Patents

Literature

86results about How to "Lower smoke temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

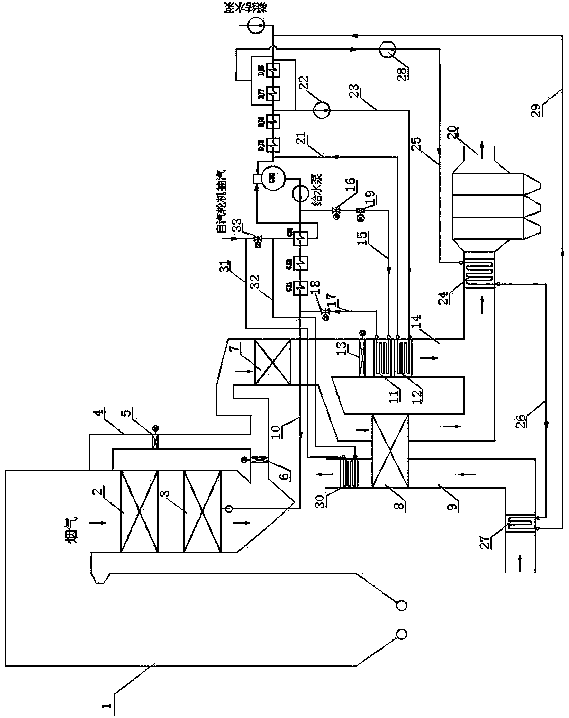

System and method for treating tail end waste water by using smoke waste heat

ActiveCN103982903AAchieve recyclingLower smoke temperatureLighting and heating apparatusWater/sewage treatmentAir preheaterCoal

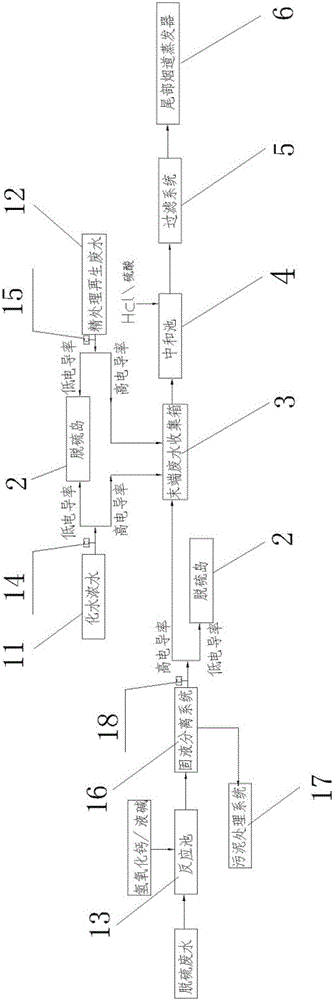

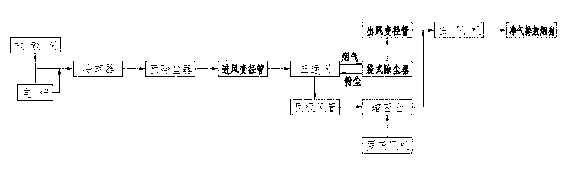

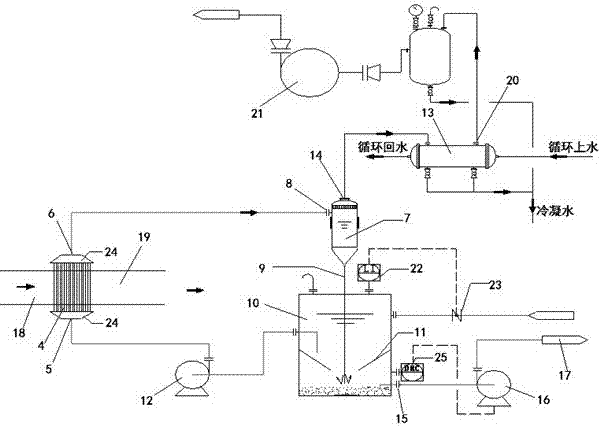

The invention discloses a system and a method for treating tail end waste water by using smoke waste heat. The system comprises a coal economizer, an air preheater, a smoke cooler, an electric deduster, a desulfurization tower, a waste water preprocessor and a waste water spraying evaporator which are communicated in sequence; a waste water pump is arranged on the pipeline for communicating the waste water processor and the waste water spraying evaporator; the smoke inlet of the waste water spraying evaporator is communicated with the pipeline between the coal economizer and the air preheater; the hot water outlet of the smoke cooler is communicated with a waste heat air heater by a circulation pump; the hot air outlet of the waste heat air heater is communicated with the air preheater. The smoke outlet of the waste water spraying evaporator is communicated with the electric deduster by the smoke cooler. The invention provides the method for treating tail end waste water by using the smoke waste heat. The smoke tampering is performed and the smoke temperature is reduced while the tail end waste water is treated, so the dedusting efficiency is improved, the low-temperature dedusting is realized, the desulfurization water consumption is reduced, the method has benefits of three aspects of energy saving, water saving and environment friendliness, and the zero emission of the waste water from a power station is truly realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

System and method for treating high salinity wastewater

ActiveCN105417817AEconomical and efficient processingAchieving zero emissionsWater contaminantsWaste water treatment from gaseous effluentsBoiling pointSalt water

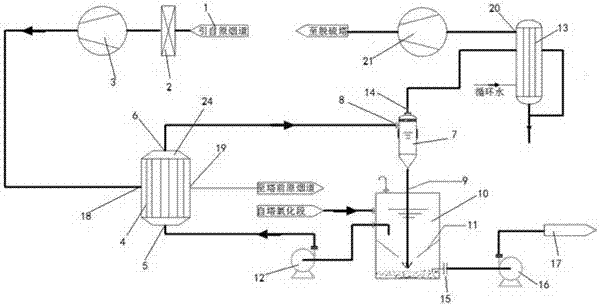

The invention discloses a treatment system and evaporating treatment method for high salinity wastewater. The treatment system comprises a desulfurization waste water conventional treatment device, a high-salinity water concentration device, a concentrated high-salinity water storage pool and an atomizer which are connected in sequence. The treatment system further comprises a high-salinity water boiling point reducing device which is arranged at any appropriate position in front of the concentrated high-salinity water storage pool. The water spraying amount of concentrated high-salinity water sprayed out of the atomizer can be adjusted. The treatment method comprises the steps that 1, after desulfurization waste water is subjected to conventional treatment, upper-layer clear water, namely, high-salinity water is collected, the high-salinity water is concentrated to be reduced, and concentrated high-salinity water is formed and stored in the concentrated high-salinity water storage pool; 2, the concentrated high-salinity water in the concentrated high-salinity water storage pool is sprayed into a flue between a hearth and a dust remover and / or the hearth through the atomizer and subjected to atomization and evaporation, and crystal substances are mixed into coal ash to be removed together, wherein the water spray amount of the concentrated high-salinity water sprayed into the flue between the hearth and the dust remover and / or the hearth is adjusted according to flue gas temperature.

Owner:高境 +1

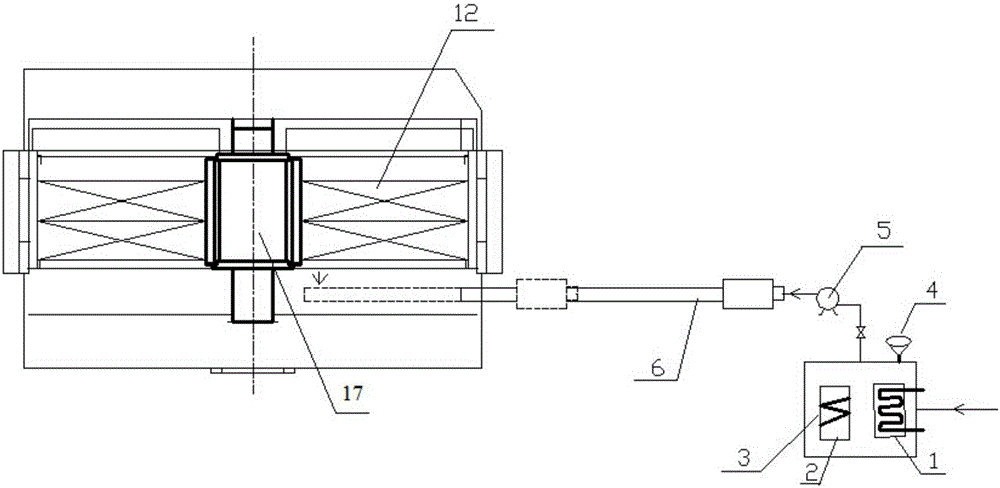

High-pressure-head low-flow non-isolated online cleaning device for rotary air preheater

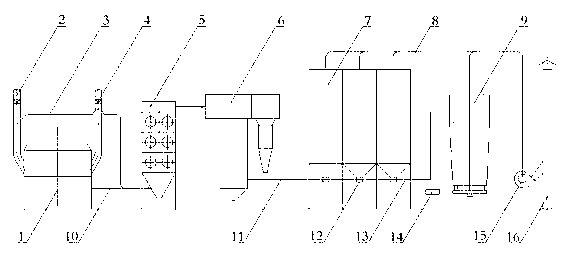

InactiveCN105758253AReduce uneven expansionLower smoke temperatureFlush cleaningSolid removalAir preheaterElectricity

The invention provides a high-pressure-head low-flow non-isolated online cleaning device for a rotary air preheater.The device comprises a steam heating device, an electric heating device, a water tank, an agentia adding device, a high-pressure water pump and a soot blower, wherein the water tank, the agentia adding device, the high-pressure water pump and the soot blower are sequentially connected, and the steam heating device and the electric heating device are both arranged in the water tank.The device is simple in structure, convenient to implement, small in influence on unit operation, and capable of efficiently cleaning a heat exchanging element of the rotary air preheater under the online non-isolated condition.

Owner:GUODIAN SCI & TECH RES INST +1

Automatic control SCR flue gas denitrification urea pyrolysis system

InactiveCN105498532AReduce plant power consumptionSolve the blockageGas treatmentCombustion processAutomatic controlUrea

The invention discloses an automatic control SCR flue gas denitrification urea pyrolysis system. The system is characterized in that a gas-gas heat exchanger is arranged in an inlet flue of an electric precipitator so as to form an air heating unit; a set of flue gas heating tube bundles are arranged in a boiler, so as to form an air reheating unit; after heated by the gas-gas heat exchanger and reheated by the flue gas heating tube bundles, air becomes high-temperature air at the temperature of heat resource required by urea pyrolysis; the high-temperature air is fed into a urea pyrolysis furnace and is mixed with a sprayed atomized urea solution, and then the pyrolysis is performed and an ammonia / air mixture is generated; the ammonia / air mixture is sprayed into an inlet flue of an SCR denitrification reactor through an AIG ammonia injection grating. The automatic control SCR flue gas denitrification urea pyrolysis system has the advantages that the technical structure is simple; the system can be widely applied to an SCR denitrification device of a coal-fired power plant; the urea atomizing pyrolysis efficiency can be effectively increased and the crystal plugging problem can be thoroughly solved; the waste-heat utilization of flue gas can be realized and the electrostatic precipitation efficiency can be increased; water used by a desulfurization system can be reduced.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

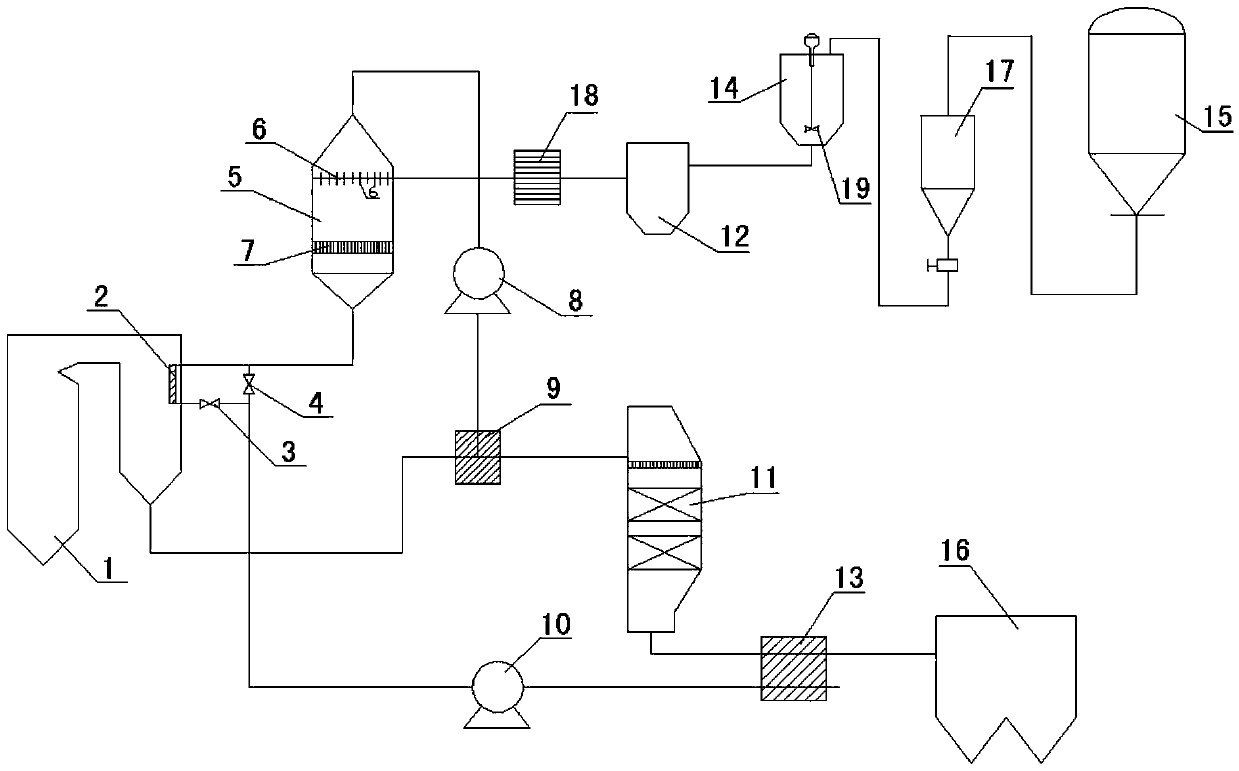

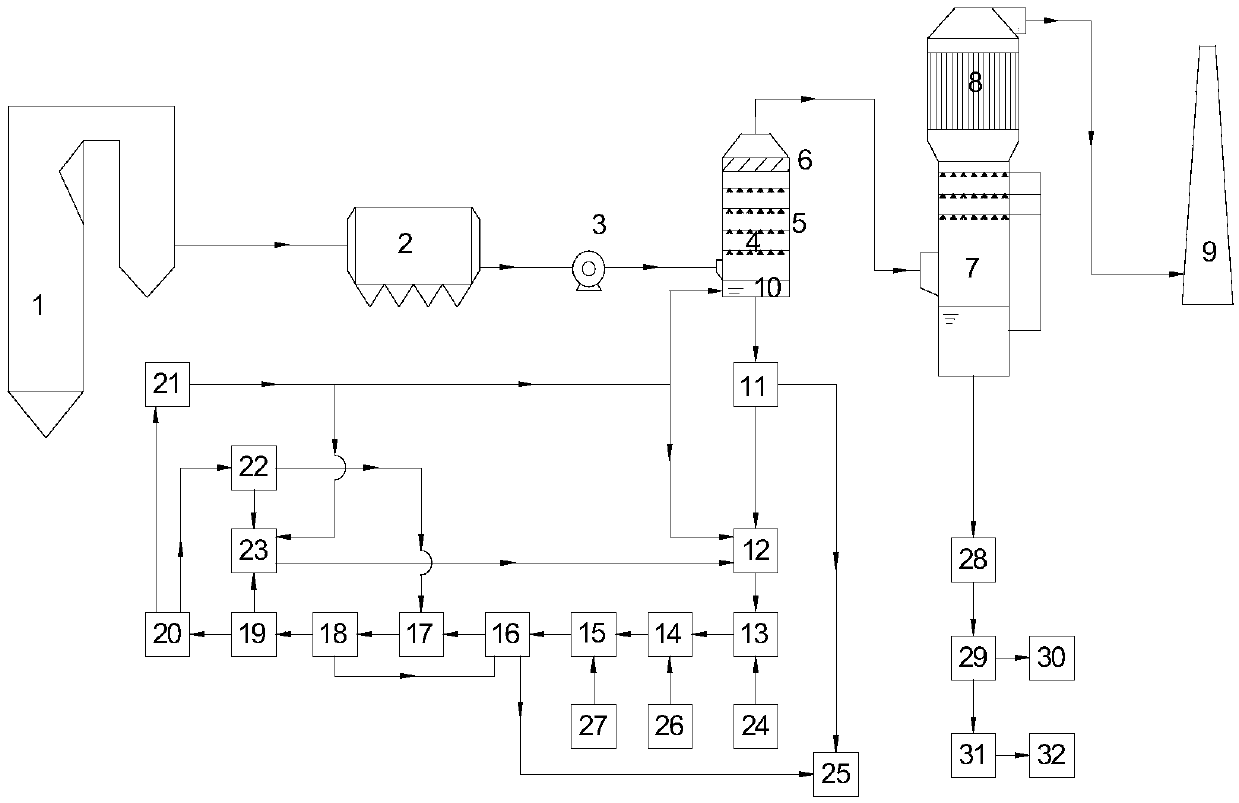

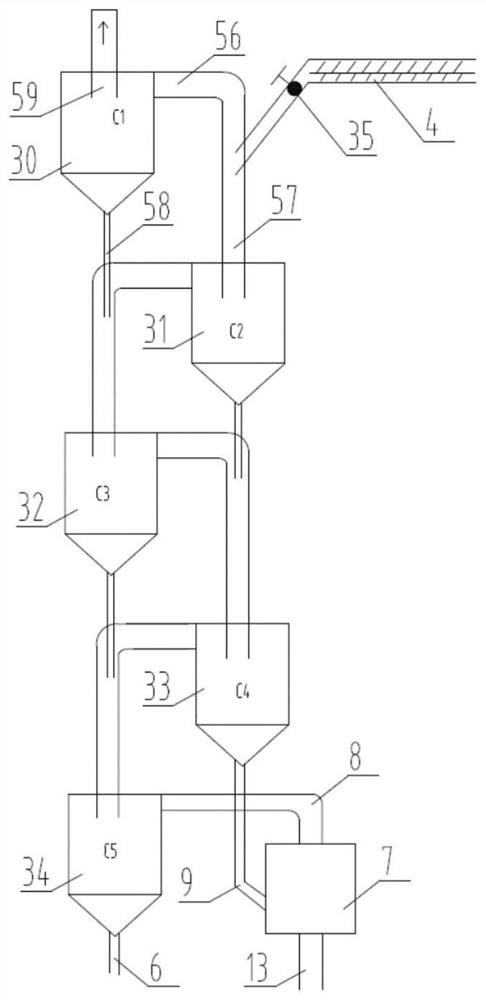

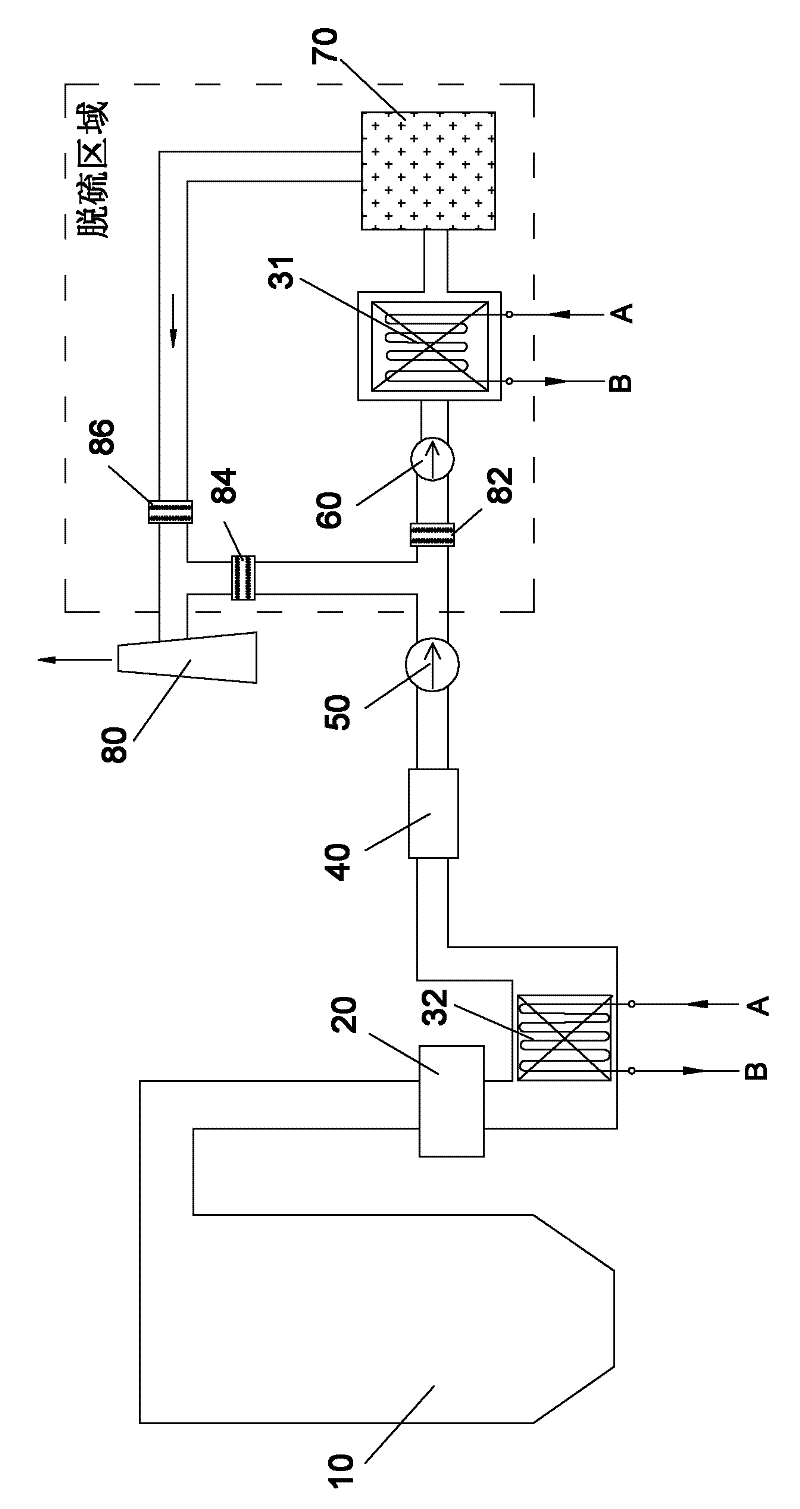

Terminal wastewater zero discharging system and method of power plant

ActiveCN106630259AAchieve recyclingLower smoke temperatureWater/sewage treatment by centrifugal separationDispersed particle separationSulfate radicalsWater vapor

The invention relates to a system. The system comprises a terminal wastewater collection system, a pretreatment system and a rear smoke channel bypass evaporator, wherein the terminal wastewater collection system comprises a concentrated chemical water collection system, a refining regeneration wastewater collection system, and a desulfurizing wastewater collection system. In the pretreatment process, softening, flocculation and clarification are adopted to decrease the scaling ion concentration of calcium, magnesium, sulfate radical and the like in water, and removing SS (suspension) in the wastewater; sending the pretreated wastewater into the rear smoke channel bypass evaporator; evaporating by the heat of the rear smoke channel fume of a boiler; after completely evaporating, sending a crystallizing matter into a deduster, and discharging along with fly ash; sending gaseous water vapor and flume into a desulfurizing adsorbing tower via the deduster, condensing, and recycling, so as to realize the terminal wastewater zero discharging of a power plant.

Owner:SHENGFA ENVIRONMENT PROTECTION TECH XIAMEN CO LTD

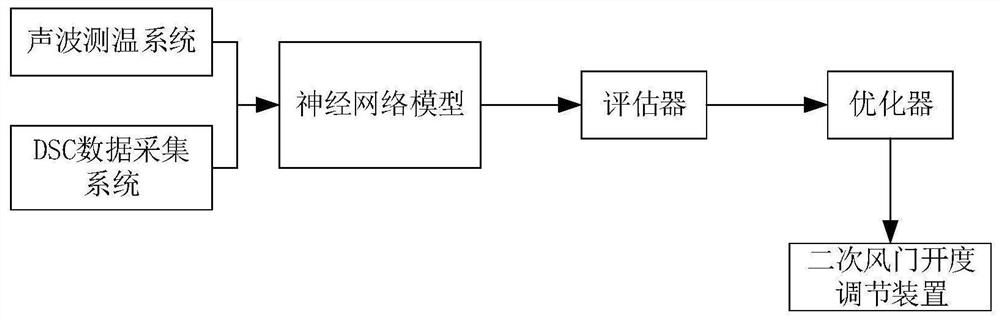

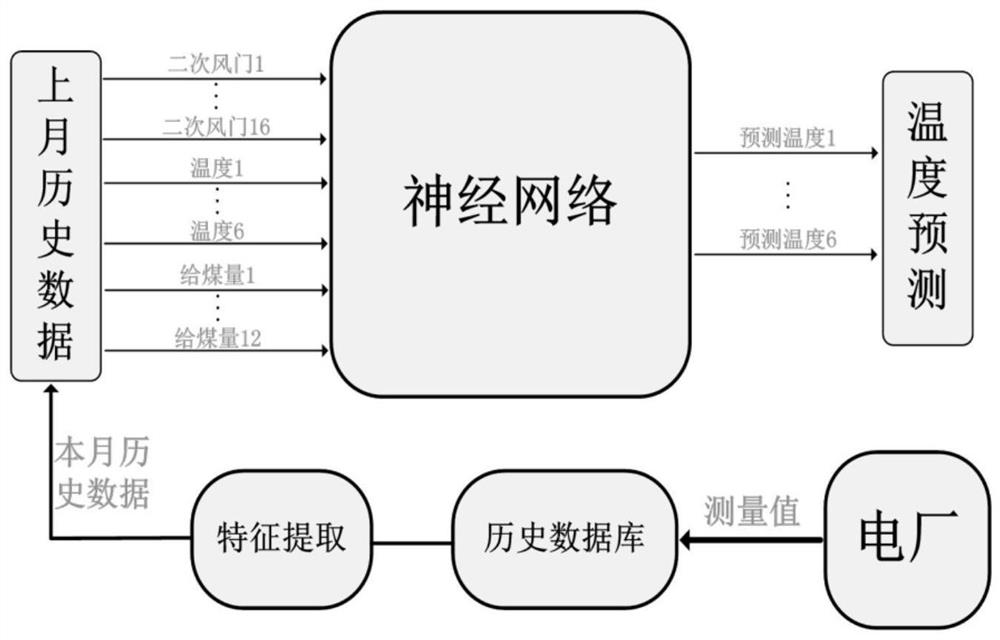

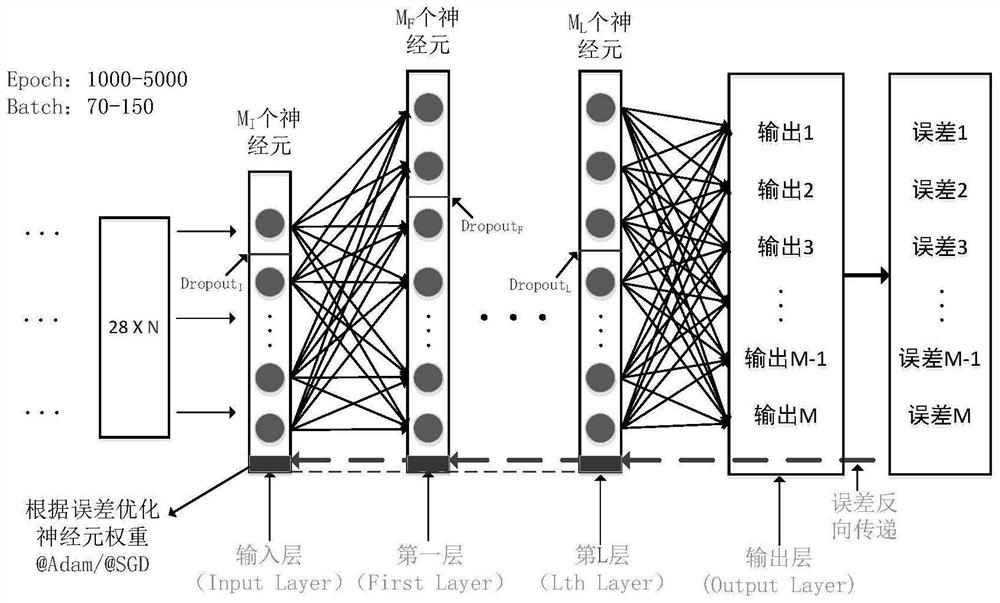

Combustion control system and control method for power plant

ActiveCN111829003AImprove generalization abilityReduce mistakesAir supply regulationTotal factory controlData acquisitionNetwork model

The invention discloses a combustion control system for a power plant. The combustion control system comprises a data acquisition part, a control part and an execution part. The data acquisition partcomprises a sound wave temperature measurement system and a DCS data acquisition system. The control part comprises a neural network model module, an evaluator and an optimizer. The execution part comprises a secondary air door opening degree adjusting device. The invention further discloses a combustion control method for the power plant. According to the system and the method, a neural network is adopted to construct a model, and extremely high universality and transportability are achieved. According to the system and the method, stable, long-term and manual intervention-free combustion canbe achieved for the power plant, and the purposes of reducing coal consumption and NOx and CO emissions as much as possible, reducing the combustion temperature of a hearth, uniform combusting and reducing the smoke temperature under the condition of a given load can be achieved.

Owner:嘉兴汇智诚电子科技有限公司

Boiler full-load denitration coupling flue gas waste heat gradient utilization system

PendingCN107687634AEasy to useSolve the problem of decouplingFeed water supplyCombustion processAir preheaterLow load

The invention relates to the field of boiler full-load denitration putting-into-operation and exhausted smoke waste heat utilization and particularly discloses a boiler full-load denitration couplingflue gas waste heat gradient utilization system. The boiler full-load denitration coupling flue gas waste heat gradient utilization system comprises a boiler; a low-temperature heater, a coal economizer, a denitration device, an air preheater and an electric dust remover are sequentially mounted in a flue gas channel of the boiler in the advancing direction of flue gas. The boiler full-load denitration coupling flue gas waste heat gradient utilization system is characterized in that a high-temperature denitration bypass flue is arranged in the position, between an inlet of the low-temperatureheater and an inlet of the denitration device, of the flue gas channel; an air preheater bypass flue is arranged in the position, between an outlet of the denitration device and an inlet of the electric dust remover, of the flue gas channel; and a high-temperature coal economizer and a medium-temperature coal economizer are sequentially arranged in the air preheater bypass flue in the advancing direction of the flue gas. According to the boiler full-load denitration coupling flue gas waste heat gradient utilization system, the denitration device can be effectively put into use under the low load condition of the boiler, and the splitting problem of the denitration device due to decreasing of the load of the boiler is solved; and gradient utilization of waste heat of the flue gas is achieved, high energy level extracted steam is effectively squeezed out, the power generation load is increased, and the overall benefits of a power plant are promoted.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

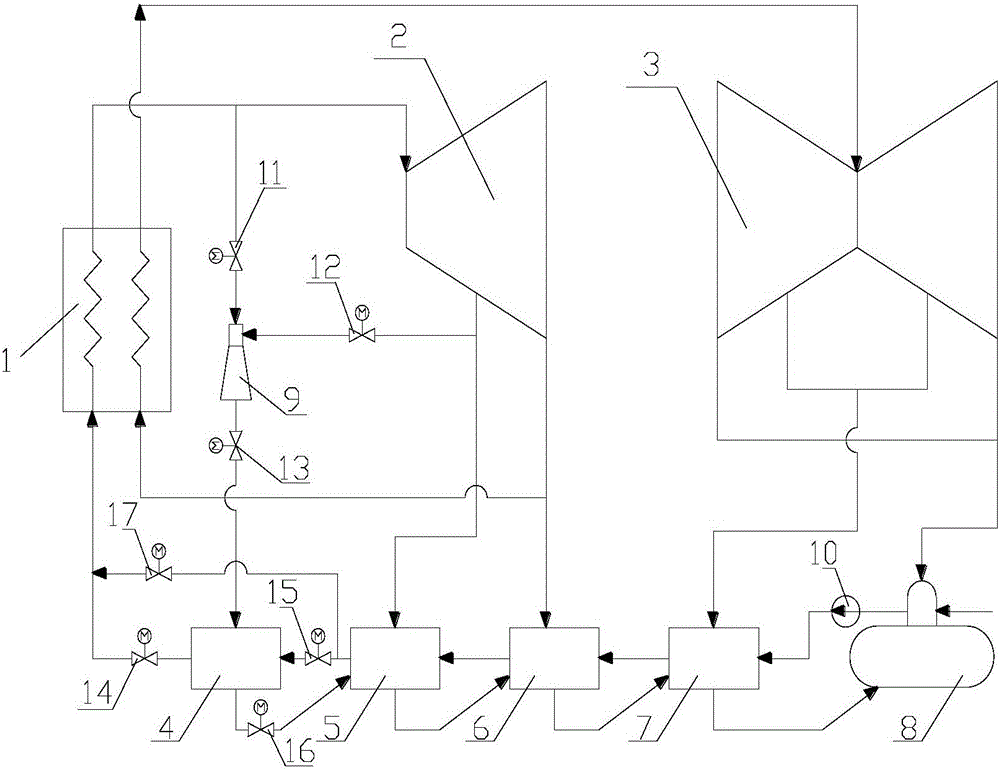

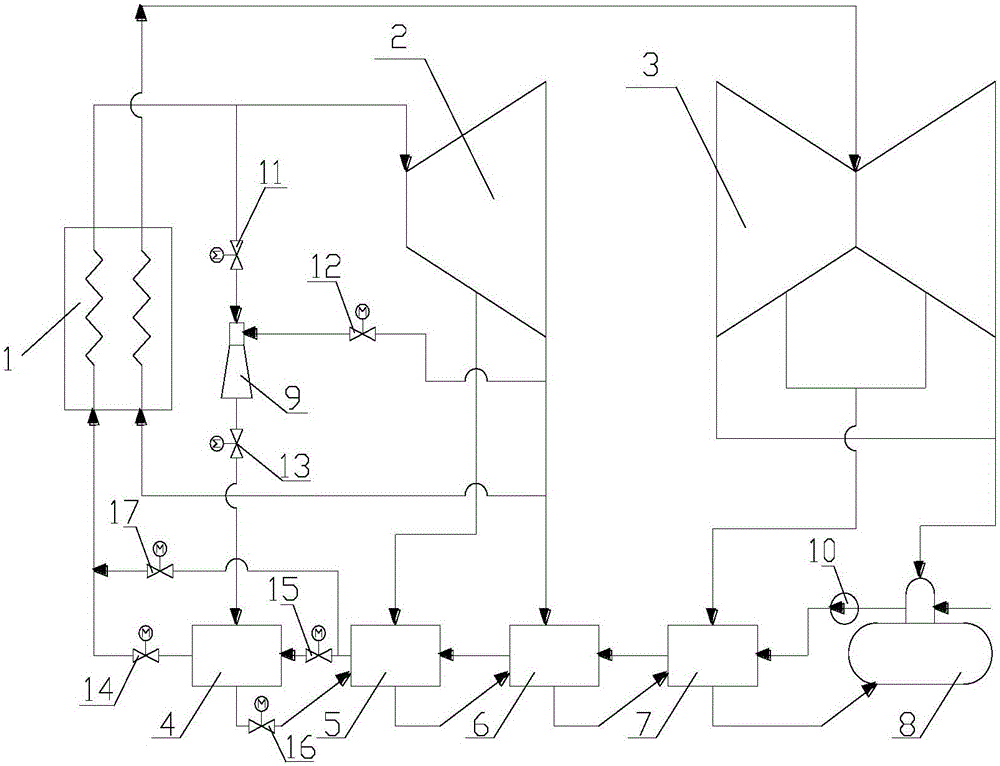

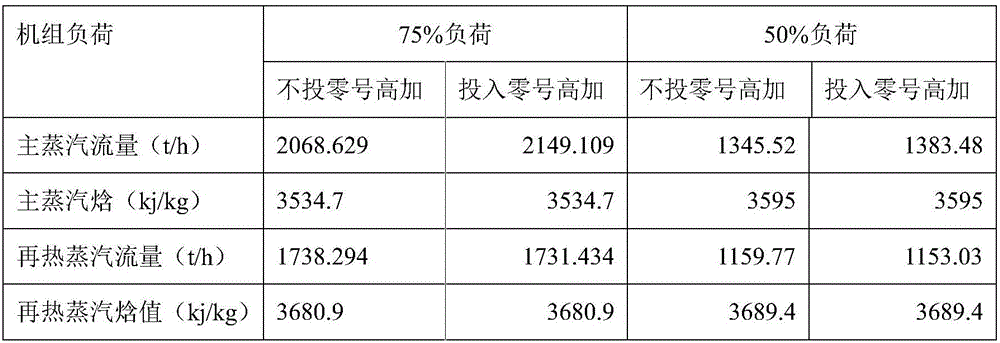

Hot-pressing type ultra supercritical unit number-zero high-pressure heater and switching system thereof

ActiveCN105953213AIncrease feed water temperatureImprove economyLiquid degasificationFeed-water heatersPipe fittingProcess engineering

The invention provides a hot-pressing type ultra supercritical unit number-zero high-pressure heater, a switching system thereof and a novel technological process for improving the low-load running economical efficiency of thermal power generating units. A hot press, the number-0 high-pressure heater and related valves and pipe fittings connected with the hot press and the number-0 high-pressure heater are used as core parts of the technological process, and all other devices are devices of existing units. The technological process has a main effect of adding a level of regenerative heating to an existing steam extraction heat recovery system, the thermal economical efficiency of the units under low loads is improved, the smoke temperature of an outlet of an economizer can be effectively improved, and the removal efficiency of a denitration system under the low-load work condition is ensured. In addition, due to input of the set of technological process, the air temperature can be effectively increased, and impact generated on the unit thermal economical efficiency and the boiler safety under the high-pressure cut-off work condition can be relieved.

Owner:张曙光

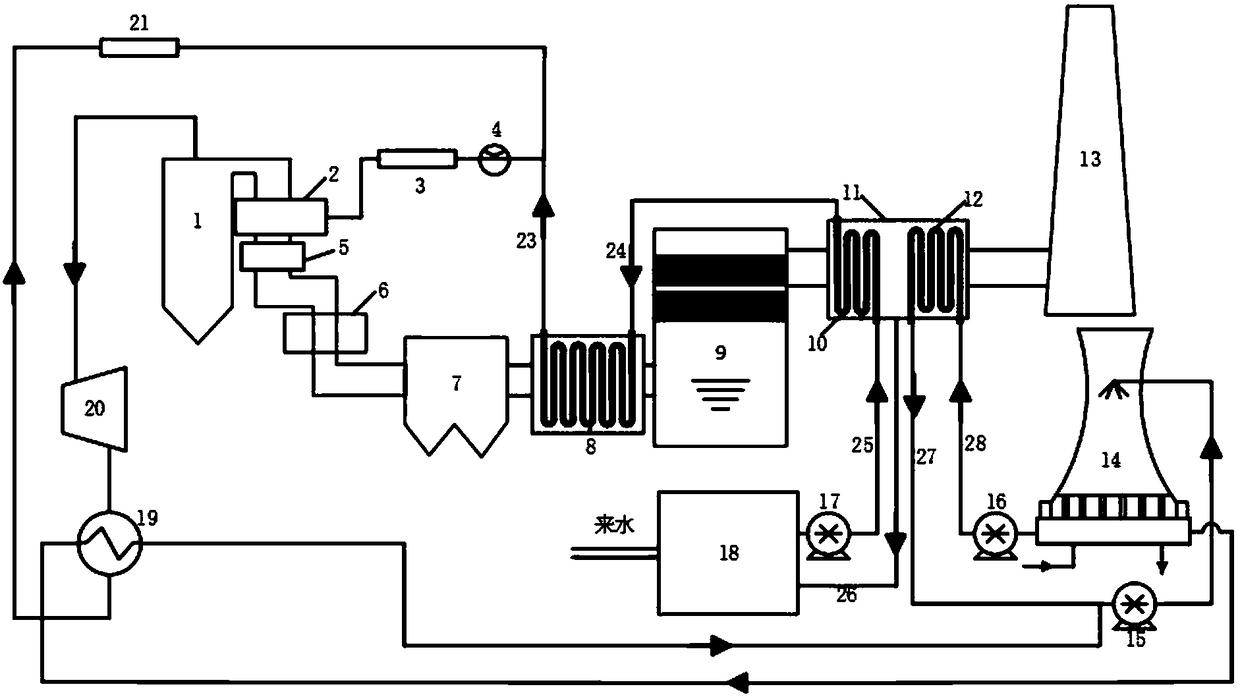

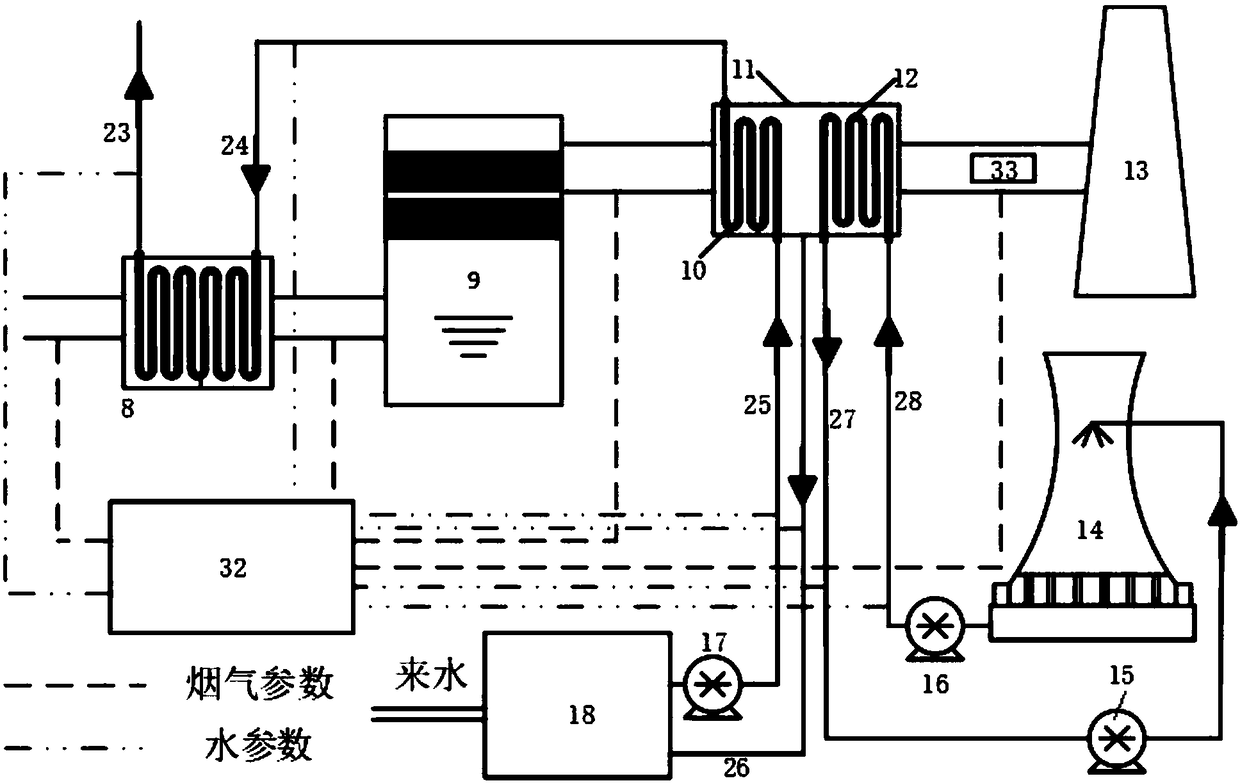

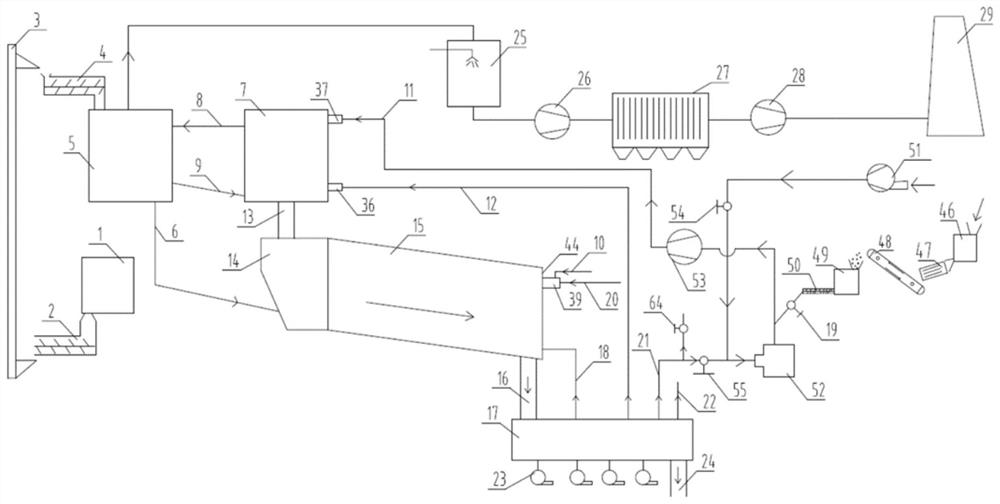

Power plant flue gas steam latent heat and water recovery system, and recovery method and control method thereof

InactiveCN108087902AHigh recovery rateReduce heating energy consumptionLiquid degasificationEmission preventionRecovery methodHazardous substance

The invention belongs to the field of waste heat resource recovery and particularly relates to a power plant flue gas steam latent heat and water recovery system, and a recovery method and control method thereof. Boiler feedwater passes shell-tube heat exchangers and an annular low finned tube heat exchanger in sequence to be preheated and conducts heat exchange with flue gas in front of a desulfurizing tower. The inlet flue-gas temperature of the desulfurizing tower can be effectively reduced. The desulfurization efficiency can be improved. The preheated boiler feedwater is directly deliveredto a deaerator. Heating energy consumption of the deaerator on the boiler feedwater can be reduced. Flue gas behind the desulfurizing tower makes contact with a cooling medium in the continuous two-stage heat exchangers and can recover vaporization latent heat and sensible heat of water vapor in saturated flue gas simultaneously. When the flue gas temperature is lowered to below the dew point ofwater vapor, the concentration of hazardous substances such as SO2 and NOX in discharged smoke can be effectively reduced, and condensate water can also be used as a water resource to be recovered. The power plant flue gas steam latent heat and water recovery system is simple in structure, low in investment and operating cost and capable of bringing remarkable economic benefits for an enterprise and has good environmental and social benefits.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

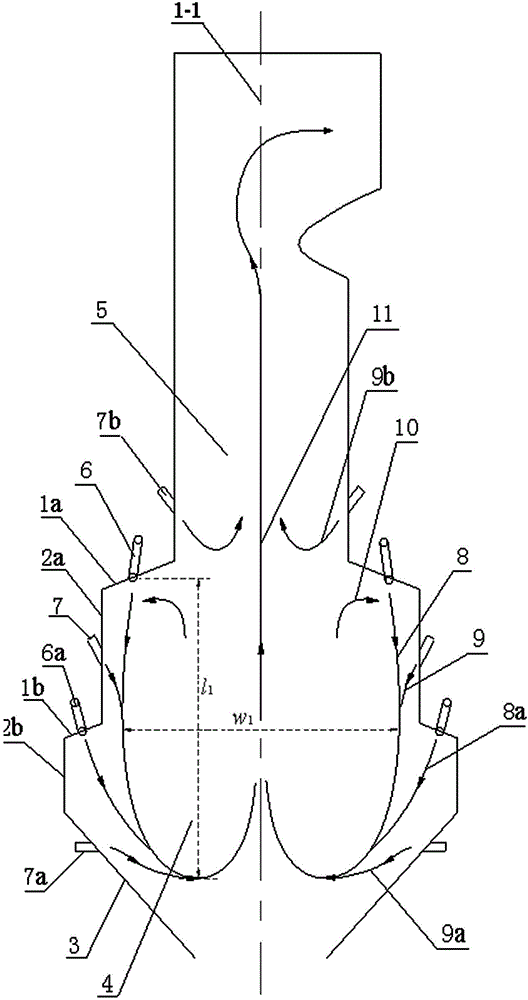

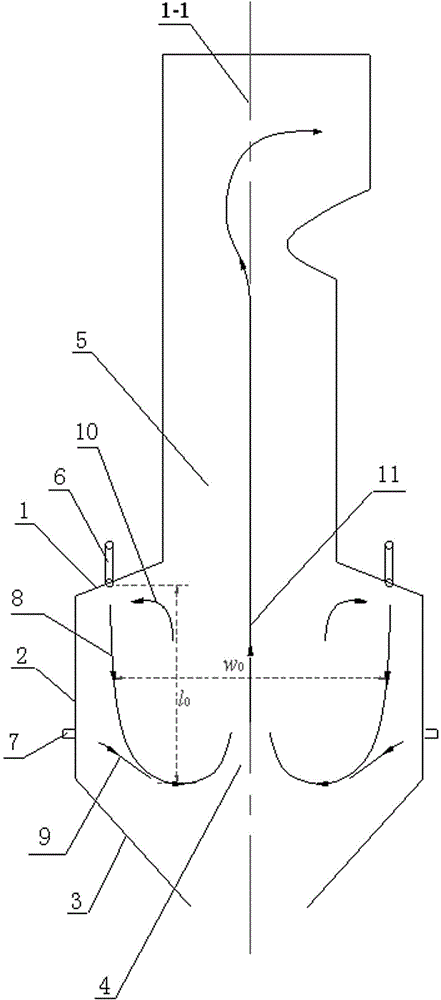

Low-NOx four-arch type W flame boiler for coupling air staging and fuel staging

ActiveCN104406160ALower shot depthImprove interception abilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a low-NOx four-arch type W flame boiler for coupling air staging and fuel staging. A furnace chamber is divided into two parts, namely the lower furnace chamber and the upper furnace chamber, and the lower furnace chamber consists of four furnace arches, a two-stage type front and rear wall and a dry bottom hopper; a pulverized coal burner inclined outwards is arranged on the upper furnace arch, declined staging air noozles are formed in the upper part of the front and rear wall, an ultrafine powder burner inclined inwards is arranged on the lower furnace arch, protective air noozles are approximately horizontally formed in the upper part of the dry bottom hopper, and over-fire air noozles inclined downwards are formed in the lower part of the upper furnace chamber. Therefore, the condition of coupling deep air staged combustion and fuel staged combustion is constructed in the furnace, and the boiler is supplemented with prolonged flame travel caused by unique combustion design and added flame fullness degree, so that low NOx combustion and high-efficiency after-combustion for the W flame boiler are realized.

Owner:CHINA JILIANG UNIV

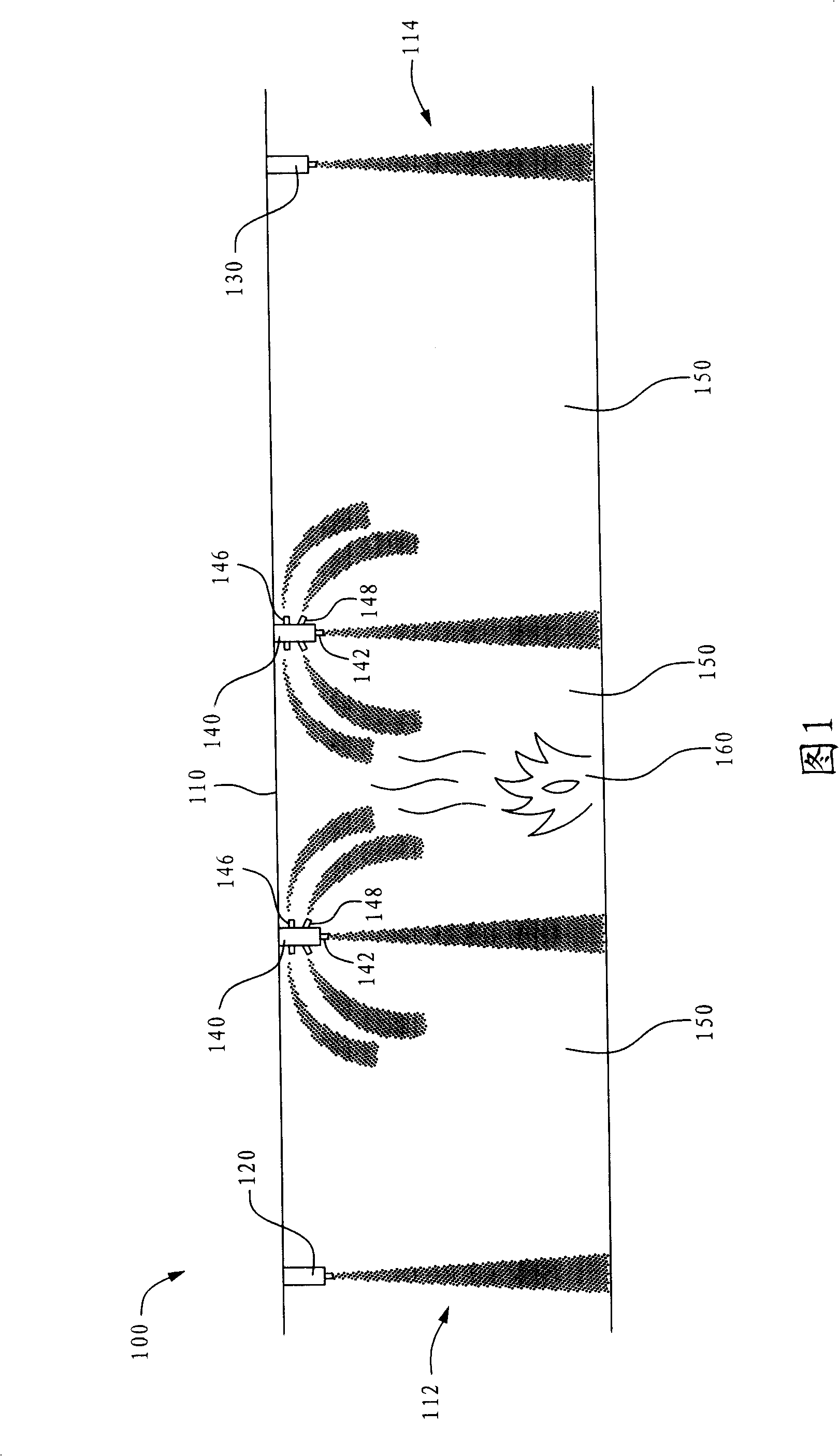

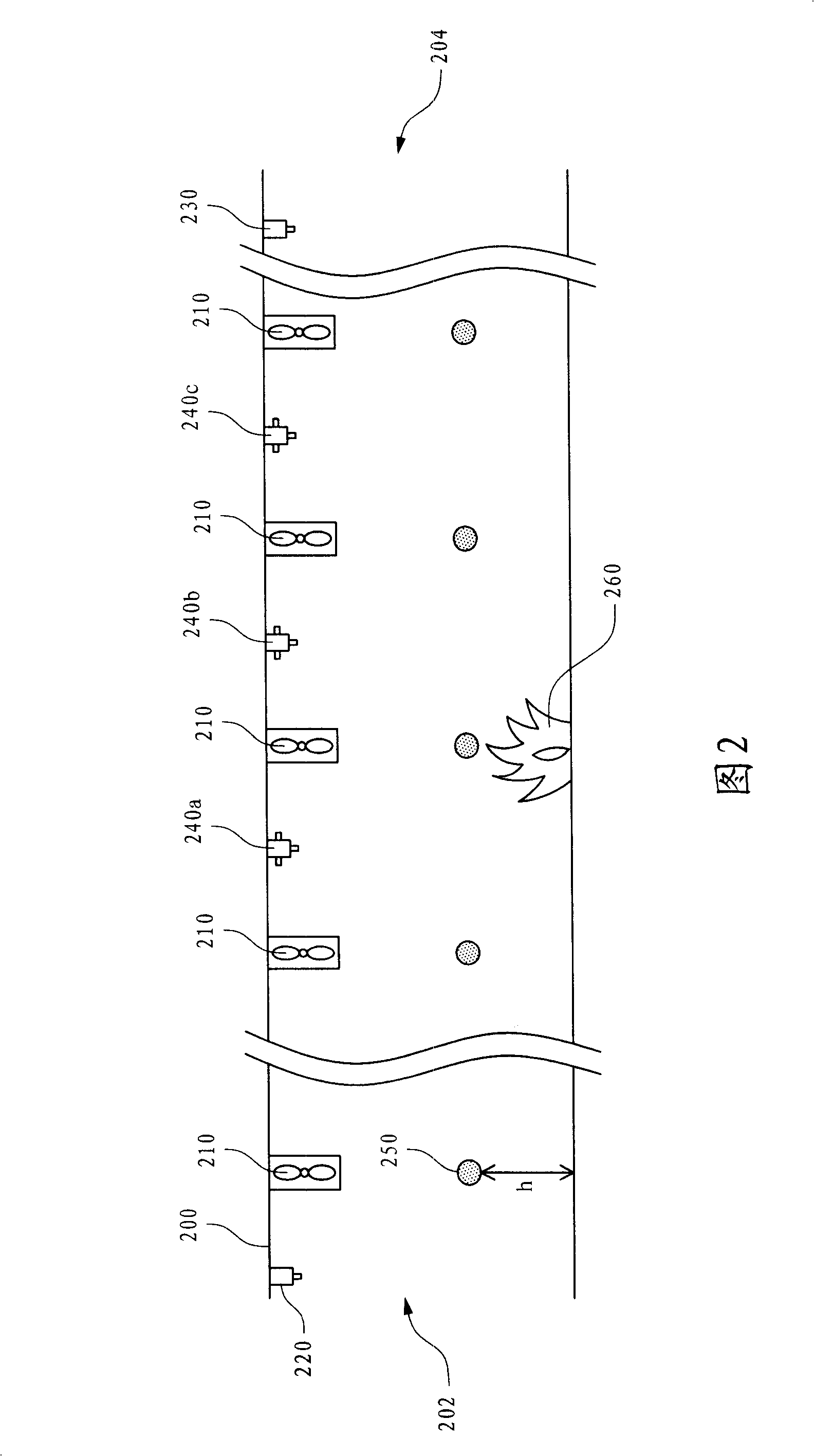

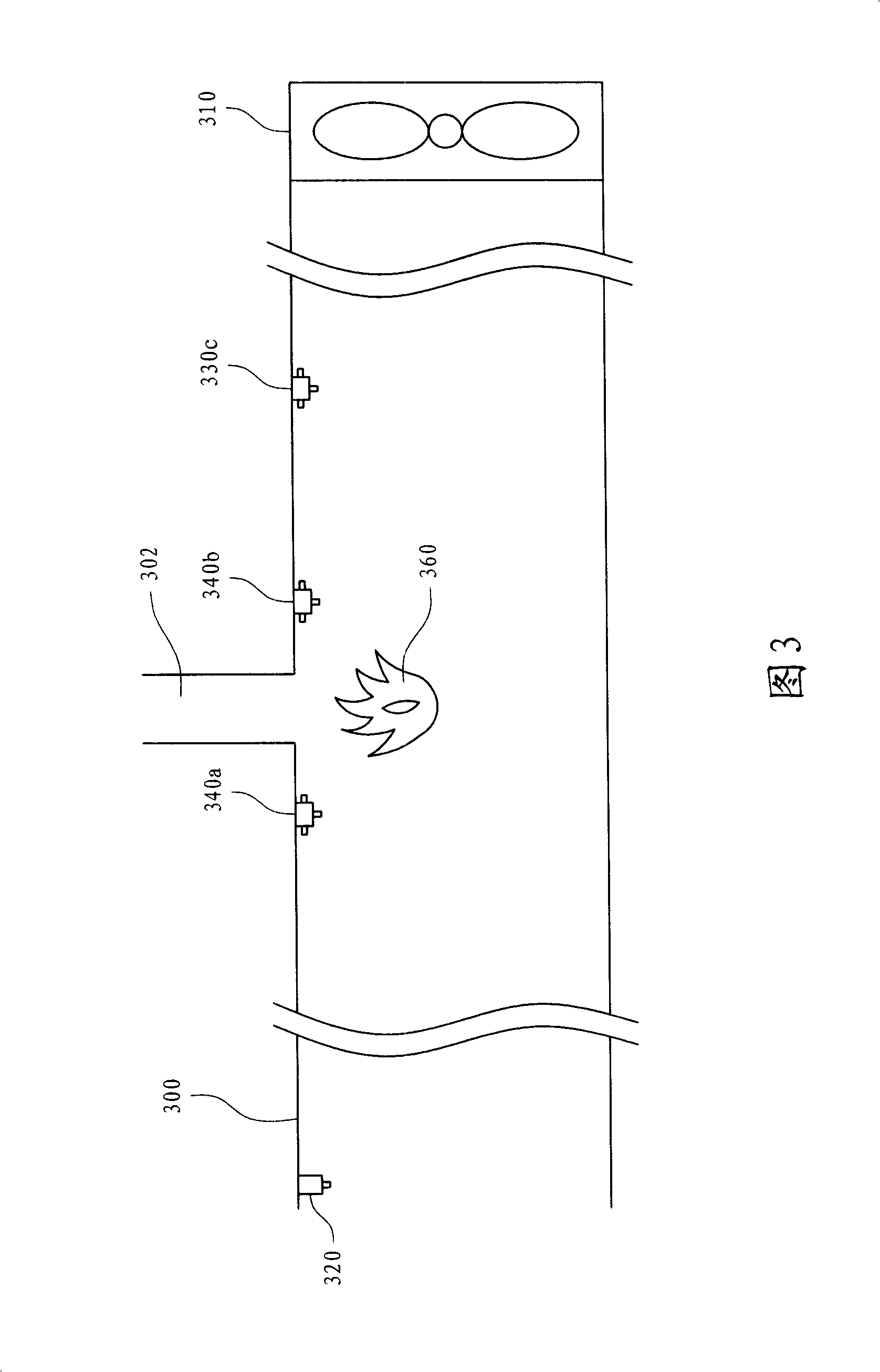

Long channel water fire extinguishing system and method

InactiveCN101244323AFast heat absorptionEasy to evaporateFire rescueFirefightingAgricultural engineering

The invention relates to a long channel firefighting system, which is applied in the long channel provided with an air inlet and an air outlet . The invention comprises a first water spray curtain device, a second water spray curtain device, and at least a third water spray curtain device, wherein the first water spray curtain device is arranged at top part of the wind inlet, the second water spray curtain device is arranged at top part of the air outlet , the third water spray curtain device is arranged at top part of the long channel between the air inlet and the air outlet so as to divide the long channel into a plurality of firefighting areas. The purpose of the invention is to prolong escape time when disaster happens, and reduce the influence of thick smoke on persons.

Owner:蔡荣锋 +1

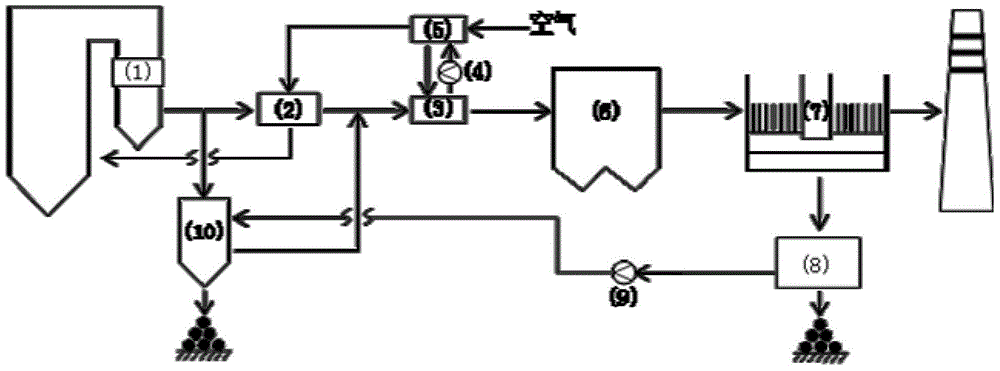

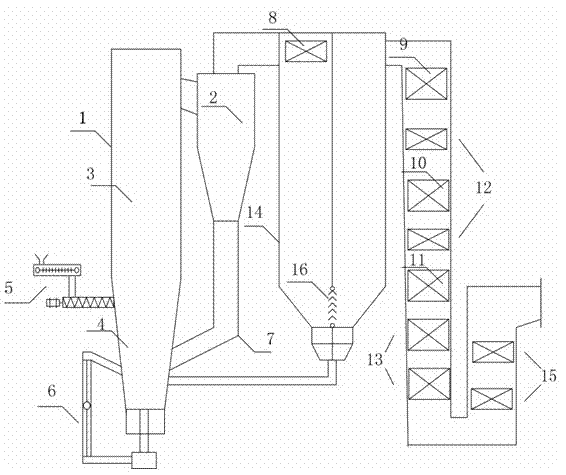

High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

ActiveCN102878569AIncineration is stable enoughFully stable combustionIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature air combustion intensifying device and method applicable to low heating value mixed garbage, wherein a low-temperature preheater is arranged on the rear side of a U-shaped tail part flue; a garbage feeding opening is arranged on the side wall of the lower part of a furnace chamber; the side wall of the upper part of the furnace chamber is connected with the upper part of a cyclone separator; the bottom part of the cyclone separator is connected with the upper end of a back feeder; the lower end of the back feeder is connected with the side wall of the lower part of the furnace chamber; the upper end of the cyclone separator is connected with the upper part of the front side of a U-shaped combustion chamber; the lower end of the U-shaped combustion chamber is connected with the side wall of the lower part of the furnace chamber; the lower end of the furnace chamber is connected with the side wall of the lower part of the furnace chamber through a water-cooled cold slag sorting and back feeding device; and the upper part of the rear side of the U-shaped combustion chamber is connected with the upper part of the front side of the U-shaped tail part flue. The method utilizing the high-temperature air to intensify the low heating value garbage mixed combustion is more suitable for the domestic characteristics that the garbage has complicated components, high moisture and low heating value, has wider fuel application range, and is more sufficient and stable in combustion, the garbage can be purely combusted without the need of coal, the energy consumption is reduced, and the operating economy is improved.

Owner:ZHEJIANG UNIV

System for treating waste fan blades in decomposing furnace and working method of system

The invention discloses a system for treating waste fan blades in a decomposing furnace and a working method of the system, and belongs to the technical field of resource recovery. The system comprises a blade crushing system, a raw material feeding system, a flue gas treatment system, a suspension preheater, a decomposing furnace, a rotary kiln, a clinker cooling device and a fan coal mill. Crushed waste fan blade particles are merged into a pneumatic conveying pipeline at the downstream of the fan coal mill and are conveyed into the decomposing furnace together for pyrolysis and combustion, heat released by combustion of organic composite materials of the waste blade particles and heat released by combustion of pulverized coal provide energy for dehydration and decomposition of raw materials together, and the potential heat value of fan blades is effectively utilized. Glass fibers in the blade particles, combusted pulverized coal and ash residues formed by combustion of the pulverized coal are mixed into the raw material together, enter a downstream suspension preheater, are finally separated and are returned to the rotary kiln to participate in clinker firing. Harmless and resourceful treatment of the waste fan blades is achieved, and good environmental protection benefits and economic benefits are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

Waste incineration boiler

ActiveCN102322640ANot easy to accumulate dustImprove cleanlinessIncinerator apparatusAir preheaterEngineering

The invention provides a waste incineration boiler, which ensures that a conventional waste incineration boiler is less in dust stratification, convenient in soot cleaning and difficult in leakage, and the operation and maintenance costs of the boiler are reduced. The waste incineration boiler comprises a furnace chamber, a furnace grate and a horizontal flue, wherein the furnace chamber is positioned above the furnace grate; a boiler barrel is arranged above the furnace chamber; a front-back arch is arranged on the lower part of the furnace chamber; secondary air is arranged on the front-back arch, and faces the furnace grate; and an air preheater, an overheater and an evaporator are arranged in the horizontal flue. The waste incineration boiler is characterized in that: the furnace chamber is connected with a vertical burn-out chamber, three vertical flues, the horizontal flue and a tail part vertical flue in turn; a coal economizer is arranged in the tail part vertical flue; a rapping apparatus is arranged on a pipeline of the air preheater, the overheater and the evaporator which are arranged in the horizontal flue; and a shockwave or steam sootblower is arranged in the tail part vertical flue.

Owner:WUXI HUAGUANG BOILER

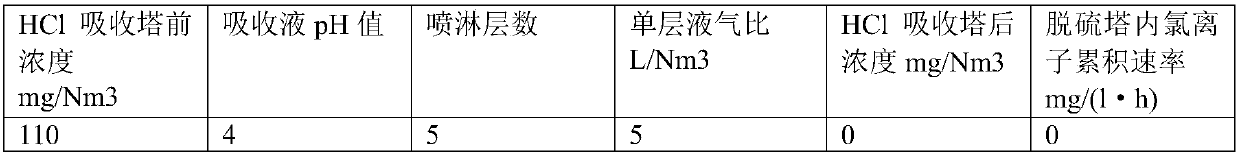

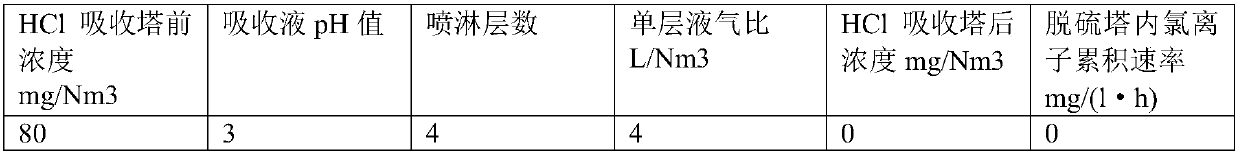

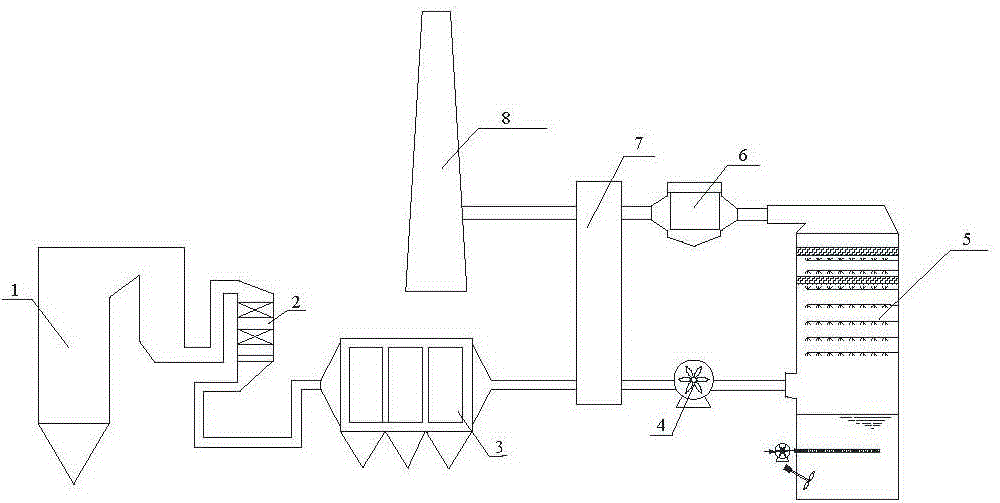

Desulfurization process and device with zero wastewater discharge

ActiveCN109647164AImprove qualityReduce moisture contentGas treatmentSludge treatmentUltrafiltrationSlurry

The invention discloses a desulfurization process and device with zero wastewater discharge. The process includes the following steps: (1) flue gas of coal-fired boiler is sent to a hydrogen chlorideabsorption process through a dust collector and an induced draft fan in order, an absorption liquid in the hydrogen chloride absorption process cyclically sprays and absorbs hydrogen chloride gas anddust in the flue gas and the purified flue gas is discharged from a chimney after desulfurization; (2) the flue gas after the removing of the dust and hydrogen chloride in the flue gas enters a desulfurization tower for desulfurization, a filtrate is returned to the desulfurization tower after gypsum slurry discharged from the desulfurization tower is dehydrated, and zero discharge of desulfurization tower wastewater is realized; and (3) wastewater discharged from the hydrogen chloride absorption process is prepared into an acid and a base used in a return system after initial sedimentation, neutralization, softening, flocculation, sedimentation, ultrafiltration, deep softening, and bipolar membrane electrodialysis. The wastewater discharged from the hydrogen chloride absorption tower of the invention is prepared into the acid and alkali for reuse, the desulfurization tower does not produce discharged wastewater, and the desulfurization process of the invention is an energy-saving andconsumption-reducing process that an absorbent is recycled.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

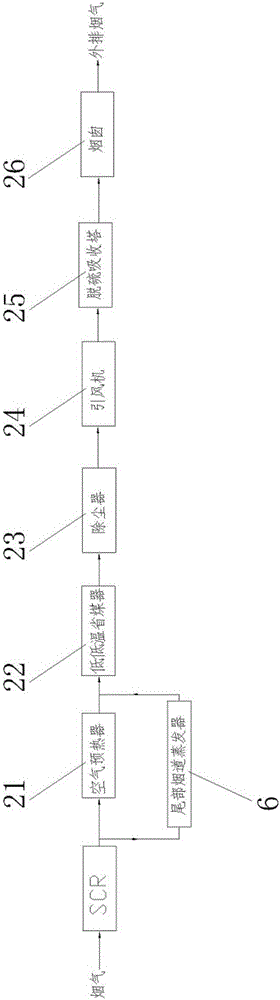

Coal-fired flue gas pollutant ultralow emission system with rotary type GGH

InactiveCN104791820AReduce dosageImprove desulfurization efficiencyLighting and heating apparatusDispersed particle separationFlue gasPollutant emissions

The invention relates to a coal-fired flue gas pollutant ultralow emission system with a rotary type GGH. The system comprises a denitrating reactor, an electrical dust precipitator, a booster fan, a desulfurizing tower, a wet-type electrostatic dust precipitator and a chimney which are connected in sequence, and the system further comprises the rotary type GGH. The rotary type GGH comprises a heat absorption segment of the rotary type GGH and a heat emission segment of the rotary type GGH, wherein the heat absorption segment of the rotary type GGH is arranged between the electrical dust precipitator and the booster fan, and the heat emission segment of the rotary type GGH is arranged between the wet-type electrostatic dust precipitator and the chimney. The heat absorption segment of the rotary type GGH is arranged in front of the booster fan, so that pressure in a purified flue gas side is negative, and by means of the GGH arrangement, the emission concentration of pollutant can be prevented from raising due to the fact that raw flue gas is leaked out to purified flue gas. By treating coal-fired flue gas, the emission concentration of NO[x] is lower than 50 mg / m<3>, the emission concentration of SO[2] is lower than 35 mg / m<3>, the emission concentration of dust is lower than 5 mg / m<3>, and the emission concentration of mercury is lower than 3 micrograms / m<3>.

Owner:ZHEJIANG UNIV

Ferroalloy electric furnace flue gas purifying and dust recovering novel technology and device thereof

InactiveCN103055619AHigh strengthExtended service lifeHuman health protectionDispersed particle filtrationFiltrationAtmospheric air

The invention discloses a ferroalloy electric furnace flue gas purifying and dust recovering novel technology and a device thereof. The technology comprises the steps of storing dust and increasing density of dust after flue gas discharged from an electric furnace is subjected to dedusting and purification dedusting, and discharging the flue gas into atmosphere through a discharging chimney, wherein a large bag-type dust collector which intakes air at the lower part, discharges air from the upper part, has negative pressure, is of inner filtration type and sucks air back from separated chambers for cleaning ash is adopted for purification dedusting; discharging purified flue gas from the top of the large bag-type dust collector, wherein the purified flue gas is discharged from the discharging chimney through an air exhaust reducing tube and a main fan; and meanwhile, carrying out back air suction ash cleaning and pneumatic ash conveying via a front negative pressure back air suction device of the main fan, so that density increasing recovery is carried out on the dust in a density increasing bin for density increasing recovery. The technology device is corresponding to the technology steps. The bag-type dust collector provided by the invention has the characteristics of high intensity and long service life, can lower the motor energy consumption, can prolong the service life of a fan, is simpler in integral structure, and is low in cost.

Owner:ZUNYI CITY GUI KE TECH

Biomass particle boiler with compact arrangement, small capacity and large output

InactiveCN104832903AReduce insulation thicknessComplete heat exchangeLiquid degasificationBoiler controlIntelligent control systemCombustion chamber

The invention relates to a biomass particle boiler with compact arrangement, small capacity and large output. The biomass particle boiler comprises an intelligent control system, a combustion chamber, a combustor, a smoke outlet, a primary fan, a secondary fan, an induced air fan, a deaerator, a heat exchange chamber, a bag type dust remover, a steam and water separator, a steam separating cylinder and a boiler water purifier, wherein the heat exchange chamber adopts a convection pipe bundle to exchange heat; the heat exchange chamber is separated into four areas from top to bottom, and spraying and blowing devices are arranged at the four areas. The biomass particle boiler has the advantages that by adopting the multi-surface surrounding type deaerator, under the condition of guaranteeing the combustion temperature in the boiler, the heat insulation thickness is reduced, and supplied water can be preheated; the combustion chamber is separated from the heat exchange chamber; the combustion chamber is arranged in a folding way, and a secondary air increasing type is adopted, so the complete combustion is guaranteed; the heat exchange chamber is separated into the multiple areas, so the heat exchange is complete on the basis of guaranteeing a clean pipeline, and the temperature of tail exhaust smoke is low; by adopting the bag type dust removal, the smoke flowing to the atmosphere is very clean; by adopting the compact type arrangement, the size of the whole boiler is minimum.

Owner:吴恩珍 +1

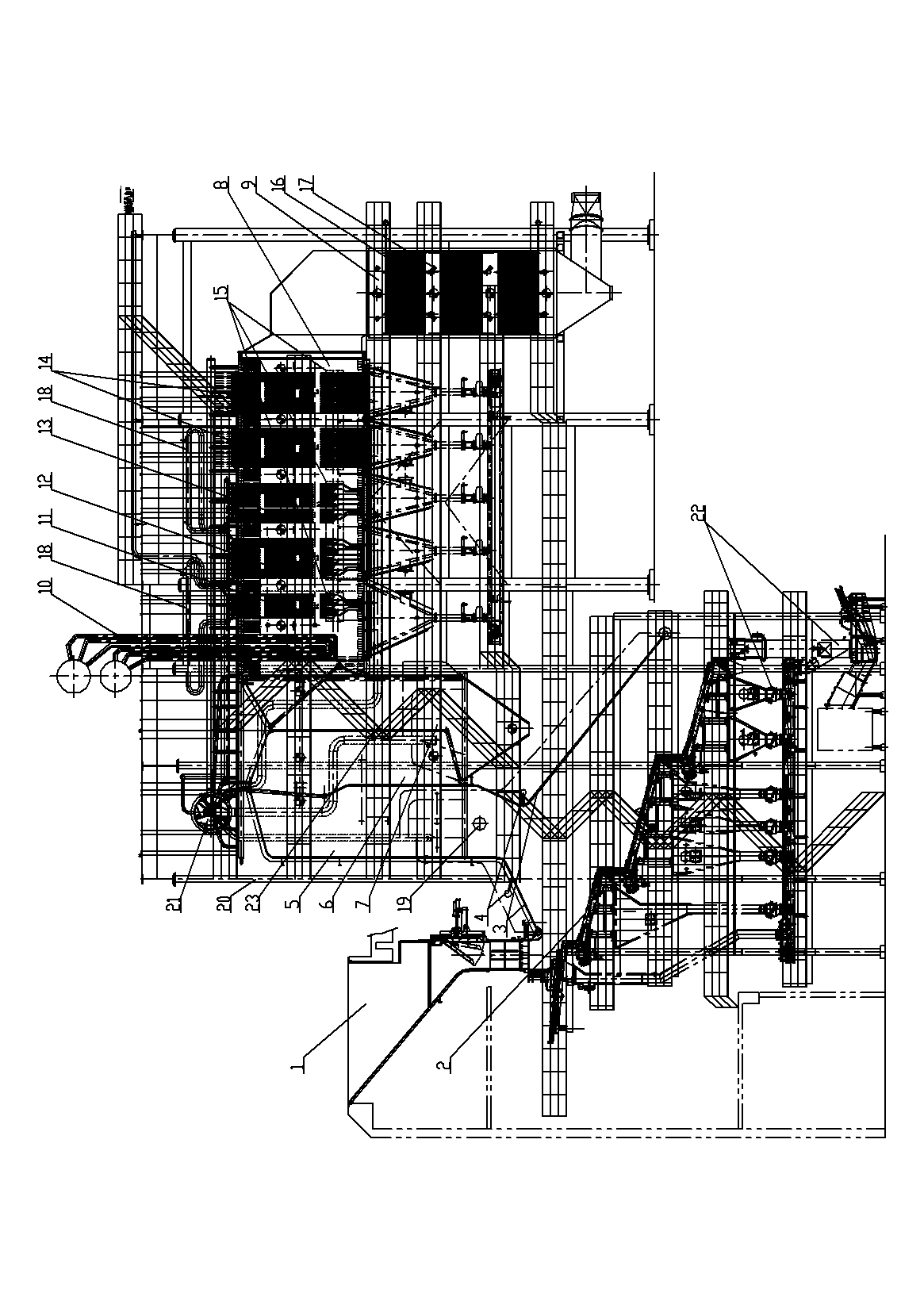

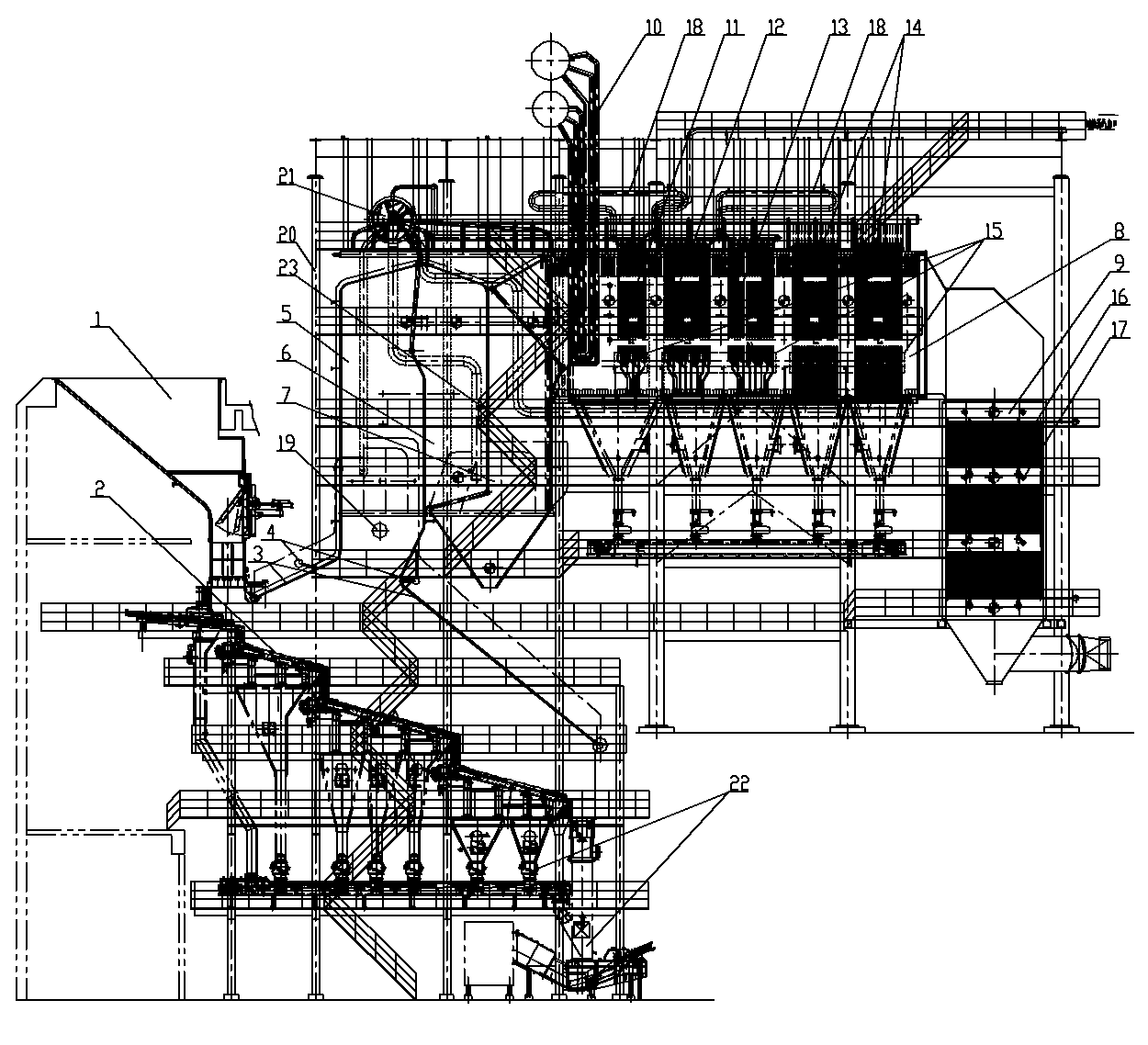

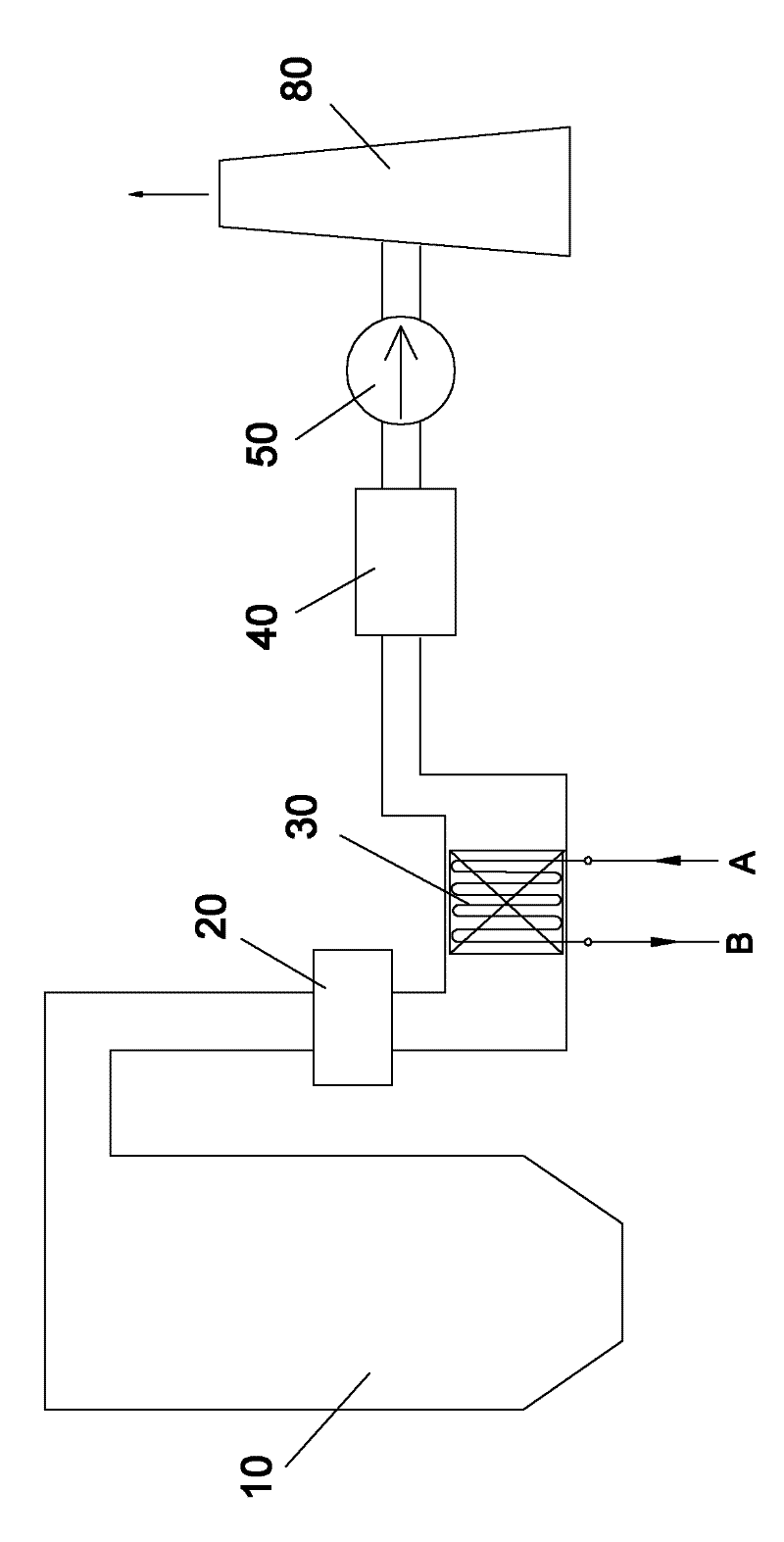

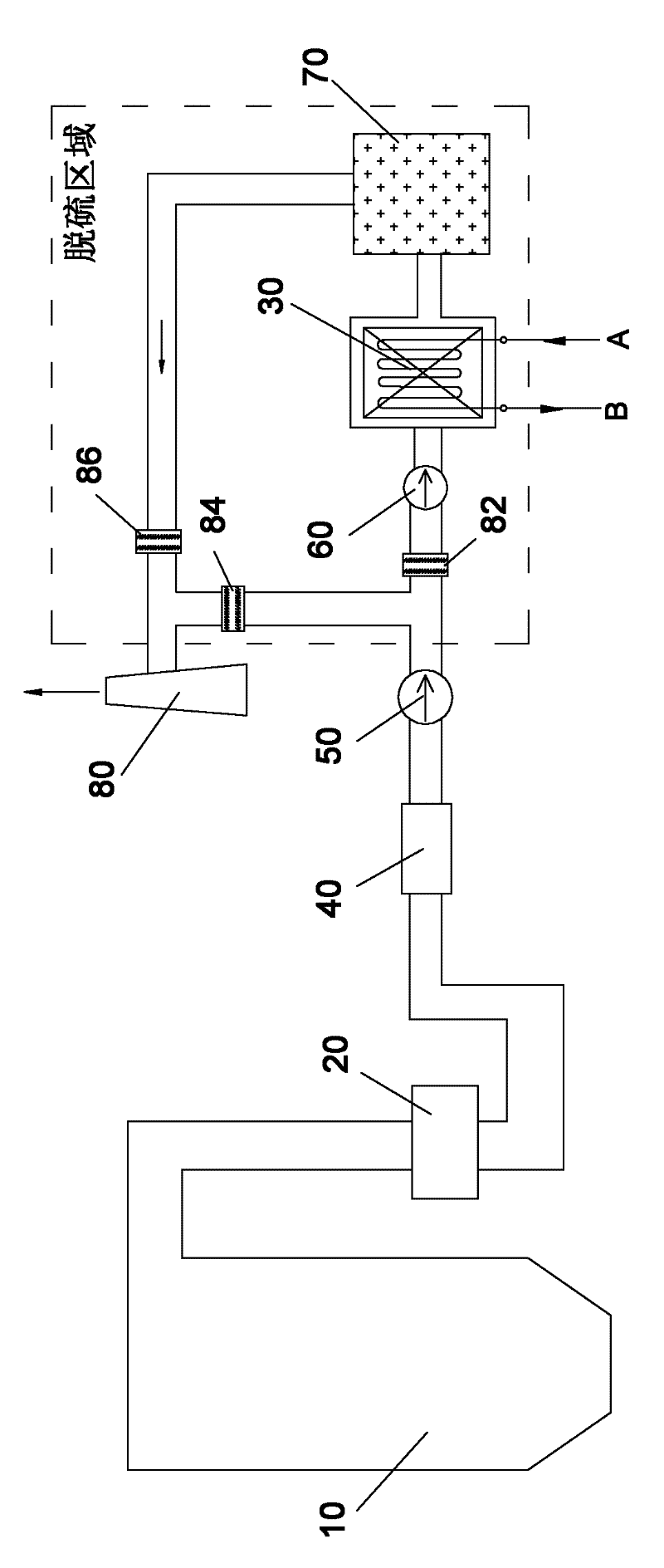

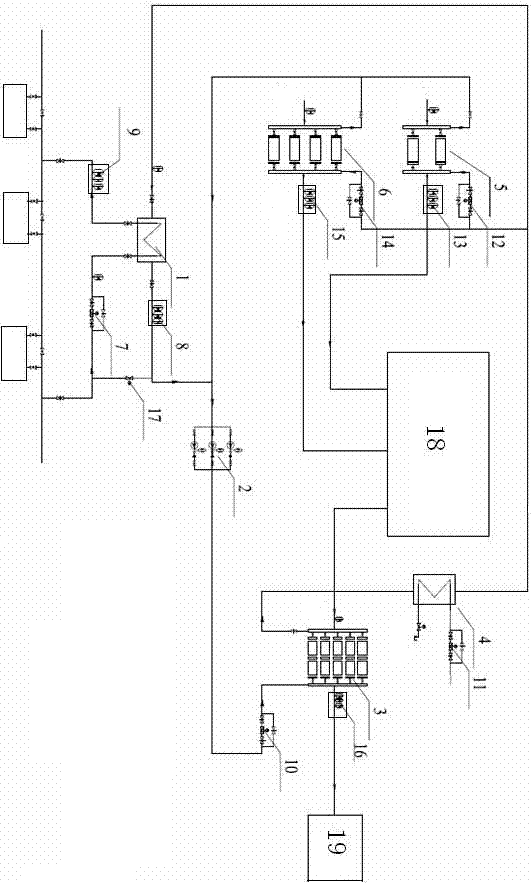

Deep recycling and gradient utilizing system and method for low-temperature flue gas waste heat of coal-fired unit

PendingCN110094750AReduce the temperatureImprove dust removal efficiencyCombustion processSteam useAir preheaterEvaporation

The invention relates to deep recycling and gradient utilizing system and method for low-temperature flue gas waste heat of a coal-fired unit. A first stage is gas-gas heat exchange; cold air is heated by utilizing an outlet flue gas of an air preheater; the flue gas waste heat is recycled, so that the temperature of an inlet flue gas of a deduster is reduced, and the dedusting efficiency is improved; and the inlet flue gas temperature of a desulfurizing tower is reduced, so that the water evaporation amount of the desulfurizing tower is reduced, and the consumption of process water is reduced. A second stage is gas-water heat exchange; hot air in the last stage is utilized for heating condensed water, so that the temperature of the condensed water is improved; and heat enters a steam turbine system, so that the heat consumption of the steam turbine is reduced. A third stage is gas-gas direct heat exchange; one path of the last-stage hot air is sent to a boiler air feeder inlet so as to be mixed with the cold air, so that secondary air is preheated; recycled heat enters a boiler system, so that the gross coal consumption rate is reduced, the boiler efficiency is improved, the cold-end temperature is improved, and the cold end of an air preheater is prevented from being corroded; and the other path of the last-stage hot air is sent to a low-temperature air feeder inlet so as tobe converged with the cold air, so that the cold end of a heat exchanger is prevented from being corroded through the low-temperature environment temperature. The system provided by the invention is simple in structure and reasonable in design, and provides a new idea for flue gas waste heat gradient utilization.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

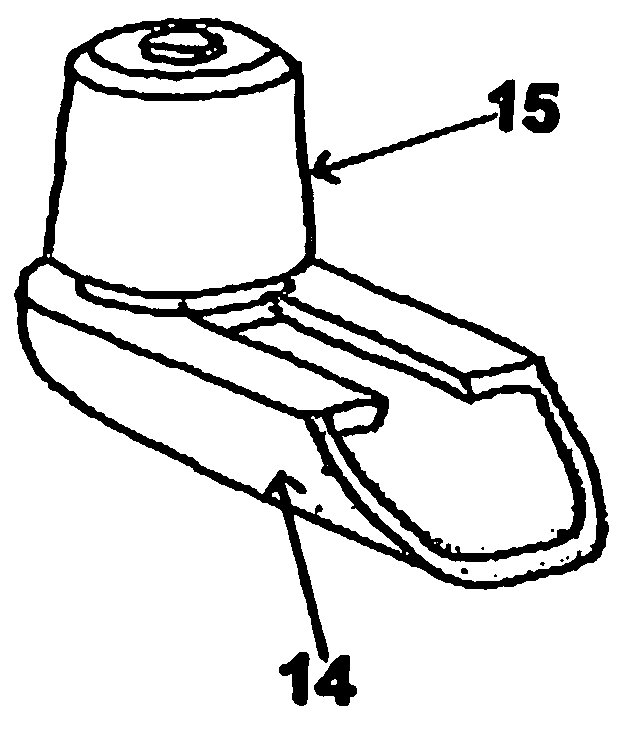

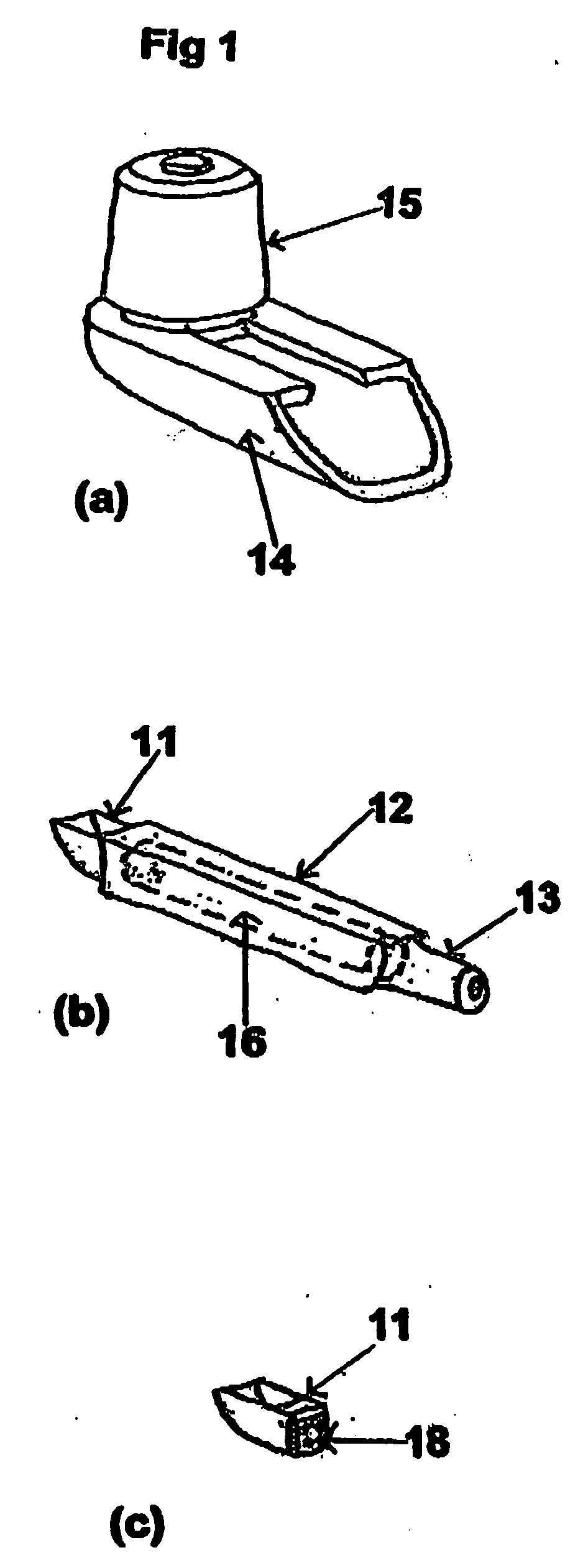

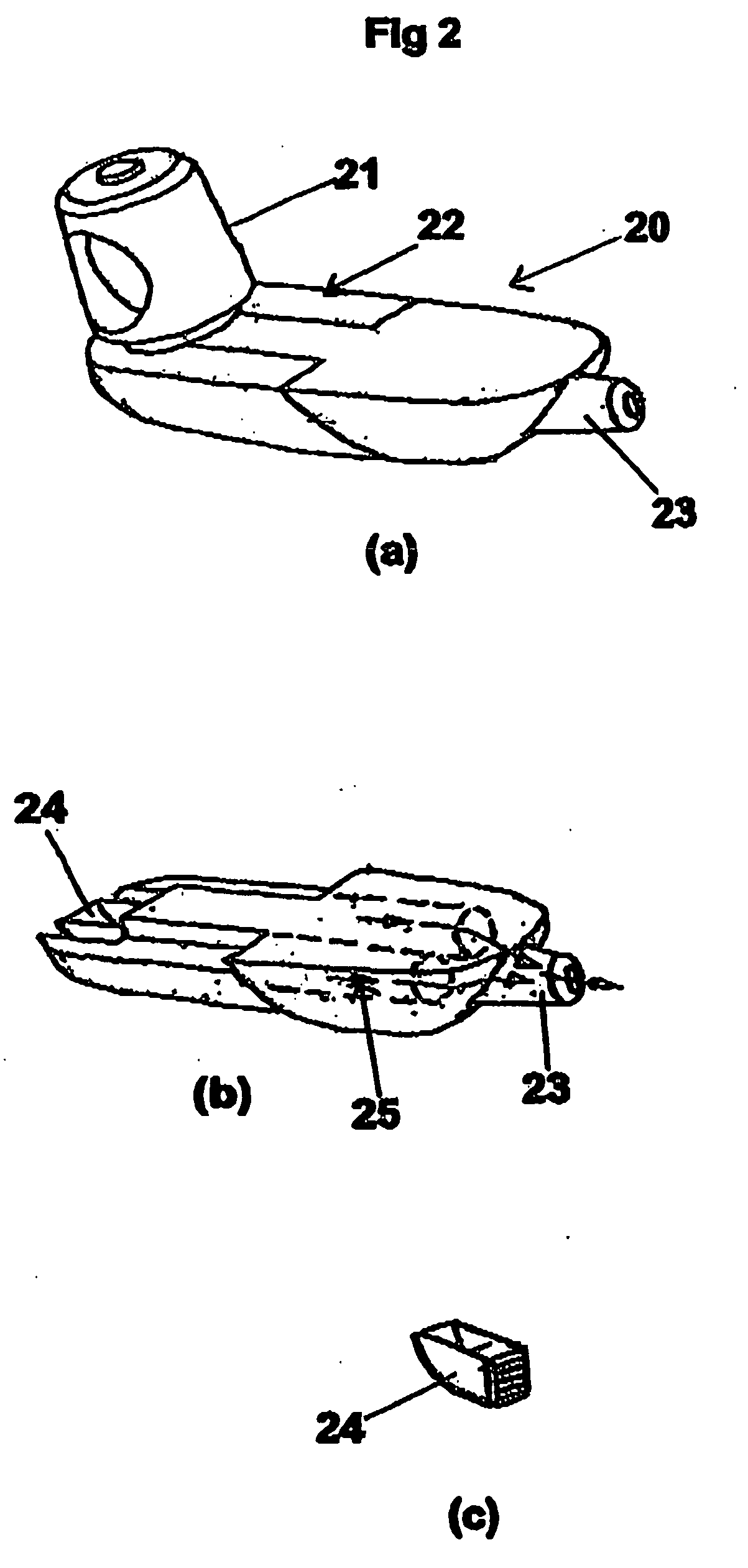

Disposable filter means for smoking

InactiveUS20050217683A1Facilitate heat exchangeLower smoke temperatureTobacco pipesTobacco devicesCombustion chamberEngineering

The present invention is directed to a disposable shank trap for use with a pipe to filter smoke from the burning chamber. The shank trap can include or be associated with other filters to further filter smoke. The advantage of the shank trap is that it can be easily replaced, avoid problems with the cleaning of the pipe, provide efficient filtering of the smoke and efficient usage of the tobacco.

Owner:PIPARETTE

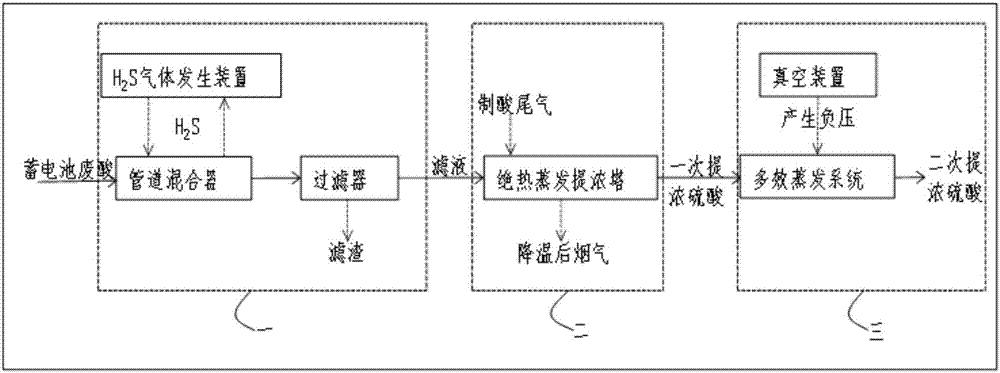

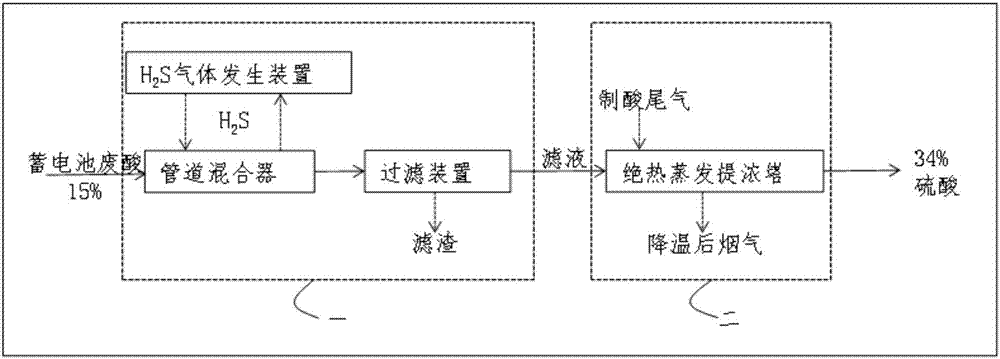

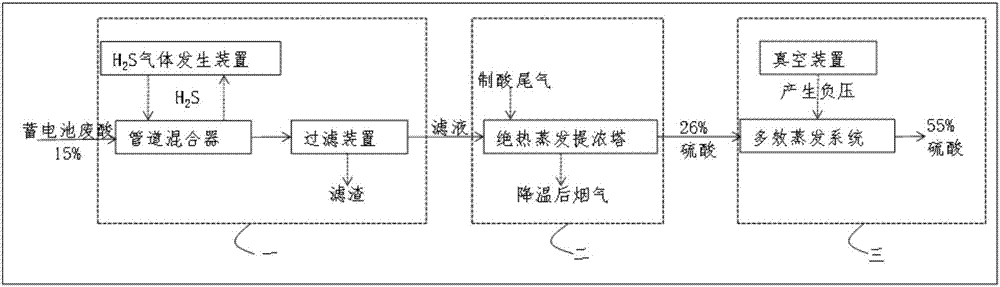

Storage battery waste acid resource treatment method

InactiveCN107162306ALow costReduce energy consumptionWater contaminantsTreatment involving filtrationEvaporationPollution

The invention discloses a storage battery waste acid resource treatment method, which comprises the following steps: (1) a H2S gas is introduced into storage battery waste acid for mixing and purification, and filter residue and filtrate are obtained by solid-liquid separation after completion of the purification; and (2) the filtrate is introduced into an adiabatic evaporation concentration tower for full contact of the filtrate and high-temperature flue gas to obtain firstly-concentrated sulfuric acid. The storage battery waste acid resource treatment method has the advantages of low energy consumption, high economic efficiency of the recycled product and realization of low cost storage battery waste acid recycling, and the recycled storage battery waste acid can meet storage battery acid standards. The storage battery waste acid resource treatment method fully utilizes high temperature acid production tail gas as a heat source in an adiabatic evaporation process, greatly reduces the energy consumption and cost, at the same time, the acid production tail gas has no change in other states except humidity increase and smoke temperature decrease, the acid production tail gas can be directly discharged, and no additional pollution is brought to the environment.

Owner:湖南求是检测科技有限公司

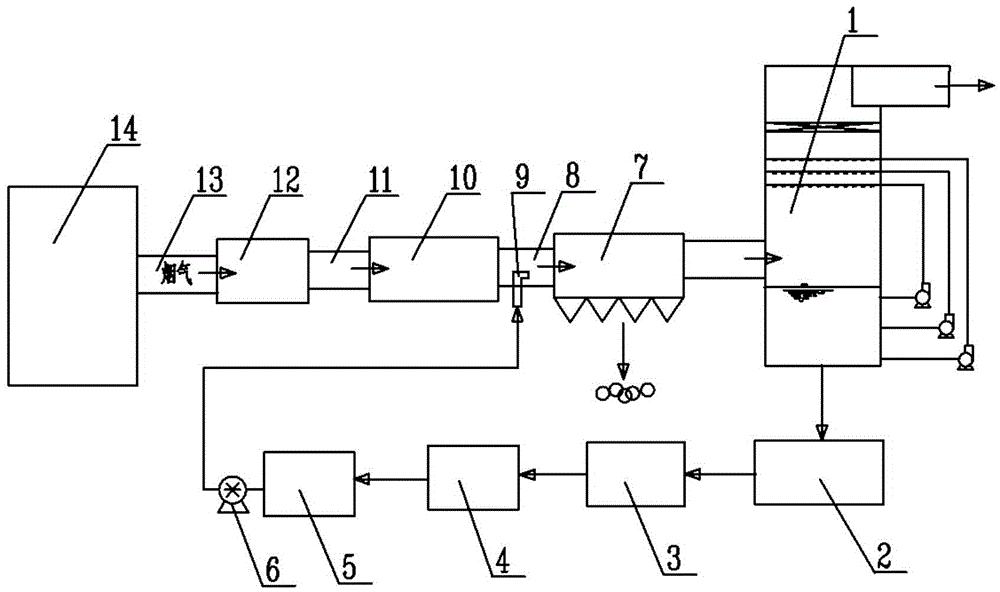

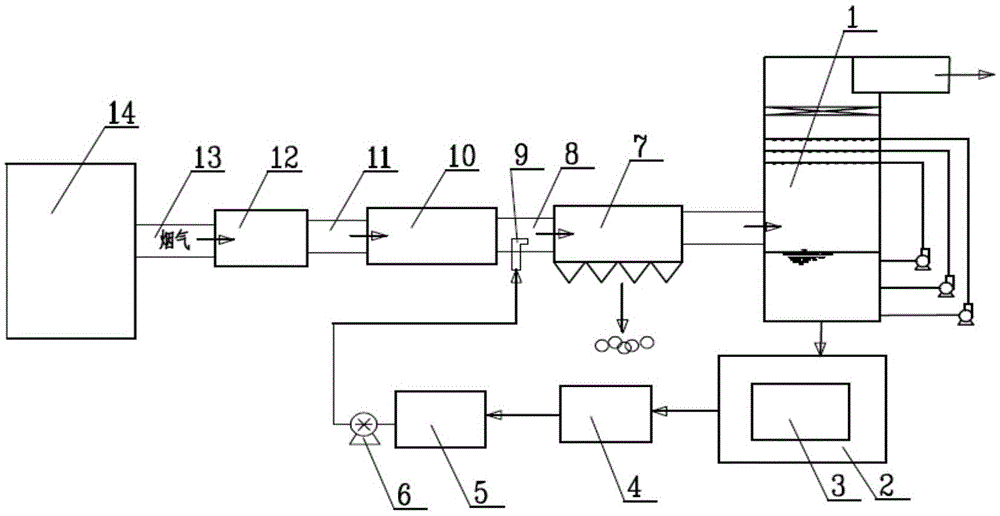

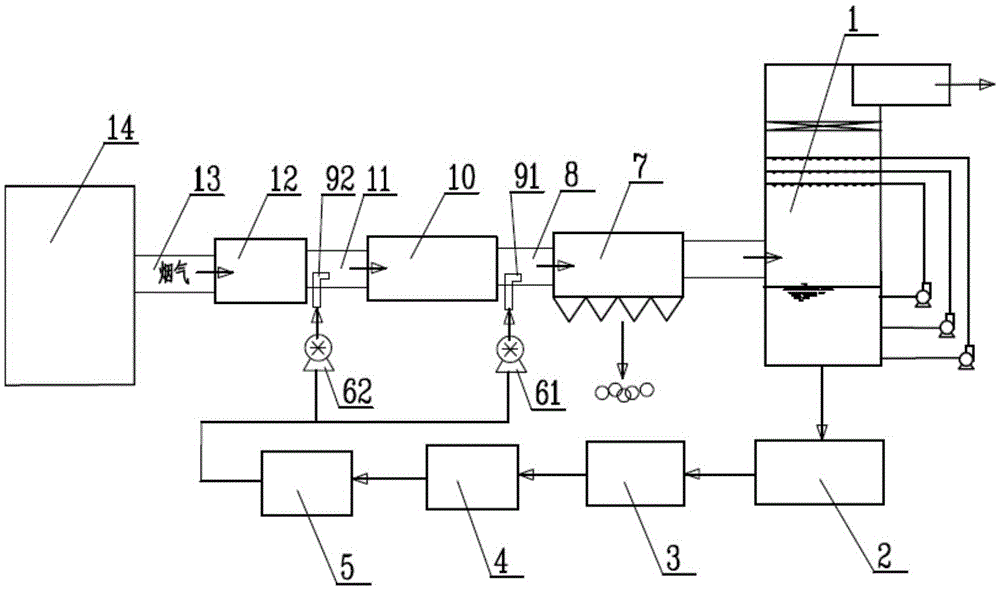

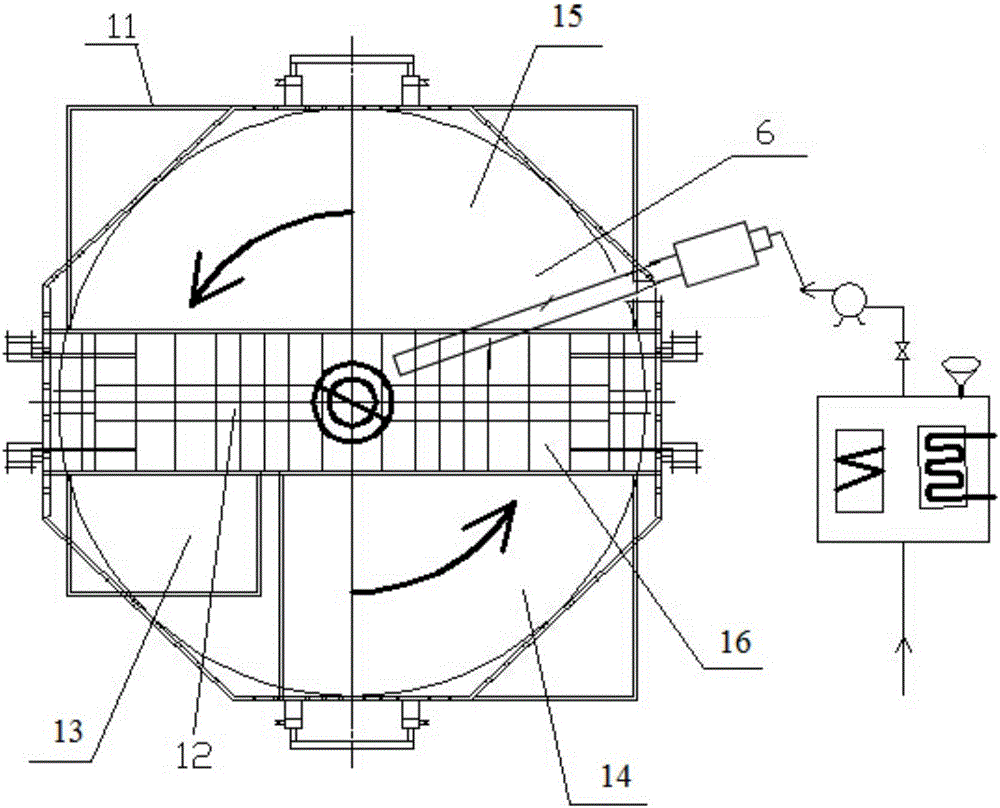

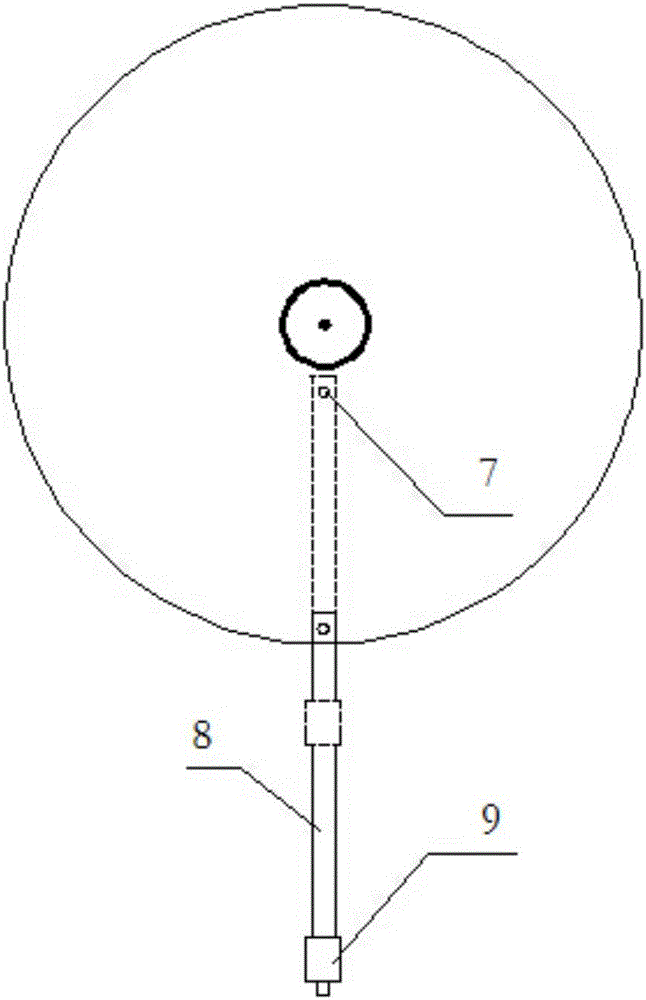

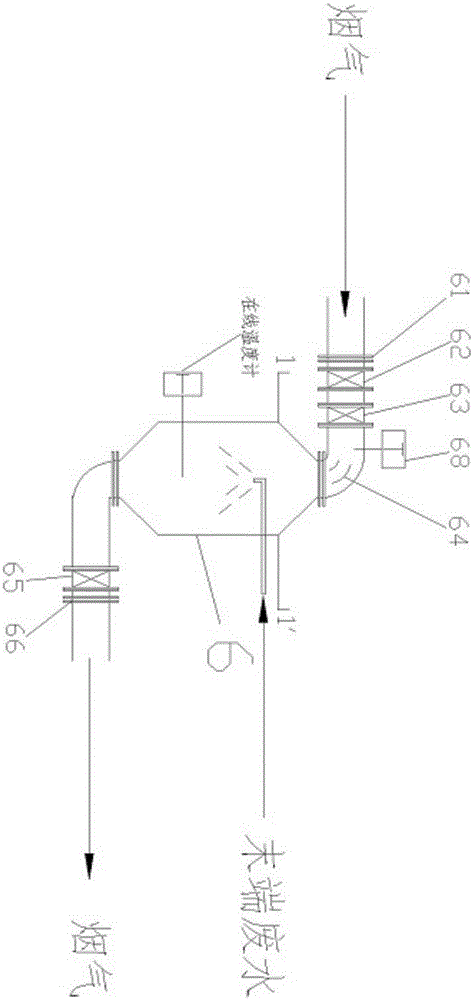

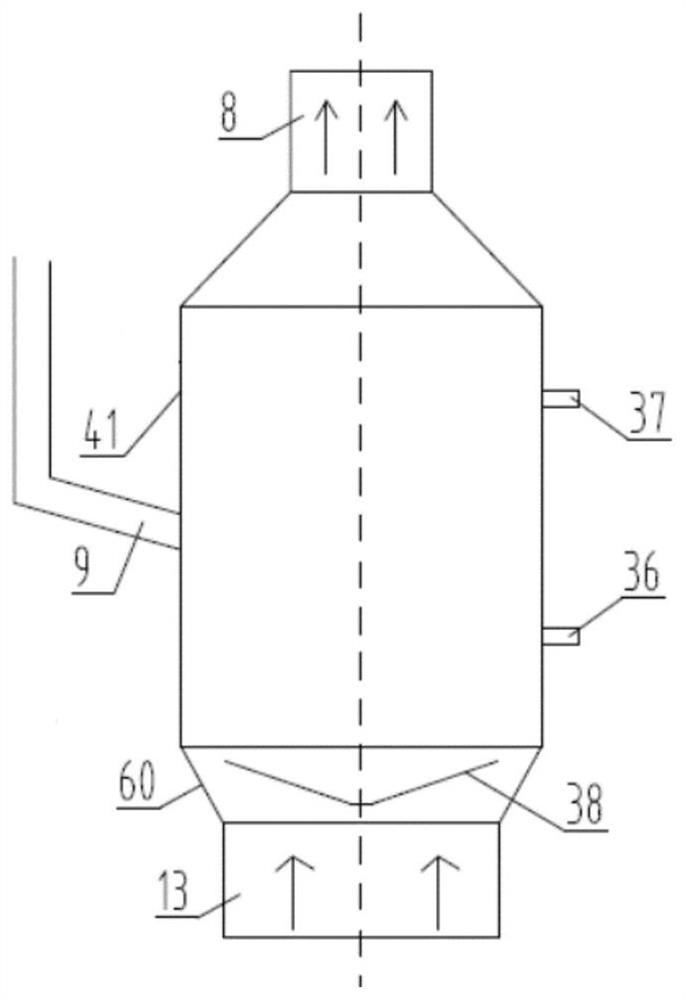

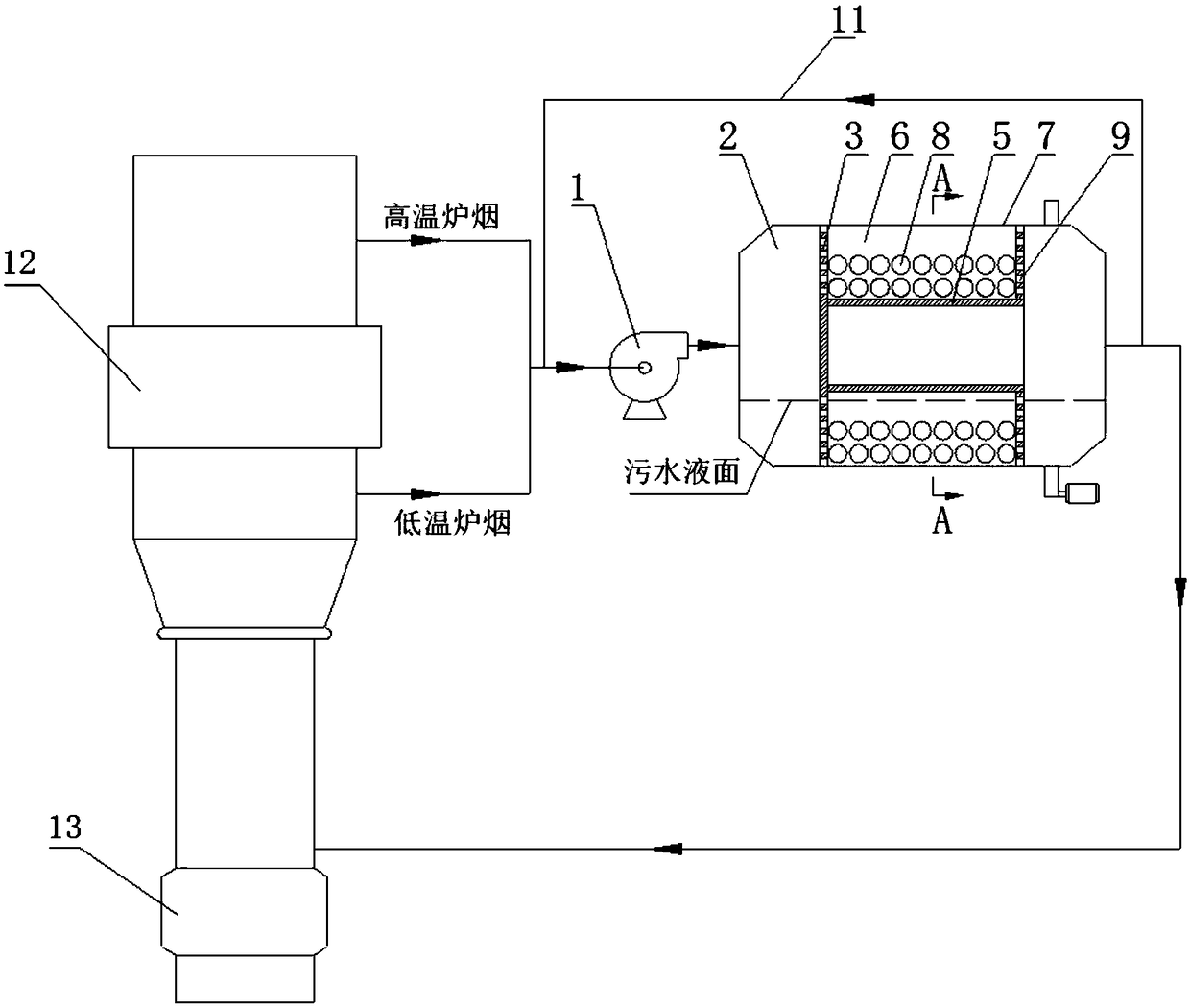

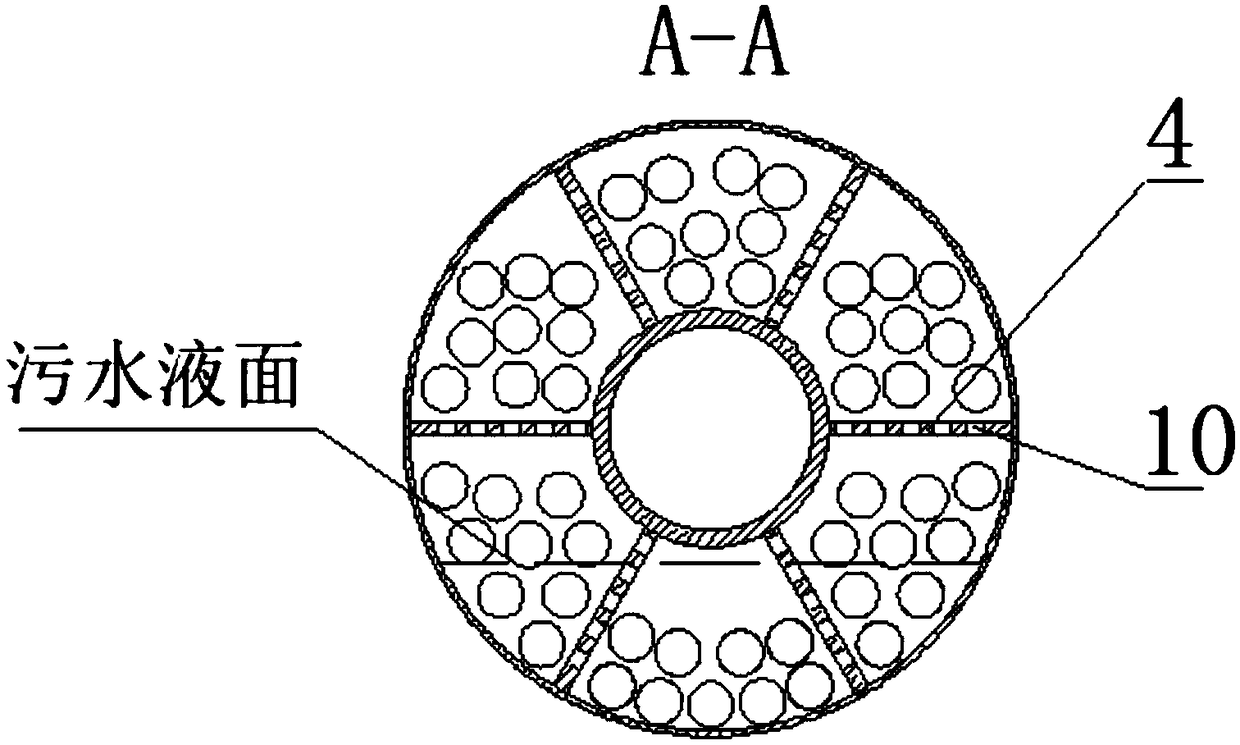

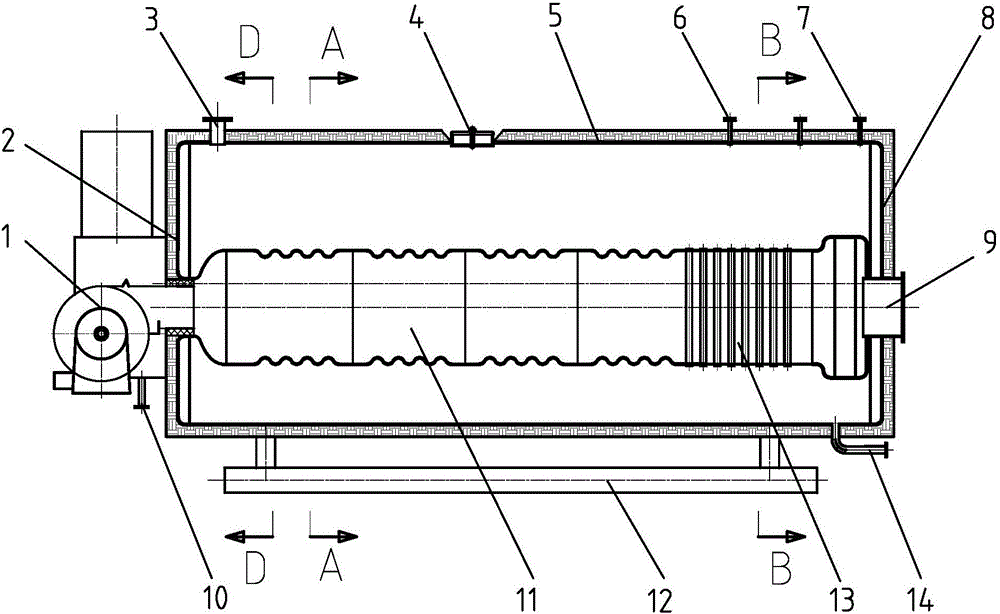

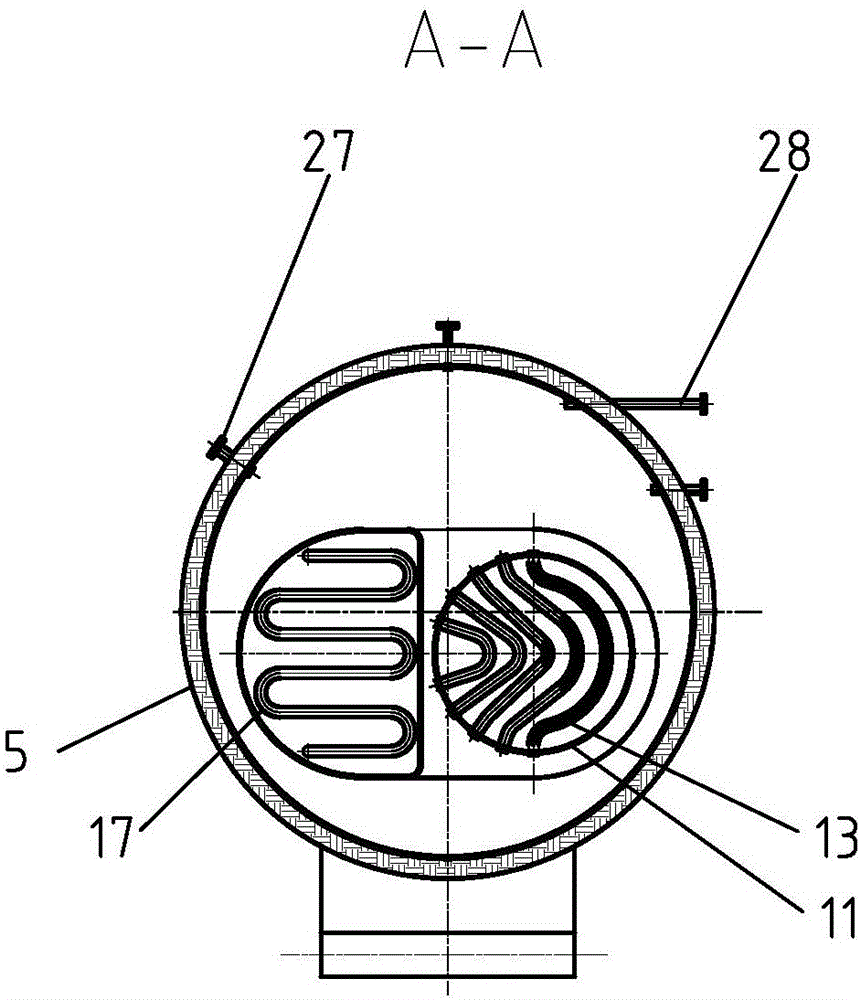

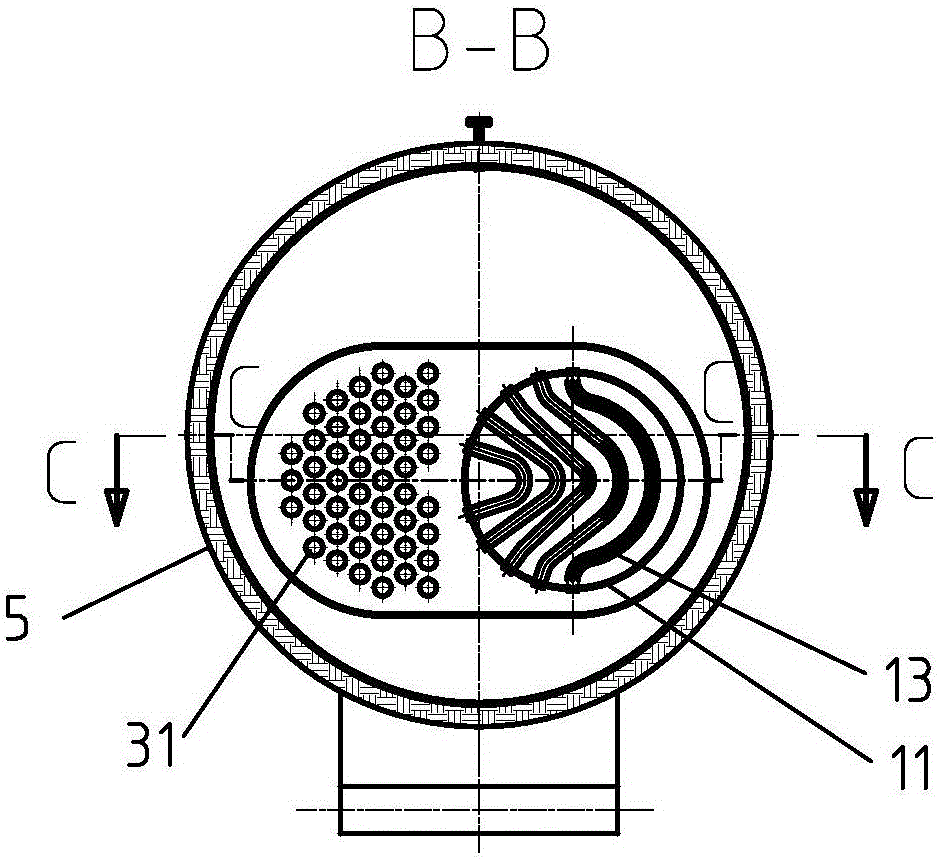

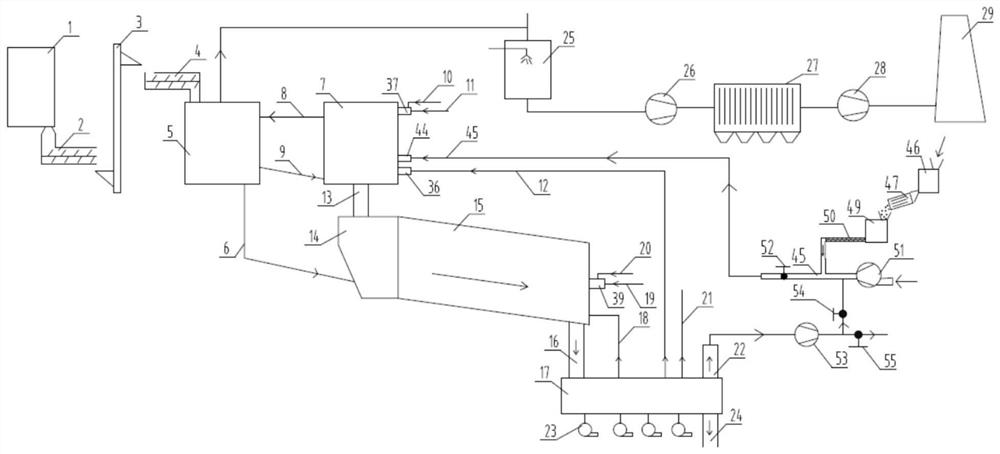

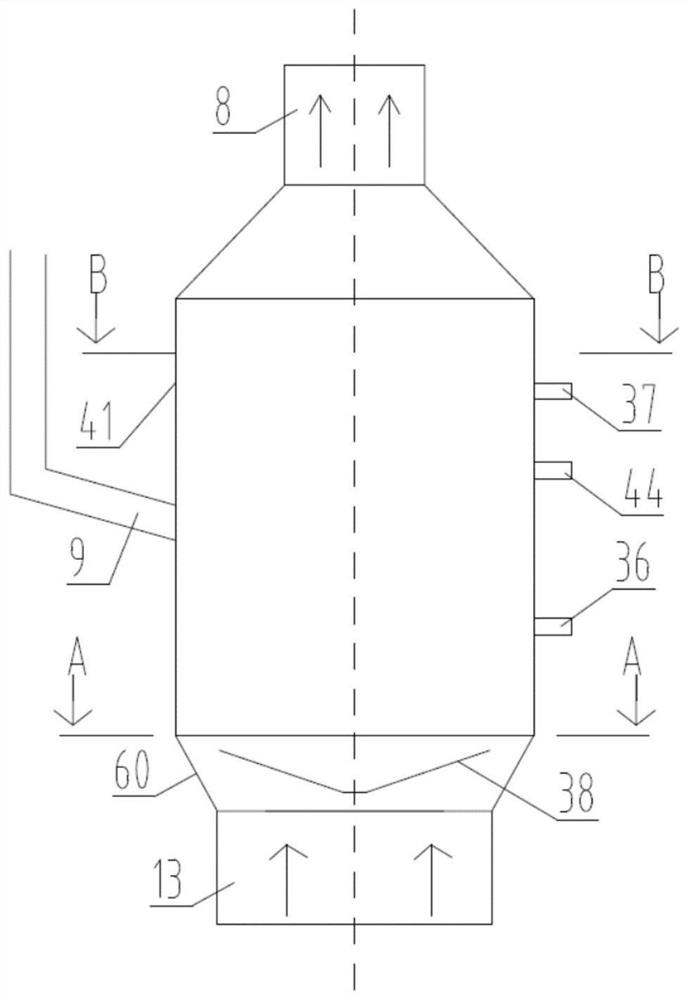

Device and method for treating waste water of power plant with flue gas

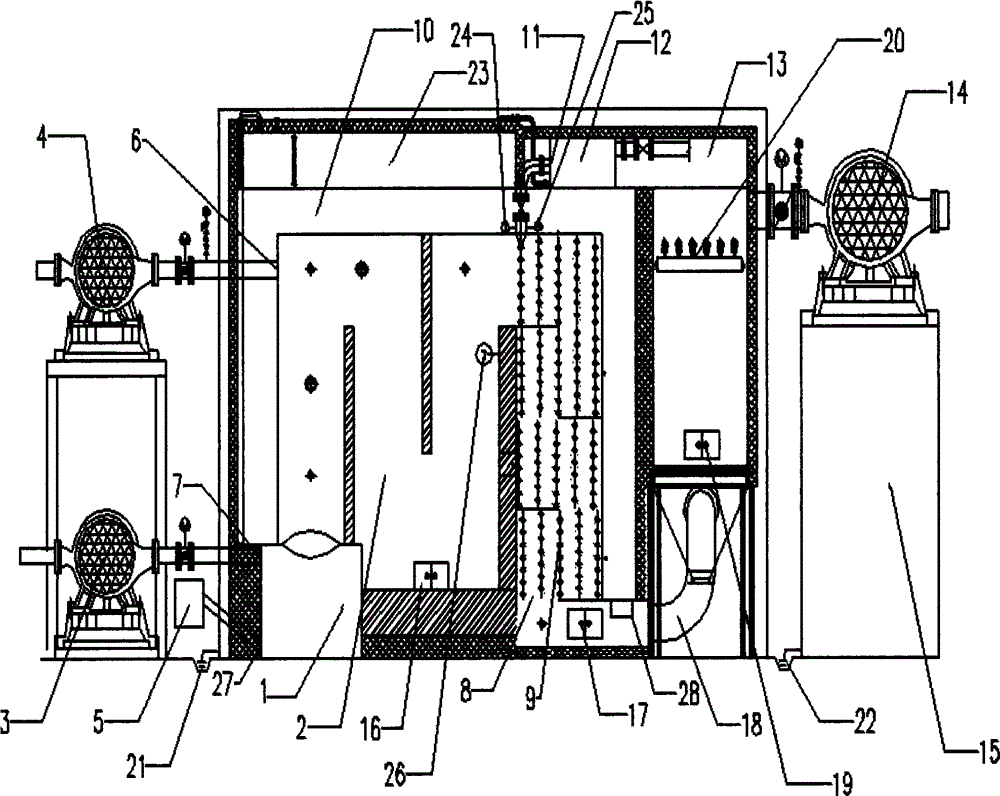

ActiveCN109467152AImprove evaporation efficiencyReduced impact on unit efficiencySpecific water treatment objectivesWater/sewage treatmentFlue gasWastewater

The invention relates to the technical field of treatment of waste water of power plants and specifically relates to a device and method for treating waste water of a power plant with flue gas. The device comprises a rotary waste water treatment device, wherein the rotary waste water treatment device comprises a rotary device shell and a rotary driving device arranged outside the rotary device shell; the rotary device shell is in a hollow cylindrical shape, a flue gas inlet is formed in one end of the rotary device shell, a flue gas outlet is formed in the other end of the rotary device shell,and an annular cavity body is coaxially arranged inside the rotary device shell; the flue gas inlet is connected to an inlet flue of an air pre-heater and an outlet flue of the air pre-heater by fluegas fans respectively and is used for leading mixed flue gas of high temperature flue gas and low temperature gas; the flue gas outlet is connected to an inlet flue of a dust remover; the cavity bodyis divided into a plurality of cavities in the circumferential direction; a steel ball is arranged in each of the cavities; every two adjacent cavities communicate with each other; two ends of each of the cavities respectively communicate with the inside of the rotary device shell; and the waste water of the power plant is contained in the rotary device shell. The device provided by the inventionis small in energy consumption, low in operating cost, high in continuous and safe operating performance and wide in range of application.

Owner:XIAN THERMAL POWER RES INST CO LTD

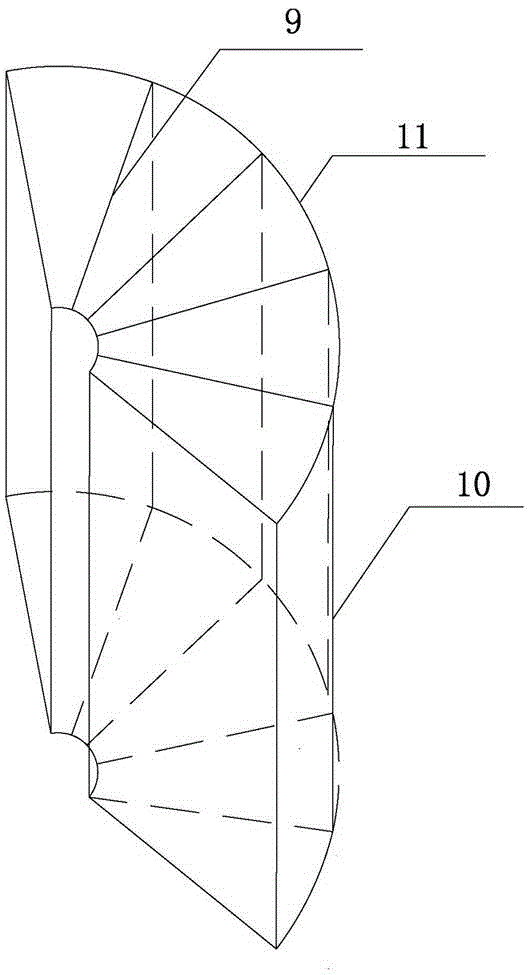

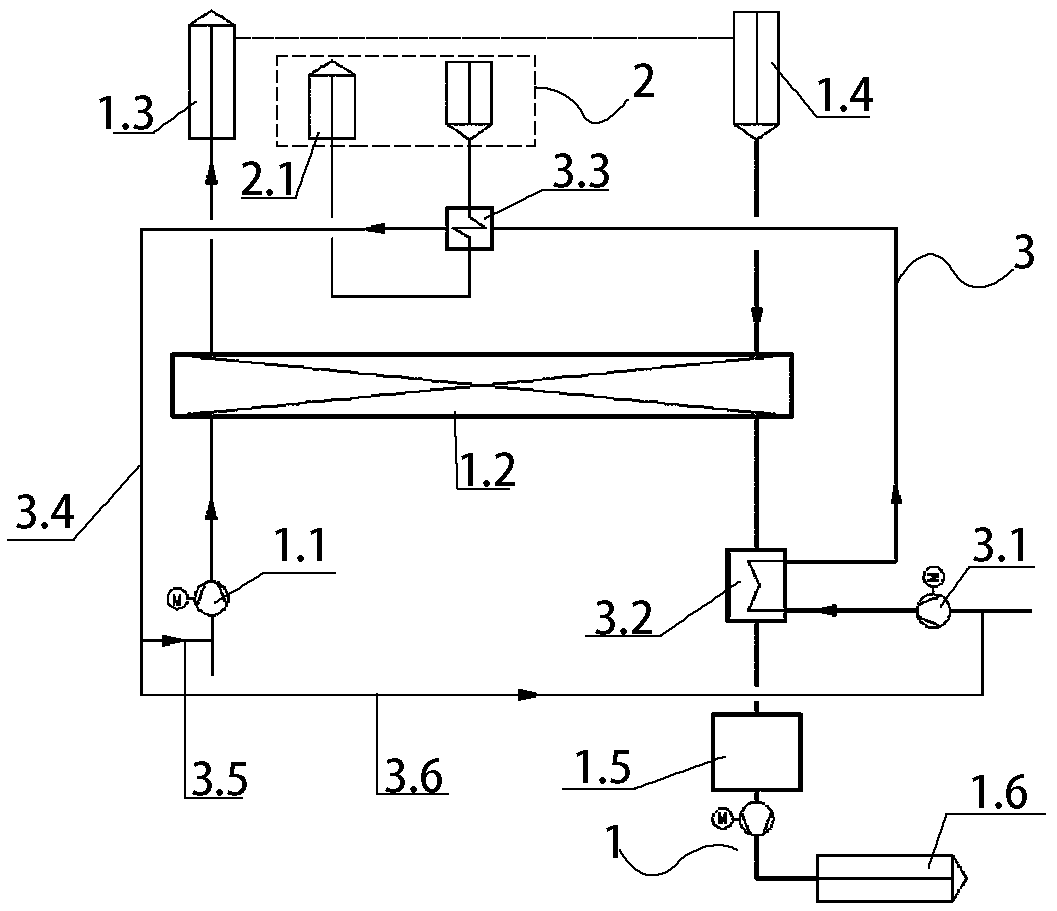

Apparatus for concentrating ammonium sulfate slurry by using flue gas enthalpy

InactiveCN106938146ALower smoke temperatureSmoke volume reductionEvaporator accessoriesAmmonium sulfatesAmmonium sulfateFlue gas

The invention provides a device for concentrating ammonium sulfate slurry by using the heat enthalpy of flue gas, which includes a tubular heat exchanger (4) connected to the flue of the desulfurization tower, and the bottom of the tube side of the tubular heat exchanger (4) is arranged There is an ammonium sulfate slurry inlet (5), and the top of the tube side of the tubular heat exchanger (4) is provided with an ammonium sulfate steam outlet (6), and the ammonium sulfate steam outlet (6) is connected to the buffer tank (7) The ammonium sulfate steam inlet (8) on the top is connected, and the bottom of the buffer tank (7) is connected with a return pipe (9) for exporting the ammonium sulfate-containing slurry, and the return pipe (9) extends into the crystallization circulation tank (10) At the bottom, a funnel-shaped crystallization tank ring plate (11) is connected to the inner wall of the crystallization circulation tank (10), and the return pipe (9) passes through the crystallization tank ring plate (11). The invention utilizes the heat enthalpy of flue gas to evaporate and concentrate the ammonium sulfate solution, and can produce high-quality ammonium sulfate products without direct gas-liquid contact.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

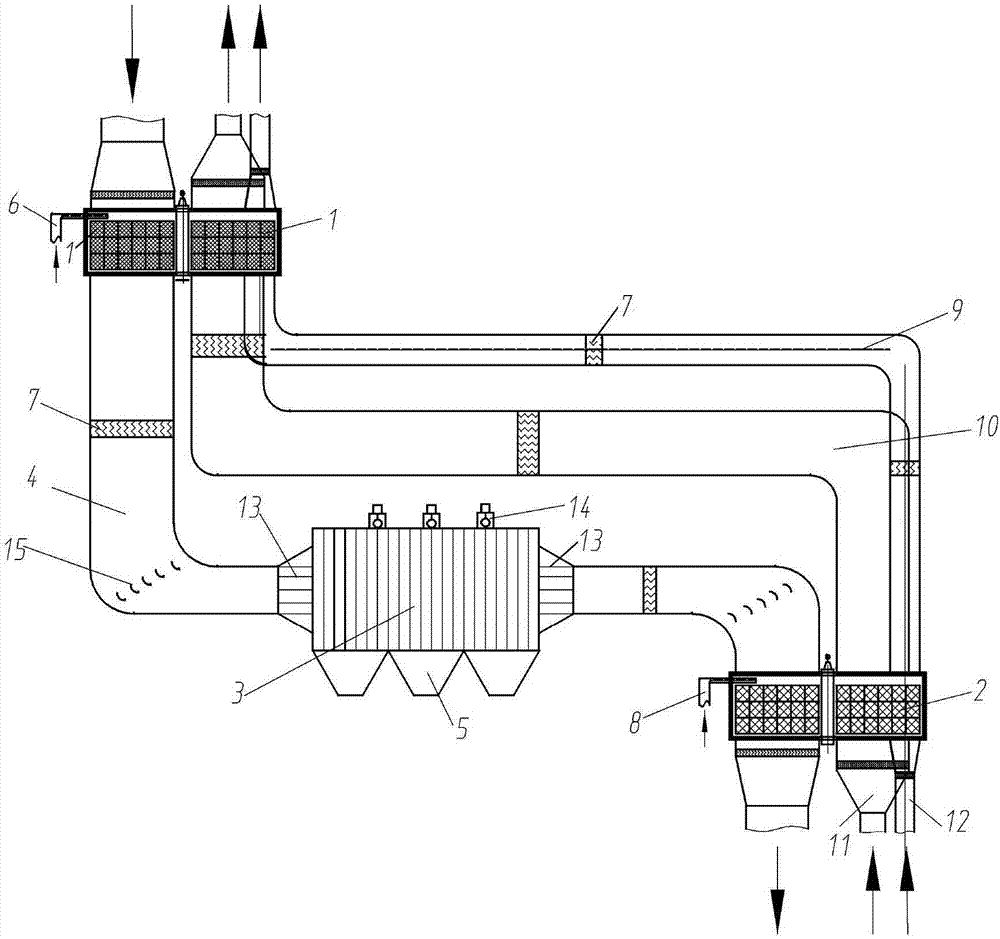

Anti-blocking segmented arrangement system for air pre-heaters

PendingCN106996577AImprove the operating environmentSolve the problem of cloggingCombustion processIndirect carbon-dioxide mitigationFlueElectrostatic precipitator

An anti-blocking segmented arrangement system for air pre-heaters comprises a high-temperature air pre-heater arranged behind a selective catalytic reduction (SCR) denitration device of a flue at the tail of a boiler; flue gas at the outlet of the high-temperature air pre-heater enters a high-temperature electrostatic precipitator through a flue; flue at the outlet of the high-temperature electrostatic precipitator enters a low-temperature air pre-heater through the flue for heat exchange; cold primary air enters the low-temperature air pre-heater through a cold primary air duct; supplied air enters the low-temperature air pre-heater through an air supply pipe; and the cold primary air and the supplied air absorb flue gas heat in the low-temperature air pre-heater and then enter a primary air side inlet and a supplied air side inlet of the high-temperature air pre-heater through an intermediate-temperate primary air pipeline and an intermediate-temperate air supply pipeline respectively. With the system, the problem of clogging of the air pre-heaters can be solved fundamentally, so that the temperature of the discharged flue gas can be effectively reduced, the temperature of the primary air and the temperature of secondary air can be increased, and the heat efficiency of the boiler can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

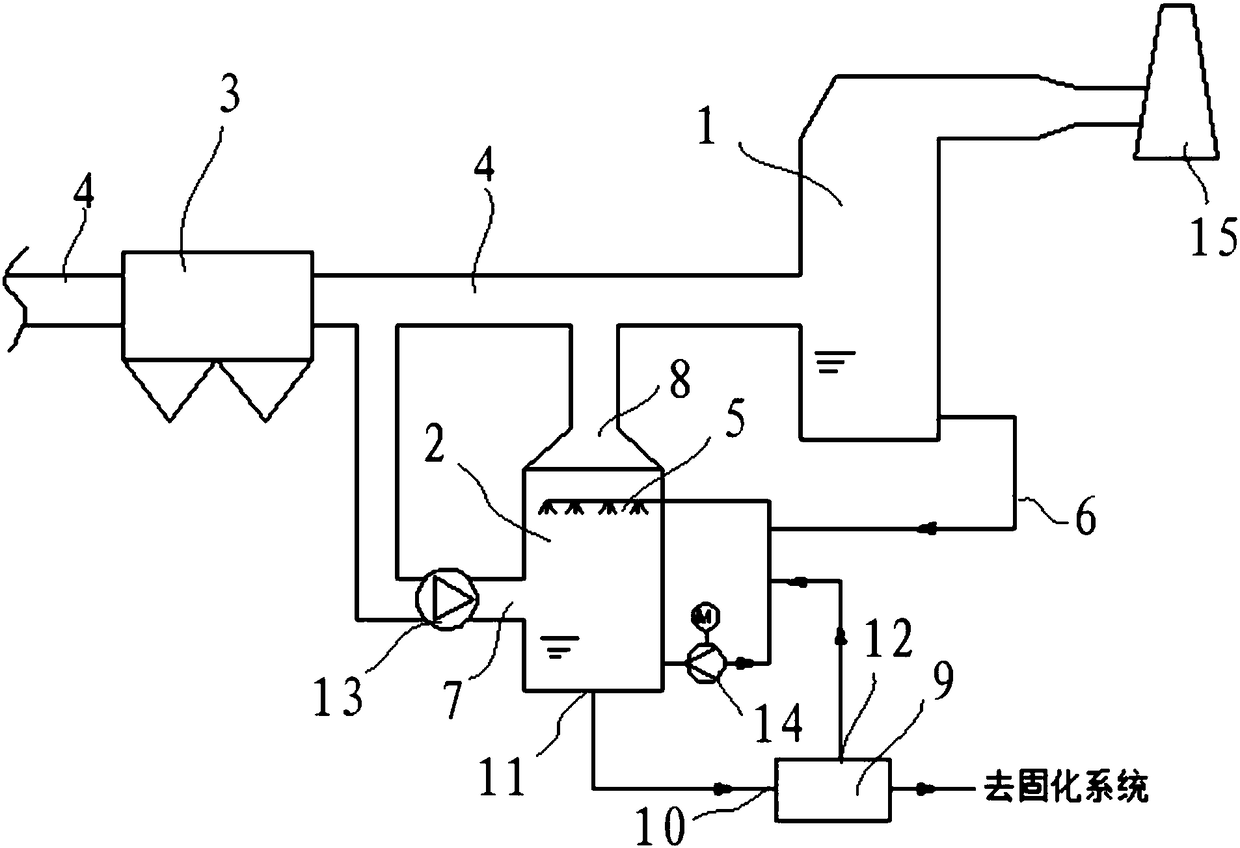

Desulphurization waste water processing system

InactiveCN108275744ALess investmentSimple processCombination devicesGas treatmentEvaporationWater processing

The invention discloses a desulphurization waste water processing system. The desulphurization waste water processing system comprises a coal fired boiler, a static dust collector, a desulphurizationdevice, and a concentration tower; the coal fired boiler, the static dust collector, and the desulphurization device are connected successively though a flue gas pipeline; nozzles are arranged in theconcentration tower; the nozzles are connected with the desulphurization device through a desulphurization waste water pipeline; the concentration tower is provided with a flue gas inlet and a flue gas outlet; the flue gas inlet is communicated with a flue gas outlet on the static dust collector, and the flue gas outlet is communicated with the flue gas pipeline on the desulphurization device. Inapplications of the desulphurization waste water processing system, direct contact heat exchanged between flue gas waste heat and high salt-containing waste water (desulphurization waste water) is adopted, so that consumption of other heat resources is not needed, the technology is simple, equipment is less, occupied space area is small, maintenance amount is small, no additive is added, treatmentcost of each ton of water is about 20 yuan; evaporation flue gas of the concentration tower is introduced into the flue gas pipeline of the desulphurization device through the flue gas outlet, the desulphurization device inlet smoke temperature is reduced, and energy utilization rate is high.

Owner:广州市瀚碧环保工程技术有限责任公司

Water-fire tube gas-steam boiler with built-in condenser

InactiveCN106500318ASmall diameterCompact structureAir heatersSustainable buildingsBoiler furnaceCombustor

The invention provides a water-fire tube gas-steam boiler with a built-in condenser, and relates to a gas-steam boiler. An existing smoke-fire tube steam boiler has the problems that the structure occupies large floor area, potential safety hazards exist in the operation process, and steel consumption is high in the using process. The water-fire tube gas-steam boiler comprises a combustor, a steam tube base, a shell, a boiler furnace, a smoke tube assembly, a backdraft chamber, a condensation chamber and a smoke box; the boiler furnace, the smoke tube assembly, the backdraft chamber and the condensation chamber are all arranged in the shell, the combustor is arranged outside the shell and communicates with an inlet of the boiler furnace, an outlet of the boiler furnace communicates with an inlet of the backdraft chamber, an outlet of the backdraft chamber communicates with an inlet of the smoke tube assembly, an outlet of the smoke tube assembly communicates with an inlet of the condensation chamber, the smoke box is arranged outside the shell and communicates with an outlet of the condensation chamber, a smoke outlet is formed in the smoke box, multiple convection banks are arranged in the boiler furnace, condensation tube bundles are arranged in the condensation chamber, and the shell communicates with the steam pipe tube base. The water-fire tube gas-steam boiler is used for generating steam.

Owner:HARBIN INST OF TECH

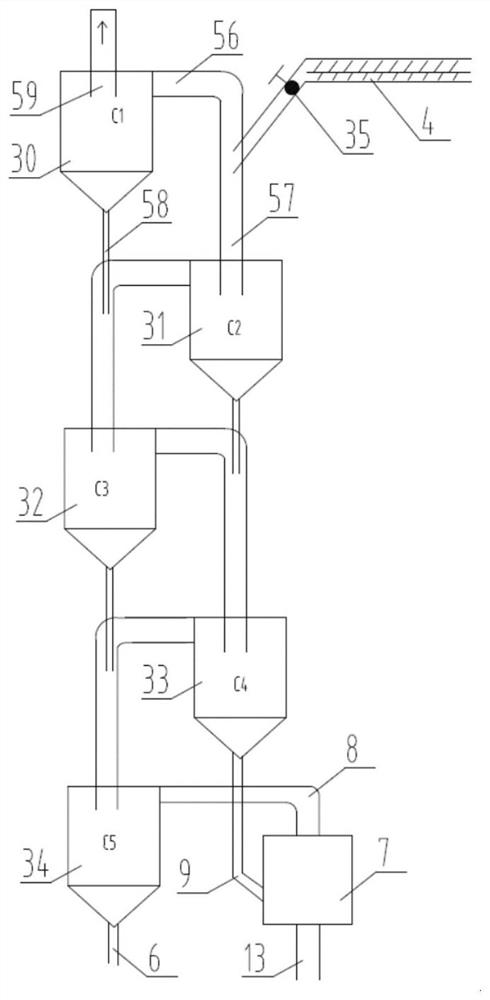

Cement rotary kiln system for disposing waste fan blades and working method of cement rotary kiln system

PendingCN113294784ALarge amount of processingEfficient use ofRotary drum furnacesCement productionFan bladeTreatment system

The invention discloses a cement rotary kiln system for disposing waste fan blades and a working method of the cement rotary kiln system, and belongs to the technical field of resource recovery. The cement rotary kiln system comprises a blade breaking and crushing system, a raw material feeding system, a flue gas treatment system, a suspension preheater, a decomposing furnace, a rotary kiln, a clinker cooling device and a blade particle pneumatic conveying system. Crushed fan blade particles are pneumatically conveyed into the decomposing furnace for pyrolysis and combustion, and a cyclone is arranged at the bottom of the decomposing furnace; heat released by combustion of an organic composite material and heat released by combustion of pulverized coal are used for preheating and decomposing raw materials together; and glass fibers in the blade particles also participate in forming the raw materials, and the glass fibers and the raw materials enter the rotary kiln together for firing clinker. The waste fan blades are effectively and comprehensively utilized, and combustion products are normally discharged together with coal-fired flue gas after being disposed by the flue gas treatment device arranged on the cement rotary kiln system. According to the cement rotary kiln system, harmless and resource treatment of the waste fan blades can be smoothly realized, and good environmental protection benefits and economic benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

Step recycling method and device of boiler flue gas waste heat

InactiveCN102191959AEfficient use ofAvoid blockingEnergy industrySteam engine plantsProcess engineeringFlue gas

The invention discloses a step recycling method of boiler flue gas waste heat. The method is used for a steam turbine generator unit, and comprises temperature rise generated by multistage heat exchange and work of parts in a flue gas passage in an energy step reclamation mode. The invention also discloses a boiler flue gas waste heat recycling device for implementing the method. The device comprises multistage heat exchangers, wherein the flue gas sides of the heat exchangers are arranged at different positions in the flue gas passage, and the water sides of the heat exchangers are connected with a low-pressure water supply system of the steam turbine generator unit. According to the method and the device, work energy of equipment such as a draught fan, a booster fan and the like in a flue gas system can be optimally utilized and absorbed, the arrangement is more flexible, and the conventional equipment and the conventional system are affected and changed little.

Owner:冯伟忠

Double-circulation heating system and double-circulation heating method for low-low temperature economizer

InactiveCN107023819AOvercome deficienciesLower smoke temperatureWater feed controlFeed-water heatersEngineeringEconomizer

The invention provides a double-circulation heating system for a low-low temperature economizer, and belongs to the technical field of energy saving. The double-circulation heating system for the low-low temperature economizer comprises an intake furnace air heating system and is characterized in that the double-circulation heating system further comprises a condensed water heating system, the intake furnace air heating system and the condensed water heating system are connected to the low-low temperature economizer through a booster pump and a water quantity regulation valve. According to the double-circulation heating system for the low-low temperature economizer, the air supply temperature of a boiler is increased and the condensed water system is heated while the smoke temperature at an electric precipitation inlet can be decreased, and the purposes of safety, stability and multi-application of waste heat are achieved.

Owner:山西中源科扬节能服务有限公司

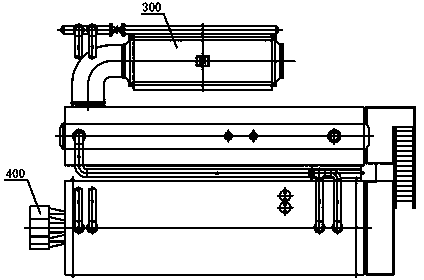

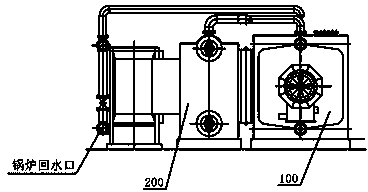

Large-module assembled high-efficiency condensing gas-fired hot water boiler

ActiveCN103363663ARealize micro positive pressure combustionImprove thermal efficiencyEnergy efficient heating/coolingAir heatersEngineeringEconomizer

The invention relates to a large-module assembled high-efficiency condensing gas-fired hot water boiler, which is characterized in that the boiler is divided into a hearth zone (100), a convection heating surface (200) and an economizer (300), the hearth zone (100) is arranged on the right side of the convection heating surface, the economizer (300) is arranged on the left side of the convection heating surface, the overall structure of the convection heating surface (200) is a dual-drum longitudinally-arranged D-shaped arrangement structure and comprises an upper drum (201), a lower drum (202), a convection tube bundle (203) and a convection heating surface full-membrane wall, and the convection tube bundle (203) is arranged between the upper drum (201) and the lower drum (202); the hearth zone (100) comprises a hearth zone upper header (101), a hearth zone lower header (102) and a hearth zone membrane wall; the economizer (300) is divided into a high-temperature section and a low-temperature section, the high-temperature section is a conventional heat exchange zone and the low-temperature section of the economizer is a condensing zone. The large-module assembled high-efficiency condensing gas-fired hot water boiler provided by the invention has the advantages that the thermal efficiency can reach 96 percent and is improved by 5 percent on the basis of the thermal efficiency of the original corresponding boiler, and the boiler resistance is controlled to be basically unchanged.

Owner:JIANGSU SHUANGLIANG BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com