Rectifying tower flow controllable type lateral-line extraction combined device

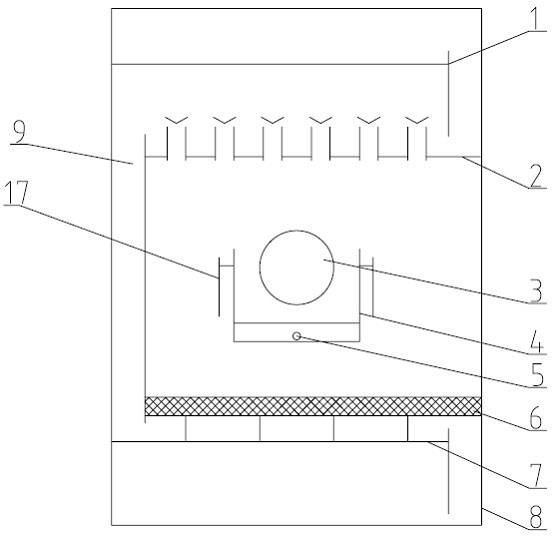

A combined device and rectification tower technology, which is applied in the field of column separation in the field of mass transfer and heat transfer, can solve the problems of difficult flow measurement and control, and achieve the effect of avoiding evaporation and purification, compact structure of the device, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A rectification tower for separating organosilicon monomers A and D in a factory, the original tower is 3 towers in series, the tower diameter is 3m, each tower has 100 theoretical plates, and the liquid phase at the top of the 3# tower is 99.99% % of dimethylformamide, 99.95% of dimethylformamide (containing 0.04~0.05% of high-boiling mixture whose boiling point is 30~100°C higher than that of dimethylformamide) was extracted from the liquid phase of the 1# column, and now the 1# tower The first technical transformation of the tower kettle is planned to adopt gas phase extraction. After the transformation, it was found that the dimethylformamide content increased to 99.97~99.99%, but the operation control was unstable, the production volume fluctuated, the heat load of the tower kettle increased sharply, and the tower pressure drop increased. Then adopt the device of the present invention to carry out secondary transformation as follows: pull down one deck t...

Embodiment 2

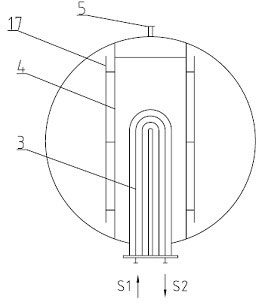

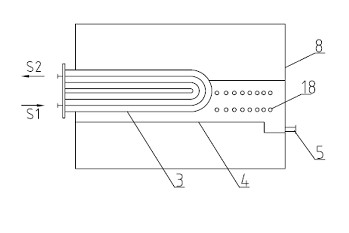

[0033] Implementation example 2: A rectification tower for separating monochloromethane and dichloromethane in a factory, with a diameter of 1.4m, structured packing is used, and the stripping section is composed of 4 sections of packing, wherein methylene chloride is composed of two layers of packing near the bottom of the tower. The side line of the liquid phase collector in between is extracted. Since the material contains a small amount of water and heavy components such as polychloroethane, the concentration of the side product is 99.92~99.95%. Now use the flow controllable side line discharge combination device of the present invention to carry out transformation, specifically: the position of the original liquid collector 2 remains unchanged, and a plug-in U-shaped condenser 3 and a condensate collection tank 4 are added below, and the plug-in U-shaped Condenser 3 has a diameter of 0.4m. It is a double-tube plug-in U-shaped condenser 3 composed of a group of 30 heat exc...

Embodiment 3

[0034]Implementation example 3: A certain factory produces hydroxyquinoline products, and its boiling point is as high as 300 ° C, so precision rectification of high-efficiency packing must be carried out under high vacuum. Because hydroxyquinoline will partially polymerize at about 220°C to produce high boiling substances (about 80°C difference from the boiling point of the product), and even if the vacuum degree of the rectifying tower is as high as 3mmHg, the theoretical temperature of the tower still must reach 225°C, so the high boiling point By-products cannot be avoided. The original device is equipped with a liquid phase and a gas phase extraction outlet between the two layers of packing near the tower kettle. When the liquid phase extraction is operated, the operation is stable but the product purity is only 92~95; when the gas phase is extracted, the product purity is higher. , reaching 95~98%, but the operation is not easy to control, the degree of vacuum varies gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com