Patents

Literature

882 results about "Demister" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A demister is a device often fitted to vapor–liquid separator vessels to enhance the removal of liquid droplets entrained in a vapor stream. Demisters may be a mesh-type coalescer, vane pack or other structure intended to aggregate the mist into droplets that are heavy enough to separate from the vapor stream.

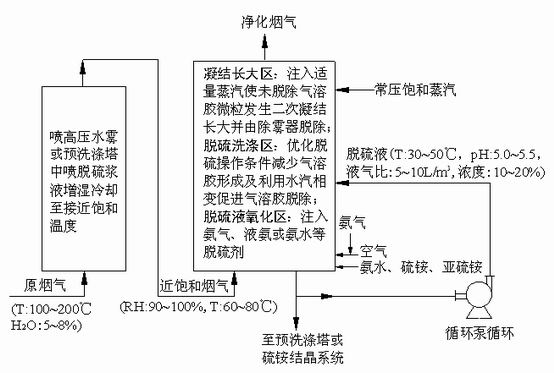

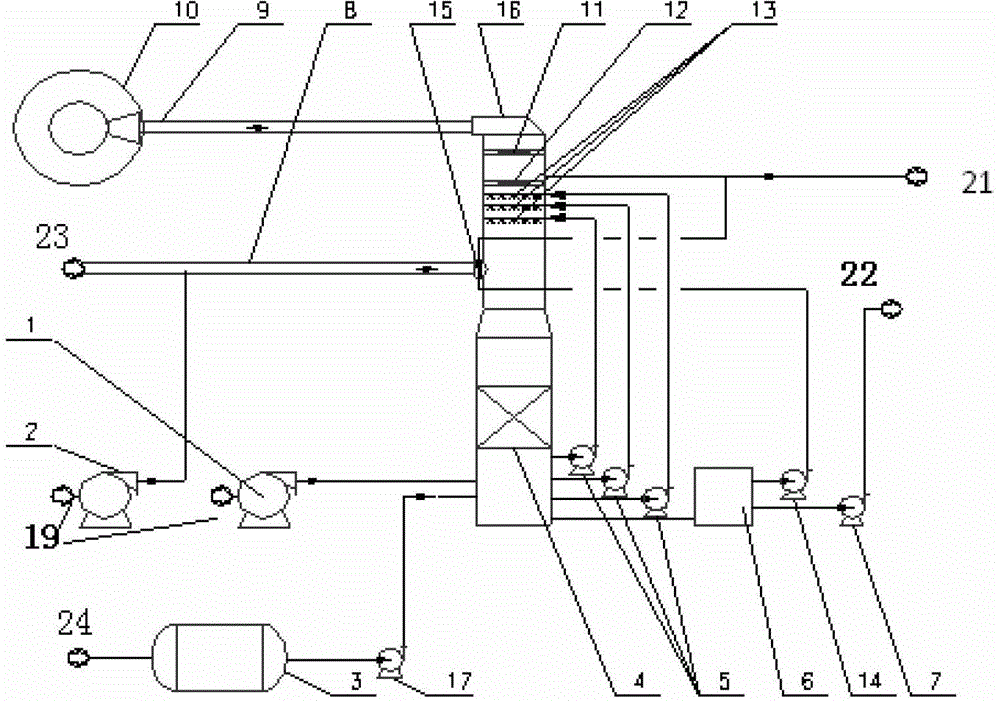

Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

InactiveCN102000490ASolve the emission problemSimple processDispersed particle separationThermodynamicsWater vapor

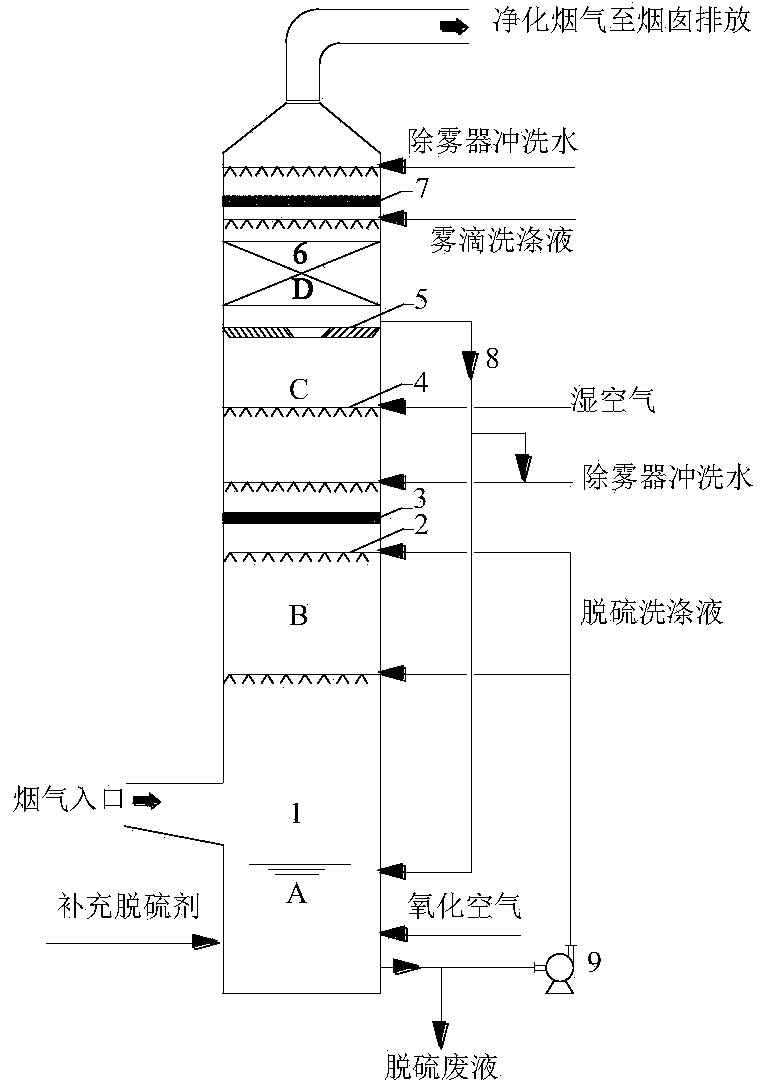

The invention discloses a control method for aerosol in flue gas desulfurization by utilizing an ammonia method and a master desulfurizing tower, and the control method is characterized in that flue gas enters the master desulfurizing tower after being cooled to the relative humidity of 90 to 100% and the temperature of 60 to 80 DEG C through high-pressure waster mist or prewashing temperature reduction; the generation of the aerosol particles in the desulfurization by utilizing the ammonia method is reduced by optimizing desulfurization operating conditions, and the formed aerosol particles are condensed to grow big and are partially washed to be eliminated through a desulfurizing solution; an appropriate amount of steam is injected into the saturated flue gas through desulfurizing and eliminating the partial aerosol particles; the oversaturated water vapor environment required by the secondary condensation and the growth of the aerosol particles is established on the top of the master desulfurizing tower; and the condensed and the grown aerosol particles are eliminated through a high-efficiency demister. The invention combines the formation mechanism of the aerosol in the flue gas desulfurization by utilizing the ammonia method; and the formation of the aerosol is reduced by optimizing the process conditions of the desulfurization operation and the elimination of the formed aerosol is promoted by utilizing a steam phase change principle at the same time so that the exhaust problem of the aerosol in the flue gas desulfurization by utilizing the ammonia method can be effectively solved.

Owner:SOUTHEAST UNIV

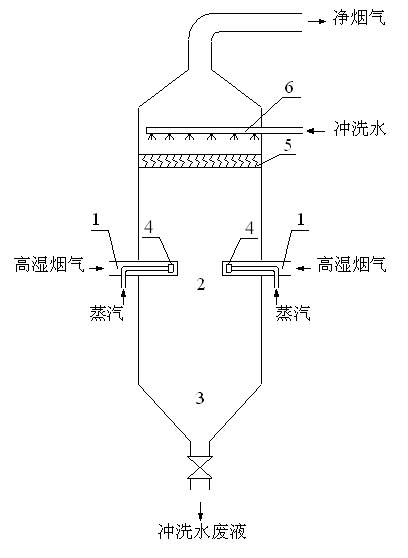

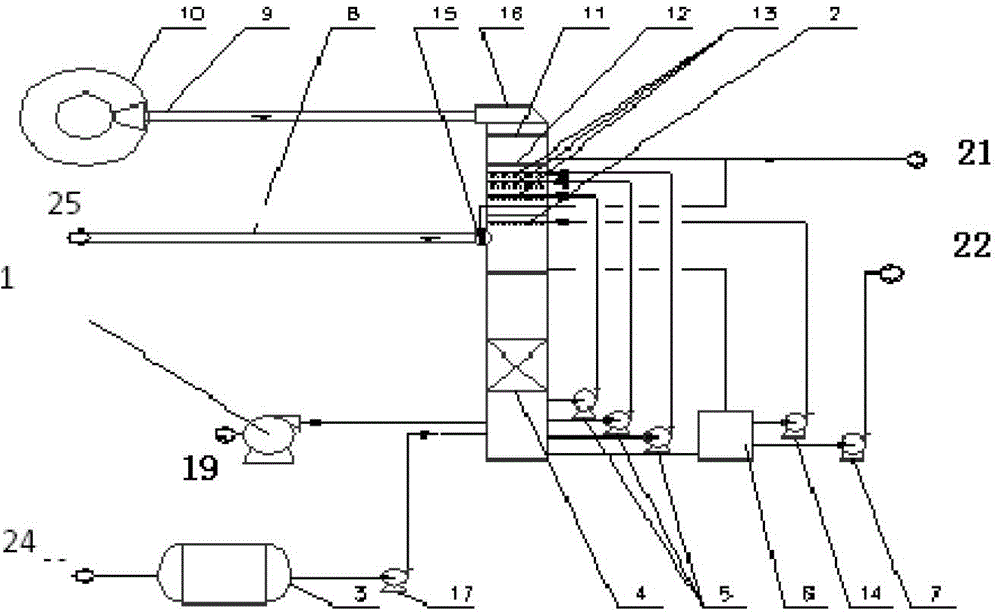

Method and device for removing fine particles in high-humidity gas fume

InactiveCN102059029ASimple processSolve the defect of particle size for efficient removalUsing liquid separation agentRinse waterEngineering

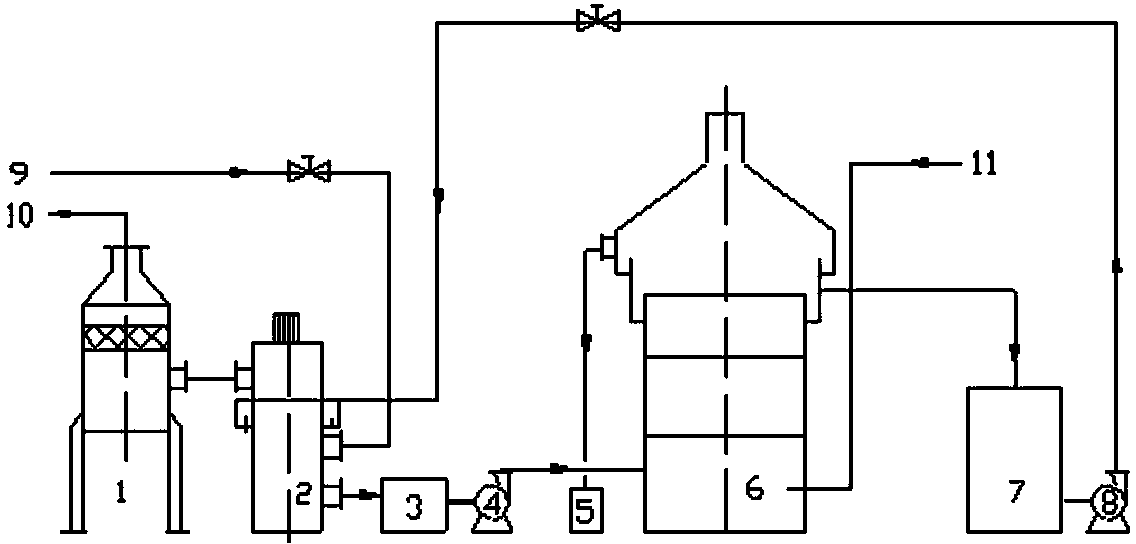

The invention relates to a method and a device for removing fine particles in high-humidity gas fume. The high-humidity gas fume enters a gas fume pipe; saturated steam under normal pressure is injected into the gas fume pipe and is premixed with the high-humidity gas fume; the high-humidity gas fume and the saturated steam under normal pressure enters a bombarding current phase change chamber main body and bombard each other so as to form a highly-turbulent bombardment area with highest concentration of fine particles in the center of the bombarding current phase change chamber main body and promote the saturated steam to be condensed on the surfaces of the fine particles; meanwhile, the fine particles of which the surfaces are condensed with water films collide each other to be coagulated to ensure that the granularity of the fine particles is increased further; and the coagulated and grown fine particles are removed by an efficient demister arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body. The device consists of the gas fume pipe, the bombarding current phase change chamber main body, the efficient demister, a demister washing water system, and a washing waste liquor storage tank; a vapor nozzle is arranged in the gas fume pipe; and the efficient demister is arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body.

Owner:SOUTHEAST UNIV

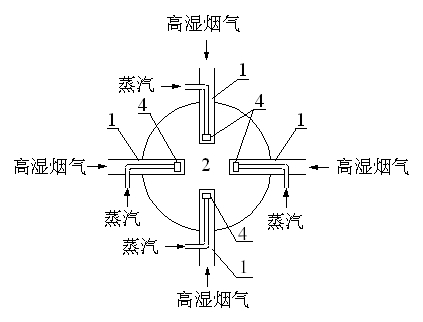

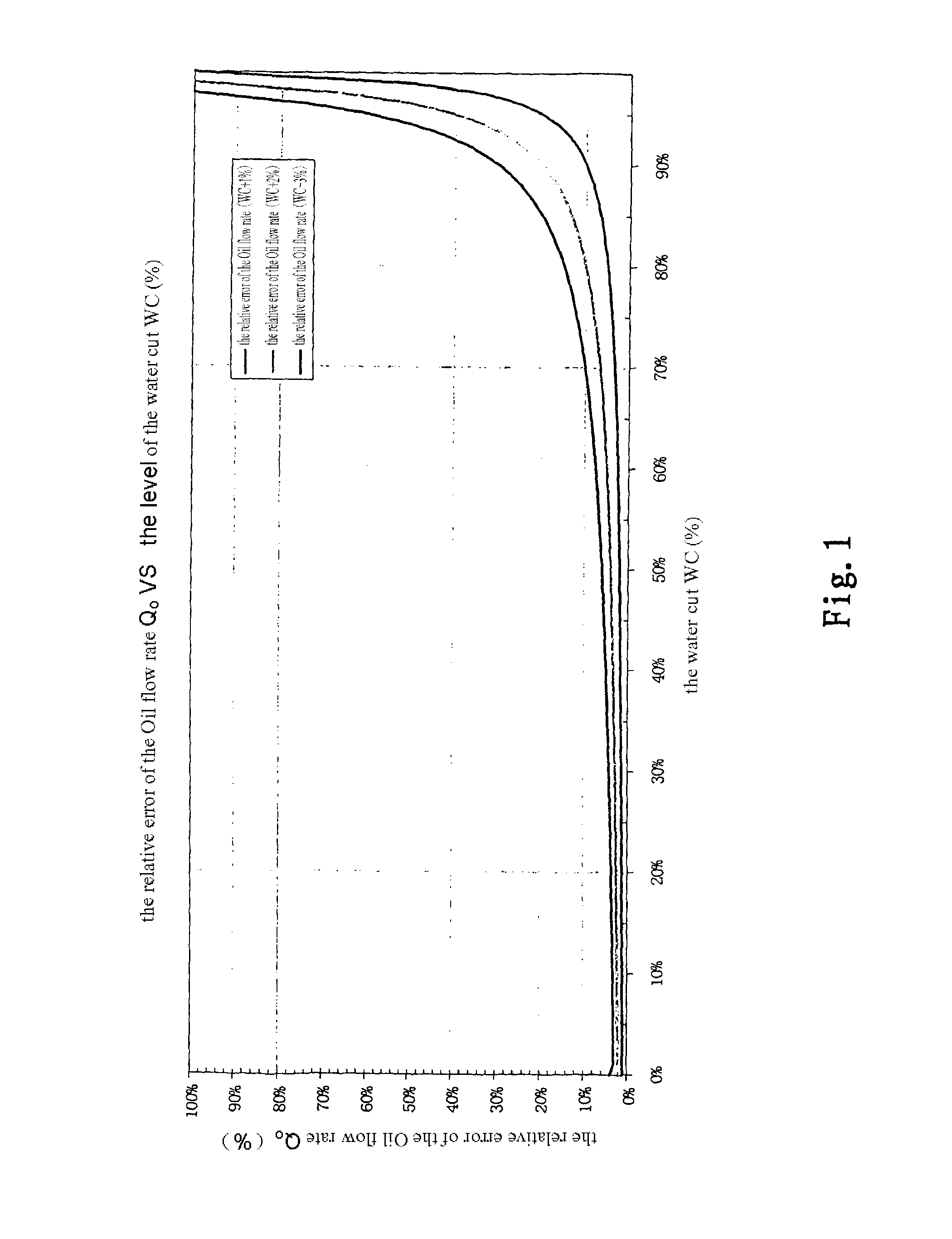

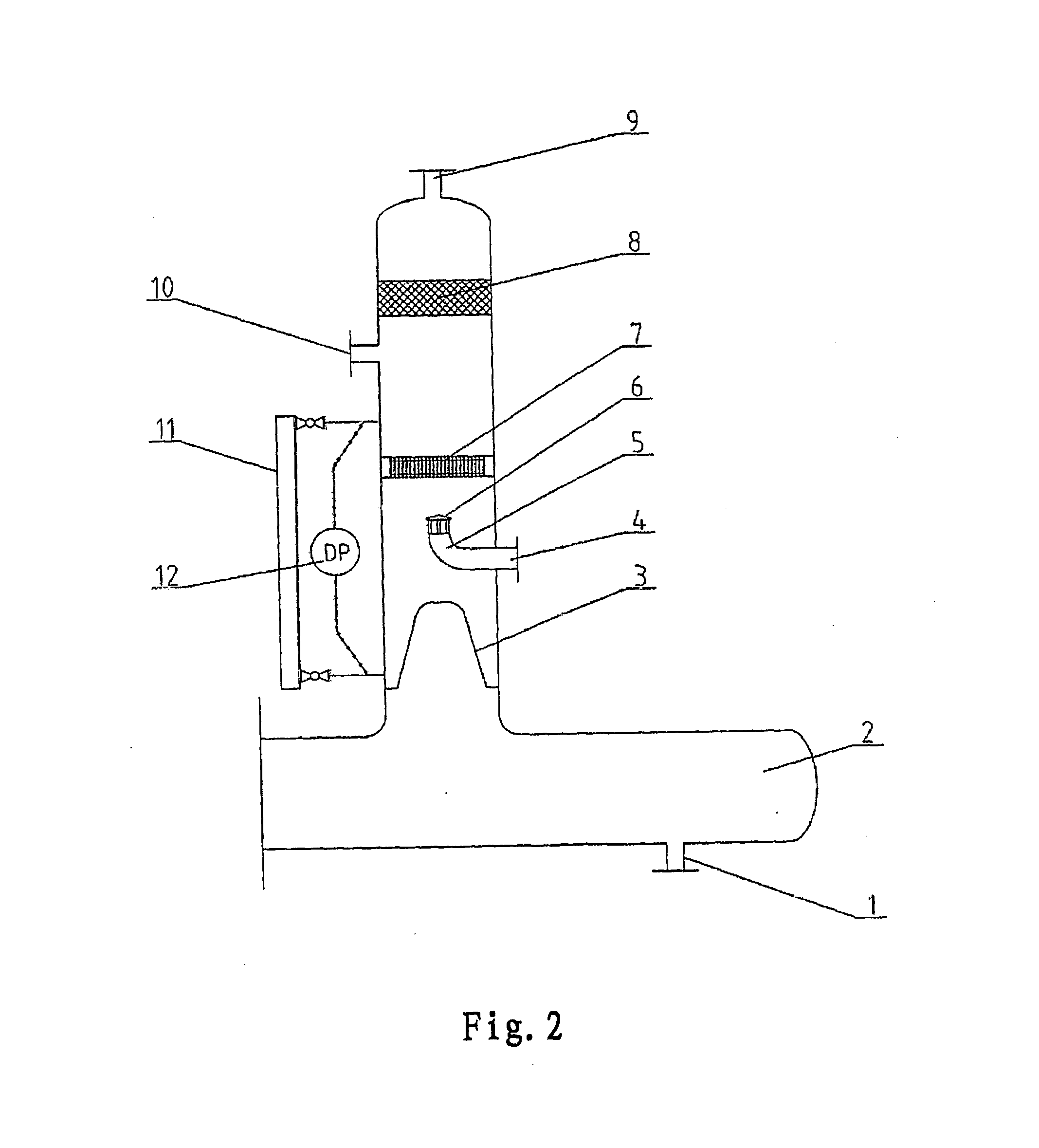

Water removing device for extremely high water content three-phase flow, and measurement device and method for extremely high water content three-phase flow

ActiveUS20120253705A1Accurate measurementHigh measurement accuracyLiquid separation auxillary apparatusLiquid suspension thickening by filtrationMeasurement deviceStream flow

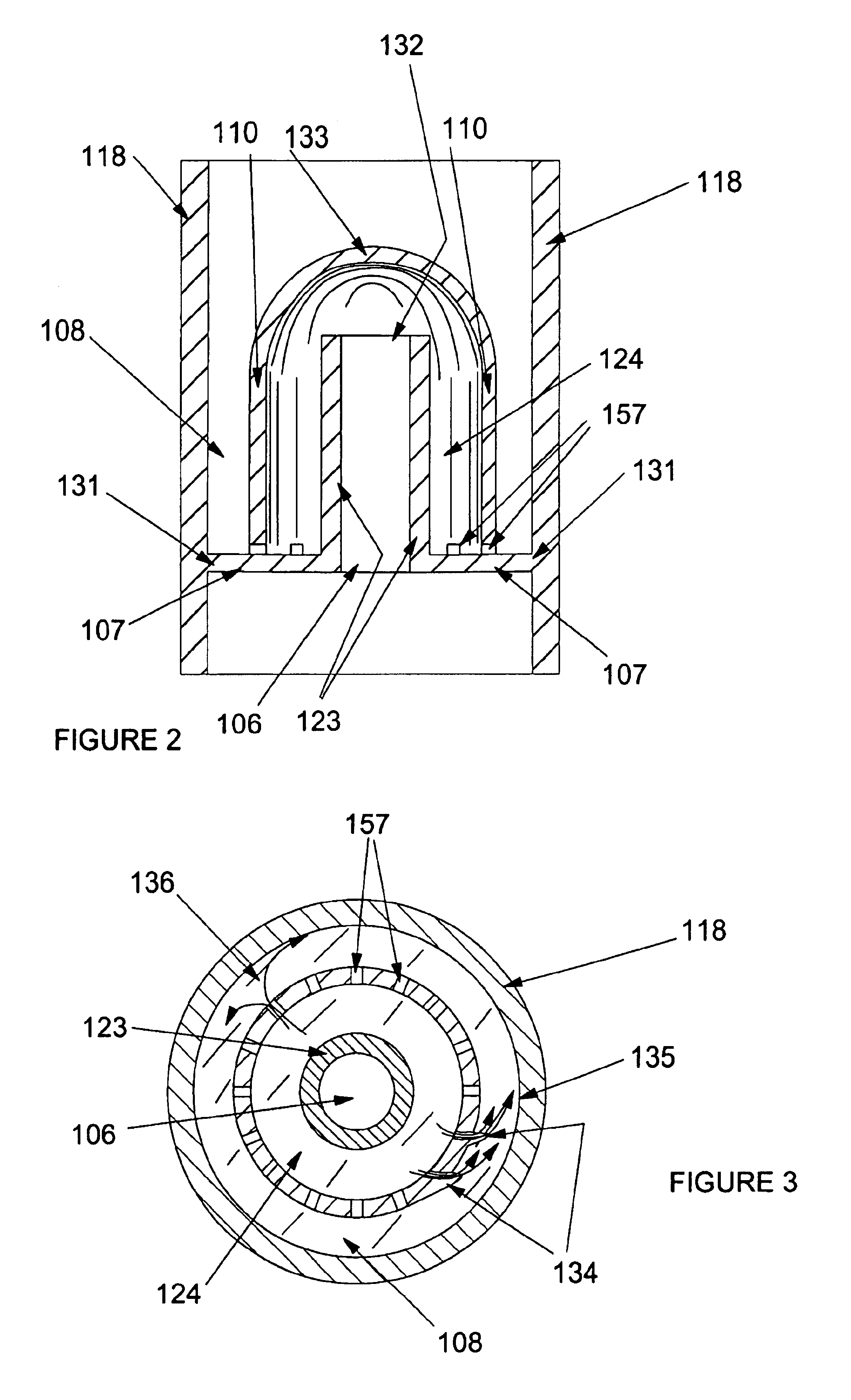

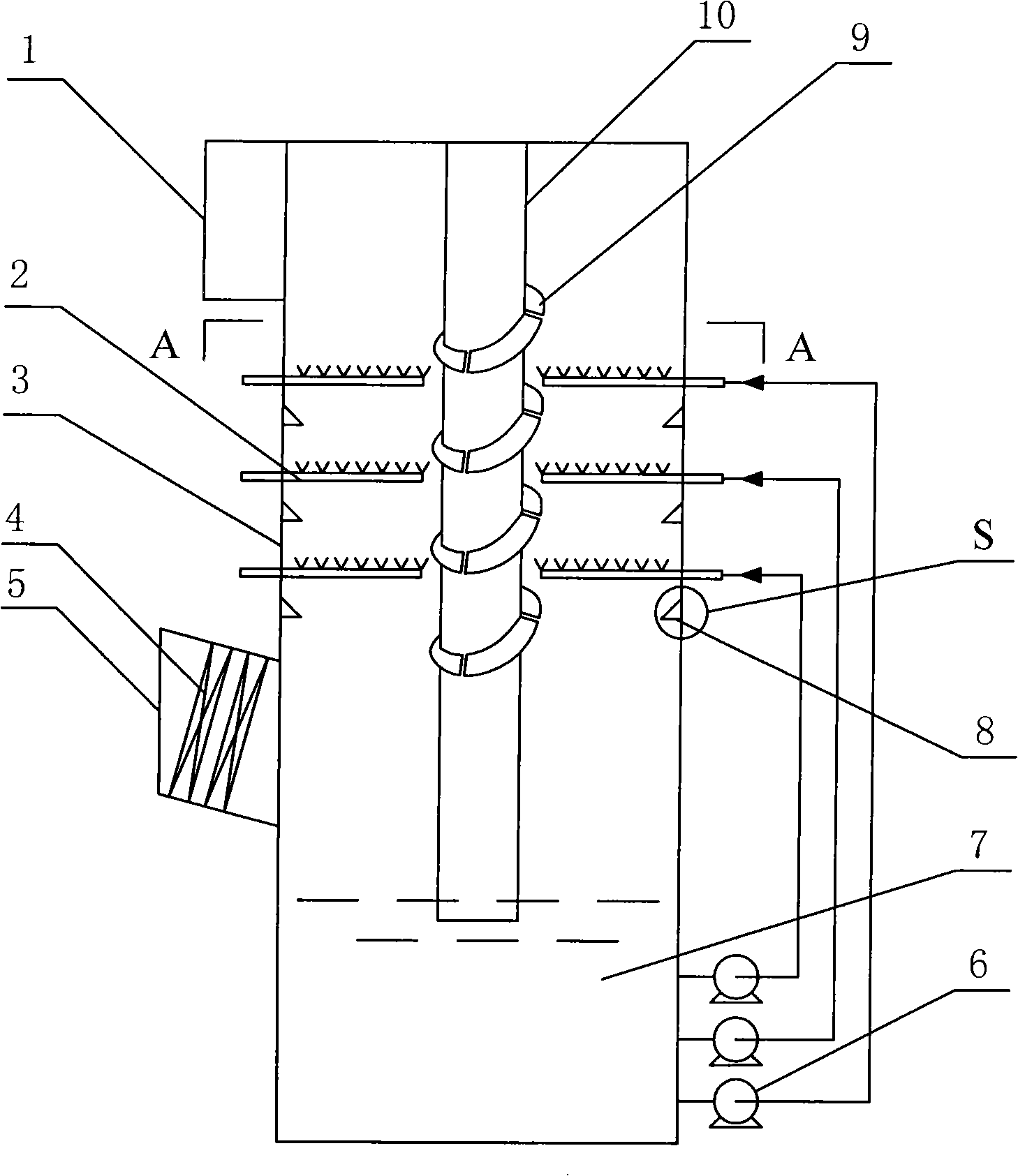

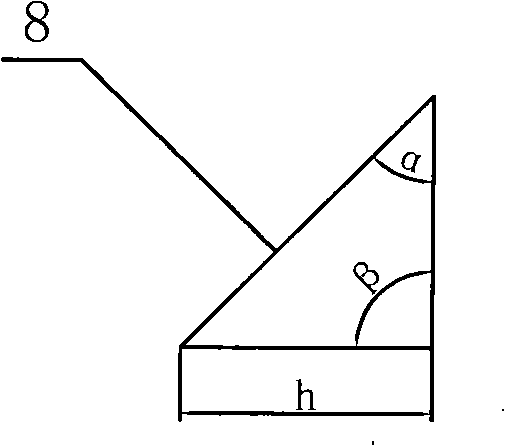

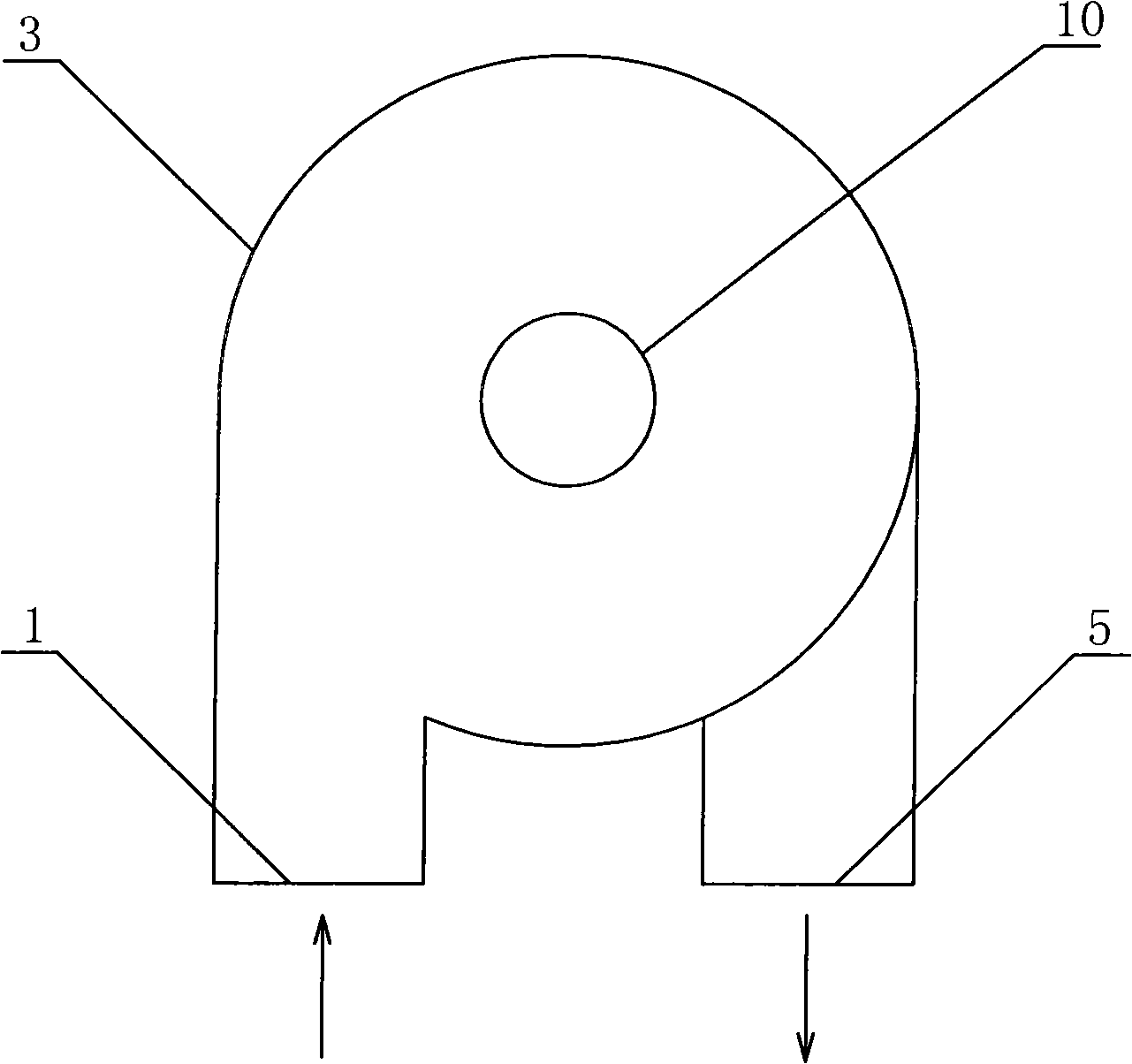

An extremely high water cut oil-gas-water three phase flow water removing device, which includes a mist eliminator (8), a fluid rectifier (7), a liquid collection chamber (2), a fluid directing duct (5), an inlet connection pipe section (10), a gas outlet connection pipe section (9), a mixture liquid exit connection pipe section (4), a free water outlet connection pipe section (1). Its function is to effectively remove most of the free water from the high water cut oil-air-water three phase flow mixture liquid. An extremely high water cut oil-air-water three phase flow measurement apparatus and a measurement method using the water removing device are also disclosed.

Owner:HAIMO TECH GRP CORP

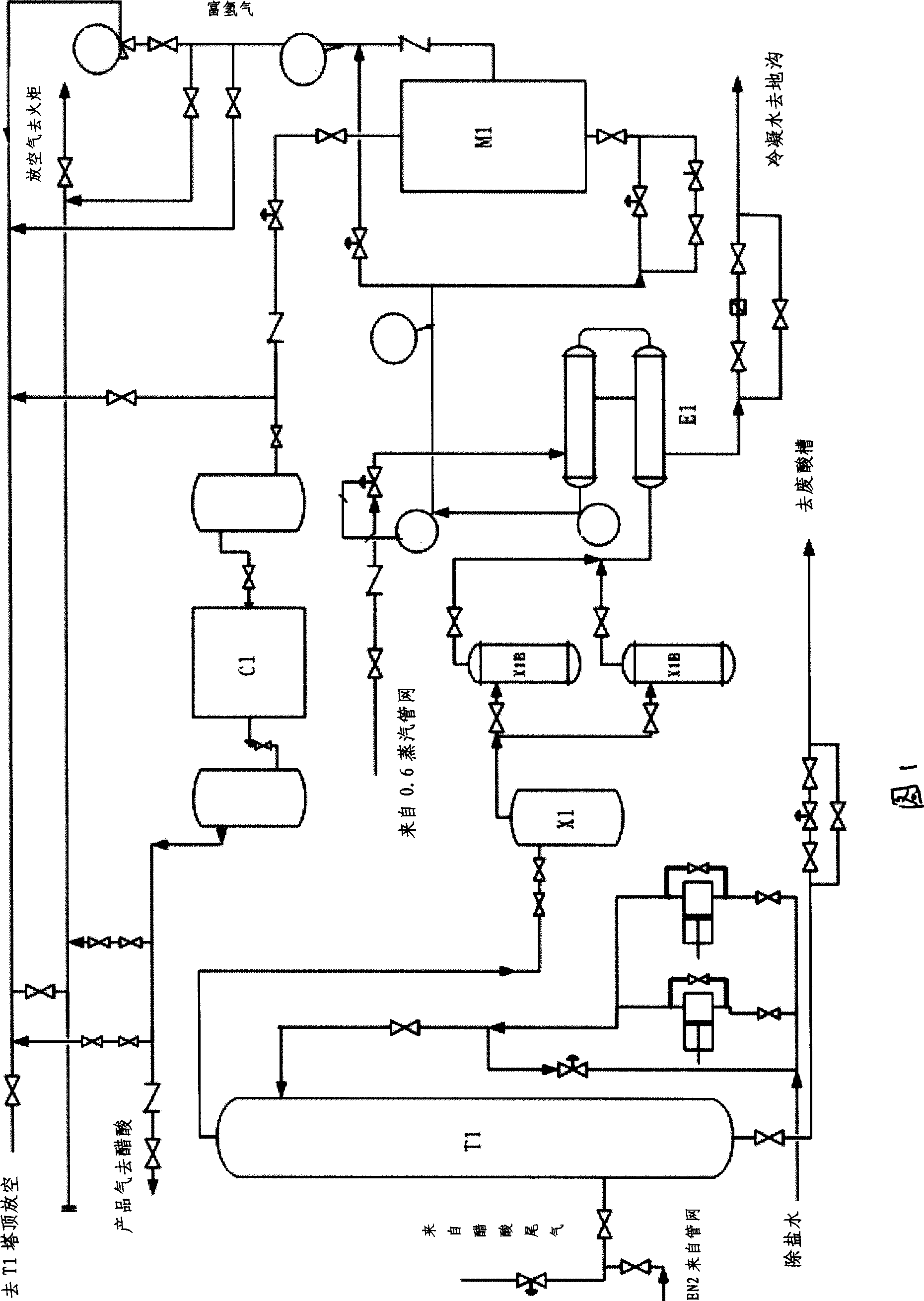

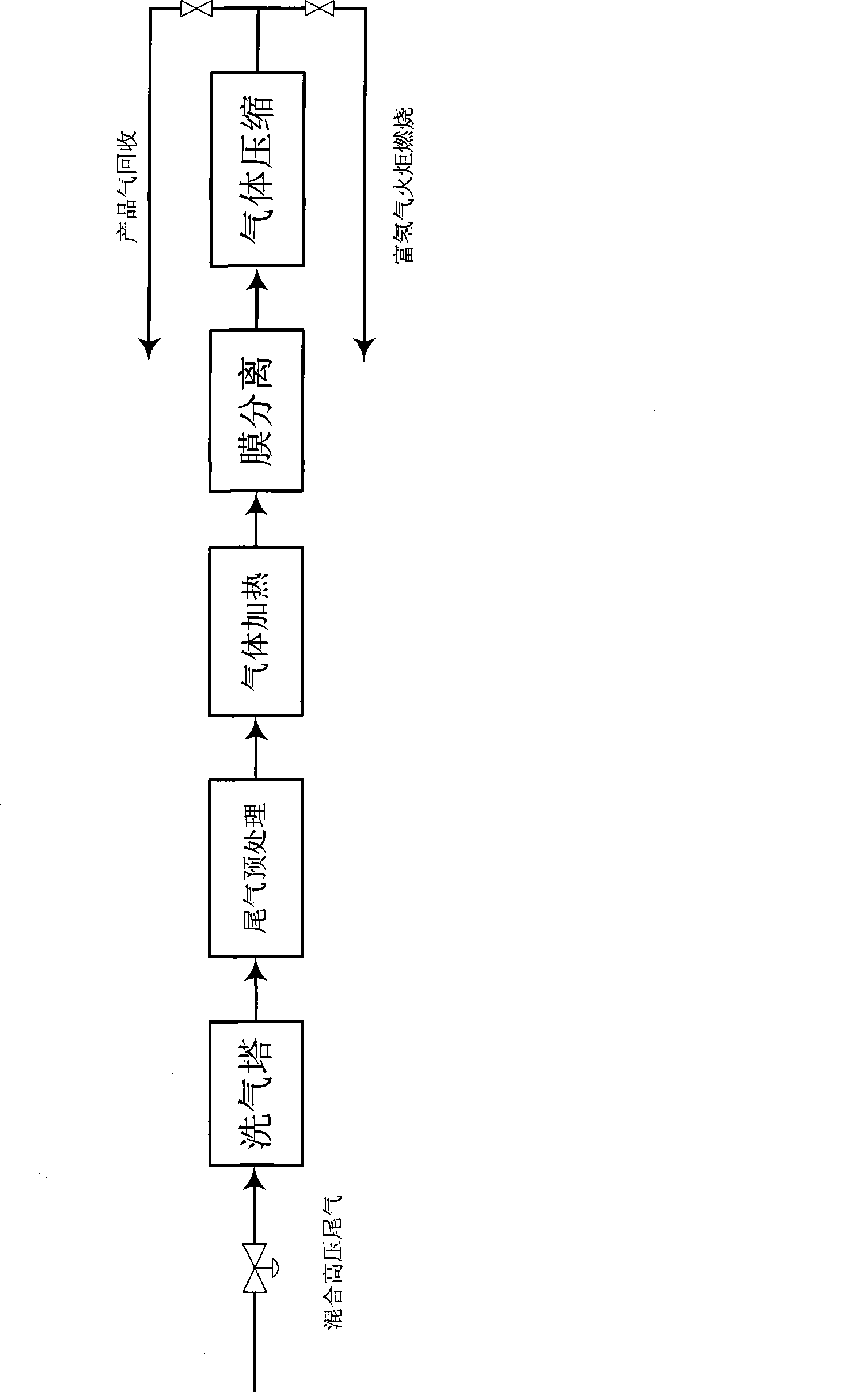

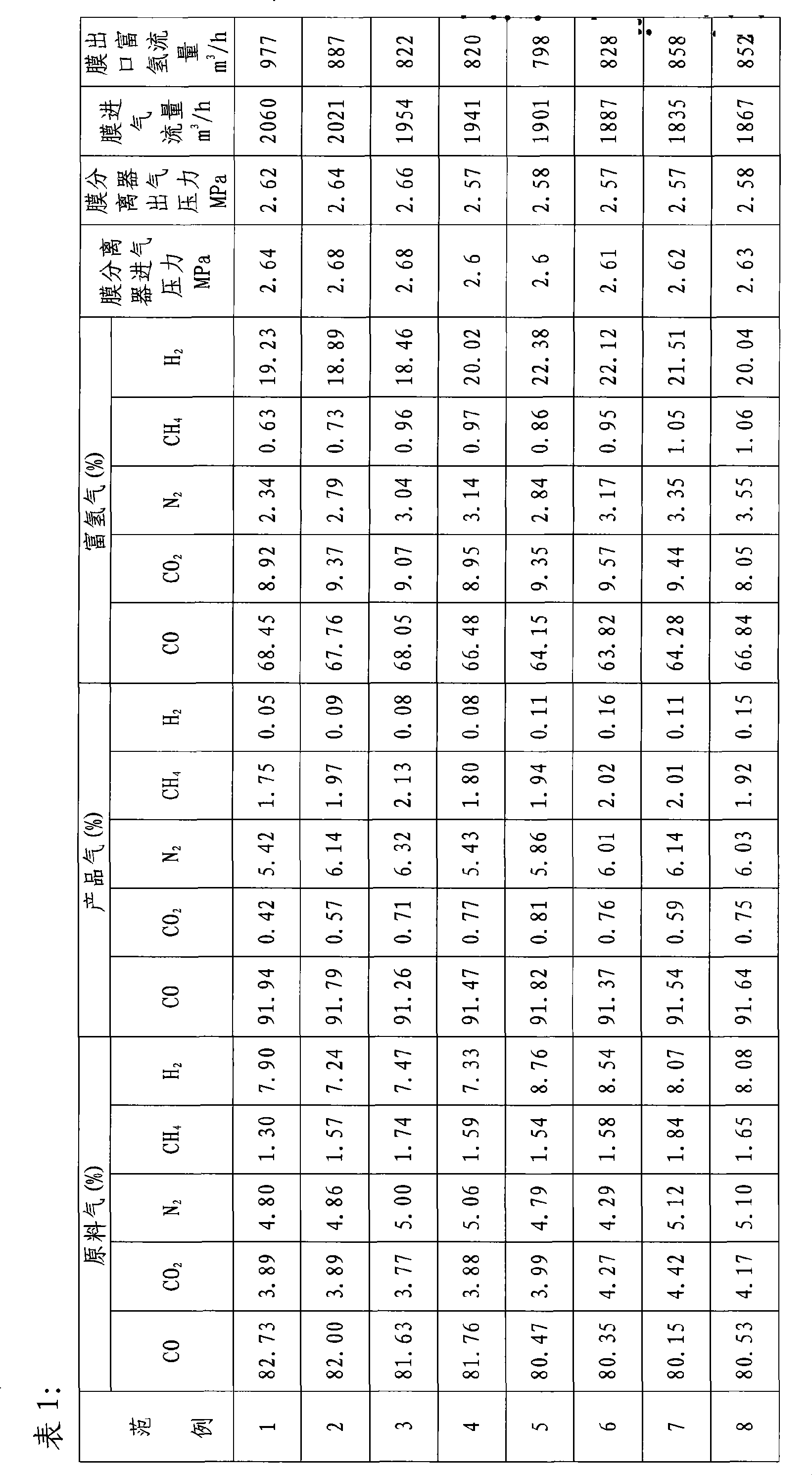

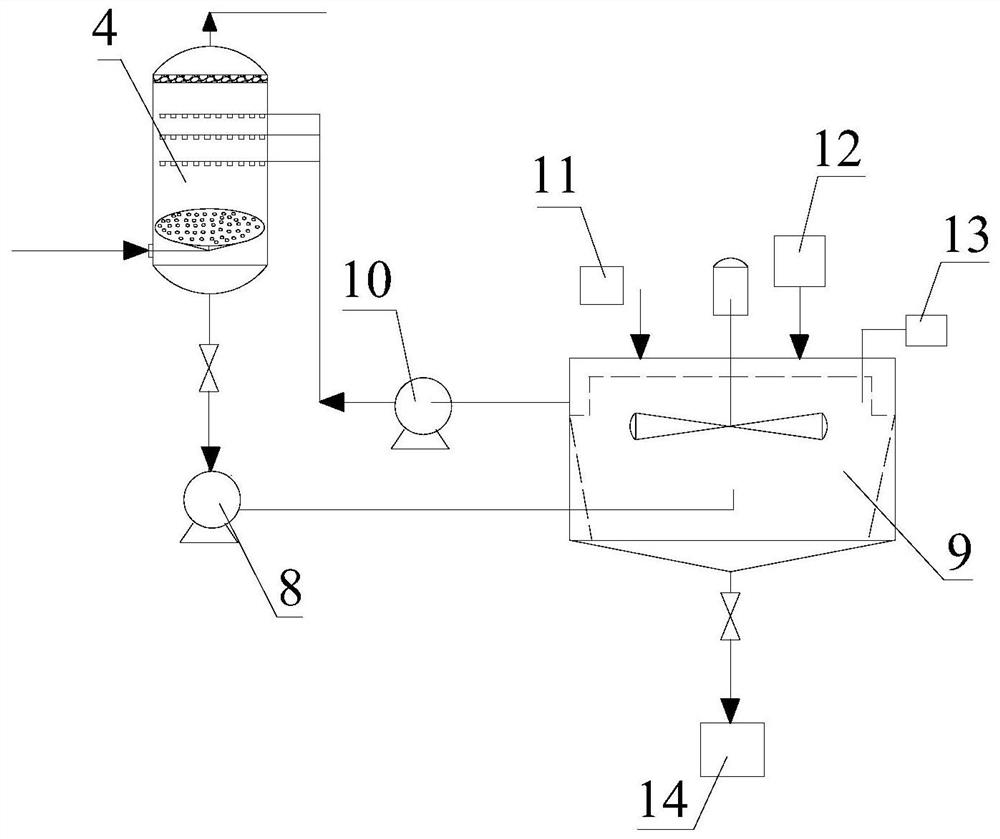

Film method for recycling CO in high-pressure exhaust from production of acetic acid by carbonylation

ActiveCN101439256AMeet the need for protectionImprove operational reliabilityOrganic compound preparationDispersed particle separationAcetic acidMaterial balance

The invention discloses a method for recovering CO from a high-pressure acetic acid tail gas produced by carbonylation through a membrane process and a device thereof. The tail gas is treated by three steps, that is, pretreatment, membrane separation and gas compression: the tail gas that passes a gas washing tower, a demister and a combined filter enters a Prisen membrane separator through a heater, the tail gas after the membrane separation enters a compressor, a product gas is recovered and reused, and hydrogen rich gas flows to a torch for burning. In the method, two Prisen membrane systems help control the amount of the feed gas entering a membrane, the product gas and the hydrogen rich gas to reach N2 material balance, ensure the CO recovery rate and achieve the purpose of the long and stable operation of a membrane separation device; and the content of the CO in the final product gas is not less than 91%.

Owner:JIANGSU SOPO CHEM

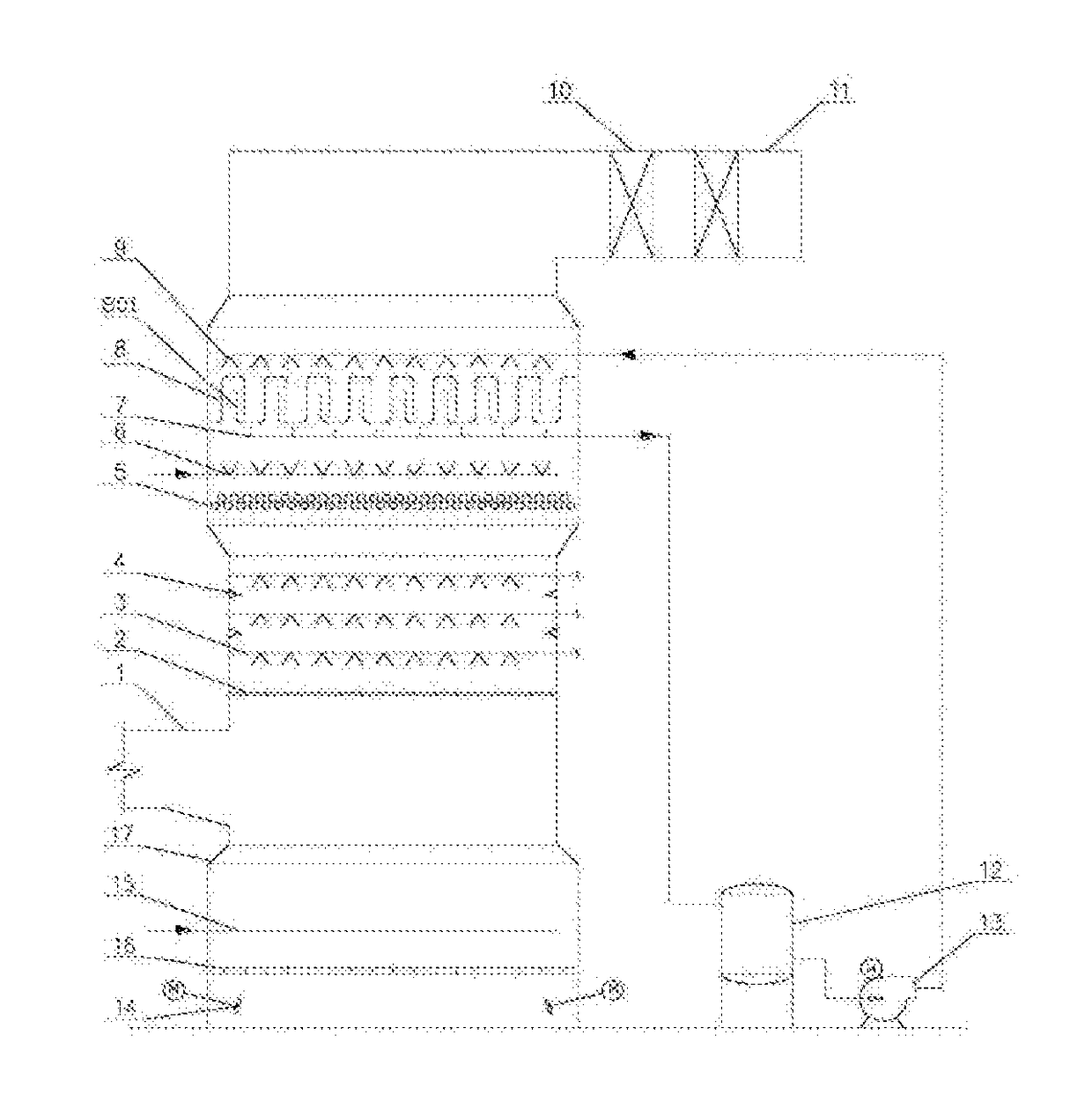

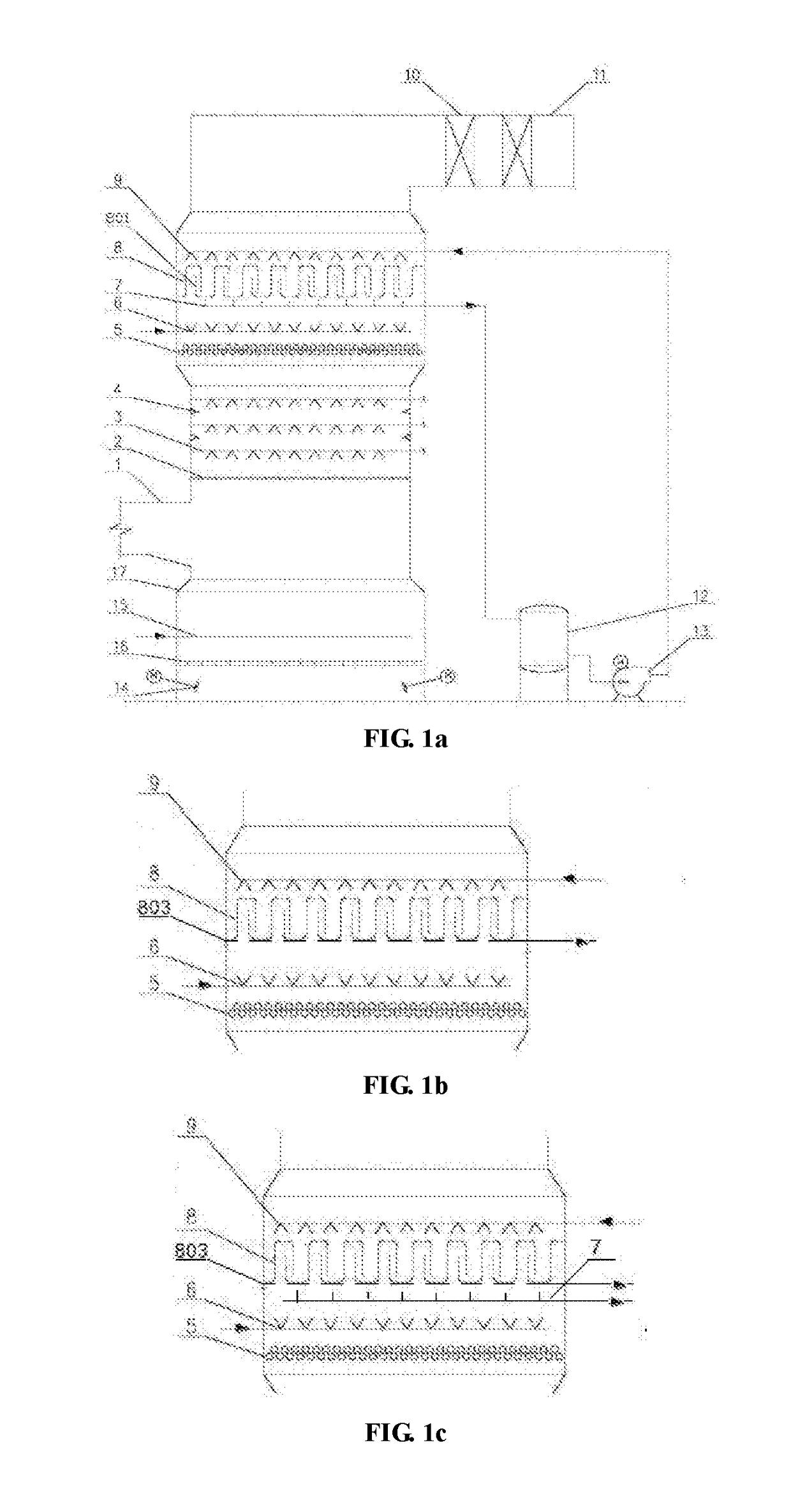

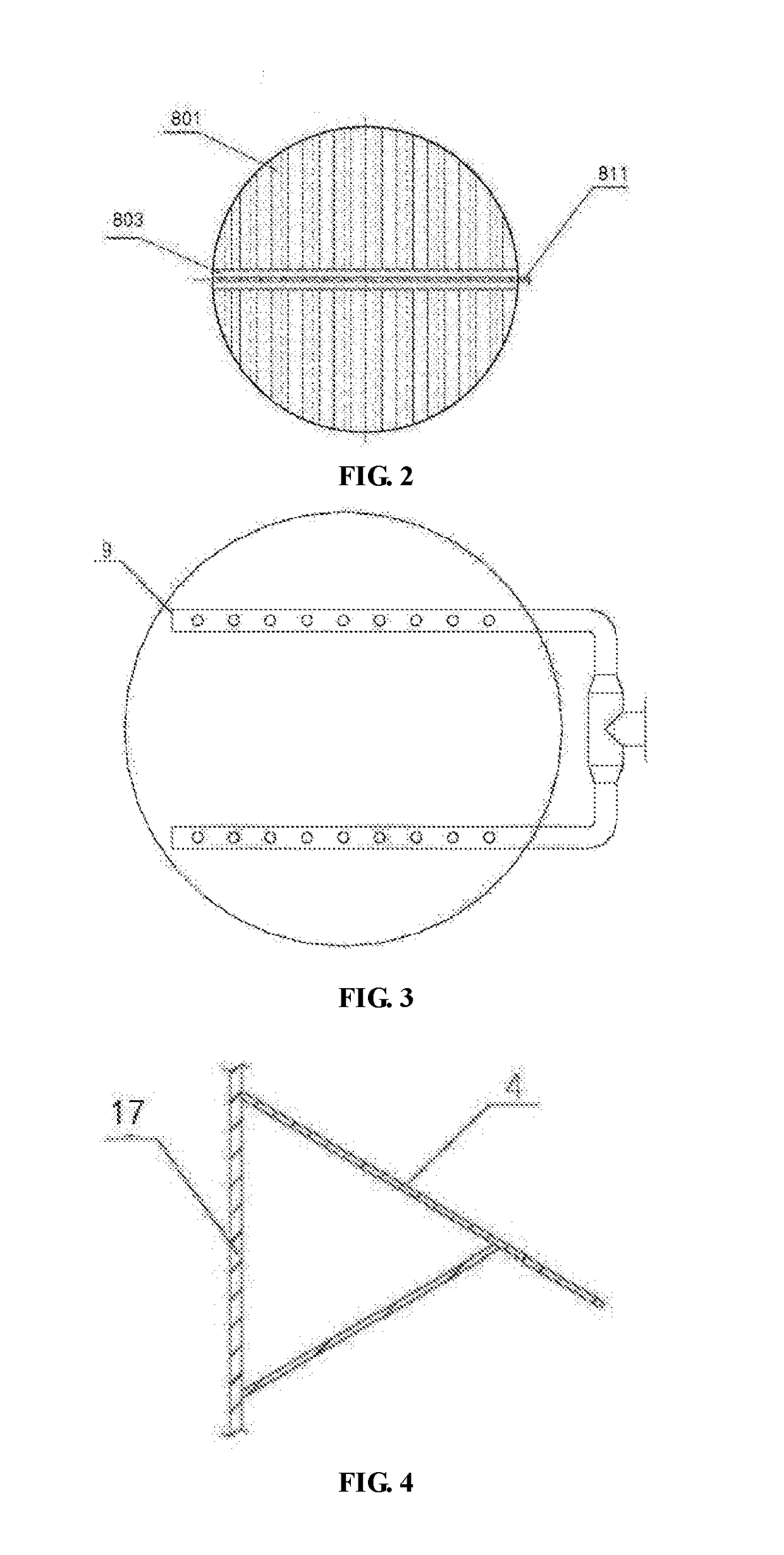

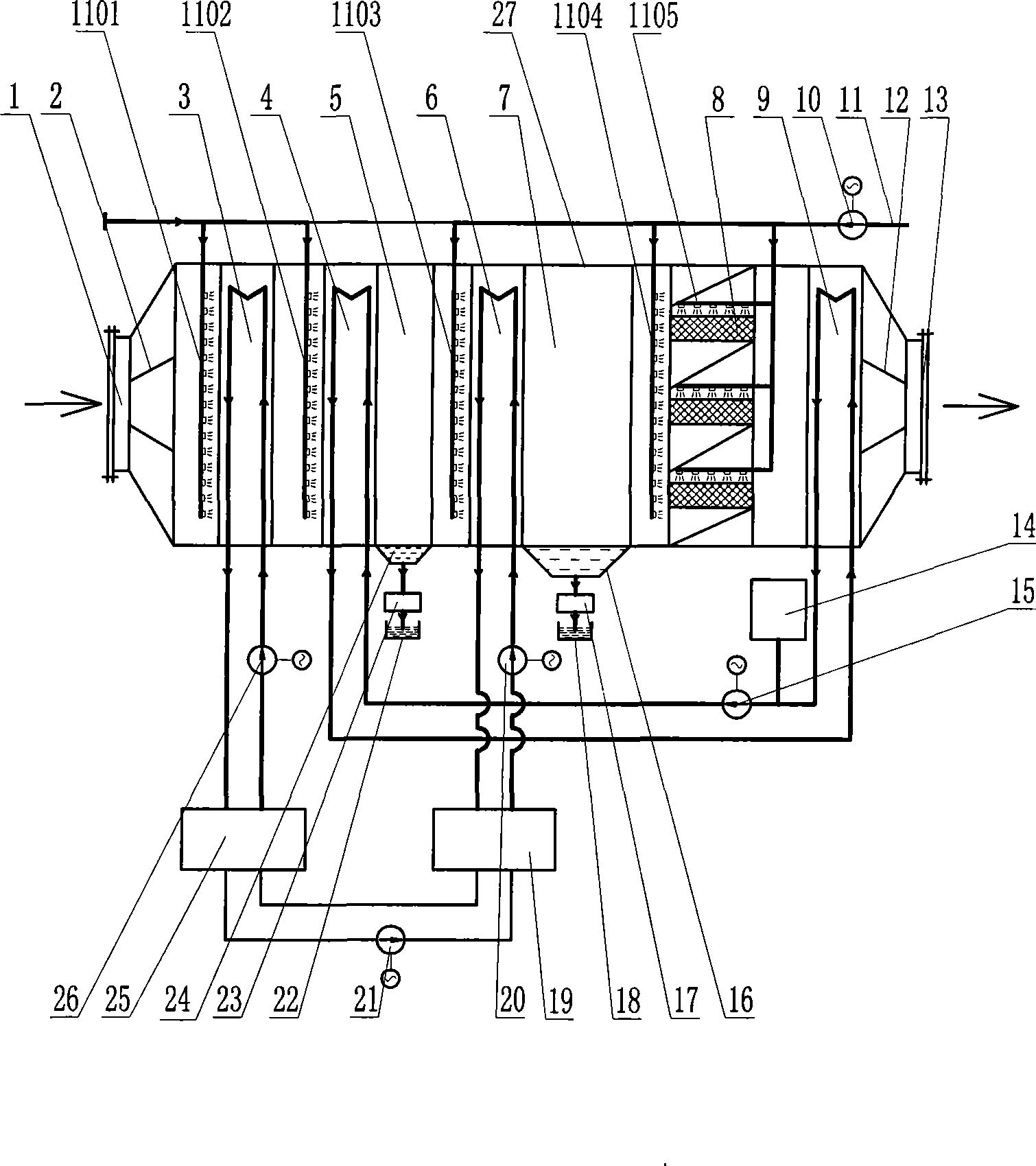

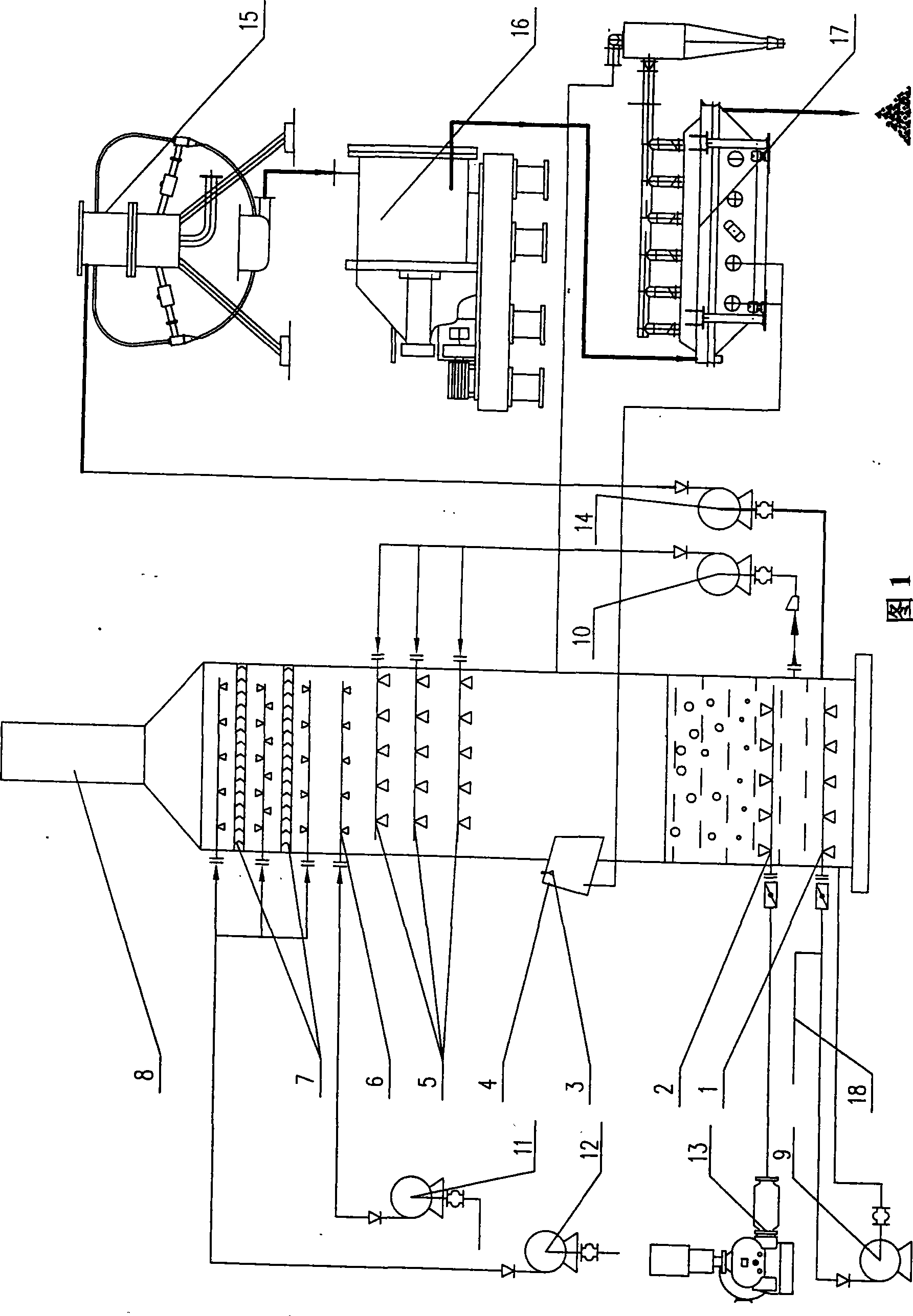

High-efficiency gradient hierarchy complex desulfurizing tower

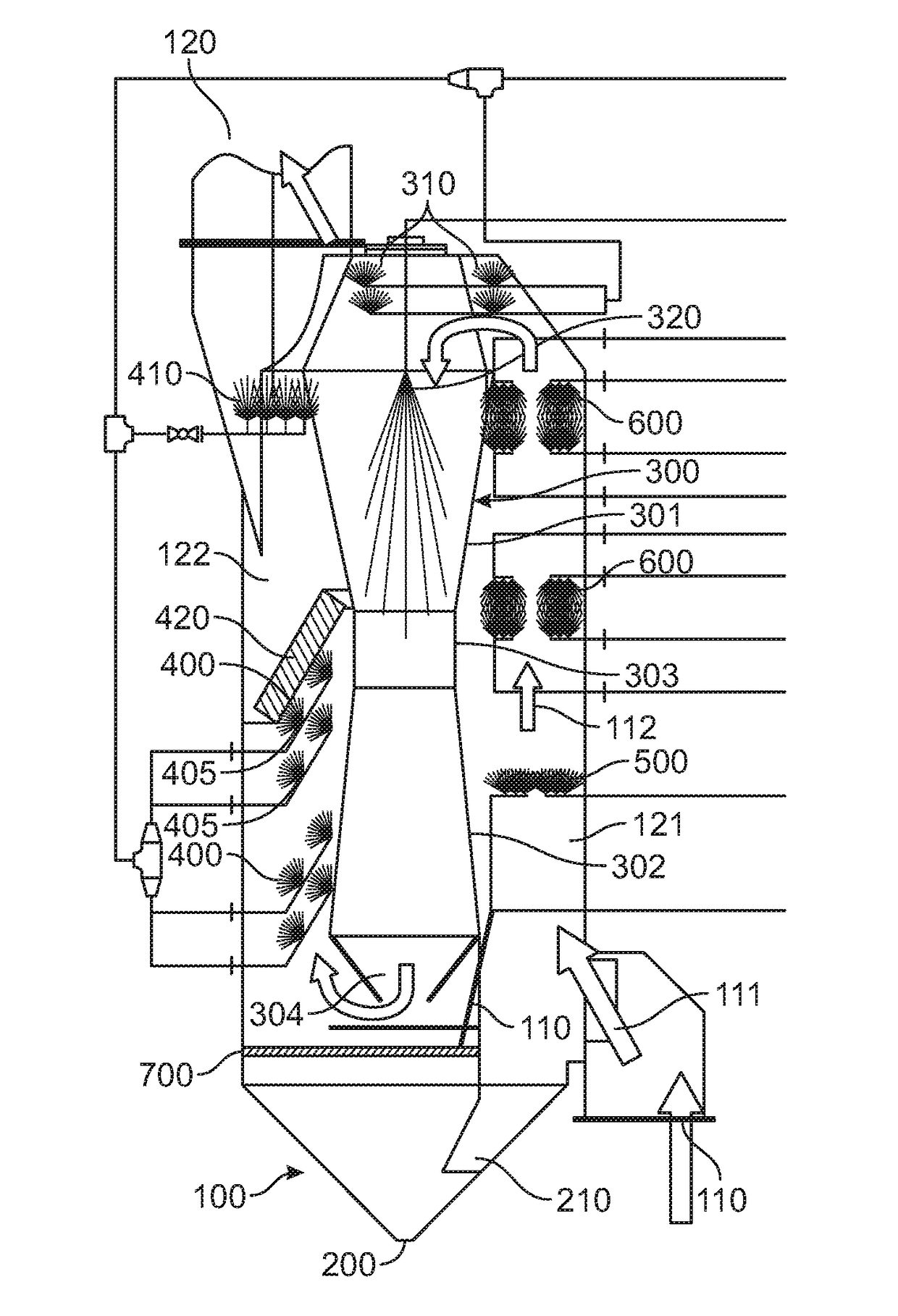

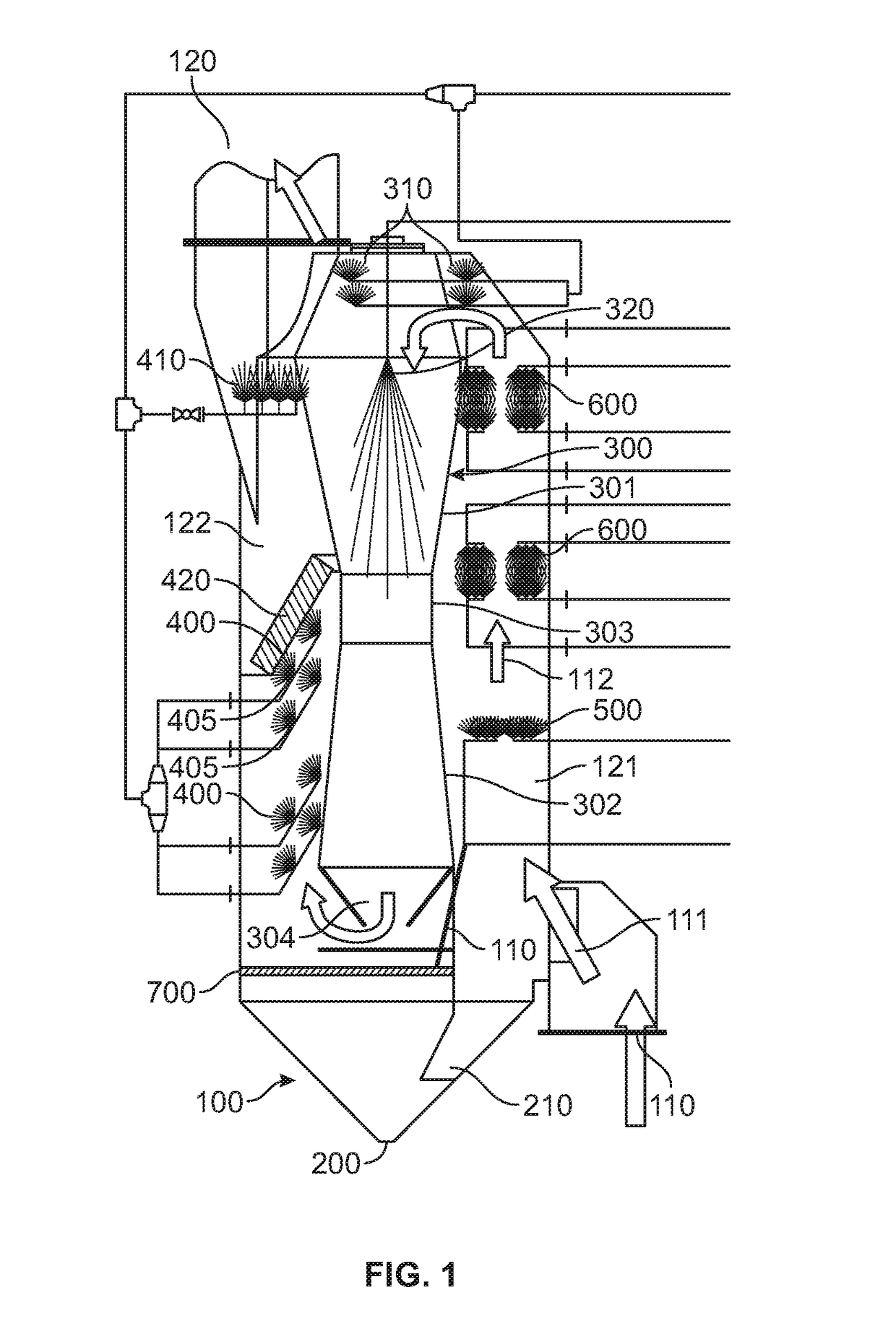

ActiveUS20180140991A1Improve desulfurization efficiencyImprove performanceGas treatmentUsing liquid separation agentSlurryProcess engineering

A high-efficiency gradient hierarchy complex desulfurizing tower includes a tower body. The tower body tower includes an oxidization and crystallization stage, a coarse desulfurization and dedusting stage, a fine desulfurization and dedusting stage, and a horizontal demisting stage from the bottom up. The oxidization and crystallization stage tower includes a pond and a separation mechanism provided in the pond and separating the pond into an upper area and a lower area. The coarse desulfurization and dedusting stage tower includes a gas distributing board and a multi-layer spray layer that are placed above a gas import, the spray layer being in connection with the pond. The fine desulfurization and dedusting stage tower includes a tube demister, a flushing layer, a film liquid holdup layer, a liquid holdup layer recycling can, the pH of slurry in the liquid holdup layer recycling can being higher than the pH of slurry in the pond.

Owner:HUANENG POWER INTERNATIONAL +1

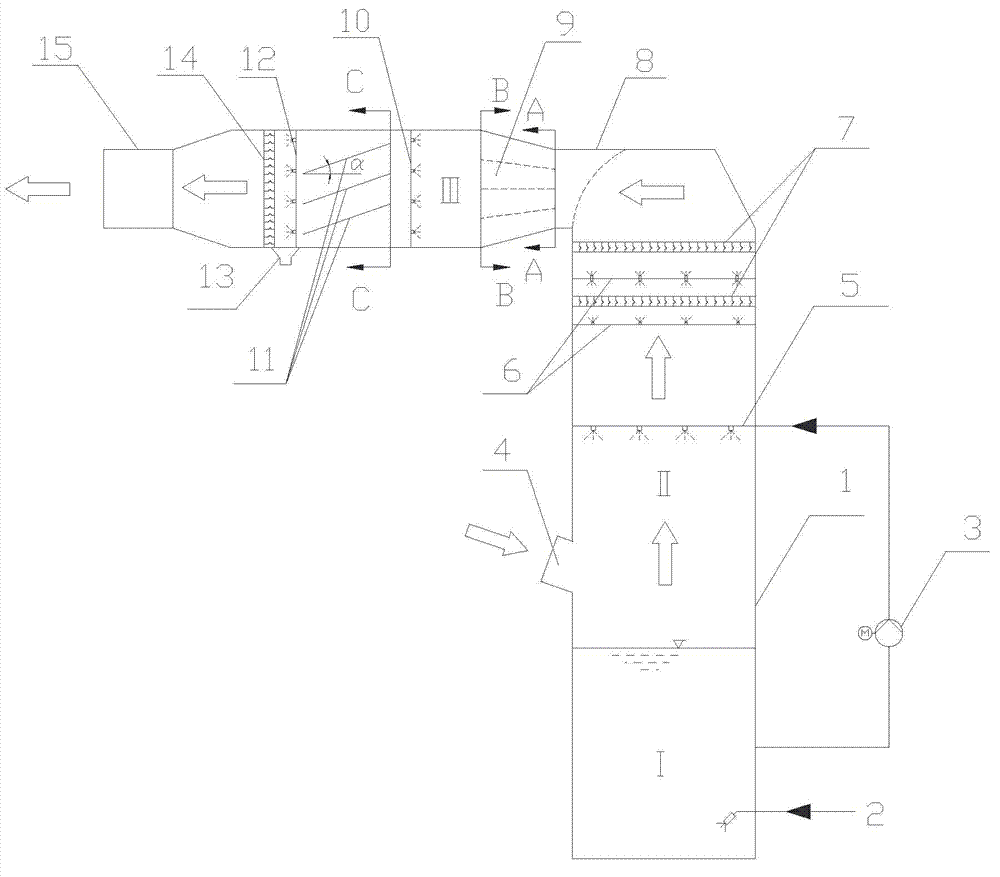

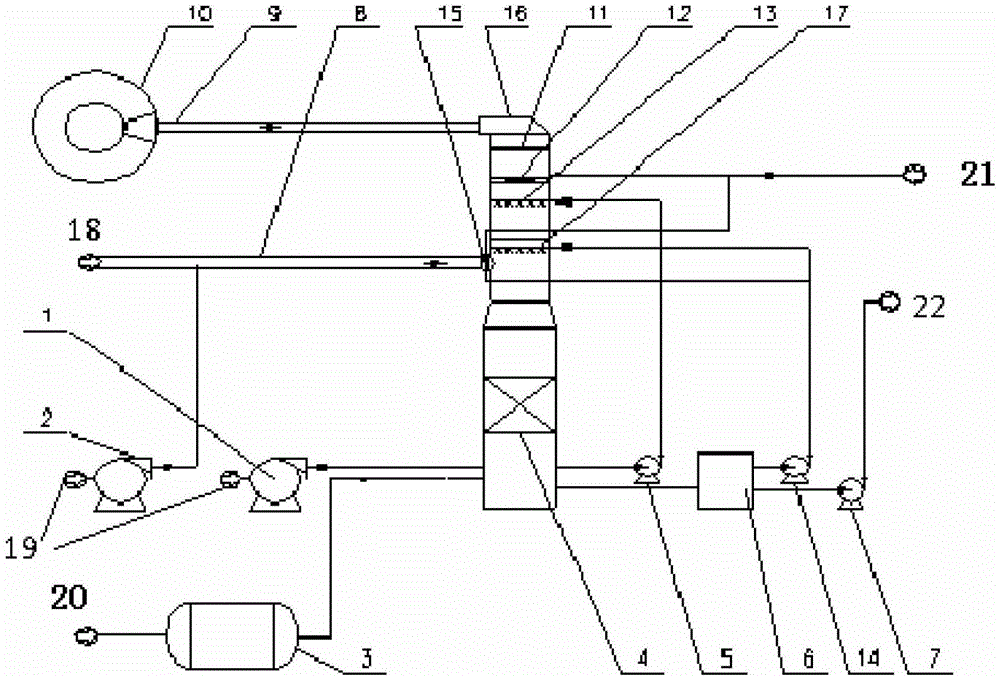

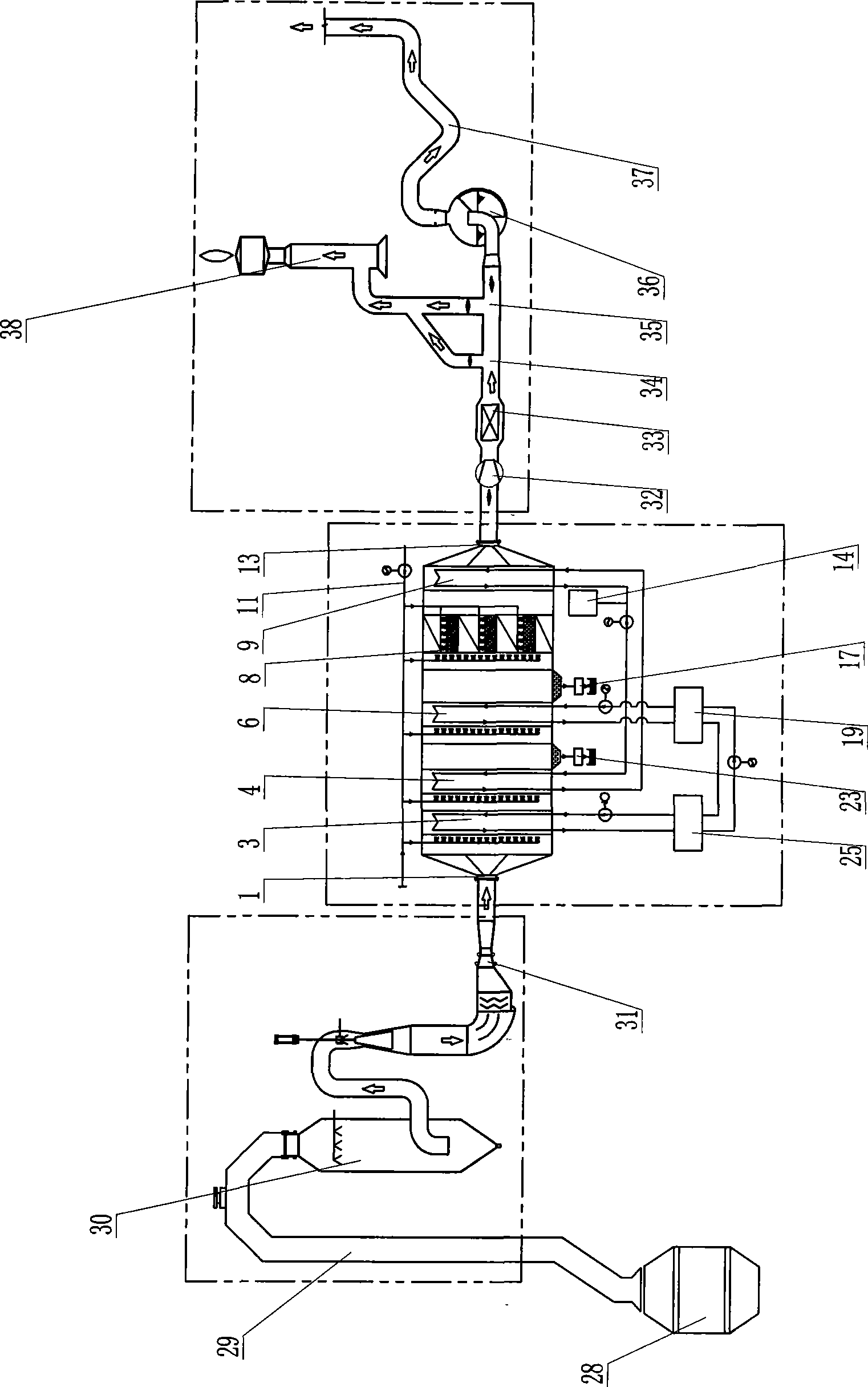

Method and device for synergistically removing fine particles via wet-process flue gas desulfurization

ActiveCN102961943AGood effect on removing fine particlesInvestment cost savingsCombination devicesFlueWater collection

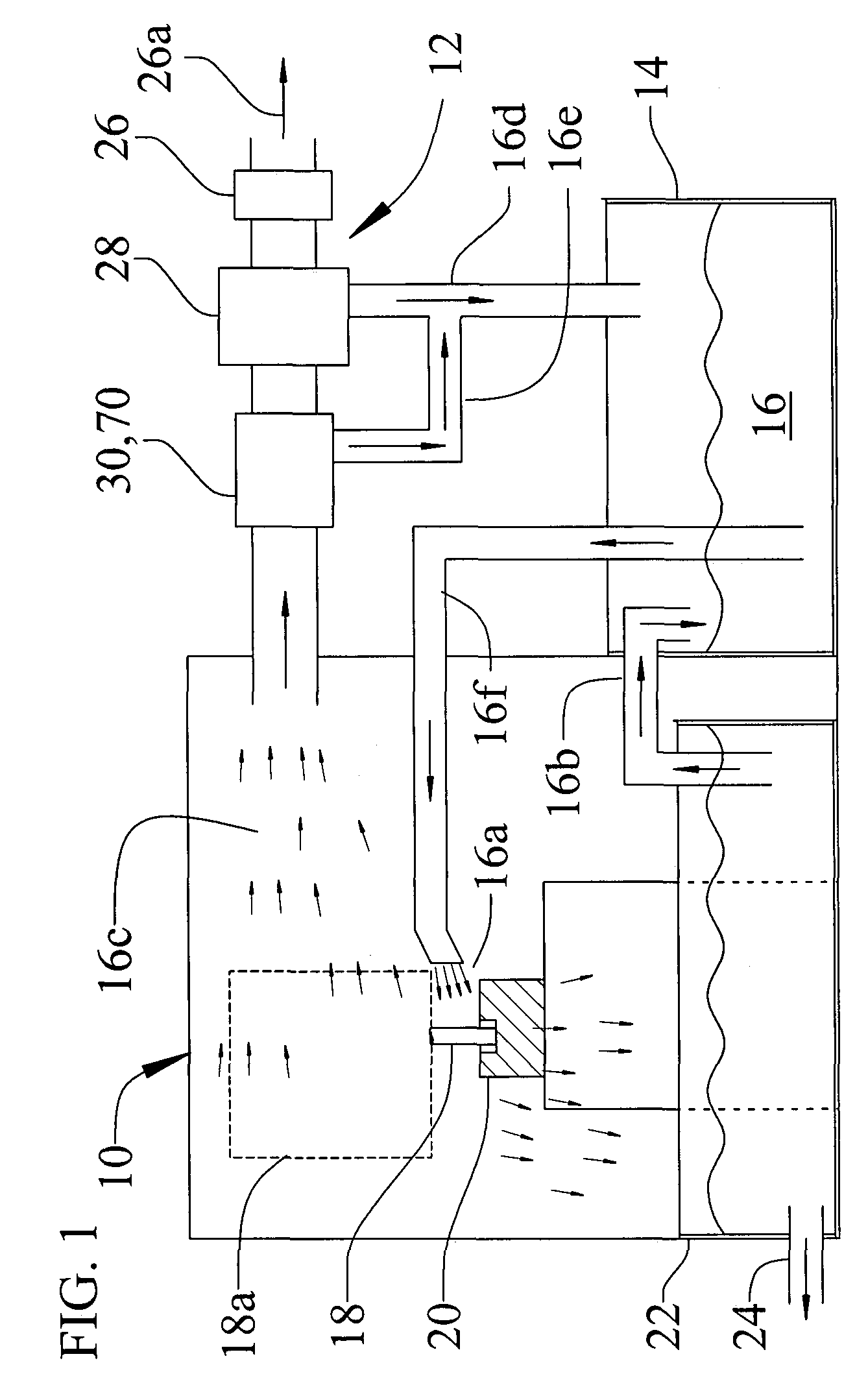

The invention provides a method and a device for synergistically removing fine particles via wet-process flue gas desulfurization, belonging to the technical field of control of fine particulate matters in smoke. The method is characterized by comprising the steps of simply reforming a desulfurization flue in a wet-process desulfurization device, establishing a steam phase change area to ensure that the fine particles condense and grow, establishing a collision condensation area to ensure that the fine particles further condense and grow, effectively capturing the condensed and grown fine particles by using a flue demister and discharging the fine particles out from an outlet of a flue. The device for realizing the method is characterized in that an outlet of an absorption tower is connected with an increasing coupling at the inlet end of the desulfurization flue, the outlet end of the desulfurization flue is connected with a reducing pipe at the outlet of the flue, and a smoke uniform distributor, a steam nozzle, a cleaning process water nozzle, a flue water collection port and the flue demister are arranged in sequence along the flow direction of the smoke. The method and the device have the beneficial effects of saving the equipment investment cost and having good fine particle removal effect through simply reforming the original facility.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

High-efficiency wet-type electric dust removal and desulfuration system and process

ActiveCN102716639AGuaranteed desulfurization efficiencyImprove dust removal system efficiencyCombination devicesGypsumWater balance

The invention discloses a high-efficiency wet-type electric dust removal and desulfuration system and a process. A wet-type electric dust remover is arranged above a demister in a desulfuration tower. First of all, the demister is used for pre-removing mist drops and dust from clean smoke; the wet-type electric dust remover is used for performing fine treatment on the clean smoke; therefore, an extremely high environment-friendly discharging requirement is met; and the desulfuration efficiency is guaranteed, the efficiency of a dust removal system of the desulfuration tower is improved, and the dust discharge concentration at the outlet of the desulfuration tower is reduced, so that the latest discharge standard required in China is met. According to the wet-type electric dust remover, the problem of gypsum rain can be solved; various pollutants can be removed at the same time; furthermore, a water accumulation plate is arranged between the demister and the wet-type electric dust remover and used for collecting and recycling washing water of the wet-type electric dust remover, so that the washing water of the wet-type electric dust remover cannot directly enter into a neutralization oxidation pond of the desulfuration tower; and therefore, the water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

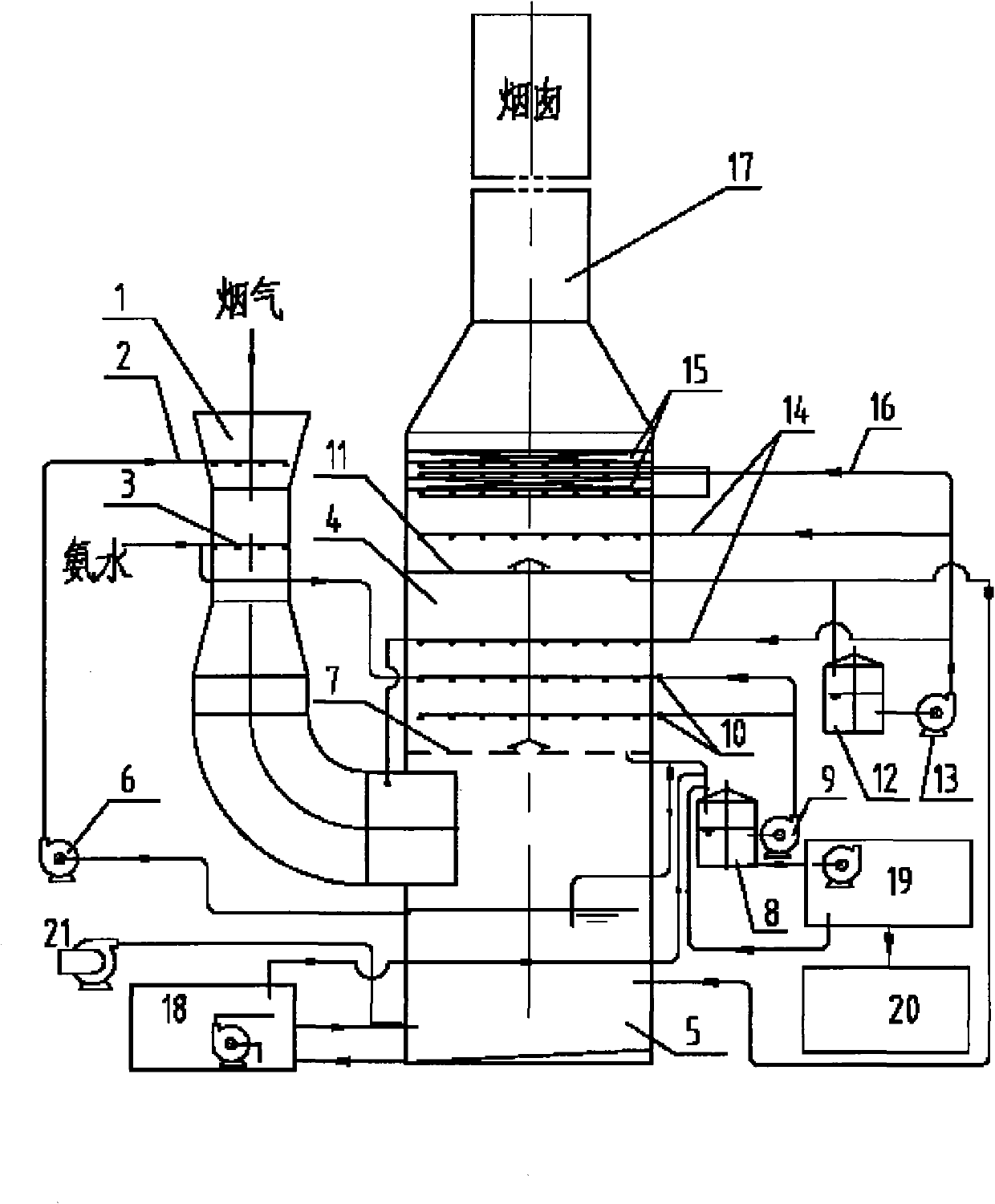

Simultaneous desulfurization and denitrification method using aqueous ammonia

The invention relates to a method for simultaneously removing sulfur oxides and nitrogen oxides in flue gas by using aqueous ammonia. According to the method, the (NH4)2SO3, which is obtained from a desulfurization reaction for absorbing SO2 by aqueous ammonia, is used as an absorption solution for a denitrification reaction; and the (NH4)2SO3 has reducibility for reducing NOx in the flue gas to N2 to achieve the denitrification purpose. The method provided by the invention comprises the following steps that: the flue gas firstly enters into a denitrification spraying layer of a contraction segment in a venturi tower and is subjected to a downstream contact reaction with a circulating liquid from an oxidation pond on the tower bottom, an aqueous ammonia spraying layer is arranged at the throat part of the venturi tower to carry out the desulfurization reaction, the concentration of the (NH4)2SO3 is instantly increased due to the desulfurization reaction, the denitrification reaction is further carried out, the liquid after reaction and the flue gas transversely enter into the middle lower part of a cylindrical tower along the lower part of the venturi tower, the liquid flows downwards to the bottom of the cylindrical tower, the flue gas moves upwards after passing through a tower plate and is countercurrent contact with the circulating liquid to further generate a desulfurization reaction and a denitrification reaction, fine liquid drops and aerosol of the purified flue gas are captured when the purified flue gas passes through the water spraying layer and a folded plate type defroster, the purified flue gas is then directly exhausted from a direct exhaust chimney connected to the tower top, and simultaneously, a by-product of the system is ammonium sulfate, which is a raw material of an agricultural nitrogenous fertilizer or a compound fertilizer.

Owner:克莱斯克(北京)环境工程有限公司 +1

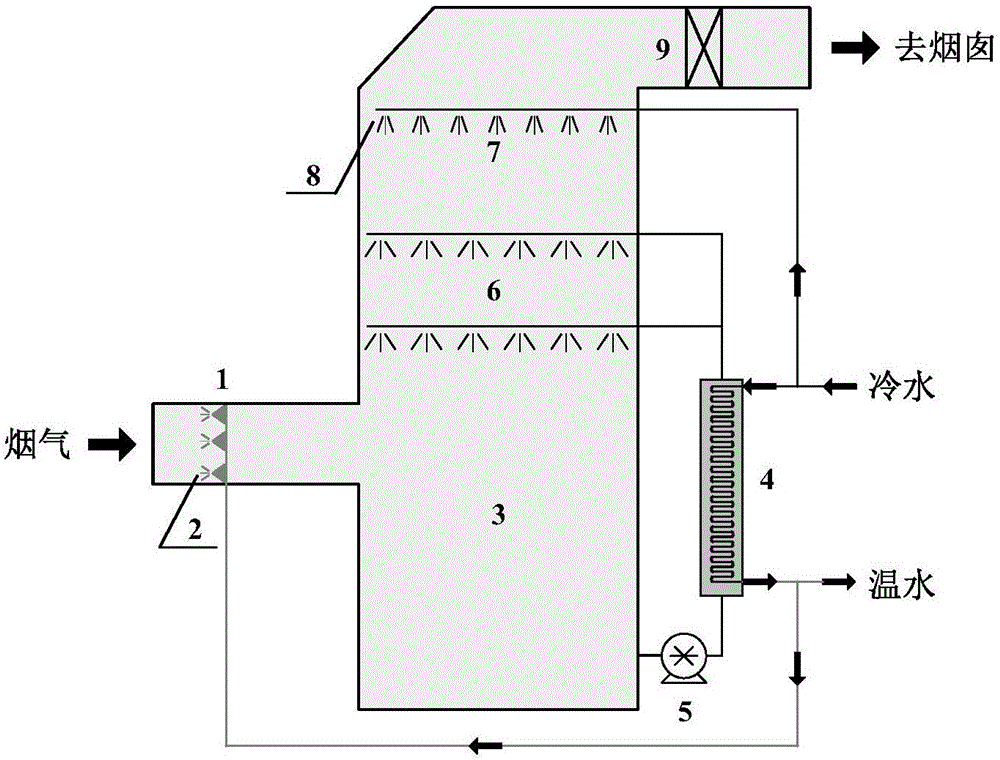

Wet desulfurization synergized fine particle and SO3 acid mist removing method and device

InactiveCN106669326AIncrease moisture contentIncreased washing removal efficiencyGas treatmentUsing liquid separation agentFlueFlue gas

The invention discloses a wet desulfurization synergized fine particle and SO3 acid mist removing method and device. The device comprises a flue gas cooling and humidifying device, a wet desulfurization tower, a desulfurization washing solution heat exchanger and a cold water spray layer at the top of the desulfurization tower. The method comprises the following steps: spraying atomized water to the inlet flue duct of the desulfurization tower for cooling and humidifying; performing heat exchange and cooling on the desulfurization washing solution; carrying out once trapping with the desulfurization washing solution when high-humidity flue gas in the desulfurization tower is over saturated in the desulfurization washing process and fine particles and SO3 acid mist are coagulated and grow up; setting a cold water spray layer between the desulfurizing liquid spray layer at the top of the tower and a high-efficient demister, and spraying and cooling with cold water to enable the flue gas to be over saturated once again, coagulating and growing the fine particles and SO3 acid mist once again, and trapping with the high-efficient demister. The method can be used for effectively reinforcing the trapping effect of a wet desulfurization system on fine particles and SO3 acid mist, the desulfurization water consumption can be reduced, and the desulfurization efficiency can be improved. The method and device are suitable for coal-fired boiler with a wet flue gas desulfurization system.

Owner:SOUTHEAST UNIV

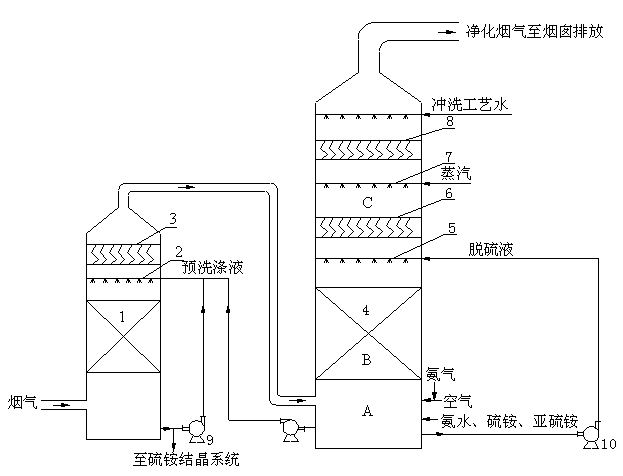

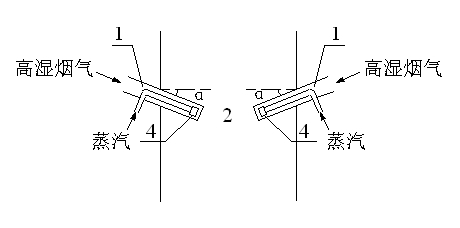

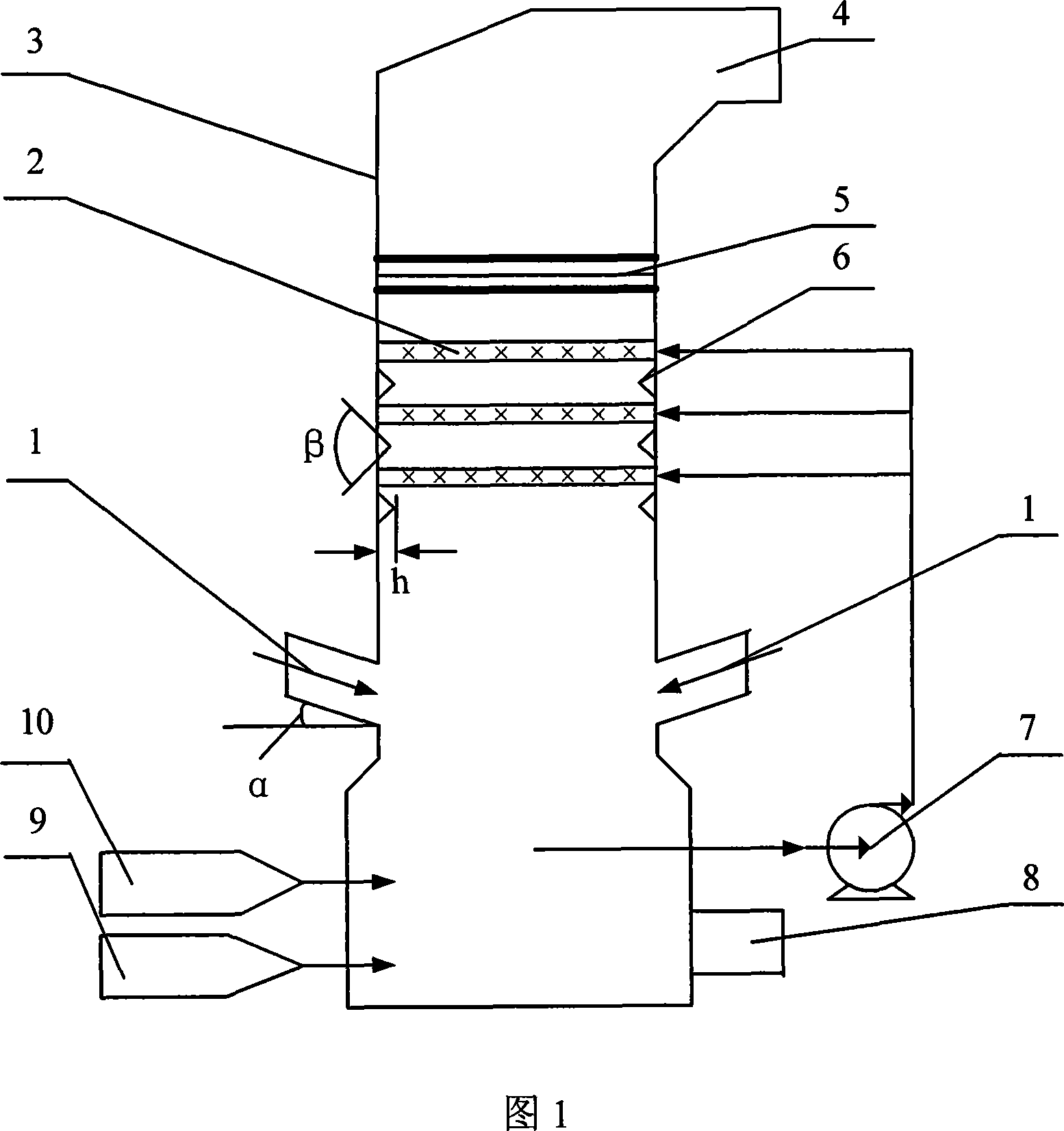

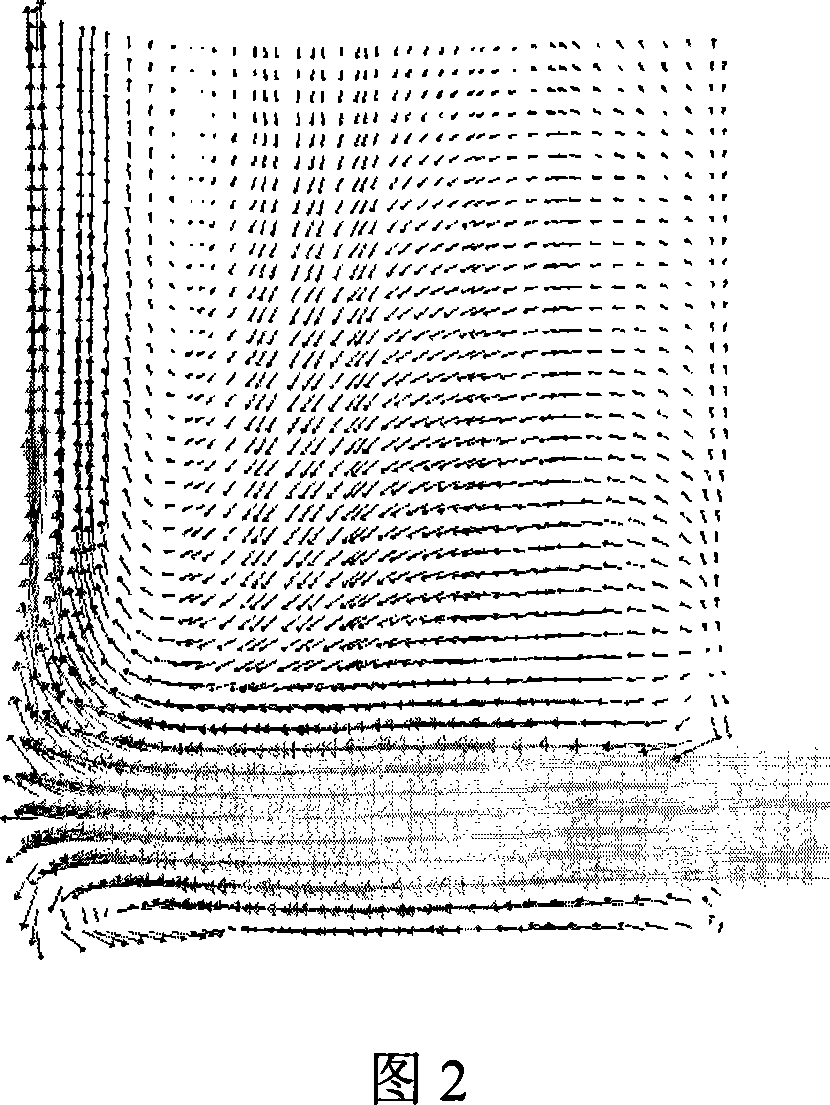

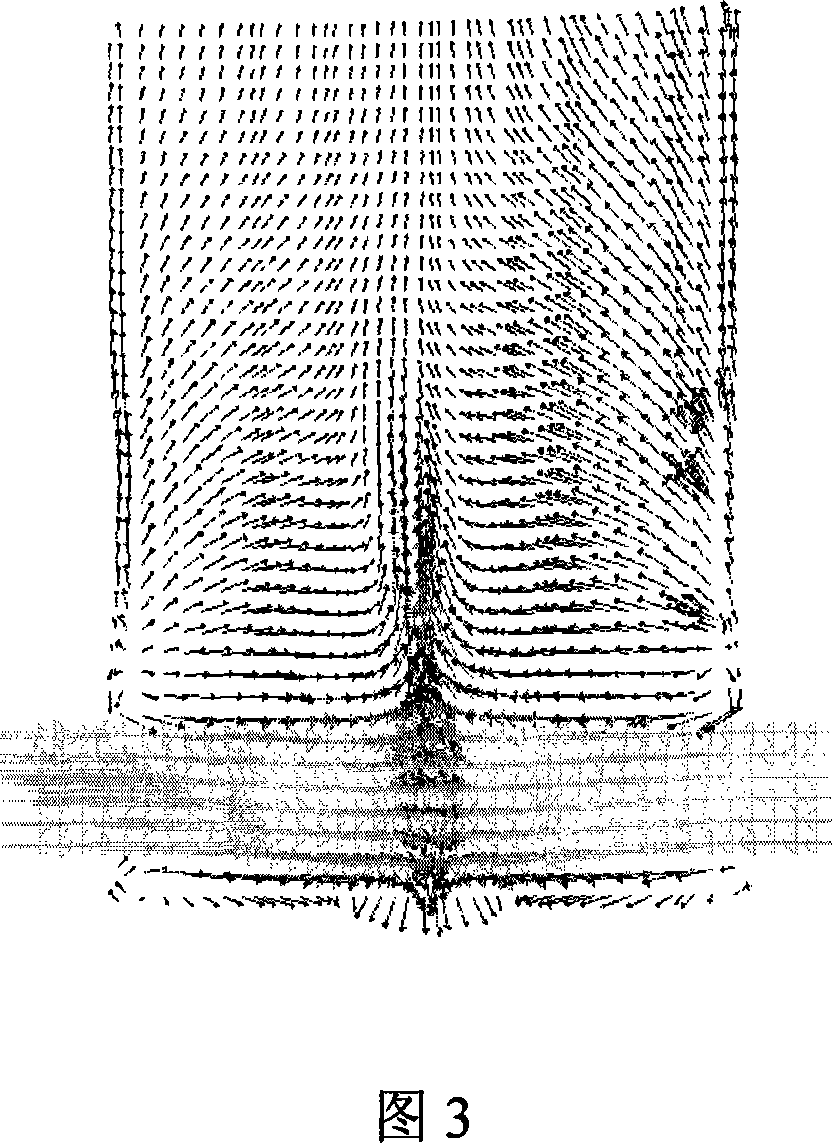

Bilateral opposite flushing inlet wet ammonia method for flue gas desulfurizing technology and device thereof

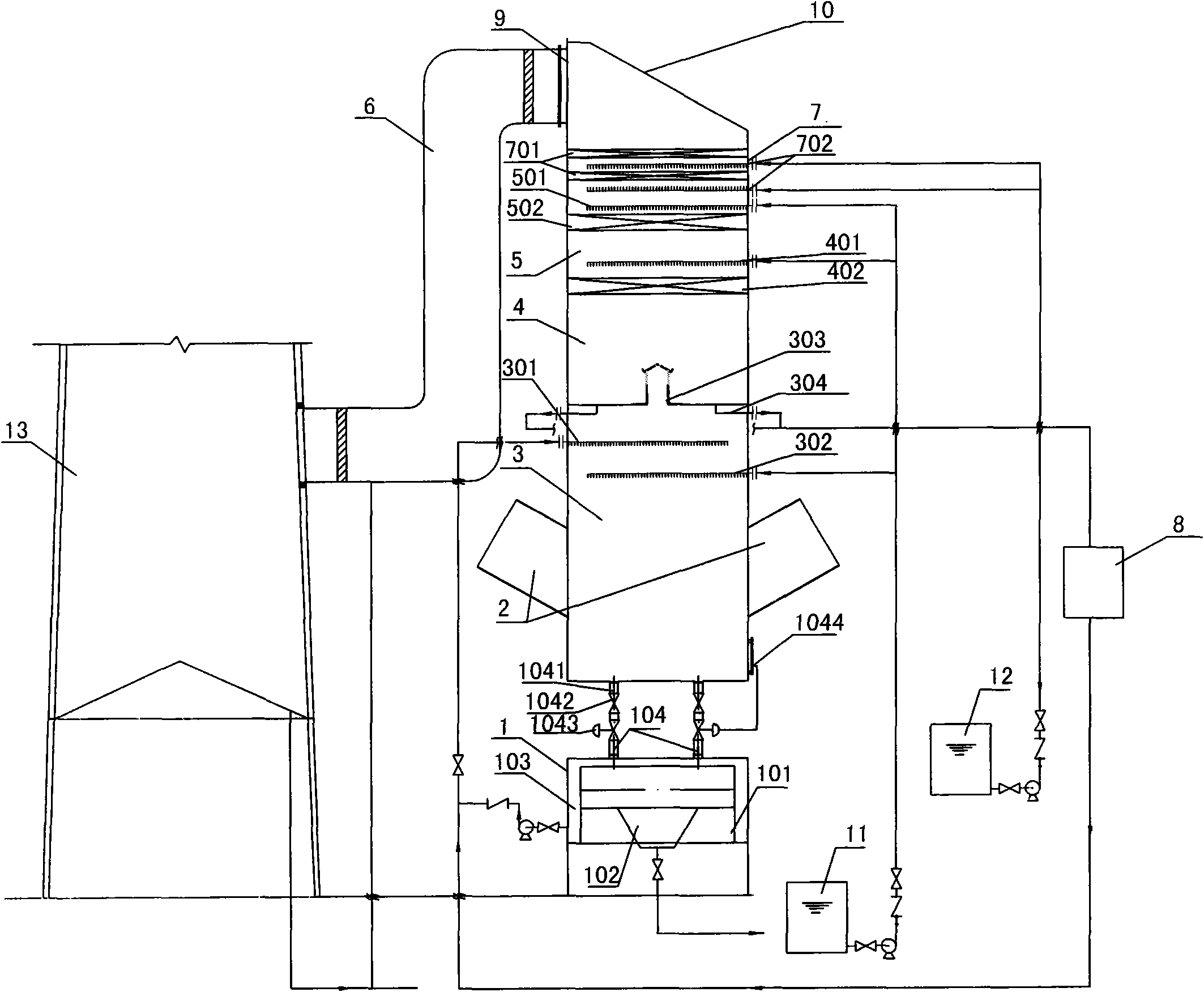

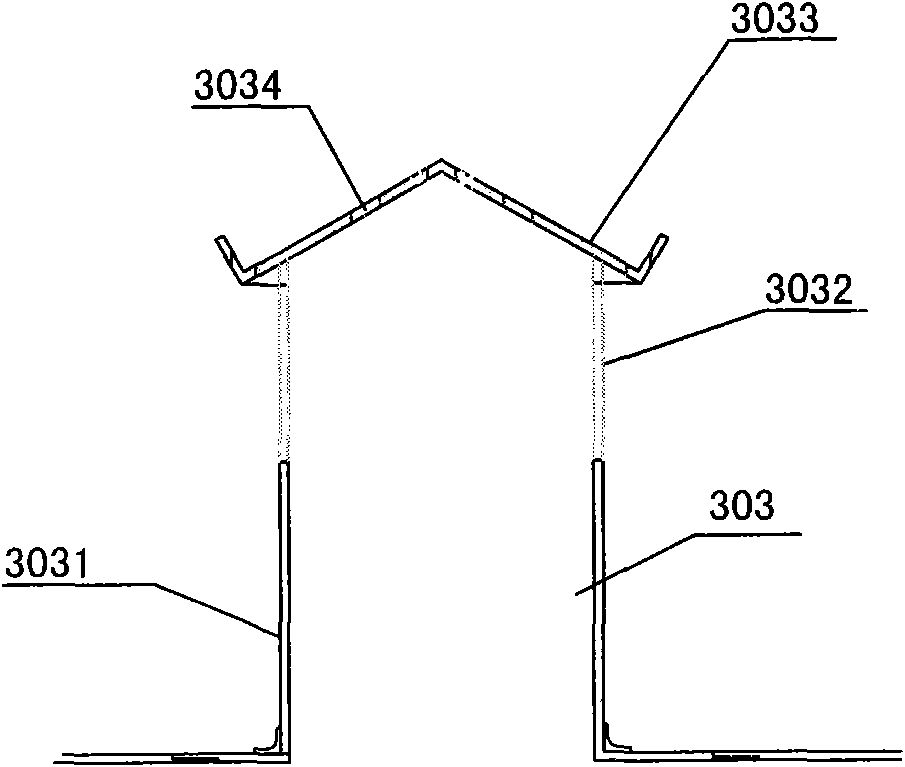

InactiveCN101053743AOptimizing the smoke flow fieldImprove desulfurization efficiencyDispersed particle separationChemistrySulfur dioxide

A wet ammonia method flue gas desulfurization process of two-side opposed inlet and device thereof, which makes the flue gas to form uniform upward opposed turbulence, then makes the flue gas to pass through flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer which are staggered arranged to rapidly transmute the sulfur dioxide in the flue gas to be ammonium salt admixture, lastly, oxidates the ammonium sulfite in the ammonium salt admixture to be ammiaonia sulfate and outputs the clear flue gas after demisted. The device comprises an ammonia replenishment system and an air feeding device at the bottom of the thionizer, an opposed flue gas inlet at the lower of the thionizer, flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer interleaving mounted at the middle of the thionizer, and a demister at upper of the thionizer, wherein the bottom of the thionizer is connected with the ammonia desulfurizer cycle spraying layer by cycle pump, the process and the device can improve the flue gas flow field effectively, enhance the gas-liquid mass transfer, and largely raise the desulfurization and the utilance of desulfurizer at the precondition without increasing the thionizer resistance and the consume of desulfurizer.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

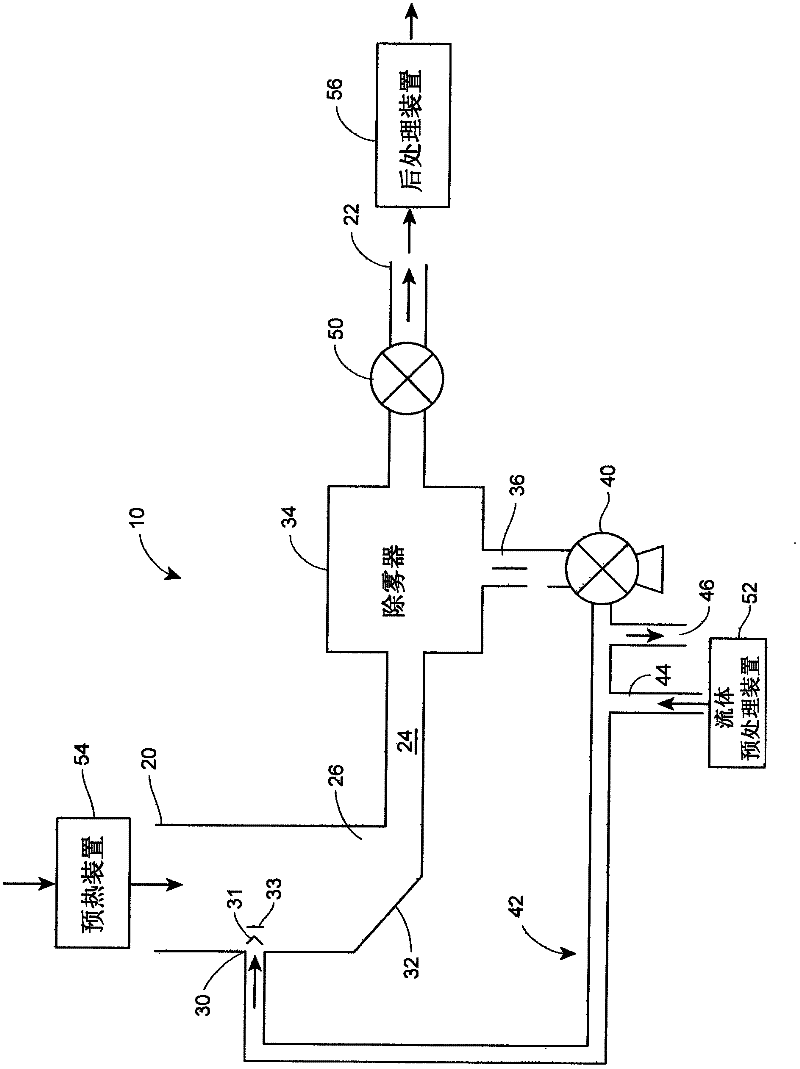

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20110061867A1High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEvaporationEngineering

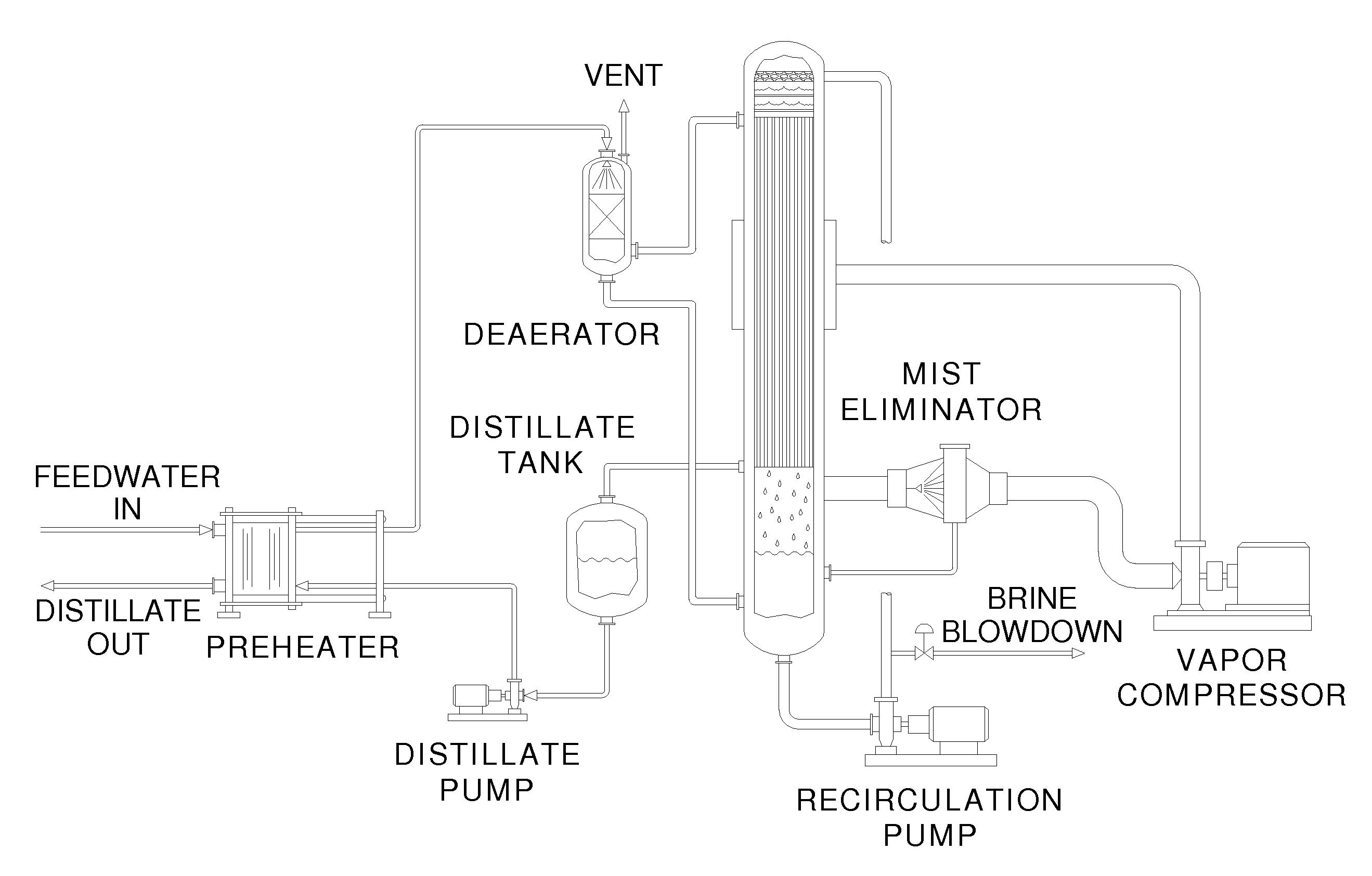

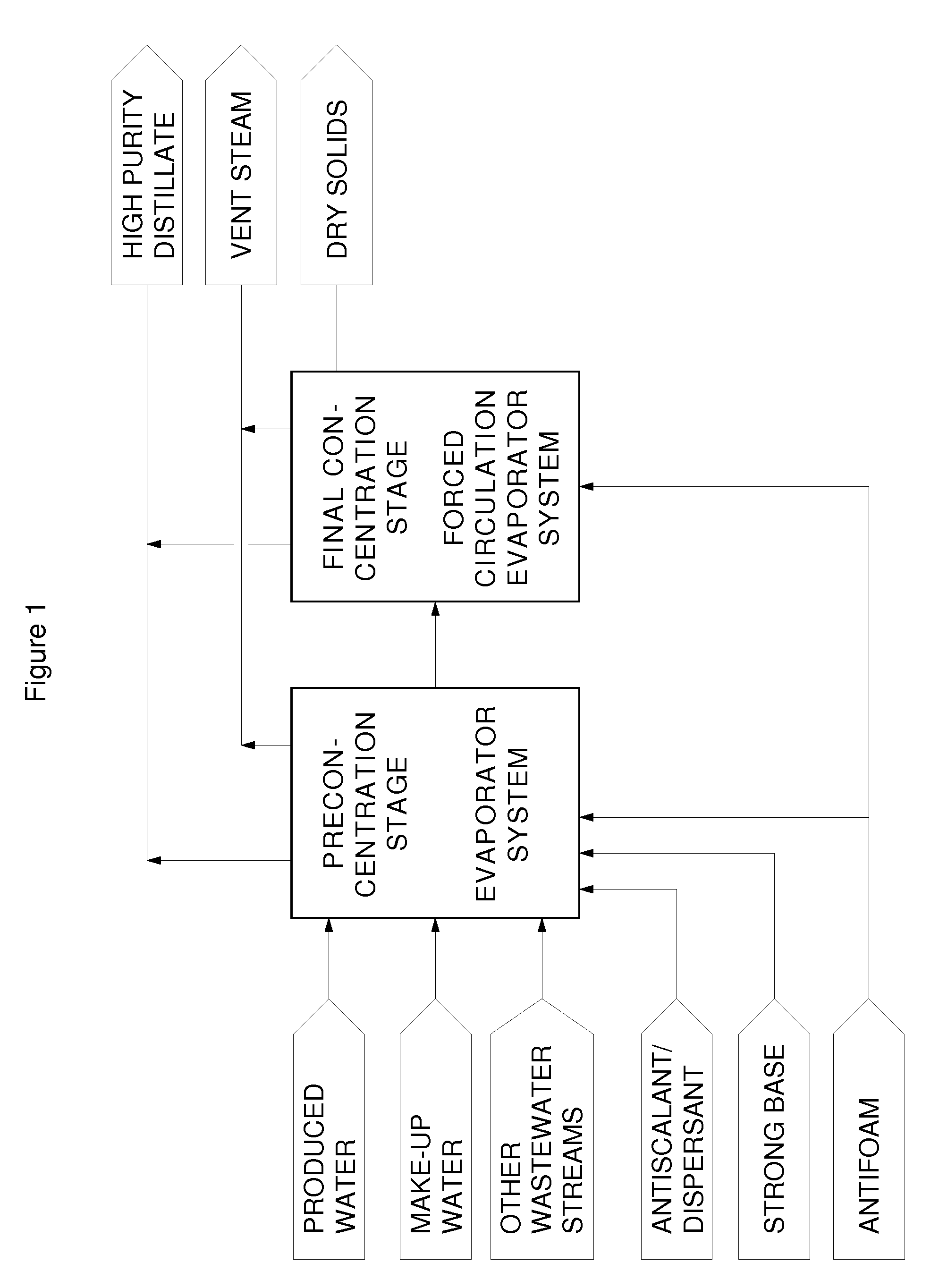

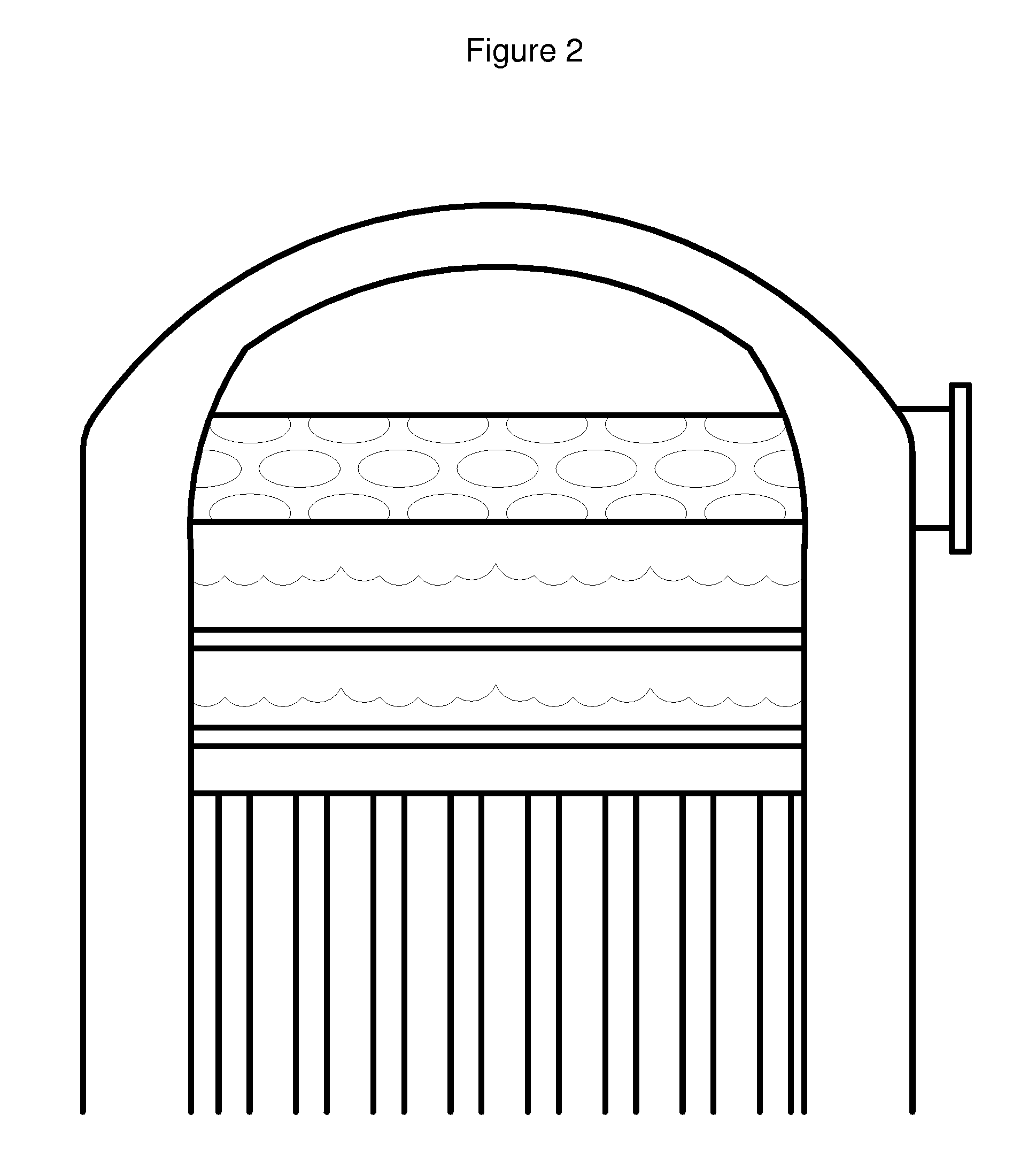

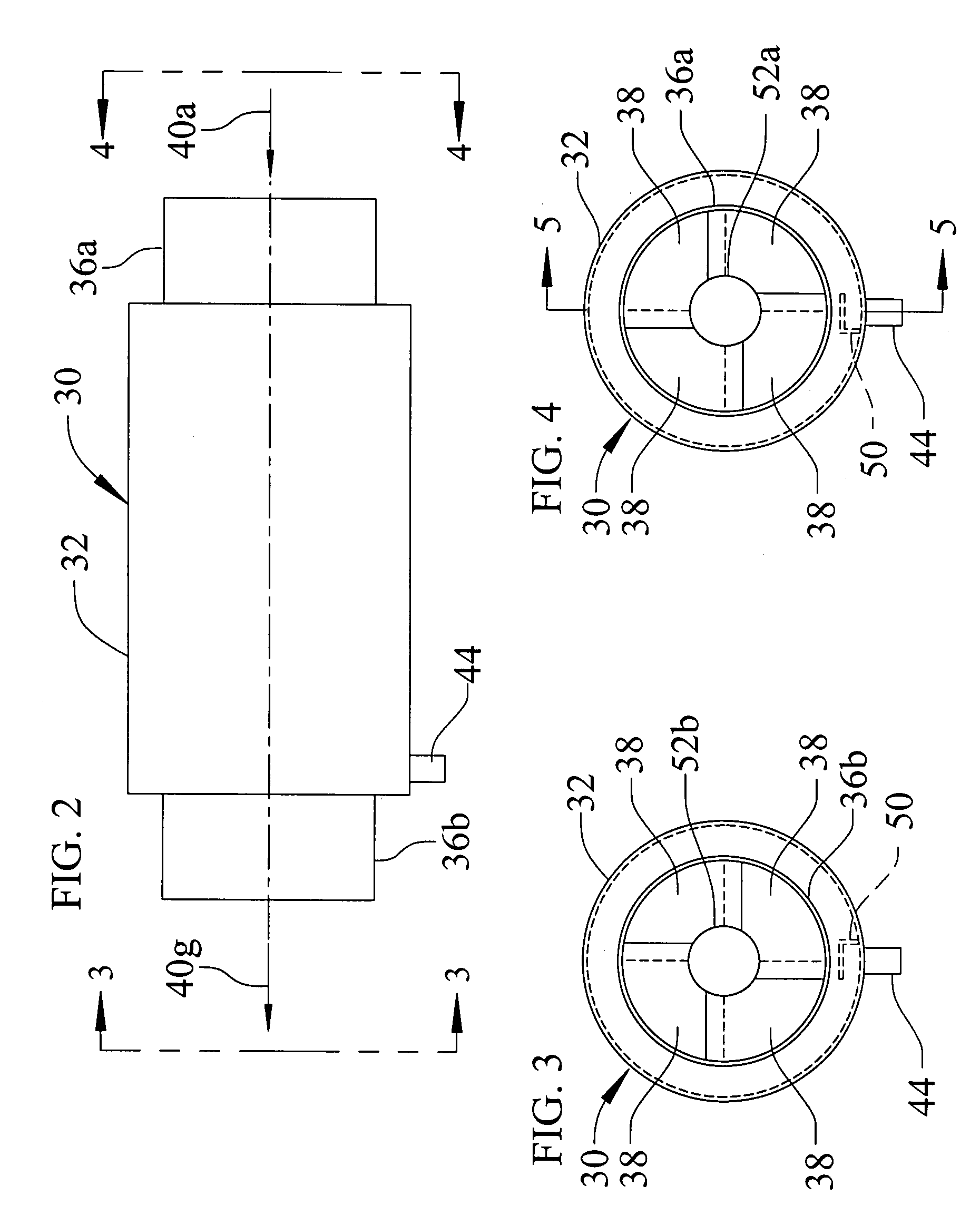

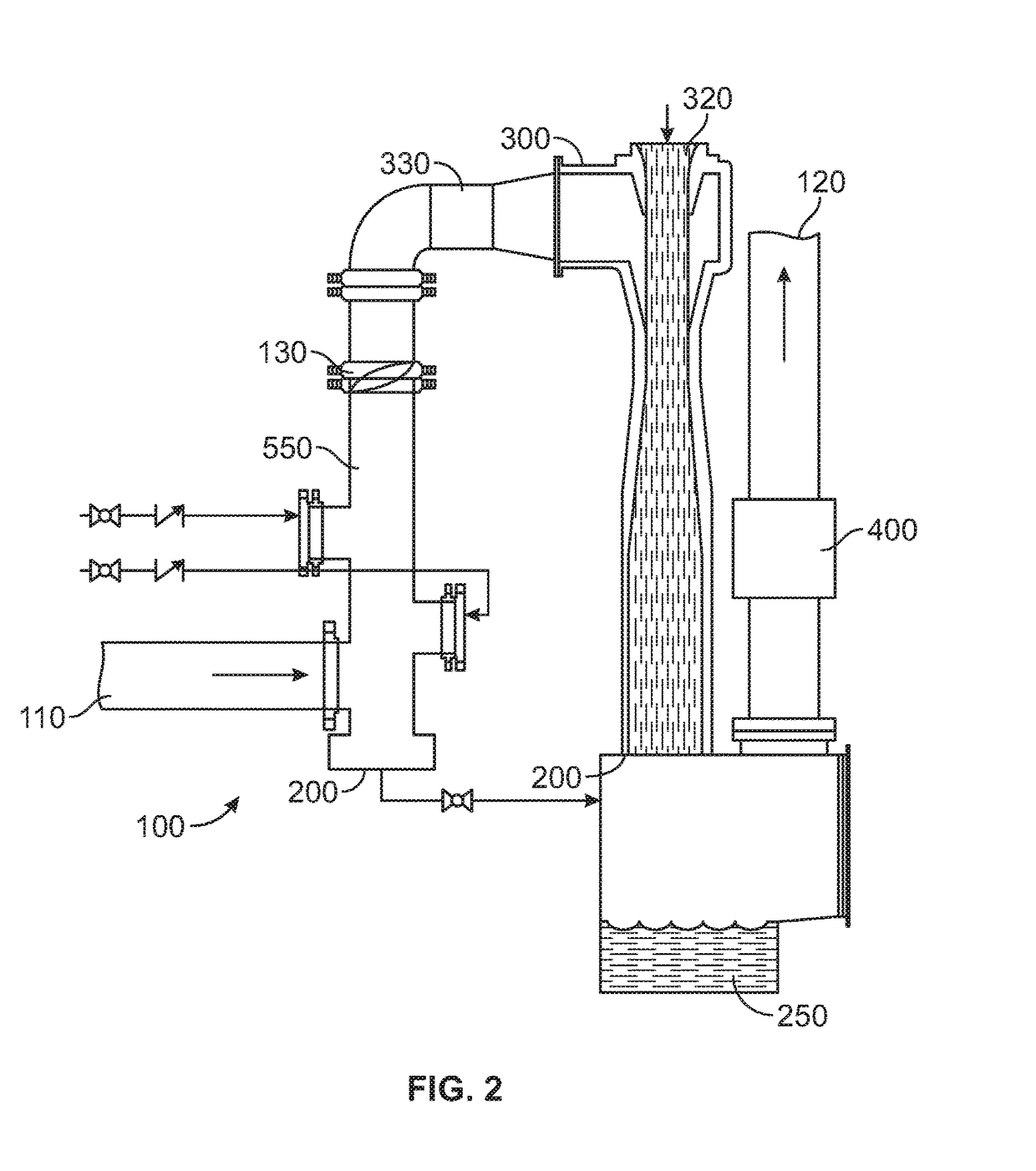

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle>98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

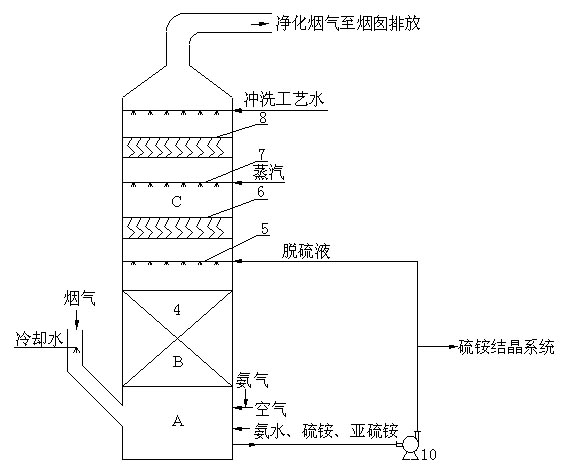

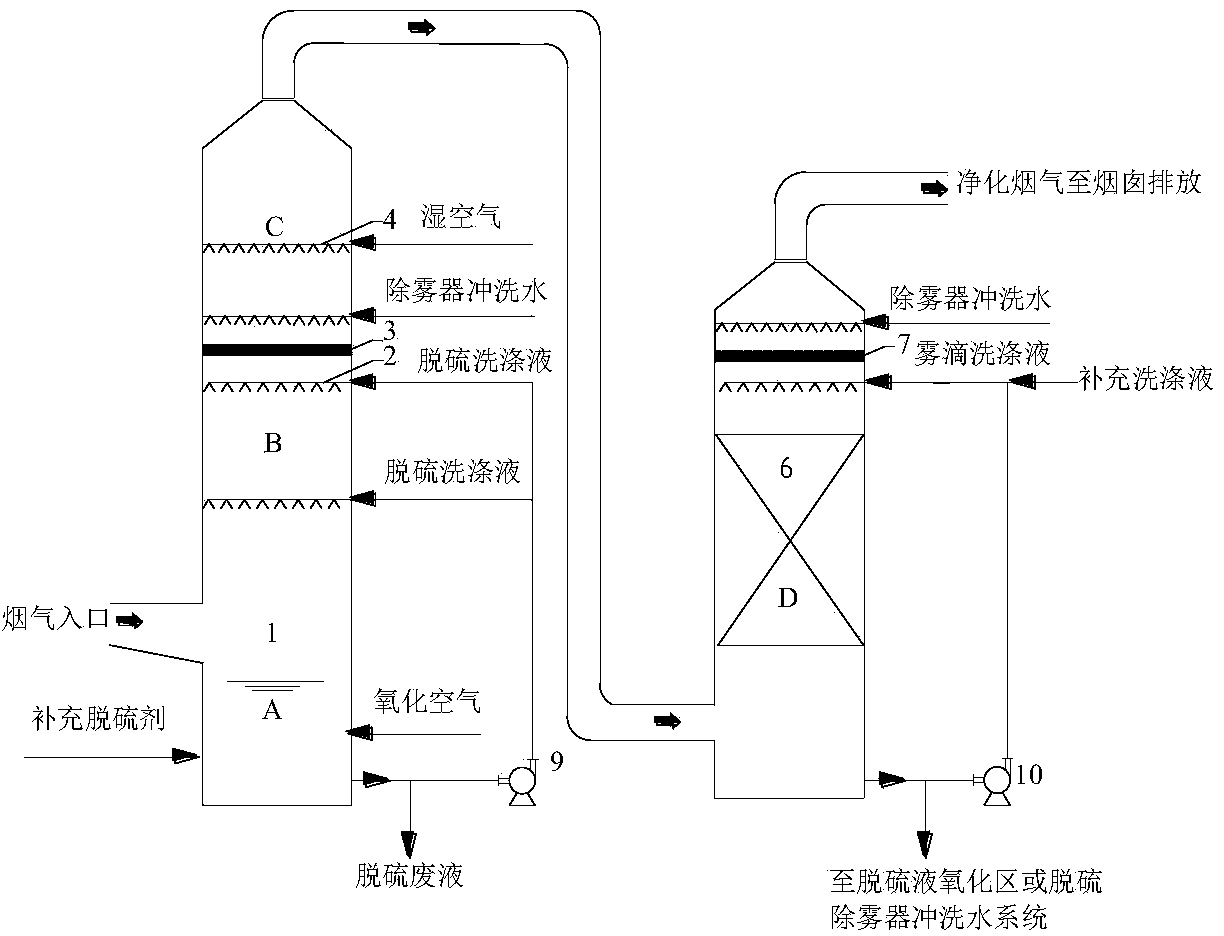

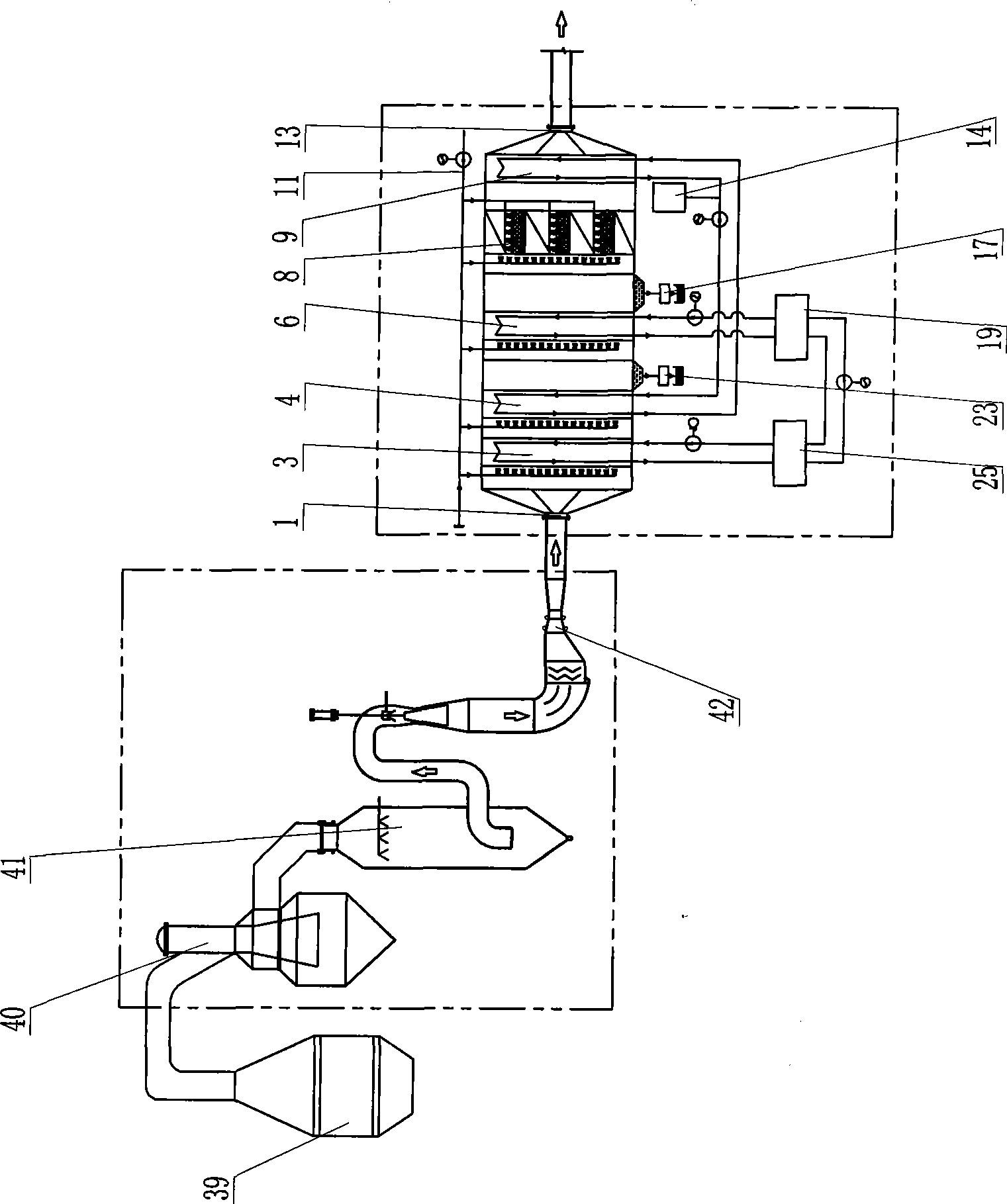

Desulfurization device and desulfurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization

ActiveCN103721548AReduce energy consumptionSolve the defect of easy cloggingCombination devicesWater vaporFlue gas

The invention discloses a desulphurization device and a desulphurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization. The desulphurization device comprises a flue gas desulphurization washing device and a fog drop collecting device which are connected in series, wherein the flue gas desulphurization washing device comprises a desulphurization liquid oxidation region, a desulphurization washing region and a water vapor phase change region which are arranged in sequence from bottom to top; the fog drop collecting device forms an integral or split structure together with the flue gas desulphurization washing device and is arranged on the flue gas desulphurization washing device or at an outlet. According to the method, flue gas enters the water vapor phase change region after SO2 is removed through the desulphurization washing region; wet air is filled through a wet air distributor, so that the clean flue gas after the wet desulphurization reaches an oversaturated state; oversaturated water vapor is nucleated and condensed on the PM2.5 surface, so that the PM2.5 is turned into dust fog drops with liquid films on the surfaces and the particle sizes are increased; the condensed expanded dust fog drops enter the fog drop collecting device and are collected through fog drop washing liquid and a defroster of the fog drop collecting device. According to the desulphurization device, the energy consumption for building an oversaturated water vapor environment can be effectively reduced and the PM2.5 emission problem of a wet flue gas desulphurization system is solved.

Owner:SOUTHEAST UNIV

Implementing method for integrated distributed desulfurization and denitrification process of boiler flue gas

InactiveCN105056746AReduced export concentrationTo achieve the goal of meeting emission standardsLighting and heating apparatusDispersed particle separationFlue gasSpray nozzle

The invention relates to an implementing method for an integrated distributed desulfurization and denitrification process of boiler flue gas. The implementing method is characterized by comprising the following steps: step I, flue gas enters a desulfurization tower from the lower part after passing through a dust remover, slurry in a slurry pond is conveyed to a spray nozzle at the upper part of the desulfurization tower through a circulating pump for spraying, and purified flue gas enters an oxidization tower after being subjected to demisting through a demister; step II, the flue gas enters the oxidization tower from the top, the slurry in the slurry pond is conveyed to a spray nozzle at the upper part of the oxidization tower through the circulating pump for spraying and oxidized flue gas passes through a wire mesh demister and then enters a denitrification tower; step III, flue gas enters the denitrification tower from the lower part, three-layer spraying exists in the tower, the first layer of slurry and the third layer slurry are respectively conveyed to a spray nozzle at the lower layer and a spray nozzle at the upper layer through the circulating pump for spraying, and in the second layer, an externally-connected H2O2 solution is used for spraying so as to realize the process of absorption-oxidation-absorption, and purified flue gas is discharged through a chimney after being subjected to demisting through the demister at the upper part of the denitrification tower.

Owner:JIANGSU YITONG ENVIRONMENTAL PROTECTION ENG TECH

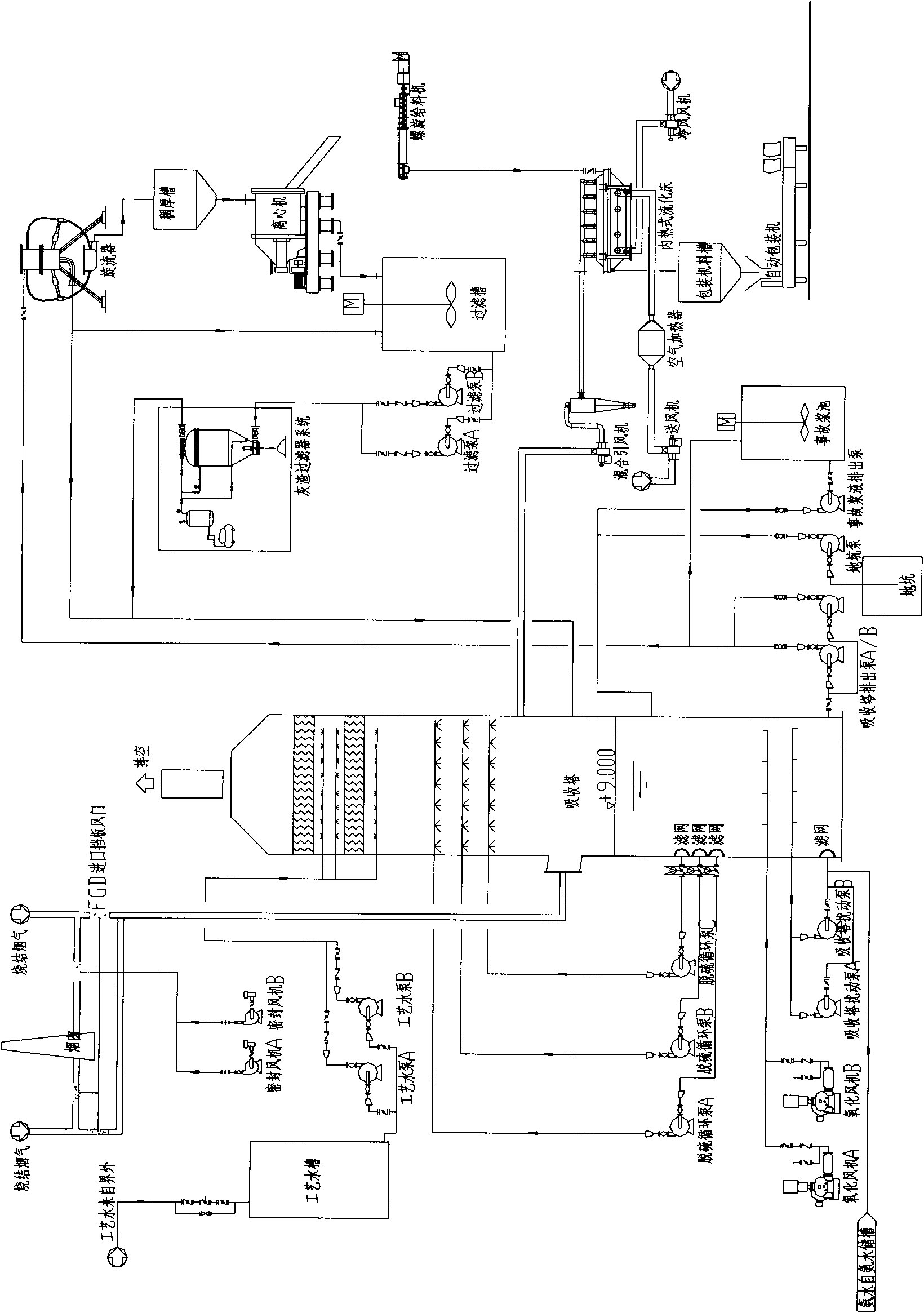

Flue gas desulfurization process suitable for sintering machine of steel mill

InactiveCN101862583AHigh desulfurization rateLow running costDispersed particle separationProcess engineeringSteel mill

The invention discloses process technology suitable for removing a sulfur dioxide byproduct, namely, ammonium sulfate chemical fertilizer in flue gas produced by a sintering machine of a steel mill and suitable for the characteristics of large sintering flue gas amount, large flue temperature fluctuation, high moisture content, high dust content and the like. The process comprises the following steps of: allowing sintering flue gas to enter from the middle of an absorption tower, wherein the flue gas is reversely contacted with absorption liquid; removing sulfur dioxide from the flue gas in a contacting process; exhausting the flue gas through a chimney on the top of the tower after the flue gas flows through a demister on the top of the tower; introducing compressed air and ammonia water into the absorption liquid, wherein ammonium sulfate in solution is saturated and 5 percent of crystal is separated out along with continuous absorbing and oxidizing processes; and rotating, filtering and drying ammonium sulfate crystal-containing suspension to obtain a finished product. Since the absorption, oxidation and condensation of the sintering flue gas are completed in the absorption tower at the same time, the process has the characteristics of refined flow, high desulfurization efficiency and high byproduct quality.

Owner:高翀

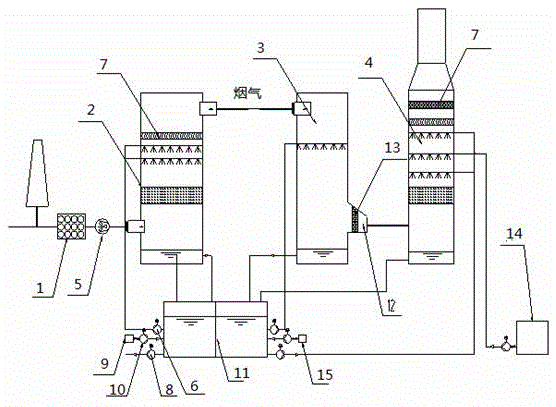

Flue gas desulfurization method and device

ActiveCN102151470ALess waterLess water droplet contentCombination devicesProcess engineeringEnvironmental engineering

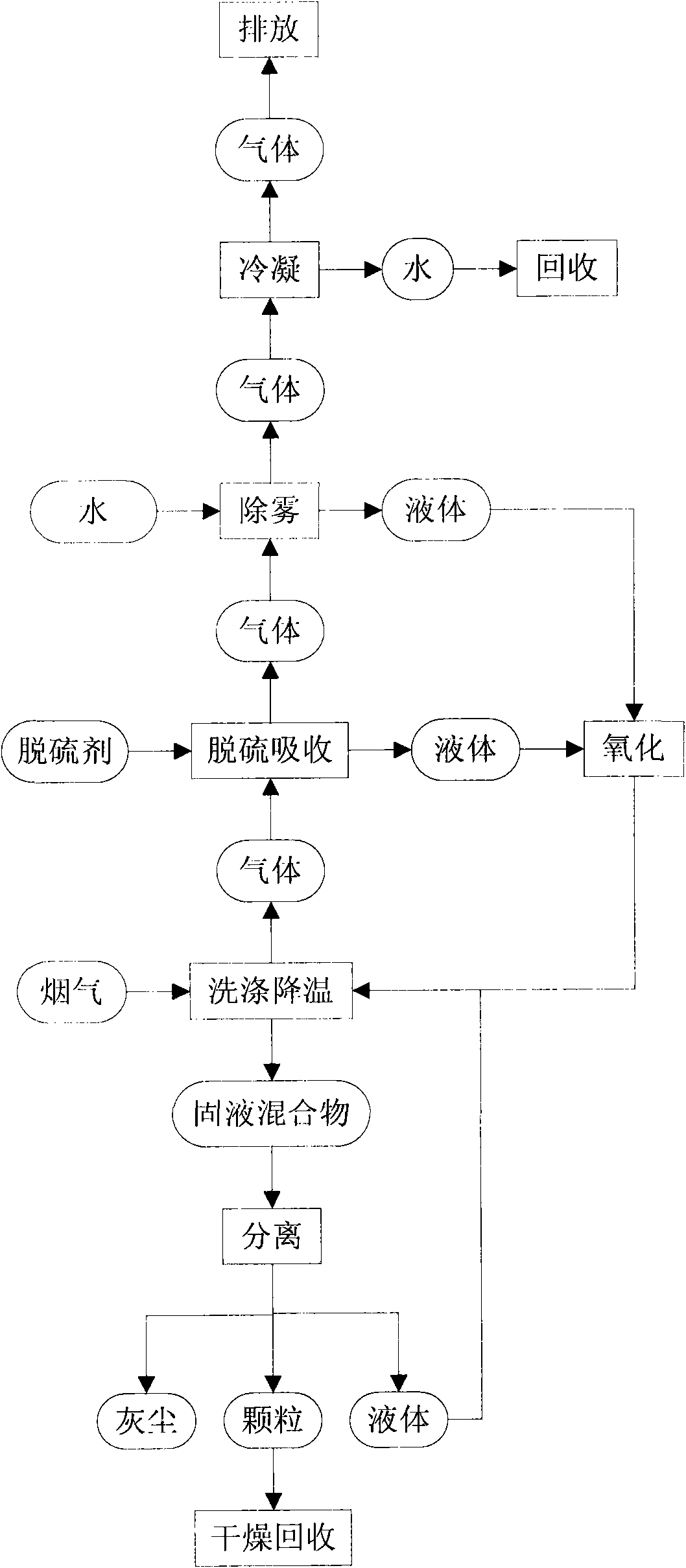

The invention discloses a flue gas desulfurization method. The method is characterized by comprising the following steps of: 1) washing and cooling: washing and cooling the flue gas entering a desulfurization tower; 2) separation: separating the dust-containing solid-liquid mixture obtained in the step 1) into dust, ammonium salt granules and ammonium sulfate-containing aqueous solution; 3) absorption: spraying a desulfurizing agent to the purified flue gas obtained in the step 1), and performing gas-liquid countercurrent contact; 4) demisting: removing dust, mist foam and liquid drops entrained in the gas through a demister; and 5) condensation: delivering the gas from the demister to a condensation device, condensing the gas and discharging the condensed gas. The invention also discloses a desulfurization device for the flue gas desulfurization method. The desulfurization device comprises the condensation device, the desulfurization tower, an oxidation device, a desulfurizing agent supply device and a water supply device. The method provided by the invention purifies the flue gas; the discharged gas contains little water, dust and ammonia; byproducts such as ammonium sulfite, ammonium sulfate and the like can be produced; and equipment cost and operating cost for desorption and hydrolysis of urea waste solution are saved at the same time.

Owner:山东华鲁恒升集团德化设计研究有限公司

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292BImprove efficiencyLess investmentDispersed particle separationAmmonium sulfatesAmmonia storageEnvironmental engineering

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Efficient wet type electrostatic-precipitation desulfurization system and process thereof

ActiveCN102764584AImprove efficiencyImprove dust removal system efficiencyDispersed particle separationExternal electric electrostatic seperatorElectricityMulti pollutant

The invention discloses an efficient wet type electrostatic-precipitation desulfurization system and a process thereof. A wet electrostatic precipitator is used for replacing an existing demister in a desulfurization tower. The wet electrostatic precipitator has more powerful capability and higher efficiency in removal of liquid drops and fine dust in flue gas than the demister, so that the wet electrostatic precipitator achieves high environmental protection discharge requirements, guarantees the desulfurization efficiency, and improves the efficiency of a dust removal system of a desulfurization tower, reduces the discharge concentration of dust at an outlet of the desulfurization tower and achieves the latest discharge standard required by the nation. By means of replacing the demister with the wet electrostatic precipitator, the gypsum rain problem is solved, and joint removal of various pollutants is achieved. Further, a water collection disc is added between a desulfurization absorption area and the wet electrostatic precipitator; as the water collection disc collects flushing water of the wet electrostatic precipitator for recycling, the flushing water of the wet electrostatic precipitator is prevented from entering a neutralization oxidation pond of the desulfurization tower directly, and water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

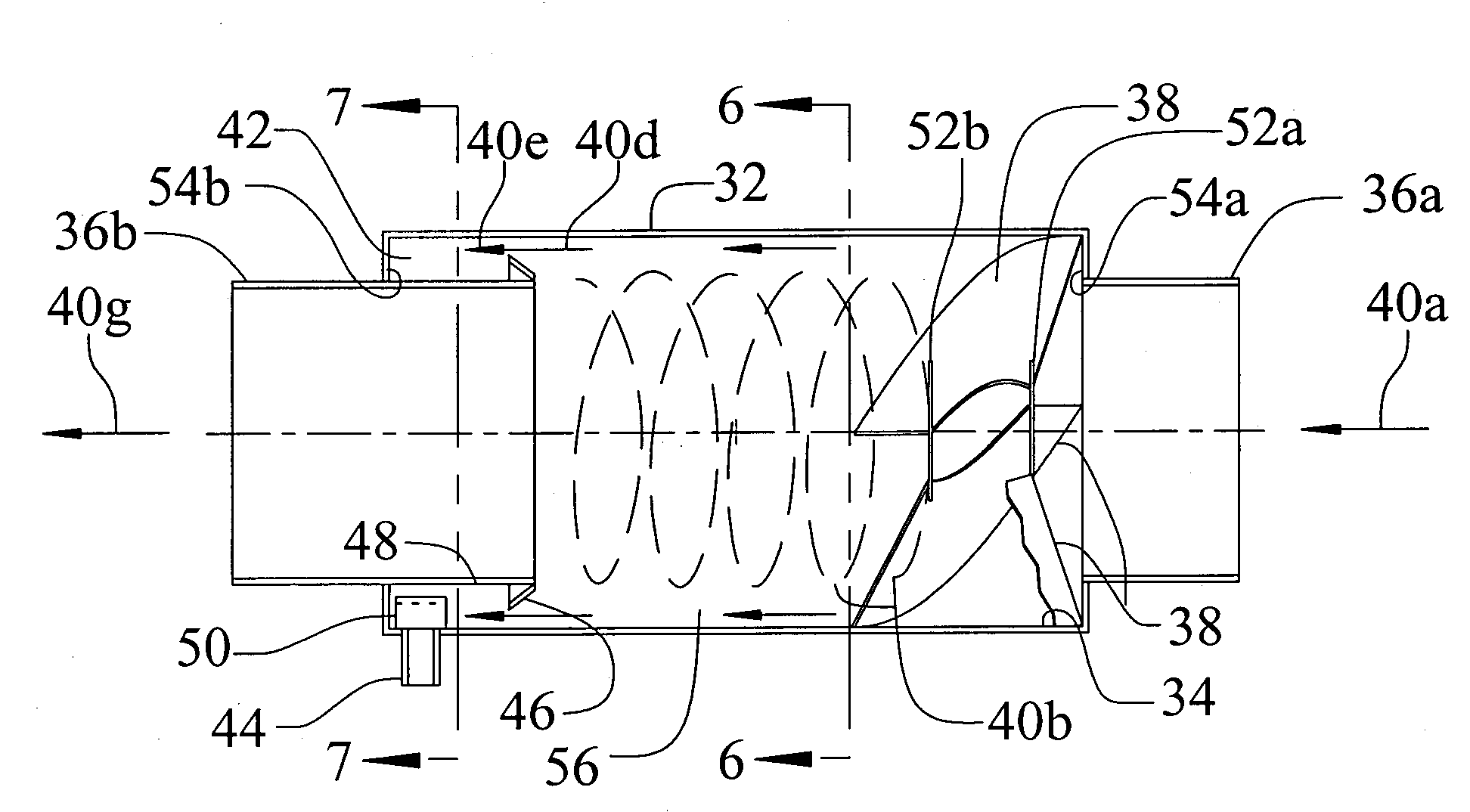

Cyclonic separator for mist collectors

InactiveUS7311744B2Decreases need for and expenseReliable removalCombination devicesLiquid surface applicatorsCollection systemAir cleaning

A separator placed in a mist collection system prior to a final air cleaning stage, and is configured to remove a substantial portion of the mist from the air. The separator includes stationary vanes in a cylindrical housing to establish a cyclonic flow therethrough, an annular flow restriction collar to establish a liquid collection area at the downstream end of the housing, a drain for discharge of the liquid from the collection area, and a flow interrupter to direct the swirling liquid into the drain.

Owner:FILTRA SYSTEMS COMPANY

Method for generating small bubbles for a smoke-filled air stream

InactiveUS6935345B2Short lifeReduction in desired performanceRespiratorsBreathing masksAir bubbleAirflow

Owner:PHX GLASS

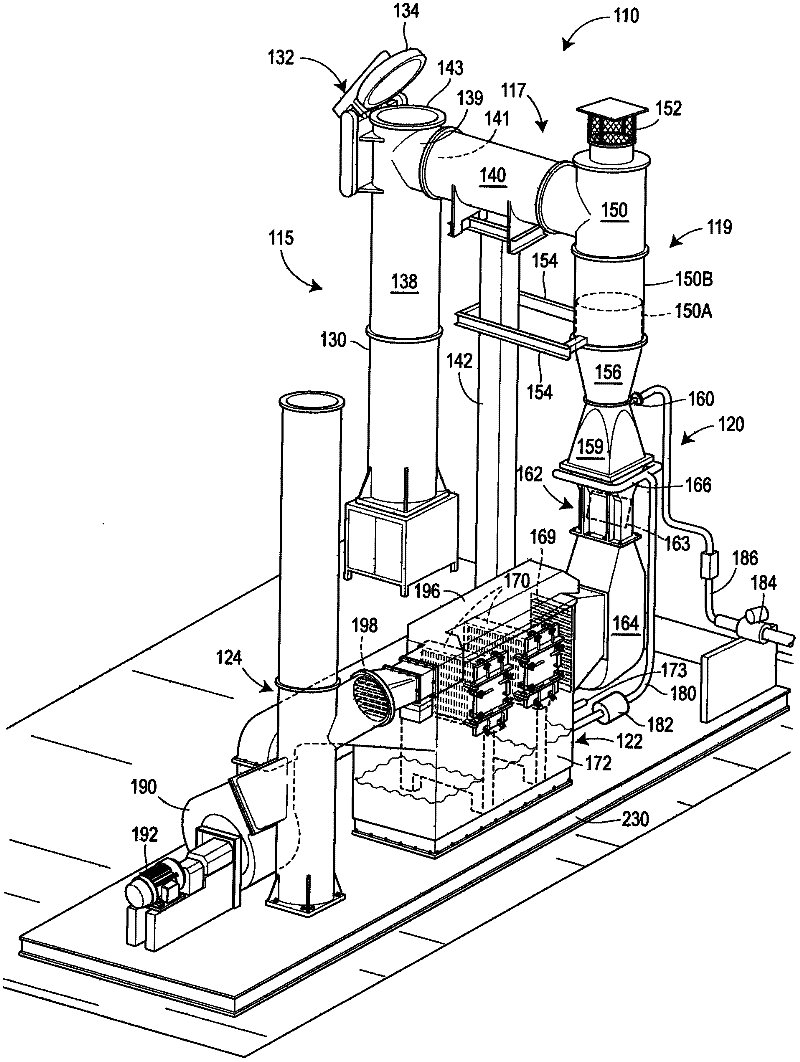

Marine exhaust gas cleaning system

InactiveUS9914094B2Increase pressureReduce stressGas treatmentUsing liquid separation agentExhaust fumesEngineering

A marine exhaust gas scrubbing device including an enclosure having a first end and a second end, an exhaust gas inlet, at least one quencher, at least one pre-treater, at least one venturi component including a venturi inlet and a venturi outlet, an impingement basket, at least one demister, an exhaust gas outlet, and a receiver, and a process for scrubbing a marine exhaust gas including cooling the exhaust gas, pre-treating the exhaust gas, washing the exhaust gas, mixing the exhaust gas and exhausting the scrubbed exhaust gas.

Owner:MARINE EXHAUST SOLUTIONS

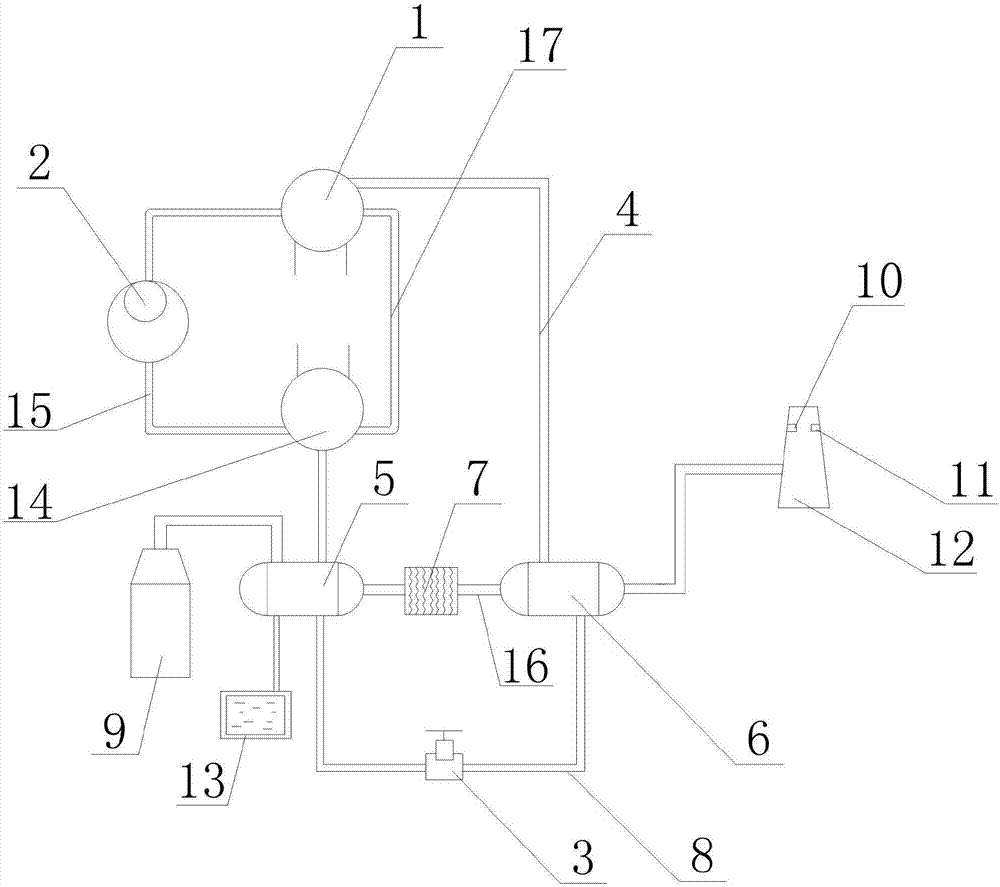

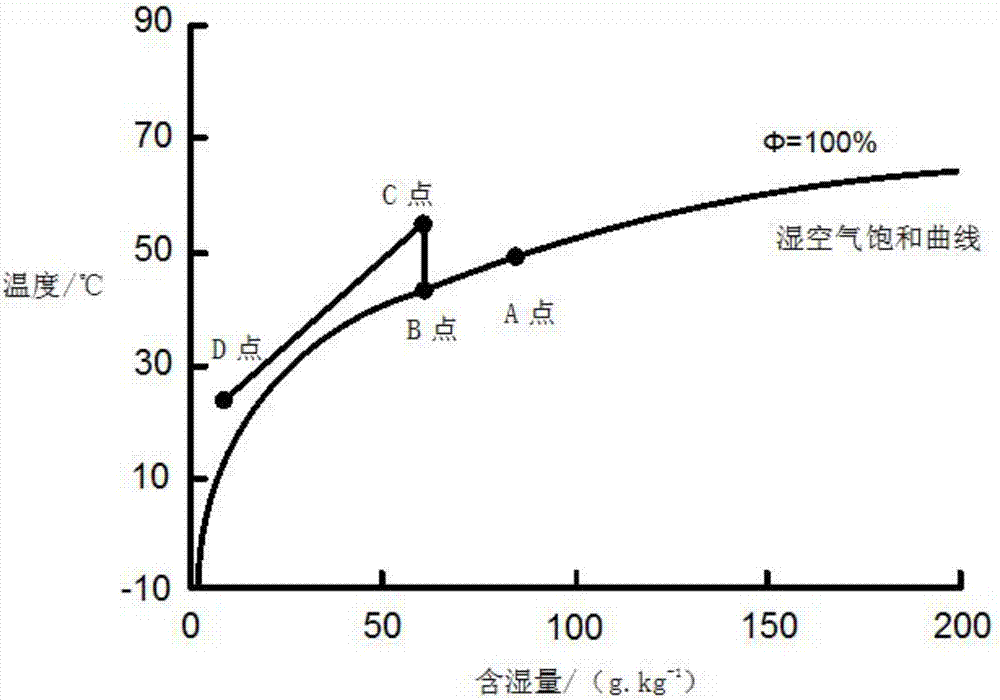

Method and device applied to coal-fired power plant for removing white smoke from chimney

PendingCN107042061AEliminates Aerosol ParticlesImprove dust removal efficiencyGas treatmentDispersed particle separationSmoke aerosolCoal plant

The invention discloses a method and device applied to a coal-fired power plant for removing white smoke from a chimney. The method comprises the following steps: (S01) reducing the moisture content of a saturated wet flue gas through reducing the temperature of the saturated wet flue gas at an outlet of a desulfurizing tower; (S02) removing aerosol particles and liquid water droplets from the saturated flue gas of which the moisture content is reduced in the step (S01) through a baffle channel-type flue demister; and (S03) heating the flue gas from which the aerosol particles and the liquid water droplets are removed to be higher than the temperature of a wet air saturation curve through a heating section heat exchanger, thereby removing the white smoke phenomenon. The device applied to the coal-fired power plant for removing the white smoke from the chimney is capable of removing the white smoke generated from the coal-fired power plant in low-temperature and high-humidity environments, effectively removing sulfur dioxide in the flue gas, removing the aerosol particles in the flue gas, improving the dust removal efficiency and reducing the energy consumption.

Owner:CHINA HUADIAN ENG +1

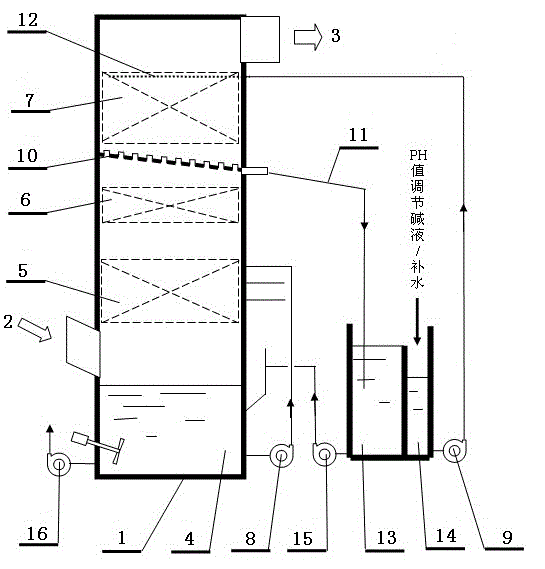

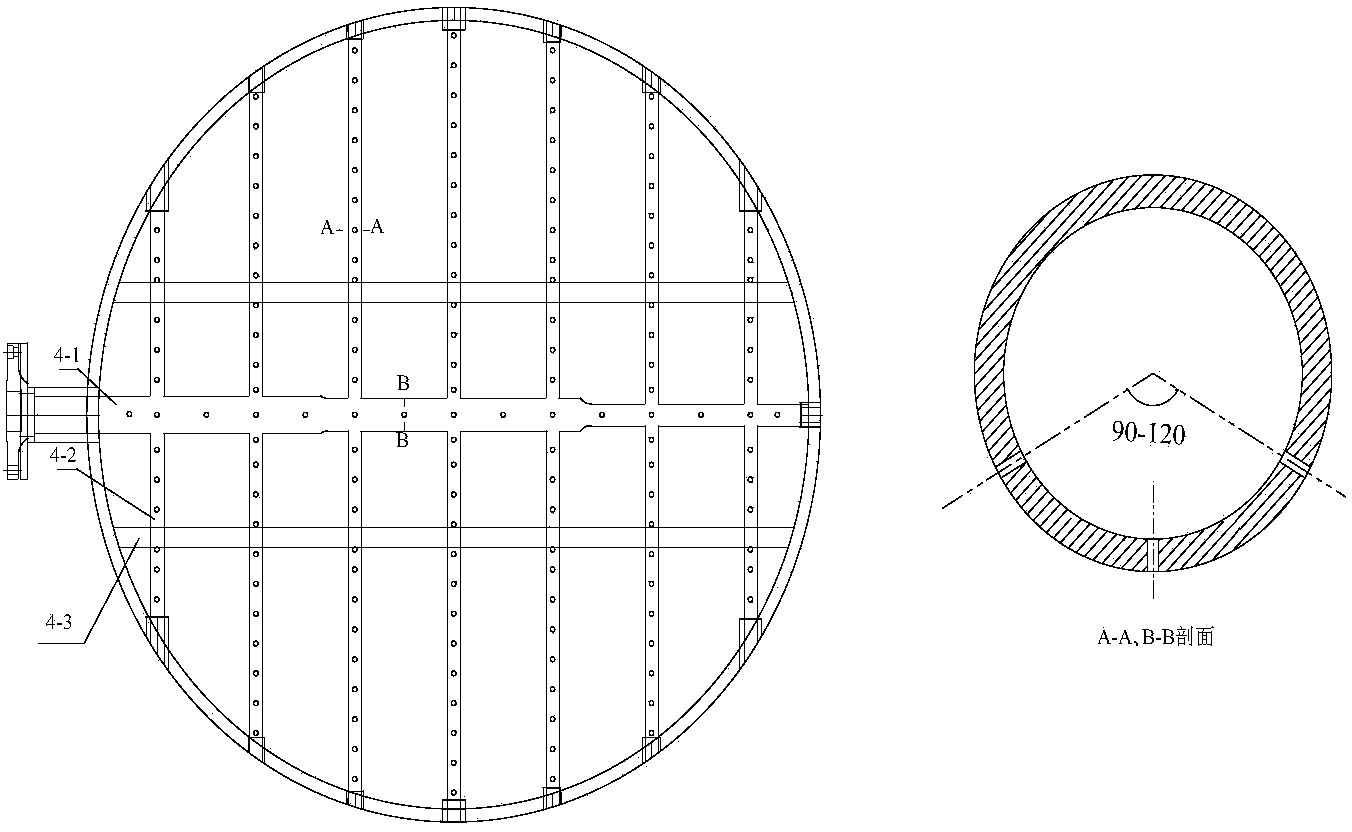

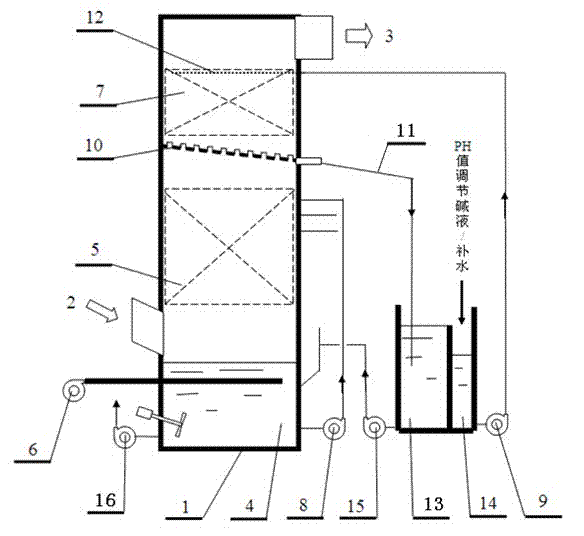

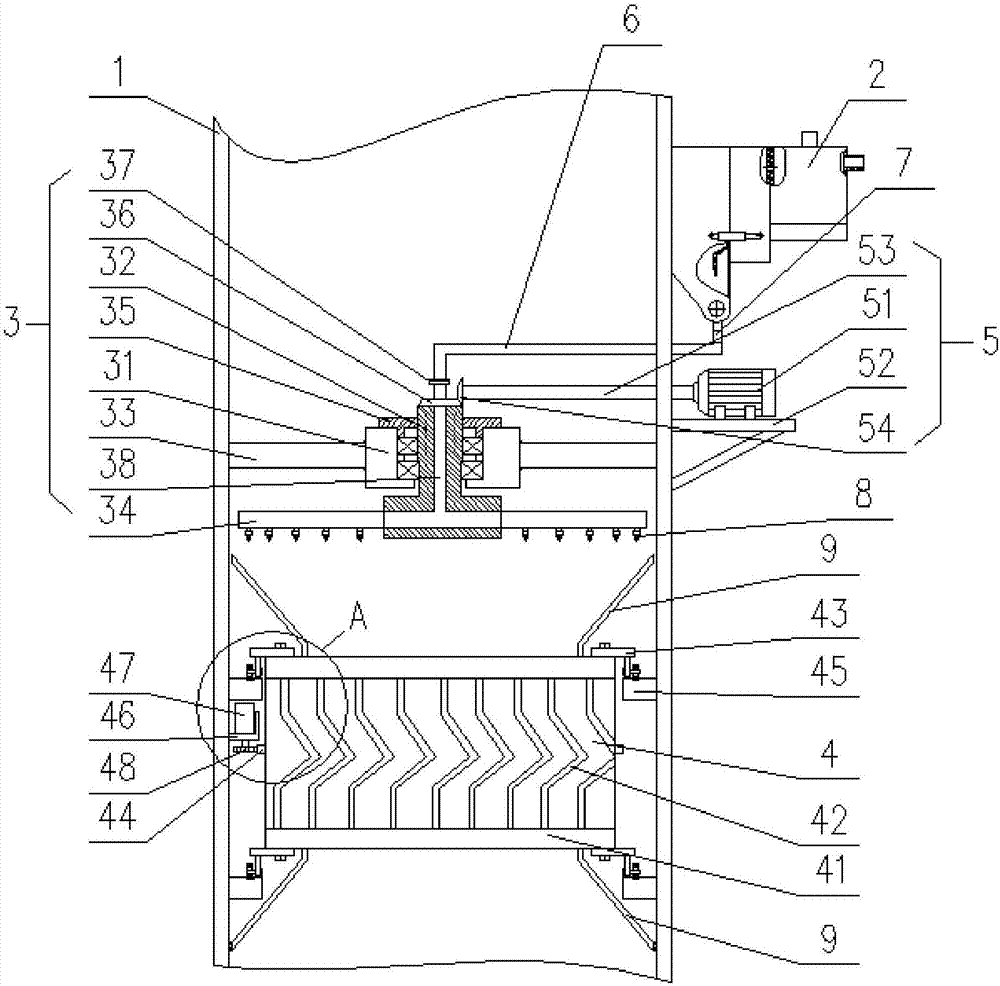

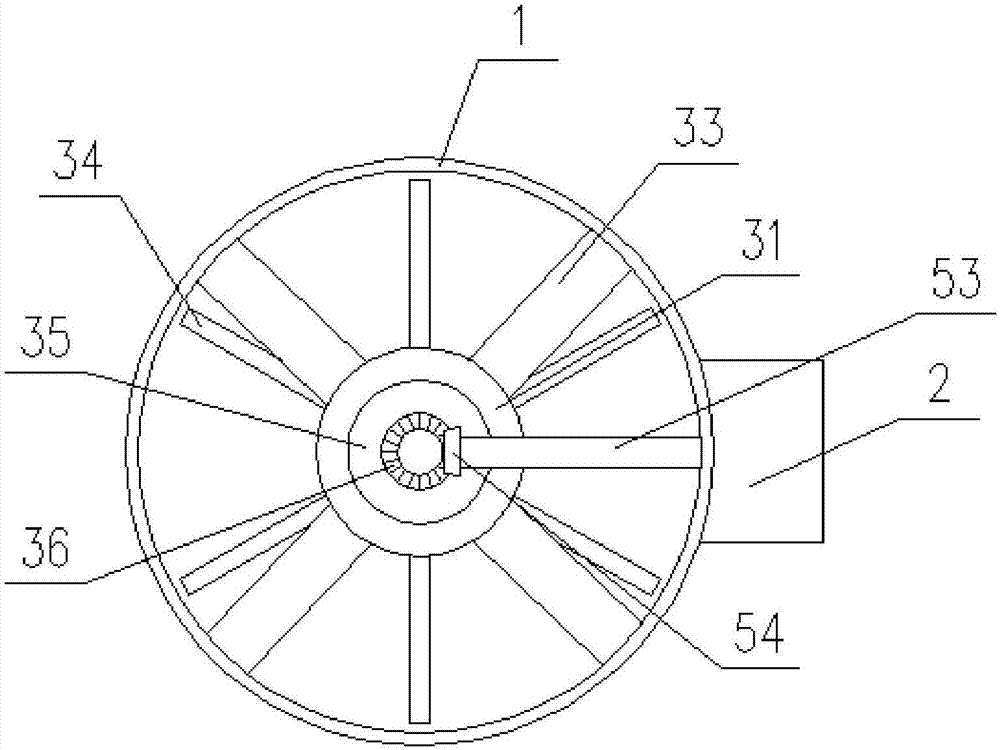

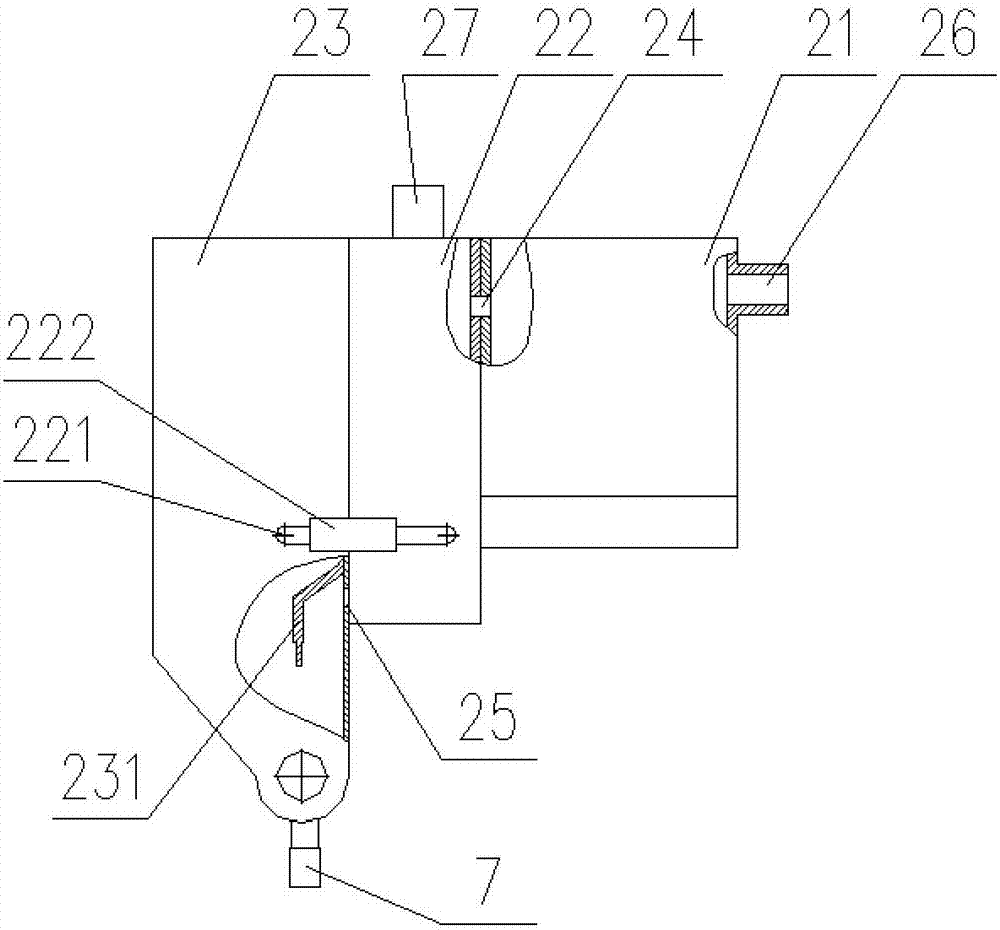

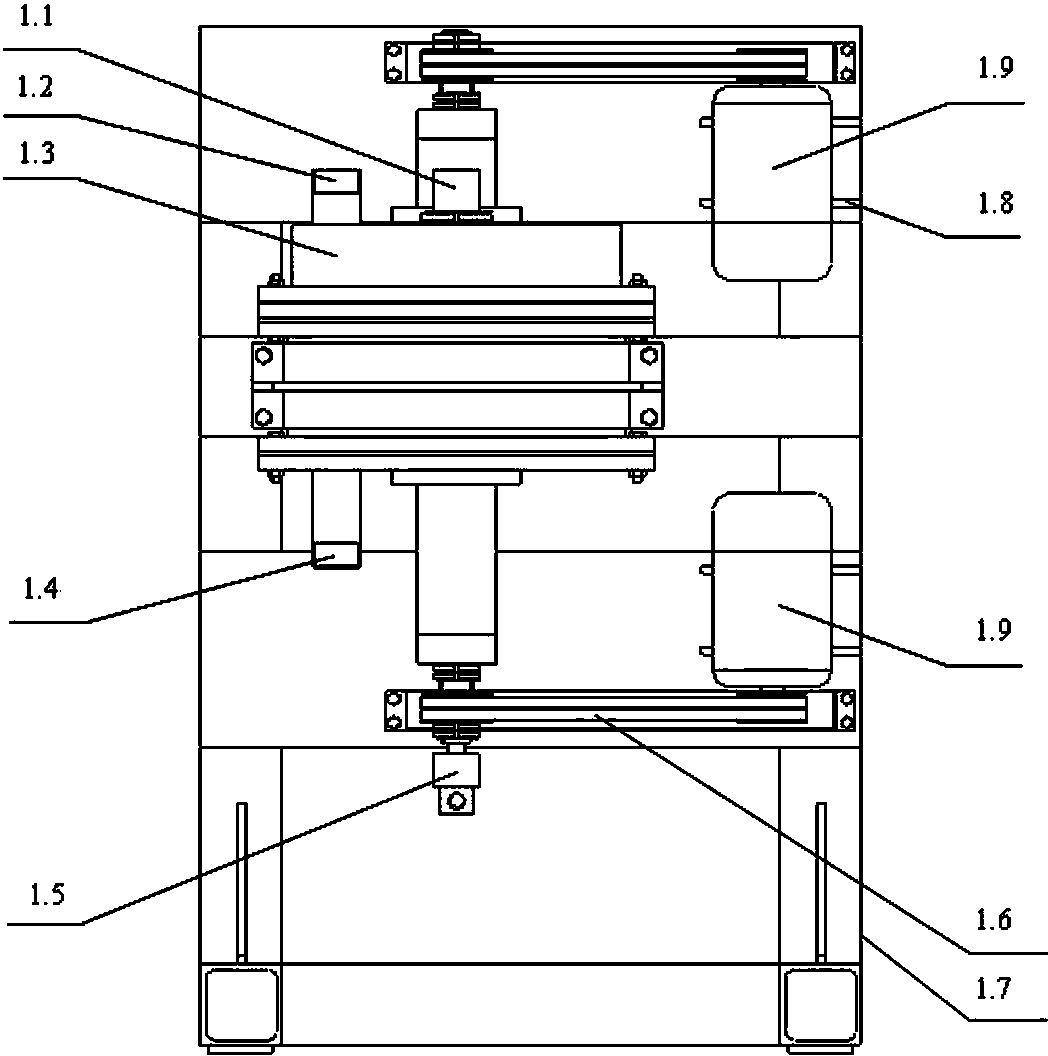

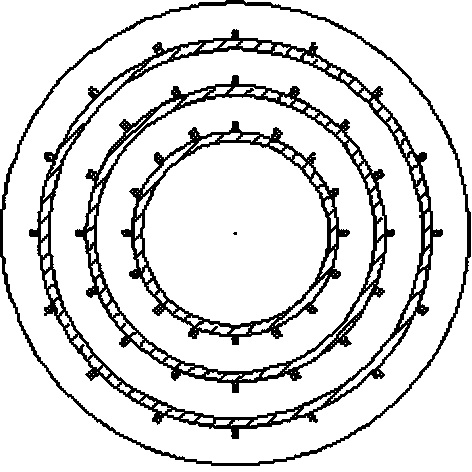

High-efficient demisting device in wet desulfurization tower

PendingCN107321164AGood defogging effectExtended service lifeDispersed particle separationProcess engineeringEnvironmental engineering

The invention relates to a high-efficient demisting device in a wet desulfurization tower, belongs to the technical field of demisters, and aims at solving the problems that an existing demisting device in a wet desulfurization tower is poor in demisting effect and attachments attached to a demister are hard to wash. The demisting device comprises a desulfurization tower body, an alkaline water mixing plant, a spraying device, a folded-plate demister and a spraying drive device; the alkaline water mixing plant is installed on the outer wall of the desulfurization tower body and provides a water source for the spraying device, the spraying device and the folded-plate demister are arranged in the desulfurization tower body from top to bottom, and the folded-plate demister is rotatably installed in the desulfurization tower body. In the high-efficient demisting device in the wet desulfurization tower, 'mist' produced in an absorption tower during wet desulfurization is processed through the spraying device and the folded-plate demister, the demisting process is accelerated, there is no need to arrange a long buffer path for the smoke, and the occupied area of a wet desulfurization system is reduced.

Owner:HARBIN WEILAN ENVIRONMENTAL PROTECTION EQUIP MFG

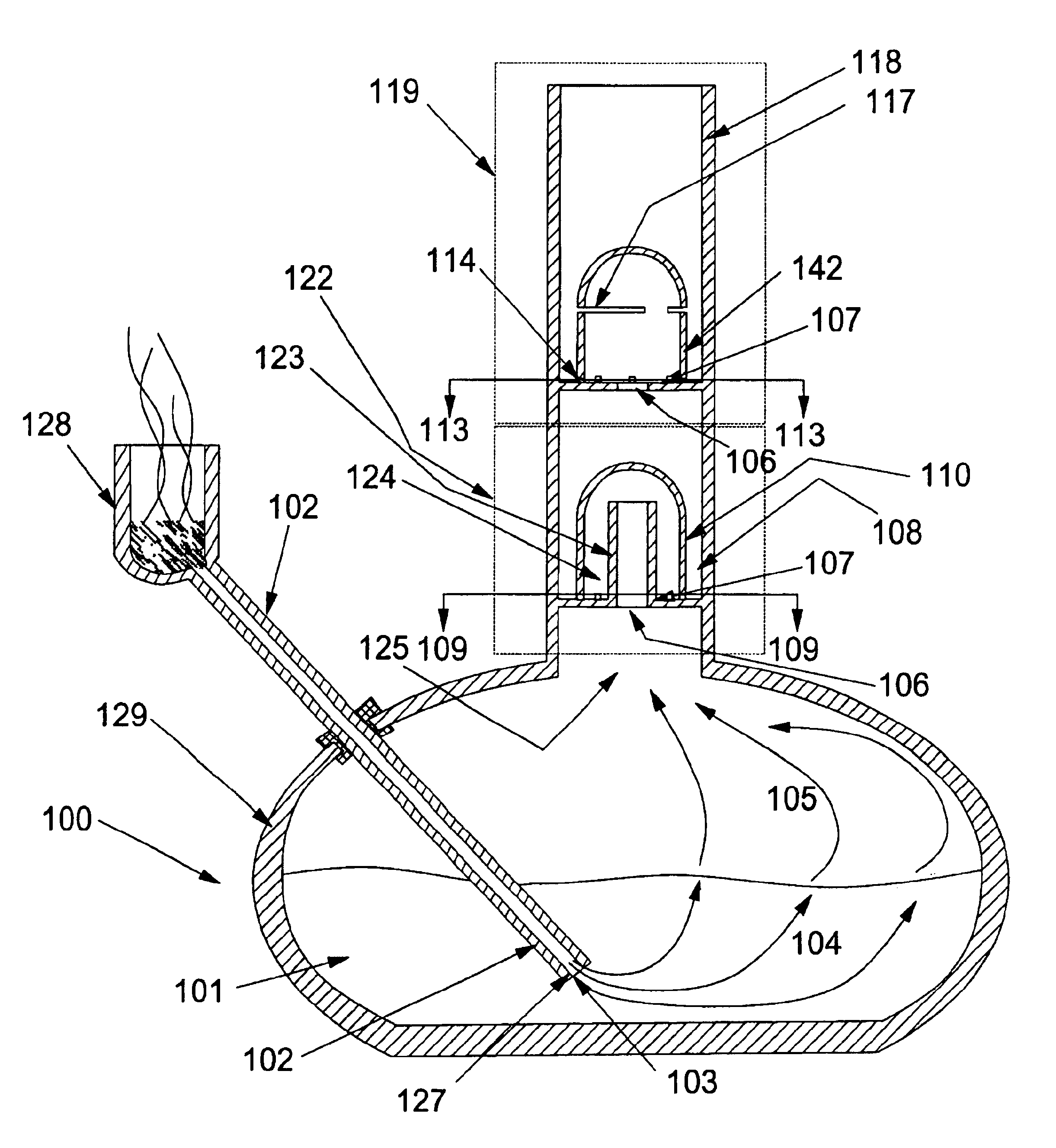

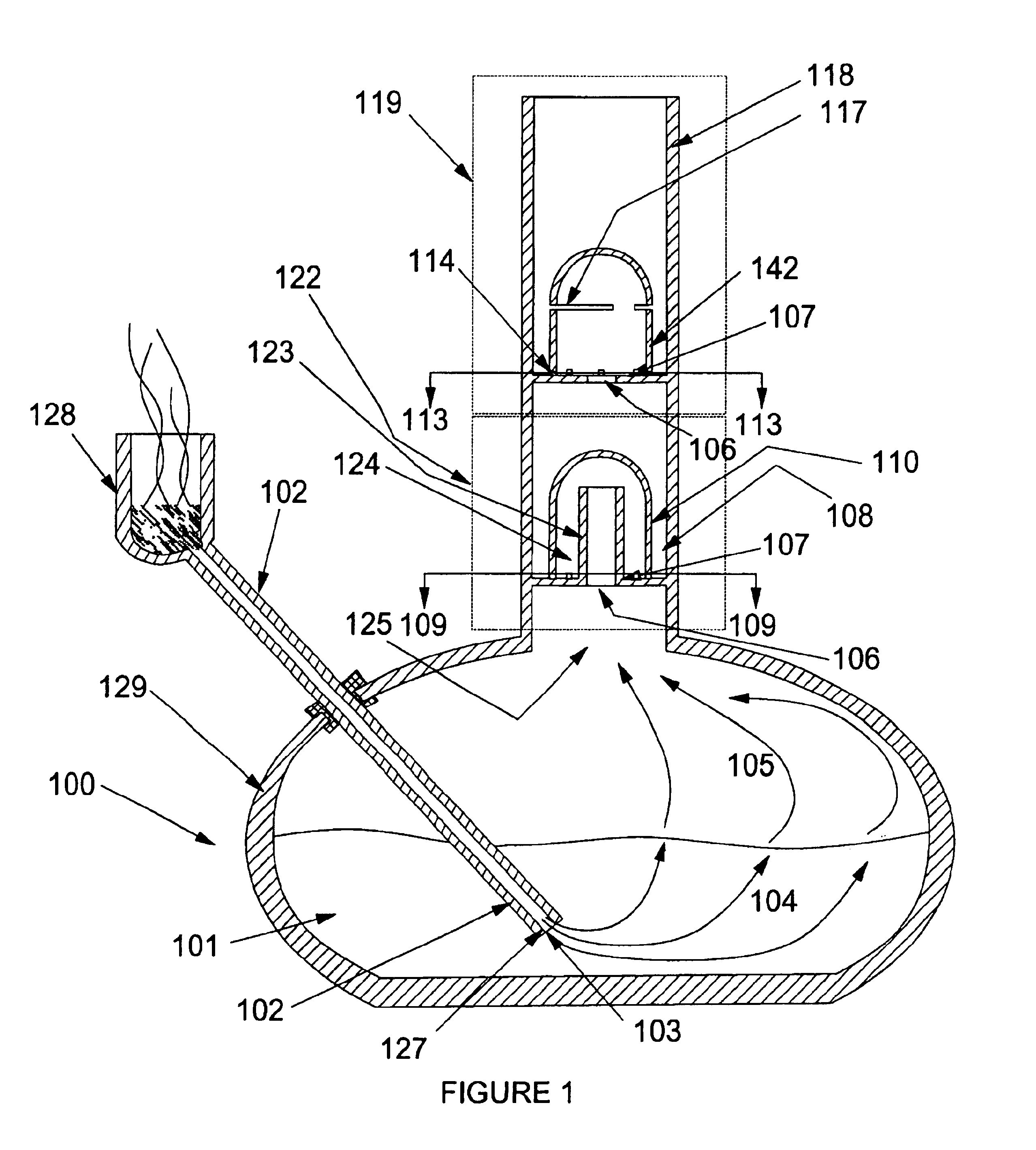

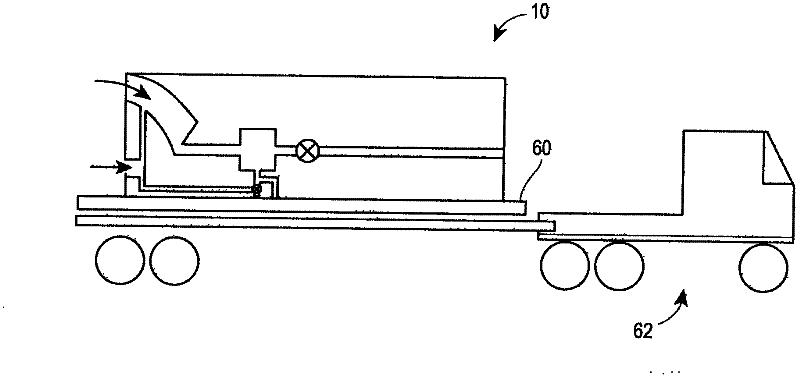

Compact wastewater concentrator using waste heat

InactiveCN102356046AEasy to transportEfficient use ofSludge treatment by de-watering/drying/thickeningWater treatment parameter controlThermodynamicsScrubber

A compact and portable liquid concentrator includes a gas inlet, a gas exit and a flow corridor connecting the gas inlet and the gas exit, wherein the flow corridor includes a narrowed portion that accelerates the gas through the flow corridor. A liquid inlet injects liquid into the gas stream at a point prior to the narrowed portion so that the gas-liquid mixture is thoroughly mixed within the flow corridor, causing a portion of the liquid to be evaporated. A demister or fluid scrubber downstream of the narrowed portion removes entrained liquid droplets from the gas stream and re-circulates the removed liquid to the liquid inlet through a re-circulating circuit. Fresh liquid to be concentrated is also introduced into the re-circulating circuit at a rate sufficient to offset the amount of liquid evaporated in the flow corridor.

Owner:HEARTLAND TECH PARTNERS

Dedusting and dehumidifying method for air with freezing method and equipment thereof

InactiveCN101480562AEmission reductionReduce pollutionDispersed particle separationVapor condensationAtmospheric airPollution

The invention relates to a dedusting and dehumidifying method and equipment thereof for furnace top coal gas of a blast furnace, a converter or a COREX furnace. The method comprises the steps of precooling, self-circulation cooling, re-cooling, demisting and self-circulation heating and rewarming. The equipment comprises a stream guide plate, a precooler, a self-circulation cooler, a first water discharge section, a cooler, a second water discharge section, a demister, a rewarming heater and an outlet stream guide plate which are sequentially arranged between a gas inlet and a gas outlet in a shell. The method and the equipment are used to reduce the emission of dust and the pollution to the air. The heat of gas at the inlet and the cold output of gas at the outlet are recycled so as to repeatedly utilize energy sources and save the energy source consumption; the relative humidity of coal gas treated by the method and the equipment is reduced, thereby the occurrence of condensed water in the process of pipeline conveying is reduced, the corrosion action to the pipeline is reduced and the safety is improved; in addition, the reduction of the relative humidity of the coal gas improves the thermal value of the coal gas.

Owner:无锡金龙石化冶金设备制造有限公司 +1

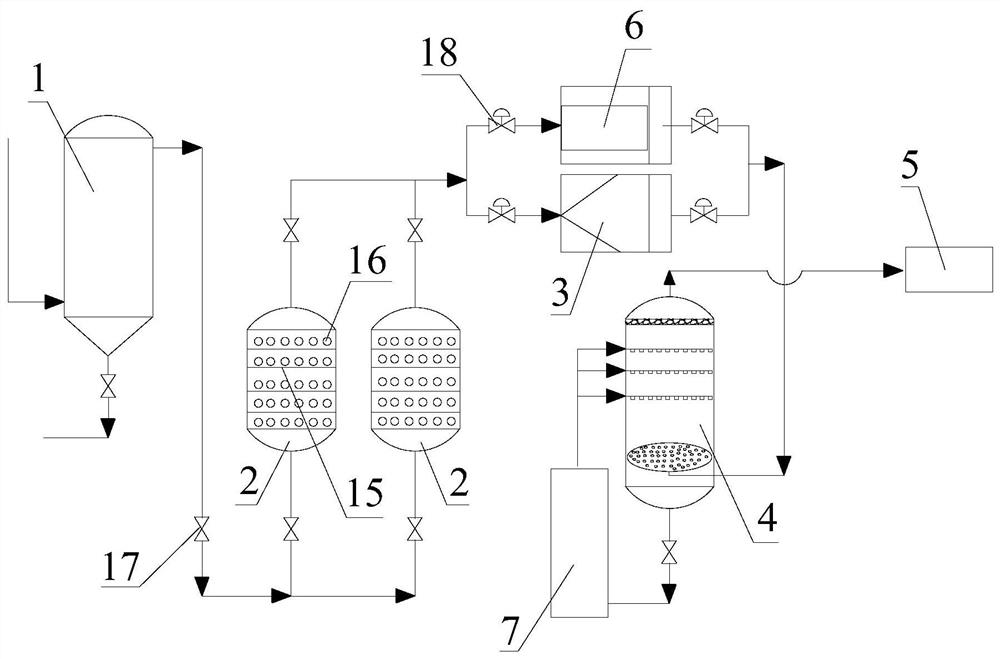

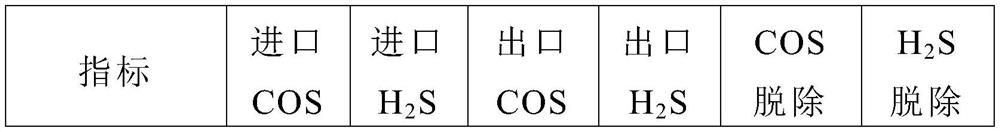

Desulfurization method and device for blast furnace gas

InactiveCN112195043AHigh calorific valueReduce corrosionGas purification by catalytic conversionDirect contact heat exchangersPtru catalystCooling tower

The invention relates to the technical field of desulfurization and purification treatment for blast furnace gas, and discloses a desulfurization method for blast furnace gas. The desulfurization method comprises the following steps: feeding the blast furnace gas having been subjected to fine dust removal by a bag-type dust remover into a hydrolysis catalytic tower for hydrolysis catalytic desulfurization so as to convert COS in the blast furnace gas into H2S in the hydrolysis catalytic tower under the action of a hydrolysis catalyst; and then allowing the blast furnace gas to pass through a blast furnace gas excess pressure turbine power generation device or a pressure reducing valve, subjecting the blast furnace gas to spraying, cooling and desulfurizing by a desulfurizing and cooling tower, then performing demisting by a demister, conducting purification and then feeding the purified gas into a gas pipe network. The invention also discloses a blast furnace gas desulfurization device. According to the desulfurization method and device for the blast furnace gas, the problem that SO2 of blast furnace gas users, such as a blast furnace hot blast stove, a heating furnace and a heat treatment furnace, exceeds a standard due to high total sulfur content of the blast furnace gas is effectively solved, and cost is low.

Owner:武汉钢铁有限公司

In-hollow column intercrystalline ammonia process of desulfurization, recovery system and method thereof

The invention relates to a crystallization ammonia process desulfurization and recycling system in an empty tower and a method thereof, which belong to the technical field of environment-friendly equipment. The system comprises a sprinkling desulfurizing tower, a hydrocyclone, a centrifuger, and a vibrating fluidized bed dryer. The method comprises the following steps: hot flue gas enters the middle part of the sprinkling desulfurizing tower, reaches the optimal temperature for ammonia process desulphurization after being cooled by process water sprinkling at the inlet of the tower, and then is subjected to absorption by a sprinkling layer, and finally gets rid of most of free water which is removed by a defogger; clean flue gas is directly sent out by a steel chimney on the top of the sprinkling desulfurizing tower; absorption liquid in a stock tank at the lower part of the tower reaches the state of supersaturation after being subjected to circulating absorption a plurality of times, is forced to be oxidized by oxygen in air and flue gas in the bottom of the tower, and finally produces an ammonium sulphate saturated solution containing a certain amount of solid; the ammonium sulphate saturated solution containing a certain amount of solid is further concentrated by a water cyclone; the concentrated solution forms powder through the centrifuger; and after being dried by the drier, ammonium sulphate products with water content of less than 0.3% can be obtained.

Owner:北京中大能环工程技术有限公司

Double return route absorption tower and method for treating fluorine contained tail gas using double return route absorption tower

InactiveCN101279196AImprove absorption rateLess investmentDispersed particle separationHigh absorptionAtmospheric air

The invention relates to a double circuit absorption tower and a method for treating tail gas with fluoride via the double circuit absorption tower. The smoke with fluoride enters a first absorption zone of the absorption tower, then enters a secondary absorption zone for a second time purification via a gas cylinder after being cooled and purified and is discharged into the atmosphere via a chimney arranged at the top of the absorption tower after the mist is removed. The lower section of the tower body is a secondary serum recirculating tank; the middle section is the first absorption zone; the lower part of the middle section is a first-level serum recirculating tank; a spraying device is arranged at the upper part of the first absorption zone; a baffle with the gas cylinder is a secondary absorption zone at the upper section of the tower body; the upper part is provided with the spraying device, a demister and a cleaning device; the chimney is arranged at the top of the absorption tower. The tower combines the original two towers into an absorption tower through arranging an upper and a lower baffle, which similarly realizes the high absorption rate of the two towers; the slaking process of limestone or lime is realized in the serum recirculating tank at the bottom of the tower, which reduces the equipment and saves the investment; at the same time, through controlling the pH value of an absorption serum, the absorption rate of the fluoride is raised on the basis of saving the limestone or the lime.

Owner:湖北三新磷钙有限公司

Helical airflow type wet method flue gas desulfurization process and spraying tower thereof

InactiveCN101279184ALow flow resistanceSimple processDispersed particle separationChemical reactionFlue gas

The invention provides a swirling air flow-type and wet flue gas desulfurization technique and a spraying tower thereof. The technique guides flue gases to enter tangentially from the upper part of a spraying tower shell; the flue gases swirl inside the spraying tower shell and leave tangentially from the lower part of the spraying tower shell; at the same time, limestone grout is sprayed upward and fog drips of the grout firstly touch the downward-swirling flue gas reverse flow, and then fall back owing to the effect of self-weight and drag force of the flue gas and then touch the forward flow of the flue gas, thus sulfur dioxide in the flue gases is absorbed owing to the quick chemical reaction with limestone grout fog drops. The spraying tower comprises a spraying tower shell; the spraying tower shell is provided with tangentially arranged flue gas inlet and outlet channels; a spraying device for spraying absorbing agents upwards is arranged between the flue gas inlet and outlet channels; a central tank is arranged in the center of the spraying tower shell; a flue gas guide plate showing a spiral descent structure is arranged on the central tank; a defroster is arranged in the flue gas inlet and outlet channels of the spraying tower shell. The desulfurization efficiency thereof is high, investment is small, and operation is safe and reliable.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

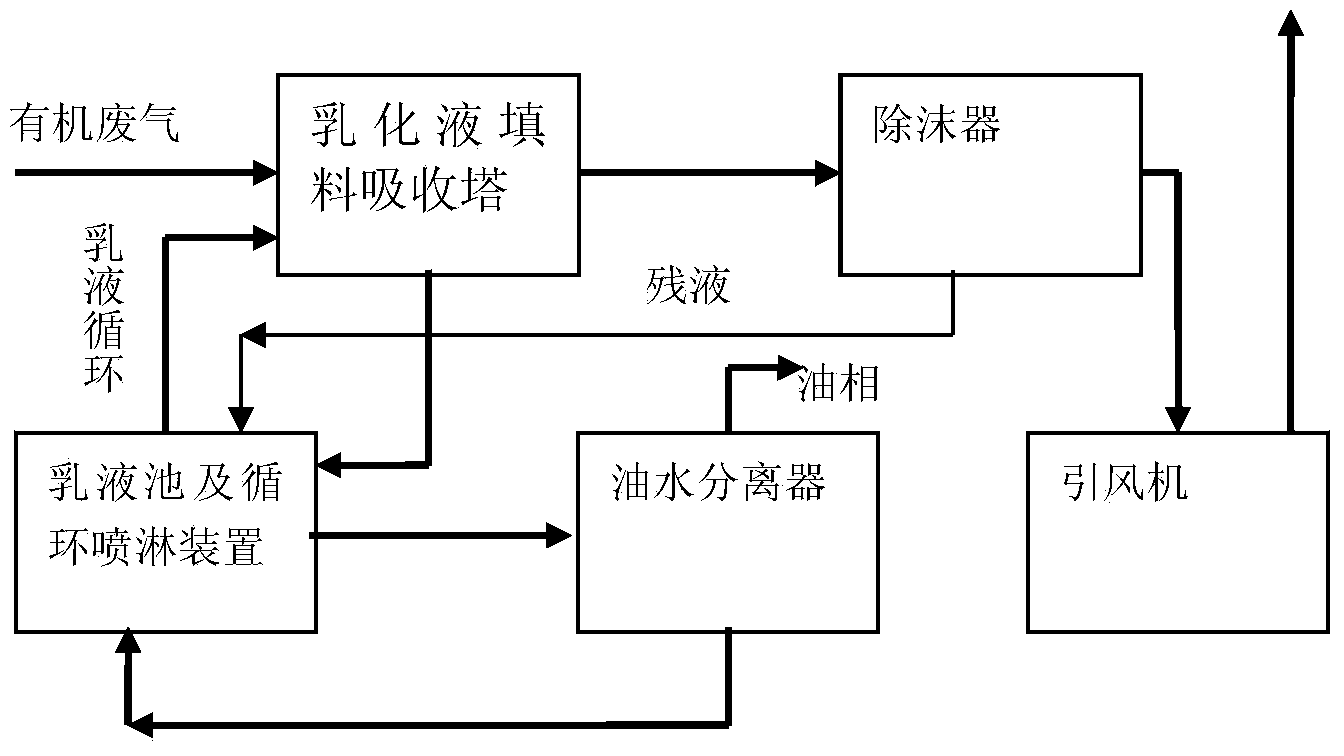

Emulsified liquid for processing organic waste gas, device for processing organic waste gas and method for processing organic waste gas

InactiveCN103537171AImprove removal efficiencyReduce pollutionTransportation and packagingDispersed particle separationTowerSorbitan

The invention aims to provide an emulsified liquid for processing organic waste gas, a device for processing the organic waste gas and a method for processing the organic waste gas. The emulsified liquid comprises polyoxyethylene sorbitan aliphatic ester or sorbitan aliphatic ester or a mixture of polyoxyethylene sorbitan aliphatic ester and orbitan aliphatic ester according to any ratio. The device for processing the organic waste gas comprises an emulsified liquid packing absorbing tower, a circulating spray system, an oil-water separator, a demister and an induced draft fan, wherein the emulsified liquid packing absorbing tower is successively connected with the circulating spray system and the oil-water separator; the emulsified liquid packing absorbing tower is also successively connected with the demister and the induced draft fan, the emulsified liquid packing absorbing tower and the circulating spray system can form a circulation loop, and the circulating spray system and the oil-water separator can form the circulation loop. The device for processing the organic waste gas provided by the invention has the advantages that the structure is simple, the use is convenient, the efficiency of removing the organic waste gas by the emulsified liquid can achieve 90%-99%, and meanwhile, the dust particulate matter removing efficiency is high.

Owner:江苏天蓝地绿环保成套设备有限公司

Device and process for removing hydrogen sulfide contained in industrial gas

ActiveCN103463954ASmall footprintReduce circulationDispersed particle separationProcess systemsIndustrial gas

The invention belongs to the technical field of removal of hydrogen sulfide contained in gases, and particularly relates to a device and a process for removing the hydrogen sulfide contained in an industrial gas, aiming at providing high-efficiency rotating packed bed equipment applicable to occasions with large flux and high treatment requirements. The device comprises a rotating packed bed and a regeneration system, wherein the liquid inlet pipe of the rotating packed bed is connected with a barren solution tank through a barren solution pump, and an air inlet pipe is connected with a sulfurous gas; the liquid discharge pipe of the rotating packed bed is connected with a pregnant solution tank, and an air outlet pipe is connected with a demister. The process comprises the following steps: preparing a desulfurizing solution; respectively introducing the desulfurizing solution and the gas which contains the hydrogen sulfide into the rotating packed bed; introducing a liquid discharged from the rotating packed bed into the regeneration system for recovery. The device and the process which are disclosed by the invention have the advantages of good desulfurization effect, small occupied area, high mass transfer efficiency, small liquid circulating amount, small gas-phase pressure drop, low operation cost and convenience for start and stop. According to the invention, the integral process system can be stable within a few minutes.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com