Device and method for treating waste water of power plant with flue gas

A technology for power plant waste water and furnace smoke, which is applied in special treatment targets, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high investment cost, large impact on unit efficiency, complex system, etc., and achieves low investment cost, The effect of improving continuous safe operation performance and system simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

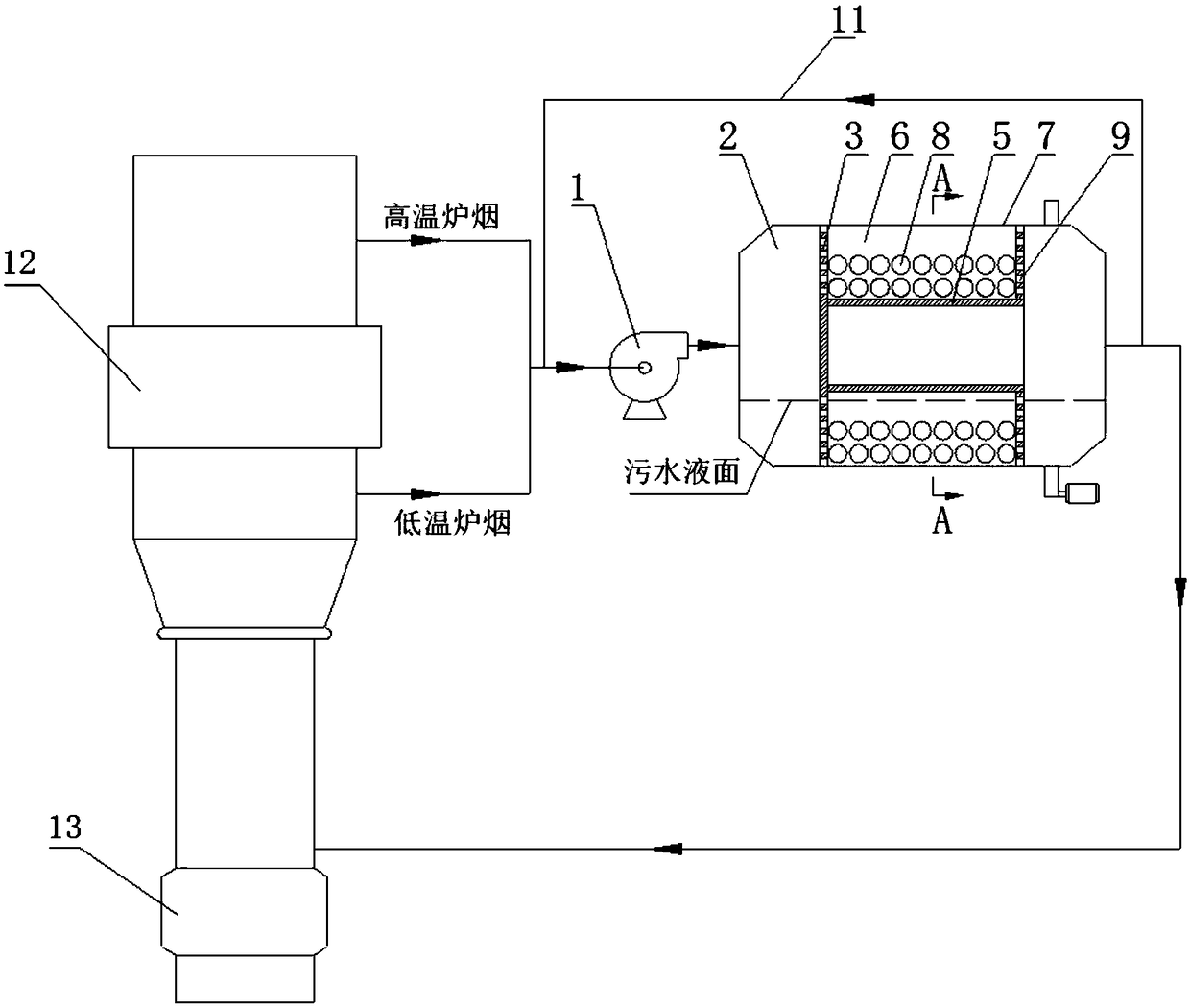

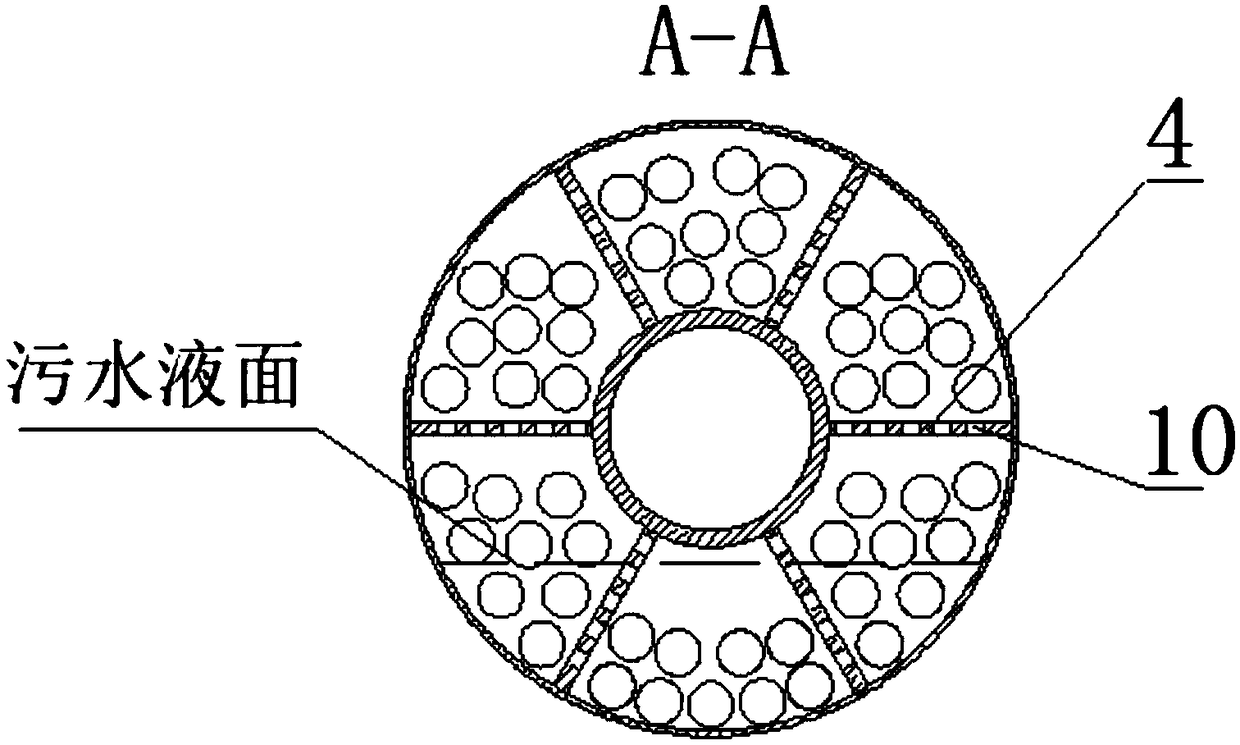

[0033] The present invention is a device for treating power plant waste water by using furnace smoke, such as figure 1 and figure 2 As shown, it includes a rotary wastewater treatment device 2, which includes a plurality of cavities 6 separated by a rotary device housing 7, a central cylinder 5, an axial partition 3, and a radial partition 4, and placed in the cavity 6 steel ball 8; the axial partition 3 is provided with a round hole 9 for the passage of a large amount of smoke and waste water; the radial partition 4 is provided with a round hole 10 for the passage of waste water, so that the waste water is always rotating The lower part of the processing device 2;

[0034] The high-temperature furnace smoke and the low-temperature furnace smoke are respectively taken at the inlet and outlet of the air preheater 12. After the high-temperature furnace smoke and the low-temperature furnace smoke are mixed, they enter the inlet of the furnace smoke fan 1, and the outlet of the ...

Embodiment 2

[0040] A method of utilizing furnace smoke to treat power plant waste water of the present invention comprises the following steps:

[0041] a. The high-temperature furnace smoke from the inlet flue of the air preheater 12 and the low-temperature furnace smoke from the outlet flue of the air preheater 12 in the flue are extracted by the furnace smoke fan 1, and the high-temperature furnace smoke and the low-temperature furnace smoke are mixed at the inlet of the furnace smoke fan 1 Send it into the rotary wastewater treatment device 2 to provide a heat source for the evaporation of sewage;

[0042] b. The mixed furnace smoke enters the rotary waste water treatment device 2 and enters the hollow body 6, and performs convective heat exchange on the steel ball 8 above the waste water liquid level at the lower part of the rotary waste water treatment device 2, and evaporates the sewage on the surface of the steel ball 8 to dryness. The steel balls 8 that have been evaporated to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com