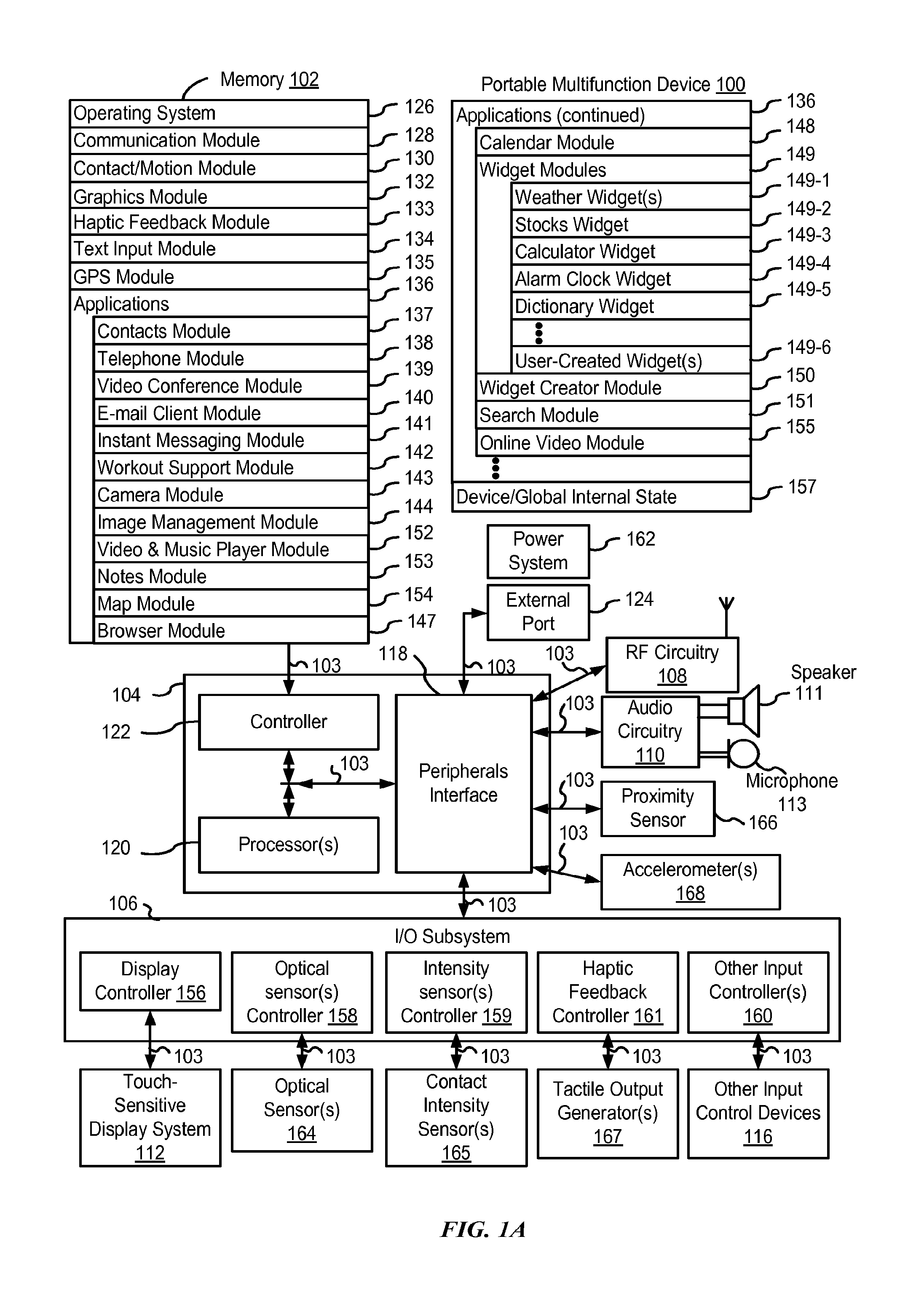

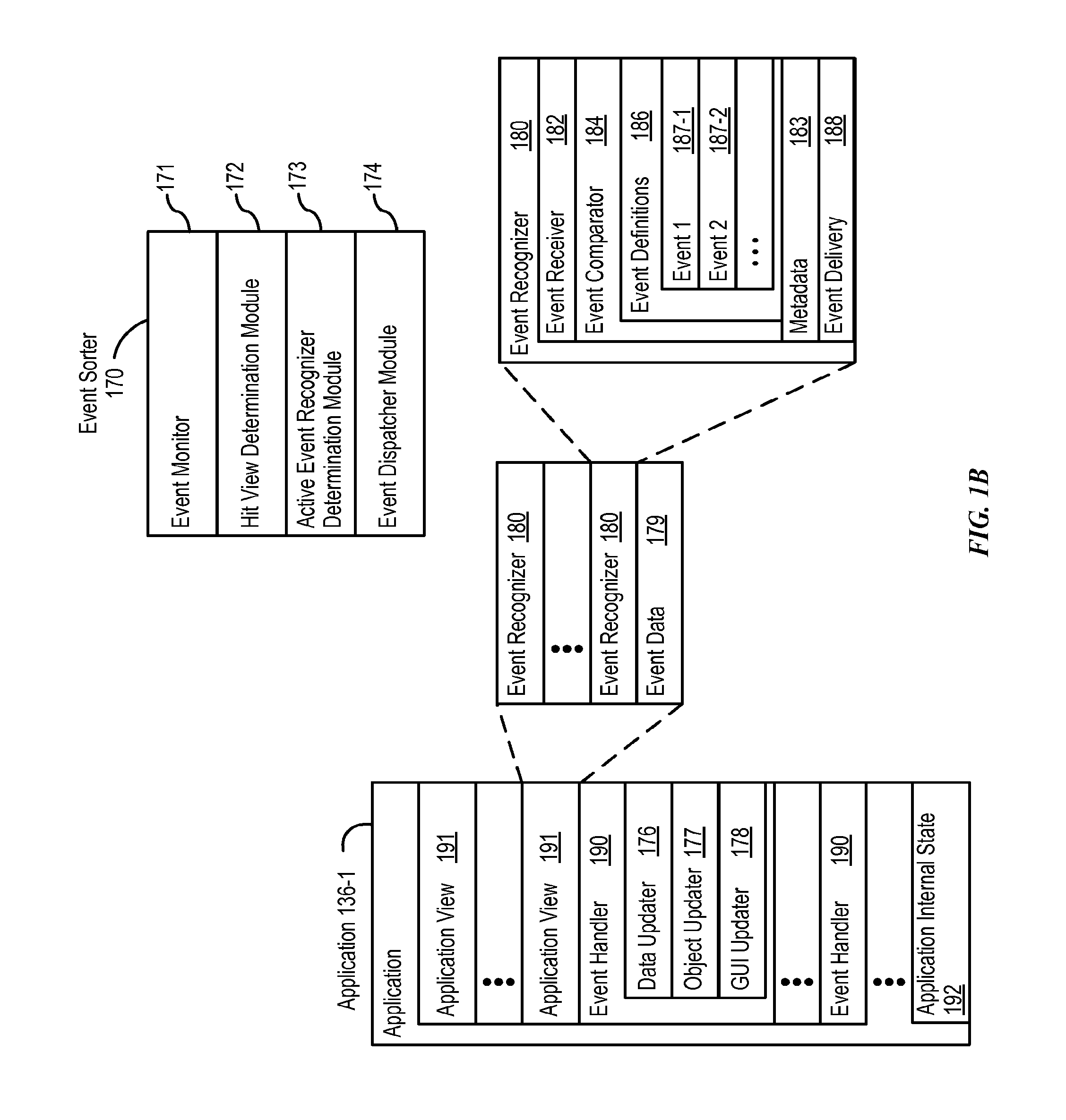

User interface for manipulating user interface objects with magnetic properties

ActiveUS20160170625A1Improve effectivenessImprove efficiencyTime-pieces with integrated devicesDetails for portable computersComputer graphics (images)Display device

The present disclosure relates to user interfaces for manipulating user interface objects. A device, including a display and a rotatable input mechanism, is described in relation to manipulating user interface objects. In some examples, the manipulation of the object is a scroll, zoom, or rotate of the object. In other examples, objects are selected in accordance with simulated magnetic properties.

Owner:APPLE INC

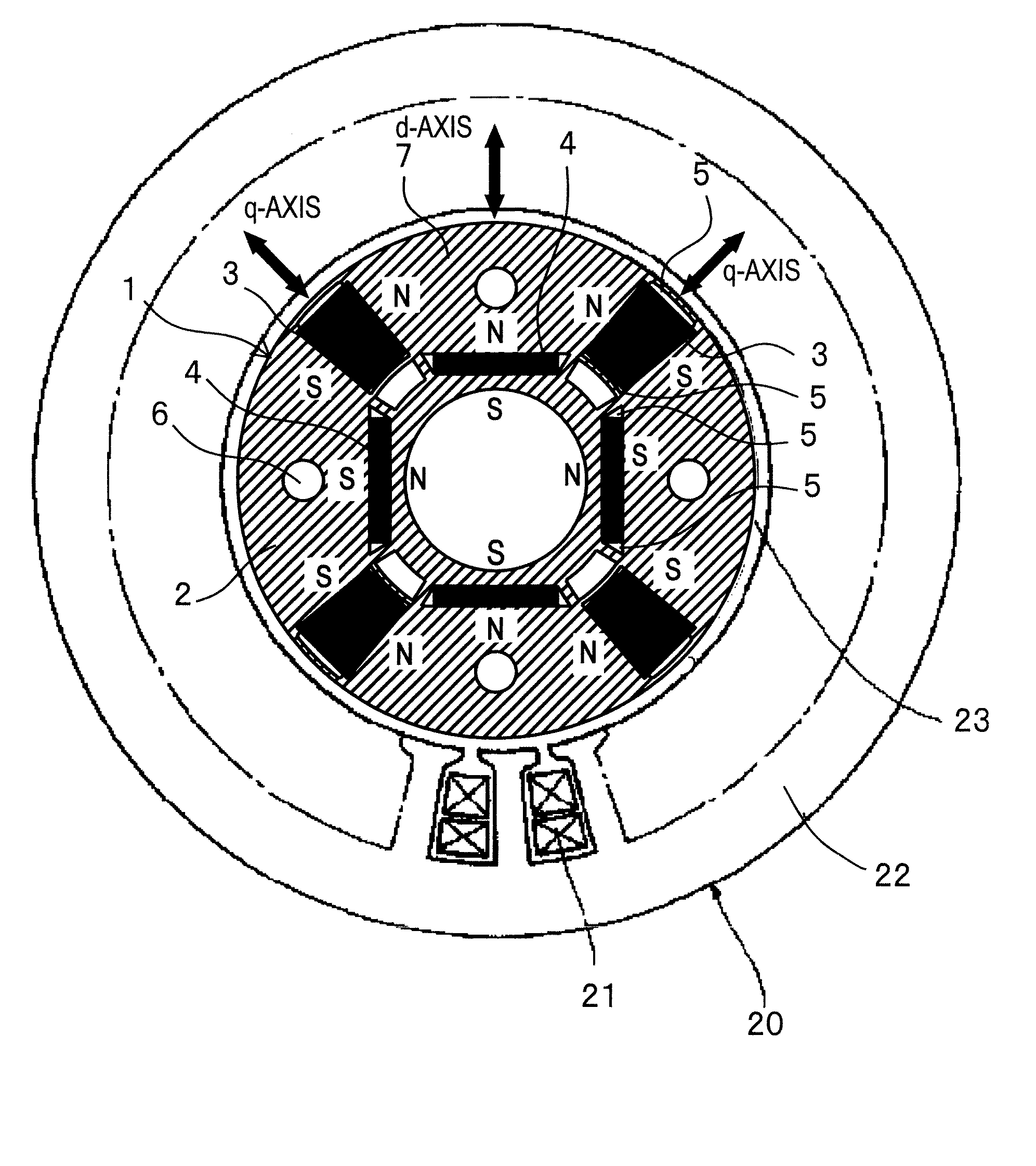

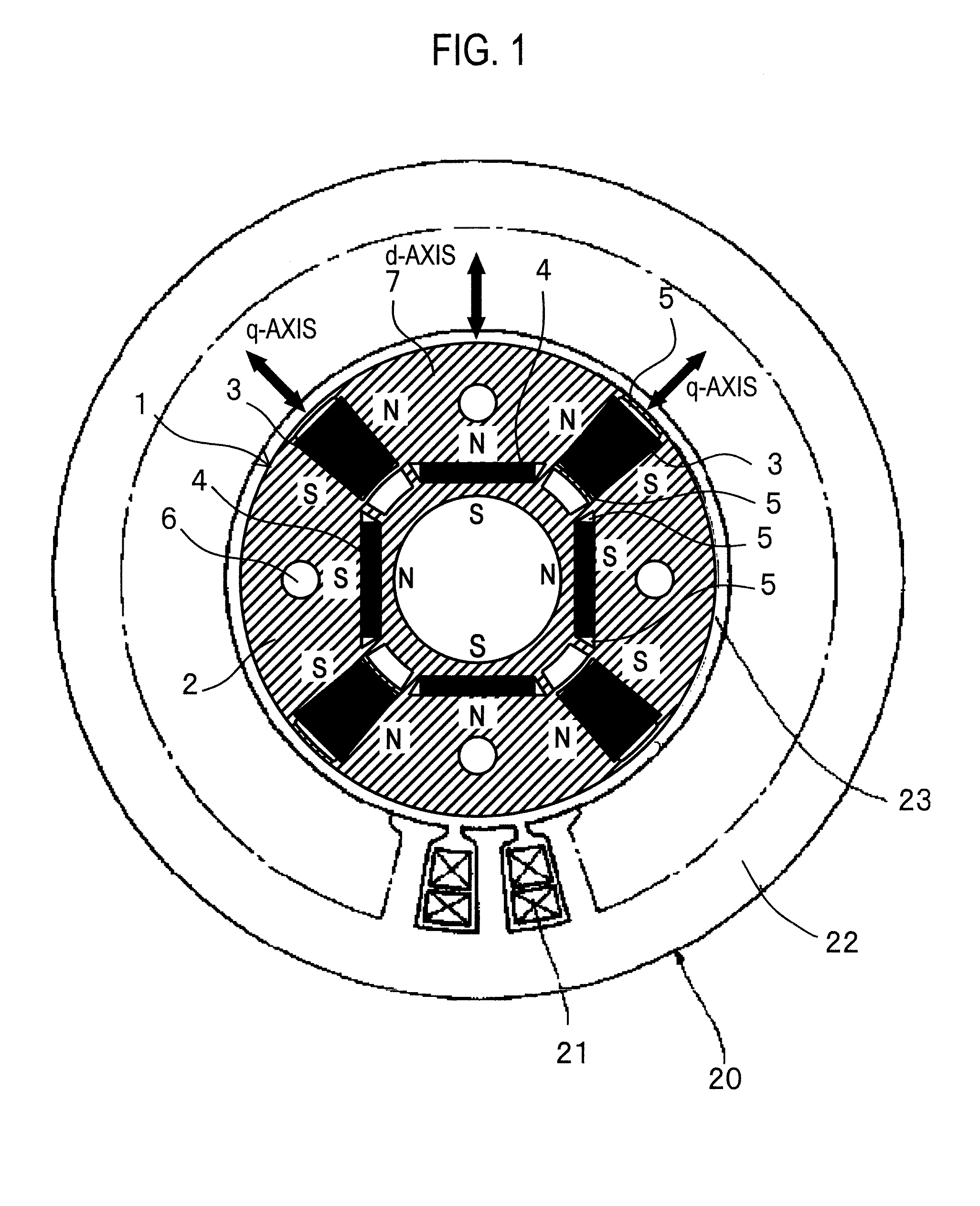

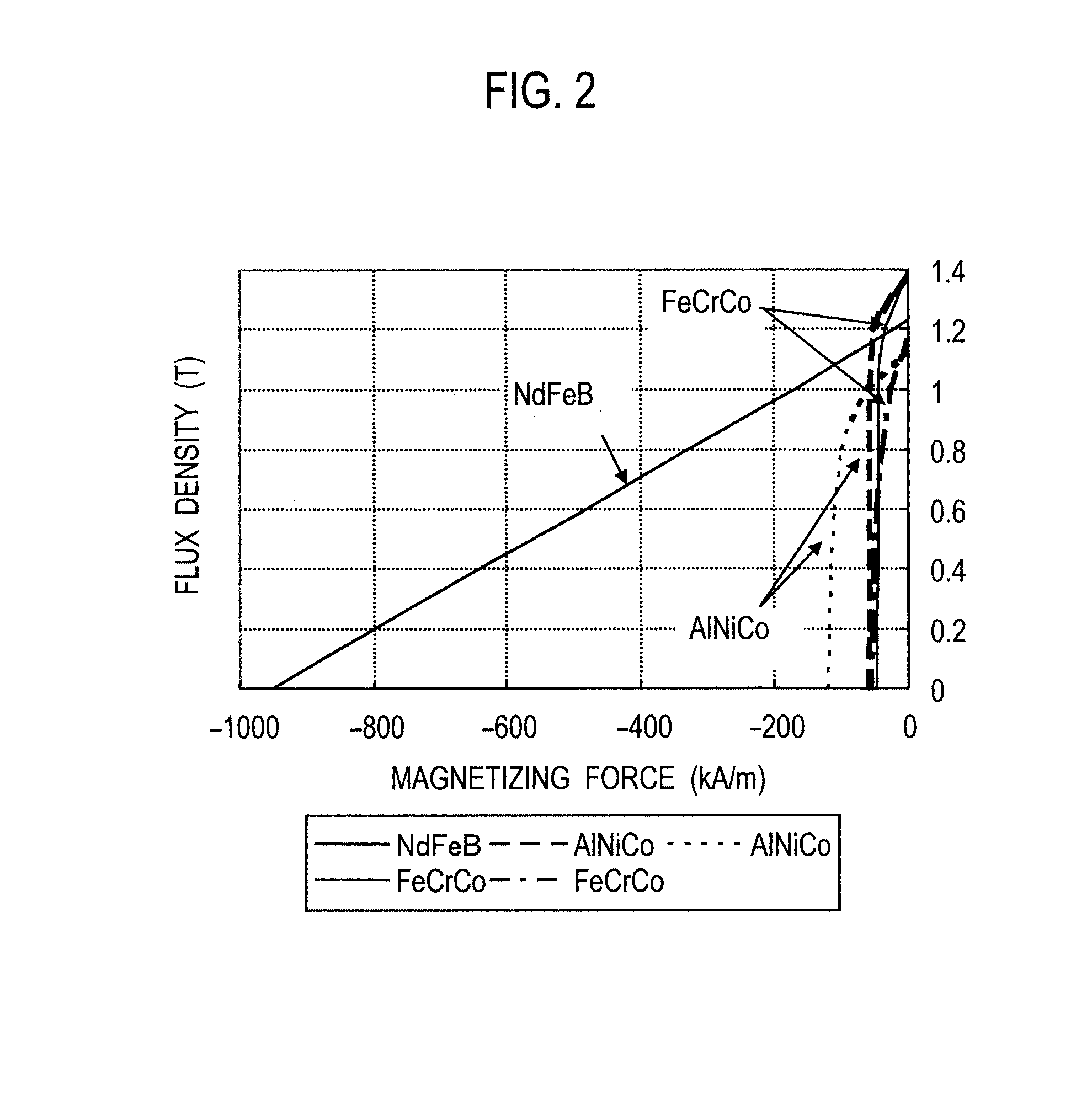

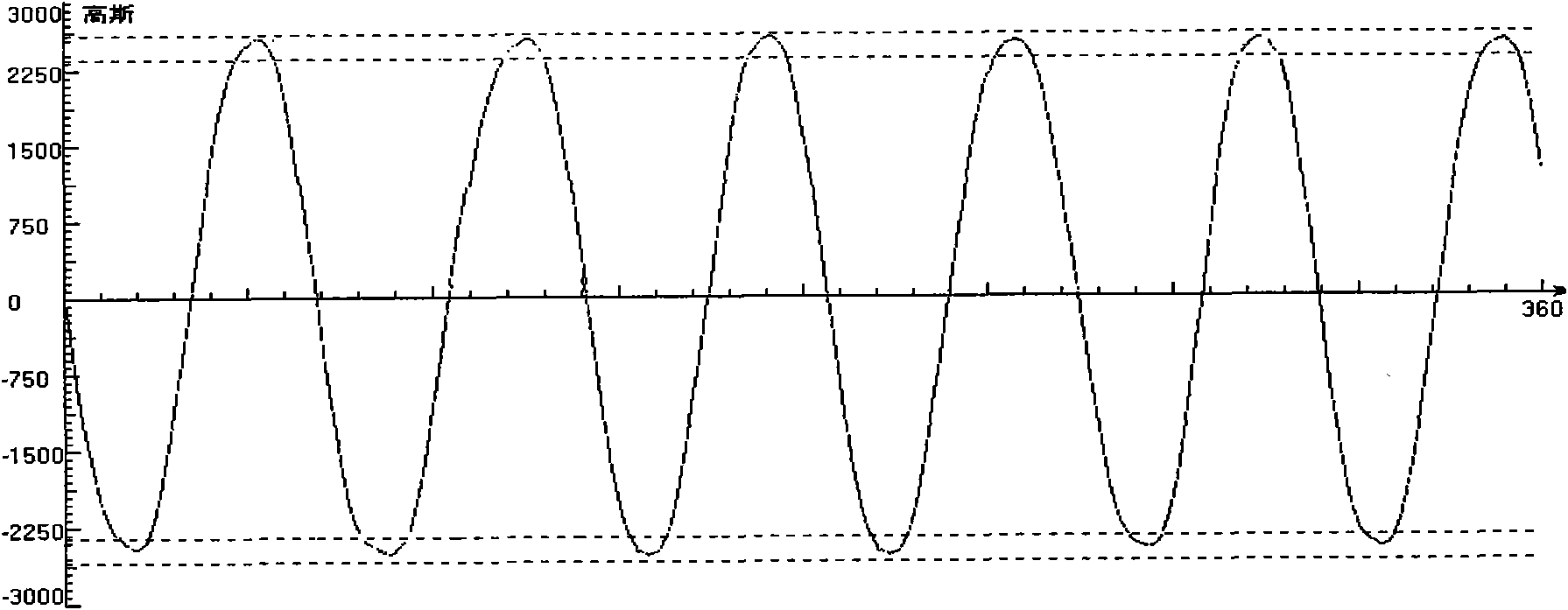

Permanent magnet rotating electrical machine and permanent magnet motor drive system

InactiveUS20100060223A1Vector control systemsManufacturing dynamo-electric machinesLow speedMagnetic poles

A permanent magnet rotating electrical machine capable of conducting a variable speed operation at high output in a wide range from low speed to high speed and improving efficiency and reliability in a wide operating range. Two kinds of permanent magnets having different shapes or different magnetic characteristics are embedded in a rotor core, to form a magnetic pole. The permanent magnets arranged at the magnetic pole include a permanent magnet whose product of coercive force and thickness along a magnetizing direction is small and the permanent magnet whose product of coercive force and thickness along the magnetizing direction is large. A magnetic field created by passing a current to an armature coil for a short time is used to irreversibly magnetize the permanent magnet whose product of coercive force and thickness along magnetizing direction is small, thereby changing a total linkage flux amount, and a positive d-axis current is passed when torque is large.

Owner:KK TOSHIBA

Method for manufacturing injection-molding rare-earth radial magnetic ring

InactiveCN101552132AIncrease the areaIncrease expansionInductances/transformers/magnets manufactureMagnetic materialsQuadrupoleMagnetic characteristic

A method for manufacturing injection-molding rare-earth radial magnetic ring belongs to the technical field of rare earth magnet preparing. The method of the invention comprises the following technical processes: mixing and drying the rare-earth magnetic powder which is coated by the coupling agent and antioxidant in negative pressure until the dissolvent and the absorbed gas is totally released, then placing the thermoplastic organic resin powder into a mixing machine for mixing to uniform in inert protective atmosphere, then placing a double-screw extruder with protective atmosphere, fully compounding the thermoplastic organic binding agent with magnetic powder, granulating for obtaining the granulate for rare-earth anisotropic bonded permanent magnet, placing the granulate into a magnetic field injector with magnetic field mold for preparing into the magnetic ring oriented along the radial direction, wherein the magnetic ring comprises radially oriented magnetic ring and multipole magnetic ring. The method of the invention has the advantage that the granulate manufactured by organic resin has excellent oxidation resistance, fluidity and magnetic characteristic. The radiating, quadrupole and multipole oriented magnetic field which is obtained by matching the permanent magnet repulsive permutation and combination and magnetic material is higher than the permanent magnetic field in which N and S are alternately permutated and combined. An energy saving effect is obtained.

Owner:BEIJING BEILILONG MAGNETIC MATERIALS TECH

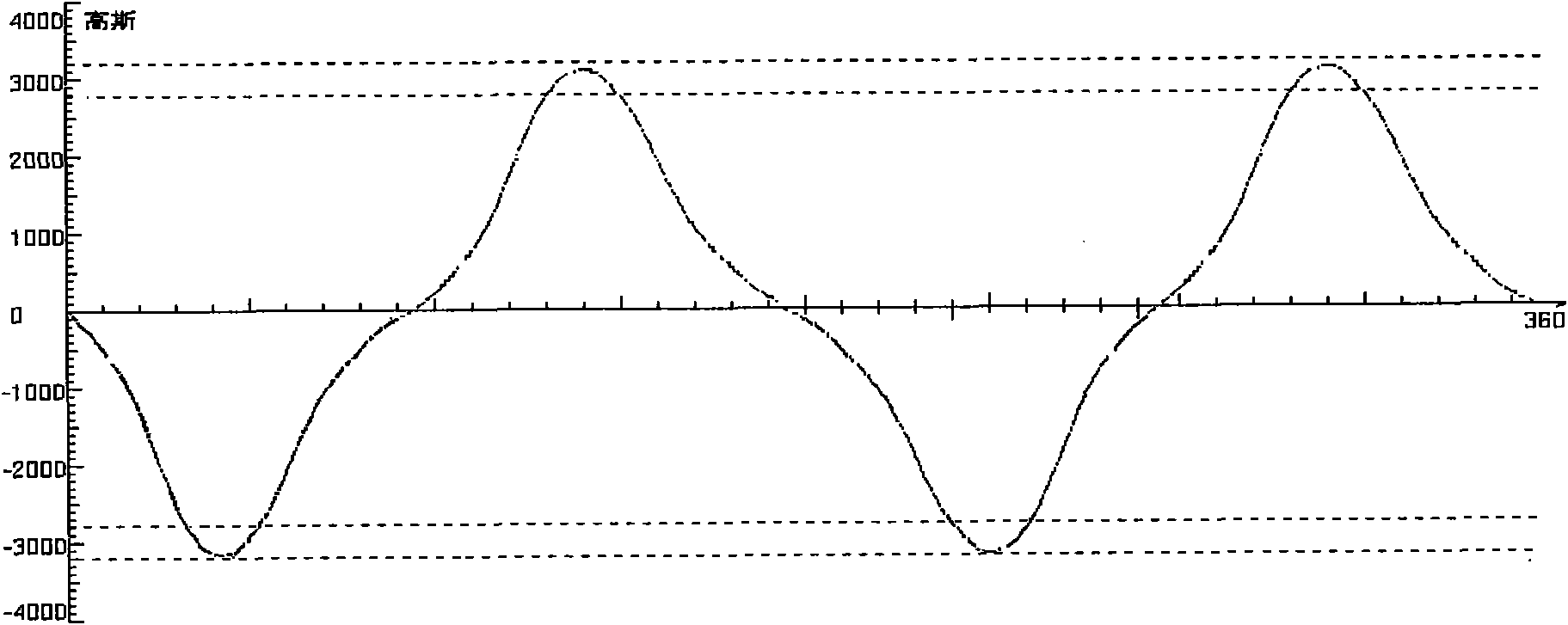

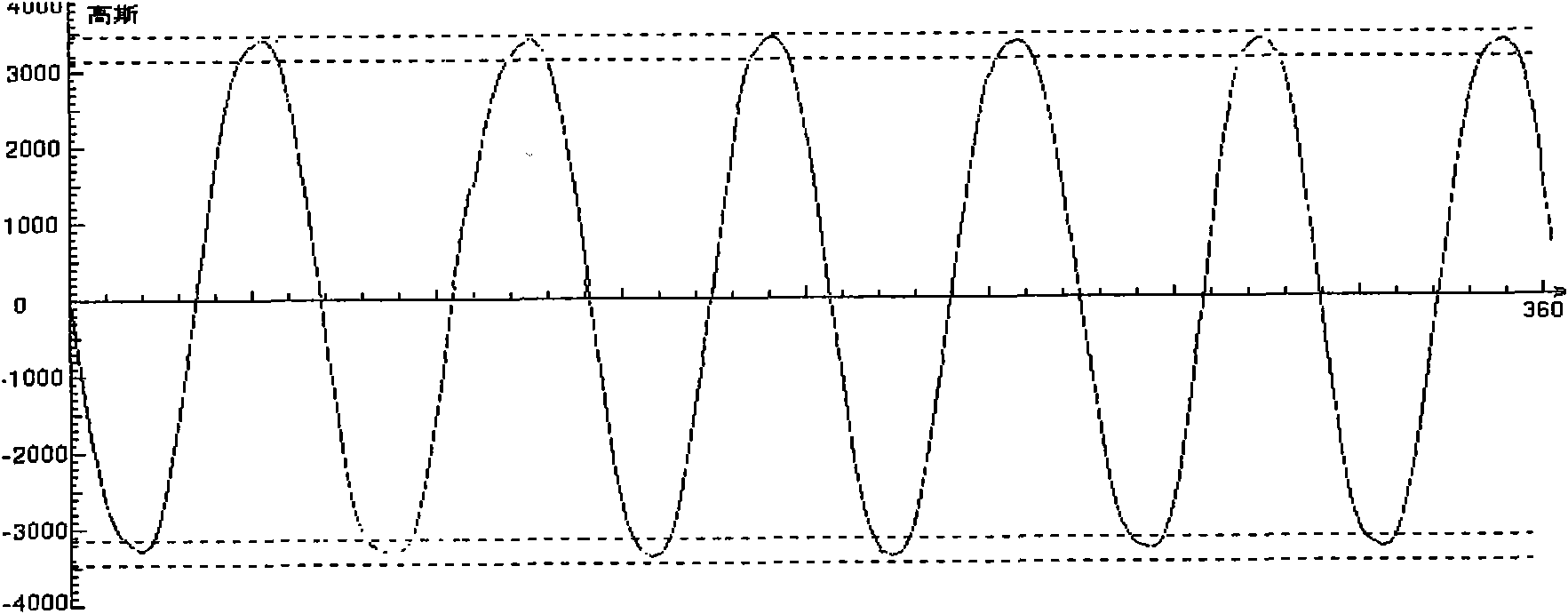

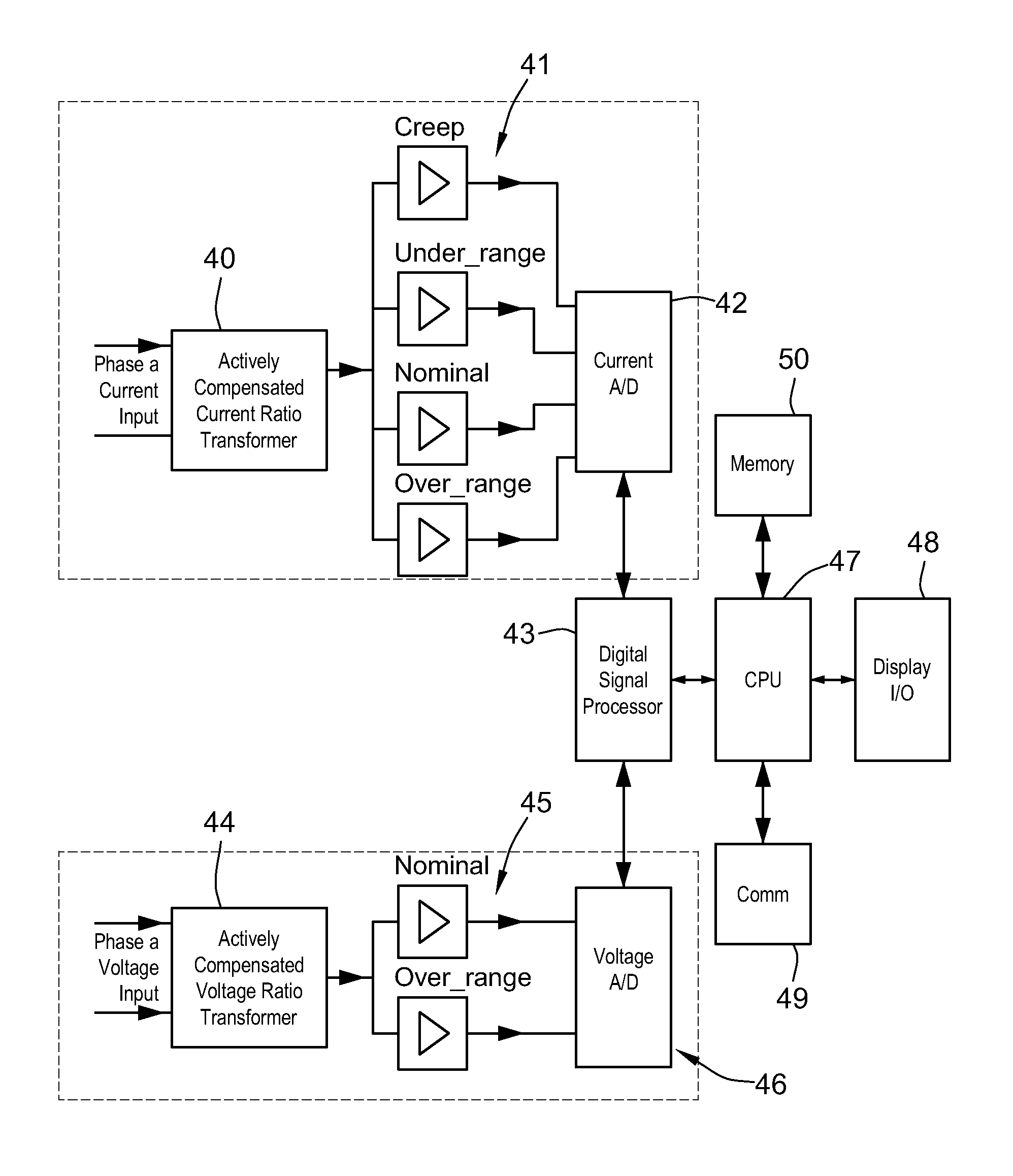

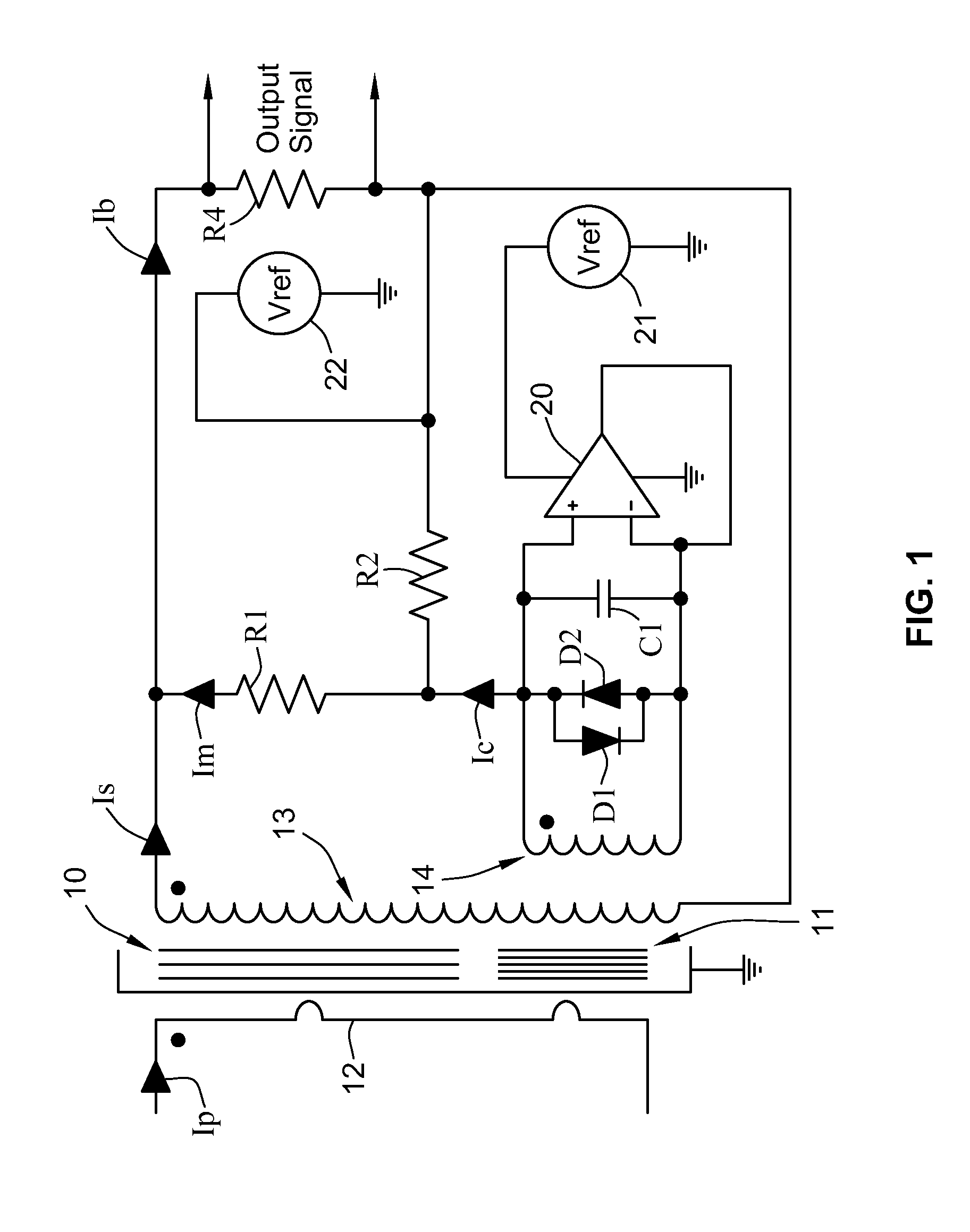

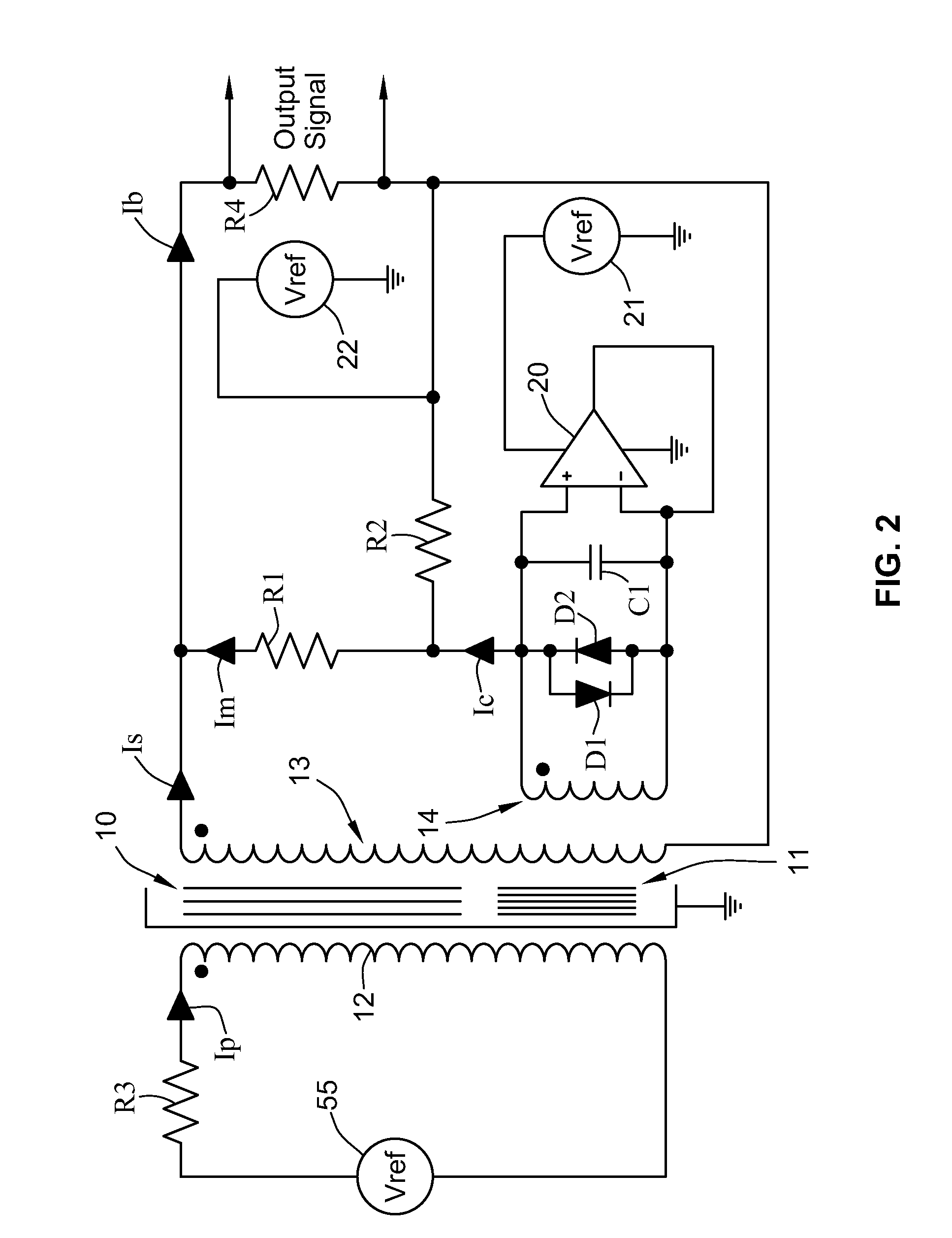

Compact, two stage, zero flux electronically compensated current or voltage transducer employing dual magnetic cores having substantially dissimilar magnetic characteristics

A device for sensing electrical current or voltage in an electrical distribution system using an actively compensated current ratio transformer that includes a first magnetic core having a first permeability and a second magnetic core having a second permeability higher than the first permeability. A primary winding having P turns is coupled with the first and second magnetic cores, a measurement winding having M turns is coupled with the first and second magnetic cores so that current in the primary winding induces current in the measurement winding, and a sense winding having S turns is coupled with the second magnetic core. An amplifier coupled to the sense winding receives a voltage developed across the sense winding and produces a compensation current in response to the received voltage. The amplifier has an output coupled to the sense winding to feed the compensation current through the sense winding to reduce the voltage developed across the sense winding voltage to substantially zero. A burden resistor is coupled to the measurement winding and the sense winding for receiving the sum of the current induced in the measurement winding and the compensation current.

Owner:SCHNEIDER ELECTRIC USA INC

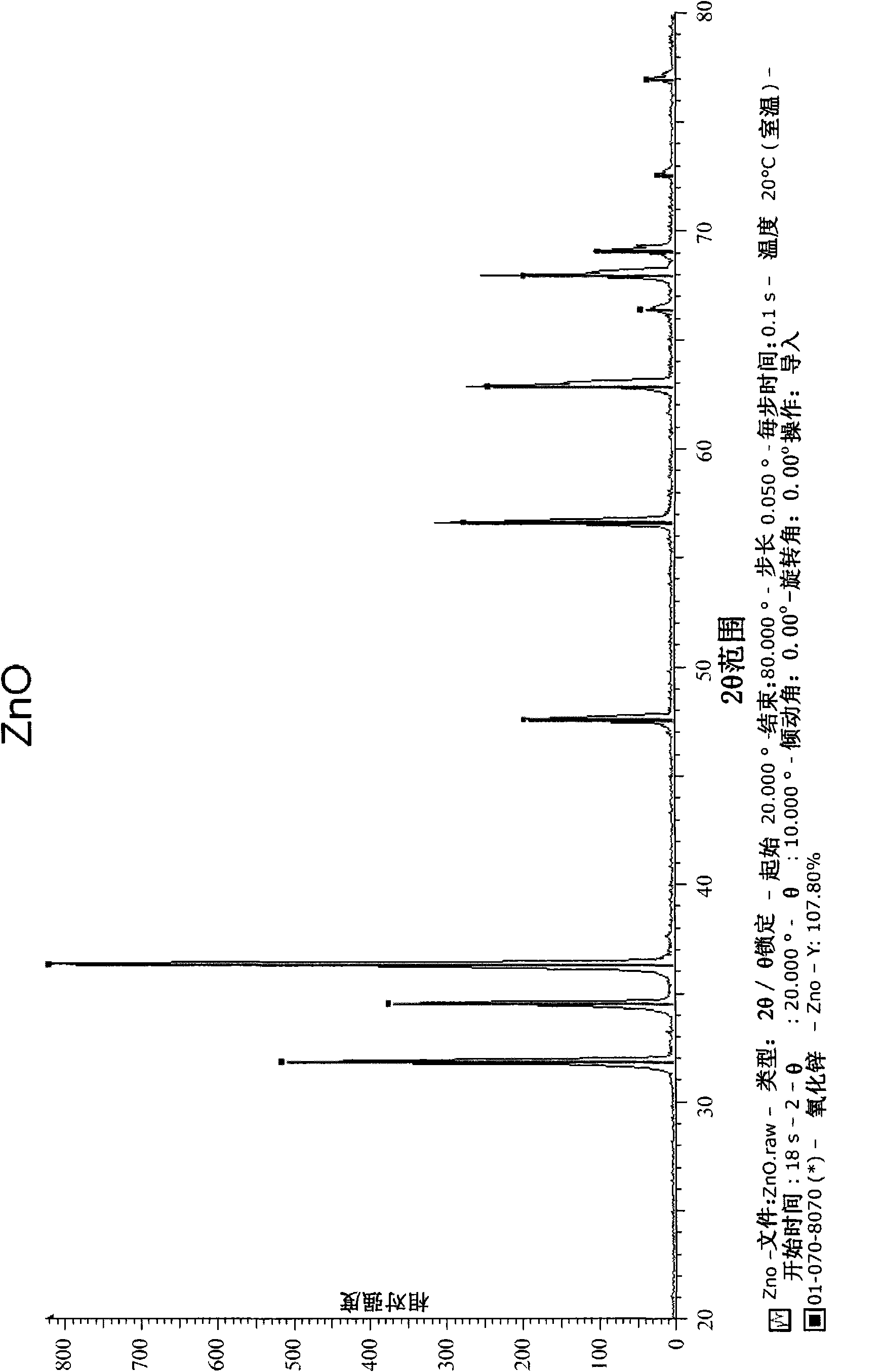

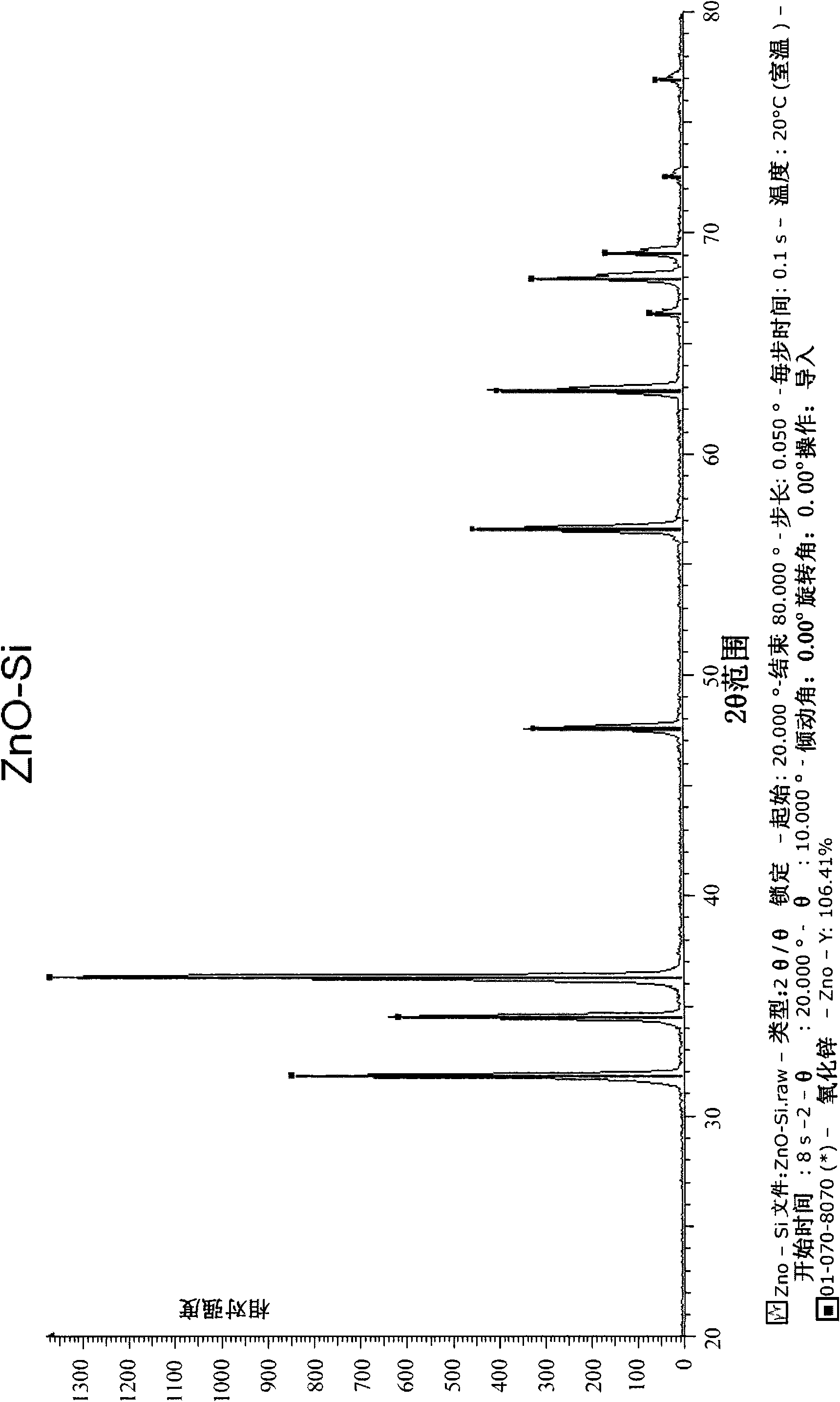

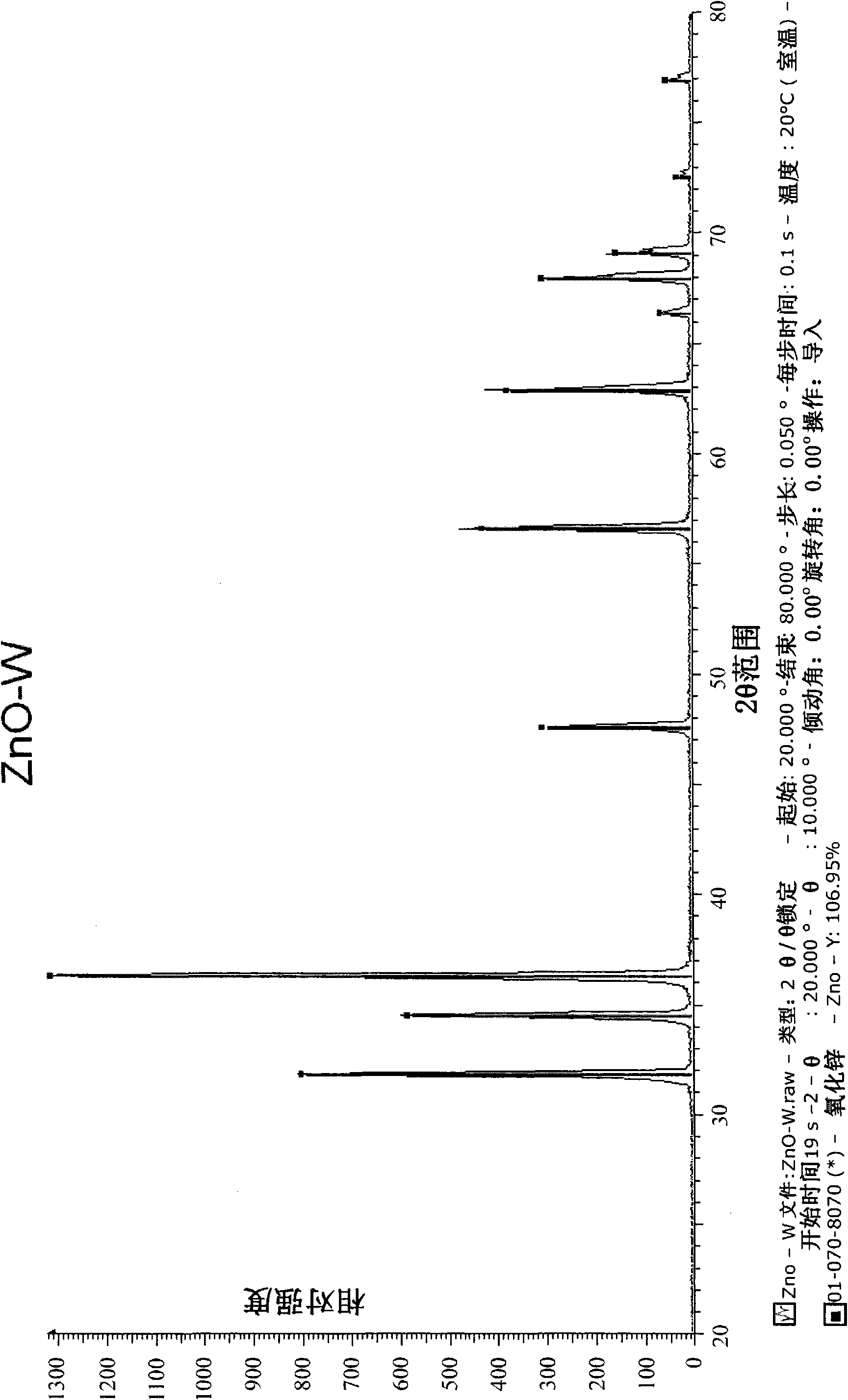

Preparation method of zinc oxide varister

ActiveCN101630553ARegulatory performanceMeet different usage needsResistor manufactureVaristor coresCapacitanceIon

The invention relates to a preparation method of a zinc oxide varister, comprising two independent steps: preparing zinc oxide granules with doping ion components; and preparing a sintering material for coating the zinc oxide granules. According to the performance requirement of the varister, the doping components of the zinc oxide granules, the components of the high-impedance sintering material and preparation conditions are prepared in advance; finally, the zinc oxide granules and the high-impedance sintering material are evenly mixed according to a certain proportion, and the zinc oxide varister is prepared according to the conventional technology. The zinc oxide varister prepared by the preparation method not only has voltage-sensitive performance, but also has one or more functions of heat sensitivity, capacitance, inductance, piezoelectricity or magnetic characteristic, and the like, can sinter at low temperature (lower than 900 DEG C) and can use fine silver as an inner electrode.

Owner:SFI ELECTRONICS TECH

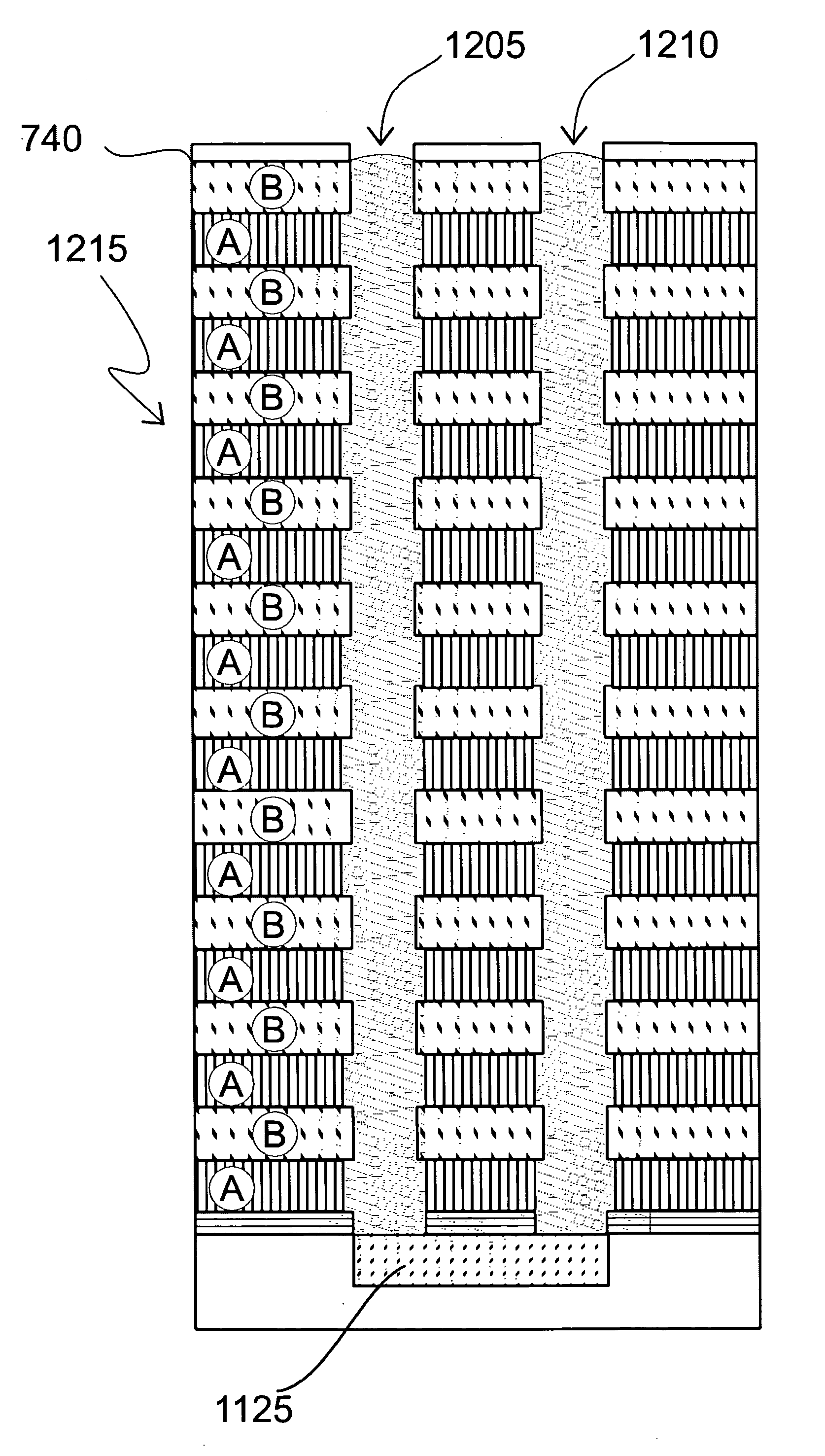

Method of fabricating a shiftable magnetic shift register

A magnetic data track used in a magnetic shift register memory system may be fabricated by forming a multilayered stack of alternating dielectric and / or silicon layers. Vias of approximately 10 microns tall with a cross-section on the order of 100 nm×100 nm are etched in this multilayered stack of alternating layers. Vias may be etched form smooth or notched walls. Vias are filled by electroplating layers of alternating types of ferromagnetic or ferrimagnetic metals. The alternating ferromagnetic or ferrimagnetic layers are comprised of magnetic materials with different magnetization or magnetic exchange or magnetic anisotropies. These different magnetic characteristics allow the pinning of magnetic domain walls at the boundaries between these layers. Alternatively, vias are filled with a homogeneous ferromagnetic material. Magnetic domain walls are formed by the discontinuity in the ferromagnetic or ferromagnetic material that occurs at the notches or at the protuberances along the via walls.

Owner:GLOBALFOUNDRIES US INC

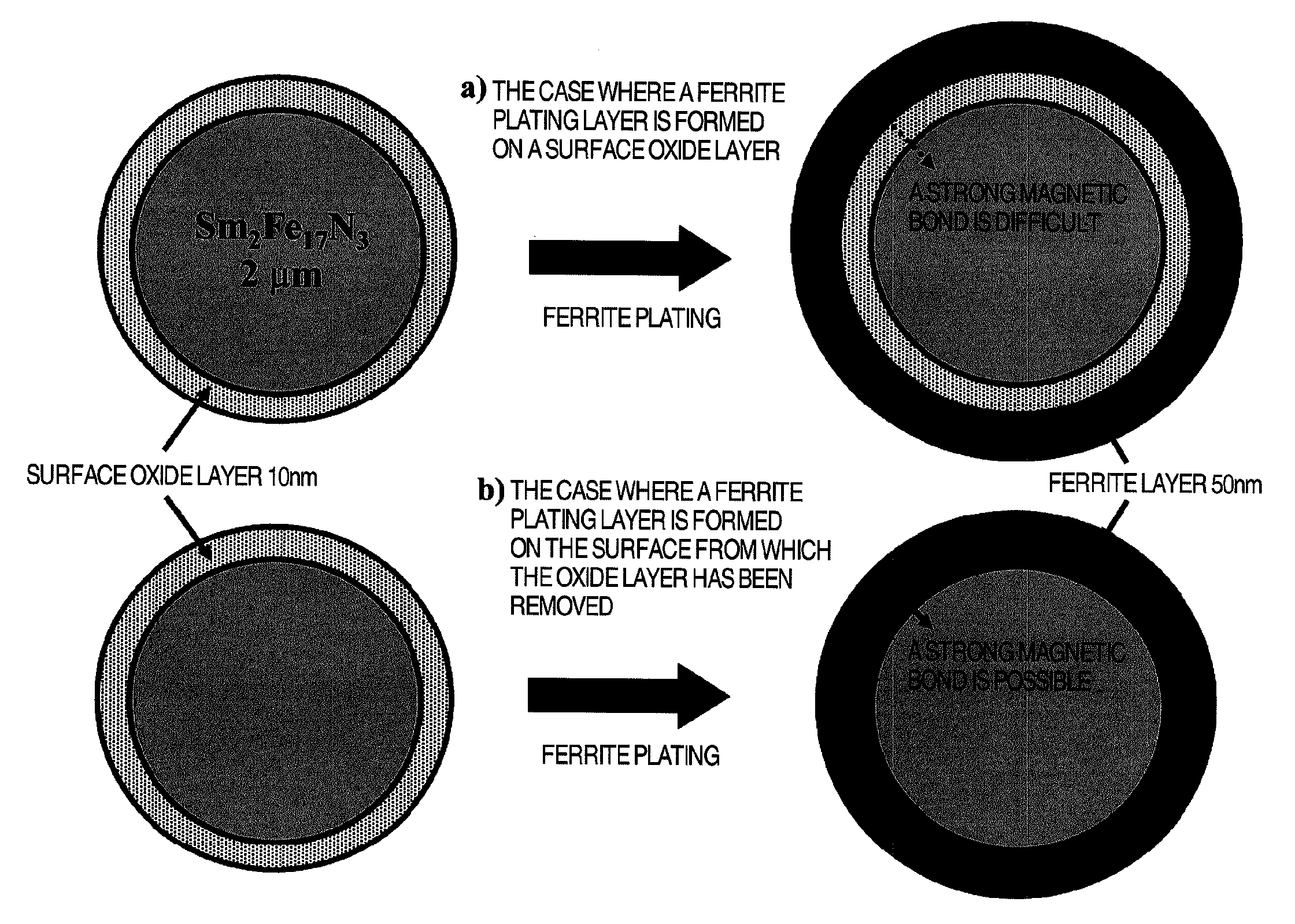

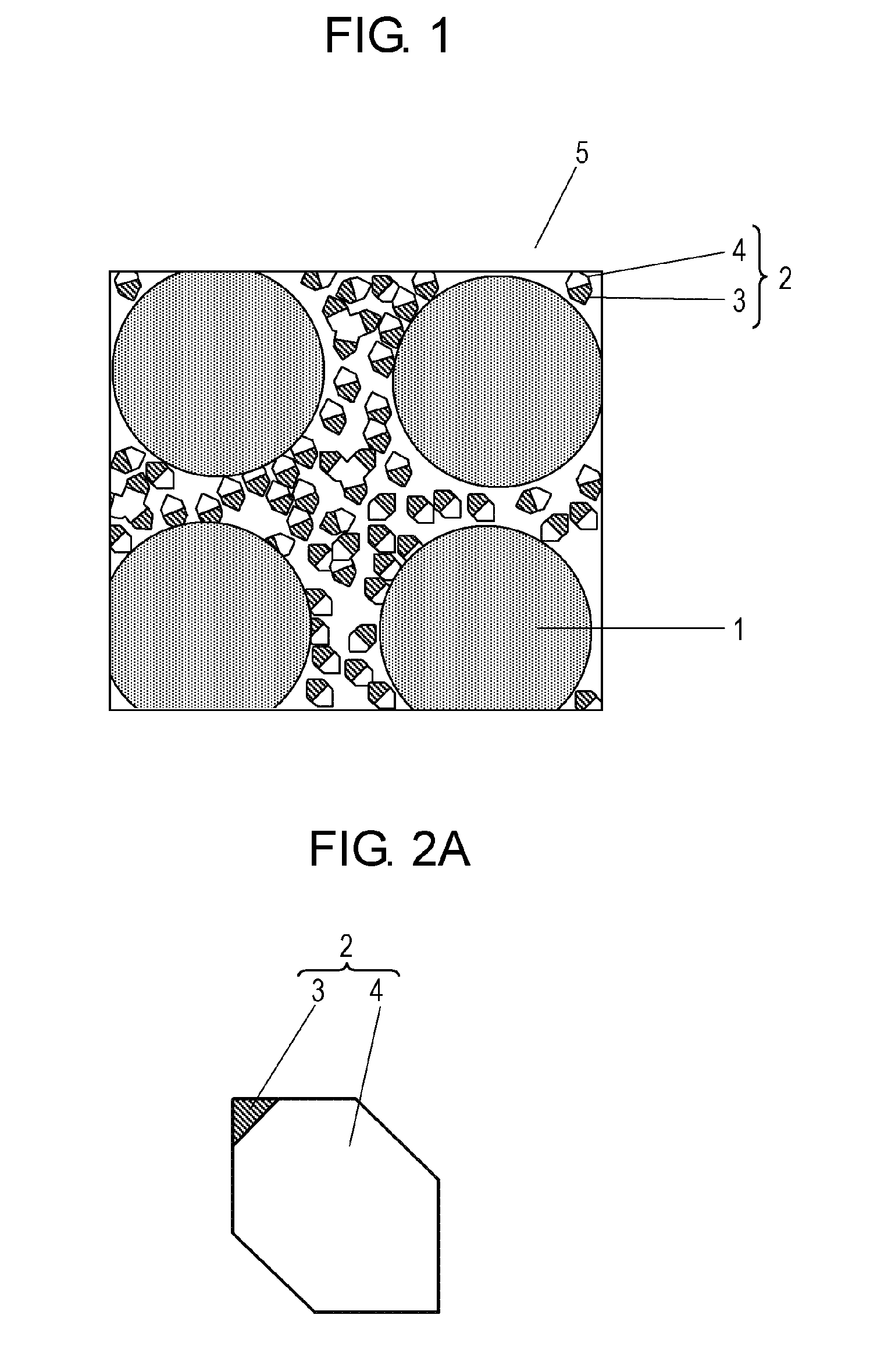

Composite magnetic material for magnet and method for manufacturing such material

InactiveUS20100261038A1Improve featuresHigh resistivityTransportation and packagingMetal-working apparatusRare earthNitrogen

Provided is a composite magnetic material having high magnetic characteristics and high electrical resistivity to be used for a magnet, especially a composite magnetic material to be suitably used for a rotary motor magnet or the like which functions in a high frequency region. The composite magnetic material for the magnet is provided by covering the surface of a rare earth-iron-nitrogen based magnetic material with a ferrite based magnetic material.

Owner:TOKYO INST OF TECH +1

Method of fabricating data tracks for use in a magnetic shift register memory device

InactiveUS6955926B2Solid-state devicesSemiconductor/solid-state device manufacturingShift registerDielectric

A magnetic data track used in a magnetic shift register memory system may be fabricated by forming a multilayered stack of alternating dielectric and / or silicon layers. Vias of approximately 10 microns tall with a cross-section on the order of 100 nm×100 nm are etched in this multilayered stack of alternating layers. Vias may be etched form smooth or notched walls. Vias are filled by electroplating layers of alternating types of ferromagnetic or ferrimagnetic metals. The alternating ferromagnetic or ferrimagnetic layers are comprised of magnetic materials with different magnetization or magnetic exchange or magnetic anisotropies. These different magnetic characteristics allow the pinning of magnetic domain walls at the boundaries between these layers. Alternatively, vias are filled with a homogeneous ferromagnetic material. Magnetic domain walls are formed by the discontinuity in the ferromagnetic or ferromagnetic material that occurs at the notches or at the protuberances along the via walls.

Owner:GLOBALFOUNDRIES INC

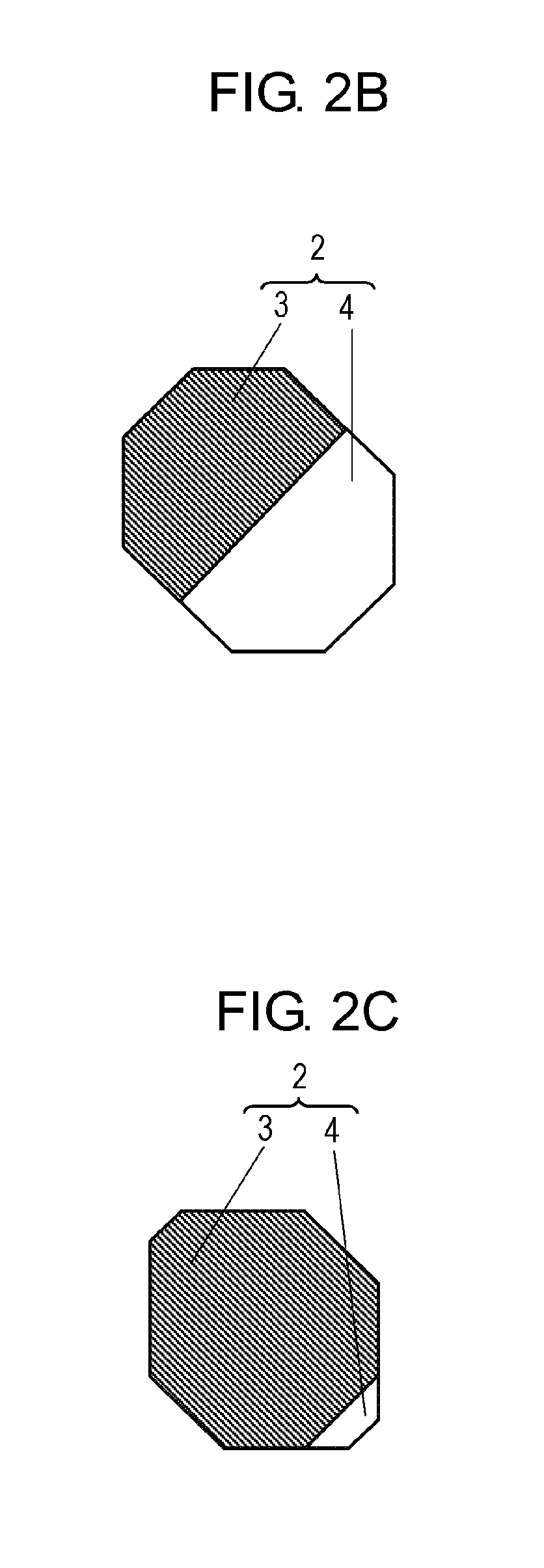

Composite magnetic material, coil component using same, and composite magnetic material manufacturing method

ActiveUS20170053729A1Excellent magnetic propertiesTransportation and packagingMetal-working apparatusMagnetic characteristicMaterials science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Proppants containing dispersed piezoelectric or magnetostrictive fillers or mixtures thereof, to enable proppant tracking and monitoring in a downhole environment

In one aspect, the invention relates to a method for “tagging” proppants so that they can be tracked and monitored in a downhole environment, based on the use of composite proppant compositions containing dispersed fillers whose electromagnetic properties change at a detectable level under a mechanical stress such as the closure stress of a fracture. In another aspect, the invention relates to composite proppant compositions containing dispersed fillers whose electromagnetic properties change under a mechanical stress such as the closure stress of a fracture. The currently preferred embodiments use substantially spherical thermoset nanocomposite particles where the matrix comprises a terpolymer of styrene, ethylvinylbenzene and divinylbenzene, a PZT alloy manifesting a strong piezoelectric effect or Terfenol-D manifesting giant magnetostrictive behavior is incorporated to provide the ability to track in a downhole environment, and carbon black particles possessing a length that is less than 0.5 microns in at least one principal axis direction may optionally be incorporated as a nanofiller.

Owner:SUN DRILLING PRODS

Magnetoresistive effect element, magentic memory device and manufacturing method of magnetoresistive effect element and magnetic memory device

InactiveUS20060187703A1Excellent magnetic propertiesExcellent write characteristicNanostructure applicationNanomagnetismBit lineMagnetic anisotropy

A magnetoresistive effect element (1) has an arrangement in which a pair of ferromagnetic material layers (magnetization fixed layer (5) and magnetization free layer (7)) is opposed to each other through an intermediate layer (6) to obtain a magnetoresistive change by causing a current to flow in the direction perpendicular to the layer surface and in which the ferromagnetic material layers are annealed by anneal including rotating field anneal and the following static field anneal. A magnetic memory device comprises this magnetoresistive effect element (1) and bit lines and word lines sandwiching the magnetoresistive effect element (1) in the thickness direction. When the magnetoresistive effect element (1) and the magnetic memory device are manufactured, the ferromagnetic material layers (5, 7) are annealed by rotating field anneal and the following static field anneal. There are provided the magnetoresistive effect element that can obtain excellent magnetic characteristics by controlling magnetic anisotropies of the ferromagnetic material layers, the magnetic memory device including this magnetoresistive effect element and which may have excellent write characteristics, and methods for manufacturing these magnetoresistive effect element and magnetic memory device.

Owner:SONY CORP

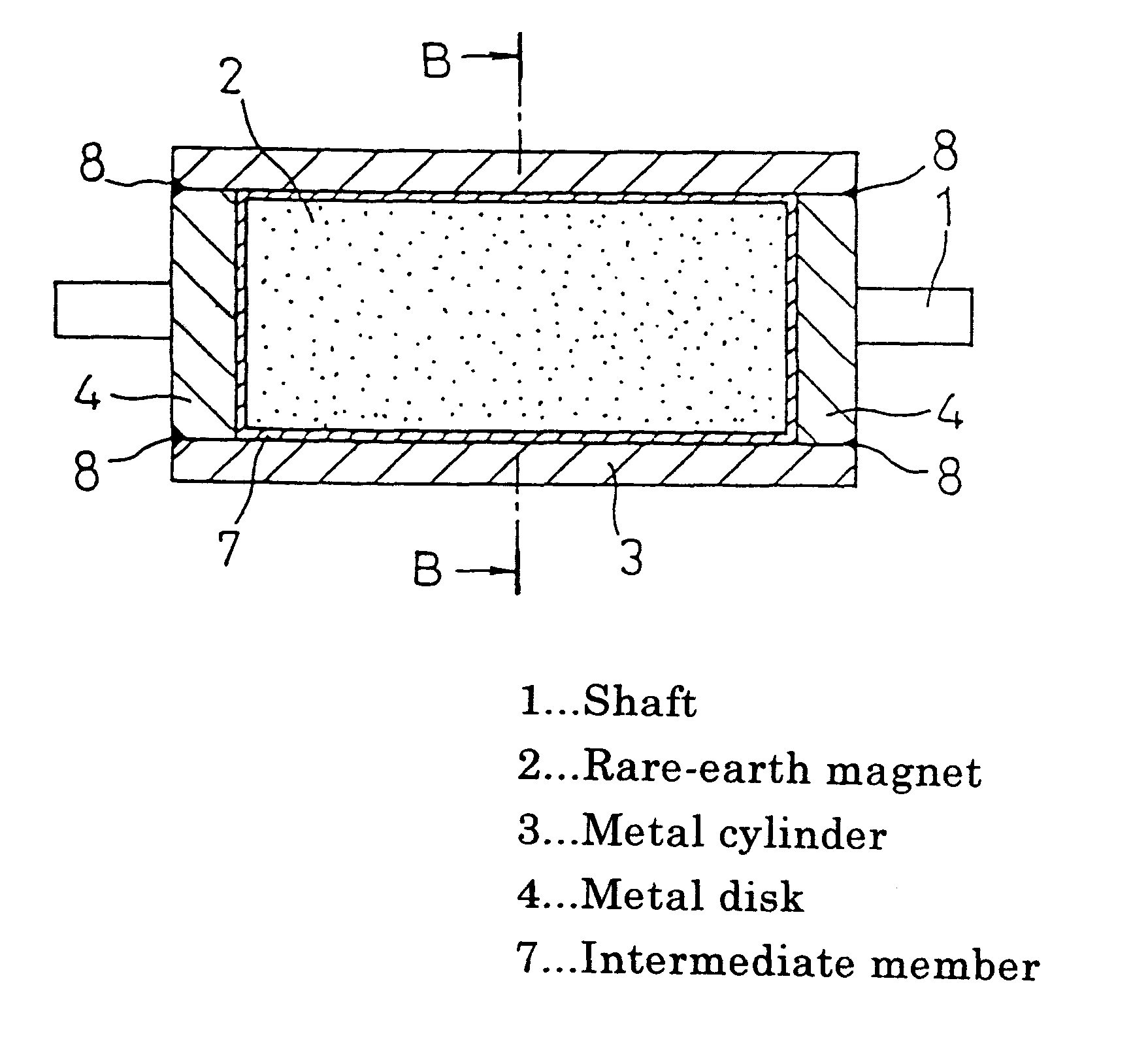

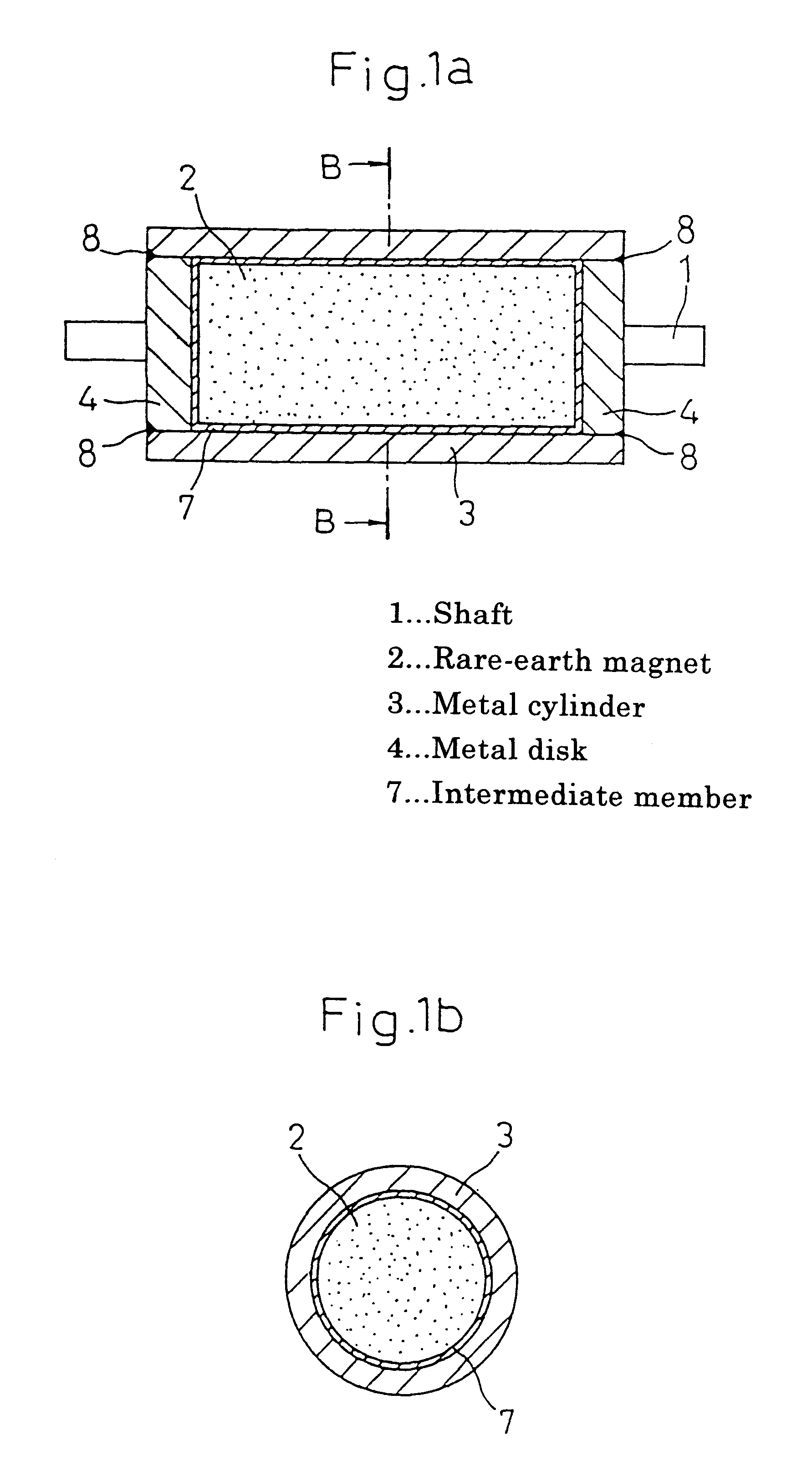

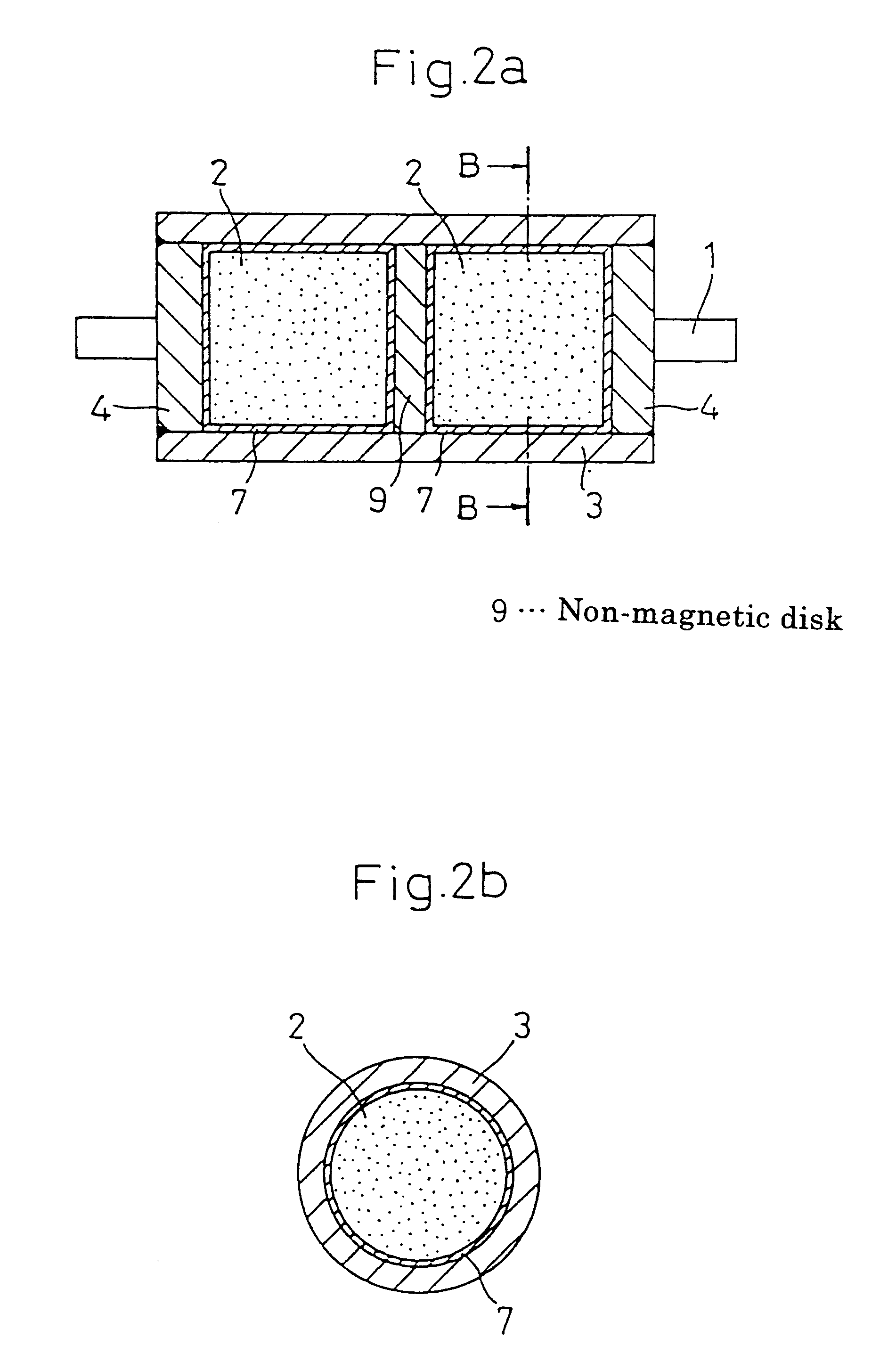

Monolithically bonded construct of rare-earth magnet and metal material and method for bonding same

InactiveUS6331214B1Manufacturing stator/rotor bodiesThin material handlingMetallic materialsHigh pressure

Its basic means is a monolithically bonded construct prepared by monolithically bonding together a rare-earth magnet 2 and a an alloy material that is a high melting point metal or a high specific-tenacity material through the solid phase diffusion bonding by the hot isostatic pressing treatment, and a monolithically bonded construct with an interposal of a thin layer of the high melting point metal between a rare-earth magnet 2 and an alloy material 3, 4 that is a high specific-tenacity material. As a method for the bonding, there is used a hot isostatic pressing treatment method in which a rare-earth An magnet and a high melting-point metal are laminated together, thereby to prepare an object to be treated, then the object is put into a hermetic-type high pressure container having an inner wall portion equipped with a heater, then the object is uniformly pressurized in all directions by a synergistic effect caused by pressure and temperature, while the object is maintained for a certain period of time under a certain pressure and temperature condition in an atmosphere of an inert gas, thereby to monolithically bond the object. With this, it is possible to obtain a bonded construct in which a magnet can monolithically be bonded with another metal member with a high strength, without deteriorating magnetic characteristics, such that the rare-earth magnet's insufficiency in brittleness, rigidity, tenacity and the like is compensated.

Owner:MEIDENSHA ELECTRIC MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com