Patents

Literature

241 results about "Heat sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat intolerance. Heat intolerance is a feeling of being overheated when the temperature around you rises. It can often cause heavy sweating. Heat intolerance usually comes on slowly and lasts for a long time, but it may also occur quickly and be a serious illness.

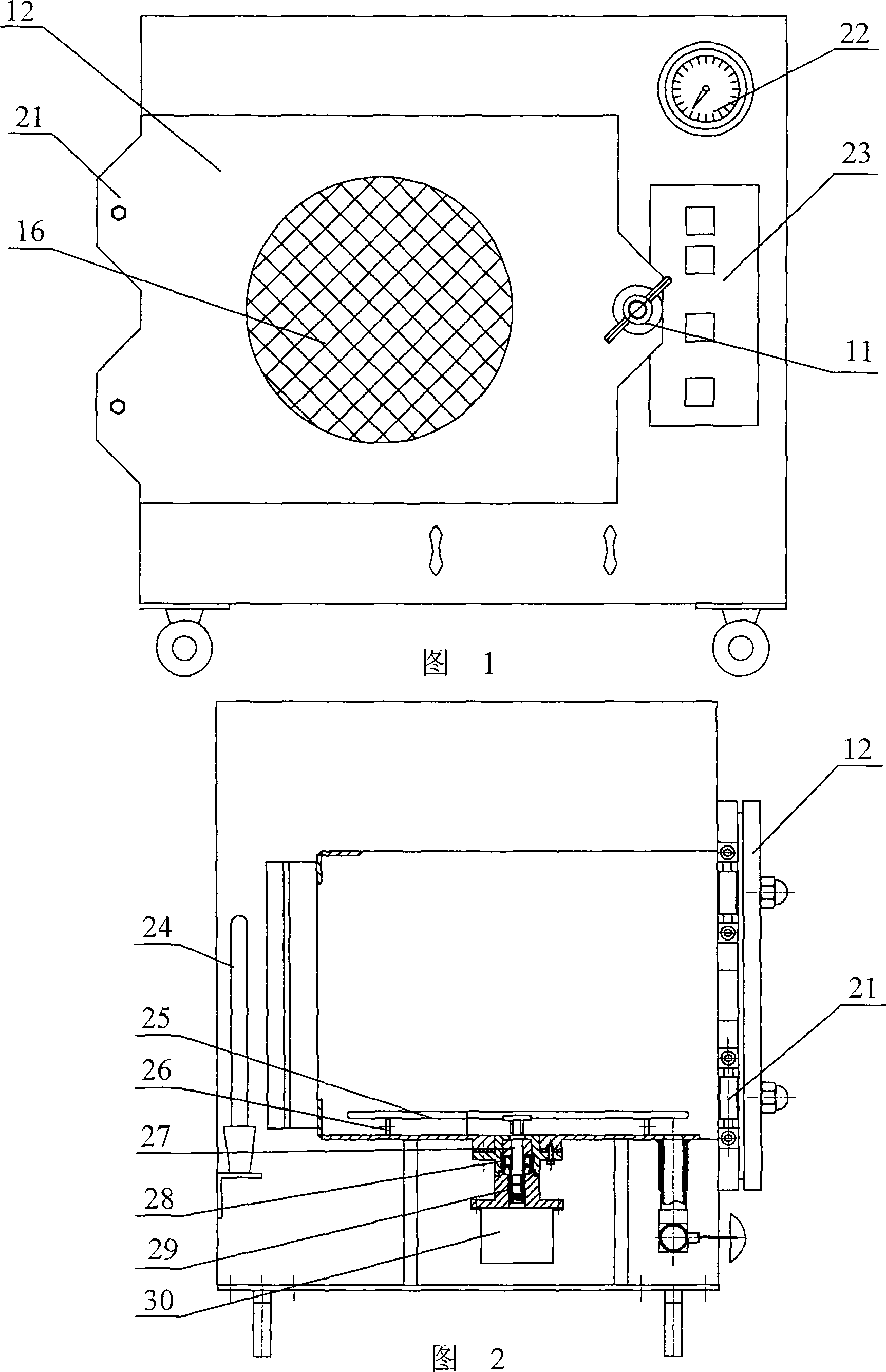

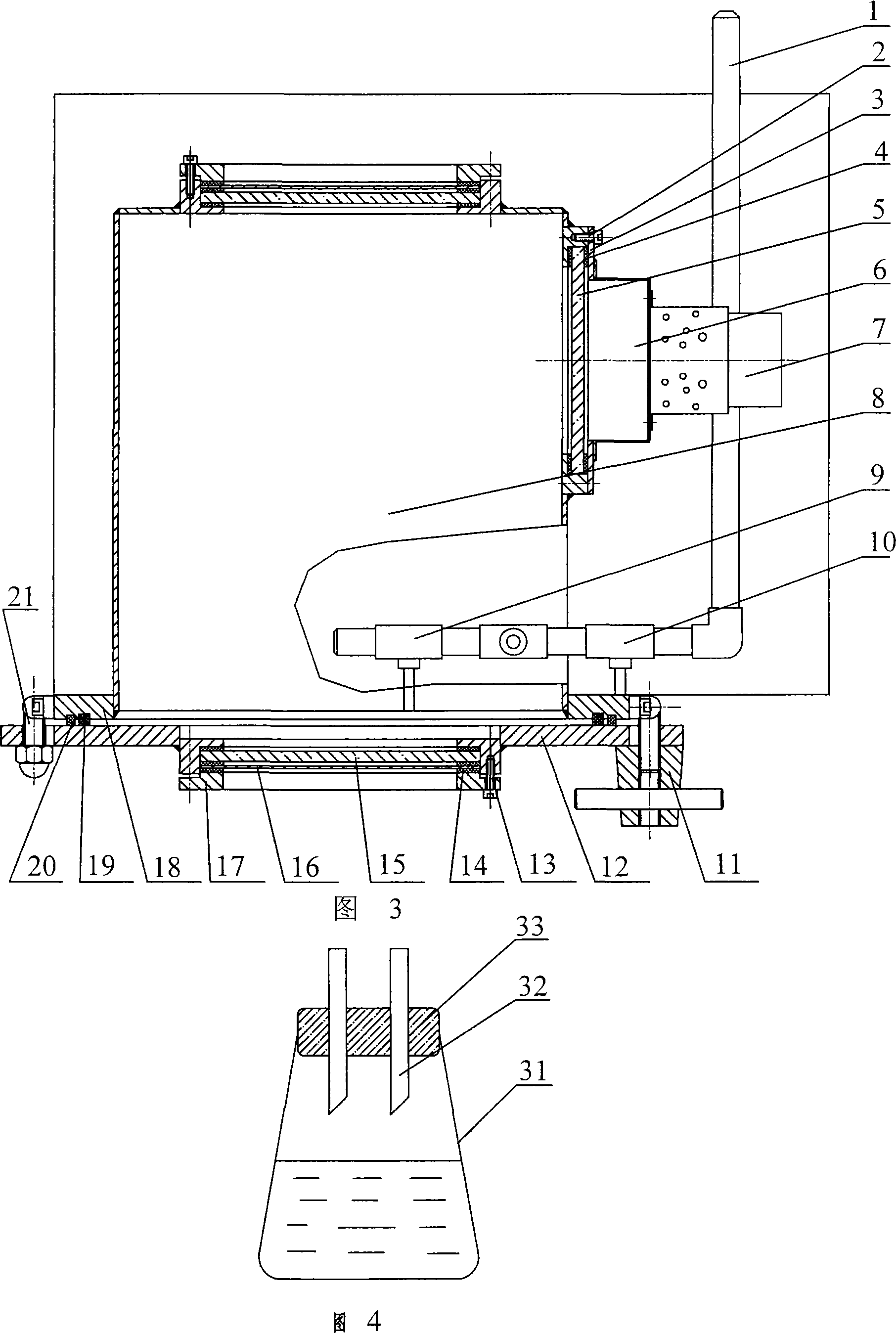

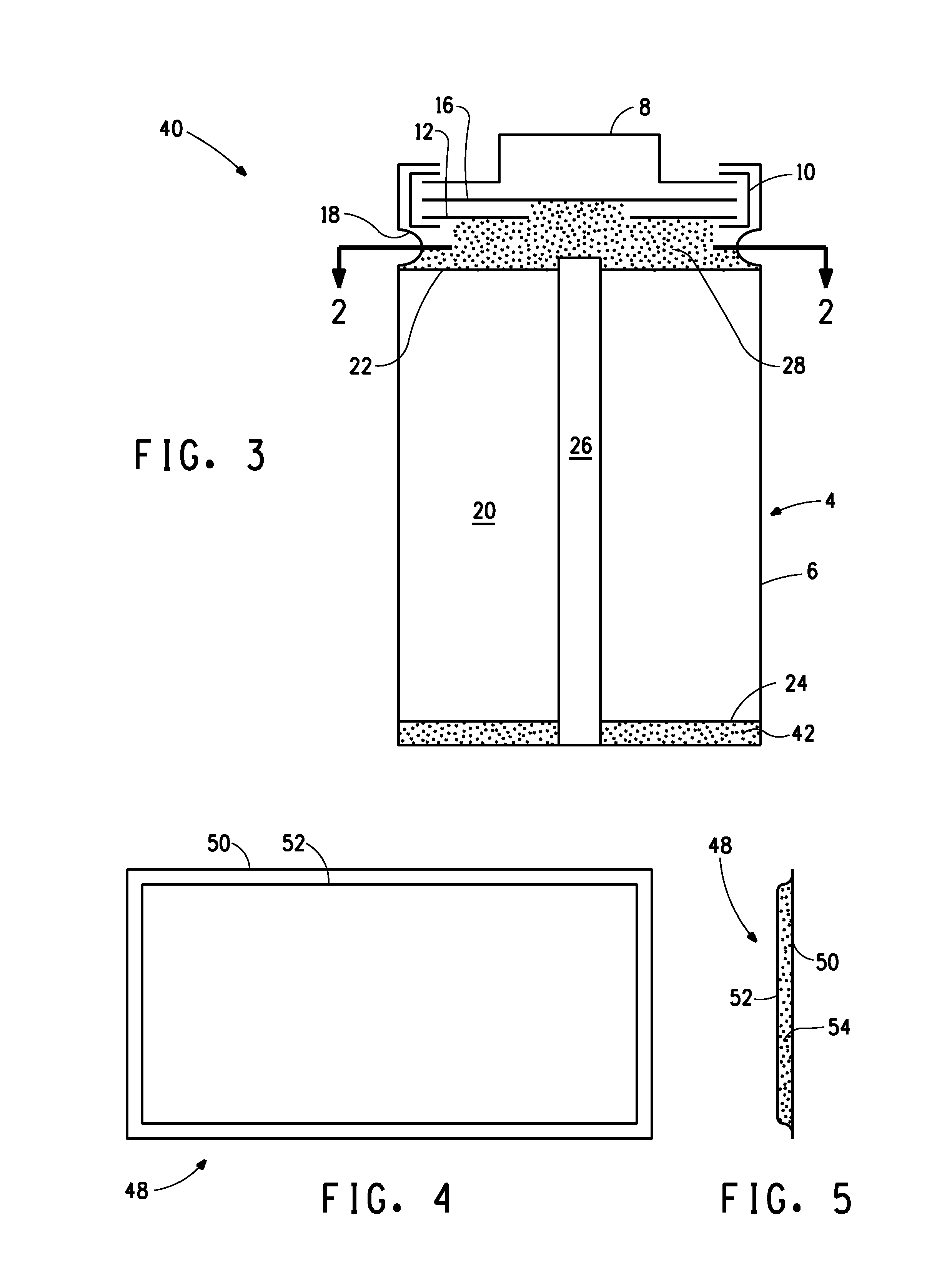

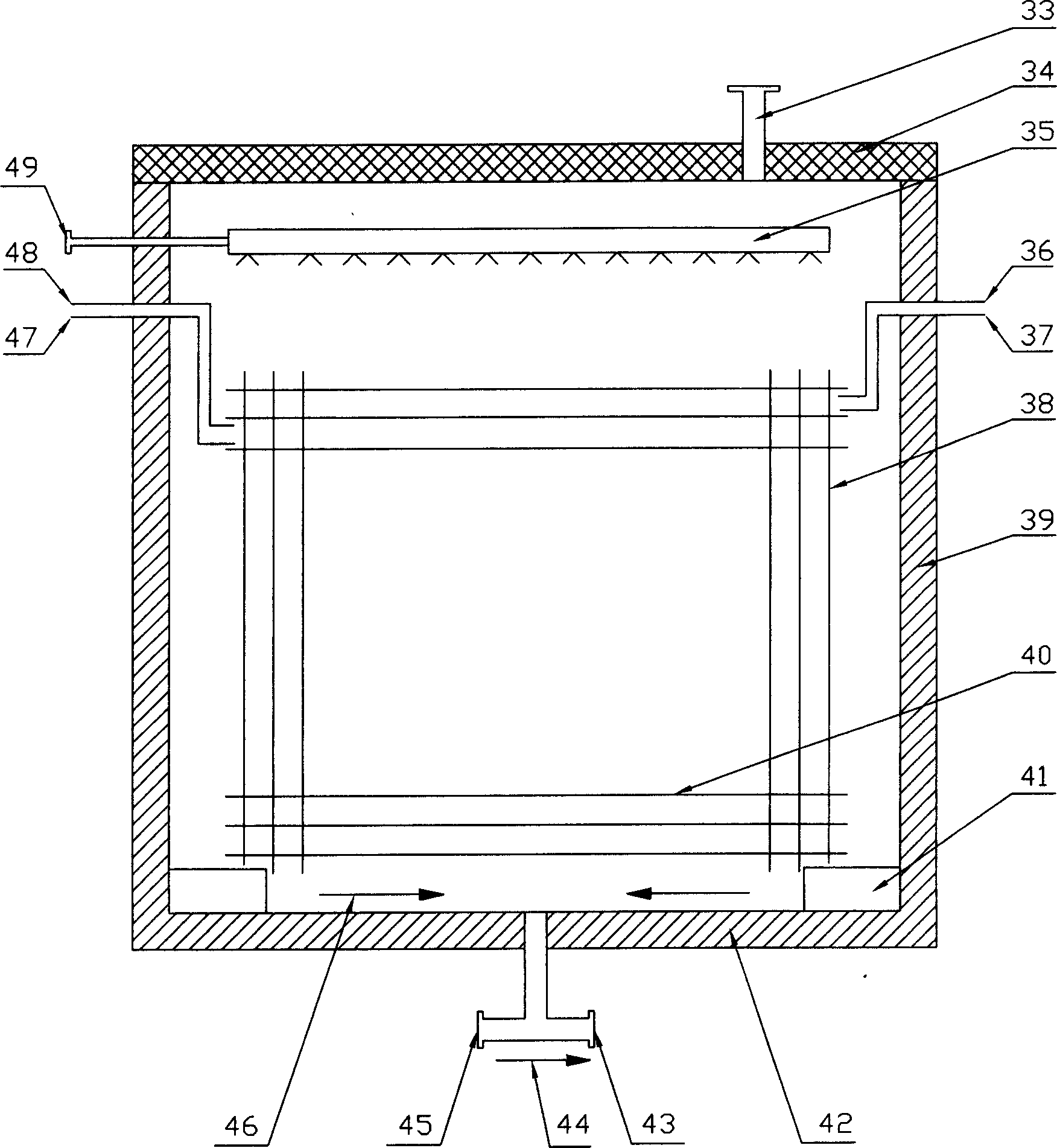

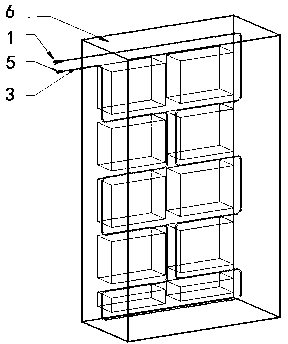

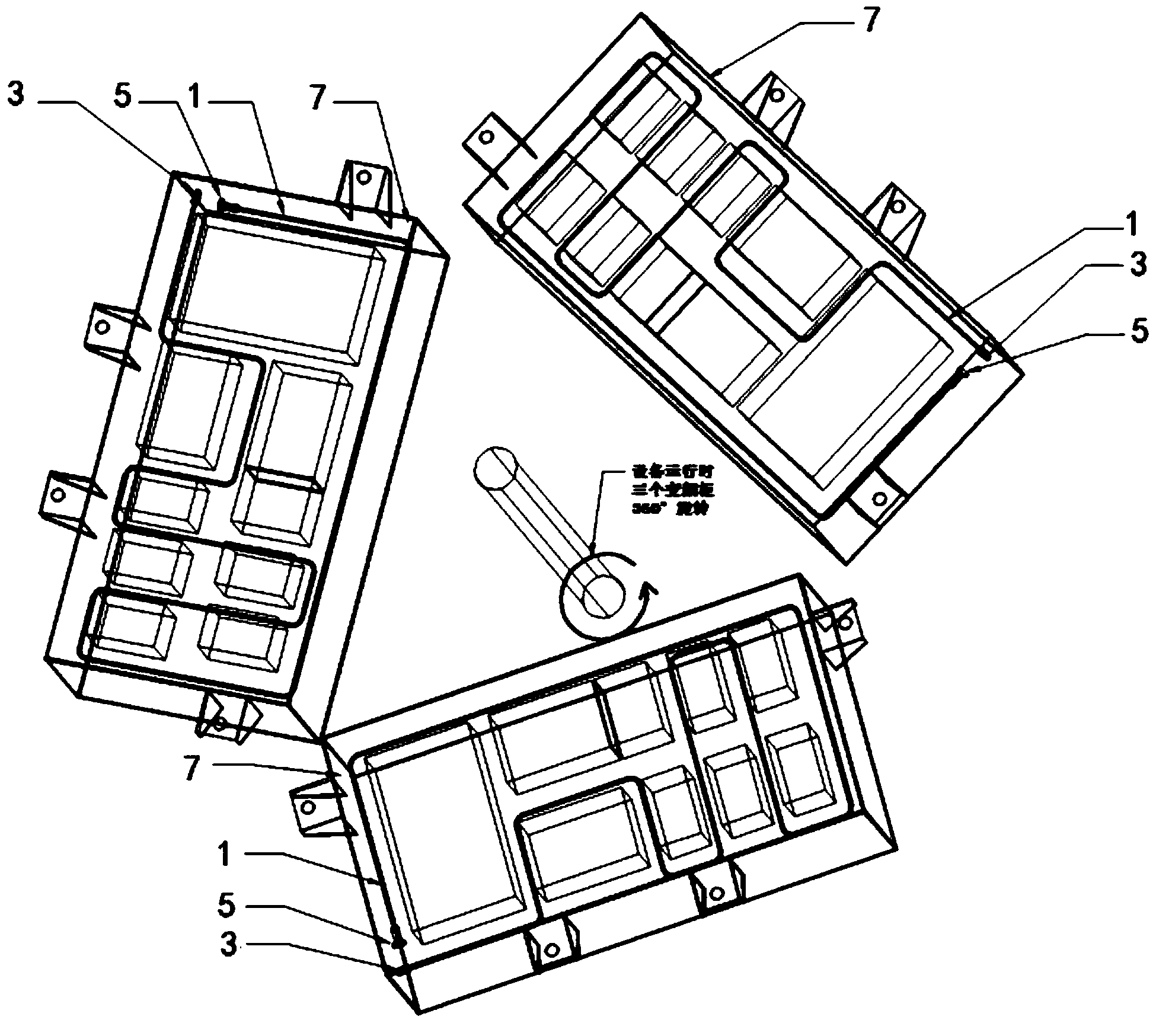

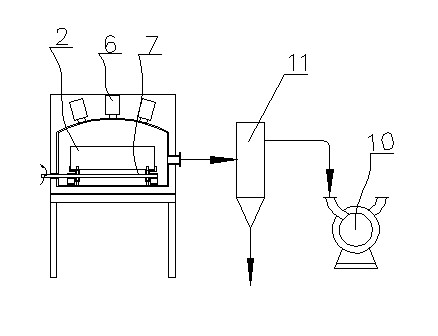

Micro-wave vacuum equipment

InactiveCN101082464AFast dryingFast concentrationDrying solid materials with heatDrying chambers/containersVacuum pumpingMicrowave

This invention relates to a sort of integral dry and dewatering set of the microwave and vacuum system, it consists of a hothouse of hermetic estate which is used to pose the materiel, the on-off door body which is propitious to gain and put materiel is fitted on the wall of the hothouse, the microwave produced by the microwave generator can cross the wall of the hothouse and it use the microwave to heat the materiel of the hothouse, there has the vacuum connector tub which is extended to the hothouse on the wall of the hothouse, the vacuum connector tub connects with the vacuum-pumping set. Because thin invention makes the microwave heating system connects with the vacuum system in the organic way, the speed of its dryness and condensation is fast, the temperature is low (25 to 45 deg. C), It very fit to the use of the lab, and fit to desiccate and condense the multifarious hydrous, and specially fit to food materiel of the heat sensitivity, and so on, and it is widely used to desiccate and condense the multifarious hydrous in the way of small-scale in the lab, such as the food, the medication, the chemical production.

Owner:JIANGNAN UNIV

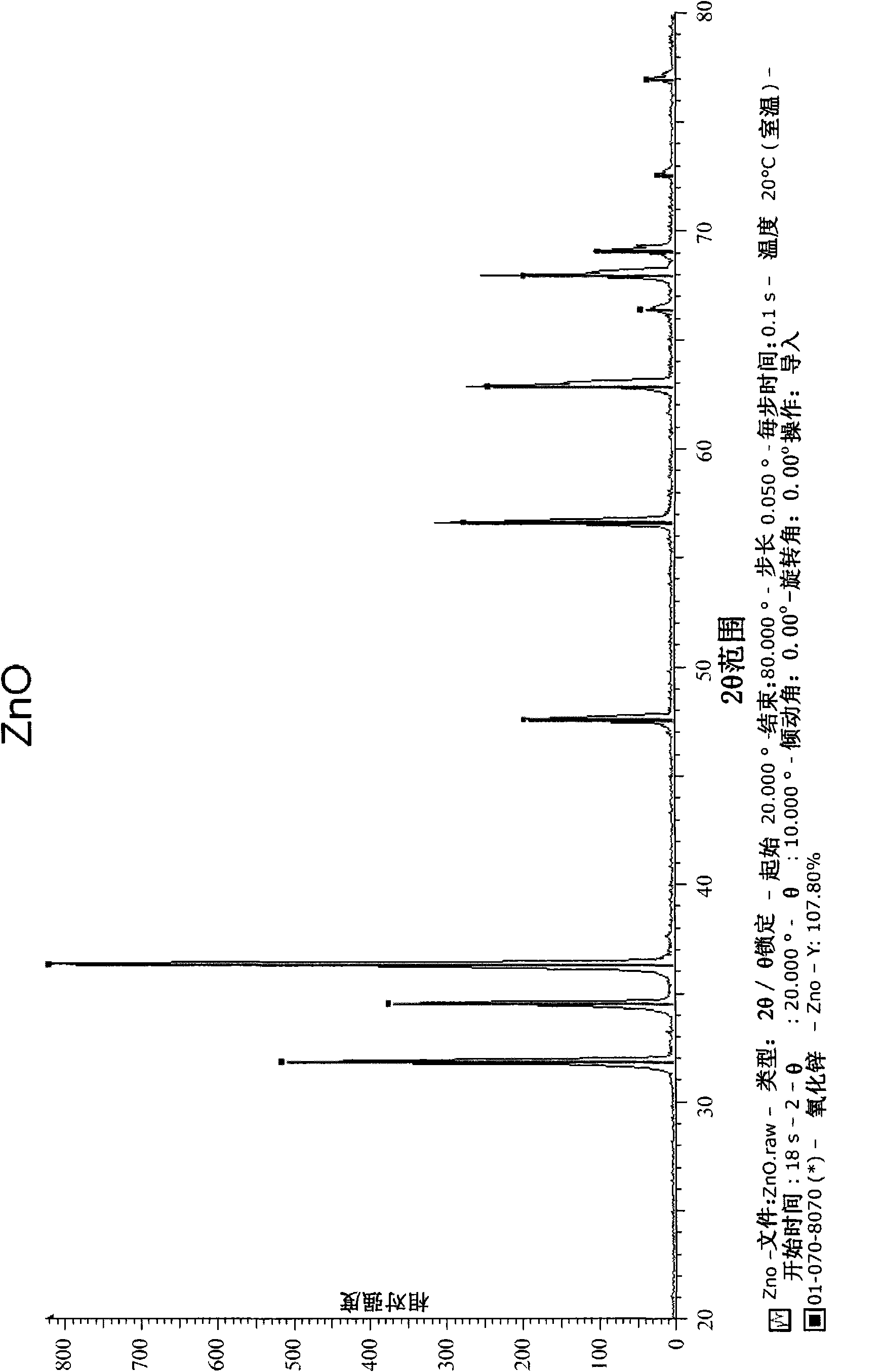

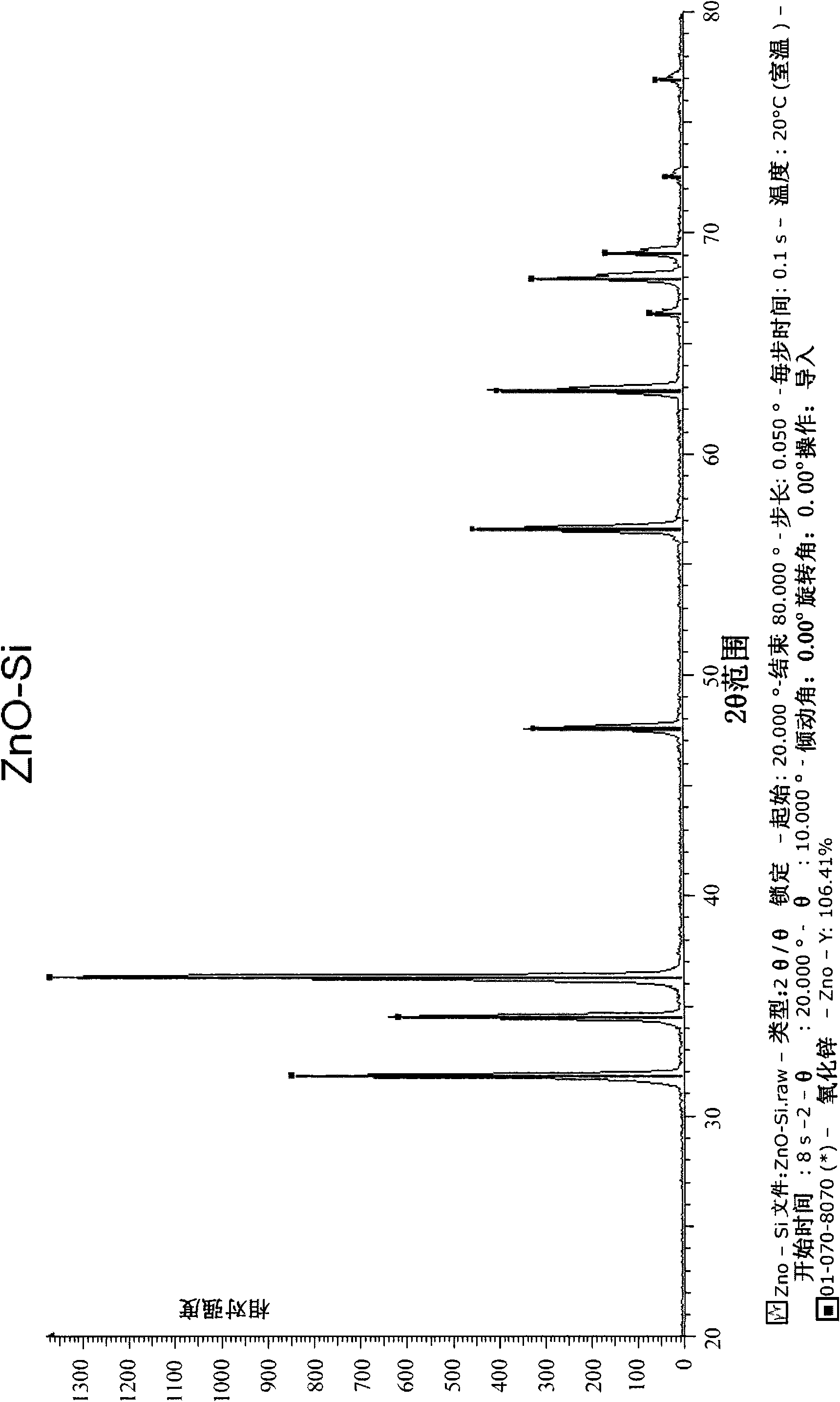

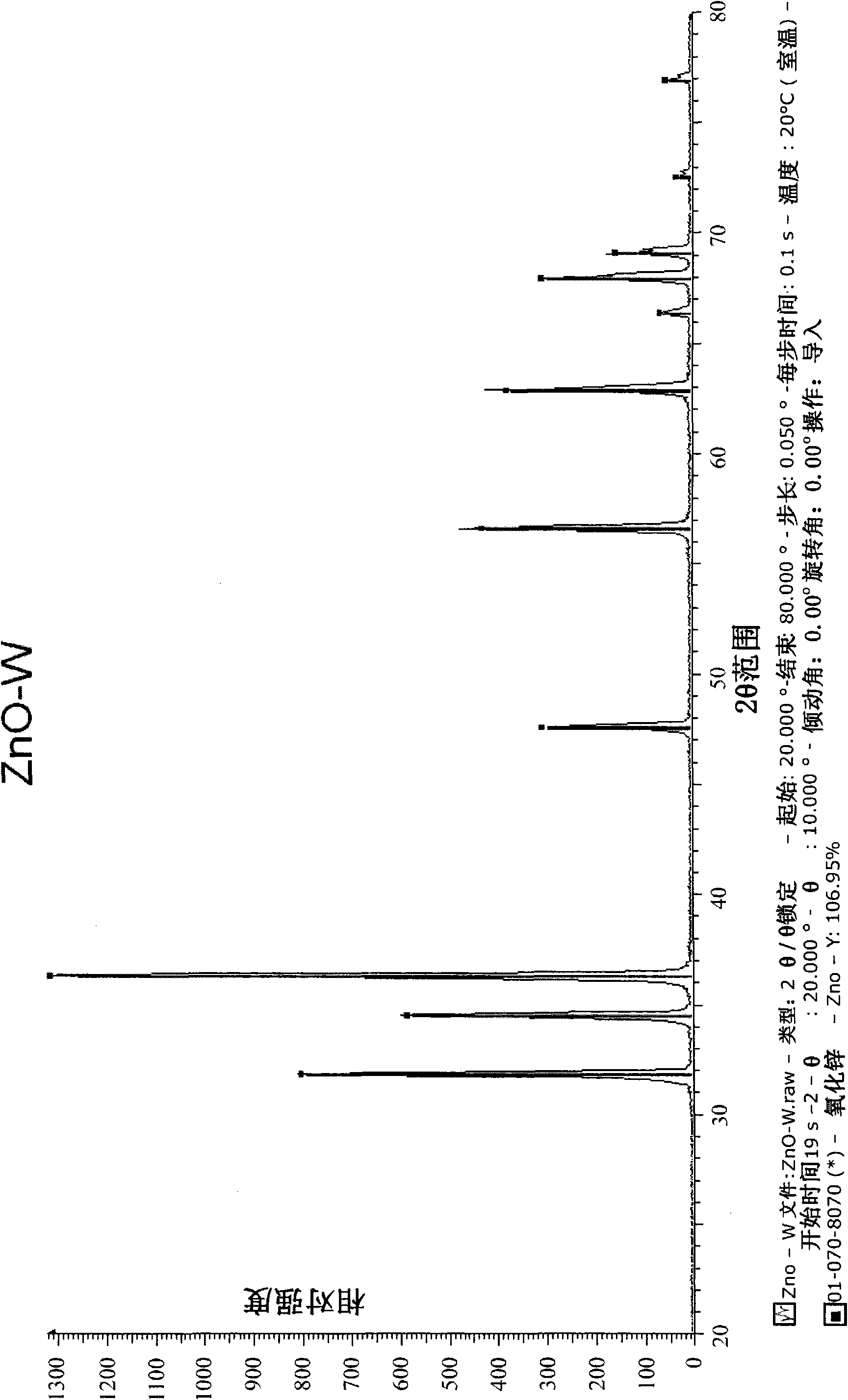

Preparation method of zinc oxide varister

ActiveCN101630553ARegulatory performanceMeet different usage needsResistor manufactureVaristor coresCapacitanceIon

The invention relates to a preparation method of a zinc oxide varister, comprising two independent steps: preparing zinc oxide granules with doping ion components; and preparing a sintering material for coating the zinc oxide granules. According to the performance requirement of the varister, the doping components of the zinc oxide granules, the components of the high-impedance sintering material and preparation conditions are prepared in advance; finally, the zinc oxide granules and the high-impedance sintering material are evenly mixed according to a certain proportion, and the zinc oxide varister is prepared according to the conventional technology. The zinc oxide varister prepared by the preparation method not only has voltage-sensitive performance, but also has one or more functions of heat sensitivity, capacitance, inductance, piezoelectricity or magnetic characteristic, and the like, can sinter at low temperature (lower than 900 DEG C) and can use fine silver as an inner electrode.

Owner:SFI ELECTRONICS TECH

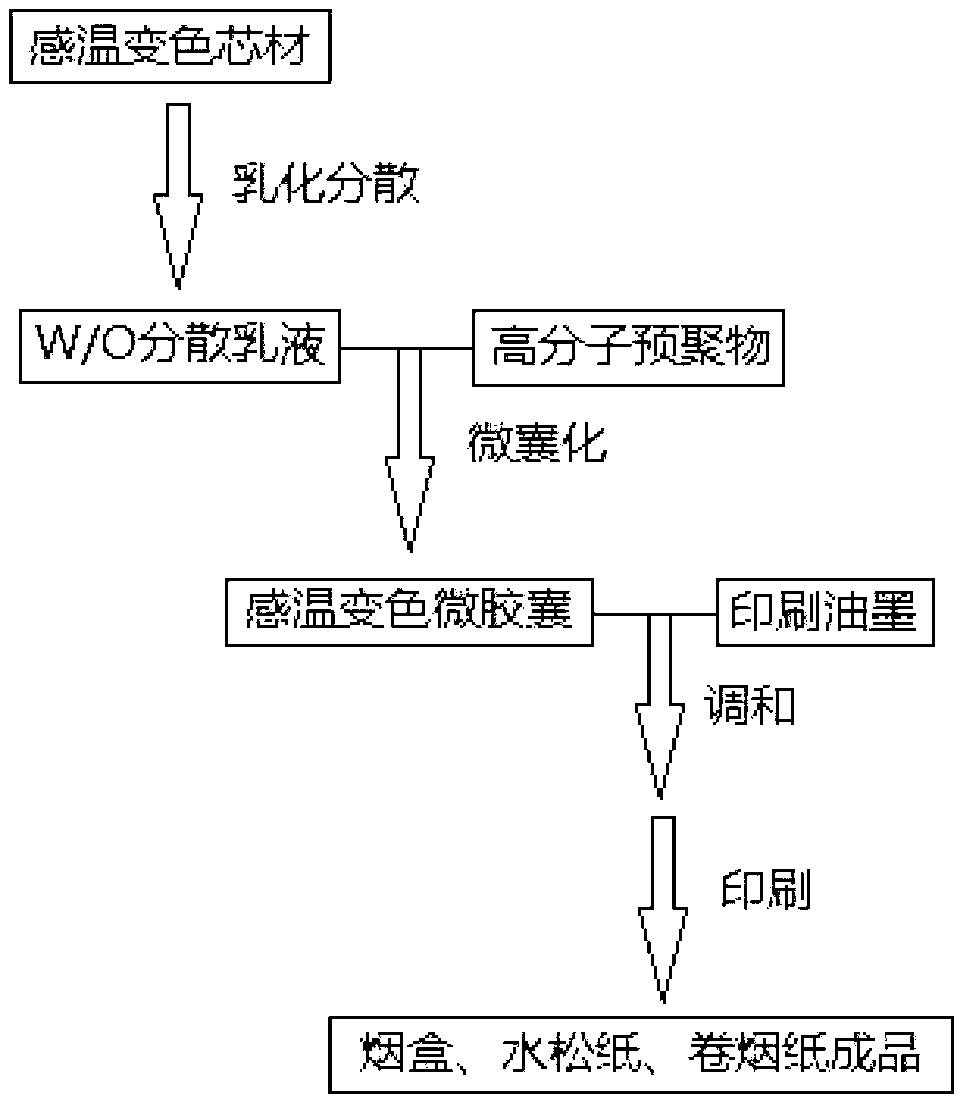

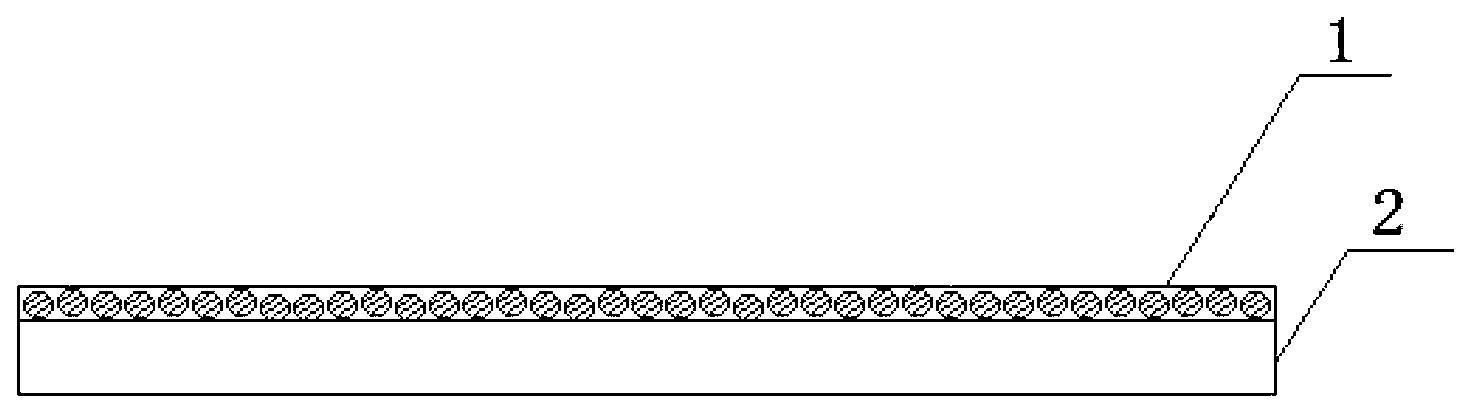

Reversible temperature-sensitive cigarette packing paper preparation method

ActiveCN103233397AOvercome limitationsImprove securityFlexible coversCoatings with pigmentsSolubilityPrinting ink

The invention discloses a reversible temperature-sensitive cigarette packing paper preparation method comprising the steps that: (1) a temperature-sensitive color-change core material is prepared by using a color-change pigment with a reversible temperature-sensitive material; (2) the temperature-sensitive color-change core material is subjected to emulsification dispersion in a W / O dispersion emulsion; (2) the emulsified temperature-sensitive color-change core material is mixed with a high-molecular prepolymer shell material, and a microencapsulation reaction is carried out, such that temperature-sensitive color-change microcapsules are prepared; and (4) the obtained temperature-sensitive color-change microcapsules are diluted and are blended into printing ink; printing is carried out upon cigarette packaging paper, and the packaging paper is air-dried. According to the invention, with a high-molecular coating technology, the color-change core material is separated from the outside through the high-molecular shell material, such that paint color, shape, weight, volume, solubility, reactivity, durability, pressure-sensitivity, heat-sensitivity, photosensitivity, and the like can be freely adjusted, and dye safety is greatly enhanced.

Owner:HUBEI CHINA TOBACCO IND

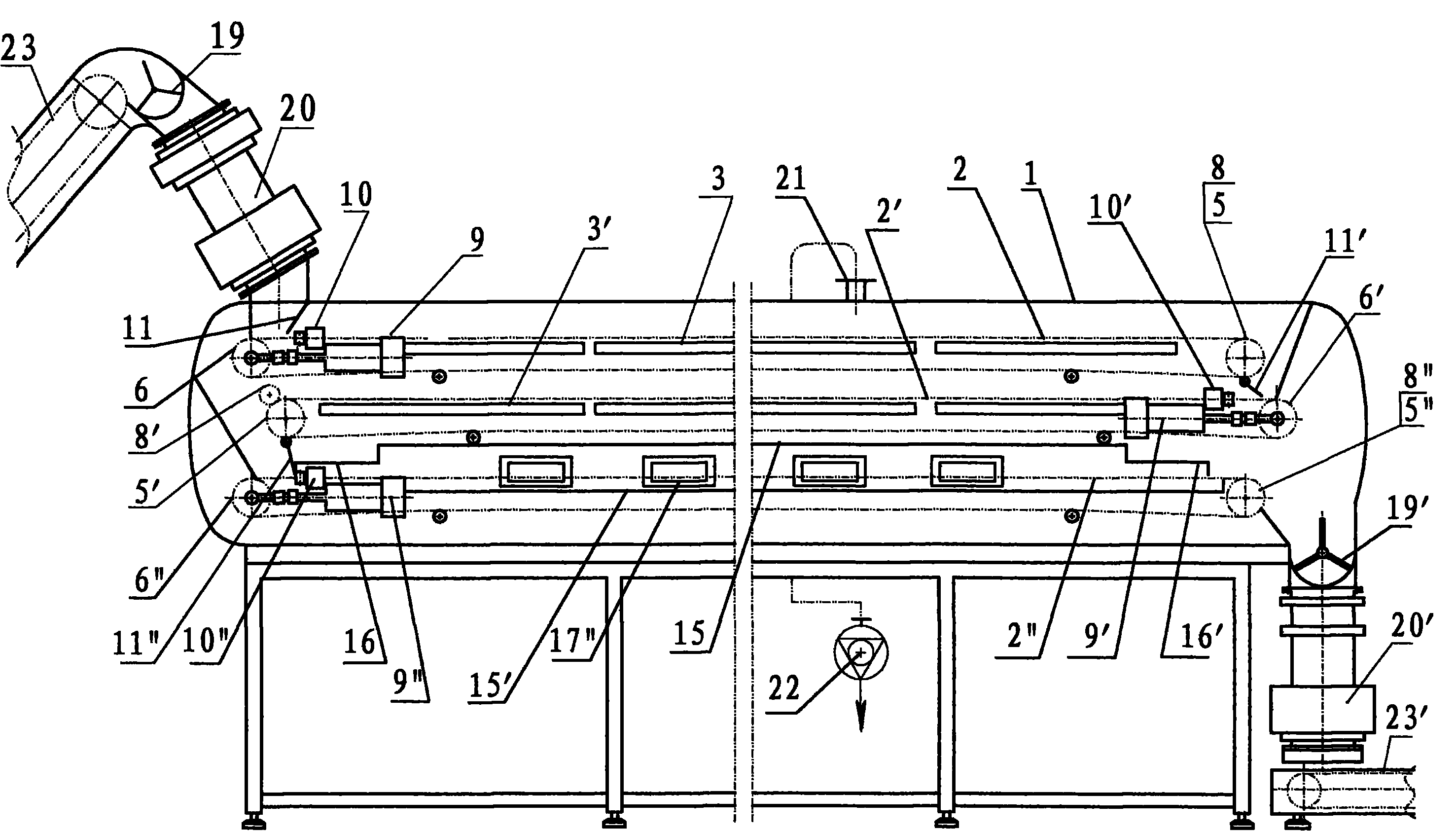

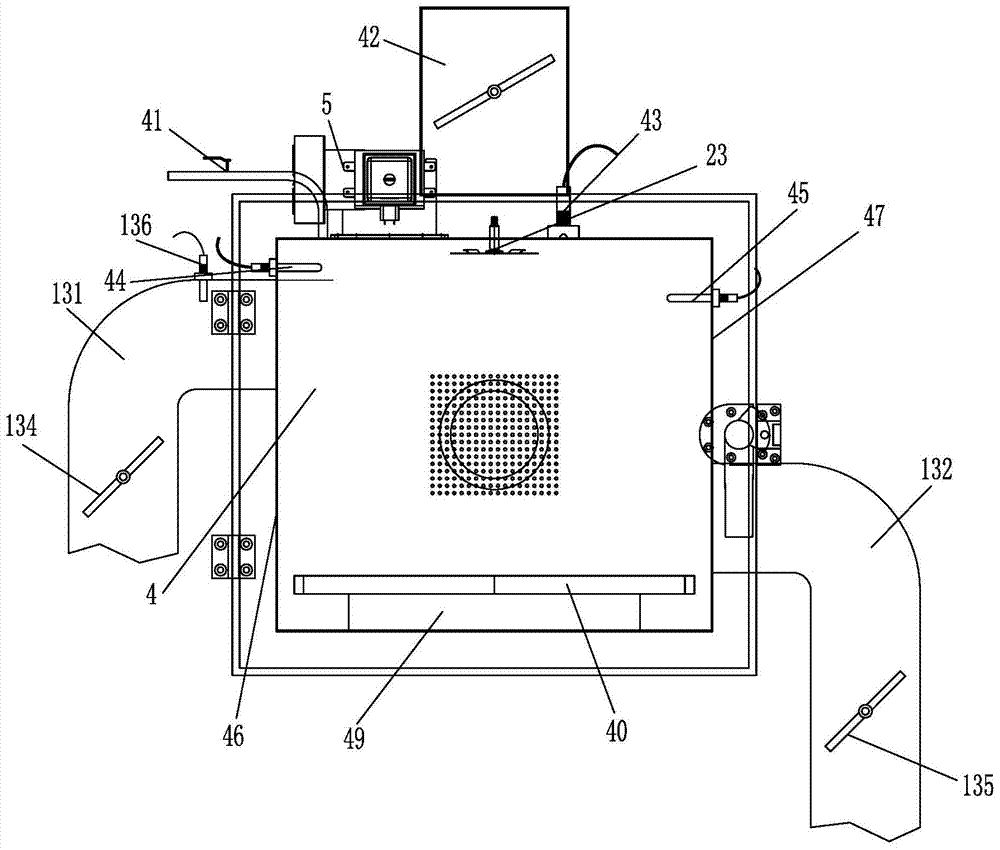

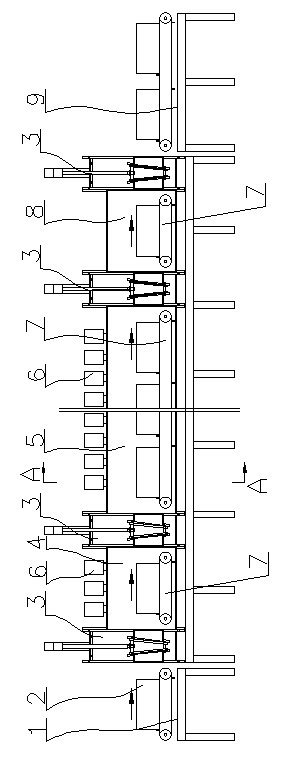

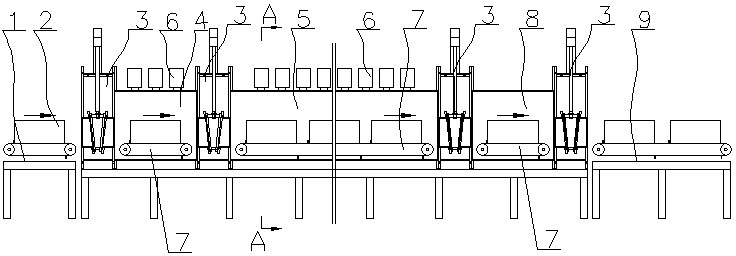

Continuous microwave vacuum drying and sterilizing processing device

InactiveCN101813408ASimple structureVacuum tightDrying using combination processesDrying solid materials with heatMicrowaveHigh energy

The invention belongs to the drying or sterilization processing machinofacture field in which solid or semi-liquid materials and the like of food, traditional Chinese medicinal materials, chemical engineering products and agricultural and sideline products can keep vacuum degree under the conditions of material feeding and discharging. The continuous microwave vacuum drying processing device is mainly formed by the combination of a feeding conveyer belt, a feeding / discharging sealing device, a vacuum chamber, a material bucket, a material fixing pump, a material distributing device, a heater, a microwave magnetic control device, a fetching device, a microwave choke device, a conveyer belt, a vacuum system, a feeding / discharging fixed supply device, a material conveyer belt and a storage tank. The equipment not only lowers drying temperature, but also quickens drying speed, has the characteristics of rapidness, high efficiency, low temperature and the like, can better retain original color, aroma and taste of processed materials of food, medicine and the like, the loss of vitamin and other thermal sensitive nutrition or active ingredients, thus obtaining better drying quality, ensuring the processed products to reach the requirement of high quality, high benefit, high energy conservation and time saving, being favorable for environmental protection and social comprehensive benefit, and having wide variety applicability.

Owner:陈长清

Method for preparing heat-sensitive moisture-retaining central line filter stick of cigarette

InactiveCN102068038ARelease stabilityReduce sensory stimulationTobacco smoke filtersMolding machineDiluent

Owner:CHINA TOBACCO GUIZHOU IND

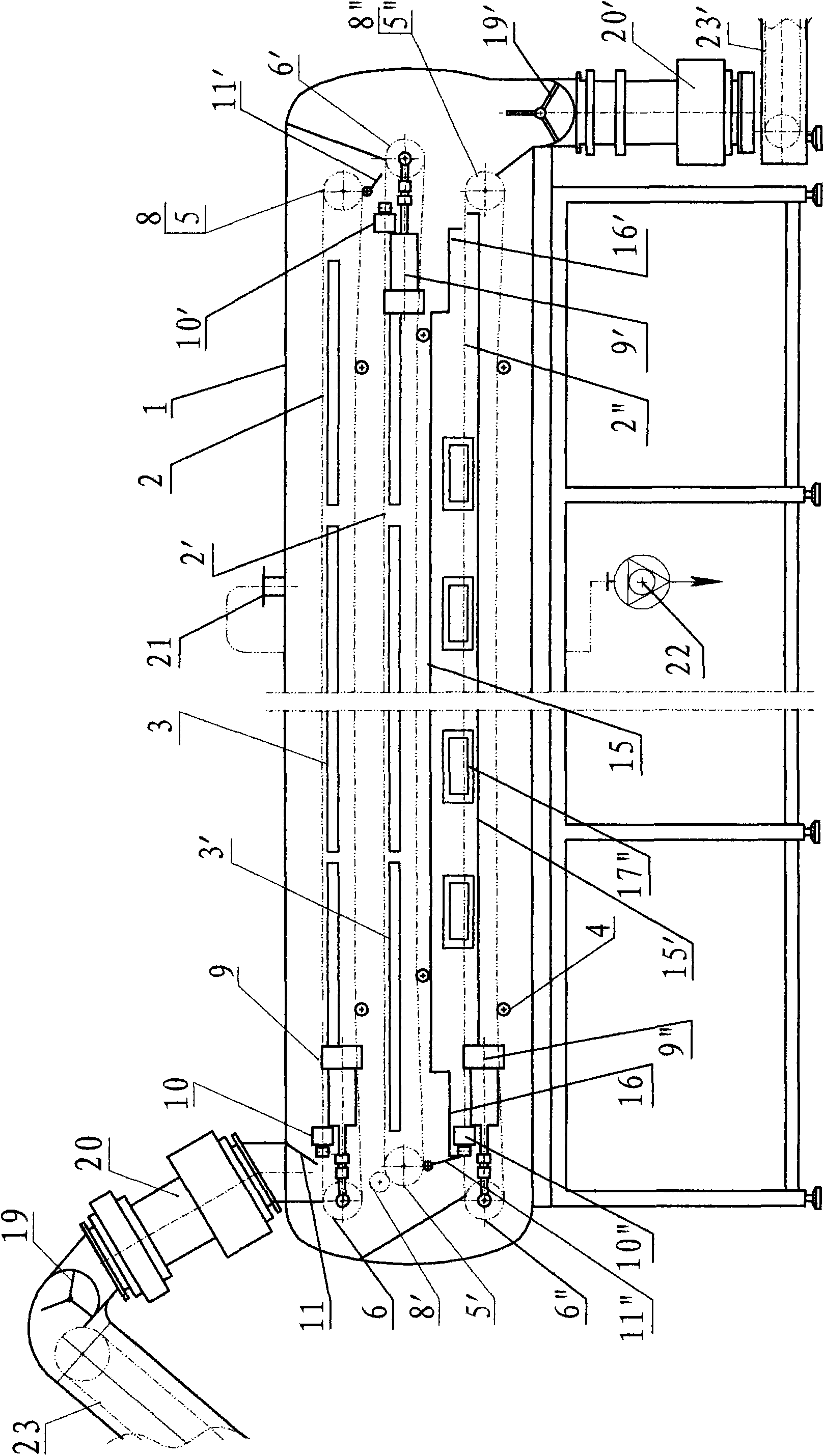

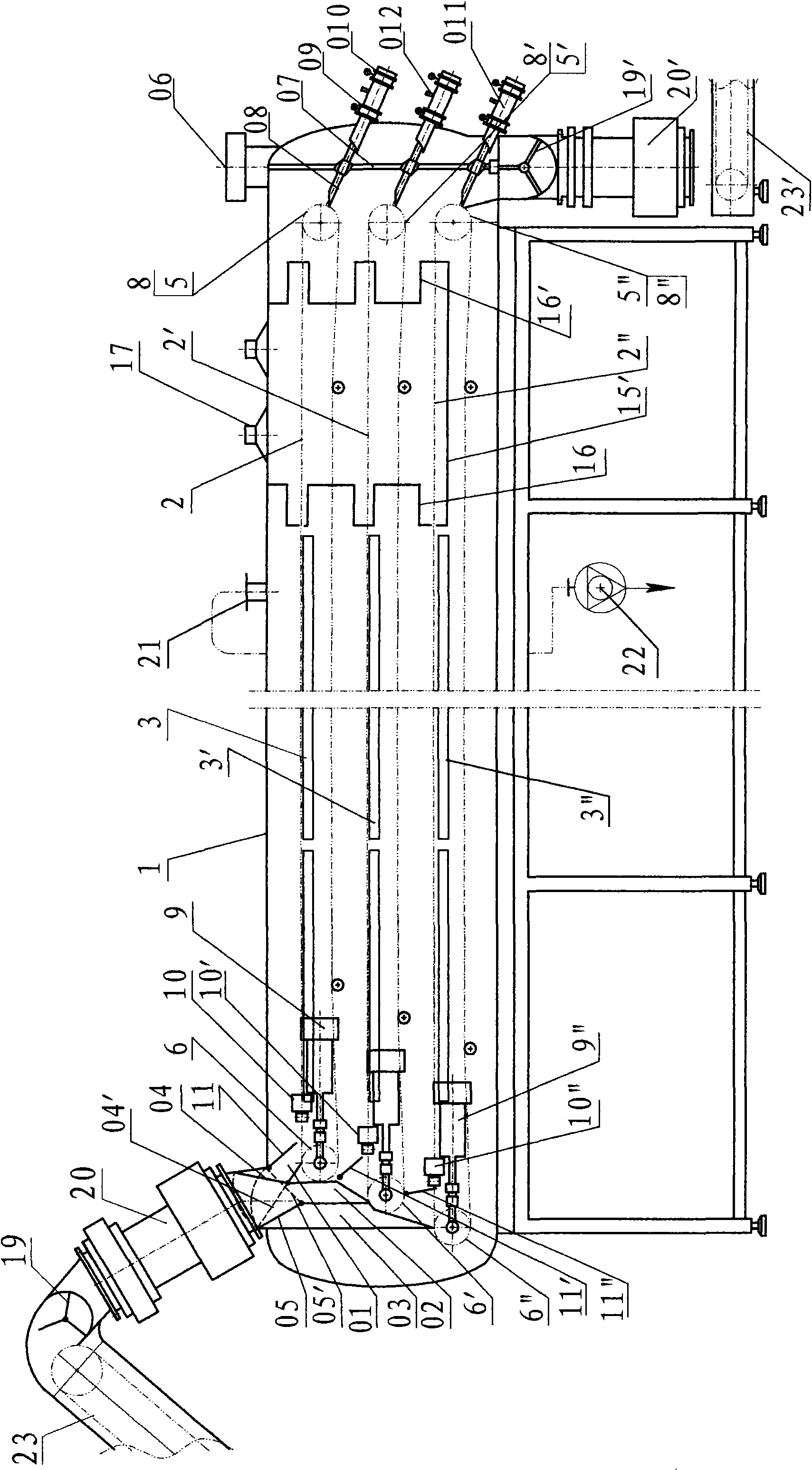

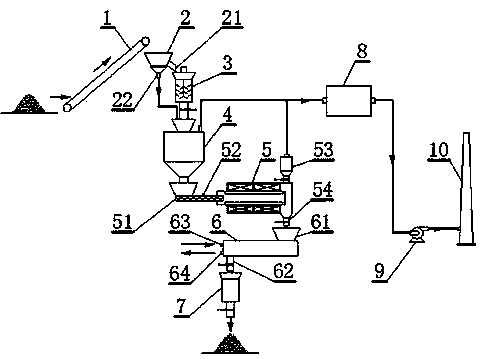

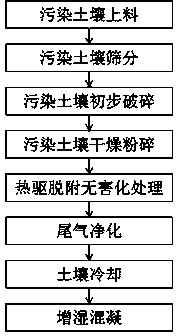

Thermal driving desorption restoration method of polluted soil

InactiveCN104307865ATake advantage ofReduce economic costsContaminated soil reclamationAutomatic controlDesorption

The invention relates to a thermal driving desorption restoration method of polluted soil. The method comprises the steps that a thermal driving desorption restoration system of the polluted soil is adopted; waste heat of high-temperature flue gas, high-temperature air, high-temperature steam or high-temperature liquid serves as a heat source; and indirect heating is performed to restore the polluted soil. The restored soil can reach a subsequent recycling requirement. The method is suitable for restoring the soil polluted by organic matters such as VOCs (volatile organic compounds), SVOCs (semi volatile organic compounds), PAHs (polycyclic aromatic hydrocarbons), PCBs (polychlorinated biphenyls), TPHs (total petroleum hydrocarbons) and pesticides, is also suitable for restoring the soil polluted by thermal-sensitive heavy metal such as Hg and As, is high in reaction speed, short in restoration cycle, safe and stable in operation, and economically feasible, adopts automatic control and real-time monitoring, has no secondary pollution, and has good environment-friendly and social benefits; and a removal rate of a pollutant reaches above 99%.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

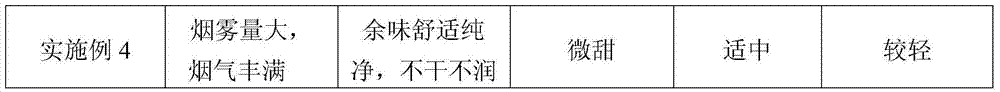

Heat-sensitivity electronic tobacco juice and preparation of heat-sensitivity electronic tobacco juice

ActiveCN104256888AChange storage formatThermoreversibleTobacco treatmentTobacco devicesCarrageenanLiquid smoke

The invention discloses heat-sensitivity electronic tobacco juice. The heat-sensitivity electronic tobacco juice comprises, by weight, 5%-8% of tobacco extracting solutions, 0.1%-3.5% of nicotine, 0.1%-2% of acidity regulators, 2%-3% of tobacco essence, 0.4%-8% of thickening agents, 15%-35% of water and the balance propylene glycol; the sum of all components is 100, and the components are evenly mixed to prepare the heat-sensitivity electronic tobacco juice. The thickening agents are one or more of gelatin, agar, acquirable burning rubber and carrageenan. The heat-sensitivity electronic tobacco juice has the heat sensitivity because of containing the thickening agents, and when the heating temperature ranges from 50 DEG C to 80 DEG C, the electronic tobacco juice is in the liquid state; when heating is stopped, the electronic tobacco juice liquidated by heating is cooled to restore to the solid state and is free of random flowing, so that the problems of liquid leakage, backflowing and volatilization of the electronic tobacco juice in the storage process and the transporting process are effectively solved, and a consumer can conveniently take and use the electronic tobacco juice. The heat-sensitivity electronic tobacco juice can be stored for a long time, and the quality, the taste and the like of the electronic tobacco juice all keep unchanged in the storage period.

Owner:CHINA TOBACCO JIANGSU INDAL

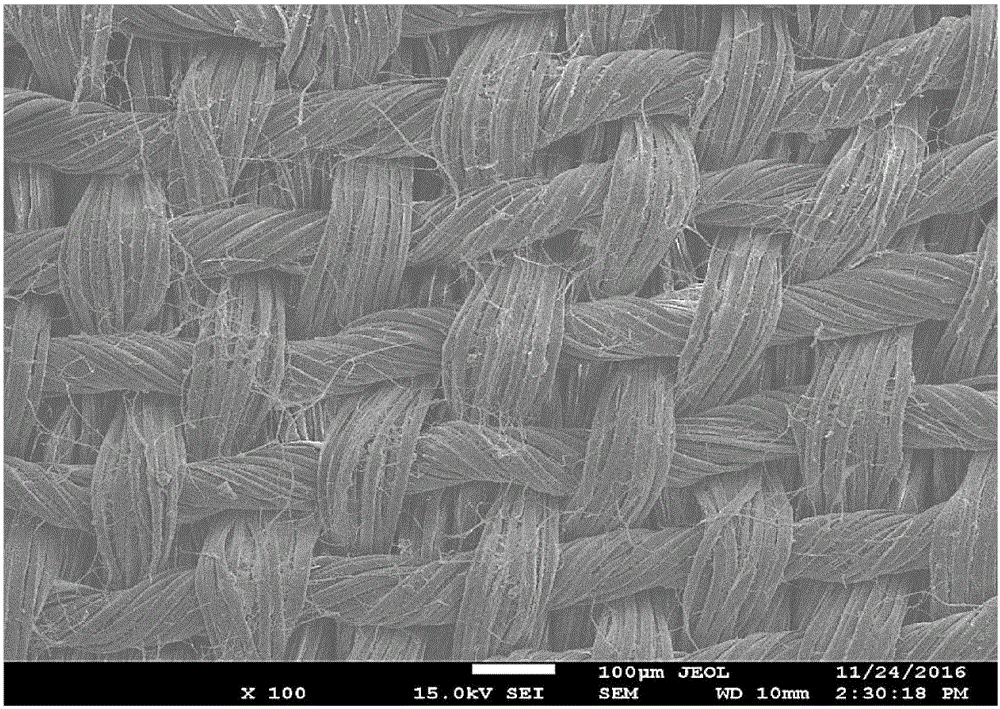

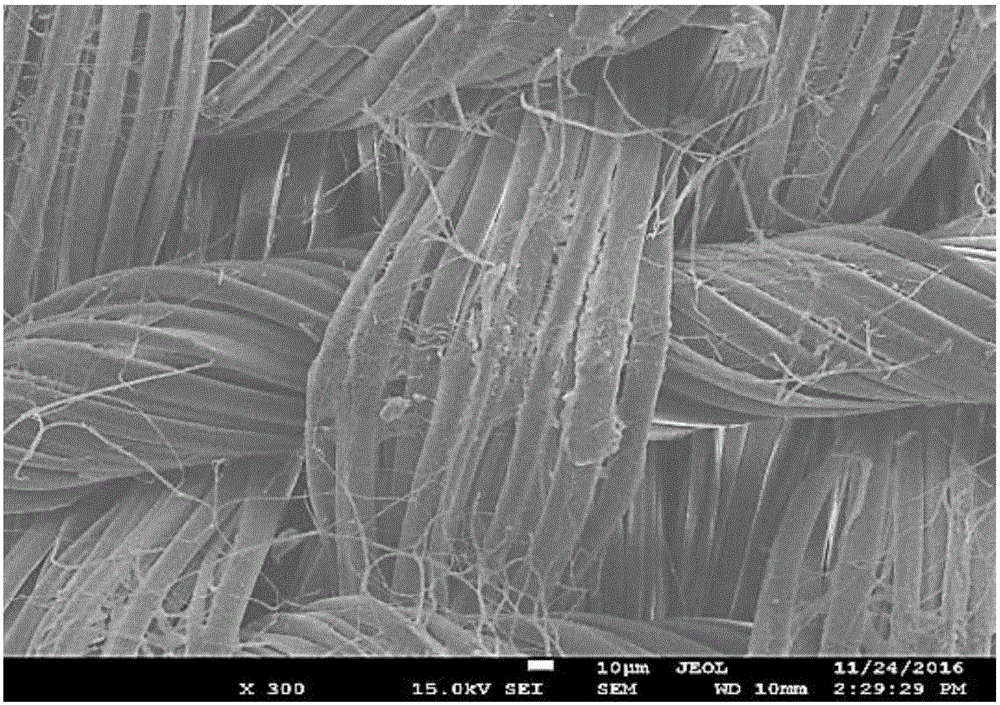

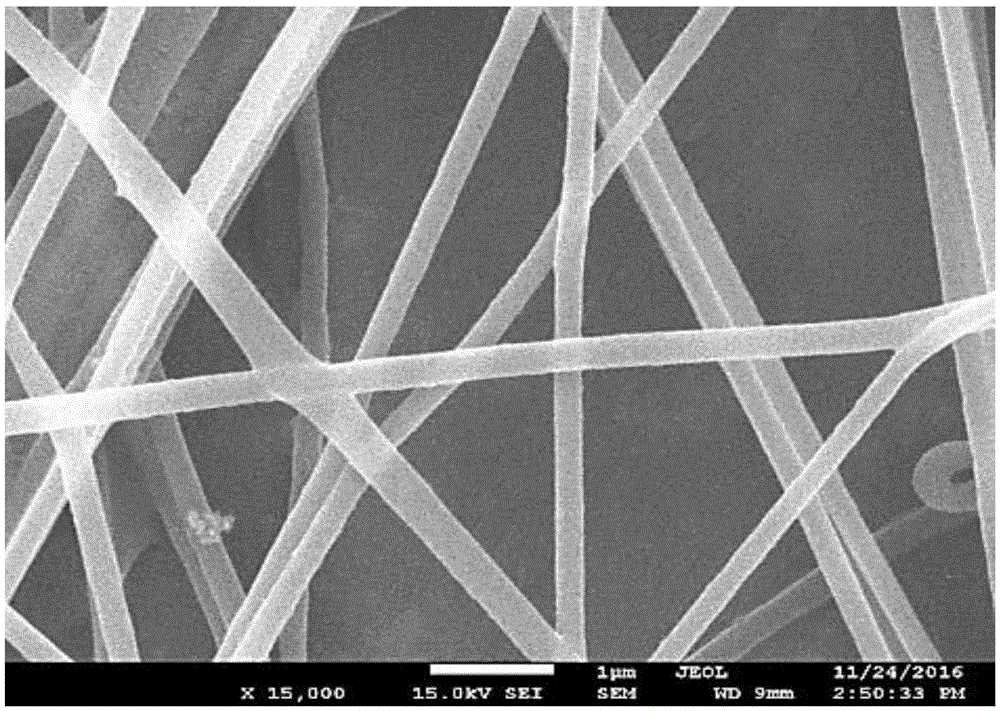

Temperature-sensitive antibacterial nanofiber and preparation method thereof

ActiveCN106757520AImprove breathabilityImprove thermal performanceConjugated synthetic polymer artificial filamentsAnimal fibresPolyethylene oxidePoly(N-isopropylacrylamide)

The invention provides temperature-sensitive antibacterial nanofiber. The temperature-sensitive antibacterial nanofiber is prepared by the following steps: adding N-isopropylacrylamide, chitosan, N,N-methylene bisacrylamide, an initiator and N,N,N,N-tetramethylethylenediamine into an acetic acid solution and performing free radical polymerization reaction to obtain chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogel; mixing the chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogen and an aqueous solution of polyethylene oxide to obtain electrostatic spinning liquid; performing electrostatic spinning on the electrostatic spinning liquid to obtain the temperature-sensitive antibacterial nanofiber. The temperature-sensitive antibacterial nanofiber provided by the invention has excellent antibacterial property and heat sensitivity.

Owner:EASTERN LIAONING UNIV

Method of preparing instant nursing barley green product through using hot-air dehydrated barley grass powder as raw material

ActiveCN104256641AHigh extraction rateReduce lossesFood thermal treatmentFood shapingSolubilityBARLEY GRASS

The invention discloses a method of preparing an instant nursing barley green product through using hot-air dehydrated barley grass powder as a raw material, and belongs to the technical field of research and development of health care foods. The method comprises the following steps: taking the hot-air dehydrated barley grass powder as the main raw material, adding other nutrient substances and food fillers (such as maltodextrin and beta-cyclodextrin) as processing auxiliary materials to produce the instant nursing barley green health care product, and specifically comprises the steps of extraction, concentration, mixing, pH value regulation, drying, packaging and the like. Compared with the conventional extraction method, the nutrients are extracted by a double-frequency ultrasonic wall breaking method from the hot-air dehydrated barley grass powder; the method is short in extraction time, high in nutrient extraction ratio and low in loss; the auxiliary materials can be added according to demands of different users, so that the quality of the barley green product can be improved, the product can achieve a better pertinence, and consumers can purchase the product with more accurate purposes; a low-temperature microwave vacuum spray drying method is adopted, so that the method is short in drying time, and low in damage to thermosensitive substances; the product is fine and smooth, and good in solubility.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

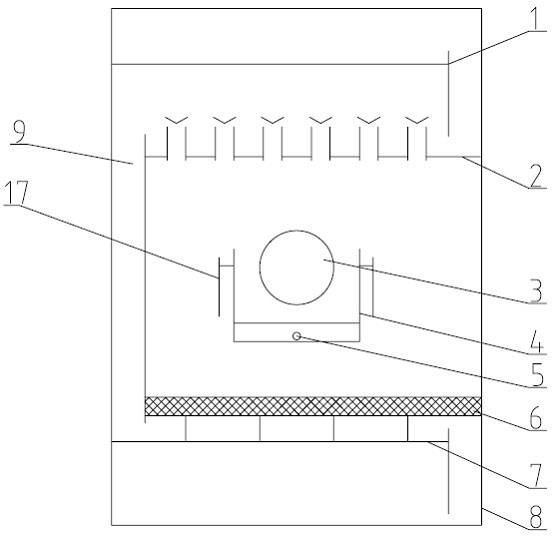

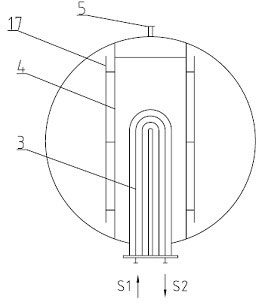

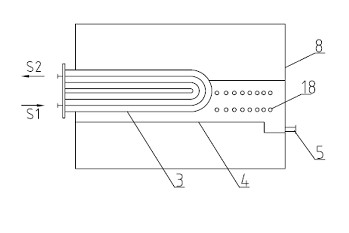

Rectifying tower flow controllable type lateral-line extraction combined device

The invention relates to a rectifying tower flow controllable type lateral-line extraction combined device, which is mainly used for the precisely controlled extraction process of gas phase lateral-line products in the rectifying tower. The rectifying tower flow controllable type lateral-line extraction combined device comprises a liquid collecting device, an inserted type condenser, a condensate collecting groove and a demister, wherein the principle of the device is as follows: the liquid and gas are reasonably divided, the phenomenon that the rising gas phase contains the liquid is avoided, and then the rising gas phase is partially condensed into liquid phase by the inner inserted type heat exchange device and is partially laterally extracted. By using the device, the difficulties that the flow is difficult to measure and control when the gas phase lateral-line extraction is performed in the rectifying tower are overcome, and at the same time, the gas phase partially condensation is equivalent to adding a layer of theoretical plate. The device has compact structure, is suitable for the rectifying tower which requires laterally extracting high-purity products in stripping section, and is in particular suitable for the separation process for high vacuum heat-sensitive materials.

Owner:NANJING UNIV

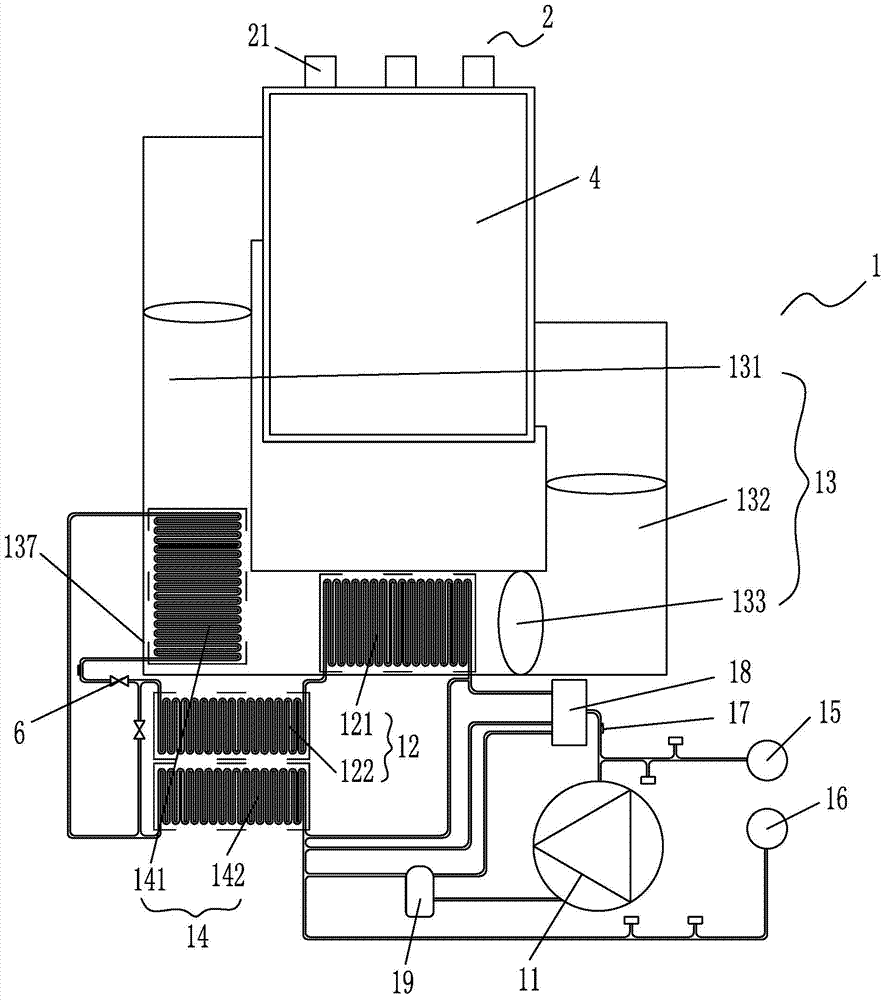

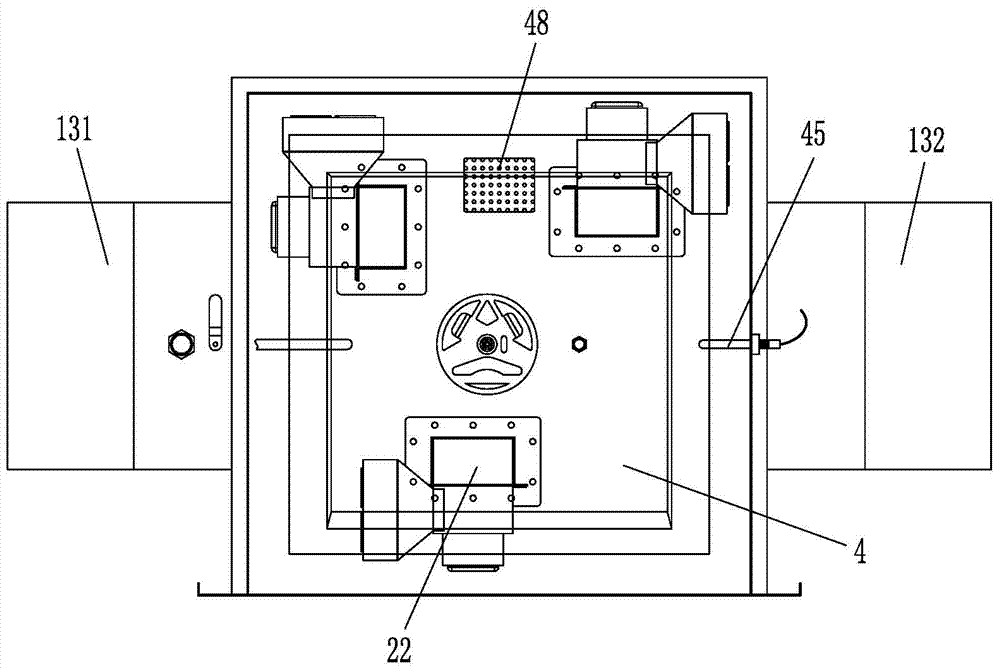

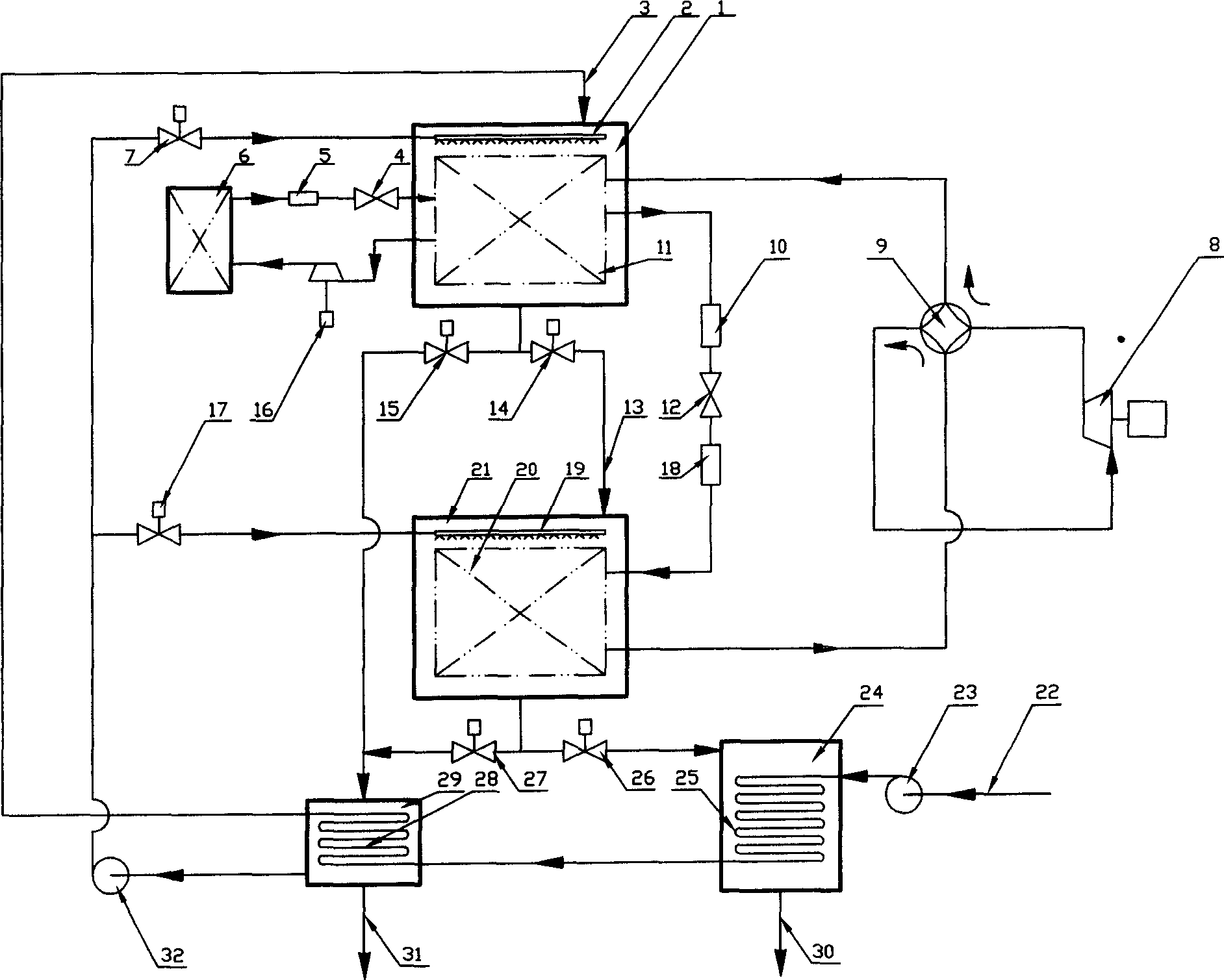

Heat pump-microwave combined drying device

ActiveCN103900355AReduce heat loadOvercoming problems that hinder the movement of internal moisture to the outsideDrying solid materials with heatChemical industryChemical industryMicrowave

A heat pump-microwave combined drying device comprises a heat pump system, a microwave system and a control system. The heat pump assembly and the microwave system share a drying chamber, the microwave system is installed on the top of the drying chamber, the heat pump system is connected with the drying chamber through a circulating air duct, and the control system is connected with the heat pump system and the microwave system, used for setting and adjusting drying conditions and online monitoring drying parameters, and capable of selecting microwave drying and / or heat pump drying according to the characteristics of materials and finished product requirements so that high water content materials with different shapes and different water contents or under high-humidity conditions can be dried. The heat pump-microwave combined drying device is reasonable in structural layout, easy to use, maintain and repair, uniform in drying, large in processing capacity, efficient, free of microbial pollution and capable of saving energy, the process is advanced, and the quality of dried products is good. The heat pump-microwave combined drying device is especially suitable for drying fruit and vegetables, drying marine products and drying materials which are high in heat sensitivity and prone to oxidization, and applied to the biological industry, the pharmaceutical industry, the chemical industry and the like.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

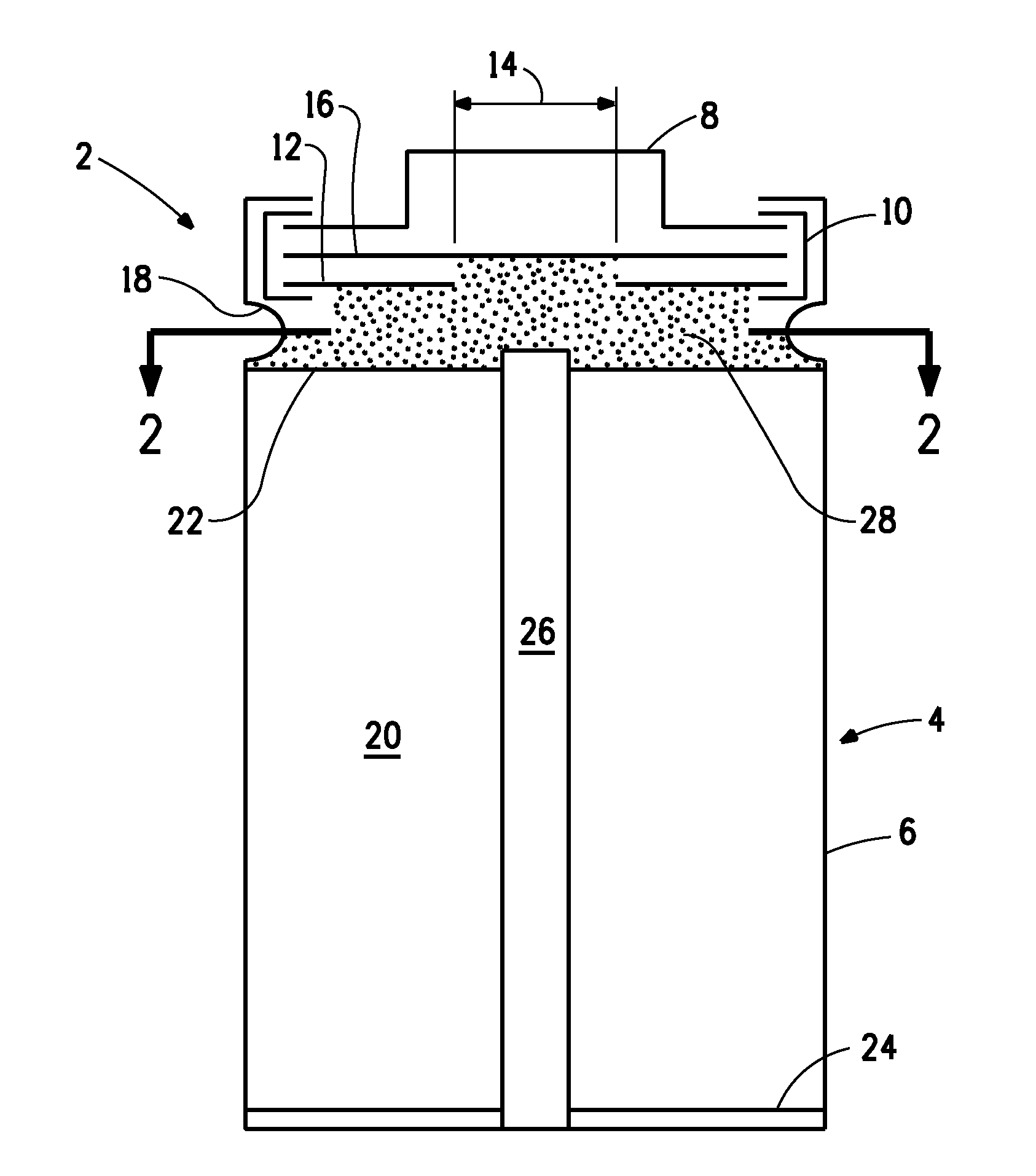

Li-ion battery having improved safety against combustion

ActiveUS20160365553A1Reduce intensityFinal product manufactureSmall-sized cells cases/jacketsCombustionPolyvinyl alcohol

The present invention provides a process comprising for modifying a Li-ion battery having a region of electrochemical activity and an enclosure therefor, said process comprising forming at least one chamber within said enclosure separate from said region of electrochemical activity, positioning combustion abatement agent within said chamber, whereby said combustion abatement agent is not in contact with said region of electrochemical activity, said chamber being pressure or heat sensitive, whereby when said region of electrochemical activity overheats, said chamber is breached, allowing said combustion abatement agent to contact said region of electrochemical activity to abate combustion of said region of electrochemical activity, wherein exemplary of combustion abatement agent is the composition comprising liquid fluoropolyether and exemplary of the of the chamber exhibiting pressure or heat sensitivity is to include a low melting, non-flammable polymer such as polyvinyl alcohol in the material of construction of the chamber.

Owner:THE CHEMOURS CO FC LLC

Rapid drying processing method of American ginseng

InactiveCN102488732AReduce lossesFast drying and dehydrationDrying solid materials with heatDigestive systemHeat sensitiveMoisture

The invention discloses a rapid drying processing method of American ginseng and belongs to the technical field of agricultural product processing. The method comprises the following operation steps: storing the American ginseng in a low temperature and high moisture environment; cleaning the American ginseng with root hairs and rhizomes removed; slicing; carrying out gas jet impingement drying with changed temperature and wind speed; and carrying out nitrogen-filled package. The invention employs the gas jet impingement technology to dry the American ginseng sheets, has fast drying and dehydration speed, high production efficiency and short processing time; temperature changing and wind speed changing drying is employed according to drying characteristics of the material and has advantages of low heat-sensitive component loss and low energy consumption; and the product is not treated with dry sulphitation and natural and pollution-free.

Owner:CHINA AGRI UNIV

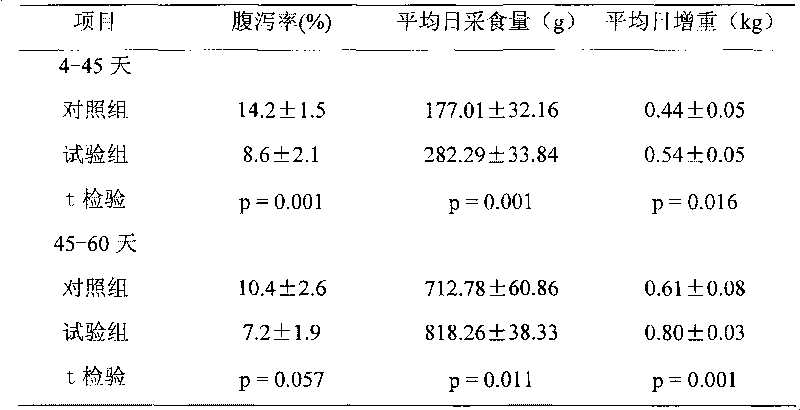

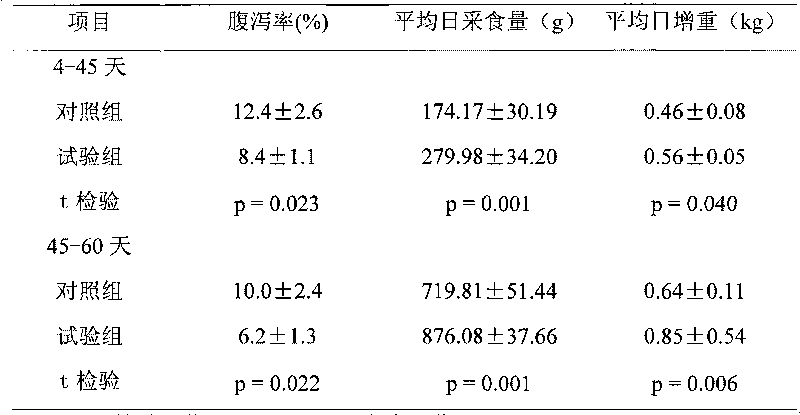

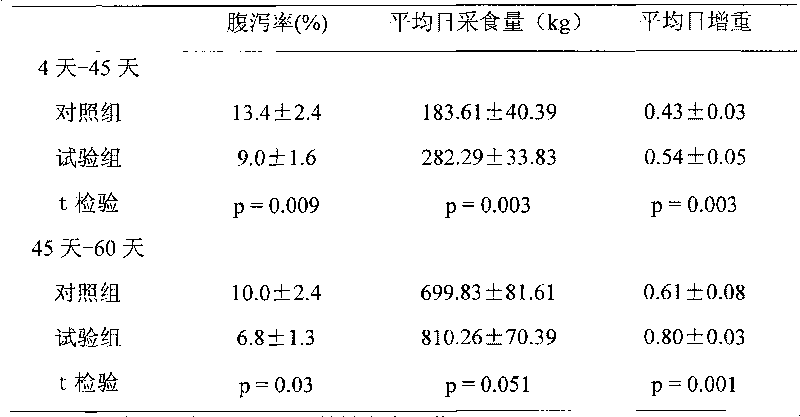

Method for preparing antidysenteric early-weaning of calf opening material

ActiveCN101692878AAvoid damageImproves nutrient digestibilityFeeding-stuffFood processingGeneration rateAdditive ingredient

The invention discloses a method for preparing antidysenteric early-weaning of calf opening material, which comprises the following steps: adopting secondary granulation process to prepare particle food, mixing the particle food and tabletting grains according to proportion, adopting an externally-spraying method to spray molasses on the surfaces of particle food and tabletting grains after evenly mixing, and getting calf opening material. When preparing particle food, the primary granulation adopts higher refining temperature for fully ripening big raw materials including corn, soya bean waste and the like, on the one hand, nutrient slaking rate is improved, on the other hand, the palatability is improved, secondary granulation adopts lower refining temperature, thereby the damage function of high temperature to thermo-sensiblity reactive component can be avoided, and meanwhile, the negative function of dairy product and saccharide components to the granulation process is lightened. Animal test results show that the calf particle food has better palatability, can effectively prompt animals to take in feed, achieves early-weaning within 45 days, can effectively control the loose bowel movement generation rate of calves, and prompts the growth of calves.

Owner:草原和牛投资有限公司

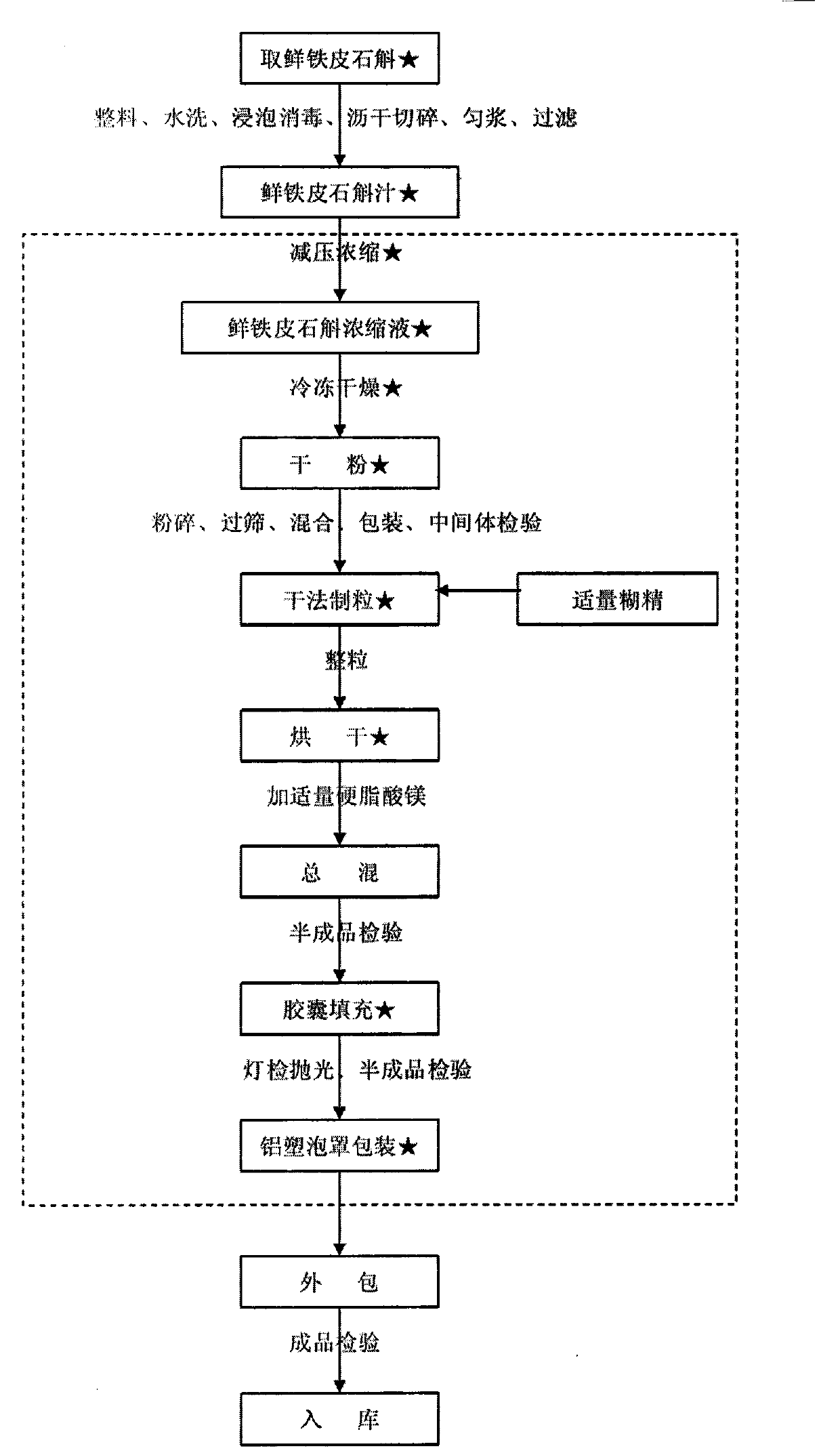

Preparation method of fresh Dendrobium officinale preparation

InactiveCN103735853AGuaranteed stabilityGuarantee stabilityPlant ingredientsFreeze-dryingSingle effect

The invention discloses a preparation method of fresh Dendrobium officinale preparation. The method comprises the following steps: fetching Dendrobium officinale, clearing and cleaning, disinfecting with ozone water, pulverizing, homogenizing, collecting juice, sieving, and obtaining a fresh Dendrobium officinale juice; conveying the fresh Dendrobium officinale juice into a single-effect condensing device for pressure reduction and condensation at 40-50 DEG C, and obtaining a concentrate with density of 1.04-1.08 g / ml; obtaining a fresh Dendrobium officinale powder by direct freeze drying of the concentrate; preparing a fresh Dendrobium officinale preparation from the fresh Dendrobium officinale powder. The invention has the advantages of simple step and easy operation, and the prepared product meets the standard with good stability. The ozone water disinfection technology and the freeze drying process can greatly reduce microbial population and keep various active effective components with heat sensitivity to the largest extent.

Owner:李兰星

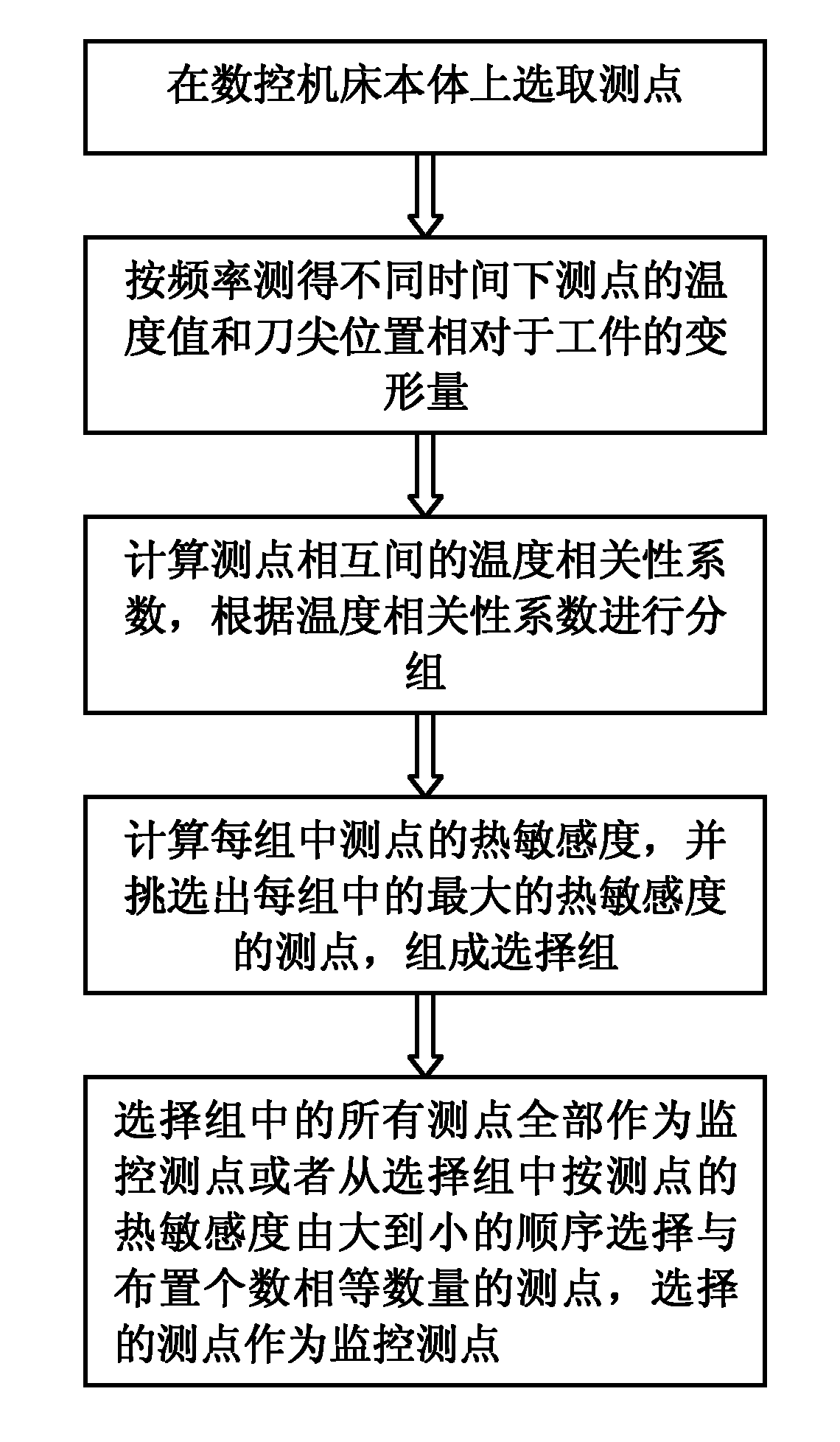

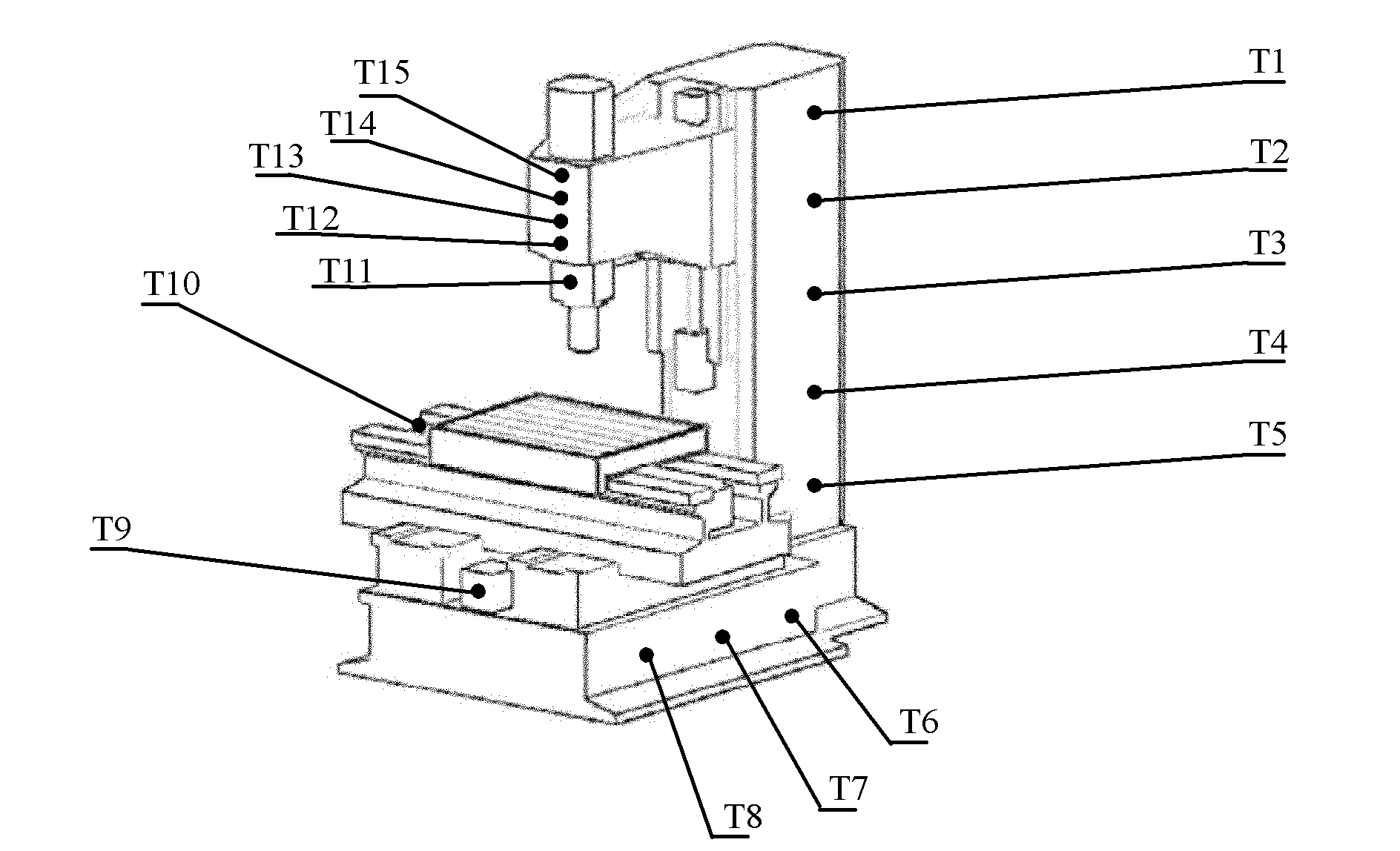

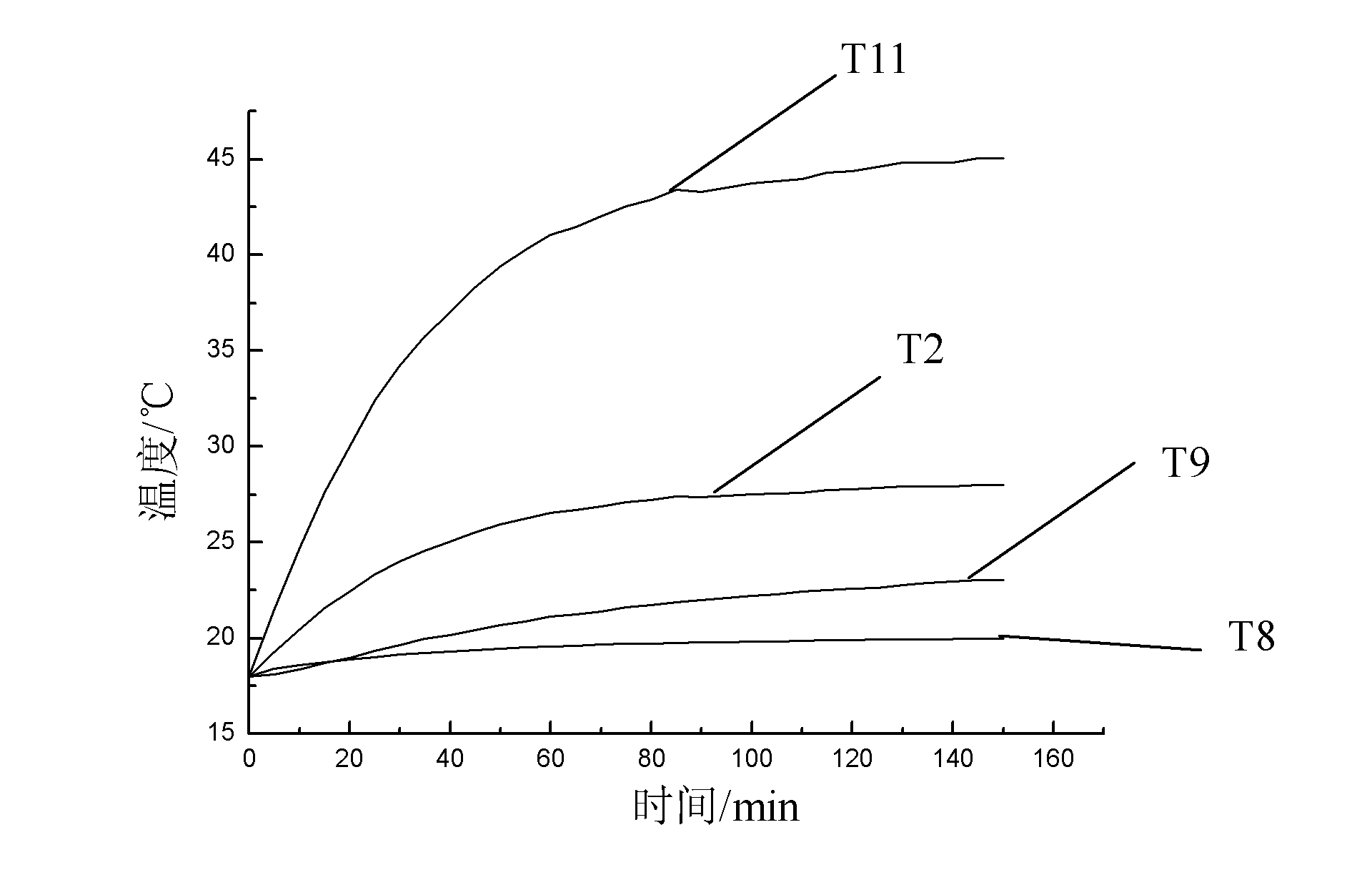

Arrangement method of heat characteristic monitoring measurement points of numerical control machine

InactiveCN102179725AReduce the number of monitoring points for thermal characteristicsAvoid strong temperature dependenciesMeasurement/indication equipmentsCorrelation coefficientNumerical control

The invention discloses an arrangement method of heat characteristic monitoring measurement points of a numerical control machine. The method comprises the following steps of: (1) selecting measurement points on a numerical control machine body, and acquiring temperature values of the measurement points under different time and deformation of a tool nose position relative to a workpiece under different time according to the frequency to form a temperature change sequence X of the measurement points and a deformation sequence delta of the tool nose position relative to the workpiece; (2) calculating temperature correlation coefficients according to the temperature change sequence X of the measurement points, and dividing the measurement points into groups; (3) performing heat sensitivity calculation on the measurement points in each group according to the data of the temperature change sequence X of the measurement points and the deformation sequence delta of the tool nose position relative to the workpiece, and selecting the measurement points with highest heat sensitivity in each group to form a selection group; and (4) selecting the measurement points serving as the heat characteristic monitoring measurement points of the numerical control machine from the selection group according to different arrangement number of the heat characteristic monitoring measurement points of the numerical control machine. The method disclosed by the invention has the advantages of simplicity, effectiveness, clear principle, simplicity in operation, good controllability and the like.

Owner:ZHEJIANG UNIV

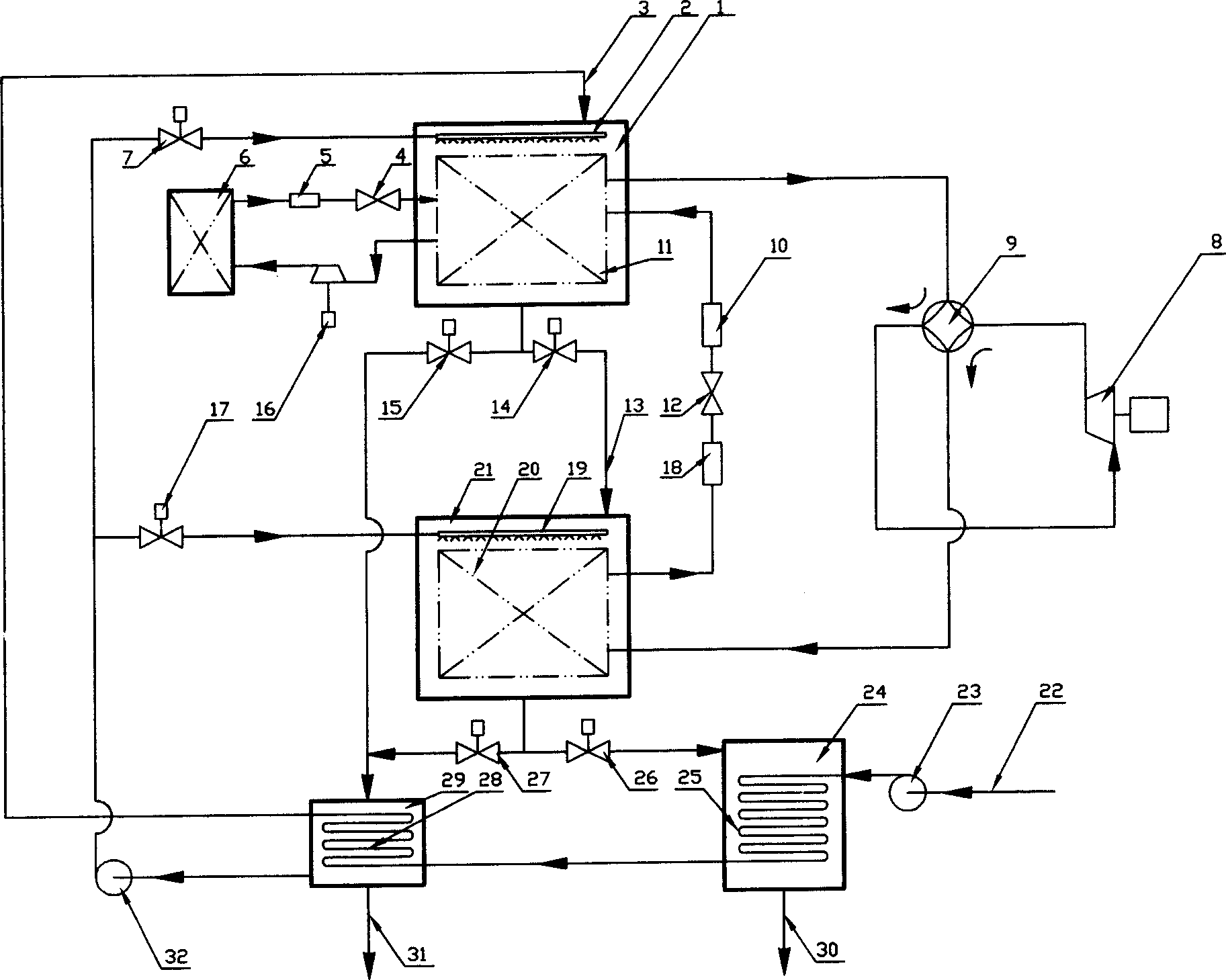

Concentration method of graduate freezing interface

InactiveCN1849937AIncrease the effective heat transfer areaEfficient cooling recoveryClimate change adaptationFood scienceIce waterEnrichment methods

The present invention relates to a method capable of utilizing closed heat pump circulation technique to implement high-effective energy-saving interfacial progressive freeze concentration. Said method includes 7 working steps of feeding aqueous solution, concentrated solution transfer and discharge, thawy water transfer and discharge, washing ice layer, heat pump circulation, auxiliary refrigeration and central control, and includes a system device formed from 7 subsystems and two icing water tanks which are communicated to implement aqueous solution interfacial progressive freeze concentration.

Owner:QINGDAO UNIV

Processing technology of freeze drying and fresh-keeping of cistanche

InactiveCN103211871ANo sex changeNo activityMetabolism disorderDrying solid materials without heatFreeze-dryingMoisture

The invention relates to a processing technology of freeze drying and fresh-keeping of cistanche, and relates to the cistanche preservation technical field. The processing technology comprises the following steps: collecting and grading, slicing, killing enzyme and disinfecting, loading in a tray, quickly freezing at ultralow temperature, performing vacuum dehydrated drying, and sealing and packaging. The defect of cistanche nutrition loss caused by current cistanche drying and fresh-keeping technology in the prior art can be effectively overcome. The invention is characterized in that the cistanche contains a heat sensitivity substance, denaturation or inactivation performance can not be generated, the volatile component loss in cistanche is little; cistanche can keep original property and structure, the dried cistanche is loosened and porous, and presents a sponginess state, the original property can be recovered after 2-4 hours by adding water, the volume is almost unchanged; the good original state can be kept after slicing the cistanche, and the sliced cistanche can be connected through several lines, which is in favor of original state recovery, the substance capable of easily being oxidized in cistanche can be protected, more than 95-99% of moisture can be eliminated after drying, so that long-term fresh keeping of the dried produce can be realized.

Owner:贺文军

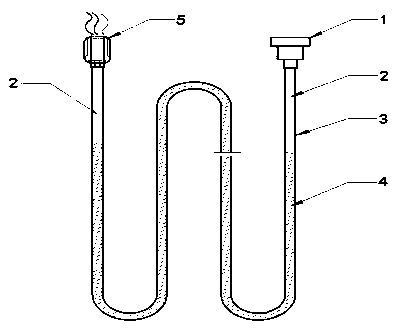

Fire exploration pipe-type temperature-sensitive self-startup extinguishing device

The invention discloses a fire exploration pipe-type temperature-sensitive self-startup extinguishing device. The fire exploration pipe-type temperature-sensitive self-startup extinguishing device comprises a sealing container and a fire extinguishing agent sealed in the sealing container. The sealing container is prepared from a heat-sensitive material, the surface of the sealing container can be softened at a high temperature and be broken under the action of inner pressure so that a jet orifice is formed. The fire exploration pipe-type temperature-sensitive self-startup extinguishing device realizes combination of the exploration member, the extinguishing agent storage container and a conveying pipe. The exploration pipe is filled directly with the extinguishing agent and driving gas so that an extinguishing agent steel cylinder is avoided and the whole structure is simple and reliable, has a low failure rate, can be installed flexibly and conveniently and has a high cost performance.

Owner:SHANGHAI WARMTEC MFG CO LTD

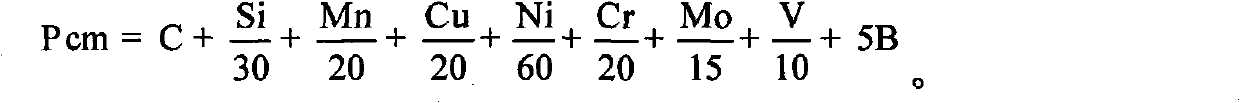

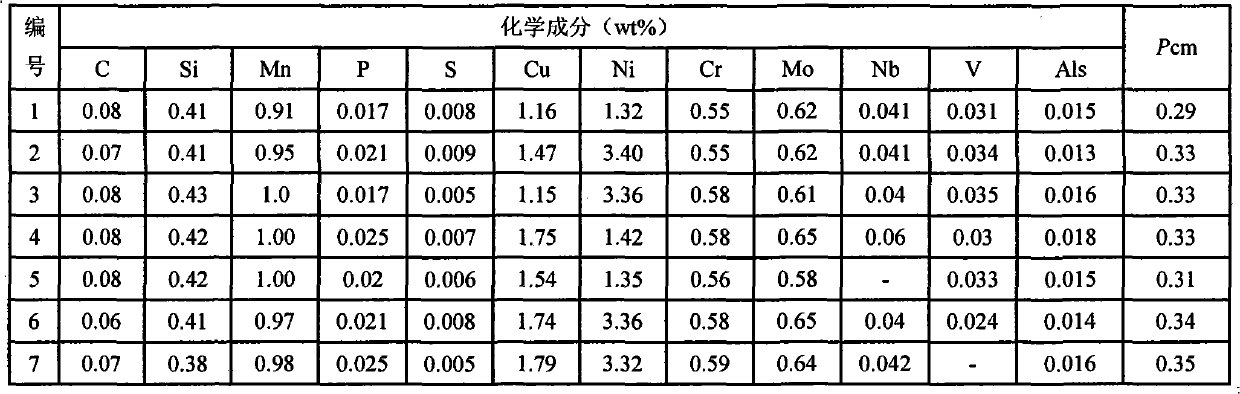

Easily welded ageing high-strength steel and heat treatment process thereof

InactiveCN102021489AImprove toughnessReduce carbon contentQuenching agentsChemical compositionRoom temperature

The invention discloses easily welded ageing high-strength steel and a heat treatment process thereof. The steel comprises the following chemical compositions in percentage by weight: one ore more of 0.02 to 0.10 percent of C, 0.05 to 0.45 percent of Si, 0.50 to 1.50 percent of Mn, 1.00 to 1.80 percent of CU, 1.00 to 4.00 percent of Ni, 0.10 to 1.00 percent of Cr, 0.10 to 0.80 percent of Mo, 0.01 to 0.06 percent of Nb and 0.01 to 0.05 percent of V, and the balance of Fe and inevitable impurities. The heat sensitivity coefficient of the steel Pcm is less than or equal to 0.35 percent. The heat treatment process comprises the following steps of: directly quenching a steel plate subjected to finished rolling, and cooling the steel plate to the temperature below martensite transition temperature at a speed of 20-50 DEG C / s; reheating the steel plate to the temperature of between 550 and 700 DEG C, and keeping the temperature for 1.2min / mm to 3min / mm; and cooling in air to room temperature. The steel plate has the yield strength of more than or equal to 850N / mm<2>, which is obviously higher than that of the traditional quenched and tempered similar steel, has the V-shaped Charpy impact energy of more than or equal to 150J at -20DEG C, and keeps good toughness.

Owner:ANGANG STEEL CO LTD

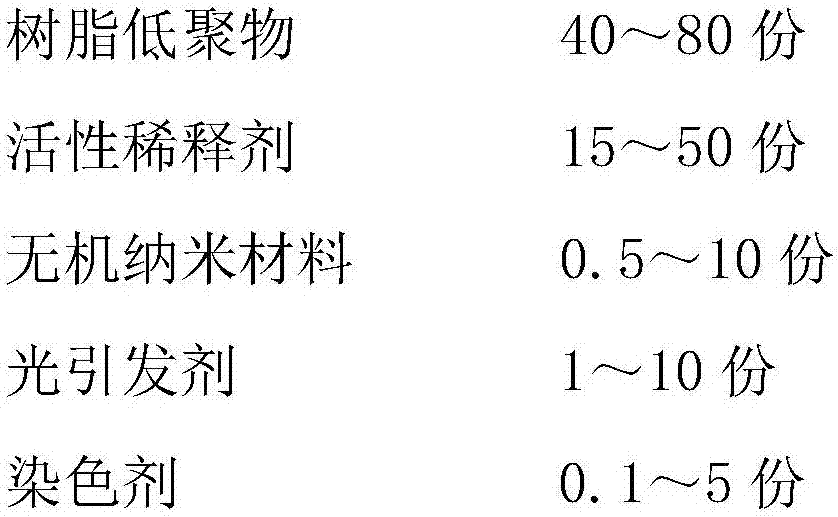

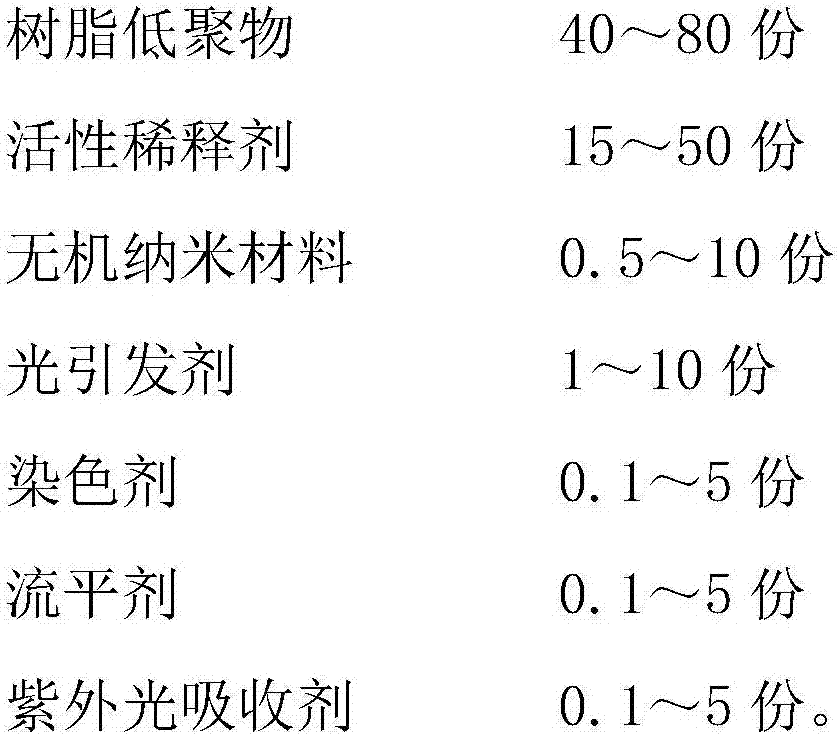

High-temperature-resistant photo-curing material and preparation method thereof

InactiveCN106986971AReduced shrinkage performanceReduce the temperatureAdditive manufacturing apparatus3D object support structuresOligomerReactive diluent

The invention discloses a high-temperature-resistant photo-curing material and a preparation method thereof. The high-temperature-resistant photo-curing material comprises, by weight, 40-80 parts of resin oligomer, 15-50 parts of reactive diluent, 0.5-10 parts of inorganic nano material, 1-10 parts of photoinitiator, 0.1-5 parts of dyeing agent, 0.1-5 parts of flatting agent and 0.1-5 parts of ultraviolet absorber. The high-temperature-resistant photo-curing material has the advantages that the material is low in viscosity, fast in curing, small in curing shrinkage, low in heat sensitivity and the like, and high device high temperature resistance is achieved after laser rapid prototyping.

Owner:HANS LASER TECH IND GRP CO LTD

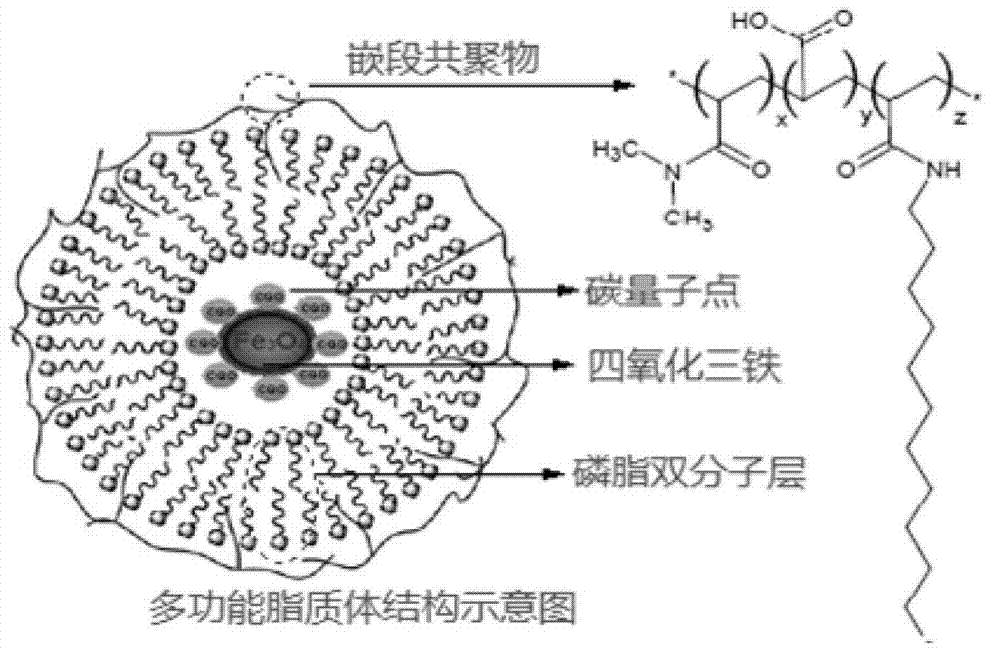

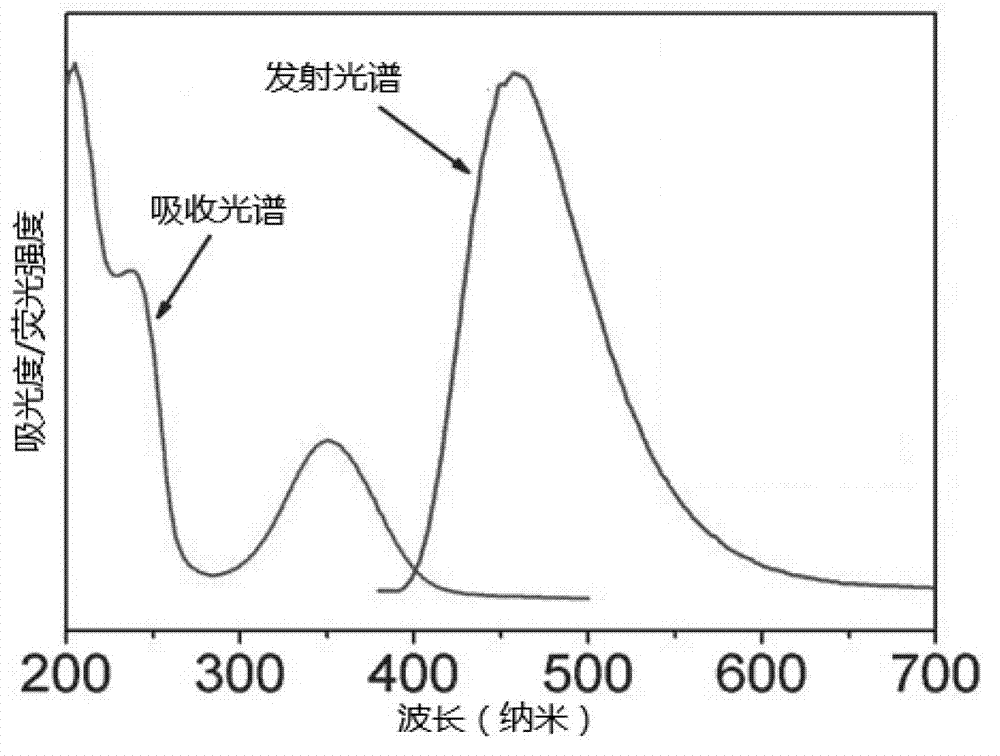

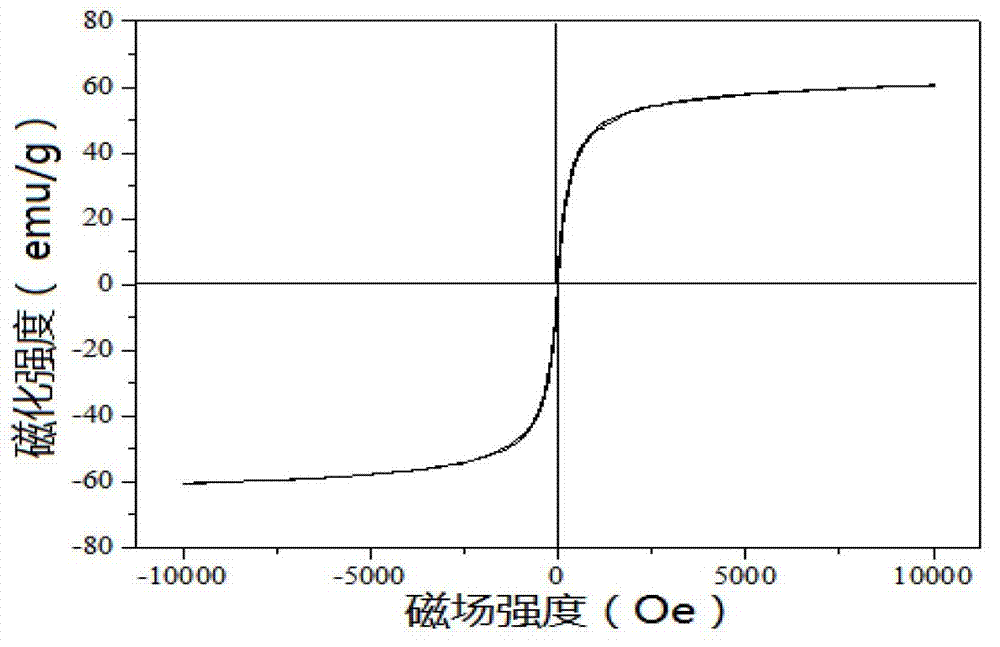

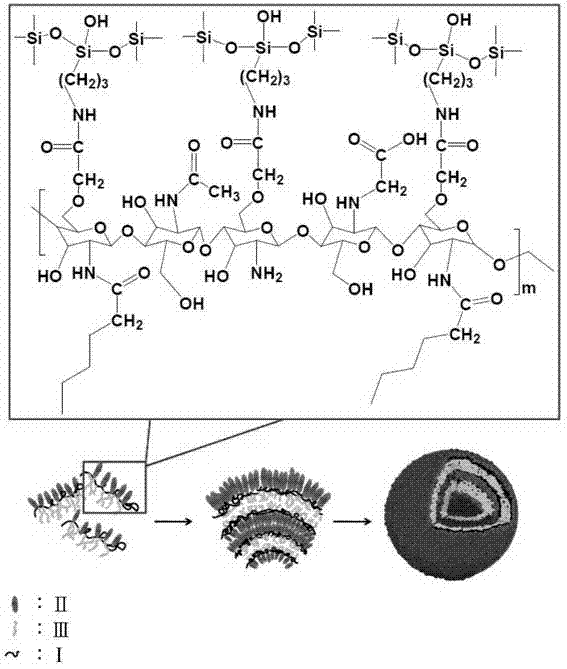

Preparation method of pH and thermal dual-sensitive lipidosome loaded with magnetic carbon quantum dots on internal water phase

InactiveCN103041409ALow costSimple methodPharmaceutical non-active ingredientsEmulsion deliveryPolymer modifiedHigh pressure

The invention relates to a preparation method of pH and thermal dual-sensitive lipidosome loaded with magnetic carbon quantum dots on an internal water phase, which concretely comprises the following steps of: 1) preparing nano ferroferric oxide by a co-precipitation method, carrying out surface modification by polyethyleneimine, preparing carbon quantum dots by a microwave pyrolysis method, and adding the carbon quantum dots into the modified magnetic particle solution to form the magnetic carbon quantum dots; and 2) loading the magnetic carbon quantum dots into the internal water phase of the lipidosome by a low-pressure film formation-high-pressure incubation method, and grafting the pH and heat sensitivity triblock copolymer on the surface of the lipidosome by hydrophobic effect to prepare the lipidosome modified by nano particles and polymer. Compared with the prior art, the preparation method is simple and lower in cost; the prepared product can be developed into a diagnosis therapeutic agent with functions of magnetic targeting, fluorescence imaging or tracing; and the medicine carrying system of pH and thermal controlled-release medicine has important reference value for developing other types of multifunctional medicine carriers.

Owner:SHANGHAI JIAO TONG UNIV

Microwave vacuum drier

InactiveCN102538423AEasy Sync PackageSmaller volumeDrying using combination processesDrying machines with progressive movementsProduction lineMicrowave

The invention discloses a microwave vacuum drier, which comprises a feeding vacuum chamber, a microwave vacuum chamber and a cooling discharging vacuum chamber, which are sequentially connected through vacuum valves. A stepping conveyor is arranged in each vacuum chamber, the vacuum valves are arranged at the front end of the feeding vacuum chamber and the rear end of the cooling discharging vacuum chamber respectively, and a microwave heating device is arranged on the side wall of the microwave vacuum chamber. The microwave vacuum drier is easier to be synchronously matched with a production line by feeding in a stepping way, microwave vacuum drying and a continuous drying way of cooling and discharging. Compared with a single-chamber microwave vacuum dryer, the microwave vacuum drier has the advantages that time for inflating the vacuum chambers after drying is complete, taking and placing feed plates and re-vacuuming after the feed plates are mounted is saved, so that working efficiency is improved; and the microwave vacuum drier is applicable to dewatering and drying for agricultural products, health care products, food, medicinal materials, fruits, vegetables, chemical raw materials and the like with high added-value and heat sensitivity, and used for low-temperature concentration of chemical products, removal of water of crystallization, dewatering and drying of traditional Chinese medicine extracts and enzyme preparations, and the like.

Owner:周跃云 +1

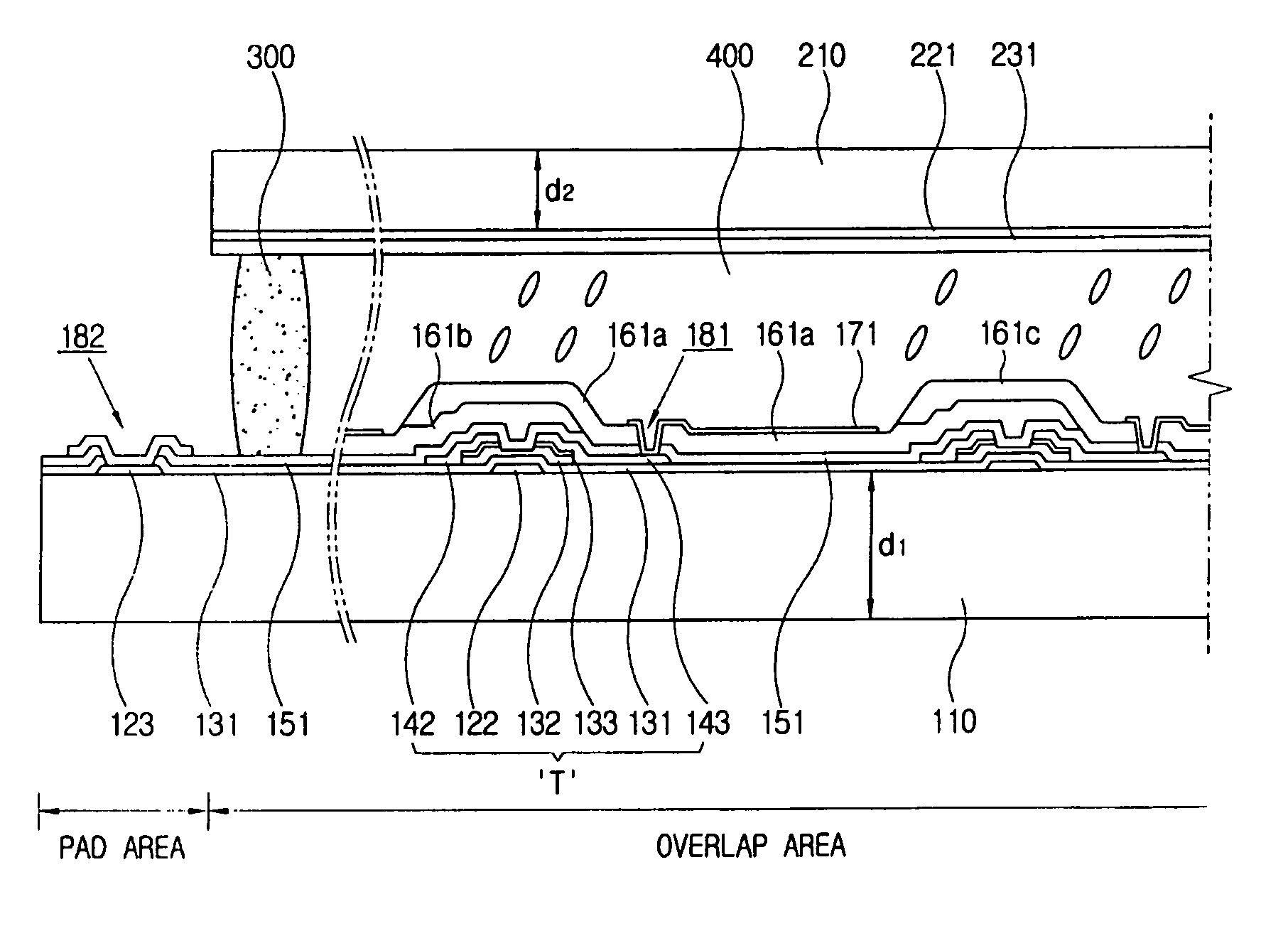

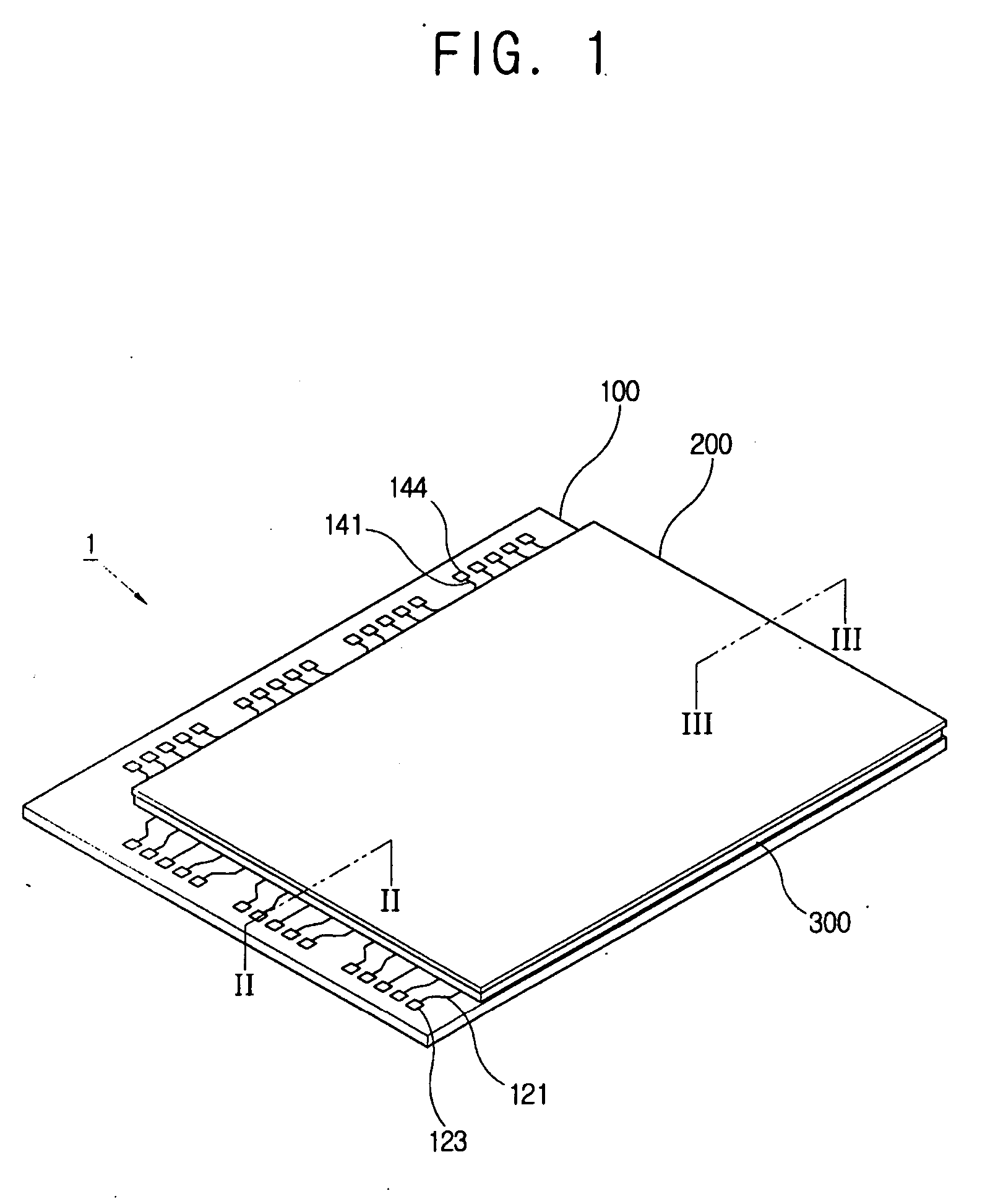

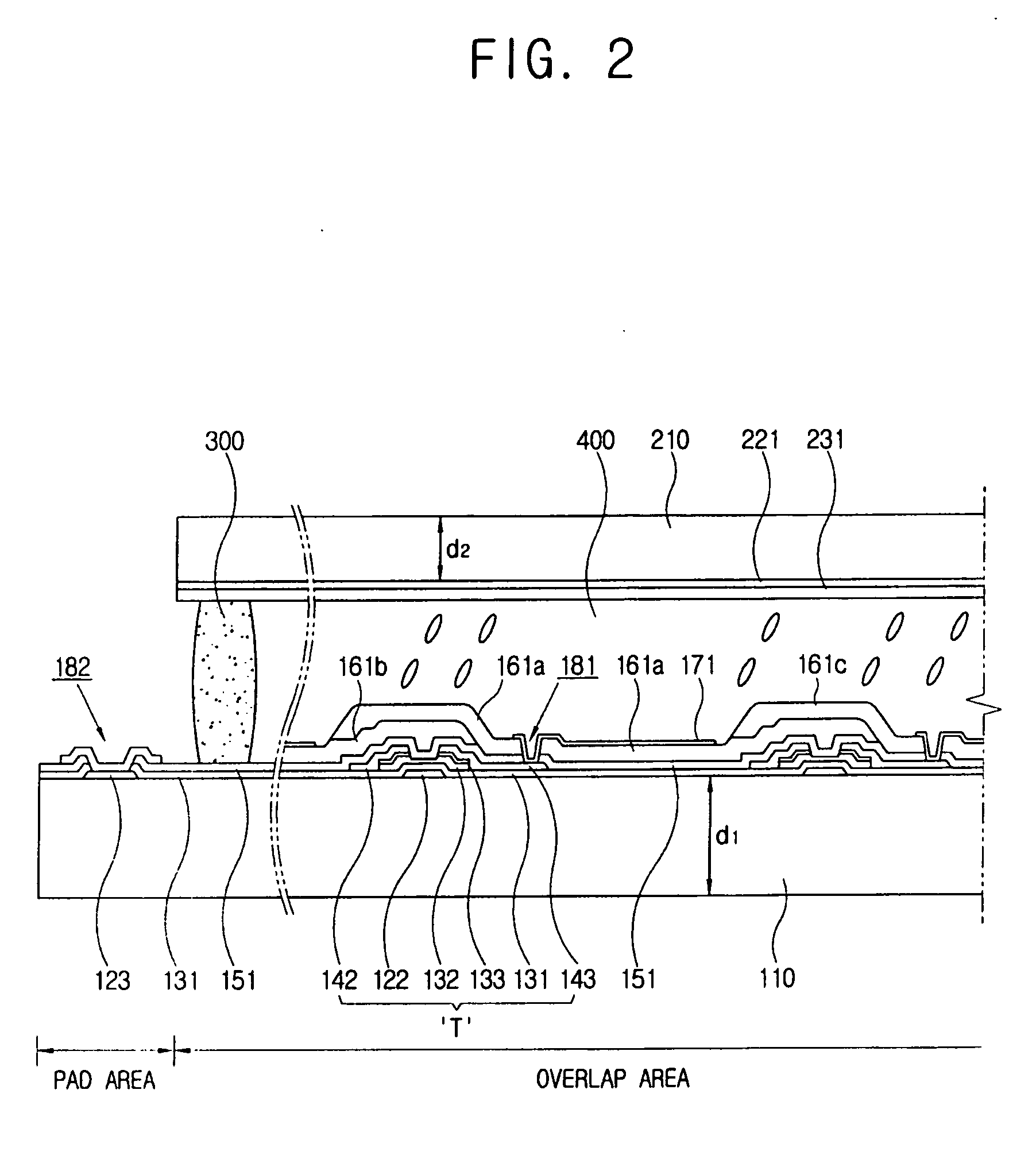

Liquid crystal display panel with different substrate materials and method of making the liquid crystal display panel

InactiveUS20070012925A1Solid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

An LCD panel with mixed substrate materials and a method of making the LCD panel are presented. The LCD panel is made of a first substrate, a second substrate disposed substantially parallel to the first substrate, and a liquid crystal layer disposed between the first substrate and the second substrate. The first substrate includes a glass substrate, a TFT formed on the glass substrate, and a color filter formed on the TFT. The second substrate includes a plastic substrate and a common electrode formed on the plastic substrate. Forming the color filter on the TFT eliminates the need to form black matrices on the second substrate, preventing misalignment of the two substrates due to different heat sensitivities. Since there is no concern of substrate misalignment caused by heat, laser beam can be used to cut the substrates during the manufacture of the LCD panel.

Owner:SAMSUNG DISPLAY CO LTD

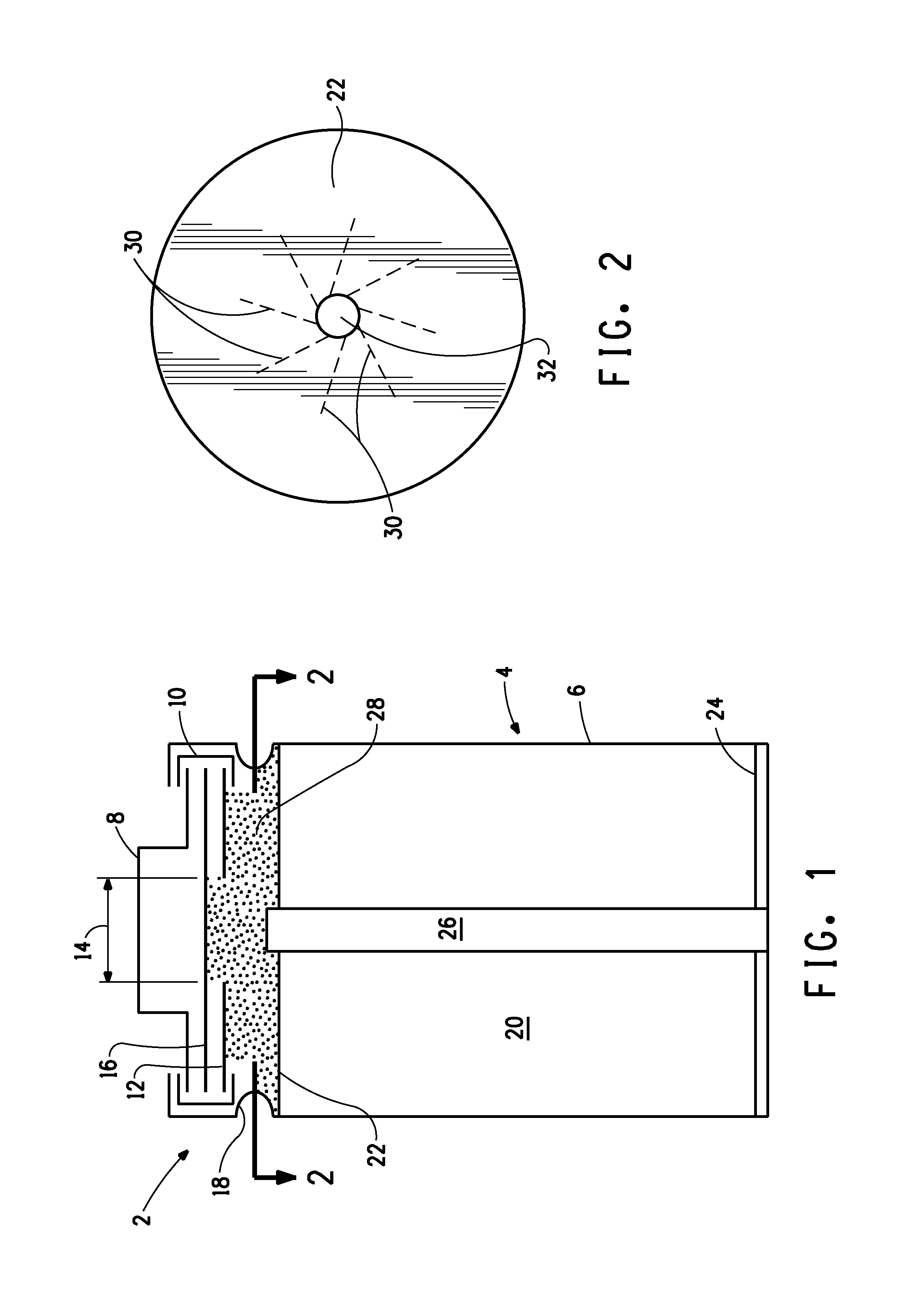

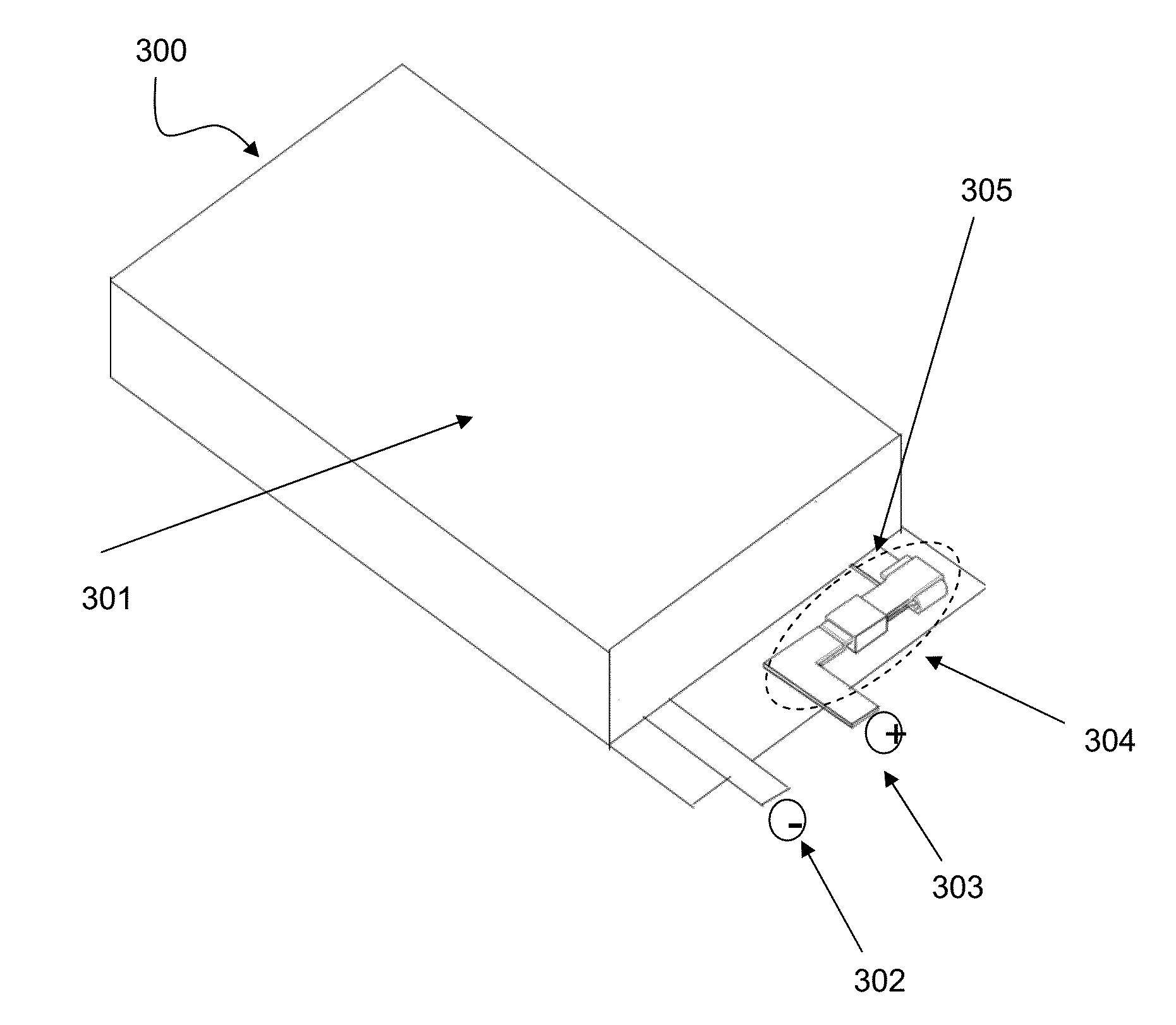

Heat sensitivity optimization for battery cells

An embodiment provides a battery cell, including: one or more contacts; a material providing output power to a device via the one or more contacts; and a tab element forming a part of a temperature cutoff mechanism; the tab element being thermally coupled to the material and conducting heat generated by the material; and the tab element being positioned proximate to a geometrically determined heat center. Other aspects are described and claimed.

Owner:LENOVO (SINGAPORE) PTE LTD

Medicine loading type contact lens and preparation method thereof

ActiveCN102778762AReduce lossesReduce the chance of side effectsSurgeryEye treatmentSide effectBiomedical engineering

Owner:SPRING FOUND OF NCTU

Micro-priming powder for detonator

InactiveCN101440011ASimple structureHigh working reliabilityNitrated pentaerythritol explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonatorAdhesive

The invention relates to micro initiating explosive for an exploder, and solves the problems of insecurity of the exploder with the initiating explosive and high cost of the exploder without the initiating explosive. The micro initiating explosive comprises more than one high explosive and more than one initiating explosive. The high explosive comprises hexogen and PETN; the initiating explosive comprises dinitrodiazophenol, lead azide, lead trinitroresorcinate, nickel hydrazine nitrate and perchloric acid tricarbohydrazide cadmium complex; and the more than one high explosive and the more than one initiating explosive are mixed to prepare the micro initiating explosive. Adhesive and surfactant can also be used. The micro initiating explosive has the advantages that the micro initiating explosive can reduce the content of the initiating explosive by 30 to 60 percent compared with the conventional exploder filled with the explosive, lower 20 to 30 percent of cost compared with the prior exploder, improve safety during assembly of the exploder, reduce static electricity, friction, impact and light and heat sensitivity while ensuring initiating force and flame sensitivity, improve safety during production, transportation, storage and use of the exploders, can reduce explosive feeding amount of the exploder, and improve free-running property of preparations.

Owner:ANHUI UNIV OF SCI & TECH

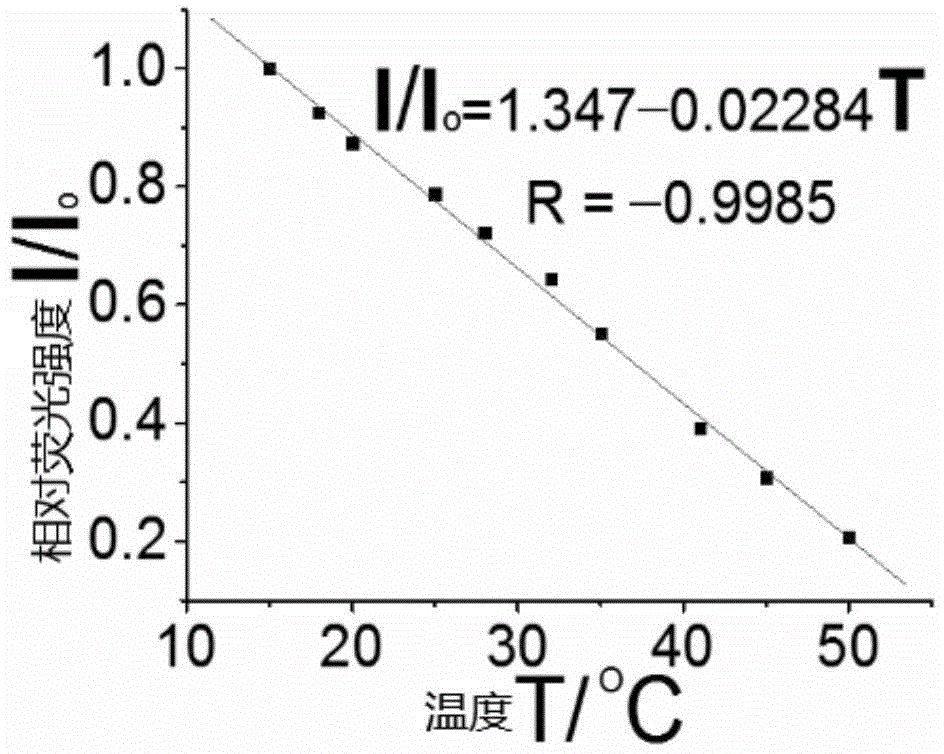

Preparation method of temperature and fluorescence probe of lipidosome loaded with gold nanocluster and anti-cancer drug

InactiveCN103599070APhotothermogenicFluorescent Intensity Temperature SensitivityOrganic active ingredientsEnergy modified materialsOctanoic AcidsCholesterol

The invention relates to a preparation method of a temperature and fluorescence probe of lipidosome loaded with a gold nanocluster and an anti-cancer drug. The method comprises the following steps of: 1) preparing a near-infrared emitting fluorescent gold nanocluster through the microwave pyrolysis method in an aqueous phase way by using dithio-octanoic acid as a protective agent, chloroauric acid as a raw material and sodium borohydride as a reducing agent; 2) dissolving lecithin and cholesterol with a mixed solvent consisting of chloroform and methyl alcohol, carrying out rotary evaporation to remove the solvent to obtain a thin and dried phospholipid membrane, dissolving with gold nanocluster turbid liquid and an anti-cancer drug aqueous solution, and then incubating by the supercritical carbon dioxide method to prepare lipidosome turbid liquid with the gold nanocluster and the anti-cancer drug loaded in an inner water phase. Compared with the prior art, the method has the advantages of being simple and relatively low in cost; the prepared lipidosome drug carrier has light-induced heat sensitivity and fluorescence intensity heat sensitivity, and a novel temperature and fluorescence probe on the basis of the lipidosome drug carrier can be developed, so that important reference value is brought for preparation and application of other drug carriers.

Owner:SHANGHAI JIAO TONG UNIV

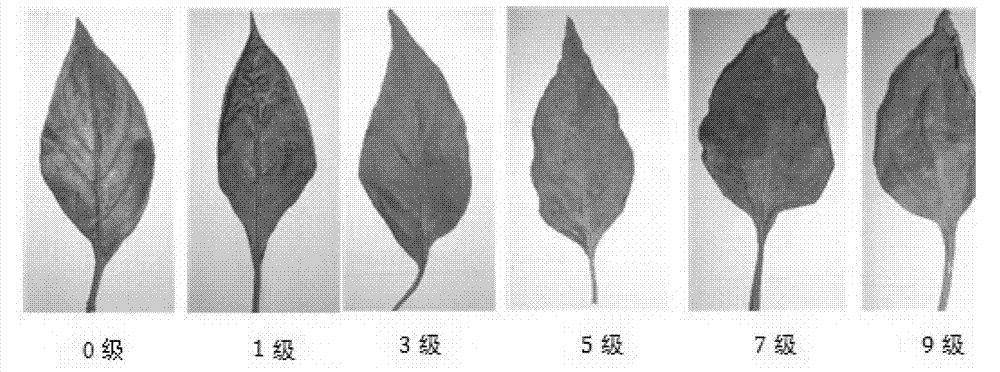

Method for identifying chilli heat resistance by using detached leaves

InactiveCN102805010AImprove heat tolerance breeding processTraumaHorticulture methodsHeat resistanceControl selection

The invention discloses a method for identifying chilli heat resistance by using detached leaves. The method comprises the following steps that a chilli heat resistance strain B35 is used as heat resistance control, a chilli heat intolerant strain B6 is used as thermosensitive control selection, the method for identifying the chilli heat resistance of the detached leaves is adopted, the detached leaf heat harm grading standard and group heat harm grading standard are made, and the like. The method is characterized in that the chilli detached leaves are treated at the specific temperature and time, different heat resistance strains have obvious differences on the leaf expression symptoms, the heat harm index of a strain group to be detected is calculated on the basis, and the chilli heat resistance strain and the thermosensitive strain can be identified according to the made group heat damage grading standard. The method is particularly suitable for genetic analysis and heat resistanceidentification of precious chilli breeding plant strains including transgenosis plant strains and the like. The method belongs to the method with the advantages that the operation is simple, the speed is high, and the heat resistance of a large number of chilli seed resources is effectively identified. The chilli heat resistance breeding process can be greatly accelerated.

Owner:NORTHWEST A & F UNIV

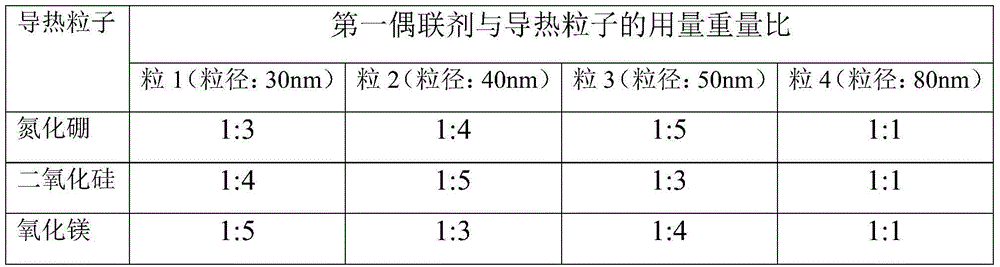

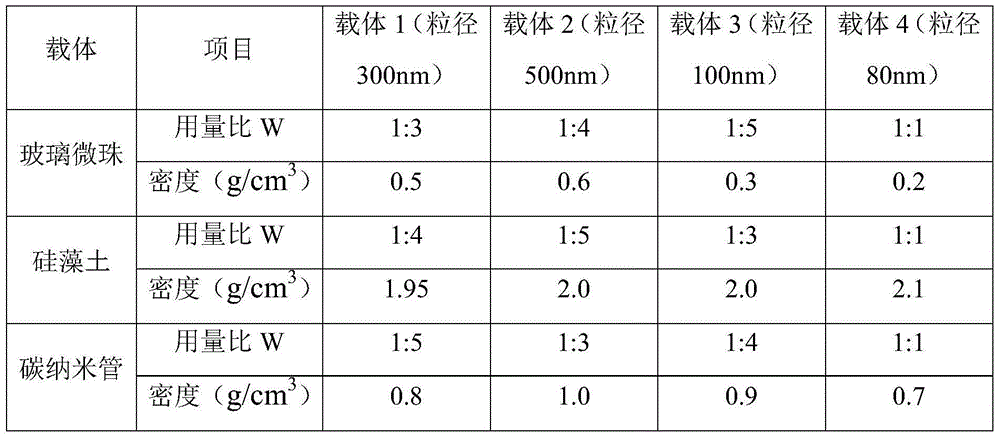

Heat-conducting composite material, rubber composition, pipe material for cooling media and preparation method for pipe material

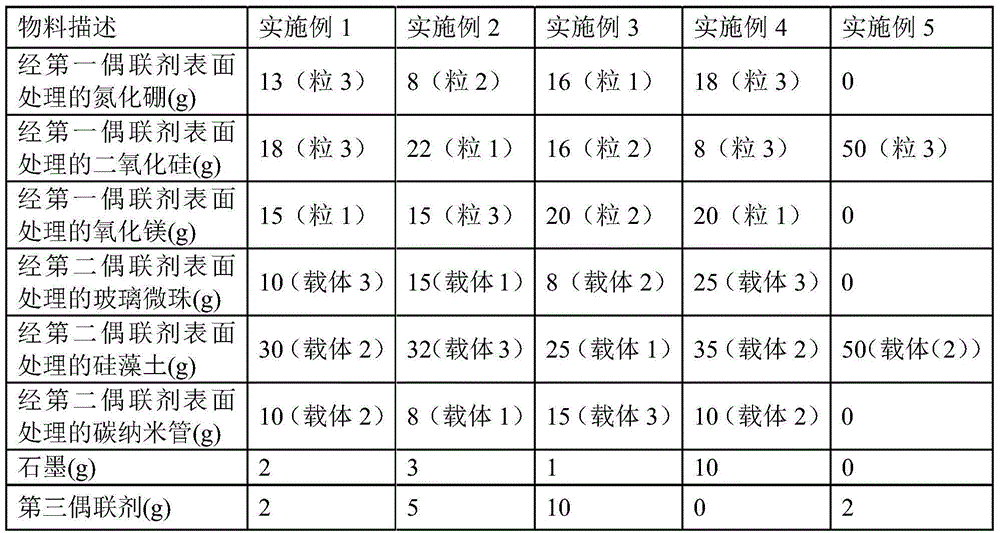

The invention discloses a heat-conducting composite material, a rubber composition, a pipe material for cooling media and a preparation method for the pipe material. The heat-conducting composite material contains heat-conducting particles and a carrier, wherein the heat-conducting particles are subjected to surface treatment by a first coupling agent, and the carrier is subjected to surface treatment by a second coupling agent; and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in the carrier which is subjected to surface treatment by the second coupling agent, and the carrier is a porous, void or hollow granular matter. According to the heat-conducting composite material, the heat-conducting particles which are subjected to surface treatment by the first coupling agent and the carrier which is subjected to surface treatment by the second coupling agent are adopted, and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in pores of the carrier which is subjected to surface treatment by the second coupling agent, so that the compatibility of the heat-conducting composite material, containing the heat-conducting particles and the carrier, with base rubber is improved; and the heat-conducting composite material is added in the rubber composition, heat conducting channels are formed in milled rubber which is prepared through mixing the rubber composition containing the heat-conducting composite material, and then, the thermal sensitivity of the milled rubber is improved.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com