Method and device applied to coal-fired power plant for removing white smoke from chimney

A technology for coal-fired power plants and white smoke, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low dust removal efficiency, low boiler efficiency, and high water consumption of desulfurization towers, so as to improve dust removal efficiency and eliminate gas. Sol particles, the effect of reducing unreasonable consumption of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: a kind of method that is applied to coal-fired power plant to eliminate chimney white smoke, comprises the following steps,

[0018] Step S01: reduce the moisture content of the saturated wet flue gas by reducing the temperature of the saturated wet flue gas at the outlet of the desulfurization tower; Fogger to remove aerosol particles and liquid water droplets in saturated flue gas;

[0019] Step S03: Heat the flue gas from which the aerosol particles and liquid water droplets have been removed through the heat exchanger in the heating section to a temperature higher than the saturation curve of the humid air, thereby eliminating the white smoke phenomenon.

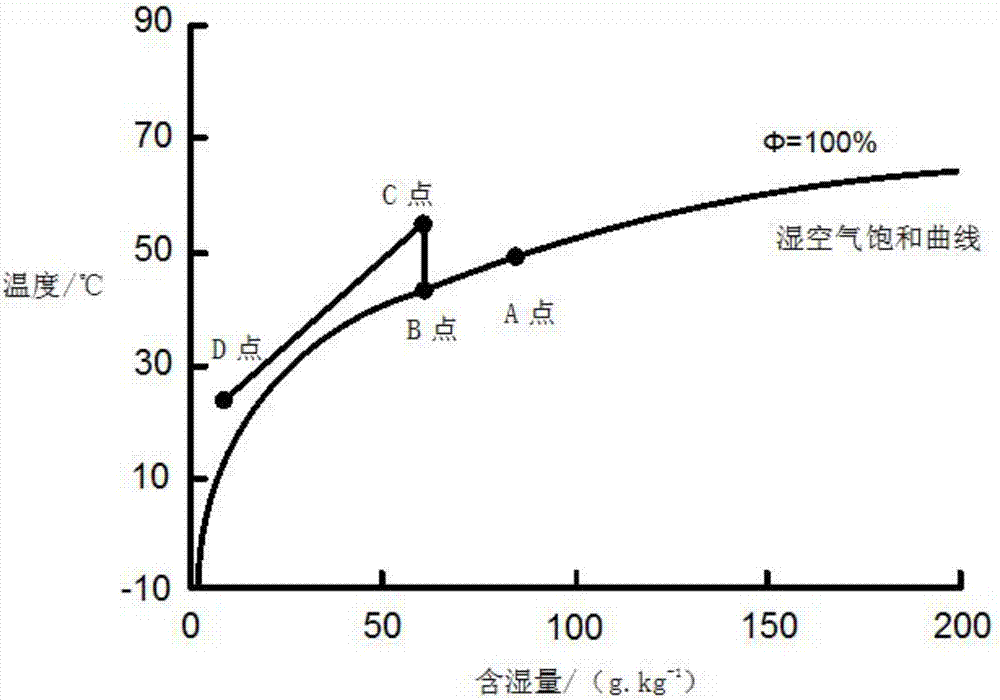

[0020] After passing through the heat exchanger in the cooling section, the flue gas drops from the flue gas state point A at the outlet of the desulfurization tower 9 to the flue gas state point B, and then rises to the flue gas state point C after passing through the heat e...

Embodiment 2

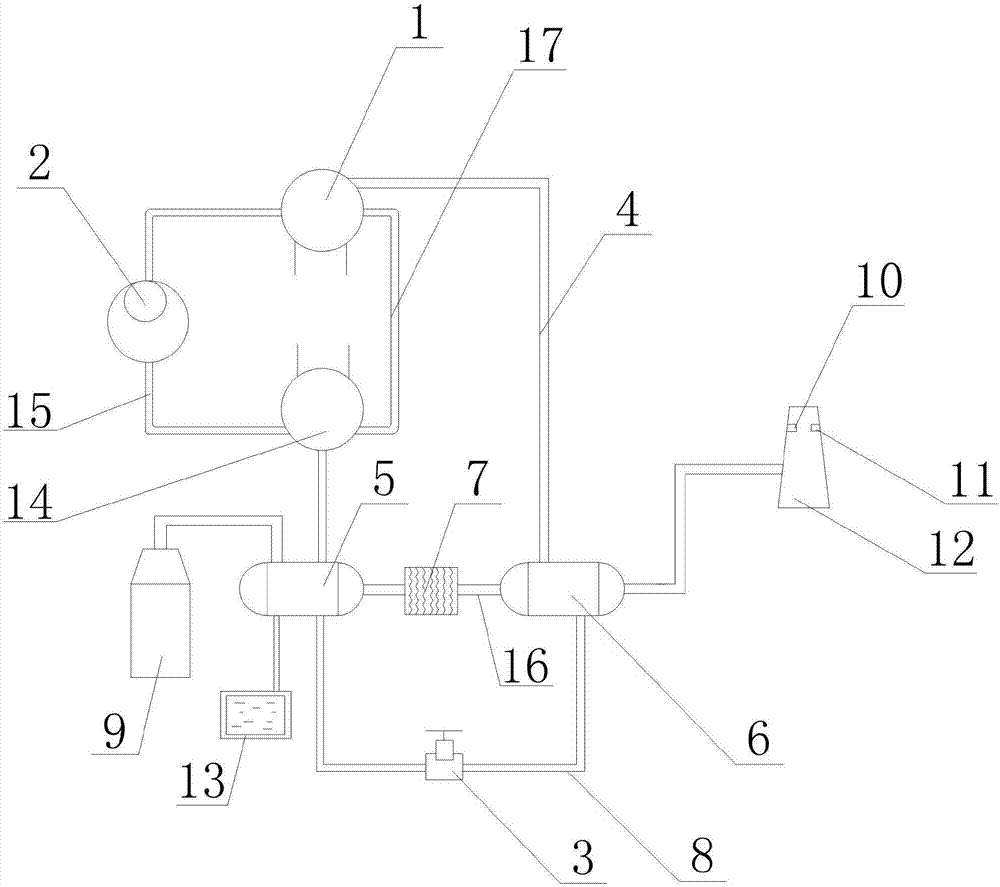

[0021] Embodiment 2 of the present invention: a device for eliminating chimney white smoke applied to a coal-fired power plant, comprising a desulfurization tower 9 connected to the heat exchanger 5 in the cooling section, and the heat exchanger 5 in the cooling section is connected to the heat exchanger 5 through the flue gas pipe 16 The heating section heat exchanger 6 is connected, and the flue gas pipe 16 between the cooling section heat exchanger 5 and the heating section heat exchanger 6 is provided with a flue demister 7, and the heating section heat exchanger 6 communicates with the chimney 12; Including a generator 1, the generator 1 is connected to the steam inlet of the heat exchanger 6 in the heating section through the steam pipe 4, the heat exchanger 6 in the heating section is connected to the heat exchanger 5 in the cooling section through a pipe 8, and the heat exchanger 5 in the cooling section is connected to the absorption The absorber 14 is connected with t...

Embodiment 3

[0022] Embodiment 3 of the present invention: a device for eliminating chimney white smoke applied to a coal-fired power plant, comprising a desulfurization tower 9 connected to a heat exchanger 5 in the cooling section, and the heat exchanger 5 in the cooling section is connected to the heat exchanger 5 through a flue gas pipe 16 The heating section heat exchanger 6 is connected, and the flue gas pipe 16 between the cooling section heat exchanger 5 and the heating section heat exchanger 6 is provided with a flue demister 7, and the heating section heat exchanger 6 communicates with the chimney 12; Including a generator 1, the generator 1 is connected to the steam inlet of the heat exchanger 6 in the heating section through the steam pipe 4, the heat exchanger 6 in the heating section is connected to the heat exchanger 5 in the cooling section through a pipe 8, and the heat exchanger 5 in the cooling section is connected to the absorption The absorber 14 is connected with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com